Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6976 results about "Maleic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Maleic acid or cis-butenedioic acid is an organic compound that is a dicarboxylic acid, a molecule with two carboxyl groups. Its chemical formula is HO₂CCH=CHCO₂H. Maleic acid is the cis-isomer of butenedioic acid, whereas fumaric acid is the trans-isomer. It is mainly used as a precursor to fumaric acid, and relative to its parent maleic anhydride, maleic acid has few applications.

Mixed dispersants for lubricants

A dispersant composition comprising the product of an amine, an alcohol, or an amino alcohol, with a hydrocarbyl-substituted succinic anhydride component exhibits improved viscosity stability and reduced chlorine content, when the hydrocarbyl-substituted succinic anhydride component comprises: (a) 10 to 95 weight percent of a component prepared by reacting a polyisobutylene with maleic anhydride in the presence of chlorine; and (b) 5 to 90 weight percent of a component prepared by reacting a polyisobutylene with maleic anhydride in the substantial absence of chlorine.

Owner:THE LUBRIZOL CORP

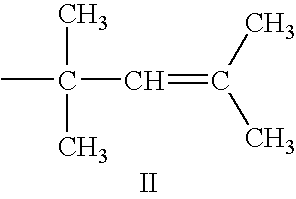

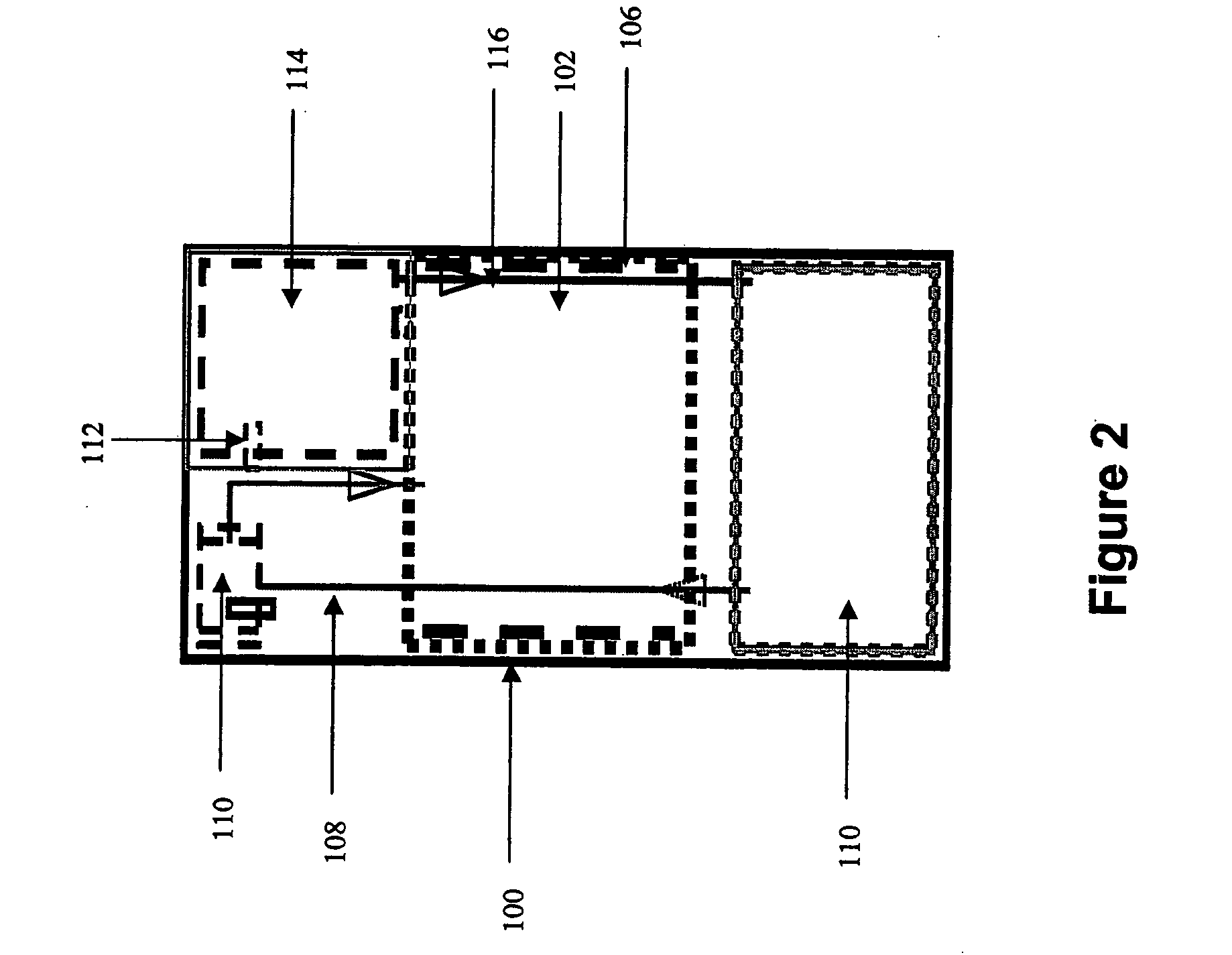

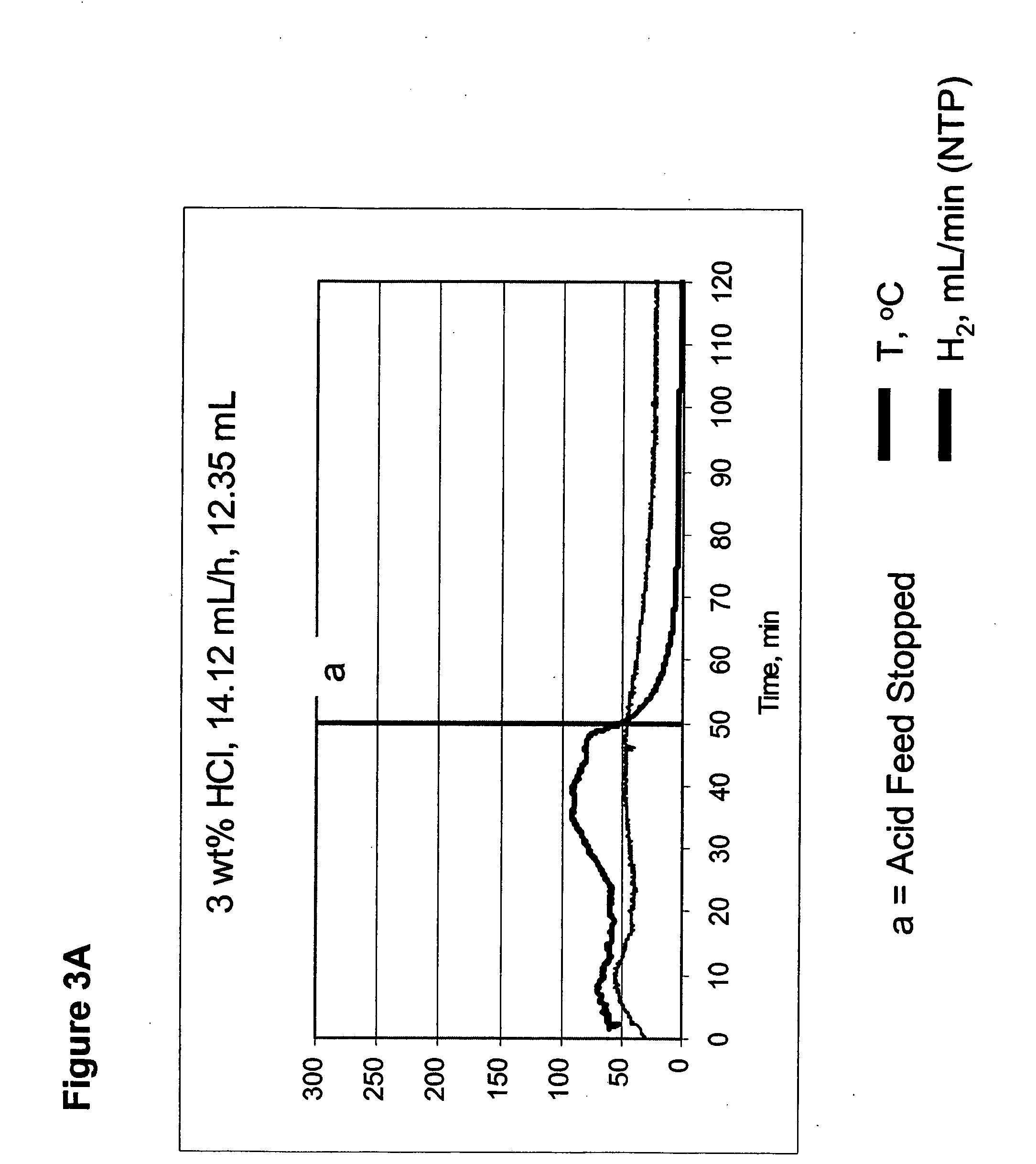

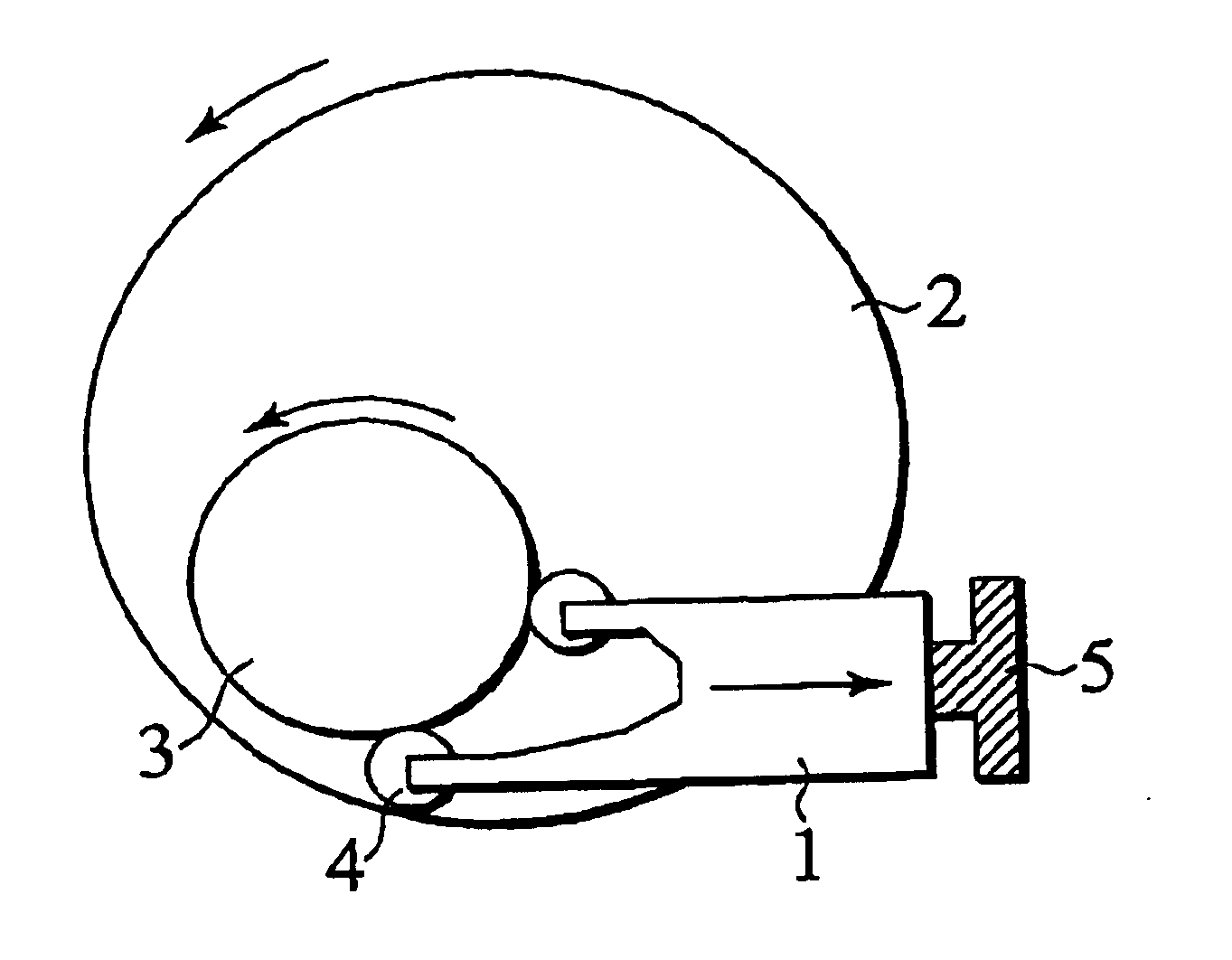

Systems and methods for hydrogen generation from solid hydrides

InactiveUS20050238573A1Regulate rateReactant parameters controlHydrogen productionO-Phosphoric AcidAlkaline earth metal

A system is disclosed for hydrogen generation based on hydrolysis of solid chemical hydrides with the capability of controlled startup and stop characteristics wherein regulation of acid concentration, acid feed rate, or a combination of both control the rate of hydrogen generation. The system comprises a first chamber for storing a solid chemical hydride and a second chamber for storing an acidic reagent. The solid chemical hydride is a solid metal borohydride having the general formula MBH4, where M is selected from the group consisting of alkali metal cations, alkaline earth metal cations, aluminum cation, zinc cation, and ammonium cation. The acidic reagent may comprise inorganic acids such as the mineral acids hydrochloric acid, sulfuric acid, and phosphoric acid, and organic acids such as acetic acid, formic acid, maleic acid, citric acid, and tartaric acid, or mixtures thereof.

