Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

389 results about "Structured packing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term structured packing refers to a range of specially designed materials for use in absorption and distillation columns and chemical reactors. Structured packings typically consist of thin corrugated metal plates or gauzes arranged in a way that force fluids to take complicated paths through the column, thereby creating a large surface area for contact between different phases.

Process for production of organic acid esters

InactiveUS20060014977A1Speed up the processPreparation by ester-hydroxy reactionOrganic compound preparationOrganic acidChemical reaction

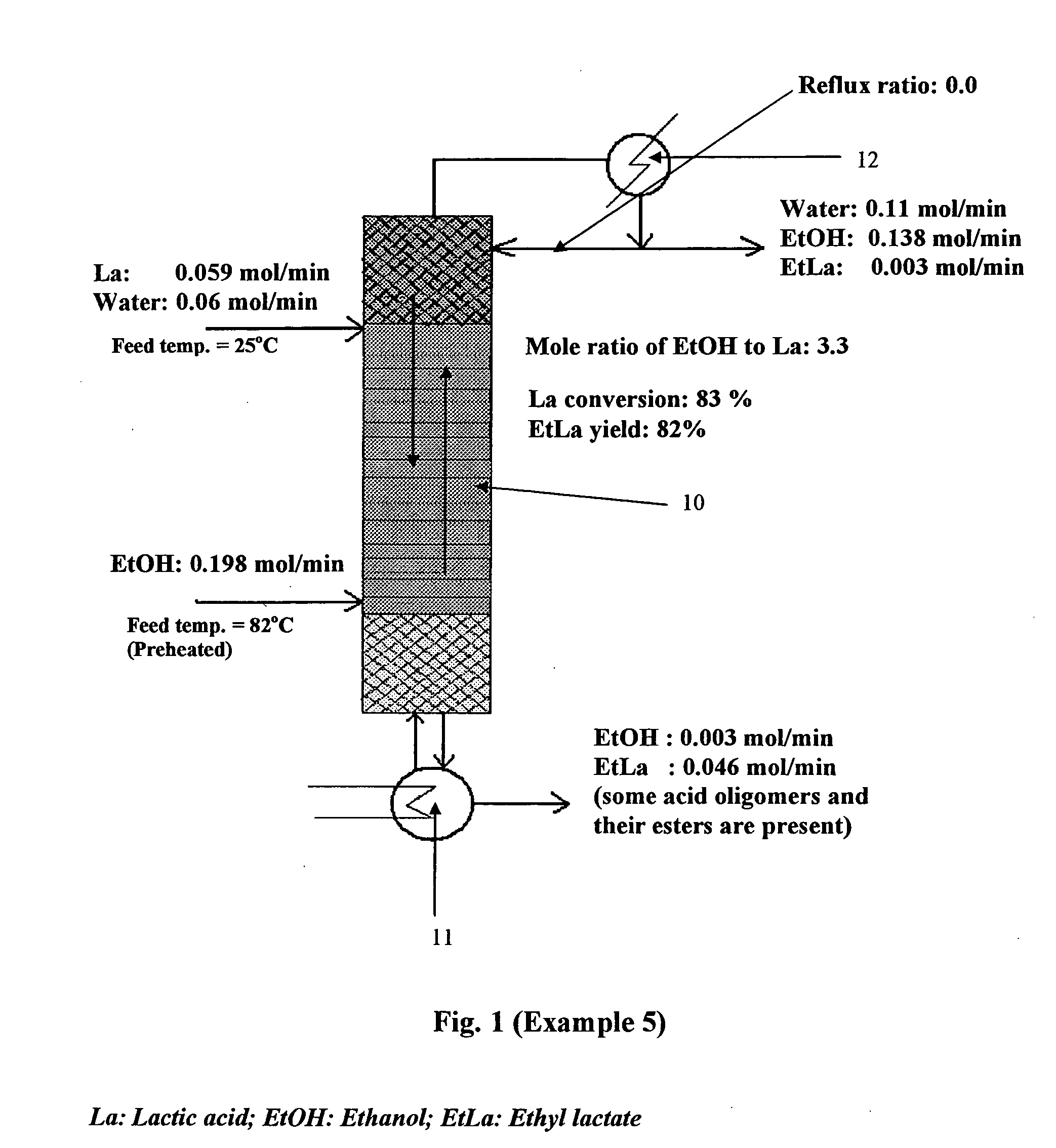

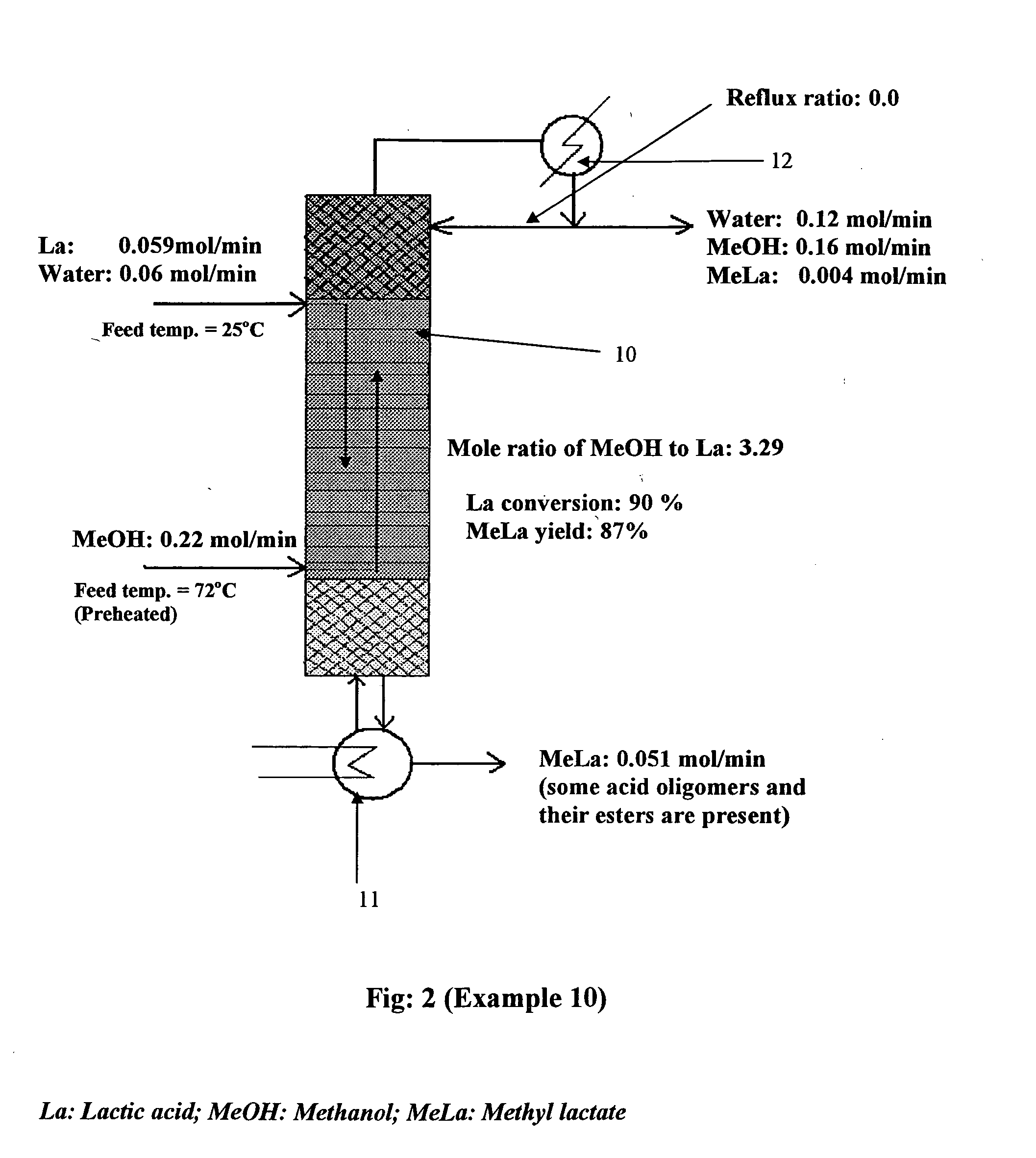

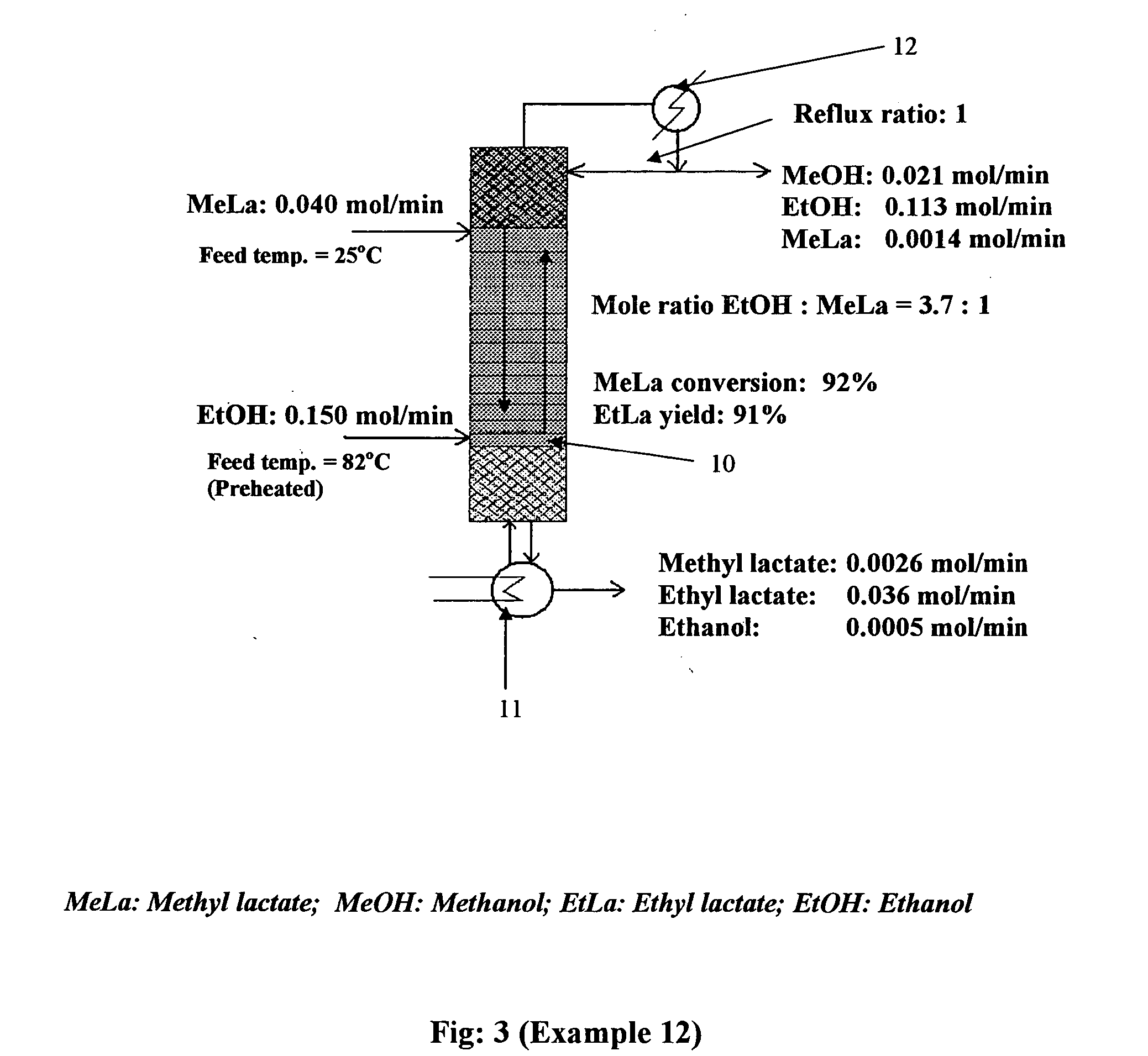

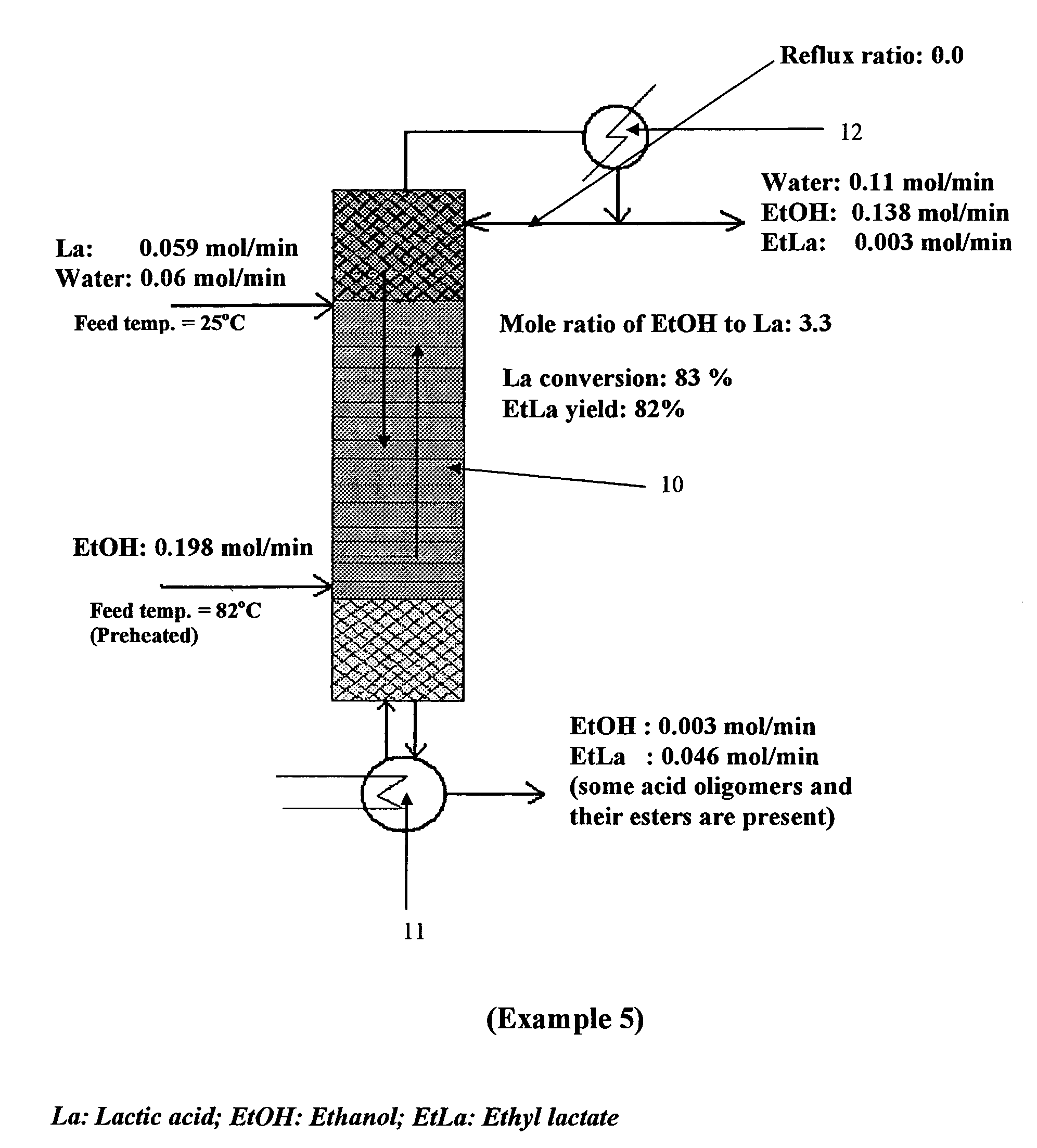

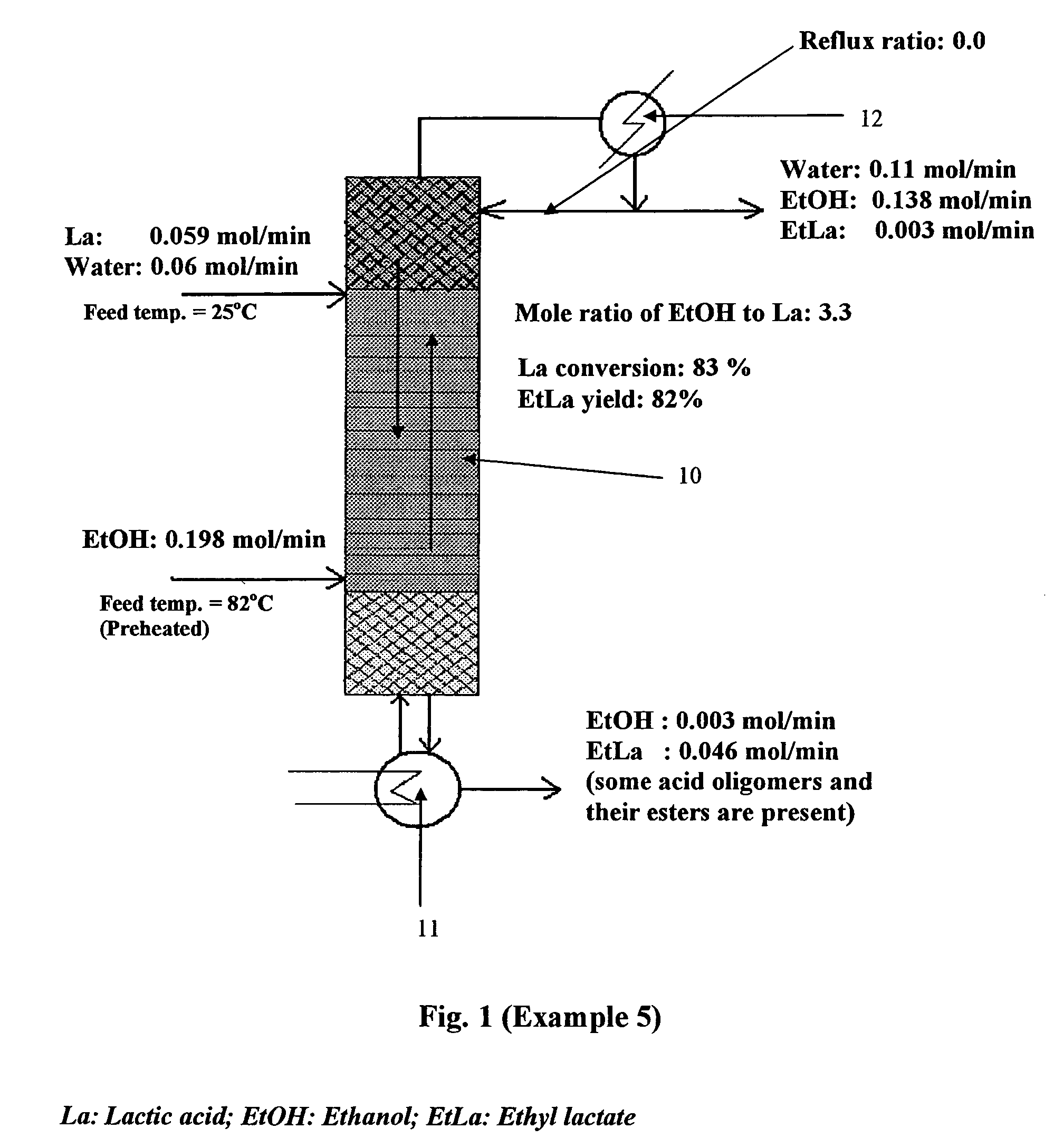

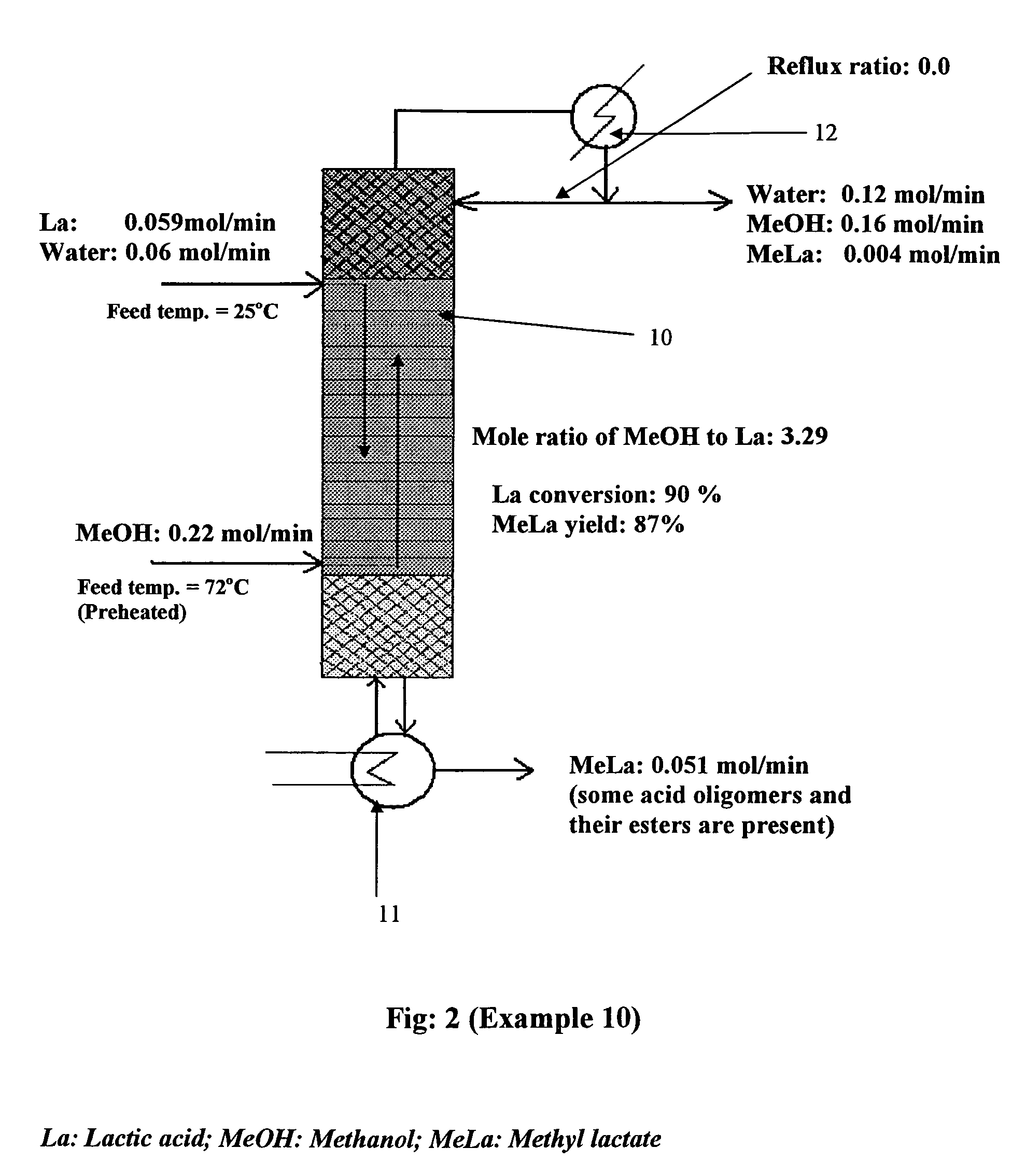

