Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5979 results about "Plasma treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma treatment uses a controlled vacuum plasma to alter the surface of a material in order to improve bonding, printing, painting, coating, or wettability. The process is performed in a plasma chamber under vacuum pressure. It is commonly used in the manufacturing of electronic devices, medical devices, textiles, plastics, rubbers, and more.

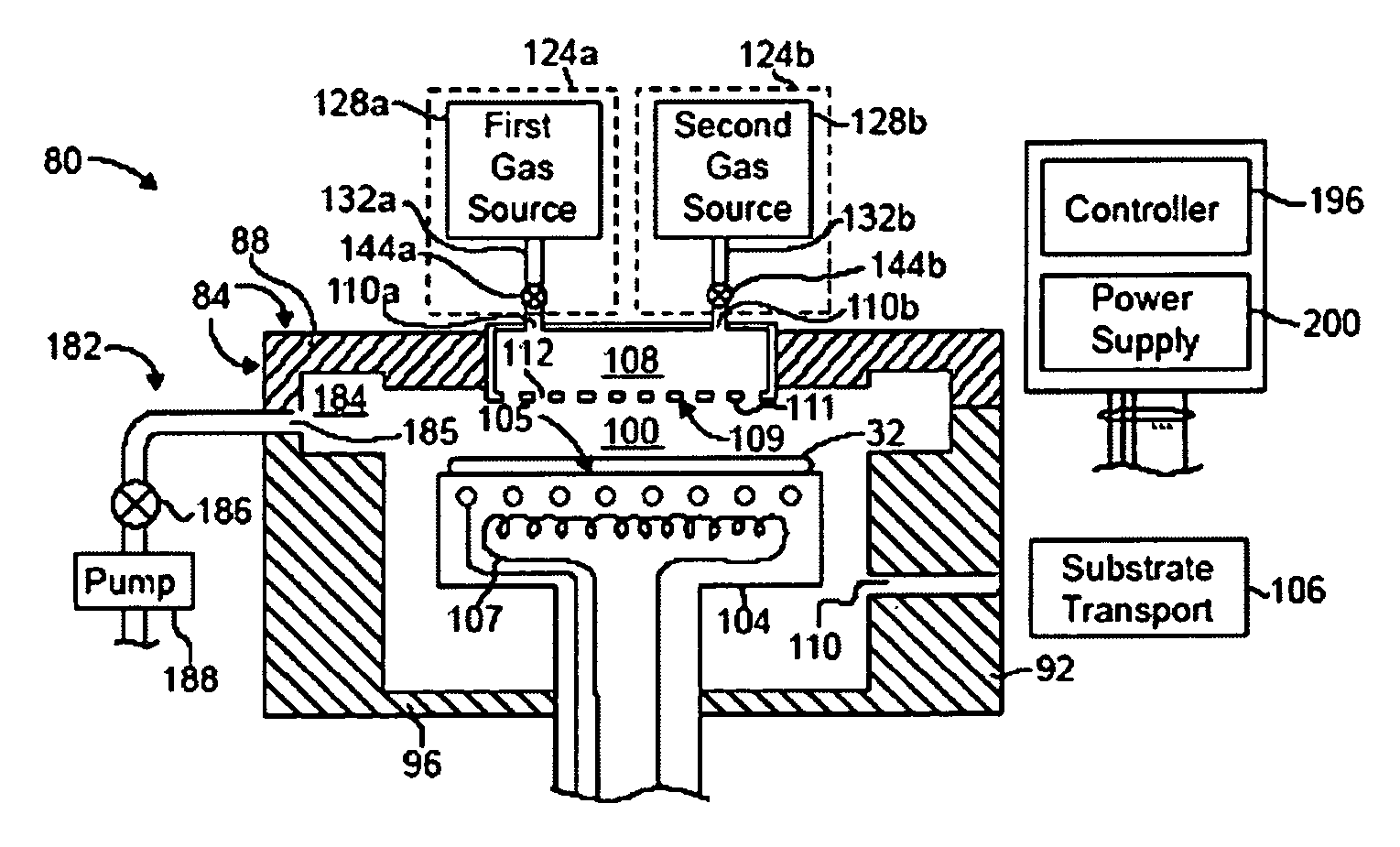

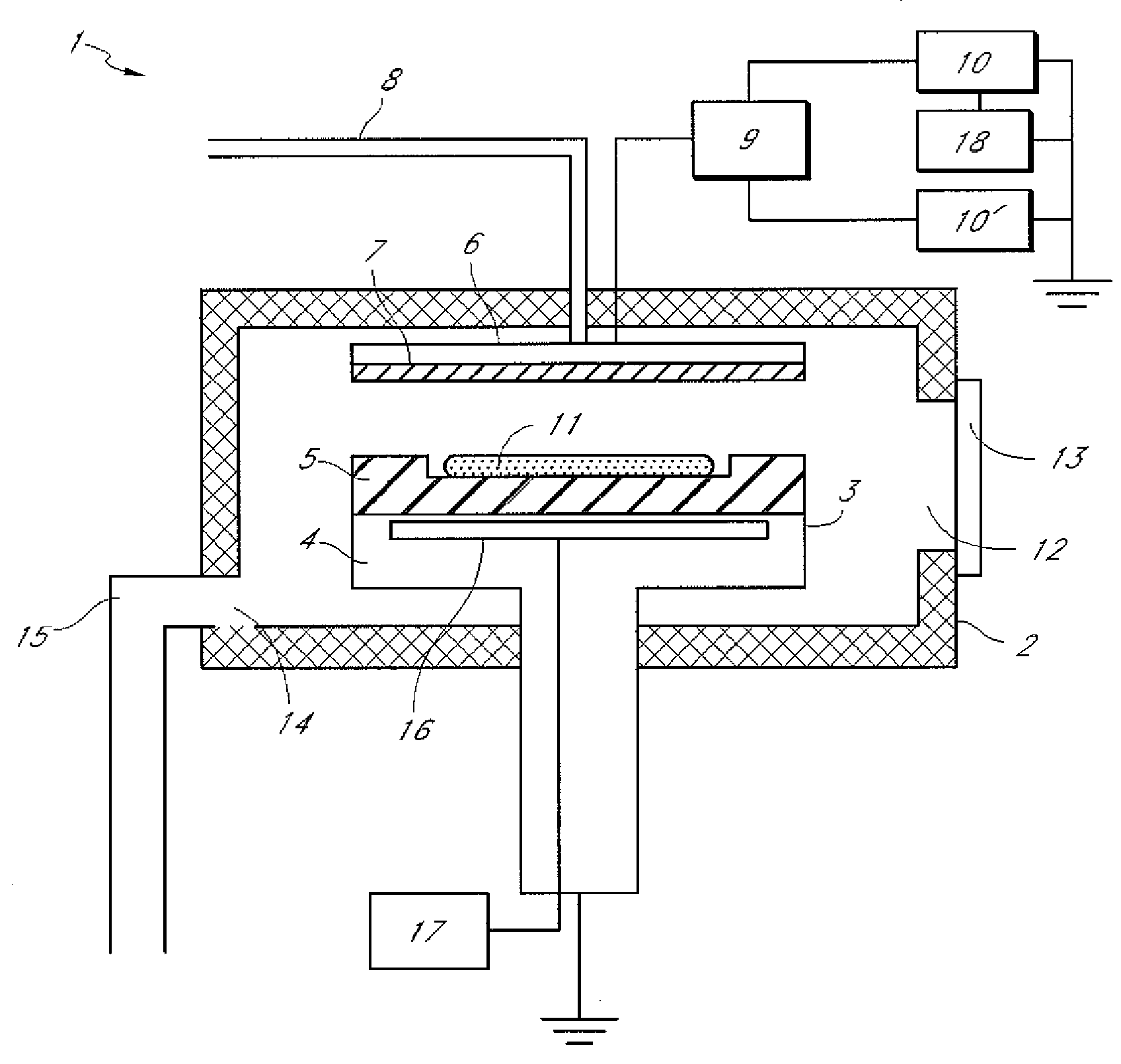

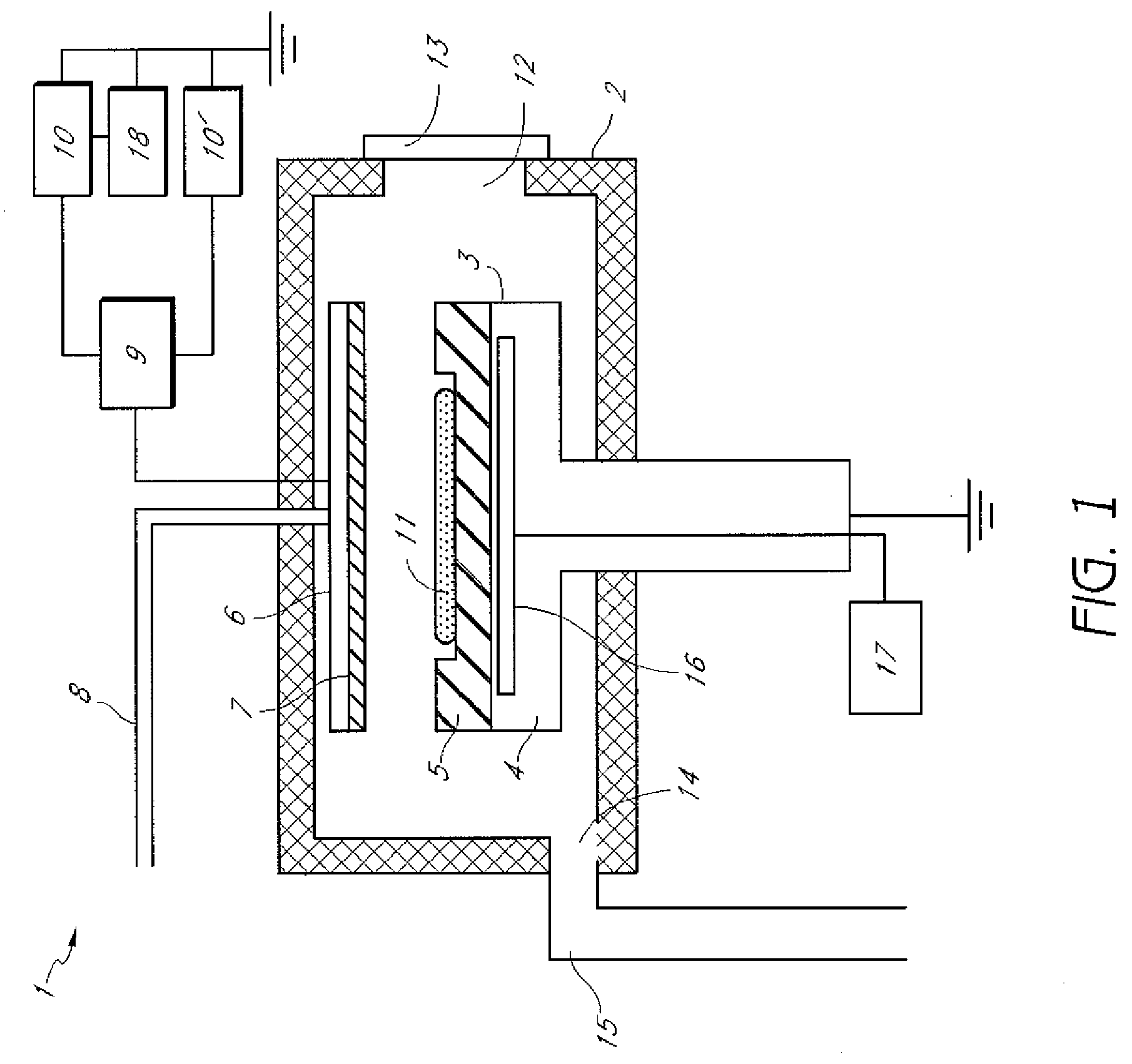

Apparatus and process for plasma-enhanced atomic layer deposition

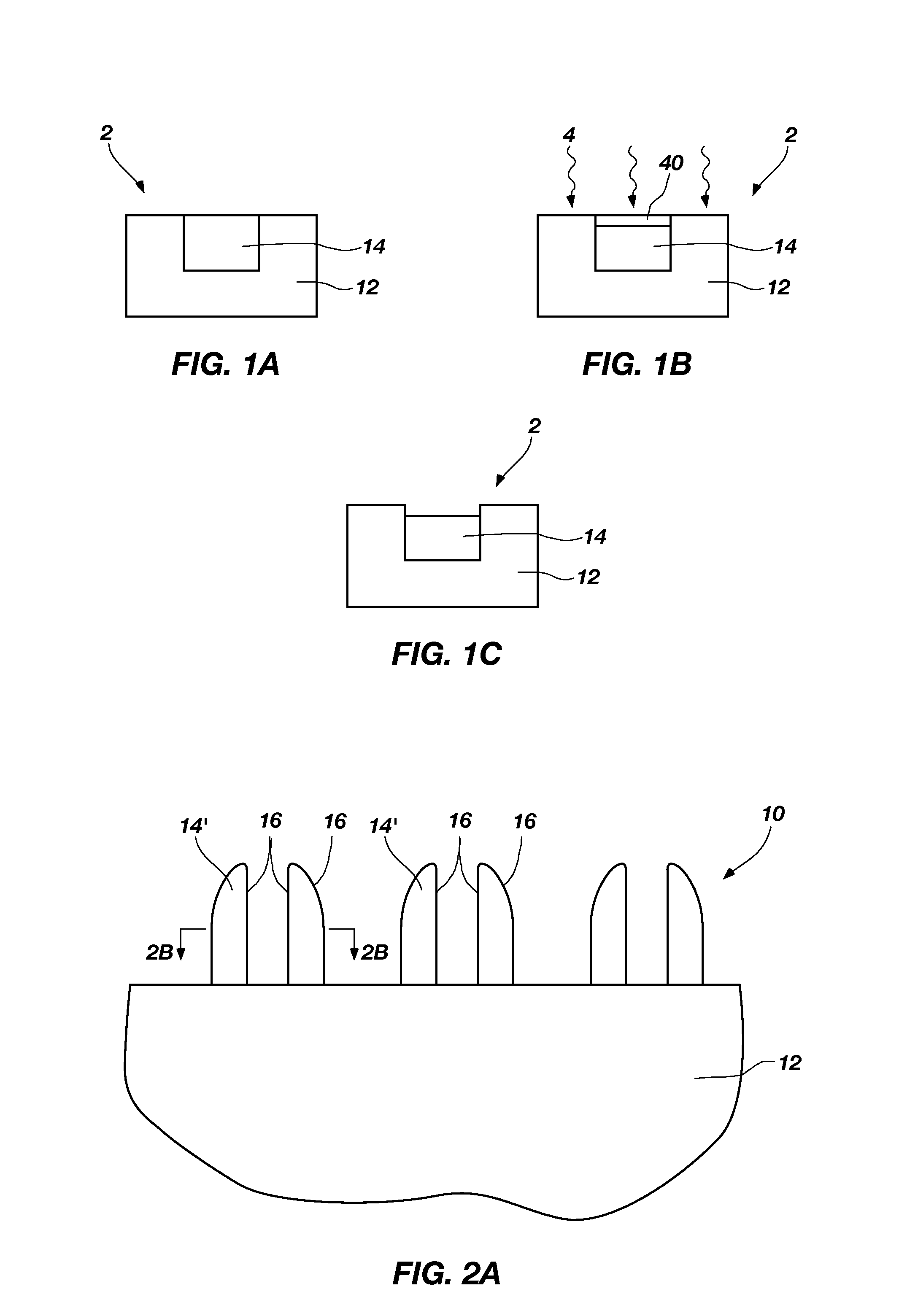

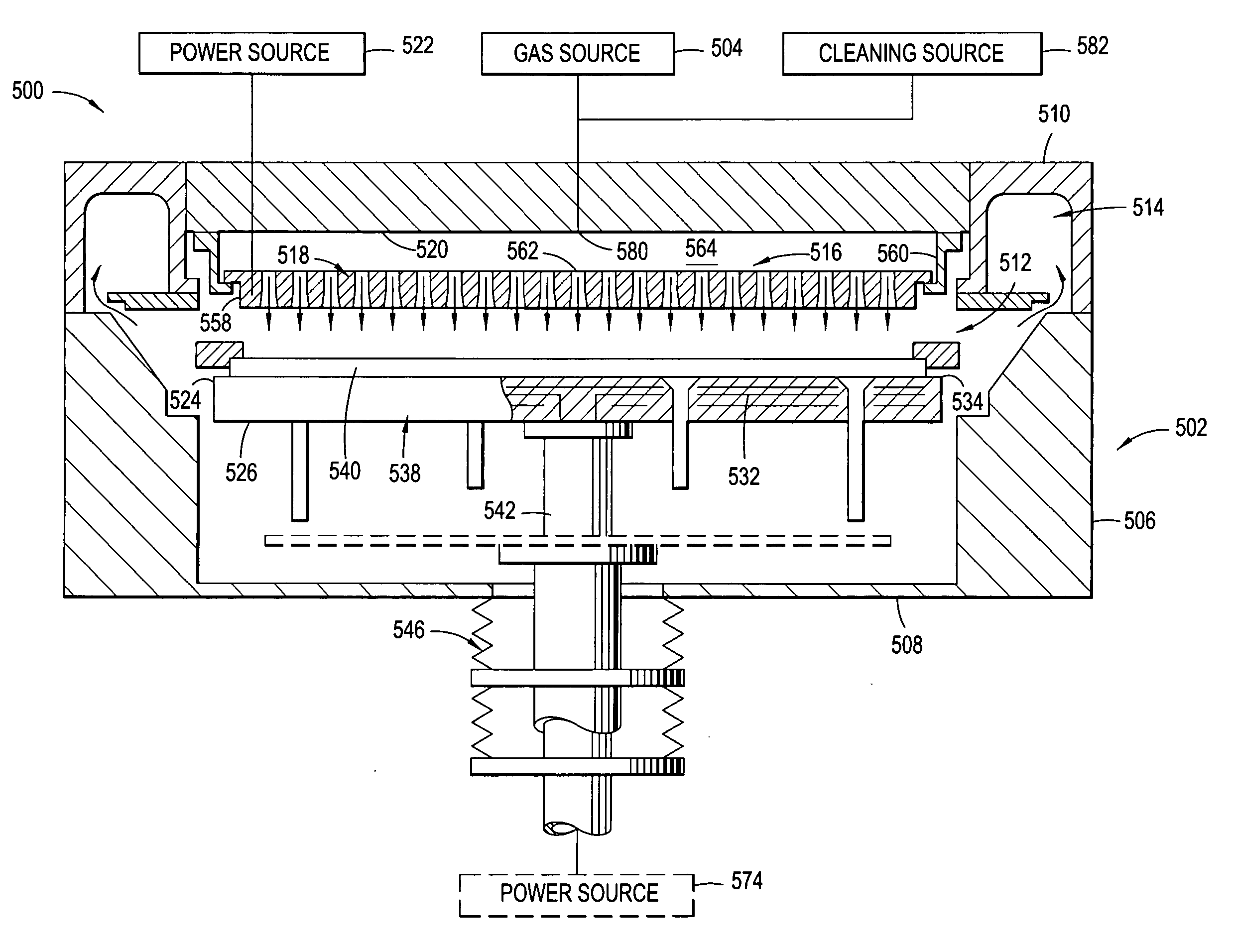

Embodiments of the invention provide an apparatus configured to form a material during an atomic layer deposition (ALD) process, such as a plasma-enhanced ALD (PE-ALD) process. In one embodiment, a process chamber is configured to expose a substrate to a sequence of gases and plasmas during a PE-ALD process. The process chamber comprises components that are capable of being electrically insulated, electrically grounded or RF energized. In one example, a chamber body and a gas manifold assembly are grounded and separated by electrically insulated components, such as an insulation cap, a plasma screen insert and an isolation ring. A showerhead, a plasma baffle and a water box are positioned between the insulated components and become RF hot when activated by a plasma generator. Other embodiments of the invention provide deposition processes to form layers of materials within the process chamber.

Owner:APPLIED MATERIALS INC

Methods of removing silicon oxide and gaseous mixtures for achieving same

ActiveUS20090275205A1Decorative surface effectsSemiconductor/solid-state device manufacturingChemical treatmentPartial oxidation

Owner:MICRON TECH INC

Vapor deposition method for ternary compounds

InactiveUS20100102417A1High resistivitySolid-state devicesSemiconductor/solid-state device manufacturingNitrogen plasmaGas phase

Embodiments provide a method for depositing or forming titanium aluminum nitride materials during a vapor deposition process, such as atomic layer deposition (ALD) or plasma-enhanced ALD (PE-ALD). In some embodiments, a titanium aluminum nitride material is formed by sequentially exposing a substrate to a titanium precursor and a nitrogen plasma to form a titanium nitride layer, exposing the titanium nitride layer to a plasma treatment process, and exposing the titanium nitride layer to an aluminum precursor while depositing an aluminum layer thereon. The process may be repeated multiple times to deposit a plurality of titanium nitride and aluminum layers. Subsequently, the substrate may be annealed to form the titanium aluminum nitride material from the plurality of layers. In other embodiments, the titanium aluminum nitride material may be formed by sequentially exposing the substrate to the nitrogen plasma and a deposition gas which contains the titanium and aluminum precursors.

Owner:APPLIED MATERIALS INC

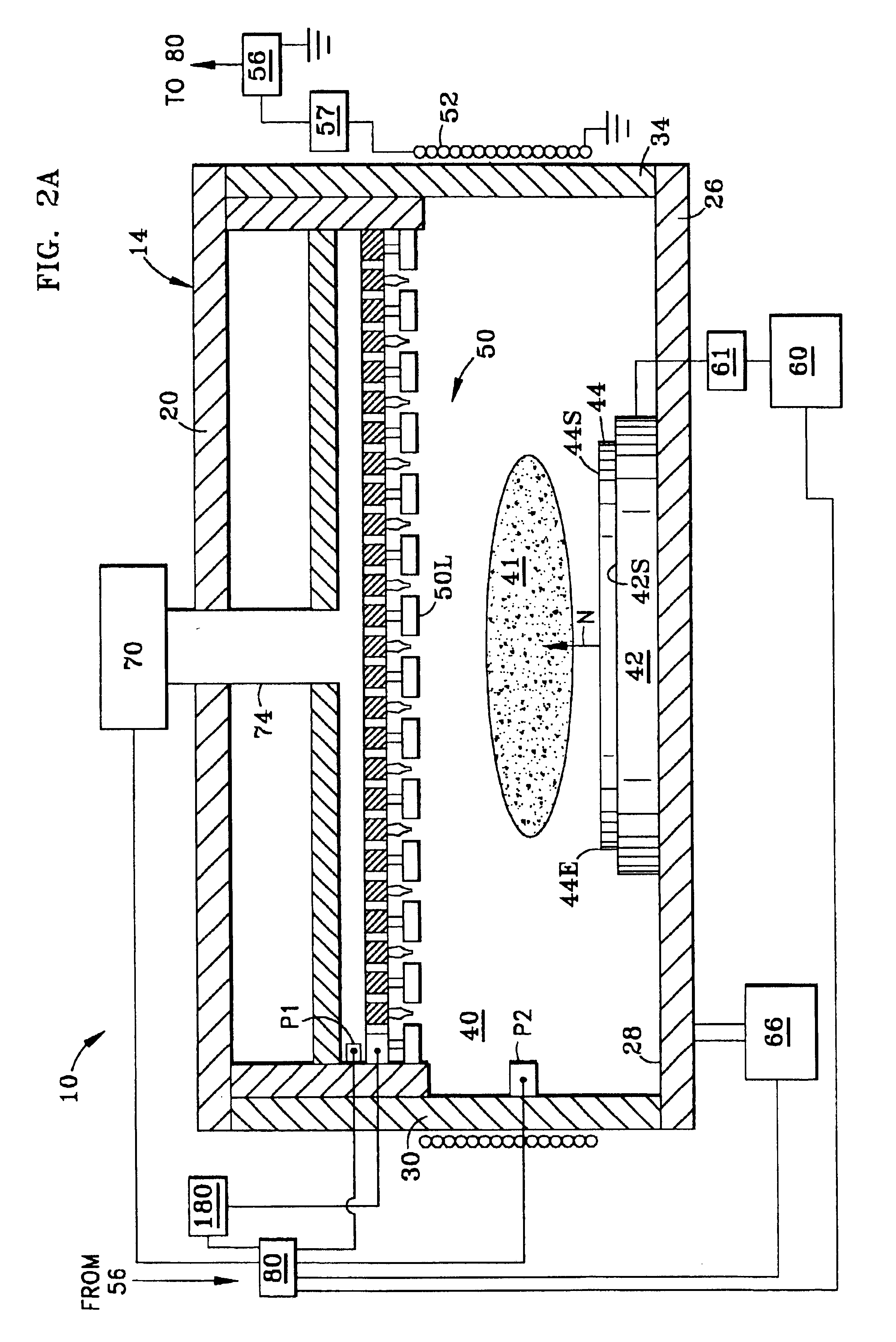

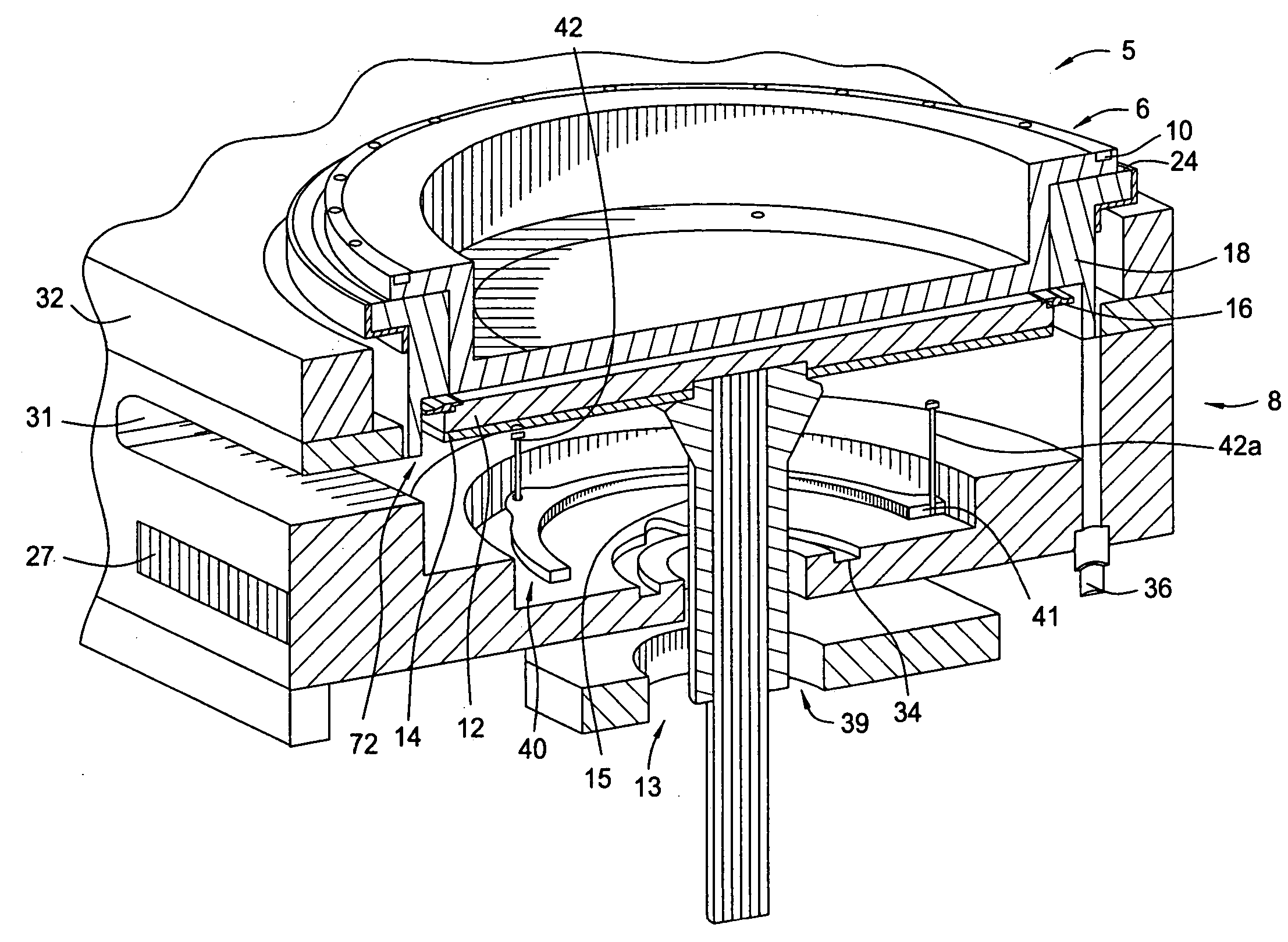

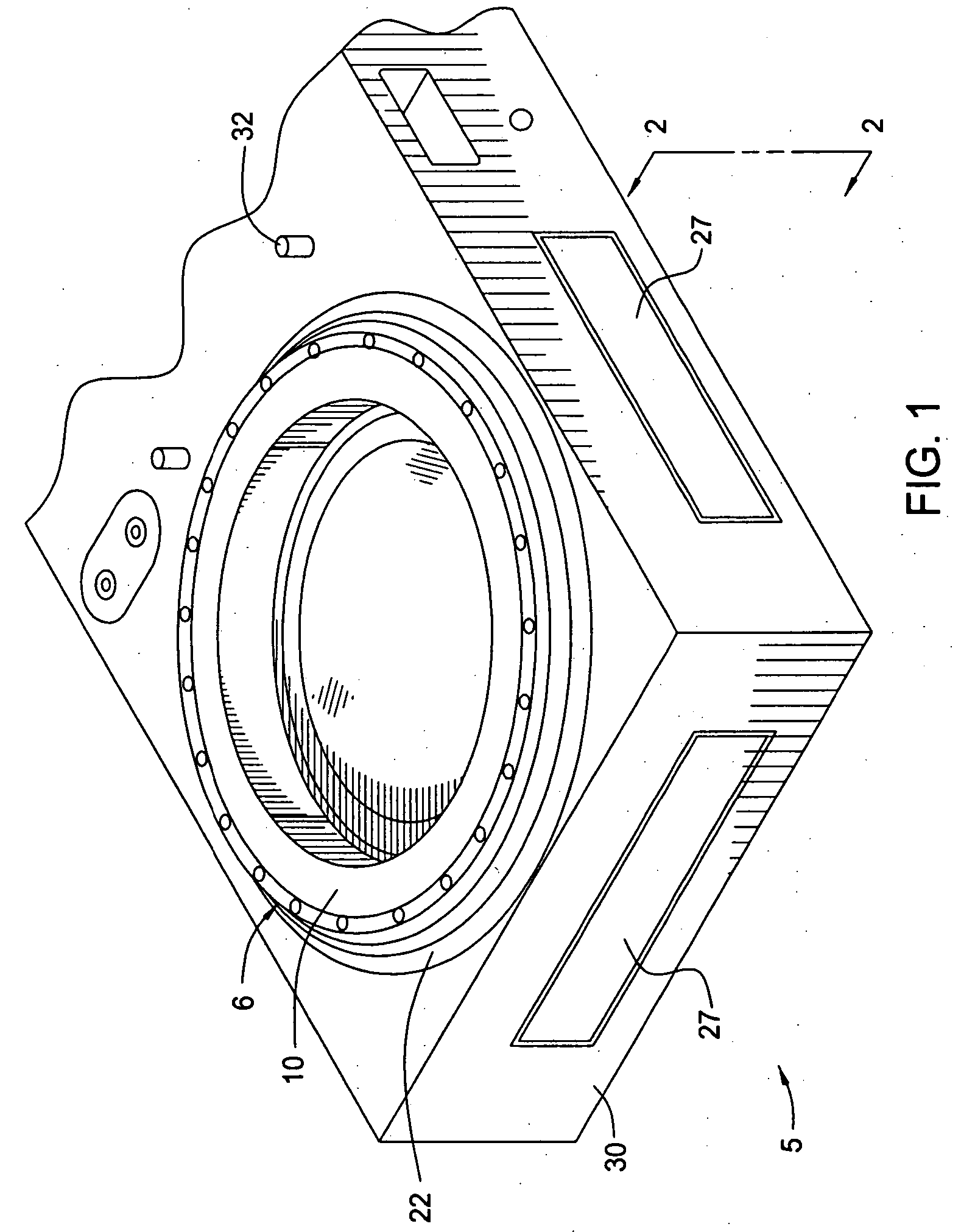

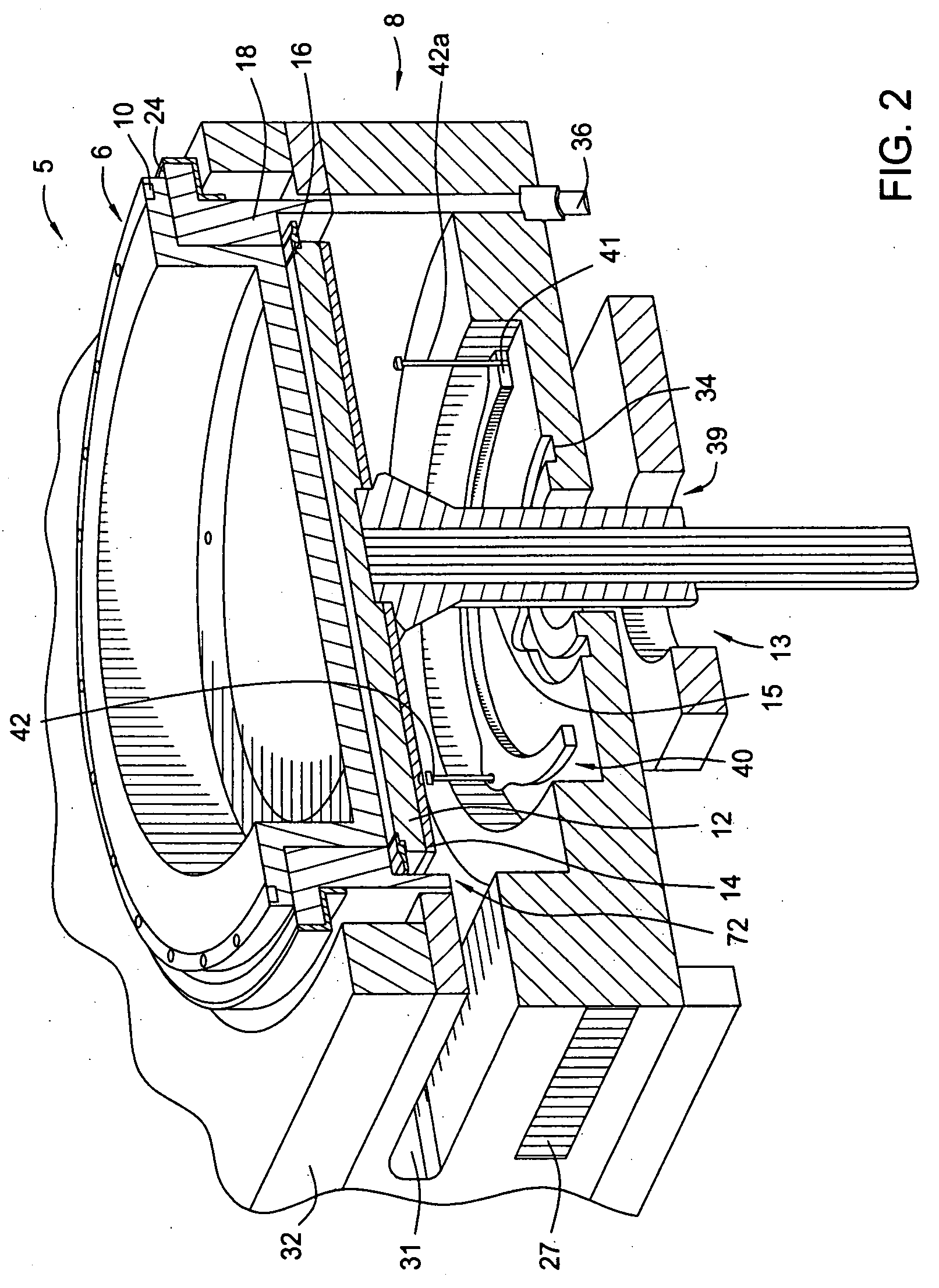

Method of and apparatus for tunable gas injection in a plasma processing system

InactiveUS6872259B2Control expansionElectric discharge tubesSemiconductor/solid-state device manufacturingElectronic communicationProduct gas