Owner:MILLENNIUM CELL

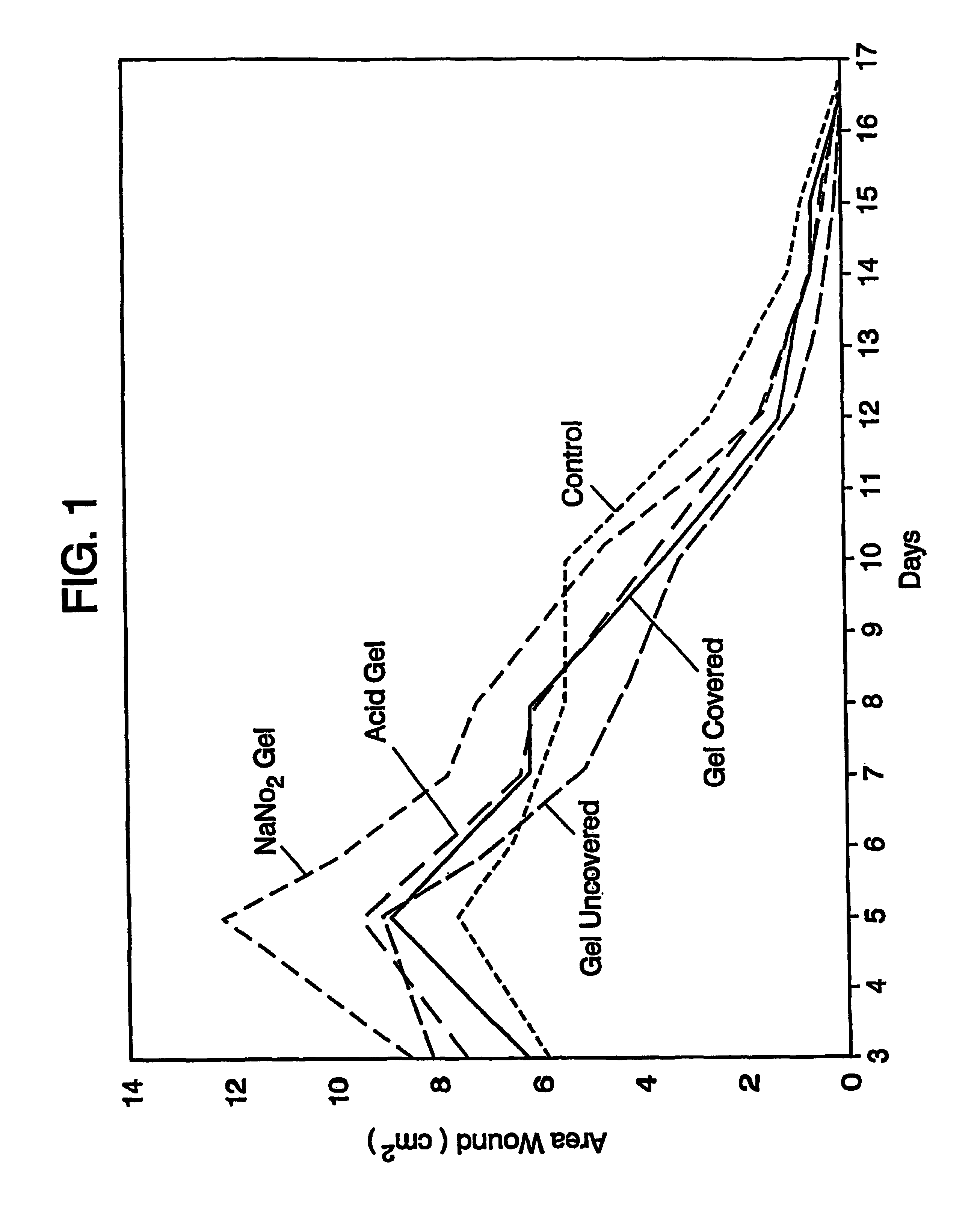

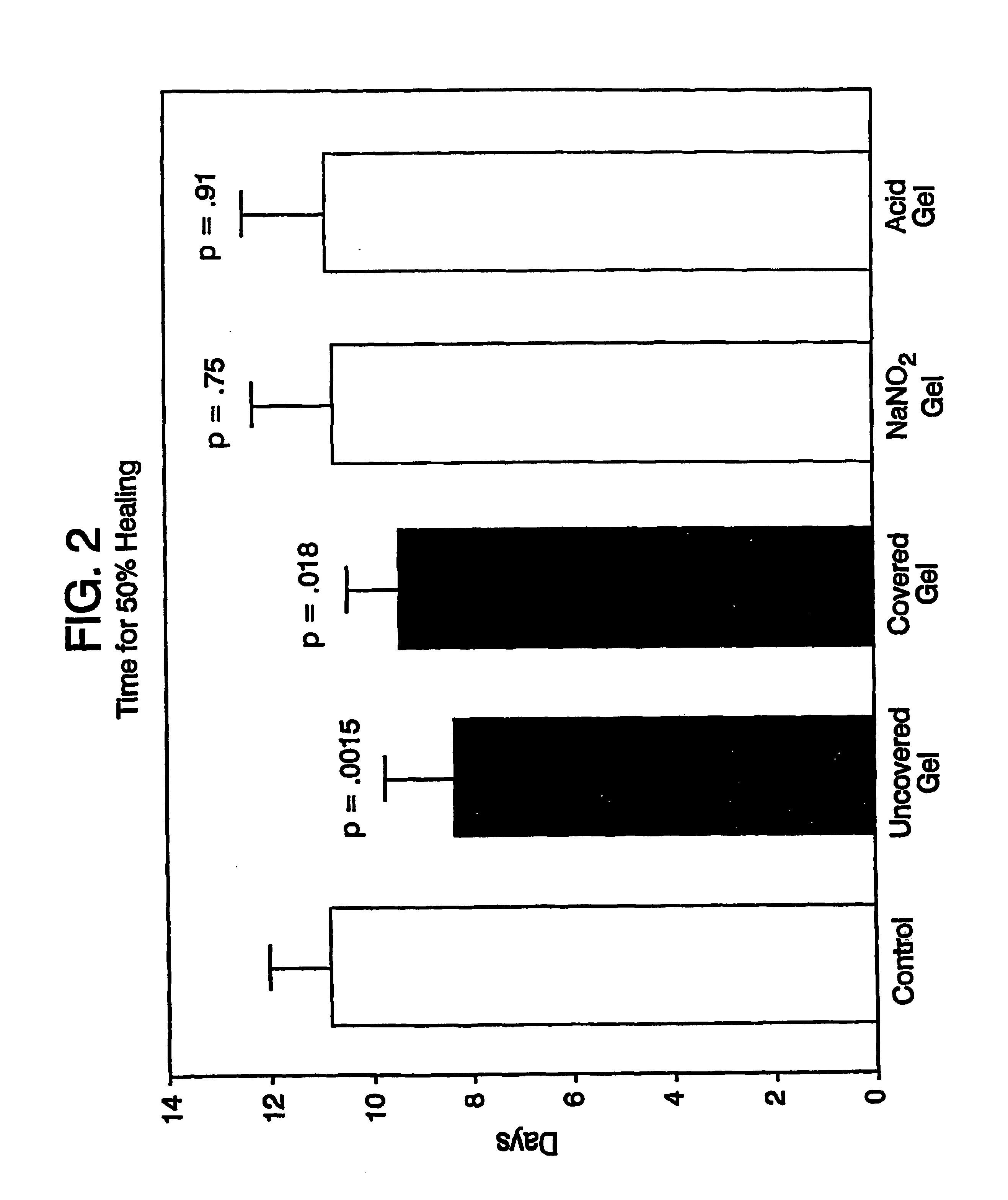

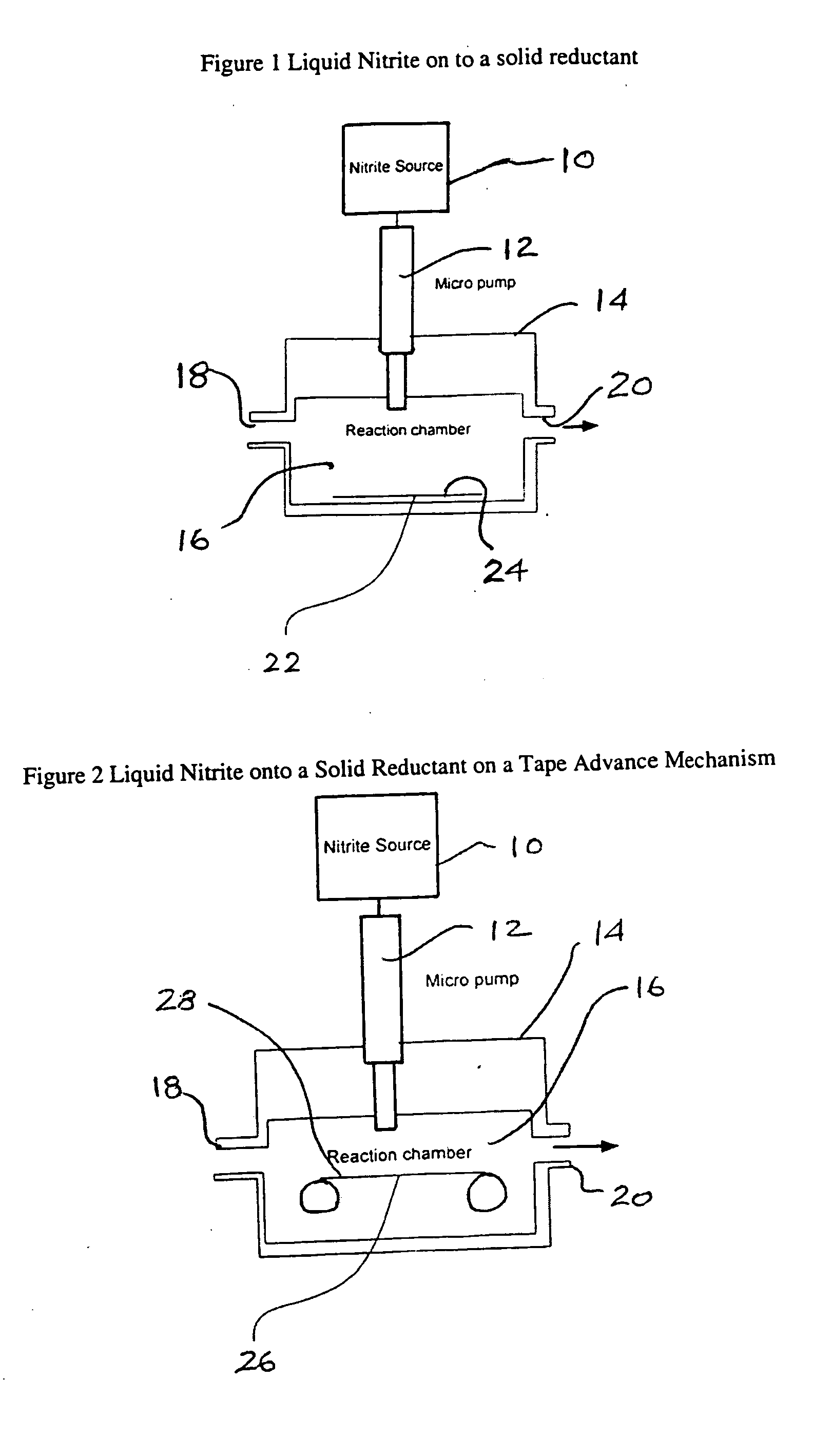

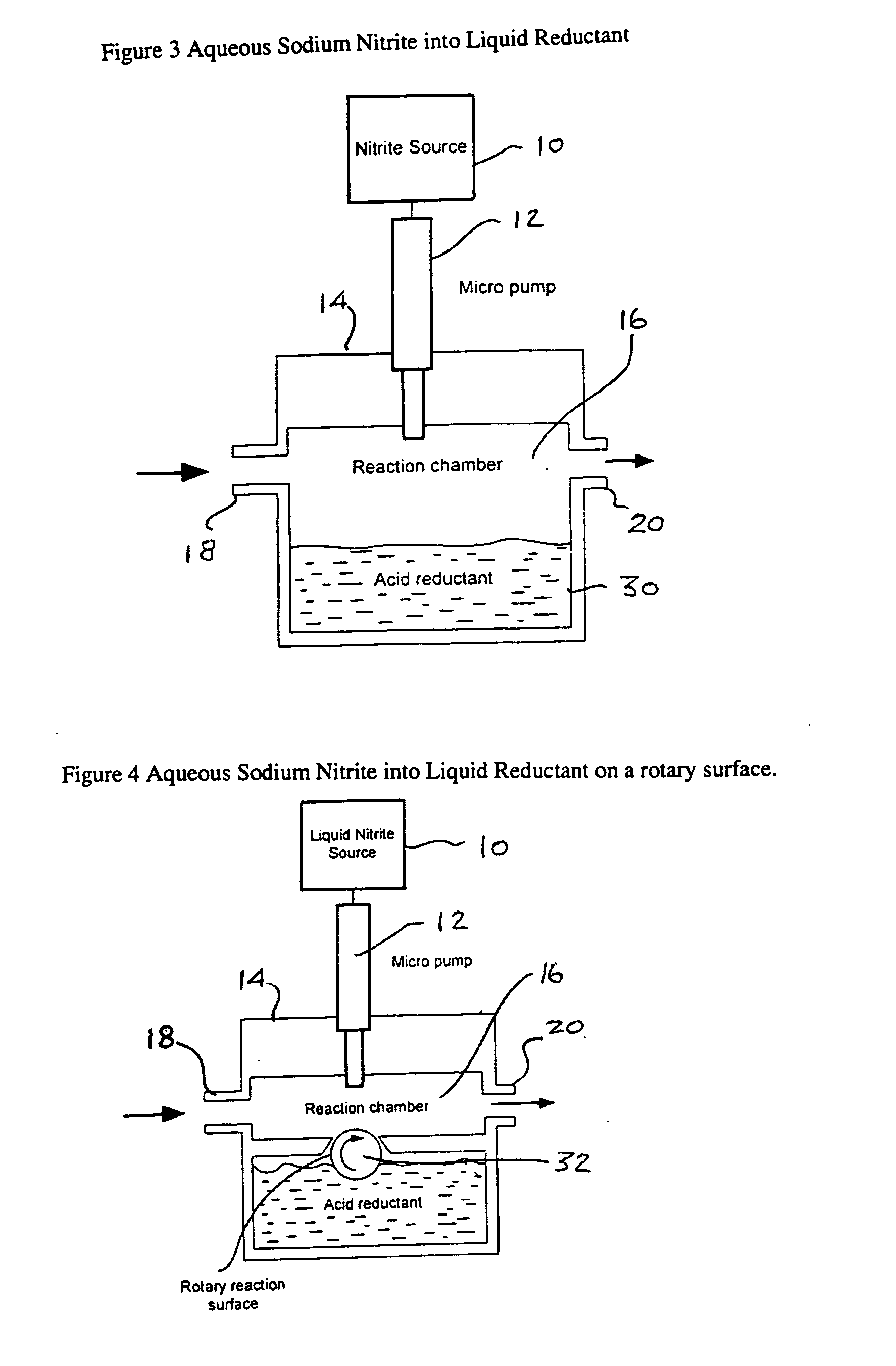

Systems and methods for topical treatment with nitric oxide

InactiveUS7048951B1Reduce skin irritationBiocideInorganic active ingredientsSandwich likeTransdermal patch

A simple, biocompatible system and procedure for generating nitric oxide (NO) is described. A mixture of powdered sodium nitrite, ascorbic acid, and maleic acid (or another organic acid of adequate strength) immediately generates nitric oxide (NO) on treatment with water. To slow down the NO generation, one may prepare an ointment from a nonaqueous medium (petrolatum, Vaseline™) and the three powdered ingredients, which on being applied topically on the skin will release NO as water permeates through this medium; alternatively, one may convert the aqueous sodium nitrite solution into a gel with hydroxyethylcellulose (or other gel-forming compound) and combine this gel with another gel obtained from aqueous ascorbic and maleic acids with hydroxyethylcellulose for topical application (on intact skin, burns intra-cavity, burns, intra-cavity, etc.). The two gels may be admixed immediately before use (possibly from a single container with separate chambers and dual nozzle, via pushing or squeezing the two gels through the nozzle), or may be applied in sandwich-like fashion (possibly as a transdermal patch) for further slowing down the delivery of NO.

Owner:NITRIC SOLUTIONS

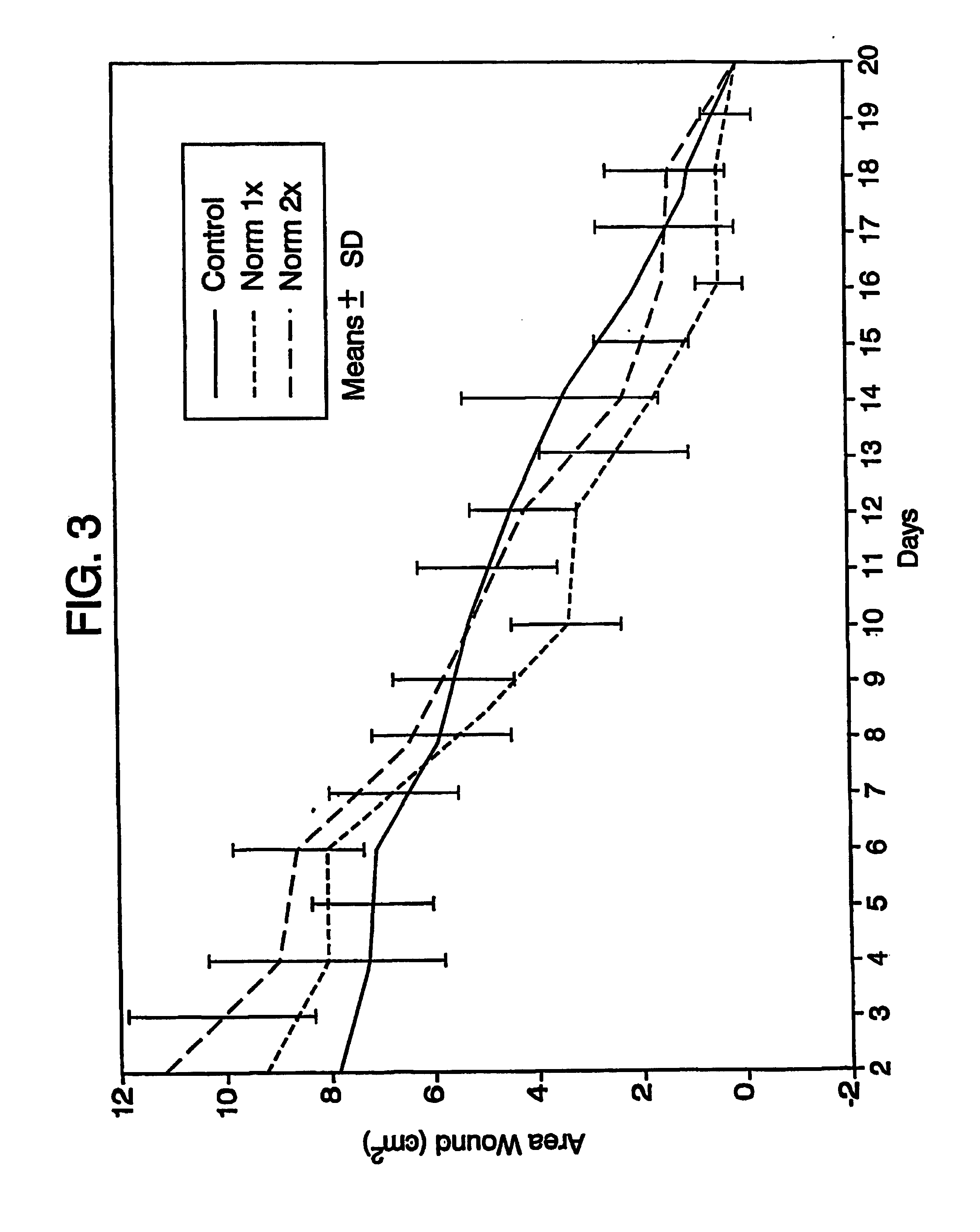

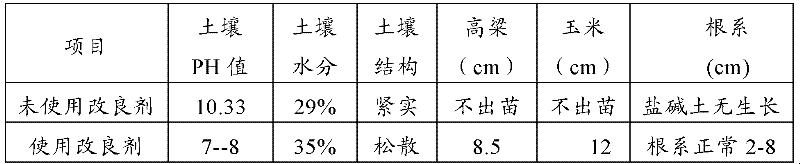

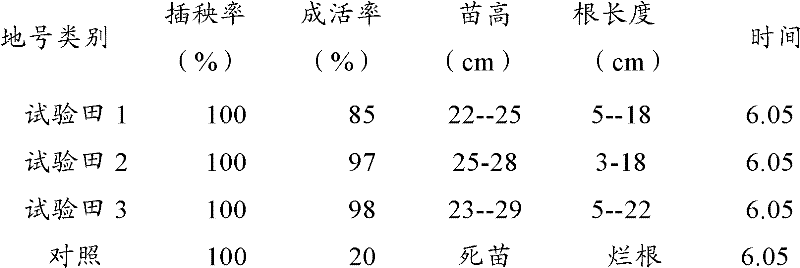

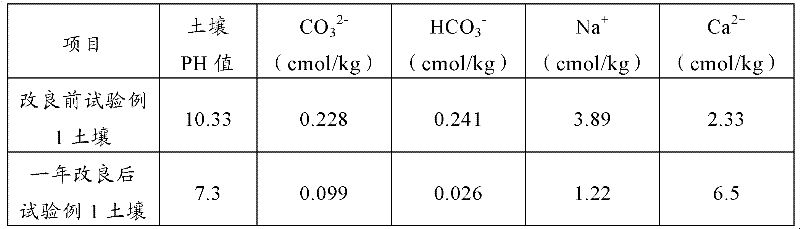

Saline-alkali soil improver

InactiveCN102517030ALower pHRaise the pHOther chemical processesOrganic fertilisersCis-Butenedioic AcidFatty alcohol

The invention relates to an improver for saline-alkali soil. The improver comprises a powder agent and a water agent, wherein the powder agent comprises the following components: organic matters, plant mycelium protein powder, active calcium, calcium superphosphate, aluminum sulfate, fatty alcohol polyoxyethylene ether ammonium sulfate, amino acid powder, bacillus subtilis and photosynthetic bacteria, and the water agent comprises the following components: citric acid, fulvic acid, humic acid, malic acid, maleic acid, fumaric acid, L-tartaric acid, pyrophosphoric acid, humic acid, lactic acid, oxalic acid, salicylic acid, sodium ion adsorbent, Tween-80 and water. The improver disclosed by the invention can improve the soil from multiple angles, namely soil structure, microorganism species, a chemical method and the like, obviously promote the release of iron and phosphorus in the soil, improve the soil structure, effectively reduce the content of sodium ions in the soil, reduce the pH value of the soil and restore land to a normal planting state after being used continuously for two years.

Owner:孙东军 +1

Method and apparatus for generating nitric oxide for medical use

ActiveUS20070190184A1Reduce weightReduce electric powerRespiratorsBiocideNitric oxide formationAcoric acid

A method and system for generating and delivering nitric oxide directly to a patient. A reaction chamber is provided that is located at or in close proximity to the patient and reactants within the reaction chamber react together to produce a predetermined amount of nitric oxide. The reaction is controlled by metering at least one of the reactants into the reaction chamber to generate a predetermined quantity of nitric oxide as required by the patient. The reactants can include a nitrite salt, such as sodium nitrite, and a reductant such as ascorbic acid, maleic acid or a mixture thereof. By generating and delivering the nitric oxide directly to the patient in close proximity thereto, the formation of NO2 is minimized. One or both of the reactants may be in liquid form.

Owner:MALLINCKRODT HOSPITAL PRODUCTS IP LTD

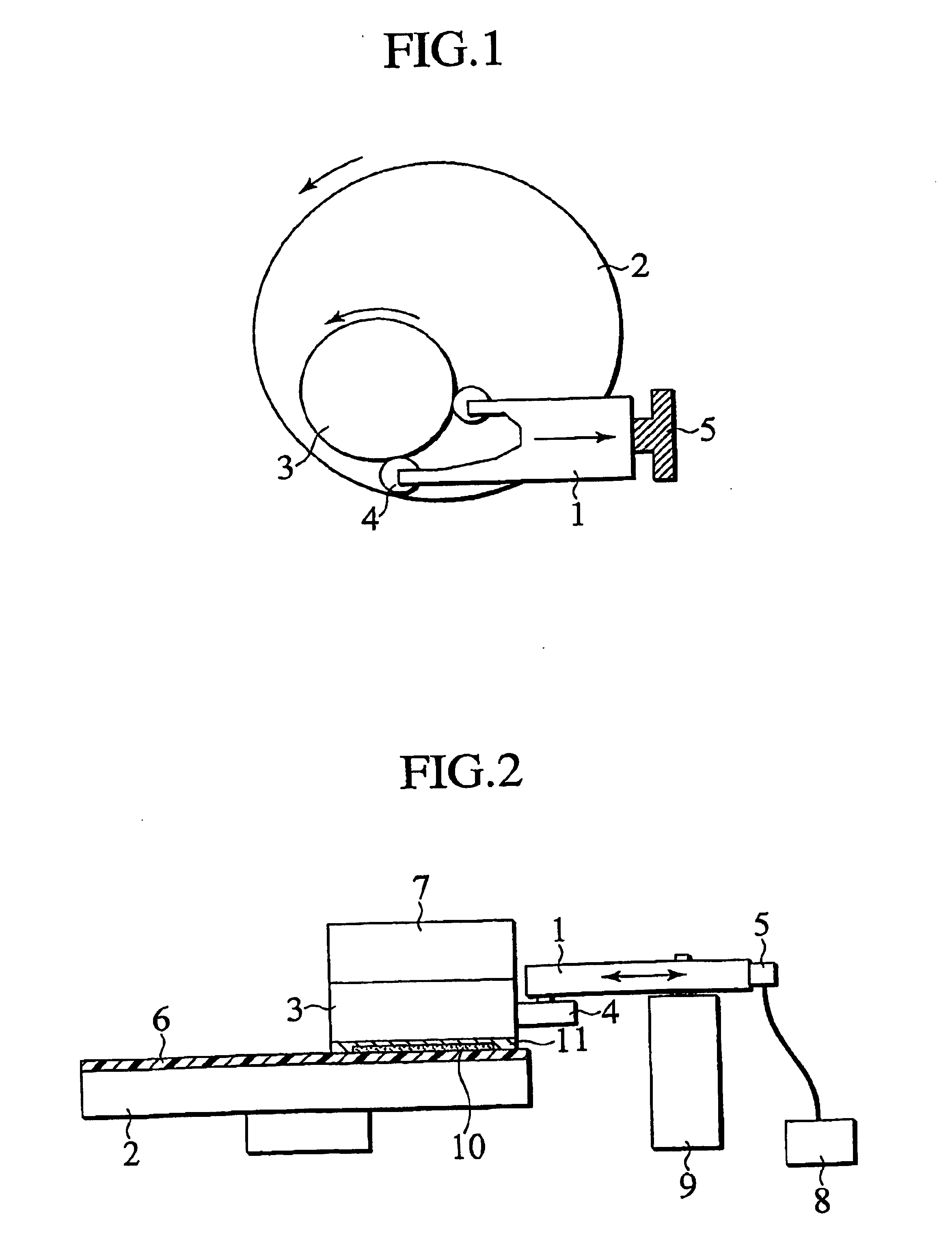

Aqueous dispersion for chemical mechanical polishing

InactiveUS6527818B2Pigmenting treatmentOther chemical processesColloidal silicaOXALIC ACID DIHYDRATE