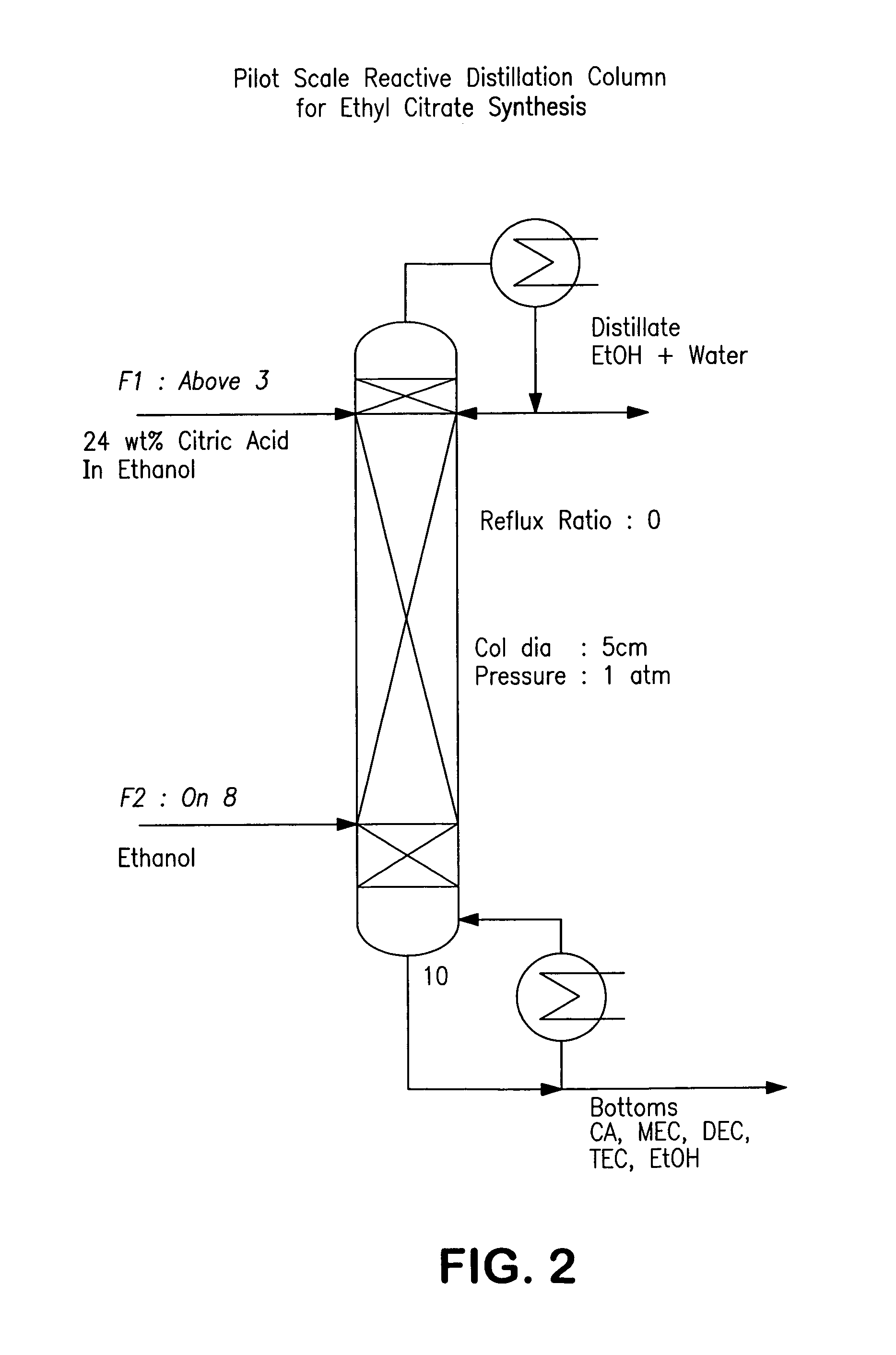

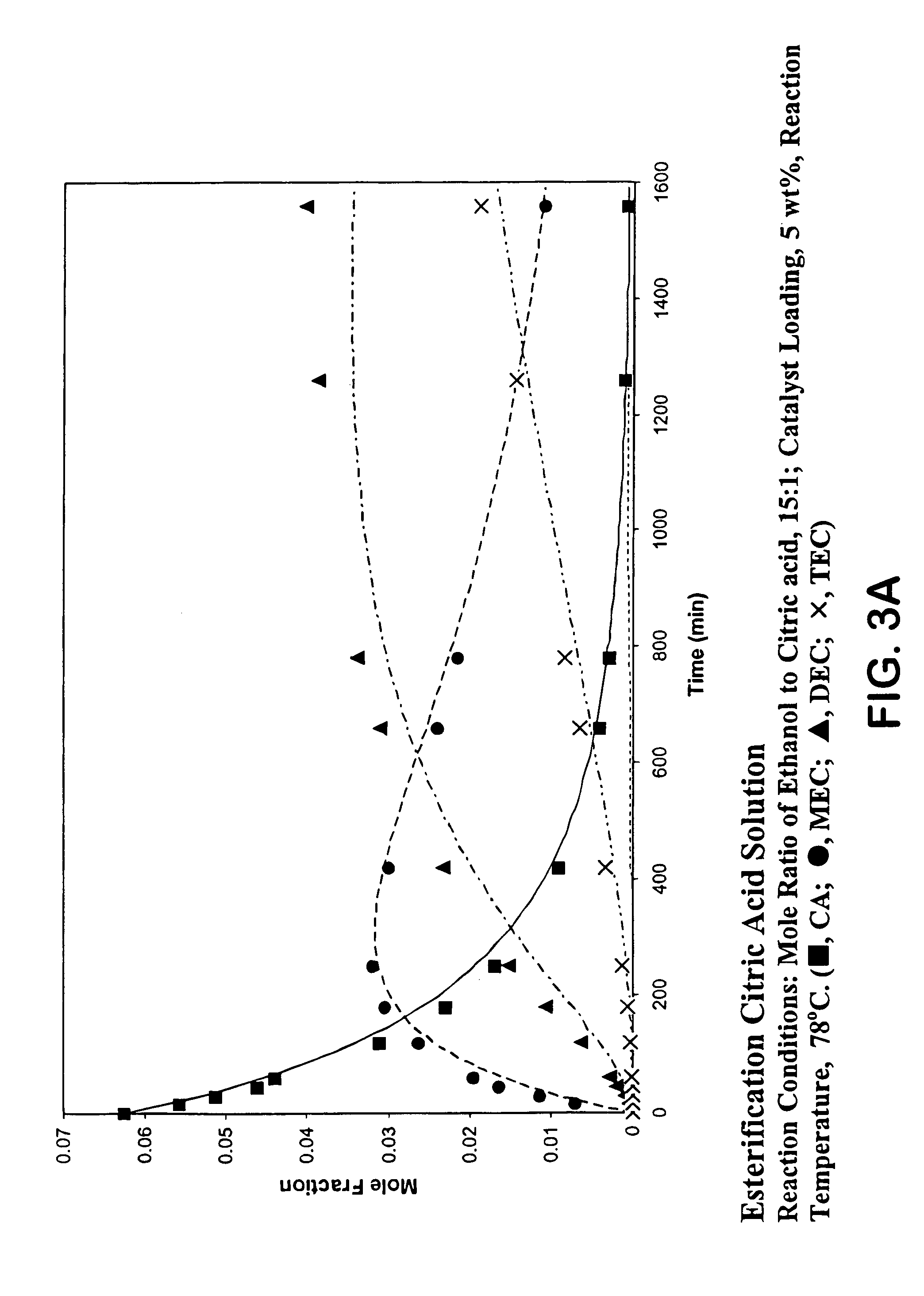

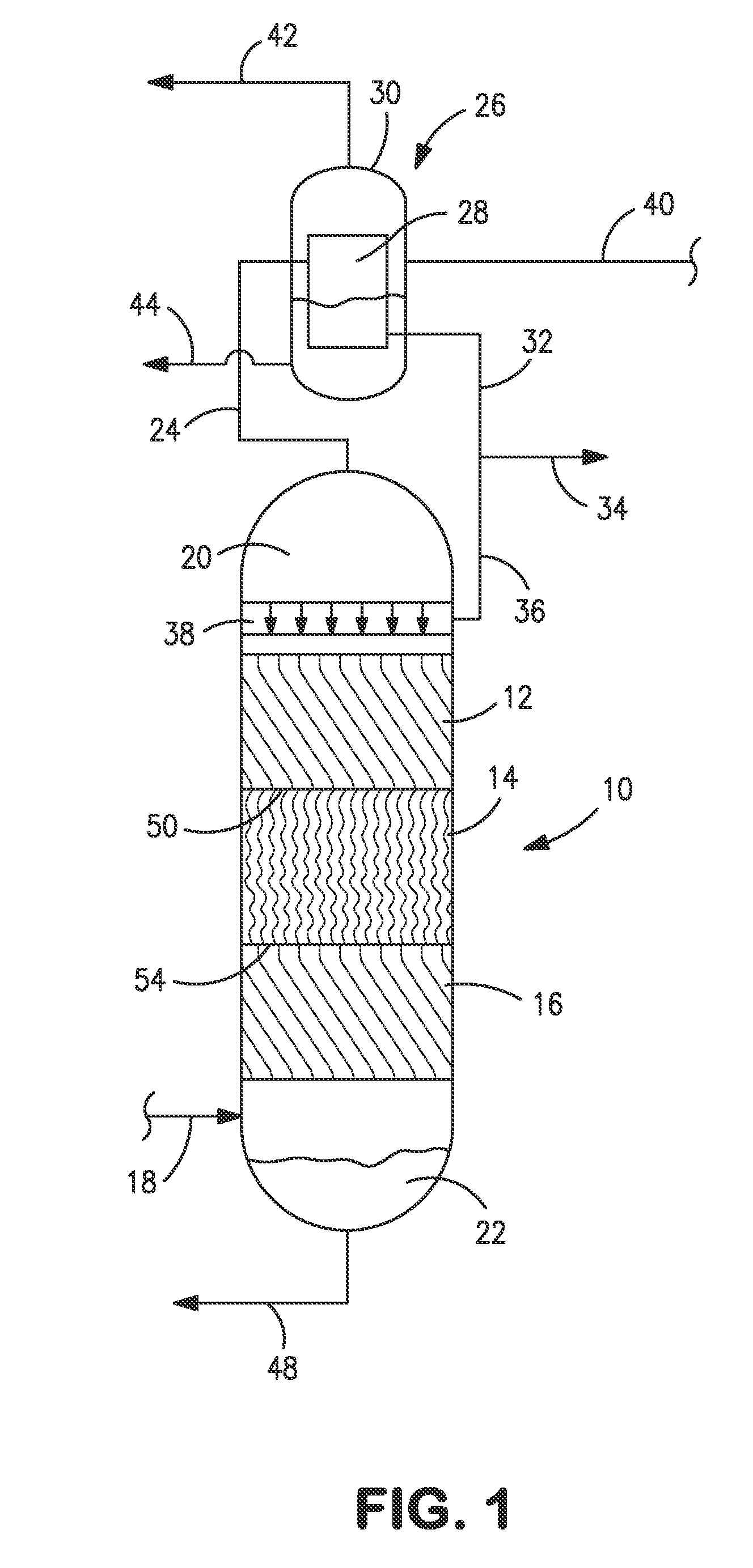

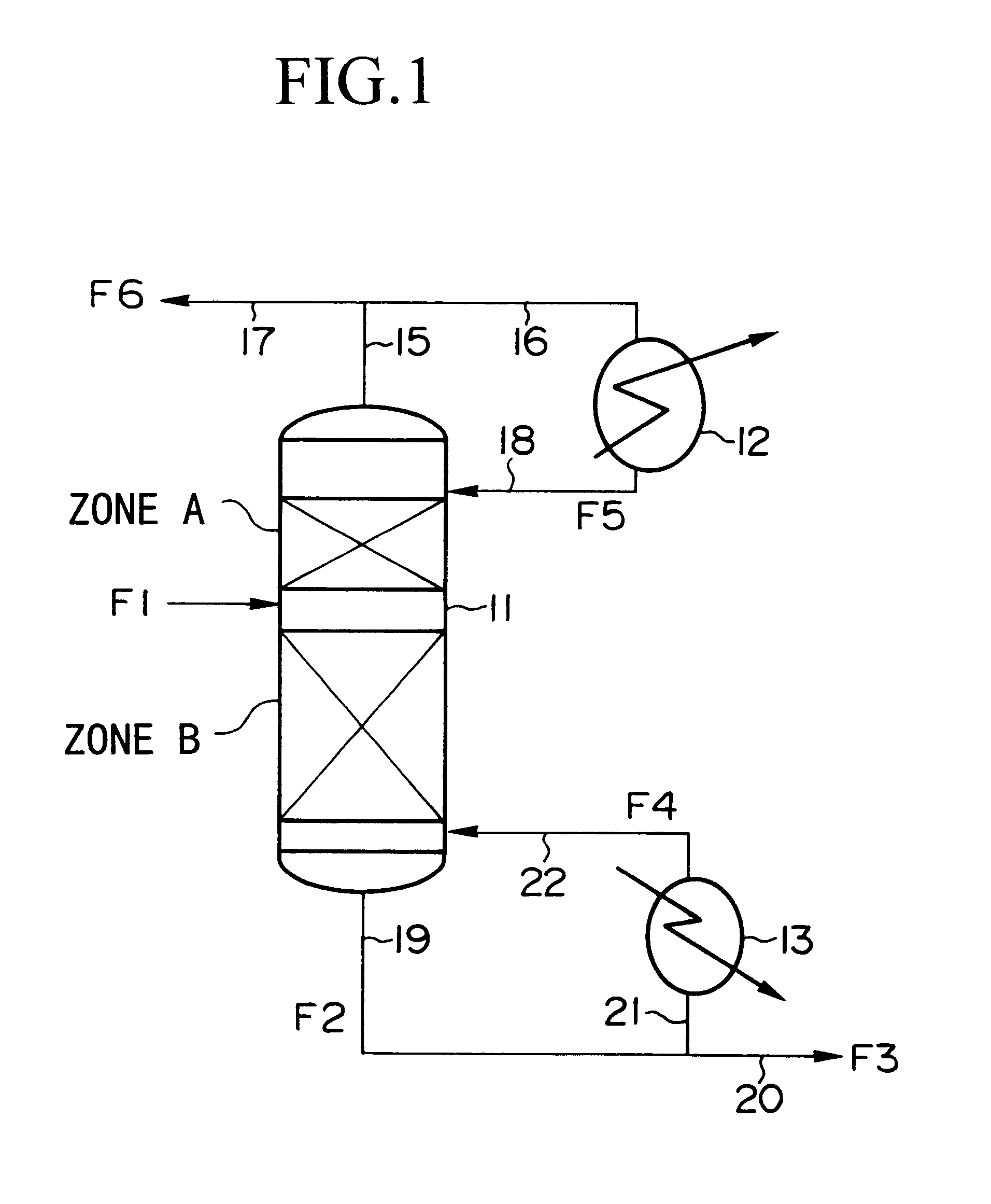

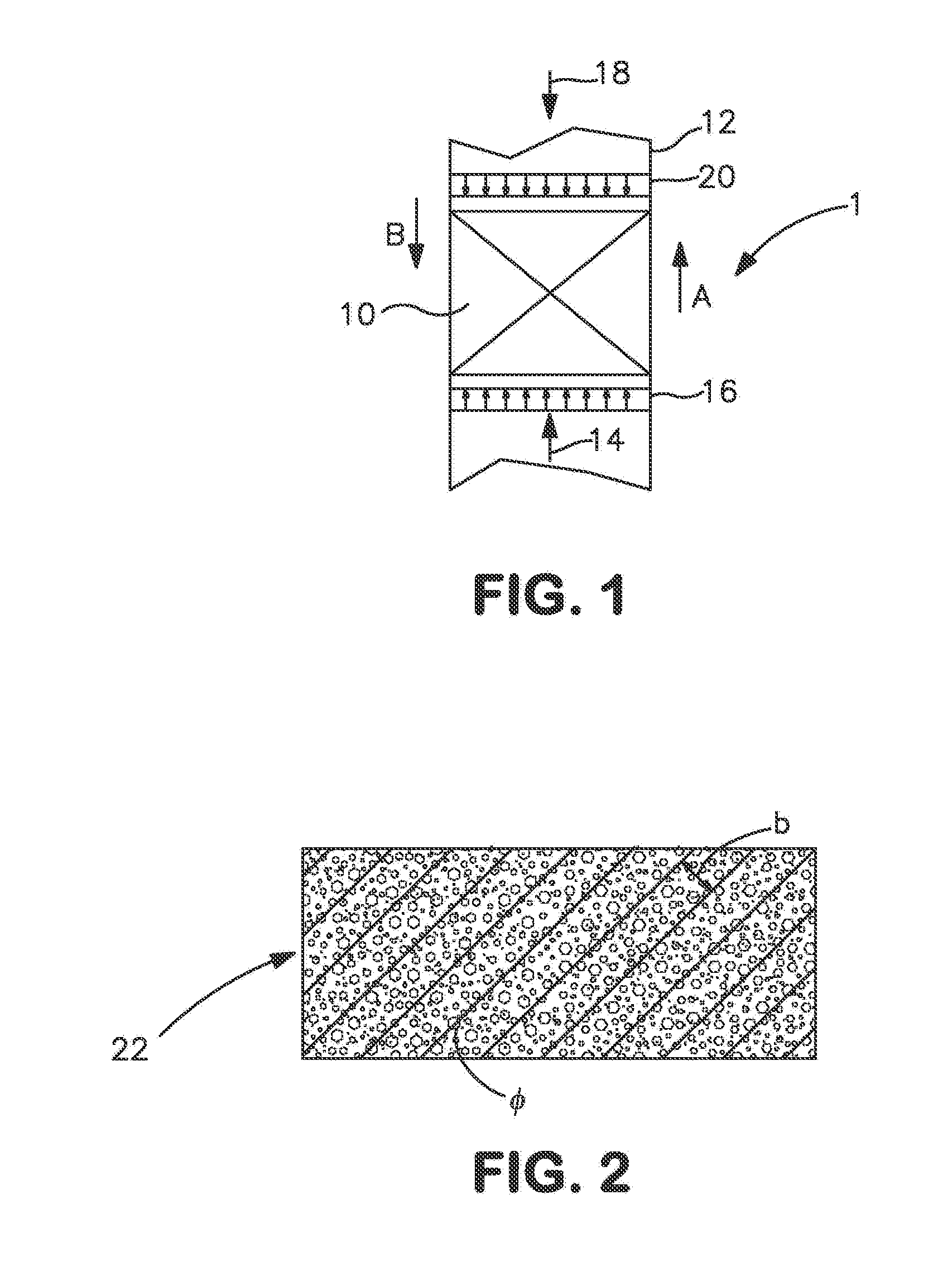

A process for producing organic acid esters using continuous countercurrent reactive distillation using acid catalysts in a structured packing in a single column (10) is described. In the reactive distillation an organic acid ester is formed by chemical reaction and can be purified to its final state within the single column. Organic acid esters are produced at relatively low cost, with less waste production, and in a less complicated manner than prior processes. Organic acid ester have uses as solvents, as intermediate chemicals, and in consumer products.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

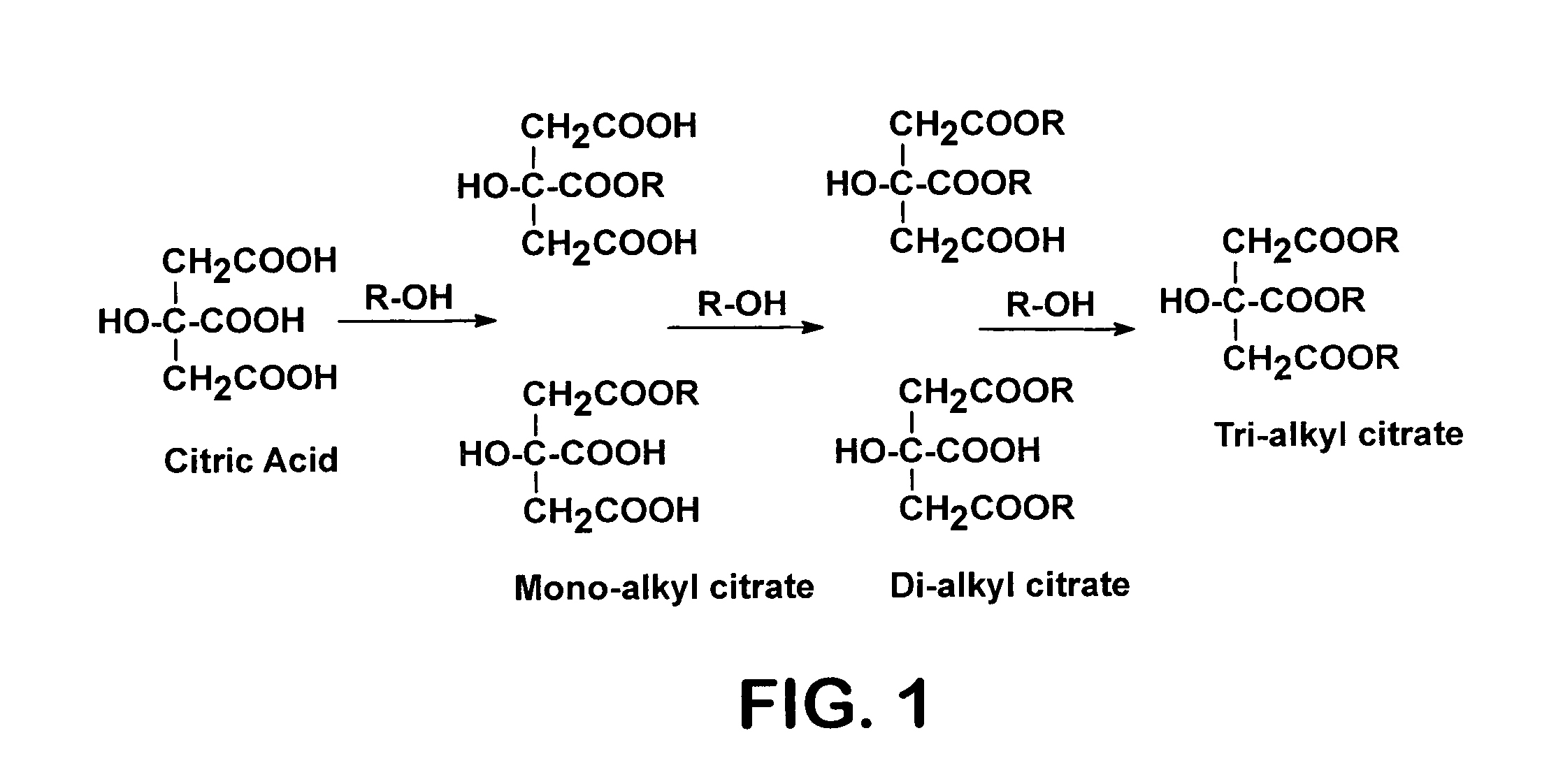

Process for reactive esterification distillation

