Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5499 results about "Kaolin clay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire-resistant panel and method of manufacture

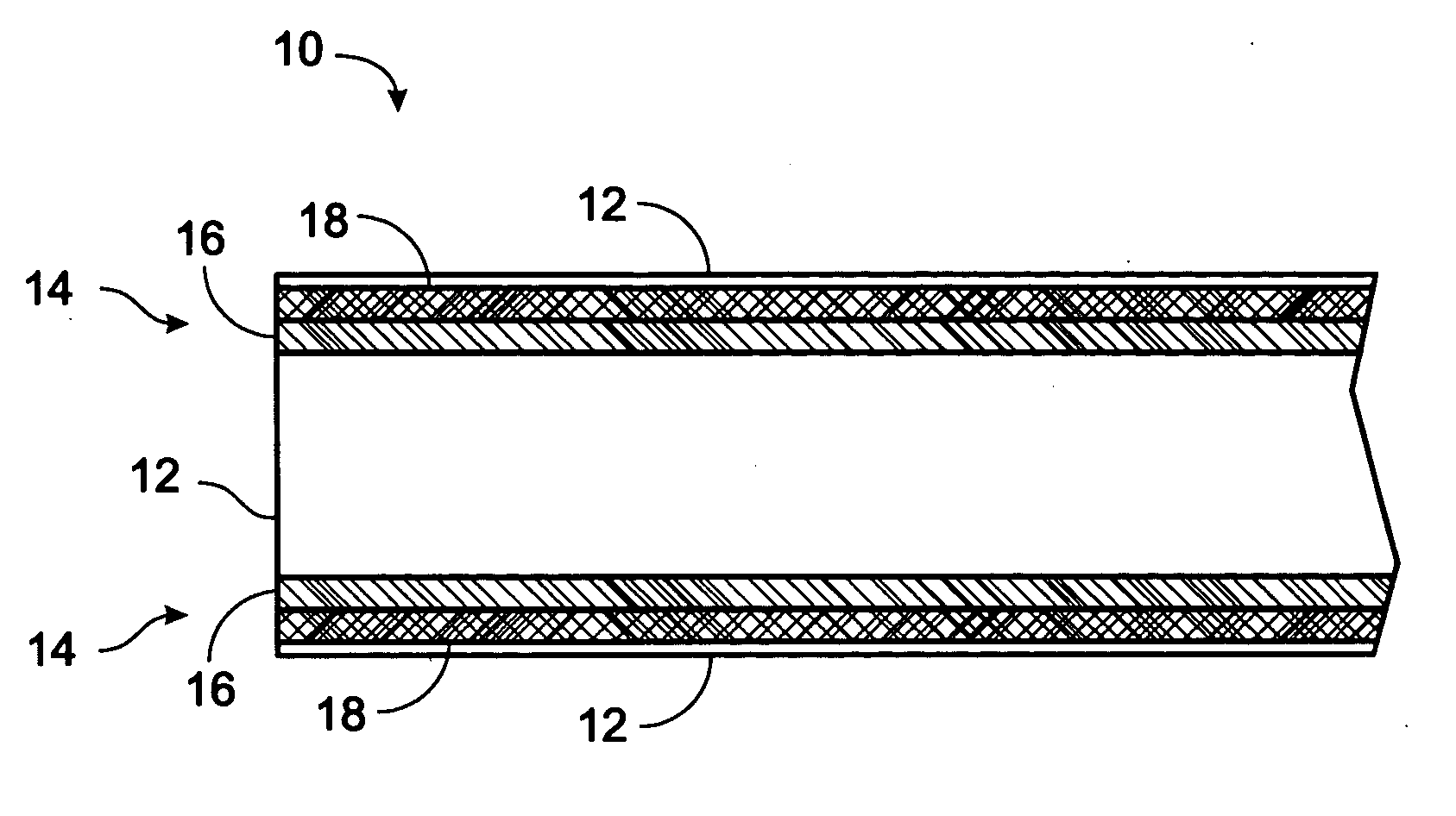

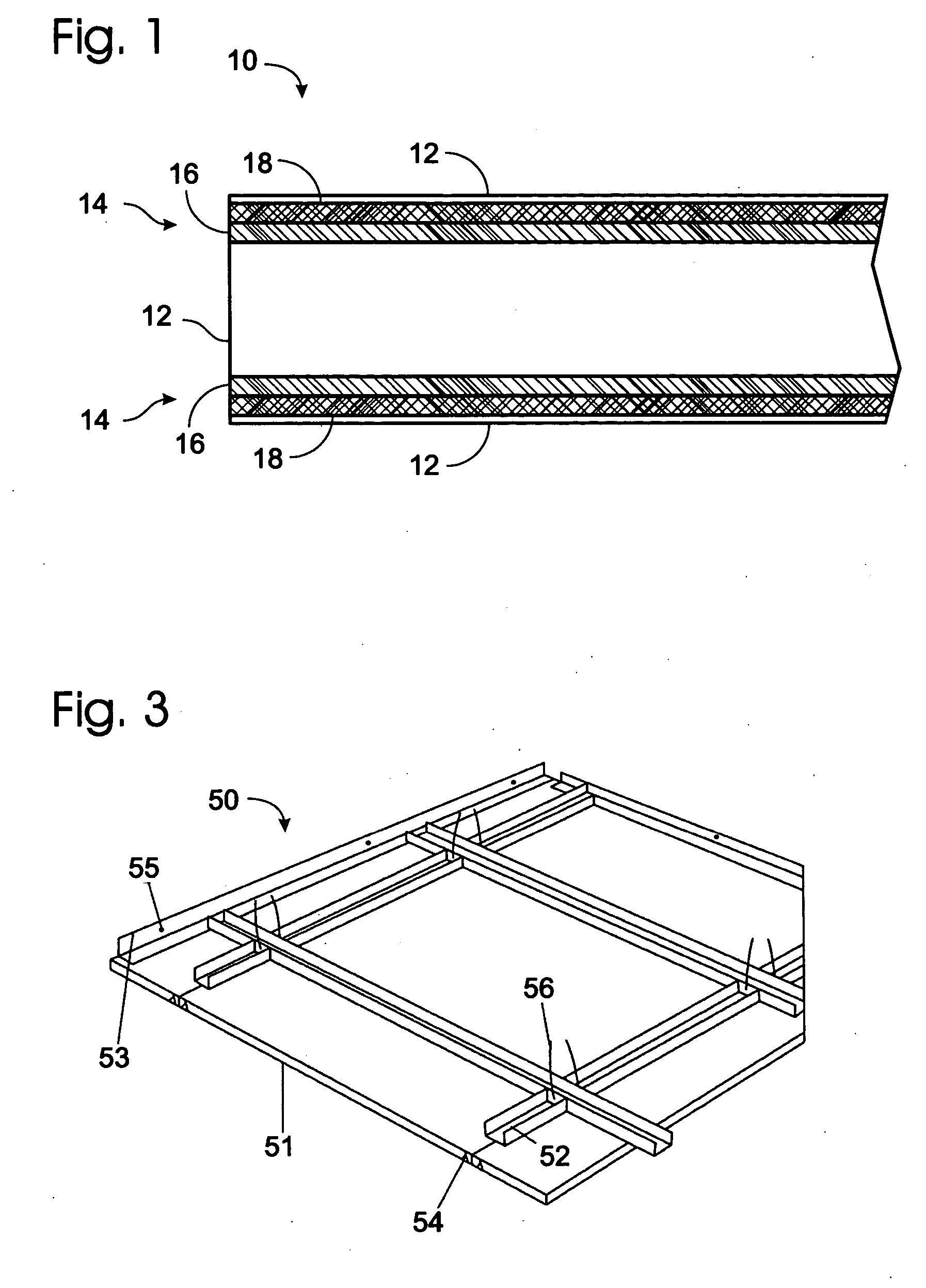

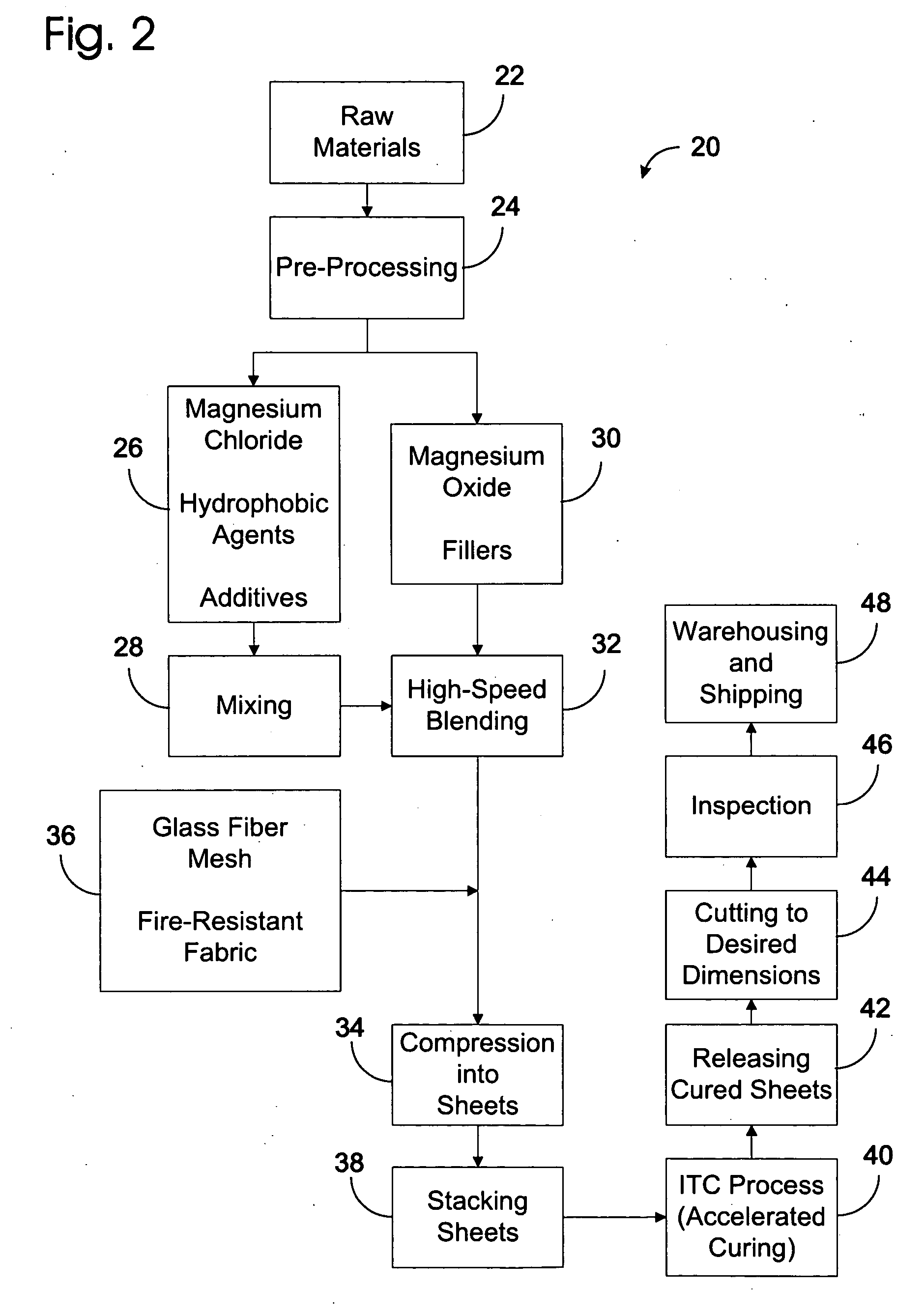

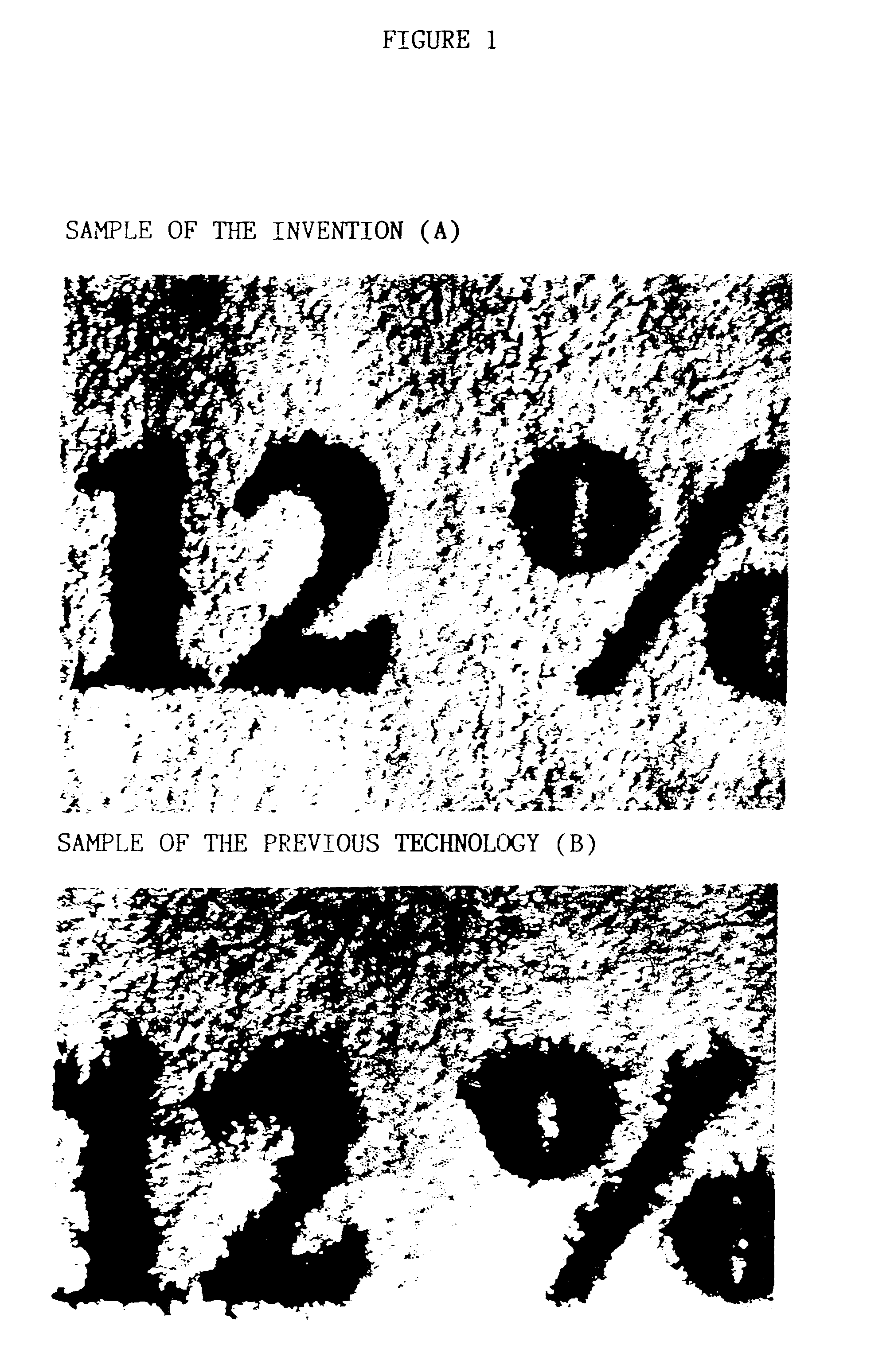

A highly fire-resistant and environmentally-friendly panel of 2 mm to 28 mm may be manufactured by a blending of magnesium compounds, sodium silicate, kaolin, fillers, and additives to form the core materials, reinforced by 4 layers of fire-resistant glass fiber meshes and fabrics. Using a proprietary ITC process that accelerates the chemical reactions of the ingredients to generate sufficient heat without external supply of energy, the panels may be completely cured within 24 hours instead of 10 days. The use of waste materials, energy-saving curing system and no gas emission manufacturing process combined to make this panel an eco-friendly product which offers the world's highest-rated fire resistance of 5 hours, high flexural strength, low density, durability and effective water-resistance.

Owner:REP TECH

Treated filler or pigment containing natural carbonate

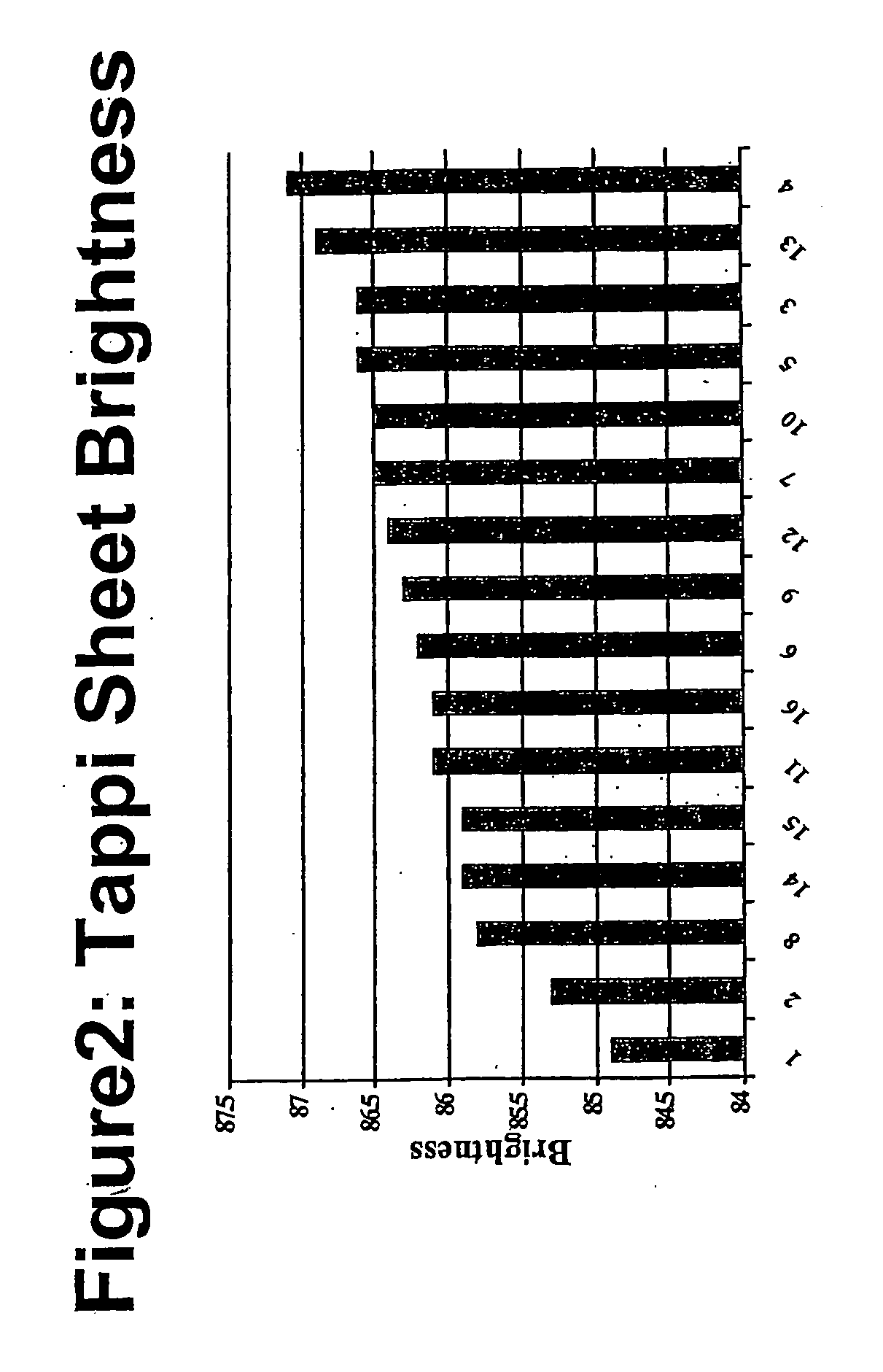

InactiveUS6666953B1Reduce weightReduce wearNatural cellulose pulp/paperSpecial paperPhysical chemistryKaolin clay

The invention concerns a pigment, filler or mineral containing a natural calcium carbonate, treated with one of more providers of H3O<+> ions and gaseous CO2, allowing a reduction in the weight of paper for a constant surface area without loss of physical properties when it is used as a pigment or coating filler for the said paper. In particular, the invention concerns a pigment, filler or mineral containing a natural calcium carbonate or dolomite or mixtures of talc and calcium carbonate, of kaolin and carbonate or carbonate alone or in combination with natural and / or synthetic fibers or similar, treated with one or more medium-strong or strong providers of H3O<+> ions in the presence of gaseous CO2. Applications are particularly in the paper industry, obtaining in particular good sheet properties i.e. a reduction its weight for a given surface area.