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

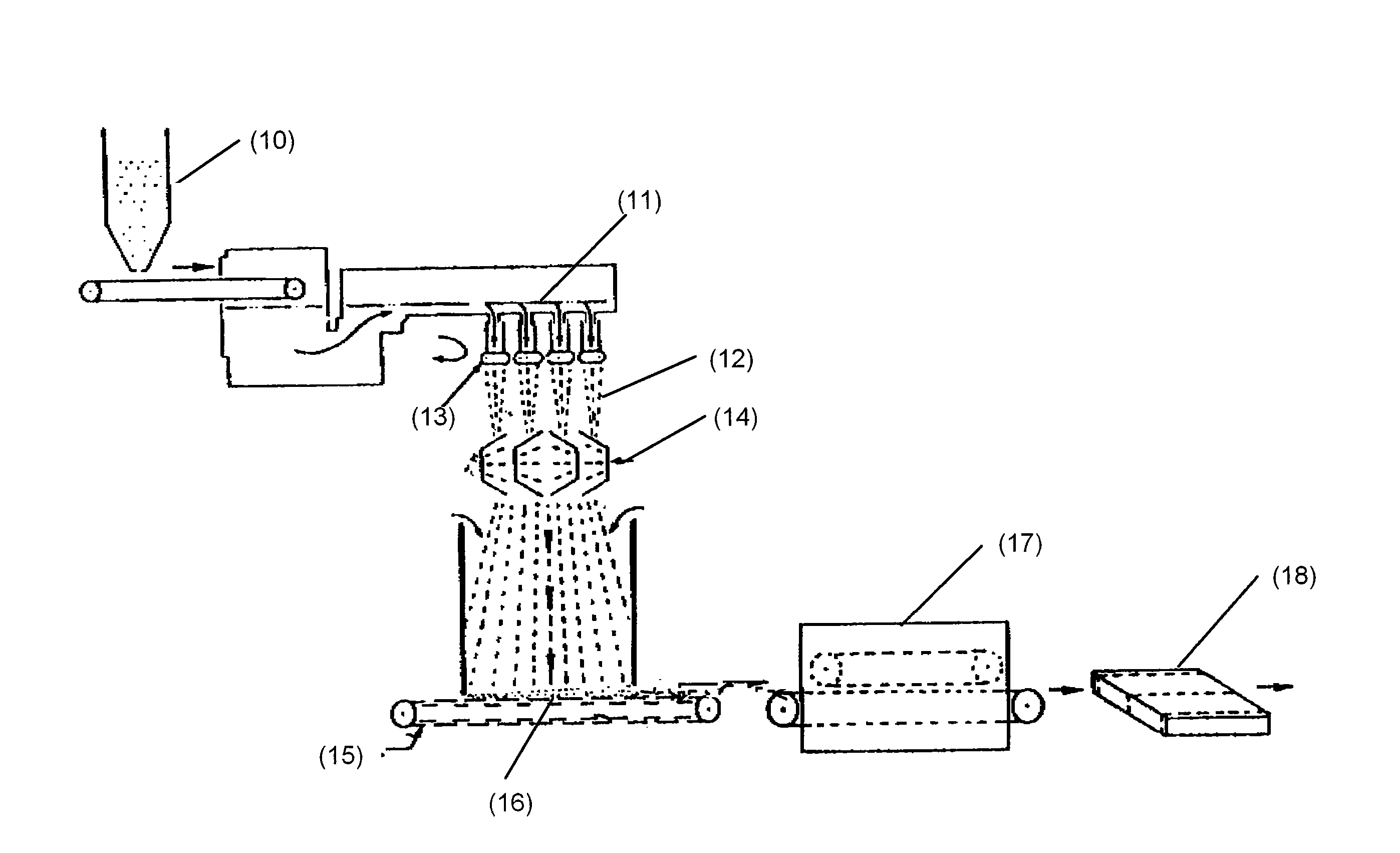

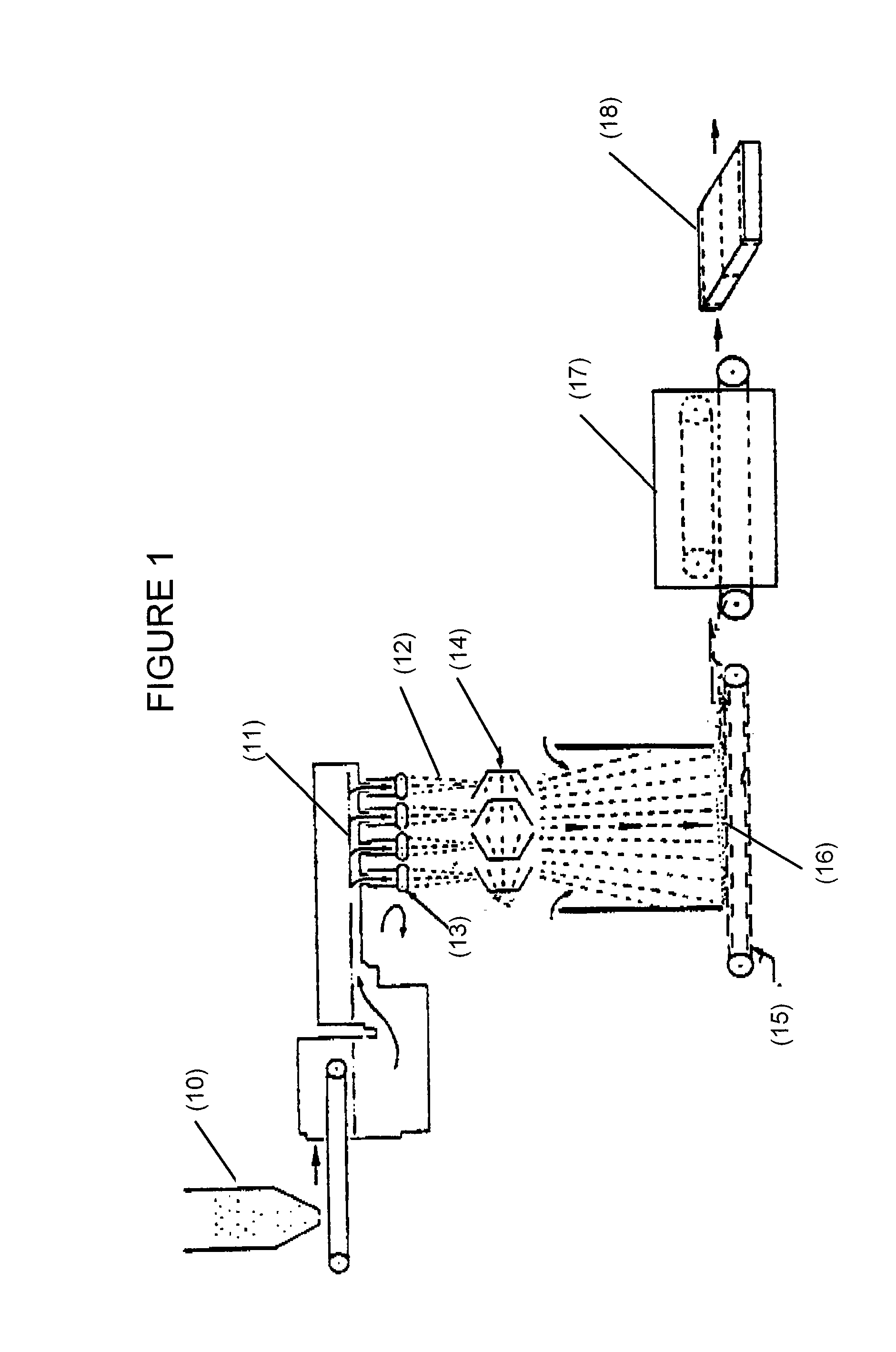

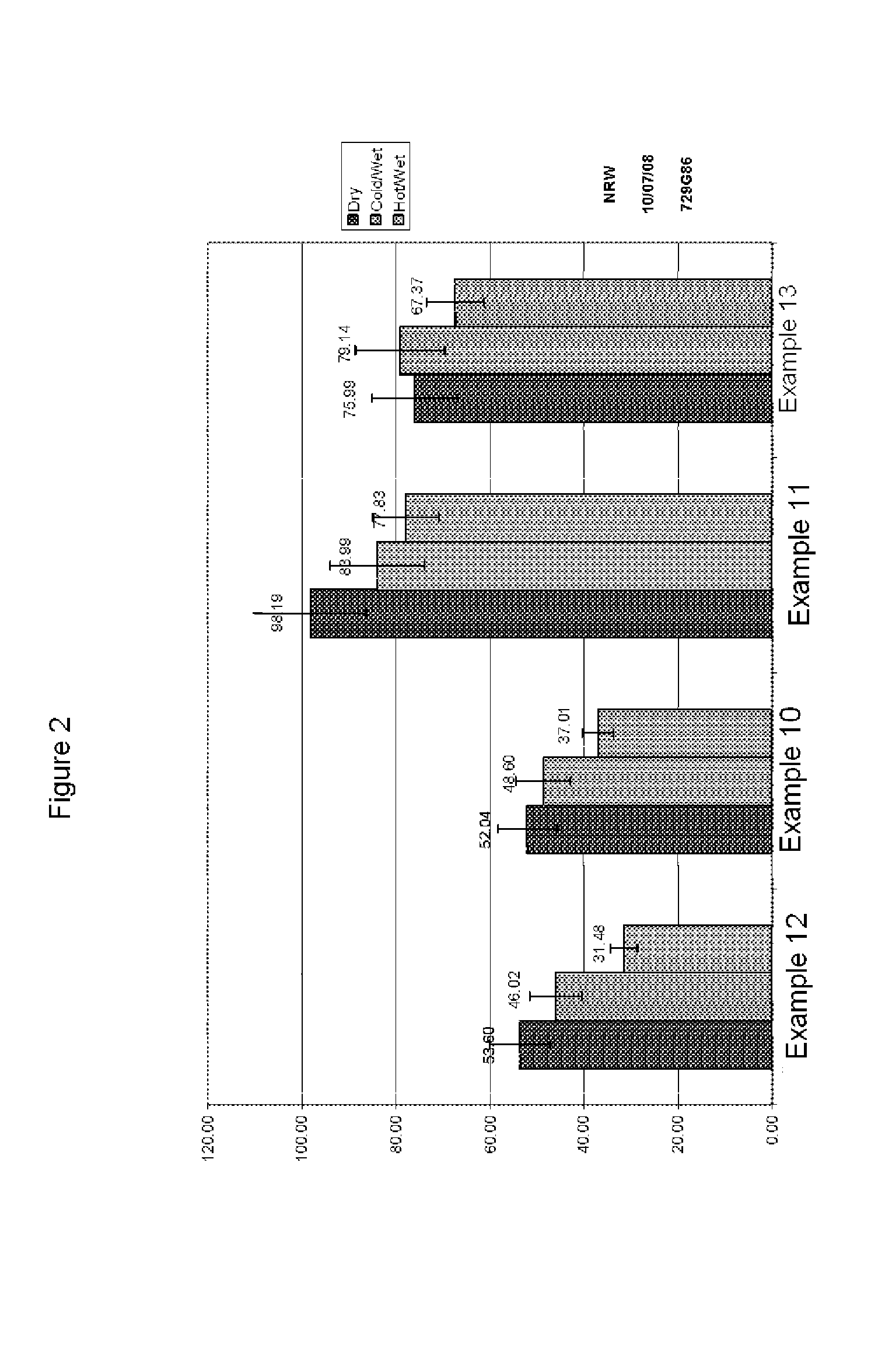

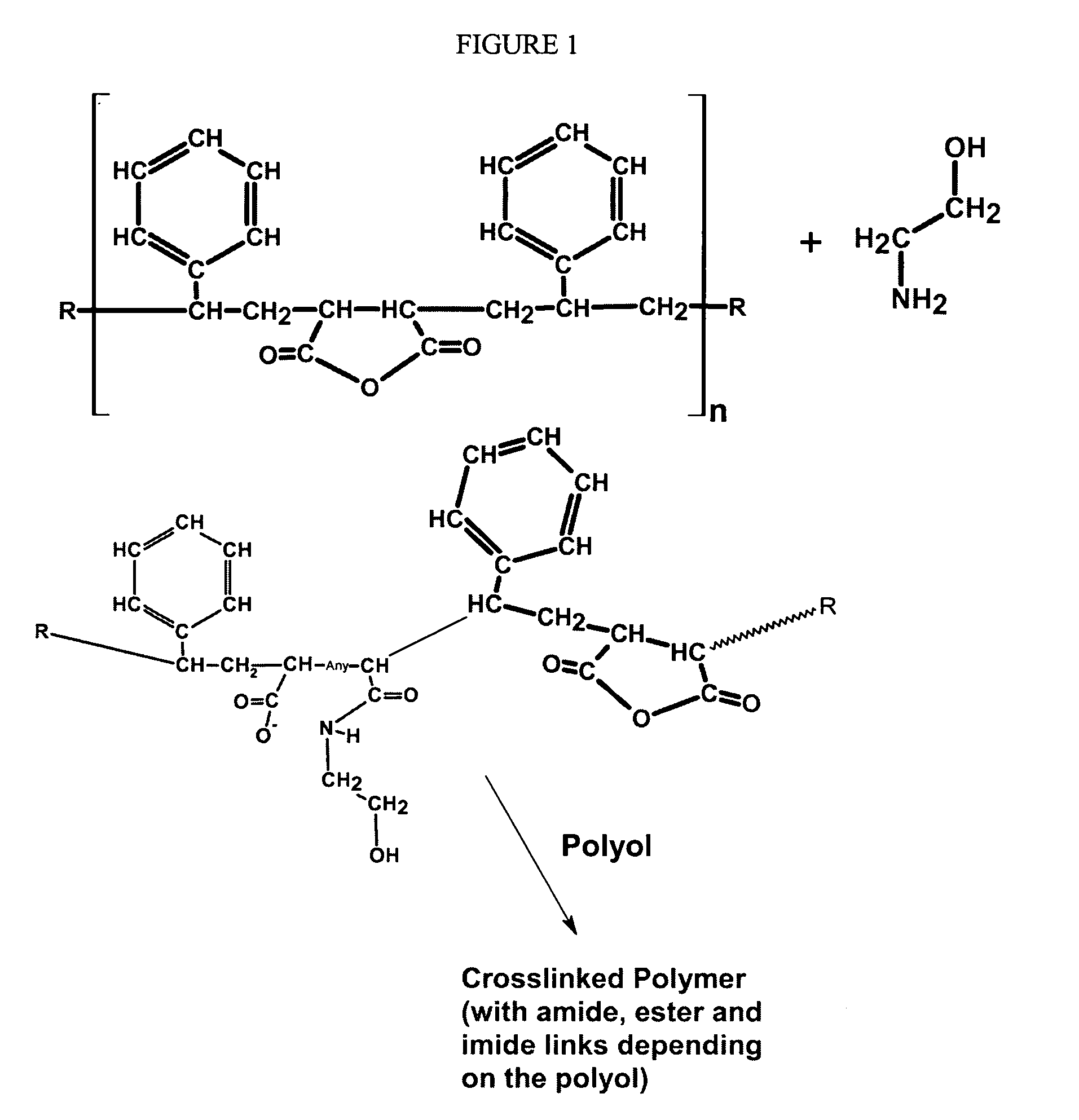

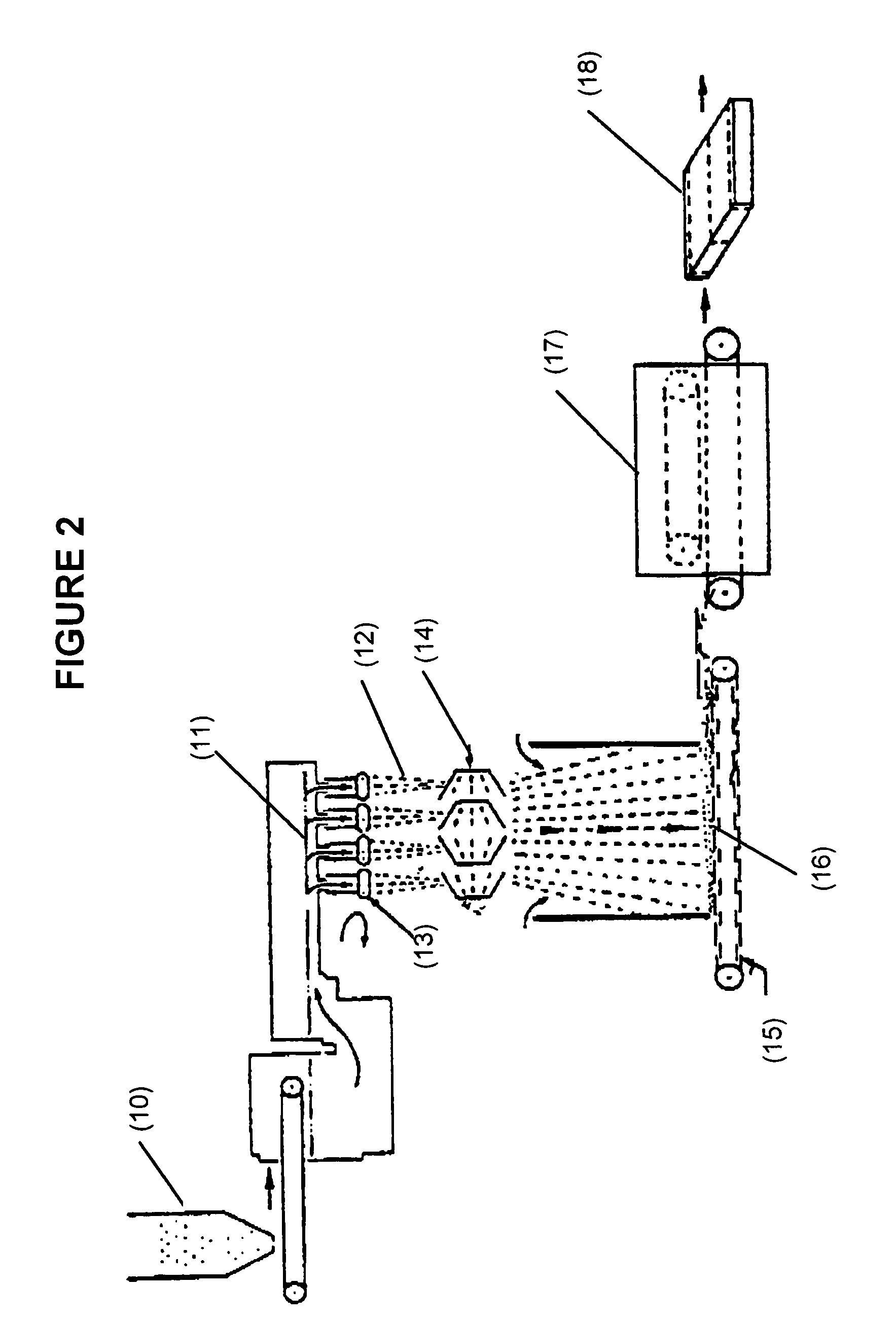

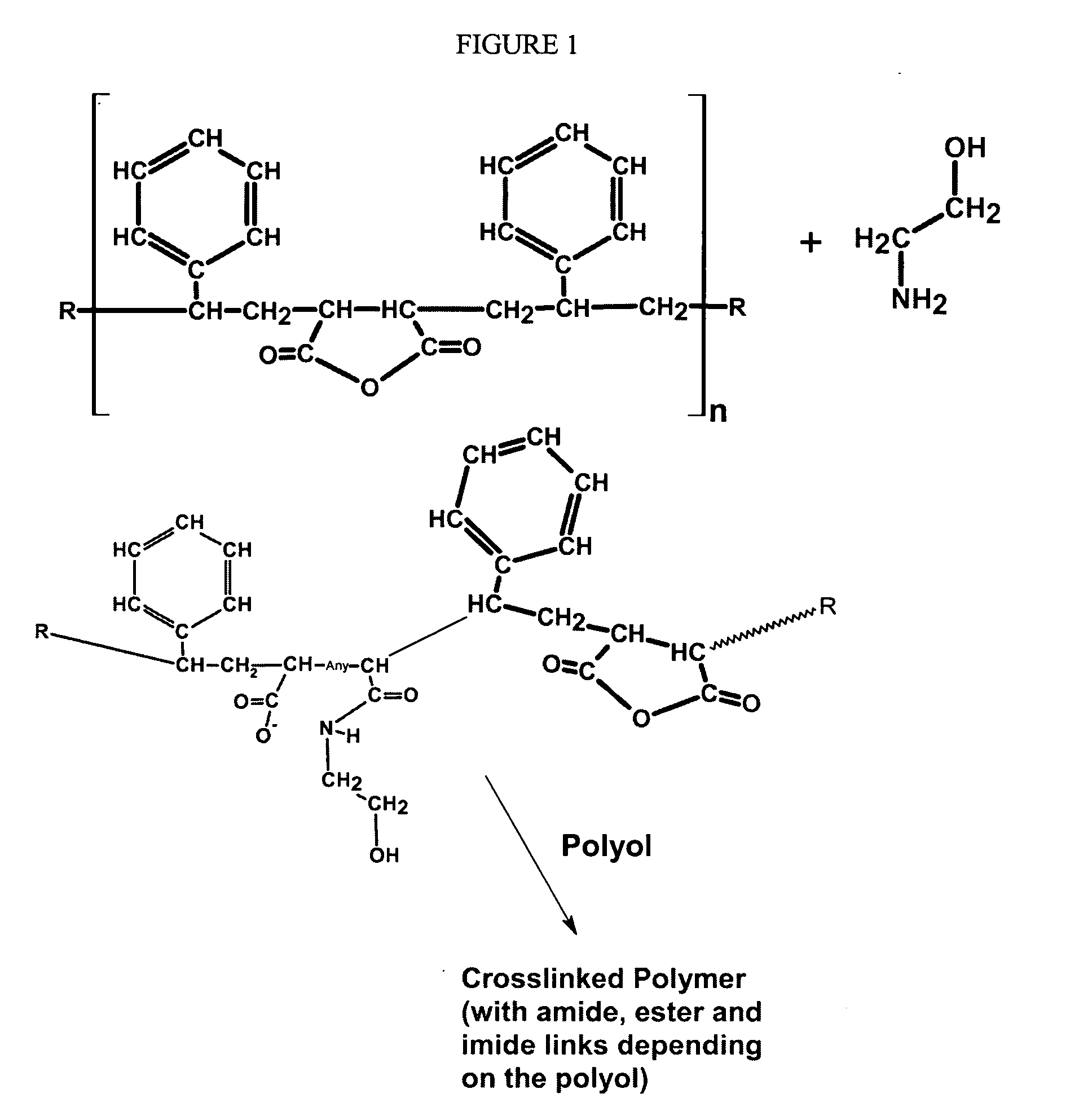

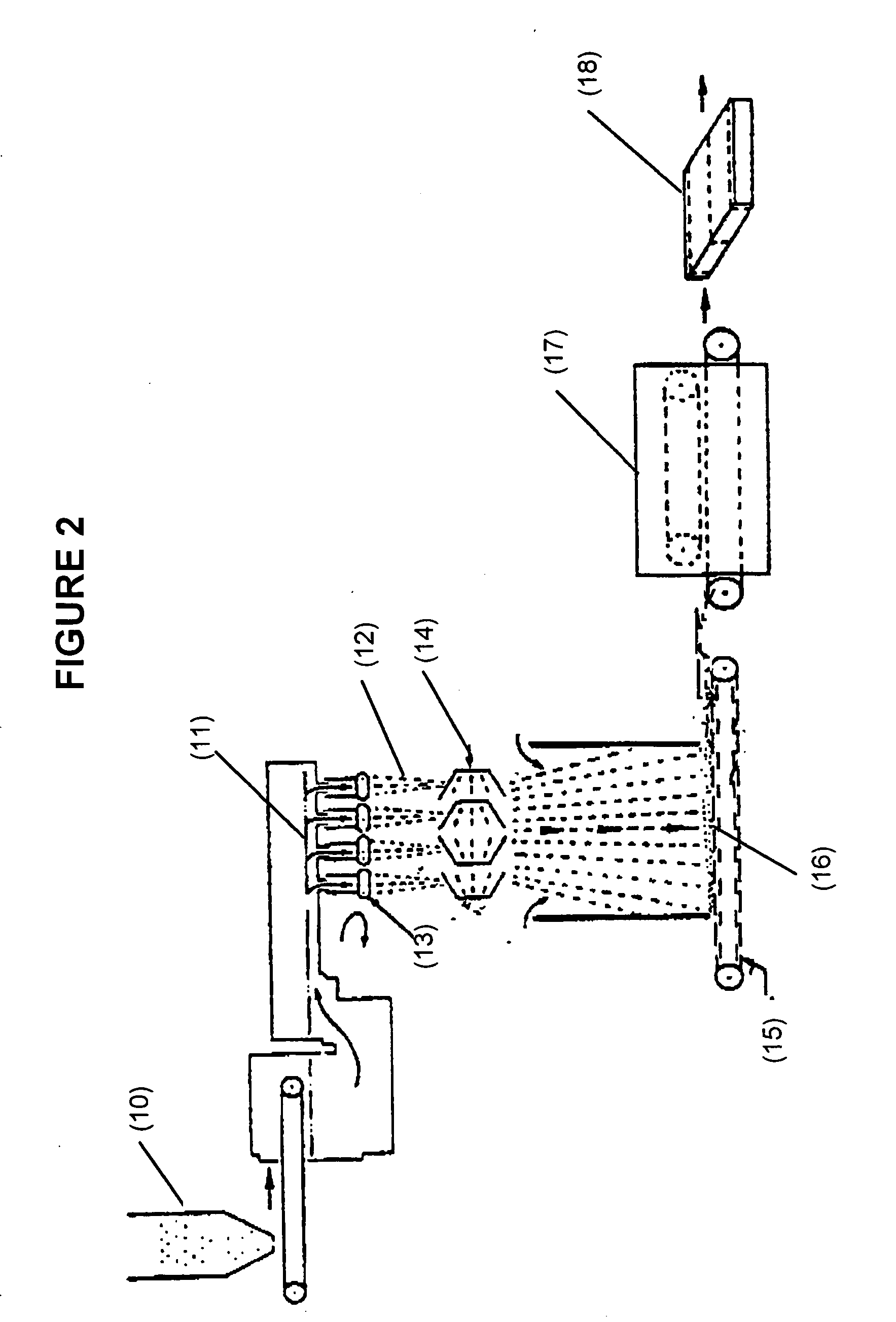

Formaldehyde free binder

An aqueous binder composition, useful for making fiber products, especially fiberglass insulation, comprising an aqueous substantially alkaline (pH of at least 5.0) solution of a polyol and a hydrolyzed (solubilized) copolymer of maleic anhydride and a vinyl aromatic compound, preferably styrene (i.e., a SMA copolymer); the copolymer is solubilized using ammonia, a secondary alkanolamine (preferably diethanolamine (DEA)), a tertiary alkanolamine (preferably triethanolamine (TEA)), or a mixture thereof and the binder composition is cured as a consequence of cross-linking, esterification reactions between pendant carboxyls on the solubilized (hydrolyzed) copolymer (SMA) chains and hydroxyl groups of the polyol, including the diethanolamine and / or triethanolamine preferably used in the solubilization of the SMA.

