Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1696 results about "Heat deflection temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The heat deflection temperature or heat distortion temperature (HDT, HDTUL, or DTUL) is the temperature at which a polymer or plastic sample deforms under a specified load. This property of a given plastic material is applied in many aspects of product design, engineering and manufacture of products using thermoplastic components.

High strength and high toughness modified poly-propylene material

The present invention belongs to the field of polymer material technology, and is especially one kind of modified polypropylene material comprising at least polymer base, strengthening agent and toughening agent. The polymer base may be polypropylene or polypropylene composition; the strengthening agent is inorganic or organic matter with great aspect ratio, such as inorganic or organic crystal whisker, fiber, mica, etc; and the toughening agent may be polypropylene beta-nucleater, rubber elastomer, etc. The modified polypropylene material has high strength, high toughness, etc and may be applied widely in automobile, pipeline, electric appliance and other fields.

Owner:FUDAN UNIV

Wood plastic composite material composection and formed board thereof and their preparation process

The present invention provides one kind of wood-plastic composition, which contains wood powder and resin as well as nanometer particle of size below 100 nm. The wood-plastic composition with nanometer particle has hardness greater than 56HRR and heat distortion temperature higher than 105 deg.c. It may be produced into plate used widely for building, transportation, packing, household decoration and daily use article.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

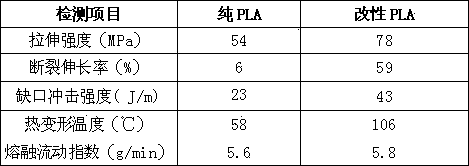

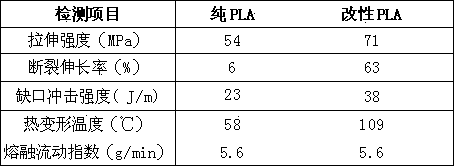

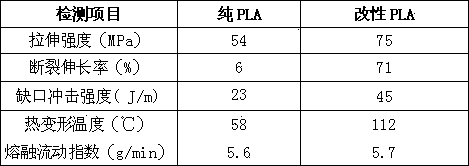

3D printing modified polylactic acid material and preparation method thereof

InactiveCN103467950AIncrease profitSelf-performance has not declinedMonocomponent polyesters artificial filamentArtifical filament manufactureHeat deflection temperaturePolymer science

A 3D printing modified polylactic acid material comprises, by weight, 70-85 parts of polylactic acid, 1-5 parts of chain extenders, 1-5 parts of cross-linking agents, 0.5-1 part of nucleating agents, 5-10 parts of polymers with low molecular weights, 5-10 parts of flexibilizers, 1-5 parts of fortifiers and 0.3-0.8 part of antioxidants. According to the 3D printing modified polylactic acid material, a low-temperature smashing hybrid reaction technology is utilized, modified processing is carried out on polylactic acid, toughness, impact strength and the heat distortion temperature for the polylactic acid are improved to a large extent, and the polylactic acid can have wider application prospects in 3D printing materials.

Owner:佛山市斯太克科技有限公司

Non-halogen flame-retardant polypropylene composite material and preparation thereof

InactiveCN101412830AImprove flame retardant performanceImprove mechanical propertiesFlexural modulusAcrylonitrile

The invention provides a halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing aid, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of glass fiber compatibilizer and 5 to 30 portions of glass fiber. The invention also provides a method for preparing the material. The material has the flame retardancy up to 1.6mm V0, the tensile strength higher than or equal to 50 MPa, the flexural modulus higher than or equal to 3,000 MPa, the notched impact strength more than or equal to 8KJ / m<2>, the shrinkage between 4 and 6 per thousand, the heat distortion temperature higher than or equal to 140 DEG C, as well as the other technical indexes up to or exceeding the standard of flame-retardant acrylonitrile-butadiene-styrene copolymer materials. As the material uses the phosphorus-nitrogen flame retardant containing no halogen, the flame-retardant effect of the material completely reaches UL94-V0 grade.

