Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

339 results about "Chloroprene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chloroprene is the common name for 2-chlorobuta-1,3-diene (IUPAC name) with the chemical formula CH₂=CCl−CH=CH2. Chloroprene is a colorless volatile liquid, almost exclusively used as a monomer for the production of the polymer polychloroprene, a type of synthetic rubber. Polychloroprene is better known as Neoprene, the trade name given by DuPont.

Environmental protection chloroprene rubber adhesive agent and production method thereof

InactiveCN101418197AHigh viscosityGood storage stabilityHalogen rubber derivative adheisvesChloroprene adhesivesGas phaseEnvironmental labeling

The invention discloses an environment-friendly chloroprene rubber adhesive agent which comprises the following compositions: neoprene, alloprene, thixotropic agent, 2402 phenolic resin, extra light calcined magnesia, catalyst, cyclohexane, acetic ether, environment-friendly solvent oil and antioxidant BHT. The invention simultaneously discloses a method for producing the environment-friendly chloroprene rubber adhesive agent. The environment-friendly chloroprene rubber adhesive agent has the following advantages: 1. the agent is environment-friendly, does not contain toxic solvents of triphen and halogenated hydrocarbon, and meets the standard requirement of Technical Requirement for Environmental Labeling Products-Adhesives HJ / T 220-2005 2. the anhydrous catalyst is adopted for the preparation of a pre-reaction solution which has high viscosity and good storage stability; 3. gas phase method silica aerogel is added as the thixotropic agent; and the thixotropic index can reach 1.5 and is convenient for construction; and 4. the neoprene and the alloprene are combined for use to greatly improve the adhesive force and peeling strength to metal and other polar materials.

Owner:GUANGDONG SANVO CHEM IND TECH

Tire puncture sealant

A tire puncture sealant including a urethane emulsion, an acrylic emulsion or a polyolefin emulsion, and an antifreezing agent has a comparatively low viscosity and an excellent storage stability while showing sealing properties equivalent to those of a conventional tire puncture sealant. A tire puncture sealant including a synthetic resin emulsion and an antifreezing agent, and having a hydrogen ion exponent of 5.5 to 8.5 has a less pungent odor and hardly causes corrosion of steel cord. A tire puncture sealant including a chloroprene emulsion and an antifreezing agent and having a hydrogen ion exponent of less than 9.0 has a comparatively low viscosity and a less odor while showing sealing properties equivalent to those of a conventional tire puncture sealant.

Owner:YOKOHAMA RUBBER CO LTD

Chloroprene rubber latex adhesive, preparation and uses thereof

InactiveCN101492594AGood value for moneyImprove initial tackEster polymer adhesivesChloroprene adhesivesPolymer scienceEmulsion

The invention discloses a neoprene latex type adhesive, a preparation method and the application thereof. The neoprene latex type adhesive adopts acrylic esters monomers such as butyl acrylate, gadoleic acid isooctyl ester and the like as well as styrene having sufficient source and low price; styrene-acrylic emulsion is prepared by simple technique; neoprene latex is modified by the emulsion and matched with coagulator solution and other accessory ingredients, so that rubber latex type chloroprene rubber adhesive agent can be prepared; the performance of the rubber latex type chloroprene rubber adhesive agent is similar to that of the commercially available solvent-borne type chloroprene rubber adhesive agent, and the rubber latex type chloroprene rubber adhesive agent even has some indexes being superior to the indexes of the commercially available solvent-borne type chloroprene rubber adhesive agent; furthermore, the neoprene latex type adhesive has high cost performance, wide application scope as well as remarkable social and economic benefits. The neoprene latex type adhesive can meet the needs of different base materials such as a mattress, a chair, a couch, a sofa, a screen, a handbag, industrial polyfoam and the like, is low in cost and simple in preparing method, and has the excellent properties of good storage stability, large temperciance, rapid intensity foundation, high bonding strength, etc.

Owner:SOUTH CHINA UNIV OF TECH

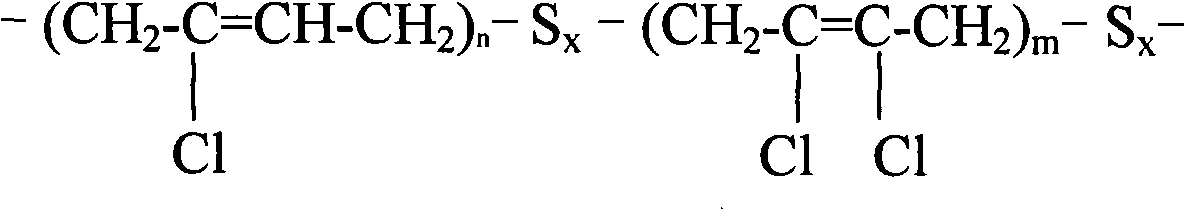

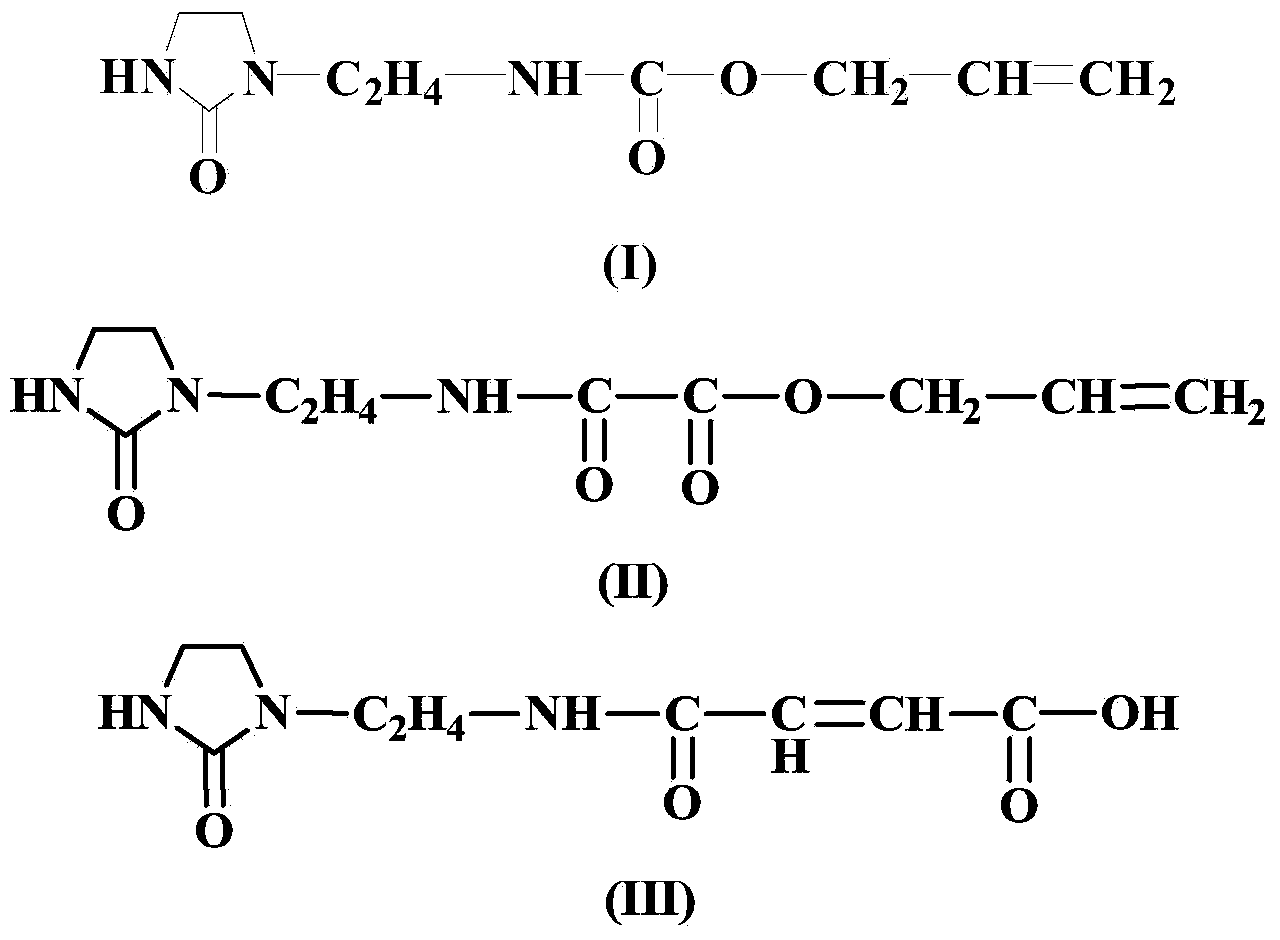

Sulfur-modified neoprene, method for preparing same and applications

ActiveCN101284894AChange regularityImprove mechanical propertiesV-beltsDriving beltsPolymer scienceDichlorobutadiene

The invention provides sulfur modified neoprene rubber, which is characterized in that the neoprene rubber is the multipolymer of chloroprene, 2, 3-dichloroprene and sulphur. The multipolymer is made up of the constitutional repeating units; moreover, the multipolymer has a weight average molar mass between 80000 and 150000, a number average molecular weight between 35000 and 70000 and a brittleness temperature between 38 DEG C below zero and 42 DEG C below zero; the multipolymer is made by polymerizing 100 weight portions of chloroprene, 2 to 30 weight portions of 2, 3- dichloroprene and 0.5 to 0.8 weight portion of sulfur by latex, wherein, the polyreaction temperature is between 20 and 45 DEG C, in the formula, n is an integer between 80 and 100, m is an integer between 2 and 10 and x is an integer between 2 and 6. The sulfur modified neoprene rubber embodies good machining performance in the aspects such as the tensile-strength, the crystallization velocity and the stability of the Mooney viscosity; in addition, the sulfur modified neoprene rubber has good rebound resilience, peeling strength, anti-tensile and chap property, antigraining performance and forming binding property, therefore, the dynamic property of the product is superior to that of the neoprene rubber of the prior art. The invention also provides a method for making the neoprene rubber and an application to the manufacture of a car transmission belt and a power conveyer belt.

Owner:重庆化医长寿化工集团有限公司

Chloroprene rubber adhesive and process for preparing same

InactiveCN1557899ALow triphenyl contentSolve pollutionChloroprene adhesivesBenzoic acidPolymer science

The chloroprene rubber adhesive is prepared with chloroprene rubber, cyclopentane-B solvent, methyl ethyl ketone, ethyl acetate, No. 120 solvent gasoline, tert-butyl phenolic resin, magnesium oxide, zinc oxide and benzoic acid-water catalyst. The present invention uses no toxic benzene solvent, and has less environmental pollution and harm to human body, and the product has good brushing performance, high adhesive strength, high lasting property and other advantages.

Owner:GUANGDONG BADESE CHEM

Aqueous Adhesive

A two part aqueous adhesive comprising a main agent containing a polychloroprene latex as a main component and a curing agent, the main agent and the curing agent being separated during storing or transporting.

Owner:DENKA CO LTD

Chloroprene rubber composition and its application

ActiveUS20100209644A1Improve heat resistanceSynthetic resin layered productsSpecial tyresPolymer scienceHeat resistance

To provide a chloroprene rubber composition with which a vulcanized rubber having further improved heat resistance without impairing mechanical properties, the compression set and the tension fatigue can be obtained, and a rubber member for an automobile, a hose, a rubber molded article and a rubber vibration insulator comprising the vulcanized rubber.A chloroprene rubber composition, which comprises 100 parts by mass of at least one chloroprene rubber selected from the group consisting of a xanthogen-modified chloroprene rubber and a mercaptan-modified chloroprene rubber, and from 15 to 200 parts by mass of carbon black having a number average particle size of from 70 nm to 600 nm and having a DBP oil absorption of from 15 ml / 100 g to 60 ml / 100 g by oil absorption method A of JIS K6221.