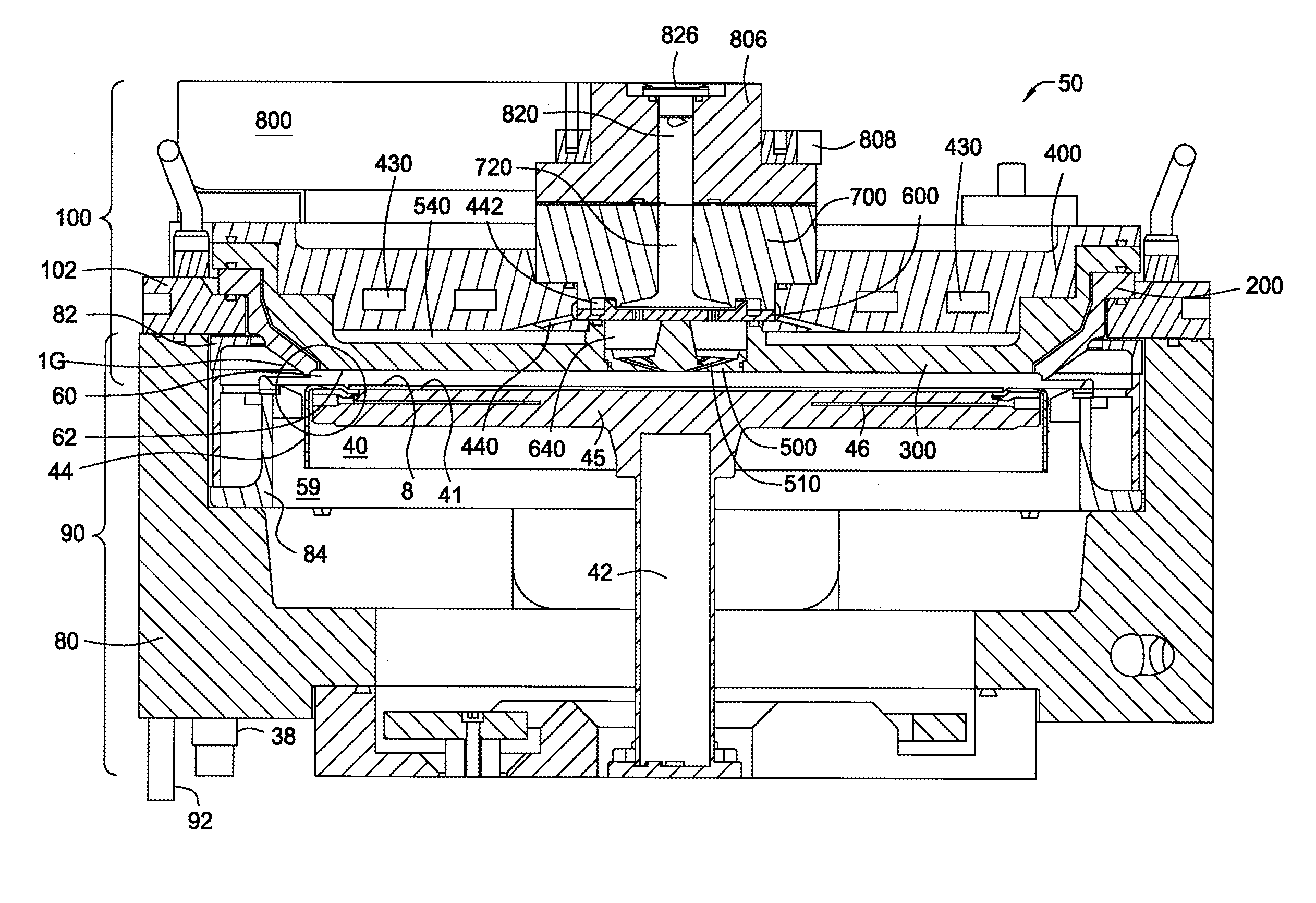

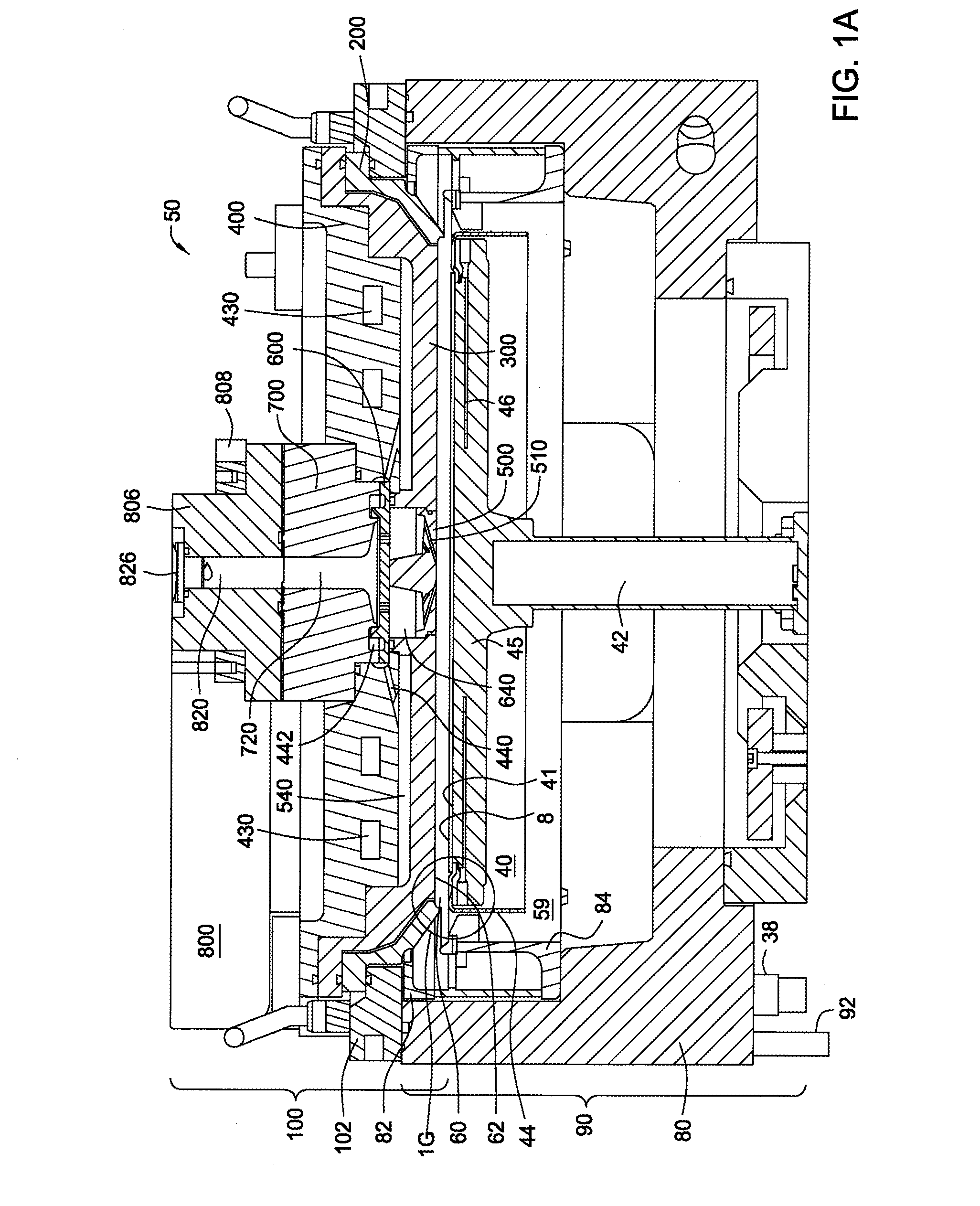

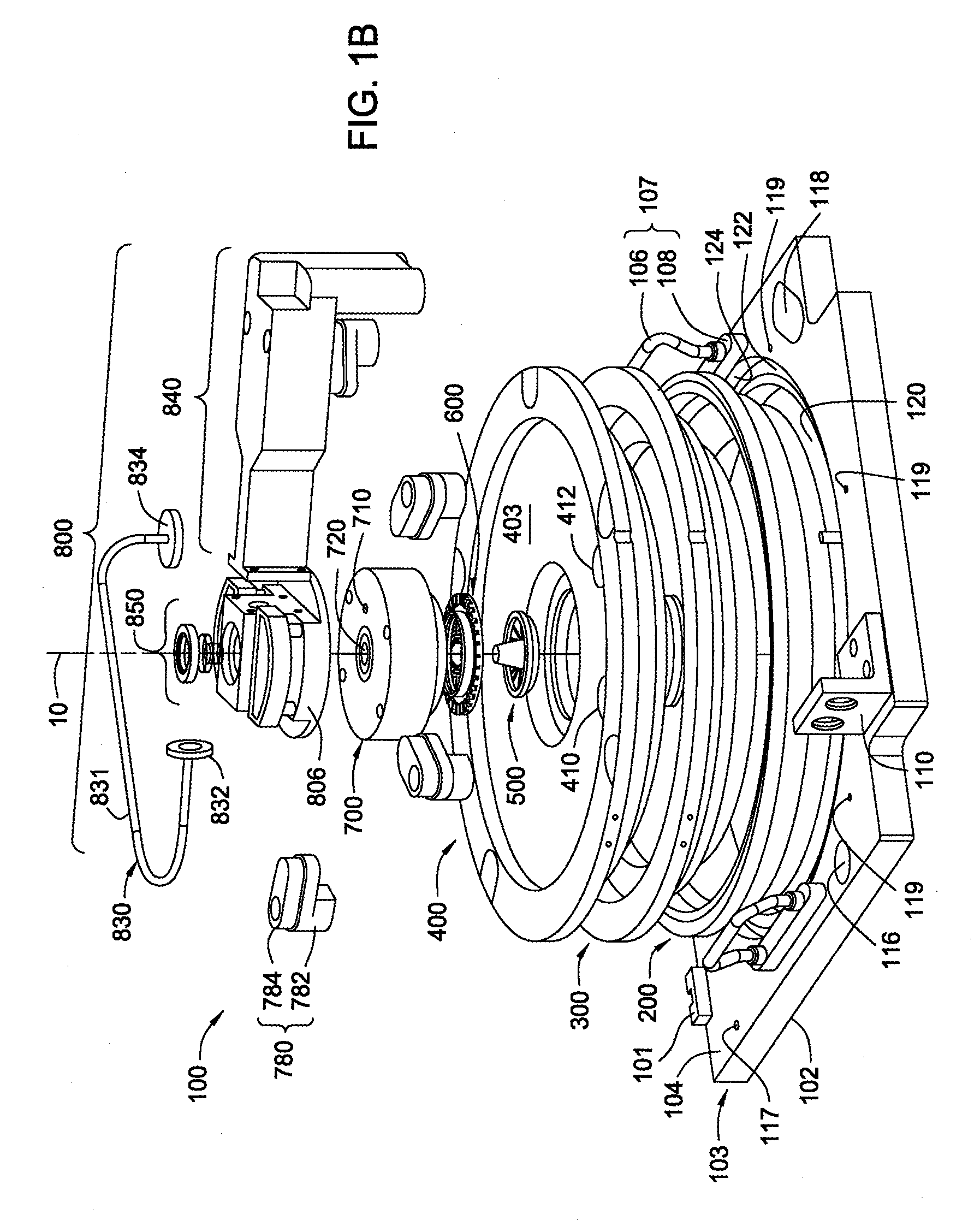

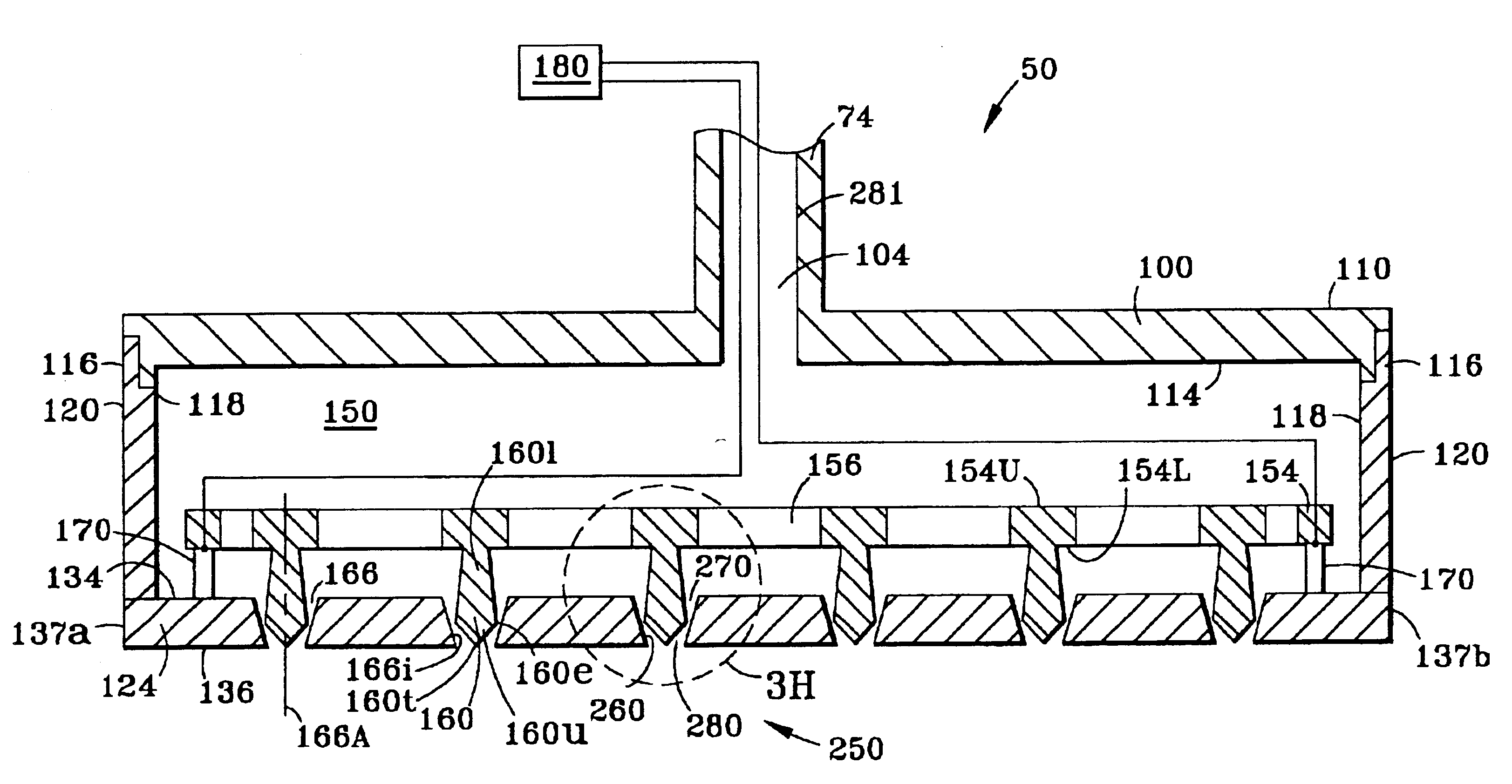

A method of and apparatus for providing tunable gas injection in a plasma processing system (10, 10′). The apparatus includes a gas injection manifold (50) having a pressurizable plenum (150) and an array of adjustable nozzle units (250), or an array of non-adjustable nozzles (502, 602), through which gas from the plenum can flow into the interior region (40) of a plasma reactor chamber (14) capable of containing a plasma (41). The adjustable nozzle units include a nozzle plug (160) arranged within a nozzle bore (166). A variety of different nozzle units are disclosed. The nozzle plugs are axially translatable to adjust the flow of gas therethrough. In one embodiment, the nozzle plugs are attached to a plug plate (154), which is displacable relative to an injection plate (124) via displacement actuators (170) connecting the two plates. The displacement actuators are controlled by a displacement actuator control unit (180), which is in electronic communication with a plasma processing system control unit (80). The gas flow into the chamber interior region is preferably controlled by monitoring the pressure in the plenum and in the chamber and adjusting the nozzle units accordingly. Where the nozzle units are not adjustable, a portion of the nozzles are sized to a first flow condition, and another portion of the nozzles are sized to a second flow condition.

Owner:TOKYO ELECTRON LTD

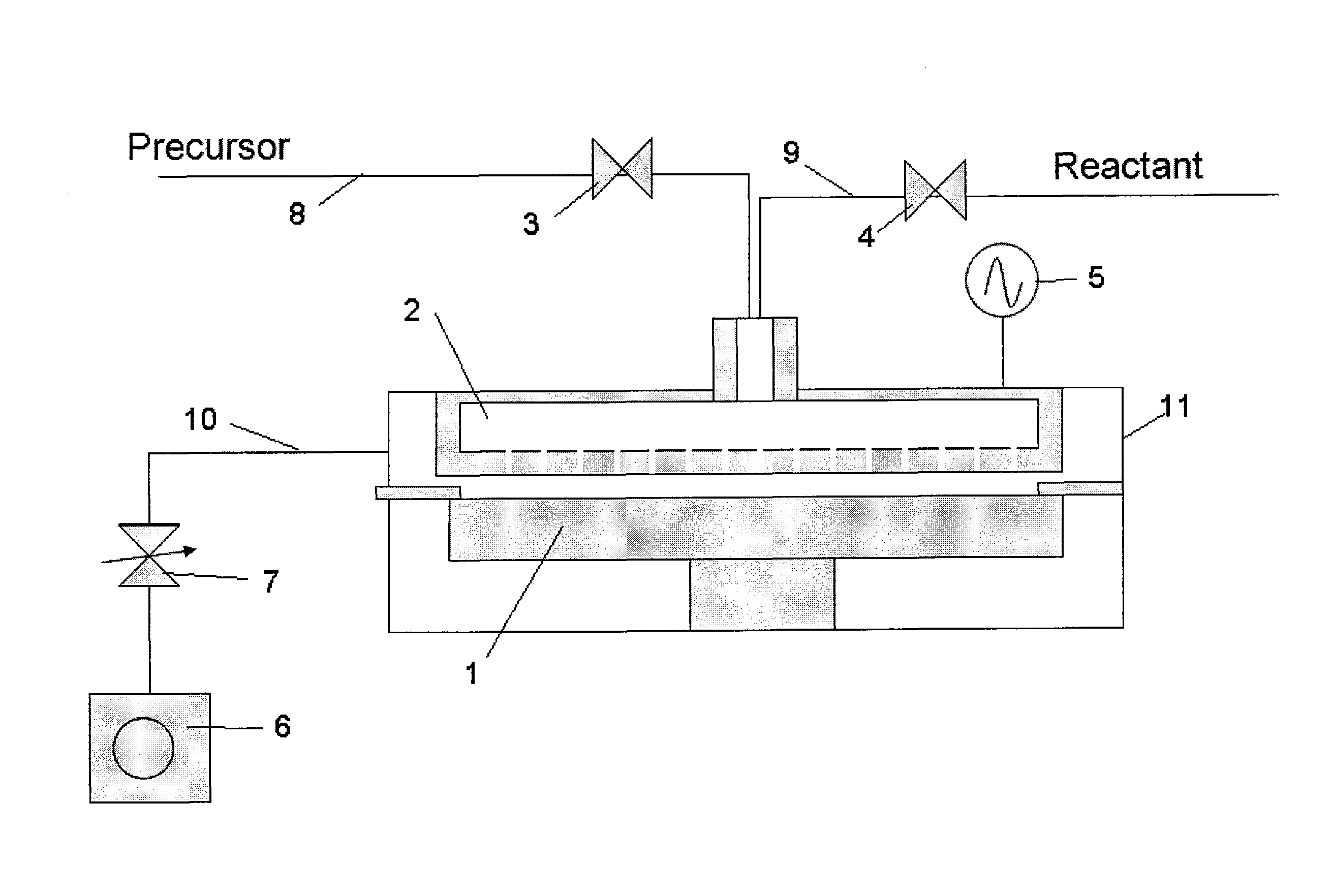

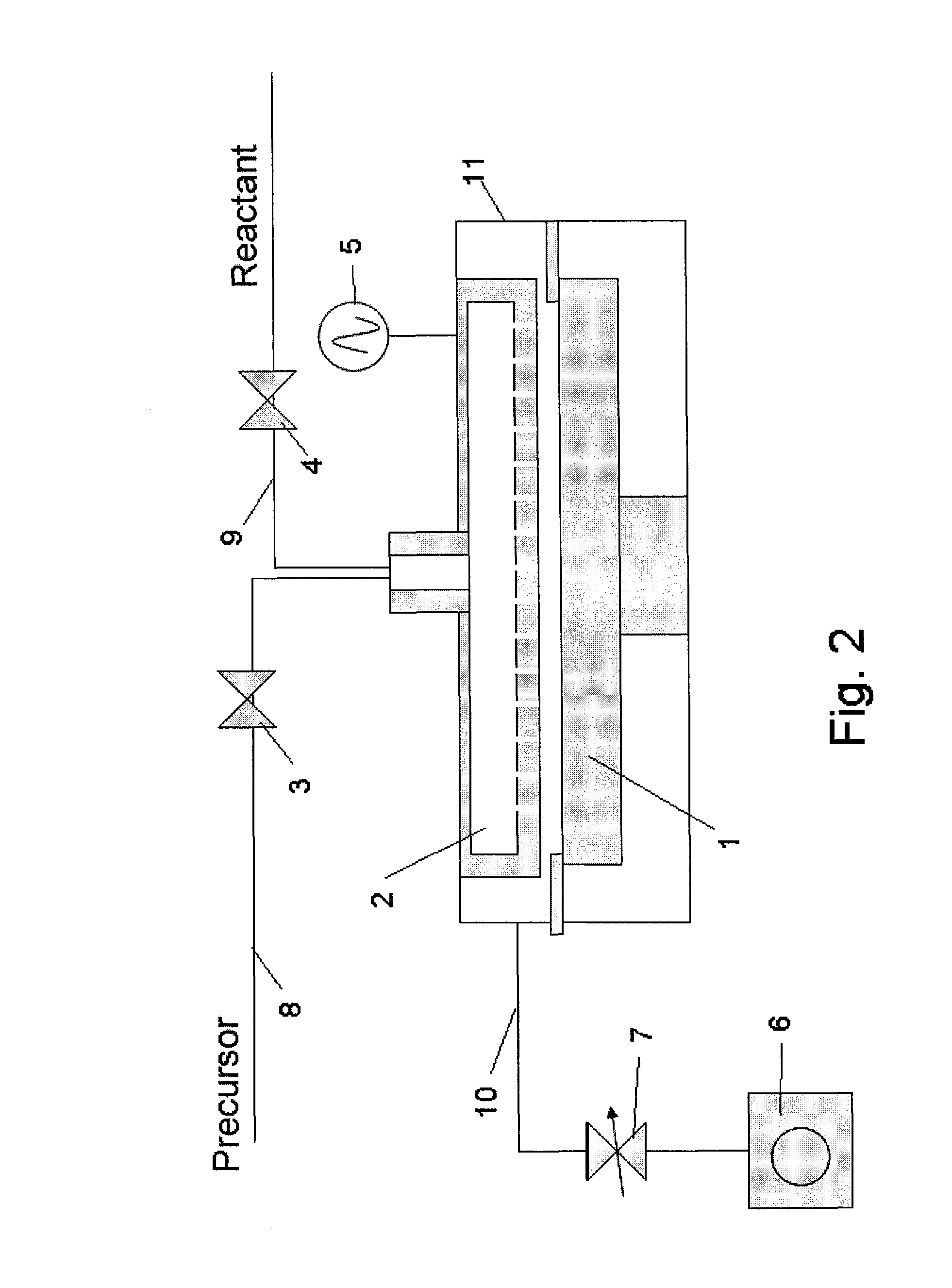

Method of Forming Insulation Film by Modified PEALD

ActiveUS20100124621A1Increase coverageImprove throughputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringPhysical chemistry

Owner:ASM JAPAN

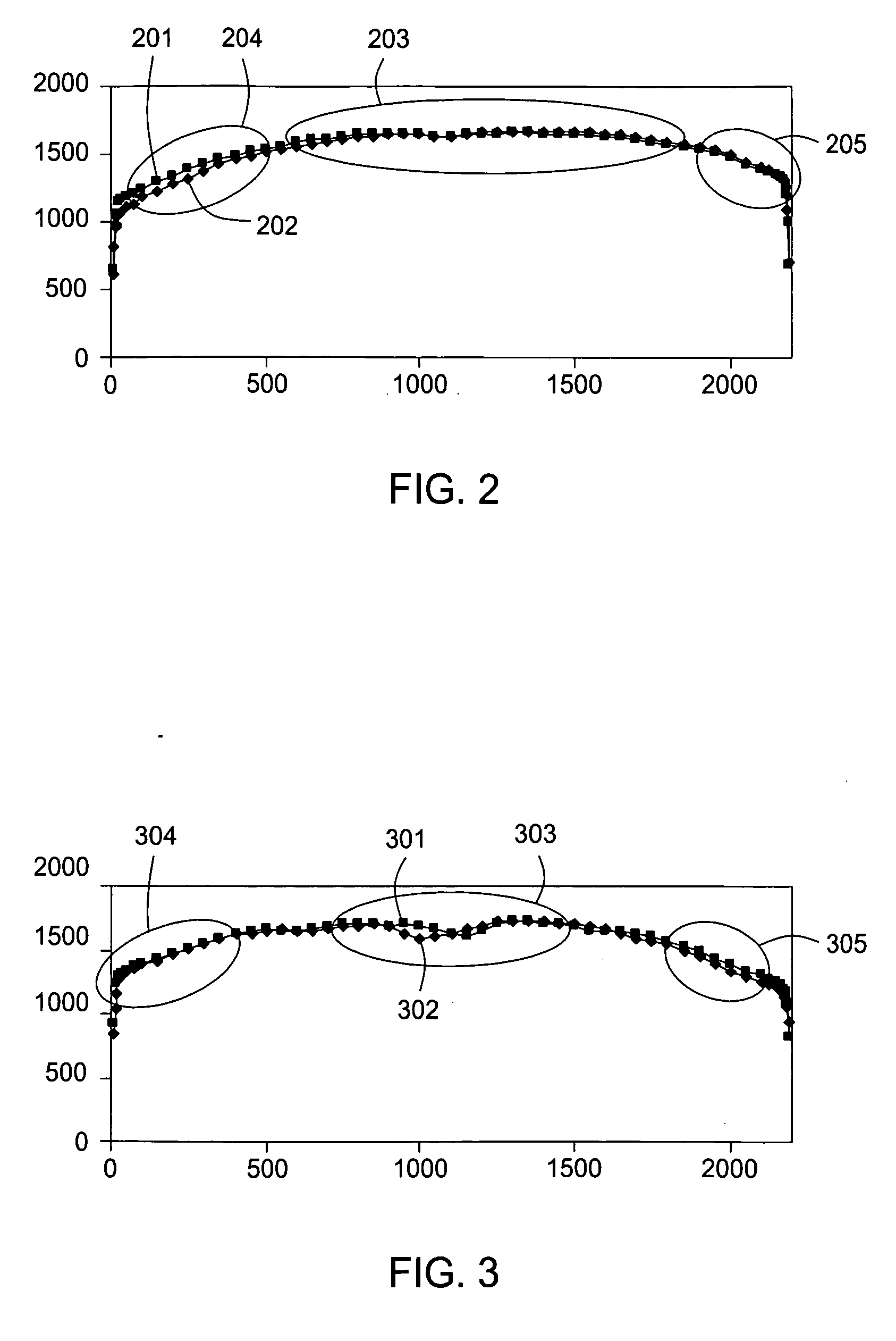

Plasma uniformity control by gas diffuser curvature

ActiveUS20060228496A1Improve thickness uniformityImprove filmElectric discharge tubesSemiconductor/solid-state device manufacturingGaseous diffusionAmorphous silicon

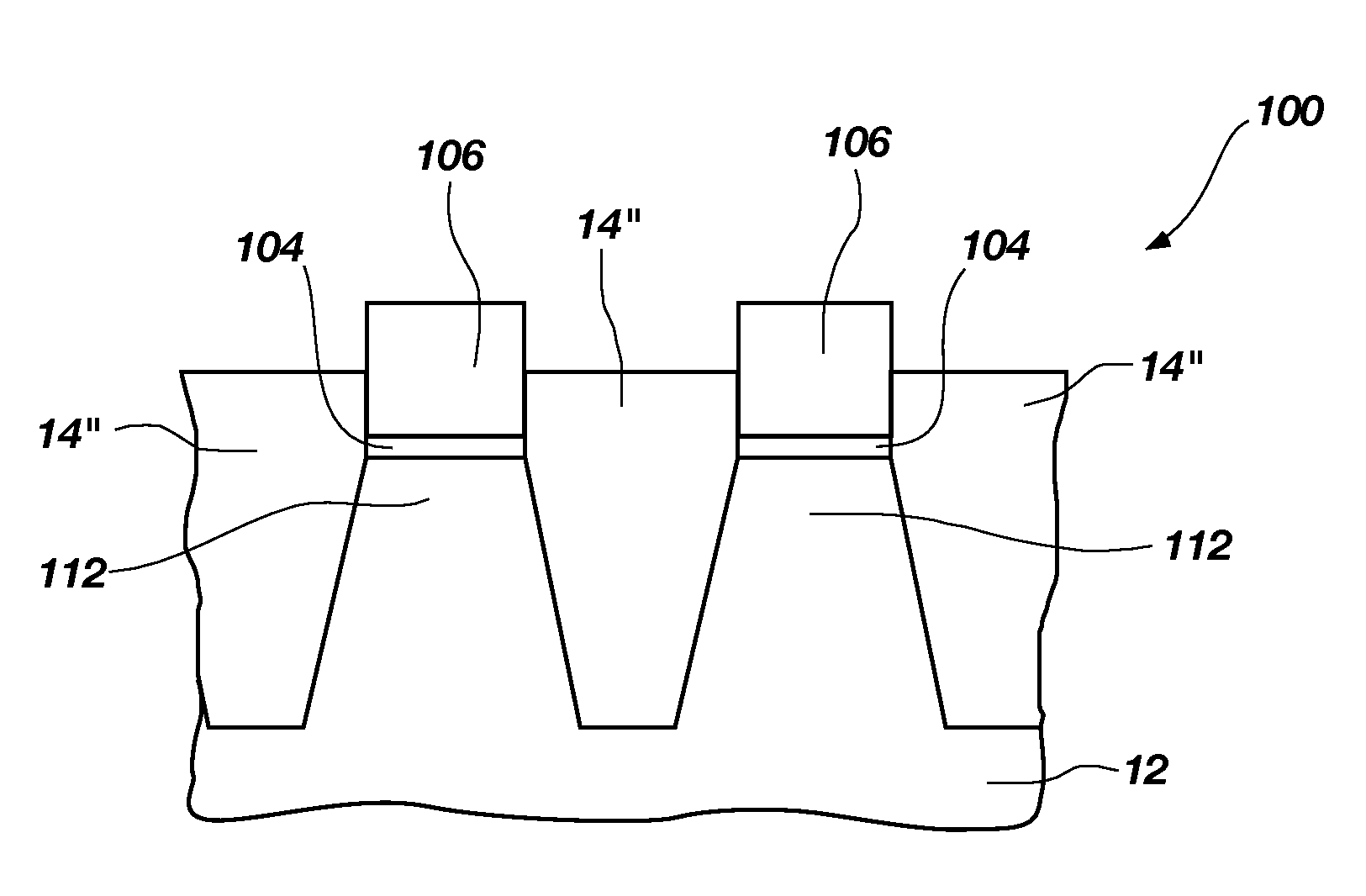

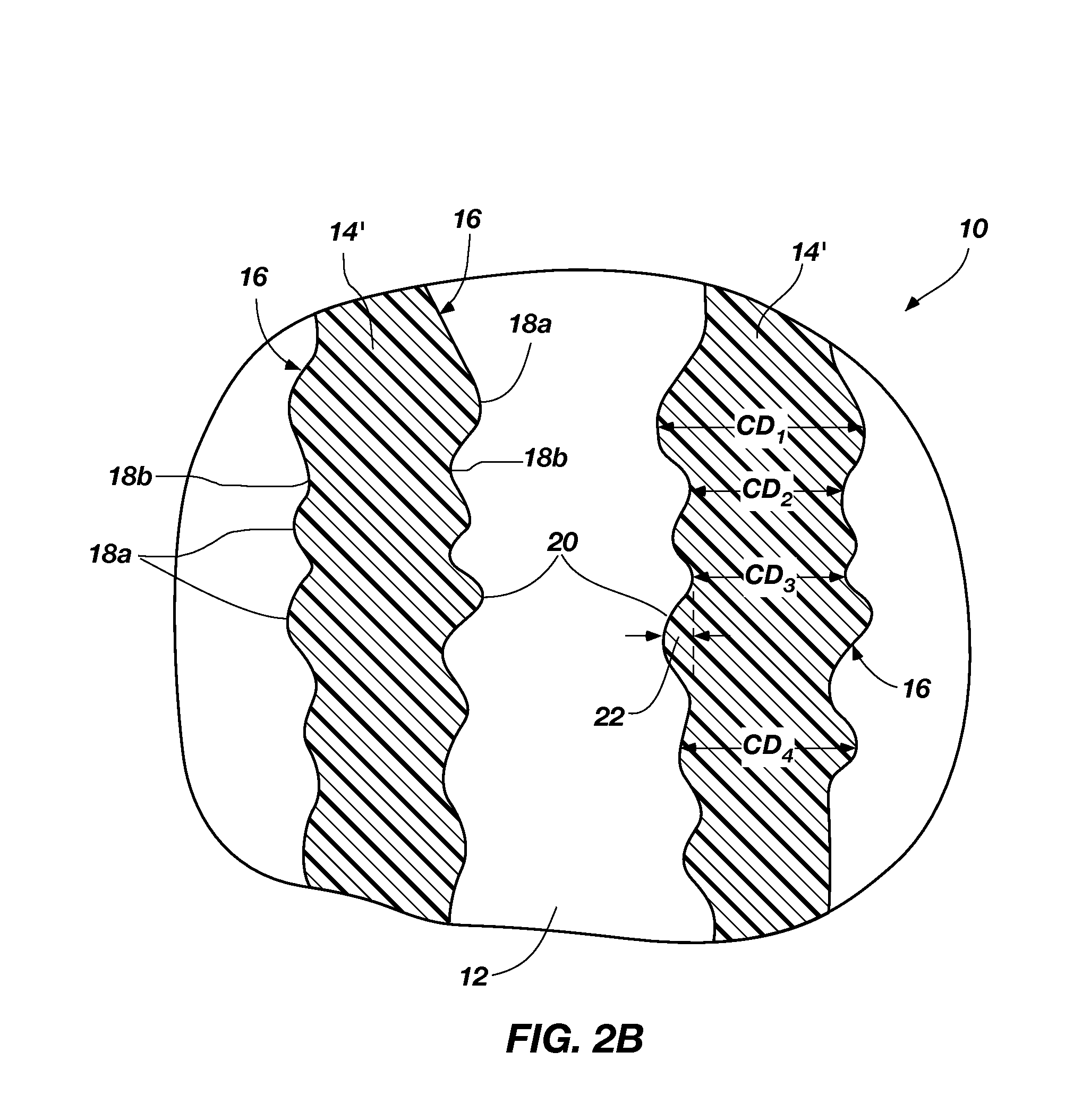

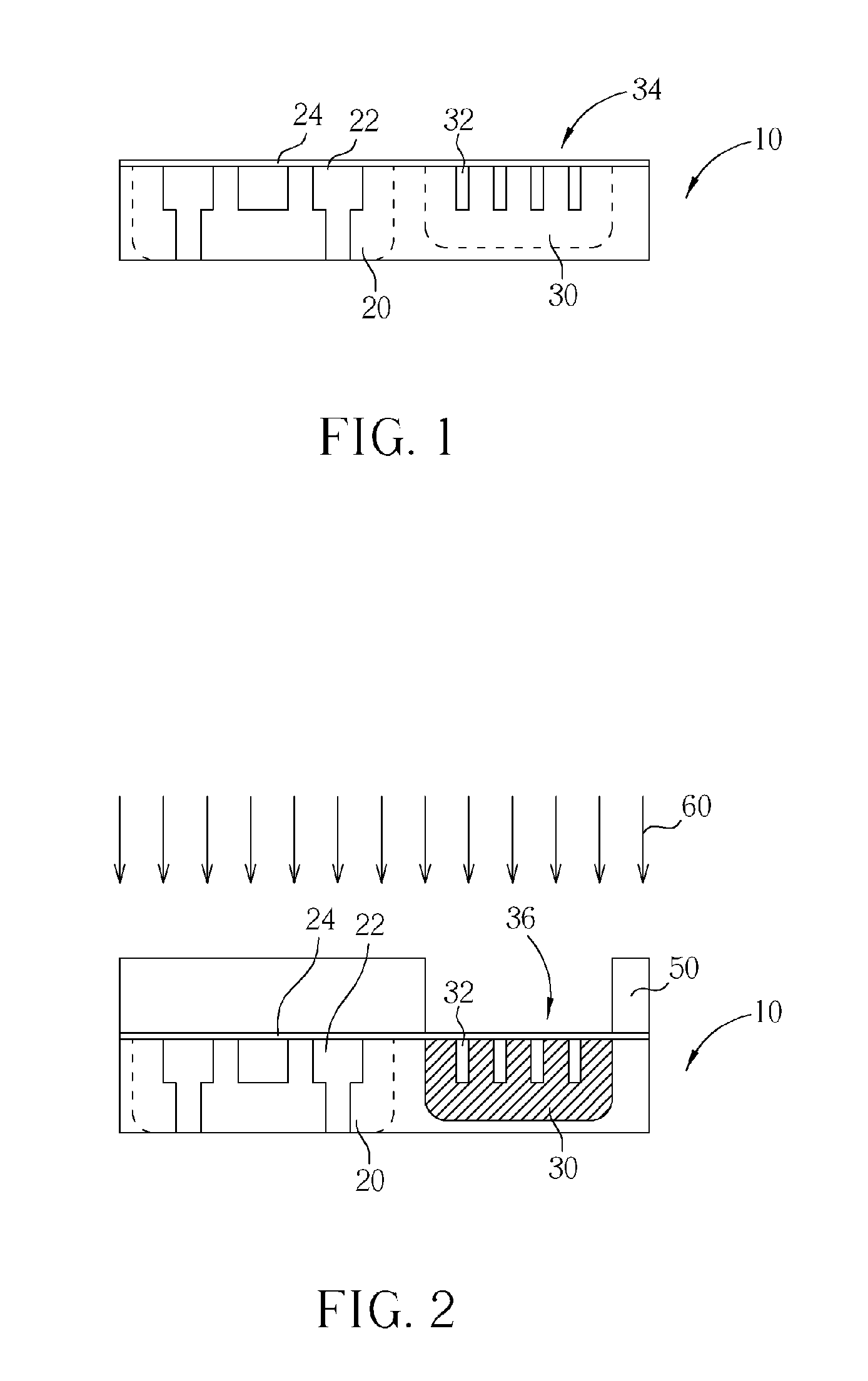

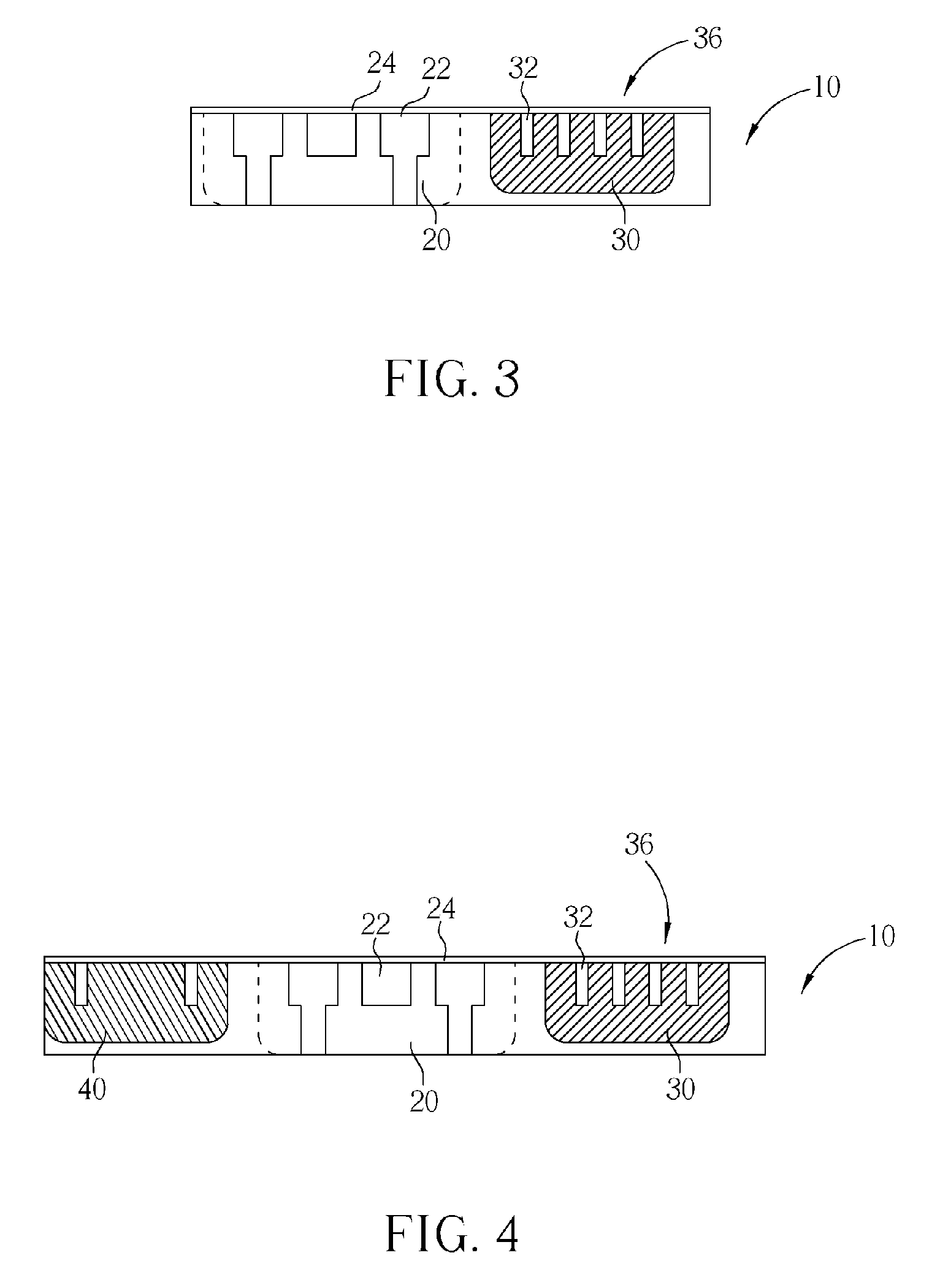

Embodiments of a gas distribution plate for distributing gas in a processing chamber are provided. In one embodiment, a gas distribution assembly for a plasma processing chamber comprises a diffuser plate with gas passages passing between its upstream and downstream sides and hollow cathode cavities at the downstream side of the gas passages. The downstream side of the diffuser plate has a curvature to improve the thickness uniformity and film property uniformity of thin films deposited by PECVD, particularly SiN and amorphous silicon films. The curvature is preferably described by an arc of a circle or ellipse, the apex thereof located at the center point of the diffuser plate. In one aspect, the hollow cathode cavity volume density, surface area density, or the cavity density of the diffuser increases from the center of the diffuser to the outer edge. Methods for manufacturing such a diffuser plate are also provided.

