Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

815 results about "High silica" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

HIGH SILICA TAPE-ZEAL-B-B. This High Silica woven Tape is made by silica fiber, contain more than 96% pure SiO2. High Temperature Woven Silica Tape retain strength and flexibility in insulation applications at 1800° (982°C.) When spiral wrapped over pipes, hoses or cables, they offer protection against molten metal or extreme radiant heat.

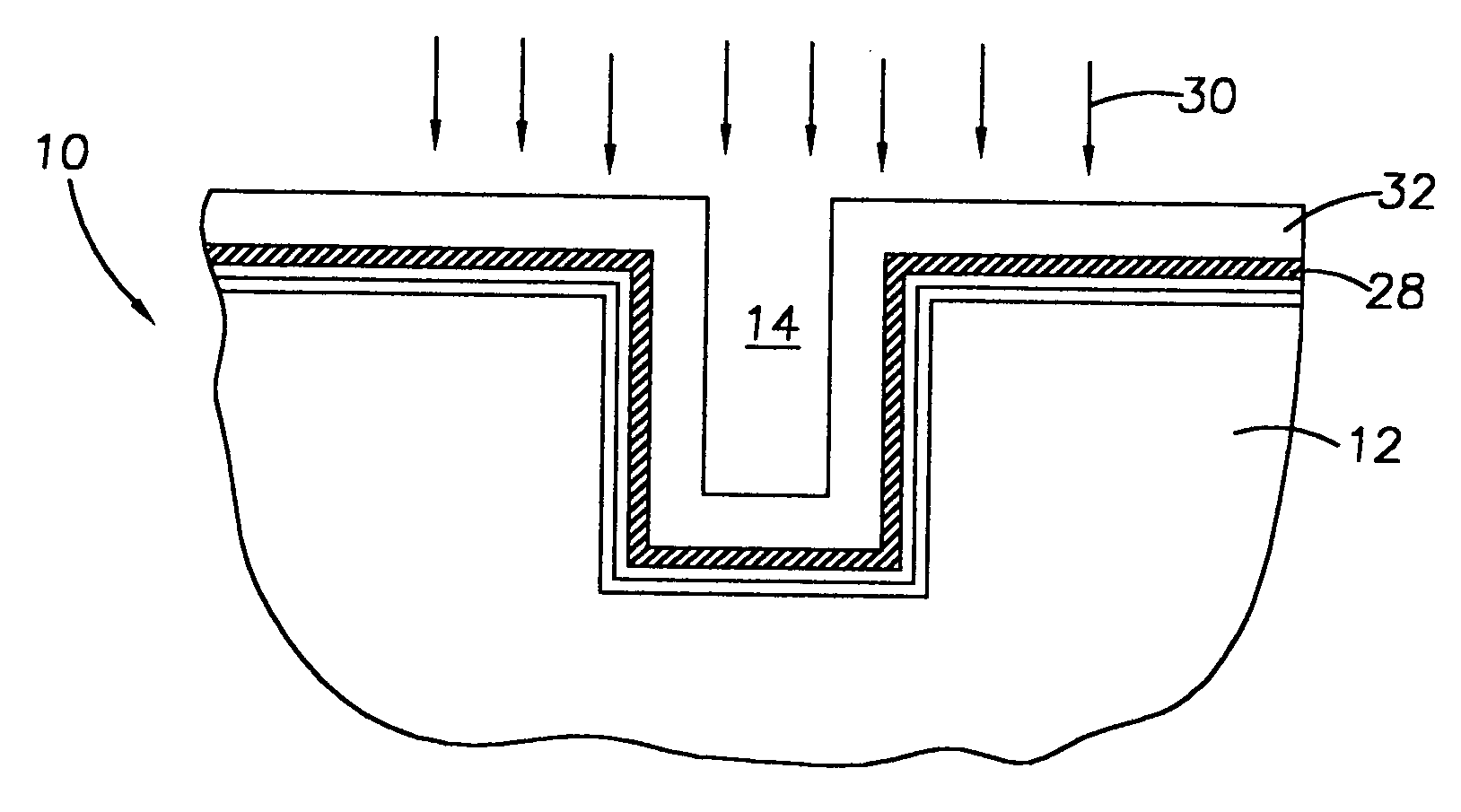

Method of increasing deposition rate of silicon dioxide on a catalyst

ActiveUS20060046518A1Good step coverageIncrease production outputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideOxygen

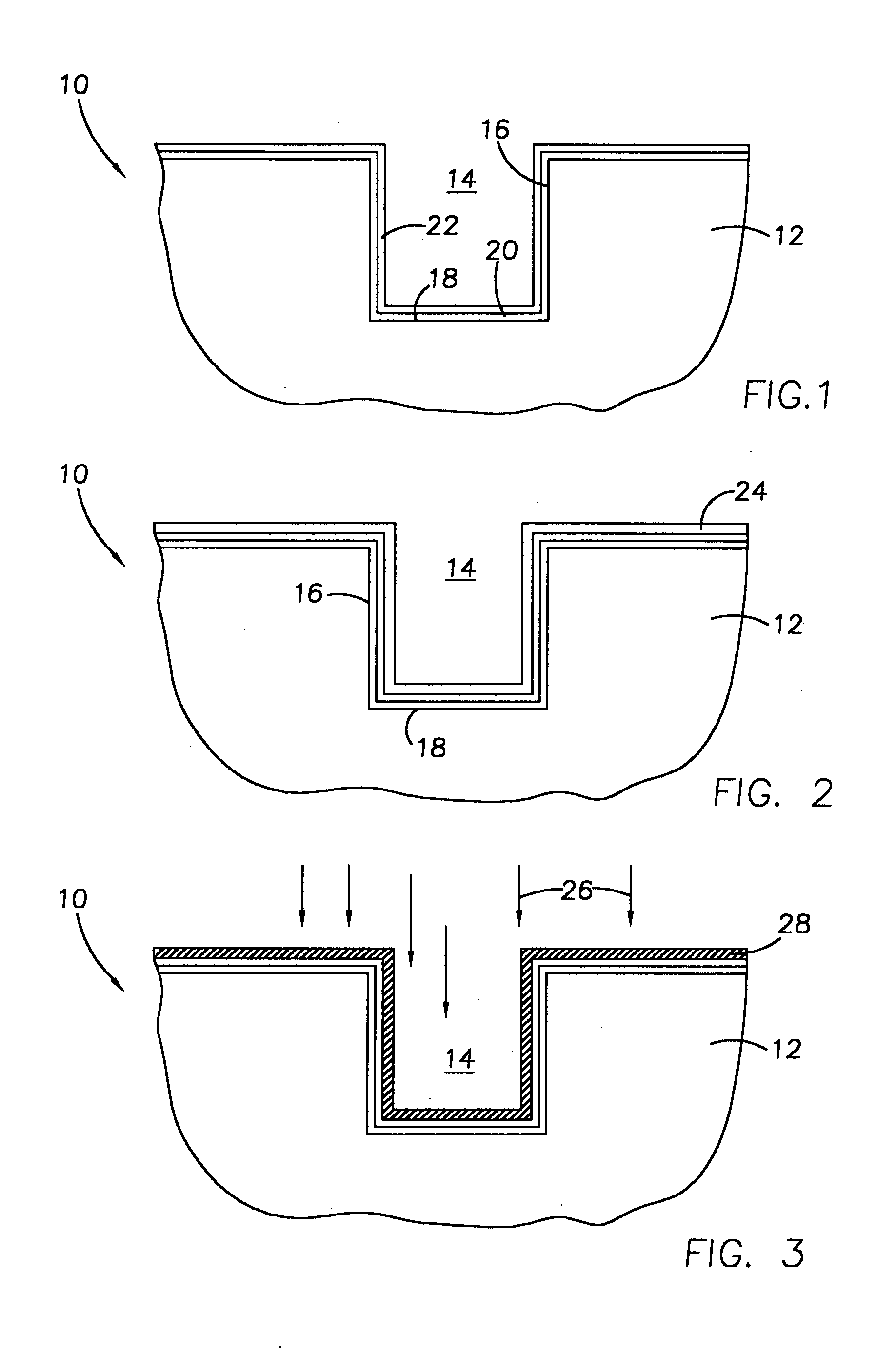

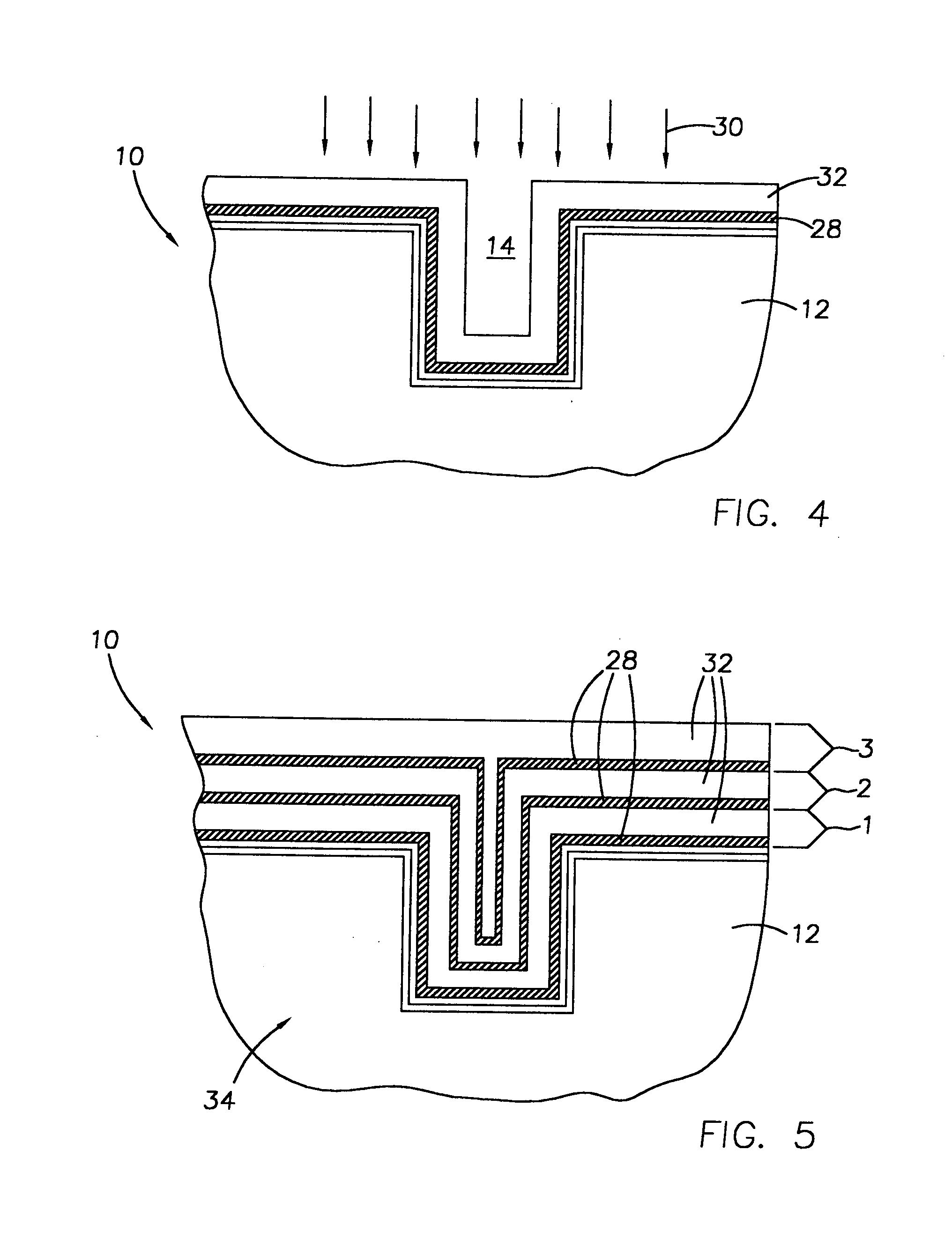

Methods for forming dielectric layers, and structures and devices resulting from such methods, and systems that incorporate the devices are provided. The invention provides an aluminum oxide / silicon oxide laminate film formed by sequentially exposing a substrate to an organoaluminum catalyst to form a monolayer over the surface, remote plasmas of oxygen and nitrogen to convert the organoaluminum layer to a porous aluminum oxide layer, and a silanol precursor to form a thick layer of silicon dioxide over the porous oxide layer. The process provides an increased rate of deposition of the silicon dioxide, with each cycle producing a thick layer of silicon dioxide of about 120 Å over the layer of porous aluminum oxide.

Owner:MICRON TECH INC

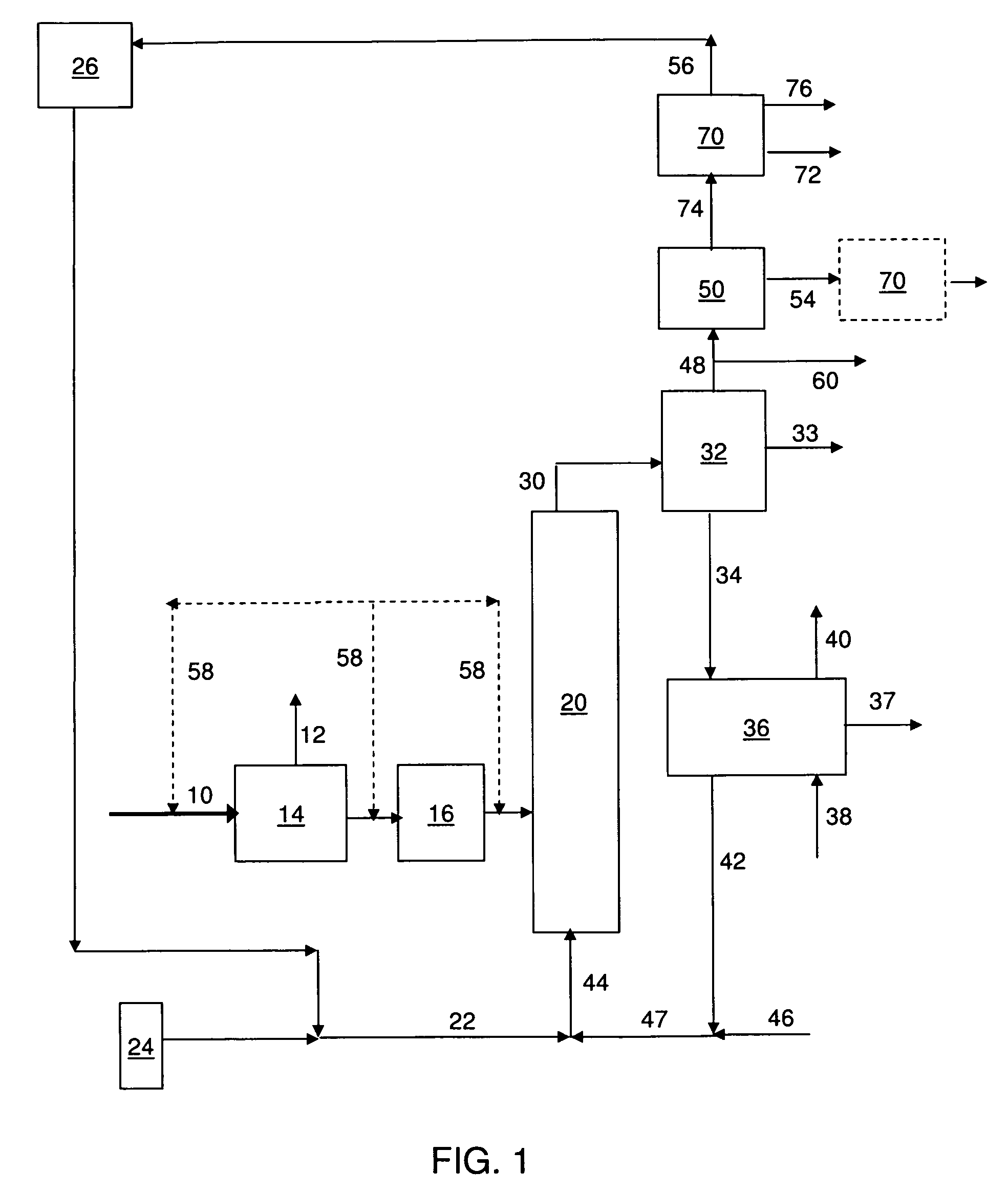

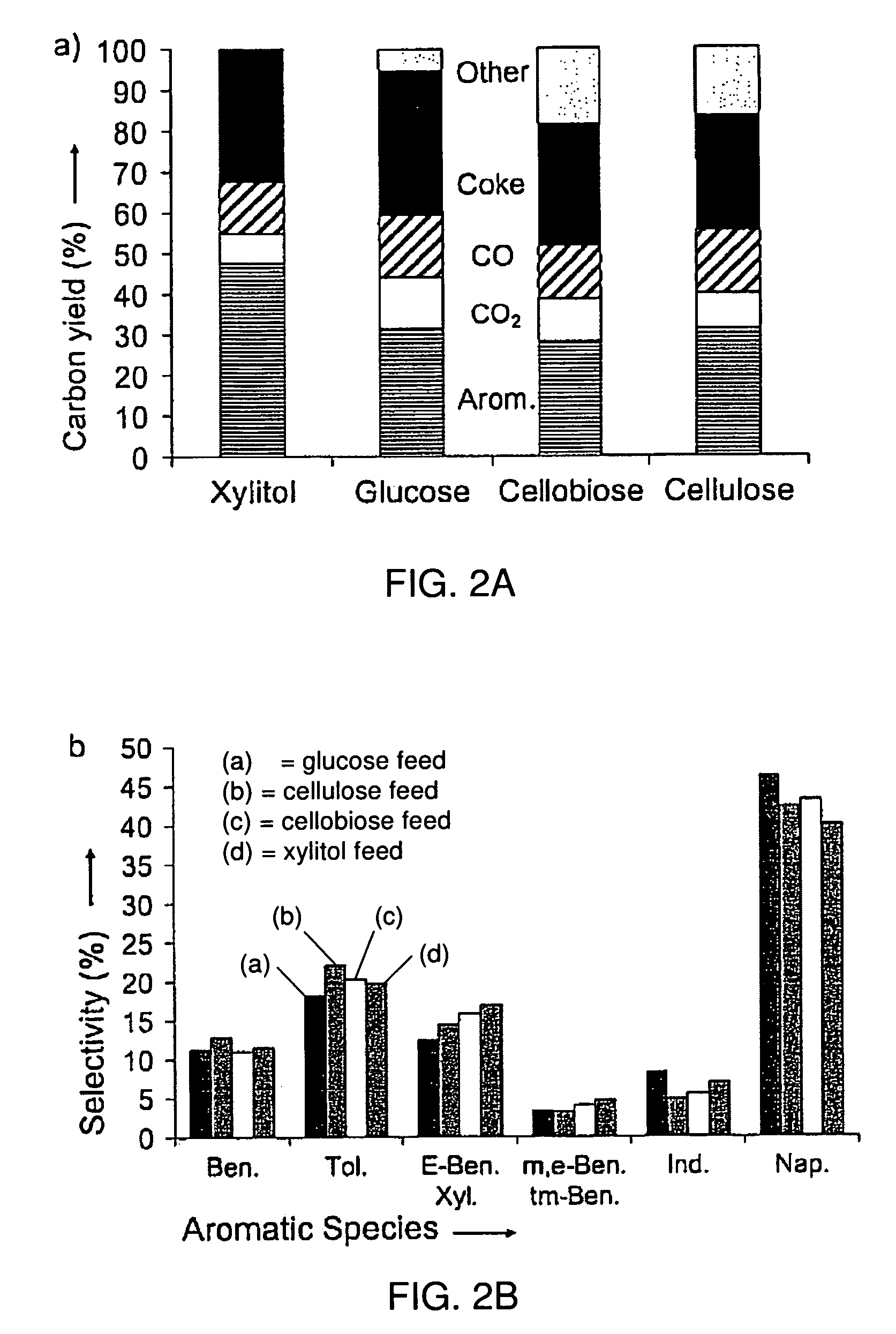

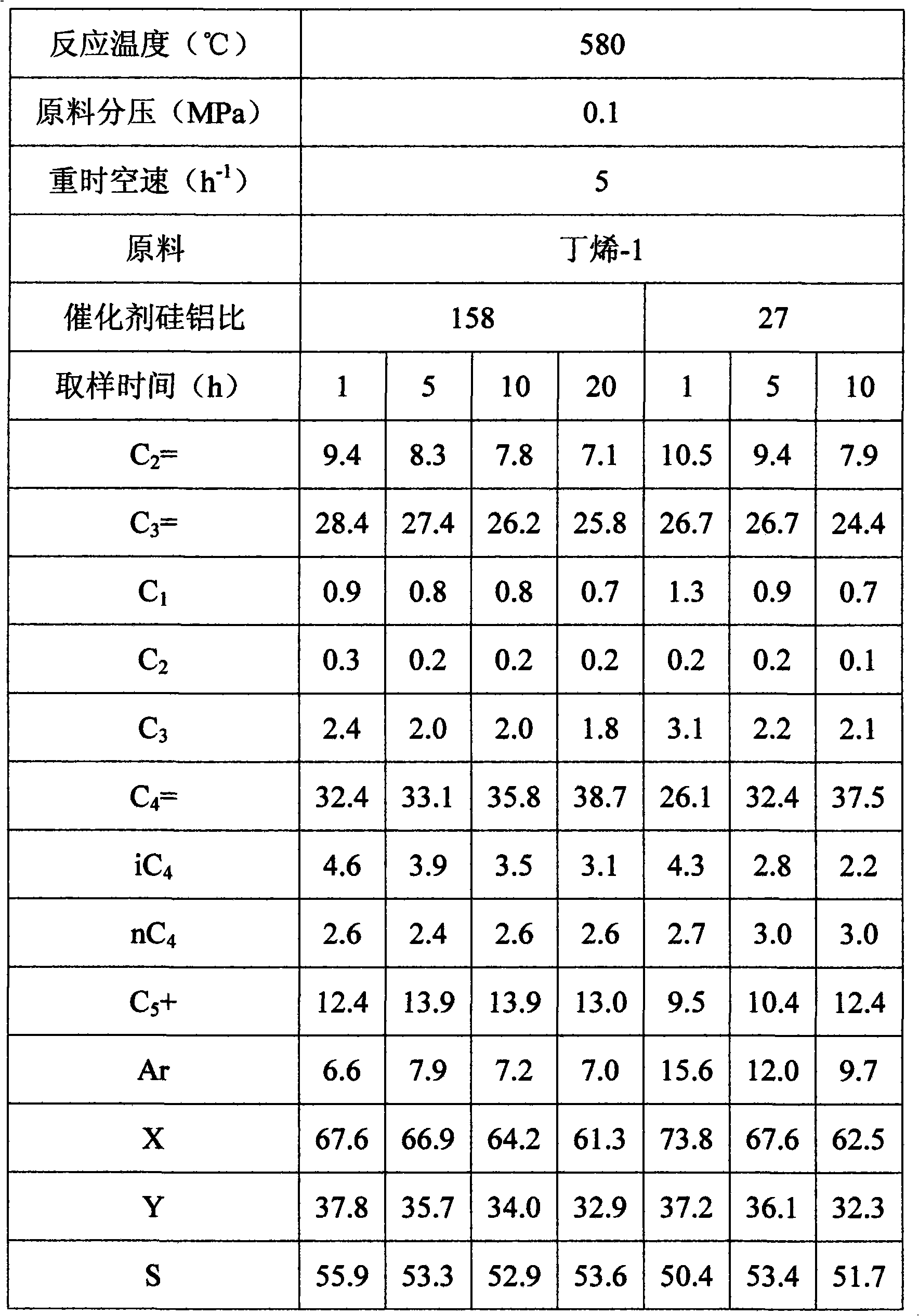

Catalytic pyrolysis of solid biomass and related biofuels, aromatic, and olefin compounds

ActiveUS8277643B2Minimize coke productionSolid fuelsHydrocarbon from oxygen organic compoundsCatalytic pyrolysisHigh rate

This invention relates to compositions and methods for fluid hydrocarbon product, and more specifically, to compositions and methods for fluid hydrocarbon product via catalytic pyrolysis. Some embodiments relate to methods for the production of specific aromatic products (e.g., benzene, toluene, naphthalene, xylene, etc.) via catalytic pyrolysis. Some such methods may involve the use of a composition comprising a mixture of a solid hydrocarbonaceous material and a heterogeneous pyrolytic catalyst component. In some embodiments, the mixture may be pyrolyzed at high temperatures (e.g., between 500° C. and 1000° C.). The pyrolysis may be conducted for an amount of time at least partially sufficient for production of discrete, identifiable biofuel compounds. Some embodiments involve heating the mixture of catalyst and hydrocarbonaceous material at high rates (e.g., from about 50° C. per second to about 1000° C. per second). The methods described herein may also involve the use of specialized catalysts. For example, in some cases, zeolite catalysts may be used; optionally, the catalysts used herein may have high silica to alumina molar ratios. In some instances, the composition fed to the pyrolysis reactor may have a relatively high catalyst to hydrocarbonaceous material mass ratio (e.g., from about 5:1 to about 20:1).

