Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

931 results about "Liquid rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

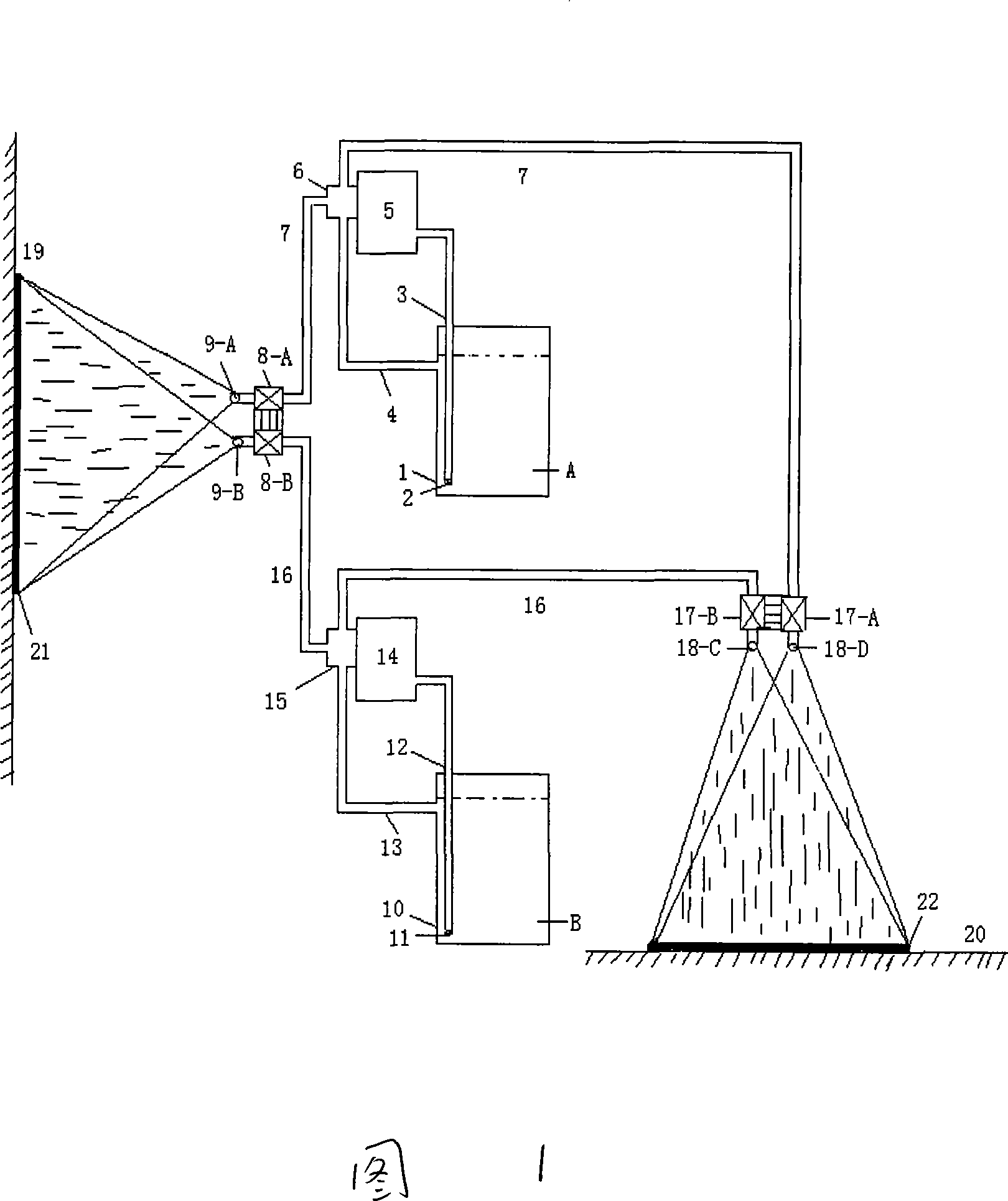

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

Methods and compositons for forming subterranean fractures containing resilient proppant packs

InactiveUS20040040713A1Point becomes highEasy to paintFluid removalFlushingFracturing fluidHigh intensity

Improved methods of forming fractures containing resilient proppant particle packs which prevent the production of sand and fines with produced fluids and prevent proppant flow-back in a subterranean zone penetrated by a well bore are provided. As the fractures are formed, a liquid hardenable resin component is mixed with a liquid hardening agent component and a liquid rubber component to form a hardenable resin composition. The hardenable resin composition is coated onto dry proppant particles which are suspended in the fracturing fluid and placed in the fractures. The hardenable resin composition on the resin composition coated proppant particles is allowed to harden and consolidate the proppant particles into high strength resilient permeable packs.

Owner:HALLIBURTON ENERGY SERVICES INC

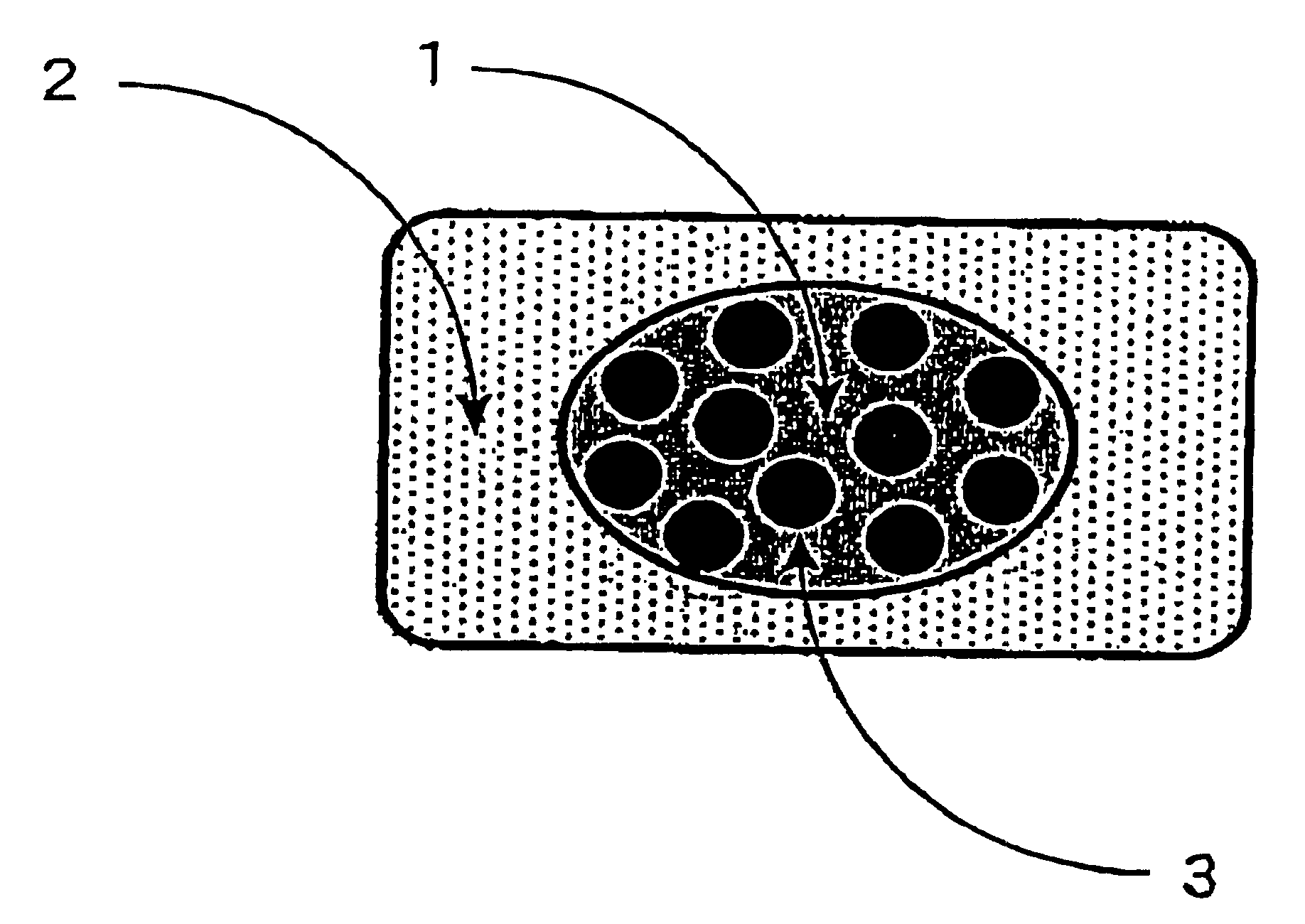

Prepreg and fiber-reinforced rubber materials

The object is to provide a carbon fiber-reinforced rubber material which is superior in heat resistance, water resistance, and dimensional stability and exhibits resistance to fatigue from flexing at a practical level. The present invention relates to a prepreg comprising a liquid rubber composition having a viscosity in a range of 0.01 Pa.s to 100 Pa.s at 70° C. and substantially containing no solvent, the liquid rubber being impregnated into a reinforcing fiber, and relates to a fiber-reinforced rubber material comprising the prepreg in which the liquid rubber is crosslinked. Also, the present invention relates to a fiber-reinforced rubber material comprising a substrate comprising a rubber component, the substrate being reinforced by a core material comprising a prepreg of a reinforcing fiber impregnated with the same rubber component.

Owner:TORAY IND INC

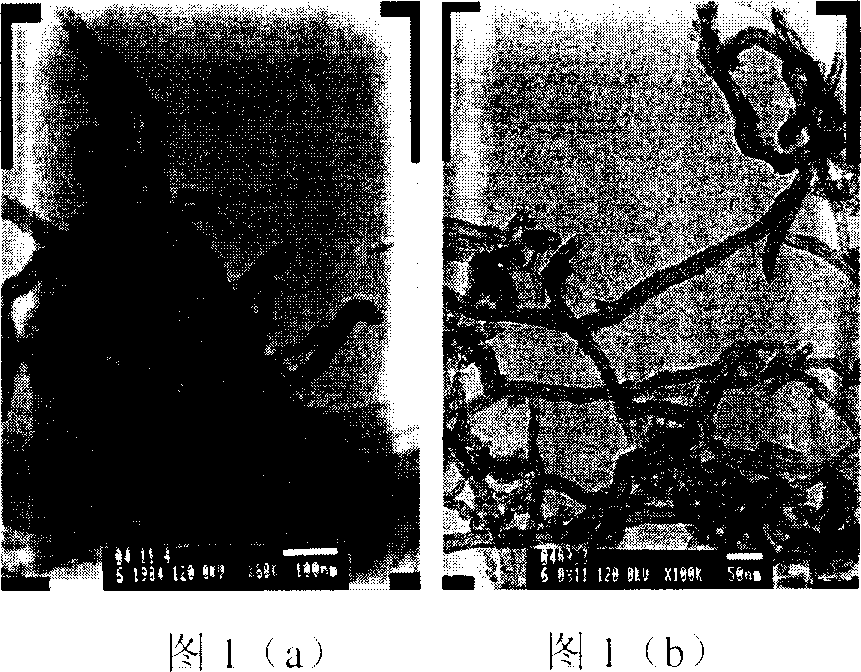

Natural liquid rubber slurry with added carbon nanotube and its prepn process

The present invention relates to composite polymer material performance improving technology. The liquid natural rubber slurry contains natural latex and carbon nanotube (CNT) and has total solid content of natural latex and CNT in 5-30 % and weight ratio between CNT and dry natural latex of 1-50 %. The liquid natural rubber slurry is prepared through surface treatment of CNT for hydrophilicity; mixing with dispersant and deionized water to obtain water suspension of CNT; regulating the pH value of the suspension to 9-12; and finally mixing with natural latex to obtain the liquid natural rubber slurry with added CNT. The liquid natural rubber slurry with homogeneously dispersed CNT is used in preparing CNT modified rubber powder and CNT modified sulfurized rubber products with greatly raised mechanical, electrically conducting, heat conducting, antistatic and other performance.

Owner:TSINGHUA UNIV

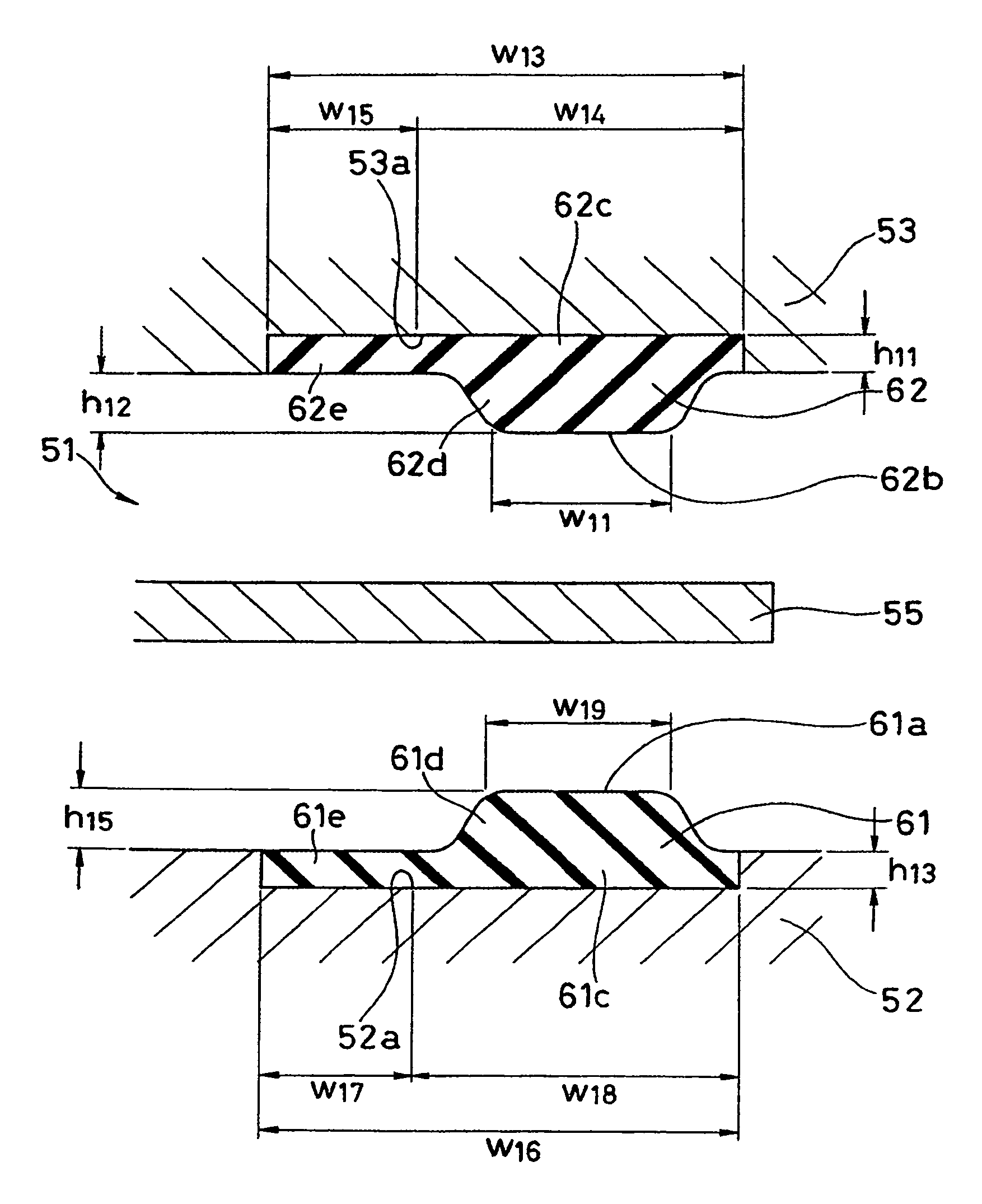

Gasket for fuel cell and method of forming it

In a gasket used for a fuel battery, in order to solve problems with respect to making a seal portion thin, improving an assembling property, preventing a position shift, making a surface pressure low, making the surface pressure uniform, and the like, a gasket lip made of a liquid rubber hardened material is integrally formed on a surface of a flat plate made of a carbon, a graphite, a conductive resin such as a conductive phenol resin or the like, an ion exchange resin, or a metal such as a stainless steel, a magnesium alloy or the like, or on a groove portion applied to the surface.

Owner:NOK CORP

Modified hydrogenated nitrile-butadiene rubber and its preparing method

The present invention relates to the preparing technology of composite rubber material. Carbon nanotube via surface treatment and liquid rubber are ultrasonically mixed and added into partial hydrogenated nitrile-butadiene rubber to prepare mother rubber; the mother rubber is mixed with the rest hydrogenated nitrile-butadiene rubber, carbon black, zinc oxide and sulfurizing agent, and the mixture is mixed in a rolling mixer or a Banbury mixer and sulfurized to obtain the carbon nanotube modified hydrogenated nitrile-butadiene rubber. The present invention has the beneficial effects of raised heat performance, antiwear performance, mechanical strength, antiageing performance, etc. raised use performance and expanded application range.

Owner:SINOPEC OILFIELD EQUIP CORP

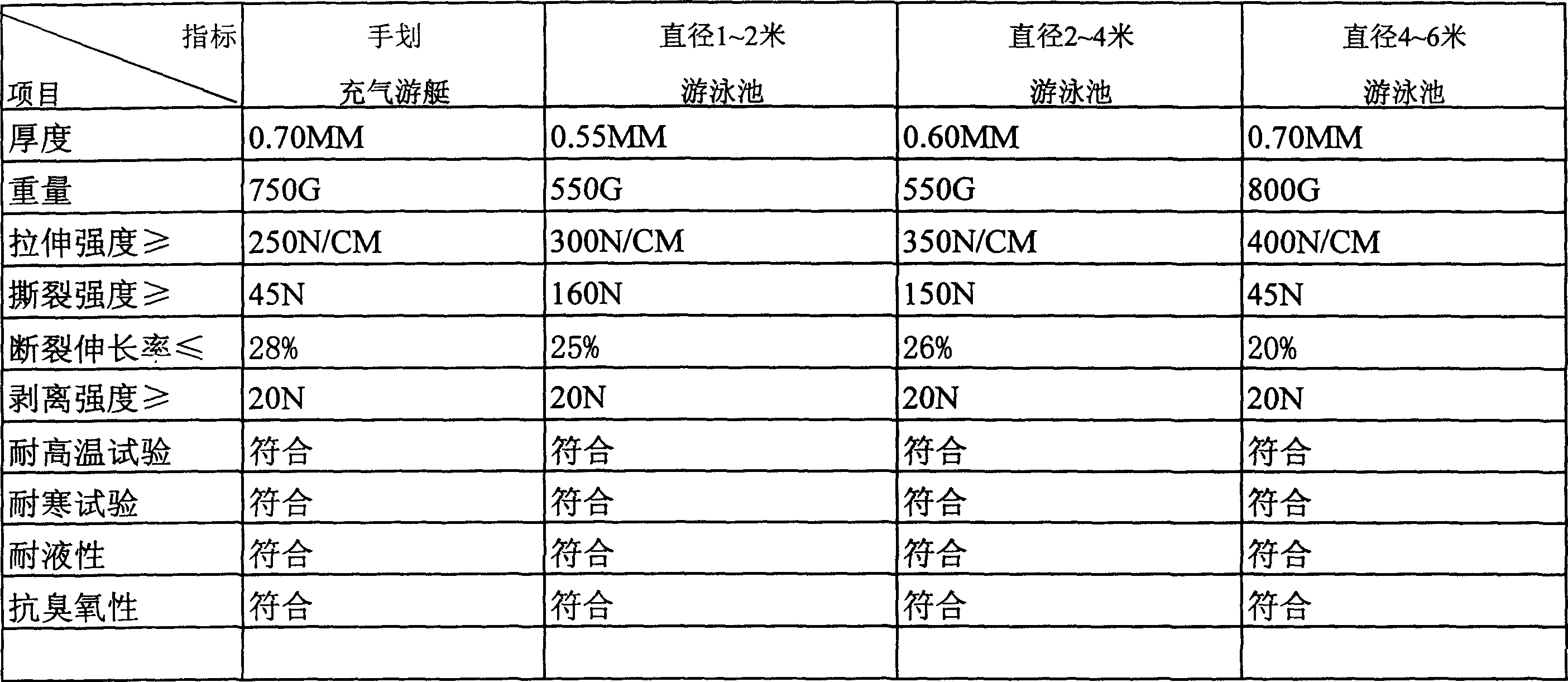

High strength anti-stamen suction water-proof net clamping cloth and its preparing method

InactiveCN1858341AGood physical propertiesGood suction resistanceLiquid/gas/vapor textile treatmentBreaking strengthGlass fiber

The present invention relates to netted fabric technology, and is especially a kind of high strength wicking-resisting waterproof netted fabric and its preparation process. The netted fabric is prepared with radial braid possessing directional structure as base fabric and through soaking with liquid rubber, stoving and adhering modified PVC films to its two sides. The netted fabric of the present invention has high tensile strength, high breaking strength, high stripping strength, powerful wicking resistance, good waterproof performance and high weather resistance, and may be used widely in making inflated toy, household swimming pool, tent, etc.

