Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54203results about How to "Improve corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

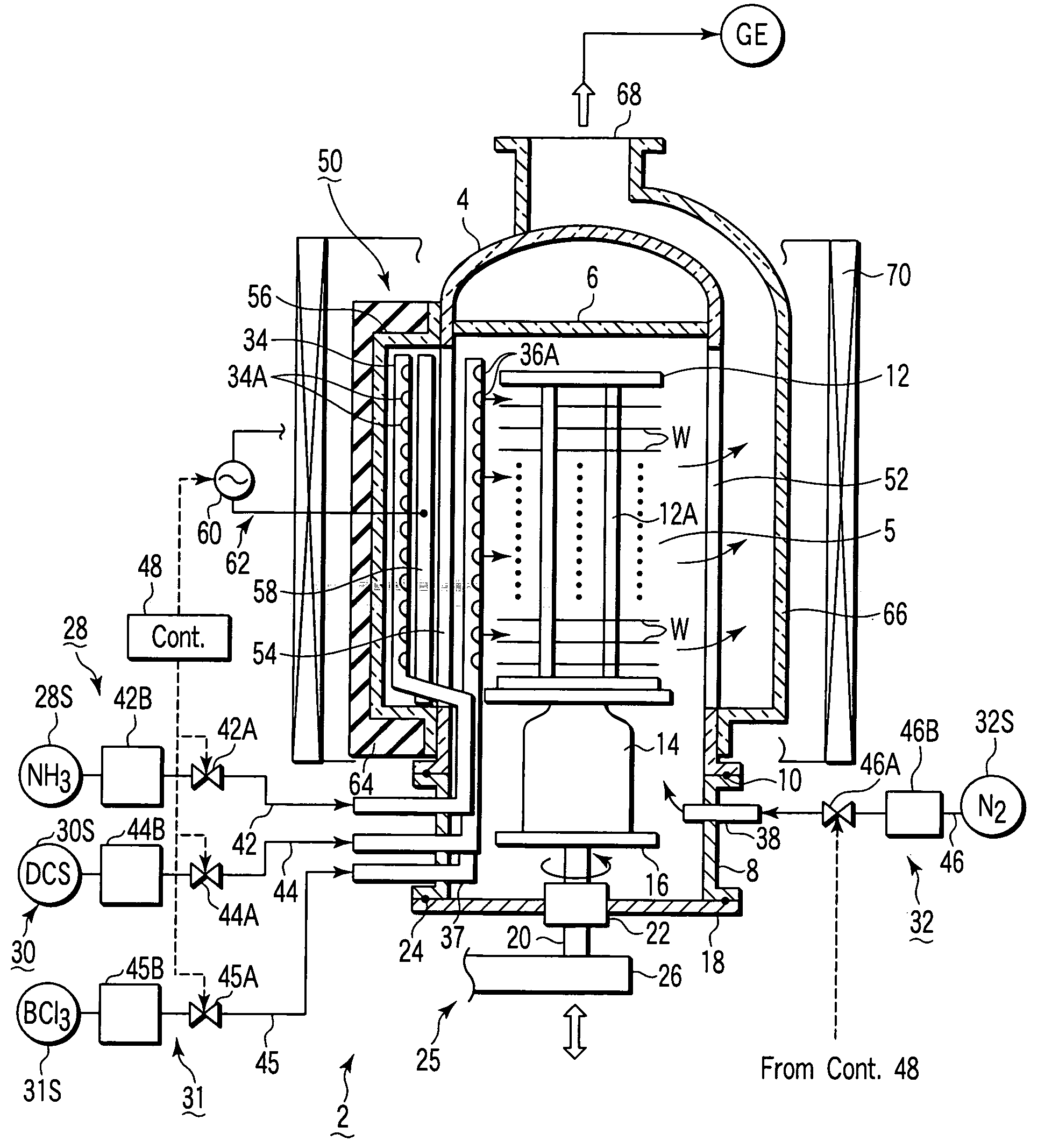

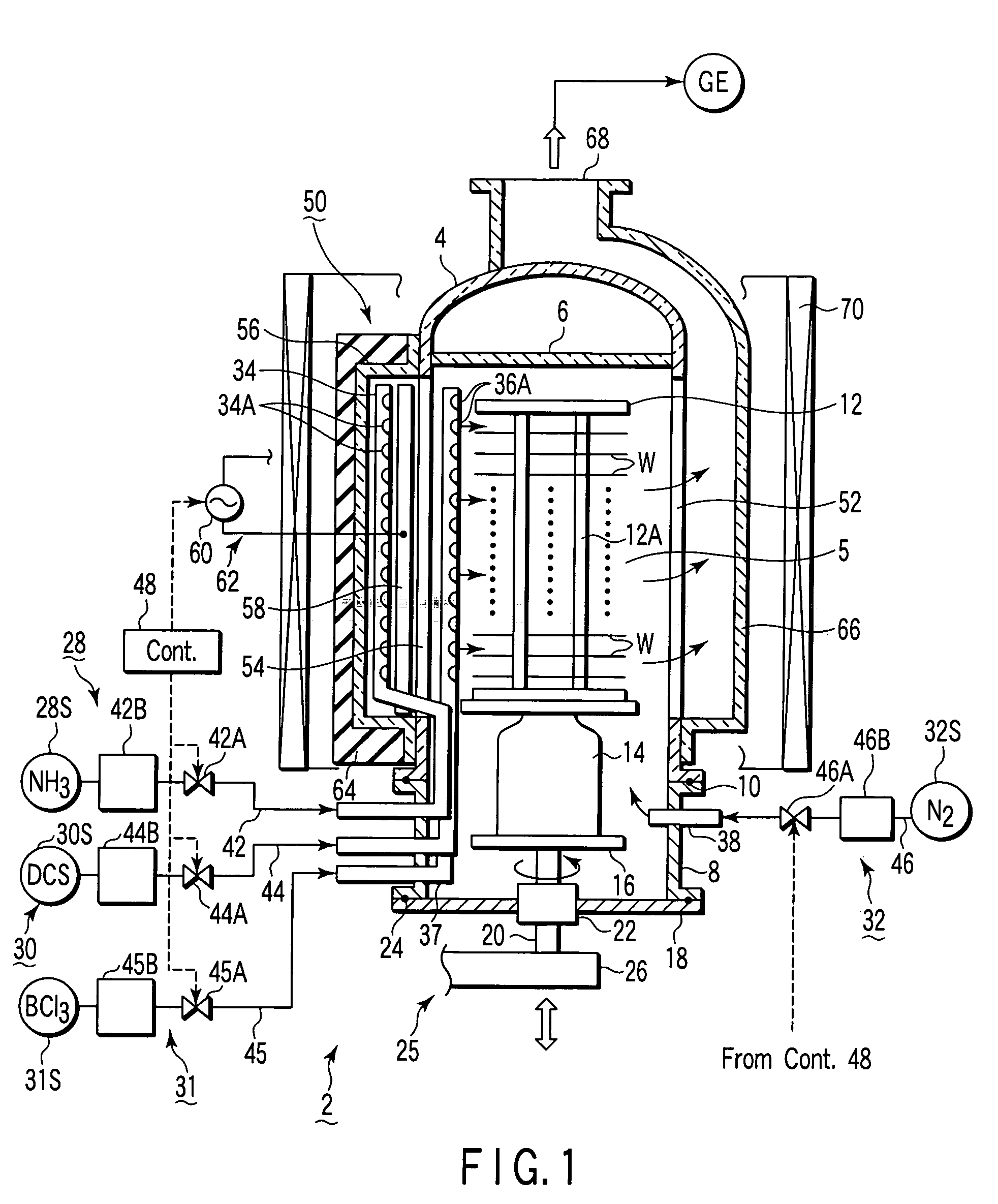

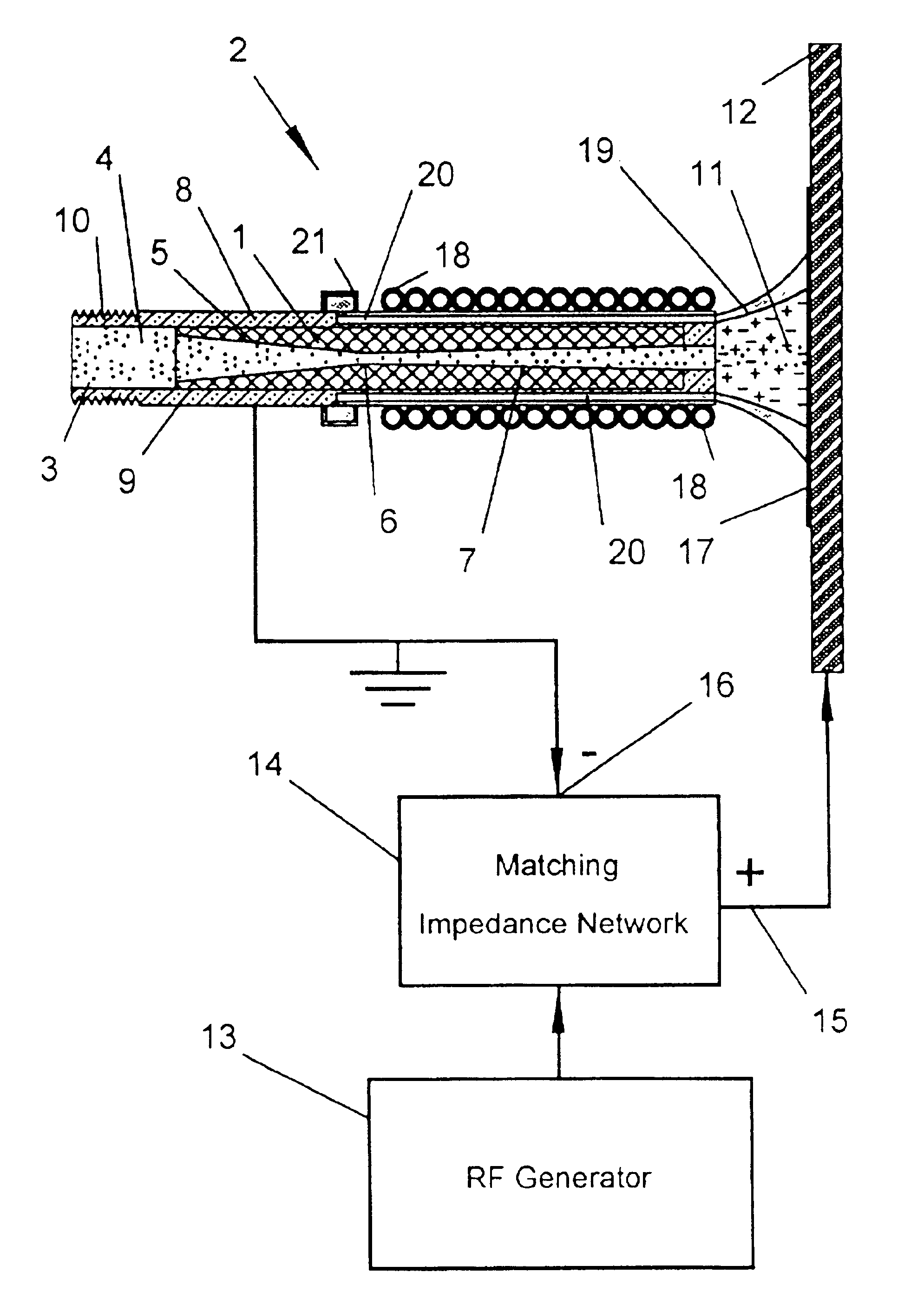

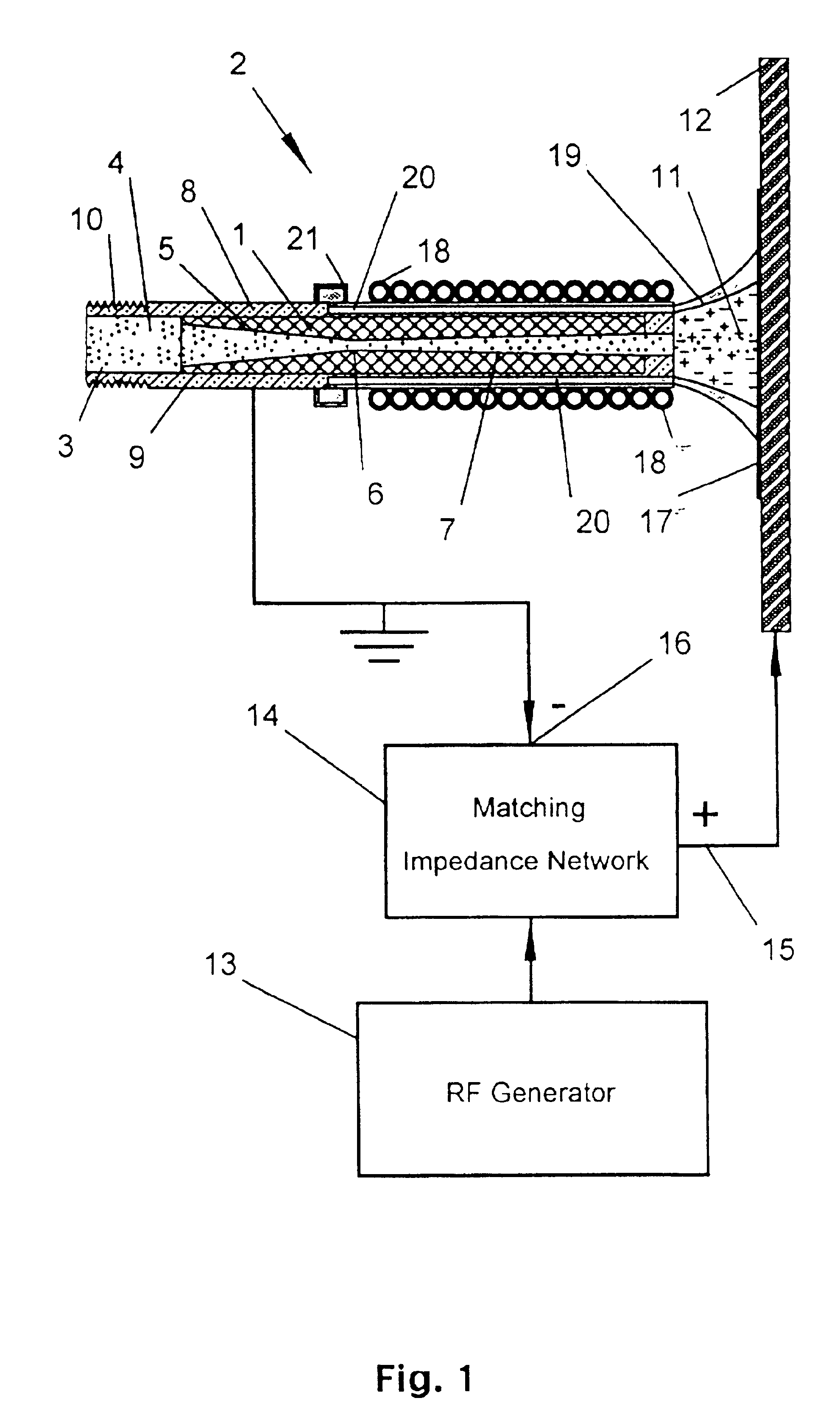

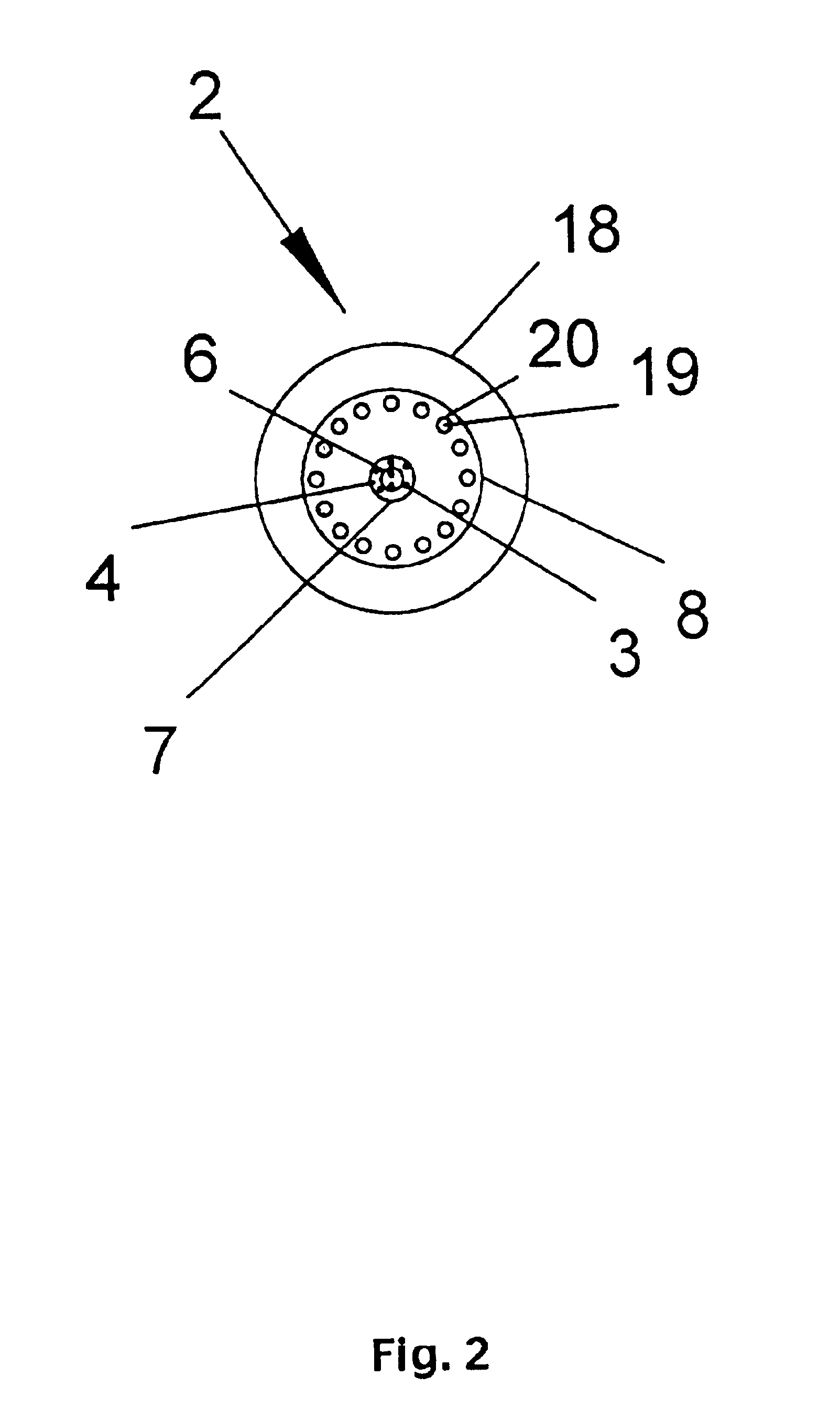

Film formation method and apparatus for semiconductor process

ActiveUS20060032443A1Low dielectric constantImprove corrosion resistanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesProcess engineering

An impurity-doped silicon nitride or oxynitride film is formed on a target substrate by CVD, in a process field to be selectively supplied with a first process gas containing a silane family gas, a second process gas containing a nitriding or oxynitriding gas, and a third process gas containing a doping gas. This method alternately includes first to fourth steps. The first step performs supply of the first and third process gases to the field. The second step stops supply of the first to third process gases to the field. The third step performs supply of the second process gas to the field while stopping supply of the first and third process gases to the field, and includes an excitation period of exciting the second process gas by an exciting mechanism. The fourth step stops supply of the first to third process gases to the field.

Owner:TOKYO ELECTRON LTD

High-nitrogen austenitic stainless steel

InactiveUS20060034724A1High strengthExcellent corrosion resistanceAustenitic stainless steelAl content

This invention provides a high-nitrogen austenitic stainless steel superior to the conventional one both in the corrosion resistance and strength, despite a low Ni content, characterized in having a Fe content of 50% by mass or more; containing Cr: 15.0% by mass to 35.0% by mass, Mo: 0.05% by mass to 8.0% by mass %, Mn: 0.2% by mass to 10.0% by mass, Cu: 0.01% by mass to 4.0% by mass and N: 0.8% by mass to 1.5% by mass, both ends inclusive, having a C content of 0.20% by mass or less, a Si content of 2.0% by mass or less, a P content of 0.03% by mass or less, a S content of 0.05% by mass or less, a Ni content of 0.5% by mass or less, an Al content of 0.03% by mass or less, and an 0 content of 0.020% by mass or less; wherein the contents of Cr, Mo, N and Mn are adjusted so that a compositional parameter η expressed by the equation: η≡(WCr+3.3WMo+16WN) / WMn where WCr is Cr content (% by mass), WMo is Mo content (% by mass) WN is N content (% by mass) and WMn is Mn content (% by mass) has a value of 5 or above. and optionally further containing either one of, or both of: W: 0.01% by mass to 1.0% by mass; and Co: 0.01% by mass to 5.0% by mass, both ends inclusive; and optionally further containing at least one of: Ti: 0.01% by mass to 0.5% by mass; Nb: 0.01% by mass to 0.5% by mass; V: 0.01% by mass to 1.0% by mass; and Ta: 0.01% by mass to 0.5% by mass, both ends inclusive; and optionally further containing at least one of: B: 0.001% by mass to 0.01% by mass; Zr: 0.01% by mass to 0.50% by mass; Ca: 0.001% by mass to 0.01% by mass; and Mg: 0.001% by mass to 0.01% by mass, both ends inclusive; and optionally further containing either one of, or both of: Te: 0.005% by mass to 0.05% by mass; and Se: 0.01% by mass to 0.20% by mass, both ends inclusive.

Owner:DAIDO STEEL CO LTD

Micro-emulsion type metal cutting liquor composition

InactiveCN101240217AEasy to handleImprove the lubrication effectAdditivesBase-materialsMaterials scienceCutting fluid

Disclosed is a microemulsifying metal-cutting-fluid composition, comprising base oil or oily agent, mixed alcohol-amine, boric acid, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative, deionized water and the like. The invention has the advantages of excellent lubricity, cooling ability, cleaning ability and a long lifetime of metal cutting fluid, being suited to various metal processing technologies such as cutting, reaming, boring, grinding. Also, the wastewater is easy to treat.

Owner:益田润石(北京)化工有限公司

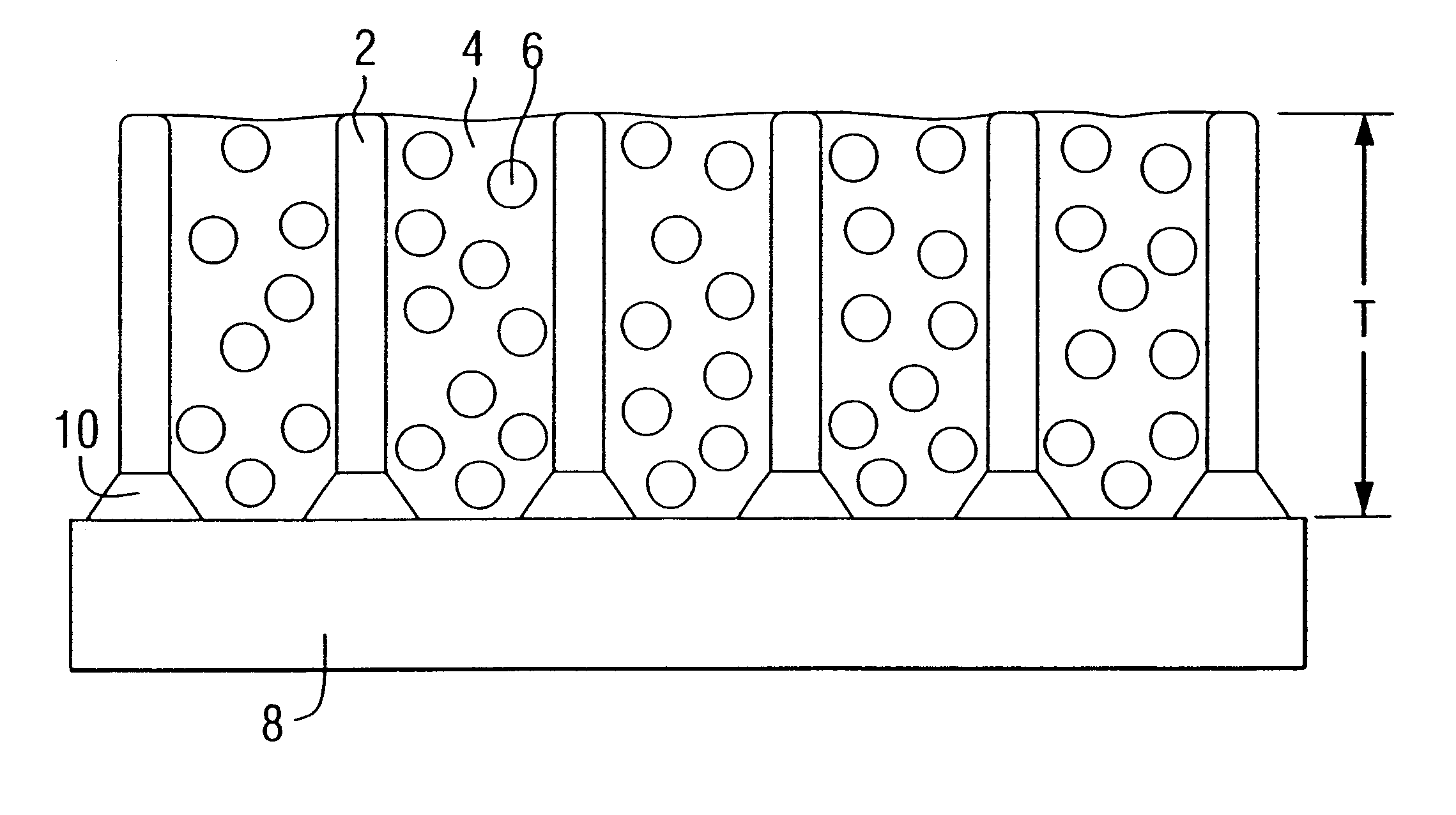

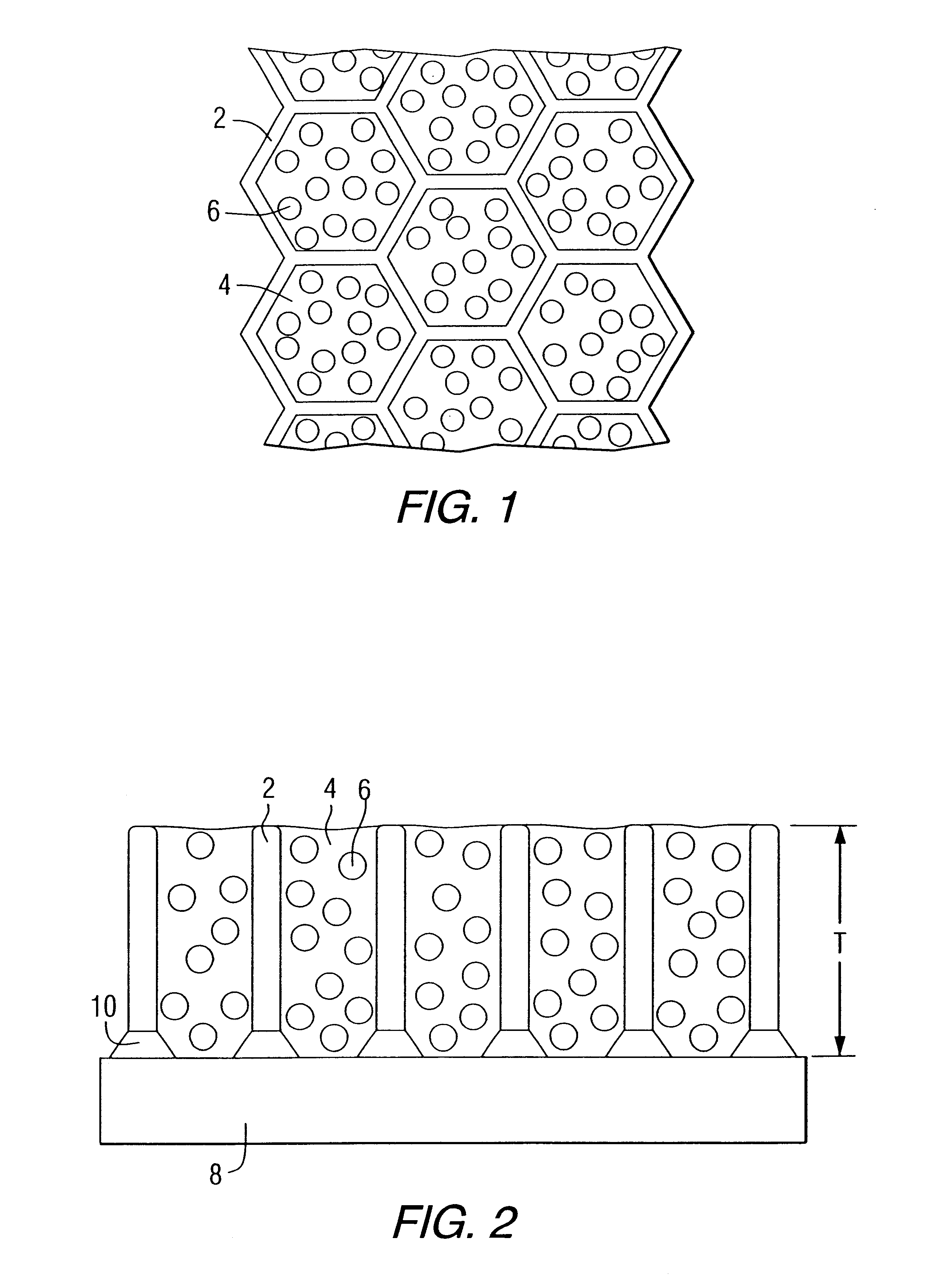

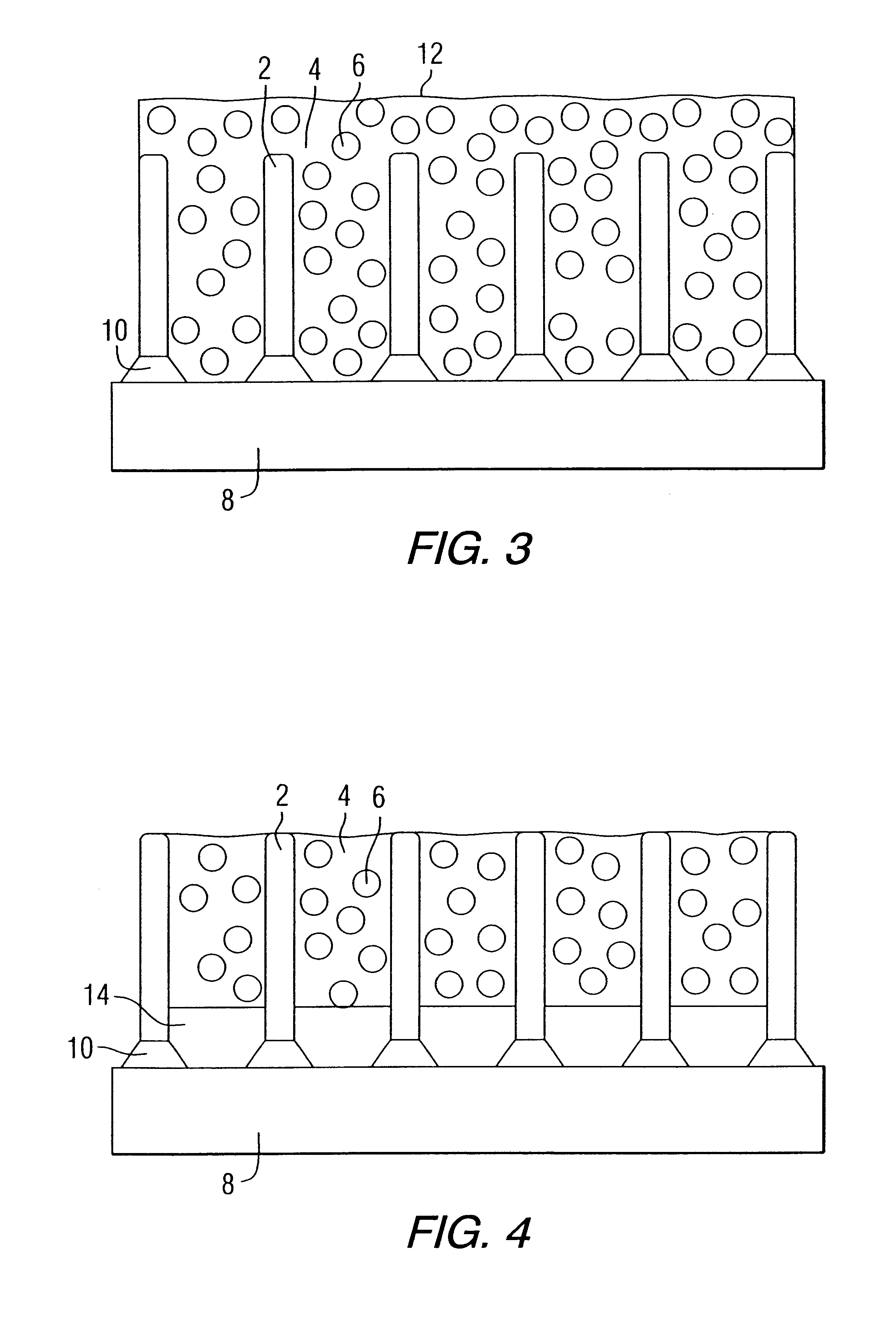

High temperature erosion resistant, abradable thermal barrier composite coating

InactiveUS6235370B1Improve wear resistanceImprove adhesionMolten spray coatingPump componentsCombustorHoneycomb

