Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

417results about How to "Increased pressure loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

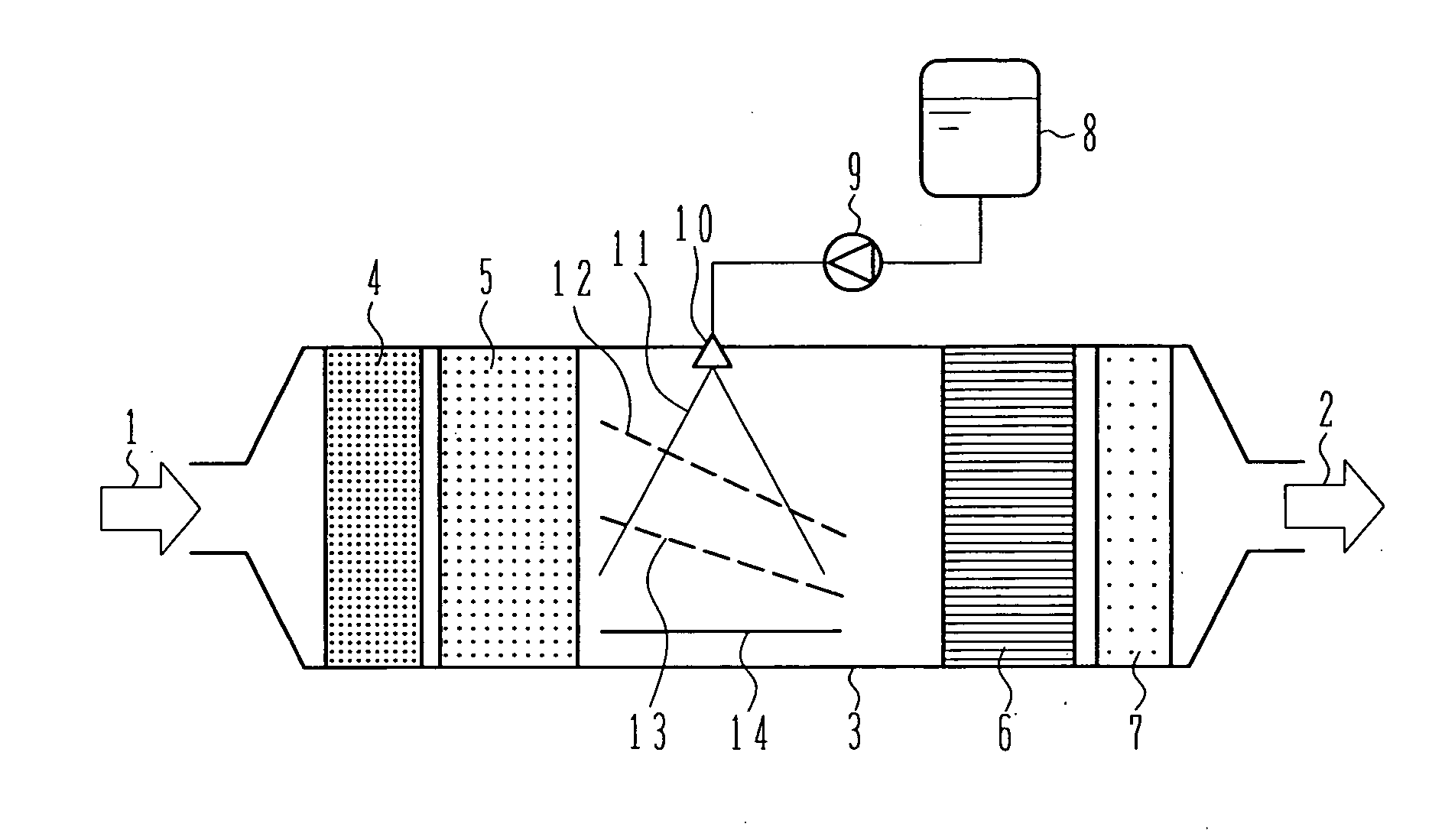

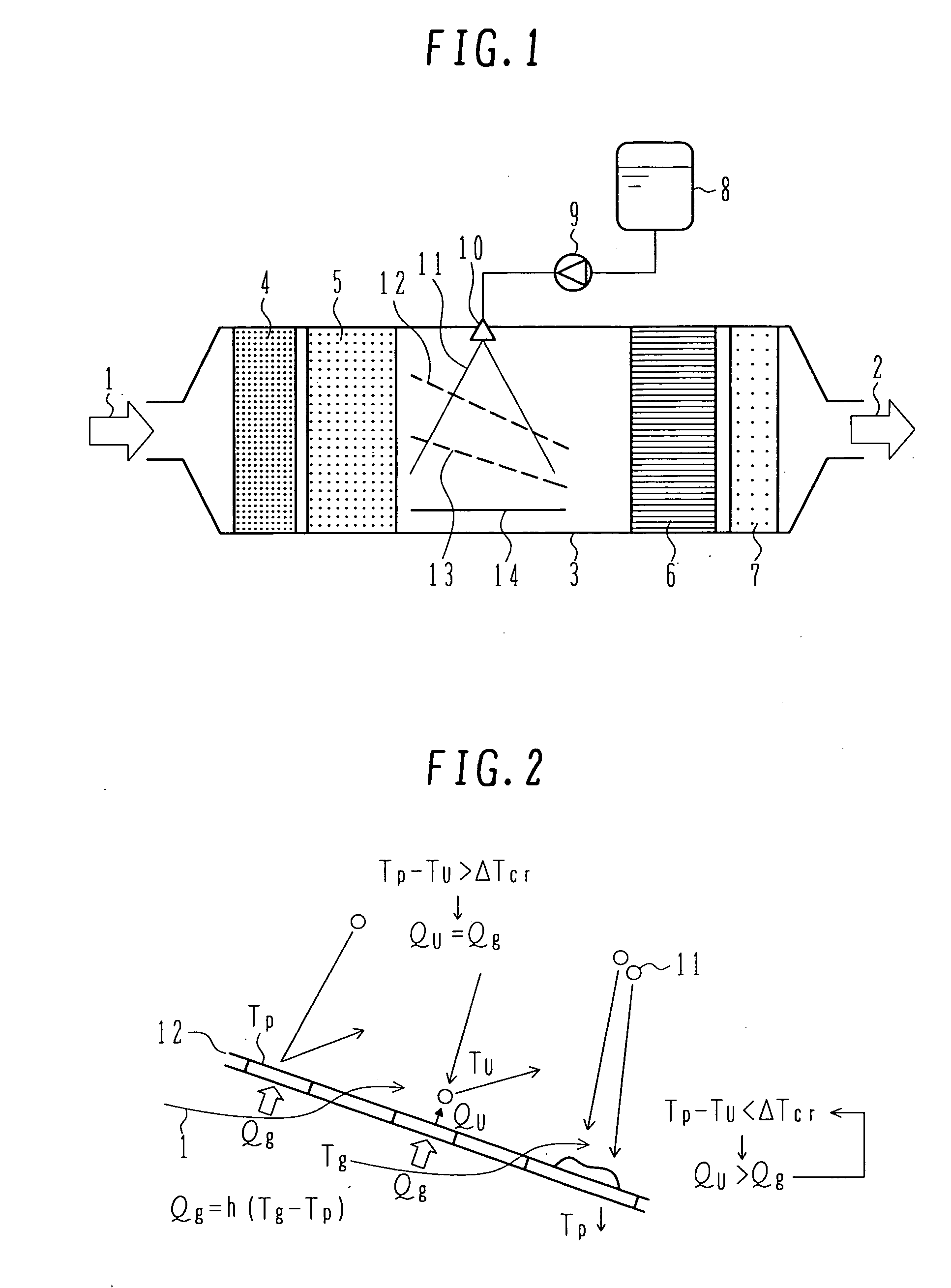

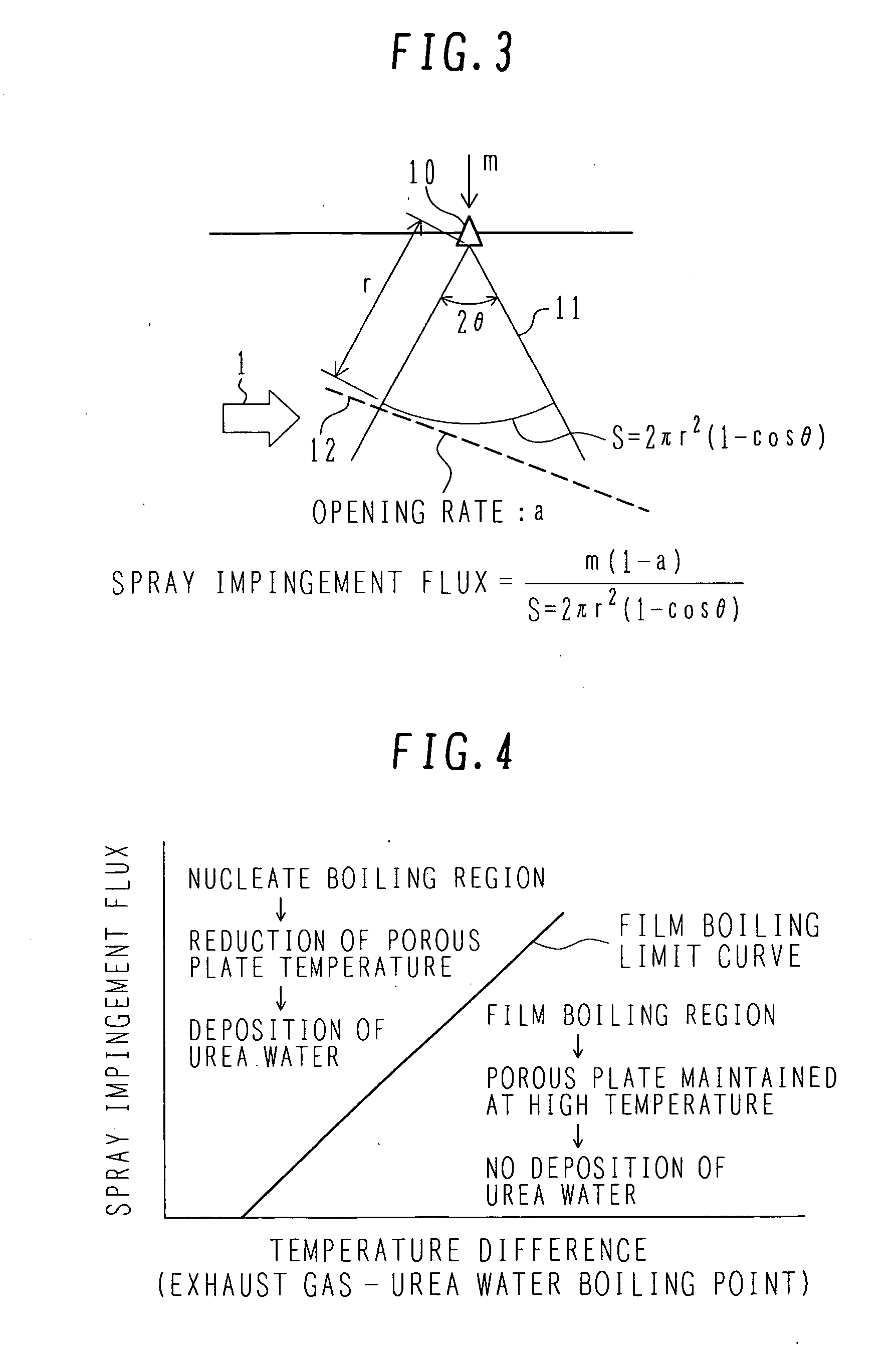

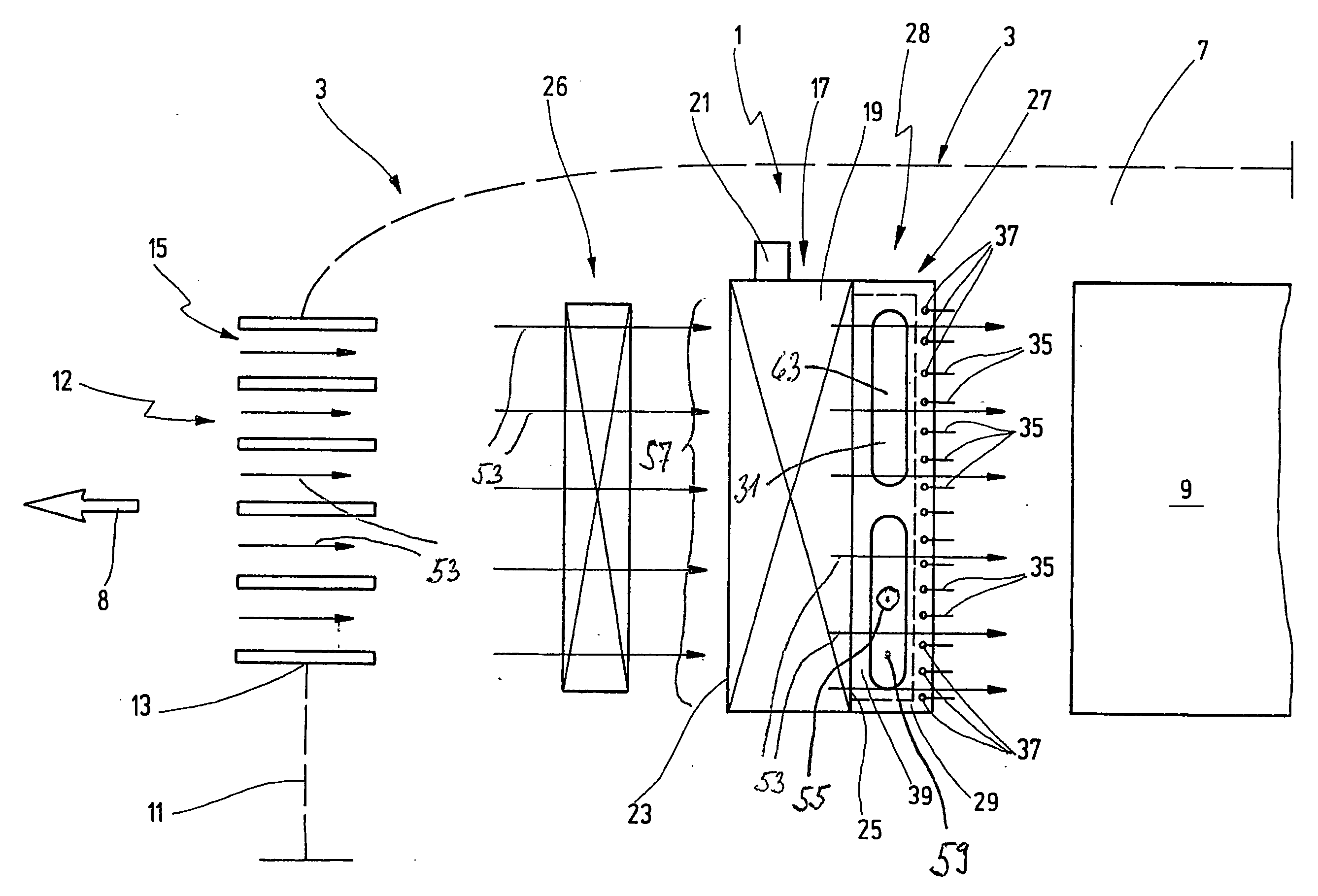

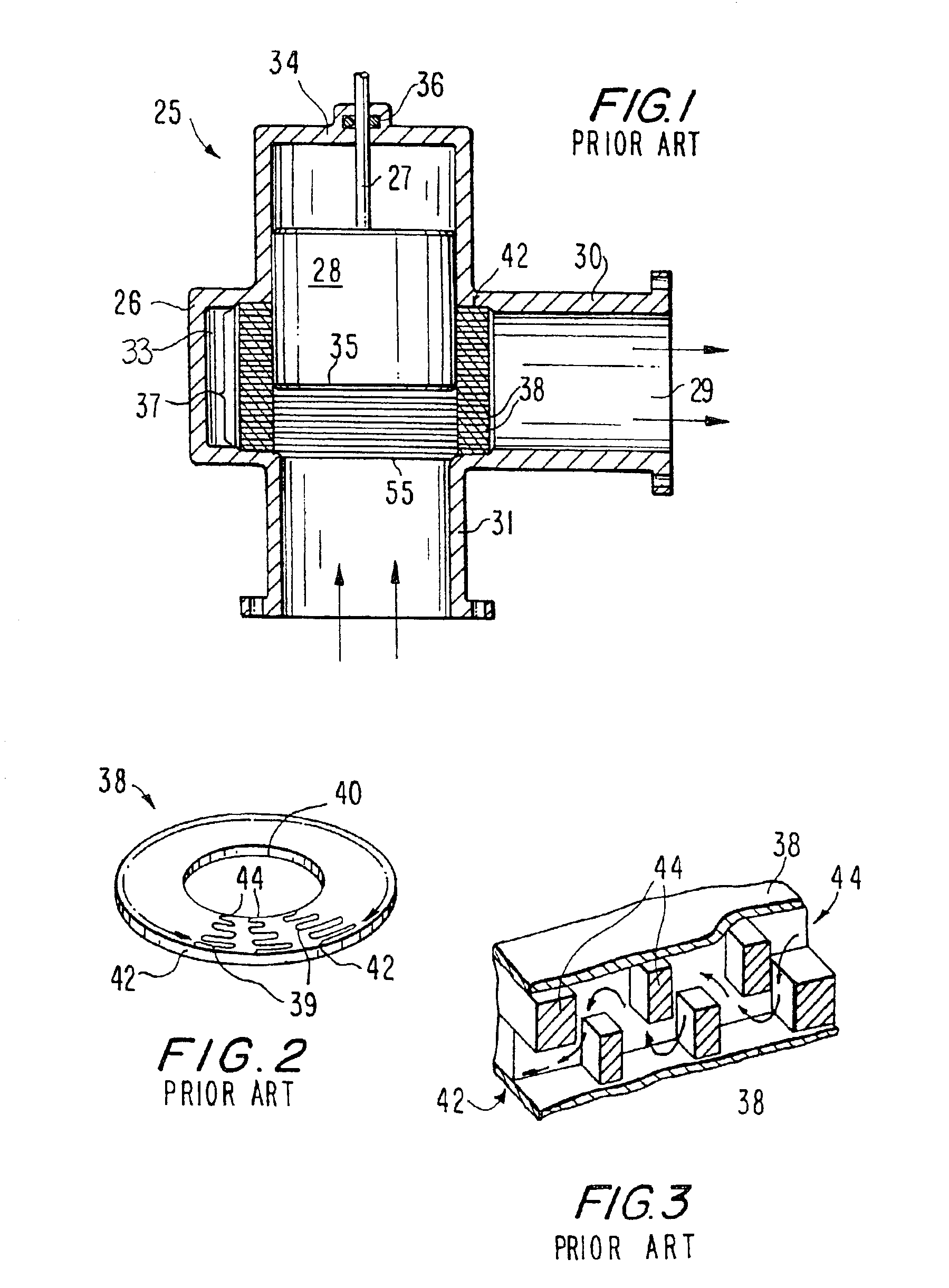

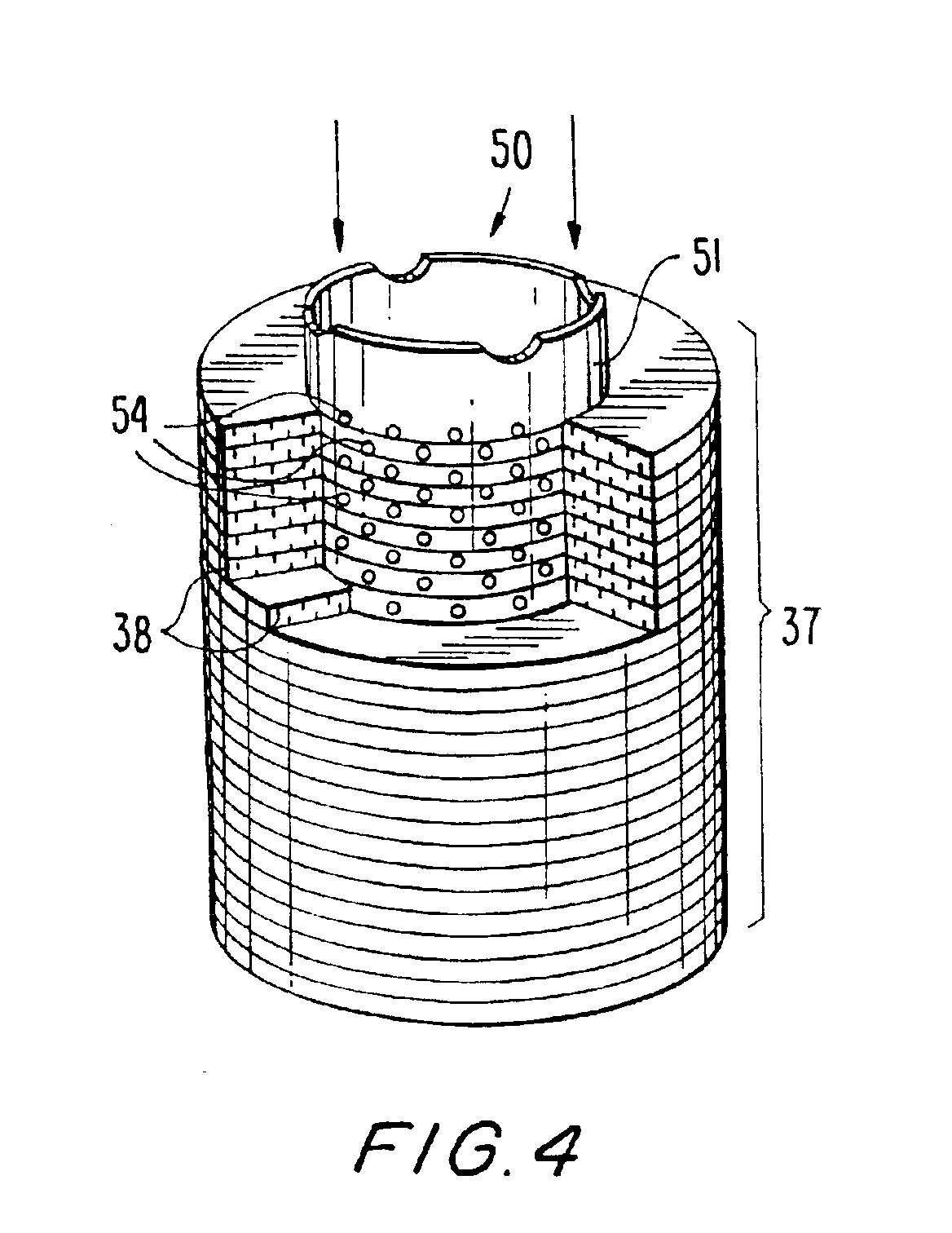

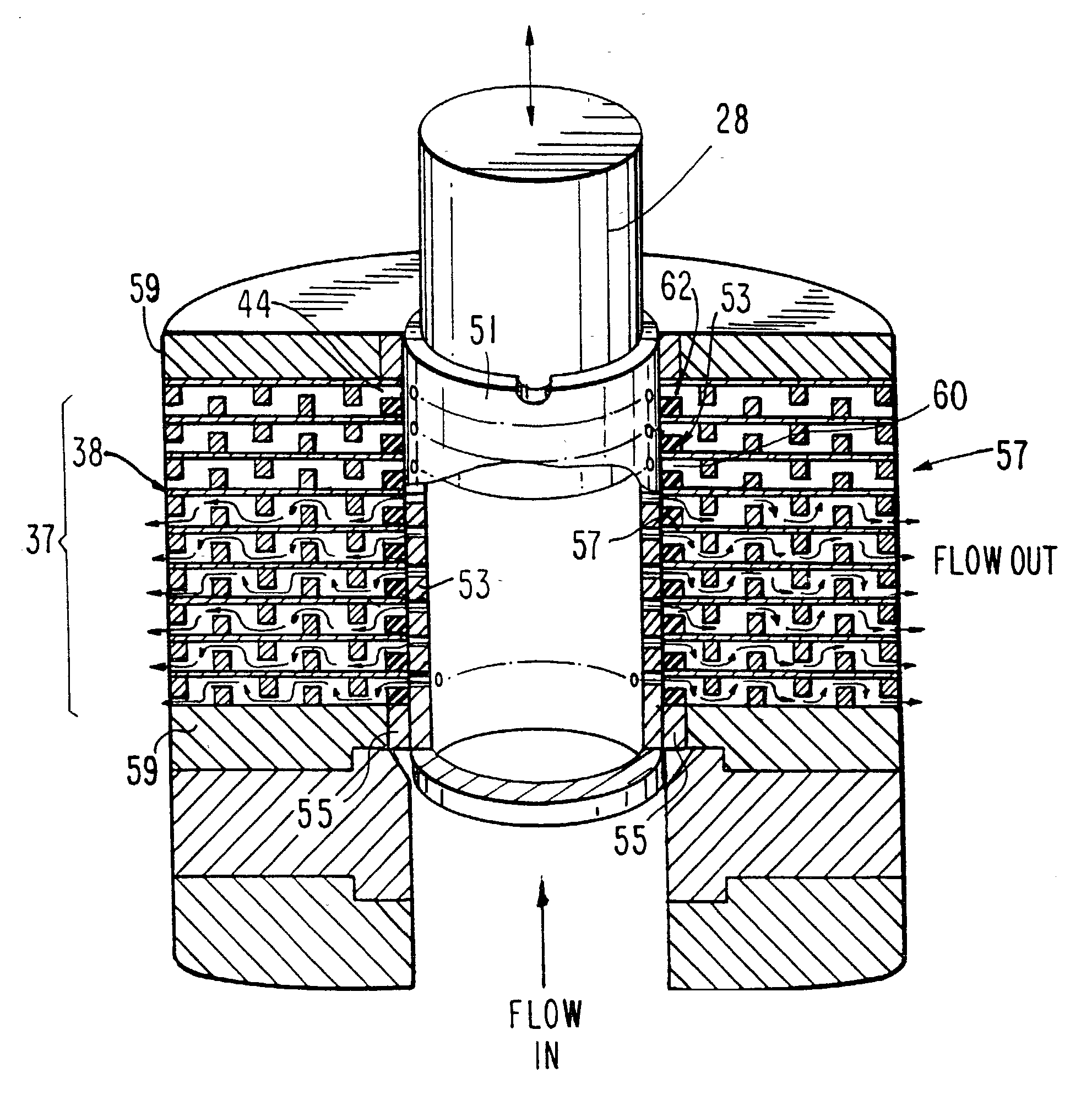

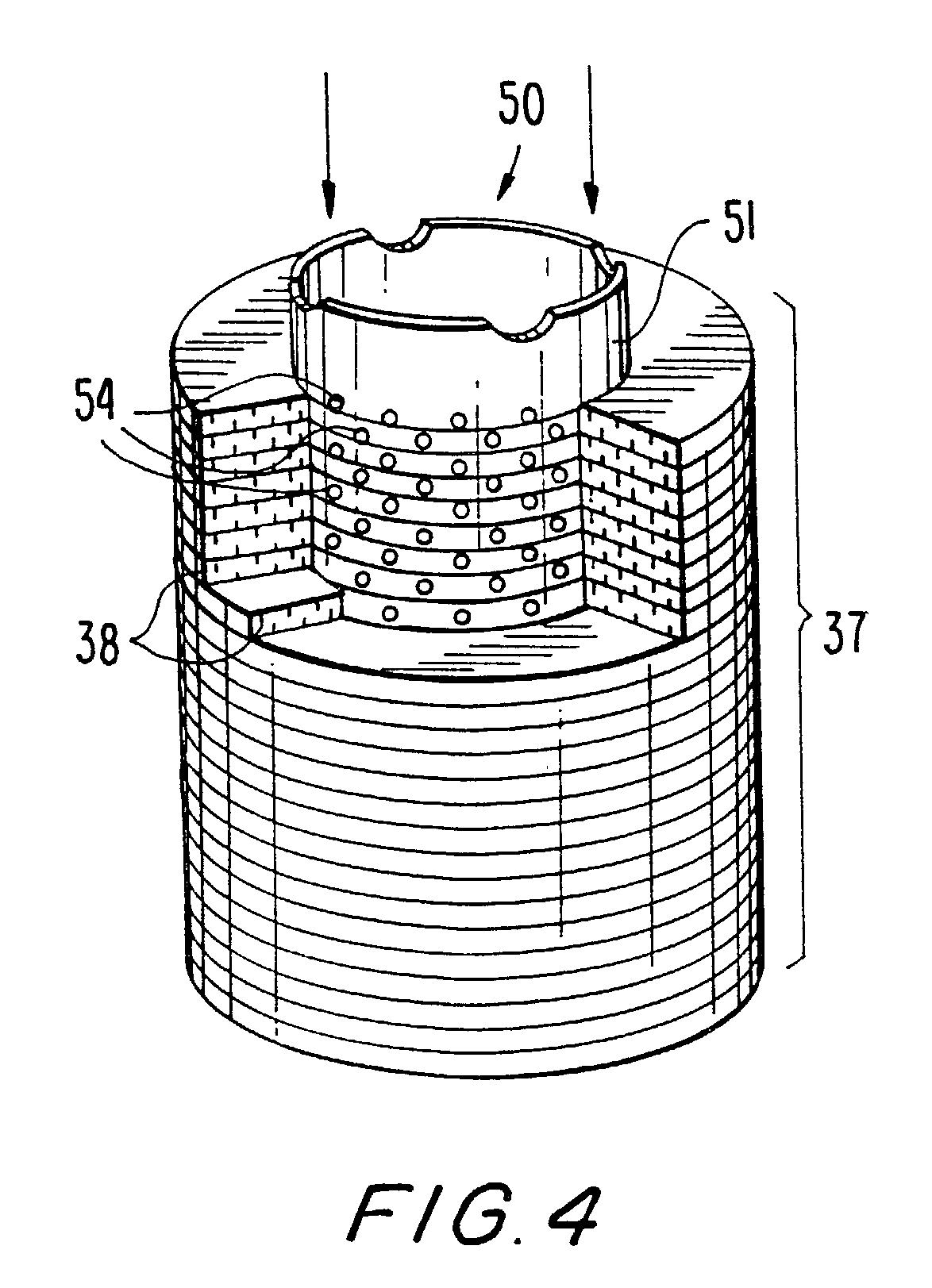

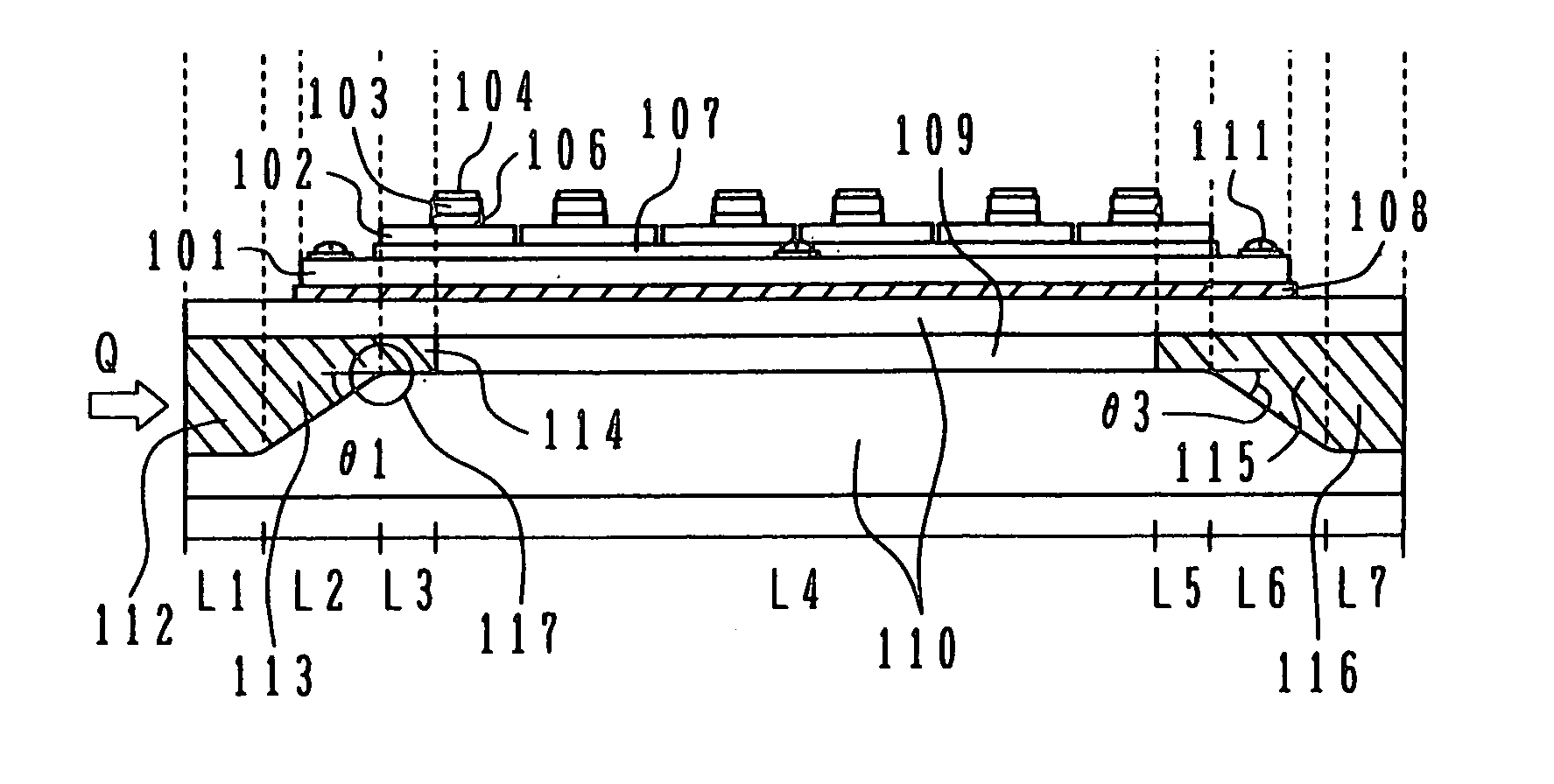

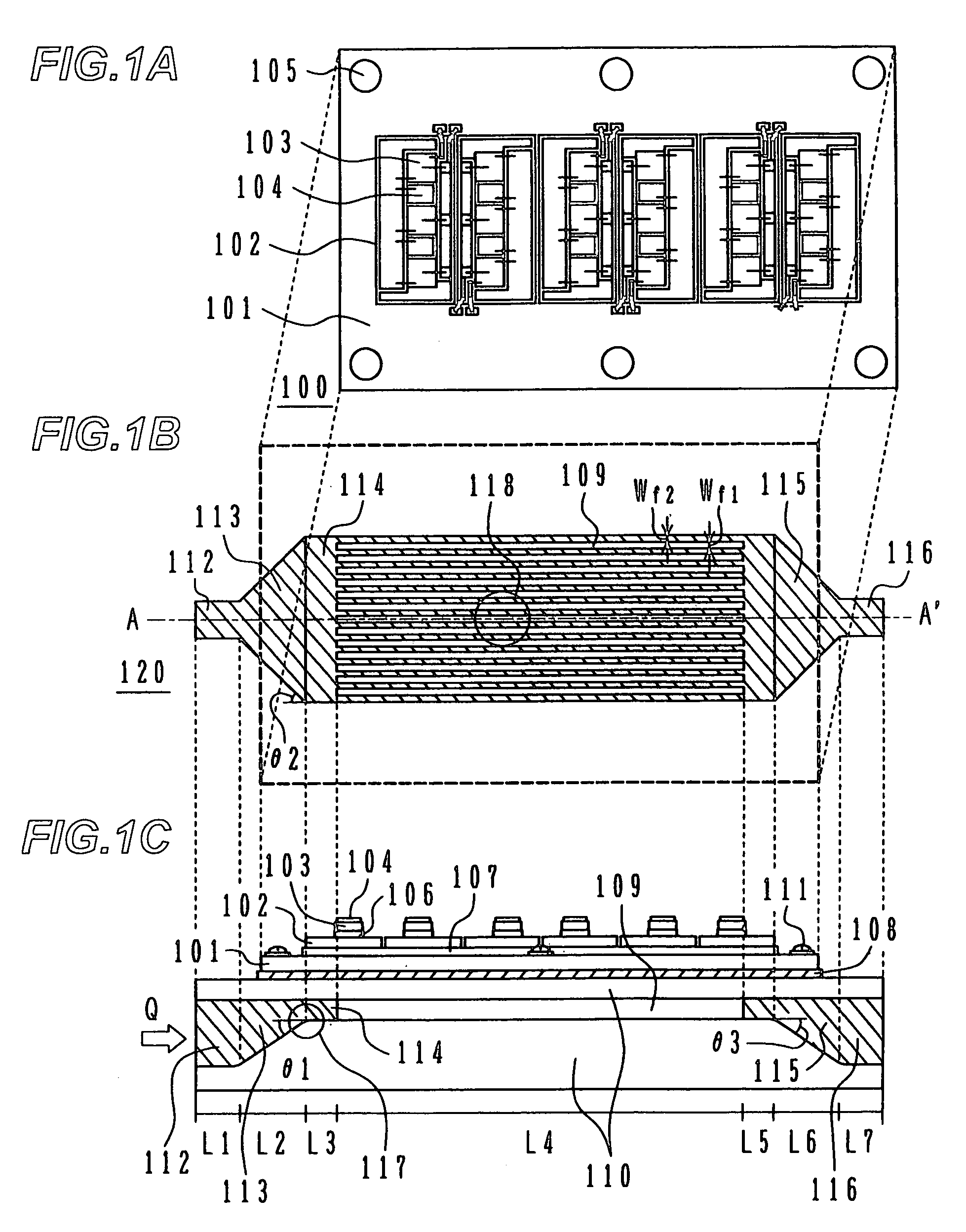

Exhaust aftertreatment system using urea water

InactiveUS20070036694A1Avoid depositionReduced responseCombination devicesInternal combustion piston enginesHandling systemMultiple stages

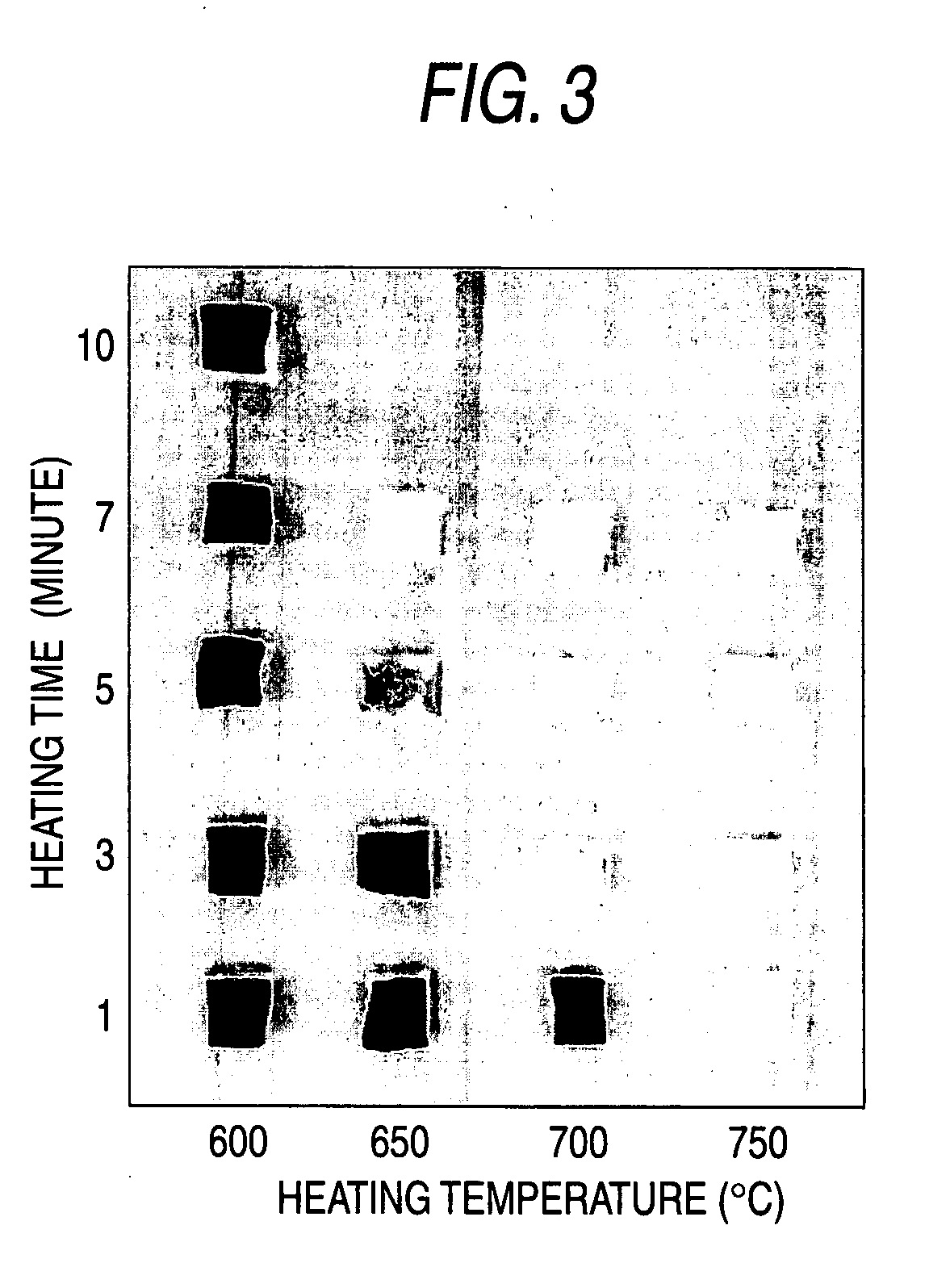

An exhaust aftertreatment system comprises an injector for injecting urea water into an exhaust duct, and a denitration catalyst disposed downstream of the injector with respect to a flow of exhaust gas. The exhaust aftertreatment system reduces nitrogen oxides in the exhaust gas by the denitration catalyst while using ammonia produced from the urea water injected from the injector. The urea water is injected along a direction of the flow of the exhaust gas within the exhaust duct, and a porous plate is disposed in multiple stages in a space of the exhaust duct such that droplets of the injected urea water impinge against the porous plate before reaching a wall surface of the exhaust duct. A surface of the porous plate subjected to the impingement of the droplets is arranged to face downstream with respect to the flow of the exhaust gas. Deposition of the urea water is prevented by causing film boiling when the droplets impinge against the porous plate, and the urea water reflected by the porous plate is uniformly dispersed into the exhaust gas. Thus, the urea water is uniformly dispersed into the exhaust gas without increasing a pressure loss of the exhaust gas. The urea water is prevented from depositing on the wall surface and producing a precipitate in the form of a solid.

