Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4807 results about "Thermal deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

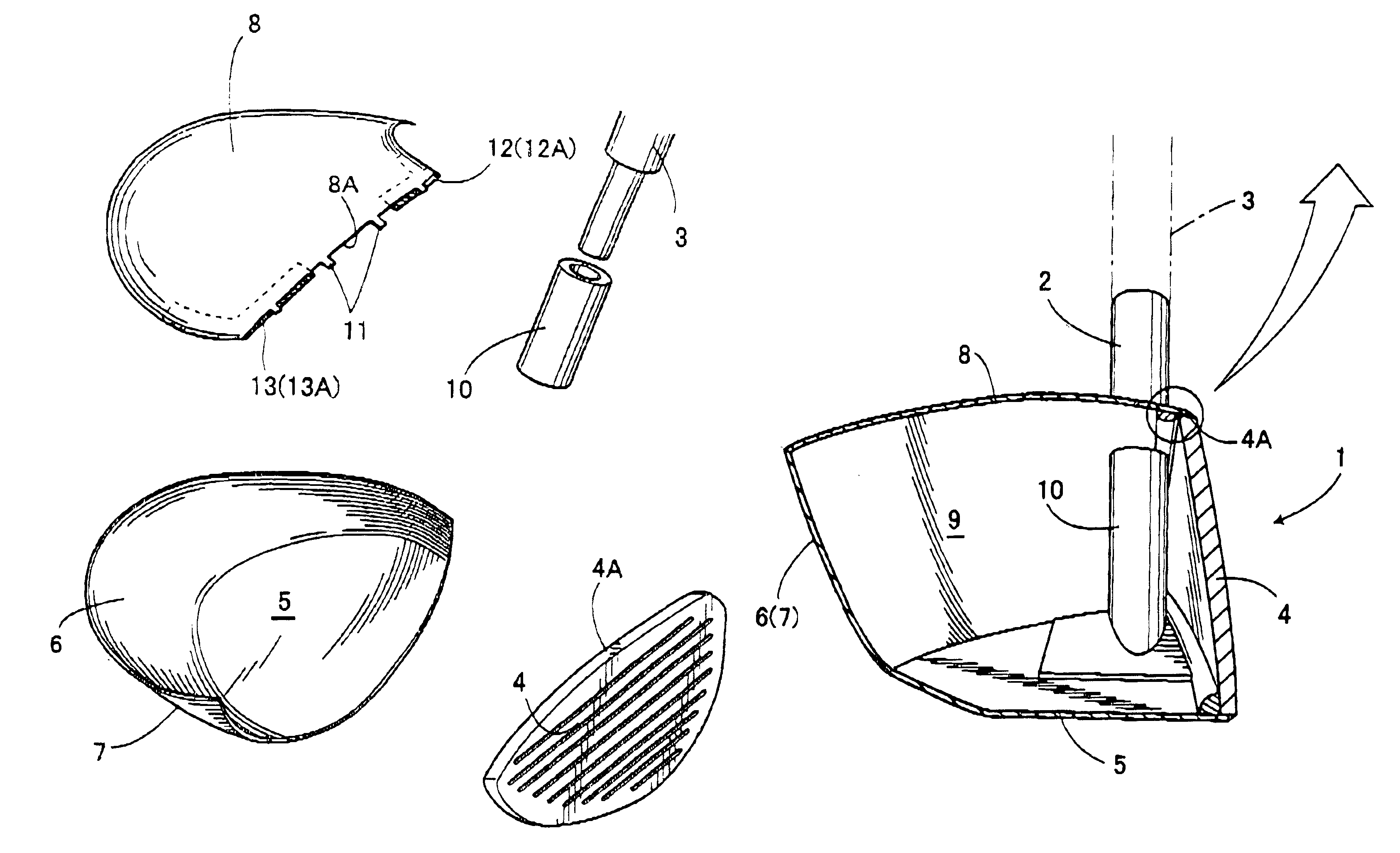

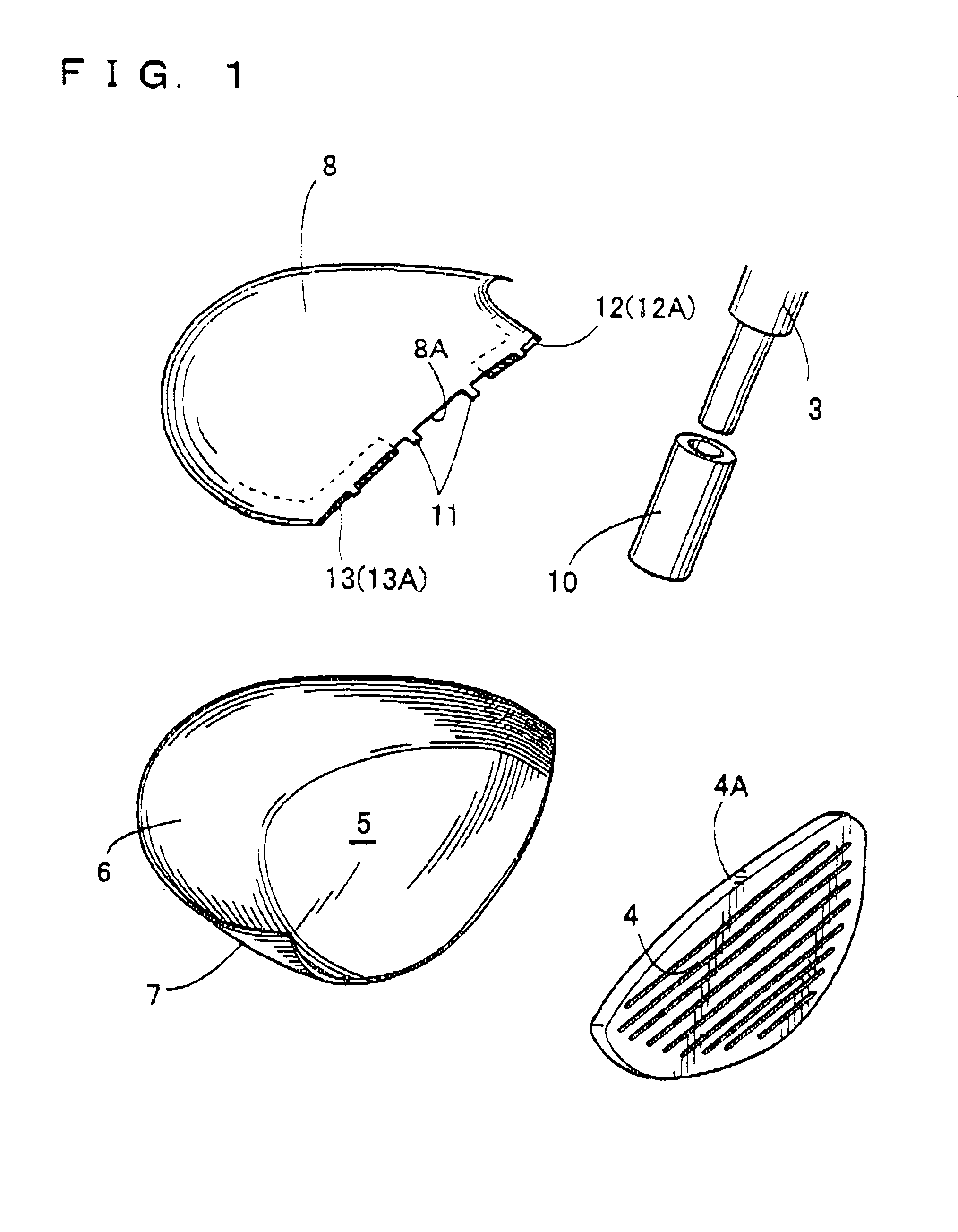

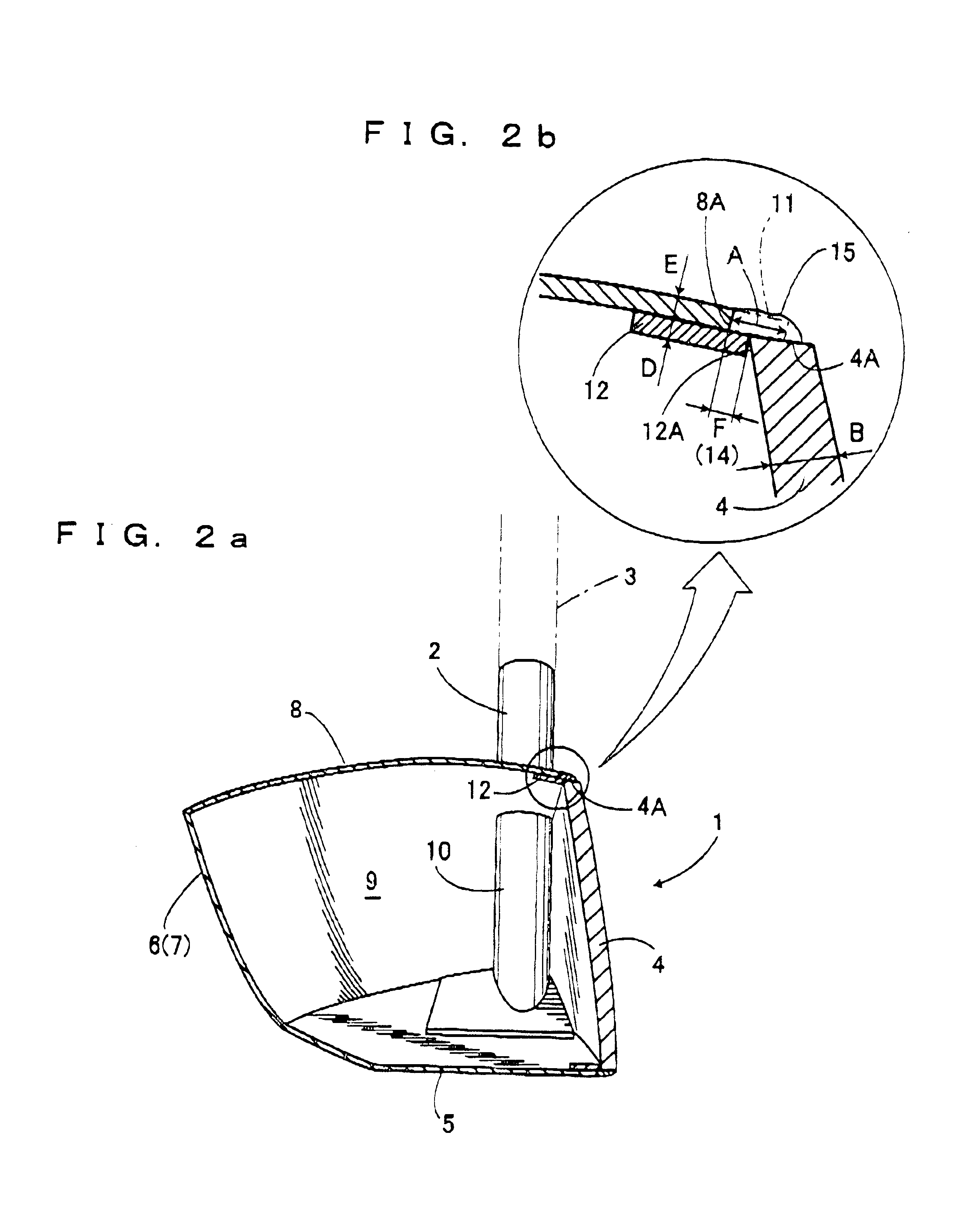

Golf club

Owner:THE YOKOHAMA RUBBER CO LTD +1

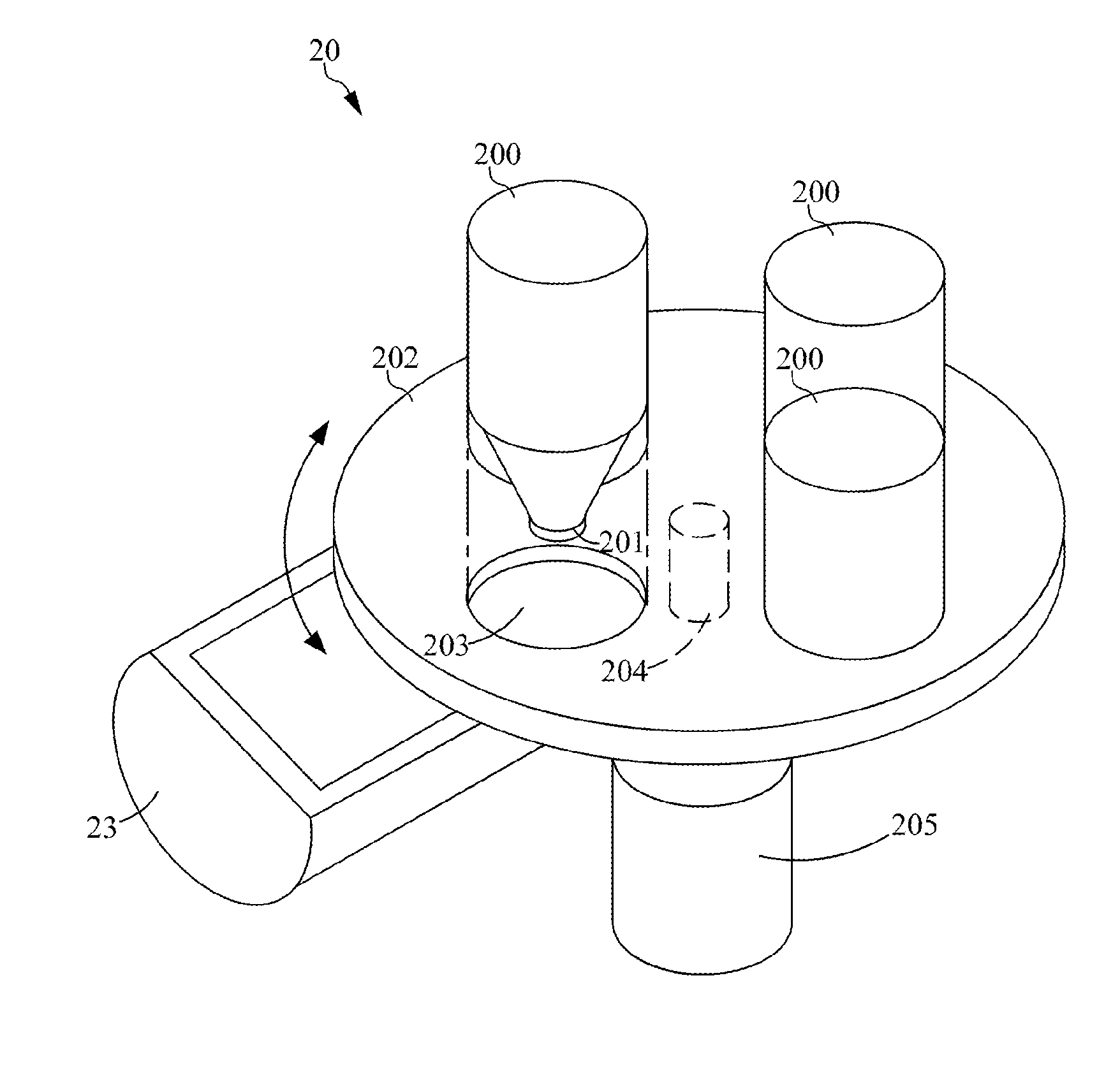

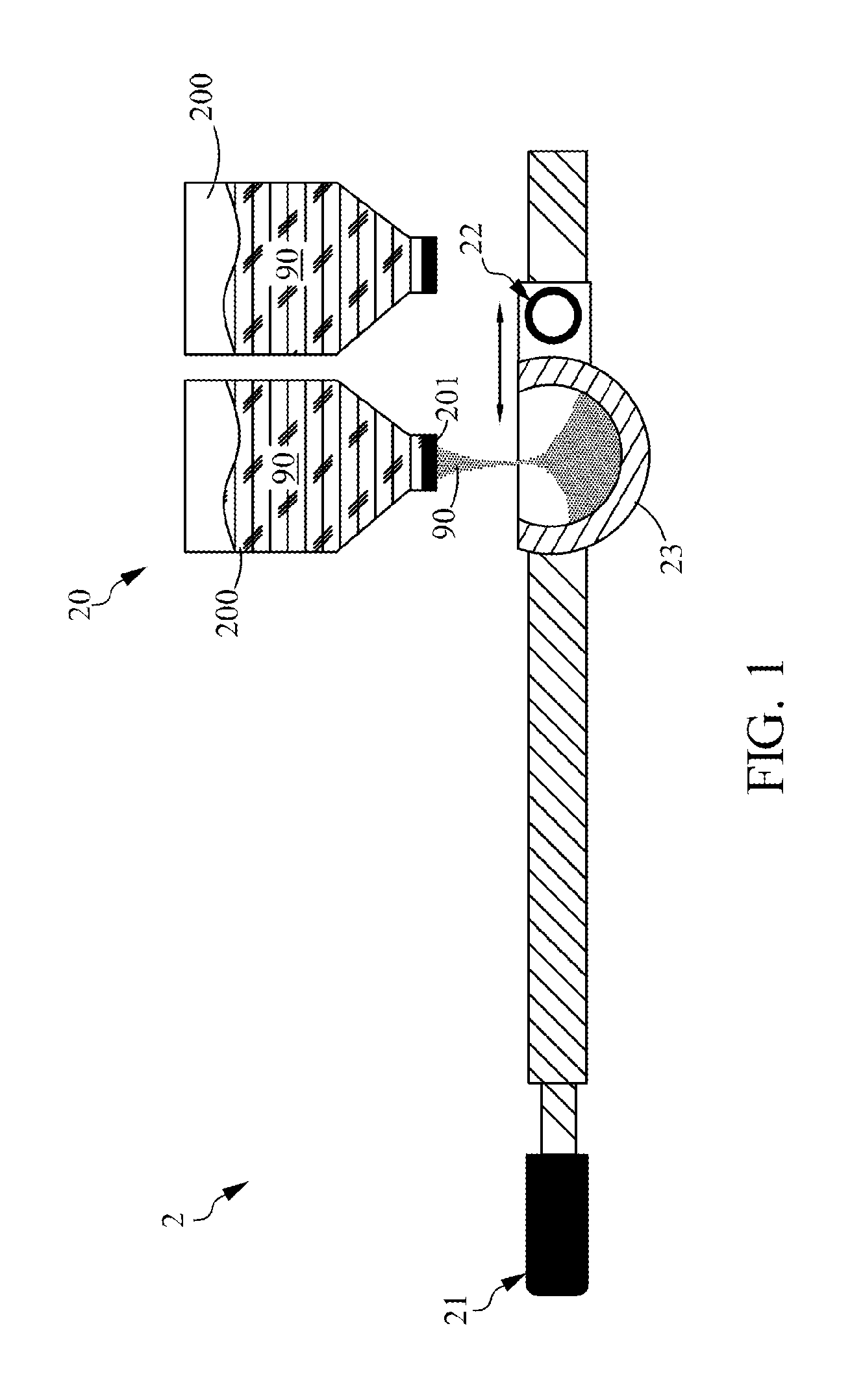

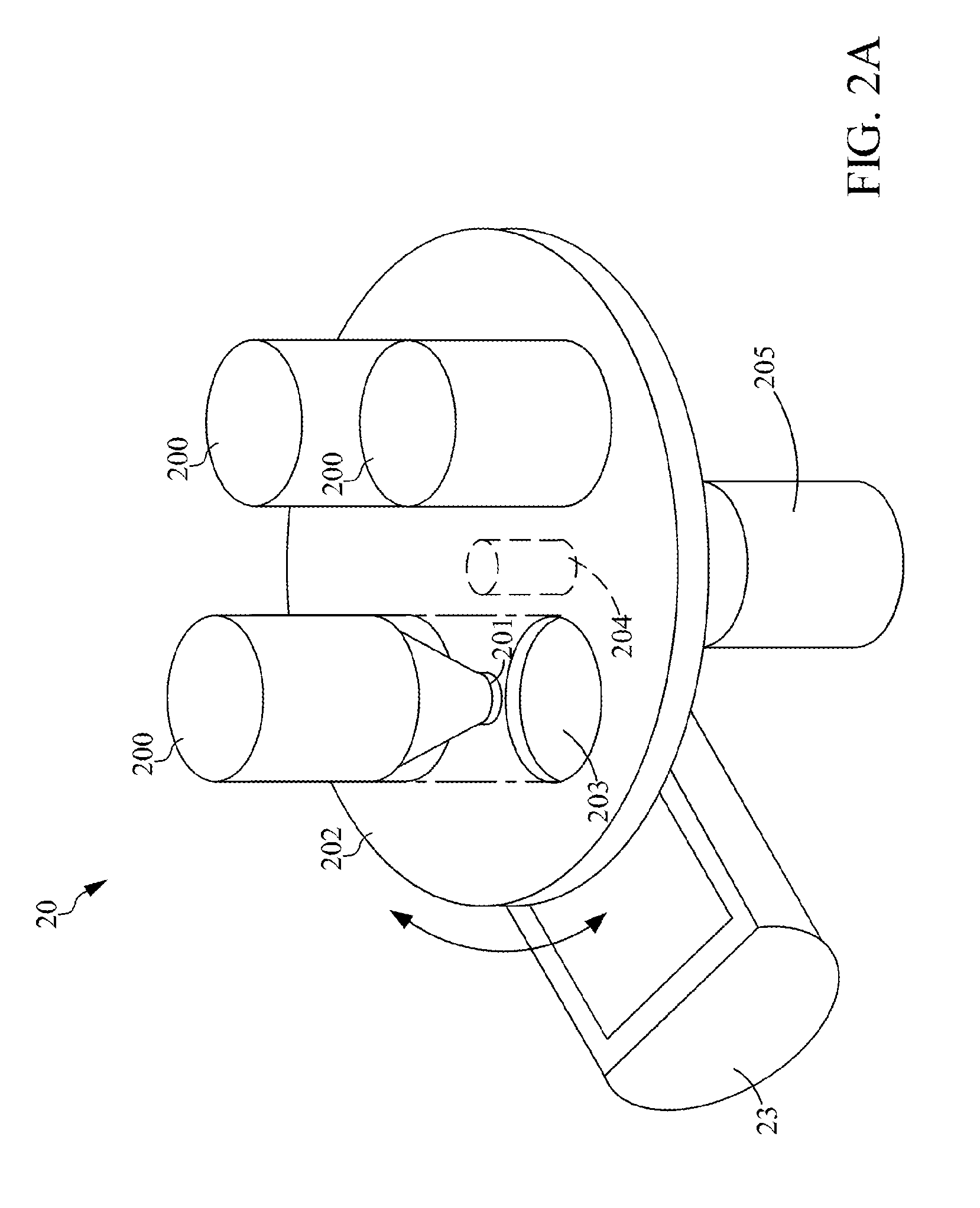

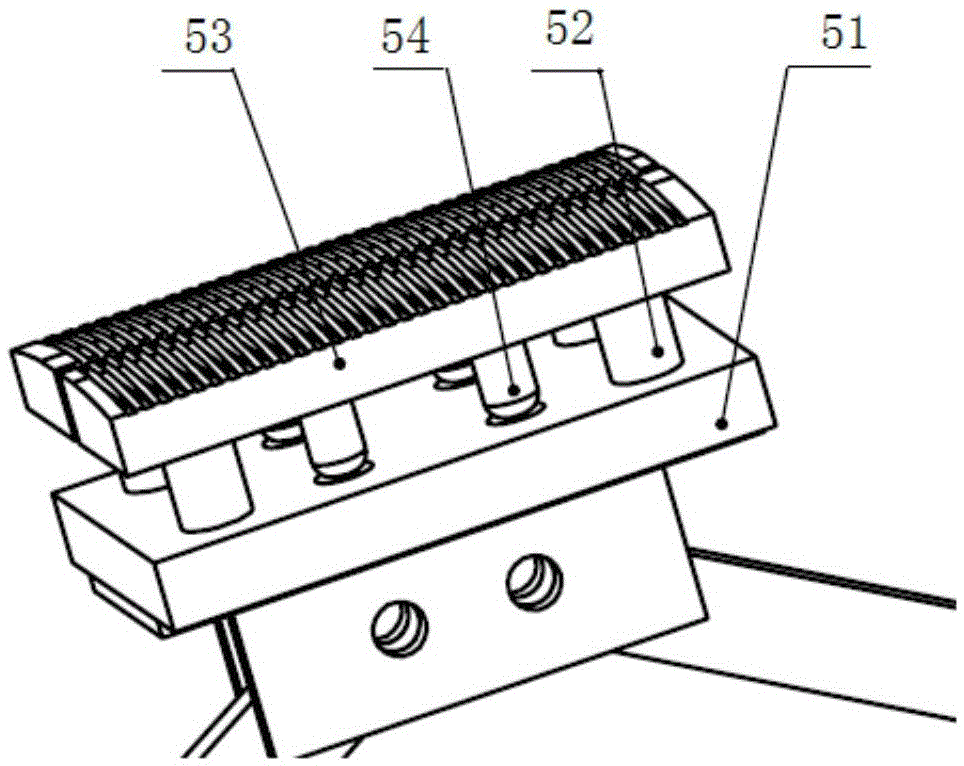

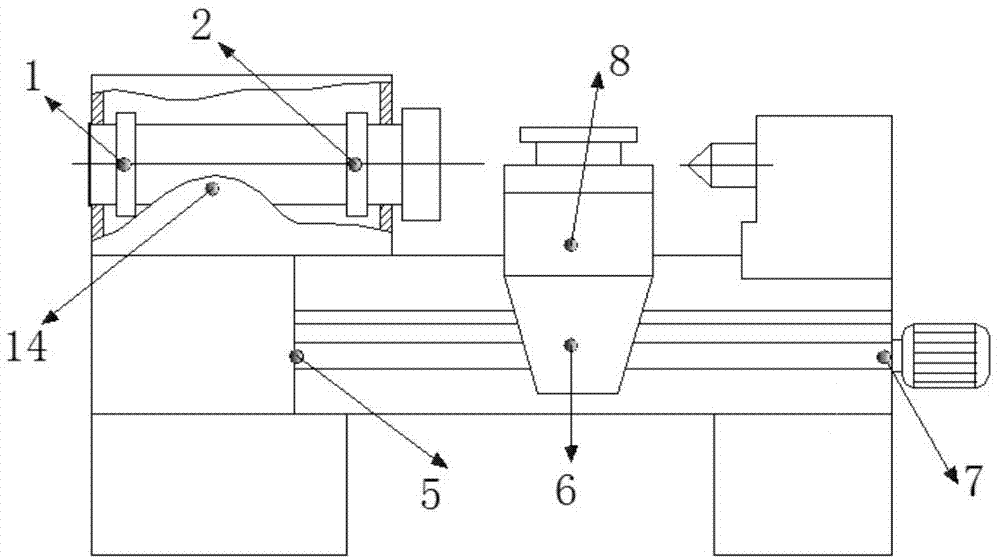

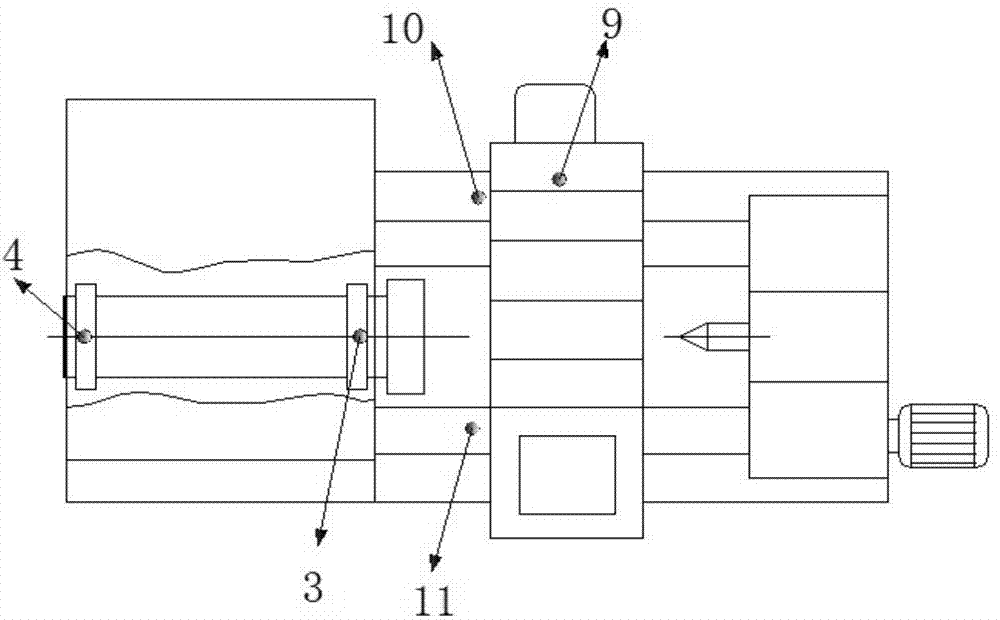

Device and method for powder distribution and additive manufacturing method using the same

ActiveUS20130186514A1Improve compactnessWell mixedLiquid surface applicatorsManufacturing driving meansMetallurgyThermal deformation

The present disclosure provides a device and method for powder distribution and an additive manufacturing method, wherein different size or kind of powders could be chosen to be accommodated within a receptacle. The receptacle can uniformly mix the powder by a rotation movement, pour out the powders by the rotation movement and distribute the powders for forming a layer by a translation movement. In another embodiment, the receptacle further comprises a heating element for preheating the powders. Not only can the present disclosure uniformly mix the powders so as to reduce the thermal deformation and distribute the powder layer compactly, but also can the present disclosure distribute different kinds of powder in different layer so as to increase the diversity in additive manufacturing.