Owner:DENKA CO LTD

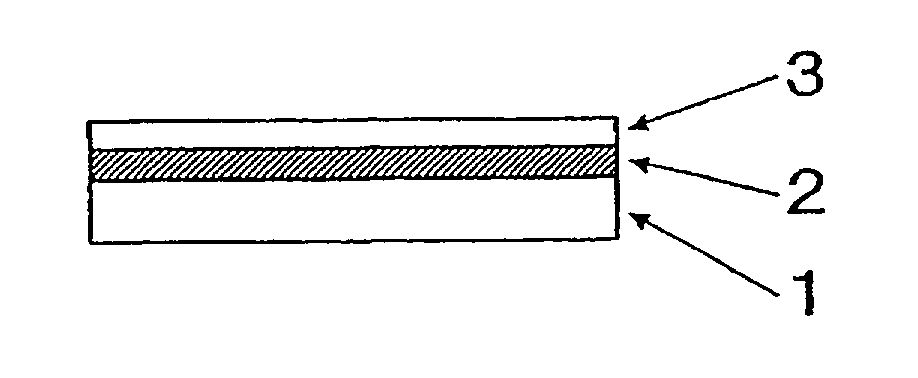

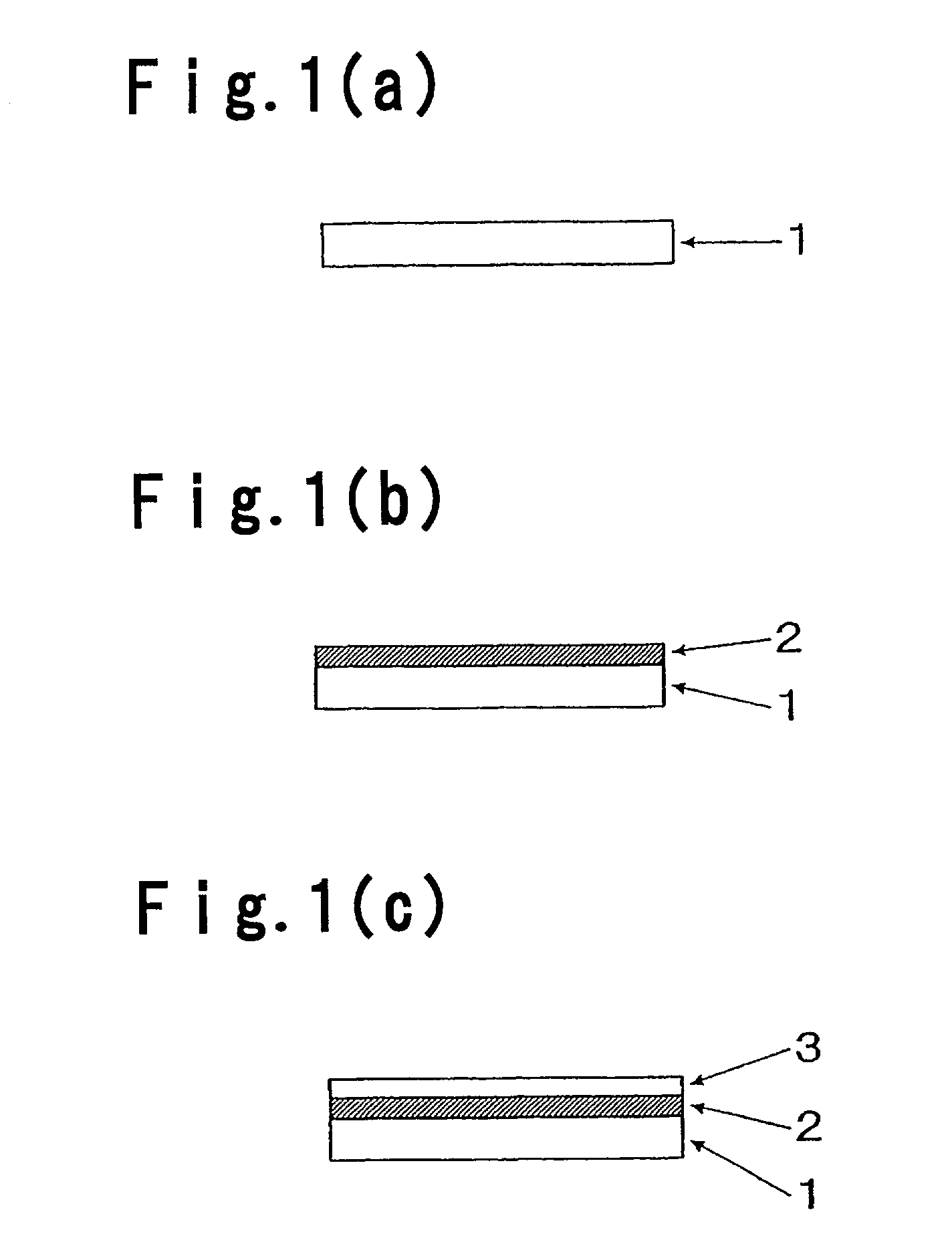

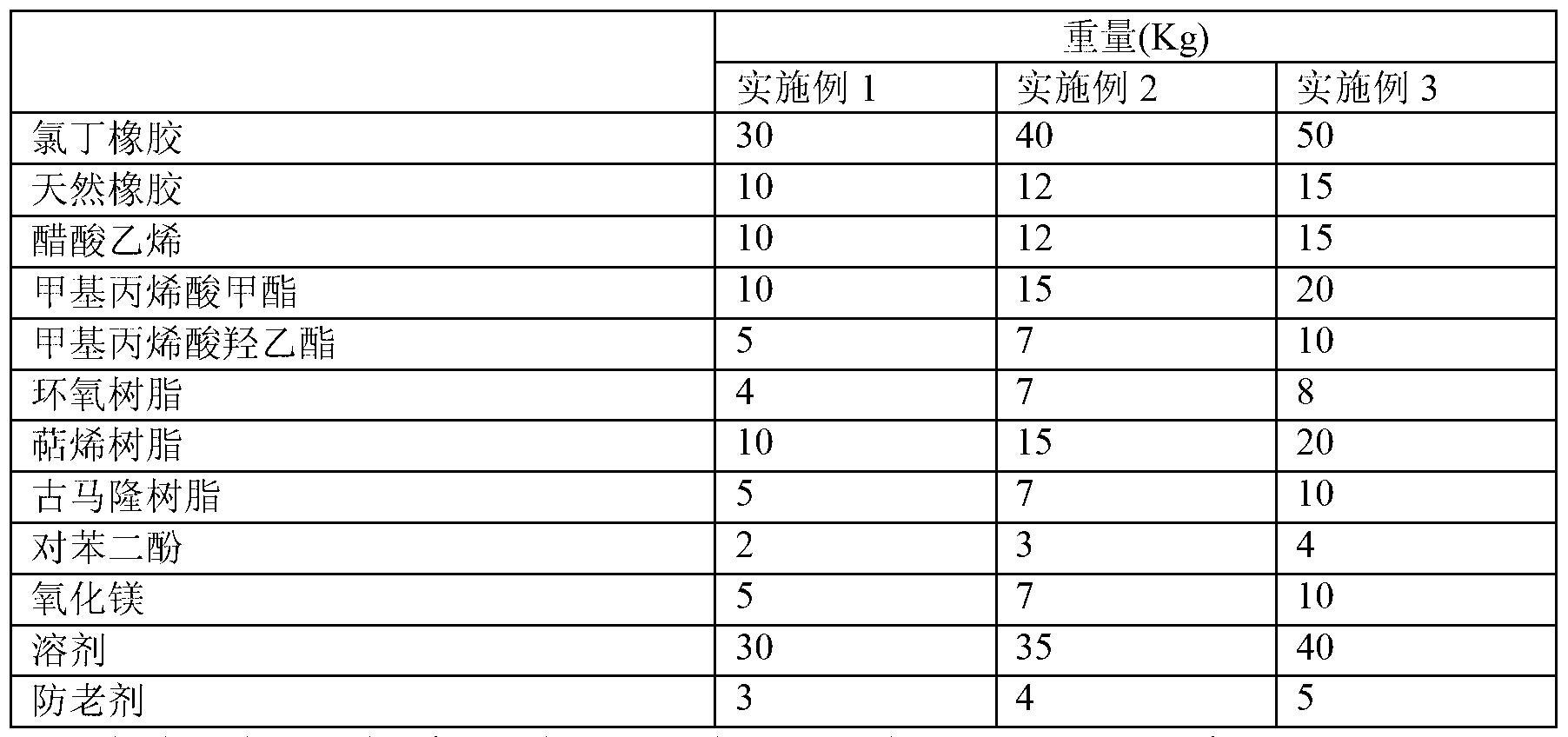

Solvent type chloroprene rubber adhesive with excellent weather ability and preparation method thereof

ActiveCN103265895AImprove cold resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyPolymer science

The invention provides an adhesive, particularly relates to a chloroprene rubber adhesive and belongs to the technical field of adhesives. The solvent type chloroprene rubber adhesive comprises the following constituents in parts by weight: 30-50 parts of chloroprene rubber, 10-15 parts of natural rubber, 10-15 parts of vinyl acetate, 10-20 parts of methyl methacrylate, 5-10 parts of hydroxyethyl methylacrylate, 4-8 parts of epoxy resin, 10-20 parts of terpene resin, 5-10 parts of coumarone resin, 2-4 parts of hydroquinone, 5-10 parts of magnesium oxide, 30-10 parts of solvent and 3-5 parts of anti-aging agent. The solvent type chloroprene rubber adhesive provided by the invention has better heat resistance and cold tolerance, the adhesive strength of the chloroprene rubber adhesive provided by the invention can be more than 130N / cm, after being placed for 7 days at minus 30 DEG C, the adhesive strength also can be 110N / cm, and after being placed for 7 days at 100 DEG C, the adhesive strength is more than 75N / cm.