Owner:HITACHI HIGH-TECH CORP +2

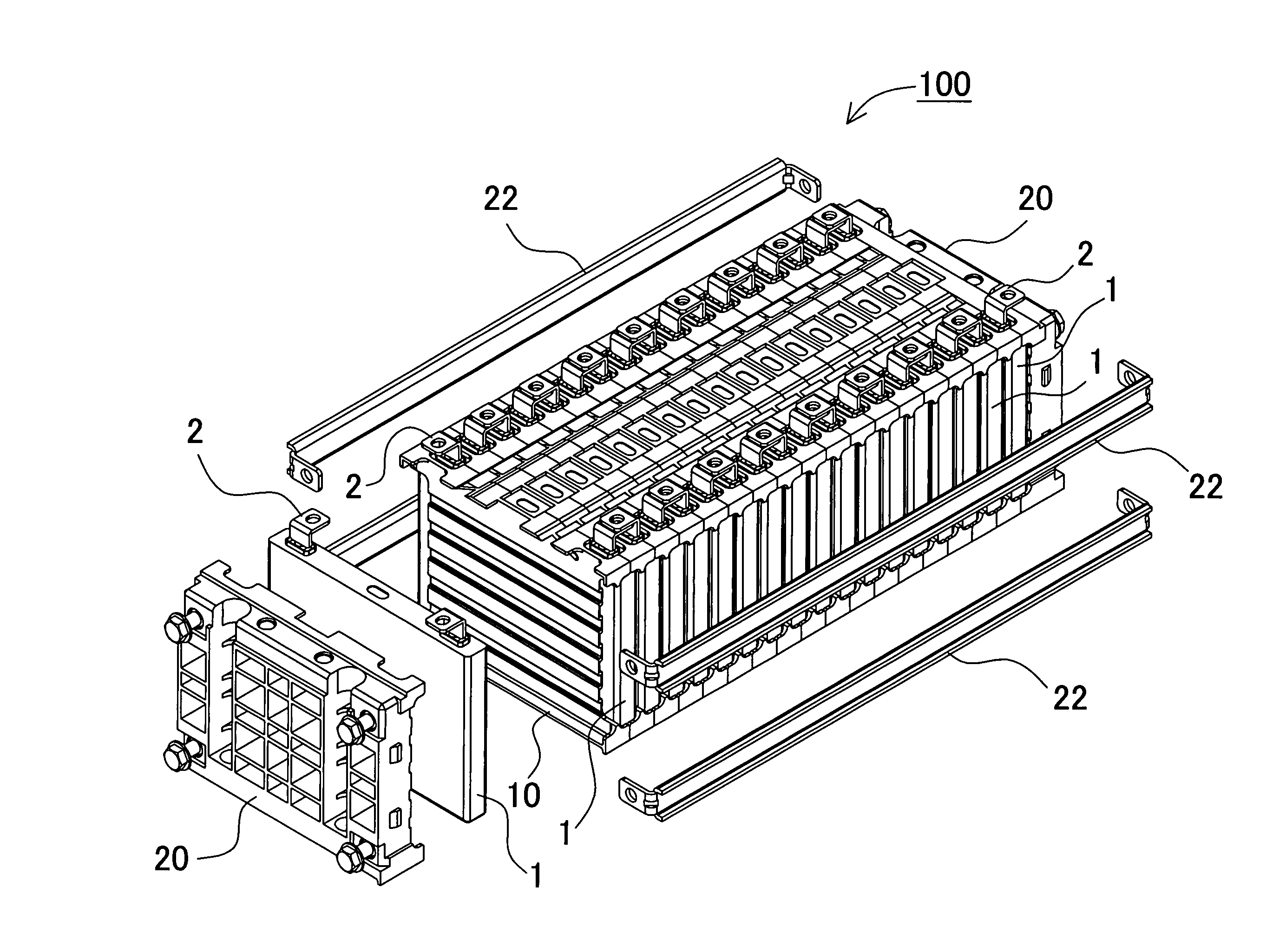

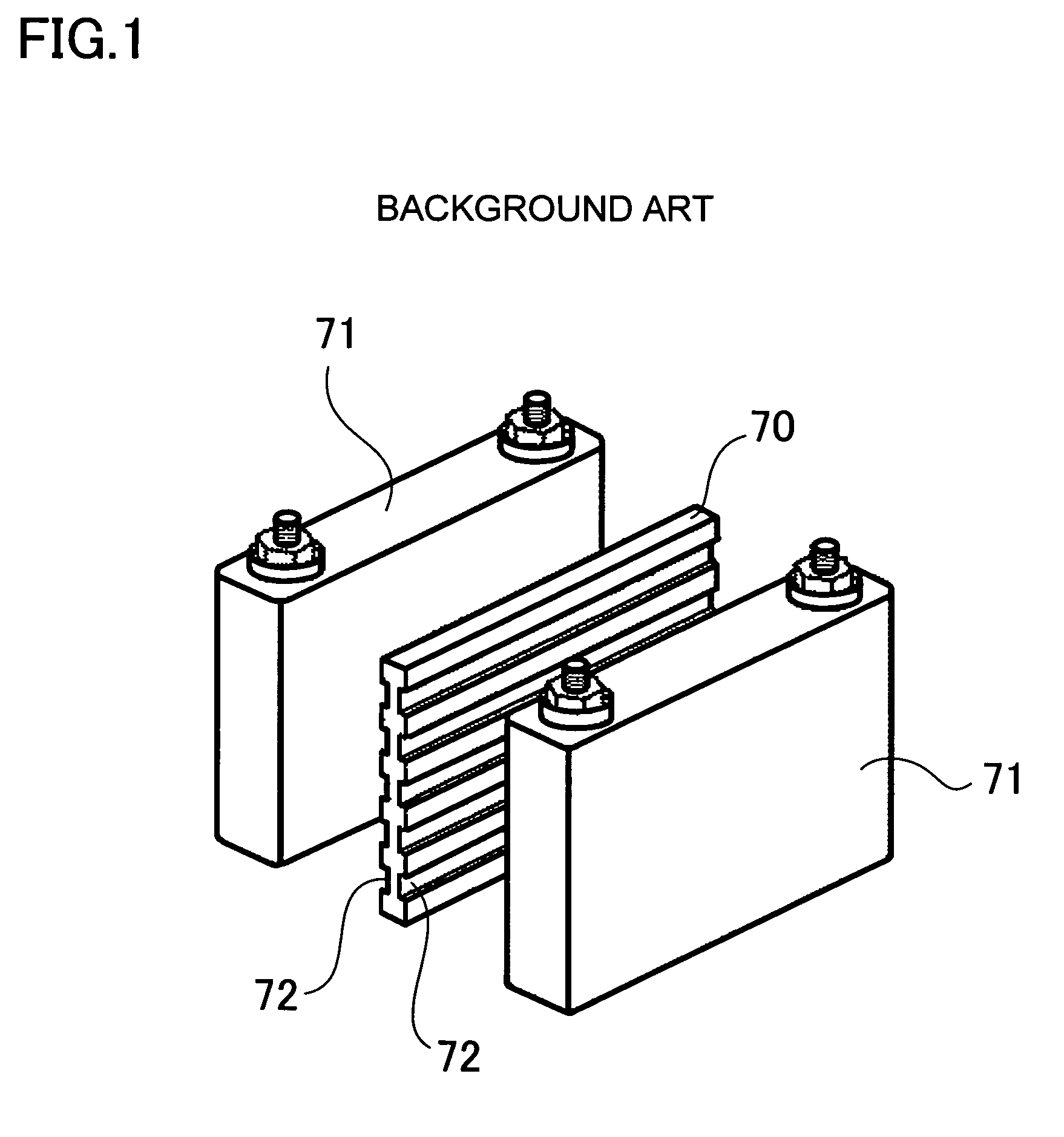

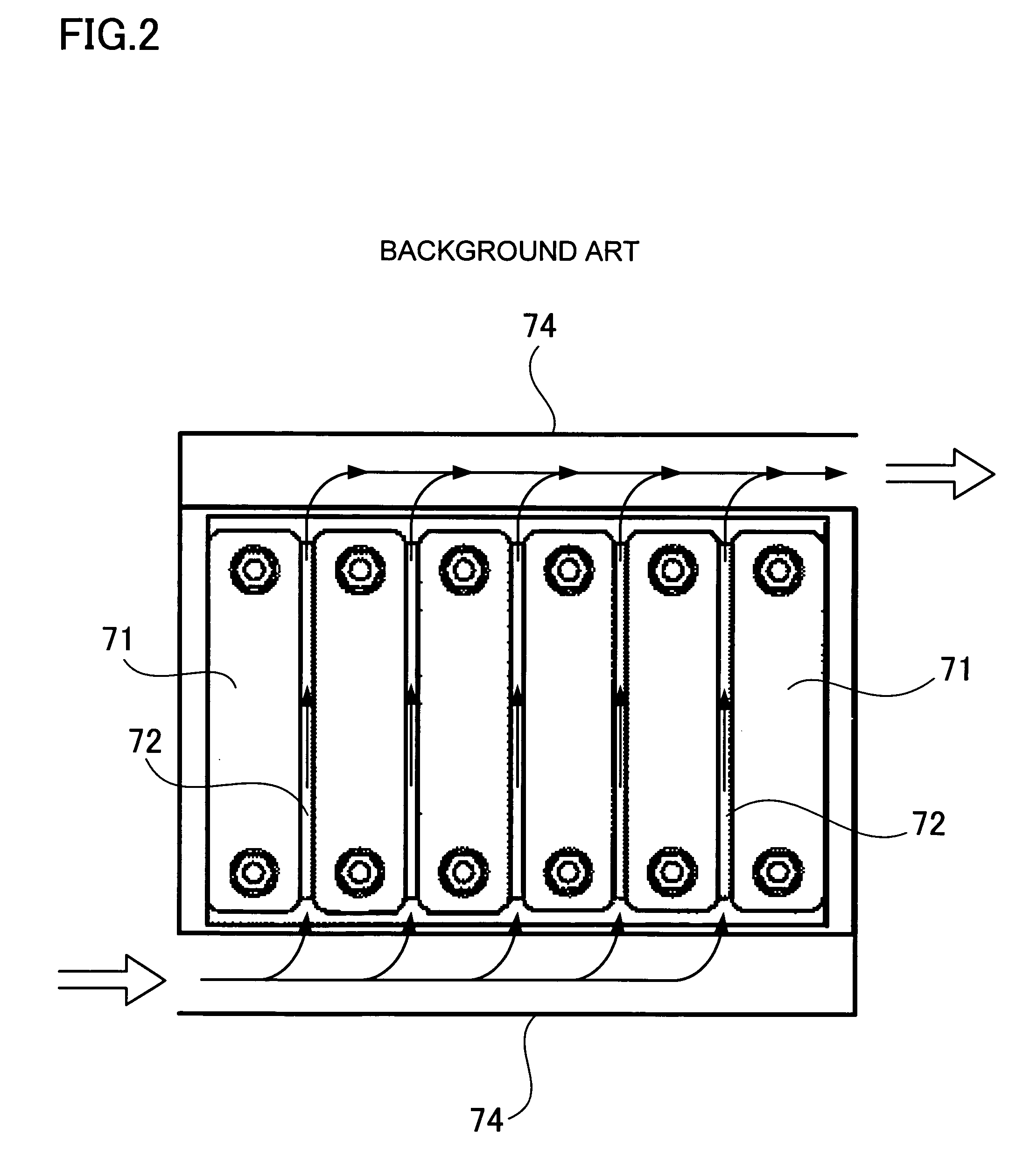

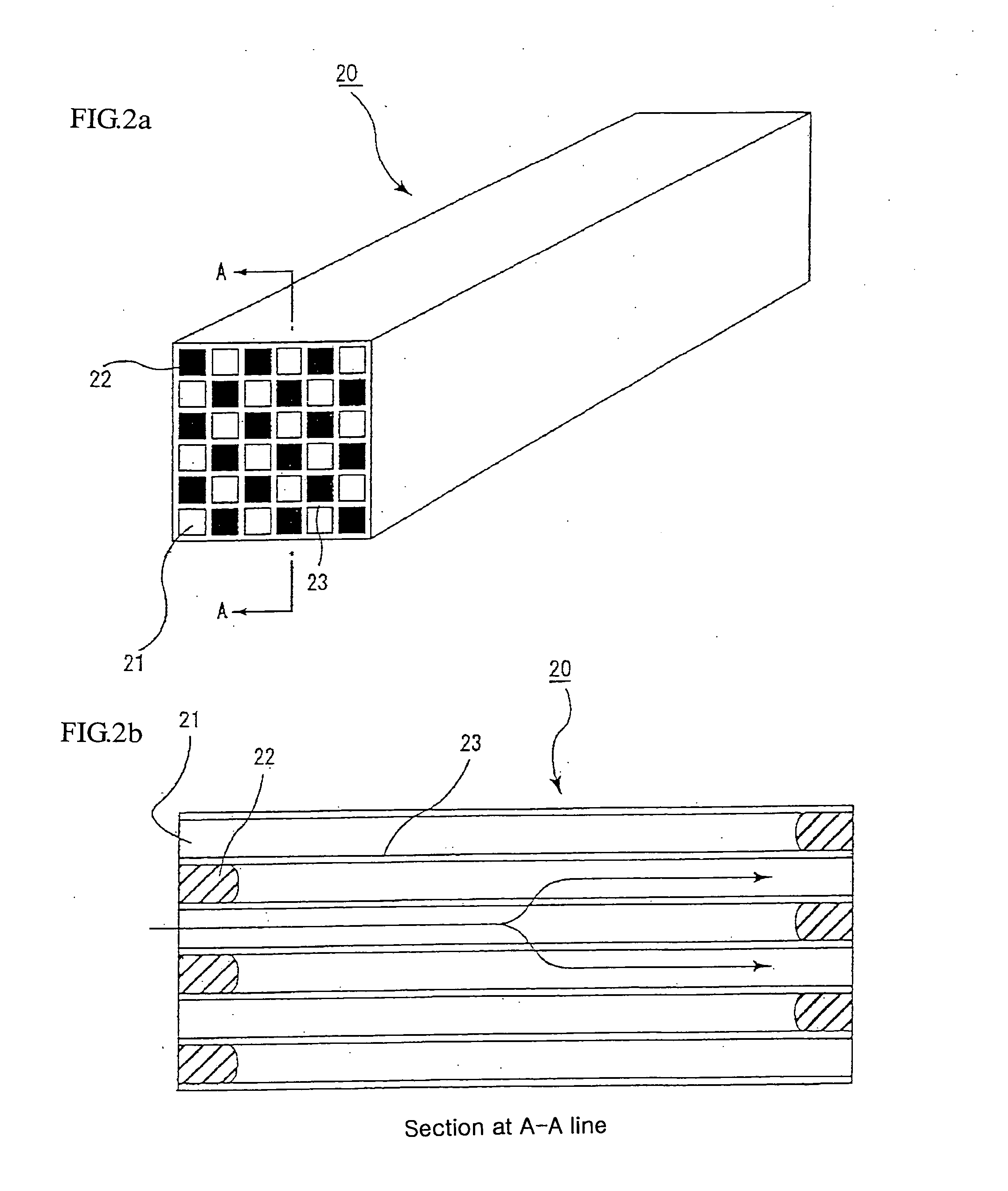

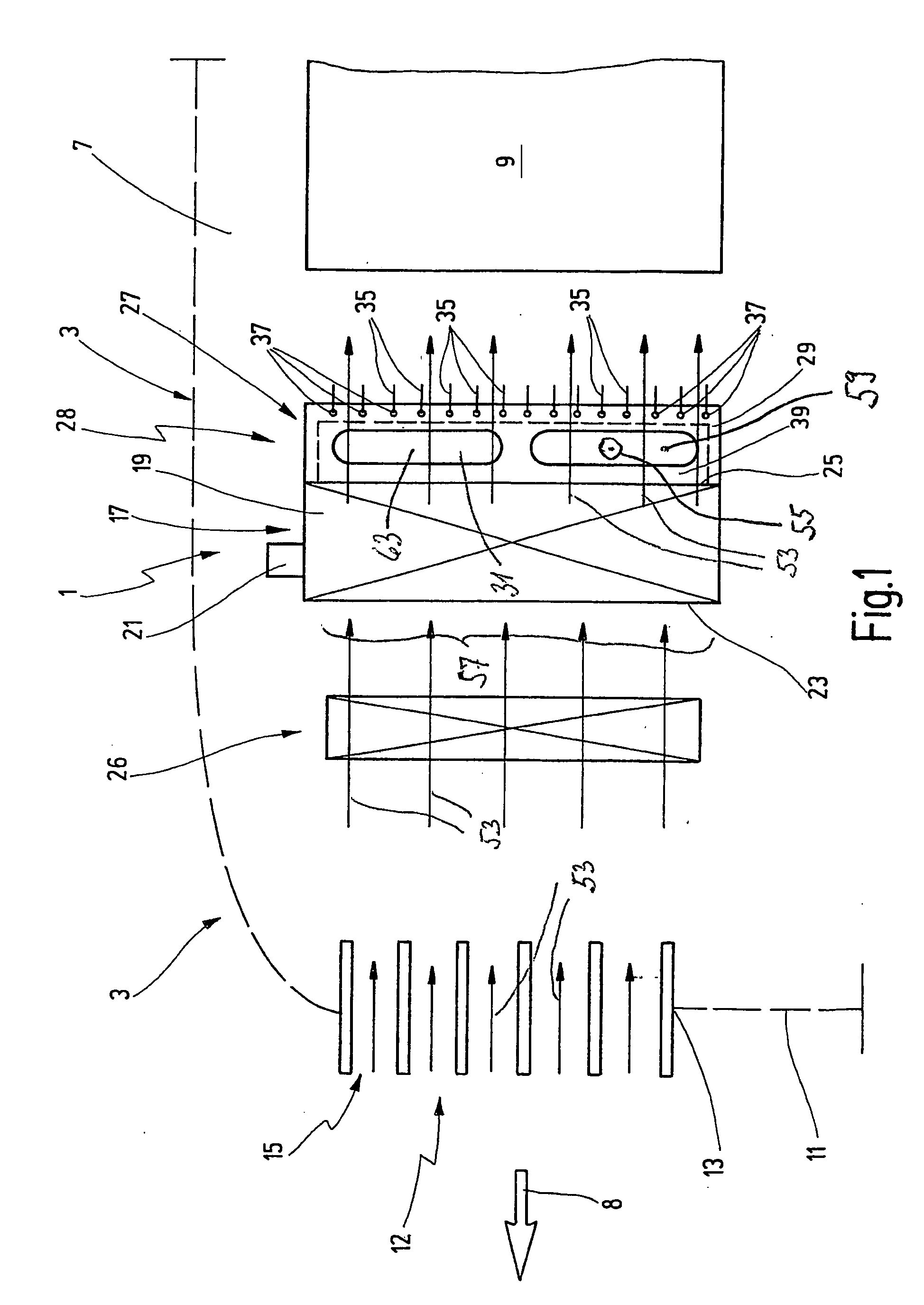

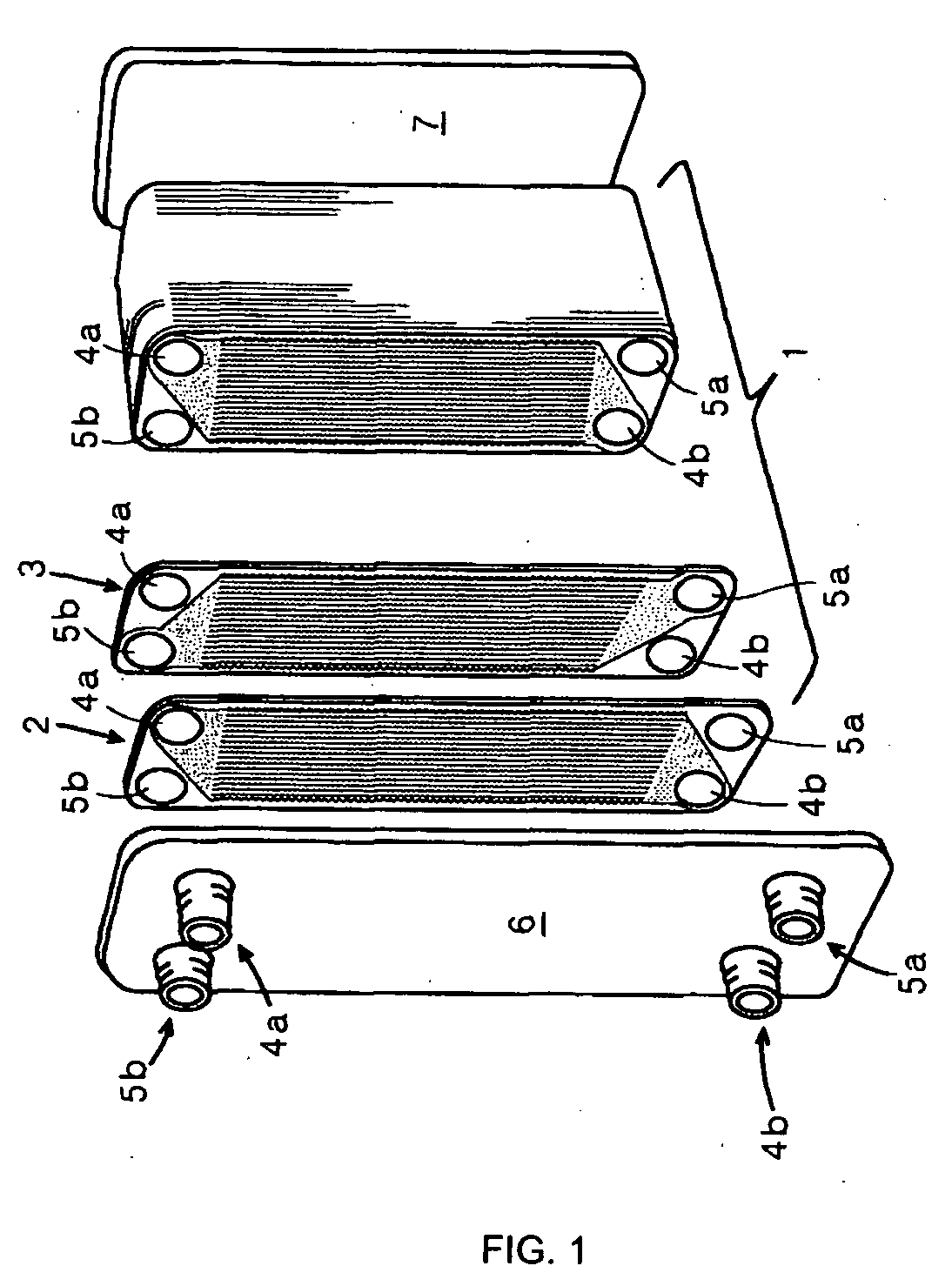

Battery pack and battery pack separator

ActiveUS20090111010A1Reduces cooling gas pressure lossDifference in pressureCell temperature controlCells cooling/heatingEngineeringBattery cell

The battery pack includes plural battery cells 1, and insulating separators 10 disposed between adjacent battery cells 1, where the plurality of battery cells 1 are disposed in a stacked configuration with a prescribed gap between adjacent battery cells 1. A separator 10 has a plural gas channels that enable the flow of cooling gas. The gas channels have cooling gas entranceways and exit ways, which open at the sides of the battery block formed by the stacked battery cells 1. A separator 10 has cut sections formed to position the entranceways and exit ways of the gas channels inward from the sides of the battery block. This allows cooling gas near entranceways and exit ways to be smoothly introduced to, and exhausted from the gas channels, and reduces cooling gas pressure losses in those regions.

Owner:SANYO ELECTRIC CO LTD

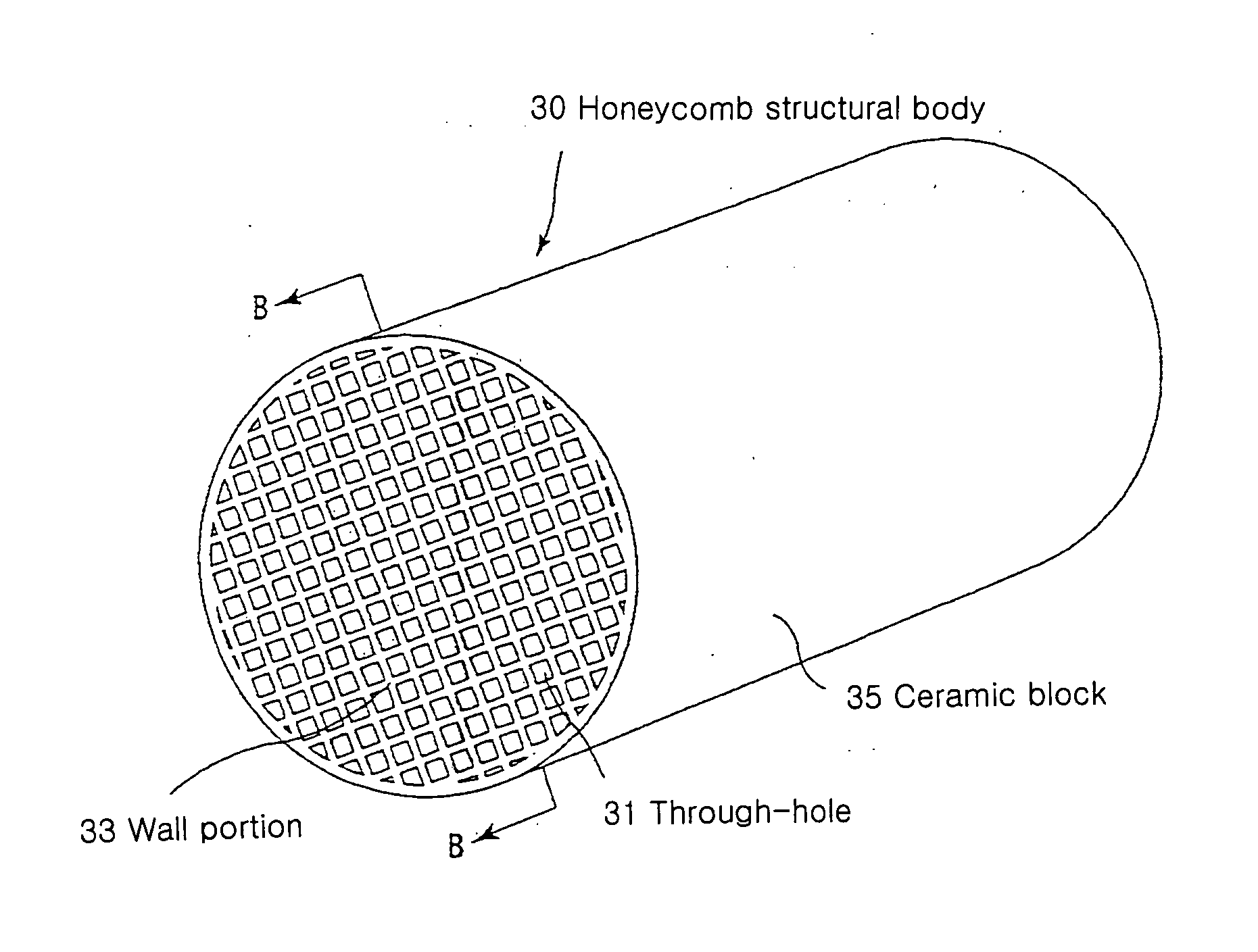

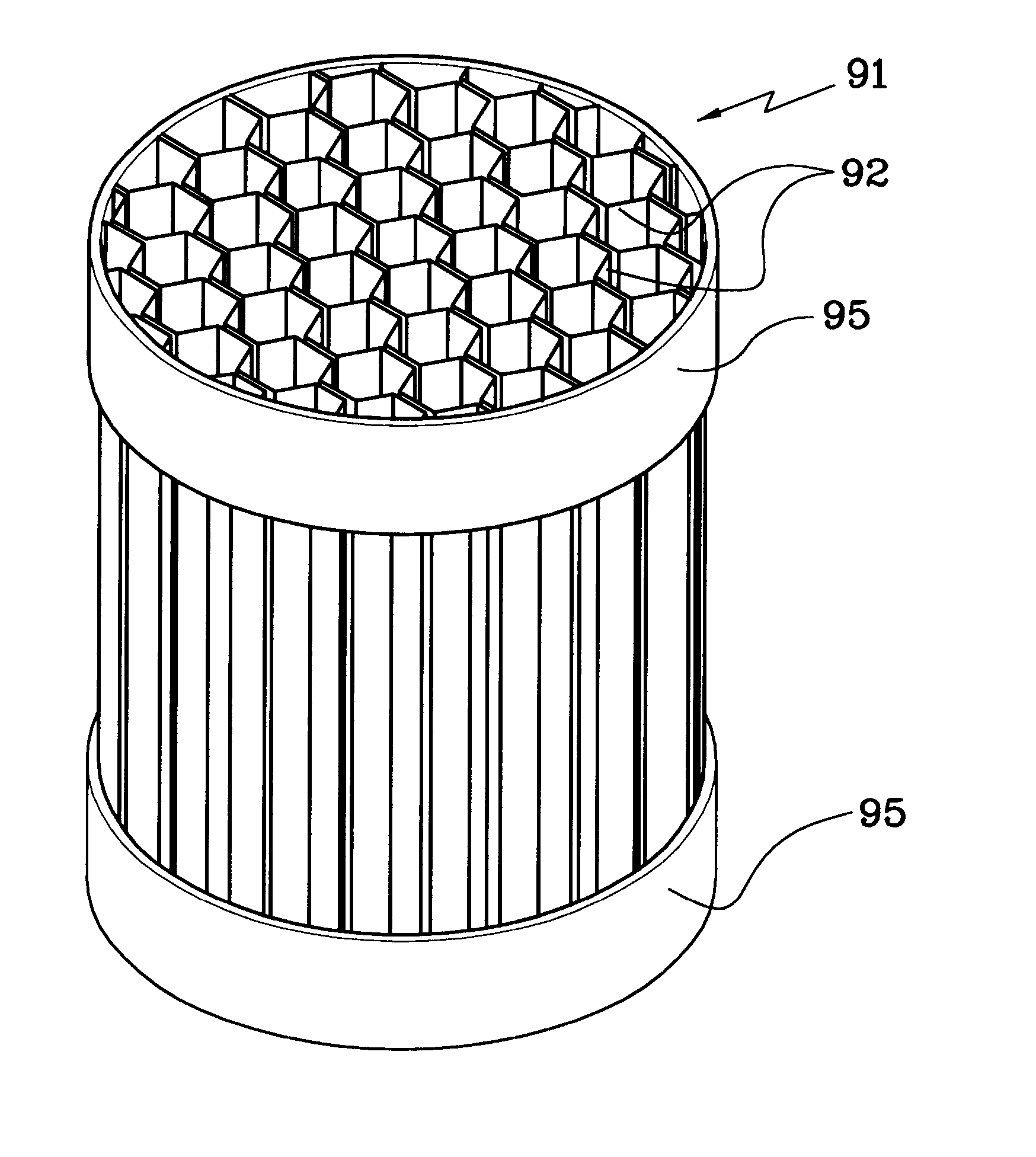

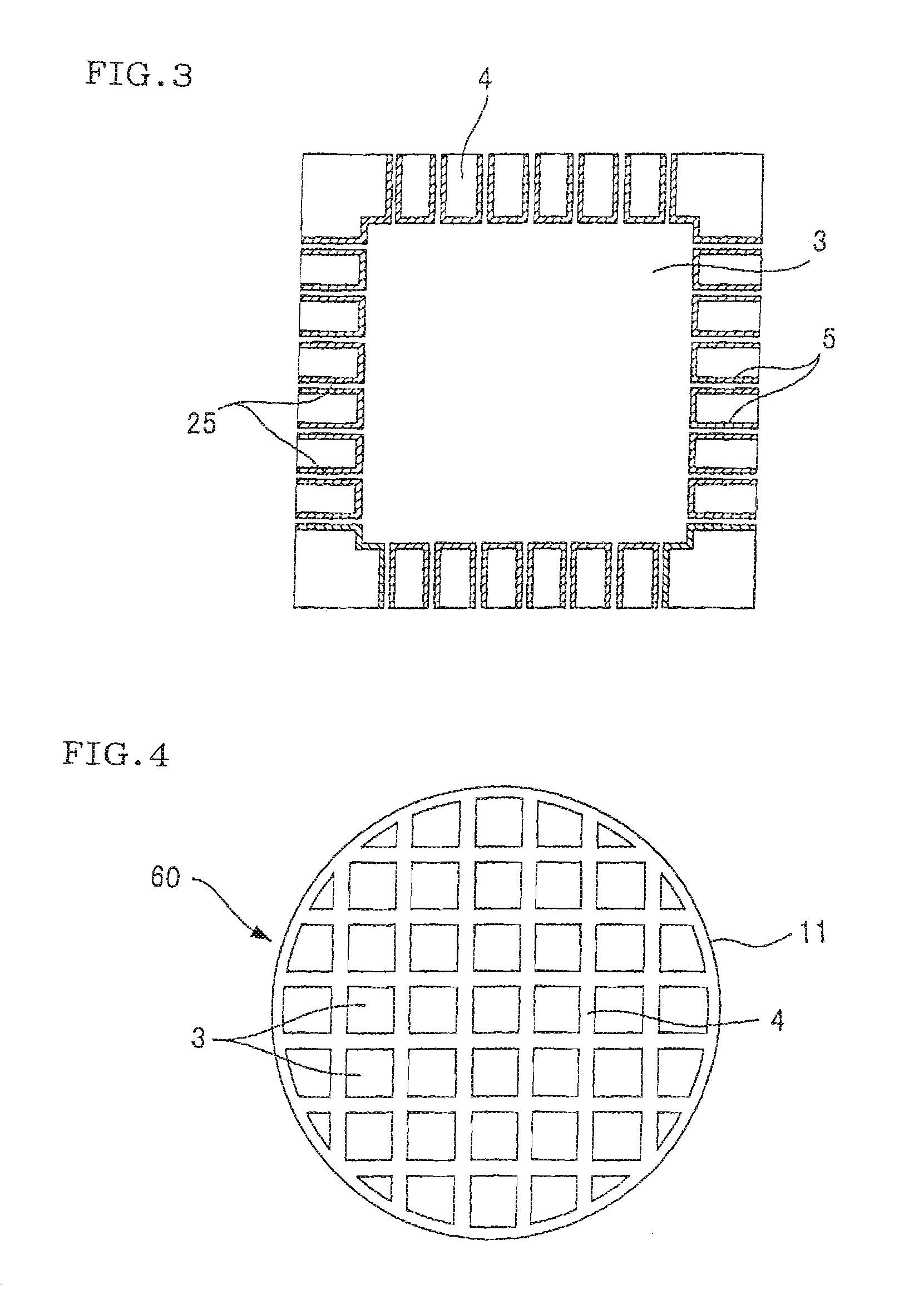

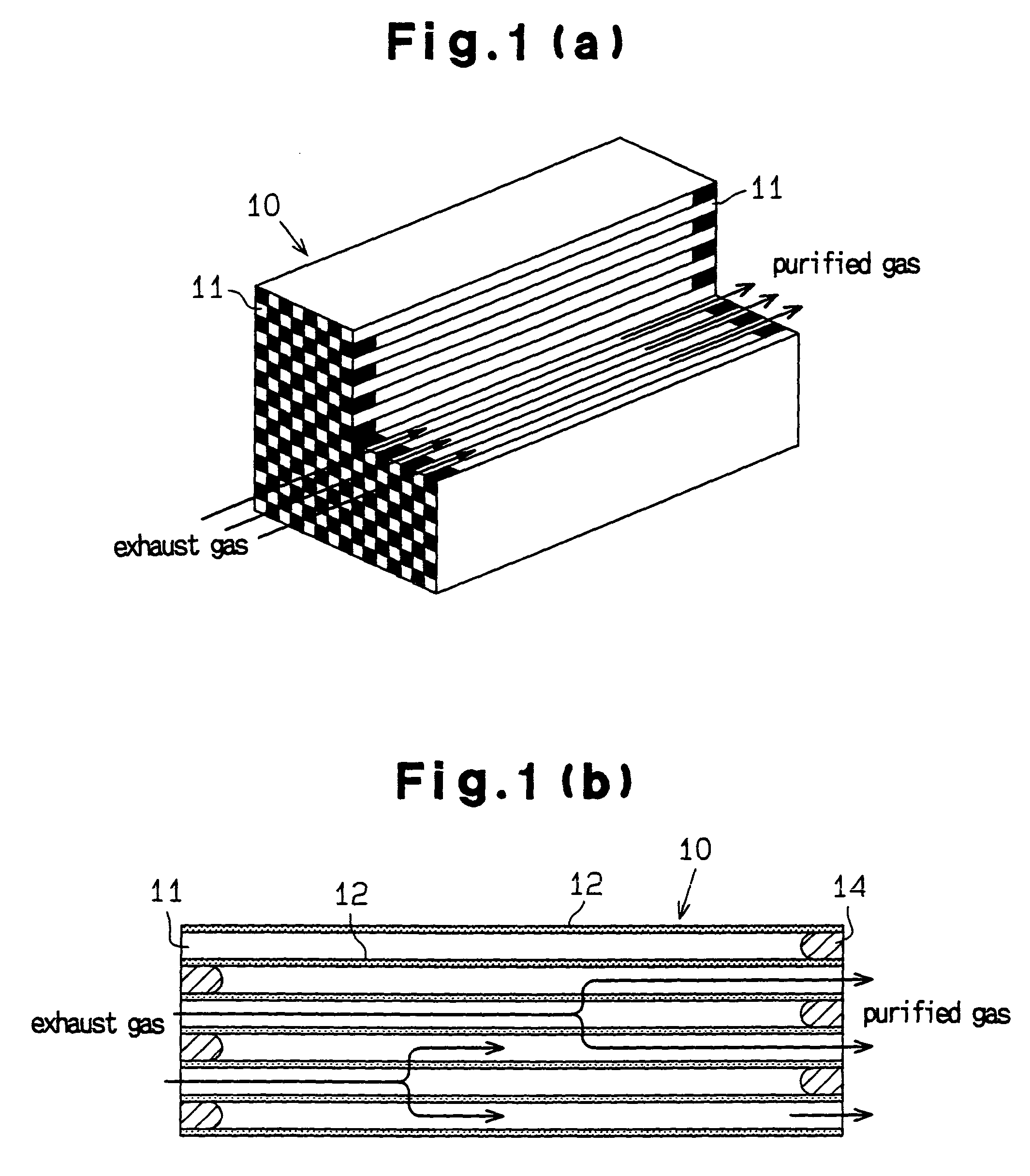

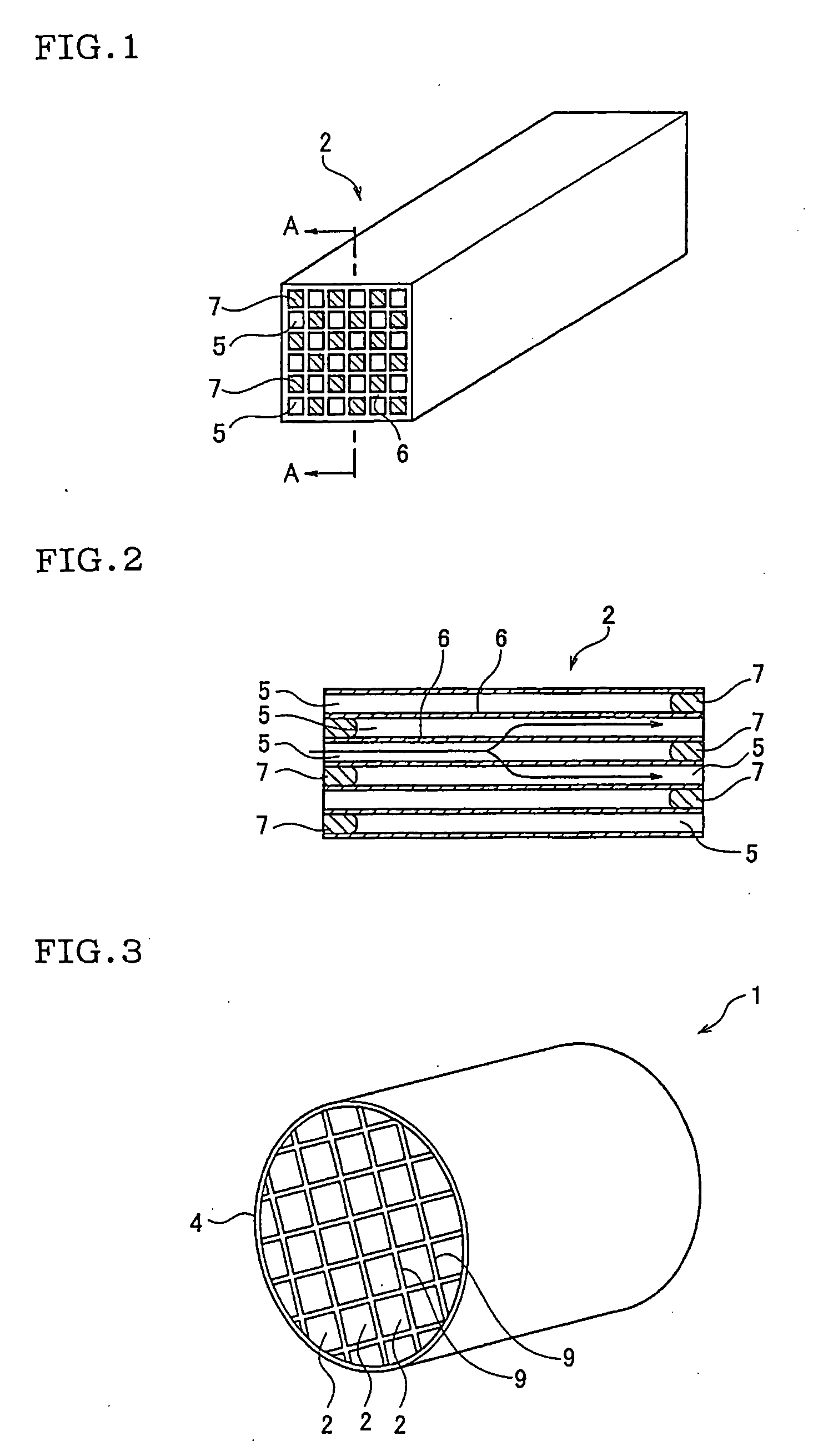

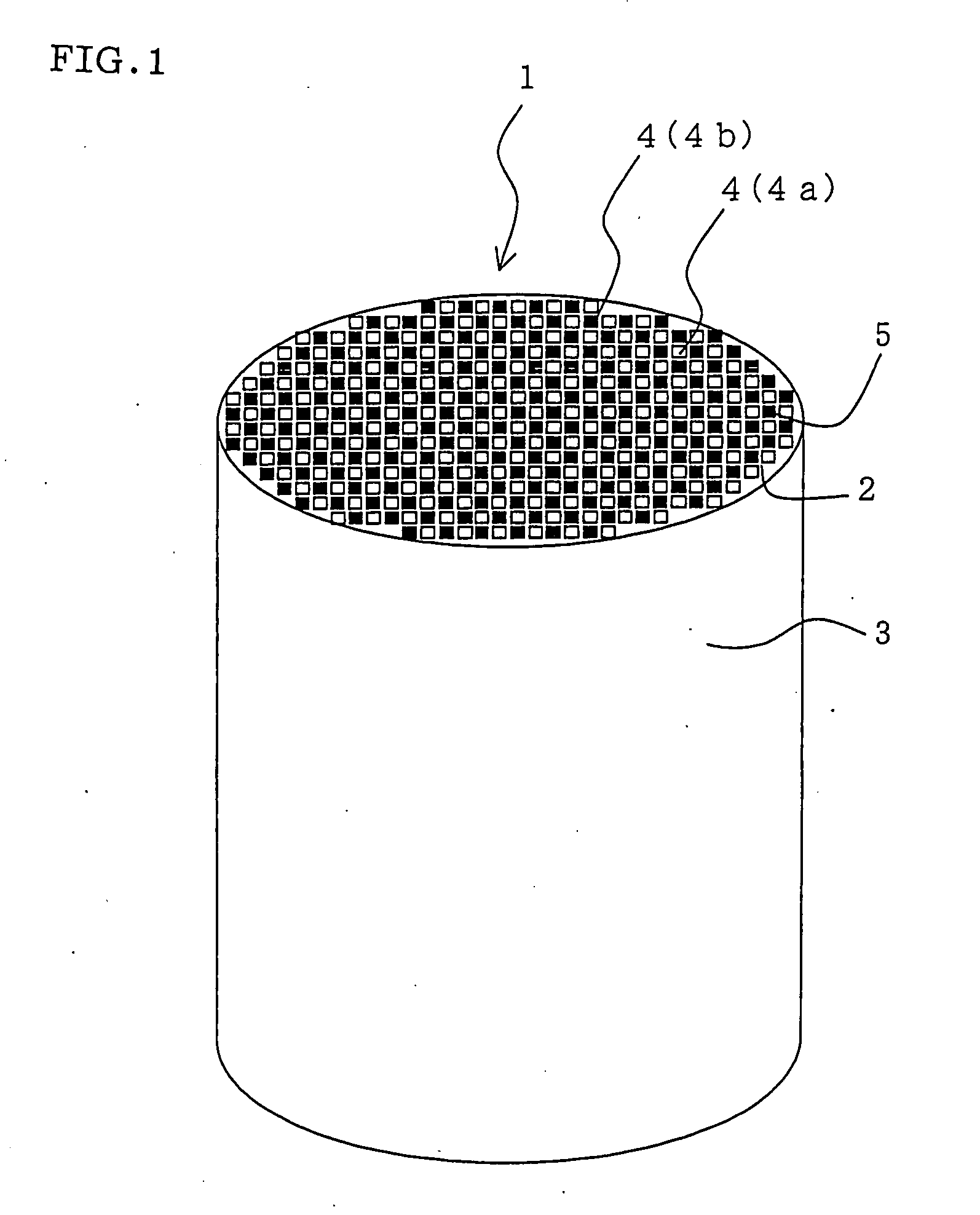

Honeycomb structural body

InactiveUS20050214504A1Certain viscosityStrength of the resulting honeycomb structural bodyCombination devicesAuxillary pretreatmentPorosityMetallurgy

A honeycomb structural body is constituted with a ceramic block made by arranging a plurality of through-holes side by side in the longitudinal direction through partition walls and sealing either one end portions of these through-holes. The ceramic block of this honeycomb structural body is made of a composite member consisting of ceramic particles and amorphous silicon, so that the honeycomb structural body has an excellent compression strength even if its porosity is increased, and is less in the lowering of mechanical strength even if it is heated to a high temperature, and is excellent in the durability.