Owner:IND TECH RES INST

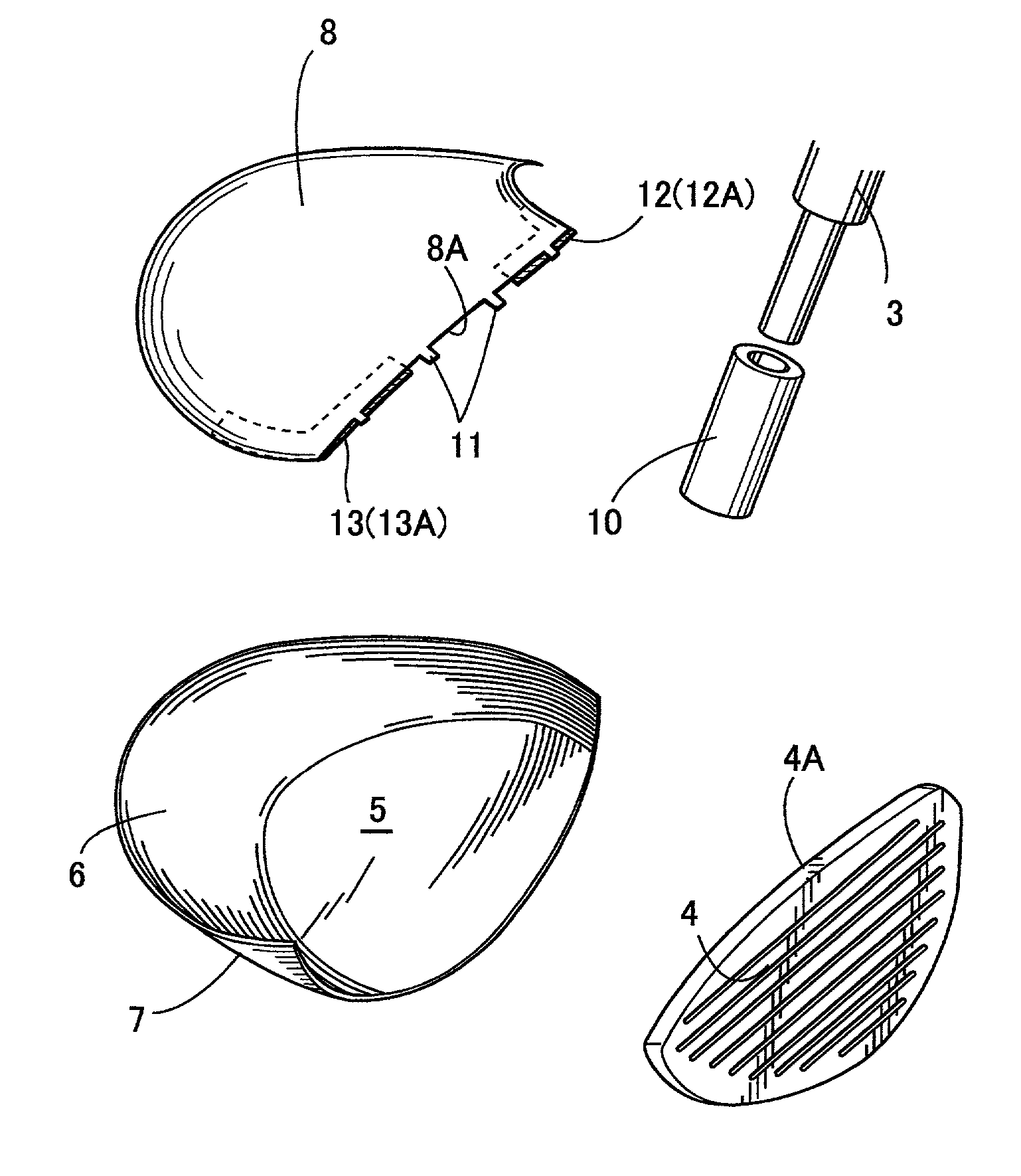

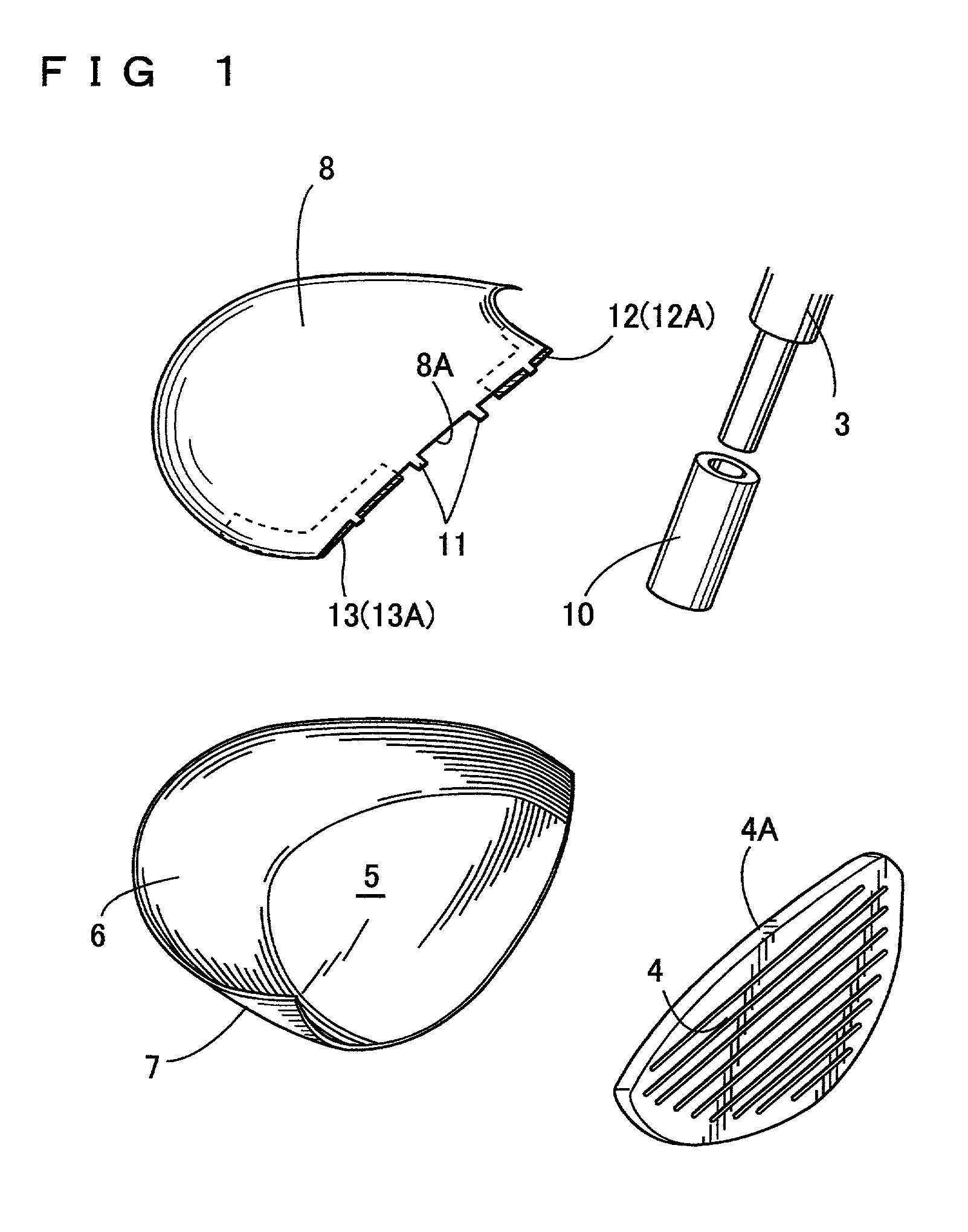

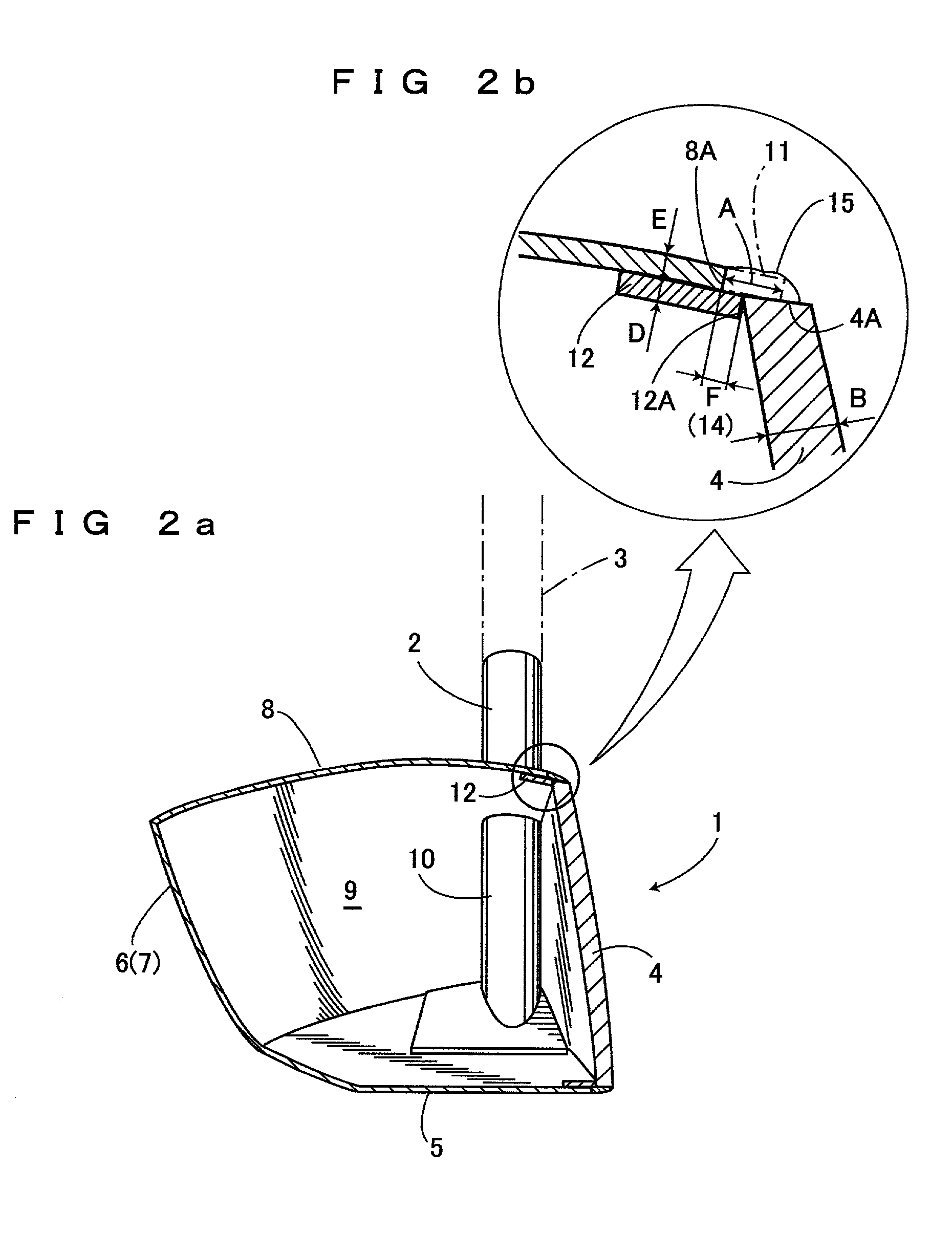

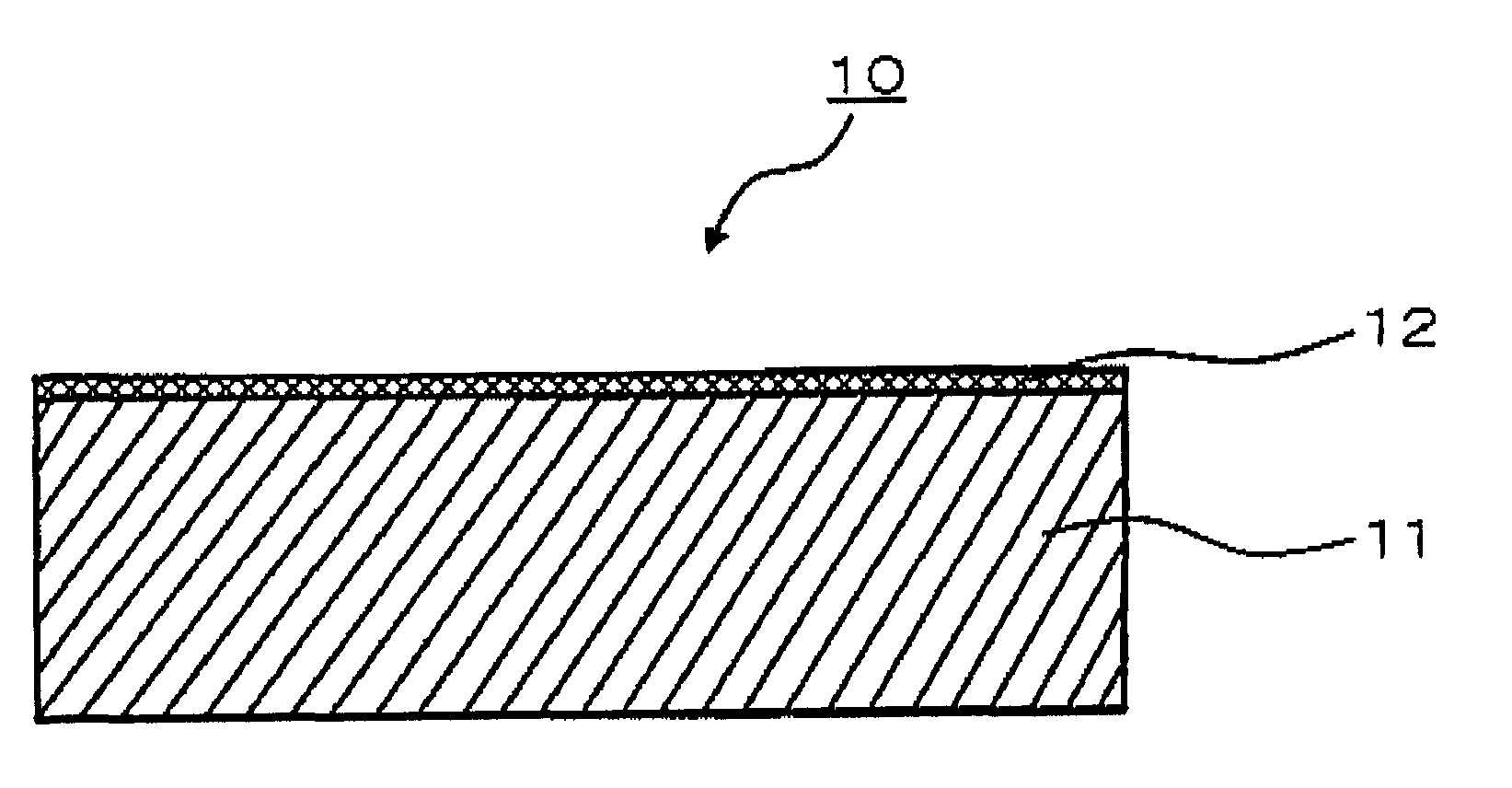

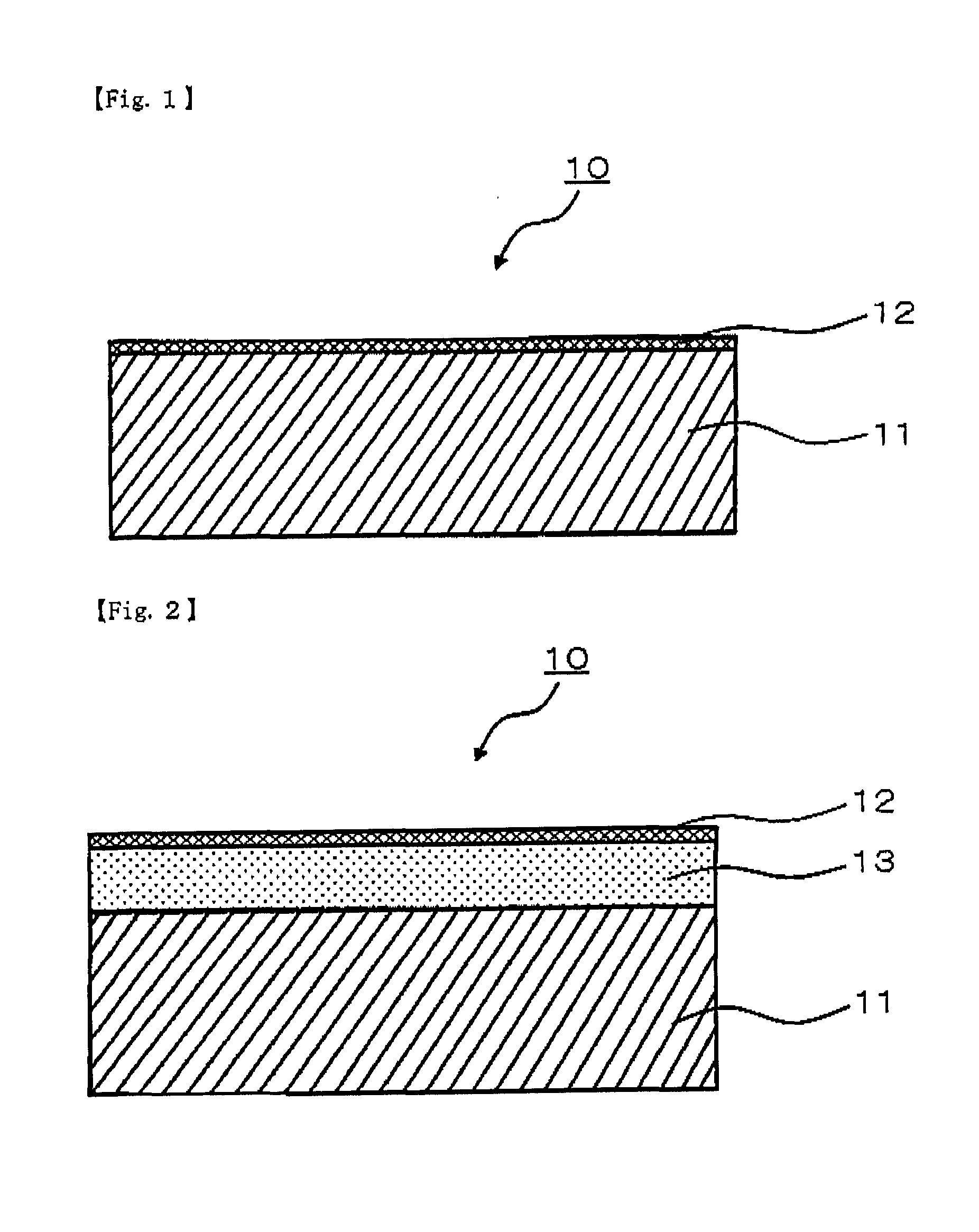

Golf club

A golf club which comprises a head which is less deformable by the heat in welding. Separate reinforcing members 12 and 13 are provided on inner surface of a front edge 8A of a crown shell 8. Thus, the front edge 8A side is thickened and then the upper edge 4A of the face shell 4 is joined to the front edge 8A of the crown shell 8, by welding. The front edge 8A of the crown shell 8 is formed with a plurality of projections 11 which are anchored by the upper edge 4A of the face shell 4. front edge 8A of the crown shell 8 is thickened by adding the thickness of the reinforcing members 12, 13 to the thickness of crown shell 8 itself. Thus, thermal deformation and the sinking of the front edge 8A at the time of welding can be prevented, thus enabling the upper edge 4A to be joined to the front edge 8A as designed.

Owner:THE YOKOHAMA RUBBER CO LTD +1

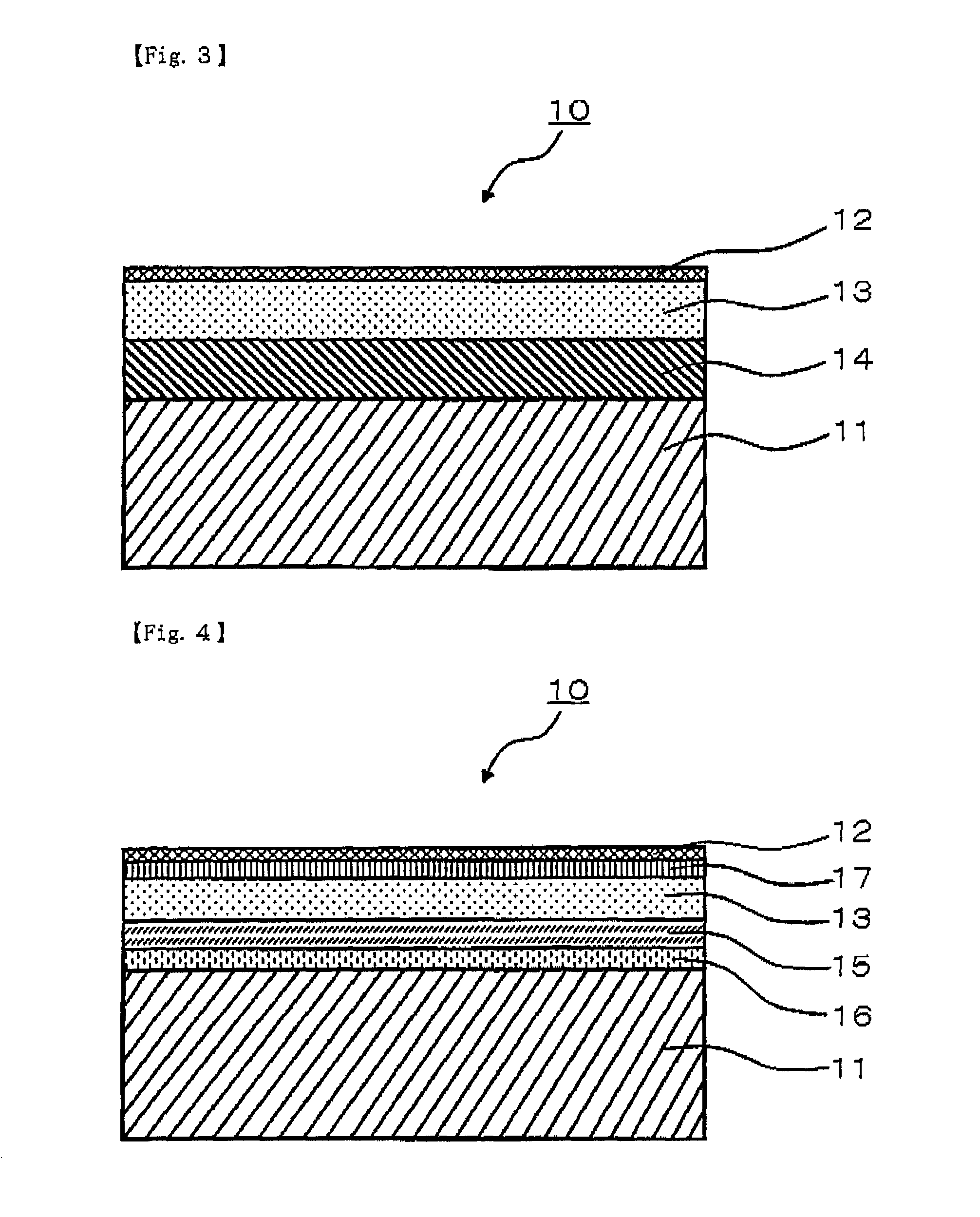

Liquid crystal polymer film, laminate, method of making them and multi-layered parts-mounted circuit board

InactiveUS6274242B1With balanceImprove thermal conductivityLiquid crystal compositionsLamination ancillary operationsThermal deformationPolymer chemistry

A polymer film capable of forming an optically anisotropic melt phase is, after having been laminated on a base material capable of supporting the shape of the film during heat treatment, is heat-treated at a temperature of from the thermal deformation temperature Tdef of the film to a temperature lower by alpha (alpha=10 to 35° C.) than the melting point Tm of the film until the fusion peak temperature TA of the film attains a temperature which is higher by beta (beta=5 to 30° C.) than the melting point Tm of the film before the heat treatment and is subsequently heat-treated at a temperature of from a temperature not lower than the melting point Tm of the film to a temperature lower than the fuision peak temperature TA for a length of time over which the TA increases by gamma (gamma=5 to 20° C.), and thereafter the base material is removed to produce the film.

Owner:KURARAY CO LTD

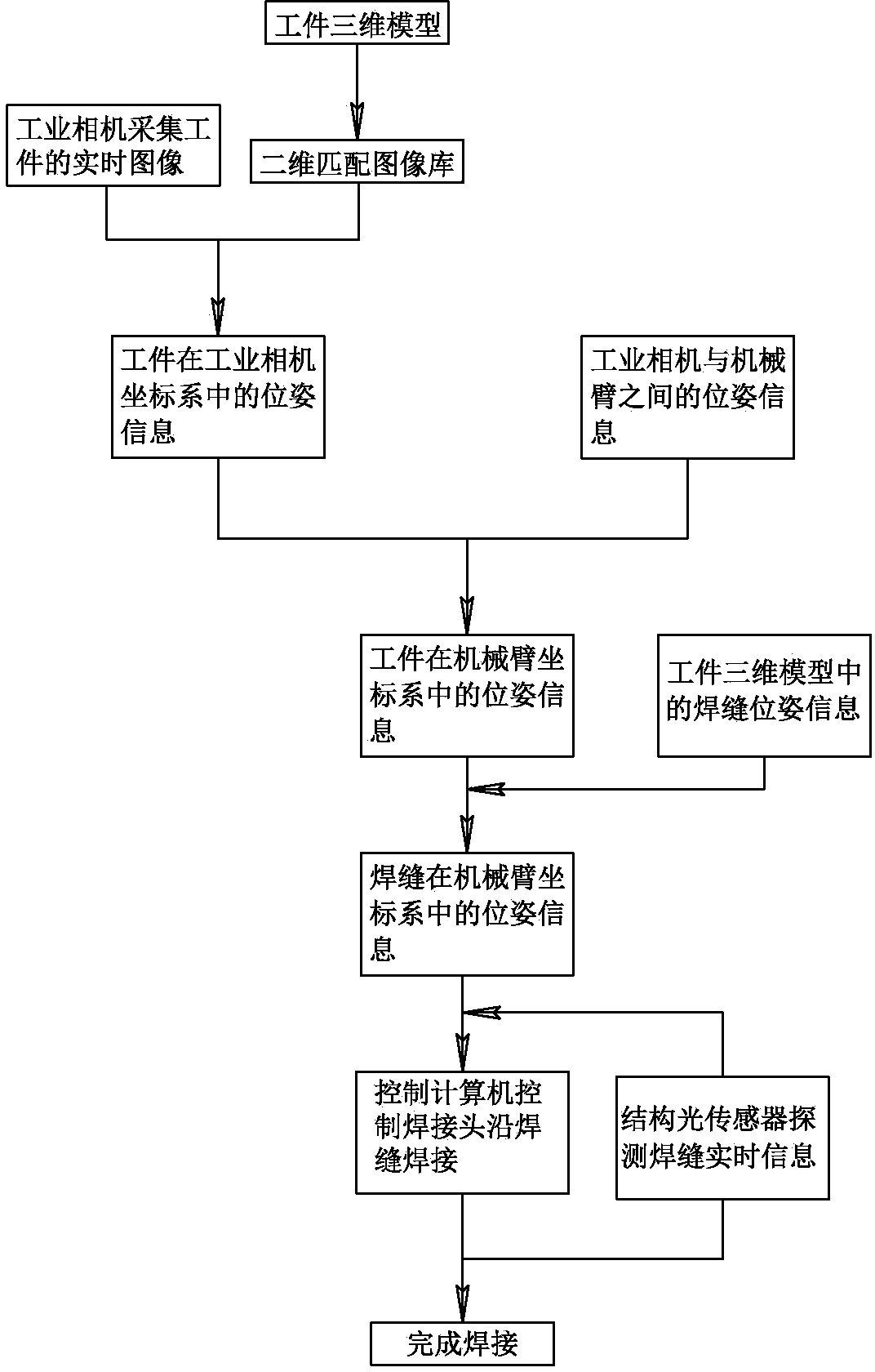

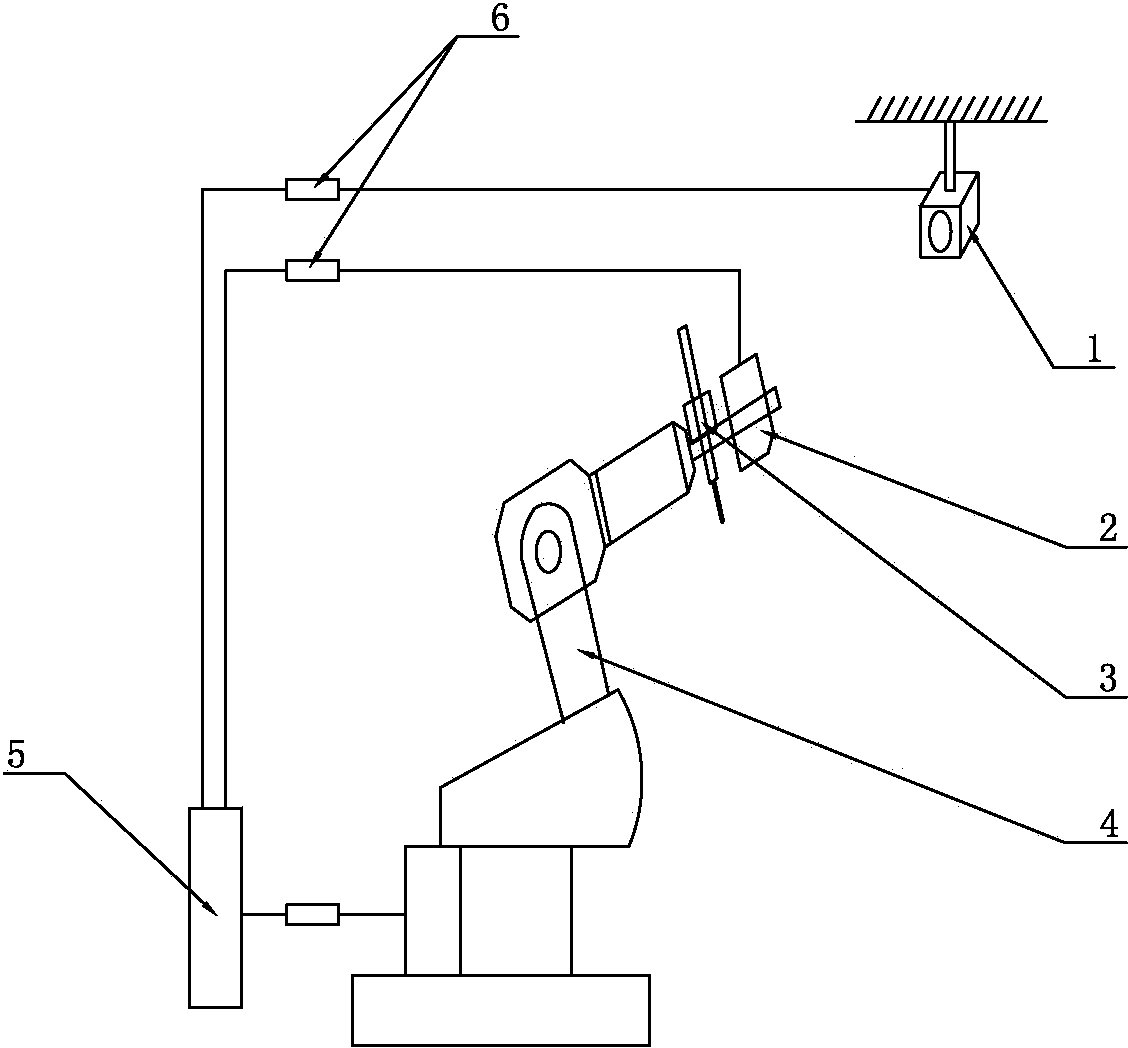

Automatic welding method based on three-dimensional model and machine vision and welding device based on three-dimensional model and machine vision

ActiveCN104384765ANo collision trackingPrecise positioningWelding/cutting auxillary devicesArc welding apparatusMachine visionThermal deformation

Owner:南京曼新智能科技有限公司

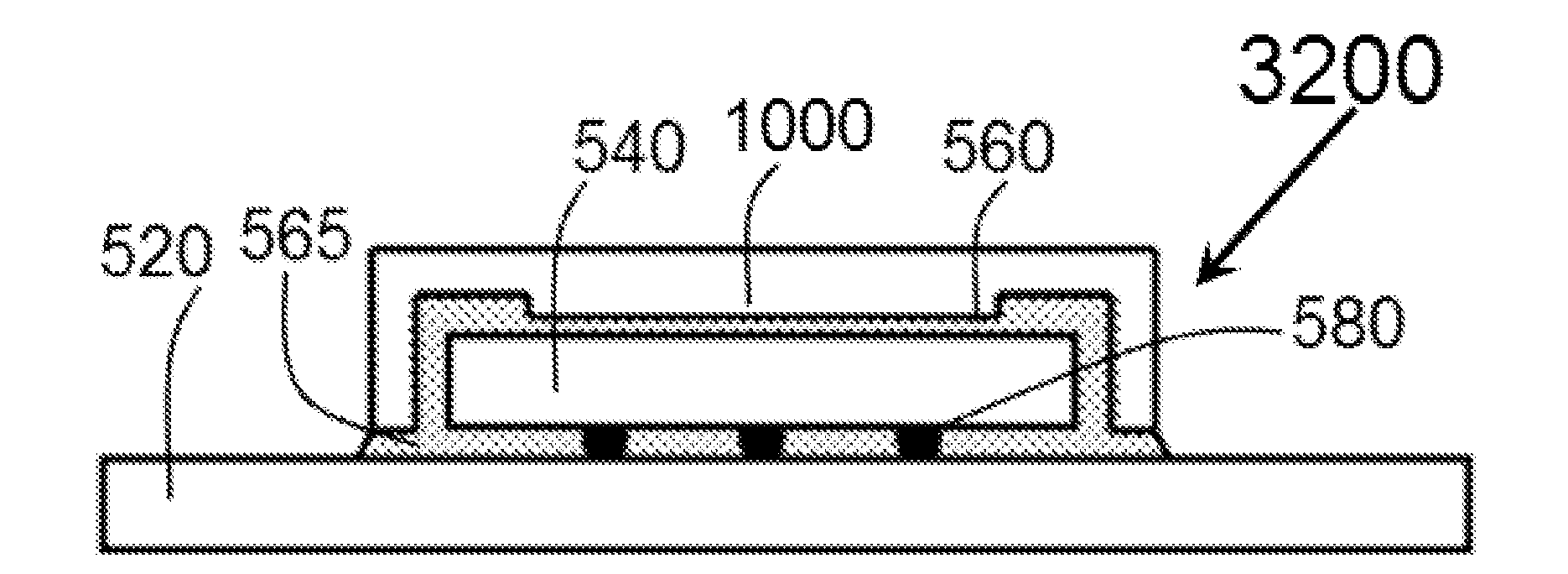

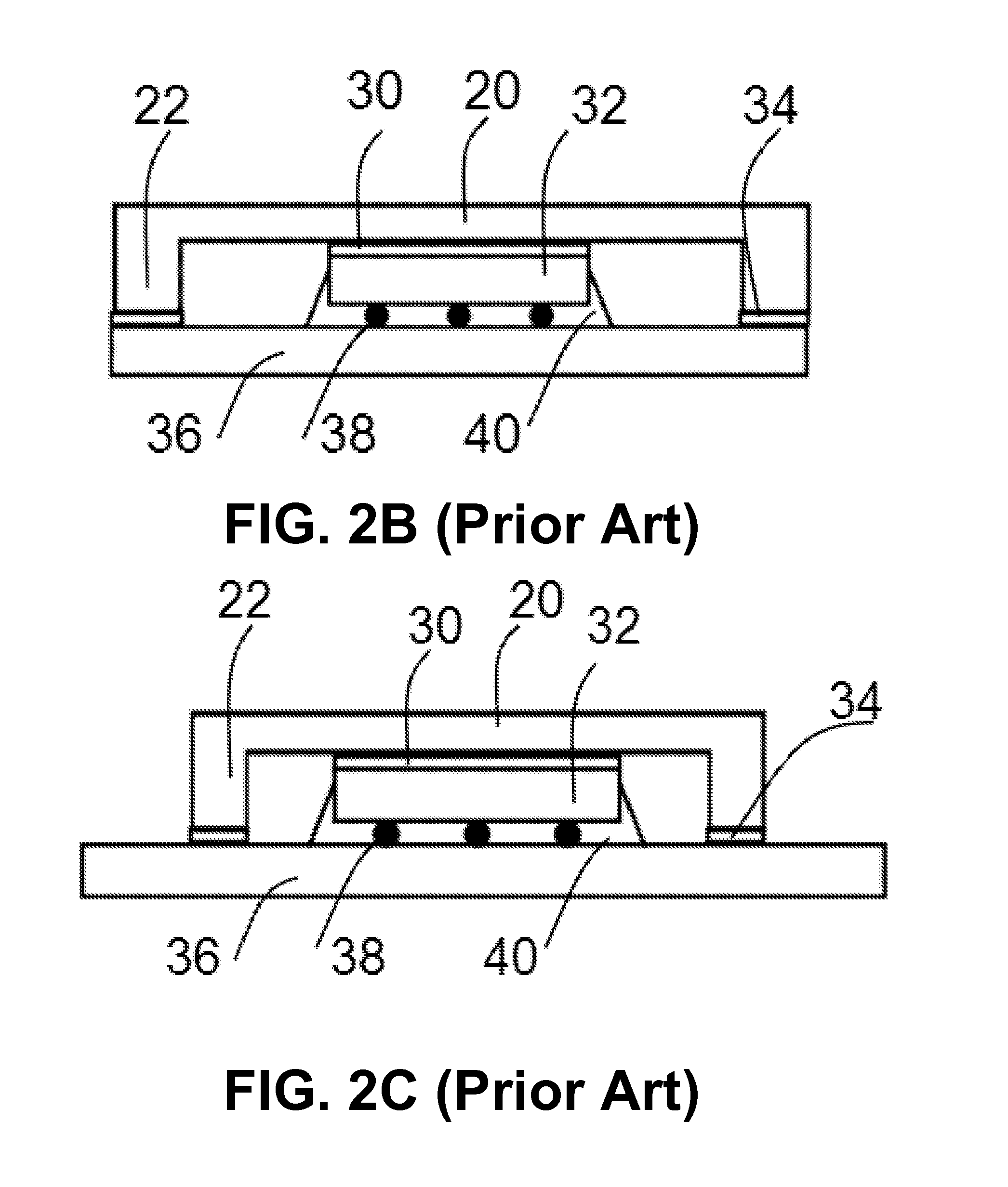

Die cap for use with flip chip package

InactiveUS20140091461A1Reduce riskImprove thermal efficiencySemiconductor/solid-state device detailsSolid-state devicesThermal dilatationThermal deformation

A die cap for use with flip chip packages, flip chip packages using a die cap, and a method for manufacturing flip chip packages with a die cap are provided in the invention. A die cap encases the die of flip chip packages about its top and sides for constraining the thermal deformation of the die during temperature change. The CTE (coefficient of thermal expansion) mismatch between the die and substrate of flip chip packages is the root cause for warpage and reliability issues. The current inventive concept is to reduce the CTE mismatch by using a die cap to constrain the thermal deformation of the die. When a die cap with high CTE and high modulus is used, the die with the die cap has a relatively high overall CTE, reducing the CTE mismatch. As a result, the warpage and reliability of flip chip packages are improved.