Owner:OMYA DEV AG

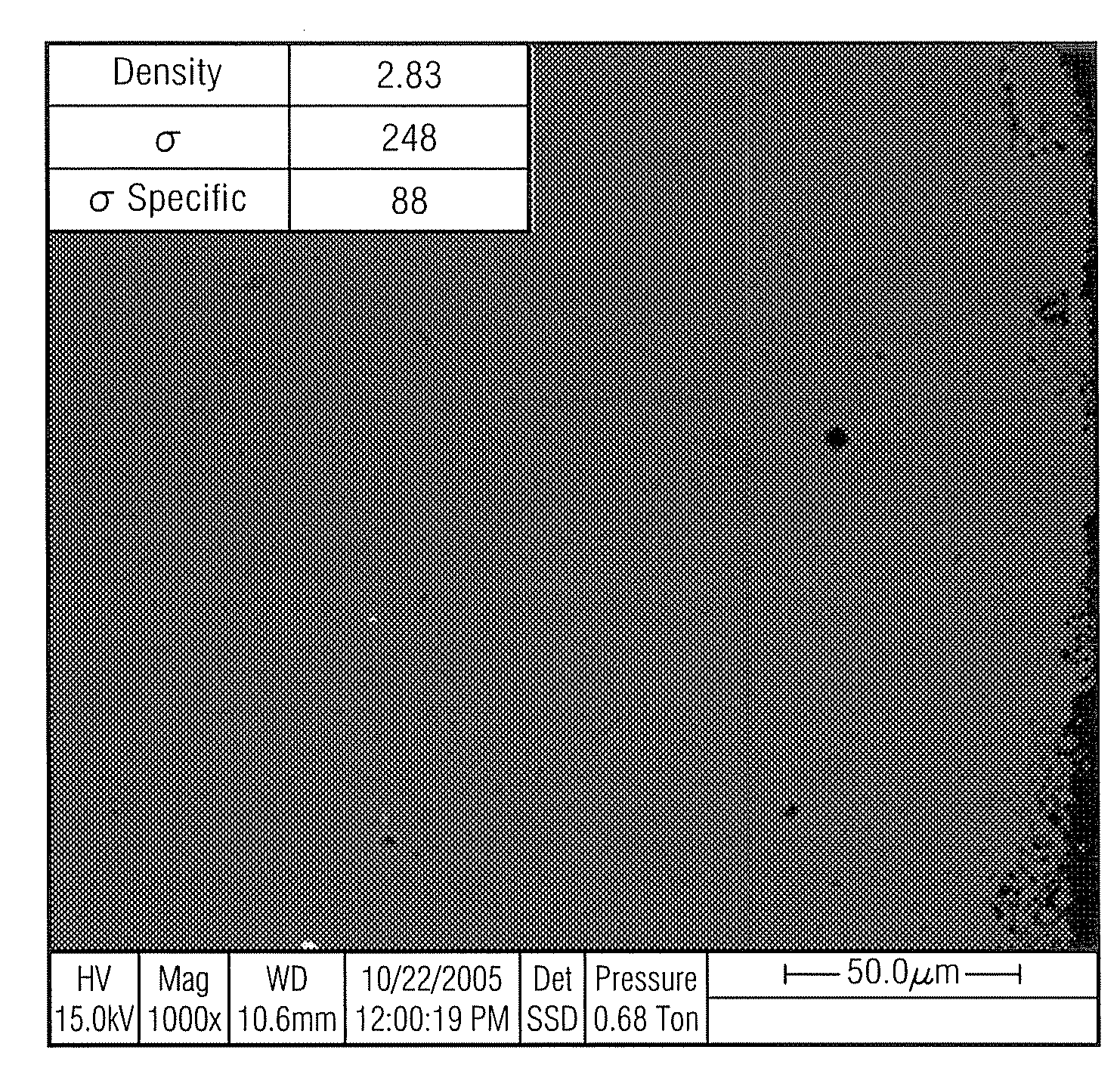

Low density proppant

Owner:CARBO CERAMICS

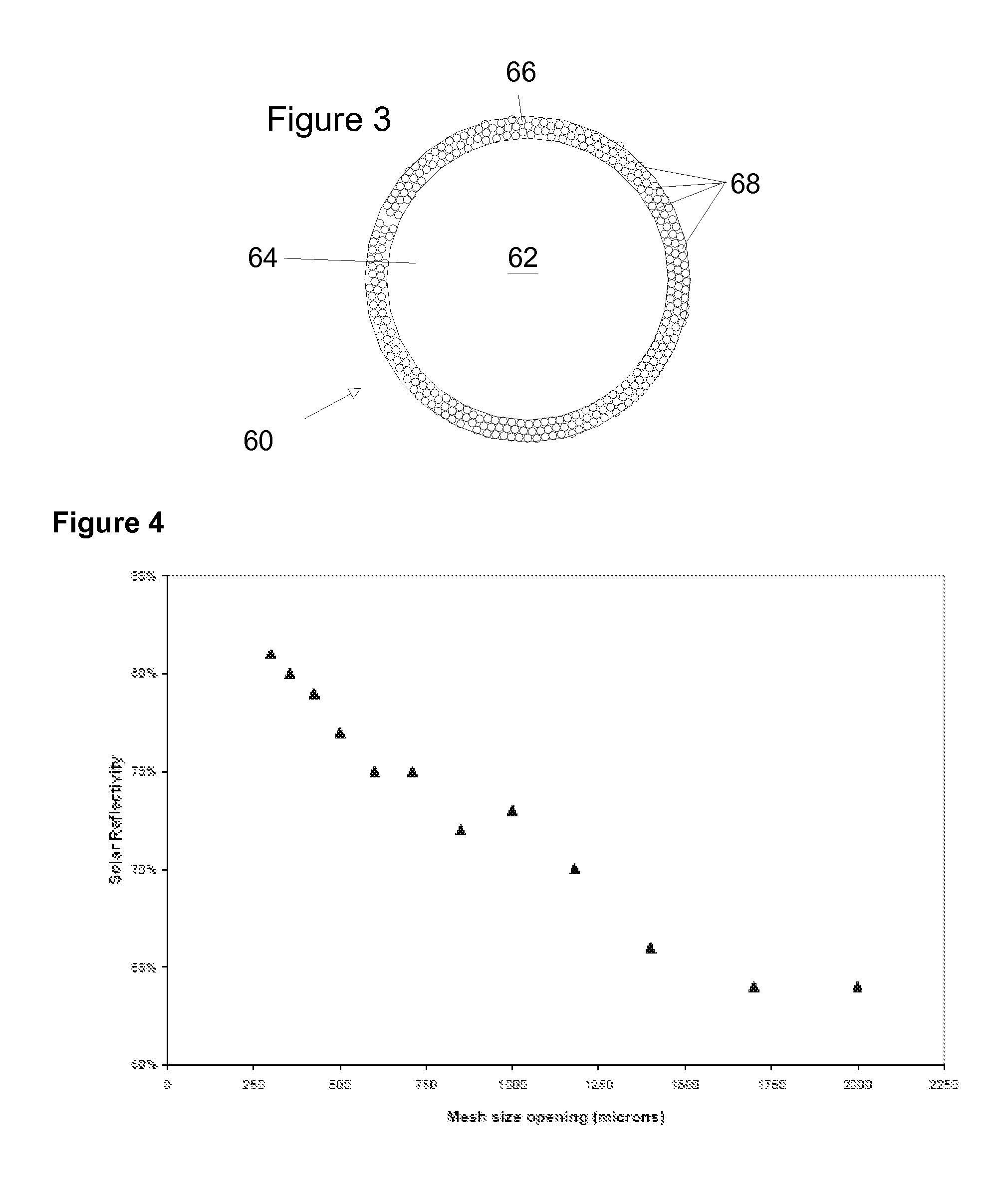

Solar heat-reflective roofing granules, solar heat-reflective shingles, and process for producing the same

ActiveUS20110086201A1Improve solar heat reflectivityRoof covering using tiles/slatesRoof improvementMetallurgyDegree Celsius

A process for preparing roofing granules includes forming kaolin clay into green granules and sintering the green granules at a temperature of at least 900 degrees Celsius to cure the green granules until the crystalline content of the sintered granules is at least ten percent as determined by x-ray diffraction.

Owner:CERTAINTEED CORP

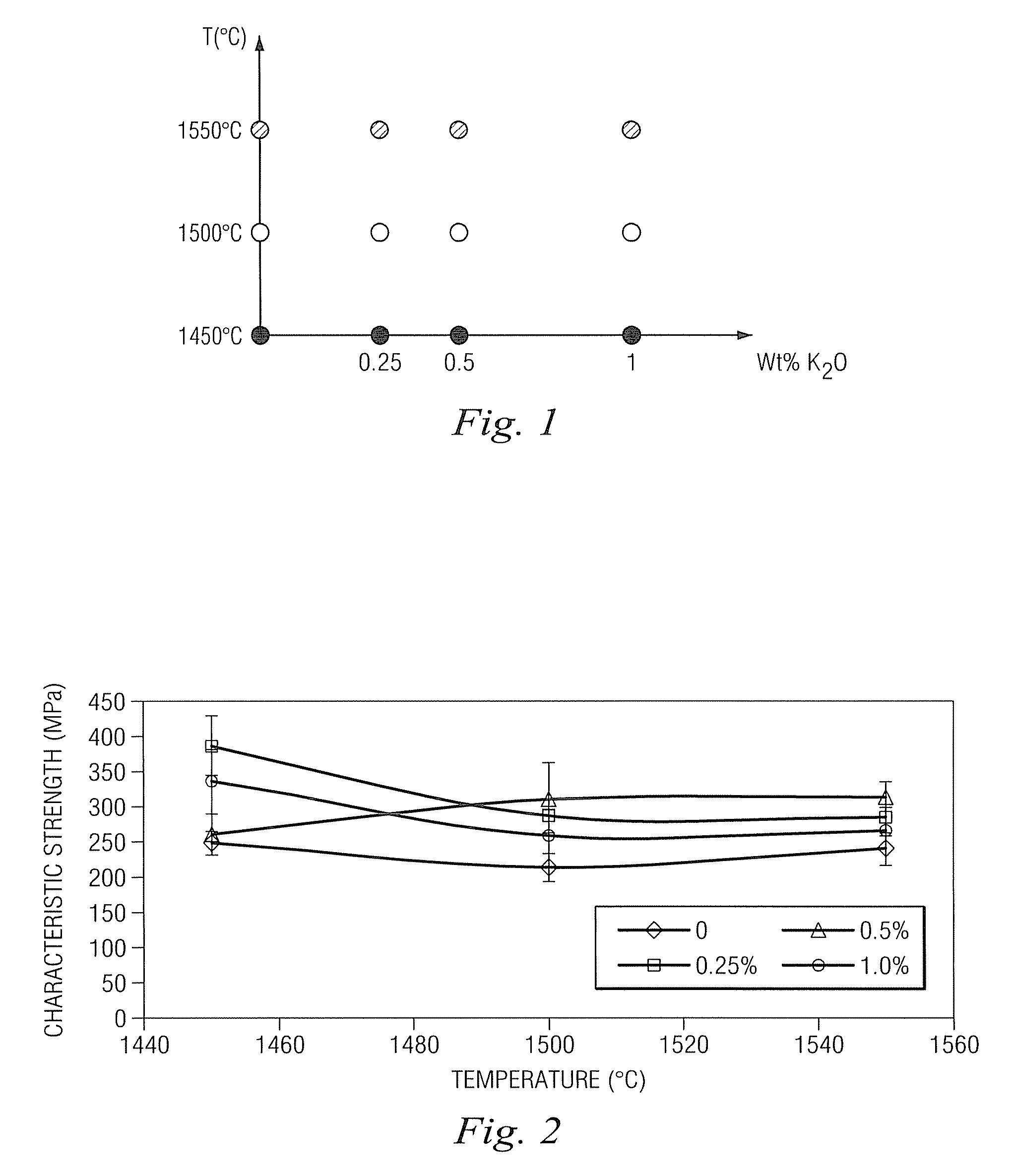

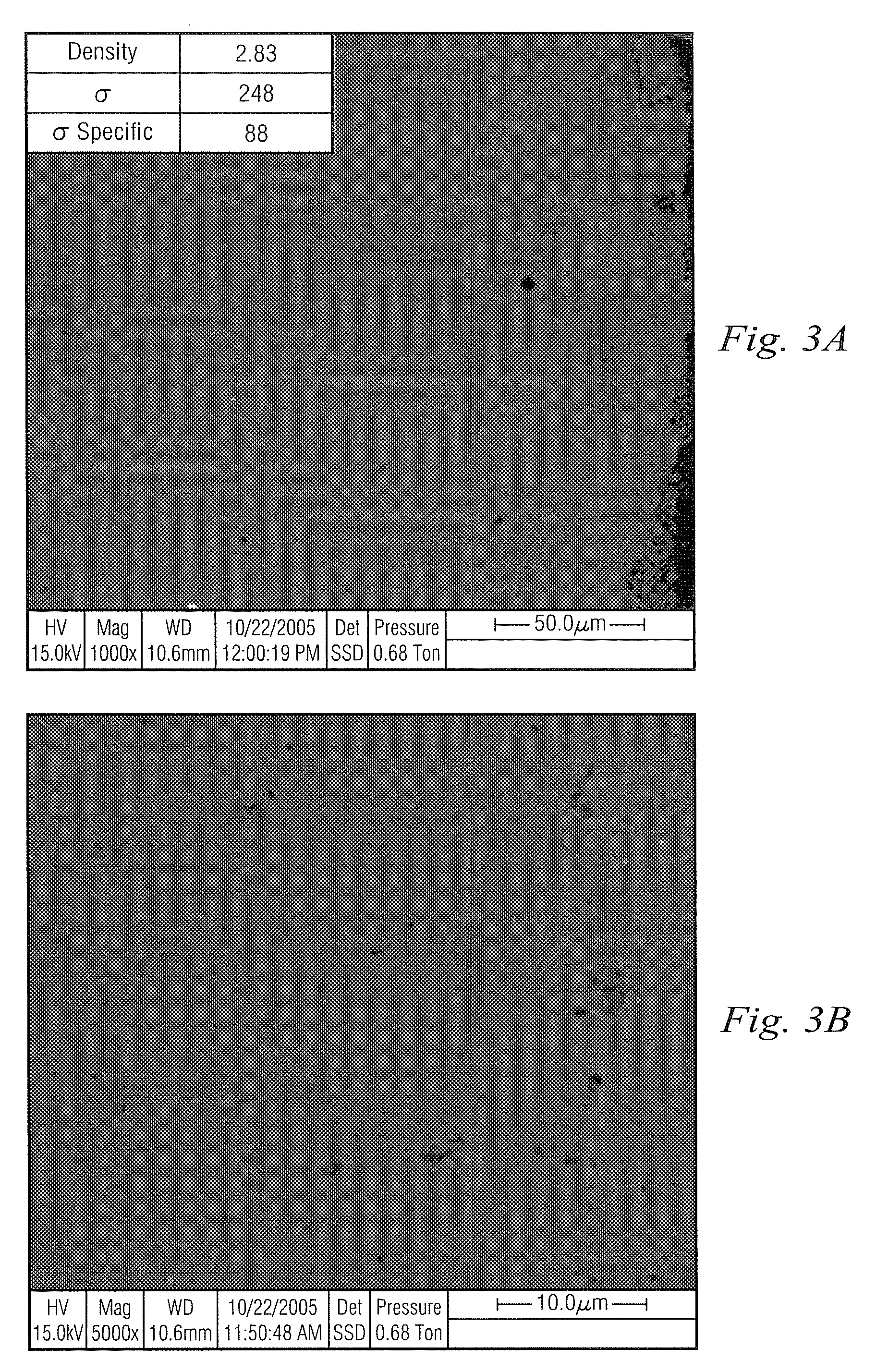

Method for producing proppant using a dopant

InactiveUS20090118145A1Enhanced mulliteEnhanced glass formationFluid removalFlushingDopantKaolin clay

A method for producing sintered pellets and sintered pellets produced therefrom including mixing a dopant with water and kaolin clay to form substantially round and spherical green pellets and sintering the pellets to form a proppant. The dopant is selected from the group consisting of potassium carbonate, potassium sulfate, potassium chloride, mica, kalsilite, and combinations thereof.

Owner:CARBO CERAMICS +1

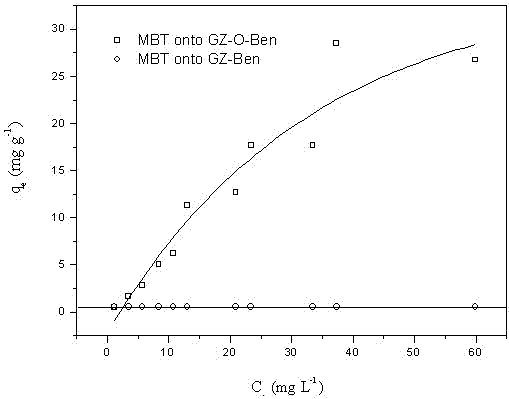

Metal heavy absorbent and preparation method and use thereof

InactiveCN102389776AEasy to operateImprove efficiencyOther chemical processesWaste water treatment from animal husbandryActive agentKaolin clay

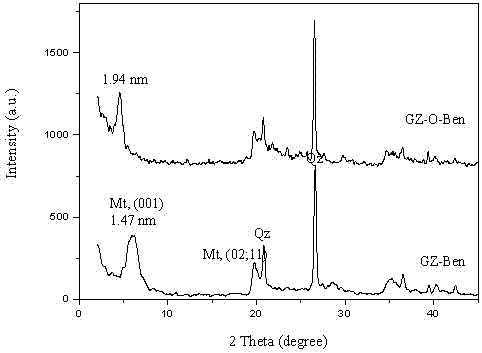

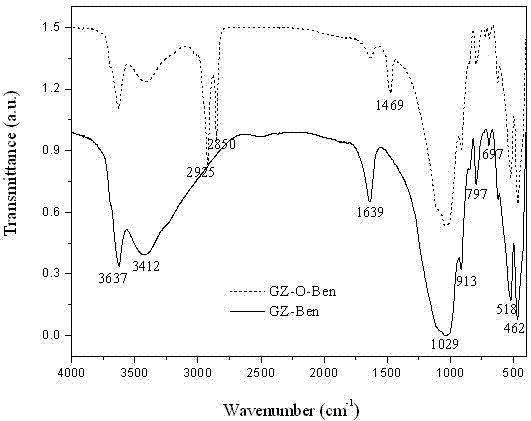

The invention discloses a heavy metal absorbent and a preparation method and use thereof. The heavy metal absorbent is prepared by using an inorganic mineral modified by a surfactant as a carrier and loading organic complexing agent on the carrier, wherein the inorganic mineral is bentonite, kaolin, kieselguhr, zeolite, aluminum oxide or iron oxide; the surfactant is cationic surfactant or nonionic surfactant; and the organic complexing agent is a compound containing a sulfydryl and an amino. The heavy metal absorbent has the advantages of stable performance, environment friendliness, high absorption capacity, high selectivity, convenient post-recovery treatment and the like. The absorption capacities of cadmium, mercury lead and other heavy metals all exceed 100mg / g, and the heavy metal absorbent can achieve good treatment effect in treatment of water and soil environments polluted by heavy metals.