ActiveUS20060252956A1Preparation by ester-hydroxy reactionOrganic compound preparationOrganic acidChemical reaction

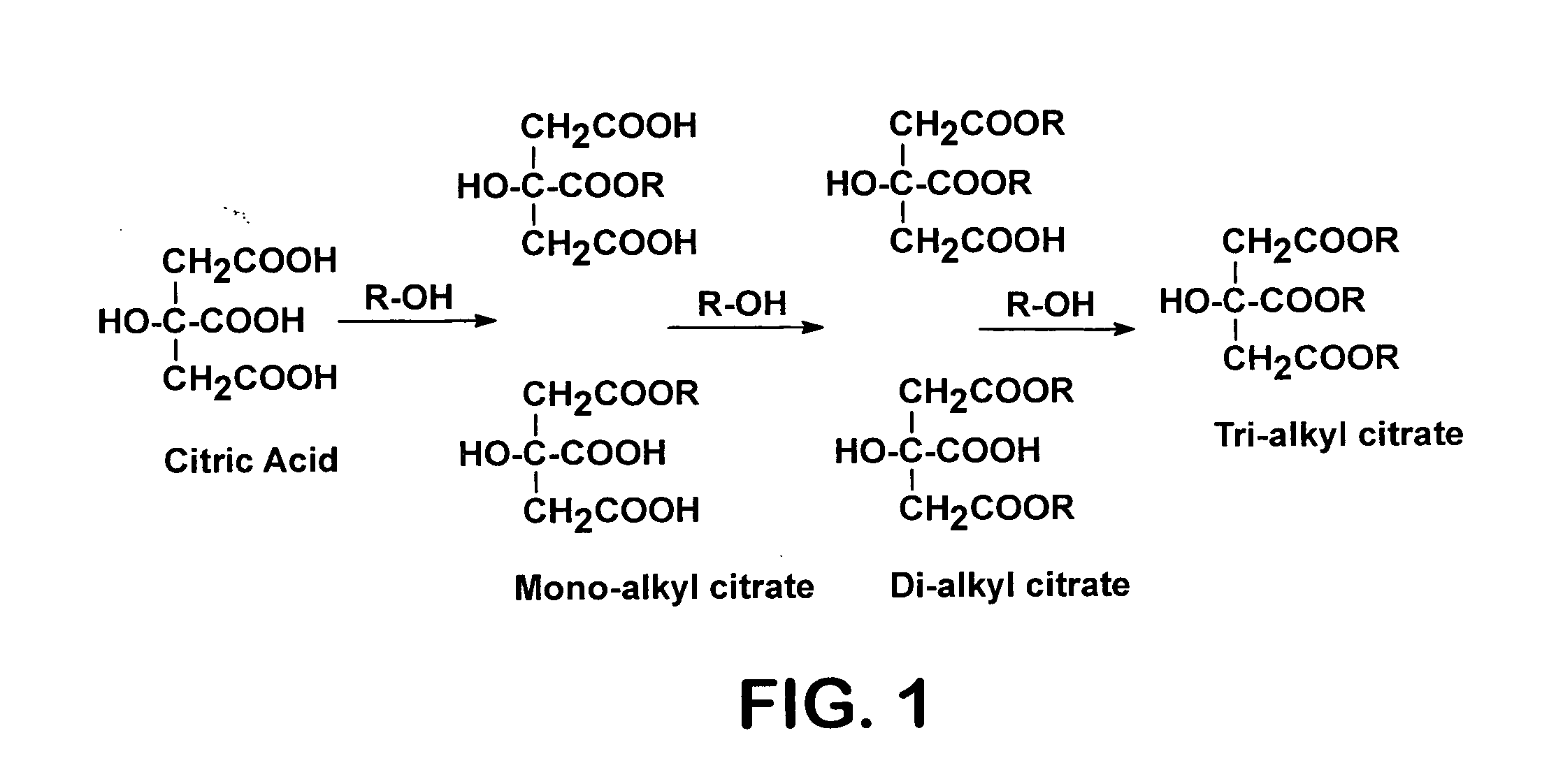

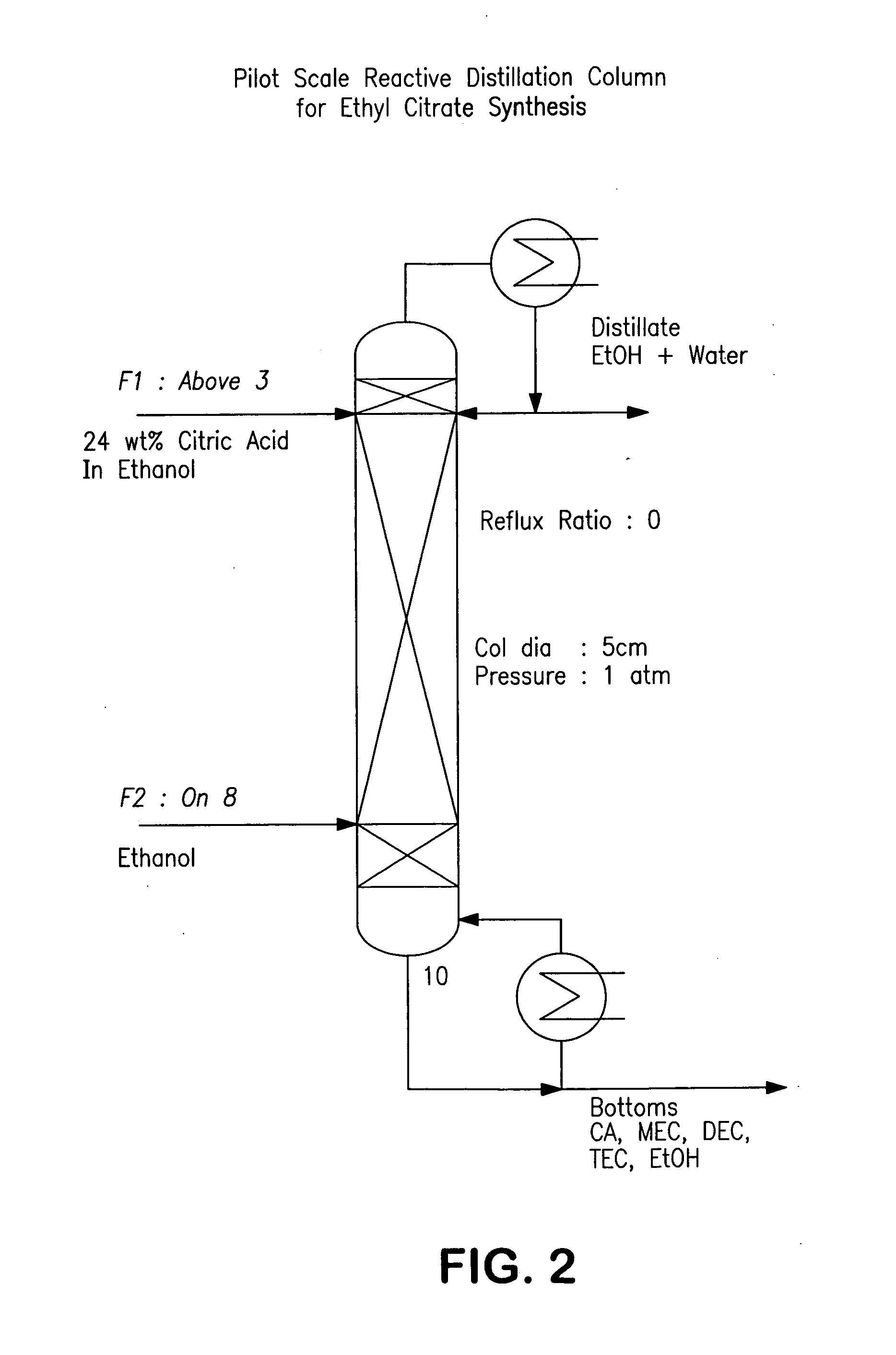

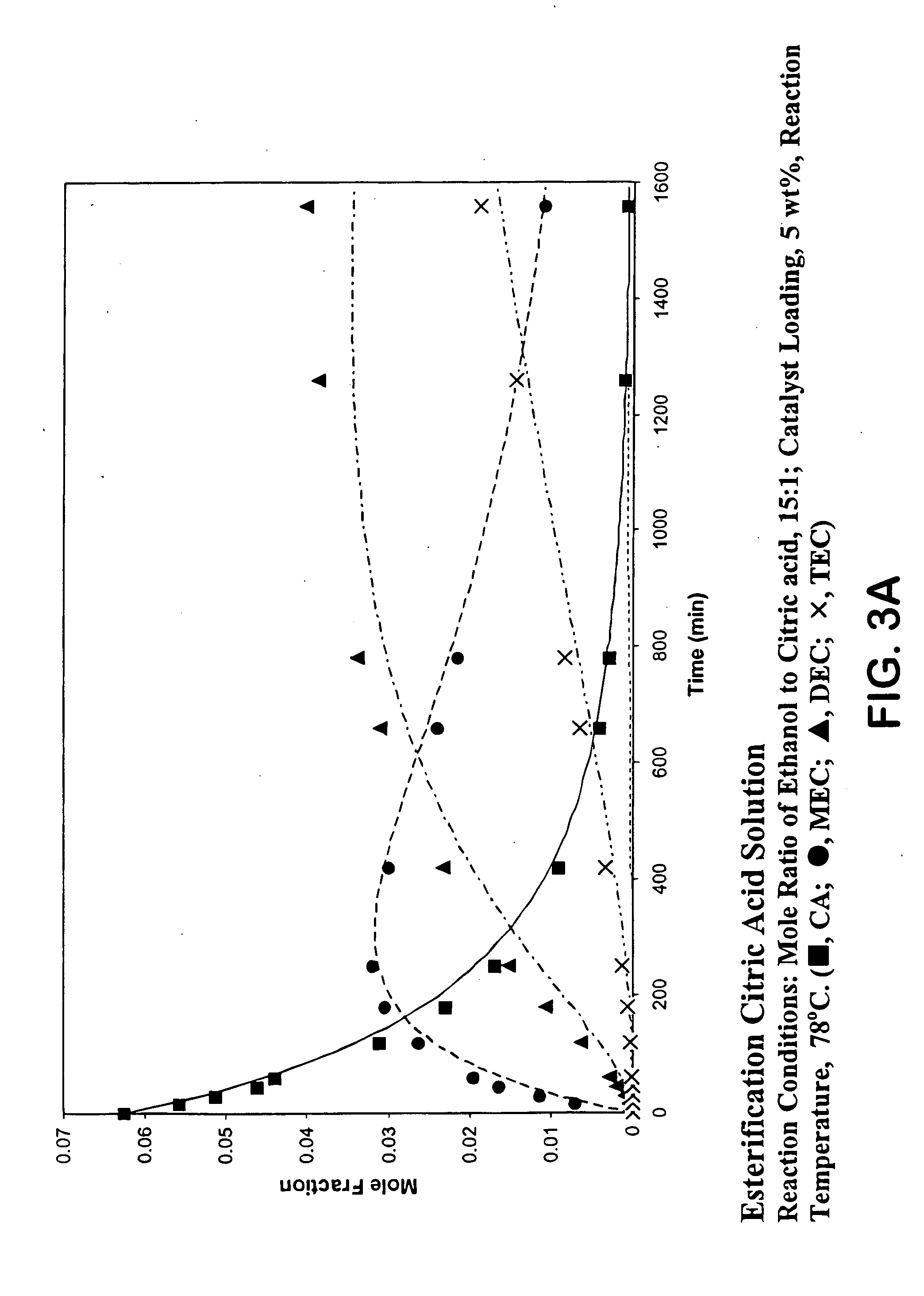

A process for producing organic acid di- or tri-esters, particularly citric acid tri-esters, with the available acid groups esterified using countercurrent reactive distillation using acid catalysts in a structured packing is described. In the reactive distillation an organic acid di- or tri-ester is formed by chemical reaction and purified to its final state within the single column. Organic acid di- or tri-esters are produced at relatively low cost, with less waste production in by-products of the reaction, and in a less complicated manner than prior processes. Organic acid di- and tri-esters have uses as solvents, as plasticizers and in conversion products.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Process for production of organic acid esters