Owner:GEORGIA PACIFIC CHEM LLC

Formaldehyde free binder

An aqueous binder composition, useful for making fiber products, especially fiberglass insulation, comprising an aqueous substantially alkaline (pH of at least 5.0) solution of a polyol and a hydrolyzed (solubilized) copolymer of maleic anhydride and a vinyl aromatic compound, preferably styrene (i.e., a SMA copolymer); the copolymer is solubilized using ammonia, an ammine, a primary alkanolamines (preferably monoethanolamine), a secondary alkanolamine (preferably diethanolamine (DEA)), a tertiary alkanolamine (preferably triethanolamine (TEA)), or a mixture thereof and the binder composition is cured as a consequence of cross-linking, esterification reactions between pendant carboxyls on the solubilized (hydrolyzed) copolymer (SMA) chains and hydroxyl groups of the polyol, including the diethanolamine and / or triethanolamine preferably used in the solubilization of the SMA.

Owner:GEORGIA PACIFIC CHEM LLC

Formaldehyde free binder

An aqueous, formaldehyde-free binder composition comprising a modified copolymer of maleic anhydride and a vinyl aromatic compound such as styrene, the copolymer being modified by reaction with a primary alkanolamine, such as monoethanolamine (MEA), to produce a modified copolymer that is self-curing and cures as a consequence of cross-linking, esterification reactions between pendant carboxyls and hydroxyl groups on the solubilized (hydrolyzed) modified copolymer chains; the invention also relates to the corresponding method of using the binder composition for making fiber products, especially fiberglass insulation.

Owner:GEORGIA PACIFIC CHEM LLC

Formaldehyde free binder

An aqueous, formaldehyde-free binder composition comprising a modified copolymer of maleic anhydride and a vinyl aromatic compound such as styrene, the copolymer being modified by reaction with a primary alkanolamine, such as monoethanolamine (MEA), to produce a modified copolymer that is self-curing and cures as a consequence of cross-linking, esterification reactions between pendant carboxyls and hydroxyl groups on the solubilized (hydrolyzed) modified copolymer chains; the invention also relates to the corresponding method of using the binder composition for making fiber products, especially fiberglass insulation.

Owner:GEORGIA PACIFIC CHEM LLC

Intercalates formed with polypropylene/maleic anhydride-modified polypropylene intercalants

InactiveUS20010033924A1Good dispersionImprove distributionThin material handlingWater-setting substance layered productPolyolefinPolymer science

A nanocomposite concentrate composition comprising about 10 weight percent to about 90 weight percent of a layered silicate material and about 10 weight percent to about 90 weight percent of a matrix polymer comprising about 90-99.8% by weight of a polyolefin and about 0.2% to about 10%, preferably about 0.2% to about 3%, more preferably about 1% to 3% by weight, of a maleic anhydride-modified polyolefin, based on the total weight of polyolefins, wherein the layered silicate material is dispersed uniformly throughout the matrix polymer. Shearing of the concentrate and later (after shear) addition of an added matrix polymer avoids thermal degradation of the added matrix polymer and optimizes the dispersion of the nanomer throughout the matrix polymer; provides increased tensile strength; and reduces degradation of the polymer by melt formation of a concentrate thereby decreasing heat degradation of added matrix polymer.

Owner:AMCOL INTERNATIONAL CORPORATION

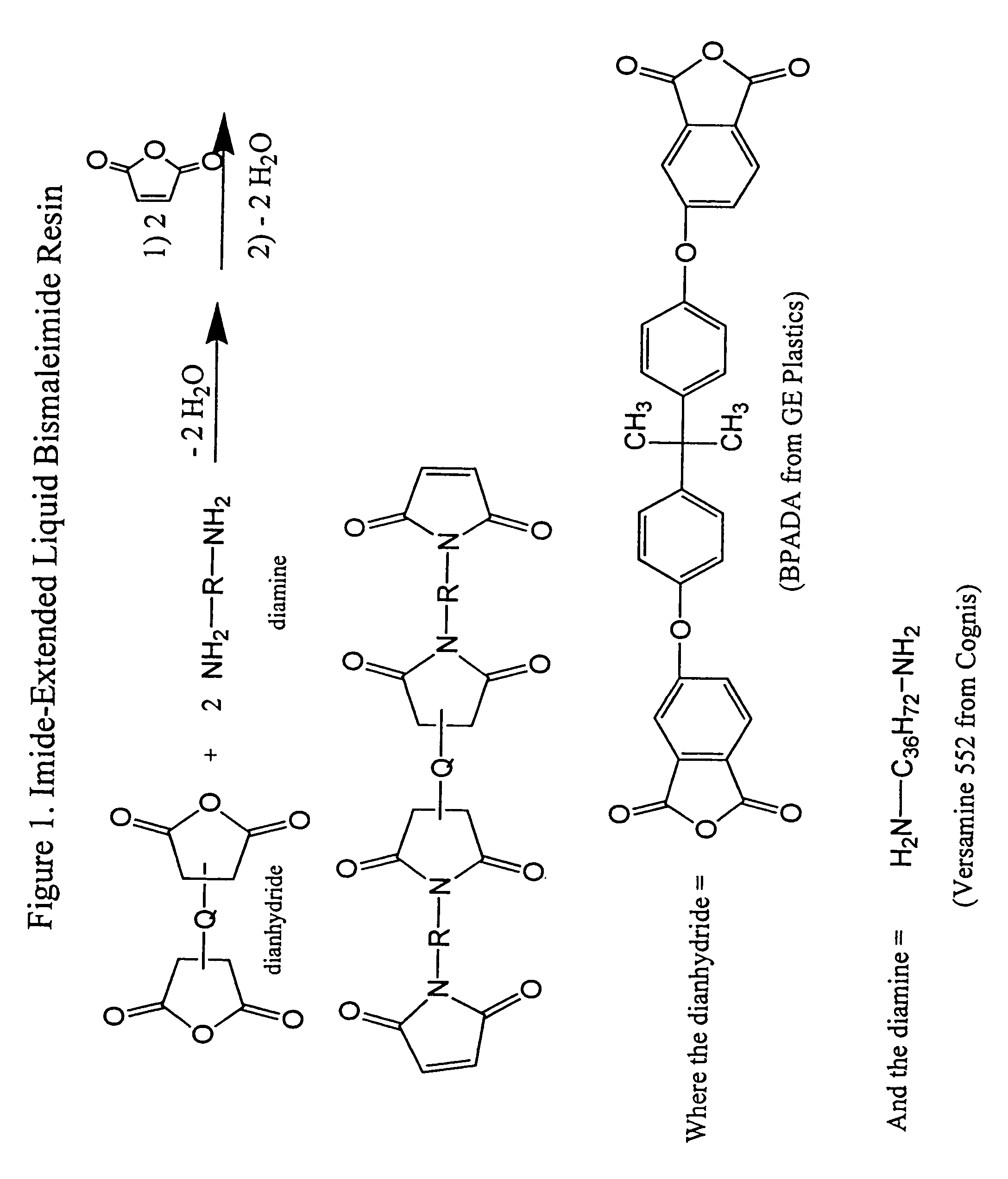

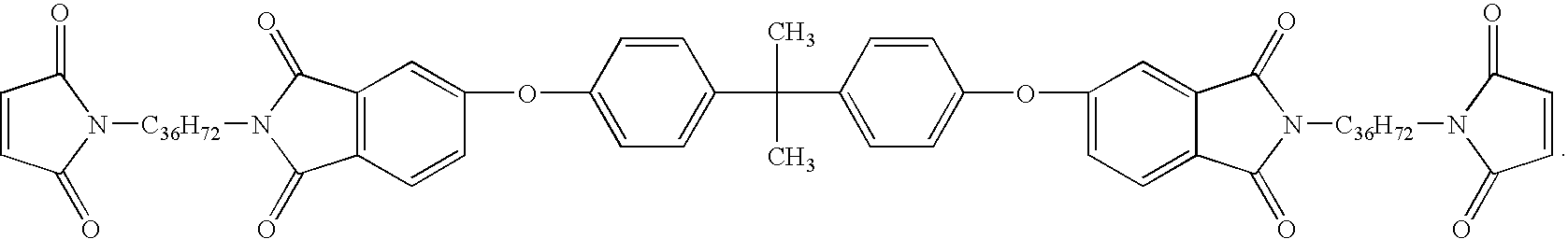

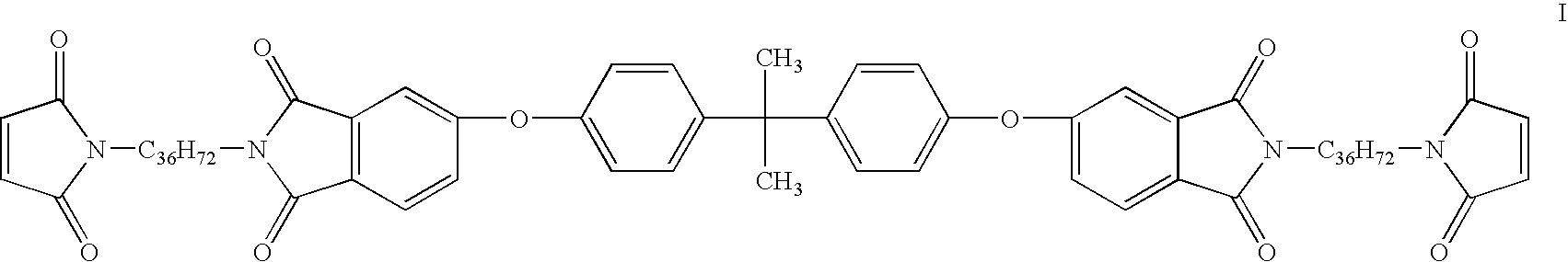

Imide-extended liquid bismaleimide resin

ActiveUS7157587B2Improve toughnessNot sacrificing thermal stabilityOrganic chemistrySynthetic resin layered productsImideDiamine

The invention is based on the discovery that a remarkable improvement in the performance of bismaleimide thermosets can be achieved through the incorporation of an imide-extended liquid bismaleimide monomer. This imide-extended liquid bismaleimide monomer is readily prepared by the condensation of an appropriate dianhydride with two equivalents of an appropriate diamine to give an amine terminated compound. This compound is then condensed with an excess of maleic anhydride to yield an imide-extended liquid bismaleimide monomer.

Owner:DESIGNER MOLECULES

Pvc/Wood Composite

InactiveUS20080261019A1Synthetic resin layered productsCellulosic plastic layered productsMethacrylateFibrous composites

The present invention relates to a thermoplastic / natural cellulosic fiber composite, and more specifically to a high molecular weight compatibilizer within that composite resulting in both a high flex strength and high modulus and significant reduction in water absorption. The compatibilizer is preferably a terpolymer comprising: a) 0.5-20 percent by weight of monomer units selected from the group consisting of maleic anhydride, substituted maleic anhydride, mono-ester of maleic anhydride, itaconic anhydride, maleic acid, fumaric acid, crotonic acid, acrylic acid and methacrylic acid; b) 0 to 40 percent by weight of monomer units selected from styrene and functionalized styrene; and c) 40 to 98.5 percent by weight of monomer units selected from the group consisting of C1-8 alkyl acrylates and methacrylates, and vinyl acetate.

Owner:ARKEMA INC

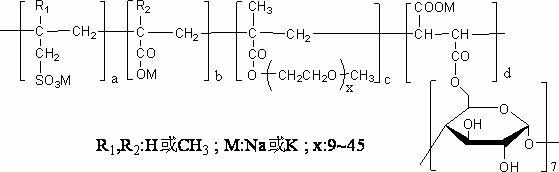

Preparation method of slow-setting polycarboxylic acid water reducing agent

The invention relates to a preparation method of a slow-setting polycarboxylic acid water reducing agent, which is implemented by carrying out free radical copolymerization reaction on allylsulfonate monomers, acrylic monomers, polyethylene glycol nono-methyl ether methacrylate macromonomers and maleic anhydride grafted beta-cyclodextrin macromonomers. The invention is characterized in that a beta-cyclodextrin side chain is introduced into a polycarboxylic acid main chain, so that the polycarboxylate water reducing agent has favorable slow setting property, micro air-entraining property and better fluidity. The obtained polycarboxylic acid water reducing agent has the advantages of stable product performance, strong adaptability to cement and favorable compatibility; and the cement paste fluidity is up to higher than 290mm (W / C=0.29), the water reducing rate of concrete is up to 30-40%, and the slump protection time is 3-5 hours. The preparation method provided by the invention has the characteristics of unique technique, excellent product performance and the like.

Owner:FUJIAN CONSTR ENG GRP BUILDING MATERIAL SCI & TECH DEV

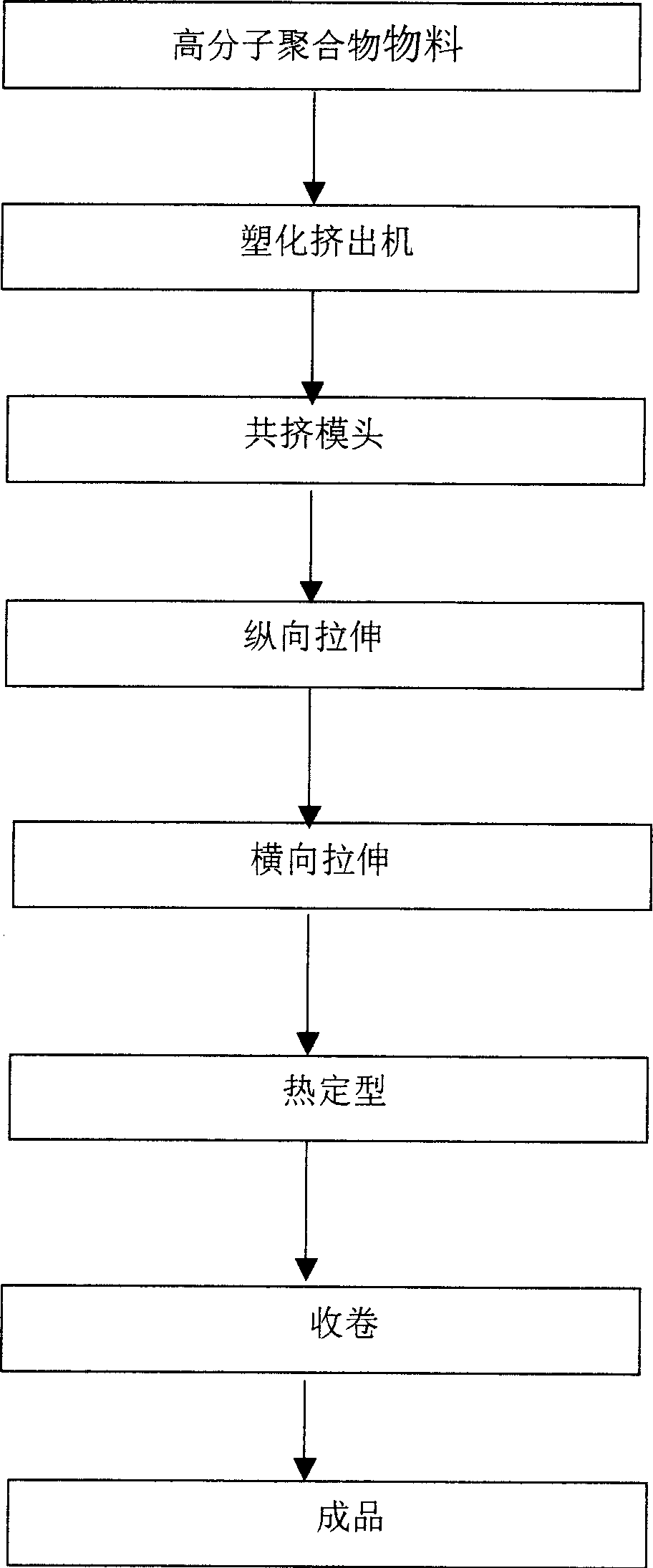

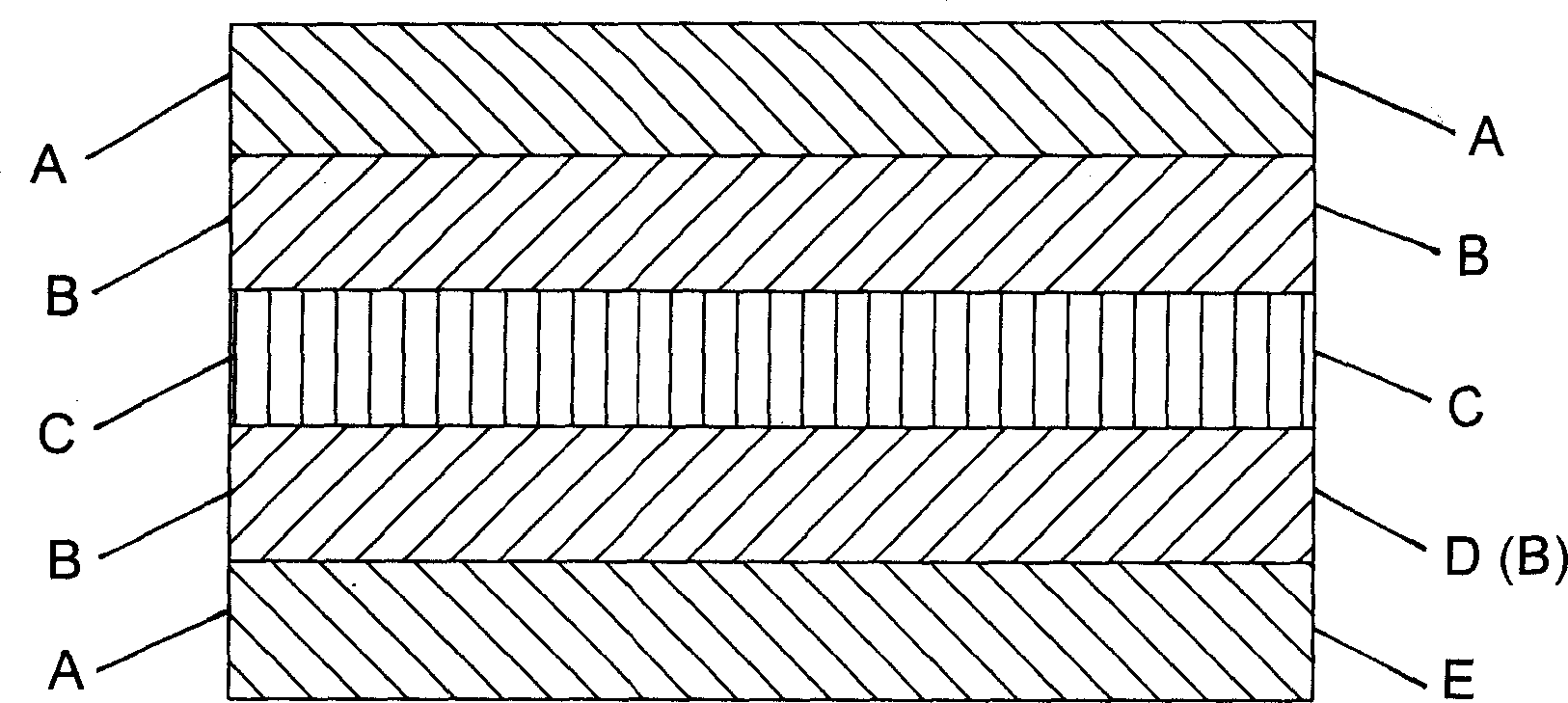

Biaxial tension co-extrusion high-obstruct base material membrane and process for preparing the same

InactiveCN1733397AImprove barrier propertiesImprove qualityTurning toolsHeat deflection temperaturePolyolefin

This invention provides biaxial tension coextrude resistive base material membrane and preparation method. Wherein, the membrane comprises at least a resistive layer that is at least one of PA, PVA, PVDC and MAD6, a splice layer belonged to EAA, EEA, ethylenemethacrylic acid copolymerized resin or polyolefin and neolyn resin that can combine the other tow layers, and a heat-sealing layer that is at least one of the polyolefin resin, EVA and PET; besides, there is nano inorganic material in resistive layer and or heat-sealing layer to improve performance. The product fits to package for all kinds goods.

