Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3821results about "Molecular sieve catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroalkylation of aromatic hydrocarbons

InactiveUS6037513AHigh activityHigh selectivityMolecular sieve catalystsOrganic compound preparationBenzeneX-ray

There is described a process and a catalyst for the hydroalkylation of an aromatic hydrocarbon, particularly benzene, wherein the catalyst comprises a first metal having hydrogenation activity and a crystalline inorganic oxide material having a X-ray diffraction pattern including the following d-spacing maxima 12.4+ / -0.25, 6.9+ / -0.15, 3.57+ / -0.07 and 3.42+ / -0.07.

Owner:MOBIL OIL CORP

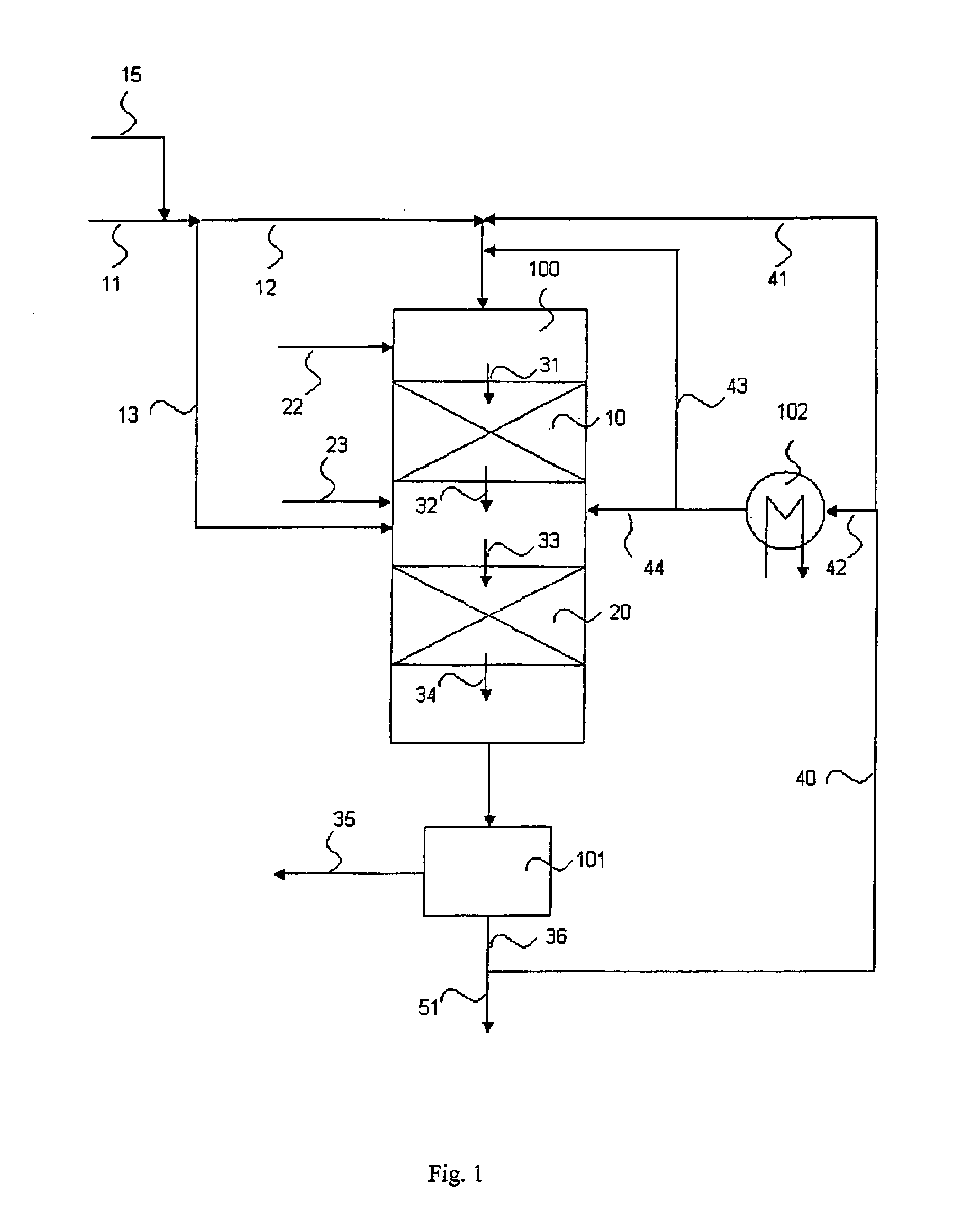

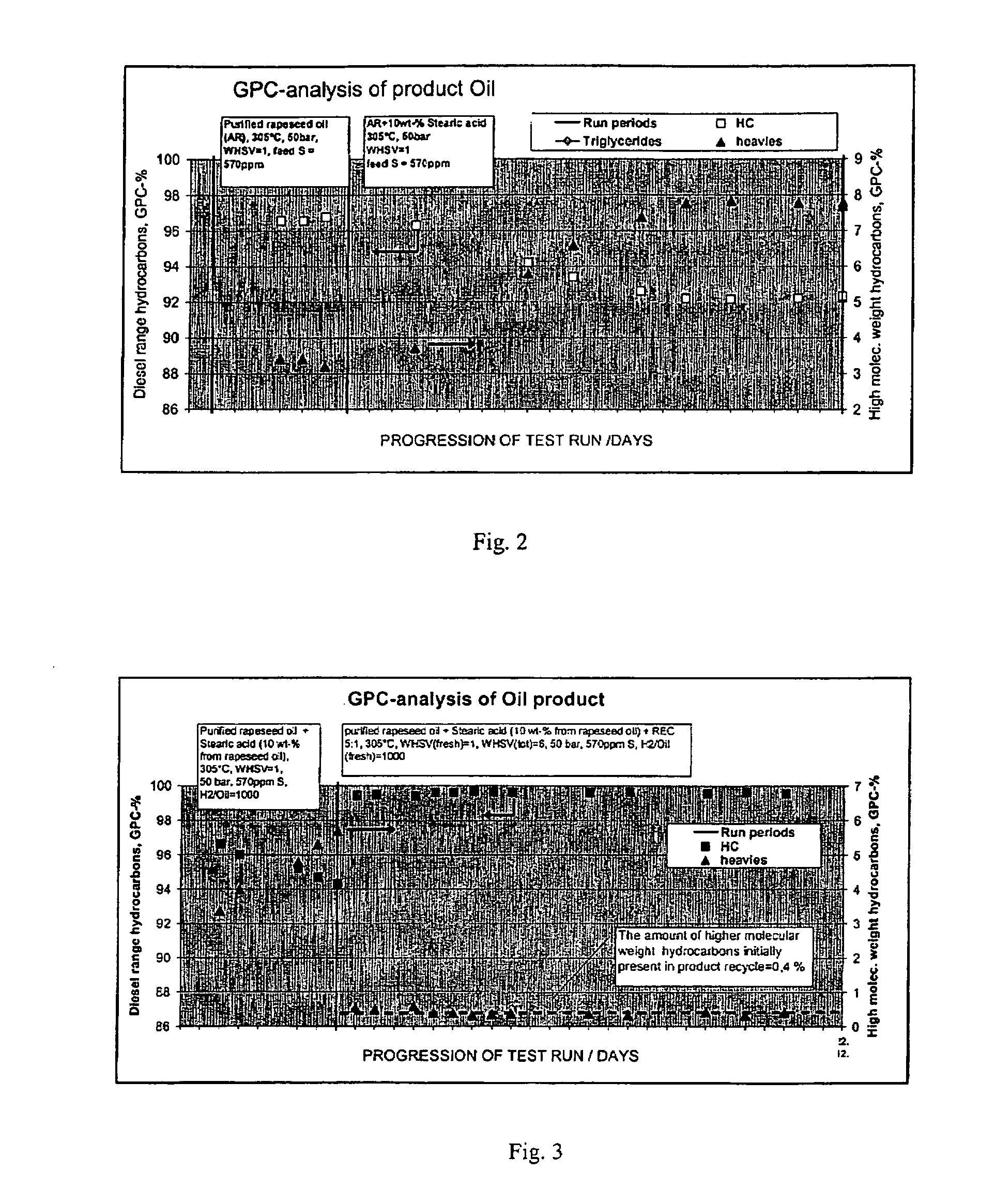

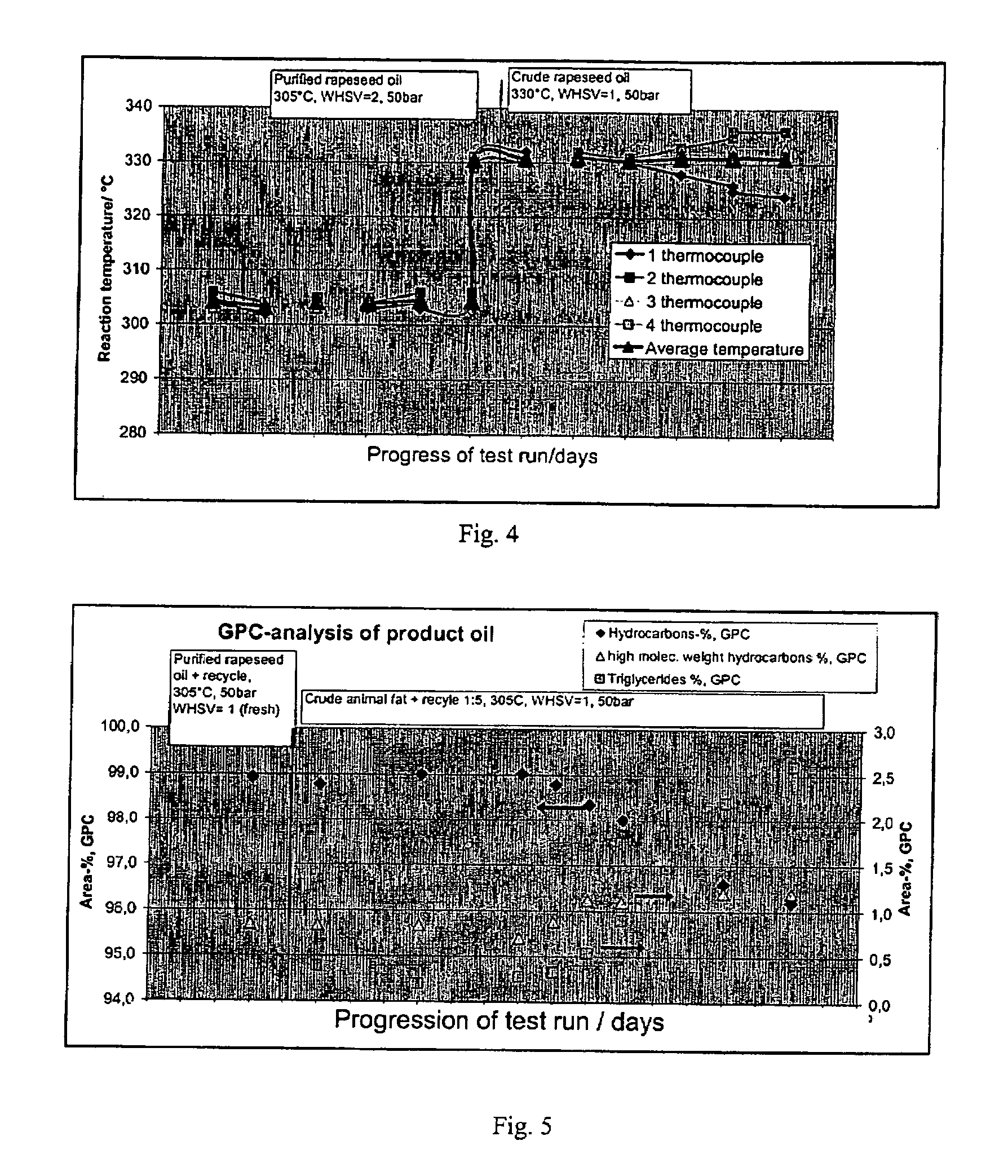

Process for the manufacture of diesel range hydrocarbons

ActiveUS20070010682A1Fatty oils/acids recovery from wasteHydrocarbon by isomerisationIsomerizationReaction temperature

The invention relates to a process for the manufacture of diesel range hydrocarbons wherein a feed is hydrotreated in a hydrotreating step and isomerised in an isomerisation step, and a feed comprising fresh feed containing more than 5 wt % of free fatty acids and at least one diluting agent is hydrotreated at a reaction temperature of 200-400° C., in a hydrotreating reactor in the presence of catalyst, and the ratio of the diluting agent / fresh feed is 5-30:1.

Owner:NESTE OIL OY

Hydroalkylation of aromatic hydrocarbons

InactiveUS6730625B1High activityHigh selectivityMolecular sieve catalystsMolecular sieve catalystBenzeneX-ray

There is described a process and a catalyst for the hydroalkylation of an aromatic hydrocarbon, particularly benzene, wherein the catalyst comprises a first metal having hydrogenation activity and a crystalline inorganic oxide material having a X-ray diffraction pattern including the following d-spacing maxima 12.4±0.25, 6.9±0.15, 3.57±0.07 and 3.42±0.07.

Owner:EXXONMOBIL CORP (US)

Alkylaromatics production

The present invention provides a process for producing a monoalkylated aromatic compound, particularly cumene, comprising the step of contacting a polyalkylated aromatic compound with an alkylatable aromatic compound under at least partial liquid phase conditions and in the presence of a transalkylation catalyst to produce the monoalkylated aromatic compound, wherein the transalkylation catalyst comprises a mixture of at least two different crystalline molecular sieves, wherein each of said molecular sieves is selected from zeolite beta, zeolite Y, mordenite and a material having an X-ray diffraction pattern including d-spacing maxima at 12.4±0.25, 6.9±0.15, 3.57±0.07 and 3.42±0.07 Angstrom.