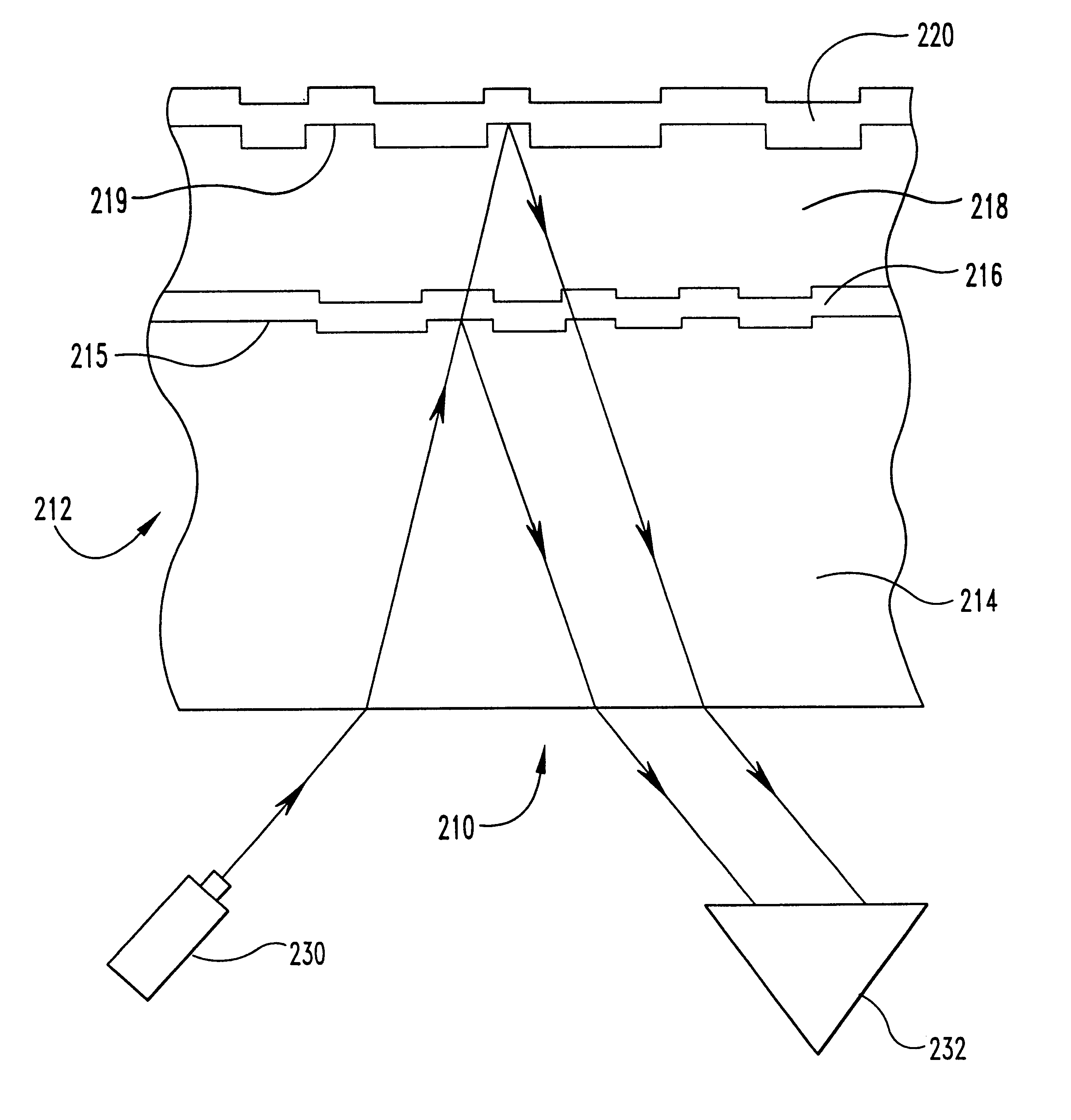

A composite thermal barrier coating system includes a honeycomb metallic structure filled with high thermal expansion ceramic hollow spheres in a phosphate bonded matrix. The composite thermal barrier coating system may be manufactured to thicknesses in excess of current thermal barrier coating systems, thereby imparting greater thermal protection. Superior erosion resistance and abrasion properties are also achieved. The composite thermal barrier coating is useful on combustion turbine components such as ring seal segments, vane segment shrouds, transitions and combustors.