Owner:SHEN YUCI

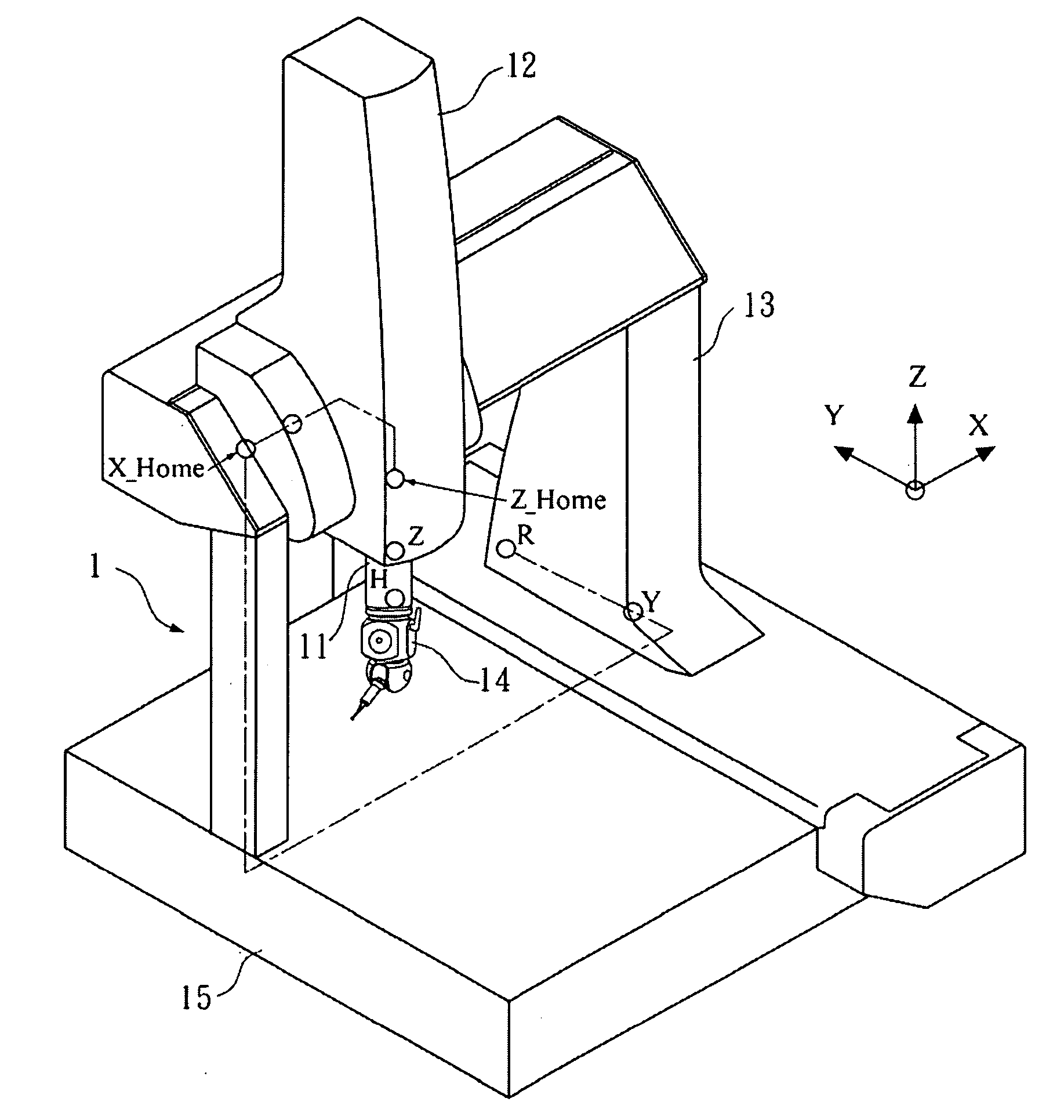

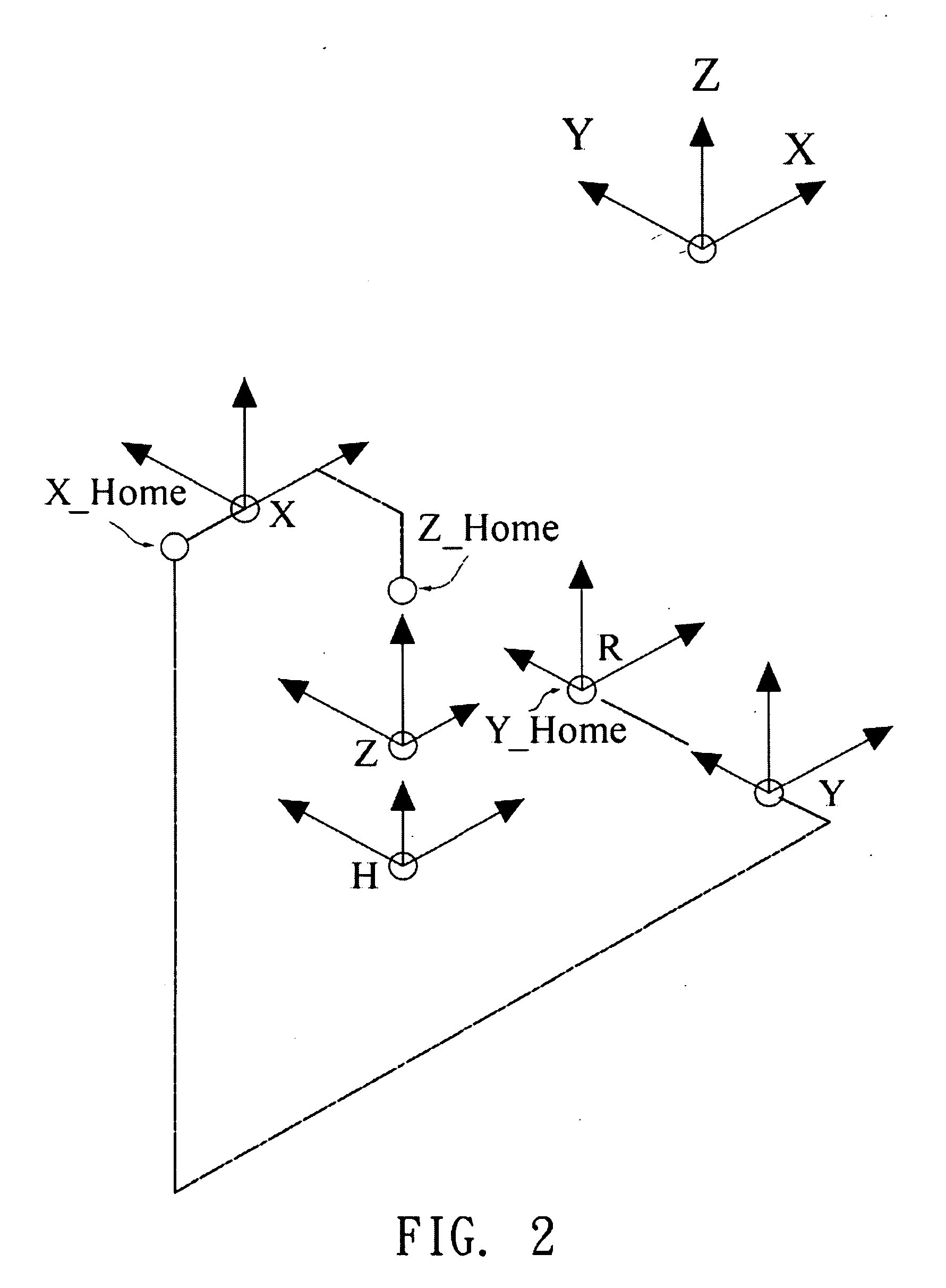

Thermal deformation error compensation method for coordinate measuring machine

InactiveUS20100299094A1Testing/calibration of speed/acceleration/shock measurement devicesSpecial data processing applicationsGeometric errorMotion parameter

A thermal deformation error compensation method for a coordinate measuring machine creates thermal deformation and geometric error data at different ambient temperatures including temperatures and machine kinematic parameters to obtain a thermal deformation and geometric error model, and inputs the model into central control unit of the coordinate measuring machine, and converts a 3D error compensation to obtain a thermal deformation and geometric error compensation model, and uses the thermal deformation and geometric error compensation model for performing compensations, so as to complete a thermal deformation and geometric error compensation of the coordinate measuring machine.

Owner:CARMAR TECH

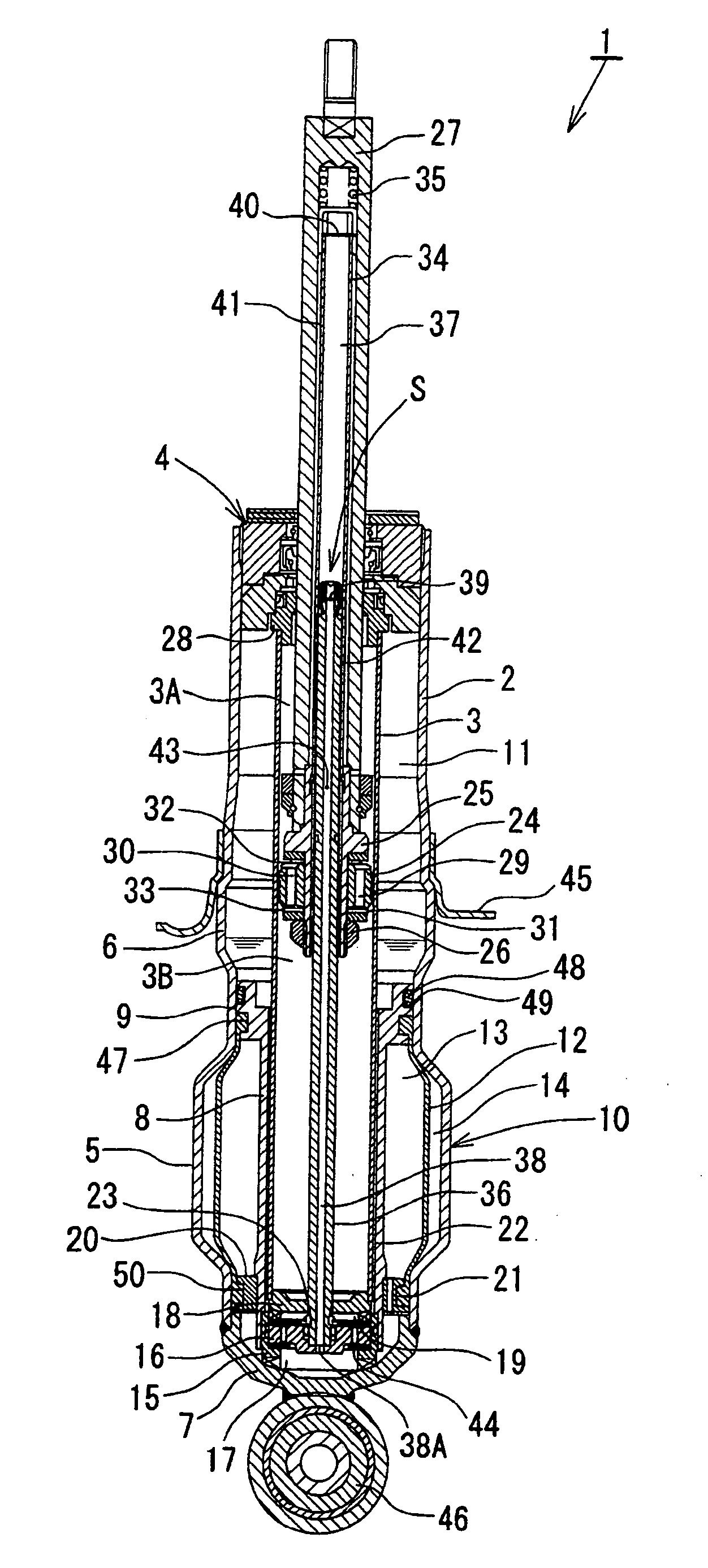

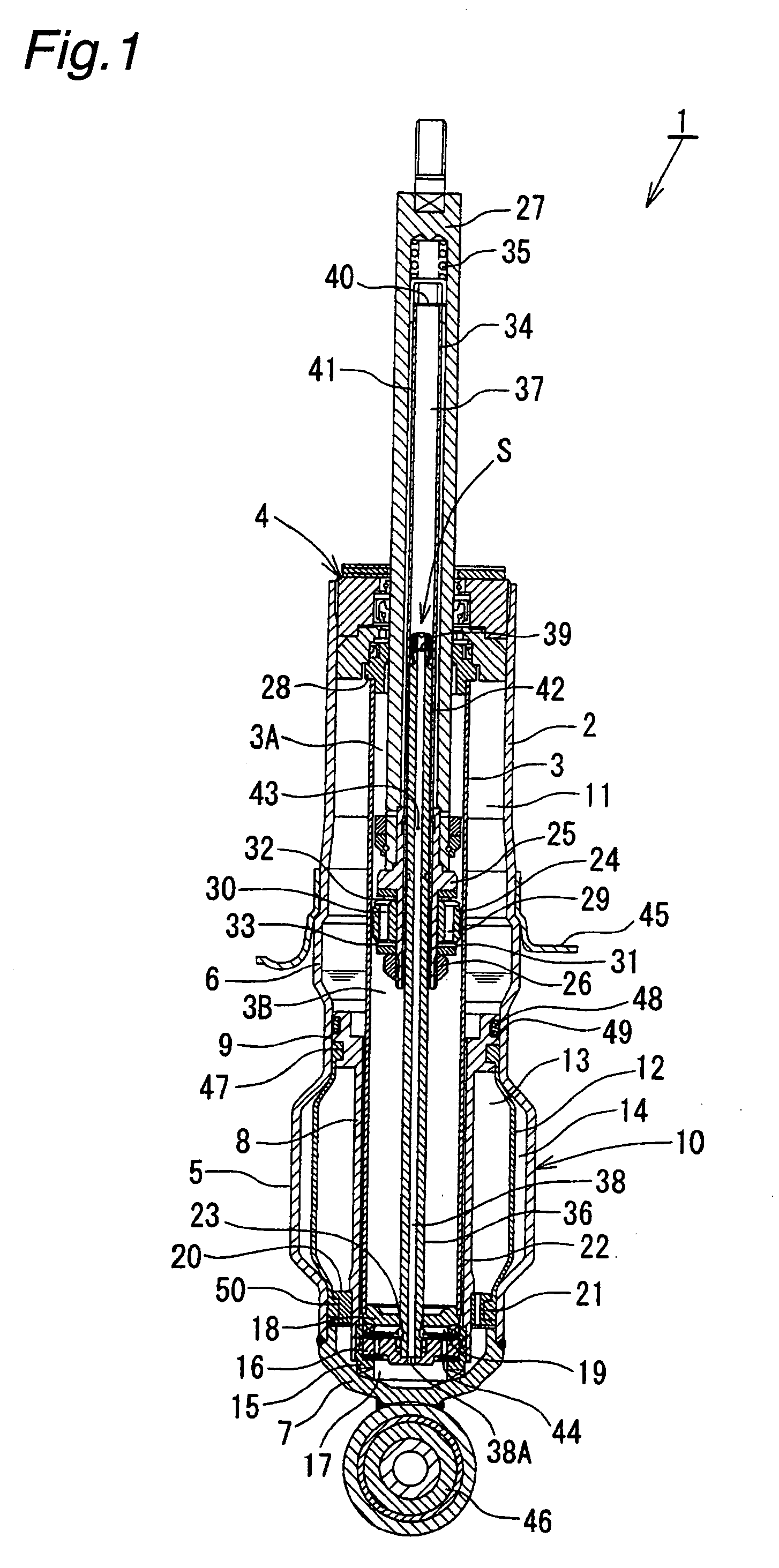

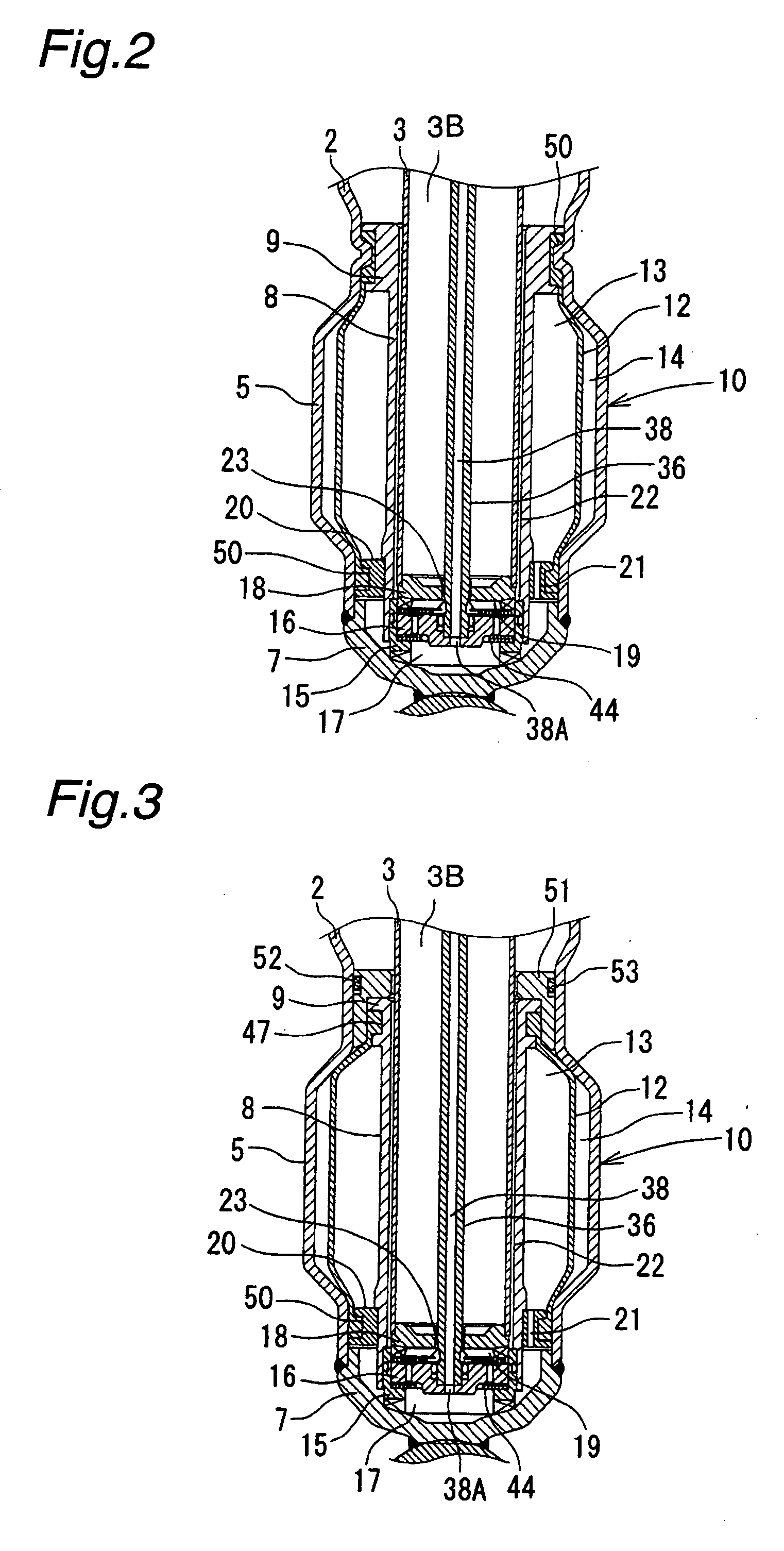

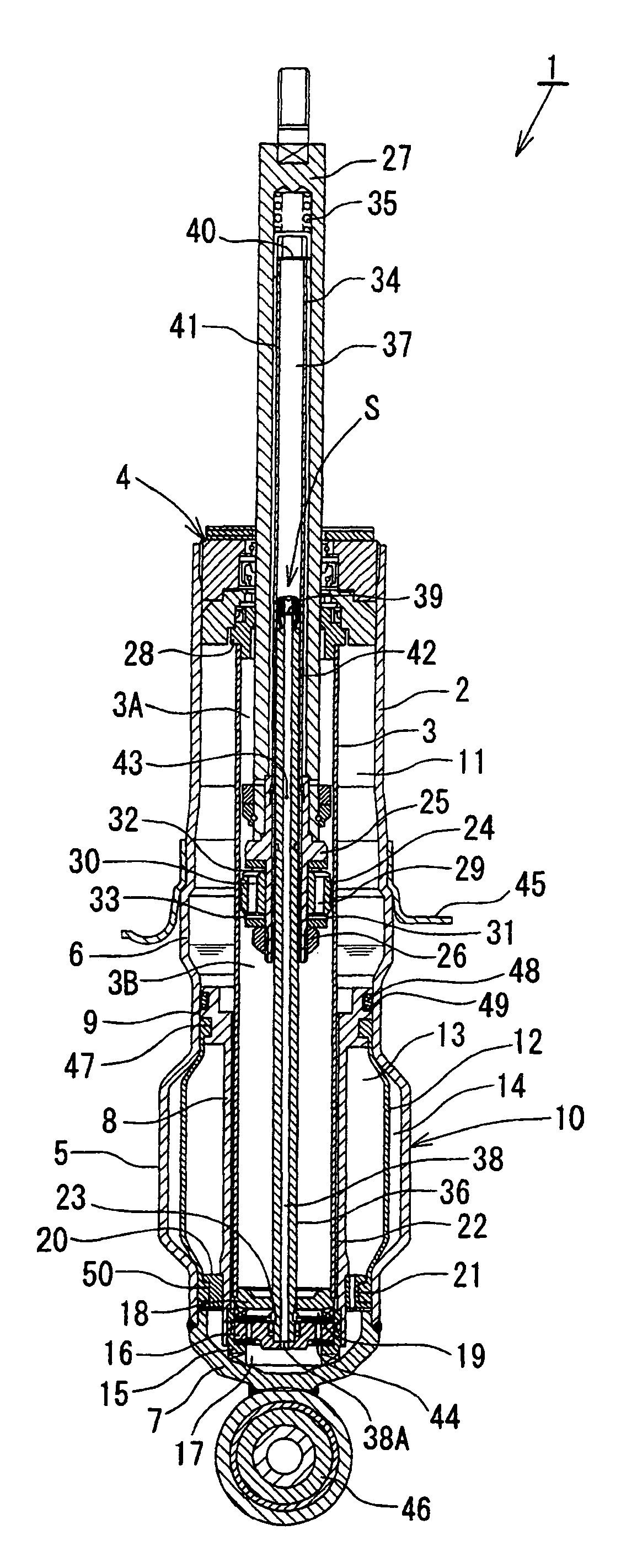

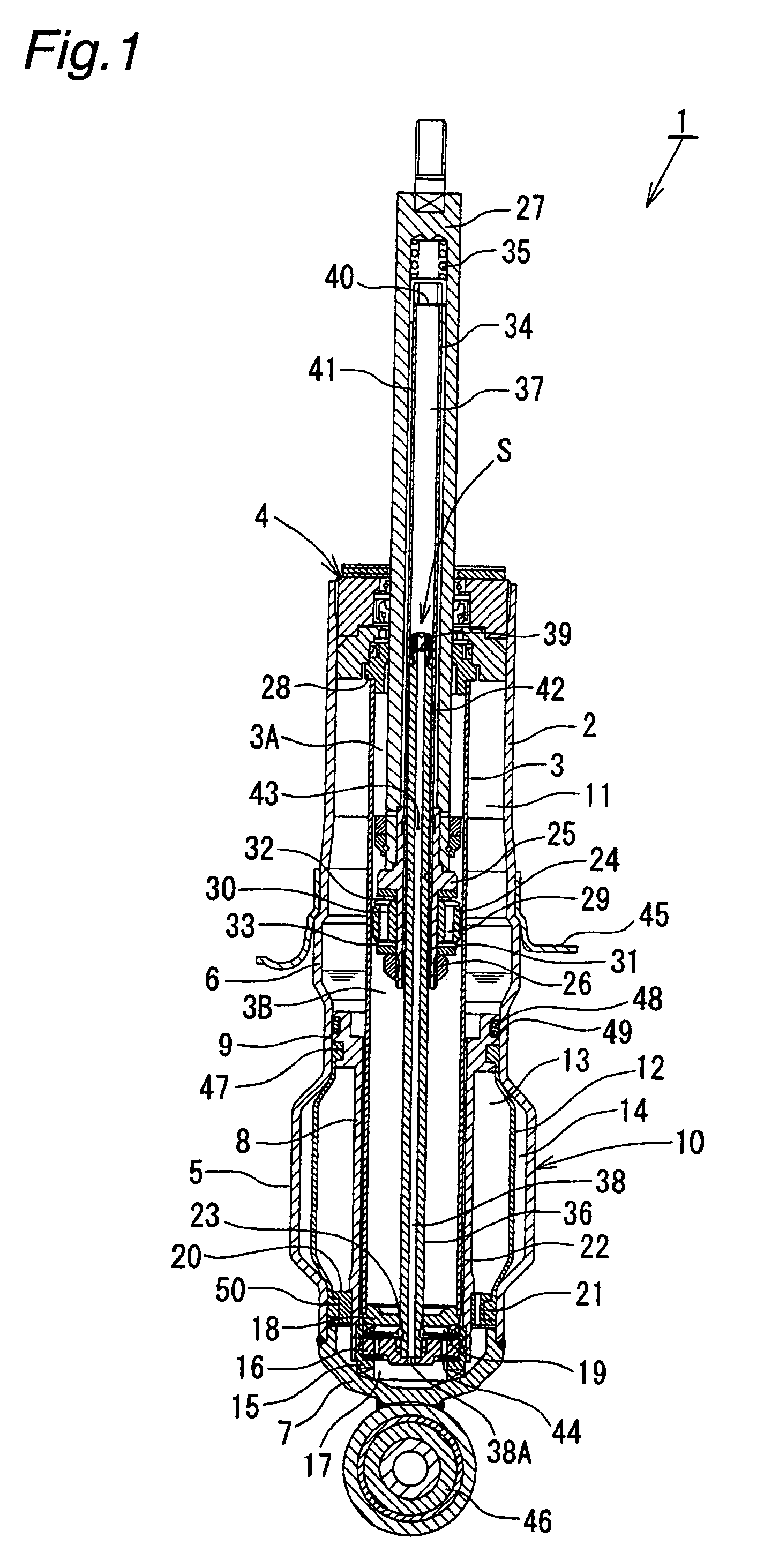

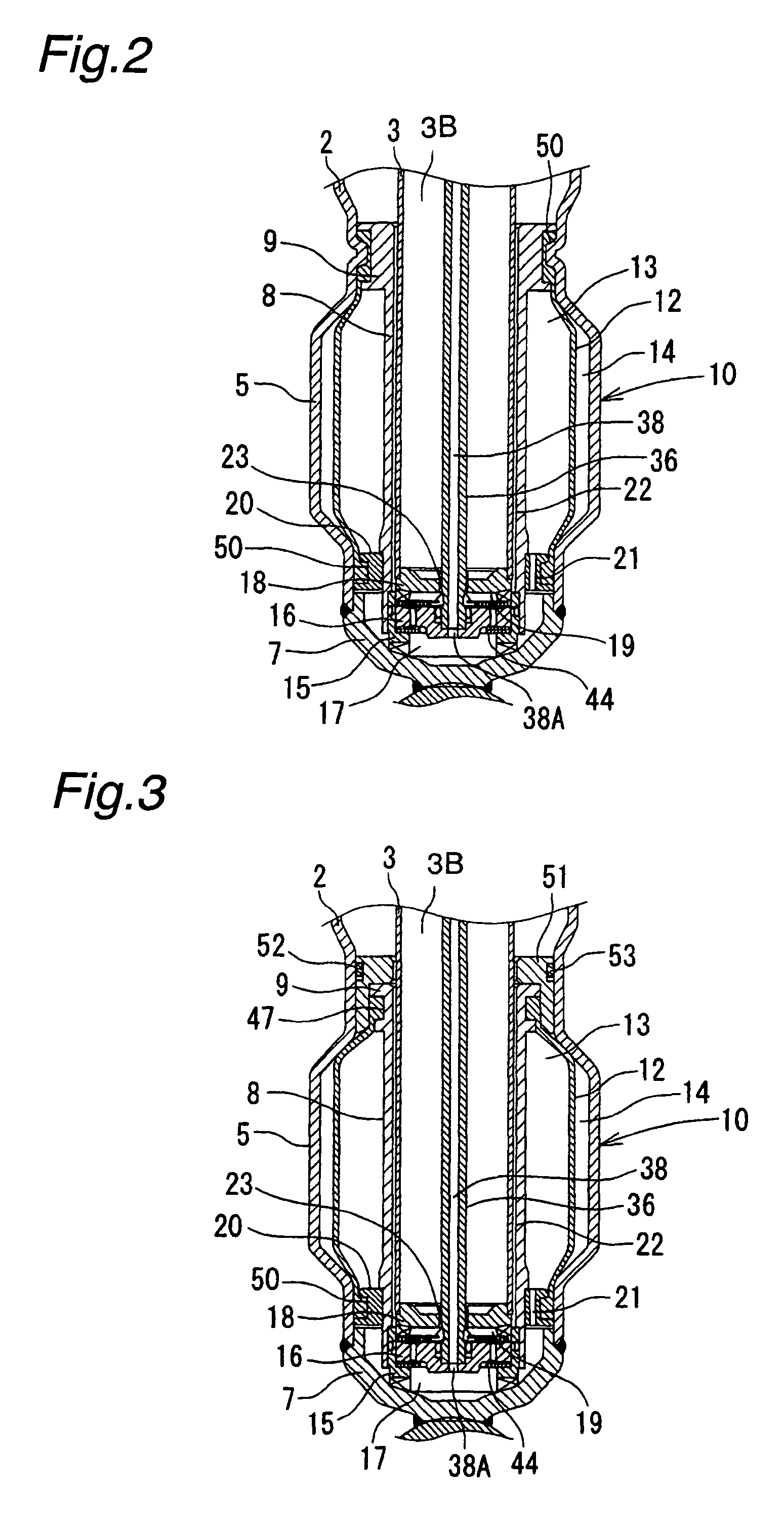

Hydraulic shock absorber

ActiveUS20080185244A1Improve space efficiencyReduce in quantitySpringsLiquid based dampersThermal deformationFuel tank

A piston connected with a piston rod is fitted in a cylinder having a hydraulic fluid sealed therein. A damping force is generated through extension and compression disk valves and an orifice. Vehicle height adjustment is performed with a self-leveling mechanism by transferring the hydraulic fluid between the cylinder and a hydraulic fluid tank. A bladder of the hydraulic fluid tank is clamped between an outer flange portion of a partition member and a casing. Because the hydraulic fluid tank is formed without welding, it is possible to avoid contamination of the hydraulic fluid by welding sputter and thermal deformation. Provision of an O-ring on the outer flange portion can reduce the pressure acting from a reservoir on the clamped portion of the bladder and hence prevent dislodging of the bladder.