Owner:上海伊克诺环境科技有限公司

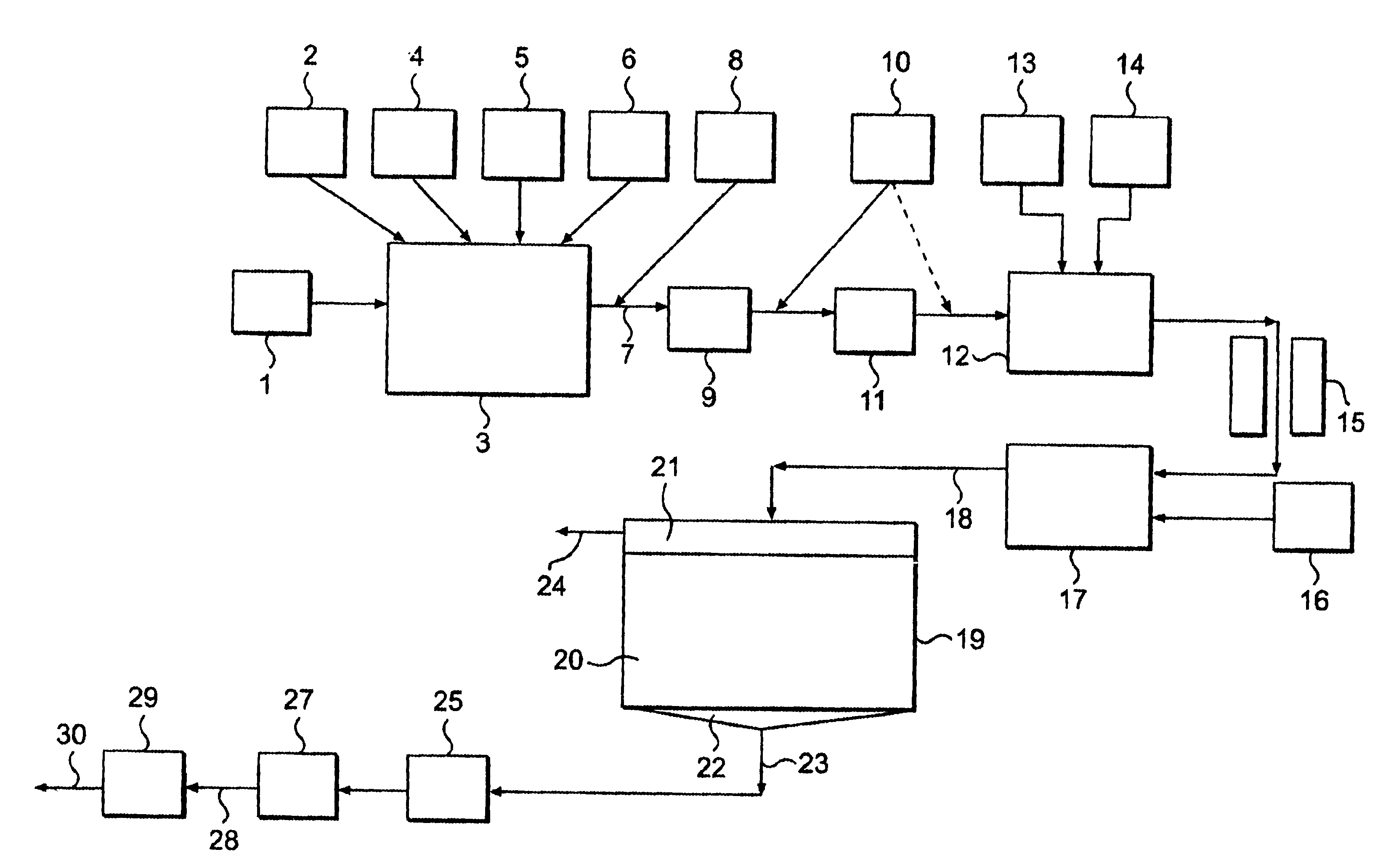

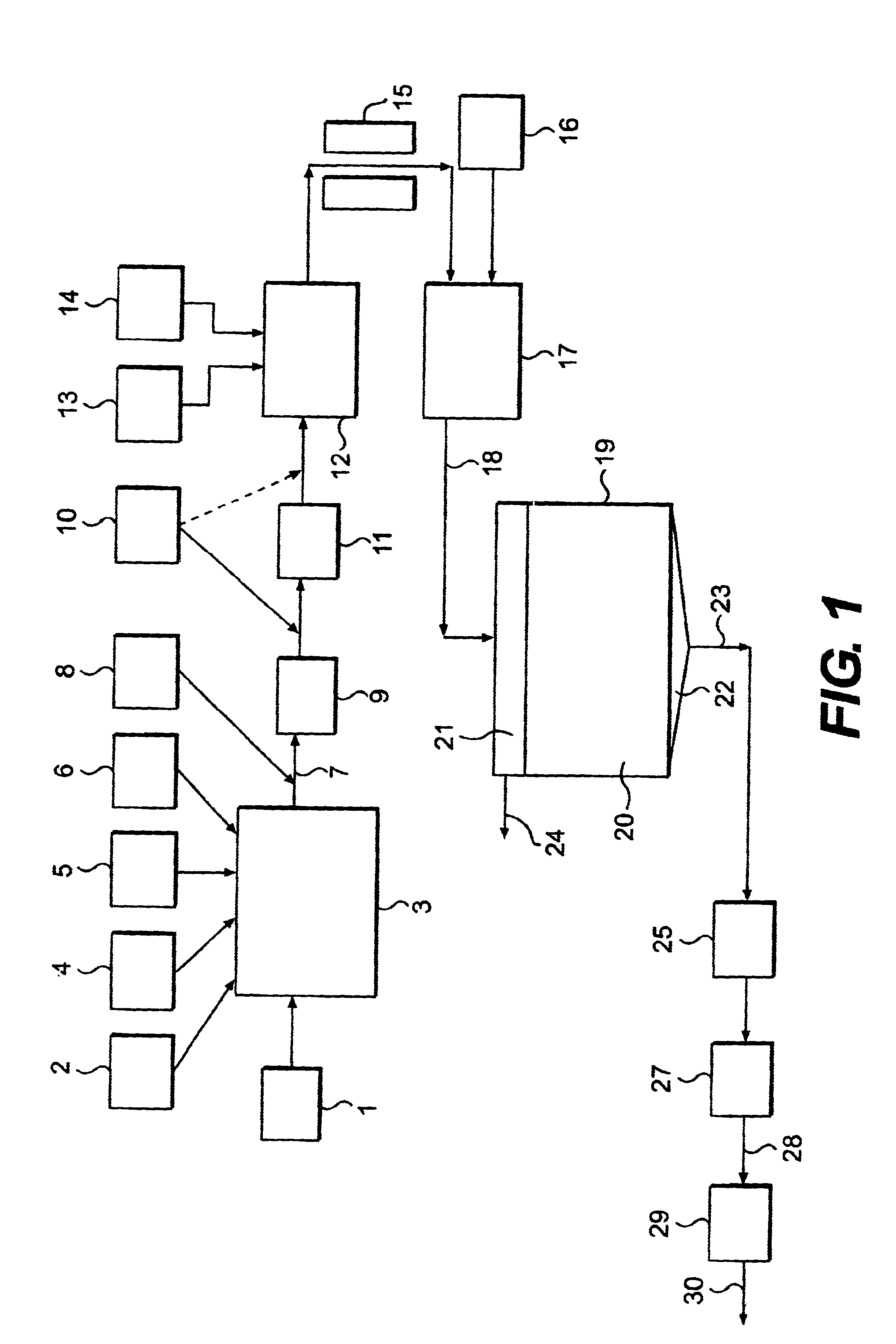

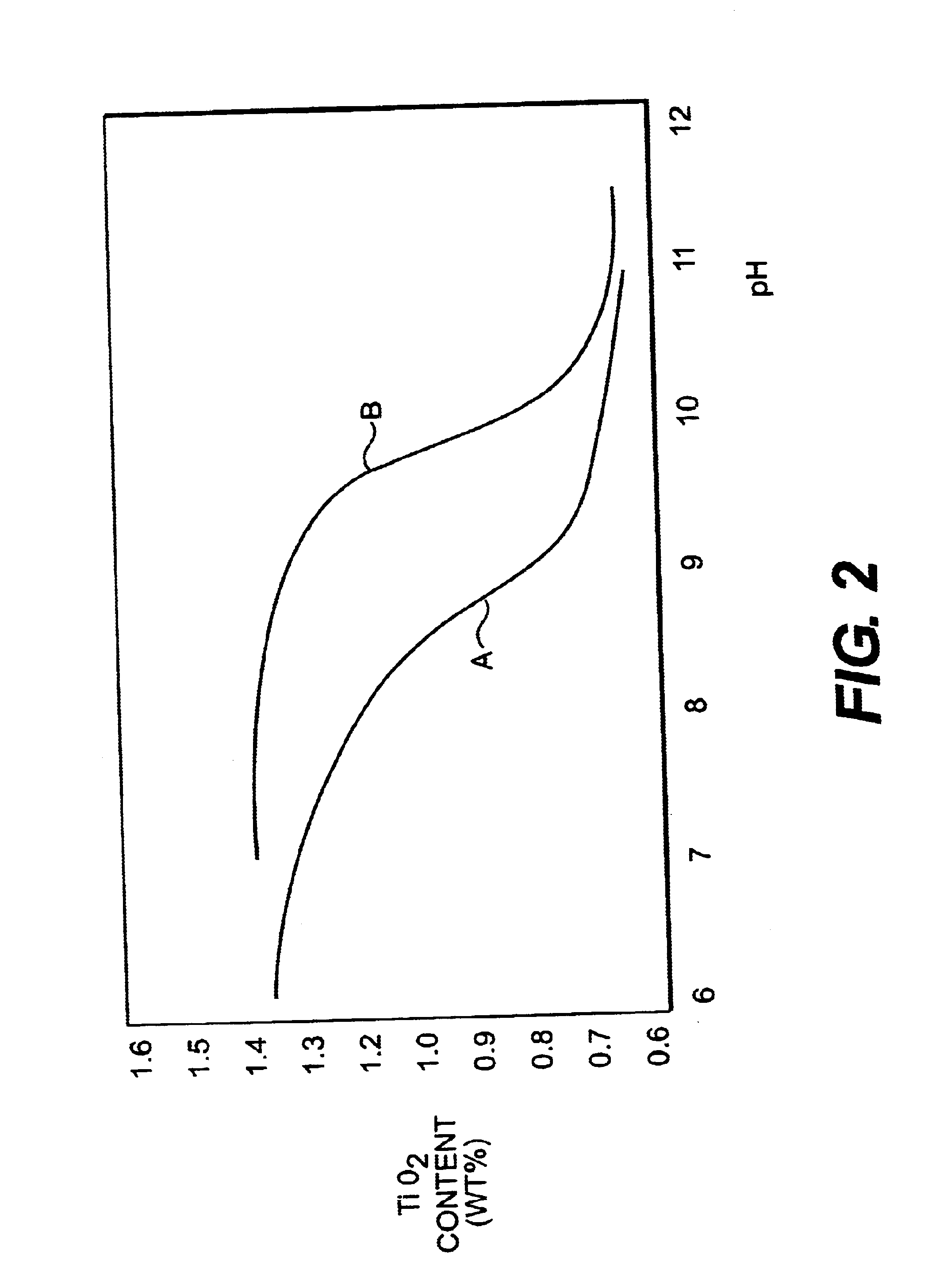

Method of treating an aqueous suspension of kaolin

InactiveUS6615987B1Improve effectivenessImproves floc formationPigmenting treatmentSedimentation separationFlocculationSolid particle

A method of treating a kaolin particulate material to improve its properties by removal of impurities which includes the steps of:(a) producing a dispersed aqueous suspension of a kaolin particulate material containing at least 0.1% by weight, based on the dry weight of the kaolin particulate material, of separable impurity by adding a dispersing agent to the kaolin particulate material to deflocculate solid particles of the material in the suspension;(b) conditioning the suspension prior to adding selective flocculation polymer thereto by allowing the suspension to age for a period of at least 30 minutes and optionally by adding one or more conditioning chemicals thereto;(c) adjusting the pH of the suspension to be at least about 9.5;(d) adding to the suspension at a pH of at least about 9.5 a selective flocculation polymer which facilitates separation of the separable impurity from the kaolin by flocculating the kaolin and allowing the separable impurity to be or remain deflocculated;(e) allowing the suspension at a pH of at least about 9.5 in a selective flocculation separator to separate into layers comprising a flocculated product layer and a deflocculated impurity layer containing the separable impurity; and(f) extracting the separated layers from the separator.