Owner:SHANGHAI KINGFA SCI & TECH +1

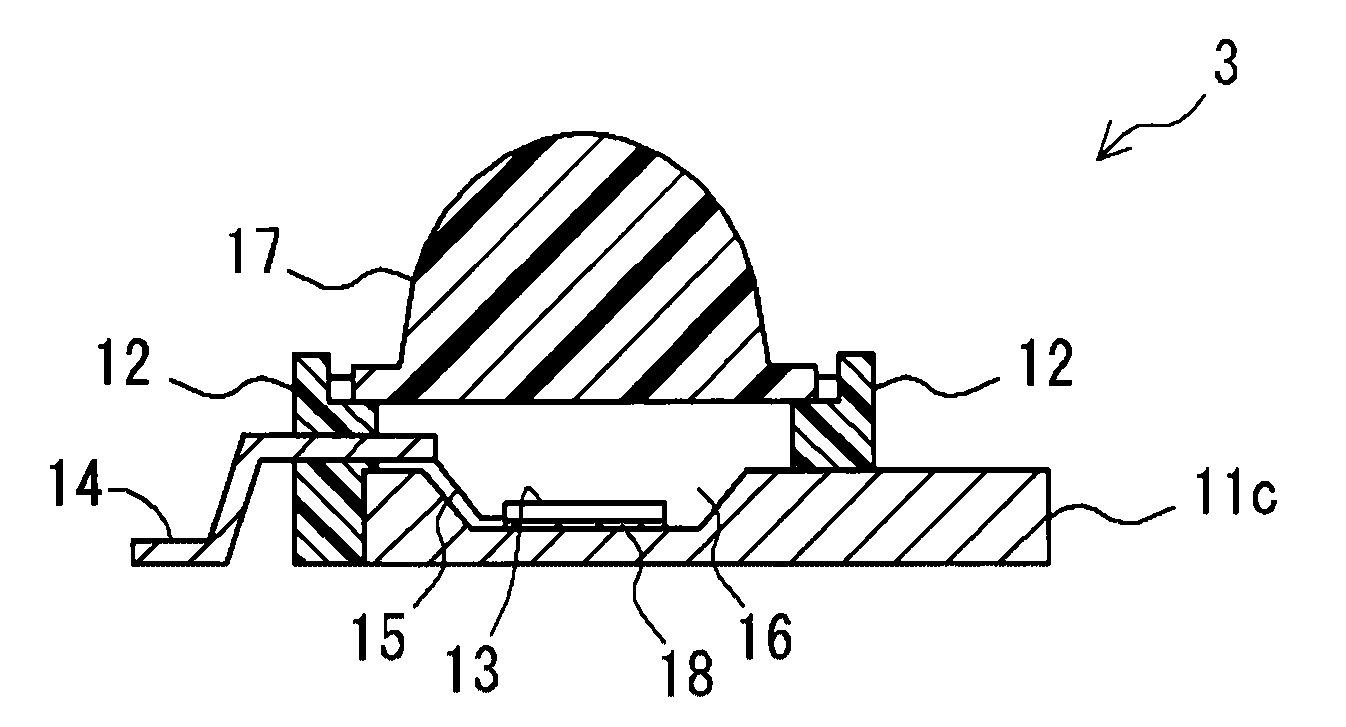

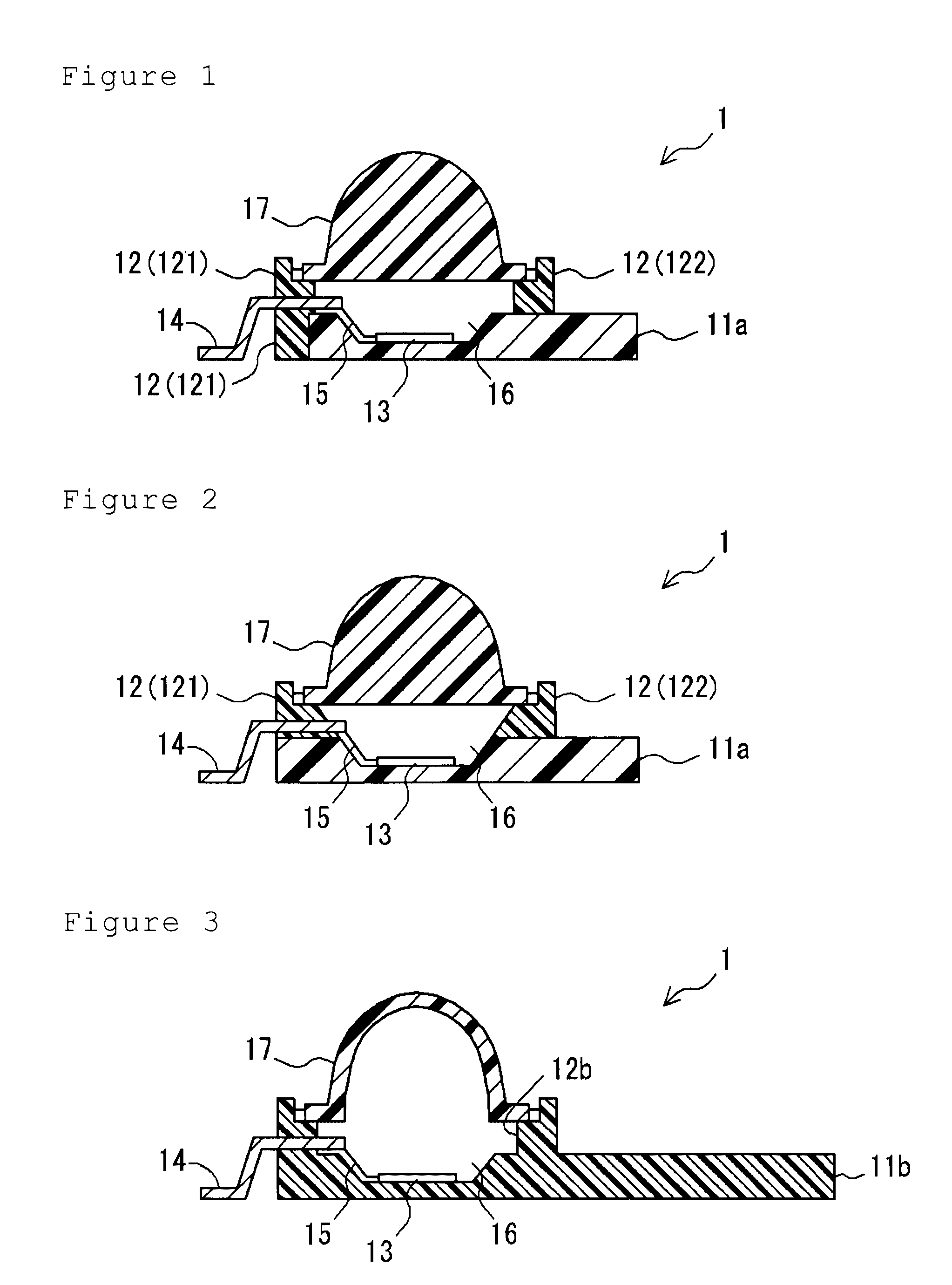

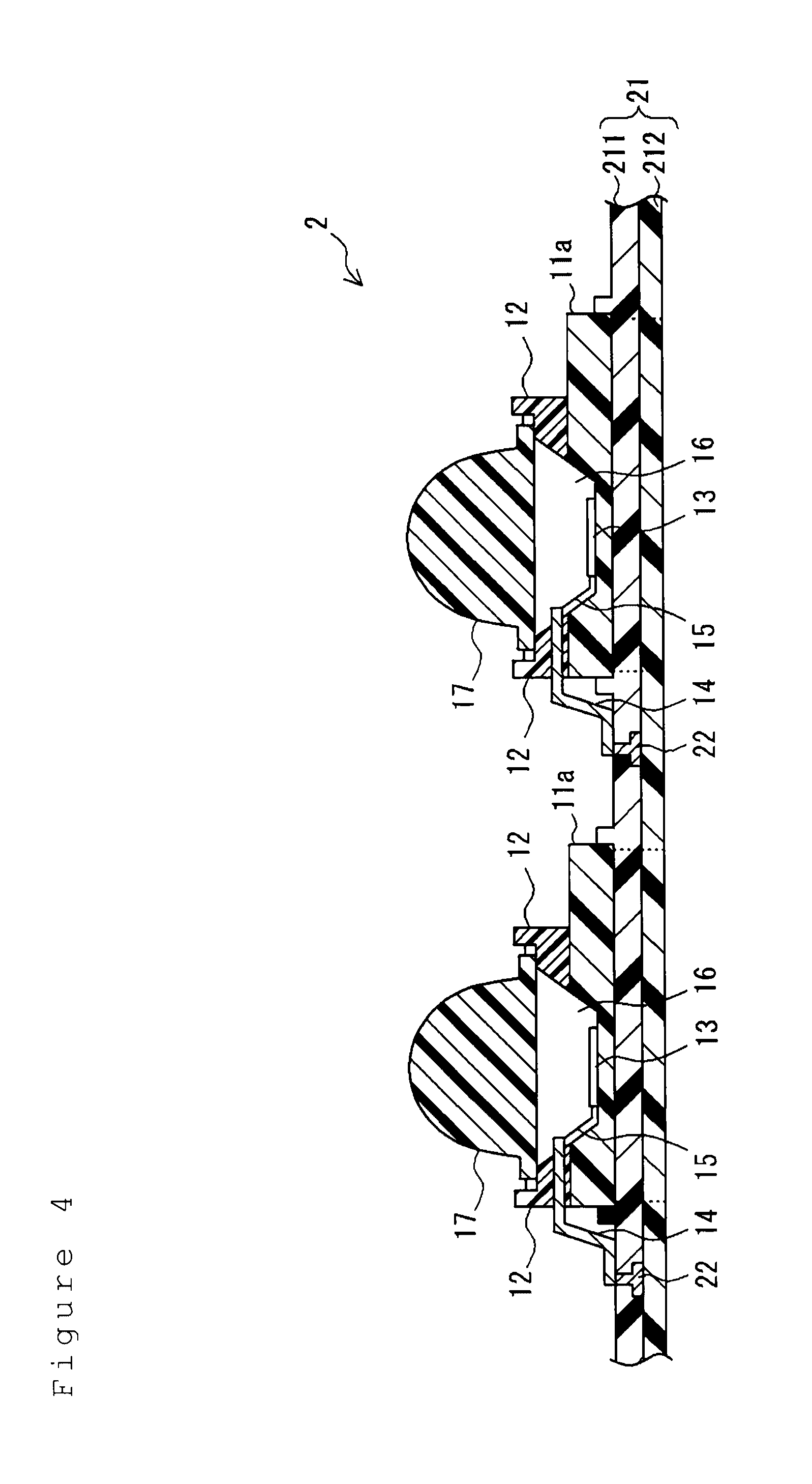

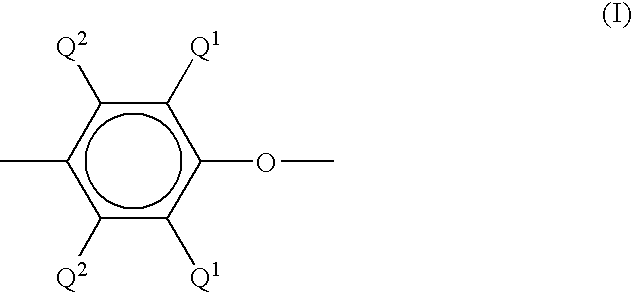

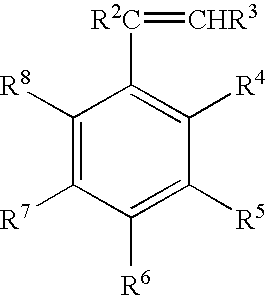

Heat-dissipating resin composition, substrate for LED mounting, reflector, and substrate for LED mounting having reflector portion

InactiveUS20100072416A1Avoid serious impactGood moldabilitySolid-state devicesHeat-exchange elementsHeat deflection temperatureOptoelectronics

The objective of the present invention is to provide a heat-dissipating resin composition that is used for forming a substrate for LED mounting or a reflector provided on the substrate for LED mounting and is excellent in heat dissipation, electrical insulation, heat resistance and light resistance while an LED element emits light, a substrate for LED mounting and a reflector comprising the composition. The present composition comprises a thermoplastic resin such as modified PBT and a thermally conductive filler consisting of scaly boron nitride or the like, and has thermal deformation temperature of 120° C. or higher, a thermal conductivity of 2.0 W / (m·K) or higher, and a thermal emissivity of 0.7 or higher.

Owner:TECHNO POLYMER CO LTD

Natural fiber reinforcement halogen-free flame retardant polypropylene composite material and preparation method thereof

InactiveCN101418099AImprove flame retardant performanceImprove mechanical propertiesGlass fiberHeat deflection temperature

The invention provides a natural fiber reinforced halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing assistant, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of compatilizer, and 5 to 30 portions of natural fiber. The invention also provides a method for preparing the material. The composite material has the advantages that the composite material has excellent flame-retardant effect and excellent comprehensive mechanical property; the flame-retardant property of the composite material can reach 1.6mm V0; the tensile strength is more than or equal to 60MPa; the bending modulus is more than or equal to 4,000MPa; the gap impact strength is more than or equal to 10KJ / m<2>; the shrinkage ratio is between 4 and 6 per thousand; the heat distortion temperature is more than or equal to 140 DEG C; and the composite material is a novel environment-friendly material, and has no safety and health problems of glass fibers.

Owner:SHANGHAI KINGFA SCI & TECH +1

Reinforced poly(arylene ether)/polyamide composition

A composition comprises greater than or equal to 20 weight percent glass fiber, based on the total weight of the composition, and a compatibilized blend of a poly(arylene ether) and an aliphatic-aromatic polyamide. The polyamide is composed of dicarboxylic acid units comprising 60 to 100 mol % of terephthalic acid units and diamine units comprising 60 to 100 mol % of 1,9-nonanediamine units and / or 2-methyl-1,8-octanediamine units. The polyamide has an amine end group content greater than 45 micromoles per gram of polyamide. The composition has a heat distortion temperature (HDT) greater than or equal to 230° C. when measured according to ASTM D 648 at 1.8 megapascals (MPa)

Owner:SABIC INNOVATIVE PLASTICS IP BV

Biodegradable resin composition for modifying toughness and heat resistance and preparation method thereof

InactiveCN101143962AImprove toughnessImprove heat resistanceHeat deflection temperatureProcedure Agents

The invention provides a biodegradable resin component with toughness and heat resistance improved and a method for preparing the same, wherein the resin component contains 100 parts by mass of biodegradable resin, 1-40 parts by mass of thermoplastic elastomer, and 0.1-30 parts by mass of inorganic additive, and preferentially contains 3-25 parts by mass of flame retardant, 0.1-10 parts by mass of performance reinforcing agent and 0.1-10 parts by mass of processing aid; the resin component is granulated by a double screw extruder after melting mixing, the forming processing cycle of the resin component is short during injection forming, and after treatment for 10 min at 110DGE C, the lzod notched impact strength is higher than 30J / m, and the heat deformation temperature is higher than 90DGE C.

Owner:CHITEC TECH

Metal-like engineering plastic composite material and preparation method thereof

The invention discloses a metal-like engineering plastic composite material and a preparation method thereof, and relates to a polymer composite material. The invention provides the metal-like engineering plastic composite material which combines plastic with metal and simultaneously keeps the advantages of the two and the preparation method thereof. The composite material comprises thermoplastic engineering plastic, high-density packing, mineral powder, glass fiber, toughener, coupling agent, lubricant and antioxidant. The metal-like engineering plastic composite material has high density, high mechanical properties, excellent thermal deformation temperature and good injection molding property. The preparation method adopts the method of being combined with the coupling agent and the optimized granulation conditions, the process is simple and easy to operate, extrusion and granulation can be carried out by adopting an ordinary twin-screw granulator, and injection molding can be carried out by adopting an ordinary injection machine.

Owner:XIAMEN RUNNER IND CORP

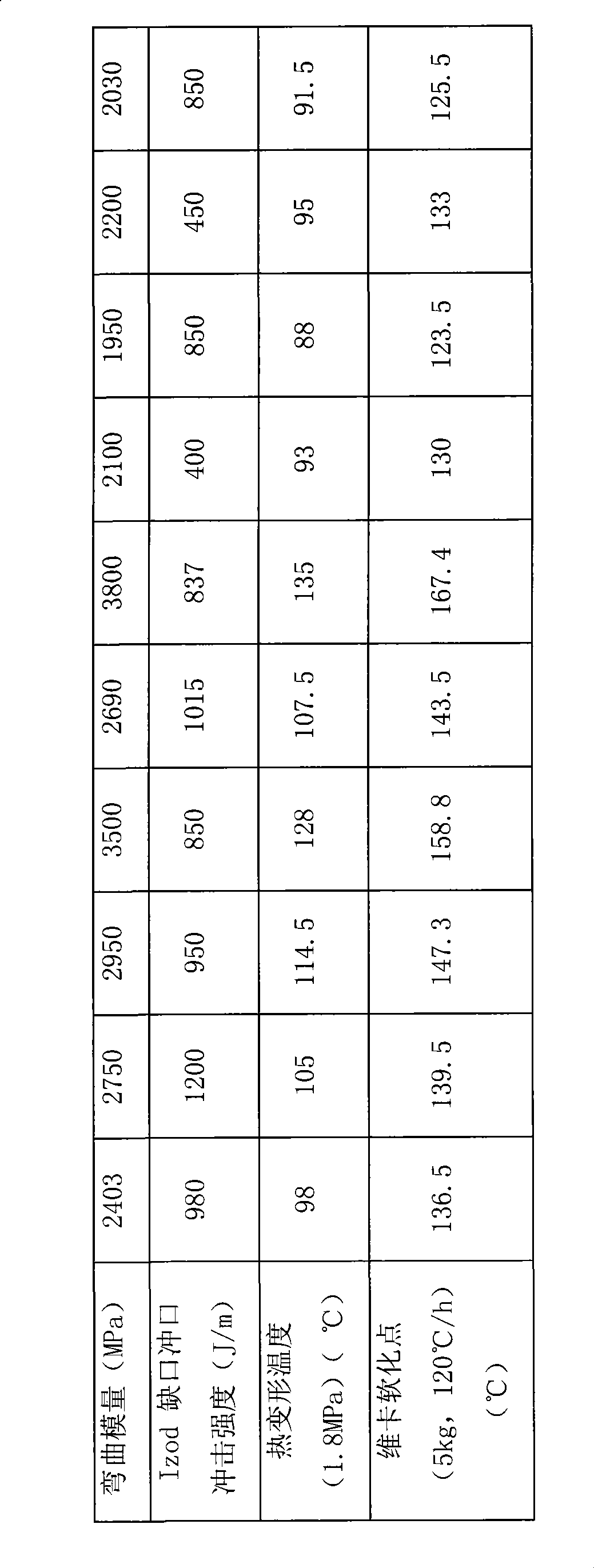

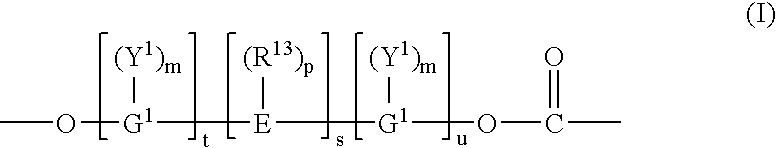

Polymer Compositions, Method of Manufacture, and Articles Formed Therefrom

ActiveUS20080242789A1Improve ductilityIncrease modulusPigmenting treatmentCeramic shaping apparatusHeat deflection temperaturePolyester

A composition comprises, based on the total weight of the composition, from 10 to 80 wt. % of a polyester; from 10 to 80 wt. % of a polycarbonate; from 0 to 20 wt. % of an impact modifier; from 1 to less than 25 wt. % of a reinforcing filler; from 0.1 to less than 2.5 wt. % of a fibrillated fluoropolymer; from 0 to 5 wt. % of an additive selected from the group consisting of antioxidants, mold release agents, colorants, quenchers, stabilizers, and combinations thereof, wherein the composition has a heat deflection temperature of at least 110° C., measured in accordance with to ASTM D648 on 3.2 mm thick molded bars at 0.455 MPa.