Owner:UNIV OF MASSACHUSETTS

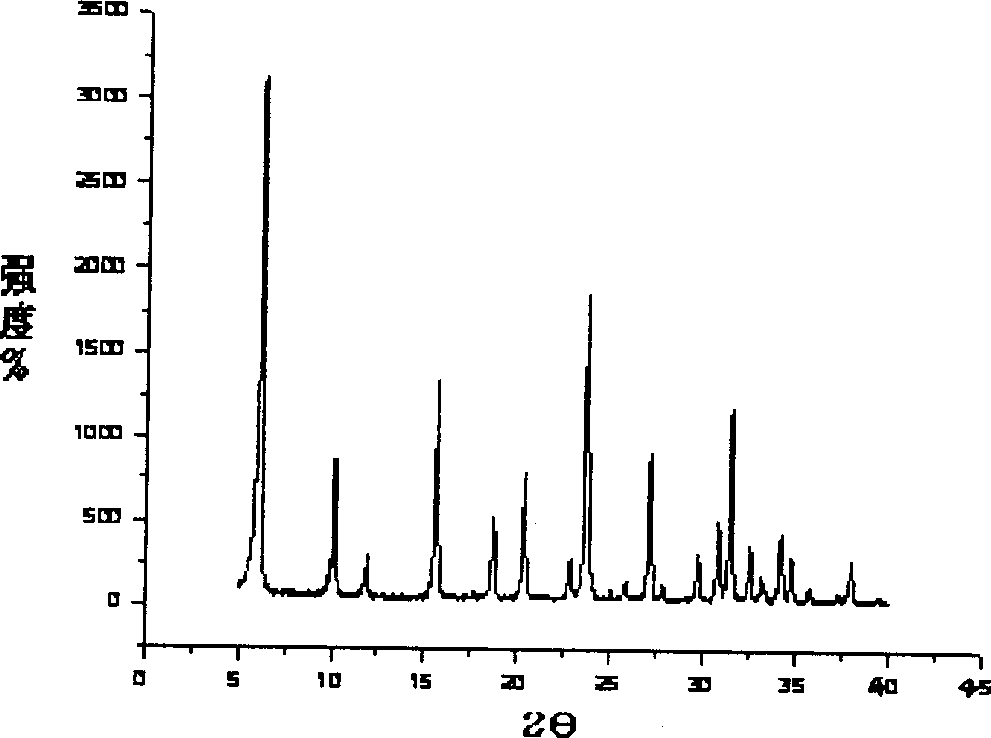

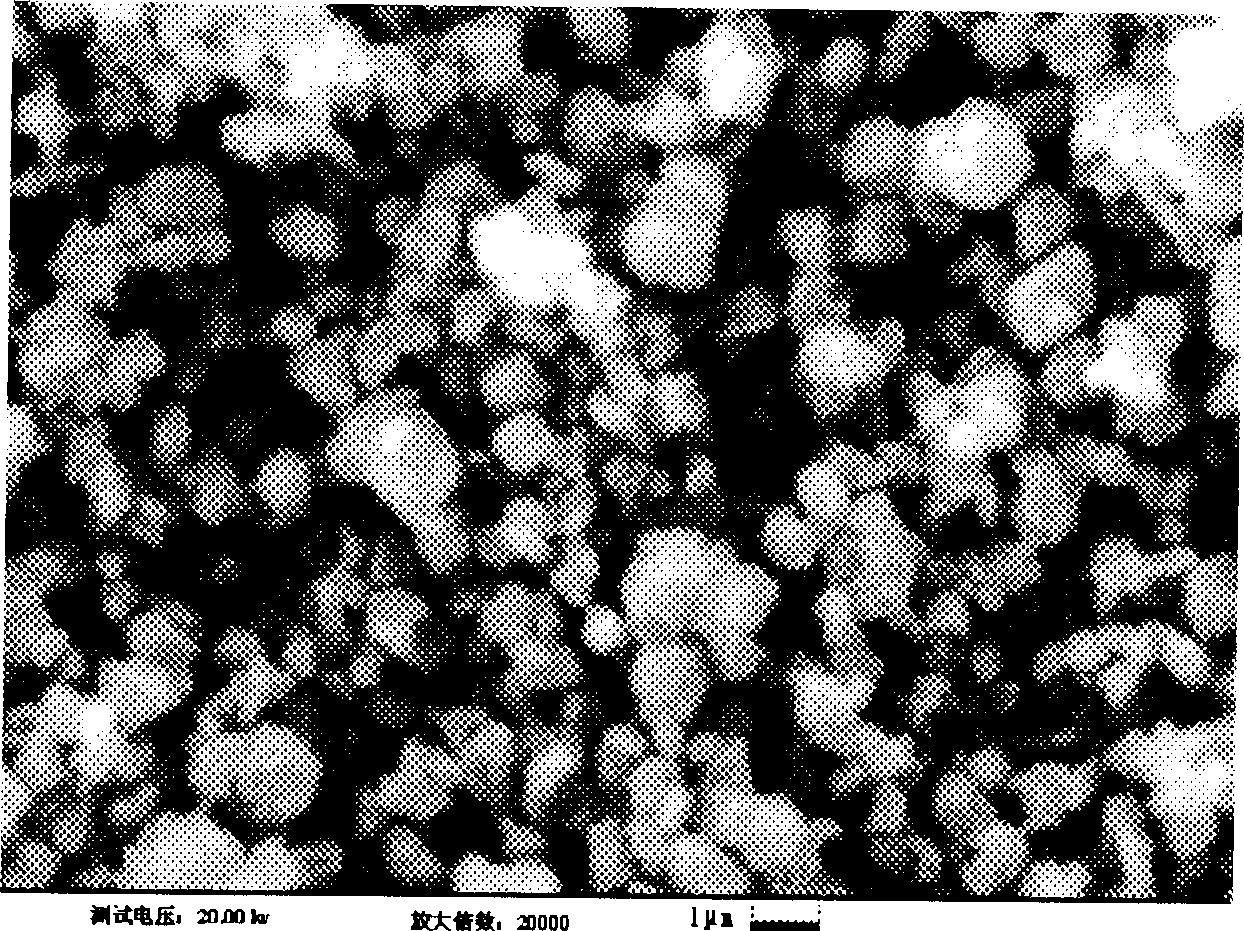

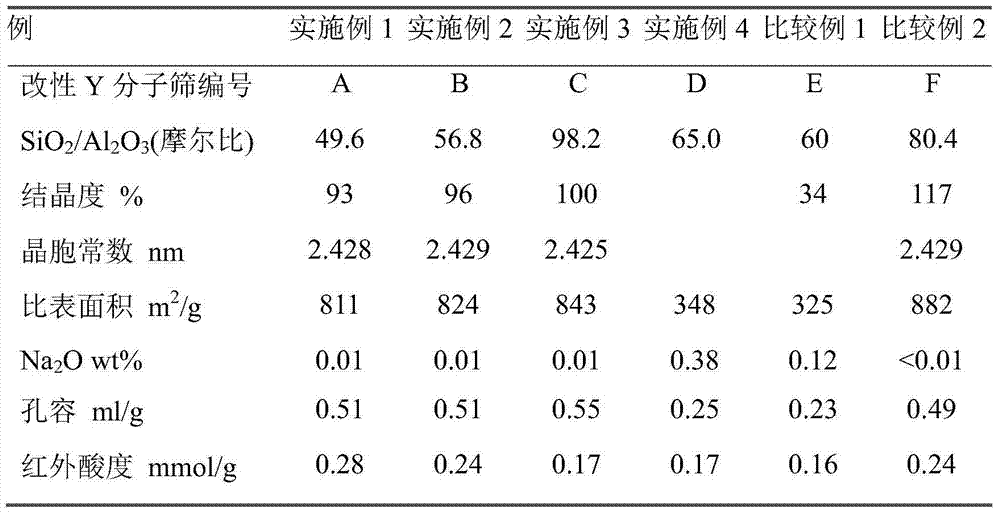

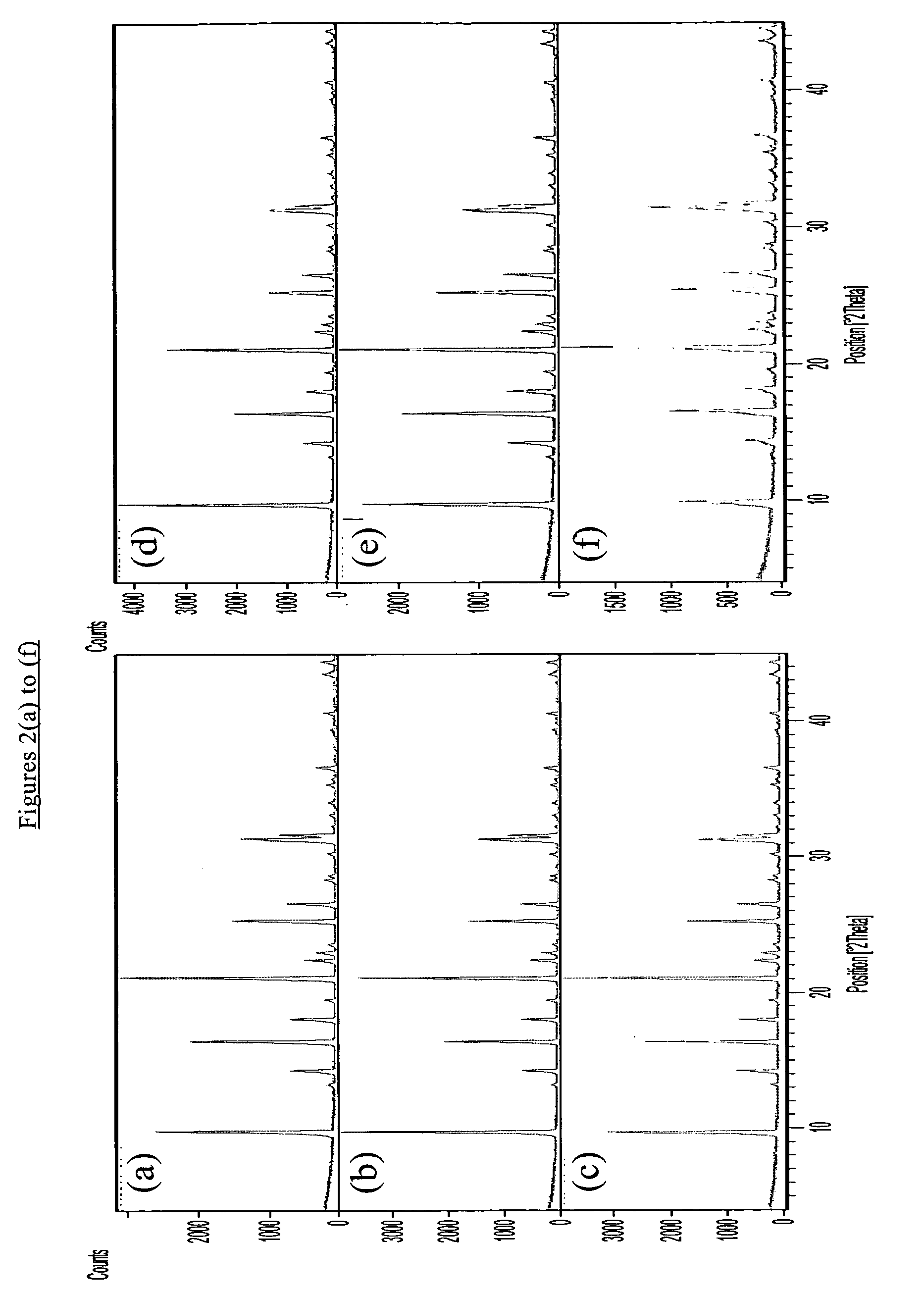

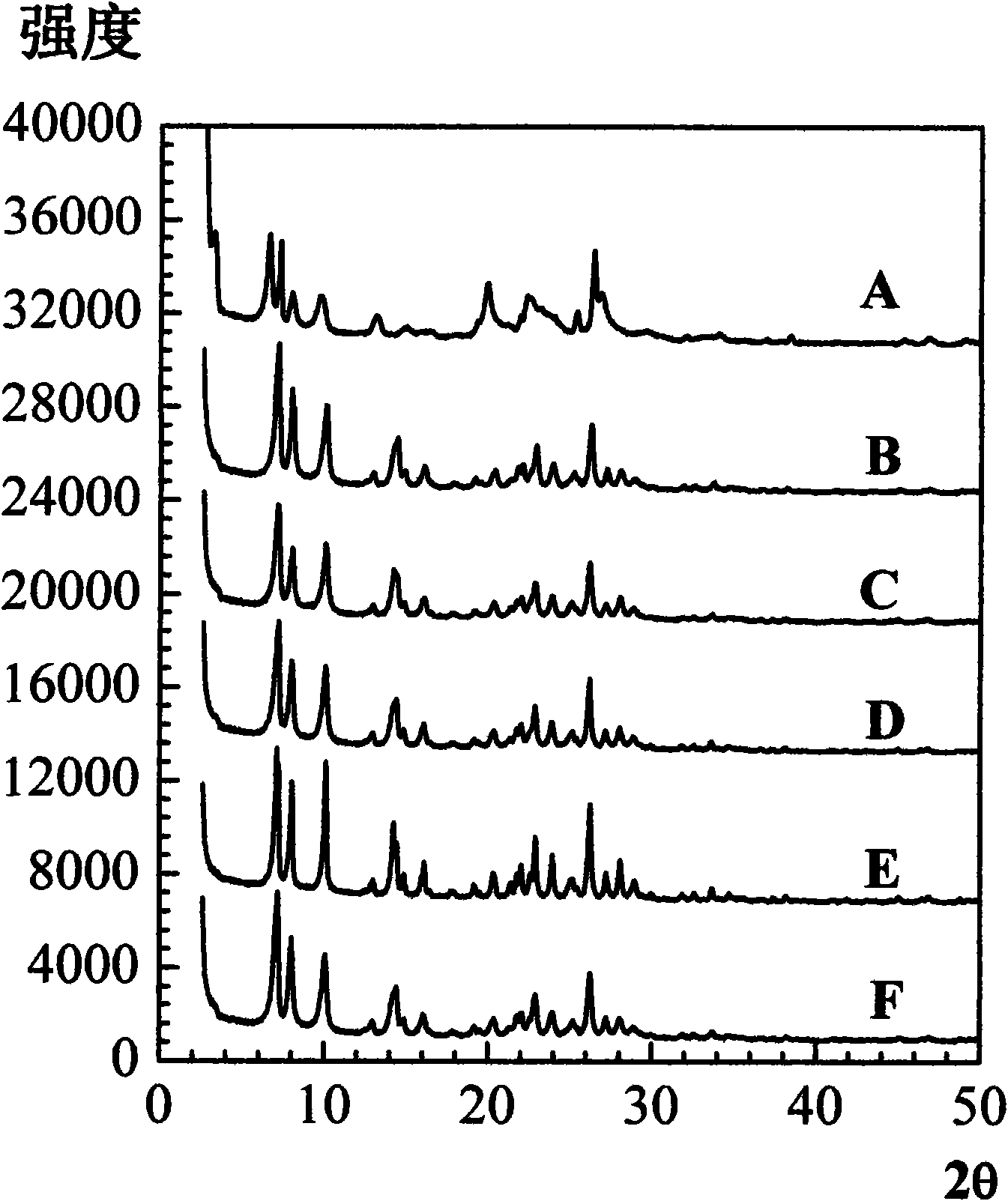

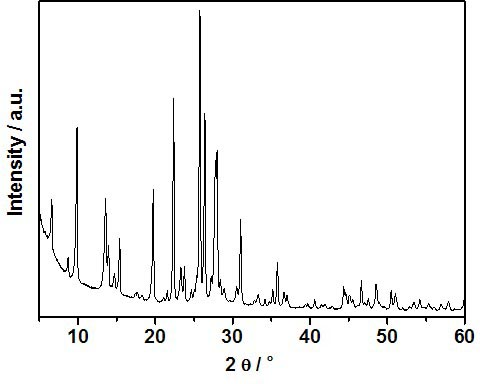

High silicon aluminium ratio small crystal NaY molecular sieve

ActiveCN1785807ALow costReduce manufacturing costFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

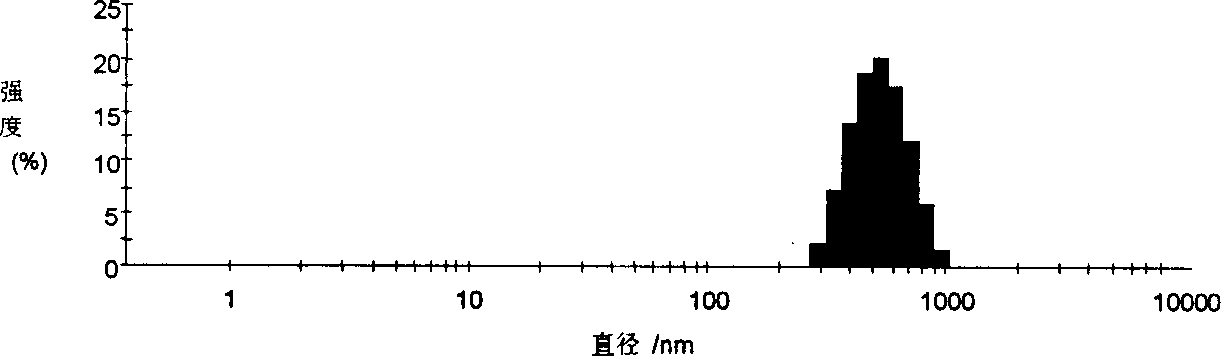

The present invention provides a high silica-alumina ratio small crystal grain NaY molecular sieve. The skeleton silica-alumina ratio of NaY molecular sieve, namely. SiO2 / Al2O3 mole ratio is 6.0-7.0, and the average grain size is 300-800 nm. It can be made up by adopting non-template agent direct synthesis process. Its preparation method includes the following steps: firstly, stirring and ageing for 0.5-48 hr at 15-60deg.C to obtain crystallization guide agent, then mixing said guide agent, water, silicon source and aluminium source to obtain reaction mixture, then crystallizing said mixture at twice, first steps is dynamic crystallization and second step is static crystallization, finally, filtering, washing and drying so as to obtain the invented high silica-alumina ratio small crystal grain NaY molecular sieve whose relative crystallinity is greater than 80%.

Owner:PETROCHINA CO LTD +1

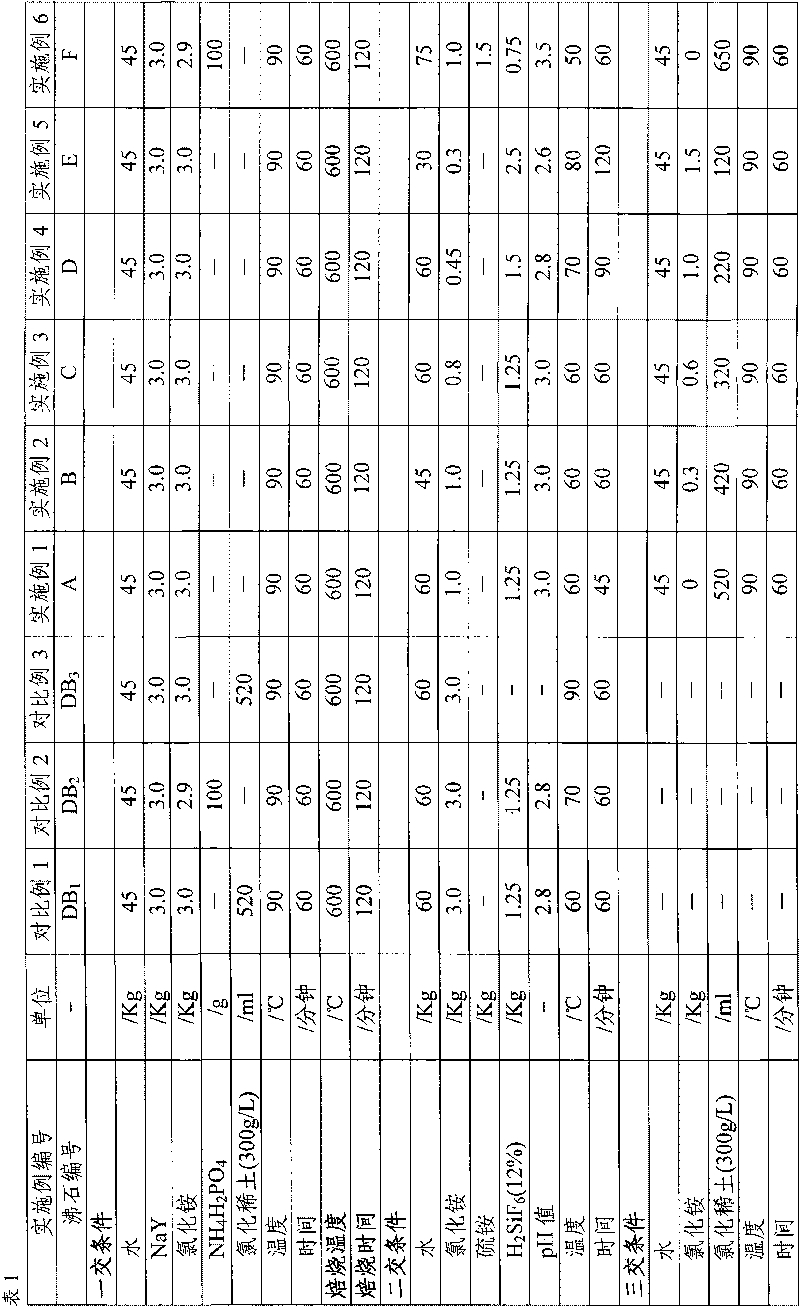

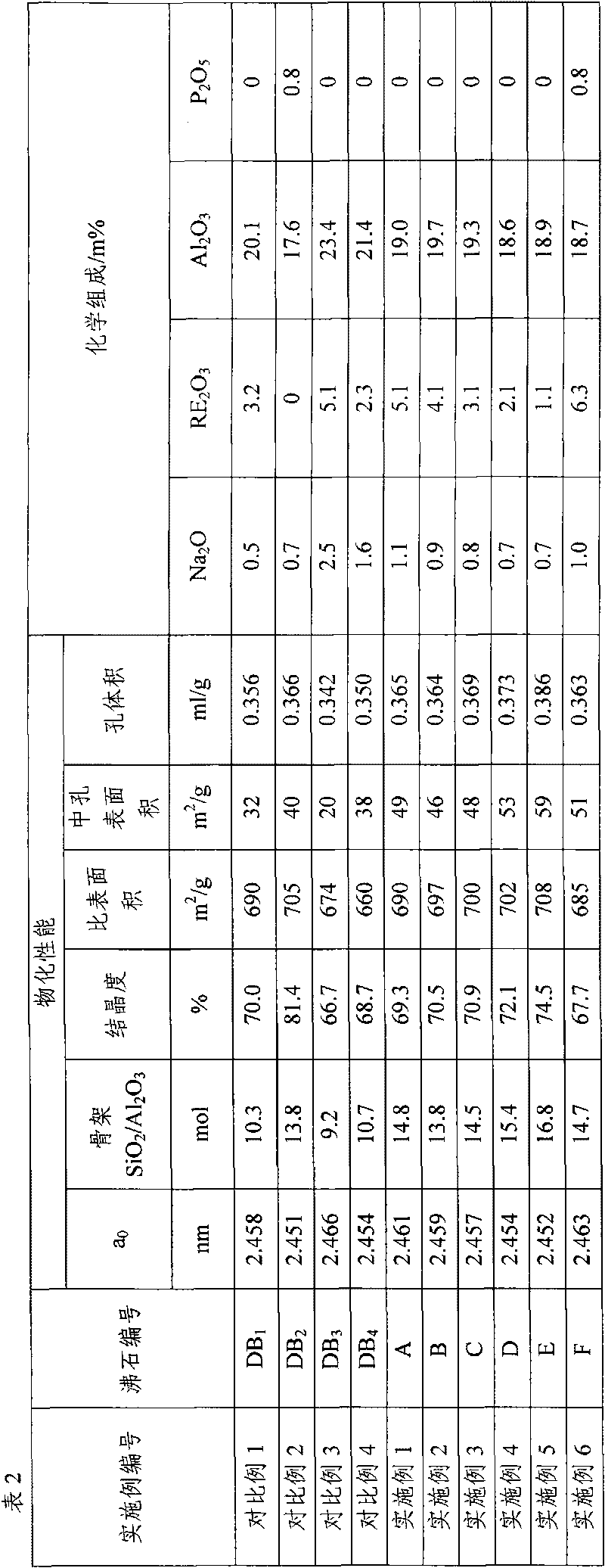

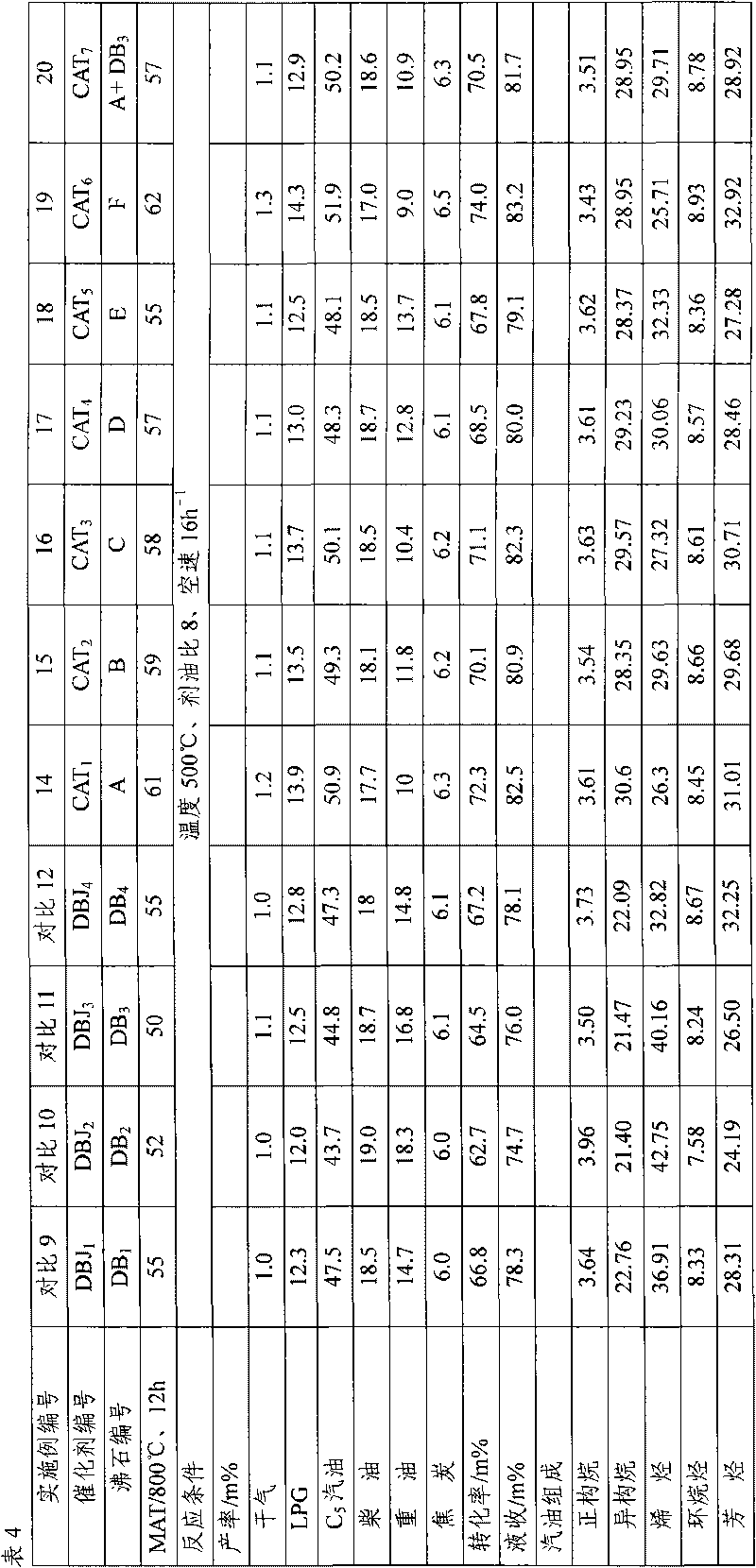

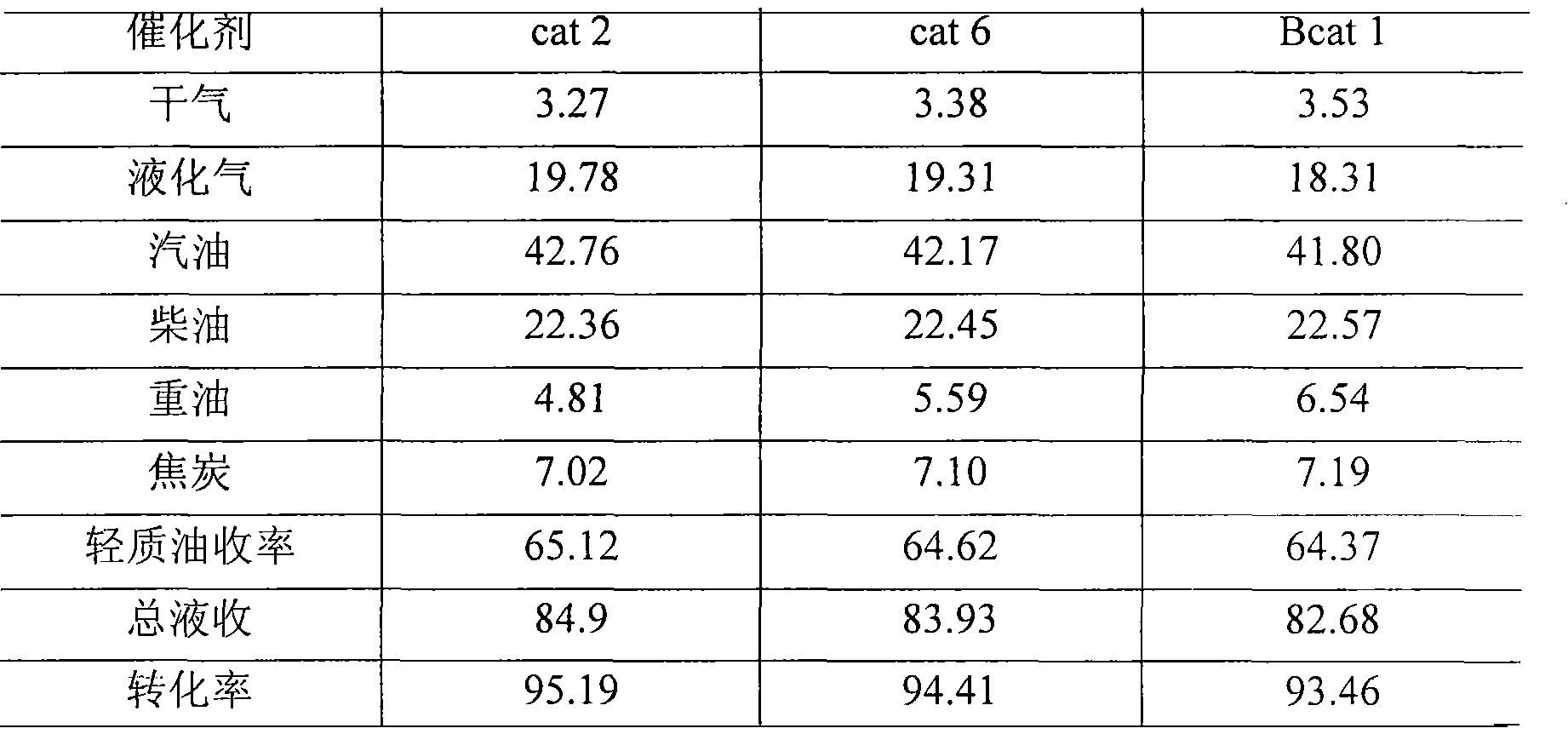

Catalytic cracking catalyst, preparation and application thereof

ActiveCN101745418AHigh yieldReduce olefin contentCatalytic crackingMolecular sieve catalystsAlkaneWater vapor

The invention provides a catalytic cracking catalyst, a preparation method and an application method thereof. The catalyst contains high silica-alumina ratio REUSY zeolite prepared by a liquid-phase villiaumite method. The method for preparing the zeolite comprises: allowing NaY zeolite and inorganic ammonium salt solution to be in contact for ion exchange and washing; ensuring that the Na2O content of zeolite is lower than 6 weight percent; roasting the obtained product in a 100 percent steam atmosphere; allowing the obtained product to be in contact with fluosilicic acid solution for liquid-phase aluminum-pumping silicon-replenishing reaction; allowing the obtained product filtered and washed to be in contact with rare earth salt solution for ion exchange. The catalyst is used for heavy oil catalytic cracking, and has good capability of cracking heavy oil macromolecules, performance of reducing the olefin content of gasoline and performance of increasing the isoparaffin content of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