Owner:SIEMENS ENERGY INC

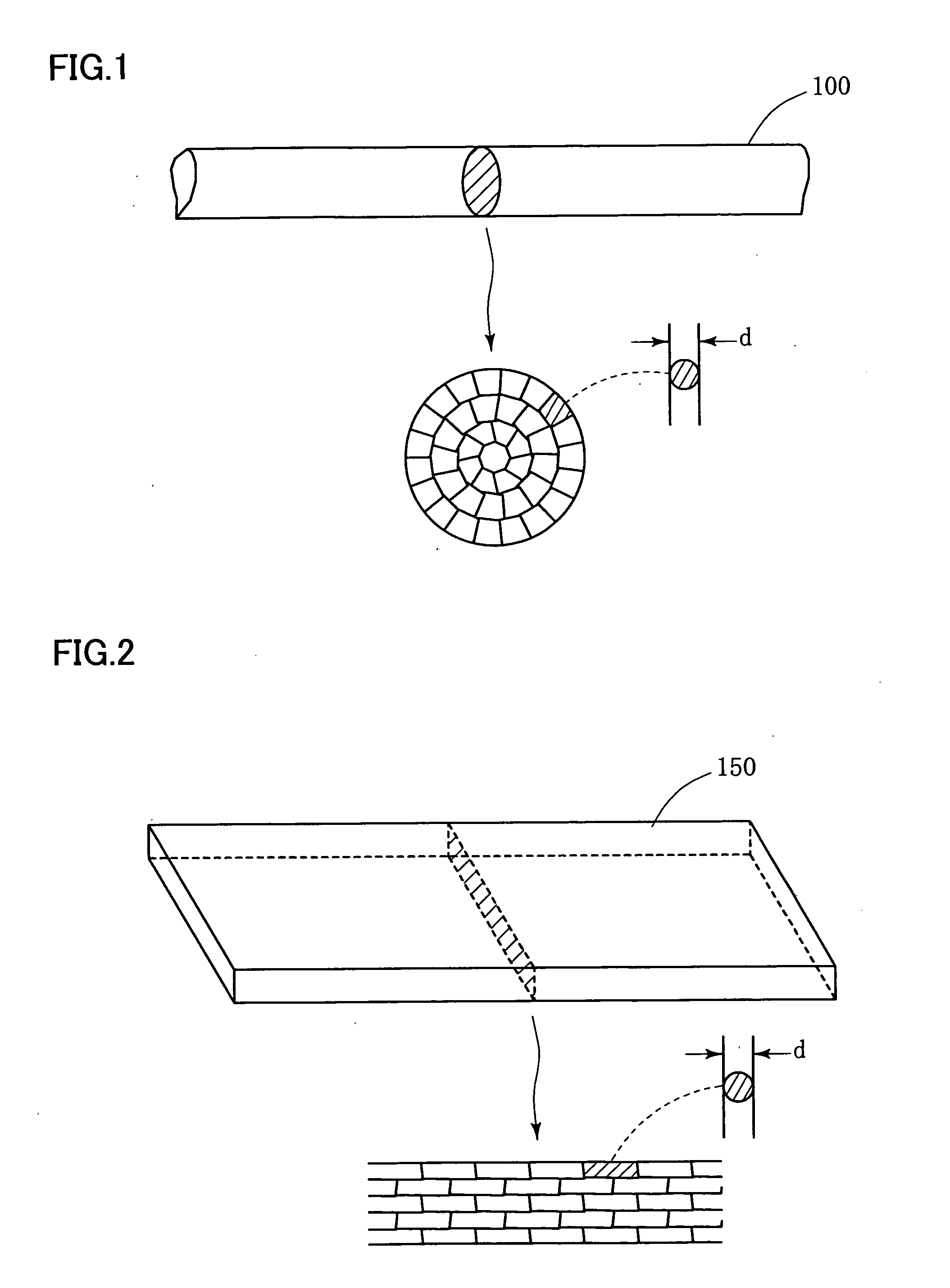

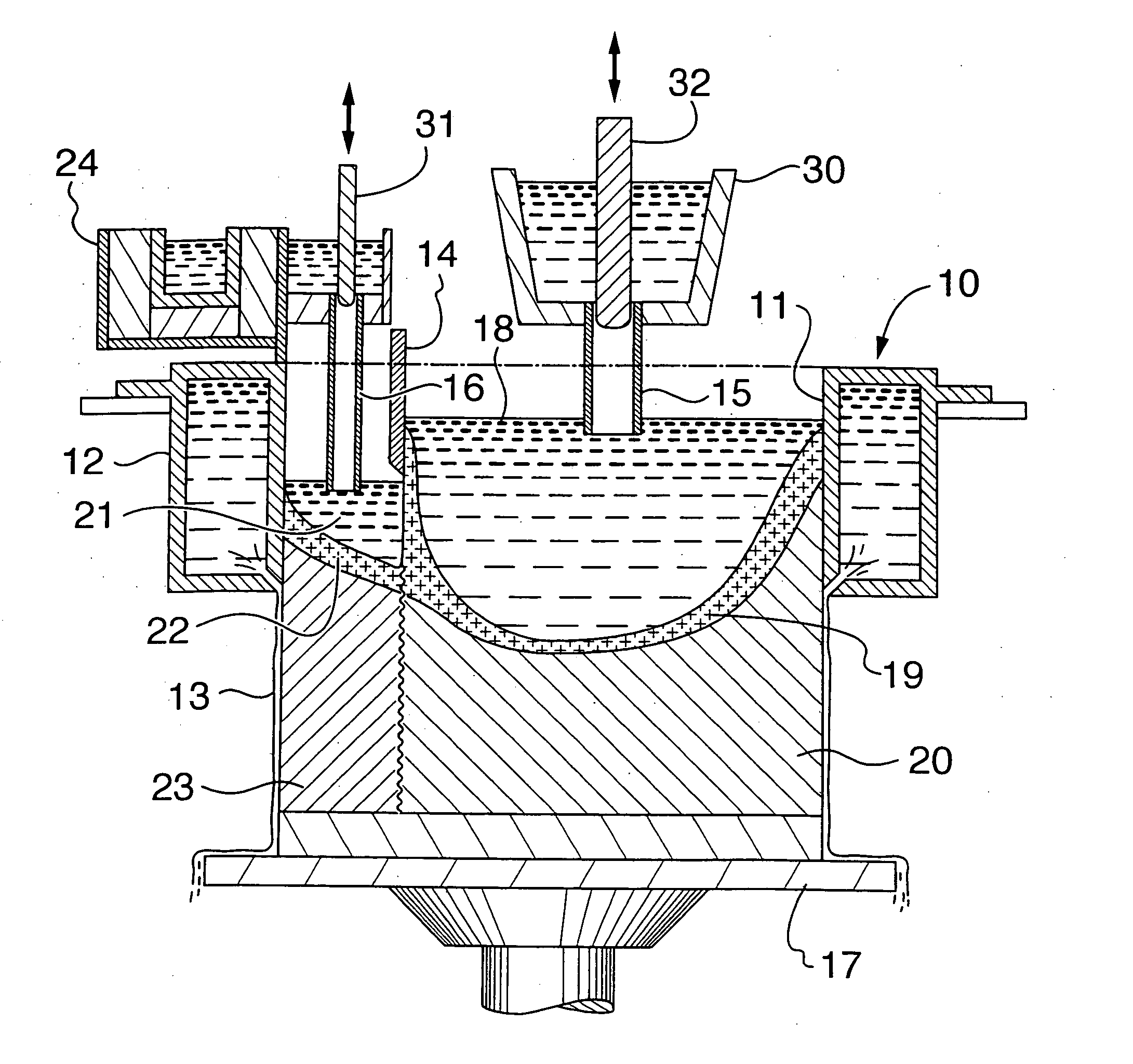

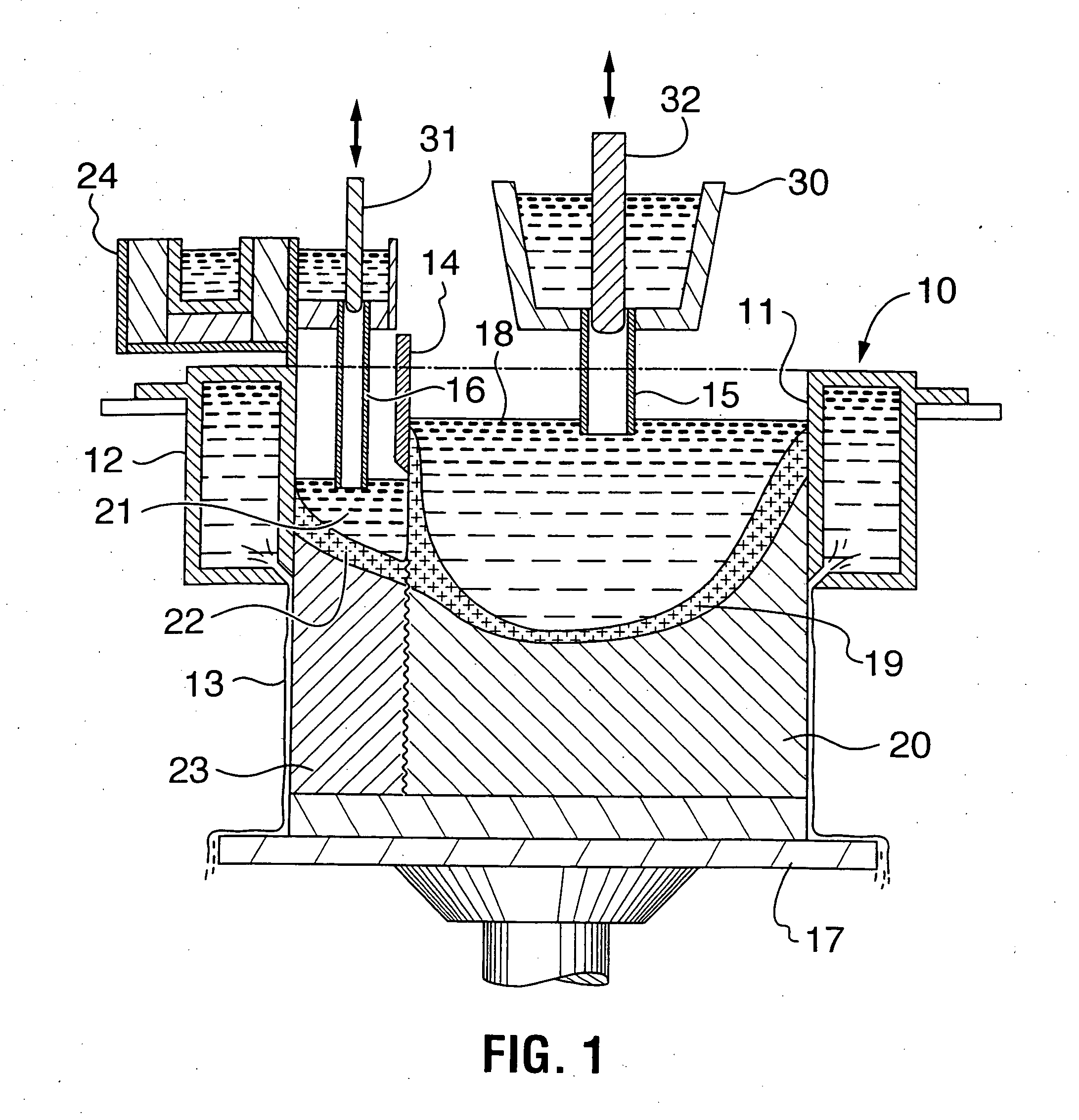

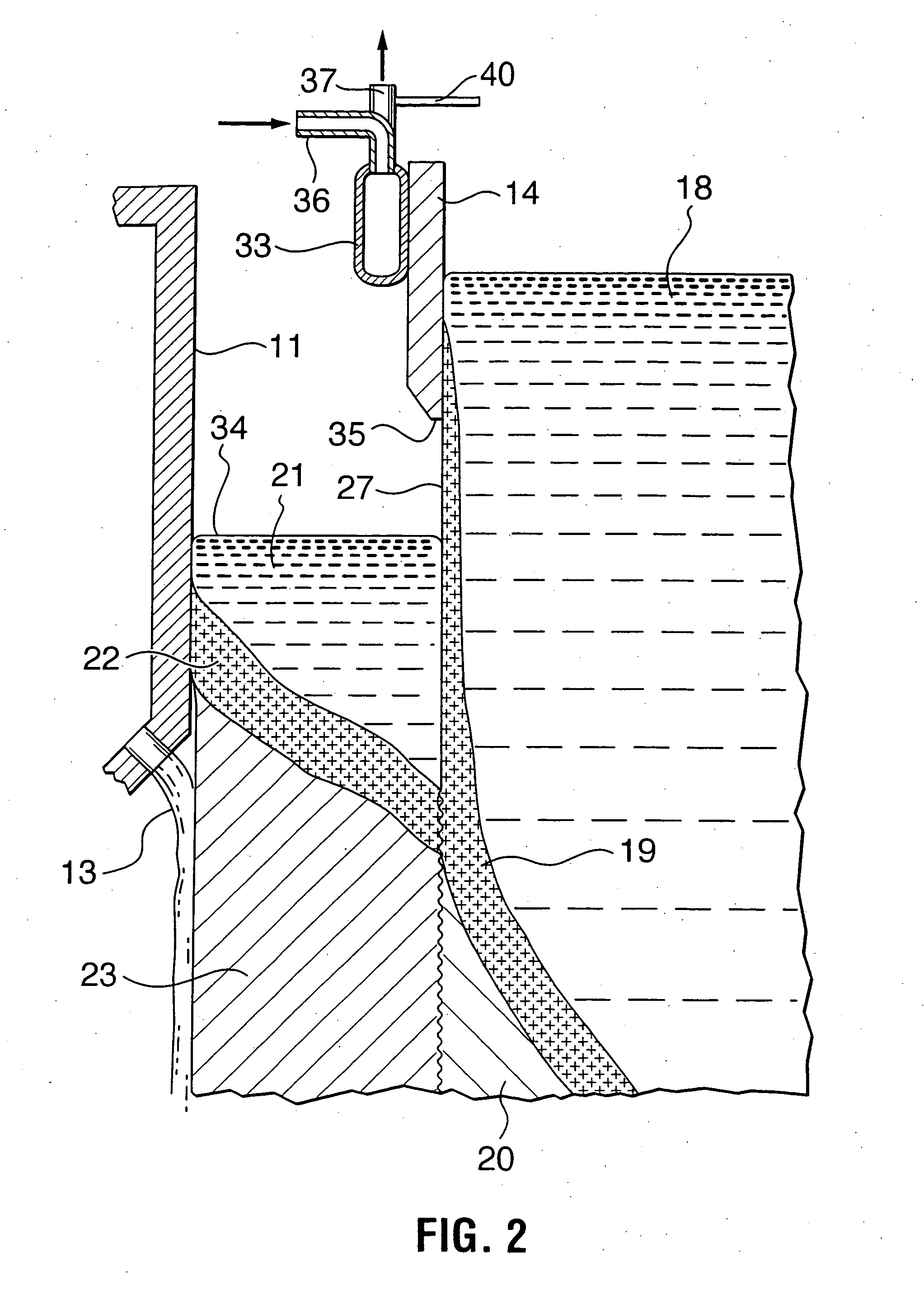

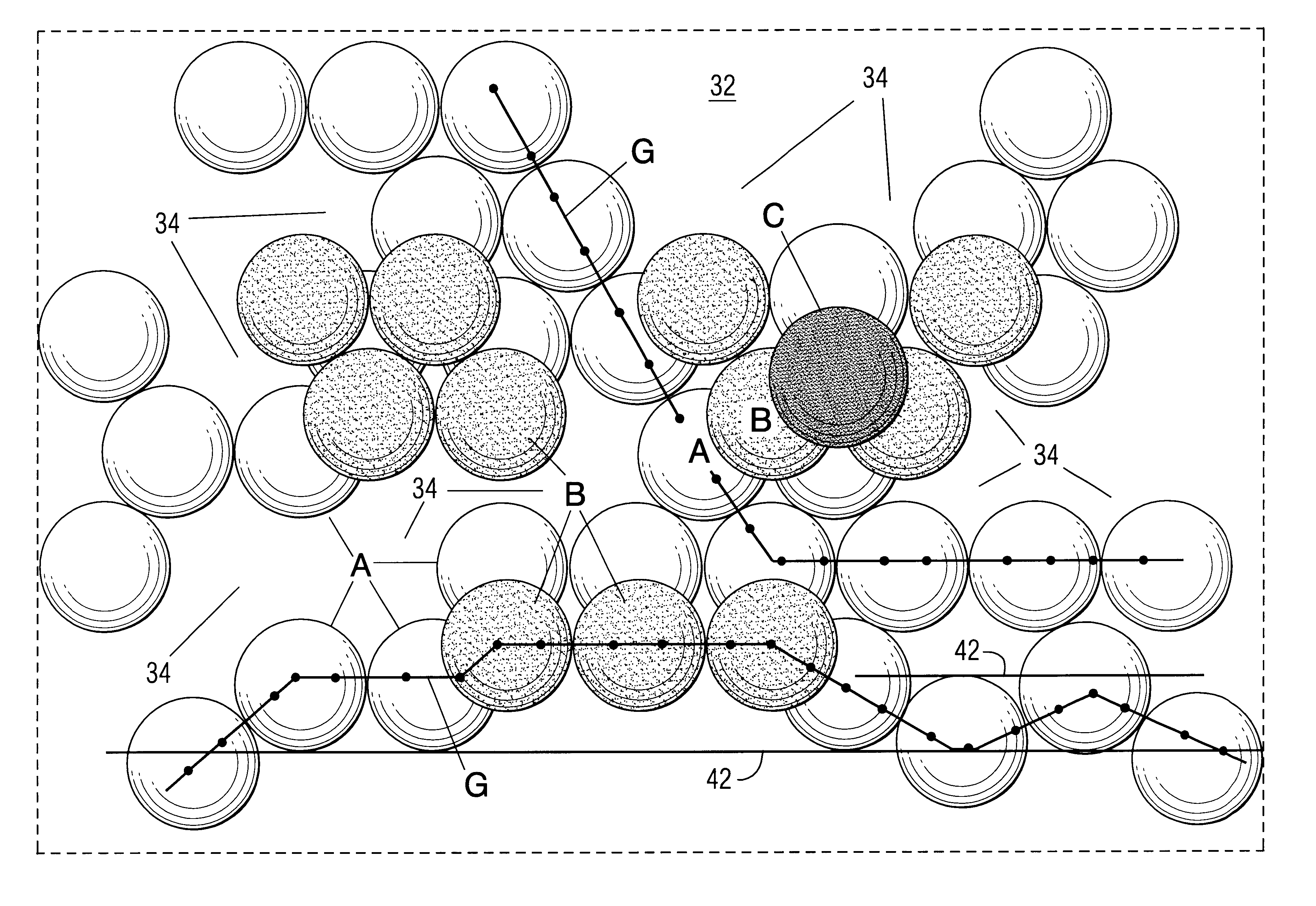

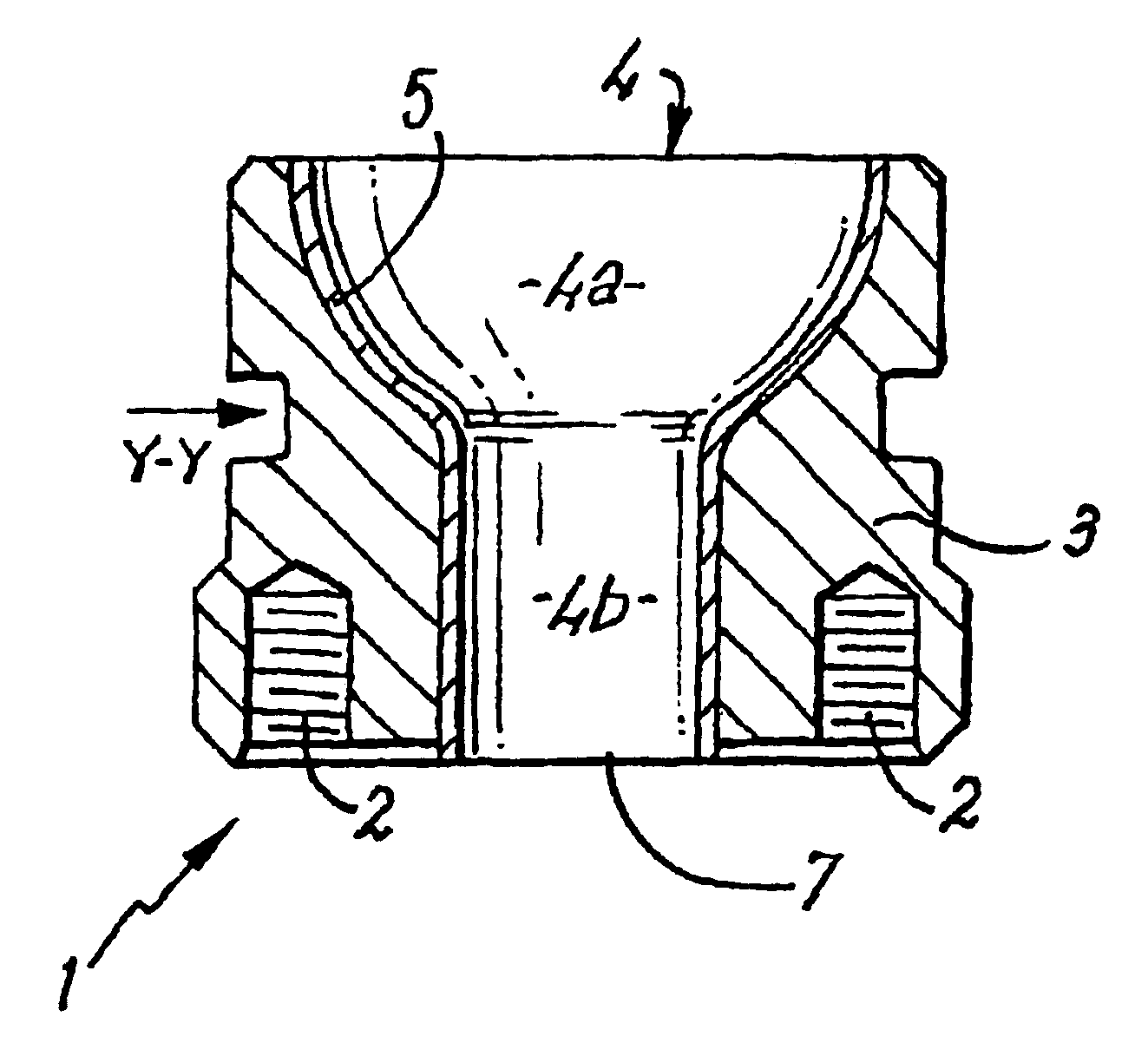

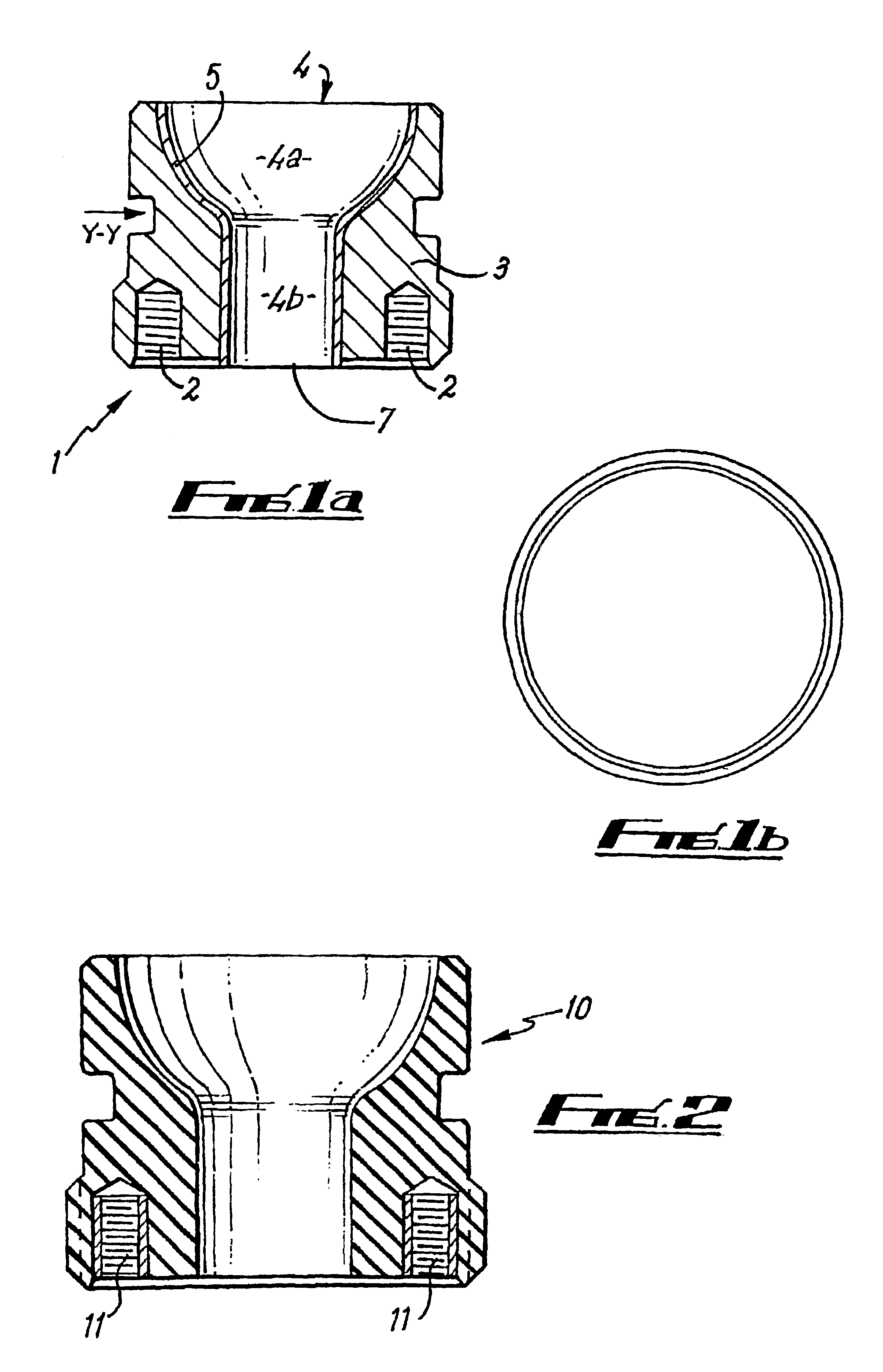

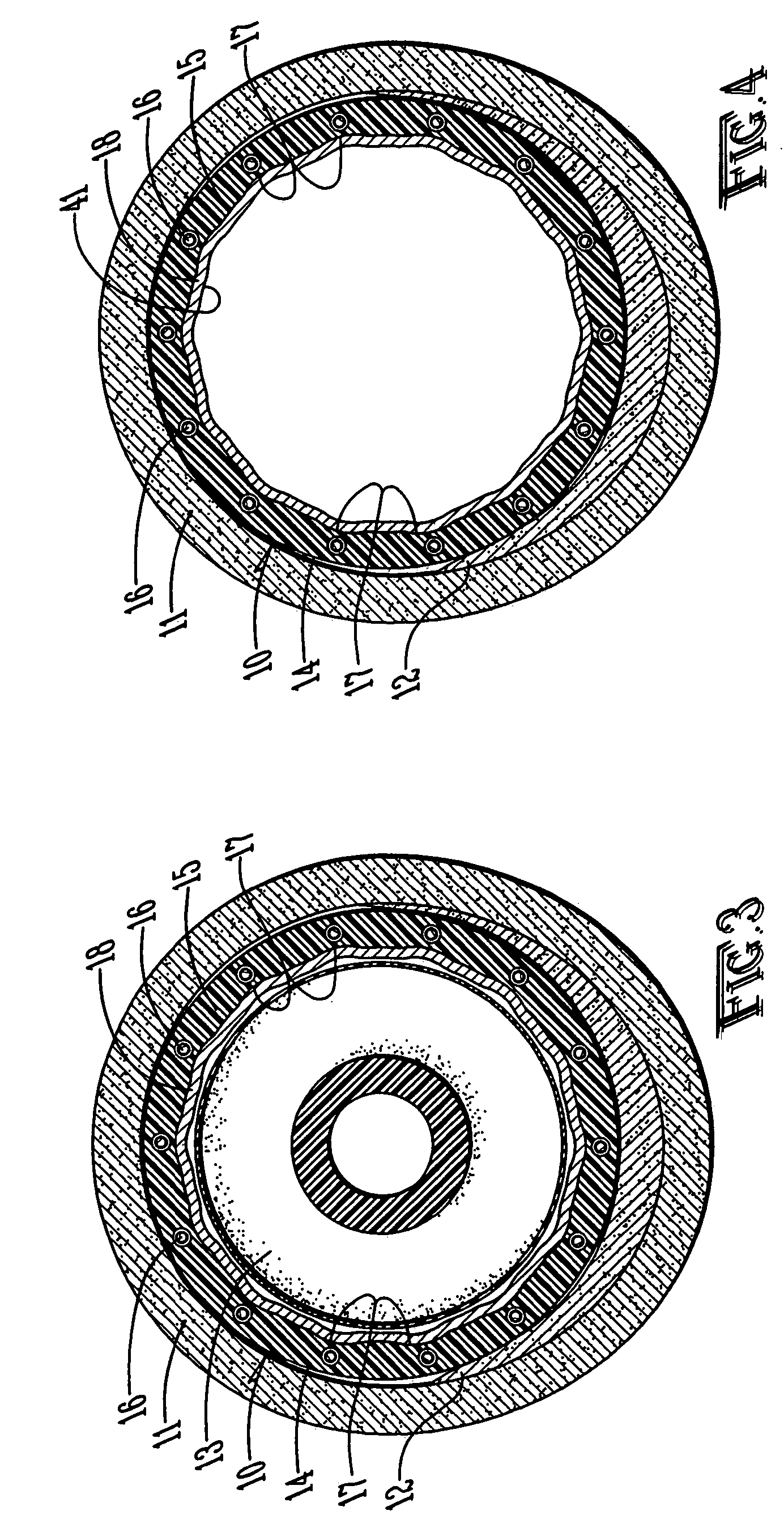

Method for casting composite ingot

ActiveUS20050011630A1Easy to controlImprove corrosion resistanceThin material handlingIngotMaterials science

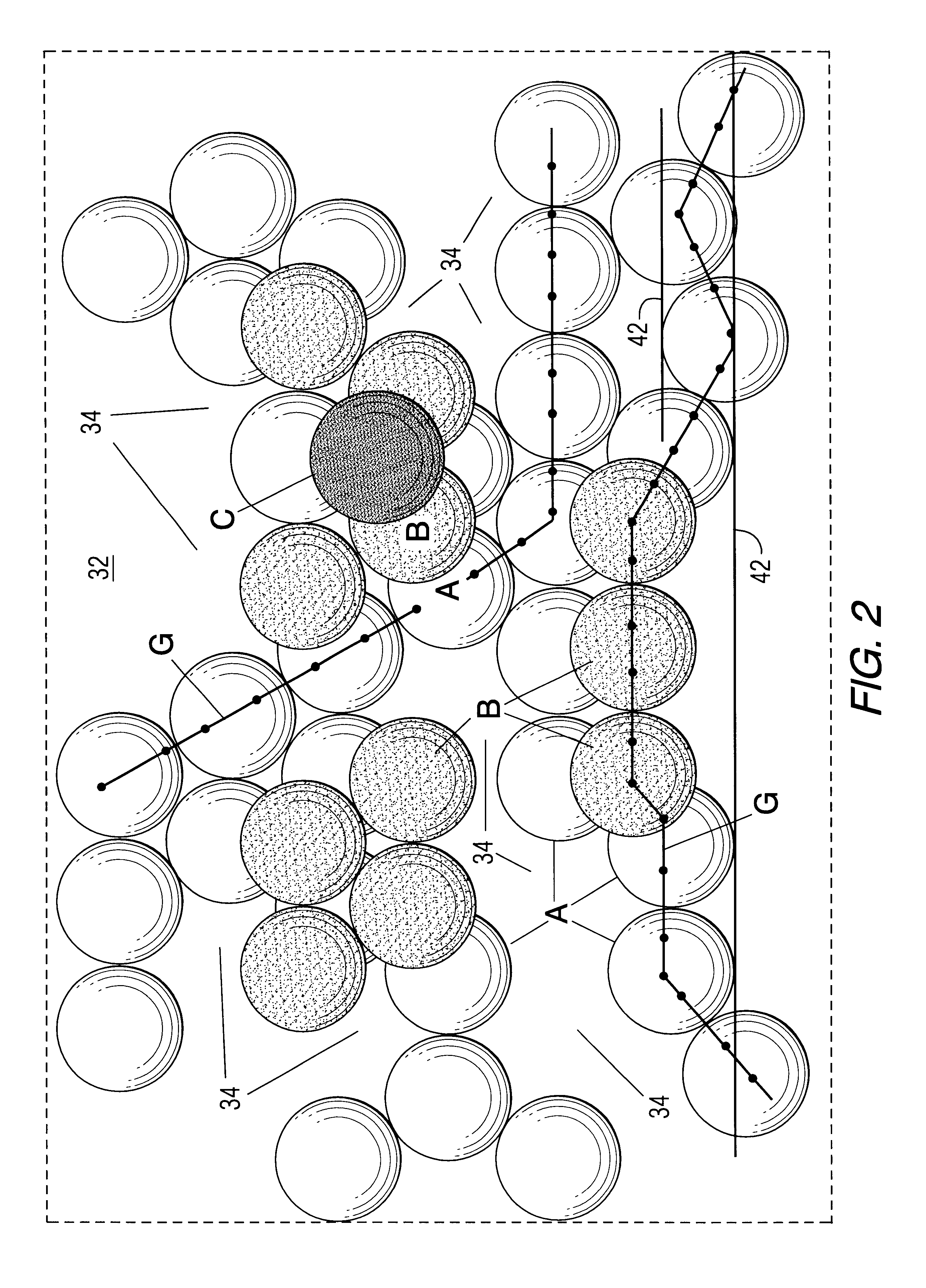

A method and apparatus are described for the casting of a composite metal ingot comprising at least two separately formed layers of one or more alloys. An open ended annular mould has a feed end and an exit end and divider wall for dividing the feed end into at least two separate feed chambers, where each feed chamber is adjacent at least one other feed chamber. For each pair of adjacent feed chambers a first alloy stream is fed through one of the pair of feed chambers into the mould and a second alloy stream is fed through another of the feed chambers. A self-supporting surface is generated on the surface of the first alloy stream and the second alloy stream is contacted with the first stream such that the upper surface of the second alloy stream is maintained at a position such that it first contacts the self-supporting surface where the self-supporting surface temperature is between the liquidus and solidus temperatures of the first alloy or it first contacts the self-supporting surface where the self-supporting surface temperature is below the solidus temperatures of the first alloy but the interface between the two alloys is then reheated to between the liquidus and solidus temperatures, whereby the two alloy streams are joined as two layers. The joined alloy layers are then cooled to form a composite ingot. This composite ingot has a substantially continuous metallurgical bond between alloy layers with dispersed particles of one or more intermetallic compositions of the first alloy in a region of the second alloy adjacent the interface.

Owner:NOVELIS INC

Cement compositions with improved corrosion resistance and methods of cementing in subterranean formations

InactiveUS6904971B2Improve corrosion resistanceSolid waste managementDrilling compositionPhosphateSlurry

Owner:HALLIBURTON ENERGY SERVICES INC

High temperature erosion resistant coating and material containing compacted hollow geometric shapes

InactiveUS6641907B1Improve corrosion resistanceReduce void volumeEngine manufactureBlade accessoriesPorosityMetallurgy

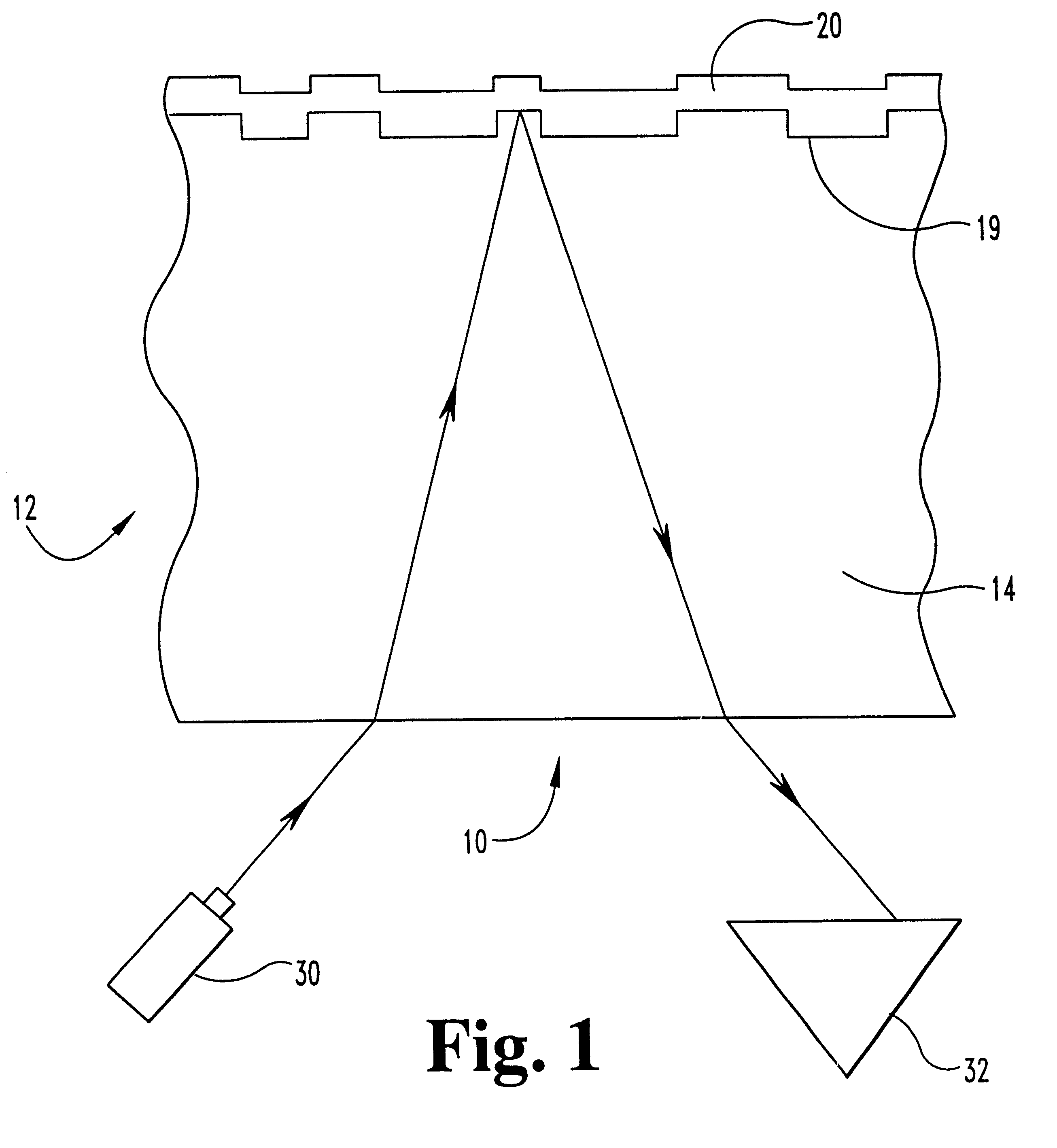

A material system (60) contains close packed hollow shapes (50, 70) having a dense wall structure (52, 66), which are bonded together and which may contain a matrix binder material (56) between the shapes, where the system has a stable porosity, and is abradable and thermally stable at temperatures up to possibly 1700° C., where such systems are useful in turbine apparatus.

Owner:SIEMENS ENERGY INC

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS6280811B1Moderate to high reflectivityImprove corrosion resistancePhotosensitive materialsRadiation applicationsIridiumMagnesium

A copper-based or silver-based alloy thin film is provided for the highly reflective or semi-reflective layer of optical discs. Alloy additions to silver include gold, palladium, copper, rhodium, ruthenium, osmium, iridium, beryllium and platinum. Alloy additions to copper include silver, cadmium, gold, magnesium, aluminum, beryllium, zirconium, and nickel. These alloys have moderate to high reflectivity and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

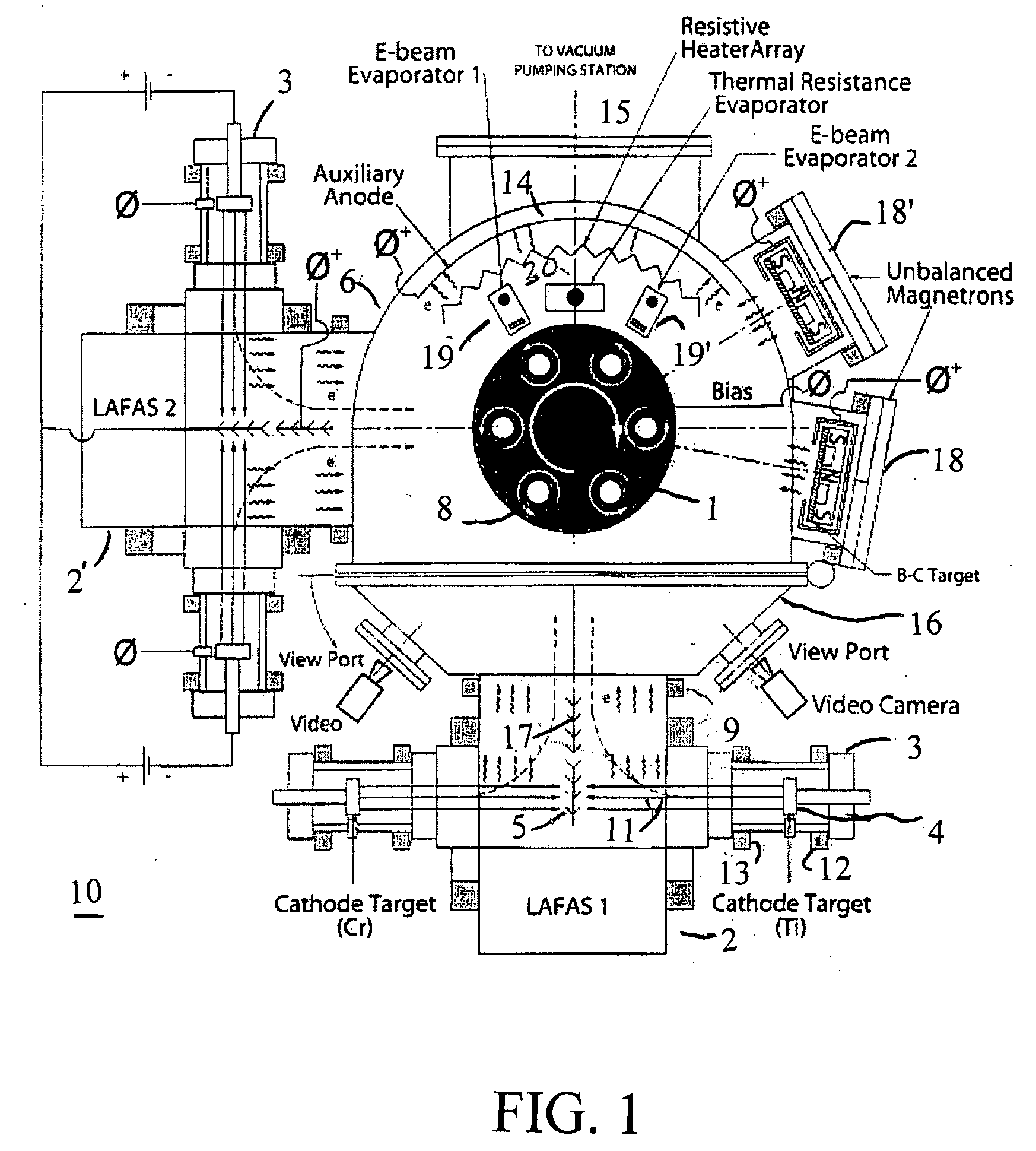

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS20070284255A1Stable cutting edgeReduce torsion fatiguePigmenting treatmentSurgeryWear resistantShape-memory alloy

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

Drillable drill bit nozzle

InactiveUS6848517B2Thin structureImprove corrosion resistanceDrill bitsDrilling rodsHigh resistanceRubber material

A drill bit nozzle providing a through bore for the passage of drilling fluid through a drill bit. The nozzle is made of a material or materials which can be drilled through by standard well bore drilling equipment. The material(s) are selected to provide a surface to the through bore which has a relatively high resistance to erosion to withstand the abrasive and corrosive impact of jetted drilling fluid. Embodiments are described using a hard chrome / copper combination and a single rubber material.

Owner:WEATHERFORD TECH HLDG LLC

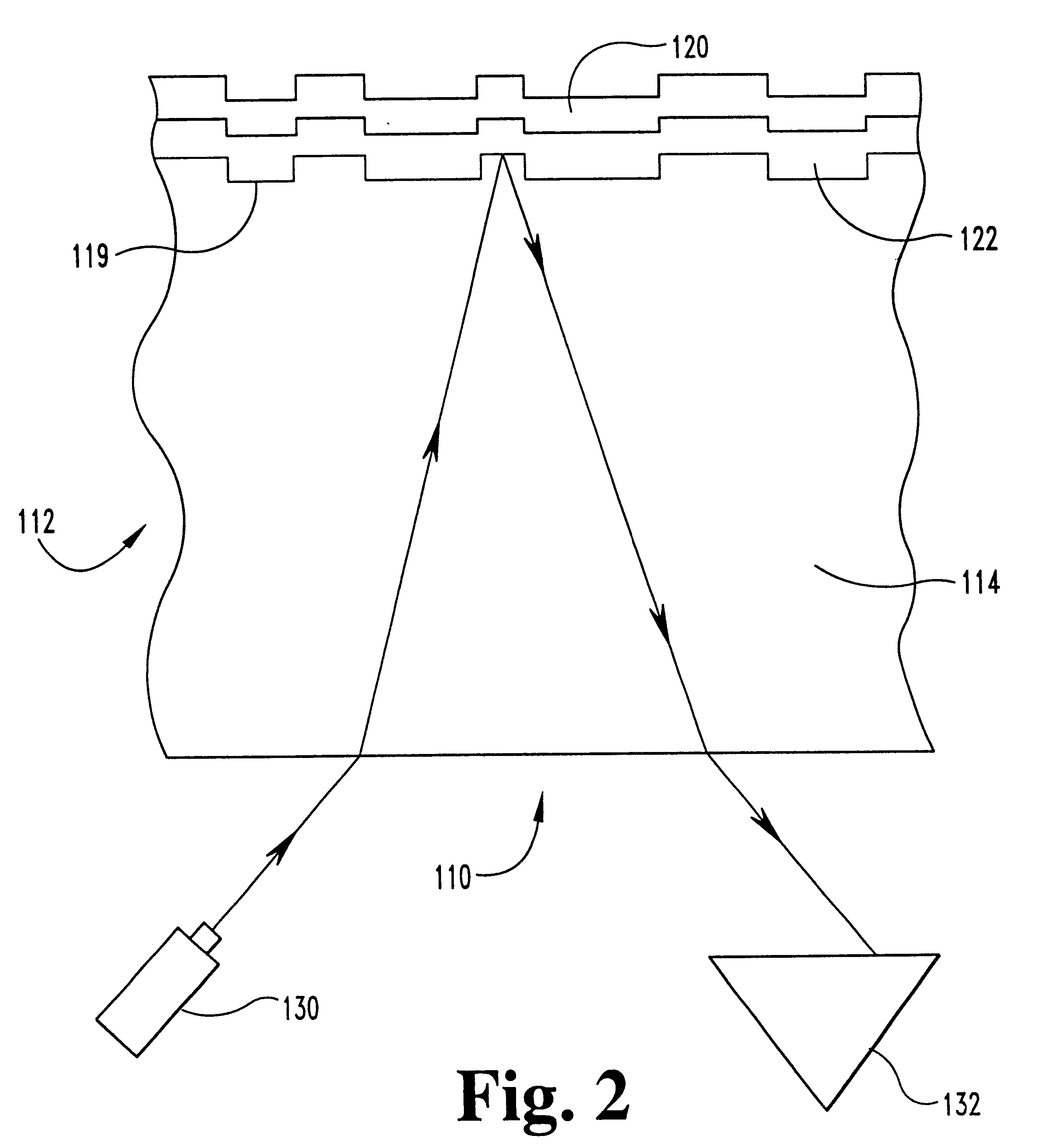

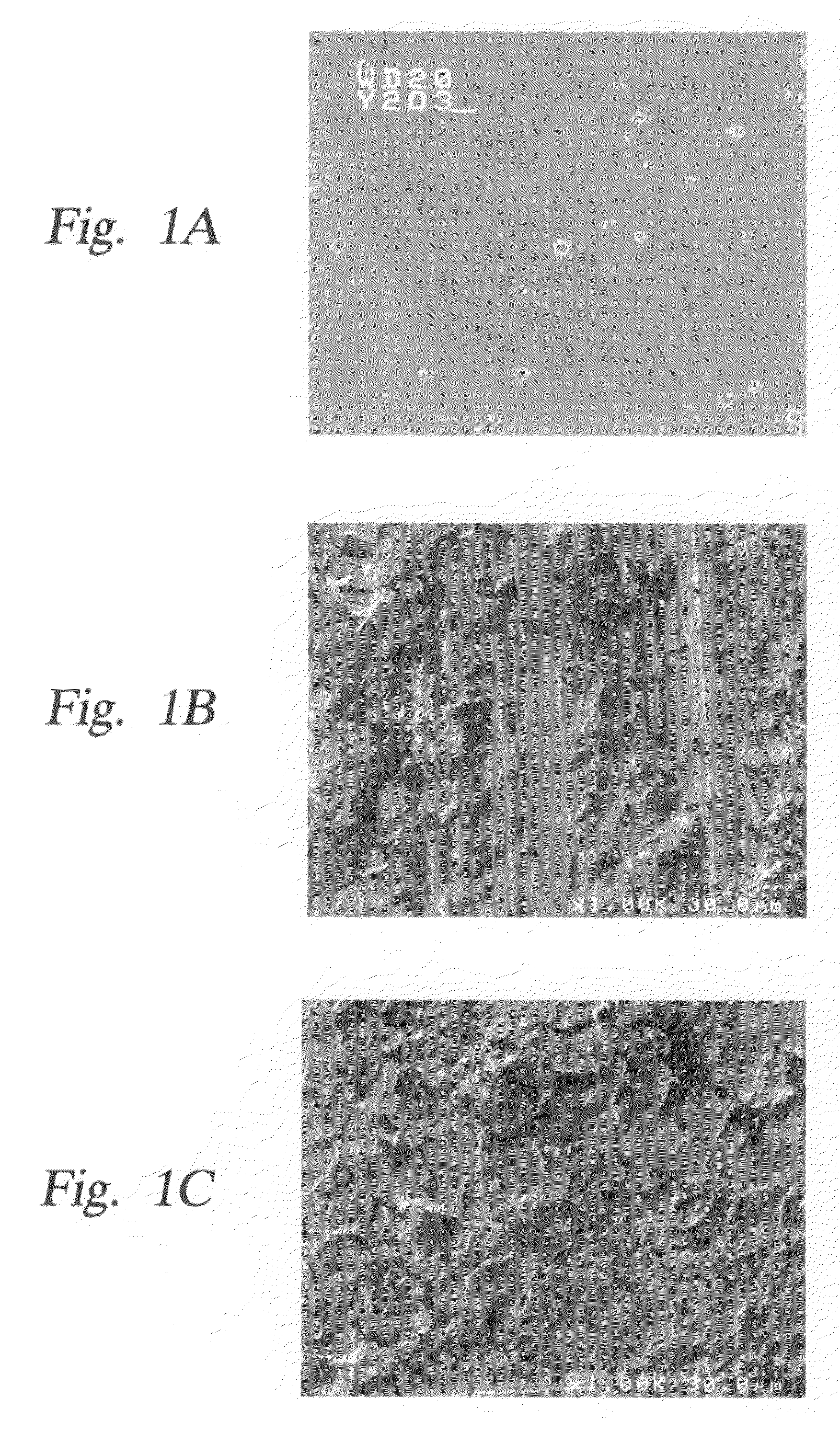

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

ActiveUS7696117B2Reduce erosion rateImprove mechanical propertiesElectric discharge tubesSemiconductor/solid-state device manufacturingErosion rateYttrium

