Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3648 results about "Partial pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In a mixture of gases, each constituent gas has a partial pressure which is the notional pressure of that constituent gas if it alone occupied the entire volume of the original mixture at the same temperature. The total pressure of an ideal gas mixture is the sum of the partial pressures of the gases in the mixture.

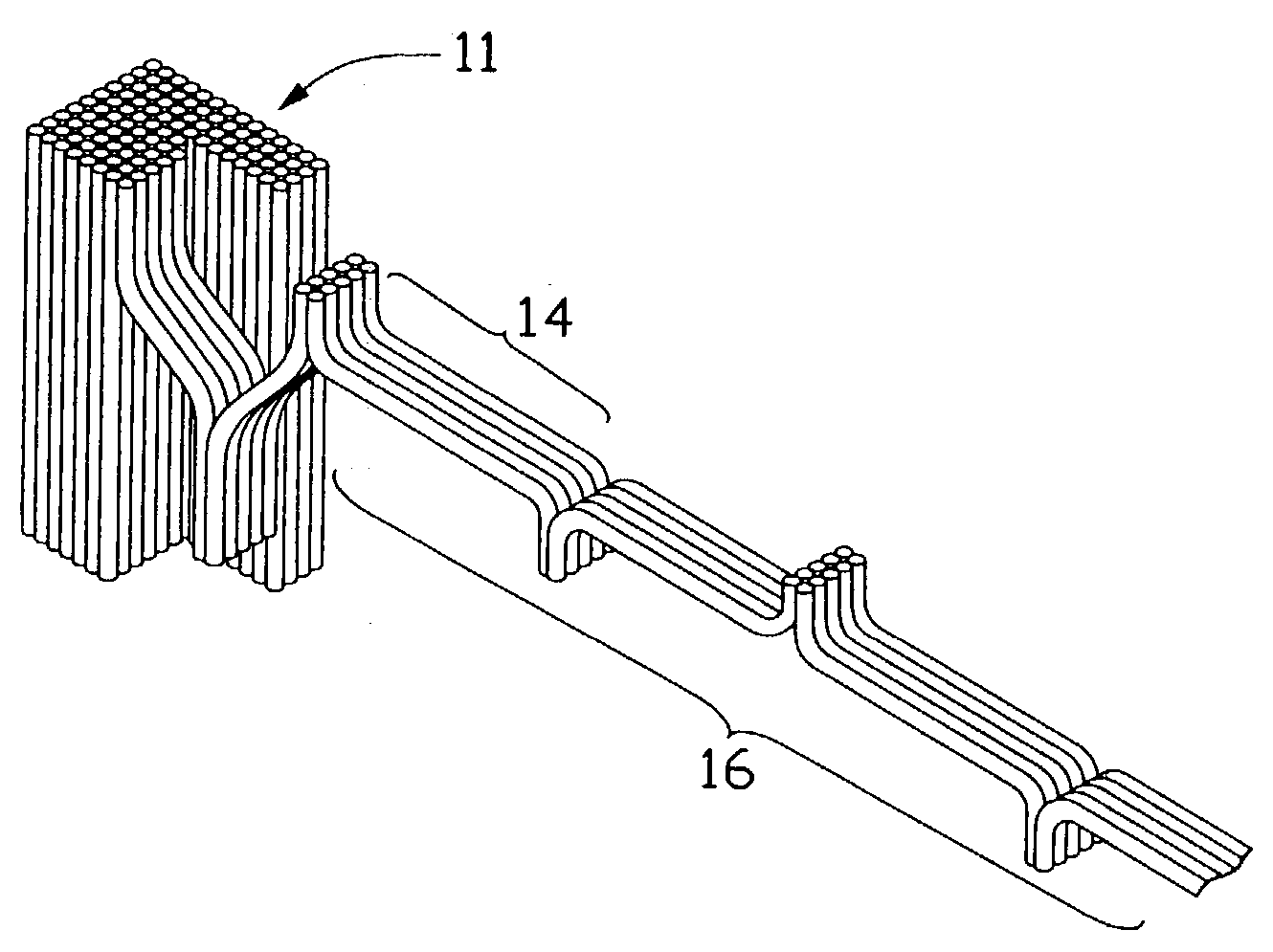

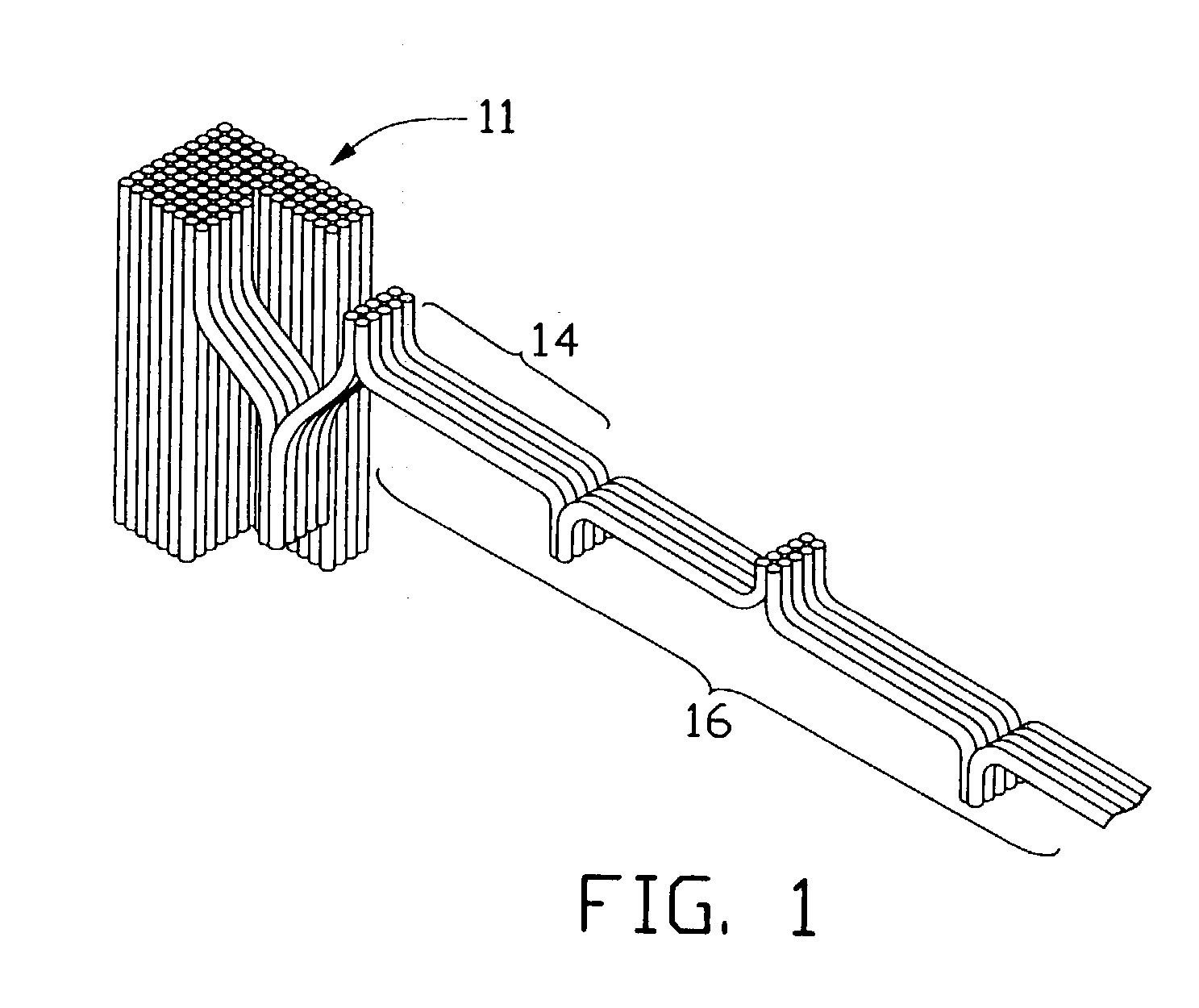

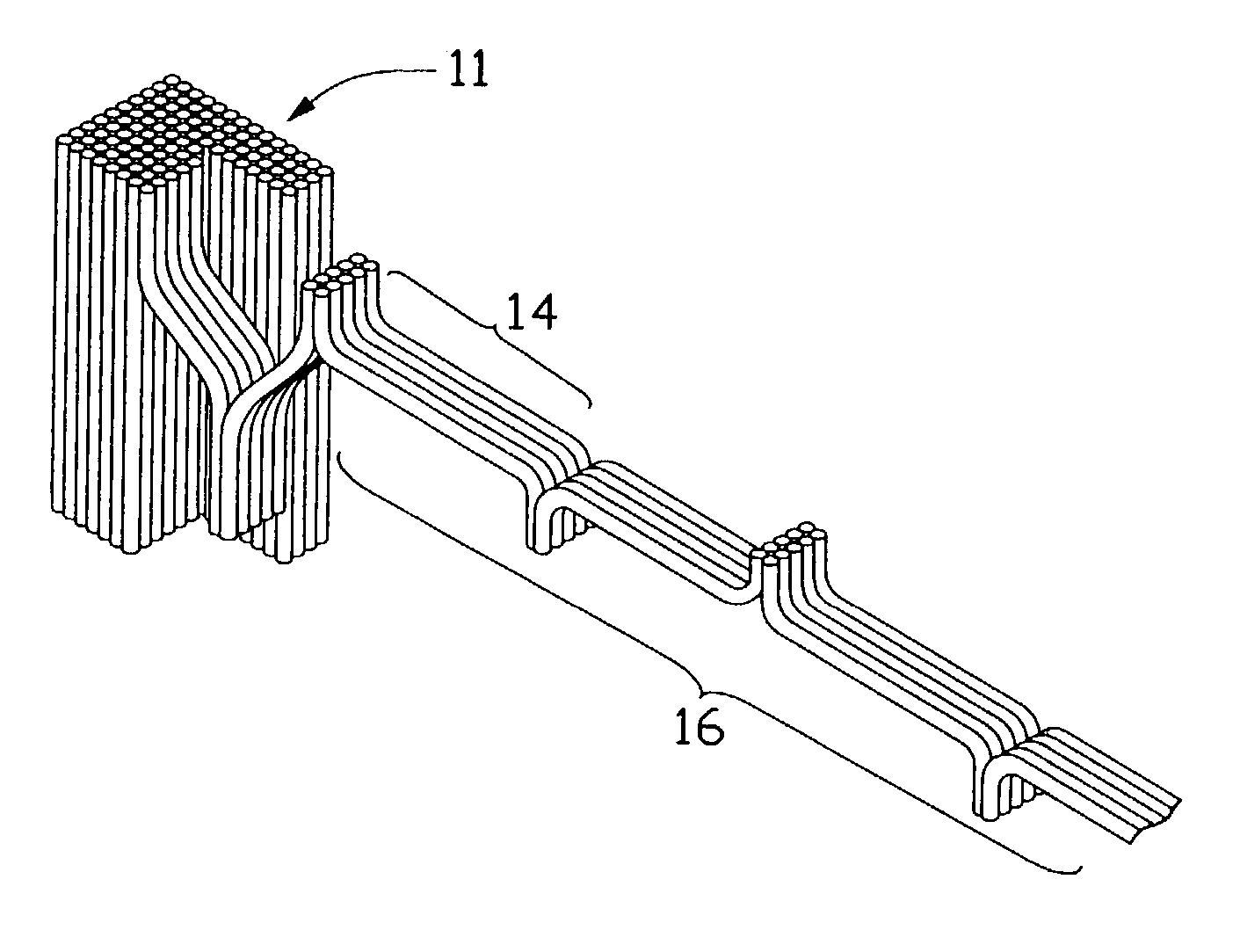

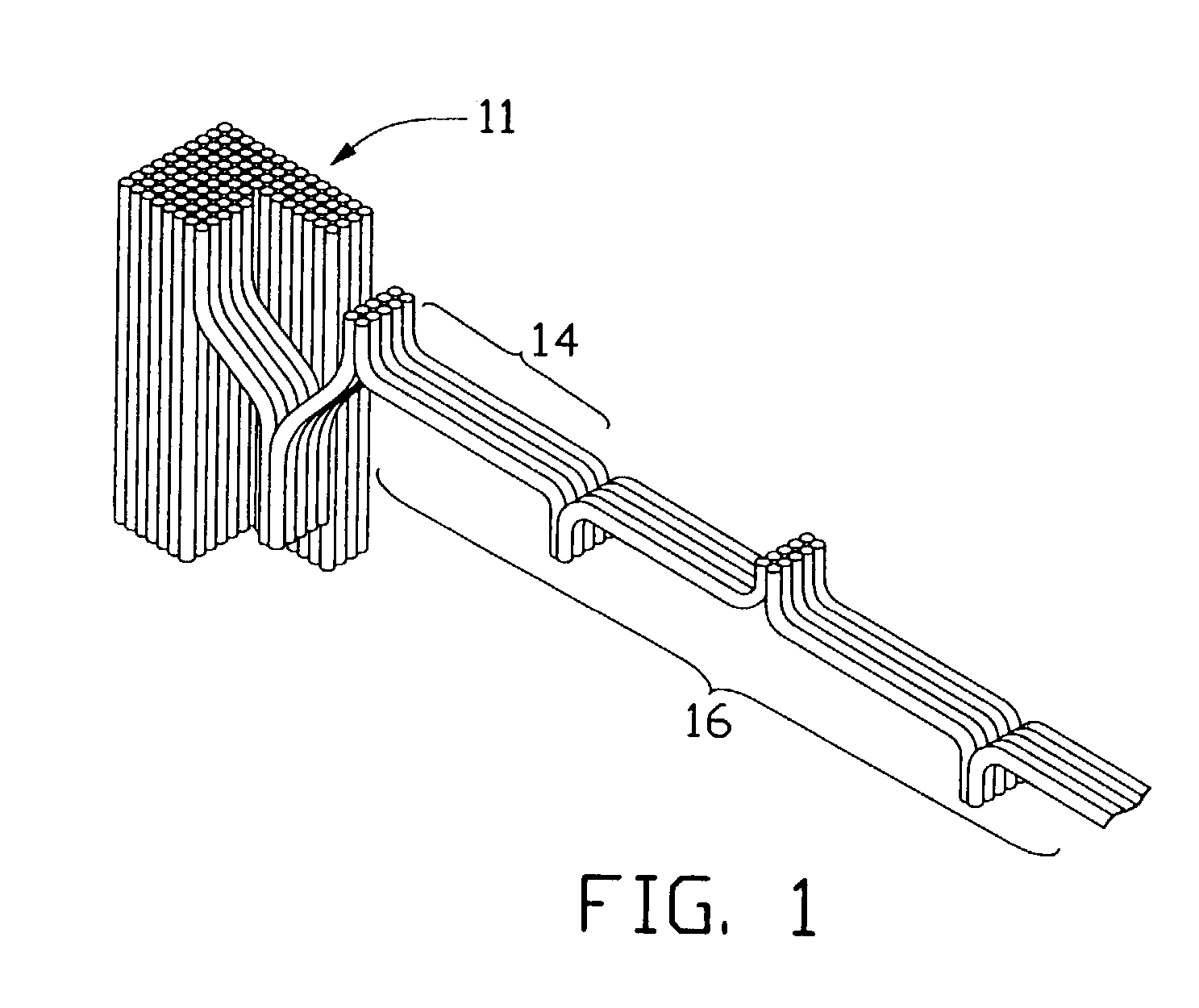

Method for fabricating carbon nanotube yarn

ActiveUS20040053780A1Material nanotechnologyCatalyst activation/preparationFurnace temperatureCarbon nanotube yarn

A method of fabricating a long carbon nanotube yarn includes the following steps: (1) providing a flat and smooth substrate; (2) depositing a catalyst on the substrate; (3) positioning the substrate with the catalyst in a furnace; (4) heating the furnace to a predetermined temperature; (5) supplying a mixture of carbon containing gas and protecting gas into the furnace; (6) controlling a difference between the local temperature of the catalyst and the furnace temperature to be at least 50° C.; (7) controlling the partial pressure of the carbon containing gas to be less than 0.2; (8) growing a number of carbon nanotubes on the substrate such that a carbon nanotube array is formed on the substrate; and (9) drawing out a bundle of carbon nanotubes from the carbon nanotube array such that a carbon nanotube yarn is formed.

Owner:HON HAI PRECISION IND CO LTD +1

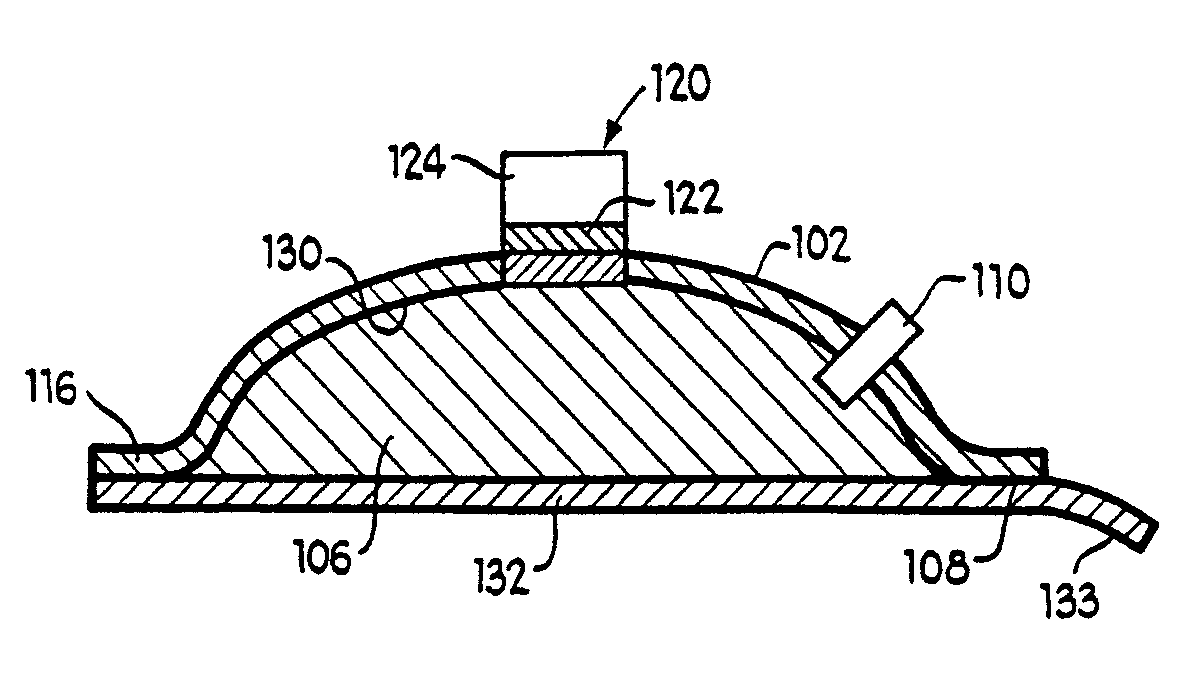

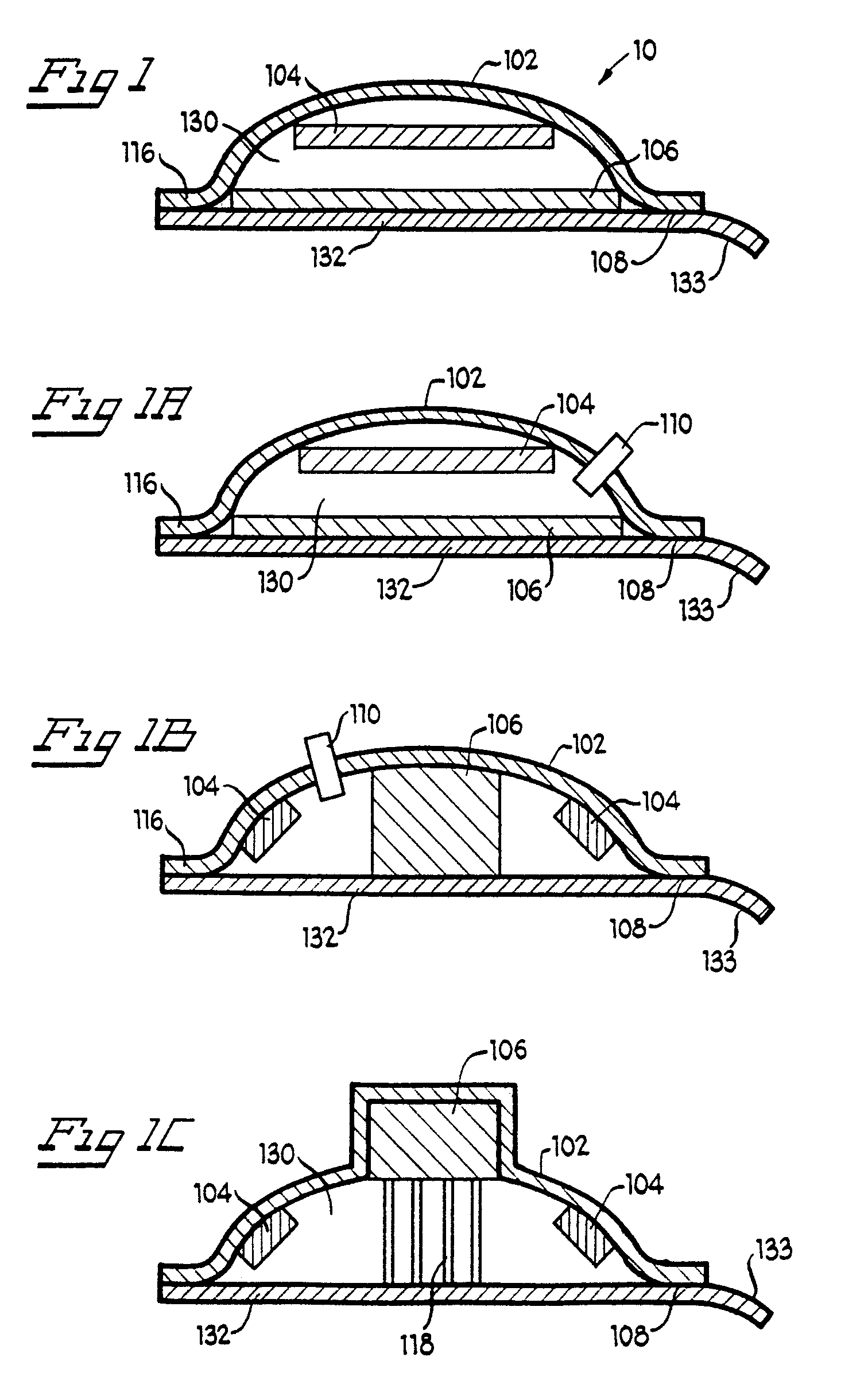

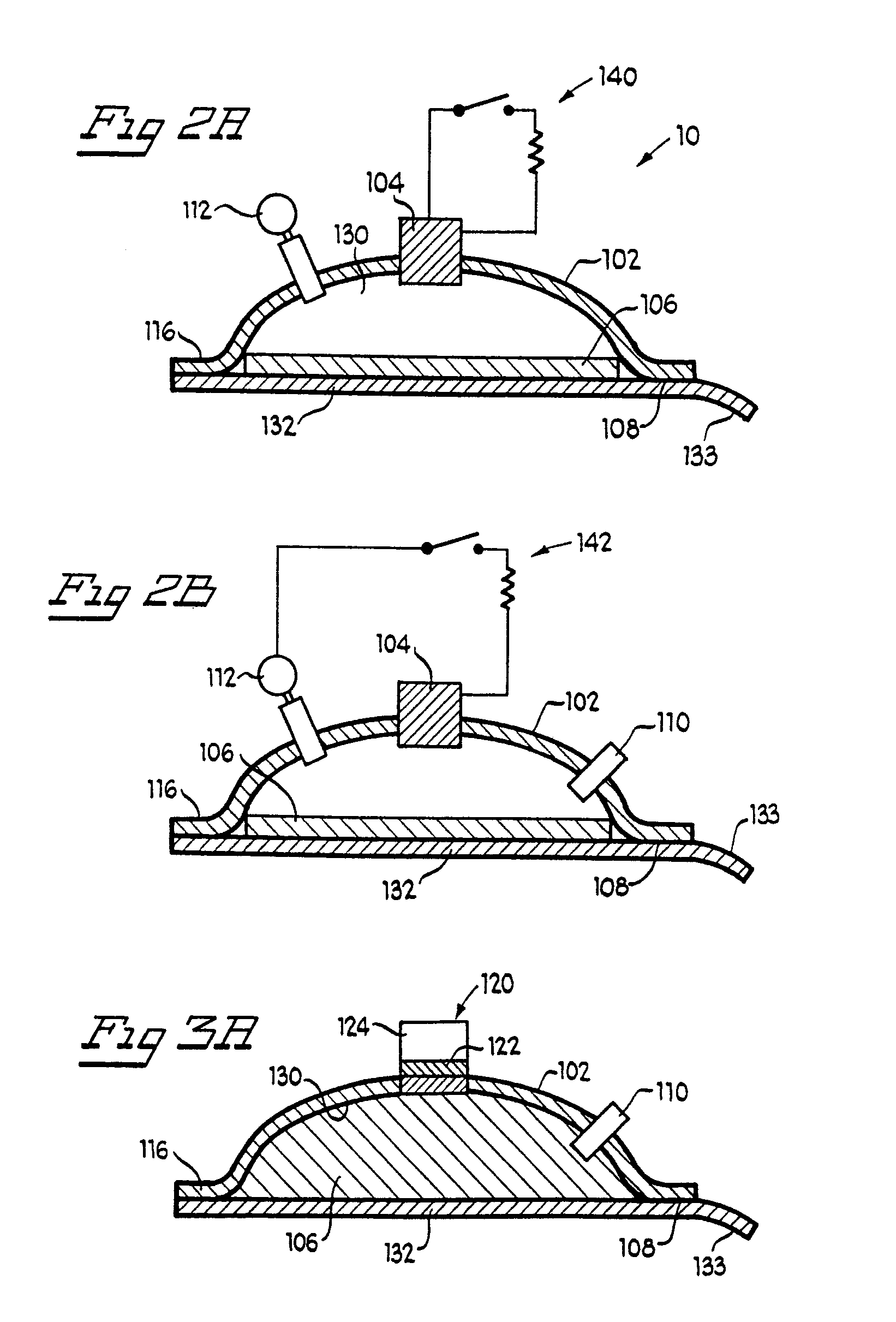

Device and method for wound therapy

A disposable wound-healing device is disclosed that incorporates a housing having a fluid-impermeable material having a cavity and a perimeter that can be sealed in an air-tight manner over a wound region of a patient. The device is capable of producing a negative pressure over the wound region by either removing oxygen from within the cavity, or absorbing fluid into the cavity and then removing the fluid from the cavity. The oxygen may be removed via chemical absorption, by an electrochemical cell or by a chemical reaction that cannibalizes oxygen from the cavity. The fluid may be removed through the use of osmotic or electro-osmotic cells, or through a one-way valve. The negative partial pressure over the wound region promotes healing.

Owner:MICROLIN

Method for fabricating carbon nanotube yarn

ActiveUS7045108B2Material nanotechnologyCatalyst activation/preparationFurnace temperatureCarbon nanotube yarn

A method of fabricating a long carbon nanotube yarn includes the following steps: (1) providing a flat and smooth substrate; (2) depositing a catalyst on the substrate; (3) positioning the substrate with the catalyst in a furnace; (4) heating the furnace to a predetermined temperature; (5) supplying a mixture of carbon containing gas and protecting gas into the furnace; (6) controlling a difference between the local temperature of the catalyst and the furnace temperature to be at least 50° C.; (7) controlling the partial pressure of the carbon containing gas to be less than 0.2; (8) growing a number of carbon nanotubes on the substrate such that a carbon nanotube array is formed on the substrate; and (9) drawing out a bundle of carbon nanotubes from the carbon nanotube array such that a carbon nanotube yarn is formed.