Owner:APPLIED MATERIALS INC

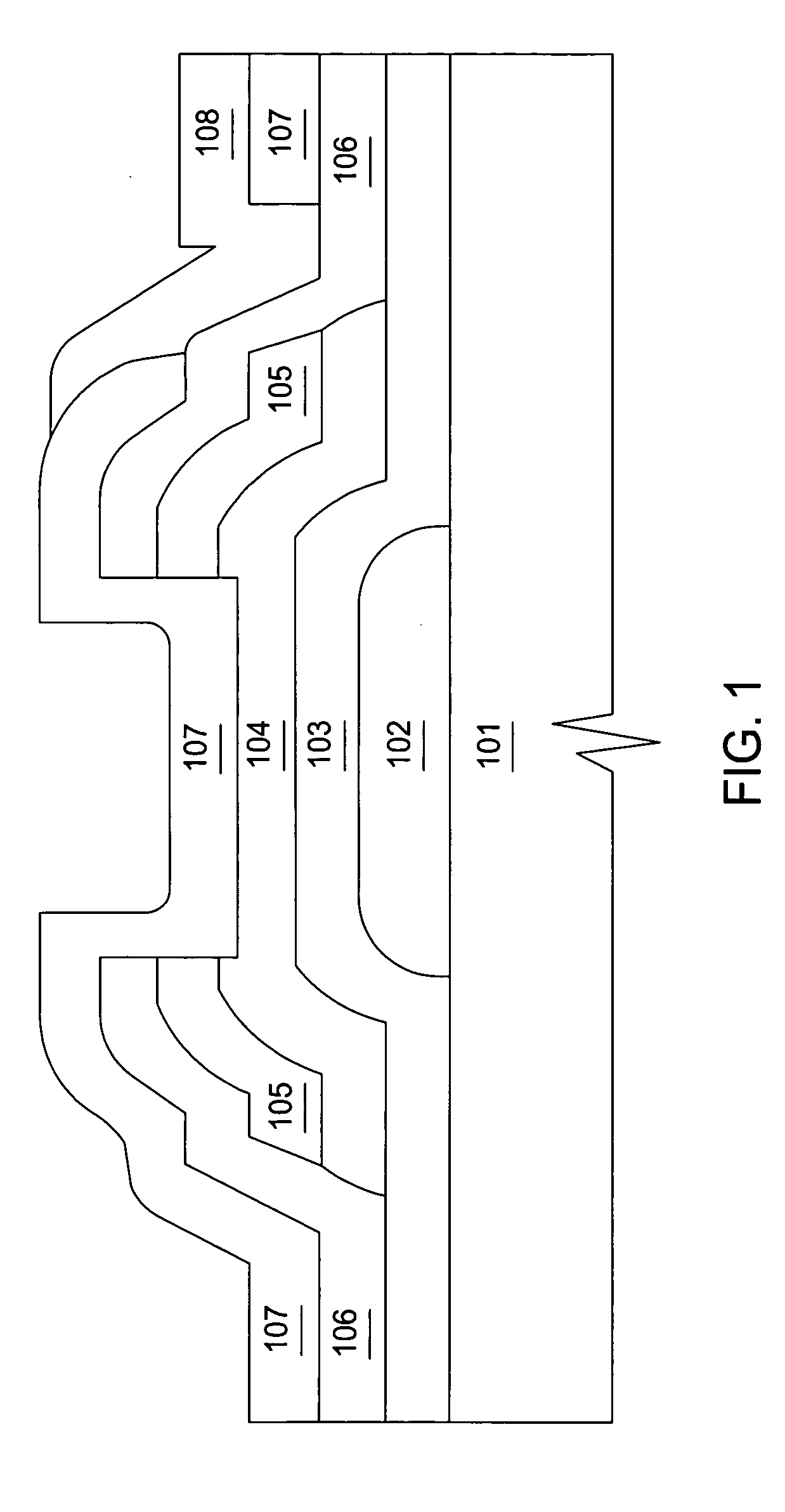

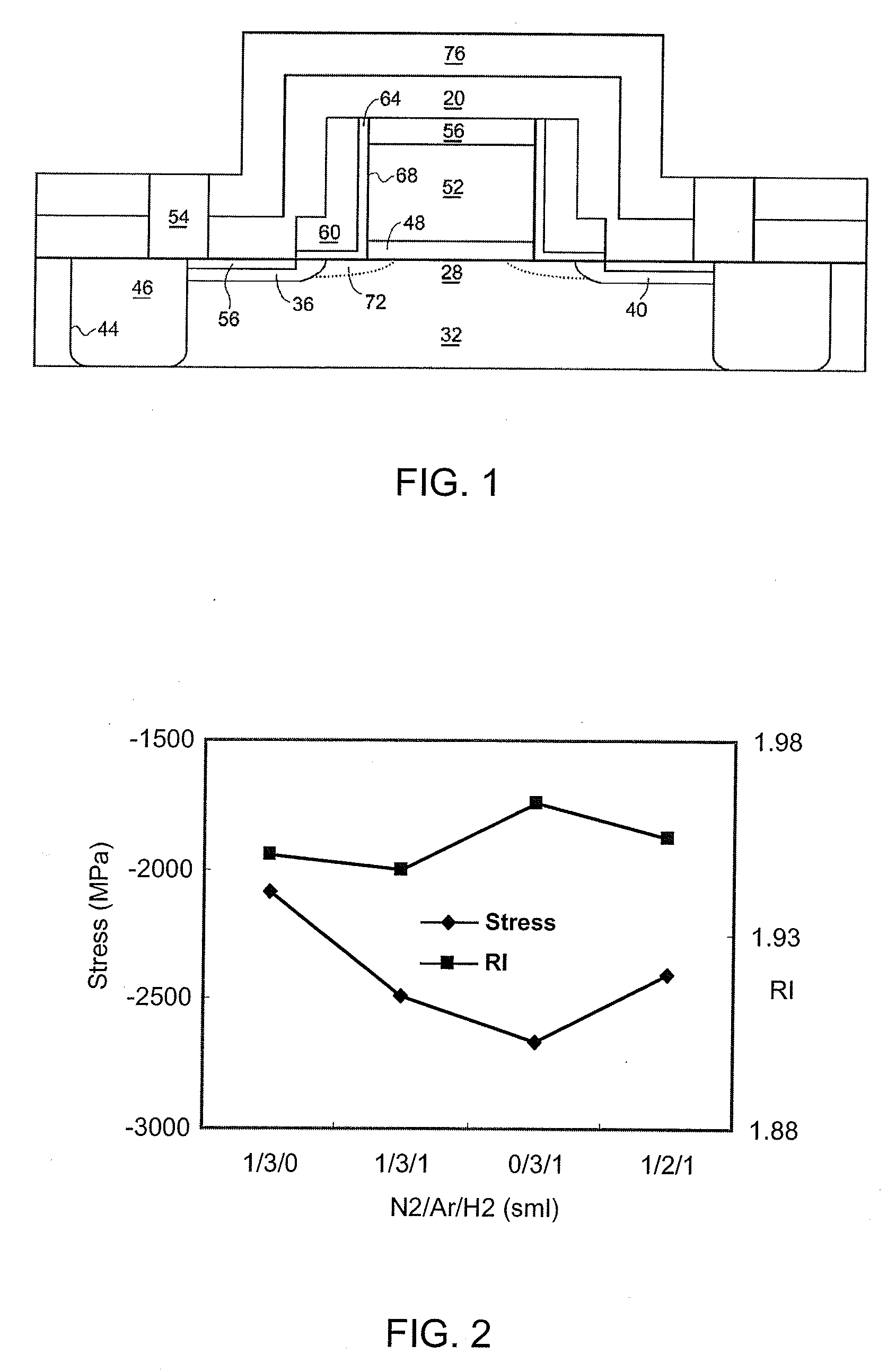

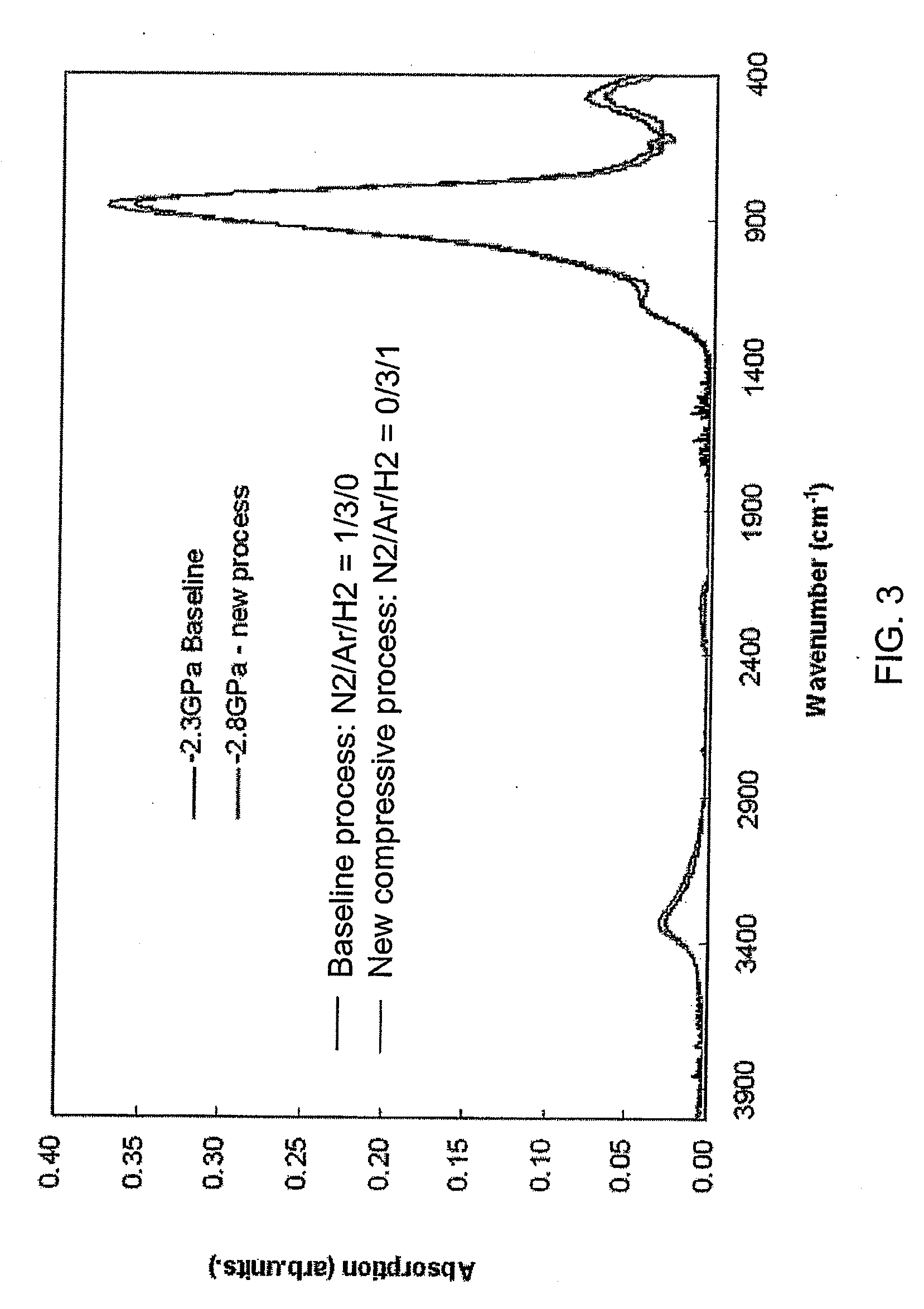

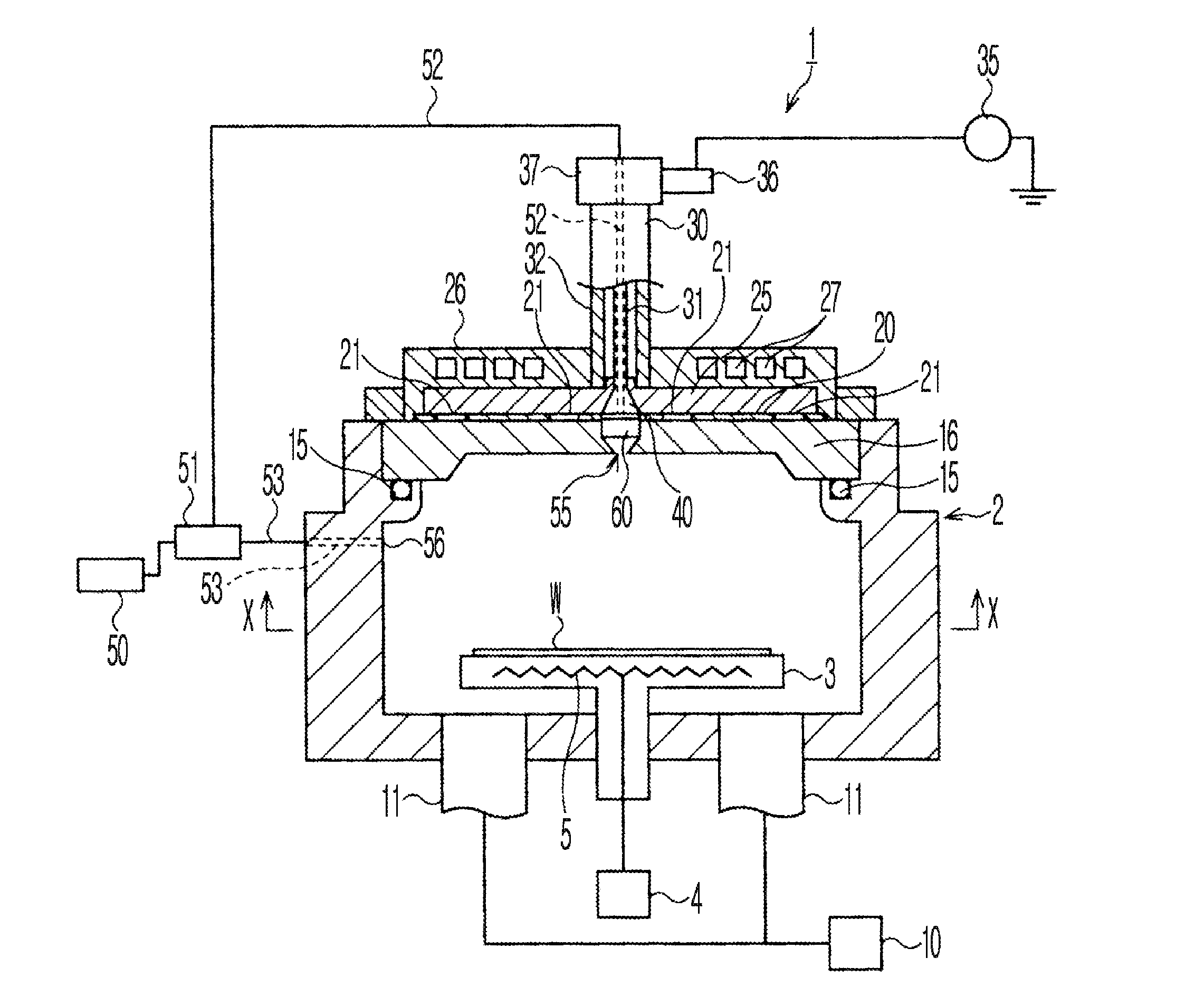

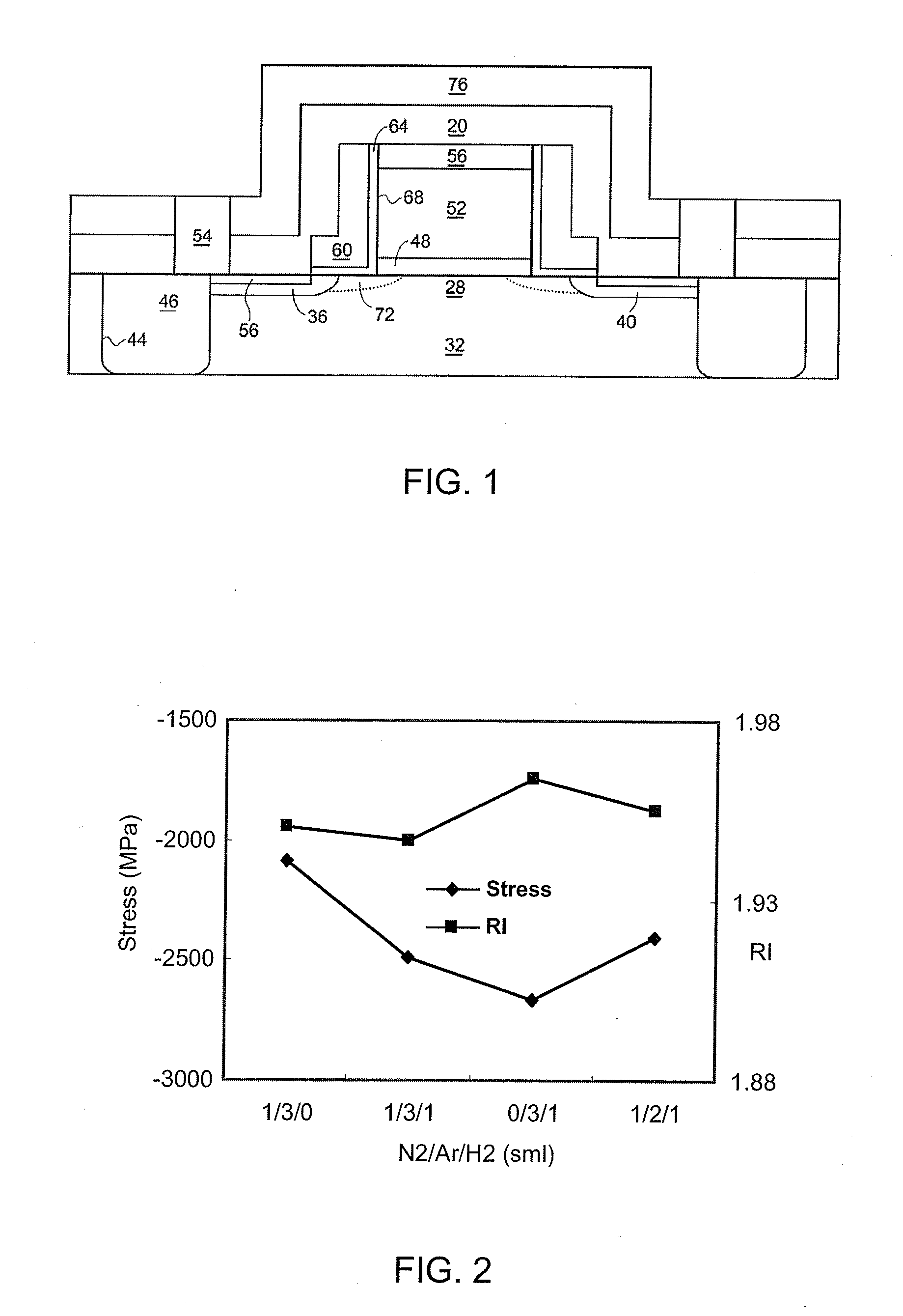

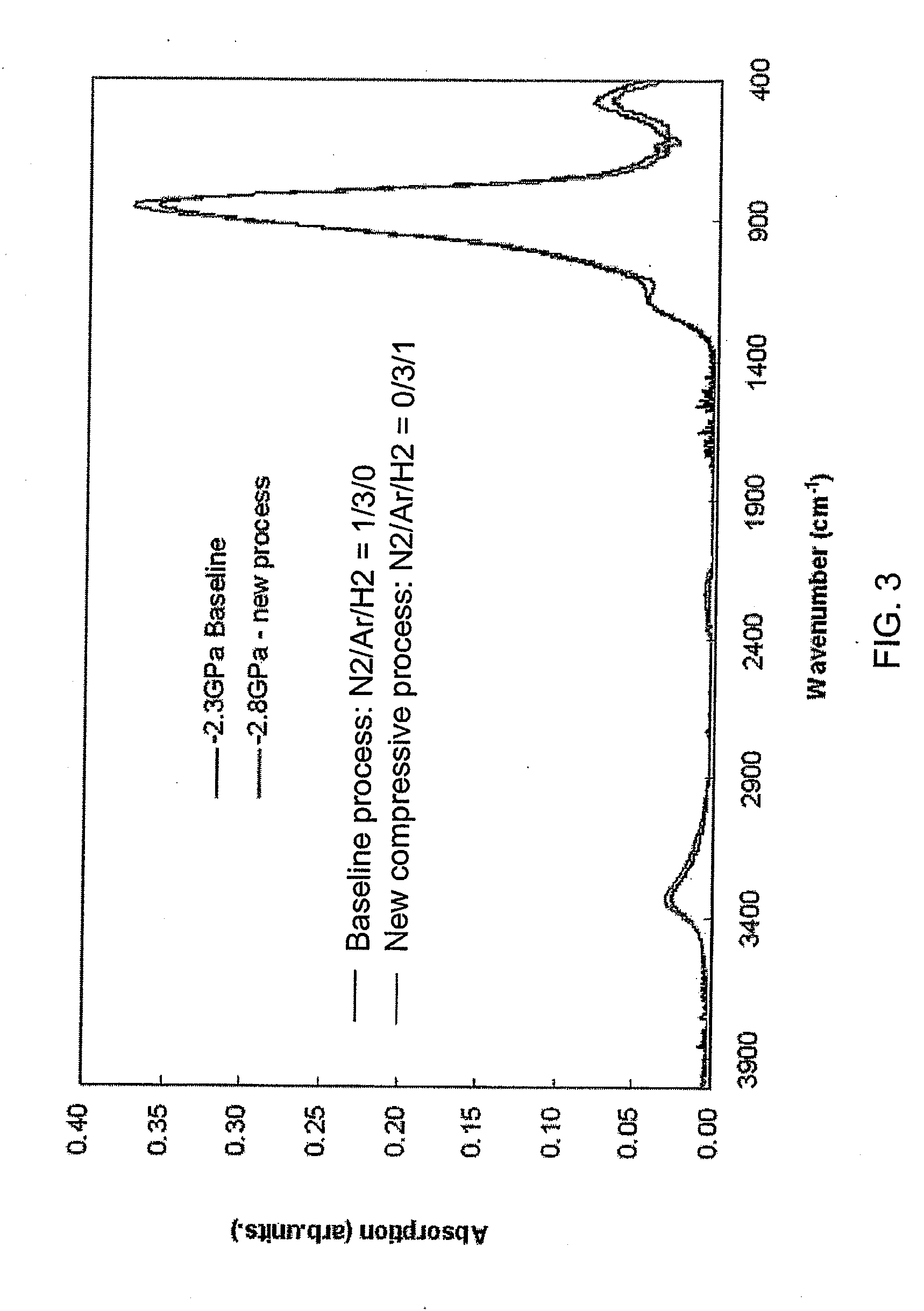

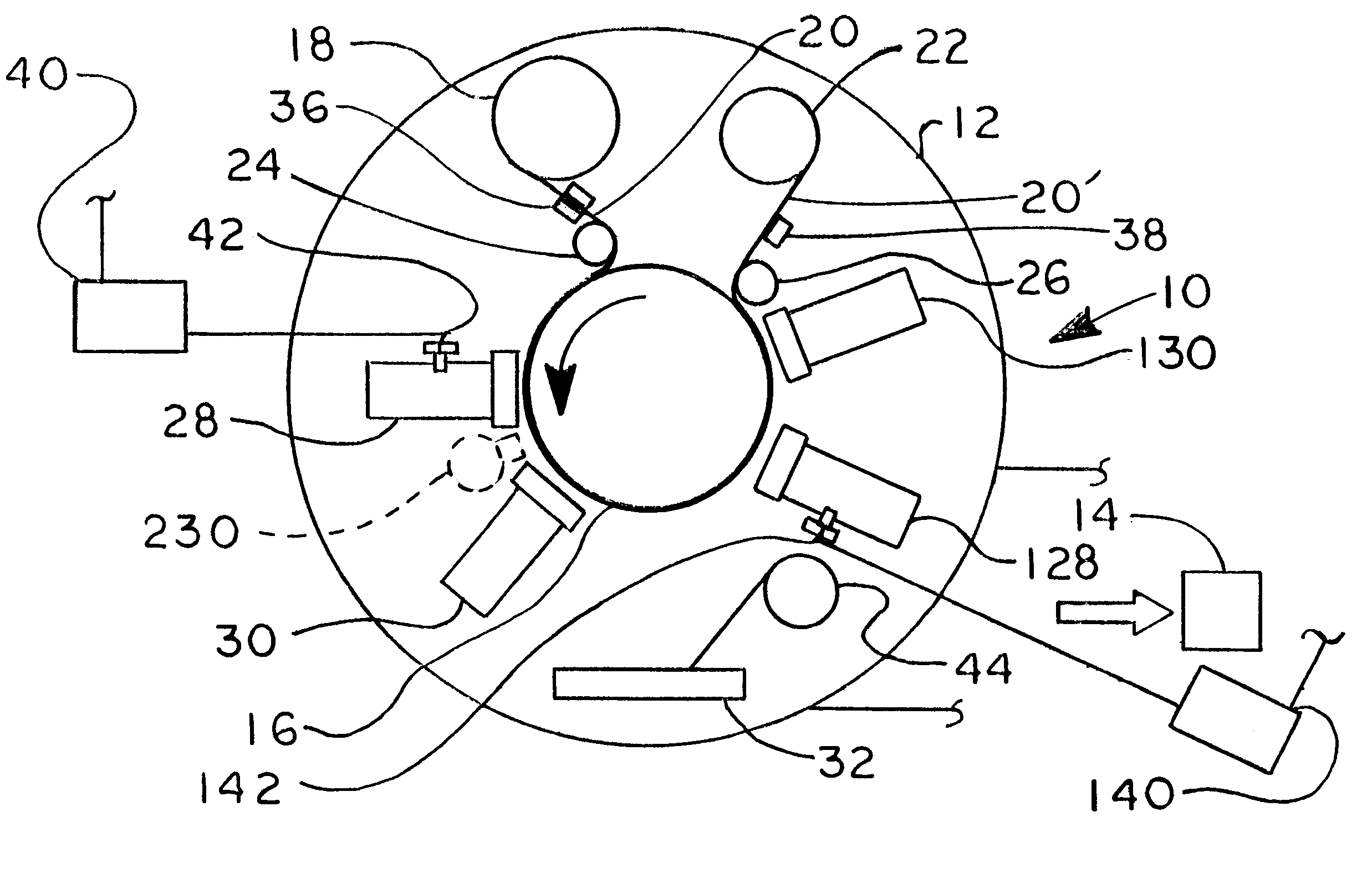

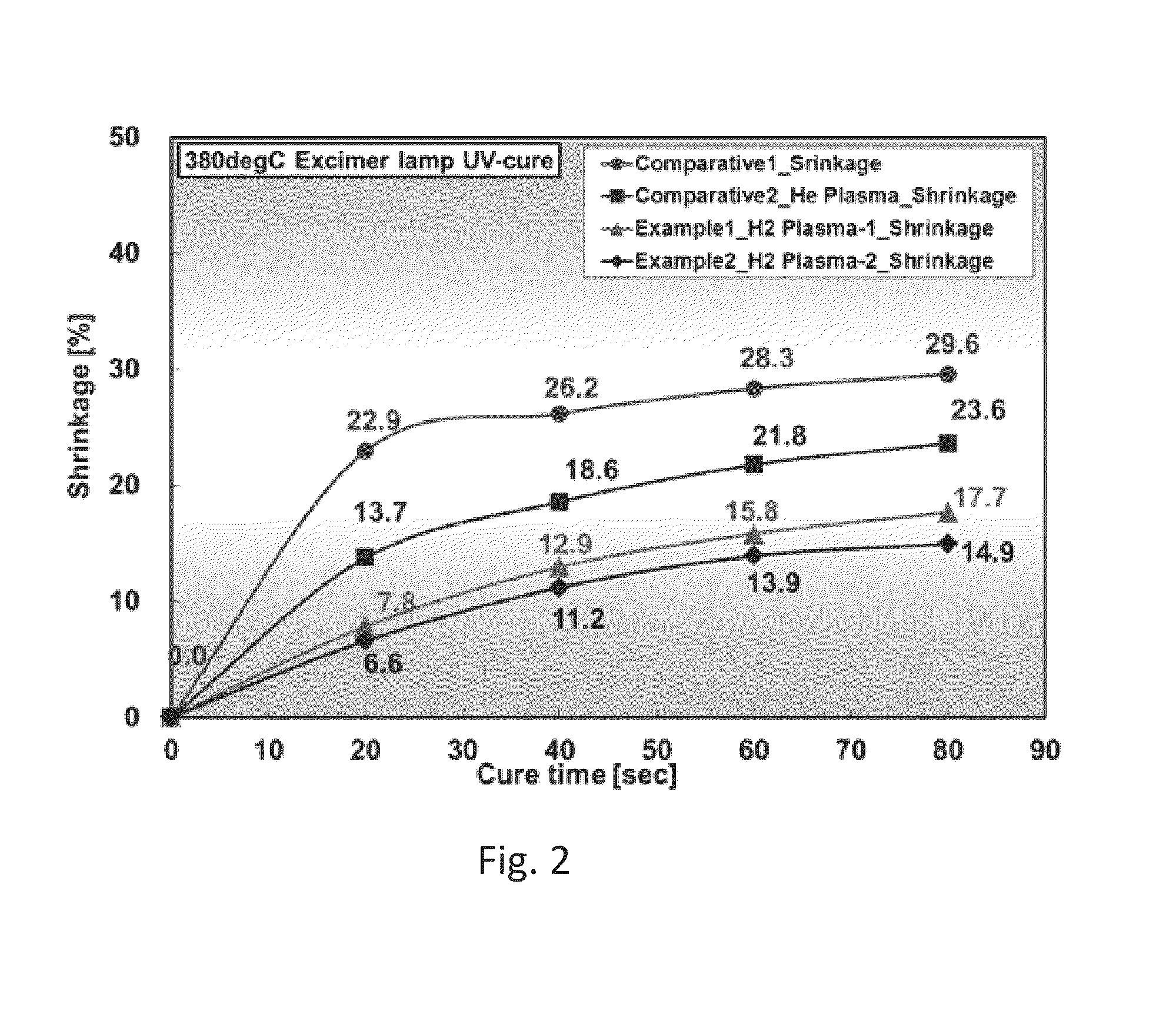

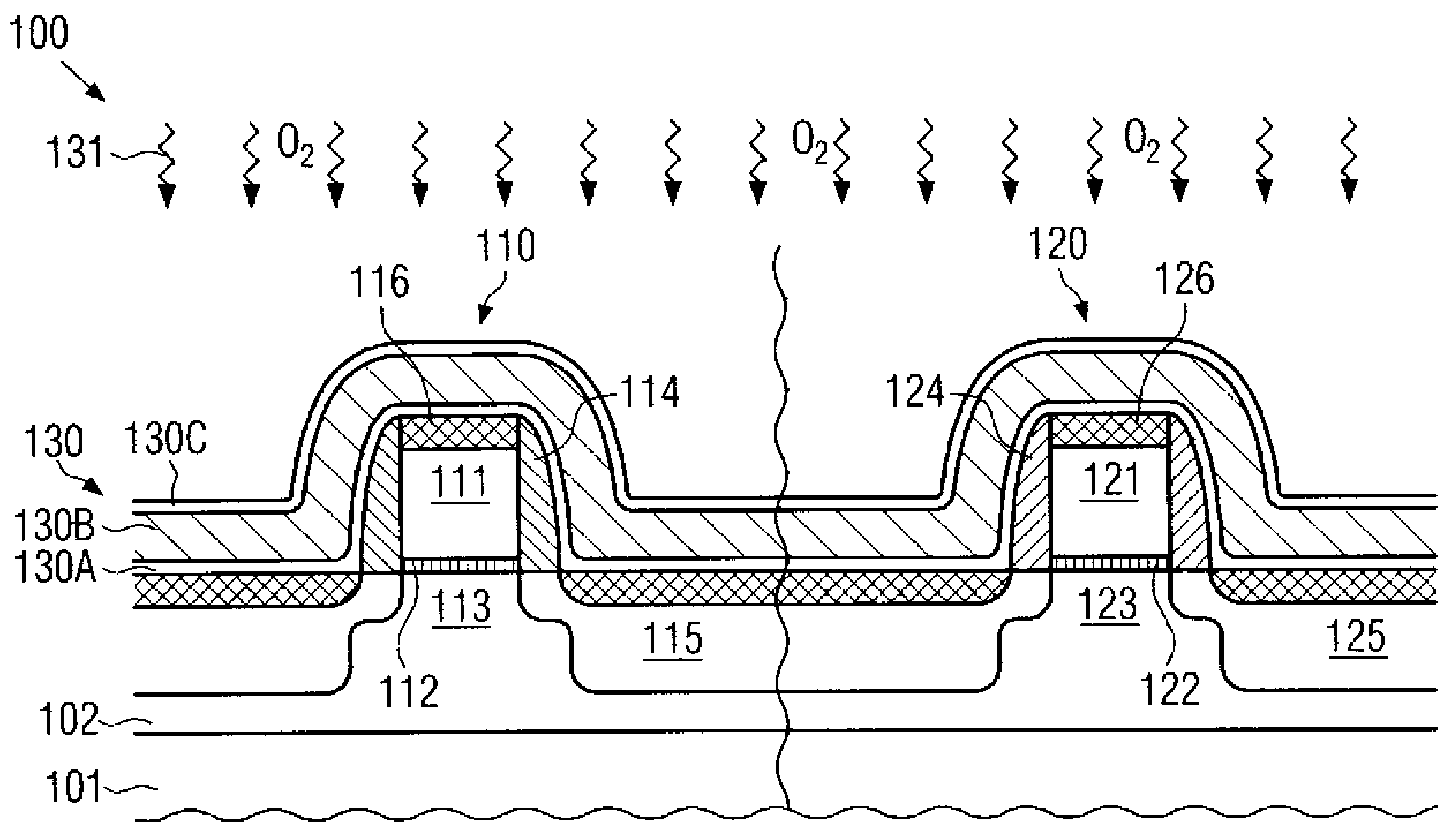

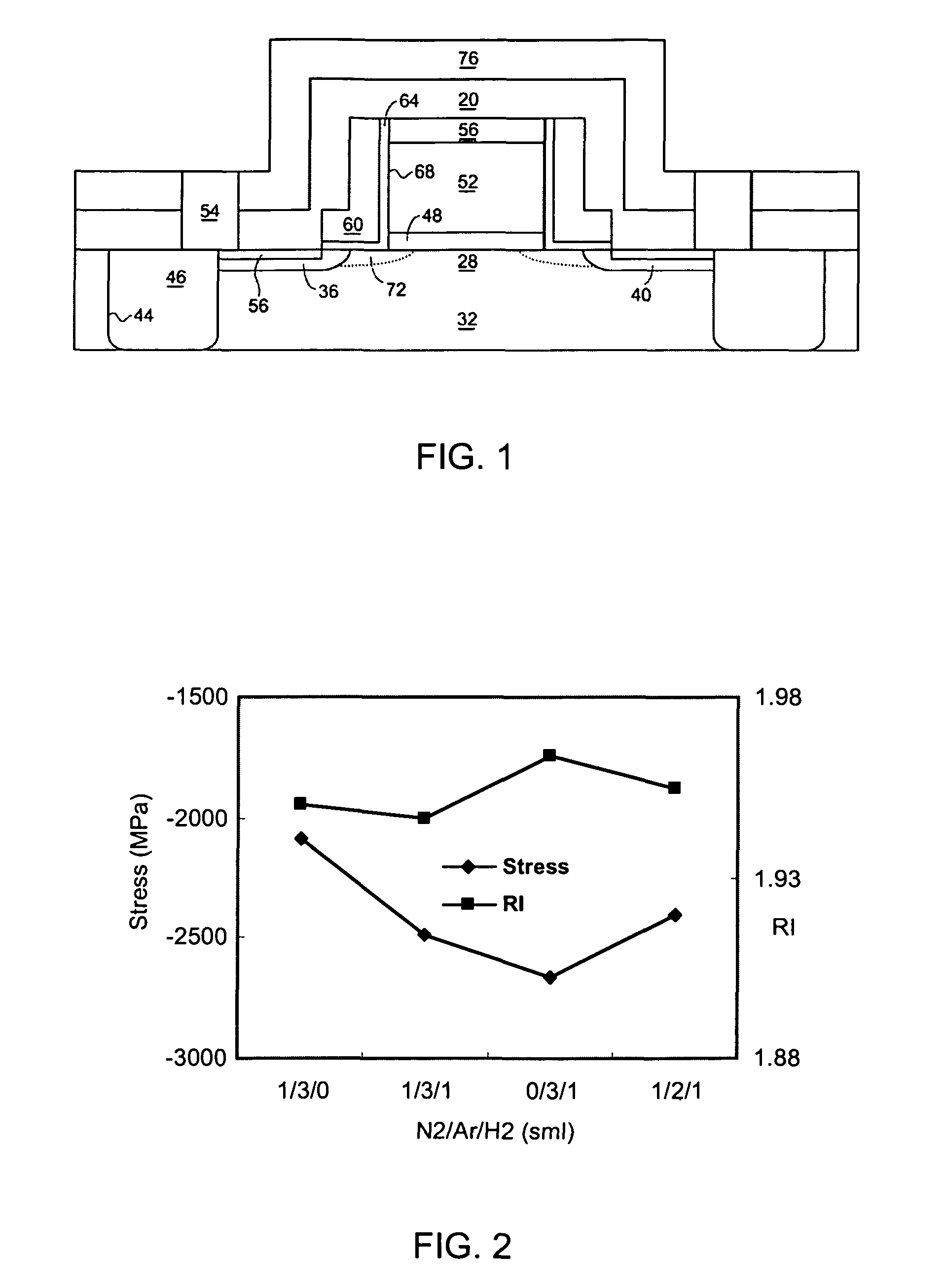

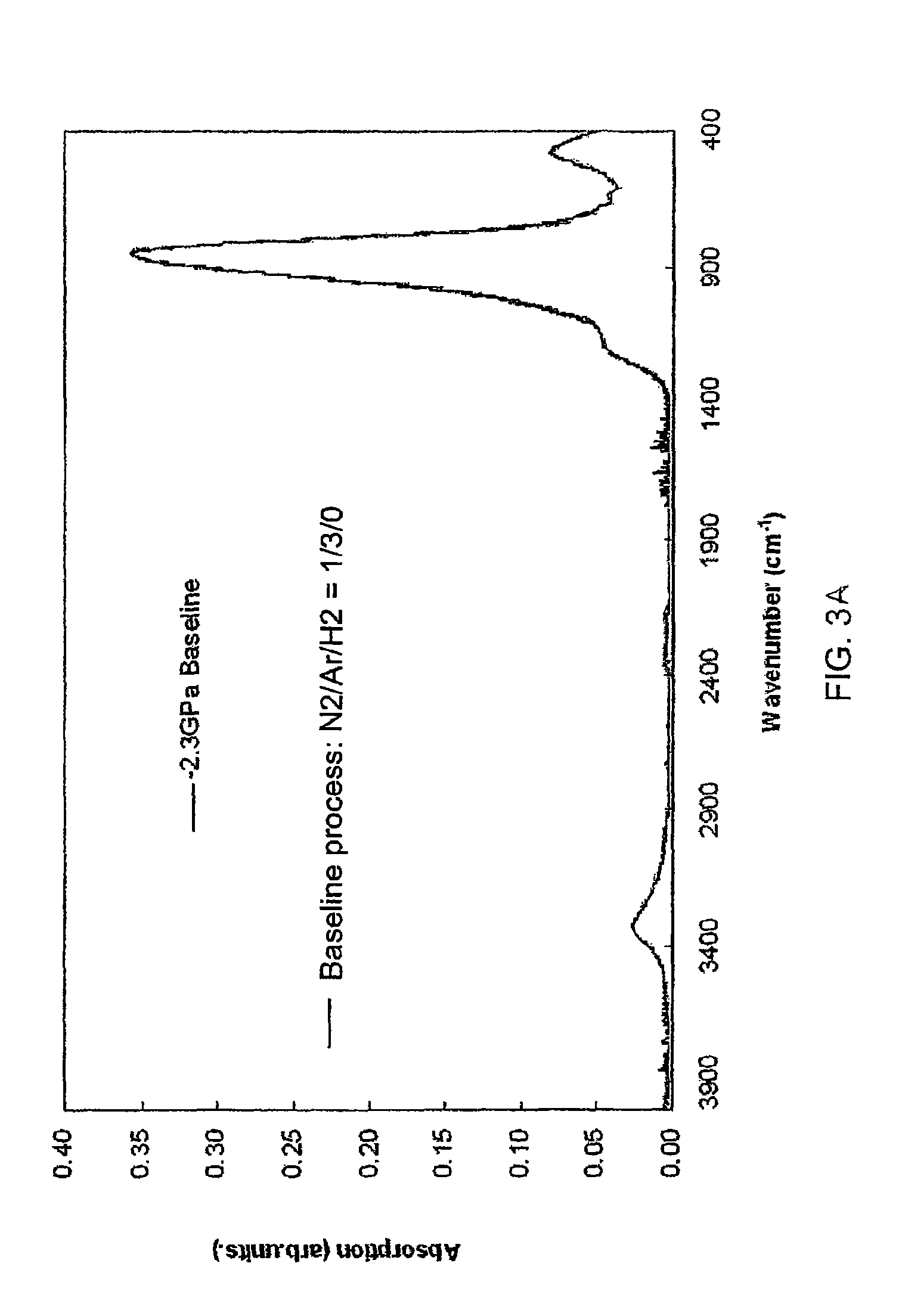

Method to increase silicon nitride tensile stress using nitrogen plasma in-situ treatment and ex-situ UV cure

ActiveUS20080020591A1Improve performanceFilm stress is increasedTransistorSemiconductor/solid-state device manufacturingNitrogen plasmaUV curing

Stress of a silicon nitride layer may be enhanced by deposition at higher temperatures. Employing an apparatus that allows heating of a substrate to substantially greater than 400° C. (for example a heater made from ceramic rather than aluminum), the silicon nitride film as-deposited may exhibit enhanced stress allowing for improved performance of the underlying MOS transistor device. In accordance with alternative embodiments, a deposited silicon nitride film is exposed to curing with ultraviolet (UV) radiation at an elevated temperature, thereby helping remove hydrogen from the film and increasing film stress. In accordance with still other embodiments, a silicon nitride film is formed utilizing an integrated process employing a number of deposition / curing cycles to preserve integrity of the film at the sharp corner of the underlying raised feature. Adhesion between successive layers may be promoted by inclusion of a post-UV cure plasma treatment in each cycle.