Owner:IMERYS USA INC

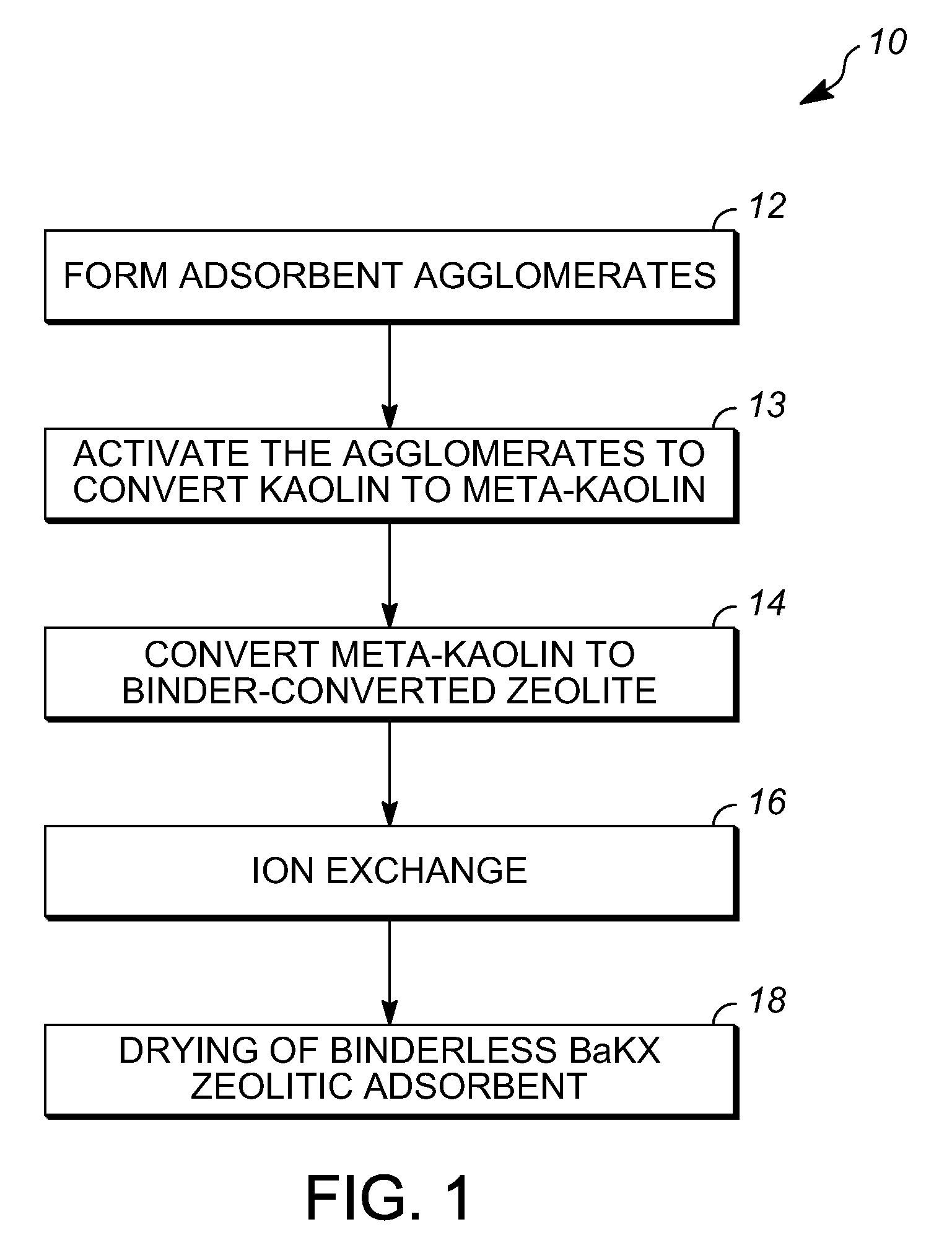

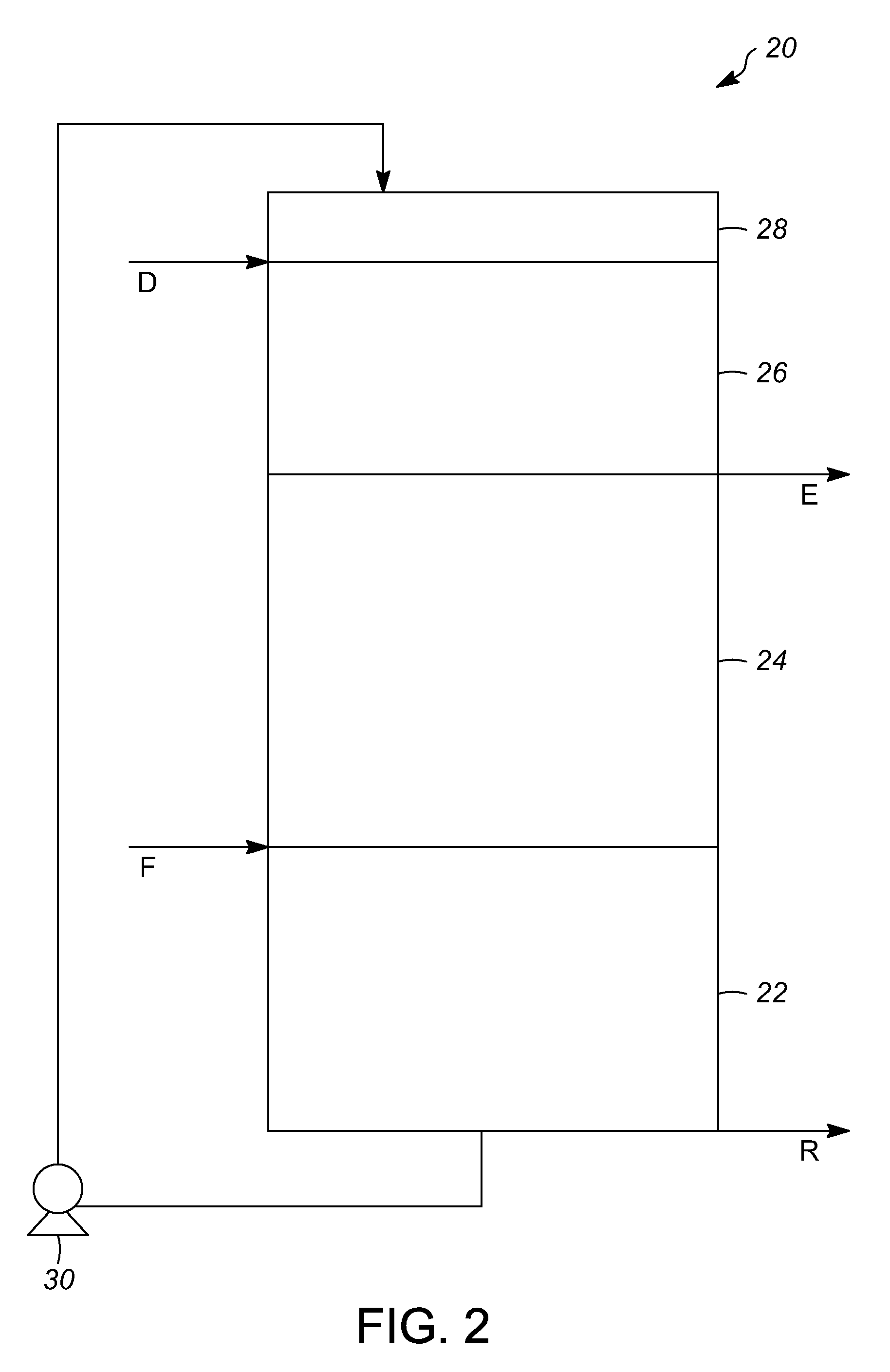

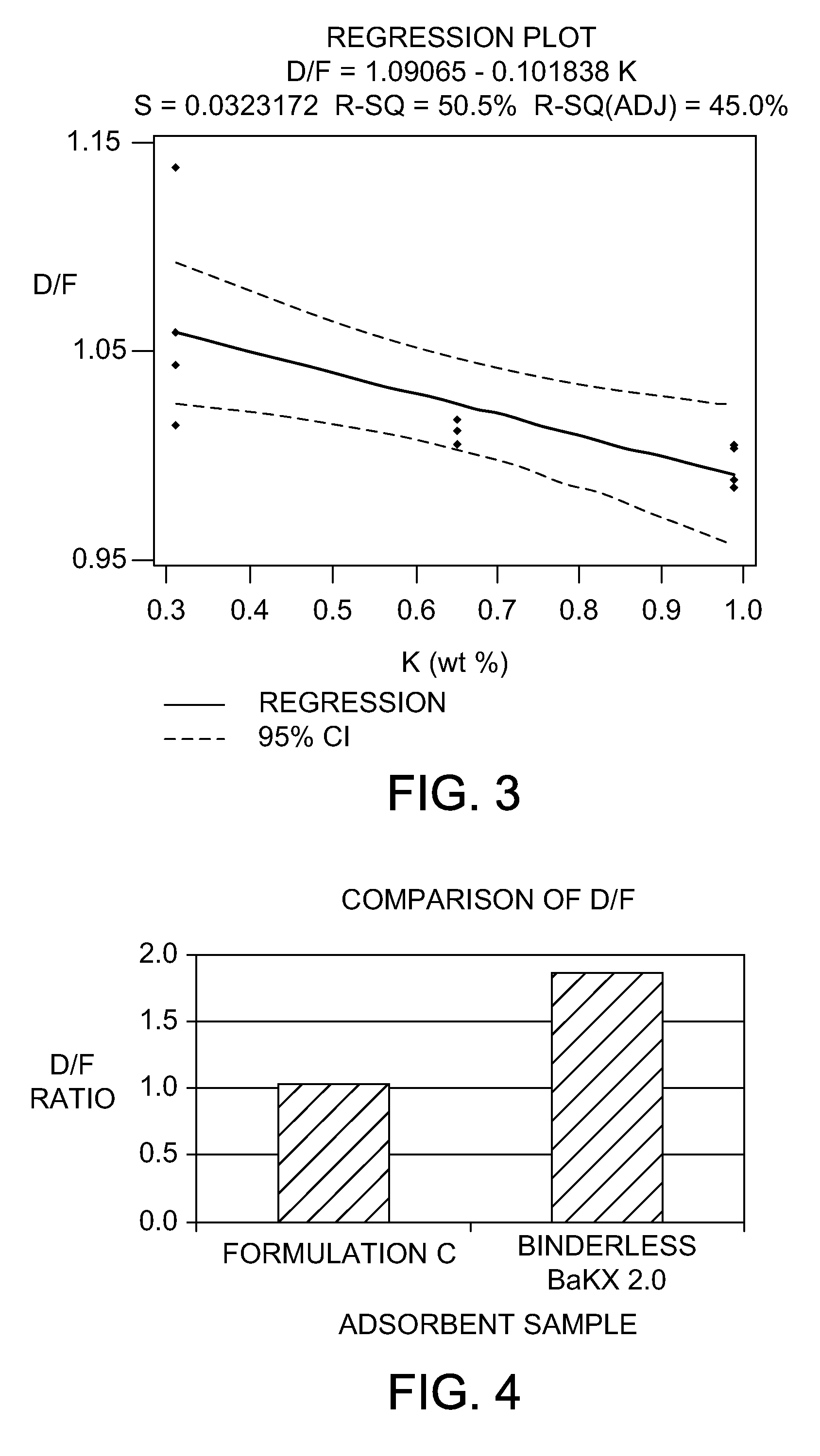

Binderless zeolitic adsorbents, methods for producing binderless zeolitic adsorbents, and processes for adsorptive separation of para-xylene from mixed xylenes using the binderless zeolitic adsorbents

Binderless BaKX zeolitic adsorbents, methods for their production, and processes for their use in a liquid phase adsorptive separation process are provided. An adsorbent includes a binder-converted zeolite portion formed from x wt % kaolin clay binder and (100-x) wt % unconverted Zeolite X with a silica:alumina molar ratio of about 2.5. The kaolin clay binder is in the range of about 10 to about 20 wt %. Ba and K occupy cationic exchangeable sites within the adsorbent. K is in the range of about 0.25 to about 0.9% by weight and Ba is greater than about 31.6% by weight of the binderless BaKX zeolitic adsorbent. Cornstarch may be added to the Zeolite X and kaolin clay binder to increase adsorbent macro-porosity and pore volume. Productivity of the adsorbent is improved decreasing process operating costs. The mechanical strength of the adsorbent is also improved.

Owner:UOP LLC

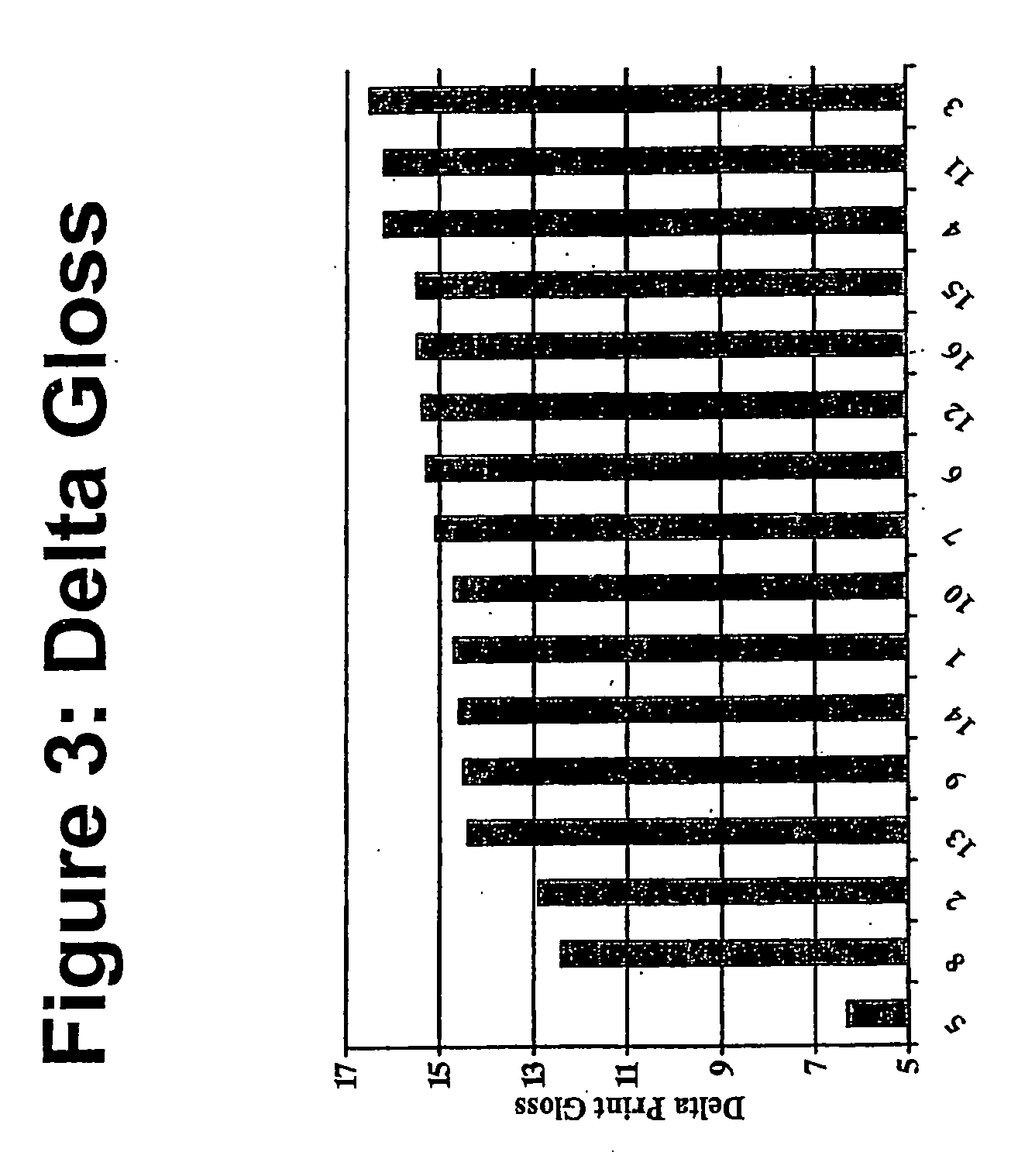

Paper coating pigments

InactiveUS20060292305A1Increase steepnessImprove smoothnessCalcium/strontium/barium carbonatesPigmenting treatmentParticulatesPrecipitated calcium carbonate

The present disclosure relates to a coating composition for use in producing a coating on paper and other substrates comprising an aqueous suspension of a particulate pigment together with a binder, wherein the particulate pigment comprises a mixture of: a first pigment component comprising particulate ground calcium carbonate (GCC) having a particle size distribution (psd) steepness factor ranging from about 30 to about 45; and a second pigment component comprising particulate precipitated calcium carbonate (PCC) having a psd steepness factor ranging from about 55 to about 75. The particulate pigment may optionally further include a particulate kaolin clay.

Owner:IMERYS PIGMENTS INC

Stabilized dual zeolite single particle catalyst composition and a process thereof

InactiveUS20030166453A1Good hydrothermal stabilityImprove stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveKaolin clay

The present invention relates to a stabilized dual zeolite catalyst for cracking heavier hydrocarbons into lighter useful products said catalyst comprising two types of zeolites viz., low silica molecular sieve and stabilized high silica zeolite, silica-alumina based binder and kaolin clay and a process for the preparation of the stabilized dual zeolite catalyst.

Owner:INDIAN OIL CORPORATION

Polyolefin and Ceramic Battery Separator for Non-Aqueous Battery Applications

InactiveUS20110171523A1Improve heat resistanceImprove carrying capacityCell component detailsVehicular energy storagePolyolefinPolymer science

A ceramic microporous polyolefin battery separator membrane, high in air permeability, low in shrinkage and improved temperature resistance addresses the safety requirements of lithium ion batteries. The separators made by the current invention consists of one or more polyolefin polymers and kaolin fillers comprised of aluminum oxide and silicon oxide. The membranes of current invention have a thickness of 5-200 microns, air permeability of 1-200 sec / 10 cc (Gurley seconds), and average pore diameter of less than 1 micron.

Owner:ADVANCED MEMBRANE SYST INC

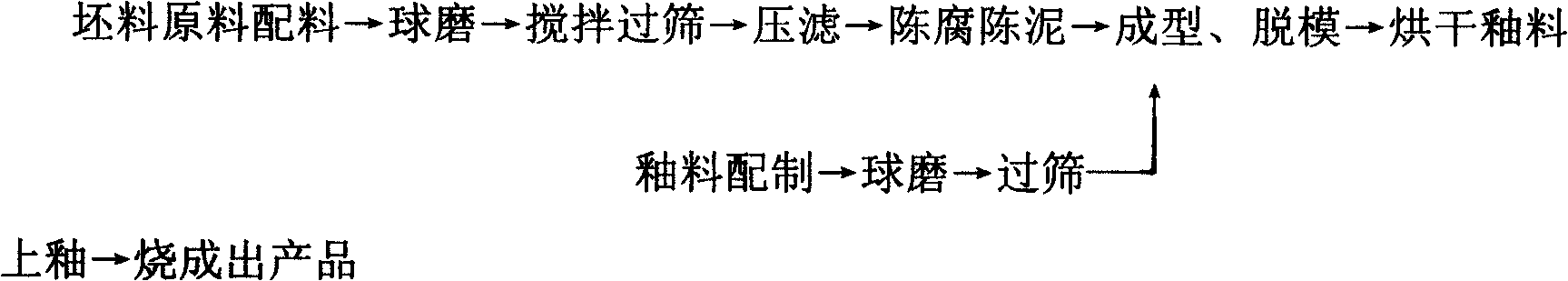

Production method of once-fired super-spar ceramic tile and ceramic tile

The invention relates to a production method of once-fired super-spar ceramic tile and the ceramic tile. The production method of the once-fired super-spar ceramic tile comprises the following steps: preparing green body powder; pressing a tile body; cleaning the green body; pouring ground glaze; printing; pouring overglaze; firing a glaze body at a high temperature; polishing; performing surface treatment; performing edge polishing; and packaging to obtain a finished product, wherein the overglaze comprises the following components in parts by weight: 5 to 13 parts of quartz powder, 3 to 20 parts of potassium feldspar, 20 to 28 parts of soda feldspar, 12 to 18 parts of dolomite, 3 to 6 parts of fired talc, 3 to 8 parts of kaolin, 14 to 22 parts of calcined kaolin, 3 to 8 parts of zinc oxide, 7 to 14 parts of barium carbonate and 3 to 6 parts of grammite. According to the invention, the problems that microlite has low wear resistance and is difficult to process in the prior art are solved, and the defect of water ripples caused by the situations that fully-polished glaze absorbs dirt, bottom is easy to expose and the tile surface is uneven is also solved. The super-spar product produced with the method has the advantages that the microlite is transparent, bright and smooth like a mirror and does not absorb dirt completely; and the fully-polished glaze is light, thin and wear-resistant.