Owner:SABIC INNOVATIVE PLASTICS IP BV

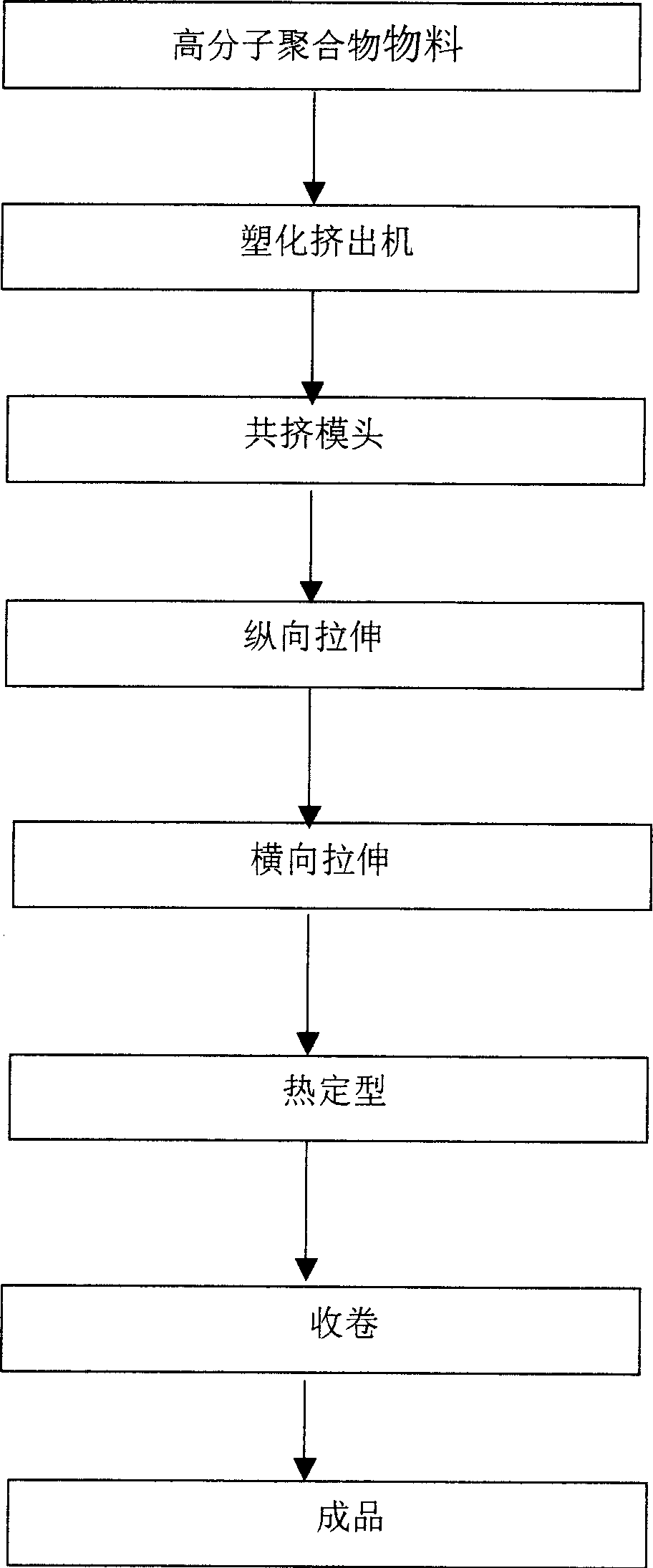

Biaxial tension co-extrusion high-obstruct base material membrane and process for preparing the same

InactiveCN1733397AImprove barrier propertiesImprove qualityTurning toolsHeat deflection temperaturePolyolefin

This invention provides biaxial tension coextrude resistive base material membrane and preparation method. Wherein, the membrane comprises at least a resistive layer that is at least one of PA, PVA, PVDC and MAD6, a splice layer belonged to EAA, EEA, ethylenemethacrylic acid copolymerized resin or polyolefin and neolyn resin that can combine the other tow layers, and a heat-sealing layer that is at least one of the polyolefin resin, EVA and PET; besides, there is nano inorganic material in resistive layer and or heat-sealing layer to improve performance. The product fits to package for all kinds goods.

Owner:朱春蕾 +4

Polyetherimide resin compositions with improved ductility

A thermoplastic resin composition containing a polyetherimide resin, a siloxane-polyetherimide copolymer and a branched polycarbonate resin exhibits exhibit high heat distortion temperature, improved room temperature impact properties and improved impact strength and ductility at low temperatures.

Owner:GENERAL ELECTRIC CO

Graphene/polymer conductive composite material

The invention belongs to the field of engineering materials, in particular relates to a preparation method of a graphene / polymer composite material with high performance and high conductivity and heat conduction. The composite material contains 80-95 wt% of high-molecular polymer, 0-15 wt% of one or more layers of graphene, 0.1-2 wt% of antioxidant, and 0.1-3 wt% of plasticizer. The prepared composite material has excellent conductivity, higher heat distortion temperature and excellent mechanical performance, and can be widely applied to supercapacitors, automobile antistatic fenders, door handles, mirror boxes and pass boxes.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

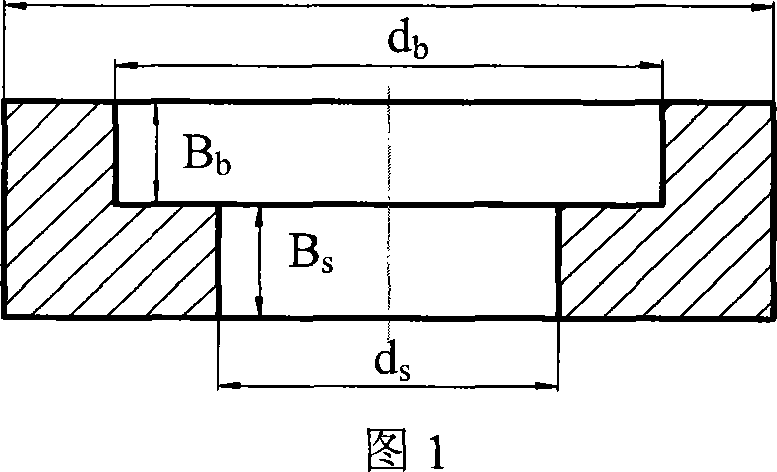

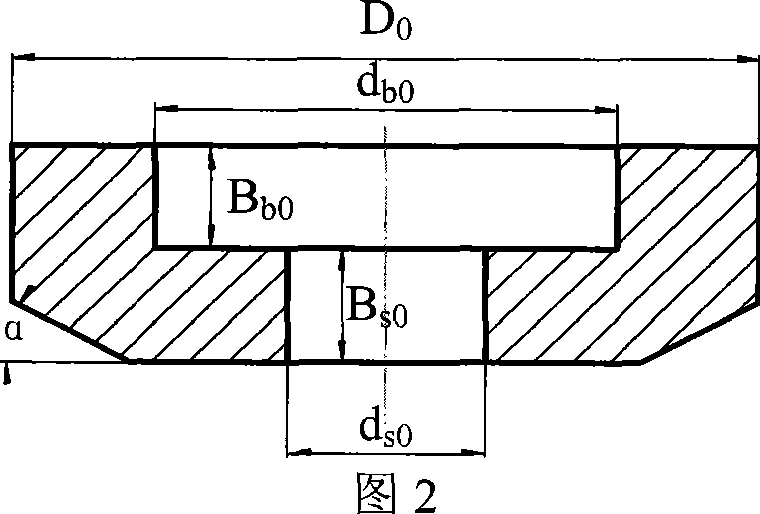

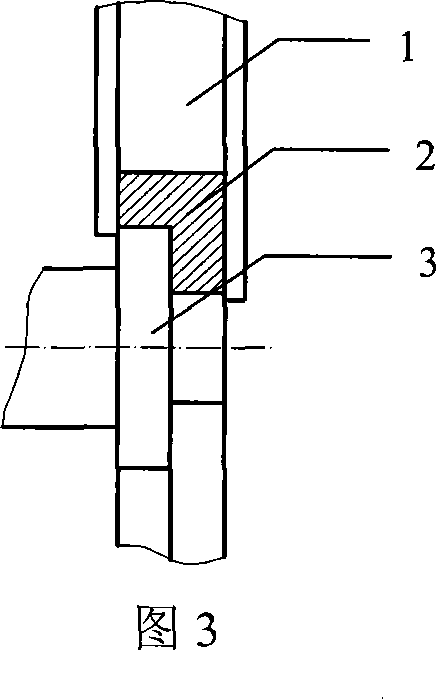

Inner step profile section ring parts rolling forming method

InactiveCN101053887AImprove metal structureImprove performanceFurnace typesHeat treatment process controlHeat deflection temperatureThermal state

The invention relates to a rolling forming method of a ring with inner step section. The rolling forming method of a ring with inner step section is characterized in that it comprises the following steps: 1) blanking; 2) preforming: uniformly heating the material section from room temperature to a heat distortion temperature with high plasticity and low resistance, then upsetting, piercing and stamping the material section in thermal state to fabricate ring blank for rolling; 3) rolling by a ring rolling mill: heating the ring blank in a heating furnace, taking out when the temperature reaches the heat distortion temperature and putting the ring blank into the ring rolling mill to carry out rolling, during the rolling process, excellent lubrication is maintained between the ring blank and the rollers, and the ring forging is formed by multiple rolling the ring blank; 4) mechanical cutting processing the ring forging to form the ring with inner step section. Accordingly, the invention has advantages of low cost and high production efficiency.

Owner:WUHAN UNIV OF TECH

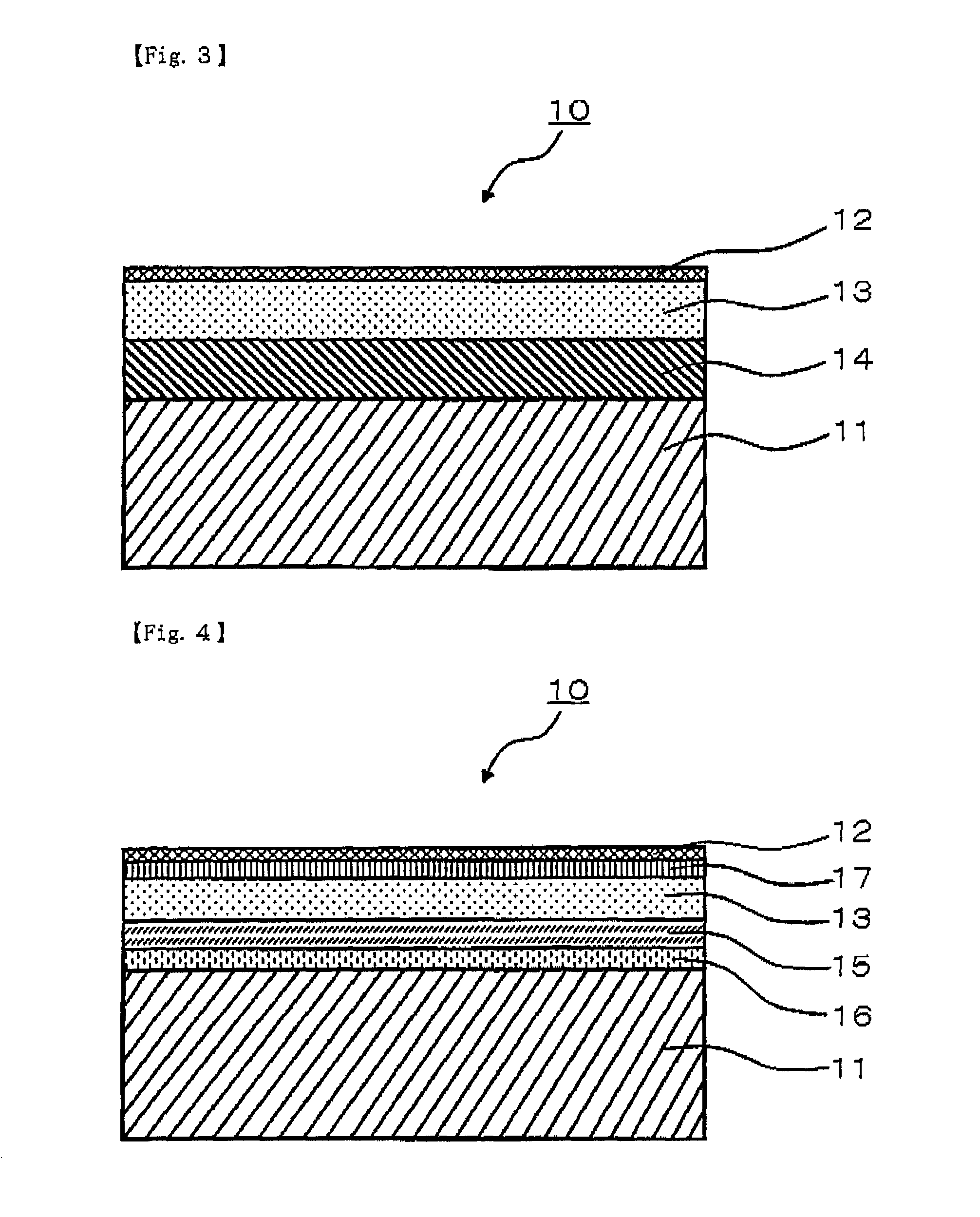

Data storage medium and method for the preparation thereof

ActiveUS20040063031A1Improve melt processingImprove moldingRadiation applicationsLayered productsHeat deflection temperatureVolatiles

A data storage medium includes a substrate, a reflective metal layer, and a haze-prevention layer between the substrate and the reflective metal layer. The substrate includes an amorphous thermoplastic resin having a heat distortion temperature of at least about 140° C., a density less than 1.7 grams per milliliter, and an organic volatiles content less than 1,000 parts per million measured according to ASTM D4526. The haze-prevention layer includes a material having a volume resistivity of at least 1x10<-4 >ohm-centimeters and a tensile modulus of at least about 3x10<5 >pounds per square inch. The data storage medium resists hazing of the reflective layer at elevated temperatures.