Owner:广东硕成科技股份有限公司

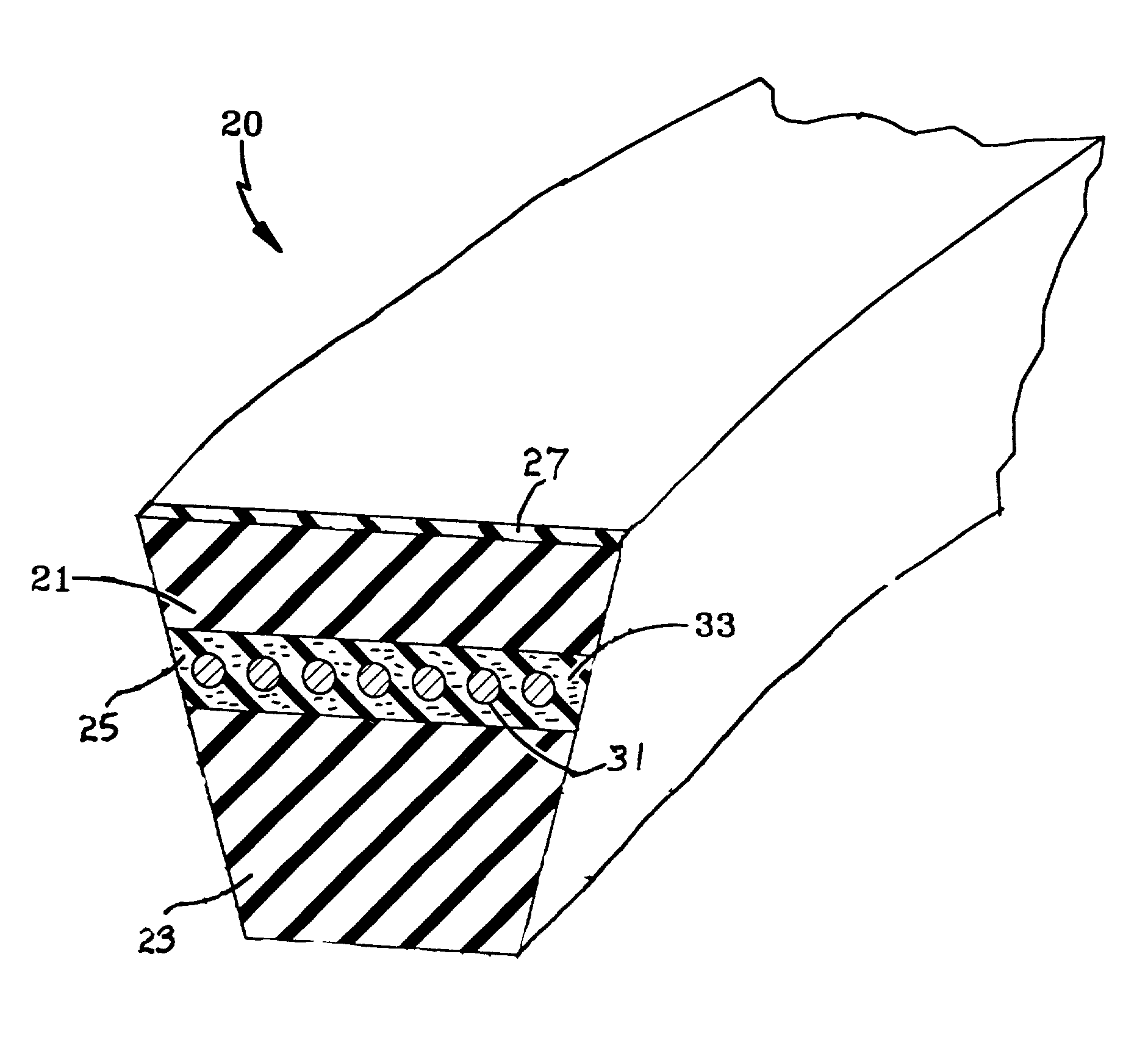

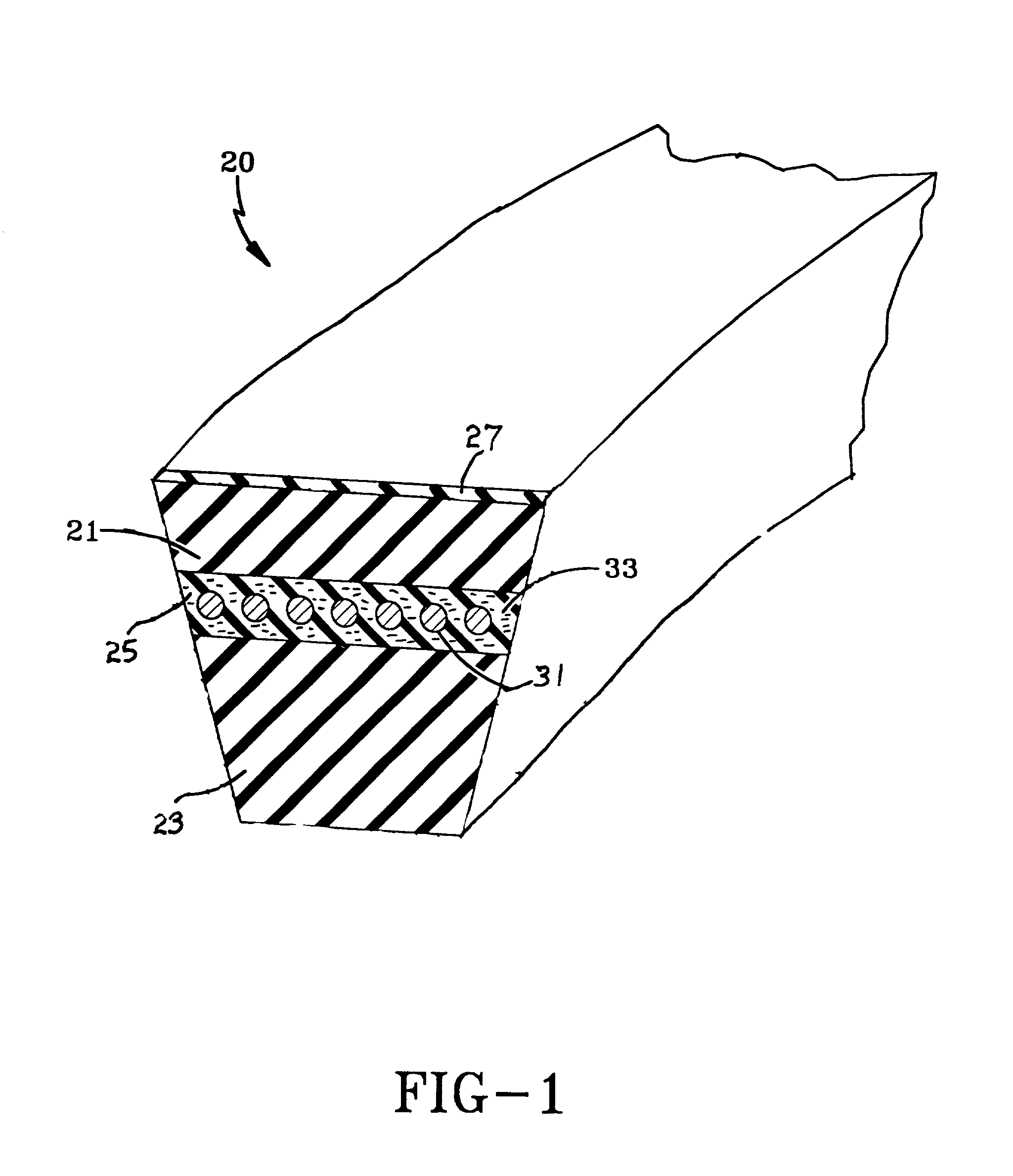

Power transmission belt

An endless single V-grooved power transmission belt having (A) a tension section; (B) a cushion section; and (C) a load-carrying section disposed between said tension section and cushion section; and the belt containing a sulfur cured elastomeric composition comprising (1) 100 parts of a rubber derived from (a) 25 to 100 parts by weight of natural rubber; and (b) 0 to 75 parts by weight of a second rubber selected from the group consisting of polychloroprene, synthetic polyisoprene, epichlorohydrin, acrylonitrile rubber, hydrogenated acrylonitrile rubber, styrene-butadiene rubber, styrene-isoprene rubber, isoprene-butadiene rubber, styrene-isoprene-butadiene rubber, 1,4-trans-polybutadiene, chlorosulfonated polyethylene, alkylated chlorosulfonated polyethylene, trans-polyoctenamer and mixtures thereof; (2) from 1 to 30 parts by weight per 100 parts by weight of total rubber (phr) of a polybutadiene adduct of maleic acid anhydride; and (3) from 5 to 50 phr of fibers distributed throughout the elastomer composition.

Owner:CONTITECH USA INC

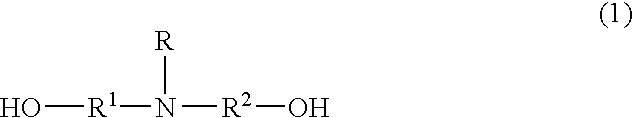

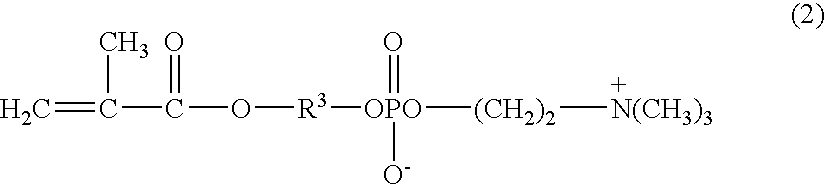

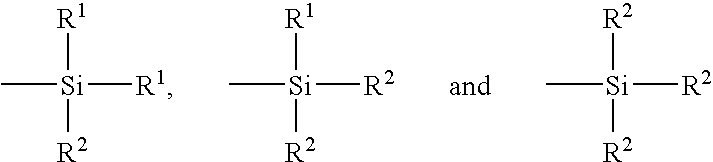

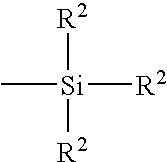

Sulfur-modified chloroprene rubber composition and molded body

An object of the invention is to provide a sulfur-modified chloroprene rubber composition improved in heat resistance. A sulfur-modified chloroprene rubber composition, comprising a sulfur-modified chloroprene rubber containing sulfur chemically bound thereto and sulfur not chemically bound to the sulfur-modified chloroprene rubber, wherein: the ratio of the amount of sulfur chemically bound to the sulfur-modified chloroprene rubber to the total amount of sulfur in the sulfur-modified chloroprene rubber composition (amount of chemically bound sulfur [mass %] / total amount of sulfur [mass %]) is 0.1 to 0.45; and the sulfur-modified chloroprene rubber has, at the molecular terminal, at least one structure represented by the following General Formula (1) or (2): —S—C(═S)—O—R1 . . . (1) (in General Formula (1), R1 represents an alkyl group having 1 to 4 carbon atoms) or —S—R2 . . . (2) (in General Formula (2), R2 represents an alkyl group having 8 to 20 carbon atoms).

