Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

655 results about "Precipitated silica" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precipitated silica is an amorphous form of silica (silicon dioxide, SiO₂); it is a white, powdery material. Precipitated silica is produced by precipitation from a solution containing silicate salts.

Cementing compositions and methods of cementing in a subterranean formation using an additive for preventing the segregation of lightweight beads.

Cementing compositions and methods of cementing in a subterranean formation are provided. The cement composition includes a hydraulic cement, lightweight beads, and a desegregating agent for inhibiting segregation of the beads. The lightweight beads may be, for example, cenospheres, glass spheres, and ceramic spheres. The desegregating agent comprises a particulate substrate such as precipitated silica. It also comprises a polar molecule producing chemical disposed on the particulate substrate. Preferably, the polar molecule producing chemical is absorbed on the particulate substrate. The polar molecule producing chemical comprises at least one of a polar molecule producing acid such as glacial acetic acid, a salt of such an acid, and an acid anhydride. The method of cementing includes forming a pumpable slurry using the cement composition, pumping the slurry into a subterranean formation, and allowing the slurry to set.

Owner:HALLIBURTON ENERGY SERVICES INC

Precipitated silica product, dentifrices containing same, and processes

InactiveUS7255852B2Reduce the possibilityIncrease volumeCosmetic preparationsPigmenting treatmentSilica particleAntimicrobial action

Owner:EVONIK OPERATIONS GMBH

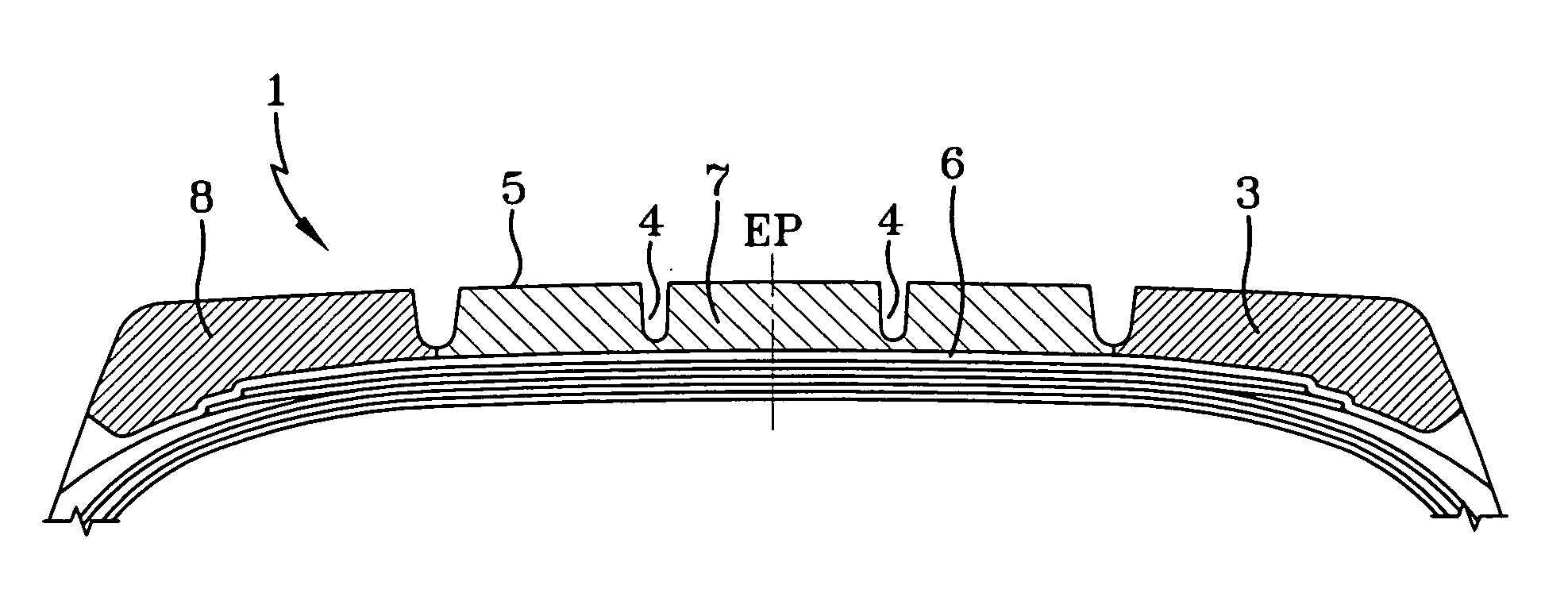

Tire with silica reinforced tread and/or sidewall components

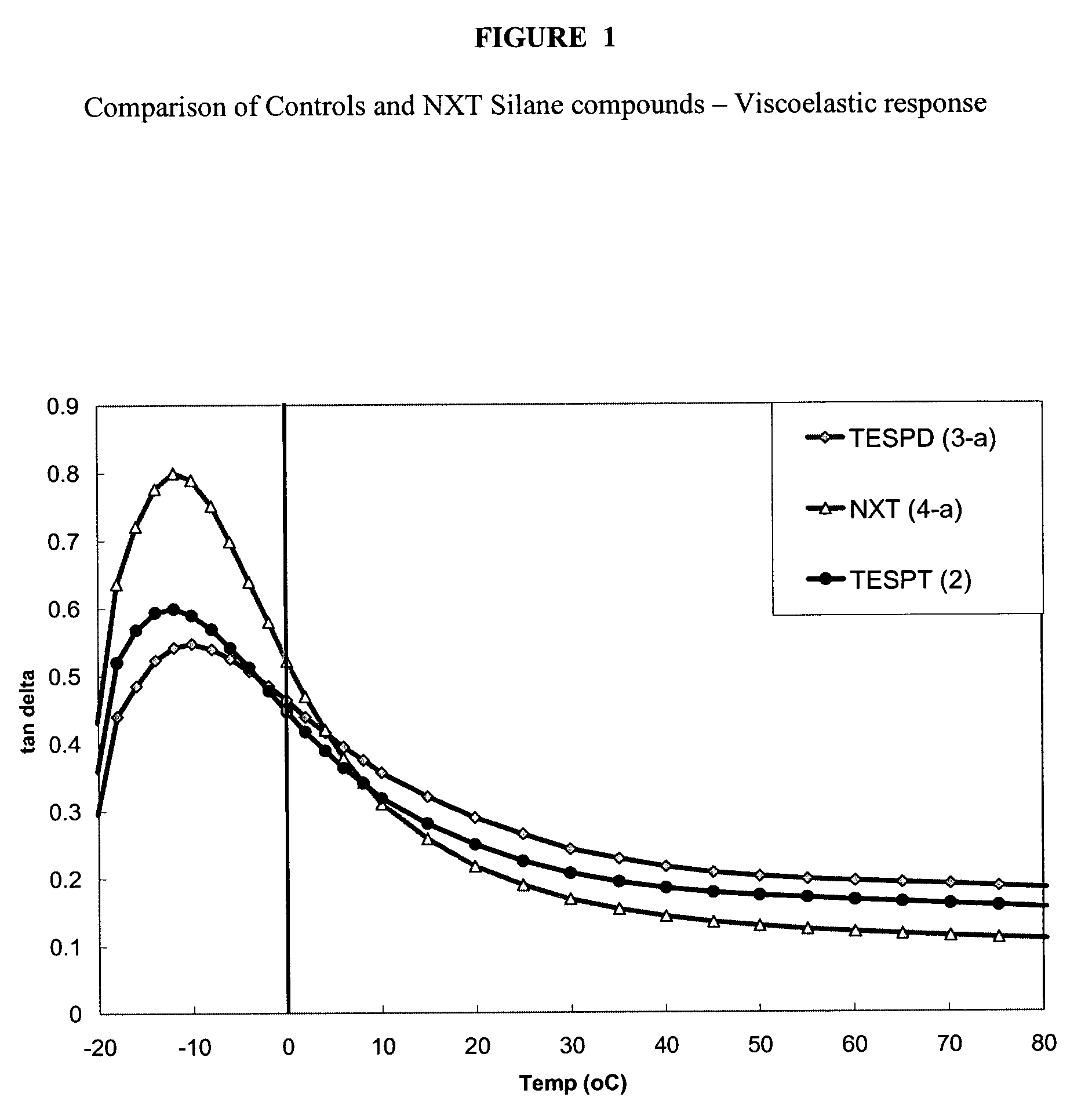

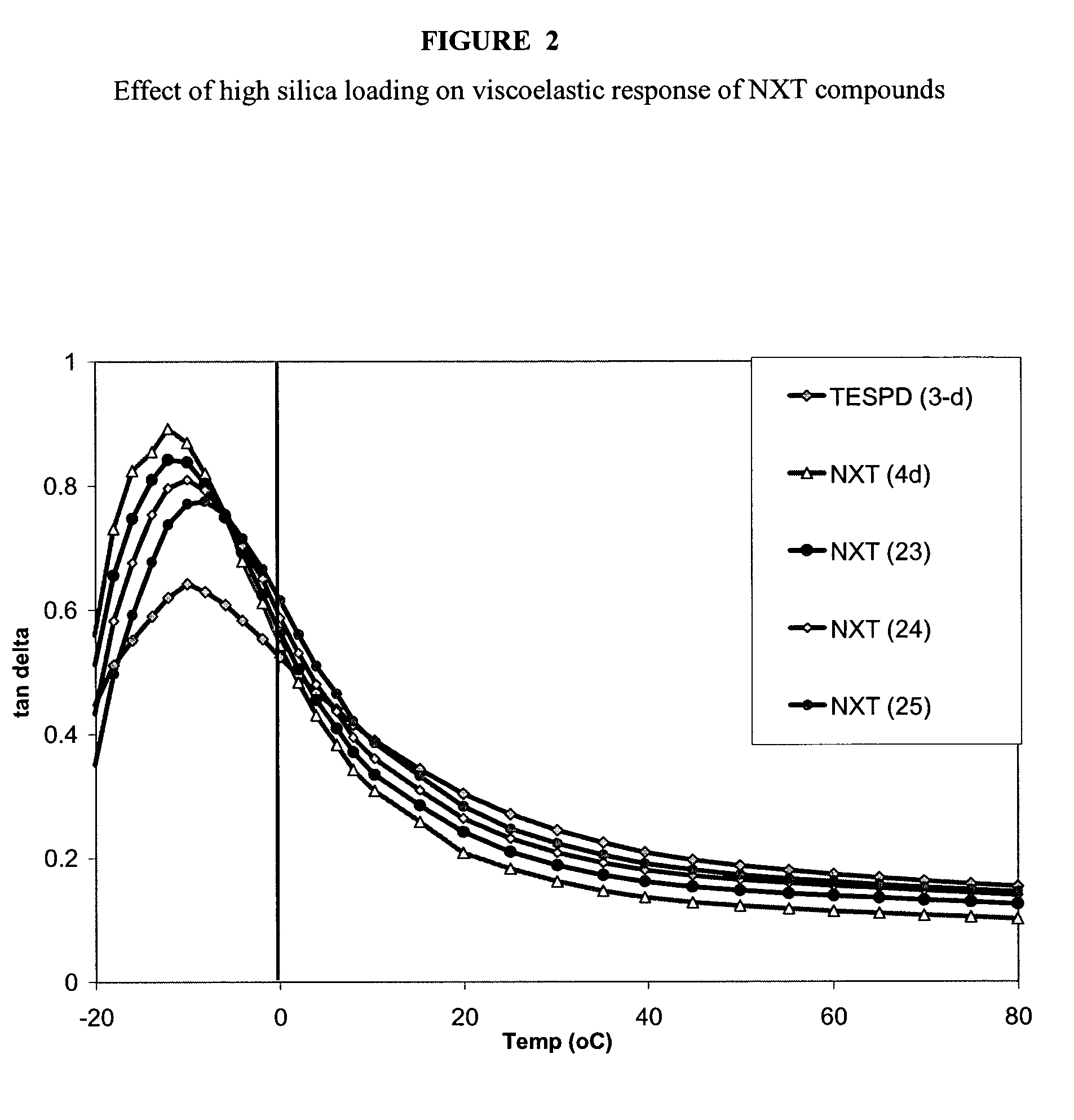

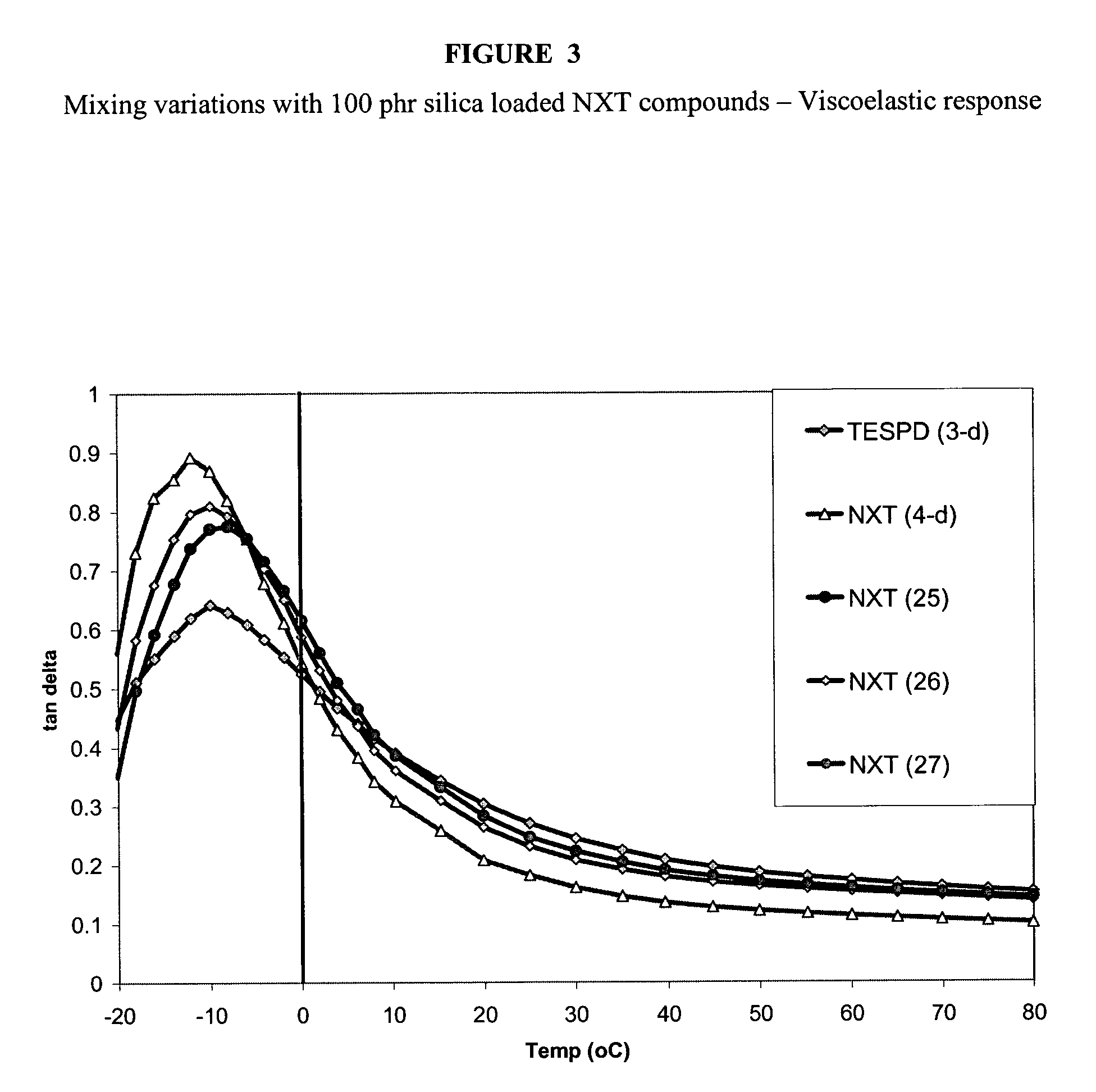

The present invention relates to the preparation of rubber compositions for tire tread and tire sidewall component applications. A tire is provided having tread of such composition designed for relatively heavy loads such as, for example, truck tires. A tire having a sidewall of such composition is also provided. Such tire component rubber compositions are of rubber compositions reinforced with precipitated silica and selected carbon black in specified amounts and prepared with a prescribed order of addition to the rubber composition and composed of elastomers as a specific combination of natural or synthetic cis 1,4-polyisoprene rubber together with cis 1,4-polybutadiene rubber or with a combination of cis 1,4-polybutadiene rubber and trans 1,4-polybutadiene rubber.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire with low hydrocarbon emission rubber combination of tread and sidewall components with compositional limitations

