Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

349 results about "Double bottom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A double bottom is a ship hull design and construction method where the bottom of the ship has two complete layers of watertight hull surface: one outer layer forming the normal hull of the ship, and a second inner hull which is somewhat higher in the ship, which forms a redundant barrier to seawater in case the outer hull is damaged and leaks.

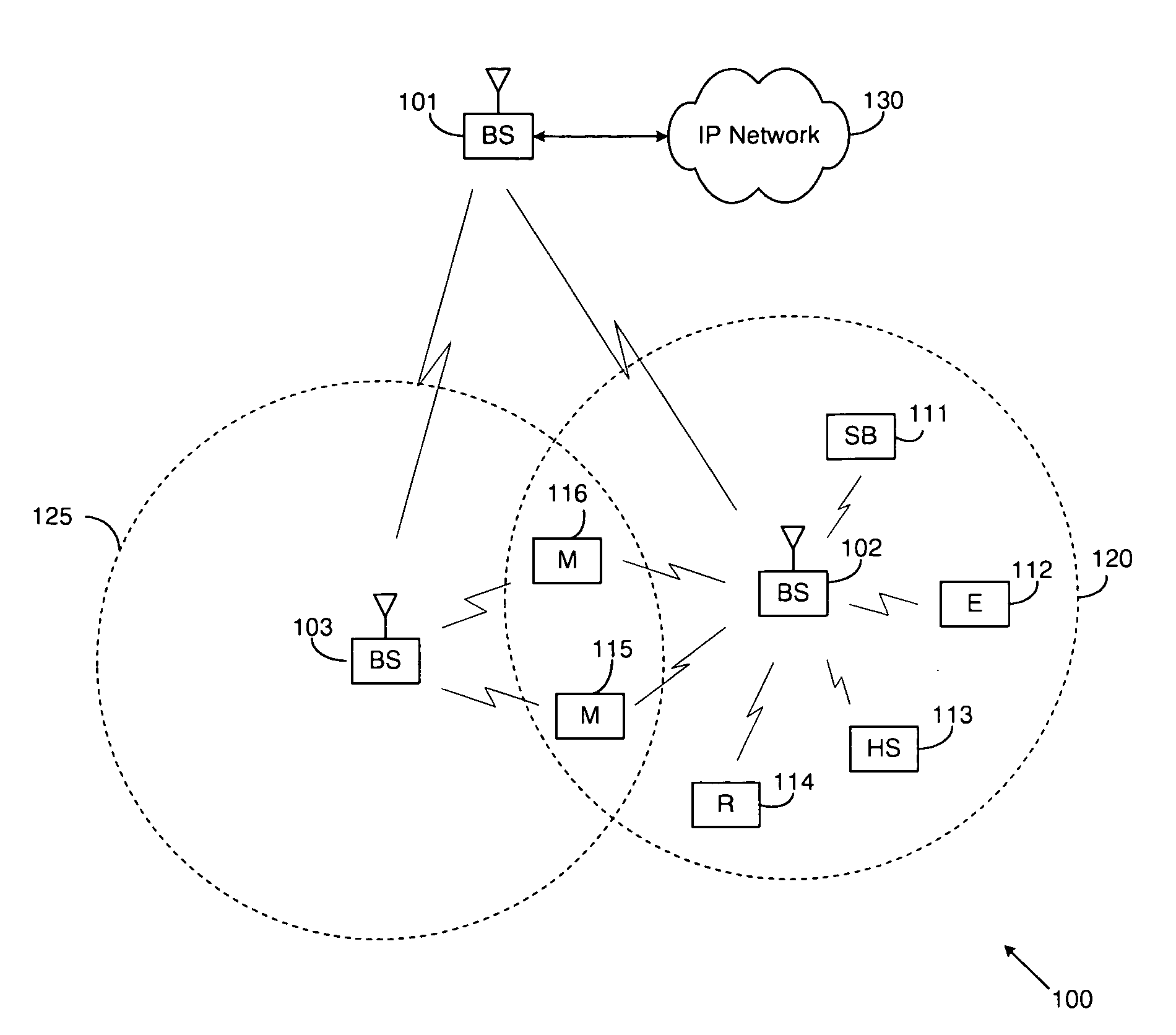

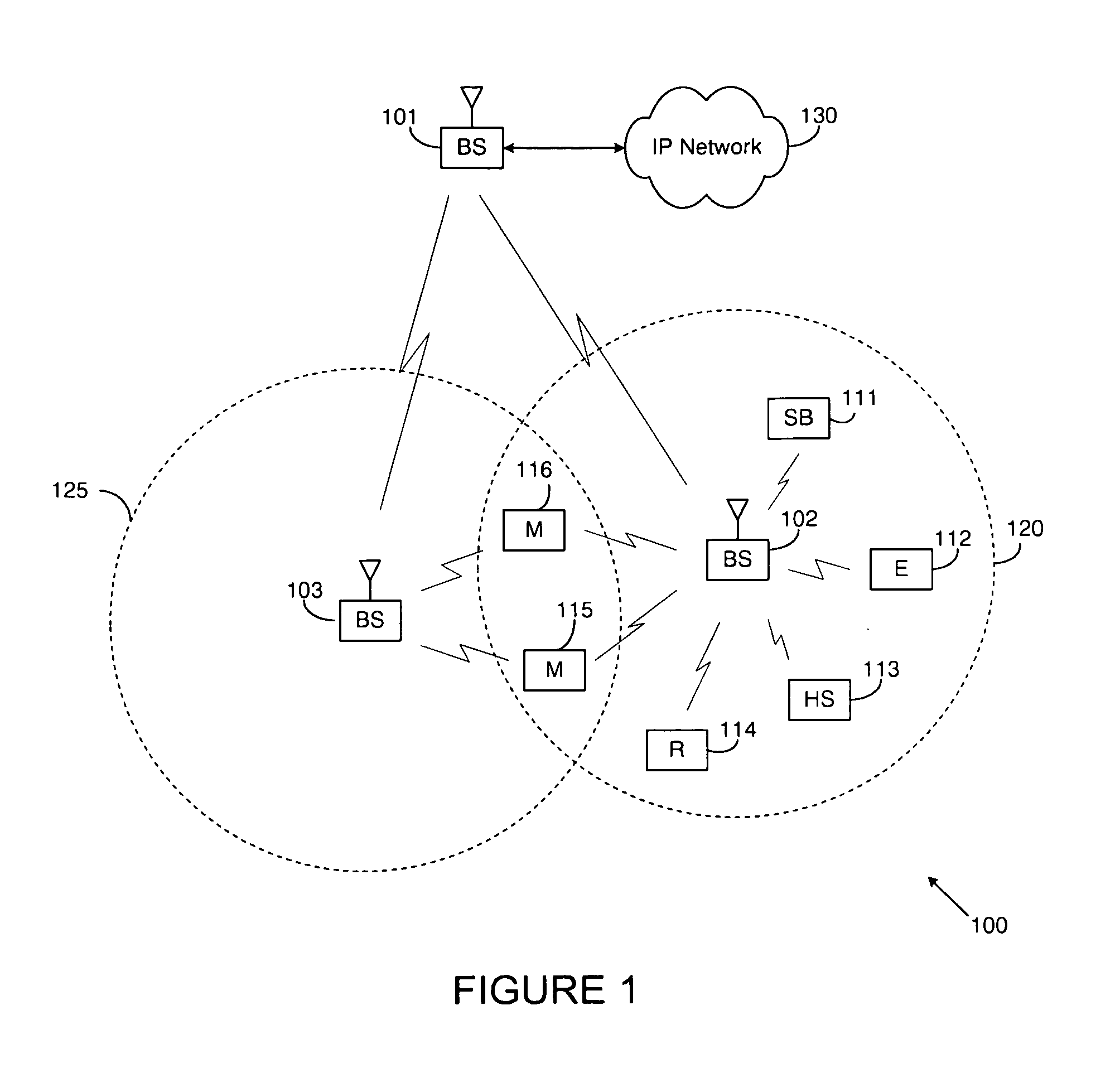

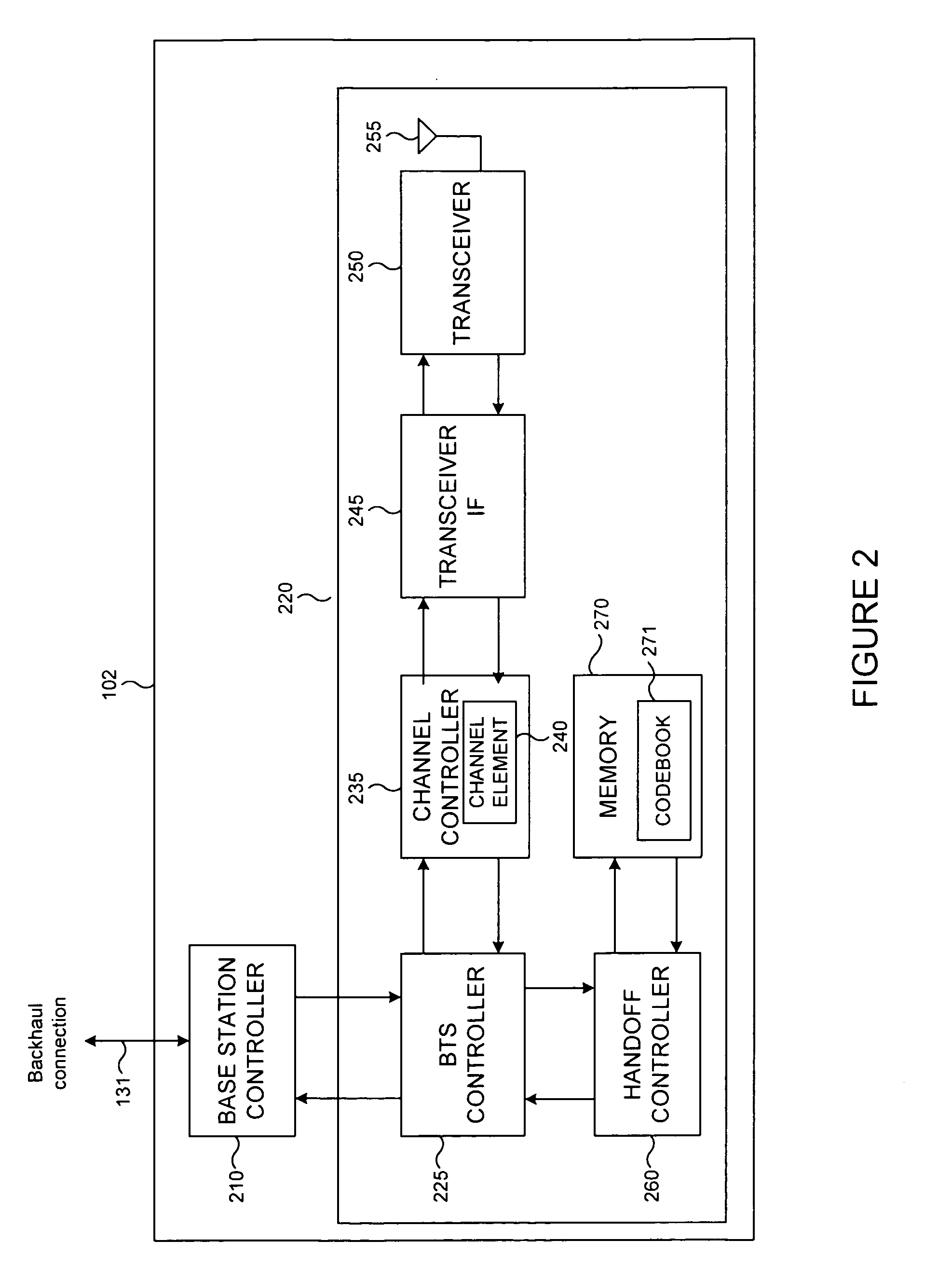

Method and apparatus for multiple input multiple output (MIMO) transmit beamforming

ActiveUS20100215112A1Diversity/multi-antenna systemsError prevention/detection by diversity receptionDouble bottomMultiple input

A wireless communications network is provided. The wireless communications network comprises a plurality of base stations. Each one of said base stations is capable of wireless communications with a plurality of subscriber stations. At least one of said plurality of base stations comprises a processor configured to select a codeword from a codebook and precode data with the selected codeword, and a transmitter configured to transmit the precoded data. Rank 1 of the codebook is selected from the following algorithm:Codebook Matrix Index(CMI)Base MatrixRank 11V8(:,:,3)V8(:,1,3)2V8(:,2,3)3V8(:,3,3)4V8(:,4,3)5V8(:,5,3)6V8(:,6,3)7V8(:,7,3)8V8(:,8,3)9V8(:,9,3)10V8(:,10,3)11V8(:,11,3)12V8(:,12,3)13V8(:,13,3)14V8(:,14,3)15V8(:,15,3)16V8(:,16,3)

Owner:SAMSUNG ELECTRONICS CO LTD

Polypropylene type aqueous dispersion, polypropylene type composite aqueous emulsion composition and its use

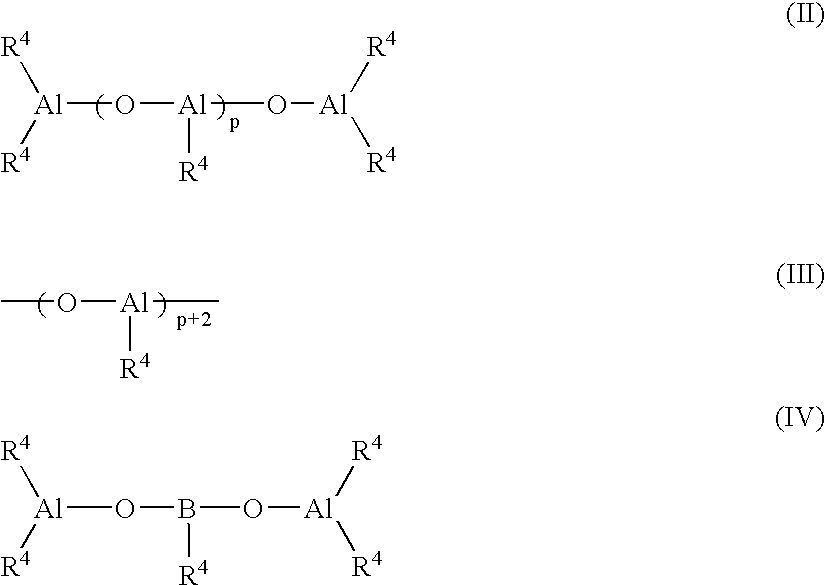

A polypropylene type aqueous dispersion comprising the following components (a) to (c): (a) a polypropylene type polymer100parts by weightand / or a modified polypropylene typepolymer(b) a surfactant1 to 100parts by weight, and(c) water100 to 1,000parts by weight,wherein the component (a) has a main chain having the following features (1) and (2) and dispersion particles in the dispersion have an average particle size of at most 0.5 μm, Feature (1) when observing a peak derived from a carbon atom of a methyl group in a propylene unit chain part comprising a head-to-tail bond by 13C-NMR and fixing a chemical shift of a peak top at a peak attributable to pentad expressed by mmmm to 21.8 ppm, a ratio (S1 / S) of an area S1 of a peak of a peak top at 21.8 ppm to a total area S of peaks at from 19.8 ppm to 22.1 ppm is at least 10% and at most 60%, and when an area of a peak (mmmr) of a peak top at 21.5 to 21.6 ppm is expressed as S2, 4+2S1 / S2>5, and Feature (2) a content ratio (mol ratio) of propylene unit (A): other olefin unit (B) is from 100:0 to 90:10.