Owner:IBIDEN CO LTD

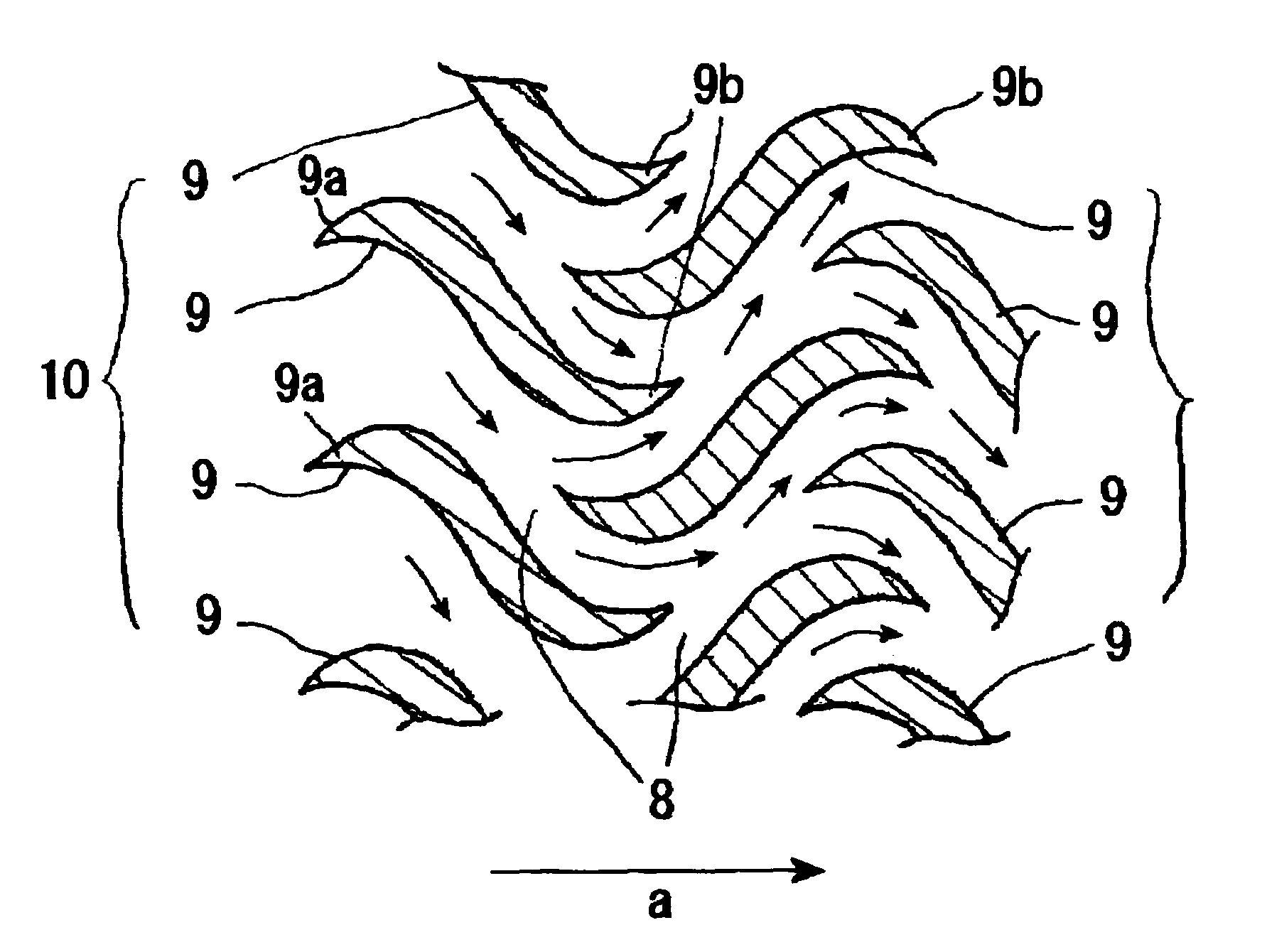

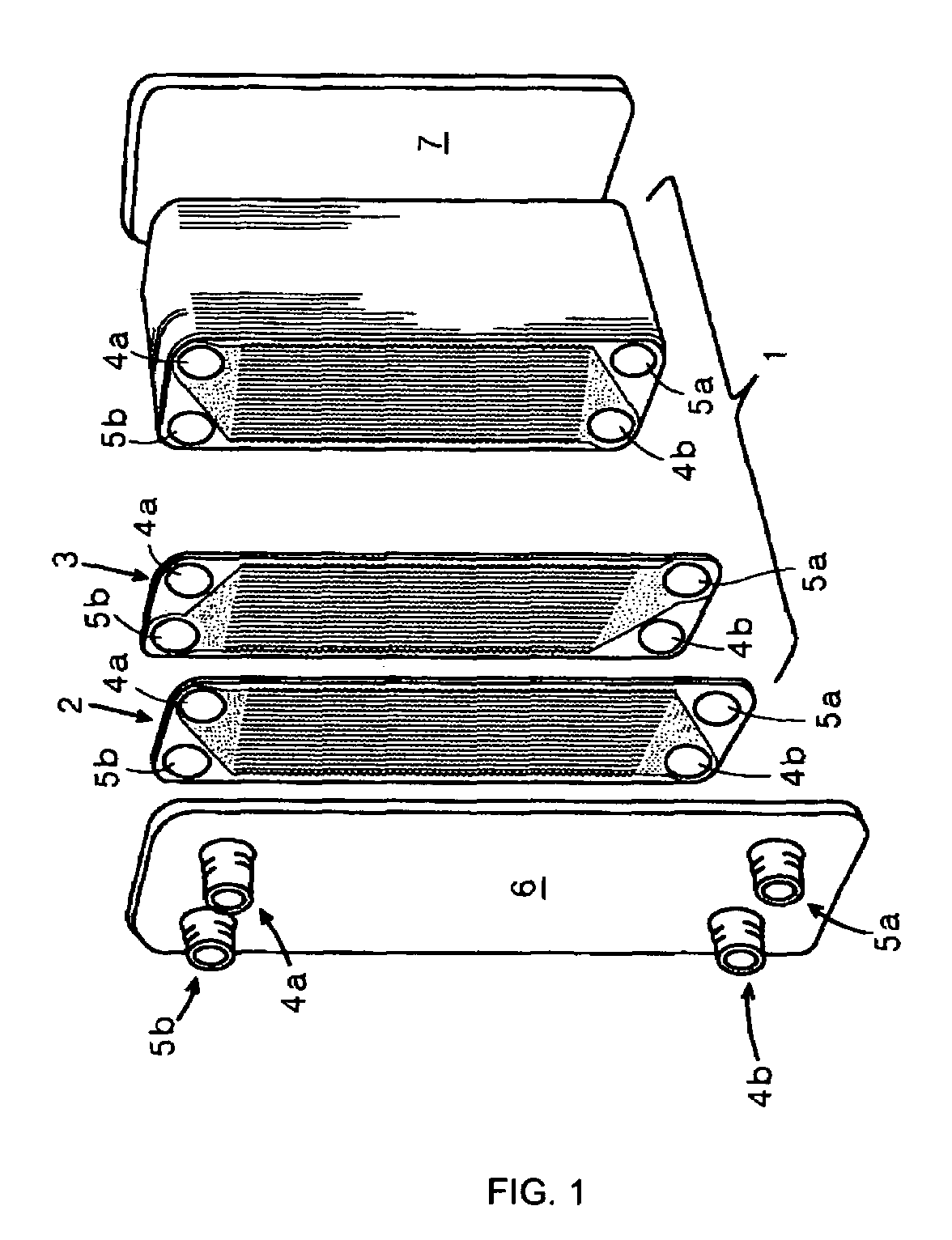

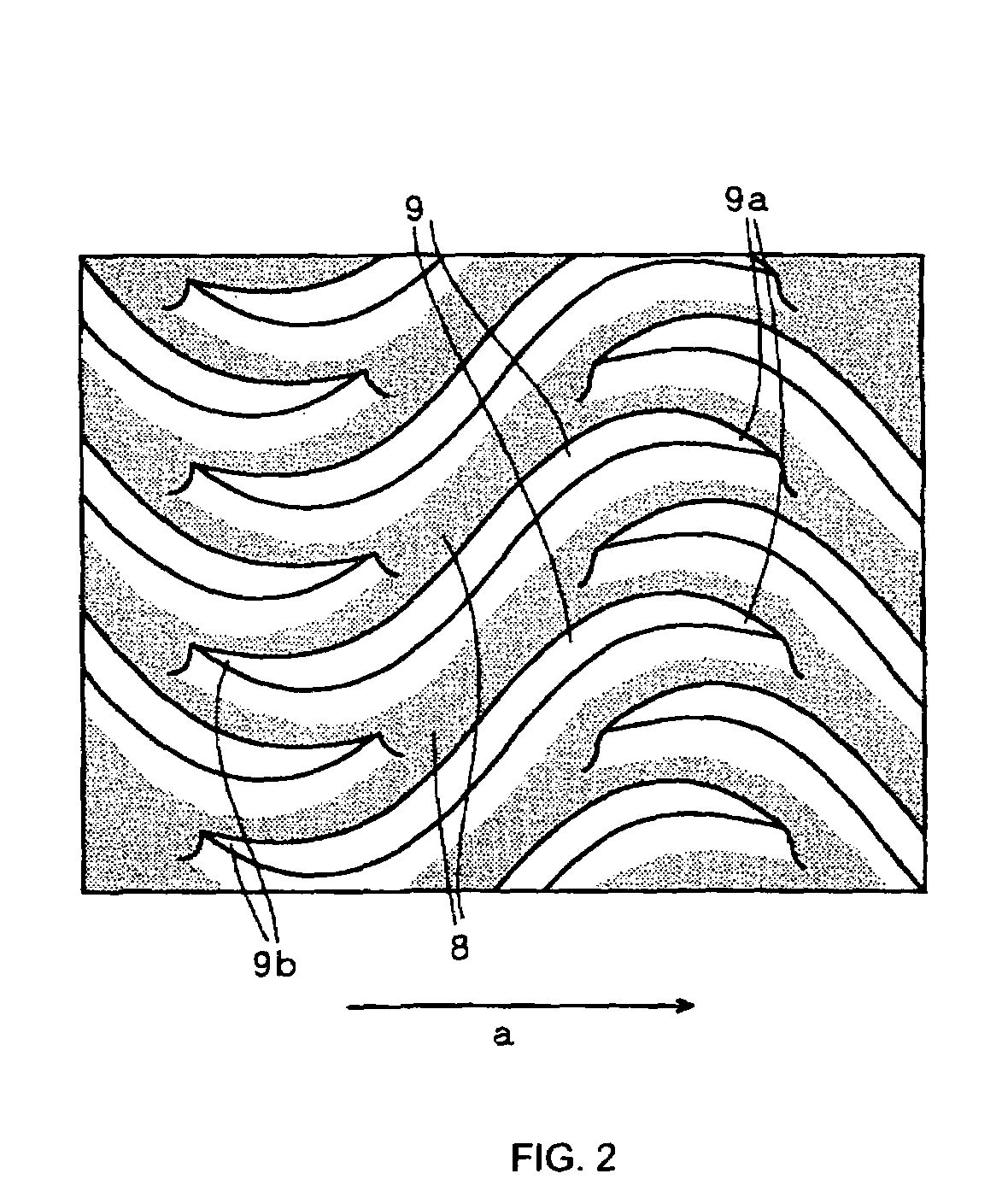

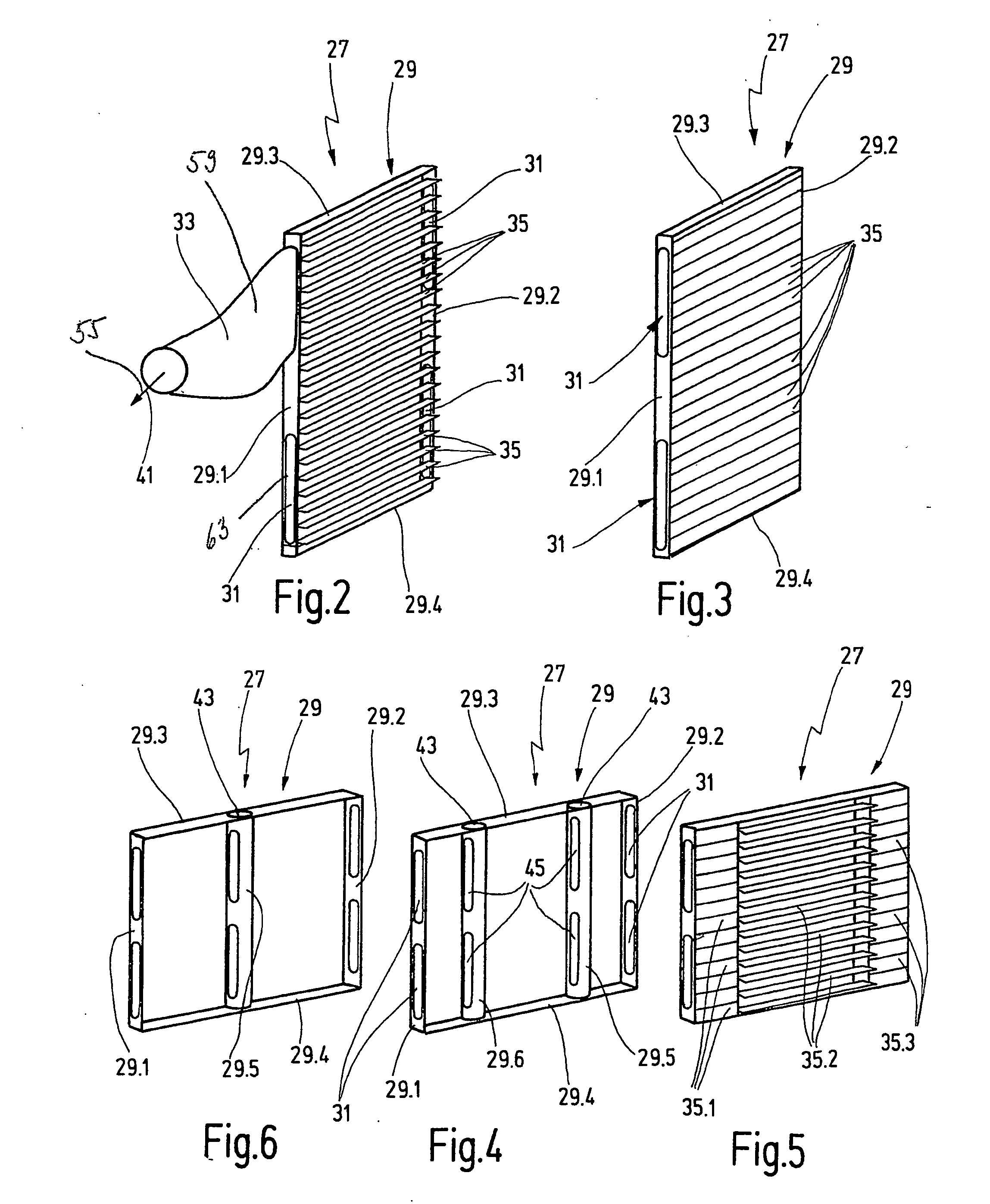

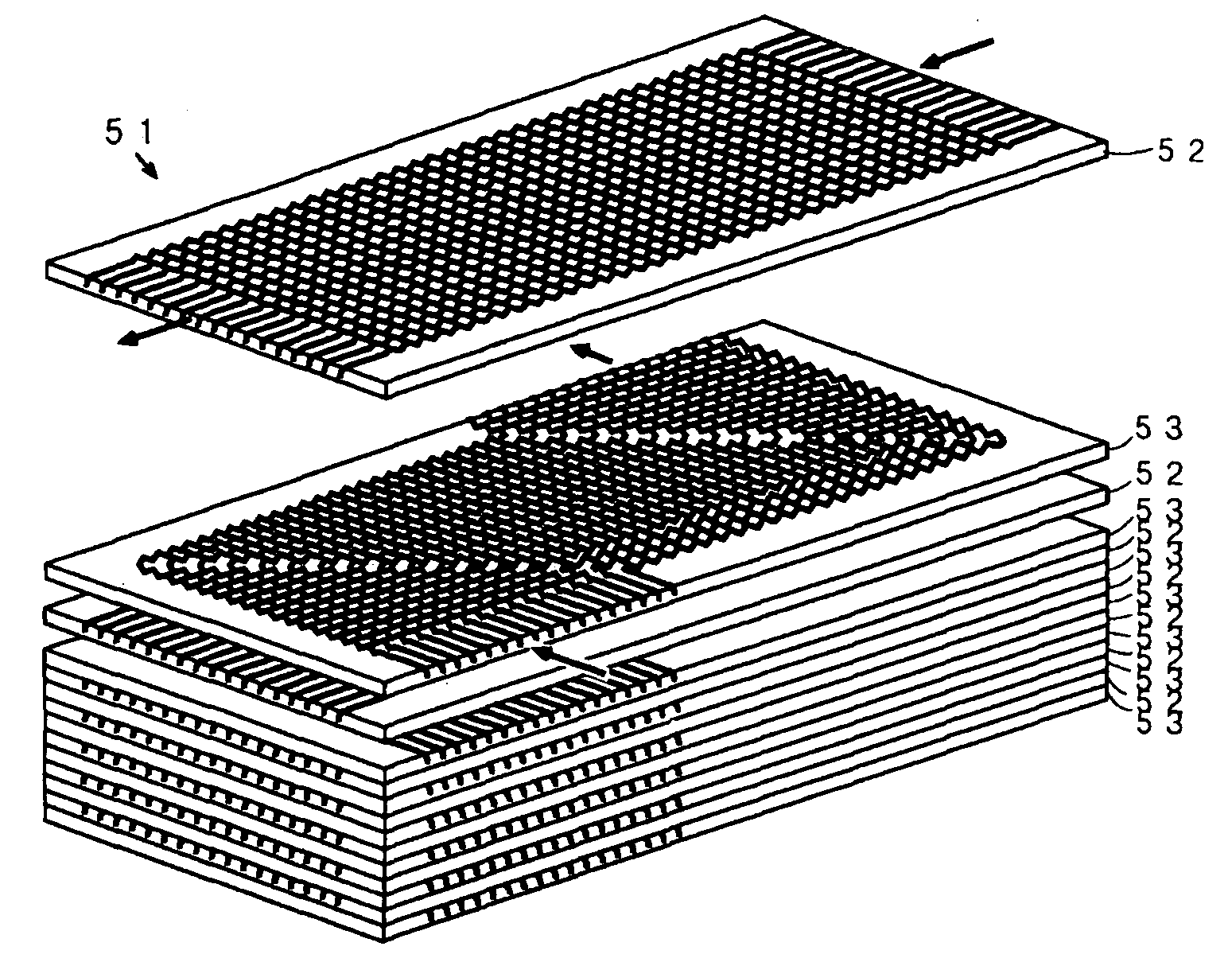

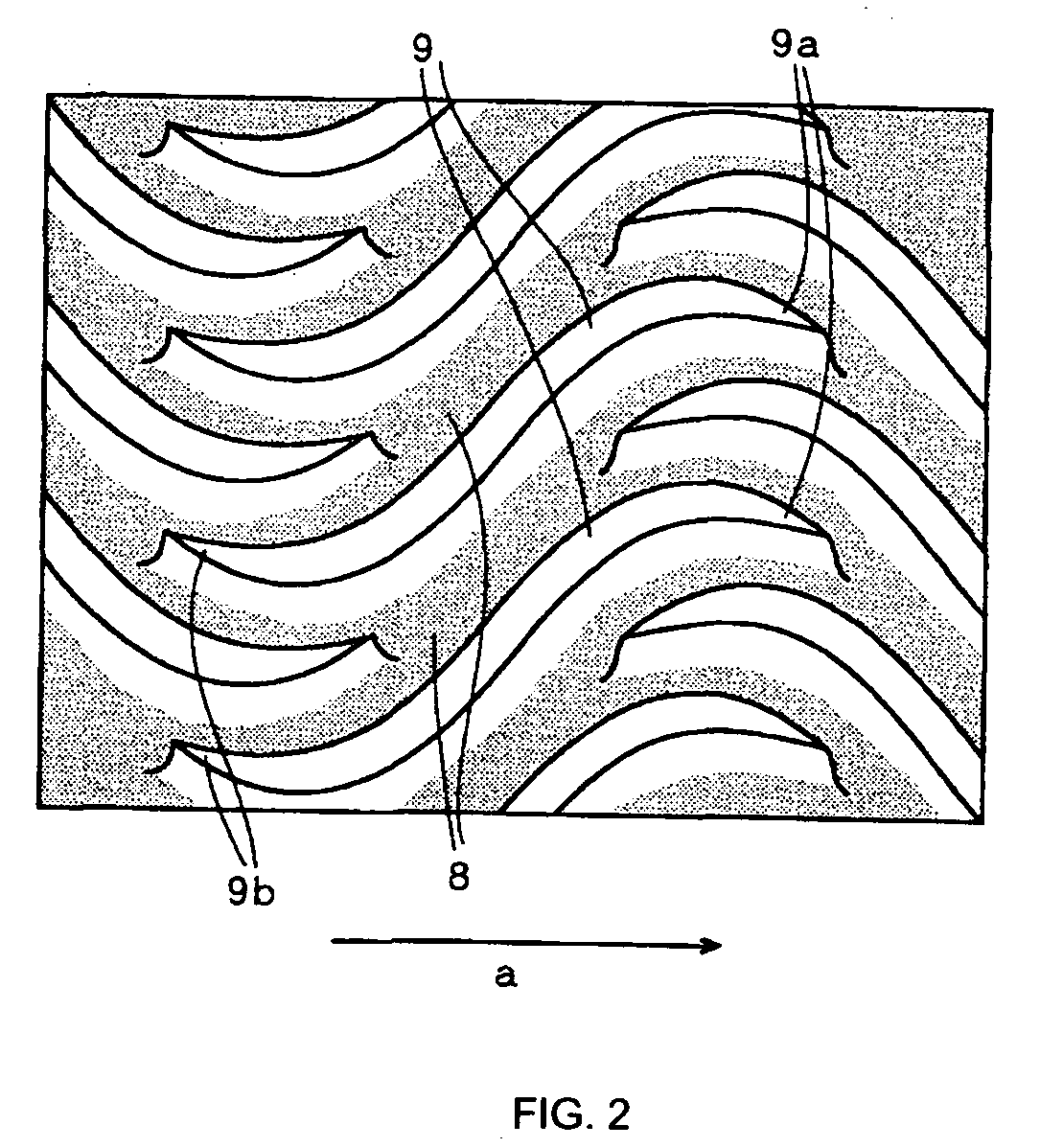

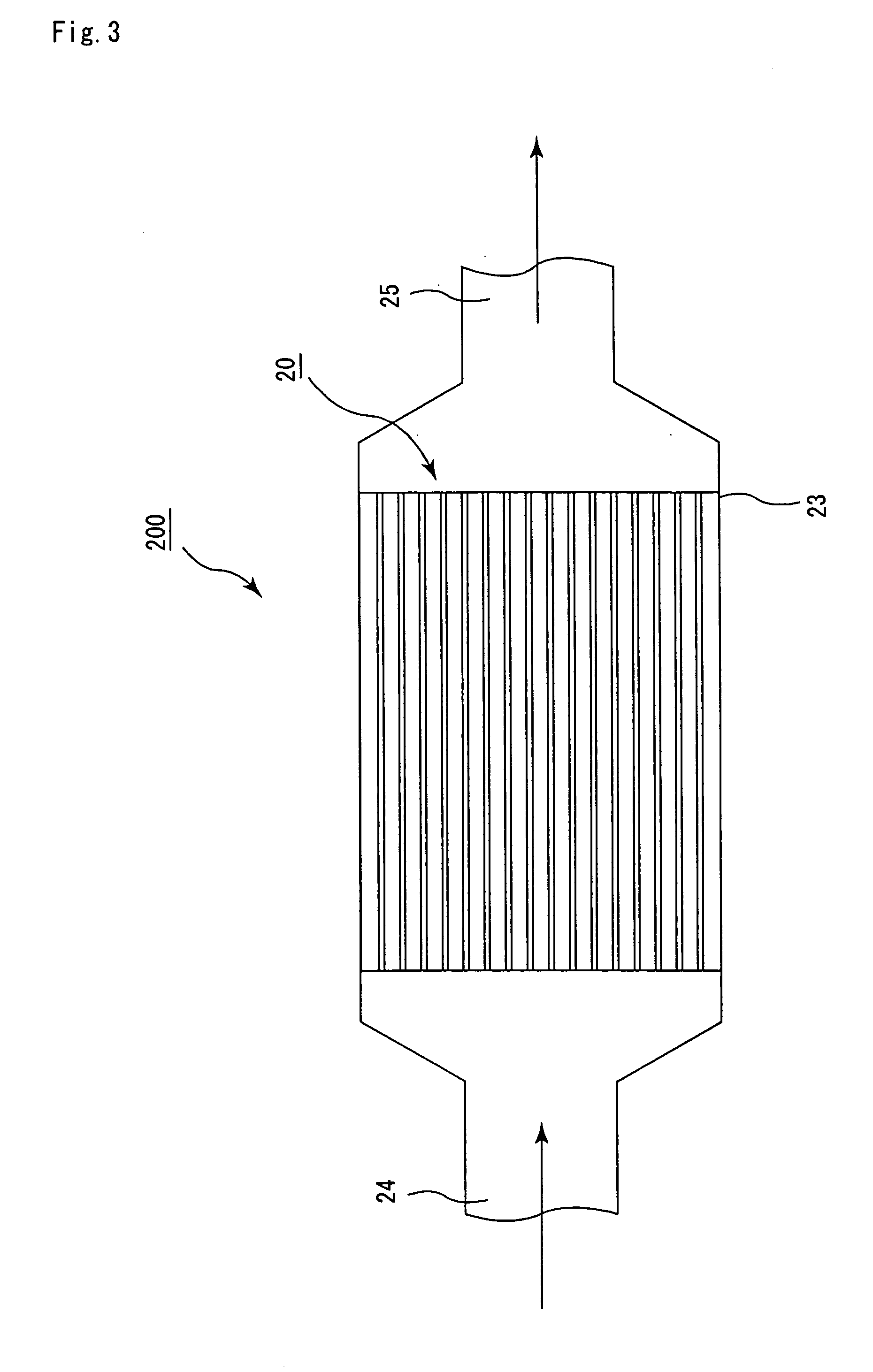

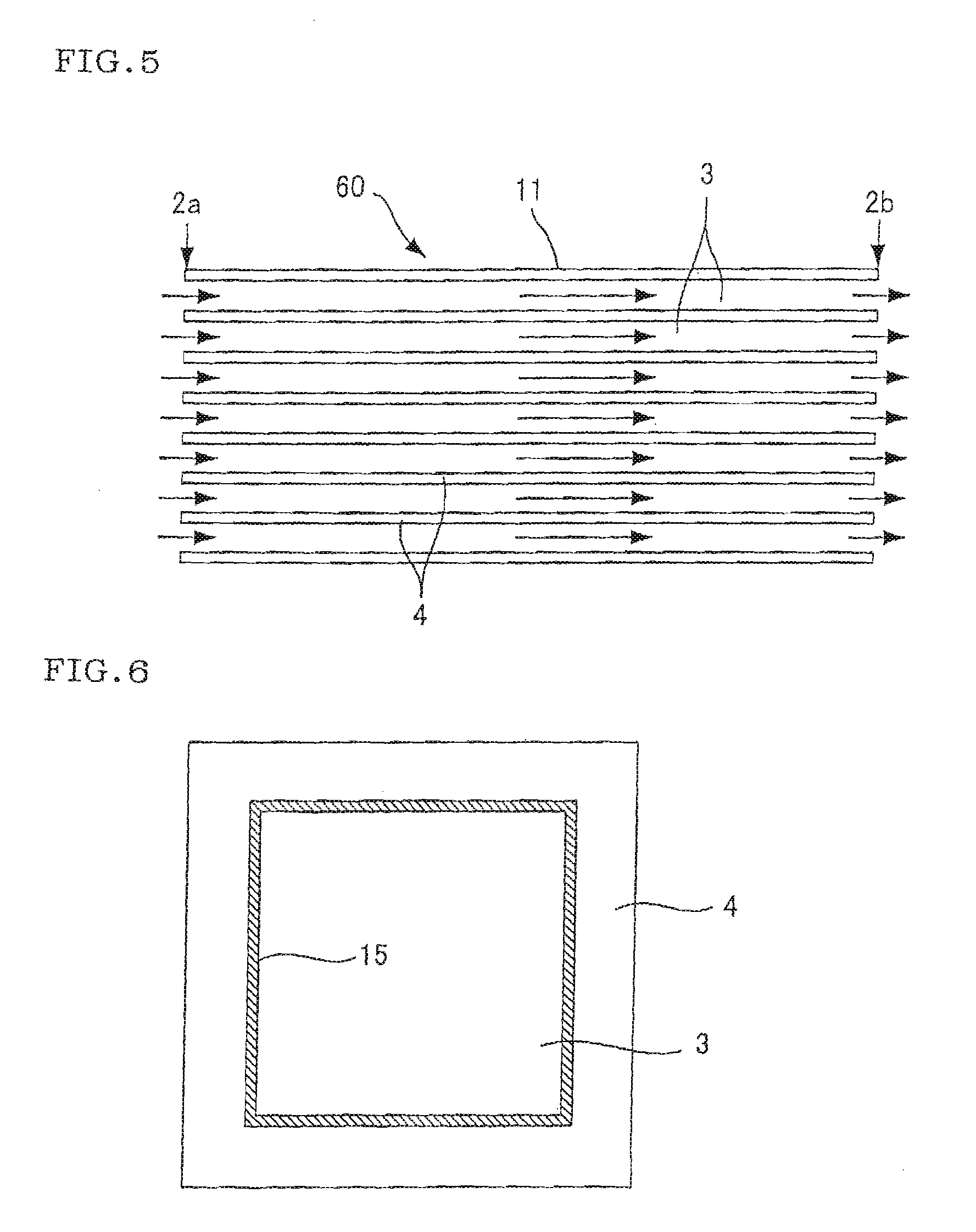

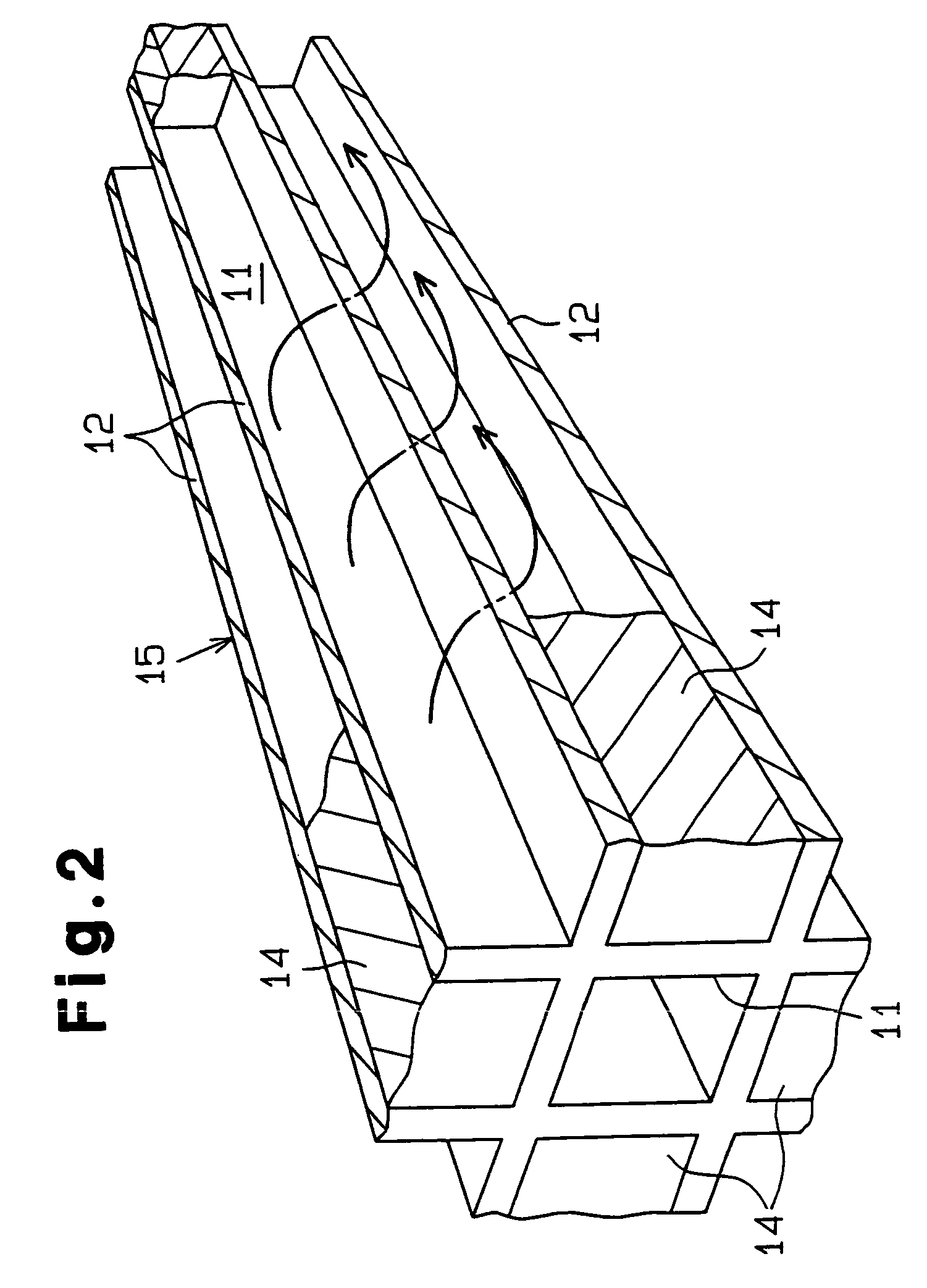

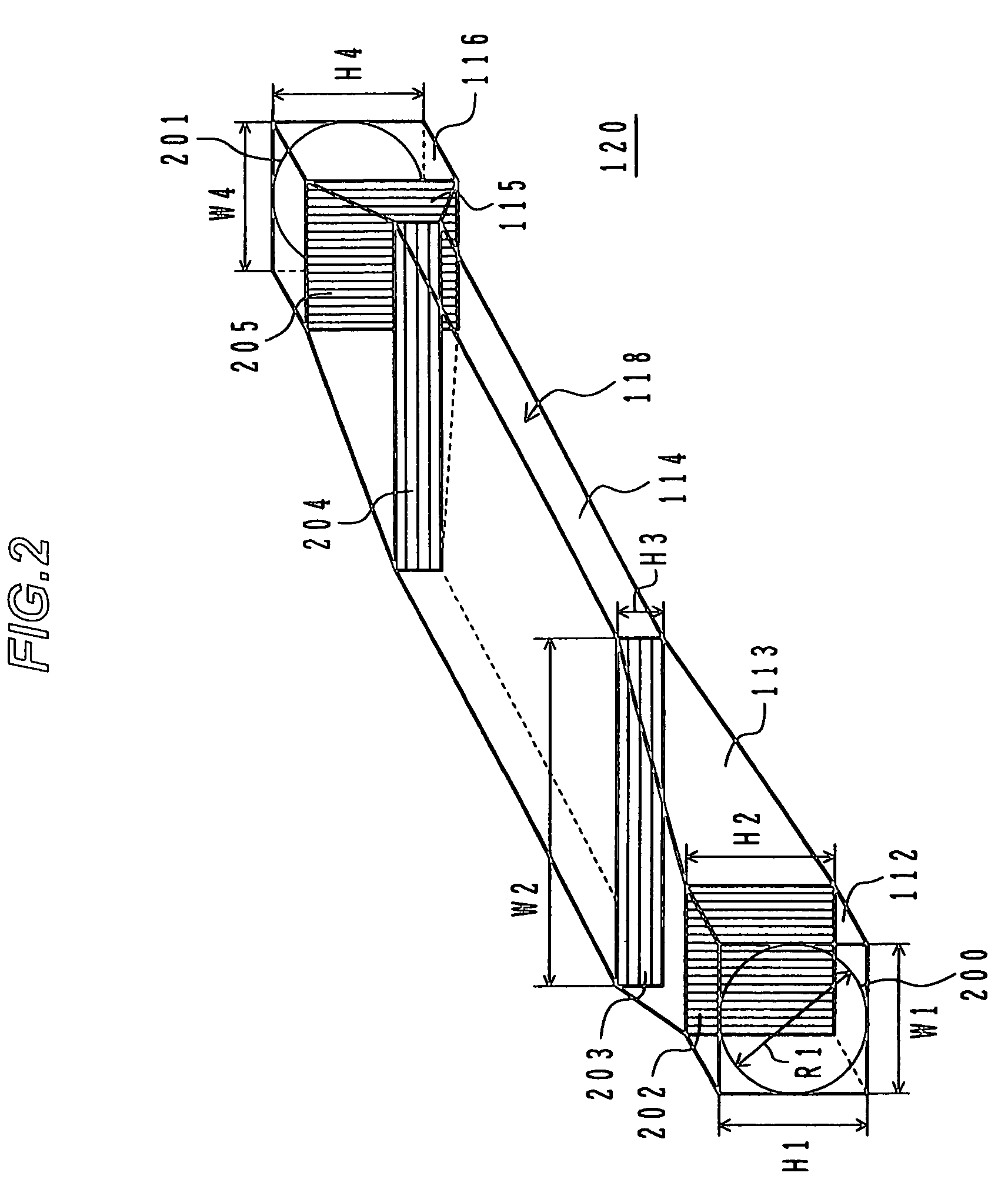

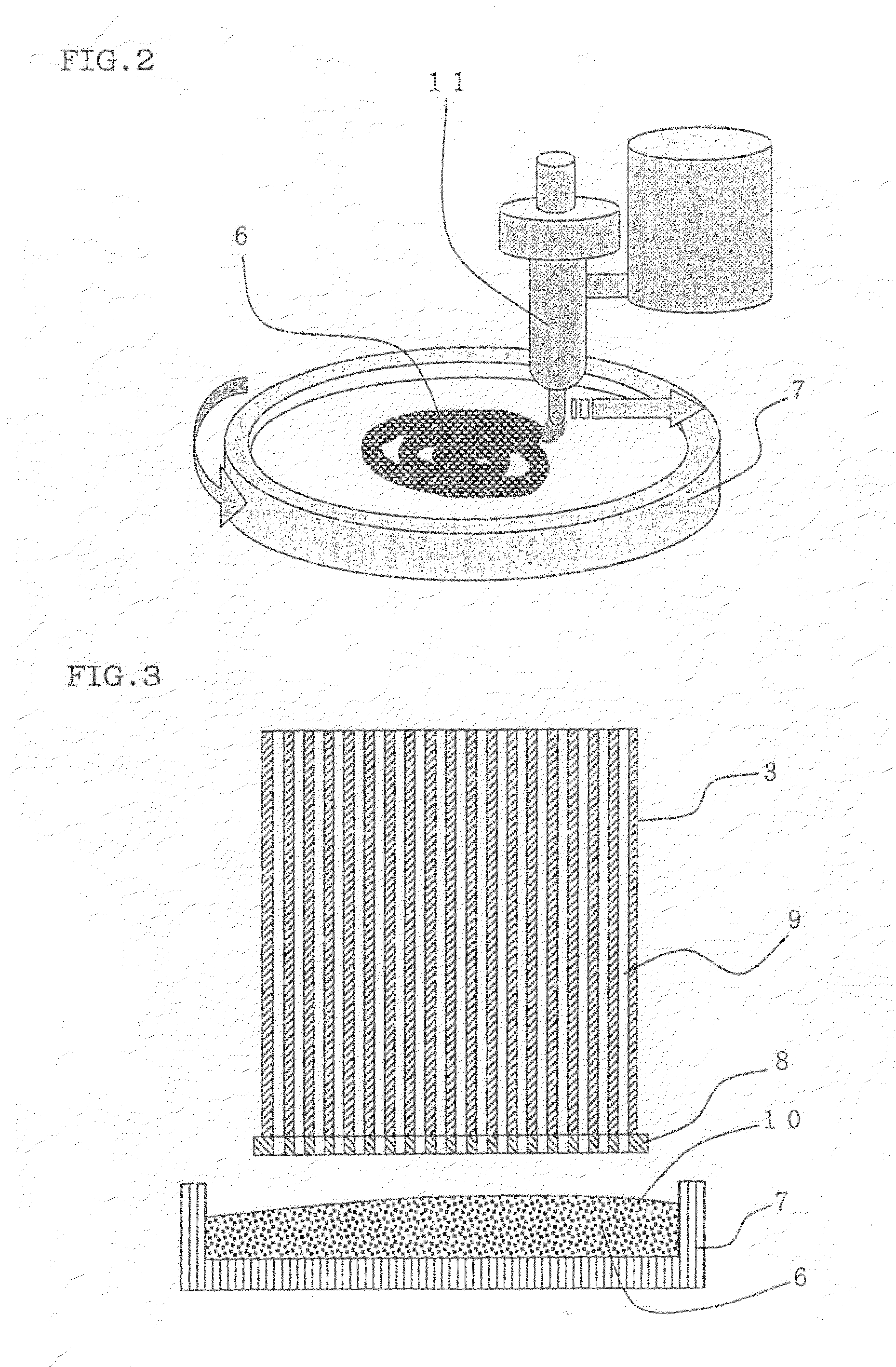

Heat exchanger

InactiveUS7334631B2Without impairment of heat transfer characteristicIncreased pressure lossHeat transfer modificationLaminated elementsThin metalPlate heat exchanger

To reduce pressure loss on a heat-exchanger fluid while downsizing a heat exchange and reducing the production cost of the heat exchanger without impairment of the heat transfer performance of the heat exchanger by forming a fluid channel in surfaces of thin metal plates such as stainless steel plates through the use of an etching technique or the like and by improving the shape of the fluid channel. In a heat exchanger in which a plurality of heat exchanger fins are provided in thin metal plates by using an etching technique or the like and a fluid channel for a heat-exchanger fluid is formed between the two opposed thin metal plates by alternately stacking the thin metal plates, the area of the fluid channel, through which the fluid flows between the heat exchanger fins, is made substantially uniform by forming the heat exchanger fins so as to have a curved cross-sectional shape from the front end thereof to the rear end.