InactiveUS7214731B2Eliminate emissionsEmission reductionSpecial tyresInflatable tyresElastomerHydrophobic silica

The invention relates to a tire of a structural combination of tire tread and sidewall components with compositional limitations containing minimal, if any, of in situ formed alcohol and methyl isobutyl ketone byproducts. The tread component rubber composition contains pre-hydrophobated silica reinforcement. The sidewall component contains low unsaturation EPDM or brominated copolymer of isobutylene and p-methylstyrene and may contain pre-hydrophobated silica reinforcement. The silica reinforcement for said tread and sidewall components is a pre-hydrophobated precipitated silica. The pre-hydrophobated silica is prepared, prior to mixing with the elastomer(s), by reacting hydroxyl groups (e.g. silanol groups) contained on the surface of a precipitated silica with an alkoxyorganomercaptosilane or a combination of an alkoxyorganomercaptosilane and a substituted alkylsilane or with a bis-3(trialkoxysilylalkyl) polysulfide which contains an average of from 2 to 4 connecting sulfur atoms in its polysulfidic bridge to form a composite thereof. The alcohol byproduct therefrom is removed from the composite prior to its introduction into the rubber composition(s). In another aspect of the invention, the connecting sidewall rubber composition, and optionally the tread composition is free of N-(1,3-dimethylbutyl)-N′-phenyl-p-phenylenediamine antidegradant (referred herein to as 6PPD) in order to prevent in situ formation of methyl isobutyl ketone byproduct from the reaction of 6PPD with atmospheric oxygen and / or ozone.

Owner:THE GOODYEAR TIRE & RUBBER CO

Silica-rubber mixtures having improved hardness

InactiveUS20050277717A1Eliminates and reduces filler network effectReduce hardnessSpecial tyresSilanesOrganic group

A method for increasing the hardness of silica / rubber mixtures is disclosed wherein the method comprises blending with said mixture at least one silane and a hardness-increasing amount of at least one member selected from the group consisting of thixotropic fumed silica; precipitated silica; an MQ resin wherein Q is SiO4 / 2, M is R1R2R3SiO1 / 2, and R1, R2, and R3 are the same or different functional or non-functional organic groups; carbon black; a thermoplastic resin; and a thermosetting resin.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

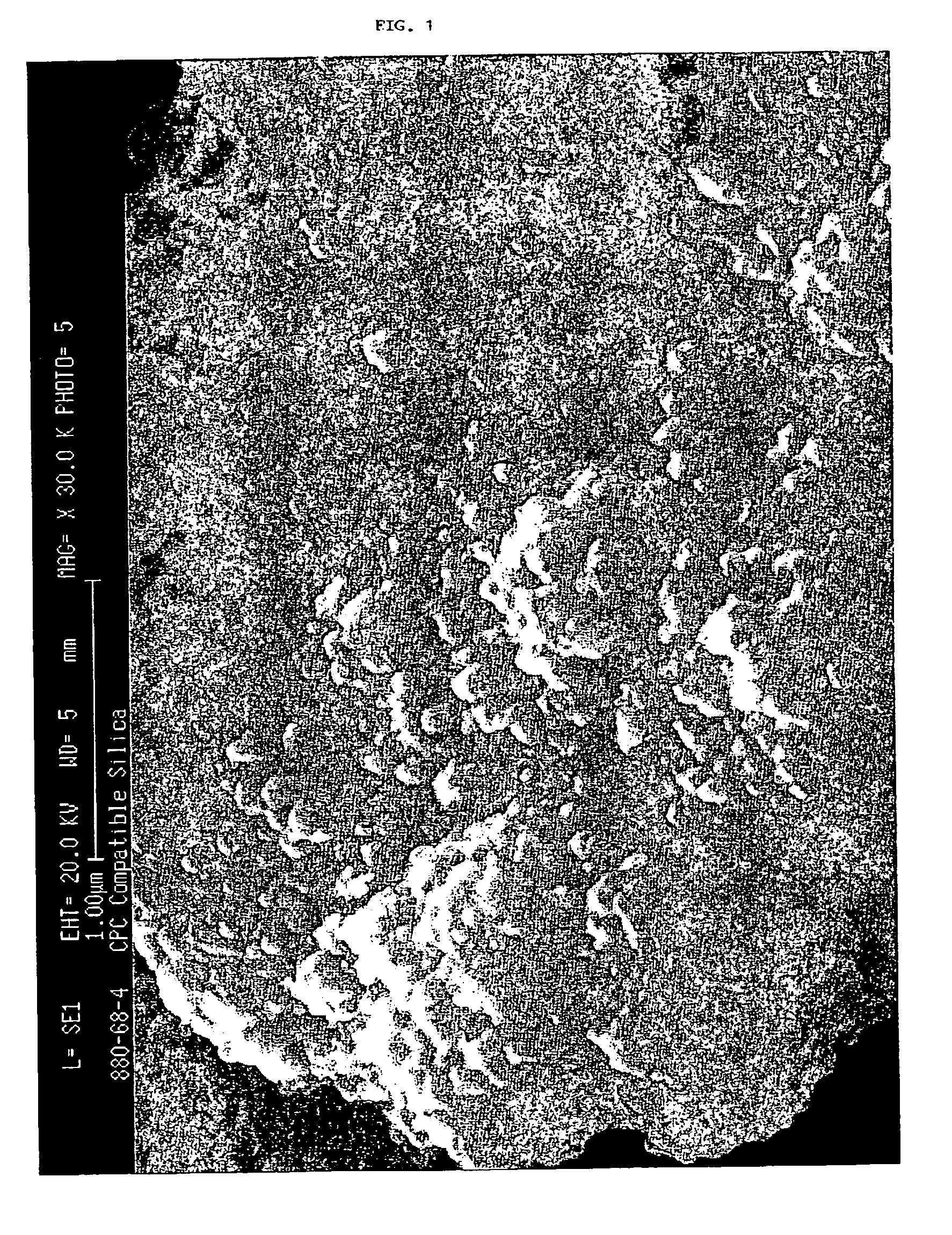

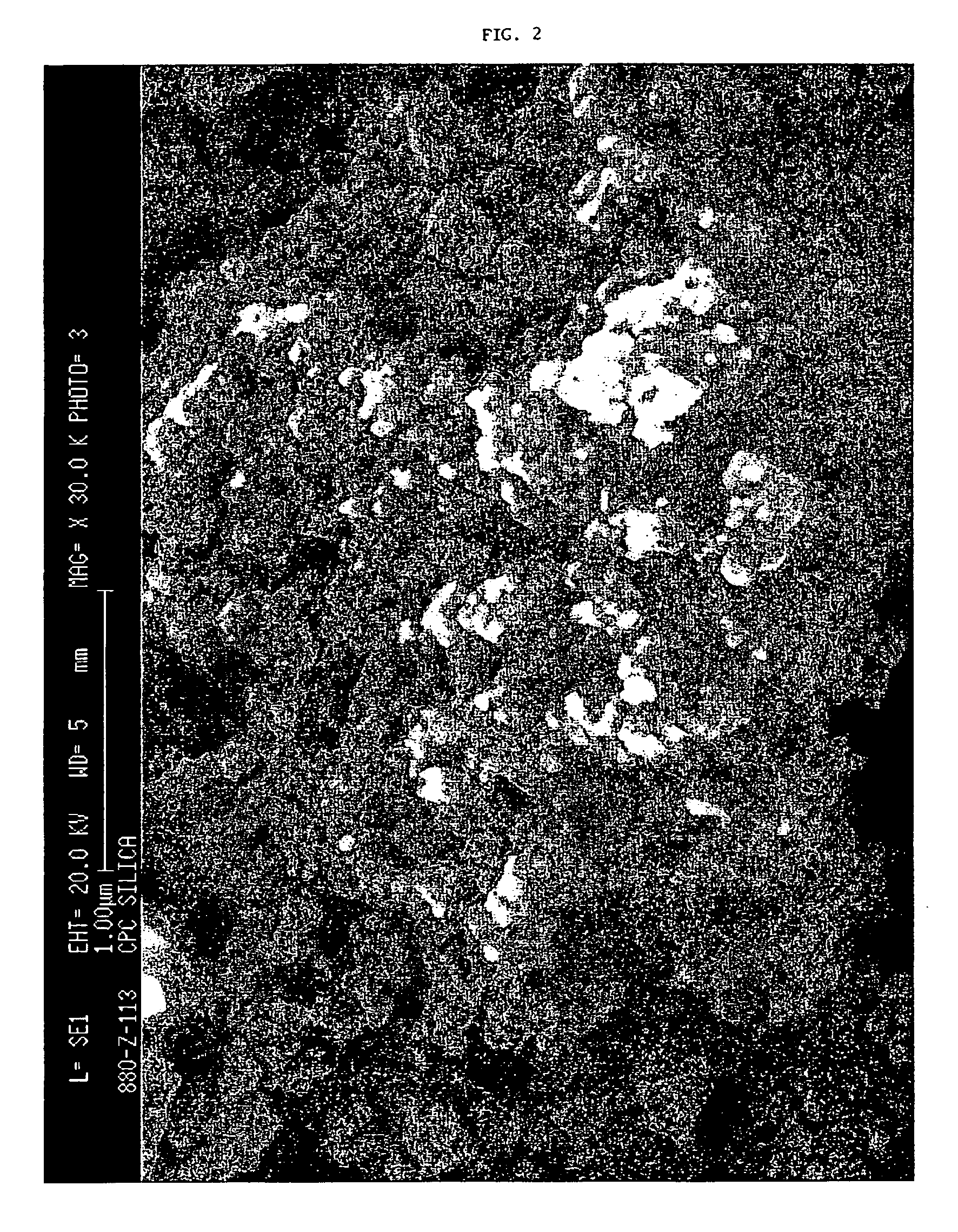

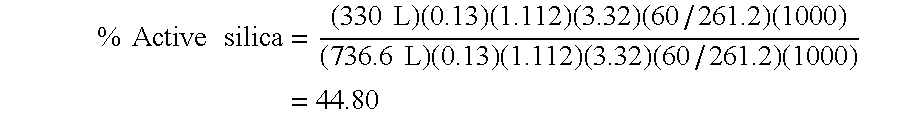

Precipitated silica materials exhibiting high compatibility with cetylpyridinium chloride

ActiveUS7438895B2Increase volumeImprove compatibilityCosmetic preparationsBiocideAntimicrobial actionSilica particle