Owner:上海光仁塑胶制品有限公司

High-strength controllable gelout chemical temporary plugging liquid rubber stopper

ActiveCN102061152AReduce harmLow viscosityDrilling compositionSealing/packingPolymer scienceDifferential pressure

The invention relates to a high-strength controllable gelout chemical temporary plugging liquid rubber stopper. The rubber stopper is characterized by being prepared from the following components in percentage by weight by carrying out solution crosslinking polymerization in water: 0.3-1 percent of amphoteric polyacrylamide, 6-12 percent of cationic monomer, 1-5 percent of anionic monomer, 0.02-0.06 percent of cross-linking agent, 0.02-0.06 percent of initiator and 81.9-93 percent of water. The liquid rubber stopper can be resistant to a temperature of 60 DEG C, the rubber forming time is adjustable in 2-50min, and the rubber stopper can bear fracture construction differential pressure higher than 15MPa and can be used for replacing a mechanical packer to effectively plug a target layer and then carry out conventional fracture construction and controlling gelout hydrating within required time.

Owner:PETROCHINA CO LTD

Bicomponent terminal mercapto polyurethane mildewproof sealant and preparation thereof

InactiveCN101434825AImprove mechanical propertiesLess irritatingOther chemical processesPolyureas/polyurethane adhesivesVulcanizationAntioxidant

The invention relates to a dual-component sulfhydryl-terminated polyurethane mildew-proof sealant and a preparation method thereof, wherein, the sealant consists of component A and component B, wherein, according to the parts by weight, the component A comprises 80-120 parts of sulfhydryl-terminated polyurethane liquid rubber, 20-200 parts of filling material, 10-100 parts of plasticizer, 0.5-10 parts of tackifier, 0.1-5 parts of mould inhibitor, 0-5 parts of vulcanization regulator, and 0-5 parts of antioxidant; the component B comprises 80-120 parts of vulcanizing agent, 20-150 parts of plasticizer, 20-200 parts of filling material, and 0-5 parts of vulcanization regulator; and the proportion of component A and component B is 10:0.5-2. The mildew-proof sealant has the tensile strength of 5.0MPa, breaking elongation rate of 1020 percent, the bonding strength with the concrete of 2.5MPa, and the mildew-proof level of being less than or equal to 1; the sealant can be used for the fields such as electrons, mechanicals, and the like, can meet the sealing and mildew-proof requirement under the conditions of long-term water immersion, damp-heat or other conditions where mildews are easy to breed, has no exhaust of three wastes and is friendly to environment.

Owner:HENAN YONGLI CHEM

High-permeability liquid rubber spray coating

InactiveCN102329566AHigh bonding strengthImprove waterproof and anti-seepage performanceUnspecified rubber coatingsConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

The invention discloses a high-permeability liquid rubber spray coating, and relates to the technical field of spray coatings. The high-permeability liquid rubber spray coating comprises a component A and a component B, wherein the component A is anionic liquid rubber asphalt emulsion; the component B is a coagulant solution; the component A has the solid content of liquid rubber asphalt emulsion of 50-75 weight percent, and comprises the following components in percentage by mass: 1 to 35 percent of rubber emulsion, 10 to 50 percent of asphalt emulsion, 0.01 to 2 percent of anionic dispersing agent, 0.01 to 2 percent of anionic surfactant, 0.1 to 10 percent of fatty alcohol-polyoxyethylene ether, 0.1 to 10 percent of alkali resistant wetting agent OEP-70 and 0.1 to 10 percent of alkali resistant wetting agent AEP; and the component B is an aqueous solution at the concentration of 3-18 percent, which is prepared by mixing calcium chloride and composite aluminum-iron polymer in percentage by mass. The wetting agents are added into the spray coating, and the coating has high permeability and wider application range.

Owner:DALIAN MEICHENTE TECH

Spraying quick-setting rubber asphalt waterproof coating material

ActiveCN103627258AWith anti-adhesive effectImprove adhesionConjugated diene hydrocarbon coatingsNatural rubber coatingsComposite constructionWater based

The invention relates to a spraying quick-setting rubber asphalt waterproof coating material. A special technology is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material. The spraying quick-setting rubber asphalt waterproof coating material is a water-based spraying paint prepared according to a ratio, and a preparation method of the spraying quick-setting rubber asphalt waterproof coating material comprises following steps: a liquid rubber asphalt latex emulsion is prepared by mixing superfine, suspended and micro-emulsion modified emulsified asphalt with high-molecular polymer rubber latex; and the liquid rubber asphalt latex emulsion is mixed with a coagulant. Cold spraying construction is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material; elastic coating film elongation is more than 1000%; restoration ratio is more than 95%. The spraying quick-setting rubber asphalt waterproof coating material possesses ultraviolet resistance, high construction efficiency, high bonding strength, excellent high-temperature resistance, excellent low temperature flexibility, and better quick setting effect; and is capable of forming films in 3 seconds. The spraying quick-setting rubber asphalt waterproof coating material is water based; is friendly to the environment; possesses no toxicity, and excellent endurance; is quick and convenient for construction; and is a novel environmental friendly waterproof paint with a wide application range. The spraying quick-setting rubber asphalt waterproof coating material is mainly used for various waterproof and anticorrosion projects. The spraying quick-setting rubber asphalt waterproof coating material is used for individual construction of waterproof projects, for composite construction of waterproof projects together with waterproof roll, and for individual construction of anticorrosion projects.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