Owner:朱春蕾 +4

Filler masterbatch used for increasing polarity of polypropylene and preparation method thereof

The invention discloses a filler masterbatch used for increasing the polarity of polypropylene and a preparation method thereof. The filler masterbatch is characterized by comprising the following components by weight percent: 50%-79% of inorganic filler, 15%-30% of carrier, 5%-17% of polar additive and 1%-3% of processing additive; and the polar additive is one or more of thermoplastic polyurethane resin (TPU), maleic anhydride grafted polypropylene, epoxy resin, ethylene acrylate, ethylene vinyl acetate, polyether amine and polybutylene polyol. In the preparation method of the invention, the added carrier can not improve the polarity of polypropylene, the inorganic filler is used to increase the rigidity of the material; the key is to introduce the polar additive with high unipolarity, thus the filler masterbatch used for increasing the polarity of polypropylene can be prepared; when the filler masterbatch is combined with the polypropylene material for production, the surface polarity of the filled and modified polypropylene material can be increased, the surface energy of the filled and modified polypropylene can be reduced, the dimension stability can be increased, the modified polypropylene material can have good paint adhesion and the material can be used to form exterior trimming parts such as bumpers and interior trimming parts such instrument panels.

Owner:KINGFA SCI & TECH CO LTD +3

Polishing fluid and polishing method

ActiveUS20050181609A1Increase chanceSuperior in dimensional accuracy and electric characteristicOther chemical processesSemiconductor/solid-state device manufacturingDevice materialSlurry

A polishing slurry including an oxidant, a metal oxide dissolver, a metal inhibitor and water and having a pH from 2 to 5. The metal oxide dissolver contains one or more types selected from one or more acids (A-group) selected from acids of which the dissociation constant (pKa) of a first dissociable acid group is less than 3.7 and from which five acids of lactic acid, phthalic acid, fumaric acid, maleic acid and aminoacetic acid are excluded, ammonium salts of the A-group and esters of the A-group, and one or more types selected from one or more acids (B-group) selected from acids of which the dissociation constant (pKa) of a first dissociable acid group is 3.7 or more and the five acids, ammonium salts of the B-group and esters of the B-group. The metal inhibitor contains one or more types selected from the group consisting of aromatic compounds having a triazole skeleton and one or more types selected from the group consisting of aliphatic compounds having a triazole skeleton and compounds having any one of pyrimidine skeleton, imidazole skeleton, guanidine skeleton, thiazole skeleton and pyrazole skeleton. The polishing slurry having a high metal-polishing rate, reducing etching rate and polishing friction, results in the production, with high productivity, of semiconductor devices reduced in dishing and erosion in metal wiring.

Owner:HITACHI CHEM CO LTD

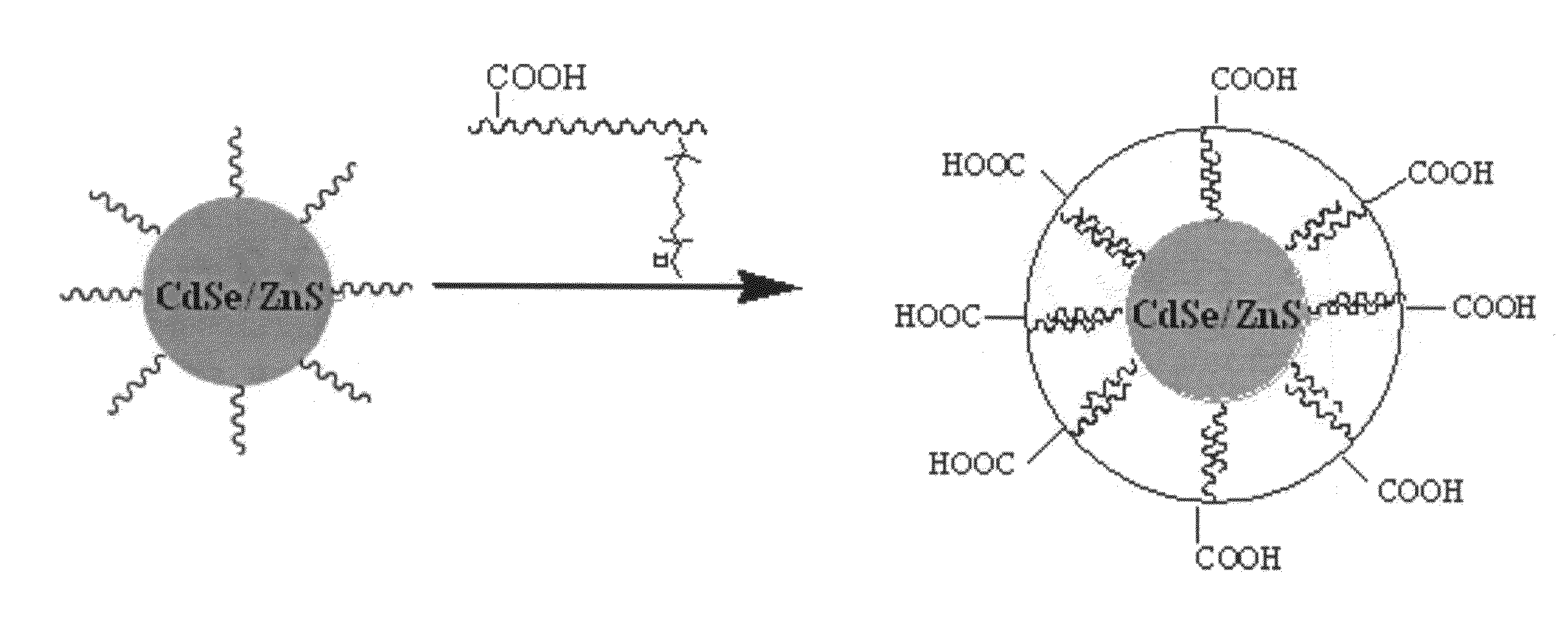

"Green" synthesis of colloidal nanocrystals and their water-soluble preparation

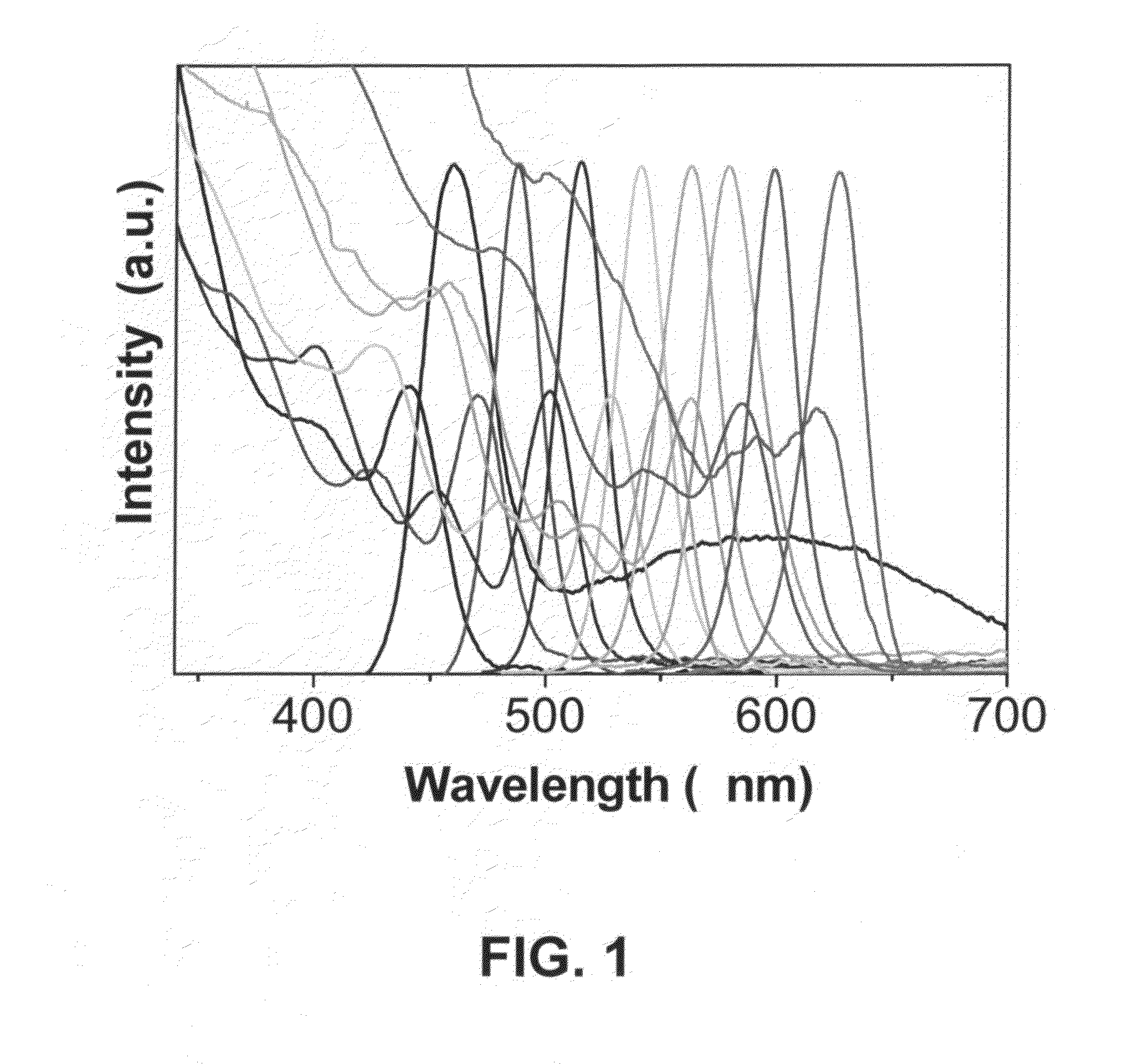

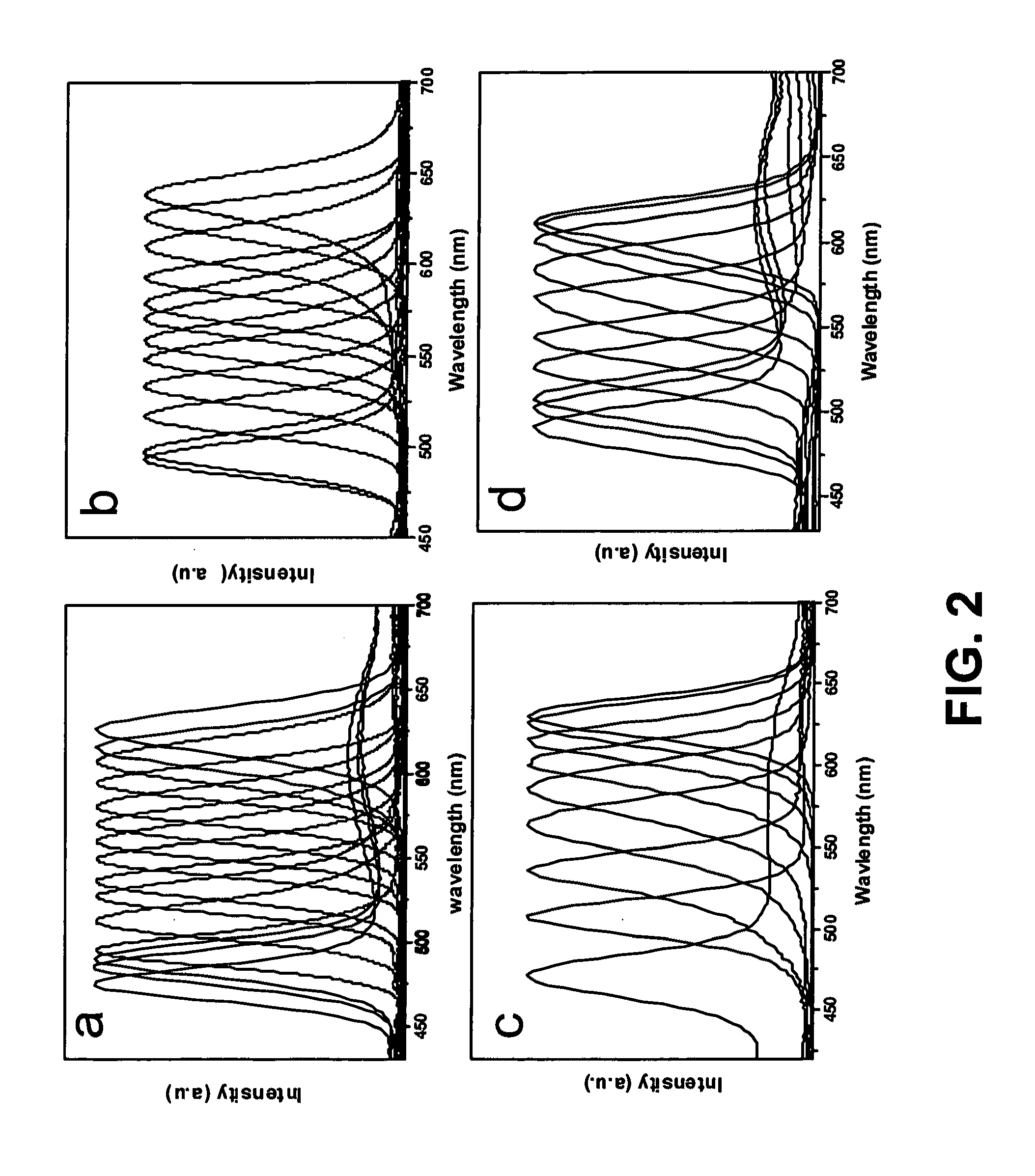

InactiveUS20120205598A1Low costFacilitate different production requirementMaterial nanotechnologyConductive materialOligomerChain length

Highly monodisperse nanocrystals (including CdSe, ZnSe, PbSe, Cu2-xSe, MnSe, Zn1-xCdxSe, CuInSe2, CuInSnSe2, CdTe, ZnTe, PbTe, etc) have been synthesized by using different “green” starting materials to prepare chalcogenide (Se and Te) precursors successfully. Air-sensitive compounds (alkylphosphine, such as trioctylphosphine (TOP) and tributylphosphine (TBP)) have been eliminated to use in the entire synthetic process. As surface coating agents, amphiphilic oligomer (polymaleic acid aliphatic alcohol ester) with different alkyl chain length has been utilized to form oligomer-coated water-soluble nanocrystals.

Owner:SHENZHEN THALES SCI & TECH

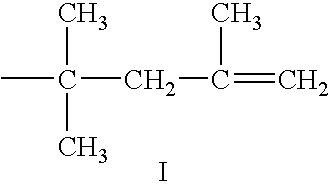

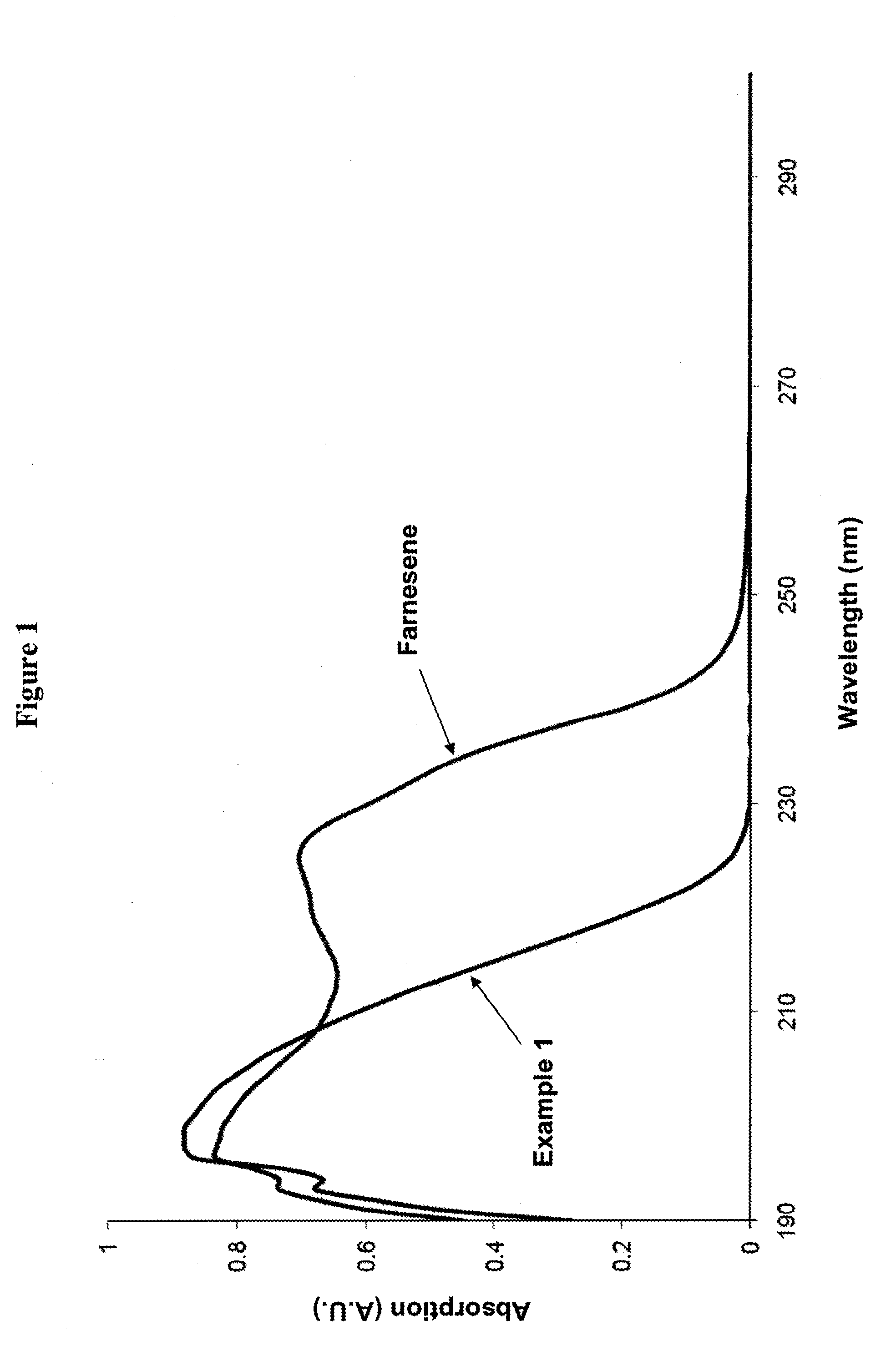

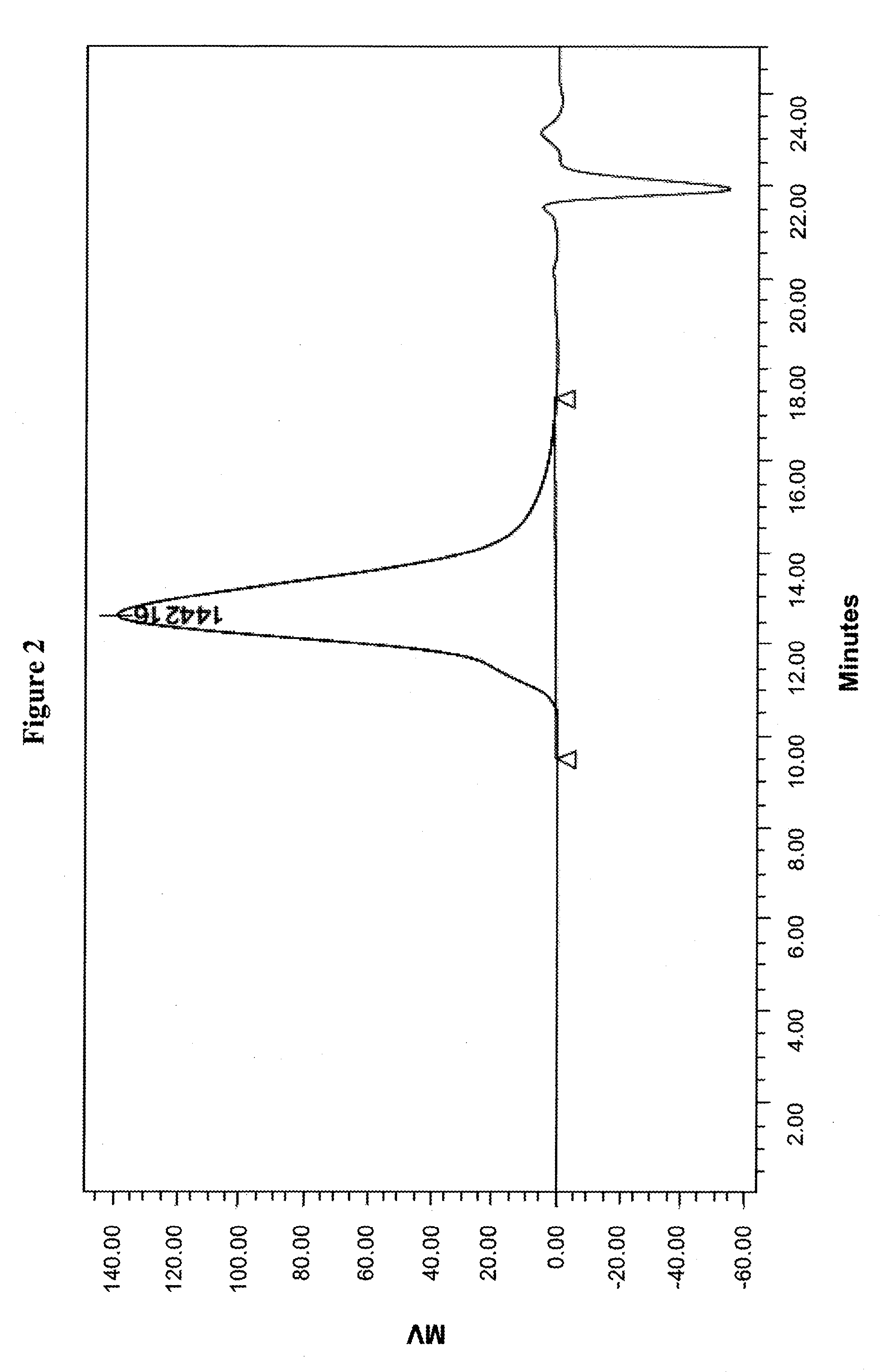

polyfarnesenes

Provided herein are polyfarnesenes derived from a farnesene and at least two different vinyl monomers. Also provided herein are polyfarnesenes derived from a farnesene; at least two different vinyl monomers, such as (meth)acrylic acid, (meth)acrylic esters, styrene, and substituted styrenes; and at least one functional comonomer such as maleic anhydride.