Owner:周予

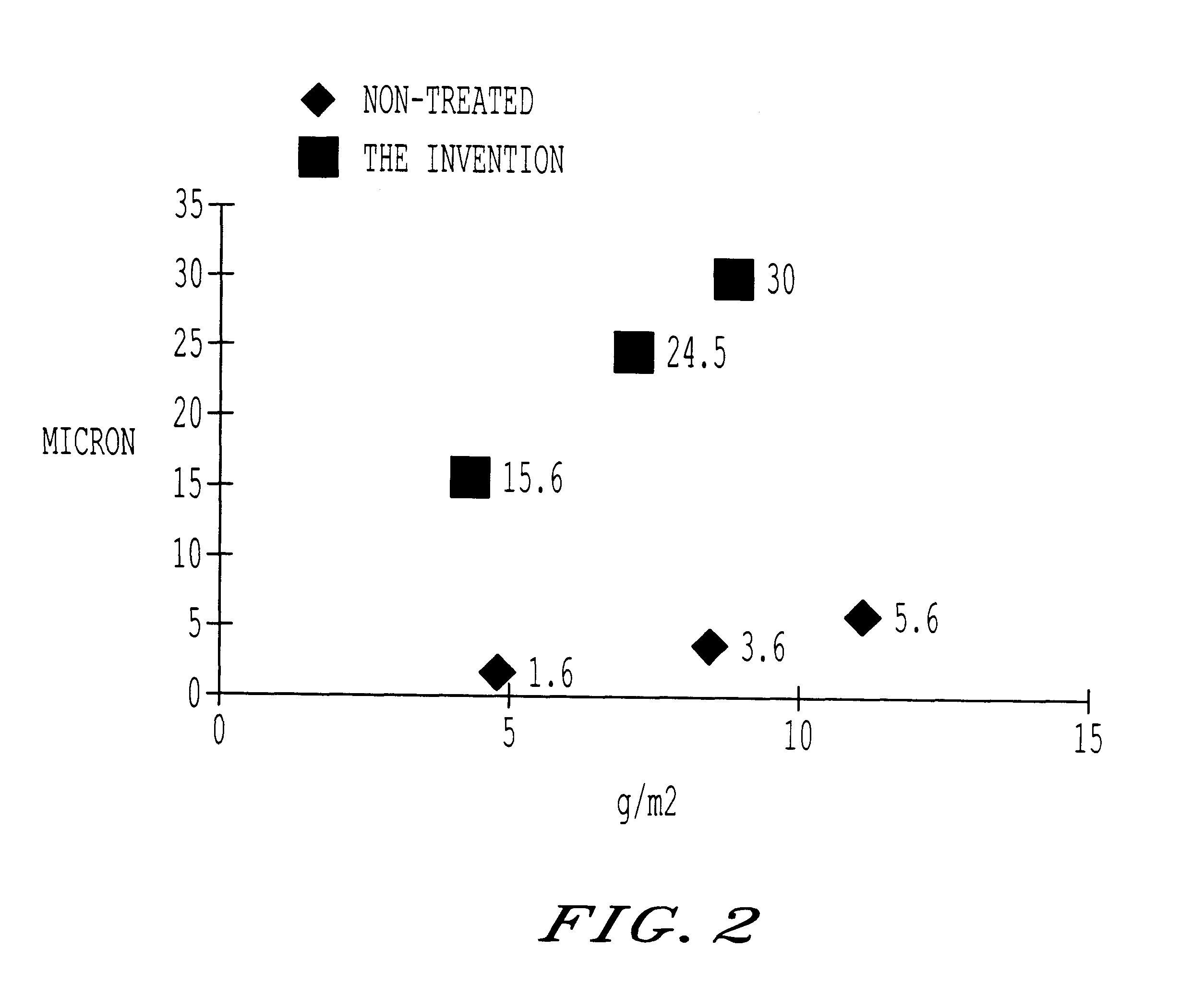

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

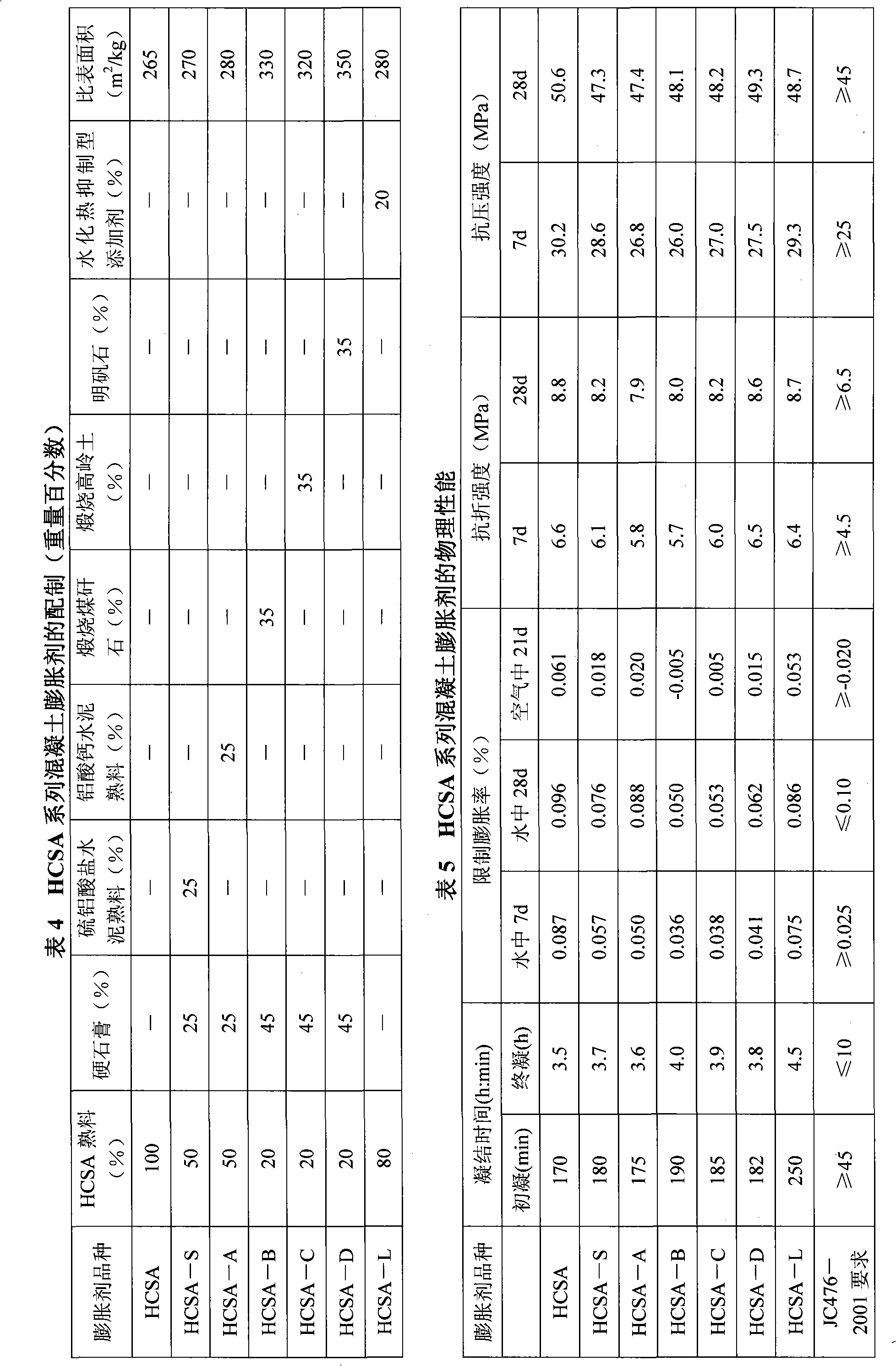

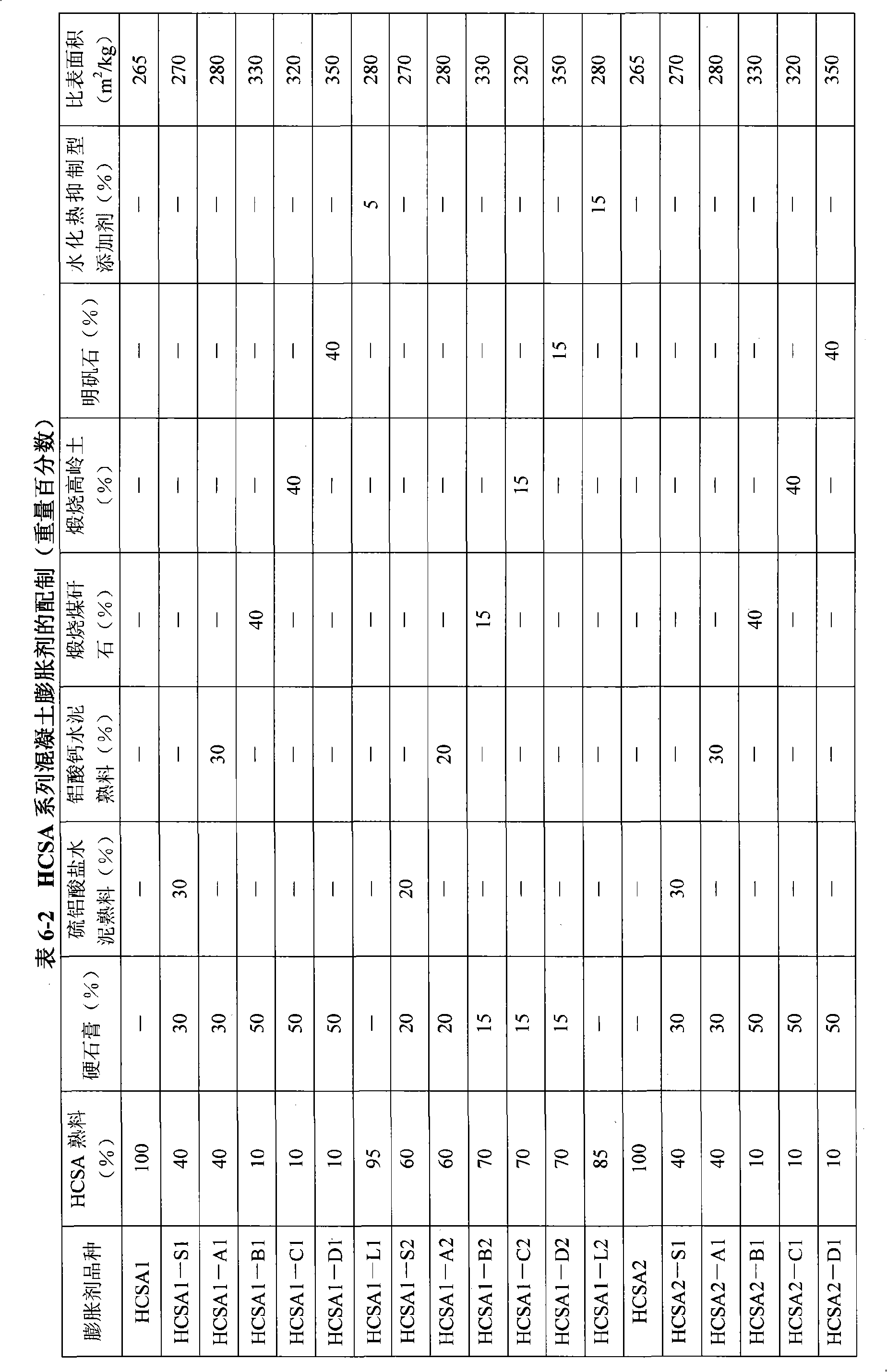

High performance expansible cement clinker expansion agent series prepared thereby

Disclosed are a high-performance expansion cement clinker, a manufacturing method of the cement clinker, a series concrete expansion agent and a manufacturing method of the concrete expansion agent. The high-performance expansion cement clinker is made as follows: firstly, 50-90 wt% of limestone, 1-20 wt% of bauxite, 5-30 wt% of gypsum and 1-5 wt% of iron powder are grinded together into raw meal, then the raw meal is calcined at 1250-1400 DEG C in a rotary kiln, a tunnel kiln or a roller kiln to get the cement clinker. The cement clinker is milled alone or in combination with sulfur calcium aluminate cement clinker, calcium aluminate cement clinker, anhydrite, calcined gangue, alunite, calcined kaolin and hydration heat inhibiting additives until the specific surface area reaches 200-400m2 / kg, so as to get the series concrete expansion agent. The high-performance expansion cement clinker disclosed in the invention is calcium hydroxide-hydrated calcium aluminate sulfate double-expansion source expansion clinker, which is fast in expansion rate and high in expansion efficiency and uses less bauxite of scarce resources; besides, the calcination temperature is low to avoid calcium oxide dead burning, so the preparation is safe and reliable.

Owner:CHINA BUILDING MATERIALS ACAD

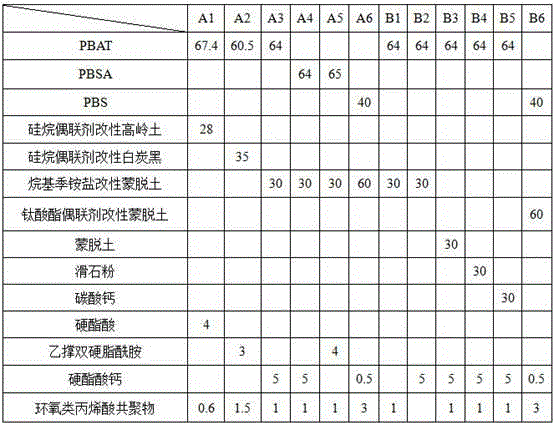

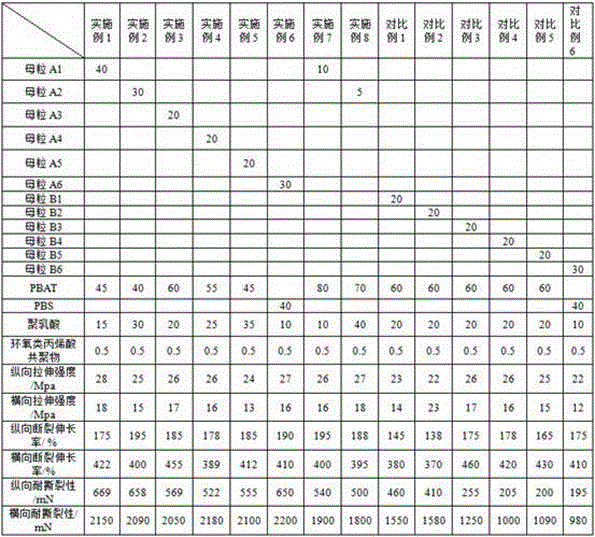

Full-biodegradable composite as well as preparation method and application of full-biodegradable composite

The invention discloses a full-biodegradable composite as well as a preparation method and application of the full-biodegradable composite. The full-biodegradable composite comprises the following components: 5-40 parts of inorganic filler full-biodegradable masterbatches, 40-80 parts of biodegradable copolyester, 10-40 parts of polylactic acid and 0.1-5 parts of a compatilizer, wherein the inorganic filler full-biodegradable masterbatches comprise the following components: 20-80 parts of the biodegradable copolyester, 20-80 parts of inorganic filler, 0.1-10 parts of a lubricating agent and 0.1-5 parts of the compatilizer; and the inorganic filler is one or a combination of modified kaolin, modified white carbon black and modified montmorillonite. According to the full-biodegradable composite, the modified montmorillonite, the modified kaolin or the modified white carbon black is added as an enhancer, and an epoxy acrylic copolymer is introduced as the compatilizer, so that the compatibility of inorganic filler and matrix resin is enhanced, and the uniform dispersion is achieved; and the masterbatches are added into the matrix resin, so that the problem of relatively low tearing strength of a blend film and a sheet can be effectively improved.

Owner:KINGFA SCI & TECH CO LTD +1

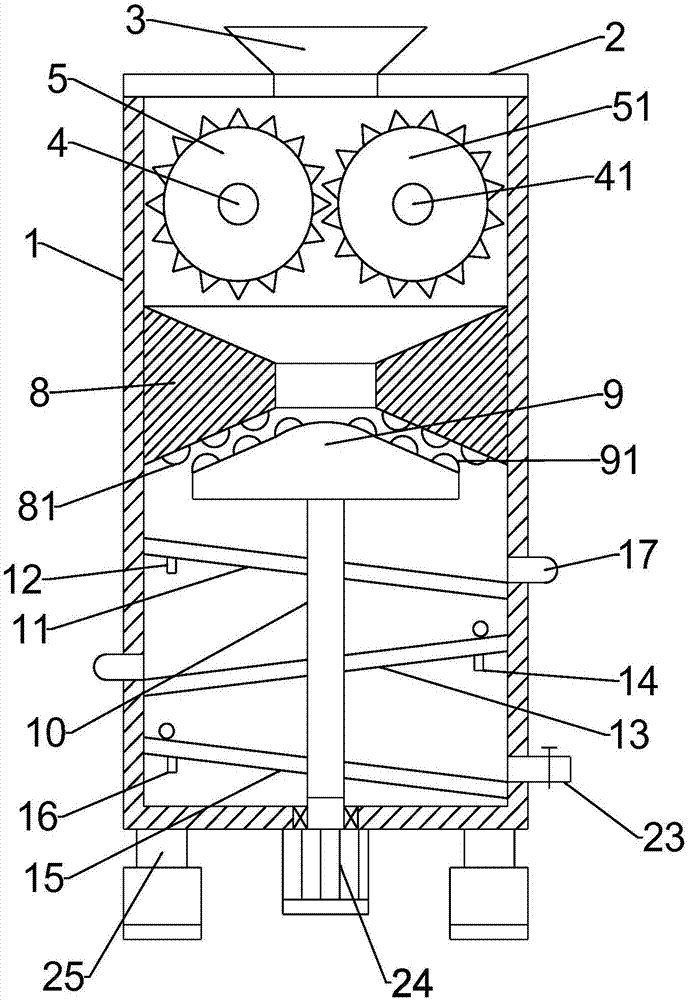

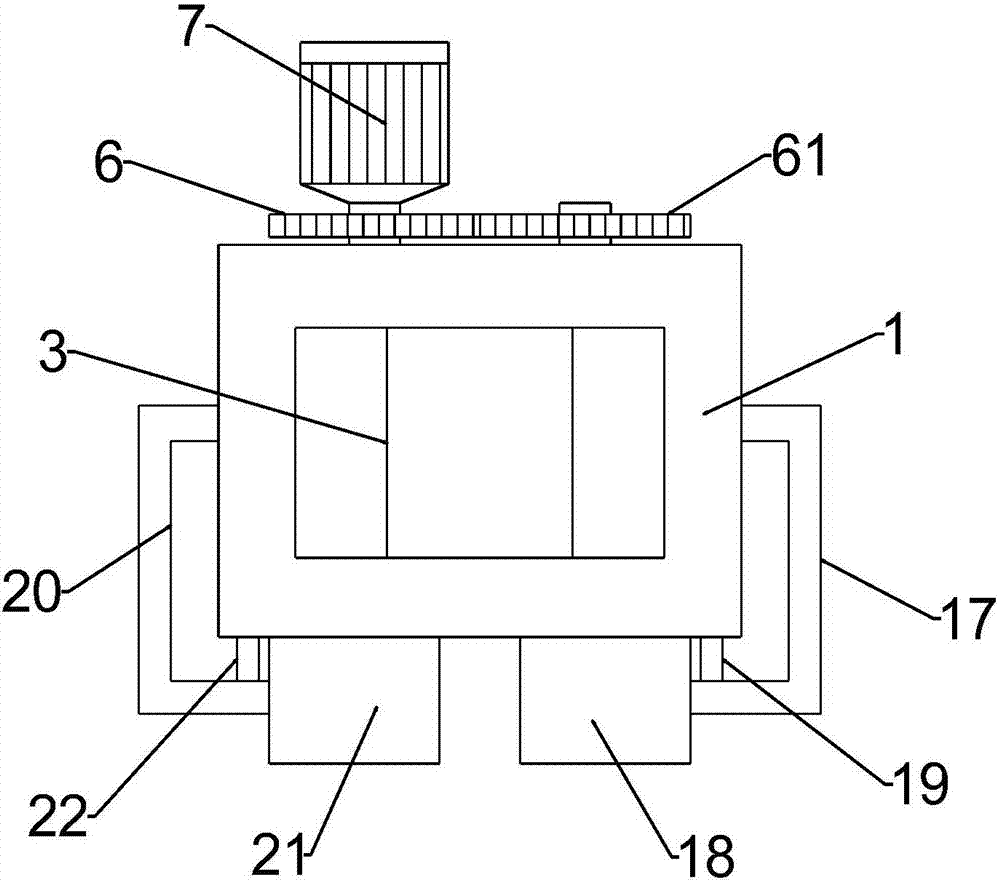

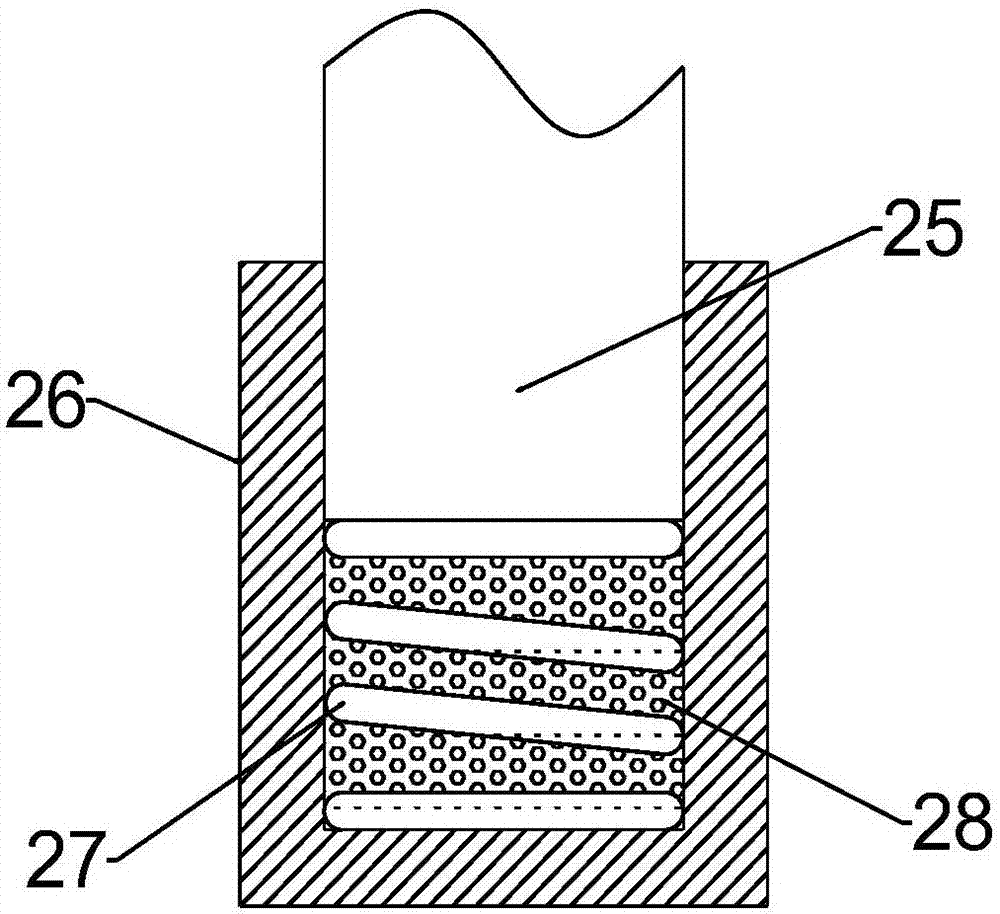

Smashing, classifying and separating device for kaolin raw ore

InactiveCN107309020AAvoid accidental adulterationStable design structureSievingScreeningGear wheelKaolin clay

The invention discloses a crushing, grading and separating device for kaolin raw ore, which comprises a casing, the upper end of the casing is provided with an upper cover, the middle part of the upper cover is provided with a feeding hopper, and the casing is provided with a left rotating shaft, a right rotating shaft, and a left crushing wheel. , right crushing wheel, concentrated guide plate, fixed grinding protrusion, grinding disc, rotating protrusion, vertical shaft, primary screen filter, first vibration motor, fine screen filter, second vibration motor, tailing deflector, The third vibrating motor is provided with a driving gear and a driven gear on the periphery of the left and right shafts, a first motor is provided at the end of the left shaft, and the right wall of the housing is provided with a primary sieve discharge pipe, a primary sieve collection box, a first return pipe and The tailings discharge pipe, the left wall of the shell is provided with a fine sieve discharge pipe, a fine sieve collection box and a second return pipe, and the lower end of the shell is riveted with a second motor, a support rod, a support sleeve, a damping spring and a shock absorber filling. The invention can efficiently grind and pulverize the kaolin and sieve and classify it.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

Non-glue diatom ooze building material

The invention discloses non-glue diatom ooze building material, which is used for wall decoration, surface dressing of boards and intermediate sandwich of the boards, and comprises the following components in parts by weight: 4-90 parts of kieselguhr below 10000 mesh, 20-60 parts of bentonite below 2000 mesh, 10-40 parts of kaolin below 2000 mesh, 5-30 parts of activated clay below 2000 mesh, 10-60 parts of quartz sand below 200 mesh, 5-40 parts of sepiolite below 800 mesh, 5-40 parts of calcium carbonate below 800 mesh, 5-30 parts of medical stone powder below 800 mesh, 2-20 parts of nanosized titania powder below 20000 mesh, 0.1-3 parts of fiber with the length being 5mm or below, 4.5-40 parts of attapulgite below 800 mesh, 2-20 parts of hydroxypropyl methyl cellulose, and 1-20 parts ofpigment. According to the non-glue diatom ooze building material, the kieselguhr and other porous natural materials with adsorption capacity are selected to manufacture interior building materials, the proportion is reasonable, chemical adhesive agents are not needed, and adhesive forming is realized through characteristics of the natural materials, so that porous structures of the natural materials can be maintained, indoor pollution can be eliminated, indoor humidity can be adjusted, odor can be removed, noise can be isolated, and flame retardant is realized.