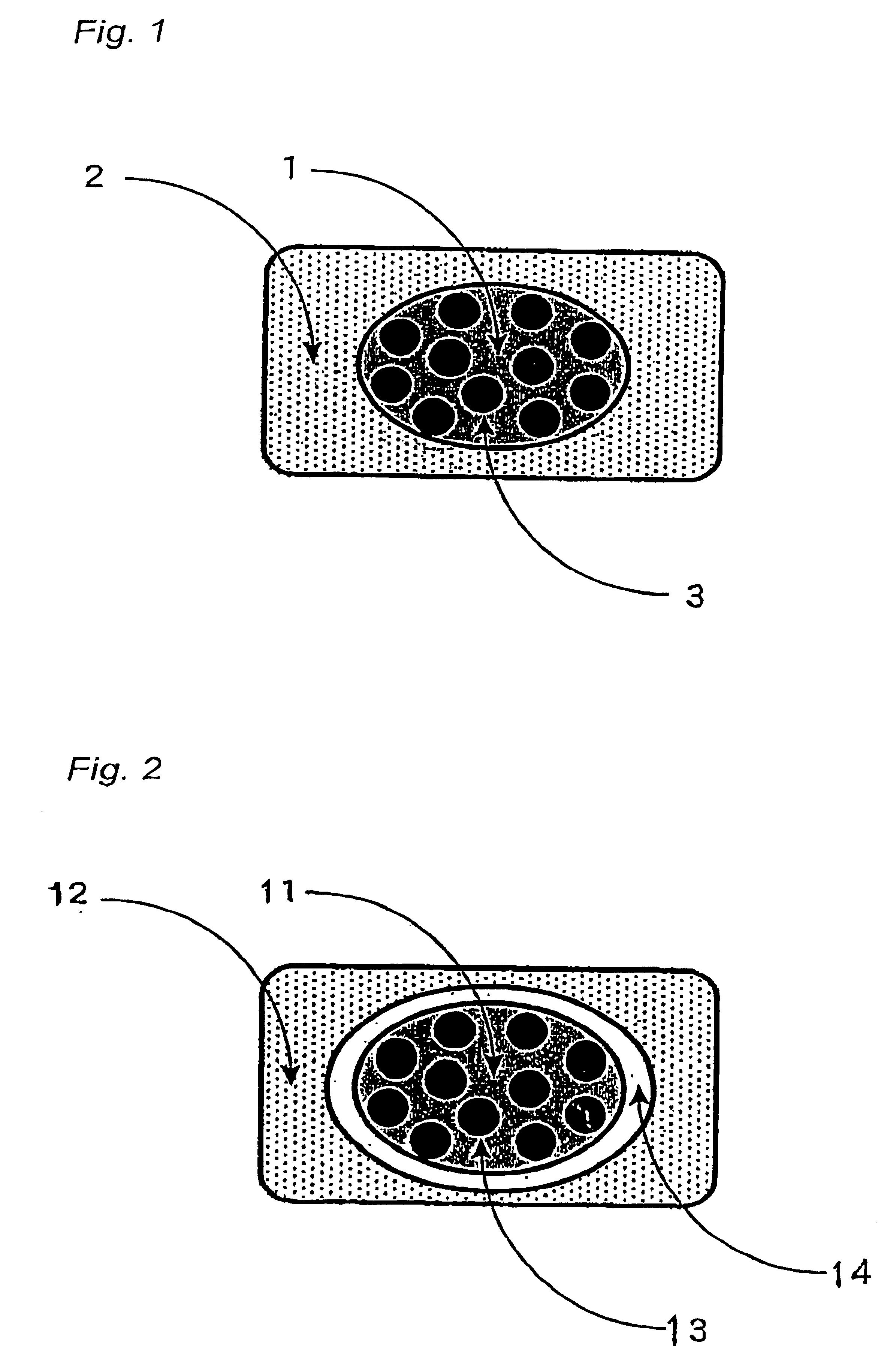

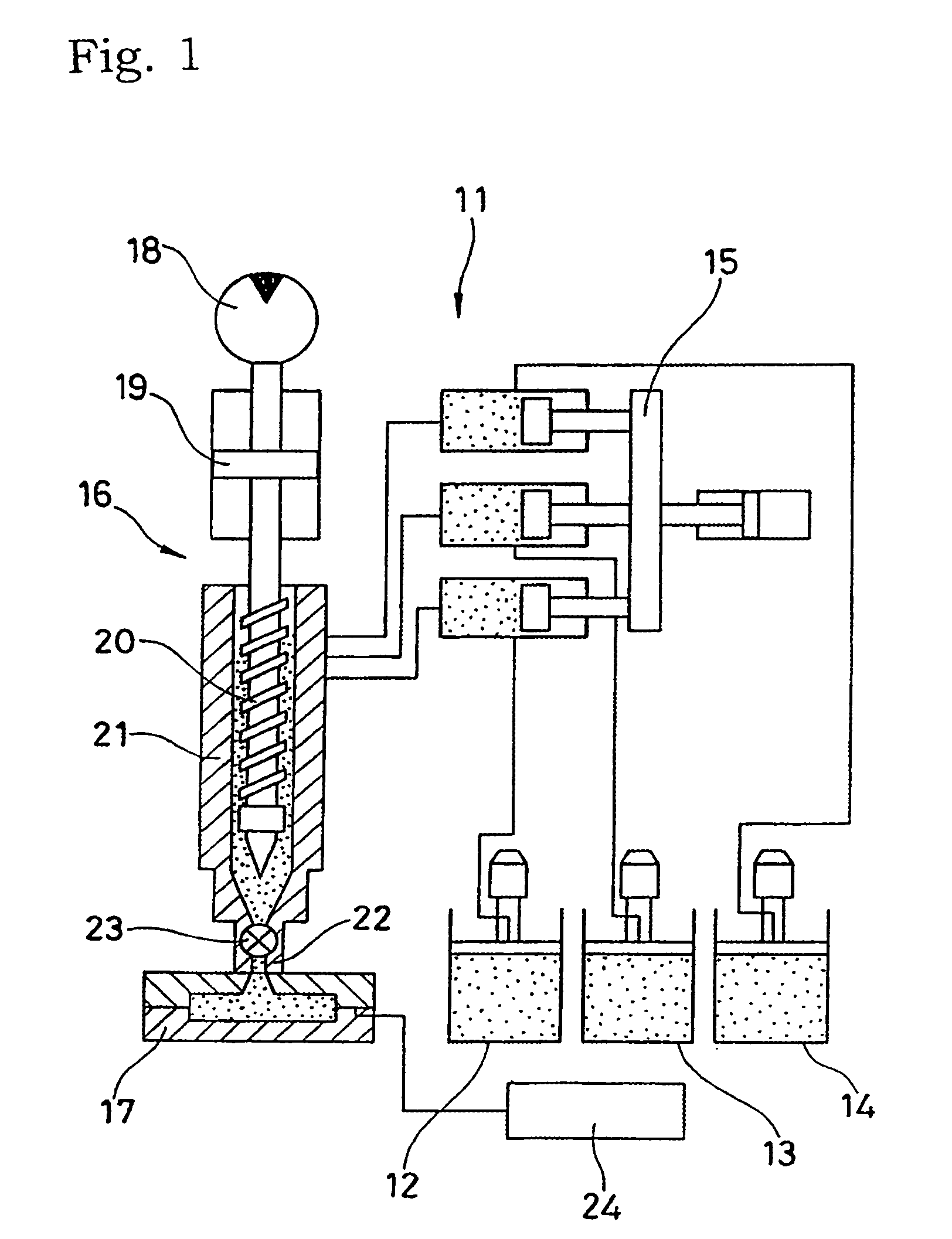

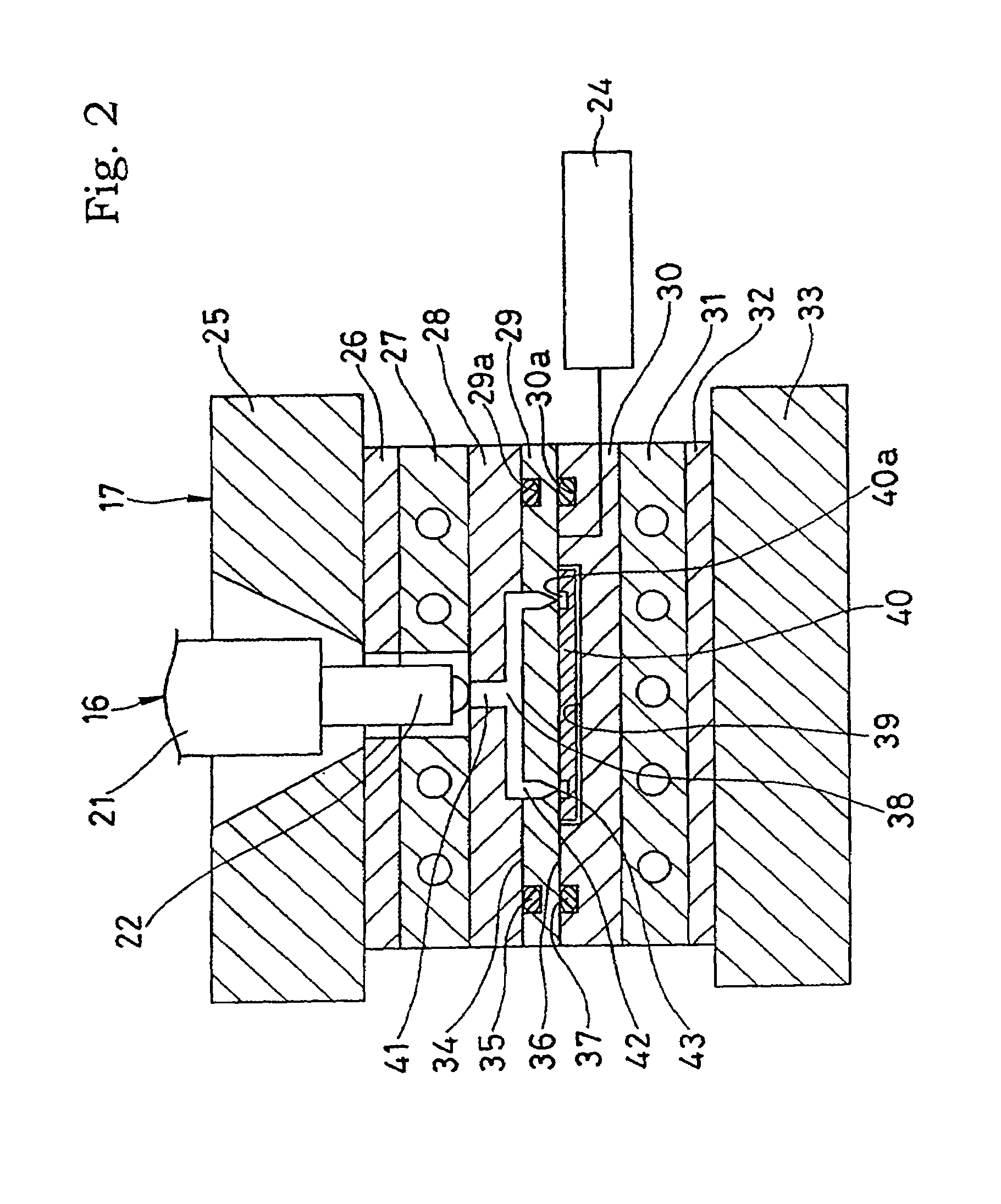

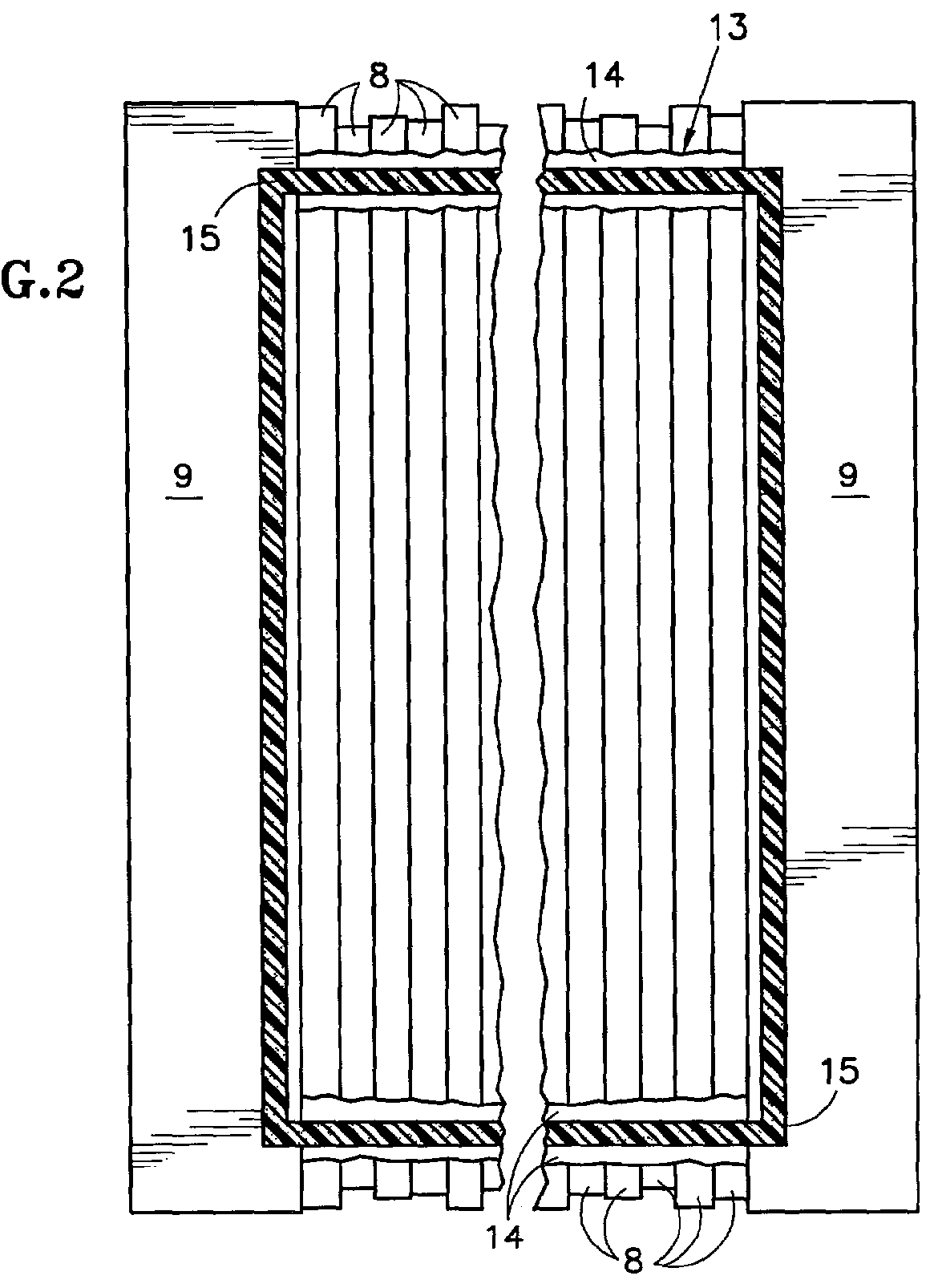

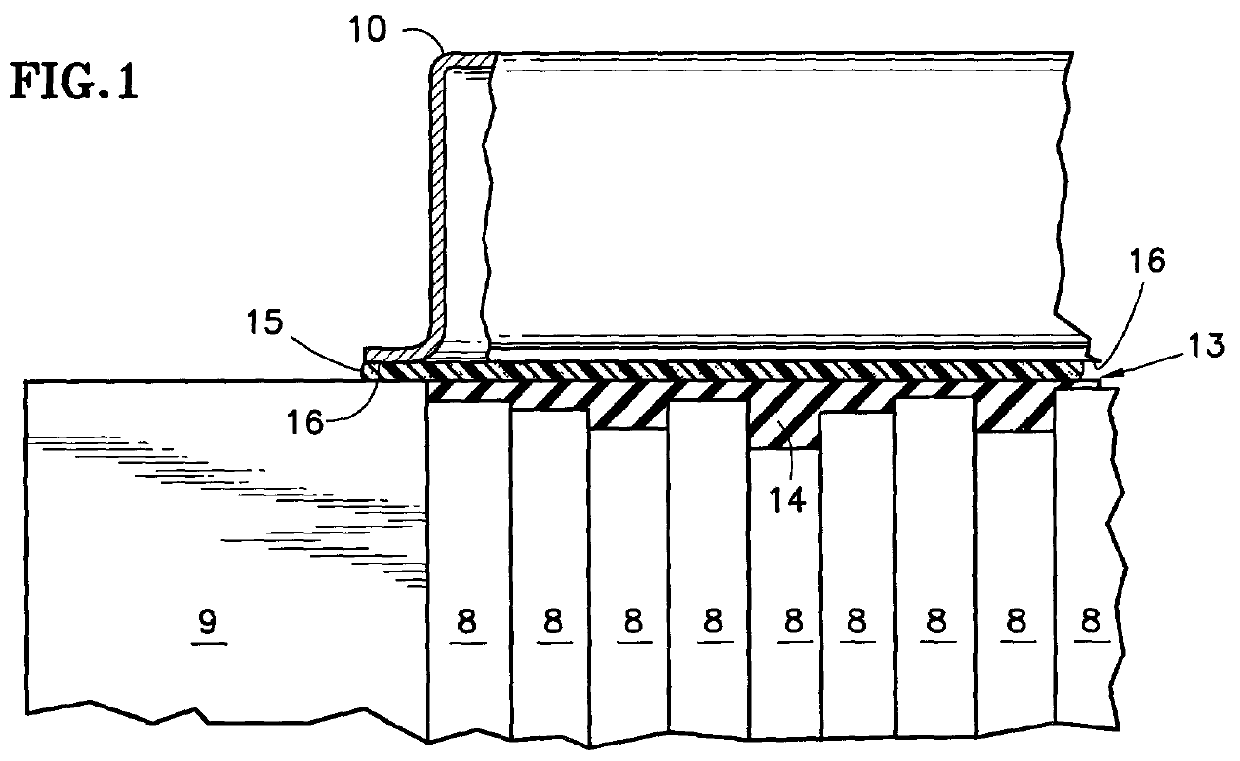

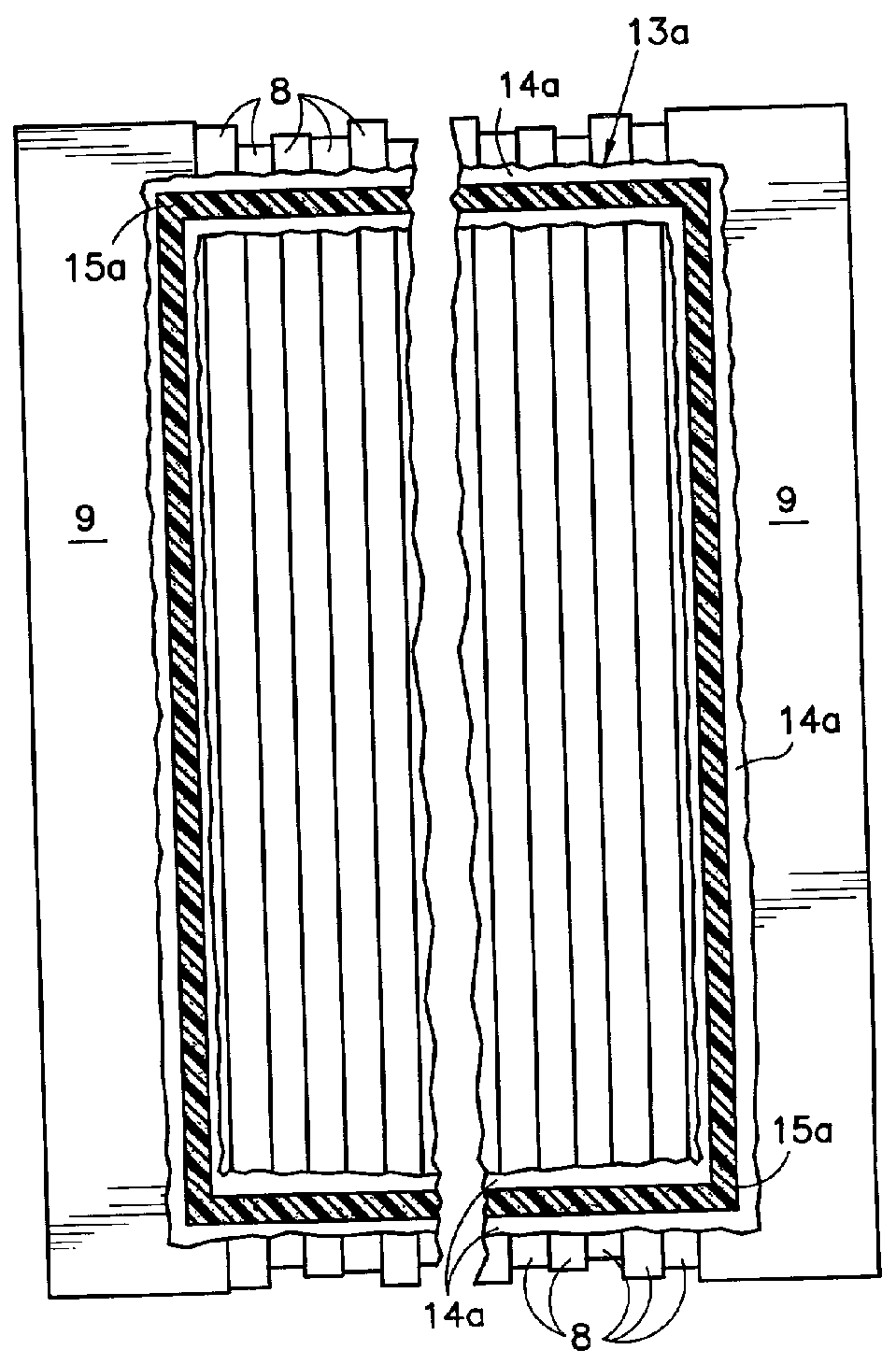

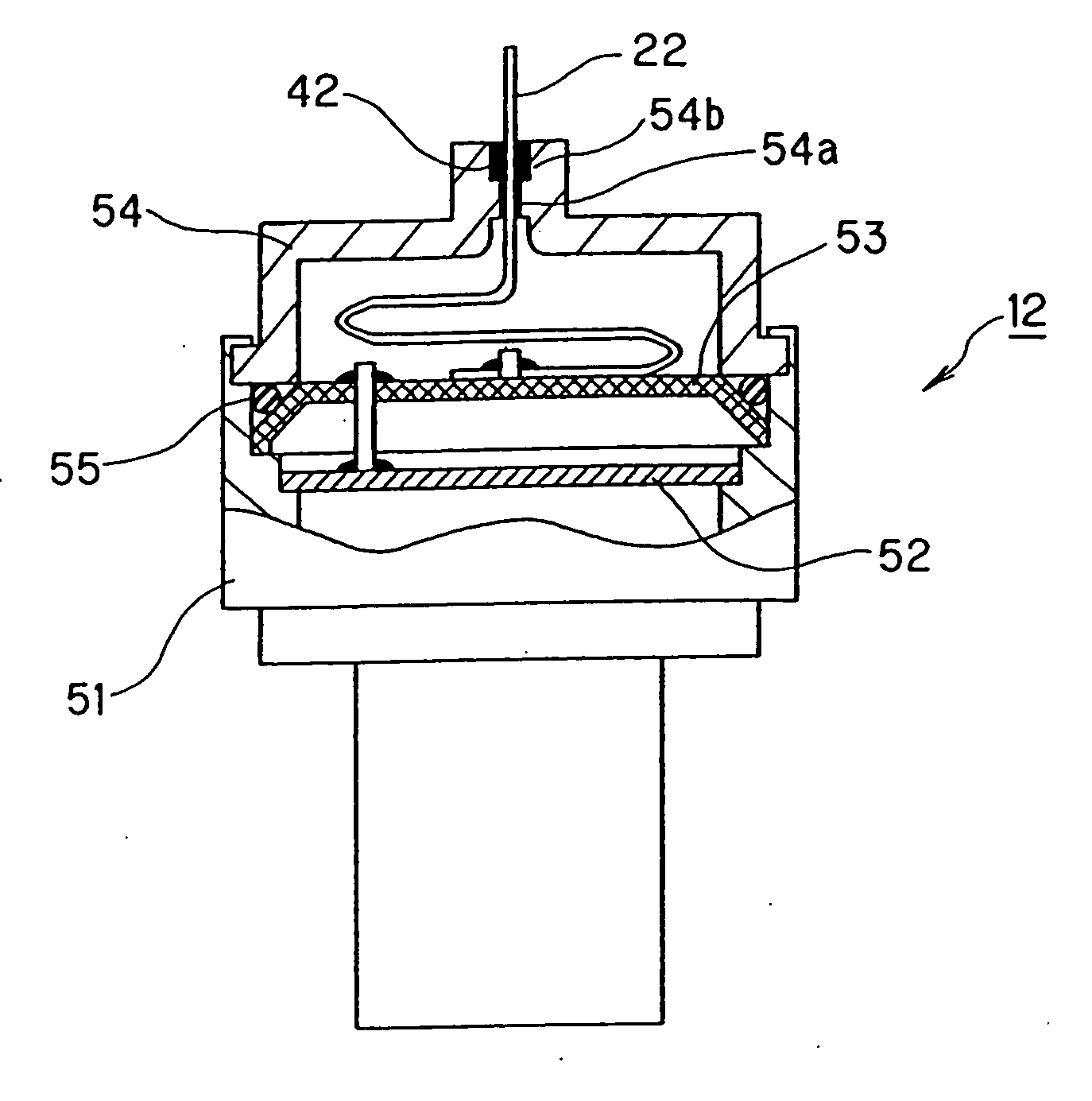

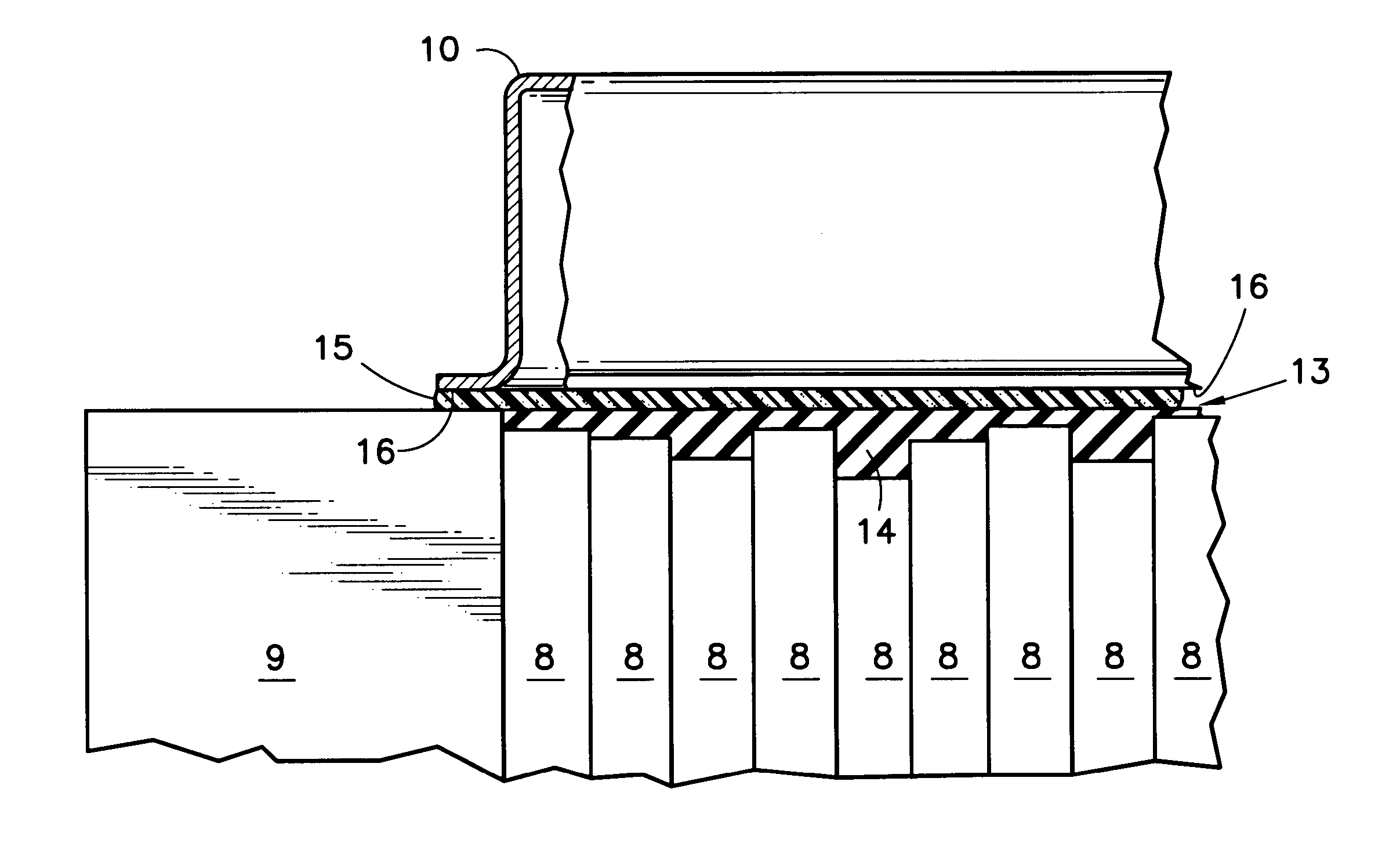

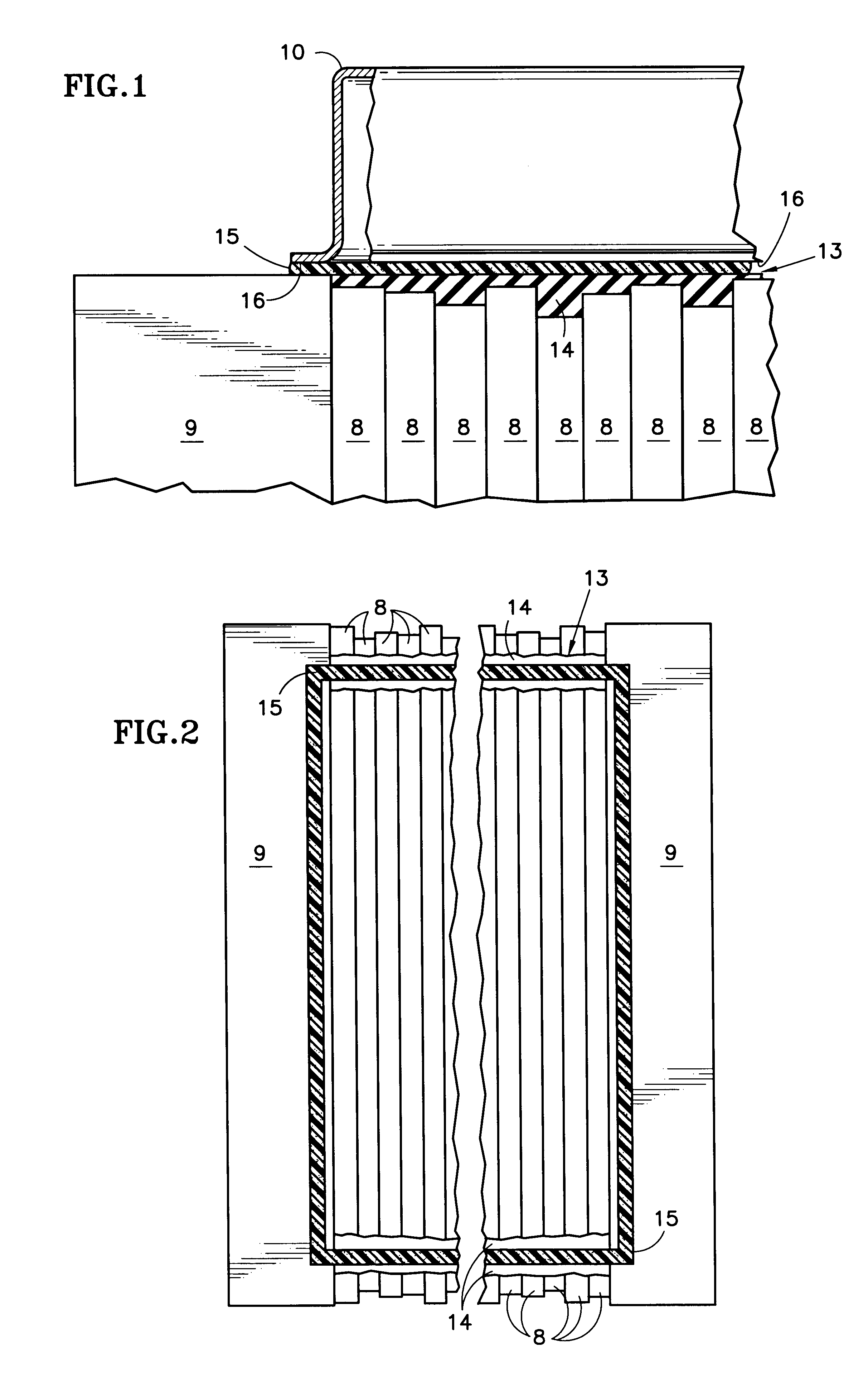

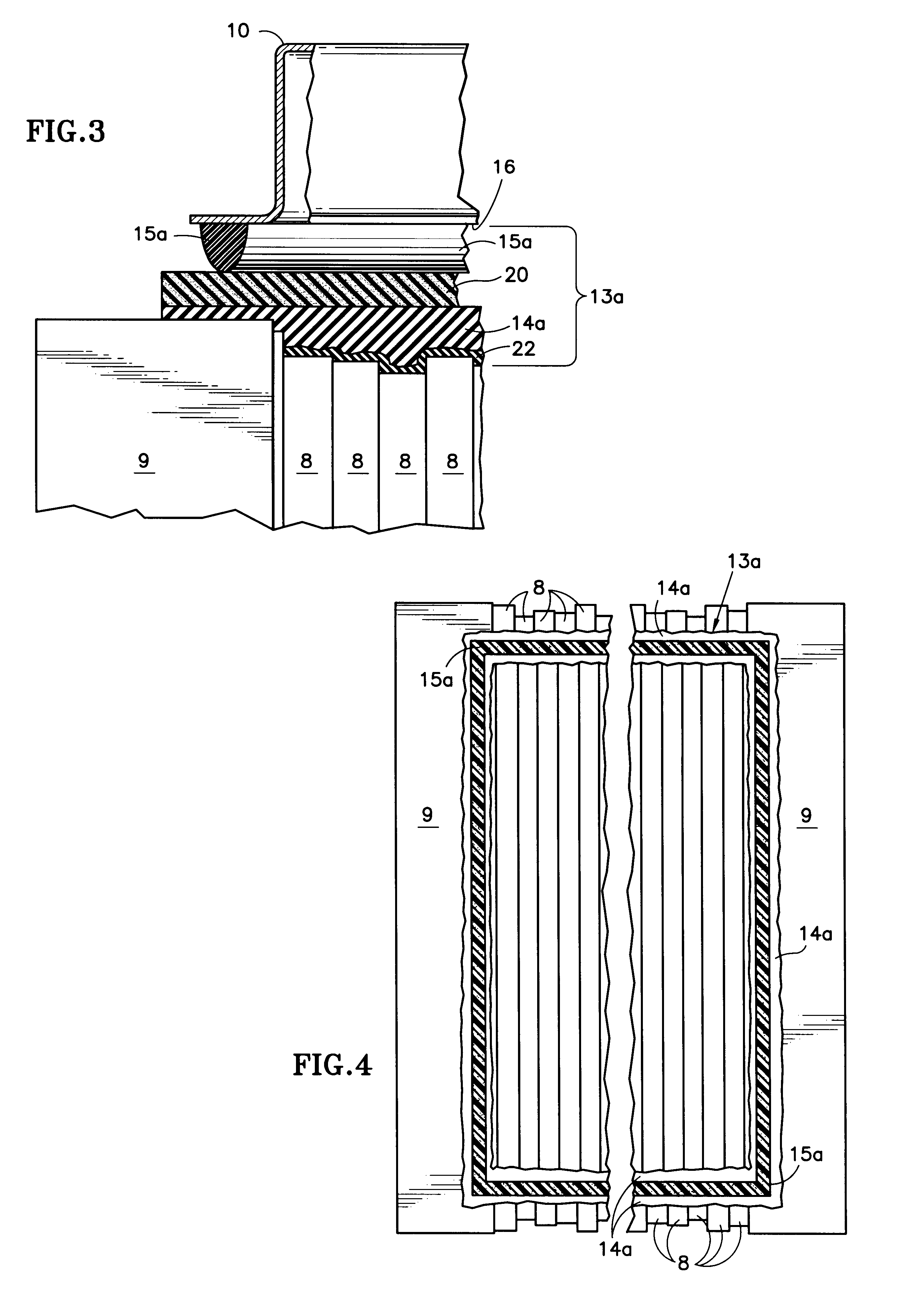

Proton exchange membrane fuel cell external manifold seal

InactiveUS20010055708A1Low creepCompressibleSolid electrolytesFuel cells groupingLow temperature curingEngineering

A sealant system 13 for a manifold 10 of a proton exchange membrane fuel cell includes low temperature cured or heat cured silicone rubber bridges 14, 14a, 14c between the end plates 9 to compensate for the uneven edges of various fuel cell component layers, and a layer 15 of silicone rubber foam or sponge, or a molded silicone rubber gasket 15a, extending across the bridges and along the end plates, around the entire contact perimeter surfaces of the manifold, to seal the manifold to the fuel cell. The cured silicone rubber may extend along the end plates between the bridges. A rubber strip 20 may be adhered to the silicone rubber bridges and end plates. The bridges may comprise a first layer 22 of low shrinkage self-leveling RTV liquid rubber with viscosity in the range of 10,000-20,000 cps and a second layer 14 of RTV liquid rubber.

Owner:AUDI AG

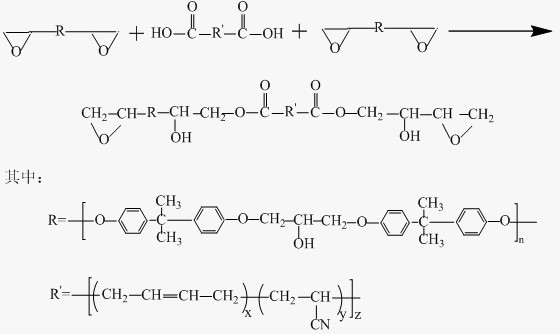

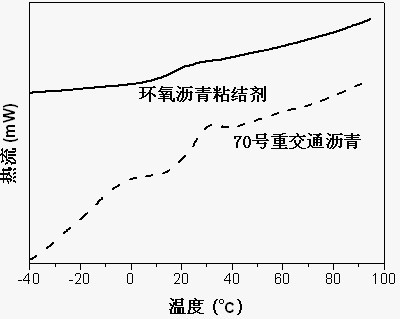

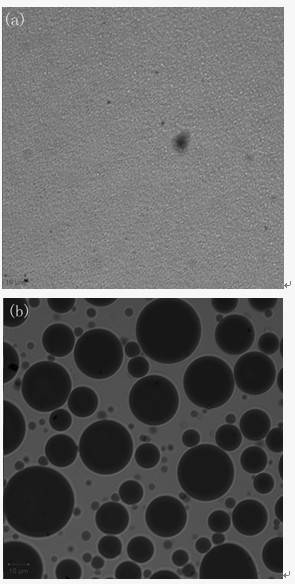

High-performance thermosetting epoxy asphalt binder and preparation method thereof

InactiveCN102559136AImprove adhesionImprove water resistanceBituminous material adhesivesCarboxyl rubber adhesivesLong chain fatty acidCross-link