Owner:AMYRIS INC

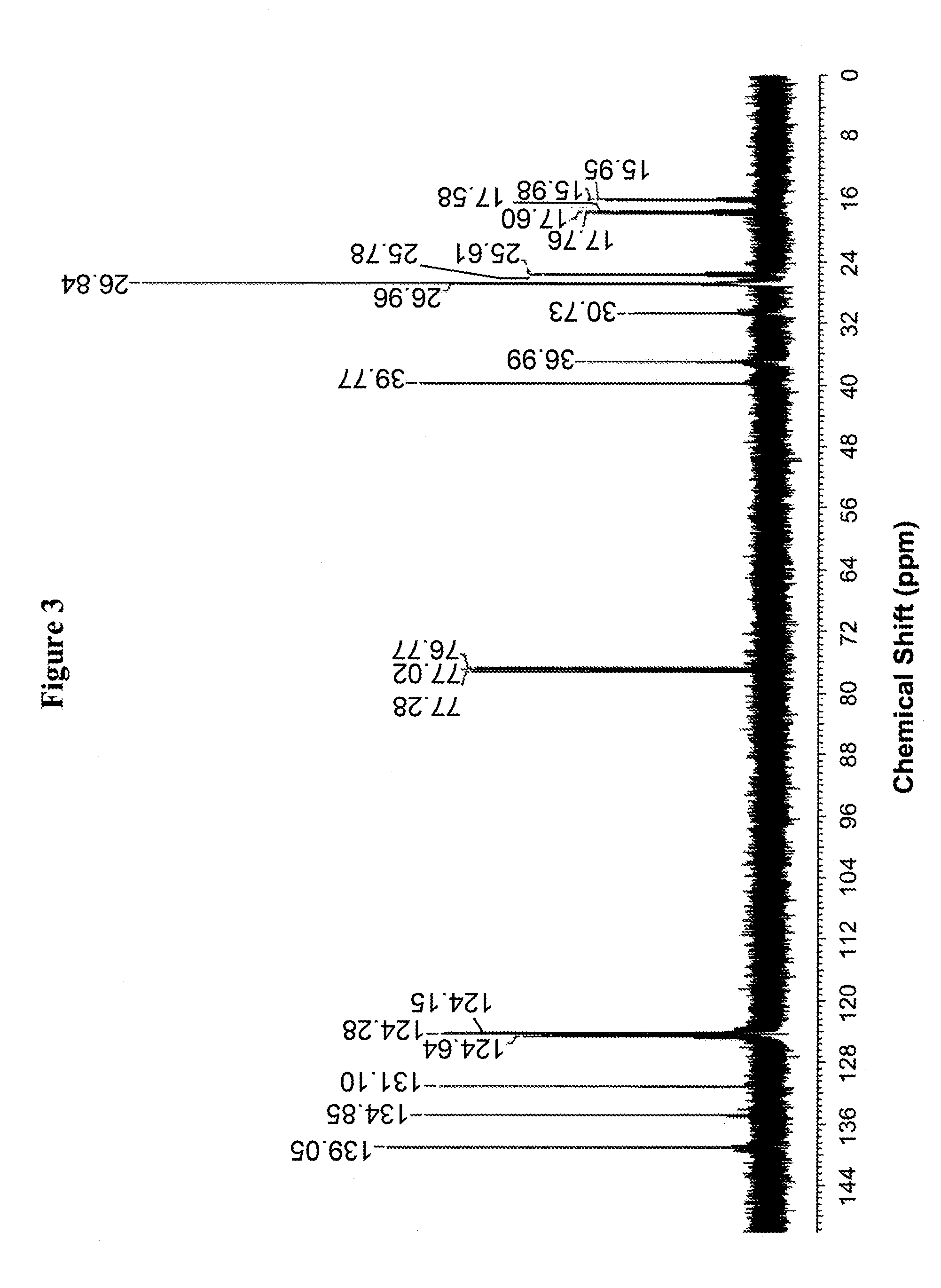

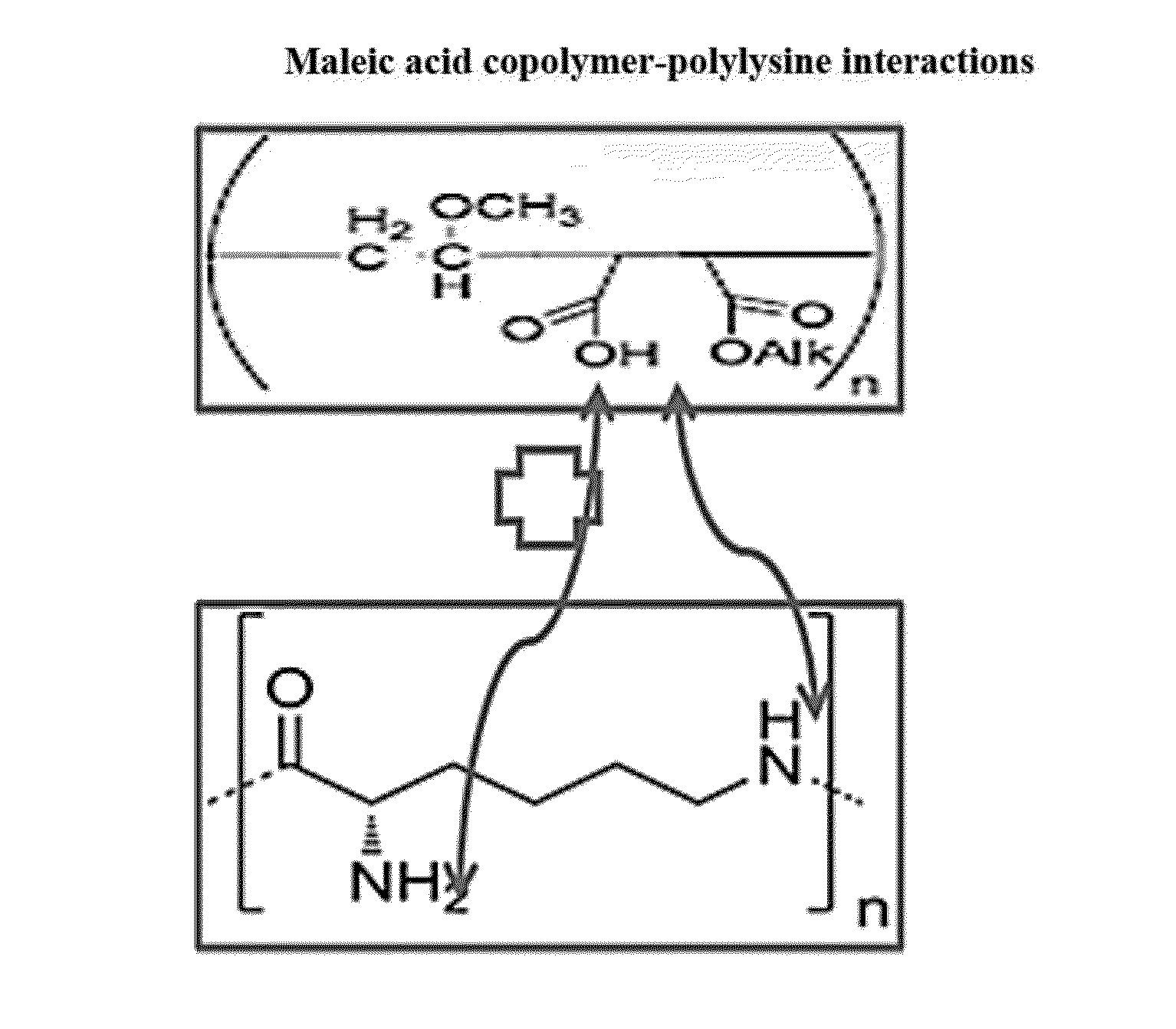

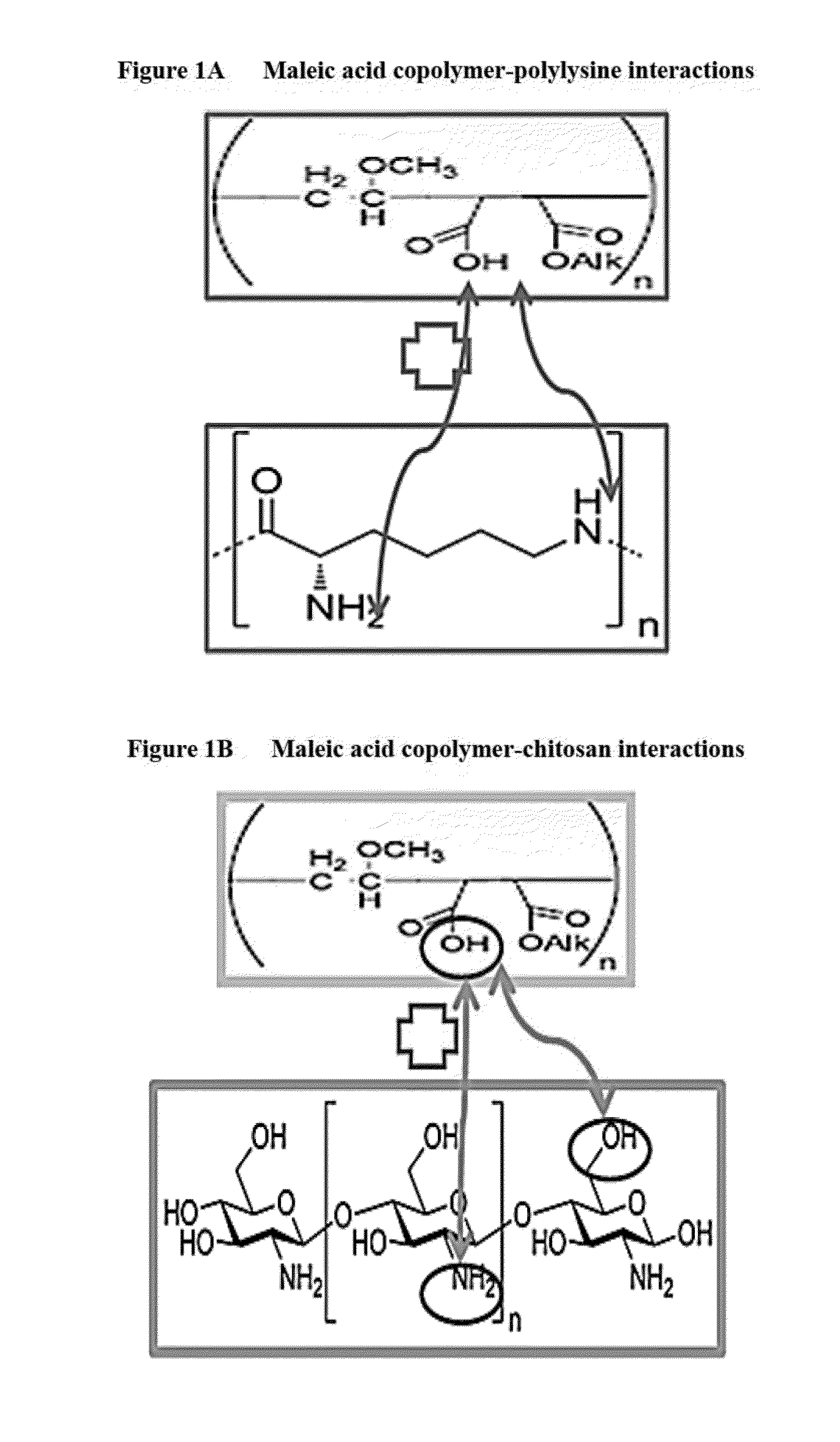

Hair cosmetic and styling compositions based on maleic acid copolymers and polyamines

Disclosed are cosmetic compositions which include hair cosmetic or styling compositions, comprising: a maleic acid copolymer; a polyamine selected from polyamino acids and aminated polysaccharides; a neutralizer; and water, wherein the polyamine is present in an amount less than 0.1% by weight based on the total weight of the composition, and methods of making and using the compositions to impart or maintain hair style.

Owner:LOREAL SA

Ultraviolet crosslinked expansion type flame-retardant polyolefin cable insulation sheath material and preparation thereof

ActiveCN101481475AAdd lessHigh flame retardant efficiencyPlastic/resin/waxes insulatorsInsulated cablesPolyolefinProcedure Agents

The invention discloses an insulating and sheathing material of ultraviolet light crosslinking expanding type phosphorus nitrogen flaming resistance polyolefine cables and a preparation method thereof. The invention is characterized in that polyethylene / PEMA and / or ethylene vinyl acetate or maleic anhydride grafted ethylene vinyl acetate or acid amide grafted ethylene vinyl acetate copolymer are taken as base, added with expanding type phosphorus nitrogen halogen-free flame retardants, light trigger, polyfunctional group cross linker and chemical inhibitor and matched with flaming retardant synergistic agent, antismoke agent and processing aid, and then squeezed out and pelleted into photo-crosslinking flame retardant cable materials; and then the flame retardant cable materials are melted and extruded on a cable conductor wire core and clad into an insulating layer and a sheathing layer; hereupon the ultraviolet light irradiation crosslinking is carried on the insulating layer or the sheathing layer. Via detecting, the oxygen index of the insulating layer or the sheathing layer is larger than 30%, the vertical flaming experiment passes through UL-94 V0 level, the tensile strength is larger than 12Mpa, the elongation at break is larger than 350%, and the electric volume resistivity is larger than 8*10 omega.cm.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

Copolymers of maleic anhydride or acid and fluorinated olefins

Novel copolymers of fluorinated olefins and maleic anhydride, maleic acid, dichloromaleic anhydride or dichloromaleic acid may be made by using as solvents for the maleic anhydride or acid a perfluorinated alkyl carboxylic acid, or liquid or supercritical hexafluoropropylene or carbon dioxide. The resulting polymers are useful as adhesives or compatibilizing agents for fluoropolymers, and in coatings.

Owner:THE CHEMOURS CO FC LLC

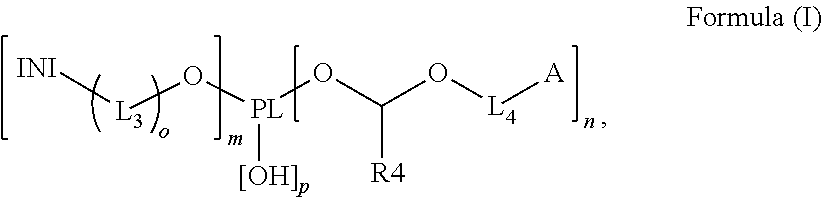

Polymerizable polymeric photoinitiators and radiation curable compositions

InactiveUS20120046376A1Simple and cost efficient procedureAvoiding unecological removal of solventInksVinyl etherPhosphine oxide

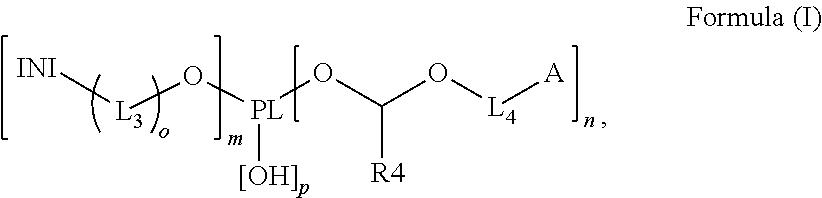

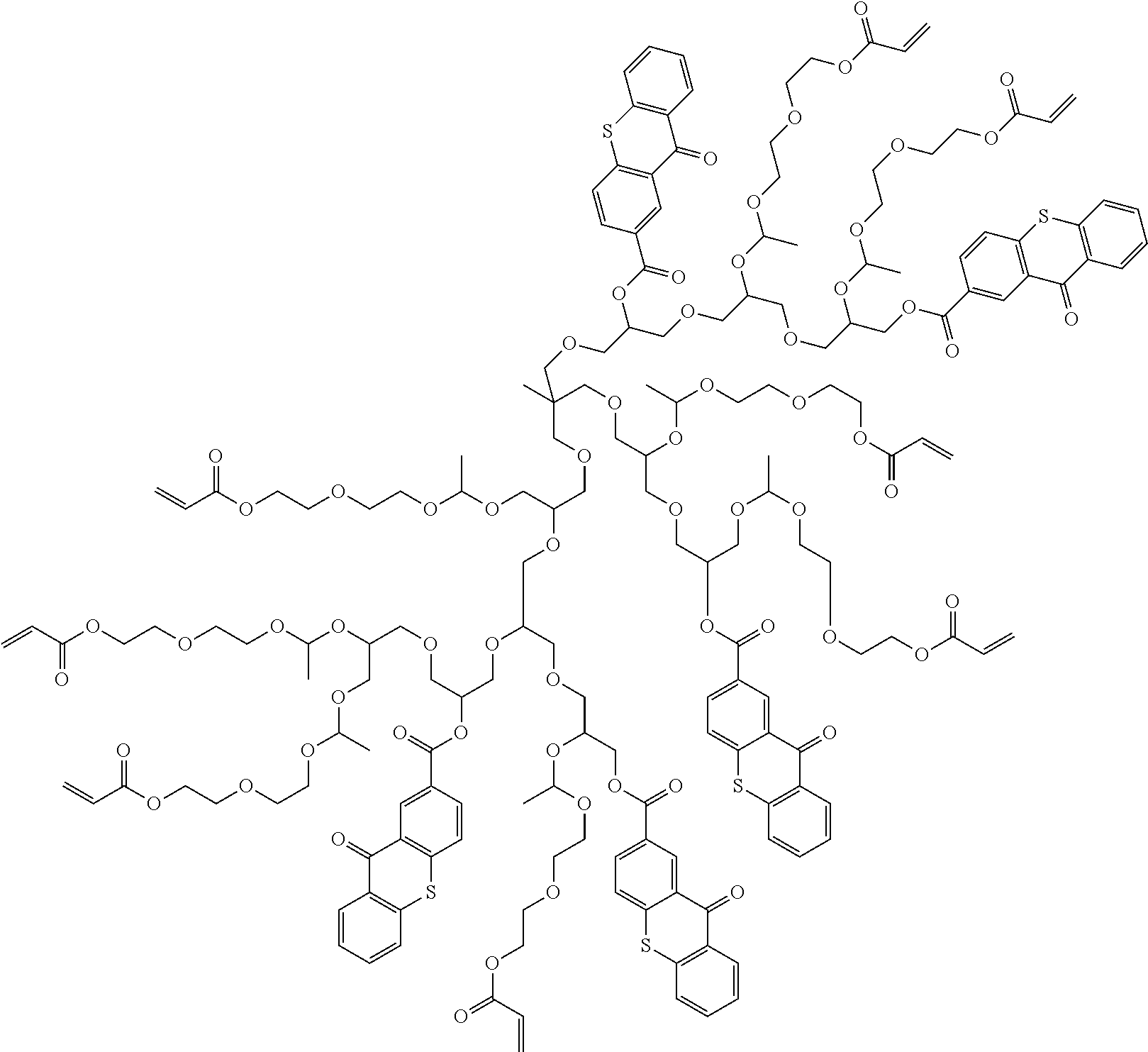

A polymerizable polymeric photoinitiator according to Formula (I):wherein:PL represents an n+m+p-functional polymeric core;n and m independently represent an integer from 1 to 30;p represents an integer from 0 to 10;o is 0 or 1;INI represents a group selected from the group consisting of a benzophenone, a thioxanthone, a carbazole, a anthraquinone, a camphor quinone, an α-hydroxyalkylphenone, an α-aminoalkylphenone, an acylphosphine oxide, a bisacyl phosphine oxide, an acylphosphine sulfide, a phenyl glyoxalate, a benzoin ether, a benzyl ketal, an α-dialkoxyacetophenone, a carbazolyl-O-acyl-oxime, an α-haloarylketone and an α-haloaryl sulfone;L3 and L4 represent a substituted or unsubstituted divalent linking group comprising 1 to 14 carbon atoms;A represents a radically polymerizable functional group selected from the group consisting of an acrylate, a methacrylate, a styrene, an acryl amide, a methacryl amide, a maleate, a fumarate, an itaconate, an vinyl ether, an allyl ether, an allyl ester, a maleimide, a vinyl nitrile and a vinyl ester; andR4 represents a substituted or unsubstituted alkyl group.Radiation curable compositions containing the polymerizable polymeric photoinitiator and methods for preparing the polymerizable polymeric photoinitiator are also disclosed.