Owner:HON HAI PRECISION IND CO LTD +1

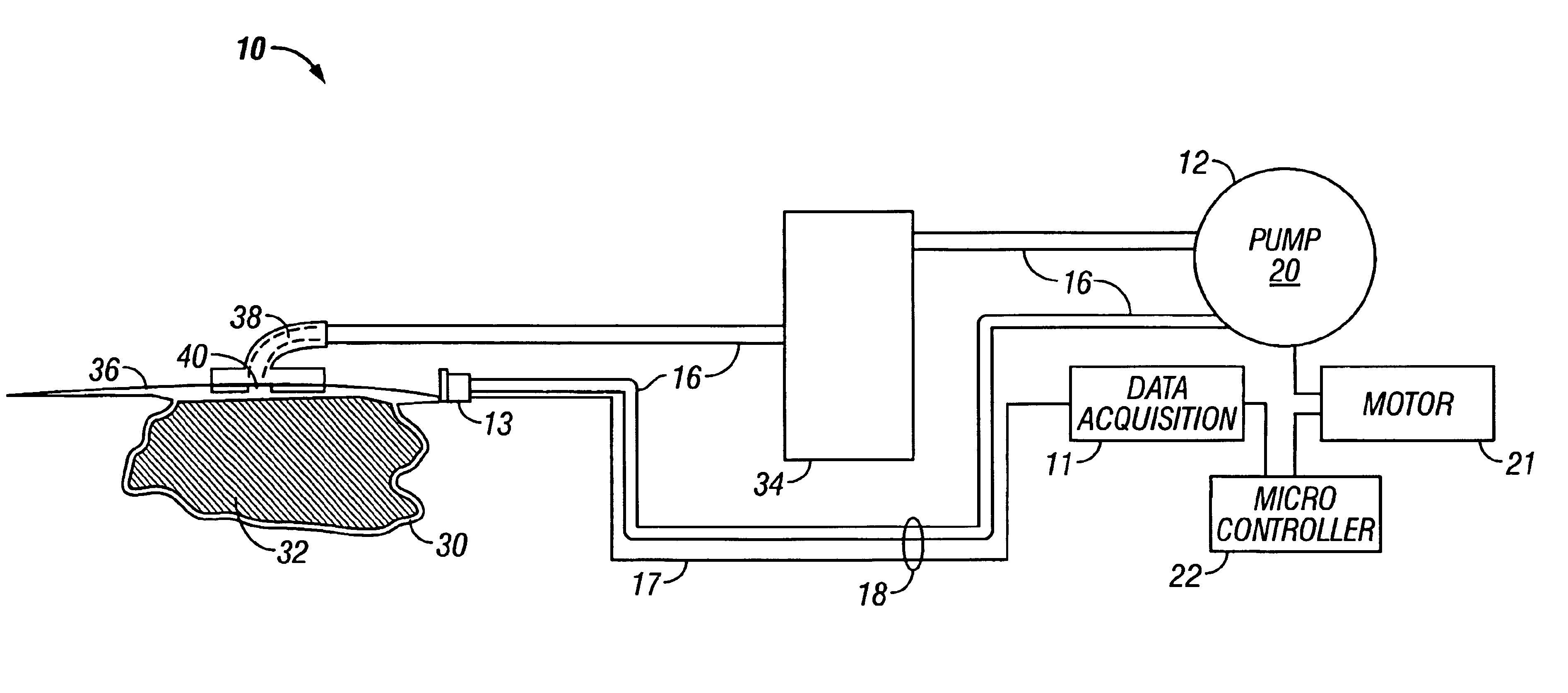

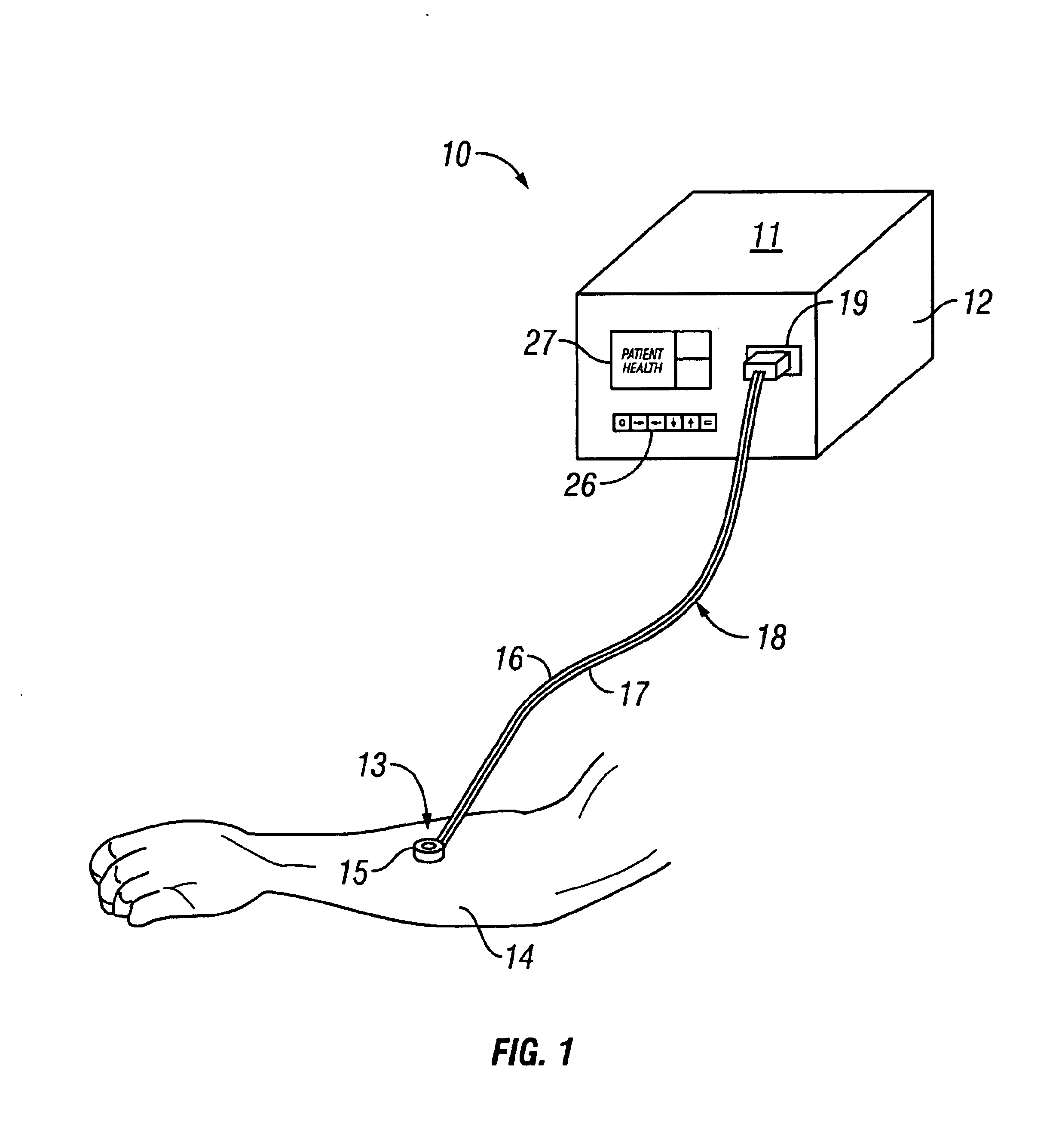

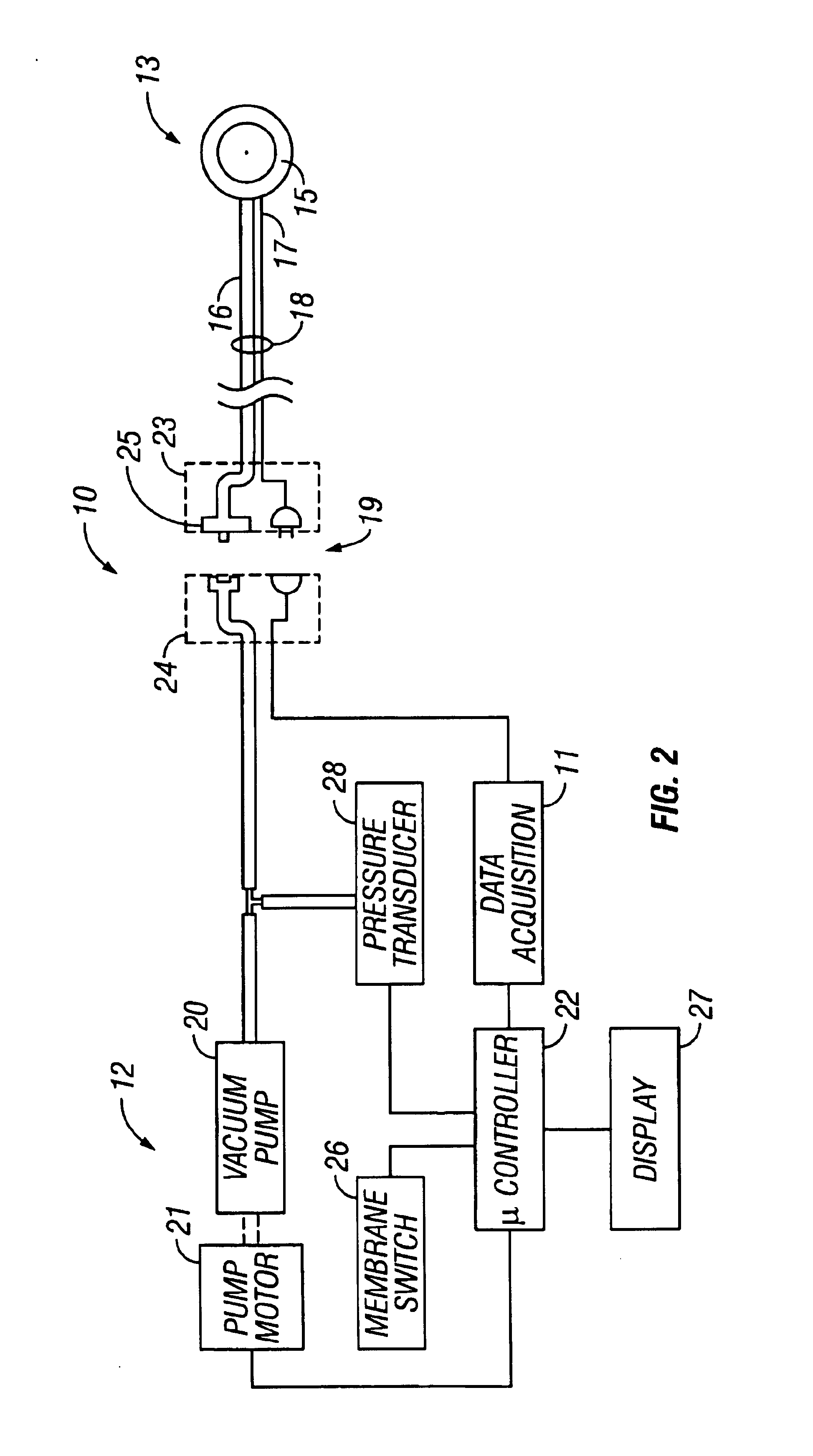

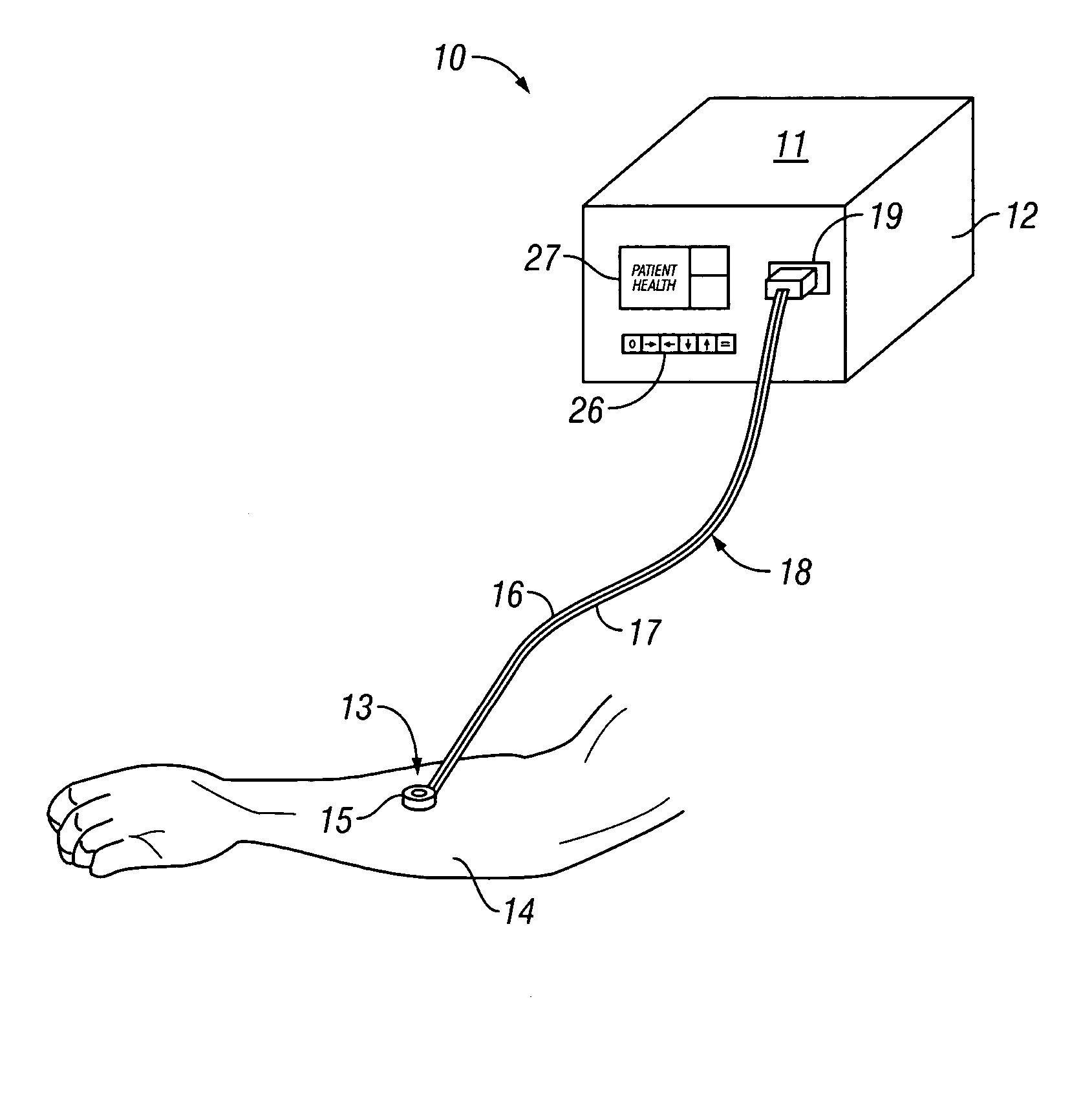

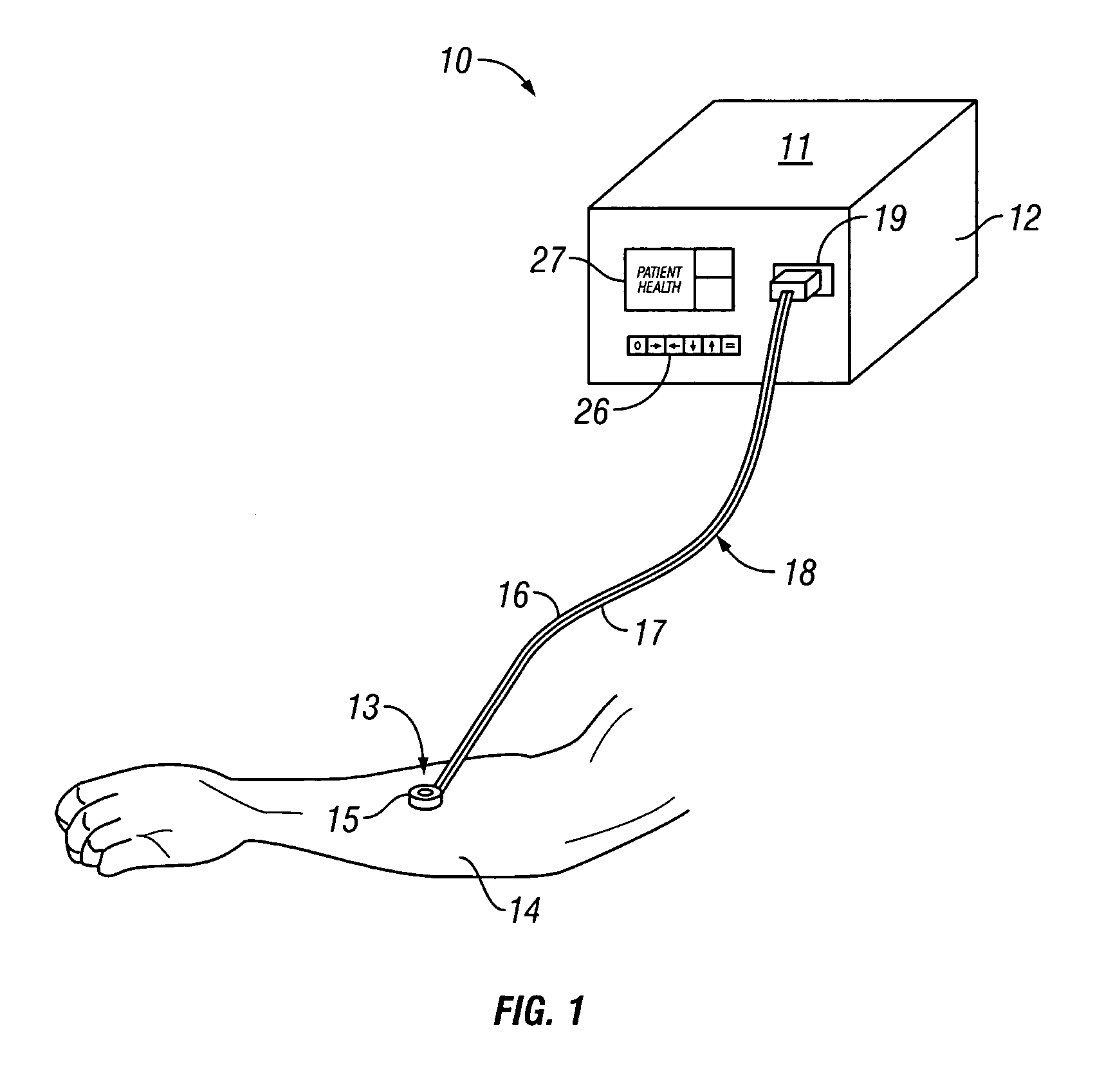

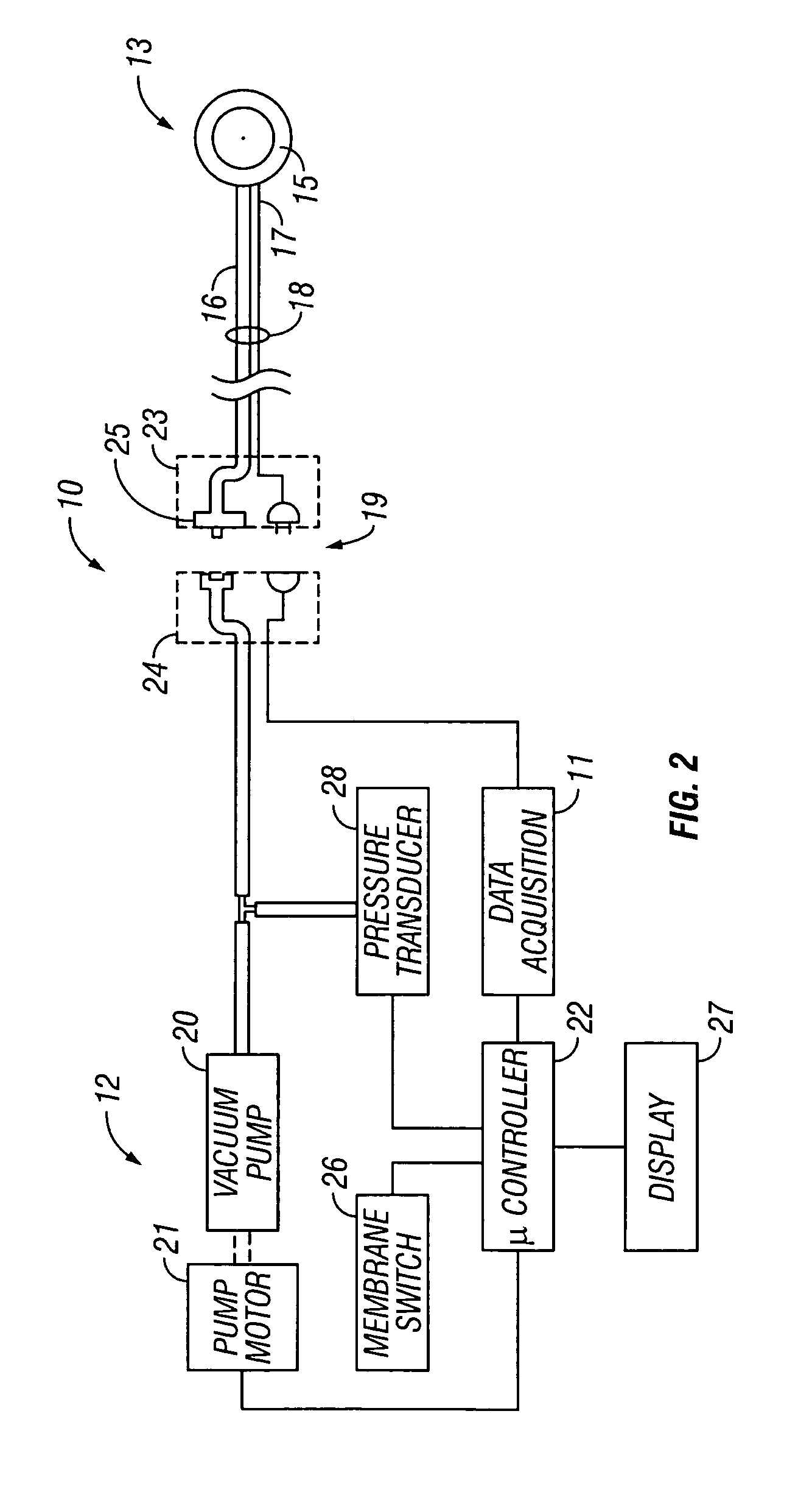

System for combined transcutaneous blood gas monitoring and vacuum assisted wound closure

InactiveUS6856821B2Eliminate opportunitySubstantial riskIntravenous devicesDiagnostic recording/measuringMicrocontrollerVacuum assisted

A method and apparatus for the transcutaneous monitoring of blood gases generally comprises a blood gas data acquisition device, a vacuum source and a blood gas transducer unit. The blood gas transducer unit is adapted for application to a patient's skin and administration of a local vacuum at the area of patient application. It further comprises an electrochemical blood gas transducer, well known to those of ordinary skill in the art, which is disposed entirely within the local vacuum at the area of patient application. The vacuum source is placed in fluid communication with the blood gas transducer unit, through a hydrophobic membrane filter for safety purposes, in order to induce a condition of hyperperfusion in the locality of the electrochemical blood gas transducer. Under the control of a microcontroller, or equivalent means, the blood gas acquisition device is then utilized to capture a measure of skin surface oxygen or carbon dioxide pressure. The microcontroller can then utilize this measure to arrive at an estimate of arterial partial pressure of oxygen or carbon dioxide, accordingly. Because vacuum induced perfusion produces the requisite condition of hyperperfusion without local heating and, therefore, without acceleration of the local metabolic function, the present invention results in more accurate than previously available estimates of partial pressure blood gas pressures and does so while eliminating a significant risk for injury to the patient.

Owner:KCI LICENSING INC

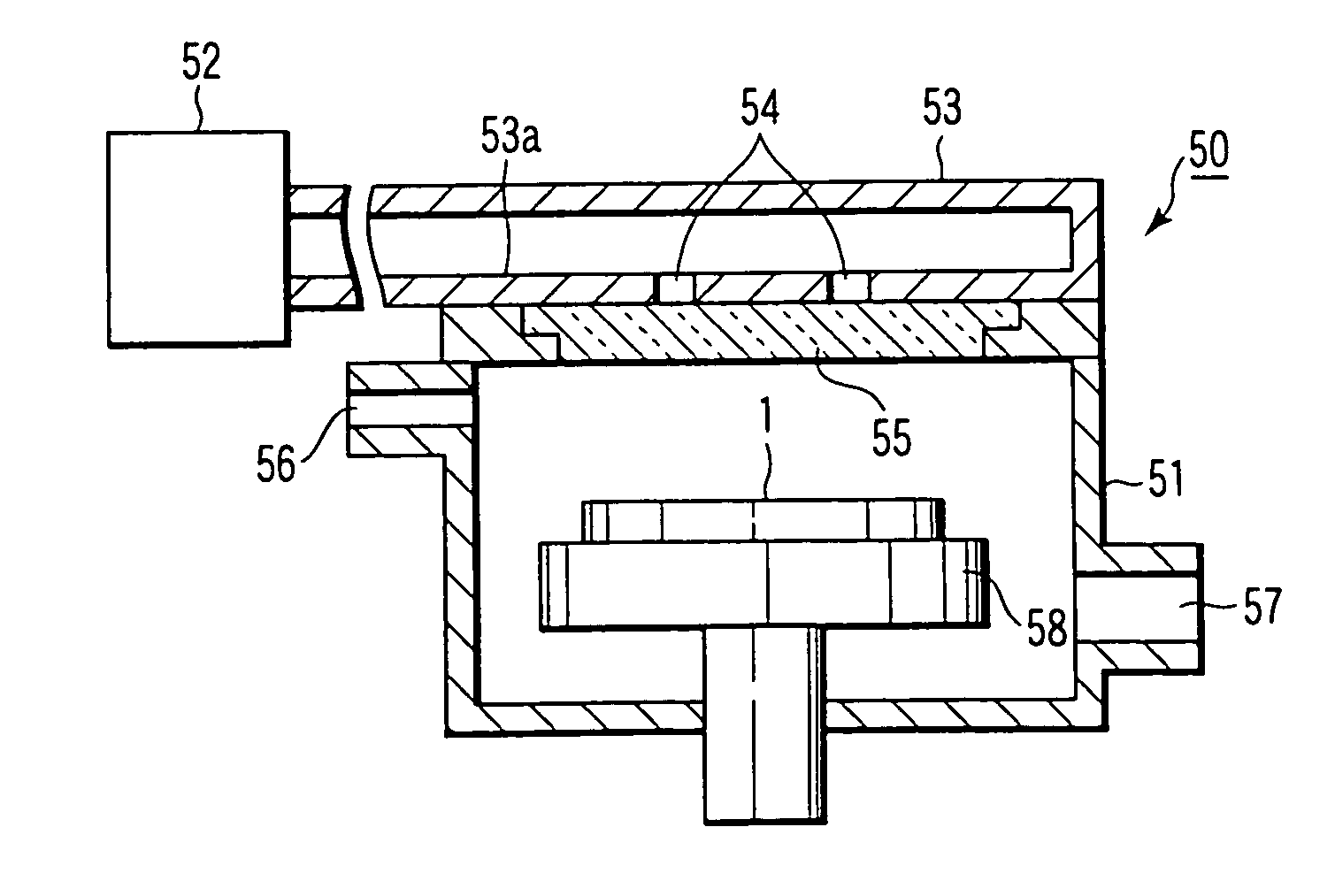

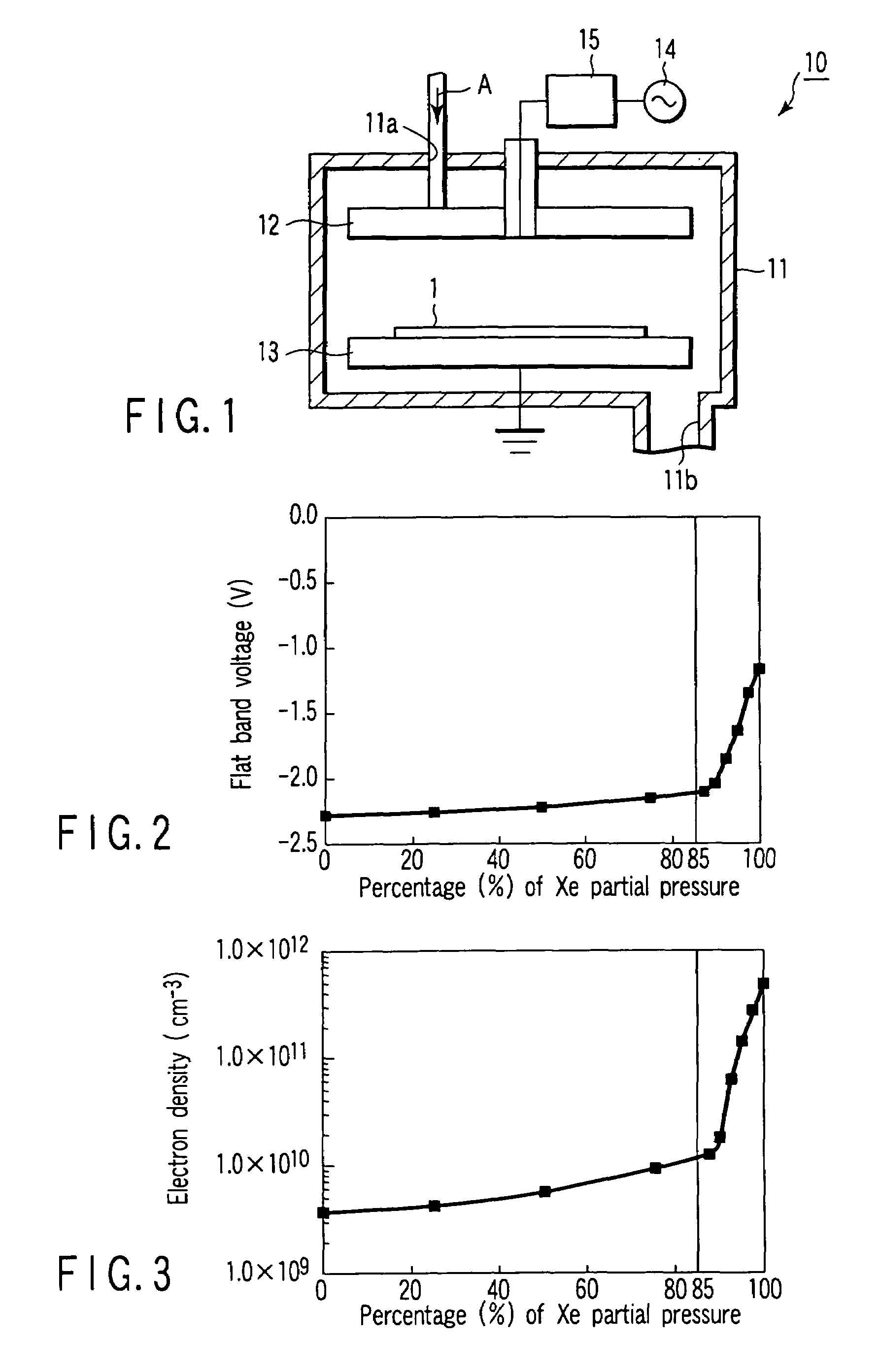

Film-forming method, method of manufacturing semiconductor device, semiconductor device, method of manufacturing display device, and display device

InactiveUS7307028B2Small currentTransistorSemiconductor/solid-state device manufacturingNoble gasDevice material

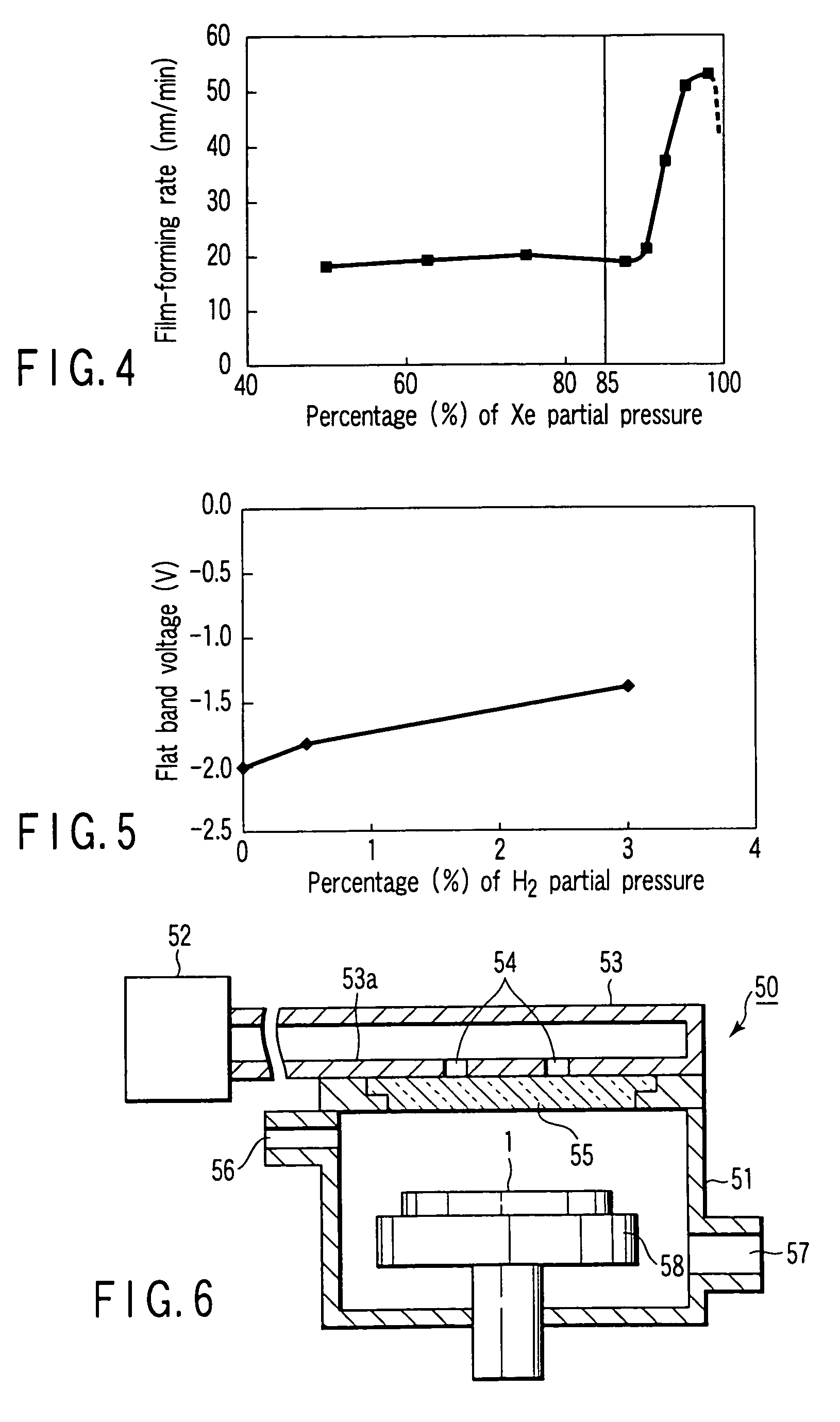

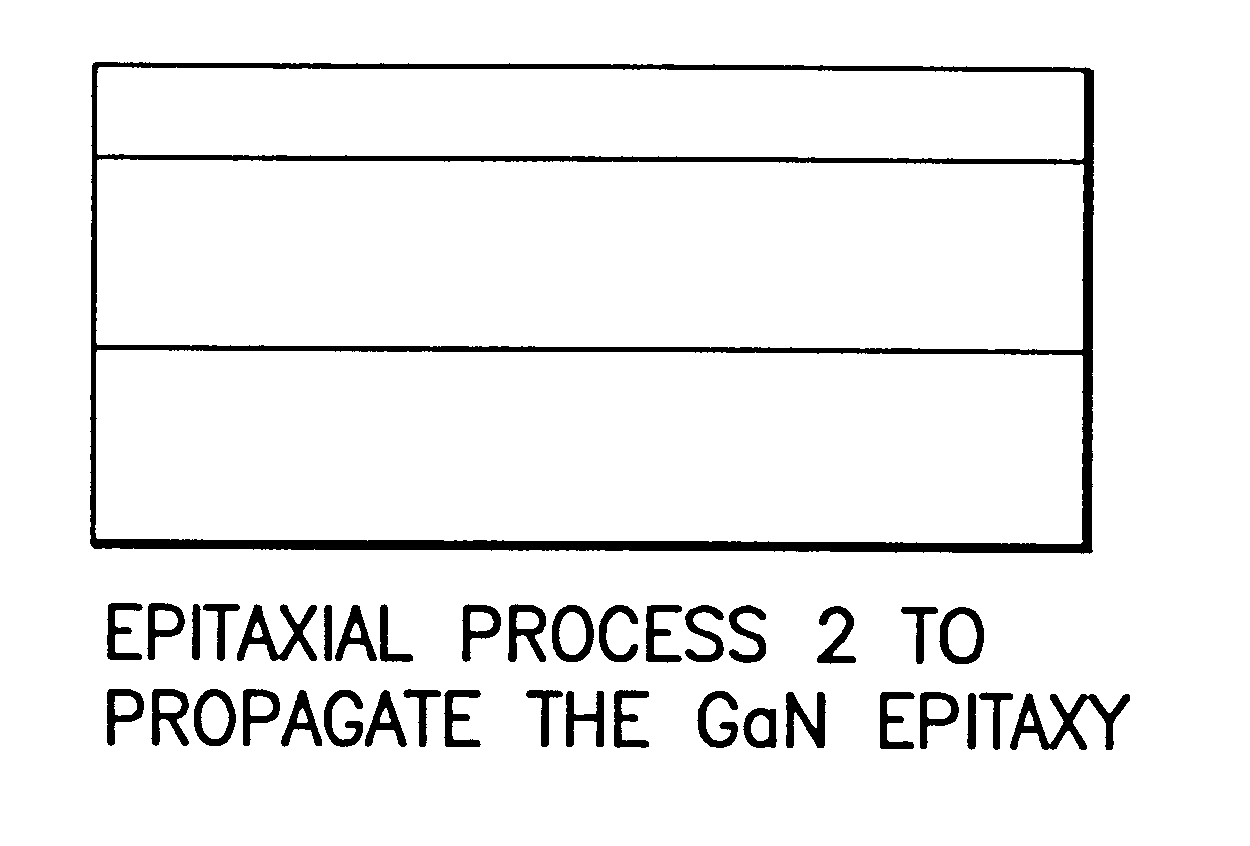

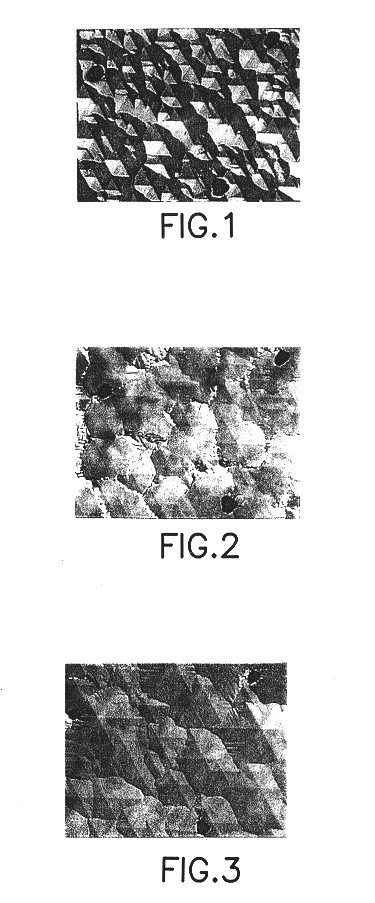

Disclosed is a film-forming method, comprising supplying into a plasma processing chamber at least three kinds of gases including a silicon compound gas, an oxidizing gas, and a rare gas, the percentage of the partial pressure of the rare gas (Pr) based on the total pressure being not smaller than 85%, i.e., 85%≦Pr<100%, and generating a plasma within the plasma processing chamber so as to form a film of silicon oxide on a substrate to be processed.