The invention discloses a high-performance thermosetting epoxy asphalt binder, comprising a part A component and a part B compound, wherein the part A component comprises 100 weight parts of epoxy resin, 20-35 weight parts of flexibilizer, 0.5-2 weight parts of promoter, and 8-20 weight parts of diluent; the part B component comprises 300-350 weight parts of asphalt, 150-160 weight parts of flexible curing agent, 10-15 weight parts of promoter, 2-5 weight parts of compatilizer, and 100 weight parts of diluent; and the ratio of the part A component to the part B component is 100:350-440. According to the invention, by using flexible long-chain fatty acid anhydride as the curing agent and carrying out solidification reaction on the curing agent with the epoxy resin, a stereo cross-linked structure is formed, and the bonding capability and water resistance of asphalt are increased; by using liquid rubber as the flexibilizer, the flexibility of the epoxy asphalt binder is raised to adapt to the flexibility of a steel plate, and by prereacting the flexibilizer with epoxy resin firstly for grafting, the compatibility between the epoxy asphalt binder and asphalt is raised. The epoxy asphalt binder is suitable for bonding and waterproofing of steel bridge floor, cement concrete bridge floor, tunnel, highway and other pavements. The invention also discloses a preparation method of the epoxy asphalt binder.

Owner:NANJING UNIV

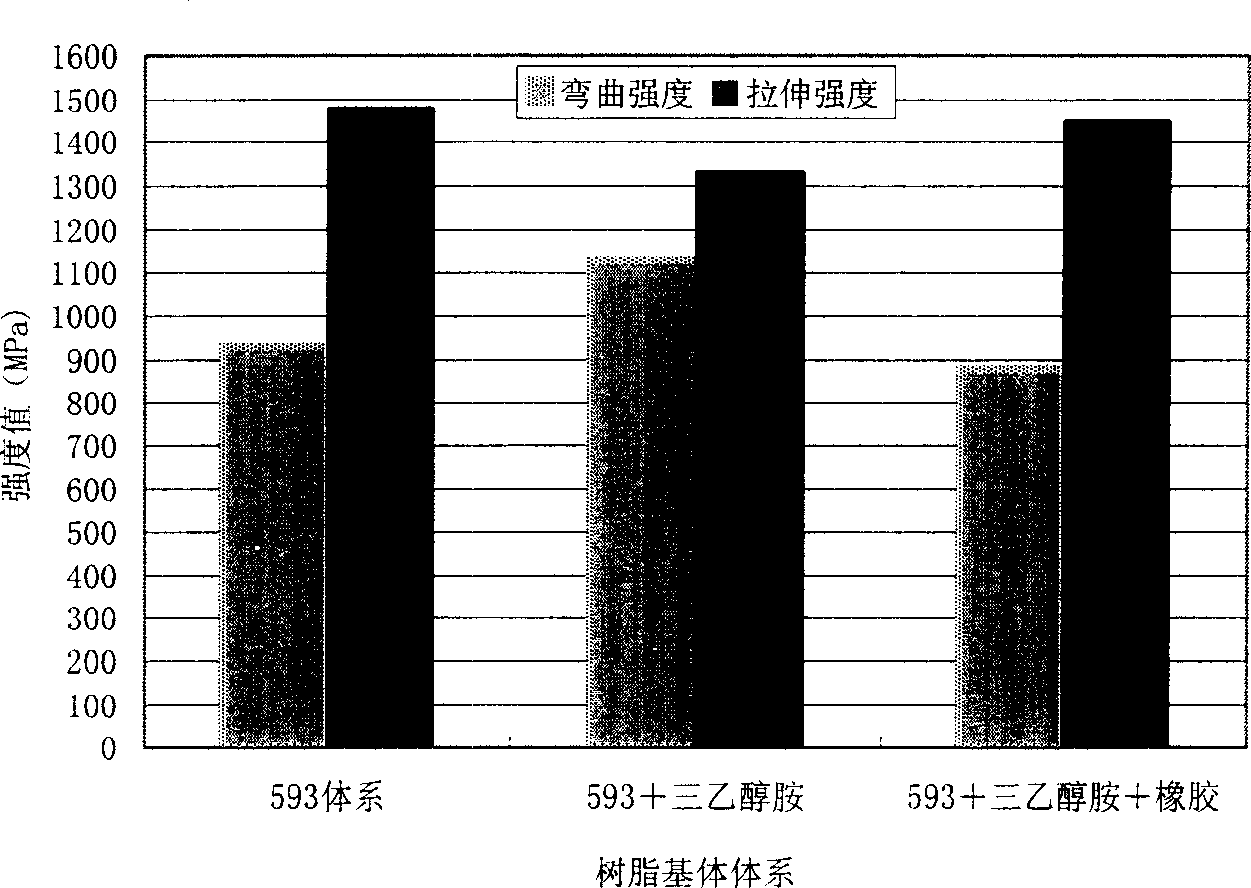

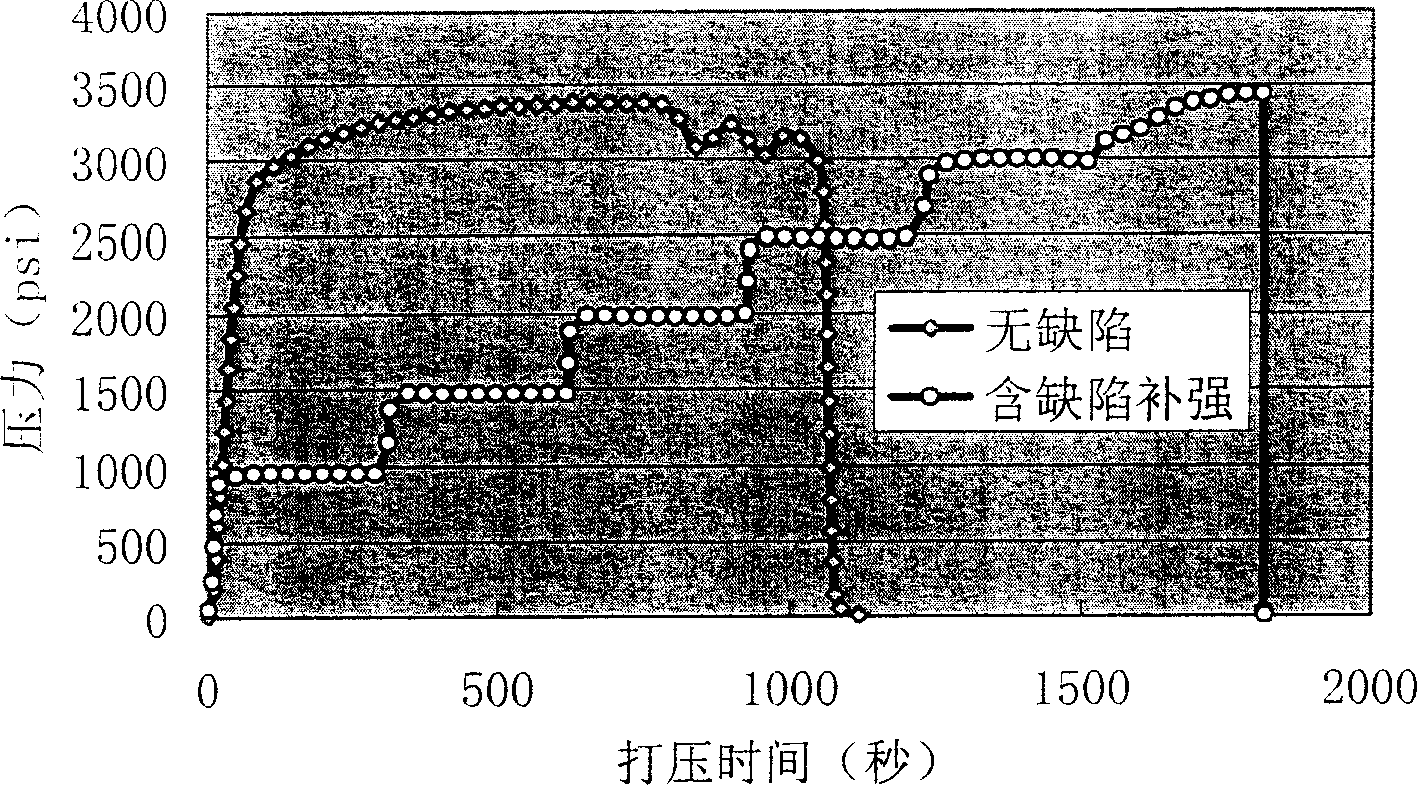

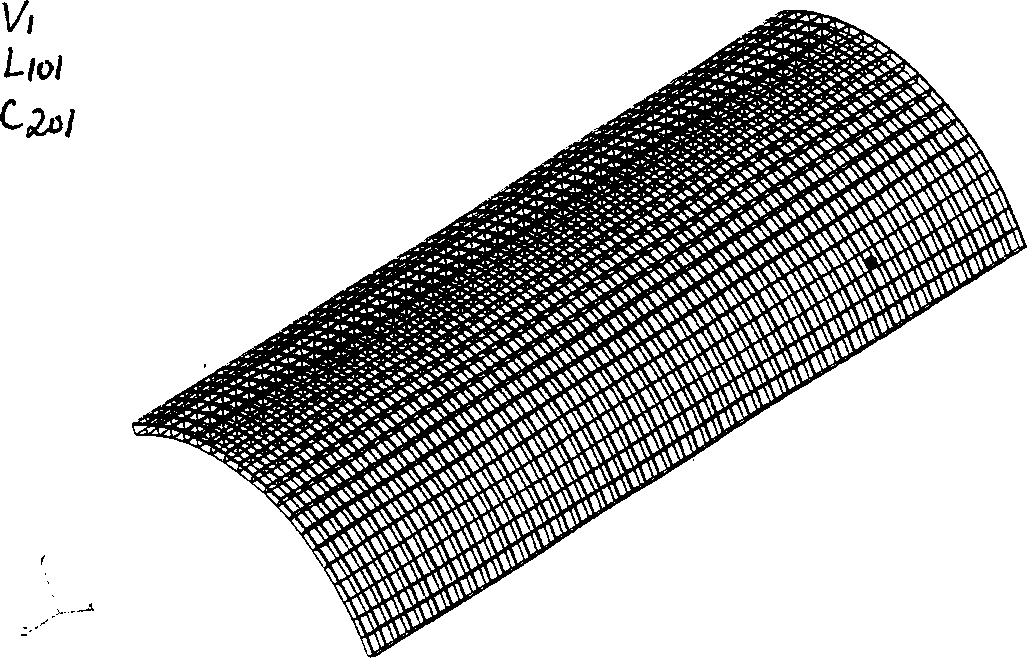

Method for reinforcing defective pipeline and composite material therefor

ActiveCN1766400AImprove pressure bearing capacityBearing capacity up toPipe elementsEpoxy resin adhesivesEpoxyGlass fiber