Owner:SHPP GLOBAL TECH BV

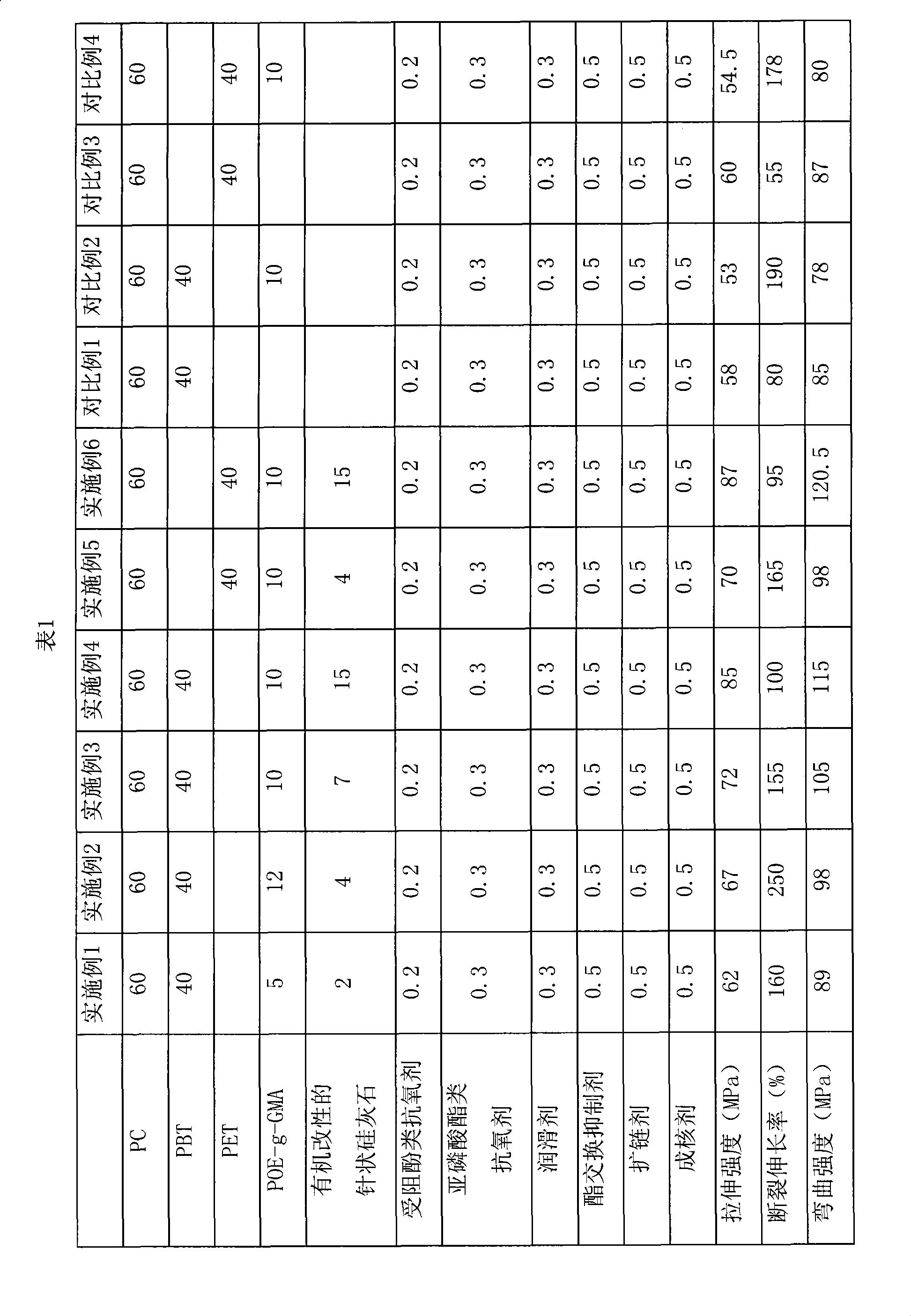

Method of manufacturing polycarbonate/polyester alloy

The invention discloses a preparation method of polycarbonate / polyester alloy. Glycidyl methacrylate grafted ethylene-octylene multipolymer / organic modified needle-shaped aedelforsite composite toughener, i.e. a technology of simultaneously using organic / inorganic rigid particle toughener is adopted; the glycidyl methacrylate grafted ethylene-octylene multipolymer, organic modified needle-shaped aedelforsite, polycarbonate and polyester are melted and mixed in a double-screw extruder, to obtain high-performance alloy material. The prepared polycarbonate / polyester alloy has excellent integrated mechanical properties and size stability, the notched impact strength reaches 1200J / m, the tensile strength reaches 67MPa, the elongation at break reaches 250 percent, the flexural strength is up to 98MPa, the flexural modulus reaches 2750MPa, and the thermal deformation temperature in high load (1.82MPa) is up to 105 DEG C. Therefore, the prepared polycarbonate / polyester alloy can be applied in cars, and to outer decorations, household electrical appliances, IT and the like industrial products.

Owner:SHANGHAI JIAO TONG UNIV +1

Polymer Compositions, Method of Manufacture, and Articles Formed Therefrom

ActiveUS20080246181A1Improve ductilityIncrease modulusMaterial nanotechnologyPigmenting treatmentPolytetramethylene terephthalateHeat deflection temperature

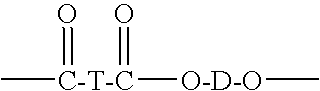

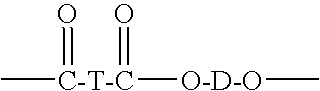

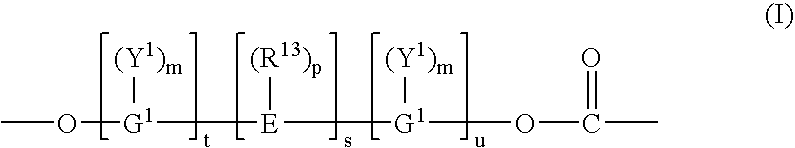

A composition comprises, based on the total weight of the composition: from 10 to 80 wt. % of a modified polybutylene terephthalate copolymer that (1) is derived from polyethylene terephthalate component selected from the group consisting of polyethylene terephthalate and polyethylene terephthalate copolymers and (2) has at least one residue derived from the polyethylene terephthalate component; from 10 to 80 wt. % of a polycarbonate; from 0 to 20 wt. % of an impact modifier; from 1 to less than 25 wt. % of a reinforcing filler; from 0.1 to less than 2.5 wt. % of a fibrillated fluoropolymer; from 0 to 5 wt. % of an additive selected from the group consisting of antioxidants, mold release agents, colorants, quenchers, stabilizers, and combinations thereof. The composition has a heat deflection temperature of at least 110° C., measured in accordance with to ASTM D648 on 3.2 mm thick molded bars at 0.455 MPa.

Owner:SHPP GLOBAL TECH BV

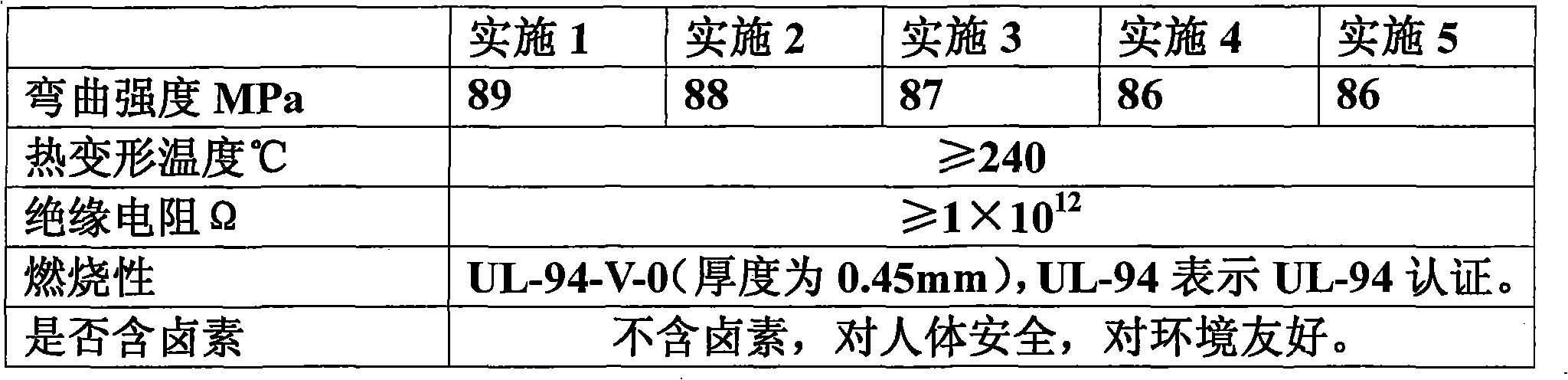

Halogen-free flame-proof phenolic plastic

The invention relates to non-halogen flame-resistant phenolic molding compound. According to the weight parts, the raw material of the non-halogen flame-resistant phenolic molding compound comprises 40 parts to 45 parts of phenolic resin, 4 parts to 9 parts of curing agent, 1.1 parts to 2.3 parts of curing accelerator, 1.5 parts to 3 parts of mould releasing agent, 4.8 parts to 6.3 parts of phosphate, 1.5 parts to 2.8 parts of metal oxide, 45 parts to 50 parts of mineral filler and 20 parts to 25 parts of reinforcing fiber. The non-halogen flame-resistant phenolic molding compound has the advantages that because halogen is not contained in the formulation, when being burnt, noxious gas and corrosive gas can not be generated, thus the physical safety and the environmental protection can be ensured; the flame-resistant performance can reach grade UL-94-V-0 (0.45 mm), the insulation resistance is greater than or equal to 1X10<12> Omega; the bending strength is more than (MPa) 85; the thermal deformation temperature is higher than or equal to 240 DEG C.