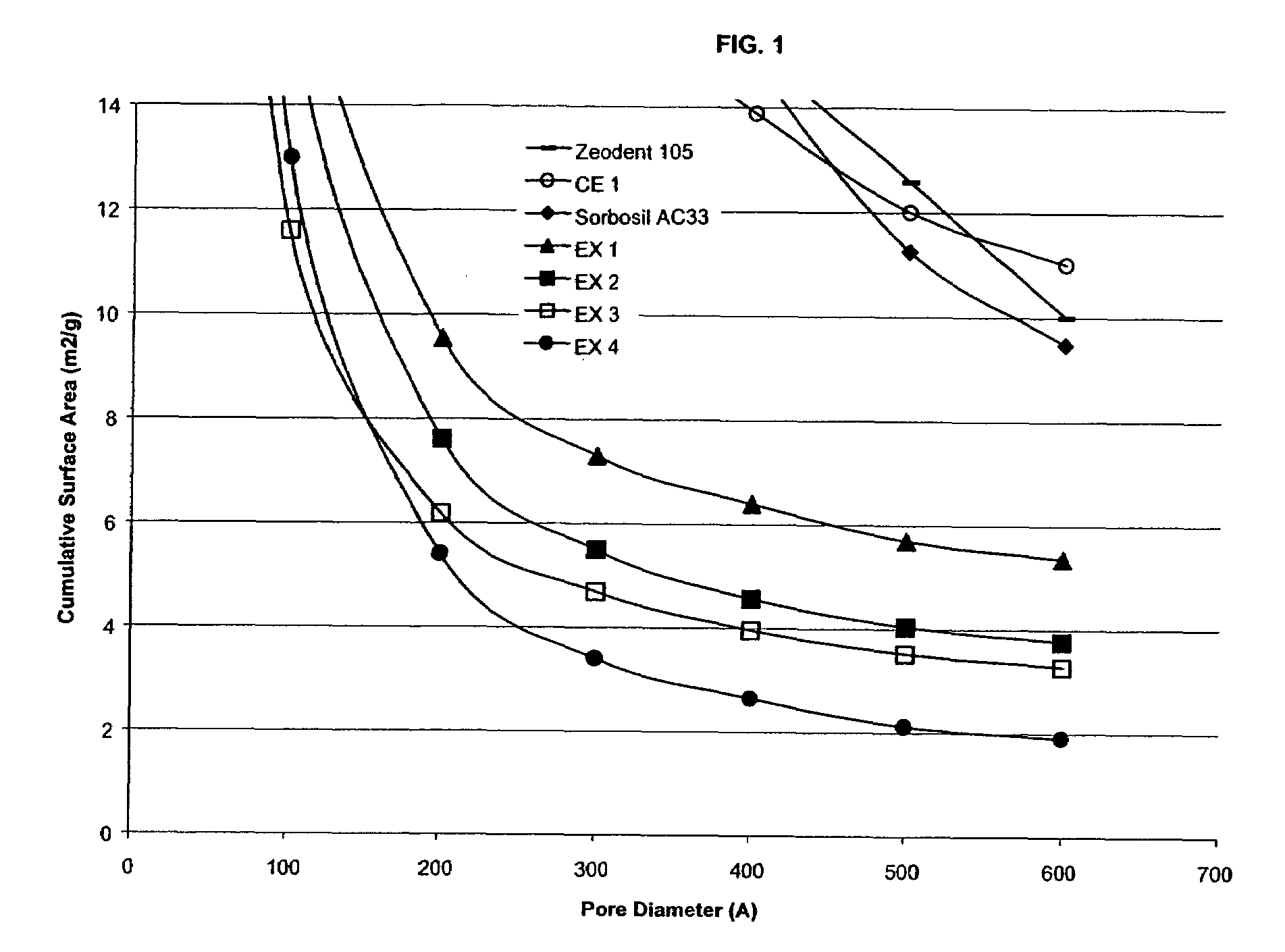

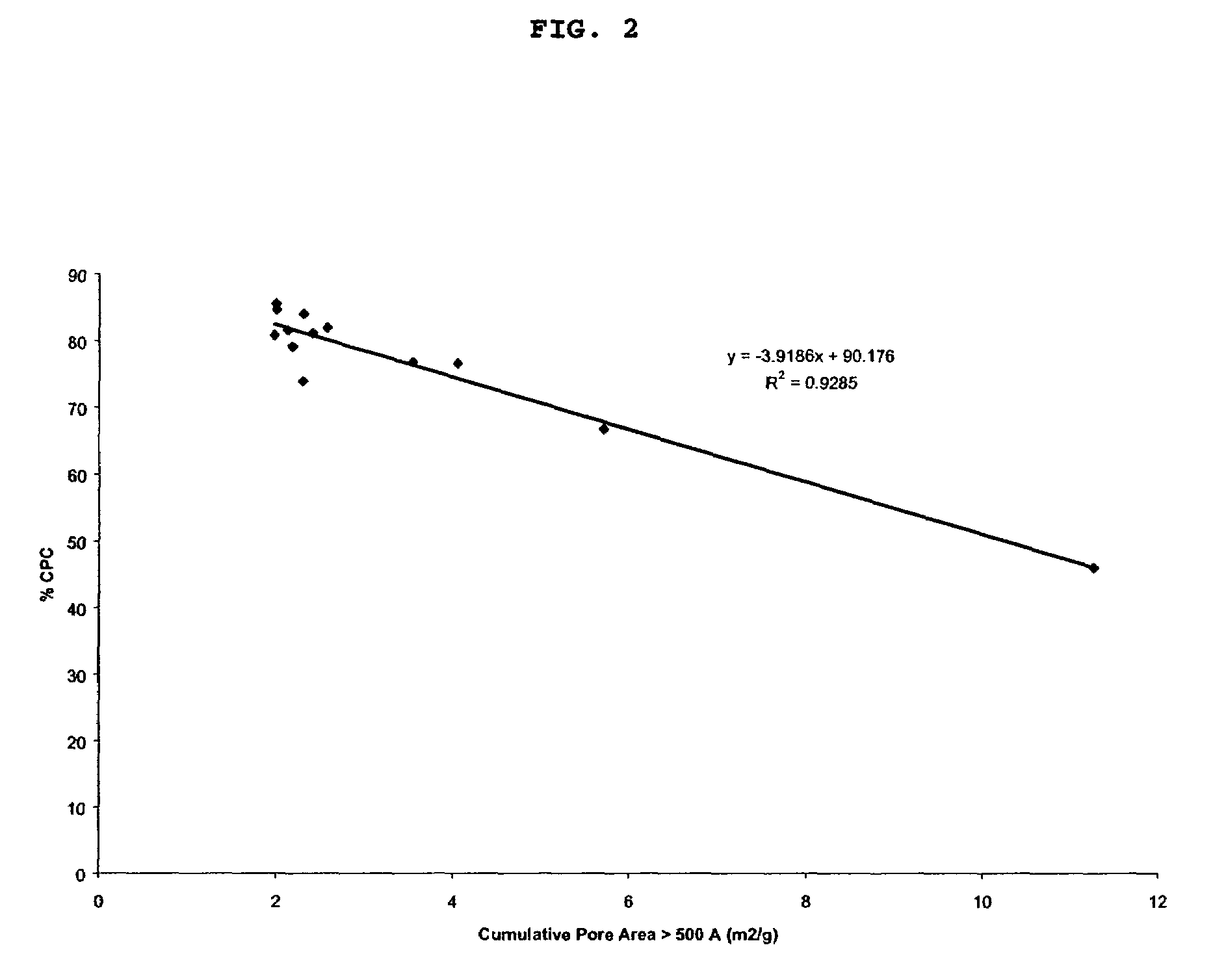

Precipitated silica comprising porous silica particles having a cumulative surface area for all pores having diameters greater than 500 Å of less than 6 m2 / g, as measured by mercury intrusion, and a percentage cetylpyridinium chloride (% CPC) Compatibility of greater than about 85%. The precipitated silica product is especially well-adapted for use in dentifrices containing cetylpyridinium chloride, which do not attach to the low surface area silica product in a meaningful level and thus remain available for antimicrobial action. Processes for making the silica product including the introduction of sodium sulfate powder during different process steps in order to enhance such a compatibility with CPC are provided.

Owner:EVONIK OPERATIONS GMBH

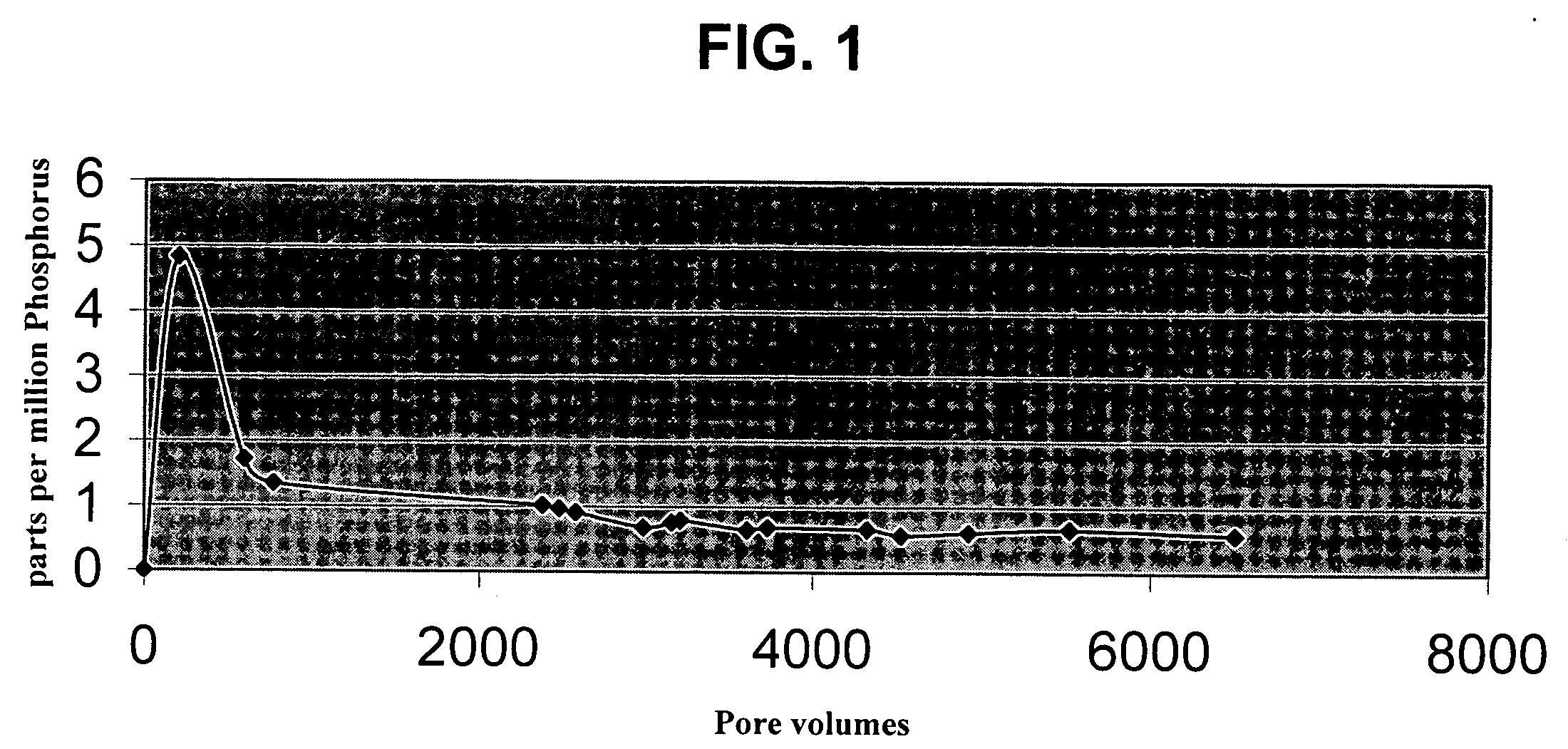

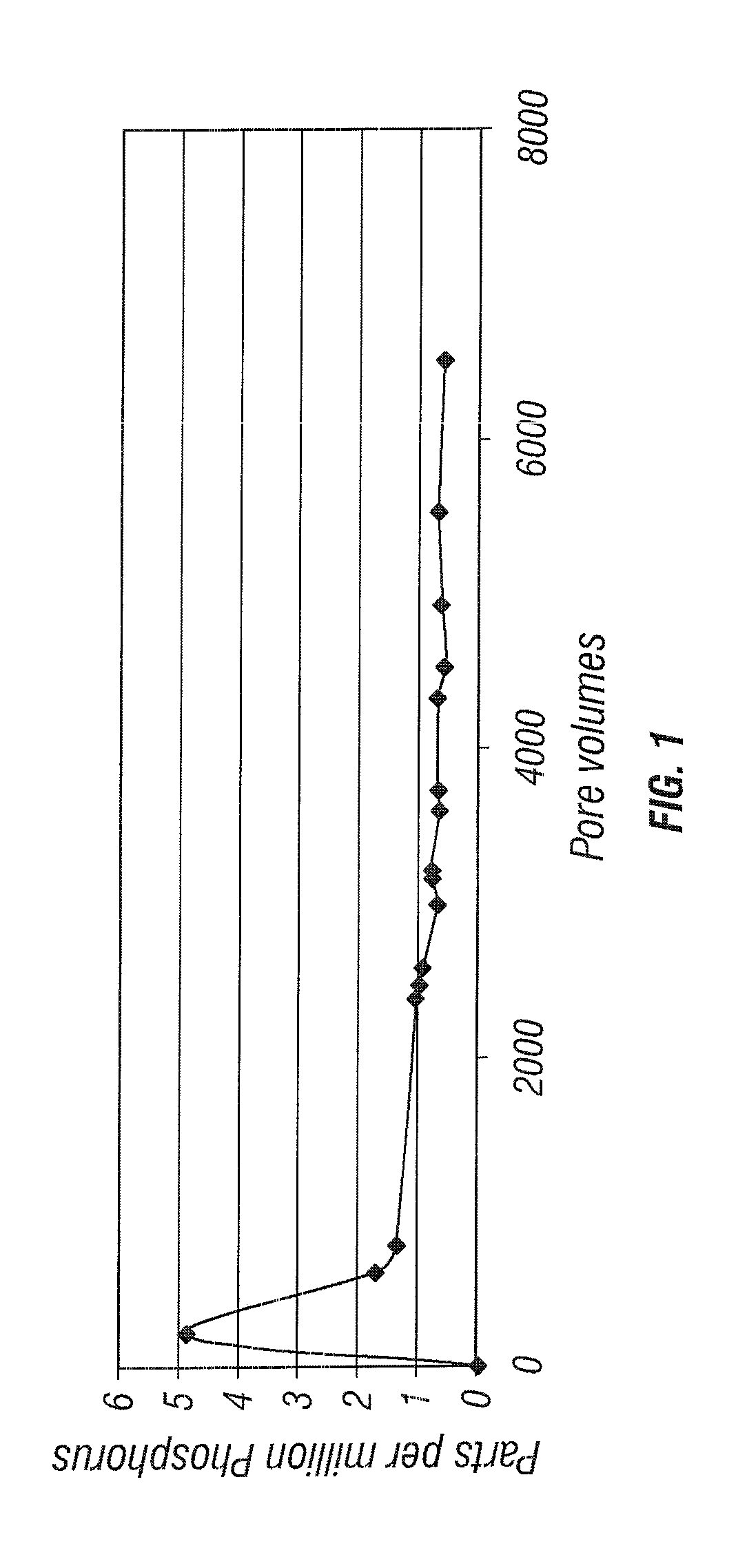

Slow release scale inhibitor composites and methods of using the same

ActiveUS20060124301A1Prevent and control formationCleaning apparatusFluid removalActivated carbonParticulates

A well treating composition of a composite containing a scale inhibitor adsorbed onto a water-insoluble adsorbent is useful in the control, formation and treatment of inorganic scales in a subterranean formation or wellbore. In addition, the well treating composition is useful in controlling the rate of release of scale inhibitor in the wellbore. The water-insoluble adsorbent may be activated carbon, silica particulate, precipitated silica, zeolite, diatomaceous earth, ground walnut shells, fuller's earth and organic synthetic high molecular weight water-insoluble adsorbents. The composite may be introduced into an oil or gas well with a carrier fluid.