Owner:ADVANCED LCD TECH DEVMENT CENT

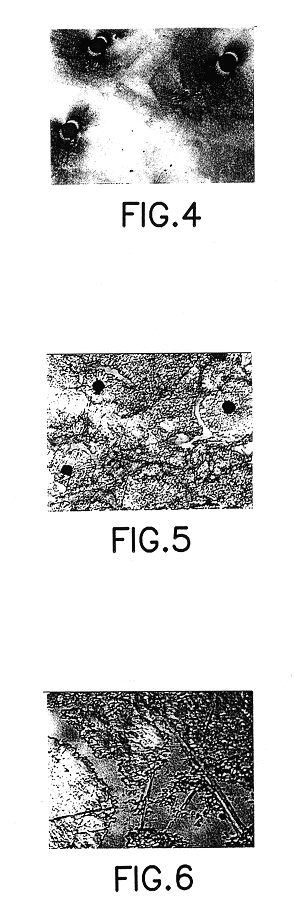

Method for achieving improved epitaxy quality (surface texture and defect density) on free-standing (aluminum, indium, gallium) nitride ((al,in,ga)n) substrates for opto-electronic and electronic devices

A III-V nitride homoepitaxial microelectronic device structure comprising a III-V nitride homoepitaxial epi layer on a III-V nitride material substrate, e.g., of freestanding character. Various processing techniques are described, including a method of forming a III-V nitride homoepitaxial layer on a corresponding III-V nitride material substrate, by depositing the III-V nitride homoepitaxial layer by a VPE process using Group III source material and nitrogen source material under process conditions including V / III ratio in a range of from about 1 to about 105, nitrogen source material partial pressure in a range of from about 1 to about 103 torr, growth temperature in a range of from about 500 to about 1250 degrees Celsius, and growth rate in a range of from about 0.1 to about 500 microns per hour. The III-V nitride homoepitaxial microelectronic device structures are usefully employed in device applications such as UV LEDs, high electron mobility transistors, and the like.

Owner:WOLFSPEED INC

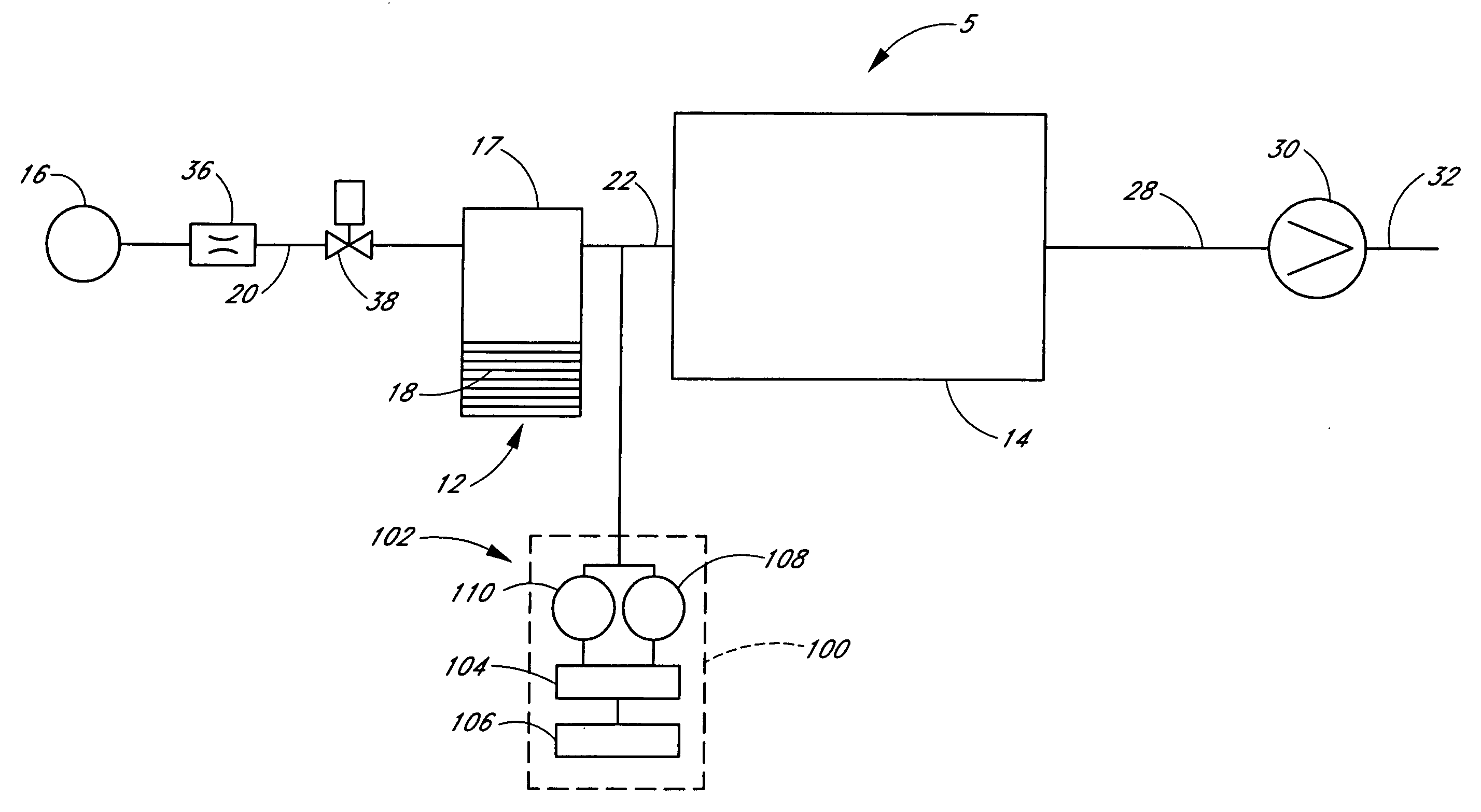

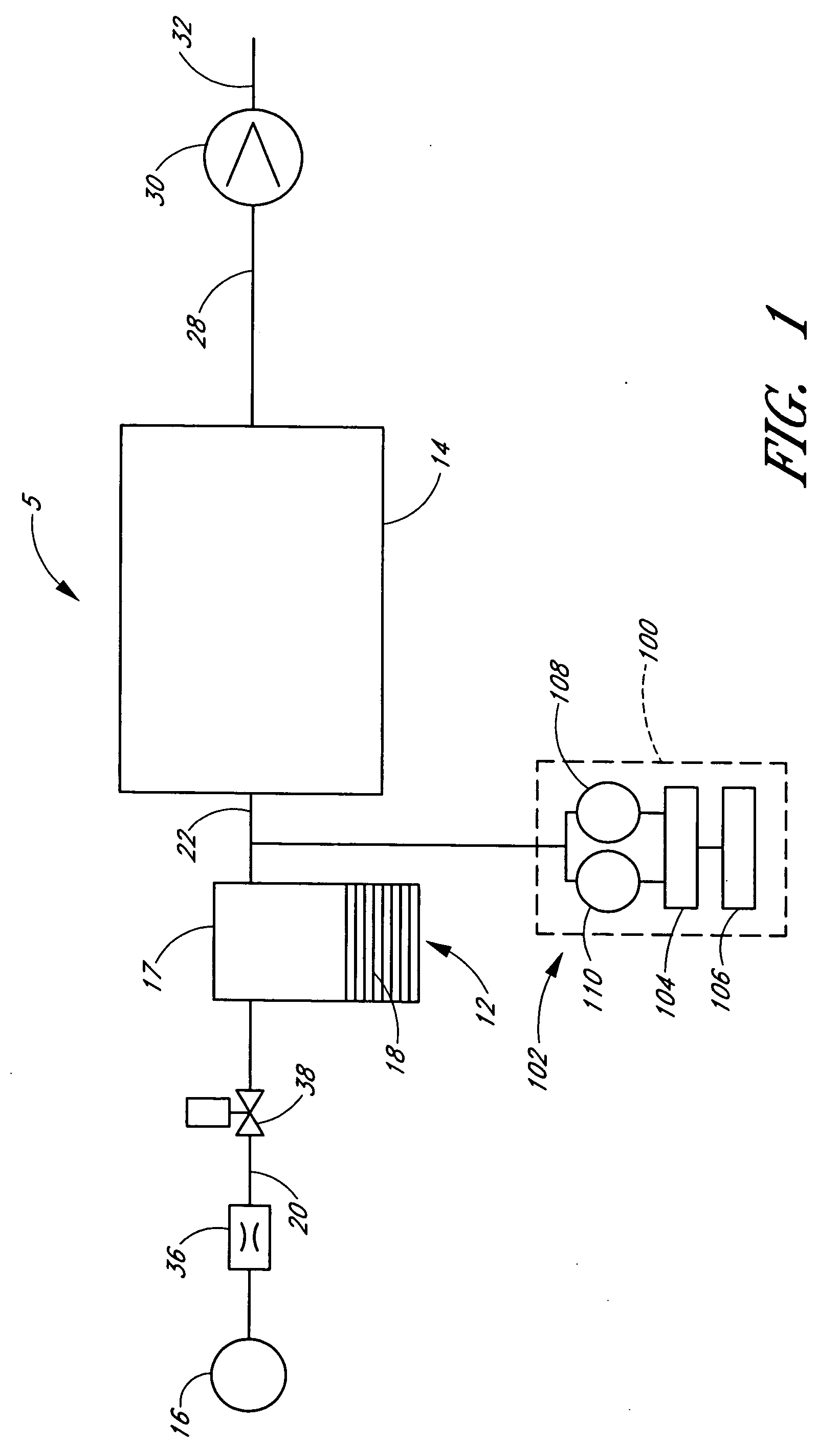

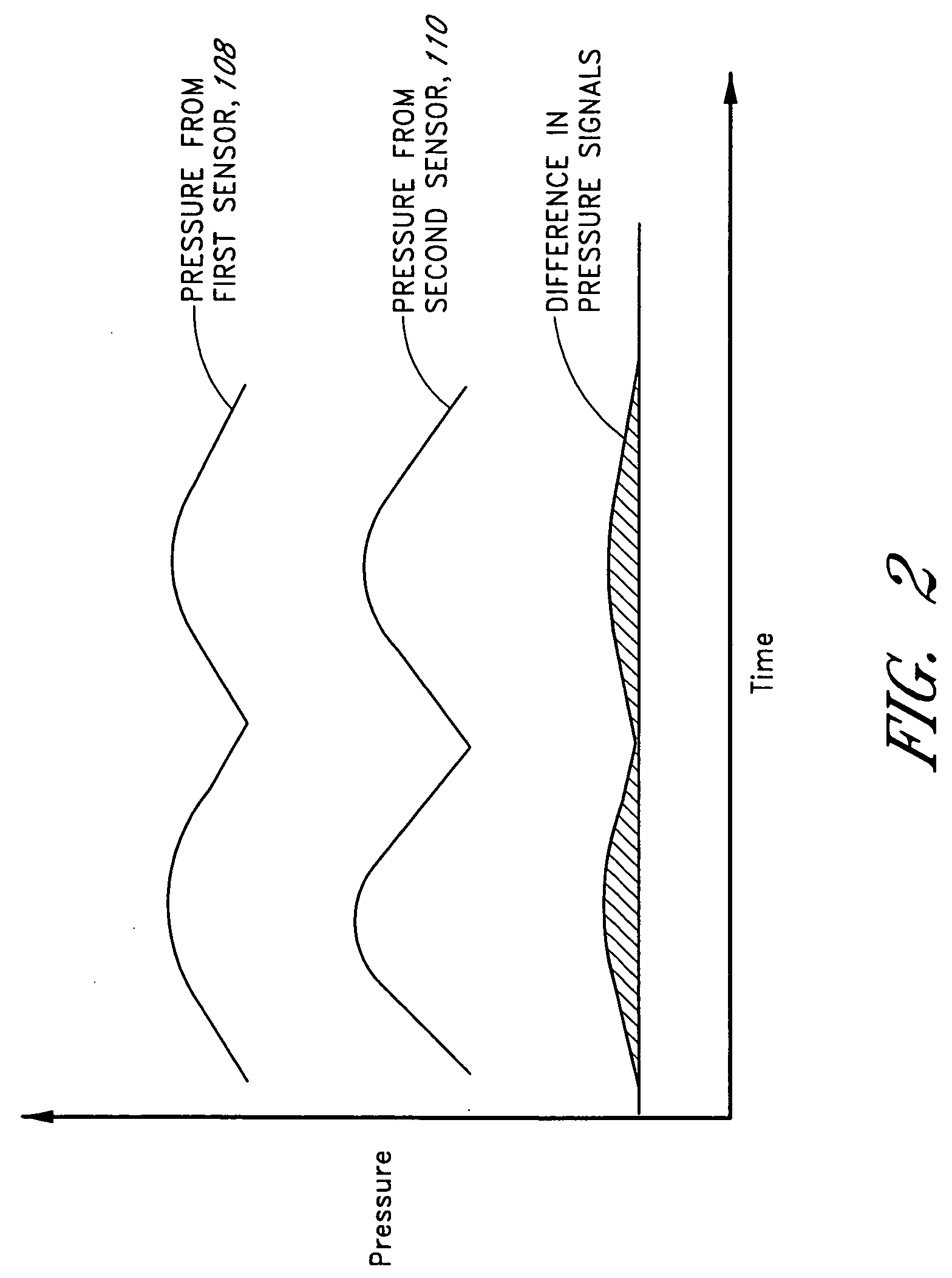

Method and apparatus for measuring consumption of reactants

InactiveUS20060107898A1Liquid surface applicatorsChemical vapor deposition coatingEngineeringForce sensor

A method and apparatus for measuring the consumption of reactants includes a partial pressure sensor for measuring the partial pressure of a reactant in a reactant stream. The partial pressure sensor includes a first pressure sensor that has a first sensitivity to the composition of the gas stream and a second pressure sensor that has a second sensitivity to the composition of the reactant stream, the second sensitivity being greater than the first sensitivity. A control unit is configured to compare a first pressure signal from the first pressure sensor to a second pressure signal from the second pressure sensor to determine the partial pressure of the reactant in the reactant stream.

Owner:BLOMBERG TOM E

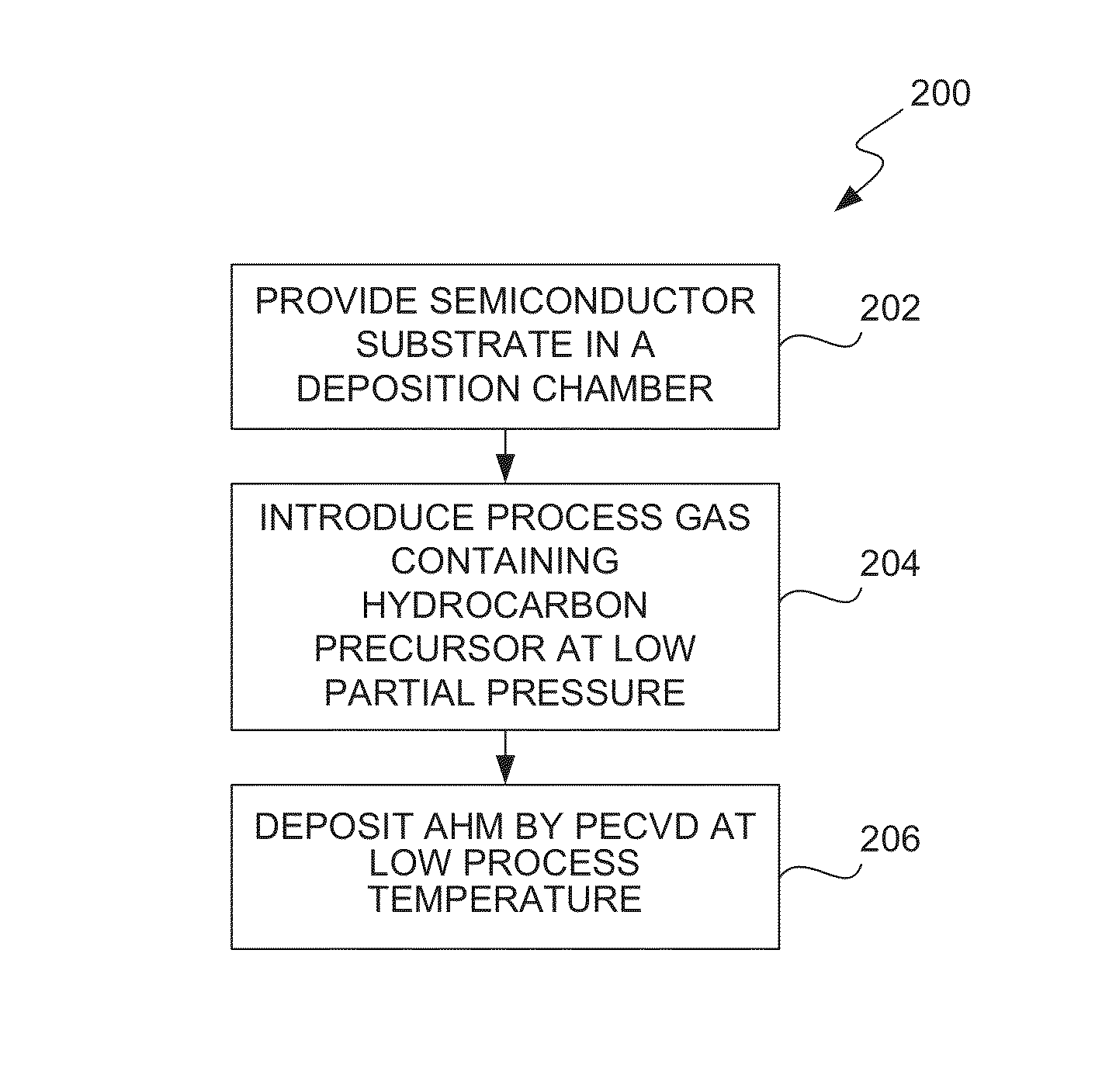

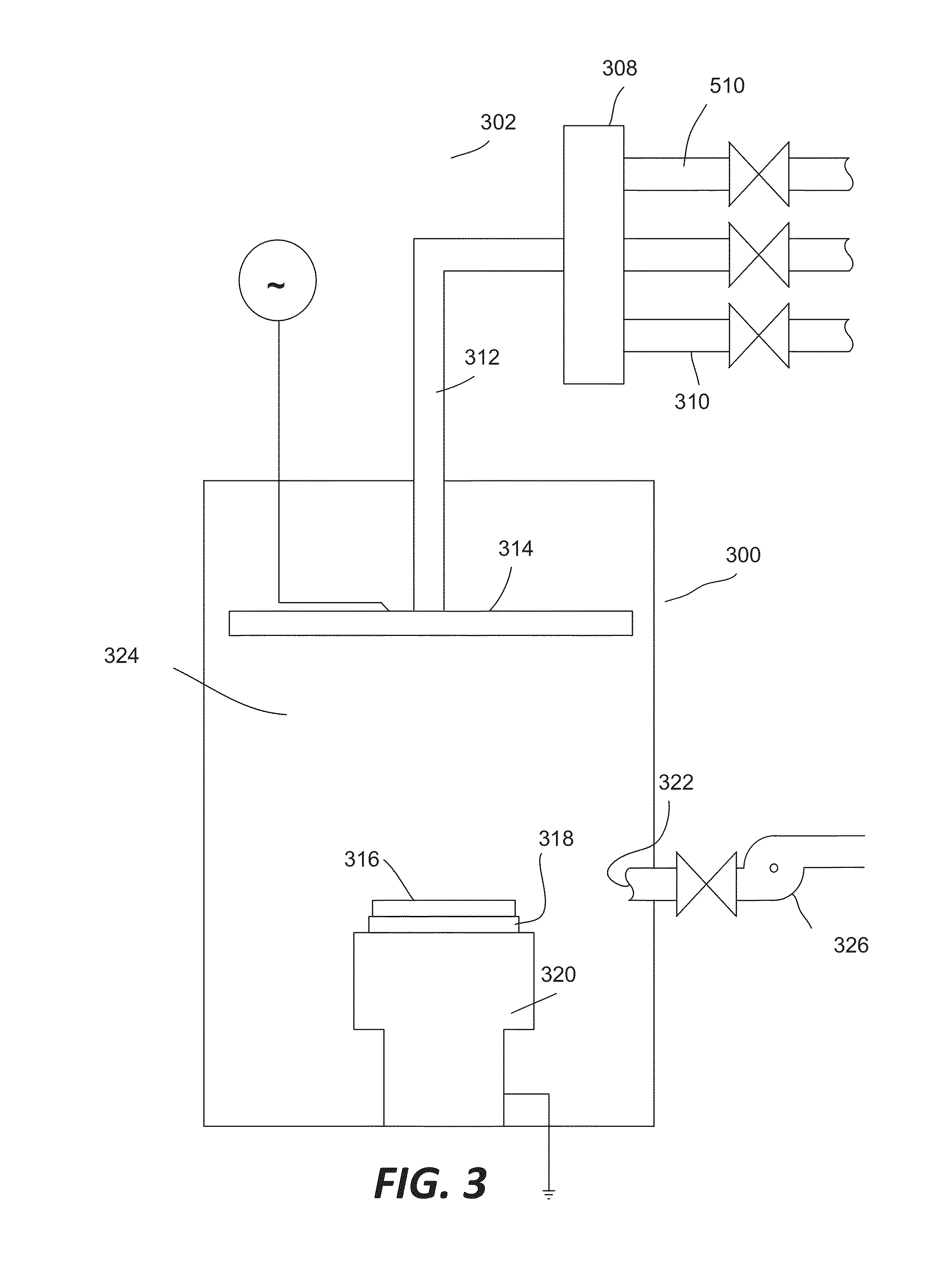

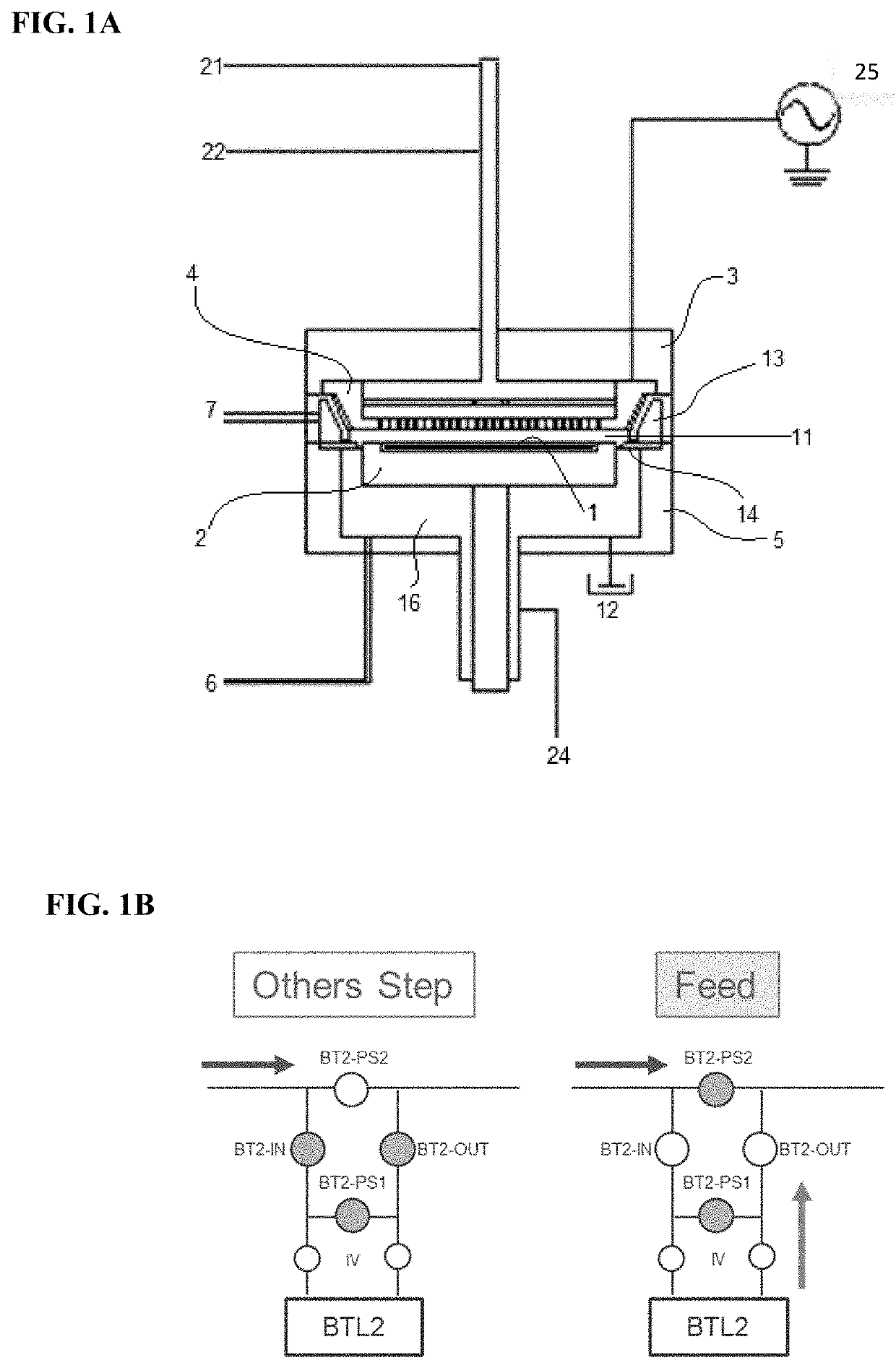

Methods and apparatus for plasma-based deposition

ActiveUS20140057454A1Reduction of overall thermal budgetImprove etch selectivityElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPartial pressure

High-deposition rate methods for forming transparent ashable hardmasks (AHMs) that have high plasma etch selectivity to underlying layers are provided. The methods involve placing a wafer on a powered electrode such as a powered pedestal for plasma-enhanced deposition. According to various embodiments, the deposition is run at low hydrocarbon precursor partial pressures and / or low process temperatures. Also provided are ceramic wafer pedestals with multiple electrode planes embedded with the pedestal are provided. According to various embodiments, the pedestals have multiple RF mesh electrode planes that are connected together such that all the electrode planes are at the same potential.