Owner:EXXONMOBIL CHEM PAT INC

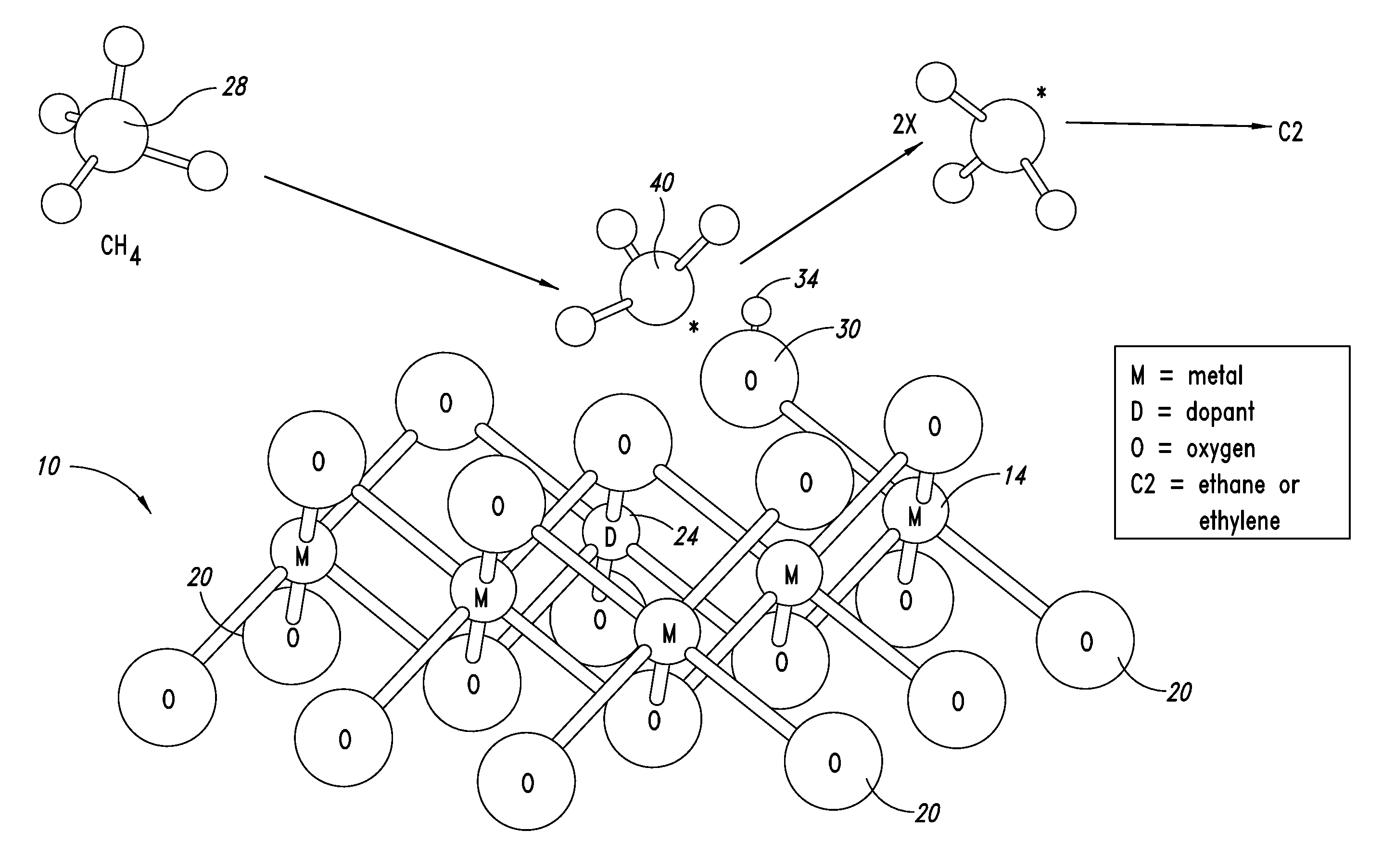

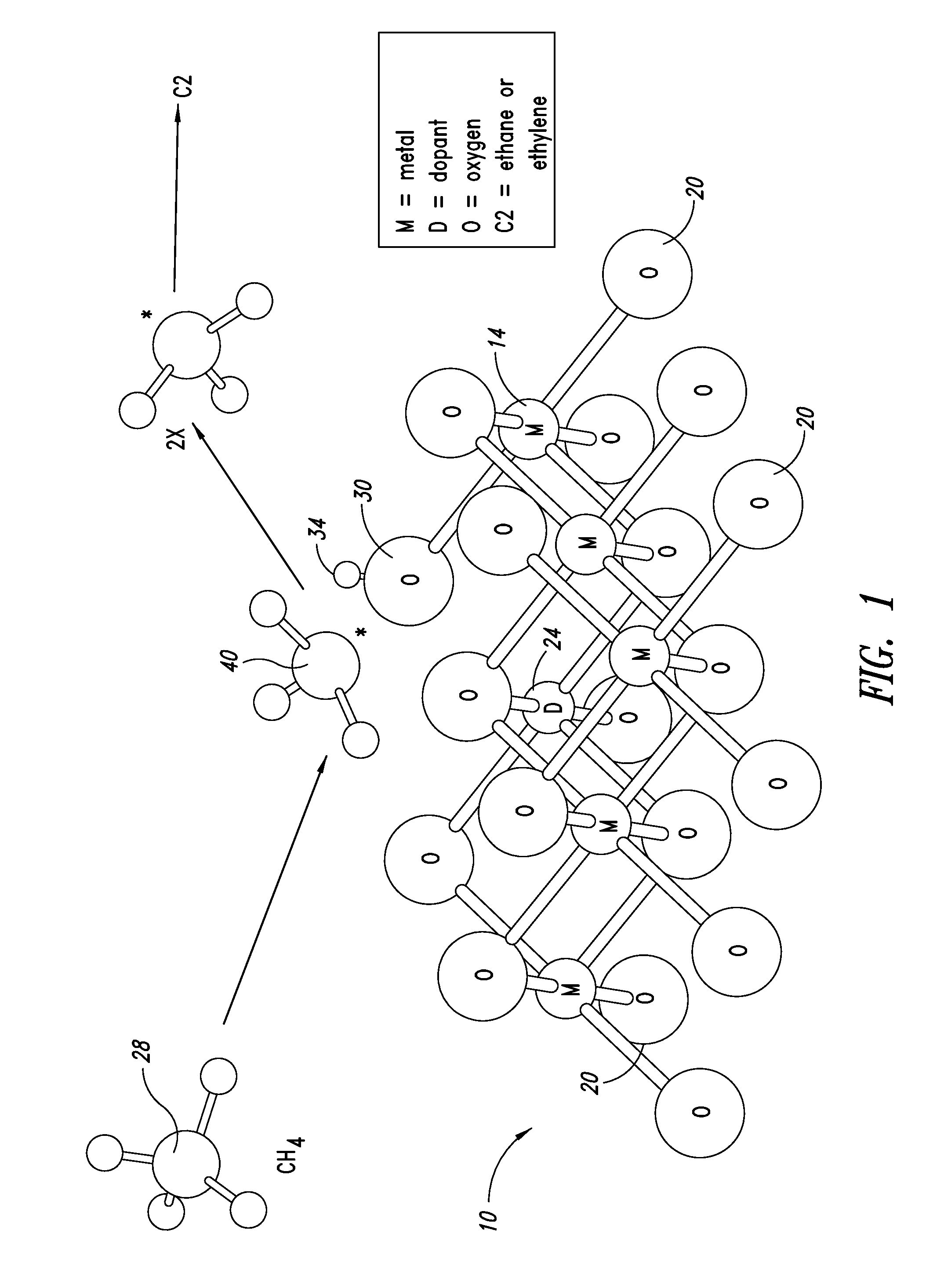

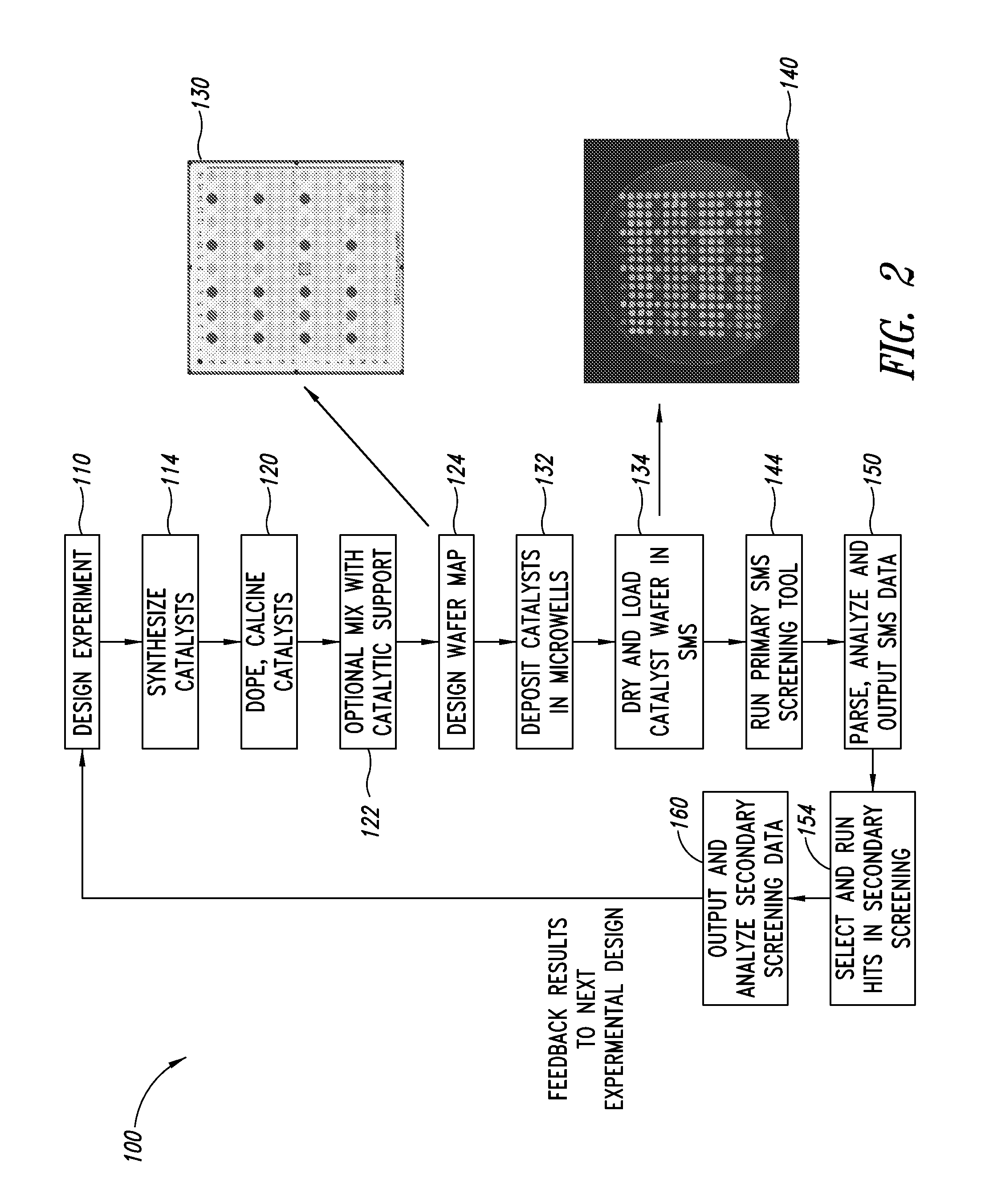

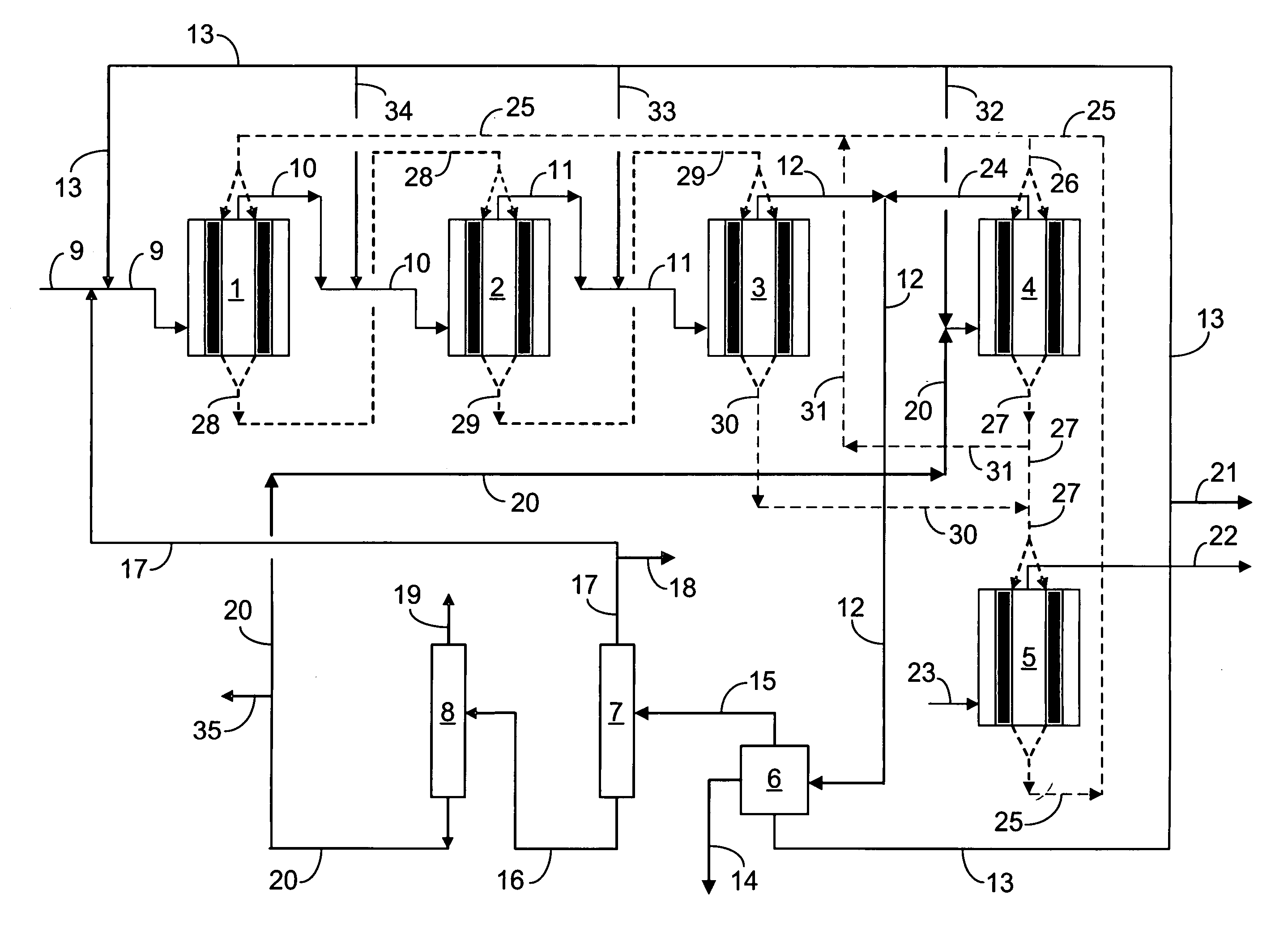

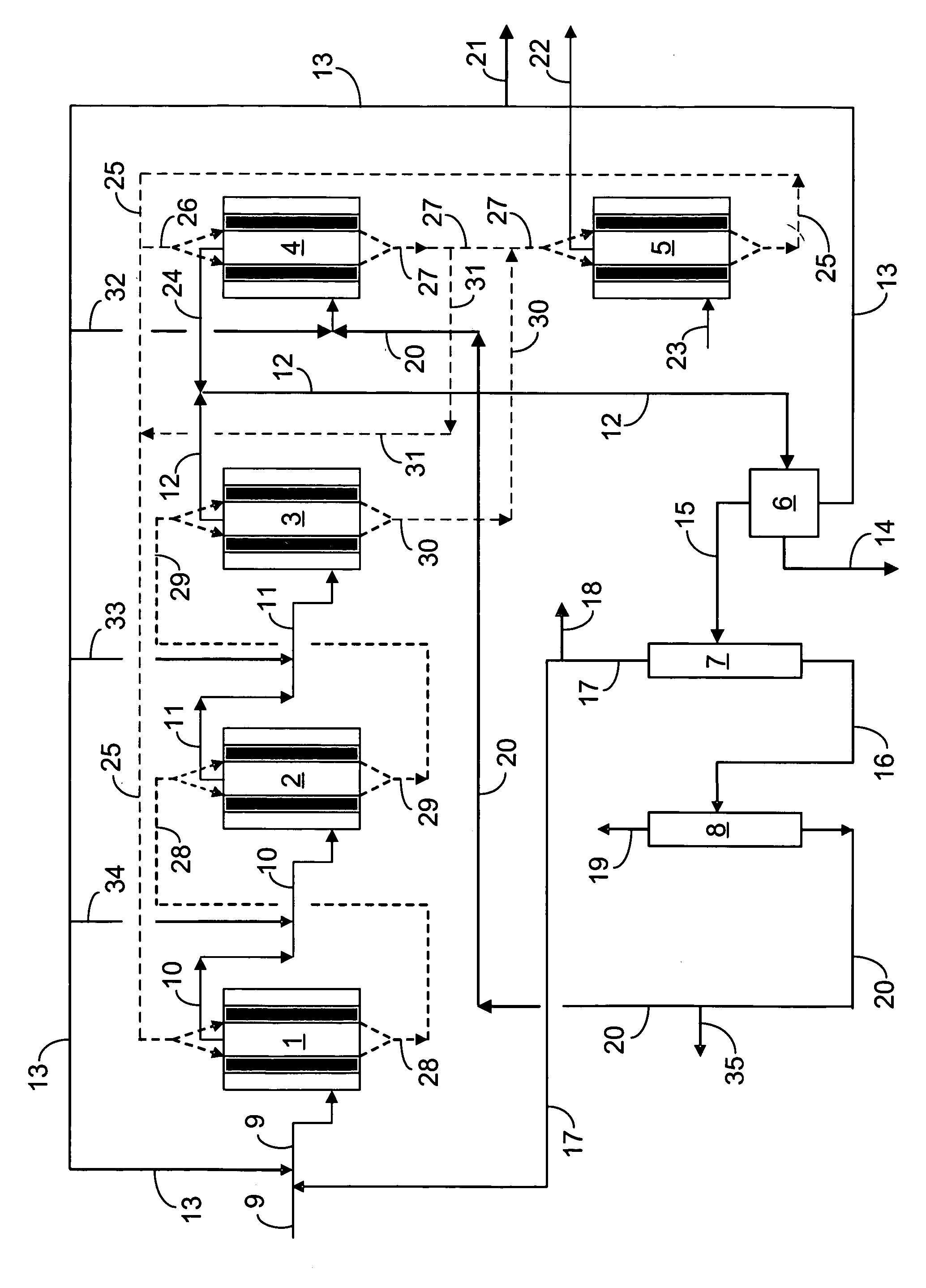

Catalysts for petrochemical catalysis

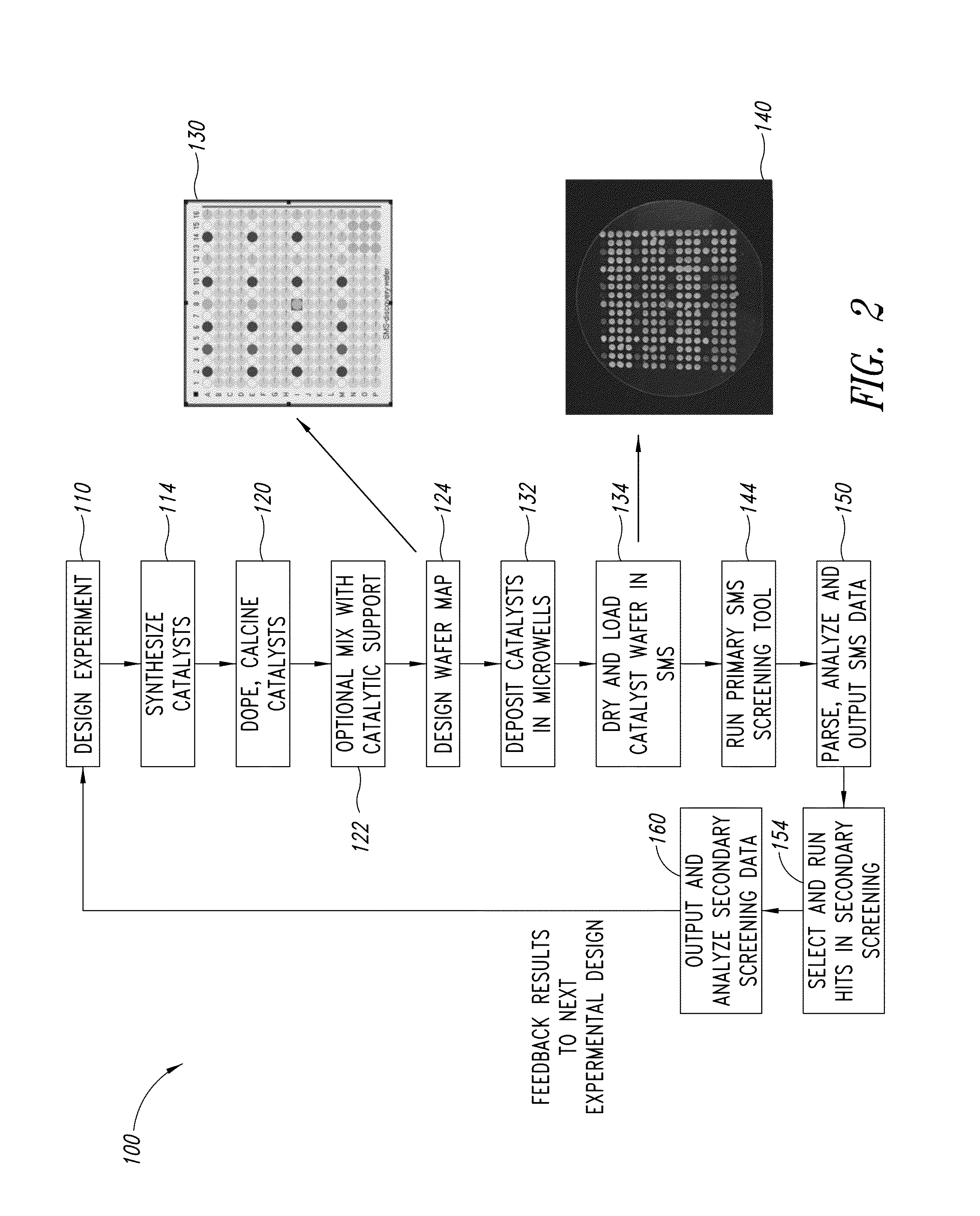

ActiveUS20130023709A1Sequential/parallel process reactionsManganese oxides/hydroxidesDopantPetrochemical

Metal oxide catalysts comprising various dopants are provided. The catalysts are useful as heterogenous catalysts in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons such as ethane and ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

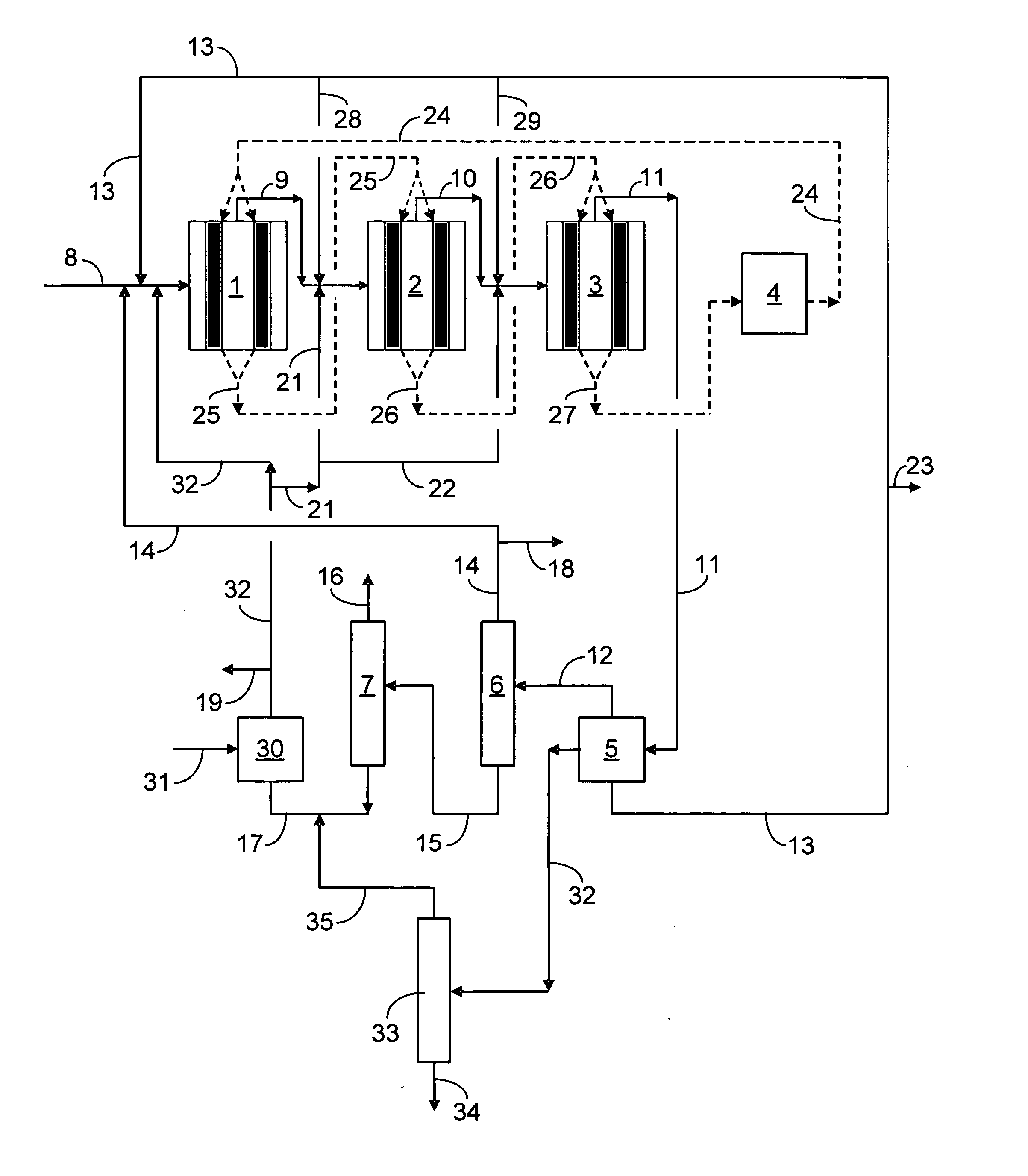

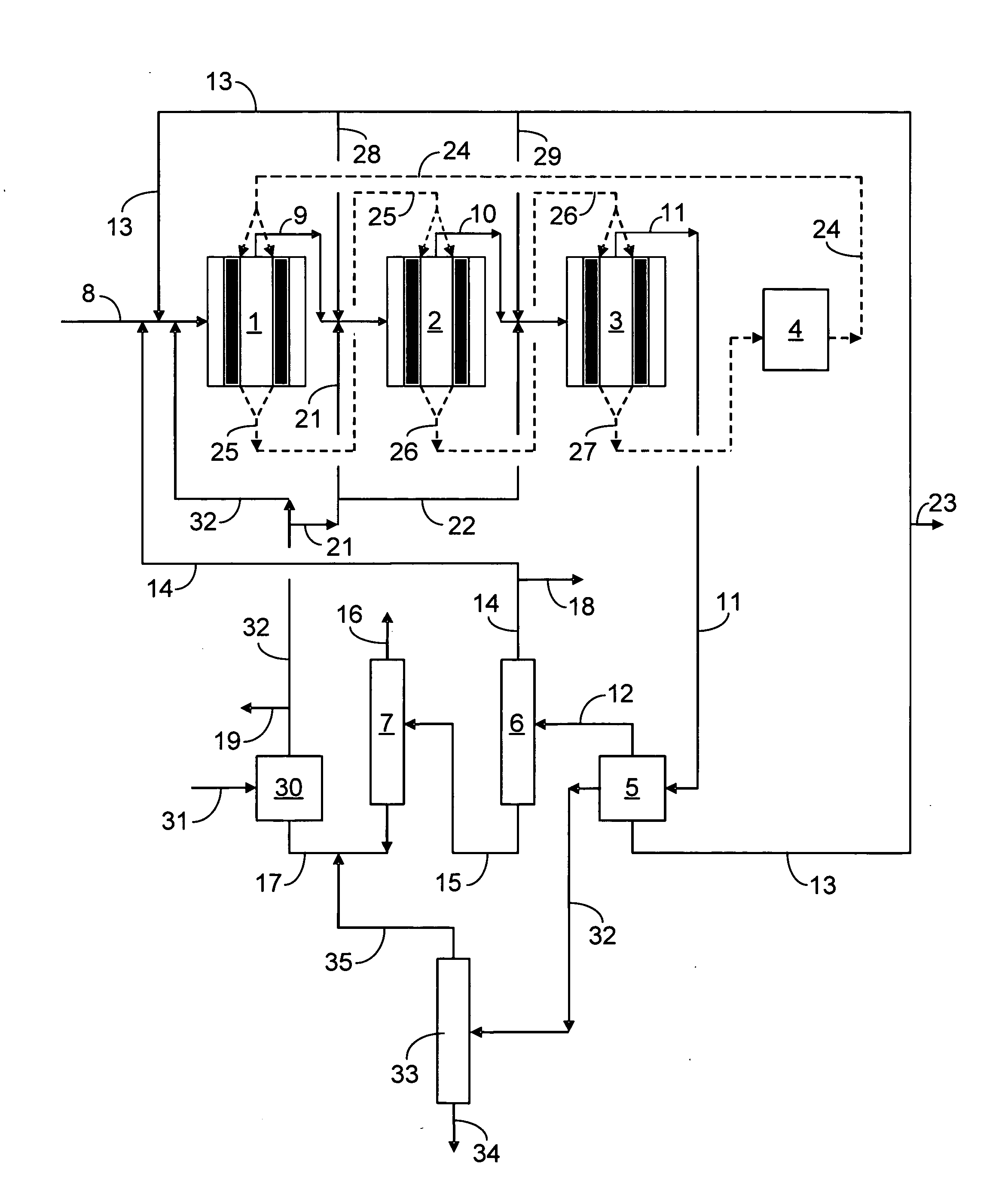

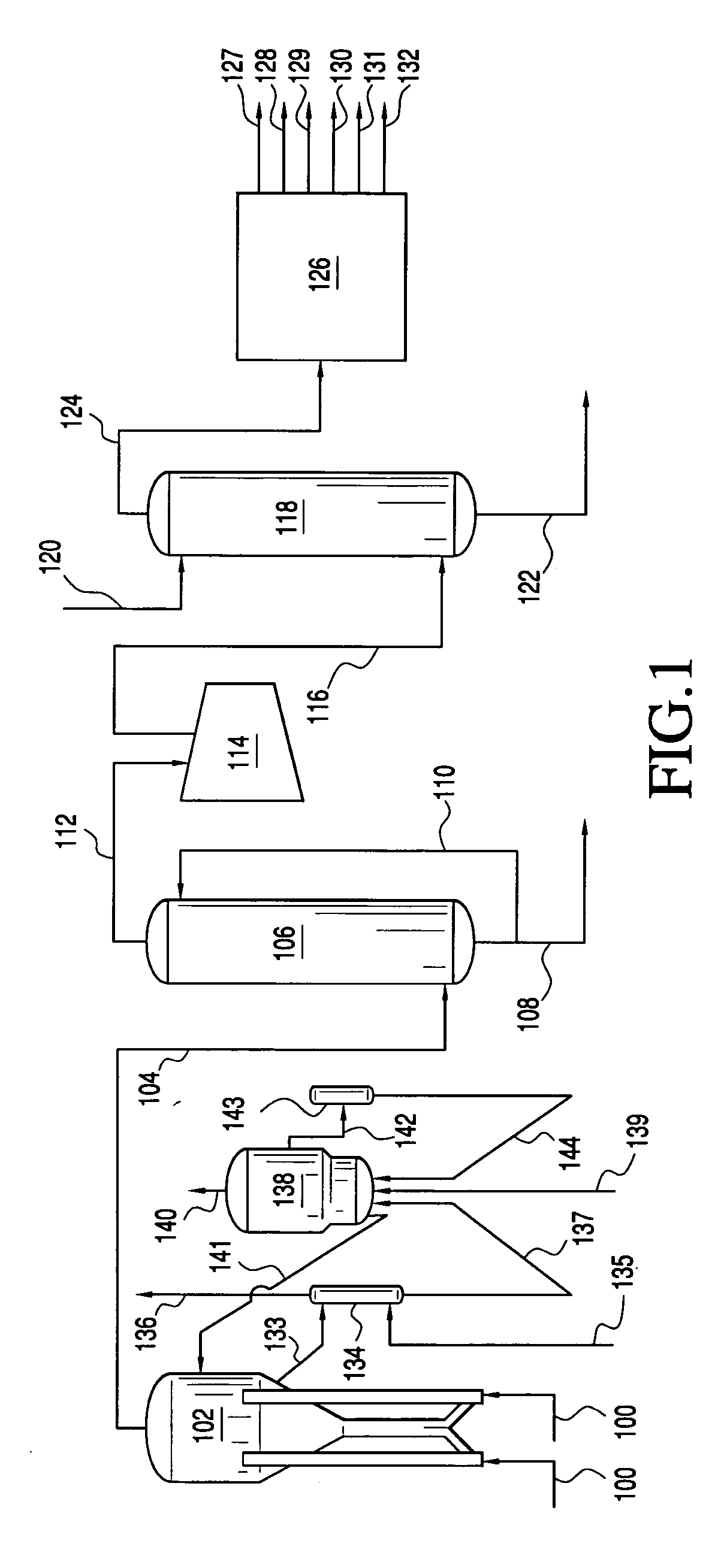

Conversion of oxygenate to propylene using moving bed technology and a separate heavy olefin interconversion step

ActiveUS20060161035A1Improve economyEfficient OTP processMolecular sieve catalystCatalystsFixed bedOxygenate

The average propylene cycle yield of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the catalytic OTP reaction step in lieu of the fixed bed technology of the prior art; 2) a separate heavy olefin interconversion step using moving bed technology and operating at an inlet temperature at least 15° C. higher than the maximum temperature utilized in the OTP reaction step; 3) C2 olefin recycle to the OTP reaction step; and 4) a catalyst on-stream cycle time of 700 hours or less. These provisions hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield for each cycle near or at essentially start-of-cycle levels.