Owner:BAKER HUGHES INC

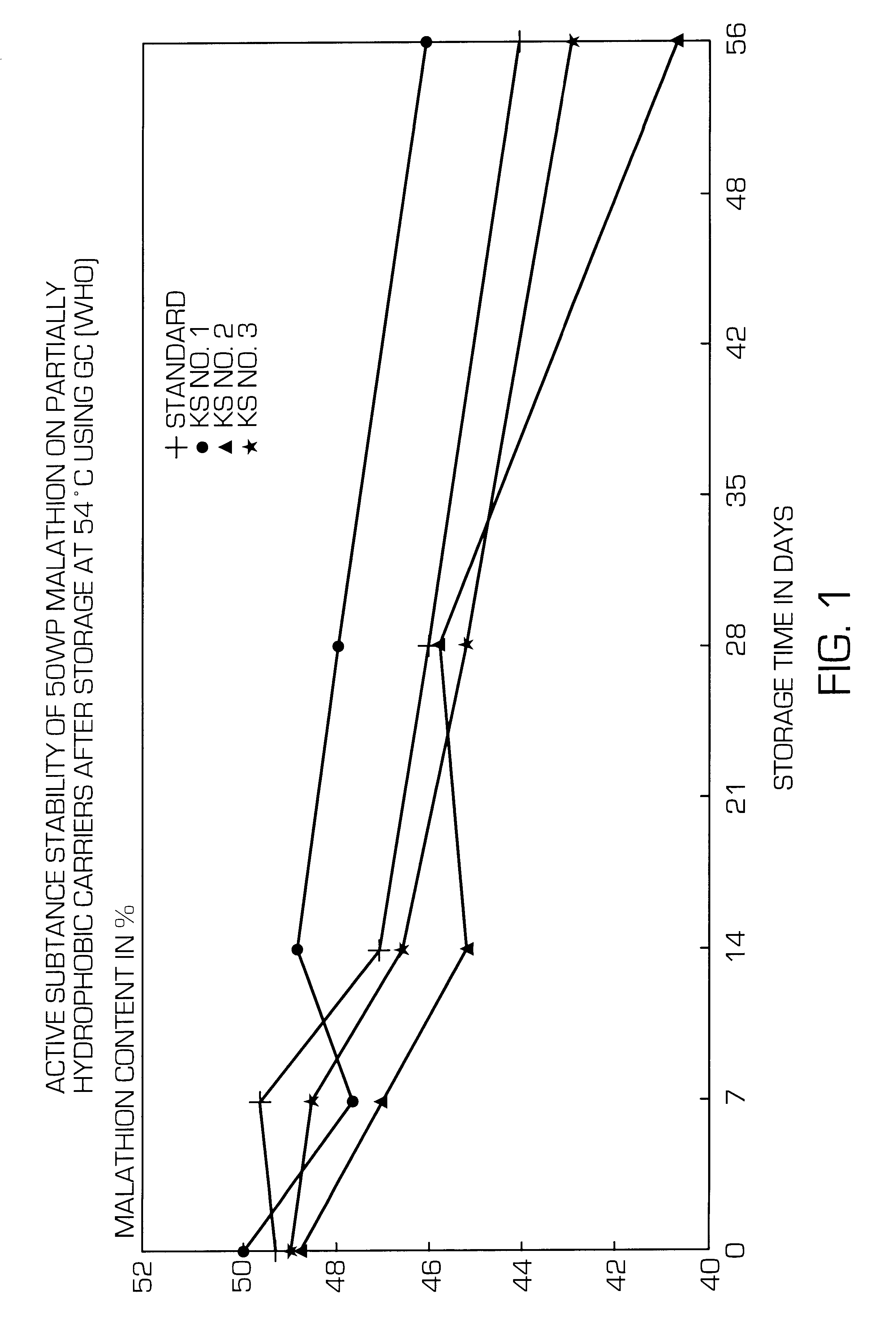

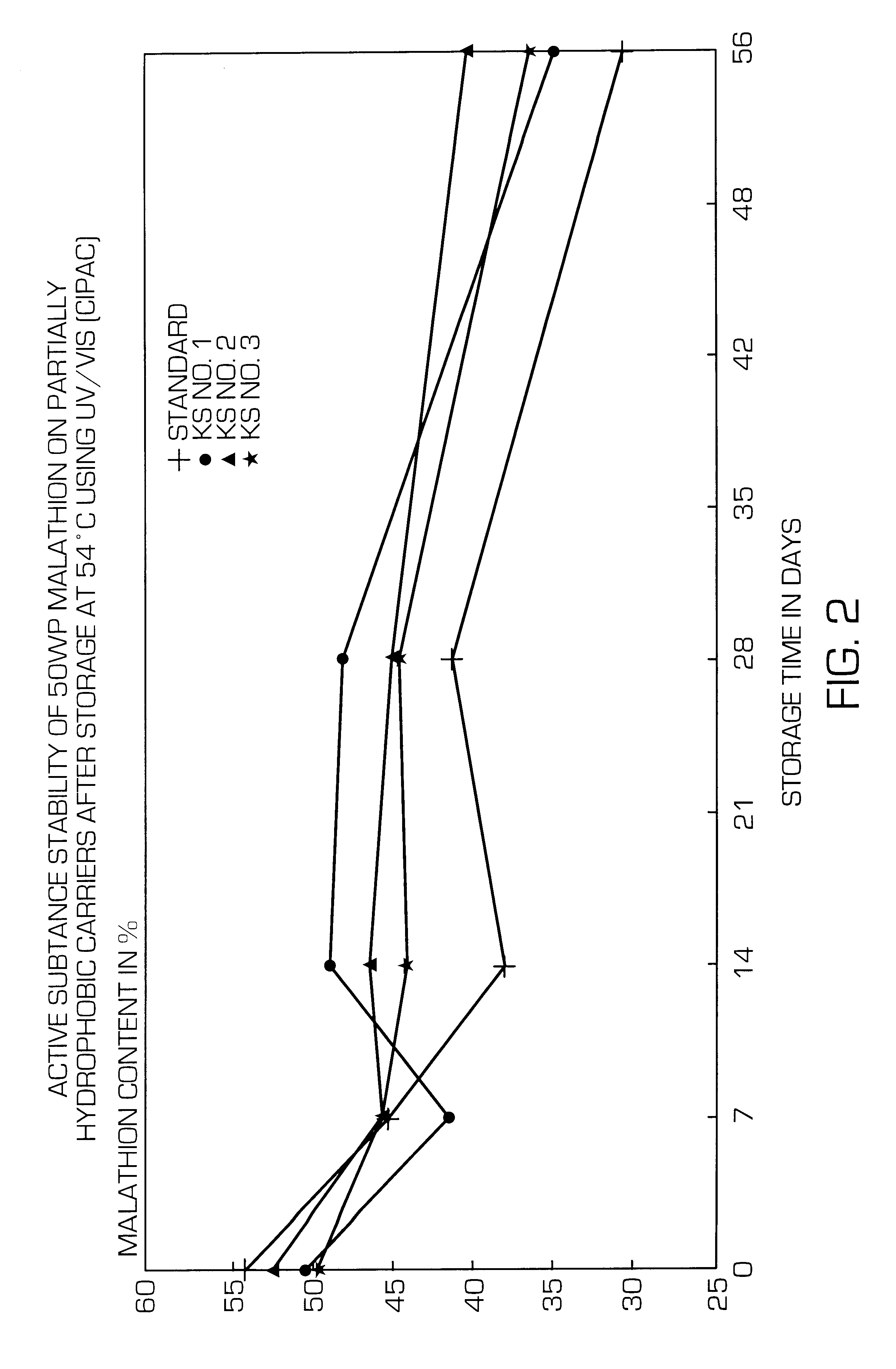

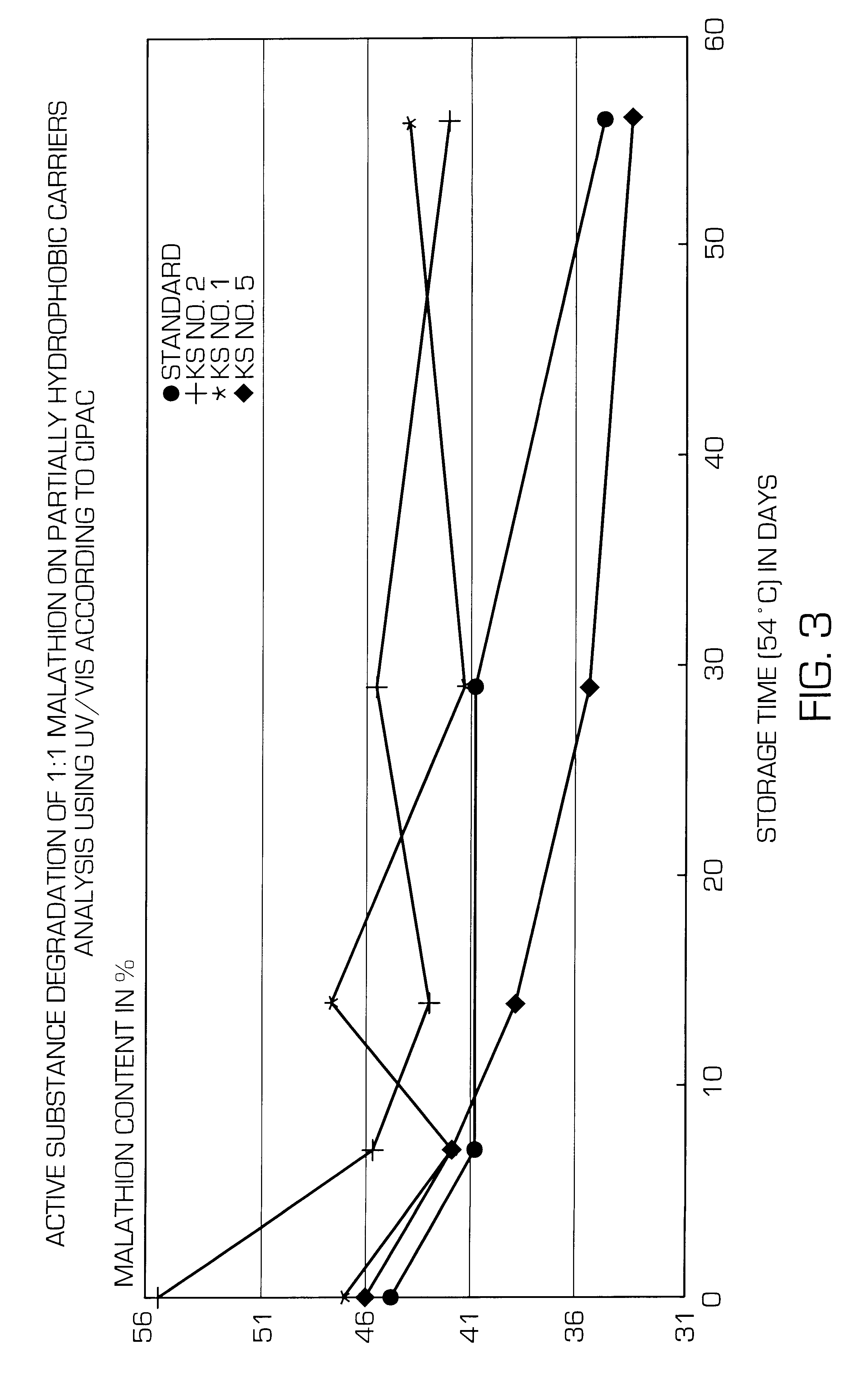

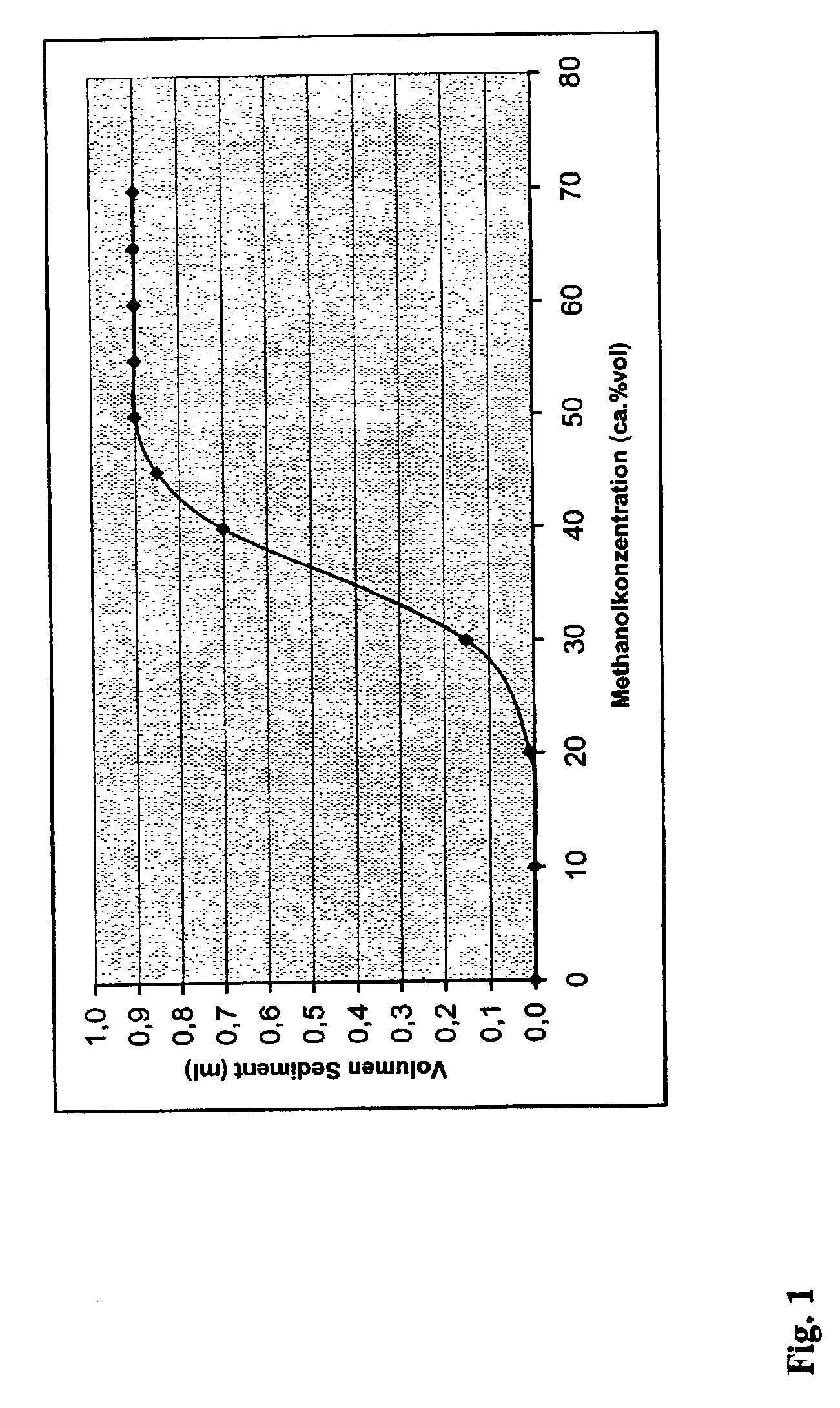

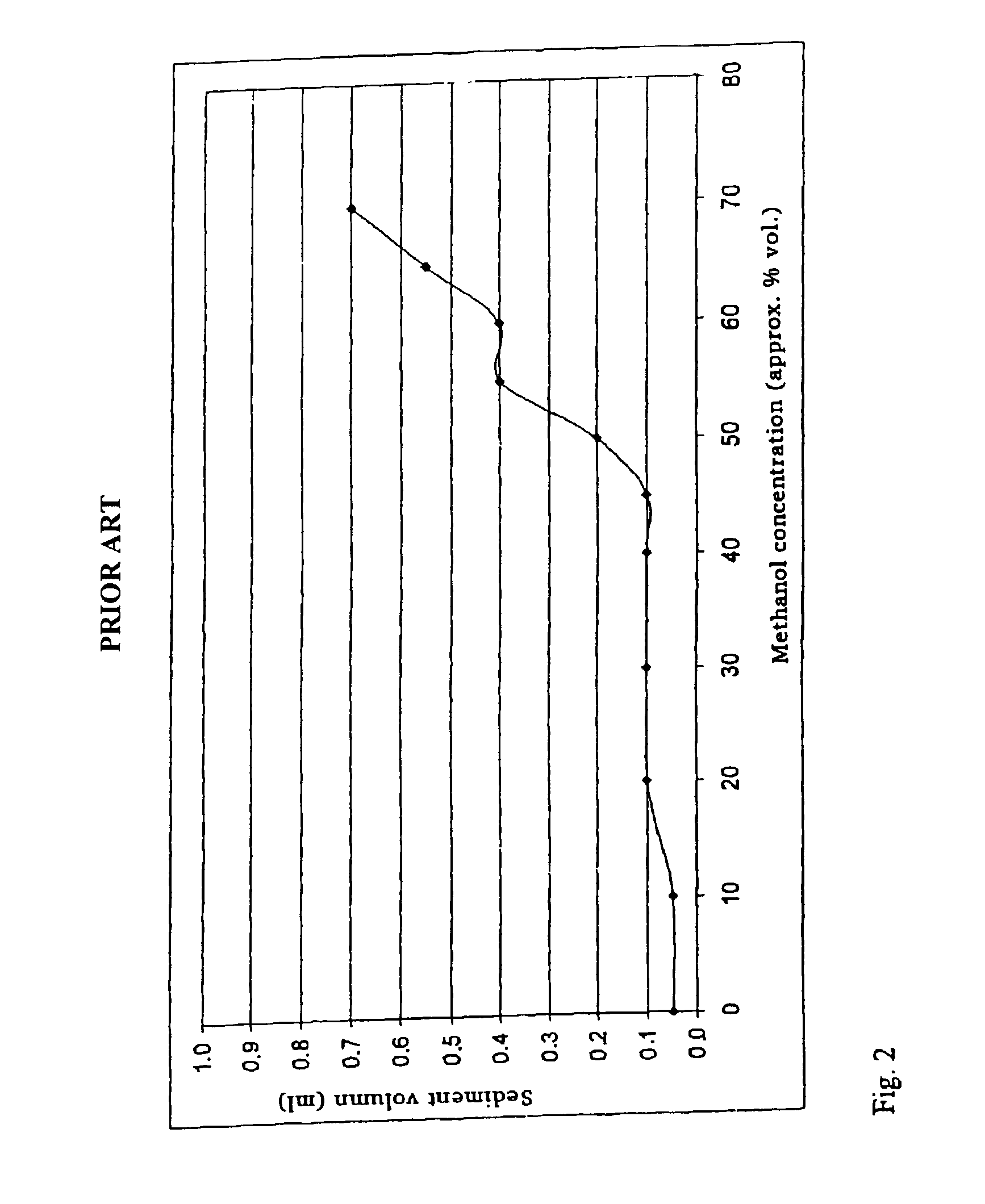

Partially hydrophobic precipitated silicas

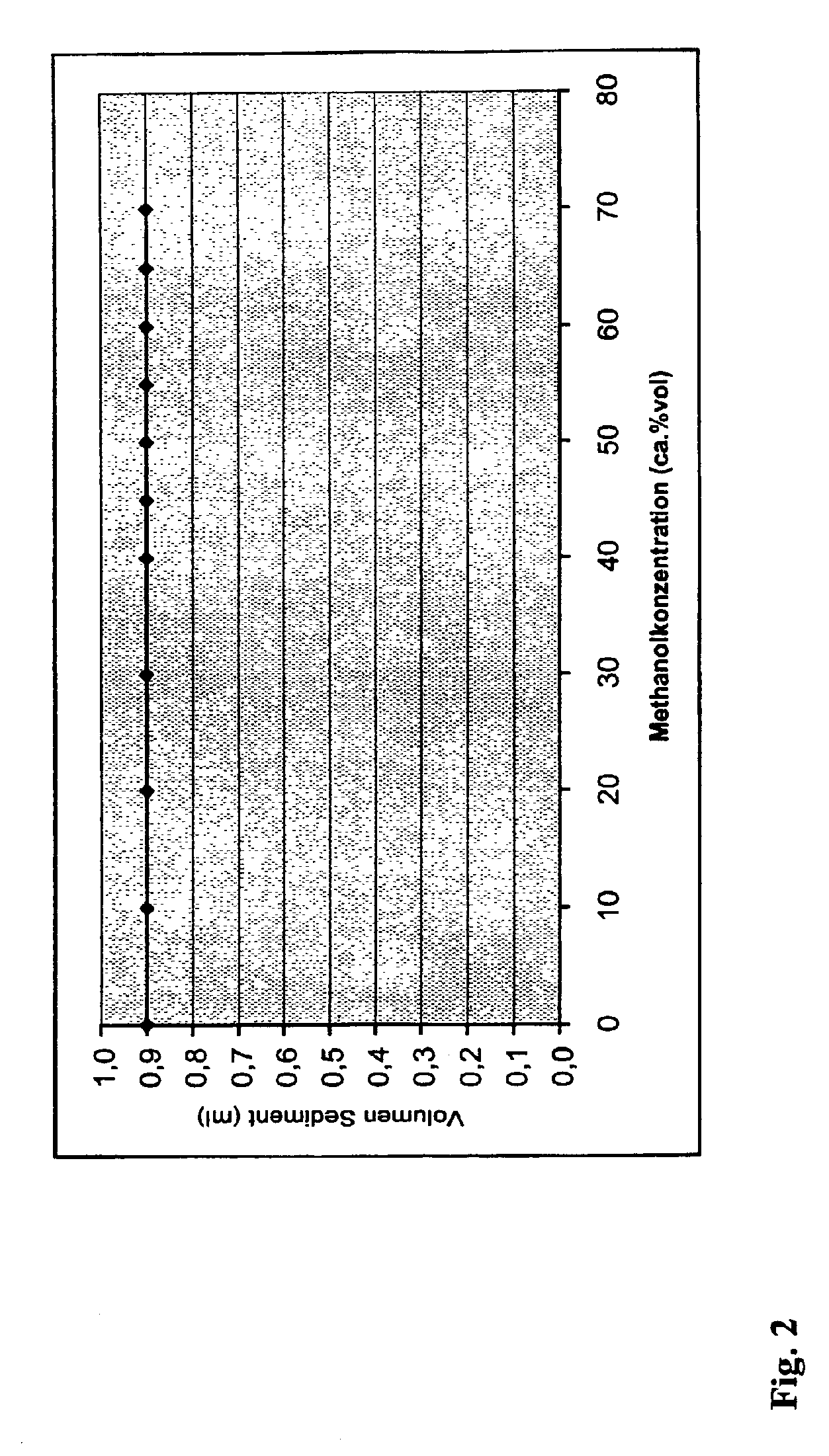

A partially hydrophobic precipitated silica having a methanol wettability of 10 to 49%, in particular with a DBP uptake on a dry basis of greater than 250 g / 100 g and a mean particle size of 1 to 12 mum and / or a carbon content of 0.3 to 1.85% and / or a loss on drying of 2.6 to 10.0% and / or a pH value of 5.5 to 10.0, is prepared by mixing the amount of water-repellent agent with the precipitated silica suspension at very short residence time and low pH value, filtering off the solid substance, washing free of salt, drying, post-treating thermally and milling. The partially hydrophobic precipitated silica can be used in active substance formulations and active substance formulations of hydrolysis-sensitive substance and in defoaming agents.