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

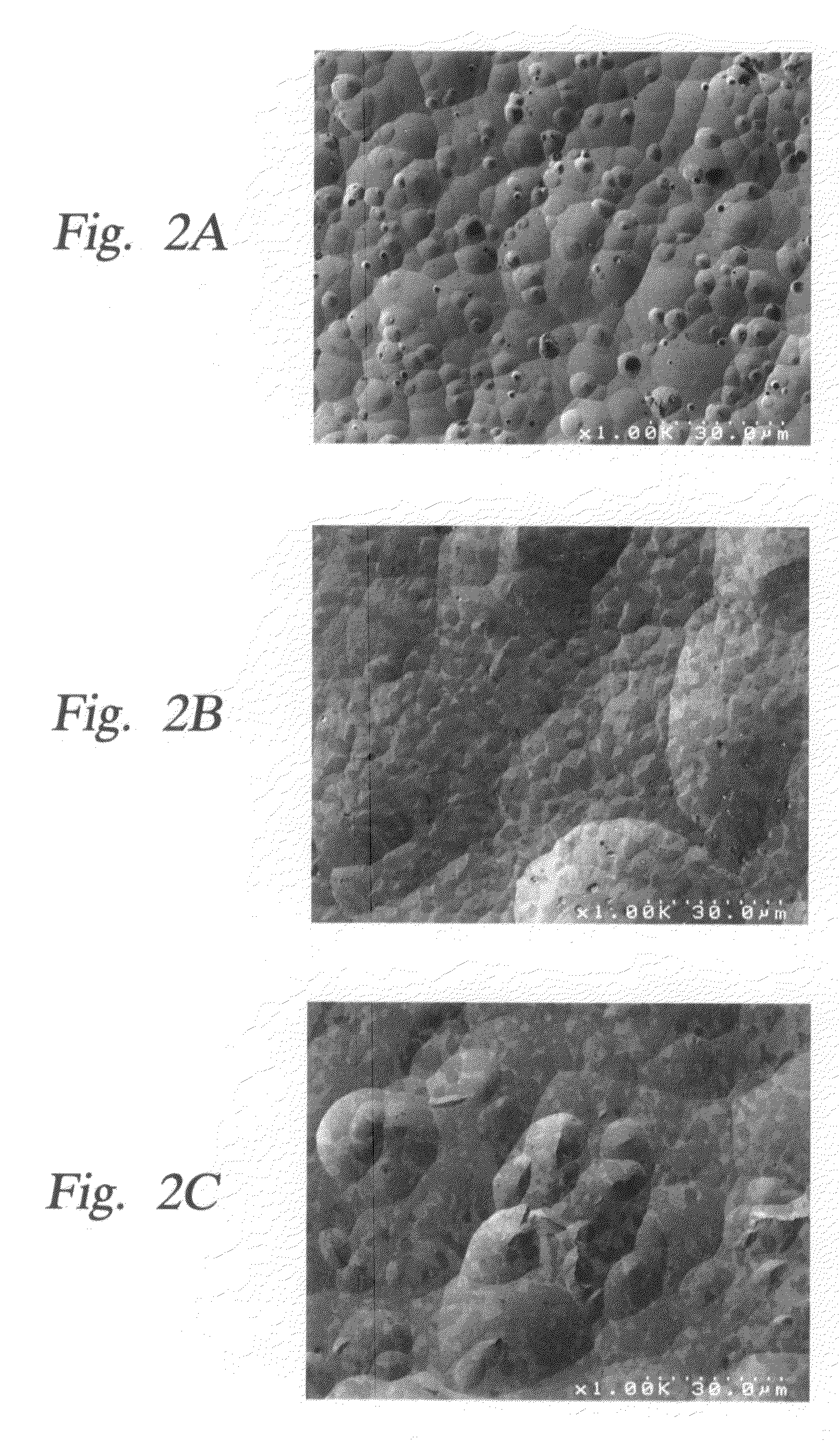

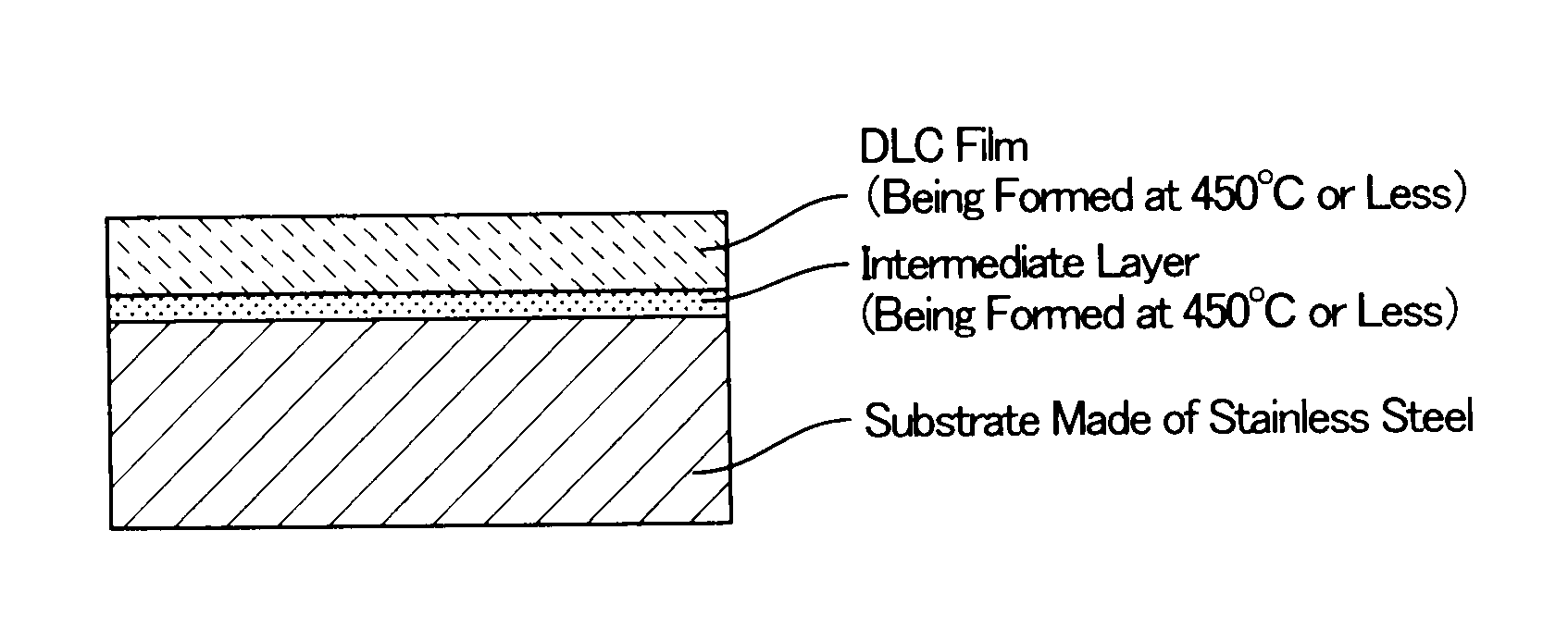

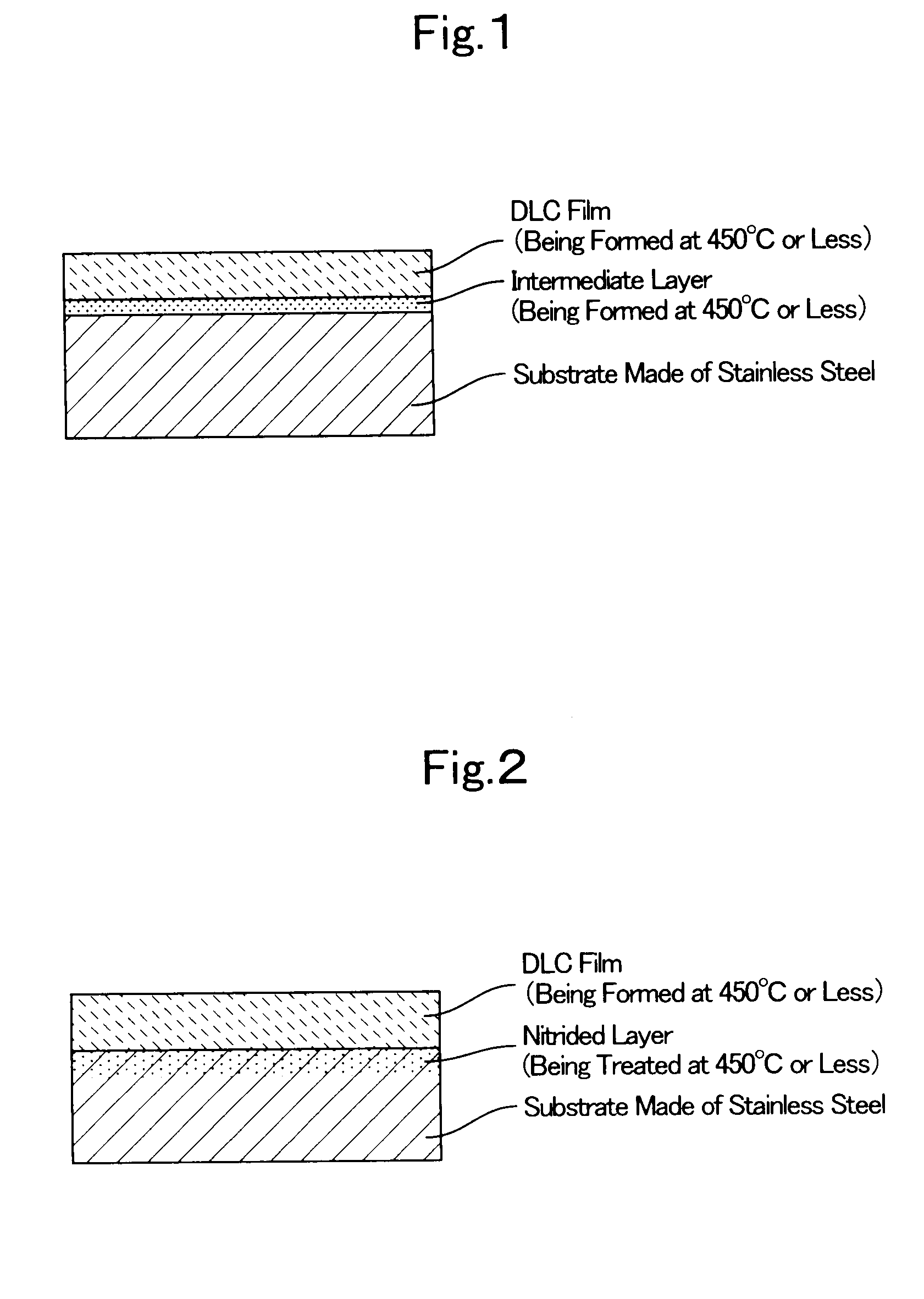

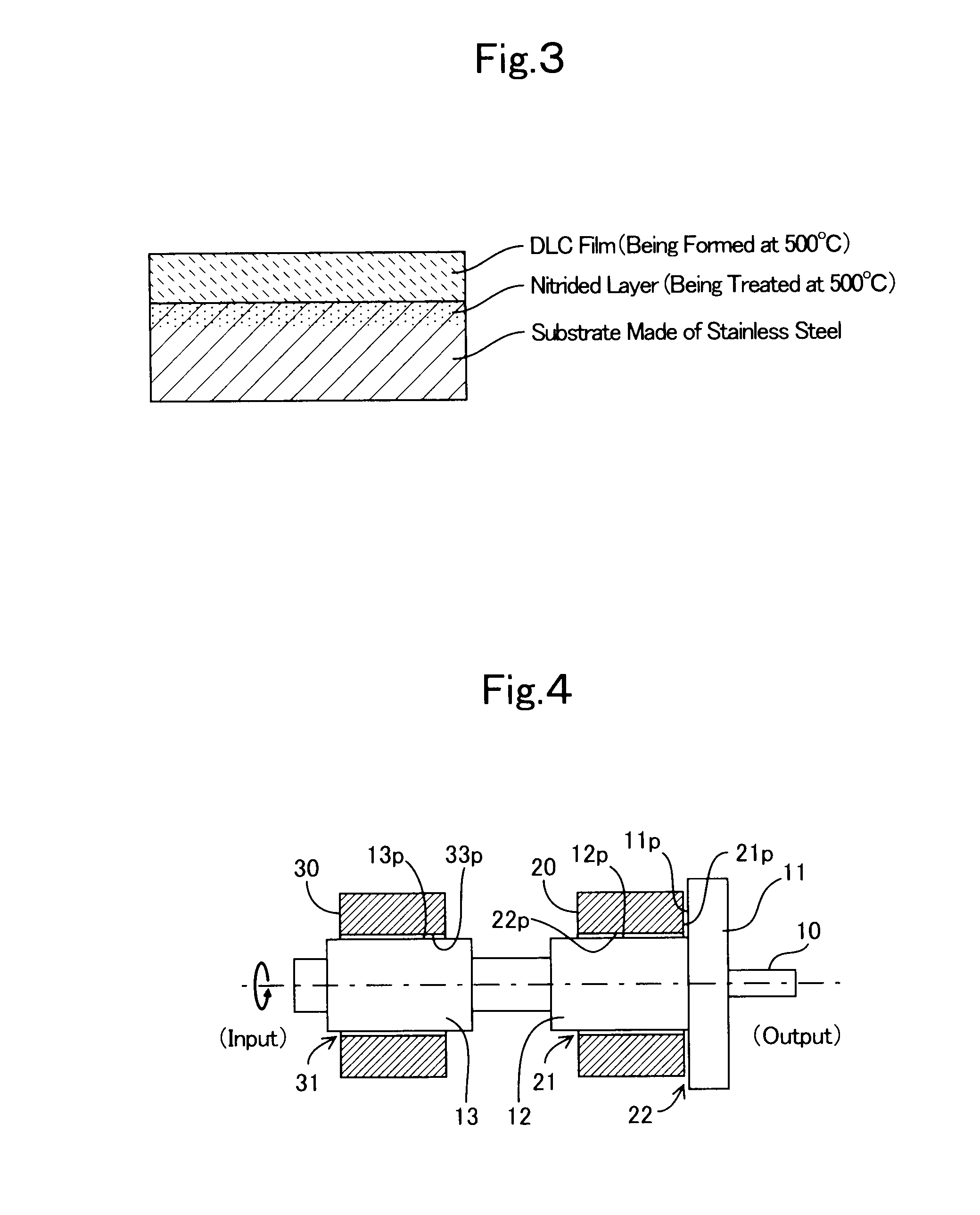

Highly corrosion-resistant member and manufacturing process for the same

InactiveUS20100314005A1Lower substrate resistanceInternal stress be generateLiquid surface applicatorsVacuum evaporation coatingCorrosion resistantAmorphous carbon

A highly corrosion-resistant member that is equipped with: a substrate made of stainless steel; an intermediate layer coated on at least a part of a surface of the substrate; and an amorphous carbon film coated on at least a part of a surface of the intermediate layer is completed by forming the intermediate layer and amorphous carbon film at such a low temperature that a temperature of the surface of the substrate is 450° C. or less. Another highly corrosion-resistant member that is equipped with: a substrate made of stainless steel, substrate whose superficial-layer portion is subjected to nitriding treatment; and an amorphous carbon film coated on at least a part of a surface of the superficial-layer portion is completed by carrying out the nitriding treatment and a formation of the amorphous carbon film at such a low temperature that a temperature of a surface of said substrate is 450° C. or less.In the aforementioned highly corrosion-resistant members, the surface of the substrate that is made of stainless steel is not exposed to high temperatures (>450° C.). Consequently, the corrosion resistance of the substrate is kept equivalent to the corrosion resistance of the original stainless steel that has not been exposed to any high temperature.

Owner:JTEKT CORP +1

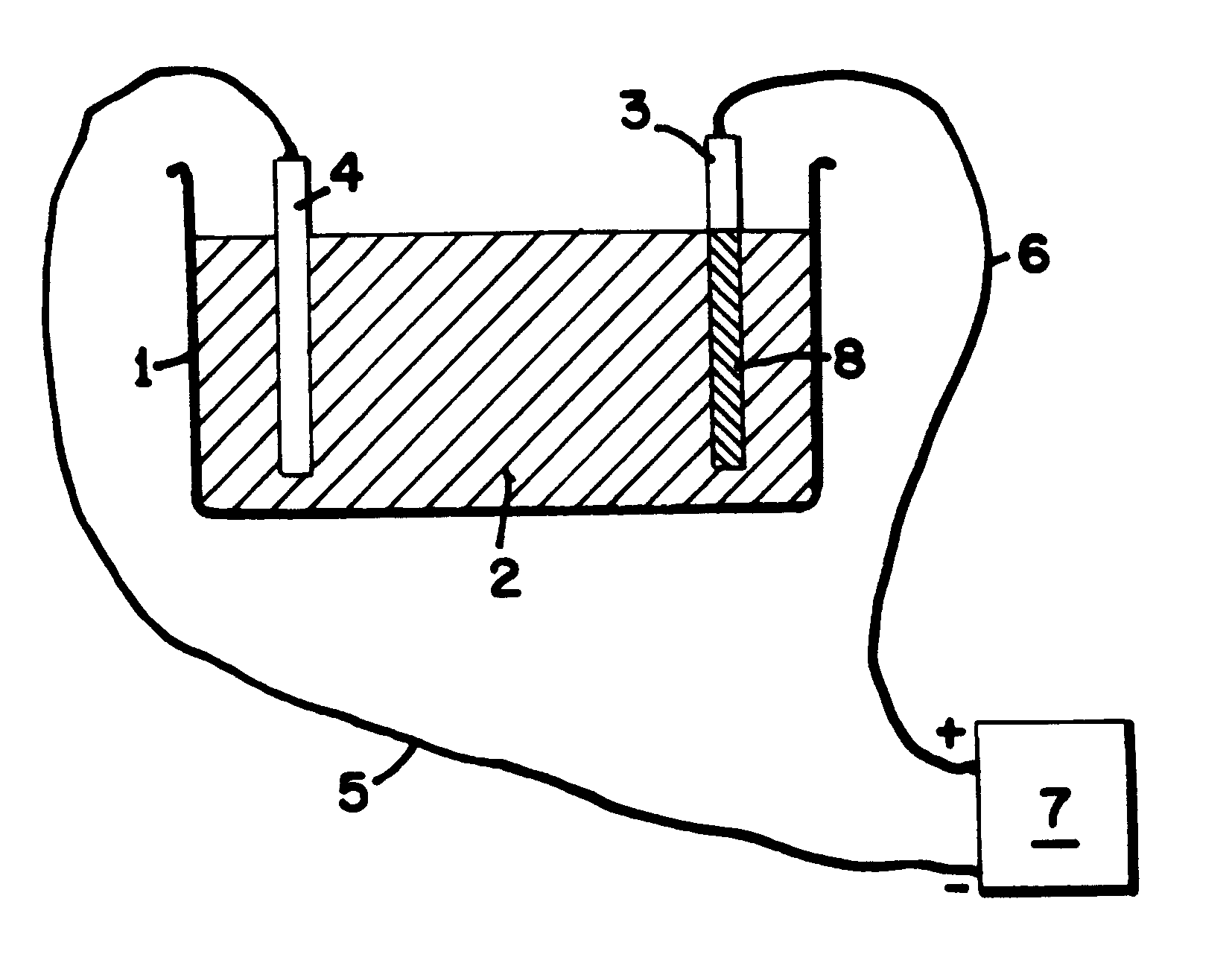

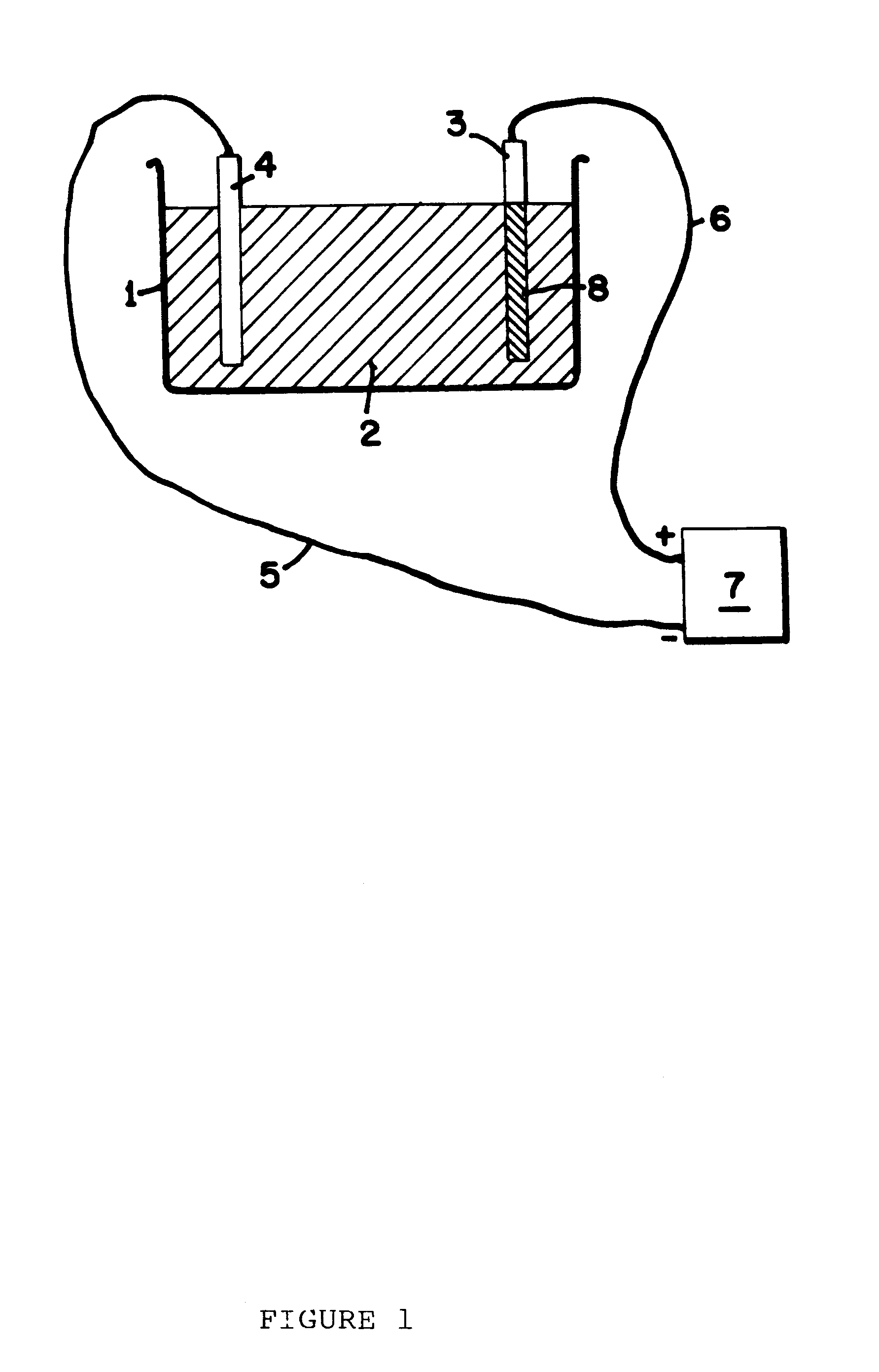

Anodization of magnesium and magnesium based alloys

This invention provides a method for the anodization of magnesium or magnesium based alloys using an electrolytic solution containing ammonia, amines or both. The use of such an aqueous electrolytic solution in at least preferred forms alters the conditions under which anodization can occur to provide a more than satisfactory coating on the magnesium material with reduced cycle times.