Owner:KATO YASUYOSHI

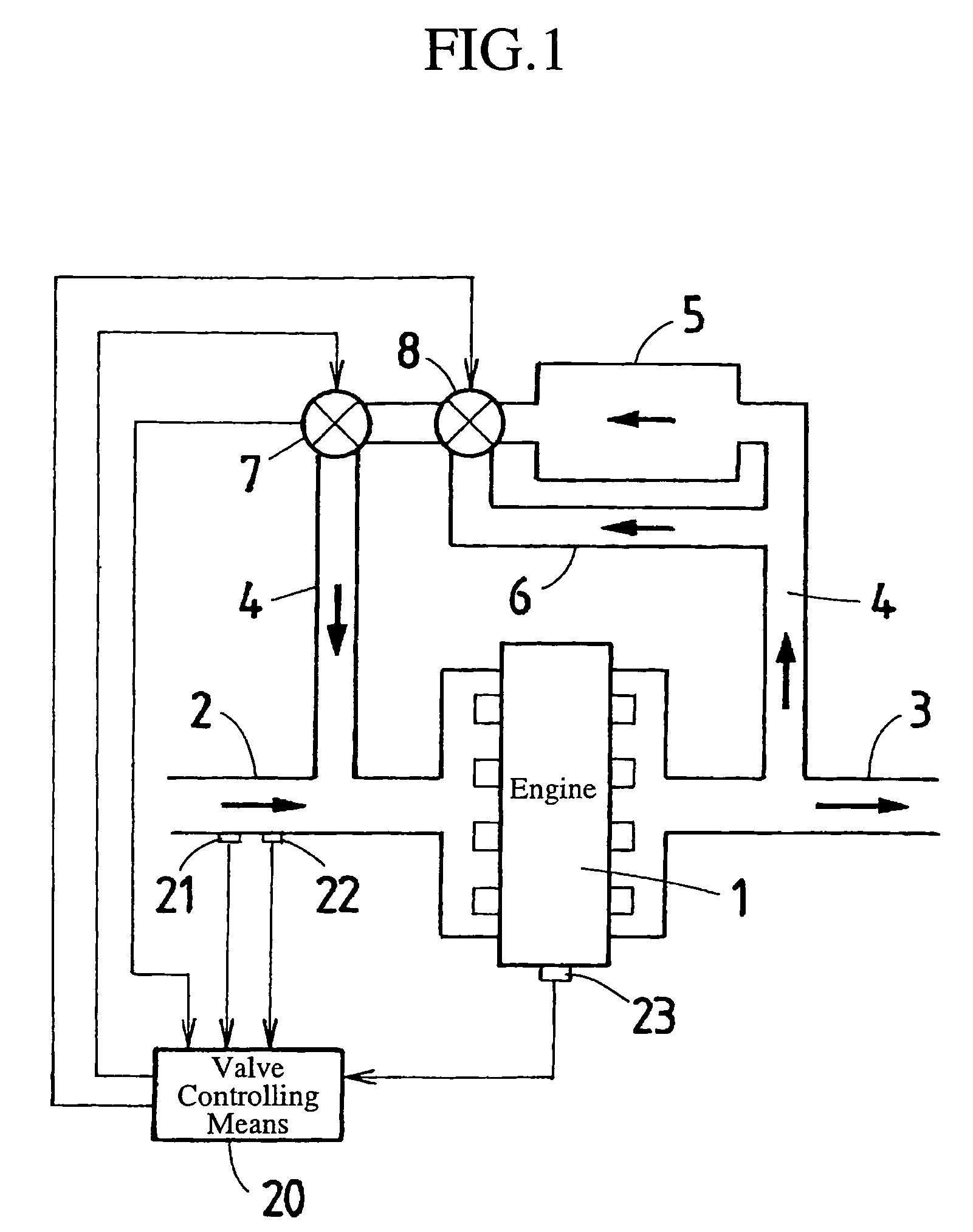

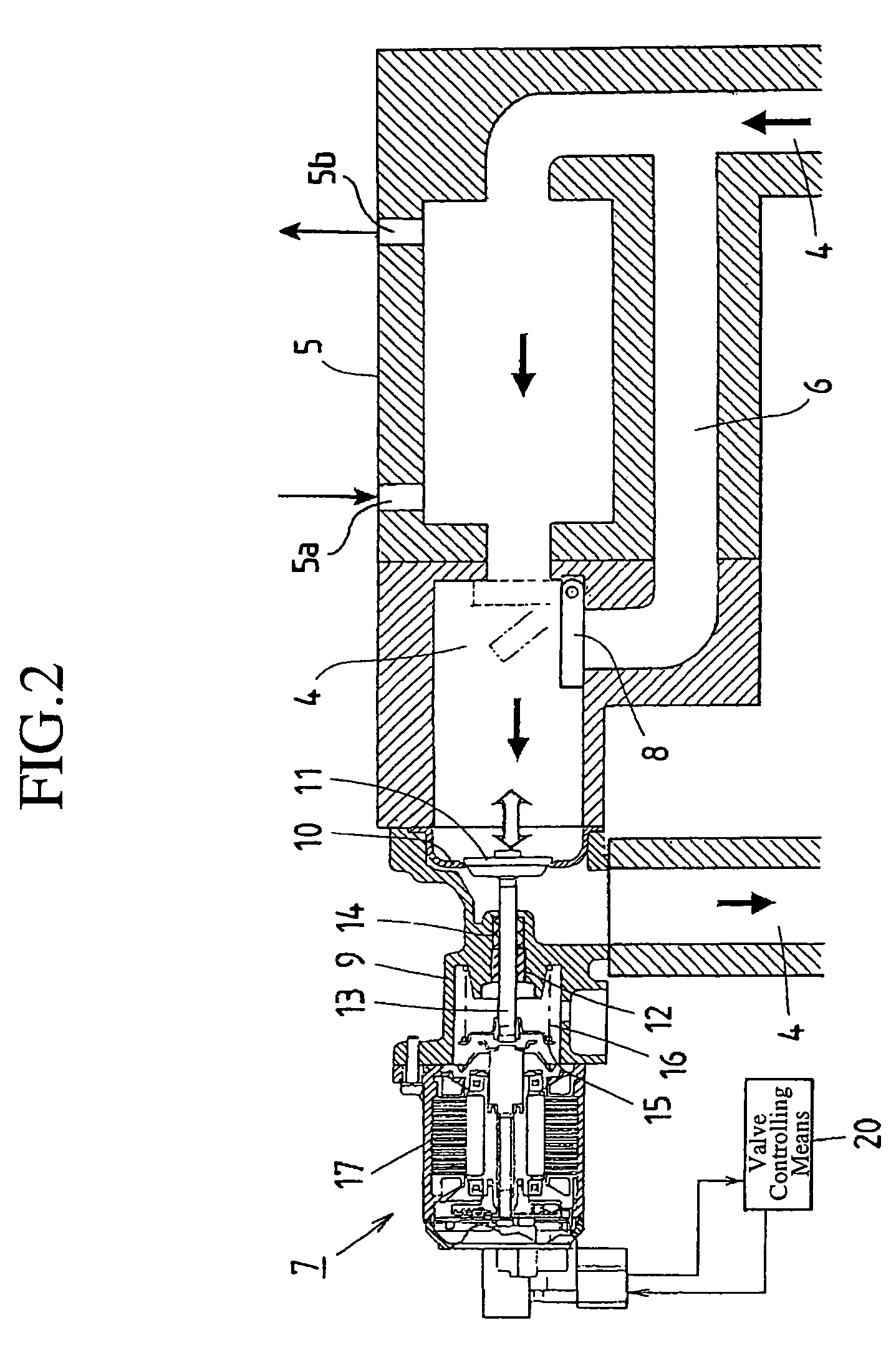

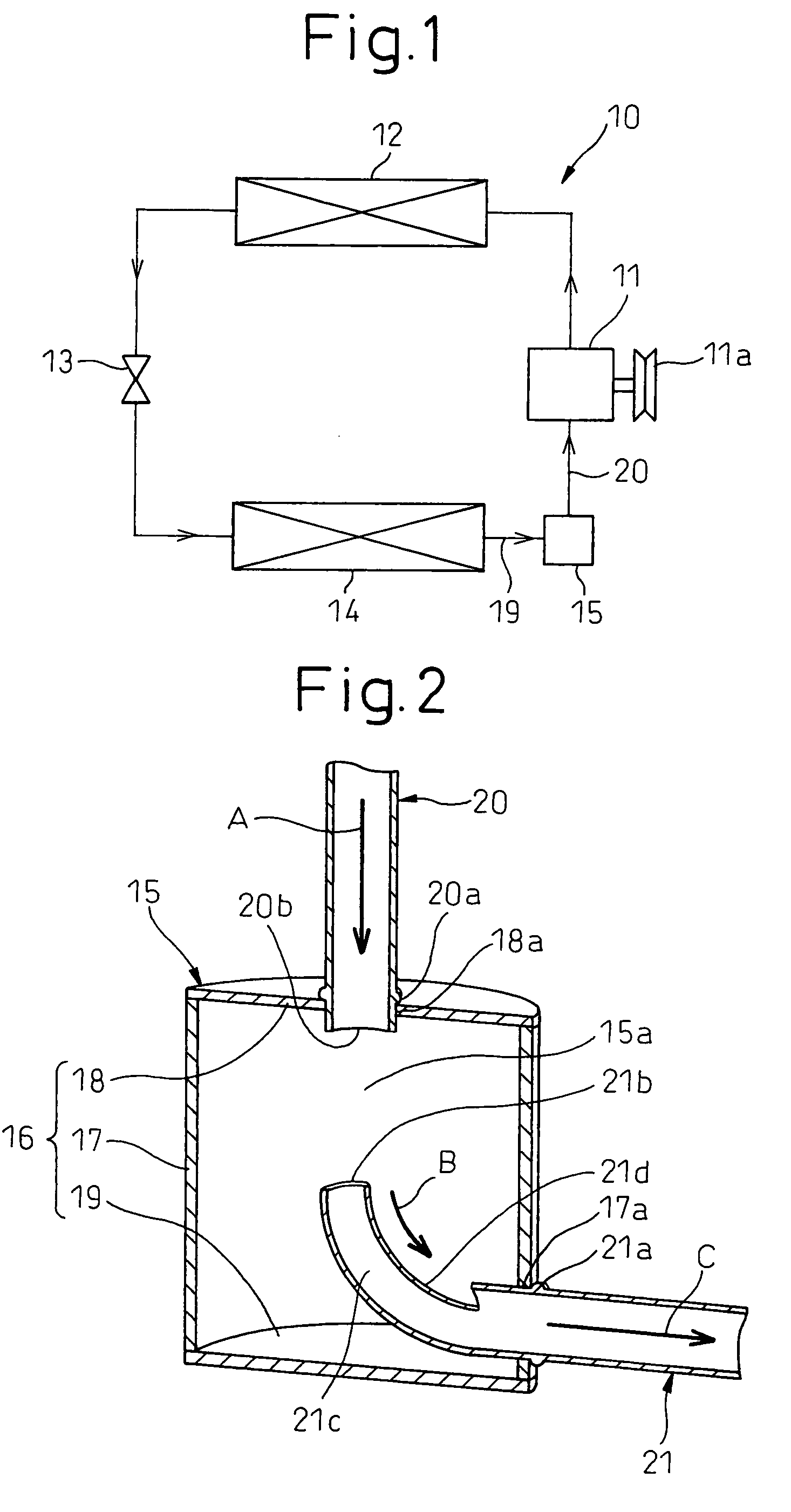

Cooling system for motor vehicles and method for controlling at least one air mass flow through a radiator

InactiveUS20060211364A1Easy to controlHeating up fastDucting arrangementsCoolant flow controlMobile vehicleEngineering

Cooling system for motor vehicles with at least one radiator to which in a first operating phase, particularly in the ram pressure phase, a first air stream can be supplied via a first air flow path and which in an alternative or simultaneous second operating phase, particularly during fan operation, can be supplied by means of at least one air-conveying device, with a second air stream flowing along a second air flow path. Among other things, it is also provided that at least in some regions the two air flow paths are oriented at an angle to each other so that the air-conveying device is disposed outside or essentially outside the first air flow path. The invention also related to a corresponding method.

Owner:ILLINOIS TOOL WORKS INC +1

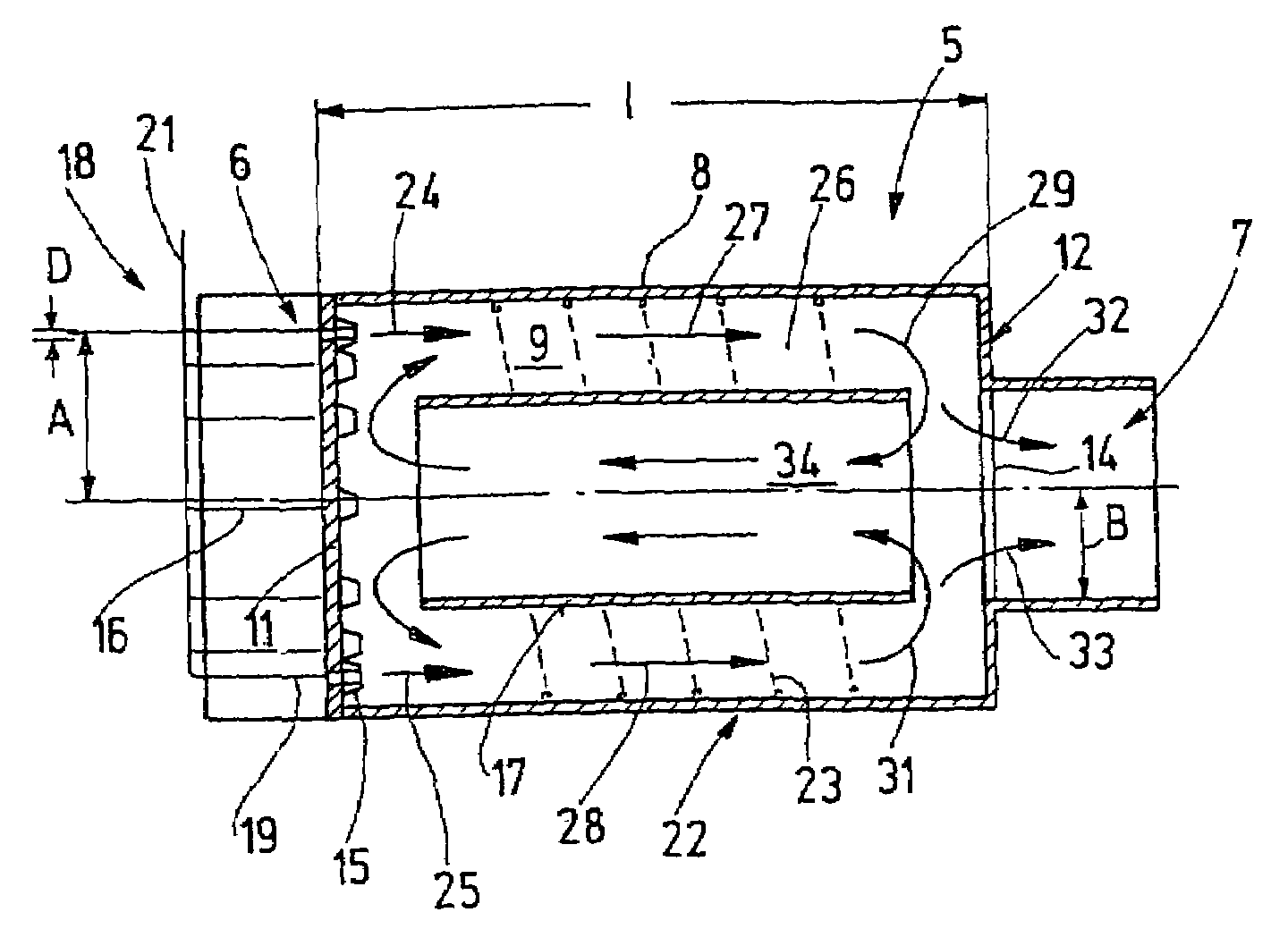

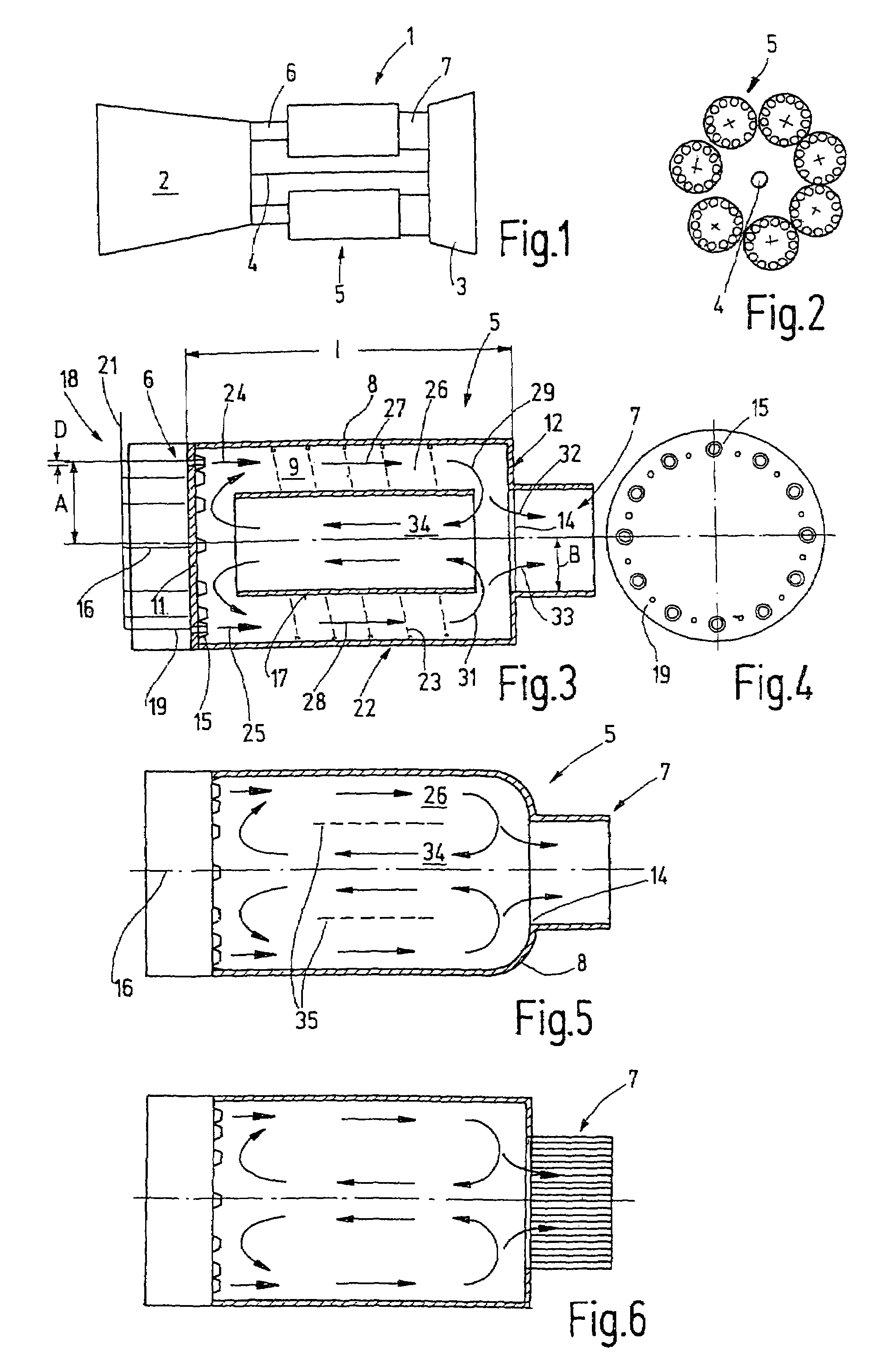

Combustion chamber with flameless oxidation

InactiveUS7062917B2Lower overall flow resistanceIncreased pressure lossContinuous combustion chamberGas turbine plantsInterior spaceCombustion chamber

A combustion chamber (5) for a gas turbine is adapted for flameless oxidation of fuels. This circulation flow has an internal space (9) in which a large-volume circulation flow is established. To this end, the combustion chamber supplies a hot exhaust stream to the introduced air, the mass flow rate of which exceeds the fresh air stream. The fresh air and the fuel are fed to the combustion chamber in the same direction, roughly parallel to the wall.

Owner:WS WARMEPROZESSTECHN

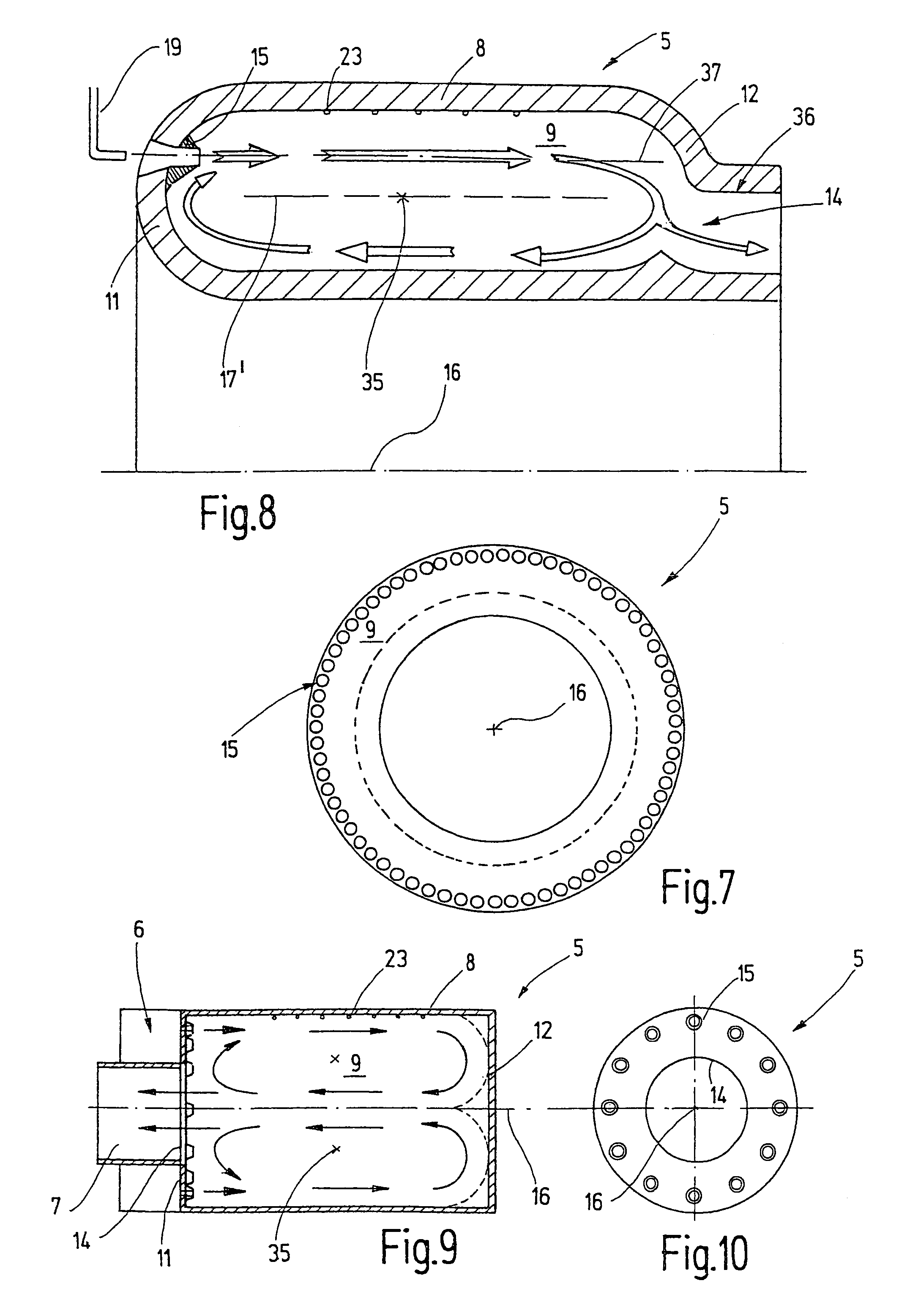

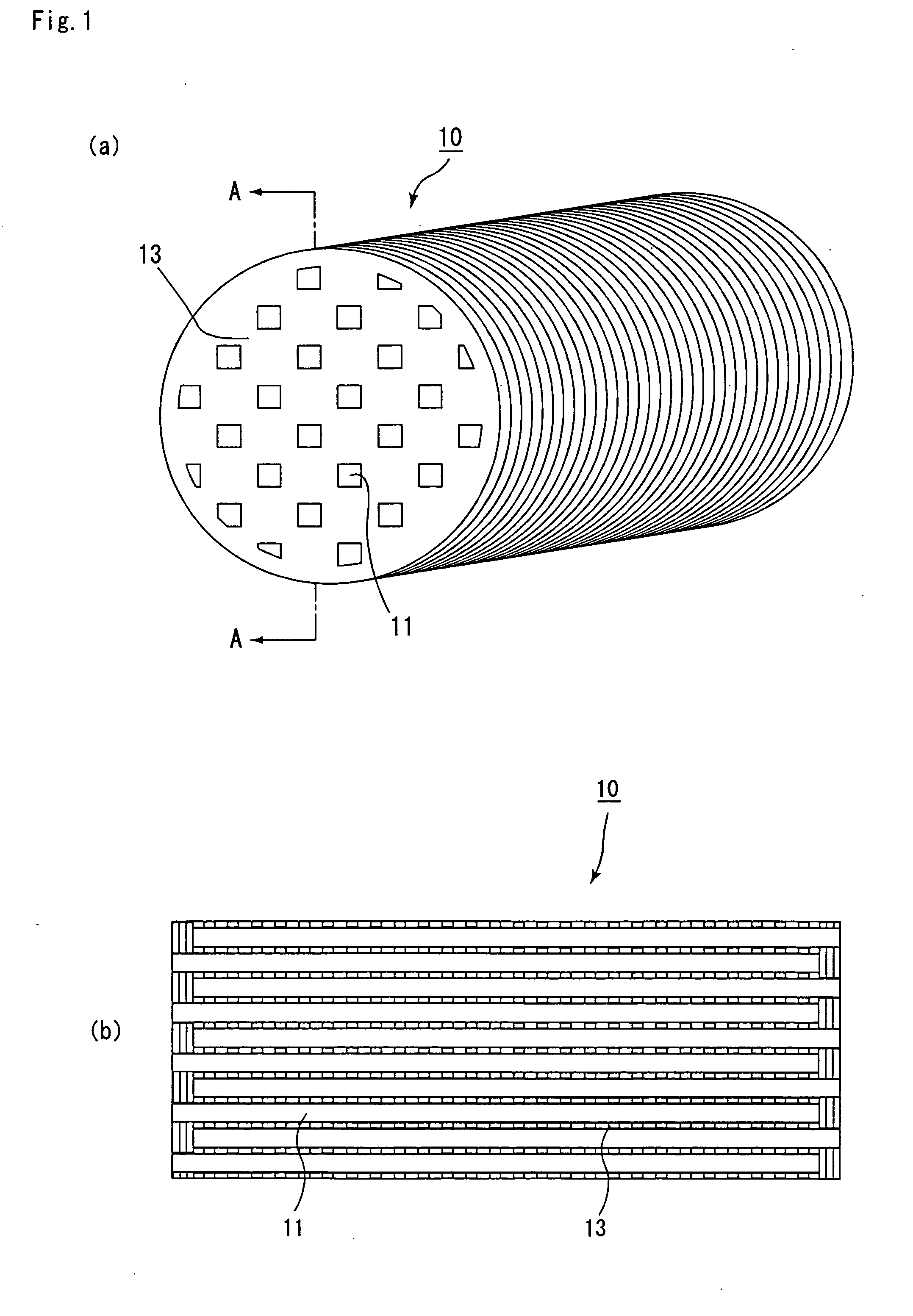

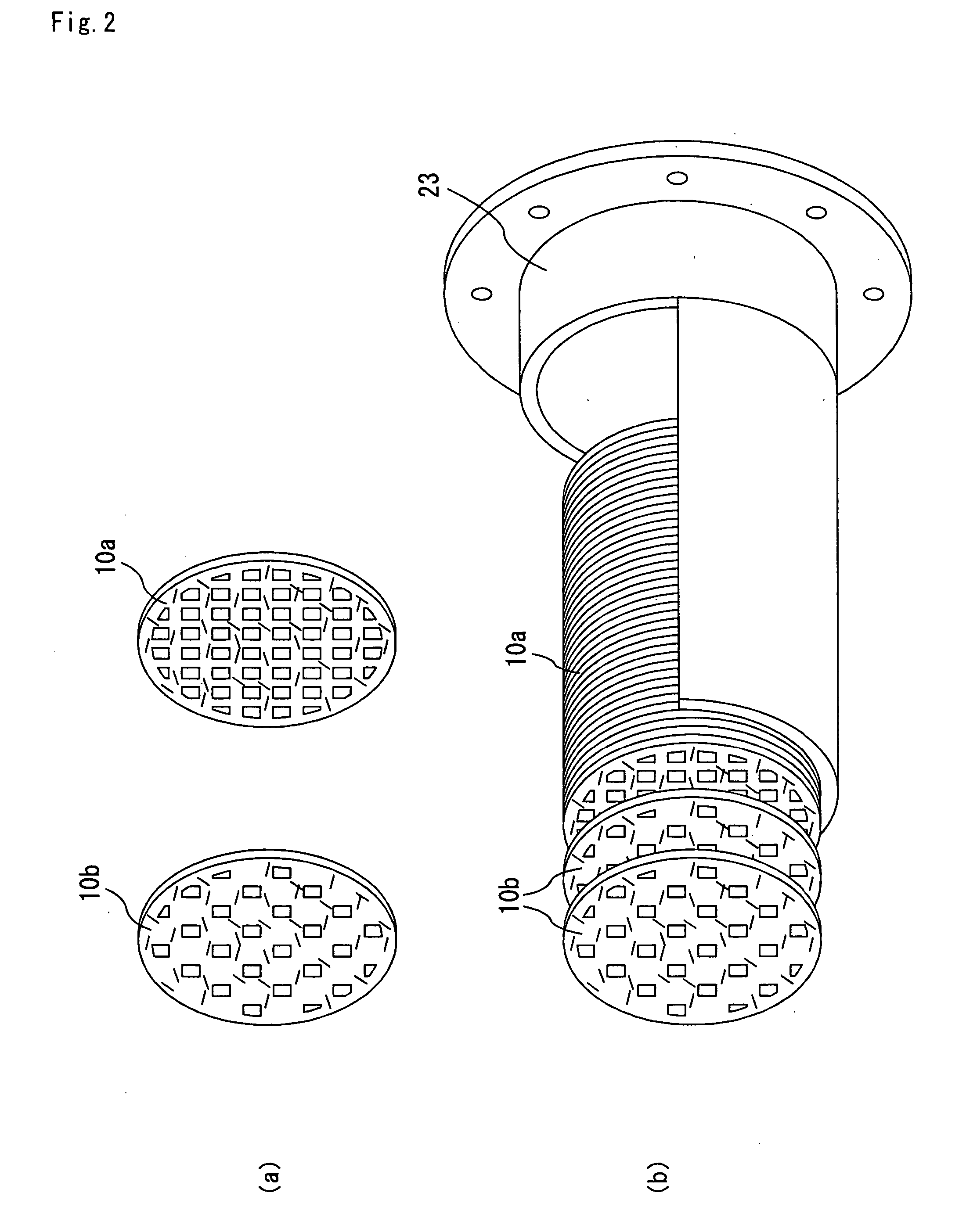

Heat exchanger

InactiveUS20060090887A1Reduce total pressure lossReduce maintenanceHeat transfer modificationLaminated elementsThin metalEngineering

To reduce pressure loss on a heat-exchanger fluid while downsizing a heat exchange and reducing the production cost of the heat exchanger without impairment of the heat transfer performance of the heat exchanger by forming a fluid channel in surfaces of thin metal plates such as stainless steel plates through the use of an etching technique or the like and by improving the shape of the fluid channel. In a heat exchanger in which a plurality of heat exchanger fins are provided in thin metal plates by using an etching technique or the like and a fluid channel for a heat-exchanger fluid is formed between the two opposed thin metal plates by alternately stacking the thin metal plates, the area of the fluid channel, through which the fluid flows between the heat exchanger fins, is made substantially uniform by forming the heat exchanger fins so as to have a curved cross-sectional shape from the front end thereof to the rear end.

Owner:KATO YASUYOSHI

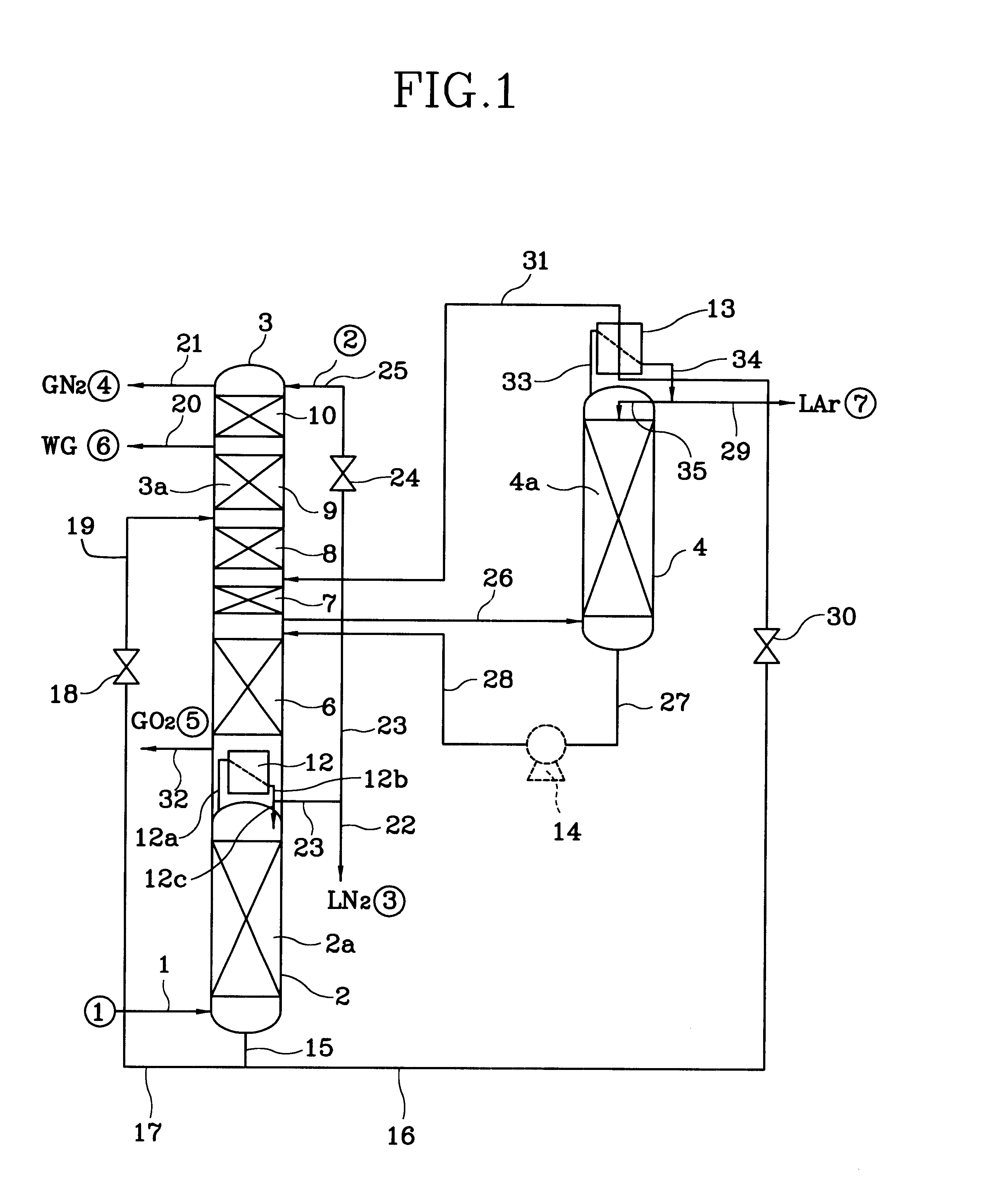

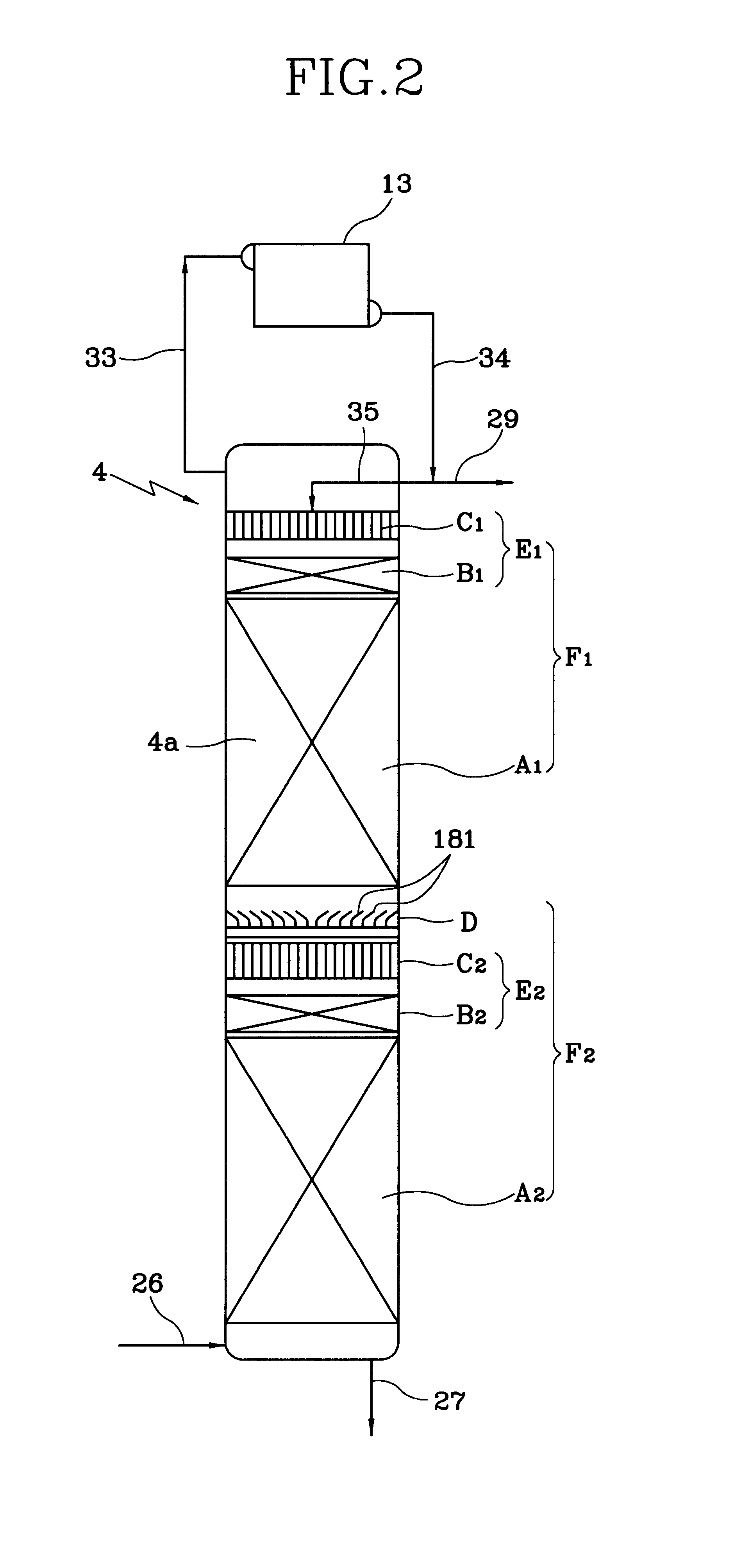

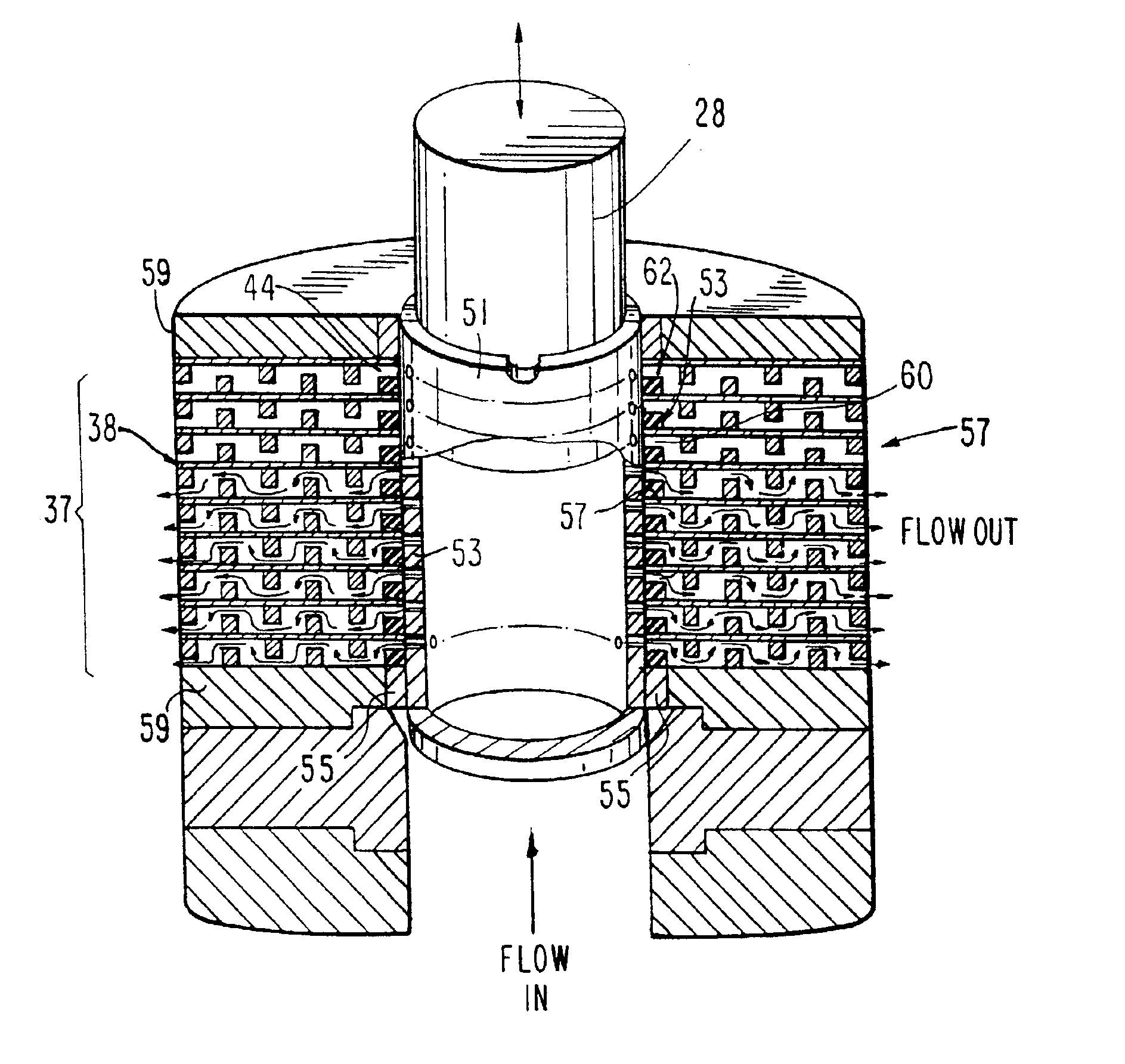

Vapor-liquid contactor, cryogenic air separation unit and method of gas separation

InactiveUS6565629B1Increased pressure lossIncrease flow resistanceCarburetting airSolidificationAir separationMechanical engineering

In an vapor-liquid contactor 4a for flowing down a liquid along the surface of a packing and contacting said liquid with the vapor while ascending the vapor, the improvement being characterized in that said packing is a non-promoting-fluid-dispersion type structured packing A1, A2 in which various types of thin sheets or tubes for determining the flow direction of the above liquid or vapor is laminated and arranged in the perpendicular direction, and said contactor includes at least one fluid distribution unit E1, E2 formed of a rough distribution part C1, C2 to distribute the liquid roughly and a minute distribution part B1, B2 to distribute the liquid minutely and equally.