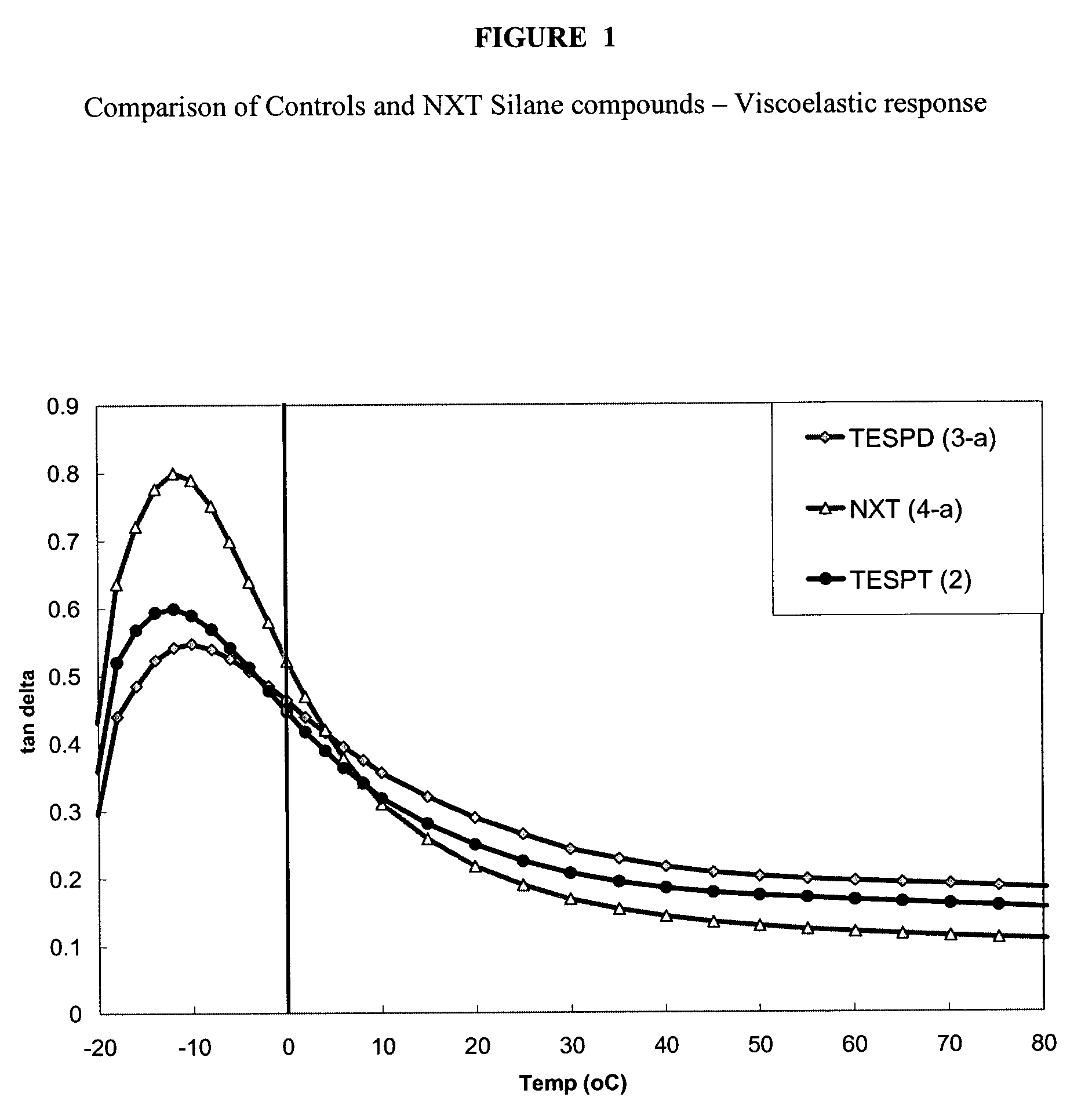

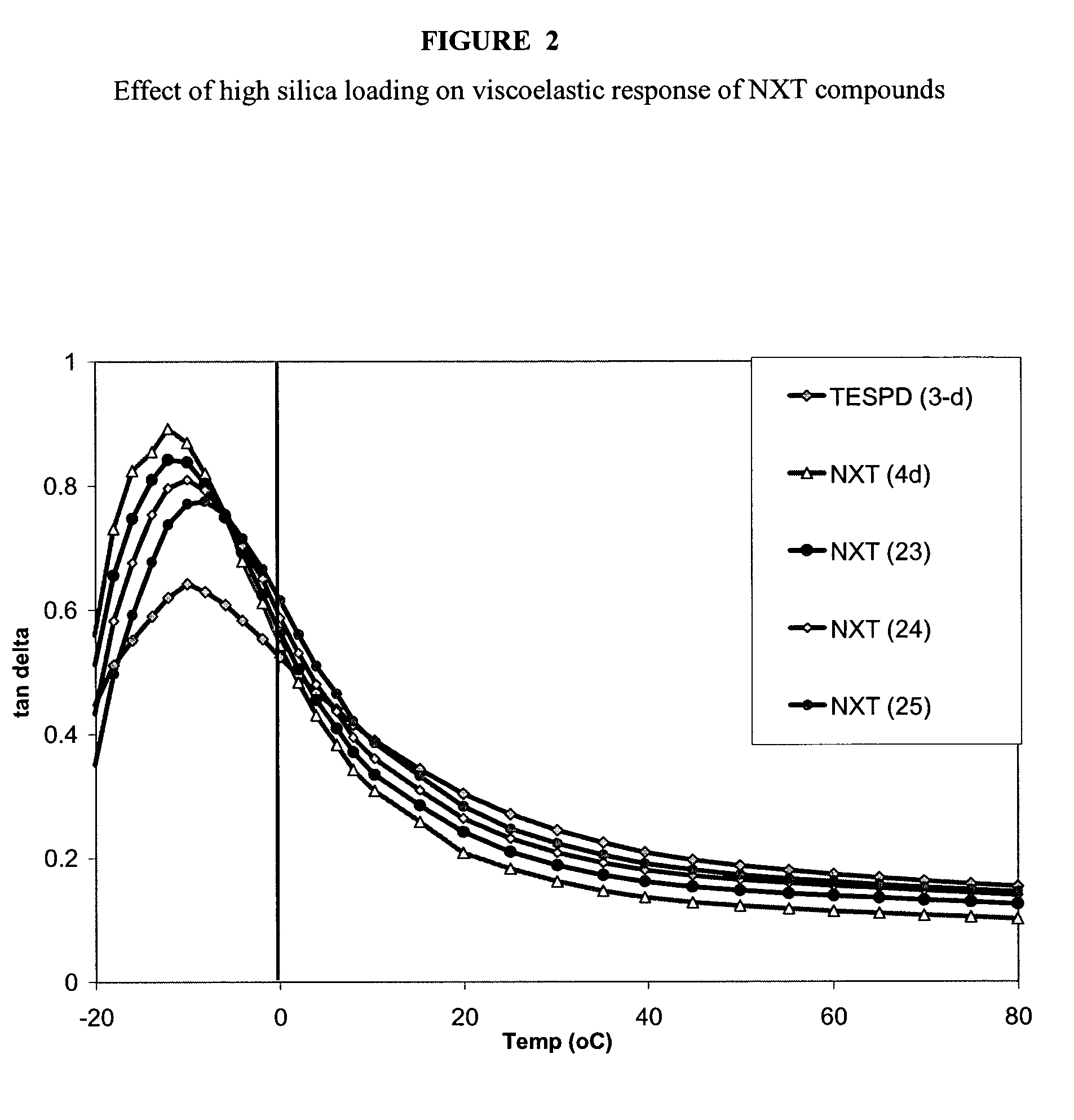

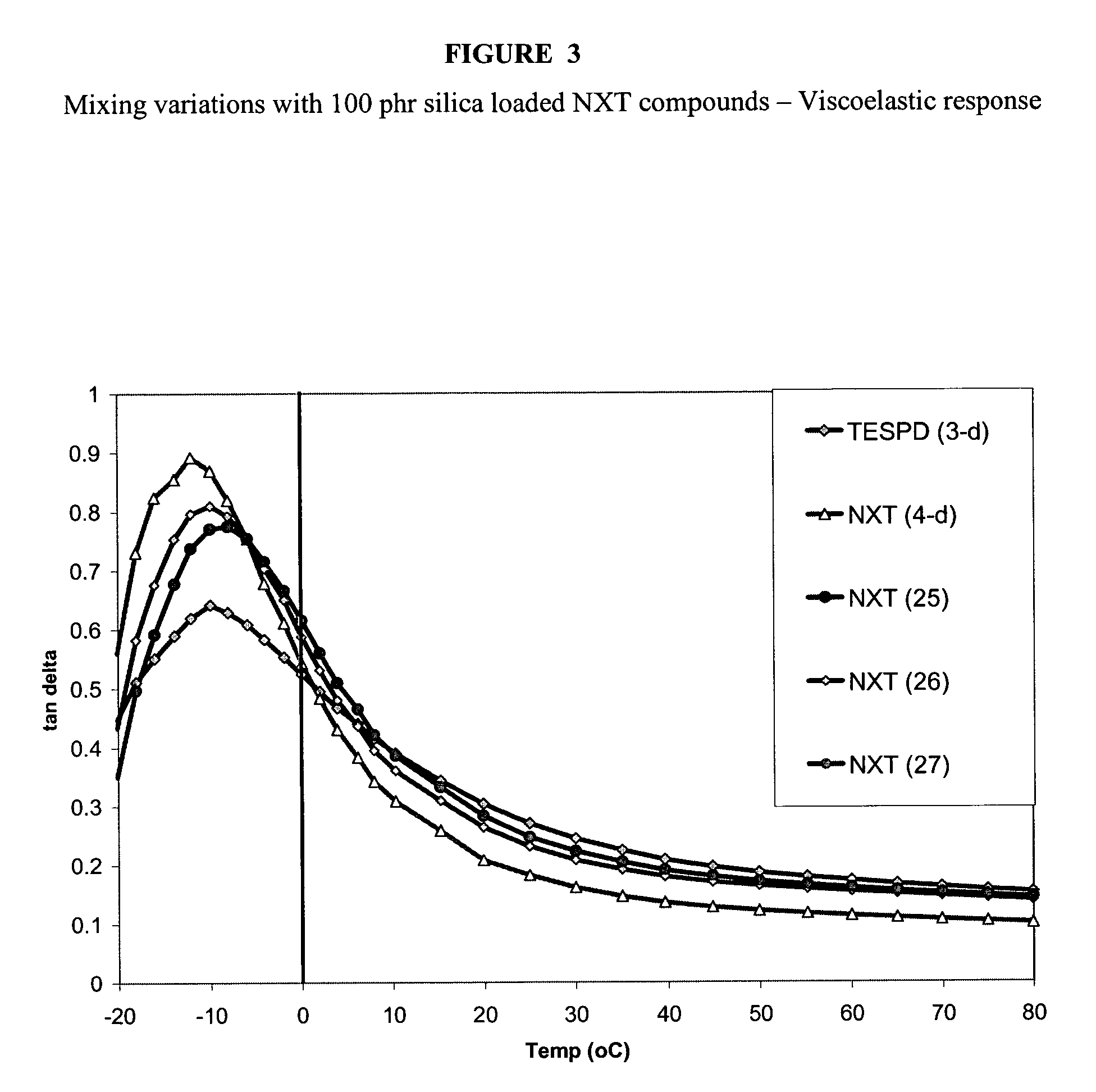

Silica-rubber mixtures having improved hardness

InactiveUS20050277717A1Eliminates and reduces filler network effectReduce hardnessSpecial tyresSilanesOrganic group

A method for increasing the hardness of silica / rubber mixtures is disclosed wherein the method comprises blending with said mixture at least one silane and a hardness-increasing amount of at least one member selected from the group consisting of thixotropic fumed silica; precipitated silica; an MQ resin wherein Q is SiO4 / 2, M is R1R2R3SiO1 / 2, and R1, R2, and R3 are the same or different functional or non-functional organic groups; carbon black; a thermoplastic resin; and a thermosetting resin.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

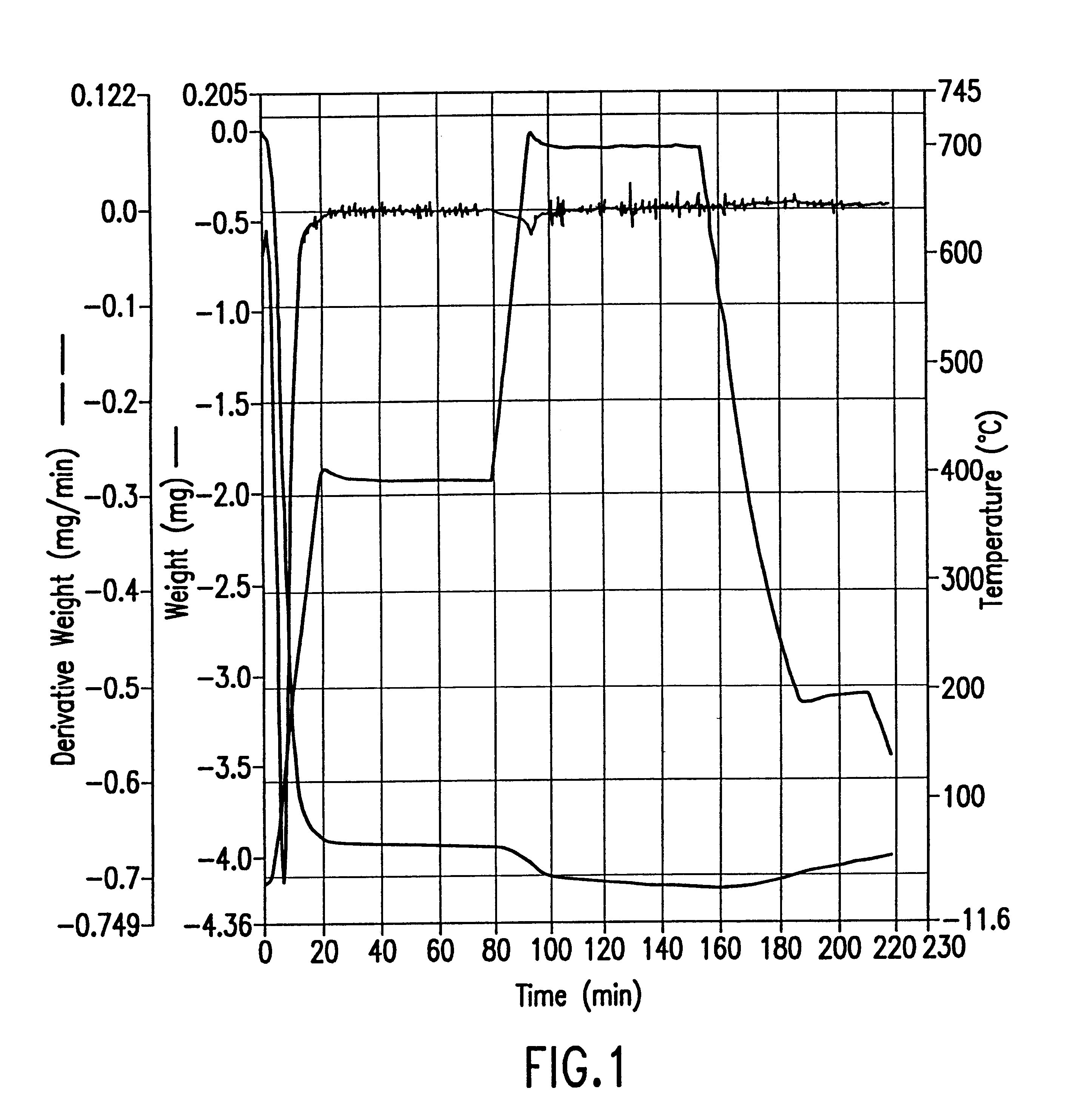

Methods for removal of water from gases using superheated zeolites

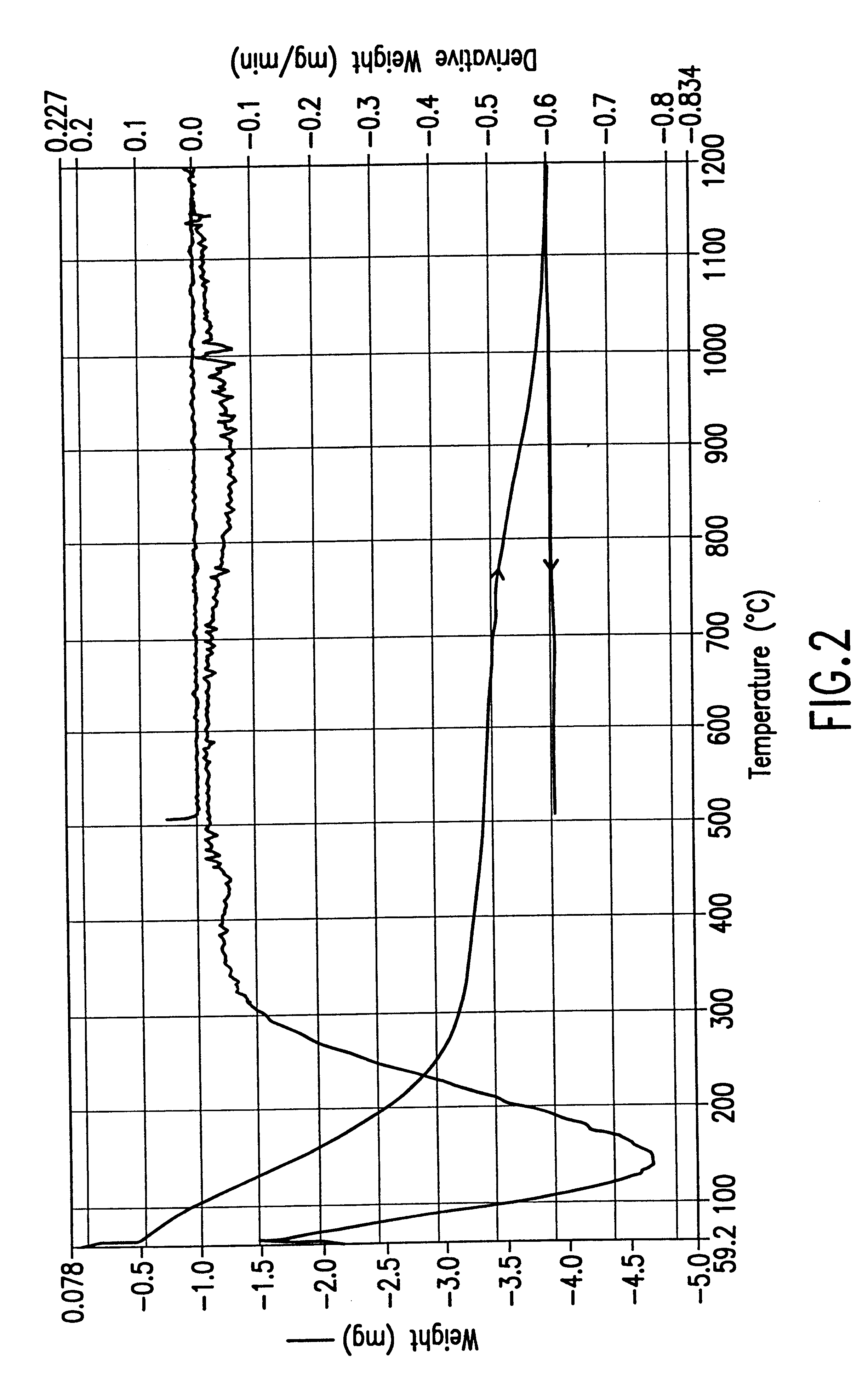

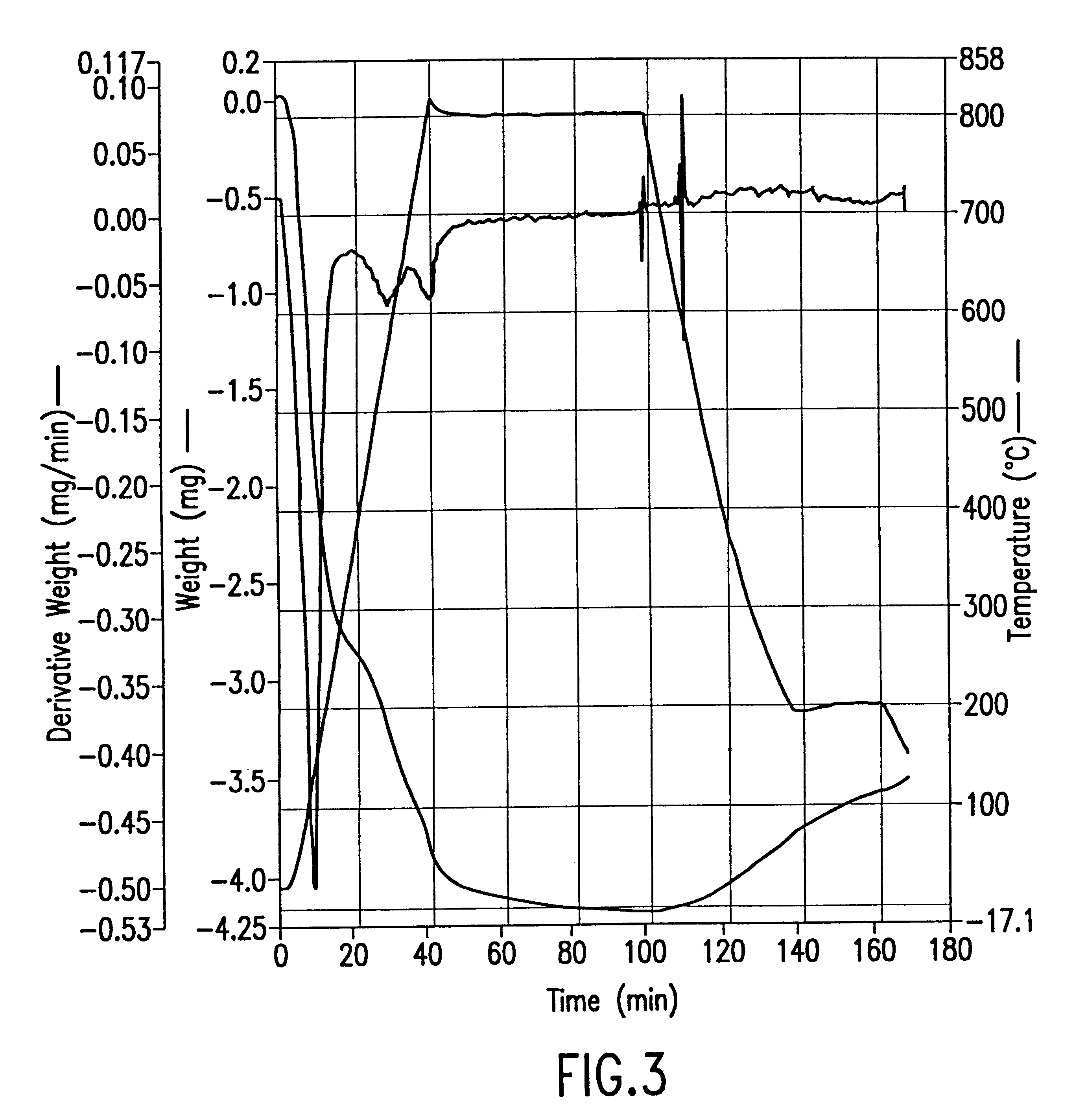

InactiveUS6110258AHigh silica-to-alumina ratioReduce metal contentGas treatmentMolecular sieve catalystsBoiling pointSilicon dioxide

A method for removing trace moisture from a gas is disclosed. The method involves heating a zeolite having a high silica-to-alumina ratio to about 400 DEG C. to remove physically absorbed water from the zeolite, followed by heating the zeolite to a temperature in excess of 650 DEG C., to form a superheated zeolite. Heating to temperatures of 650 DEG C. or above is believed to cause dehydroxylation of the zeolite. A method for the preparation of a dehydroxylated zeolite is also disclosed. The superheated zeolite is contacted with the gas, thereby adsorbing water from the gas. A dehydroxylated zeolite for removing trace moisture from a gas wherein the zeolite has a high silica-to-alumina ratio and a low level of metallic impurities is also disclosed. The zeolite and methods of the invention are particularly useful for removing trace water from acid gases such as hydrogen chloride and hydrogen bromide.