Owner:APPLIED MATERIALS INC

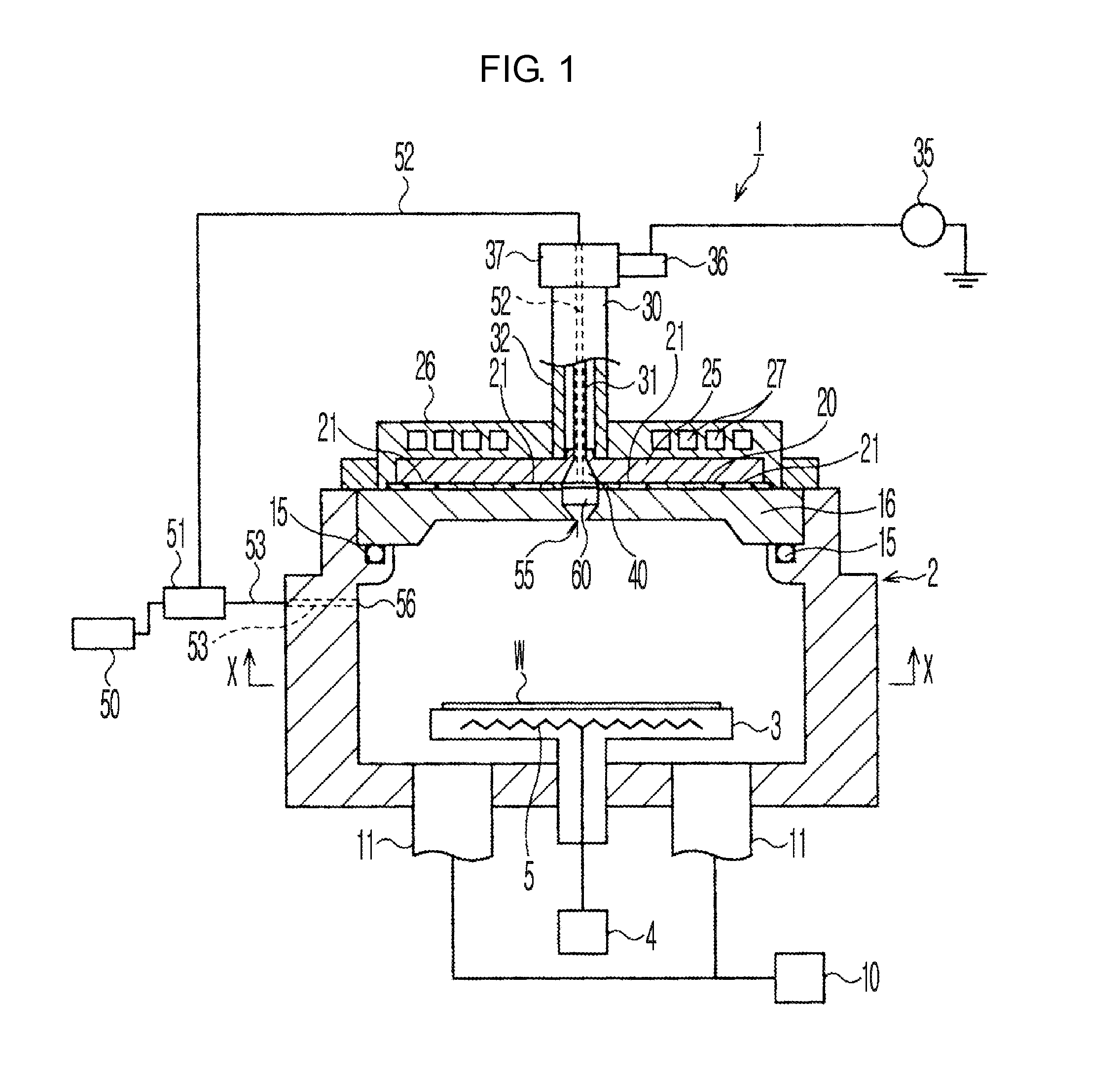

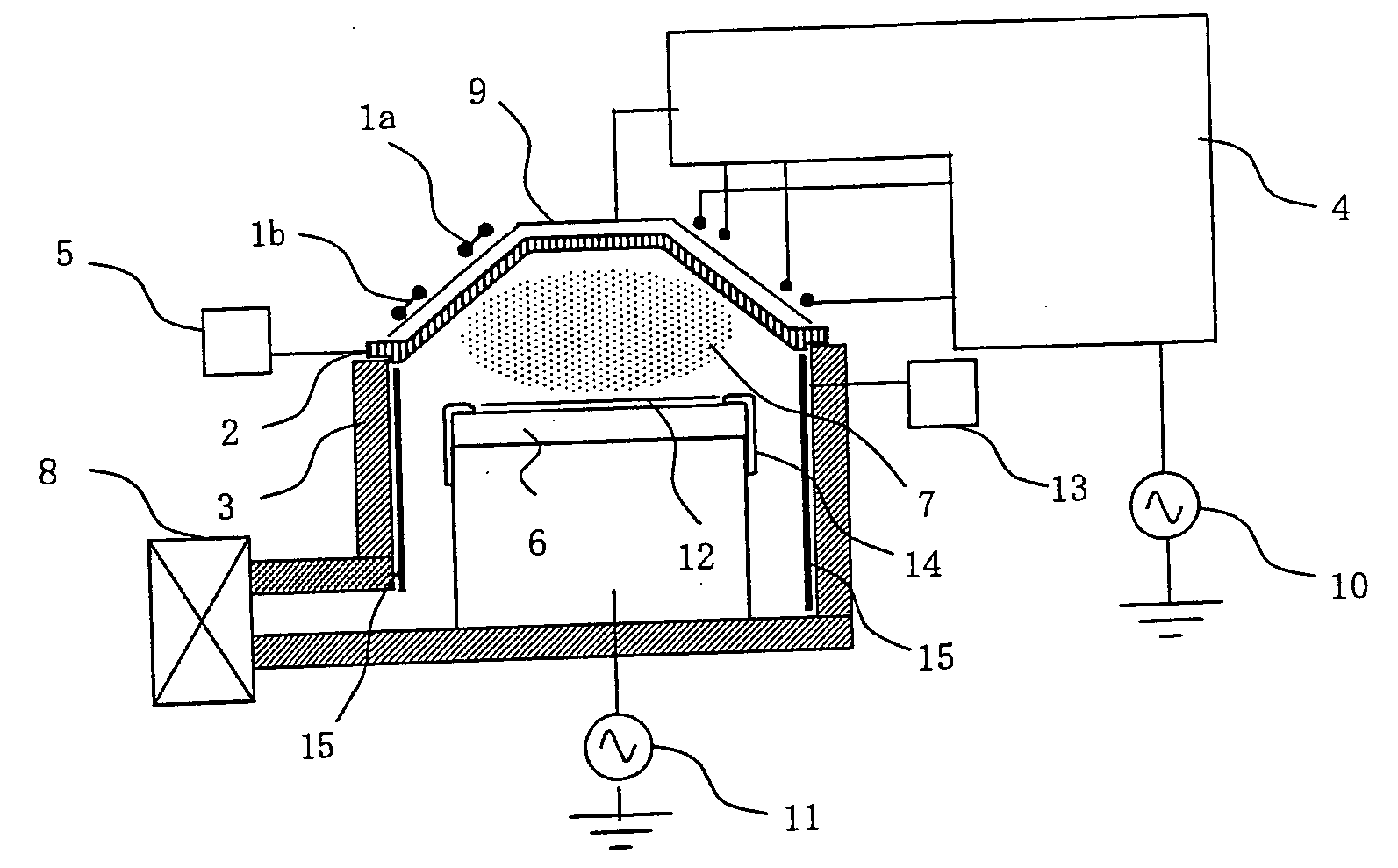

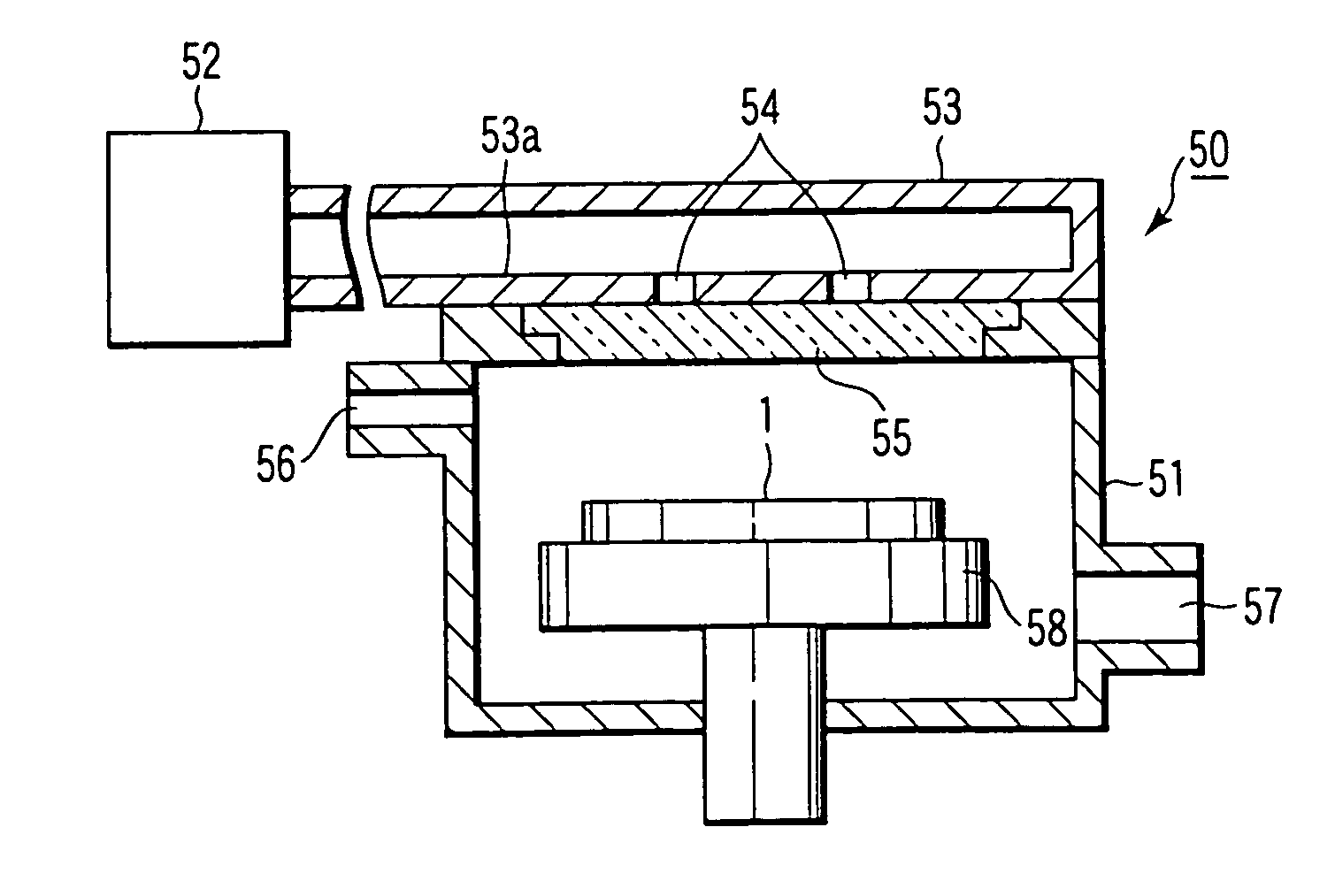

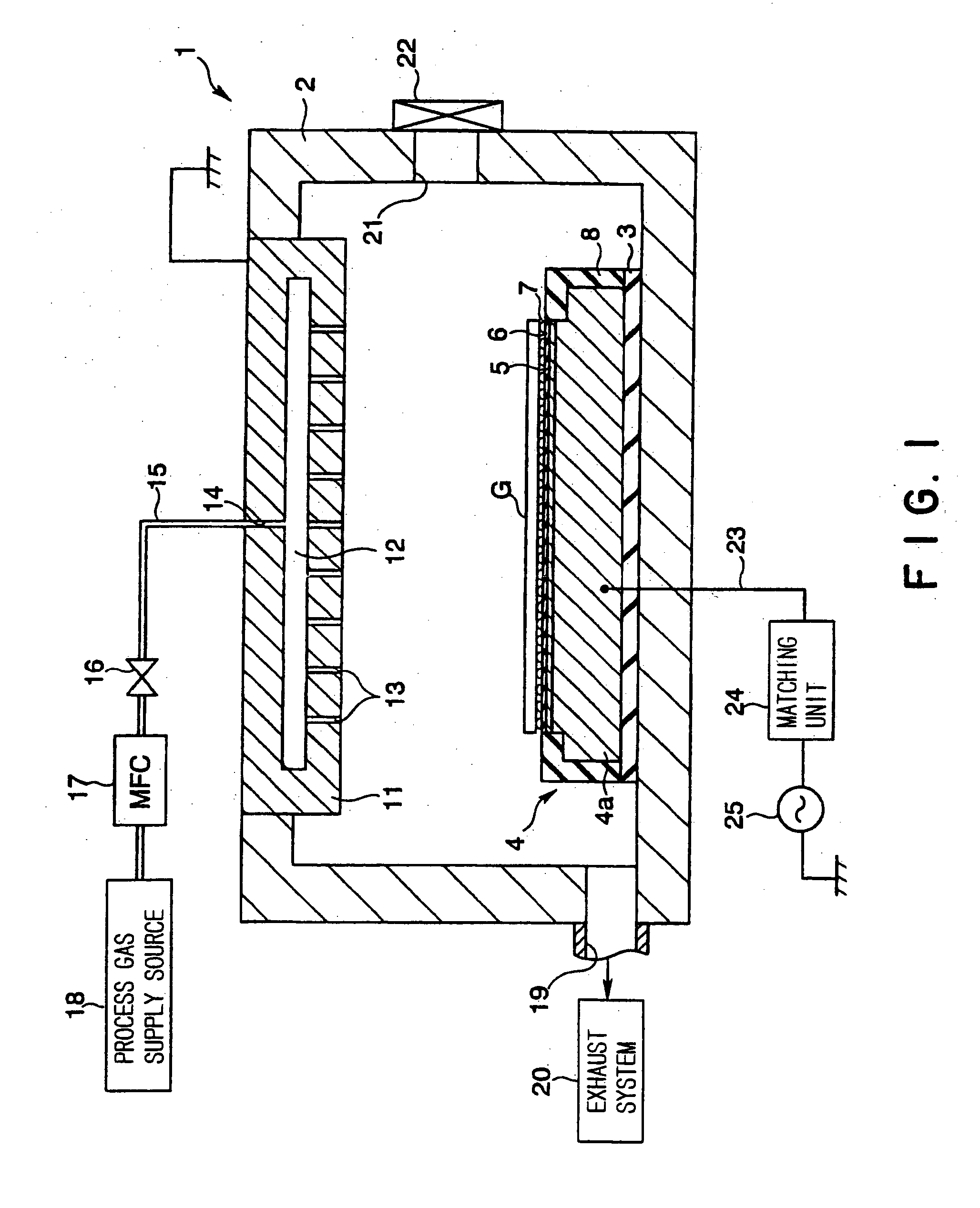

Plasma processing apparatus

ActiveUS20110048642A1Improve removabilityElectric discharge tubesSemiconductor/solid-state device manufacturingProcess engineeringGas retention

In a plasma processing apparatus for processing a substrate by plasmatizing a process gas introduced into a processing container, an introducing unit which introduces the process gas is formed on a ceiling surface of the processing container; a gas retention portion which gathers the process gas supplied from the outside of the processing container through a supply passage, and a plurality of gas ejection holes which allow communication between the gas retention portion and the inside of the processing container are formed in the introducing unit; a gas ejection hole is not formed in a location of the gas retention portion that faces an opening of the supply passage; and a cross section of each of the gas ejection holes has a flat shape.

Owner:TOKYO ELECTRON LTD

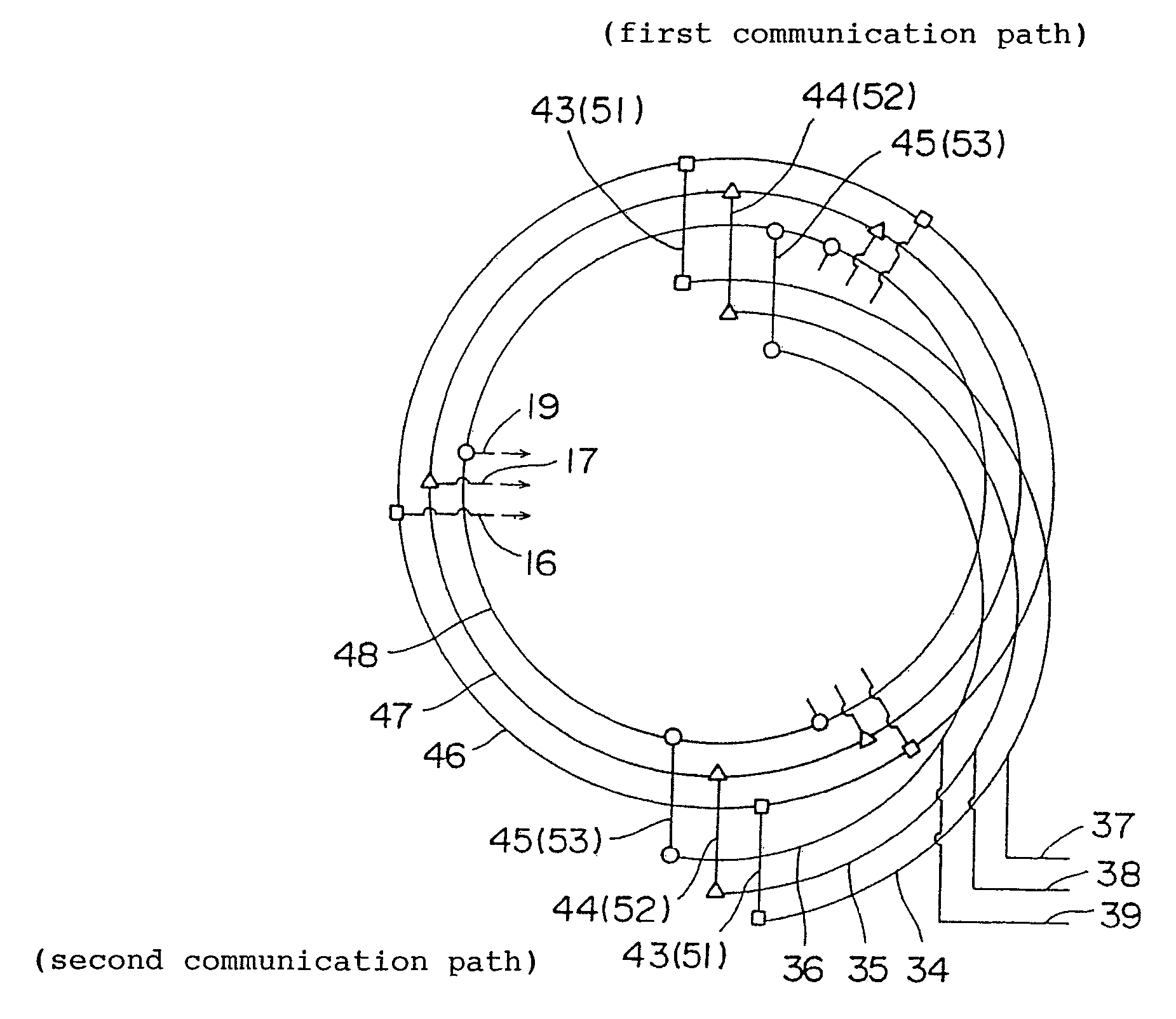

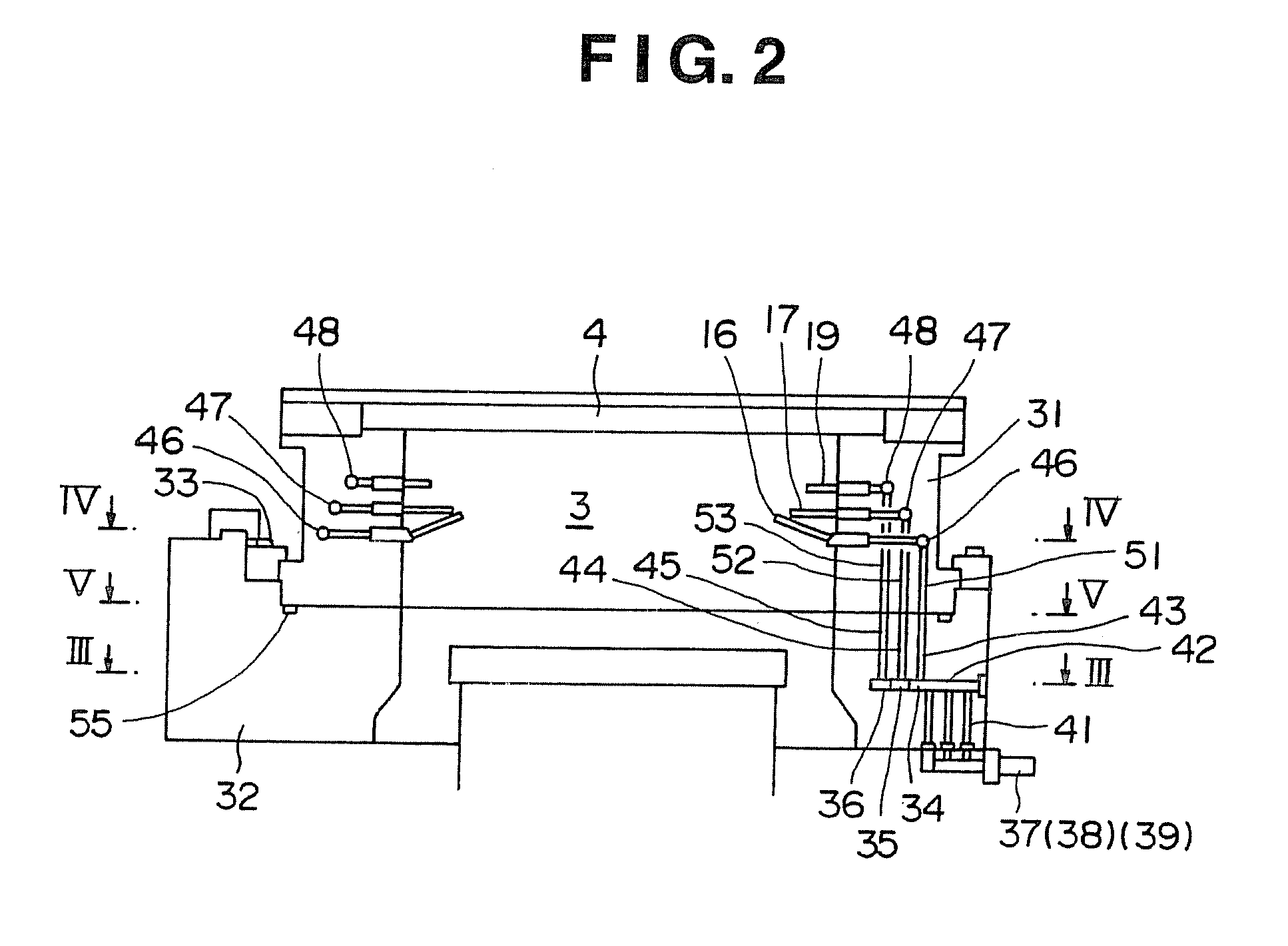

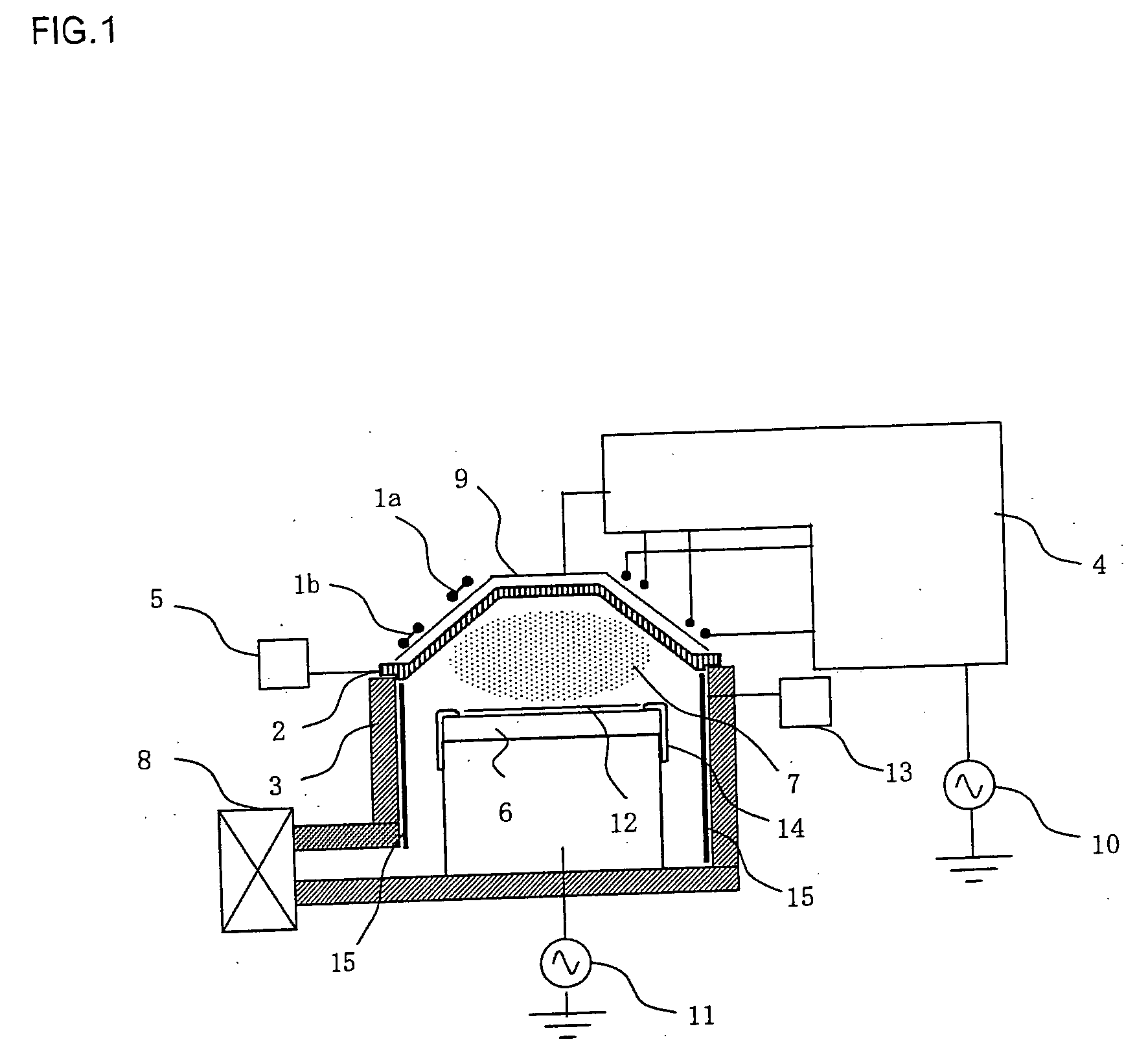

Plasma treatment apparatus

InactiveUS7806078B2Simply the configuration of the containerContainer can be simplifiedElectric discharge tubesSemiconductor/solid-state device manufacturingProduct gasEngineering

A plasma CVD apparatus has a container, and channels composed of introduction grooves and circumferential grooves for different types of gases are formed within the container. The gases introduced through source gas piping, auxiliary gas piping, and cleaning gas piping are equally supplied to a plurality of supply nozzles, a plurality of auxiliary gas supply nozzles, and a plurality of cleaning gas nozzles. The configuration of the container can be simplified without complicating pipings for the gases.

Owner:MITSUBISHI HEAVY IND LTD

Method to increase silicon nitride tensile stress using nitrogen plasma in-situ treatment and ex-situ UV cure

InactiveUS20120196450A1Increase pressureImprove performanceTransistorSemiconductor/solid-state device manufacturingNitrogen plasmaHydrogen

Stress of a silicon nitride layer may be enhanced by deposition at higher temperatures. Employing an apparatus that allows heating of a substrate to substantially greater than 400° C. (for example a heater made from ceramic rather than aluminum), the silicon nitride film as-deposited may exhibit enhanced stress allowing for improved performance of the underlying MOS transistor device. In accordance with some embodiments, a deposited silicon nitride film is exposed to curing with plasma and ultraviolet (UV) radiation, thereby helping remove hydrogen from the film and increasing film stress. In accordance with other embodiments, a silicon nitride film is formed utilizing an integrated process employing a number of deposition / curing cycles to preserve integrity of the film at the sharp corner of the underlying raised feature. Adhesion between successive layers may be promoted by inclusion of a post-UV cure plasma treatment in each cycle.

Owner:APPLIED MATERIALS INC

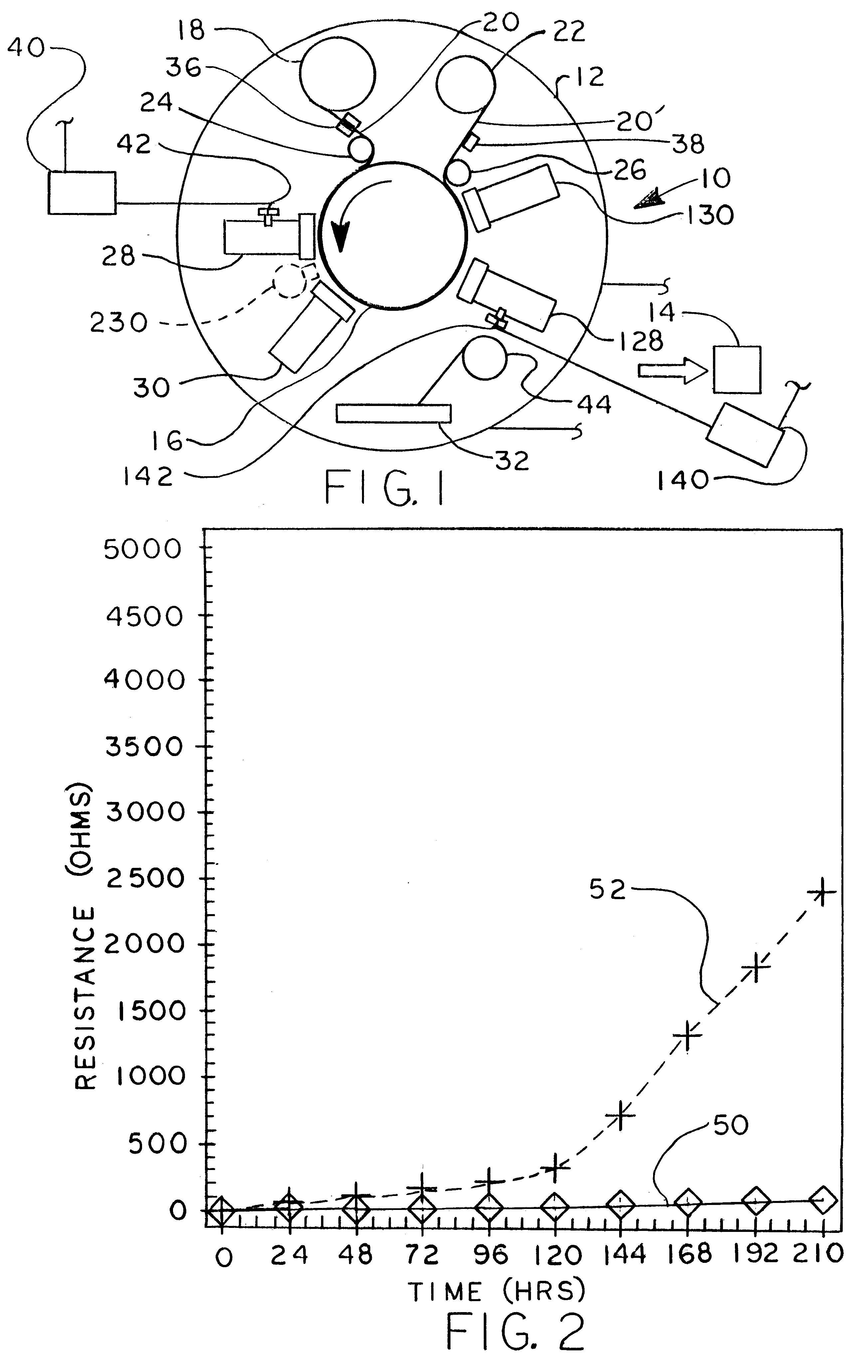

Method of forming a hybrid polymer film

InactiveUS6214422B1Fine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-liked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

Plasma pre-treating surfaces for atomic layer deposition

ActiveUS7498242B2Improve barrier propertiesSemiconductor/solid-state device detailsVacuum evaporation coatingSelf limitingAtomic layer deposition

Owner:ASM IP HLDG BV

Method of cleaning etching apparatus

ActiveUS20060191555A1Clean interiorMaintain repeatabilityHollow article cleaningElectrostatic cleaningBoron trichlorideOxygen

To provide a cleaning method for an etching apparatus for a metal film that efficiently removes an etching residue deposited in an etching process chamber, assures the reproducibility of the etching performance, and keeps the etching process chamber in a low-dust-emission condition. Each time one workpiece with a metal film is etched (S1), the interior of the vacuum chamber is cleaned by replacing the workpiece with a dummy substrate (S2), performing a first step of plasma processing using oxygen (O2) and carbon tetrafluoride (CF4) to remove a carbon-based deposit pile (S3), and performing a second step of plasma processing using boron trichloride (BCl3) and chlorine (Cl2) to remove a residue that could not be removed by the first step and an etching residue of the metal film (S4).