Owner:MAGNESIUM TECHNOLOGY LIMITED

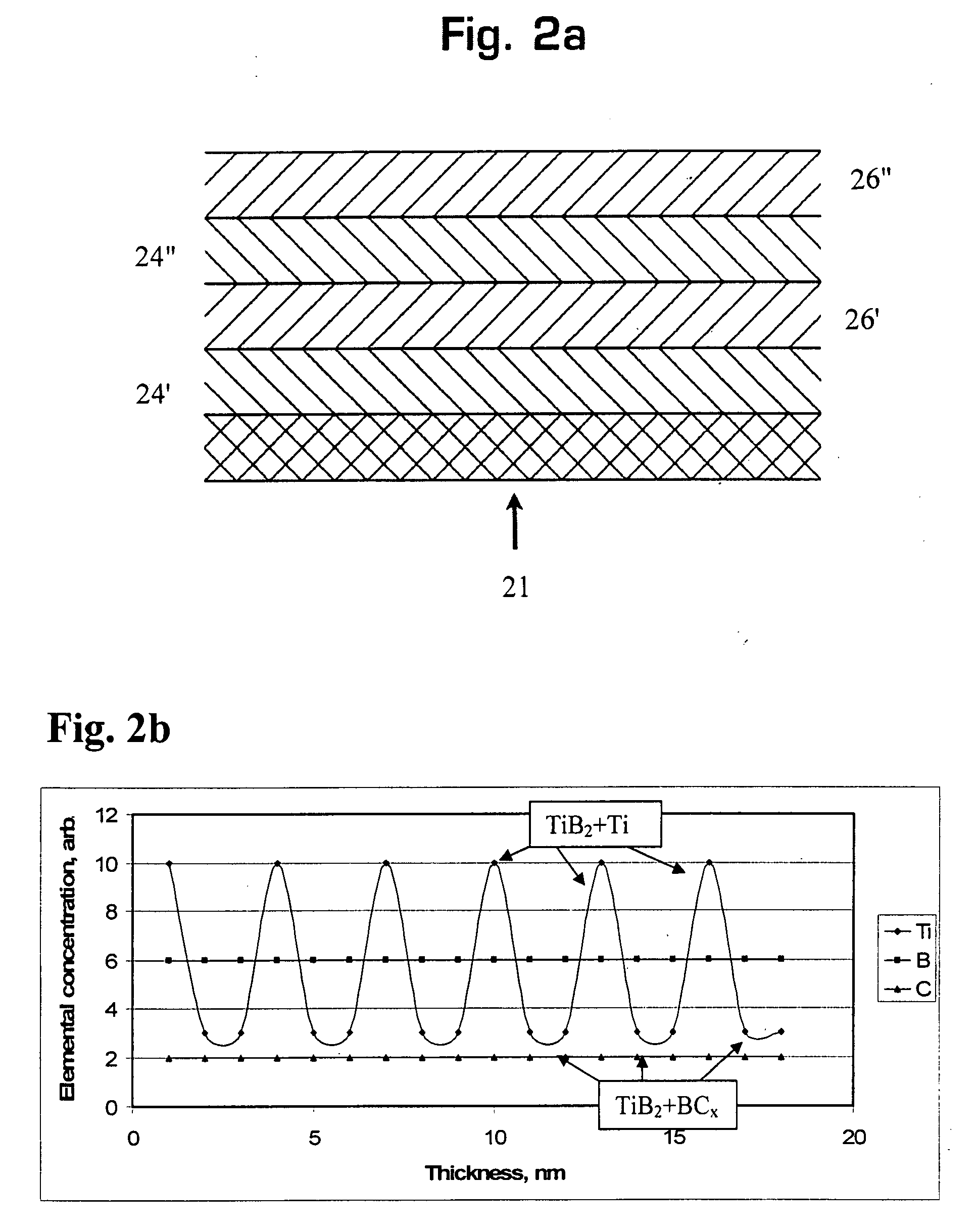

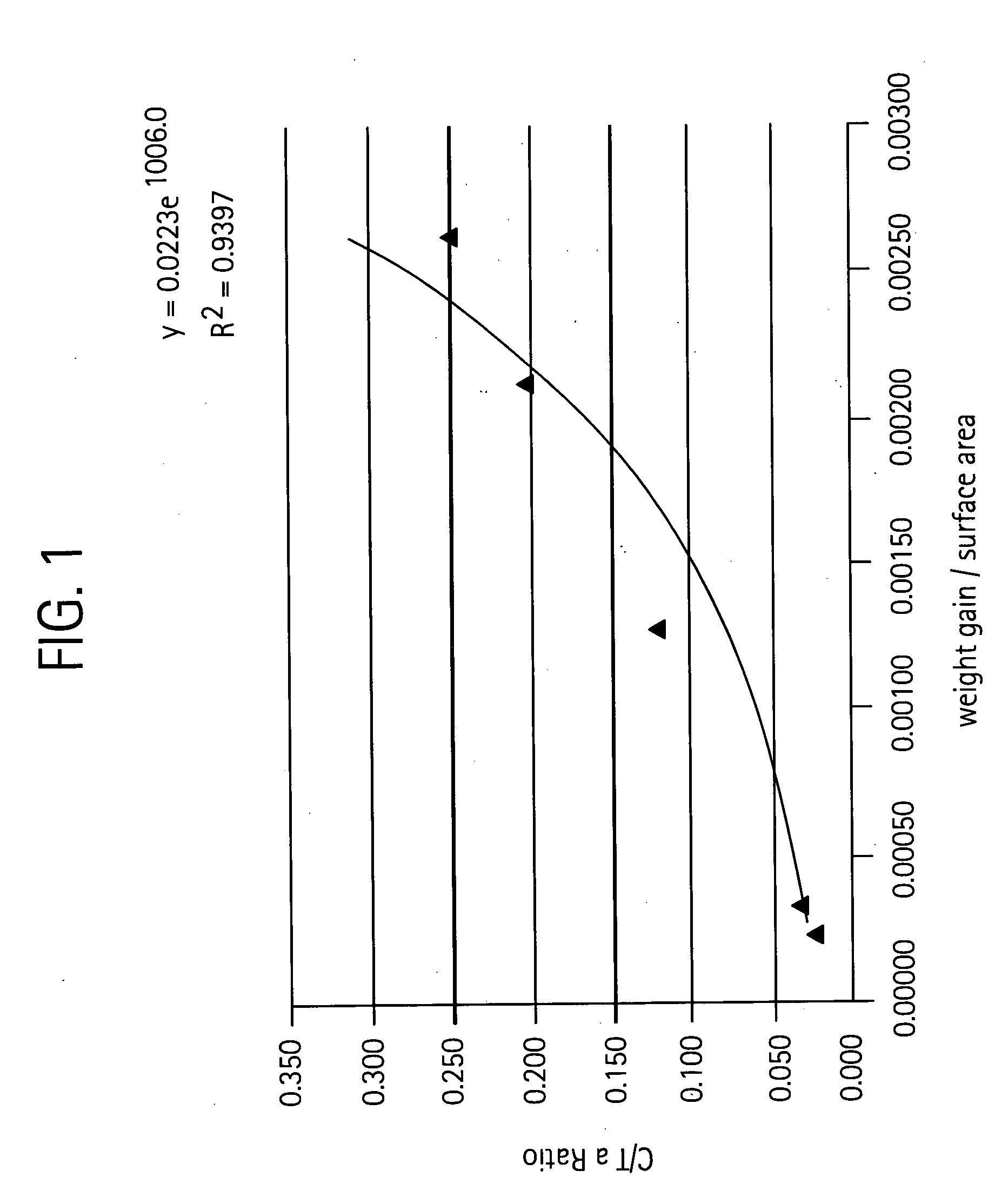

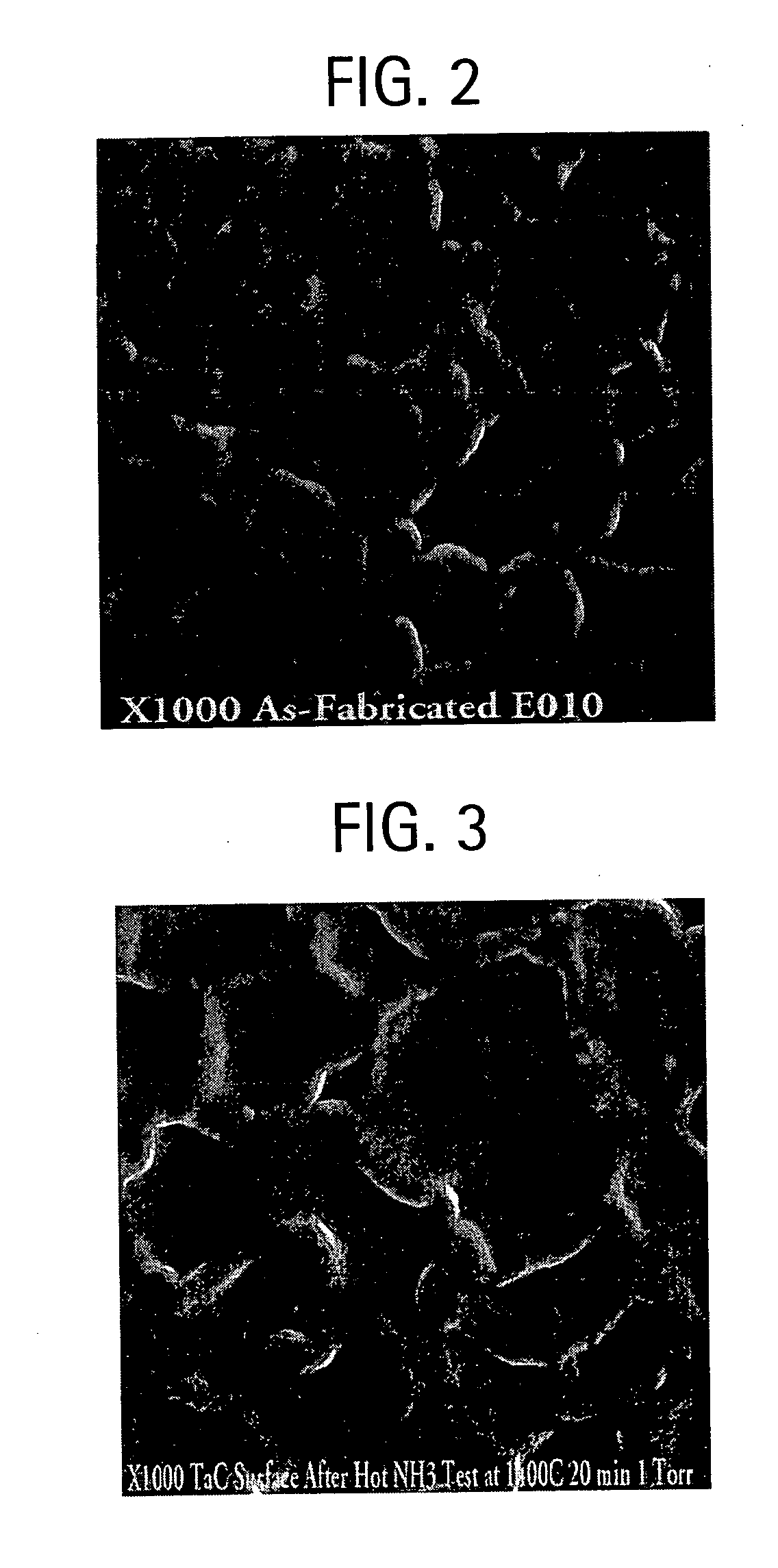

Composite refractory metal carbide coating on a substrate and method for making thereof

InactiveUS20050064247A1Improved corrosion resistance propertyIncreased emissivity insensitivityLiquid surface applicatorsSemiconductor/solid-state device manufacturingBeryllium carbideMagnesium

A composite coating for use on semi-conductor processing components, comprising a refractory metal carbide coating with its surface modified by at least one of: a) a carbon donor source for a stabilized stoichiometry, and b) a layer of nitride, carbonitride or oxynitride of elements selected from a group B, Al, Si, refractory metals, transition metals, rare earth metals which may or may not contain electrically conducting pattern, and wherein the metal carbide is selected from the group consisting of silicon carbide, tantalum carbide, titanium carbide, tungsten carbide, silicon oxycarbide, zirconium carbide, hafnium carbide, lanthanum carbide, vanadium carbide, niobium carbide, magnesium carbide, chromium carbide, molybdenum carbide, beryllium carbide and mixtures thereof. The composite coating is characterized as having an improved corrosion resistance property and little emissivity sensitivity to wavelengths used in optical pyrometry under the normal semi-conductor processing environments.

Owner:GENERAL ELECTRIC CO

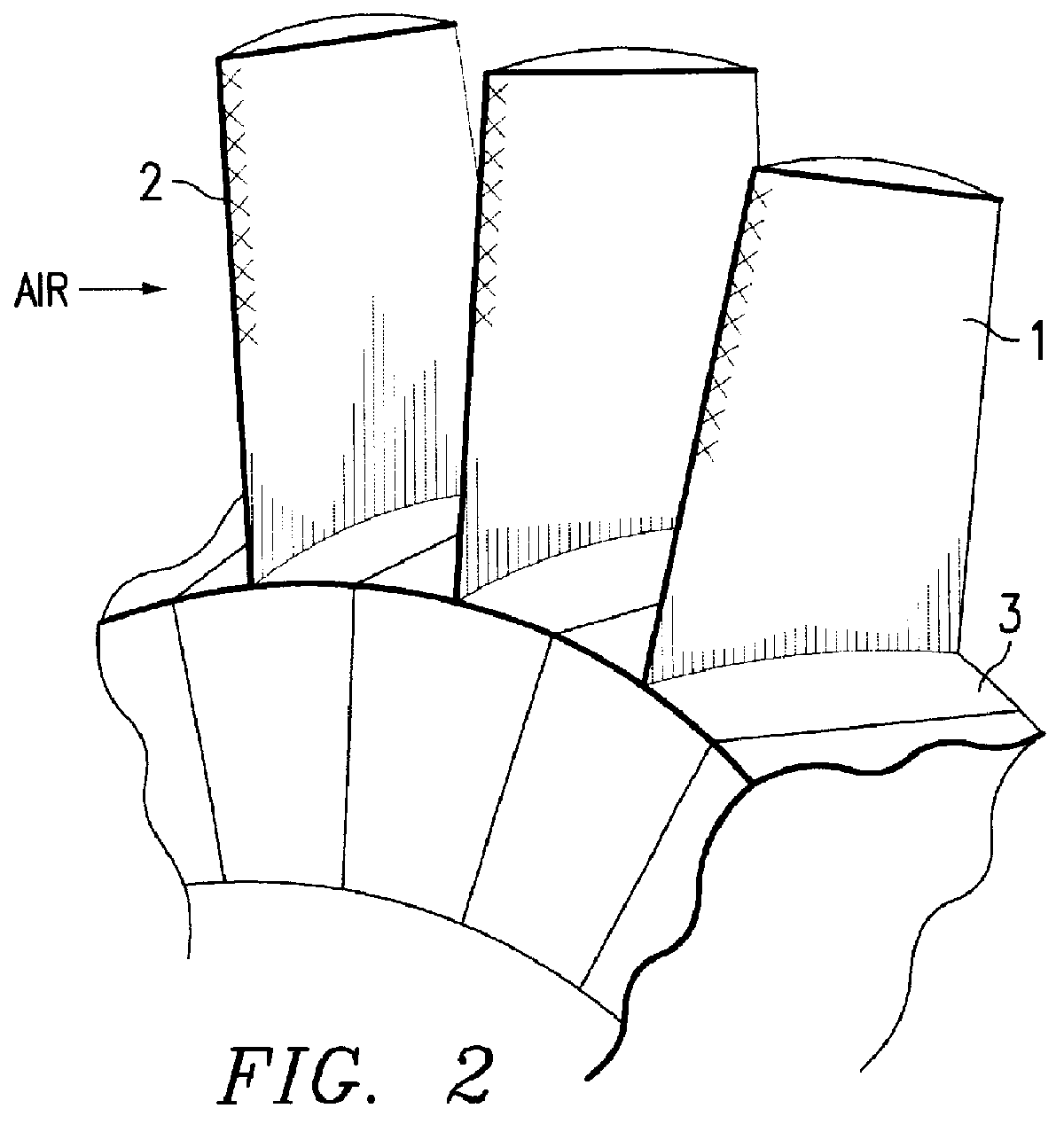

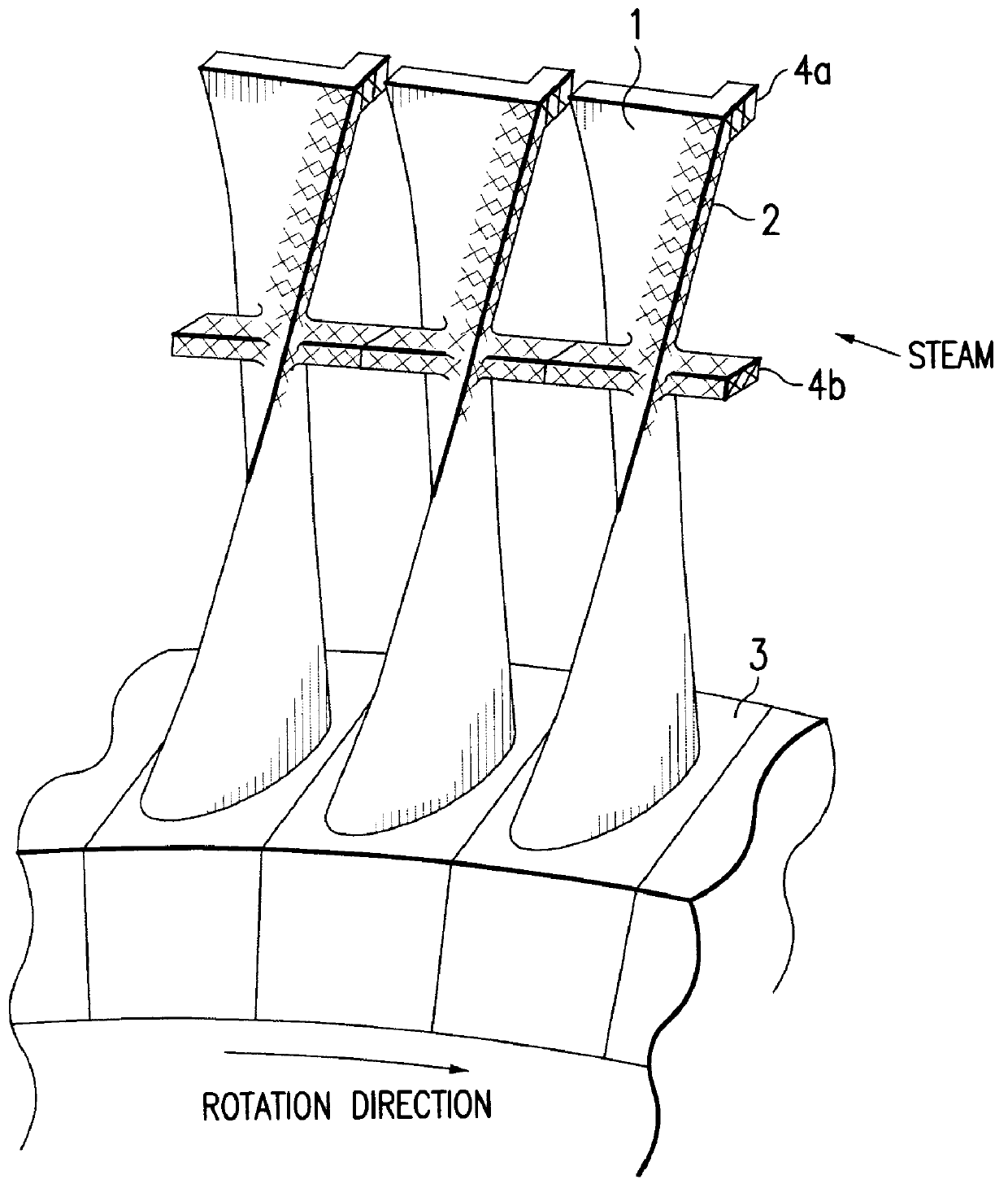

Method for producing titanium alloy turbine blades and titanium alloy turbine blades

InactiveUS6127044ALess abrasionSuperior in water droplet erosion resistancePropellersEngine manufactureLeading edgeTurbine blade

PCT No. PCT / JP95 / 01817 Sec. 371 Date Jun. 2, 1998 Sec. 102(e) Date Jun. 2, 1998 PCT Filed Sep. 13, 1995 PCT Pub. No. WO97 / 10066 PCT Pub. Date Mar. 20, 1997A method for producing titanium alloy turbine blades comprising the steps of (a) forming turbine blades of titanium alloy through hot forging or machining, (b) cooling leading edges on tip portions of the turbine blades including covers thereof formed through hot forging or machining faster than blade main body after final hot forging or solid solution treatment, and (c) heat treating the cooled turbine blades. With this method, it is possible to manufacture titanium turbine blades in an economical fashion and obtain titanium alloy turbine blades superior in reliability by preventing erosion.

Owner:KK TOSHIBA +1

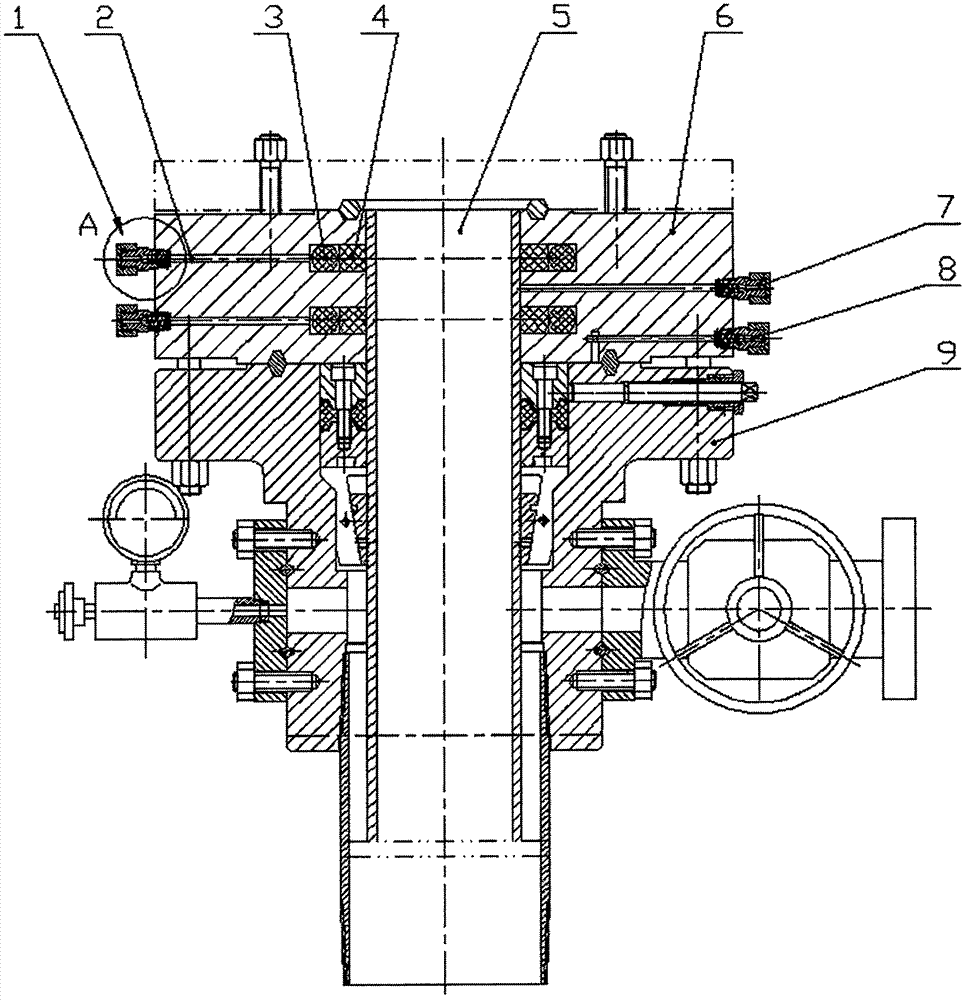

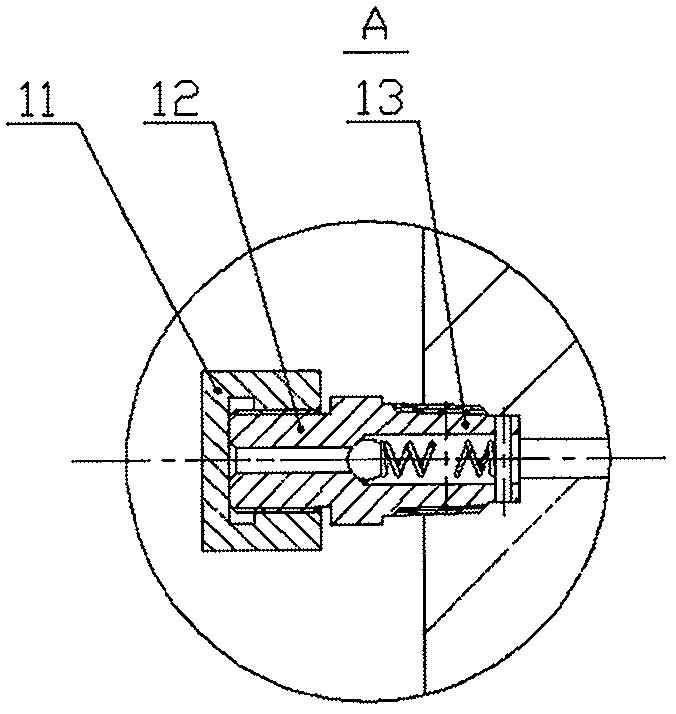

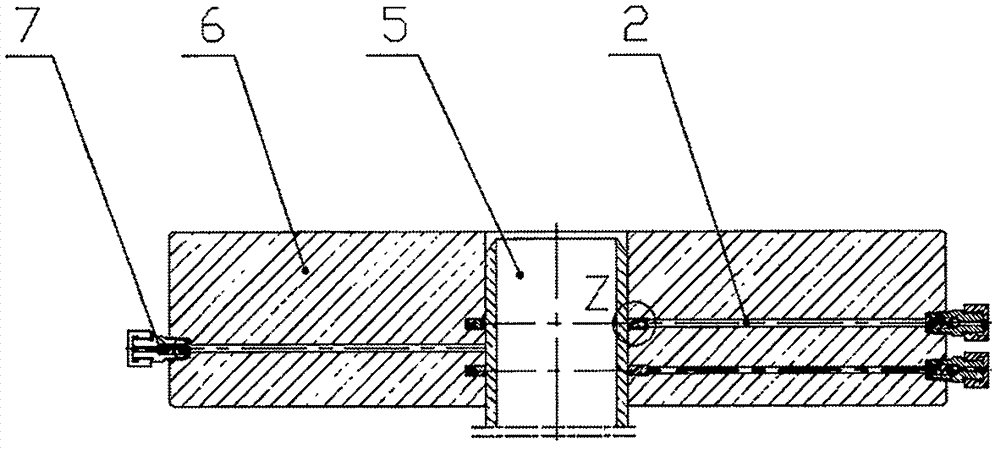

Petroleum wellhead annular space sealing device

PendingCN107143298AGood corrosion resistanceDirectionalSealing/packingWellheadMechanical engineering

The invention discloses a petroleum wellhead annular space sealing device. The petroleum wellhead annular sealing device is used for sealing an annular space between a wellhead sealing body and a petroleum pipe, at least one annular groove is formed in the inner wall surface of the sealing body, and the sealing body is provided with an injection hole which is communicated to a centrifugal end of the annular groove; the petroleum wellhead annular space sealing device further comprises a sealing ring, a power ring, and an injection component, wherein the sealing ring is embedded into the annular groove, the sealing ring is used for sealing the groove in the radial direction by being jointed to the wall surface of the annular groove, and is used for sealing the annular space by being jointed to the outer wall of the petroleum pipe, the power ring is installed in the annular groove and is located between the groove bottom of the annular groove and the sealing ring, and the injection component is installed in an inlet of the injection hole, and is used for injecting fluid with given pressure so as to make the power ring push the sealing ring to tightly press the petroleum pipe. In the petroleum wellhead annular space sealing device, the requirement for deformation capability of a sealing part is low, and meanwhile the sealing capability can be effectively improved.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

Cement compositions with improved corrosion resistance and methods of cementing in subterranean formations

InactiveUS20050056191A1Improve corrosion resistanceSolid waste managementDrilling compositionCorrosionPhosphate

This invention provides cement compositions that comprise a high alumina cement, vitrified shale, a soluble phosphate, and water sufficient to form a slurry. This invention also presents methods of enhancing the corrosion resistance of a cement composition that comprise the step of adding vitrified shale to the cement composition.

Owner:HALLIBURTON ENERGY SERVICES INC

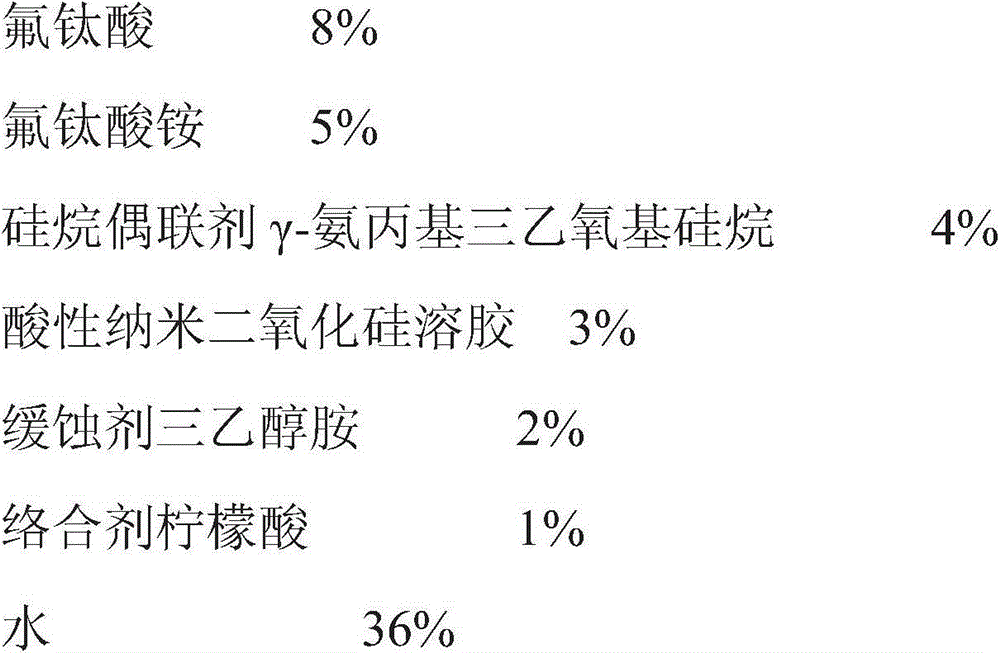

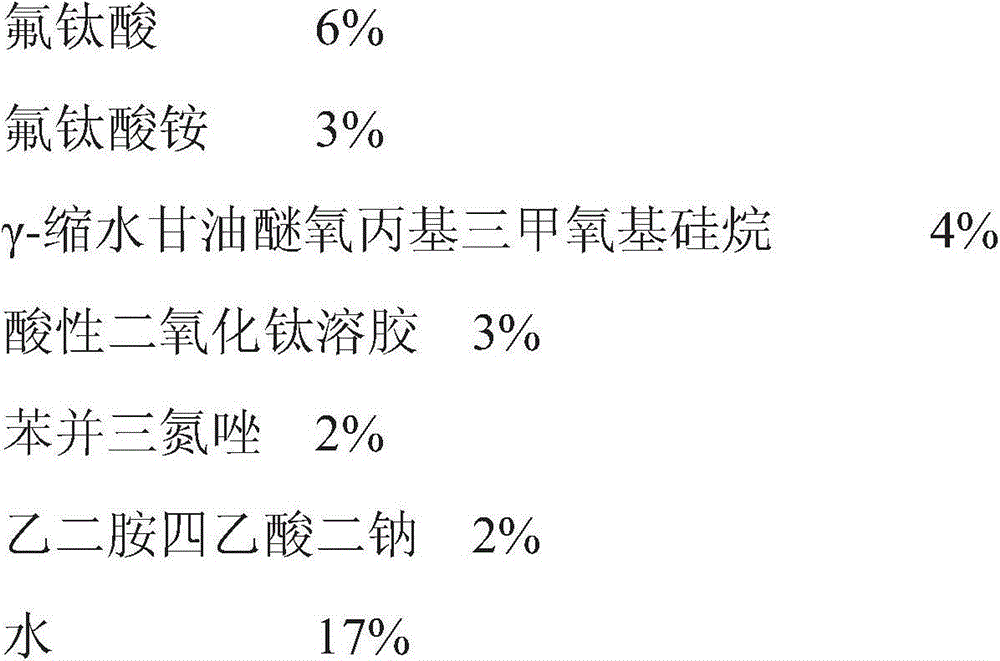

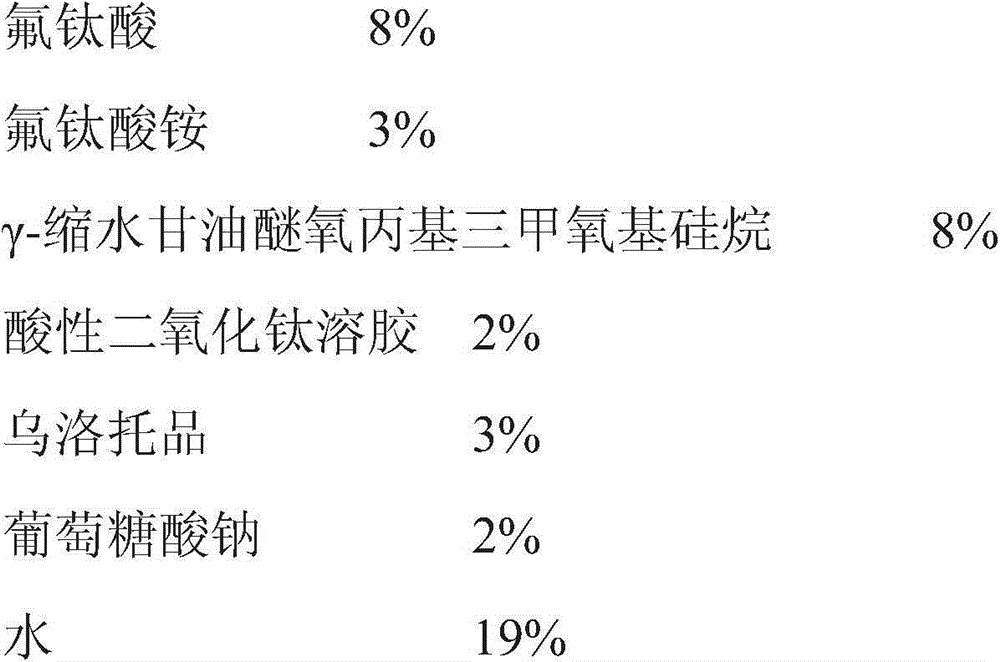

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS6451402B1Good corrosion resistanceHigh reflectivityRecord information storageThin material handlingIridiumCorrosion

A silver-based alloy thin film is provided for the highly reflective or semi-reflective layer of optical discs. Alloy additions to silver include gold, palladium, copper, rhodium, ruthenium, osmium, iridium, and platinum. These alloys have moderate to high reflectivity and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