Owner:DENKA CO LTD

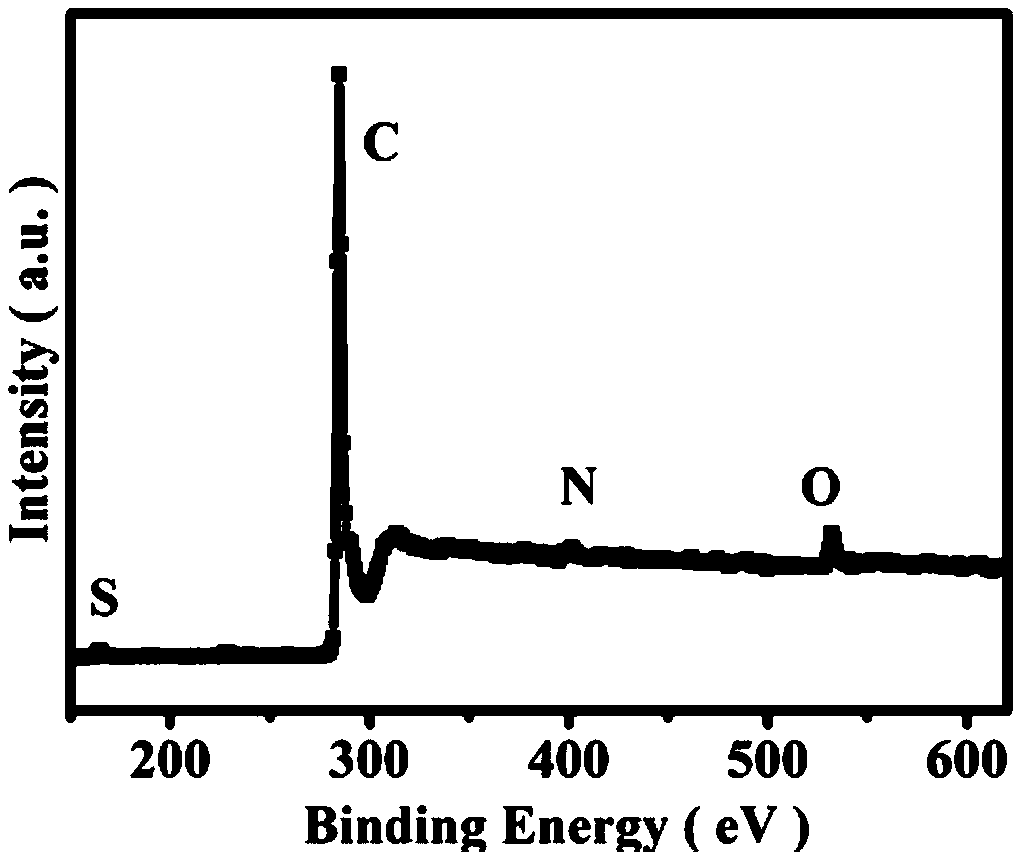

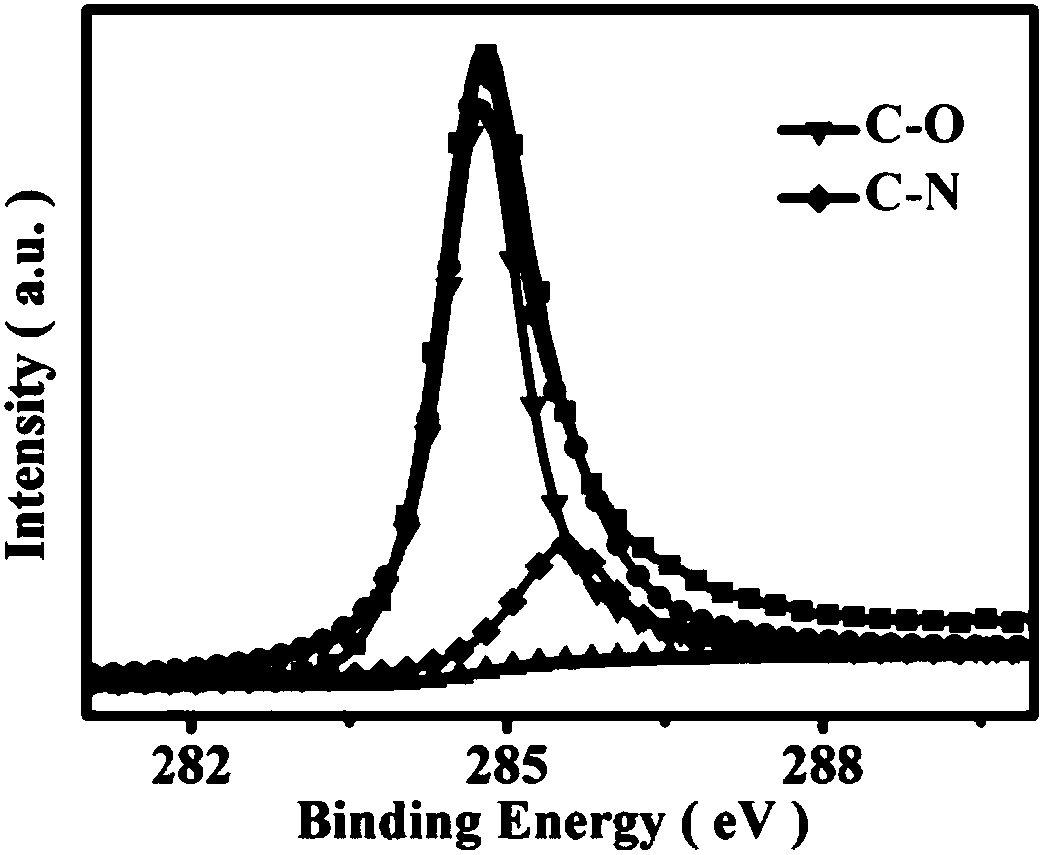

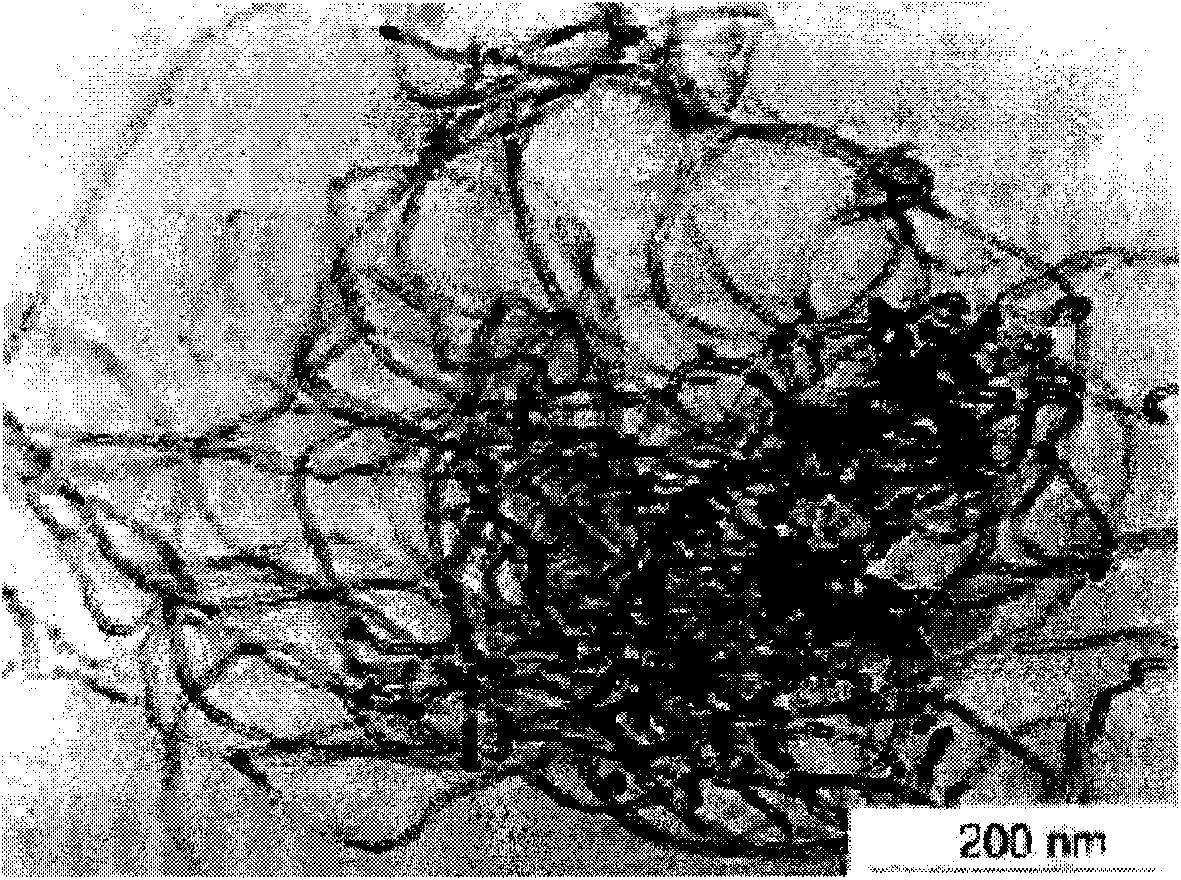

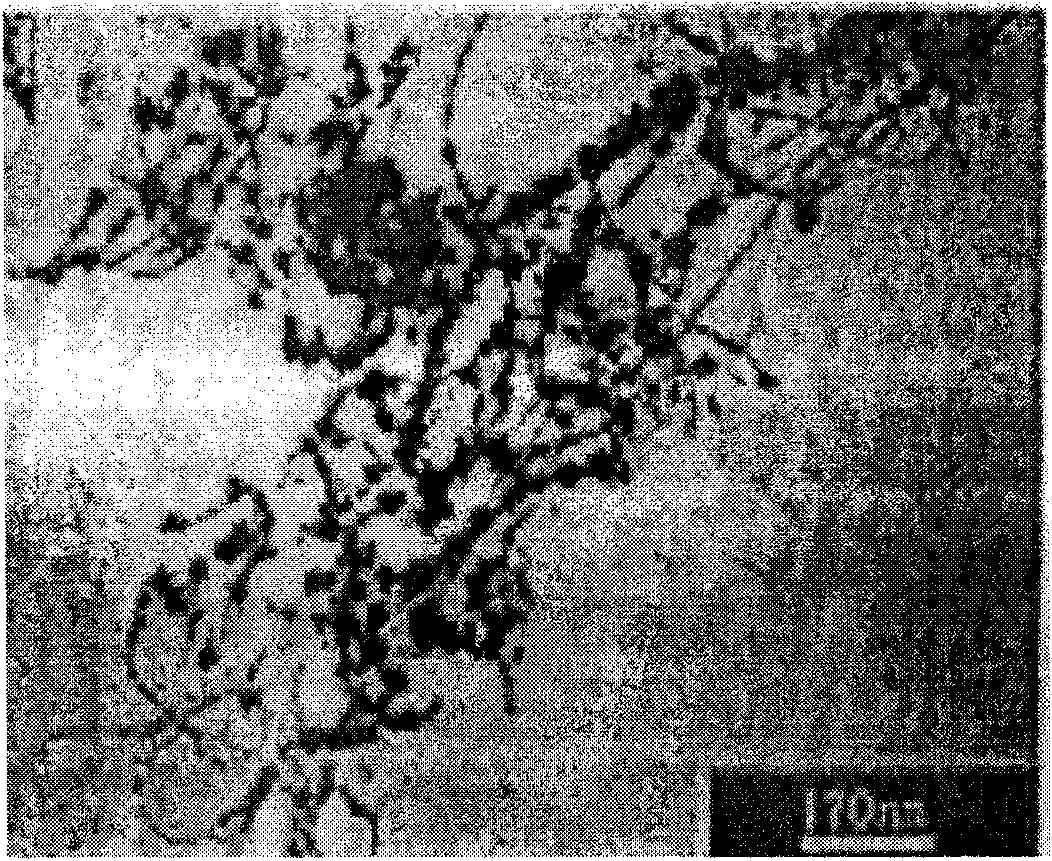

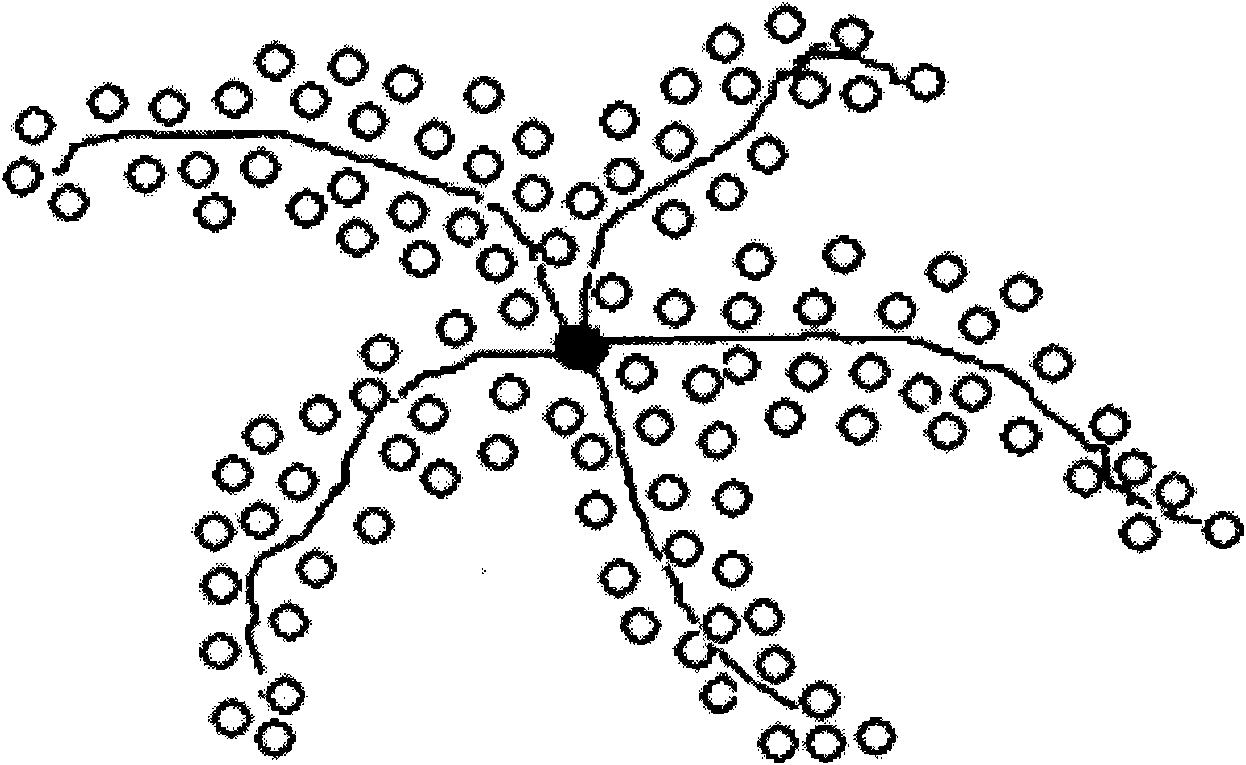

Nitrogen and sulfur co-doped porous carbon microsphere, preparation method and application thereof and oxidization-reduction electrode

ActiveCN107658474AImprove performanceImprove electrochemical performanceCell electrodesPorous carbonMicrosphere

The invention relates to a preparation method of a nitrogen and sulfur co-doped porous carbon microsphere composite material. The method comprises the following steps of S1, performing closed reactionon hexachlorobutadiene, tellurium diethyl dithiocarbamate (TDEC) and a solvent under high temperature and high pressure; S2, relieving pressure to normal pressure after reaction is completed, naturally cooling to a room temperature, and drying the obtained solid to obtain a dried sample; and S3, performing high-temperature roasting processing on the dried sample under protection of inert gas so as to obtain the nitrogen and sulfur co-doped porous carbon microsphere composite material. The invention also relates to the composite material, application thereof and oxidization-reduction performance comprising the composite material. The nitrogen and sulfur co-doped porous carbon microsphere composite material has excellent performance and can be used for preparing an oxidization-reduction electrode of a fuel cell, so that the nitrogen and sulfur co-doped porous carbon microsphere composite material can be used in the fuel cell, shows excellent electrochemical performance and has huge application potential and industrial value in the field of electrochemistry.

Owner:INST OF NEW MATERIALS & IND TECH WENZHOU UNIV

Chemical resistant glove

InactiveUS20100138978A1Good chemical resistanceImprove protectionChemical protectionHeat protectionPolymer scienceChloroprene

A chemical resistant glove is provided which comprises a chloroprene-based rubber as a first layer and a mixed rubber layer containing a nitrile-butadiene-based rubber and a chloroprene-based rubber as a second layer sequentially formed on a fabric glove, wherein a mixing ratio of the nitrile-butadiene-based rubber and the chloroprene-based rubber in the mixed rubber layer as the second layer is 60:40 to 10:90 in a solid weight ratio. The chemical resistant glove of the present invention is excellent in chemical resistance, tactile feeling and the abrasion resistance.

Owner:SHOWA GLOVE

Modified chloroprene rubber V band and method for preparing same

The invention discloses a modified chloroprene rubber V band and a method for preparing the same. The rubber matrix of the modified chloroprene rubber V band is prepared by mixing the following raw materials in portion by weight: 100 portions of chloroprene rubber, 20 to 50 portions of acid modification carbon nano-tube, 10 to 20 portions of carbon black, 2 to 10 portions of phosphorus oxide, 12 to 18 portions of sulfur, 0.3 to 5 portions of anti-aging agent, 1 to 5 portions of filler, 3 to 7 portions of softener, 2 to 10 portions of plasticizer, and 1 to 6 portions of promoter. The modified chloroprene rubber V band has good properties of heat resistance, oil corrosion resistance, static resistance and fire retardation, and can be widely applied to mechanical transmission systems under special operation environments in the industries such as coal mines, petroleum, chemical engineering, paper making and the like.

Owner:SANLUX

Pneumatic tire

A pneumatic tire having a rubber sidewall including(A) 30 to 80 phr of natural rubber;(B) 20 to 70 phr of cis 1,4-polybutadiene rubber;(C) from 10 to 100 phr of silica; and(D) from 1 to 30 phr of a particulate rubber gel filler selected from the group consisting of polybutadiene gel, styrene butadiene gel, acrylonitrile-butadiene gel, chloroprene gel, natural rubber gel, and mixtures thereof.