Owner:NIPPON SANSO CORP

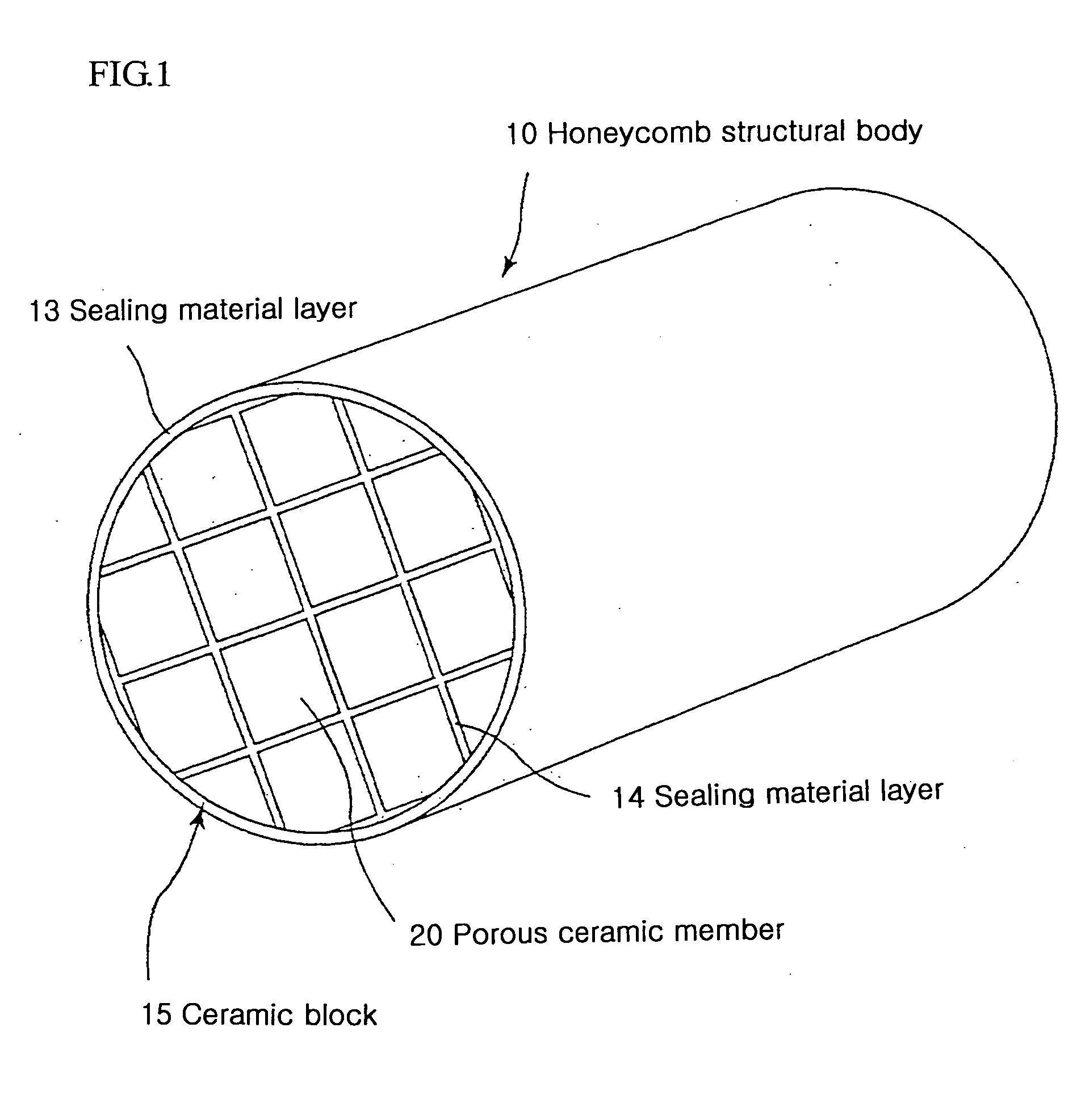

Honeycomb structural body

InactiveUS20050266991A1Improve purification functionReduce initial pressure lossCombination devicesAuxillary pretreatmentFiberToxic gas

An object of the present invention is to provide a honeycomb structural body for use in a filter, which can be provided with a large amount of catalyst, can suppress an increase in pressure loss upon collecting particulates, can have a high particulate collecting capability and can efficiently carry out a regenerating process and a toxic gas purifying process. The honeycomb structural body of the present invention is a pillar-shaped honeycomb structural body that is mainly composed of inorganic fibers and has a structure in that a large number of through holes are placed in parallel with one another in the length direction with a partition wall interposed therebetween. Herein, the inorganic fibers, which form the honeycomb structural body, are arranged in such a manner that more fibers are aligned along a face perpendicular to the forming direction of the through holes rather than aligned along a face in parallel with the forming direction of the through holes.

Owner:IBIDEN CO LTD

Honeycomb catalytic structure, precoated support for producing honeycomb catalytic structure, and process for producing honeycomb catalytic structure

ActiveUS20080125316A1Reduce stagnationGood catalytic activityCombination devicesGas treatmentUnit volumeHoneycomb structure

According to the present invention, there is provided a honeycomb catalytic structure comprising:a honeycomb structure comprising porous partition walls having a large number of pores, disposed so as to form a plurality of cells extending between the two end faces of the honeycomb structure and plugging portions disposed at either one end of each cell, anda catalyst layer containing a catalyst, supported at least on the inner surfaces of the pores of the honeycomb structure,wherein the mass of the catalyst layer per unit volume (1 cm3) of the honeycomb structure (g / cm3) is 60% or less of the volume of pores per unit volume (1 cm3) of the honeycomb structure (cm3 / cm3).

Owner:NGK INSULATORS LTD

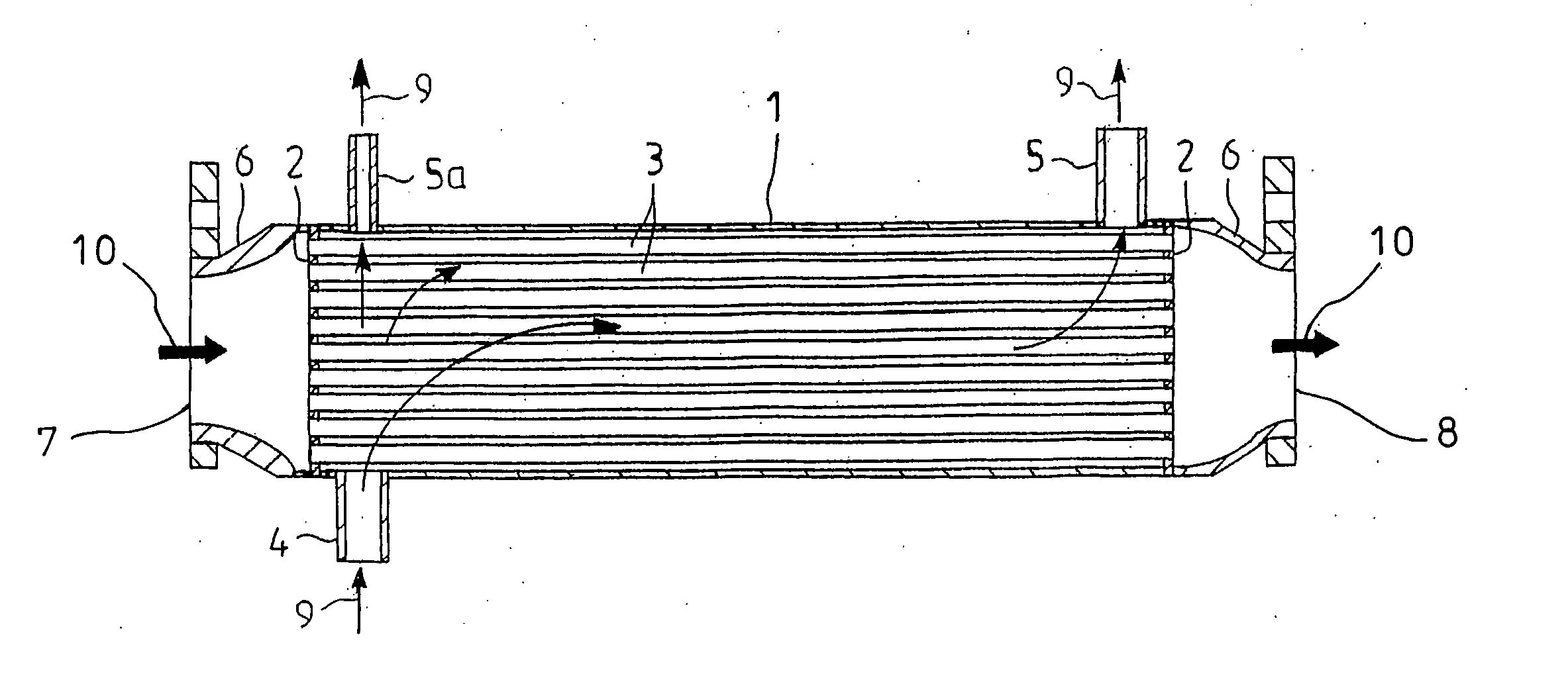

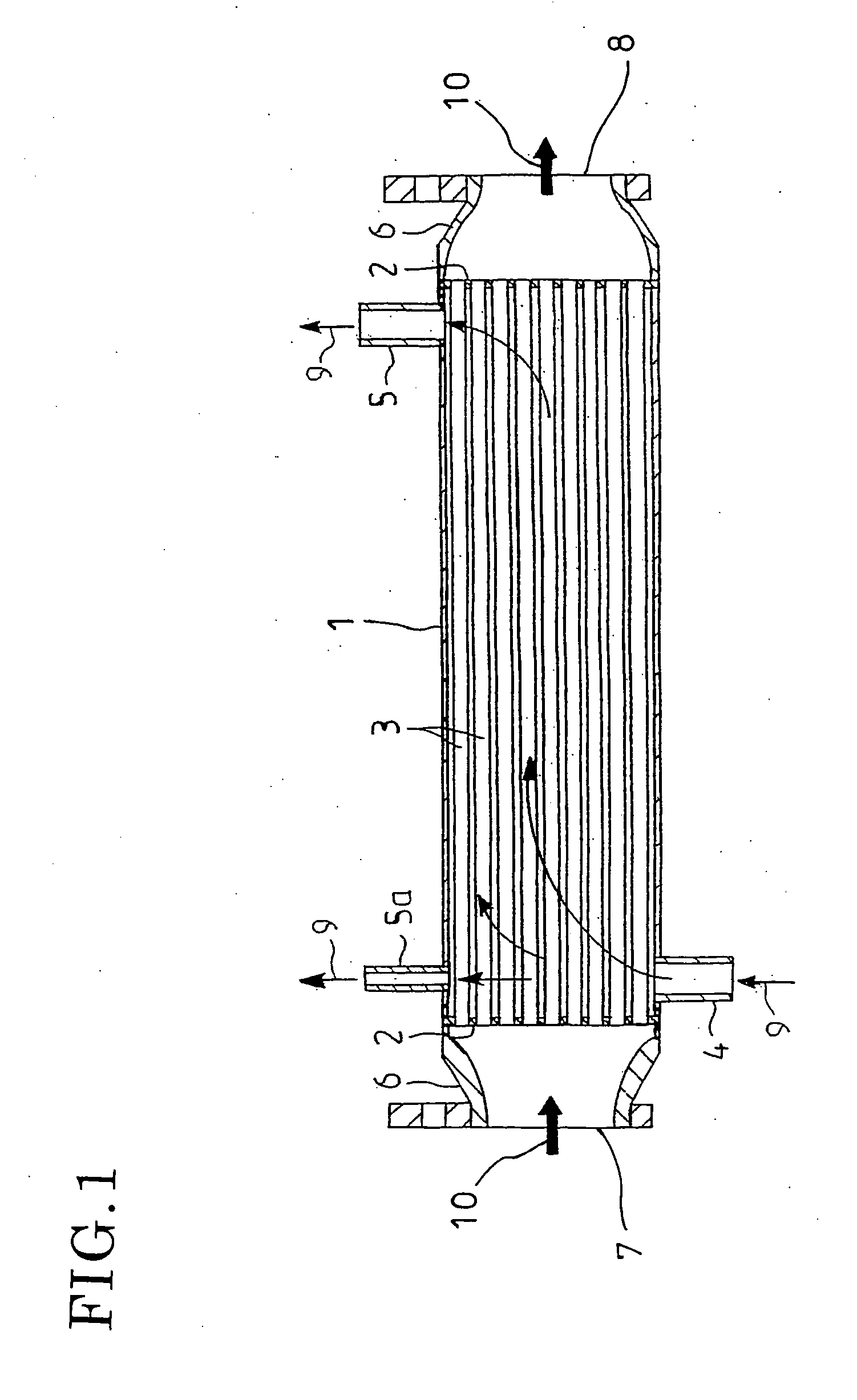

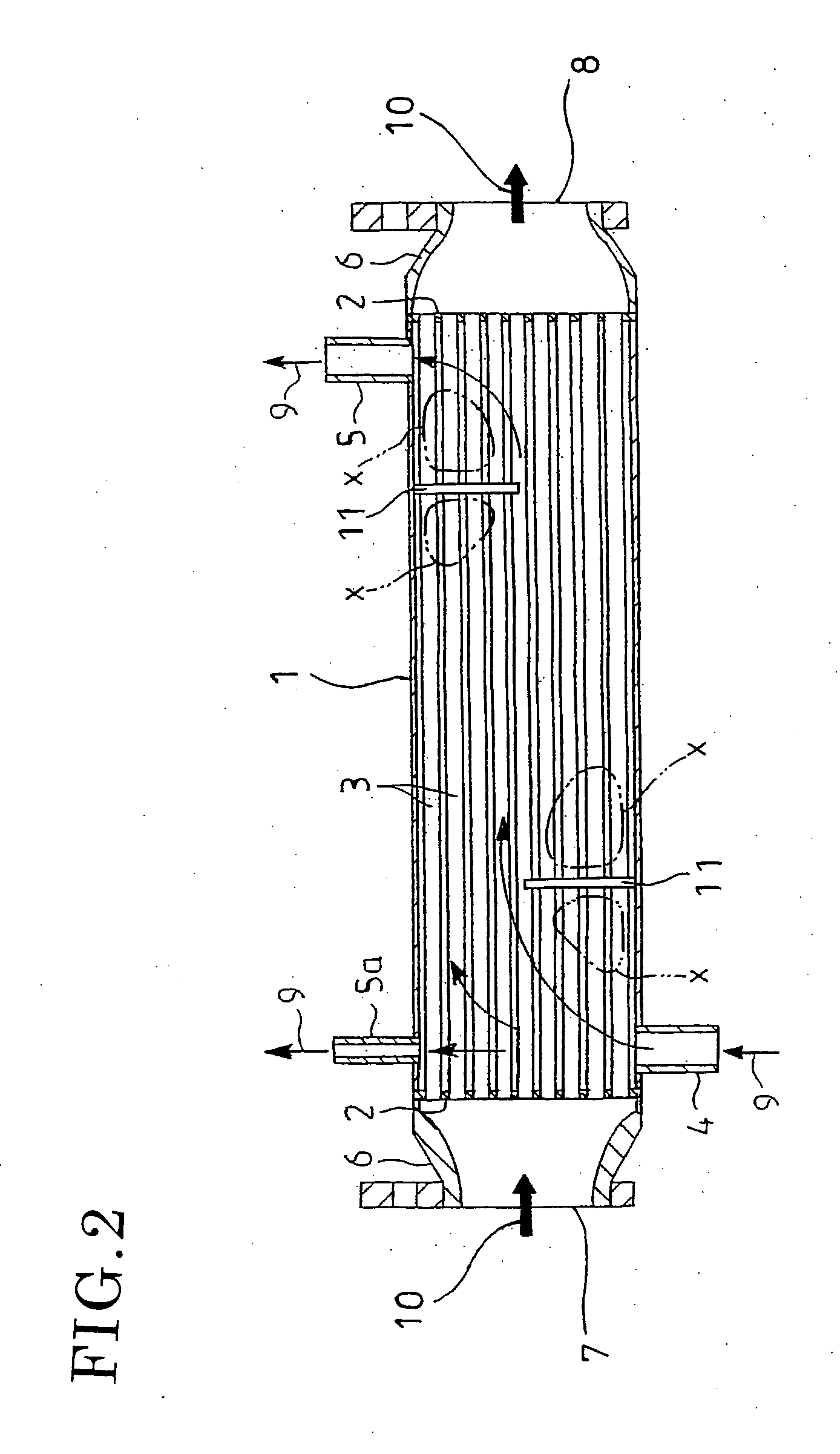

Egr cooler

InactiveUS20060231243A1Increased pressure lossImprove the exhaust effectNon-fuel substance addition to fuelInternal combustion piston enginesThermal deformationEngineering

Provided is an EGR cooler which can solve the problem of the vibrated tubes without causing thermal deformation due to stagnation of the coolant water, without complexity of piping in the coolant water system and without increase in pressure loss. The EGR cooler comprises tubes 3 and a shell surrounding the tubes 3, the coolant water being supplied and discharged to and from the shell 1 and being passed through the respective tubes 3 so as to make heat exchange of the exhaust gas with the coolant water. In the shell 1, an intermediate support plate 13 with a plurality of through-holes 14 is arranged and mutually adjacent ones of the tubes 3 are grouped for penetratingly fixture to the through-hole 14. A coolant water passage 15 is ensured between the tubes 3 grouped and penetratingly fixed to the same through-hole 14 of the intermediate support plate 13 for free communication between the tubes 3.

Owner:HINO MOTORS LTD +1

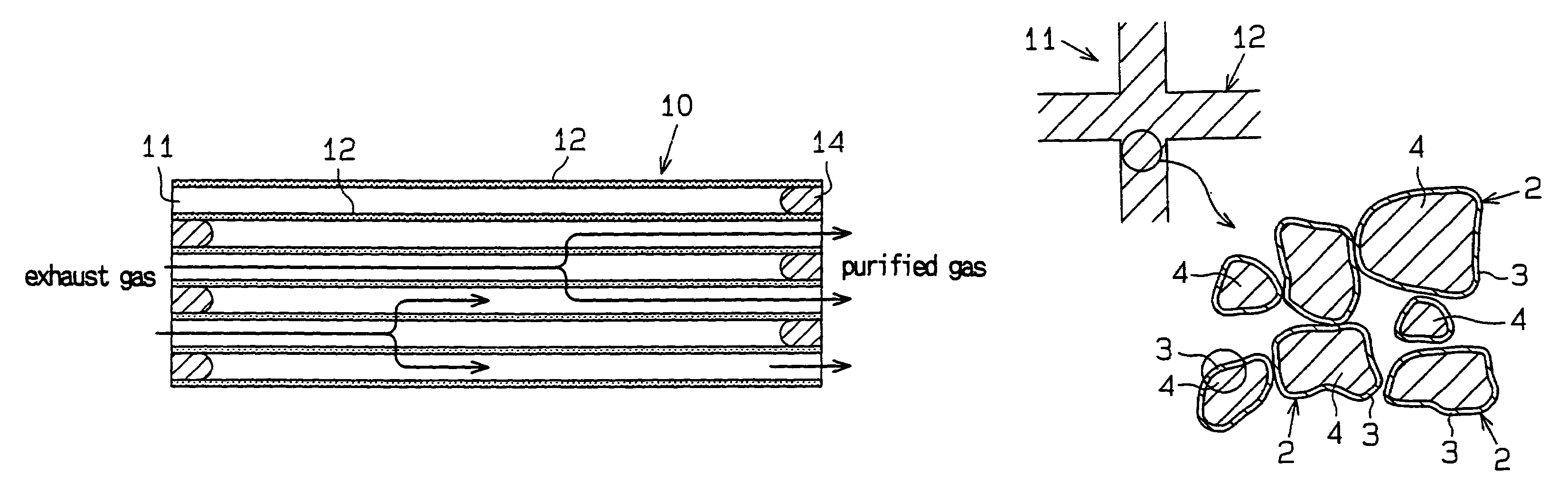

Catalyst-carrying filter

ActiveUS7625529B2Improve propertiesEasy to useUltrasonic/sonic/infrasonic diagnosticsCombination devicesPorosityCarrier material

A catalyst holding filter reducing a pressure loss. A catalyst holding filter (10) is made of a ceramic support (4) of SiC covered with a catalyst layer (2). An average pore size of the ceramic support is 10-250 μm, and a porosity of the ceramic support is 40-80%. The catalyst layer contains a catalyst, a cocatalyst and a support material.

Owner:IBIDEN CO LTD +1

Poppet valve with diverging-converging flow passage and method to reduce total pressure loss

ActiveUS20100024891A1Stabilizing dynamic openingImprove performanceCheck valvesValve members for absorbing fluid energyEngineeringMechanical engineering

A poppet valve is disclosed that include a valve body, a poppet guide disposed inside the valve body so as to form a a flow passage from a flow inlet to a flow outlet of the valve, a poppet shutter disposed inside the poppet guide, and a converging-diverging flow passage formed by a portion of an outer surface of the poppet shutter and a corresponding portion of an inner surface of valve body. A method for reducing a closing pressure force acting on a poppet shutter of a poppet valve is also disclosed.

Owner:NUOVO PIGNONE TECH SRL

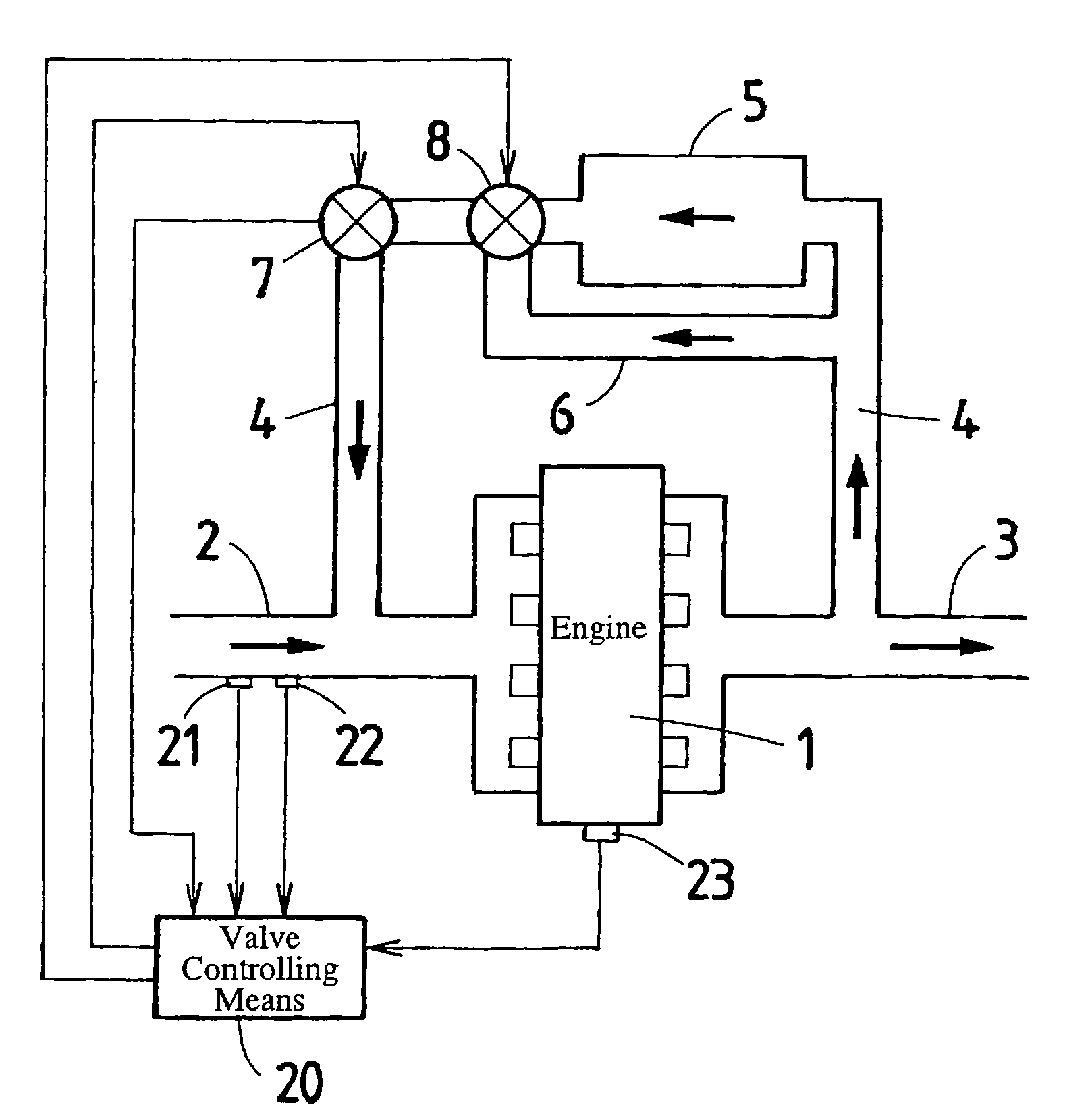

Exhaust gas recirculation apparatus

ActiveUS7284544B2Increased pressure lossIncreased durabilityInternal combustion piston enginesNon-fuel substance addition to fuelExhaust fumesEngineering

An exhaust gas recirculation device includes: an exhaust gas recirculation passage of an engine; an EGR cooler provided within this exhaust gas recirculation passage; a bypass passage connected between the upstream and the downstream sides of the EGR cooler in the exhaust gas recirculation passage; an EGR valve provided within the exhaust gas recirculation passage on the downstream side of the EGR cooler; a bypass valve for opening and closing the bypass passage; and a valve controlling unit determining the timing period of flowing the high-temperature exhaust gas diverted from the EGR cooler into the EGR valve, and switchingly controlling the bypass valve such that during the timing period, the high-temperature exhaust gas is diverted from the EGR cooler and flown into the EGR valve through the bypass passage, and except during the timing period, the high-temperature exhaust gas is flown into the EGR valve to be circulated.