Owner:青岛泉佳美硅藻泥科技有限公司

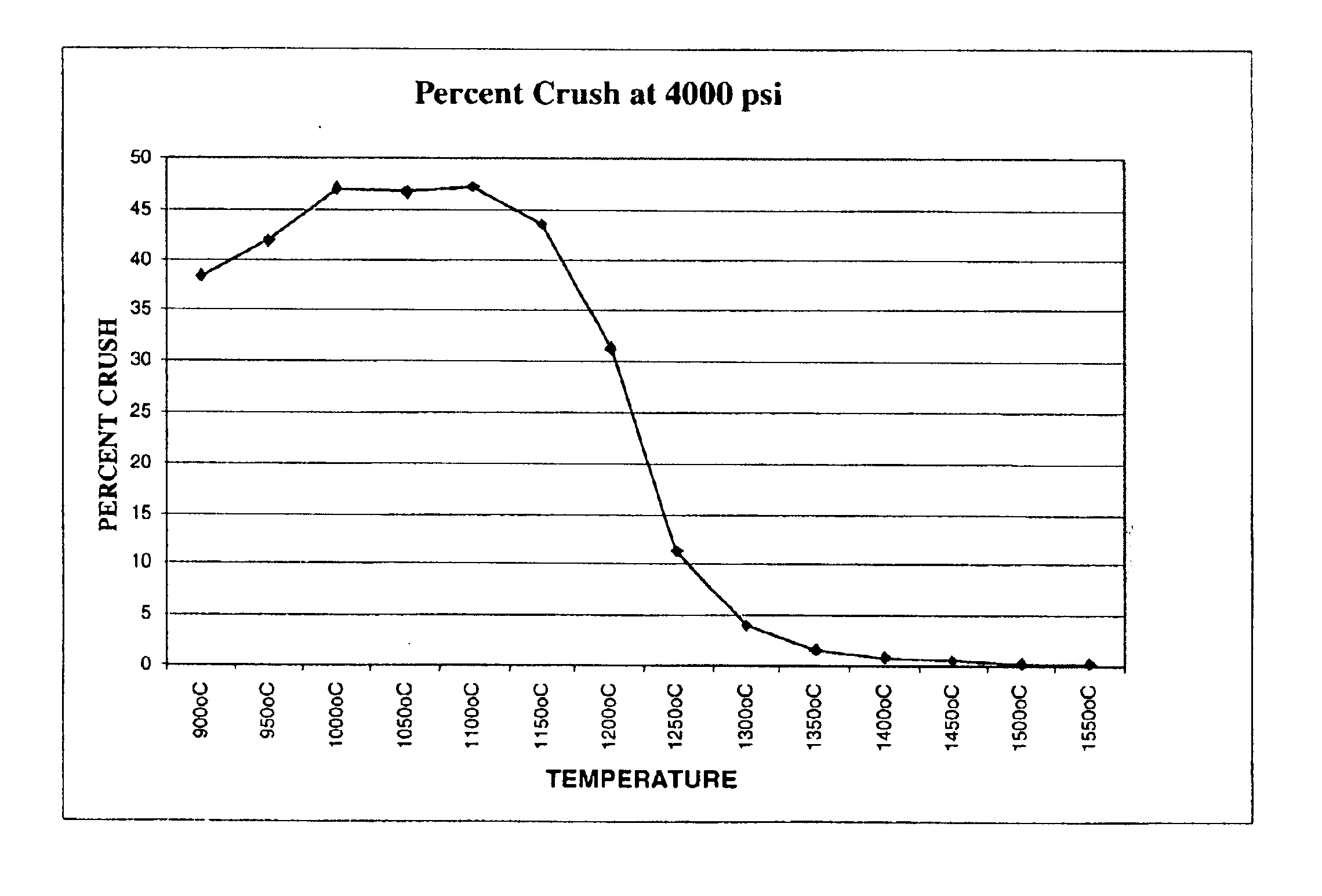

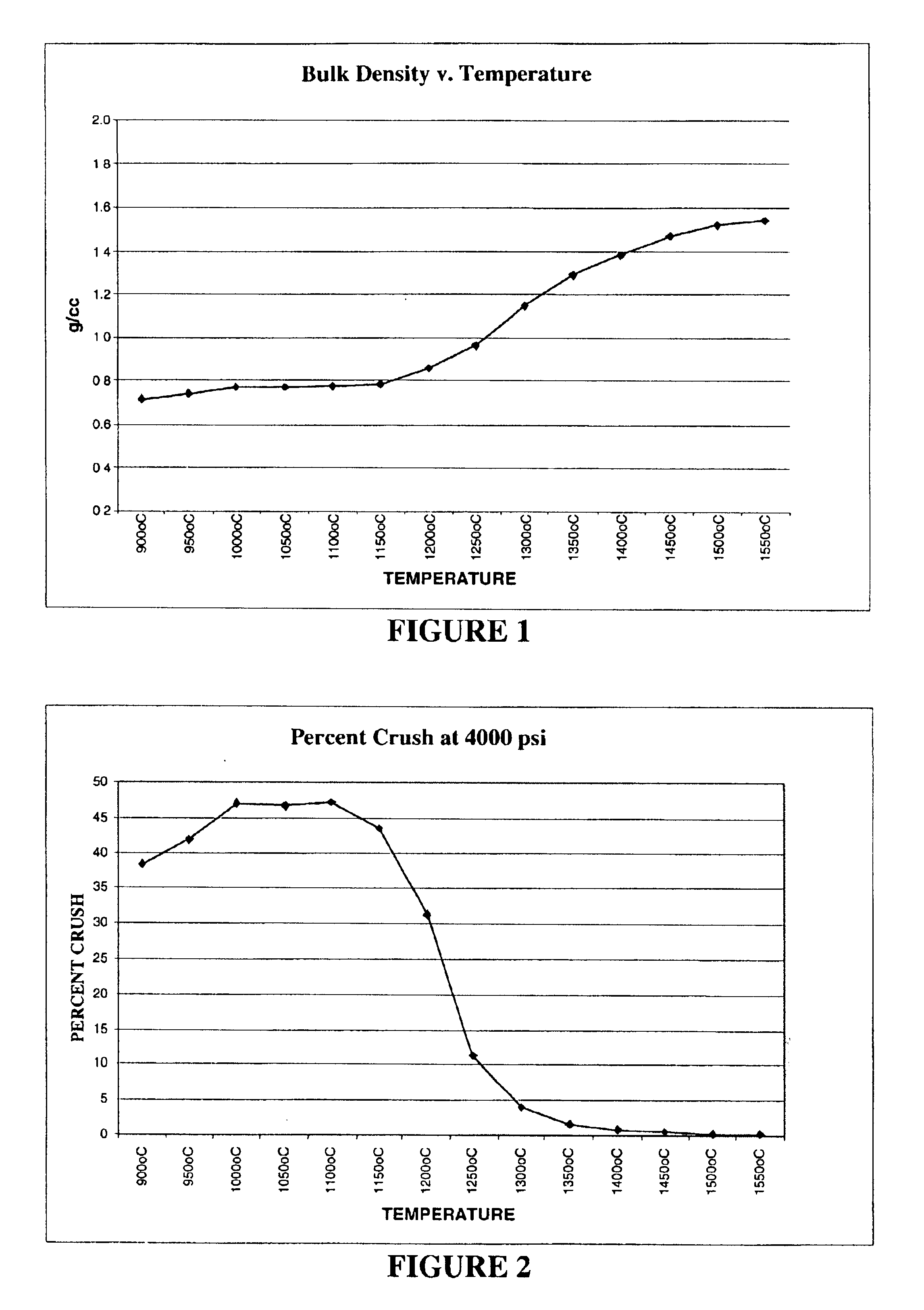

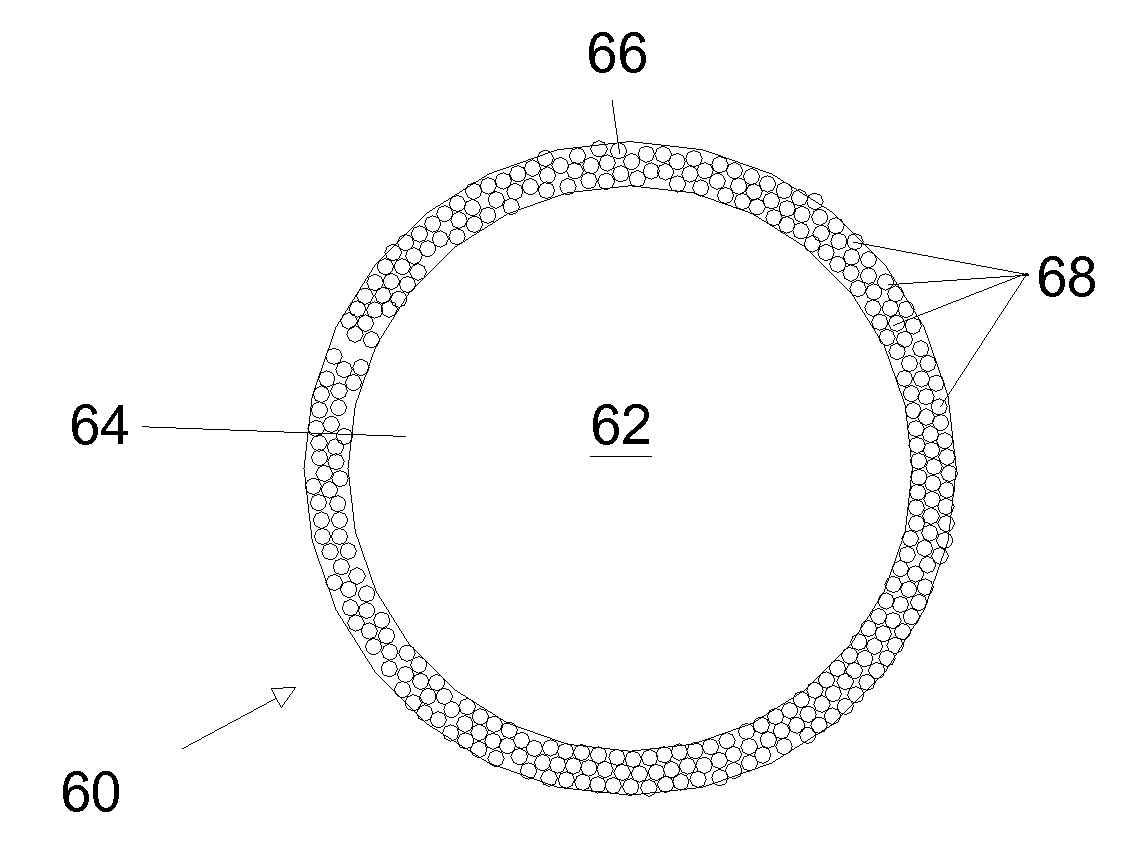

Low density proppant

A low density, spherical proppant made from kaolin clay having an alumina content distributed homogeneously throughout the pellets, an apparent specific gravity of from about 1.60 to about 2.10 g / cc, and a bulk density of from about 0.95 to about 1.30 g / cc. The low density is achieved by controlling the time and temperature of the firing process to be from about 1200 to about 1350° C. This low density proppant is useful in hydraulic fracturing of shallow oil and gas wells.

Owner:CARBO CERAMICS

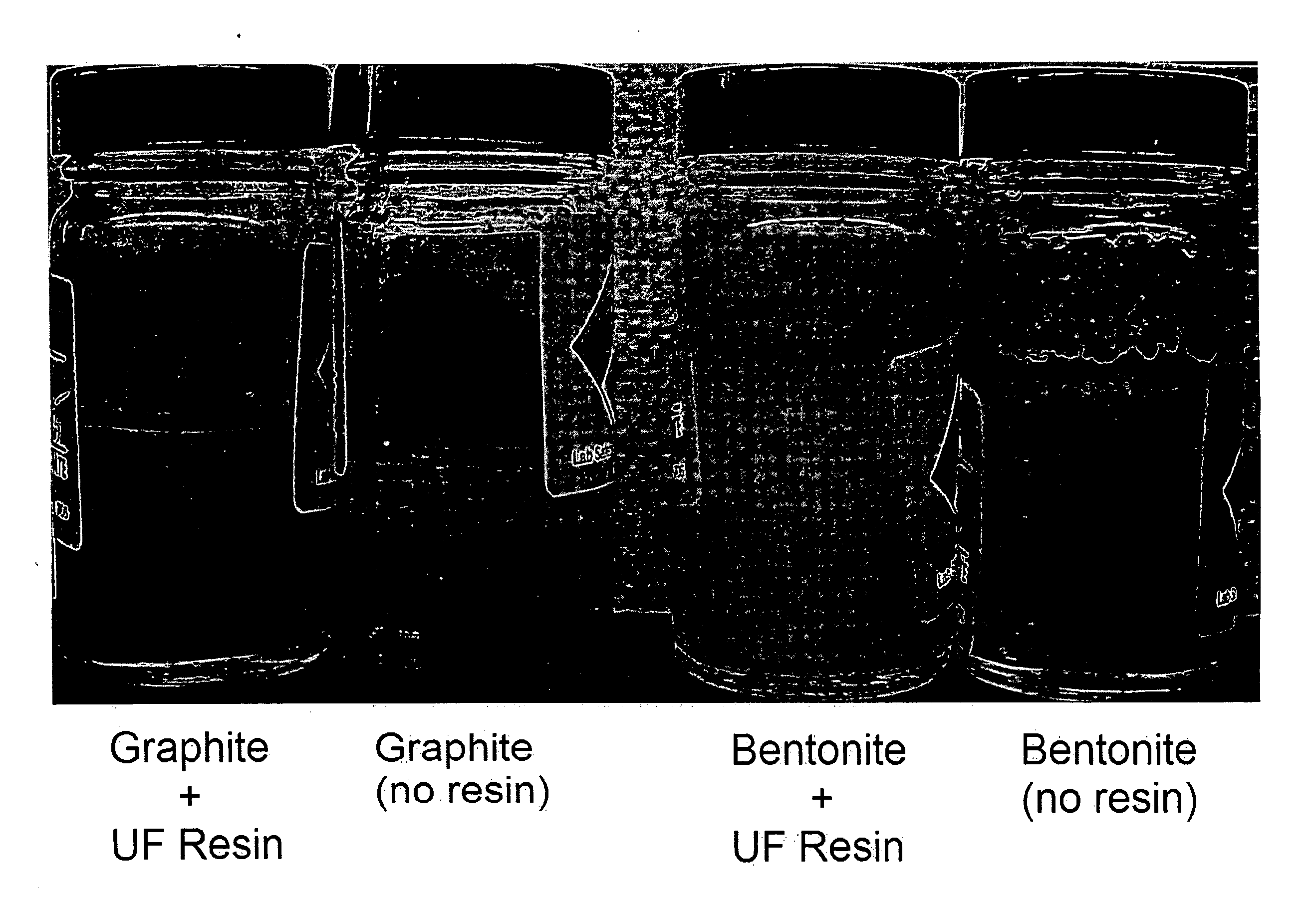

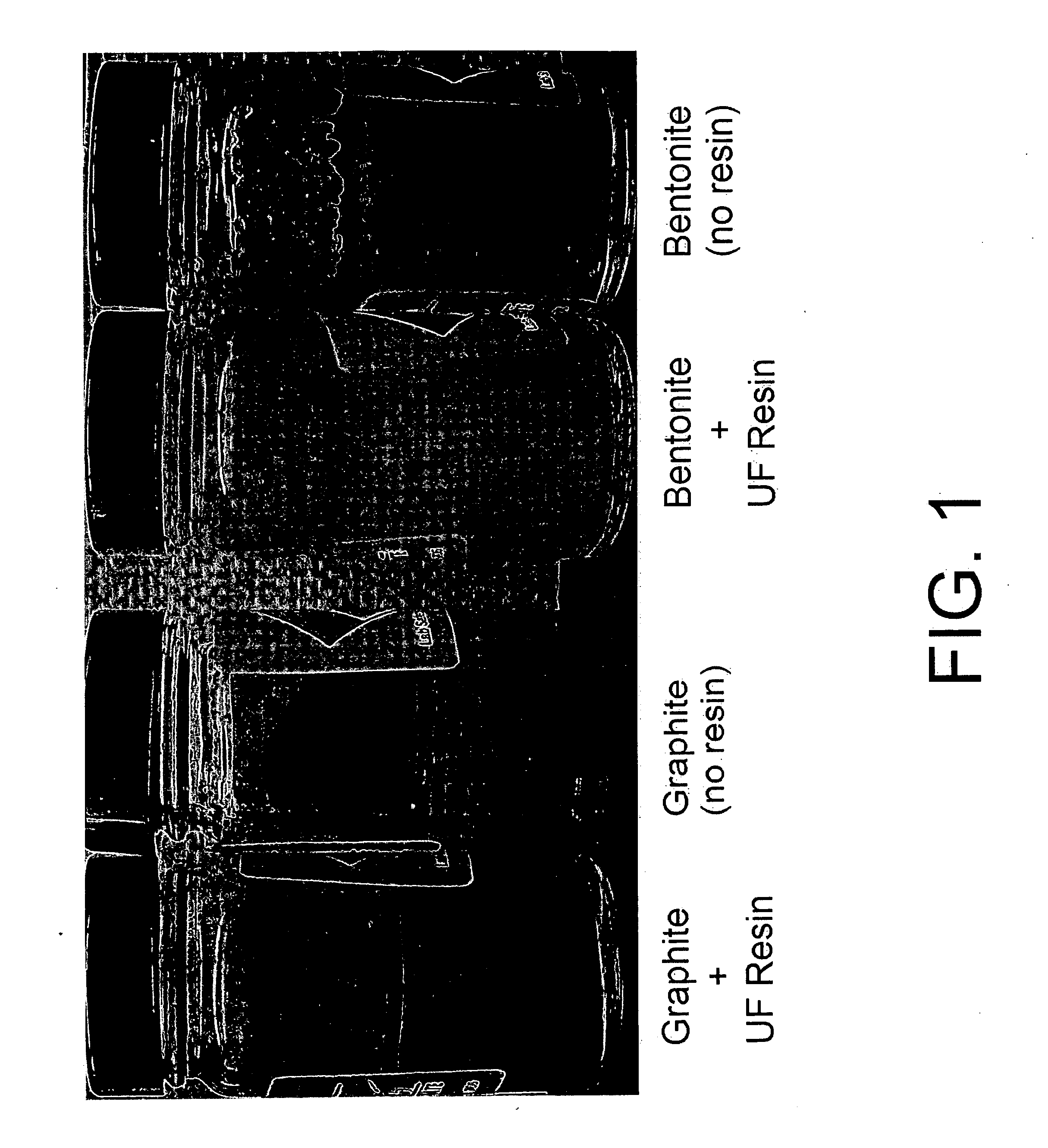

Amine-aldehyde resins and uses thereof in separation processes

InactiveUS20060151397A1Highly versatileEffective isolationWaste water treatment from quariesWaste water treatment from ceramic industriesParticulatesKaolin clay

Amine-aldehyde resins are disclosed for removing a wide variety of solids and / or ionic species from the liquids in which they are suspended and / or dissolved. These resins are especially useful as froth flotation depressants in the separation of bitumen from sand and / or clay or in the beneficiation of clay (e.g., kaolin clay) from an impure clay-containing ore. The resins are also useful for treating aqueous liquid suspensions to remove solid particulates, as well as for removing metallic ions in the purification of water.

Owner:INGEVITY SOUTH CAROLINA

Amine-aldehyde resins and uses thereof in separation processes

InactiveUS20080029460A1Highly versatileHigh selectivitySpecific water treatment objectivesWater contaminantsParticulatesKaolin clay

Amine-aldehyde resins are disclosed for removing a wide variety of solids and / or ionic species from the liquids in which they are suspended and / or dissolved. These resins are especially useful as froth flotation depressants, for example in the beneficiation of value materials (e.g., bitumen, coal, or kaolin clay) to remove impurities such as sand. The resins are also useful for treating aqueous liquid suspensions to remove solid particulates, as well as for removing metallic ions in the purification of water.