Owner:THE GOODYEAR TIRE & RUBBER CO

Aromatic hydrocarbon-free environment-protection chloroprene rubber adhesive with high adhesive strength

InactiveCN101177599AHigh bonding strengthWide range of usesMineral oil hydrocarbon copolymer adhesivesConjugated diene hydrocarbon adhesivesThermoplasticMethyl carbonate

The invention discloses aromatic hydrocarbon-free neoprene adhesive with high adhesive strength, which is characterized in that graft adhesive is firstly prepared according to the following formula: 10 percent-40 percent of methyl cyclohexane, 5 percent -30 percent of ethyl acetate, 0 percent-10 percent of butanone, 5 percent -30 percent of dimethyl carbonate, 8 percent-15 percent of chlorobutadiene rubber, 0 percent-2.5percent of SBS (thermoplastic styrene-butadiene rubber), 7 percent-15 percent of MMA (methyl methacrylate), 0.1percent-0.2 percent of initiator and 0.1 percent-0.5percent of antioxidant; then the invention is prepared by 100 portions of the graft adhesive prepared according to the formula, 0-10 portions of tackifying resin, 0-3 portions of strengthening agent , 0-3 portions of plasticizers and 0-20 portions of diluents. The product of the invention has the advantages of environmental protection, and high adhesive strength, etc.

Owner:GOOD CHEM SCI & TECH

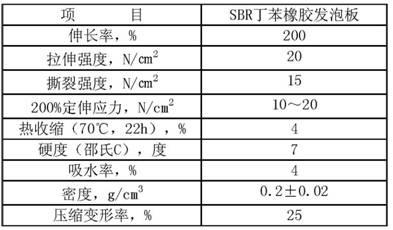

Foaming styrene chloroprene rubber (SCR) and manufacturing method thereof

The invention relates to foaming SCR and a manufacturing method thereof. The foaming SCR comprises a main ingredient, a plasticizer, a dispersing agent, a foaming agent, sulfur, a promoter, an activator, a protective agent and a filler and particularly comprises 100 weight parts of main ingredient, 35 to 60 weight parts of plasticizer, 1 to 2 weight parts of dispersing agent, 5 to 15 weight parts of foaming agent, 4 to 8 weight parts of active zinc oxide, 1 to 2 weight parts of stearic acid, 1 to 2 weight parts of high-activity magnesium oxide, 0.4 to 1 weight part of sulfur, 0.7 to 3 weight parts of promoter, 3 to 6 weight parts of protector and 100 to 200 weight parts of filler. In the main ingredient, the weight part ratio of neoprene to emulsion polymerized butadiene styrene rubber to cis-polybutadiene rubber to solution polymerized butadiene styrene rubber is 30:(10-20):(20-40):(20-30). The foaming SCR offers a soft handfeel, is very elastic and has a uniform and fine close pore structure, high waterproof performance, high thermal-insulation performance and high seawater pumping resistance.

Owner:扬州动易运动用品有限公司

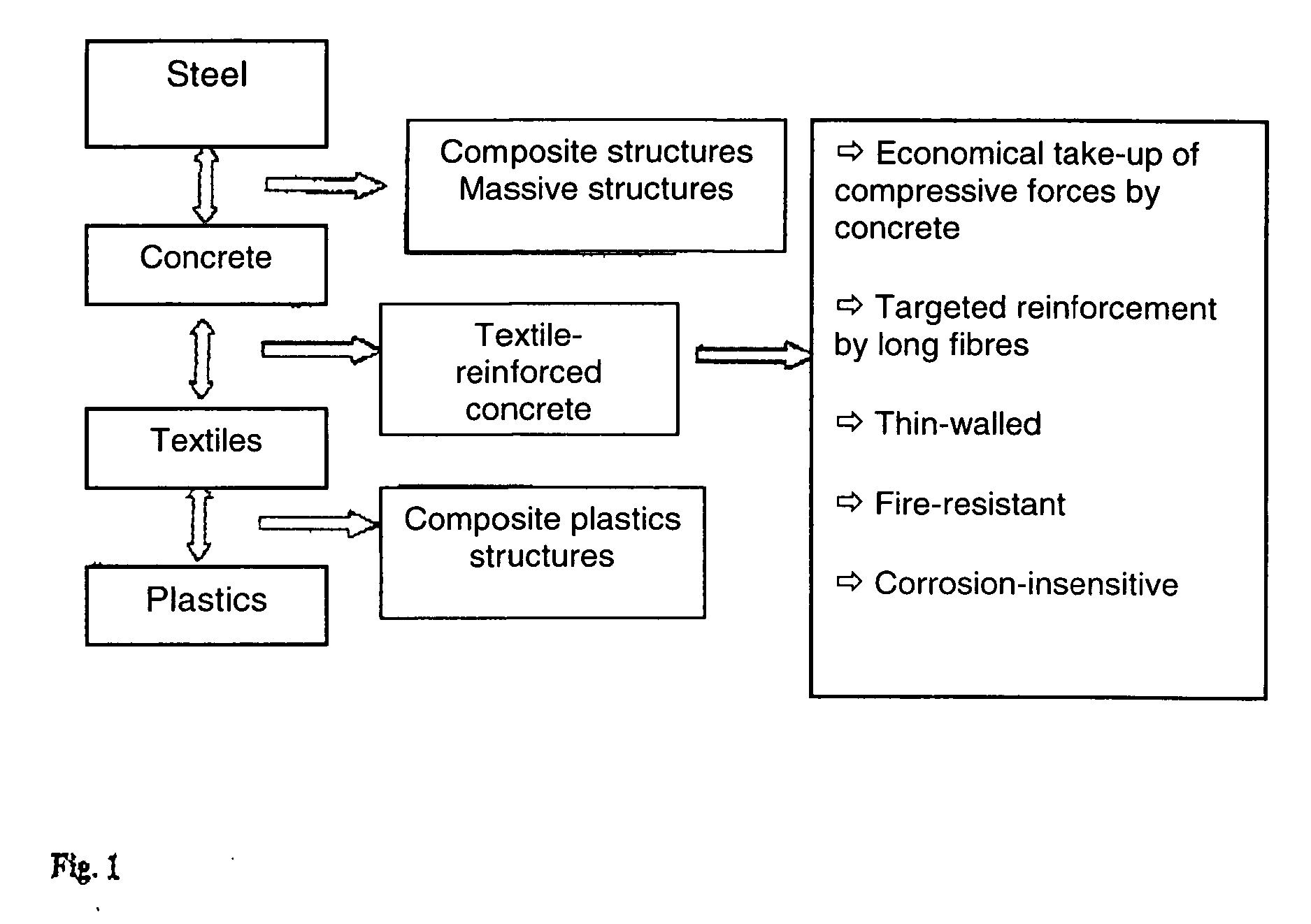

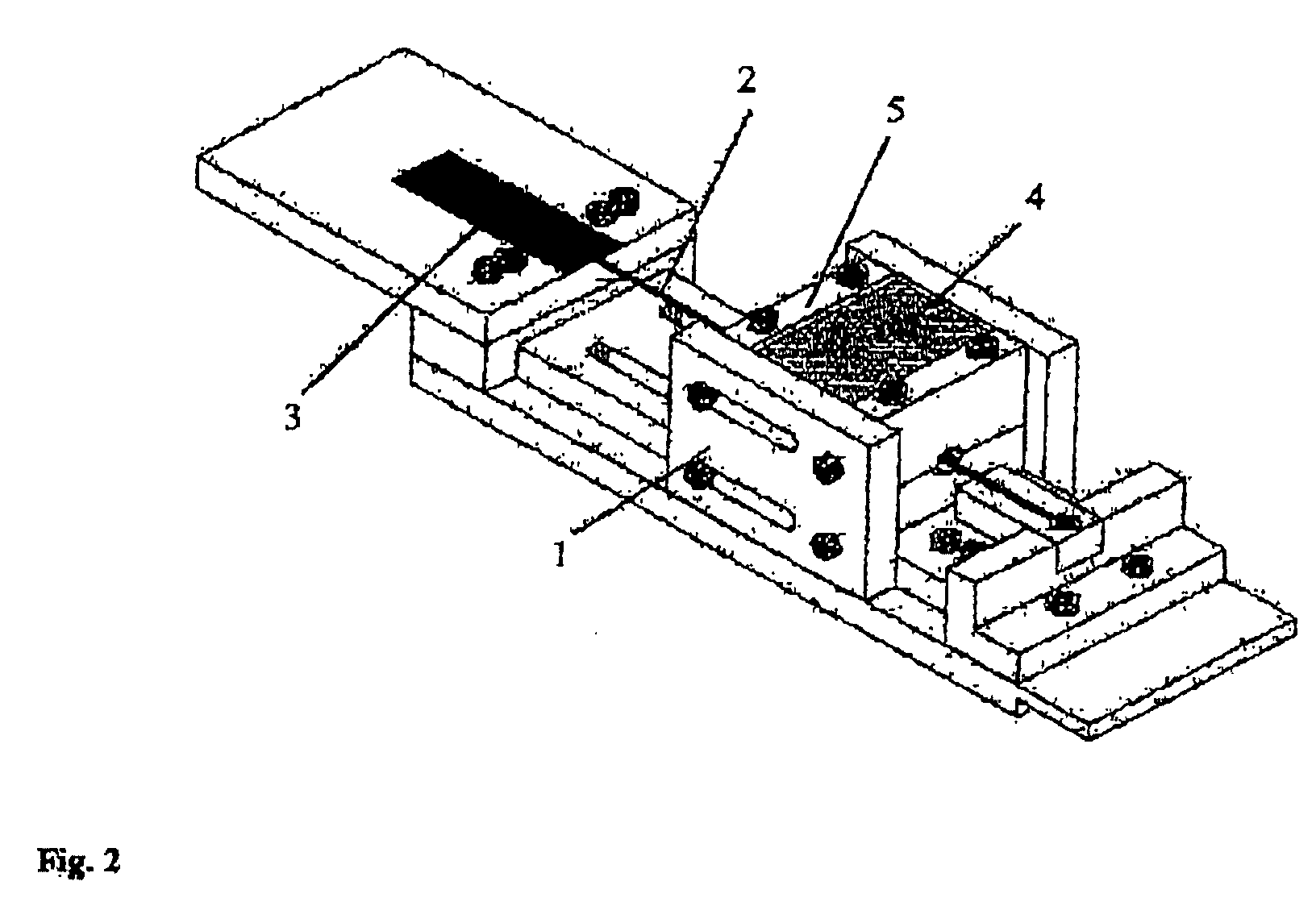

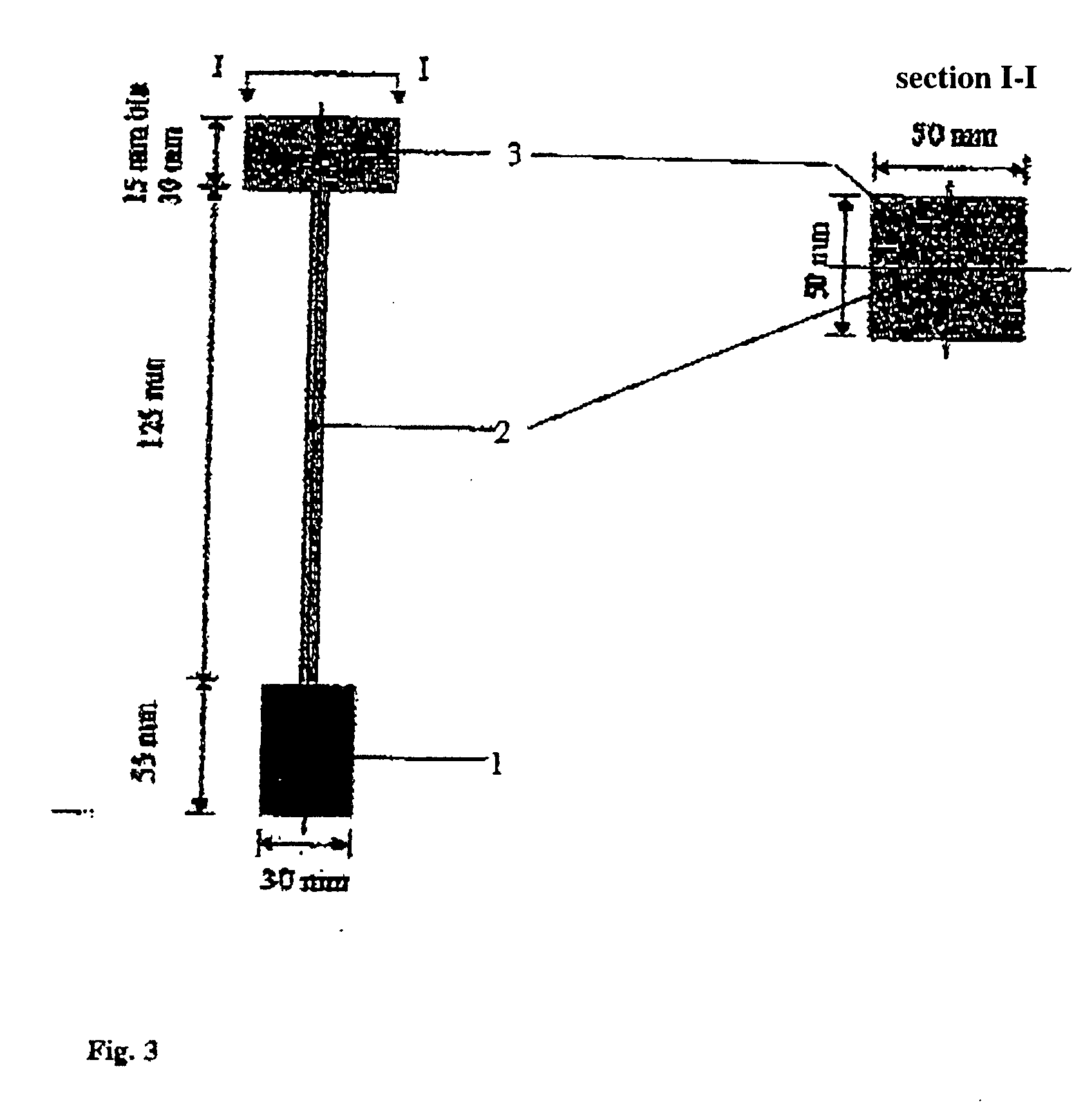

Preparations for use in concrete

InactiveUS20060115642A1Improve propertiesChloropene polymer coatingsThin material handlingPolymer sciencePolychloroprenes

The present invention provides a process for finishing fibrous products with a preparation based on aqueous dispersions of polychloroprene and a process for preparing textile-reinforced and fiber-reinforced concrete and other cement-based products including those finished products.