Owner:UOP LLC

Process for producing light olefins

InactiveUS6046372AMolecular sieve catalystsMolecular sieve catalystAlkyl transferCrystalline materials

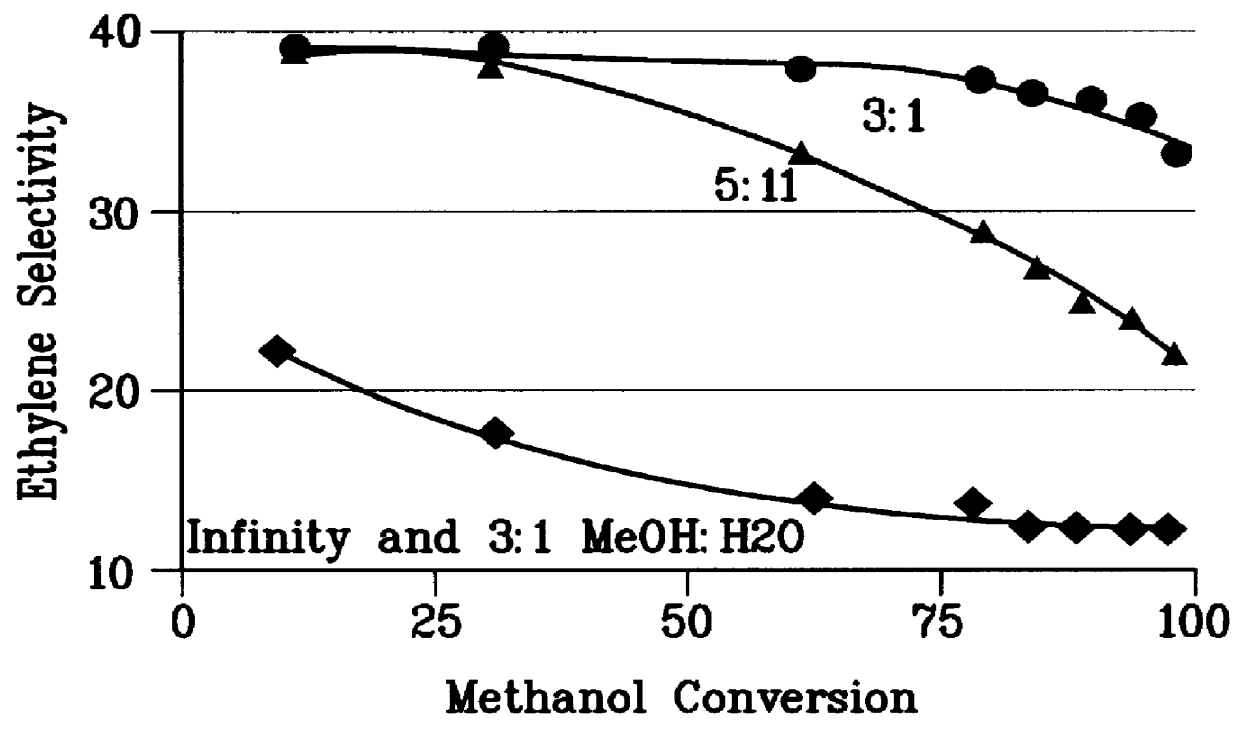

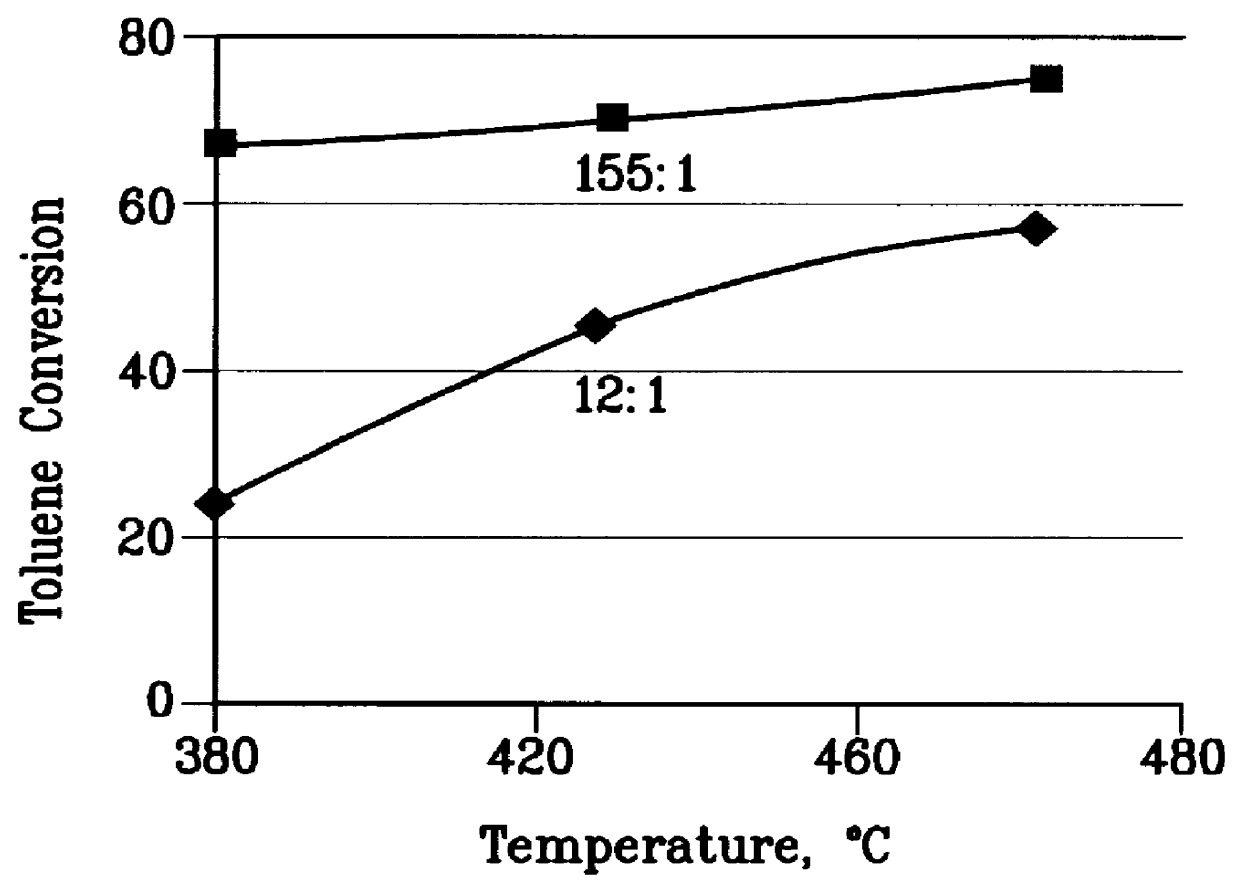

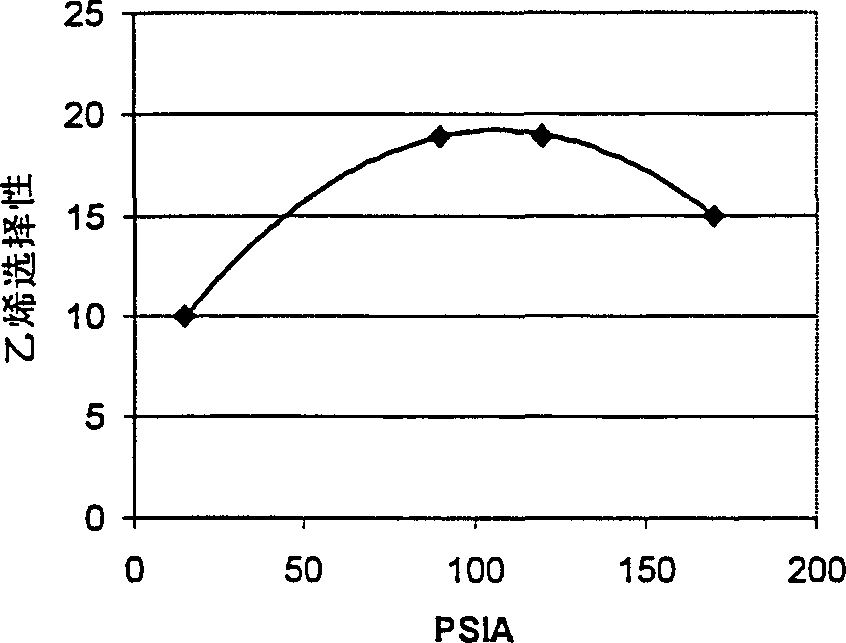

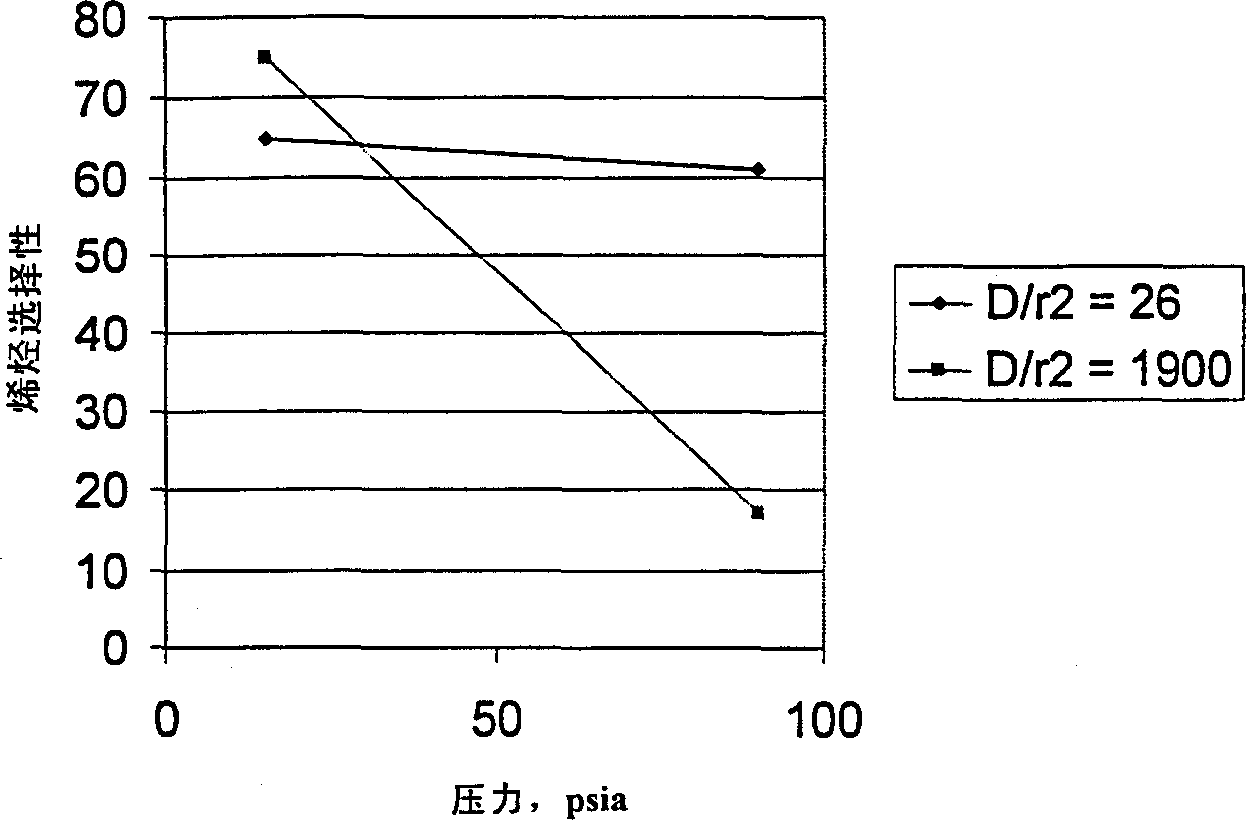

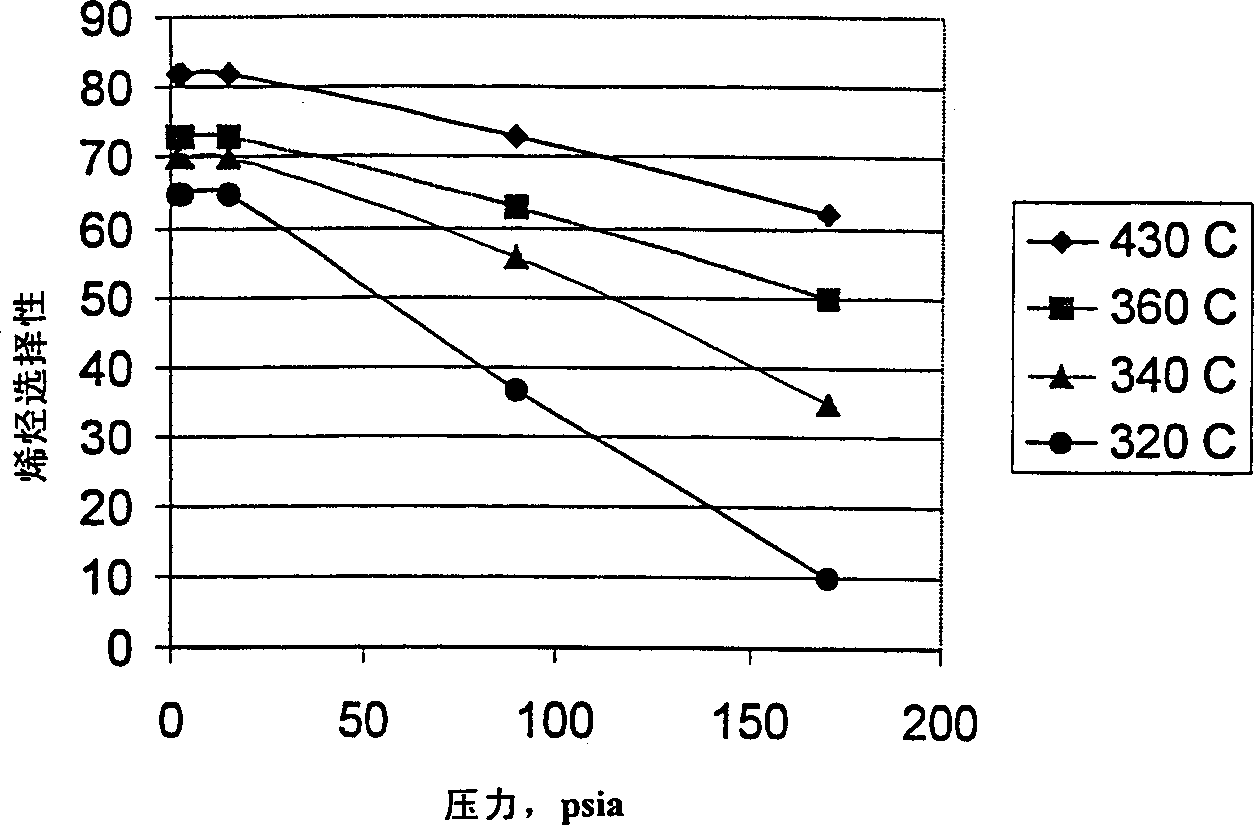

There is provided a process for converting methanol and / or dimethyl ether to a product containing C2 to C4 olefins which comprises the step of contacting a feed which contains methanol and / or dimethyl ether with a catalyst comprising a porous crystalline material, said contacting step being conducted in the presence of an aromatic compound under conversion conditions including a temperature of 350 DEG C. to 480 DEG C. and a methanol partial pressure in excess of 10 psia (70 kPa), said porous crystalline material having a pore size greater than the critical diameter of the aromatic compound and the aromatic compound being capable of alkylation by the methanol and / or dimethyl ether under said conversion conditions.

Owner:MOBIL OIL CORP

Catalyst and process for converting methanol to hydrocarbons

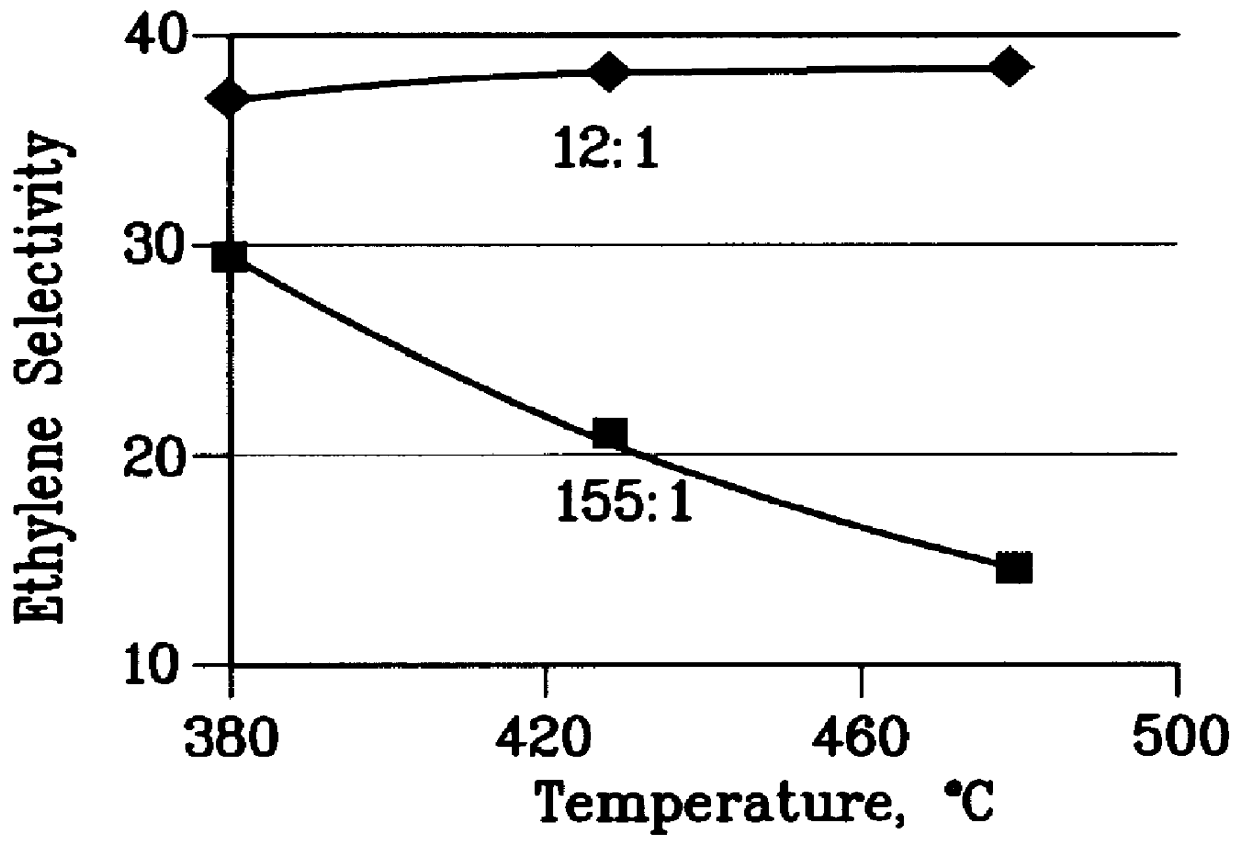

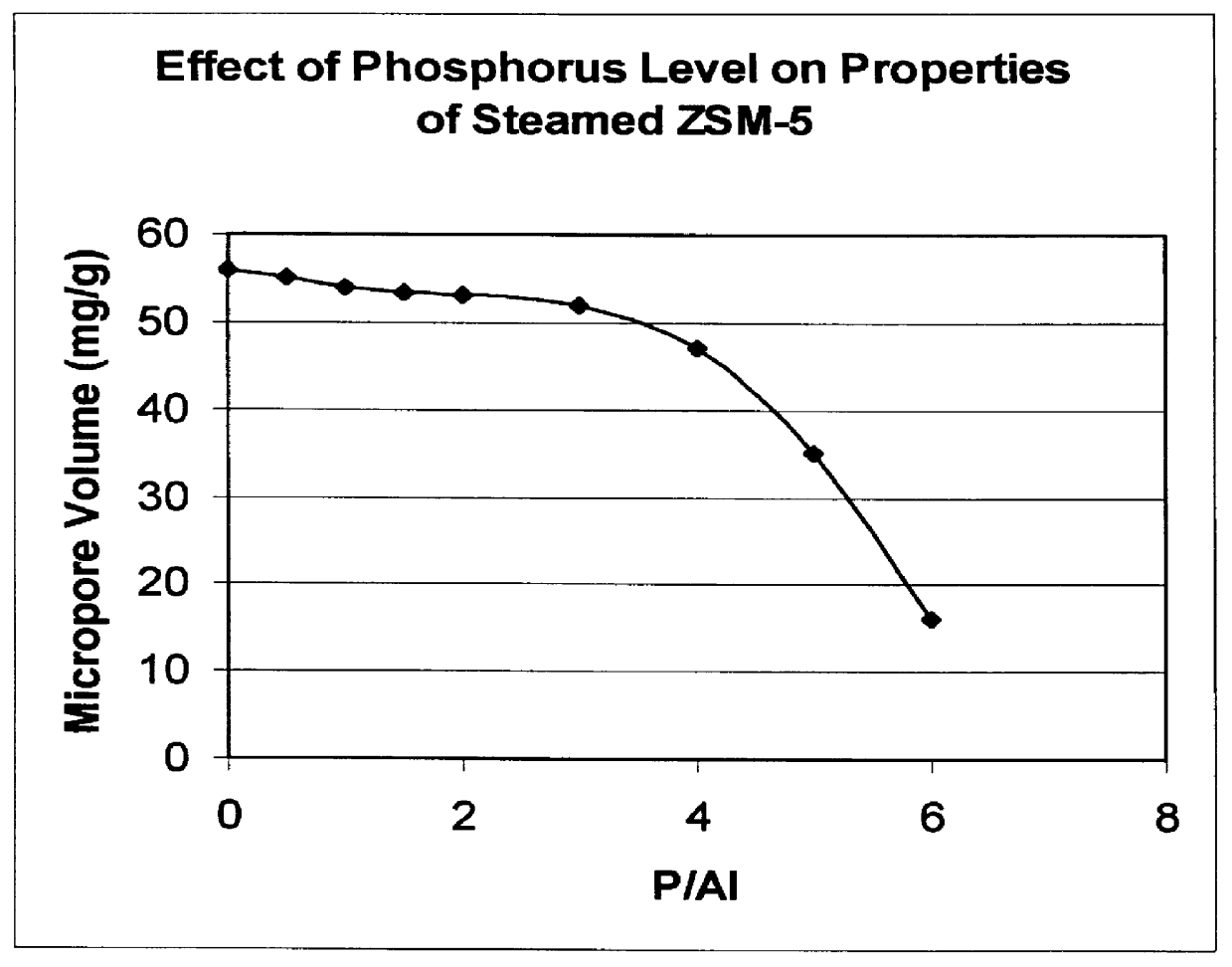

InactiveUS6048816AMolecular sieve catalystsMolecular sieve catalystCrystalline materialsDimethyl ether