Owner:NOVELLUS SYSTEMS

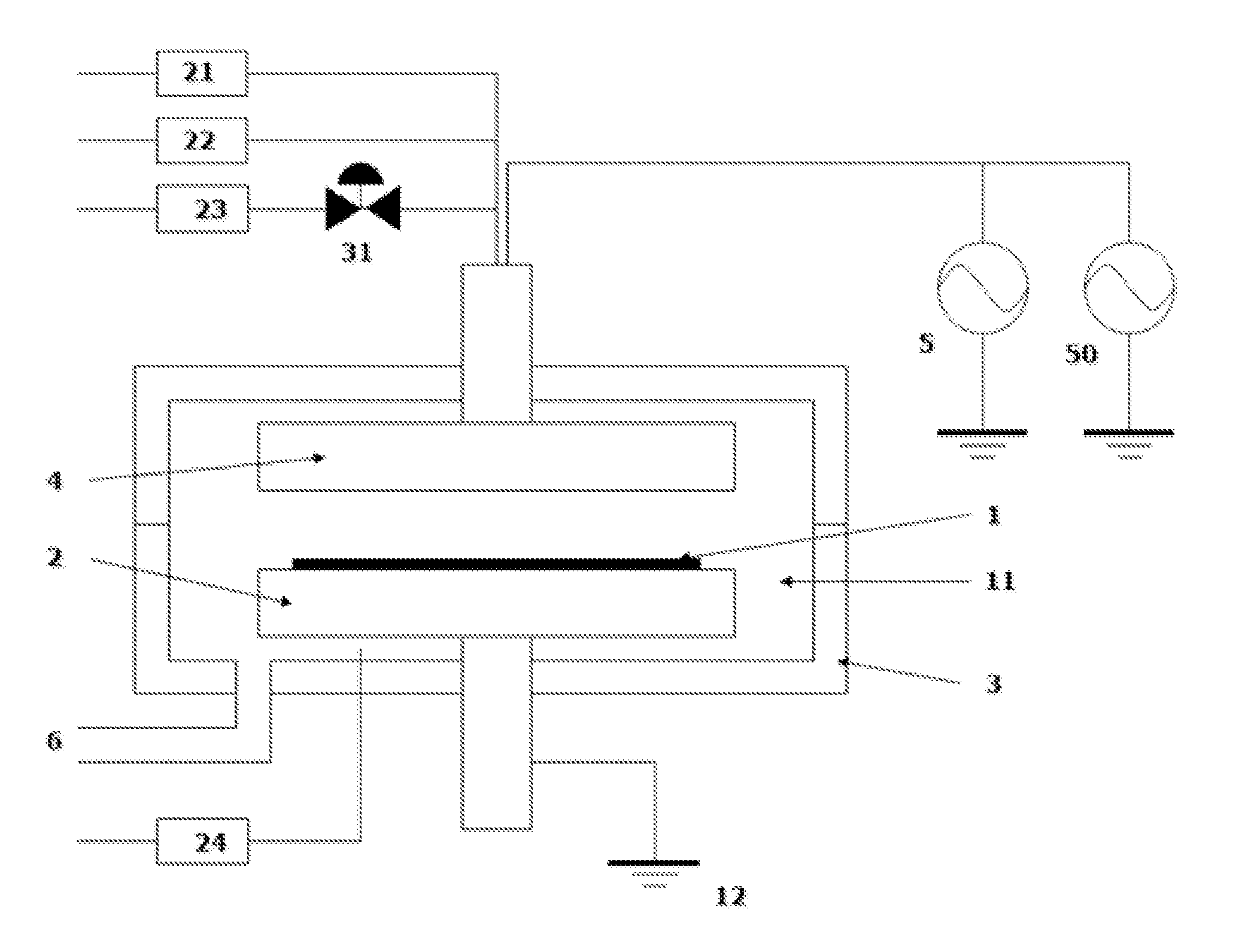

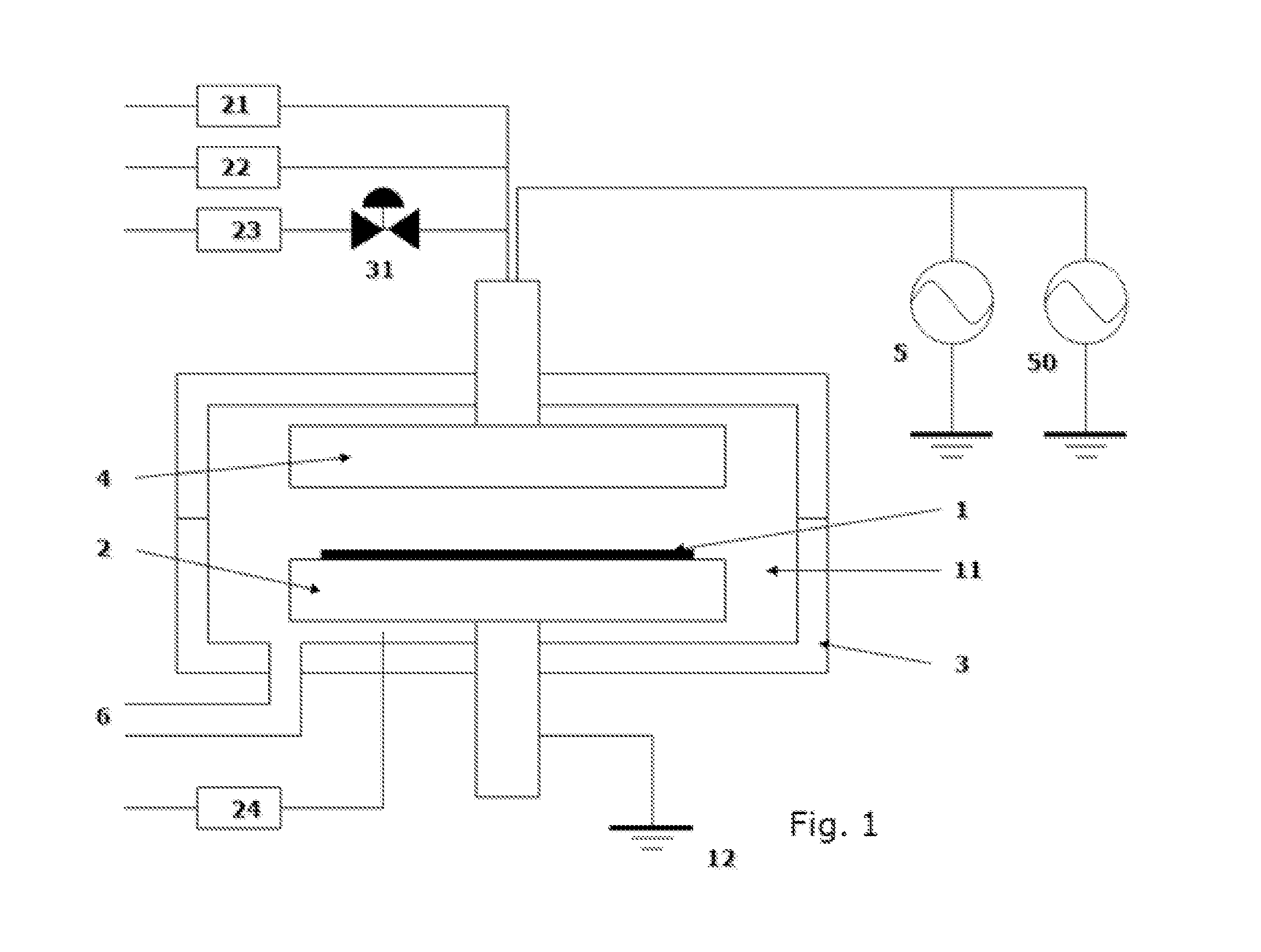

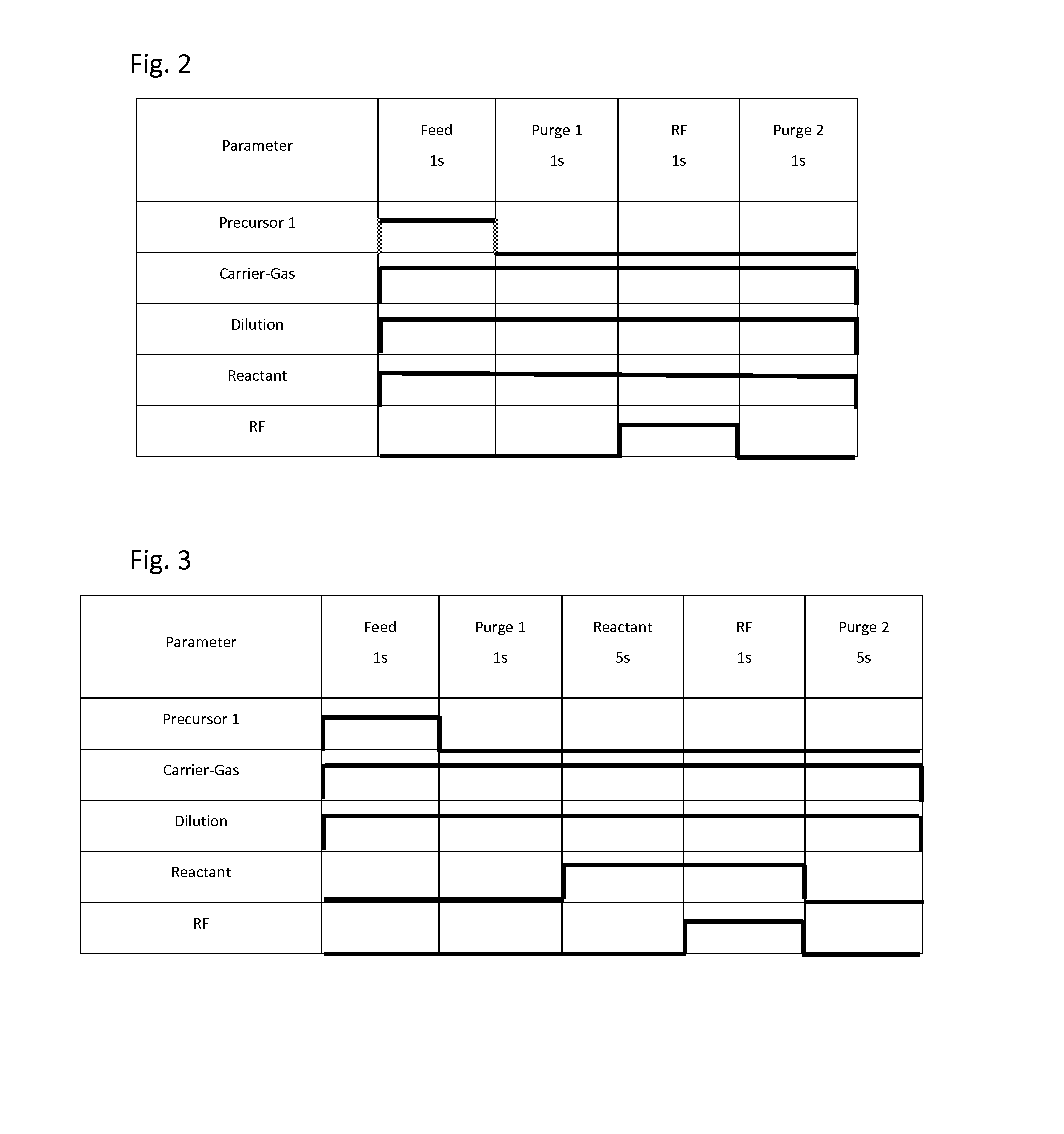

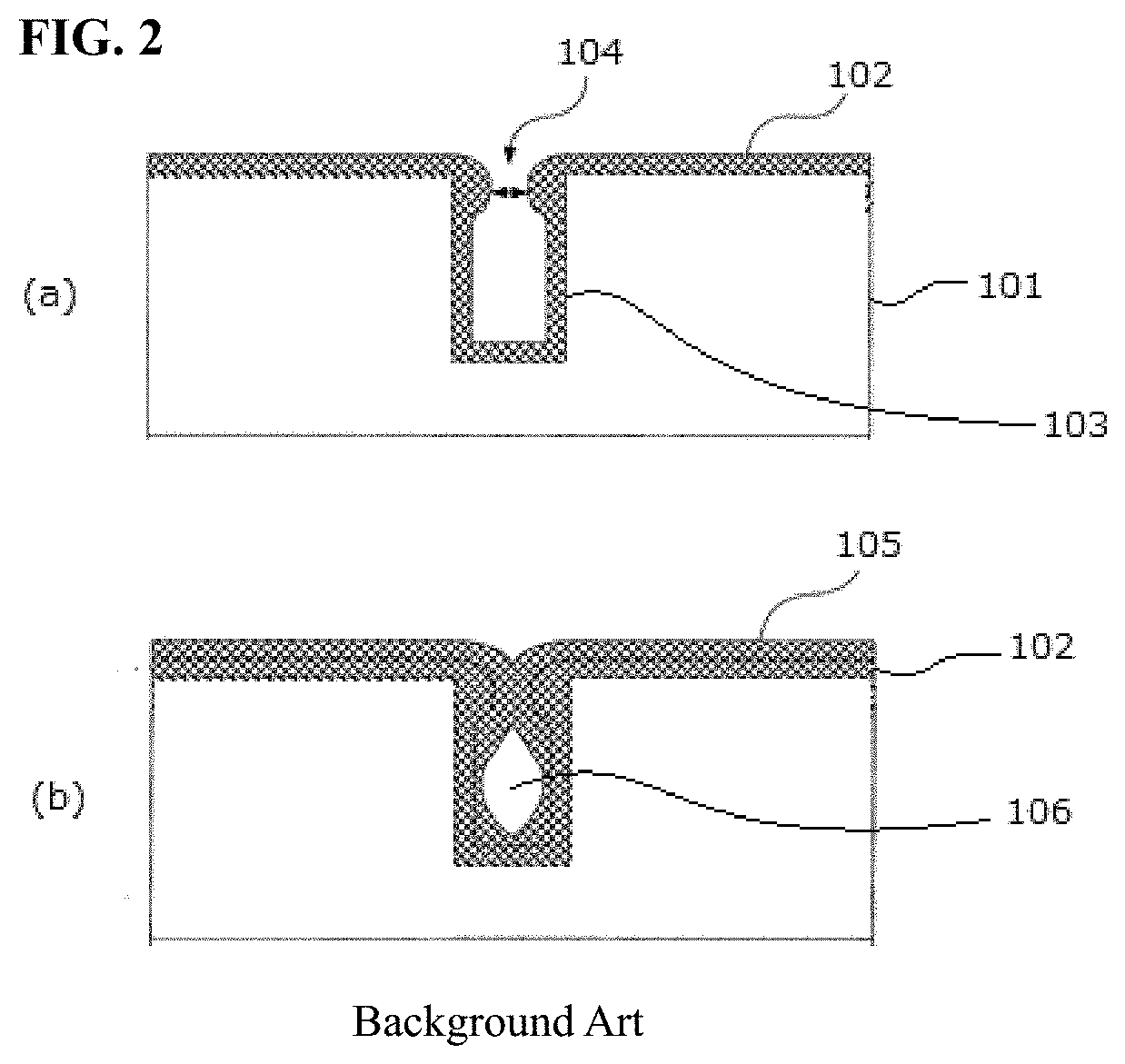

Method for depositing metal-containing film using particle-reduction step

InactiveUS20160168699A1Reduce surface roughnessSolve the lack of resistanceChemical vapor deposition coatingPlasma techniqueAMINO BASENitride

A method for forming a metal oxide or nitride film on a substrate by plasma-enhanced atomic layer deposition (PEALD), includes: introducing an amino-based metal precursor in a pulse to a reaction space where a substrate is placed, using a carrier gas; and continuously introducing a reactant gas to the reaction space; applying RF power in a pulse to the reaction space wherein the pulse of the precursor and the pulse of RF power do not overlap, wherein conducted is at least either step (a) comprising passing the carrier gas through a purifier for reducing impurities before mixing the carrier gas with the precursor, or step (b) introducing the reactant gas at a flow rate such that a partial pressure of the reactant gas relative to the total gas flow provided in the reaction space is 15% or less.

Owner:ASM IP HLDG BV

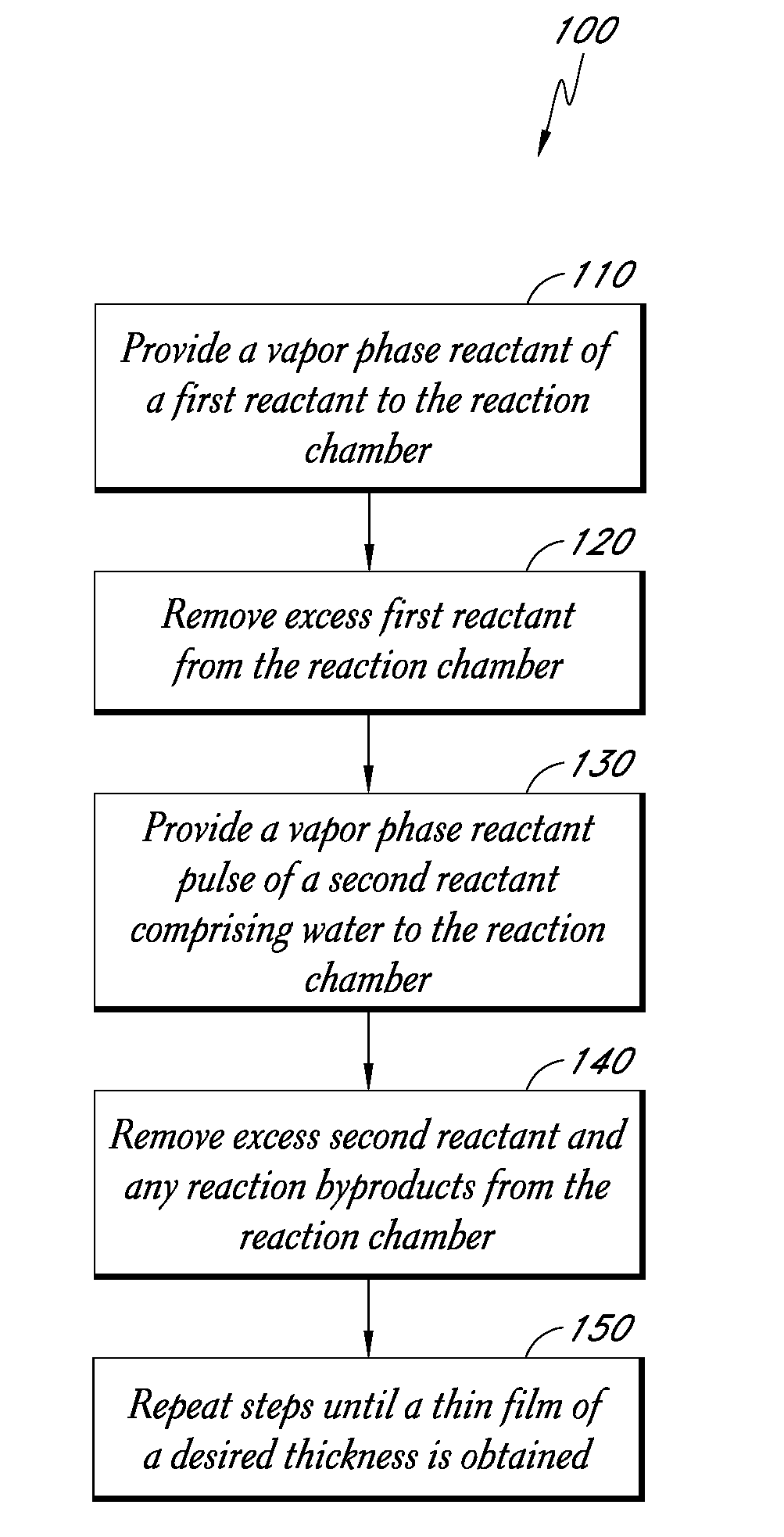

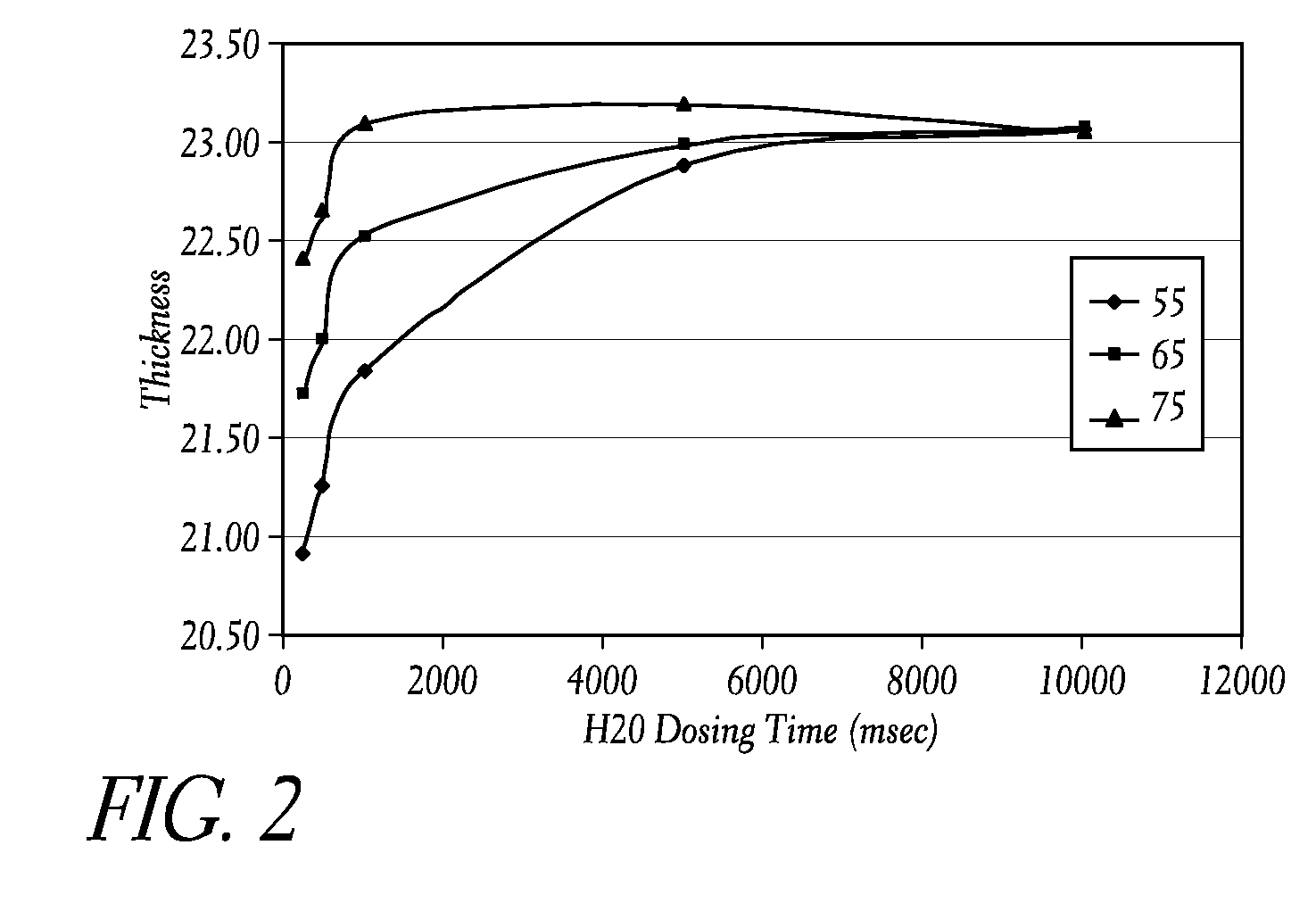

High concentration water pulses for atomic layer deposition

ActiveUS20110053383A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh concentrationAtomic layer deposition

Methods are provided herein for forming thin films comprising oxygen by atomic layer deposition. The thin films comprising oxygen can be deposited by providing higher concentration water pulses, a higher partial pressure of water in the reaction space, and / or a higher flow rate of water to a substrate in a reaction space. Thin films comprising oxygen can be used, for example, as dielectric oxides in transistors, capacitors, integrated circuits, and other semiconductor applications.

Owner:ASM IP HLDG BV

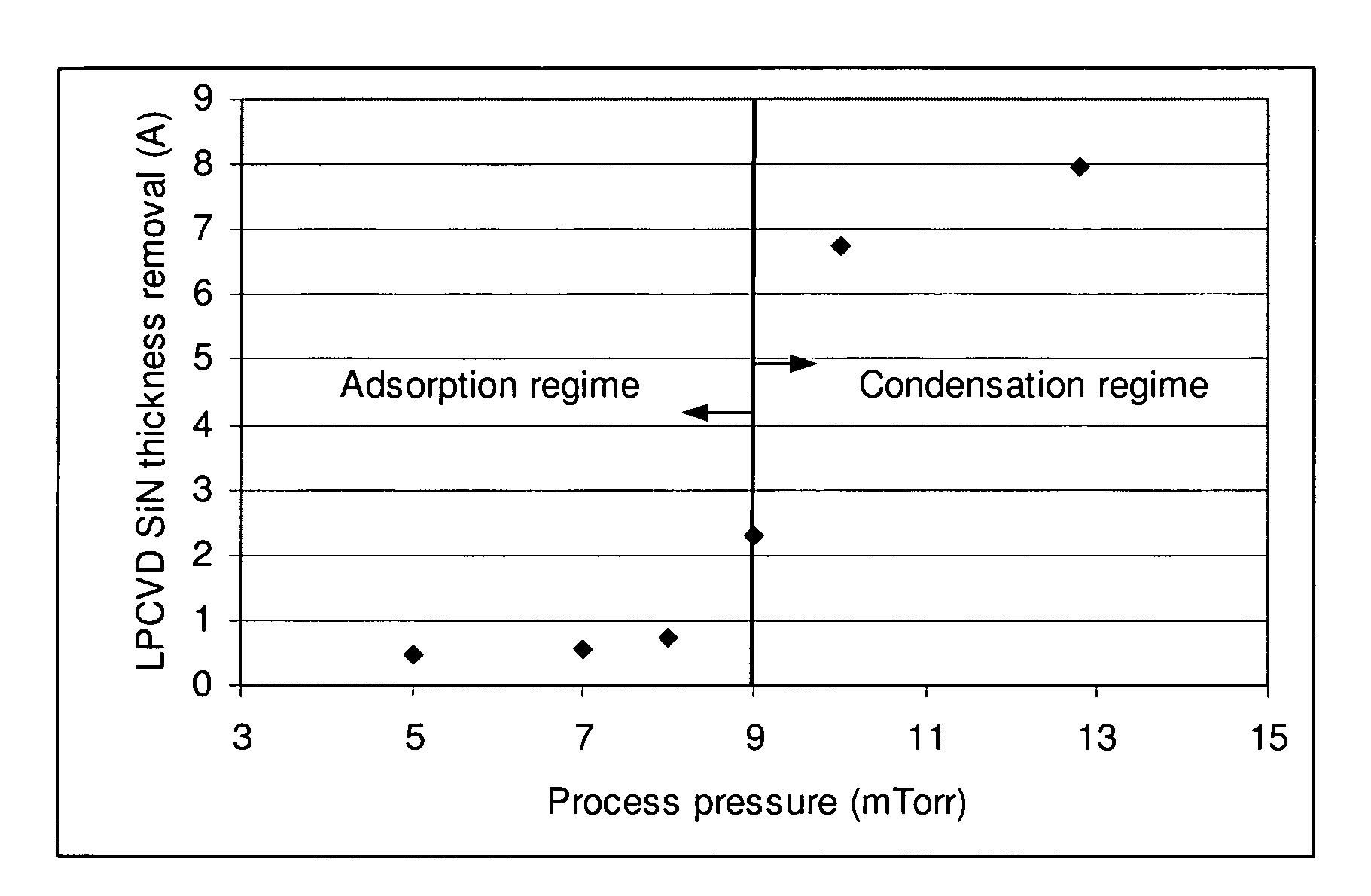

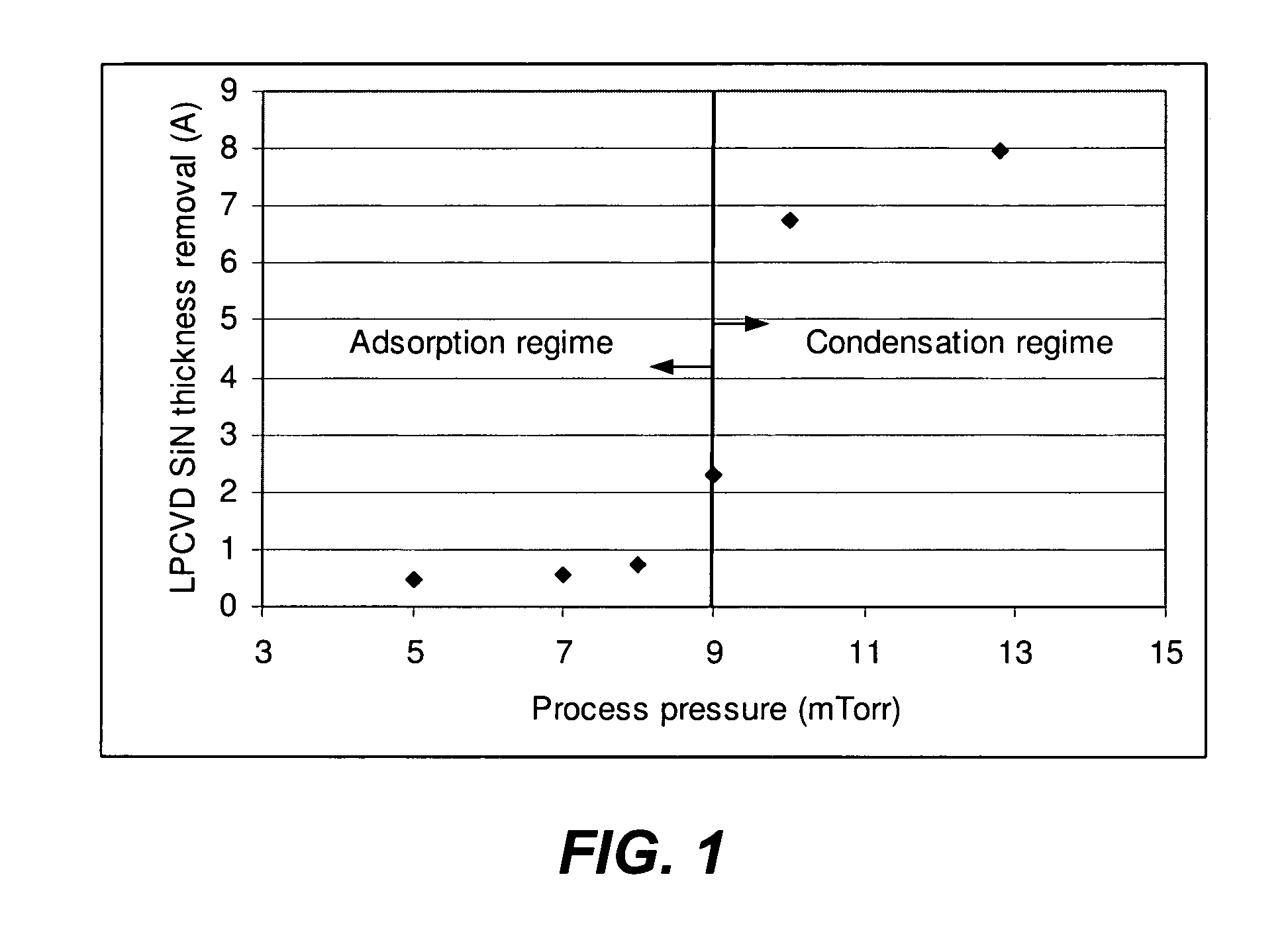

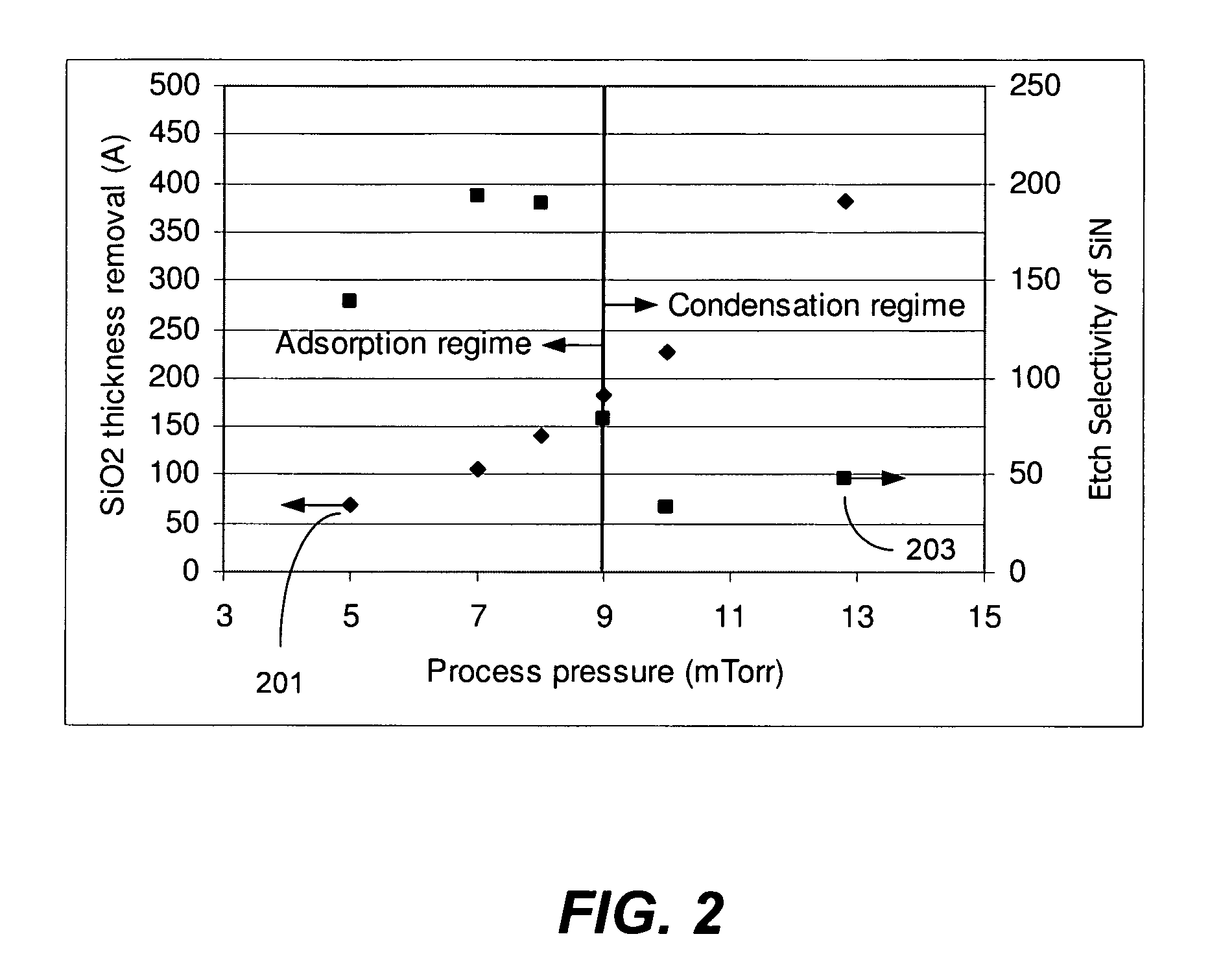

Modulating etch selectivity and etch rate of silicon nitride thin films

ActiveUS8187486B1Decorative surface effectsSemiconductor/solid-state device manufacturingNitrideMolecular physics

Etching of nitride and oxide layers with reactant gases is modulated by etching in different process regimes. High etch selectivity to silicon nitride is achieved in an adsorption regime where the partial pressure of the etchant is lower than its vapor pressure. Low etch selectivity to silicon nitride is achieved in a condensation regime where the partial pressure of the etchant is higher than its vapor pressure. By controlling partial pressure of the etchant, very high etch selectivity to silicon nitride may be achieved.