Owner:MITSUBISHI CHEM CORP

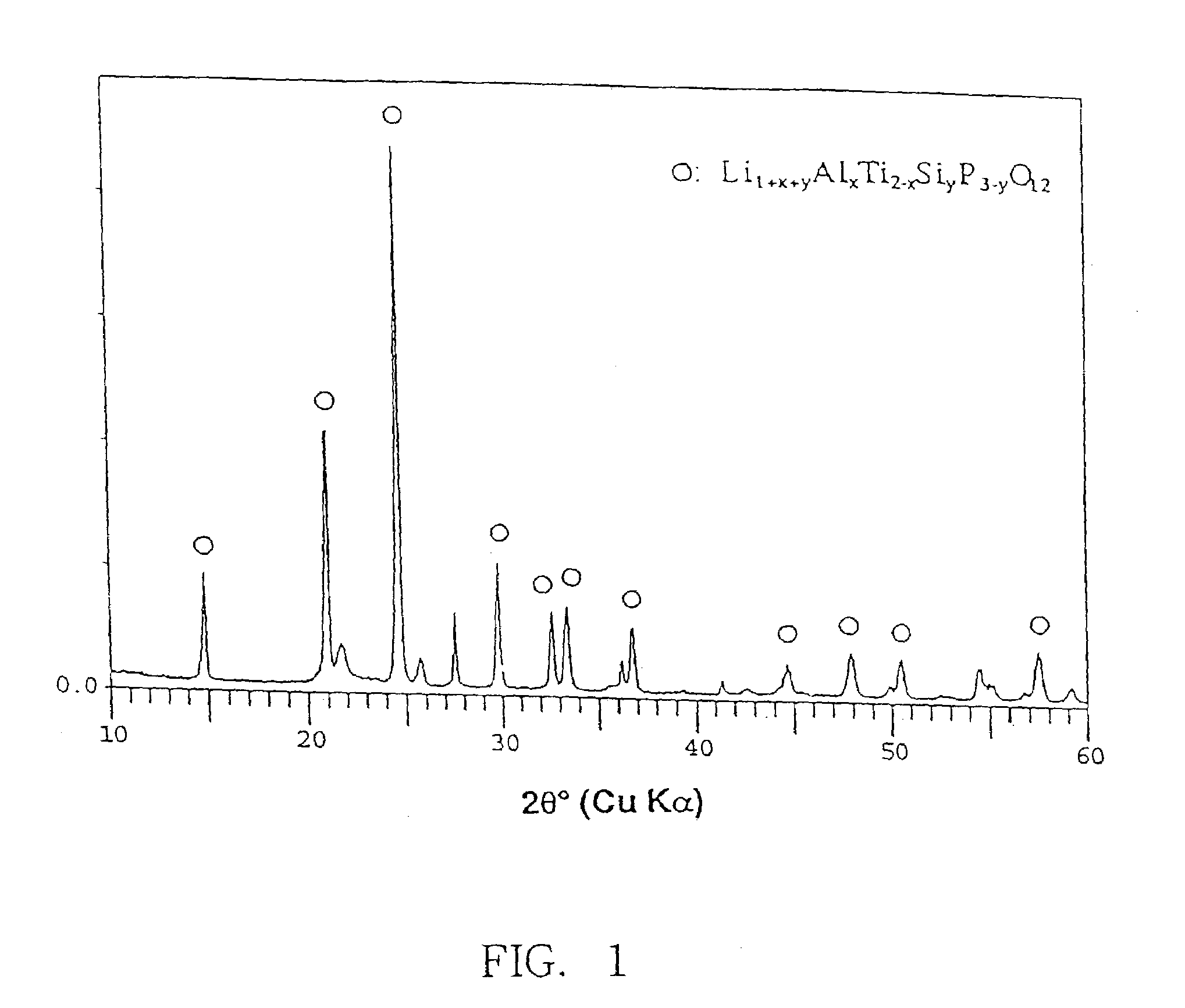

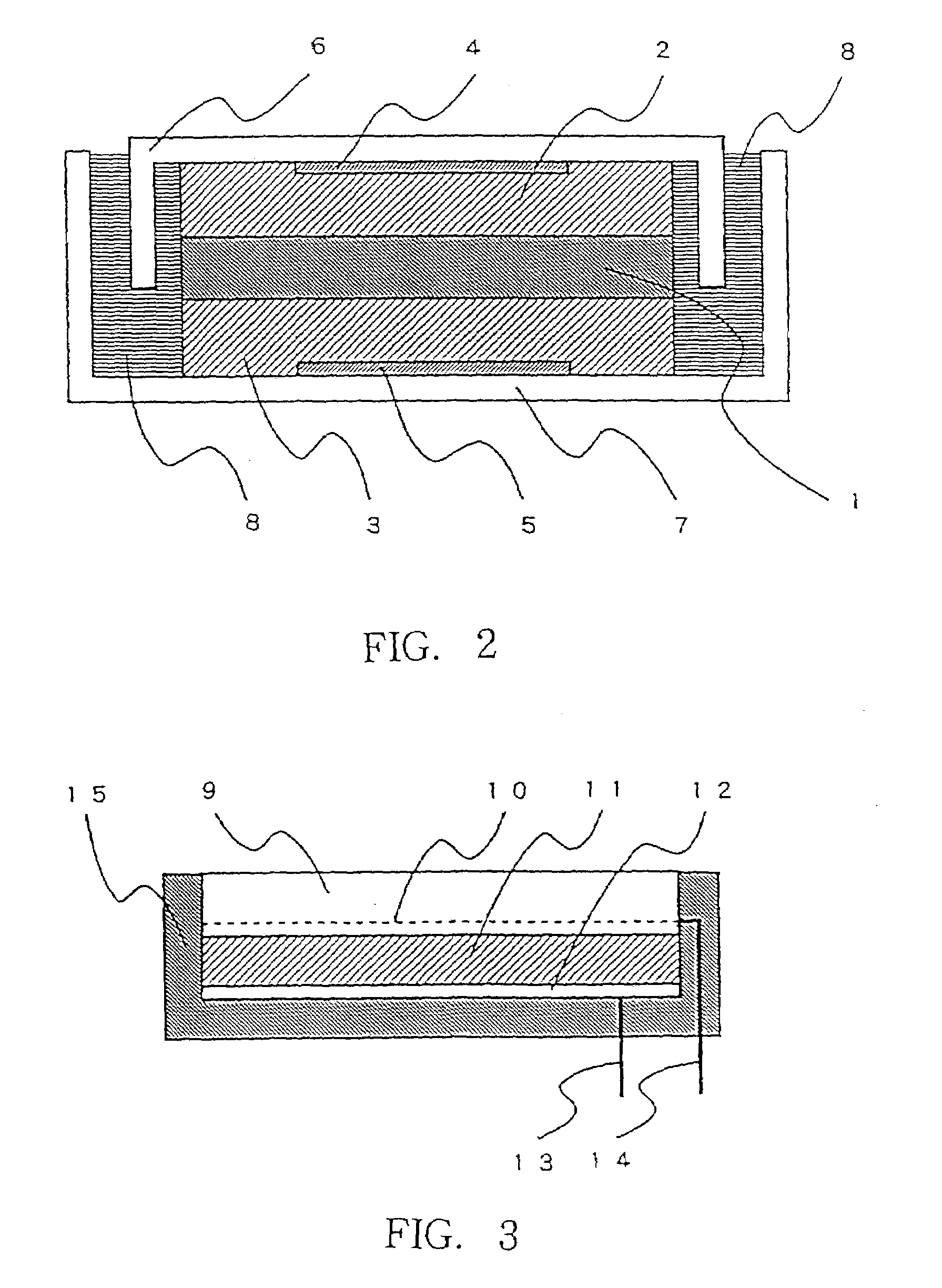

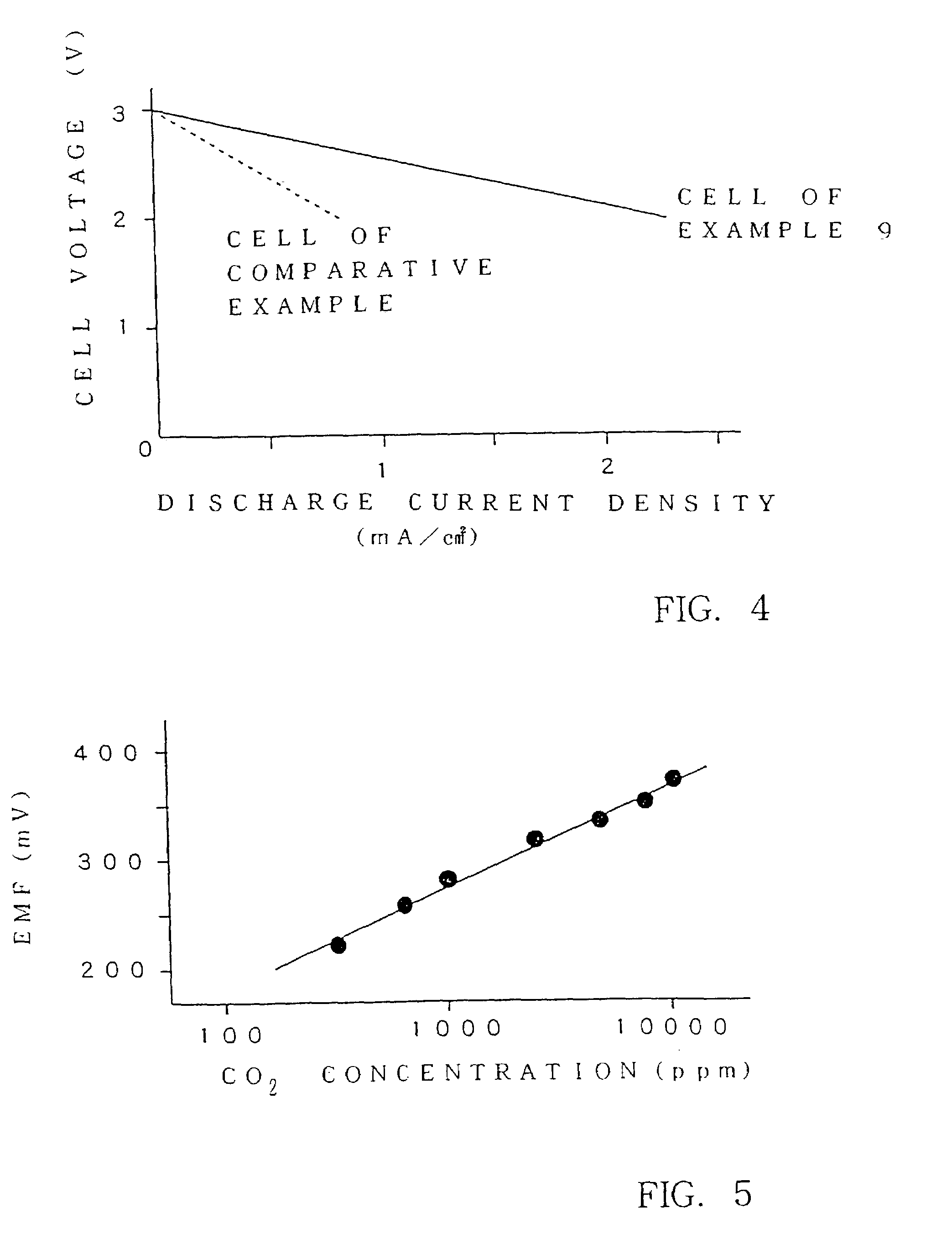

Alkali ion conductive glass-ceramics and electric cells and gas sensors using the same

InactiveUS7211532B2Improve performanceImprove conductivityMaterial analysis by electric/magnetic meansSecondary cellsLithiumAlkali ions

There are provided glass-ceramics having a high lithium ion conductivity which include in mol %:P2O538–40%TiO225–45%M2O3 (where M is Al or Ga) 5–15%Li2O10–20%and contain Li1+X(Al, Ga)XTi2−X(PO4)3 (where 0<X<0.8) as a main crystal phases. There are also provided glass-ceramics having a high lithium ion conductivity which include in mol %:P2O5 26–40%SiO20.5–12%TiO2 30–45%M2O3 (where M is Al or Ga) 5–10%Li2O 10–18%and contain Li1+X+YMXTi2−XSiYP3−YO12 (where 0<X≦0.4 and 0<Y≦0.6) as a main crystal phase. There are also provided solid electrolytes for an electric cell and a gas sensor using alkali ion conductive glass-ceramics, and a solid electric cell and a gas sensor using alkali ion conductive glass-ceramics as a solid electrolyte.

Owner:OHARA

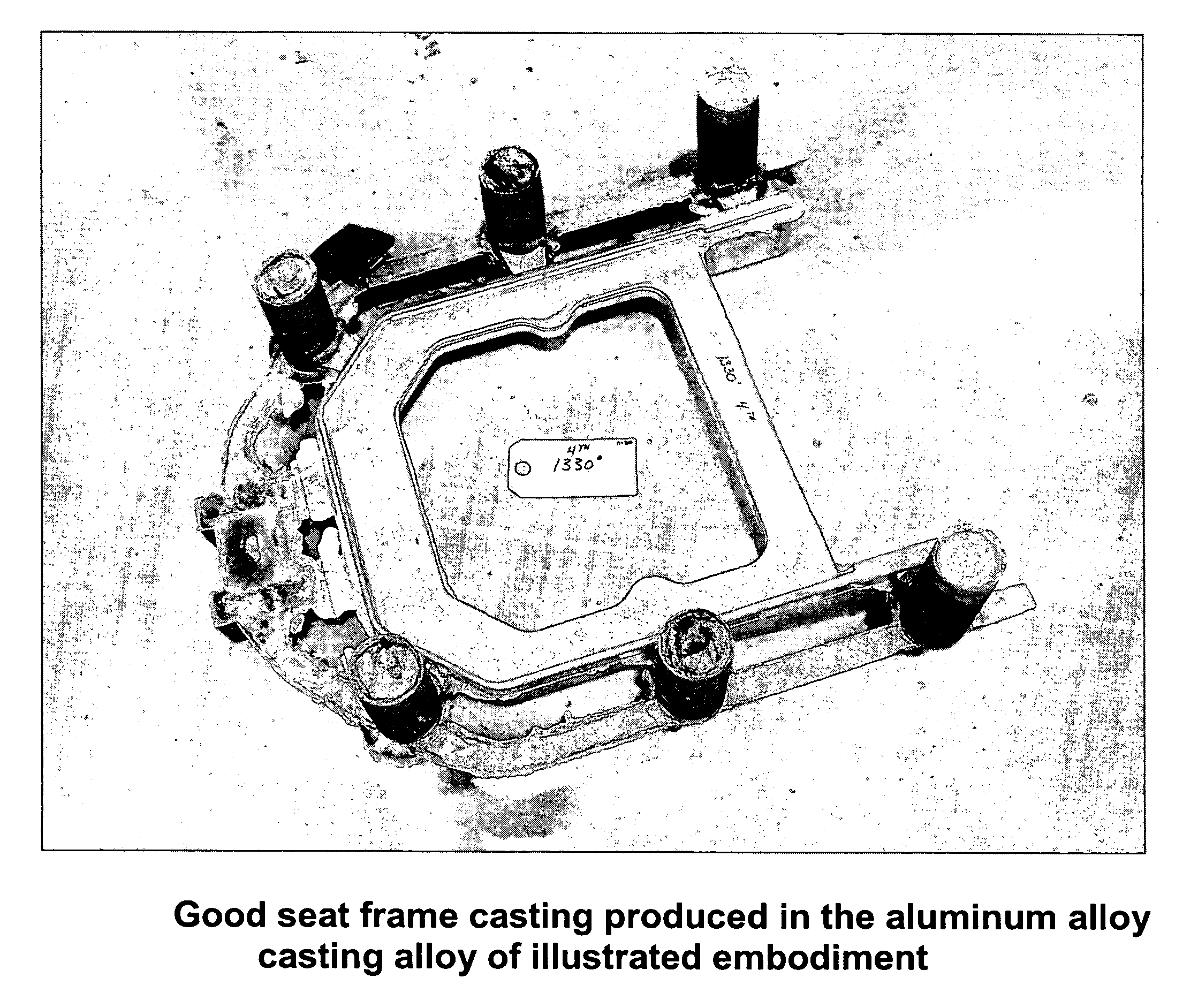

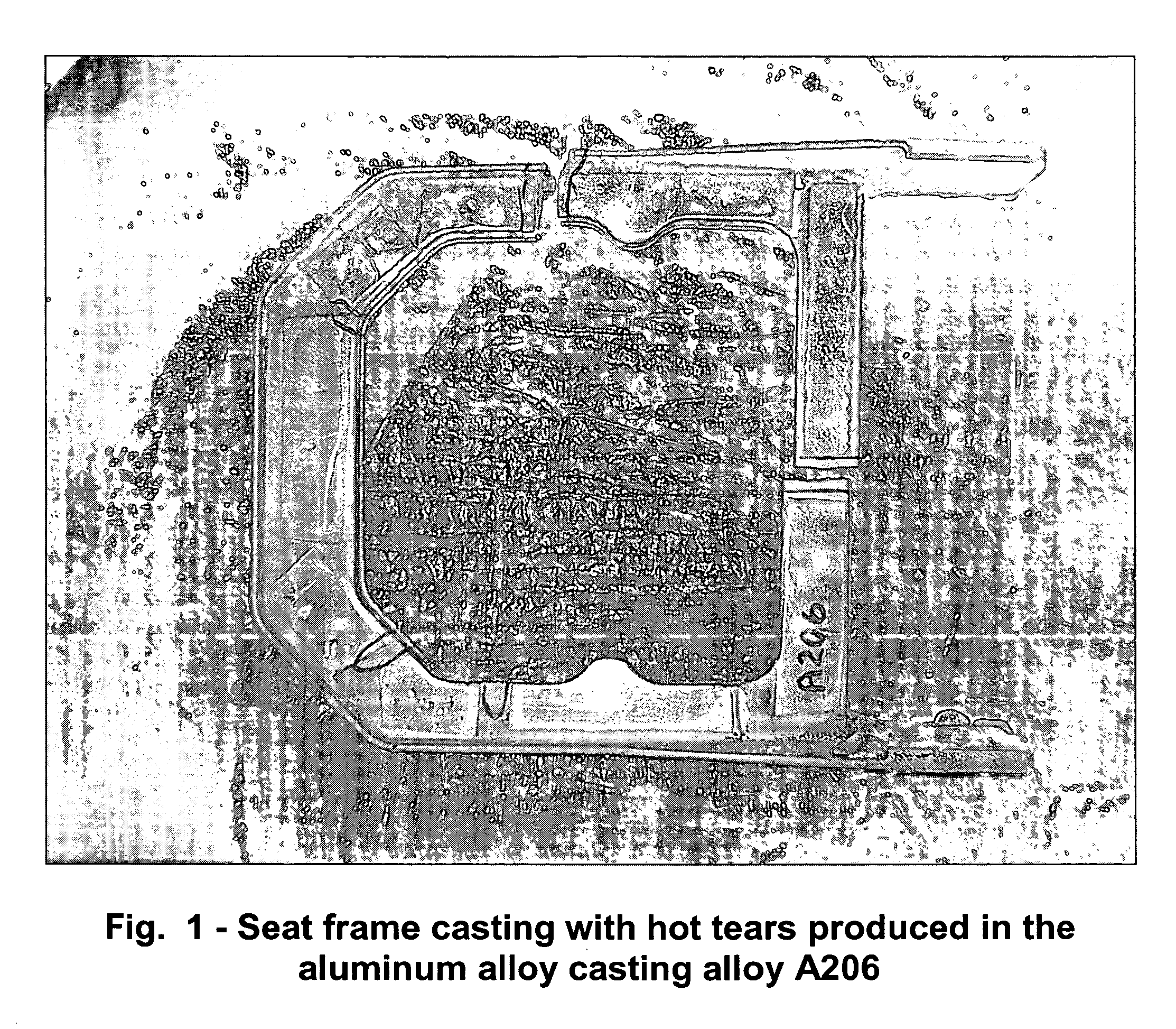

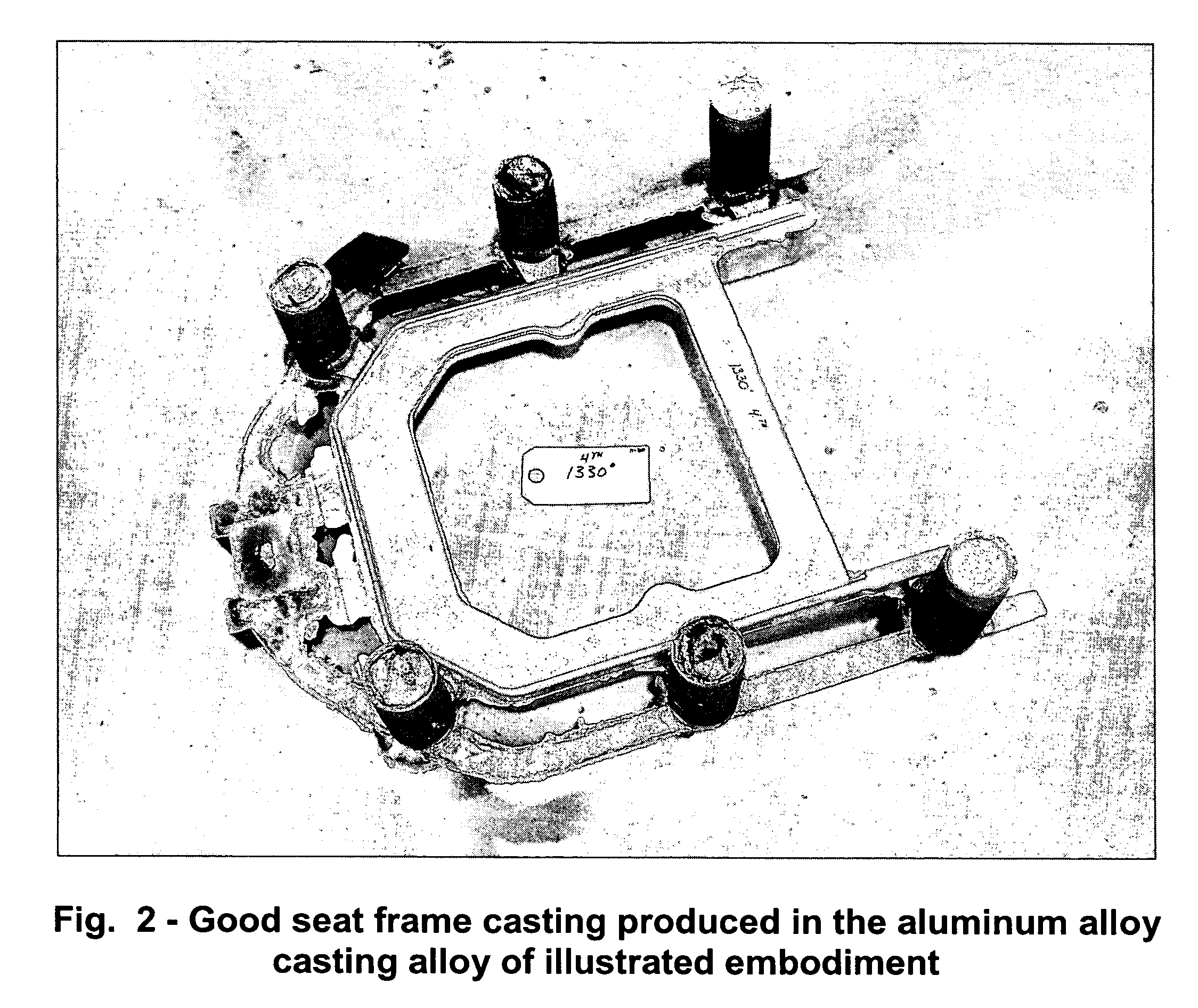

High strength, high toughness, weldable, ballistic quality, castable aluminum alloy, heat treatment for same and articles produced from same

An aluminum alloy cast product is composed of: Cu5.00-6.75weight %,Mg0.05-0.50weight %,Mn0.05-0.65weight %,Ti0.05-0.40weight %,Ag0.00-0.40weight %,Cr0.00-0.20weight %,V0.00-0.40weight %,Zr0.00-0.30weight %,Fe<0.15weight %,Si<0.15weight %,Ni<0.05weight %,Zn<0.05weight %,impurities<0.05each weight %,<0.25total weight %,AlbalanceSuch an aluminum alloy cast product is heat treated to eliminate the interdendritic network of second phase particles. The heat treatment of such an aluminum alloy casting alloy includes solution heat treatment before hot isostatic pressing.

Owner:BAC OF VIRGINIA

Clear glass composition

Glass is provided so as to have high visible transmission and / or fairly clear or neutral color. In certain example embodiments, the glass may include a base glass (e.g., soda lime silica base glass) and, in addition, by weight percentage:total iron (expressed as Fe2O3):0.01 to 0.30%erbium oxide (e.g., Er2O3):0.01 to 0.30%.