The invention discloses a defect pipe reinforced method and composite material, which is characterized by the following: adapting reinforced composite material, defect filling material and interlaminar adhesive agent to restore and reinforce the defect position; disposing the defect surface only; filling the defect position with the reinforced filling material; wrapping the reinforced film on the pipe; adapting interlaminar adhesive agent and hardening agent among layers, wherein the reinforced composite material piece is high-strength glass fiber unidirectional cloth or carbon fiber unidirectional cloth, which is composed of 593 hardening agent or triethanolamine hardening agent, epoxide-resin glue of acrylate liquid rubber and interlaminar adhesive agent. The invention can restore the defect pipe of more than half thickness without welding, leakage and cracking, which displays normal pipe after restoring the explosion-hole.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

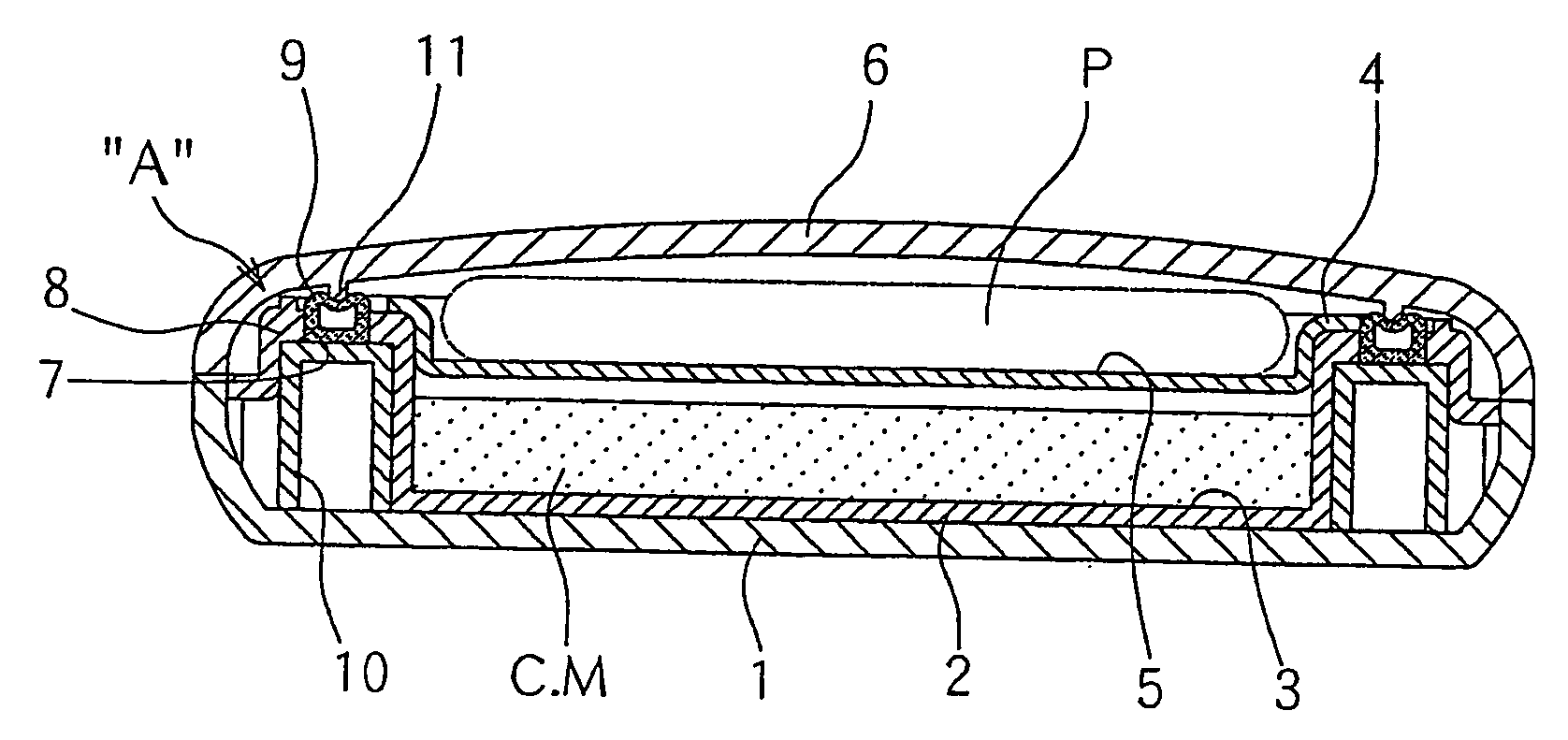

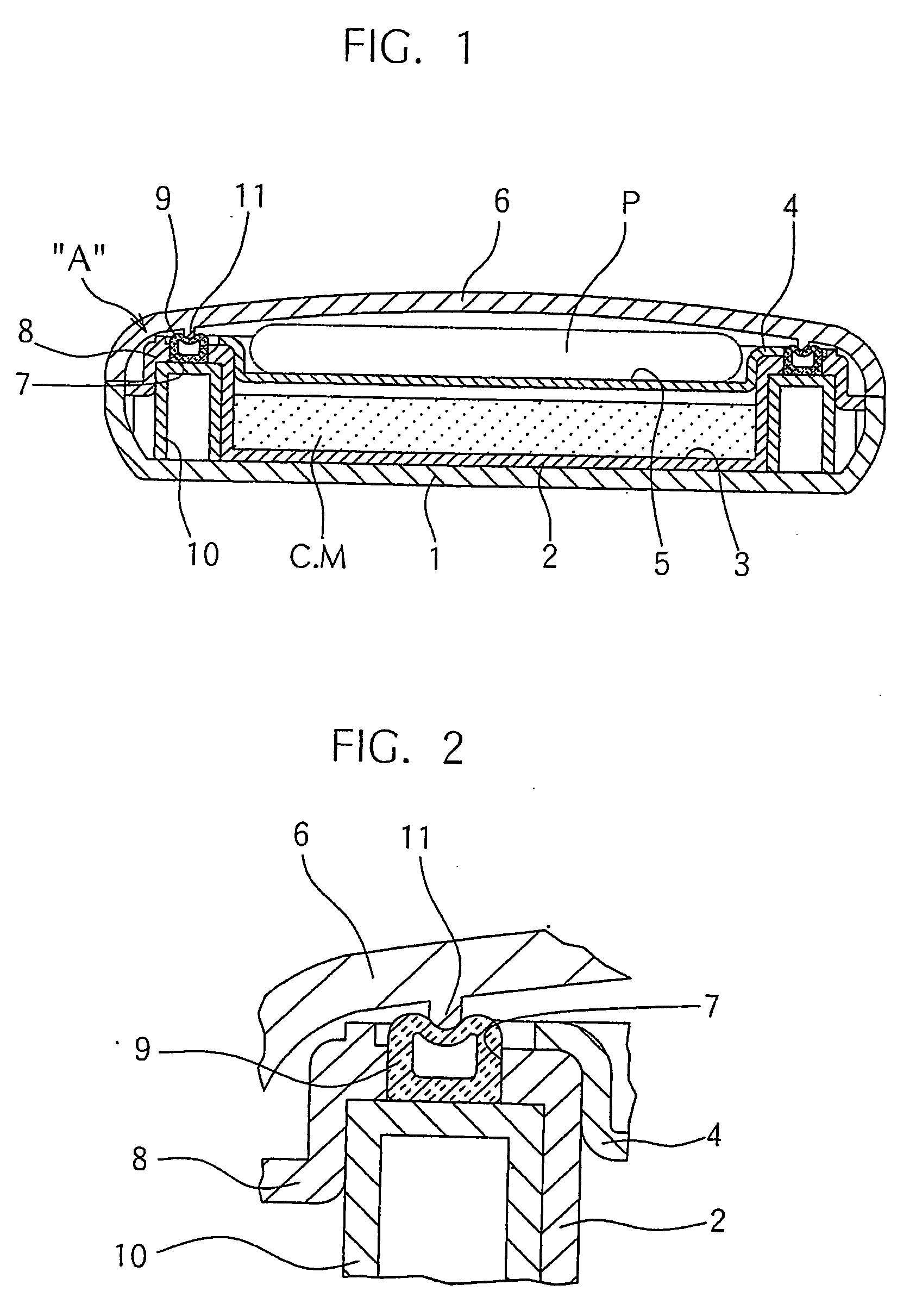

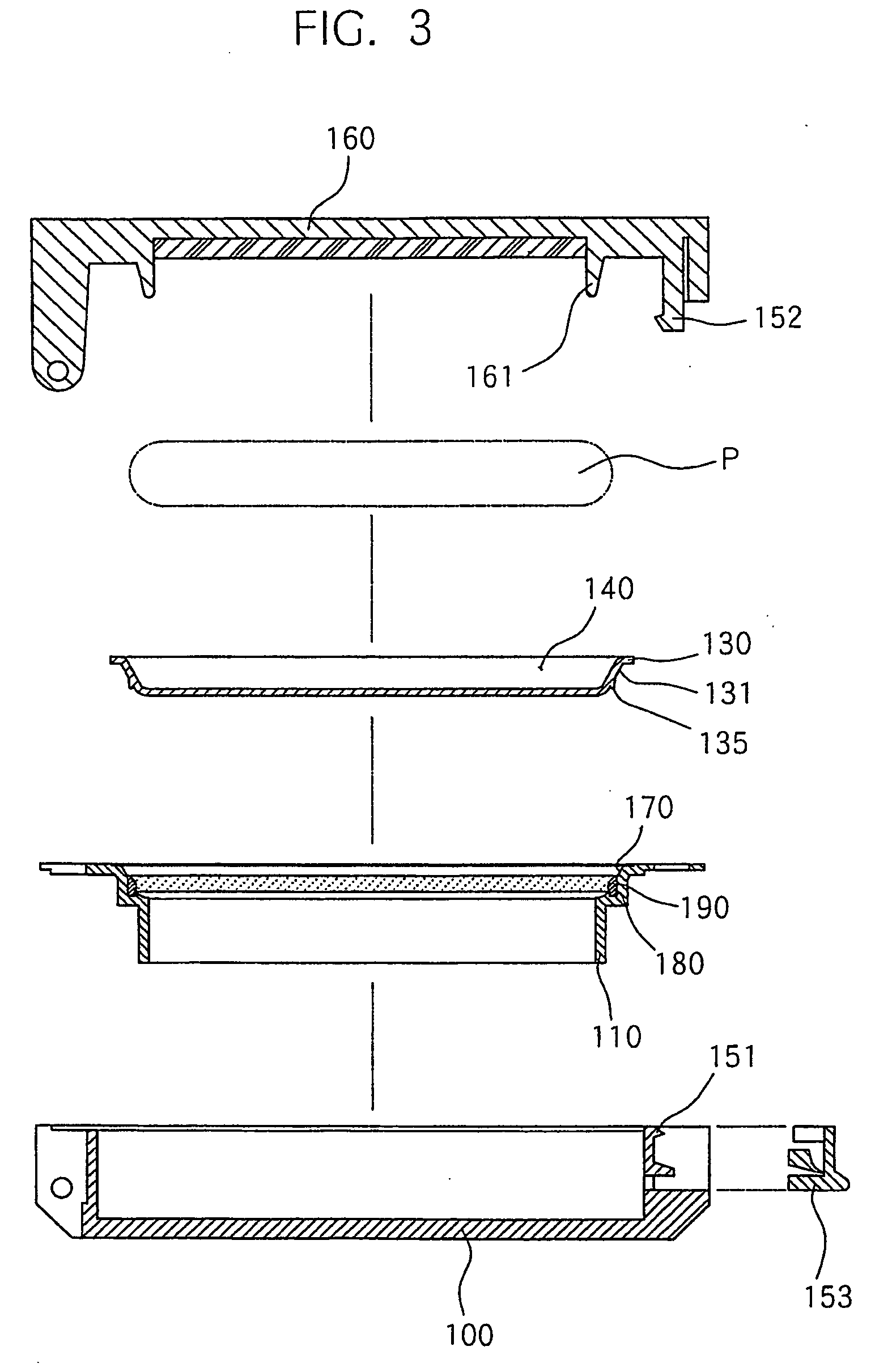

Compact cosmetic case with airtight sealed structure

InactiveUS20060151355A1Improve sealingQuality improvementOther accessoriesPackaging toiletriesHermetic sealLiquid rubber

Compact cosmetic case with airtight sealed structure, which has a simple construction and enhances its airtight sealed effect to prevent a leakage of cosmetics, such as powder, thus improving quality, increasing productivity and reducing the production costs. The compact cosmetic case includes a body, an inner casing to contain the powder, an inner lid hinged the inner casing and having a powder puff seat, and an outer lid hinged to the body and having a locking part. A groove is formed around an upper surface of the inner casing, with liquid rubber filling the groove to form a rubber seal. A locking hole is formed on the inner casing, while a locking lever having a locking projection is formed on the inner lid to be locked to the locking hole.

Owner:CHO HEE RAE

Method for preparing non-woven fabric polishing abrasive tool with high abrasion resistance

InactiveCN101913121AHigh viscosityImprove adhesionFibre typesGrinding devicesSilanesMagnesium stearate

The invention relates to a method for preparing a non-woven fabric polishing abrasive tool with high abrasion resistance. The method comprises the following steps of: taking 20 to 40 mass parts of epoxy resin, adding 4 to 25 mass parts of curing agent, 20 to 45 mass parts of abrasive, 8 to 15 mass parts of diluent, 2 to 8 mass parts of toughening agent, 1 to 3 mass parts of silane coupling agent and 3 to 8 mass parts of auxiliary materials into the epoxy resin, mixing the materials uniformly, then spraying the mixture onto a non-woven fabric, curing the mixture at a high temperature, and then performing punch forming, wherein the toughening agent comprises reactive epoxy toughening agent, terminal carboxyl liquid nitrile rubber and / or terminal carboxyl polybutadiene liquid rubber; the silane coupling agent comprises gamma-aminopropyltriethoxysilane, gamma-glycidyl ether oxypropyl trimethoxy silane and / or gamma-(methacryloyloxy) propyltrimethoxysilane; and the other auxiliary materials comprise 2,4,6-tri(dimethylaminomethyl) phenol DMP-30 accelerator, wax powder, graphite, pigment, magnesium stearate and / or zinc stearate. The non-woven fabric polishing abrasive tool is mainly used for polishing treatment of metal surfaces.

Owner:SOUTH CHINA UNIV OF TECH +1

Synthesis method of high-performance multipurpose urethane elastomer

The invention discloses a synthetic method to prepare polyurethane elastic body with hydroxyl-ended oligomer polyol as raw material, which is characterized by the following: reacting hydroxy-terminated liquid rubber or poly-tetrahydropyran ether alcohol with polyisocyanates; getting end isocyanate group pie polymer in fixing reacting time, temperature; giving in A component; compositing chain-extending agent, flux, antiager with gallant; getting curative; giving in B component; hardening A component and B component under indoor temperature proportional mixing; getting high-performance multipurpose polyurethane elastic body; The stretching intensity is: 10.0-47.0Mpa, splitting extensibility>300%, 300% load at certain intensity: 5.0-35.0Mpa.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