Owner:BAYER MATERIALSCIENCE AG

Acid corrosion resistant chloroprene rubber

The invention relates to an acid corrosion resistant chloroprene rubber which is completely made of crude chloroprene rubber so as to greatly enhance the acid corrosion resistance of the sizing material. Barium sulfate and kaolin are added to enhance the acid corrosion resistance of the sizing material. Plasticizer SUNDEX790 is added to replace the traditional ester plasticizer to improve the acid resistance of the sizing material because the plasticizer SUNDEX790 has good compatibility with the chloroprene rubber and can not be easily extracted by acid corrosion. In addition, because the plasticizer SUNDEX790 has a flash point higher than 230 DEG C and superior high-temperature aging performance, so that the thermal aging performance of the chloroprene rubber is enhanced. The rubber stopper produced from the chloroprene rubber can meet the requirements for production and using, and the durability of the rubber stopper is three times better than that of the product made according to the traditional formula, thus prolonging the service life of the product so as to lower the production cost. The chloroprene rubber can also be used for producing rubber tubes, rubber strips, rubber plates, rubber linings and other relevant acid resistant rubber products.

Owner:TIANJIN PENGYI GRP CO LTD

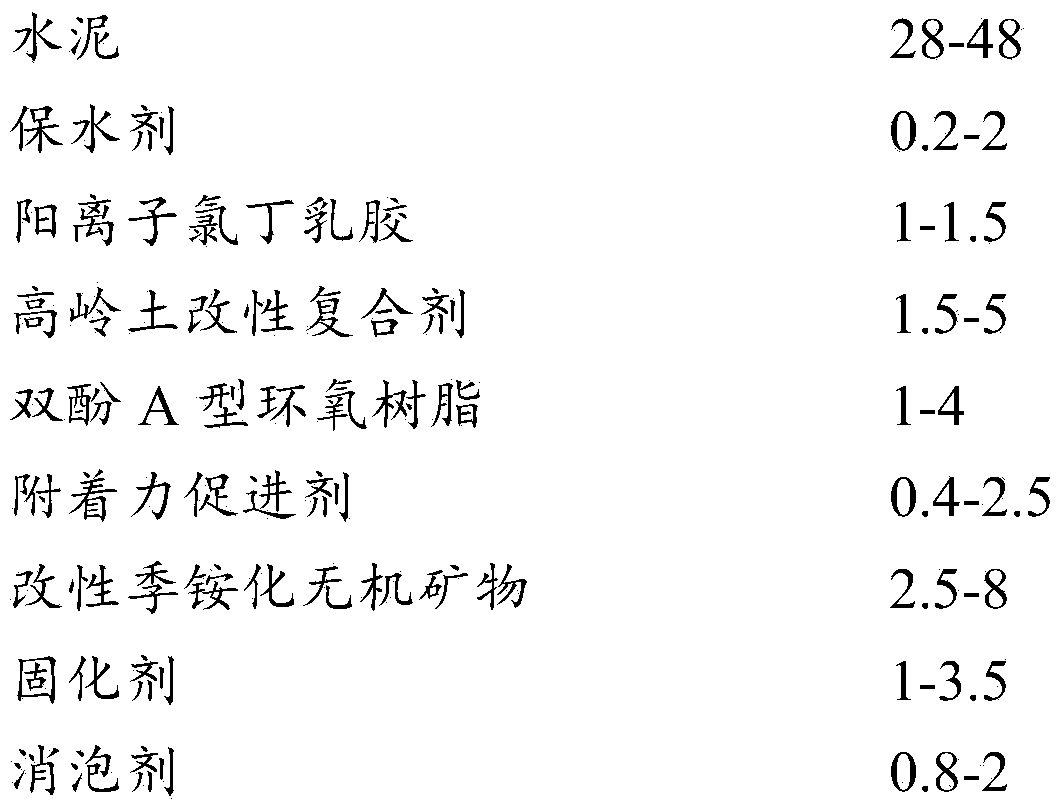

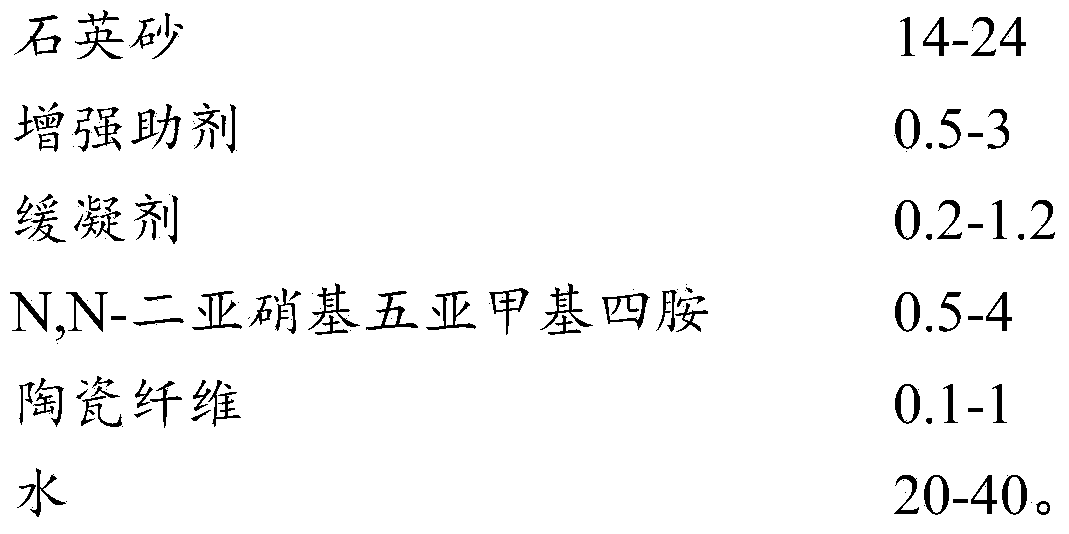

Cement-based finishing slurry and preparation method thereof

The invention relates to cement-based finishing slurry and a preparation method thereof. The cement-based finishing slurry comprises cement, a water-retaining agent, cationic chloroprene latex, a kaolin-modified complexing agent, bisphenol A epoxy resin, an adhesion promoter, modified quaternized inorganic mineral, a curing agent, an antifoaming agent, quartz sand, a reinforcement additive, a retarder, N,N-dinitrosopentamethylenetetramine, ceramic fibers and water. The cement-based finishing slurry has good waterproof and anticorrosion performances, high bonding strength, high stability, wide industrial application prospects and high market values.

Owner:广东景龙建设集团有限公司

Foamable rubber particles

ActiveCN103804737AControllable physical propertiesMeet physical index requirementsElastomerPolymer science

The invention discloses foamable rubber particles which comprise a rubber composition and rubber ingredients, wherein the rubber composition consists of polychloroprene, standard natural rubber, EVA (ethylene vinyl acetate copolymer), POE (polyolefin elastomer), ethylene propylene ternary gel or nitrile rubber; the rubber ingredients consist of filler, a fortifier, a disperser, a modifying flowable agent, a foaming agent and a vulcanizer. After the rubber composition and the rubber ingredients, which are prepared according to proportion, are prepared into the foamable rubber particles through fusion granulation, the rubber particles are heated and pressured by any one of stand type injection molding machine to form turbulent state rubber, the turbulent state rubber is injected into a mould cavity, the turbulent state rubber in the mould cavity is vulcanized, and the rubber particles are vulcanized and foamed, so that the weight of the foamed rubber product can be reduced and the elasticity of the foamed rubber product can be improved under the condition that the other physical properties are invariable.

Owner:QUANZHOU SHENXIANG RUBBER

Environmentally friendly adhesives for bonding vulcanized rubber

InactiveUS6841600B2Improve adhesionGood layover characteristicNon-macromolecular adhesive additivesOrganic dyesElastomerZinc phosphate

Adhesive compositions effective for bonding runner to metal and containing no more than about 1000 ppm of lead especially adapted to bond vulcanized elastomers to rigid substrates, like metal are disclosed. The adhesives are useful in combination with primer coats, and as one-coat adhesives and provide durable, rubber tearing primary adhesive bonds after exposure to harsh conditions. The adhesives exhibit excellent bond versatility, sweep resistance, and in-can storage stability. In one embodiment, the adhesive compositions of the present invention consist essentially of less than 1000 ppm of lead, at least one diluent as water or organic solvent, a halogen-containing film former, optionally a nitroso compound, brominated dichlorobutadiene, and / or adhesion promoter, and an acid scavenger comprising zinc phosphate.

Owner:LORD CORP

Low-smoke flame-retardant rubber cable material and preparation method thereof

InactiveCN104961929ALow smoke productionImprove flame retardant performanceRubber insulatorsElastomerPolymer science

The invention relates to cable materials and a preparation method thereof, in particular to a low-smoke flame-retardant rubber cable material and the preparation method thereof. The low-smoke flame-retardant rubber cable material is composed of the following raw materials including, by weight, 40-100 parts of natural rubber, 40-80 parts of chloroprene rubber, 30-40 parts of nitrile rubber, 4-5 parts of stearic acid, 4-5 parts of a coupling agent, 5-6 parts of zinc oxide, 5-6 parts of antioxidant BHT, 3-5 parts of accelerator, 100-120 parts of a fire retardant and 60-100 parts of a filling agent. The main component of the natural rubber is polyisoprene which is one of the air-dried rubber piece and crepe; the accelerator is rubber accelerator TMTD; the chloroprene rubber is an elastic body generated through alpha-polymerization with chloroprene as a main raw material. The low-smoke flame-retardant rubber cable material and the preparation method thereof have the advantages that low-smoke, fire-retardant and weather-resistance effects of the cable material are achieved, environmental-protection and safety are achieved, the physical and mechanical properties and the machining processing property of the prepared cable material are good, the machining is easy, the raw materials are more environmental, the toxicity is low, and the popularization strength is large.