Owner:GUARDIAN GLASS LLC

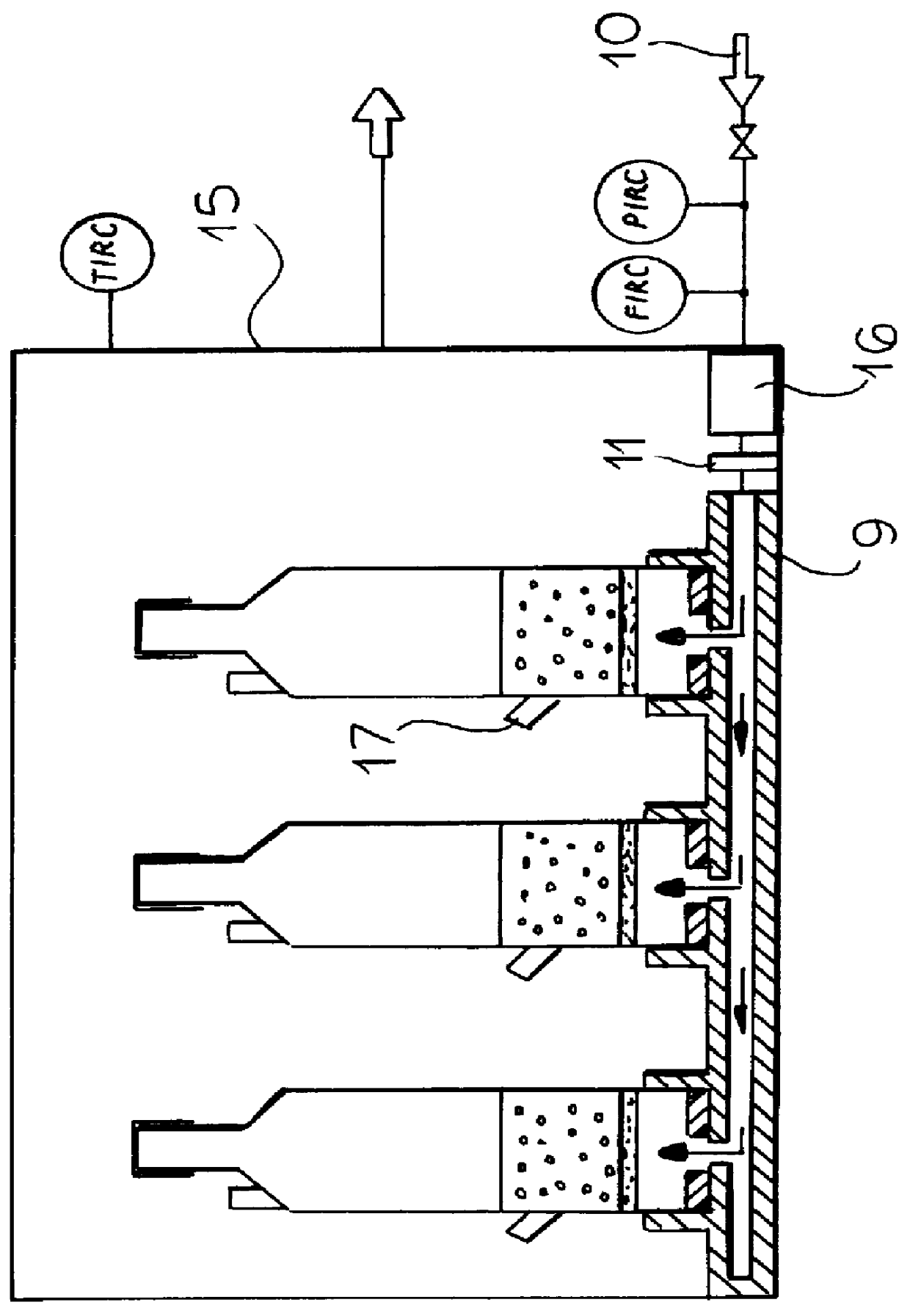

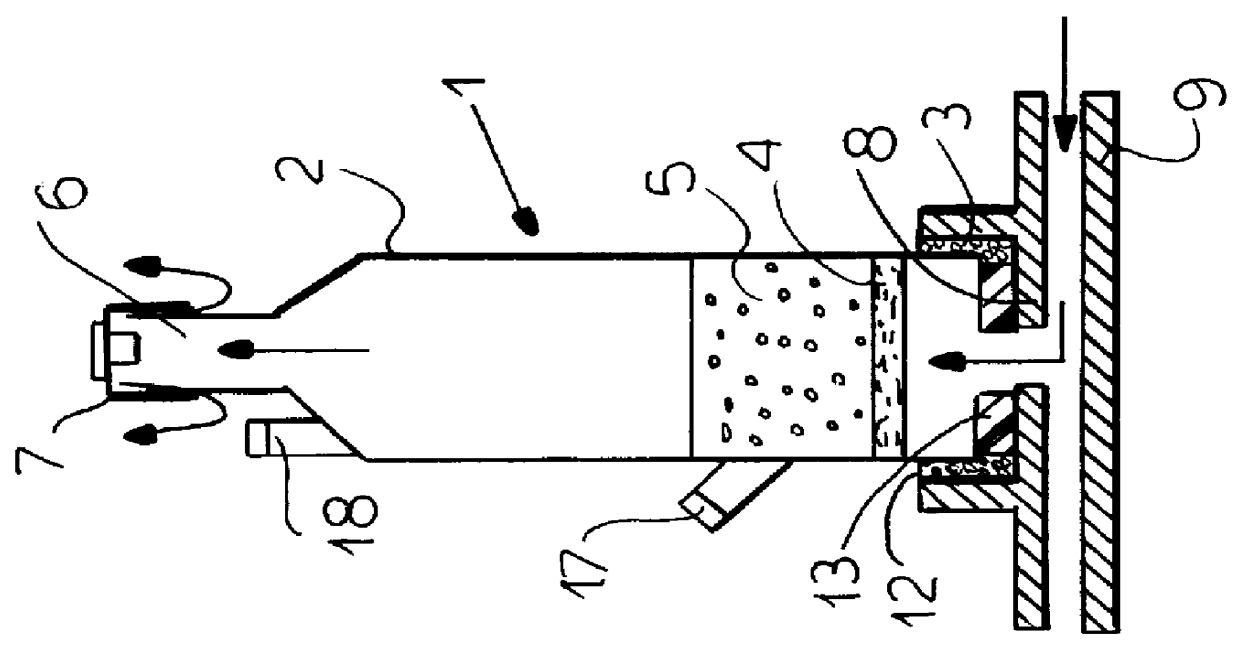

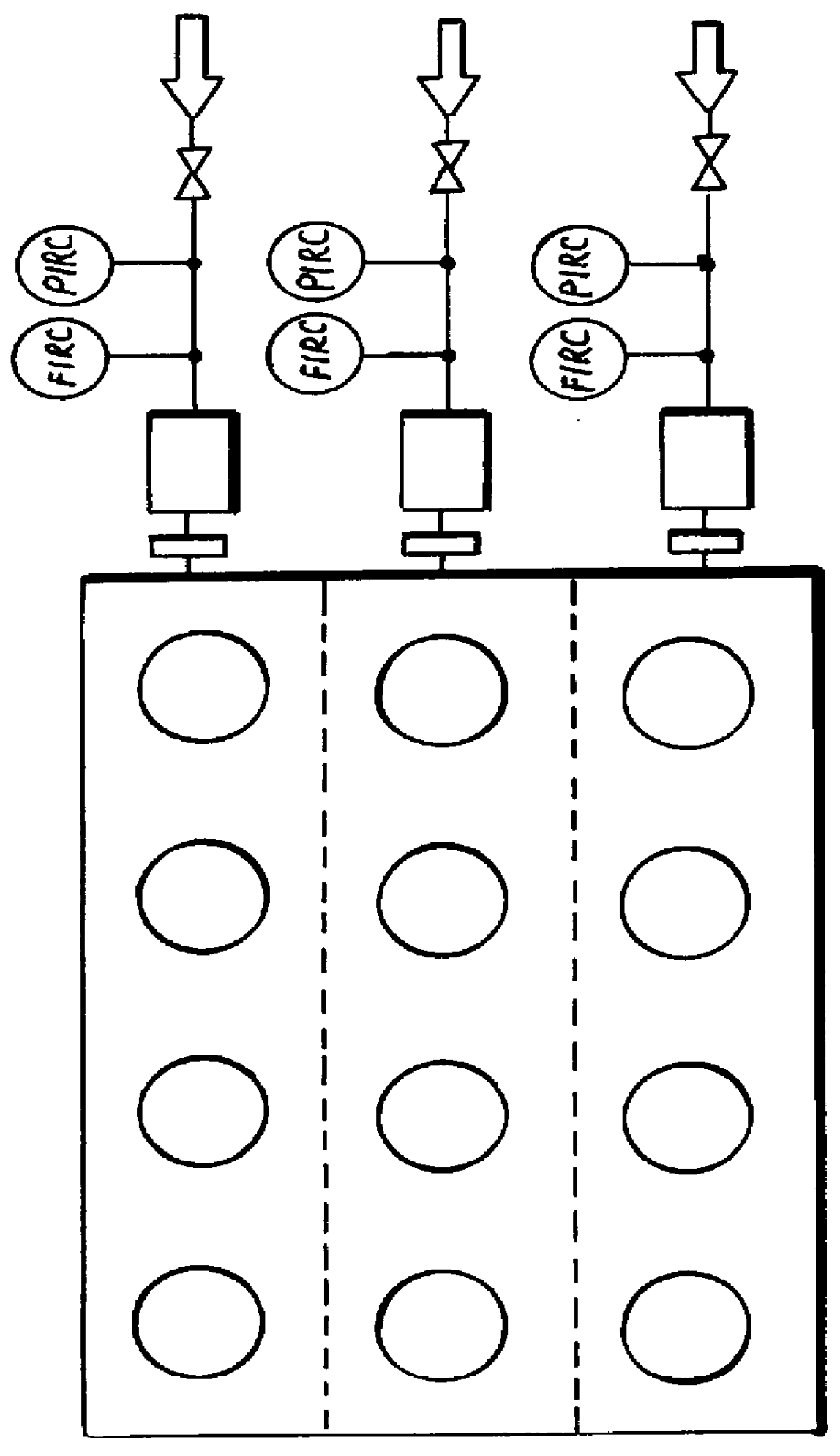

Device for the series cultivation of micro-organisms or cells in gasified liquid columns

InactiveUS6063618AConvenient ArrangementSatisfactory gasificationBioreactor/fermenter combinationsBiological substance pretreatmentsProduct gasEngineering

PCT No. PCT / DE96 / 01485 Sec. 371 Date Feb. 4, 1998 Sec. 102(e) Date Feb. 4, 1998 PCT Filed Aug. 3, 1996 PCT Pub. No. WO97 / 06239 PCT Pub. Date Feb. 20, 1997A reaction apparatus has a plurality of reaction flasks whose bottoms can communicate with a sterile gas source and are provided with porous filter plates which permit the gas to flow into the vessel but prevent the liquid from passing out through the plates. The culture flasks are received in pockets on an upper plate of a double-bottom structure which can communicate through the upper plate between a space within the double bottom and the bottom of the culture flasks. The spiral gas feed is connected to the double-bottom space.

Owner:FORSCHUNGSZENTRUM JULICH GMBH

Glass for substrate and glass substrate

A glass for substrate, which consists, as represented by mass percentage, essentially of:SiO240 to 59%,Al2O3 5 to 20%,B2O3 0 to 8%,MgO 0 to 10%,CaO 0 to 12%,SrO 2 to 20%,BaO 0 to 2%,ZnO 0 to 4%,Li2O 0 to 2%,Na2O 0 to 10%,K2O 0 to 12%,TiO2 0 to 10%, andZrO2 0 to 5%,wherein MgO+CaO+SrO+BaO is at least 15%.

Owner:ASAHI GLASS CO LTD

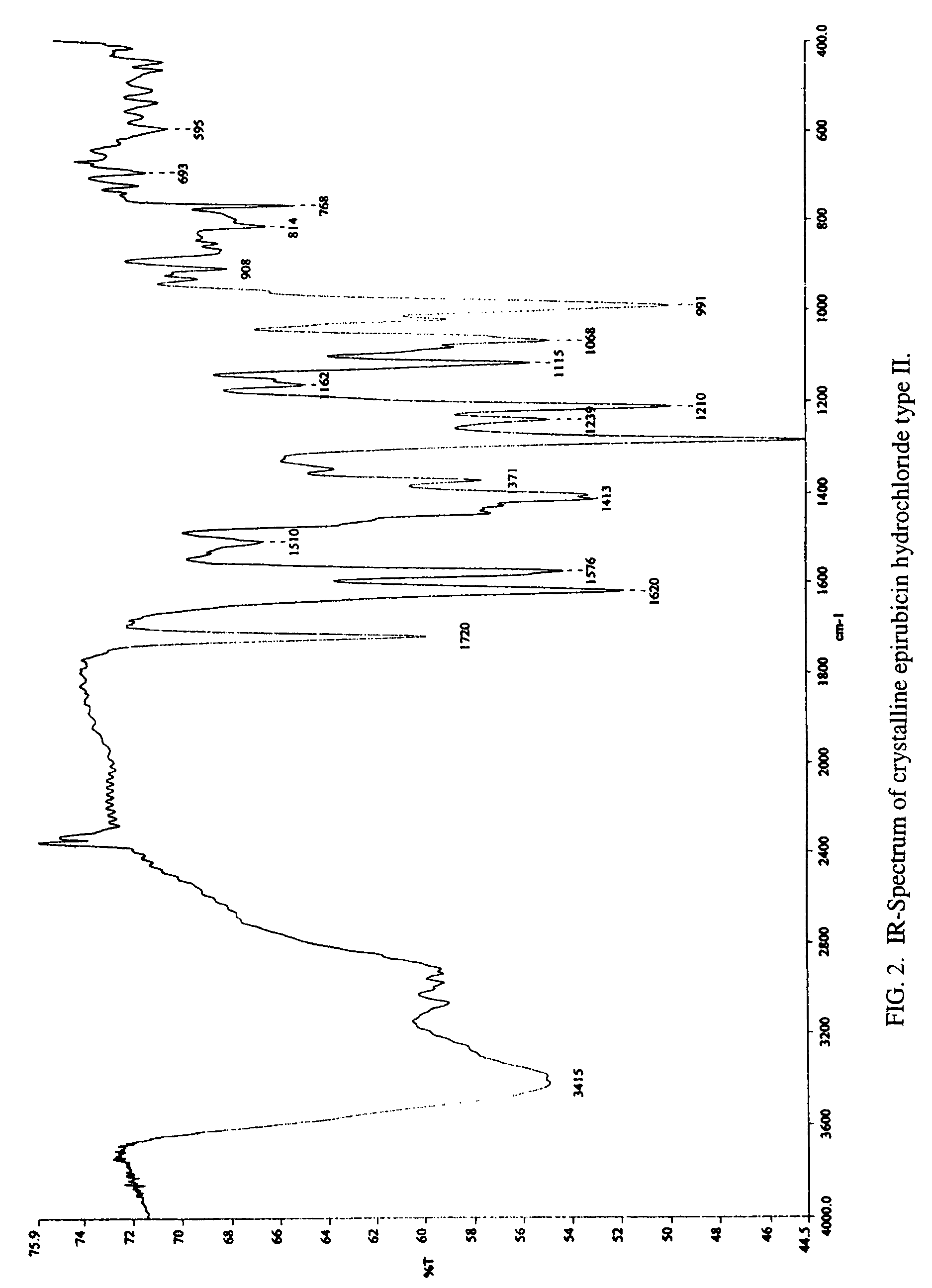

Thermally stable crystalline epirubicin hydrochloride and method of making the same

ActiveUS7485707B2Improve thermal stabilityImprove featuresSugar derivativesMedical preparationsCrystallographyThermal stability

A crystalline form of epirubicin hydrochloride, named herein as “type II” crystalline epirubicin hydrochloride, has excellent thermal stability. Type II crystalline epirubicin hydrochloride has a powder X-ray diffraction pattern having average values of diffraction angle (2θ) and relative intensity P(%) as presented in the following table:DiffractionAngleRelative Intensity2ΘP (%)5.2369.89.21212.513.73215.516.4464.818.234521.1149.722.52925.524.07129.925.87918.427.76216.529.75710.134.3924.438.15713.144.2935.964.6997.777.815100.

Owner:SYNBIAS PHARMA

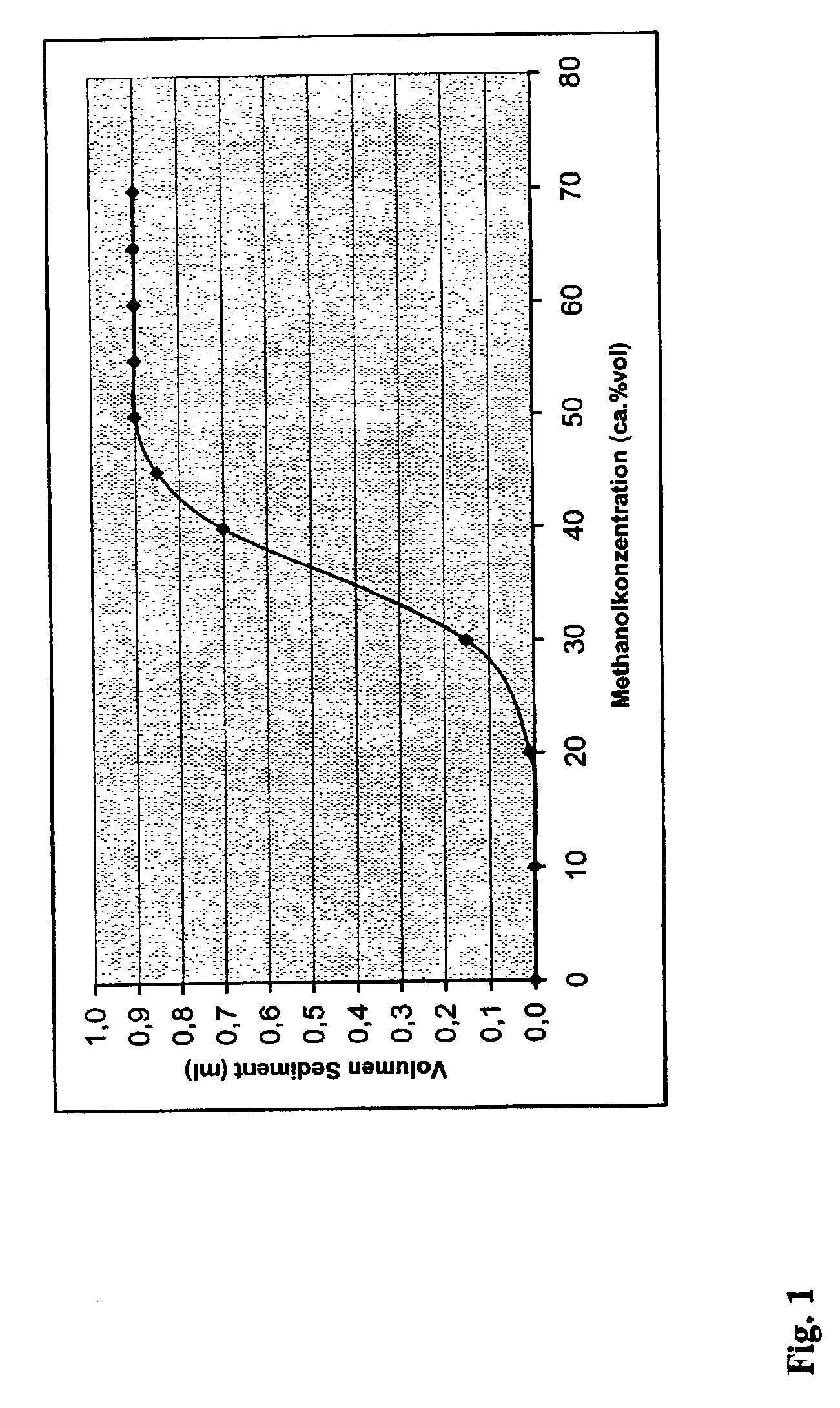

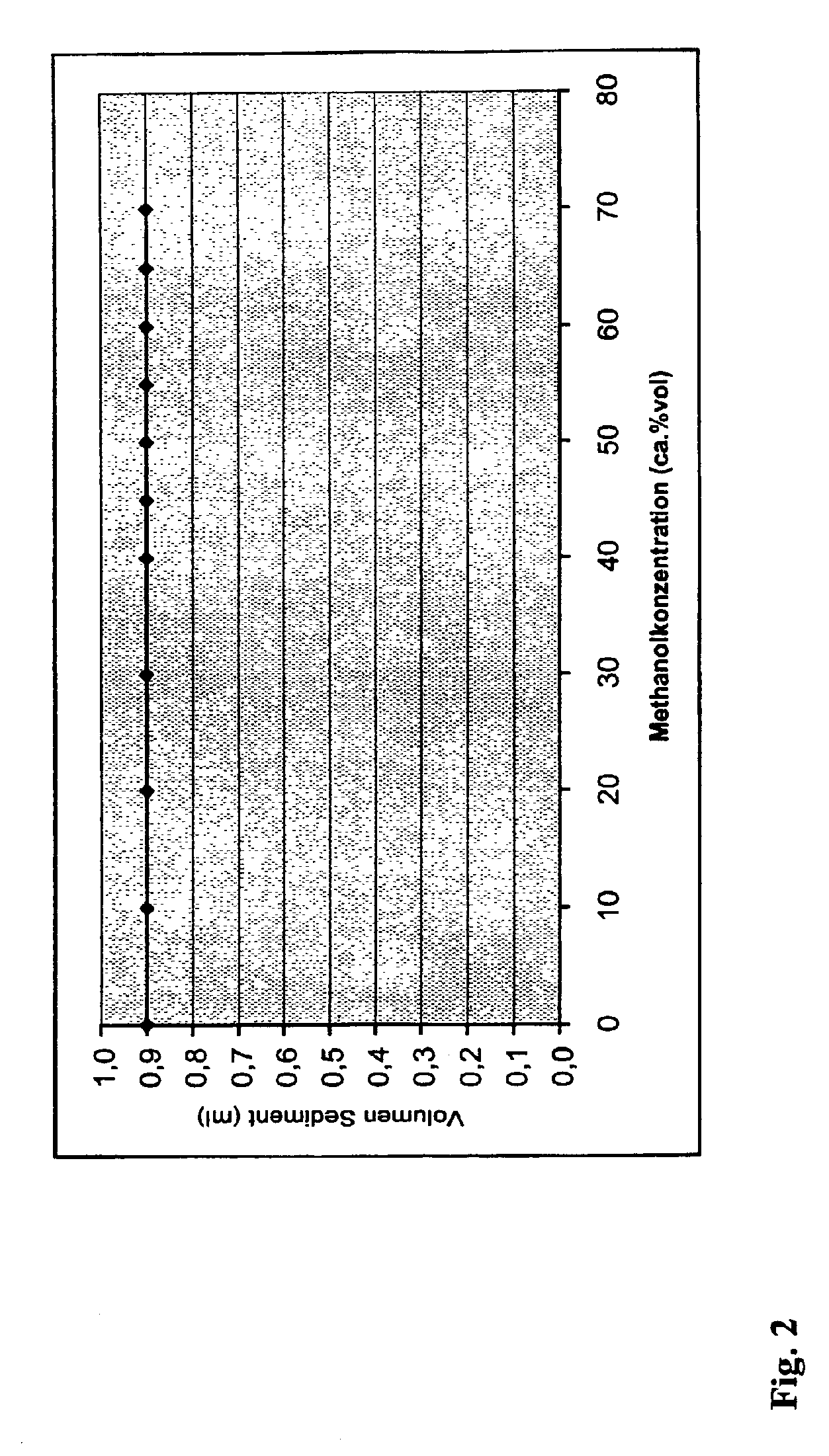

High-whiteness, non-heat-treated hydrophobic precipitated silica

InactiveUS6899951B2High whitenessImprove reinforcementSilicaGlass/slag layered productsDouble bottomSilicon dioxide

The present invention provides a hydrophobic precipitated silica having the following properties:carbon content1.0-8.0%methanol wettability 20-55%reflectance>94%BET / CTAB ratio ≦1DBP absorption<250 g / 100 gBET surface area 50-110 m2 / gCTAB surface area100-150 m2 / gSears number<13.The present invention also provides methods for making and using the hydrophobic precipitated silica and articles and compositions which include the same.