Owner:MATHESON TRI GAS INC

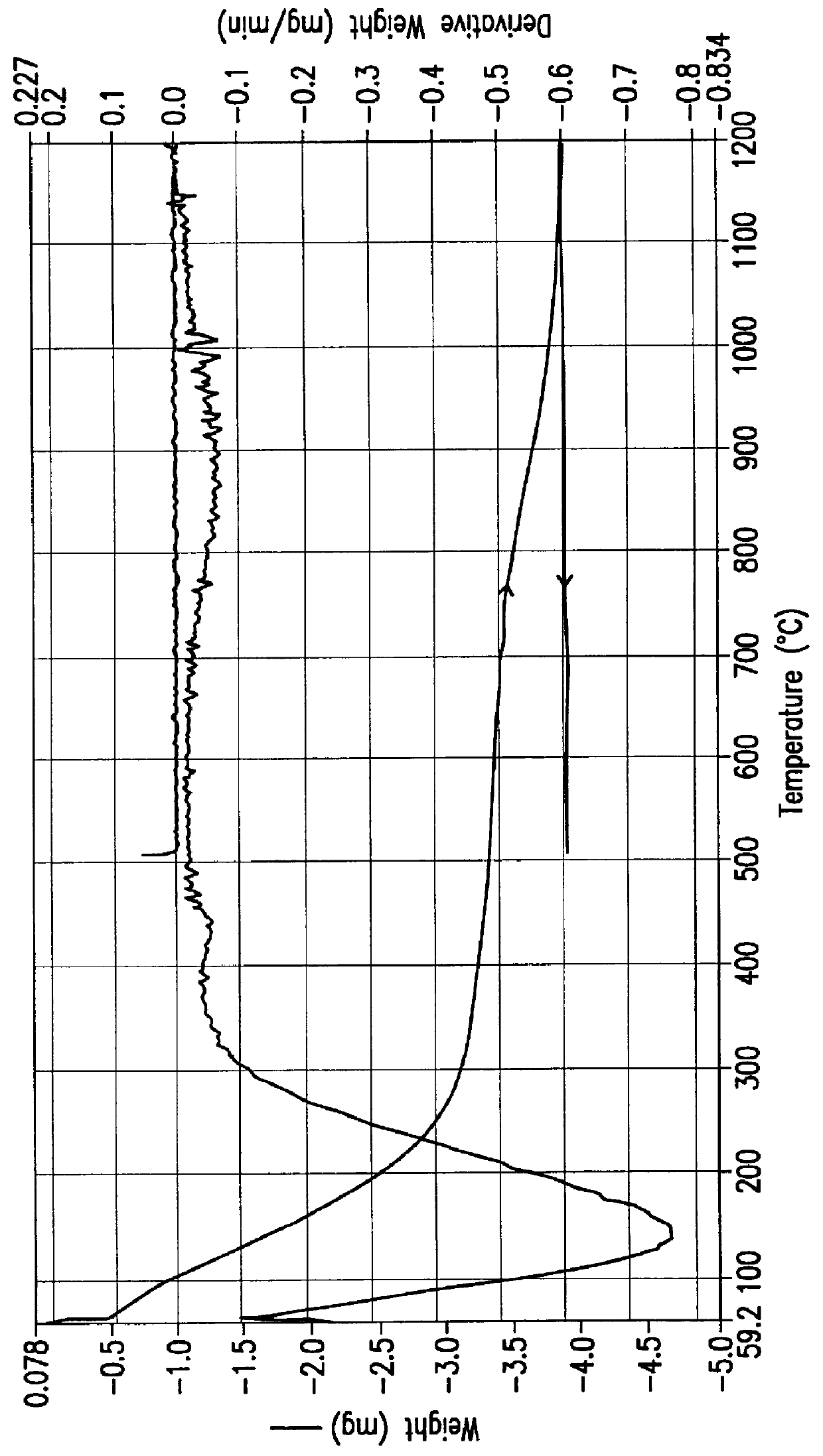

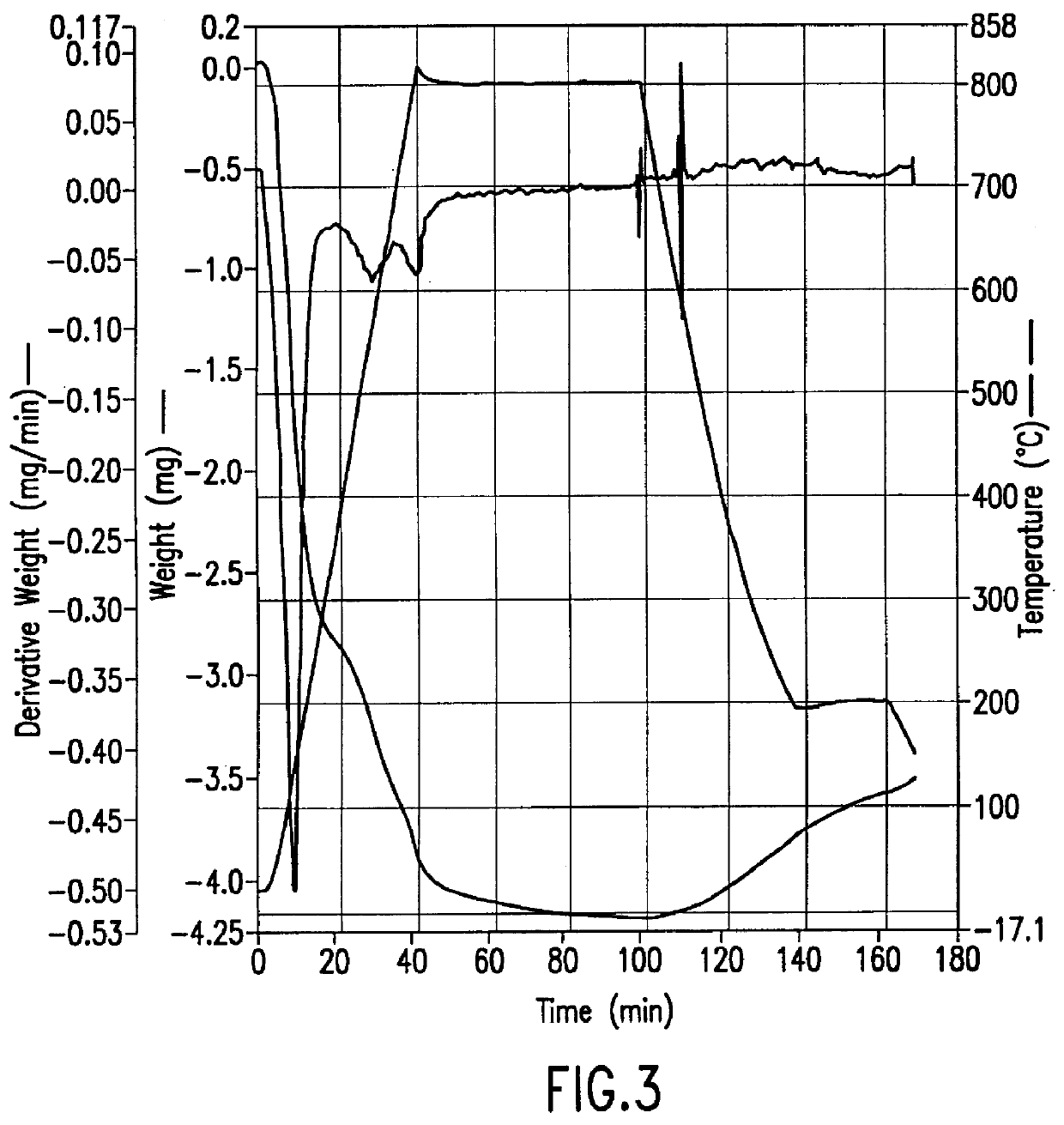

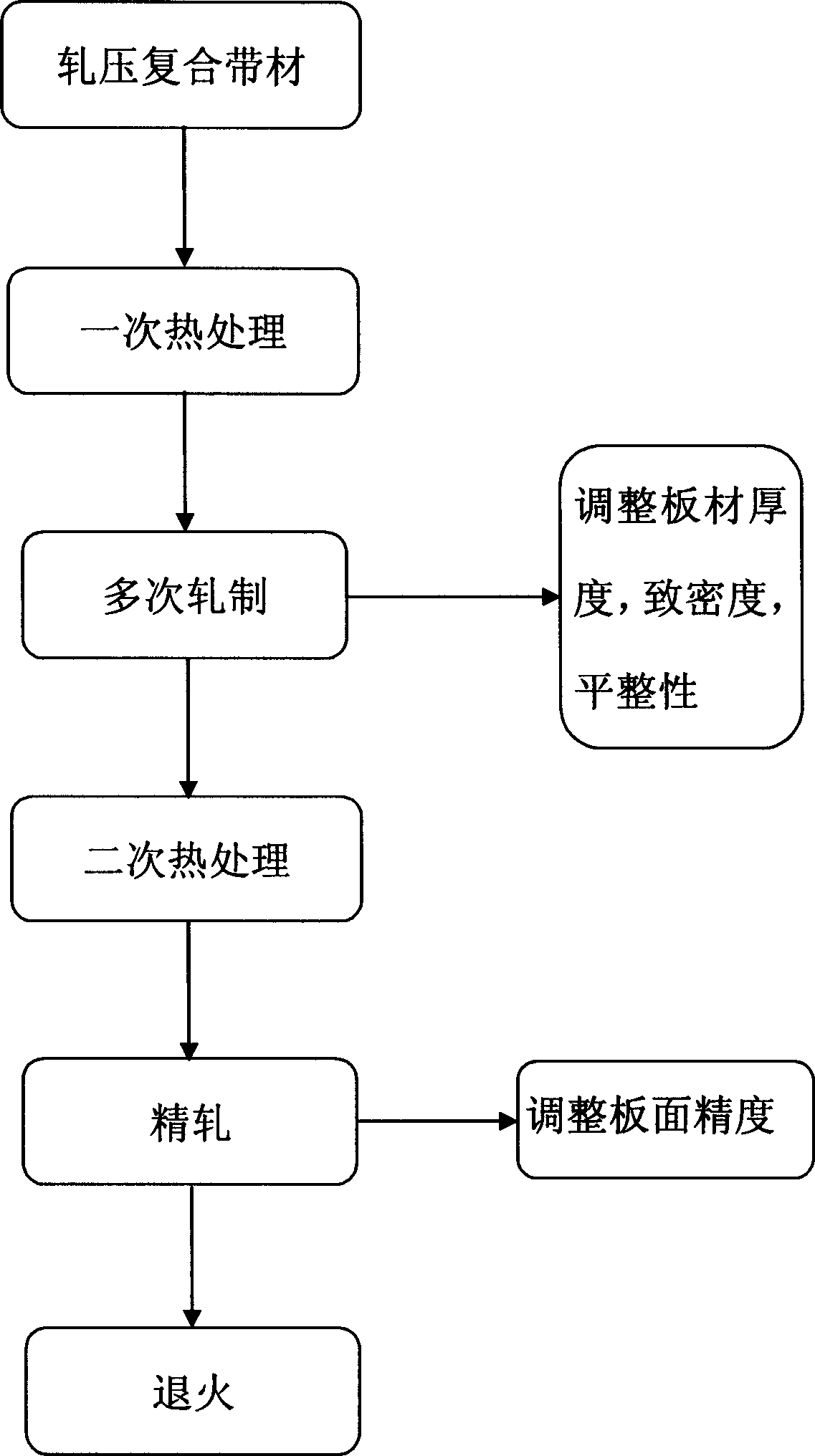

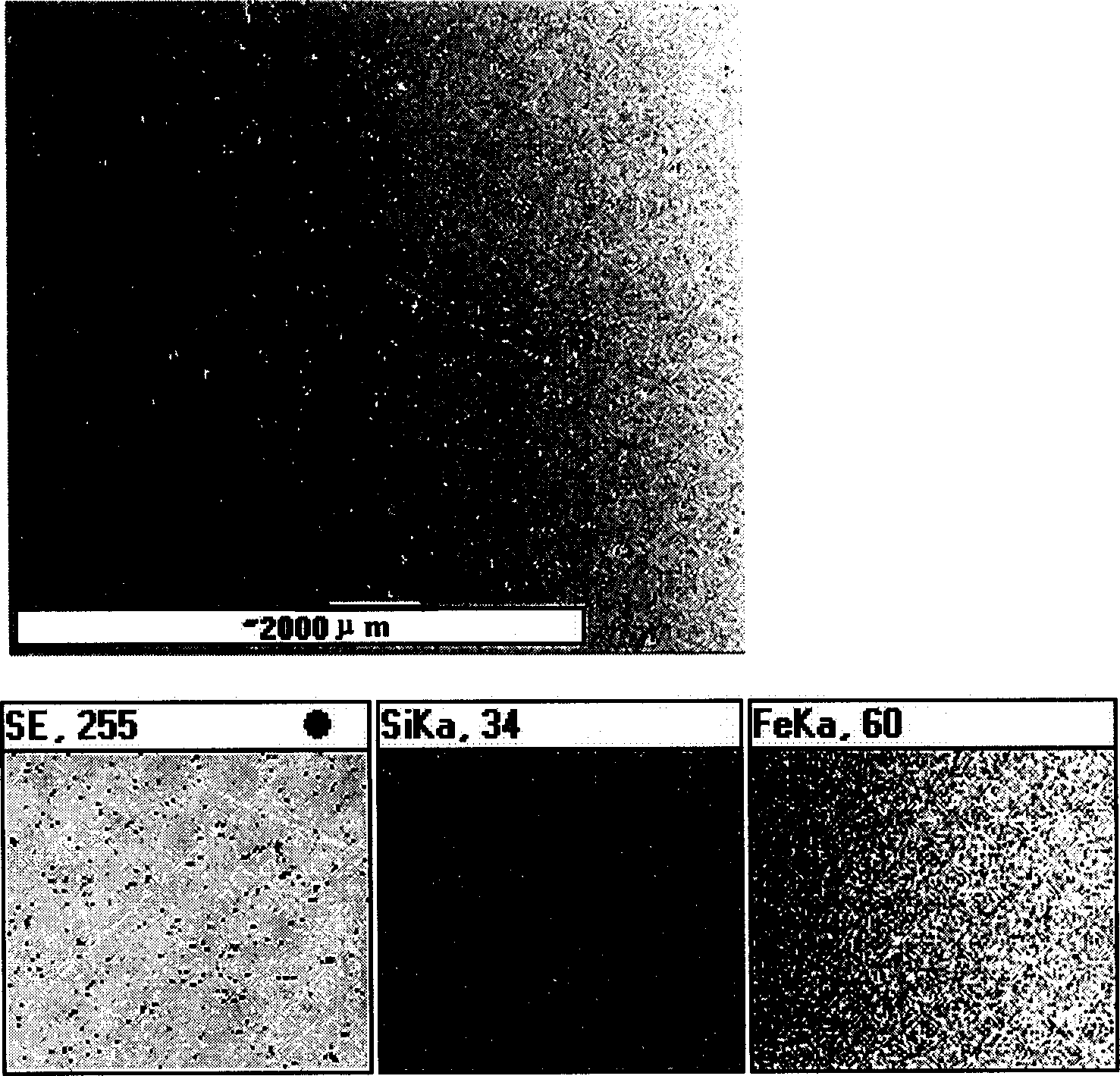

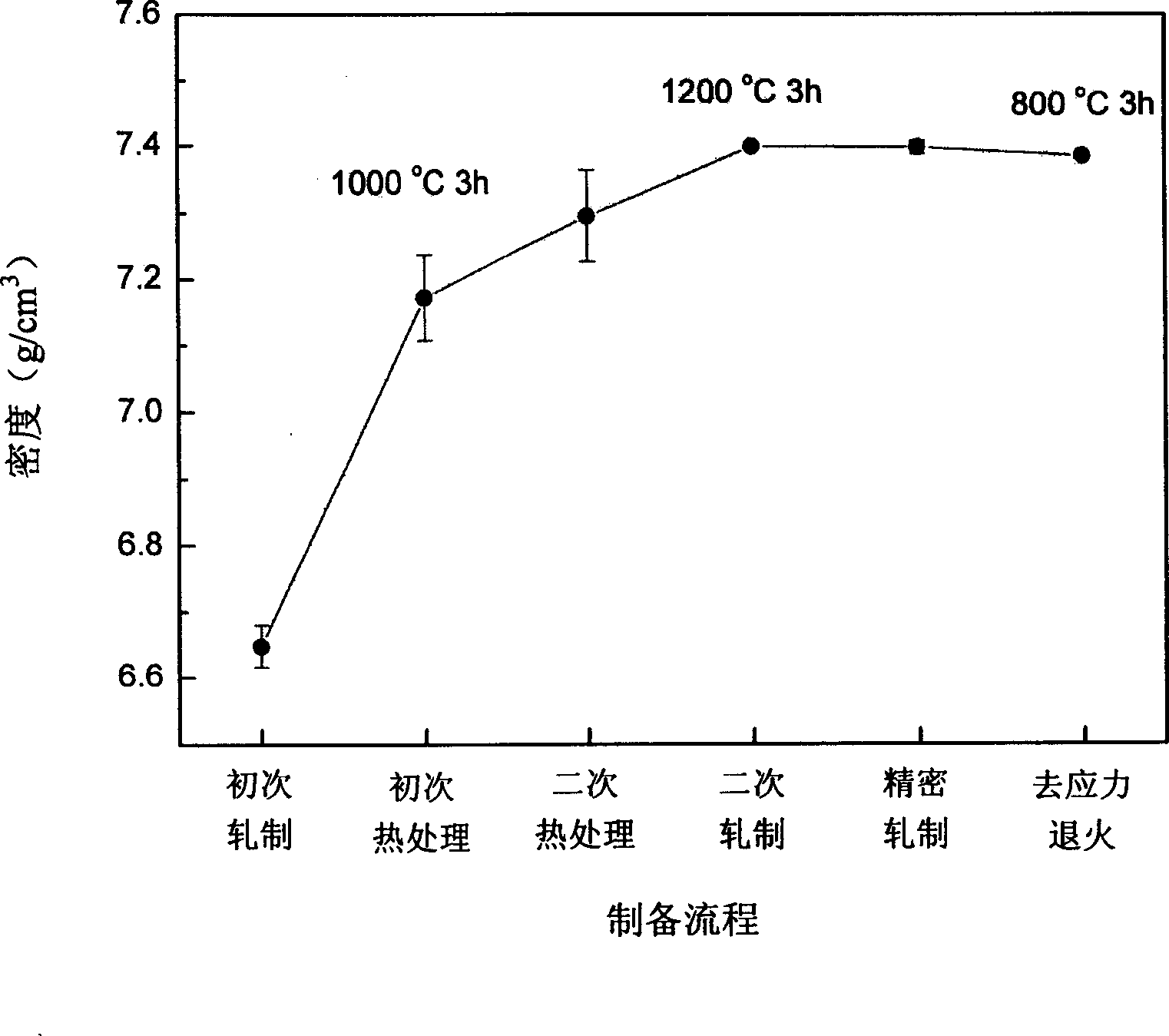

High-silica silicon-steel sheet heat treatment and multiple cold-rolling method

InactiveCN1528921AOvercoming limitations that cannot be processed by calenderingEasy to operateHigh silicaSilicon

The invention provides a method for producing high brittleness silicon steel board by using two times of heat process and multiple tracks cold-roll adjustment compound technology in different temperature range to control the extending performance of belt material rolling. It carries on baking process to high silicon steel shin board green compact produced by powder pressing method in low temperature range, controls the content of silicon in irn particles in shin boards, the board material can maintain the malleability. It carries on multiple rolling cold process when the silicon steel board is brittled, thus controls the thickness smooth property, and compactability of board. Then carries on secondary baking processing in high temperature, thus there obtains th even silicon steel board. Finally, carries on stress adjustment and relief annealing process, thus the product can be obtained.

Owner:WUHAN UNIV OF TECH

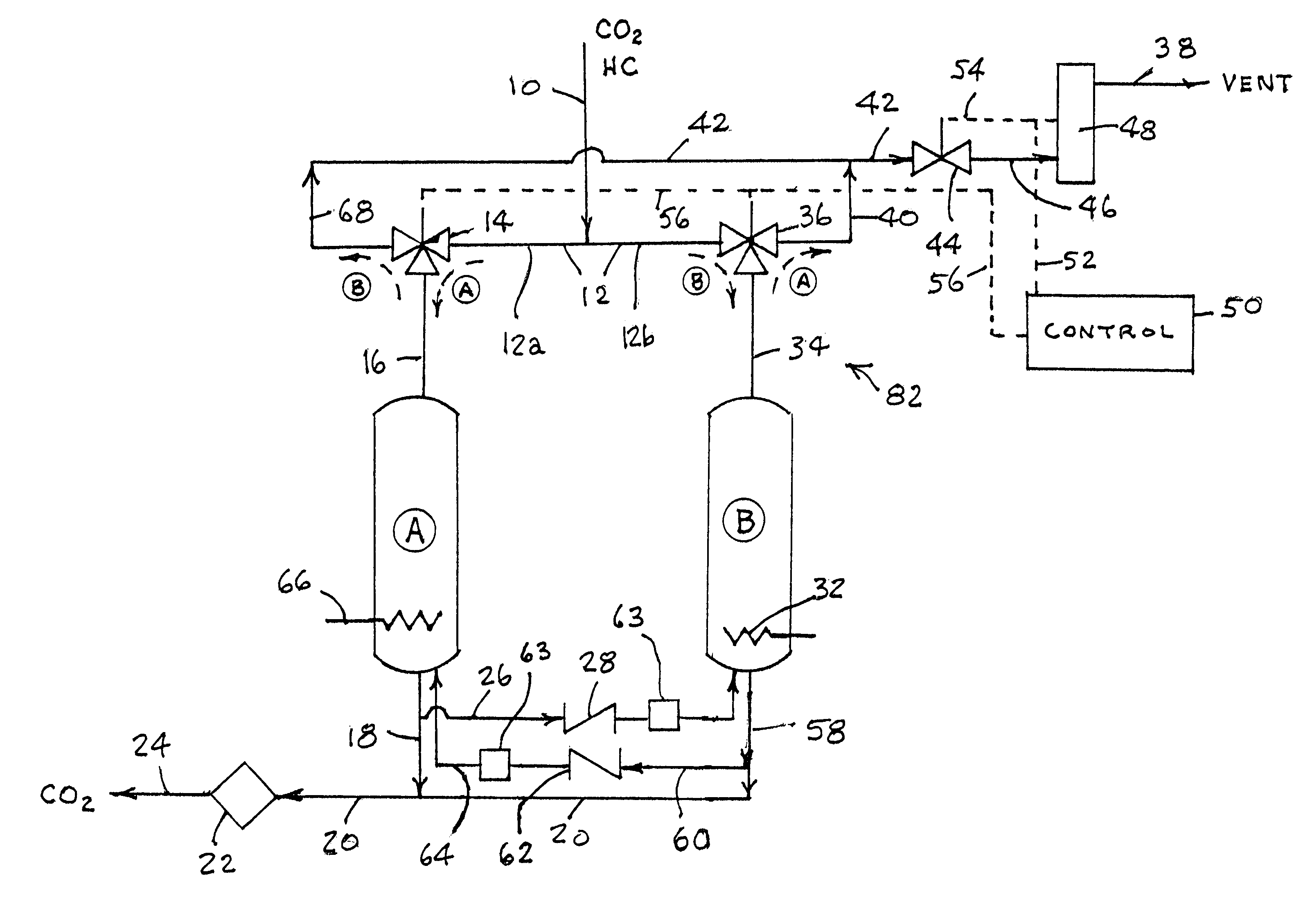

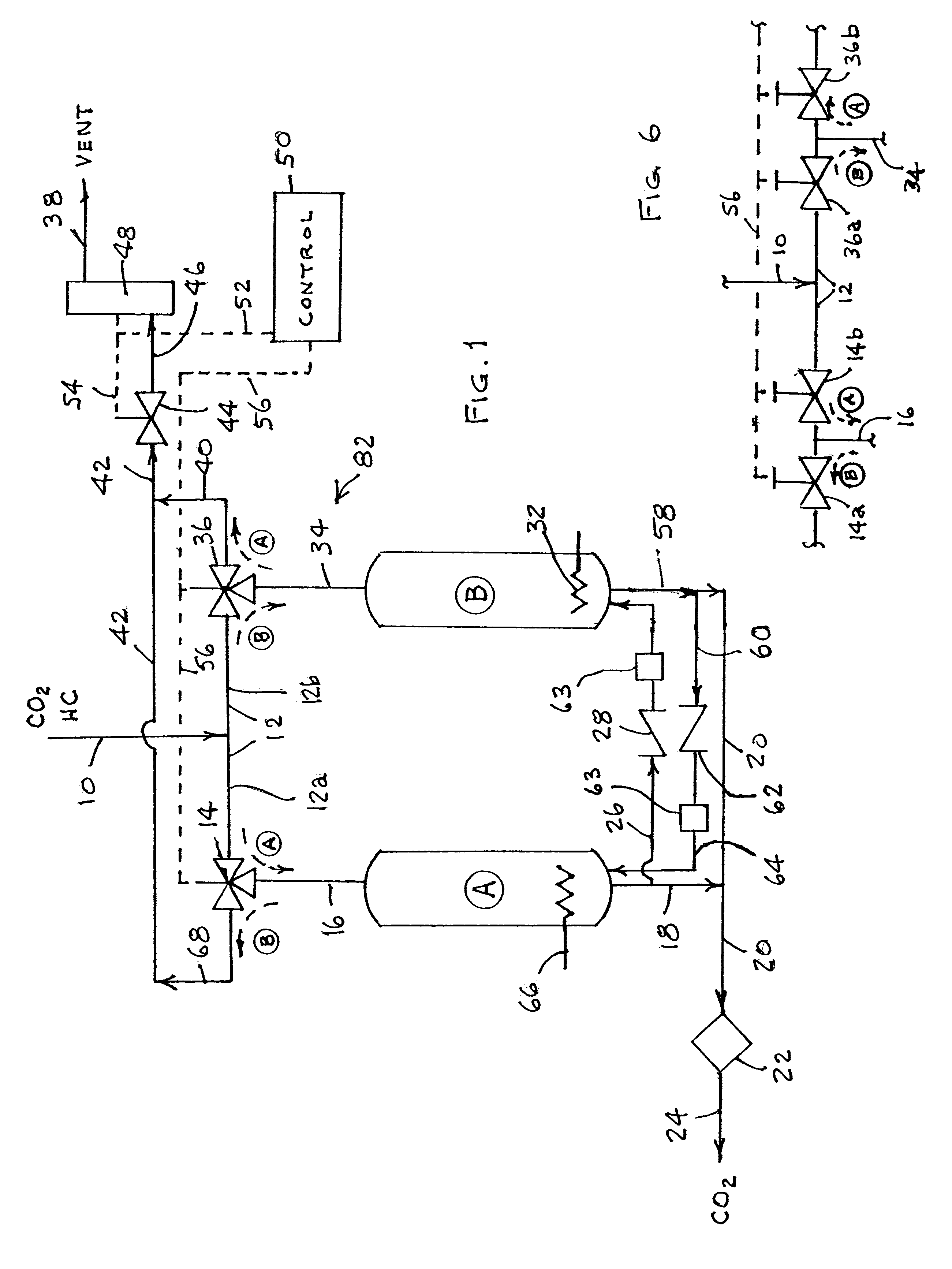

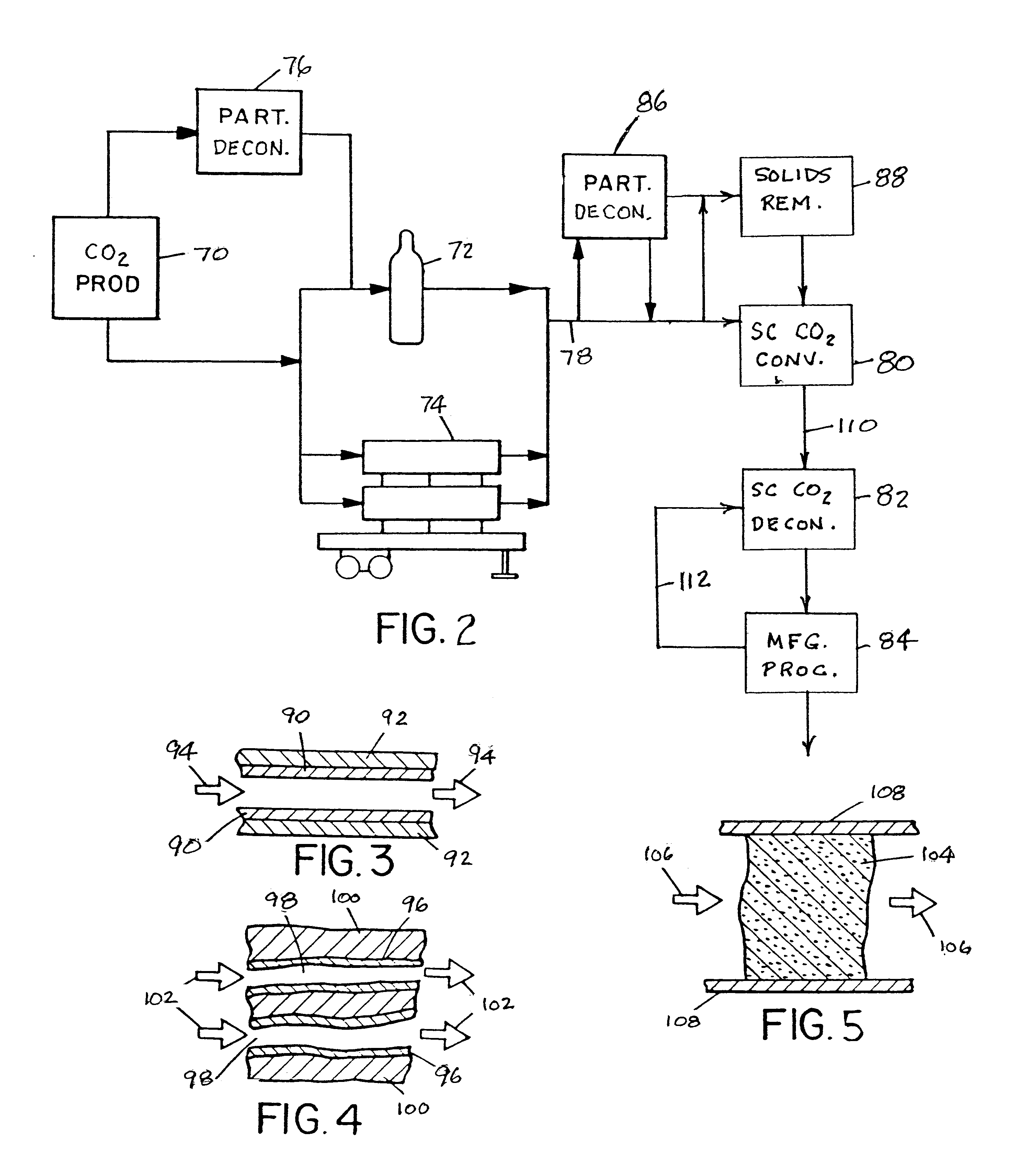

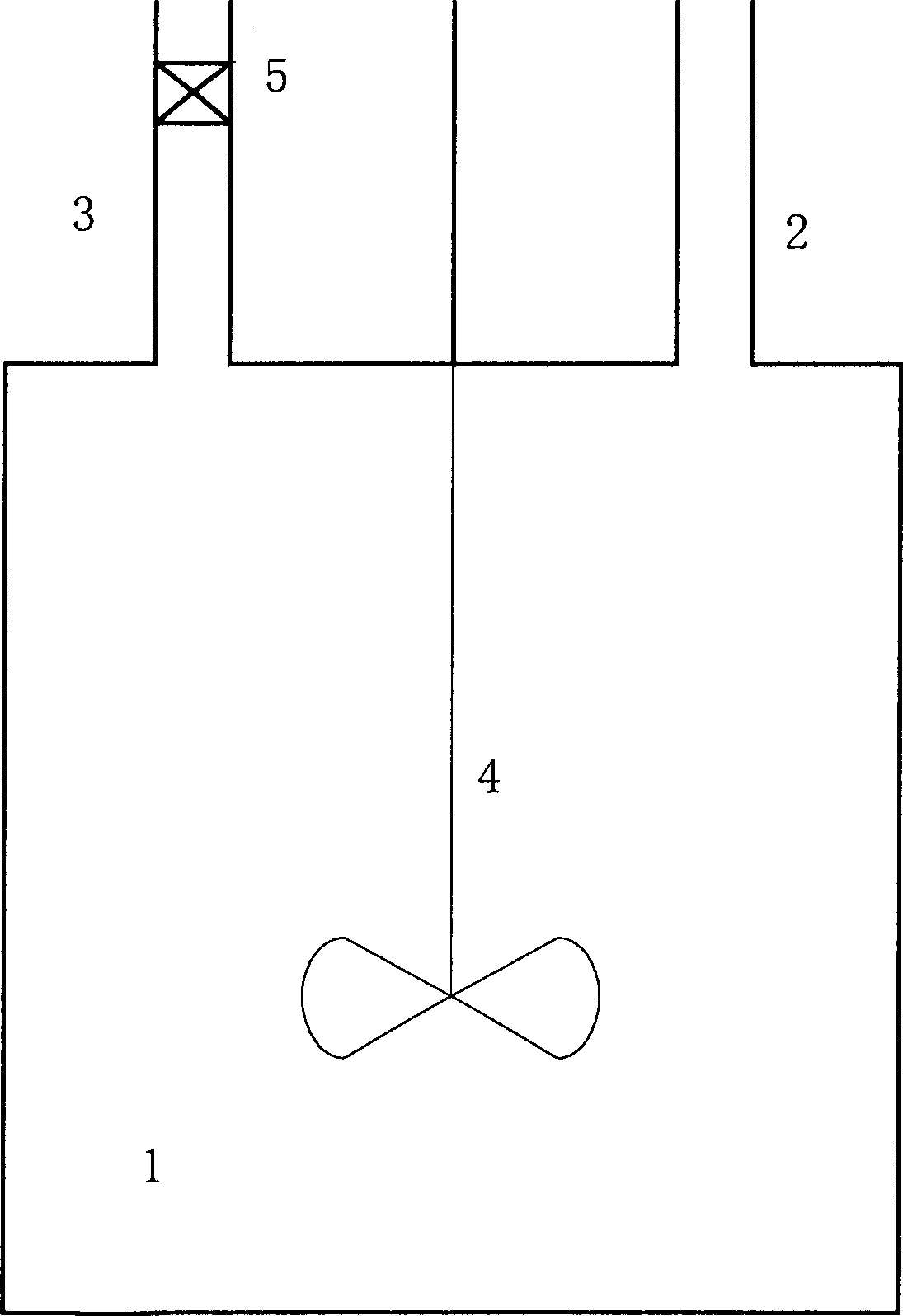

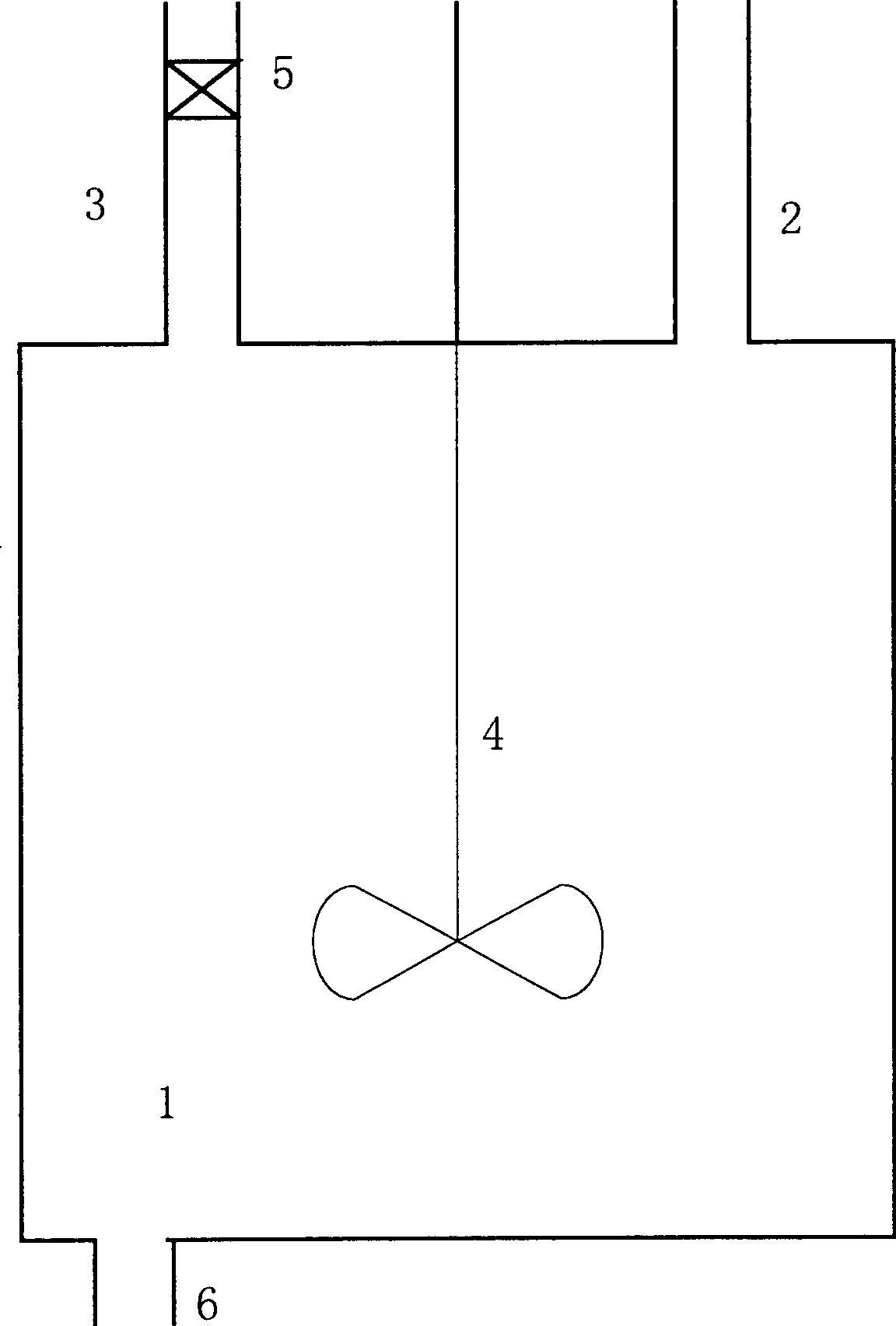

Self-regenerative process for contaminant removal from liquid and supercritical CO2 fluid streams