InactiveUS7652167B2Speed up the processPreparation by ester-hydroxy reactionOrganic compound preparationOrganic acidChemical reaction

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

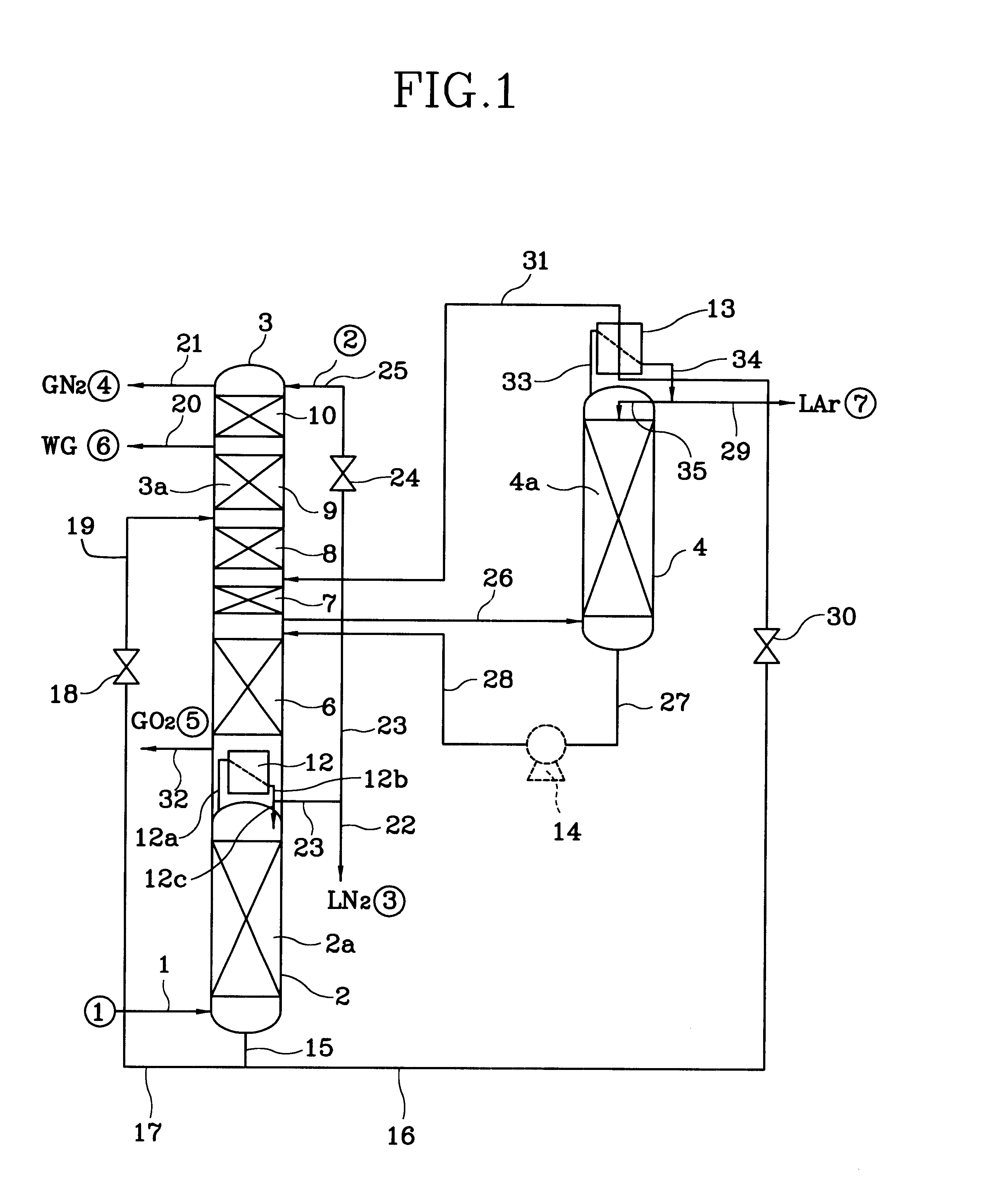

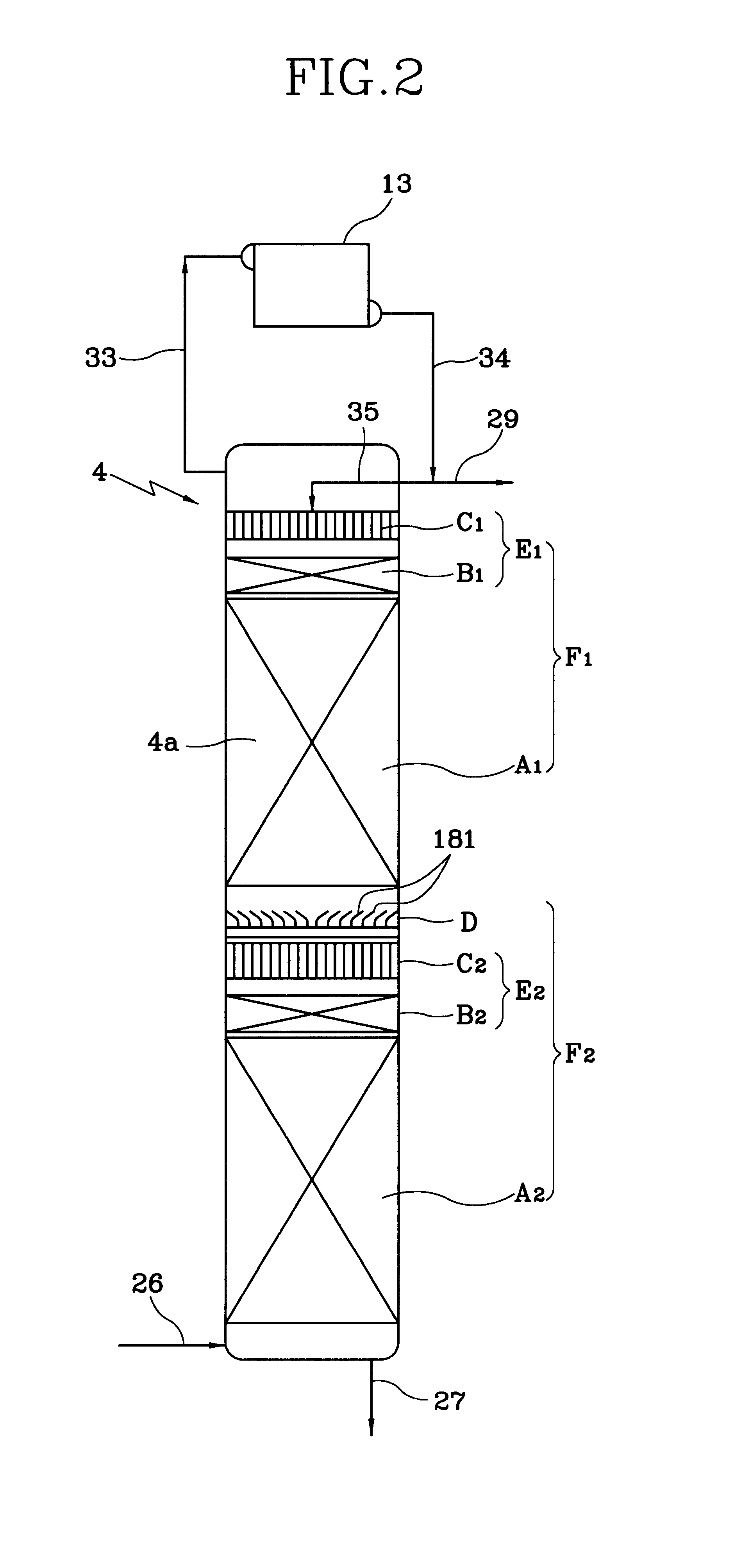

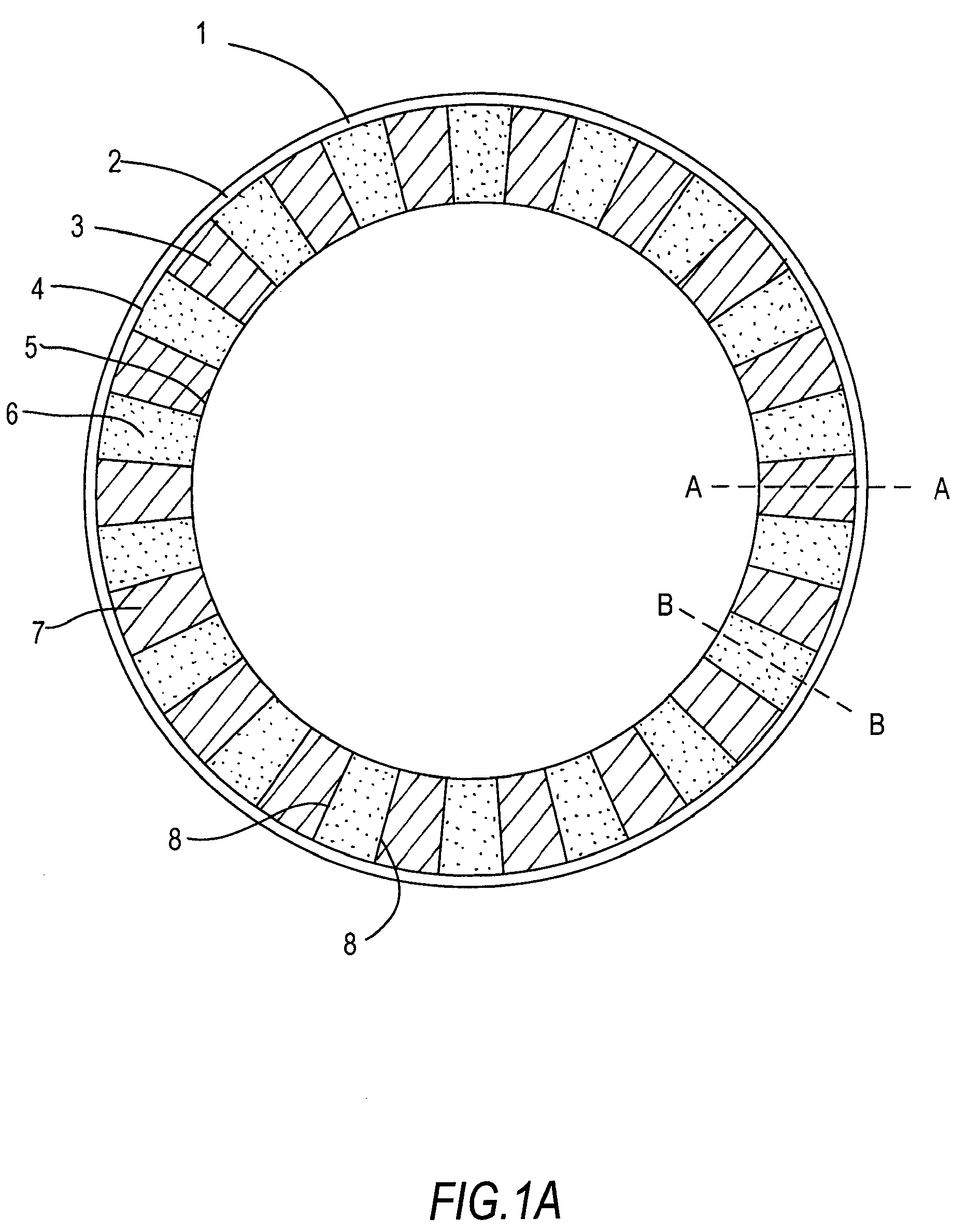

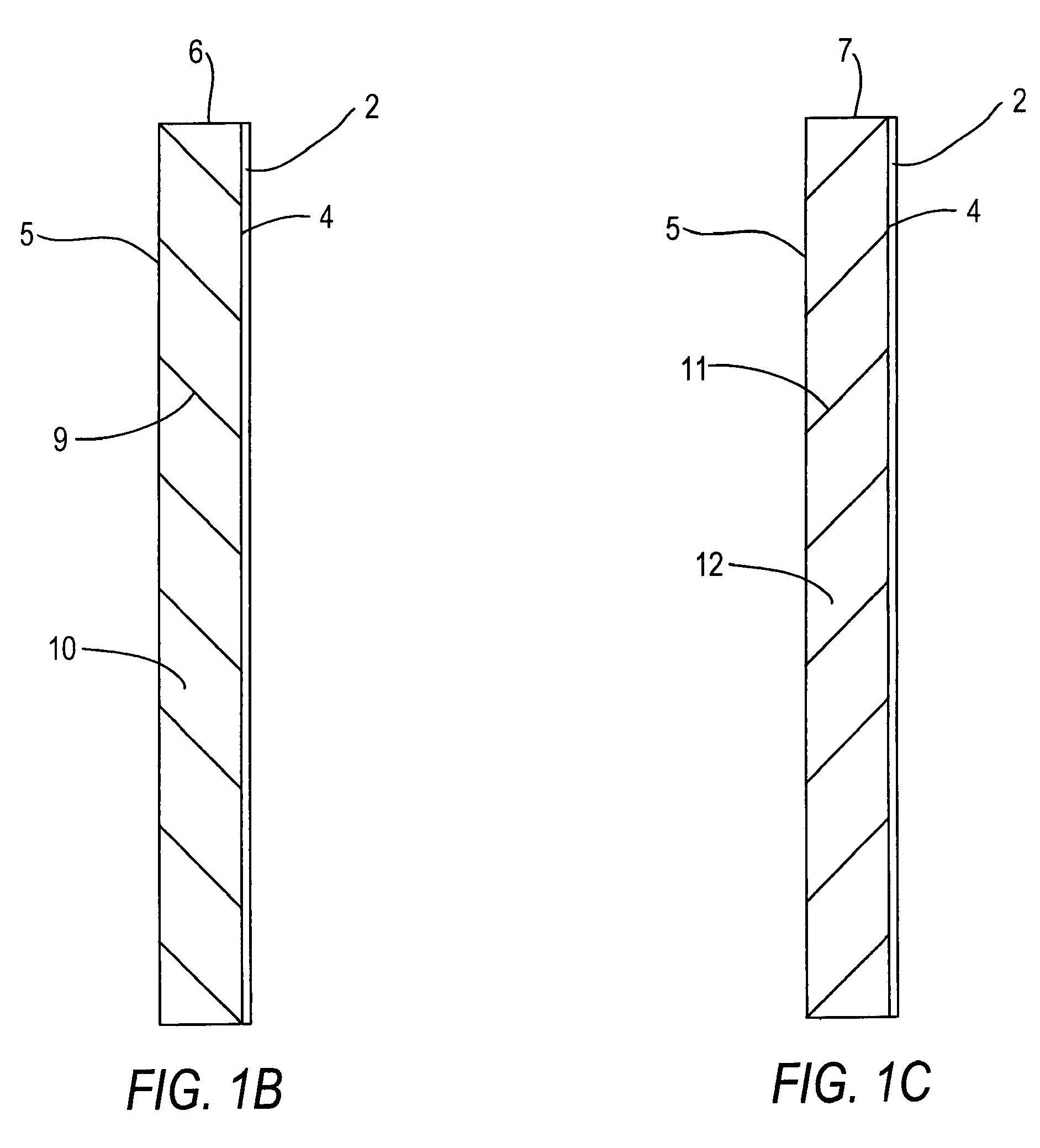

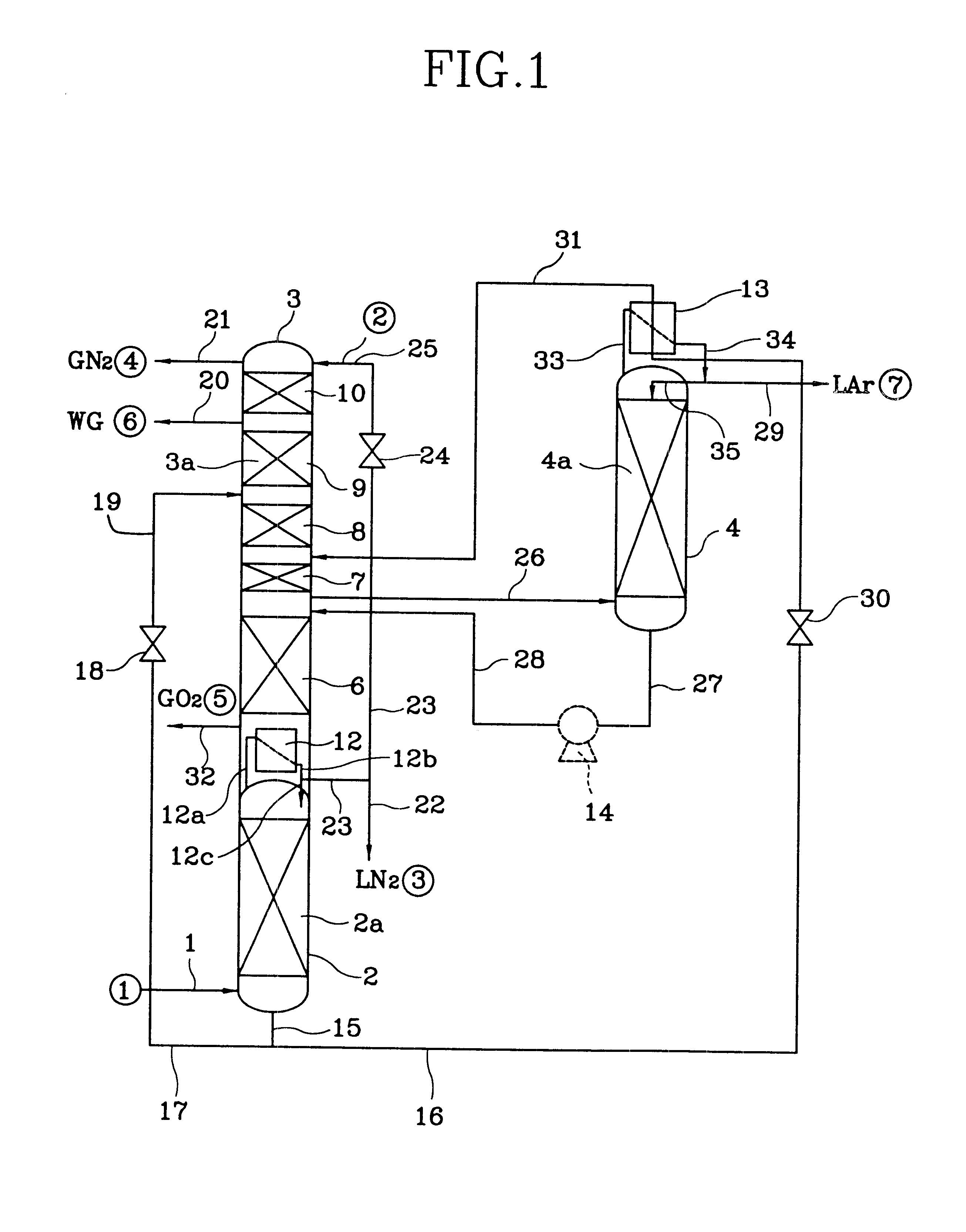

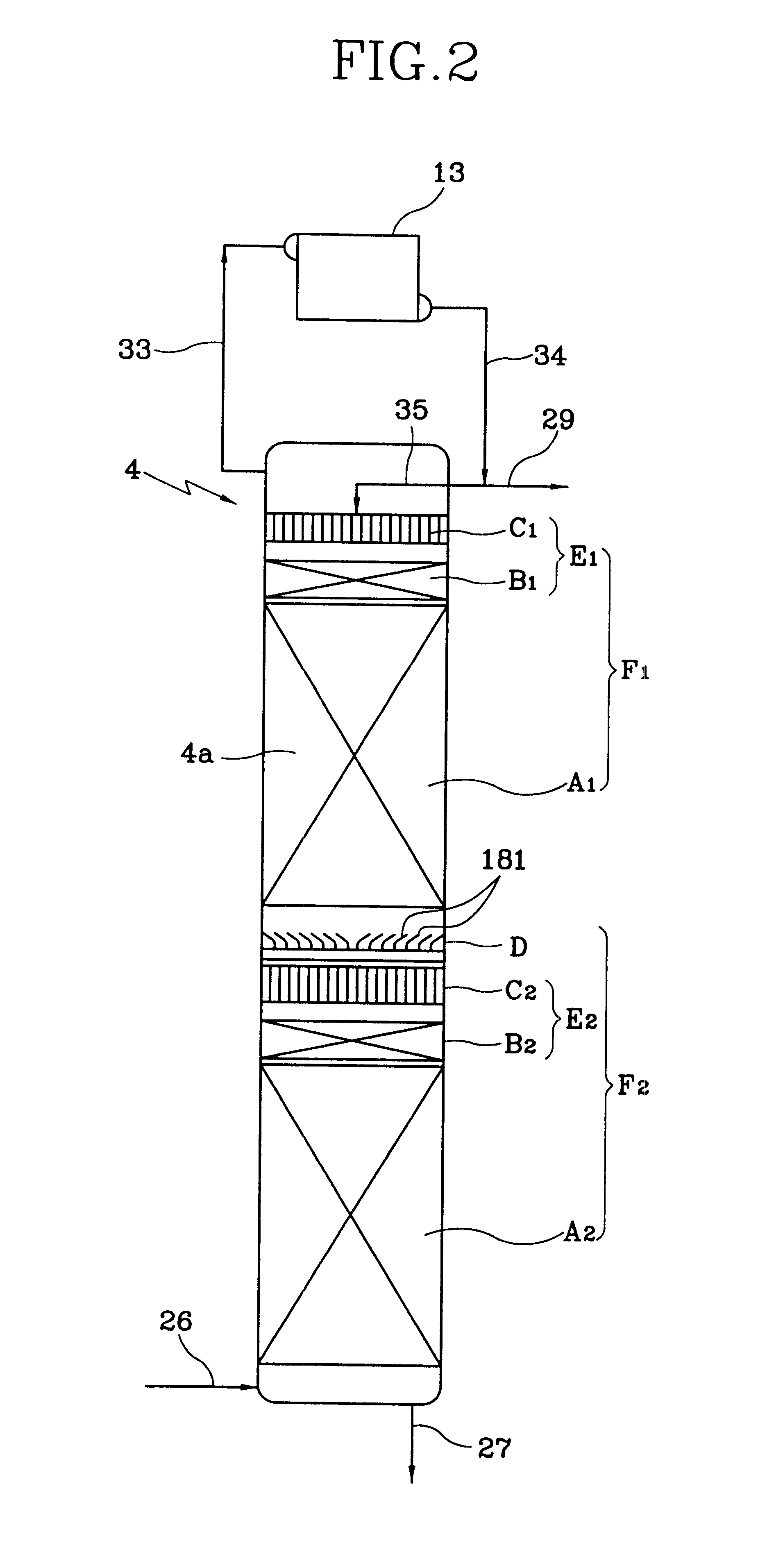

Vapor-liquid contactor, cryogenic air separation unit and method of gas separation

InactiveUS6565629B1Increased pressure lossIncrease flow resistanceCarburetting airSolidificationAir separationMechanical engineering

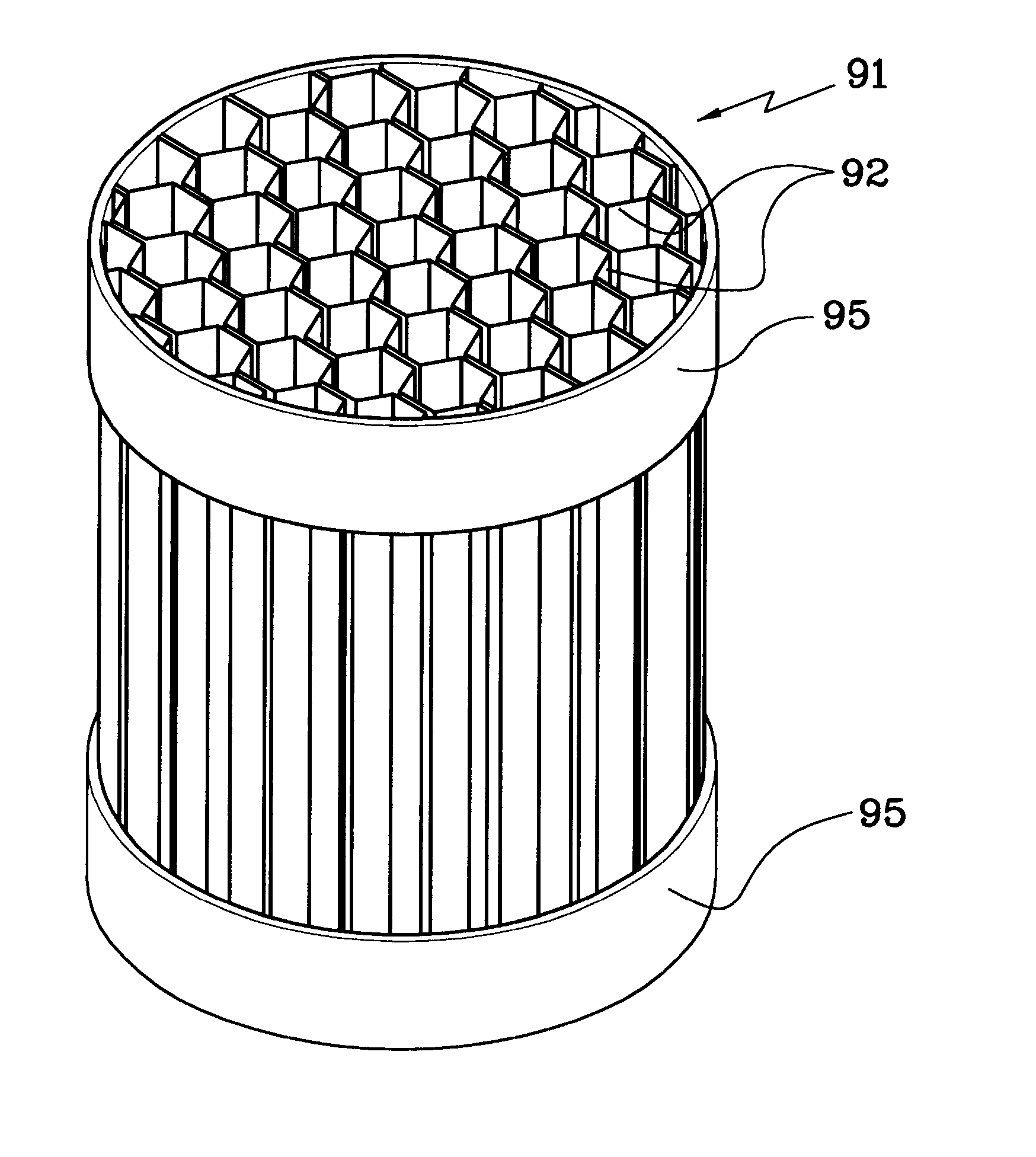

In an vapor-liquid contactor 4a for flowing down a liquid along the surface of a packing and contacting said liquid with the vapor while ascending the vapor, the improvement being characterized in that said packing is a non-promoting-fluid-dispersion type structured packing A1, A2 in which various types of thin sheets or tubes for determining the flow direction of the above liquid or vapor is laminated and arranged in the perpendicular direction, and said contactor includes at least one fluid distribution unit E1, E2 formed of a rough distribution part C1, C2 to distribute the liquid roughly and a minute distribution part B1, B2 to distribute the liquid minutely and equally.