Owner:EVONIK DEGUSSA GMBH

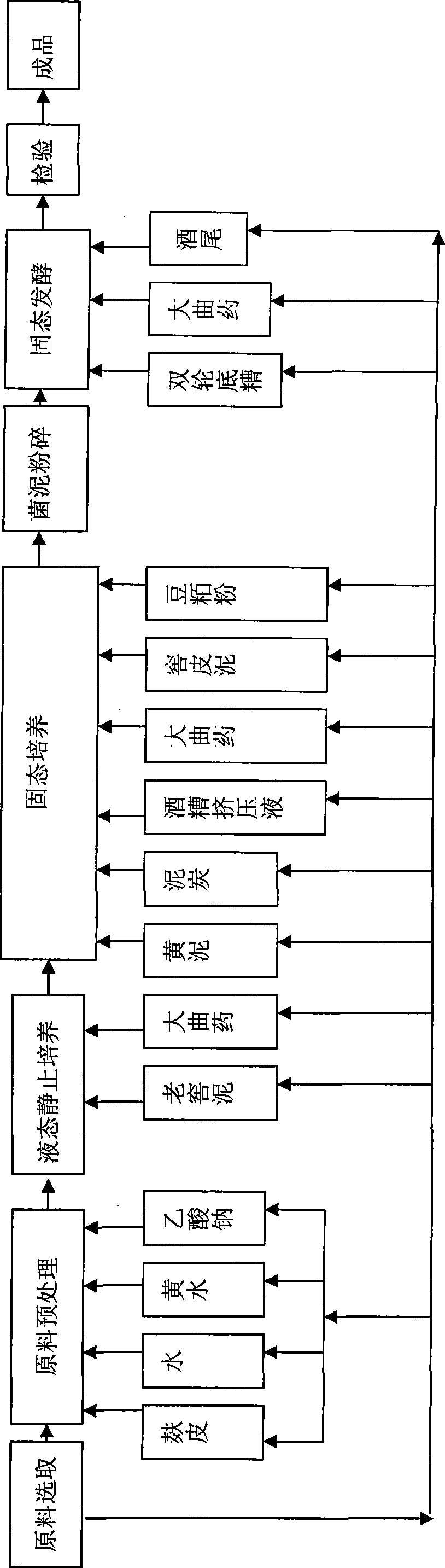

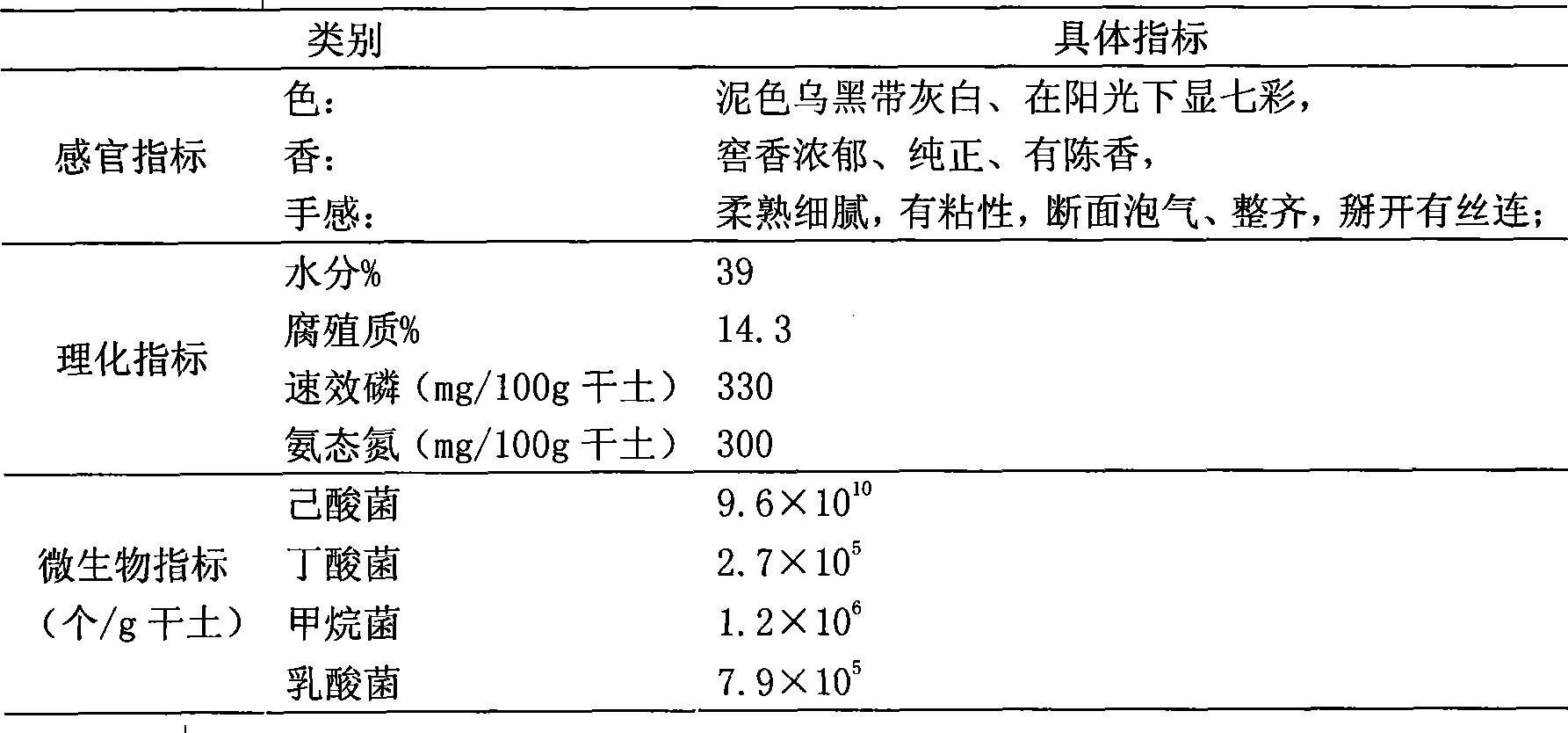

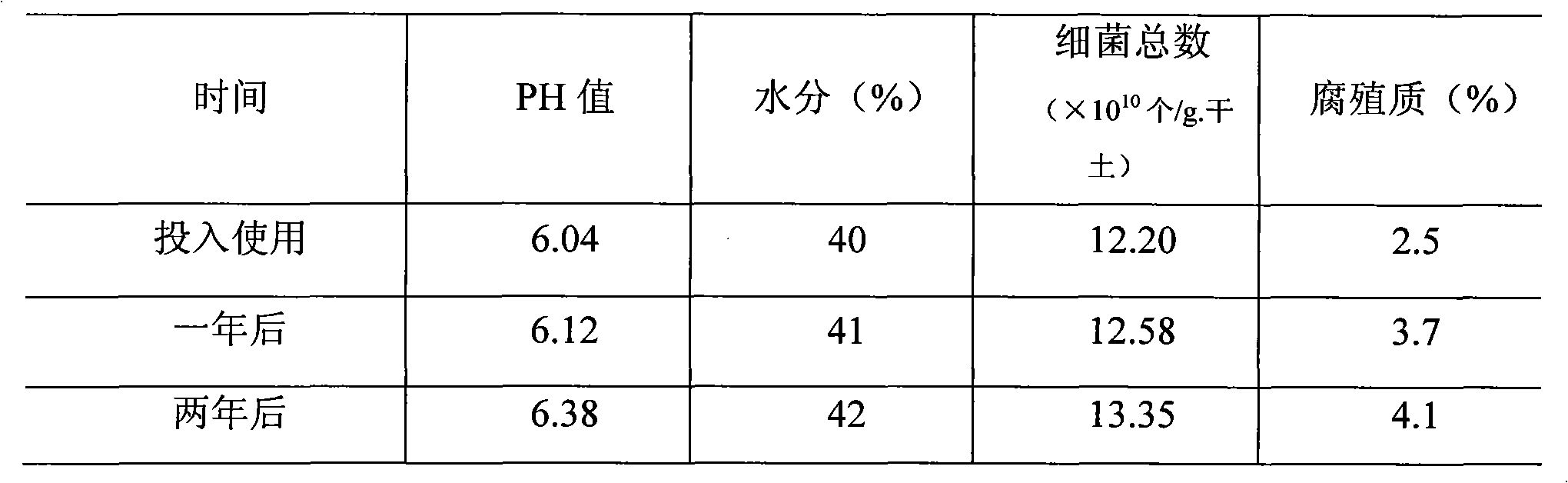

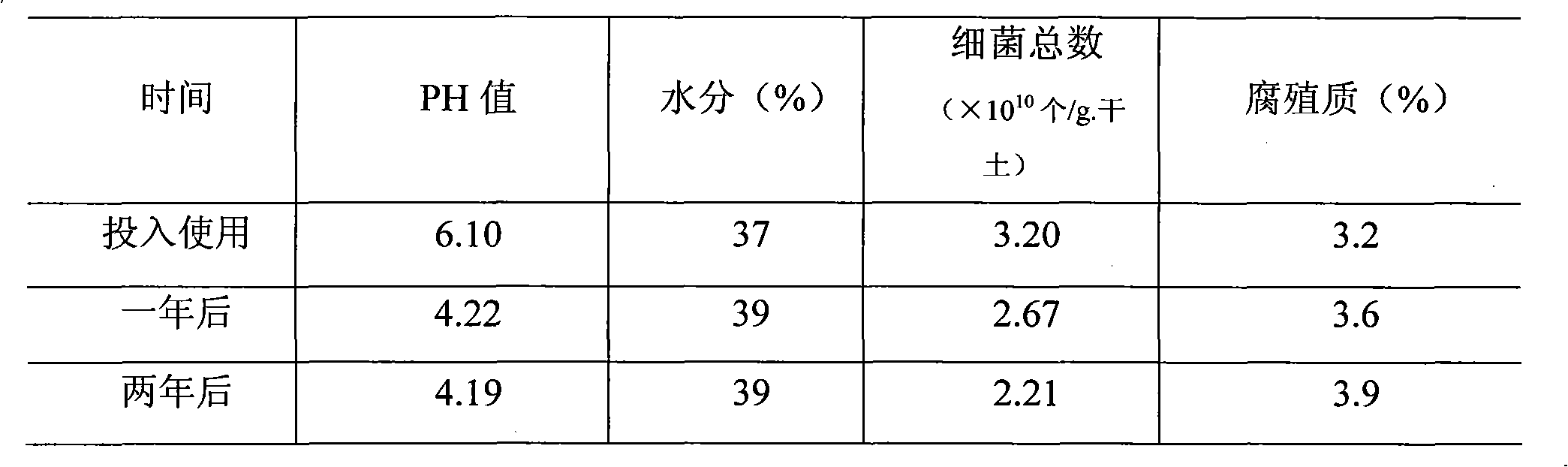

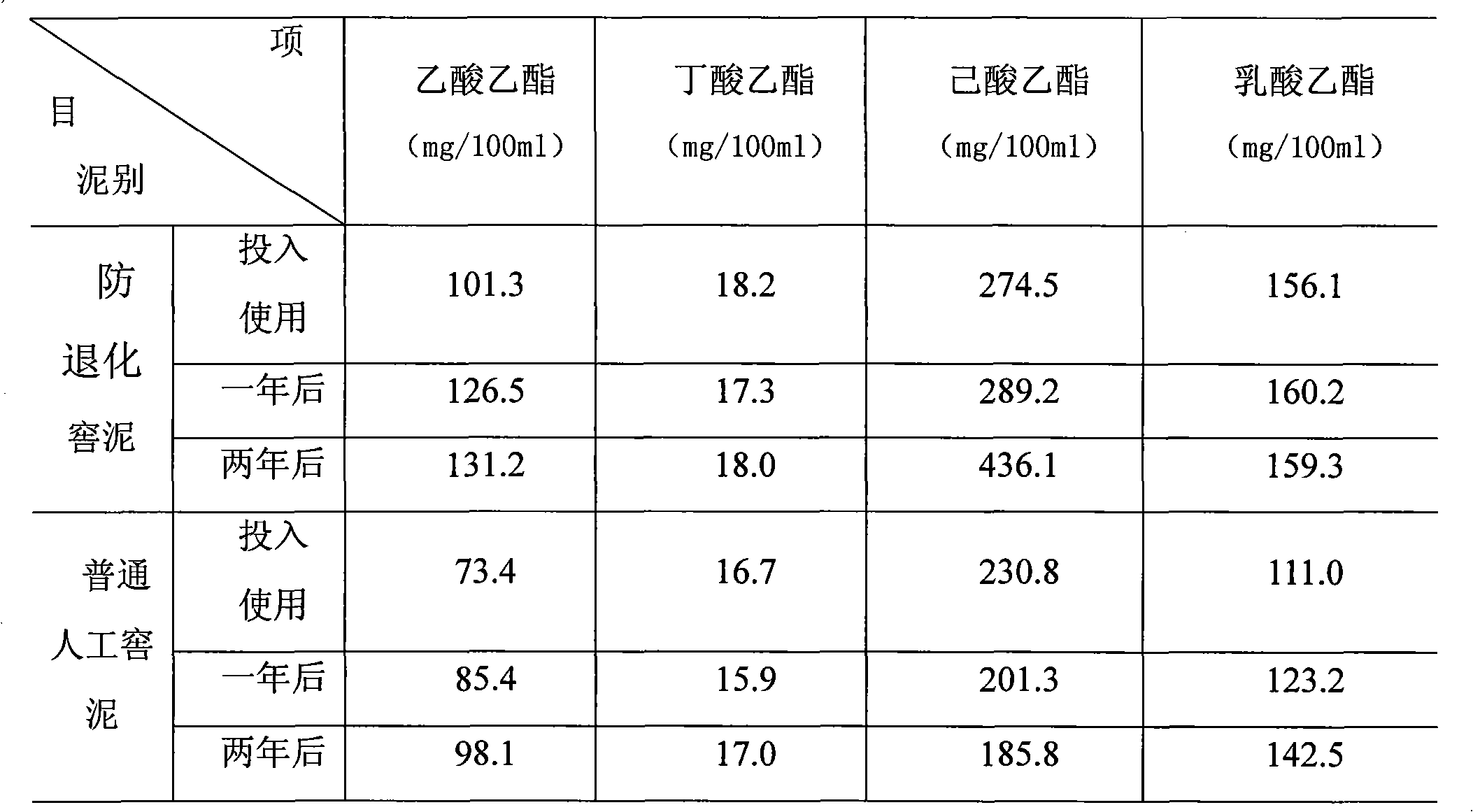

Preparation of artificial pit mud for improving aged aroma of aroma type white spirit

ActiveCN101503655AComfortable scentReach functional levelAlcoholic beverage preparationSodium acetatePeat

The invention discloses an artificial pit mud preparation method capable of improving the stale flavor of highly-concentrated fragrance white spirit, which comprises the following steps: mixing qualified bran, water, yellow water and sodium acetate in a proper proportion, and filling the mixture in a fermentation tank for sterilization; and when the temperature of the materials in the fermentation tank drops to 36 DEG C, adding a proper amount of aged pit mud and a Daqu drug into the fermentation tank, uniformly mixing the material and the aged pit mud and the Daqu drug, adjusting the pH value, covering the surface of material liquid with grease for isolating the material liquid from oxygen, standing the materials in the fermentation tank at 32 to 35 DEG C for anaerobic culture for 72 hours, taking out a bacterium solution, adding yellow mud, peat, vinasse squeezed fluid, the Daqu drug, pit surface mud and bean dreg powder in a proper proportion into the bacterium solution, culturing the mixture at room temperature for 7 to 10 days after uniform mixing, grinding bacterium mud, adding a certain amount of double bottom grains, the Daqu drug and ending beer, stacking the materials after uniform mixing for natural fermentation at normal temperature for 30 to 40 days, and obtaining the artificial pit mud. The 'aging degree' of the artificial pit mud is the same as that of aged pit mud naturally aging for more than 10 years, and the stale flavor of the freshly brewed liquor is the same as that of white spirit stored for more than three years in a ceramic jar.