A method for the decontamination of fluid (liquid or supercritical) carbon dioxide fluid, especially of hydrocarbon contaminants, down to <=100 ppb concentration are described. The critical component is a high silica zeolite, preferably a high silica Y-type zeolite, ZSM-5 or a high silica mordenite, which in a variety of physical forms is capable of decontaminating such fluid CO2 to <=100 ppb, <=10-50 ppb, or ~1 ppb, without being detrimentally affected by the supercritical operating environment. The high silica zeolite may be produced by the removal of alumina from a natural or synthetic zeolite while retaining the desirable zeolite structure, to a silica:alumina ratio of from 20-2000:1. Preferably the zeolite is disposed in separate quantities in at least two vessels, which operate alternately. A portion of the purified product from the operating vessel is directed to the other vessel and there used to remove accumulated contaminants from that vessel's zeolite. The process thus provides self-regeneration, in that regeneration of one vessel occurs while the other vessel decontaminates contaminated fluid carbon dioxide, so that use of the two can be alternated for substantially continual production of purified fluid carbon dioxide. The invention provides purified fluid carbon dioxide used in manufacture of such products as high purity electronic, optical, prosthetic or similar products or polymers or pharmaceuticals or in beverages.

Owner:ENTEGRIS INC

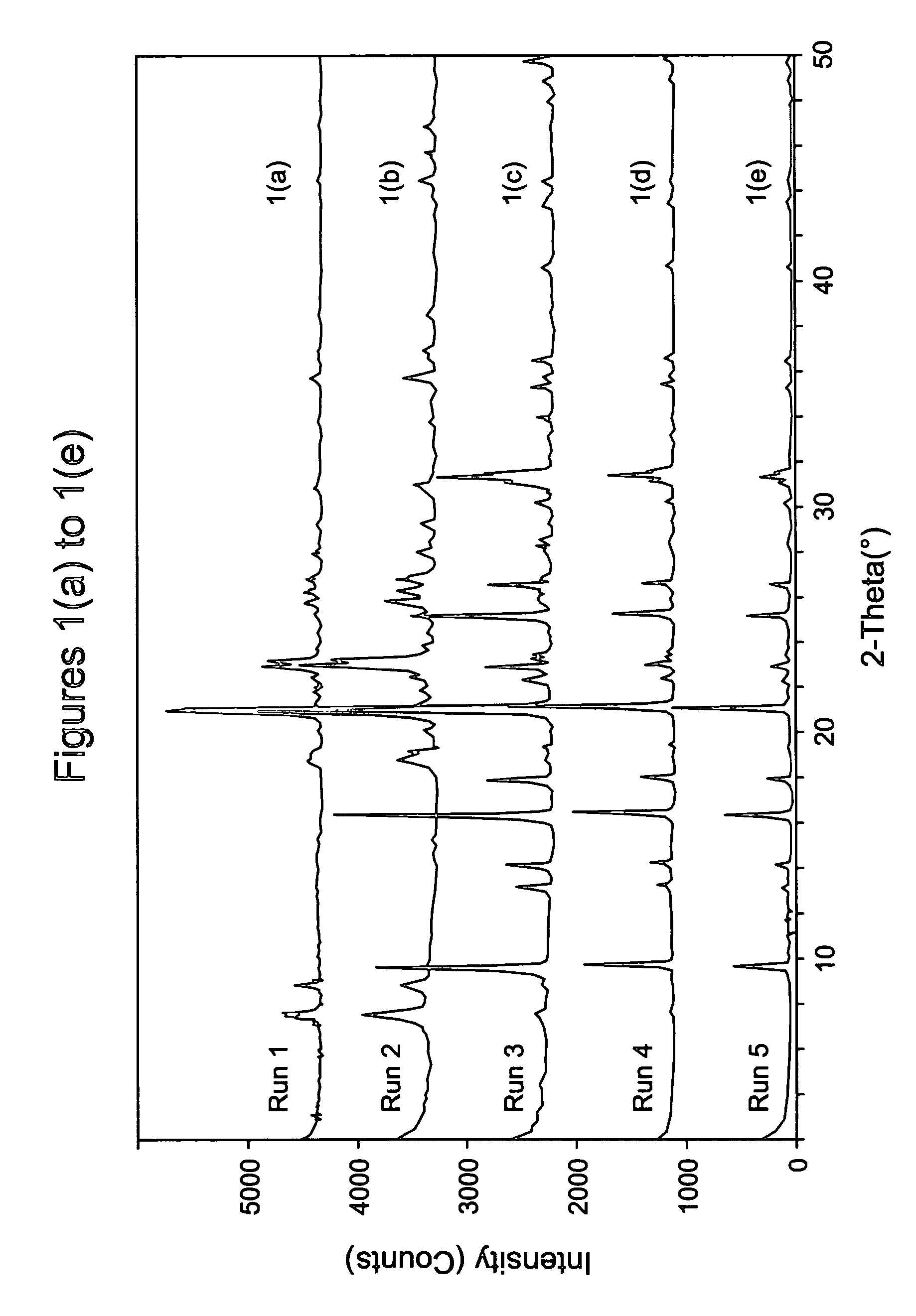

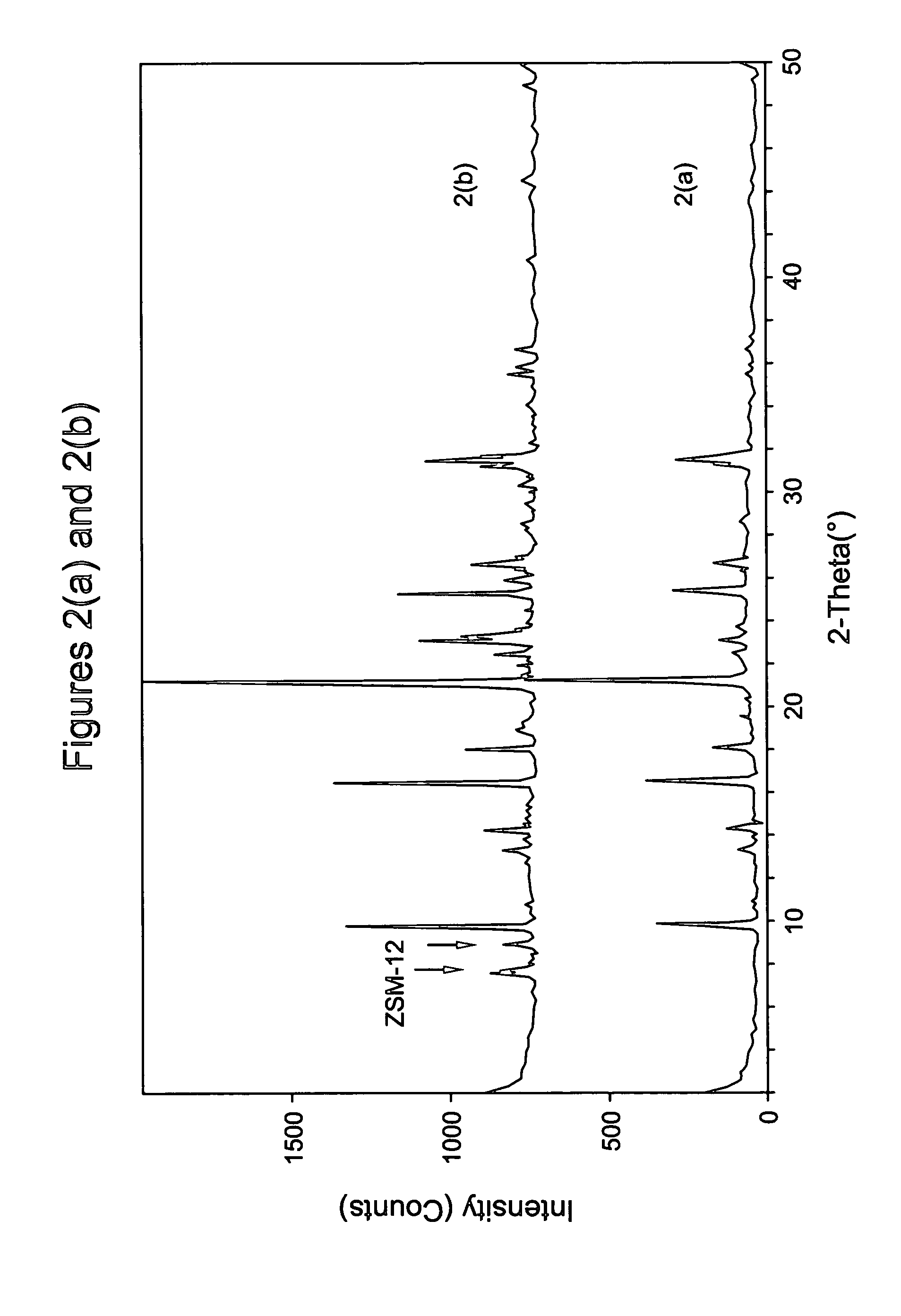

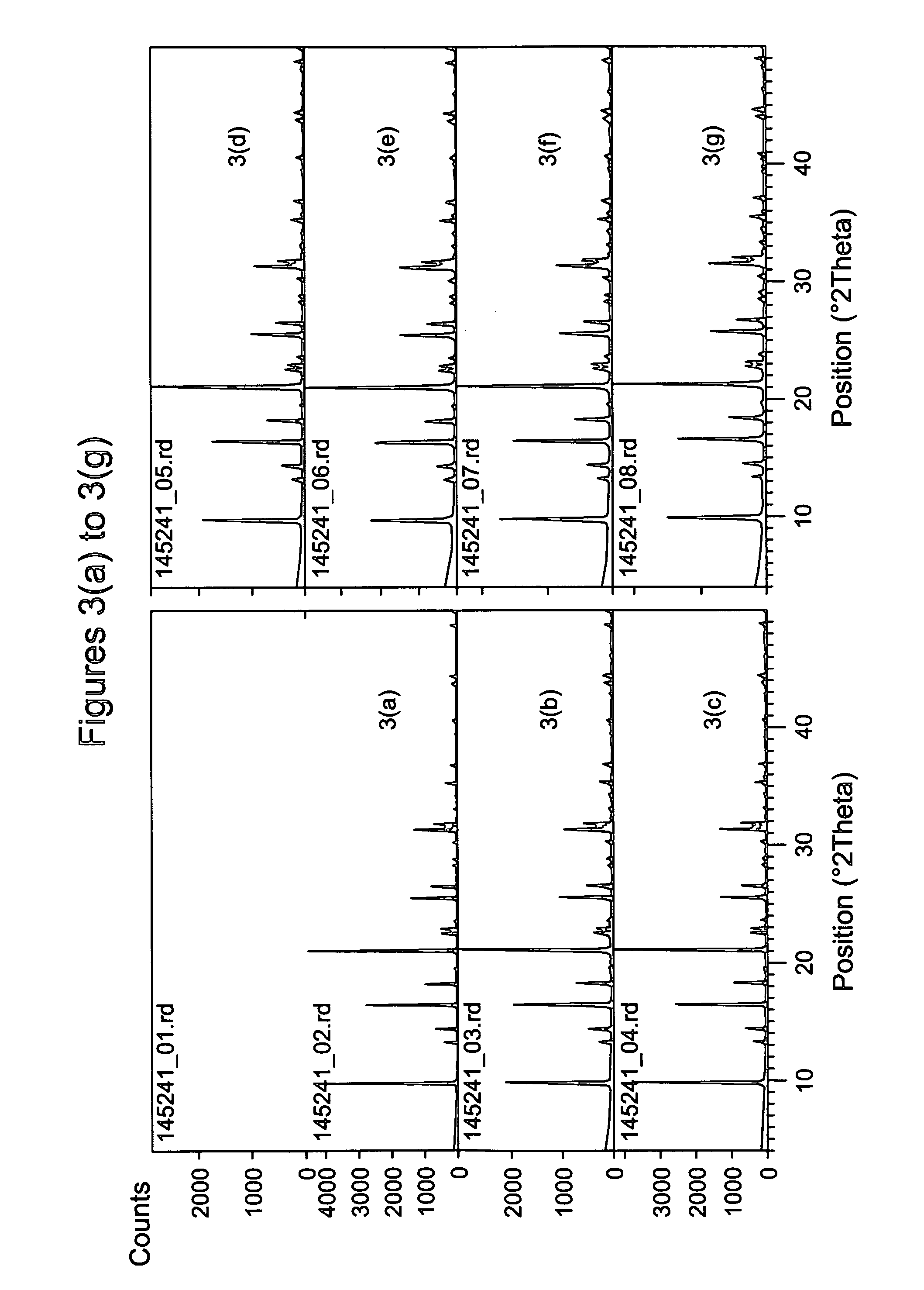

Synthesis of chabazite-containing molecular sieves and their use in the conversion of oxygenates to olefins

The synthesis of a crystalline material, in particular, a high silica zeolite, comprising a chabazite-type framework molecular sieve is conducted in the presence of an organic directing agent having the formula: [R1R2R3N—R4]+Q−wherein R1 and R2 are independently selected from hydrocarbyl groups and hydroxy-substituted hydrocarbyl groups having from 1 to 3 carbon atoms, provided that R1 and R2 may be joined to form a nitrogen-containing heterocyclic structure, R3 is an alkyl group having 2 to 4 carbon atoms and R4 is selected from a 4- to 8-membered cycloalkyl group, optionally, substituted by 1 to 3 alkyl groups each having from 1 to 3 carbon atoms; and a 4- to 8-membered heterocyclic group having from 1 to 3 heteroatoms, said heterocyclic group being, optionally, substituted by 1 to 3 alkyl groups each having from 1 to 3 carbon atoms and the or each heteroatom in said heterocyclic group being selected from the group consisting of O, N, and S, or R3 and R4 are hydrocarbyl groups having from 1 to 3 carbon atoms joined to form a nitrogen-containing heterocyclic structure; and Q− is a anion.

Owner:EXXONMOBIL CHEM PAT INC

Methods for removal of impurity metals from gases using low metal zeolites

InactiveUS6395070B1High silica-to-alumina ratioReduce metal contentGas treatmentMolecular sieve catalystsBoiling pointTrace metal

A method for removing trace moisture from a gas is disclosed. The method involves heating a zeolite having a high silica-to-alumina ratio to about 400° C. to remove physically adsorbed water from the zeolite, followed by heating the zeolite to a temperature in excess of 650° C., to form a superheated zeolite. The superheated zeolite is contacted with the gas, thereby adsorbing water from the gas. A dehydroxylated zeolite for removing trace moisture from a gas wherein the zeolite has a high silica-to-alumina ratio and a low level of metallic impurities is also disclosed. A method for removing metallic impurities from a gas using the low metals zeolite is also disclosed. The zeolites and methods of the invention are particularly useful for removing trace water and trace metal impurities from acid gases such as hydrogen chloride and hydrogen bromide.

Owner:MATHESON TRI GAS INC

Stabilized dual zeolite single particle catalyst composition and a process thereof

InactiveUS20030166453A1Good hydrothermal stabilityImprove stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveKaolin clay

The present invention relates to a stabilized dual zeolite catalyst for cracking heavier hydrocarbons into lighter useful products said catalyst comprising two types of zeolites viz., low silica molecular sieve and stabilized high silica zeolite, silica-alumina based binder and kaolin clay and a process for the preparation of the stabilized dual zeolite catalyst.

Owner:INDIAN OIL CORPORATION

High silicon Y-type zeolite containing rare-earth and its preparing method

ActiveCN1281493CThe initial unit cell constant is smallThe equilibrium cell constant is largeFaujasite aluminosilicate zeoliteGasolineRare earth

A rare-earth-containing high-silicon Y-type zeolite, the zeolite contains rare earths, is characterized in that the silicon-aluminum ratio of the zeolite is 5-30, the initial unit cell constant is 2.430-2.465 nanometers, and the balance unit cell constant and the initial unit cell constant The ratio is at least 0.985. The zeolite has the characteristics of small initial unit cell constant and large equilibrium unit cell constant. It has high structural stability and hydrothermal stability. The cracking catalyst containing this zeolite is not easy to deactivate. The choice of gasoline, diesel oil, dry gas and coke Good sex.