Owner:常熟东南塑料有限公司

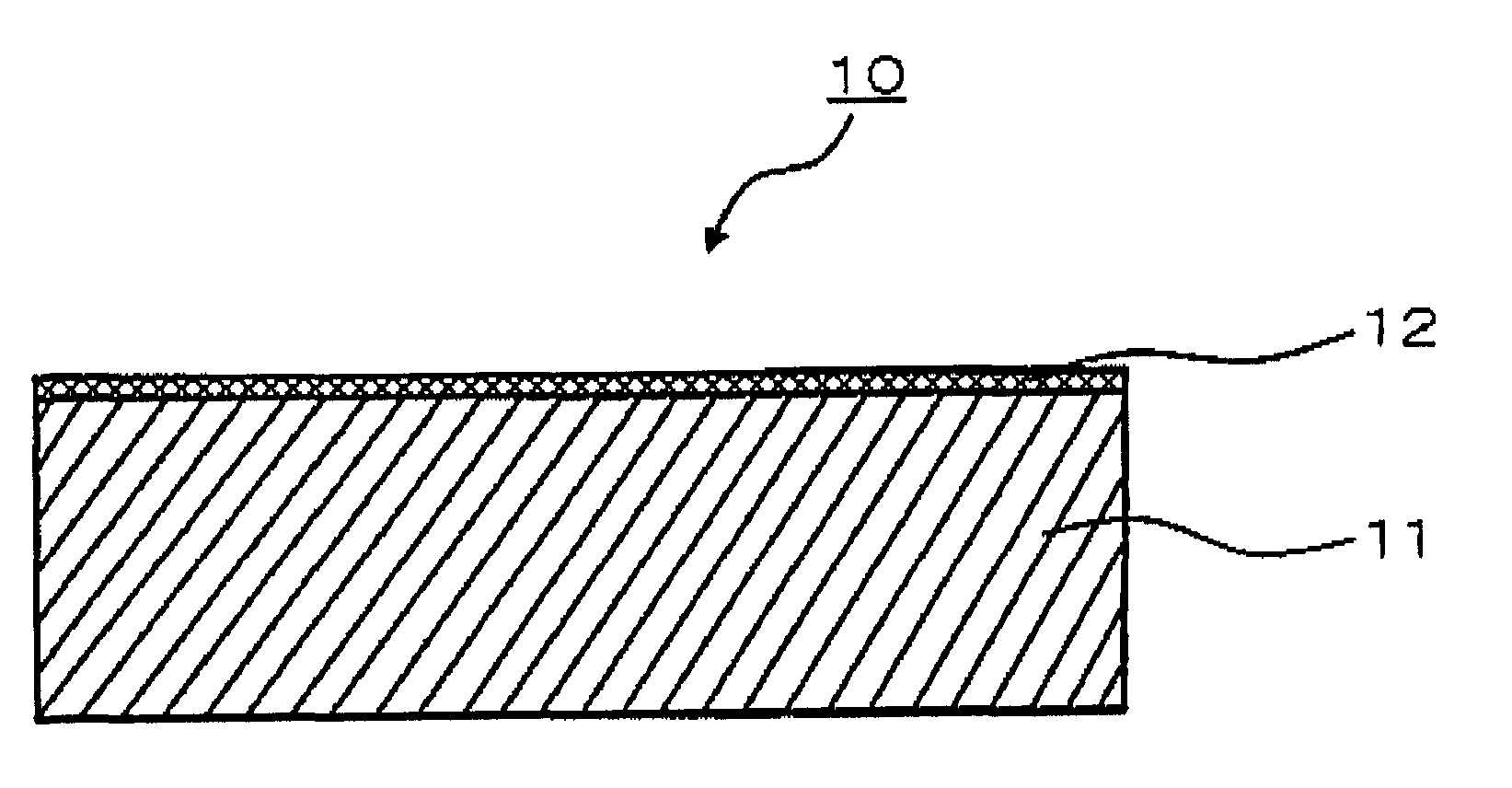

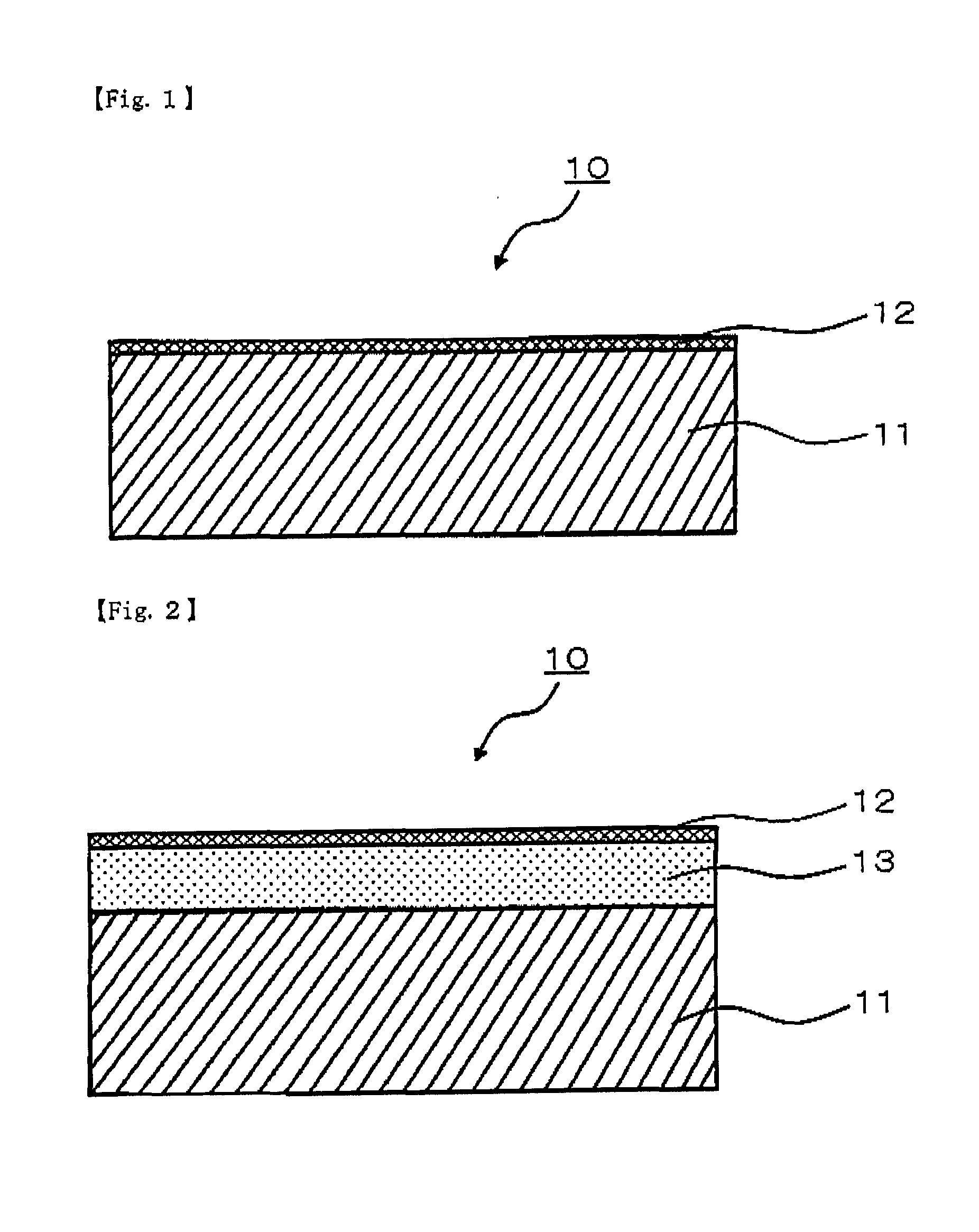

Decorative sheet for three-dimensional work

ActiveUS20110045284A1Good molding effectGood die releaseDecorative surface effectsSynthetic resin layered productsCross-linkHeat deflection temperature

Provided is a decorative sheet for three-dimensional processing comprising a support and at least a surface protective layer laminated thereon, wherein the above decorative sheet for three-dimensional processing has a breaking elongation (according to JIS K 7127) exceeding 300% at temperature higher by 40° C. than a thermal deformation temperature of the above support measured by an ASTM D648 method, and the above surface protective layer is obtained by cross-linking and curing an ionizing radiation curable resin composition and has a film thickness of 0.2 to 6.0 μm.Capable of being provided is a decorative sheet for three-dimensional processing which is improved in a molding property and has good die release and does not produce cracks and scratches on a surface in molding and which is improved as well in an abrasion resistance and a solvent resistance.

Owner:DAI NIPPON PRINTING CO LTD

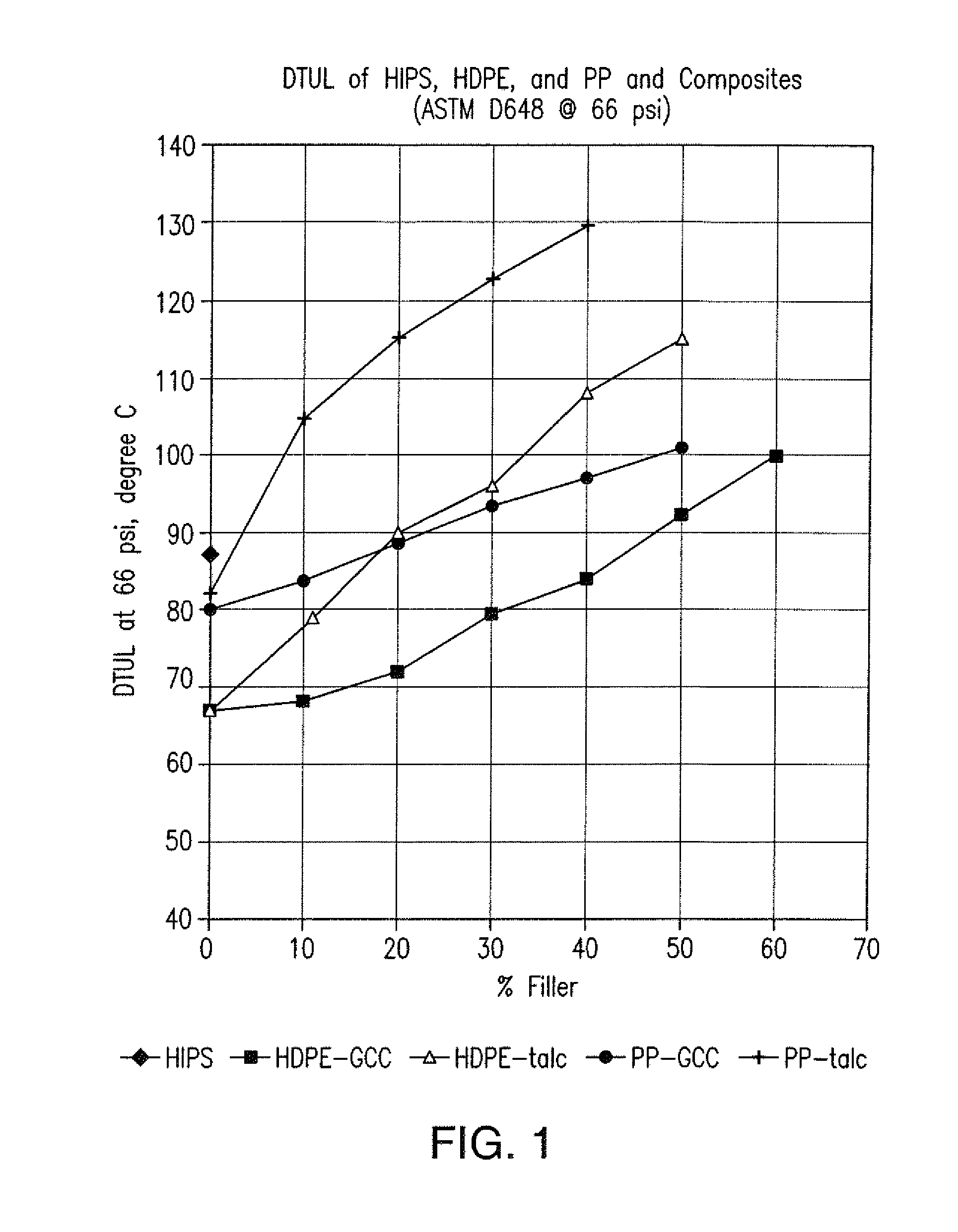

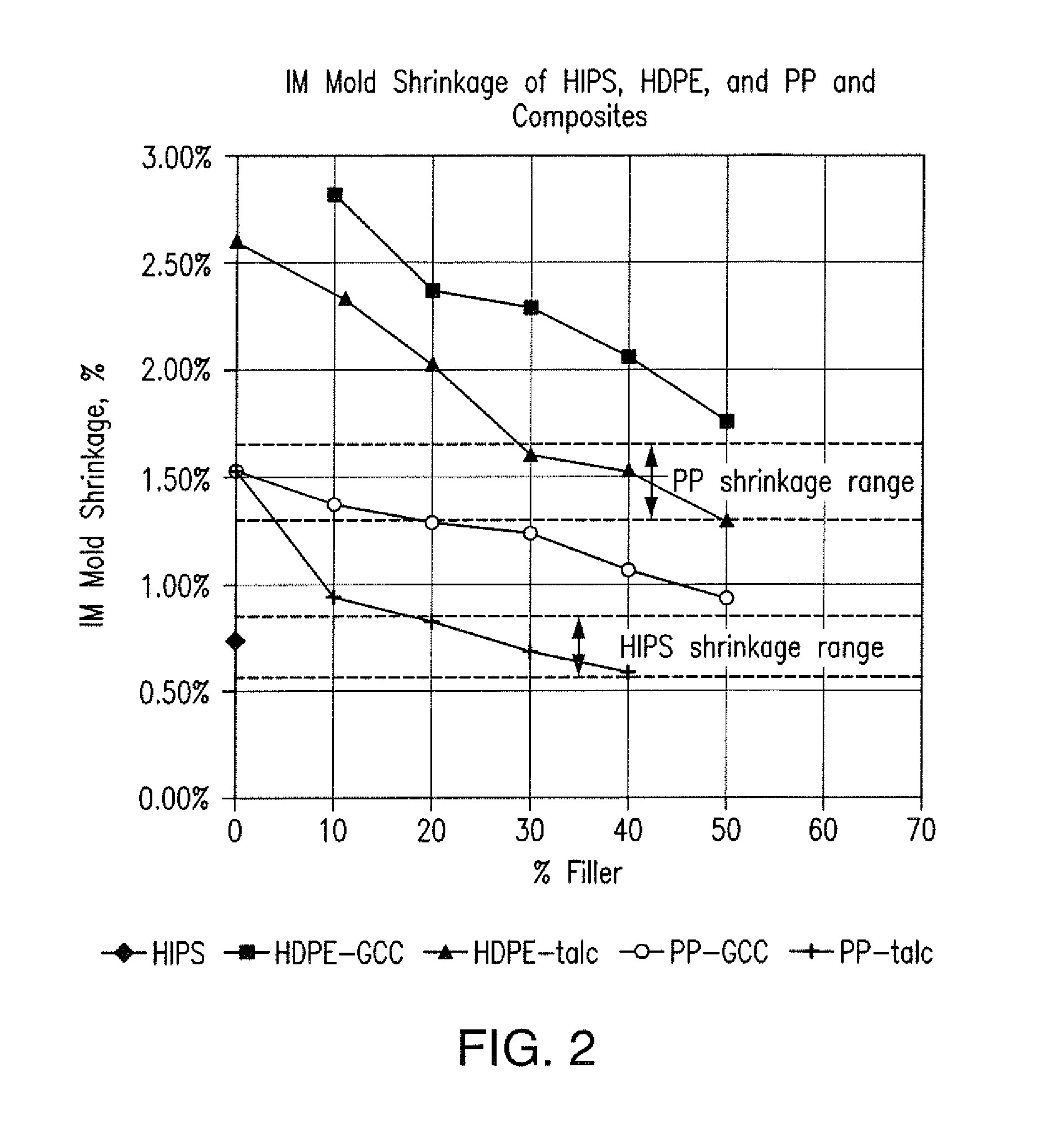

Disposable lid having polymer composite of polyolefin and mineral filler

InactiveUS20120267368A1High densityCapsClosure using stoppersHeat deflection temperaturePolymer science

Disposable lid comprises a thermoformed sheet in the shape of a lid for a hot beverage container. The sheet comprises a polymer composite of a polyolefin and at least one mineral filler. The sheet has a thickness less than about 0.035 inches and a heat deflection temperature at least comparable to that of high impact polystyrene.