Owner:SICHUAN TUOPAI SHEDE WINE

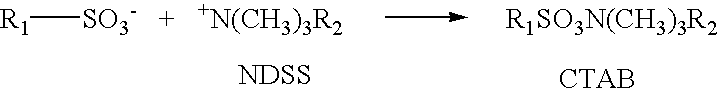

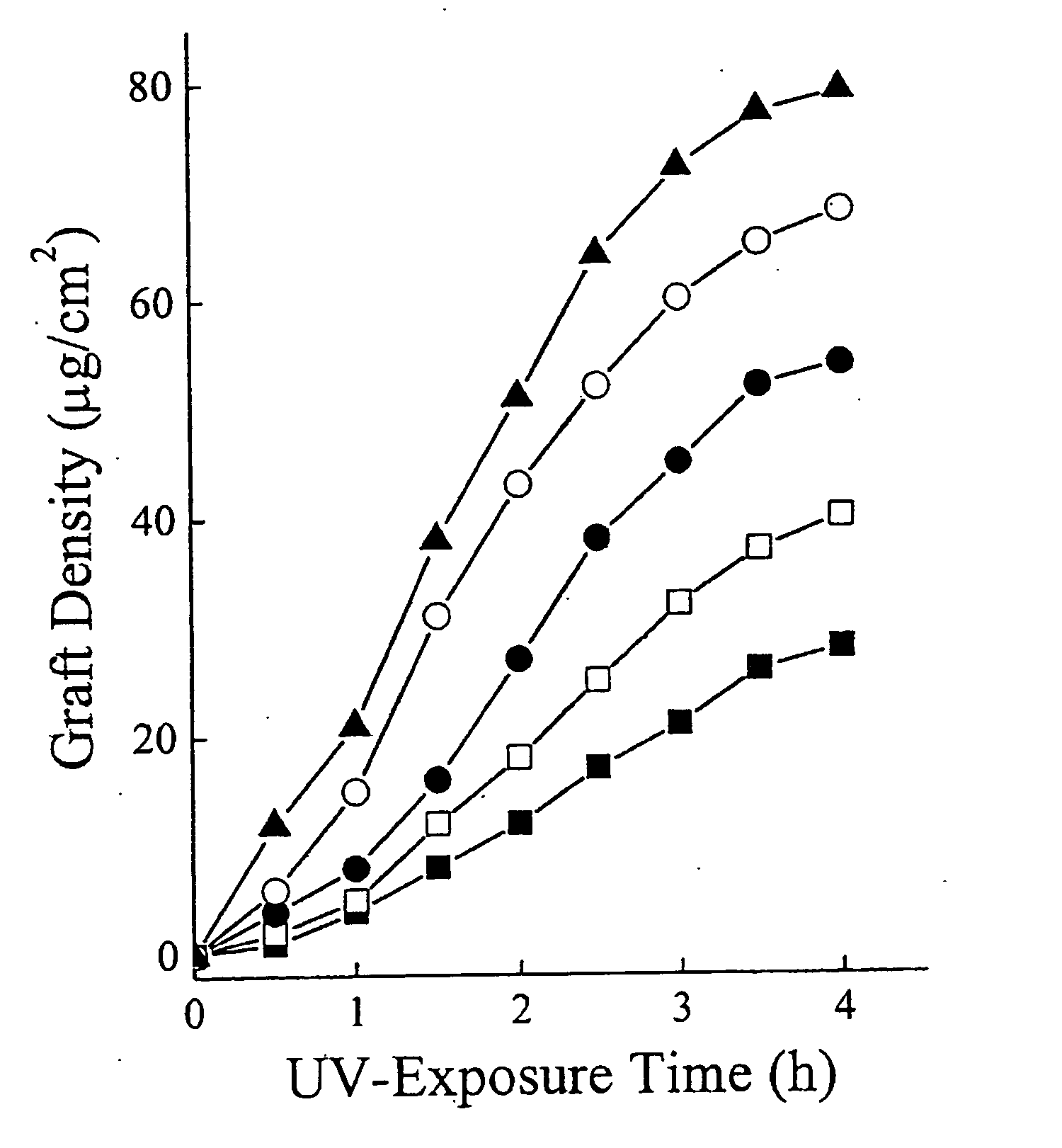

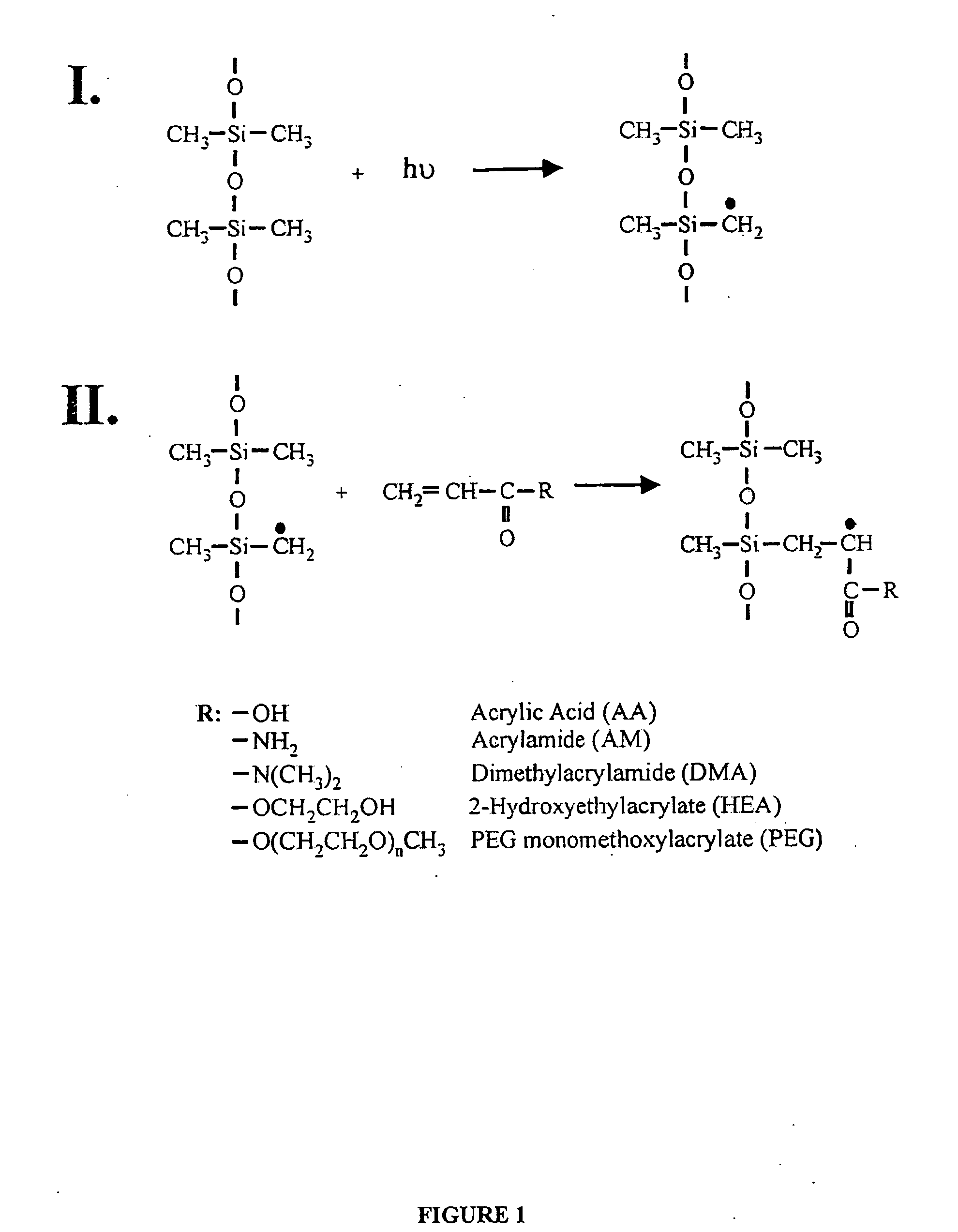

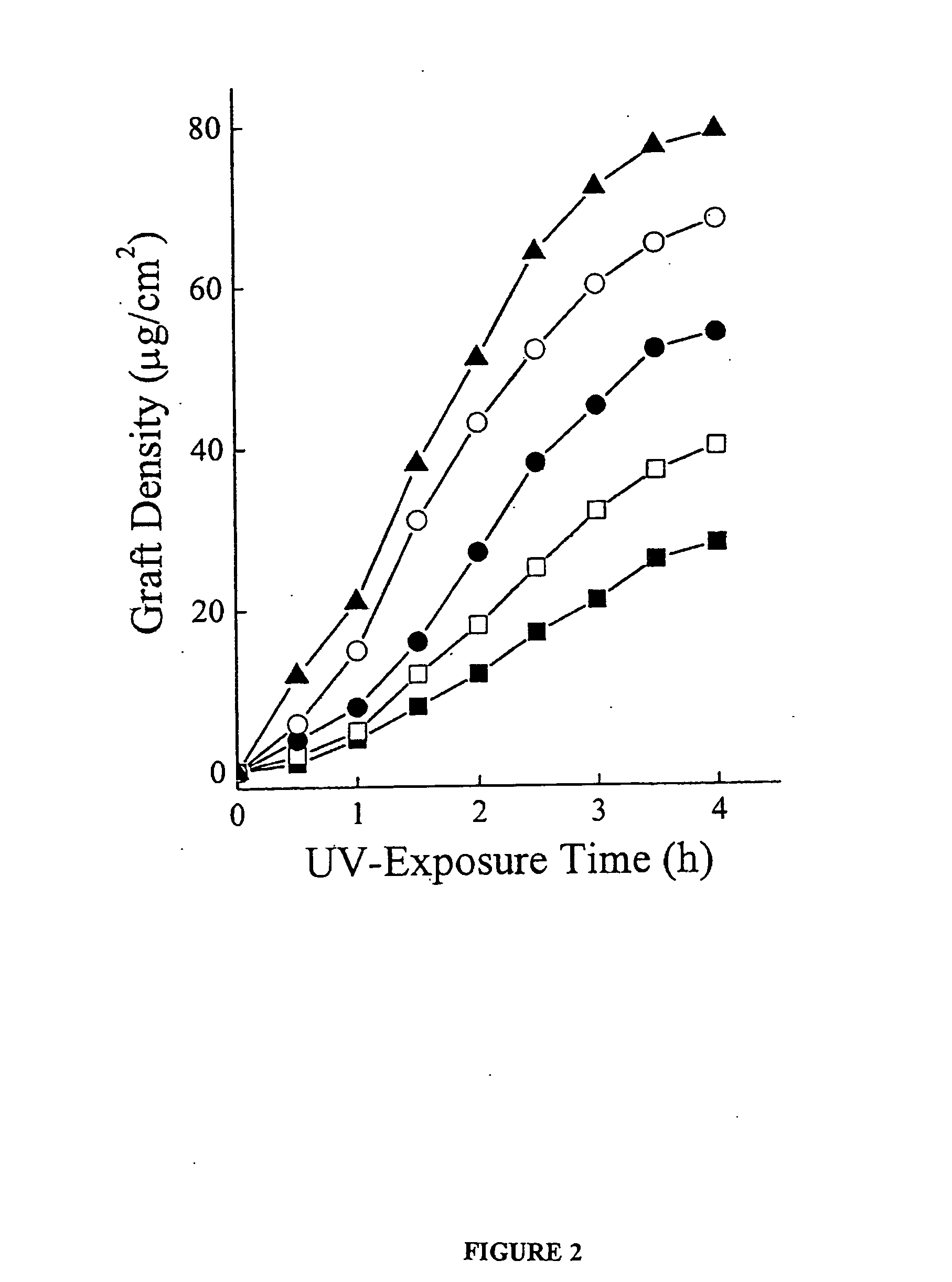

Chemical modifications to polymer surfaces and the application of polymer grafting to biomaterials

InactiveUS20050237480A1Numerous polymerizationQuality improvementMaterial analysis by electric/magnetic meansOptical partsPolymeric surfacePolymer science

Polymer-based biomaterials are popular due to ease of fabrication and low costs. However, many polymer substrates have undesirable surface properties. The invention provides a procedure to covalently apply a graft polymer to the surface of a polymer substrate by ultraviolet graft polymerization. The graft polymer is formed from monomers such as PEG, AA, monomethoxy acrylate PEG, HEMA, or DMA. Also, mixed monomers may be used to create the graft and the surface properties of the graft may be tailored for different properties, including hydrophobicity, friction coefficient, electroosmotic mobilities and electrophoretic separations. The invention has particular utility in tailoring surface chemistries in ocular lenses and polymer microdevices. I.II.R:—OHAcrylic Acid(AA)—NH2Acrylamide (AM)—N(CH3)2Dimethylacrylamide (DMA)—OCH2CH2OH2-Hydroxyethylacrylate (HEA)—O(CH2CH2O)nCH3PEG monomethyoxylacrylate (PEG)

Owner:RGT UNIV OF CALIFORNIA

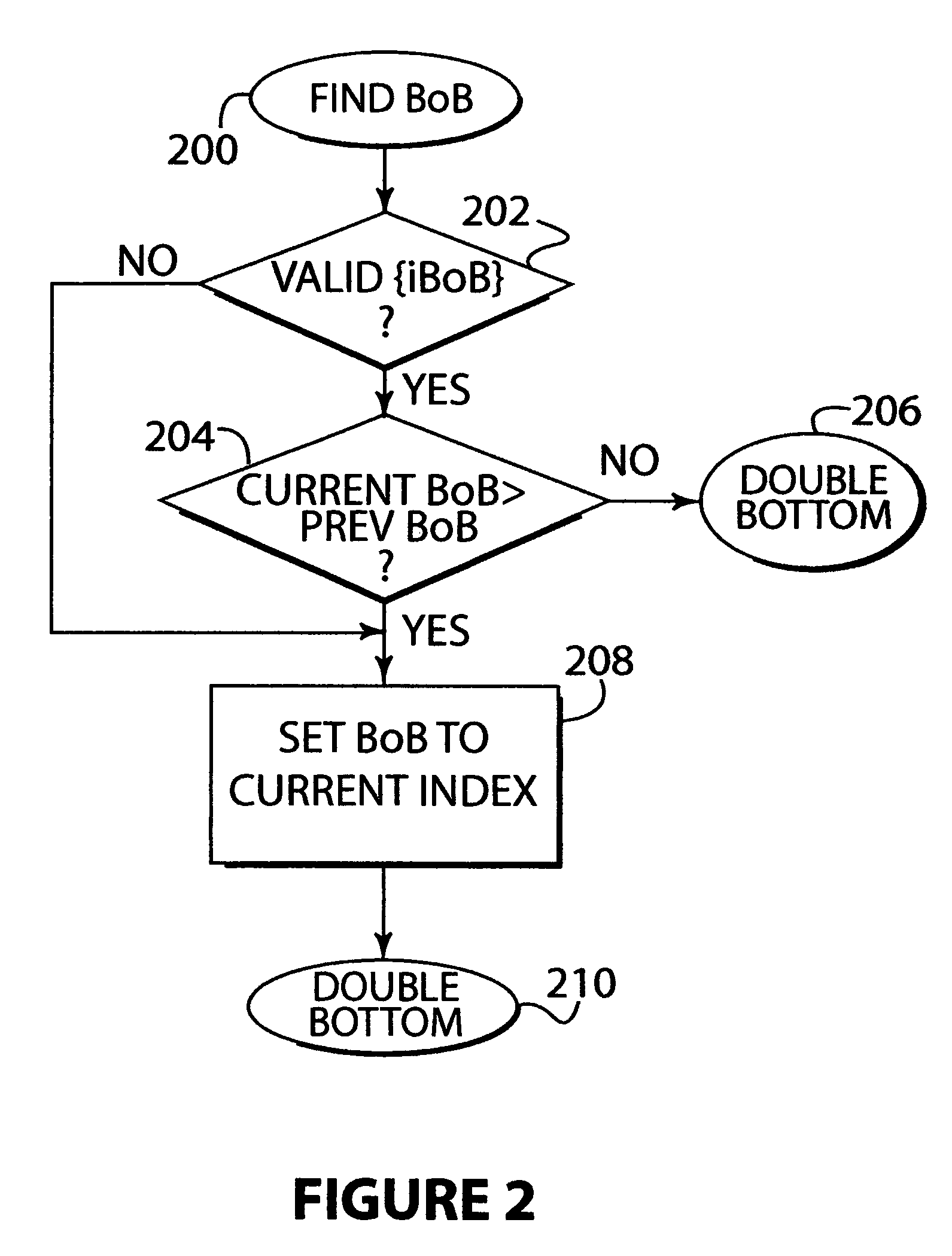

System and method for analyzing a waveform to detect specified patterns

Disclosed are techniques for analyzing waveforms to determine the existence of certain patterns in those waveforms. The existence of certain patterns can be used by investors to make decisions regarding the purchase or sale of stocks. The processes include a determination of the formation of a base, whether the pattern formed in the base is a cup or saucer, whether there is a double bottom in the base, if a base has broken out and if a handle exists on a cup, as well as other patterns.

Owner:MARKEL STEVEN

Wind turbine blade planforms with twisted and tapered tips

A blade for a wind turbine includes a total backward twist of between approximately 6 degrees and approximately 15 degrees between an outer approximately 1 percent to 10 percent of a rotor radius of the blade; and an approximate planform distribution within the following rangesr / Rc / R(LE)c / R(TE).960.60 to 0.65%−1.42 to −1.34%.9680.54 to 0.59%−1.31 to −1.34%.9740.39 to 0.58%−1.36 to −1.22%.98060.13 to 0.57%−1.45 to −1.06%.9856−0.23 to 0.56% −1.56 to −0.74%.9906−0.76 to 0.55% −1.74 to −0.24%.9956−1.44 to 0.54% −1.99 to 0.23% 1.00−2.17 to 0.54% −2.27 to 0.44% where “r / R” is an approximate normalized distance outward from a center of rotation of the blade along a span of the blade; and “c / R(LE)” and “c / R(TE)” are approximate relative positions of a leading (LE) and trailing edge (TE) of a chord “c” expressed as a percentage of a distance outward from the center of rotation at each r / R.

Owner:GENERAL ELECTRIC CO

Clear glass composition

Glass is provided so as to have high visible transmission and / or fairly clear or neutral color. In certain example embodiments of making glass according to examples of the invention, the glass batch may include a base glass (e.g., soda lime silica base glass) and, in addition, by weight percentage:total iron (expressed as Fe2O3): 0.01 to 0.30%erbium oxide (e.g., Er2O3): 0.01 to 0.30%cerium oxide (e.g., CeO2):0.005 to 0.30%.Optionally, neodymium oxide (e.g., Nd2O3) may also be provided in the glass in certain example embodiments. In other embodiments, the cerium oxide may be replaced with or supplemented by NaNO3 or some other nitrate(s) as an oxidizer.

Owner:GUARDIAN GLASS LLC

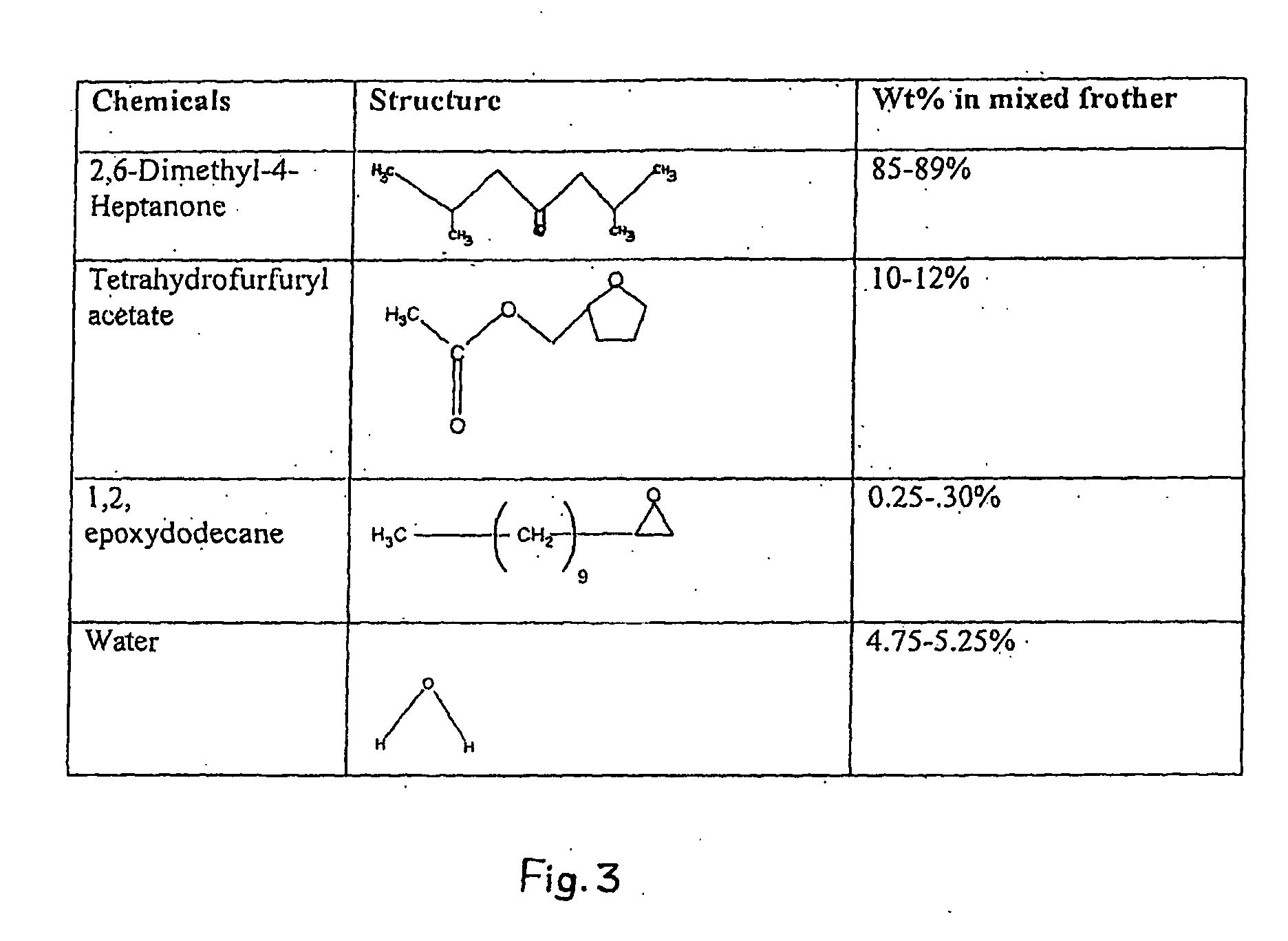

Blended frother for producing low ash content clean coal through flotation

An improved frothing agent adaptable to froth flotation process to enhance coal selectivity for separation and efficiency of the forth flotation process comprises:-A blended mixture ofKetone (2,6 Dimethl-4-Heptanone)85-89%(Wr %)Ester molecule(Tetrahydrofurfuryl acetate)10-12%(Wt %)Epoxide conditioner (1,2-Epoxydodecane)0.25-0.30%(Wt %)Water4.75-5.25%(Wt %)