Owner:CHINA PETROLEUM & CHEM CORP +1

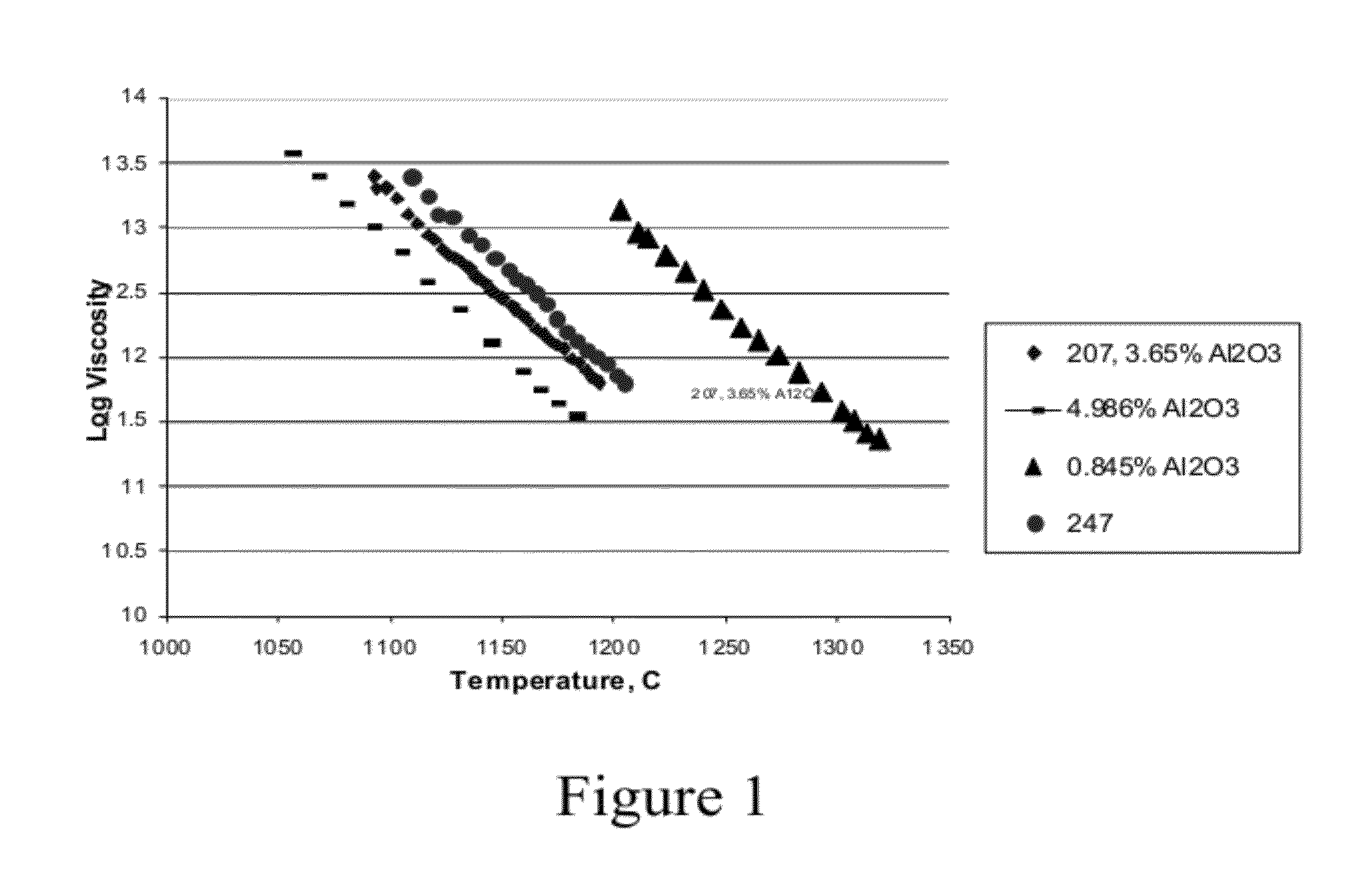

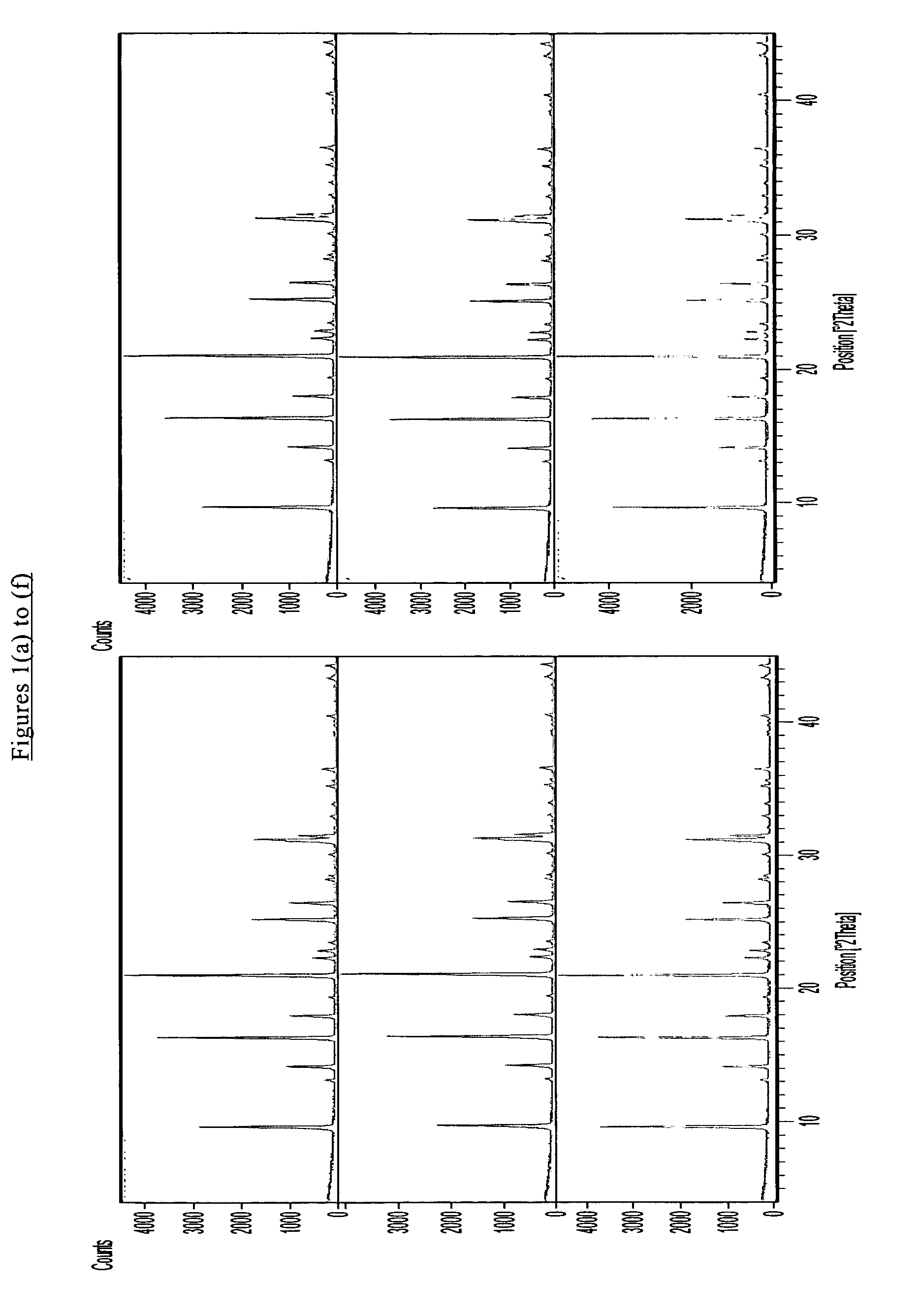

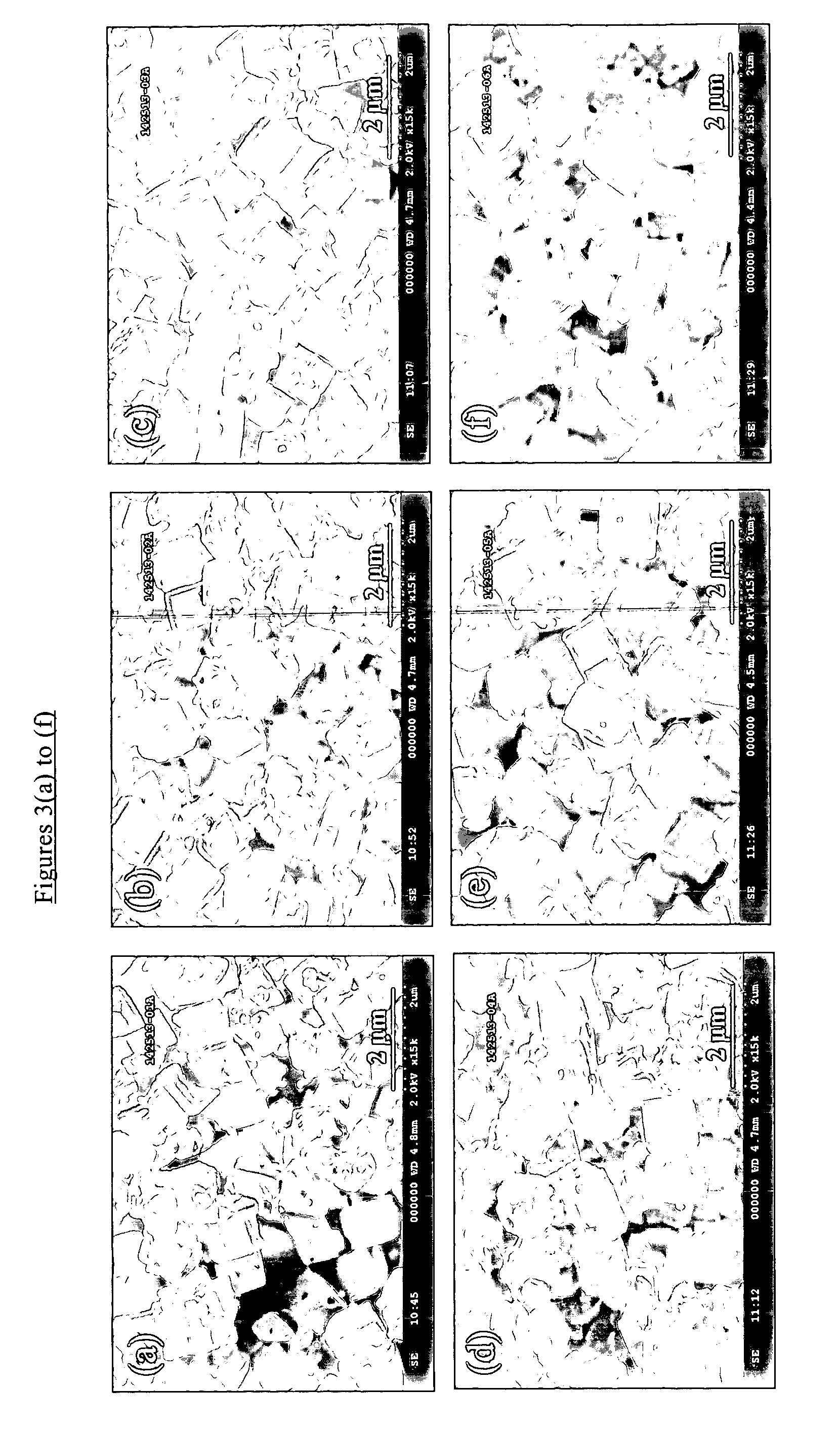

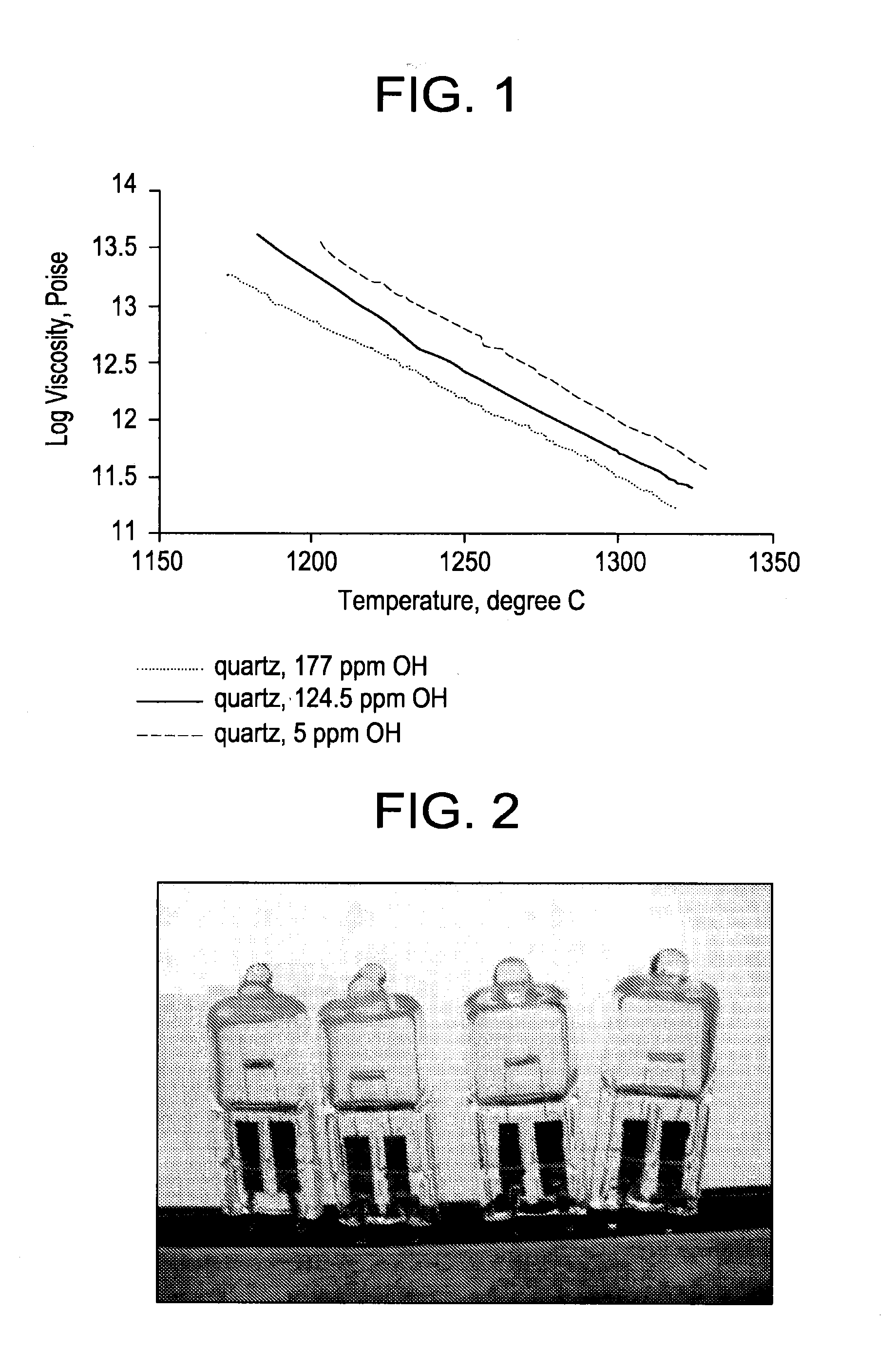

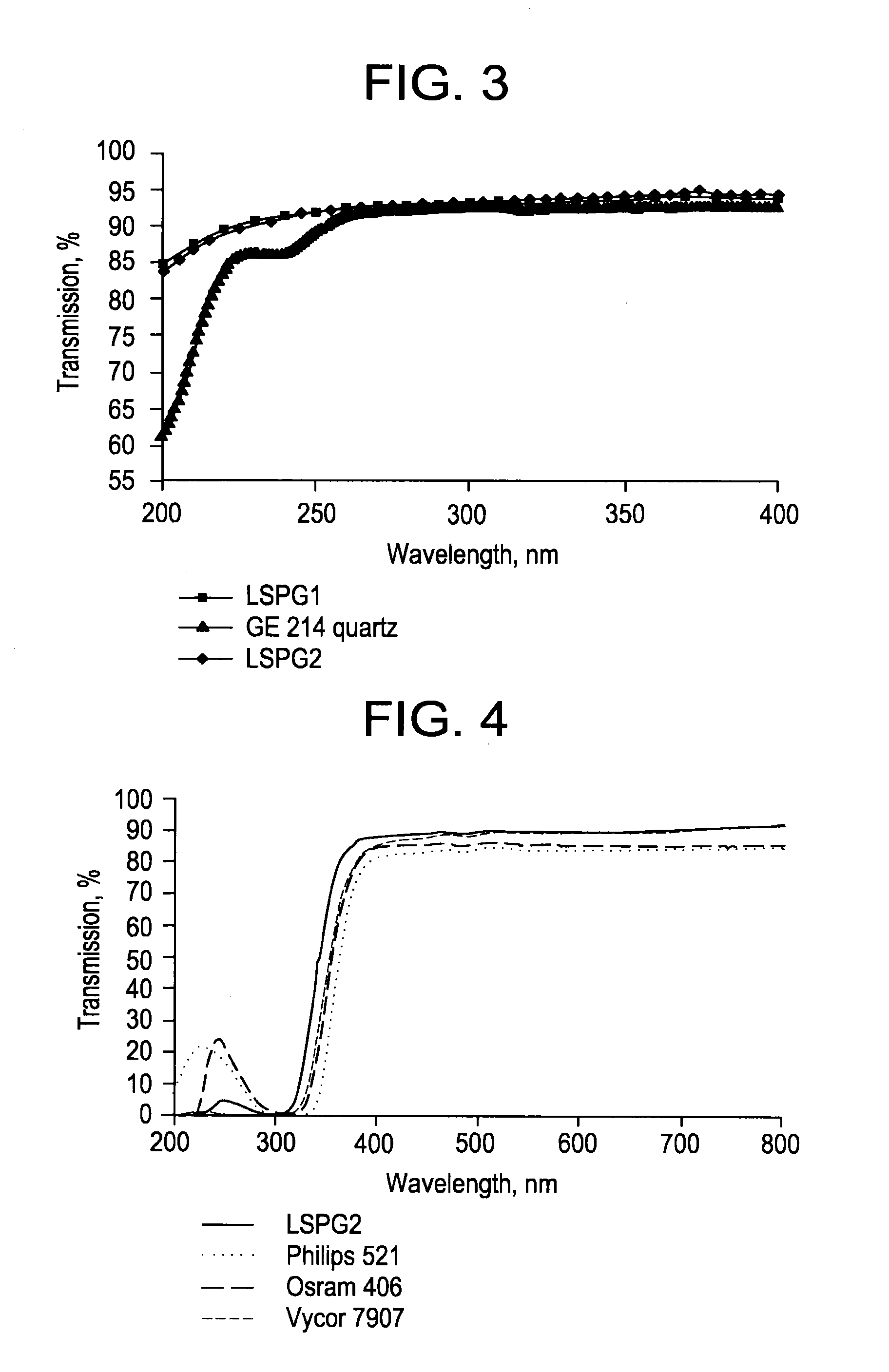

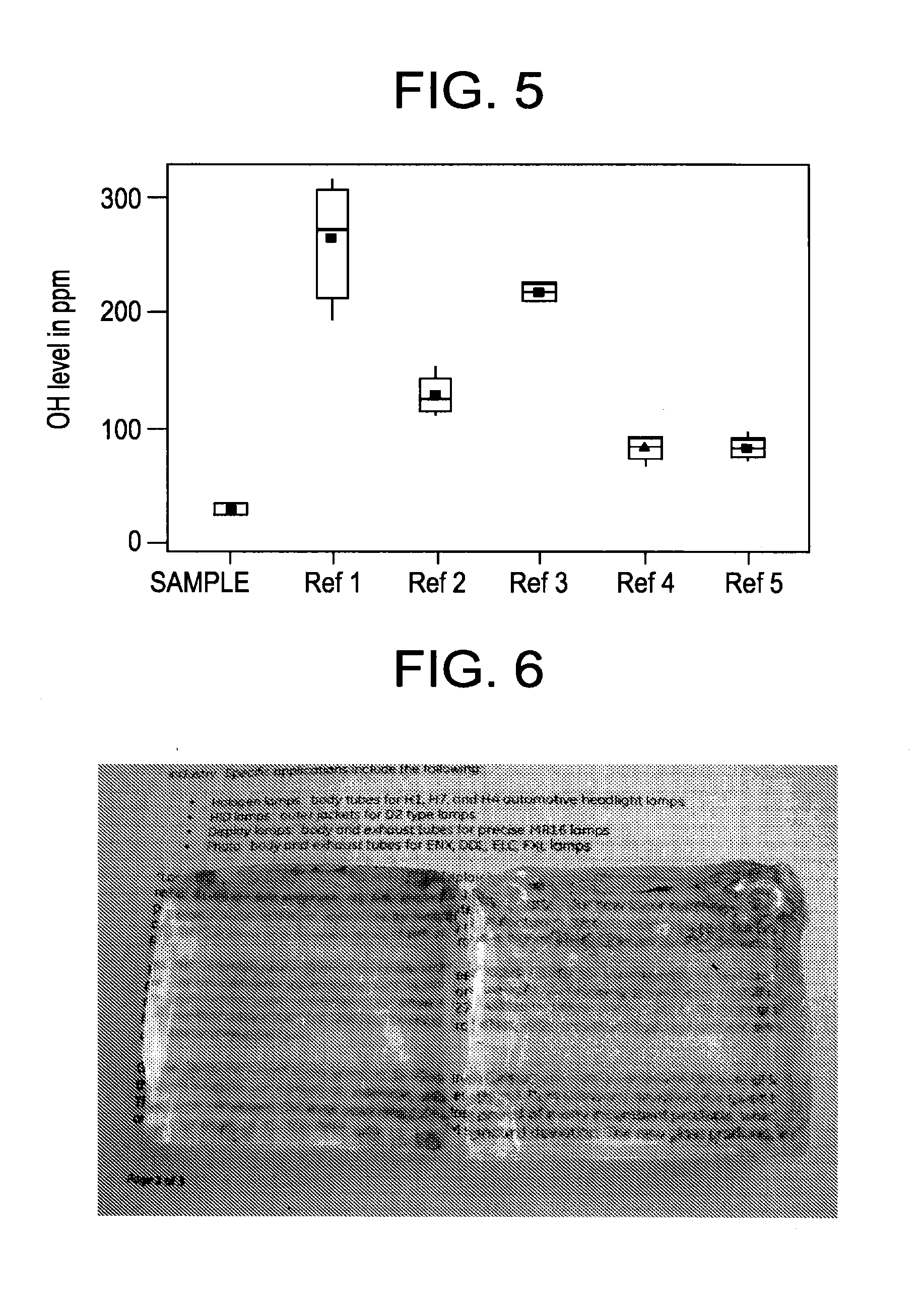

Fused quartz tubing for pharmaceutical packaging

InactiveUS20120148770A1Reduce softeningLow working point temperatureLayered productsPharmaceutical containersRare earthWorking temperature

A high silica glass composition comprising about 82 to about 99.9999 wt. % SiO2 and from about 0.0001 to about 18 wt. % of at least one dopant selected from Al2O3, CeO2, TiO2, La2O3, Y2O3, Nd2O3, other rare earth oxides, and mixtures of two or more thereof. The glass composition has a working point temperature ranging from 600 to 2,000° C. These compositions exhibit stability similar to pure fused quartz, but have a moderate working temperature to enable cost effective fabrication of pharmaceutical packages. The glass is particularly useful as a packaging material for pharmaceutical applications, such as, for example pre-filled syringes, ampoules and vials.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

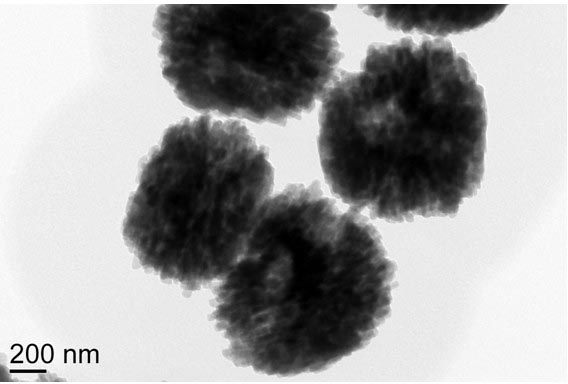

Chabazite-type molecular sieve, its synthesis and its use in the conversion of oxygenates to olefins

The synthesis of a crystalline material, in particular a high silica zeolite, having a chabazite-type framework is aided by the addition to the synthesis mixture of seeds of an AEI framework-type material. The chabazite-type product has a relatively small crystal size and exhibits activity and selectivity in the conversion of methanol to lower olefins, especially ethylene and propylene.

Owner:EXXONMOBIL CHEM PAT INC +1

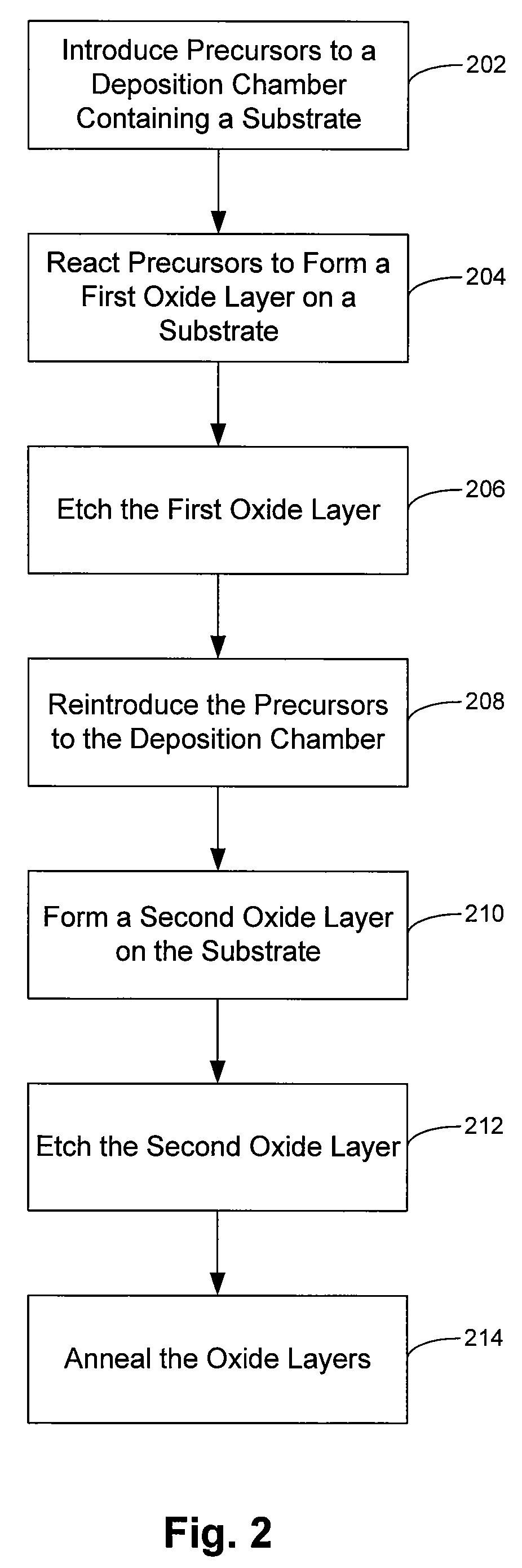

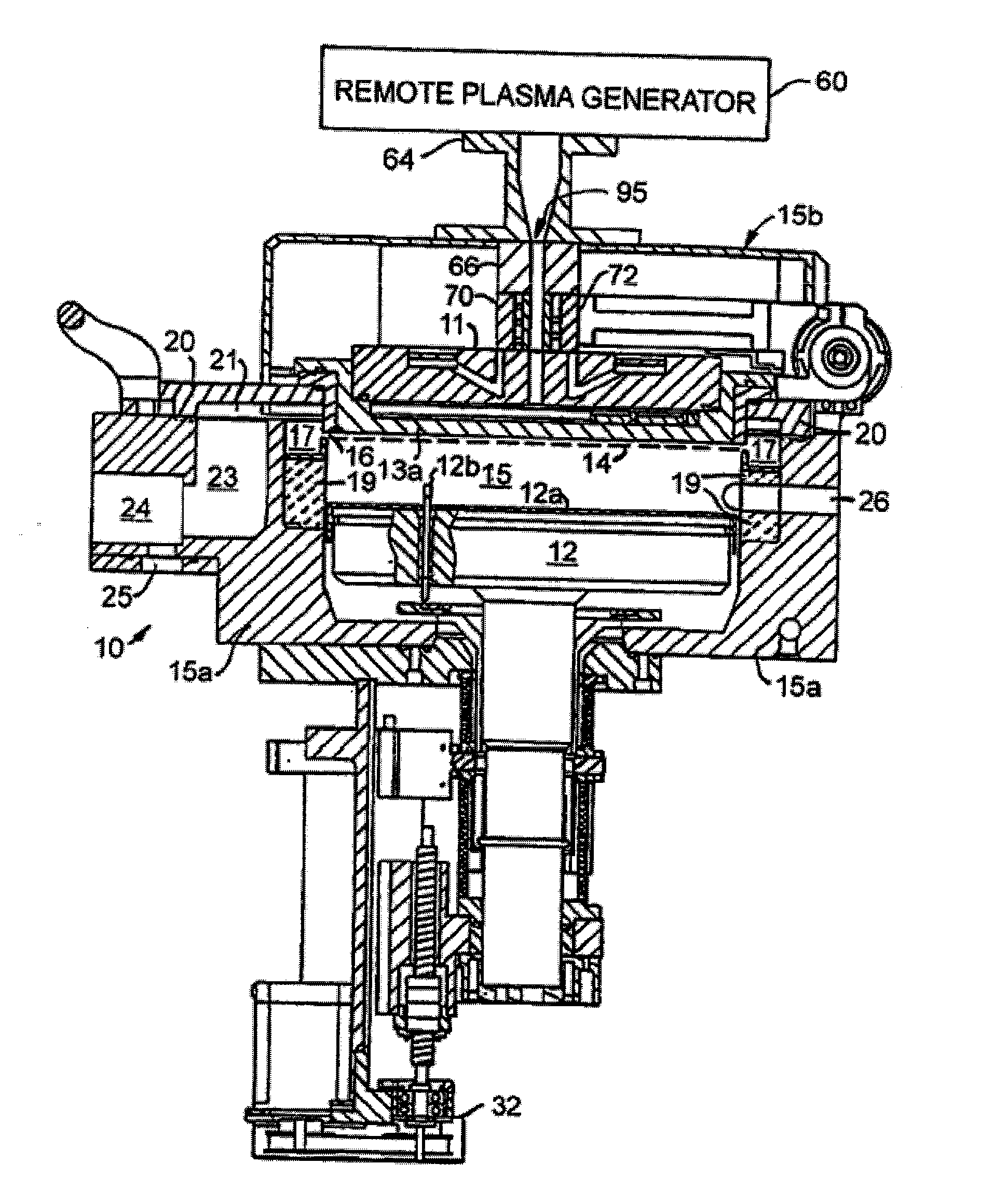

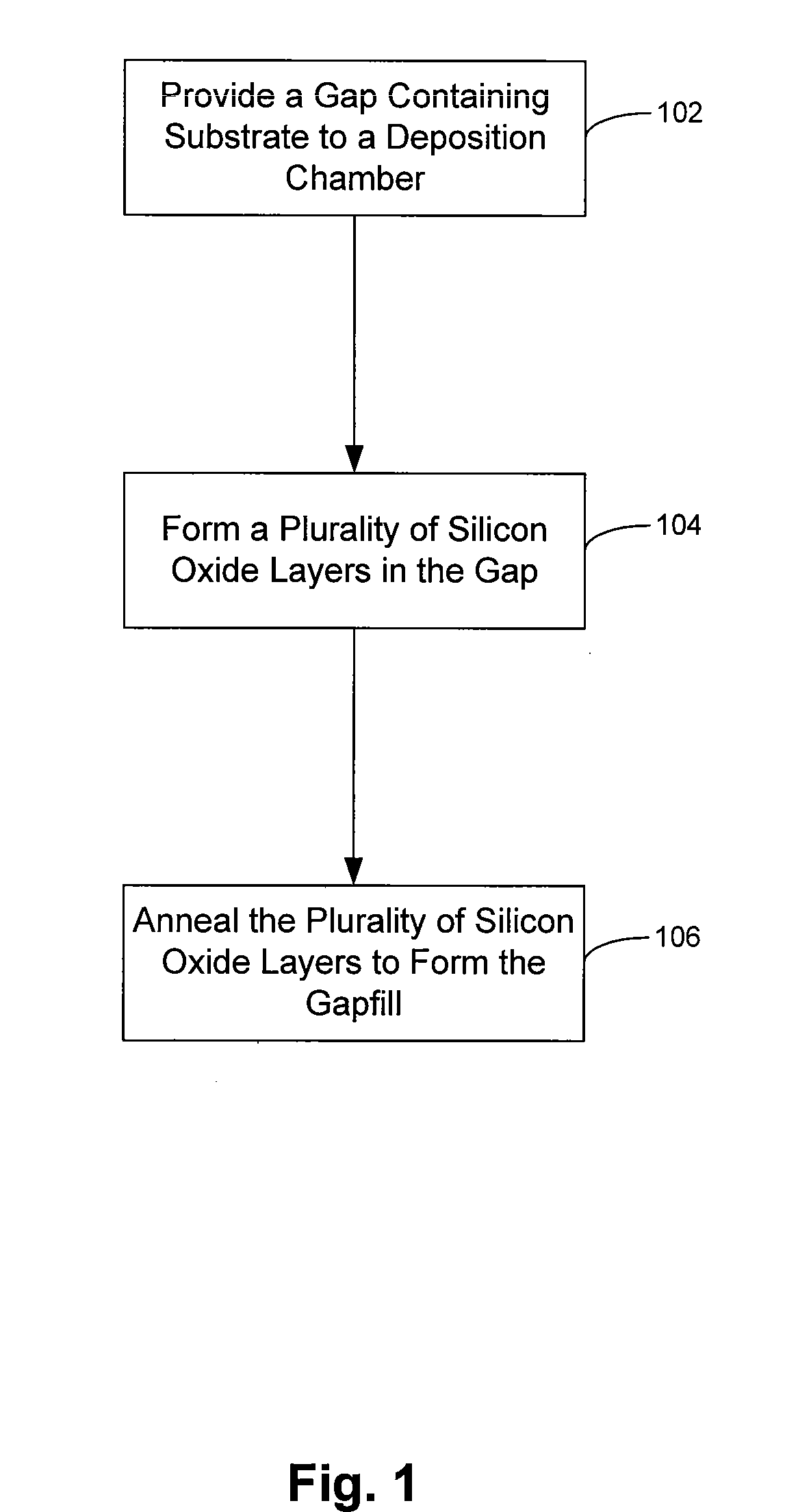

Deposition-plasma cure cycle process to enhance film quality of silicon dioxide

ActiveUS7902080B2Decorative surface effectsSemiconductor/solid-state device manufacturingSilicon monoxideSilicon oxide

Owner:APPLIED MATERIALS INC

Fused quartz tubing for pharmaceutical packaging

ActiveUS20130095261A1Low working point temperatureHigh wt % contentDiagnosticsLayered productsDopantWorking temperature

A high silica glass composition comprising about 92 to about 99.9999 wt. % SiO2 and from about 0.0001 to about 8 wt. % of at least one dopant selected from Al2O3, CeO2, TiO2, La2O3, Y2O3, Nd2O3, other rare earth oxides, and mixtures of two or more thereof. The glass composition has a working point temperature ranging from 600 to 2,000° C. These compositions exhibit stability similar to pure fused quartz, but have a moderate working temperature to enable cost effective fabrication of pharmaceutical packages. The glass is particularly useful as a packaging material for pharmaceutical applications, such as, for example pre-filled syringes, ampoules and vials.