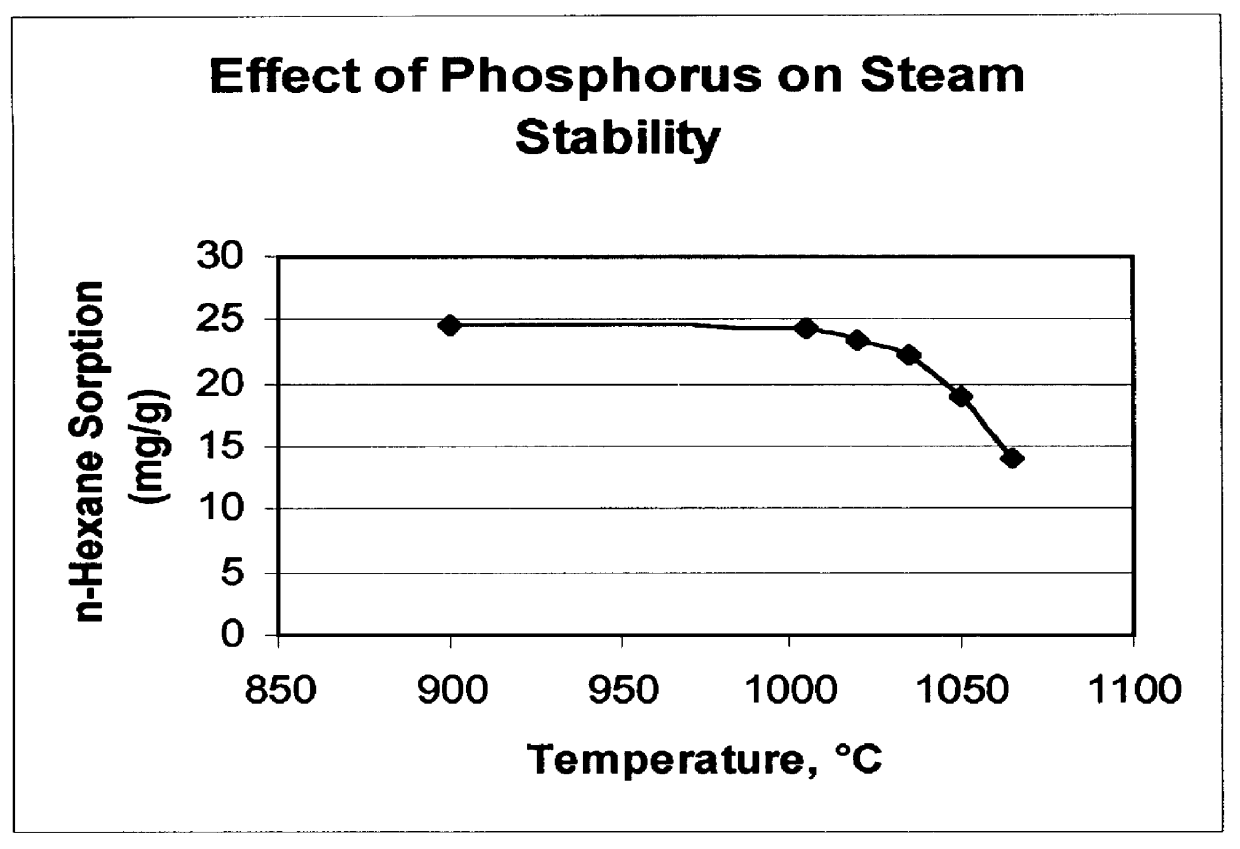

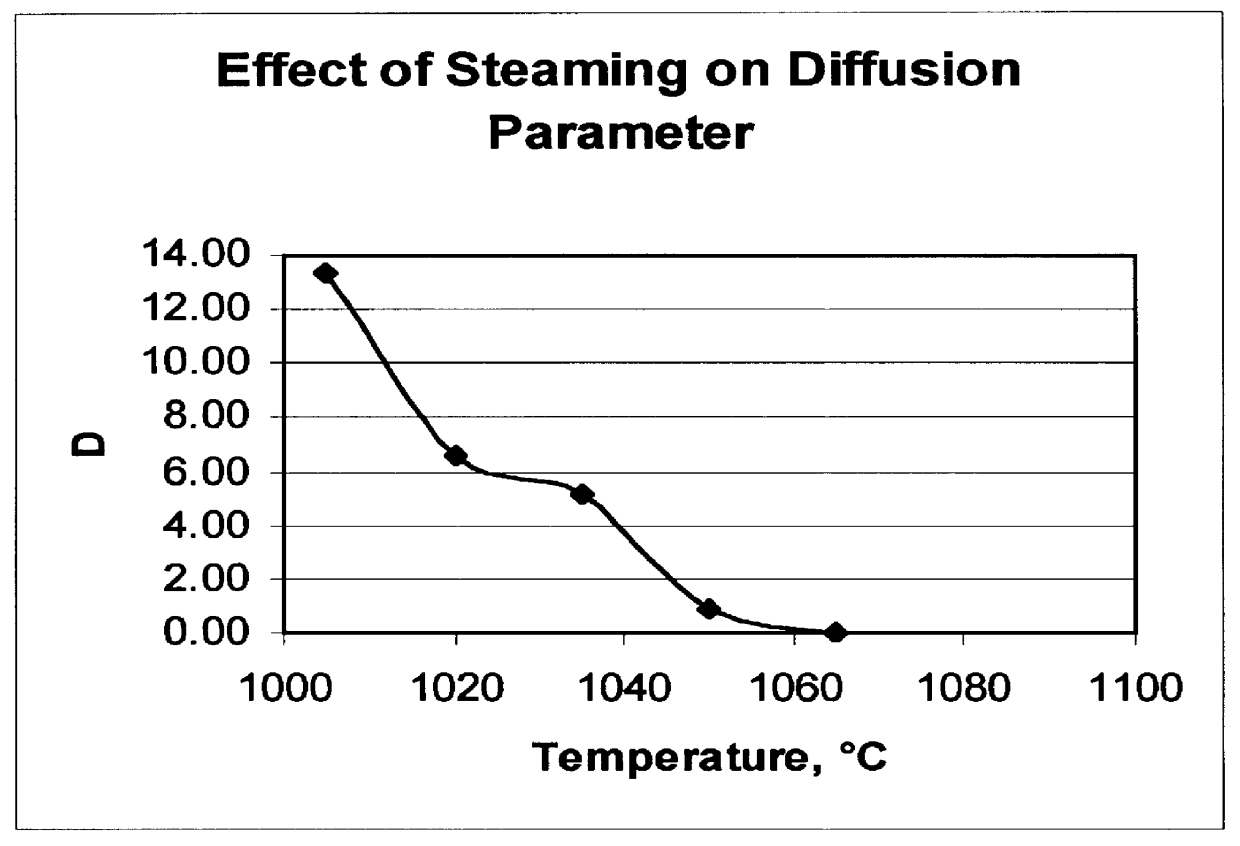

There is provided a catalyst and a process for converting methanol or dimethyl ether to a product containing C2 to C4 olefins. The catalyst comprises a porous crystalline material having a Diffusion Parameter for 2,2-dimethylbutane of about 0.1-20 sec-1 when measured at a temperature of 120 DEG C. and a 2,2-dimethylbutane pressure of 60 torr (8 kPa). In addition, the catalyst is characterized by a hydrothermal stability such that, after steaming the catalyst at 1025 DEG C. for 45 minutes in 1 atmosphere steam, the catalyst exhibits a methanol conversion activity of at least 50% when contacted with methanol at a methanol partial pressure of 1 atmosphere, a temperature of 430 DEG C. and 0.5 WHSV. The porous crystalline material is preferably a medium-pore zeolite, particularly ZSM-5, which contains phosphorus and has been severely steamed at a temperature of at least 950 DEG C.

Owner:MOBIL OIL CORP

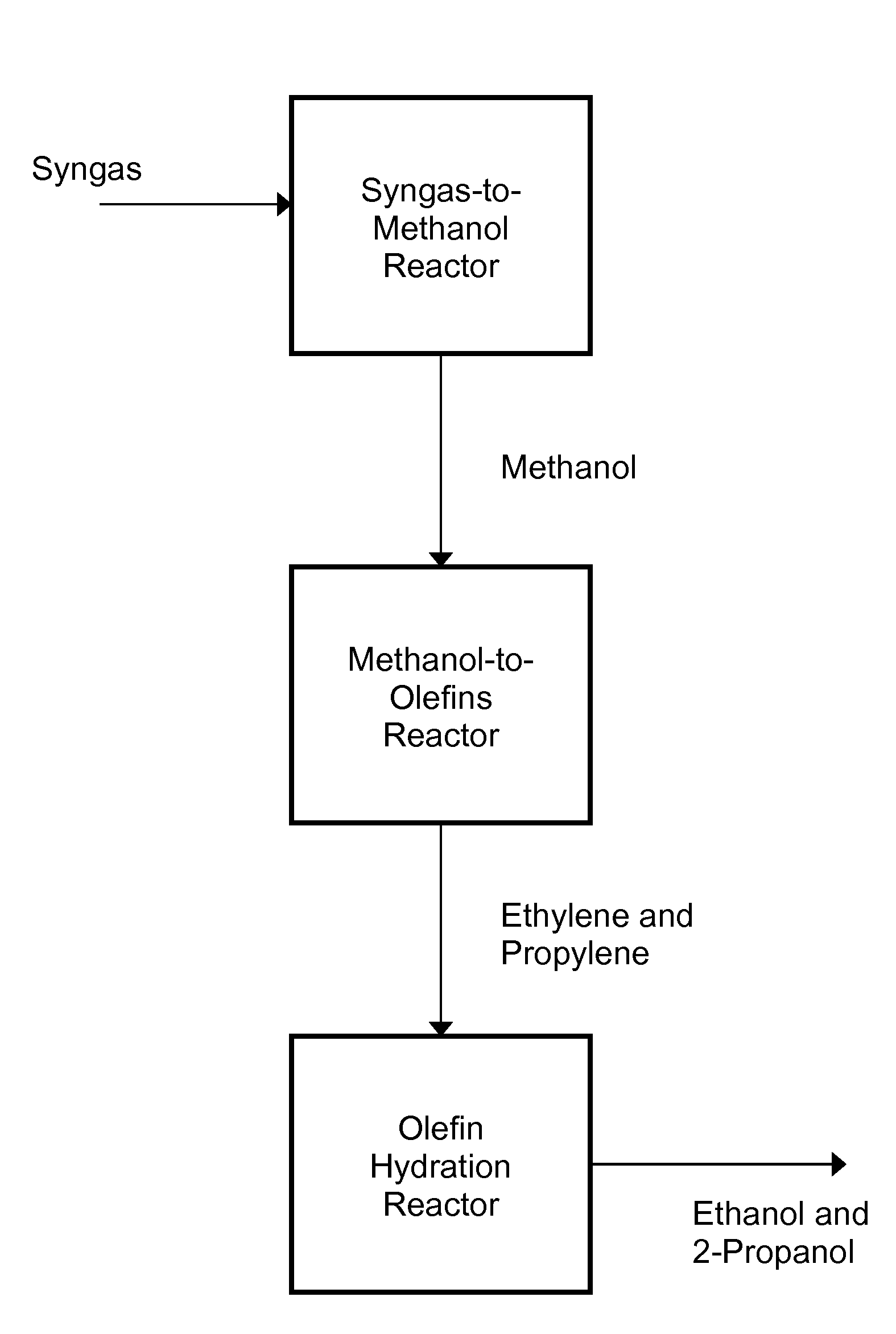

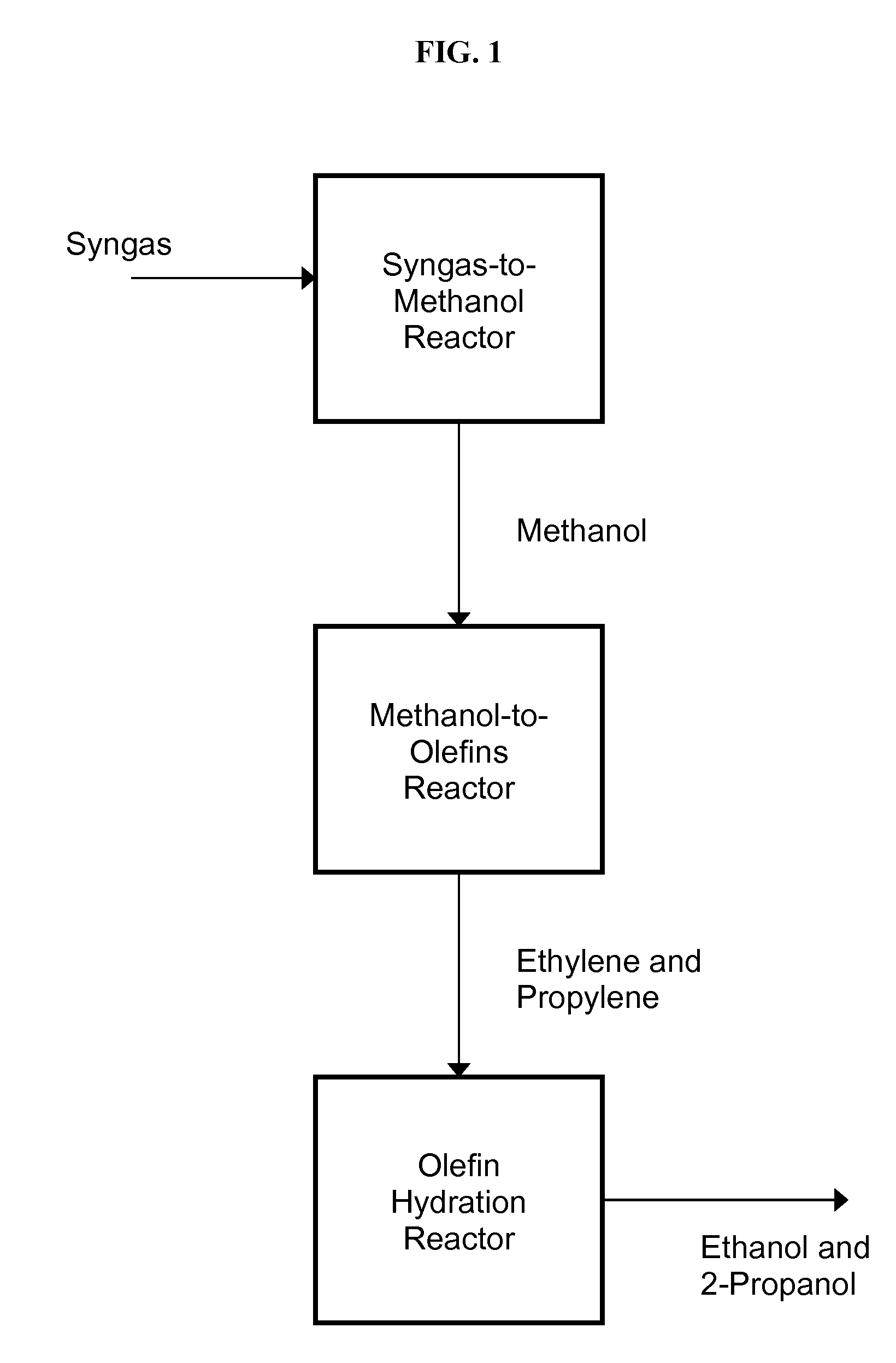

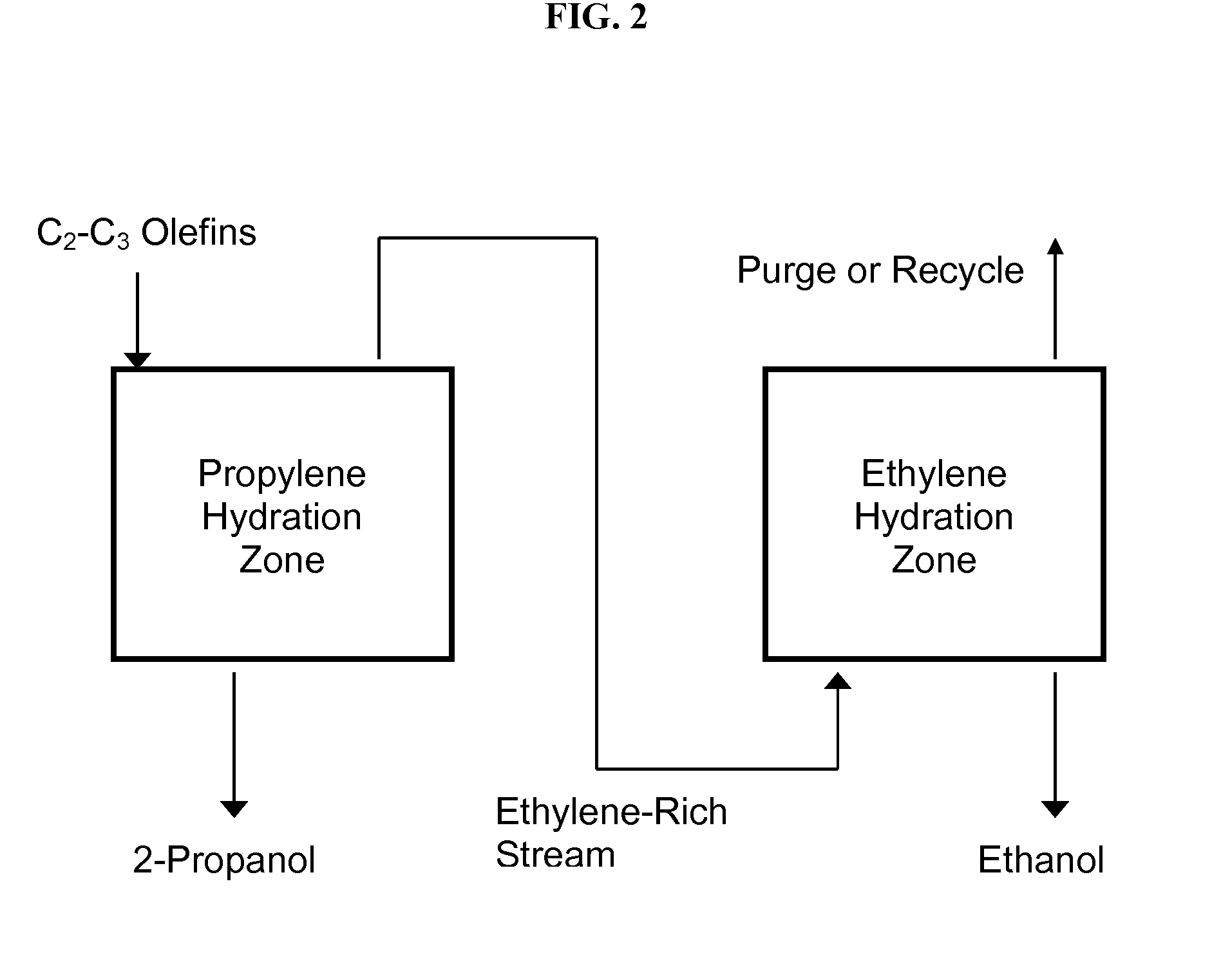

Methods and apparatus for synthesis of alcohols from syngas

This invention provides a method for producing ethanol and 2-propanol from syngas, the method comprising: (a) converting syngas into methanol using a methanol-synthesis catalyst; (b) converting methanol into ethylene and propylene using a methanol-to-olefins catalyst; and (c) hydrating ethylene into ethanol and propylene into 2-propanol. As taught herein, the combined yield of the ethanol and the 2-propanol from biomass can be at least 100 gallons per dry ton biomass. In certain embodiments, the yield of ethanol is at least 100 gallons per dry ton biomass. In some embodiments, the yield of 2-propanol is at least 50 gallons per dry ton biomass.

Owner:ALBEMARLE CORP +1

Catalyst composition, its preparation and use

A catalyst composition which comprises: a) a carrier which comprises at least 30 wt % of a binder selected from silica, zirconia and titania; at least 20 wt % of a pentasil zeolite, having a bulk silica to alumina ratio in the range of from 20 to 150 and being in its H+ form; and less than 10 wt % of other components, all percentages being on the basis of total carrier; b) platinum in an amount in the range of from 0.001 to 0.1 wt %, on the basis of total catalyst; and c) tin in an amount in the range of from 0.01 to 0.5 wt %, on the basis of total catalyst; its preparation and use; are provided.

Owner:SHELL OIL CO

Catalytically inactive heat generator and improved dehydrogenation process

An improved dehydrogenation catalyst bed system for olefin production utilizing classical processing techniques is disclosed. The catalyst bed system comprises a dehydrogenation catalyst comprising an active component selected from an oxide of a metal of Group 4 or Group 5 or Group 6 and combinations thereof and a support selected from aluminum oxide, aluminas, alumina monohydrate, alumina trihydrate, alumina-silica, transition aluminas, alpha-alumina, silica, silicate, aluminates, calcined hydrotalcites, zeolites and combinations thereof mixed with a first inert material selected from any material that is catalytically inactive when subjected to reaction conditions that can effect dehydrogenation of olefins and that has a high density and high heat capacity and that is not capable of producing heat during any stage of the dehydrogenation process, and the dehydrogenation catalyst plus the first inert material then being physically mixed with a secondary component comprising a heat-generating inert material and a carrier capable of supporting the heat-generating inert material, wherein the secondary component is catalytically inert with respect to dehydrogenation reactions or to cracking or to coking and generates heat after being exposed to reducing and / or to oxidizing reaction conditions.

Owner:CLARIANT INT LTD

Alkylaromatics production

The present invention provides a process for producing a monoalkylated aromatic compound, particularly ethylbenzene or cumene, in which a polyalkylated aromatic compound is contacted with an alkylatable aromatic compound in the liquid phase and in the presence of a transalkylation catalyst comprising TEA-mordenite having an average crystal size of less than 0.5 micron.

Owner:EXXONMOBIL CORP (US)

Processes for converting oxygenates to olefins at reduced volumetric flow rates

InactiveUS20060020155A1Reduction in effluent volumetric flow rateMolecular sieve catalystCatalystsSyngasMolecular sieve

This invention provides processes for forming light olefins from methanol and / or from syngas through a dimethyl ether intermediate. Specifically, the invention is to converting methanol and / or syngas to dimethyl ether and water in the presence of a first catalyst, preferably comprising γ-alumina, and converting the dimethyl ether to light olefins and water in the presence of a second catalyst, preferably a molecular sieve catalyst composition.