Owner:HITACHI HIGH-TECH CORP

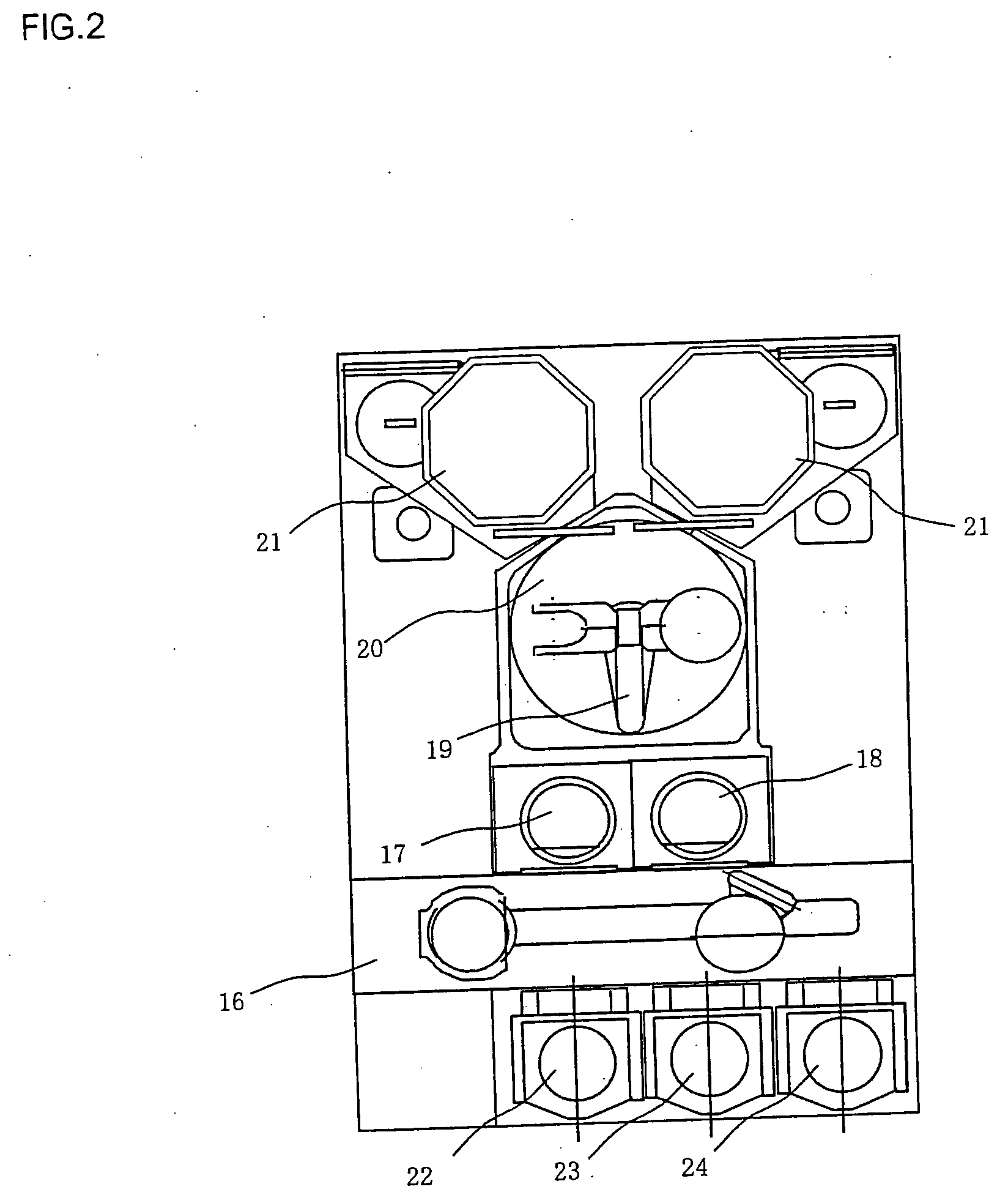

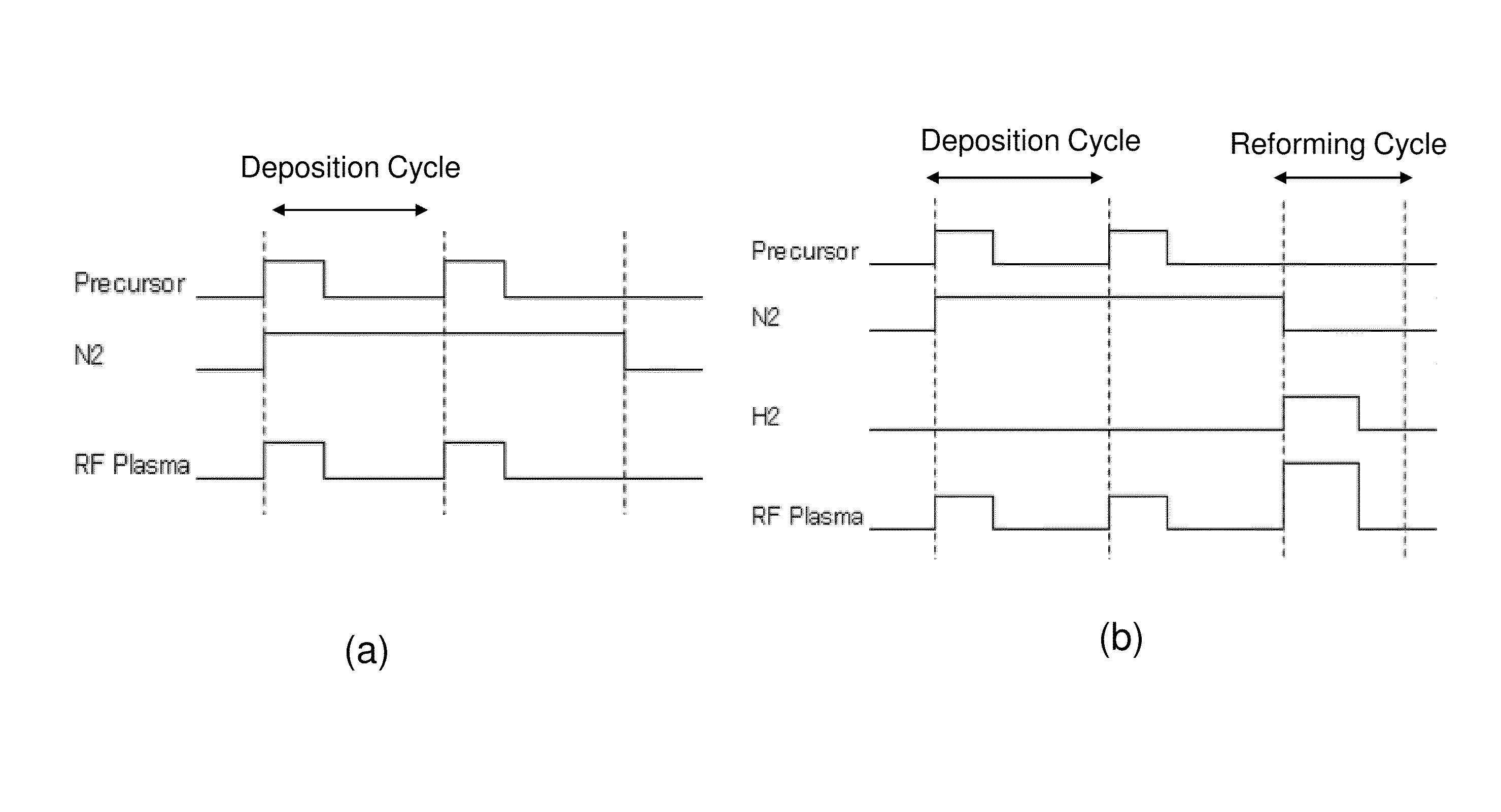

Method of forming insulation film using plasma treatment cycles

ActiveUS8647722B2Improve film qualityIncrease coverageChemical vapor deposition coatingPlasma techniqueEngineeringMono layer

A film forming cycle based on pulse CVD or ALD is repeated multiple times to form a single layer of insulation film, while a reforming cycle is implemented in the aforementioned process, either once or multiple times per each film forming cycle, by treating the surface of formed film using a treating gas that has been activated by a plasma.

Owner:ASM JAPAN

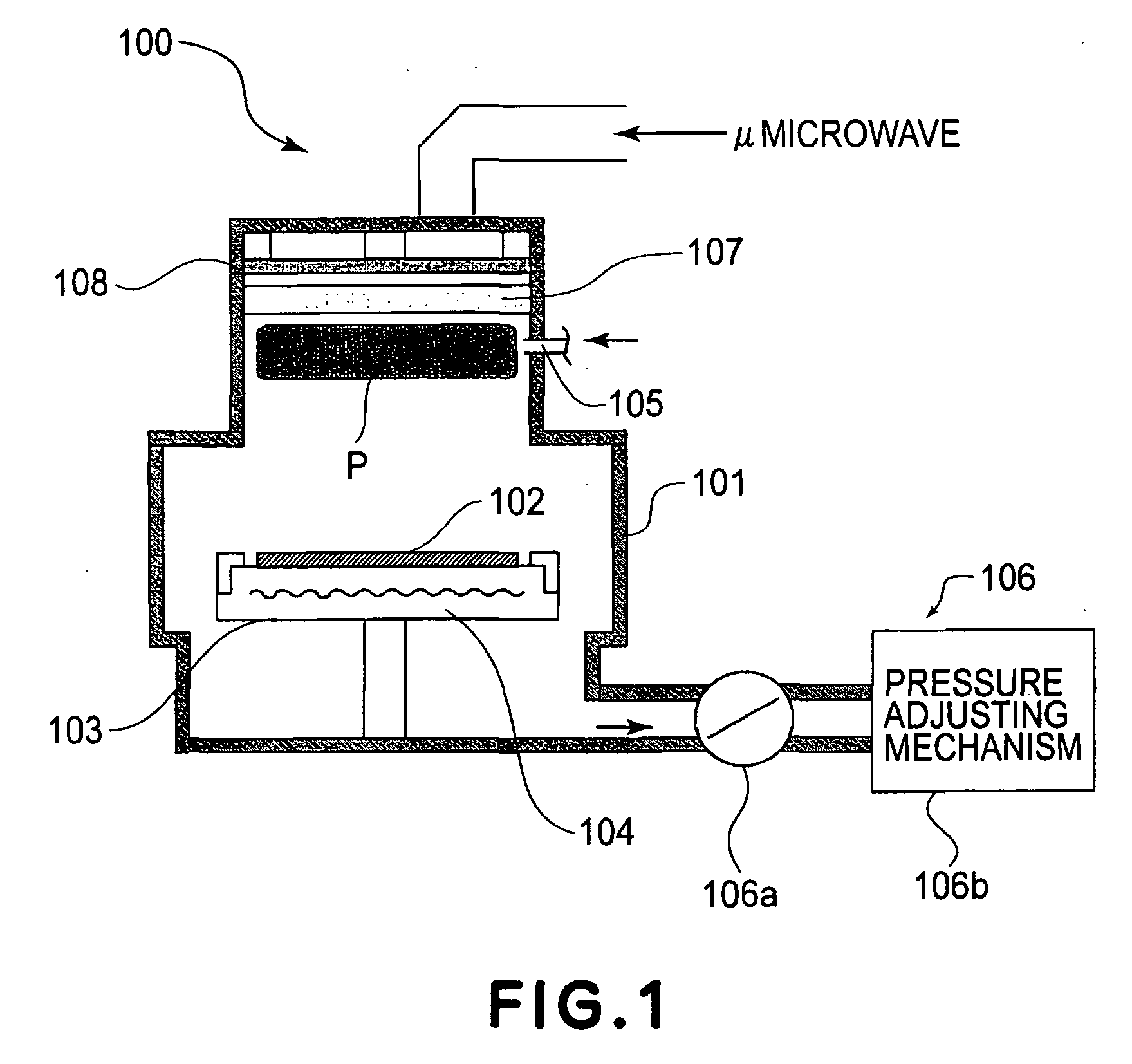

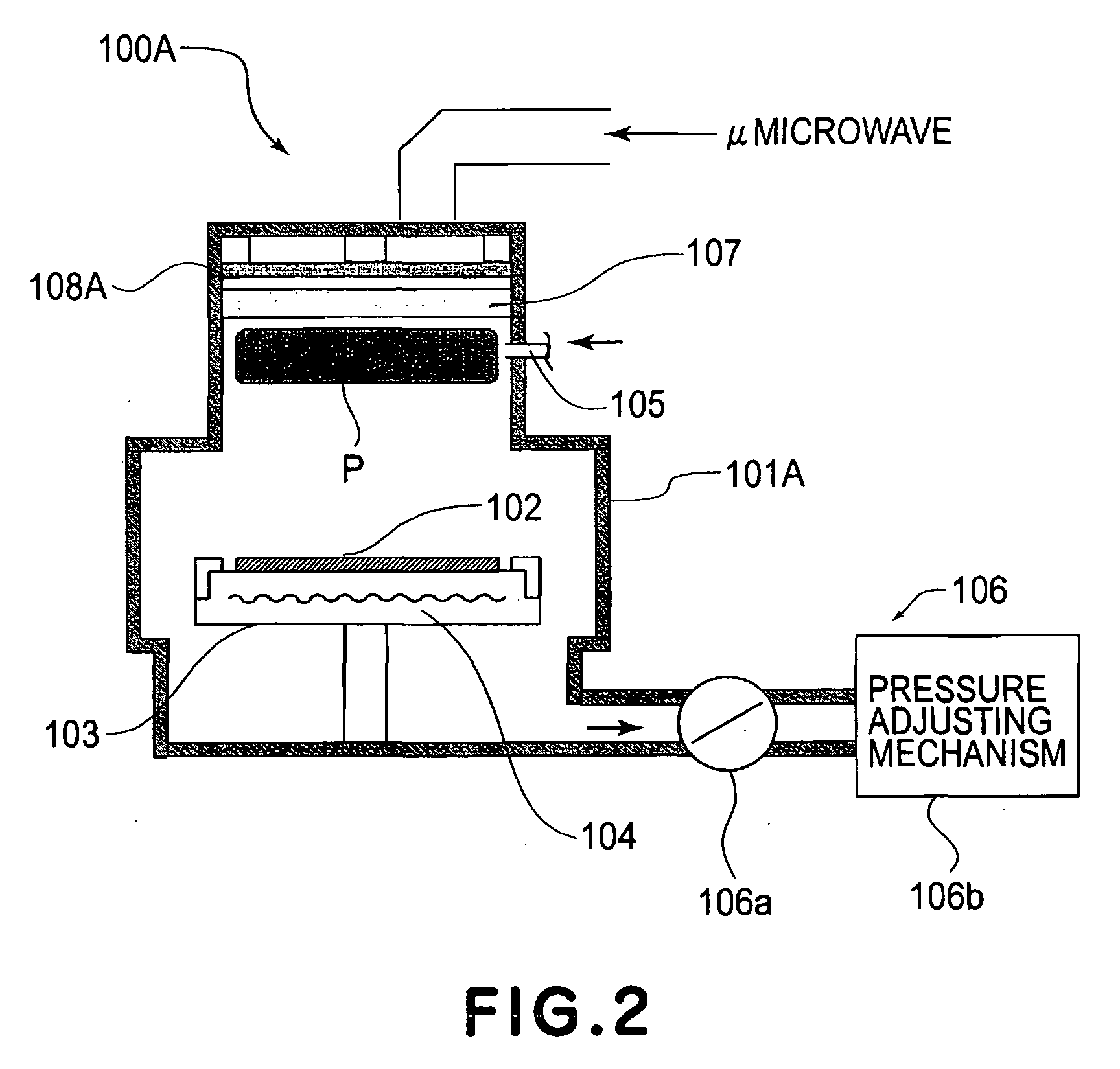

Method and apparatus for forming insulating film

InactiveUS20060110934A1Improve reliabilityImprove insulation performanceElectric discharge tubesSemiconductor/solid-state device manufacturingHydrogenHydrogen atom

The present invention provides a method and apparatus for forming an insulating film having good reliability, in accordance with a process without high-temperature heating. In accordance with the present invention, in a process for forming an insulating film for a semiconductor device by oxidizing a material to be processed, exposed at the surface of a substrate to be processed, in accordance with plasma oxidation method, the plasma processing is carried out by use of at least a gas that contains hydrogen atoms other than H2 and H2O and a gas that contains oxygen atoms other than H2O.

Owner:CANON KK

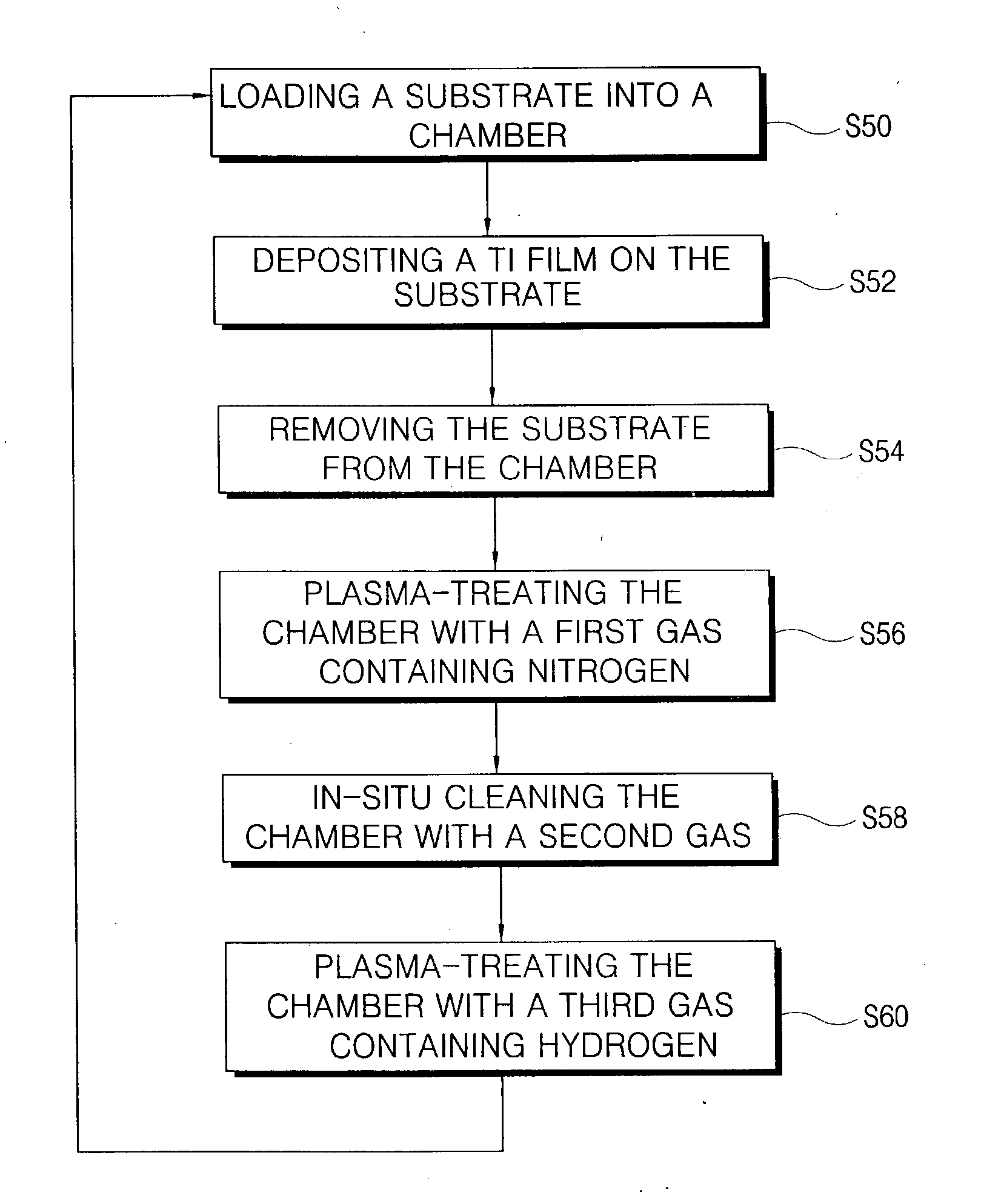

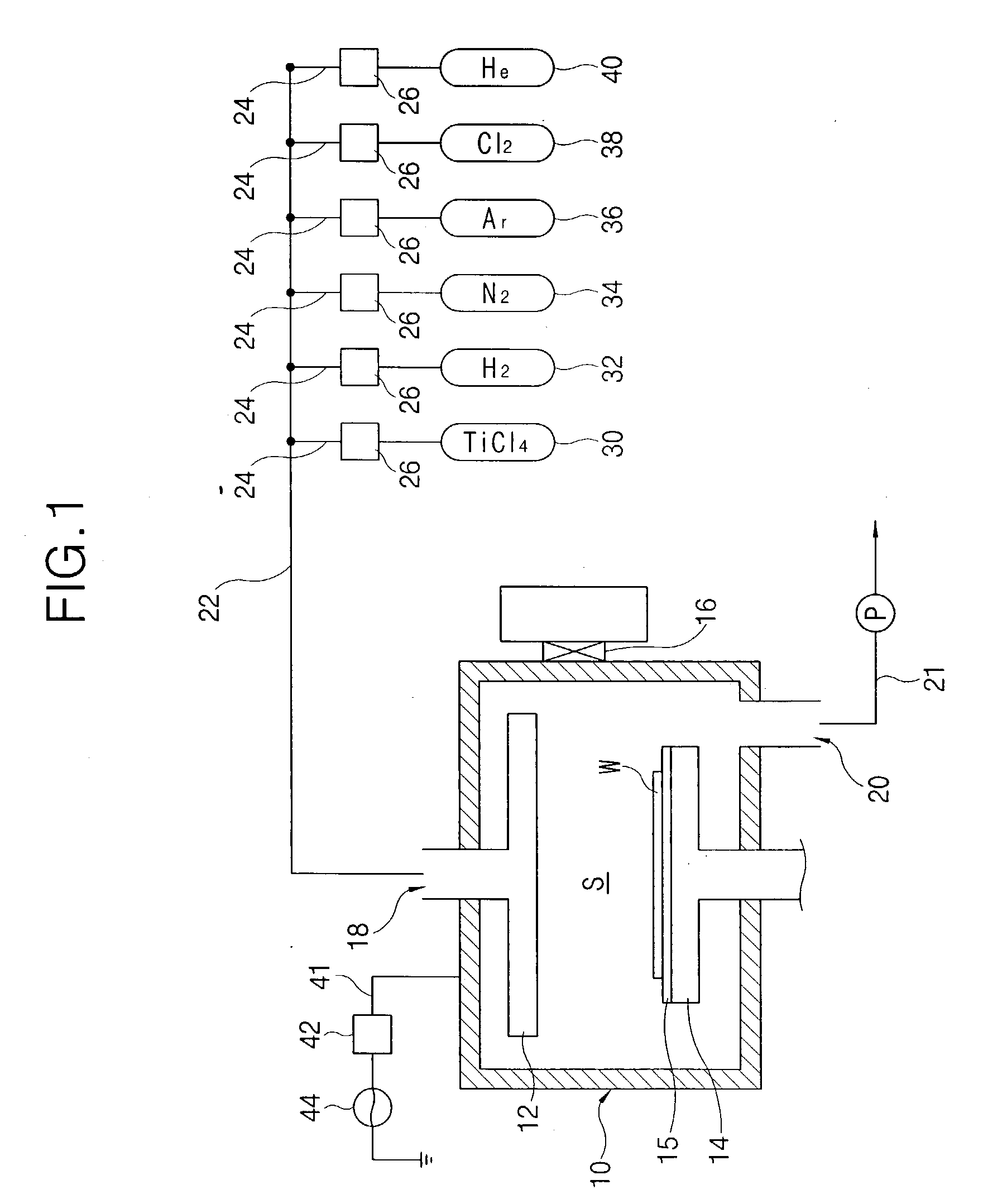

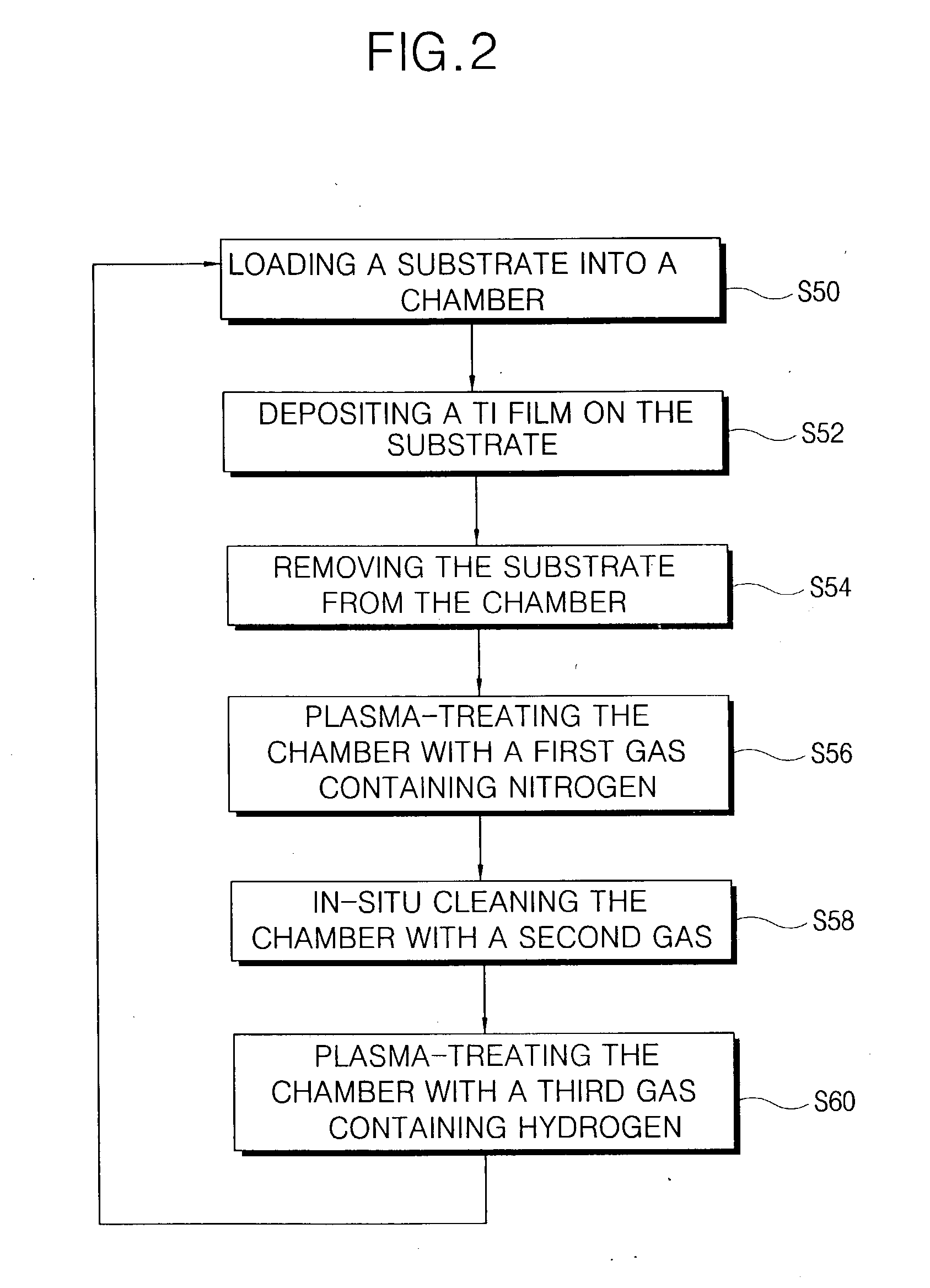

Method of cleaning a chemical vapor deposition chamber

InactiveUS20040013818A1Reduce the amount requiredIncrease resistanceHollow article cleaningElectrostatic cleaningHydrogenNitrogen

After a processing chamber is used to deposit a refractory metal film on a substrate, the chamber is plasma-treated with a gas including either nitrogen and / or hydrogen and in-situ cleaned. By plasma-treating the chamber with a gas including nitrogen, the refractory metal film that forms on interior surfaces of the chamber during substrate processing is nitrided. The nitrided refractory metal film can be removed from the chamber during the in-situ cleaning. By plasma-treating the chamber with a gas including hydrogen, reaction by-products generated in the chamber is diluted and removed. The chamber may be plasma-treated in a gas ambient including both nitrogen and hydrogen. Also, the plasma treatment may be performed before and after the in-situ cleaning.