Owner:HITACHI ASTEMO LTD

Metal-like engineering plastic composite material and preparation method thereof

The invention discloses a metal-like engineering plastic composite material and a preparation method thereof, and relates to a polymer composite material. The invention provides the metal-like engineering plastic composite material which combines plastic with metal and simultaneously keeps the advantages of the two and the preparation method thereof. The composite material comprises thermoplastic engineering plastic, high-density packing, mineral powder, glass fiber, toughener, coupling agent, lubricant and antioxidant. The metal-like engineering plastic composite material has high density, high mechanical properties, excellent thermal deformation temperature and good injection molding property. The preparation method adopts the method of being combined with the coupling agent and the optimized granulation conditions, the process is simple and easy to operate, extrusion and granulation can be carried out by adopting an ordinary twin-screw granulator, and injection molding can be carried out by adopting an ordinary injection machine.

Owner:XIAMEN RUNNER IND CORP

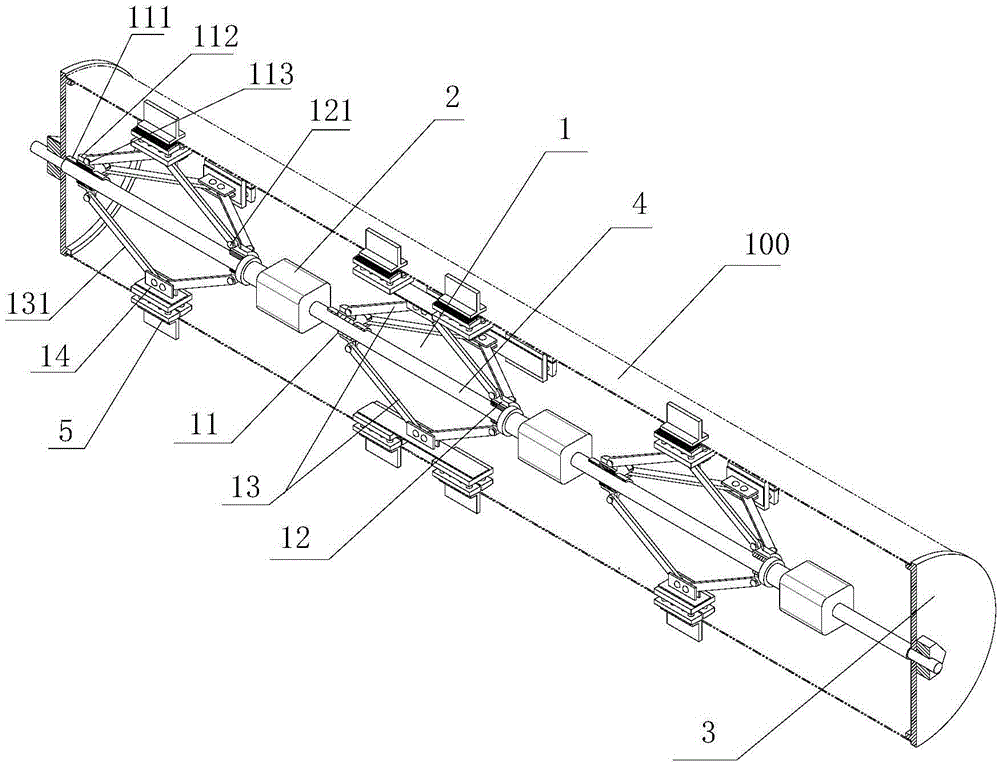

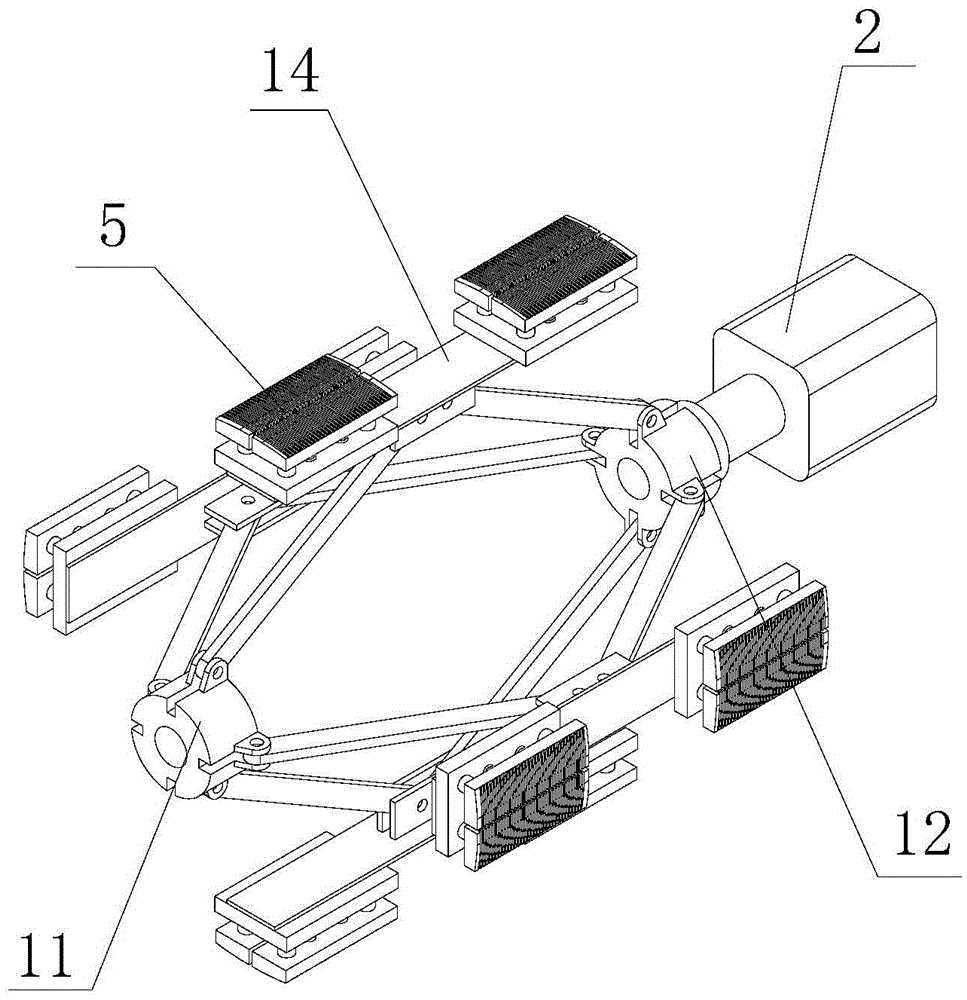

Rhombic internal support clamp for round pipe welding

ActiveCN105598631ASolve protection problemsImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesDiagonalThermal deformation

The invention discloses a rhombic internal support clamp for round pipe welding. The rhombic internal support clamp comprises at least one rhombic internal support unit, push cylinders corresponding to the rhombic internal support units one to one, two end covers, a main shaft and a plurality of pressing back-blowing modules, wherein the main shaft is arranged at the center of a round pipe, and both ends of the main shaft are respectively fixed in the centers of the two end covers; each push cylinder is fixedly arranged on the main shaft; each rhombic internal support unit comprises a positioning ring, a movable ring and at least one rhombic supporting frame; the positioning rings fixedly sleeve the main shaft; the movable rings sleeve the main shaft and can move back and forth along the main shaft along with the pushing of the corresponding push cylinders; one pair of diagonals of each rhombic supporting frame is respectively hinged to the corresponding positioning ring and the corresponding movable ring, and the other pair of diagonals of each rhombic supporting frame is respectively hinged to two supporting platforms; at least one pressing back-blowing module is fixed on each supporting platform. According to the rhombic internal support clamp, the internal protection problem for pipe welding is solved, the quality of welds is improved, and thermal deformation is relieved.

Owner:SHANGHAI PURUIMA INTELLIGENT TECH CO LTD

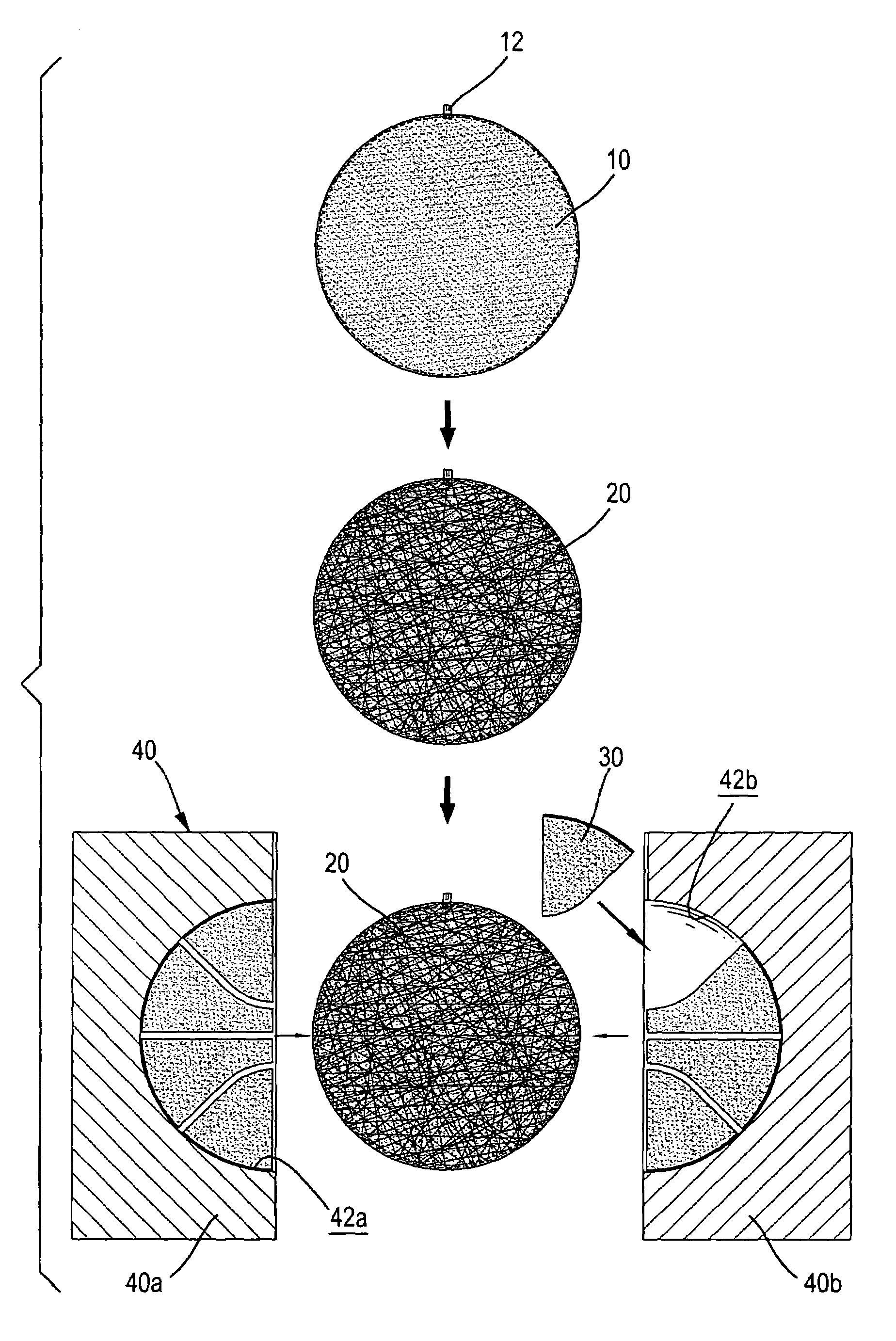

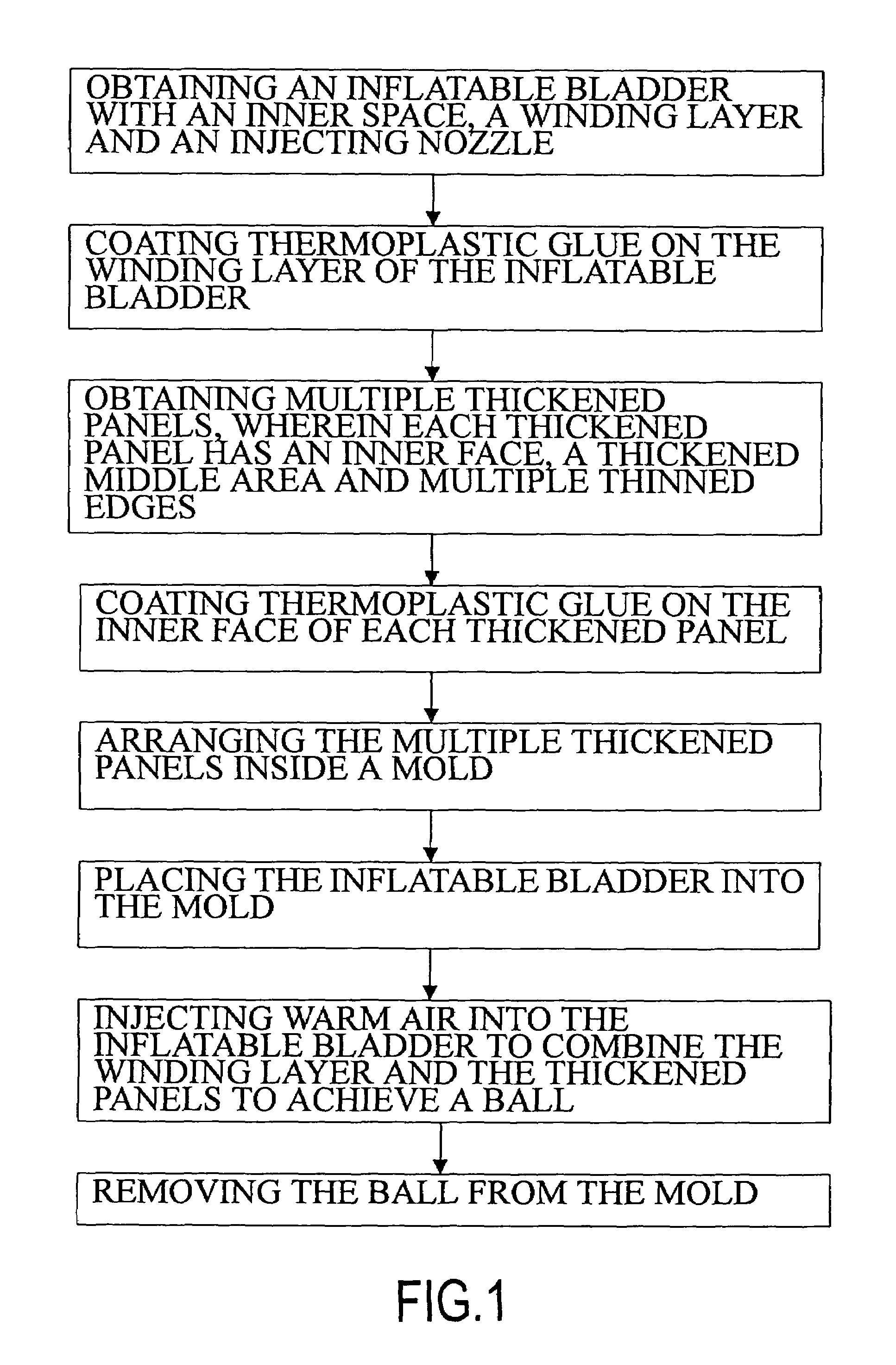

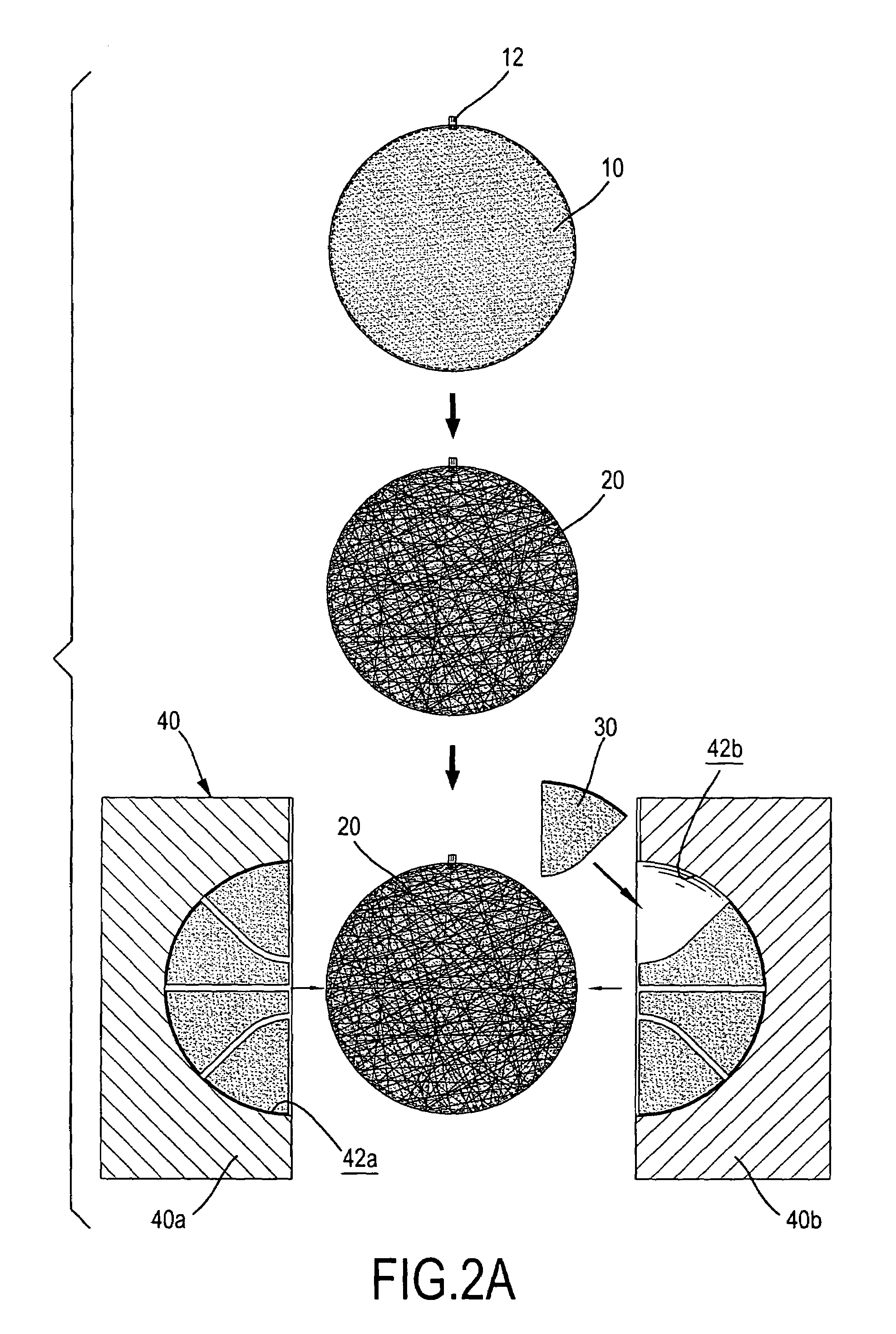

Method for manufacturing an inflatable ball and a ball made with the method

InactiveUS7066853B2Quick and simplified procedureGood appearanceHollow inflatable ballsHollow non-inflatable ballsVulcanizationThermal deformation

A method for manufacturing an inflatable ball has the following acts of: obtaining an inflatable bladder with a winding layer; coating thermoplastic glue on the winding layer; obtaining multiple thickened panels; coating thermoplastic glue on the thickened panels; arranging the thickened panels and the inflatable bladder inside a mold; and injecting thermal air into the inflatable bladder to make the winding layer combine with the multiple thickened panels. Wherein, each thickened panel is made of a leather layer and an optional filling layer and has a thickened middle area and multiple thinned edges around the thickened middle area. By eliminating the rubber layer in the prior arts, vulcanization is avoided. Moreover, heating the inflatable ball from inside of the mold avoids thermal deformation of outer pebbled patterns of the panels.

Owner:CHANG YEN LI

Hydraulic shock absorber

ActiveUS8556048B2Reduce in quantityAvoid pollutionSpringsLiquid based dampersThermal deformationFuel tank

A piston connected with a piston rod is fitted in a cylinder having a hydraulic fluid sealed therein. A damping force is generated through extension and compression disk valves and an orifice. Vehicle height adjustment is performed with a self-leveling mechanism by transferring the hydraulic fluid between the cylinder and a hydraulic fluid tank. A bladder of the hydraulic fluid tank is clamped between an outer flange portion of a partition member and a casing. Because the hydraulic fluid tank is formed without welding, it is possible to avoid contamination of the hydraulic fluid by welding sputter and thermal deformation. Provision of an O-ring on the outer flange portion can reduce the pressure acting from a reservoir on the clamped portion of the bladder and hence prevent dislodging of the bladder.

Owner:HITACHI ASTEMO LTD

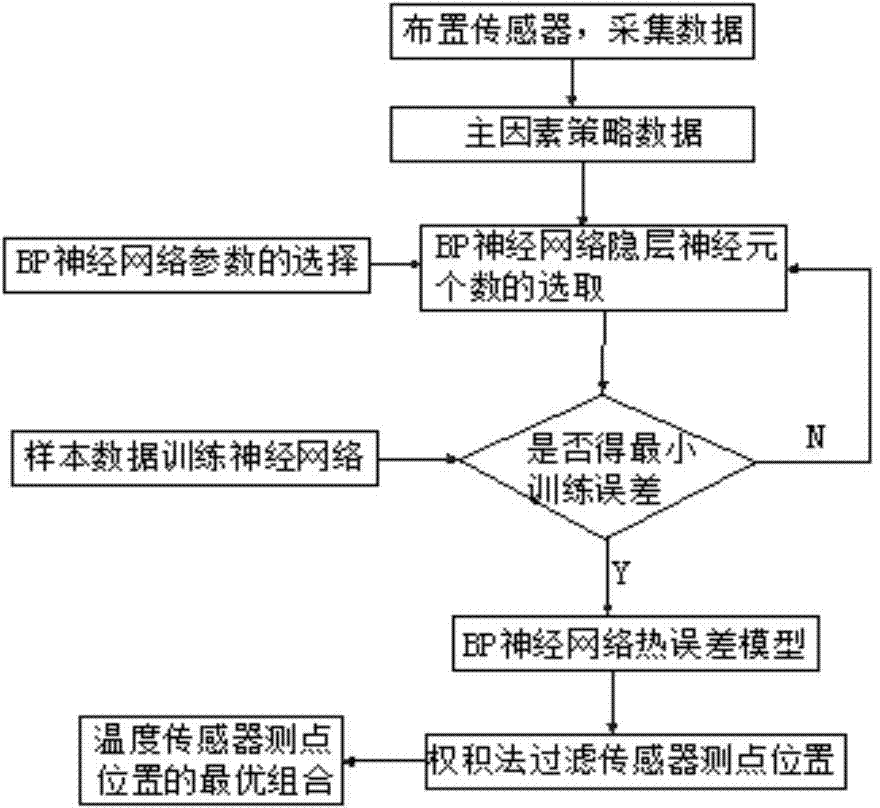

Selection optimization method of numerically-controlled machine tool thermal error compensation modeling temperature measuring point combination

The invention relates to a selection method of numerically-controlled machine tool thermal error compensation temperature sensor measuring point positions. The influence of temperature measuring points at all positions on a machine tool thermal error is identified on the basis of a main factor strategy and a weight product method theory. The method comprises the specific steps that firstly, k temperature sensors are arranged at special positions of a machine tool to measure the real-time temperature values, changing along with the time, in running of the machine tool, and meanwhile thermal displacement of a main shaft arranged on a tool rest is recorded; secondly, part of temperature measuring point positions are removed according to the main factor strategy; thirdly, a BP neural network model capable of simulating changes of the thermal error is built; fourthly, the weight product method is utilized for identifying the influence of remaining measuring point positions. According to the method, the problem that in the process of numerically-controlled machine tool thermal error compensation modeling, the temperature measuring points are too many or the robustness of the compensation model is poor is solved. According to the method, temperature measuring modeling with the fewest temperature sensors is utilized for predicating the error generated by dynamic thermal deformation of the numerically-controlled machine tool, the number of the machine tool temperature measuring points is reduced, and cost is saved.

Owner:JIANGSU QIHANG CNC MASCH TOOL CO LTD +1

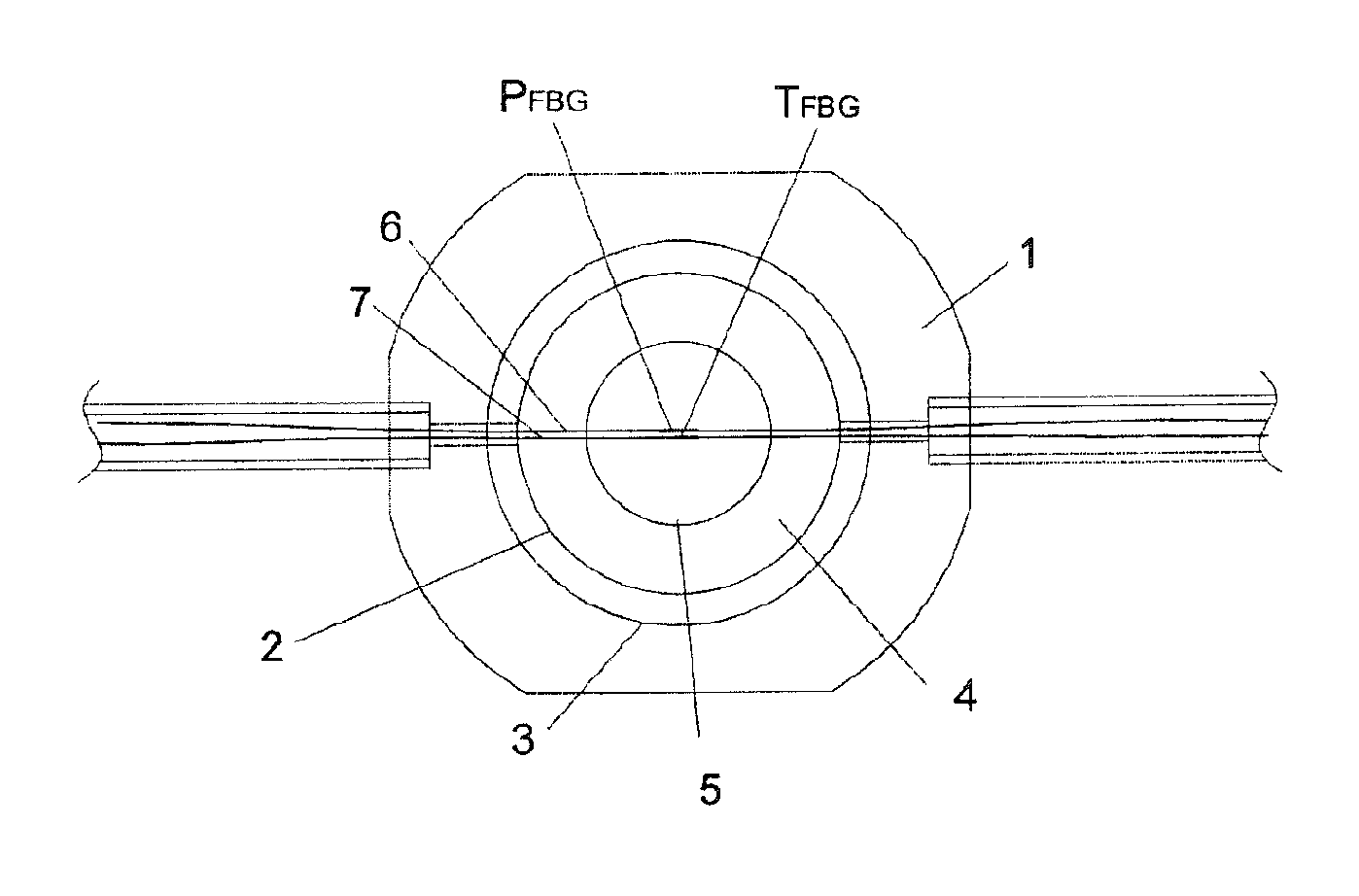

Pressure sensor assembly and method of using the assembly

A pressure sensor assembly comprises a sensor housing having a flexible wall that is configured to deform in response to a pressure difference between the interior and exterior of the sensor housing; —a first fiber optical cable section that is bonded to the flexible wall of the sensor housing such that the length of the first fiber optical cable section changes in response to deformation of the wall in response to the said pressure difference; a second fiber optical cable section which is bonded to a thermal reference body, which body is connected to the sensor housing by a strain decoupled connection mechanism, such as a tack weld or flexible glue, and is configured to deform substantially solely in response to thermal deformation, such that the length of the second fiber optical cable section solely changes in response to thermal deformation of the thermal reference body.