Owner:EXXONMOBIL CHEM PAT INC

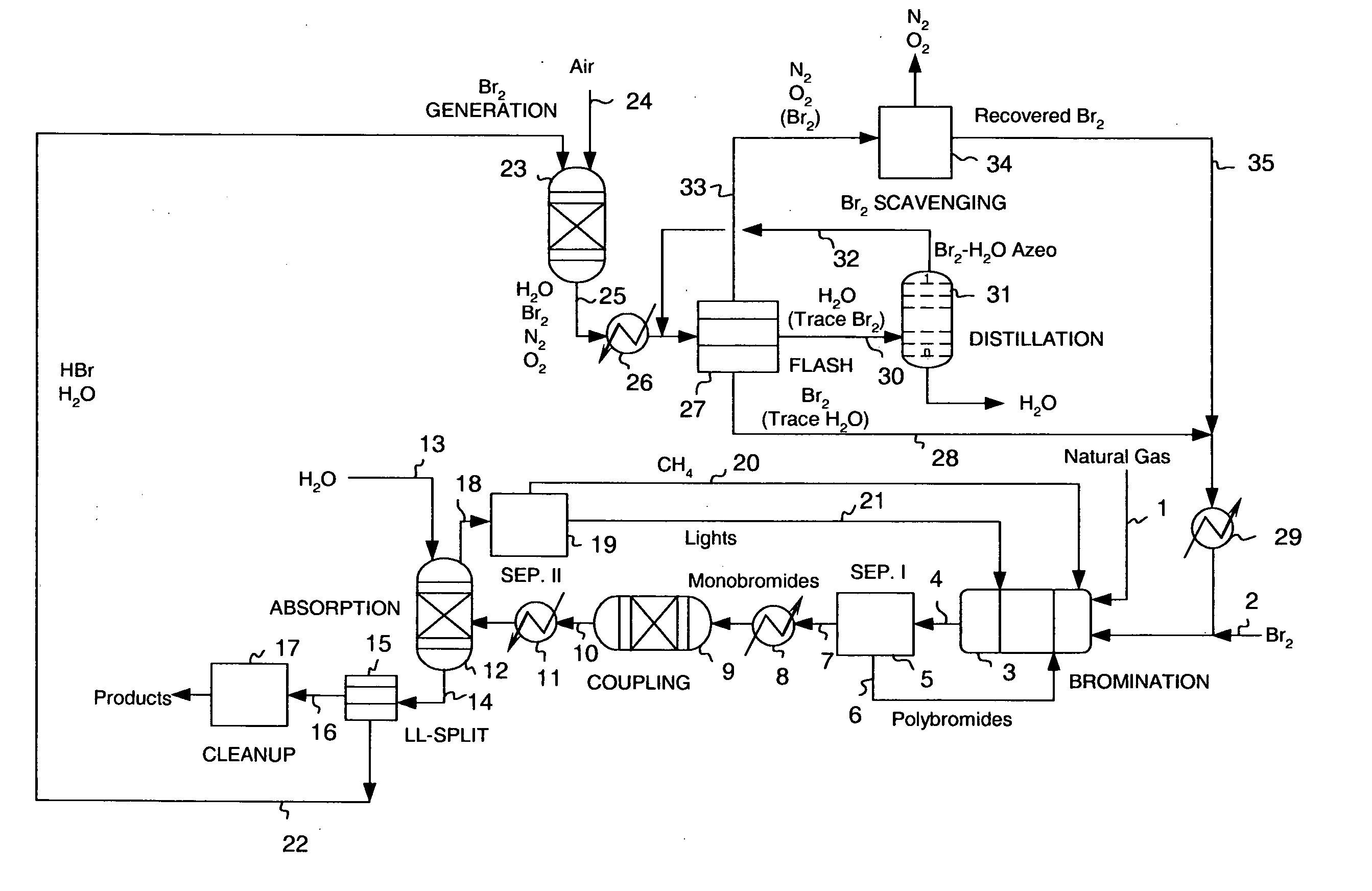

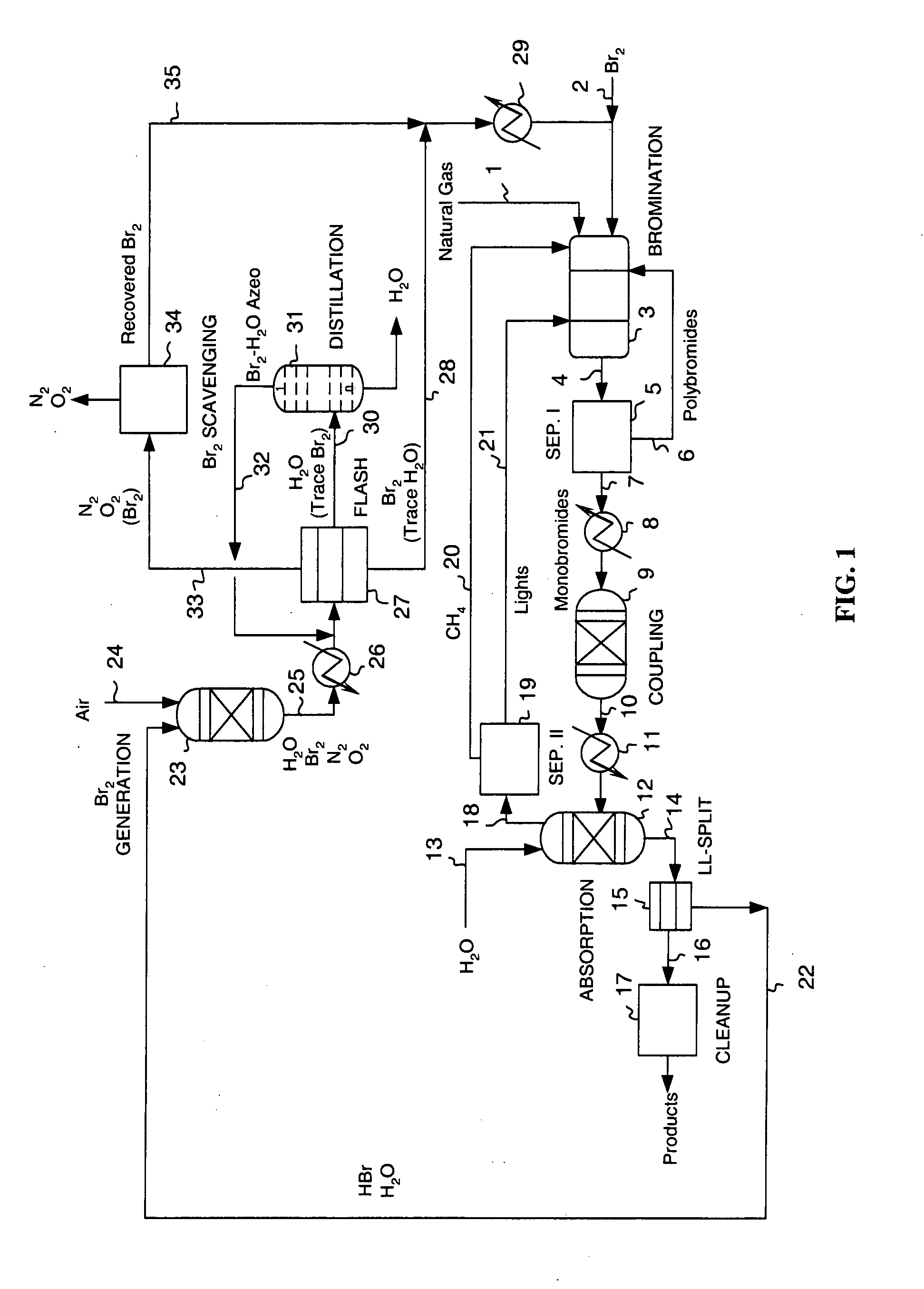

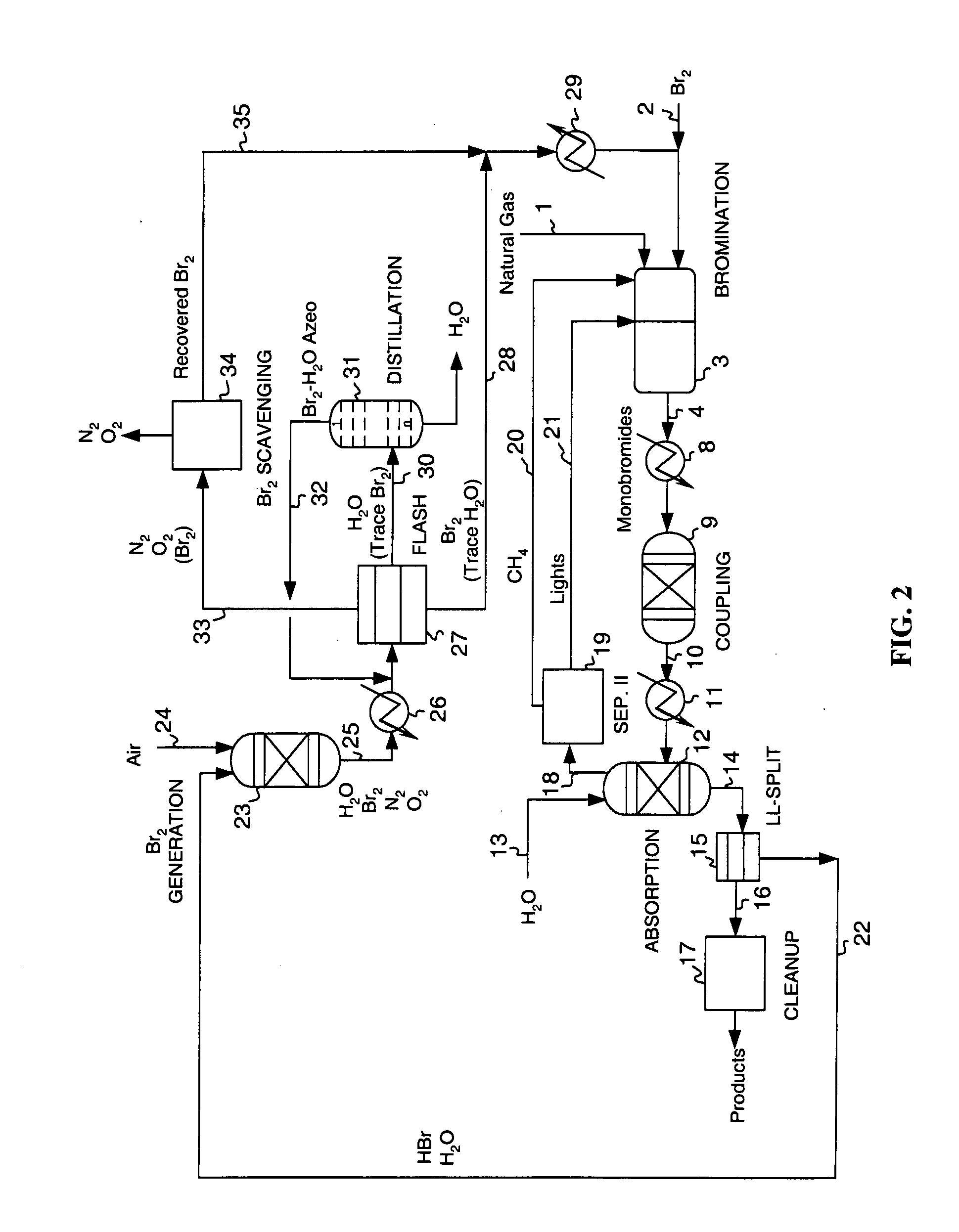

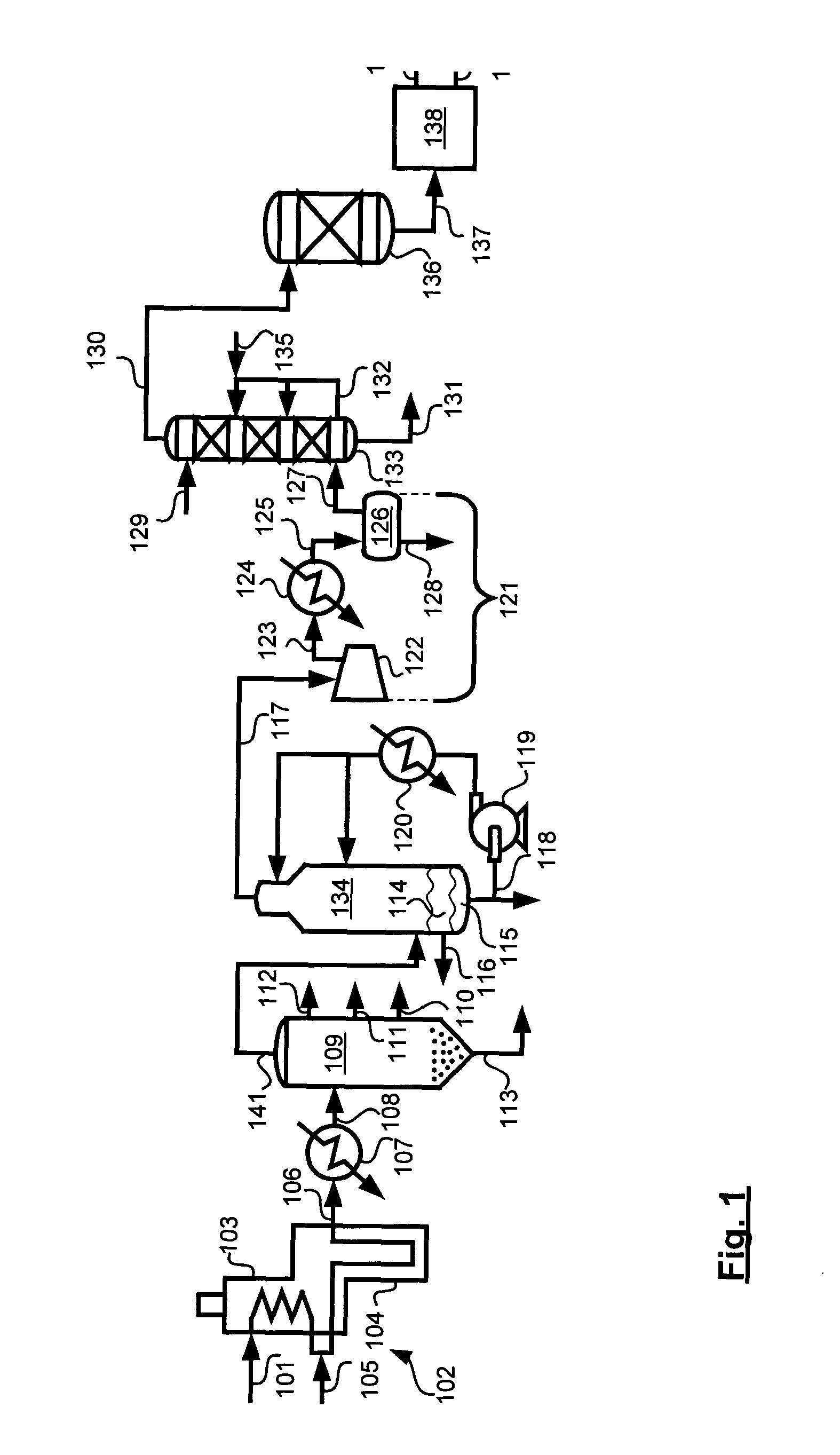

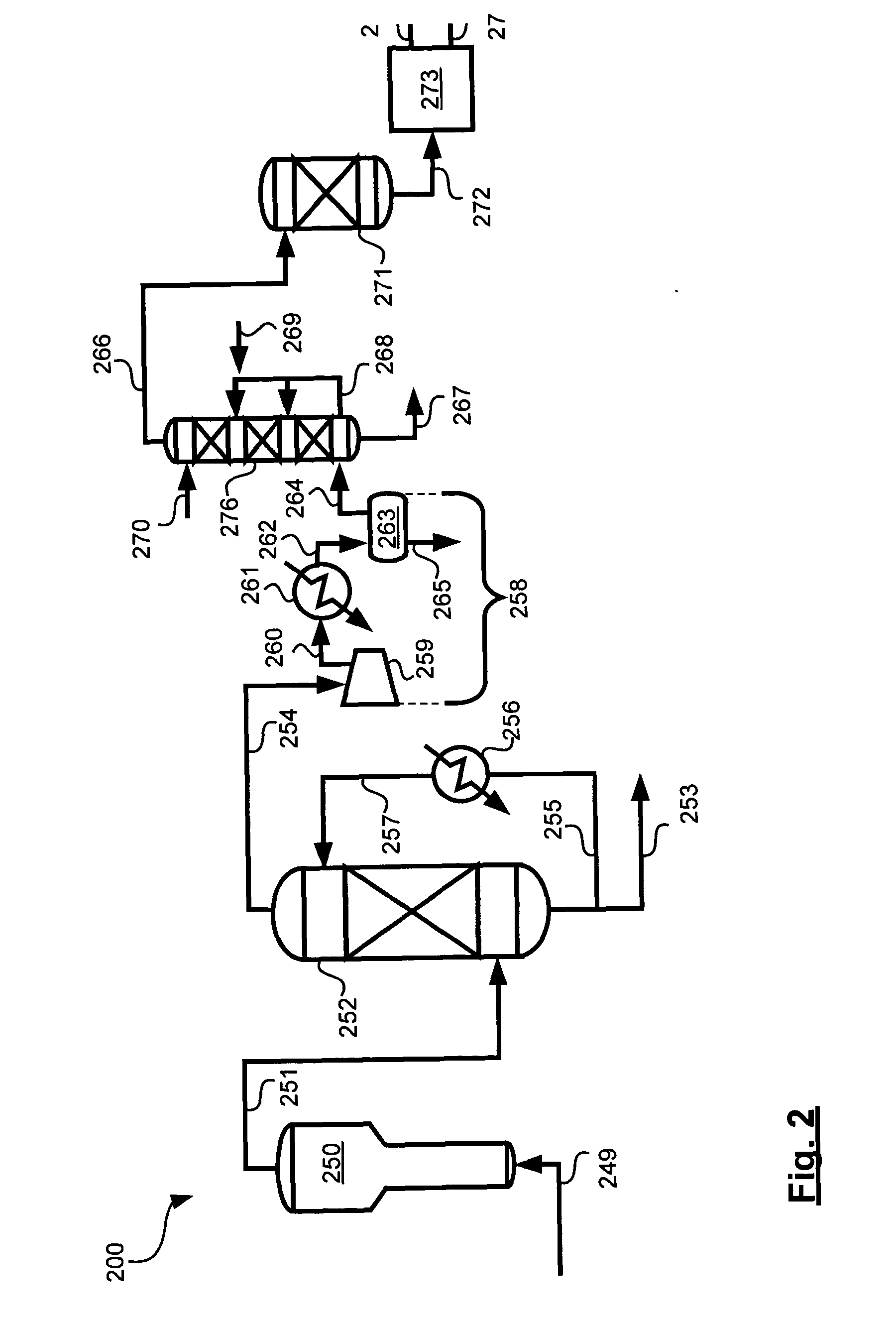

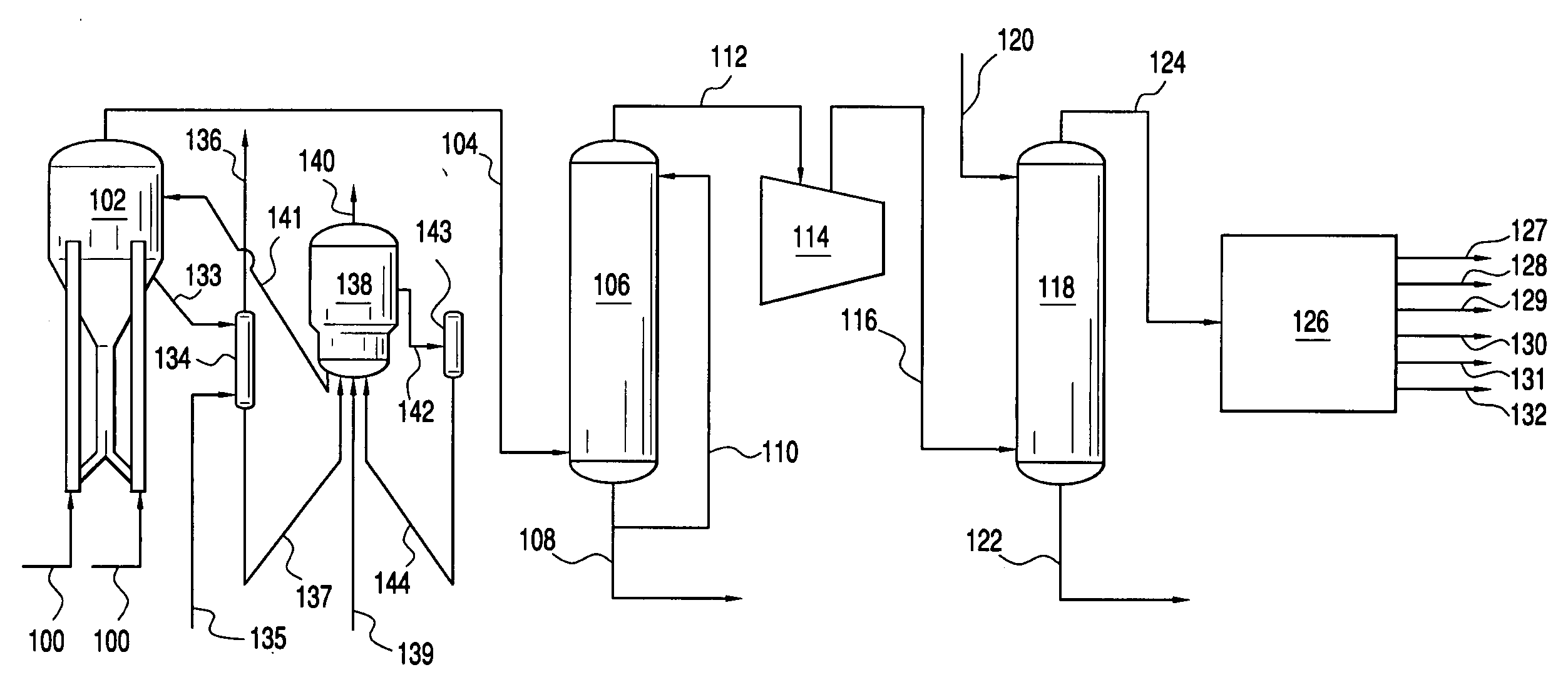

Continuous process for converting natural gas to liquid hydrocarbons

InactiveUS20070238909A1Easily toleratedContinuous regenerationMolecular sieve catalystLiquid hydrocarbon mixture recoveryAlkaneOxygen

An improved continuous process for converting methane, natural gas, or other hydrocarbon feedstocks into one or more higher hydrocarbons or olefins by continuously cycling through the steps of alkane halogenation, product formation (carbon-carbon coupling), product separation, and regeneration of halogen is provided. Preferably, the halogen is continually recovered by reacting hydrobromic acid with air or oxygen. The invention provides an efficient route to aromatic compounds, aliphatic compounds, mixtures of aliphatic and aromatic compounds, olefins, gasoline grade materials, and other useful products.