Owner:MOMENTIVE PERFORMANCE MATERIALS QUARTZ INC

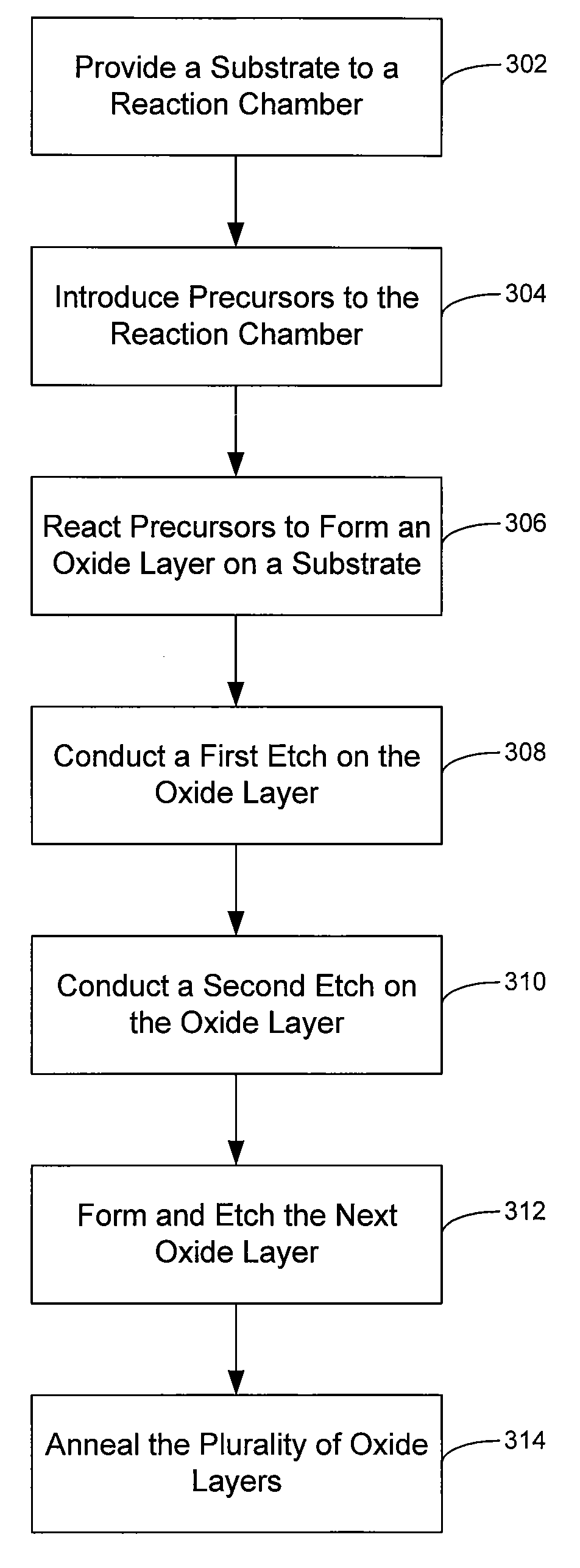

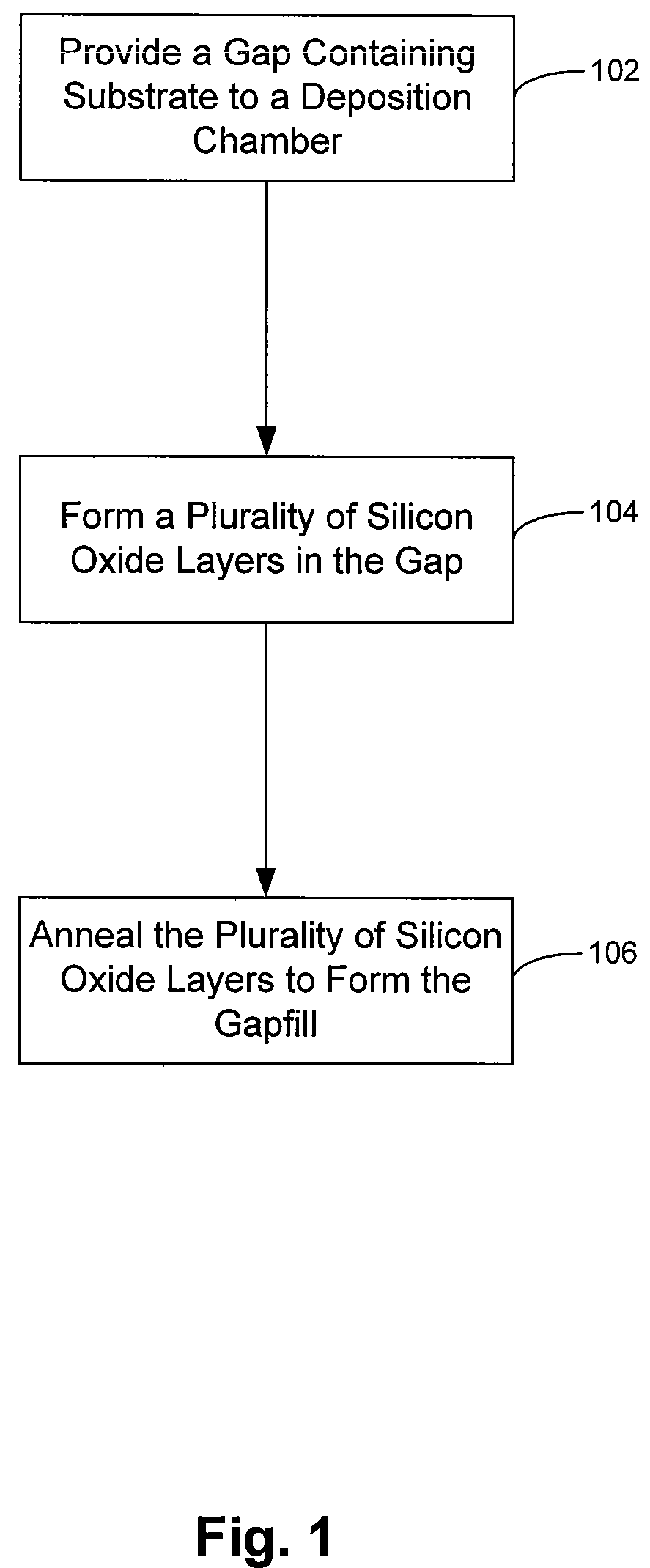

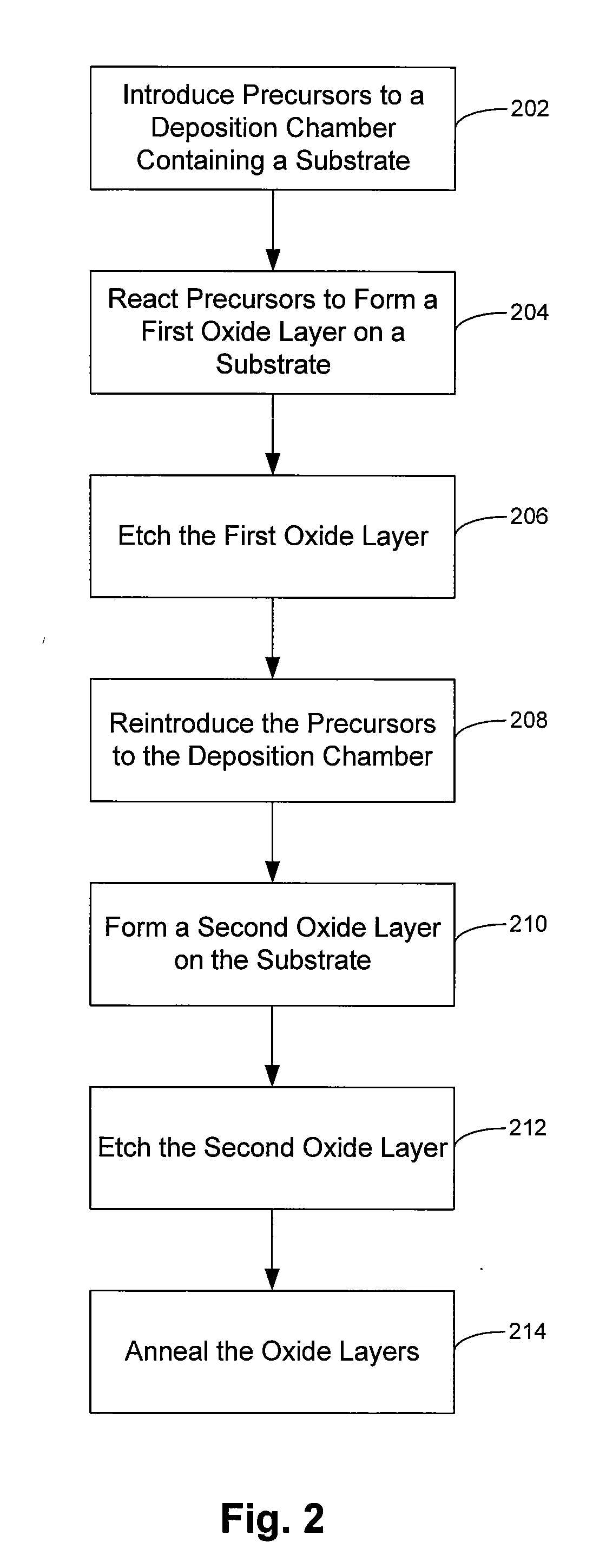

Novel deposition-plasma cure cycle process to enhance film quality of silicon dioxide

ActiveUS20070281448A1Reduce carbon contentDecorative surface effectsSemiconductor/solid-state device manufacturingSilicon oxideOxygen

Methods of filling a gap on a substrate with silicon oxide are described. The methods may include the steps of introducing an organo-silicon precursor and an oxygen precursor to a deposition chamber, reacting the precursors to form a first silicon oxide layer in the gap on the substrate, and etching the first silicon oxide layer to reduce the carbon content in the layer. The methods may also include forming a second silicon oxide layer on the first layer, and etching the second layer to reduce the carbon content in the second layer. The silicon oxide layers are annealed after the gap is filled.

Owner:APPLIED MATERIALS INC

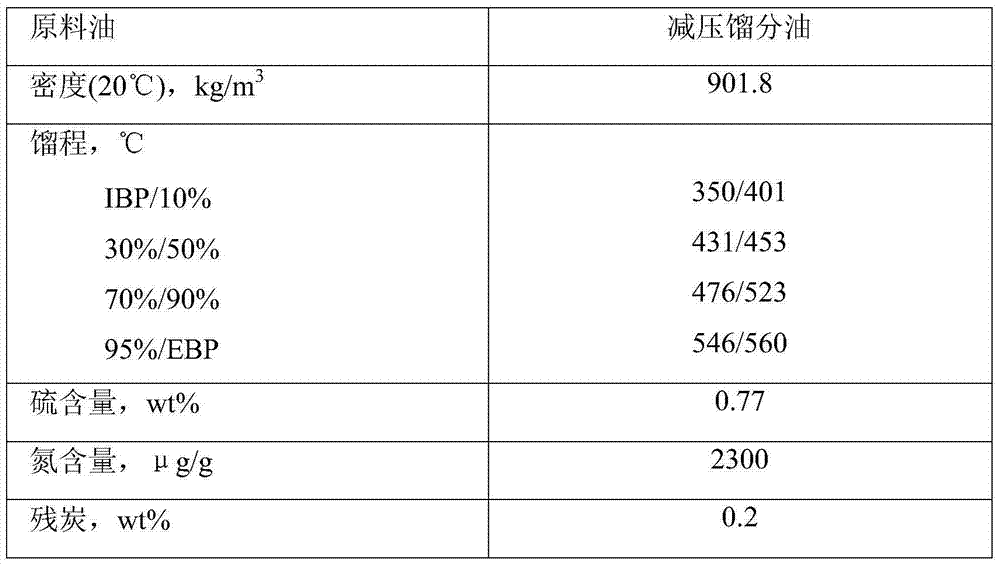

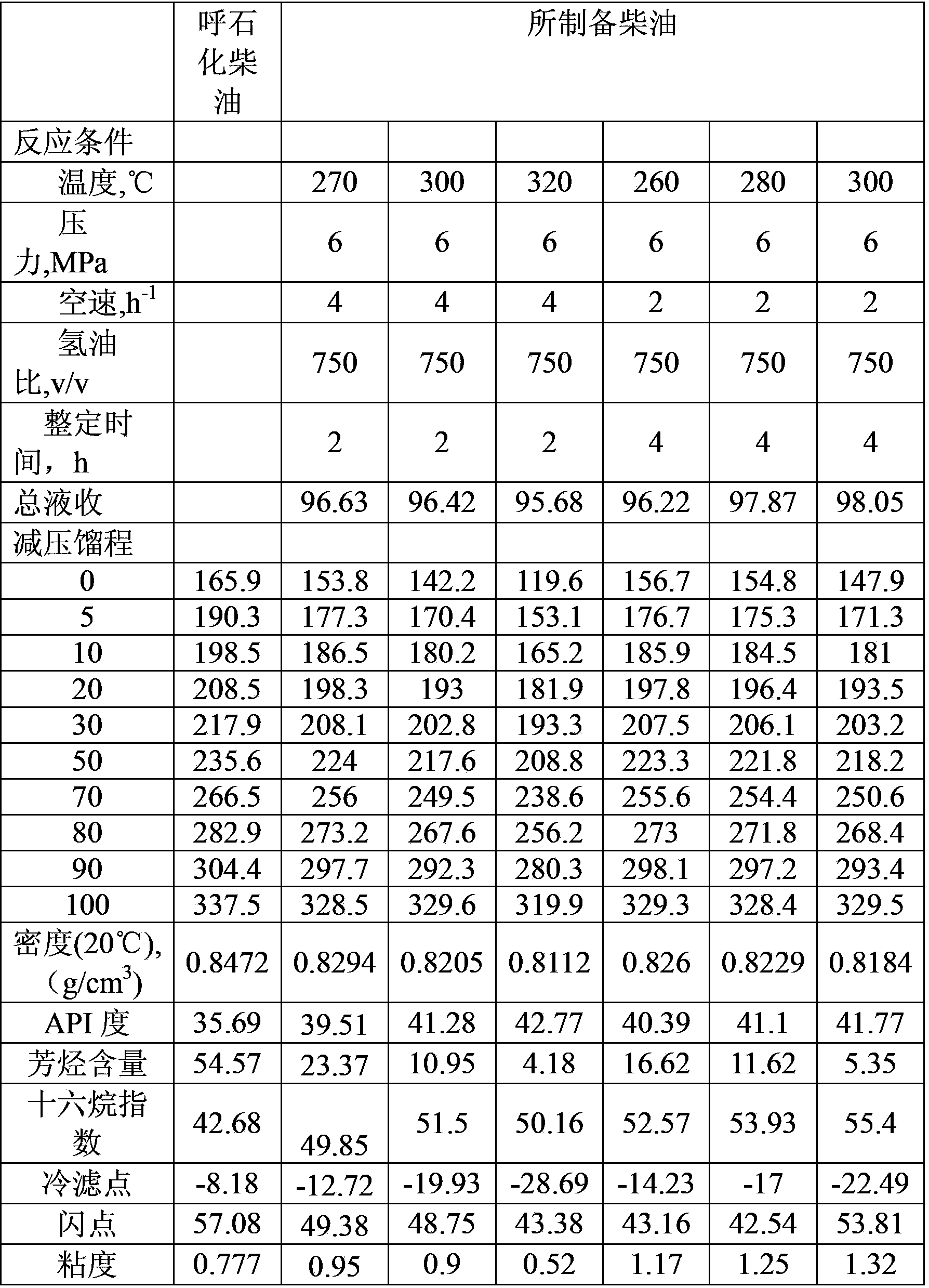

Diesel production from hydrogenation upgrading isomerizing pour-point reduction

ActiveCN1712499ALittle impact on yieldLowering the freezing pointRefining to change hydrocarbon structural skeletonIsomerizationCrystallinity

Production of hydrogenated and pour-point reducing modified isomerization diesel oil is carried out by using fraction oil as raw material from one-stage or series process flow, passing fraction oil raw material and hydrogen gas into catalyst bed which consists of beta molecular sieve 1í½9wt%, and obtaining clean high-quality diesel product and naphtha product with low sulfur nitrogen and high arene content. The beta molecular sieve has small crystal grain, low acidity, high silica-alumina ratio and crystallinity. It achieves simple process, higher productivity and less impurities, and improves density and freezing point.

Owner:CHINA PETROLEUM & CHEM CORP +1

In-situ crystallization cracking catalyst and preparation method thereof

ActiveCN101250428AHigh crystallinityLow selectivityCatalytic crackingIn situ crystallizationMicrosphere

The invention relates to an in-situ crystallization type cracking catalyst and the process for preparation, which is characterized in that the process for preparation comprises mixing roasting kaolin microsphere, water glass, sodium hydroxide and guiding agent, and then crystallizing in original position after heating up to 80-110 DEG C, adding aluminum source in the in the process of crystallizing during 1-48hours, and getting crystallization product, filtering and washing the crystallization product, exchanging, roasting, lowering natrium, modifying to get cracking catalyst, wherein the cracking catalyst contains Y-shaped molecular screen with high degree of crystallization and high silica alumina ratio, which is suitable for catalyzing and cracking heavy oil.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Environment-friendly efficient filter filtering paper and preparation method thereof

ActiveCN102888784AImprove efficiencyImprove filtration efficiencyNon-fibrous pulp additionPaper/cardboardSolubilityGlycerol

The invention discloses an environment-friendly efficient filter filtering paper. The environment-friendly efficient filter filtering paper is prepared by the following raw materials in part by weight: 40-50 parts of softwood pulp, 30-40 parts of waste paper pulp, 20-30 parts of high-silica glass fiber, 2-5 parts of modified vermiculite, 1-3 parts of zeolite molecular sieve, 2-4 parts of nanometer calcium, 1-2 parts of modified pulverized fuel ash, 2-3 parts of water-solubility organic silicon resin emulsion, 1-2 parts of water-solubility polytetrafluoroethylene emulsion, 0.5-0.8 parts of ammonium polyphosphate, 3-4 parts of glycerol triacetate, 0.5-1 parts of diethanolamide, 0.5-1 parts of silane coupling agent KH560, 0.4-0.8 parts of sodium dodecyl sulfate, 0.5-1 parts of antioxidant DSTP, and 4-6 parts of polyethylenimine. The filtering paper prepared by the method provided by the invention has the advantages of being good in water permeability, large in filtering area, small in maximum diameter of hole, high in filtering precision, strong in bursting strength, high-temperature-resistant, good in water resistance and the like, can achieve the filtering efficiency by 99.98%, has stable performance index at atmospheric and high-temperature working conditions, as well as better temperature resistance and filtering effects.

Owner:ANHUI PHOENIX INT CO LTD

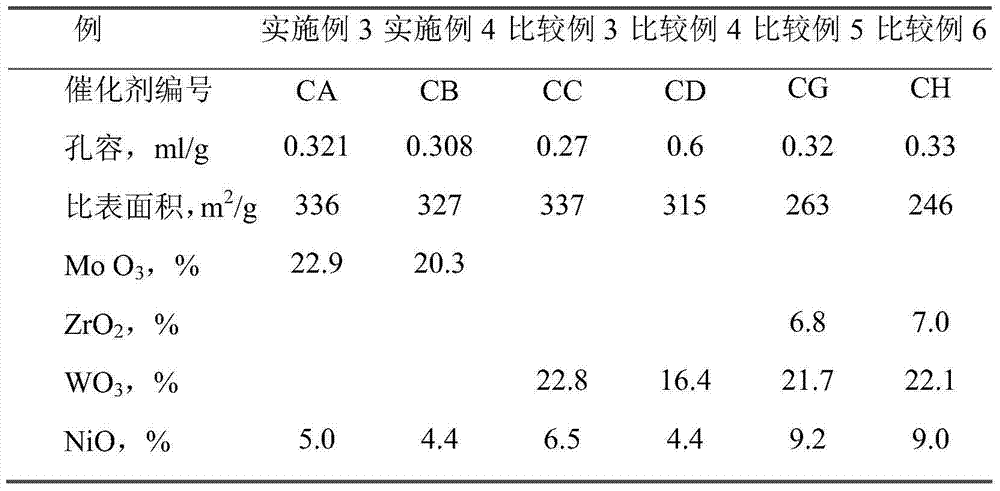

Composite molecular sieve-containing medium oil type hydrocracking catalyst, preparation method and application thereof

ActiveCN103551186BHigh crystallinityIncrease surface areaMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention relates to a composite molecular sieve-containing medium oil type hydrocracking catalyst, which comprises an active component and a binder, wherein the active component adopts amorphous SiO2-Al2O3 as a carrier, adopts a composite molecular sieve as an acid component, and adopts a group VIB metal and a group VIII metal as hydrogenation activity components, and the composite molecular sieve comprises a Y molecular sieve and a ZSM-23 molecular sieve. According to the present invention, the deep dealuminzation modified Y molecular sieve has characteristics of high crystallinity, large surface area, high silica-alumina ratio, low cell constant, rich secondary pore, low acid center density, high moderate-intensity acid center ratio, and the like; the modified ZSM-23 molecular sieve has characteristics of smooth pore channel, less acid center and outstanding isomerism performance, wherein a light naphtha component is isomerized so as to increase an octane number of naphtha; the composite molecular sieve compounded from the Y molecular sieve and the ZSM-23 molecular sieve is adopted as the acid cracking component so as to provide advantages of the Y molecular sieve and the ZSM-23 molecular sieve, and compounding is performed according to the ratio of the present invention, such that the best catalysis effect can be obtained, and the obtained catalyst is suitable for the medium oil type hydrocracking catalyst; and the catalyst prepared from the composite molecular sieve has characteristics of excellent medium oil selectivity, good activity and good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Chabazite-type molecular sieve, its synthesis and its use in the conversion of oxygenates to olefins

The synthesis of a crystalline material, in particular a high silica zeolite, having a chabazite-type framework is aided by the addition to the synthesis mixture of seeds of an AEI framework-type material. The chabazite-type product has a relatively small crystal size and exhibits activity and selectivity in the conversion of methanol to lower olefins, especially ethylene and propylene.

Owner:EXXONMOBIL CHEM PAT INC +1

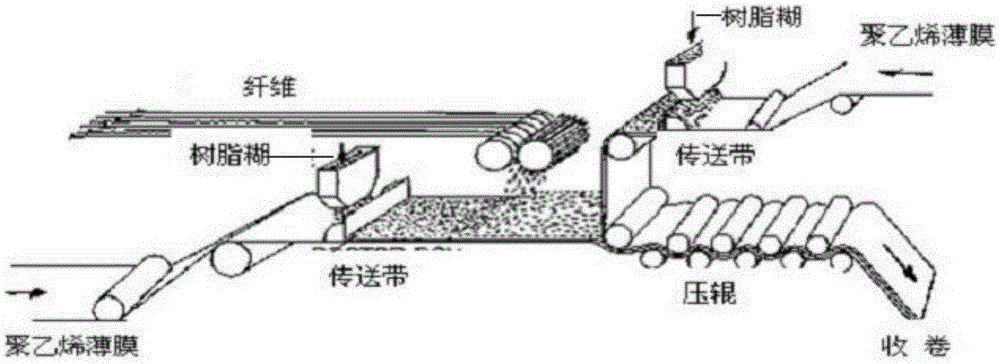

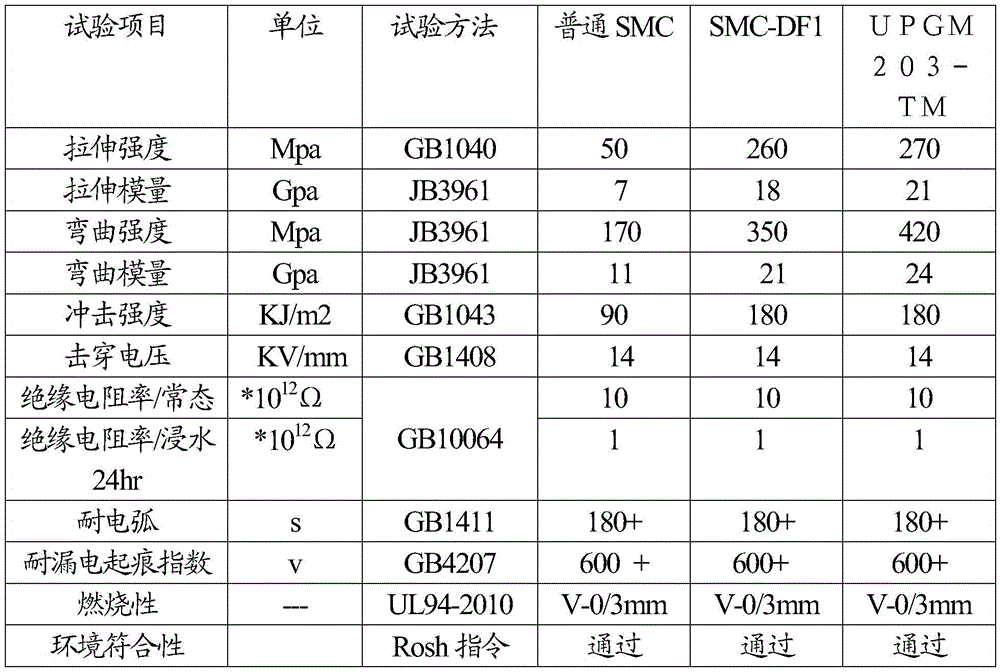

Unsaturated polyester resin fiber reinforced sheet-shape molding compound and preparation method thereof

The invention discloses an unsaturated polyester resin fiber reinforced sheet-shape molding compound, comprising unsaturated polyester resin, a low shrinkage agent, a filler, a curing agent, a thickener, a mold release agent, a reinforcing material, a colorant and an additive. The unsaturated polyester resin is characterized by comprising one or more of o-phenylene resin, m-phenylene resin and vinyl ester resin in mixing; the filler is modified aluminium hydroxide; the reinforcing material is made of one or more selected from the group containing alkali-free chopped glass fiber, alkali-free untwisted continuous glass fiber rove, high silica glass fiber and Kevlar fiber. The molding compound combines light weight, high strength, retardance, corrosion resistance and insulation, has the advantages of high weight percentage of reinforced material, good electrical properties, significantly improved mechanical properties, tensile strength of not less than 100Mpa, bending strength of not less than 300Mpa, impact strength not less than 260 KJ / m<2>, dielectric strength of not less than 12KV / mm, flame retardance of UL94V-0 and product thickness of up to 60mm, and can be used for compression molding of electrical insulation structural parts.