Owner:NIPPON SANSO CORP

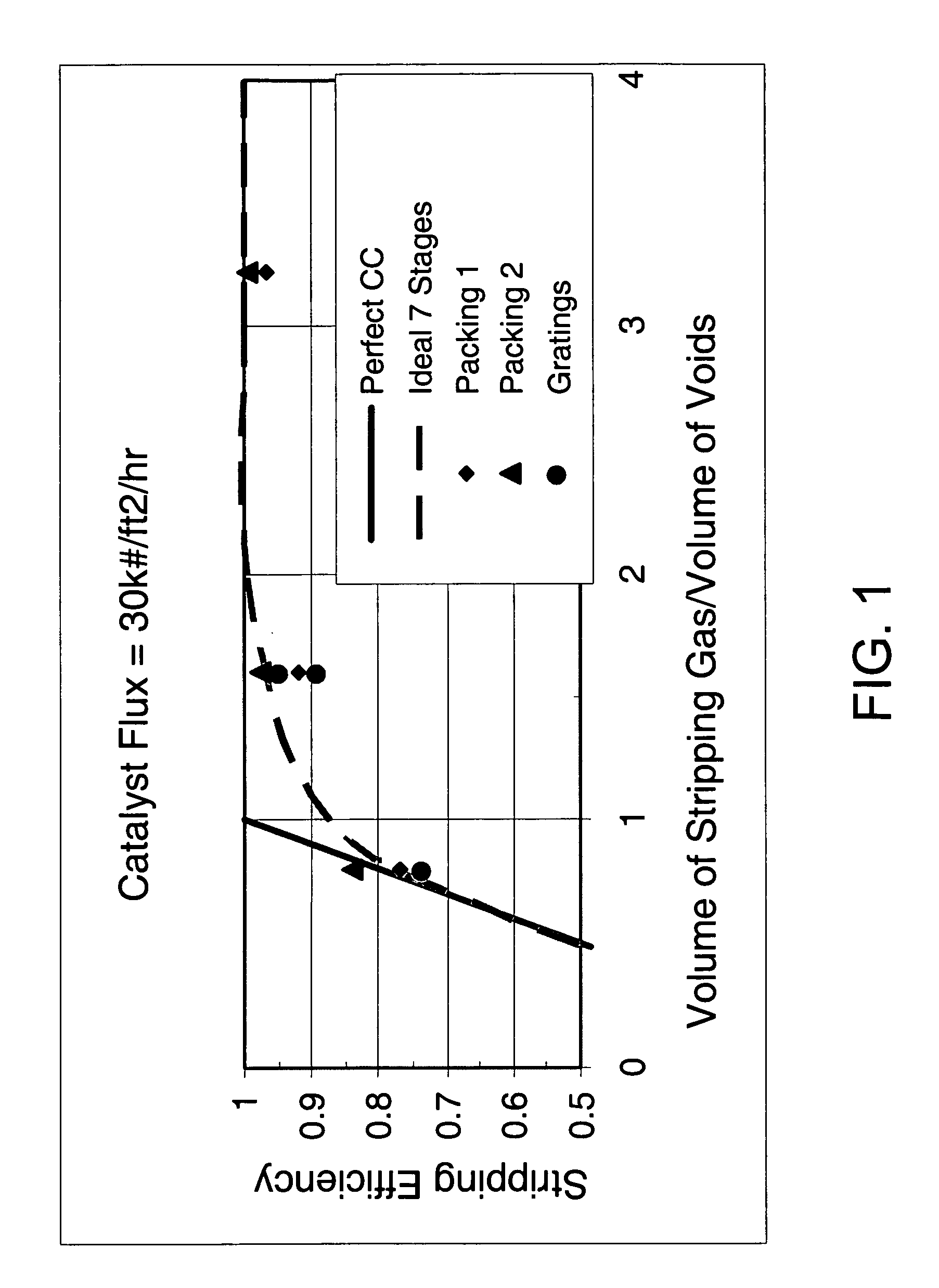

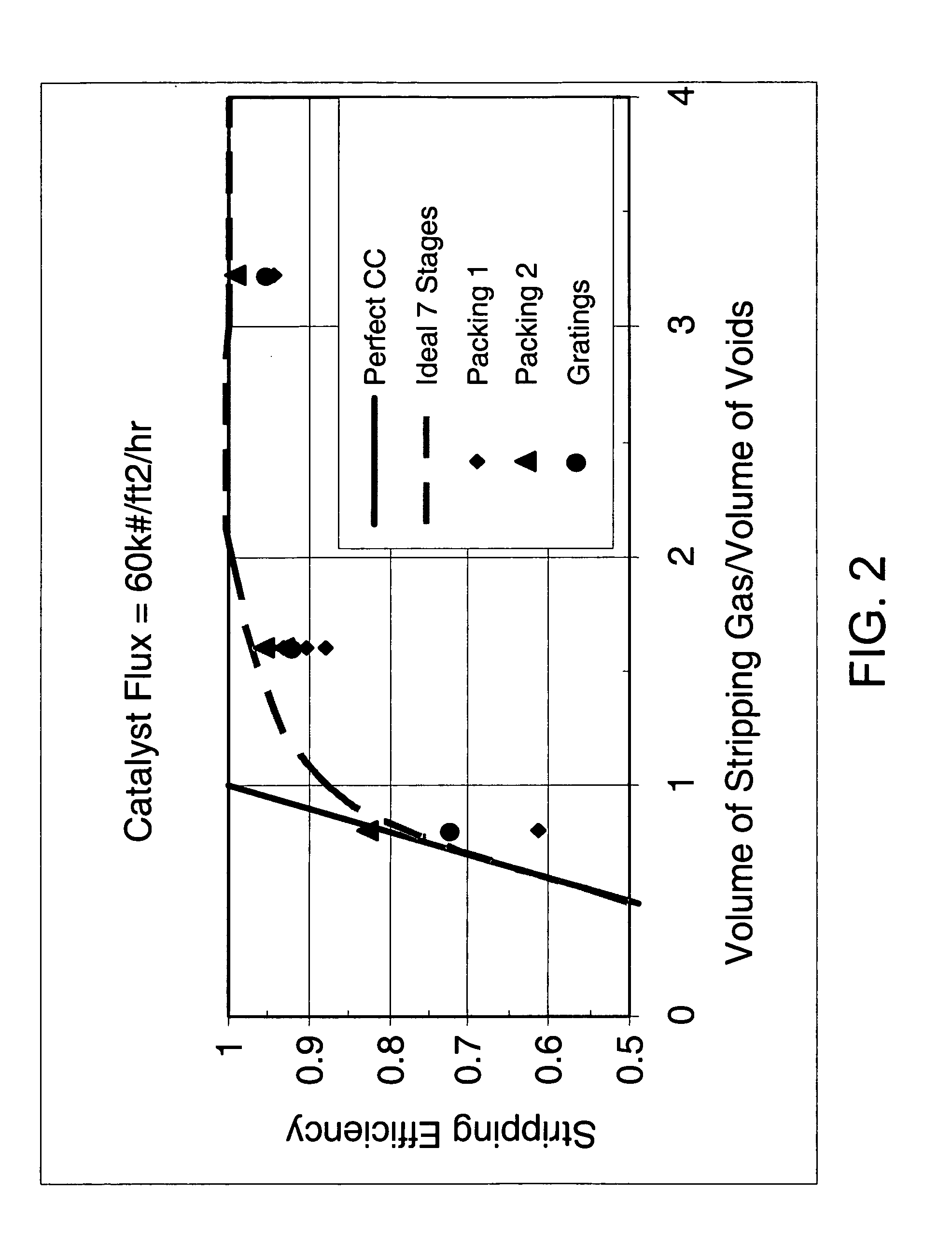

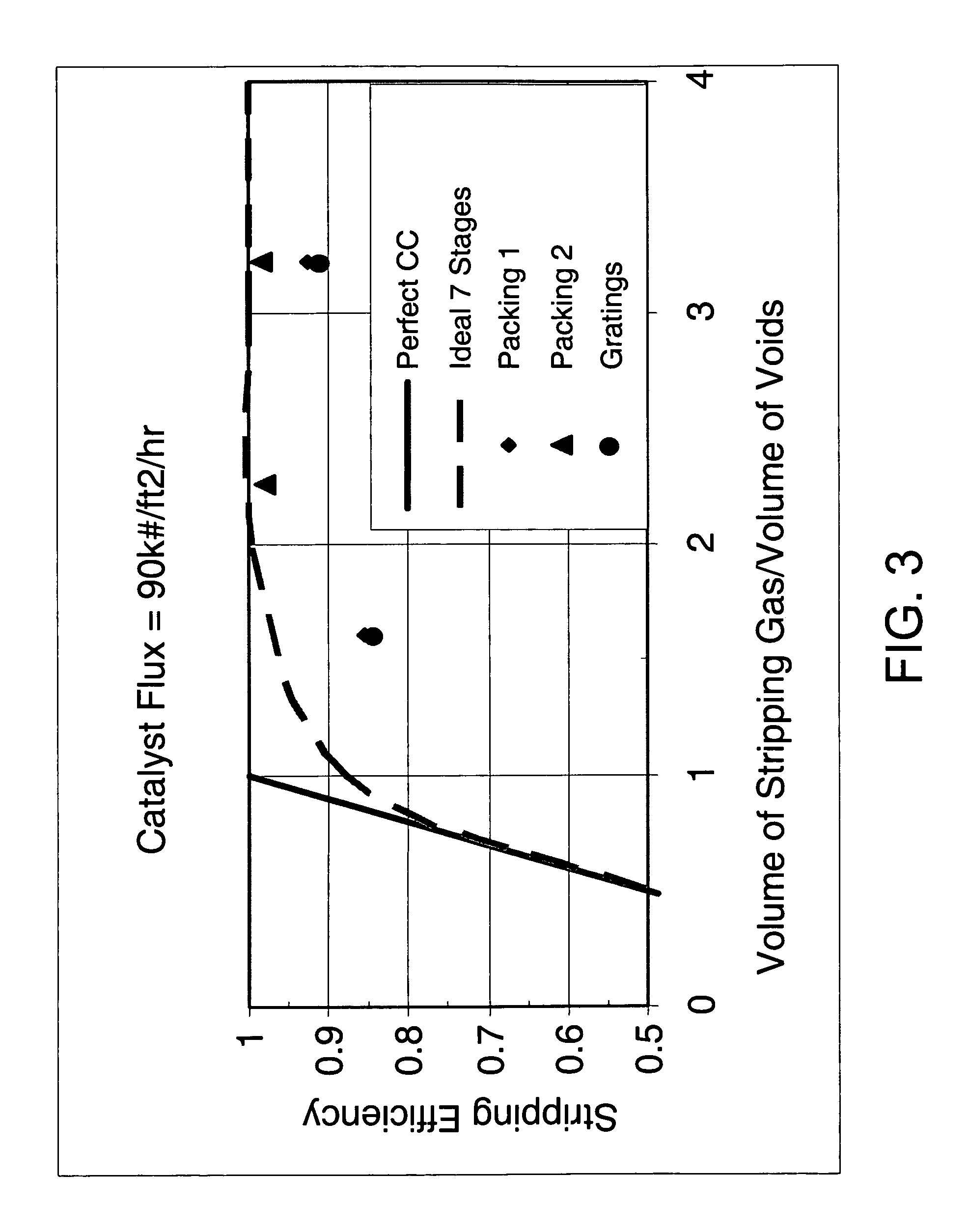

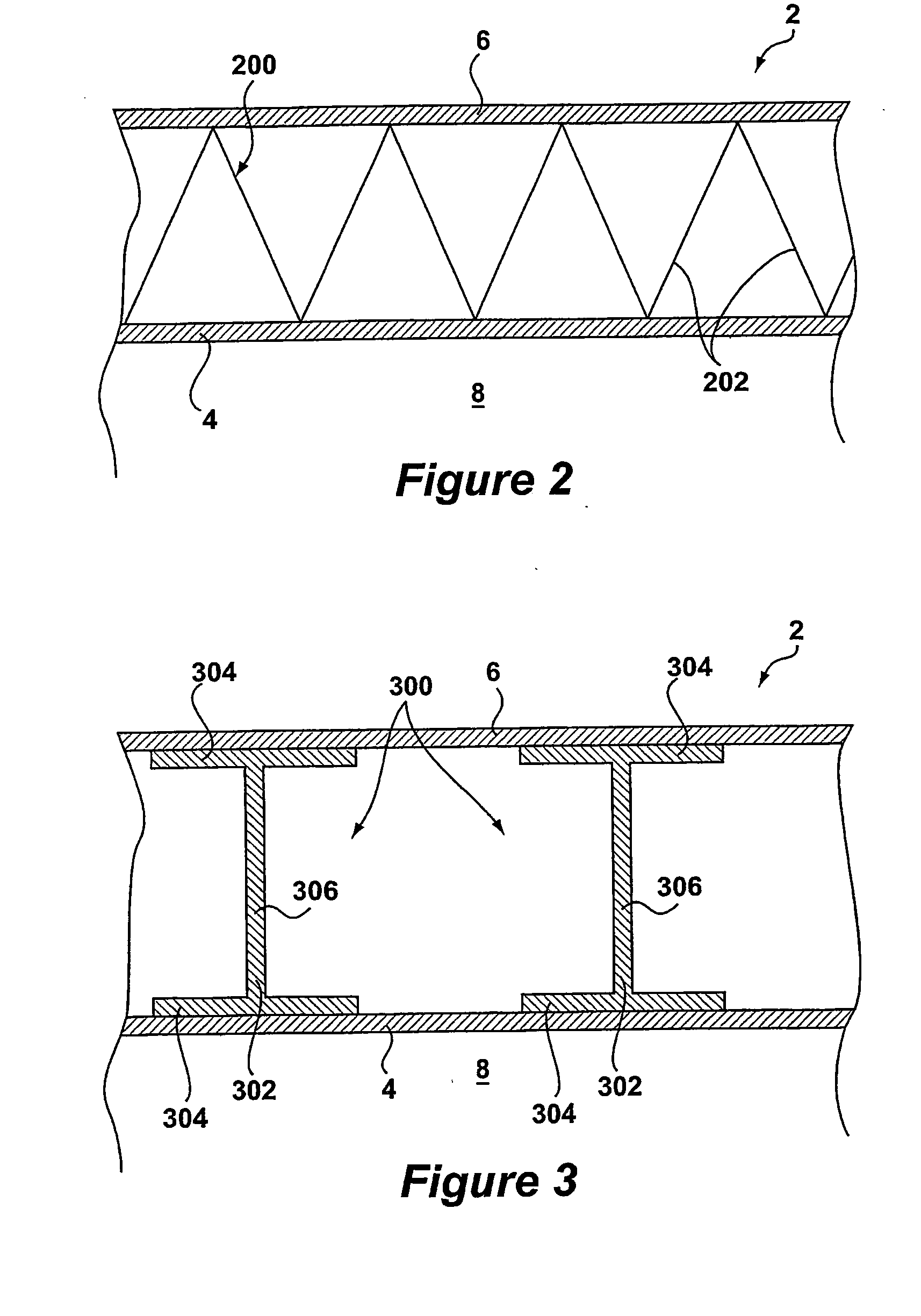

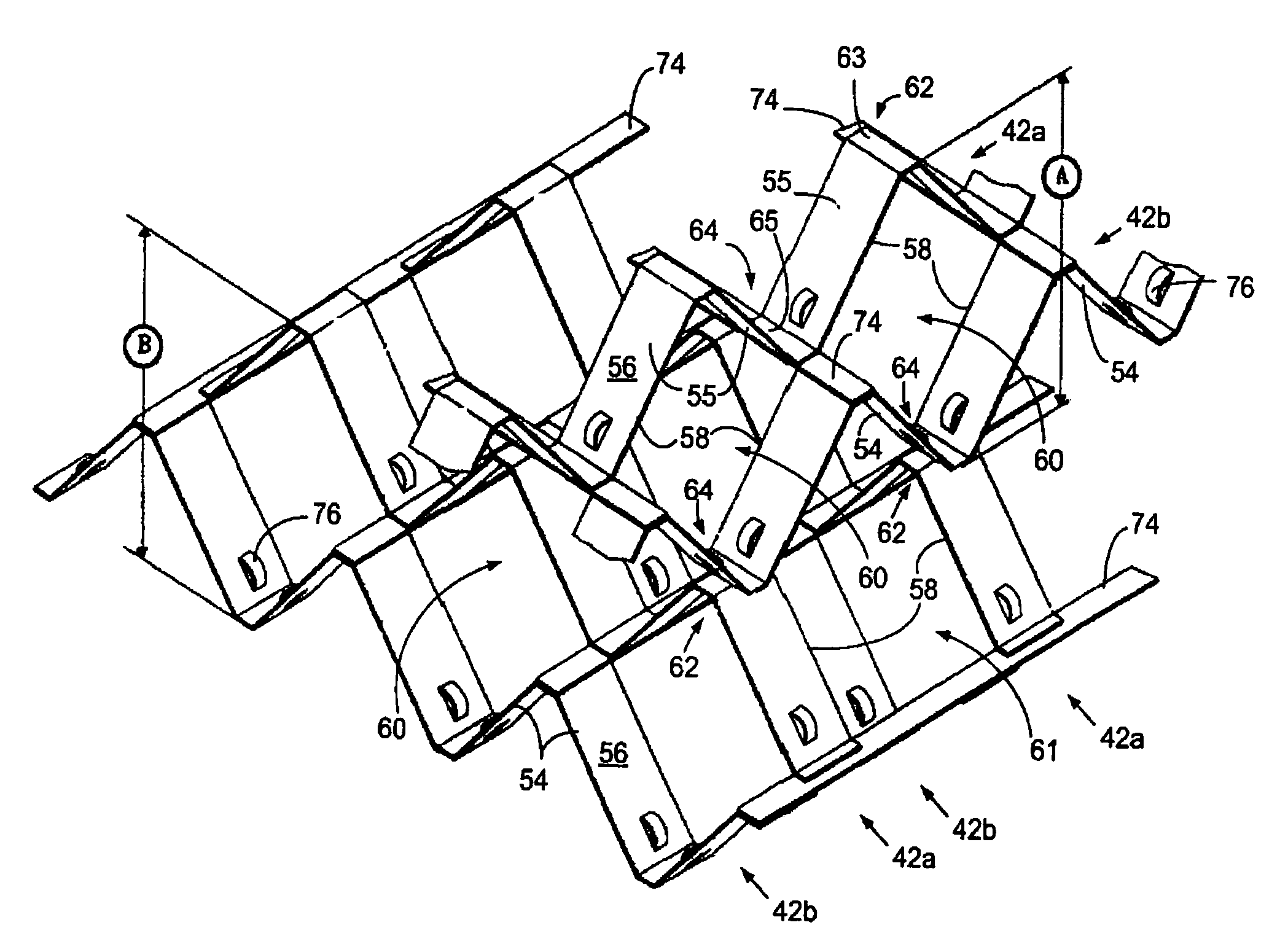

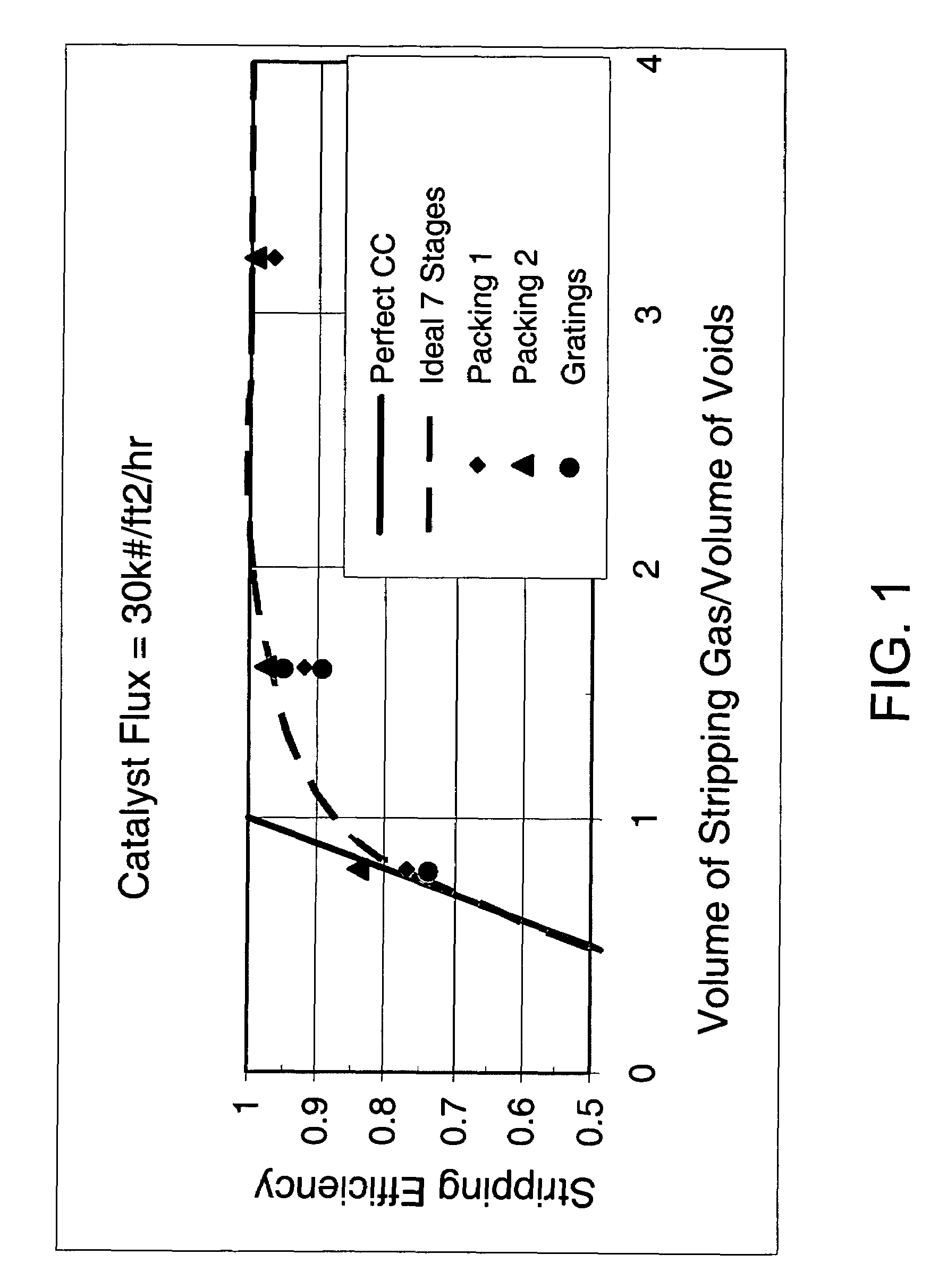

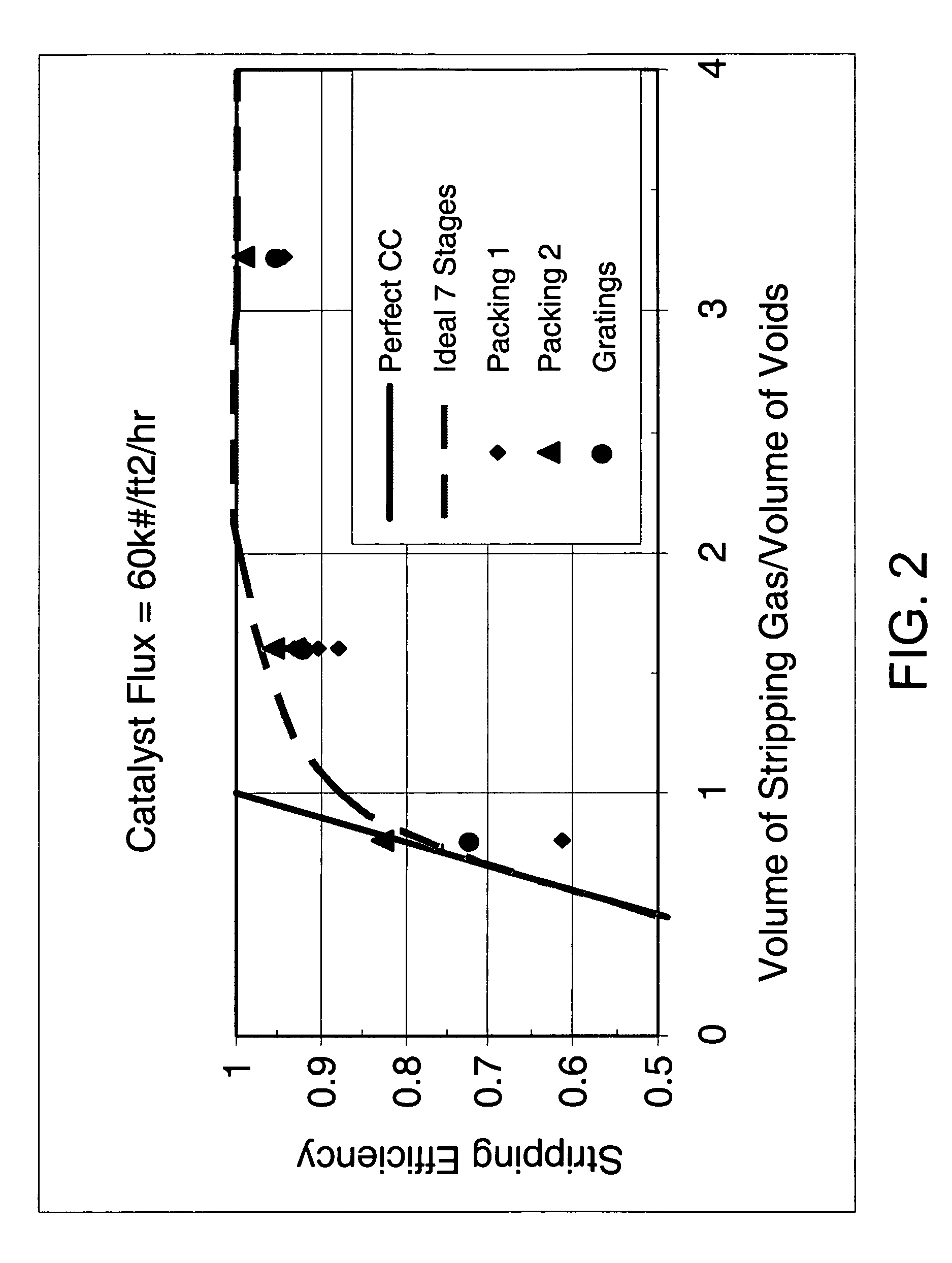

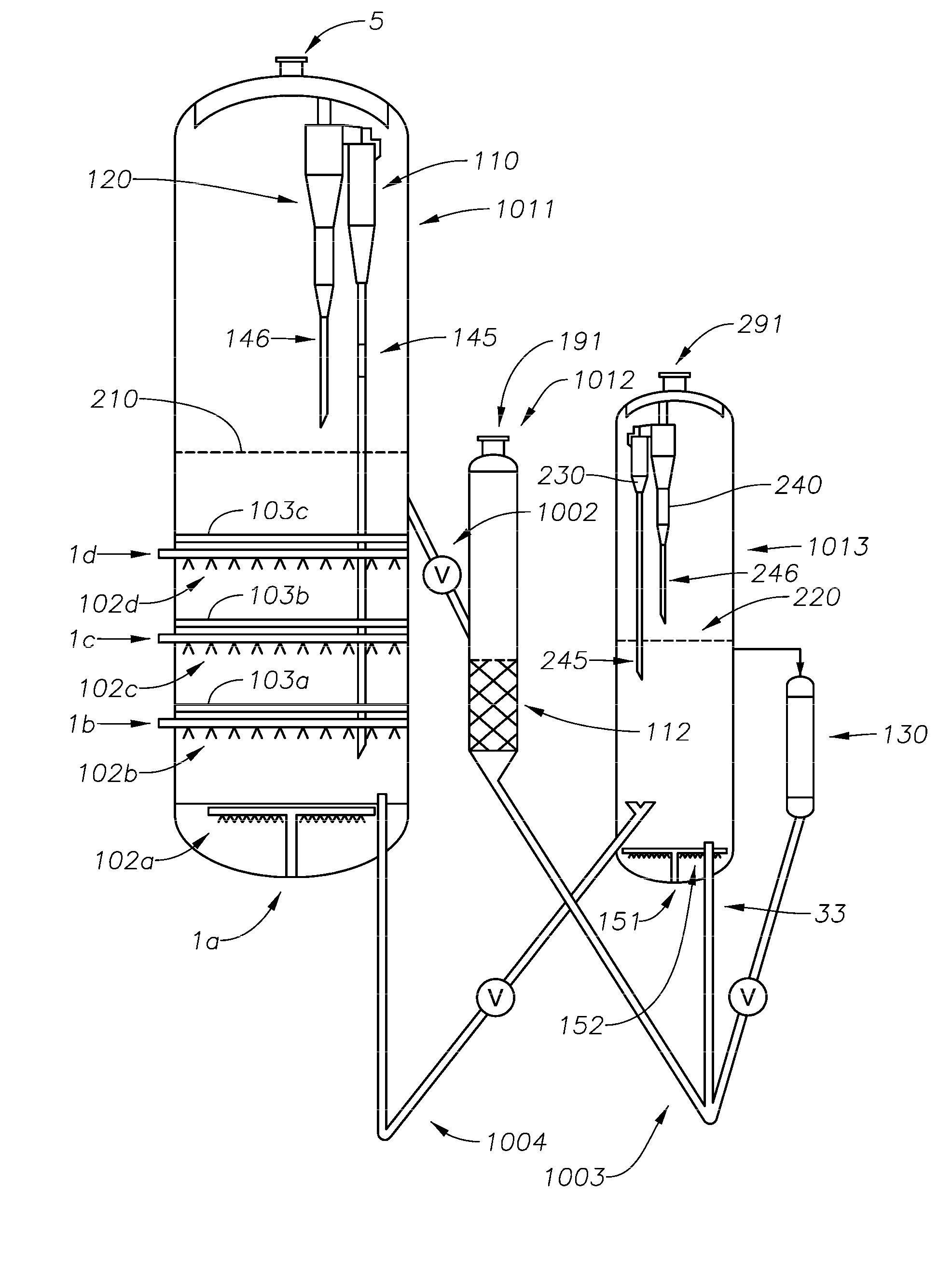

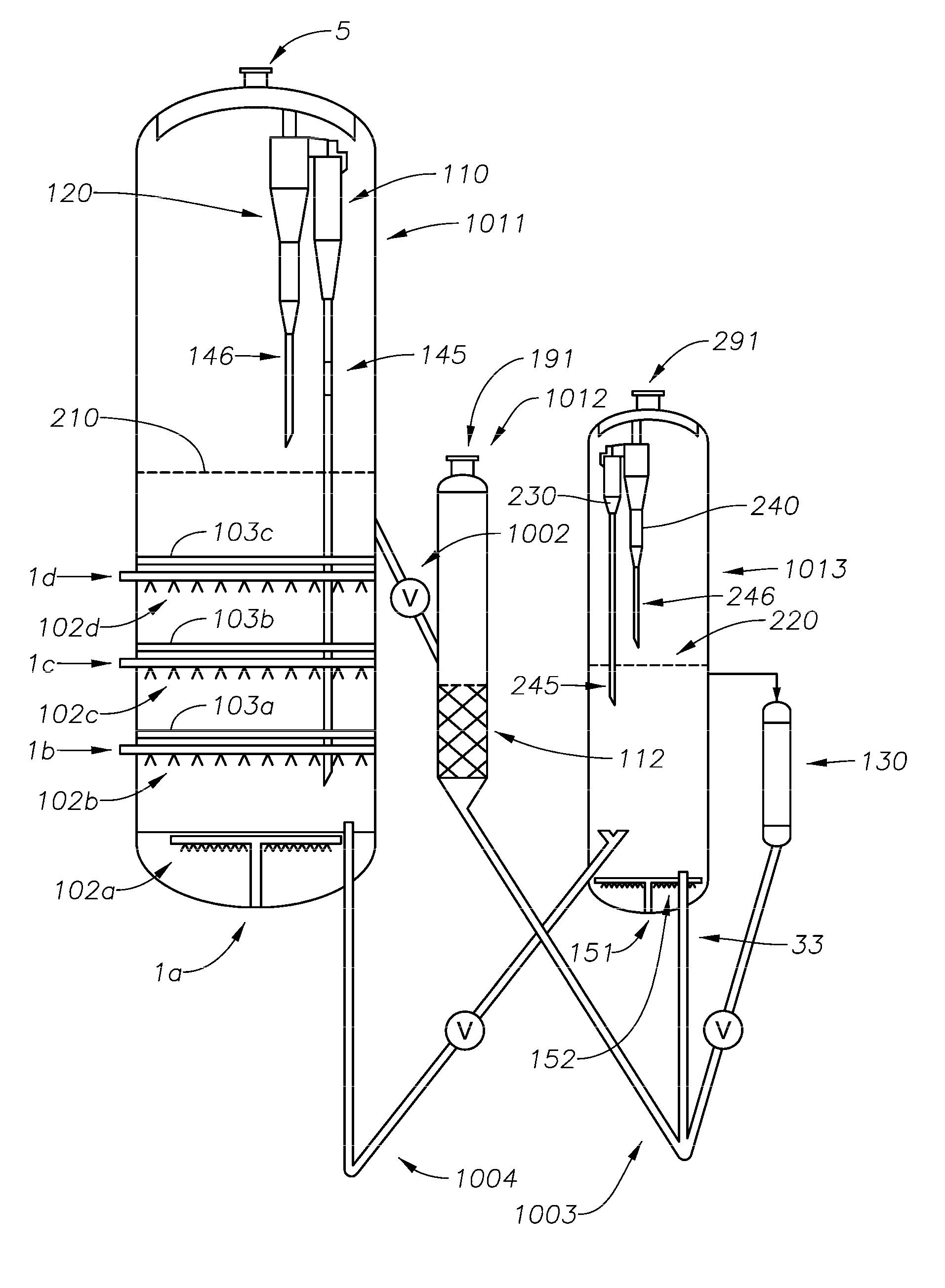

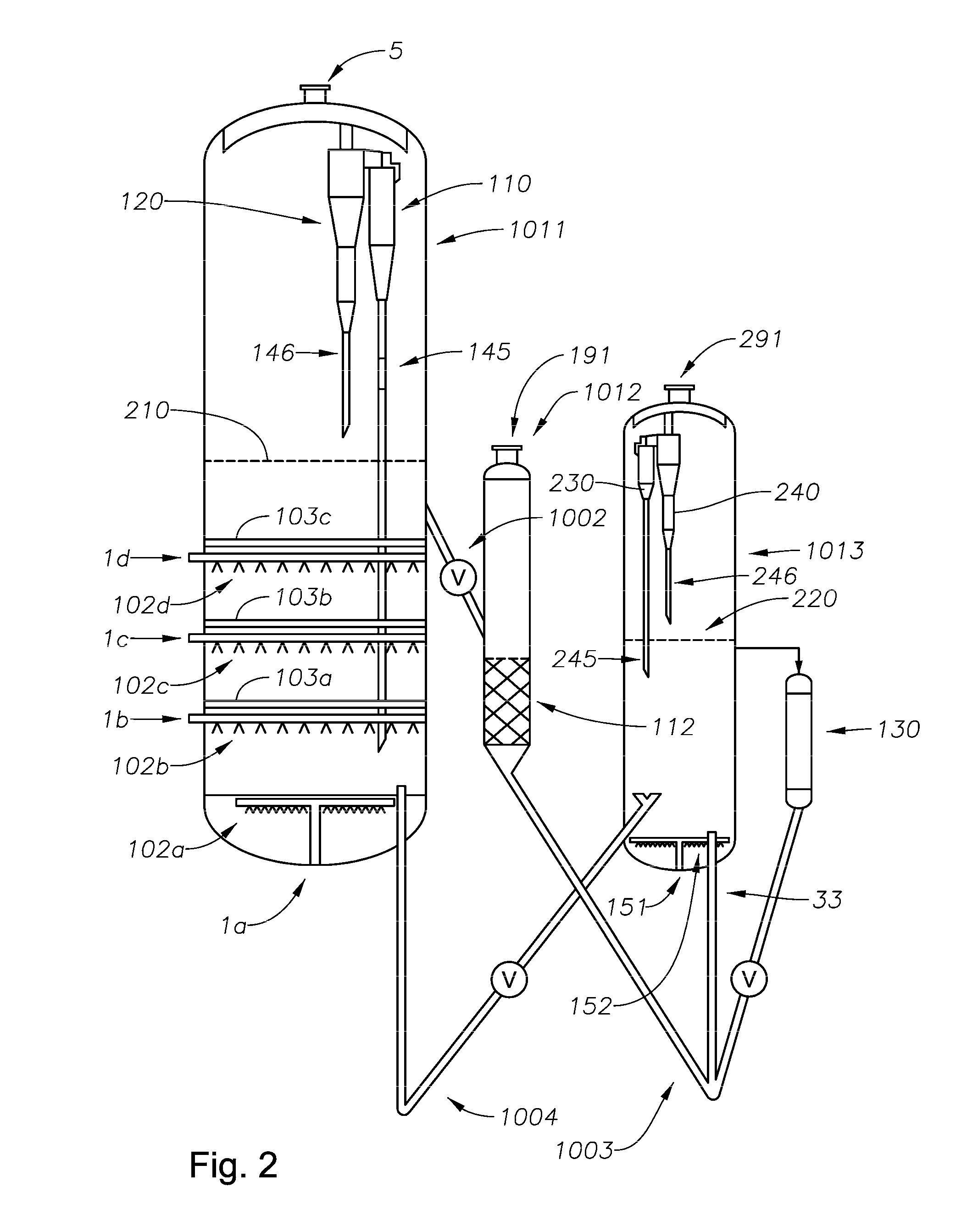

Stripping apparatus and process

ActiveUS20050205467A1Install UnityCatalytic crackingCatalytic naphtha reformingSolid particleMechanical engineering

An apparatus and process for stripping gases from solids comprises a structured packing in a stripping section of a vessel. The structured packing comprises a plurality of corrugated ribbons with each corrugated ribbon having at least two faces angular to each other. The ribbons at least partially obstruct passage of the solid particles. Edges of adjacent ribbons defining openings for the passage of contacted particles.

Owner:UOP LLC

Process for reactive esterification distillation

ActiveUS7667068B2Organic compound preparationPreparation by ester-hydroxy reactionOrganic acidChemical reaction

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