Owner:EVONIK DEGUSSA GMBH

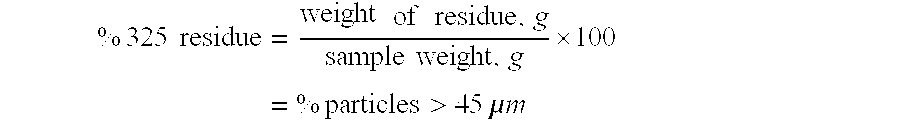

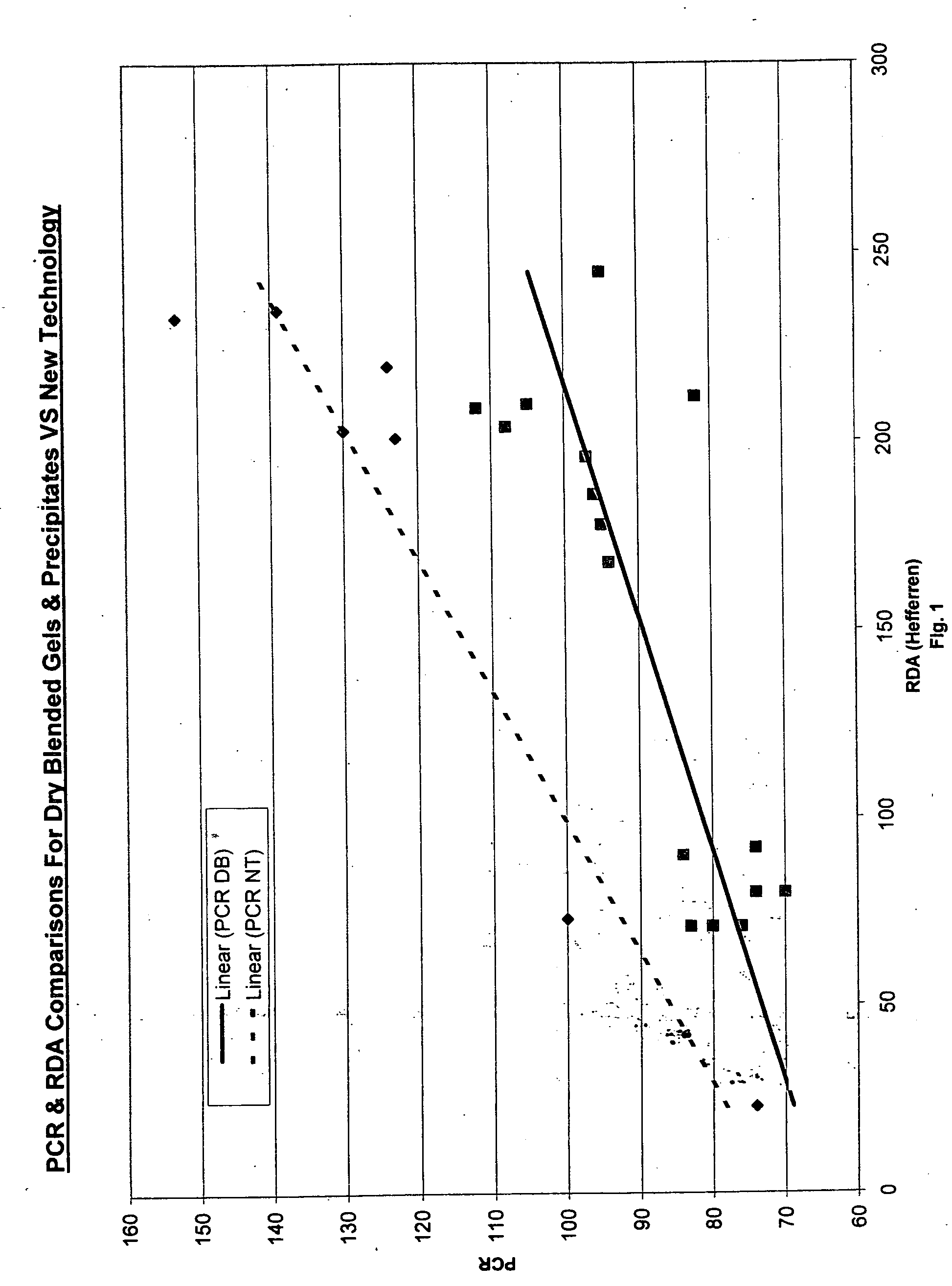

Classified silica for improved cleaning and abrasion in dentifrices

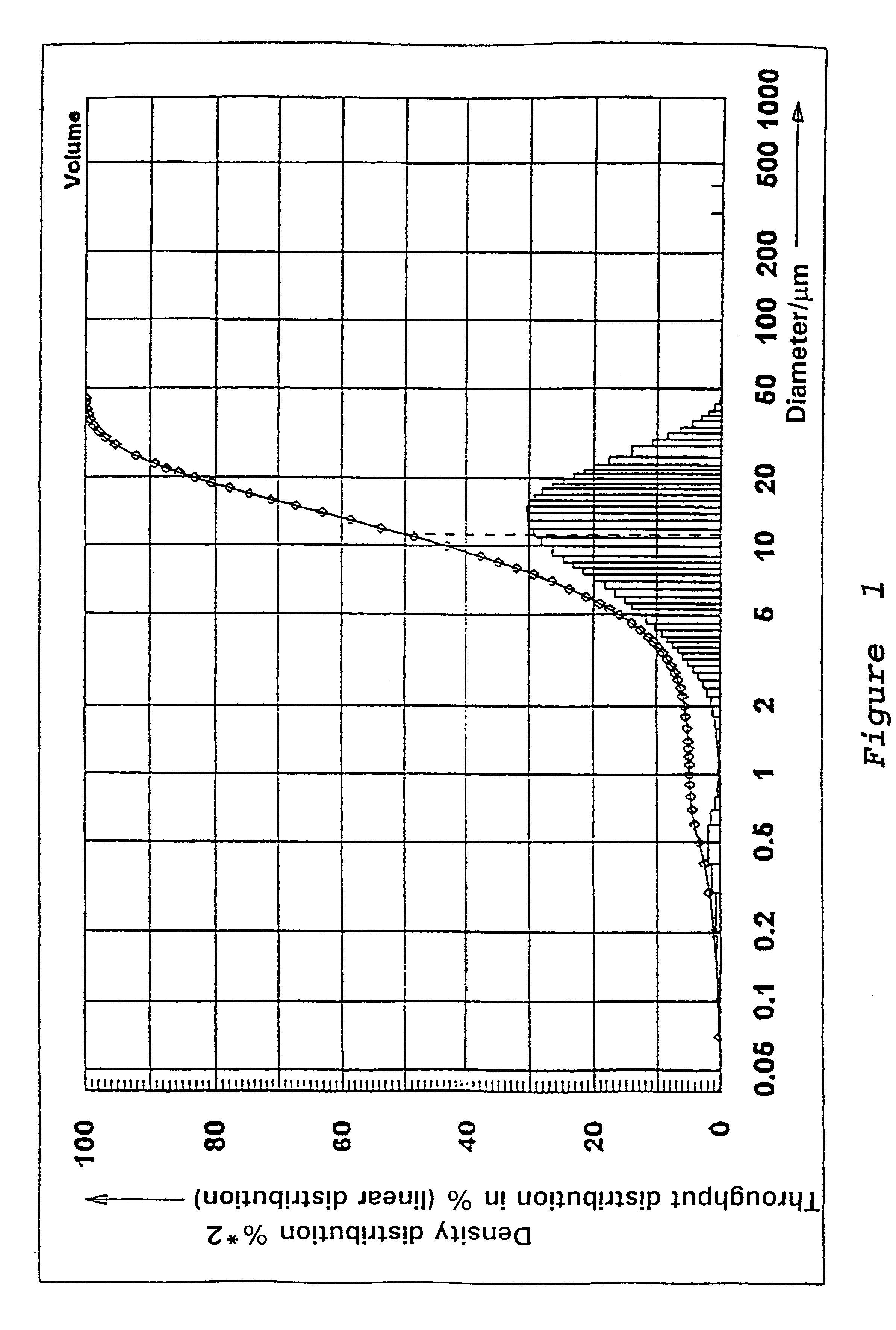

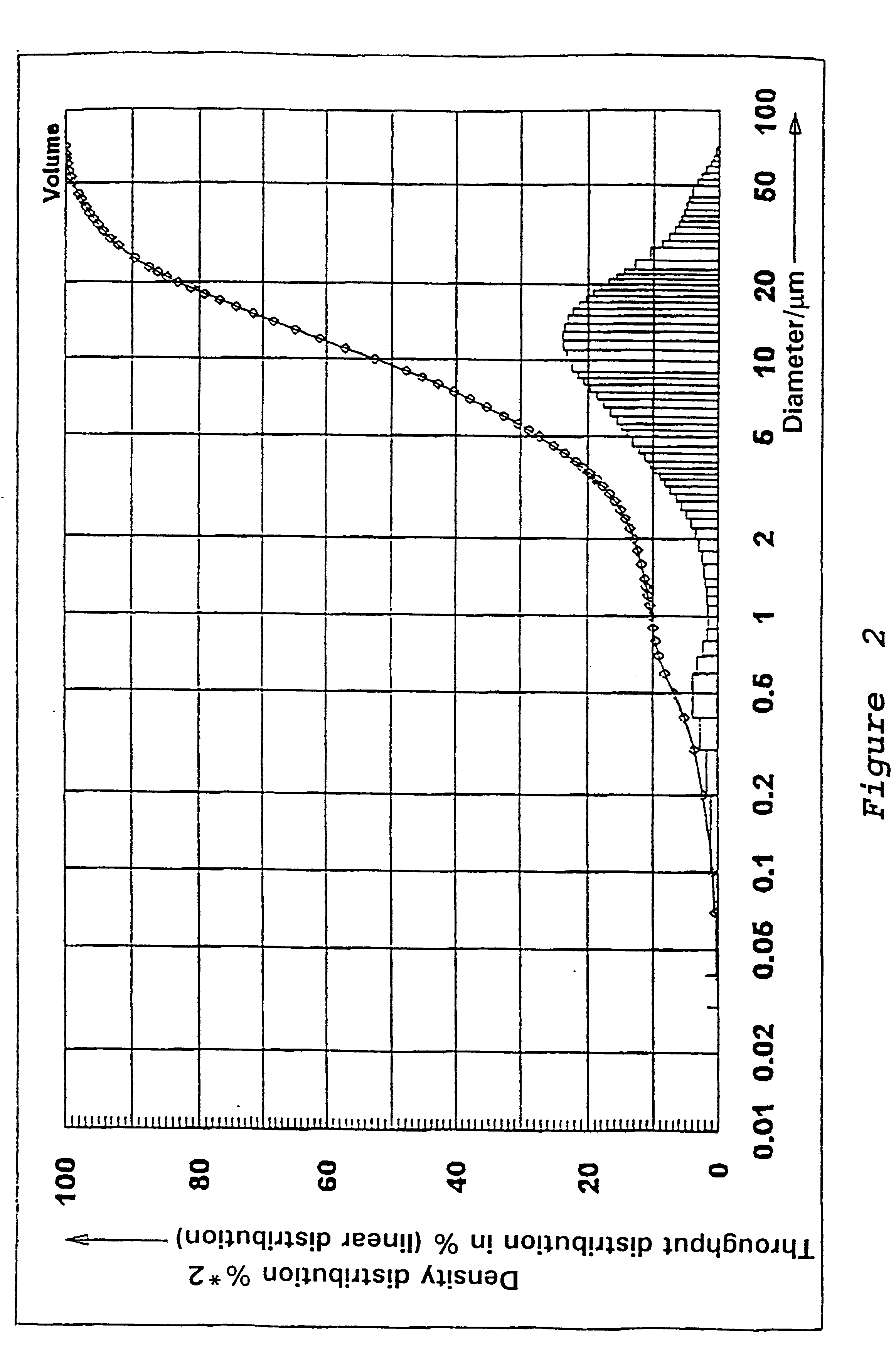

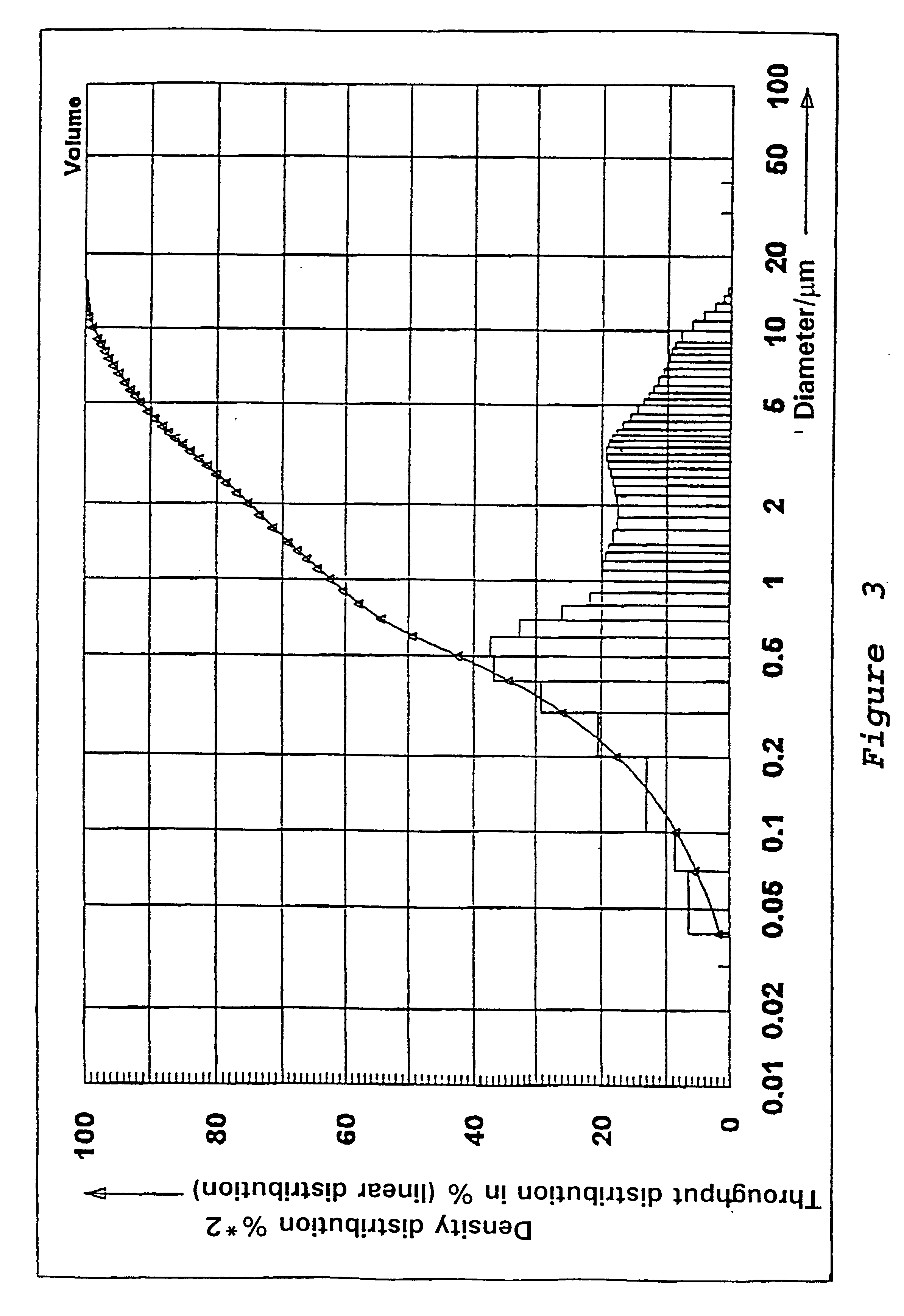

InactiveUS20060140878A1Improve uniformityPrecision cleaningCosmetic preparationsSilicaToothpastePhysical chemistry

A method of making precipitated silica abrasive compositions having excellent cleaning performance and lower abrasiveness with post-reactor sizing of the abrasive particles being performed via air classification techniques is provided. By targeting a specific particle size range, it has been determined that higher pellicle film cleaning levels may be achieved without also increasing the dentin abrasion properties of the silica products themselves. As a result, dentifrices including such classified abrasive silica products, and exhibiting particularly desirable cleaning benefits, can be provided for improved tooth polishing, whitening, and the like, without deleteriously affecting the hard tooth surfaces. Also encompassed within this invention also are products of this selective process scheme and dentifrices containing such classified silica products.

Owner:J M HUBER CORP

Method of inhibiting or controlling formation of inorganic scales

A well treating composition of a composite containing a scale inhibitor adsorbed onto a water-insoluble adsorbent is useful in the control, formation and treatment of inorganic scales in a subterranean formation or wellbore. In addition, the well treating composition is useful in controlling the rate of release of scale inhibitor in the wellbore. The water-insoluble adsorbent may be activated carbon, silica particulate, precipitated silica, zeolite, diatomaceous earth, ground walnut shells, fuller's earth and organic synthetic high molecular weight water-insoluble adsorbents. The composite may be introduced into an oil or gas well with a carrier fluid.

Owner:BAKER HUGHES INC

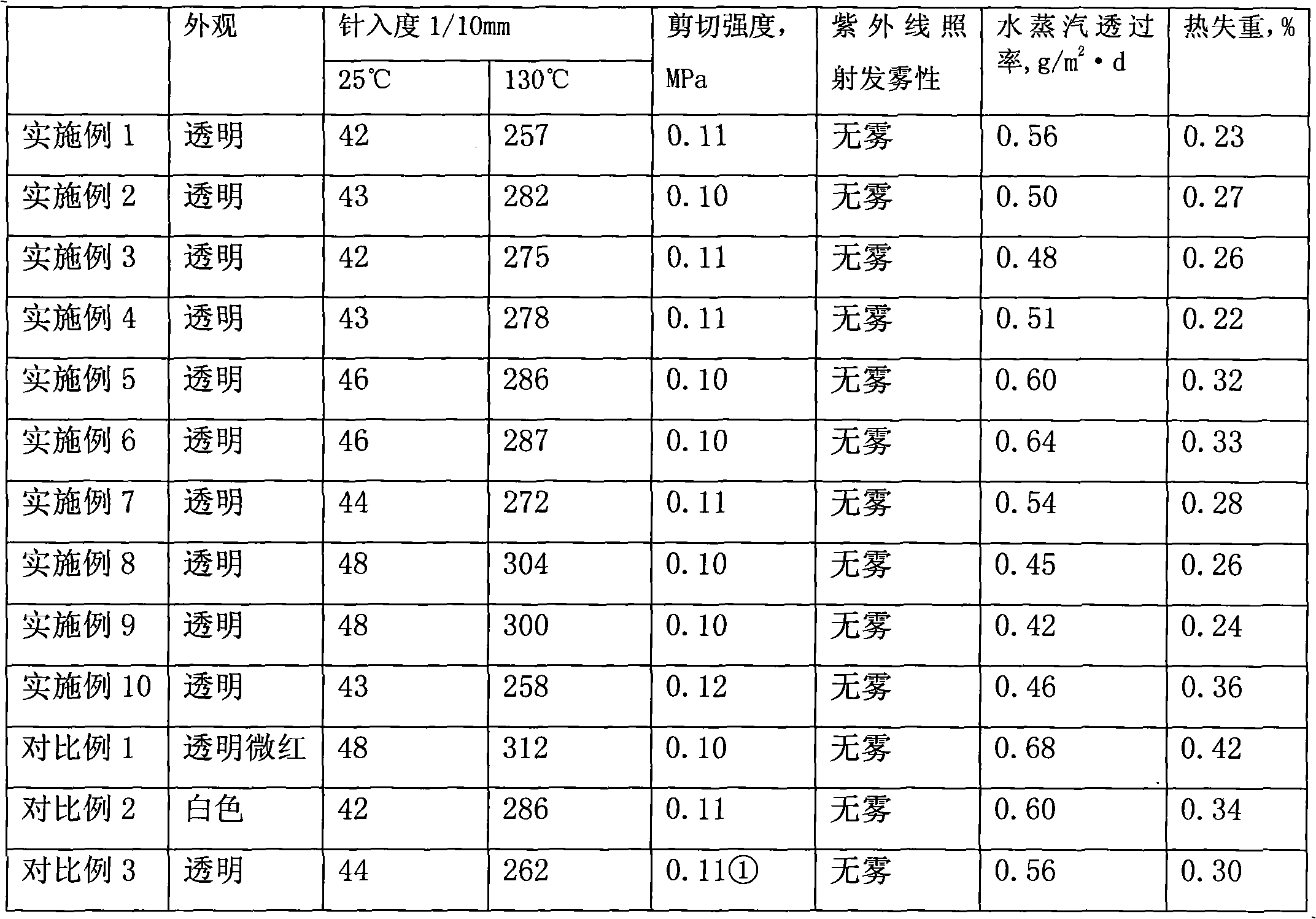

Transparent butyl hot-melt sealant and preparation method thereof

ActiveCN101805569AHigh strengthGood construction performanceNon-macromolecular adhesive additivesOther chemical processesSealantFumed silica

The invention relates to a transparent butyl hot-melt sealant, which is prepared with the following raw materials in parts by weight: 1-20 of butyl rubber, 10-80 of polyisobutylene, 5-30 of plasticizer, 3-10 of tackifier, 3-10 of softener, 0.1-5 of stabilizer, 5-30 of filler and 0.1-5 of adhesion promoting agent. The matching use of the butyl rubber and the polyisobutylene with different molecular weights facilitates the improvement of the strength and workability of the transparent butyl hot-melt sealant. The filler is selected from fumed silica or precipitated silica, which ensures the appearance transparency of the product. Due to the addition of the stabilizer and the strict control of the production process, the appearance transparency and the physical and chemical properties of the product are enhanced. The use of the active group substituted alkoxy silane as a coupling agent improves the adhesion of the product to glass, aluminum and other substrates.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

Method for making particulate compositions and products thereof

InactiveUS20070001037A1Easy to produceImprove uniformityCosmetic preparationsOther chemical processesParticulatesSilicon dioxide

A method of making abrasive compositions, and more particularly, it relates to a method of making precipitated silica abrasive compositions having excellent cleaning performance and lower abrasiveness with post-reactor sizing of the abrasive particles being performed directly via wet comminution and centrifugation, optionally followed by hydraulic chamber press filtering combined with vacuum dewatering and de-agglomeration is provided. By targeting a specific particle size range, it has been determined that higher pellicle film cleaning levels may be achieved without also increasing the dentin abrasion properties of the silica products themselves. As a result, dentifrices including such classified abrasive silica products, exhibiting particularly desirable cleaning benefits, can be provided for improved tooth polishing, whitening, and the like, without deleteriously affecting the hard tooth surfaces. Also encompassed within this invention also are products of this selective process scheme and dentifrices containing such particularly manufactured and classified silica products.

