Method of manufacturing polycarbonate/polyester alloy

A polycarbonate and polyester alloy technology, which is used in the preparation of polymer alloys and the preparation of polycarbonate/polyester alloys, can solve the problems of polyester crystallization rate and crystallinity decrease, high price, stress cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

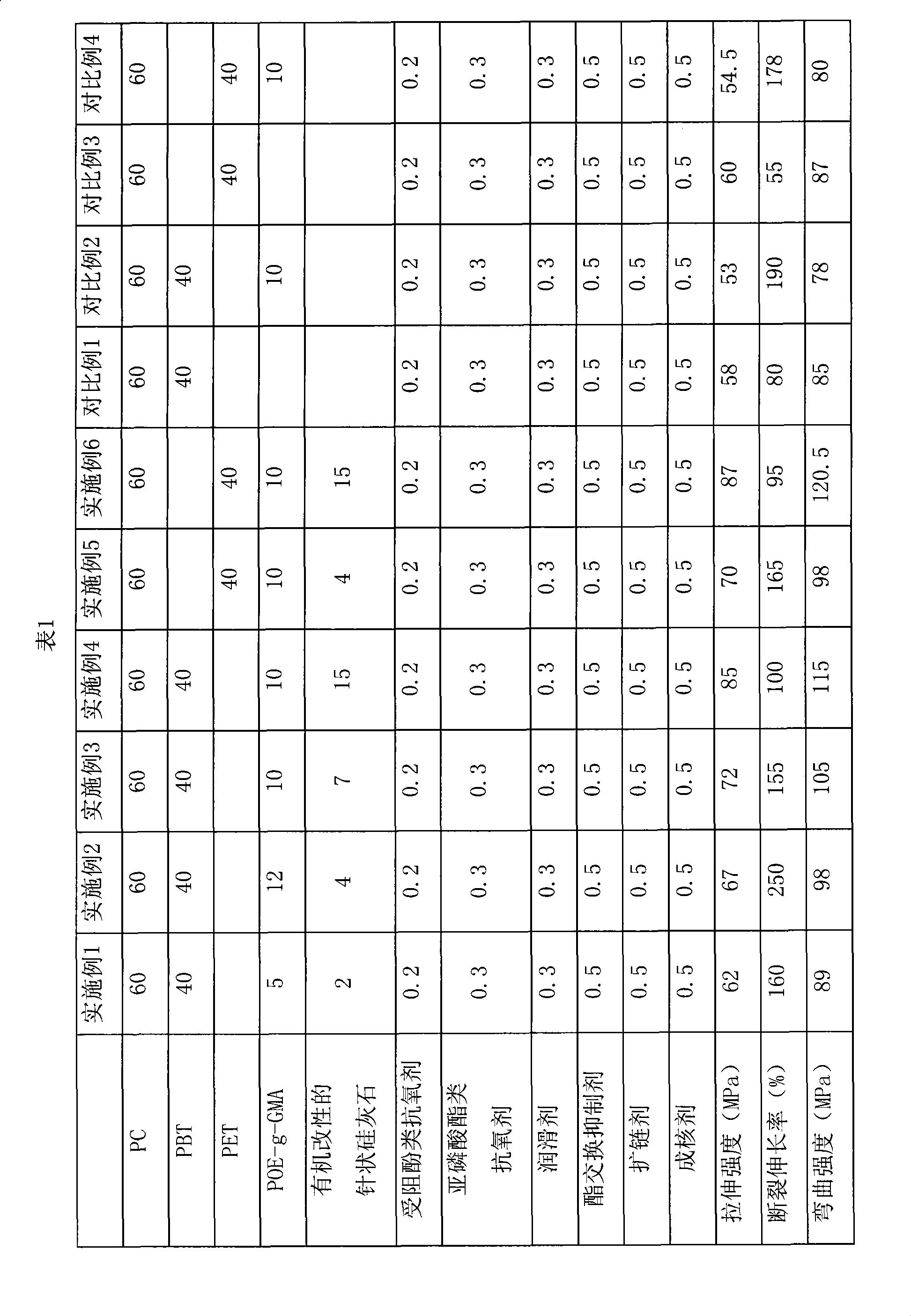

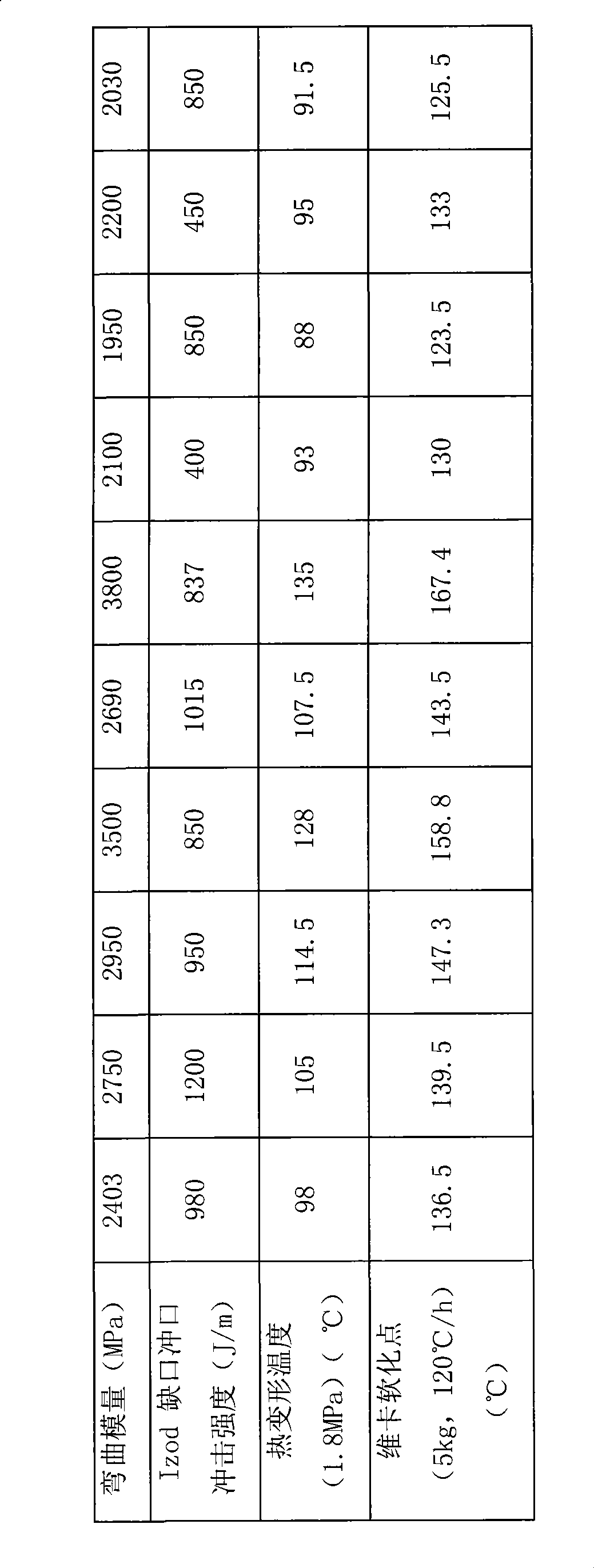

Examples

Embodiment 1-4

[0043] 1. Preparation of glycidyl methacrylate grafted ethylene-octene copolymer (POE-g-GMA)

[0044] 100 parts of ethylene-octene copolymer, 2 parts of glycidyl methacrylate, 0.2 part of dicumyl peroxide, 2 parts of styrene and 0.35 part of stearic acid were uniformly mixed with a high-speed mixer and then added to the twin-screw extruder. Melt blending is carried out in the machine, the temperature of the first zone is 160°C, the temperature of the second zone is 165°C, the temperature of the third zone is 170°C, the temperature of the fourth zone is 180°C, the temperature of the fifth zone is 190°C, and the temperature of the sixth zone is 200°C. The temperature in the seventh zone is 200°C, the temperature in the eighth zone is 200°C, the temperature in the ninth zone is 