Owner:SAMSUNG ELECTRONICS CO LTD

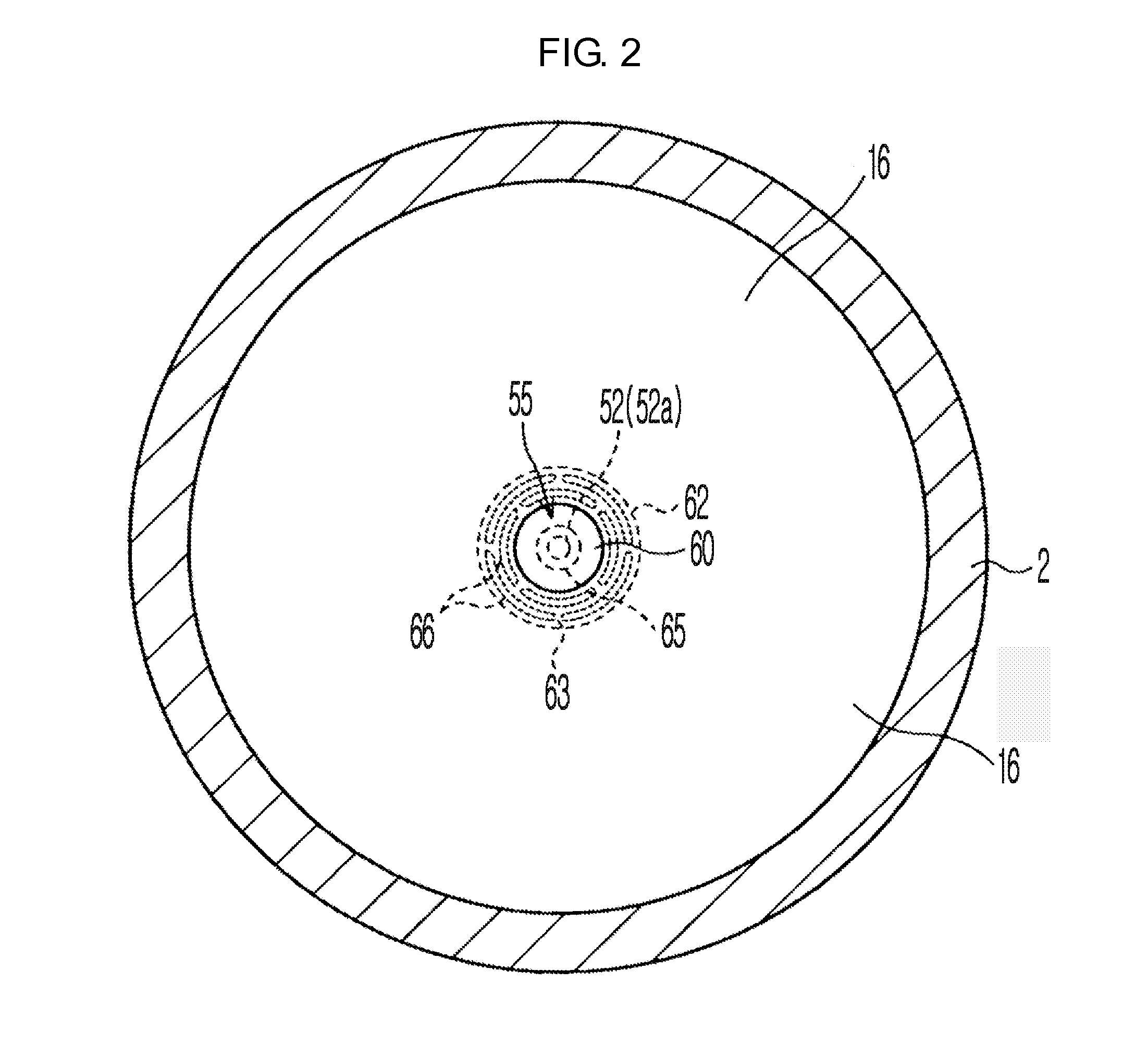

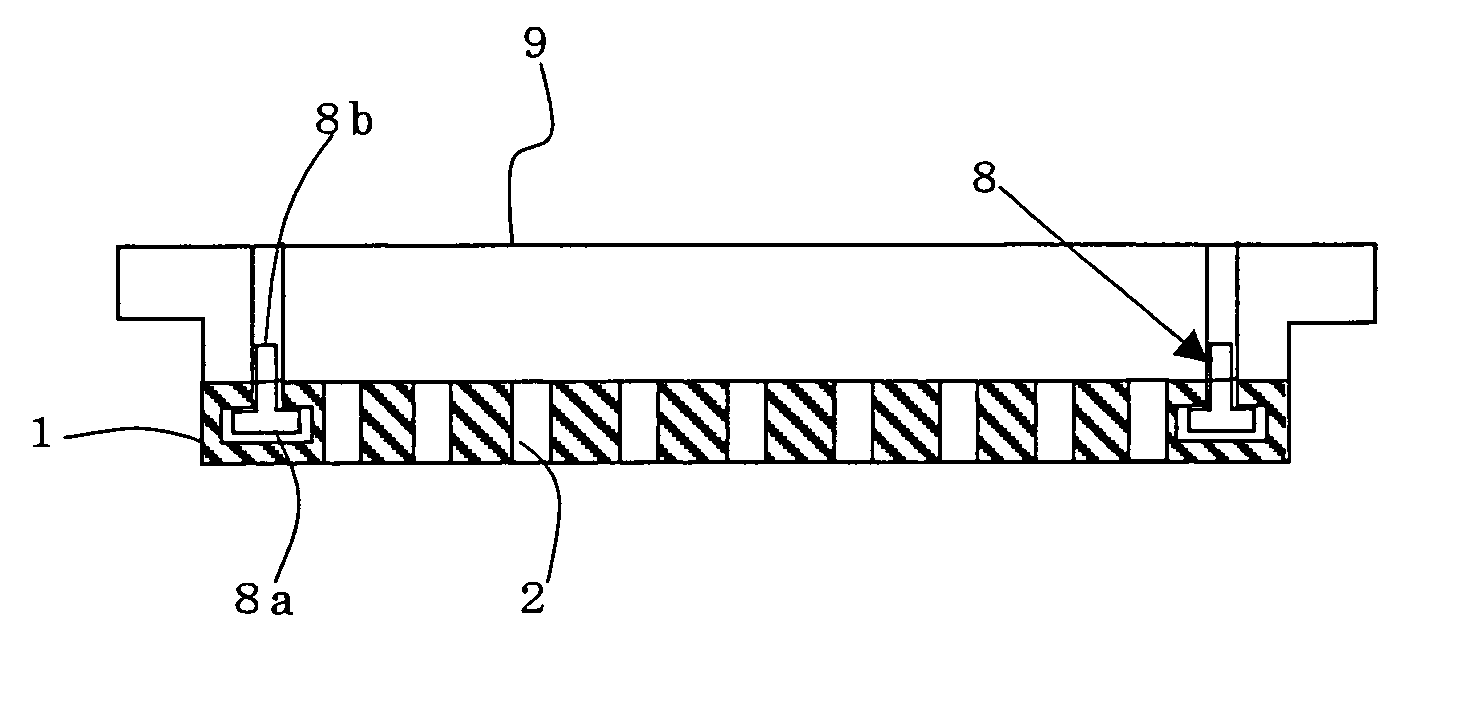

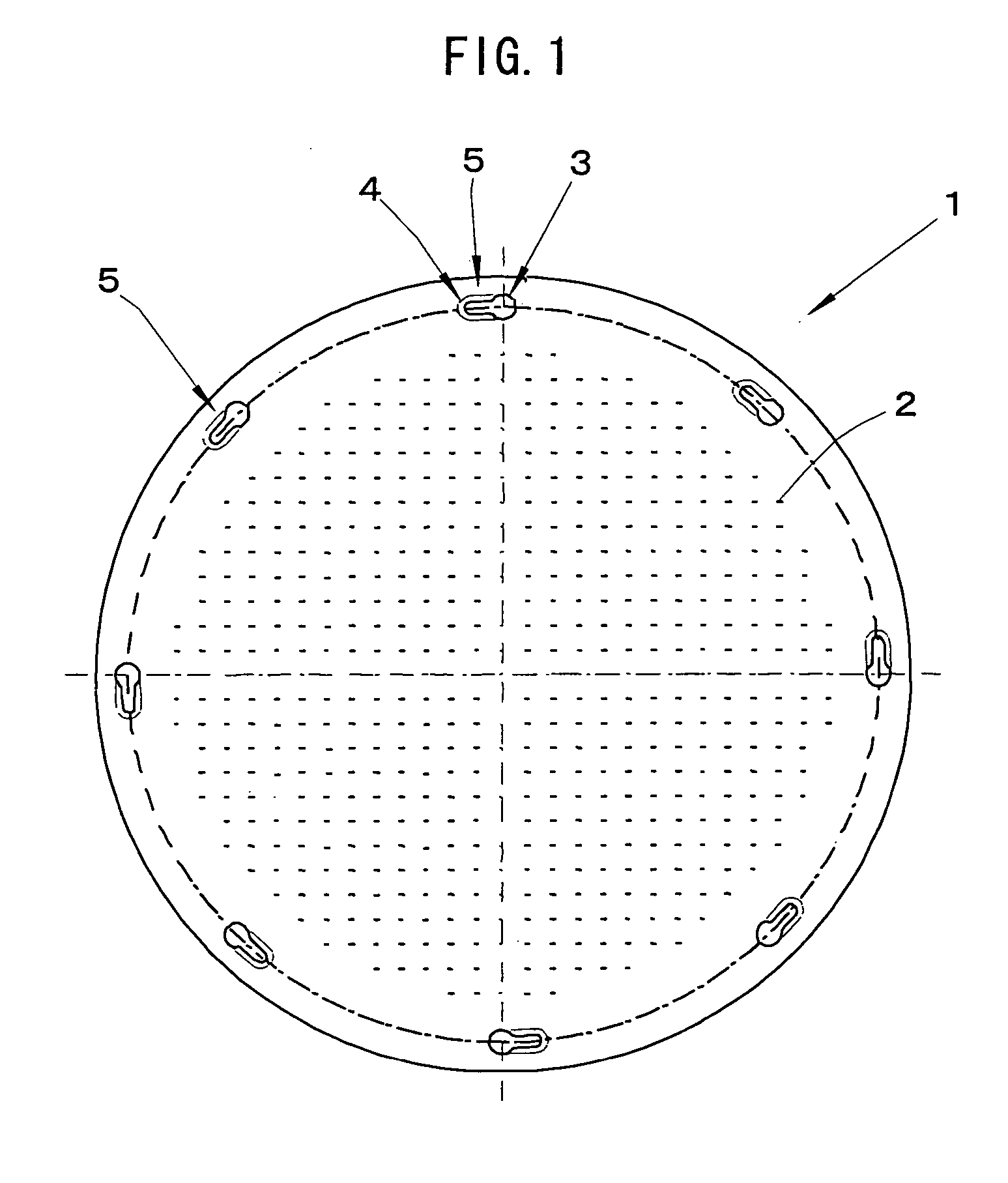

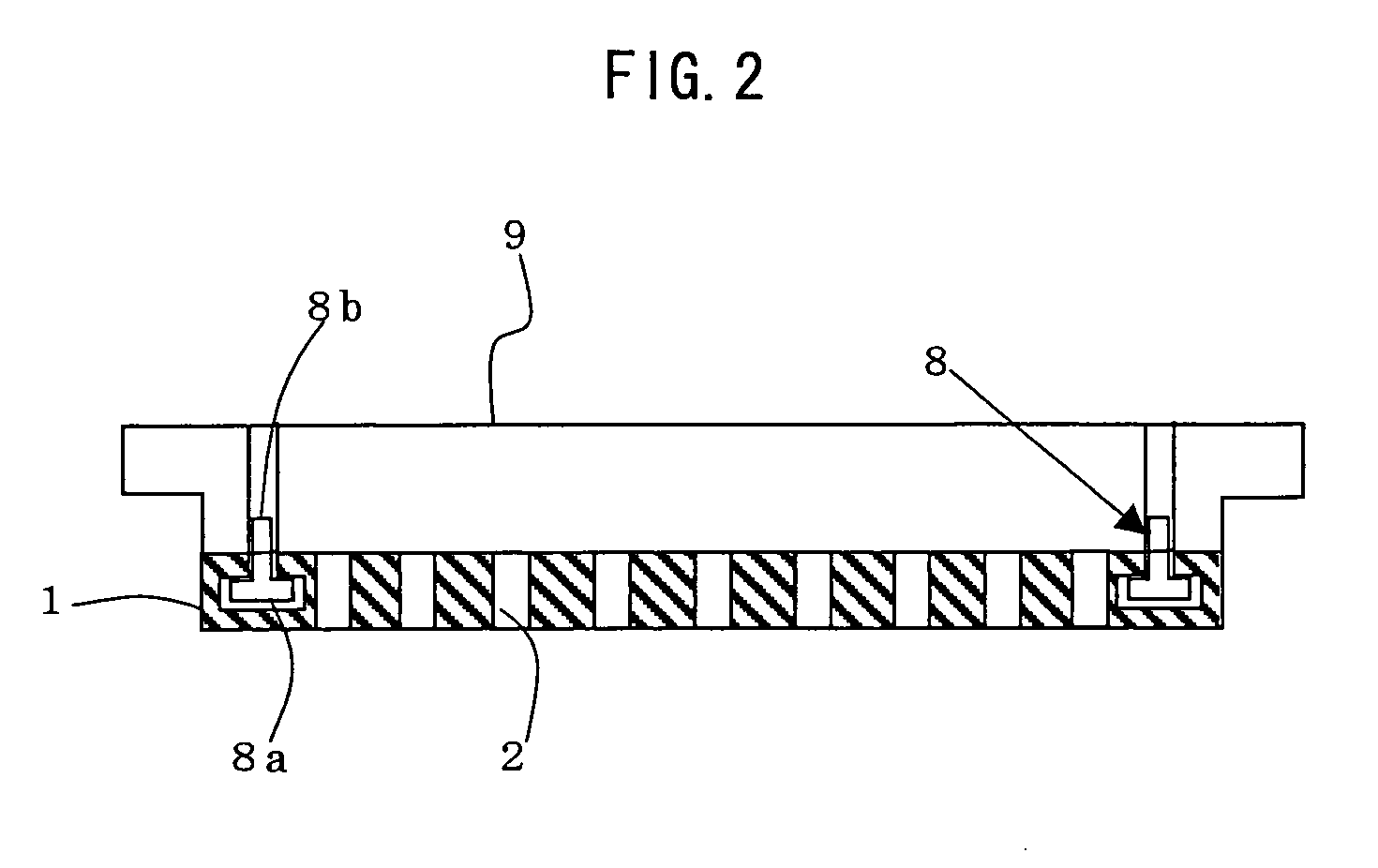

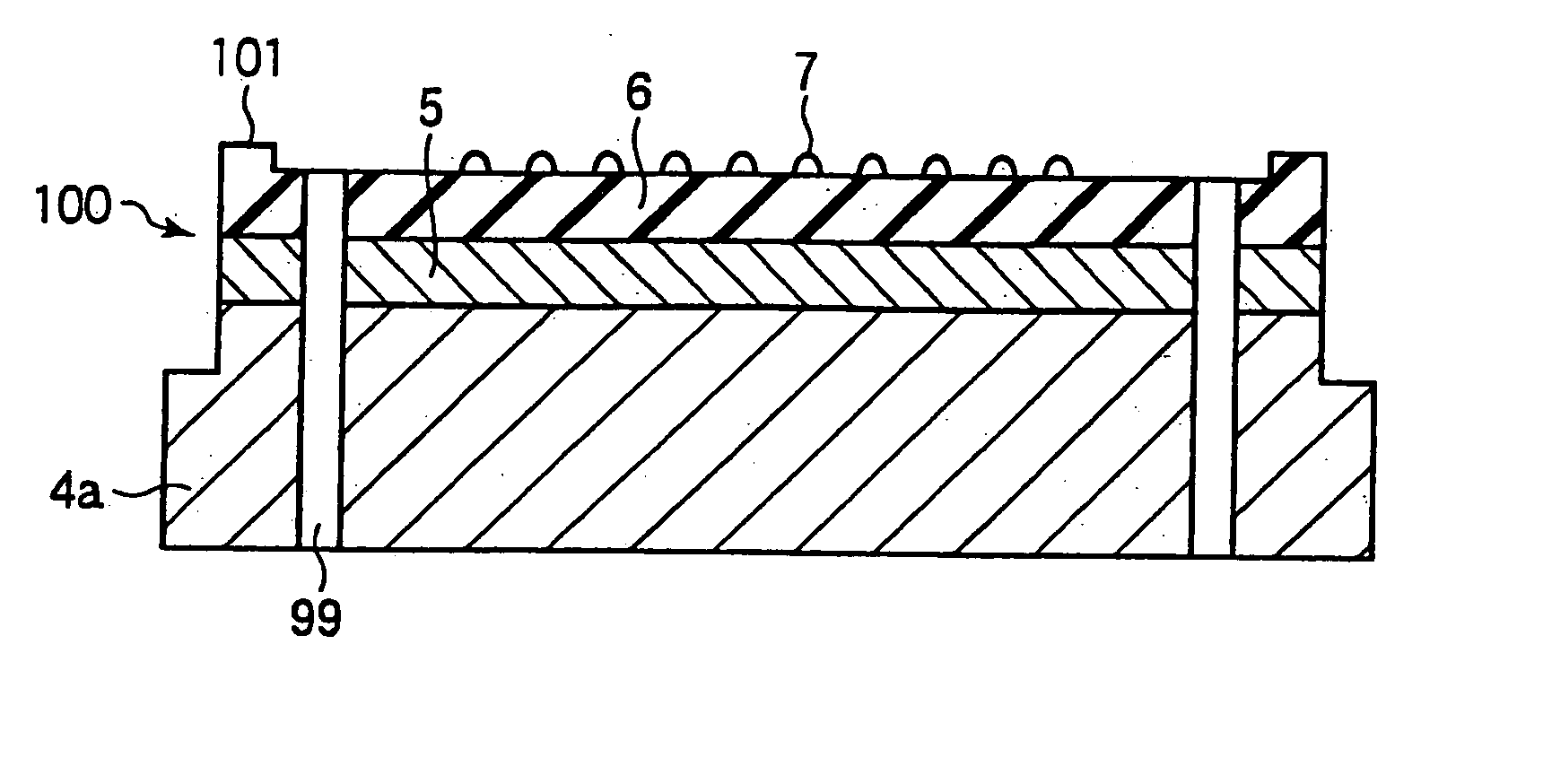

Shower plate for plasma processing apparatus and plasma processing apparatus

InactiveUS20050258280A1Easy to manufactureAvoid pollutionElectric discharge tubesMovable spraying apparatusEngineeringContamination

There is disclosed a shower plate 1, wherein the shower plate has a plurality of holes 3 for inserting the head of the fastening member and holes 4 for fitting the head are formed integrally along a concentric circle in the outside region of the gas feeding holes 2 on a side facing the supporting member, each hole for fitting extending in one direction of the concentric circle from each hole for insertion, each hole for fitting has a groove portion 4b through which the shank of the fastening member is to pass and a fitting portion 4a which is wider than the groove portion and in which the head of the fastening member is to be fitted, and the head of the fastening member fixed in the supporting member is inserted into the hole for insertion of the shower plate and the shower plate is turned so that the head of the fastening member is fitted in the fitting portion, and thereby the shower plate is supported by the supporting member without exposure of the fastening member. There can be provided a shower plate for a plasma processing apparatus, wherein effective diameter is large enough, contamination of a substrate to be treated can be prevented, it is easy to manufacture, and it is easy to fix to a supporting member.

Owner:SHIN ETSU CHEM IND CO LTD

Method for treating SiOCH film with hydrogen plasma

ActiveUS9029272B1Avoid crackingAvoid disconnectionSemiconductor/solid-state device manufacturingPhysical chemistryThin membrane

Owner:ASM IP HLDG BV

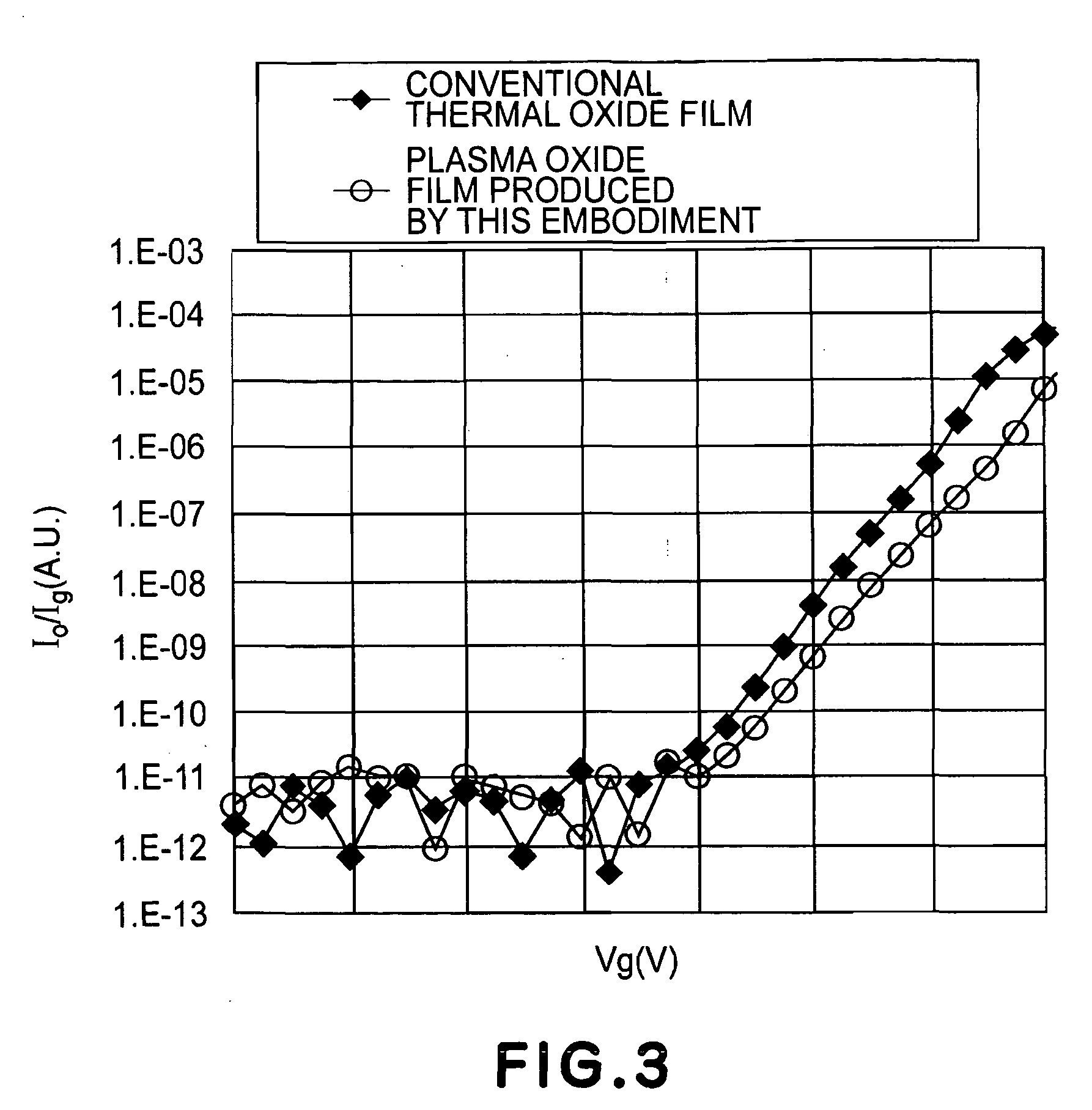

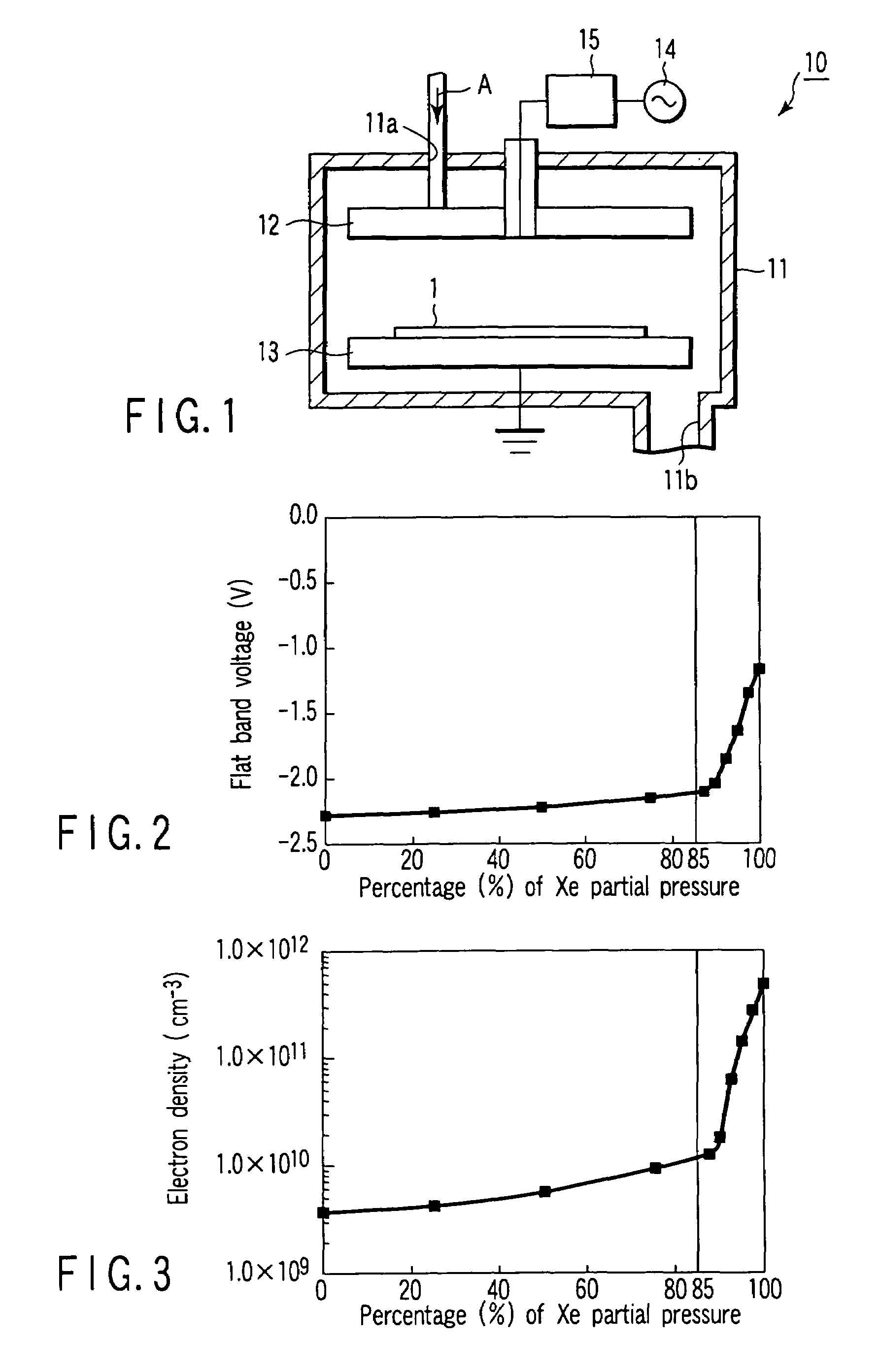

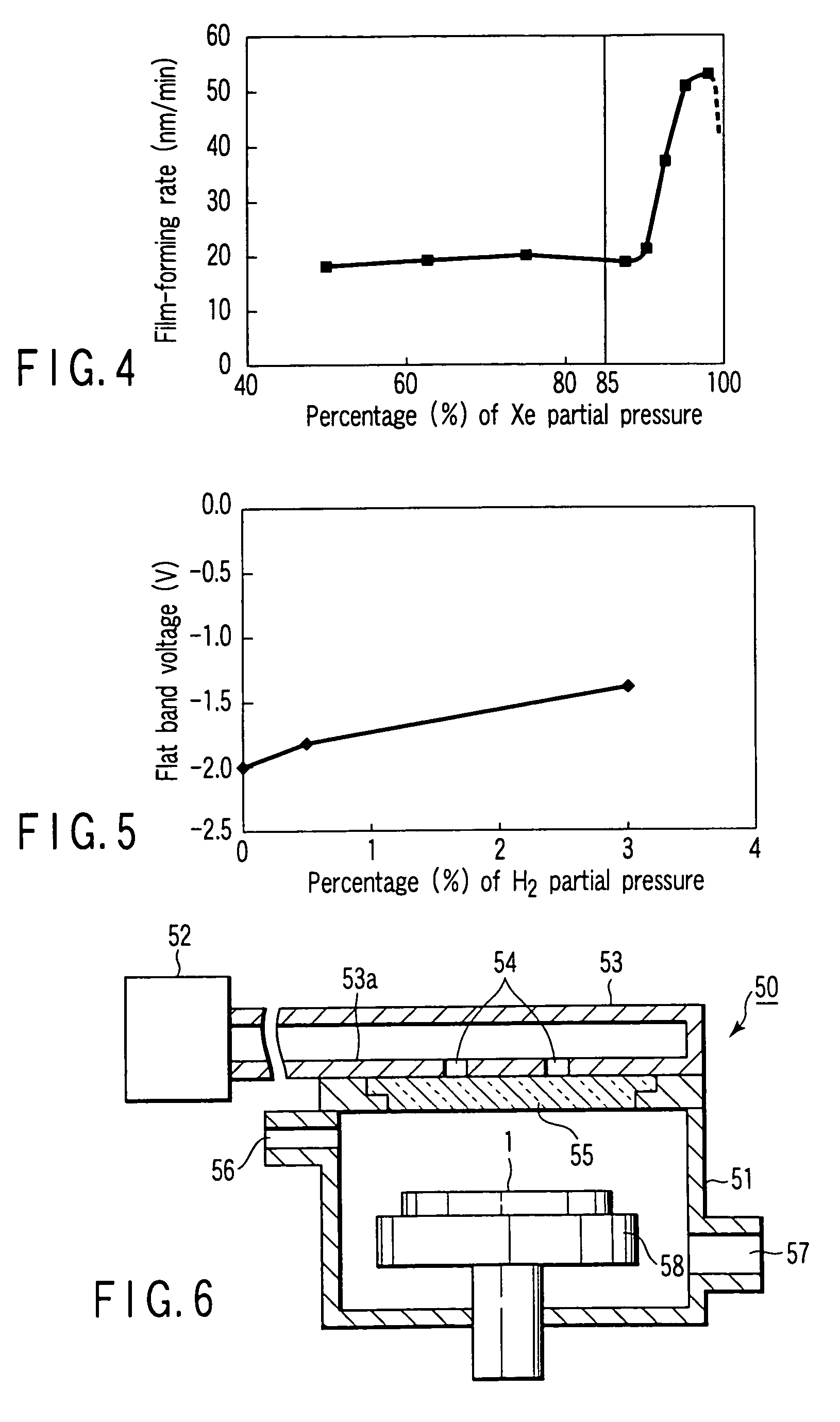

Film-forming method, method of manufacturing semiconductor device, semiconductor device, method of manufacturing display device, and display device

InactiveUS7307028B2Small currentTransistorSemiconductor/solid-state device manufacturingNoble gasDevice material

Disclosed is a film-forming method, comprising supplying into a plasma processing chamber at least three kinds of gases including a silicon compound gas, an oxidizing gas, and a rare gas, the percentage of the partial pressure of the rare gas (Pr) based on the total pressure being not smaller than 85%, i.e., 85%≦Pr<100%, and generating a plasma within the plasma processing chamber so as to form a film of silicon oxide on a substrate to be processed.

Owner:ADVANCED LCD TECH DEVMENT CENT

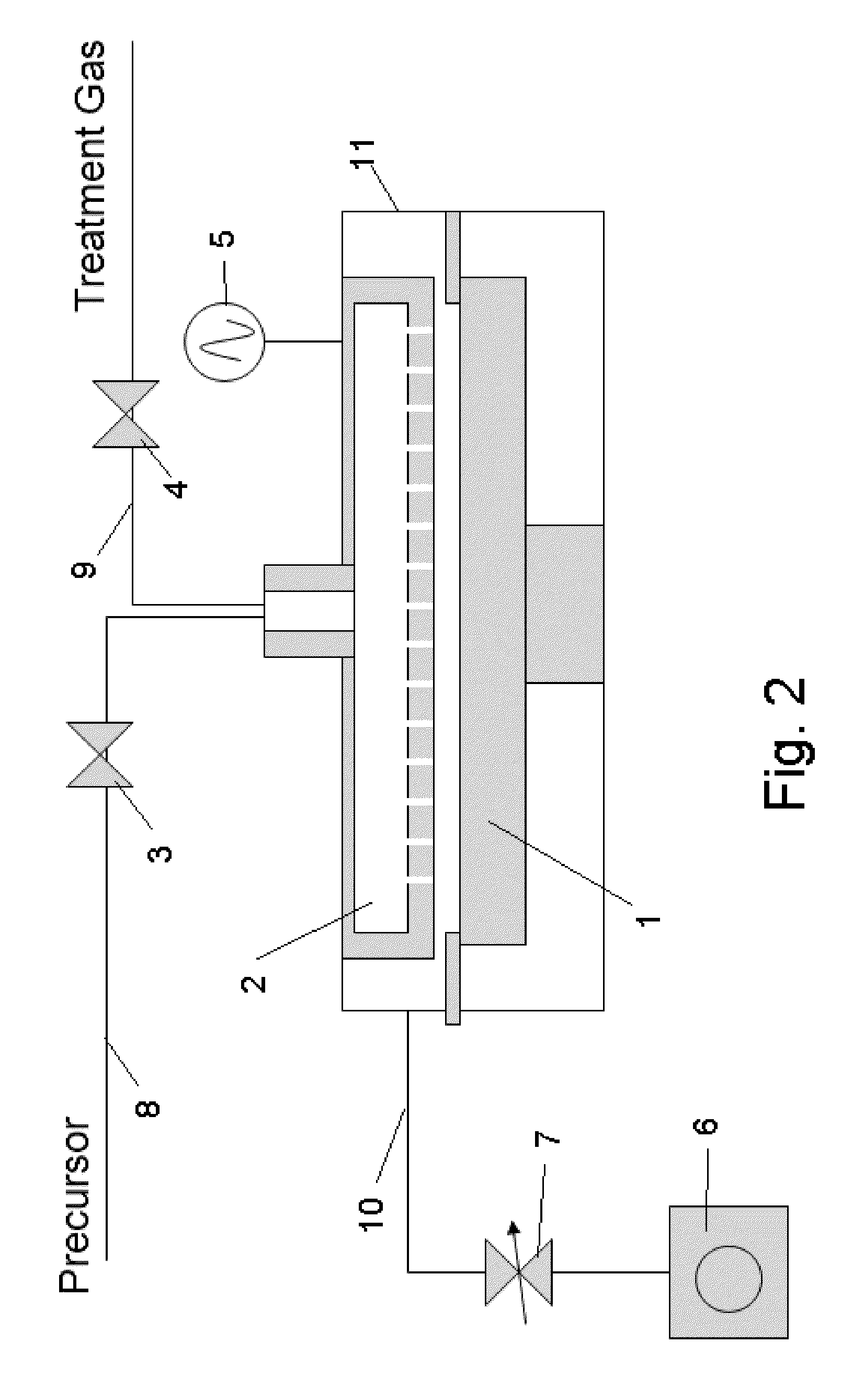

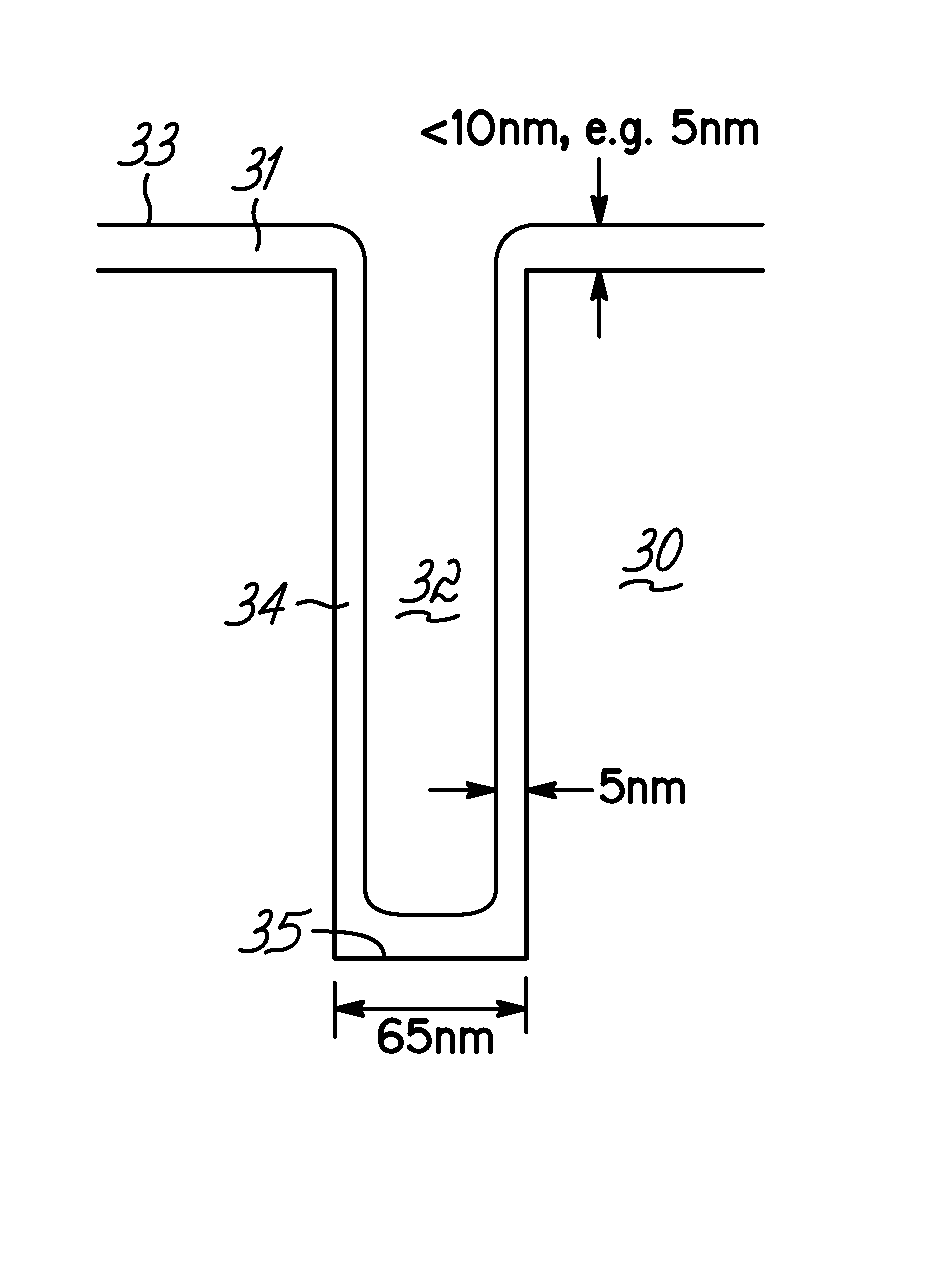

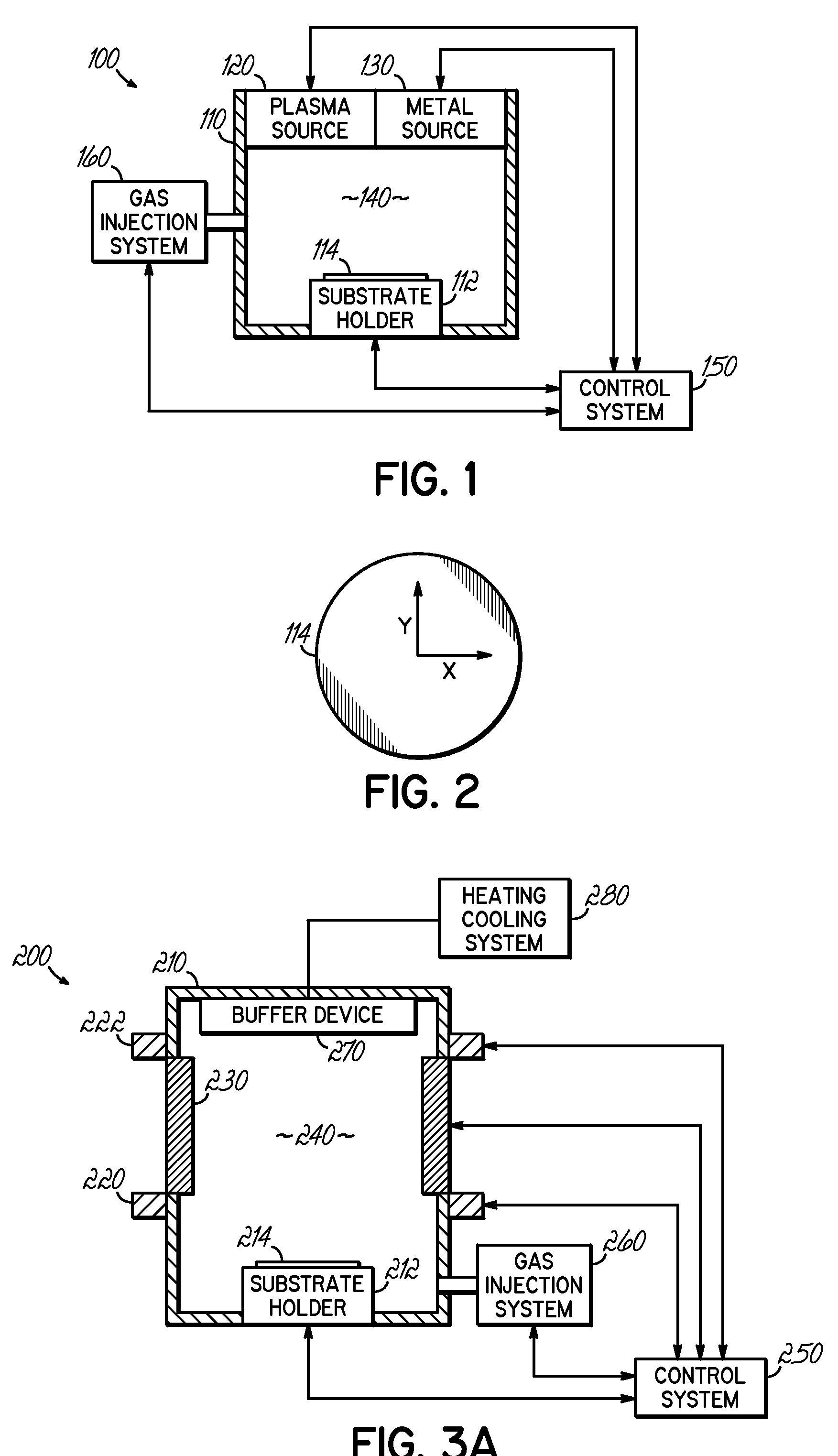

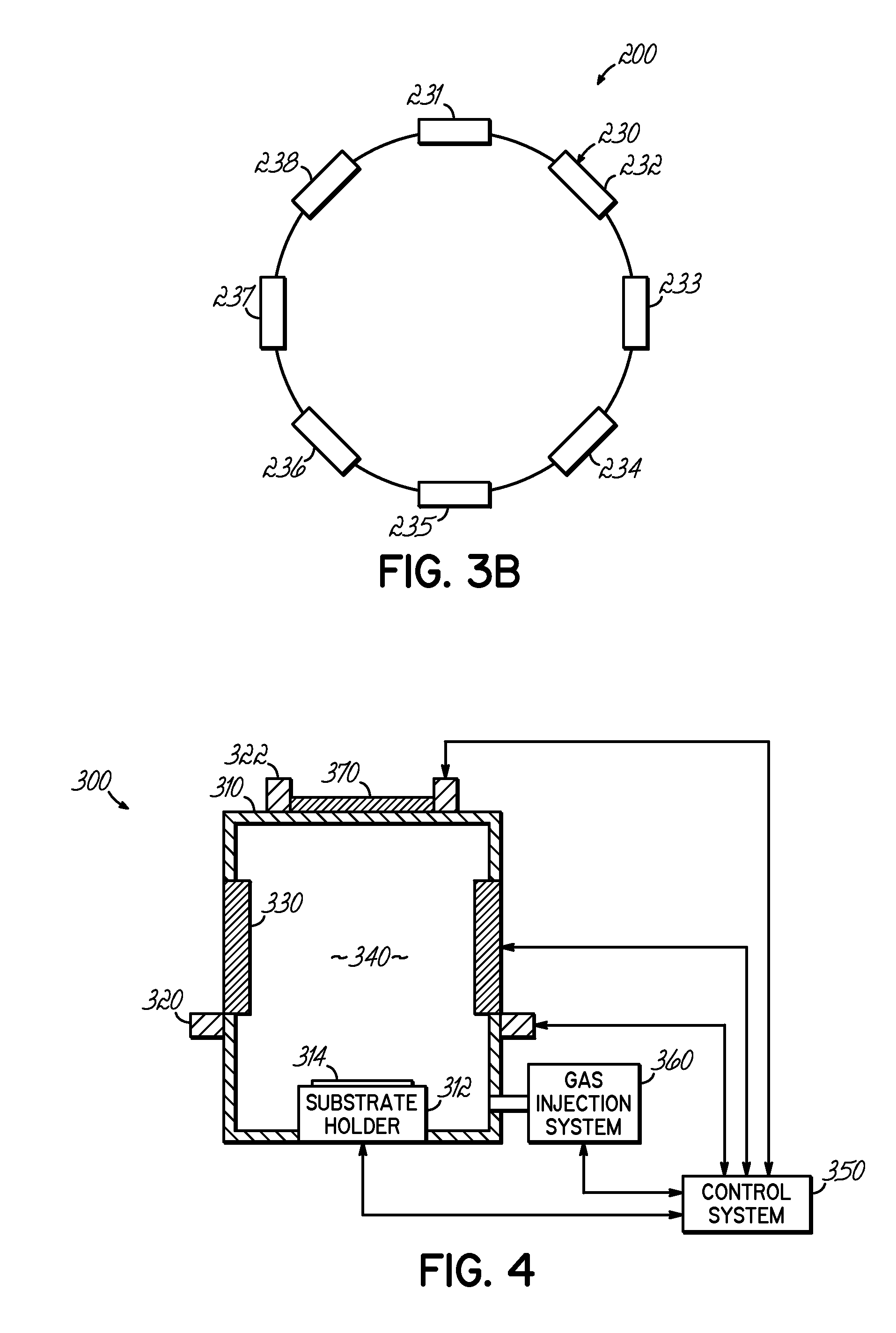

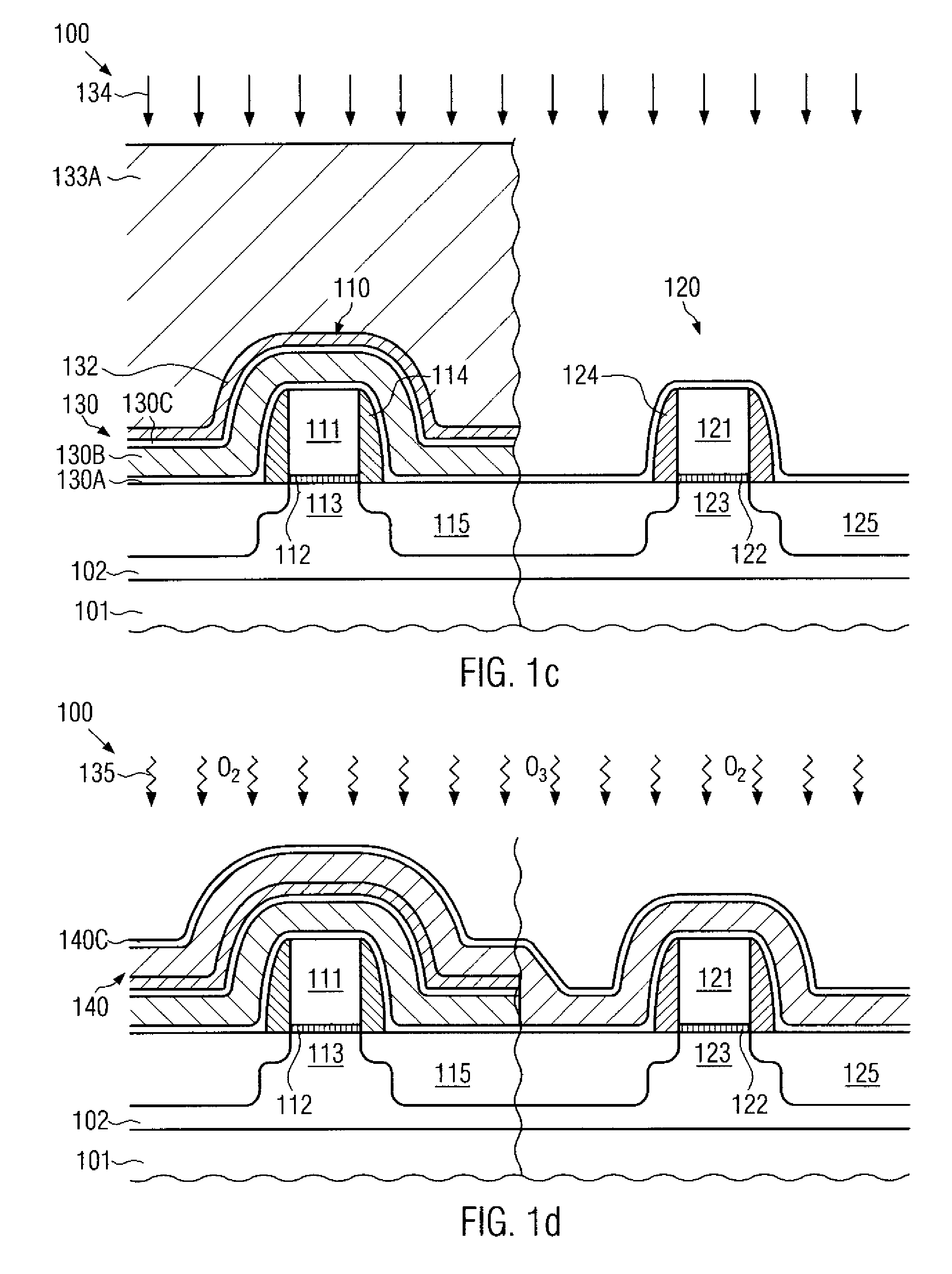

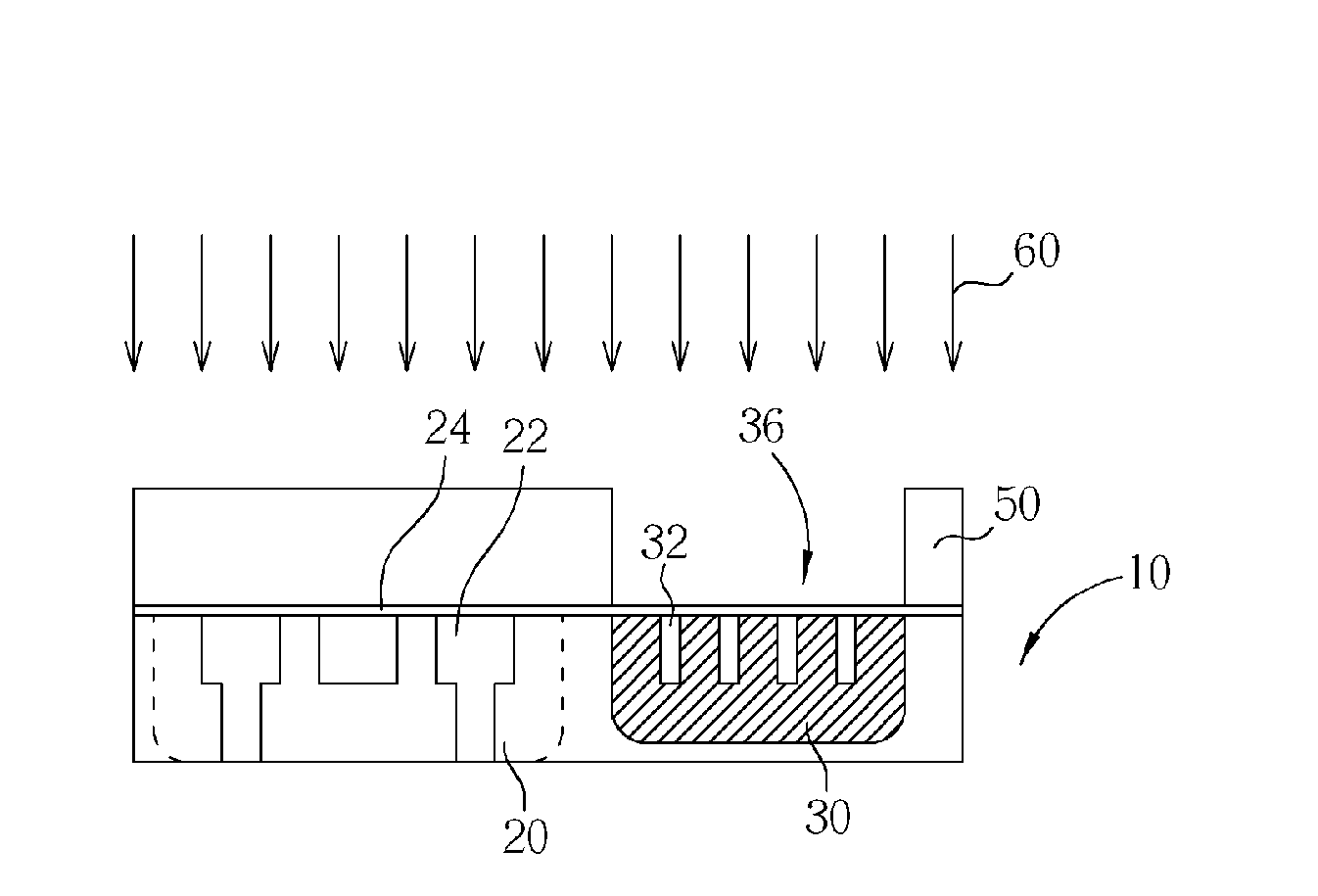

Method and apparatus of distributed plasma processing system for conformal ion stimulated nanoscale deposition process

InactiveUS20080026574A1Good coverageHigh aspect ratio (HAR) featuresVacuum evaporation coatingSputtering coatingPlasma densityHigh density

A deposition system and method of operating thereof is described for depositing a conformal metal or other similarly responsive coating material film in a high aspect ratio feature using a high density plasma is described. The deposition system includes a plasma source, and a distributed metal source for forming plasma and introducing metal vapor to the deposition system, respectively. The deposition system is configured to form a plasma having a plasma density and generate metal vapor having a metal density, wherein the ratio of the metal density to the plasma density proximate the substrate is less than or equal to unity. This ratio should exist at least within a distance from the surface of the substrate that is about twenty percent of the diameter of the substrate. A ratio that is uniform within plus or minus twenty-five percent substantially across the surface of said substrate is desirable. The ratio is particularly effective for plasma density exceeding 1012 cm−3, and for depositing film on substrates having nanoscale features with maximum film thickness less than half of the feature width, for example, at ten percent of the feature width.