Owner:NOVELLUS SYSTEMS

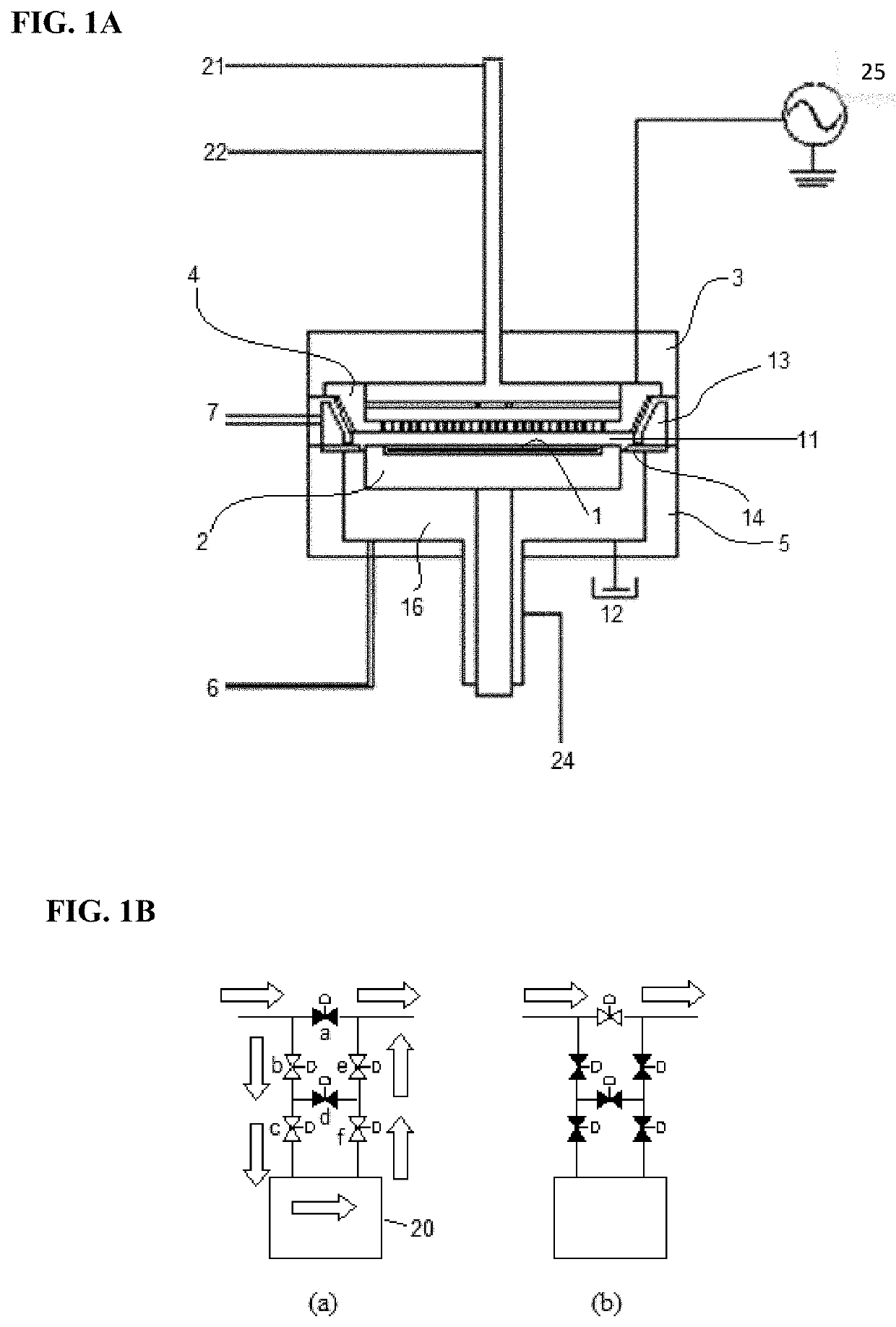

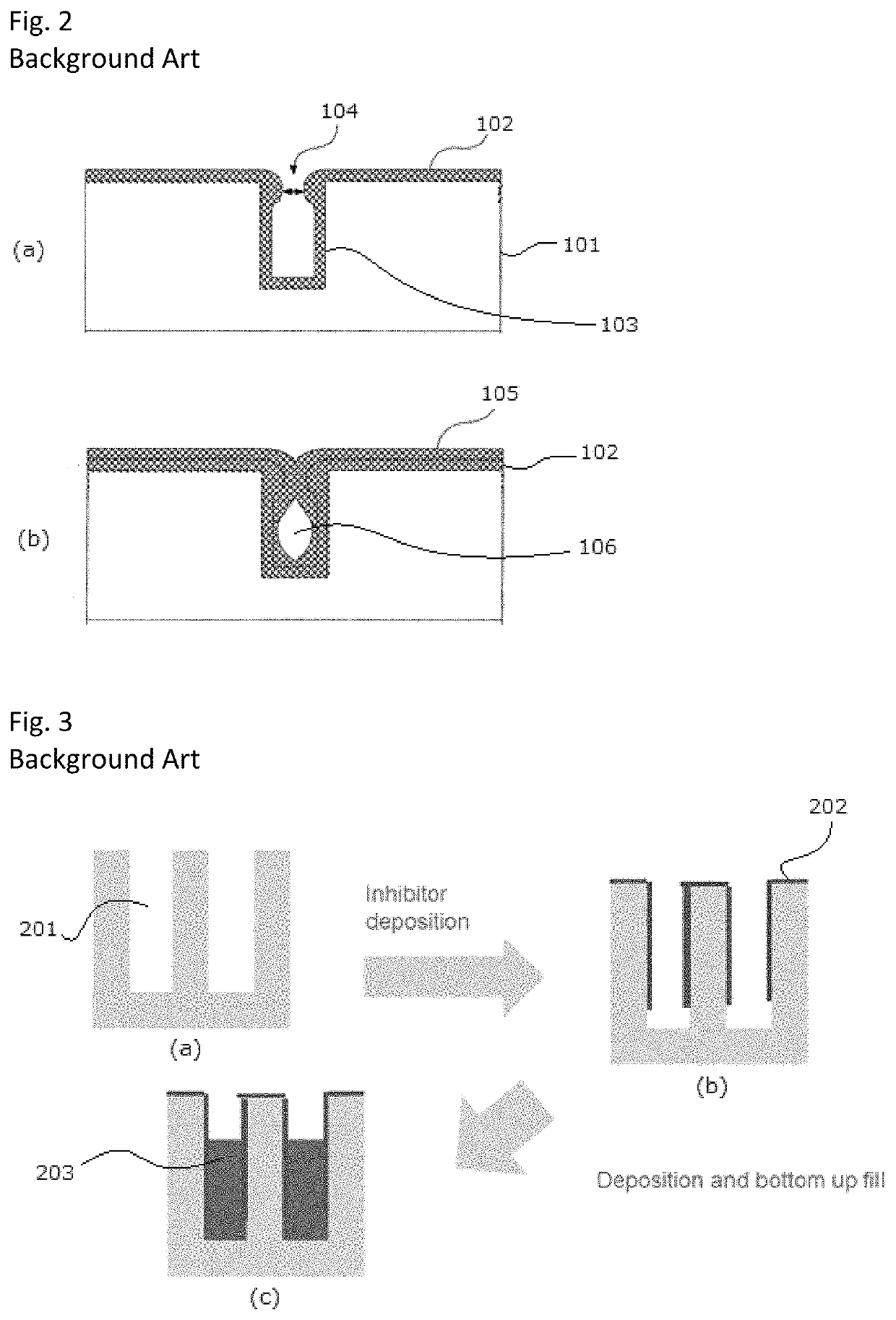

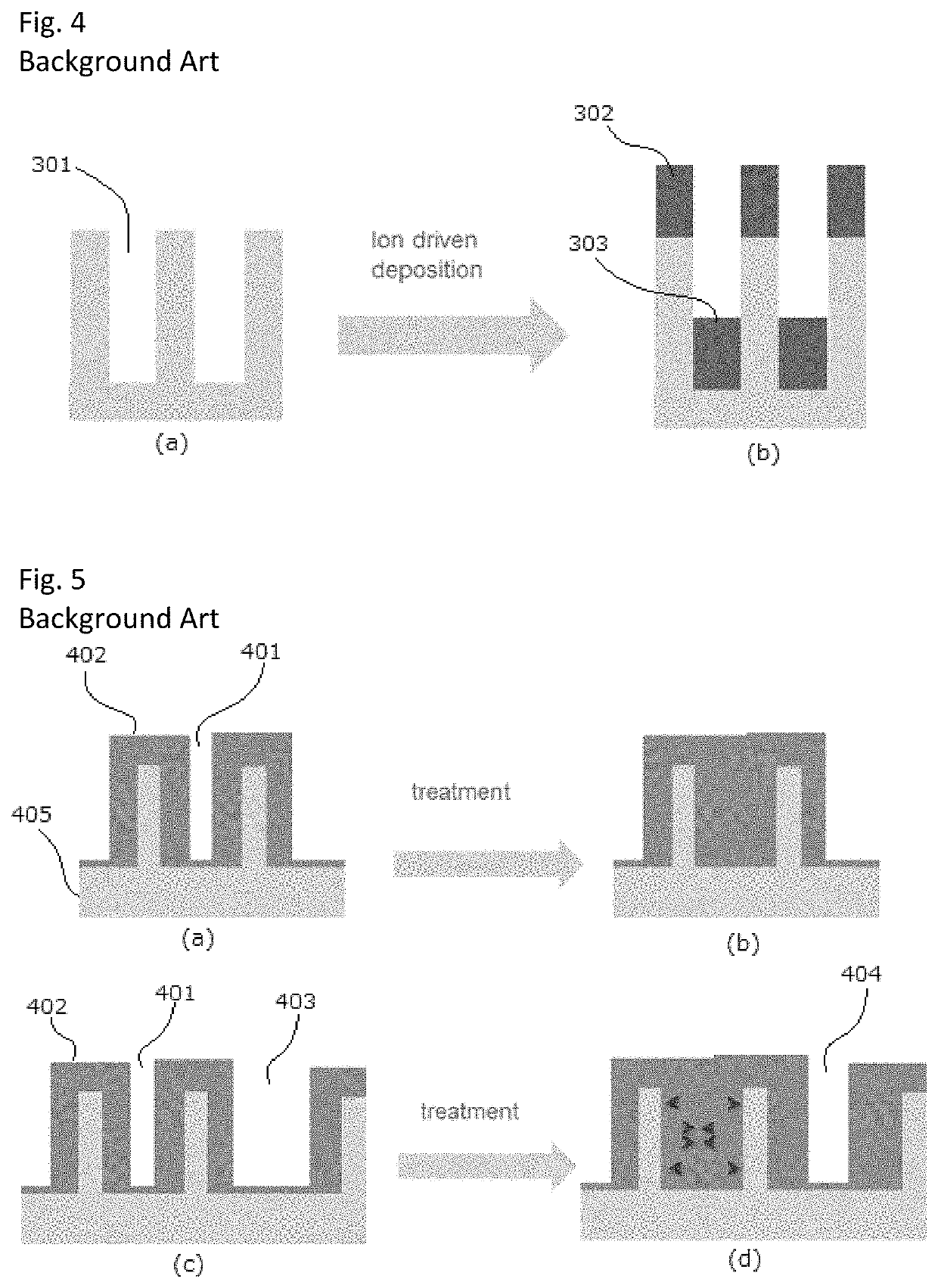

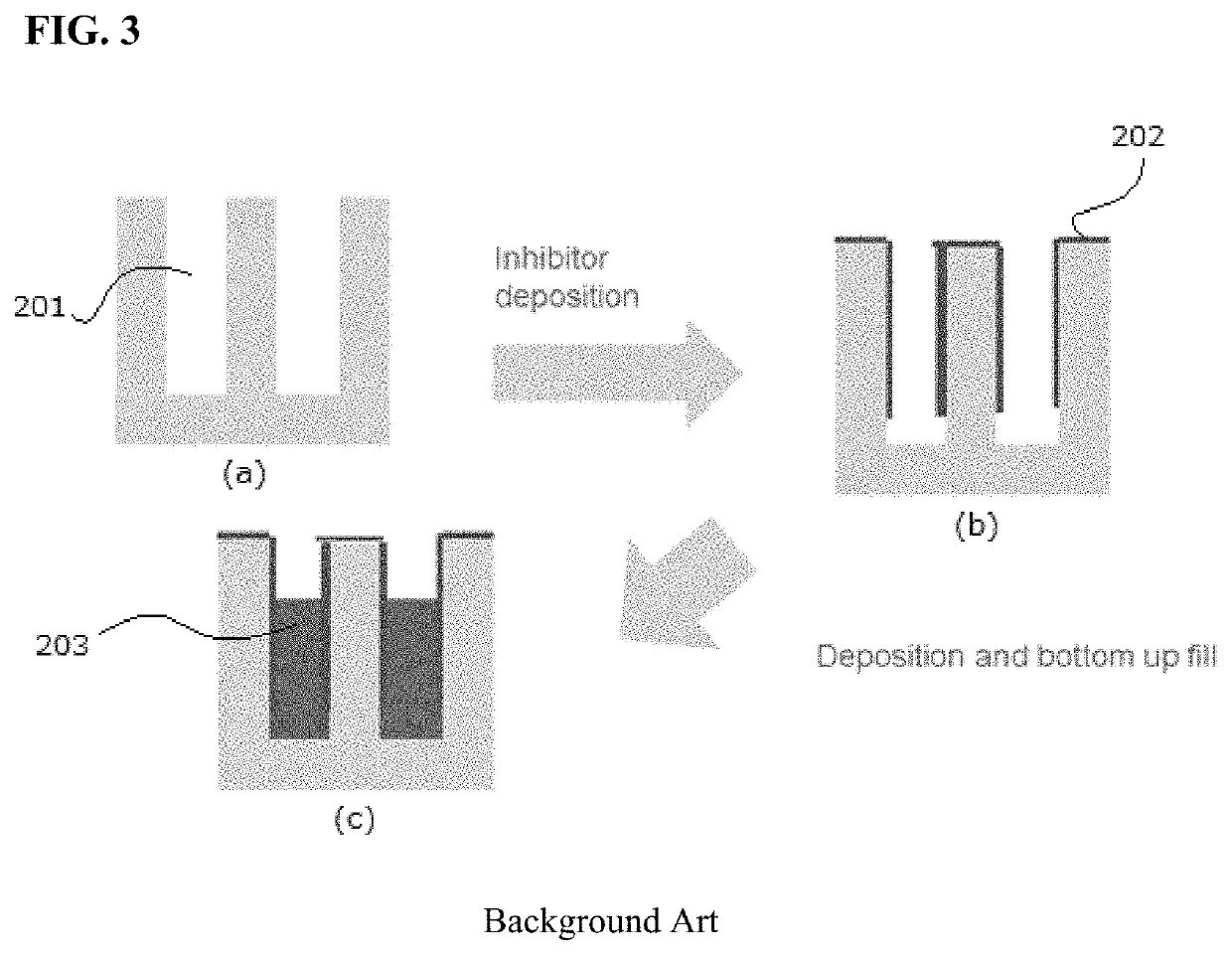

Method for depositing silicon-free carbon-containing film as gap-fill layer by pulse plasma-assisted deposition

ActiveUS20200013613A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingPolymer scienceWafering

A Si-free C-containing film having filling capability is deposited by forming a viscous polymer in a gas phase by striking an Ar, He, or N2 plasma in a chamber filled with a volatile hydrocarbon precursor that can be polymerized within certain parameter ranges which define mainly partial pressure of precursor during a plasma strike, and wafer temperature.

Owner:ASM IP HLDG BV

Method for depositing silicon-free carbon-containing film as gap-fill layer by pulse plasma-assisted deposition

ActiveUS10388513B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseSilicon

A Si-free C-containing film having filling capability is deposited by forming a viscous polymer in a gas phase by striking an Ar, He, or N2 plasma in a chamber filled with a volatile hydrocarbon precursor that can be polymerized within certain parameter ranges which define mainly partial pressure of precursor during a plasma strike, and wafer temperature.

Owner:ASM IP HLDG BV

Method for depositing silicon-free carbon-containing film as gap-fill layer by pulse plasma-assisted deposition

ActiveUS20200365391A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingPolymer scienceWafering

A film having filling capability is deposited by forming a viscous polymer in a gas phase by striking an Ar, He, or N2 plasma in a chamber filled with a volatile hydrocarbon precursor that can be polymerized within certain parameter ranges which define mainly partial pressure of precursor during a plasma strike, and wafer temperature.

Owner:ASM IP HLDG BV

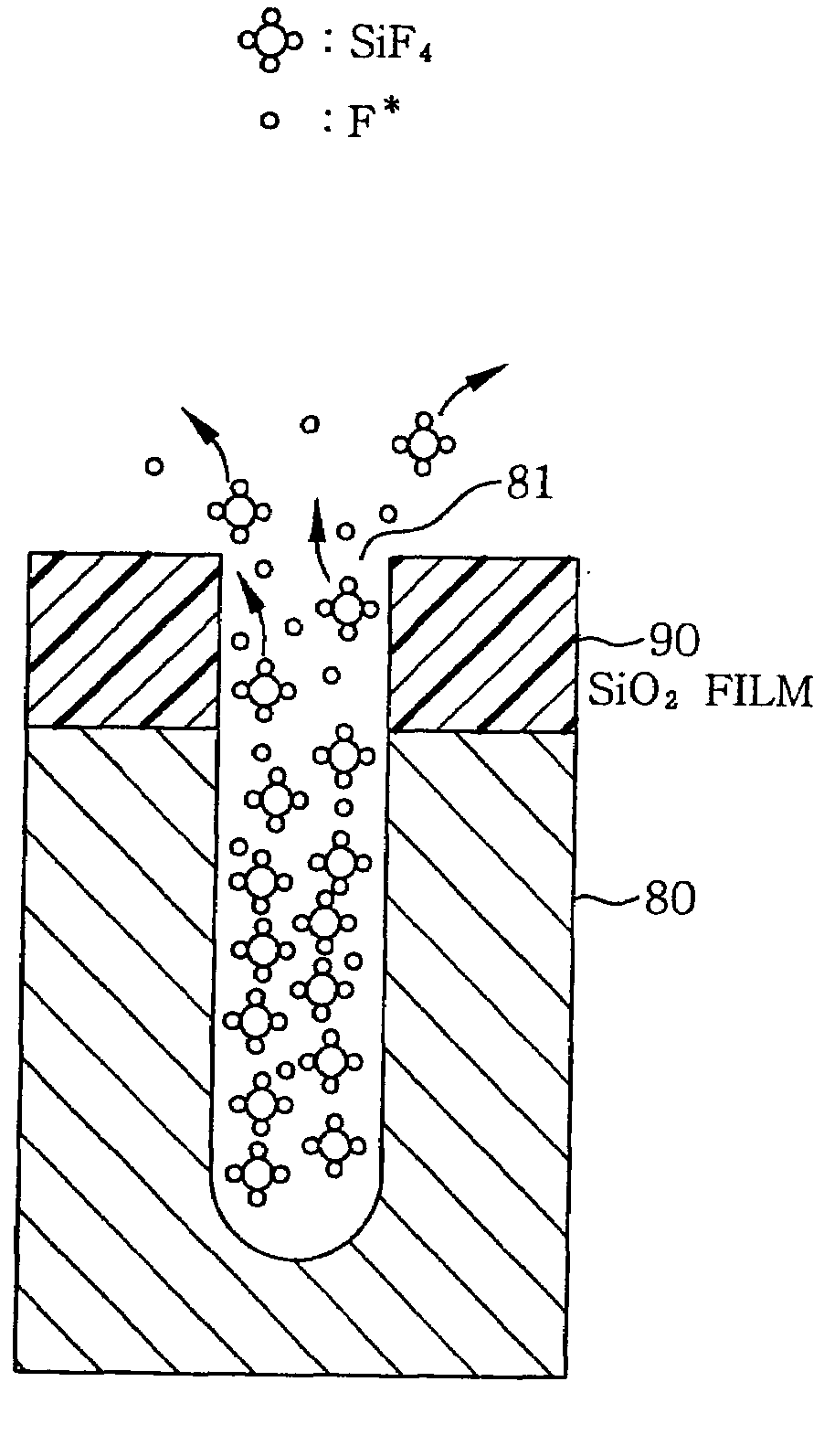

Plasma etching method and apparatus therefor

InactiveUS20090045167A1Increase chanceIncrease etch rateElectric discharge tubesVacuum gauge using ionisation effectsPeak intensityFluorine containing

A fluorine-containing compound gas, e.g., SF6 gas, is converted into a plasma and a silicon portion of an object to be processed is etched by the plasma. At the same time, using a light source having a peak intensity of light in a wavelength range of light absorption of a reaction product, e.g., SiF4, for which, to be more precise, ranges from 9 μm to 10 μm, the light is irradiated onto a surface of an object to be processed from the light source. The SiF4 molecules absorb the light, become activated and gain kinetic energy to be used in gaining an easy escape from a hole. As a consequence, an amount (a partial pressure) of fluorine radicals (F*) used as an etchant is increased and an etching rate of a silicon is increased.

Owner:TOKYO ELECTRON LTD

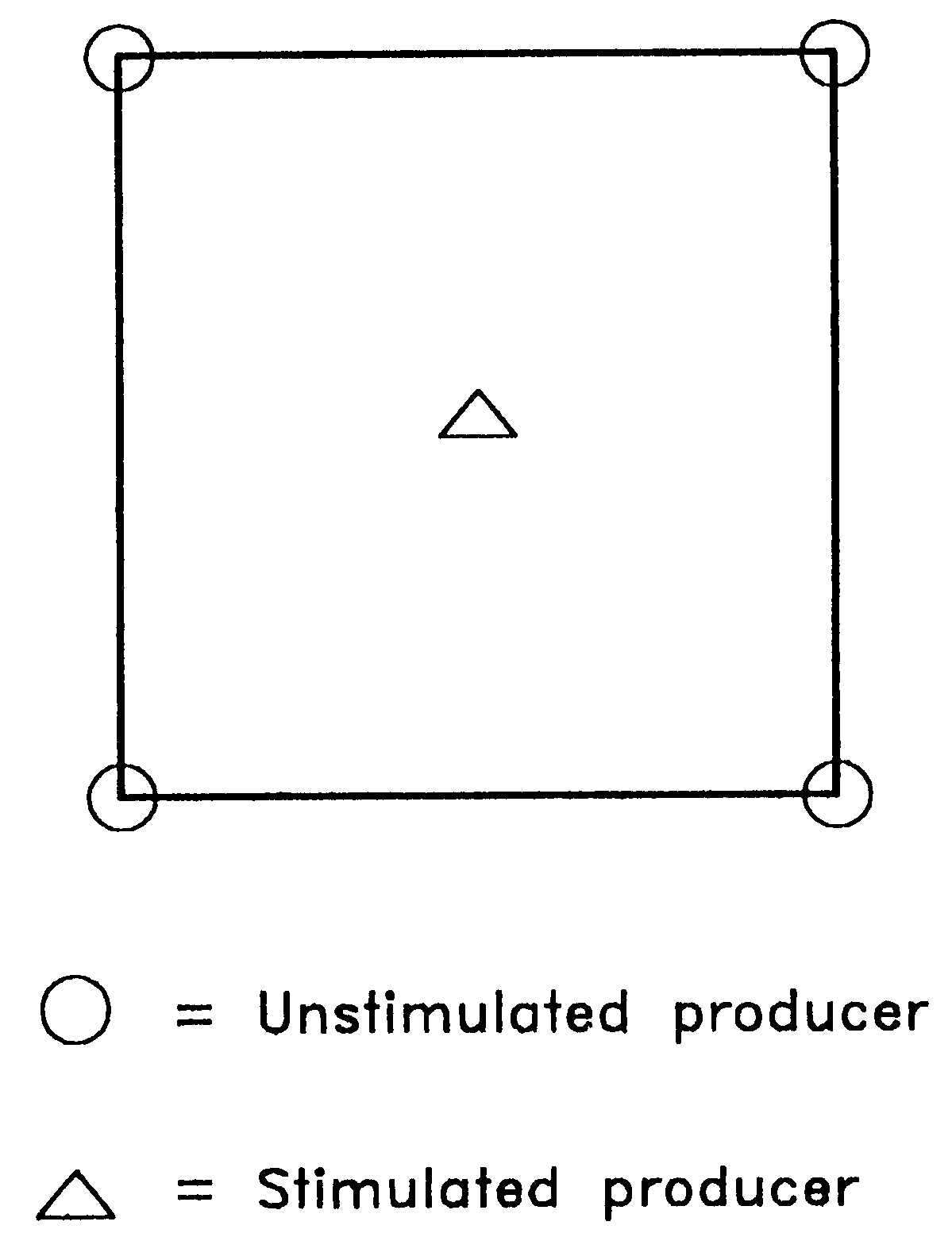

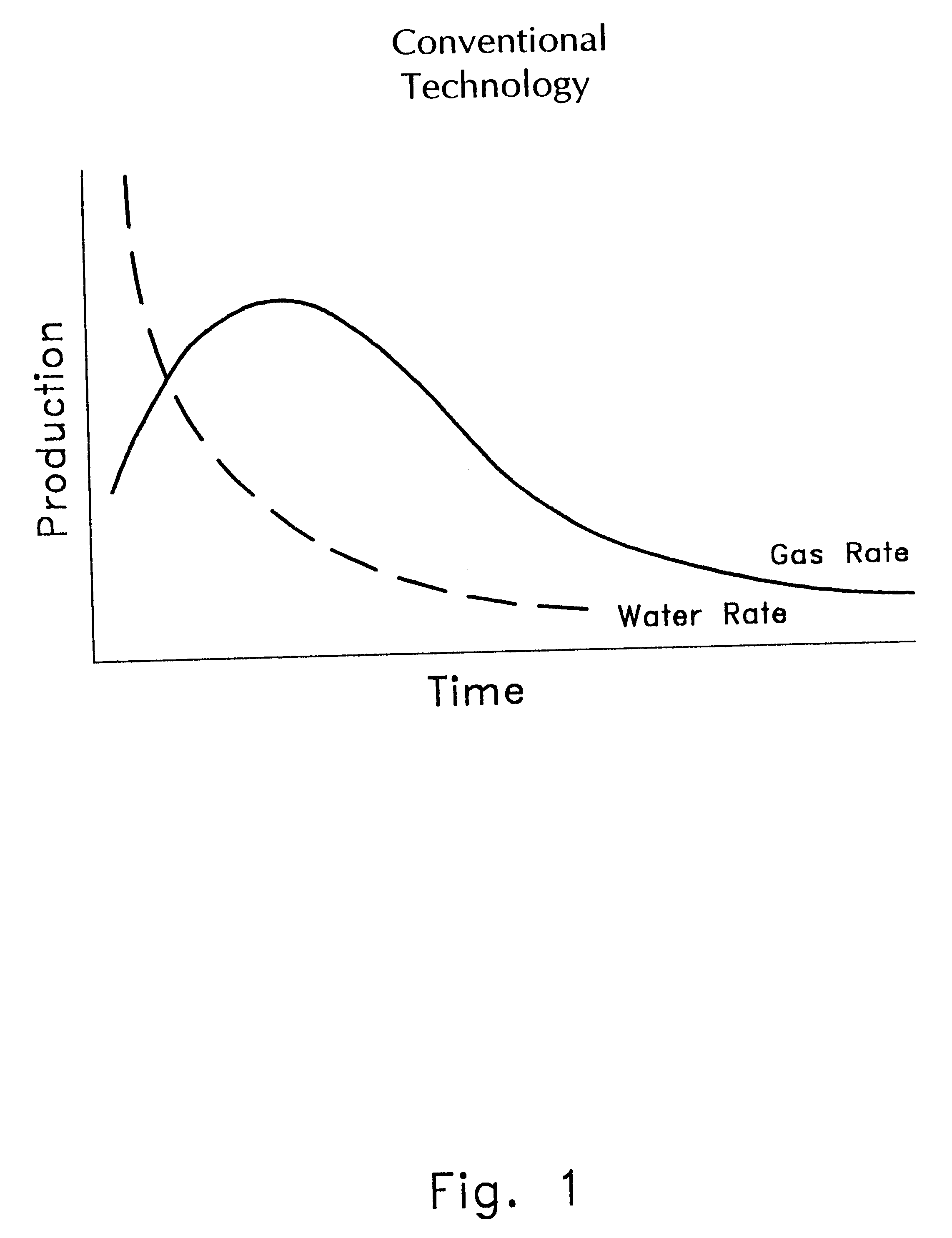

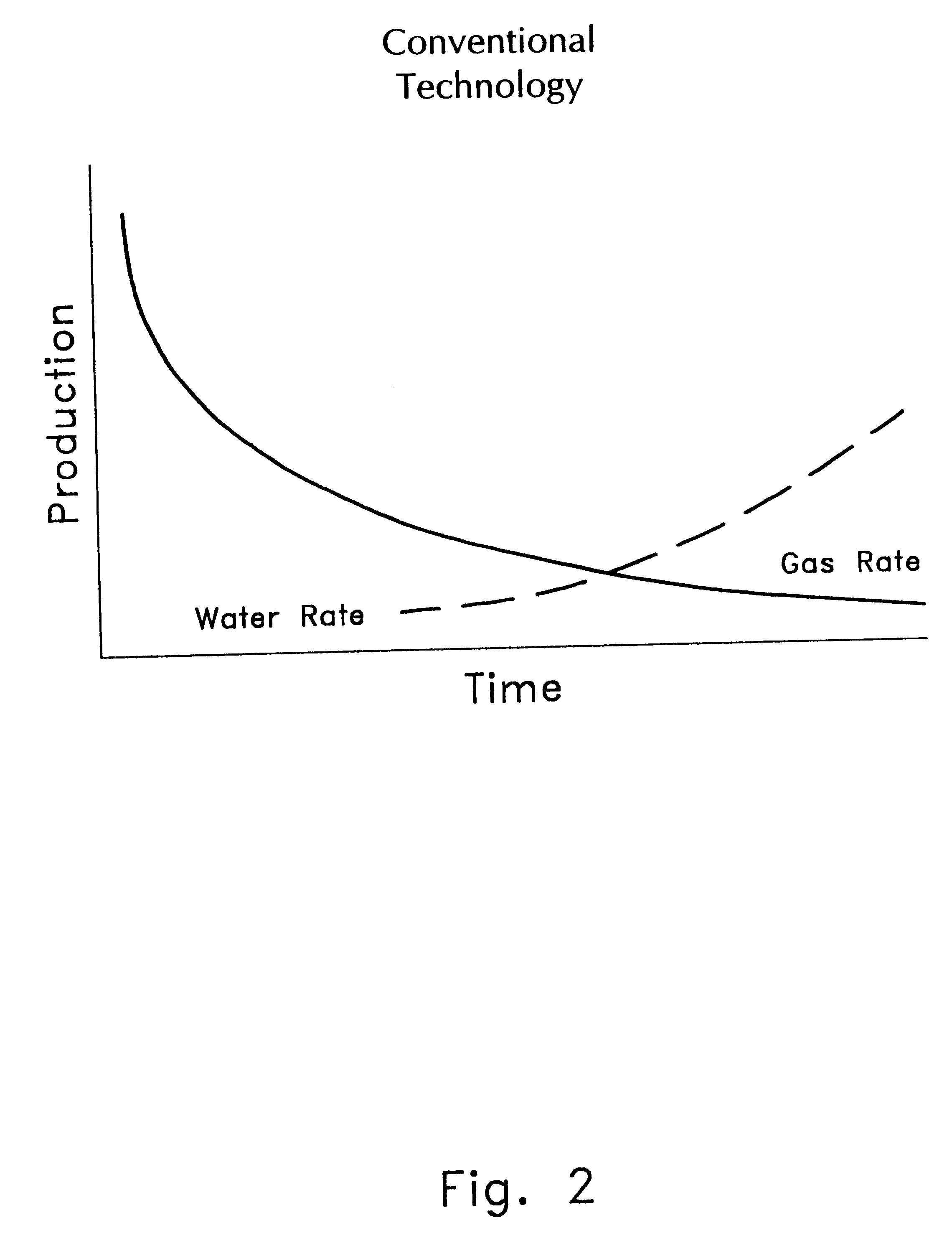

System for improving coalbed gas production

InactiveUS6244338B1Change in permeabilityPromote recoverySurveyDrilling rodsCoal matrixWater production

A method of stimulating coalbed methane production by injecting gas into a producer and subsequently placing the producer back on production is described. A decrease in water production may also result. The increase in gas production and decrease in water production may result from: (1) the displacement of water from the producer by gas; (2) the establishment of a mobile gas saturation at an extended distance into the coalbed, extending outward from the producer; and (3) the reduction in coalbed methane partial pressure between the coal matrix and the coal's cleat system.

Owner:THE UNIVERSITY OF WYOMING RESEARCH CORPORATION DBA WESTERN RESEARCH INSTITUTE

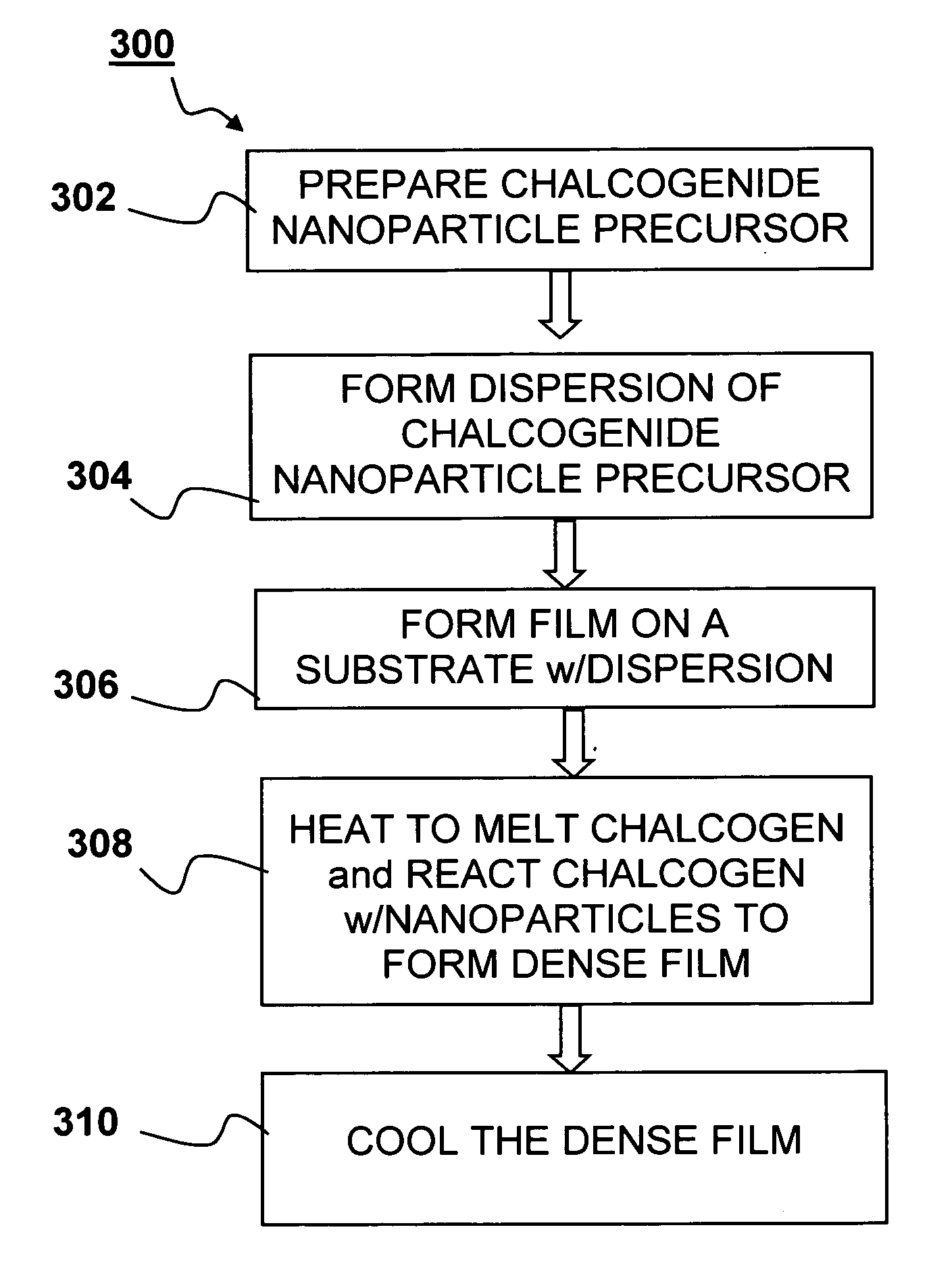

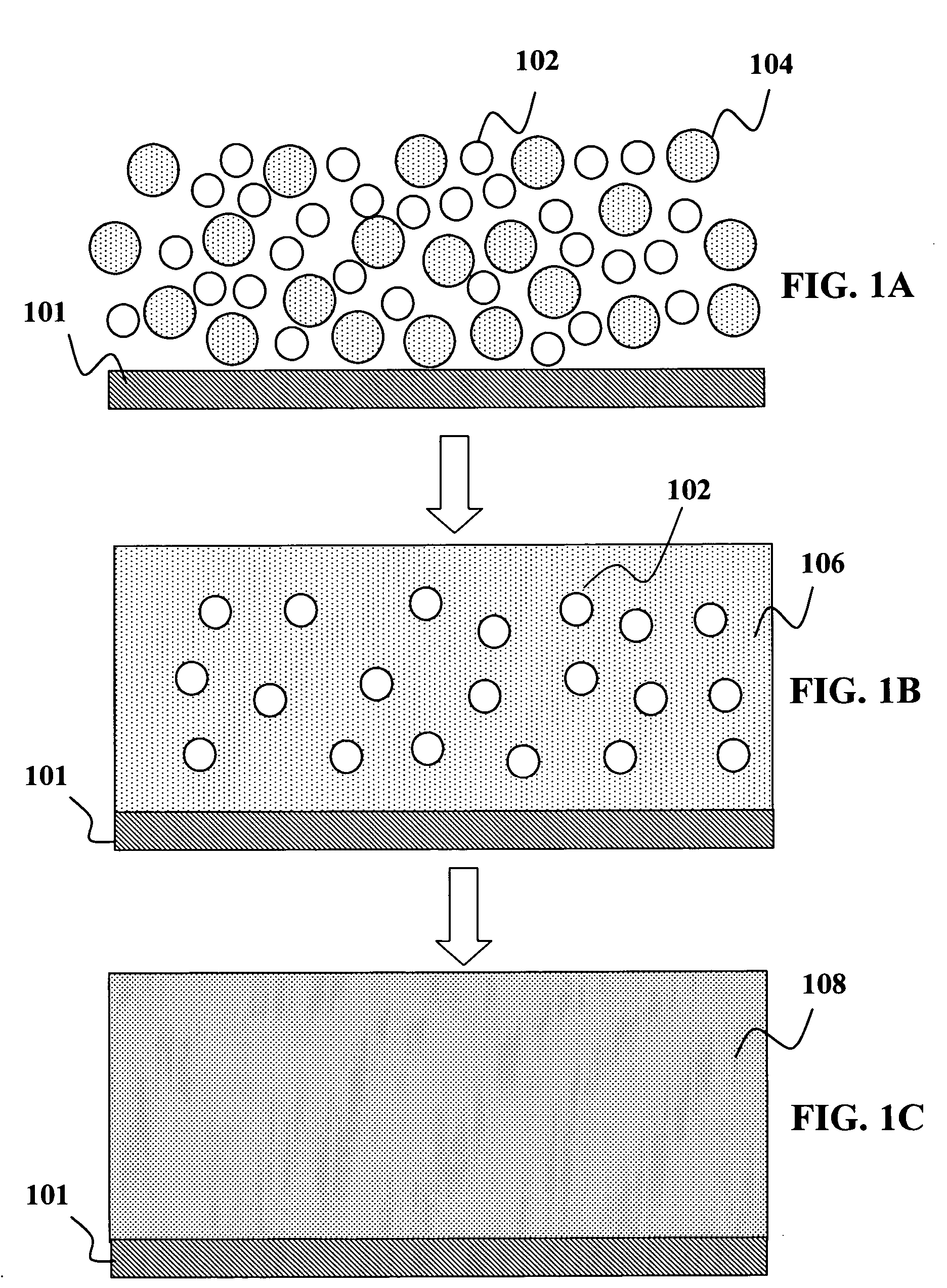

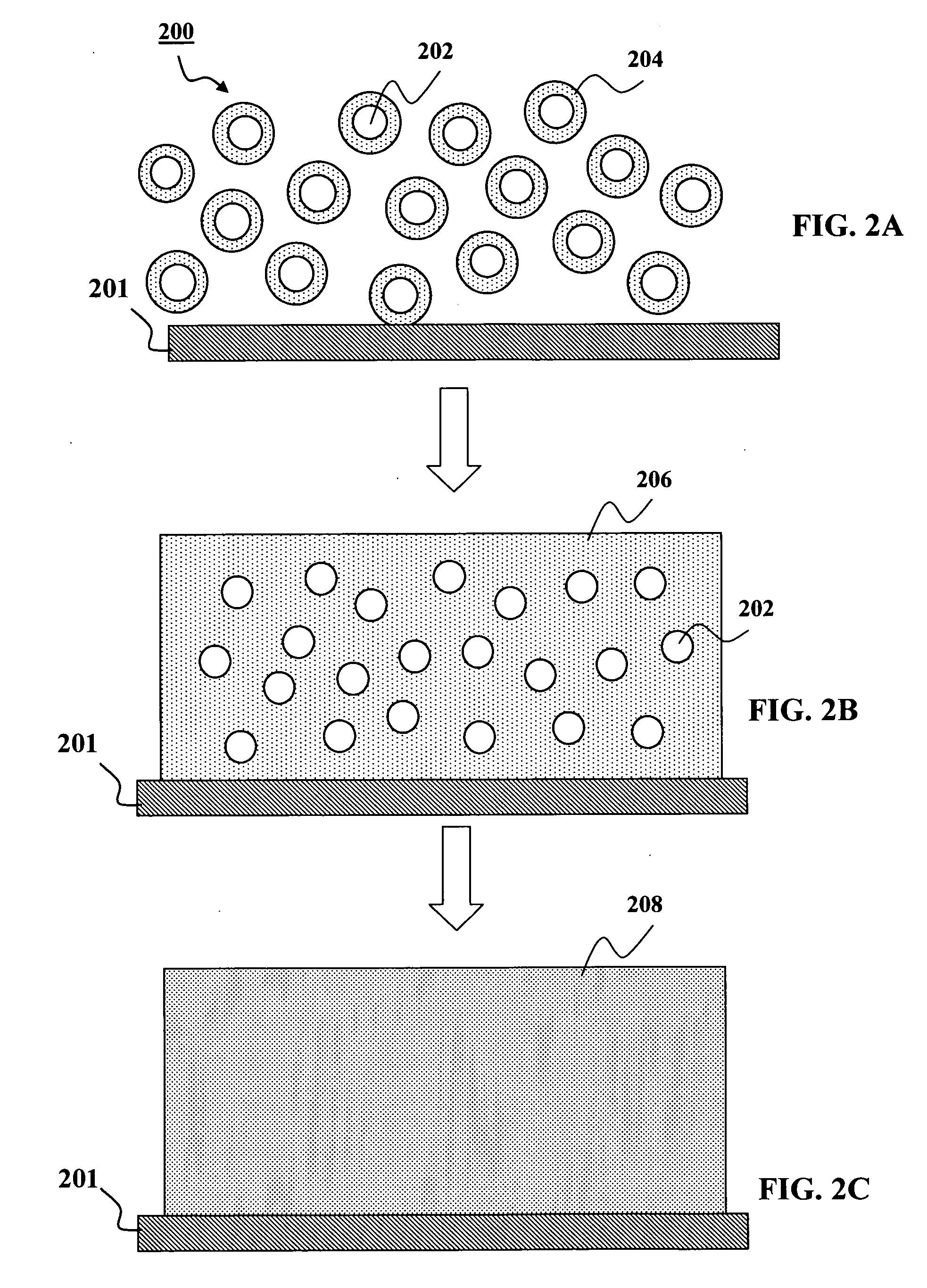

High-throughput printing of semiconductor precursor layer by use of chalcogen-containing vapor