Owner:TATA STEEL

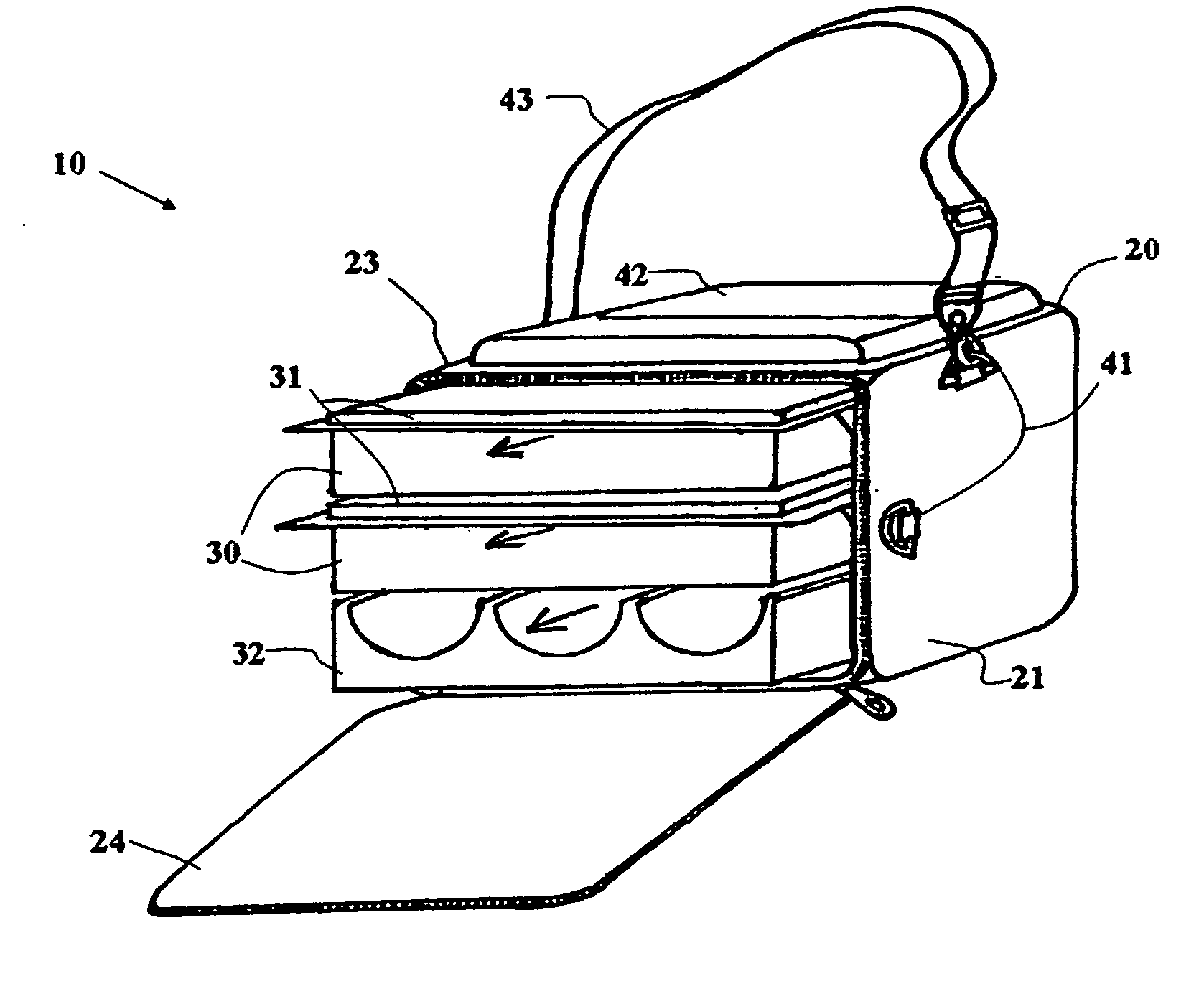

Dual-use lunch box

A dual-use lunch box comprises of an outer rectangular housing unit with one opening supported by five side walls in bond with each other. Herein container railing affixed to two parallel sidewalls serves to support removable food and beverage storage containers. An outer fabric cover with a zippered front flap encloses the rectangular box and is encased with insulation to maintain constant temperature. The outside of said fabric cover includes side pockets or pouches. Two sets of connectors are flanked 90 degrees apart on the outer sidewalls of said fabric cover to fasten a carrying strap in two different positions. The dual-use lunch box is distinctive in that it has a dual function. It allows food and beverage items to be stored in an organized manner in removable storage containers. The other function allows the storage containers to be removed to accommodate larger food items.References CitedU.S. Patent Documents5,181,612January 1993Liu5,277,329January 1994Pomroy et al.5,485,921January 1996Tolendano5,595,302January 1997Maydwell et al.5,842,571December 1998Rausch5,950,834September 1999Woodnorth et al.7,334,684February 2008Fontanilla et al.

Owner:MARQUEZ JAMES EUGENE

Method of manufacturing technology of ultra-deep large cylinder-shaped drilling platform main hull

The invention discloses a method of a manufacturing technology of an ultra-deep large cylinder-shaped drilling platform main hull, which comprises the following steps: division of construction stage of the cylinder-shaped drilling platform main hull, construction of double bottom total stage, manufacturing folding of a cylinder body, folding of deck section, and carry and hoisting of superstructure. The invention is provided with a platform structure for strengthening the whole resistance, can be applicable to various marine environments, is free from changing navigation bearing with the wind, has better stability, and can achieve the safety level of preventing immeasurable wind waves.

Owner:COSCO SHIPPING (QIDONG) OFFSHORE CO LTD +2

High strength aluminium alloy brazing sheet, brazed assembly and method for producing same

ActiveUS7226669B2Good brazing property and formability characteristicHigh strengthFurnace typesWelding/cutting media/materialsHigh intensityDouble bottom

The present invention a high strength aluminium alloy brazing sheet, comprising an Al-Zn core layer and at least one clad layer, the core layer including the following composition (in weight percent): <tables id="TABLE-US-00001" num="00001"> <tgroup align="left" colsep="0" rowsep="0" cols="3"> <colspec colname="offset" colwidth="56pt" align="left" / > <colspec colname="1" colwidth="14pt" align="left" / > <colspec colname="2" colwidth="147pt" align="center" / > <ROW> <ENTRY / > <entry namest="offset" nameend="2" align="center" rowsep="1" / > < / ROW> <ROW> <ENTRY / > <ENTRY>Zn< / ENTRY> <ENTRY>1.2 to 5.5< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Mg< / ENTRY> <ENTRY>0.8 to 3.0< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Mn< / ENTRY> <ENTRY>0.1 to 1.0< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Cu< / ENTRY> <ENTRY><0.2< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Si< / ENTRY> <ENTRY> <0.35< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Fe< / ENTRY> <ENTRY><0.5< / ENTRY> < / ROW> <ROW> <ENTRY / > <entry namest="offset" nameend="2" align="center" rowsep="1" / > < / ROW> < / TGROUP> < / TABLES> optionally one or more of: <tables id="TABLE-US-00002" num="00002"> <tgroup align="left" colsep="0" rowsep="0" cols="3"> <colspec colname="offset" colwidth="56pt" align="left" / > <colspec colname="1" colwidth="14pt" align="left" / > <colspec colname="2" colwidth="147pt" align="char" / > <ROW> <ENTRY / > <entry namest="offset" nameend="2" align="center" rowsep="1" / > < / ROW> <ROW> <ENTRY / > <ENTRY>Zr< / ENTRY> <ENTRY><0.3< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Cr< / ENTRY> <ENTRY><0.3< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>V< / ENTRY> <ENTRY><0.3< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Ti< / ENTRY> <ENTRY><0.2< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Hf< / ENTRY> <ENTRY><0.3< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Sc< / ENTRY> <ENTRY><0.5,< / ENTRY> < / ROW> <ROW> <ENTRY / > <entry namest="offset" nameend="2" align="center" rowsep="1" / > < / ROW> < / TGROUP> < / TABLES> the balance aluminium and incidental elements and impurities. The clad layer includes an Al-Si based filler alloy and is applied on at least one side of the core layer. The invention relates furthermore to a brazed assembly including such brazing sheet, to the use of such brazing sheet and to method for producing an aluminium alloy brazing sheet.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

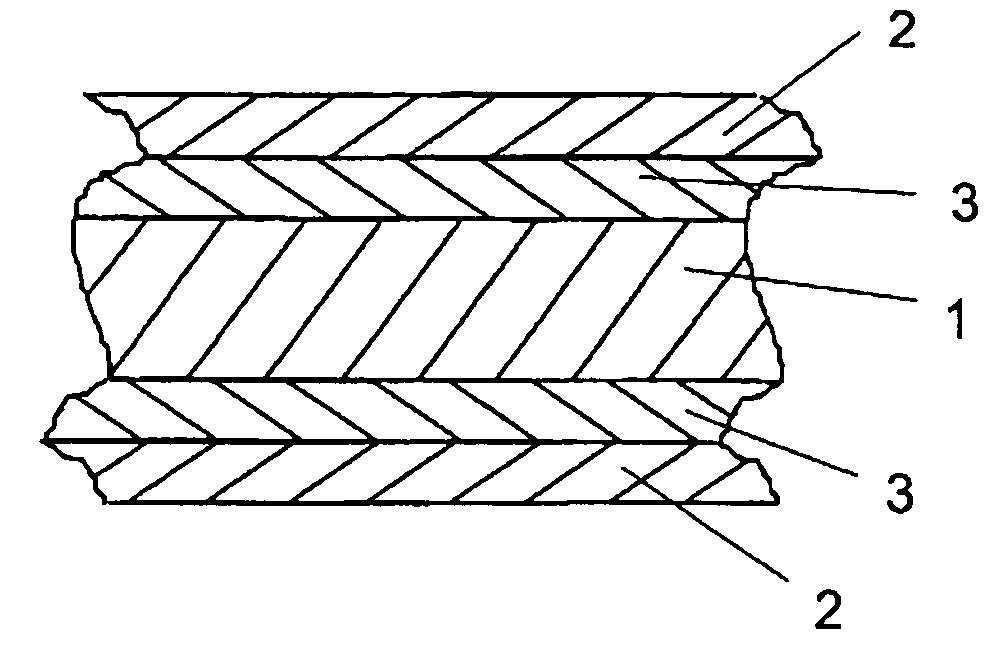

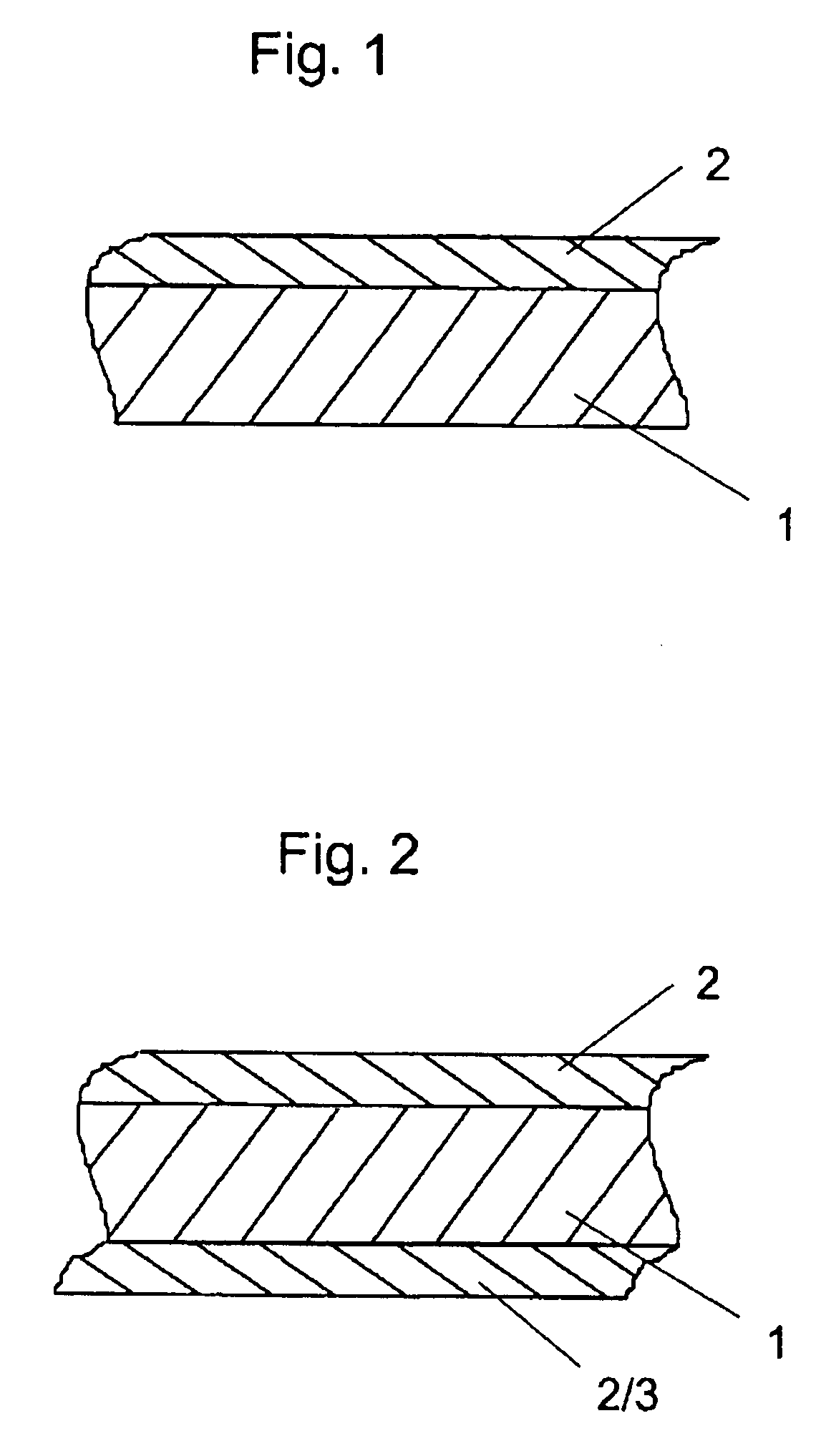

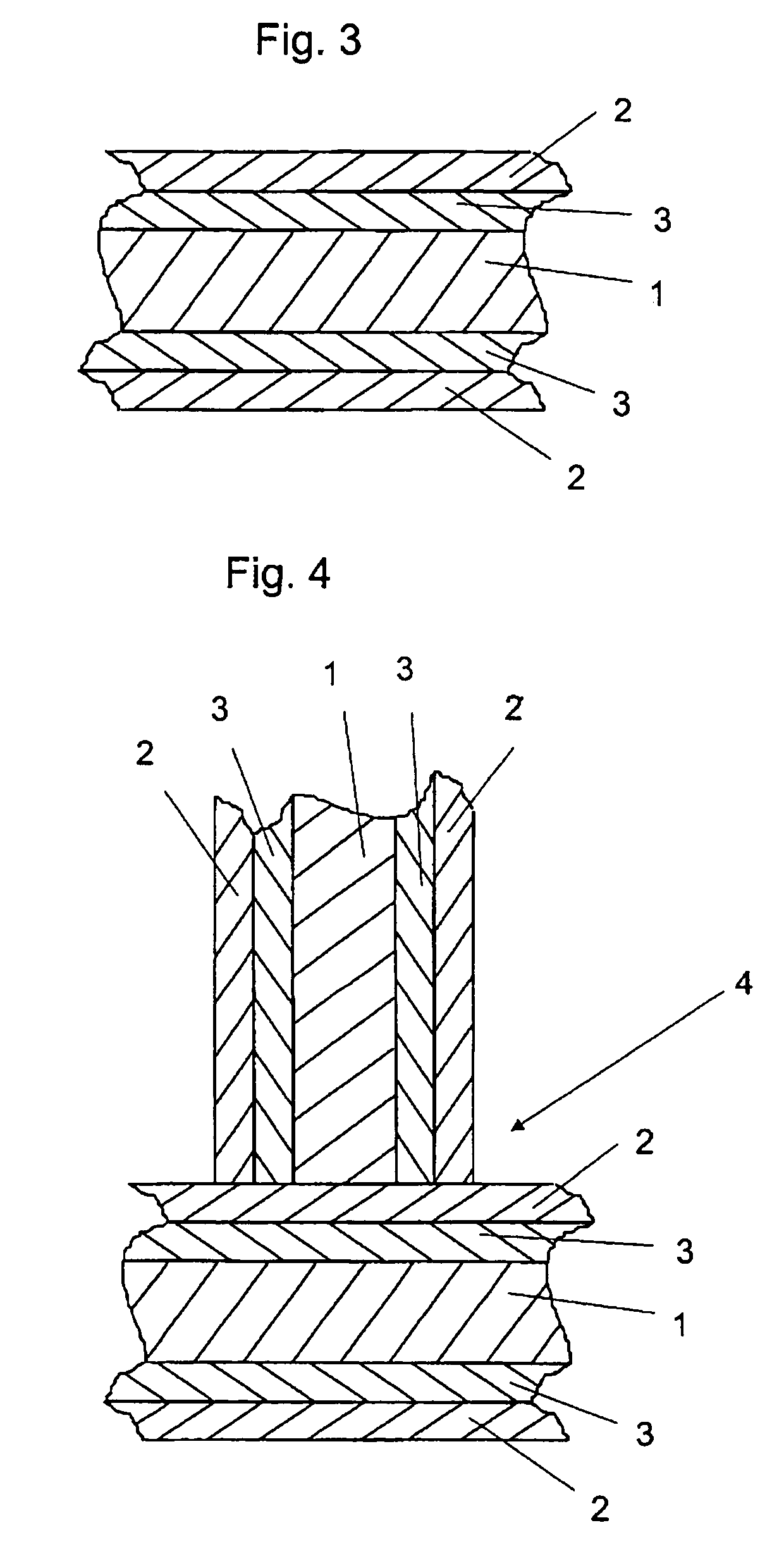

Glas ceramic having a low thermal expansion

ActiveUS20050197242A1Handling using diffraction/refraction/reflectionSemiconductor/solid-state device manufacturingThermal expansionDouble bottom

The present invention relates to a novel glass ceramic having a low or small average thermal expansion together with good polishability and processability, to the use of the glass ceramic according to the invention, and to optical components made of the glass ceramic. In particular, a glass ceramic is provided which comprises the following composition (in % by weight based on oxide): SiO250-70Al2O317-32P2O5 3-12Li2O2.5-5 Na2O0-2K2O0-2MgO0-2CaO0.1-4 BaO 0-<1SrO0-2ZnO0-4TiO21.5-5 ZrO2 0-2.5