Owner:梁忠顺

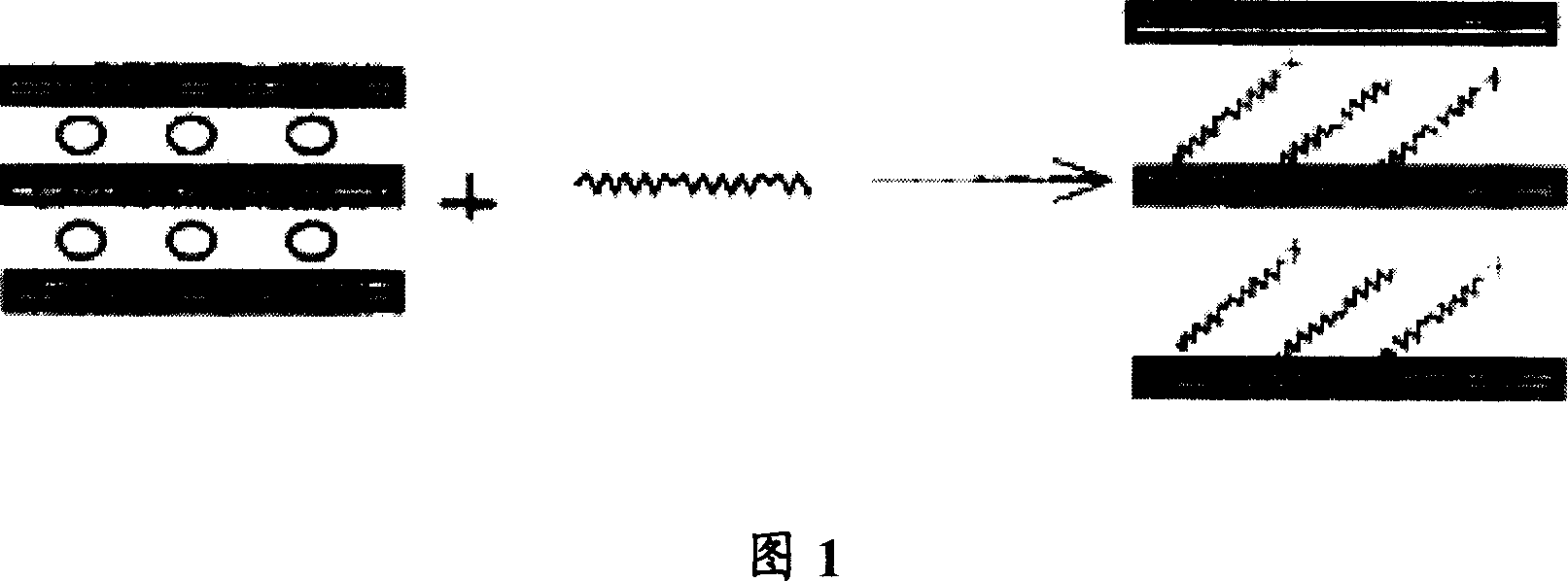

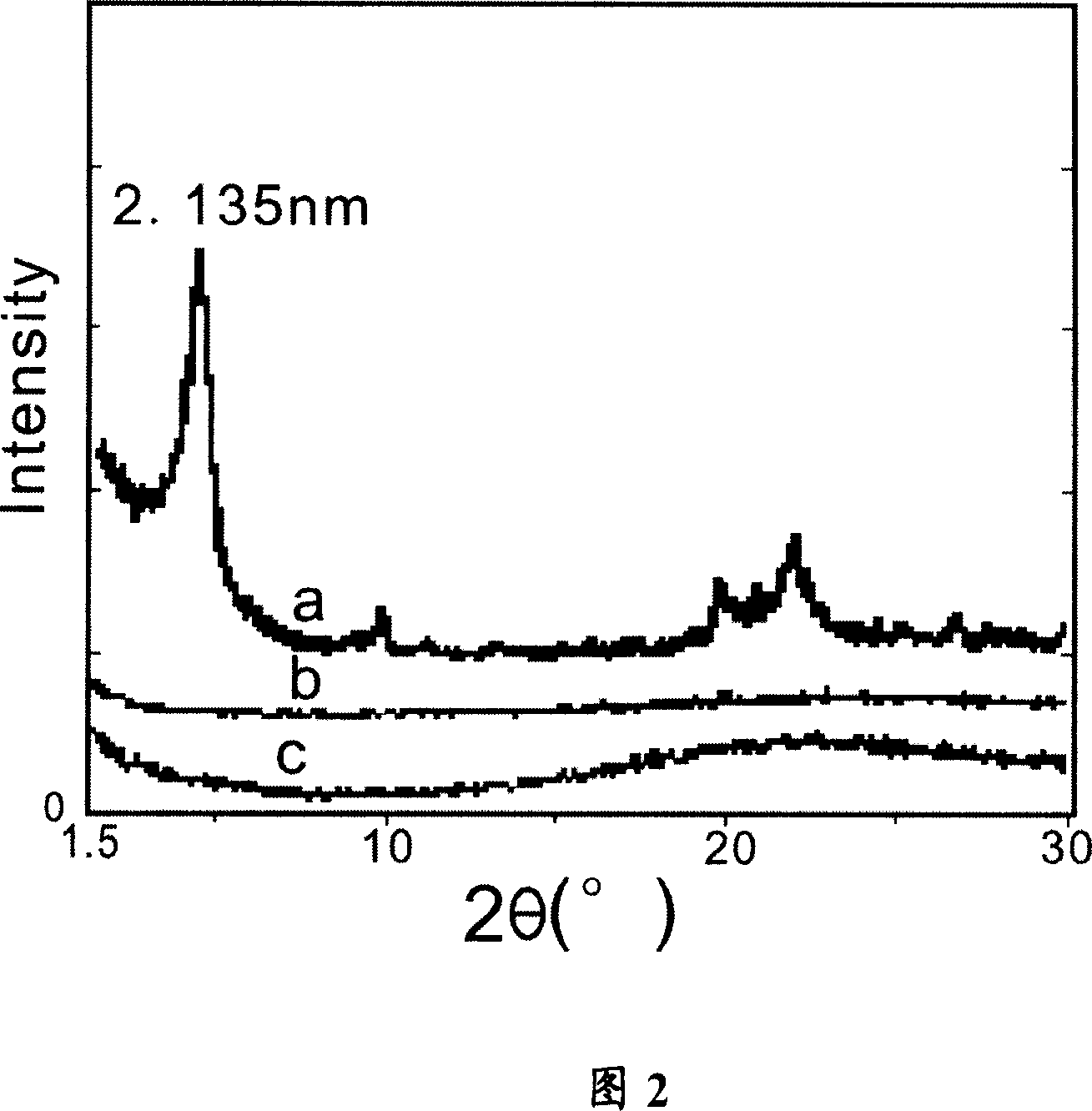

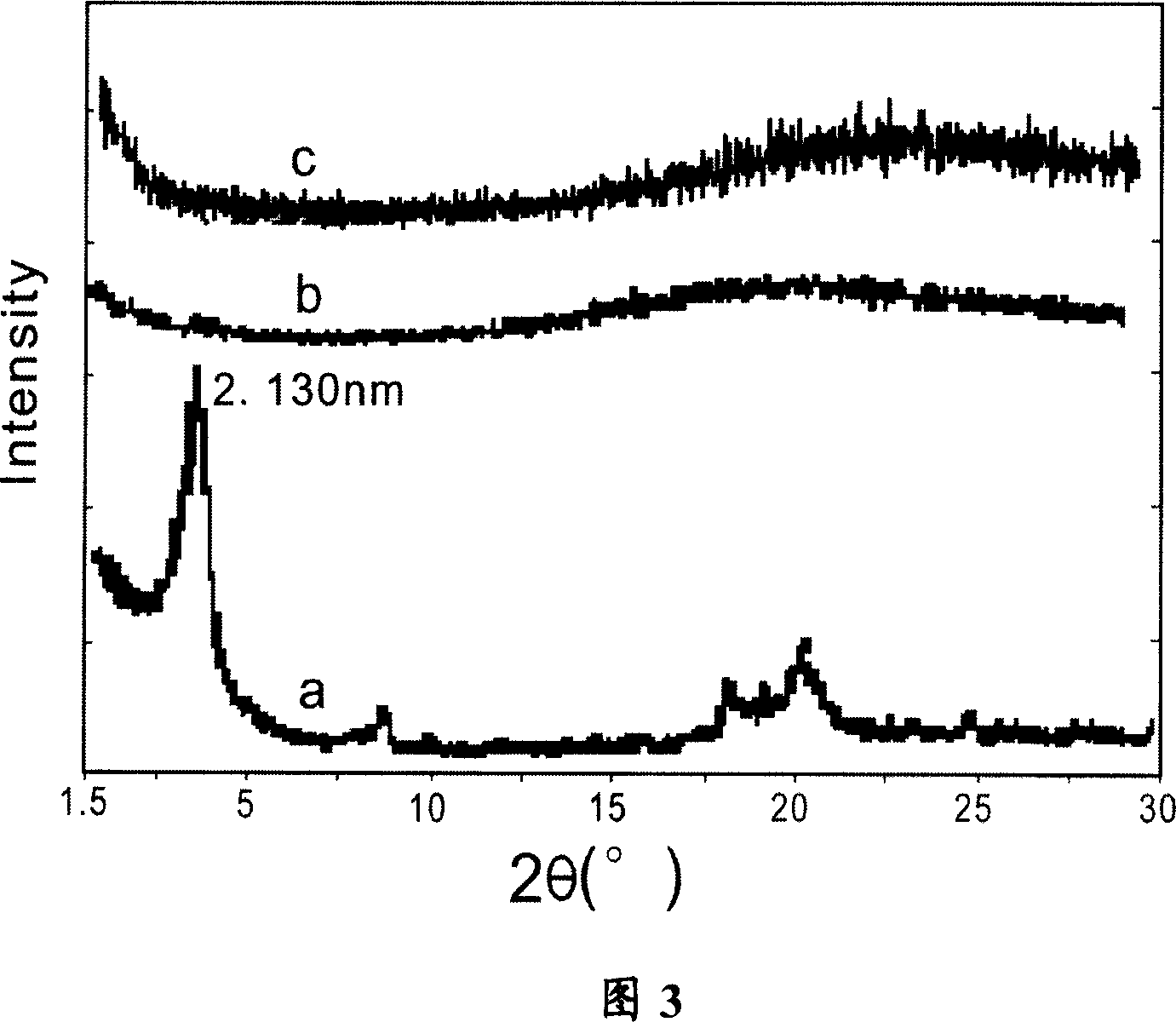

Chloroprene rubber/montmorillonite nano-composite material and its preparation method

InactiveCN1948376AImprove mechanical propertiesImprove antistatic performanceOrganificationMontmorillonite

This invention relates to a stripping chloronorgutta(CR) / montmorillonite nanometer composite which is of high mechanical performance and fine antistatic static electricity performance and its preparation. The preparation includes: purify montmorillonite and carry out natrium change; carry out montmorillonite Organification; prepare nanometer composite of chloronorgutta crude rubber / montmorillonite; and prepare nanometer composite of chloronorgutta / montmorillonite.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