Owner:PACTIV CORP

3D printing modified polyamino acid material and preparation method thereof

Owner:INST OF CHEM CHINESE ACAD OF SCI

Automotive articles prepared from filled TPO compositions, and methods of making the same

An automotive part containing at least one component formed from a composition comprising the following: (i) a crystalline, isotactic propylene homopolymer, (ii) an ethylene / α-olefin elastomeric impact modifier, and (iii) a reinforcing grade of filler, for example, talc. The crystalline isotactic propylene homopolymer has a flex modulus of greater than about 1930 MPa and a heat deflection temperature (HDT) of greater than about 100° C.; the ethylene / α-olefin interpolymer has a Tg of less than about −30° C., and a tan delta measured at 0.1 radians / s at 190° C. of less than about 2; and the filler has a HDT reinforcing efficiency of at least about 2. The automotive part has an HDT of greater than about 100° C. and a flex modulus of greater than about 1930 MPa.

Owner:DOW GLOBAL TECH LLC +2

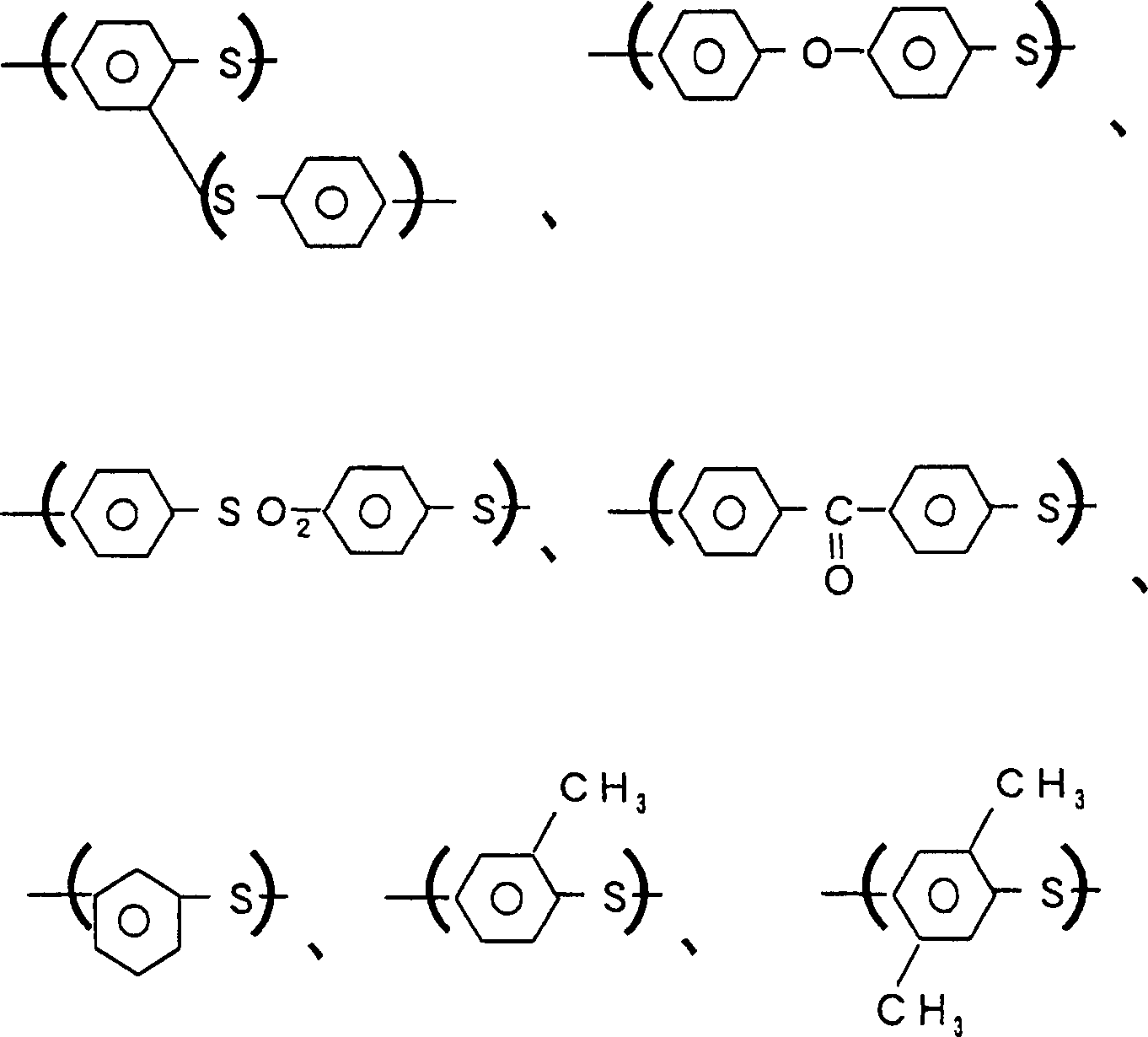

Polyphenylene sulfide resin compositions

A polyphenylene sulfide resin composition which comprises 100 parts by weight of a polyphenylene sulfide resin (A) and, compounded therewith, 1 to 100 parts by weight of glass fibers (B) having a single-fiber diameter of 12 [mu]m or lager and has a crystallization temperature during cooling of 205 DEG C or lower. Also provided is a polyphenylene sulfide resin composition which comprises 100 parts by weight of a polyphenylene sulfide resin (A) and, compounded therewith, 1 to 100 parts by weight of glass fibers (B) having a single-fiber diameter of 10 to 12 [mu]m, excluding 12 [mu]m, has a crystallization temperature during cooling of 205 DEG C or lower and a chloroform-extractable content of 0.5 wt.% or lower, and gives a 2 mm-thick molding which has a transmittance of 15% or higher for laser light having a wavelength of 940 nm and a heat distortion temperature of 230 DEG C or higher under a load of 1.82 MPa.