Owner:INGEVITY SOUTH CAROLINA

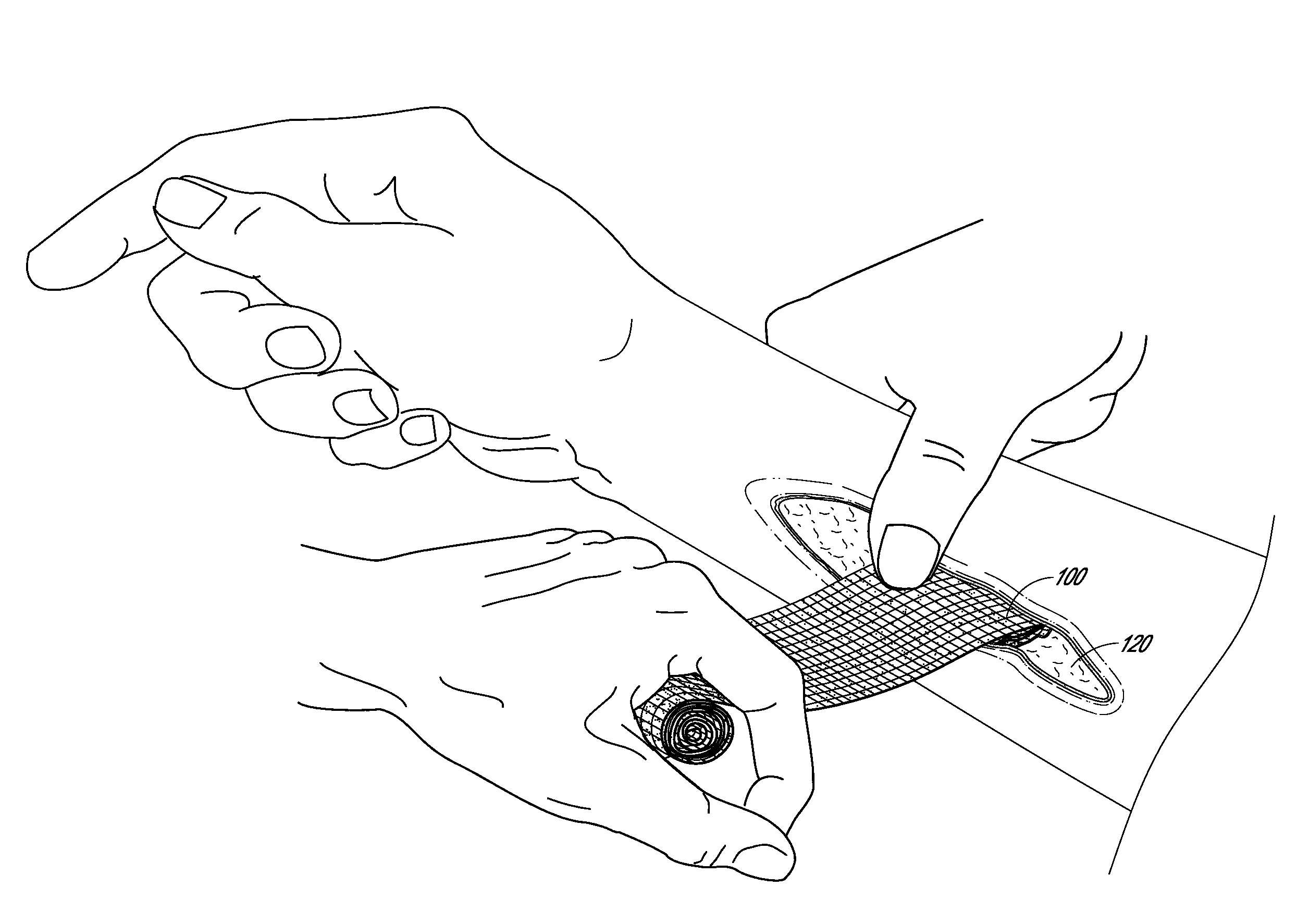

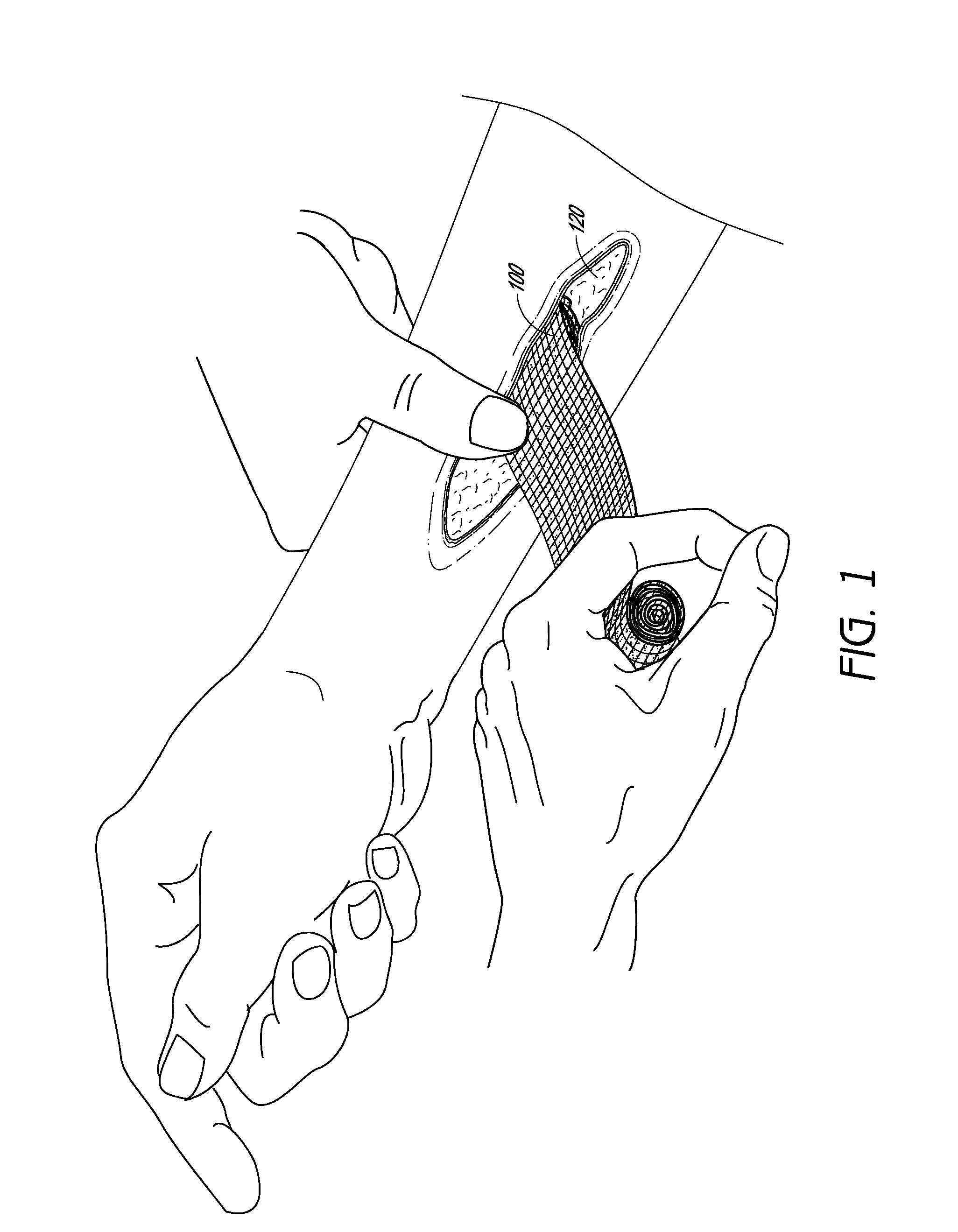

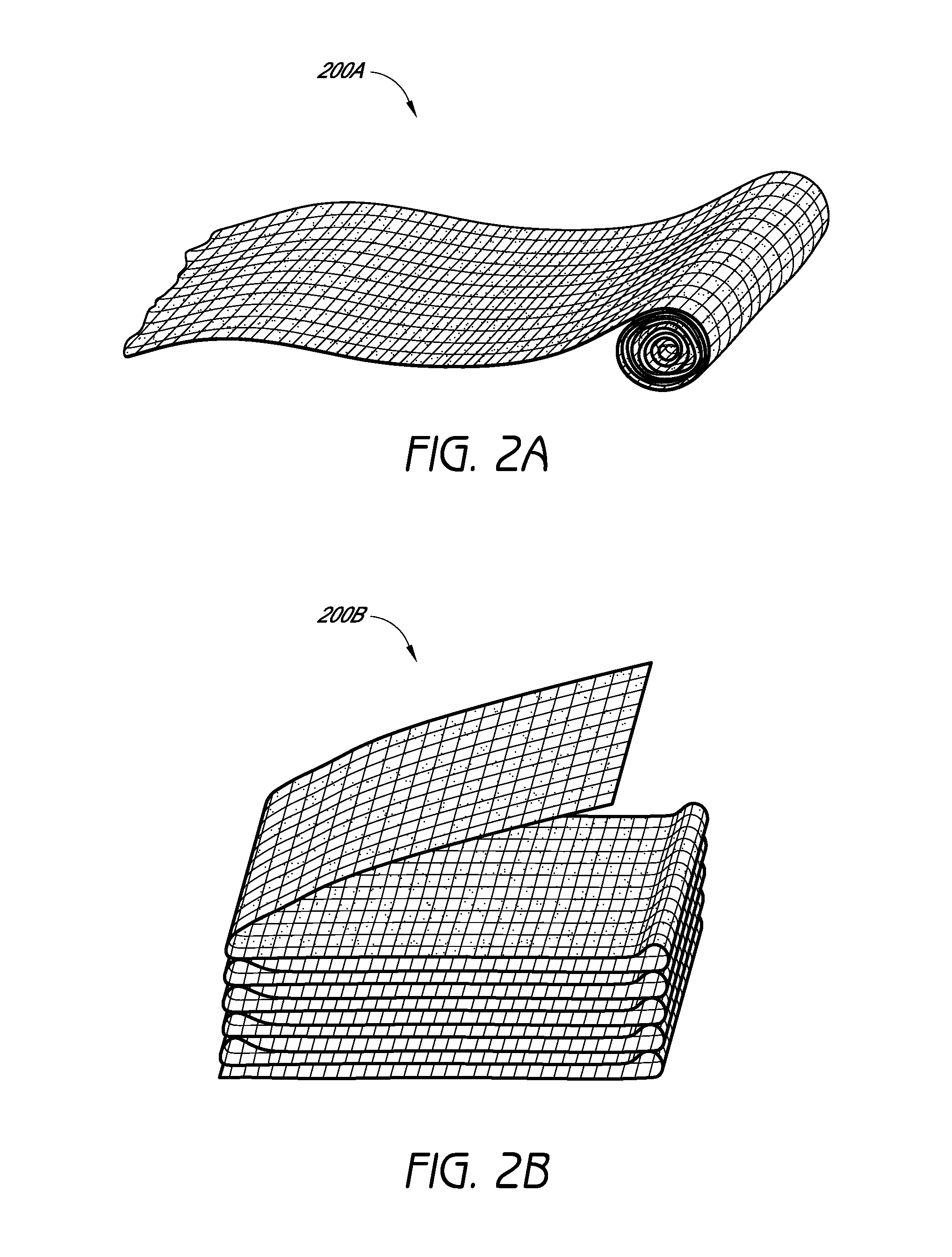

Hemostatic devices

ActiveUS20130344131A1Reduce the amount requiredConvenient and cost-effective for manufacturingBiocidePowder deliveryFiberSolubility

Hemostatic devices for promoting blood clotting can include a substrate (e.g., gauze, textile, sponge, sponge matrix, one or more fibers, etc.), a hemostatic material disposed thereon such as kaolin clay, and a binder material such as crosslinked calcium alginate with a high guluronate monomer molar percentage disposed on the substrate to substantially retain the hemostatic material material. When the device is used to treat a bleeding wound, at least a portion of the clay material comes into contact with blood to accelerate clotting. Moreover, when exposed to blood, the binder has low solubility and retains a majority of the clay material on the gauze. A bandage that can be applied to a bleeding wound to promote blood clotting includes a flexible substrate and a gauze substrate mounted thereon.

Owner:TELEFLEX LIFE SCI LTD

Pulling roll material for manufacture of sheet glass

A pulling roll for glass manufacture comprised of a high-temperature millboard material. The millboard comprises aluminosilicate refractory fiber, silicate, mica, and kaolin clay. A method of manufacturing a pulling roll is disclosed, together with a roll produced by the methods disclosed herein. The method comprises forming a pulling roll and densifying at least a portion of the pulling roll by exposing to the pulling roll to high temperatures.

Owner:CORNING INC

Soft tissue paper containing fine particulate fillers

InactiveCN1244899ALess quantityExcellent optical propertiesSpecial paperPaper/cardboardFiberWater insoluble

Soft, strong, and low dusting tissue paper webs useful in the manufacture of soft, absorbent sanitary products such as bath tissue, facial tissue, and absorbent towels are disclosed. The tissue papers copmrise fibers such as wood pulp and a non-cellulosic, water insoluble particulate filler such as kaolin clay and possess biased surface properties.

Owner:INSTITUTE OF PAPER SCIENCE AND TECHNOLOGY

Inorganic artificial combining stone and preparation method thereof

InactiveCN102557571AExpand raw material resourcesLow costCeramic shaping apparatusCement productionFiberKaolin clay

The invention discloses inorganic artificial combining stone and a preparation method thereof. The artificial combining stone uses silicon acid-base solution to arouse metakaolin to react and generate geopolymer to serve as an inorganic cementing agent, and the artificial combining stone mainly contains the metakaolin, the silicon acid-base solution, natural stone aggregate, decoration aggregate, a thickening time control agent, inorganic pigment and fibers. The preparation method is firstly enabling the thickening time control agent and the inorganic pigment to be dissolved in the silicon acid-base solution to obtain mixed serous fluid, evenly blending the metakaolin, the natural stone aggregate, the decoration aggregate, the fibers and the mixed serous fluid, preparing the artificial combining stone through model entering or material distribution, vibration under the vacuum condition, molding in a pressing mode, maintaining, cutting, polishing, burnishing and surface protection. The artificial combining stone not only has decoration features which can be equal to that of resin artificial stone, but also is non-toxic, environment-friendly, low in cost, resisting in corrosion of most majority of acid-base salts, durable in high temperature and excellent in durable performance, obviously avoids whiting and saltpetering phenomena after a long time use, and is strong in pollution resisting capability.