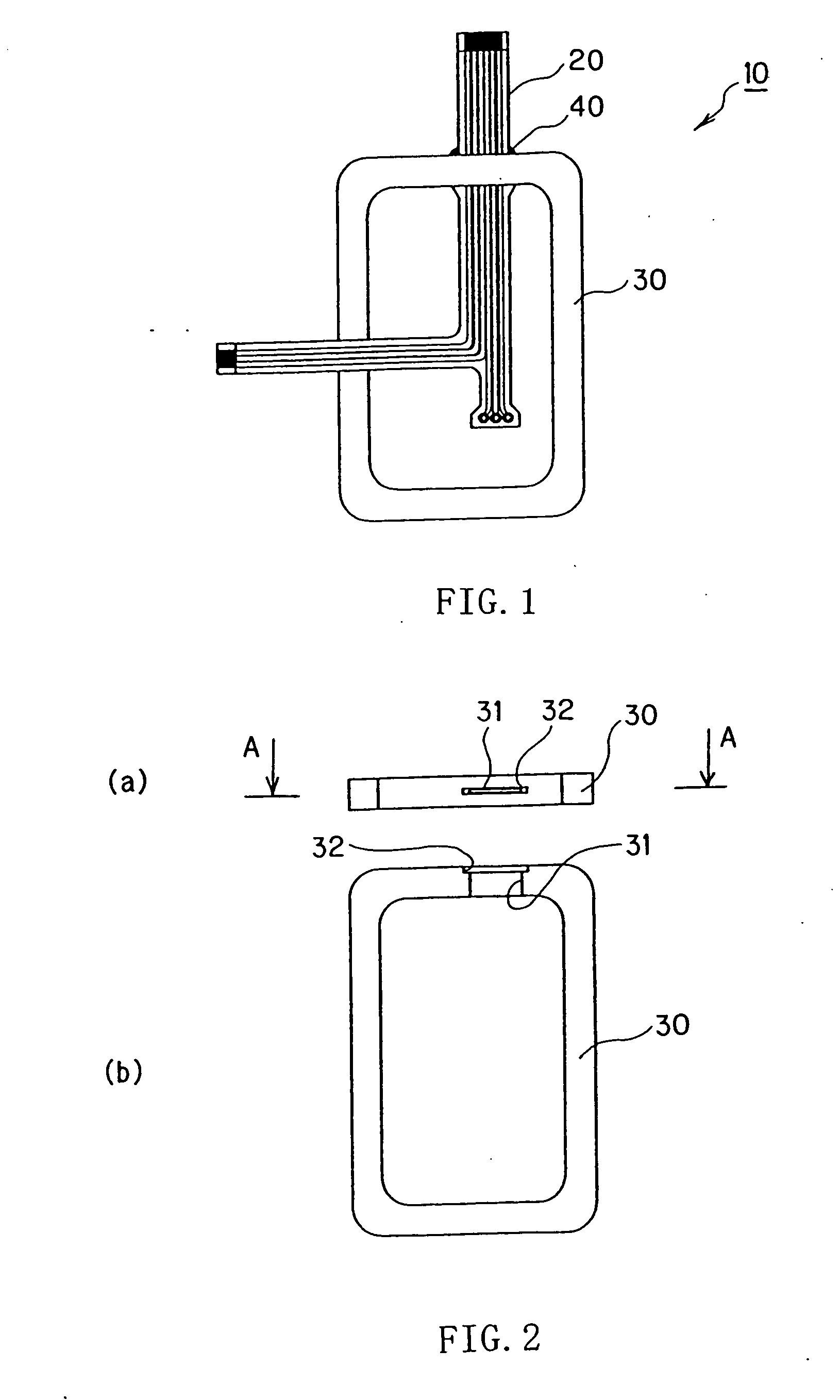

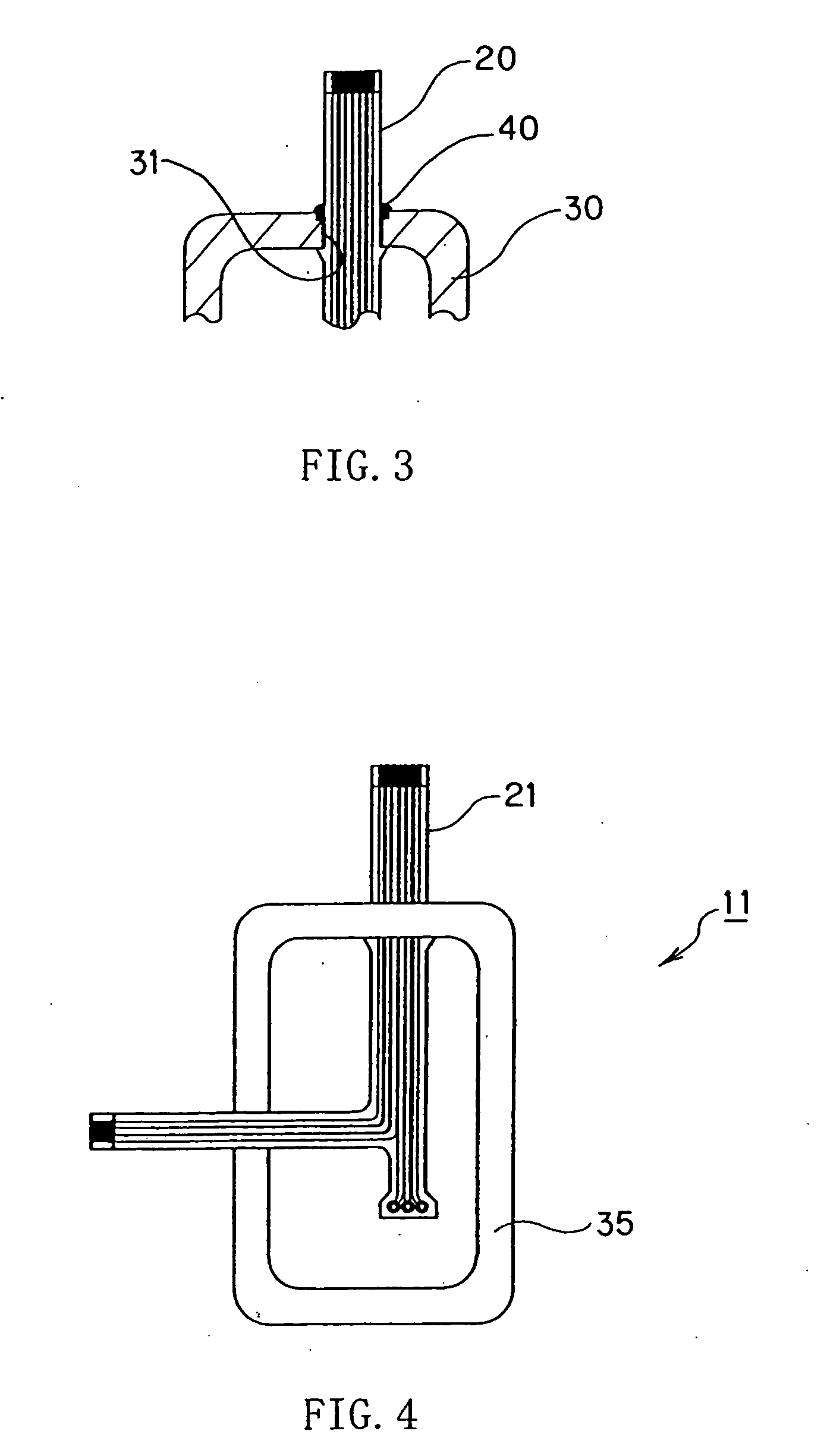

Sealing structure

InactiveUS20060032653A1Well formedSimple structureEngine sealsSemiconductor/solid-state device detailsHeat resistanceLiquid state

The present invention relates to a hermetic structure having a flat cable. Liquid rubber is charged into a gap to be sealed, the charged liquid rubber is subjected to a physical action at the normal temperature and under the normal pressure, and the liquid rubber is cured to form a seal. By forming the seal in this manner, the limitation of heat resistance and pressure resistance is moderated, the flexibility of selection of materials for various constituent members is enhanced, and the structure is simplified.

Owner:NOK CORP

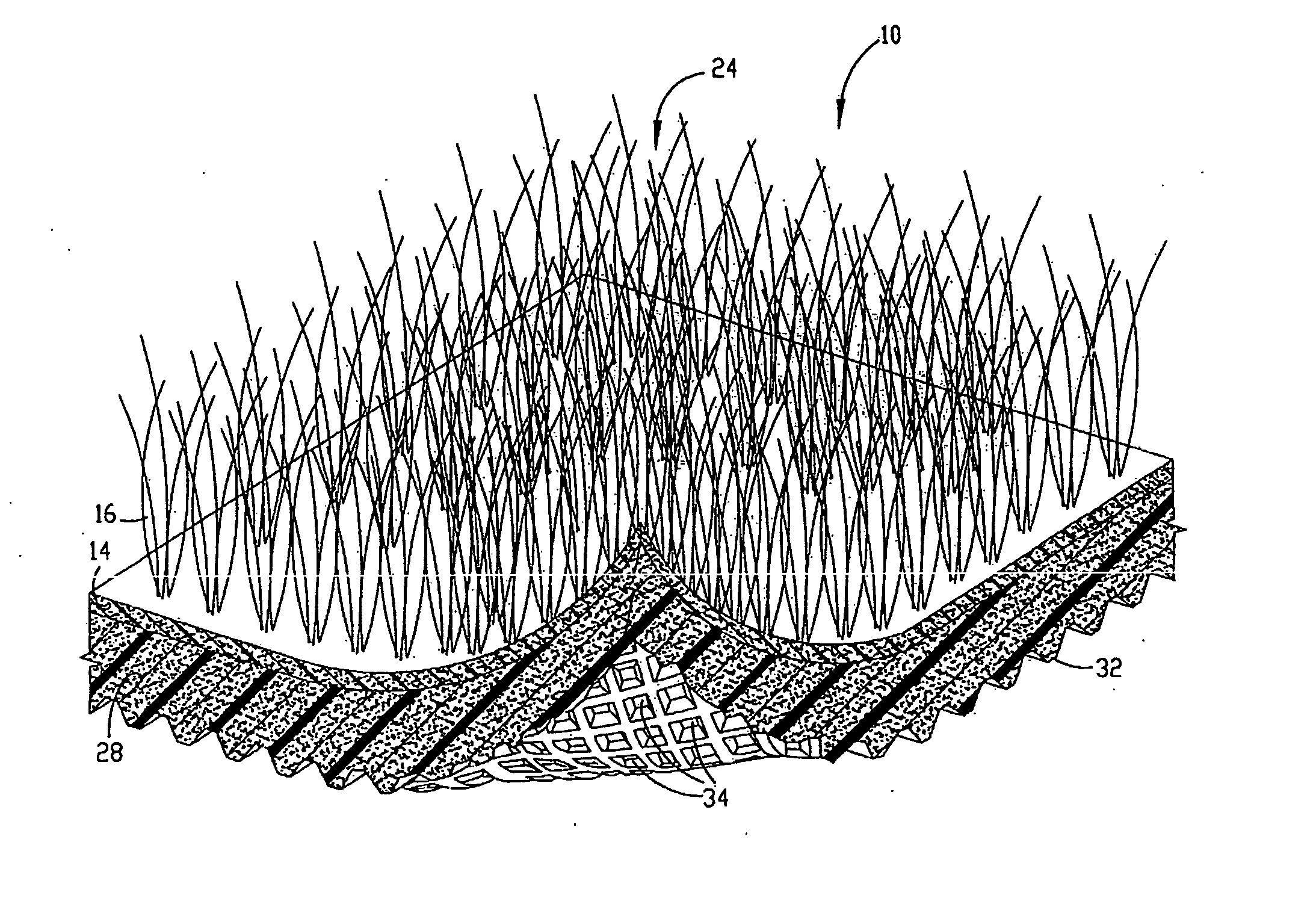

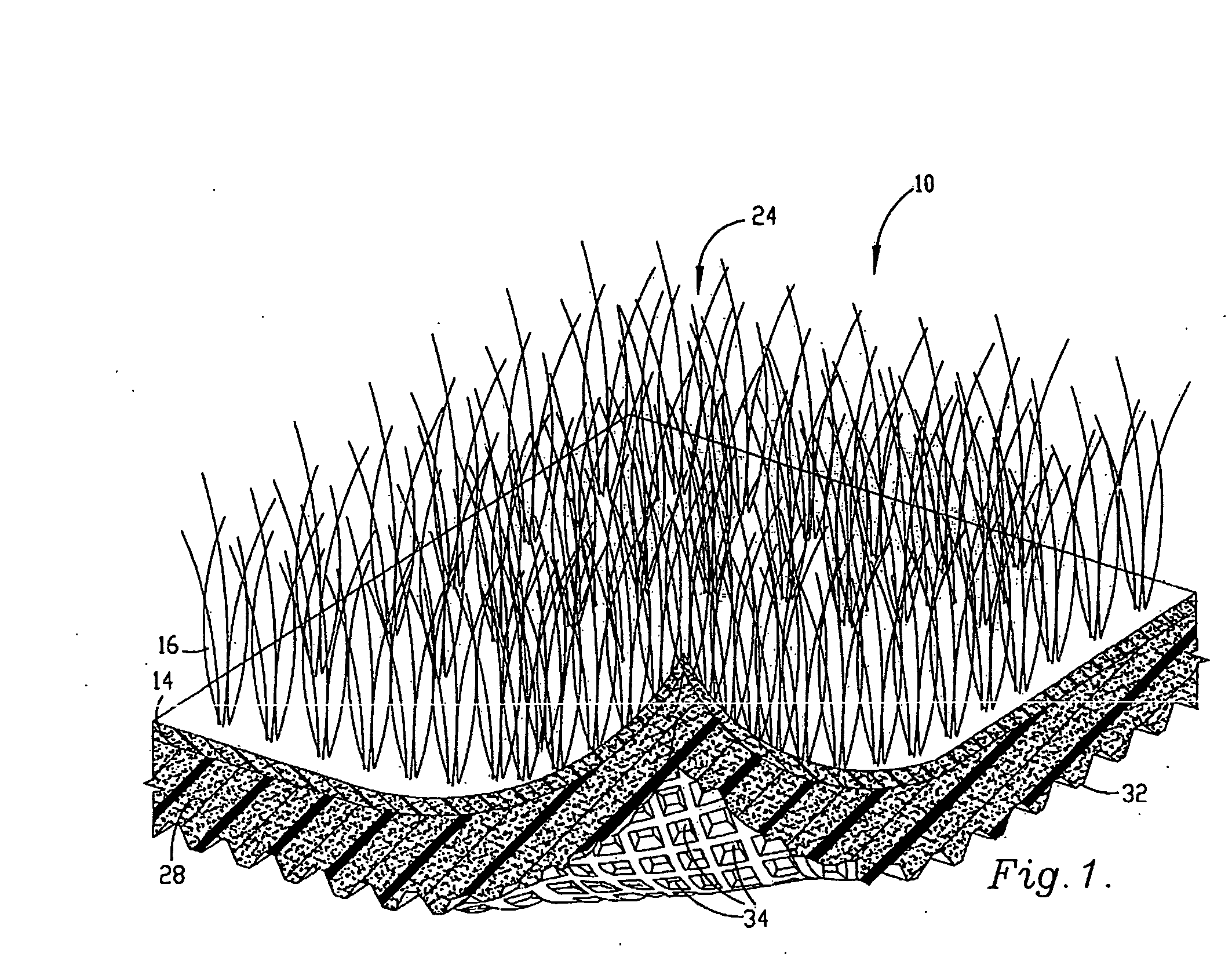

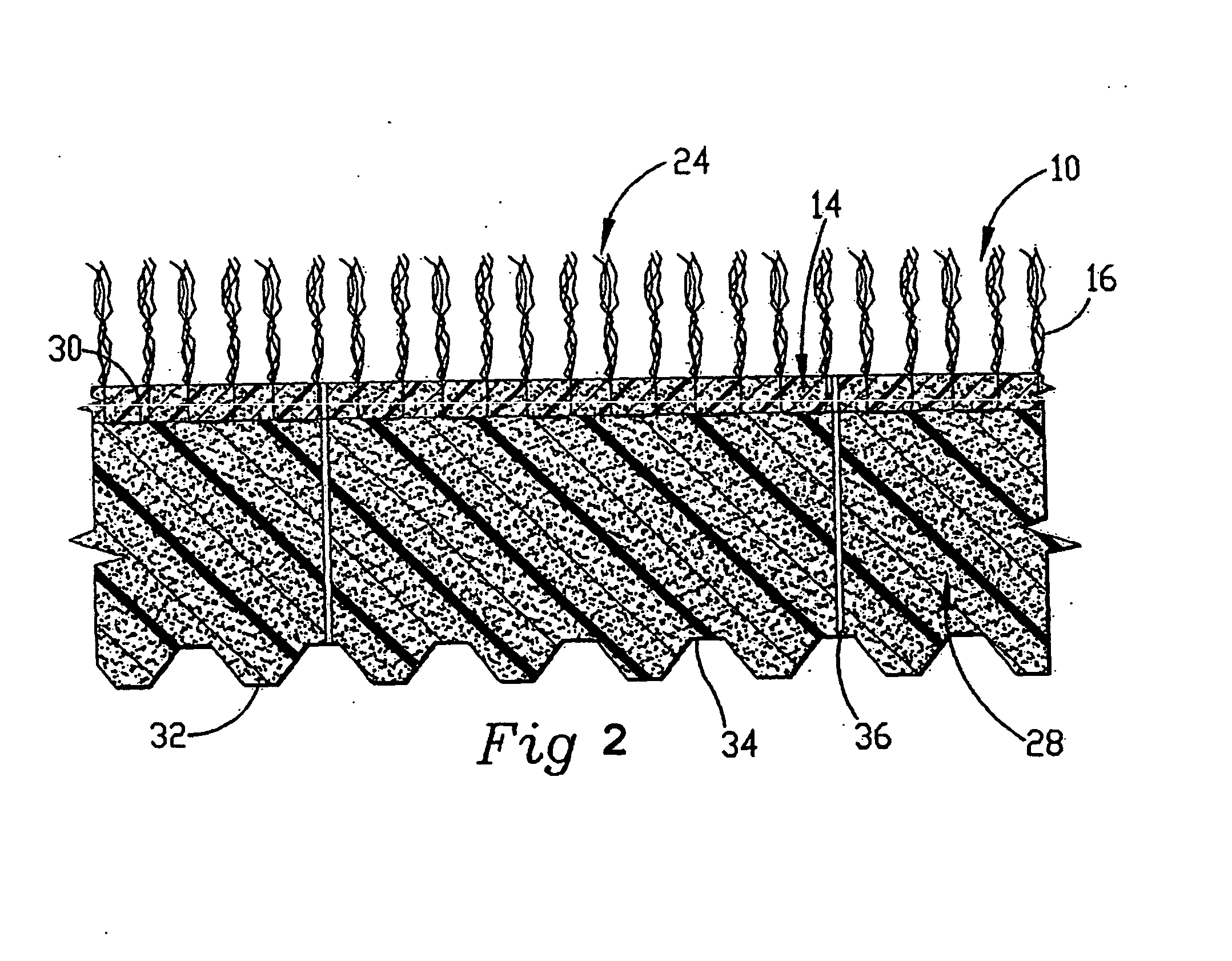

Rubber Compositions, Methods of Making Rubber Compositions Rubber and Rubber-Containing Articles

InactiveUS20070231532A1Improve bindingEnhancing tuft lockTextile/flexible product manufactureConstructions elementsCompression moldingPolymer science

The application discloses coherent, processable rubber compositions containing cured rubber particles, especially recycled crumb rubber, dispersed in a curable base rubber. A processable composition, particularly one which can be roll-processed into a self-sustaining web is achieved by including in the curable rubber a low-viscosity curable rubber component such as a liquid rubber. This component wets the crumb rubber enabling it to disperse fully during mixing and connect intimately into the structure upon curing. This technique enables larger quantities and / or smaller particle sizes of the crumb rubber to be successfully incorporated while maintaining processability. Inert fillers can be used or omitted, reducing density. The novel rubber compounds are particularly suitable for making into layer products such as mats and flooring materials. Desirably these are laminated with fabric such as tufted textiles. This can be done in a compression moulding process.