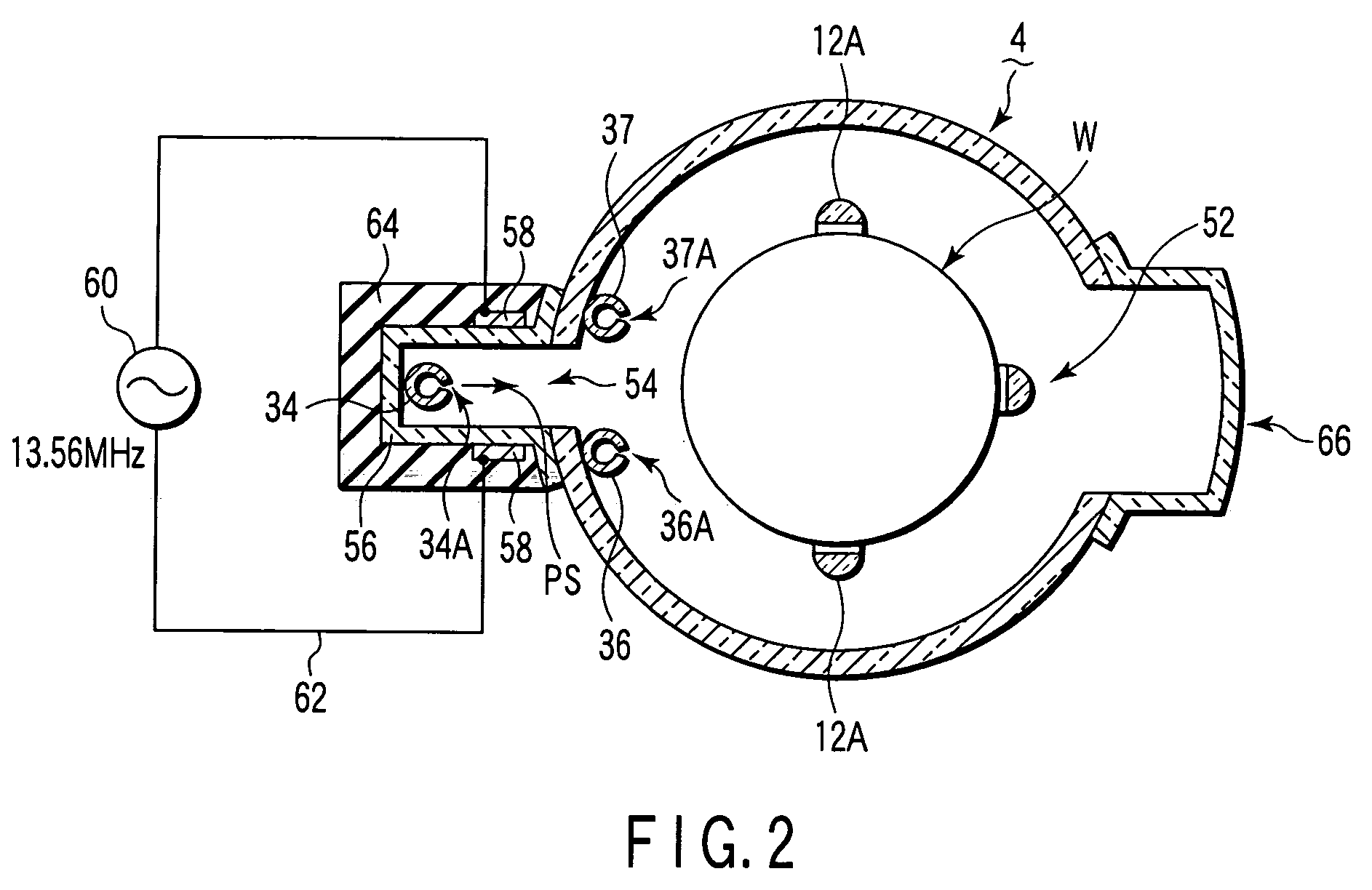

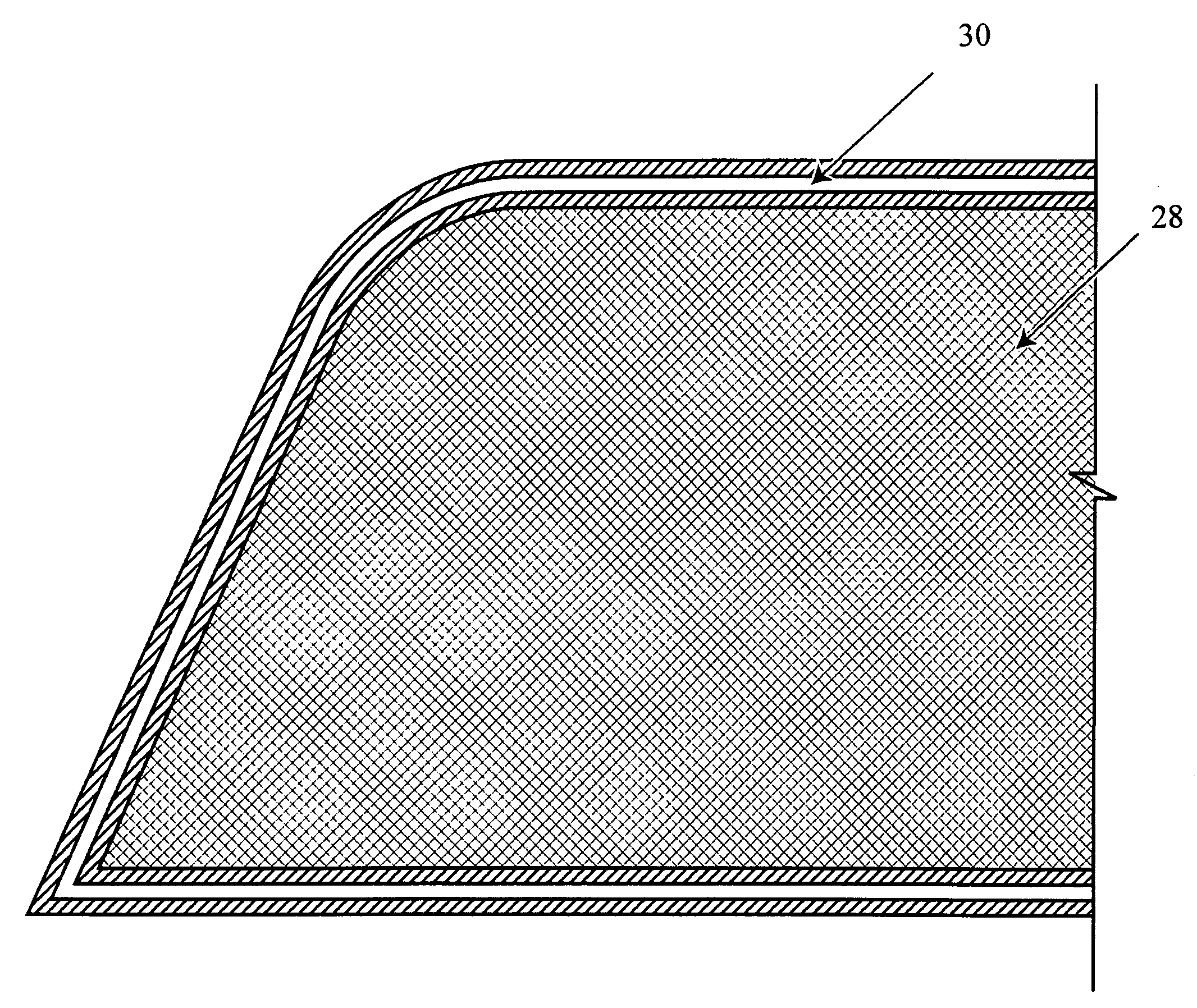

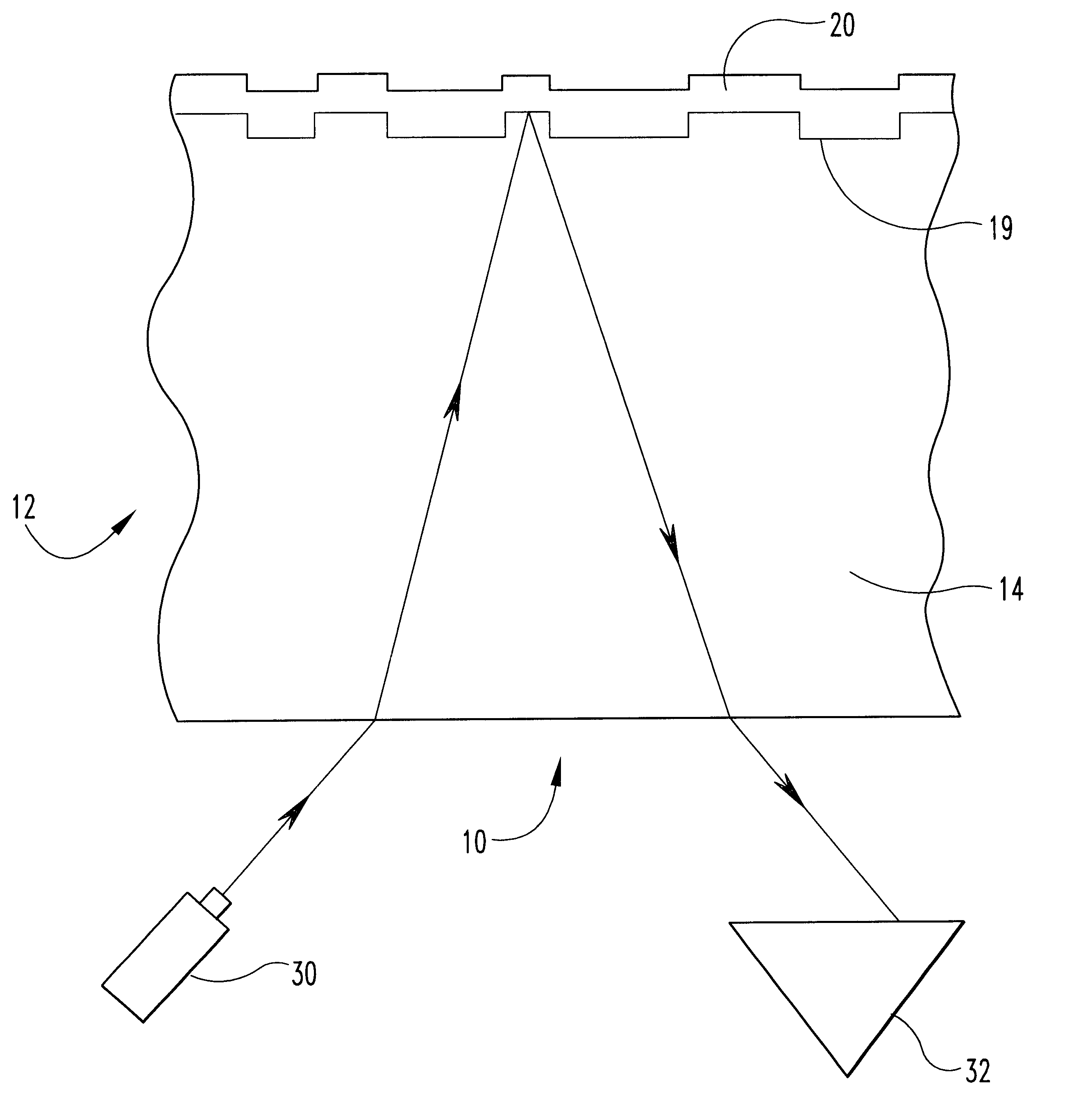

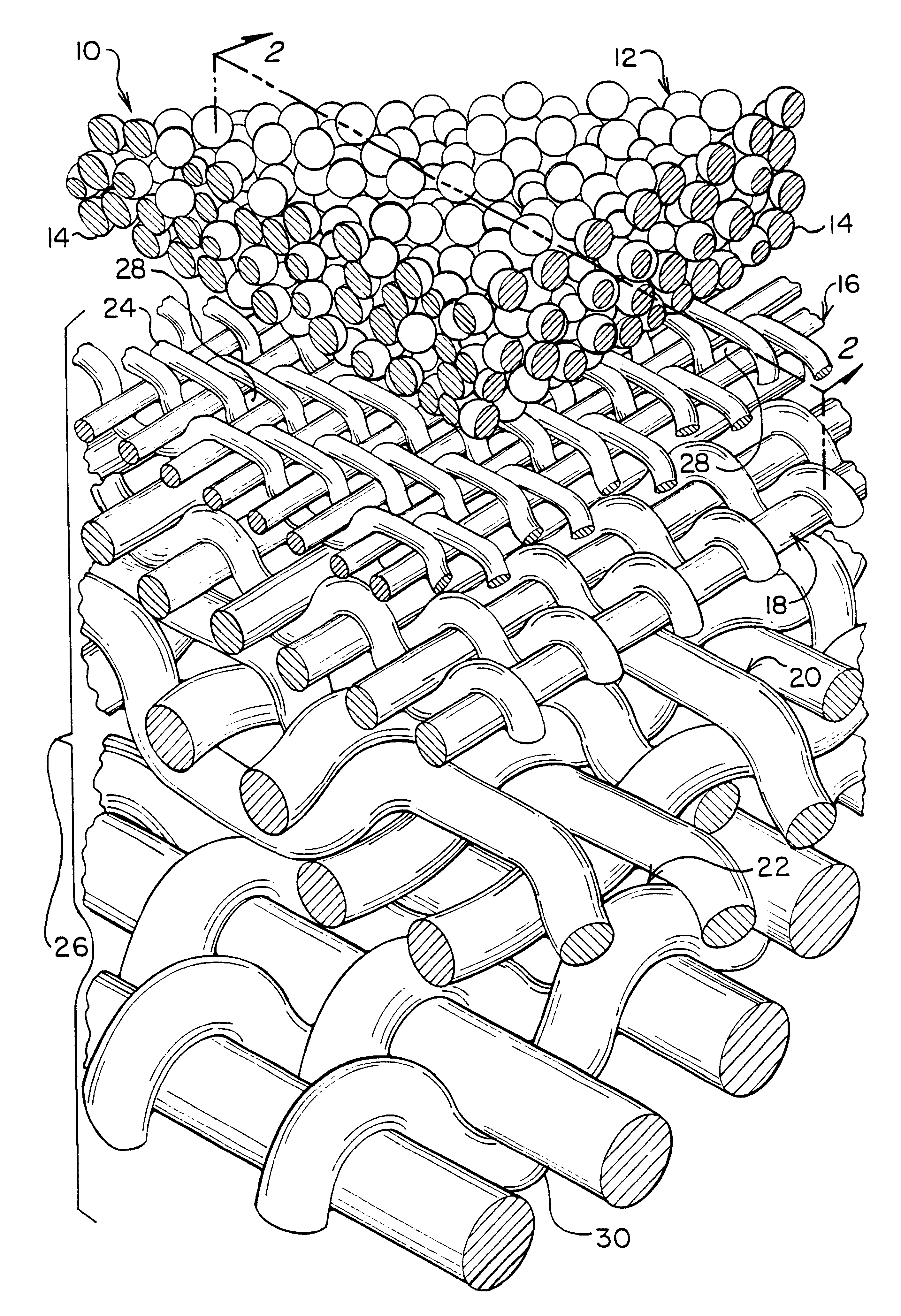

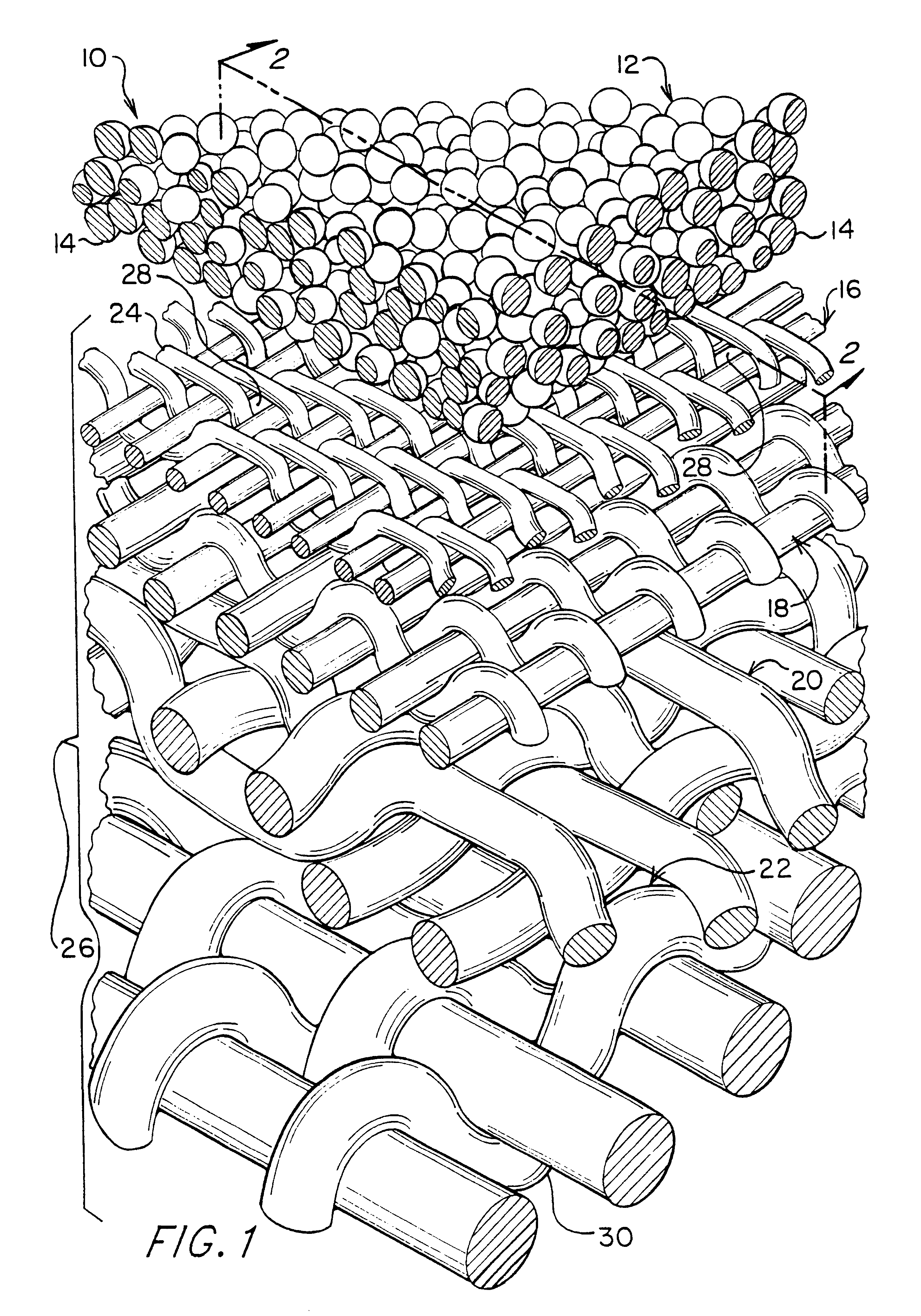

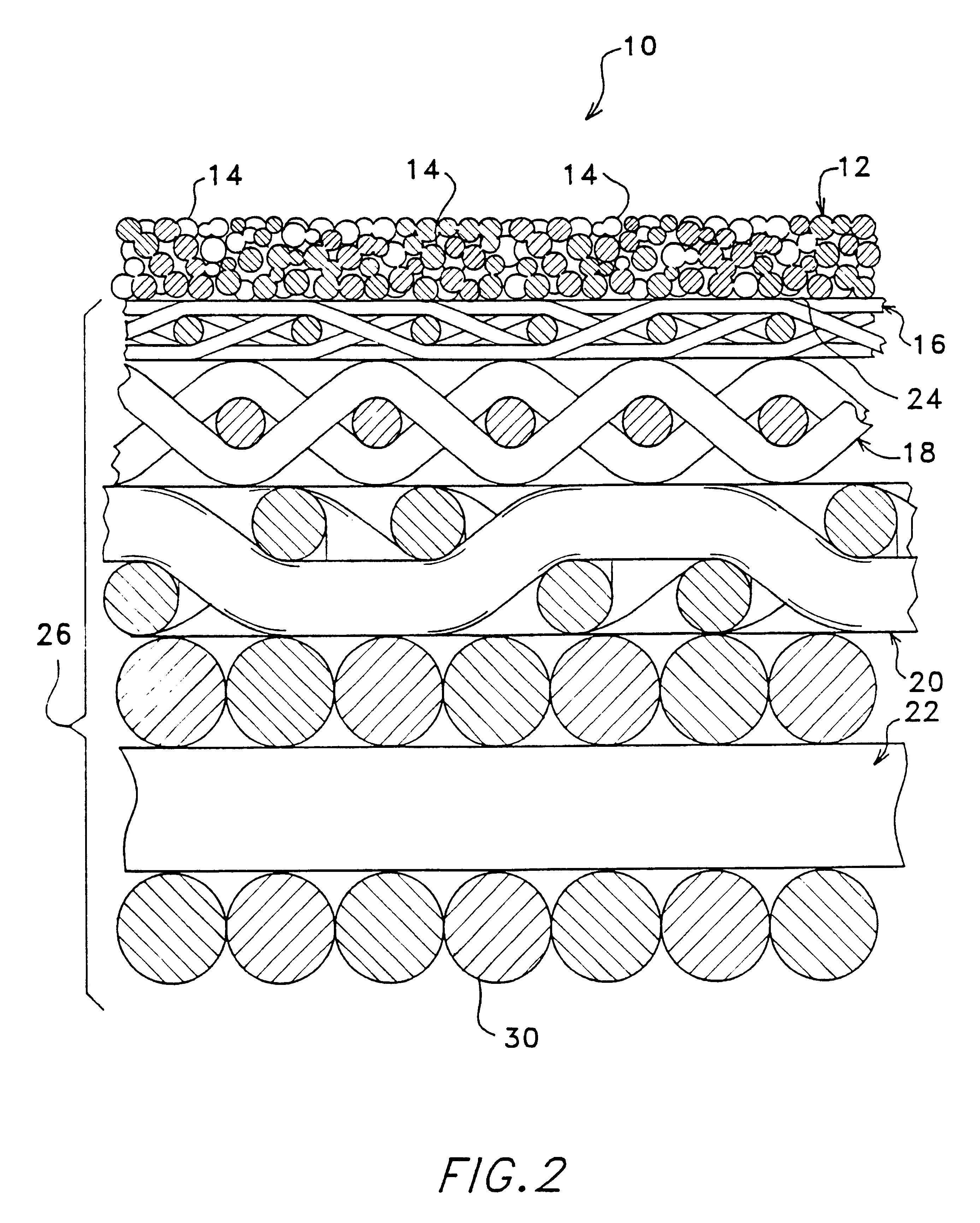

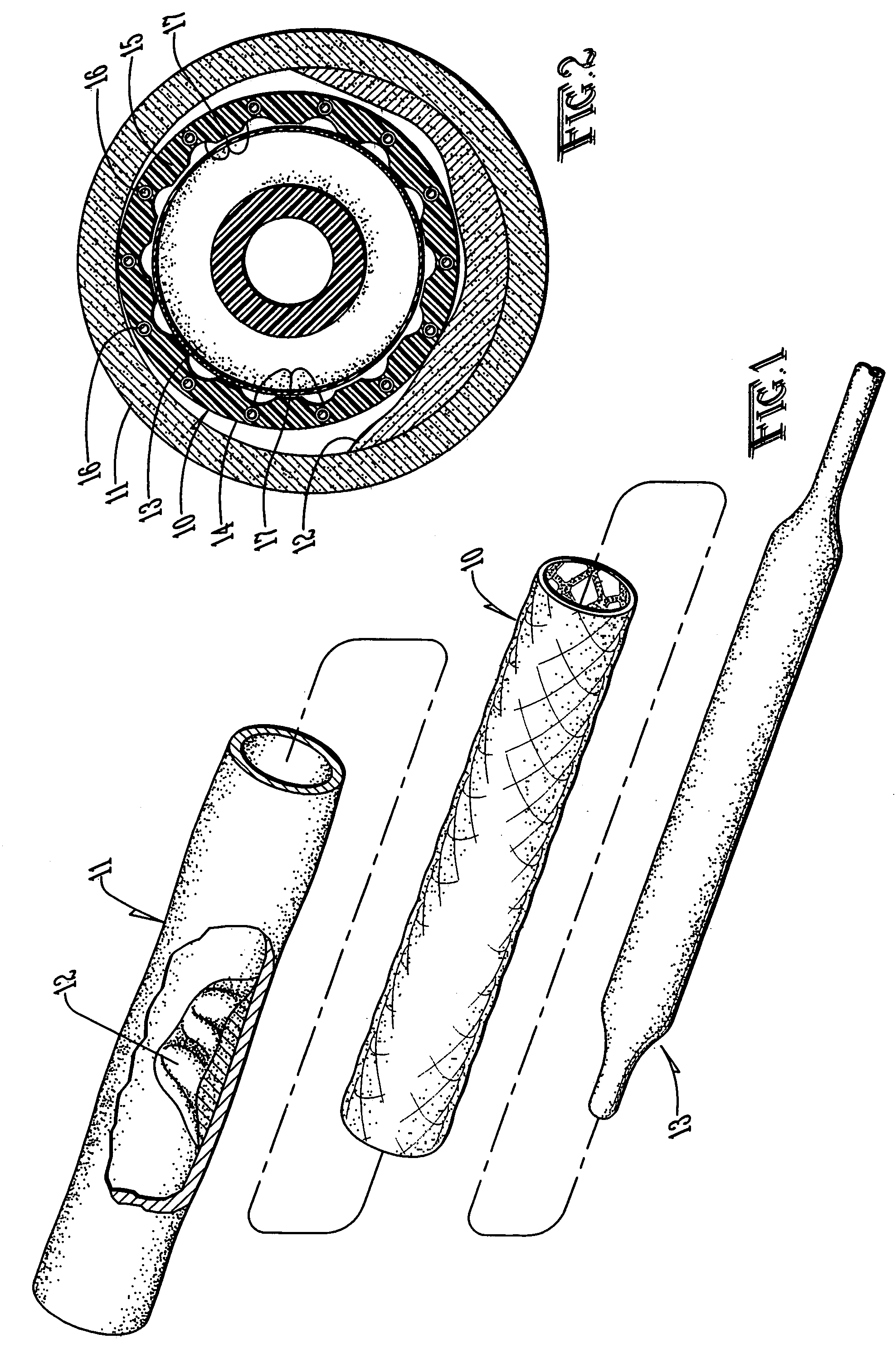

Micro and ultrafilters with controlled pore sizes and pore size distribution and methods for making

InactiveUS6309546B1High permeabilityMinimal pressure dropSemi-permeable membranesMembranesMicrometerPore diameter