Owner:REACTION 35 LLC

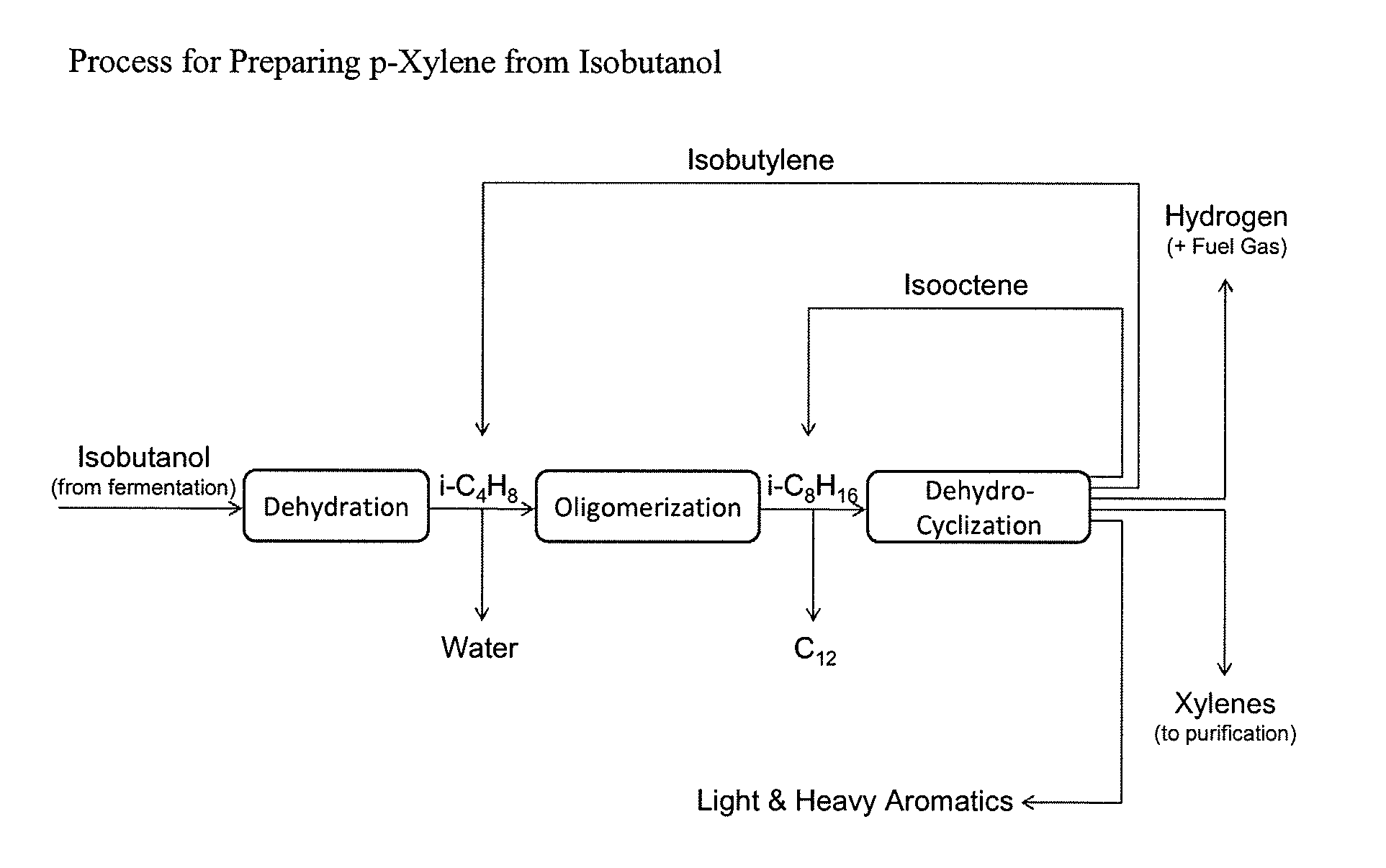

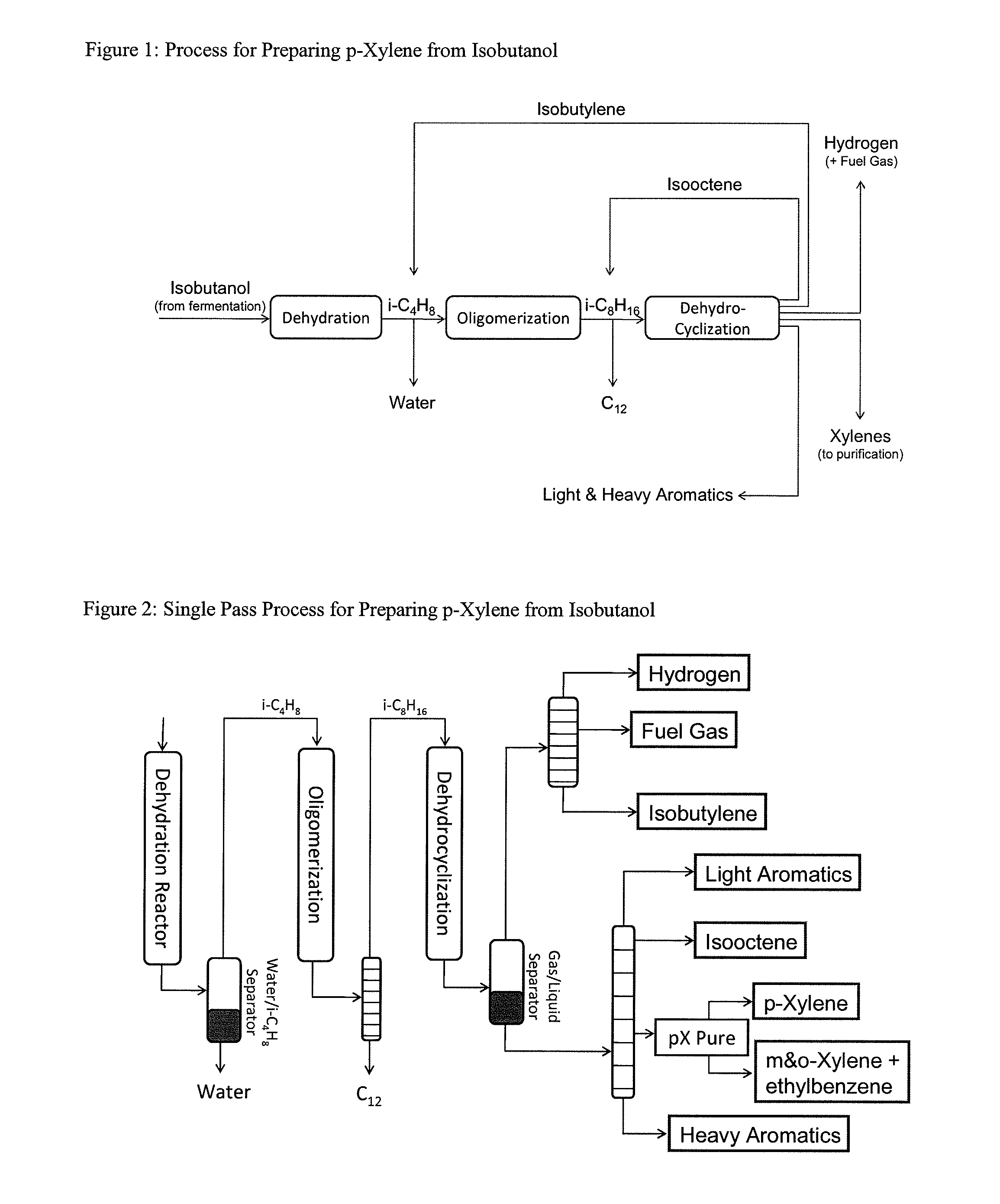

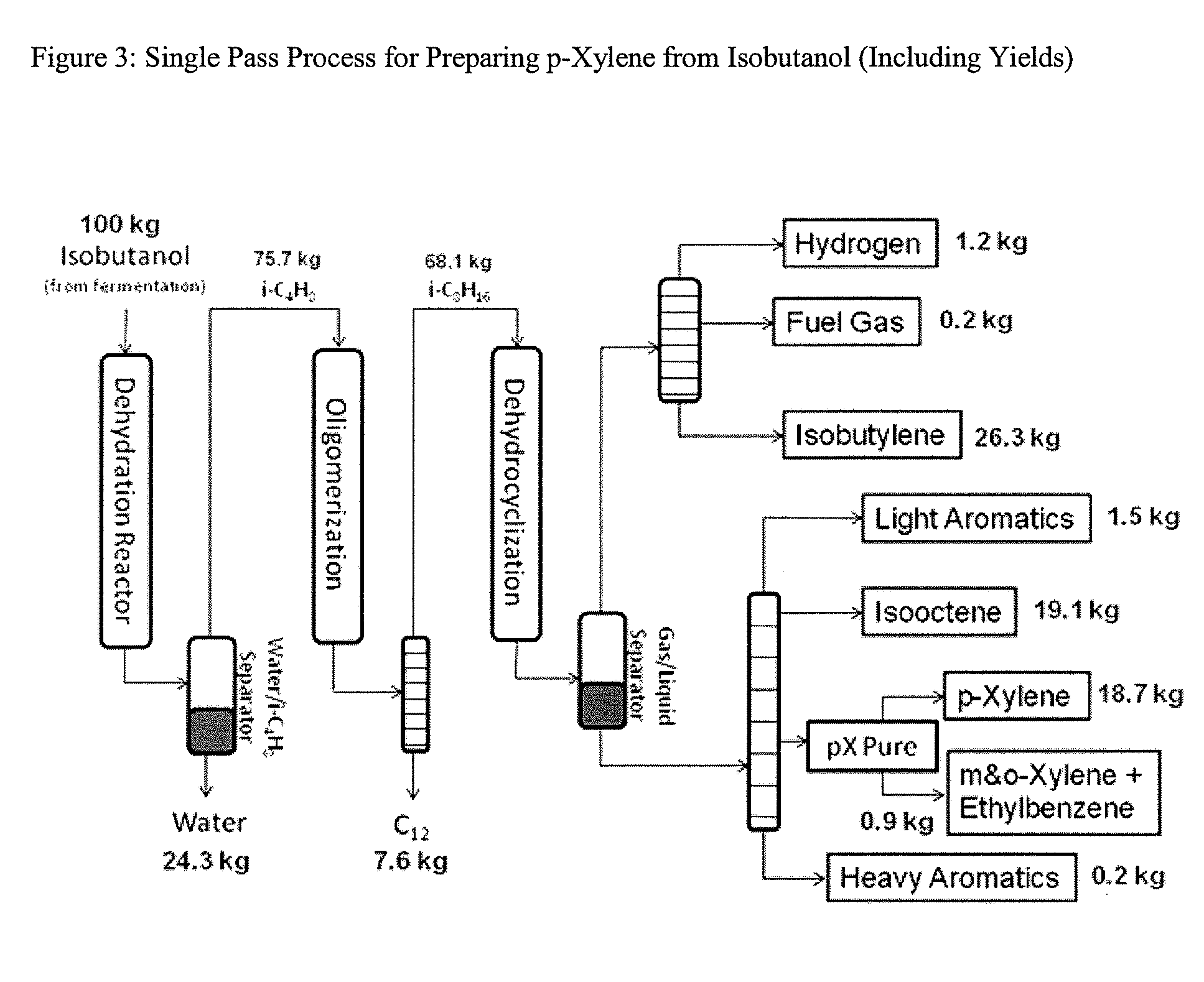

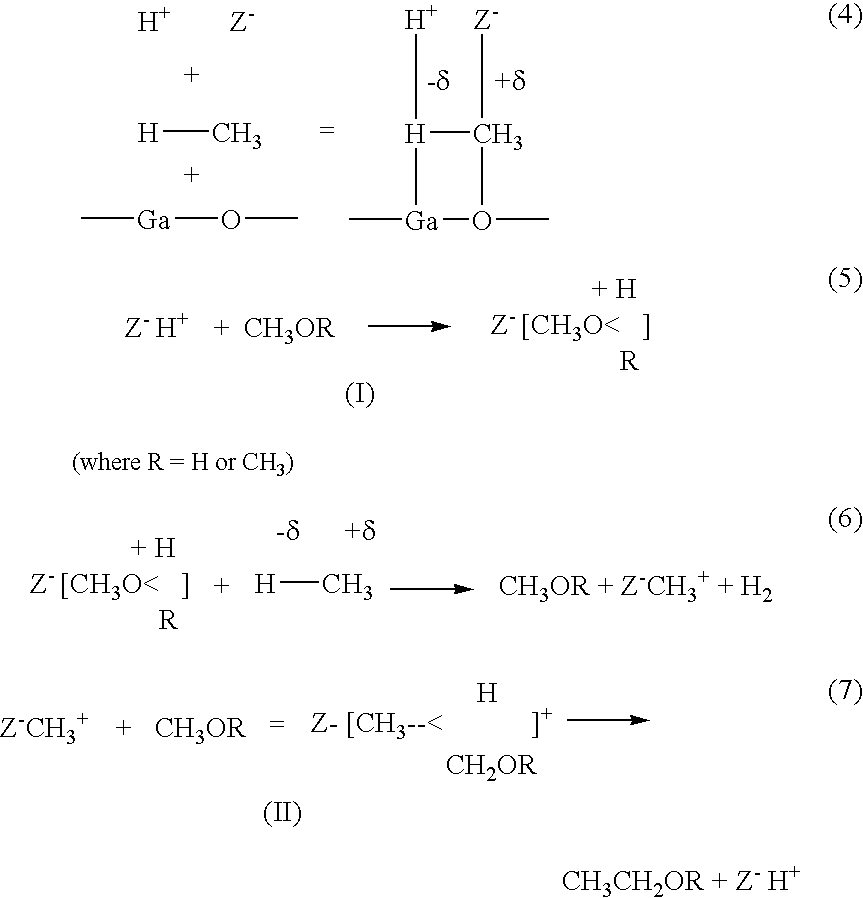

Integrated Process to Selectively Convert Renewable Isobutanol to P-Xylene

The present invention is directed to a method for preparing renewable and relatively high purity p-xylene from biomass. For example, biomass treated to provide a fermentation feedstock is fermented with a microorganism capable of producing a C4 alcohol such as isobutanol, then sequentially dehydrating the isobutanol in the presence of a dehydration catalyst to provide a C4 alkene such as isobutylene, dimerizing the C4 alkene to a form one or more C8 alkenes such as 2,4,4-trimethylpentenes or 2,5-dimethylhexene, then dehydrocyclizing the C8 alkenes in the presence of a dehydrocyclization catalyst to selectively form renewable p-xylene in high overall yield. The p-xylene can then be oxidized to form terephthalic acid or terephthalate esters.

Owner:GEVO INC

Process for the simultaneous conversion of methane and organic oxygenate to C2 to C10 hydrocarbons

A process for the non-oxidative conversion of methane simultaneously with the conversion of an organic oxygenate, represented by a general formula: CnH2n+1OCmH2m+1, wherein C, H and O are carbon, hydrogen and oxygen elements, respectively; n is an integer having a value between 1 and 4; and m is an integer having a value between zero and 4, to C2+ hydrocarbons, particularly to gasoline range C6–C10 hydrocarbons and hydrogen, using a bifunctional pentasil zeolite catalyst, having strong acid and dehydrogenation functions, at a temperature below 700° C. is disclosed. In this process the moles of methane converted per mole of oxygenate converted is above 1.0, depending upon the process conditions.

Owner:COUNCIL OF SCI & IND RES

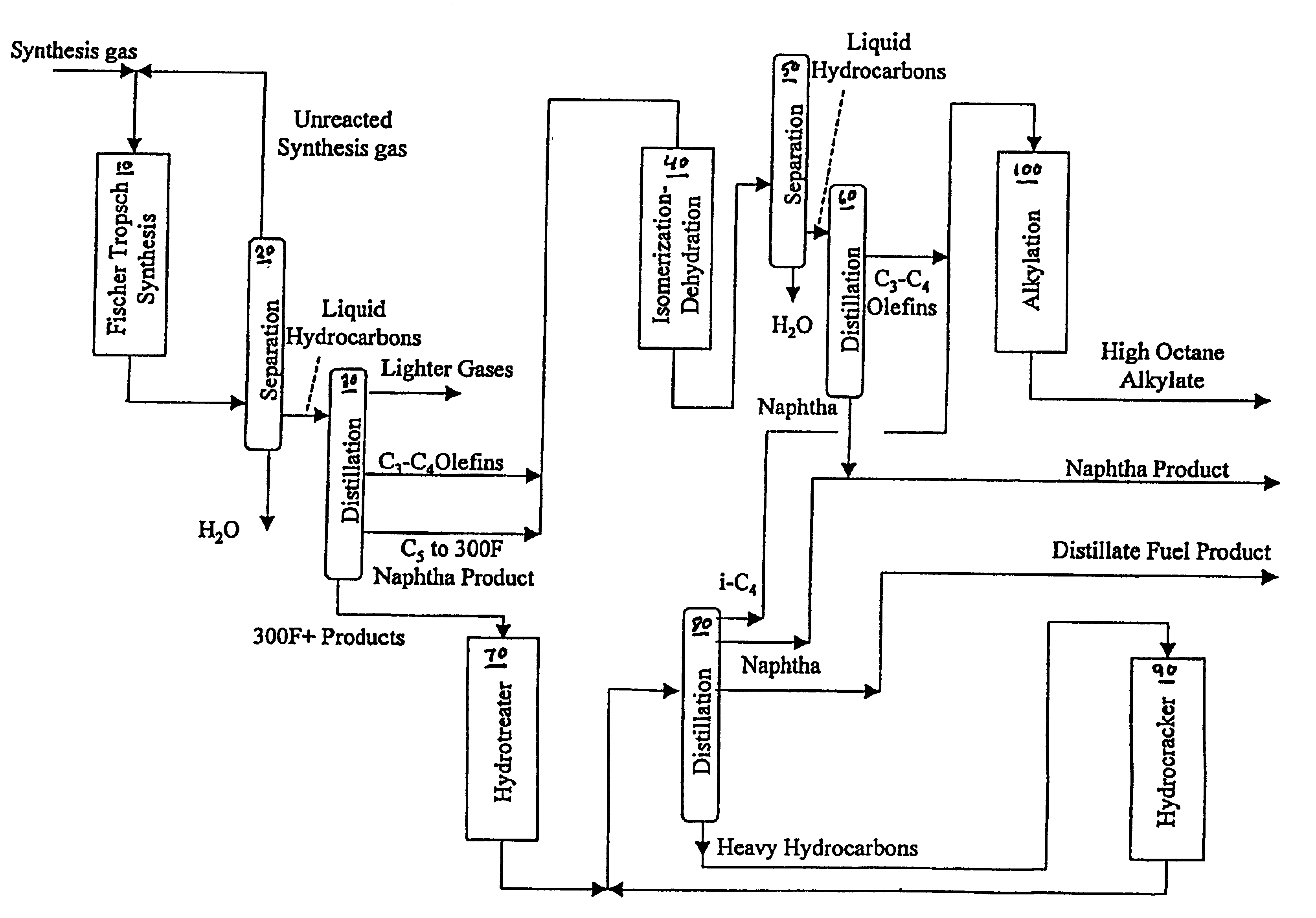

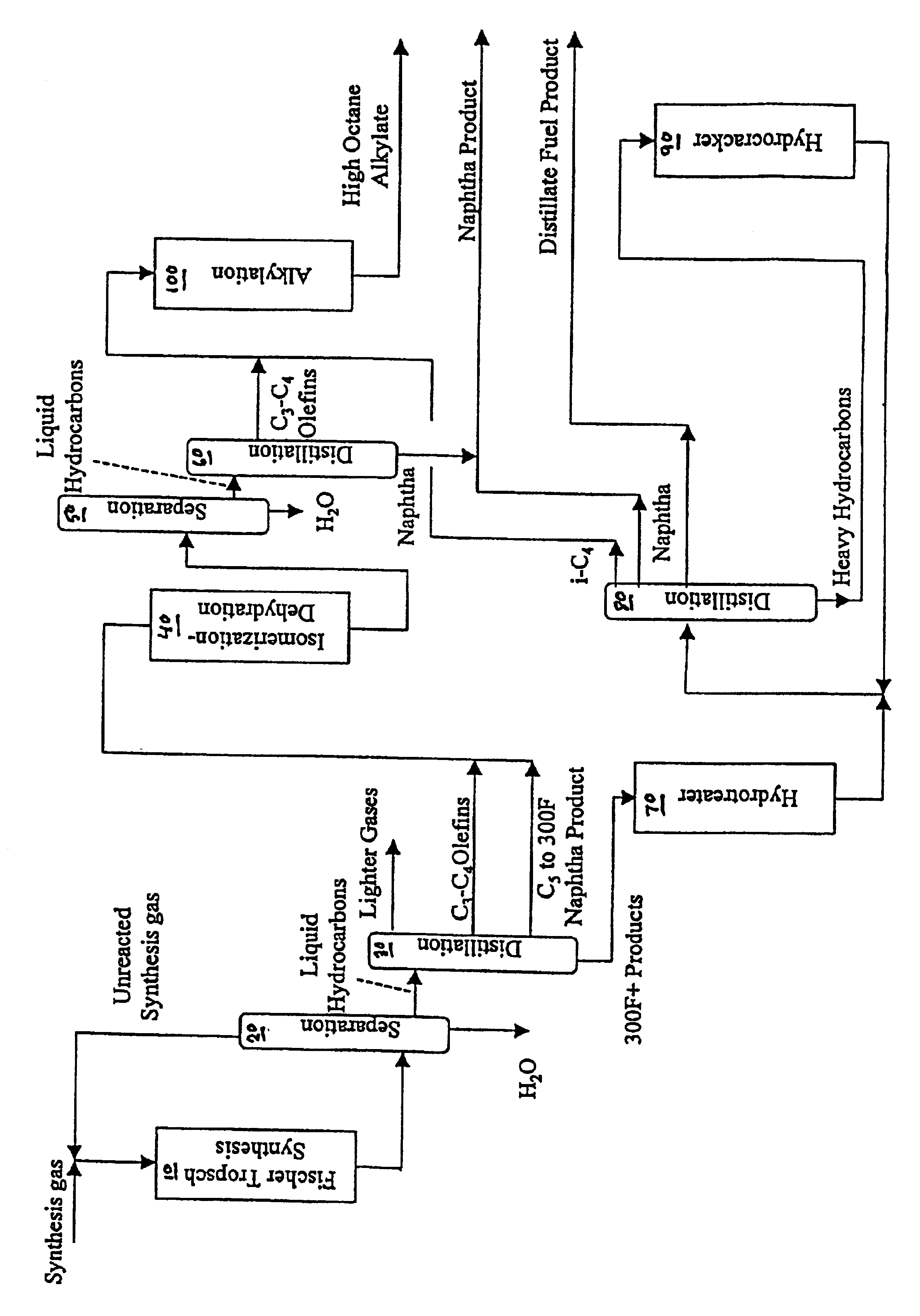

Manufacture of high octane alkylate

InactiveUS6768035B2Hydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonAlcoholGasoline

A Fischer-Tropsch C3-C4 olefin stream is simultaneously dehydrated and isomerized to convert alcohols to olefins and 1-butenes to 2-butenes and thereby lower the oxygenate content. Another Fischer-Tropsch fraction is hydrotreated and hydrocracked to provide an isobutane stream. The treated C3-C4 olefin stream having an oxygenate content less than 4000 ppm, is reacted with the isobutane stream to provide a highly branched, high octane isoparaffinic alkylate. The alkylate is useful as a blending component in motor gasoline.