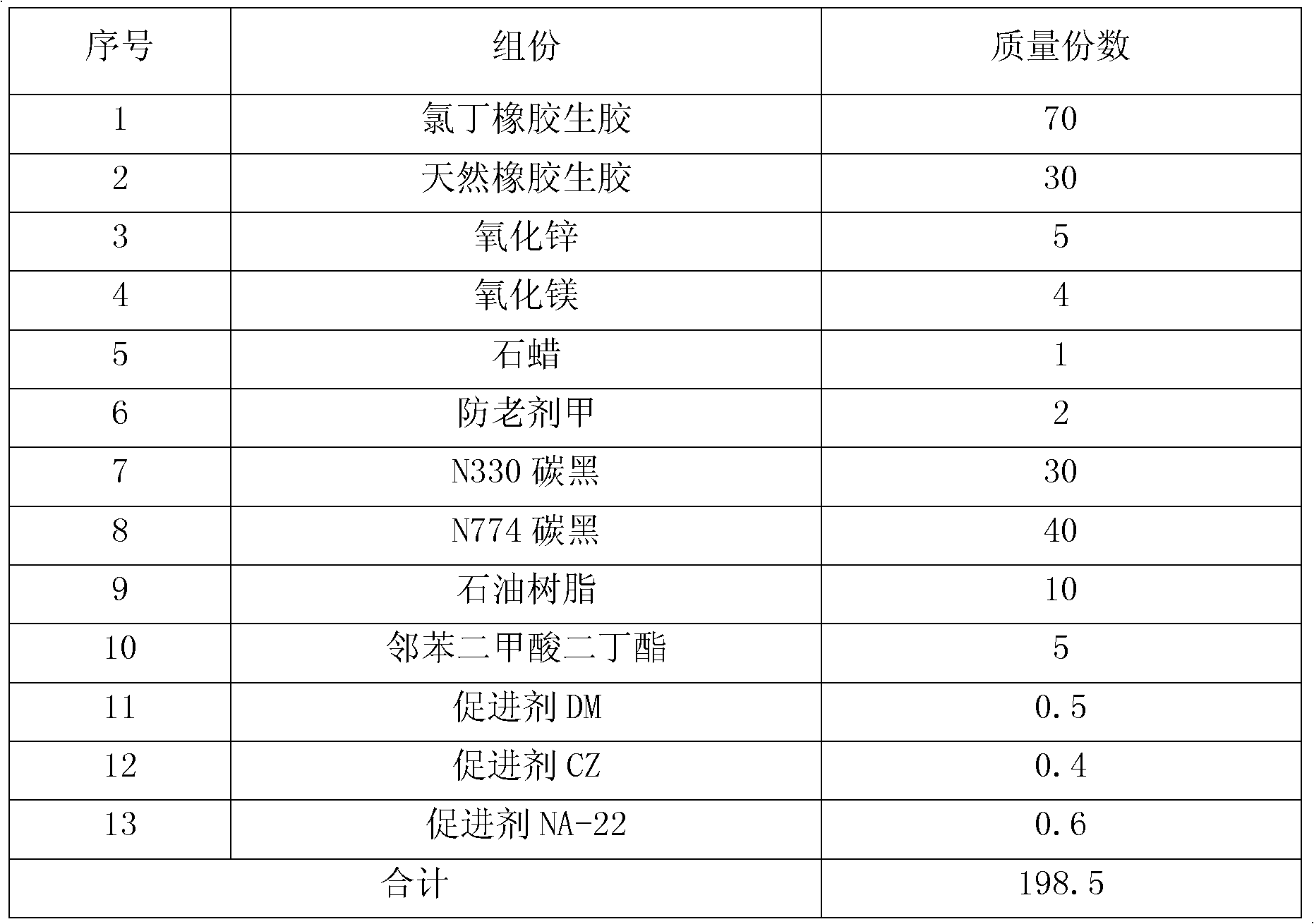

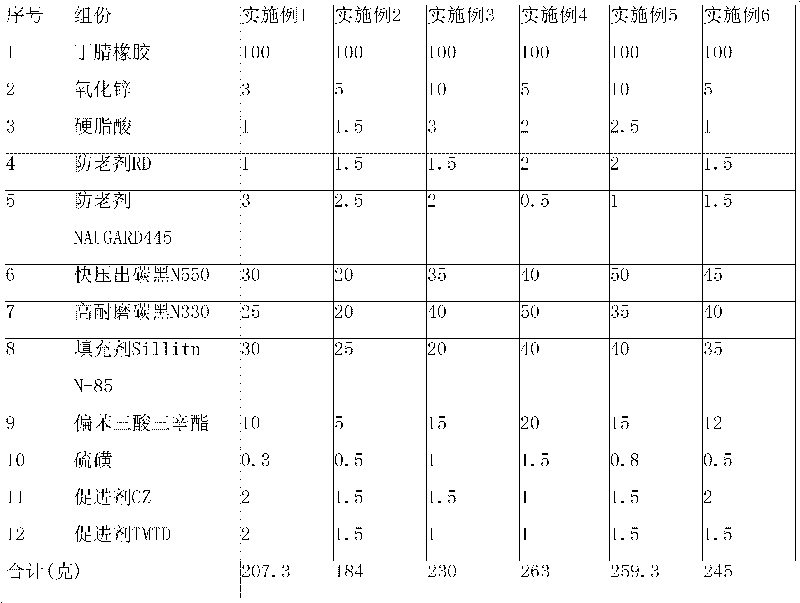

Automobile power-steering pipe structure and rubber formula

InactiveCN101716834ASolve the costSteering columnsRubber layered productsHeat resistanceAcrylonitrile

The invention relates to an automobile power-steering pipe structure and a rubber formula; the automobile power-steering pipe is that: an inner layer adopts butyronitrile inner rubber and an outer layer adopts chloroprene outer rubber; the structure is that: butyronitrile inner rubber / braided wires / butyronitrile middle rubber / braided wires / butyronitrile outer rubber; or butyronitrile inner rubber / braided wires / butyronitrile outer rubber; meanwhile, the invention provides a butyronitrile inner rubber formula and a chloroprene outer rubber formula; the conveying medium of the inner rubber layeradopts the butyronitrile rubber, as the butyronitrile rubber contains acrylonitrile and has polarity, besides the oil resistivity, the butyronitrile rubber has the characteristics of ageing resistance and low ventilation property; the outer layer adopts chloroprene rubber which has god heat resistance and ozone resistance. By adopting contrastive analysis of the butyronitrile rubber, the chloroprene rubber formula and chlorosulfonated polyethylene rubber formula, the formula performance can meet standard requirements. The automobile power-steering pipe which is prepared by the formula which replaces the chlorosulfonated polyethylene rubber formula can meet normal production conditions and performance and reduce the material cost.

Owner:TIANJIN PENGYI GRP CO LTD

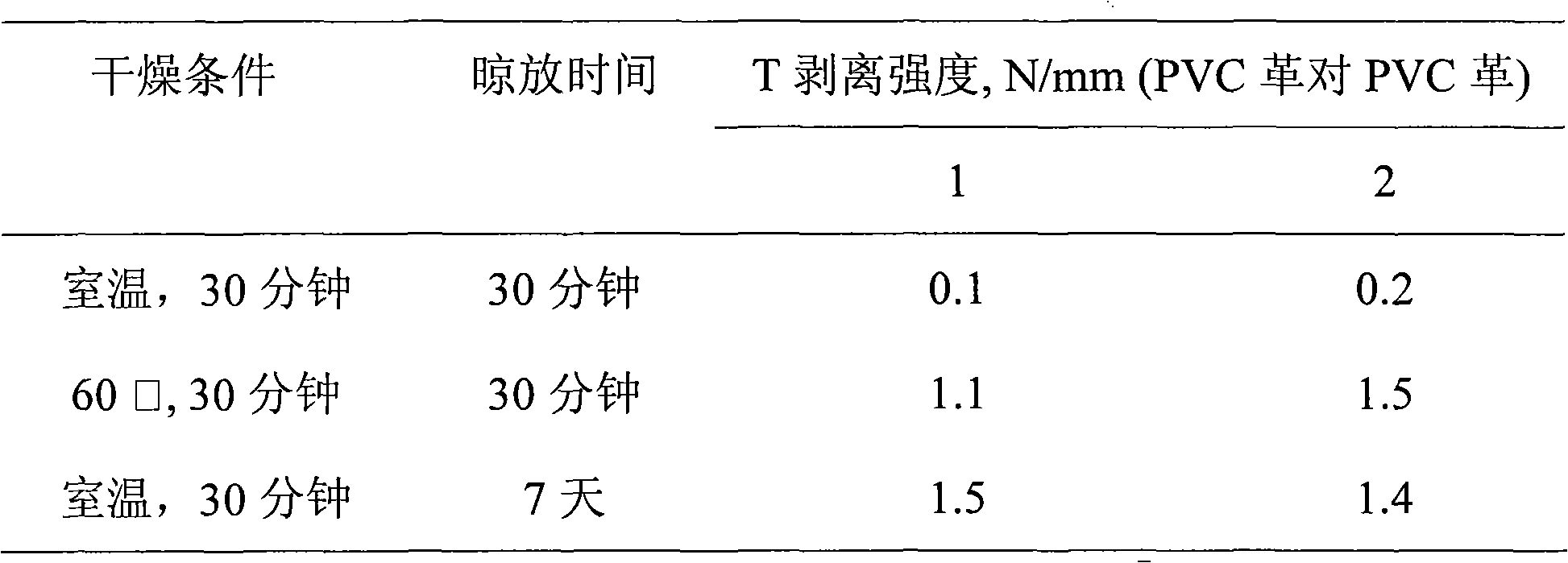

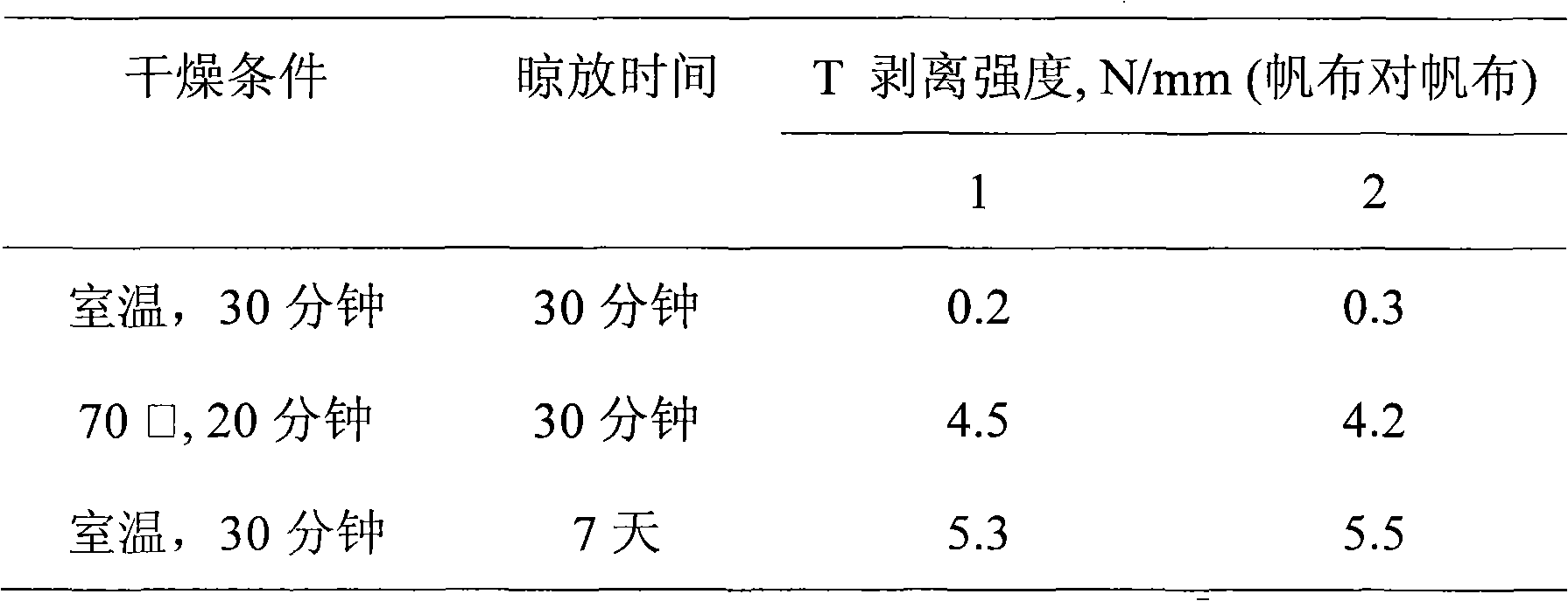

Water-based polychloroprene adhesive

InactiveUS8118969B2Excellent rheology for sprayingHigh bonding strengthSynthetic resin layered productsFire rescuePolymer scienceAcrylic resin

The use of a carboxylated acrylic resin for blending with a medium gel, medium crystallinity polychloroprene gives a waterborne adhesive formulation with an excellent combination of green strength, heat resistance, bond strength and sprayability unobtainable by other techniques reported by those skilled in the art. The adhesives described in the invention are environmentally friendly and have particular usefulness in postforming operations where a combination of green strength and heat resistance are critical.

Owner:ILLINOIS TOOL WORKS INC

High temperature-resistant low-smoke flame-retardant rubber cable material and preparation method thereof

InactiveCN105001465ALow smoke productionImprove flame retardant performanceRubber insulatorsElastomerEngineering

The invention relates to a cable material and a preparation method thereof and concretely relates to a high temperature-resistant low-smoke flame-retardant rubber cable material and a preparation method thereof. The high temperature-resistant low-smoke flame-retardant rubber cable material comprises, by weight, 40-100 parts of natural rubber, 40-80 parts of chloroprene rubber, 30-40 parts of nitrile rubber, 4-5 parts of stearic acid, 4-5 parts of a coupling agent, 5-6 parts of zinc oxide, 4-5 parts of a stabilizing agent, 3-5 parts of a promoter, 100-120 parts of a fire retardant and 60-100 parts of a filler. The natural rubber mainly comprises polyisoprene and is one of an air-dried rubber sheet and crepe. The promoter is a rubber promoter TMTD. The chloroprene rubber is an elastomer formed by alpha-polymerization of chloroprene as a main raw material. The cable material has the advantages of low smoke, flame resistance, weather resistance, environmental friendliness, safety, excellent physical and mechanical properties and processability, processing easiness, environmentally friendly raw materials, low toxicity and good generalization performance.

Owner:梁忠顺

Elastomeric film-forming compositions and articles made from the elastomeric film

The invention relates to an elastomeric film-forming composition comprising (a) a copolymer formed from monomers consisting of chlorobutadiene and an ethylenically unsaturated carboxylic acid or ester, and (b) one or more cross-linking agents. The invention also relates to dipped articles, gloves, methods of manufacture and uses involving the composition.

Owner:SKINPROTECT CORPORATION SDN BHD

Chloroprene rubber adhesive agent and preparation method thereof

InactiveCN103045134AWith finishFunctionalAldehyde/ketone condensation polymer adhesivesGraft polymer adhesivesPolymer scienceBenzoyl peroxide

The invention discloses a chloroprene rubber adhesive agent and a preparation method thereof, aiming at solving the problem that the attractive appearance of the shoes is affected because the existing synthetic material always becomes aged and yellow rapidly. The chloroprene rubber adhesive agent provided by the invention comprises chloroprene rubber, a solvent and an additive, wherein the additive consists of the following components based on the weight percentage of the chloroprene rubber: 10-20% of titanium dioxide, 5-10% of light calcium carbonate, 3-6% of zinc oxide, 7-10% of magnesium oxide, 0.15-0.3% of aluminate coupling agent, 20-25% of methyl methacrylate, 0.7-1.0% of benzoyl peroxide, 0.4-0.6% of hydroquinone, 0.4-0.7% of 2,6-di-tert butyl p-cresol and 15-20% of tert butyl phenolic resin; and the weight ratio of the chloroprene rubber to the solvent is 1: (5.2-6.5). The chloroprene rubber adhesive agent disclosed by the invention has double functions of coating and binding, and is resistant to become aged and yellow.

Owner:CHENGDU SHENGERJIA SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com