Owner:TOKYO ELECTRON LTD

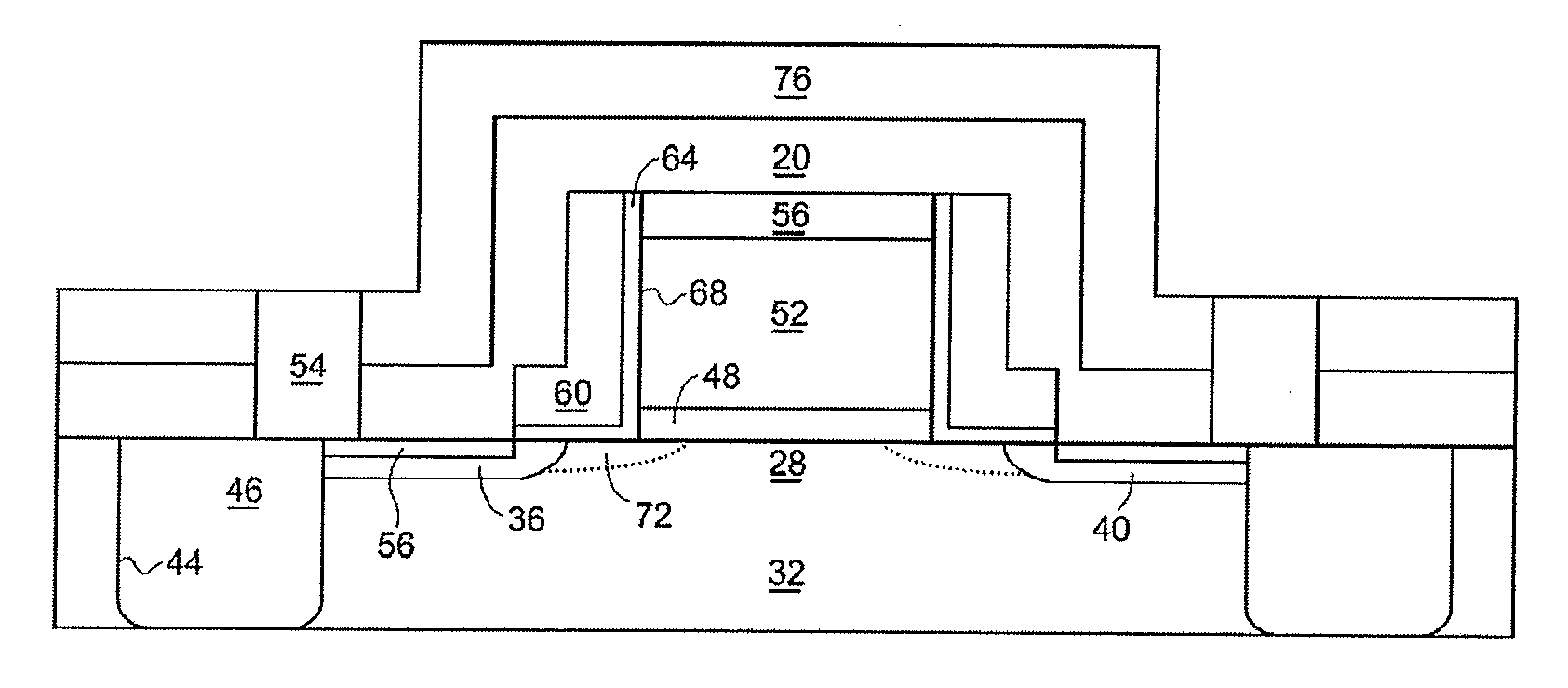

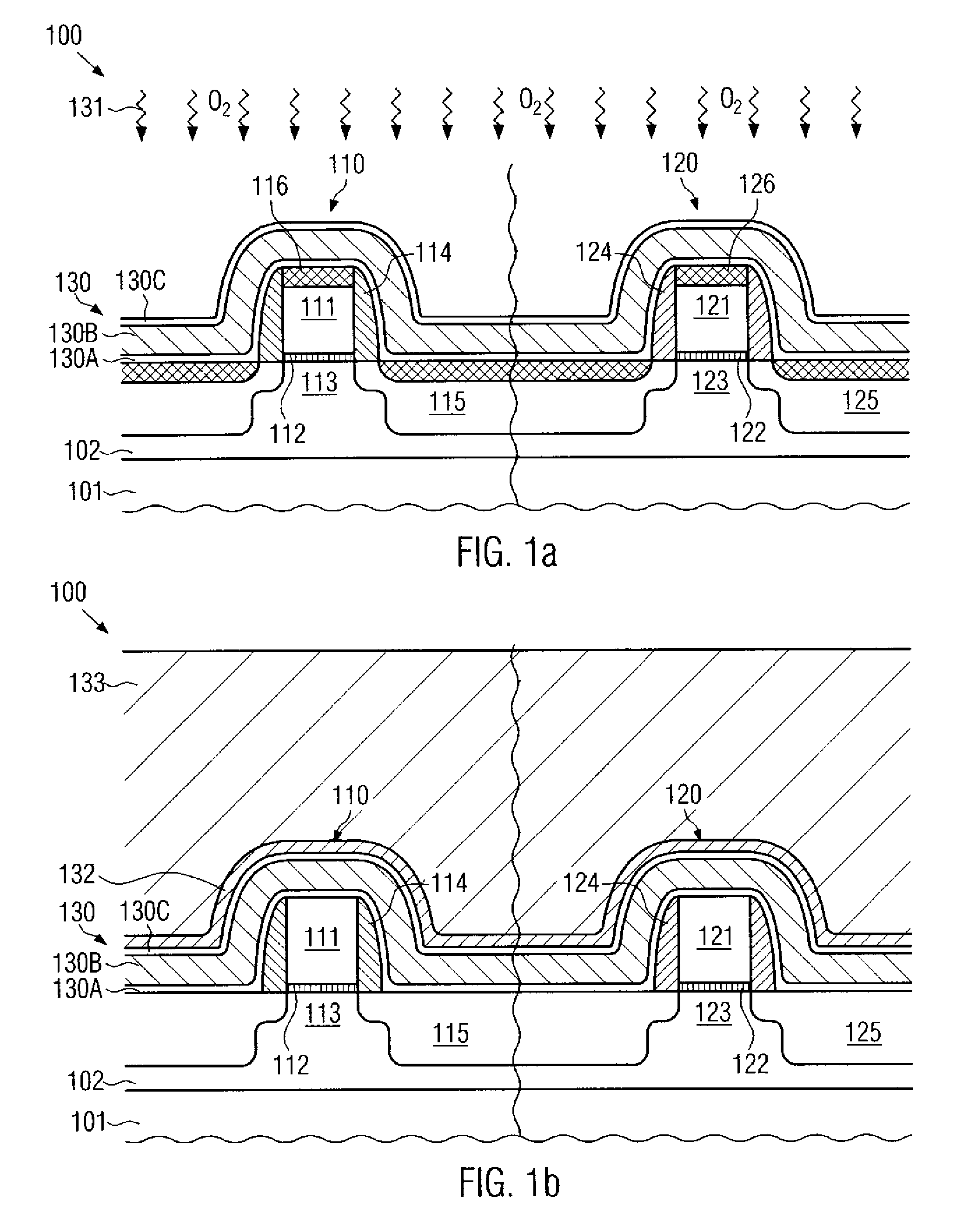

Method for reducing resist poisoning during patterning of silicon nitride layers in a semiconductor device

ActiveUS7550396B2Improve performanceReduce diffuseSemiconductor/solid-state device manufacturingSemiconductor devicesResistNitrogen

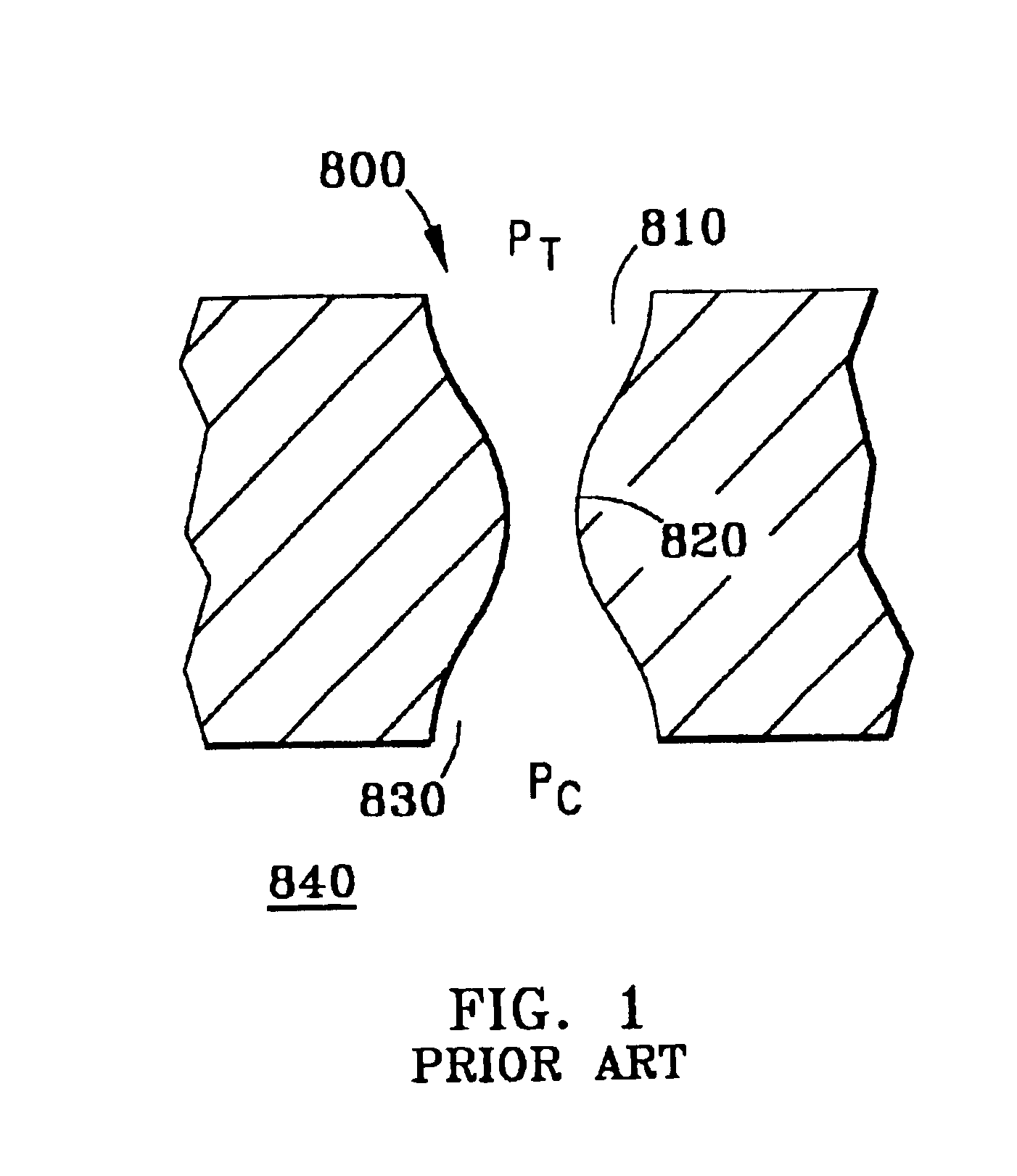

By performing a plasma treatment for efficiently sealing the surface of a stressed dielectric layer containing silicon nitride, an enhanced performance during the patterning of contact openings may be achieved, since nitrogen-induced resist poisoning may be significantly reduced during the selective patterning of stressed layers of different types of intrinsic stress.

Owner:TAIWAN SEMICON MFG CO LTD

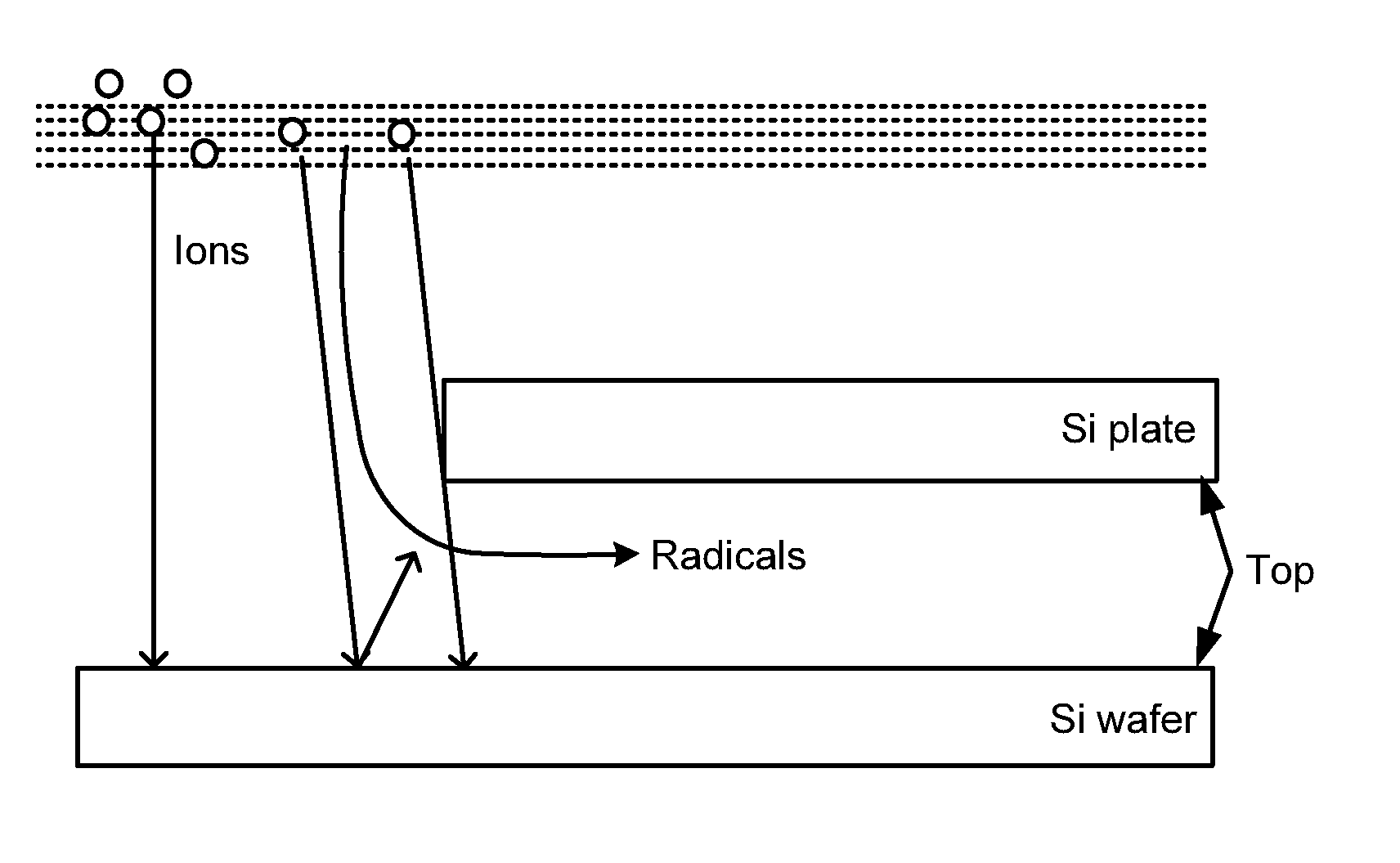

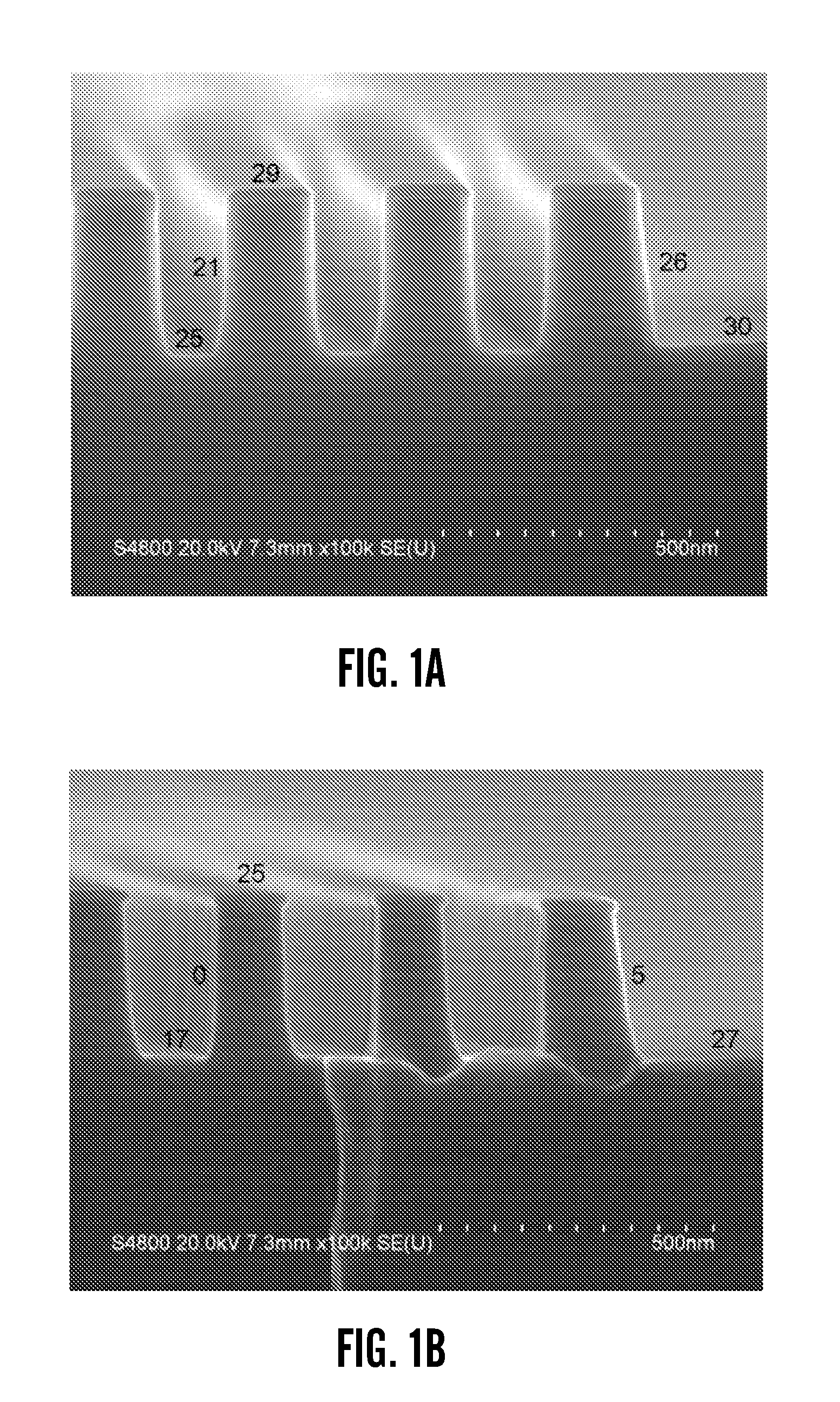

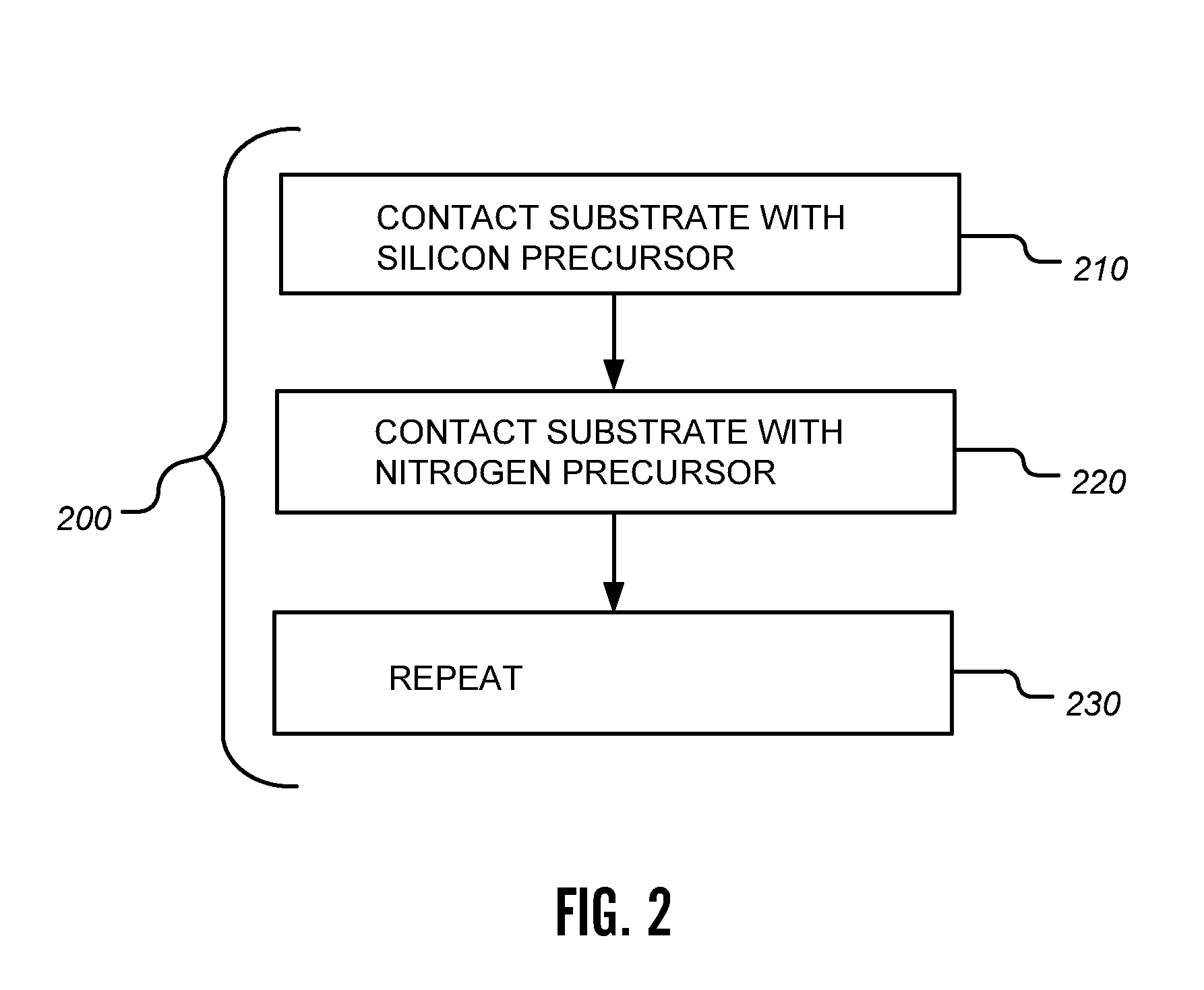

Deposition of SiN

ActiveUS20160079054A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen plasmaAtomic layer deposition

Methods and precursors for forming silicon nitride films are provided. In some embodiments, silicon nitride can be deposited by atomic layer deposition (ALD), such as plasma enhanced ALD. In some embodiments, deposited silicon nitride can be treated with a plasma treatment. The plasma treatment can be a nitrogen plasma treatment. In some embodiments the silicon precursors for depositing the silicon nitride comprise an iodine ligand. The silicon nitride films may have a relatively uniform etch rate for both vertical and the horizontal portions when deposited onto three-dimensional structures such as FinFETS or other types of multiple gate FETs. In some embodiments, various silicon nitride films of the present disclosure have an etch rate of less than half the thermal oxide removal rate with diluted HF (0.5%). In some embodiments, a method for depositing silicon nitride films comprises a multi-step plasma treatment.