Owner:HAYDALE

Water-based liquid rubber waterproof paint and preparation method thereof

InactiveCN103965783AStrong surface adhesionImprove stabilityConjugated diene hydrocarbon coatingsChloropene polymer coatingsWater basedMagnesium salt

The invention discloses a water-based liquid rubber waterproof paint, comprising a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 35-65 parts of emulsified asphalt, 5-40 parts of chloroprene rubber emulsion, 5-40 parts of styrene-butadiene latex, 0.1-10 parts of polyvinyl alcohol (PVA) stabilizer, 0.1-5 parts of anionic dispersant, 0.1-5 parts of defoamer and 0.1-10 parts of pH modifier; the component B comprises the following raw materials in parts by weight: 75-95 parts of water and 5-25 parts of soluble calcium salt and magnesium salt. The water-based liquid rubber waterproof paint belongs to a water-based dual-component waterproof paint, and the component A and the component B are sprayed and mixed by special spray equipment in use according to a certain ratio, so as to instantaneously solidify and form a film. The water-based liquid rubber waterproof paint can be sprayed on any substrate surface, and is especially good in surface adhesion on metal, concrete, plastic and the like.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

High-temperature resistant spray fast-setting rubber asphalt waterproof coating

ActiveCN102965016ANo pollutionExtended service lifeConjugated diene hydrocarbon coatingsNatural rubber coatingsPolymer scienceSpray coating

The invention relates to a high-temperature resistant spray fast-setting rubber asphalt waterproof coating which is a high-temperature resistant water-based spray coating prepared proportionally by adding a vulcanizing agent and a composite reinforcing agent into liquid rubber asphalt mastic emulsion prepared from modified emulsified asphalt and high-molecular polymer rubber latex and then mixing with a coagulating agent. The high-temperature resistant spray fast-setting rubber asphalt waterproof coating provided by the invention is a novel spray fast-setting rubber asphalt environment-friendly waterproof material which is nontoxic, tasteless and pollution-free and can be subjected to cold construction at normal temperature; and meanwhile, the high-temperature resistant spray fast-setting rubber asphalt waterproof coating has good heat resistance (160 DEG C), high elongation at break (greater than 1,000%), high elasticity recovery rate (greater than 90%), high bonding strength (greater than 0.5MPa), excellent low temperature resistance (without breakage at -30 DEG C) and excellent ageing resistance, acid / alkali resistance, cohesiveness and shear resistance, and can prevent structural damage caused by water penetration so as to prolong the service life of highway bridges.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

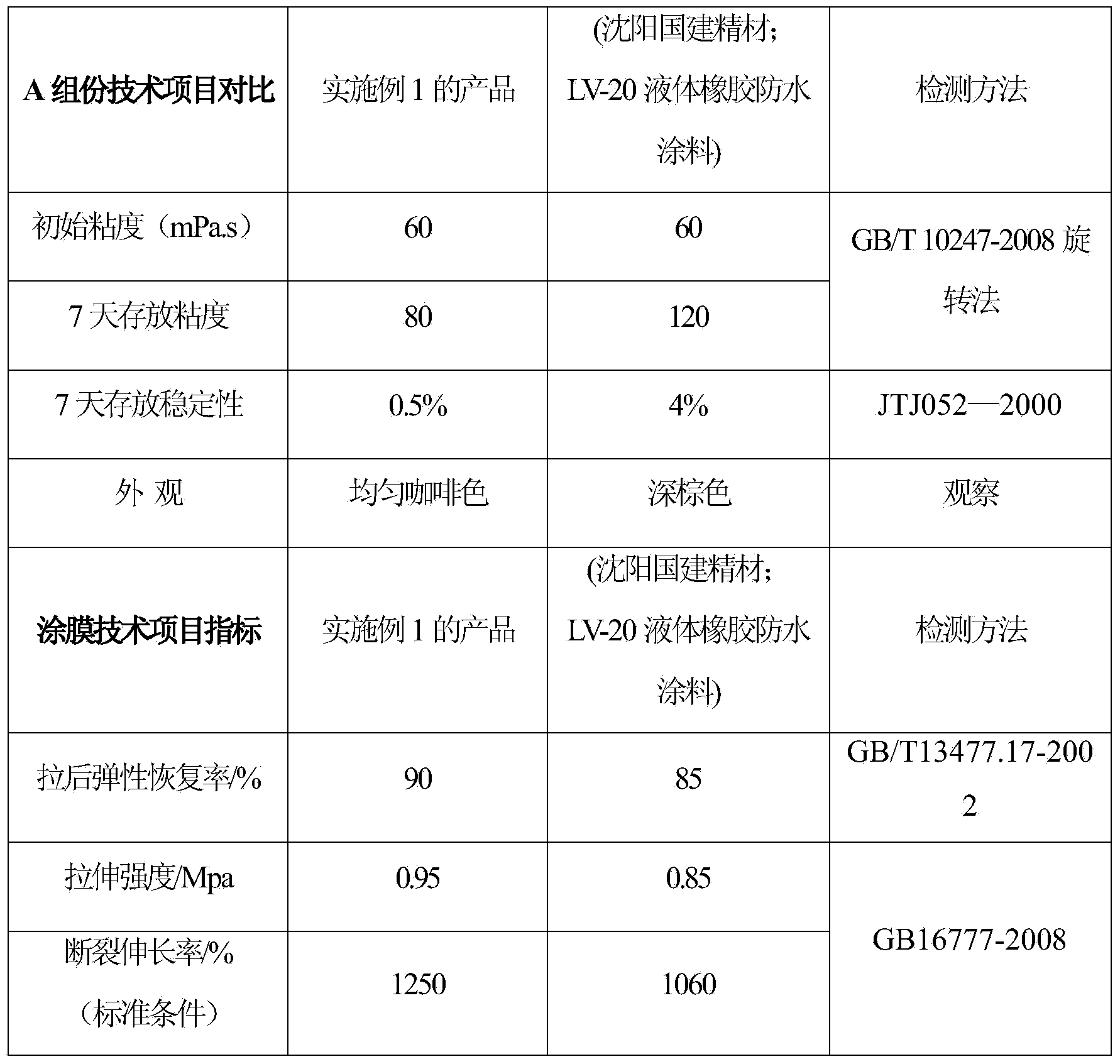

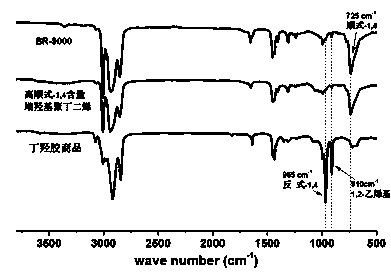

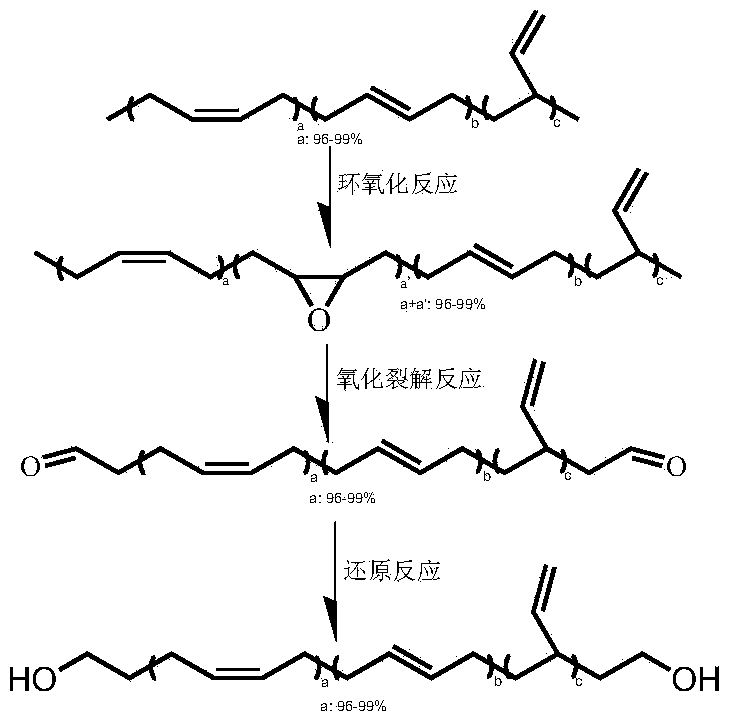

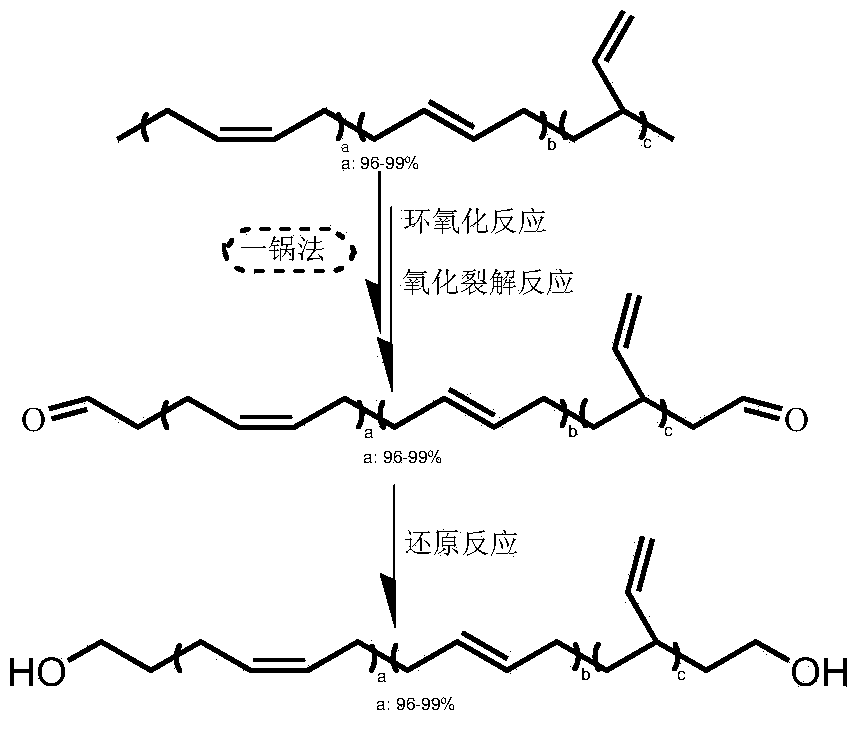

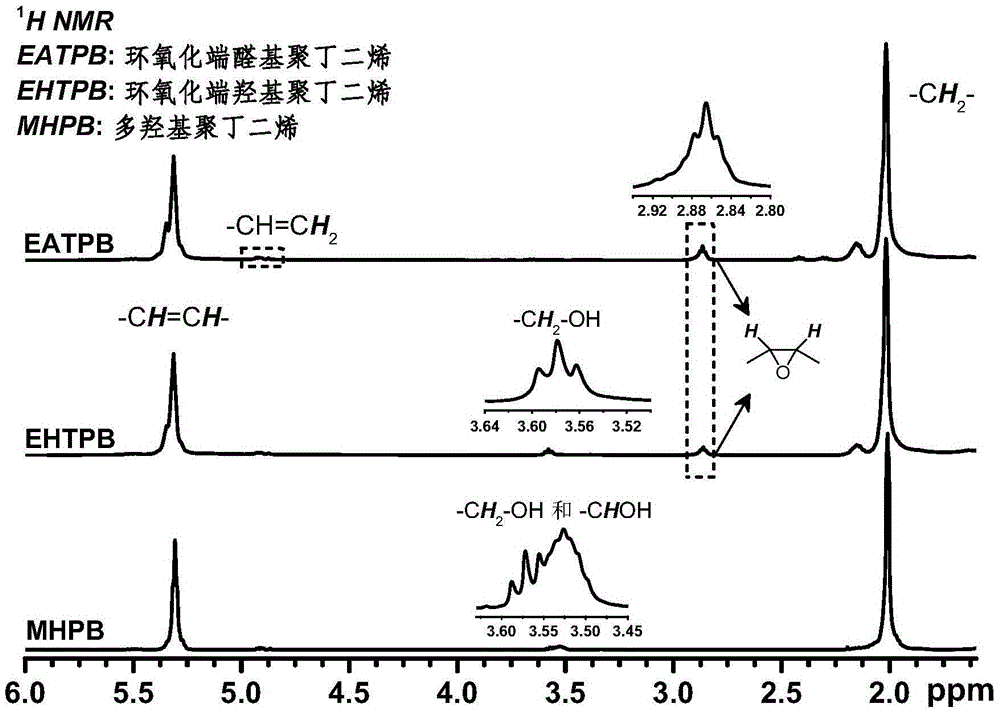

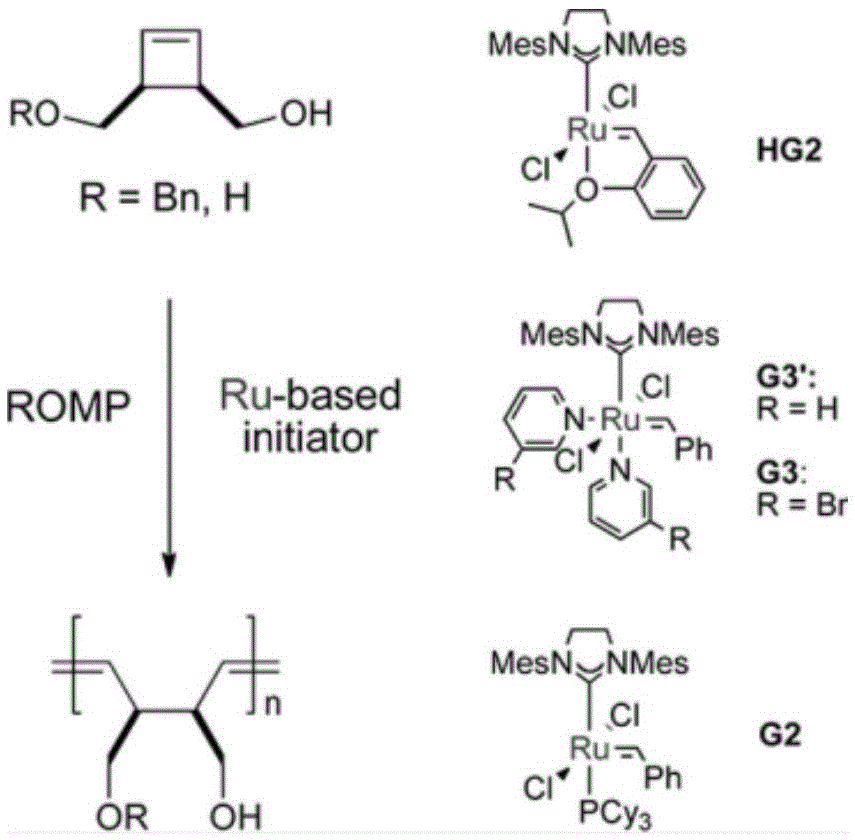

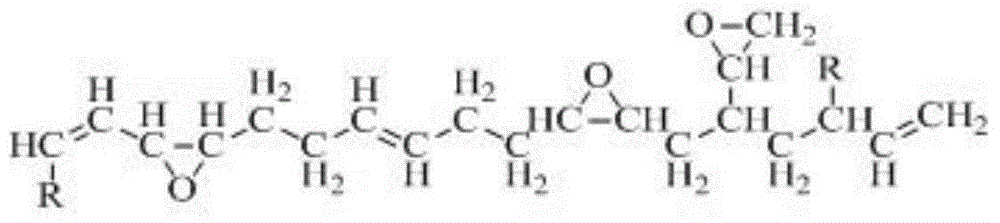

High-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber and preparation method thereof

The invention discloses a high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber and a preparation method thereof. The method includes following steps: (1) preparing epoxidized butadiene rubber from butadiene rubber; (2) preparing high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber from the epoxidized butadiene rubber; (3) preparing high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber from the butadiene rubber in a one-pot manner; (4) reducing the high-cis-1,4-content aldehyde group-terminated polybutadiene liquid rubber to prepare the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber. In the method, the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber is prepared from the butadiene rubber and the content of cis-1,4 can reach 95.0-99.0%. A number-average molecular weight of the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber can be regulated between 2000 g / mol and 10000 g / mol. A molecular weight distribution is 1.2-3.0 and a degree of functionality is 1.9-2.2. On the basis of excessive supply in raw rubber of butadiene rubber and increased tensing situation of petroleum sources, by means of the method, the high-cis-1,4-content hydroxyl-terminated polybutadiene liquid rubber can be prepared through oxidative pyrolysis of the butadiene rubber, so that the method has a quite important practical significance.

Owner:ZHEJIANG UNIV

Proton exchange membrane fuel cell external manifold seal

InactiveUS6660422B2Effective seal to the fuel cellEasy to disassembleSolid electrolytesFuel cells groupingLow temperature curingEngineering

A sealant system 13 for a manifold 10 of a proton exchange membrane fuel cell includes low temperature cured or heat cured silicone rubber bridges 14, 14a, 14c between the end plates 9 to compensate for the uneven edges of various fuel cell component layers, and a layer 15 of silicone rubber foam or sponge, or a molded silicone rubber gasket 15a, extending across the bridges and along the end plates, around the entire contact perimeter surfaces of the manifold, to seal the manifold to the fuel cell. The cured silicone rubber may extend along the end plates between the bridges. A rubber strip 20 may be adhered to the silicone rubber bridges and end plates. The bridges may comprise a first layer 22 of low shrinkage self-leveling RTV liquid rubber with viscosity in the range of 10,000-20,000 cps and a second layer 14 of RTV liquid rubber.

Owner:AUDI AG

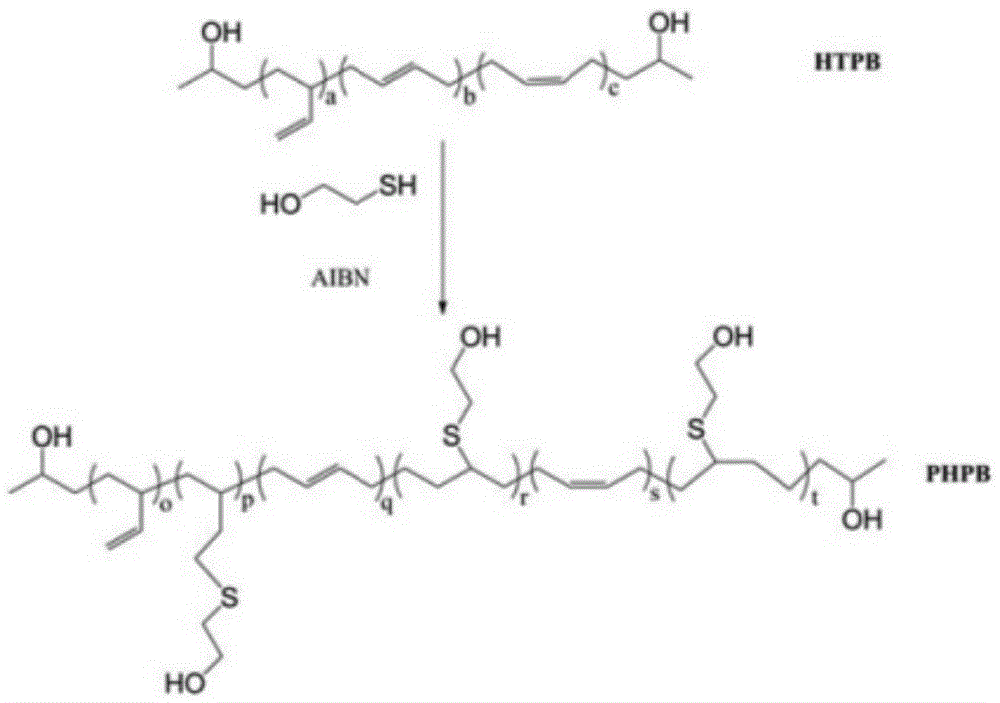

Polyhydroxy polybutadiene liquid rubber and controllable preparation method thereof

The invention discloses a polyhydroxy polybutadiene liquid rubber and a controllable preparation method thereof. According to the method, the polyhydroxy polybutadiene liquid rubber is prepared by carrying out oxidative pyrolysis and a reduction-process on commercialized cis-1,4-polybutadiene rubber. The number-average molecular weight of the polyhydroxy polybutadiene liquid rubber prepared from the cis-1,4-polybutadiene rubber is adjustable within the range of 1000-15000 g / mol; the molecular weight distribution is 1.2-3.0; the cis-1,4 content is greater than 90%; the glass transition temperature is -100 to -80 DEG C; the hydroxy functionality is 5-30; and the hydroxy groups are distributed on the head and tail ends of the polybutadiene molecular chain and in the molecular chain. Under the background of overstocked unvulcanized cis-1,4-polybutadiene rubber and increasingly deficient petroleum resources, the polyhydroxy polybutadiene liquid rubber prepared by cis-1,4-polybutadiene rubber oxidative pyrolysis has very important practical meanings.

Owner:ZHEJIANG UNIV

Highly-toughened bulk molding composition

The invention discloses a highly-toughened bulk molding composition which is obtained by polymerization of the following raw materials by weight: 60-80 parts of unsaturated resin, 10-40 parts of low shrinkage agents, 1-2 parts of curing agents, 2-5 parts of mold release agents, 4-20 parts of toughening agents, 30-80 parts of whiskers, 2-5 parts of coupling agents, 100-250 parts of filling materials, 50-150 parts of glass fibers. The invention adopts end active group liquid rubber and whiskers to toughen the BMC material. The toughness of the BMC material is increased by end vinyl liquid butadiene-acrylonitrile rubber; the strength of the BMC material is increased by calcium carbonate whiskers treated by the active end styrene coupling agent; and the trend of the decrease of the strength of the material due to the addition of the liquid rubber is counteracted. Therefore, the highly-toughened BMC material is obtained without the decrease of the strength.