Owner:TORAY IND INC

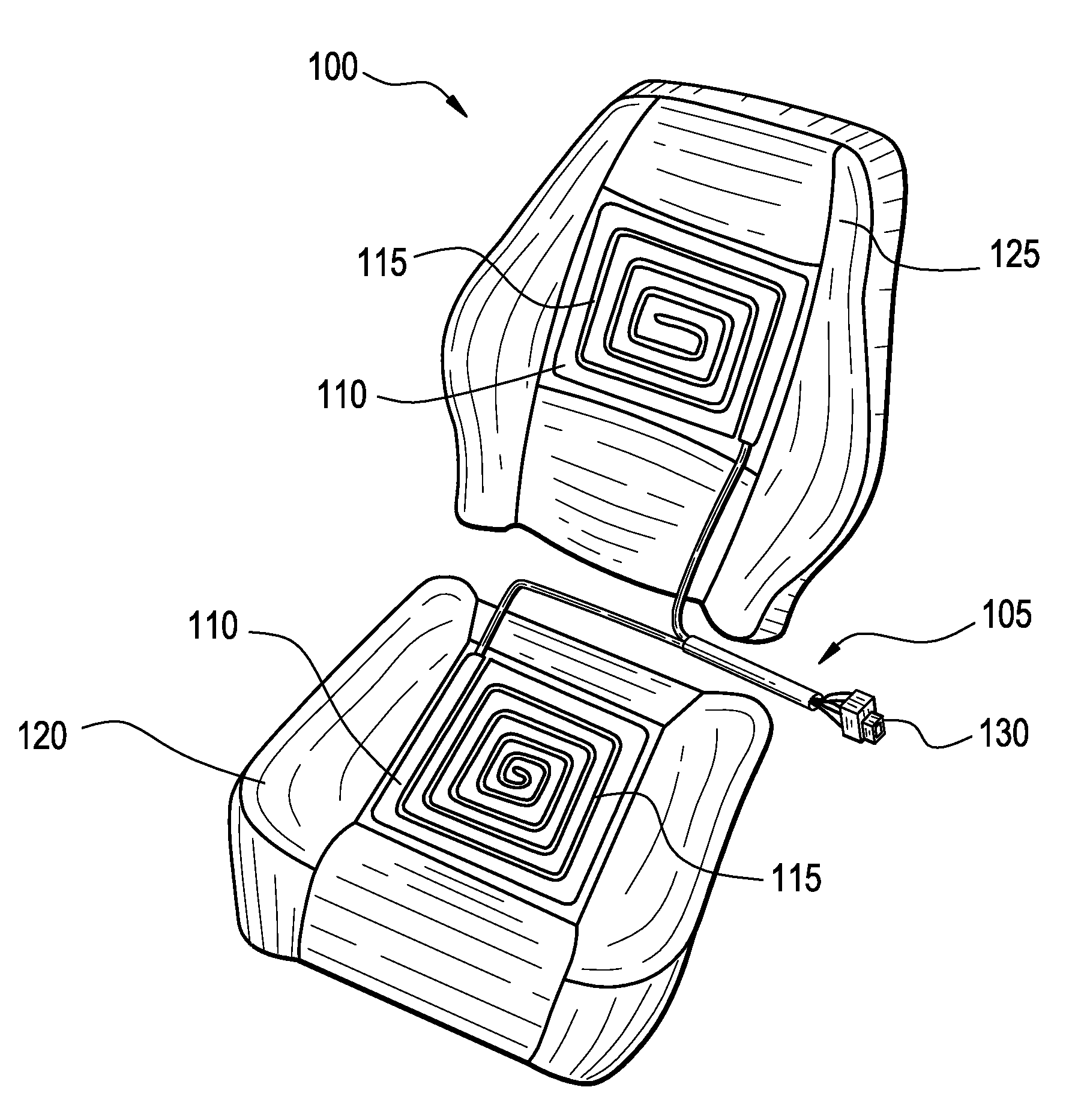

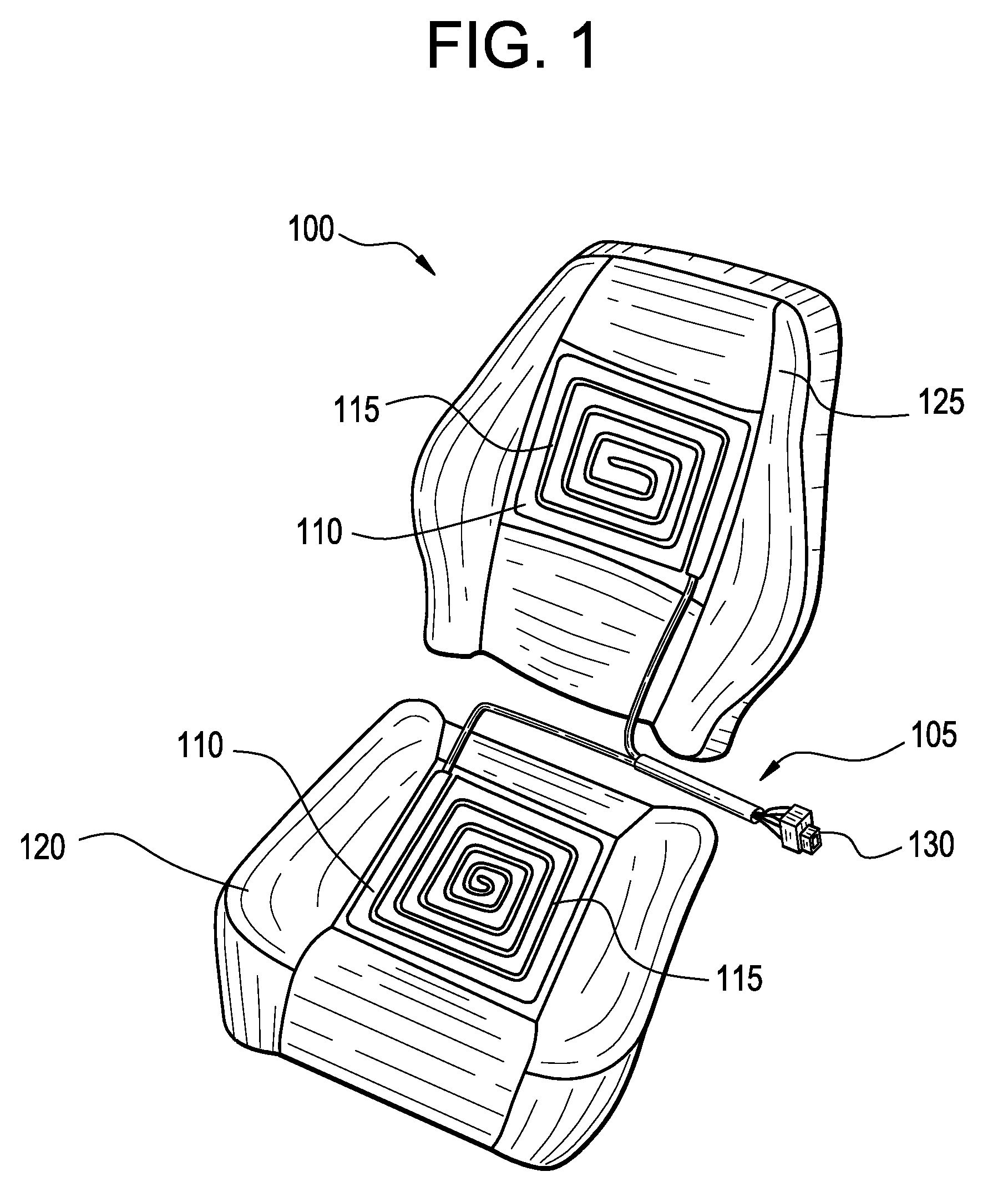

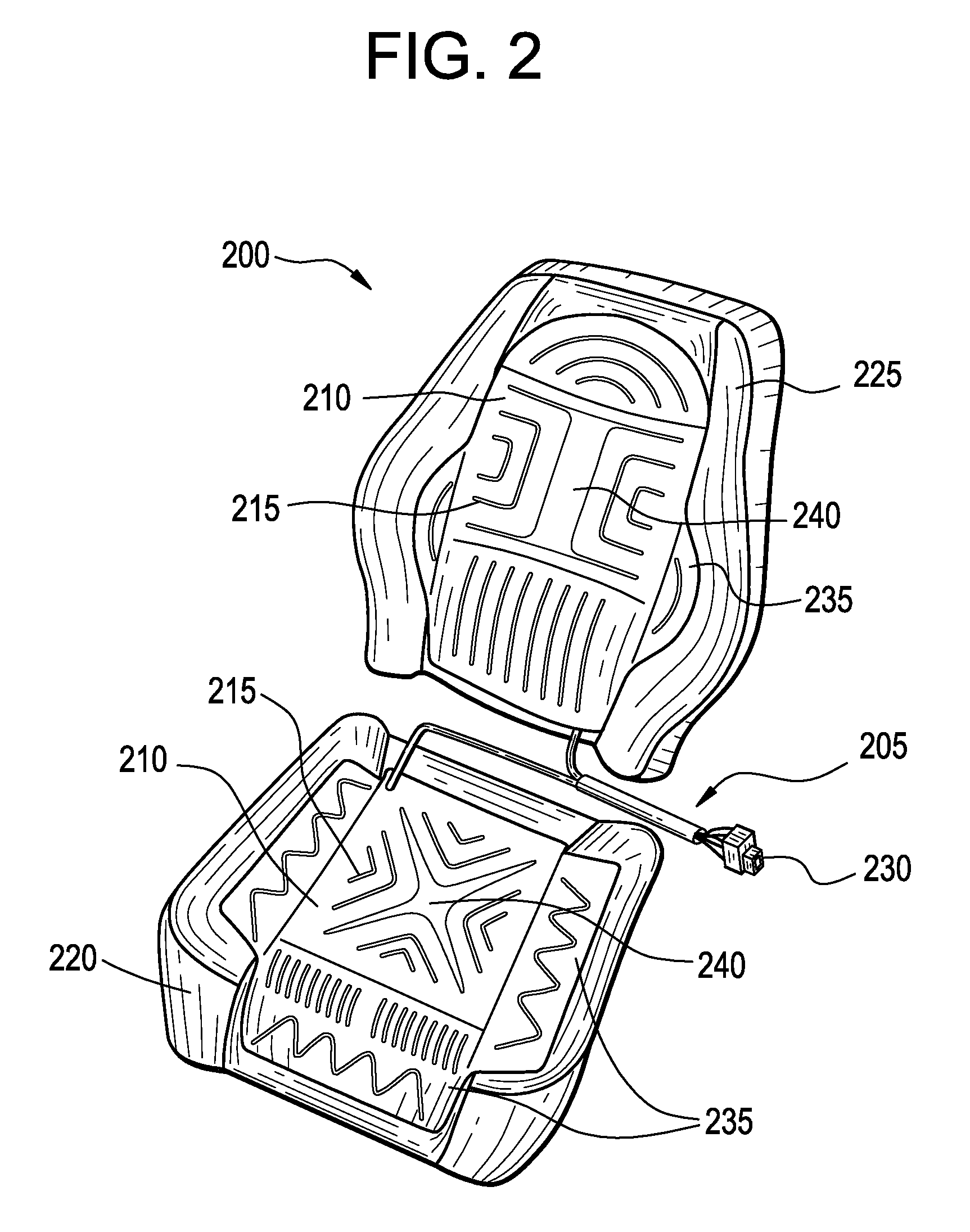

Thermally regulated heater for motor vehicles

InactiveUS20080142494A1Heating evenlyReduce the temperatureVehicle seatsHeating element materialsHeat deflection temperatureTemperature control

A thermally regulating heater and a heated seat made using these heaters wherein the resulting heated seat provides enhanced temperature control without the need of any temperature control system. The heaters include the use of a polymeric positive temperature coefficient composition that operates at lower trip temperatures than previous polymeric positive temperature coefficient compositions. The polymeric positive temperature coefficient composition have a trip temperature below the heat deflection temperature of the composition such that the polymeric positive temperature coefficient composition heats the heated seat to a temperature closer to the comfort level of an individual using the heated seat. Since the polymeric positive temperature coefficient composition uses plastic materials, the polymeric positive temperature coefficient composition can be formed into different shapes as needed using a molding process, such as injection molding.