InactiveUS20070169810A1Well mixedReduce lossesLiquid/solution decomposition chemical coatingPhotovoltaic energy generationSulfurChalcogen

A high-throughput method of forming a semiconductor precursor layer by use of a chalcogen-containing vapor is disclosed. In one embodiment, the method comprises forming a precursor material comprising group IB and / or group IIIA particles of any shape. The method may include forming a precursor layer of the precursor material over a surface of a substrate. The method may further include heating the particle precursor material in a substantially oxygen-free chalcogen atmosphere to a processing temperature sufficient to react the particles and to release chalcogen from the chalcogenide particles, wherein the chalcogen assumes a liquid form and acts as a flux to improve intermixing of elements to form a group IB-IIIA-chalcogenide film at a desired stoichiometric ratio. The chalcogen atmosphere may provide a partial pressure greater than or equal to the vapor pressure of liquid chalcogen in the precursor layer at the processing temperature.

Owner:NANOSOLAR

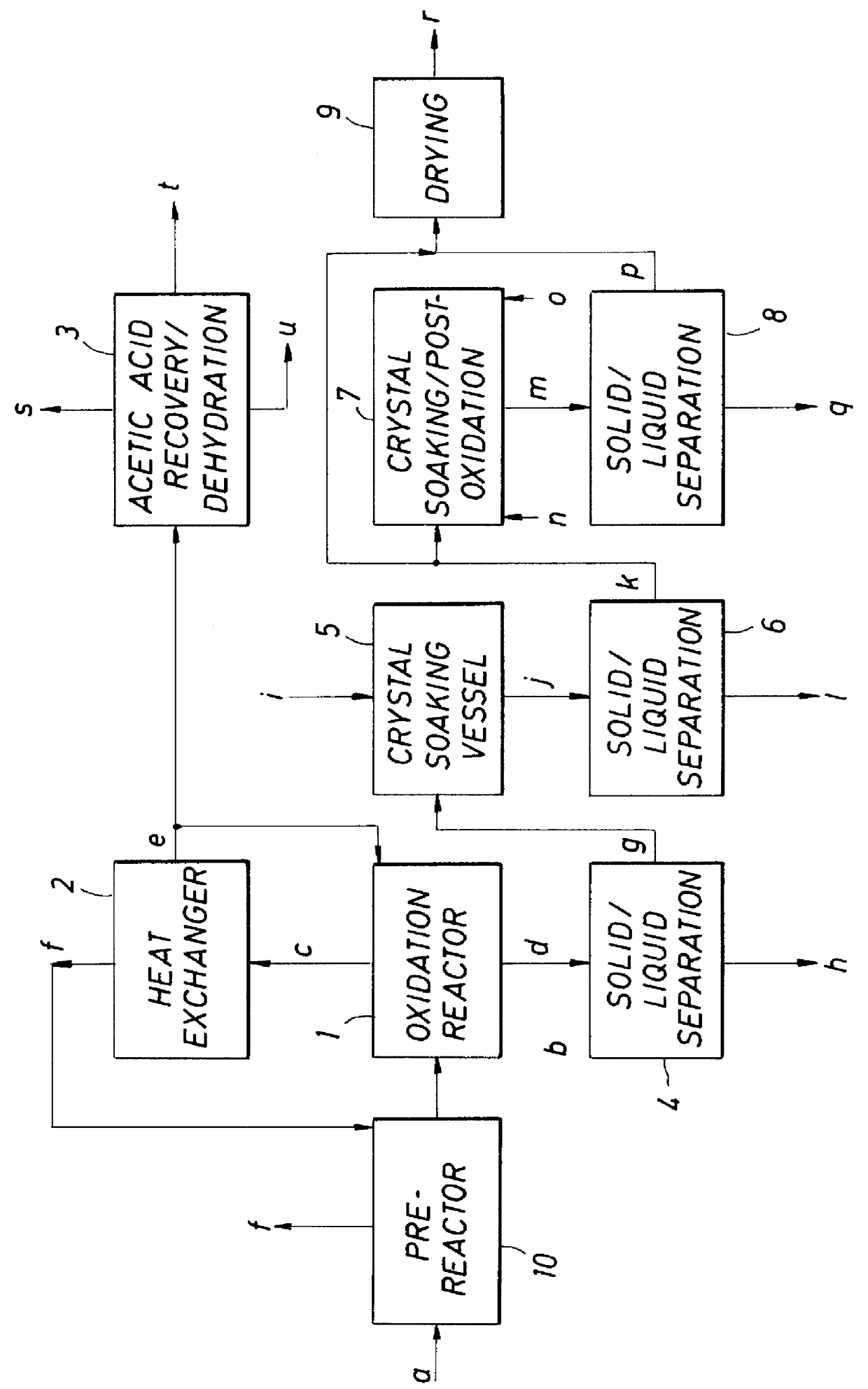

Method to produce aromatic dicarboxylic acids using cobalt and zirconium catalysts

InactiveUS6153790AAvoid problemsEfficient removalOrganic compound preparationChemical recyclingOrganic acidWater vapor

A process to produce terephthalic acid is provided, the process including the steps of: providing a feed stream comprising a dialkyl substituted aromatic and in an organic acid solvent: contacting the feed stream with an oxidant, the oxidant containing at least 50% by volume oxygen and at an oxygen partial pressure of at least 1 psia, at a temperature between about 80 DEG C. and about 130 DEG C., in the presence of a catalyst system comprising zirconium and cobalt, wherein the contacting is done in a stirred tank reactor; removing from the stirred tank reactor a vapor stream comprising the organic acid, water vapor and unreacted oxidant; condensing at least a portion of the organic acid and water from the vapor stream; separating at least a portion of the water from the organic acid back to the stirred tank reactor; returning at least a portion of the condensed organic acid back to the stirred tank reactor; continuously recovering from the stirred tank reactor a product comprising a diacid substituted aromatic; isolating solid crystals of diacid substituted aromatic from the reactor product; and recovering from the solid crystals a diacid substituted aromatic having a purity of preferably at least 97% by weight.

Owner:SHELL OIL CO

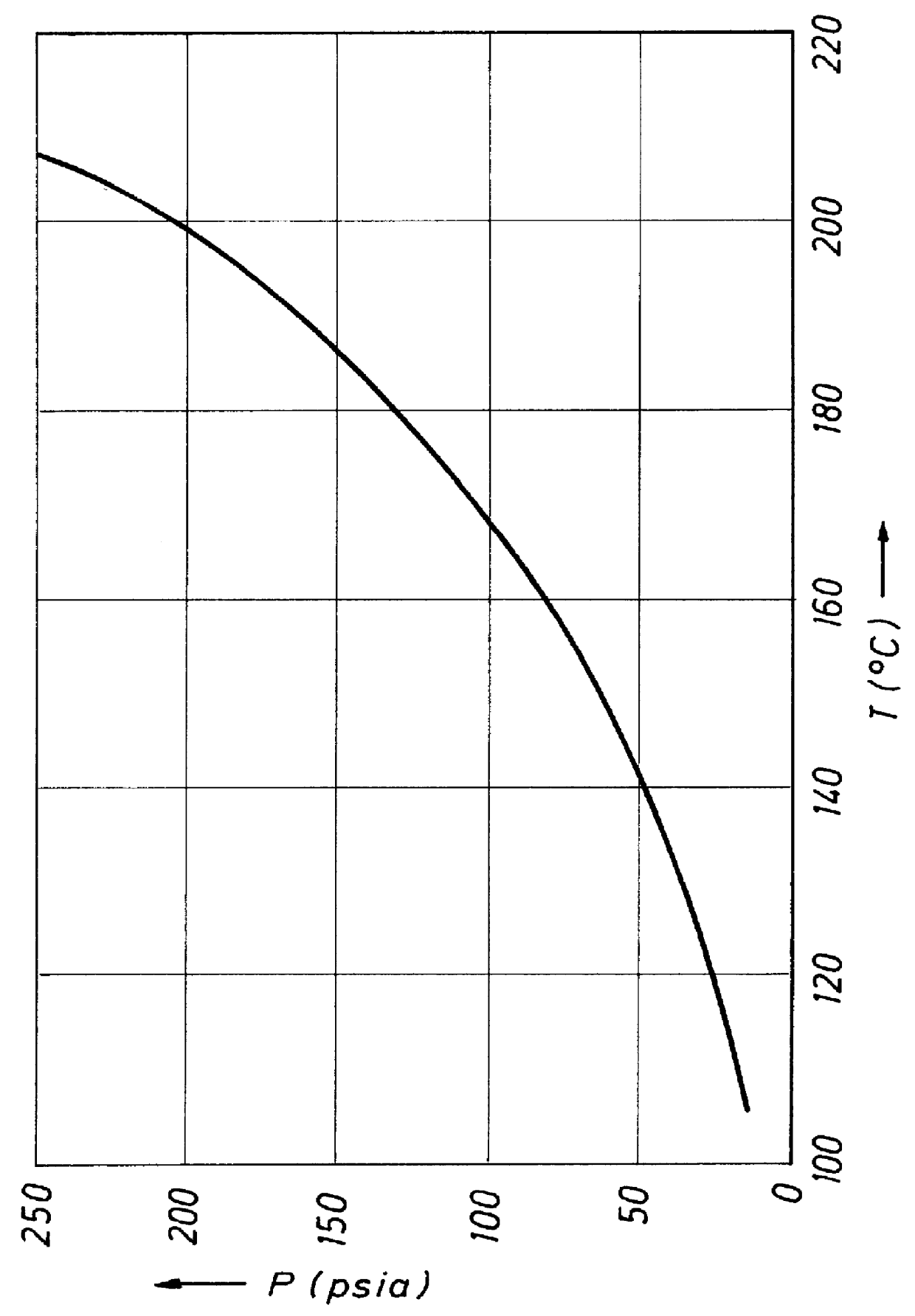

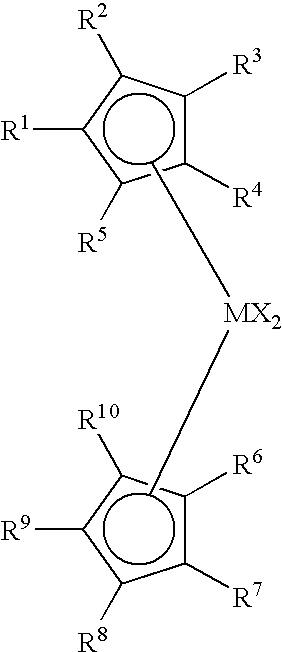

Process to produce low viscosity poly-alpha-olefins

ActiveUS20070043248A1Hydrocarbon by hydrogenationHydrocarbons from unsaturated hydrocarbon additionPolyolefinAlpha-olefin

This invention relates to a process to produce a polyalpha-olefin comprising: 1) contacting one or more alpha-olefin monomers having 3 to 24 carbon atoms with an unbridged substituted bis cyclopentadienyl transition metal compound having: 1) at least one non-isoolefin substitution on both cyclopentadientyl rings, or 2) at least two substitutions on at least one cyclopentadienyl ring, a non-coordinating anion activator, and optionally an alkyl-aluminum compound, where the molar ratio of transition metal compound to activator is 10:1 to 0.1:1, and if the alkyl aluminum compound is present then the molar ratio of alkyl aluminum compound to transition metal compound is 1:4 to 4000:1, under polymerization conditions wherein: i) hydrogen is present at a partial pressure of 0.1 to 50 psi, based upon the total pressure of the reactor or the concentration of the hydrogen is from 1 to 10,000 ppm or less by weight; ii) wherein the alpha-olefin monomer(s) having 3 to 24 carbon atoms are present at 10 volume % or more based upon the total volume of the catalyst / activator / alkylaluminum compound solutions, monomers, and any diluents or solvents present in the reaction; iii) the residence time of the reaction is at least 5 minutes; iv) the productivity of the process is at least 43,000 grams of total product per gram of transition metal compound; v) the process is continuous or semi-continuous, and vi) the temperature in the reaction zone does not rise by more than 10° C. during the reaction; and vii) ethylene is not present at more than 30 volume % of the monomers entering the reaction zone; and 2) obtaining a polyalpha-olefin (PAO), optionally hydrogenating the PAO, wherein the PAO comprises at least 50 mole % of a C3 to C24 alpha-olefin monomer, and wherein the PAO has a kinematic viscosity at 100° C. of 20 cSt or less.

Owner:EXXONMOBIL CHEM PAT INC

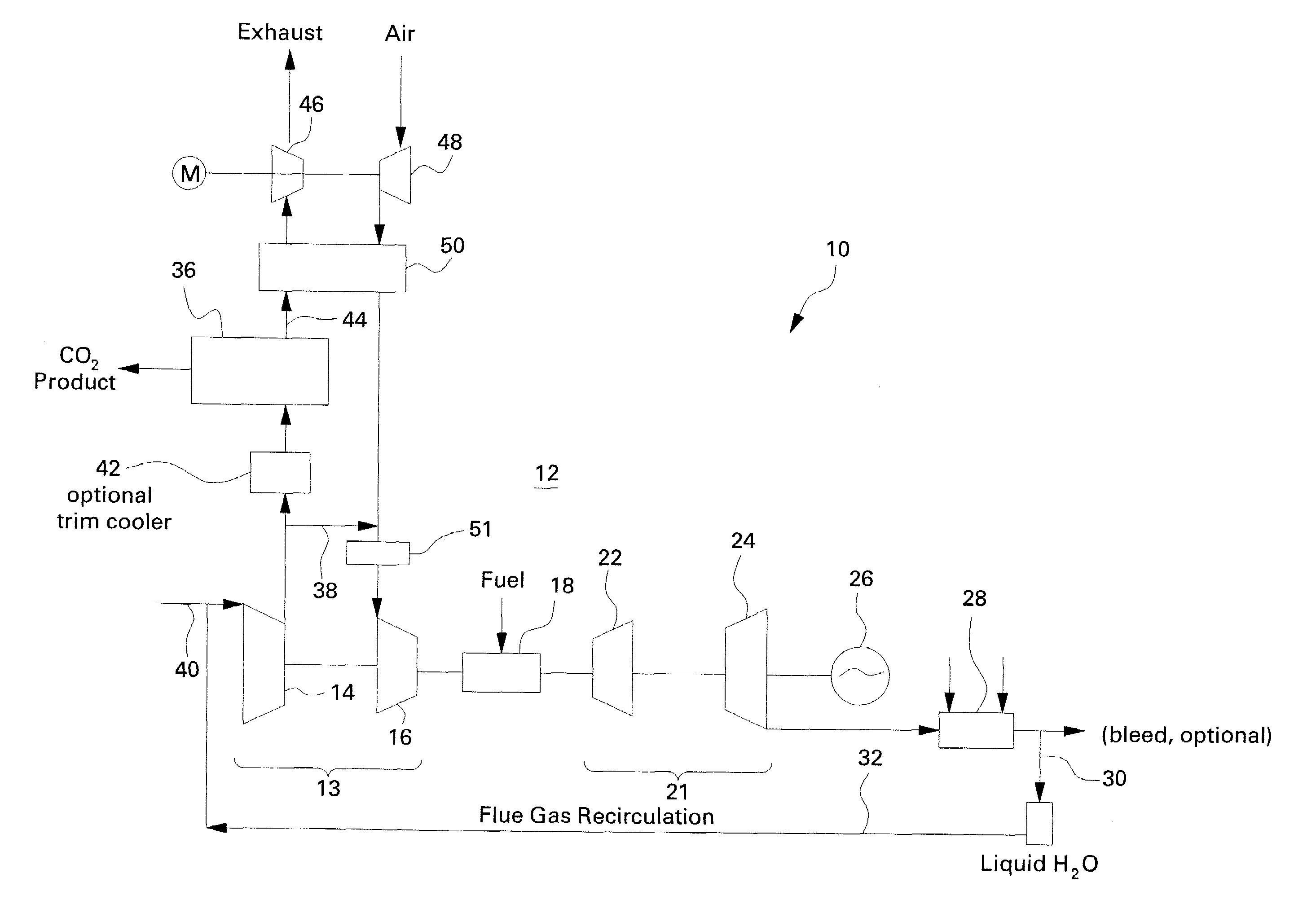

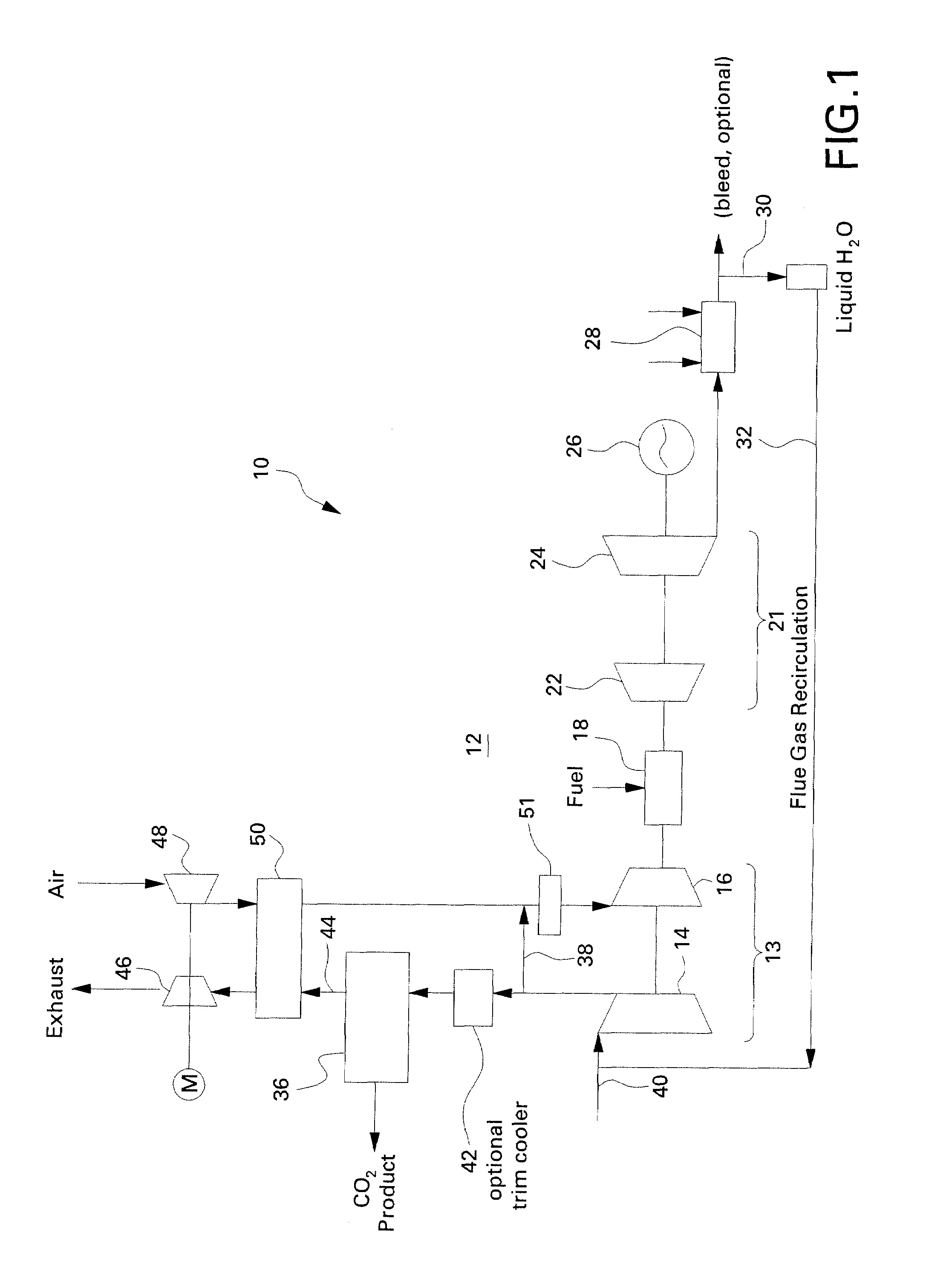

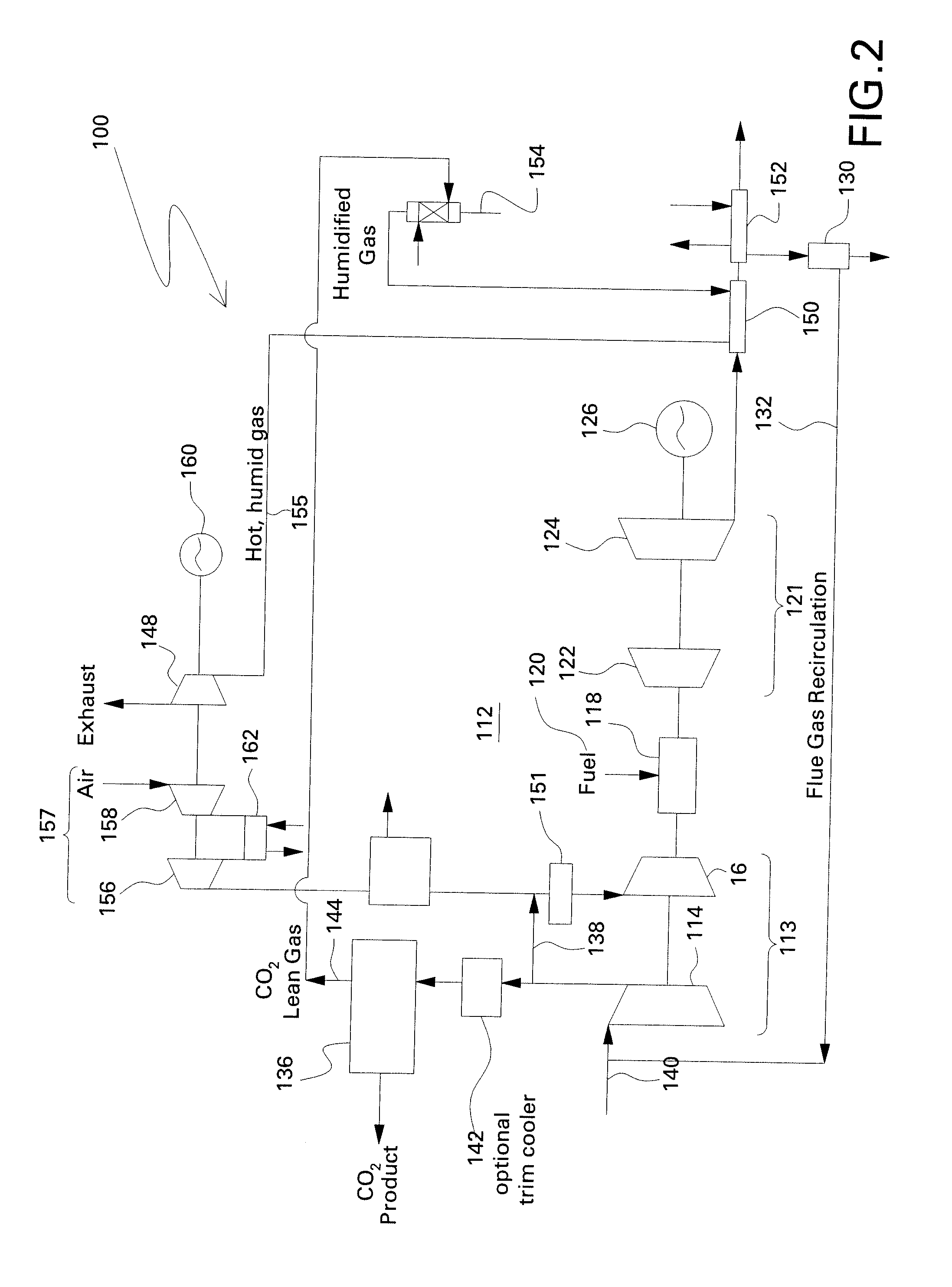

Power plants that utilize gas turbines for power generation and processes for lowering co2 emissions

ActiveUS20080104958A1Reduce carbon dioxide emissionsEmission reductionGas treatmentInternal combustion piston enginesPower stationWorking fluid

Power plants and process for lowering CO2 emissions generally includes extracting a portion of the recirculated CO2-rich flue gas mid-way through the compression pathway of a gas turbine and removing the CO2 in a separation unit. The remaining portion of the CO2 rich flue gas (i.e., the portion of the recirculated flue gas that was not fed to the separation unit) is mixed with fresh air coming from an additional compressor-expander and then fed back to the compression pathway. As a result, flue gas recirculation increases the CO2 concentration within the working fluid, leading to an additional increase in CO2 partial pressure. As the concentration and partial pressure of CO2 is increased, a lower energy penalty is observed to remove the CO2. Moreover, a reduced volume is fed to the CO2 separation unit during operation. Consequently, the size of the separation equipment can be reduced as well as the energy required for the separation process.