Owner:SHELL USA INC

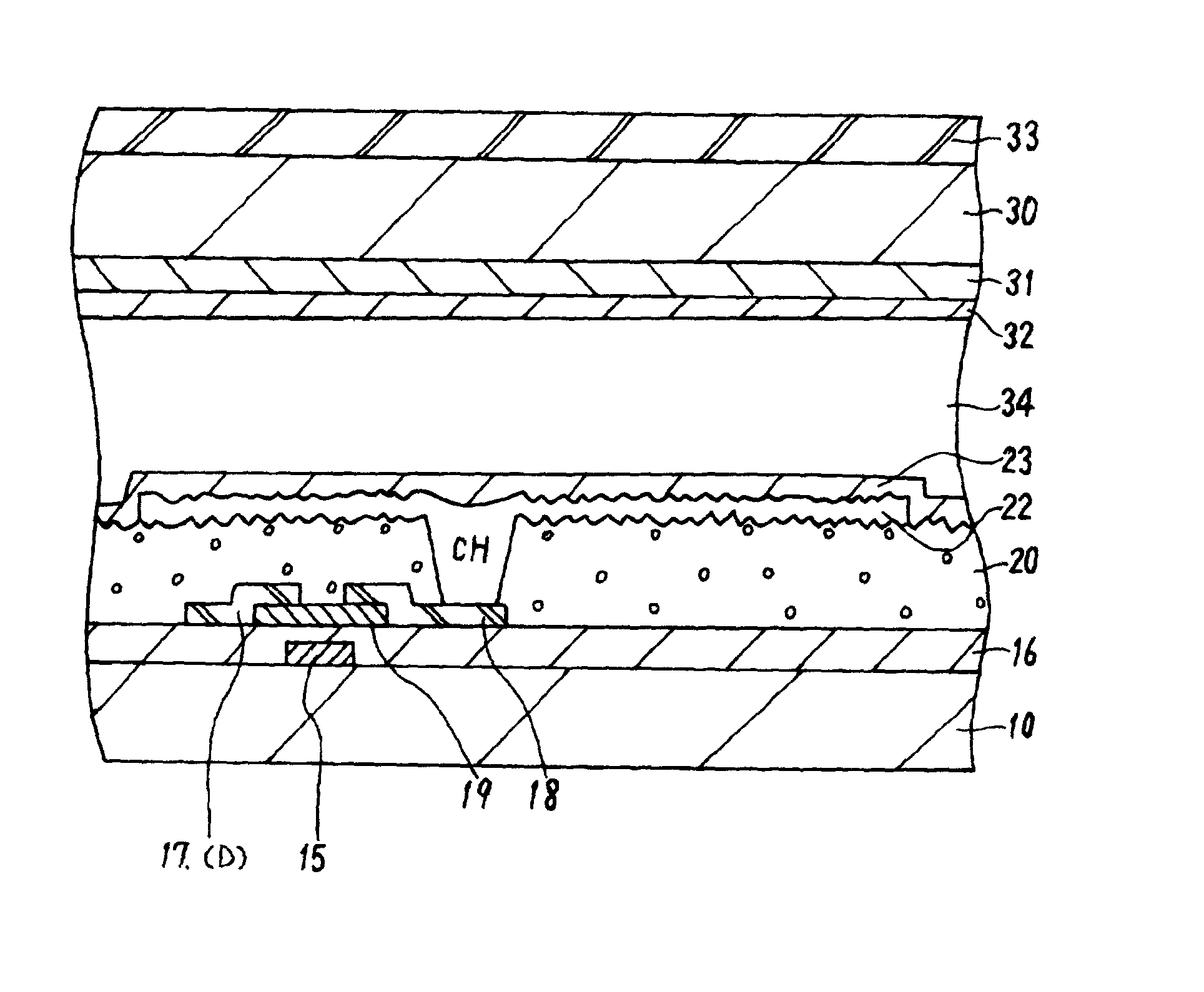

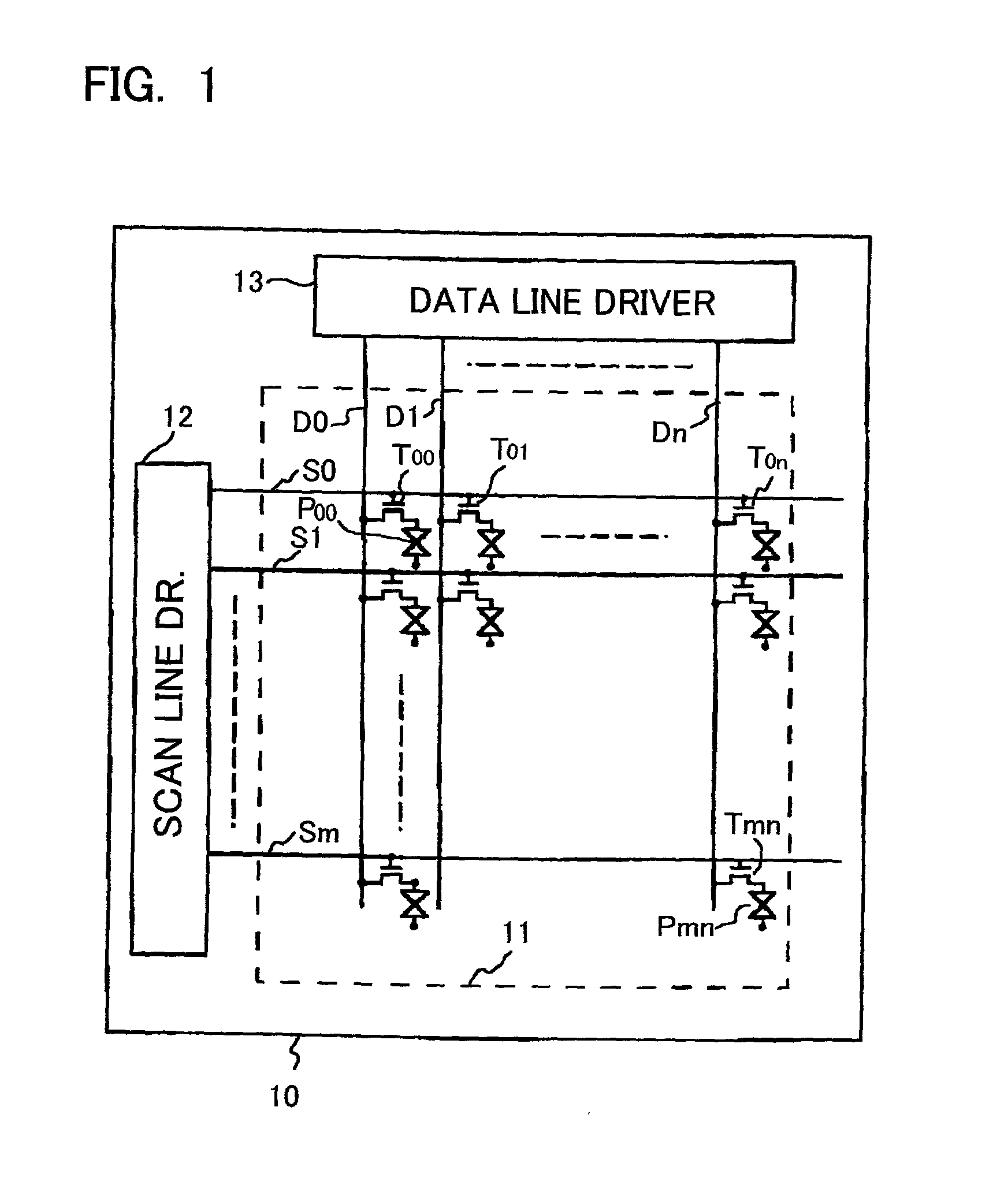

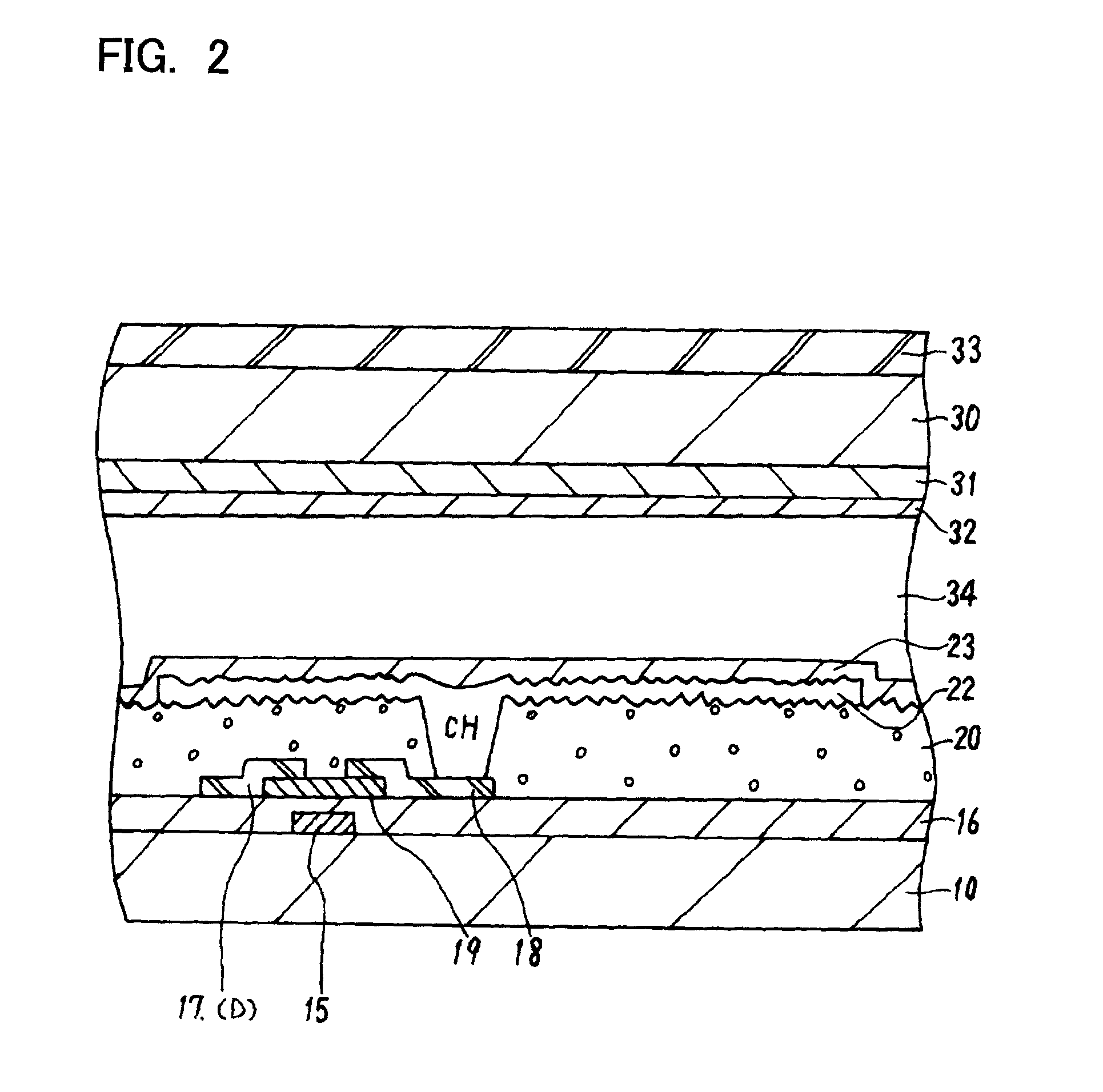

Reflection type liquid crystal display device and manufacturing method thereof

InactiveUS20020140886A1Improve reflectivityIncrease contrastSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayThermal deformation

The present invention is a method of manufacturing a liquid crystal display device, wherein light having an exposure energy is irradiated on the surface of a photo-sensitive resin layer having a predetermined film thickness, and a distribution of thermal deformation characteristics in the thickness direction (or the plane direction) of the photo-sensitive resin layer is formed, then heat treatment is performed to form random undulation (micro-grooves or micro-wrinkles) on the surface of the photo-sensitive resin layer.

Owner:SHARP KK

High-strength discontinuously-reinforced titanium matrix composites and method for manufacturing the same

The invention relates to manufacturing the flat or shaped titanium matrix composite articles having improved mechanical properties such as lightweight plates, sheets for aircraft and automotive applications, heat-sinking lightweight electronic substrates, armor plates, etc. High-strength discontinuously-reinforced titanium metal matrix composite (TMMC) comprises (a) titanium matrix or titanium alloy as a major component, (b) ceramic and / or ≦50 vol. % intermetallic hard particles dispersed in matrix, (c) complex carbide- and / or boride particles at least partially soluble in matrix at sintering or forging temperatures such as ≦50 vol. % AlV2C, AlTi2Si3, AlTi6Si3, VB2, TiVSi2, TiVB4, Ti2AlC, AlCr2C, TiAlV2, V2C, VSi2, Ta3B4, NbTiB4, Al3U2C3 dispersed in matrix. Method for manufacturing these TMMC materials is disclosed. Sintered TMMC density exceeds 98% and closed discontinuous porosity allows performing hot deformation in air without encapsulating. Near-full density near-net shape TMMC parts with acceptable mechanical properties were manufactured without hot deformation.

Owner:ADVANCED MATERIALS PRODS

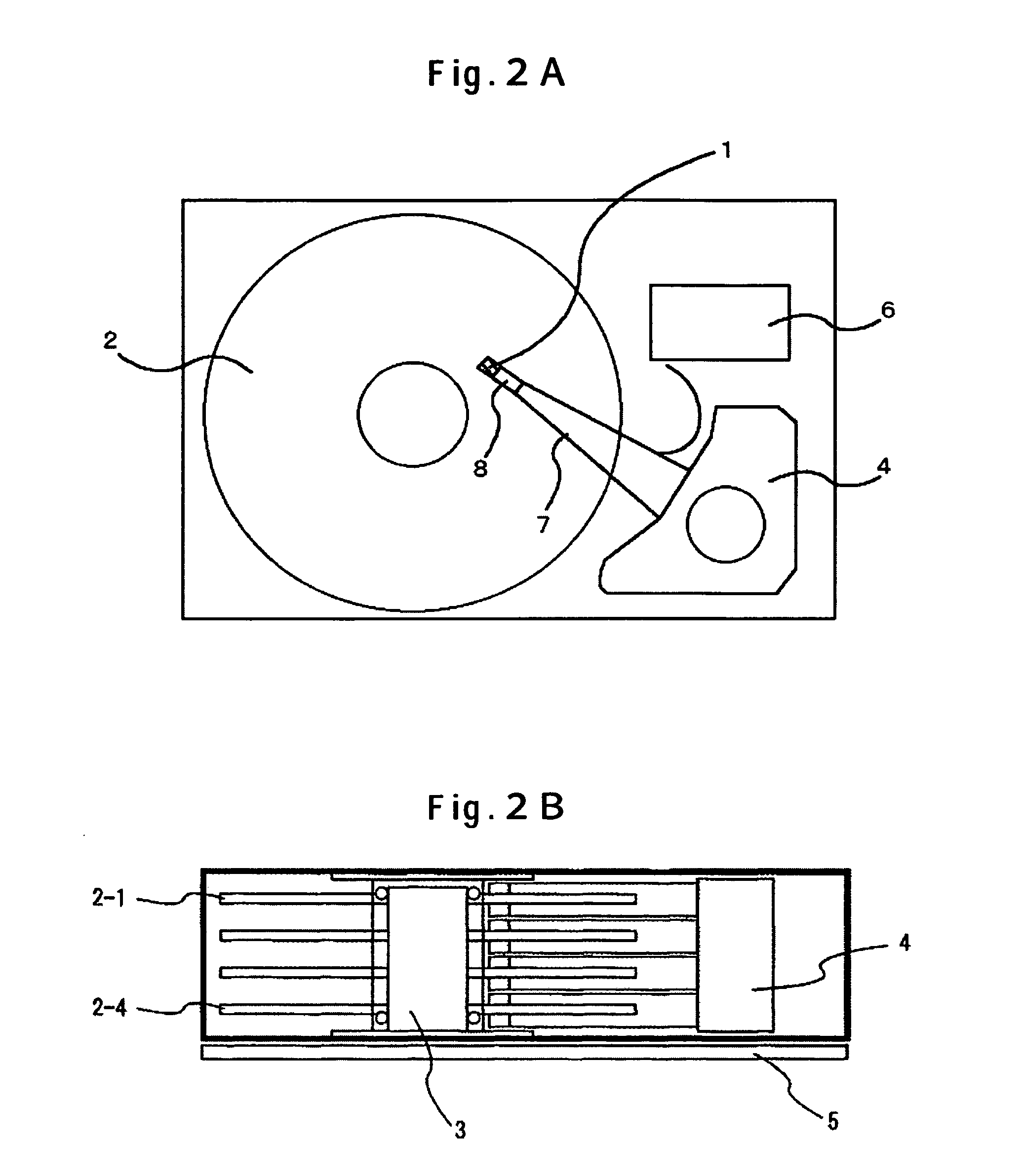

Magnetic head for perpendicular recording

InactiveUS20060087765A1Reduce leakage fieldReduce protrusionConstruction of head windingsRecord information storageElectrical conductorThermal deformation

Embodiments of the invention provide a perpendicular recording magnetic head capable of reducing leakage magnetic fields from the soft magnetic films on the air bearing surface side and reducing the protrusion of the soft magnetic films in the direction of the air bearing surface side due to thermal deformation of the soft magnetic films. In one embodiment, the write functional section includes a coil conductor, second soft magnetic film pattern and first soft magnetic film pattern that cover the coil conductor from top and bottom and are magnetically coupled to each other, and a main magnetic pole piece determining a track width. The read functional section includes a reading element sandwiched between two magnetic shield films. A pedestal magnetic pole pattern is formed at the frontal end position of the first soft magnetic film pattern.

Owner:WESTERN DIGITAL TECH INC

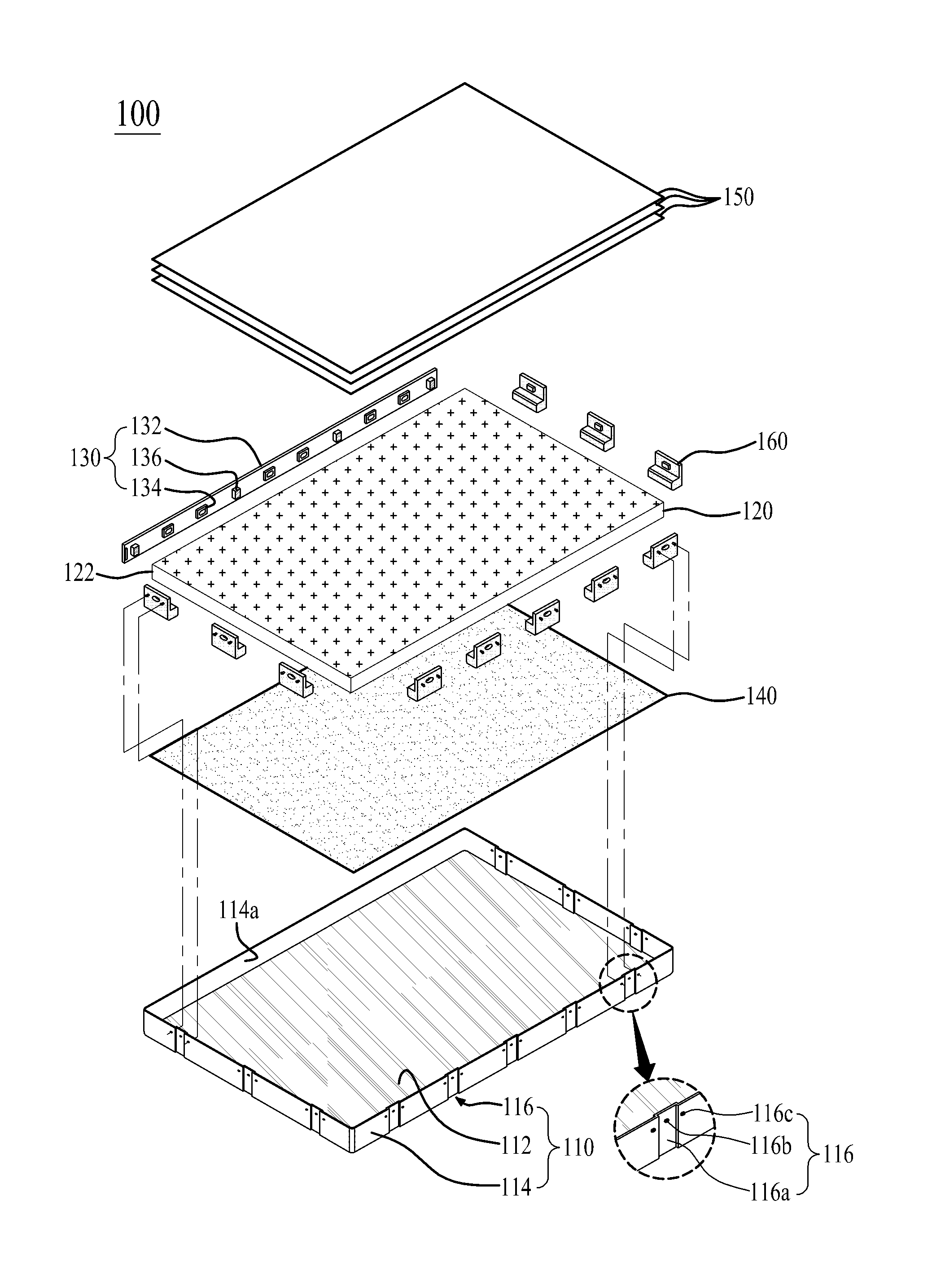

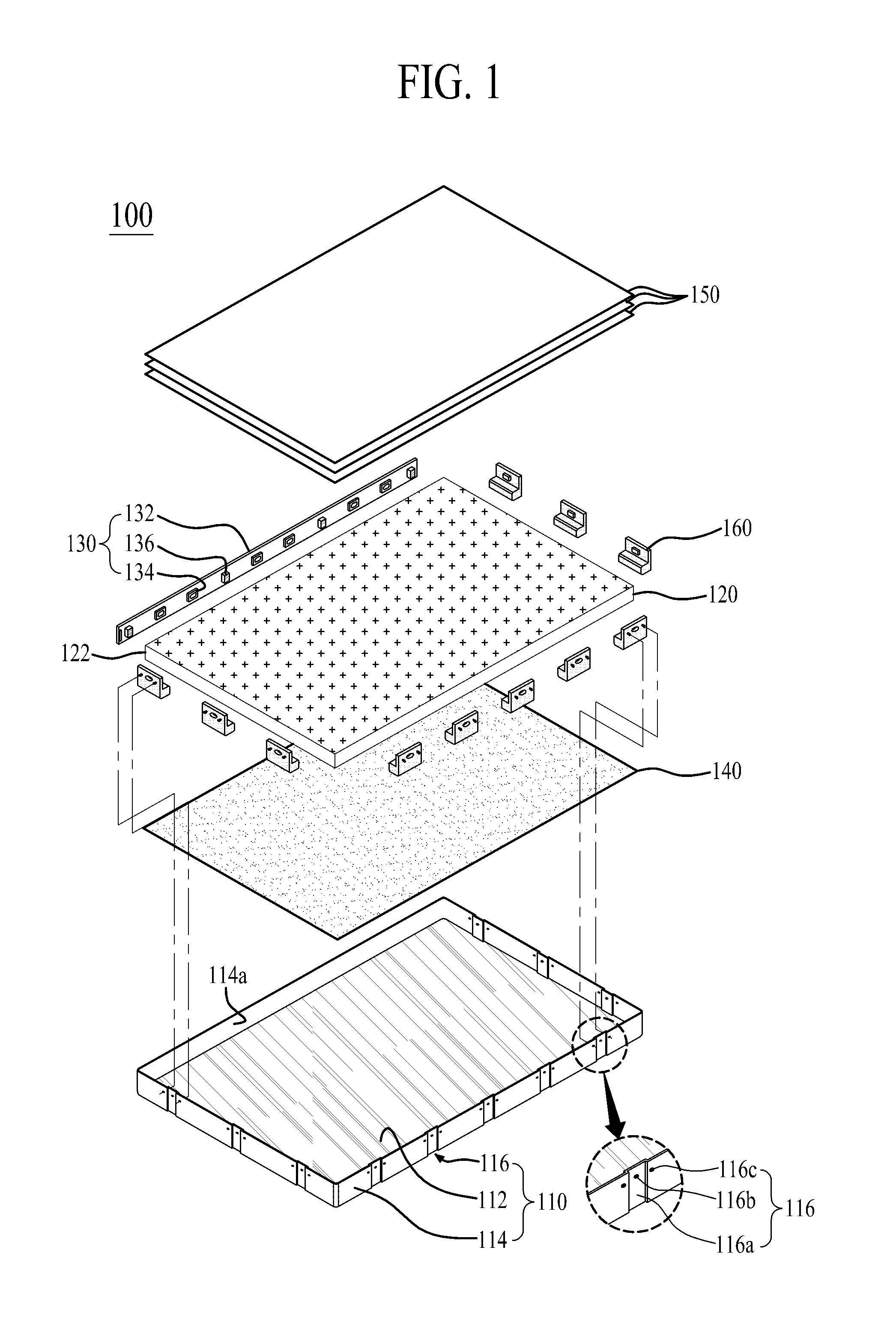

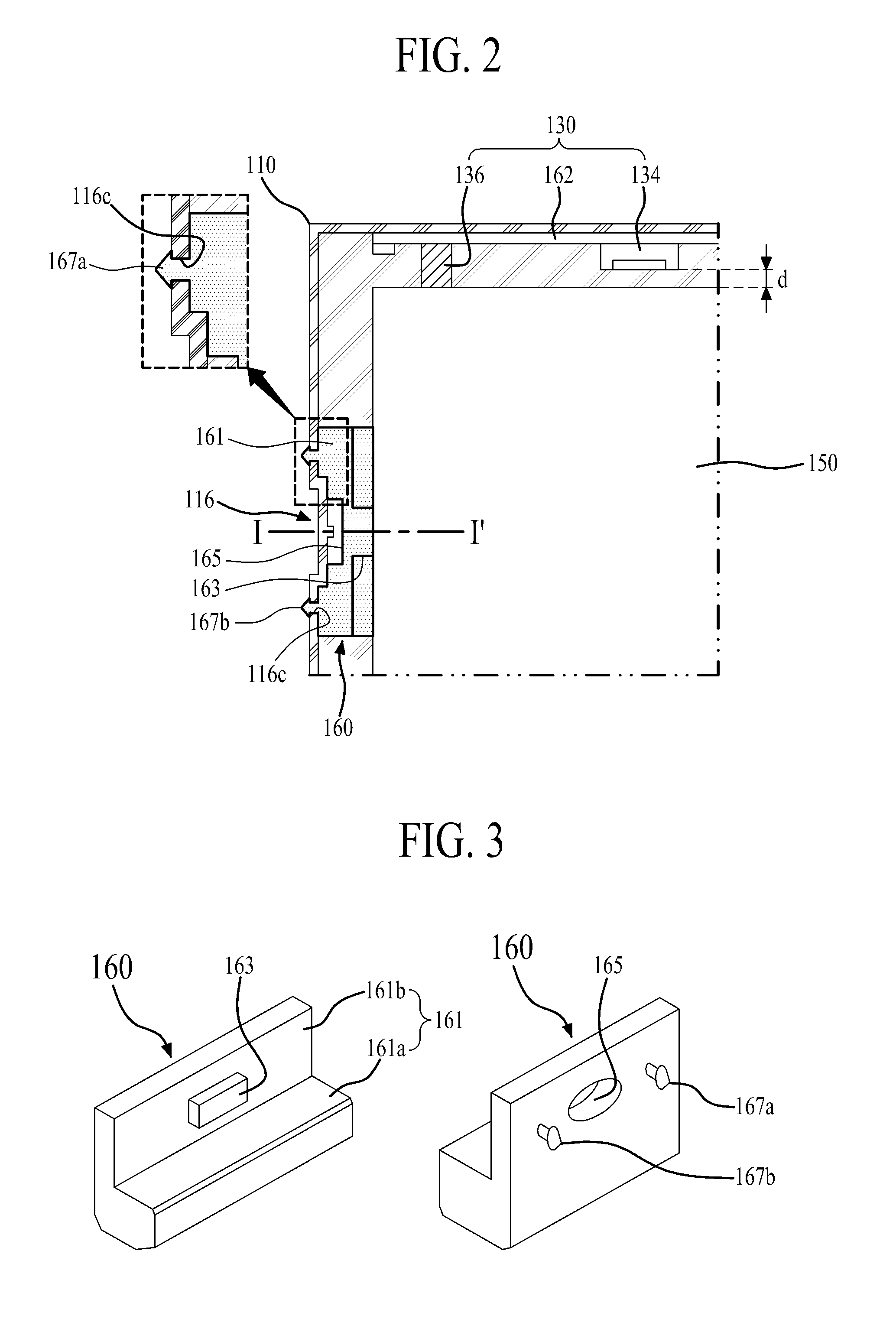

Backlight unit and liquid crystal display device including the same

ActiveUS20130308074A1Prevent movementPrevent thermal deformationMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLight guide

Discussed are a backlight unit and an LCD device including the same, which prevent the thermal deformation and movement of a light guide plate and realize uniform luminance. The backlight unit includes a supporting case supporting a supporting side wall having a receiving space, a light guide plate placed in the receiving space of the supporting case, a light source member irradiating light on a light incident surface prepared in a side surface of the light guide plate, an optical sheet member disposed on the light guide plate, and a plurality of holder members disposed at certain intervals between the supporting side wall and some side surfaces of the light guide plate except the light incident surface. The holder members are deformed in shape by thermal deformation of the light guide plate.

Owner:LG DISPLAY CO LTD

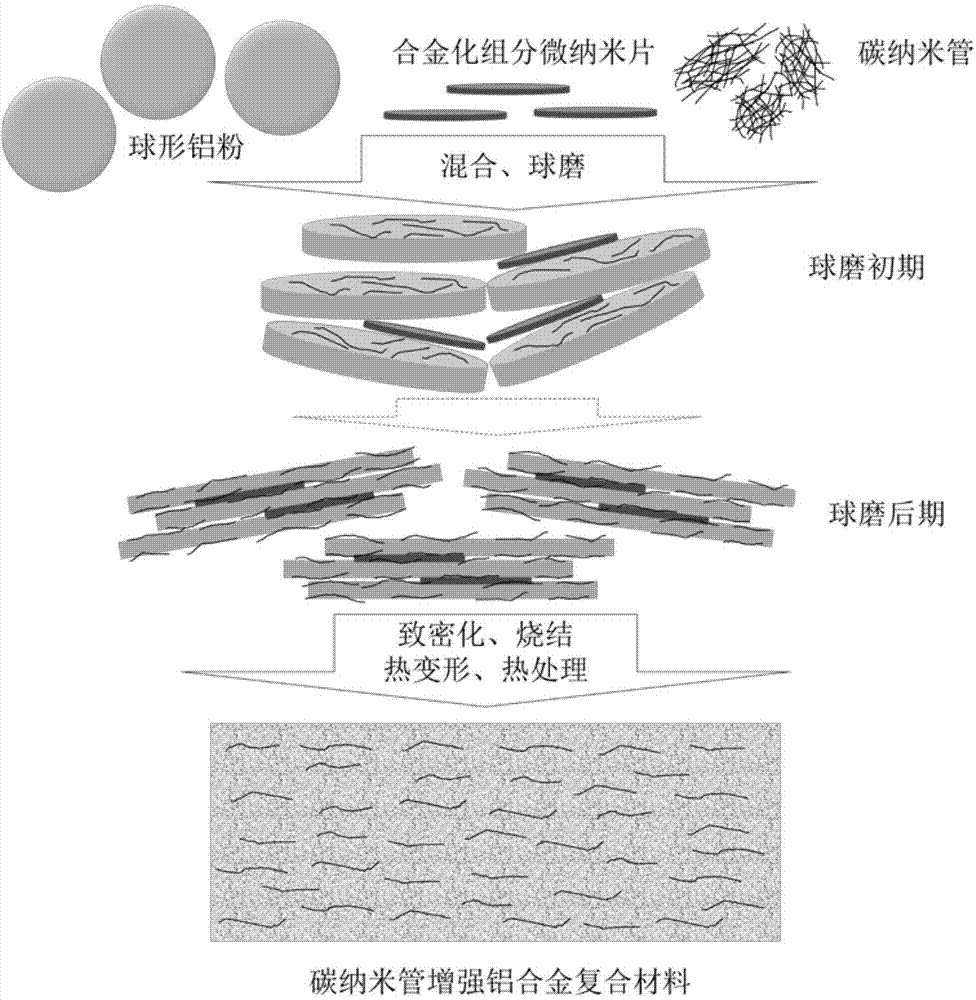

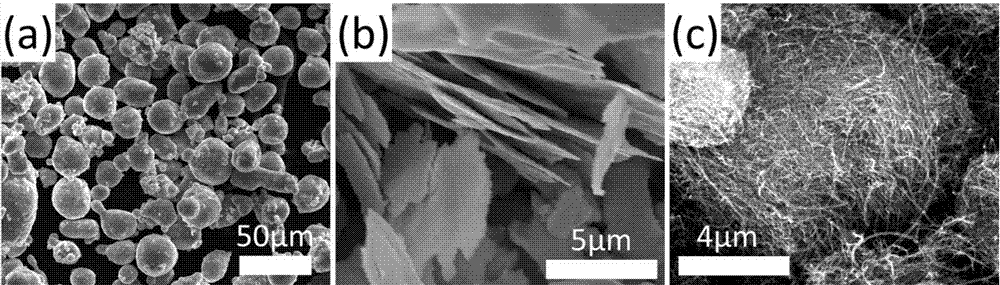

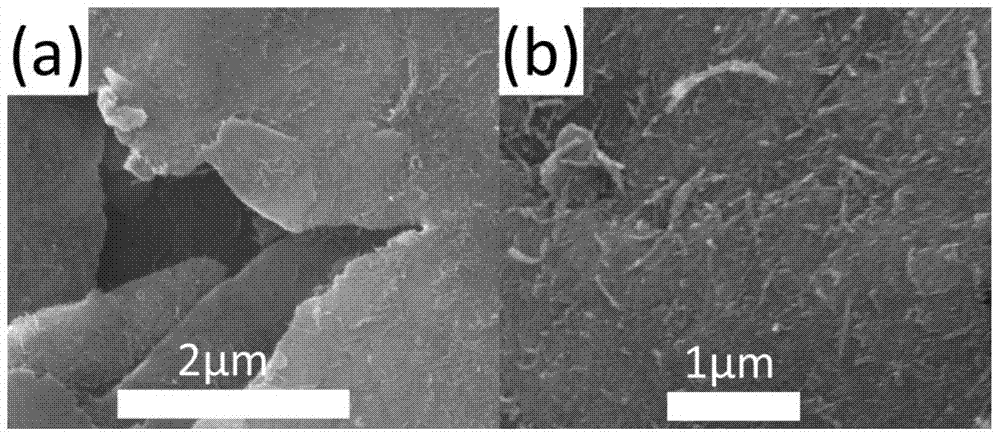

Powder metallurgy preparation method of carbon nanotube reinforced aluminum alloy composite material

ActiveCN103789564ARapid precipitation strengtheningReliable and efficient processMicro nanoThermal deformation

The invention provides a powder metallurgy preparation method of a carbon nanotube reinforced aluminum alloy composite material. The method comprises the following steps: pre-preparing micro-nano flake powder of an alloying component, subsequently ball-milling the powder with a carbon nanotube and spherical pure aluminum powder to prepare flake composite powder, and further performing densifying, sintering, thermal deformation processing and thermal treatment to achieve alloying so as to finally obtain the carbon nanotube reinforced aluminum alloy composite material. Uniform compounding of the matrix aluminum powder, the carbon nanotube and the alloying component can be achieved through limited ball-milling, and meanwhile dangerous elements or uneasy grinding elements such as magnesium and silicon which are high in activity and likely to combust and explode are avoided by adopting the stable and easily ground pre-alloying aluminum powder, so that the security and the reliability are improved; in addition, because of large interlayer boundary and small layer thickness distance, the flake structure is beneficial for uniformly dispersing the alloying component and forming refined dispersed separated phase. The method is beneficial for bringing the effects of composite reinforcement of carbon nanotubes and alloy reinforcement into play to the maximum extent, is energy-saving and time-saving, and is safe and feasible.