Owner:ASM IP HLDG BV

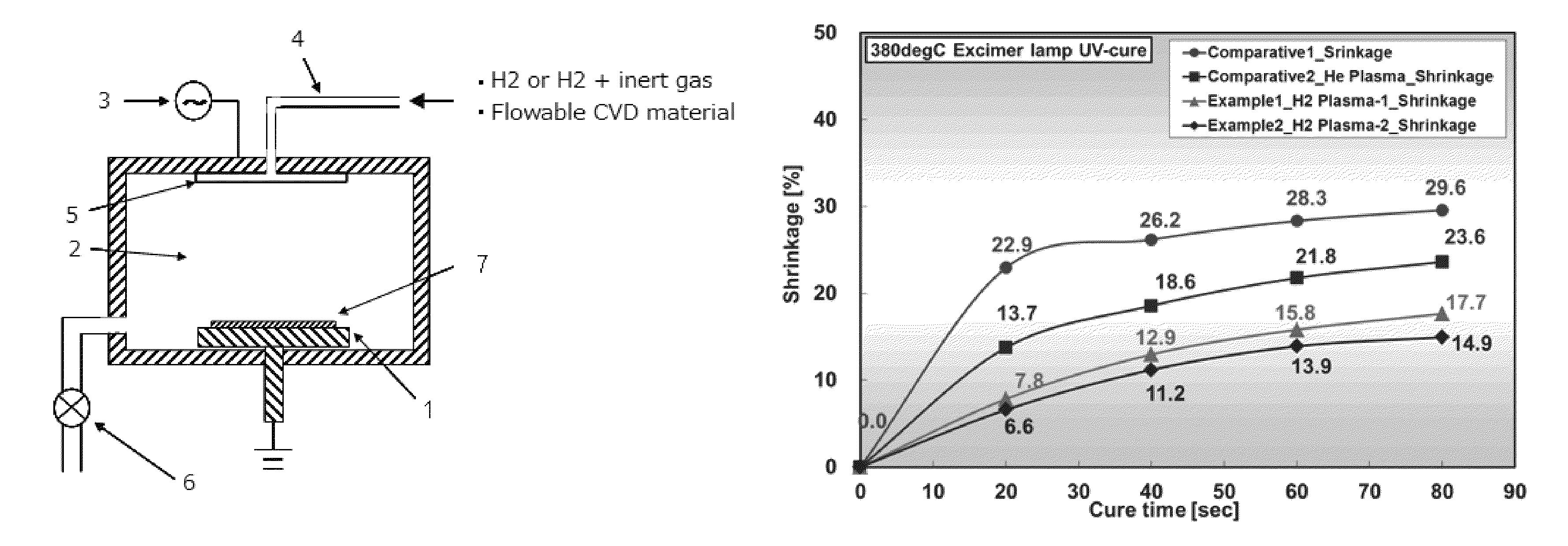

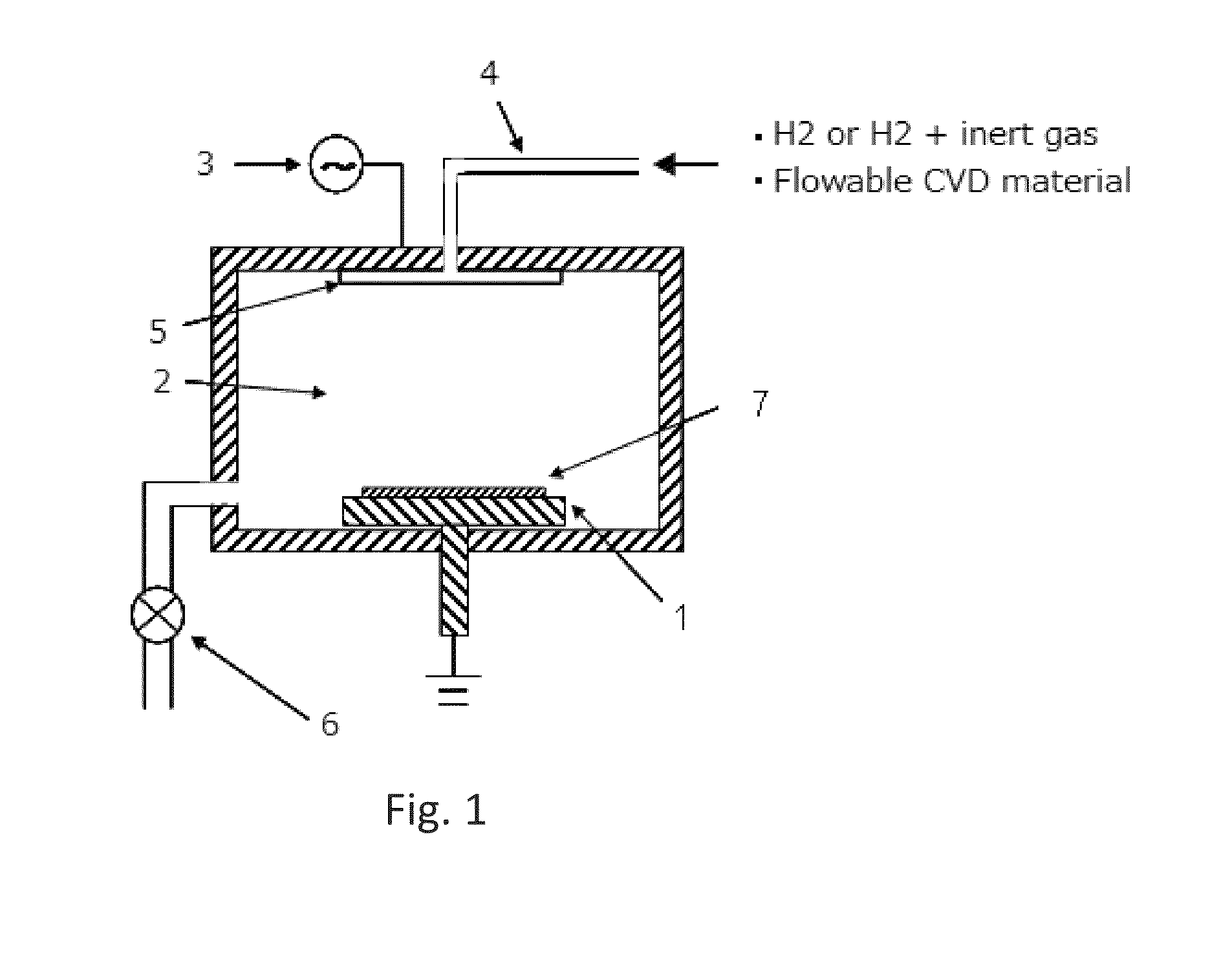

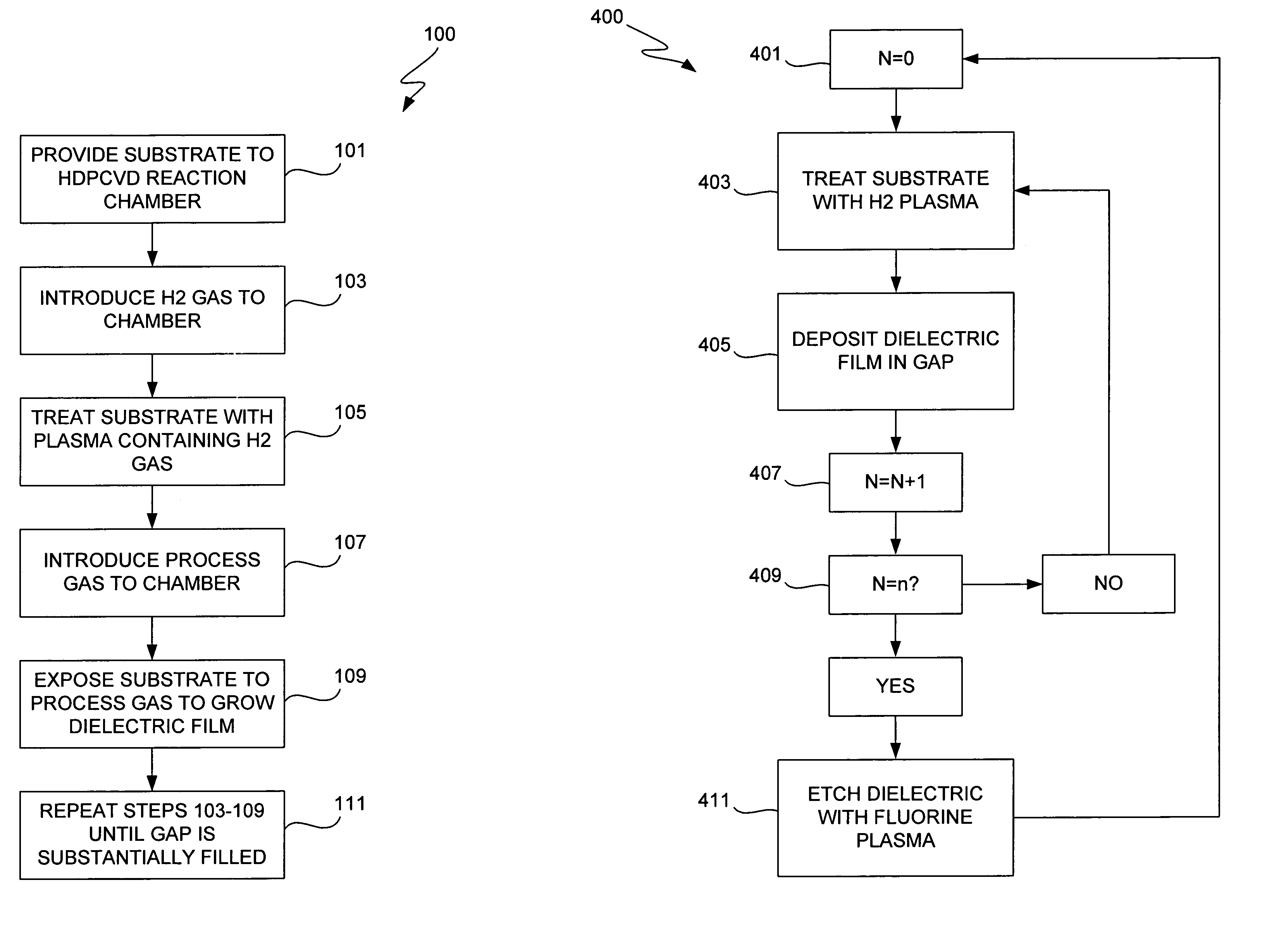

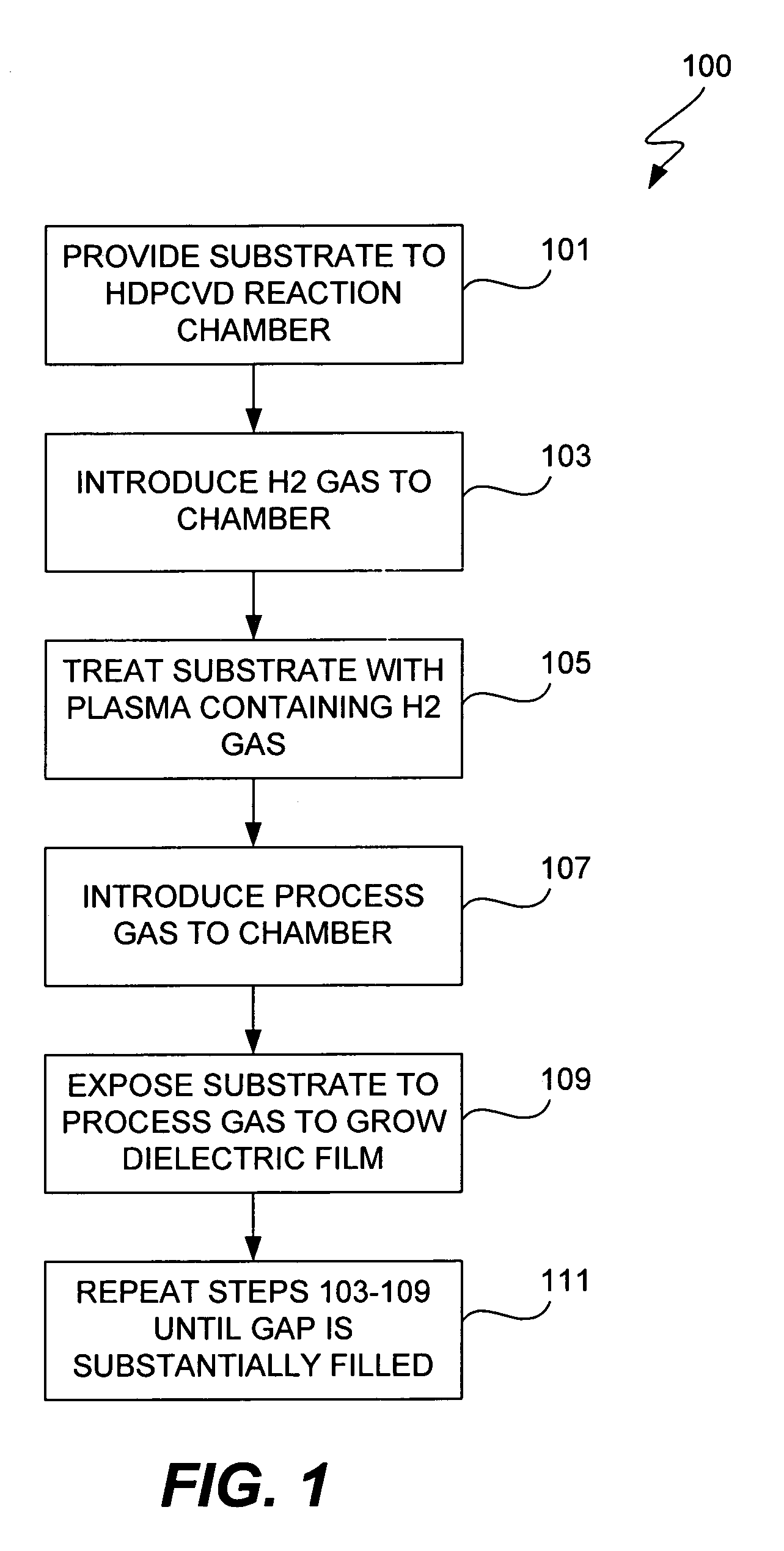

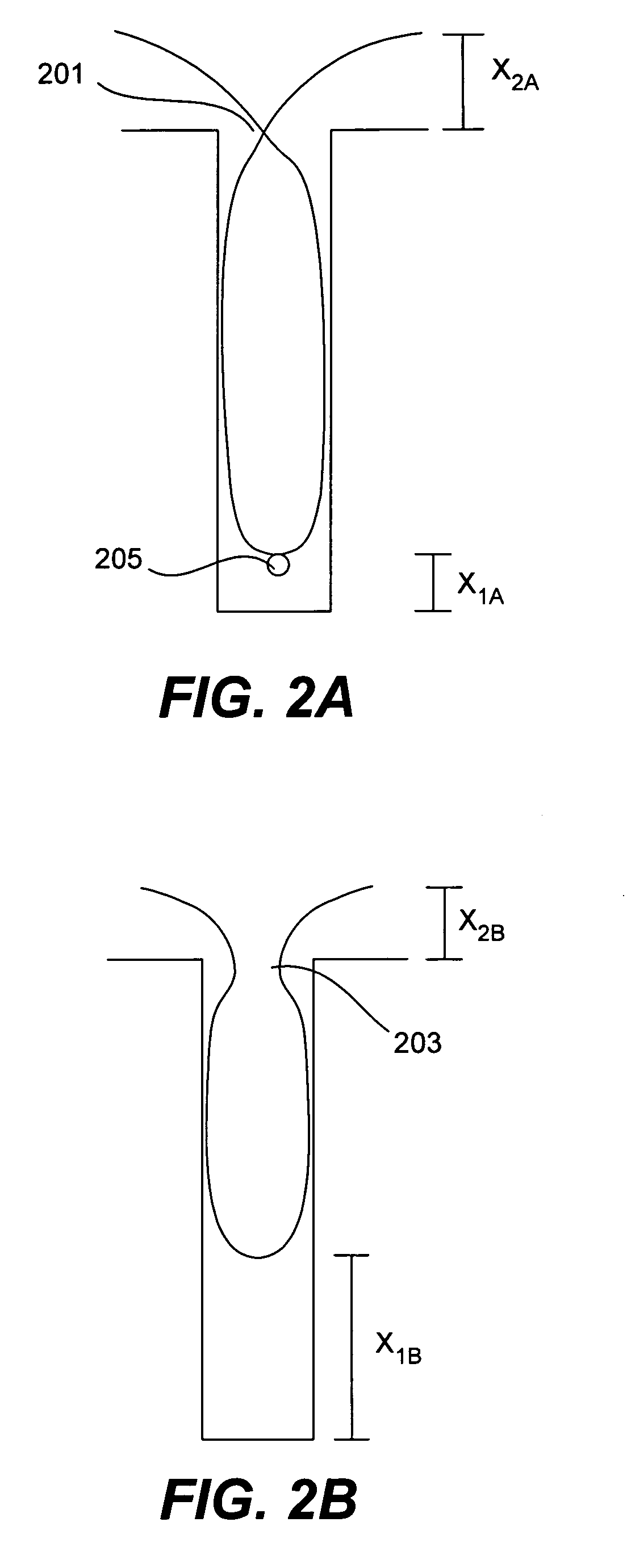

Hydrogen treatment enhanced gap fill

ActiveUS7211525B1Reduce and eliminate depositionReduce or eliminate the need for etch stepsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectric membranePhysical chemistry

Methods of filling gaps on semiconductor substrates with dielectric film are described. The methods reduce or eliminate sidewall deposition and top-hat formation. The methods also reduce or eliminate the need for etch steps during dielectric film deposition. The methods include treating a semiconductor substrate with a hydrogen plasma before depositing dielectric film on the substrate. In some embodiments, the hydrogen treatment is used is conjunction with a high rate deposition process.

Owner:NOVELLUS SYSTEMS

High productivity plasma processing chamber

InactiveUS20050229849A1Maximizing allowable timeReduce probabilityElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlProduction rate

Embodiments of the present invention are generally directed to apparatus and methods for a plasma-processing chamber requiring less maintenance and downtime and possessing improved reliability over the prior art. In one embodiment, the apparatus includes a substrate support resting on a ceramic shaft, an inner shaft allowing for electrical connections to the substrate support at atmospheric pressure, an aluminum substrate support resting on but not fixed to a ceramic support structure, sapphire rest points swaged into the substrate support, and a heating element inside the substrate support arranged in an Archimedes spiral to reduce warping of the substrate support and to increase its lifetime. Methods include increasing time between in-situ cleans of the chamber by reducing particle generation from chamber surfaces. Reduced particle generation occurs via temperature control of chamber components and pressurization of non-processing regions of the chamber relative to the processing region with a purge gas.

Owner:APPLIED MATERIALS INC

Plasma curing process for porous low-k materials

InactiveUS6913796B2Improving elastic modulusImproving material hardnessSilicaLayered productsHardnessMaterials science

Low dielectric constant porous materials with improved elastic modulus and hardness. The process of making such porous materials involves providing a porous dielectric material and plasma curing the porous dielectric material to produce a plasma cured porous dielectric material. Plasma curing of the porous dielectric material yields a material with improved modulus and hardness. The improvement in elastic modulus is typically greater than or about 50%, more typically greater than or about 100%, and more typically greater than or about 200%. The improvement in hardness is typically greater than or about 50%. The plasma cured porous dielectric material can optionally be post-plasma treated. The post-plasma treatment of the plasma cured porous dielectric material reduces the dielectric constant of the material while maintaining an improved elastic modulus and hardness as compared to the plasma cured porous dielectric material. The post-plasma treated, plasma cured porous dielectric material has a dielectric constant between about 1.1 and about 3.5 and an improved elastic modulus and hardness.

Owner:DOW CORNING CORP

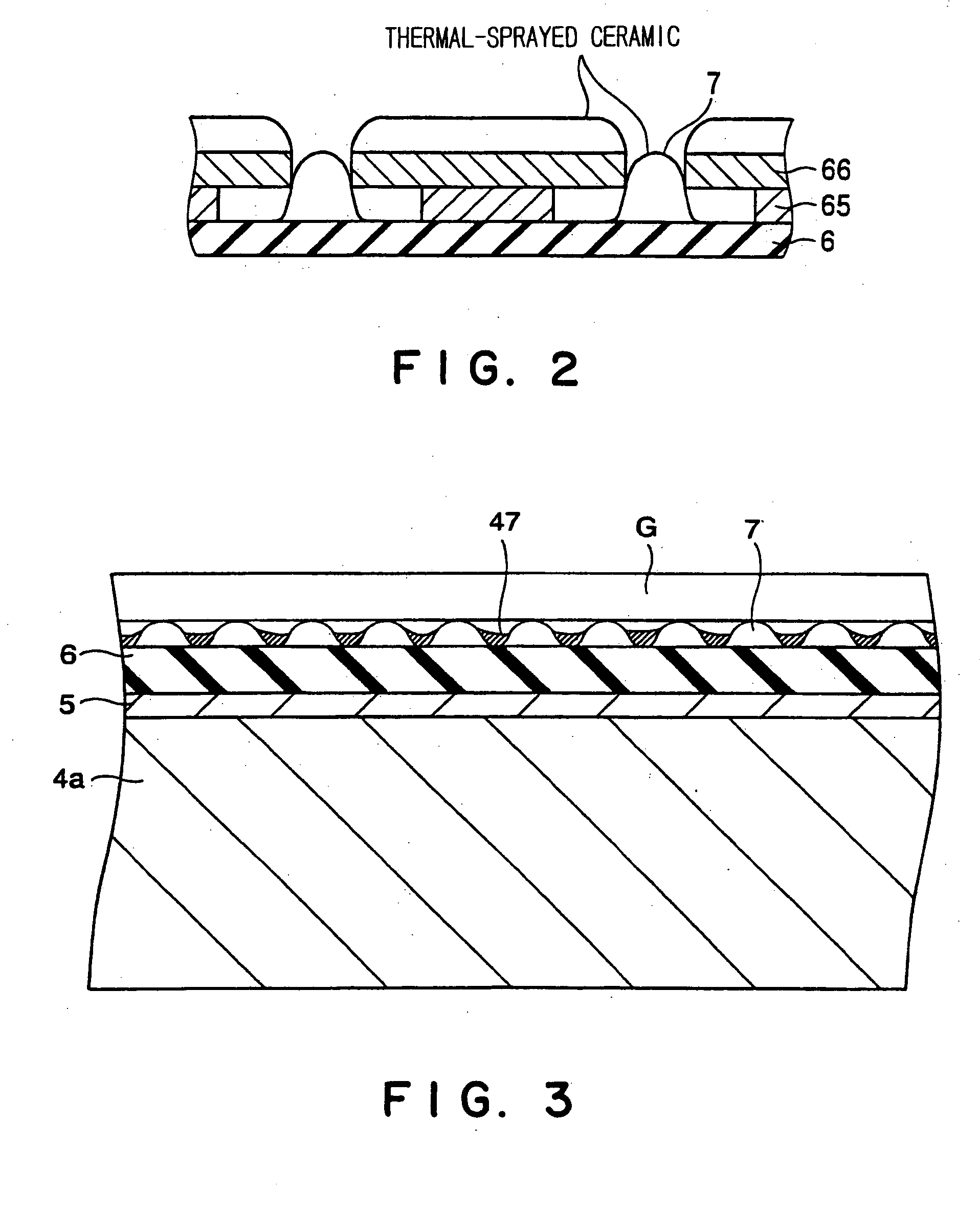

Substrate supporting table, method for producing same, and processing system

InactiveUS20050120962A1Avoid processing irregularityAvoid formingSleeve/socket jointsElectric discharge tubesSusceptorThermal spraying

A plasma processing system has a susceptor, provided in a processing vessel, for supporting thereon a substrate. A process gas is supplied into the processing vessel to produce the plasma of the process gas. The susceptor has a dielectric film formed on a base, and a plurality of protrusions formed on the film. The protrusions of the susceptor are formed by thermal-spraying a ceramic onto the dielectric film via an aperture plate having a plurality of circular apertures.

Owner:USHIODA JOICHI +3

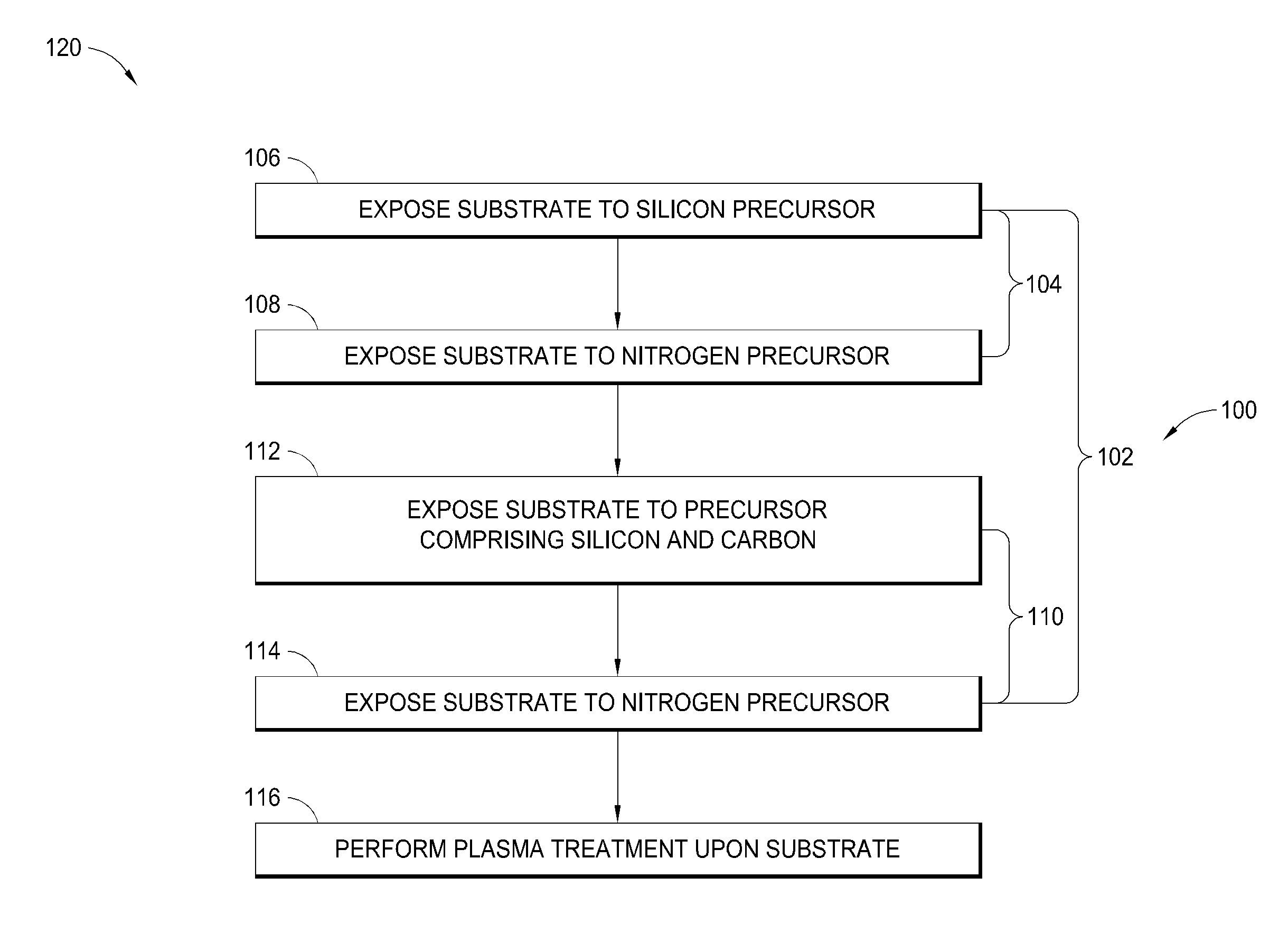

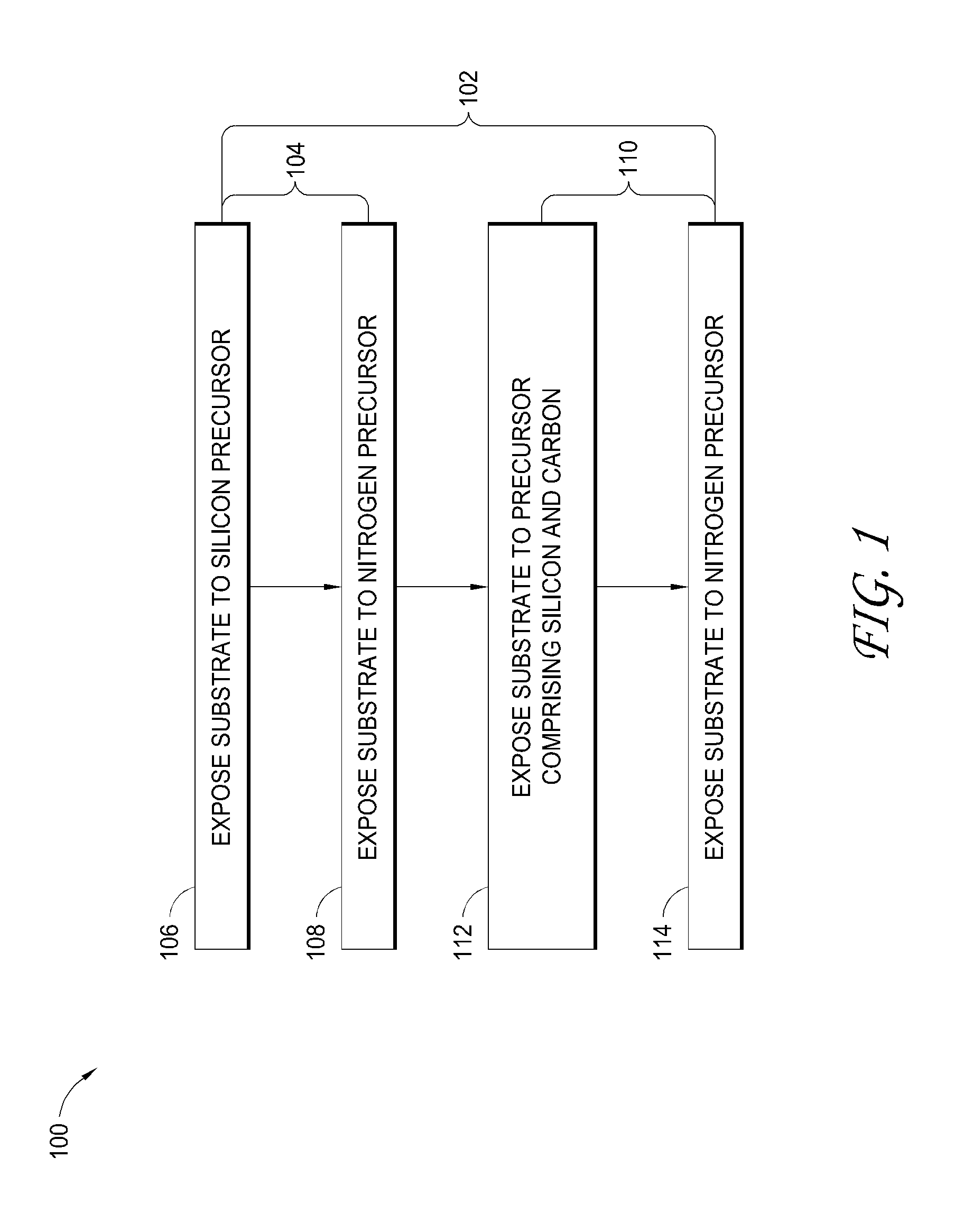

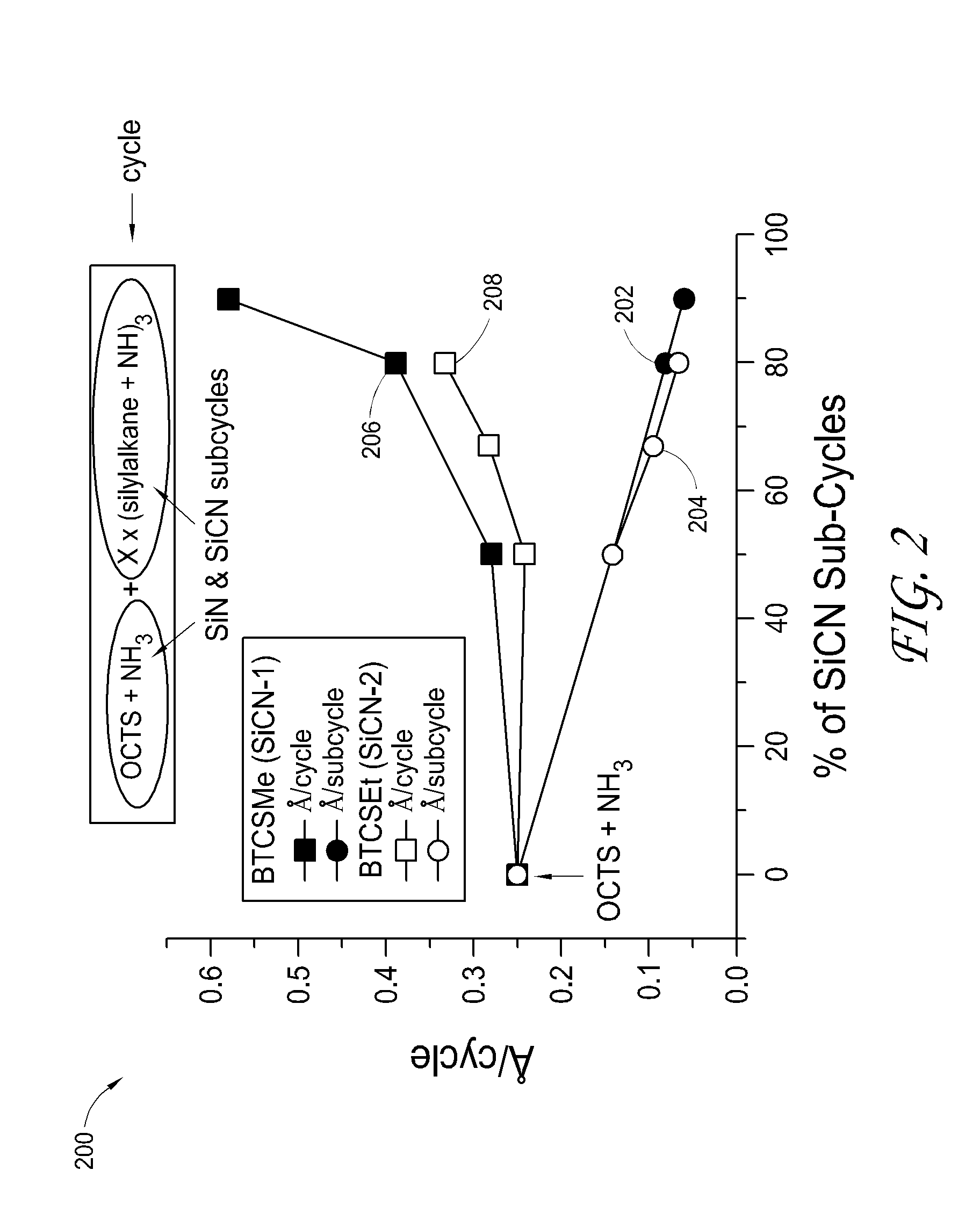

Atomic layer deposition of silicon carbon nitride based materials

ActiveUS20150162185A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon nitrideNitrogen

A process for depositing a silicon carbon nitride film on a substrate can include a plurality of complete deposition cycles, each complete deposition cycle having a SiN sub-cycle and a SiCN sub-cycle. The SiN sub-cycle can include alternately and sequentially contacting the substrate with a silicon precursor and a SiN sub-cycle nitrogen precursor. The SiCN sub-cycle can include alternately and sequentially contacting the substrate with carbon-containing precursor and a SiCN sub-cycle nitrogen precursor. The SiN sub-cycle and the SiCN sub-cycle can include atomic layer deposition (ALD). The process for depositing the silicon carbon nitride film can include a plasma treatment. The plasma treatment can follow a completed plurality of complete deposition cycles.

Owner:ASM IP HLDG BV

Method to increase tensile stress of silicon nitride films using a post PECVD deposition UV cure

ActiveUS8129290B2Increasing the thicknessSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen plasmaThin membrane

High tensile stress in a deposited layer such as silicon nitride, may be achieved utilizing one or more techniques, employed alone or in combination. High tensile stress may be achieved by forming a silicon-containing layer on a surface by exposing the surface to a silicon-containing precursor gas in the absence of a plasma, forming silicon nitride by exposing said silicon-containing layer to a nitrogen-containing plasma, and then repeating these steps to increase a thickness of the silicon nitride created thereby. High tensile stress may also be achieved by exposing a surface to a silicon-containing precursor gas in a first nitrogen-containing plasma, treating the material with a second nitrogen-containing plasma, and then repeating these steps to increase a thickness of the silicon nitride formed thereby. In another embodiment, tensile film stress is enhanced by deposition with porogens that are liberated upon subsequent exposure to UV radiation or plasma treatment.

Owner:APPLIED MATERIALS INC

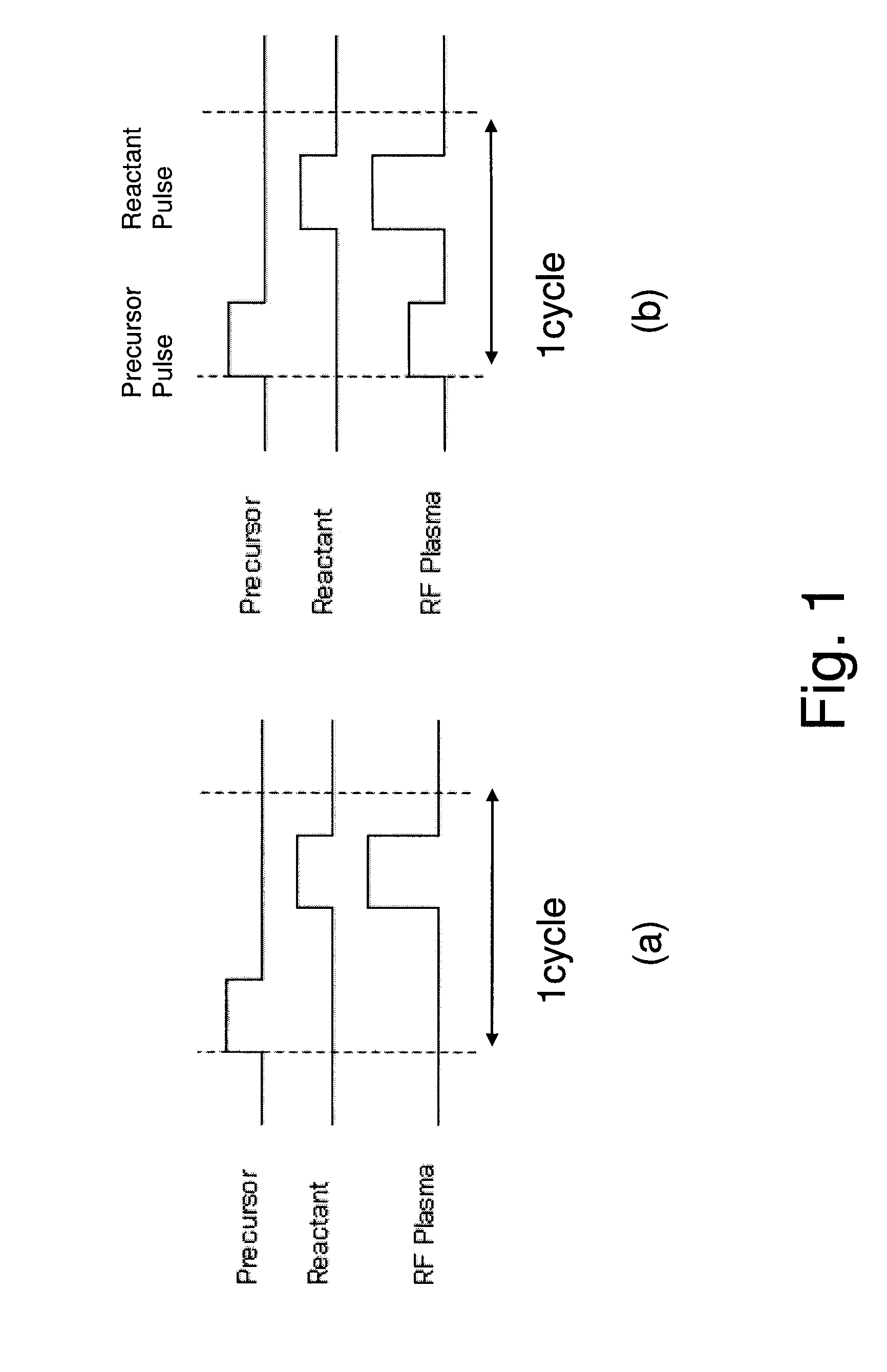

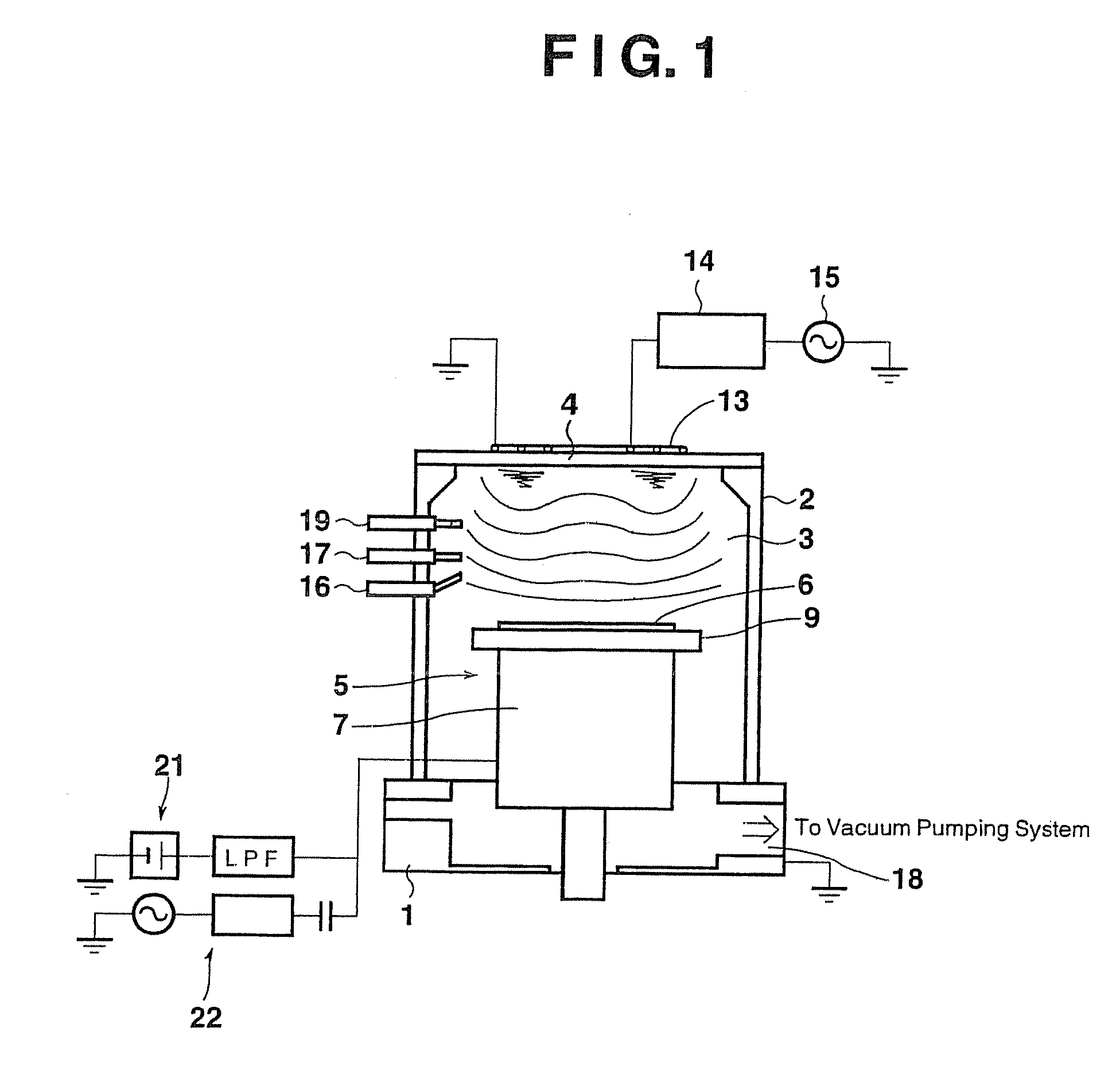

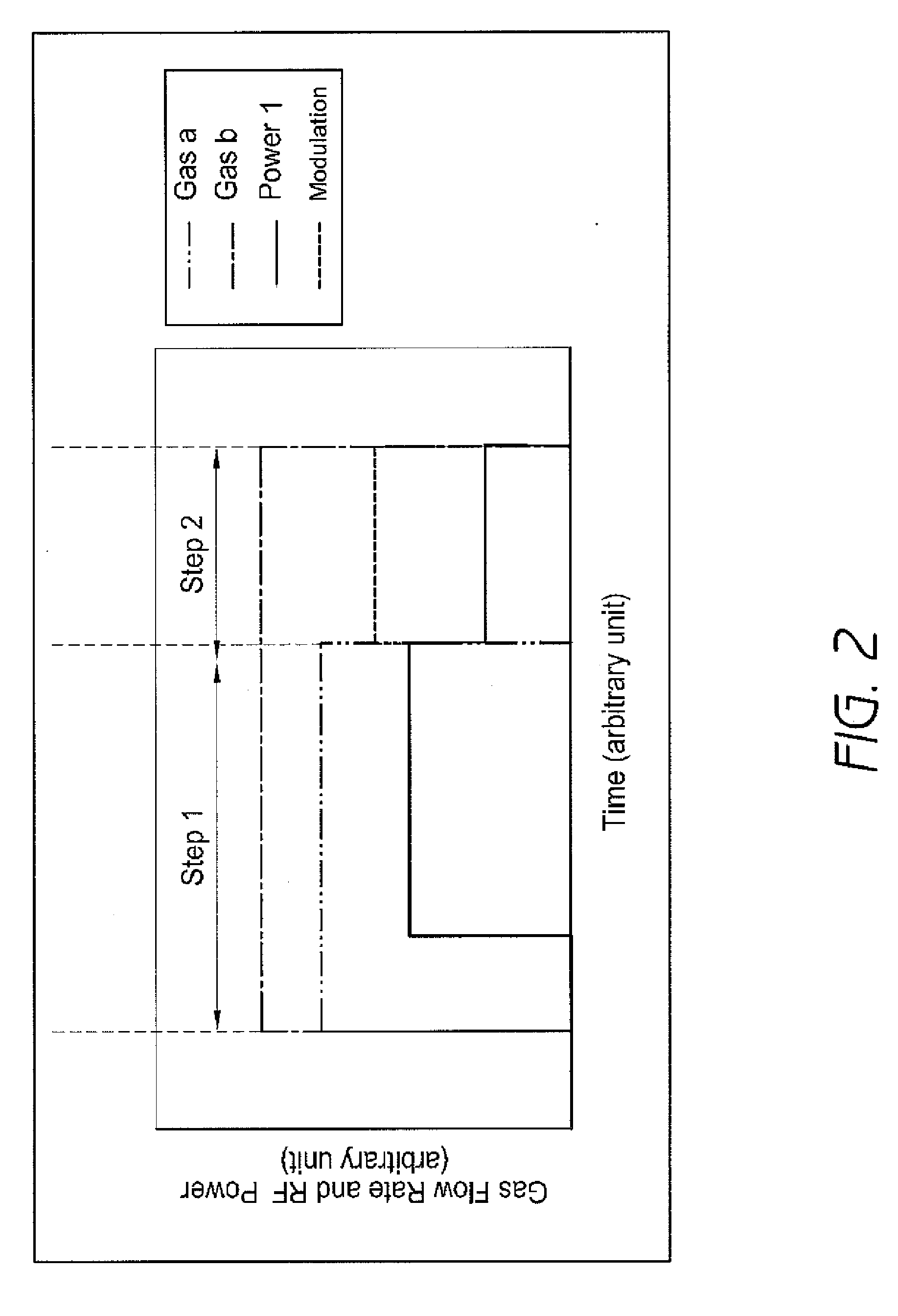

Method of plasma treatment using amplitude-modulated RF power

ActiveUS20090136683A1Reduce floating potentialSufficient voltageElectric discharge tubesVacuum evaporation coatingSusceptorForming gas

A method for processing a substrate by plasma CVD includes: (i) forming a film on a substrate placed on a susceptor by applying RF power between the susceptor and a shower plate in the presence of a film-forming gas in a reactor; and (ii) upon completion of step (i), without unloading the substrate, applying amplitude-modulated RF power between the susceptor and the shower plate in the absence of a film-forming gas but in the presence of a non-film-forming gas to reduce a floating potential of the substrate.

Owner:ASM JAPAN

Metal capacitor and method of making the same

ActiveUS8114734B2Increase capacitanceAvoid delaySemiconductor/solid-state device detailsSolid-state devicesCapacitanceInterconnection

A method of making a metal capacitor includes the following steps. A dielectric layer having a metal interconnection and a capacitor electrode is provided. Then, a treatment is performed to increase the dielectric constant of the dielectric layer surrounding the capacitor electrode. The treatment can be UV radiation, a plasma treatment or an ion implantation. Accordingly, the metal capacitor will have a higher capacitance and RC delay between the metal interconnection and the dielectric layer can be prevented.

Owner:MARLIN SEMICON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com