Owner:SCHOTT AG

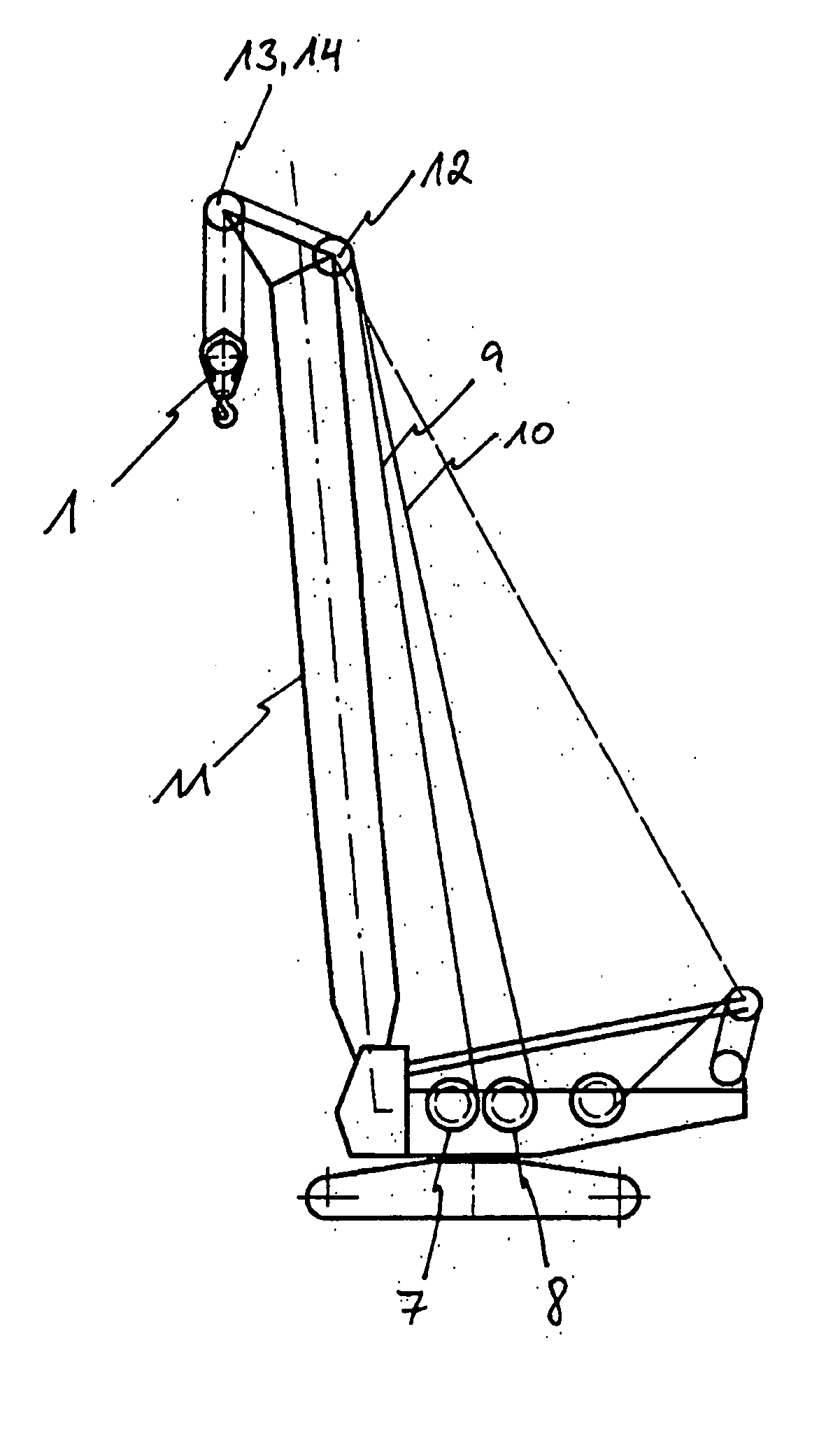

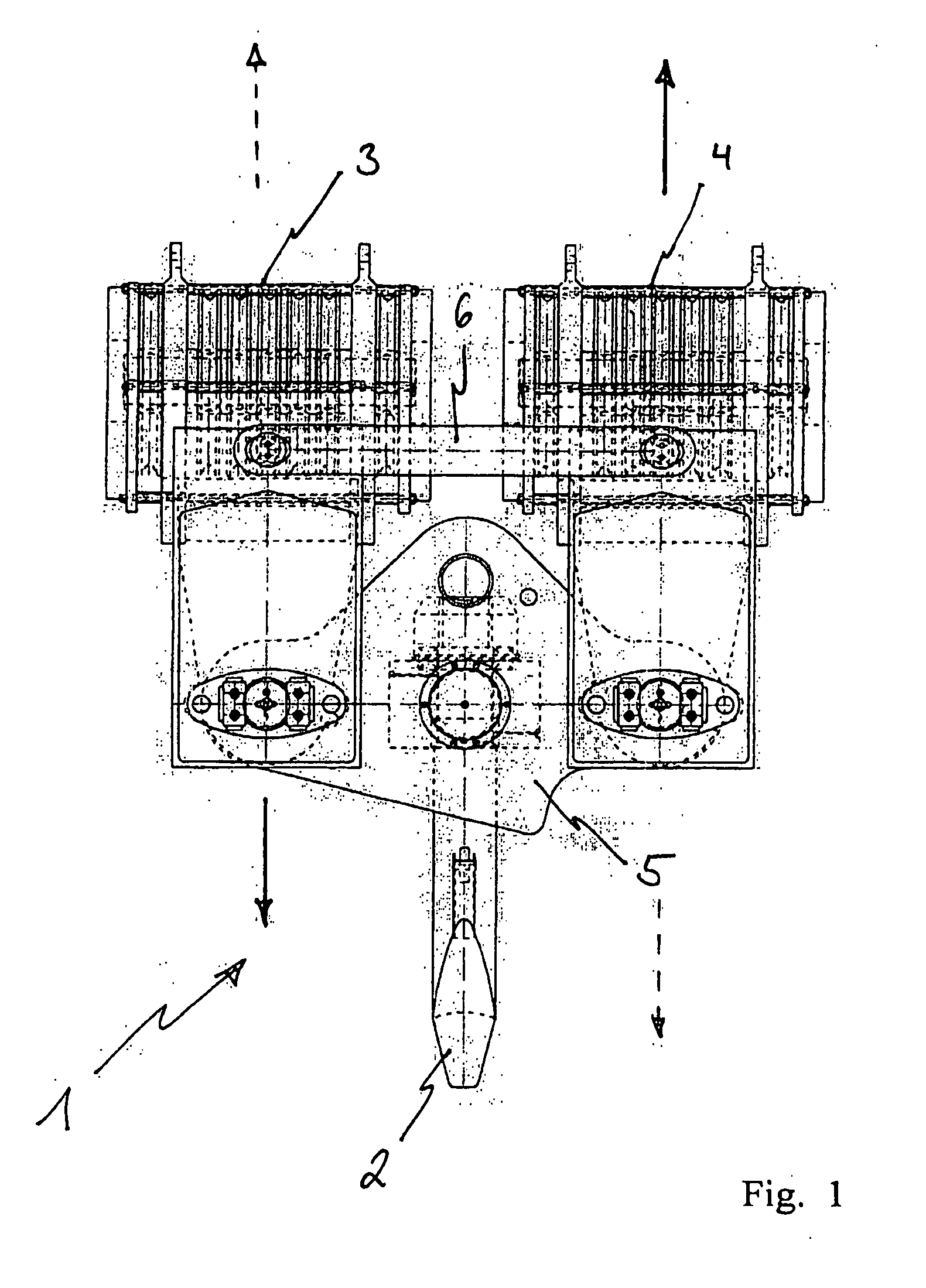

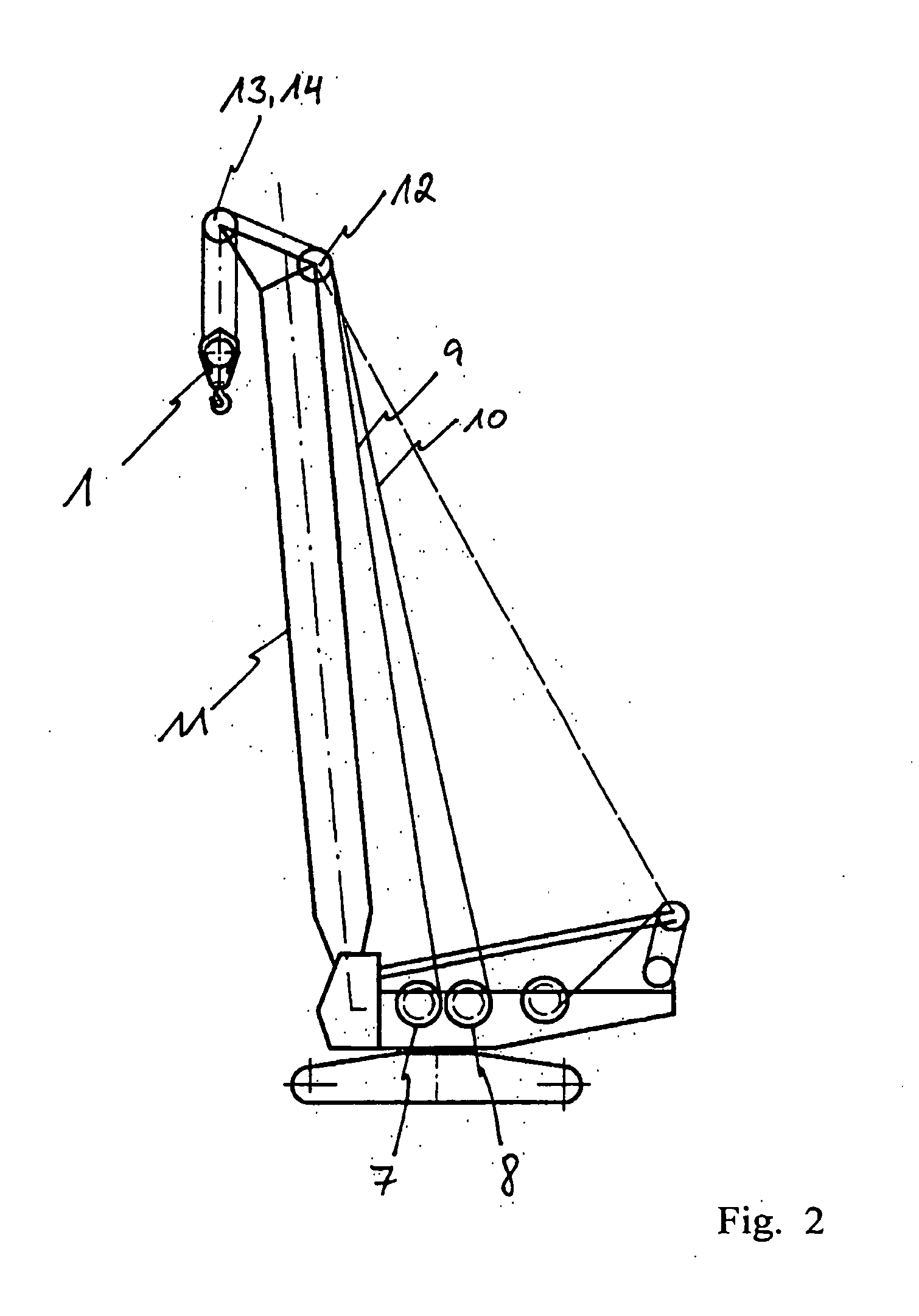

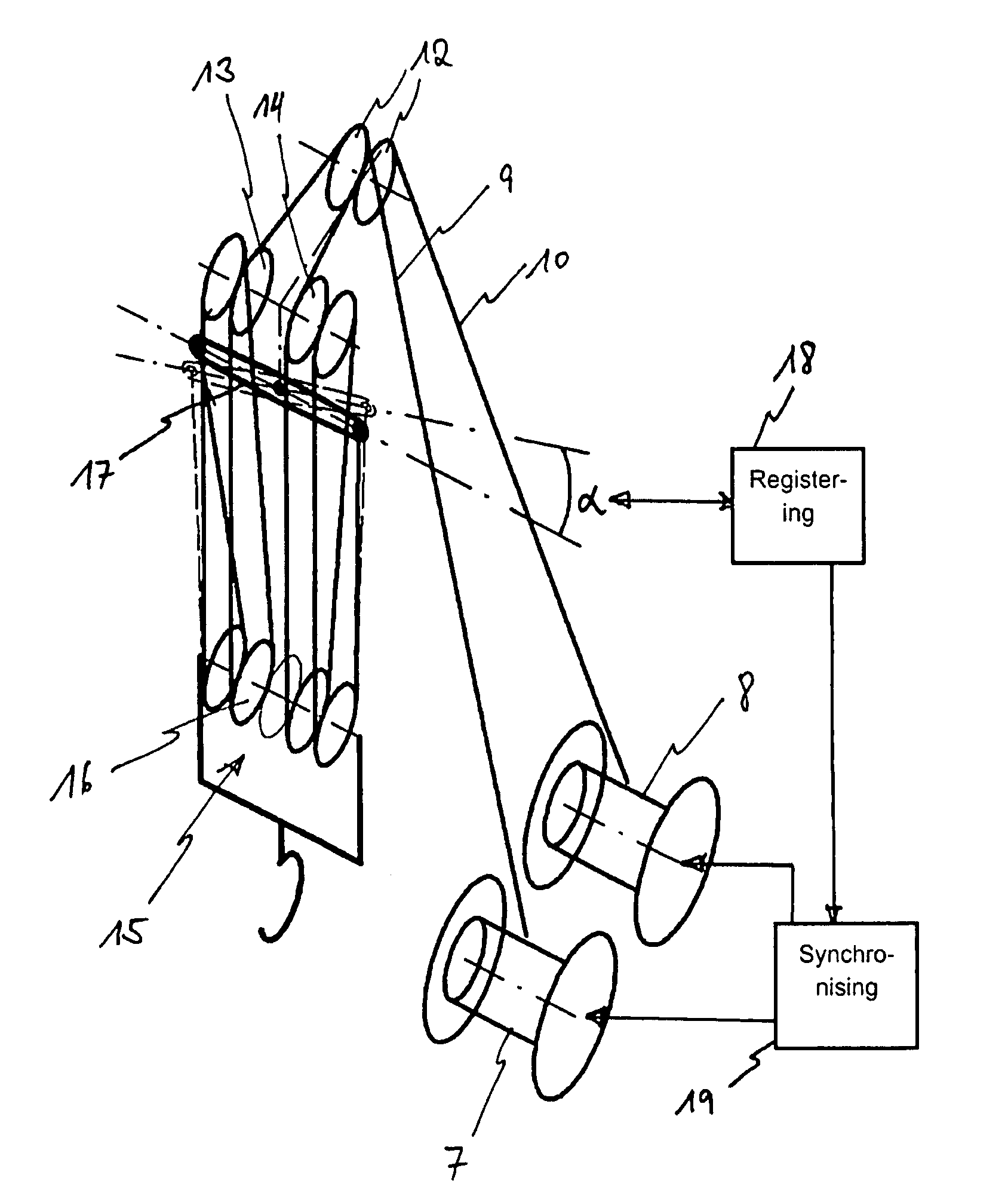

Hoisting-Cable Drive Comprising a Single Bottom-Hook Block and Two Winches

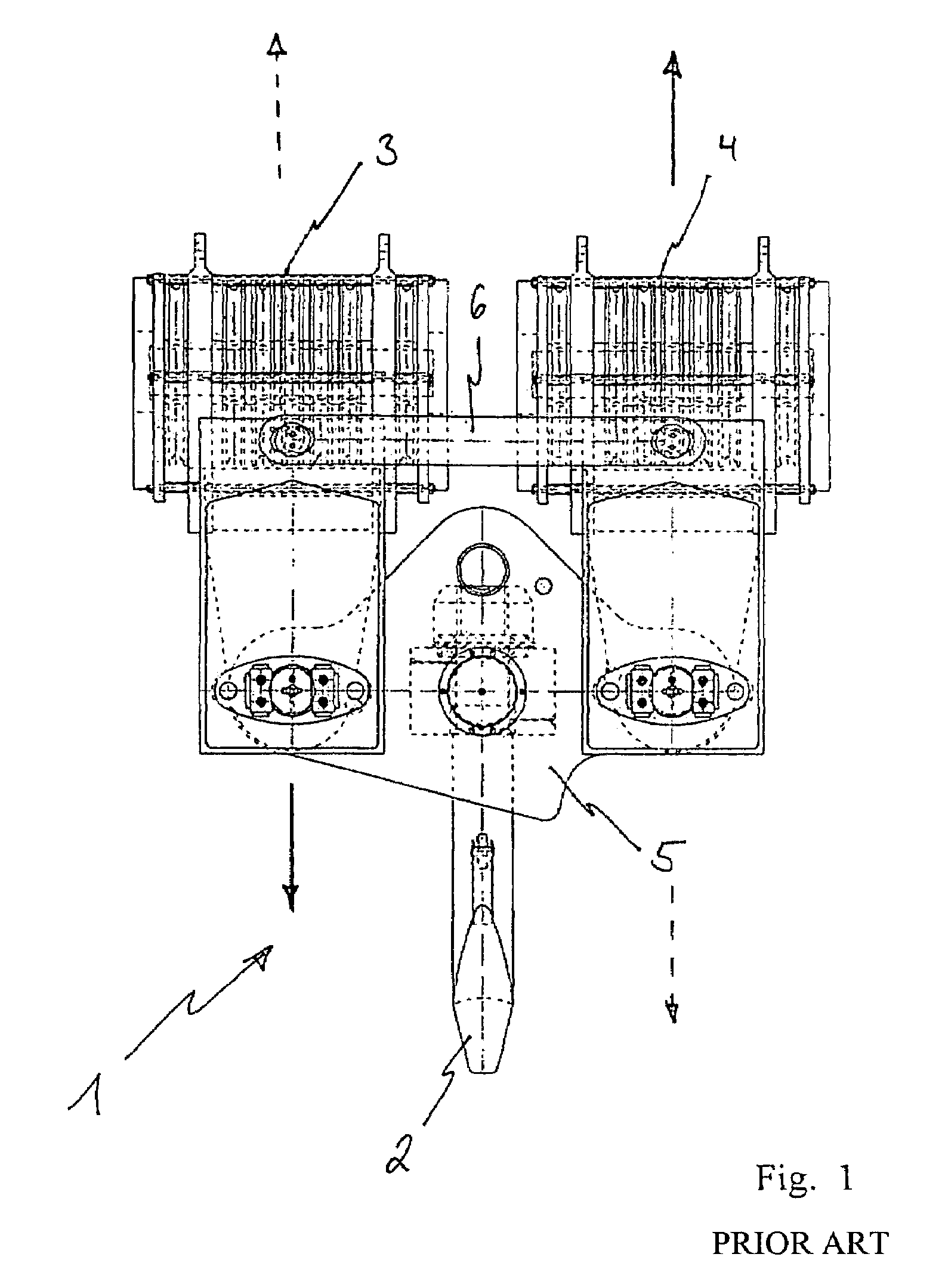

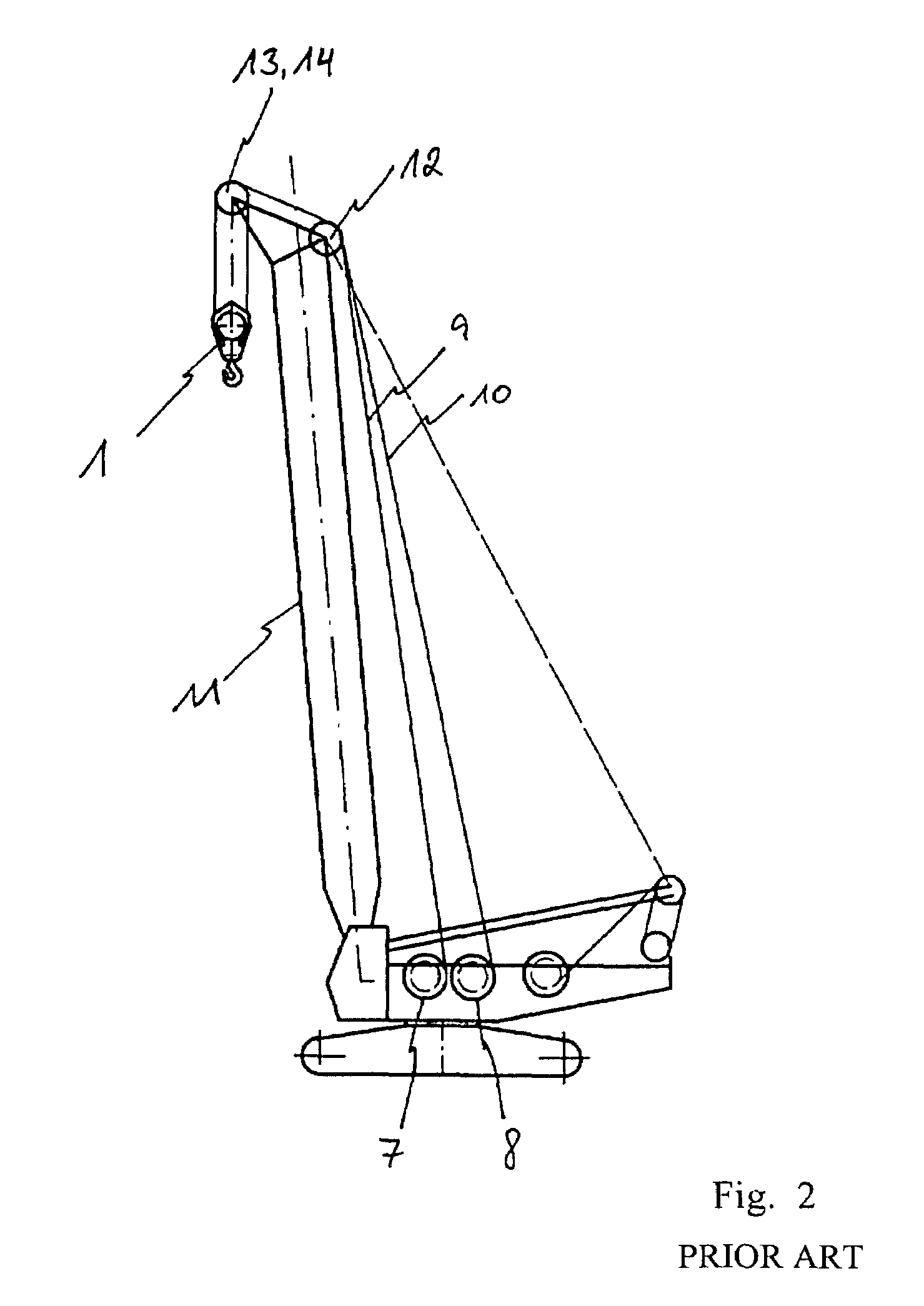

ActiveUS20070290182A1Easy to handleSolid and difficult to handlePortable liftingWinding mechanismsForce equilibriumDouble bottom

The invention proposes a hoisting-cable drive for a mobile crane, which hoisting-cable drive uses a single bottom-hook block (15) instead of a known double bottom-hook block. However, to prevent this single bottom-hook block (15) from tilting in the two cable lines (9, 10), for example due to possible variations in the elongation of the two cable drives, the hoisting-cable drive according to the invention comprises a kinematic force equilibrium device (17, 21), which can equalize such differences. To this effect, another embodiment of the hoisting-cable drive according to the invention uses a hoisting-cable load pickup (21) within each cable line arrangement so that the rotary speed of the winches (7, 8) can be varied, taking into account any load differences in the individual hoisting-cable lines (9, 10). Furthermore, the invention also proposes that the rotary speed of the winches (7, 8) be adjusted, taking into account the geometric winch states and crane states.