Owner:SHANGHAI JIAO TONG UNIV

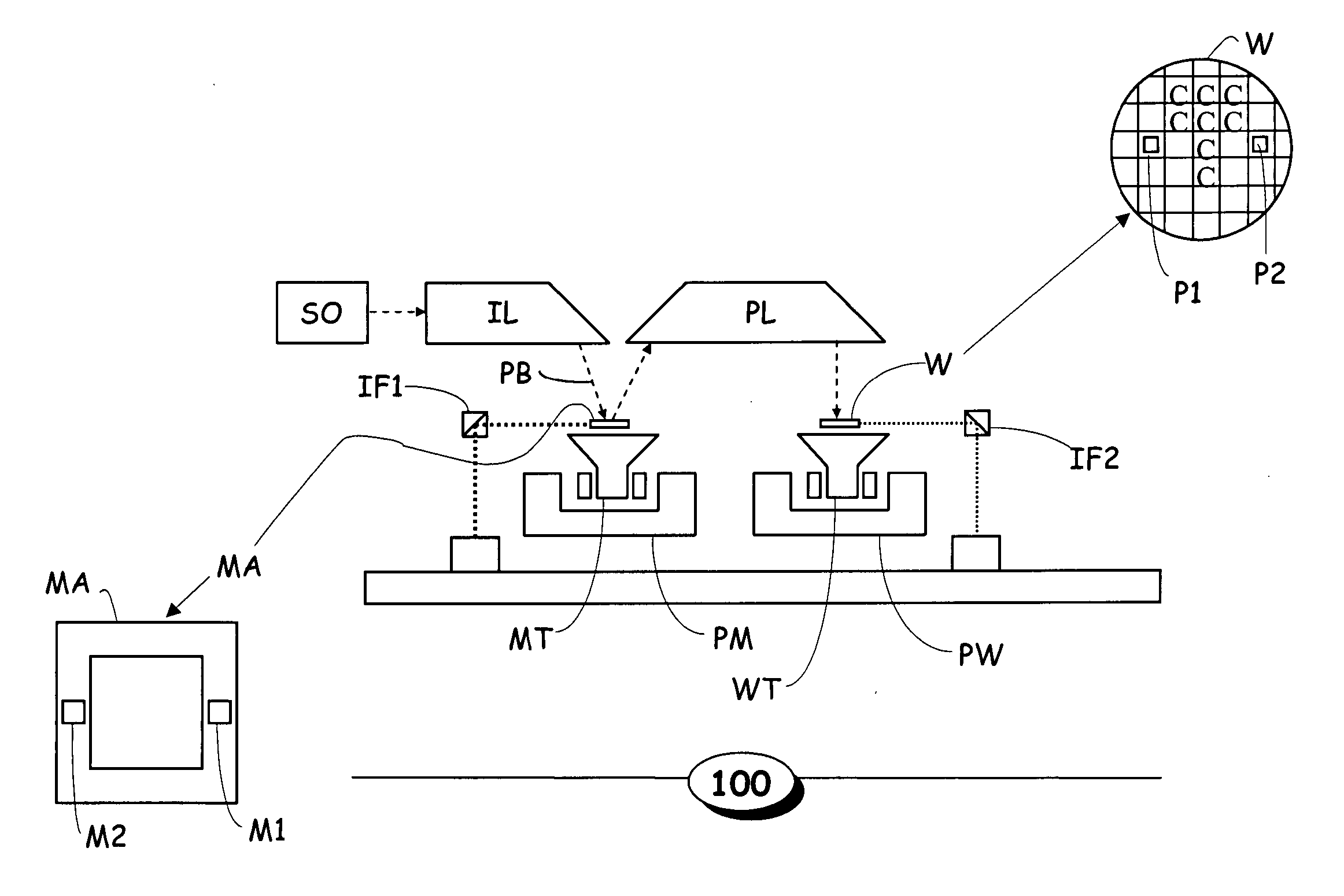

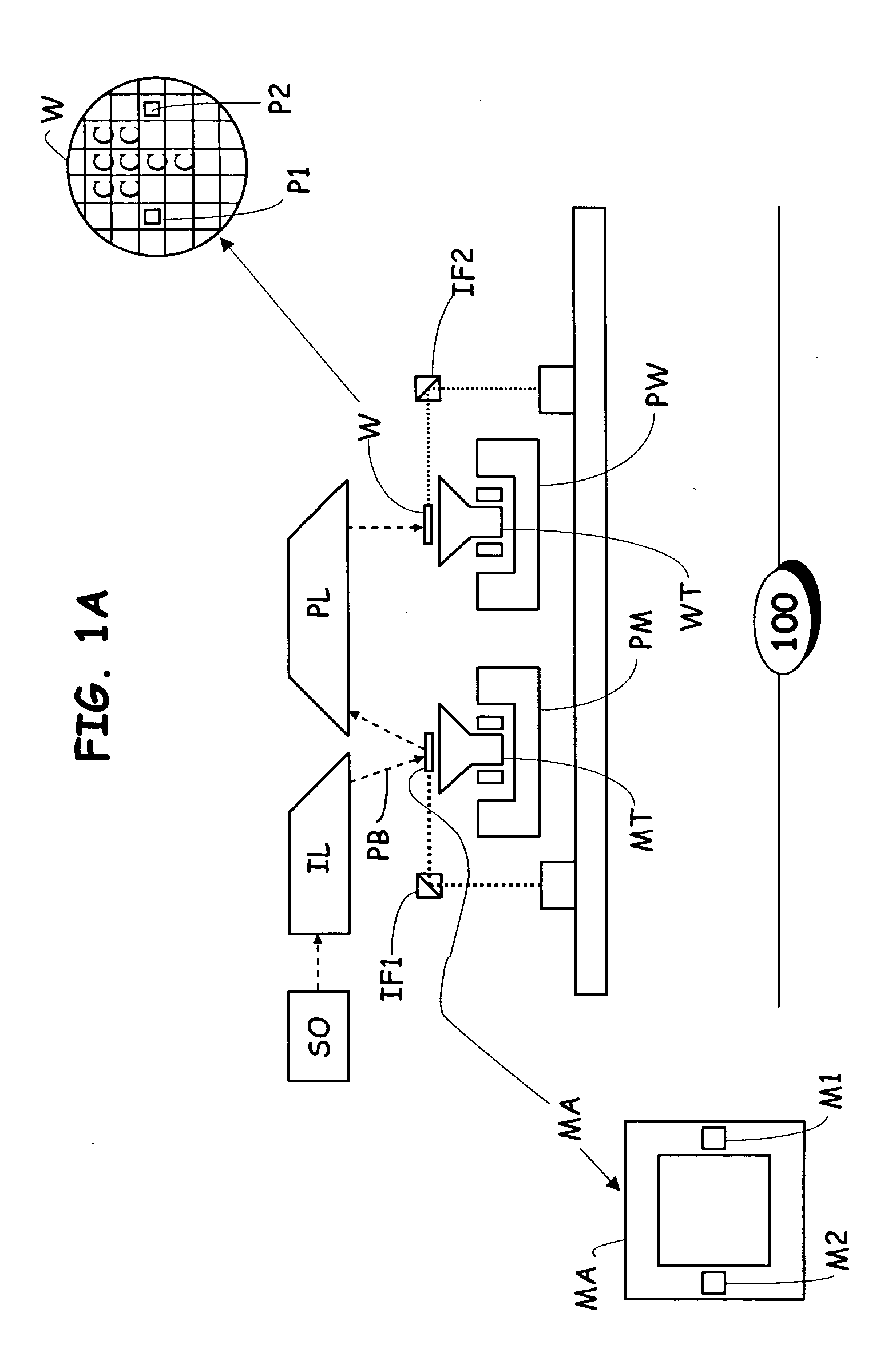

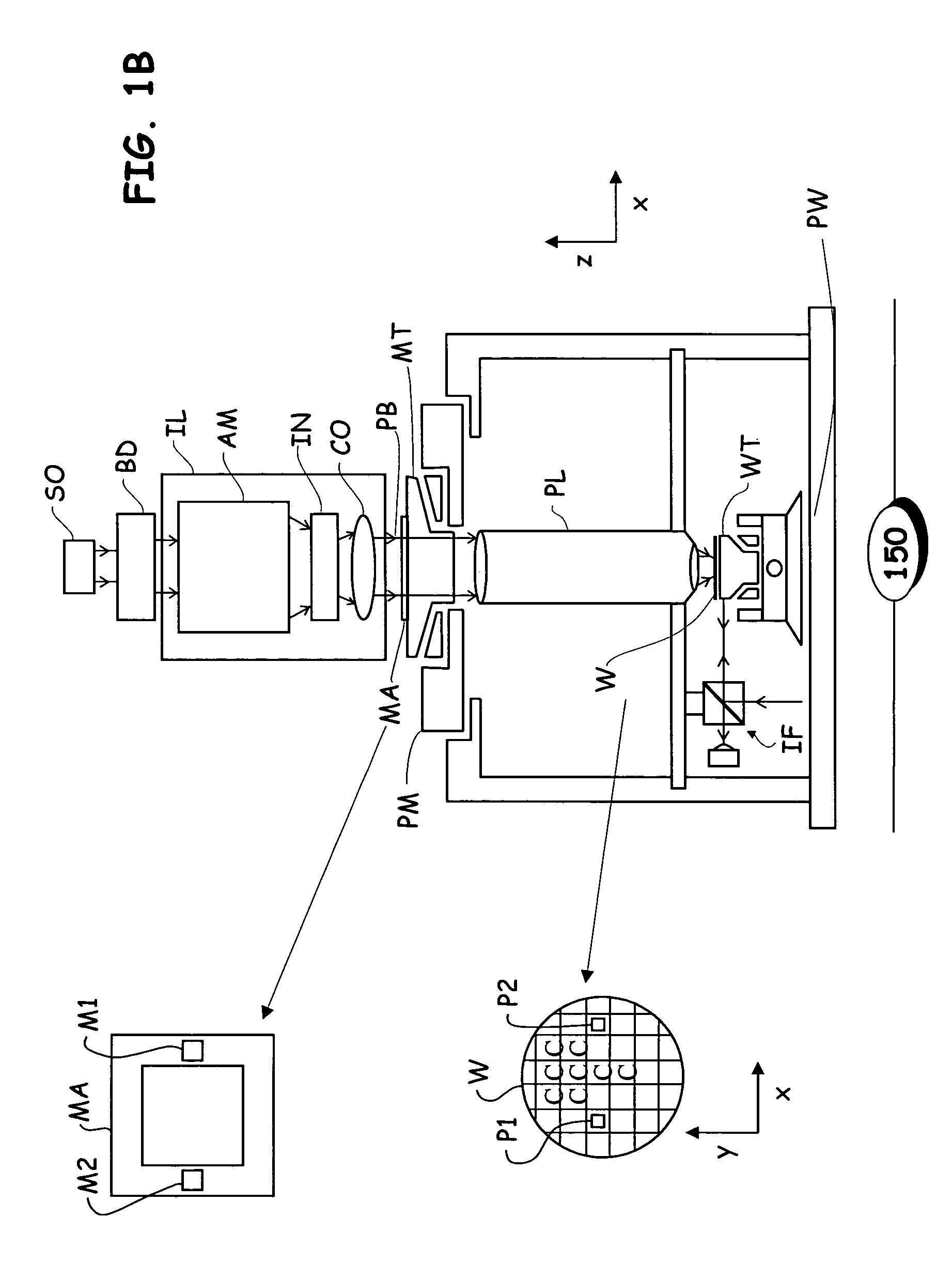

Optimized correction of wafer thermal deformations in a lithographic process

InactiveUS20050136346A1Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusThermal deformationThermal effect

A method and apparatus of correcting thermally-induced field deformations of a lithographically exposed substrate, is presented herein. In one embodiment, the method includes exposing a pattern onto a plurality of fields of a substrate in accordance with pre-specified exposure information and measuring attributes of the fields to assess deformation of the fields induced by thermal effects of the exposing process. The method further includes determining corrective information based on the measured attributes, and adjusting the pre-specified exposure information, based on the corrective information, to compensate for the thermally-induced field deformations. Other embodiments include the use of predictive models to predict thermally-induced effects on the fields and thermographic imaging to determine temperature variations across a substrate.

Owner:ASML NETHERLANDS BV

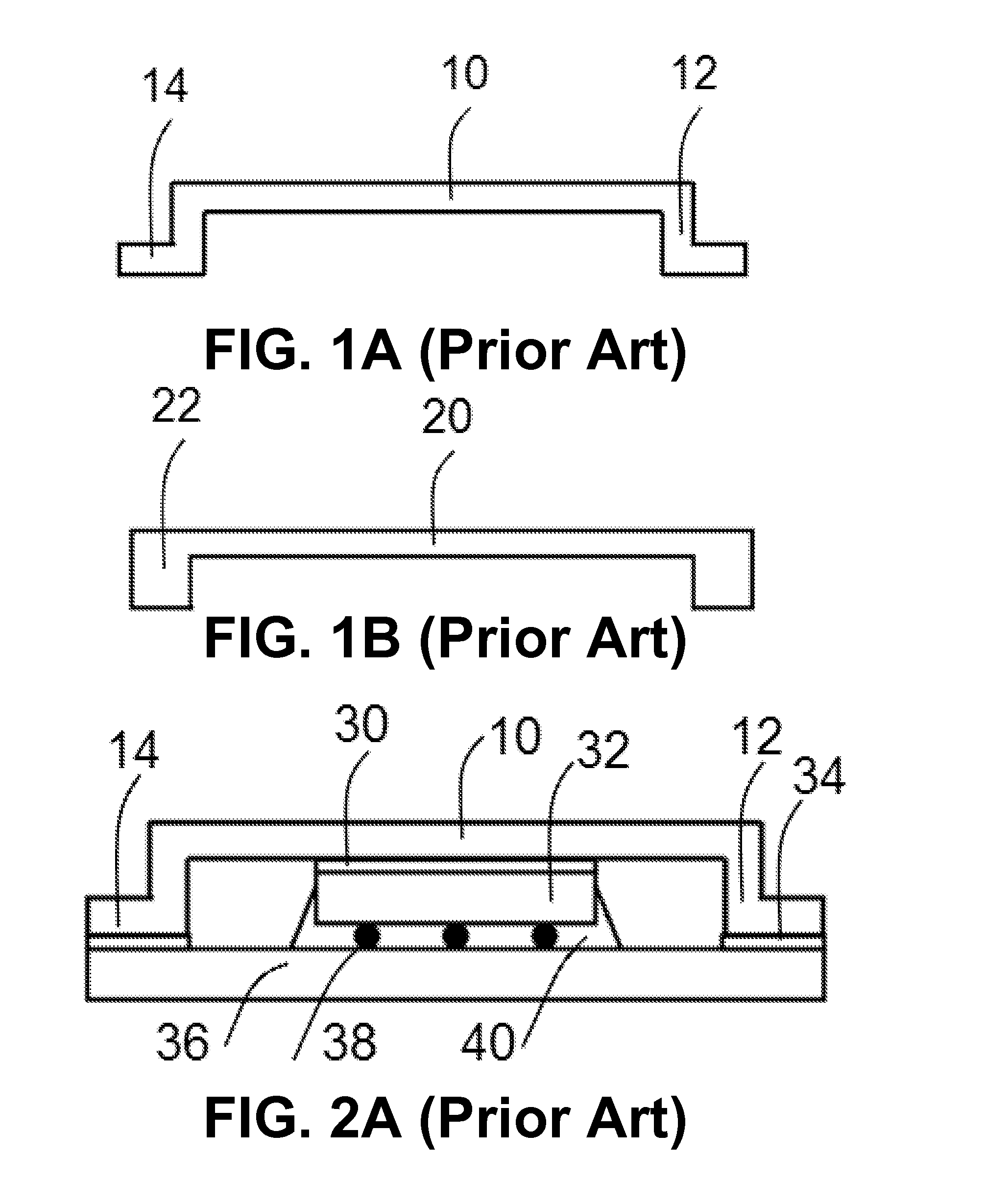

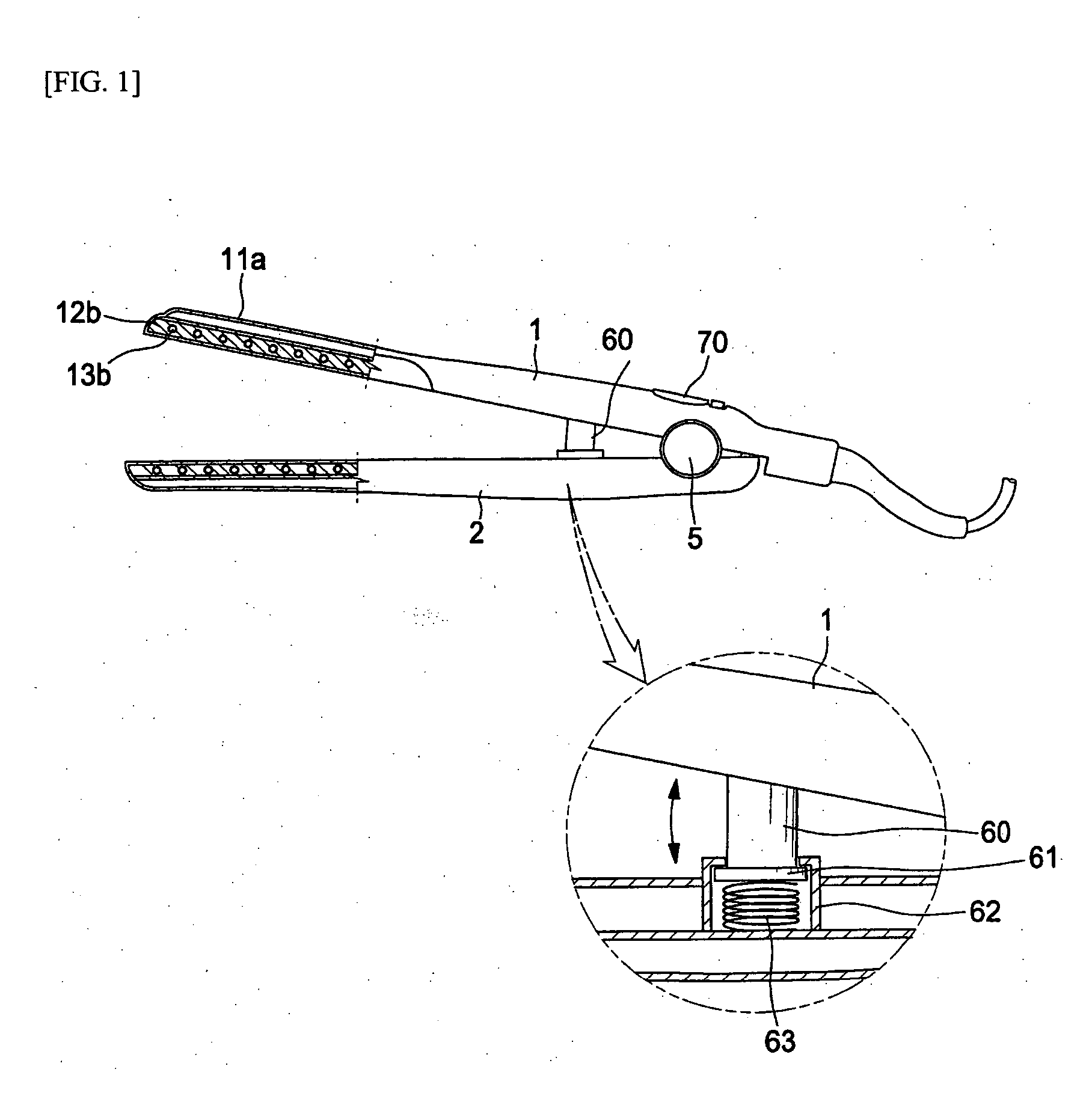

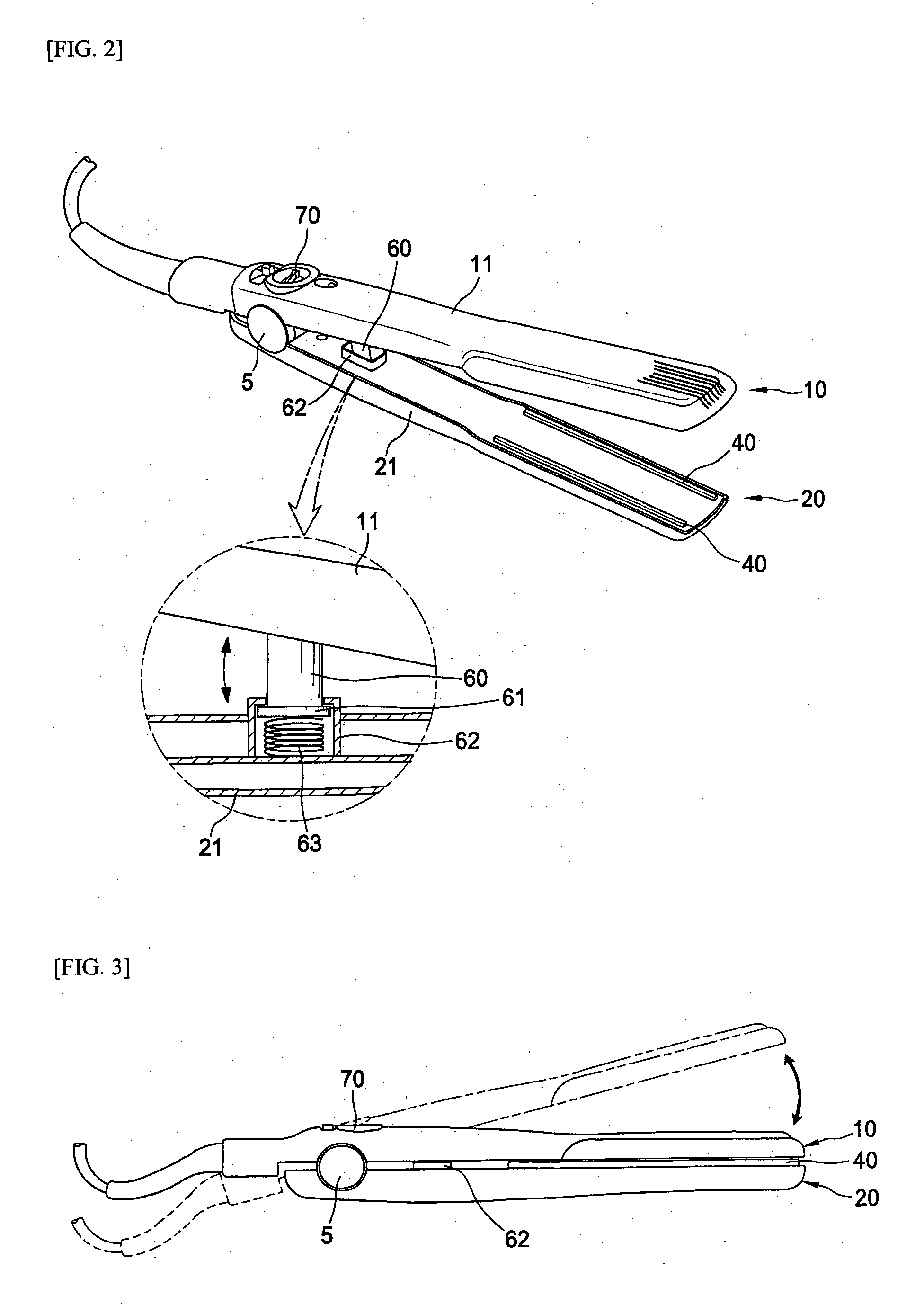

Hair iron having buffer member

InactiveUS20060196523A1Prevent thermal deformationStraightened smoothlyCurling-ironsCurling-tongsSheet steelThermal deformation

The present invention relates to a hair iron having a buffer member, particularly to a hair iron having a buffer member, which is located in between two opposing steel plates to help hair passing through the steel plates to be straightened smoothly and prevent thermal deformation of hair. The invention is characterized by a hair iron comprising a first pressing member 10 and a second pressing member 20 to which steel plates 12, 22 having built-in thermal wire heaters 13, 23 are attached, respectively. A buffer member 40 is attached to the steel plate 22 which is attached to the second pressing member 20.