Owner:CHEVROU USA INC

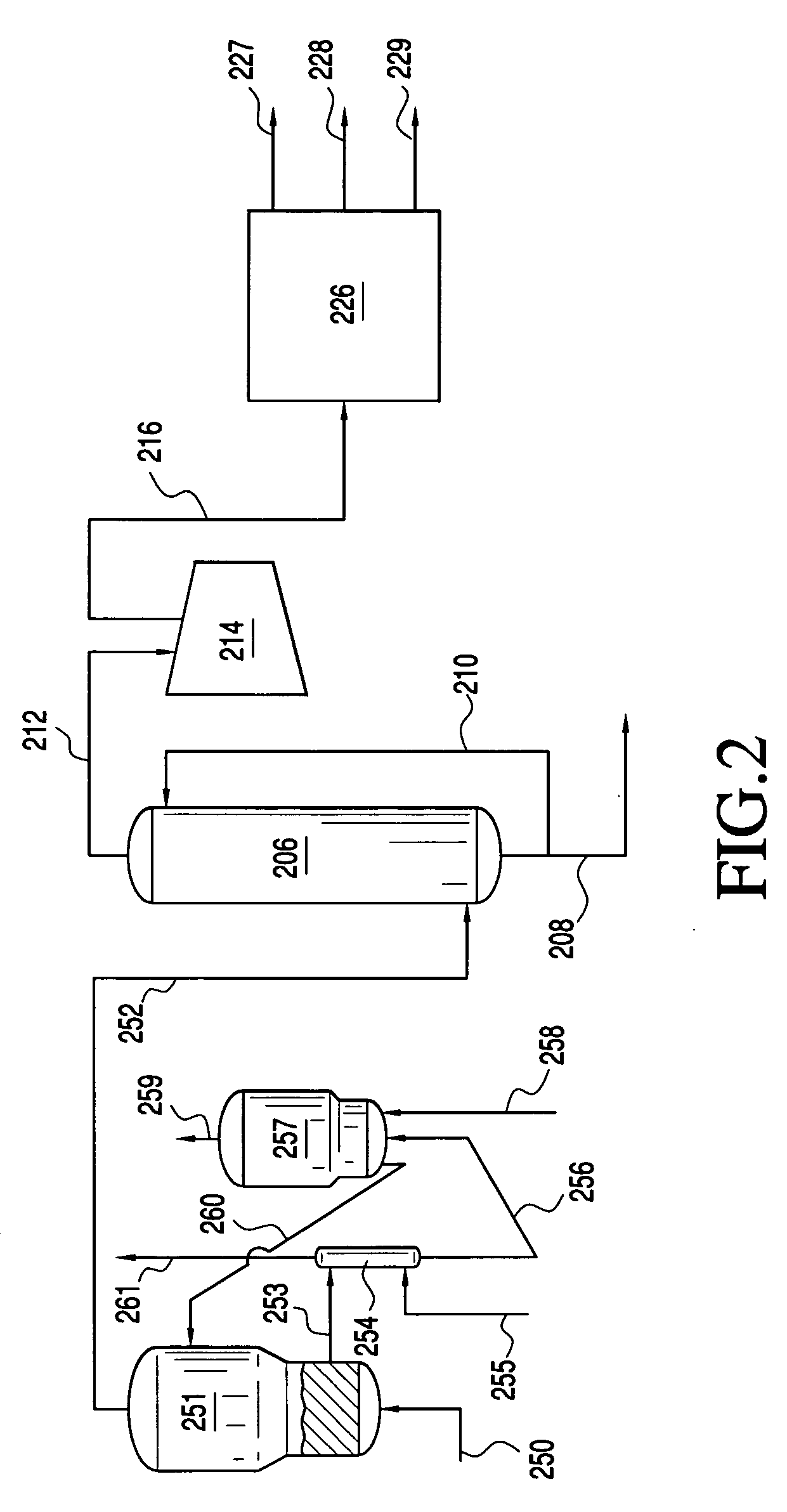

Integrating a methanol to olefin reaction system with a steam cracking system

InactiveUS20050038304A1Shorten the counting processReduce the amount requiredThermal non-catalytic crackingMolecular sieve catalystOxygenateFractionating column

The present invention provides an integrated system for producing ethylene and propylene from an oxygenate to olefin (OTO) reaction system and a steam cracking system. In a preferred embodiment, at least a portion of an effluent stream from a steam cracking furnace is combined with at least a portion of an effluent stream from an OTO reaction system. Preferably the combined effluent stream is processed by one or more quench units, compression units, and / or fractionation columns. By integrating a steam cracking system with an OTO reaction system, equipment count can be reduced at a significant commercial savings. Compressor efficiency per pound of ethylene and propylene can also be advantageously increased over conventional steam cracking systems. Moreover, the amount of pollutants produced per pound of ethylene and propylene produced can be significantly reduced over the amount of pollutants produced per pound of ethylene and propylene produced in a steam cracking system.

Owner:EXXONMOBIL CHEM PAT INC

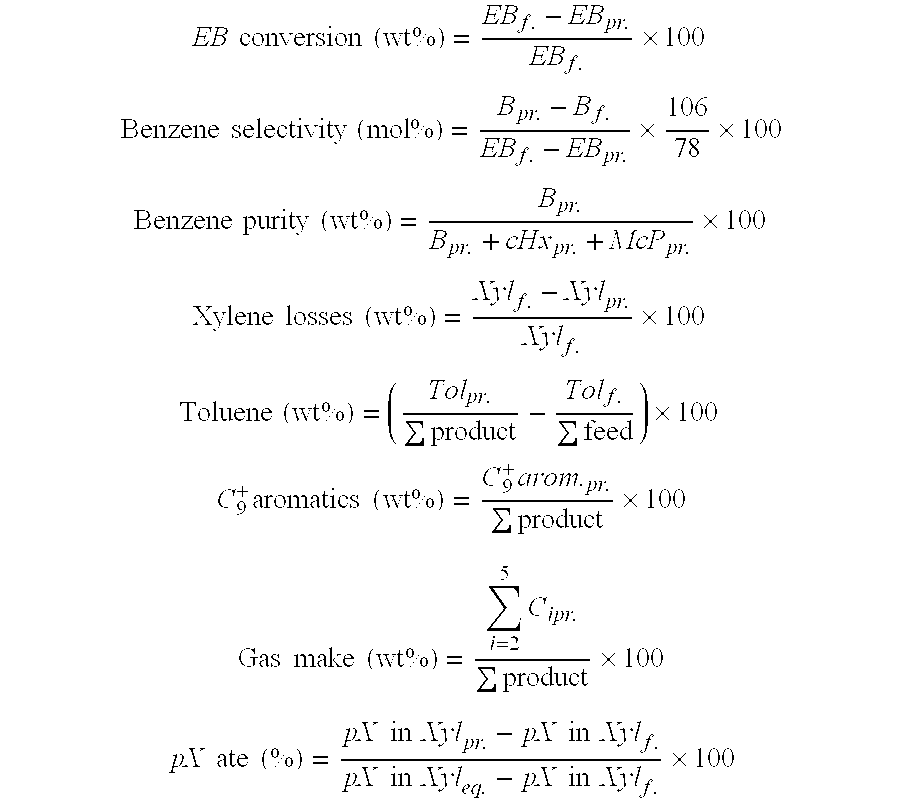

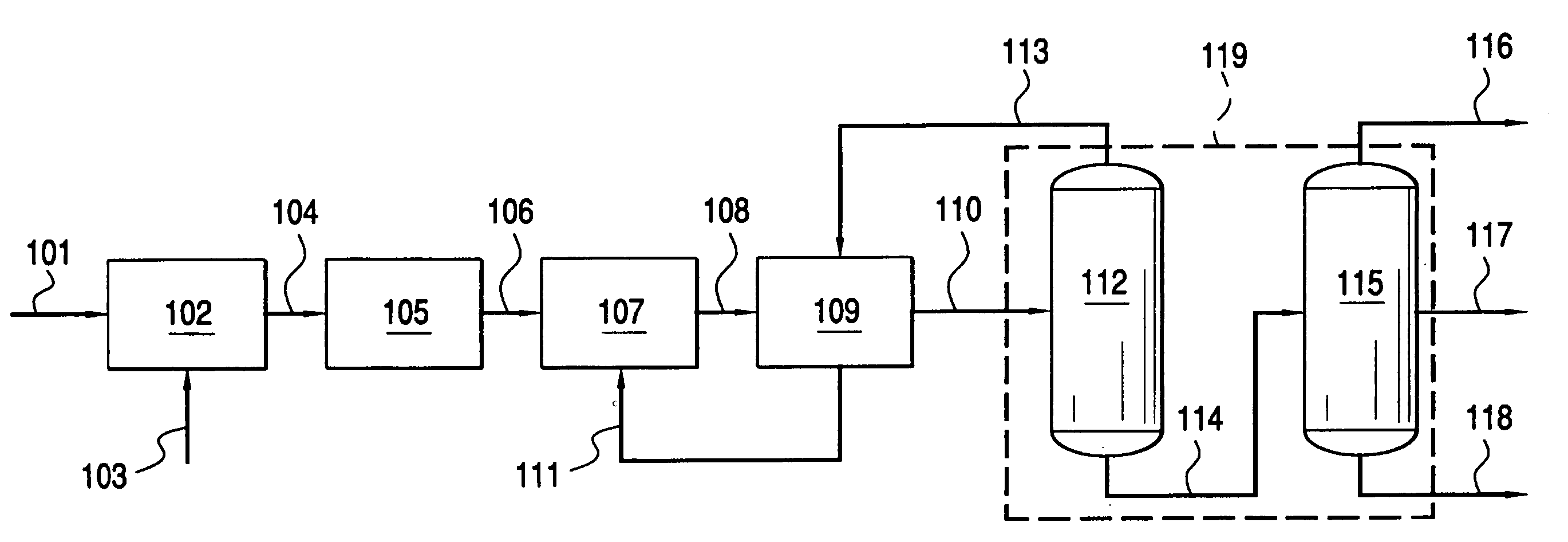

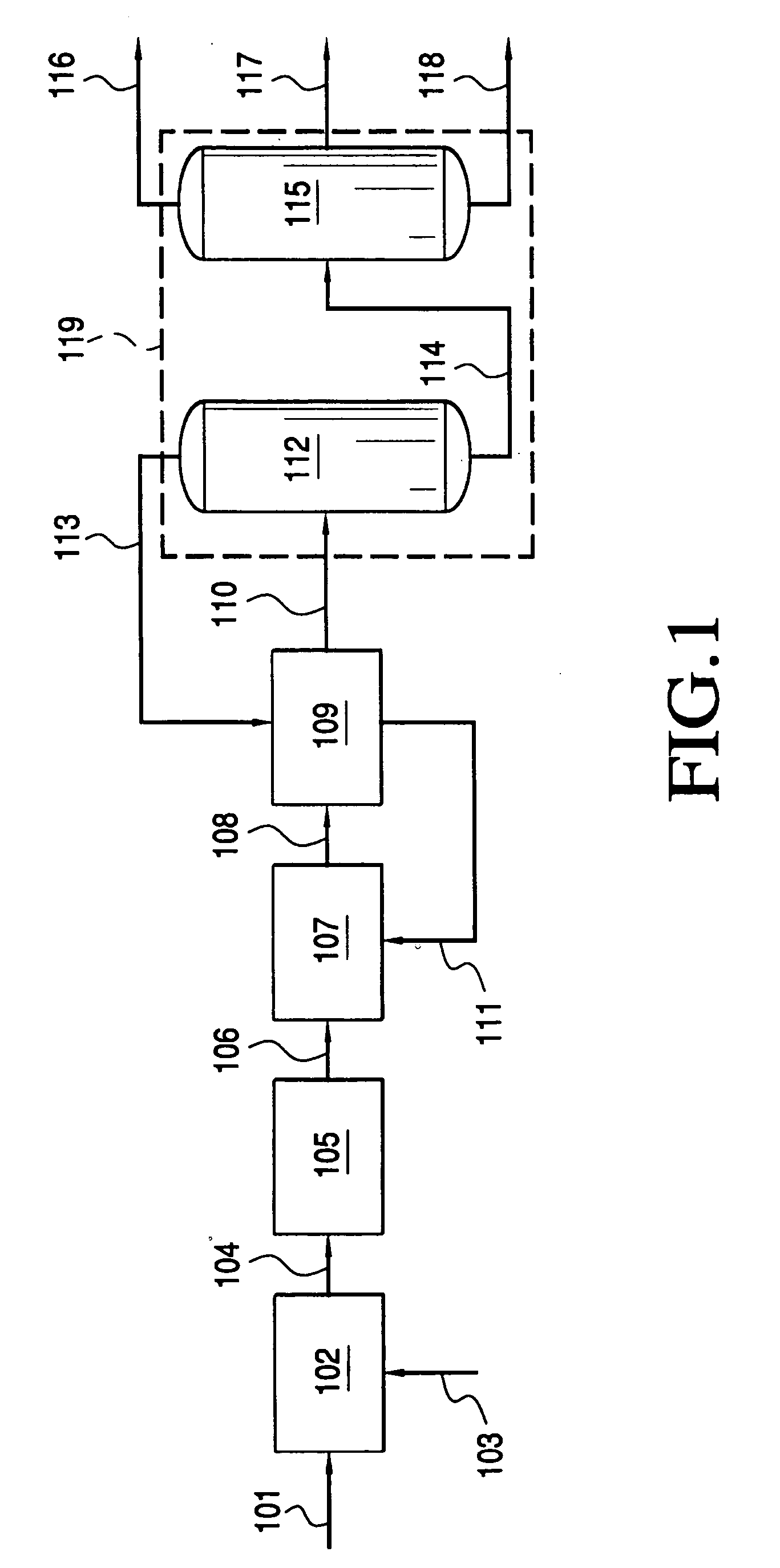

Liquid phase process for C8 alkylaromatic isomerization

InactiveUS6872866B1Saving considerable capitalImprove stabilityHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationAcid washing

A liquid or partially liquid phase process for isomerizing a non-equilibrium mixture of xylenes and ethylbenzene uses a zeolitic catalyst system preferably based on zeolite beta and on pentasil-type zeolite. The invention obtains an improved yield of para-xylene from the mixture relative to prior art processes in a more economical manner. A preferred beta zeolite is a surface-modified zeolite beta resulting from acid washing of a templated native zeolite at conditions insufficient to effect bulk dealumination. A preferred pentasil zeolite is a MTW-type with a silica-to-alumnina ratio between 20 and 45.

Owner:UOP LLC

Process for converting methanol or dimethyl ether to olefins

There is provided a process for converting methanol or dimethyl ether to a product containing C2 to C4 olefins, which comprises the step of contacting a feed containing methanol or dimethyl ether with a catalyst which comprises a zeolite having 10-ring intersecting channels, such as ZSM-5, and which has a Diffusion Parameter for 2,2-dimethylbutane of less than 100 sec-1 when measured at a temperature of 120 DEG C. and a 2,2-dimethylbutane pressure of 60 torr (8 kPa). The contacting step is conducted at a temperature of 370 to 480 DEG C., a methanol partial pressure of 30 to 150 psia and a methanol conversion per pass of less than 95%.

Owner:EXXONMOBIL CORP (US)

Selective conversion of oxygenate to propylene using moving bed technology and a hydrothermally stabilized dual-function catalyst

ActiveUS20060106270A1Improve economyAvoid severe deactivationMolecular sieve catalystCatalystsMolecular sieveFixed bed

The average propylene cycle selectivity of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the hydrocarbon synthesis portion of the OTP flow scheme in lieu of the fixed bed technology of the prior art; 2) a hydrothermally stabilized and dual-functional catalyst system comprising a molecular sieve having dual-function capability dispersed in a phosphorus-modified alumina matrix containing labile phosphorus and / or aluminum anions; and 3) a catalyst on-stream cycle time of 400 hours or less. These provisions stabilize the catalyst against hydrothermal deactivation and hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield near or at essentially start-of-cycle levels.

Owner:UOP LLC

Selective xylenes isomerization and ethylbenzene conversion

This invention is drawn to a process for isomerizing a non-equilibrium mixture of xylenes and ethylbenzene using an oil-dropped catalyst comprising a zeolite, a platinum-group metal and an aluminophosphate binder, resulting in a greater yield of para-xylene at favorable conditions compared to processes of the known art.

Owner:UOP LLC

Process for alkane aromatization using platinum-zeolite catalyst

InactiveUS20050143610A1Formation is suppressedHigh selectivityMolecular sieve catalystsMolecular sieve catalystAlkanePlatinum

Aromatization of alkanes having one to four carbon atoms per molecule to aromatics, such as benzene, toluene and xylenes (BTX), uses a catalyst of a crystalline zeolite on which platinum has been deposited, specifically a platinum-containing ZSM-5. A byproduct of the process is a light gas fraction of methane and ethane. The use of a platinum-containing ZSM-5 catalyst in an alkane aromatization process, such as the Cyclar process, suppresses the formation of methane and increases selectivity to BTX. The high content of ethane relative to methane in the light gas fraction allows this process effluent to be a feedstream for a cracker.

Owner:SAUDI BASIC IND CORP SA

Process for the conversion of ethane to aromatic hydrocarbons

ActiveUS20090209794A1Limit initial cracking activitySacrificing activityMolecular sieve catalystsMolecular sieve catalystBenzenePlatinum

A process for producing aromatic hydrocarbons which comprises (a) contacting ethane with a dehyroaromatization aromatic catalyst which is comprised of about 0.005 to about 0.1 wt % platinum, an amount of gallium which is equal to or greater than the amount of the platinum, from about 10 to about 99.9 wt % of an aluminosilicate, and a binder, and (b) separating methane, hydrogen, and C2-5 hydrocarbons from the reaction products of step (a) to produce aromatic reaction products including benzene.

Owner:SHELL USA INC

Hydrocarbon synthesis

InactiveUS20050171393A1Valid conversionMolecular sieve catalystLiquid hydrocarbon mixtures productionHydrogen halideOxygen

A method of synthesizing hydrocarbons from smaller hydrocarbons includes the steps of hydrocarbon halogenation, simultaneous oligomerization and hydrogen halide neutralization, and product recovery, with a metal-oxygen cataloreactant used to facilitate carbon-carbon coupling. Treatment with air or oxygen liberates halogen and regenerates the cataloreactant.

Owner:REACTION 35 LLC

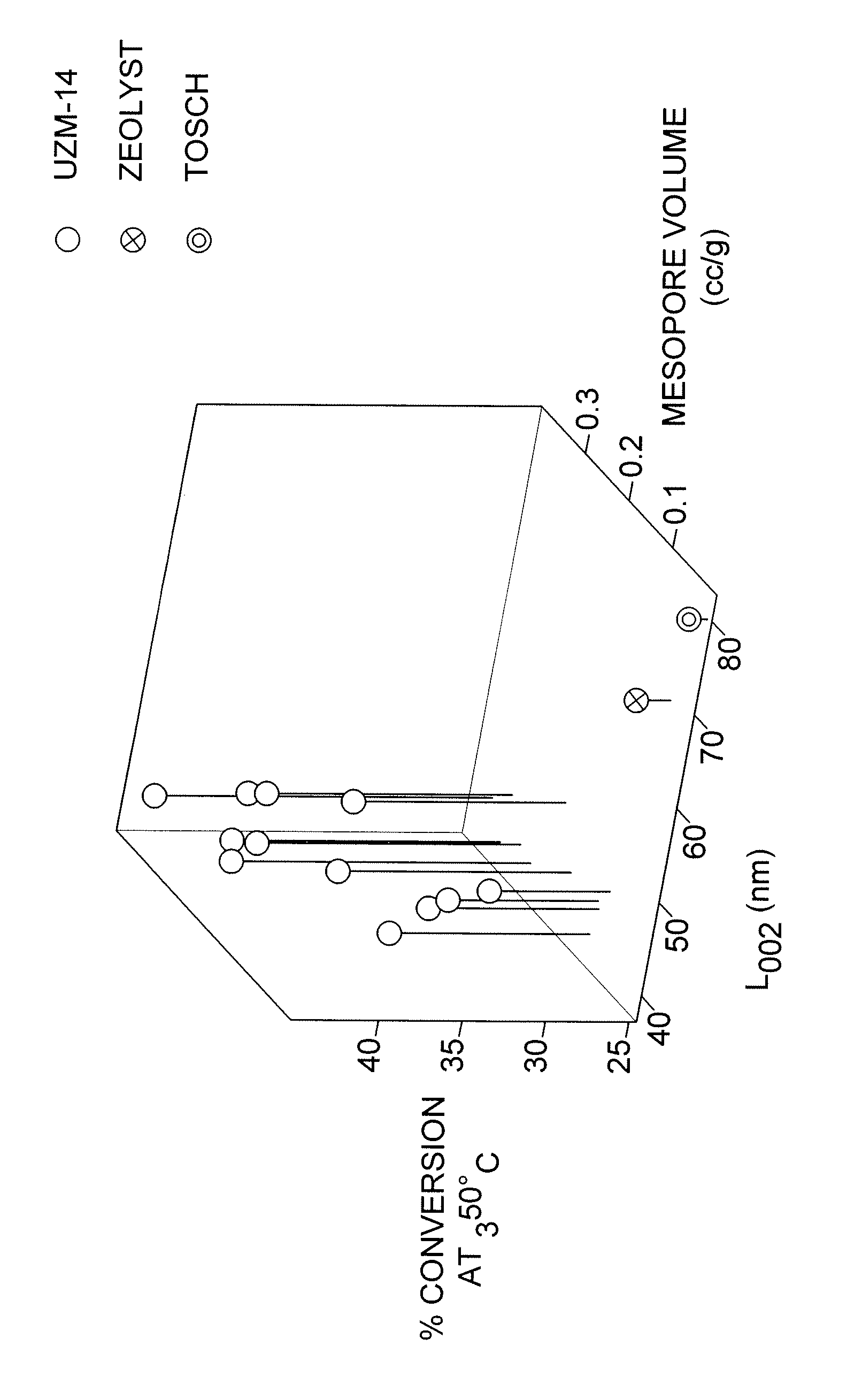

Selective catalyst for aromatics conversion

The subject invention comprises a novel UZM-14 catalytic material comprising globular aggregates of crystallites having a MOR framework type with a mean crystallite length parallel to the direction of 12-ring channels of about 60 nm or less and a mesopore volume of at least about 0.10 cc / gram. Catalysts formed from the novel material are particularly effective for the transalkylation of aromatics.

Owner:UOP LLC

Converting methanol and ethanol to light olefins

InactiveUS20060149109A1Minimize formationMolecular sieve catalystChemical industryMolecular sievePhotochemistry

The present invention provides processes for producing light olefins from a feedstock comprising methanol and ethanol. The ethanol is converted to ethylene and water over a dehydration catalyst, while the methanol is converted to light olefins and water over a molecular sieve catalyst. These conversion steps may occur in two separate reactors operating in series or in parallel, or in a single reactor containing a mixture of dehydration catalyst and molecular sieve catalyst.