Owner:SABIC INNOVATIVE PLASTICS IP BV

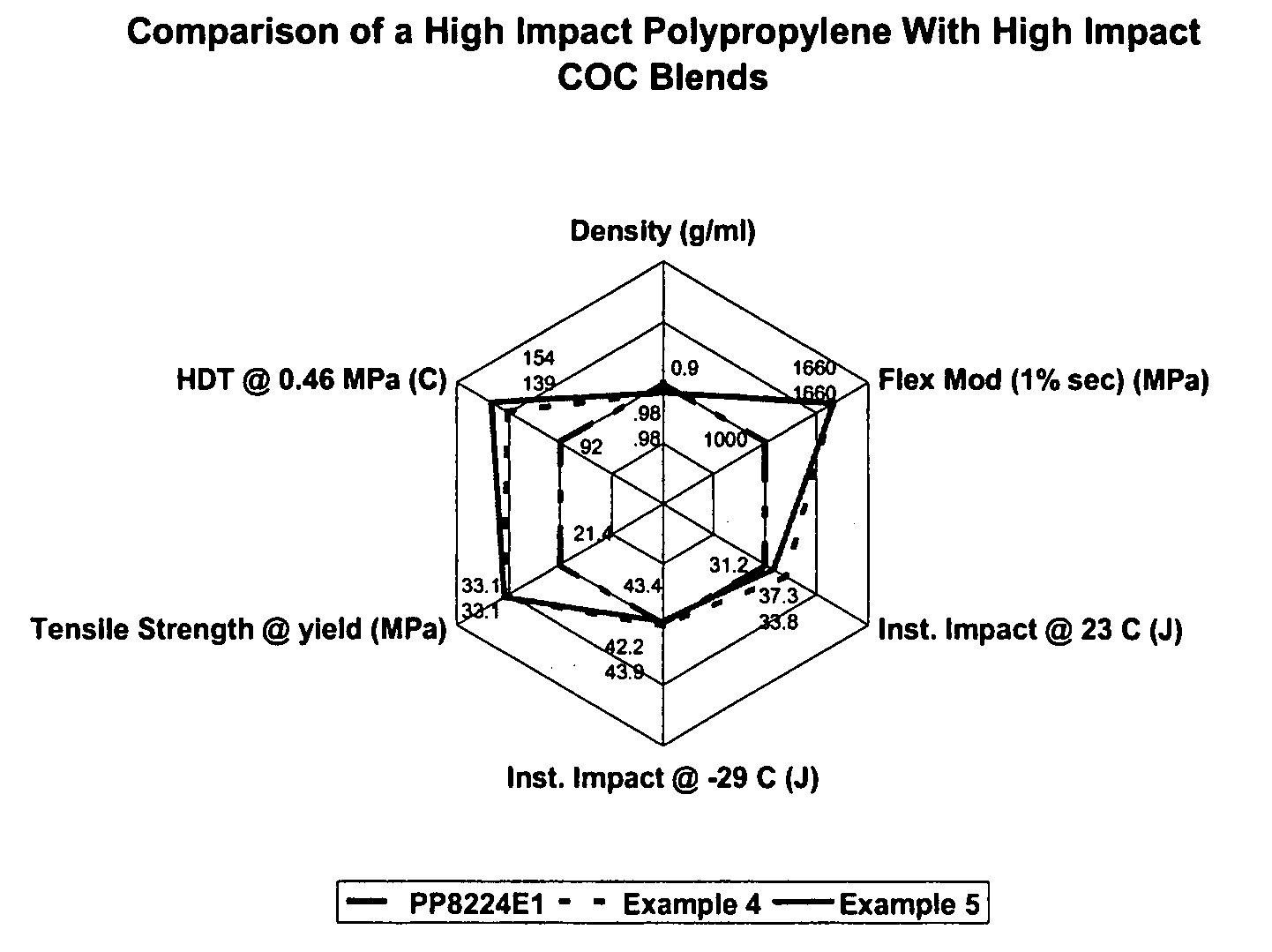

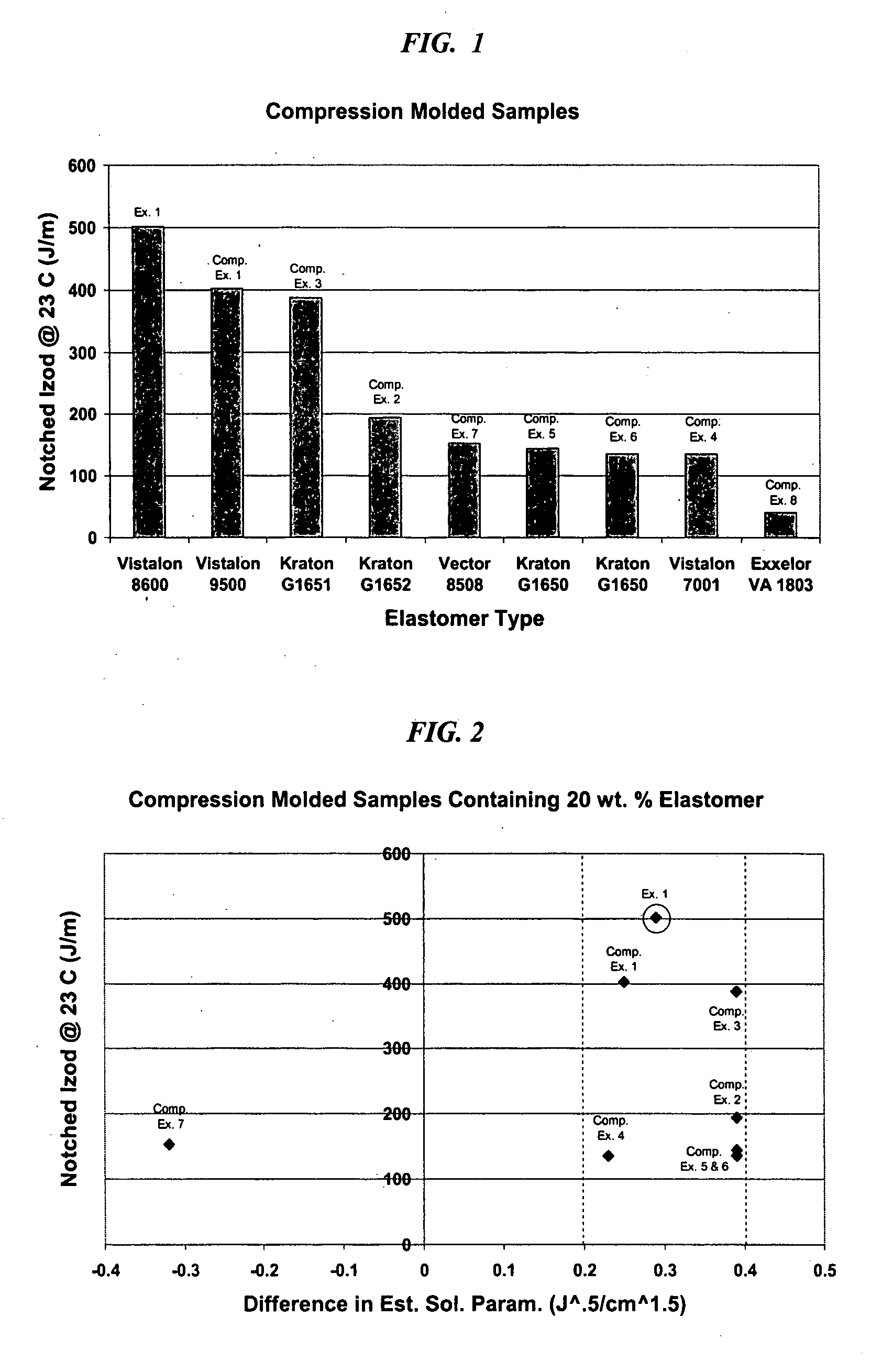

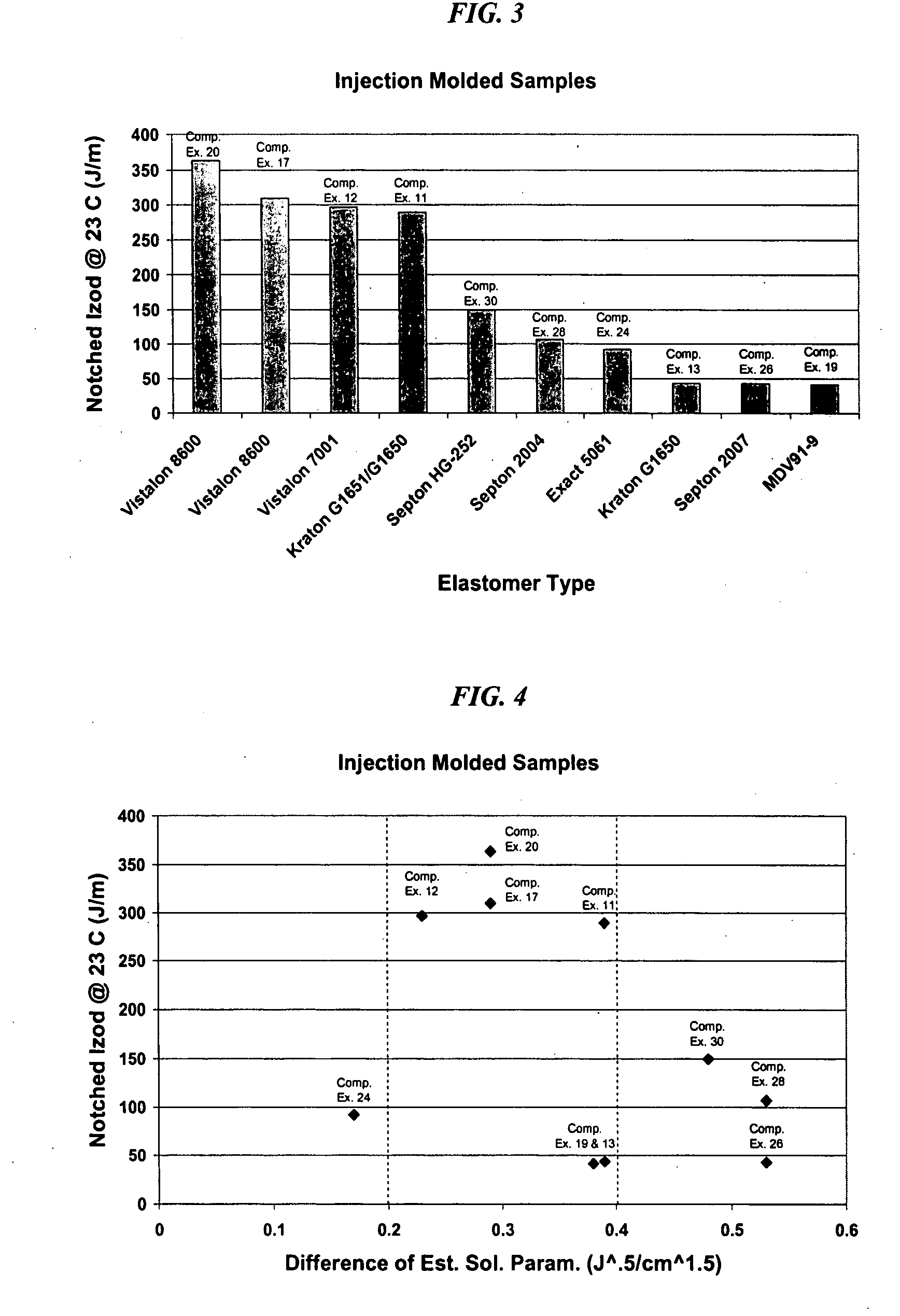

Polymer compositions comprising cyclic olefin copolymers and polyolefin modifiers

A polymer composition comprises (a) greater than 50 wt % (based upon the weight of the composition) of a cyclic olefin copolymer comprising at least one acyclic olefin and at least 20 weight % of one or more cyclic olefins (based upon the weight of the cyclic olefin copolymer), wherein at least a portion of the cyclic olefin copolymer has a glass transition temperature of greater than 150° C.; and (b) less than 50 wt % (based upon the weight of the composition) of an acyclic olefin polymer modifier, at least a portion of the modifier having a glass transition temperature of less than −30° C.; and no portion of the modifier having a softening point greater than +30° C., wherein the Bicerano solubility parameter of the modifier being no more than 0.6 J0.5 / cm1.5 less than the Bicerano solubility parameter of the cyclic olefin copolymer. The polymer composition has a notched Izod impact resistance measured at 23° C. of greater than 500 J / m and a heat distortion temperature measured using a 0.46 MPa load of greater than 135° C.

Owner:EXXONMOBIL CHEM PAT INC

Toughened cold-resistant transparent modified polypropylene material and preparation

The invention provides a toughening cold-resistant transparent modified polypropylene material and a preparation method. The material is mainly made from the following components in parts by weight: 60-90 parts of homogeneous polypropylene, 10-30 parts of a toughening agent, 0.1-0.4 part of an alpha-nucleation agent, 0.1-0.4 part of a beta-nucleation agent and 0.2-0.4 part of an antioxidant. The material is added with propylene made from alpha-olefin with the same refractive index as polypropylene and a semi-crystalline polymer of the alpha-olefin as the toughening agent, thus the material can reduce effect on transparence of the polypropylene material and realize cold resistance and toughening of the polypropylene, and can be used together with an alpha-crystallographic form nucleating agent after compounding with a beta-crystallographic form nucleating agent to control proportions of polypropylene alpha-crystallographic form to polypropylene beta-crystallographic form, thus improving transparence of the polypropylene, compensating rigidity at room temperature and heat deformation temperature of the polypropylene and finally realizing development of the toughening cold-resistant transparent modified polypropylene.

Owner:浙江富丽新材料有限公司

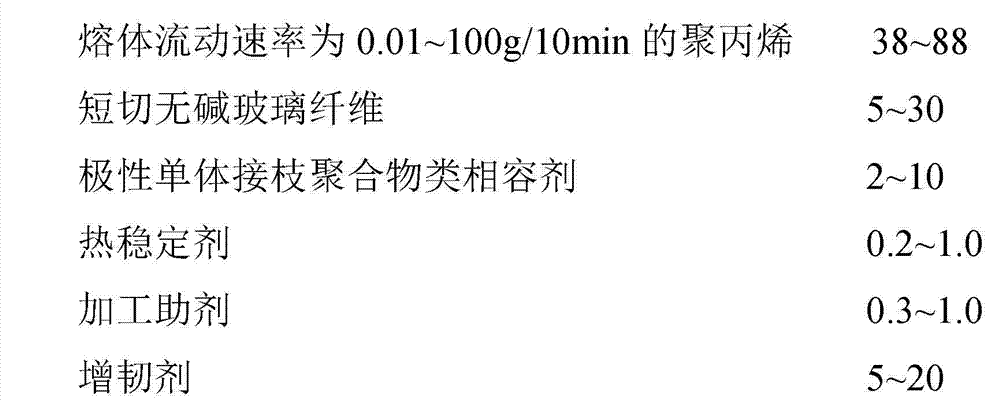

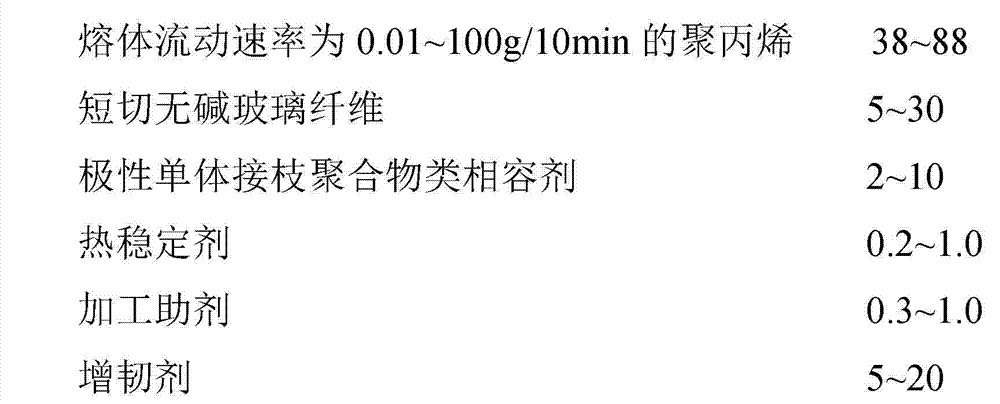

Low gloss scratch resistant glass fiber reinforced PP composite material and preparation method thereof

The invention discloses low gloss scratch resistant glass fiber reinforced PP (Propene Polymer) composite material and a preparation method thereof. The composite material comprises the following components in weight percentage: 38 to 88 wt% of polypropylene with the rate being of 0.01 to 100g / 10min, 5 to 30 wt% of chopped alkali-free glass fiber, 2 to 10 wt% of polar monomer graft polymer compatilizer, 0.2 to 1.0 wt% of heat stabilizer, 0.3 to 1.0 wt% of processing agent and 5 to 20 wt% of flexibilizer. The composite material has excellent rigidity, heat resistance, normal-temperature and low-temperature impact performance, low gloss and scratch resistance, the tensile strength is larger than or equal to 35Mpa, the elongation at break is larger than or equal to 5 percent, the bending modulus is larger than or equal to 2000 Mpa, the heat deflection temperature (0.45Mpa) is larger than or equal to 120 DEG C, the notch impact strength at 23 DEG C is larger than or equal to 35 KJ / m<2>, the notch impact strength at minus 30 DEG C is larger than or equal to 15KJ / m<2>, the gloss Gs (60 DEG C) is smaller than or equal to 2.4 GU, and the chromatic aberration Delta L of the composite material is smaller than or equal to 1.5 after the composite material is scratched by 10N force.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Polypropylene composite material for automobile bumper and prepn. thereof

InactiveCN1834145AImprove performanceReduce surface defectsBumpersHeat deflection temperaturePolypropylene composites

This invention discloses a kind of polypropylene composite materials for automobile bumpers and its preparation method. This kind of materials comprises 93.3~56.5wt% polypropylene, 0.2~1.5wt% thermo-stabilizers, 0.3~1wt% photo-stabilizers, 0.2~1% auxiliary reagents, 1~20wt% activating and reinforcing masterbatches and 5~20wt% stuffing masterbatches. The product in this invention has high surface activity, low thermo expansion rate and high thermo expansion temperature. The surface tension is 40mN / m, the linear thermo expansion rate is 10 to the power -6 to 10 to the power -7 mm per mm per deg. C, the thermo deformation temperature is 55 deg. C and some other technological indices all reach or exceed current standards for automobile materials. Thanks to the high surface tension and strong paint-adhesion of the bumpers made of this kind of materials, paints can be directly sprayed rather than flame processing. The thermo expansion rate is low, and therefore, loosening due to significant deformation might not occur with large temperature variation. Besides, it also has the advantages of high the thermo resistant temperature, short baking time and high production efficiency.

Owner:SHANGHAI KINGFA SCI & TECH

Heat-proof ABS resin composition for blow-molding and preparation method thereof

The invention discloses a heat-proof ABS resin compound for blow molding formation and a preparation process thereof. The ABS resin compound is adopts ABS rubber powder with high molecular weight and appropriate rubber content, AS resin with high molecular weight, heat resisting agent with appropriate thermal deformation temperature, is matched with toughening agent with high molecular weight and other auxiliary agent, and is prepared through fusion, commixture and extrusion in a twin-screw extruder. The ABS resin compound has high flux strength, impact property and tension property, which is especially suitable for containers with large size and blow molding shape of car tail wings.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Polypropylene material filled with inorganic mineral powder, and its preparation method and application

InactiveCN102206376AExcellent resistance to folding fatigueImprove cold resistanceFlexural modulusMicrosphere

The invention discloses a polypropylene material filled with inorganic mineral powder, and its preparation method and application. The polypropylene material comprises, by weight, 43 to 90% of polypropylene, 0 to 1% of a heat stabilizer, 0 to 1% of a lubricant, 0 to 15% of a flexibilizer and 10 to 40% of an inorganic mineral powder filler, wherein the inorganic mineral powder filler is one selected from the group consisting of calcium carbonate, powdered steatile, kaolin, mica, wollastonite, glass microballoons, ceramic microspheres and barium sulfate or a mixture of the above-mentioned materials. When used as a material for hinges, the polypropylene material filled with inorganic mineral powder in the invention has excellent folding resistance which is similar to that of a pure polypropylene material, good fatigue durability and comprehensive mechanical properties, outstanding cold resistance and high thermal deformation temperature, wherein tensile strength is no less than 30 MPa, flexural modulus is no less than 2000 MPa, the thermal deformation temperature is no less than 110 DEG C; the material can be used for a long time at a temperature of from -35 to 85 DEG C and can be used to prepare hinge materials which have requirements for high heat resistance and cold resistance.

Owner:SHANGHAI KINGFA SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com