Owner:J M HUBER CORP

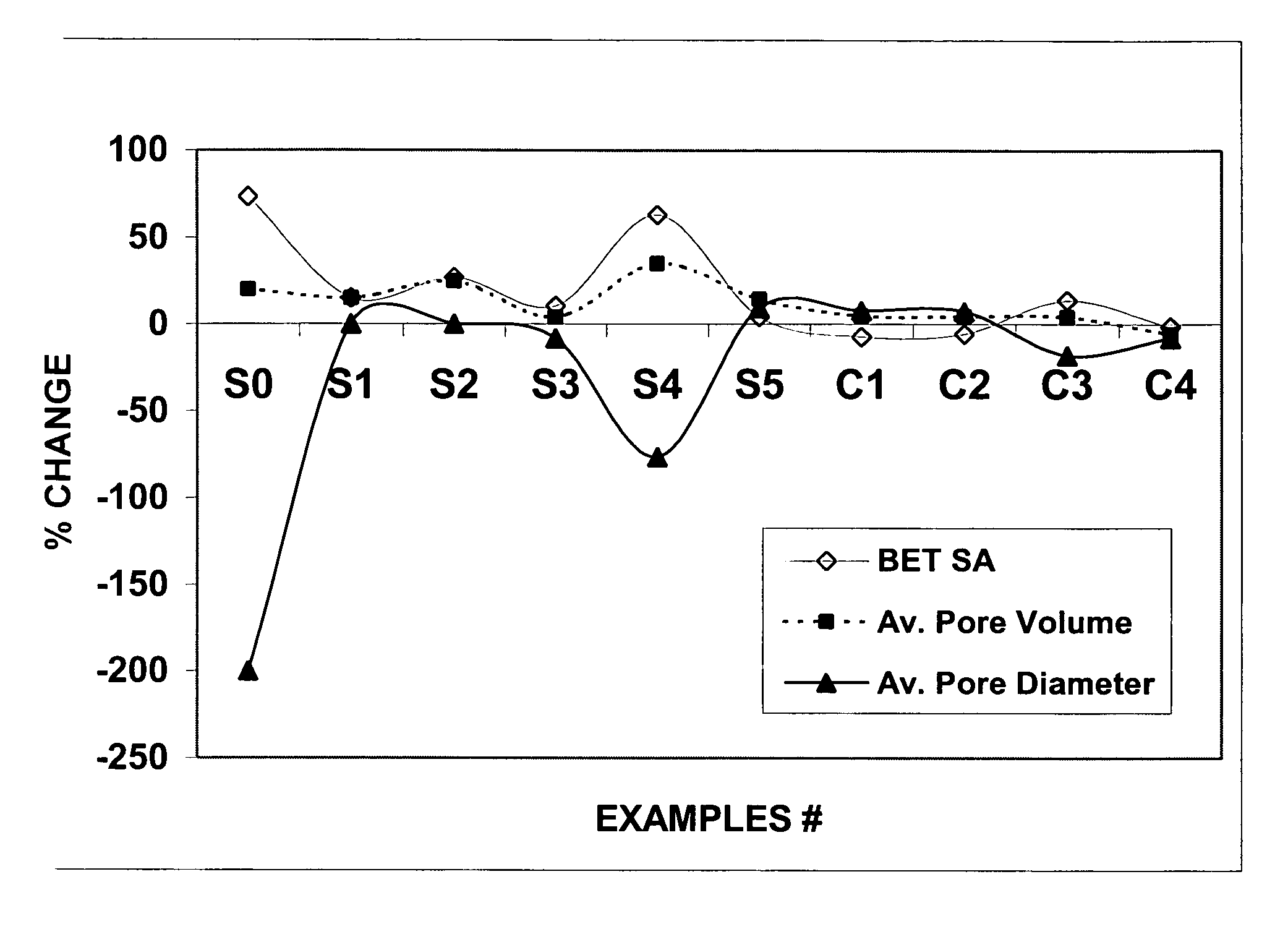

Precipitated silicic acid

InactiveUS6268424B1Easily dispersible in tire carcassExtended service lifePigmenting treatmentSilicaSilicic acidPhysical chemistry

Precipitated silica having the following parameters:is prepared by reacting alkali silicate with mineral acids and aluminum sulfate solution at temperatures of 60-95° C. at a pH of 7.0-10.0 while stirring constantly, wherein the reaction is continued to a solids concentration of 40-110 g / l, the pH is adjusted to a value between 3 and 5, and the precipitated silica is filtered off, washed and then dried, and optionally ground or granulated.

Owner:EVONIK DEGUSSA GMBH

Fischer-Tropsch processes and catalysts using stabilized supports

ActiveUS7071239B2Good hydrothermal stabilityImprove stabilityCatalyst carriersOrganic compound preparationSlurryHYDROSOL

A catalyst and method for producing hydrocarbons using a catalyst support having an improved hydrothermal stability, such as under Fischer-Tropsch synthesis conditions. The stabilized support is made by a method comprising treating a boehmite material in contact with at least one structural stabilizer. Contacting the boehmite with at least one structural stabilizer can include forming a mixture comprising the boehmite material and at the least one structural stabilizer. The mixture can be a sol or a slurry. The treating preferably includes drying or spray drying the mixture, and calcining in an oxidizing atmosphere to obtain the stabilized support. Preferred structural stabilizers can include an element, such as cobalt, magnesium, zirconium, boron, aluminum, barium, silicon, lanthanum, oxides thereof, or combinations thereof; or can include precipitated oxides, such as a co-precipitated silica-alumina.

Owner:CLARIANT INT LTD

Tire with rubber tread composed of a primary and at least one lateral tread portion containing a dispersion of short carbon fibers

ActiveUS20070221303A1Easy to handleIncreasing low strain stiffnessSpecial tyresPneumatic tyre reinforcementsFiberCarbon fibers

The invention relates to a tire having a circumferential rubber tread of a cap / base construction composed of a cap rubber layer as the tire running surface and an internal base rubber layer underlying said tread cap layer. The said tread cap layer is composed of a primary tread cap portion and one or two lateral tread cap portions of rubber compositions containing precipitated silica and / or rubber reinforcing carbon black reinforcement and wherein the rubber composition of at least one of said lateral tread cap portions contains a dispersion of short carbon fibers. Said primary tread cap portion contains a major portion of the running surface of the tread and is comprised of a silica-rich or carbon black-rich, preferably silica-rich, reinforcement-containing rubber composition, and said lateral tread portion(s) contains a minor portion of the running surface of the tread and is comprised of a silica-rich or carbon black-rich, preferably carbon black-rich, reinforcement-containing rubber composition. Where said primary tread cap portion is comprised of a silica-rich rubber composition, said lateral tread cap portion(s) is comprised of a carbon black-rich rubber composition and visa versa. The said tread cap portions are load bearing portions in the sense of extending from the running surface of the tread radially inward to said underlying tread base layer. In one aspect, the portioned rubber tread cap layer and the rubber tread base layer are co-extruded together to form a unitary composite thereof.

Owner:THE GOODYEAR TIRE & RUBBER CO

High-whiteness, non-heat-treated hydrophobic precipitated silica

InactiveUS6899951B2High whitenessImprove reinforcementSilicaGlass/slag layered productsDouble bottomSilicon dioxide

The present invention provides a hydrophobic precipitated silica having the following properties:carbon content1.0-8.0%methanol wettability 20-55%reflectance>94%BET / CTAB ratio ≦1DBP absorption<250 g / 100 gBET surface area 50-110 m2 / gCTAB surface area100-150 m2 / gSears number<13.The present invention also provides methods for making and using the hydrophobic precipitated silica and articles and compositions which include the same.

Owner:EVONIK DEGUSSA GMBH

Polishing composition and polishing method

InactiveUS20050205837A1Suitable for useOther chemical processesDecorative surface effectsColloidal silicaTetramethylammonium hydroxide

A polishing composition includes silicon dioxide, an alkaline compound, an anionic surfactant, and water. The silicon dioxide is, for example, colloidal silica, fumed silica, or precipitated silica. The alkaline compound is, for example, potassium hydroxide, sodium hydroxide, ammonia, tetramethylammonium hydroxide, piperazine anhydride, or piperazine hexahydrate. The anionic surfactant is at least one selected from a sulfonic acid surfactant, a carboxylic acid surfactant, and a sulfuric acid ester surfactant. The polishing composition can be suitably used in applications for polishing a silicon wafer.

Owner:FUJIMI INCORPORATED

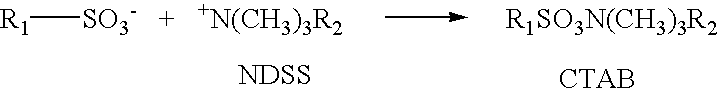

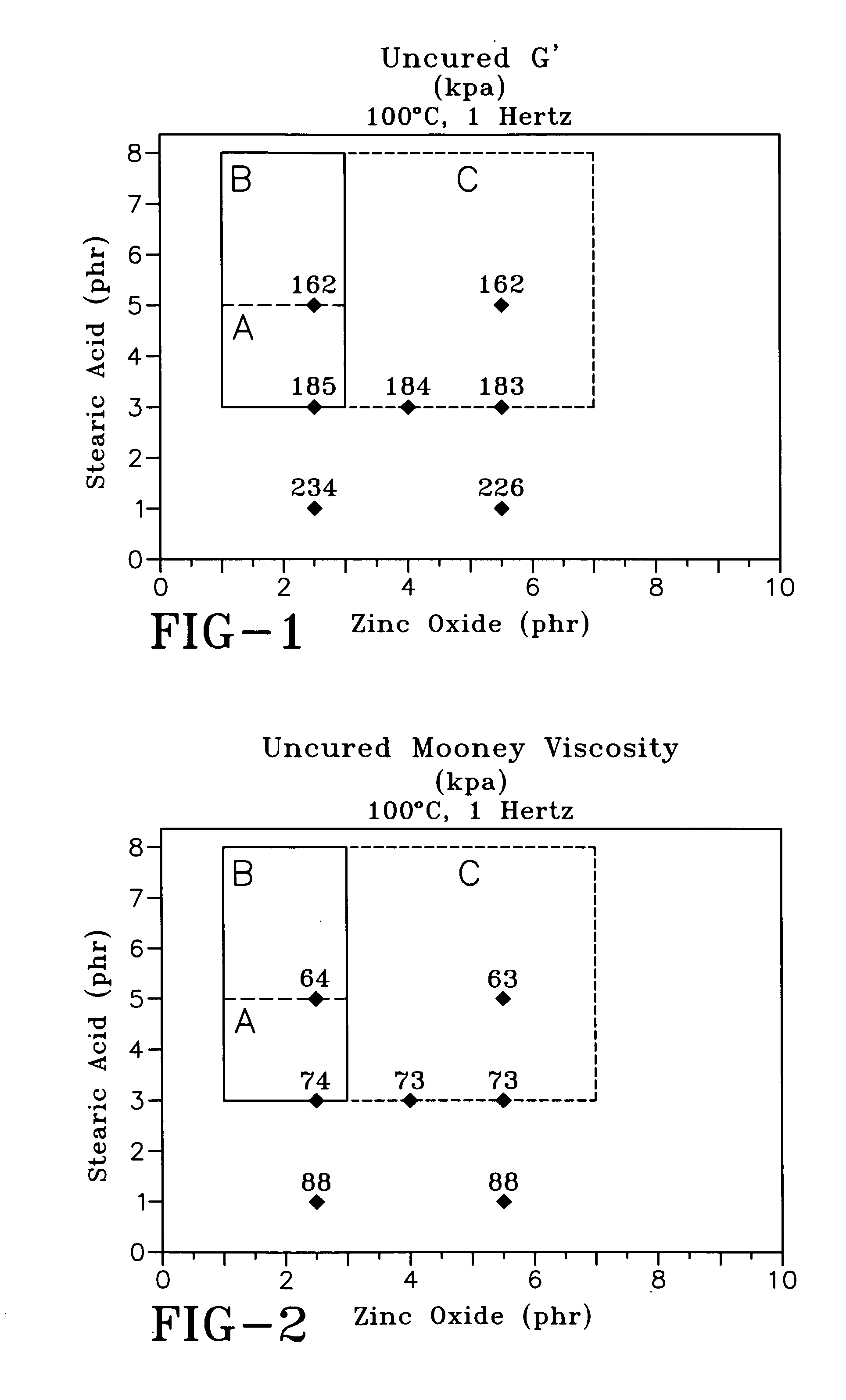

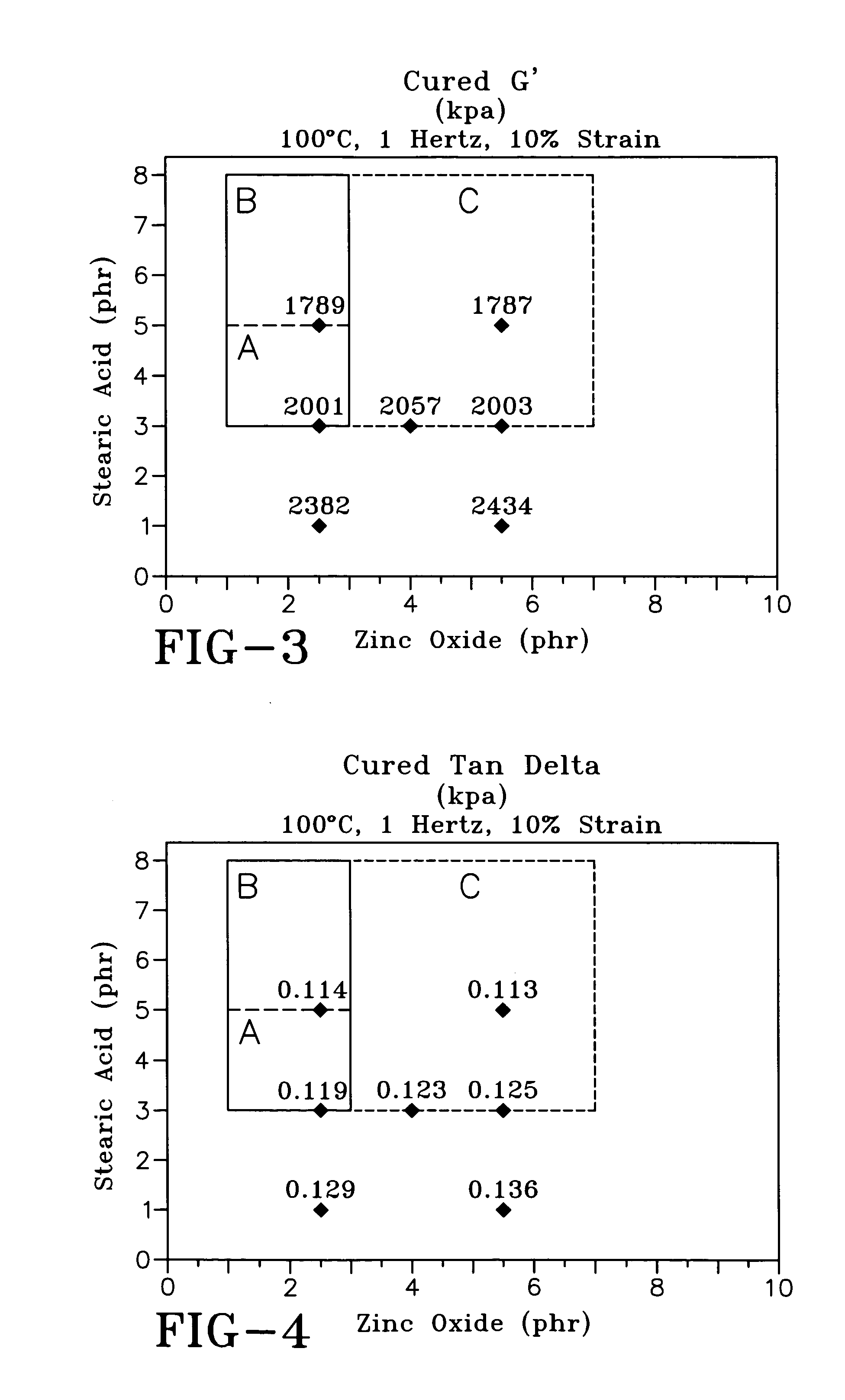

Silica reinforced rubber composition and use in tires

InactiveUS20080027162A1Promote migrationReduce hysteresisSpecial tyresSolid ballsCouplingCarboxylic acid

This invention relates to the preparation of silica-rich rubber compositions which contain silica reinforcement and silica coupler together with a specified combination of zinc oxide and long chain (fatty) carboxylic acid such as stearic acid. The silica, silica coupling agent, zinc oxide and stearic acid are combined in a manner to form a complex network. The silica is a precipitated silica in a form of silica aggregates which contain hydroxyl groups on its surface. A preferred silica coupling agent is a bis (3-trialkoxysilylalkyl) polysulfide which contains an average of from 2 to about 4, preferably from 2 to about 2.6, connecting sulfur atoms in its polysulfidic bridge. The invention further relates to tires having a component thereof such as, for example, a tread.