Owner:EXXONMOBIL CHEM PAT INC

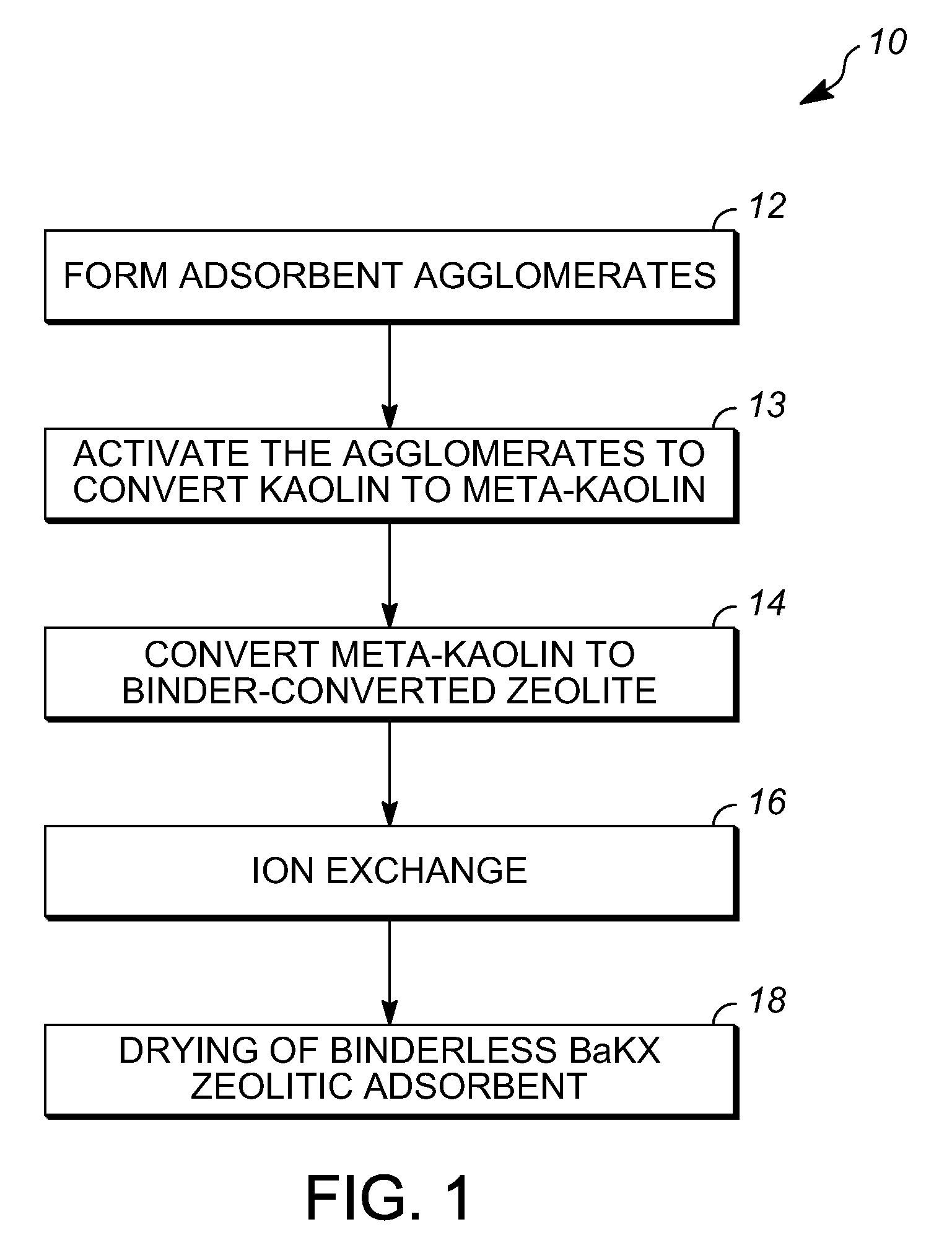

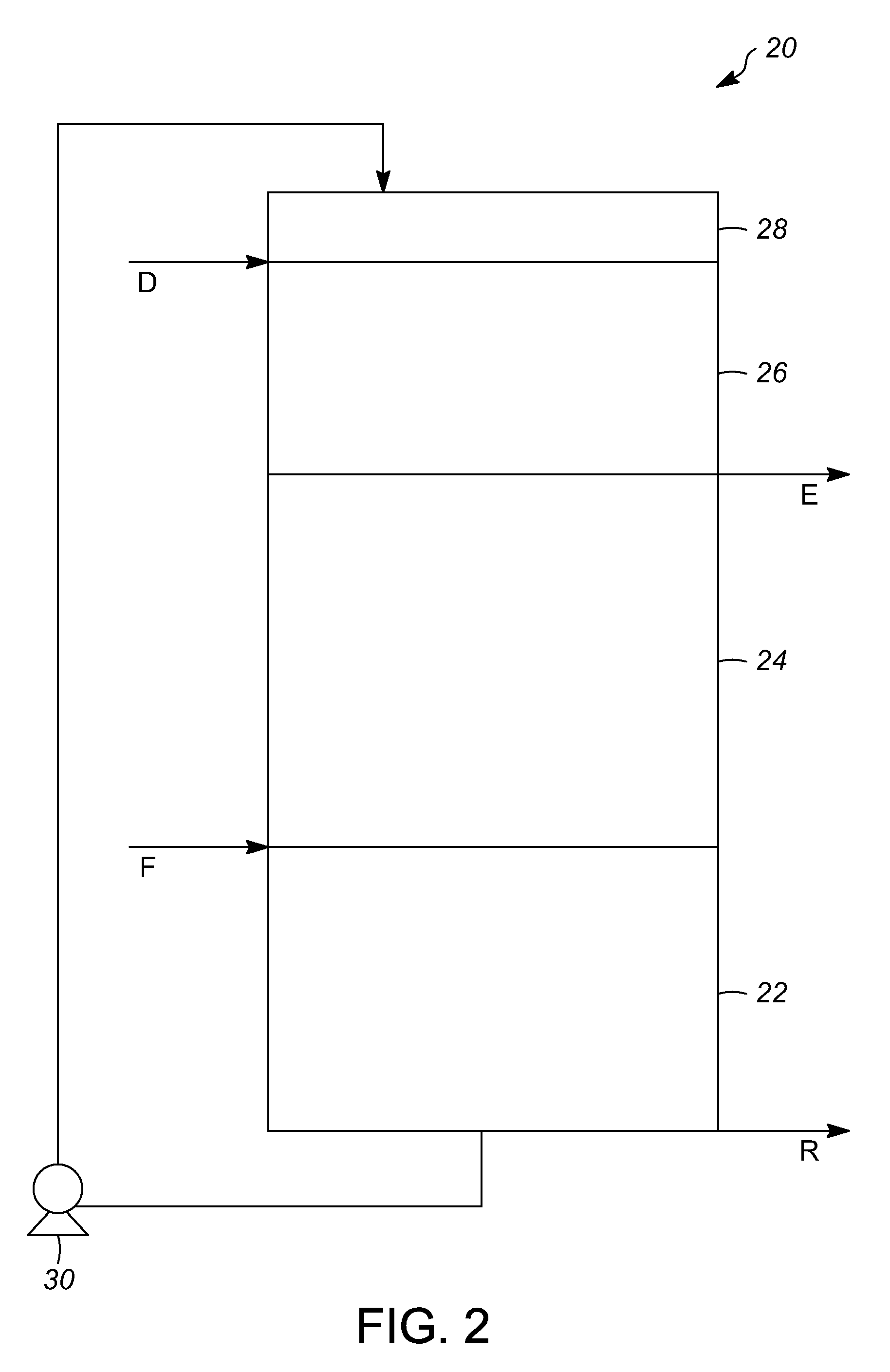

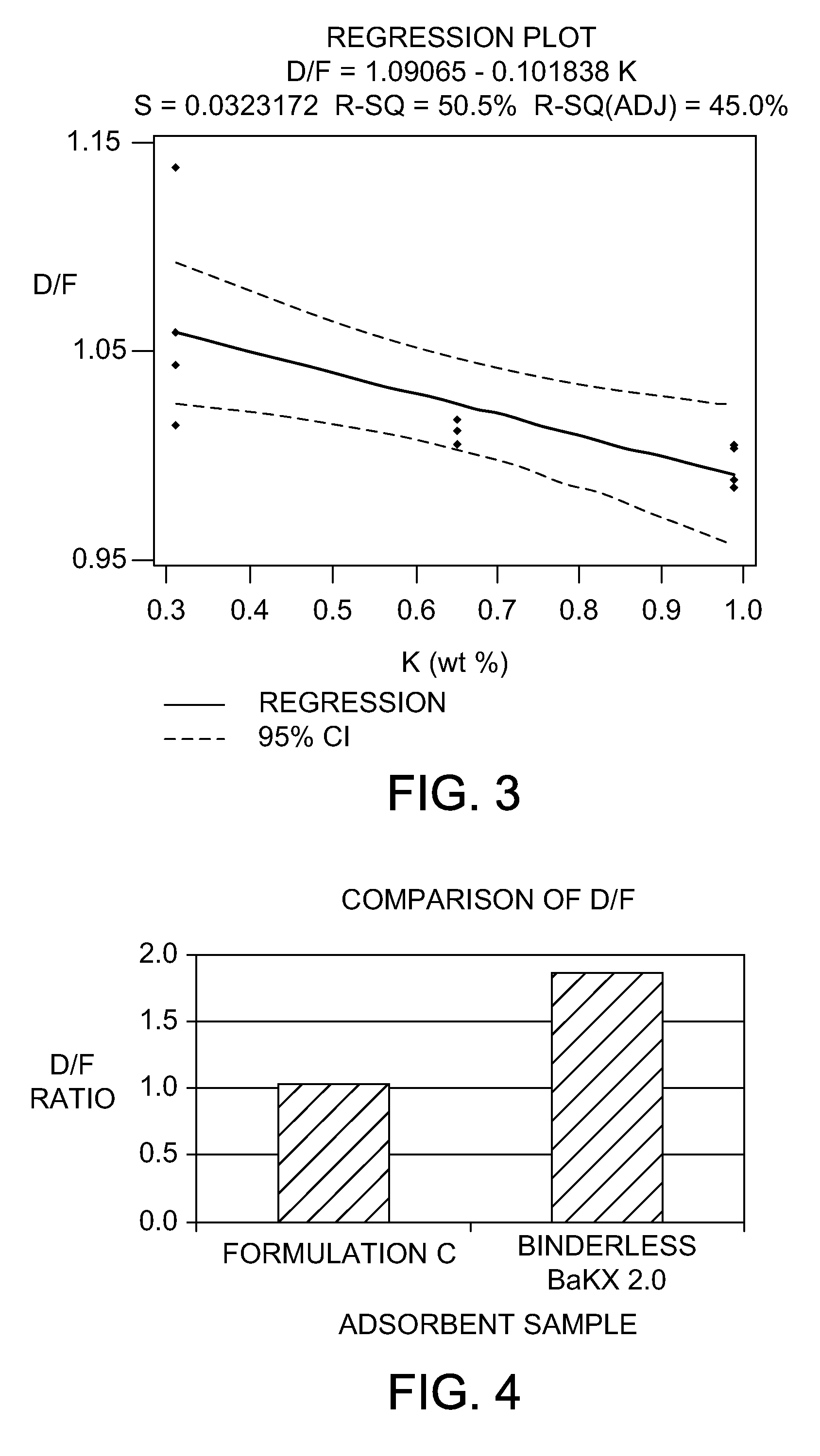

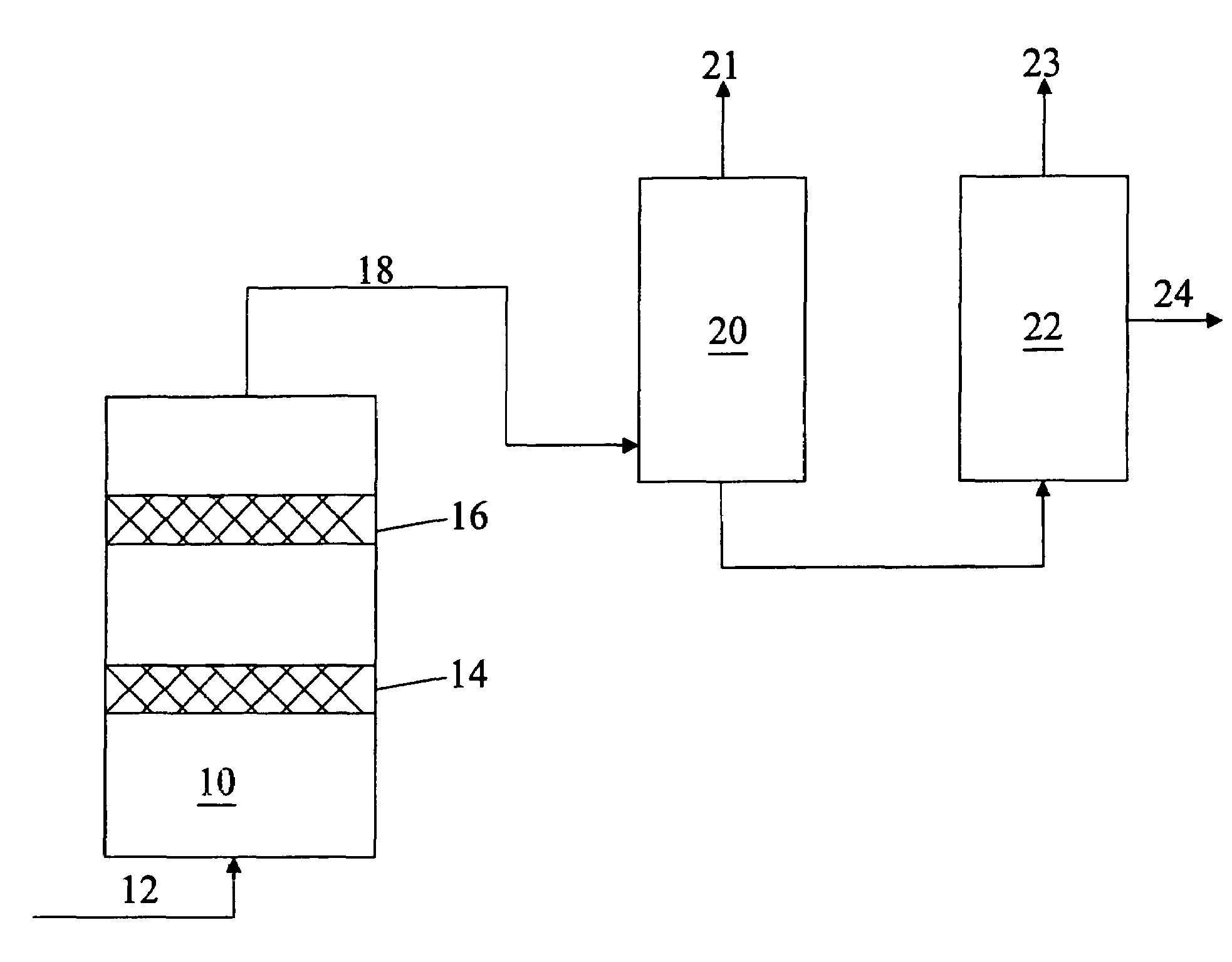

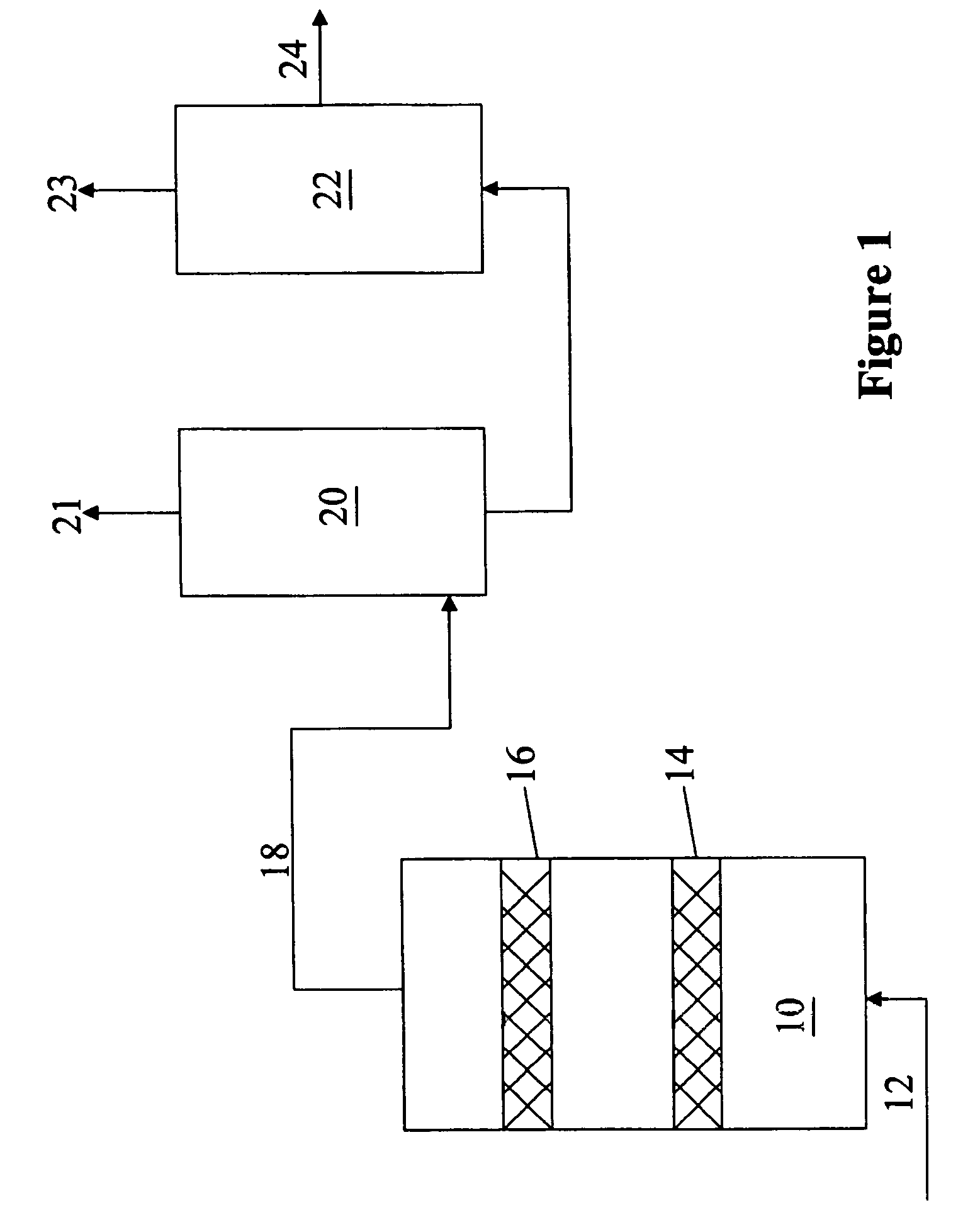

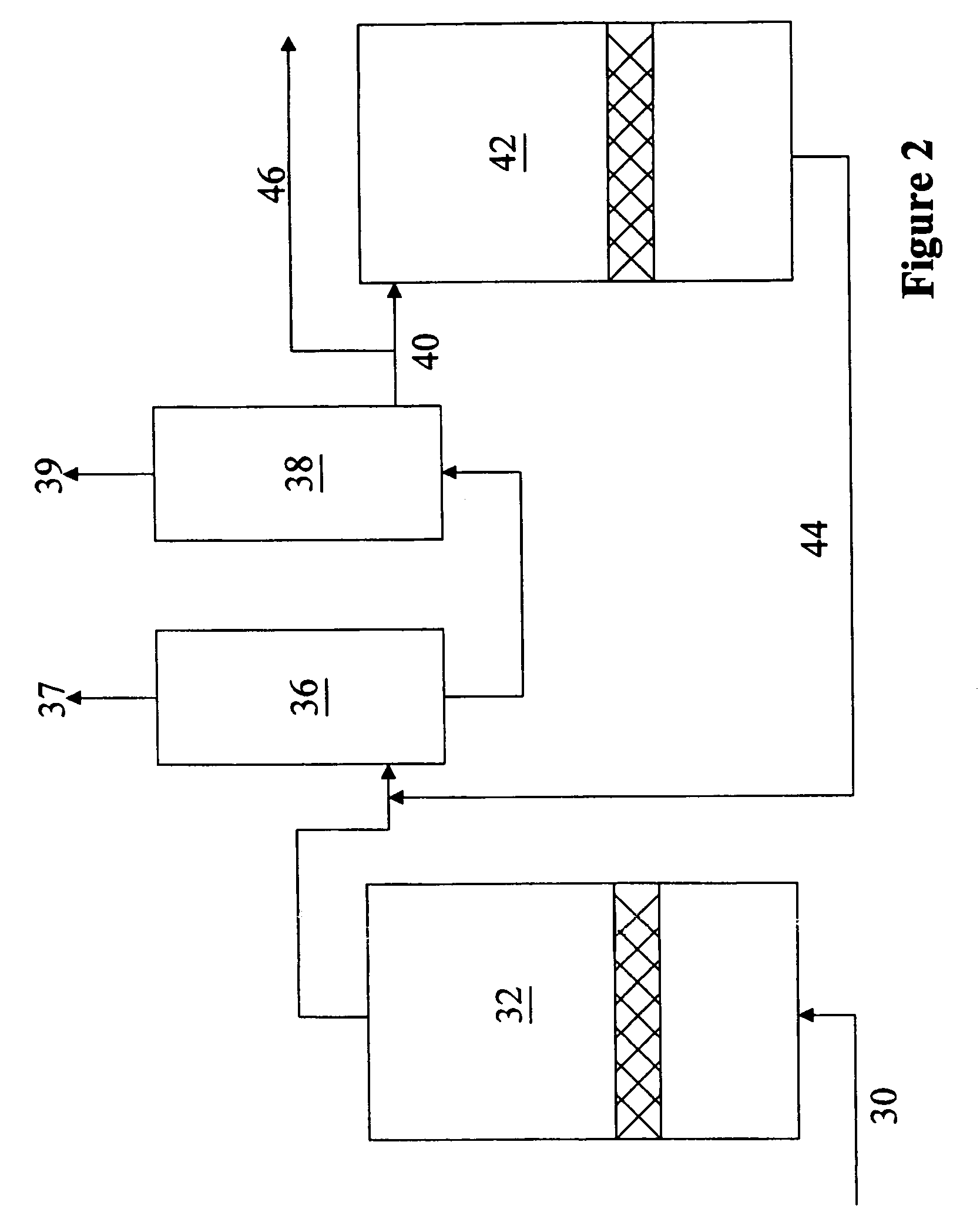

Binderless zeolitic adsorbents, methods for producing binderless zeolitic adsorbents, and processes for adsorptive separation of para-xylene from mixed xylenes using the binderless zeolitic adsorbents

Binderless BaKX zeolitic adsorbents, methods for their production, and processes for their use in a liquid phase adsorptive separation process are provided. An adsorbent includes a binder-converted zeolite portion formed from x wt % kaolin clay binder and (100-x) wt % unconverted Zeolite X with a silica:alumina molar ratio of about 2.5. The kaolin clay binder is in the range of about 10 to about 20 wt %. Ba and K occupy cationic exchangeable sites within the adsorbent. K is in the range of about 0.25 to about 0.9% by weight and Ba is greater than about 31.6% by weight of the binderless BaKX zeolitic adsorbent. Cornstarch may be added to the Zeolite X and kaolin clay binder to increase adsorbent macro-porosity and pore volume. Productivity of the adsorbent is improved decreasing process operating costs. The mechanical strength of the adsorbent is also improved.

Owner:UOP LLC

Two catalyst process for making olefin

This invention is to a process of making olefin, particularly ethylene and propylene, from an oxygenate feed. The invention uses two or more zeolite catalysts. Examples of zeolite catalysts include a first catalyst containing of ZSM-5, and a second catalyst containing a 10-ring molecular sieve, including but not limited to, ZSM-22, ZSM-23, ZSM35, ZSM-48, and mixtures thereof. The ZSM-5 can be unmodified, phosphorous modified, steam modified having a micropore volume reduced to not less than 50% of that of the unsteamed ZSM-5, or various mixtures thereof.

Owner:EXXONMOBIL CHEM PAT INC

Catalysts for petrochemical catalysis

Metal oxide catalysts comprising various dopants are provided. The catalysts are useful as heterogenous catalysts in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons such as ethane and ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

Popular searches

Hydrocarbon from oxygen organic compounds Hydrocarbons Hydrocarbon by hydrocarbon and non-hydrocarbon condensation Hydrocarbon by addition and hydrogenation Fatty-oils/fats refining Fatty-oils/fats separation Liquid hydrocarbon mixture production Treatment with hydrotreatment processes Bio-feedstock Hydrocarbon oils treatment products

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com