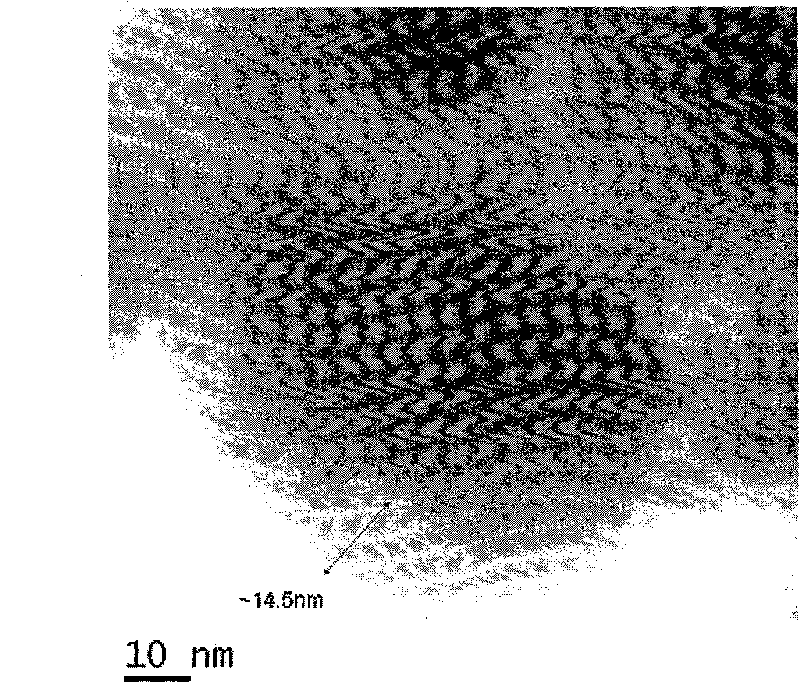

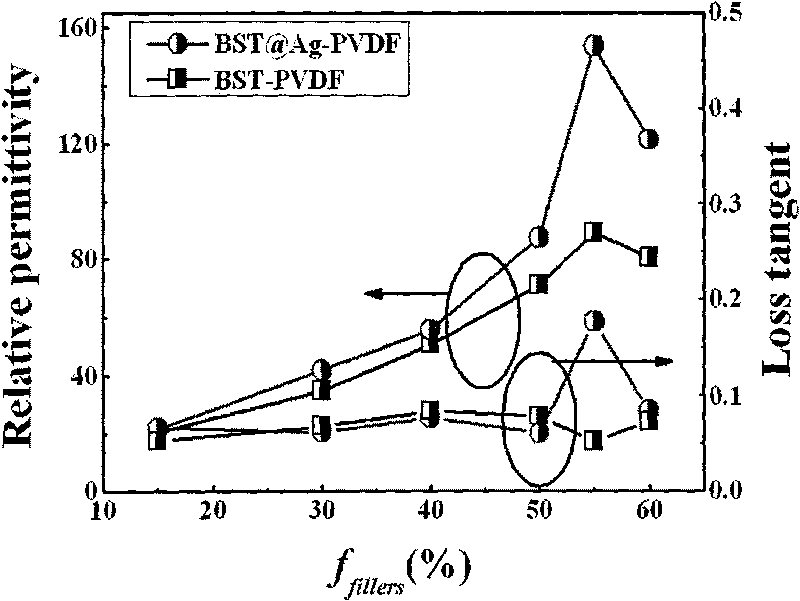

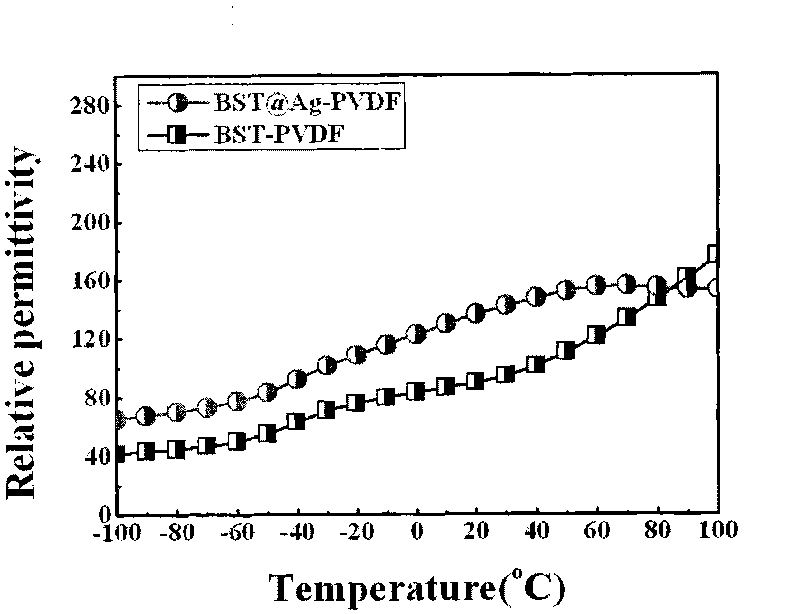

Nuclear shell structured packing/polymer-based composite material and preparation method thereof

InactiveCN101712784AHigh dielectric constantExcellent dielectric propertiesPigment physical treatmentPigment treatment with non-polymer organic compoundsDielectric lossThermal treatment

The invention relates to a nuclear shell structured packing / polymer-based composite material and a preparation method thereof. The nuclear shell structured packing / polymer-based composite material comprises a nuclear shell structured packing and a polymer formed by coating ceramic particles with metal, wherein the nuclear shell structured packing is coated by the polymer completely. The nuclear shell structured packing / polymer based composite material prepared by the method has the advantages of high dielectric constant, low dielectric loss, excellent dielectric property and temperature stability and the like, and the preparation method has the characteristics of simple operation, low thermal treatment temperature, low cost, suitability for industrial production, environmental protection and the like.