Owner:AGFA NV

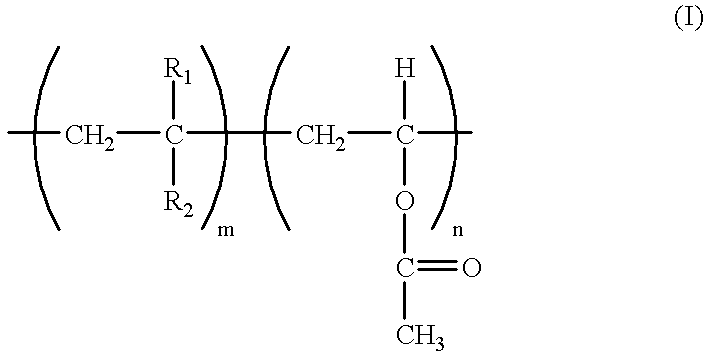

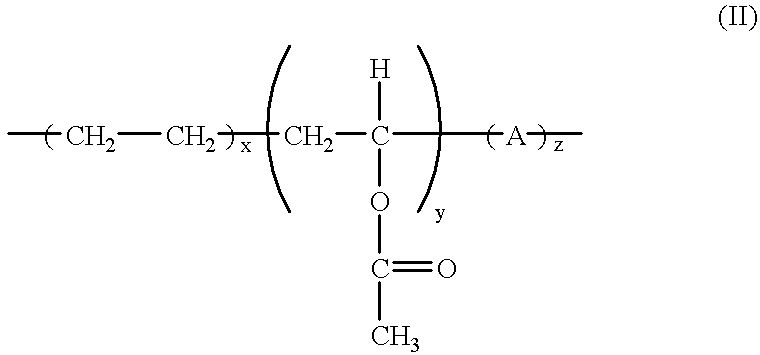

Gel polymer electrolyte of vinyl acetate

InactiveUS6268088B1Enhanced interactionImprove ionic conductivityOrganic electrolyte cellsSolid electrolyte cellsSolventFluid electrolytes

A gel polymer electrolyte according to the present invention comprises a polymer selected from the group consisting of vinyl acetate copolymer, poly(ethylene / vinylacetate / carbon oxide: EVACM), and poly(ethylene / vinylacetate / maleic acid anhydride: EVAMA); an inorganic filler; and a liquid electrolyte that a lithium salt is dissolved in an aprotic solvent. It is preferable that the polymer material in a gel polymer electrolyte according to the present invention is in the range of 20 to 30% by weight, the inorganic material filler is in the range of 5 to 20% by weight, and the liquid electrolyte is in the range of 60 to 80 % by weight. As a specific functional group which has a high compatibility with a liquid electrolyte in the present invention is contained in the polymer material, a lithium ion becomes to move with ease in electrolyte, and the ionic conductivity is over 0.5 mS / cm which is the demand level of a gel polymer electrolyte. Also, it provides the gel polymer electrolyte material with a high film formability, a good property of containing an electrolyte, a good adhesion, and a good mechanical strength.

Owner:CHEIL IND INC

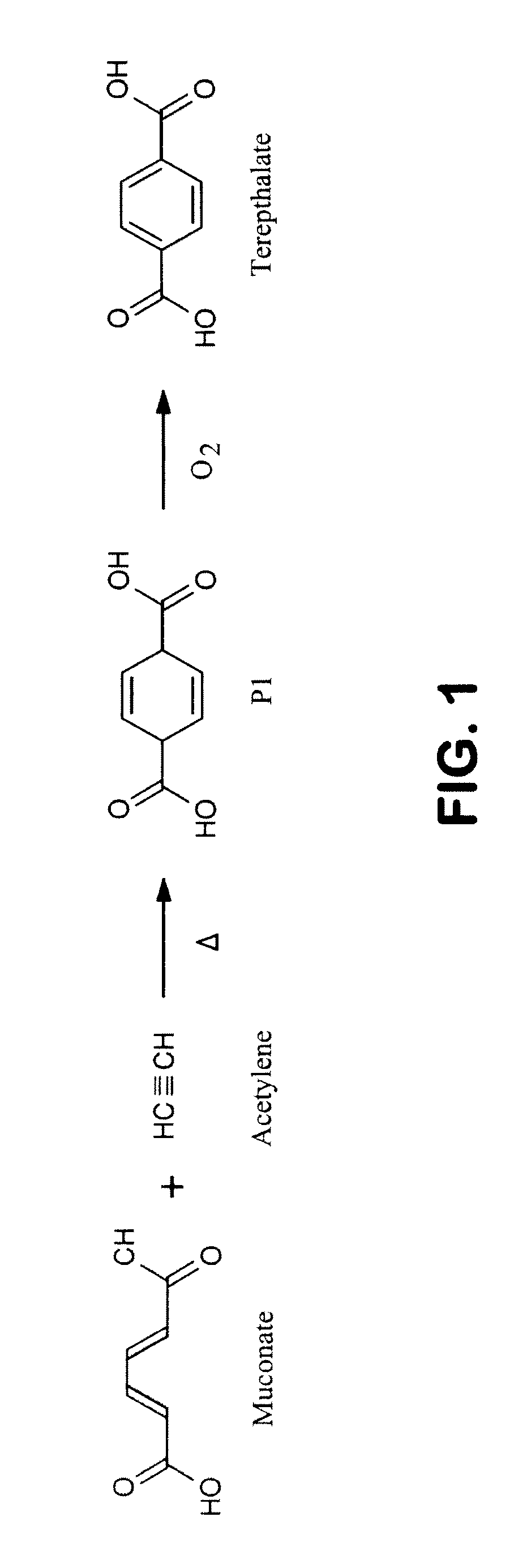

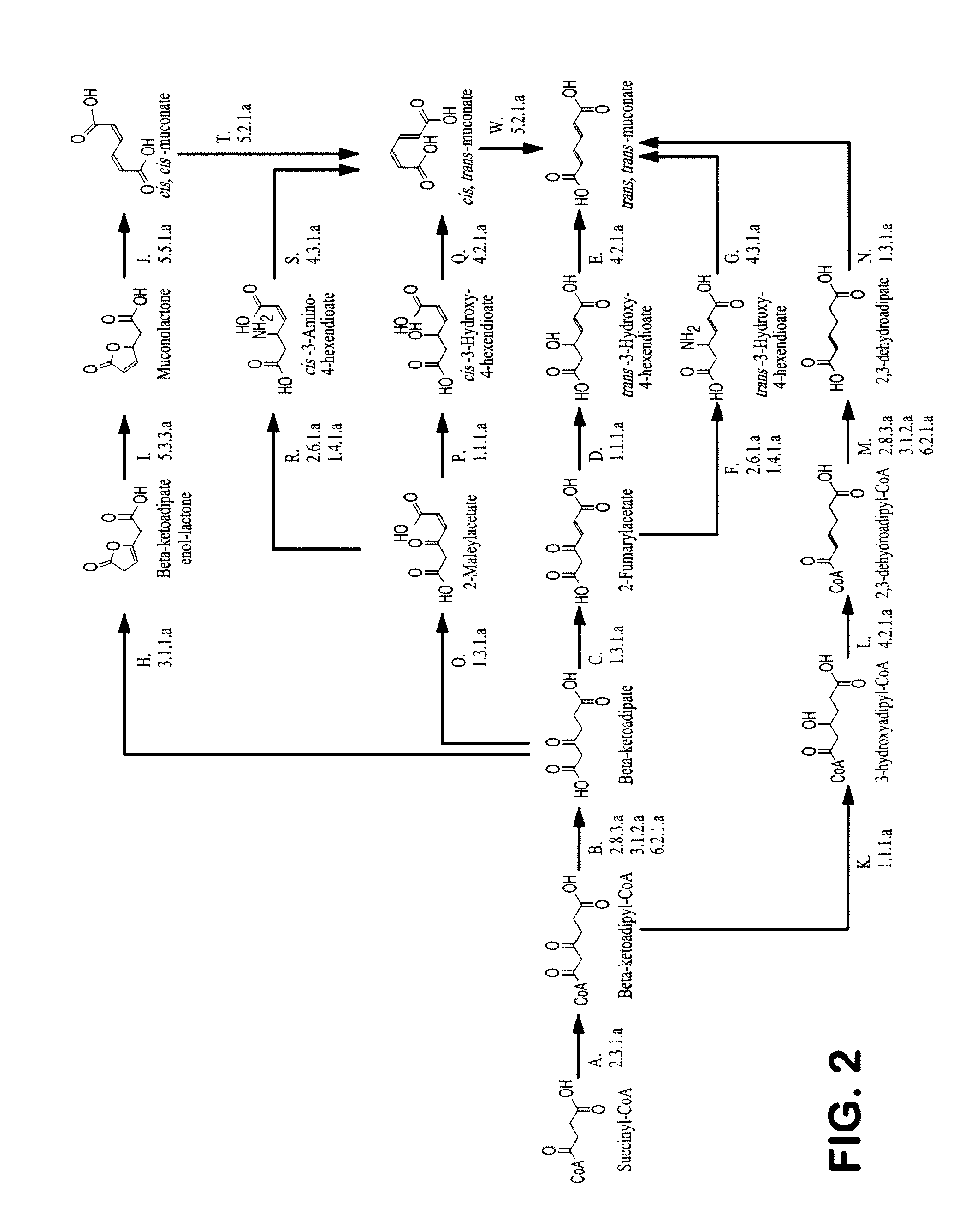

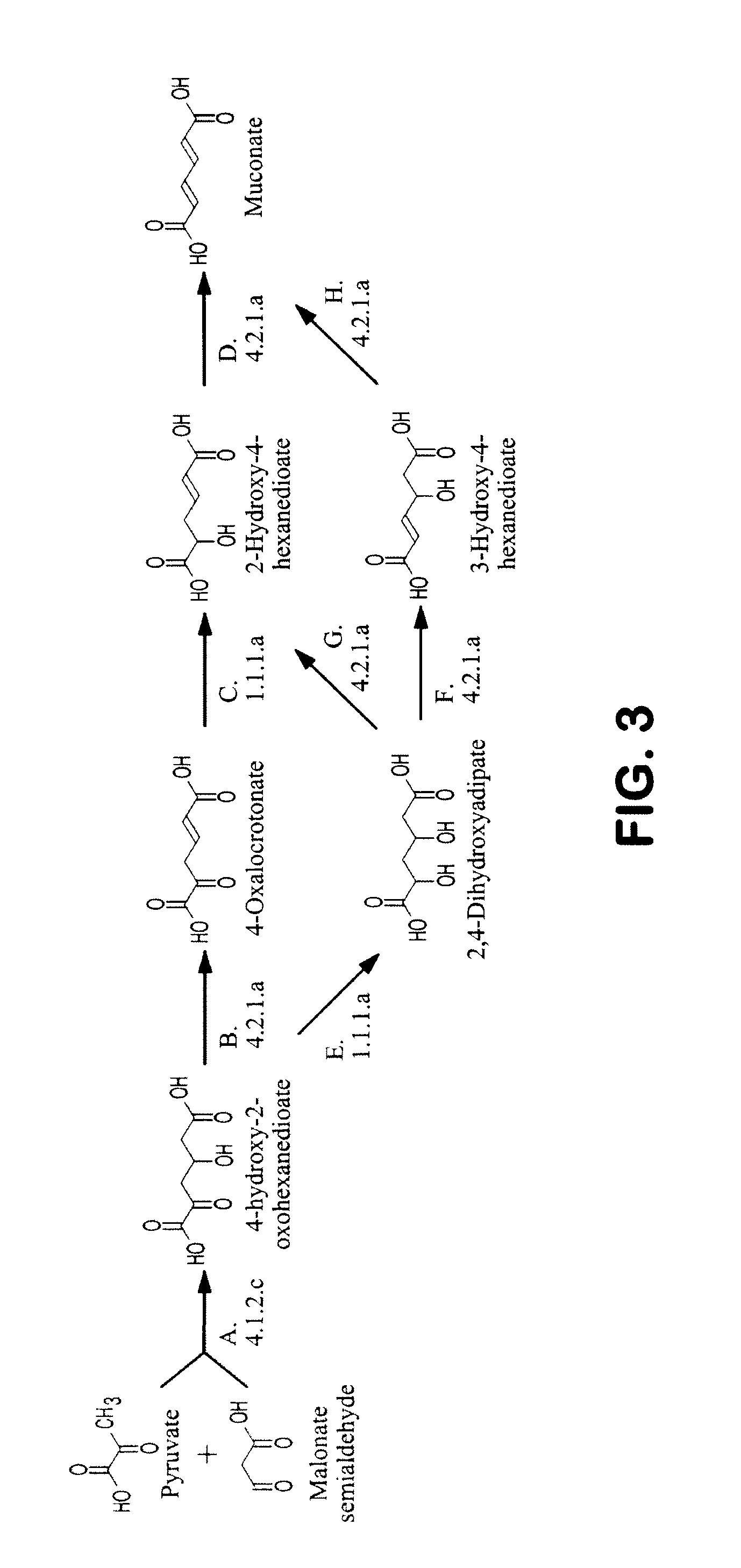

Semi-synthetic terephthalic acid via microorganisms that produce muconic acid

The invention provides a non-naturally occurring microbial organism having a muconate pathway having at least one exogenous nucleic acid encoding a muconate pathway enzyme expressed in a sufficient amount to produce muconate. The muconate pathway including an enzyme selected from the group consisting of a beta-ketothiolase, a beta-ketoadipyl-CoA hydrolase, a beta-ketoadipyl-CoA transferase, a beta-ketoadipyl-CoA ligase, a 2-fumarylacetate reductase, a 2-fumarylacetate dehydrogenase, a trans-3-hydroxy-4-hexendioate dehydratase, a 2-fumarylacetate aminotransferase, a 2-fumarylacetate aminating oxidoreductase, a trans-3-amino-4-hexenoate deaminase, a beta-ketoadipate enol-lactone hydrolase, a muconolactone isomerase, a muconate cycloisomerase, a beta-ketoadipyl-CoA dehydrogenase, a 3-hydroxyadipyl-CoA dehydratase, a 2,3-dehydroadipyl-CoA transferase, a 2,3-dehydroadipyl-CoA hydrolase, a 2,3-dehydroadipyl-CoA ligase, a muconate reductase, a 2-maleylacetate reductase, a 2-maleylacetate dehydrogenase, a cis-3-hydroxy-4-hexendioate dehydratase, a 2-maleylacetate aminoatransferase, a 2-maleylacetate aminating oxidoreductase, a cis-3-amino-4-hexendioate deaminase, and a muconate cis / trans isomerase. Other muconate pathway enzymes also are provided. Additionally provided are methods of producing muconate.

Owner:GENOMATICA INC

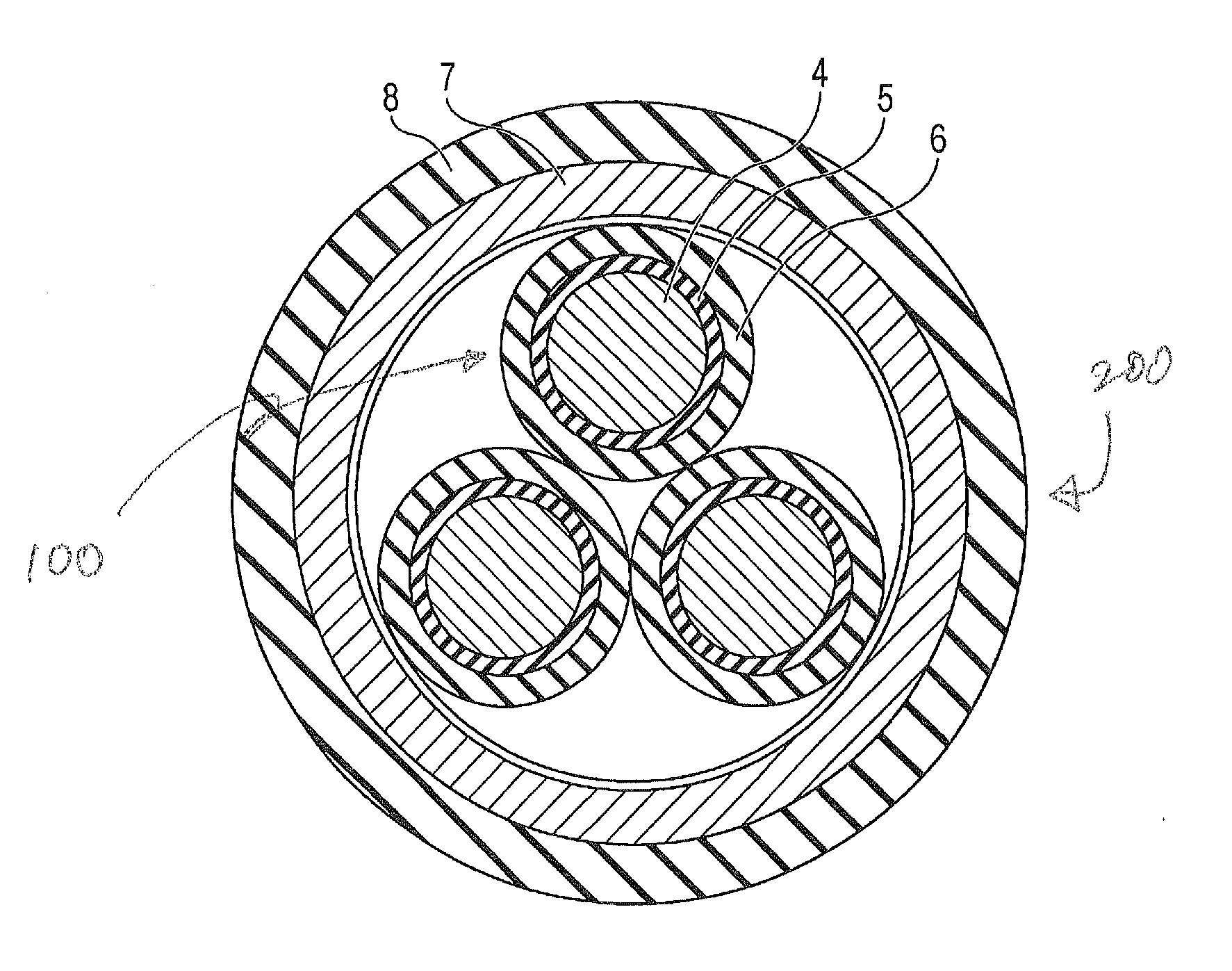

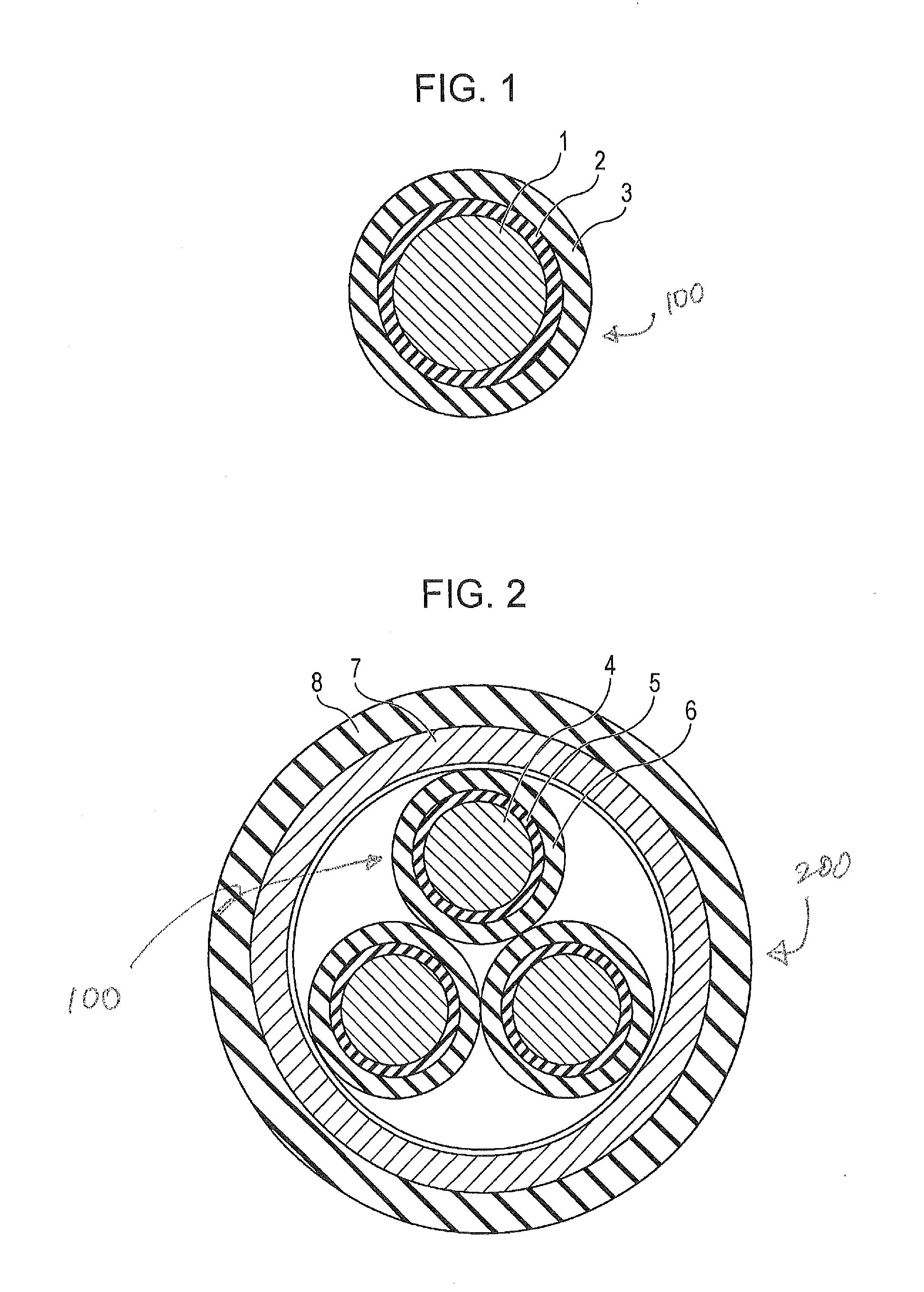

Halogen-free flame-retardant polymer composition, insulated electric wire, and cable

A halogen free flame-retardant polymer composition includes flame retardancy and excellent oil resistance / fuel resistance, low-temperature characteristics, and injury resistance, and an insulated electric wire and a cable include the composition. The halogen-free flame-retardant polymer composition includes a base polymer including 60 to 70% by mass of LLDPE, 10% by mass or more of EVA having a melt flow rate (MFR) of 100 or more, and 10 to 20% by mass of maleic acid-modified polyolefin, a metal hydroxide added at a ratio of 150 to 220 parts by mass relative to 100 parts by mass of the base polymer, and carbon black. The addition ratio (metal hydroxide / carbon black) between the metal hydroxide and the carbon black is 15:1 to 100:1.