Owner:MITSUBISHI ELECTRIC CORP

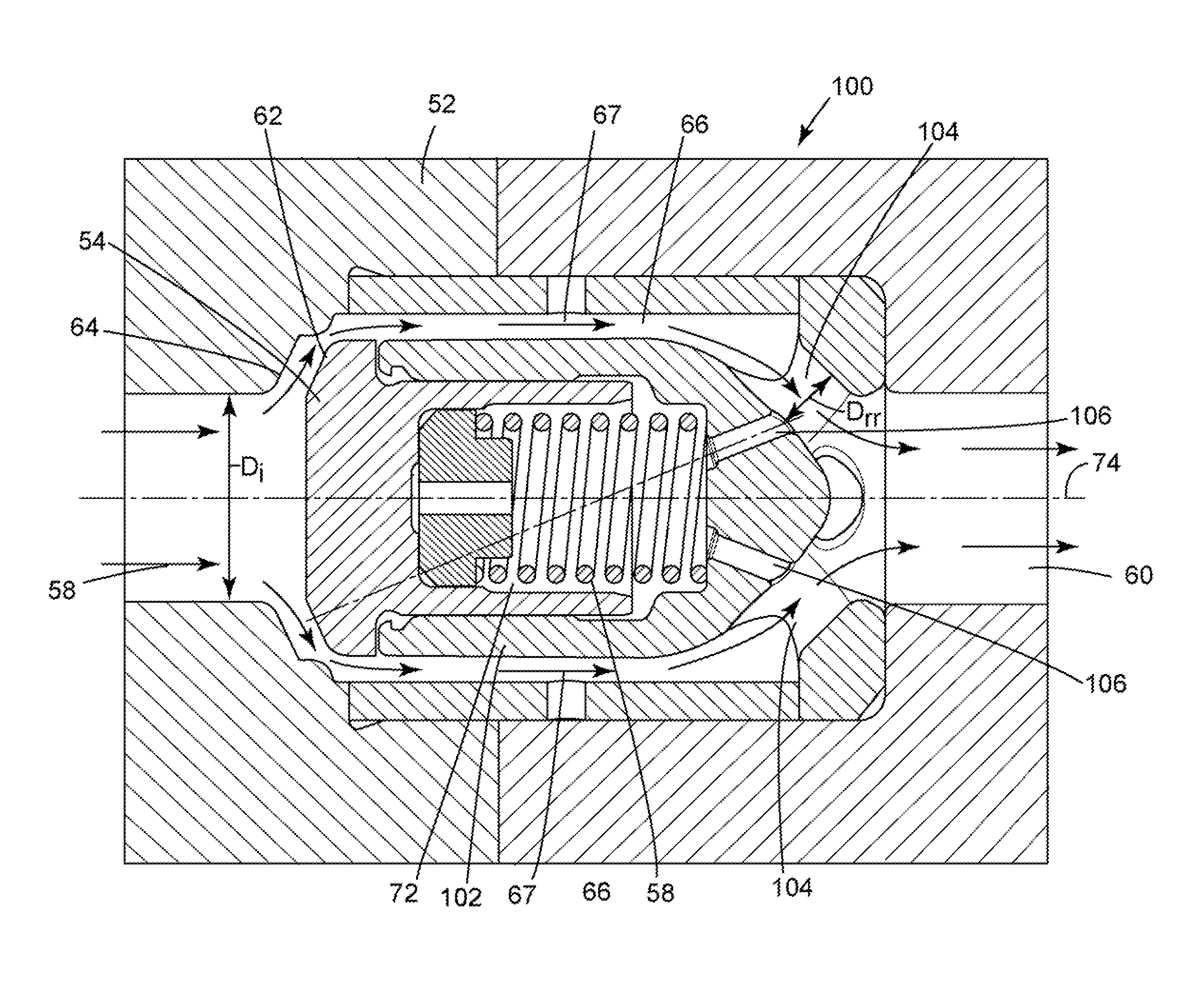

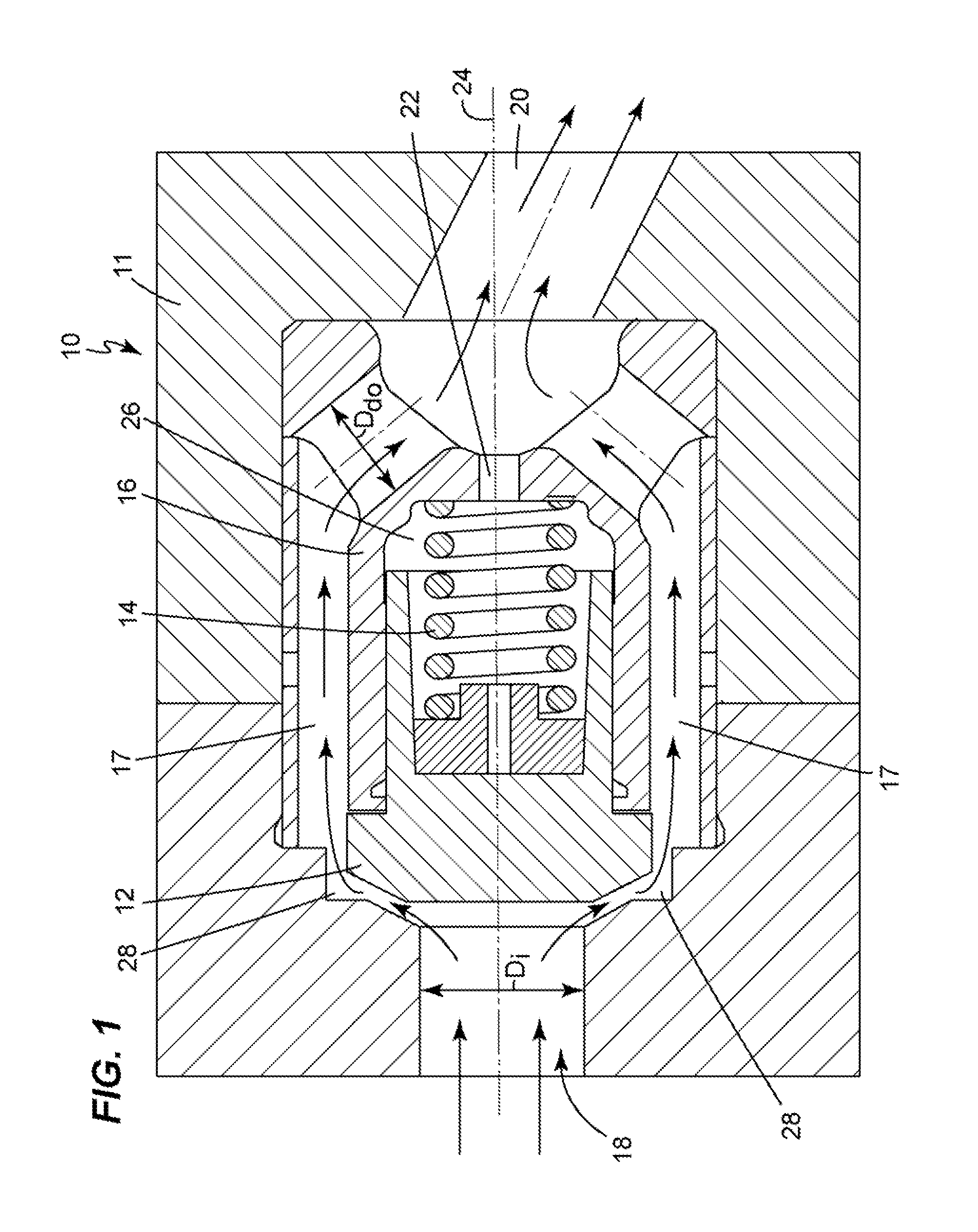

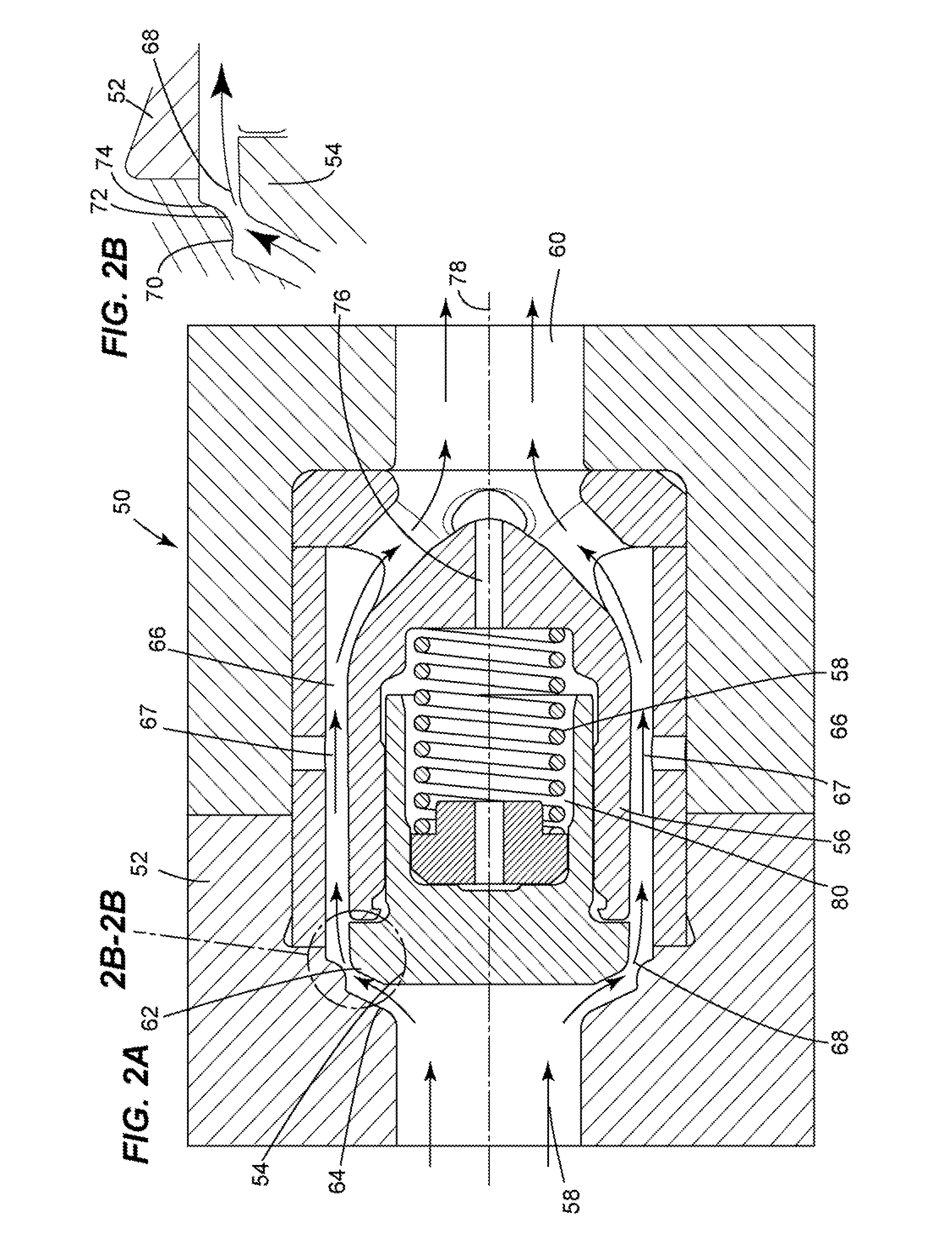

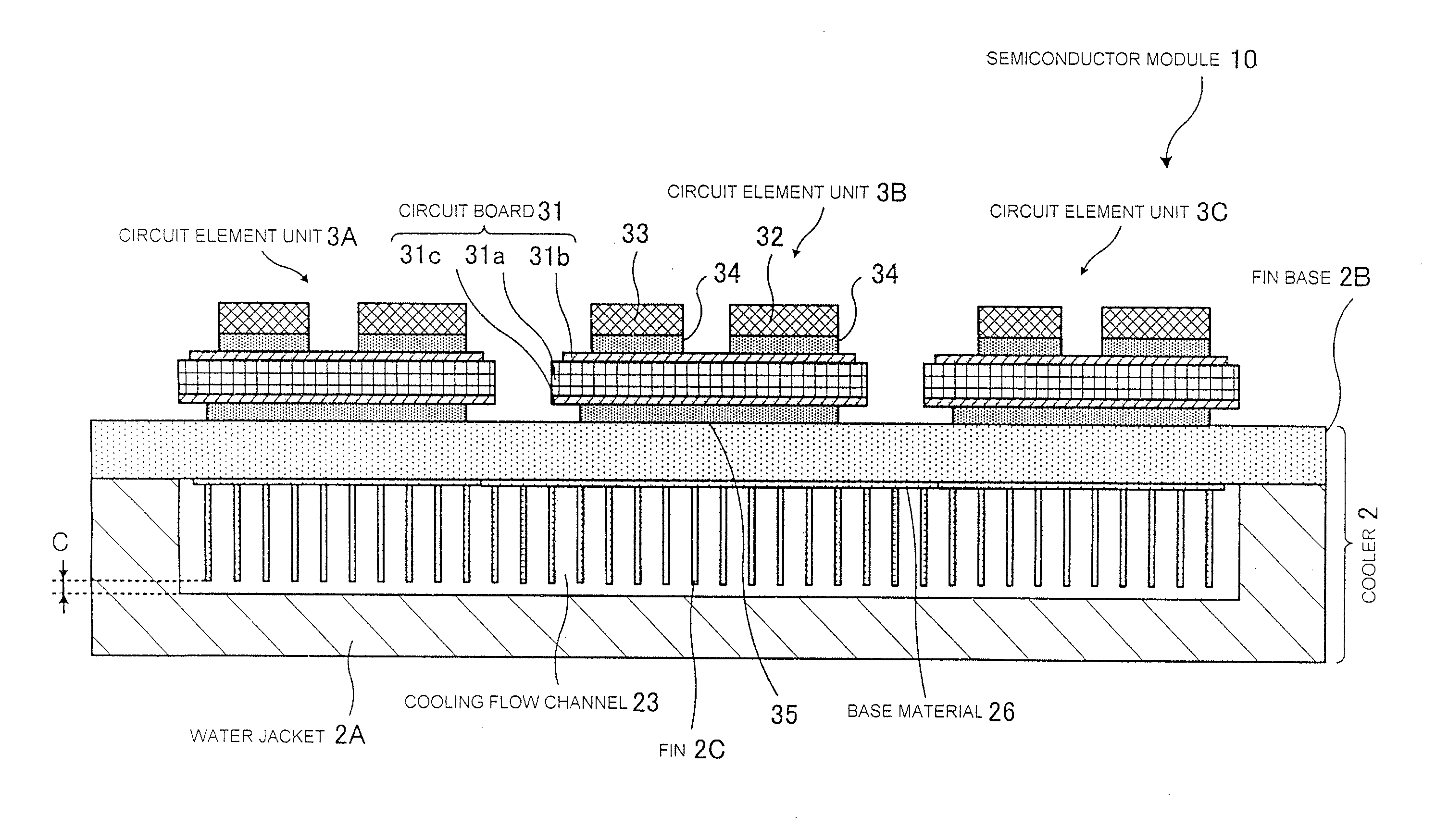

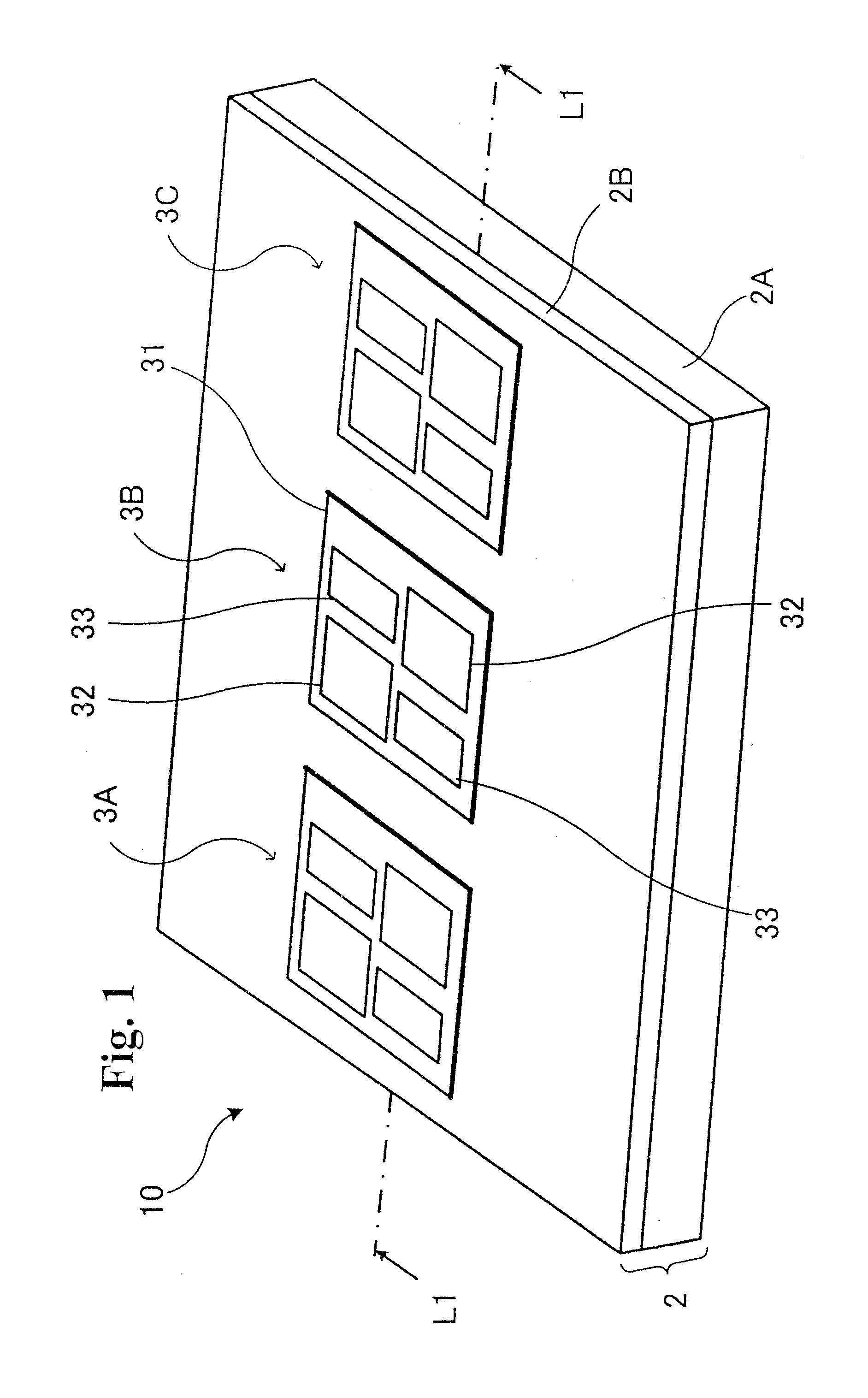

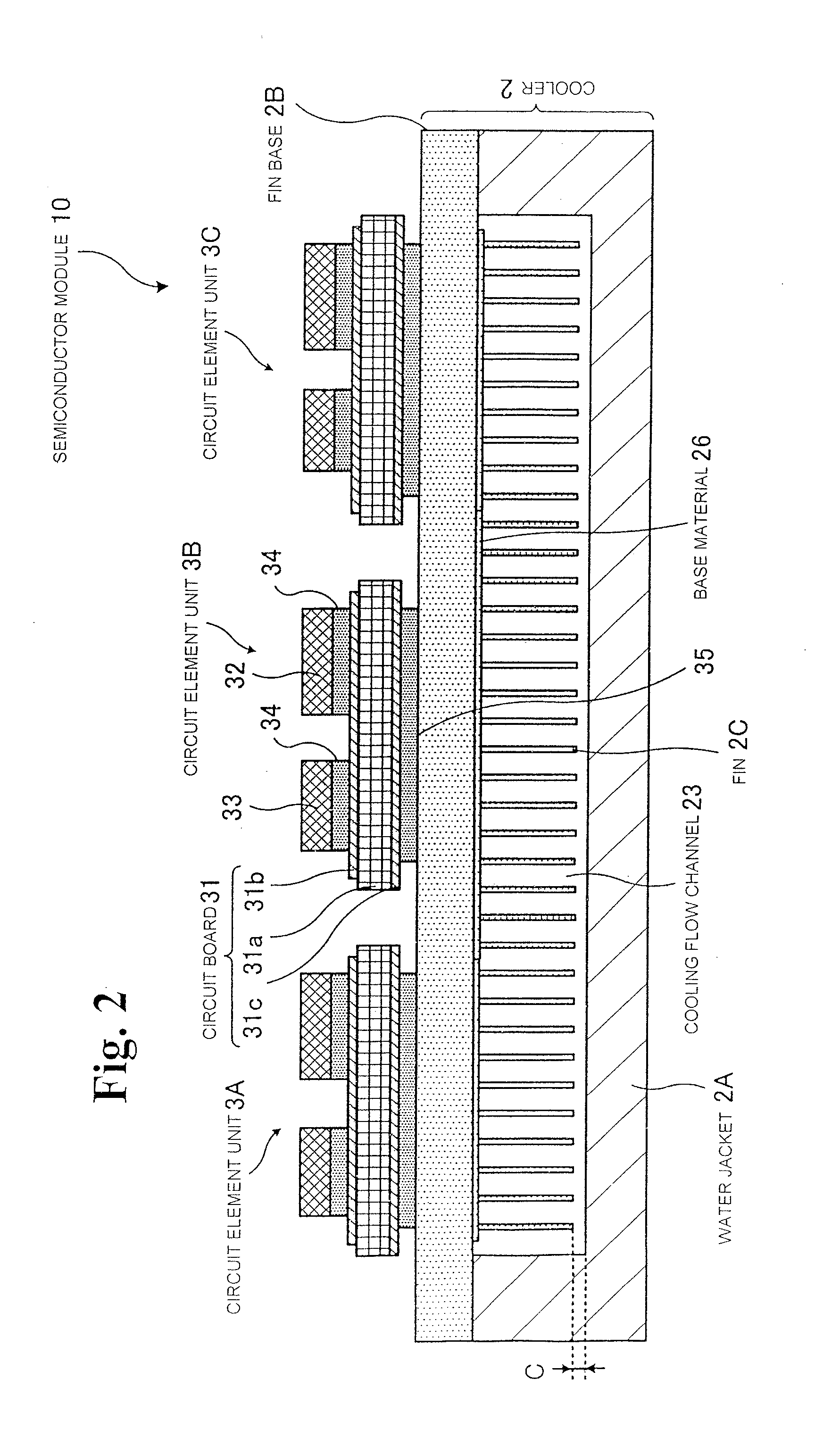

Semiconductor module cooler and semiconductor module

ActiveUS20140043765A1Increased flow velocityPressure loss increaseSemiconductor/solid-state device detailsSolid-state devicesPhysicsWater jacket

A semiconductor module cooler supplies a coolant to a water jacket from outside and cools a semiconductor device arranged on an outer surface of the cooler. The semiconductor module cooler has a heat sink thermally connected to the semiconductor device; a first flow channel arranged inside the water jacket with a guide section extending from a coolant inlet and having an inclined surface for guiding the coolant toward one side surface of the heat sink; a second flow channel arranged inside the water jacket in parallel to the first flow channel and extending to a coolant outlet; and a third flow channel formed inside the water jacket at a position connecting the first flow channel and the second flow channel. The coolant inlet and the coolant outlet are formed on a same wall surface of the water jacket, and the heat sink is arranged in the third flow channel.

Owner:FUJI ELECTRIC CO LTD

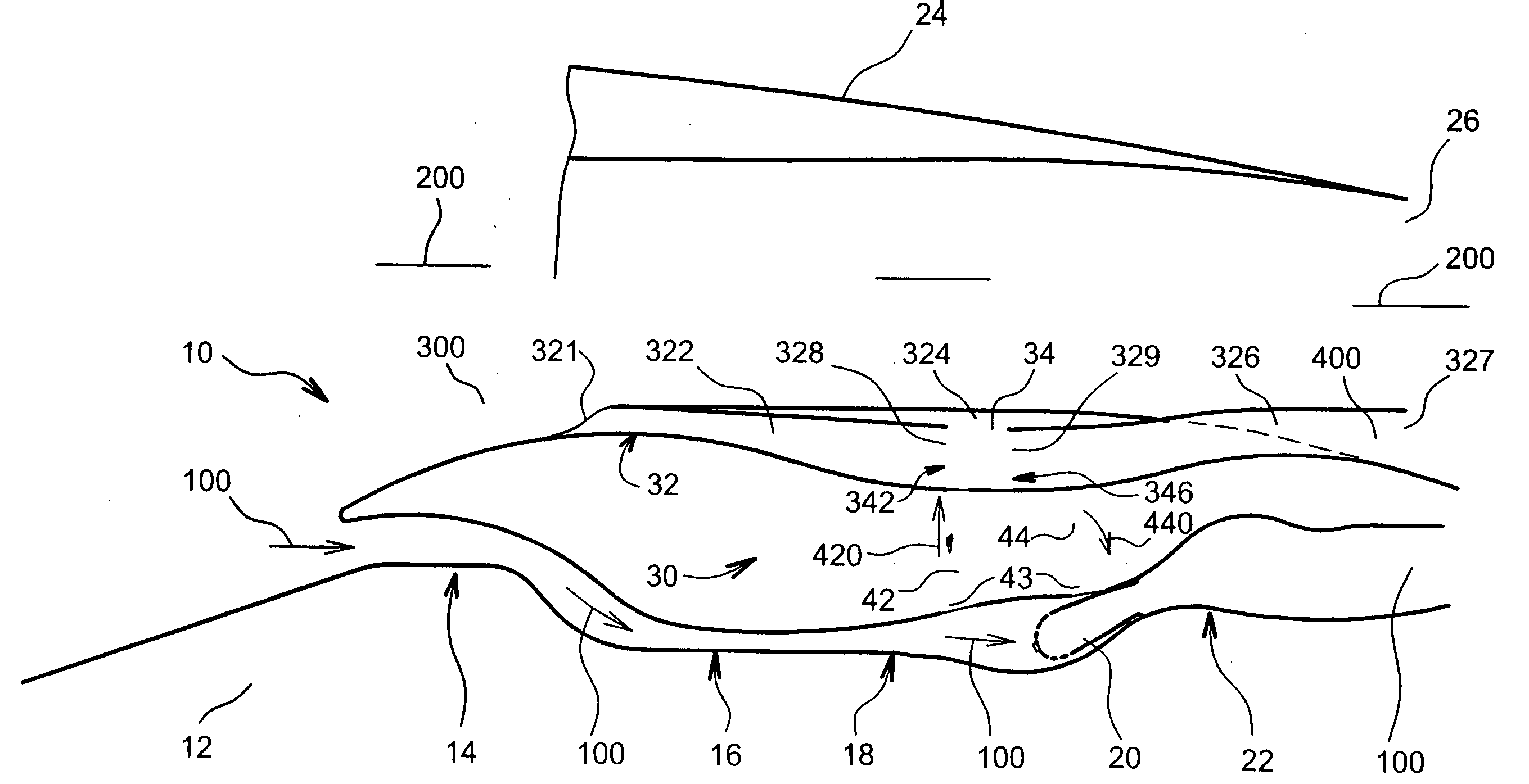

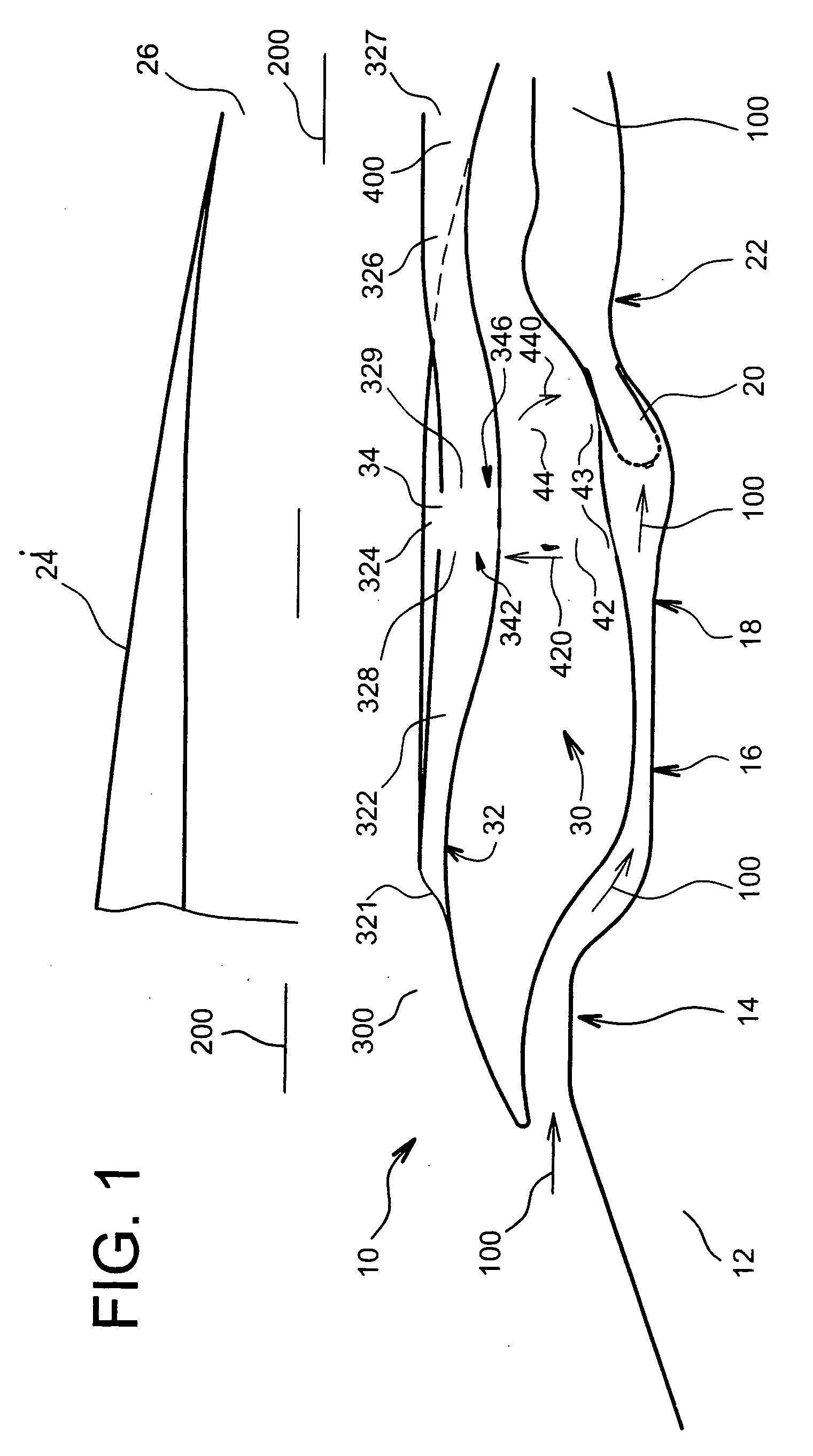

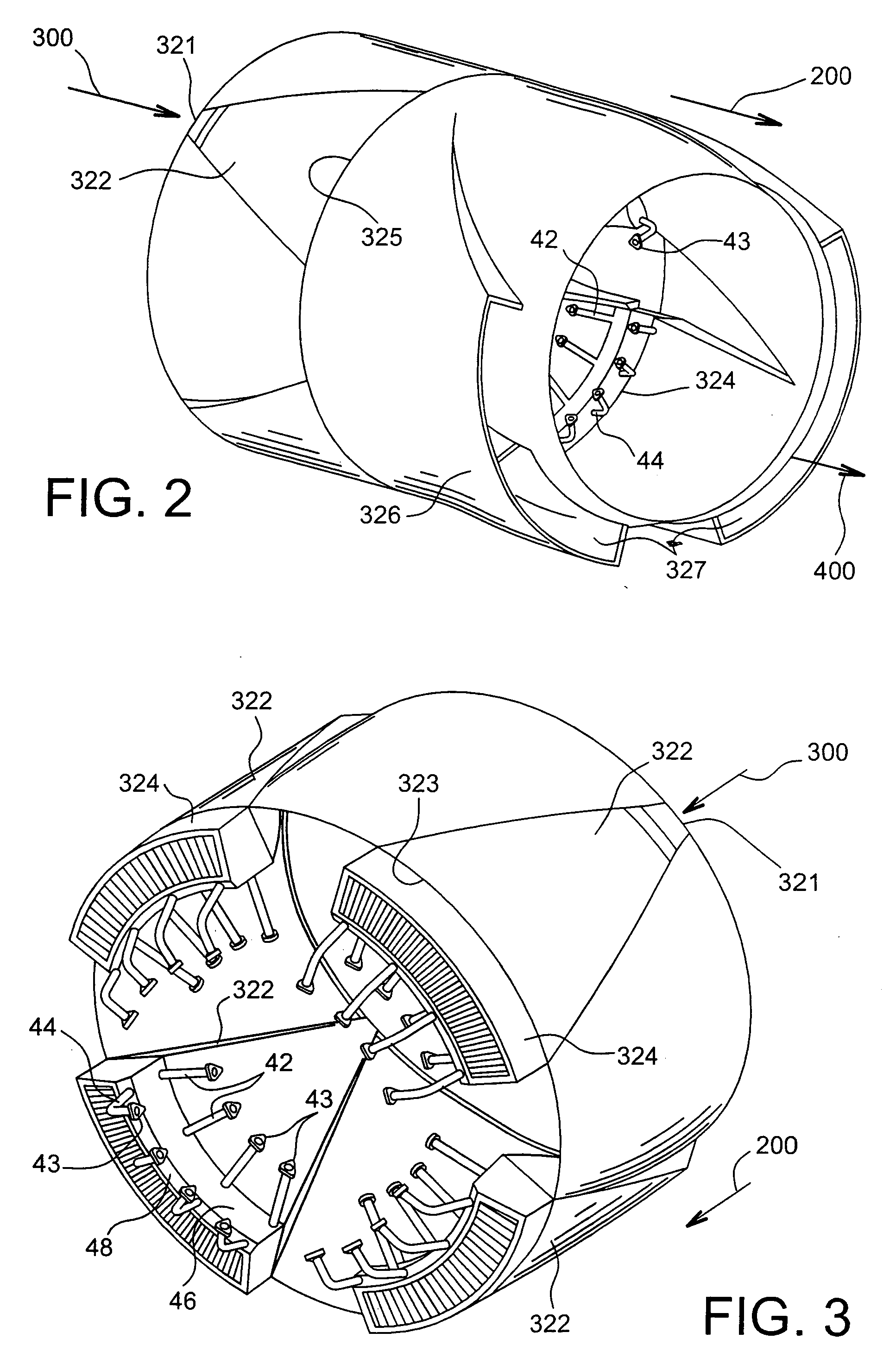

Cooling system for hot parts of an aircraft engine, and aircraft engine equipped with such a cooling system

InactiveUS20050150970A1Eliminate riskIncreased pressure lossRecuperative heat exchangersEngine fuctionsCold airNacelle

The cooling system (30) for an aircraft engine (10) comprises a channel (32) that draws off cold air in the secondary air flow (200), and a heat exchanger (34) located in the channel (32) and in which hot air circulates. The channel (32) comprises: a supply pipe (322) and an evacuation pipe (326) fixed to the nacelle (324), an intermediate box (324) located between the supply pipe (322) and the evacuation pipe (326), fixed to the engine (10), and in which the heat exchanger (34) is placed. Application to cooling of hot parts (22) in an aircraft engine (10).

Owner:SNECMA MOTEURS SA

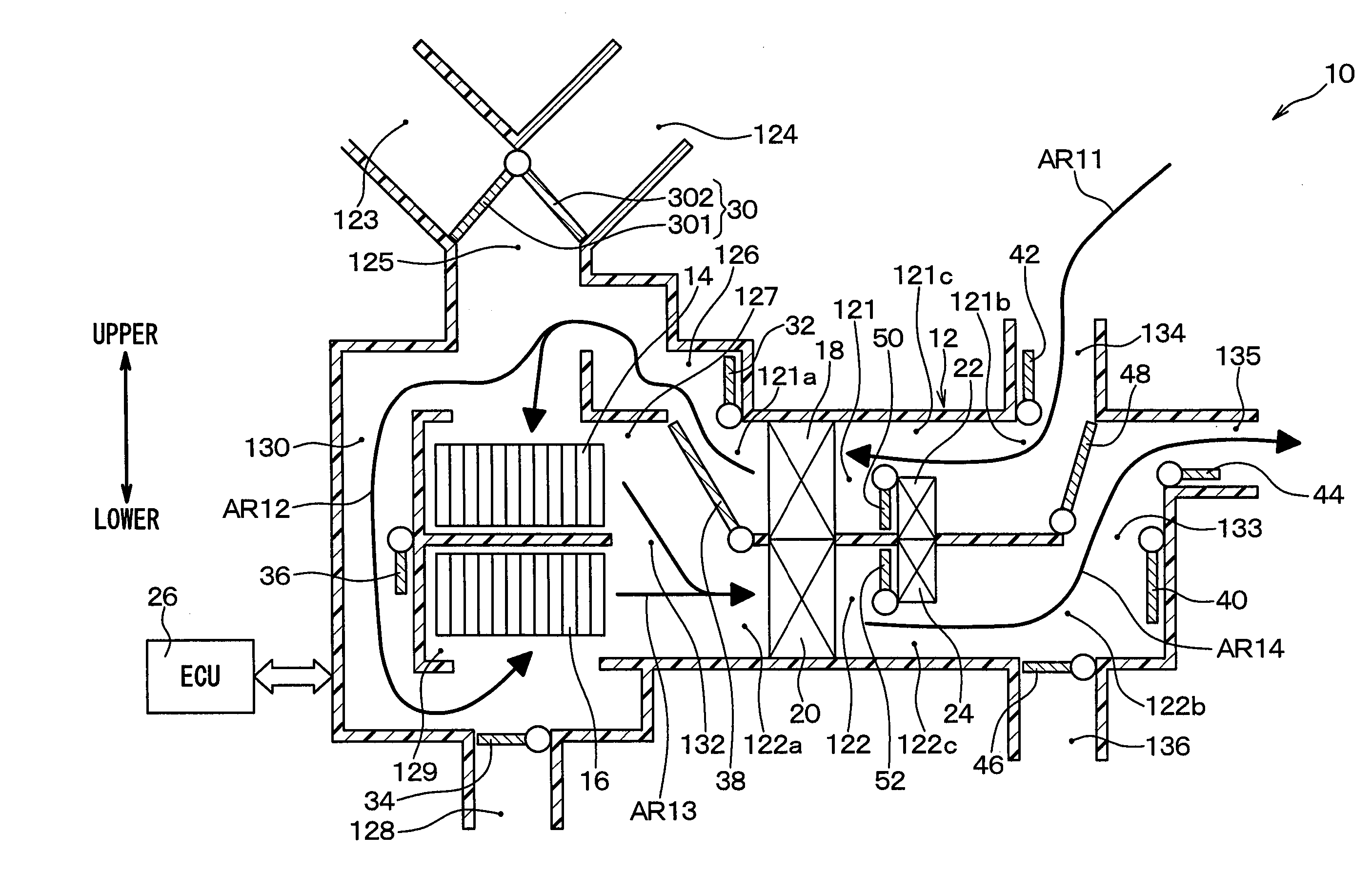

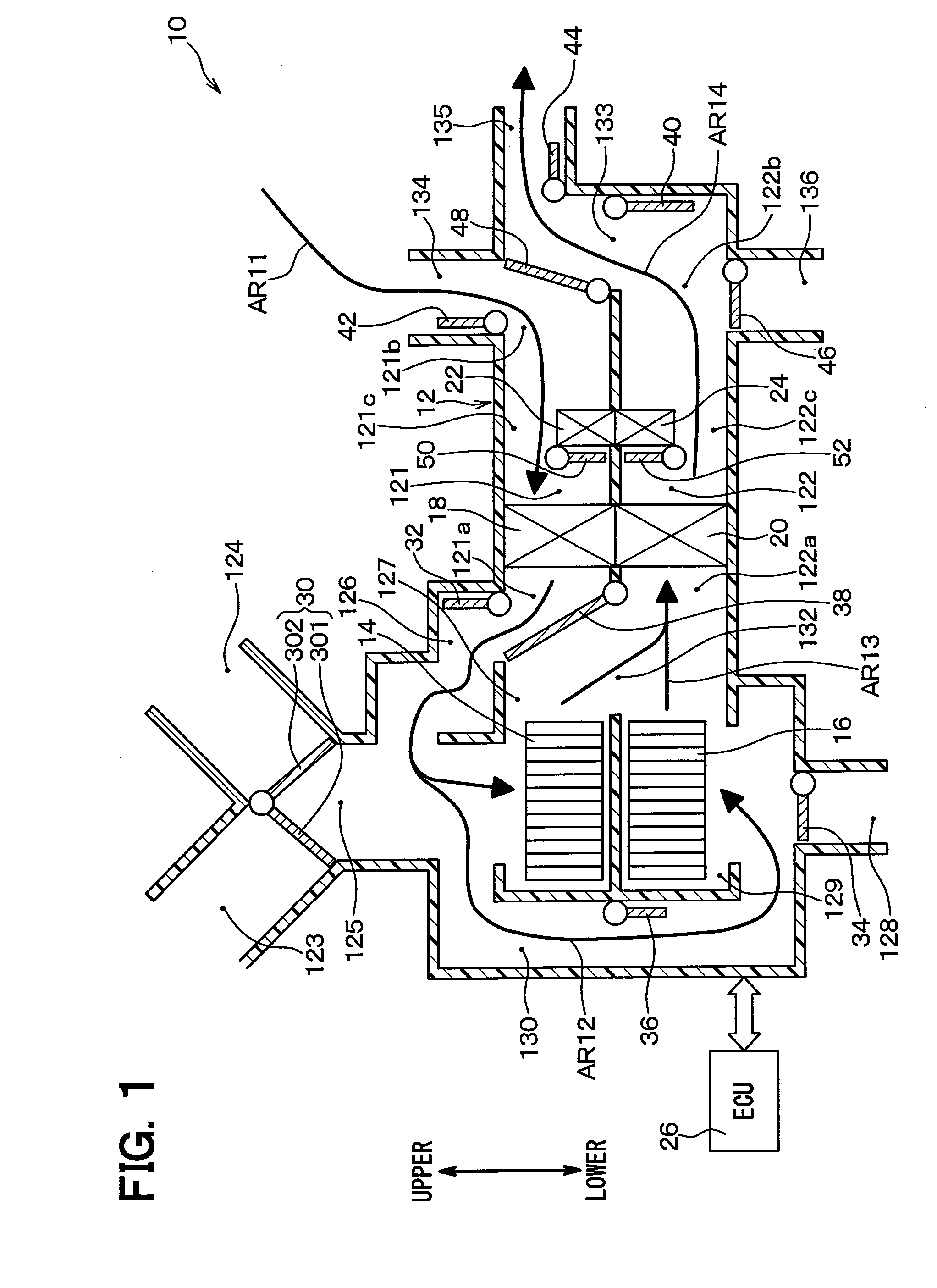

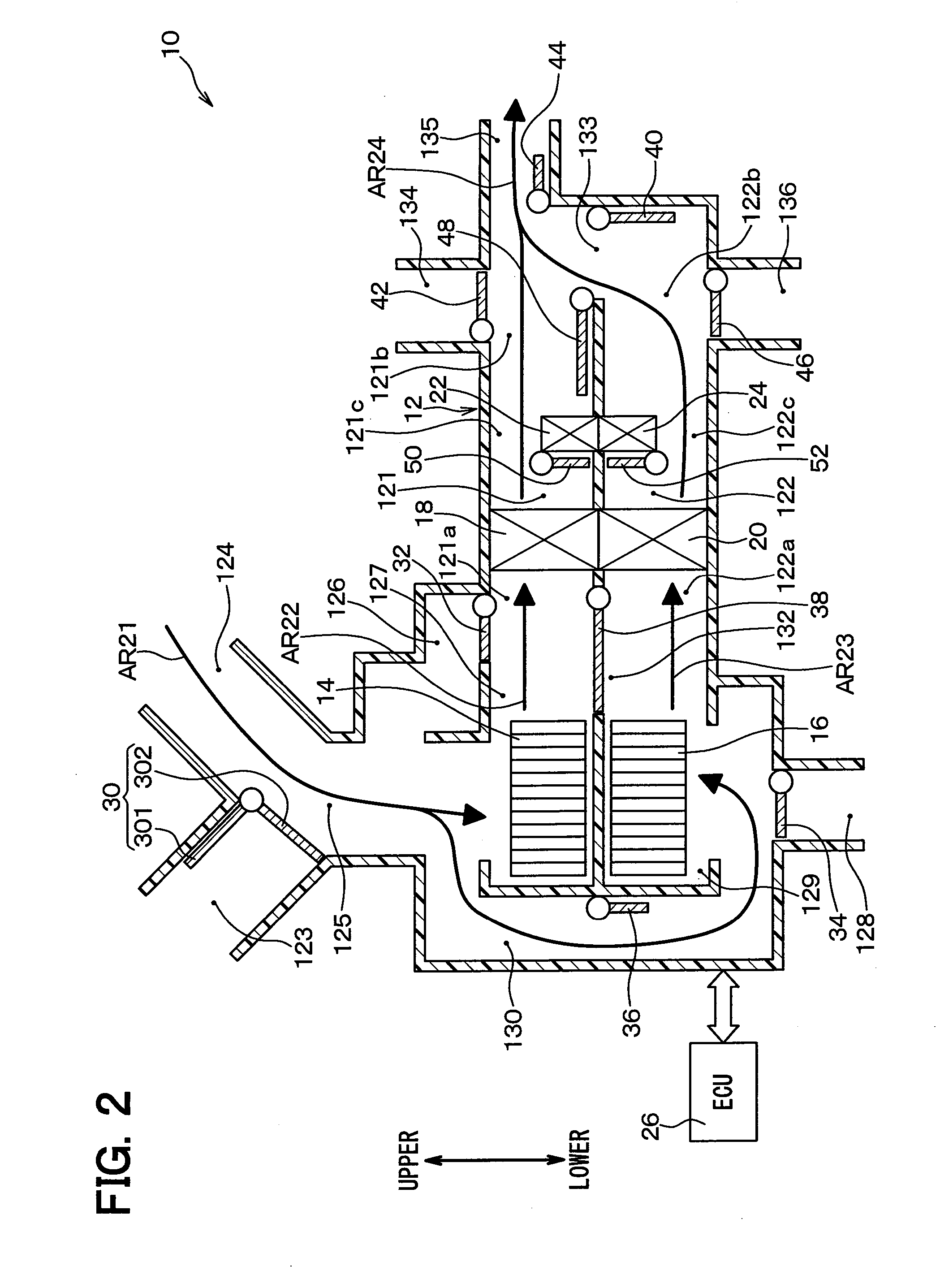

Vehicular air-conditioning unit

InactiveUS20160229266A1Effective regulationReduce total pressure lossAir-treating devicesVehicle heating/cooling devicesEngineeringMode switching

A vehicular air-conditioning unit has an air-conditioning case, a first ventilation passage and a second ventilation passage, a first communication-ventilation passage defined in the air-conditioning case, the first communication-ventilation passage through which one end of the first ventilation passage communicates with one end of the second ventilation passage, a first heat exchanger that heats or cools air flowing in the first ventilation passage, a second heat exchanger that heats or cools air flowing in the second ventilation passage, and a blowing mode switching device setting any one of blowing modes. The blowing modes include (i) a first blowing mode in which air is blown into a vehicle compartment after flowing through the first ventilation passage and in which air is blown into the vehicle compartment after flowing through the second ventilation passage and (ii) a second blowing mode in which air flows into the second ventilation passage through the first communication-ventilation passage after flowing through the first ventilation passage and is blown into the vehicle compartment.

Owner:DENSO CORP

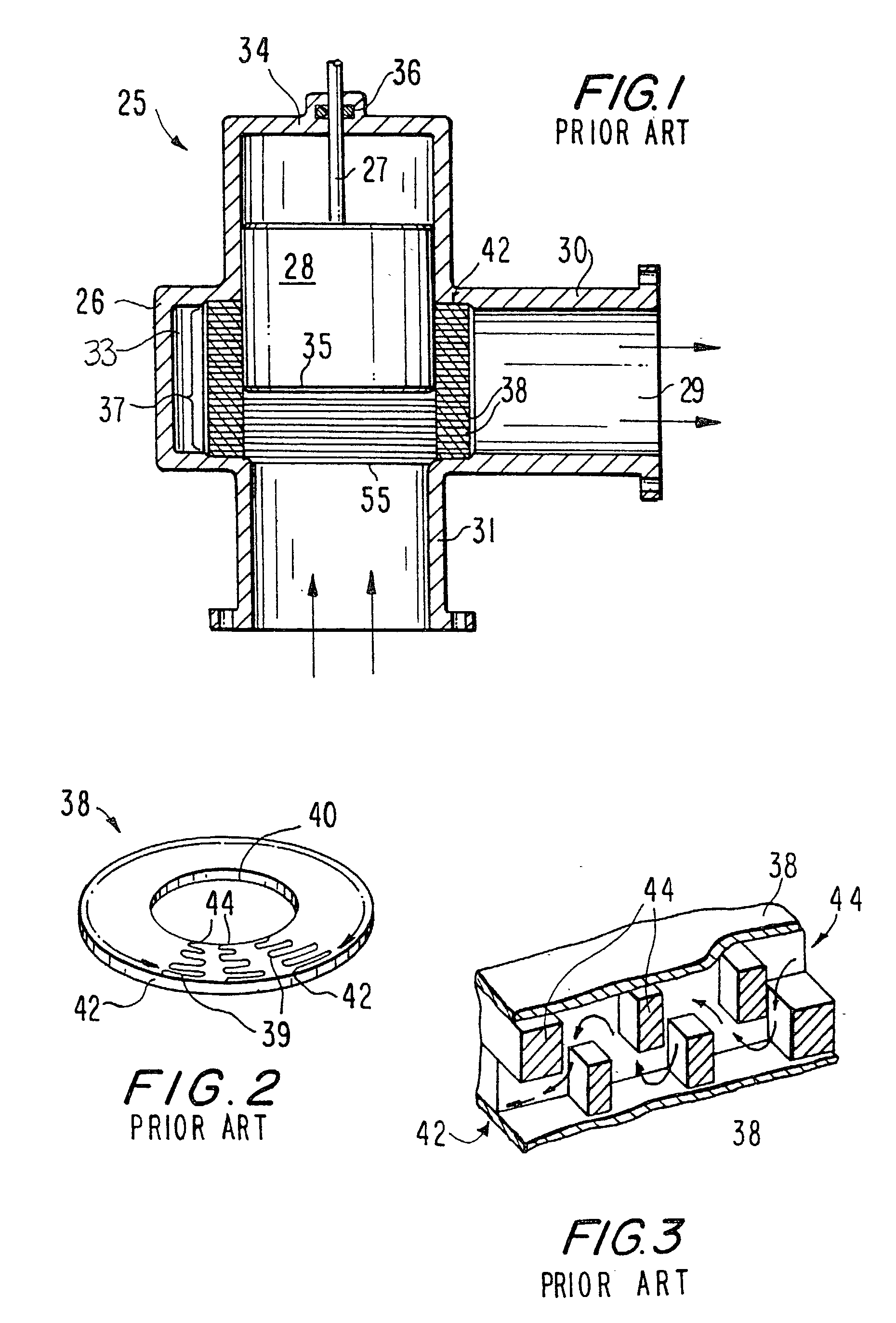

Pressure-reducing control valve for severe service conditions

InactiveUS6926032B2Improve sealingIncreased pressure lossValve members for absorbing fluid energyMultiple way valvesCircular discNoise level

Owner:SAUDI ARABIAN OIL CO

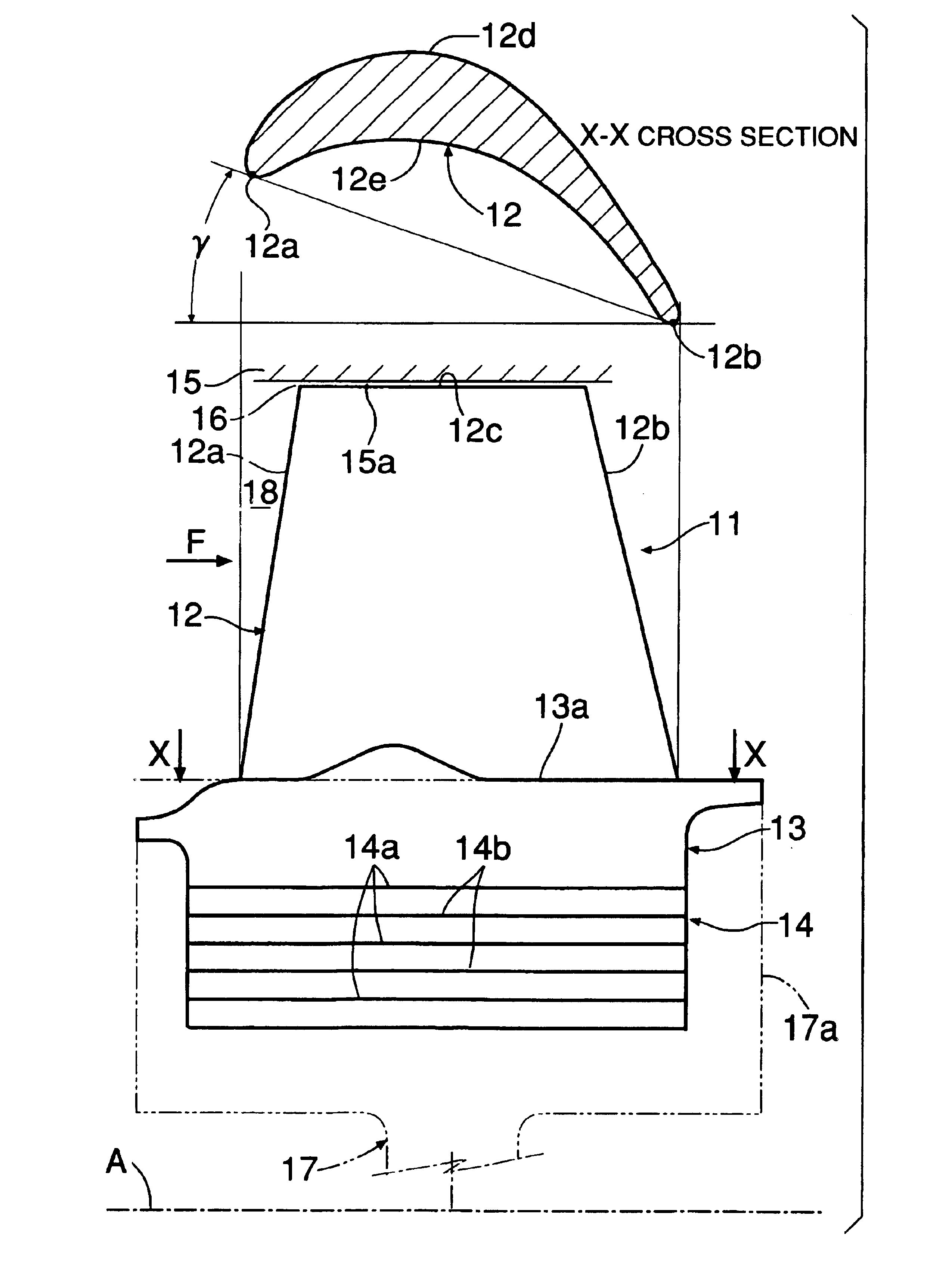

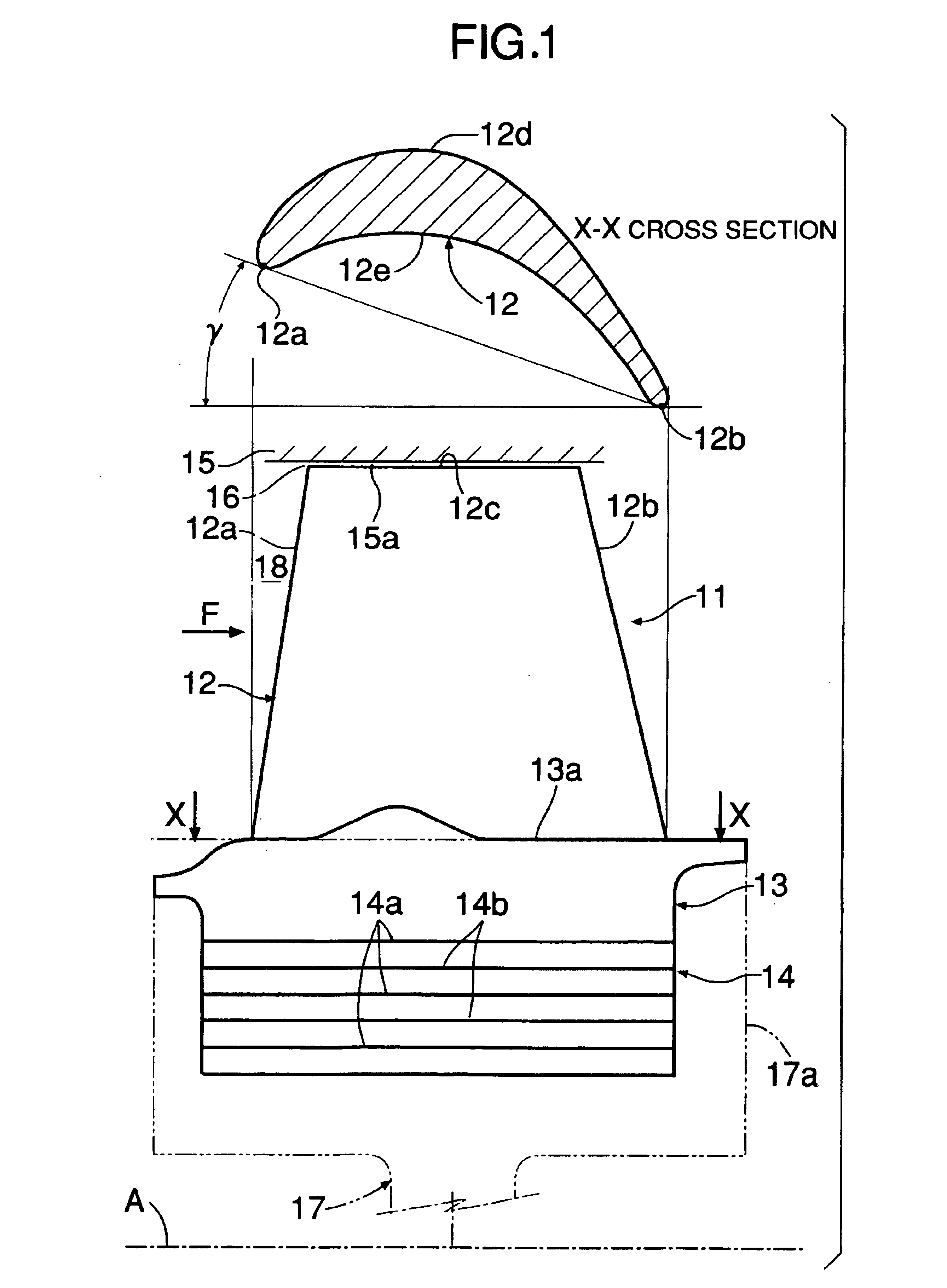

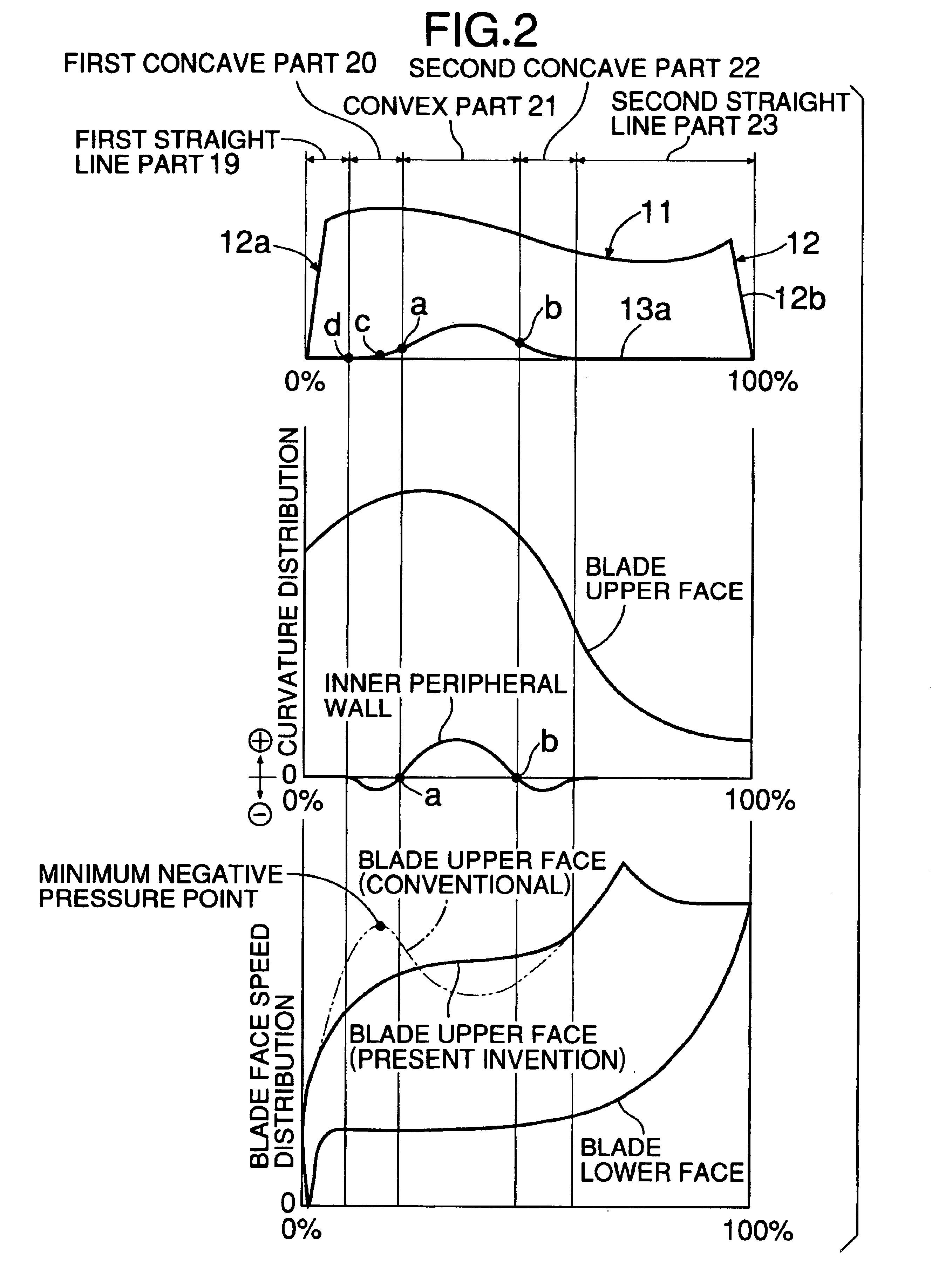

Gas turbine engine

InactiveUS6837679B2Reduce weightMaintain performancePropellersEngine manufactureShock waveTurbine blade

A gas turbine engine has, in a cross section in the axial direction of an annular inner peripheral wall connected to a blade main body of a turbine blade, a concave part and a convex part on the front edge side and the rear edge side. The concave part has a negative curvature and is concave toward the axis, and the convex part has a positive curvature and is convex away from the axis. The flow rate on the upper face of the blade main body can be reduced in the concave part on the front edge side, thus suppressing generation of a shock wave, and the flow rate can be increased in the convex part on the rear edge side following the concave part, thus smoothly changing the flow rate on the upper face of the blade main body and thereby minimizing the pressure loss. In this way, the thickness of the blade main body can be reduced while ensuring the performance of the gas turbine engine, thereby contributing to a reduction in weight.