Owner:江苏美赫家居有限公司

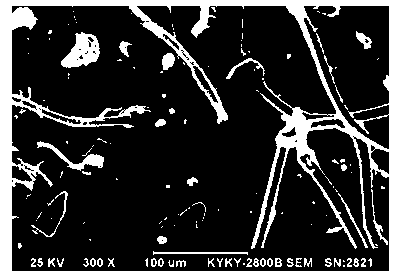

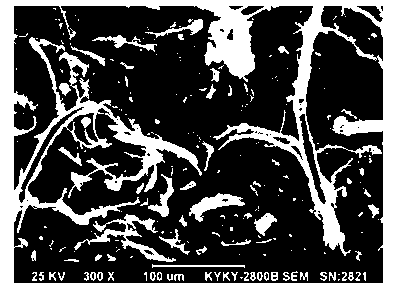

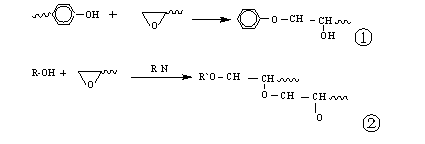

Surface modification method of aramid, and reinforced natural rubber material and preparation method thereof

The invention discloses a surface modification method of aramid, a reinforced natural rubber material and a preparation method thereof. The surface modification method of aramid comprises the following steps of: dipping aramid fibre for 0.5-3h by using phosphoric acid solution at 20-50 DEG C, after cleaning and drying, dipping aramid fibre for 1-2h by using acetone solution of epoxy resin with the mass percentage concentration of 5-20% at normal temperature, and then modifying the surface of aramid after drying. According to the invention, active groups of surface modified aramid and terminated hydroxyl of epoxy resin and liquid rubber are chemically reacted simultaneously at mixing temperature, so that the interfacial bonding strength is improved; liquid rubber and matrix rubber are vulcanized together in the subsequent vulcanizing process of mixing rubber, so that a cross-linked network tightly combined with aramid fibre is formed; the problem that the matrix rubber in an original physical manner forms a self cross-linked network while being vulcanized is overcome, and therefore, negative phenomena of a rubber and aramid fibre interface can be reduced; and the aramid reinforced rubber composite material having good interfacial bonding and fibre dispersion can be formed.

Owner:GUIZHOU UNIV

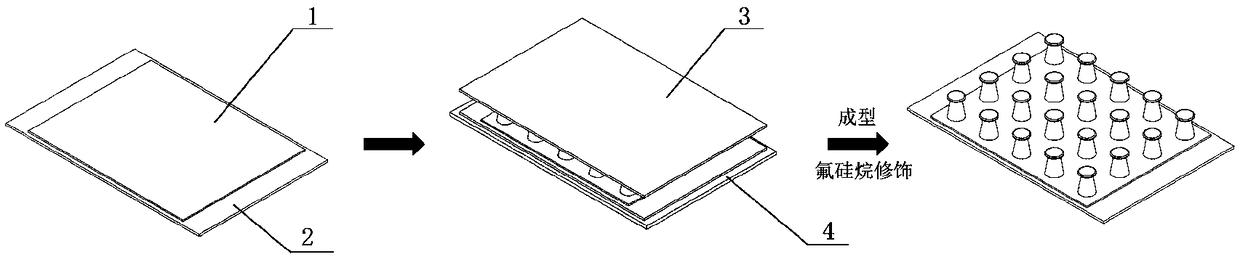

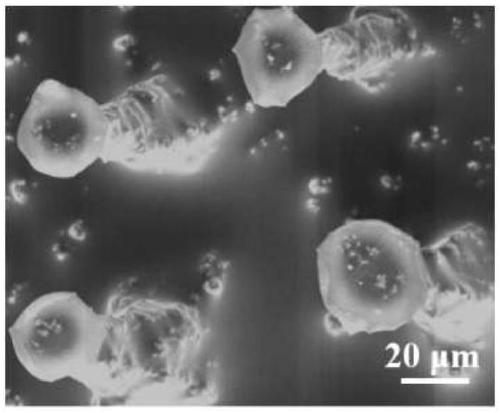

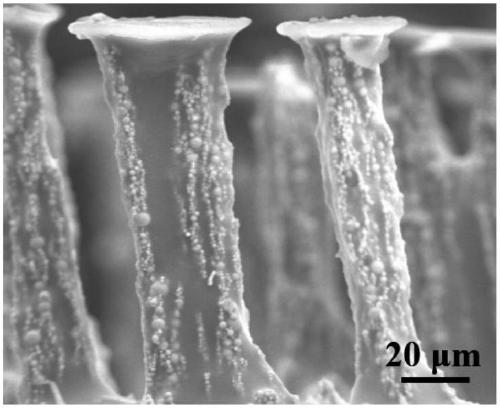

Intelligent surface construction method capable of achieving wettability conversion and device therefor

The invention discloses an intelligent surface construction method capable of achieving wettability conversion. Liquid rubber and magnetic microparticles are mixed in a certain ratio, and then coat asubstrate, and an anti-adhesion plate is fixed at a certain distance above the substrate. A vertical upward magnetic field is applied to the whole device from the bottom of the substrate, a mushroom column array structure is formed by liquid rubber self-assemble, after solidification molding, a microcolumn array is modified by fluorosilane to obtain an intelligence surface capable of achieving wettability conversion relying on microstructure control. By induction of the external magnetic field, the mushroom-like column array structure of the surface can be bent and deformed to lead reversibleconversion between a low-adhesion super-hydrophobic and oileophobic state and a high-adhesion hydrophobic oleophobic state of the wet state of water and oil on the surface. The preparation method hasthe advantages of simple process, no complicated equipment, and no template assistance, and is advantageous for large-scale manufacturing and practical application of the intelligence surface capableof achieving wettability conversion.

Owner:JILIN UNIV

Ultraviolet-heat dual curing optical adhesive containing epoxidized polybutadiene resin

ActiveCN104449419ASynergistic priming effect is goodIncrease the polymerization rateOrganic non-macromolecular adhesivePolyolefinFast tempo

The invention belongs to the technical field of adhesives, and particularly relates to an ultraviolet-heat dual curing optical adhesive containing epoxidized polybutadiene resin. The ultraviolet-heat dual curing optical adhesive comprises the following components in percentage by weight: 14.5%-45% of epoxidized polybutadiene resin, 10%-40% of alicyclic epoxy modified resin, 5%-15% of polyolefin liquid rubber, 25.5%-35% of an acrylic ester reactive diluent, 2.4%-3.4% of a free radical photoinitiator, 0.1%-0.2% of a cationic photoinitiator and 2%-2.5% of a peroxide initiating curing agent. The optical adhesive disclosed by the invention is relatively completely solidified at a shaded part, a dark adhesive layer part or a thick adhesive layer part, has excellent optical properties such as high refractive index and high transmittance after being solidified, has the advantages of shock resistance, low yellowing coefficient, low haze, low shrinking percentage, easiness in repairing and good flexibility, meets the requirements of optical, physical and chemical properties of display devices, and is suitable for fast-tempo and high-efficiency production processes.

Owner:信泰永合(烟台)新材料有限公司

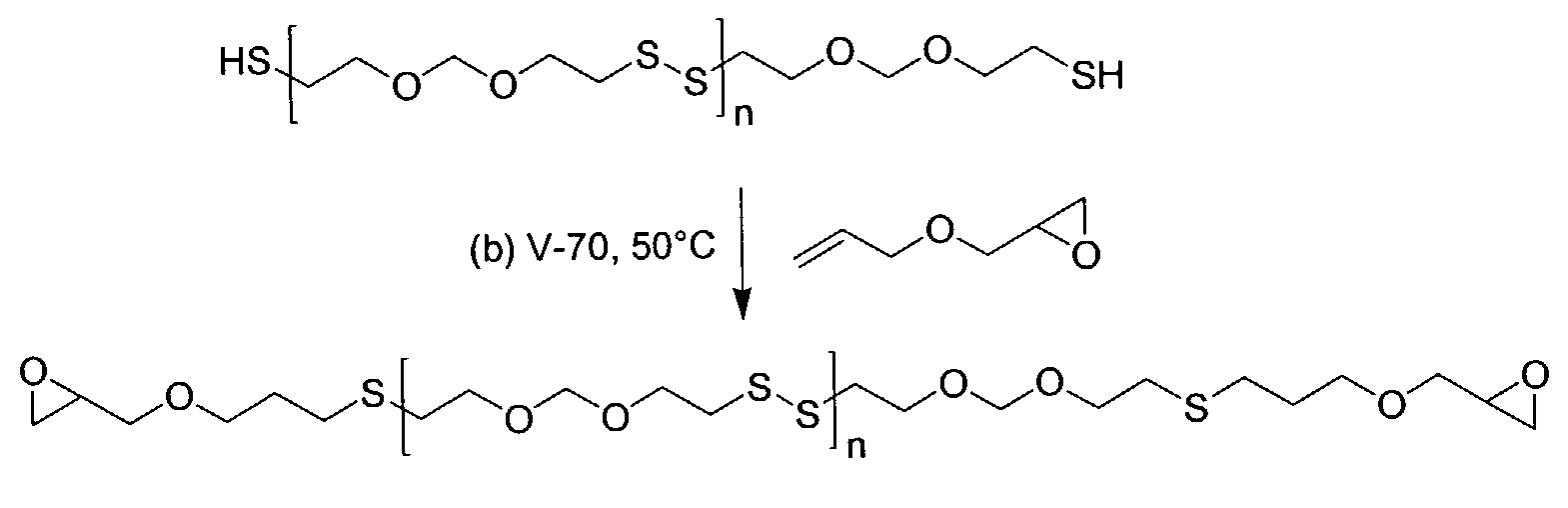

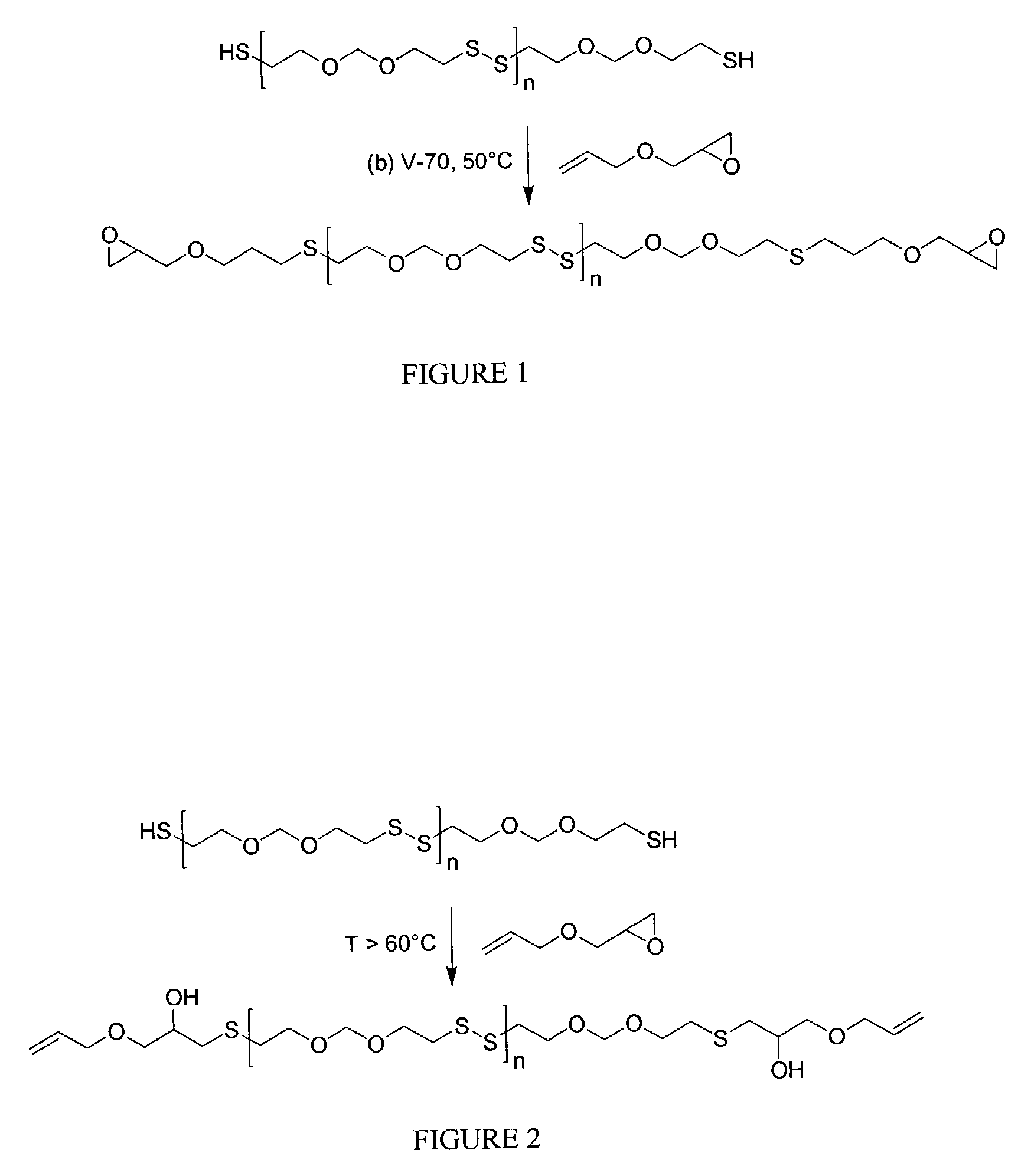

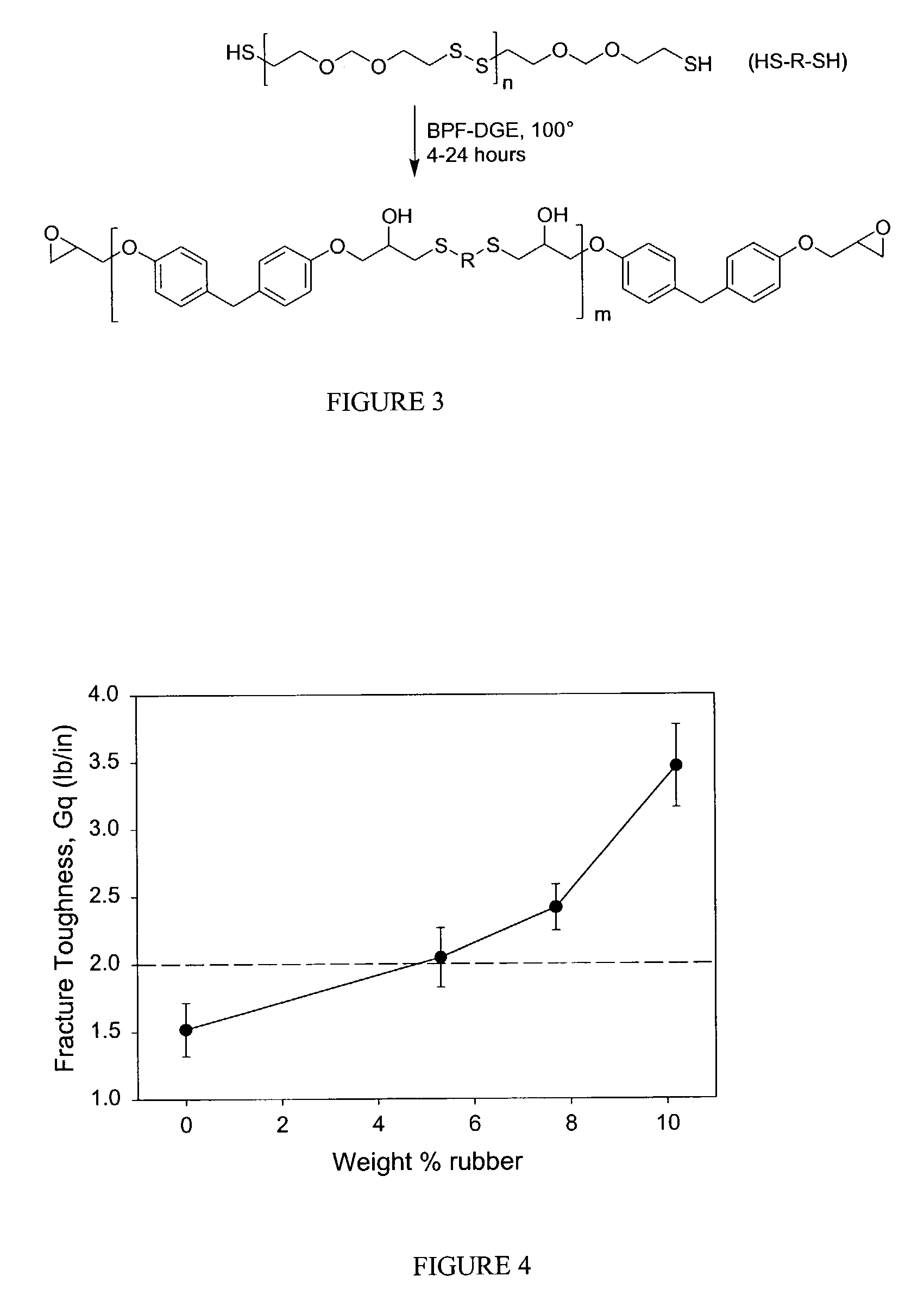

Polysulfide-based toughening agents, compositions containing same and methods for the use thereof

InactiveUS7087304B1Improved performance characteristicsImprove fracture toughnessSemiconductor/solid-state device detailsSynthetic resin layered productsEpoxyAdhesive

In accordance with the present invention, there are provided toughening agents which are useful for improving the performance properties of epoxy-based adhesive formulations. For example, epoxidized polysulfides have been found to be useful toughening agents of component level underfill adhesive compositions. Invention materials are liquid rubbers which provide improved fracture toughness while maintaining satisfactory capillary flow properties. Invention materials can be synthesized in neat (solventless) reactions from readily available low-cost raw materials and isolated in high yields. They have linear and branched telechelic structures with terminal epoxide functional groups, and are prepared without substantially increasing the molecular weight of the starting polysulfide materials. Invention materials are compatible with common epoxy formulations and may be used without purification. At low levels of incorporation, they provide adhesives that meet the minimum fracture toughness (Gq>2.0 lb / in) and capillary flow specifications (flow time<180 seconds) for many commercial underfill applications. In accordance with a further embodiment of the present invention, there are provided adhesive compositions comprising invention compounds and methods for use thereof. In additional embodiments of the present invention, there are provided methods for the preparation of invention toughening agents, methods for adhesively attaching a device to a substrate, and assemblies comprising first article(s) adhered to second article(s).

Owner:HENKEL IP & HOLDING GMBH

Pigment printing binding agent and synthesizing method thereof

ActiveCN102182080AGood flexibilityImprove breathabilityDyeing processHazardous substanceALLYL SUCROSE

The invention provides a pigment printing binding agent and a synthesizing method thereof. The binding agent is prepared from silicone-acrylate copolymer, aqueous polyurethane, liquid rubber, an emulsifying agent and the like. By taking advantage of the high film-forming property of polyacrylic acid, the high flexibility of organic silicone, the high air permeability of polyurethane and the high elasticity of the liquid rubber, the high-fastness and super-soft pigment printing binding agent is prepared by a complex synergistic technology. The binding agent has high film-forming property, air permeability, flexibility and elasticity, good handfeel and high color fastness. After the binding agent is applied to a printing fabric, the release amount of a harmful substance, namely formaldehyde, is small.

Owner:成都德美精英化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com