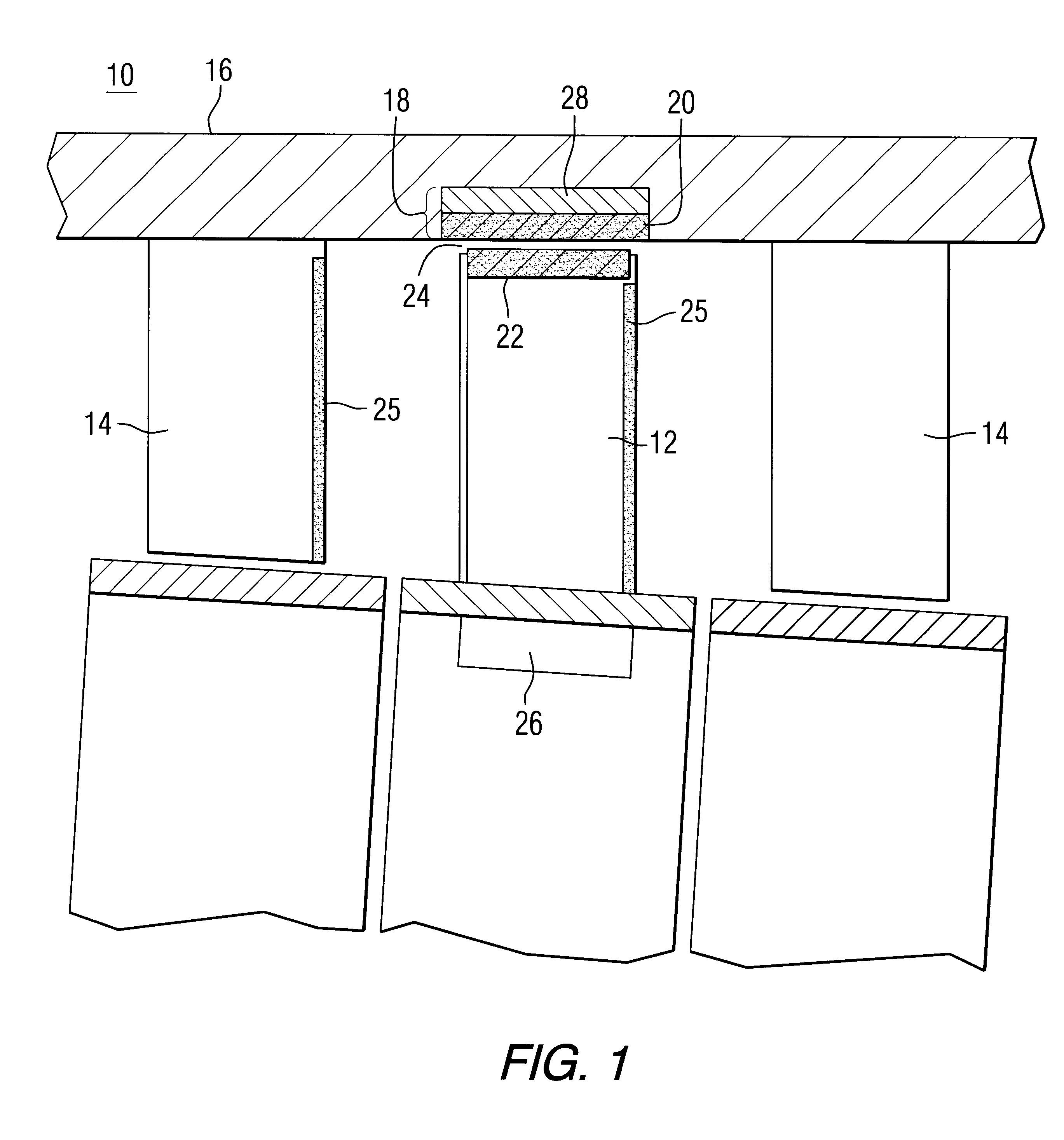

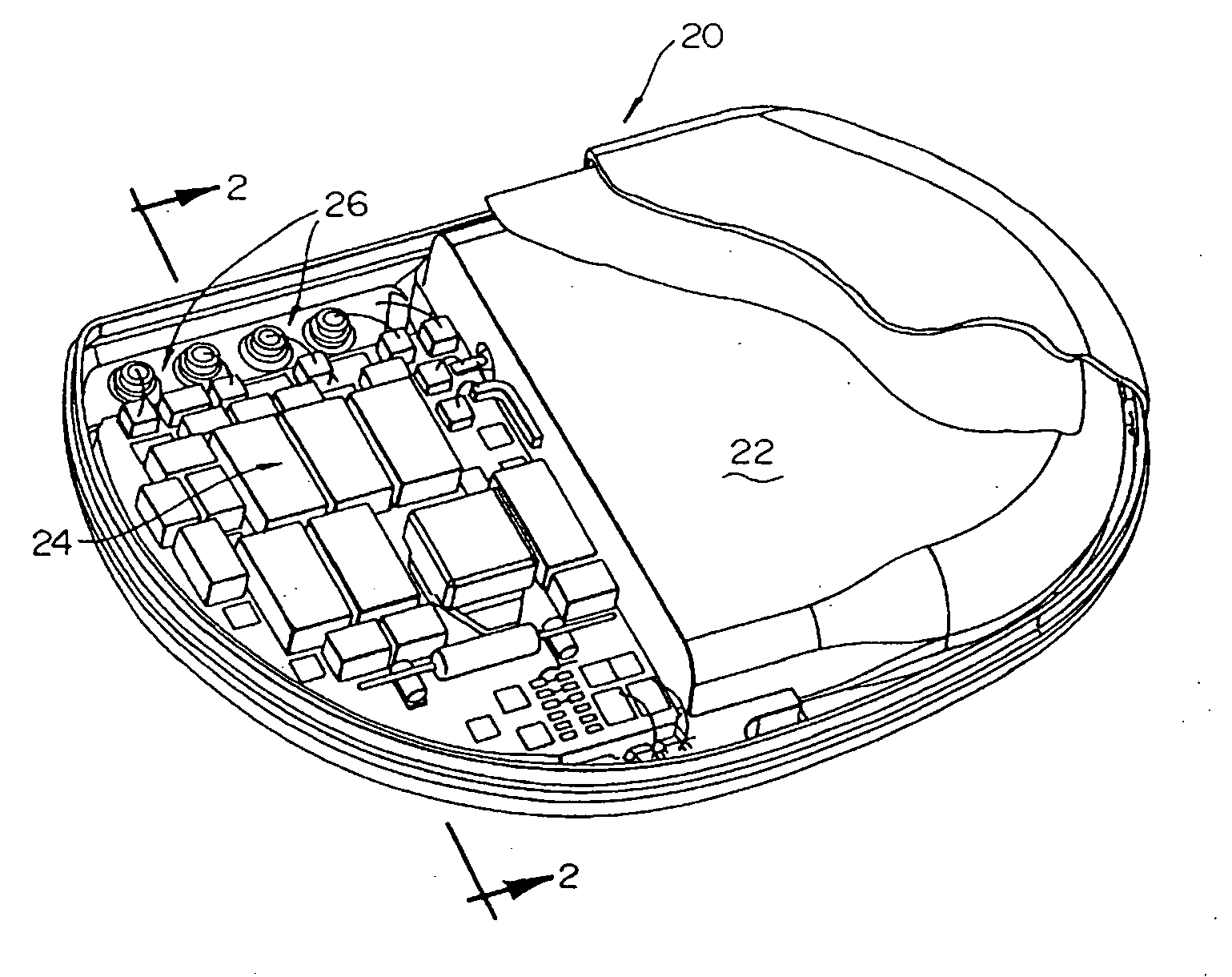

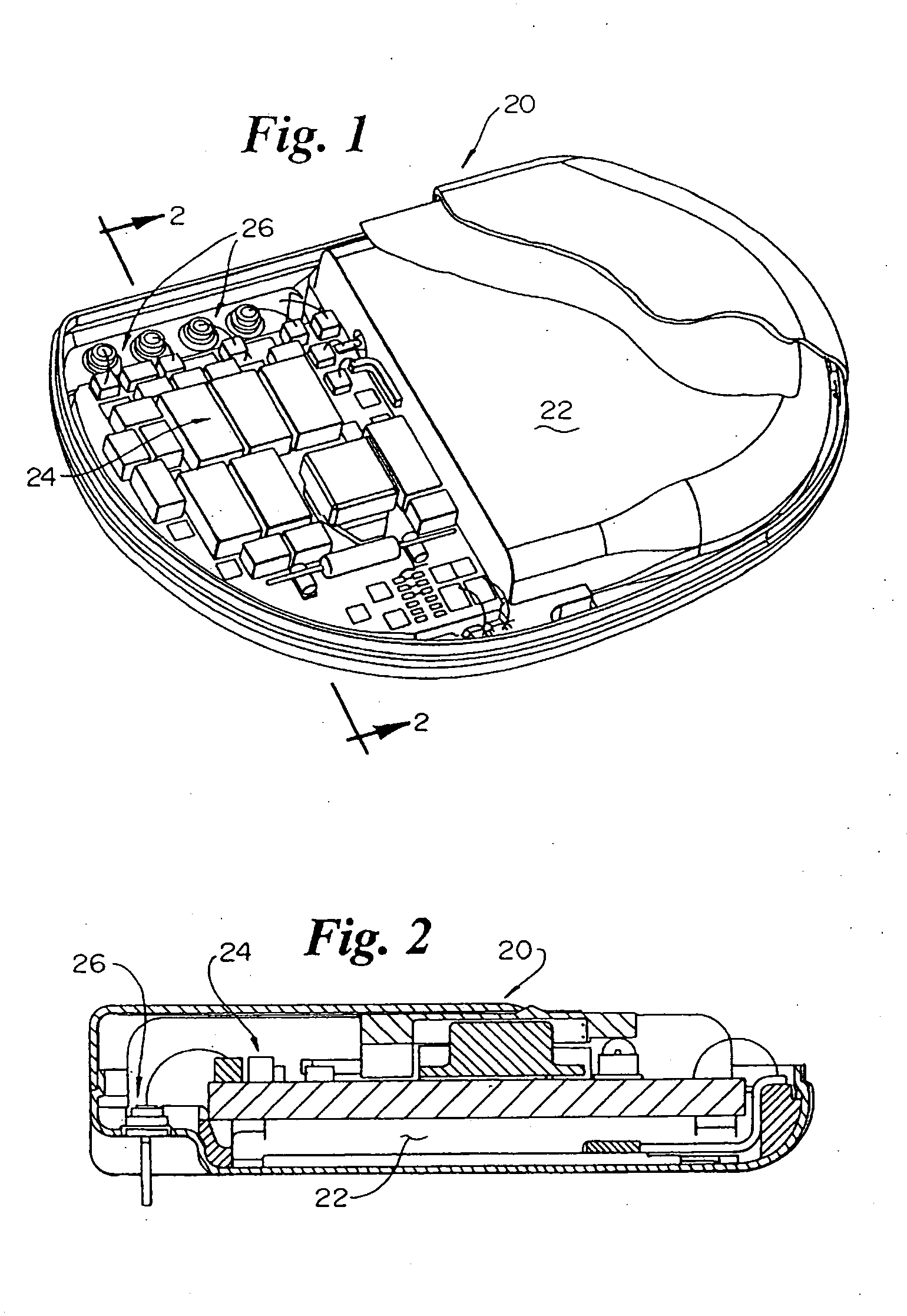

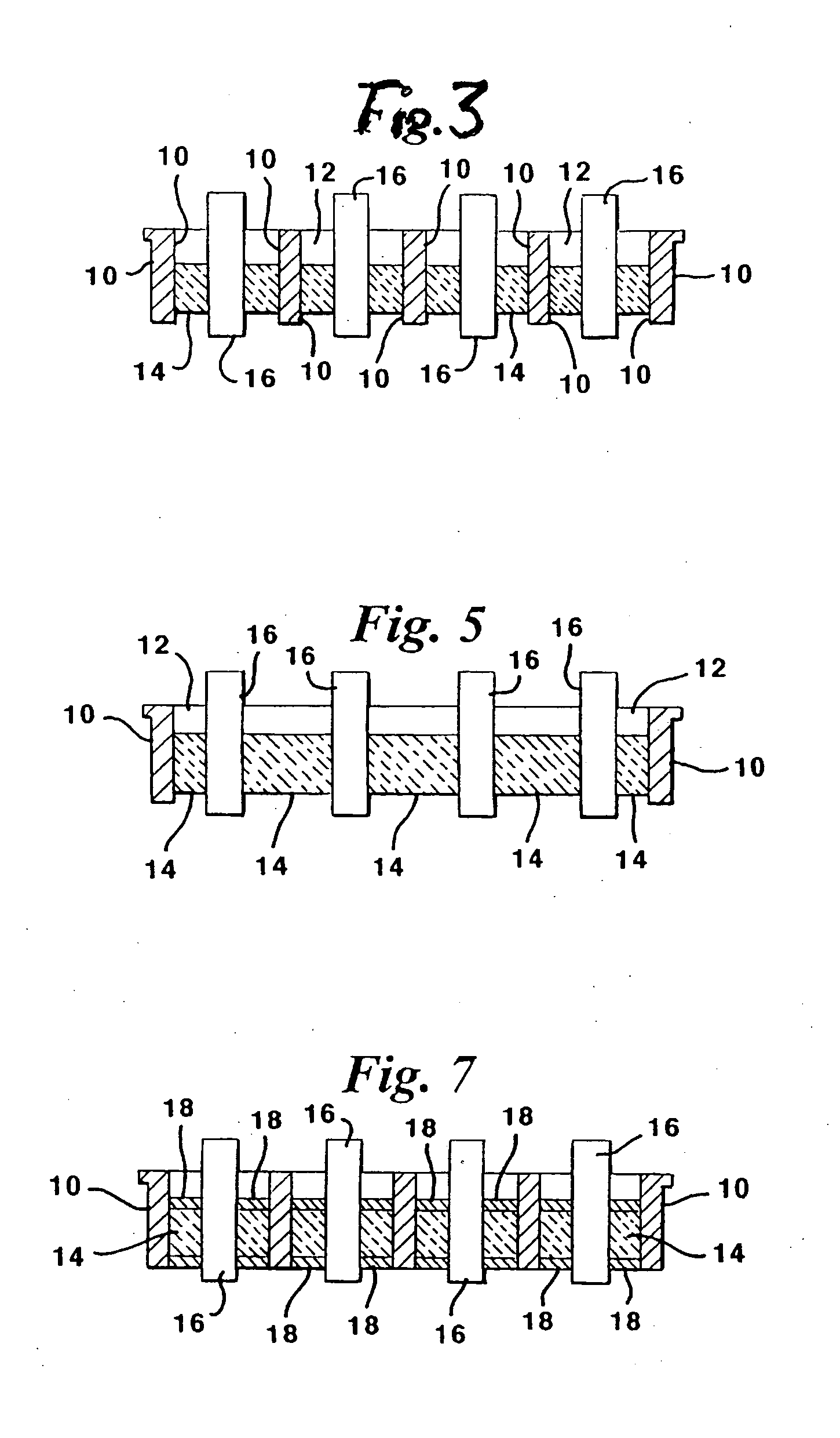

A micro / ultrafiltering element (10) and method for making a filter element are provided. The filtering element comprises a multi-level support (26) having a filtering membrane layer (12) formed thereon comprising sintered particles (14) of uniform diameter. The filtering membrane preferably has an average pore size of from about 0.005-10 micrometers. The filter element is capable of being formed in a variety of geometrical shapes based on the shape of the porous support,

Owner:ELLIPSIS CORP

System and process for solid-state deposition and consolidation of high velocity powder particles using thermal plastic deformation

InactiveUS6915964B2Modulus is reducedLower yield strengthMolten spray coatingSurface layering apparatusFlow stressAcoustic wave

The invention relates to an apparatus and process for solid-state deposition and consolidation of powder particles entrained in a subsonic or sonic gas jet onto the surface of an object. Under high velocity impact and thermal plastic deformation, the powder particles adhesively bond to the substrate and cohesively bond together to form consolidated materials with metallurgical bonds. The powder particles and optionally the surface of the object are heated to a temperature that reduces yield strength and permits plastic deformation at low flow stress levels during high velocity impact, but which is not so high as to melt the powder particles.

Owner:INNOVATION TECH INC

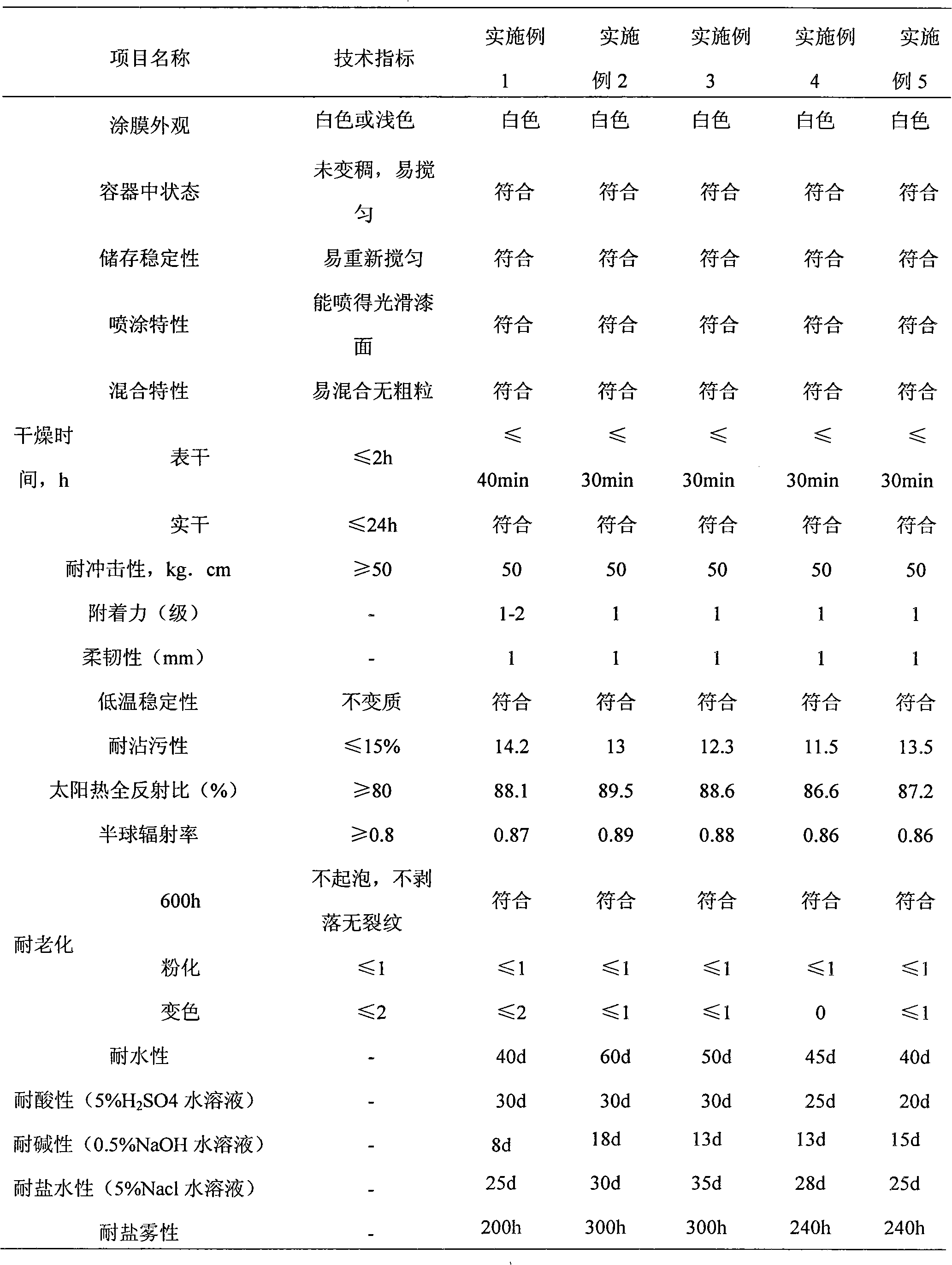

Nanometer compound water-based heat insulation anticorrosion paint used for metal and preparation method thereof

ActiveCN101665645AGood heat insulationImprove corrosion resistanceAnti-corrosive paintsReflecting/signal paintsWater basedAcrylic resin

The invention discloses a nanometer compound water-based heat insulation anticorrosion paint used for metal and a preparation method thereof. The raw materials of the paint consists of the following components: tap water, watercraft acrylic resin, rustproofing pigment, reflection pigment and filler, hollow micro-beads, watercraft nanometer size, anti-settling agent, wetting and dispersing agent A,wetting and dispersing agent B, film-forming assistant, defoaming agent, flatting agent, anti-flash rustproofing agent and thickening agent. Watercraft polyacrylic emulsion is styrene-crylic acid copolymerization emulsion, pure crylic acid polymerization emulsion or organic silicon-crylic acid copolymerization emulsion. The wetting and dispersing agent A is block macromolecule copolymer, multivalence carboxylate polymer and / or synthetic macromolecule copolymer, and the wetting and dispersing agent B is anion wetting agent and / or nonionic wetting agnet. The product contains no organic solvent,heavy metal and other harmful substances, is extremely excellent in environmental conservation, integrates the functions of anticorrosion and heat insulation as a whole and is simple and convenient for construction, safe in storage and stable in performance.

Owner:GUANGZHOU JOINTAS CHEM

Glass-to-metal feedthrough seals having improved durability particularly under AC or DC bias

A hermetic implantable medical device (IMD) is provided with a single or multi-pin arrangement including selected glass to metal seals for a feedthrough including a ceramic disk member coupled to the sealing glass surface in potential contact with body fluids. By judicious selection of component materials (ferrule, seal insulator and pin) provides for either compression or match seals for electrical feedthroughs (having a single or multi-pin array) provide corrosion resistance and biocompatibility required in IMDs. The resultant feedthrough configuration accommodates one pin within a single ferrule or at least two pins in a single ferrule having a pin surrounded by insulator material (e.g., alumina ceramic, zirconia ceramic, zirconia silicate ceramic, mullite, each having higher melting points than the sealing glass distributed around the pin within the ferrule, or feldspar porcelain materials or alumino-silicate glasses having a lower melting point than the sealing glass) distributed around the pin within the ferrule.

Owner:MEDTRONIC INC

Polymeric composite including nanoparticle filler

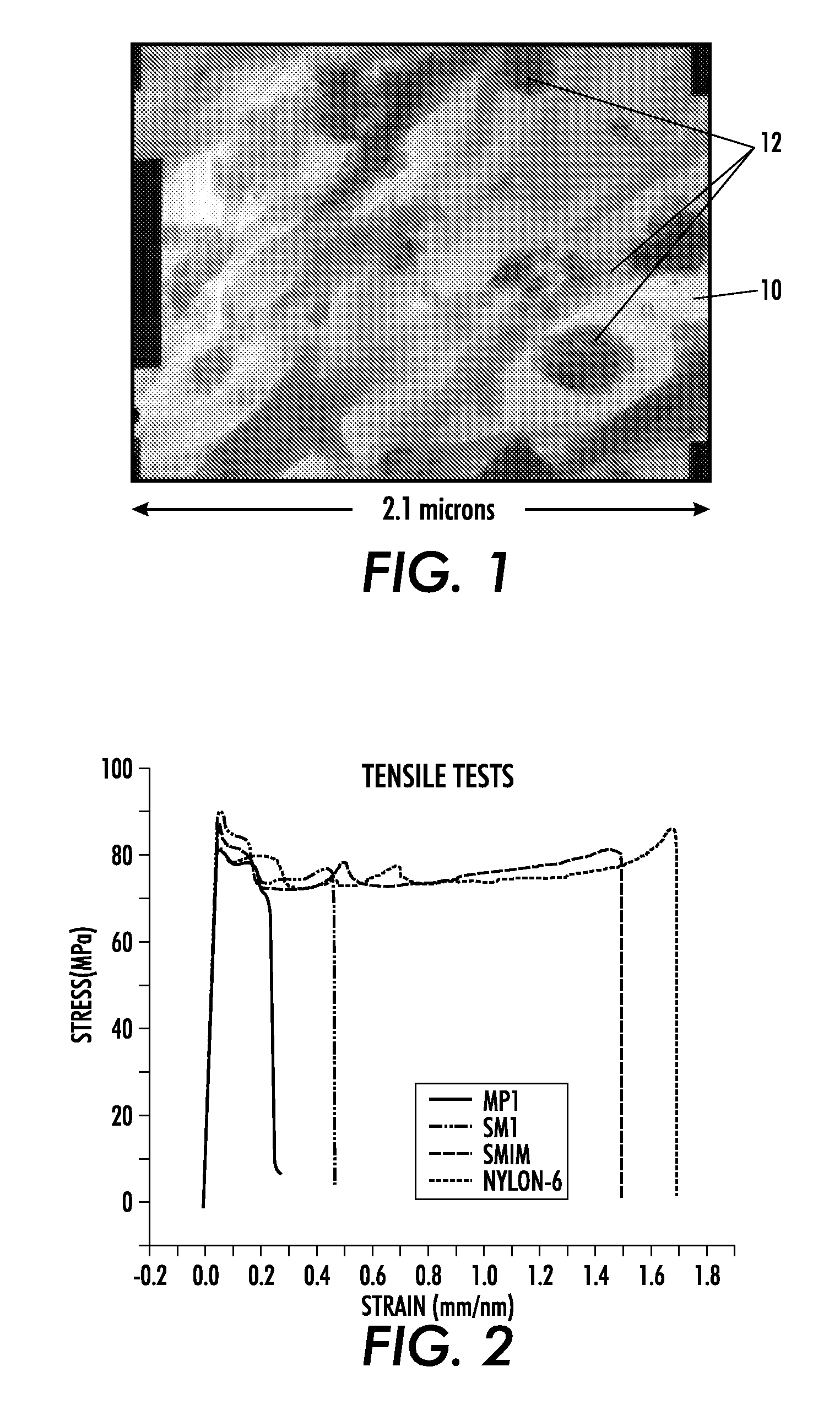

InactiveUS20070106006A1Increase potential environmental impactReduce load levelHalloysiteNanoparticle

Disclosed is a novel polymeric composite including a nanoparticle filler and method for the production thereof. More particularly, the present invention provides a novel halloysite nanoparticle filler which has the generally cylindrical or tubular (e.g. rolled scroll-like shape), in which the mean outer diameter of the filler particle is typically less than about 500 nm. The filler is effectively employed in a polymer composite in which the advantages of the tubular nanoparticle filler are provided (e.g., reinforcement, flame retardant, chemical agent elution, etc.) with improved or equivalent mechanical performance of the composite (e.g., strength and ductility).

Owner:NATURALNANO CORP

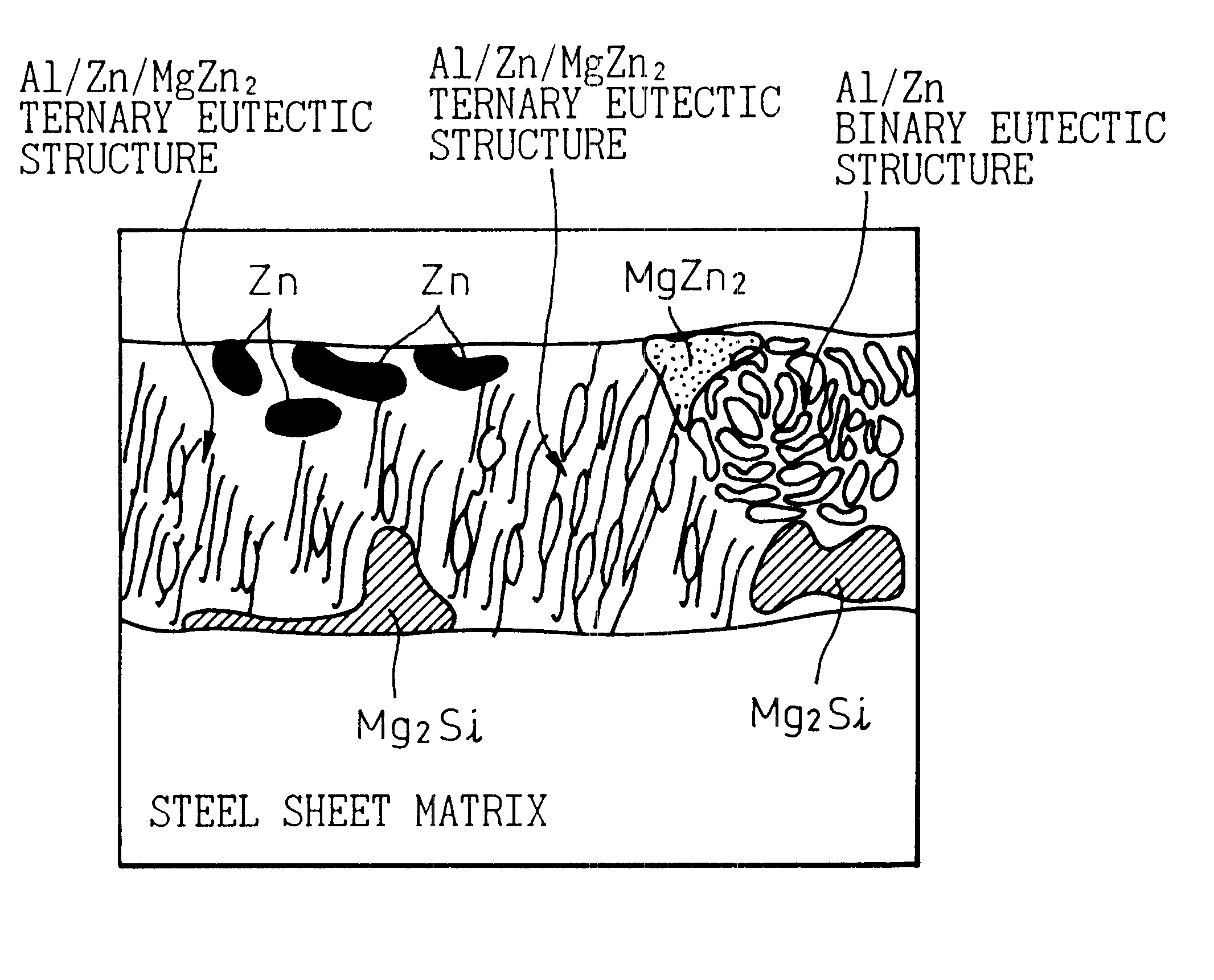

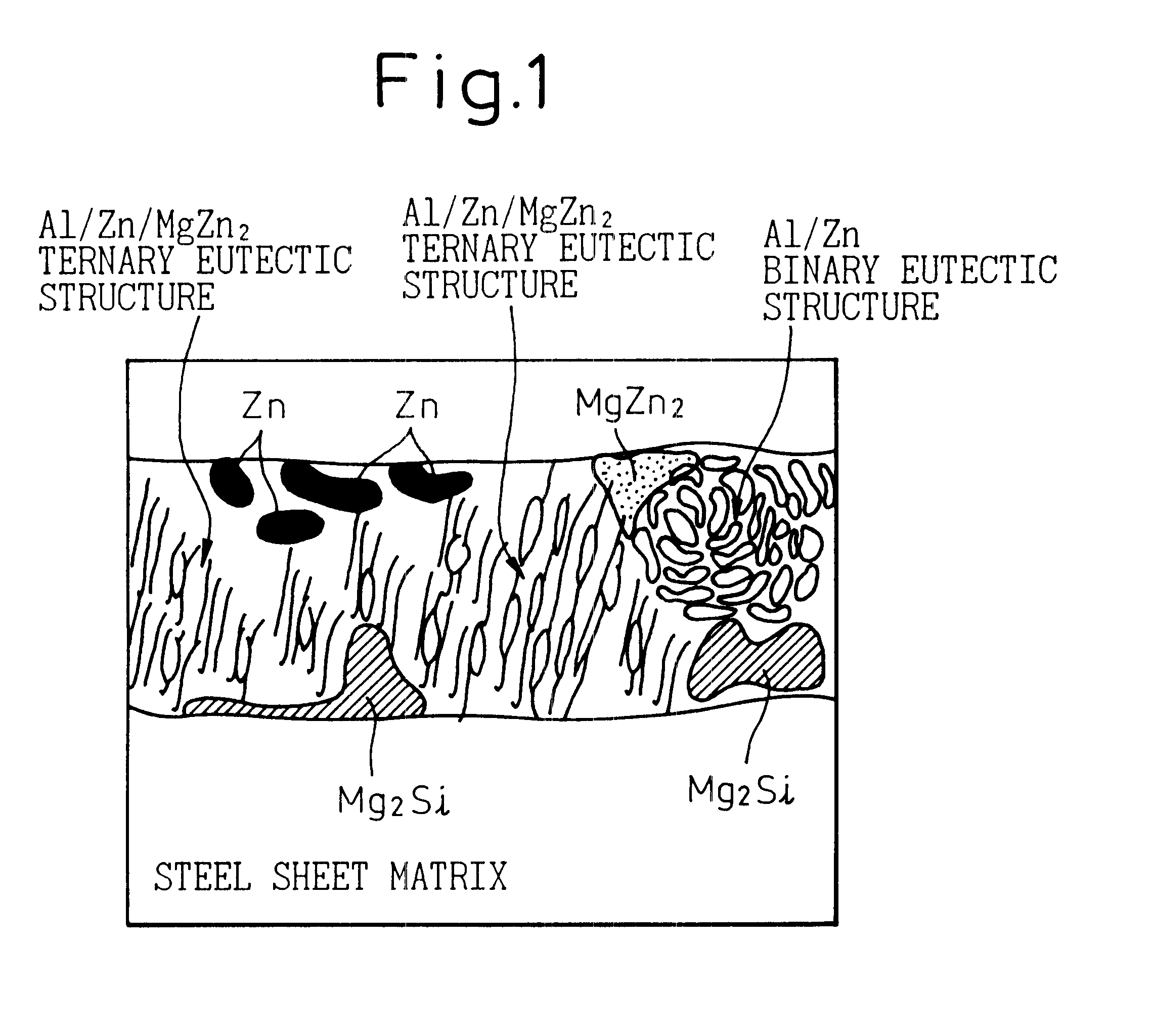

-Zn coated steel material, ZN coated steel sheet and painted steel sheet excellent in corrosion resistance, and method of producing the same

InactiveUS6465114B1Improve corrosion resistanceResistance to red rustHot-dipping/immersion processesLiquid surface applicatorsSheet steelAlloy coating

A coated steel material excellent in corrosion resistance and a method of producing the same, wherein a coated steel material has on the surface of the steel sheet a Zn-alloy coating layer containing 1-10 wt % of Mg, 2-19 wt % of Al and 0.01-2 wt % of Si, where Mg and Al satisfy Mg (%)+Al (%)<=20%, the balance being Zn and unavoidable impurities, and has a coating layer structure of a Mg intermetallic compound or the like. As a base metal treatment, it is preferably provided with a Ni coating layer. The coated Zn-alloy coated steel sheet may have provided on the coating layer, as an intermediate layer, a chromate film layer, and, as an upper layer, an organic coating layer. The Zn-alloy coating layer may further contain one or more of 0.01-1 wt % of In, 0.01-1 wt % of Bi and 1-10 wt % of Sn. The coated steel material may be painted.