Owner:HITACHI METALS LTD

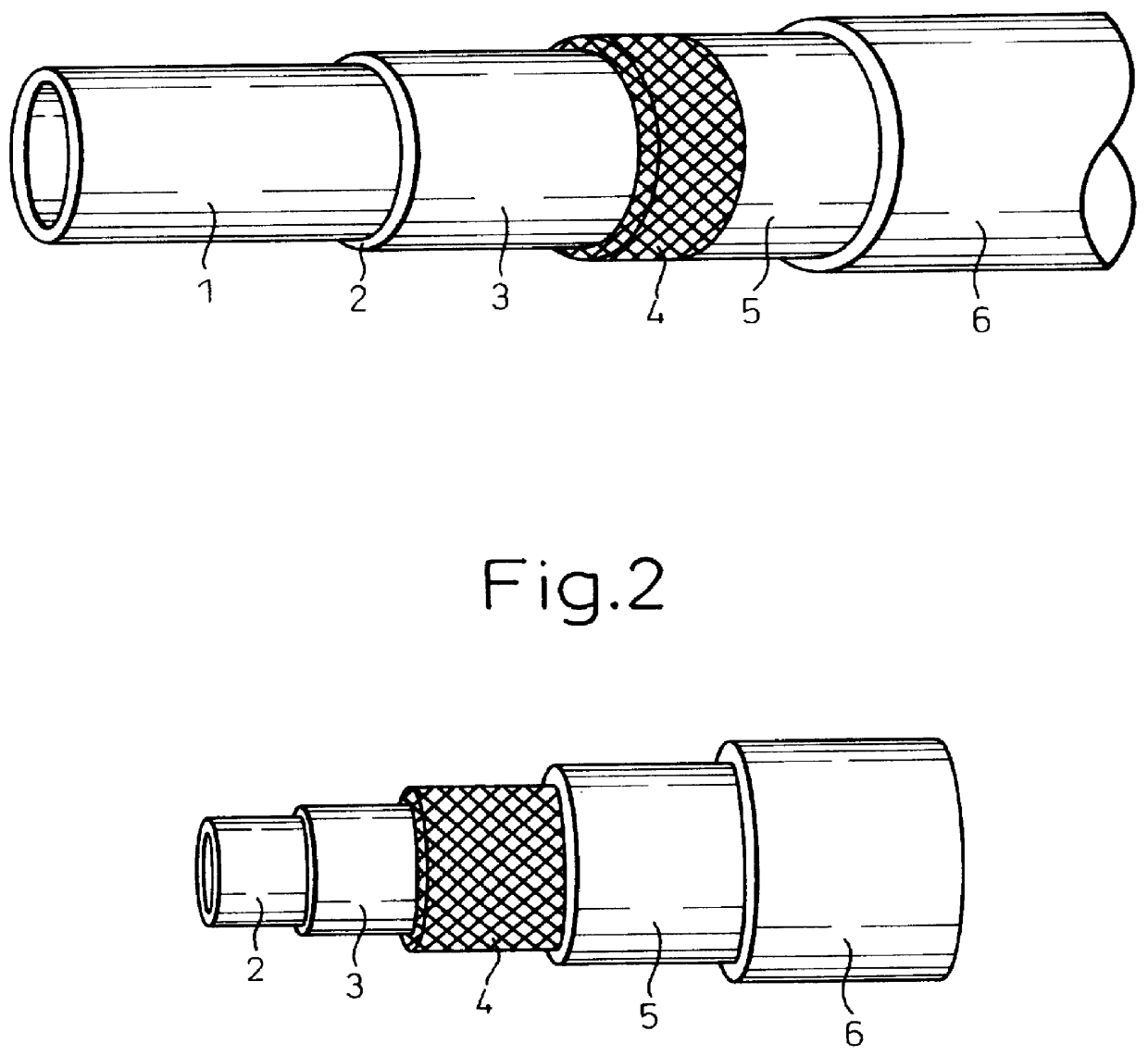

Thermoplastic elastomer composition, hose comprising thermoplastic elastomer composition and process of production thereof

InactiveUS6166143AImprove compatibilitySolve the lack of flexibilityClosuresClosure using stoppersThermoplasticCross-link

PCT No. PCT / JP97 / 03987 Sec. 371 Date Jul. 2, 1998 Sec. 102(e) Date Jul. 2, 1998 PCT Filed Oct. 31, 1997 PCT Pub. No. WO98 / 20068 PCT Pub. Date May 14, 1998A thermoplastic elastomer composition containing a component (A) (thermoplastic polyolefin resin), component (B) (epoxy-group-containing ethylene acrylic ester copolymer rubber), and component (C) (acid-modified polyolefin resin) comprising a continuous phase of the component (A) in which the component (B) is dispersed as a dispersed phase and is cross-linked by a peroxide; a thermoplastic elastomer composition comprising a continuous phase of a thermoplastic polyolefin resin (A) and a dispersed phase of an epoxy-group-containing ethylene-acrylic ester copolymer rubber component (B) and acrylonitrile butadiene rubber component (C), which is dynamically cross-linked; and a hose having an inner tube, at least one reinforcing layer, and an outer cover, wherein the inner tube and the outer cover contain a thermoplastic elastomer composition comprised of a thermoplastic resin in which is blended an at least partially cross-linked elastomer component, the reinforcing layer is a brass-plated wire, and the reinforcing layer and inner tube and the reinforcing layer and outer cover have between them a maleic-acid-modified polyolefin thermoplastic resin.

Owner:YOKOHAMA RUBBER CO LTD

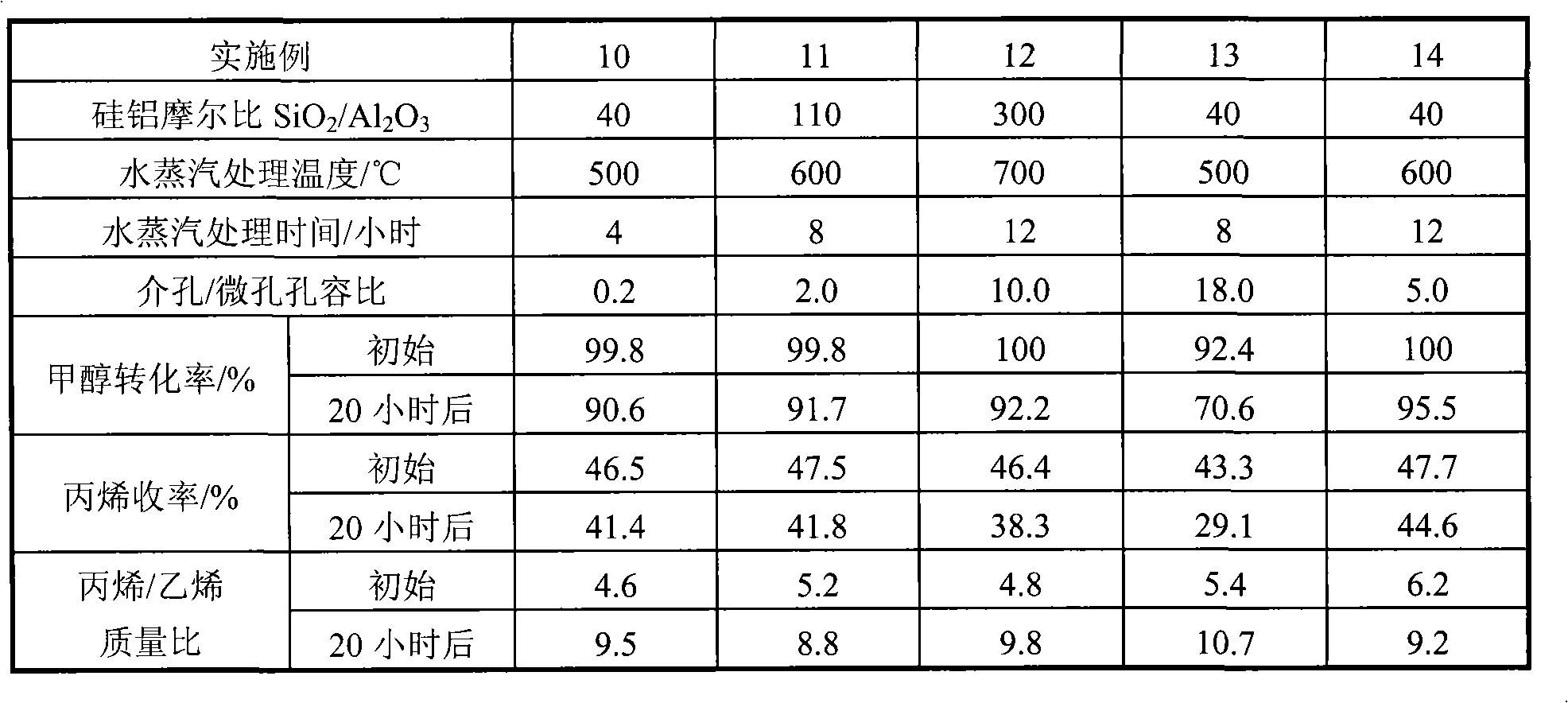

ZSM-5 mesoporous molecular sieve catalyst for preparing propylene from methanol and preparation thereof

ActiveCN101279282AMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMaleopimaric acidAmmonium nitrate

The present invention relates to a ZSM-5 mesoporous molecular sieve catalyst used for manufacturing propylene by methanol and a preparation method thereof, which mainly solves the problems of low propylene selectivity, low propylene / ethylene mass ratio as well as poor thermal stability of molecular sieve and poor water thermal stability in the prior art. The present invention adopts the technical proposal of adopting ZSM-5 mesoporous molecular sieve raw powder with a silicon-aluminum mol ratio SiO2Al2O3 of 20 to 1000 and a weight percentage of 20 to 100 percent as well as at least one caking agent selected from SiO2, clay and Al2O3 to extrude, tablet or spray into shape; then treating for 1 to 8 hours by 0.1 to 3 mol / l of at least one ammonium liquor from ammonium nitrate, ammonium chloride or ammonium sulphate or 0.1 to 8.5 mol / l of at least one acid liquor from muriatic acid, nitric acid, vitriol or acetic acid under a temperature of 20 to 90 DEG C; then using steam to treat for 2 to 15 hours under the temperature condition of 400 to 700 DEG C; using a liquor of 0.1 to 3mol / l selected from at least one of oxalic acid, citric acid or maleic acid under a temperature condition of 20 to 90 DEG C to dip for 2 to 5 hours to obtain the modified molecular sieve catalyst, thus better solving the problems. The present invention can be used in the industrial production of propylene by being converted from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

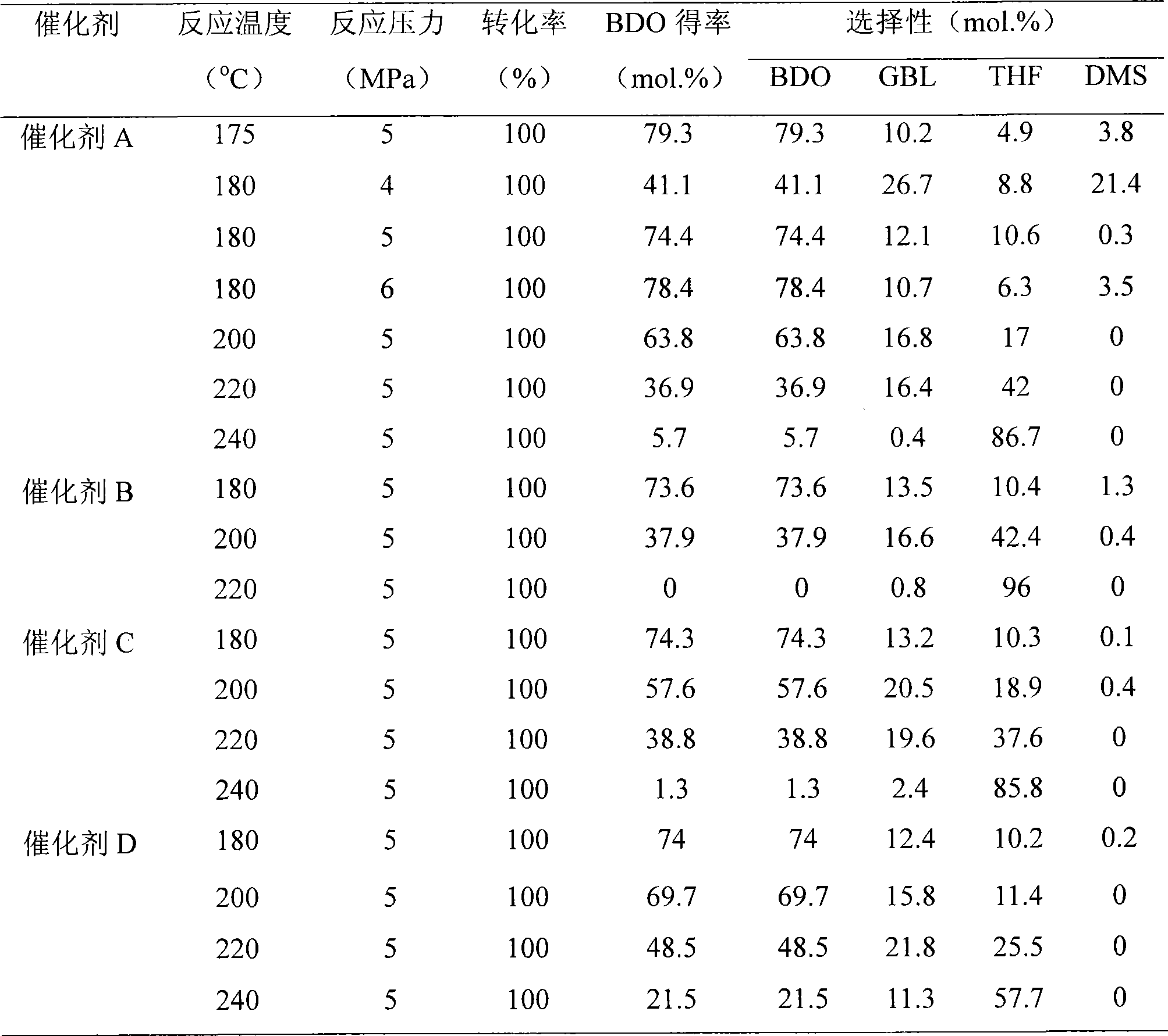

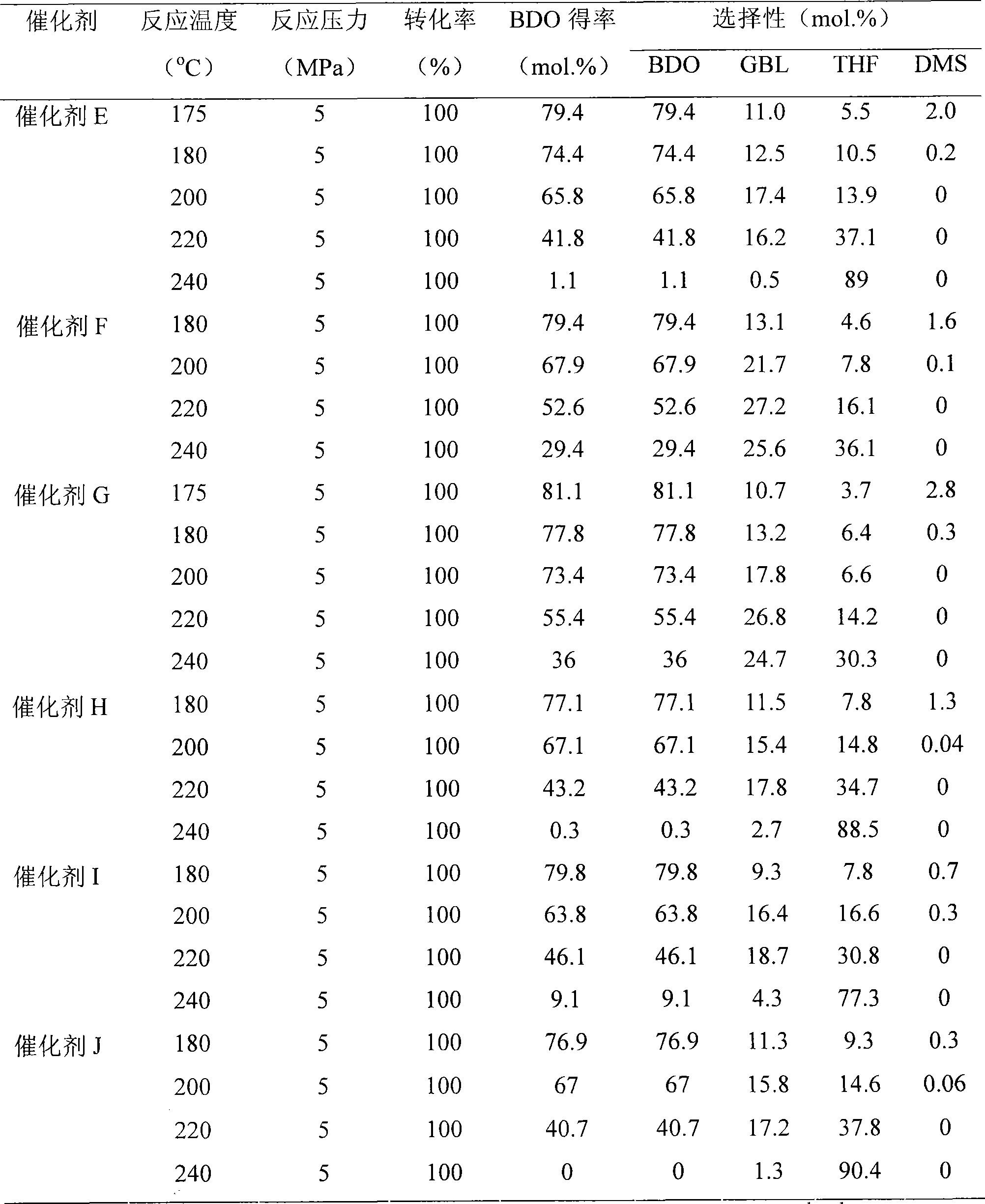

Catalyst for preparing 1,4-butanediol or tetrahydrofuran from selective hydrogenation of dimethyl maleate and preparation method thereof

ActiveCN101502803AHigh selectivitySolve filterabilityOrganic compound preparationHydroxy compound preparationMonoethyl maleateHydrogenation reaction

The invention belongs to the field of chemical technology, and in particular relates to a catalyst for preparing 1, 4-butanediol or tetrahydrofuran by selective hydrogenation of dimethyl maleate and a preparation method thereof. The catalyst consists of Cu, Zn, Al, M and O, and the mol content of each metal element is as follows: 30 to 60 percent of Cu, 10 to 50 percent of Zn, 5 to 20 percent of Al and 0 to 10 percent of M, wherein M is any one of Mn, Mg and Cr. The preparation method for the catalyst comprises precipitation, ageing, washing, drying and baking of a catalyst precursor, and reduction activation before use. The catalyst is applied to the hydrogenation reaction of the dimethyl maleate, and the yield of the 1, 4-butanediol at a reaction temperature of 180 DEG C is 73.6 percent; and the yield of the tetrahydrofuran is 96 percent at a reaction temperature of 220 DEG C. Product composition of the catalyst can be well adjusted by changing the reaction condition to adapt to different market demands, and the catalyst has extremely high industrial application value.

Owner:FUDAN UNIV +1

Synthesis method of drilling fluid filtrate reducer

InactiveCN101805595ANo pollution in the processFast polymerization rateDrilling compositionSynthesis methodsOil phase

The invention relates to a synthesis method of drilling fluid filtrate reducer. The method comprises: a, nonionic compound emulsifying agent is dissolved in oil and oil phase is made up; a first monomer chosen from fumaric acid, maleic acid, itaconic acid or crylic acid, a second monomer chosen from N, N- dimethylacrylamide, N, N-diethylacrylamide or acrylamide and a third monomer chosen from 4-vinylbenzenesulfonic acid sodium salt, sodium allylsulfonate, 3-allyloxy-2-dydroxy-1-sodium allylsulfonate, 2- methacryloxypropyl-2-methyl propanesulfonic acid, 2-acrylamido-2-methyl propanesulfonic acid or SMAS are dissolved in water with the molar ratio of 1:1 to 5:1 to 5, the pH value of the solution is adjusted to be between 8 and 11, evocating agent is added and water phase solution is made up; and b, the water solution is added to the oil phase solution and the temperature rises to 40 to 70 DEG C for polymerization. The method of the invention has the advantages of fast polymerization speed, high outcome molecular weight and high outcome stability, good filtrate reducing performance, high temperature resistance and high salt resistant performance.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com