Owner:HONDA MOTOR CO LTD

Pressure-reducing control valve for severe service conditions

InactiveUS20040050433A1Increased energy lossImprove sealingValve members for absorbing fluid energyMultiple way valvesCircular discNoise level

A severe service condition pressure reduction valve that is resistant to damage by debris carried by high-pressure process fluid stream and operates at acceptable noise levels includes a first stage annular member in the form of a tube or sleeve that is closely fitted into the axial annular opening of a disk stack trim or drag valve, the first stage member having a plurality of radial openings extending through the wall of the tube or sleeve that are aligned with, and correspond in radial and axial or longitudinal spacing to the flow paths in the disk stack valve. The external surface of the first stage member is provided with axially-spaced circumferential raised areas or rings that engage the internal surface of the disk stack annulus to prevent axial flow along the exterior surface of the sleeve.

Owner:SAUDI ARABIAN OIL CO

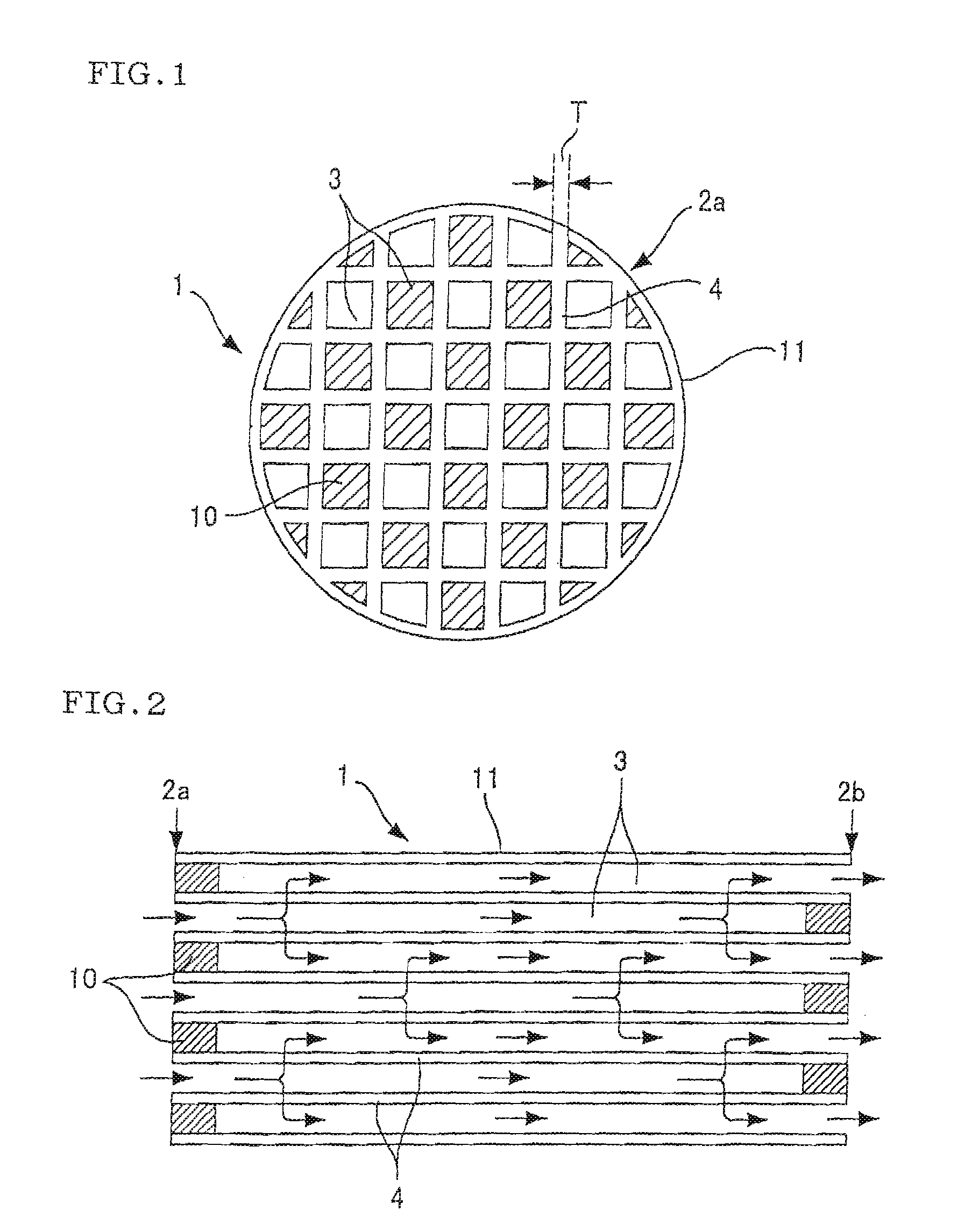

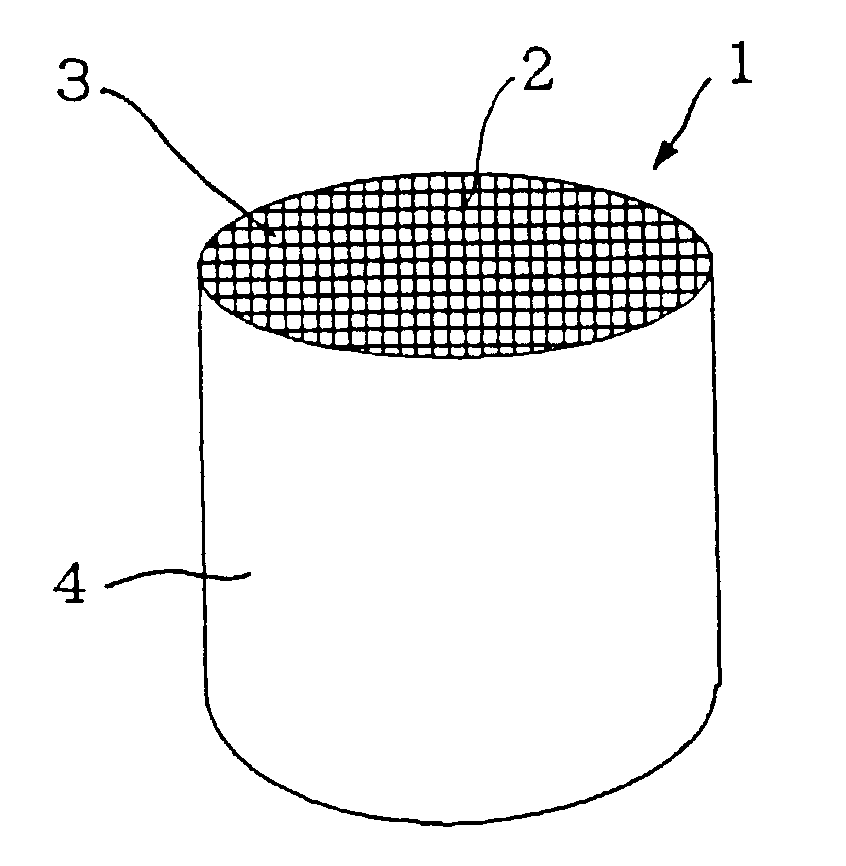

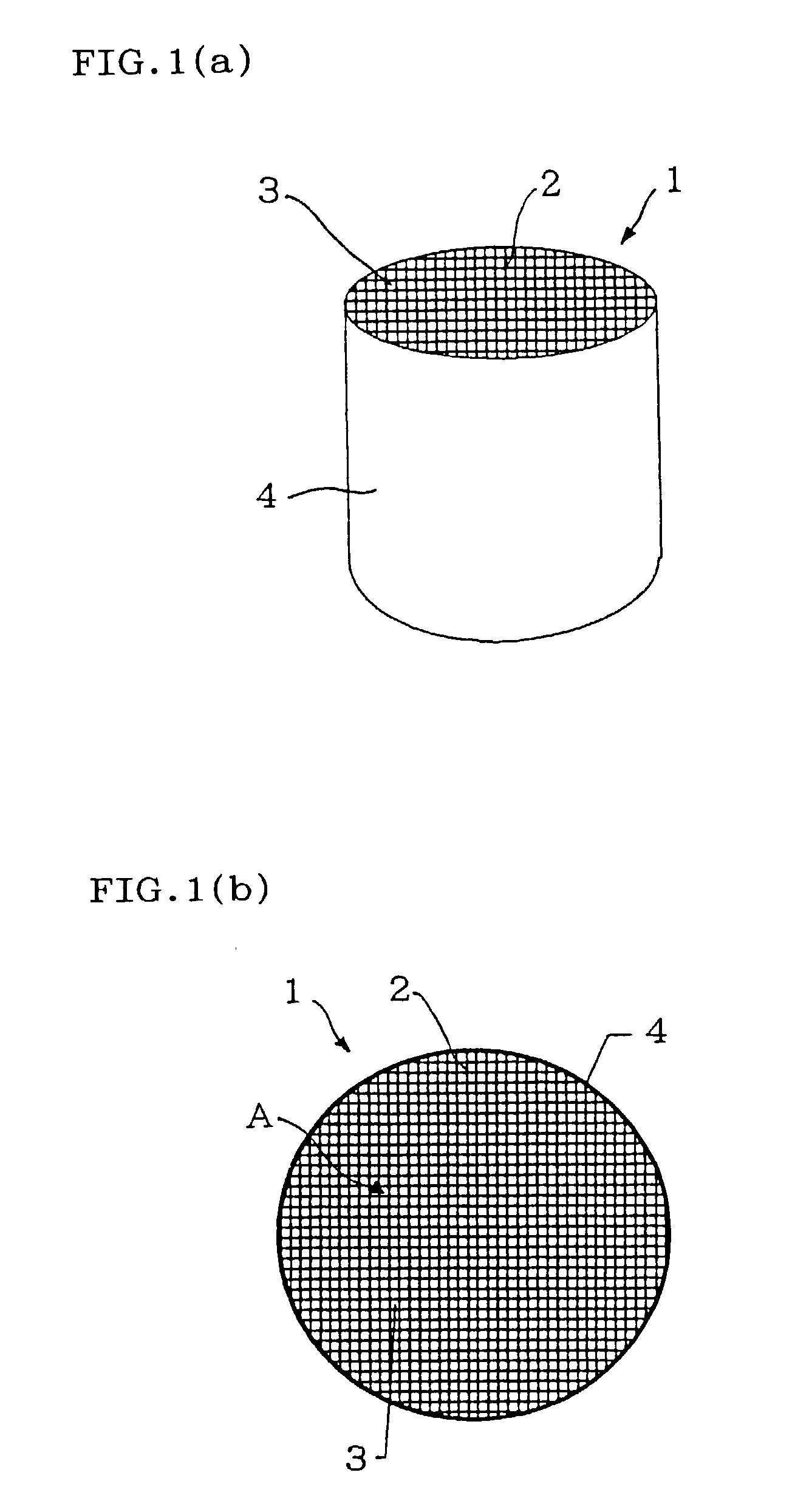

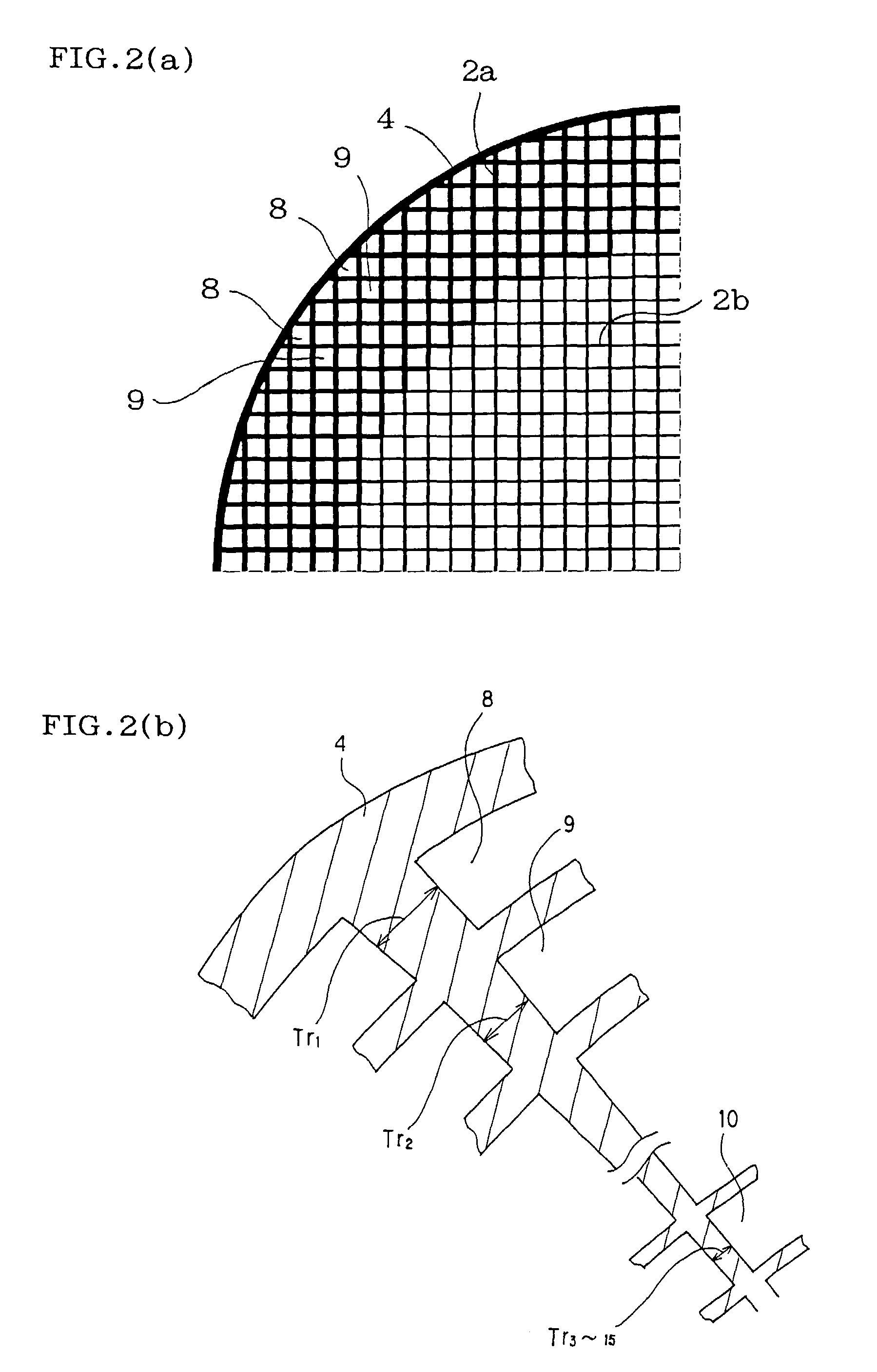

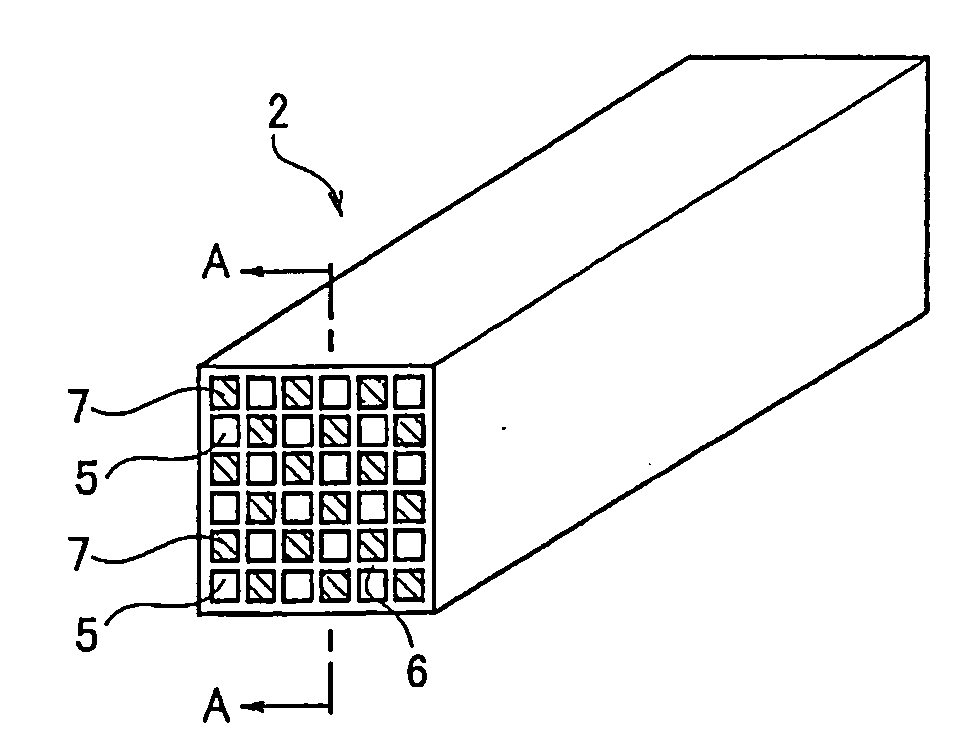

Ceramic honeycomb structure

InactiveUS20020192426A1Increased pressure lossReduced thermal shock resistanceCombination devicesDead plant preservationCell wallHoneycomb structure

A ceramic honeycomb structure (1) constituted by cell walls (ribs) (2) forming a composite structure from a plurality of cells (3) being adjacent each other and a honeycomb outer wall (4) surrounding and holding the outermost peripheral cells located at the circumference of the composite structure; said composite structure satisfying the followings: the basic thickness of the cell walls (2) (the basic cell wall thickness) (Tc) is Tc<=0.12 mm, the outer wall thickness (Ts) of the honeycomb structure is Ts >=0.05 mm, and the open frontal area (P) is P>==80%, and there is a relation shown by formula: <paragraph lvl="0"><in-line-formula>1.10<=(Tr1~Tr3-20) / Tc<=3.00 < / in-line-formula>between the basic cell wall thickness (Tc) and each cell wall thickness (Tr1~Tr3-20) of cells existing between an outermost peripheral cell and any cell within a first end cell from a fifth cell to a twentieth cell extending inwardly, taking the outermost peripheral cell as a first staring cell.

Owner:NGK INSULATORS LTD

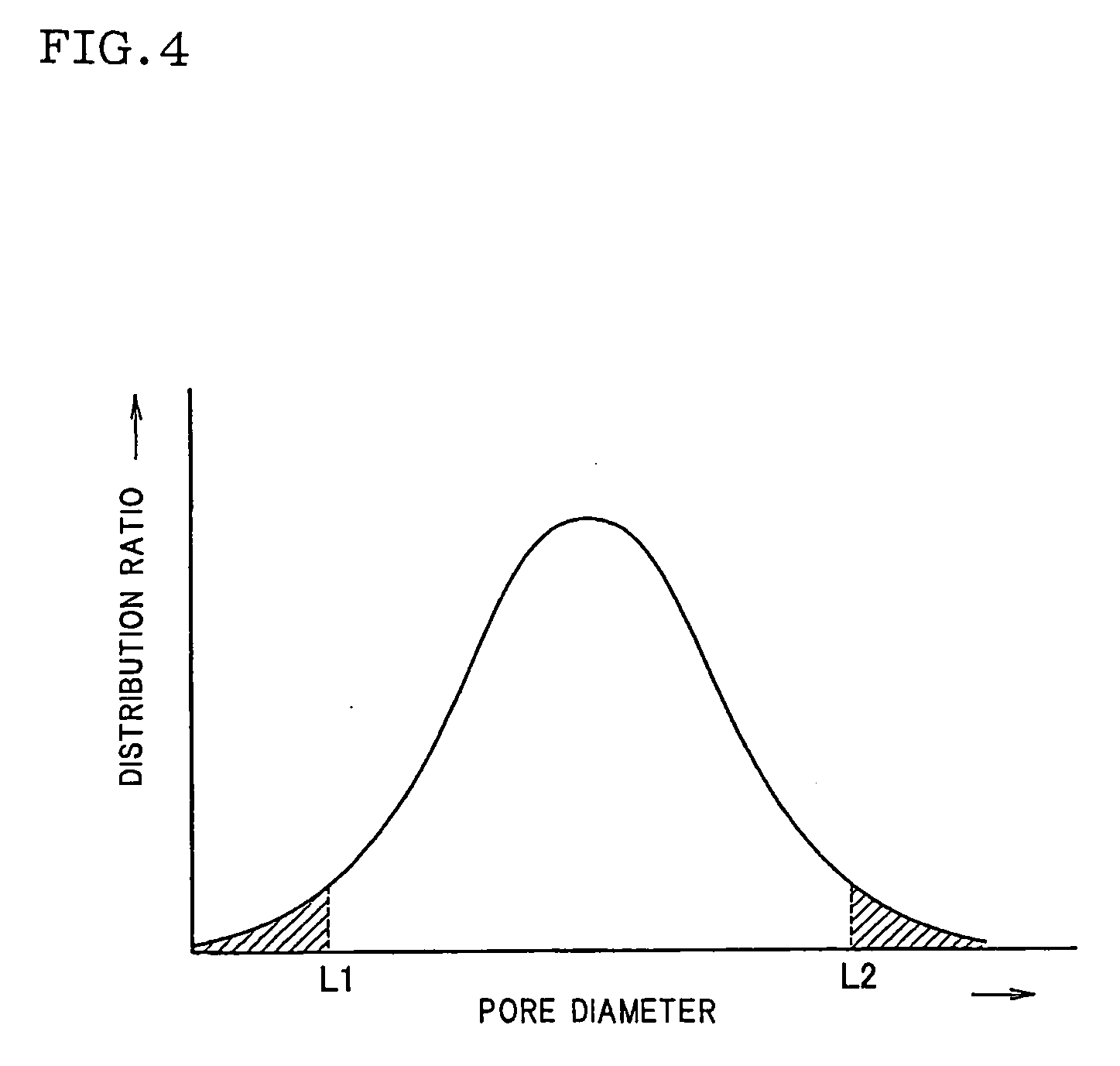

Porous Honeycomb Filter

InactiveUS20080092499A1Drop in trapping efficiencyIncreased pressure lossPhysical/chemical process catalystsDispersed particle filtrationPore distributionHoneycomb

There is disclosed a porous honeycomb filter whose trapping efficiency does not drop even when a porosity fluctuates and which is capable of balancing the trapping efficiency and a pressure loss. The porous honeycomb filter is a filter whose pore distribution has been controlled. A volume of pores having a pore diameter of 15 μm or less is 0.07 cc / cc or less, and a volume of pores having a pore diameter of 40 μm or more is 0.07 cc / cc or less.

Owner:NGK INSULATORS LTD

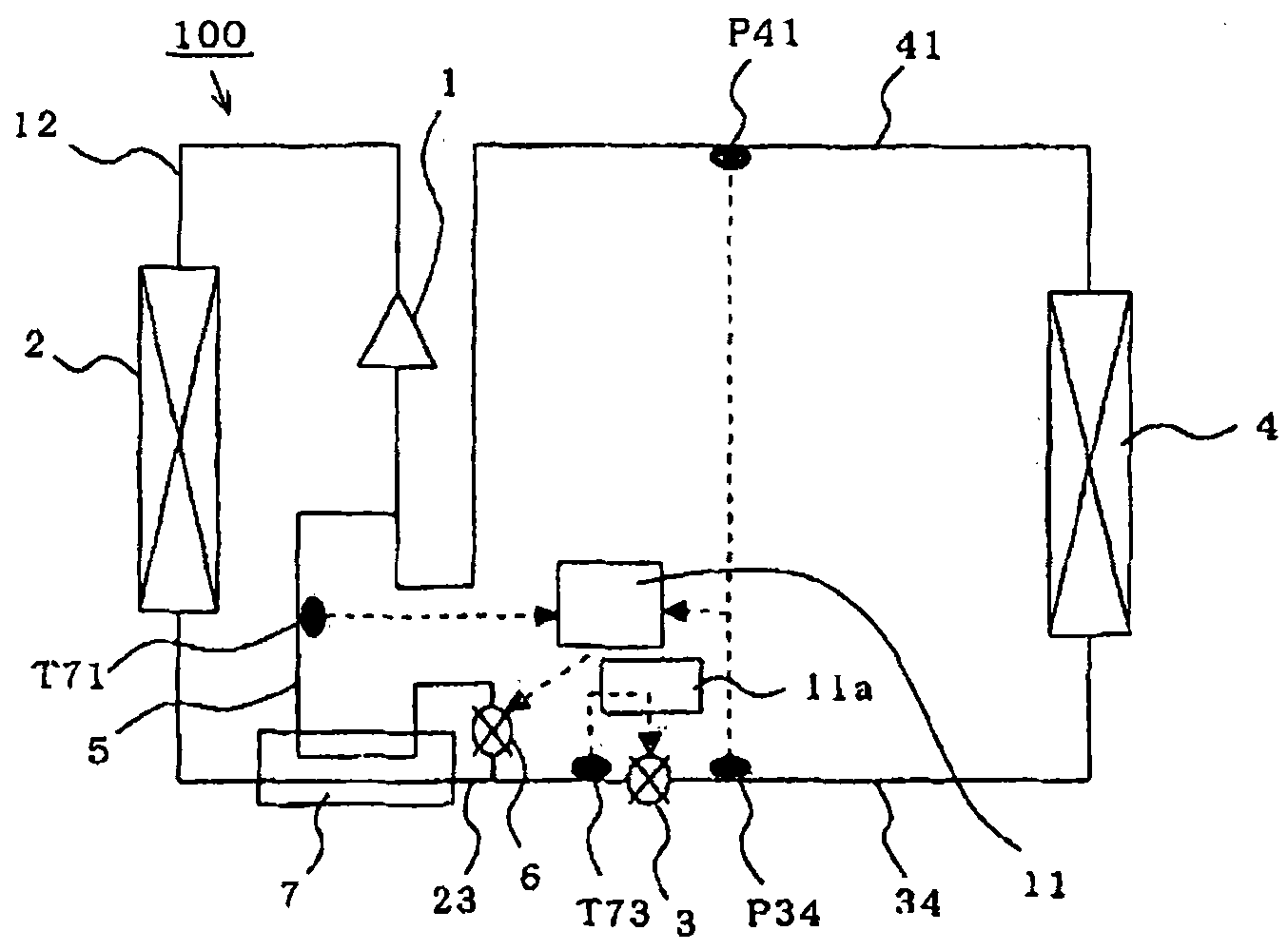

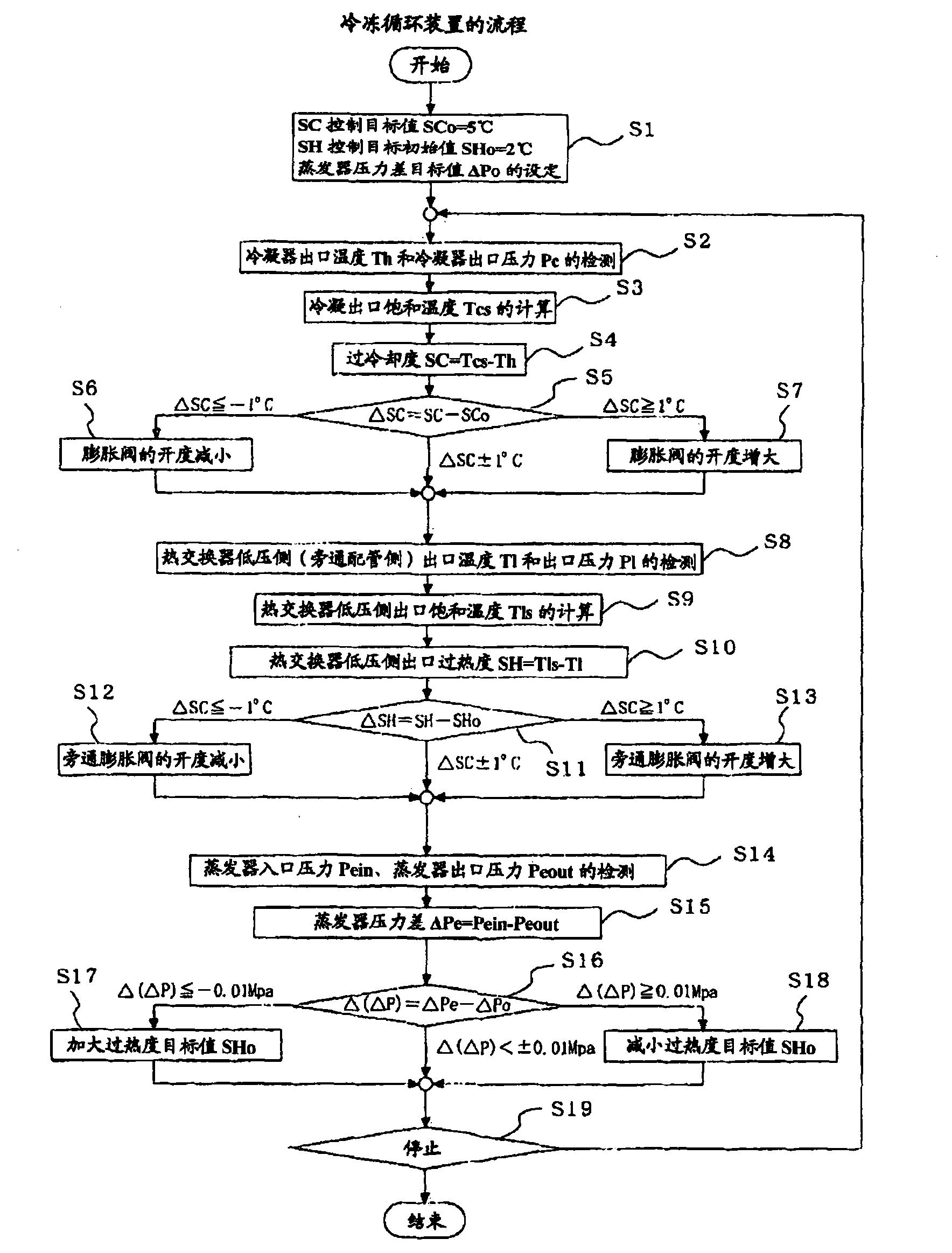

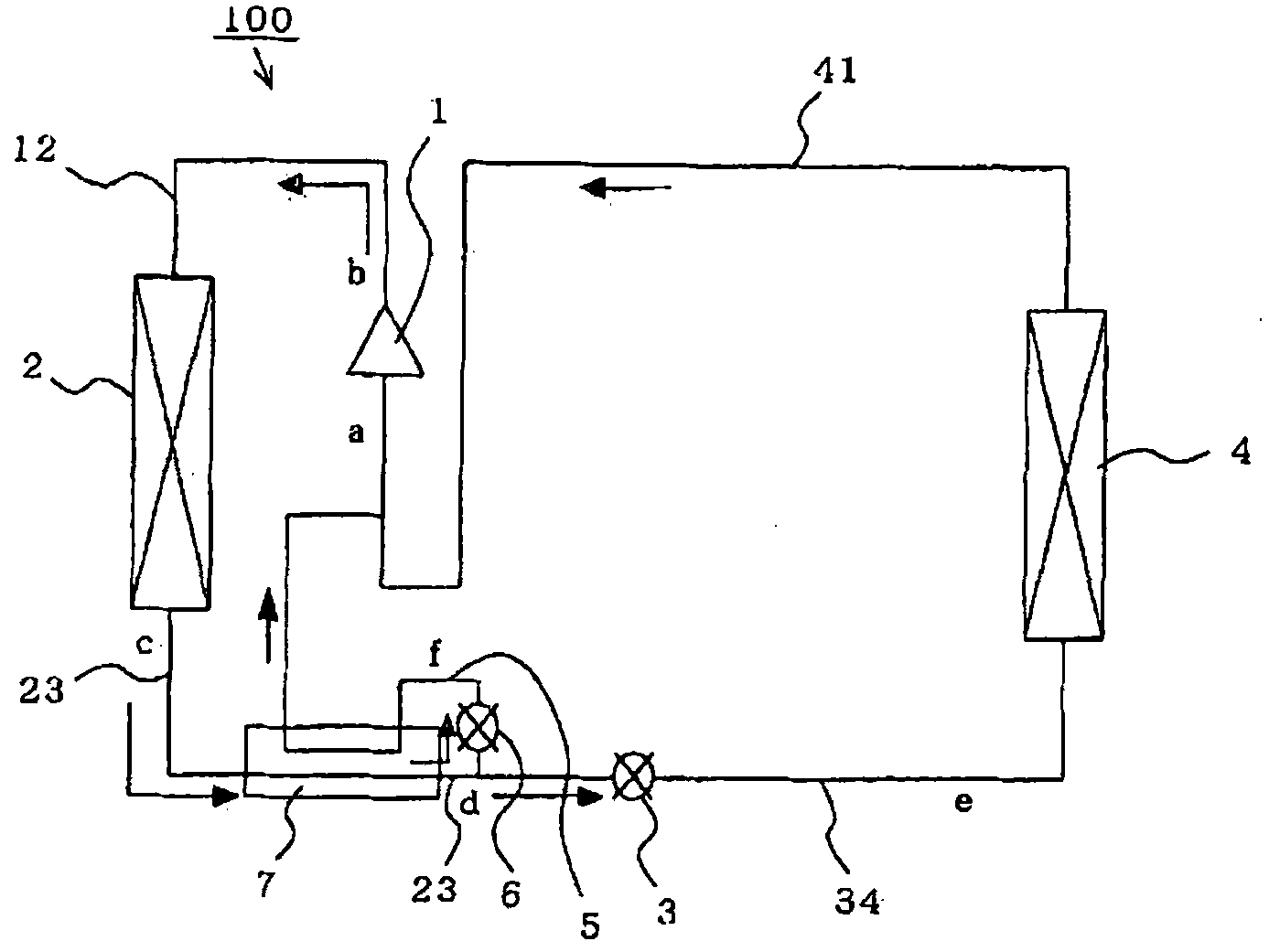

Refrigeration cycle device and control method therefor

ActiveCN102066851AEasy to operateIncreased pressure lossMechanical apparatusSpace heating and ventilation safety systemsEngineeringControl valves

A refrigeration cycle device (100) in which a flammable refrigerant circulates comprises a bypass pipeline (5) connected such that part of the refrigerant flowing through a circulation pipeline from a condenser (2) to a flow control valve (3) bypasses the flow control valve (3) and an evaporator (4), a bypass flow control valve (6) for controlling the flow rate of the refrigerant flowing through the bypass pipeline (5), a heat exchanger (7) for allowing the refrigerant flowing through the bypass pipe line (5) after flowing out from the bypass flow control valve (6) and the refrigerant flowingthrough the circulation pipeline after flowing out from the condenser (2) to exchange heat with each other, and a supercooling degree sensor (T73) for detecting the supercooling degree of the refrigerant at an inlet of the flow control valve (3). At least either the flow control valve (3) or the bypass flow control valve (6) is so controlled that the supercooling degree of the refrigerant at the inlet of the flow control valve (3) is equal to or more than a predetermined value.