Owner:SOUTH CHINA UNIV OF TECH

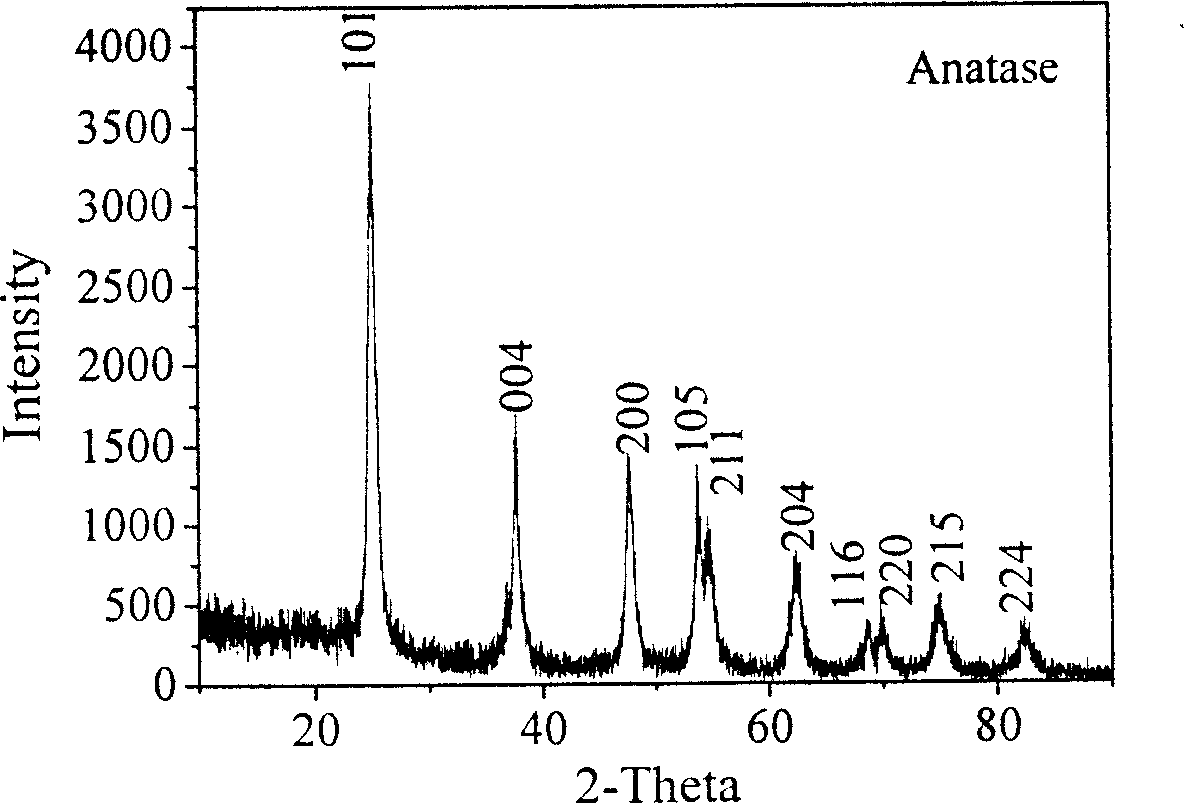

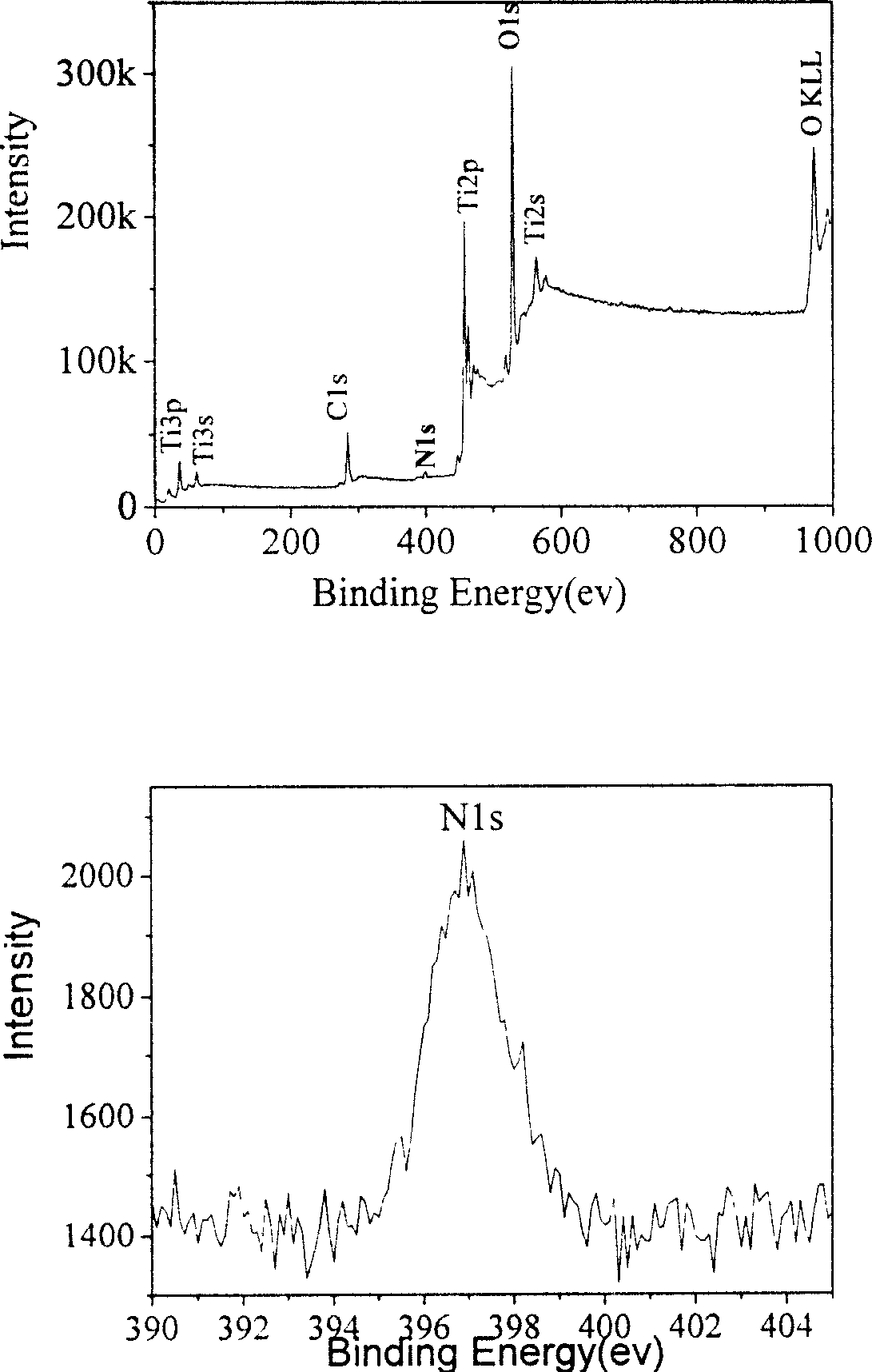

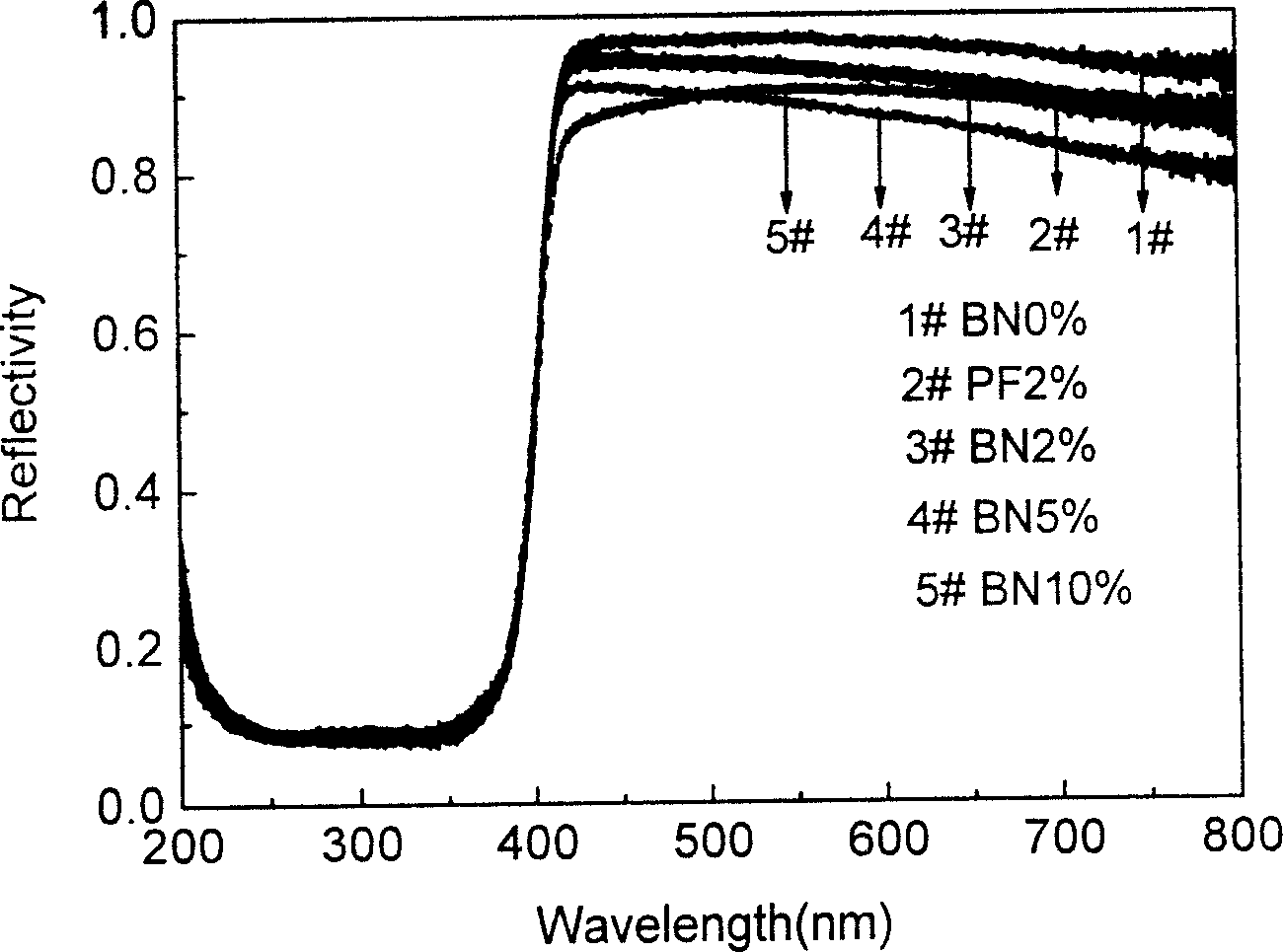

Light catalyzed coating modified by nitrogen dopen Nano titanium dioxide and preparation method

InactiveCN1696228AImprove efficiencyGood bactericidal and antibacterial effectCoatingsUltravioletTitanium oxide

A nitrogen doped nano-TiO2 modified photocatalytic paint with low content of volatile VOC, and high ultraviolet shielding-absorbing and antibacterial effect is prepared from silicic acrylate emulsion, nitrogen doped nano-TiO2, ordinary nano-TiO2, titanium oxide powder, kaolin, heavy and light calcium carbonate, wallastonite powder, assistant, water, ammonia water, defoaming agent and antimildew agent through proportional mixing, stirring and filtering.

Owner:UNIV OF SCI & TECH BEIJING

Oxygen-containing coal bed gas deoxidation catalyst and preparation thereof as well as applications

InactiveCN101322942ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsMordeniteAluminum silicate

The invention discloses a deoxidizing catalyst for a coal-seam gas containing oxygen and a preparation method as well as an application thereof. The deoxidizing catalyst of the invention consists of an active component, an active auxiliary and a porous carrier. The active component is the compound of Co; the active auxiliary is one or more compounds of Mn, Fe, Zn and Cu; the porous carrier is one or more of aluminum oxide, titanium oxide, zirconium oxide, magnesium oxide, calcium oxide, silicon oxide, a phosphor-aluminium molecular sieve, an A-typed molecular sieve, an X-typed molecular sieve, a Y-typed molecular sieve, a mordenite, a ZSM-5 zeolite, diatomaceous earth, kaolinite, natural clay, aluminum silicate and magnesium silicate; calculated by oxide, the weight percentage of the active component is 1 to 60 percent; the weight percentage of the active auxiliary is 1 to 50 percent; the rest is the carrier. The catalyst of the invention has certain sulfur-resistance performance, is applicable to the deoxidization treatment of coal-seam gas with an oxygen content of 3 to 6 percent (V / V) and is capable of causing the oxygen content in the coal-seam gas to be lower than 0.5 percent by deoxidization.

Owner:HAO HUA CHENGDU TECH

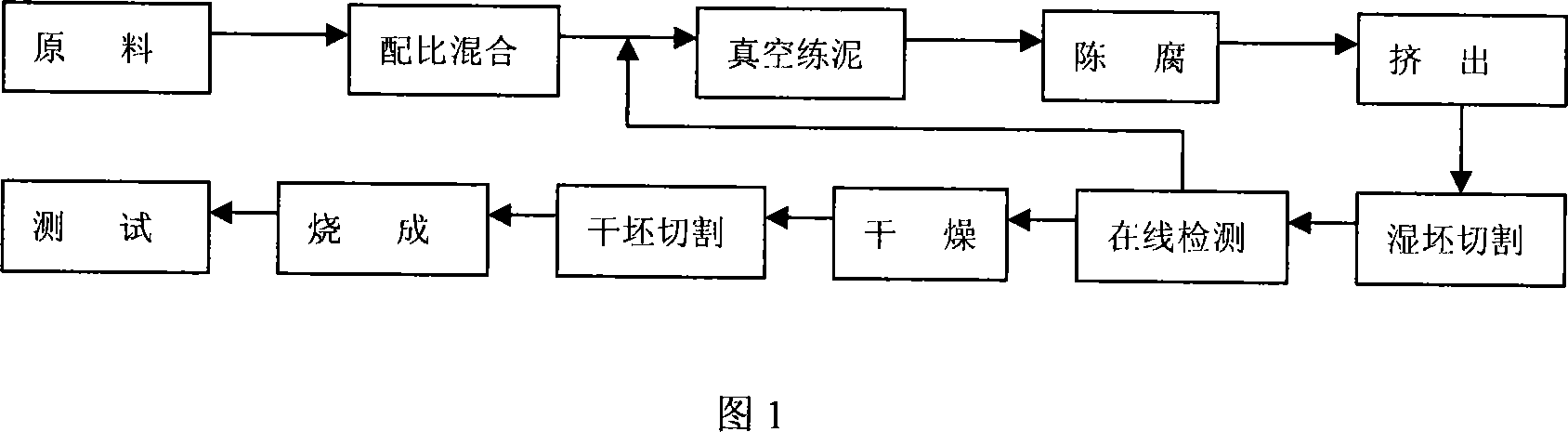

Iolite cellular ceramic and preparation method

A high-porosity thin-wall cordierite-type cellular ceramics is prepared proportionally from LiO2, talc, kaolinite, calcined kaolinite, alpha-AlO, aluminum hydroxide, silicon powder, solid adhesive, and the liquid organic additive prepared from water, propanetriol, liquid adhesive, surfactant and lubricant. Its preparing process is also disclosed.

Owner:JIANGSU GAOCHUN CERAMICS +1

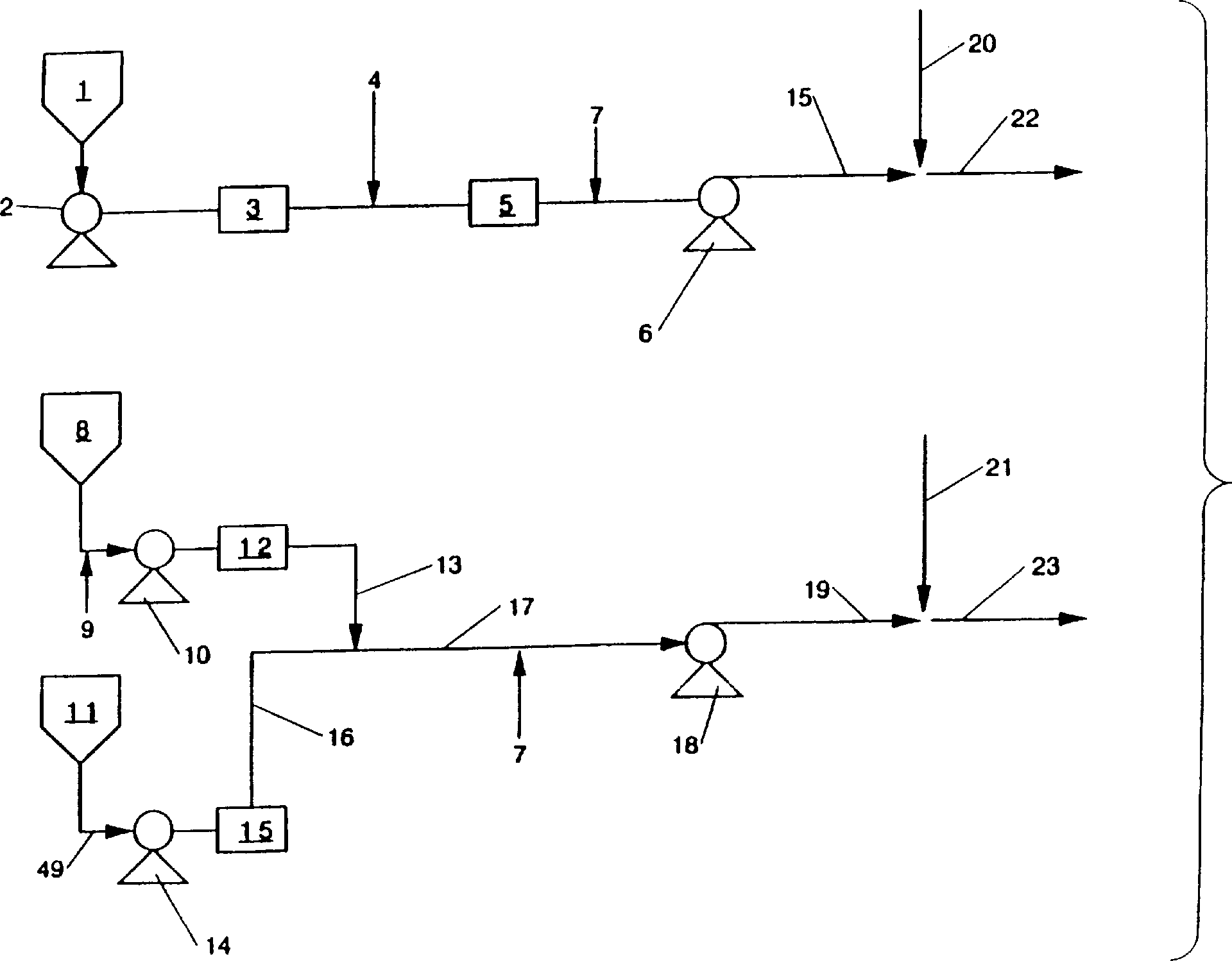

Treatment and production technique for calcining kaolin

A process for preparing the calcined kaolinite includes such steps as dressing ore, crushing, pulverizing by 325 meshes, mixing with water and disperser, pulverizing by 4500-6000 meshes, drying, pulverizing, calcining at 970-990 deg.C for 30-40 min while adding whitening agent, and breaking. Its features high whiteness and fineness.

Owner:SANBAO KAOLINIE CLAY INNER MONGOLIA

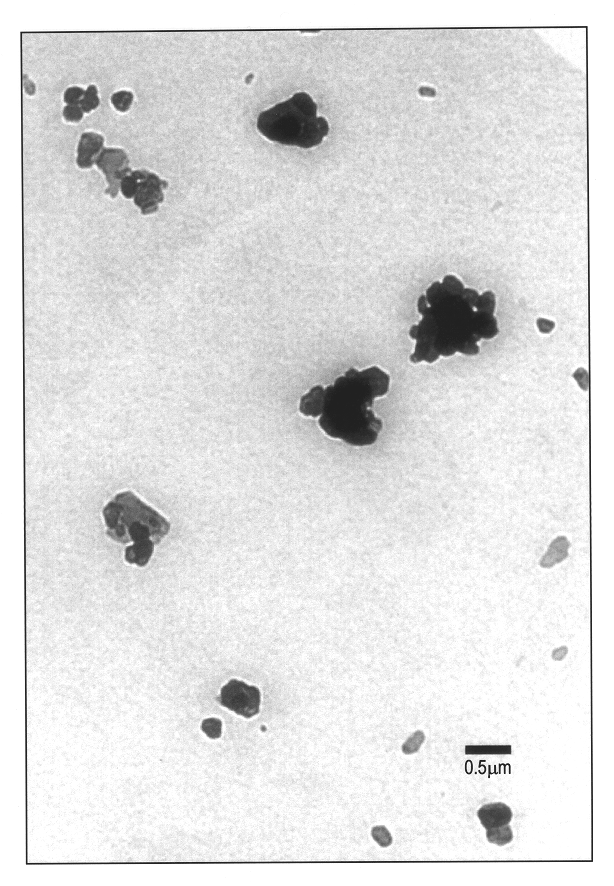

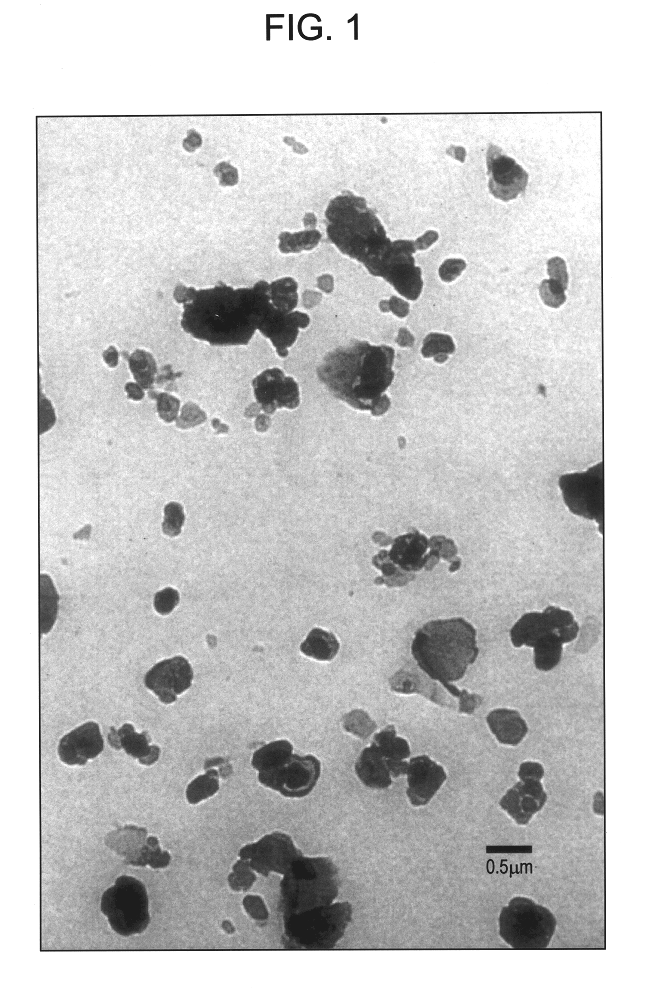

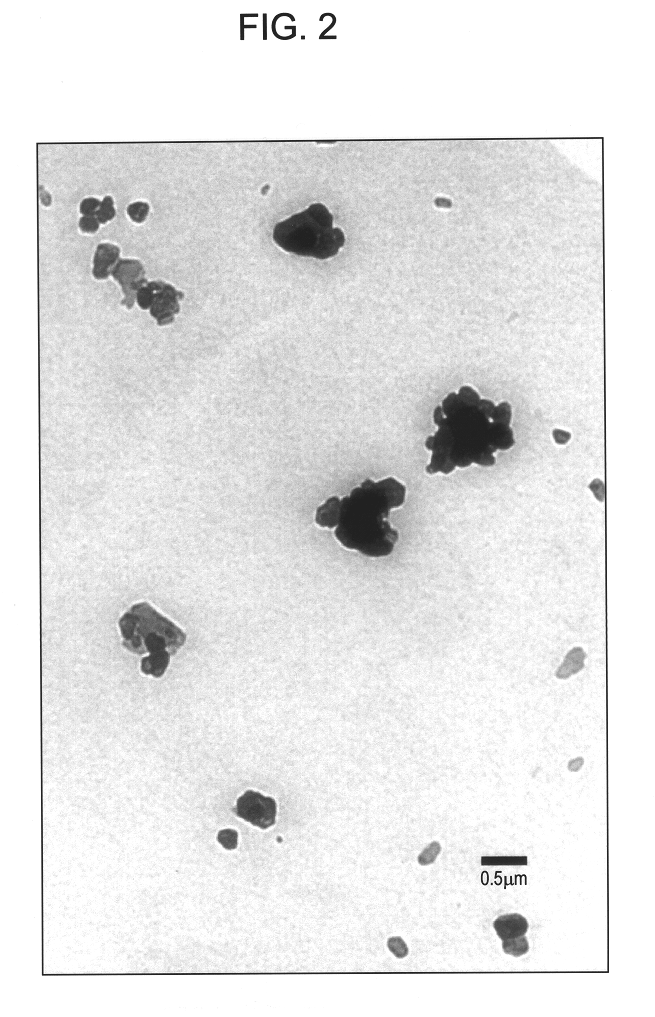

Kaolin clay glossing pigment and preparation thereof

Novel nanosized kaolin clay particles are prepared by agitating a fine particle size fraction of kaolin clay in a Netzsch mill until the particle size is reduced, aspect ratio is decreased and surface area is increased. The ultrafine kaolin particles are especially useful as a pigment to provide high surface gloss to ink jet printing papers.

Owner:IMERYS USA INC

Heat resisting red porcelain chinaware

The invention discloses a heat-resistant purple sand ceramic tool. The manufacture material includes stock and glaze; wherein, the stock is formed by the following components according to weight percentage: 1 to 15 percent of purple sand soil, 25 to 38 percent of triphane, 5 to 30 percent of bauxite clay, 5 to 30 percent of kaolin, 2 to 6 percent of talc, 5 to 20 percent of alum clay, 5 to 20 percent of grog and 5 to 25 percent of attaclay; the glaze is formed by the following components according to weight percentage: 20 to 35 percent of paste, 10 to 25 percent of petalite, 15 to 25 percent of grog, 8 to 15 percent of clinker, 12 to 25 percent of yellow earth, 6 to 9 percent of iron red, 0 to 0.15 percent of trimeric sodium phosphate and 1 to 2 percent of water glass. The adoption of triphane in the material of ceramics can largely enhance the heat-resistant capability, and the ceramics can be heated by electricity or fire and even the firing without water causes no crack. The heat-resistant purple sand ceramics can be adopted either as tableware or as drinking vessel.

Owner:熊禄生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com