Owner:CHOI YOUNG BUM

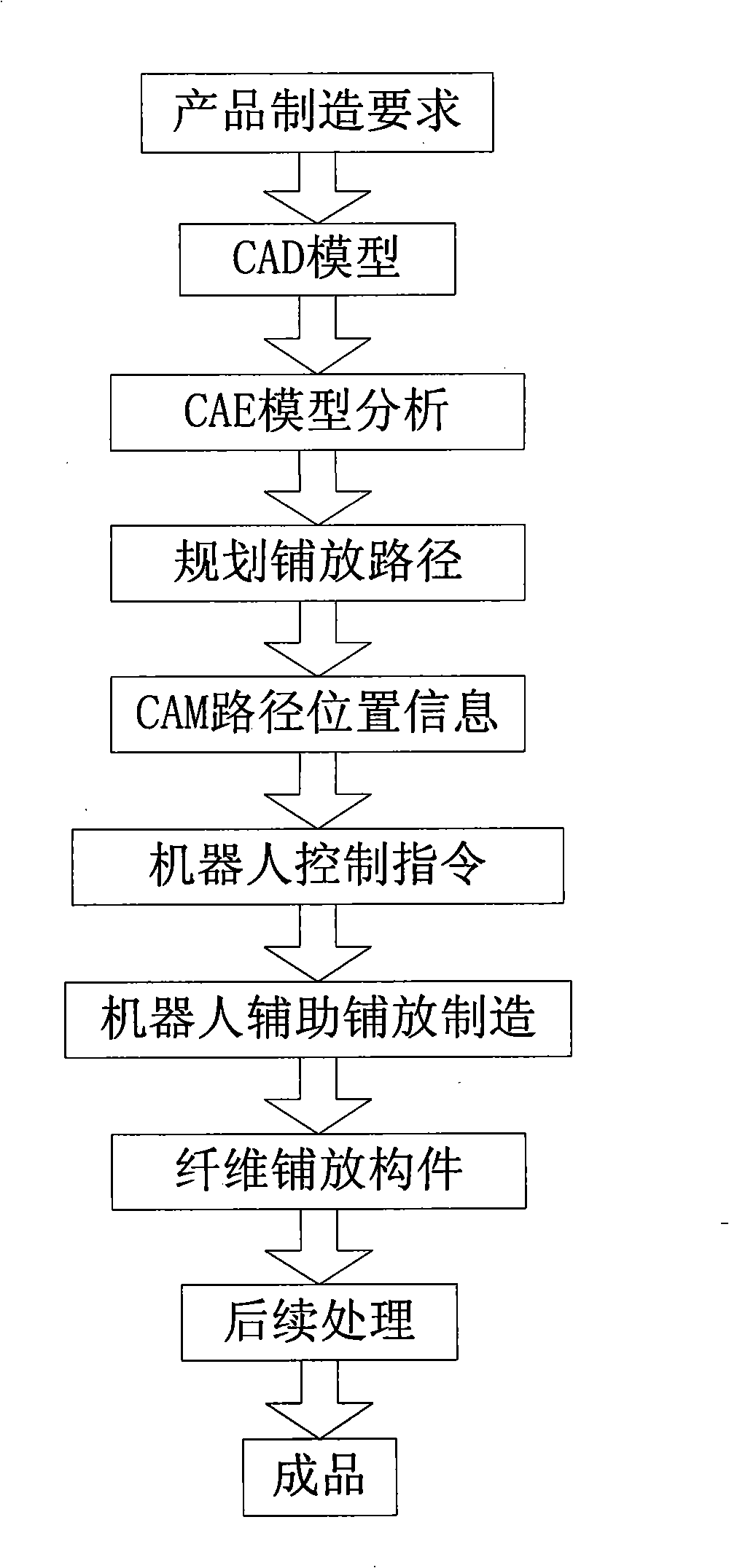

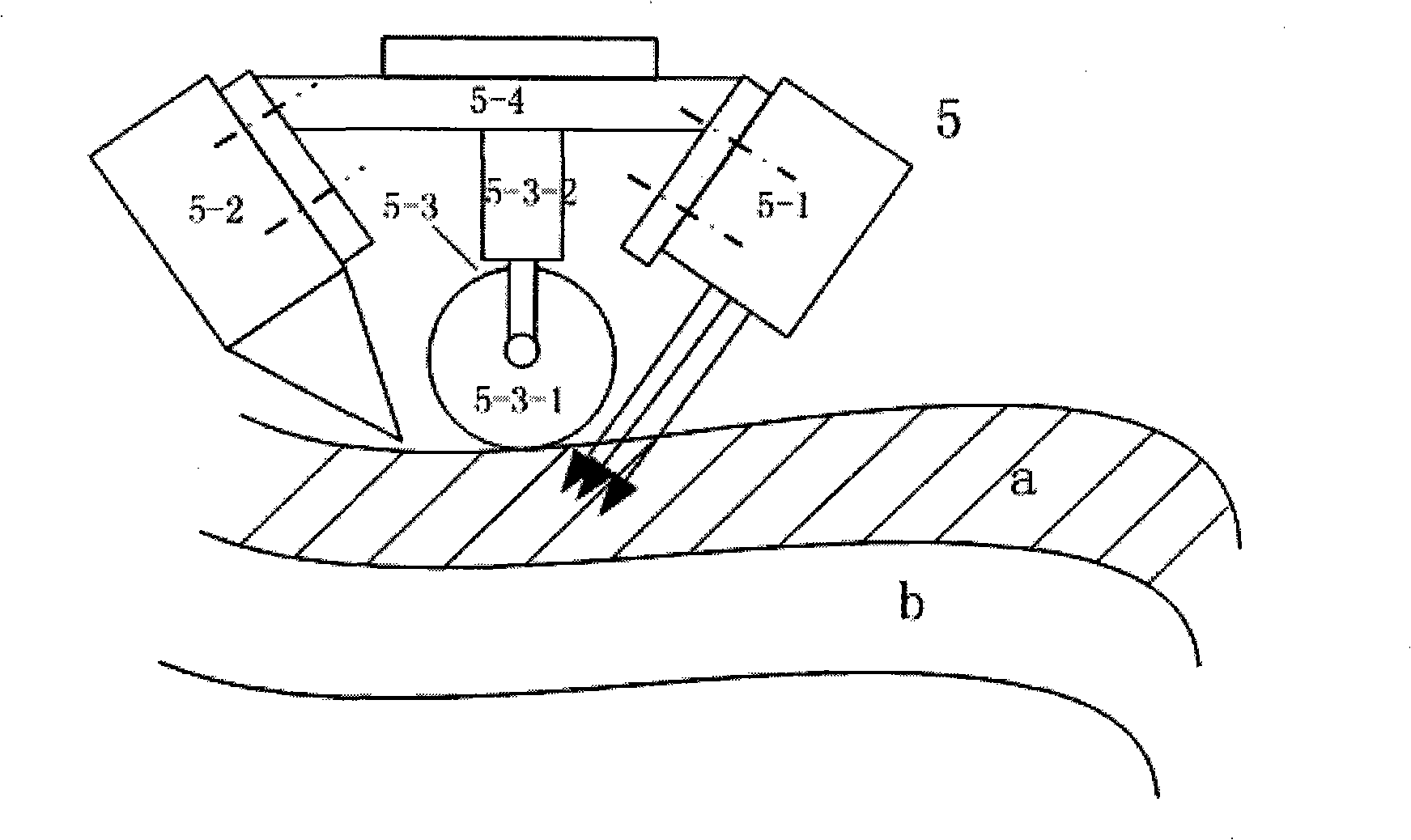

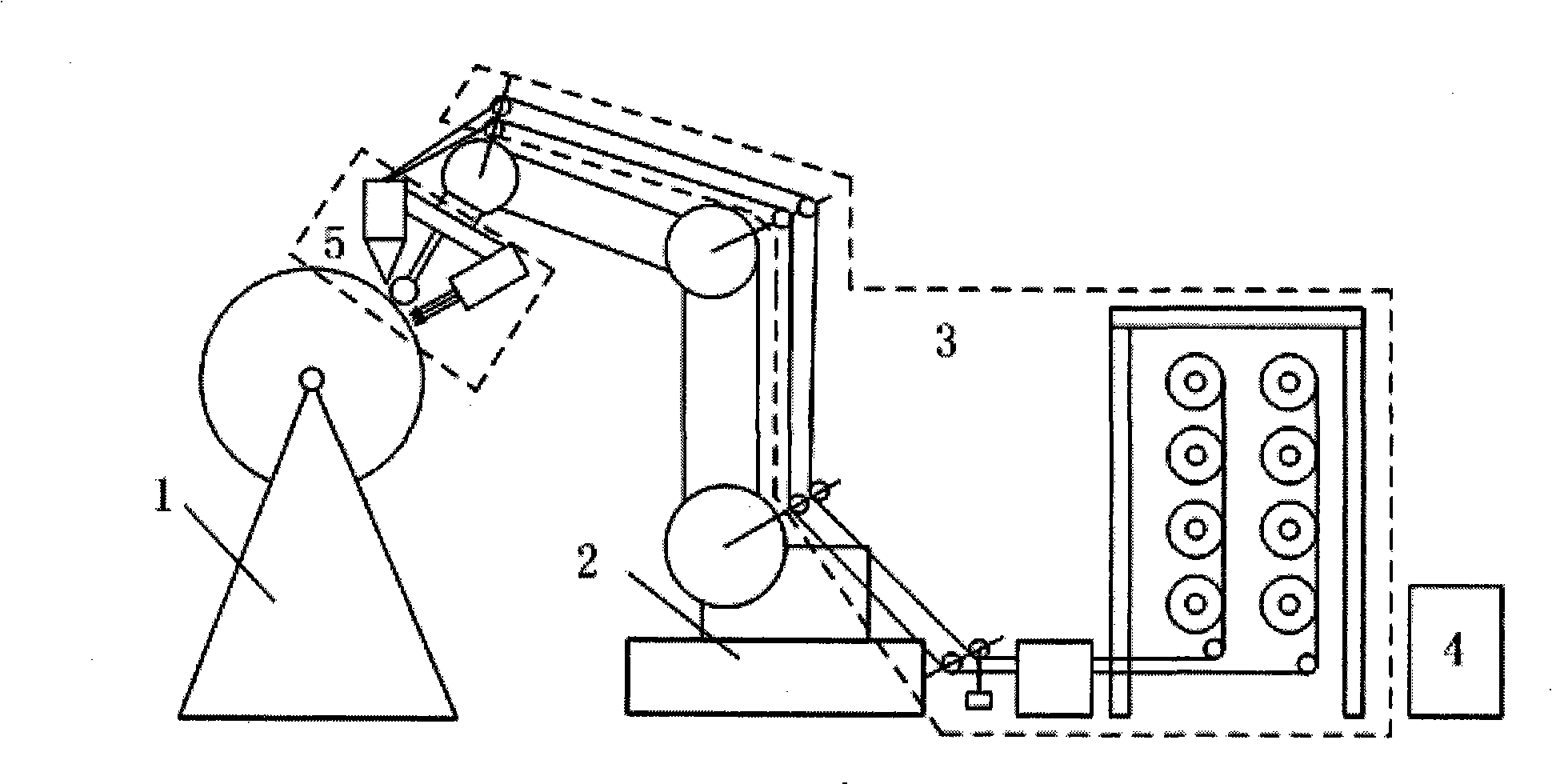

In-situ consolidation fibre laying method and device for producing resin-based compound material component

InactiveCN101254652ASimple manufacturing processShorten the manufacturing cycleCrazingThermal deformation

The invention discloses a method and a device for manufacturing resin-based composite material component by using fiber placement technology. By adopting fiber placement technology, the method and the device can place a fiber placement layer on the surface of a core die by a compaction mechanism to solve the problem of conventional winding equipment that is incapable of manufacturing surface component with negative curvature and non-gyrorotor component. Meanwhile, in-situ instantaneous stratified radiation curing is adopted to eliminate the influence of a tensile force in the fiber placement layer on the shape of the product and to solve the problems and disadvantages of large thermal deformation and easy generation of cracks due to autoclave curing treatment, the restriction of the autoclave volume on the component size, high production cost, and long production period. Based on industrial robot as the manufacture body, the device can improve the problems of prior placement equipment such as the deficiency of the flexibility in manufacturing more complex surface and complex structure.

Owner:XI AN JIAOTONG UNIV

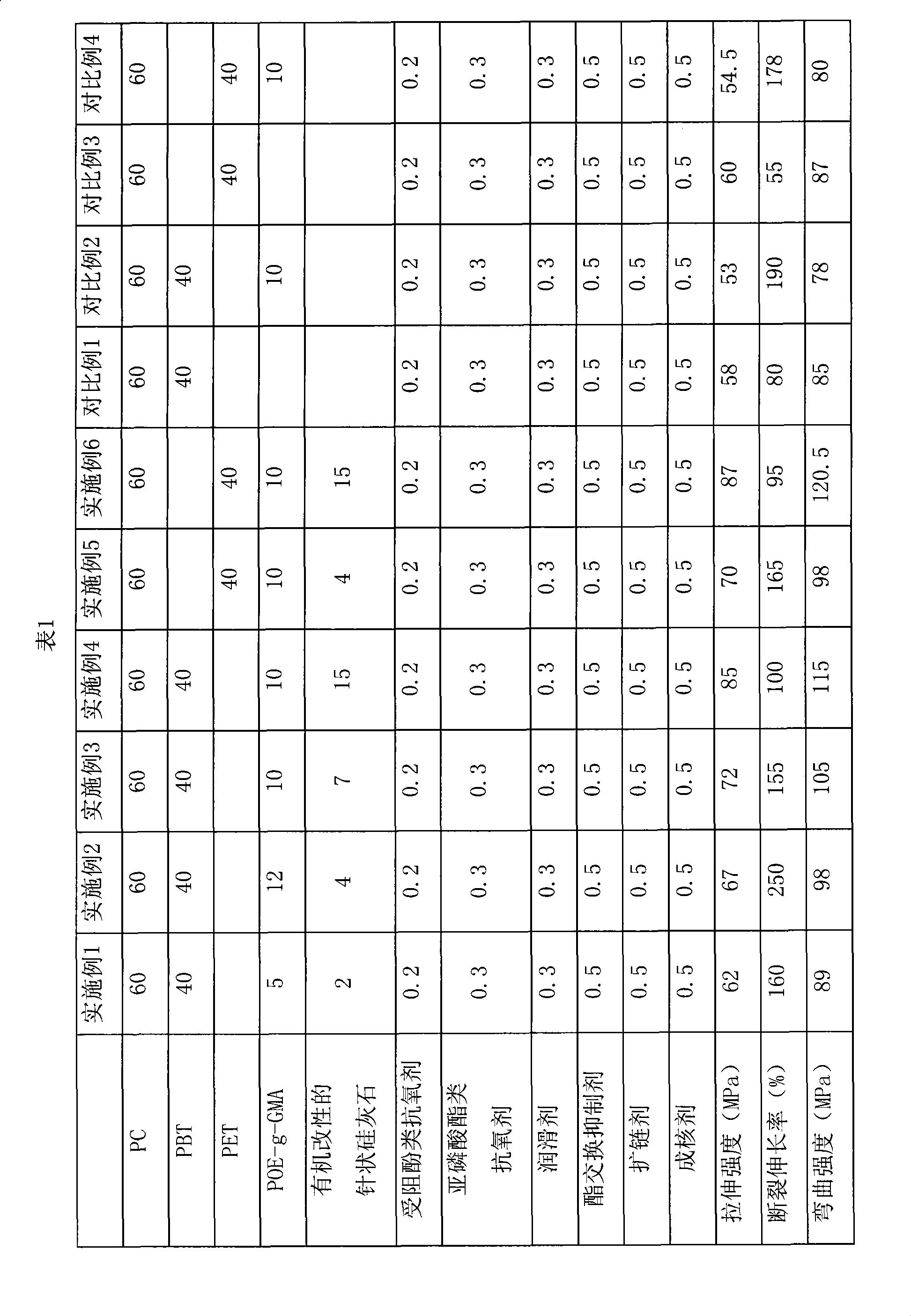

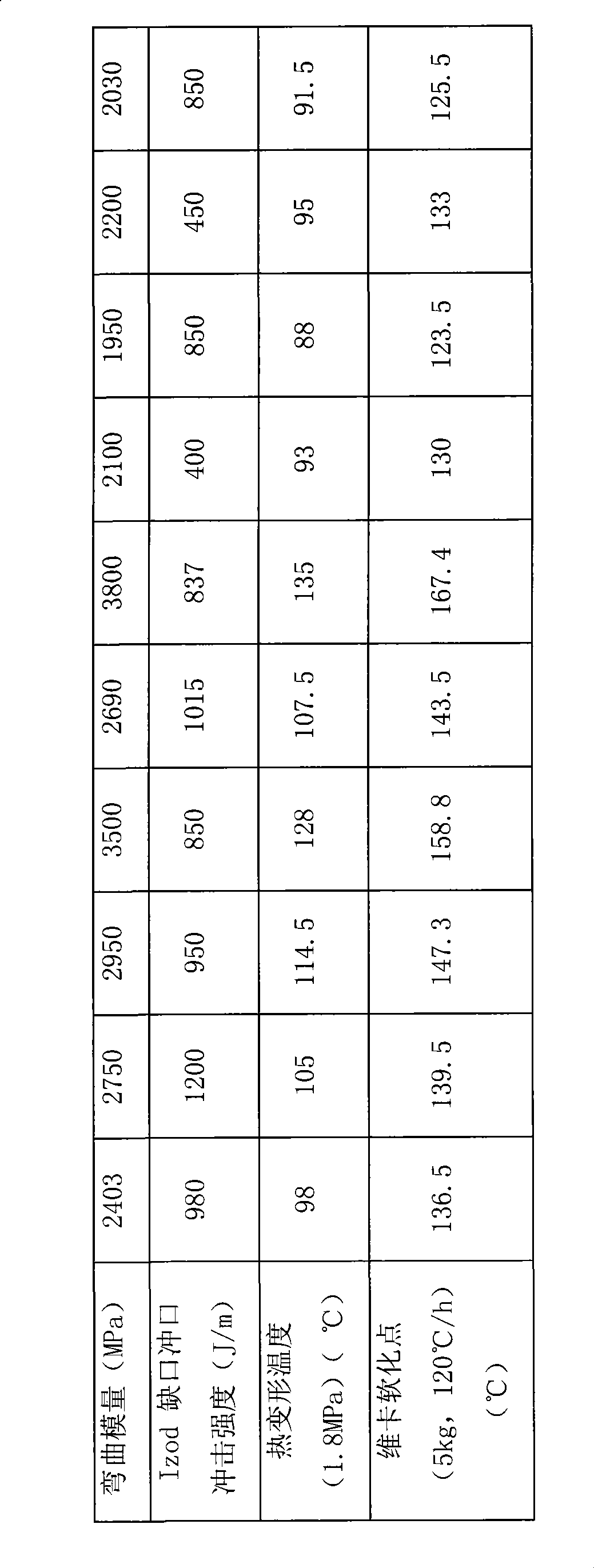

Method of manufacturing polycarbonate/polyester alloy

The invention discloses a preparation method of polycarbonate / polyester alloy. Glycidyl methacrylate grafted ethylene-octylene multipolymer / organic modified needle-shaped aedelforsite composite toughener, i.e. a technology of simultaneously using organic / inorganic rigid particle toughener is adopted; the glycidyl methacrylate grafted ethylene-octylene multipolymer, organic modified needle-shaped aedelforsite, polycarbonate and polyester are melted and mixed in a double-screw extruder, to obtain high-performance alloy material. The prepared polycarbonate / polyester alloy has excellent integrated mechanical properties and size stability, the notched impact strength reaches 1200J / m, the tensile strength reaches 67MPa, the elongation at break reaches 250 percent, the flexural strength is up to 98MPa, the flexural modulus reaches 2750MPa, and the thermal deformation temperature in high load (1.82MPa) is up to 105 DEG C. Therefore, the prepared polycarbonate / polyester alloy can be applied in cars, and to outer decorations, household electrical appliances, IT and the like industrial products.

Owner:SHANGHAI JIAO TONG UNIV +1

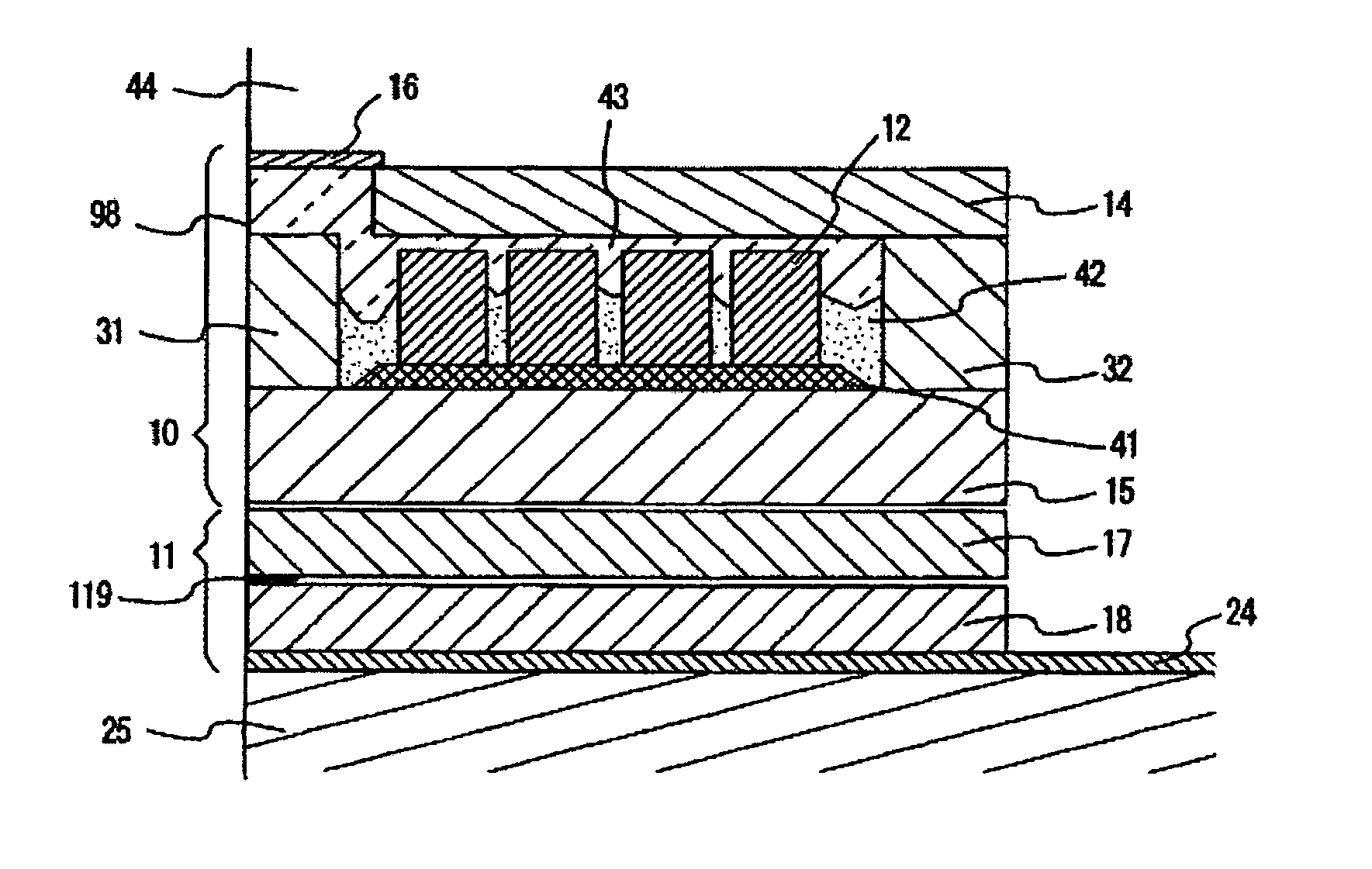

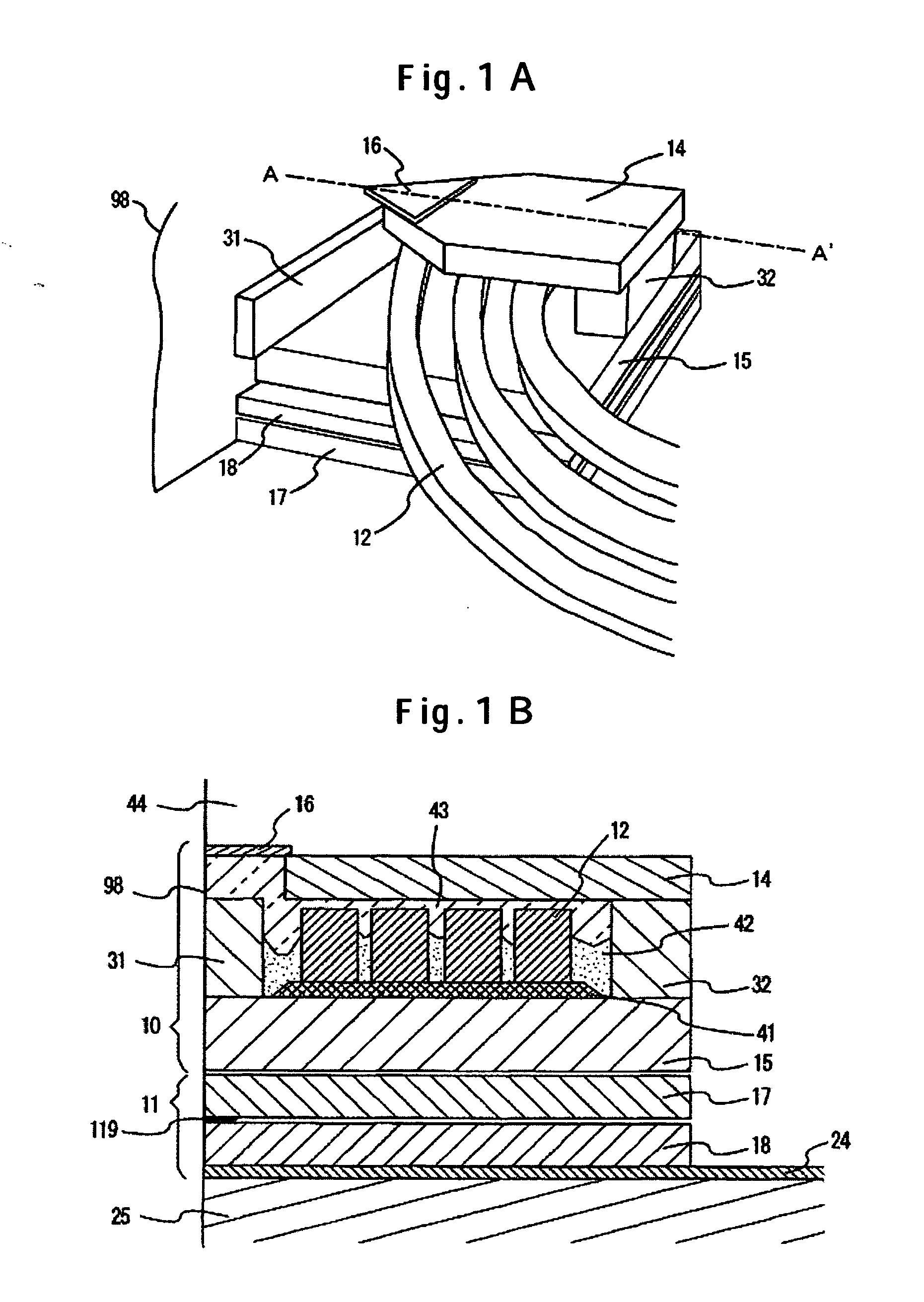

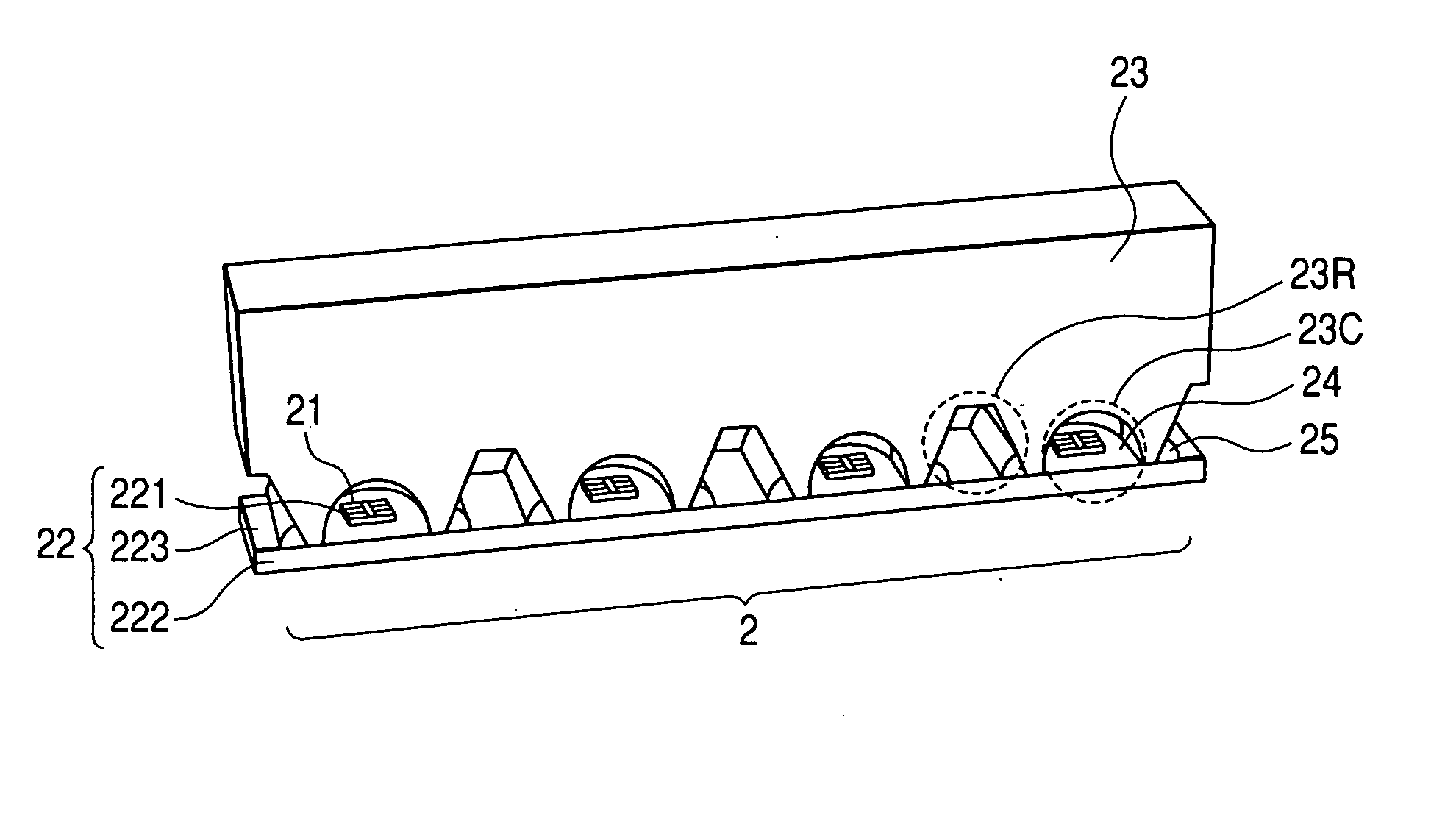

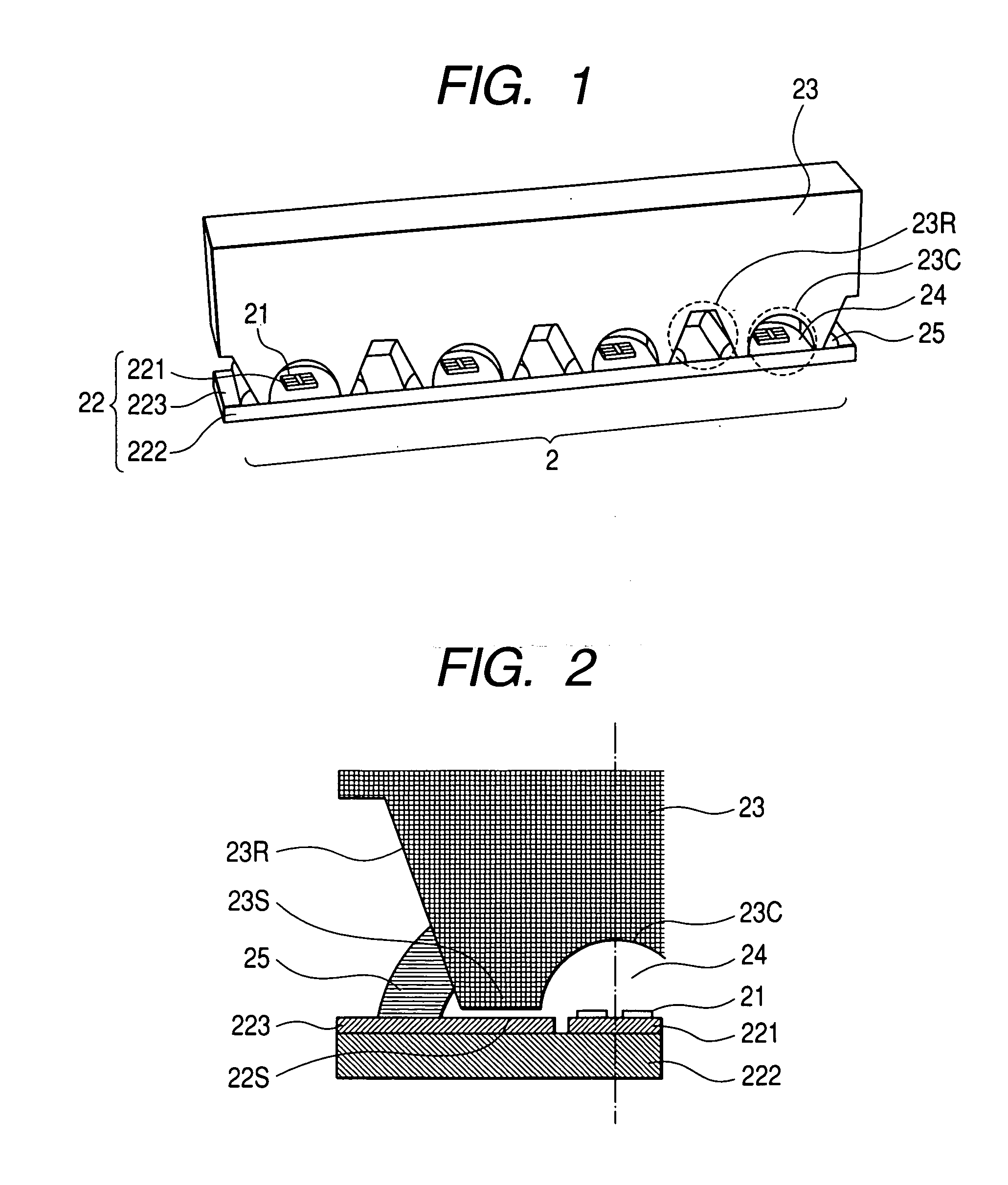

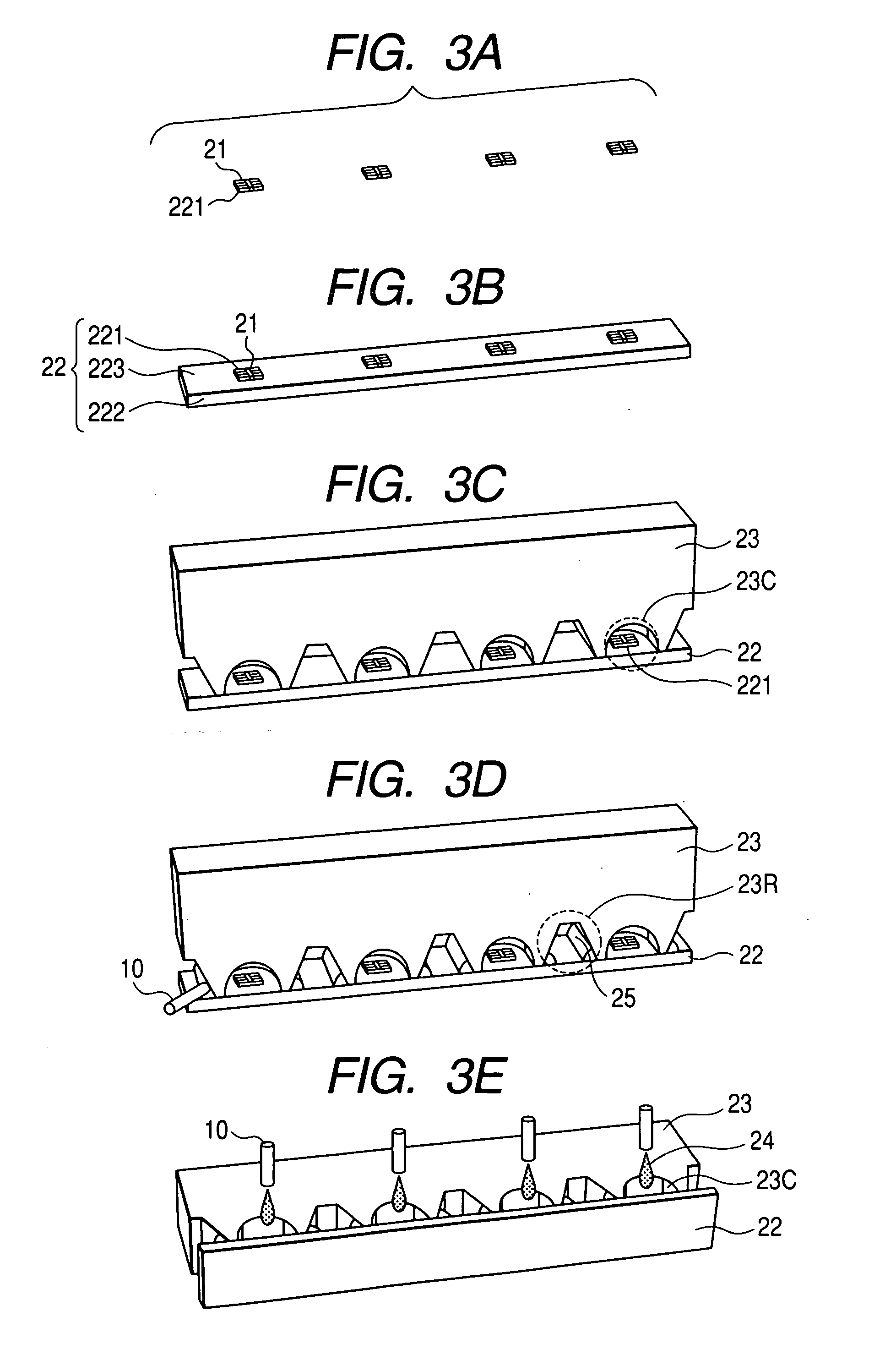

Liquid crystal display, illuminant module and its manufacturing method

InactiveUS20070076433A1Improve image qualityImprove extraction efficiencyDischarge tube luminescnet screensPoint-like light sourceBond interfaceLiquid-crystal display

When a long illuminant module is constructed, debonding of a bonded interface or bending occurs due to a difference in a magnitude of thermal deformation between a lens material and a metal substrate. In an illuminant module including light emitting elements, a substrate on which the light emitting elements are mounted, a transparent encapsulating resin which encapsulates the light emitting elements, and a lens material having cavities formed therein, in which the respective light emitting elements and transparent encapsulating resin are stored, notches are formed in a surface of the lens material on the side of the substrate, and the notch surfaces of the notches and the surface of the substrate are bonded using a bonding material.