Owner:HUA KUO CHIH +3

Method for preparation of hydrophobic precipitated silica

A method for the preparation of hydrophobic precipitated silica. The method comprises contacting an aqueous suspension of a hydrophilic precipitated silica with (1) a catalytic amount of an acid and (2) an organosilicon compound in the presence of (3) a water-miscible organic solvent in an amount sufficient to facilitate reaction of the hydrophilic precipitated silica with the organosilicon compound to form a hydrophobic precipitated silica.

Owner:DOW CORNING CORP

Precipitated silica product with low surface area, dentifrices containing same, and processes

ActiveUS6946119B2Reduce the possibilityIncrease volumePigmenting treatmentCosmetic preparationsAntimicrobial actionFood flavor

Precipitated silica product having low surface area and enhanced flavor compatibility. The precipitated silica product is especially well-adapted for use in dentifrices containing cetylpyridinium chloride, which do not attach to the low surface area silica product in a meaningful level and thus remain available for antimicrobial action. Processes for making the low surface area silica product are also provided.

Owner:EVONIK OPERATIONS GMBH

Hydrophobic precipitated silica

Hydrophobic precipitated silica having the physical / chemical parameters:is produced by mixing a precipitated silica suspension with a silane emulsion and drying it. The hydrophobic precipitated silica may be used for the production of defoamers and in papermaking.

Owner:DEGUSSA AG

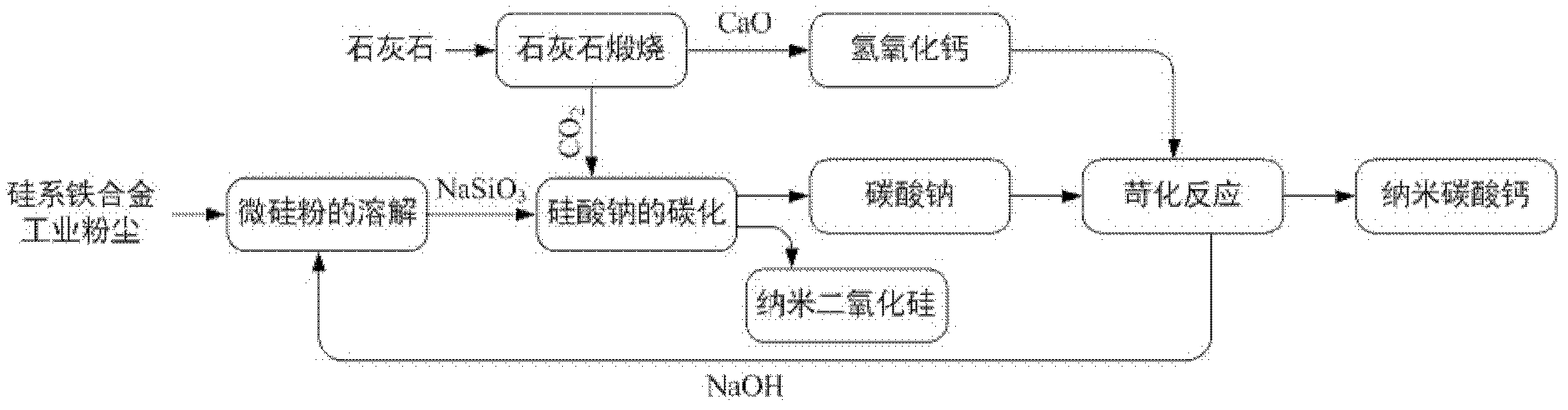

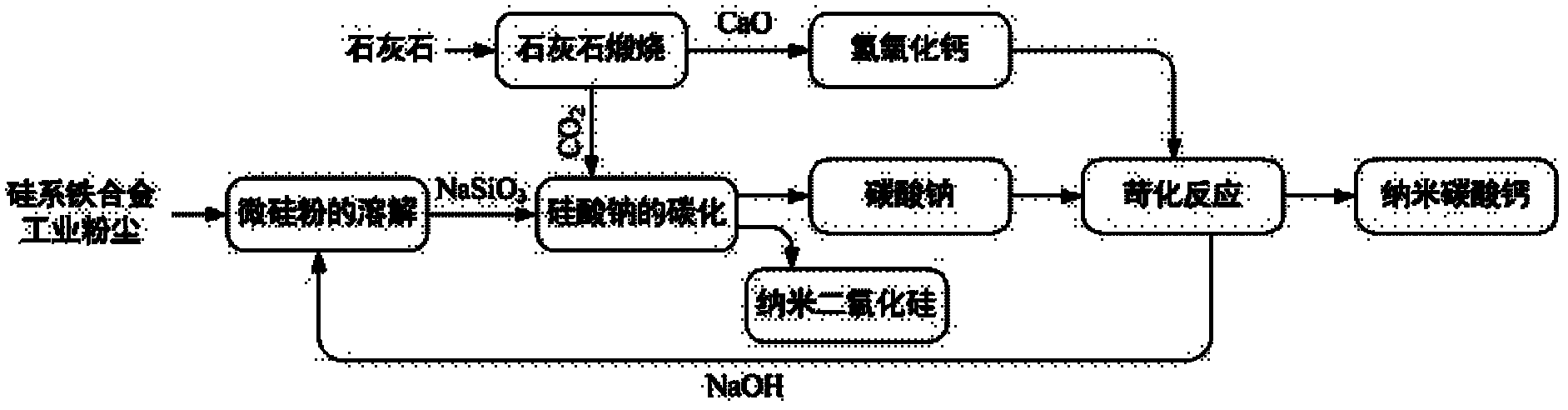

Method for preparing white carbon black cogeneration nanometer calcium carbonate by integrally utilizing micro silicon powder

InactiveCN102424392AReduce manufacturing costEmission reductionCalcium/strontium/barium carbonatesProductsCarbonizationCogeneration

The invention relates to a method for preparing white carbon black cogeneration nanometer calcium carbonate by integrally utilizing micro silicon powder, which belongs to the technical field of integrative utilization of silicon iron alloy industrial waste resources and industrial kiln gas carbon dioxide. The method comprises the following process steps that: micro silicon powder is dissolved by sodium hydroxide hot alkali for preparing water glass; lime is prepared through lime stone calcination, and carbon dioxide raw material gas is released; precipitated silica is prepared through water glass carbonization; carbonization filter liquid is subject to sodium carbonate causticization for preparing sodium hydroxide solution to coproduce nanometer calcium carbonate; and the sodium hydroxide solution is circulated to a hot alkali dissolving and boiling kettle for dissolving micro silicon powder to prepare water glass. The method has the advantages that the process circulation of integrally utilizing the micro silicon powder for preparing the white carbon black cogeneration nanometer calcium carbonate is realized, and a new method is provided for goals of changing metallurgy chemical industrial waste materials into resources and utilizing the waste materials at high value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

Preparation of silica reinforced polyisoprene-rich rubber composition and tire with component thereof

This invention relates to the preparation of a cis 1,4-polyisoprene rubber-rich rubber composition containing precipitated silica which has been pre-treated with a fatty alcohol and / or epoxidized soybean oil together with an organosilane containing polysulfide coupling agent and to tires having at least one component comprised of such rubber composition. The invention particularly relates to a process of (a) preparing a natural rubber-rich rubber composition comprised of pre-treating precipitated silica aggregates prior to blending with, or in the presence of, dry natural rubber with a fatty alcohol and / or epoxidized soybean oil to the exclusion of sulfur curative for the natural rubber, mixing an organalkoxysiloxane based polysulfide coupling agent with said dry natural rubber coincidentally with or subsequent to said precipitated silica aggregate fatty alcohol and / or epoxidized soybean oil pre-treatment to form a composite thereof, to the exclusion of sulfur curative, followed by (b) mixing the resulting rubber mixture with sulfur curative and (c) curing the resulting rubber composition.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire having tread with colored groove configuration

InactiveUS20020174924A1Improve performanceSpecial tyresTyre tread bands/patternsElastomerEngineering

The present invention relates to a tire having a rubber tread of a lug and groove configuration and of a co-extruded cap / base construction; wherein the tread cap is of a rubber composition which contains carbon black and is thereby of a black color; wherein a visible surface of at least one groove is of a rubber composition exclusive of carbon black and is of a non-black color and wherein said visible non-black colored rubber composition is a rubber layer which underlies said tread cap. Said visible non-black colored rubber is exclusive of any appreciable portion of, and preferably exclusive of, the surface of said tread lugs intended to be ground-contacting. In one aspect of the invention, said non-black colored rubber composition contains an amorphous precipitated silica reinforcement, preferably a pre-hydrophobated precipitated silica. In another aspect of the invention, said non-black colored rubber composition, and alternately, carbon black containing black colored rubber compositions adjoining said non-black colored rubber composition, is comprised a blend of at least one diene based elastomer and a brominated copolymer of isobutylene and p-methylstyrene together with an organo phosphite.

Owner:GENERAL ELECTRIC CO +1

Flame-retardant and environmentally-friendly polyurethane cable material and its preparation method

ActiveCN102977585AImprove flame retardant performanceExcellent non-flammabilityElastomerDecabromodiphenyl ether

The invention provides an flame-retardant and environmentally-friendly polyurethane cable material. The cable material is prepared from the following raw materials, by weight, 20-30 parts of chloroprene rubber, 60-80 parts of a polyurethane thermoplastic elastomer, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of chlorinated paraffin, 0.5-1.0 part of stearic acid, 1-3 parts of barium stearate, 4-6 parts of iron oxide, 0.5-1.0 part of ammonium trimolybdate, 30-50 parts of precipitated silica, 10-13 parts of modified argil, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenyl oxide, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance, and the cables processed through using the cable material can prevent the harms of mice and termites and simultaneously have the efficacies of low smoke, environmental protection and flame retardation.

Owner:蚌埠尚维知识产权运营有限公司

High-whiteness hydrophobic precipitated silica with ultralow moisture absorption

InactiveUS7022375B2Increase loadLow water absorptionBiocideSilicaPhysical chemistryMoisture absorption

Owner:EVONIK DEGUSSA GMBH

Microporous material

ActiveUS20110256364A1Synthetic resin layered productsTobacco devicesPolyolefinVolumetric Mass Density

Microporous materials that include thermoplastic organic polyolefin polymer (e.g., ultrahigh molecular weight polyolefin, such as polyethylene), particulate filler (e.g., precipitated silica), and a network of interconnecting pores, are described. The microporous materials of the present invention possess controlled volatile material transfer properties. The microporous materials can have a density of at least 0.8 g / cm3; and a volatile material transfer rate, from the volatile material contact surface to the vapor release surface of the microporous material, of from 0.04 to 0.6 mg / (hour*cm2). In addition, when volatile material is transferred from the volatile material contact surface to the vapor release surface, the vapor release surface is substantially free of volatile material in liquid form.

Owner:PPG IND OHIO INC

Silicon rubber cross-linked flame-retardant cable material and its preparation method

ActiveCN102977605AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsInsulated cablesCalcium silicateAntimony trioxide

The invention provides a silicon rubber cross-linked flame-retardant cable material. The cable material is prepared from the following raw materials, by weight, 100 parts of silicon rubber, 20-30 parts of ethylene propylene diene monomer, 8-10 parts of chlorinated polyethylene, 15-20 parts of acetylene black, 0.5-1.0 part of dimethyl silicone oil, 0.2-0.5 parts of dicumyl peroxide (DCP), 20-30 parts of high-density polyethylene, 15-25 parts of calcium silicate, 0.5-1.0 part of modified argil, 30-40 parts of precipitated silica, 1-3 parts of a silane coupling agent, 0.2-0.5 parts of an antioxidant 4040, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of a vulcanizing agent BP, 2-4 parts of tribasic lead sulfate, 12-15 parts of antimony (III) oxide, and 6-8 parts of zinc borate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good high and low temperature resistances, good corrosion resistance, good water resistance, good ozone resistance, and good ageing resistance.

Owner:佛山市石湾陶瓷工业研究所有限公司

Microporous material

Microporous materials that include thermoplastic organic polyolefin polymer (e.g., ultrahigh molecular weight polyolefin, such as polyethylene), particulate filler (e.g., precipitated silica), and a network of interconnecting pores, are described. The microporous materials of the present invention possess controlled volatile material transfer properties. The microporous materials can have a density of at least 0.8 g / cm3; and a volatile material transfer rate, from the volatile material contact surface to the vapor release surface of the microporous material, of from 0.04 to 0.6 mg / (hour*cm2). In addition, when volatile material is transferred from the volatile material contact surface to the vapor release surface, the vapor release surface is substantially free of volatile material in liquid form.

Owner:PPG IND OHIO INC

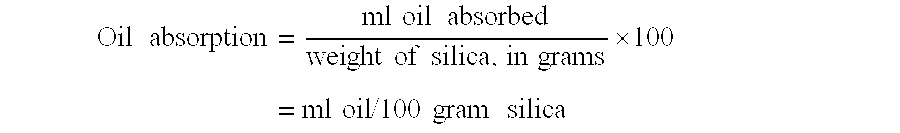

High-cleaning/low abrasive silica and materials and dentifrice containing such materials

InactiveUS20060110338A1Desirable abrasiveGood thickening effectPigmenting treatmentCosmetic preparationsSilica gelSilicon dioxide

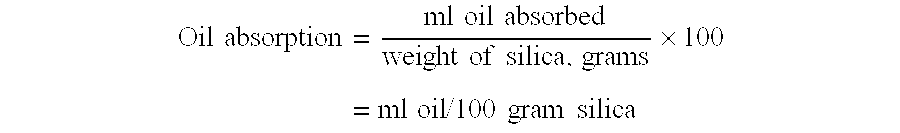

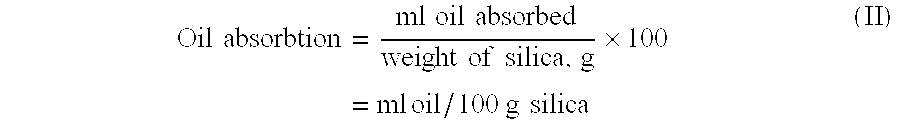

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com