Owner:GENERAL ELECTRIC CO +1

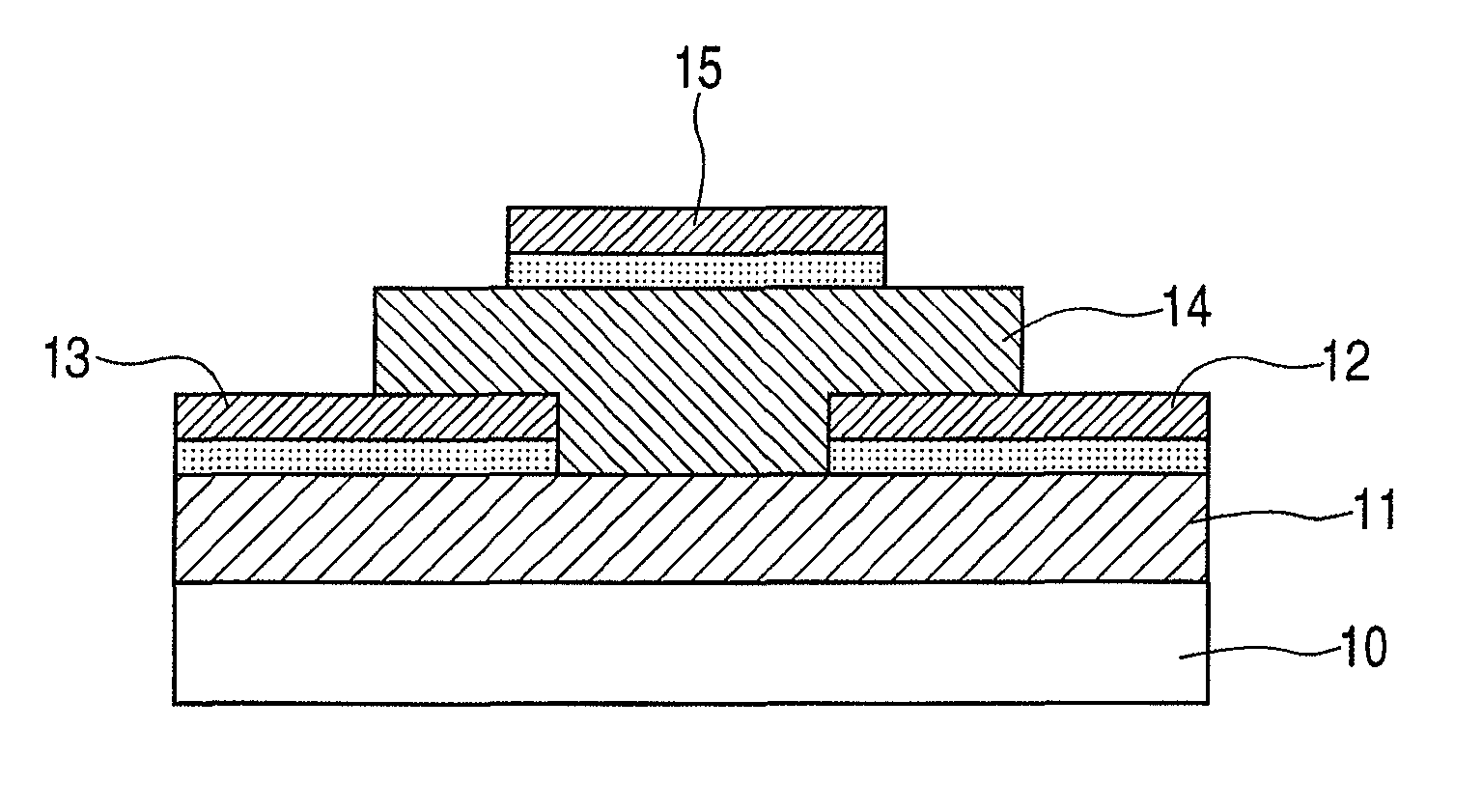

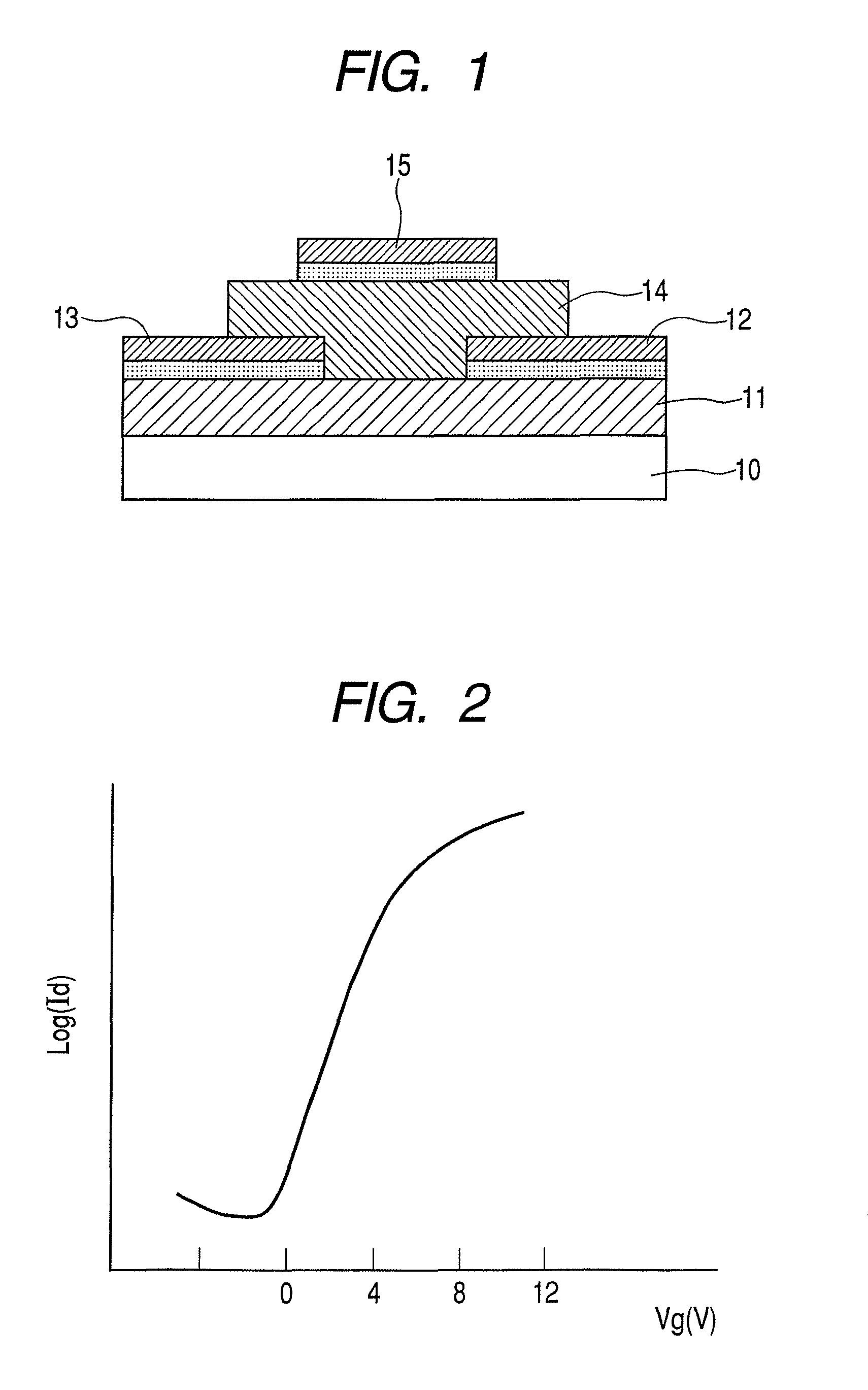

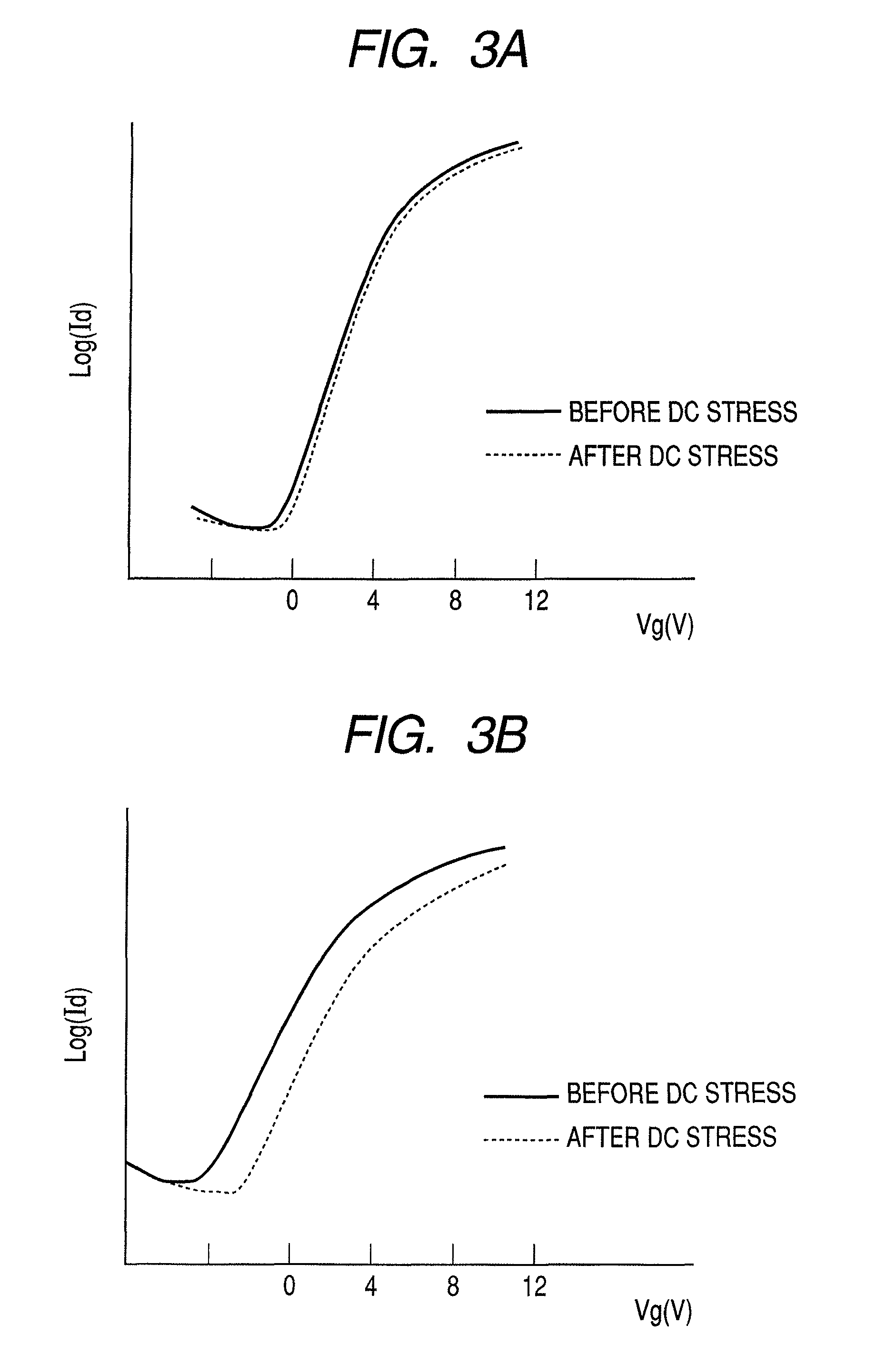

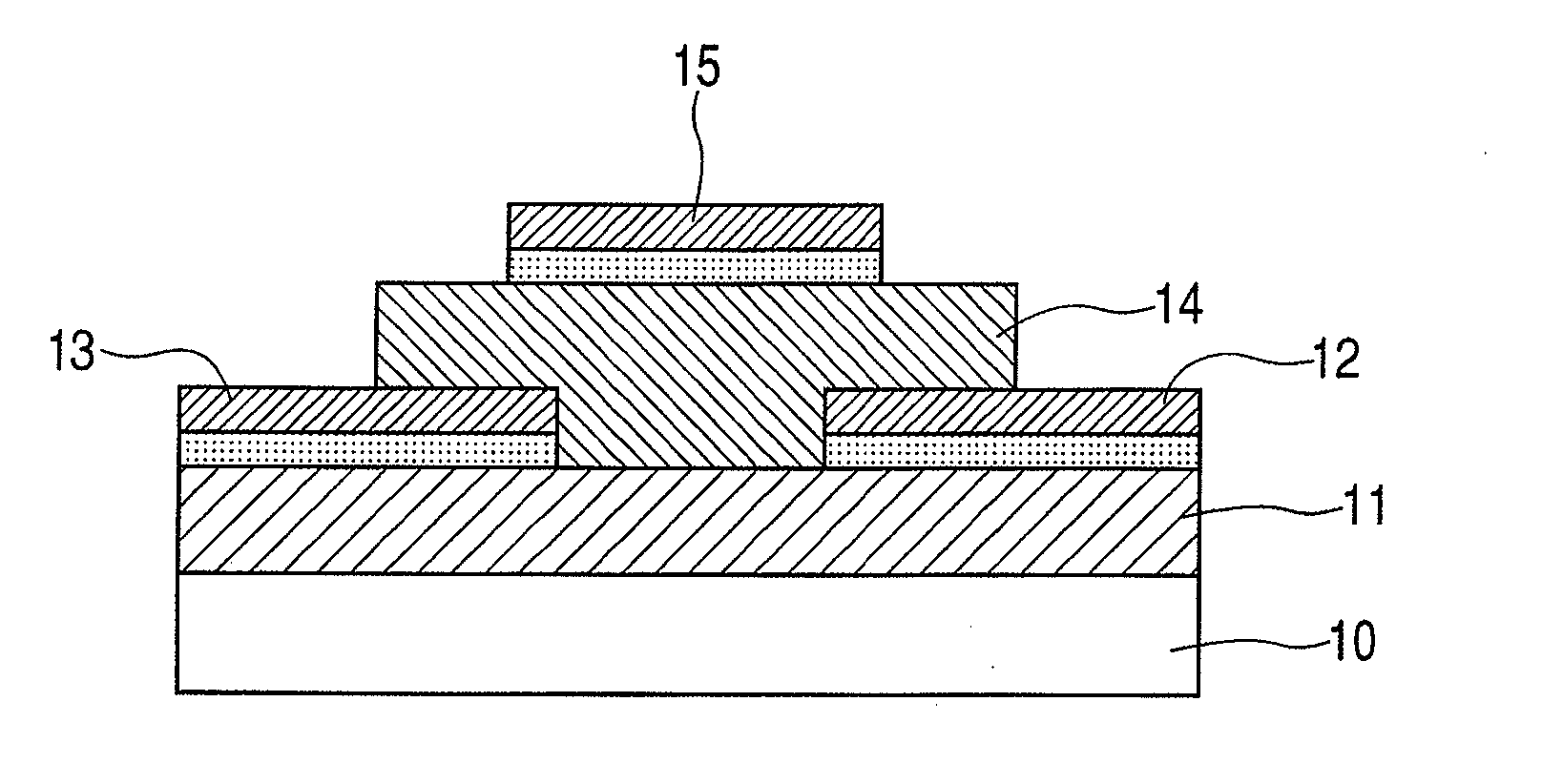

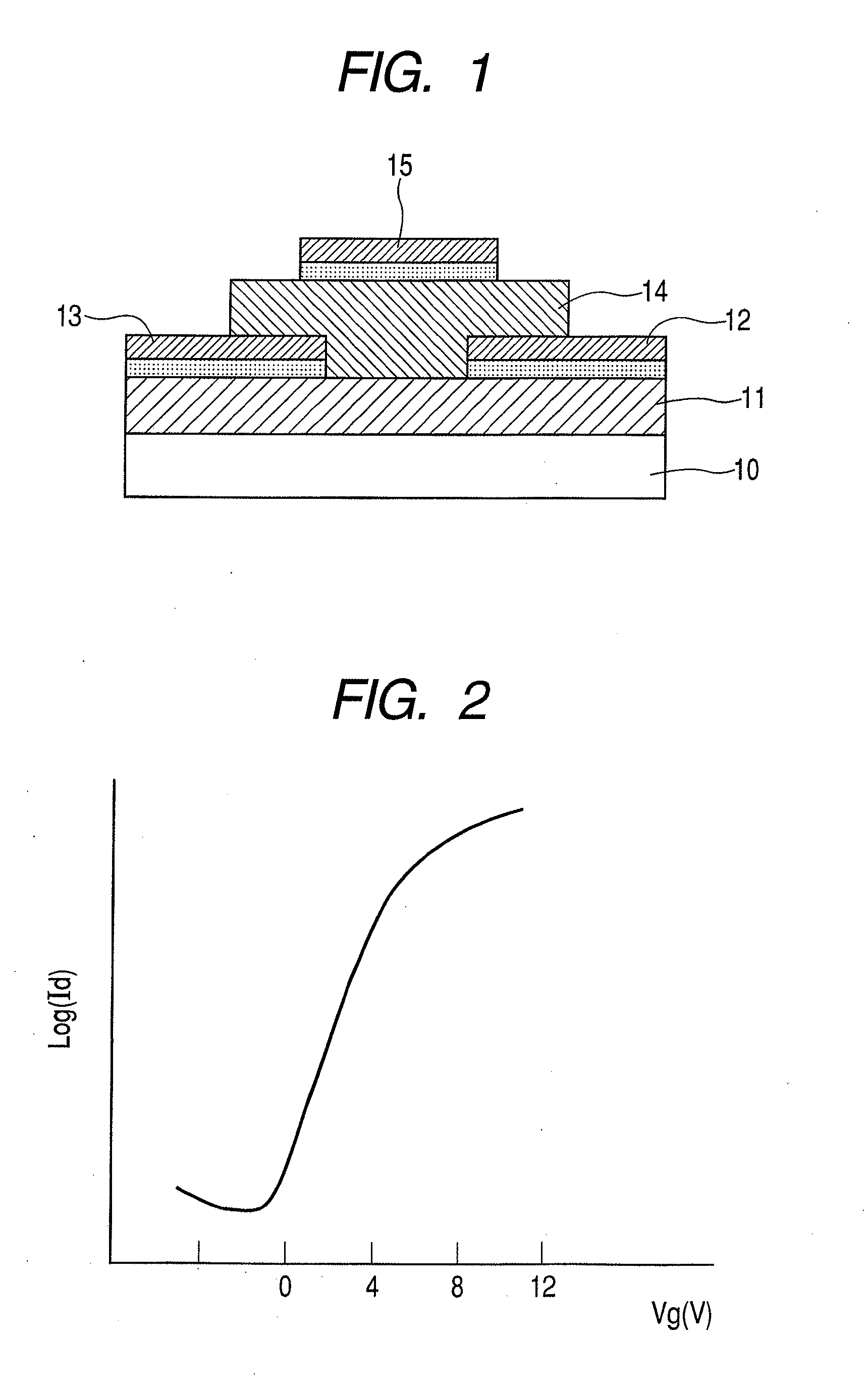

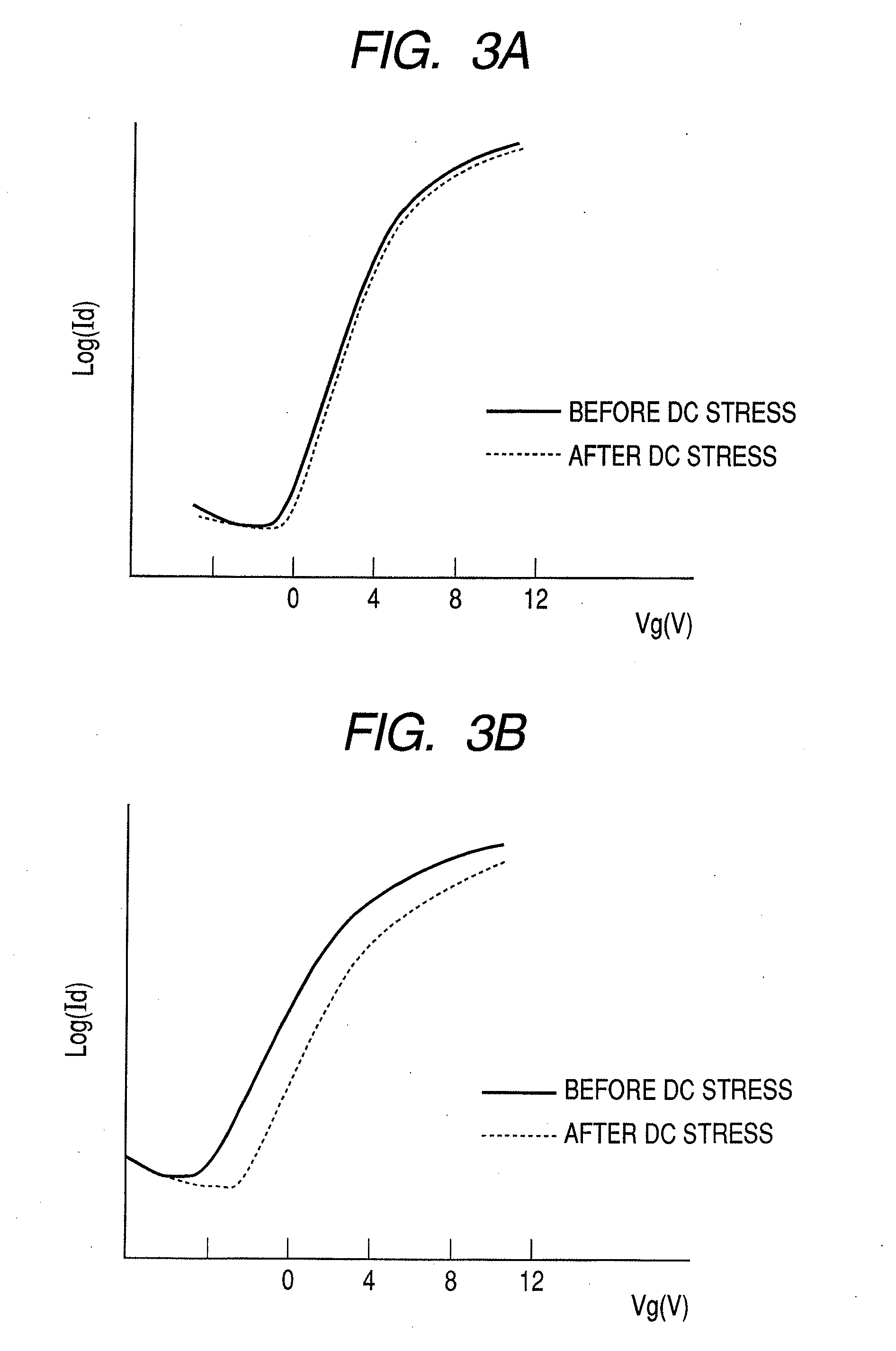

Production method of thin film transistor using amorphous oxide semiconductor film

ActiveUS8415198B2Satisfactory characteristicEffective controlSemiconductor/solid-state device manufacturingSemiconductor devicesActive layerPartial pressure

A production method of a thin film transistor including an active layer including an amorphous oxide semiconductor film, wherein a step of forming the active layer includes a first step of forming the oxide film in an atmosphere having an introduced oxygen partial pressure of 1×10−3 Pa or less, and a second step of annealing the oxide film in an oxidative atmosphere after the first step.

Owner:CANON KK

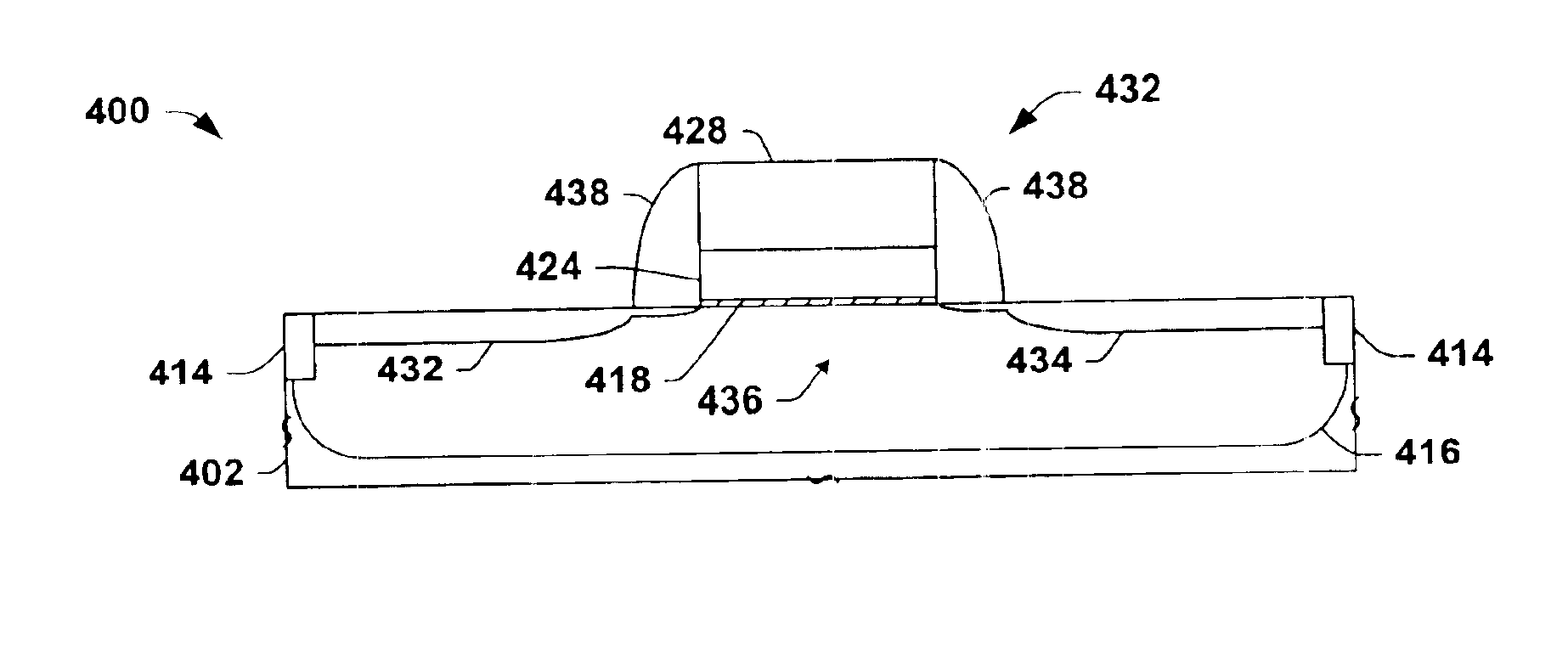

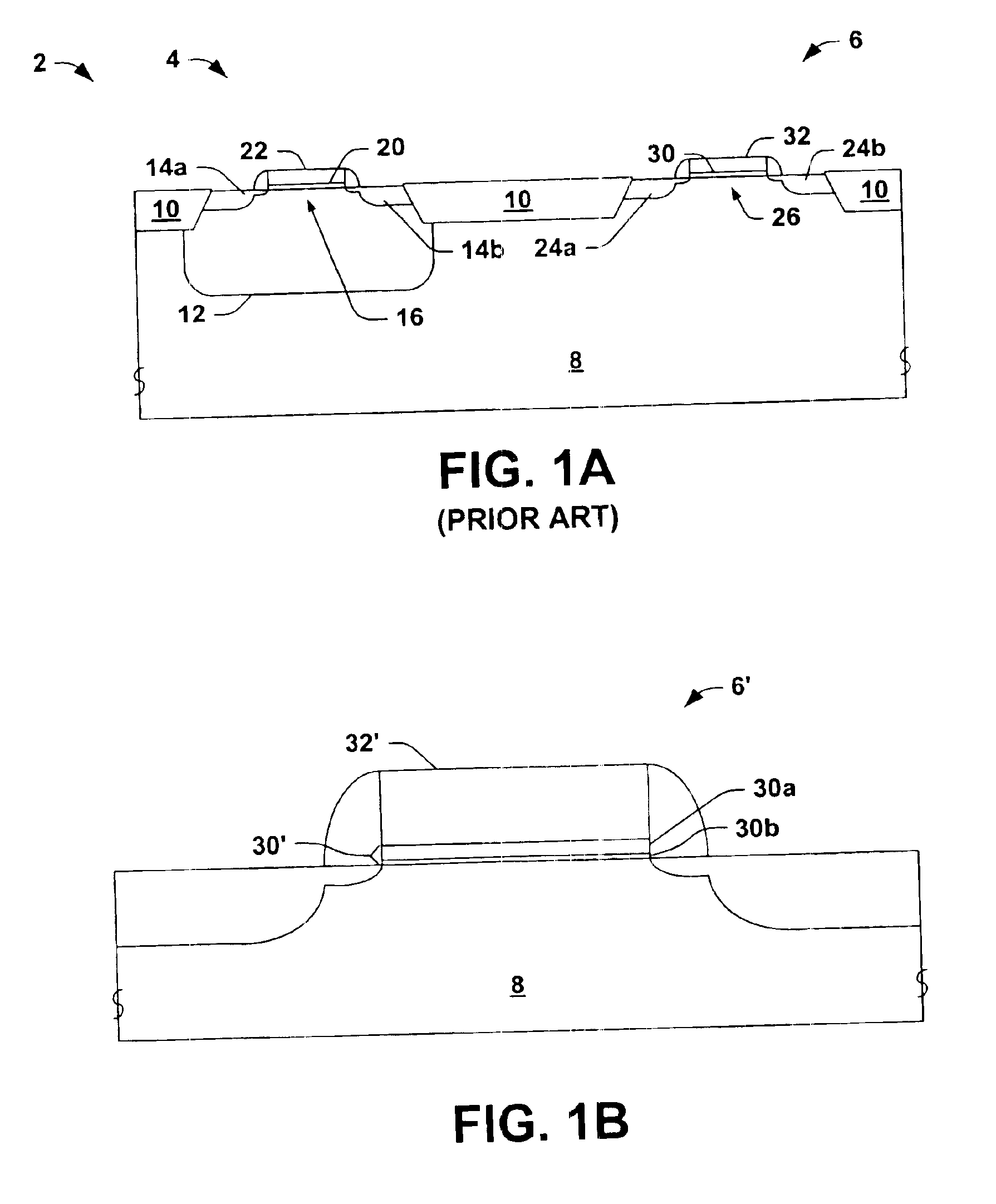

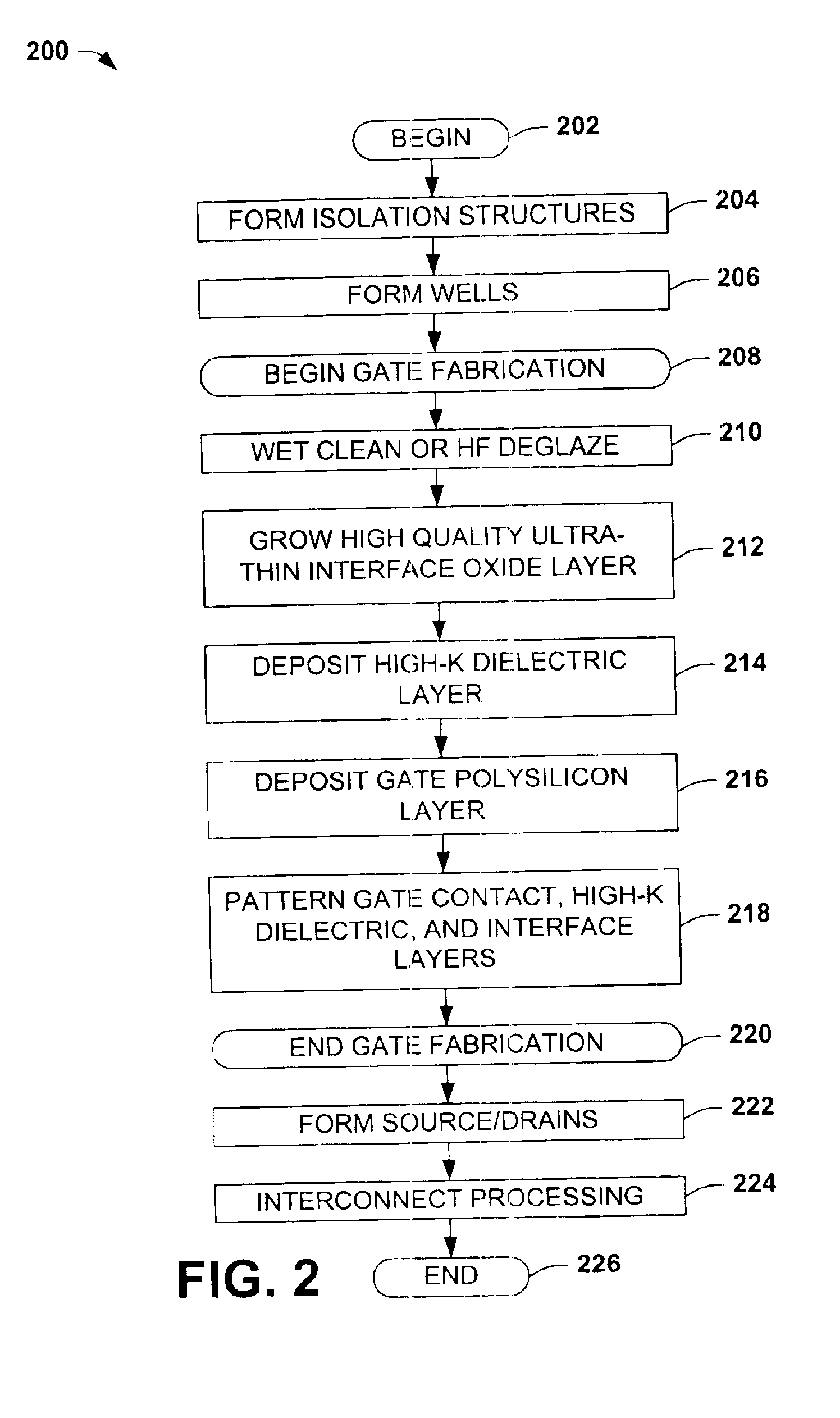

High temperature interface layer growth for high-k gate dielectric

InactiveUS6852645B2Semiconductor/solid-state device manufacturingCapacitorsInterfacial oxideCelsius Degree

The present invention pertains to methods for forming high quality thin interface oxide layers suitable for use with high-k gate dielectrics in the manufacture of semiconductor devices. An ambient that contains oxygen and a reducing agent is utilized to grow the layers. The oxygen facilitates growth of the layers, while the reducing agent simultaneously counteracts that growth. The rate of growth of the layers can thus be controlled by regulating the partial pressure of the reducing agent, which is the fraction of the reducing agent in the gas phase times the total pressure. Controlling and slowing the growth rate of the layers facilitates production of the layers to thicknesses of about 10 Angstroms or less at temperatures of about 850 degrees Celsius or more. Growing the layers at high temperatures facilitates better bonding and production of higher quality layers, which in turn yields better performing and more reliable resulting products.

Owner:PACIFIC SEISMIC PRODS +1

III-V Nitride homoepitaxial material of improved MOVPE epitaxial quality (surface texture and defect density) formed on free-standing (Al,In,Ga)N substrates, and opto-electronic and electronic devices comprising same

InactiveUS20030213964A1Improve material qualityReduce dislocation densityPolycrystalline material growthAfter-treatment detailsCelsius DegreeSource material

A III-V nitride homoepitaxial microelectronic device structure comprising a III-V nitride homoepitaxial epi layer of improved epitaxial quality deposited on a III-V nitride material substrate, e.g., of freestanding character. Various processing techniques are described, including a method of forming a III-V nitride homoepitaxial layer on a corresponding III-V nitride material substrate, by depositing the III-V nitride homoepitaxial layer by a VPE process using Group III source material and nitrogen source material under process conditions including V / III ratio in a range of from about 1 to about 10<5>, nitrogen source material partial pressure in a range of from about 1 to about 10<3 >torr, growth temperature in a range of from about 500 to about 1250 degrees Celsius, and growth rate in a range of from about 0.1 to about 10<2 >microns per hour. The III-V nitride homoepitaxial microelectronic device structures are usefully employed in device applications such as UV LEDs, high electron mobility transistors, and the like.

Owner:WOLFSPEED INC

Production method of thin film transistor using amorphous oxide semiconductor film

ActiveUS20090325341A1Effective controlSatisfactory characteristicSemiconductor/solid-state device manufacturingSemiconductor devicesActive layerPartial pressure

A production method of a thin film transistor including an active layer including an amorphous oxide semiconductor film, wherein a step of forming the active layer includes a first step of forming the oxide film in an atmosphere having an introduced oxygen partial pressure of 1×10−3 Pa or less, and a second step of annealing the oxide film in an oxidative atmosphere after the first step.

Owner:CANON KK

Method of measuring cardiac related parameters non-invasively via the lung during spontaneous and controlled ventilation

InactiveUS20070062531A1RespiratorsOperating means/releasing devices for valvesAnatomical dead spaceGas concentration

An apparatus to measure cardiac output (Q) and other parameters such as alveolar ventilation (VA), minute CO2 elimination from the lung (VCO2 ), minute oxygen consumption (VO2), oxygenated mixed venous partial pressure of CO2, (PvCO2-oxy), true mixed venous partial pressure of CO2(PvCO2), PaCO2, mixed venous oxygen saturation (SvO2), pulmonary shunt, and anatomical dead space, consisting of: a) a breathing circuit with characteristics that: i. on exhalation, exhaled gas is kept substantially separate from inhaled gas; ii. oninhalation, when VE is greater than FGS flow, the subject inhales FGS first and then inhales a gas that is substantially SGS, for the balance of inhalation; b) gas sensor means for monitoring gas concentrations at the patient-circuit interface c) a first gas set (FGS), and a second gas set (SGS), said second gas set which may comprise previously exhaled gases or exogenous gases or both d) a gas flow control means for controlling the rate of FGS flow into the breathing circuit e) means to identify phase of breathing, said means may consist of pressure sensors or analysis of signal generated by gas sensors or other means known to those skilled in the art; f) machine intelligence consisting of a computer or logic circuit capable of controlling the gas flow control means, receiving the output of the gas sensor means and means to identify phased of breathing, and performing the calculations for measuring cardiac output and other parameters as outlined in the disclosure.