190°C, the screw speed is 150 rpm, and the residence time is 2.5 minutes. After cooling, drying and pelletizing, glycidyl methacrylate is obtained. Grafted ethylene-octene copolymer (POE-g-GMA), glycidyl m...

Embodiment 5-6

[0048] 1. Preparation of glycidyl methacrylate grafted ethylene-octene copolymer (POE-g-GMA)

[0049] 100 parts of ethylene-octene copolymer, 2 parts of glycidyl methacrylate, 0.2 part of dicumyl peroxide, 2 parts of styrene and 0.35 part of stearic acid were uniformly mixed with a high-speed mixer and then added to the twin-screw extruder. Melt blending is carried out in the machine, the temperature of the first zone is 160°C, the temperature of the second zone is 165°C, the temperature of the third zone is 170°C, the temperature of the fourth zone is 180°C, the temperature of the fifth zone is 190°C, and the temperature of the sixth zone is 200°C. The temperature in the seventh zone is 200°C, the temperature in the eighth zone is 200°C, the temperature in the ninth zone is 190°C, the screw speed is 150 rpm, and the residence time is 2.5 minutes. After cooling, drying and pelletizing, glycidyl methacrylate is obtained. Grafted ethylene-octene copolymer (POE-g-GMA), glycidyl m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com