Owner:HITACHI LIGHTING

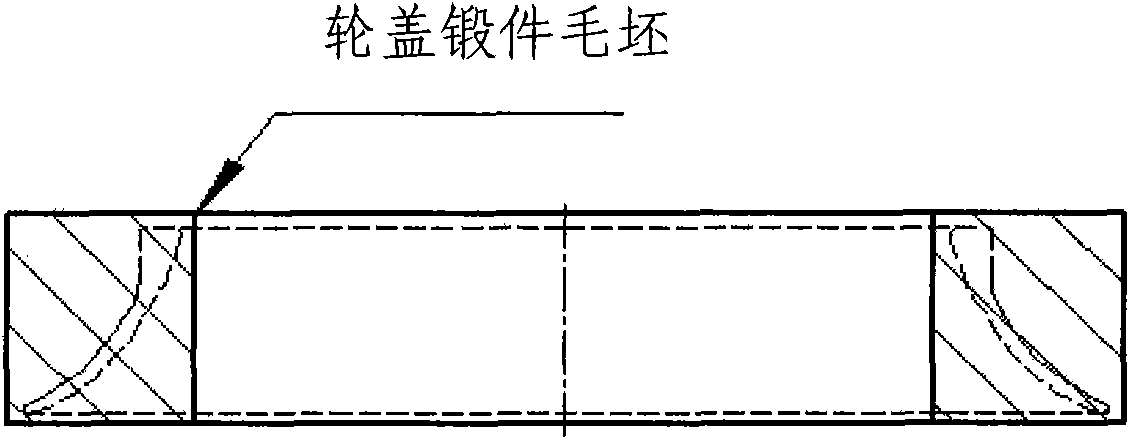

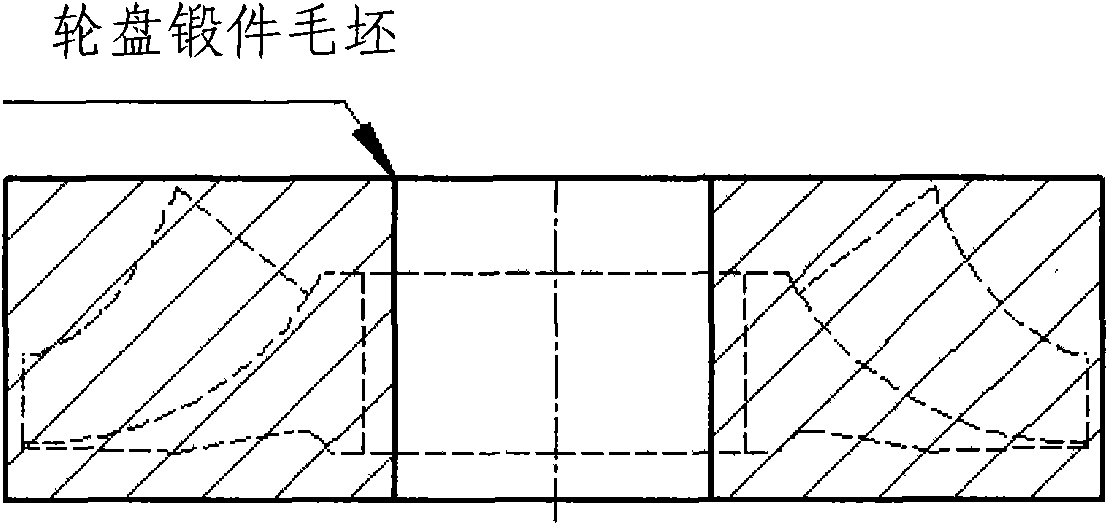

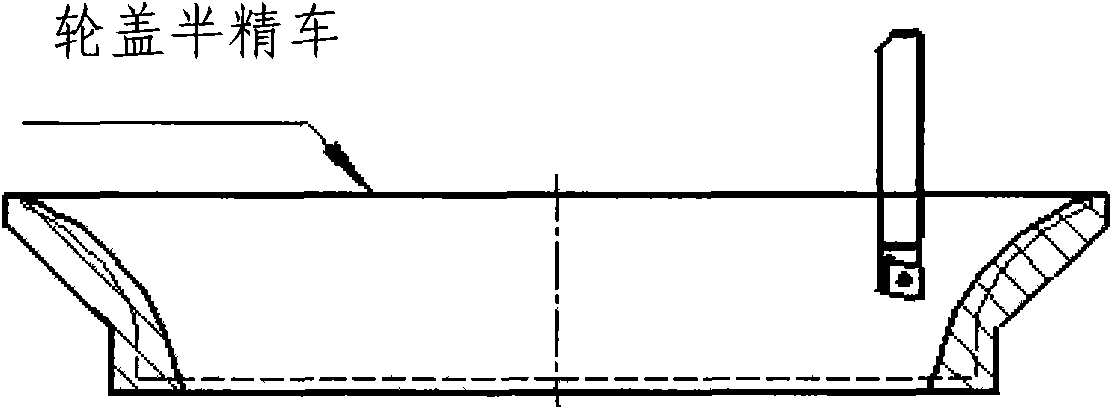

Machining method of three-dimensional closed impeller

ActiveCN102091919ASave raw materialsReduce manufacturing costMilling equipment detailsNumerical controlImpeller

The invention relates to a machining process of an impeller of a compressor, in particular to a machining method of a three-dimensional closed impeller, which is to clamp a semi-finish turned forge piece on a five-axis linked computer numerical control machining center to perform closed channel overall milling including drilling, coarse machining, semi-precision machining, back chipping and finish machining to mill the entire impeller and impeller channels. Compared with the conventional welding method, the machining method has the advantages that: the raw materials are saved and production cost is reduced as only one entire forge piece blank is used; the working efficiency is improved greatly because fewer machining process procedures are adopted and machining speed is high; the machining quality is high as quality defects caused by thermal deformation and welding are avoided; the machined impeller has high strength and high corrosion resistance; and the machining time of the impeller is reduced and the life index of a tool is improved because the flow the overall milling machining method is optimized according to the material, structure, specification and technical requirements of the workpiece and an applicable tool is configured according to different machining process procedures.

Owner:SHENYANG BLOWER WORKS GROUP CORP +1

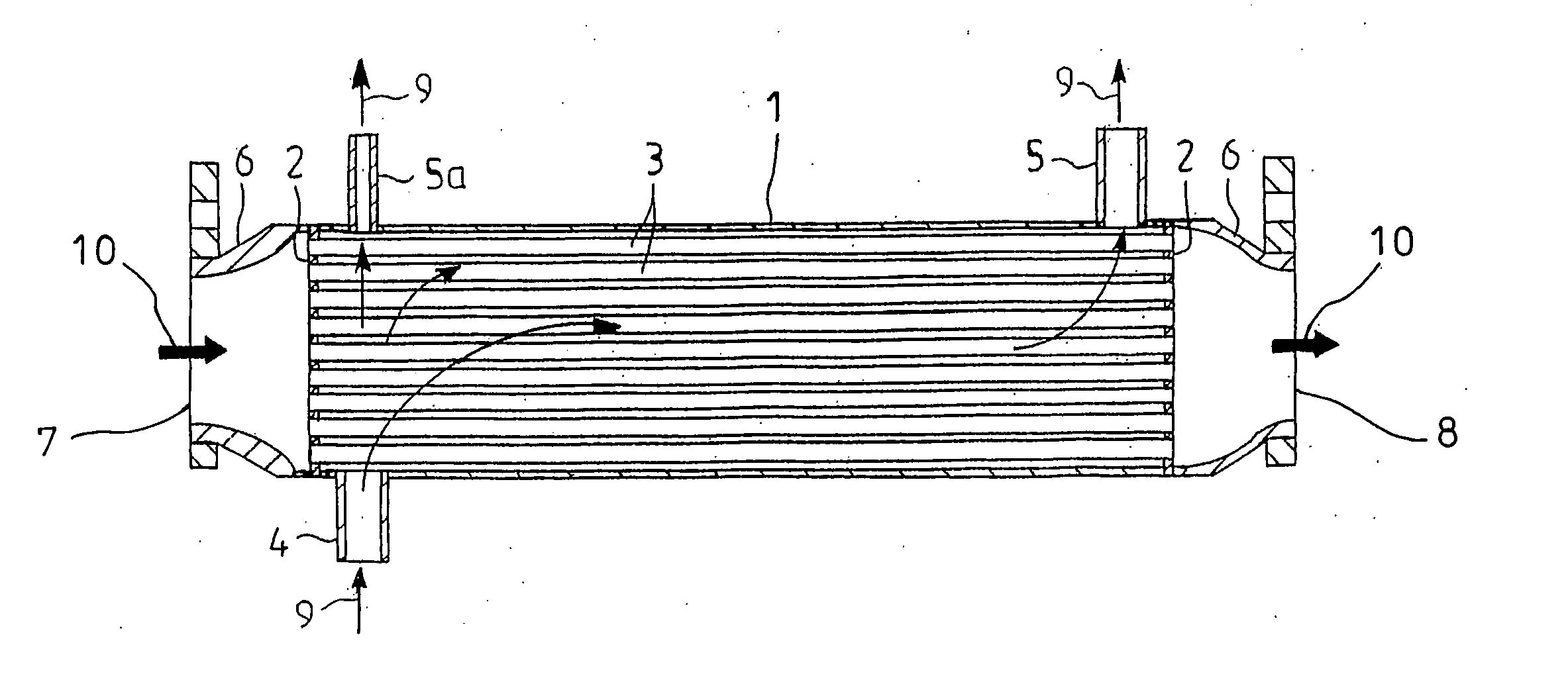

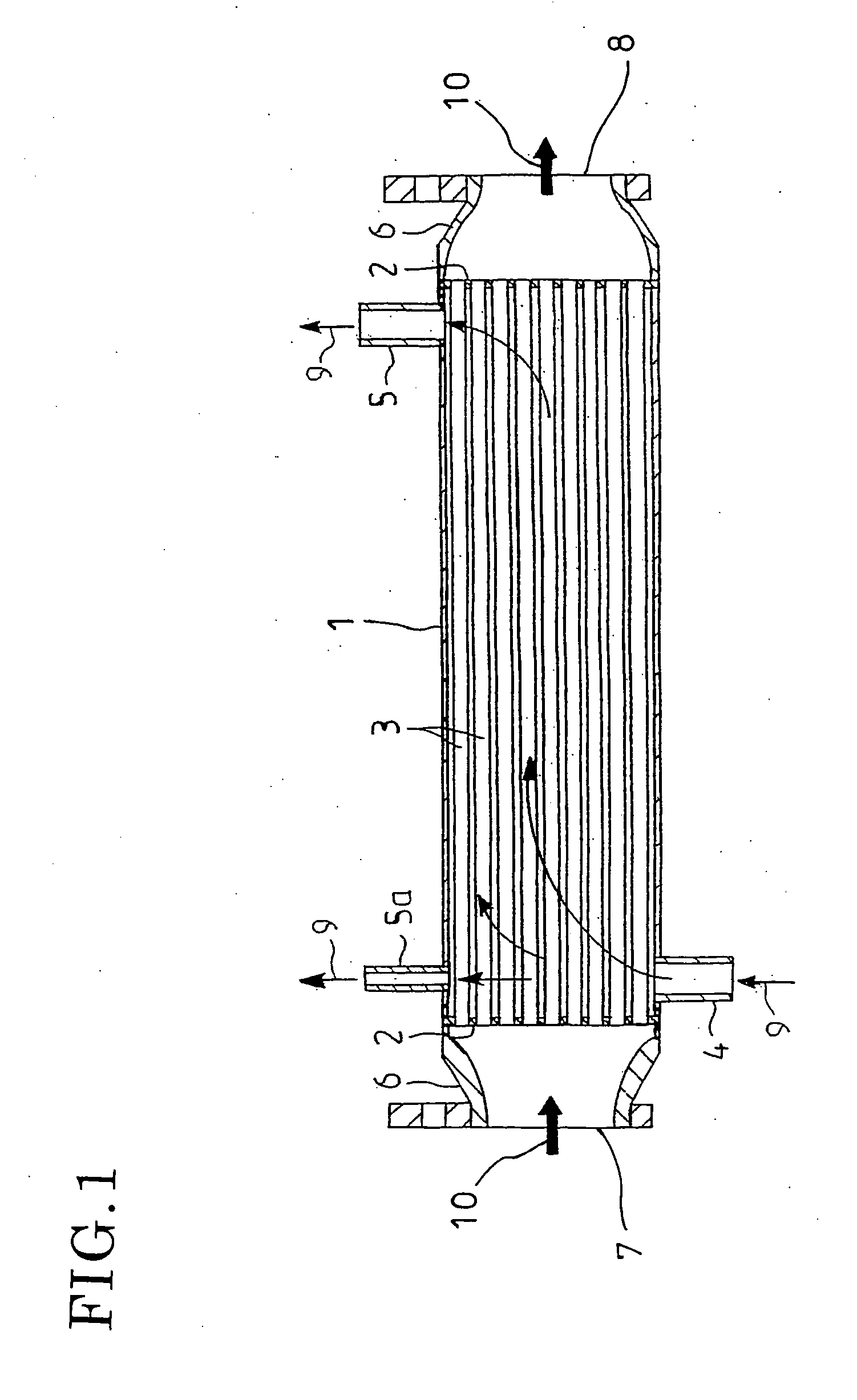

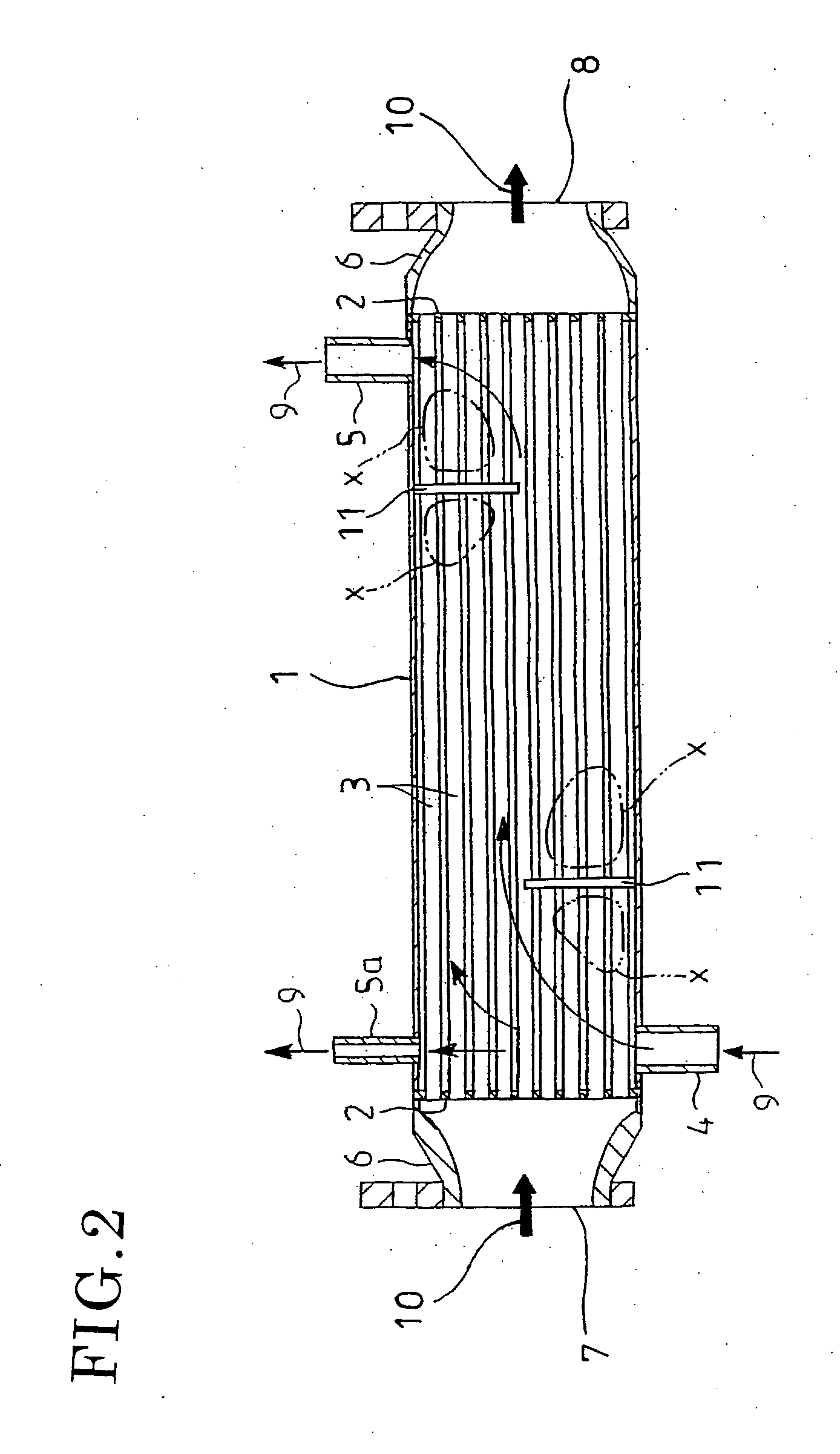

Egr cooler

InactiveUS20060231243A1Increased pressure lossImprove the exhaust effectNon-fuel substance addition to fuelInternal combustion piston enginesThermal deformationEngineering

Provided is an EGR cooler which can solve the problem of the vibrated tubes without causing thermal deformation due to stagnation of the coolant water, without complexity of piping in the coolant water system and without increase in pressure loss. The EGR cooler comprises tubes 3 and a shell surrounding the tubes 3, the coolant water being supplied and discharged to and from the shell 1 and being passed through the respective tubes 3 so as to make heat exchange of the exhaust gas with the coolant water. In the shell 1, an intermediate support plate 13 with a plurality of through-holes 14 is arranged and mutually adjacent ones of the tubes 3 are grouped for penetratingly fixture to the through-hole 14. A coolant water passage 15 is ensured between the tubes 3 grouped and penetratingly fixed to the same through-hole 14 of the intermediate support plate 13 for free communication between the tubes 3.

Owner:HINO MOTORS LTD +1

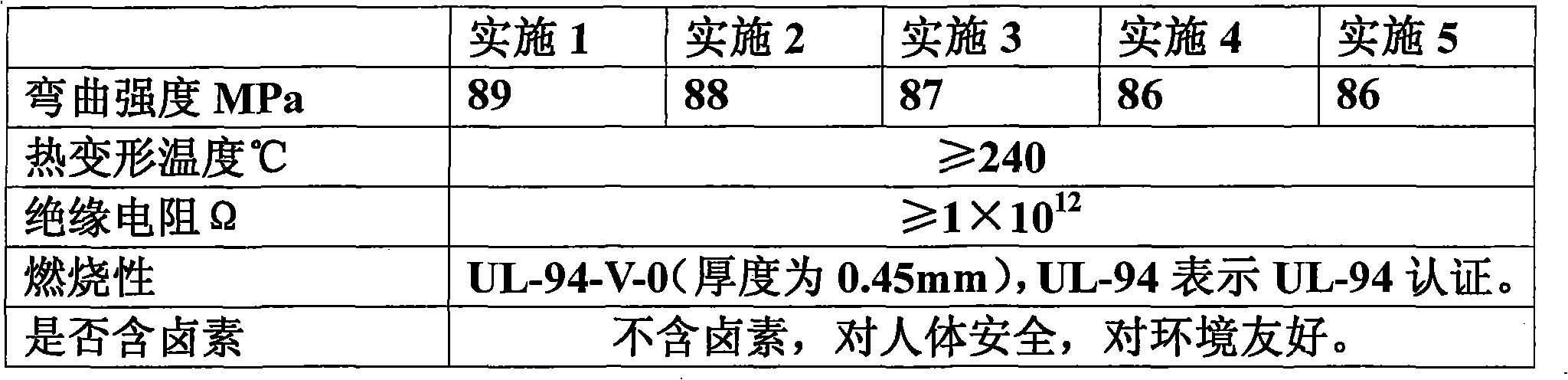

Halogen-free flame-proof phenolic plastic

The invention relates to non-halogen flame-resistant phenolic molding compound. According to the weight parts, the raw material of the non-halogen flame-resistant phenolic molding compound comprises 40 parts to 45 parts of phenolic resin, 4 parts to 9 parts of curing agent, 1.1 parts to 2.3 parts of curing accelerator, 1.5 parts to 3 parts of mould releasing agent, 4.8 parts to 6.3 parts of phosphate, 1.5 parts to 2.8 parts of metal oxide, 45 parts to 50 parts of mineral filler and 20 parts to 25 parts of reinforcing fiber. The non-halogen flame-resistant phenolic molding compound has the advantages that because halogen is not contained in the formulation, when being burnt, noxious gas and corrosive gas can not be generated, thus the physical safety and the environmental protection can be ensured; the flame-resistant performance can reach grade UL-94-V-0 (0.45 mm), the insulation resistance is greater than or equal to 1X10<12> Omega; the bending strength is more than (MPa) 85; the thermal deformation temperature is higher than or equal to 240 DEG C.

Owner:常熟东南塑料有限公司

Production technology of aluminum alloy sectional bar for automobile bumper

ActiveCN102978488AUniform chemical compositionUniform temperatureStirring devicesFiltrationThermal deformation

The invention discloses a production technology of an aluminum alloy sectional bar for an automobile bumper and belongs to the technical field of metal machining. The aluminum alloy sectional baral bar for the bumper is processed through the steps of mixing, melting, permanent magnetic stirring, temperature measurement, sampling, ingredient and temperature adjustment, turning down, refining(first purification), standing still, online addition of Al-Ti-B wire, online removal of gas and sand (secondary purification), two-stage filtration, same-level hot top casting, cast ingot homogenization, machining of cast ingot, inspection of cast ingot, heating of cast ingot by an induction furnace, extrusion, precise on-line quenching, stretching and straightening, aging, structure and property inspection of sectional bars, and delivery. The aluminum alloy sectional bar processed by the technology is excellent in thermal deformation performance, and high in strength due to on-line quenching during extrusion. The product has excellent welding performance and corrosion resistance, certain resistance to stress corrosion, and especially has strong shock absorption and folding resistance.

Owner:丛林铝业科技(山东)有限责任公司

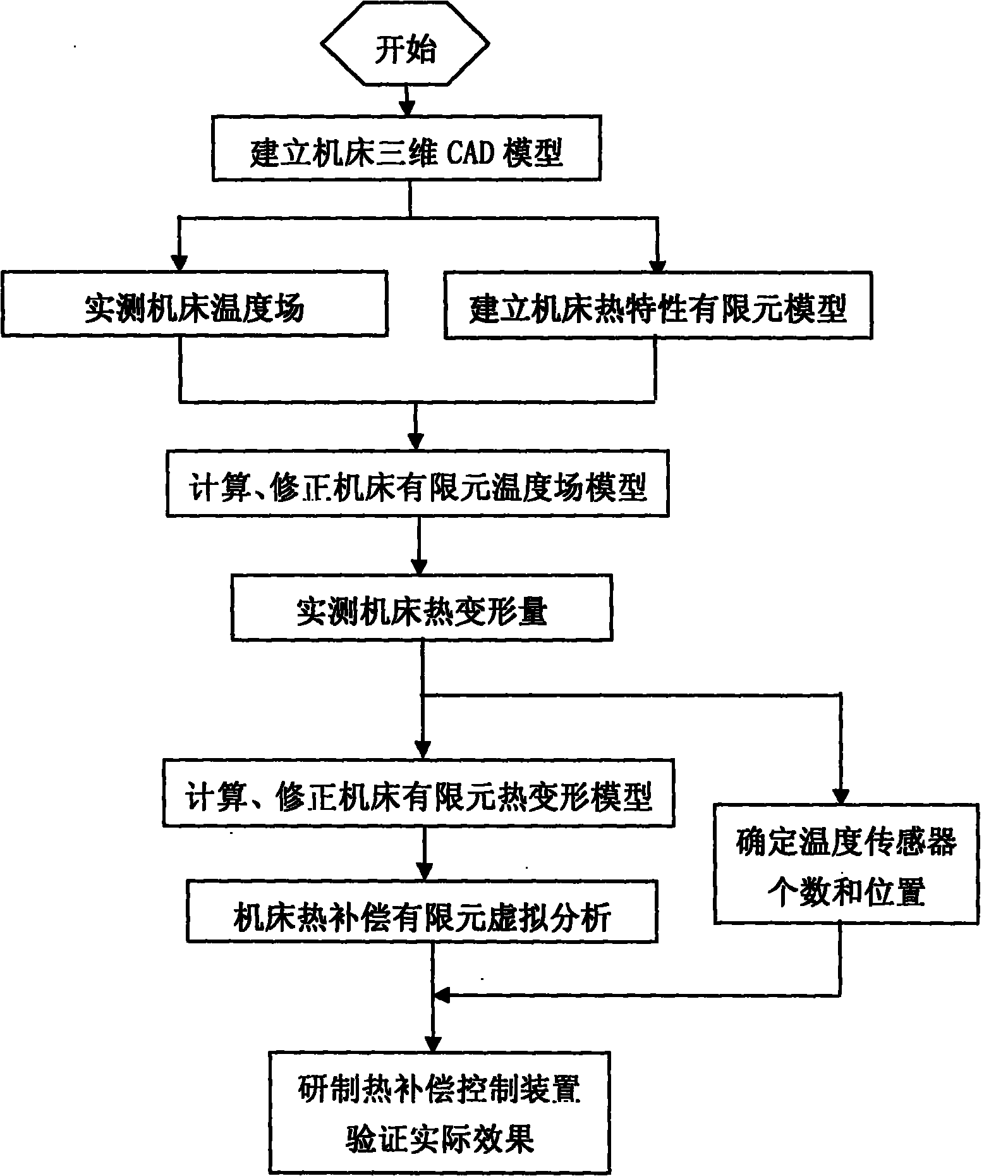

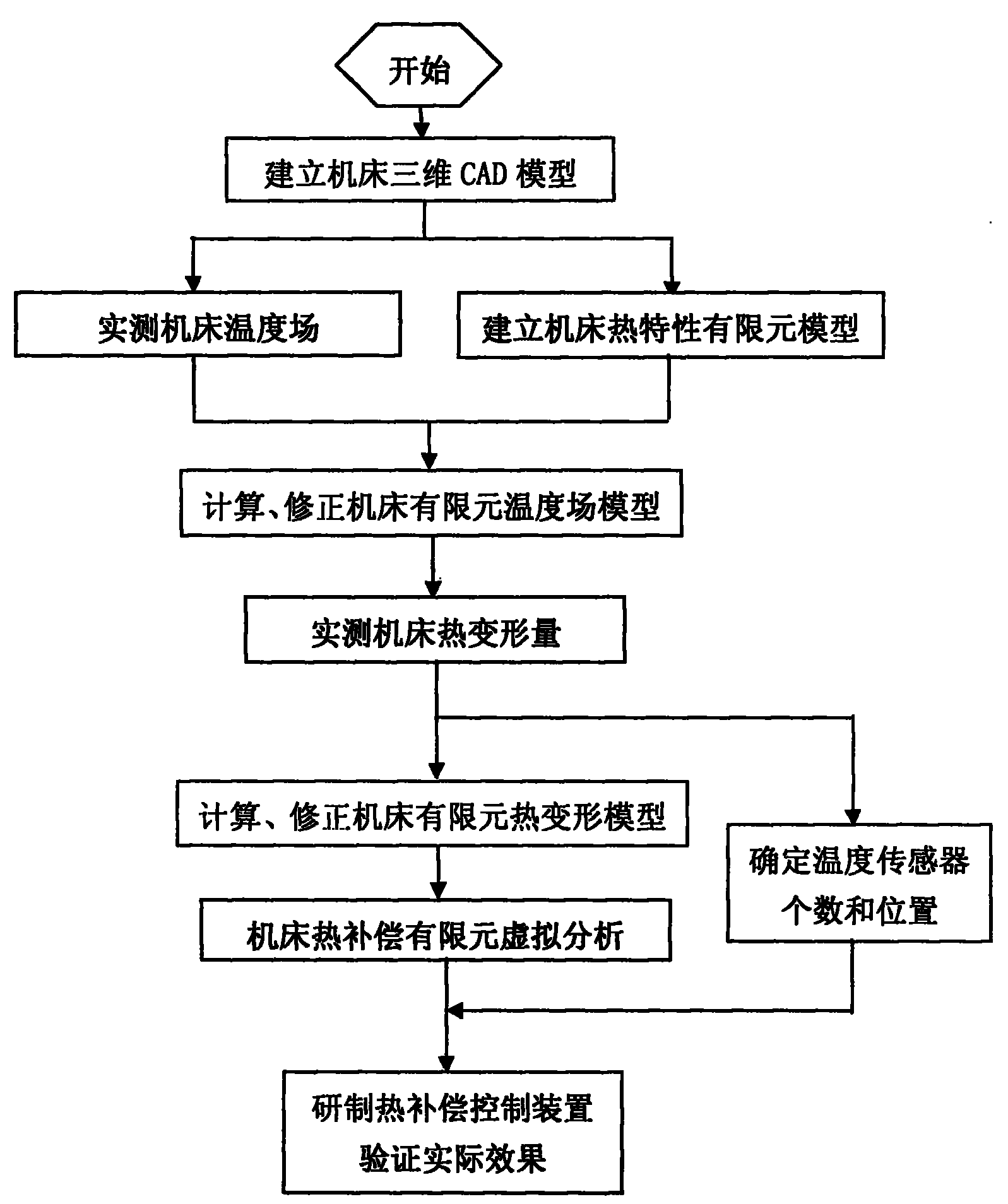

Implementation method of automatic compensation for thermal deformation of machine tool

InactiveCN101804581AShorten the development cycleHigh compensation accuracyAutomatic control devicesFeeding apparatusElement modelThermal deformation

The invention discloses an implementation method of automatic compensation for thermal deformation of a machine tool, which comprises the following steps: (1) establishing a three-dimensional CAD model of the machine tool; (2) actually measuring the temperature field of the machine tool; (3) establishing a thermal characteristic finite element model of the machine tool; (4) calculating and correcting a finite element temperature field model; (5) actually measuring the thermal deformation of the machine tool; (6) determining the number and positions of temperature sensors; (7) calculating and correcting a finite element thermal deformation model of the machine tool; and (8) virtually analyzing the thermal compensation finite element of the machine tool. The method corrects the finite element temperature field and the thermal deformation model of the machine tool, so that the established finite element model of the machine tool can truly reflect the practical situation of the thermal deformation of the machine tool; and thus, the invention has the advantages of high compensation precision and good stability. In the method, multiple thermal compensation testing processes on the machine tool are completed by a computer through virtual analysis, thereby shortening the development cycle and reducing the development cost.

Owner:四川普什宁江机床有限公司

Decorative sheet for three-dimensional work

ActiveUS20110045284A1Good molding effectGood die releaseDecorative surface effectsSynthetic resin layered productsCross-linkHeat deflection temperature

Provided is a decorative sheet for three-dimensional processing comprising a support and at least a surface protective layer laminated thereon, wherein the above decorative sheet for three-dimensional processing has a breaking elongation (according to JIS K 7127) exceeding 300% at temperature higher by 40° C. than a thermal deformation temperature of the above support measured by an ASTM D648 method, and the above surface protective layer is obtained by cross-linking and curing an ionizing radiation curable resin composition and has a film thickness of 0.2 to 6.0 μm.Capable of being provided is a decorative sheet for three-dimensional processing which is improved in a molding property and has good die release and does not produce cracks and scratches on a surface in molding and which is improved as well in an abrasion resistance and a solvent resistance.

Owner:DAI NIPPON PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com