Owner:NIPPON STEEL CORP

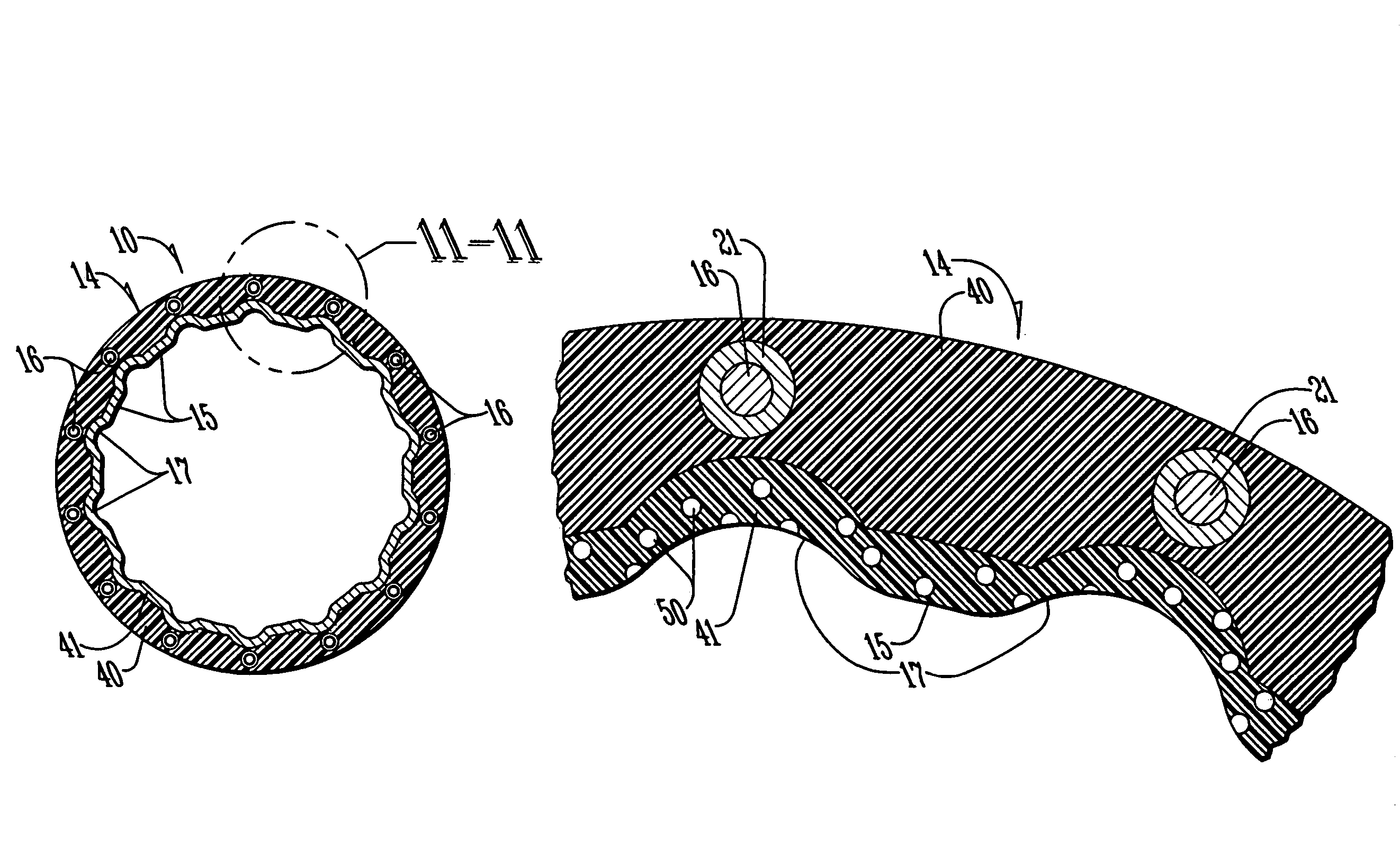

Encased stent

InactiveUS7311727B2Prevent restenosisImprove scalabilityStentsSurgeryCell Cycle InhibitionPolyethylene glycol

An encased stent that discourages restenosis by having a homogenous endothelial cell lining along the inner wall of the stent. The endothelial cell lining may be coated on the stent before the stent is placed in the artery, or the endothelial cell lining may be grown after placement by several factors that encourage such growth and discourage restenosis. The endothelial cells to coat the stent may be genetically modified to enhance the growth of the endothelial cells into a homogeneous lining. The stent has a continuous lining in the form of a multi-layer polymer coating, including a conducting biocorrosion inhibiting layer and a continuous film of polyurethane coupled by a coupling agent to polyethylene glycol. Various drugs and cell factors may be incorporated into the lining, such as anti-thrombin, anti-inflammatory and anti-coagulant drugs, cell cycle inhibitors, and vascular endothelial growth factors.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

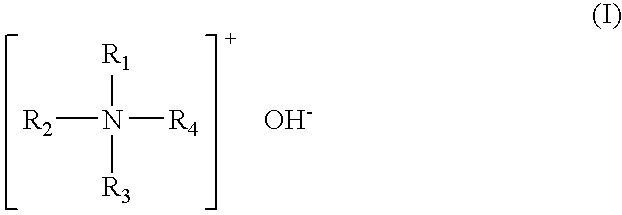

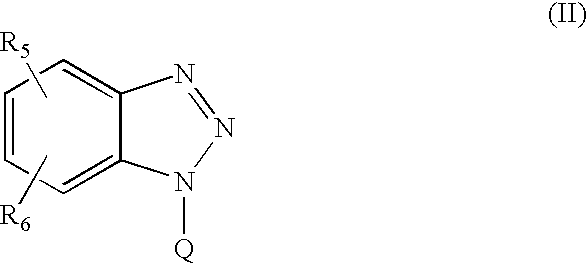

Method for removing photoresist

InactiveUS20050176259A1Improve corrosion resistanceEfficient strippingDecorative surface effectsSemiconductor/solid-state device manufacturingAmmonium hydroxideCopper

Disclosed is a method for stripping a photoresist comprising: (I) providing a photoresist pattern on a substrate where the substrate has at least a copper (Cu) wiring and a low-dielectric layer thereon, and selectively etching the low-dielectric layer by using the photoresist pattern as a mask; (II) contacting the substrate after the step (I), with ozone water and / or aqueous hydrogen peroxide; and (III) contacting the substrate after the step (II), with a photoresist stripping solution that contains at least a quaternary ammonium hydroxide. The present invention provides a method for stripping a photoresist that enables to strip effectively photoresist films and etching residues after etching step even in a process not including an O2 plasma ashing treatment in micropatterning of a substrate having at least Cu wiring and a low-dielectric layer thereon, as in a dual damascene forming process, and, in addition, the method of the invention does not have any negative influence on the dielectric constant of the low-dielectric layer, and ensures an excellent anti-corrosivity.

Owner:TOKYO OHKA KOGYO CO LTD

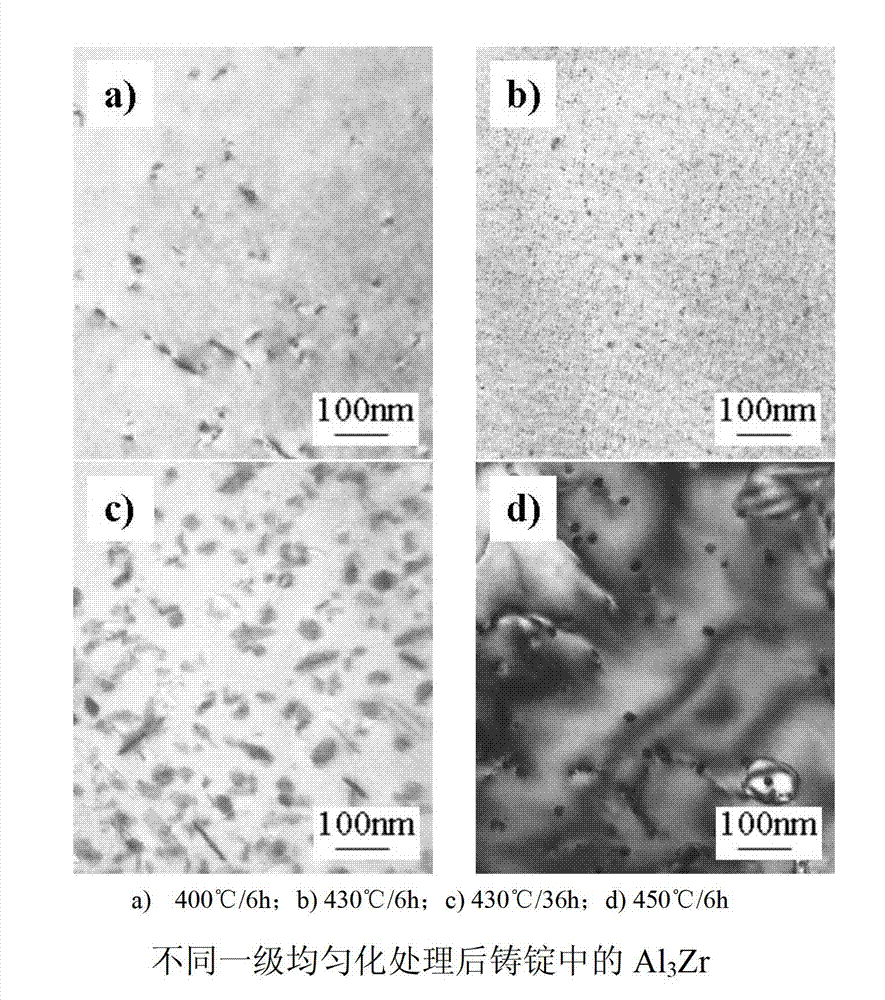

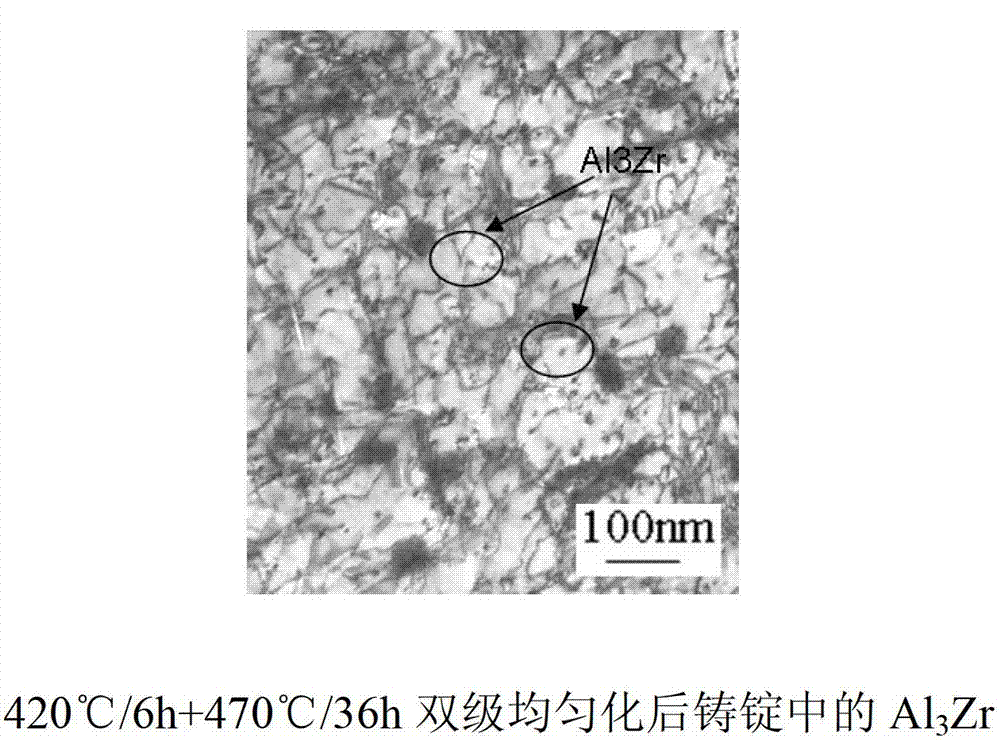

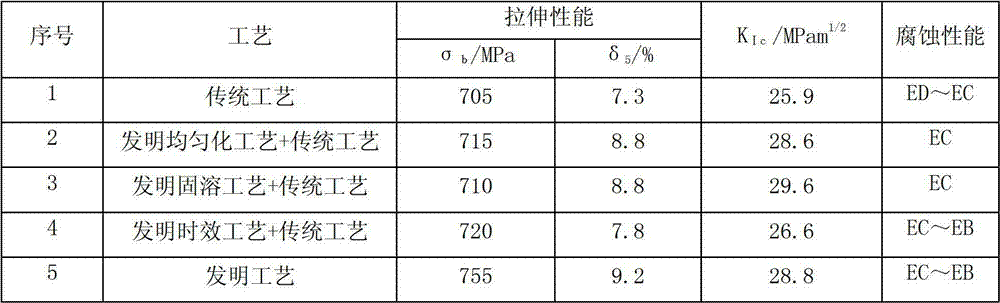

7000 series aluminum alloy material and preparation method thereof

The invention relates to a 7000 series aluminum alloy material and a preparation method thereof. The aluminum alloy material has alloy components of, by weight: 7.6-11.0% of Zn, 1.2-3.0% of Mg, 1.3-2.6% of Cu, 0.04-0.30% of Zr, 0.10-0.60% of Cr, no more than 0.08% of Si, no more than 0.10% of Fe, no more than 0.10% of Ti, no more than 0.15% of total other impurities (wherein the content of single other impurity is no more than 0.05%), and balance of Al. The alloy elements Zr and Cr can be added optionally or simultaneously. The materials are prepared according to the alloy composition; the raw materials are molten; in-furnace refining and standing are carried out; and the material is cast into alloy ingots with required specifications. The alloy ingots are subjected to a preferable graded uniformization process, and is forged or extruded, such that the alloy ingots are molded; the molded materials are subjected to graded solid solution treatment, and are quenched; and artificial forced aging is carried out, such that the material can be processed into parts. The microstructures of the material are uniform, and the property of the material is stable. The ultimate tensile strength of the material can be more than 750MPa. The extensibility of the material is higher than 10%. The T-L direction KIc of the material reaches 28MPam1 / 2.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

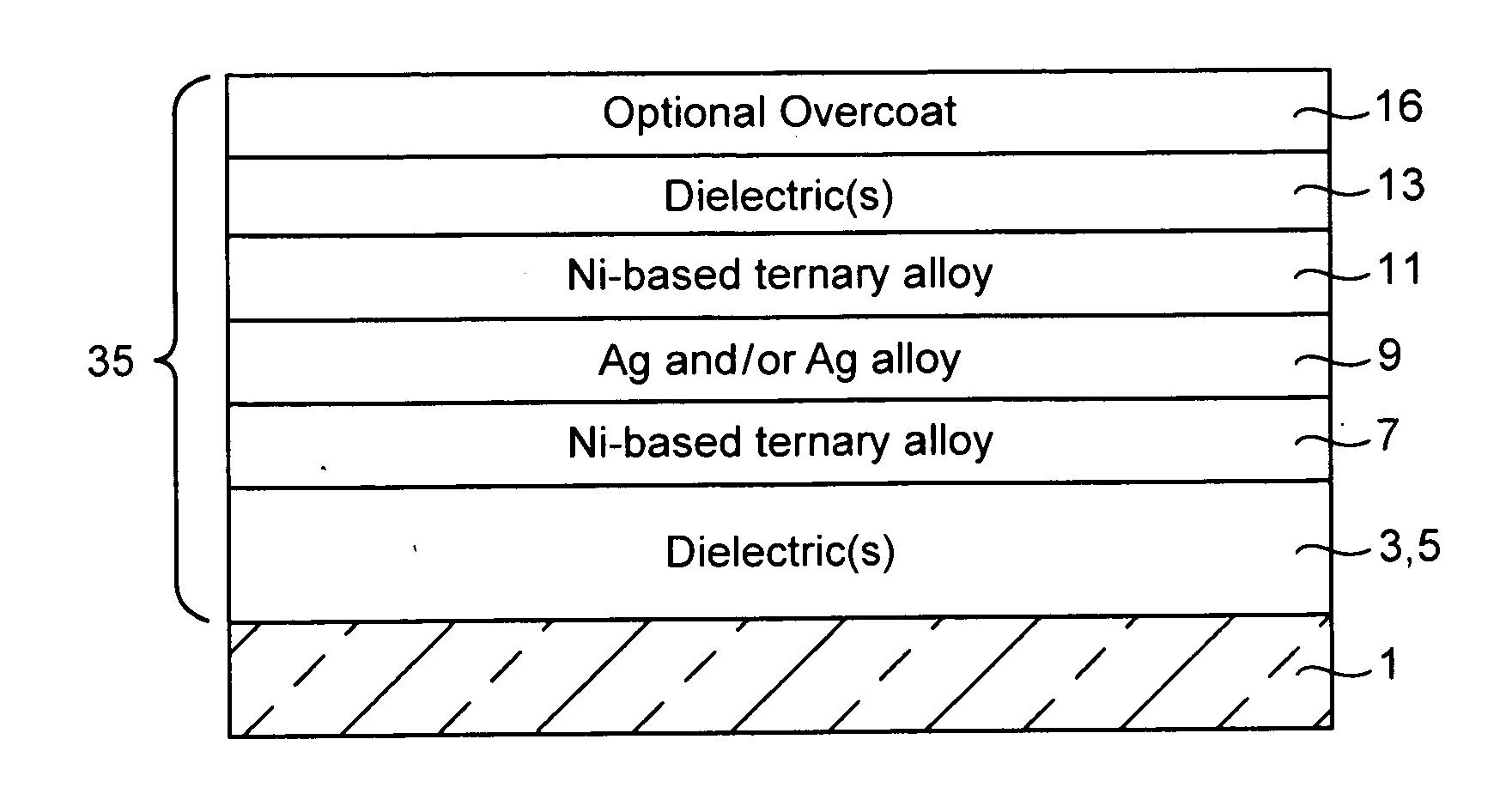

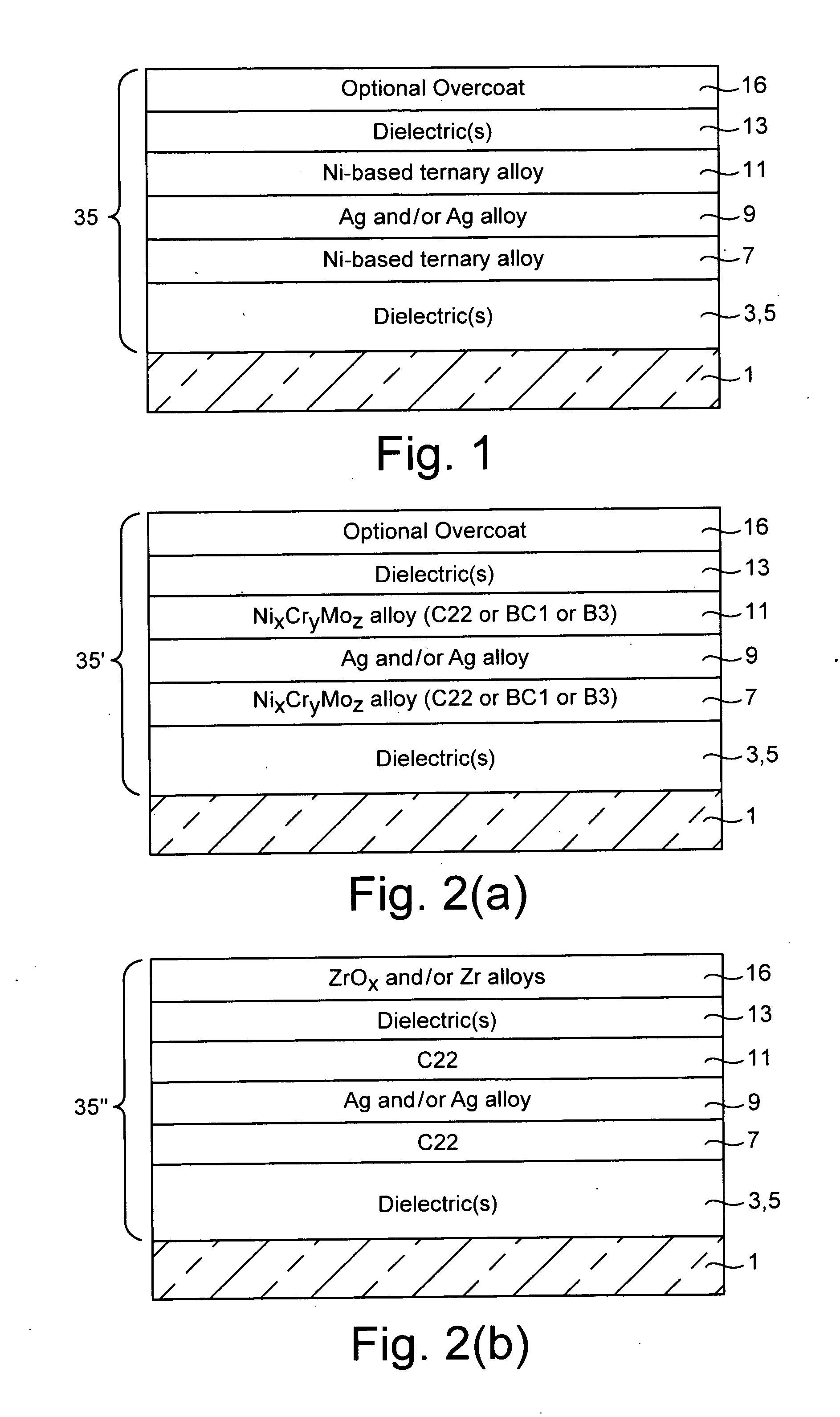

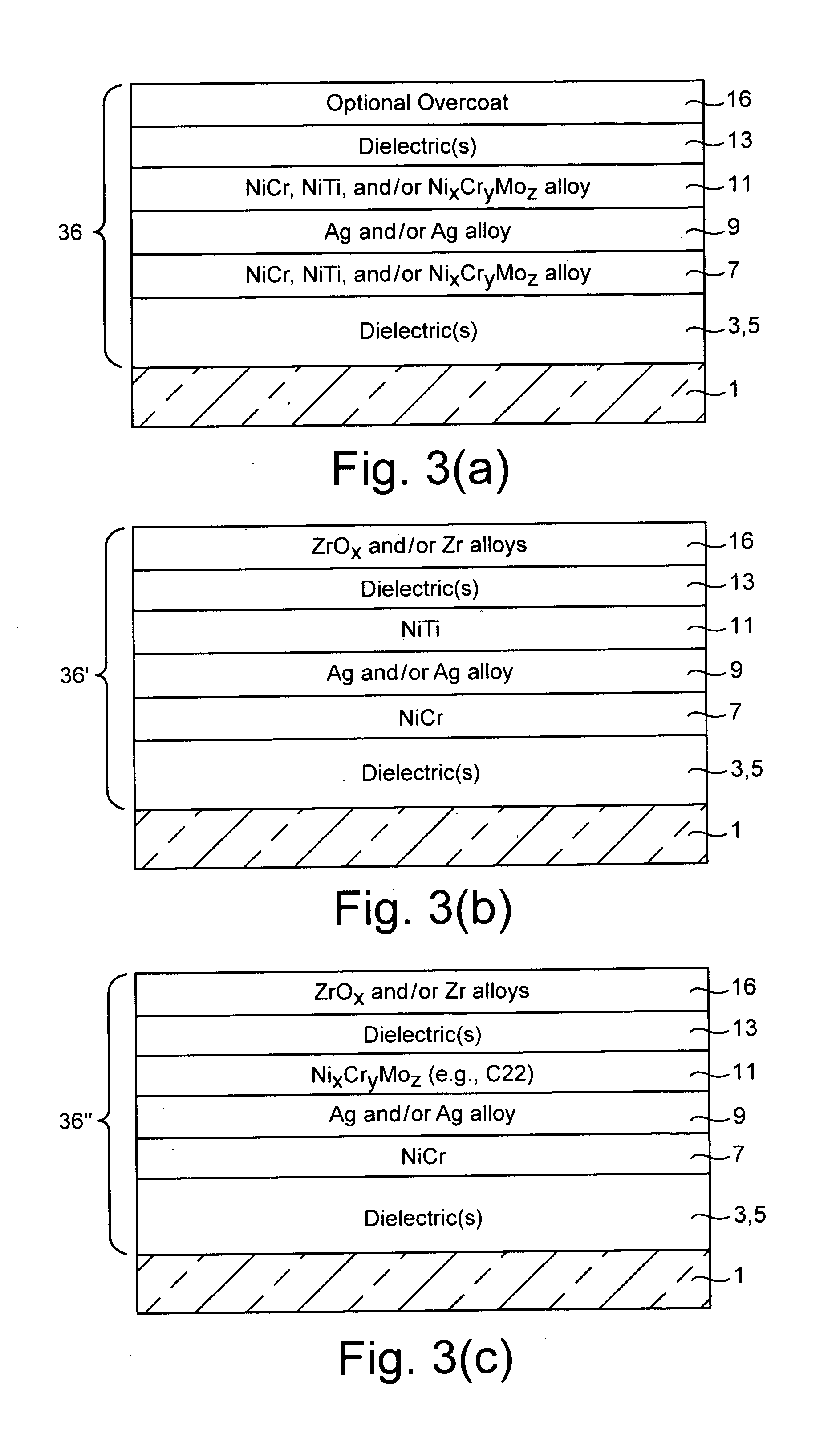

Barrier layers comprising Ni-inclusive ternary alloys, coated articles including barrier layers, and methods of making the same

ActiveUS20120225317A1Reduce sheet resistanceImprove transmittanceVacuum evaporation coatingSputtering coatingMaterials scienceChromium

Certain example embodiments relate to Ni-inclusive ternary alloy being provided as a barrier layer for protecting an IR reflecting layer comprising silver or the like. The provision of a barrier layer comprising nickel, chromium, and / or molybdenum and / or oxides thereof may improve corrosion resistance, as well as chemical and mechanical durability. In certain examples, more than one barrier layer may be used on at least one side of the layer comprising silver. In still further examples, a NixCryMoz-based layer may be used as the functional layer, rather than or in addition to as a barrier layer, in a coating.

Owner:GUARDIAN GLASS LLC

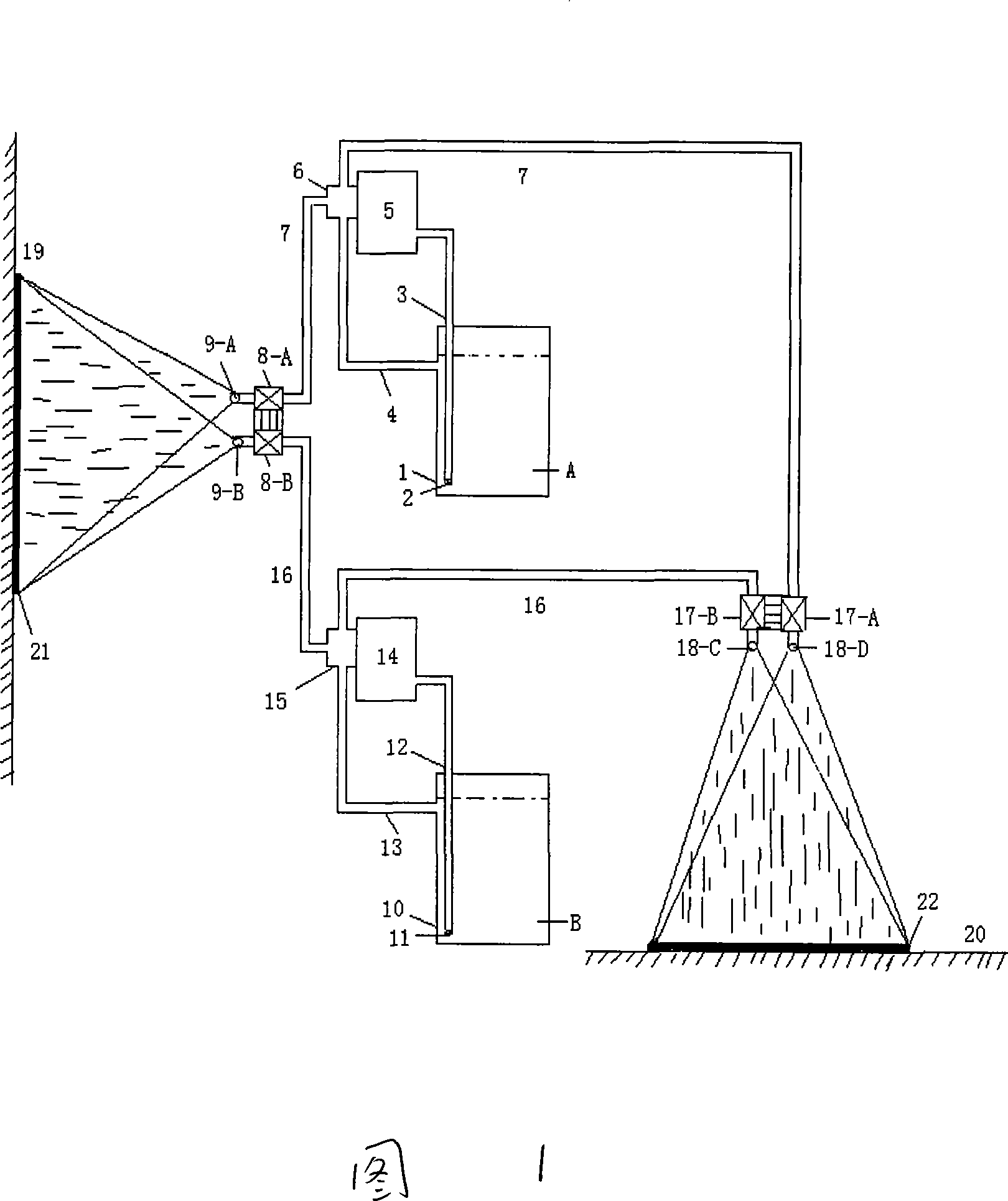

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com