Owner:TADANO DEMAG GMBH

Automated airport luggage system

InactiveUS20050192701A1Facilitate the wagon's entryFacilitate the mounting of the wagonDigital data processing detailsTrain hauling devicesJet aeroplaneEngineering

An airport terminal (100) has a department area (200) which includes at least one, and preferably a plurality of check-in counters (202), at least one, and preferably a plurality of airplane-loading zones (204), and a track system (110), arranged for the movement of wagons (10). Wagon (10) is for automatically transporting and sorting luggage, responsive to commands from a computerized management system (80). The wagon (10) includes a rigid frame for containing the luggage. The frame includes four sides and a double bottom having an upper plate, a lower plate, and an internal compartment.

Owner:BEN EZRA ELISHAH

Method for preparing granular animal feed additive and granular animal feed additive prepared by the method

ActiveUS20050220933A1Efficient preparationMaintenance contentAnimal feeding stuffAccessory food factorsIon contentTotal solid content

Provided are a method for preparing a granular animal feed additive and the granular animal feed additive prepared by the method. The method includes: filtering, with a membrane filter, a fermentation broth obtained from a lysine producing microorganism cultured in a lysine producing condition to obtain a lysine-containing filtrate and a microorganism-containing sludge; drying the filtrate to obtain a concentrate with a total solid content of 48 to 52 wt %; granule-drying the concentrate at a temperature of 50° C. to 60° C. to obtain granules; and coating the granules with a coating agent containing one or more selected from the group consisting of the sludge, a diluent or a free lysine as a lysine content adjustor, and a moisture prevention agent, to obtain lysine granules having the following properties: Lysine content (lysine sulfate)65% or moreGrain size 300-1,200 μm, 90% or moreApparent density 620-720 kg / m3Protein content 10-15%Total sugar content >0-1%Inorganic material content >0-3%Water content >0-3%Carboxylic acid content >0-8%SO4− ion content 20-25%

Owner:CJ CHEILJEDANG CORP

Hoisting-cable drive comprising a single bottom-hook block and two winches

ActiveUS7416169B2Easy to handleSolid and difficult to handleWinding mechanismsLoad-engaging elementsForce equilibriumDouble bottom

The invention proposes a hoisting-cable drive for a mobile crane, which hoisting-cable drive uses a single bottom-hook block (15) instead of a known double bottom-hook block. However, to prevent this single bottom-hook block (15) from tilting in the two cable lines (9, 10), for example due to possible variations in the elongation of the two cable drives, the hoisting-cable drive according to the invention comprises a kinematic force equilibrium device (17, 21), which can equalize such differences. To this effect, another embodiment of the hoisting-cable drive according to the invention uses a hoisting-cable load pickup (21) within each cable line arrangement so that the rotary speed of the winches (7, 8) can be varied, taking into account any load differences in the individual hoisting-cable lines (9, 10). Furthermore, the invention also proposes that the rotary speed of the winches (7, 8) be adjusted, taking into account the geometric winch states and crane states.

Owner:TADANO DEMAG GMBH

Glass Substrates for flat screens

A glass substrate, method for providing a glass substrate, and composition having or using a chemical composition including the following constituents, expressed in percentages by weight based on total weight: SiO258 to 70B2O310 to 16Al2O314 to 25CaO 2 to 10MgO 1 to 10BaO 0 to 10SrO 0 to 10M2O0 to 1M2O denoting one or more alkali metal oxides, where at least one of the following provisos are met: 1.) BaO less than 1% and MgO greater than or equal to 2%; 2.) MgO greater than or equal to 4%; 3.) B203 greater than or equal to 12%.

Owner:SAINT-GOBAIN GLASS FRANCE

Process for producing alkali free glass and alkali free glass plate

InactiveUS20080127679A1Small coefficient of thermal expansionLess bubbleGlass furnace apparatusGlass productionTO-18Platinum

To provide a process for producing and alkali free glass for effectively suppressing bubbles, and an alkali free glass produced by the process, which is suitable as a glass substrate for flat panel displays and has few bubbles.A process for producing an alkali free glass containing substantially no alkali metal oxide, which comprises melting a glass starting material having a matrix composition of the following composition, and subjecting the molten glass to a treatment process of removing bubbles under reduced pressure, stirring or transferring under a condition where the molten glass is in contact with a platinum member, wherein the starting material is prepared so as to contain SnO2 in an amount of from 0.01 to 2.0% per 100% of the total amount of the above matrix composition; the starting material is melted under heating at from 1,500 to 1,650° C.; then bubbles contained in the molten glass are permitted to rise to the surface of the molten glass, together with oxygen bubbles generated by a reduction reaction in which SnO2 in the molten glass is reduced to SnO; and in the above treatment process, the oxygen bubbles generated at the interface between the molten glass and the platinum member are permitted to be absorbed by an oxidation reaction in which SnO is oxidized to SnO2, under a condition where the molten glass is from 1,300 to 1,500° C.Composition as represented by the mass percentage:SiO258.4 to 66.0%,Al2O315.3 to 22.0%,B2O3 5.0 to 12.0%,MgO 0 to 6.5%,CaO 0 to 7.0%,SrO 4 to 12.5%,BaO 0 to 2.0%,MgO + CaO + SrO + BaO 9.0 to 18.0%.

Owner:ASAHI GLASS CO LTD

Glass ceramic having a low thermal expansion

ActiveUS7220690B2Handling using diffraction/refraction/reflectionSemiconductor/solid-state device manufacturingThermal expansionDouble bottom

The present invention relates to a novel glass ceramic having a low or small average thermal expansion together with good polishability and processability, to the use of the glass ceramic according to the invention, and to optical components made of the glass ceramic. In particular, a glass ceramic is provided which comprises the following composition (in % by weight based on oxide):SiO250–70Al2O317–32P2O5 3–12Li2O2.5–5 Na2O0–2K2O0–2MgO0–2CaO0.1–4 BaO 0–<1SrO0–2ZnO0–4TiO21.5–5 ZrO2 0–2.5.

Owner:SCHOTT AG

Composition and Method for Enhancing Flouride Uptake Using Bioactive Glass

InactiveUS20090324516A1Increasing fluoride uptakeCosmetic preparationsToilet preparationsFlavorAlcohol

A method for increasing fluoride uptake onto a tooth structure of a patient comprises contacting the tooth structure with an oral care composition, which comprises bioactive glass and fluoride. The oral care composition has the following formulation:IngredientWeight PercentGlycerin0-90PEG0-40Abrasive0-30Thickening Agent0.1-10 Bioactive glass0.5-15 Surfactant0-10Colorant 0-2.0Flavor0.1-2.0 Fluoride 0-5.0Gum Binder 0-2.0Sweetener 0-1.0Colophony Resin0-75Ethyl Alcohol0-25

Owner:NOVAMIN TECH

Anti-deterioration cellar mud and preparation method thereof

ActiveCN101914424AReasonable adjustmentAdjust ratioMicroorganism based processesAlcoholic beverage preparationMixed cultureYeast

The invention discloses anti-deterioration cellar mud and a preparation method thereof. Based on 100 percent of yellow clay, the anti-deterioration cellar mud comprises the following components: 3 to 5 percent of yeast powder, 8 to 10 percent of double bottom dreg, 5 to 8 percent of mixed culture solution of caproic acid bacteria and liquid cellar mud, 2 to 3 percent of M type microbial fermentation liquor, 15 to 20 percent of peat, 5 to 8 percent of cellar mud, 10 to 12 percent of yellow water, 1 to 2 percent of propionibacterium liquid, 4 to 6 percent of impure alcohol, 2 to 3 percent soybean cake powder and 0.05 to 0.1 percent of K2HPO4. The cellar mud realizes the rational regulation of pH value, moisture, humus, nutrient substance, N, P, K and the like by the regulation of a formula and the ratio of the mixed culture solution of the M type microbe to the propionibacterium liquid to the caproic acid bacteria to the liquid cellar mud is well regulated, so that the pH value of the active and excellent cellar mud is always maintained between 5 and 7.

Owner:SICHUAN MIANYANG FORGOOD DISTILLERY

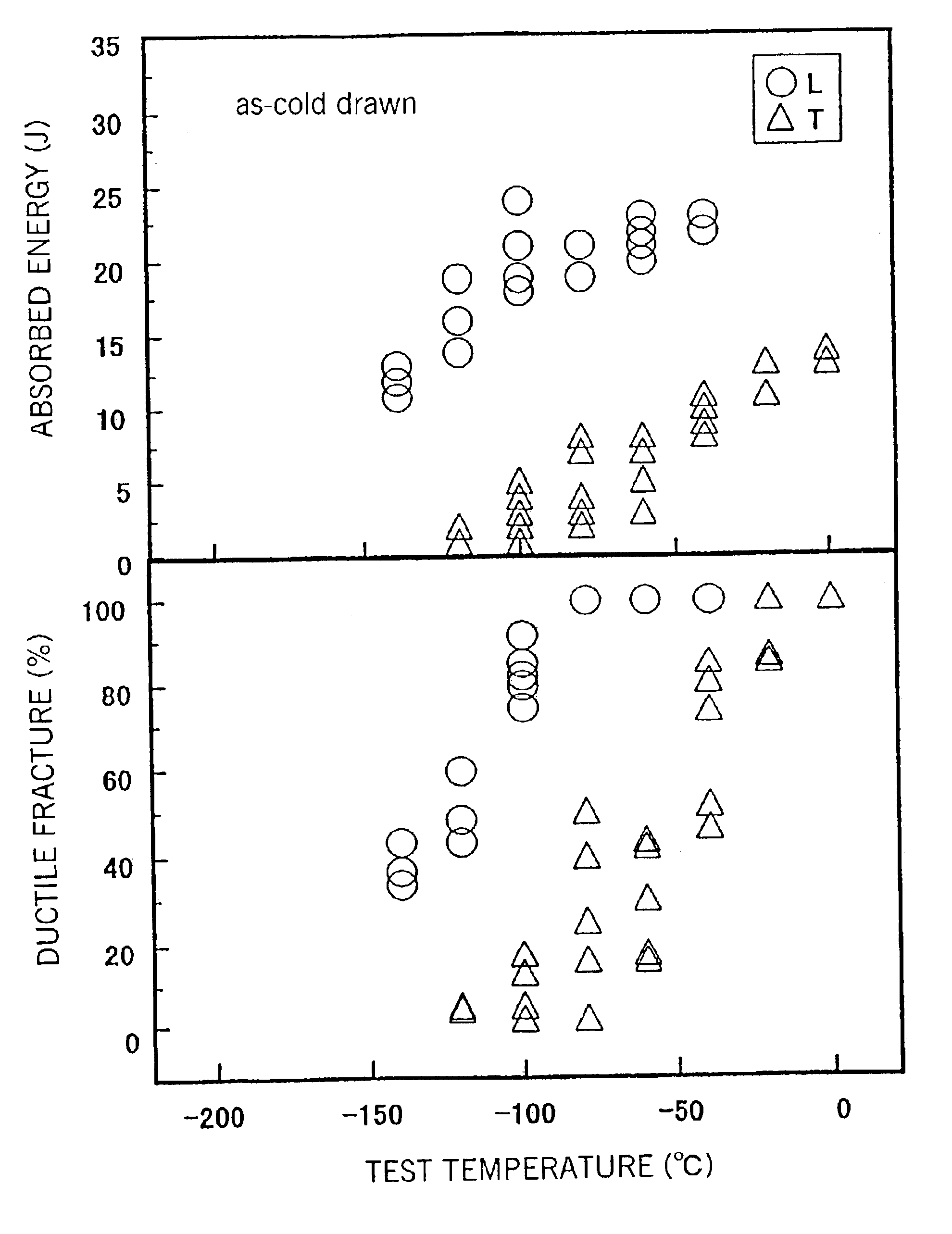

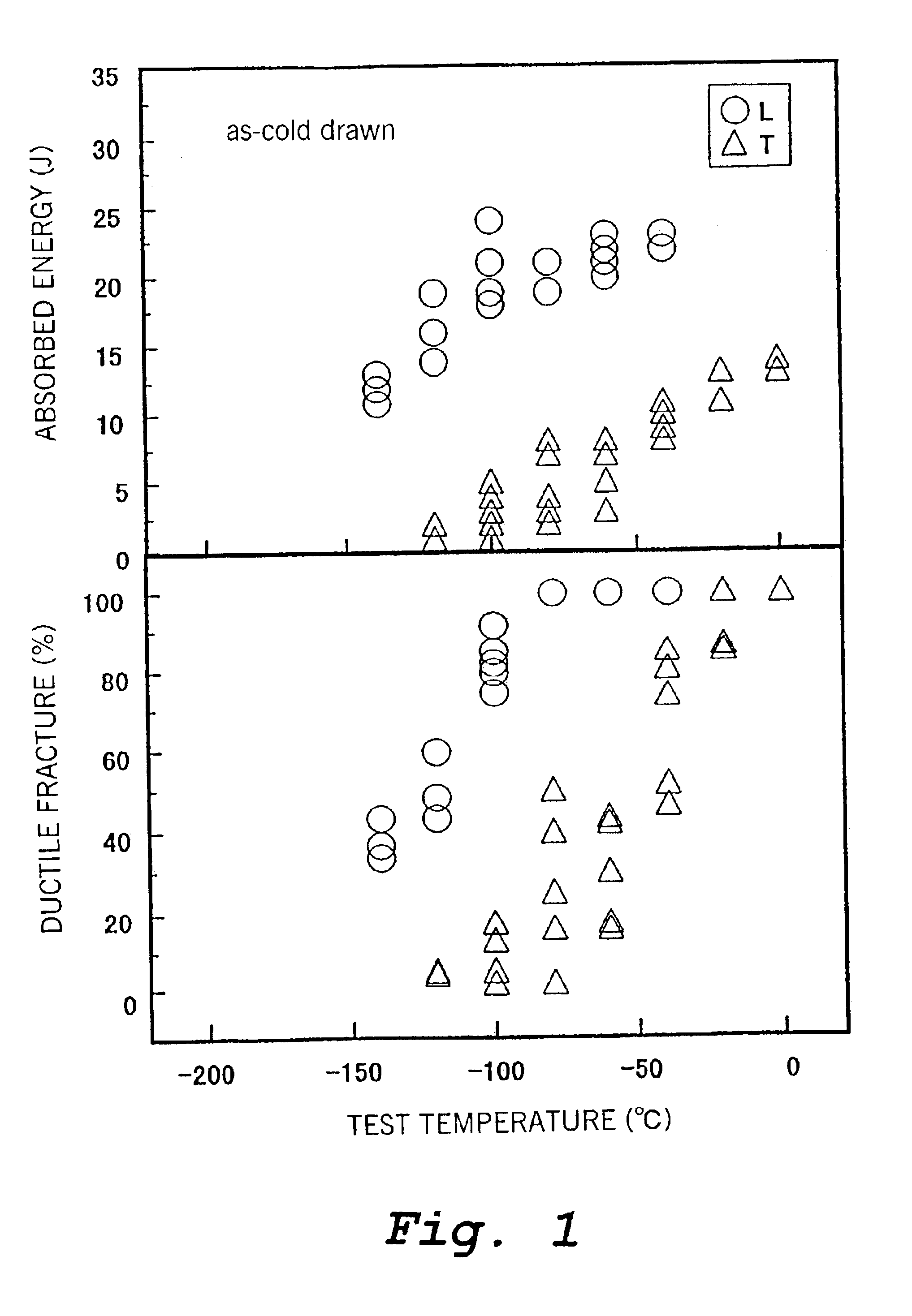

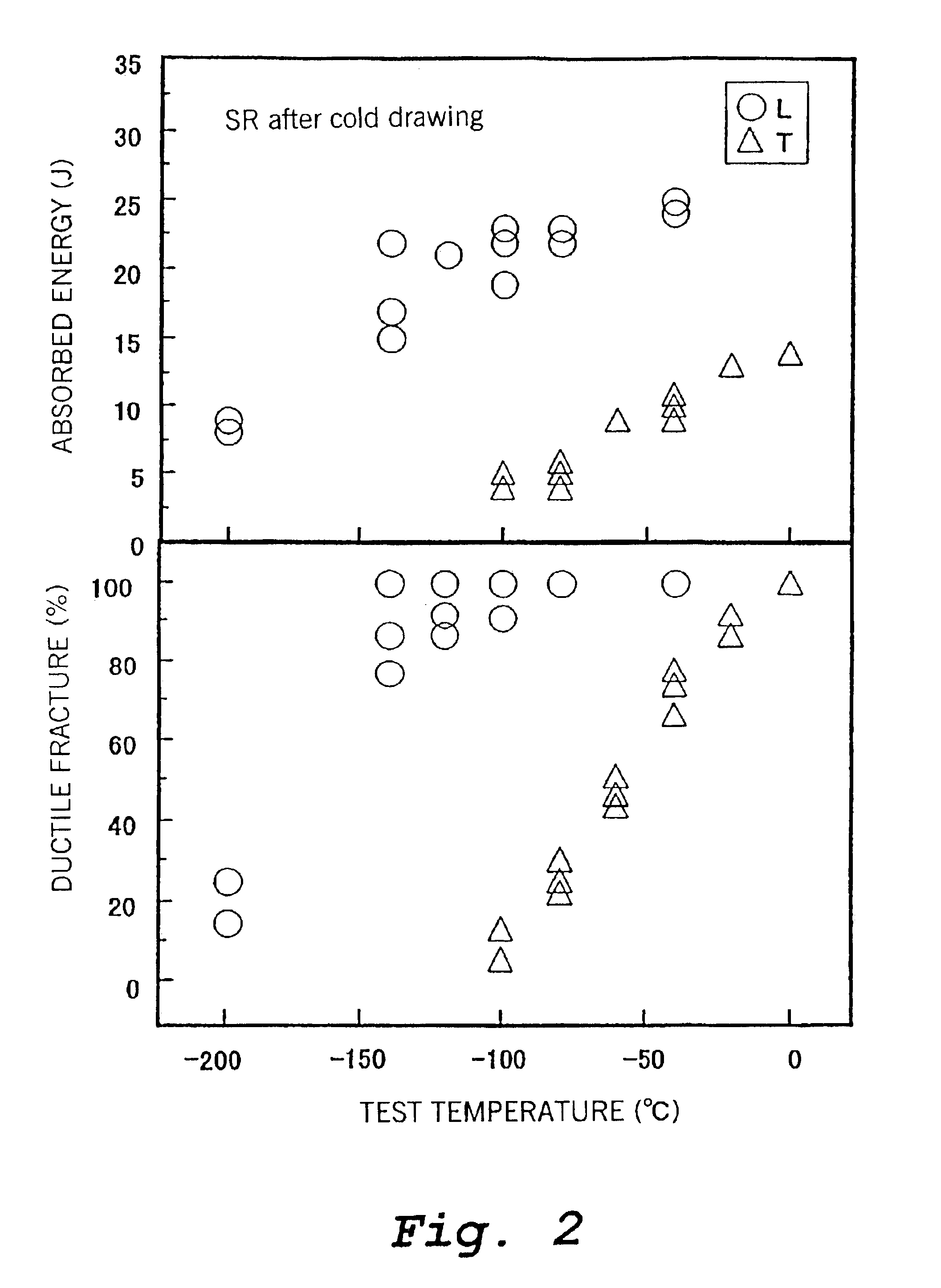

High strength steel pipe for an air bag and a process for its manufacture

InactiveUS6878219B2High strengthGood weldabilityPedestrian/occupant safety arrangementFurnace typesRare-earth elementHigh intensity

In order to manufacture a steel pipe for an air bag which can cope with increase in the pressure of gas blown into an air bag and decreases in the wall thickness of an accumulator, a steel having a composition, mass %, of:C: 0.05-0.20%,Si: 0.1-1.0%,Mn: 0.20-2.0%,P: at most 0.025%,S: at most 0.010%,Cr: 0.05-1.0%,Al: at most 0.10%,if necessary at least one of Mo: at most 0.50%, Ni: at most 1.5%, Cu: at most 0.5%, V: at most 0.2%, Ti: at most 0.1%, Nb: at most 0.1%, and B: at most 0.005%, andalso if necessary, at least one of Ca: at most 0.01%, Mg: at most 0.01%, and REM (rare earth elements): at most 0.01%,and a remainder of Fe and impurities is used to produce a steel pipe, and the pipe is then subjected to cold working to predetermined dimensions, then to heating to a temperature of at least the Ac1 transformation temperature followed by quenching, and then to tempering at a temperature no higher than the Ac1 transformation temperature.

Owner:NIPPON STEEL CORP

Clear glass composition

Glass is provided so as to have high visible transmission and / or fairly clear or neutral color. In certain example embodiments of making glass according to examples of the invention, the glass batch may include a base glass (e.g., soda lime silica base glass) and, in addition, by weight percentage:total iron (expressed as Fe2O3):0.01 to 0.30%erbium oxide (e.g., Er2O3):0.01 to 0.30%cerium oxide (e.g., CeO2): 0.005 to 0.30%. Optionally, neodymium oxide (e.g., Nd2O3) may also be provided in the glass in certain example embodiments. In other embodiments, the cerium oxide may be replaced with or supplemented by NaNO3 or some other nitrate(s) as an oxidizer.

Owner:GUARDIAN GLASS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com