Owner:SICHUAN D&F ELECTRICAL TECH

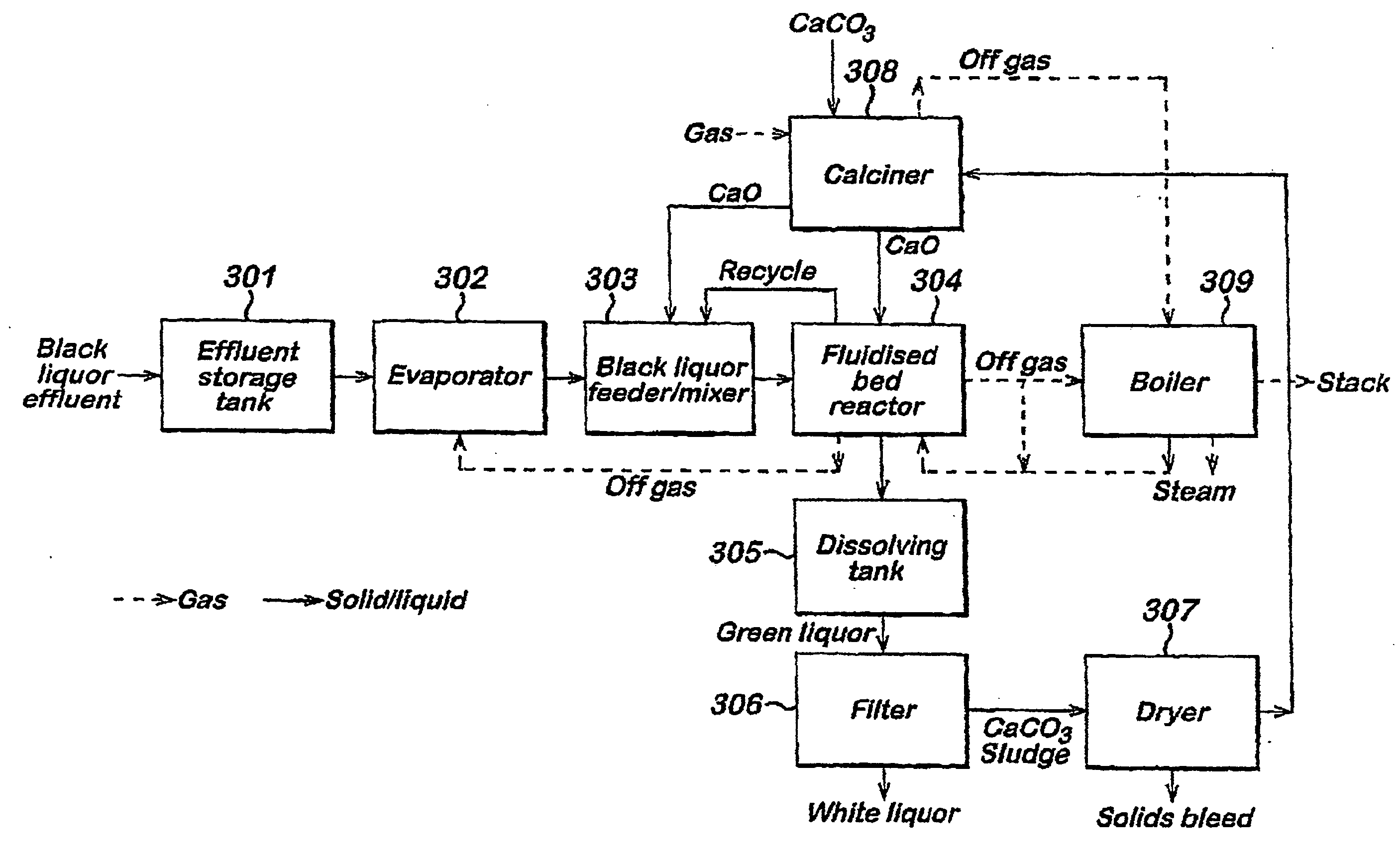

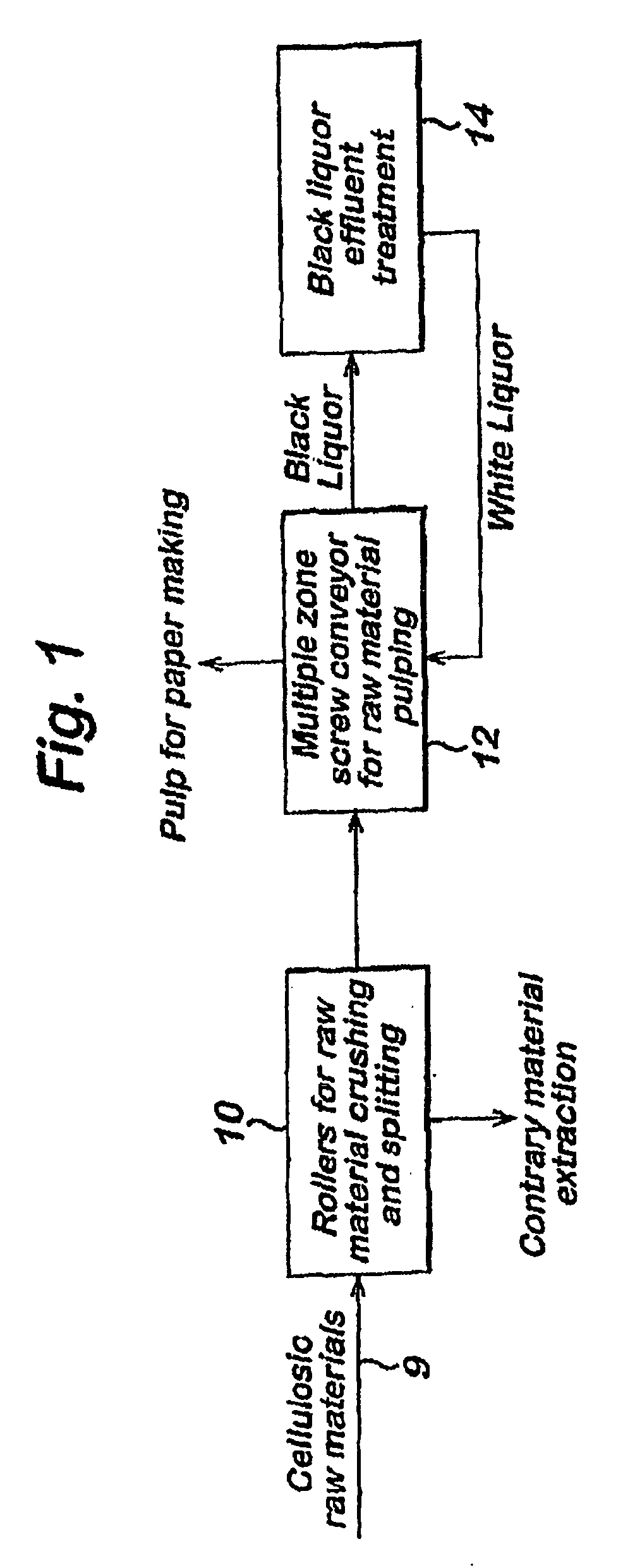

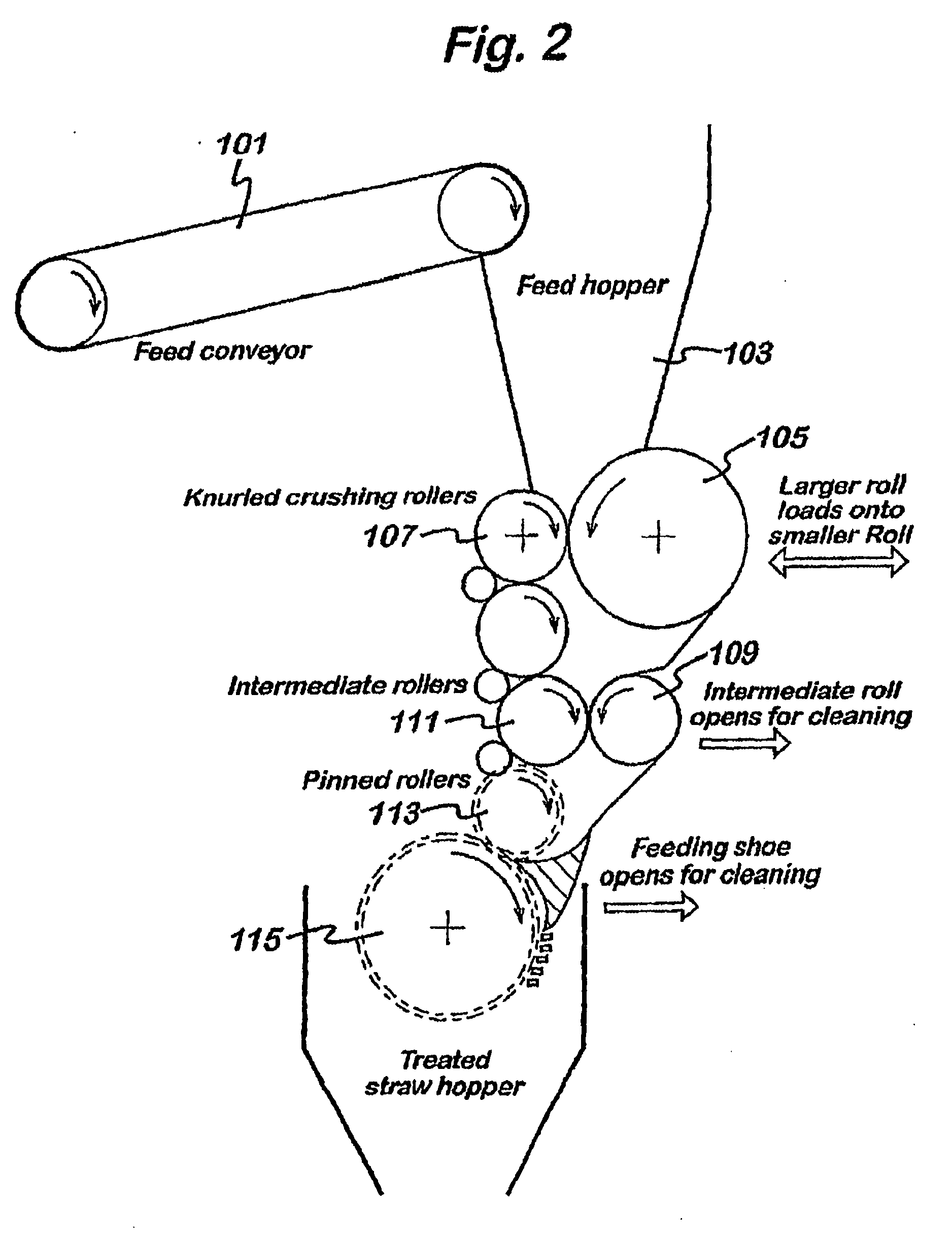

Methods for producing pulp and treating black liquor

InactiveUS20060201641A1Maintaining output qualityRaise the reaction temperaturePretreatment with water/steamPulp liquors combustionCalcium silicateOrganic content

A method is provided for treating black liquor particularly derived from non-wood pulp, by heating with an alkaline earth metal oxide in a toroidal fluidised bed reactor at a temperature of above 650° C. The method may be used alone or as part of a method of converting graminaceous raw material to pulp for paper or board, said method comprising (a) digesting said raw material with a white liquor based on sodium hydroxide and further comprising calcium hydroxide in an amount effective to substantially convert silica of said raw material to calcium silicate; (b) recovering pulp and black liquor substantially free of uncombined silica; (c) heating the black liquor in a fluidized bed reactor containing calcium oxide for catalysing conversion of organic content of said black liquor to gas and for providing recovered solids including sodium values of said white liquor and calcium oxide; and regenerating said white liquor using said recovered solids. The use of the above mentioned white liquor permits treatment of wheat straw, rice straw and other high-silica materials without resulting in a black liquor that is difficult to treat.

Owner:BIOREGIONAL MINIMILLS UK

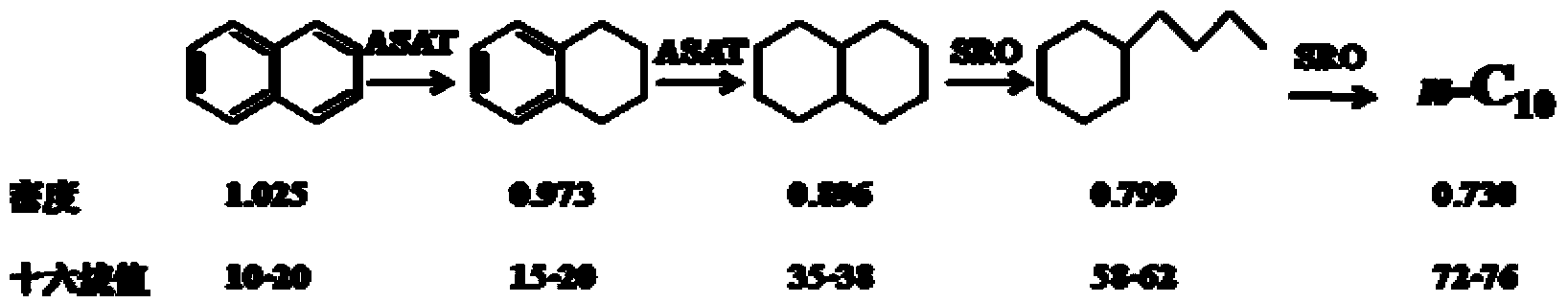

Catalyst used for hydrogenation ring opening reaction of polycyclic aromatic hydrocarbon, and preparation method and application thereof

InactiveCN104117386AAchieve conversion rateLower cold filter pointMolecular sieve catalystsHydrocarbon oils treatmentIsomerizationAcid strength

The invention relates to a catalyst used for hydrogenation ring opening of polycyclic aromatic hydrocarbon and advanced hydrogenation dearomatization and isomeric pour point depression of diesel oil, and a preparation method thereof. The catalyst is formed by using modified H-Beta molecular sieve with a high silica-alumina ratio and an inorganic oxide as a carrier, and precious metal Pt, Pd or Ir as an active component. The catalyst has a high metal dispersion ability, and has suitable acid kind, acid strength and pore structure. The catalyst can inhibit advanced cracking, and promotes the selective ring opening of aromatic hydrocarbon and product isomerization. The catalyst is suitable for advanced hydrogenation saturation of diesel oil with low sulfur and nitrogen content, selective ring opening and isomerization, can reduce the aromatic hydrocarbon content in the diesel oil, can improve the cetane number of oil products, and can reduce the condensation point of the diesel oil.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of high silica alumina ratio MCM-22 molecular sieve catalyst

InactiveCN101554592AReduce aluminum contentLess acidic surfaceMolecular sieve catalystsHydrocarbon by hydrocarbon crackingAir atmosphereIon exchange

The invention provides a preparation method of a high silica alumina ratio MCM-22 molecular sieve catalyst. The method comprises the following steps: raw materials of sodium source, silicon source, aluminium source, boron source, templeting agent and deionized water are put in a synthesis reactor according to the mixture ratio and statically or dynamically crystallized for 1-20 days at the crystallization temperature of 110-200 DEG C, and the product is filtered, washed and dried to obtain molecular sieve initial powder; and the obtained molecular sieve initial powder is roasted in the air atmosphere at the high temperature of 450-750 DEG C so as to remove the templeting agent and is exchanged into an ammonium type molecular sieve by an ammonium ion exchange method, the ammonium type molecular sieve is roasted at the temperature of 450-750 DEG C to obtain a corresponding hydrogen type molecular sieve, and the hydrogen type molecular sieve is prepared into the high silica alumina ratio MCM-22 molecular sieve catalyst after being molded. By using the method, the MCM-22 molecular sieve catalyst with controllable silica alumina ratio, high crystallization degree and high silica alumina ratio can be prepared, and the invention breaks through the range of the silica alumina ratio of the MCM-22 molecular sieve catalyst of the conventional method and overcomes the problem of descending of crystallization degree generally existing in the post-processing method.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method of increasing deposition rate of silicon dioxide on a catalyst

ActiveUS20060110936A1Good step coverageIncrease deposition rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideOxygen

Methods for forming dielectric layers, and structures and devices resulting from such methods, and systems that incorporate the devices are provided. The invention provides an aluminum oxide / silicon oxide laminate film formed by sequentially exposing a substrate to an organoaluminum catalyst to form a monolayer over the surface, remote plasmas of oxygen and nitrogen to convert the organoaluminum layer to a porous aluminum oxide layer, and a silanol precursor to form a thick layer of silicon dioxide over the porous oxide layer. The process provides an increased rate of deposition of the silicon dioxide, with each cycle producing a thick layer of silicon dioxide of about 120 Å over the layer of porous aluminum oxide.

Owner:MICRON TECH INC

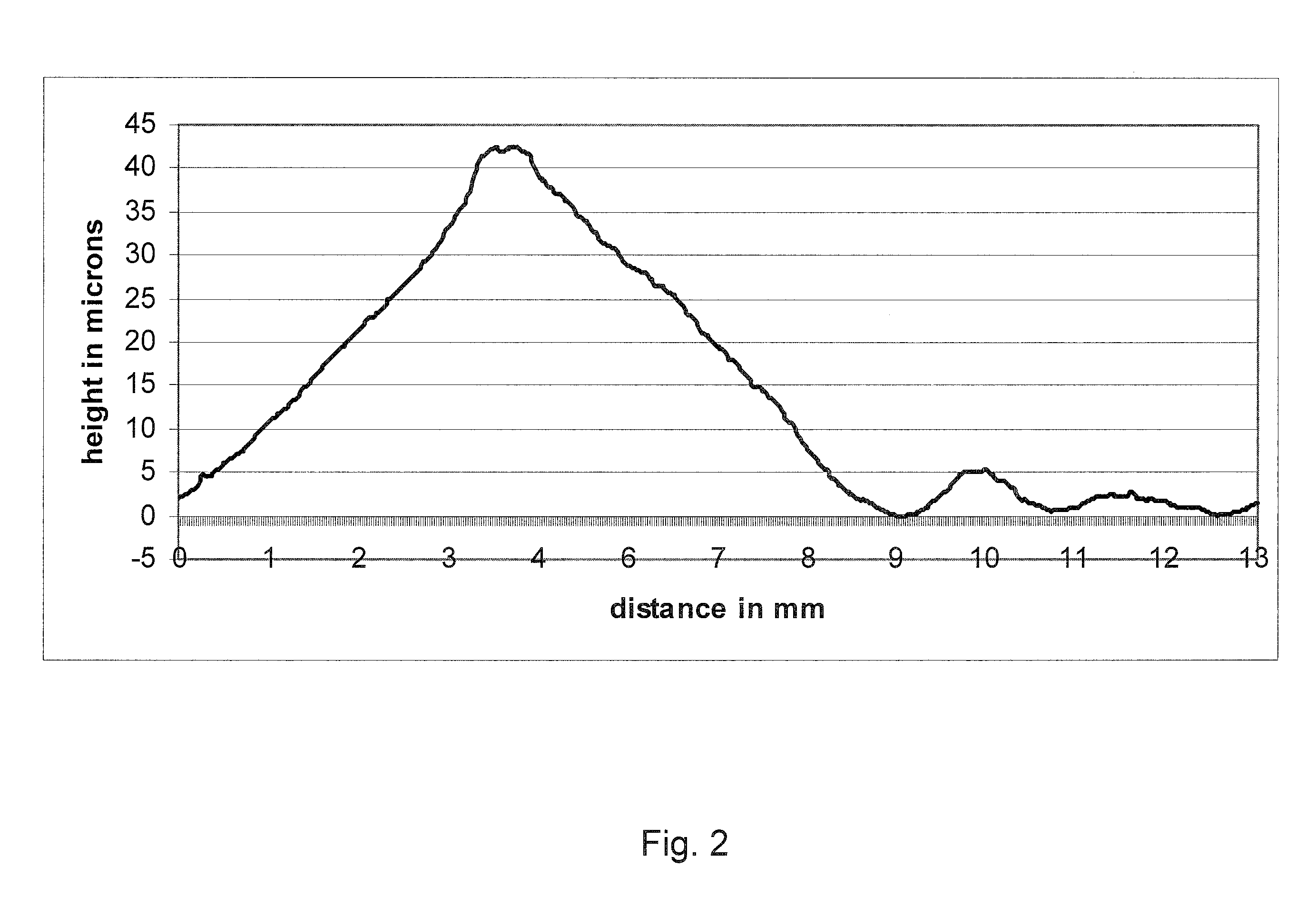

Roll-to-roll glass material attributes and fingerprint

ActiveUS20100291346A1Improve surface qualitySynthetic resin layered productsRecord information storageSurface roughnessHigh silica

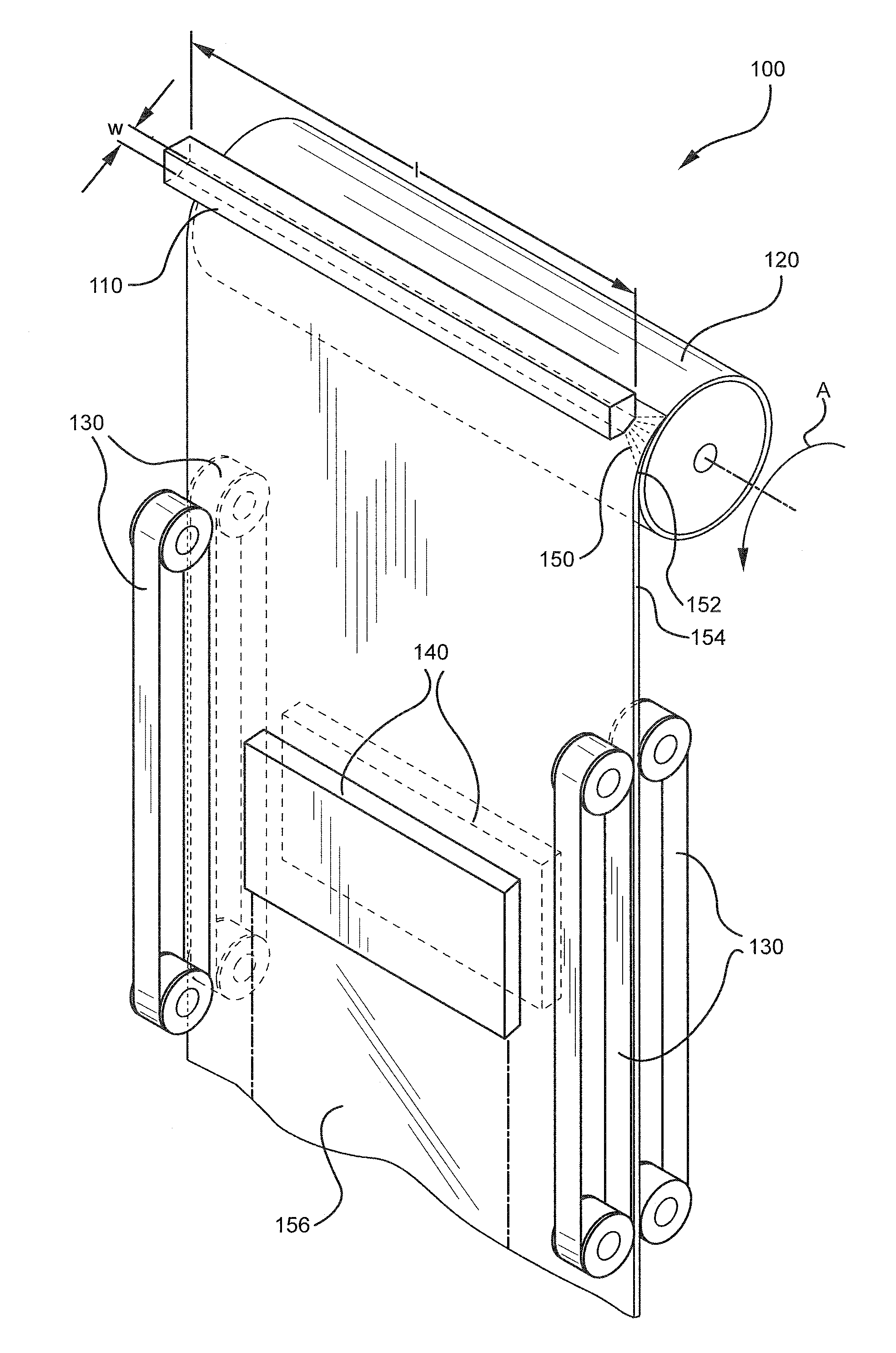

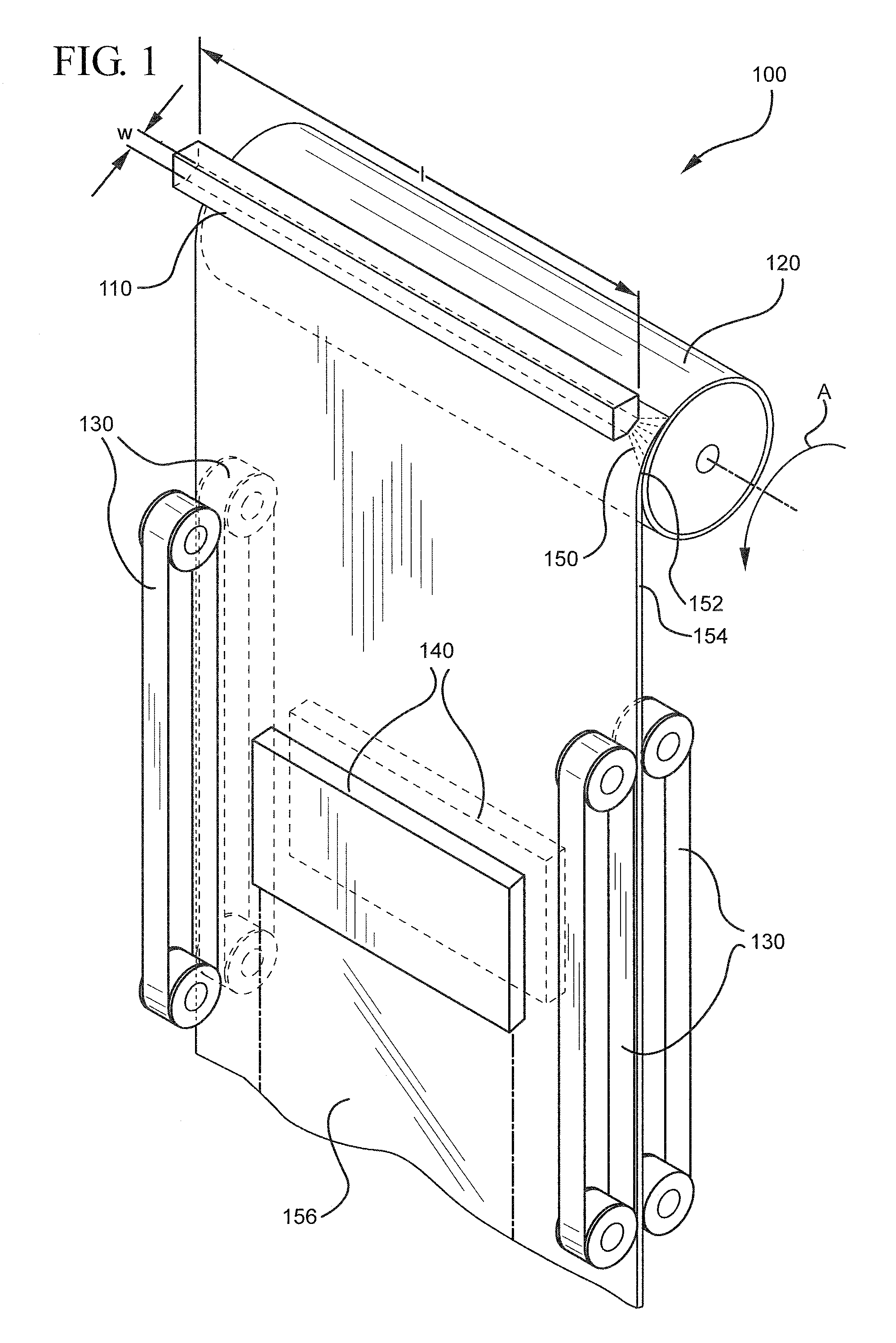

A high-silica glass sheet has an average thickness of less than 150 microns and an average surface roughness over one or both of its two major surfaces of less than 1 nm. The glass sheet is formed using a roll-to-roll glass soot deposition and sintering process. The glass sheet may comprise a plurality of substantially parallel surface protrusions, which are visible only when a major surface of the glass sheet is viewed at an angle sufficiently removed from normal incidence.

Owner:CORNING INC

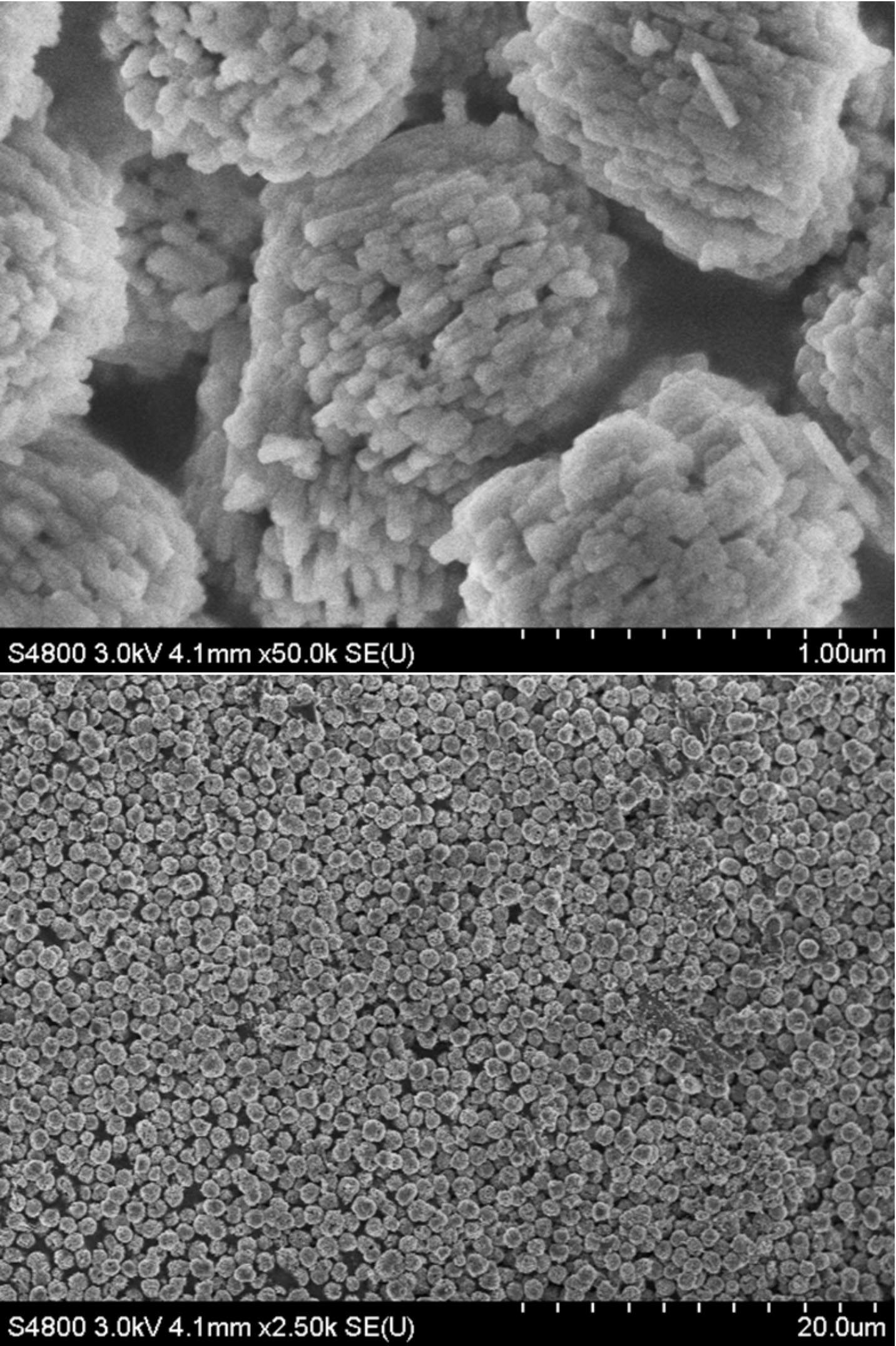

Preparation method of mesoporous mordenite

ActiveCN102602958ANovel Crystal MorphologyAbundant secondary stacking poresNanotechnologyMordenite aluminosilicate zeoliteFiltrationSynthesis methods

The invention discloses a method for synthesizing a mesoporous mordenite molecular sieve. The method comprises the following steps of: dissolving an aluminum source in a sodium hydroxide solution; adding a silicon source and stirring to disperse for a certain period of time at room temperature under strong magnetic force, wherein the uniformly dispersed solution of silicon source and aluminum source is mixed into glue at room temperature; adding a dealuminated mordenite molecular sieve as seed crystal; stirring and uniformly mixing at room temperature under strong magnetic force, and transferring the product into a reaction crystallization kettle; performing crystallization reaction at 150-170 DEG C for 0.5-3 days; and performing conventional suction filtration, washing and drying to obtain a solid product. The synthesis method disclosed by the invention has the characteristics that the expensive organic amine template agent is not used as a structure directing agent, and the cheap and easily-available inorganic layered precursor with wide source is used as the seed crystal to directly synthesize a mordenite molecular sieve with high silica-alumina ratio; and the prepared nano mordenite molecular sieve has the advantages of high crystallinity and purity, abundant accumulation meso pores, controllable particle size, form and low cost, less environment pollution and convenience for industrial large-scale production.

Owner:EAST CHINA NORMAL UNIV

Cyanide-free zinc dipping solution and cyanide-free electroplating method of filter aluminium alloy by using the same

The invention discloses a cyanide-free zinc dipping solution and a cyanide-free electroplating method of filter aluminium alloy by using the cyanide-free zinc dipping solution. The cyanide-free zinc dipping solution, measured as per liter of cyanide-free zinc dipping solution, comprises 450-600 ml of plating bath solution and 400-550 ml of water, wherein the plating bath solution comprises 20-40 g / L zinc ions, 2-10 g / L nickel ions, 0.001-0.400 g / L copper ions, 0.05-1.00 g / L iron ions, 1-4 g / L cobalt ions, 80-200 g / L alkali metal hydroxide, 50-100 g / L main complexing agent, 13-40 g / L auxiliary complexing agent, and 0.07-2.00 g / L crystallization refiner. Zinc dipping and electroplating on materials with high silica content can be carried out by using the cyanide-free zinc dipping solution by just conducting zinc dipping once, the operation is simple, and the control is easy.

Owner:GUANGZHOU HONWAY TECH CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com