Owner:THORNHILL SCI INC

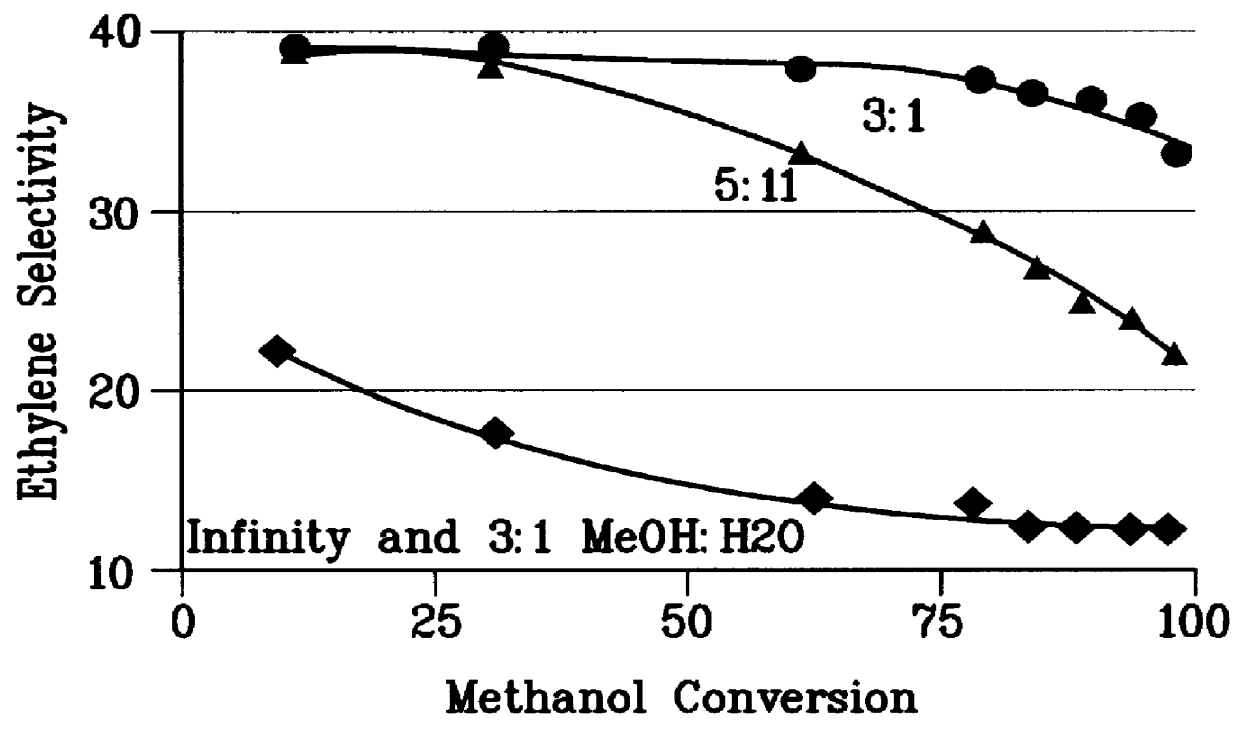

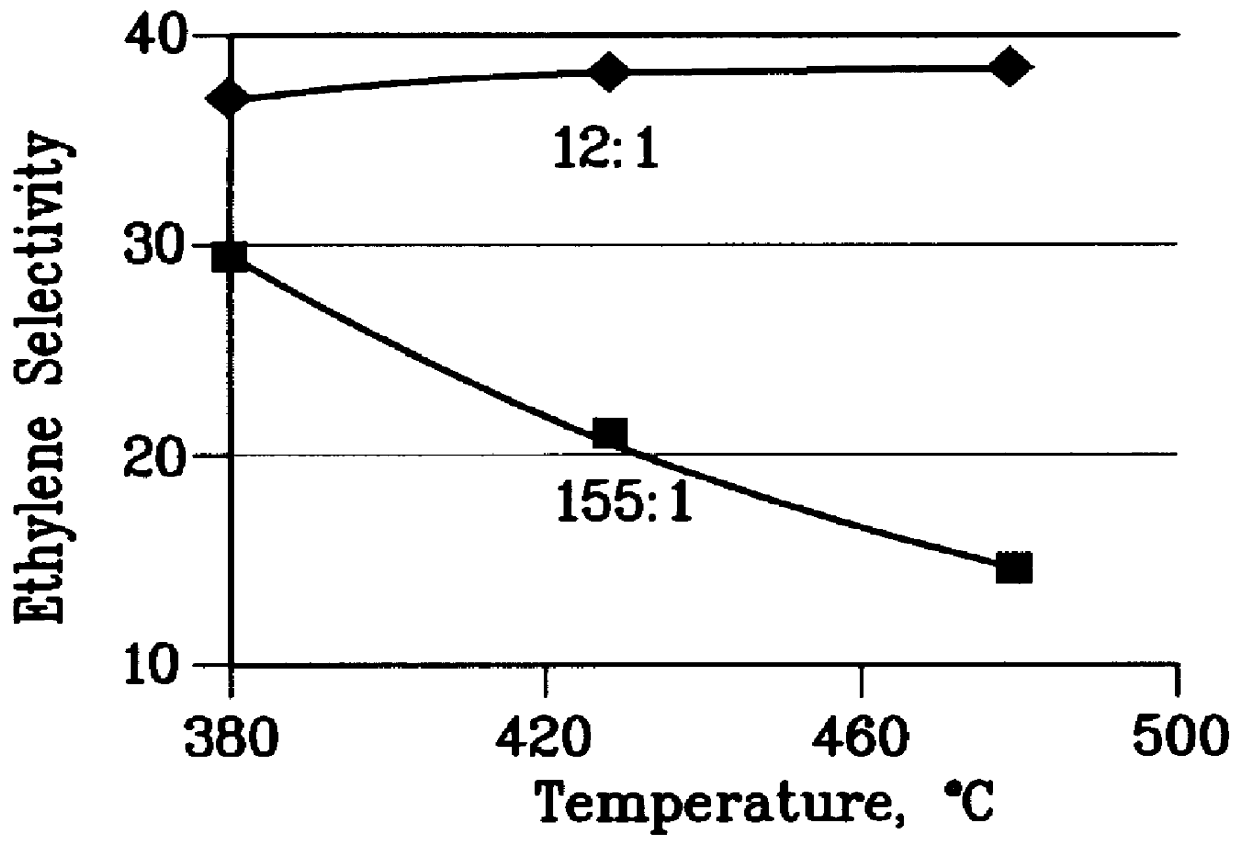

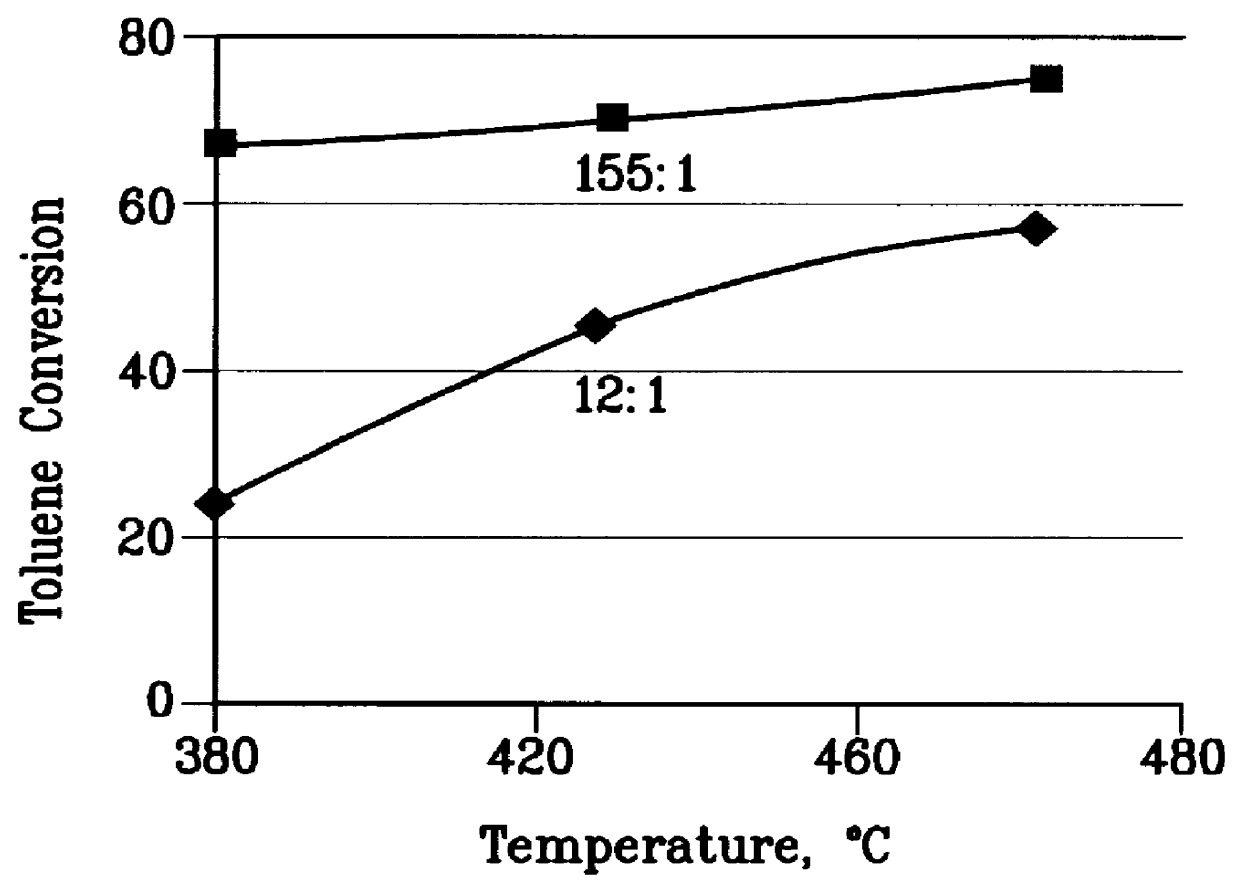

Process for producing light olefins

InactiveUS6046372AMolecular sieve catalystsMolecular sieve catalystAlkyl transferCrystalline materials

There is provided a process for converting methanol and / or dimethyl ether to a product containing C2 to C4 olefins which comprises the step of contacting a feed which contains methanol and / or dimethyl ether with a catalyst comprising a porous crystalline material, said contacting step being conducted in the presence of an aromatic compound under conversion conditions including a temperature of 350 DEG C. to 480 DEG C. and a methanol partial pressure in excess of 10 psia (70 kPa), said porous crystalline material having a pore size greater than the critical diameter of the aromatic compound and the aromatic compound being capable of alkylation by the methanol and / or dimethyl ether under said conversion conditions.

Owner:MOBIL OIL CORP

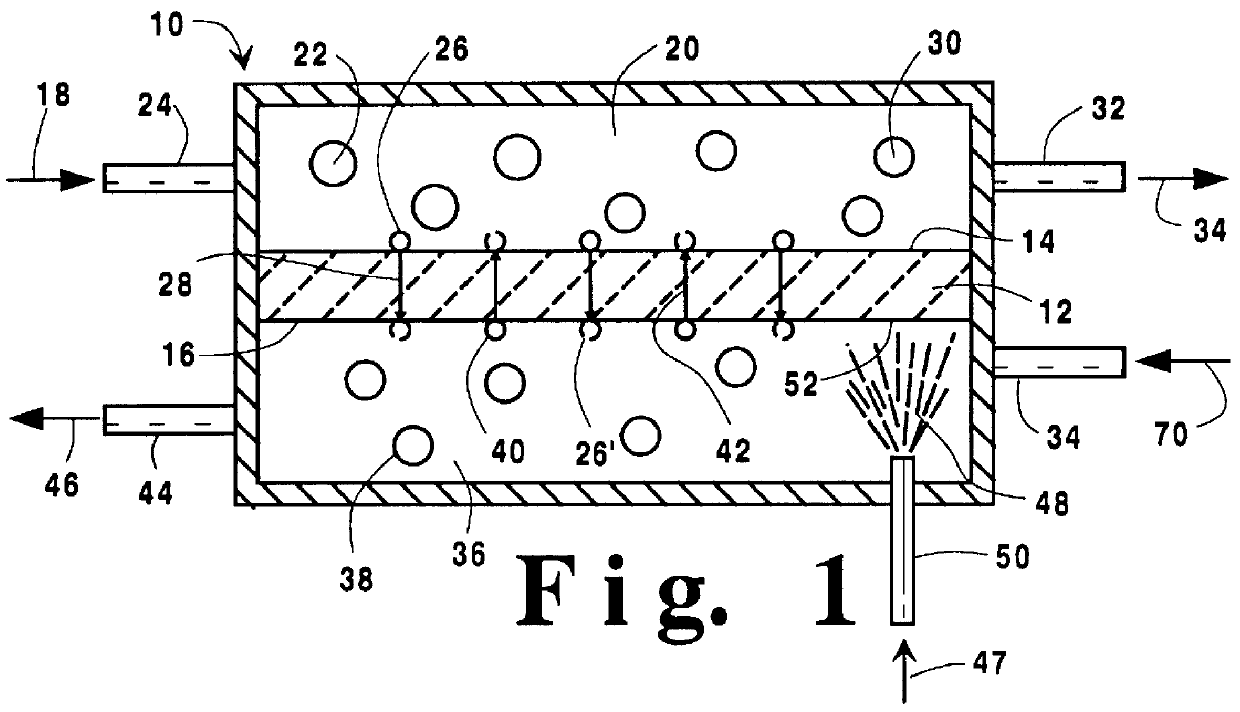

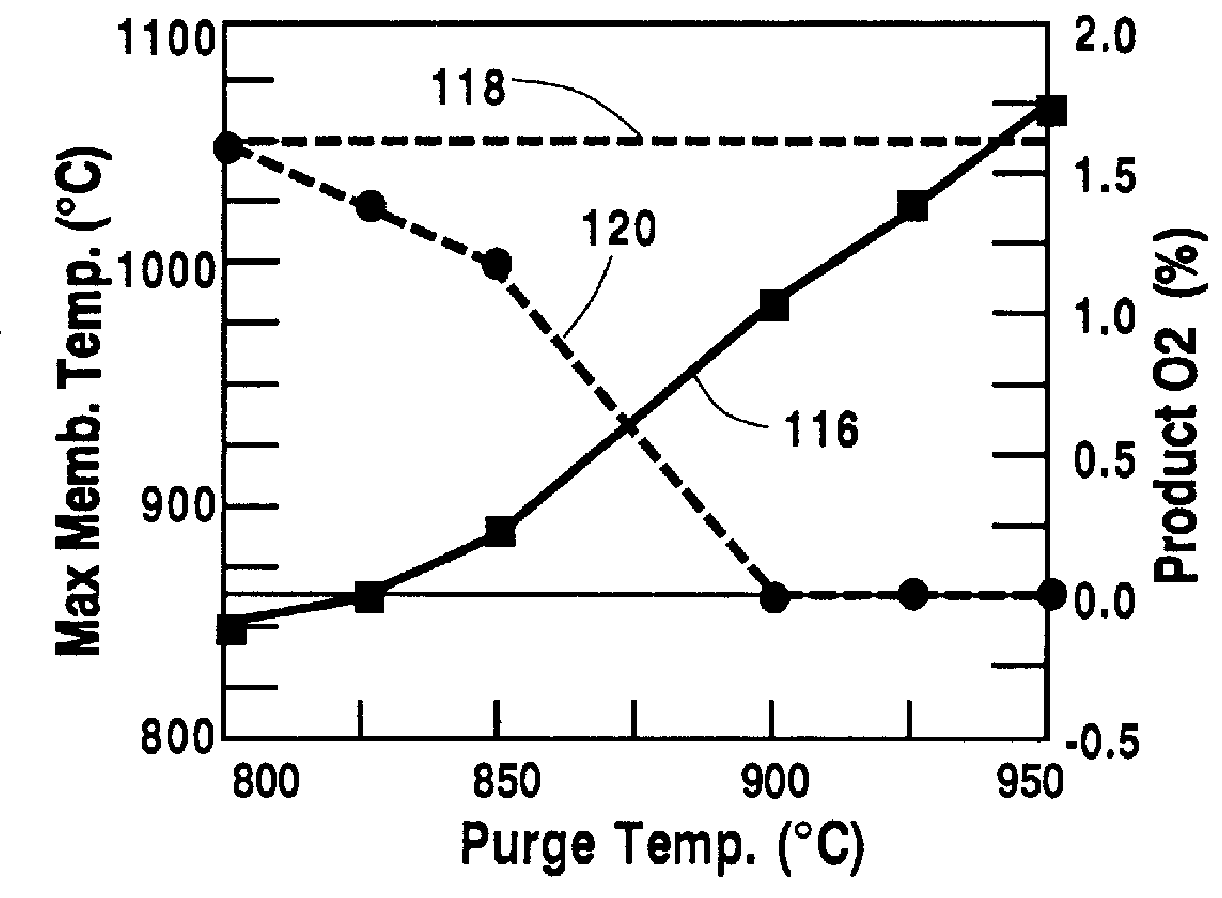

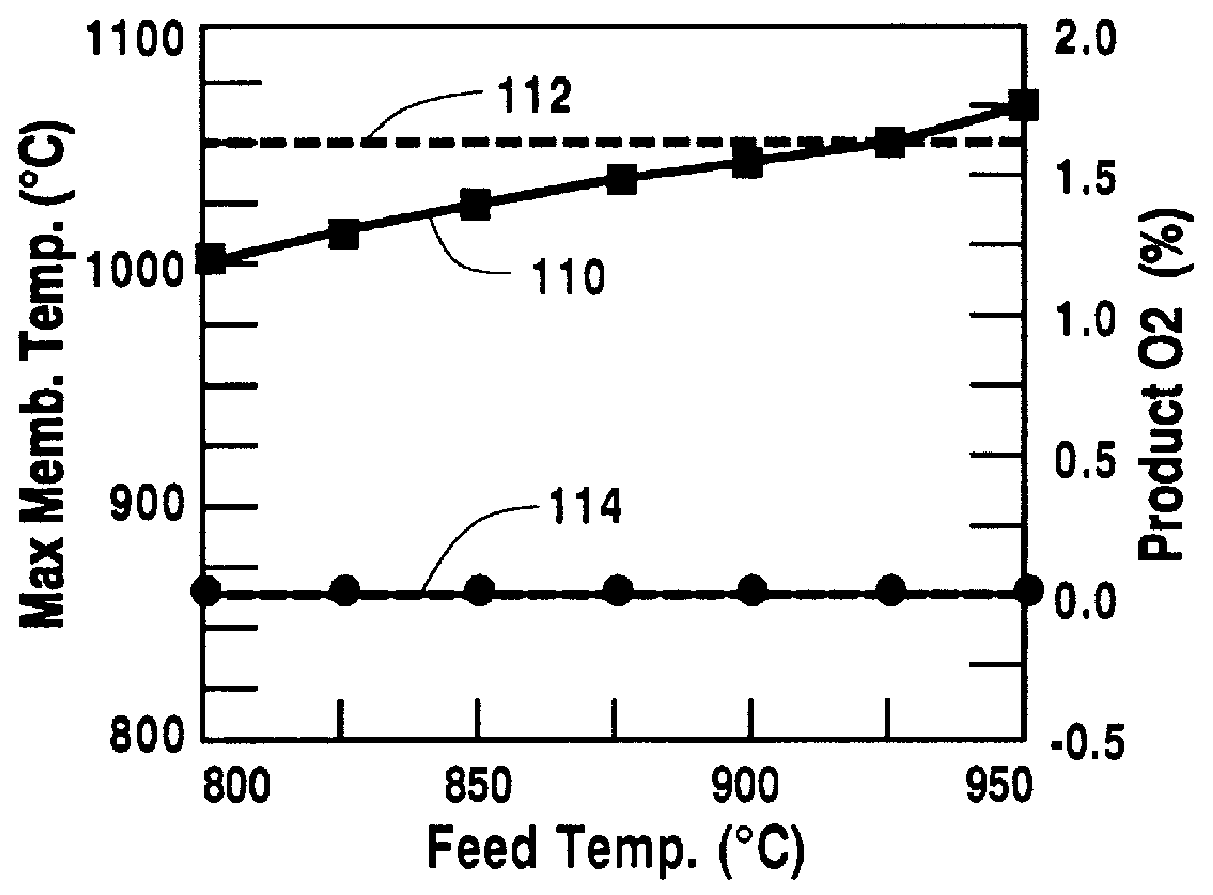

Temperature control in a ceramic membrane reactor

InactiveUS6010614AEnhance exchangeFine surfaceHydrogenLiquid separation by electricityTemperature controlOxygen ions

A method for maintaining the temperature of an oxygen-selective ion transport membrane within a desired temperature range includes providing an ion transport reactor with the oxygen-selective ion transport membrane. An oxygen-donating feed gas is delivered to a cathode side at a first temperature, at a first rate, and at a first oxygen partial pressure and a reactant gas is supplied to an anode side at a second temperature and a second rate. A physical condition is then established within the ion transport reactor that favors the transport of elemental oxygen through the oxygen selective ion transport membrane as oxygen ions. One or more process variables are then regulated to maintain the temperature of the oxygen selective ion transport membrane within the desired range.

Owner:PRAXAIR TECH INC

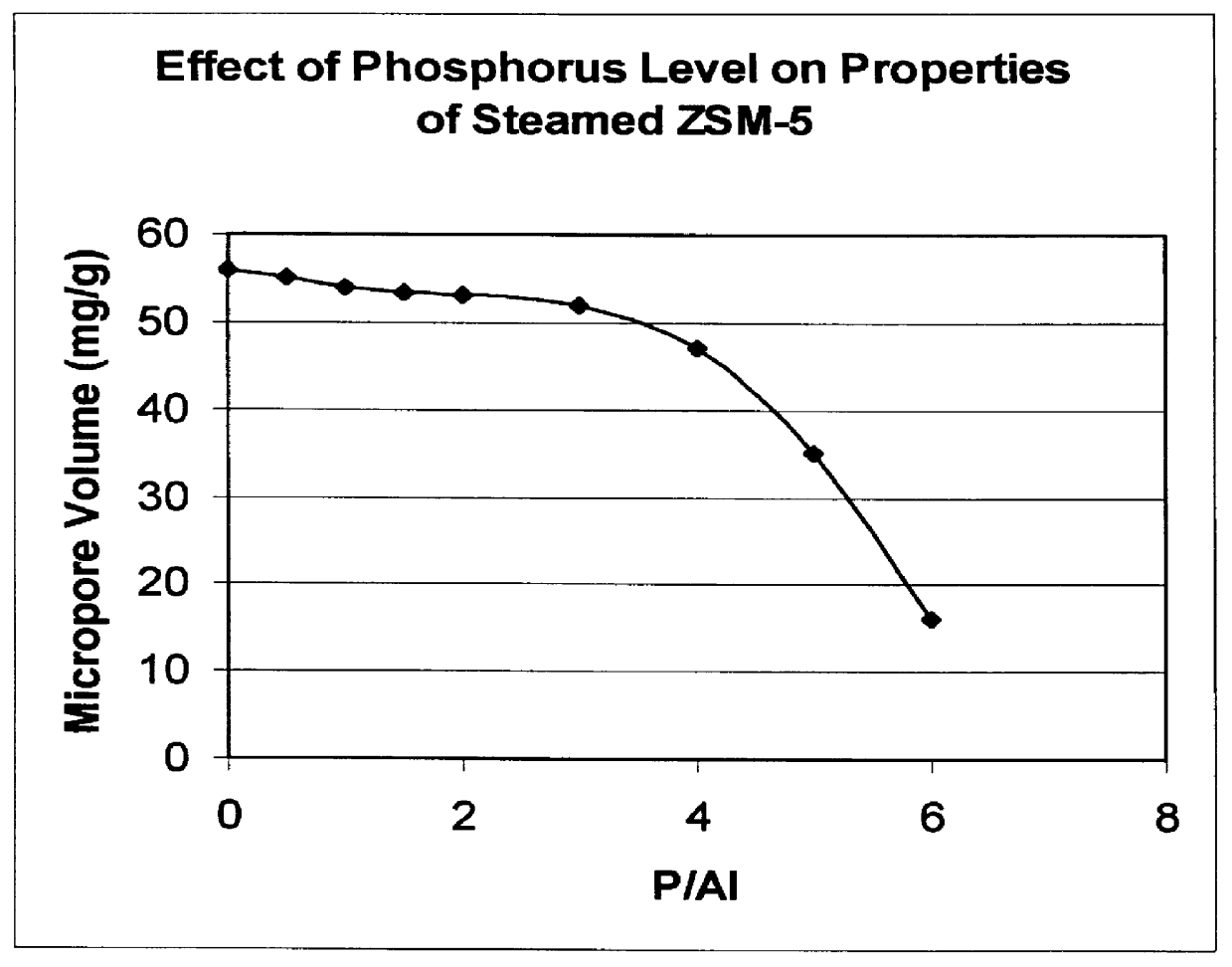

Catalyst and process for converting methanol to hydrocarbons

InactiveUS6048816AMolecular sieve catalystsMolecular sieve catalystCrystalline materialsDimethyl ether

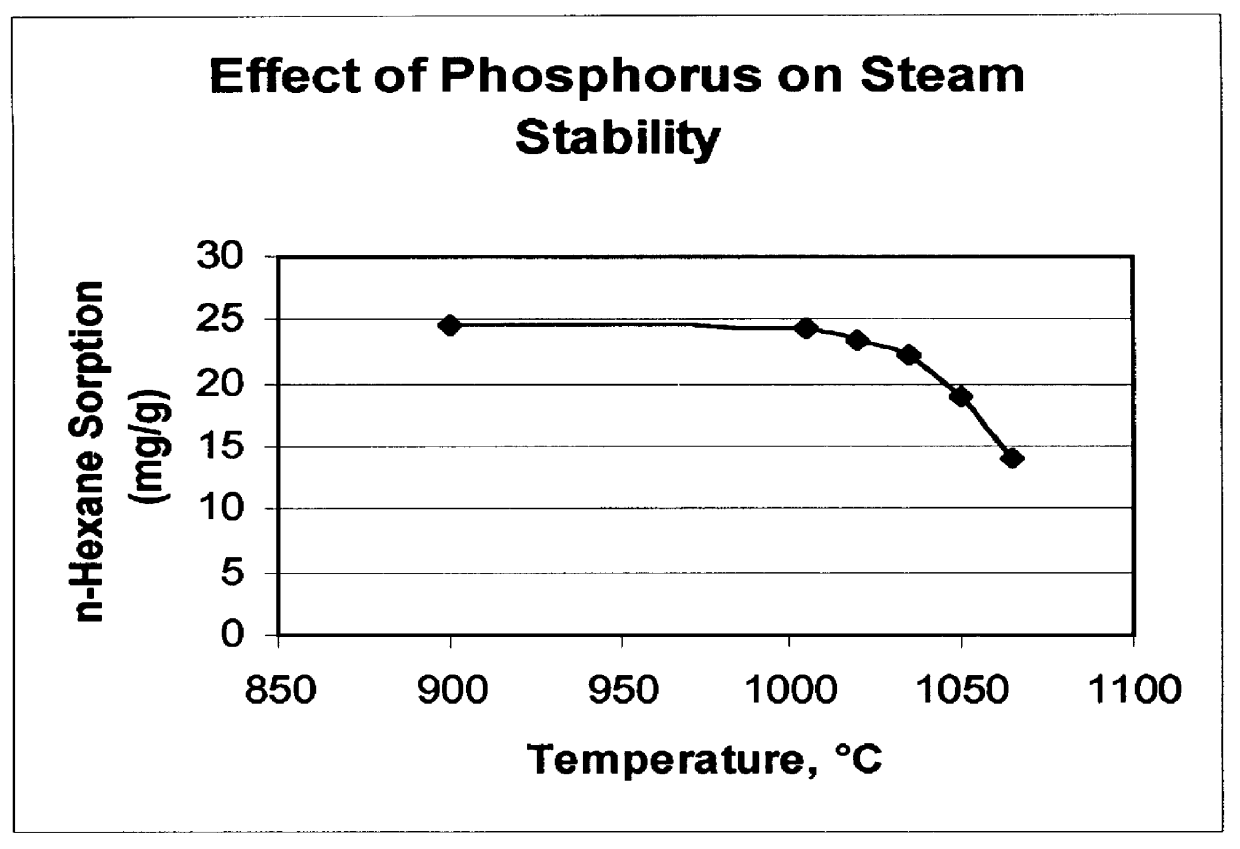

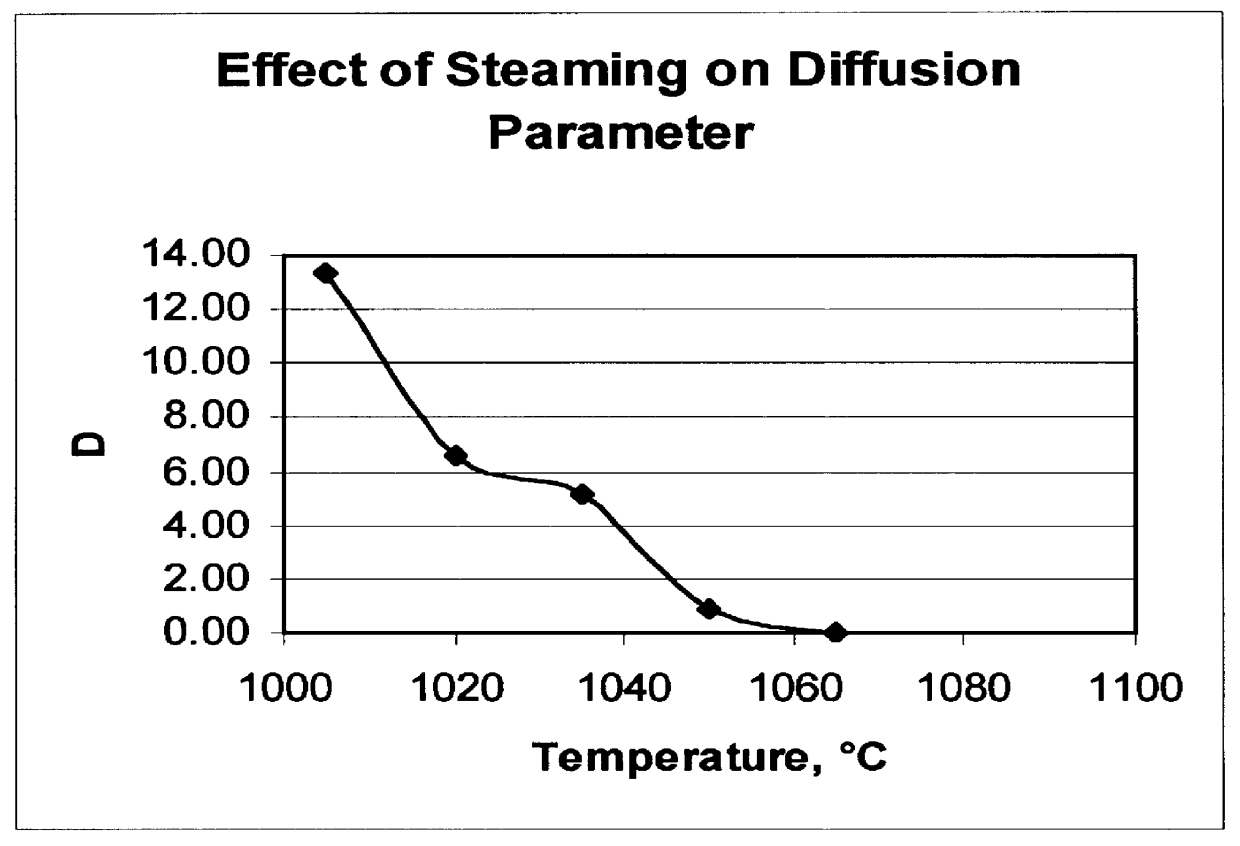

There is provided a catalyst and a process for converting methanol or dimethyl ether to a product containing C2 to C4 olefins. The catalyst comprises a porous crystalline material having a Diffusion Parameter for 2,2-dimethylbutane of about 0.1-20 sec-1 when measured at a temperature of 120 DEG C. and a 2,2-dimethylbutane pressure of 60 torr (8 kPa). In addition, the catalyst is characterized by a hydrothermal stability such that, after steaming the catalyst at 1025 DEG C. for 45 minutes in 1 atmosphere steam, the catalyst exhibits a methanol conversion activity of at least 50% when contacted with methanol at a methanol partial pressure of 1 atmosphere, a temperature of 430 DEG C. and 0.5 WHSV. The porous crystalline material is preferably a medium-pore zeolite, particularly ZSM-5, which contains phosphorus and has been severely steamed at a temperature of at least 950 DEG C.

Owner:MOBIL OIL CORP

System for combined transcutaneous blood gas monitoring and negative pressure wound treatment

InactiveUS7524286B2Substantial riskAccurate estimateIntravenous devicesDiagnostic recording/measuringMicrocontrollerSignificant risk

Owner:KCI LICENSING INC

Onboard fuel separation apparatus for an automobile

InactiveUS6972093B2Increase volumeBoost octaneInternal combustion piston enginesUsing liquid separation agentVolatilesEngineering

An onboard fuel separation apparatus separates a material fuel (gasoline) into a high-octane fuel having a higher octane value than the material fuel and a low-octane fuel having a lower octane value than the material fuel using a separation membrane which selectively allows high-octane value components (such as aromatic components) permeate through the membrane. The apparatus increases the ratio of the amount of the high-octane value components permeating through the membrane to the amount of the high-octane value components contained in the material fuel by, (A) Controlling the temperature of the material fuel supplied to the membrane (B) Increasing partial pressure of the low-octane value components on the high-octane fuel side of the membrane and removing volatiles from the permeate, and (C) Bypassing volatiles in the material feed around the membrane.

Owner:EXXON RES & ENG CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com