Owner:MITSUBISHI ELECTRIC CORP

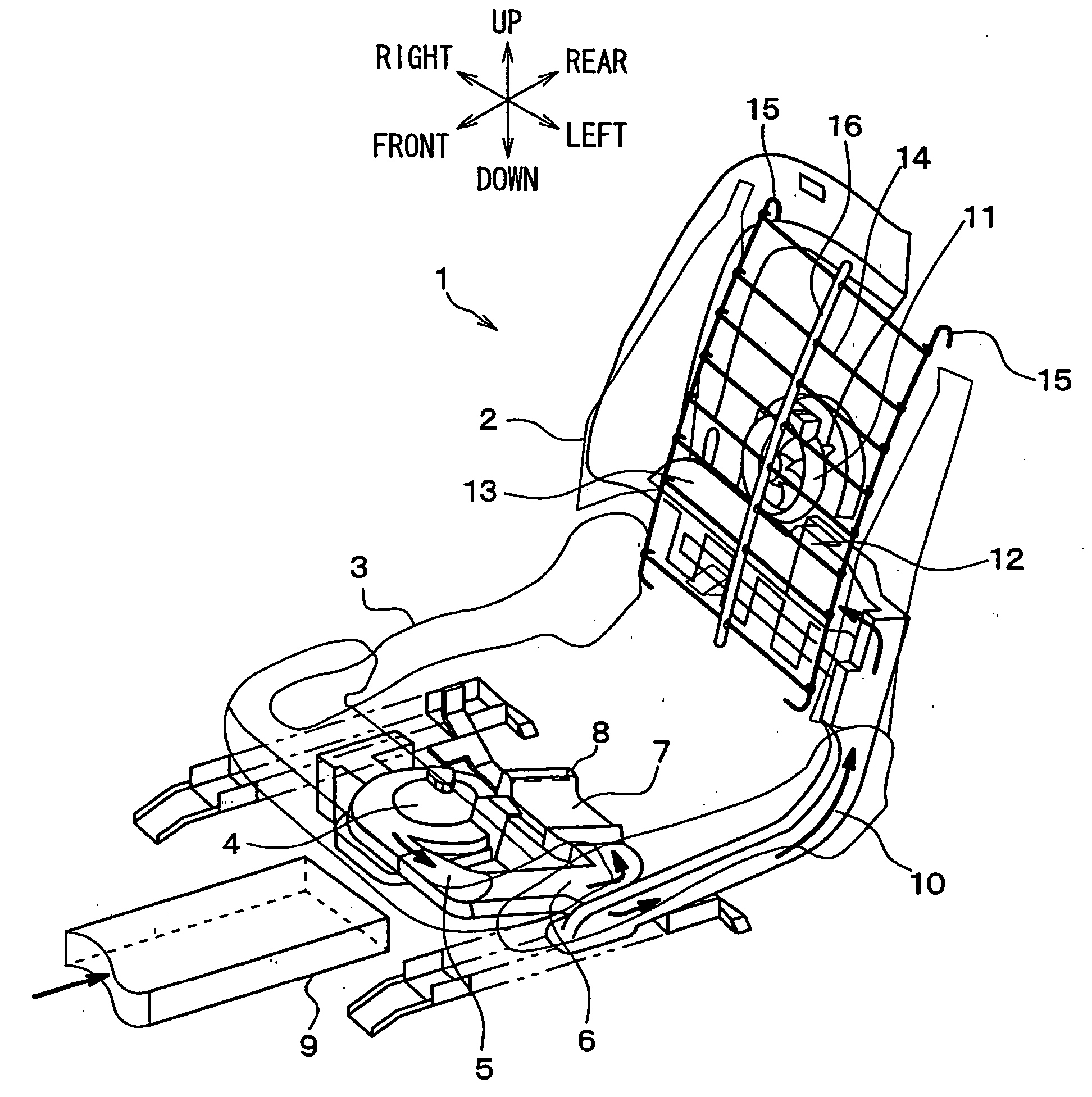

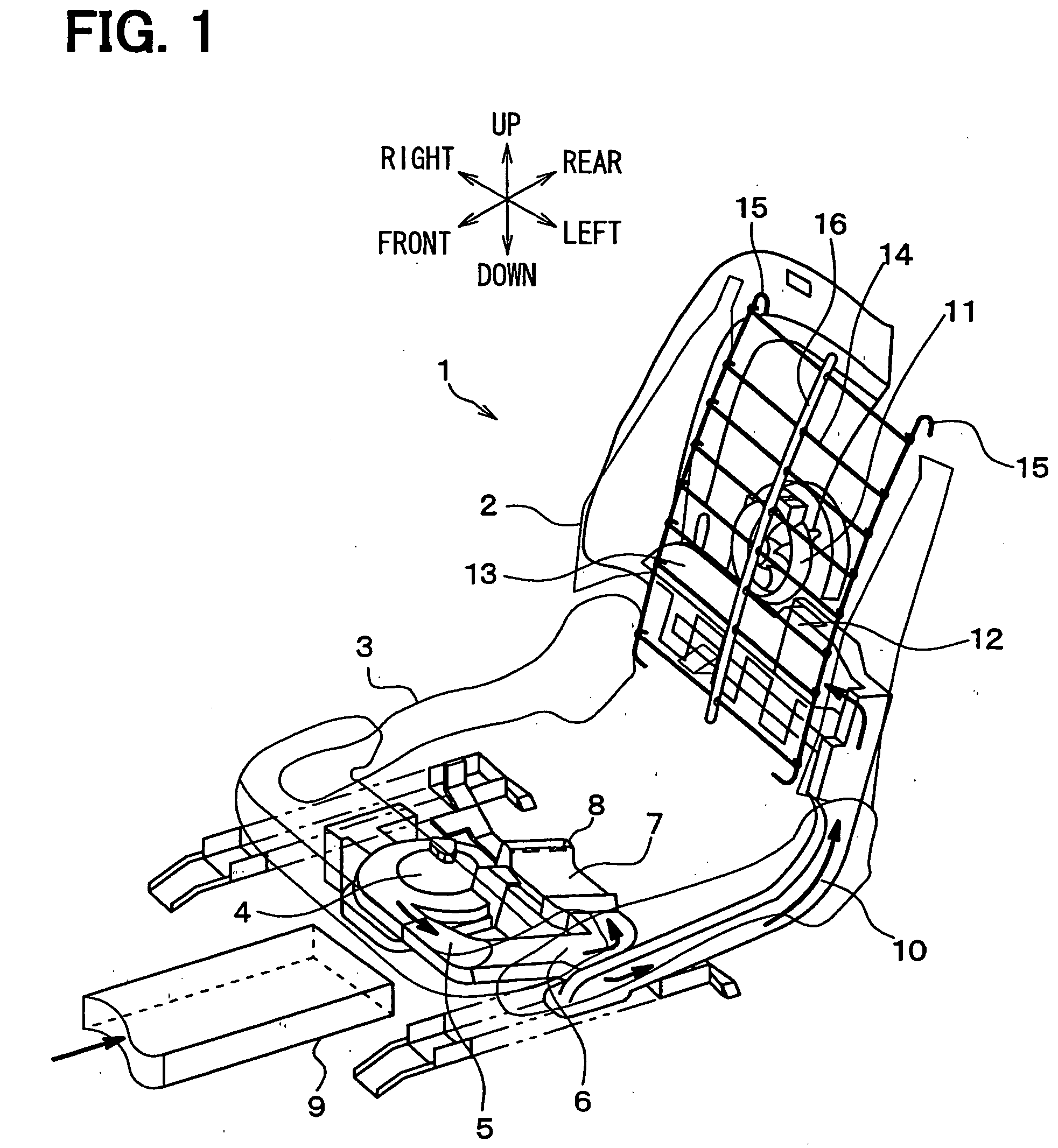

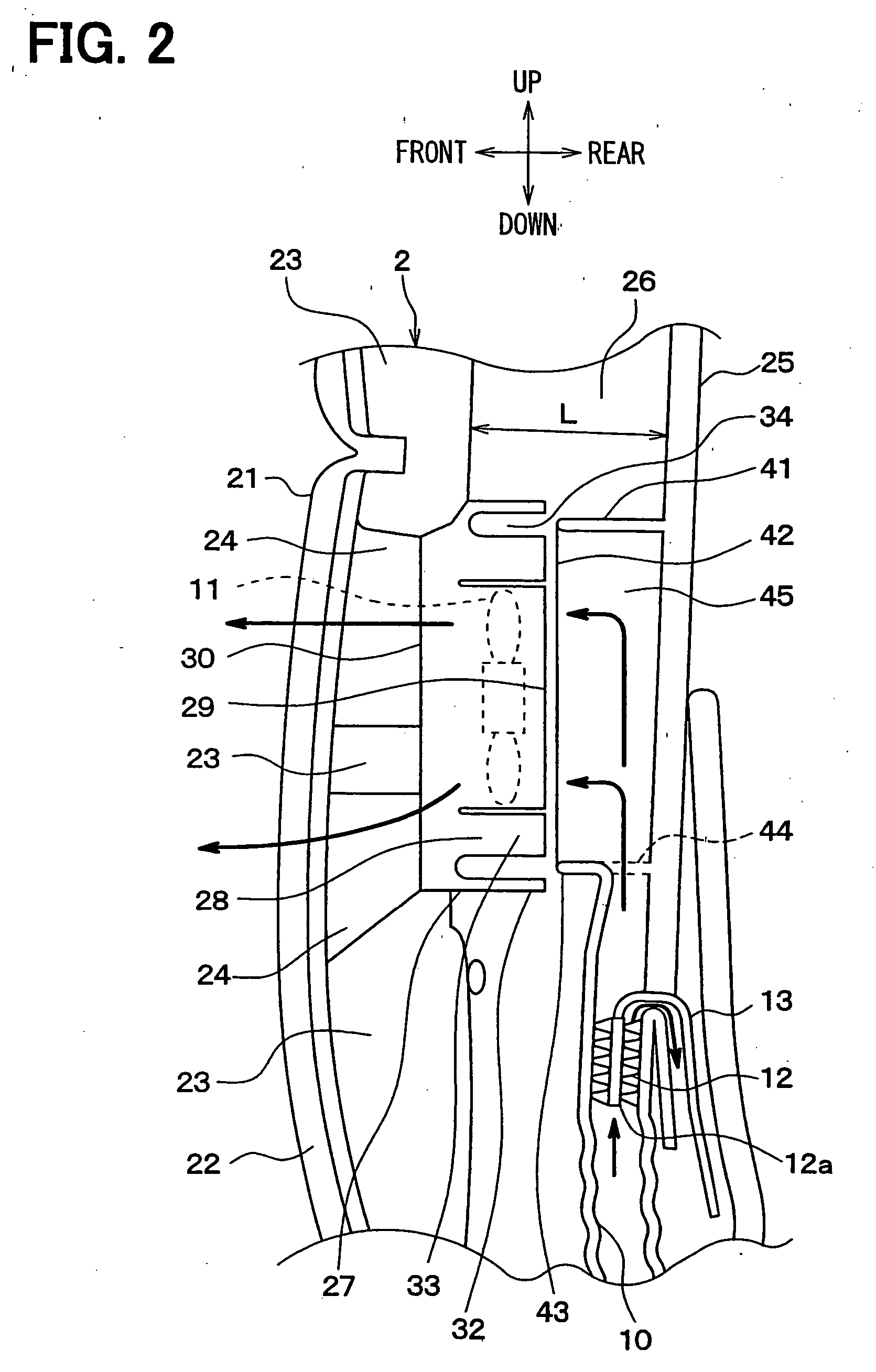

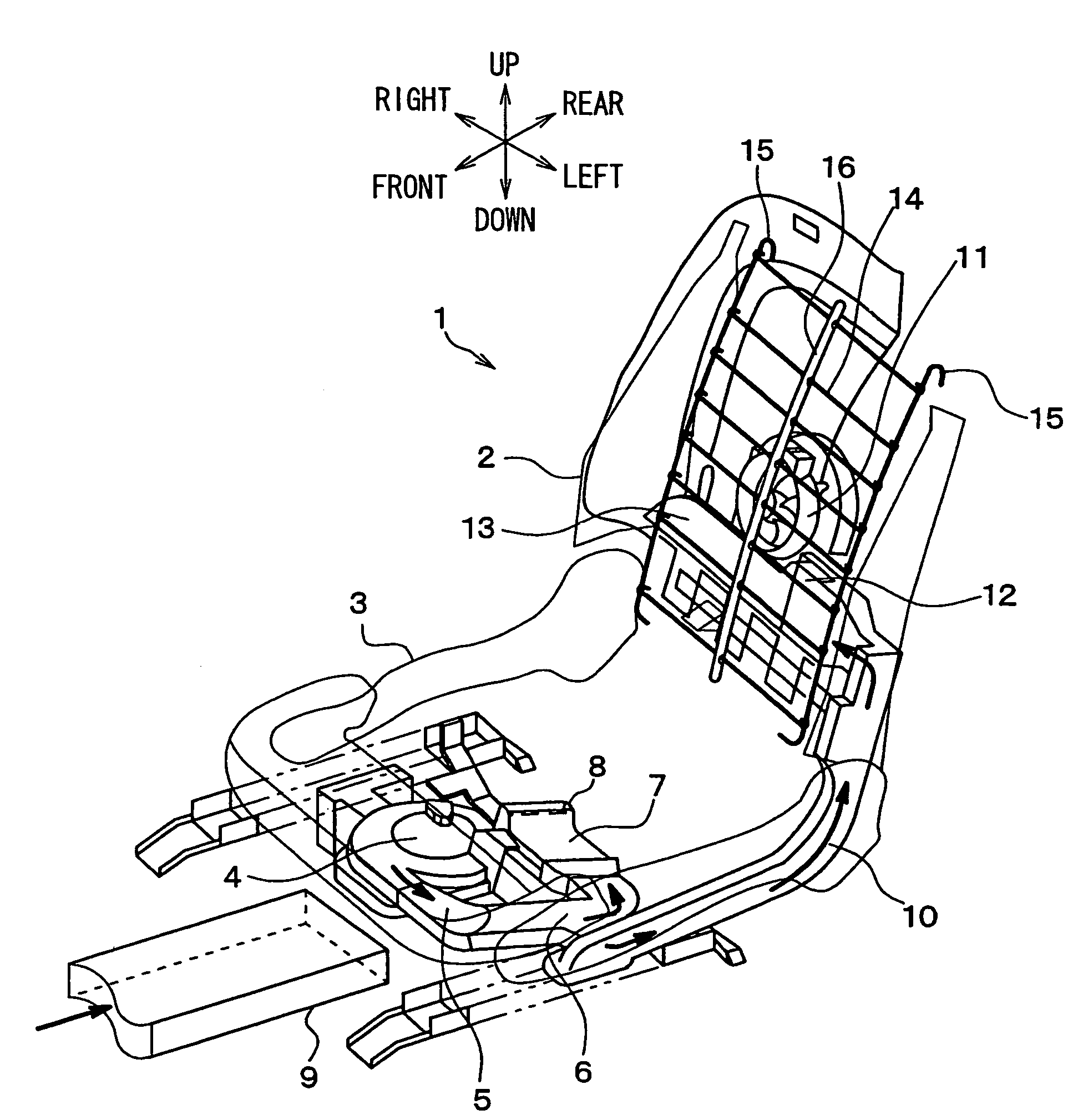

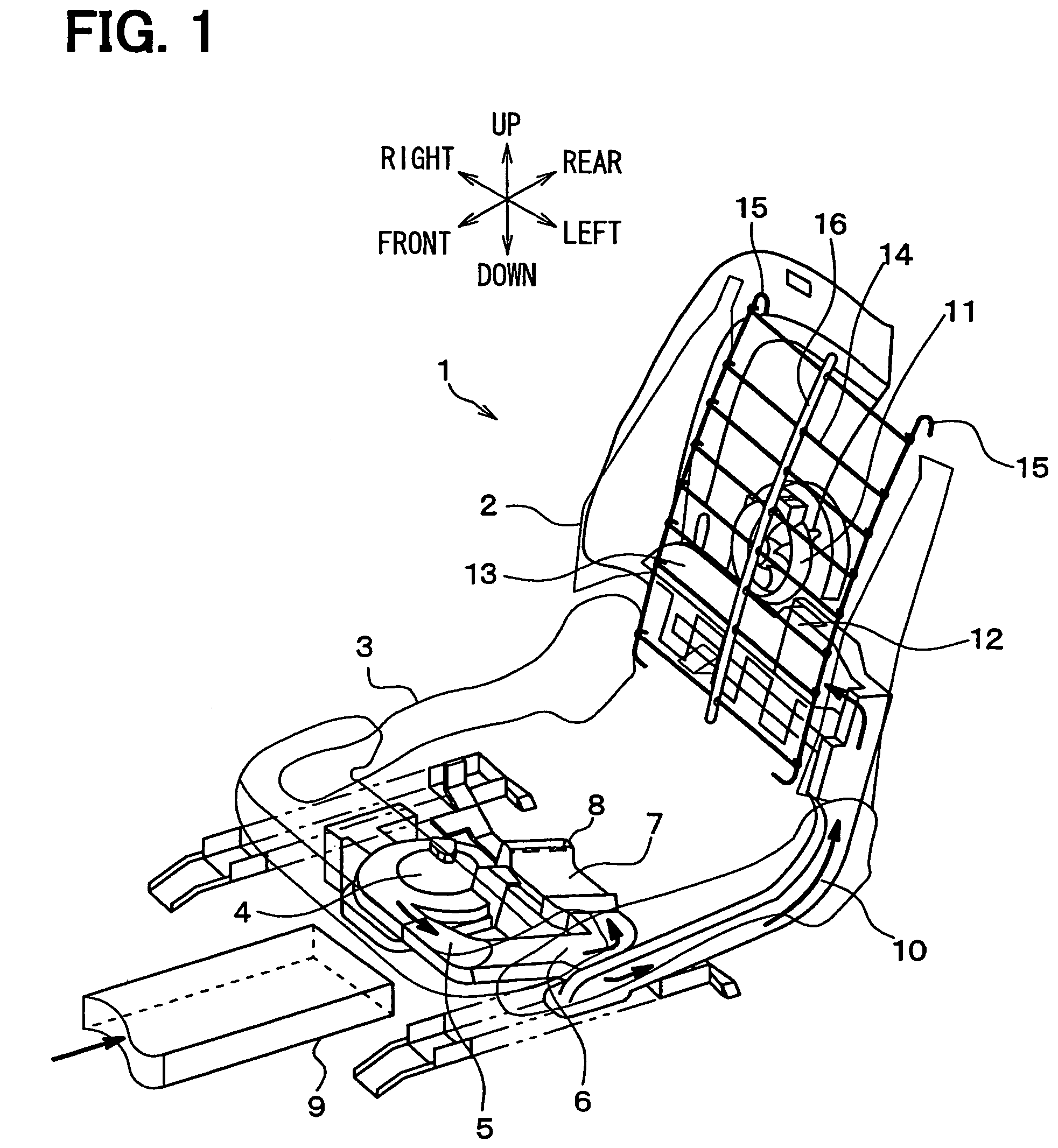

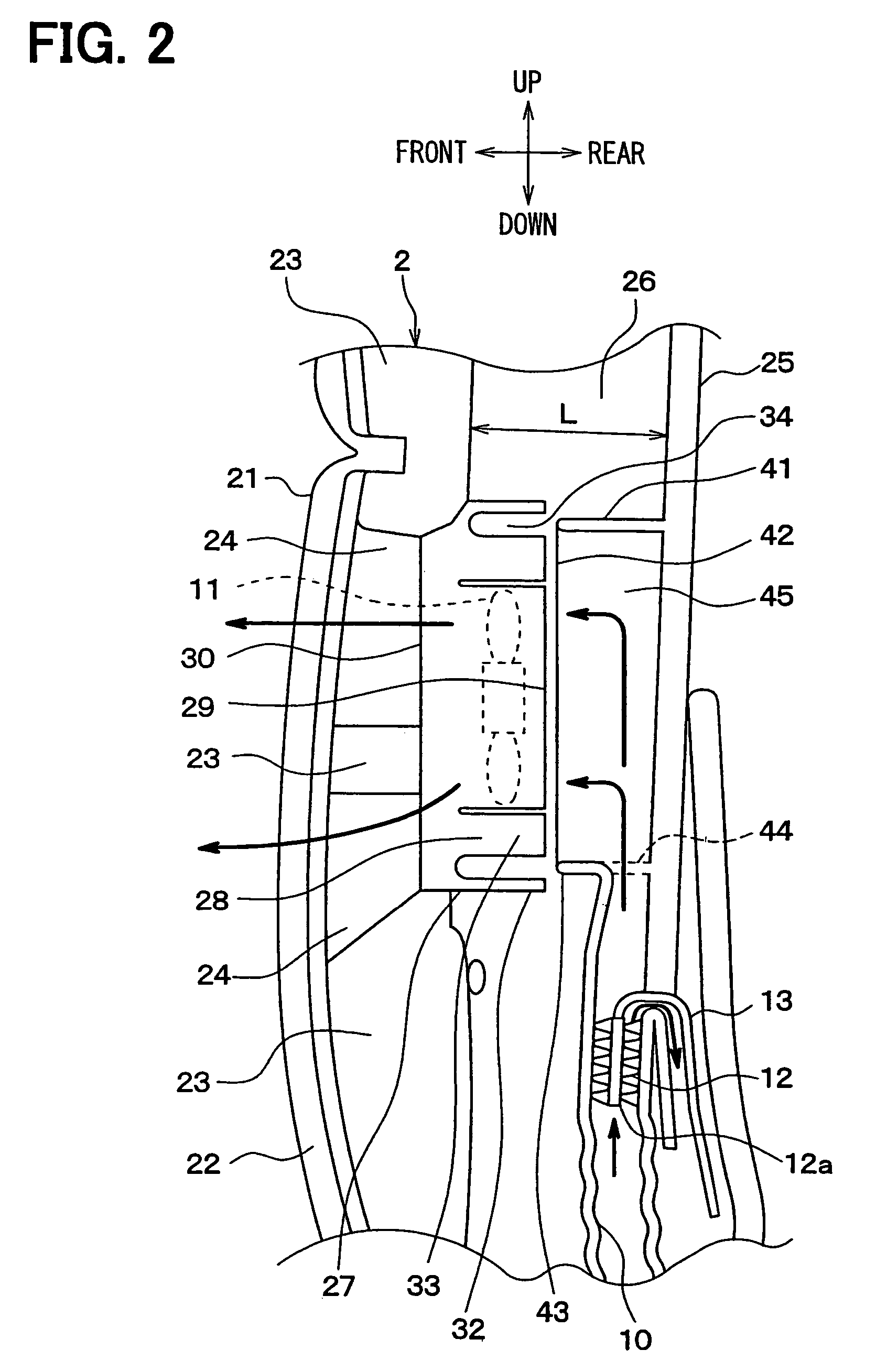

Air conditioning unit for seat

InactiveUS20060290176A1Effectively introducing airIncreased pressure lossVehicle seatsAir-treating devicesAir conditioningCushion

An air conditioning unit for introducing air to a surface of a seat back has a first air guide, a second air guide and a flexible connecting part. The first air guide is disposed on a rear side of a cushion member of the seat back to follow an elastic deformation of the cushion member. An upstream portion of the first air guide defines an inlet port. A downstream portion of the first air guide communicates with a seat back opening formed in the cushion member. The second air guide is disposed on a back board, which is located on the rear side of the cushion member with a space. The second air guide has an inlet port at an upstream portion thereof and an outlet port at a downstream end thereof. The flexible connecting part flexibly connects the outlet port of the second air guide and the inlet port of the first air guide.

Owner:DENSO CORP

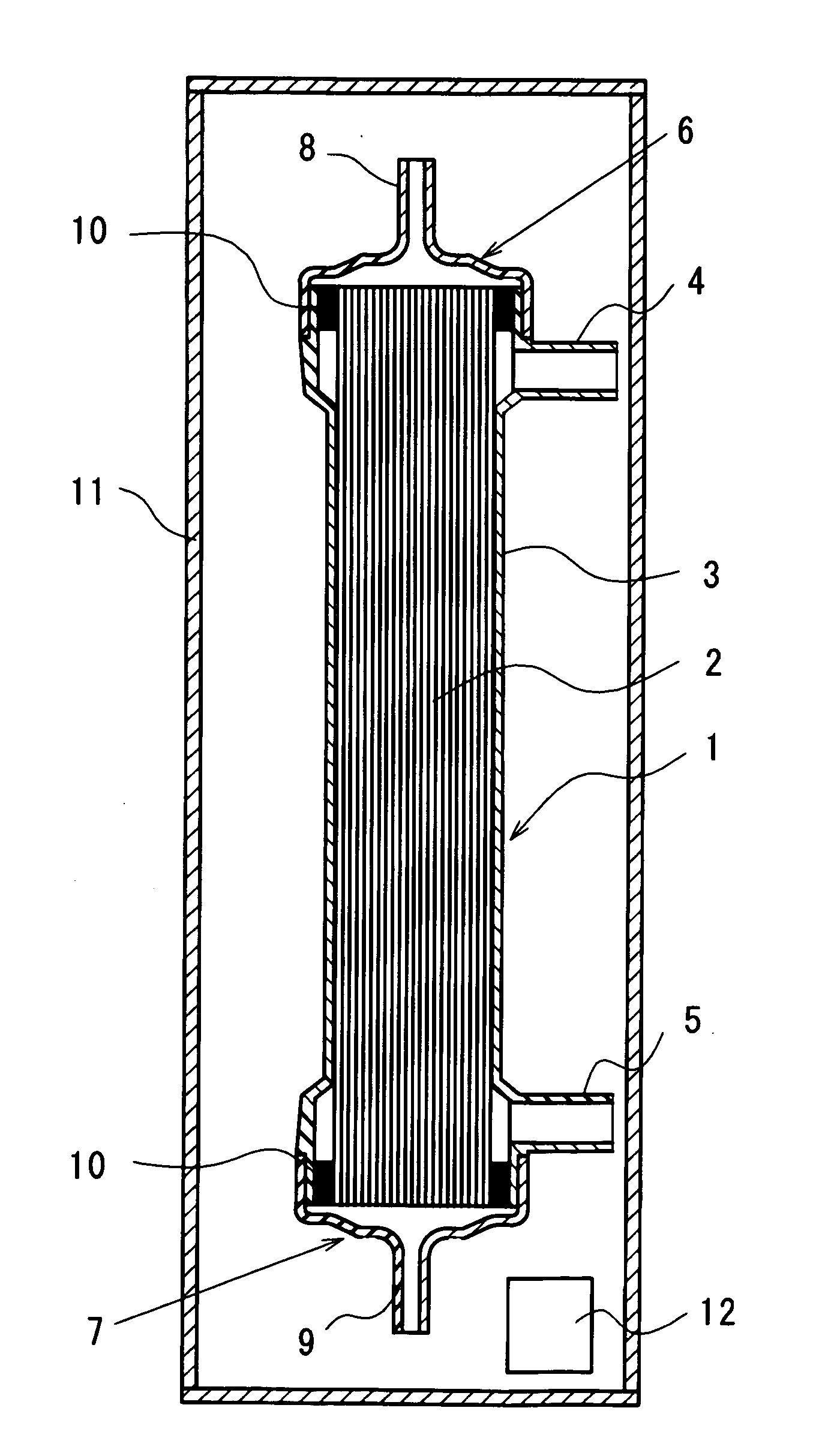

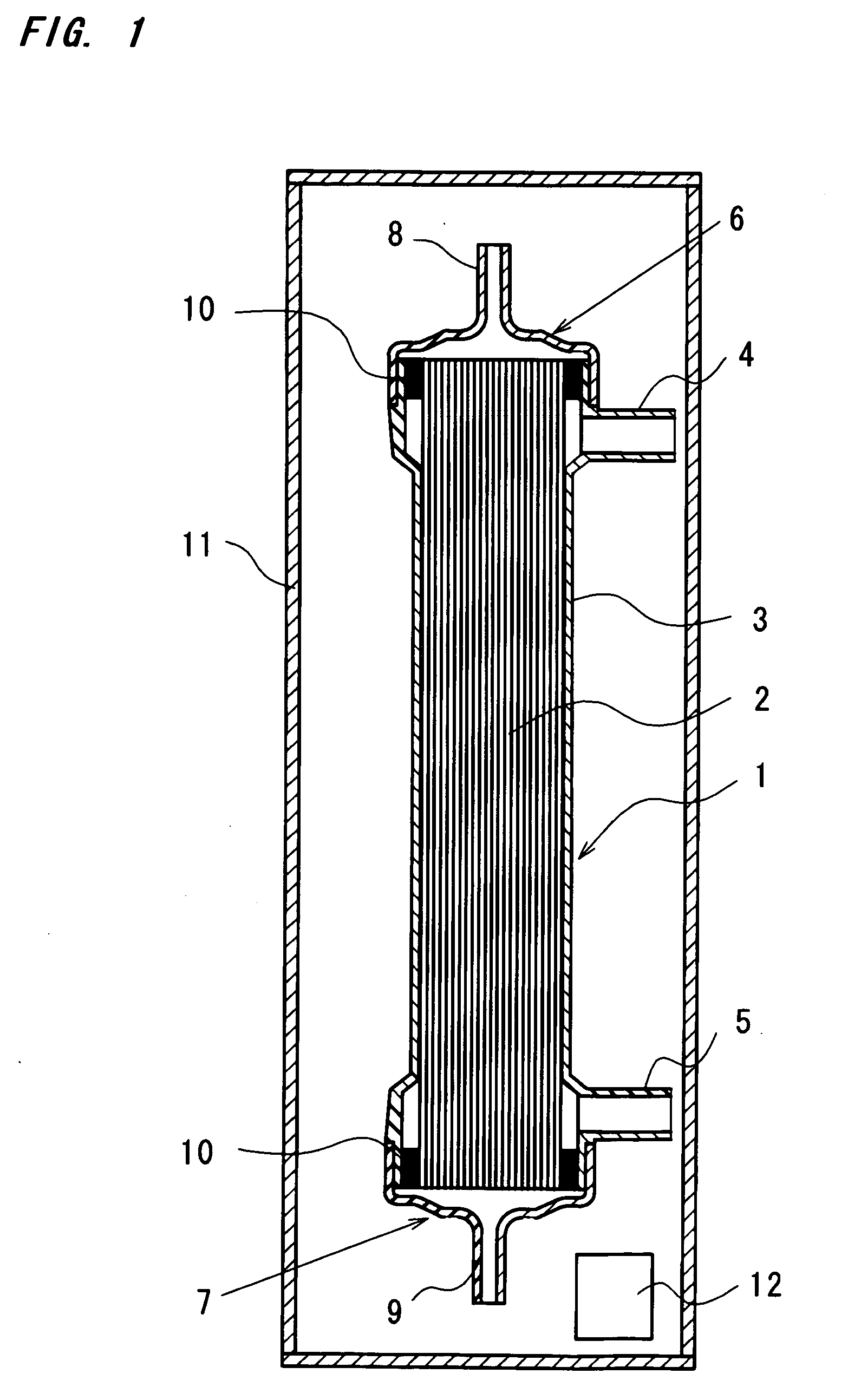

Hollow fiber blood-processing device and method for packaging and sterilizing such devices

ActiveUS20050063859A1Minimize damageIncreased pressure lossSemi-permeable membranesDialysis systemsFiberHollow fibre

A hollow fiber blood-processing device comprises a bundle of hollow fibers and is sealed in a gas-impermeable container together with a deoxidizer of a water-releasing type and radiation sterilized. The blood processing device is produced by a method comprising the steps of sealing a hollow fiber blood-processing device in a gas-impermeable container together with a deoxidizer of a water-releasing type, and radiation sterilizing the blood-processing device held in the sealed gas-impermeable container.

Owner:NIPRO CORP

Electrical apparatus, cooling system therefor, and electric vehicle

InactiveUS7090044B2Increased pressure lossIncrease in sizeSpeed controllerSemiconductor/solid-state device detailsWater flowEngineering

An inverter apparatus includes a liquid path in which cooling water flows, and in which the cooling water performs cooling at a cooling part located directly underneath the power circuit part of the inverter apparatus. The liquid path includes a first partial structure part formed between a feed pipe and the cooling part, and having a liquid path cross-sectional profile that is gradually reduced in the short-side direction of the cooling part and that is gradually enlarged in the long-side direction thereof; and a second partial structure part formed between the cooling part and a drain pipe, and having a liquid path cross-sectional profile that is gradually enlarged from the short-side of the cooling part and that is gradually reduced from the long-side thereof.

Owner:HITACHI LTD

Air conditioning unit for seat

InactiveUS7275984B2Effectively introducing airIncreased pressure lossAir-treating devicesSeat heating/ventillating devicesEngineeringAir conditioning

Owner:DENSO CORP

Particulate matter removal apparatus

InactiveUS20080066621A1Improve heating efficiencyRegenerate in small quantityCombination devicesAuxillary pretreatmentParticulatesThermal energy

A filter is made with heat-insulating ceramic fibers, and where the filter is increased in pressure loss due to particulate matter captured after filtration of exhaust gas, gas flow is blocked, a heating element is used to heat the surface of the filter, thereby burning and removing particulate matter. The filter is of heat insulating properties, by which a heat insulating material is arranged near the particulate matter capturing face of the filter, and the heating element is incorporated between the surface of the filter and the heat insulating material. The filter can be regenerated at a higher heating efficiency in a smaller quantity of thermal energy. The heat insulating material is also used as a filter, by which the apparatus can be made more compact. A charging element is arranged upstream of the filter material, by which the filter material is increased in particulate matter capturing performance, thereby suppressing the rate of increase in the pressure loss and improving heating efficiency of particulate matter.

Owner:NISSIN ELECTRIC CO LTD

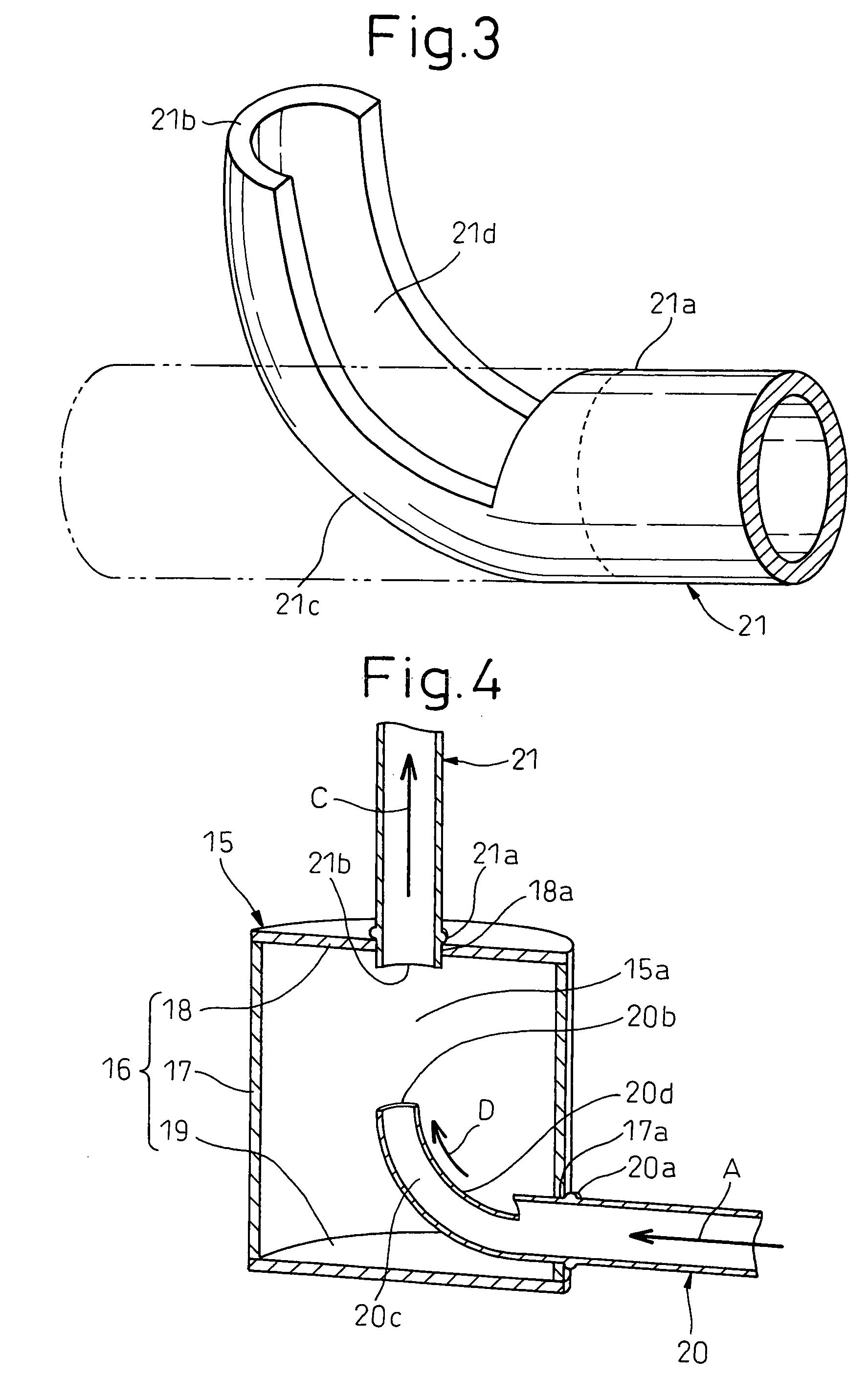

Silencer for refrigeration cycle system

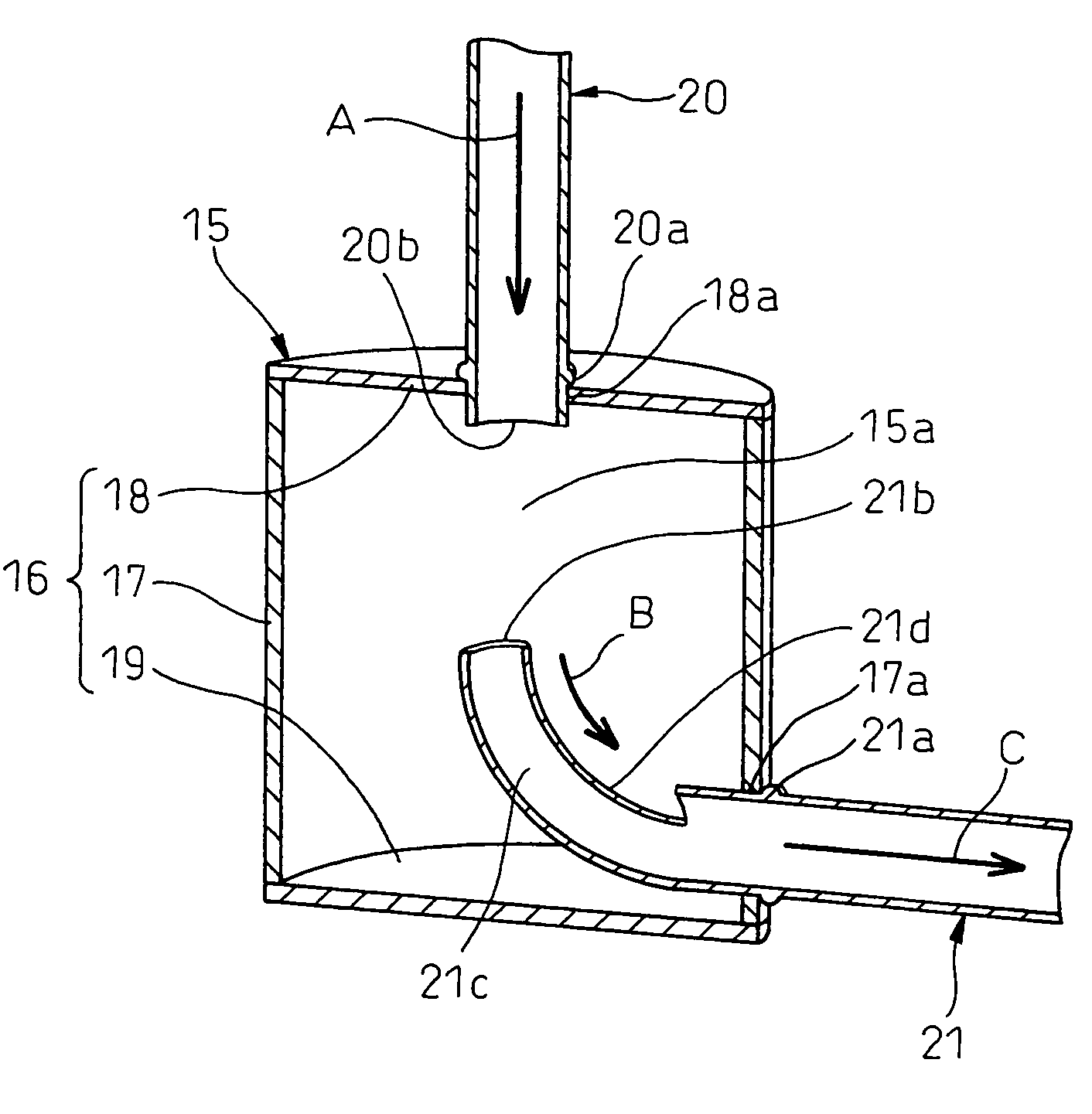

InactiveUS20090090579A1Easy to assembleWell formedPositive displacement pump componentsSilencing apparatusRefrigerantRefrigeration

A silencer for a refrigeration cycle system is disclosed. The silencer includes a silencing chamber 15a formed in a housing 16, an inlet pipe 20 connected to the housing 16 to allow the refrigerant to flow into the silencing chamber 15a, and an outlet pipe 21 connected to the housing 16 to allow the refrigerant to flow out of the silencing chamber 15a. The direction in which the inlet pipe 20 is connected to the housing 16 and the direction in which the outlet pipe 21 is connected to the housing 16 cross each other. A bend 21c projected into the silencing chamber 15a and curved toward the upstream end 20b of the inlet pipe 20 is formed at the upstream end 21b portion of the outlet pipe 21. The bend 21c is formed with an opening 21d to open the inside part thereof. As a result, the refrigerant that has flowed into the silencing chamber 15a can be guided smoothly to the outlet pipe 21 while at the same time avoiding a case in which the bend 21c suppresses the interference of the pressure wave.

Owner:DENSO CORP

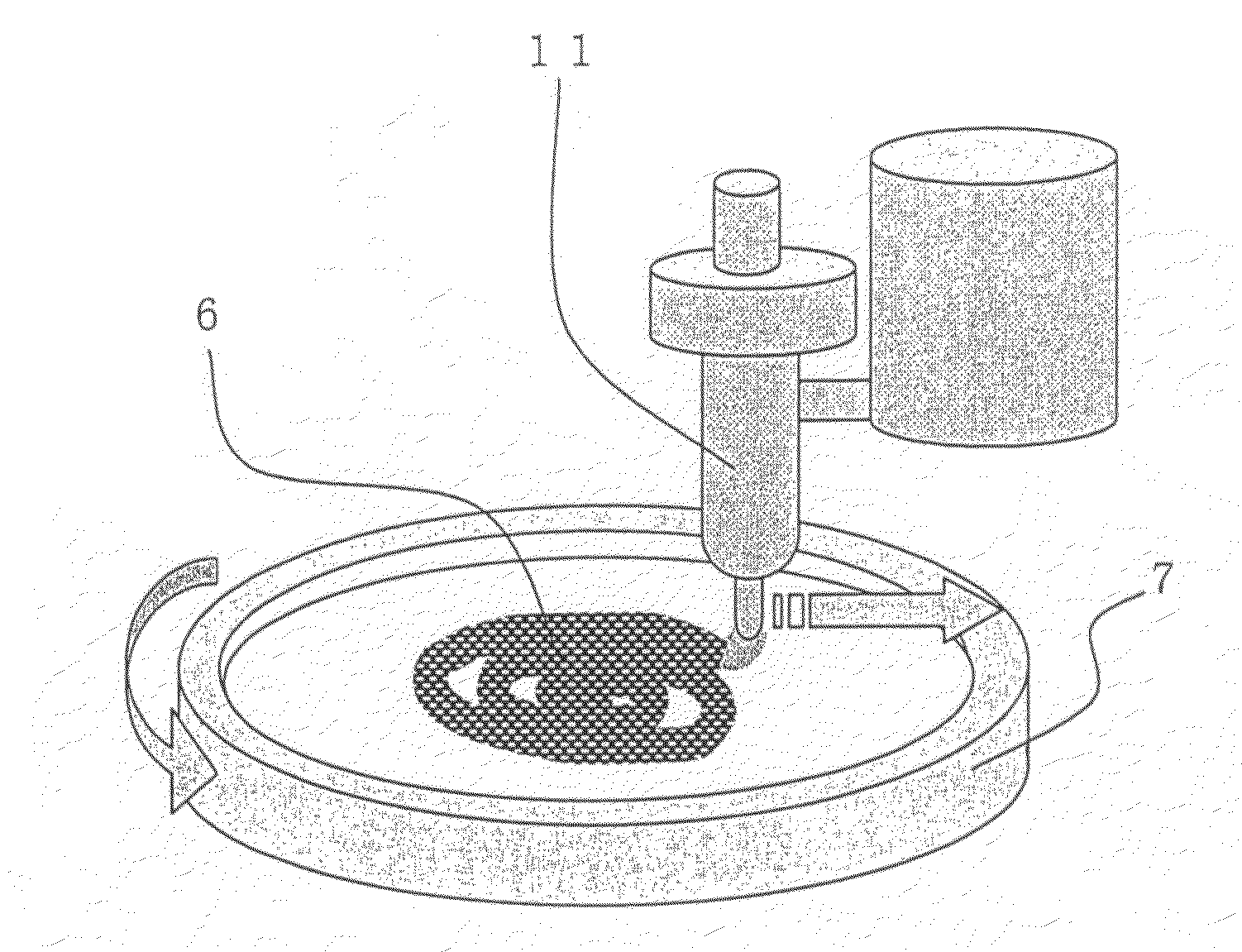

Method for Manufacturing Plugged Honeycomb Structure

InactiveUS20080128082A1Improve trapping efficiencyReduce total pressure lossGas treatmentDispersed particle filtrationEngineeringSlurry

There is provided a method for manufacturing a plugged honeycomb structure, where slurry 6 functioning as a raw material for the plugged portions is stored in a storage container 7 so that the slurry 6 may have a flat interface, and the plugged portions are formed by pressing an end face of the honeycomb structure 3 having a mask 8 for forming plugged portions disposed so as to cover open end portions of the cells other than the cells 9 to be plugged of the honeycomb structure 3 against the slurry 6 stored in the storage container 7 to introduce the slurry 6 into the inside of the cells 9 to be plugged.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com