Owner:XI AN JIAOTONG UNIV

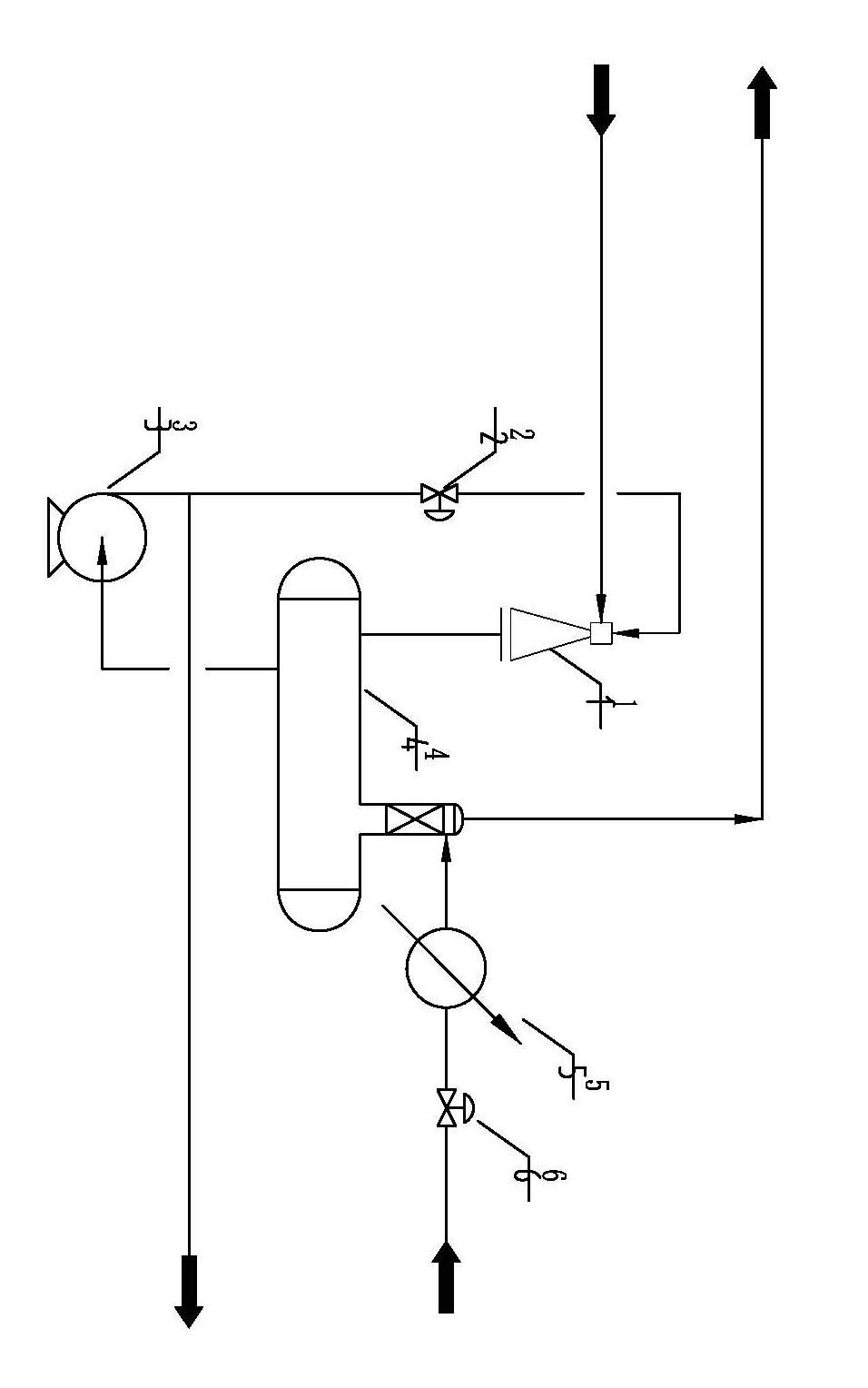

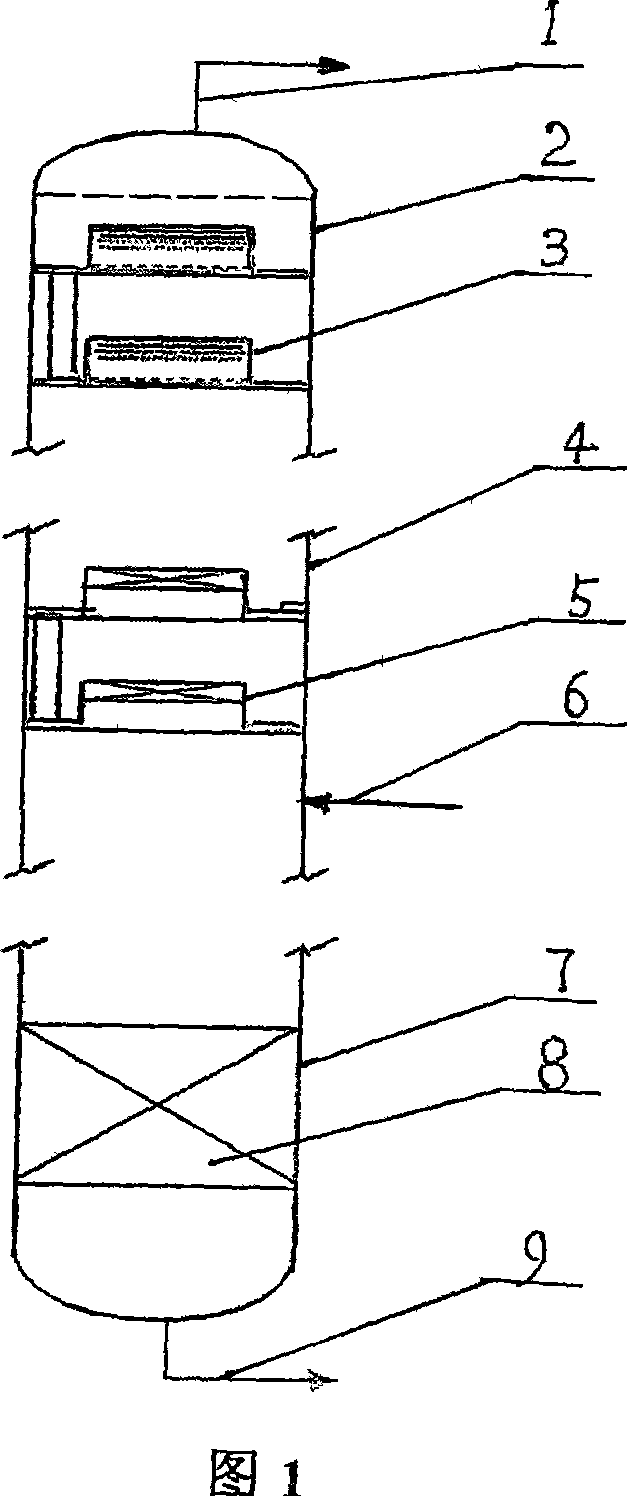

Pressure reduction gas desulfurization method

The invention relates to a pressure reduction gas desulfurization method which belongs to the technical field of chemical technology. The pressure reduction gas desulfurization method comprises the following steps of: firstly, performing injection desulfurization with an absorbent; secondly, performing absorption desulfurization with an absorbent in a recycling tank; and then performing absorption again with absorbing structured packing after absorption desulfurization. In the specific operations of the vacuum gas desulfurization method, the absorbent is recycled through a circulation line; a circulating pump and the recycling tank are connected to the circulation line; an injector is connected to an upstream circulation line of the recycling tank; sulfur-contained gas is connected to the injector; and the top of the recycling tank is provided with a clean gas outlet. The pressure reduction gas desulfurization method has the advantages of simple process, convenience of operation, low construction investment and low failure rate. Moreover, the content of hydrogen sulfide after gas desulfurization can be reduced to be less than 500ppm, thus the desulfurization and purification effects are good and the desulfurization efficiency is high.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

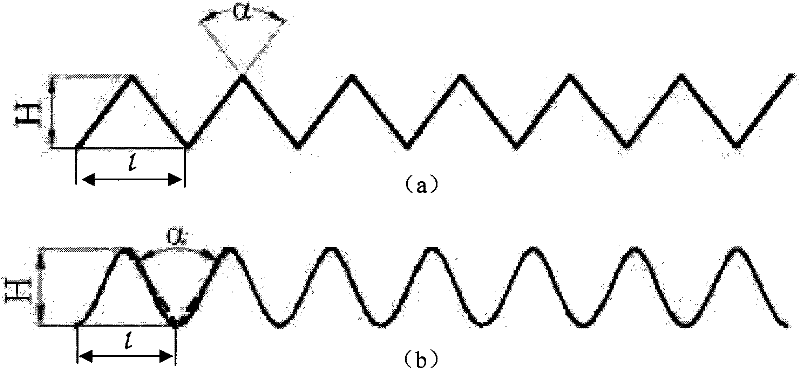

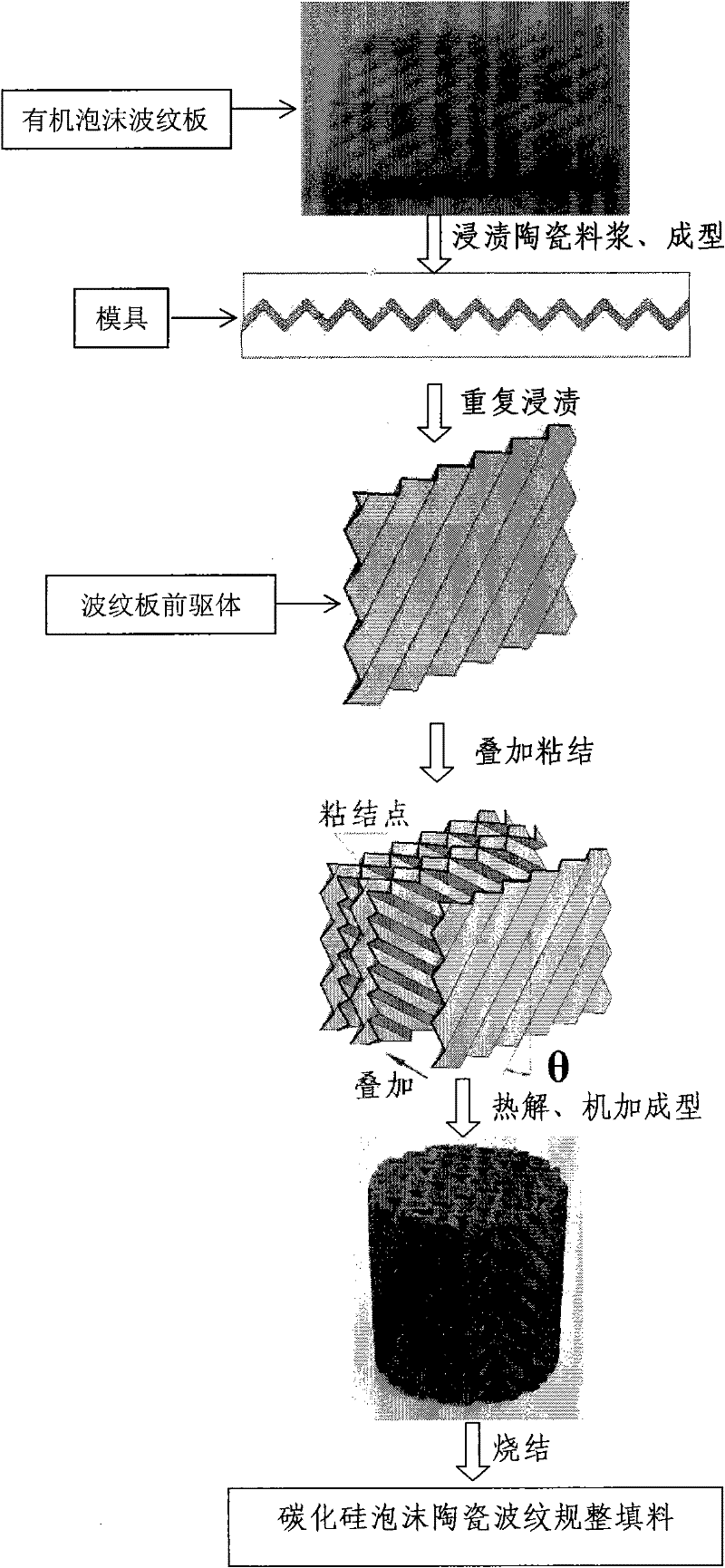

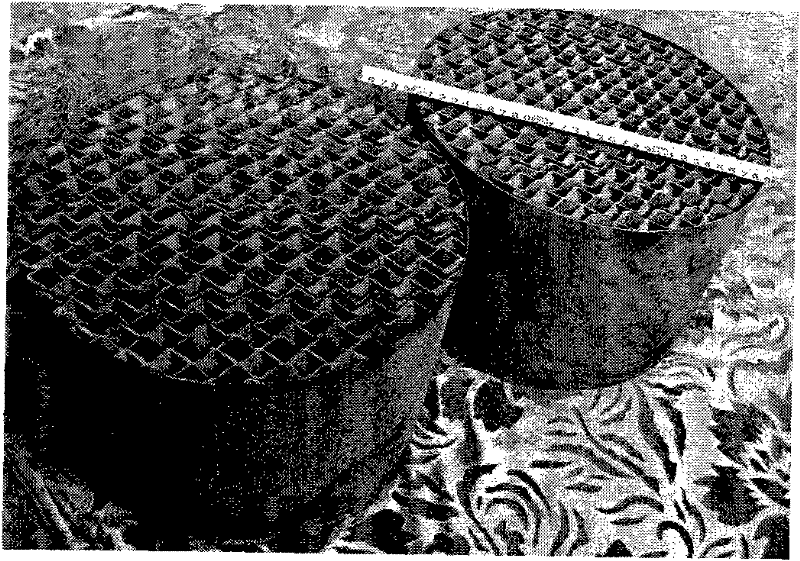

Silicon carbide foamed ceramics corrugated structured packing and preparation method and applications thereof

InactiveCN102218293AResolve compressionSolve the problem of elongation deformationPress rollersDistillation separationNetwork structureDeformation Problem

The invention relates to the field of structured packing, and in particular relates to silicon carbide foamed ceramics corrugated structured packing and a preparation method and applications thereof. The packing is formed by the stacking and combining silicon carbide foamed ceramics packing units of corrugated geometrical shapes; the packing unit plates are silicon carbide foamed ceramics of three-dimensional communicated network structures; the foam pore size is between 10PPi and 80PPi; the volume fraction can be controlled between 10% and 70%; and the corrugated shape of the packing units are triangles or smooth waves. The organic foam is cut into required corrugated shapes in advance, and then is subjected to press molding or double-roll extrusion molding, the deformation problem of compression and elongation of foam holes in the molding process is solved well, the shape of the foam holes of the obtained packing units is regular, and the original three-dimensional communicating structure of the organic foamed templates is maintained preferably; and the structured packing and the preparation method provided by the invention are suitable for a plurality of operation processes, especially are suitable for the separation process of systems difficult to be separated, adapt to the requirements of high efficiency and low energy consumption, and are especially suitable for the separation process of various high-corrosion systems.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

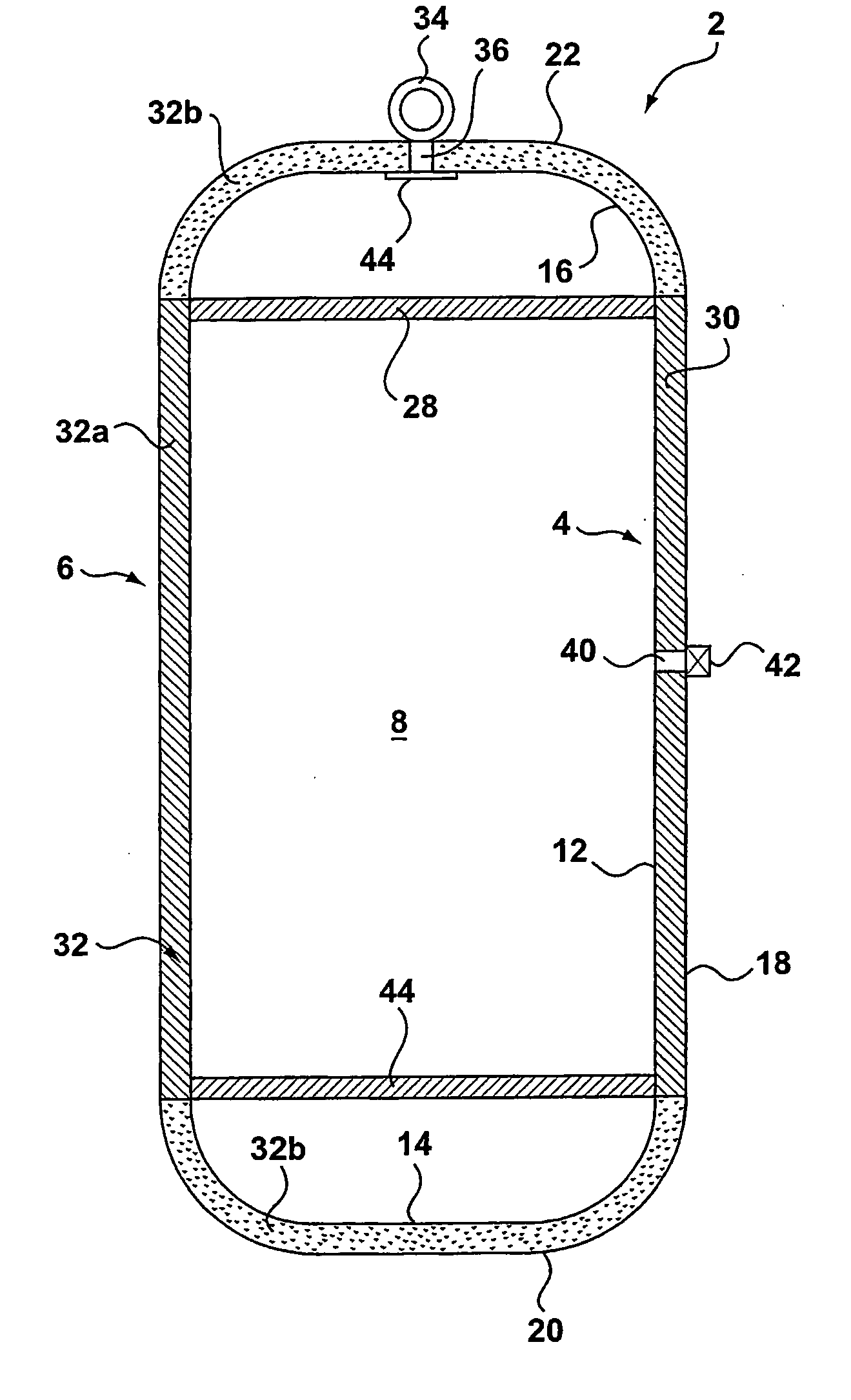

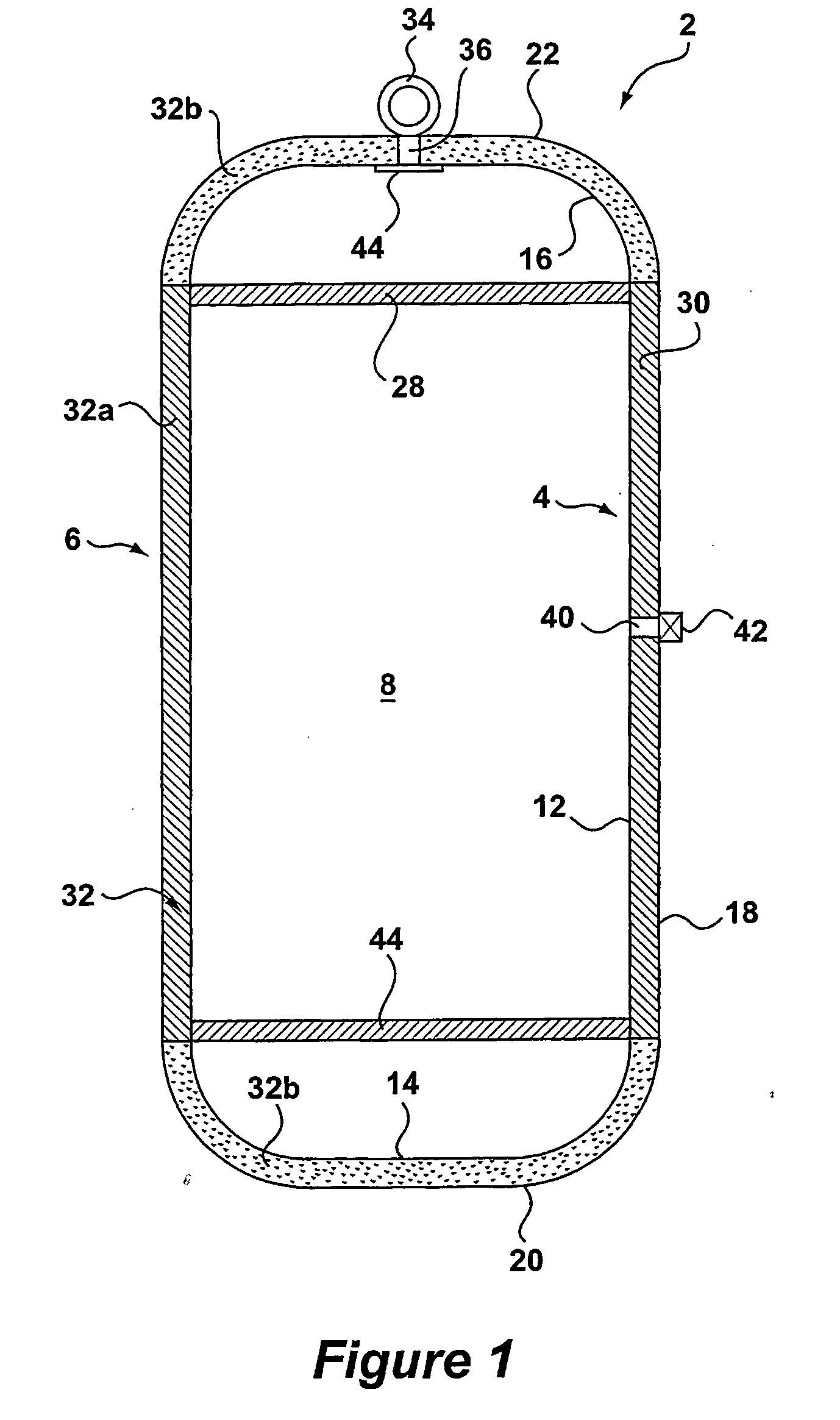

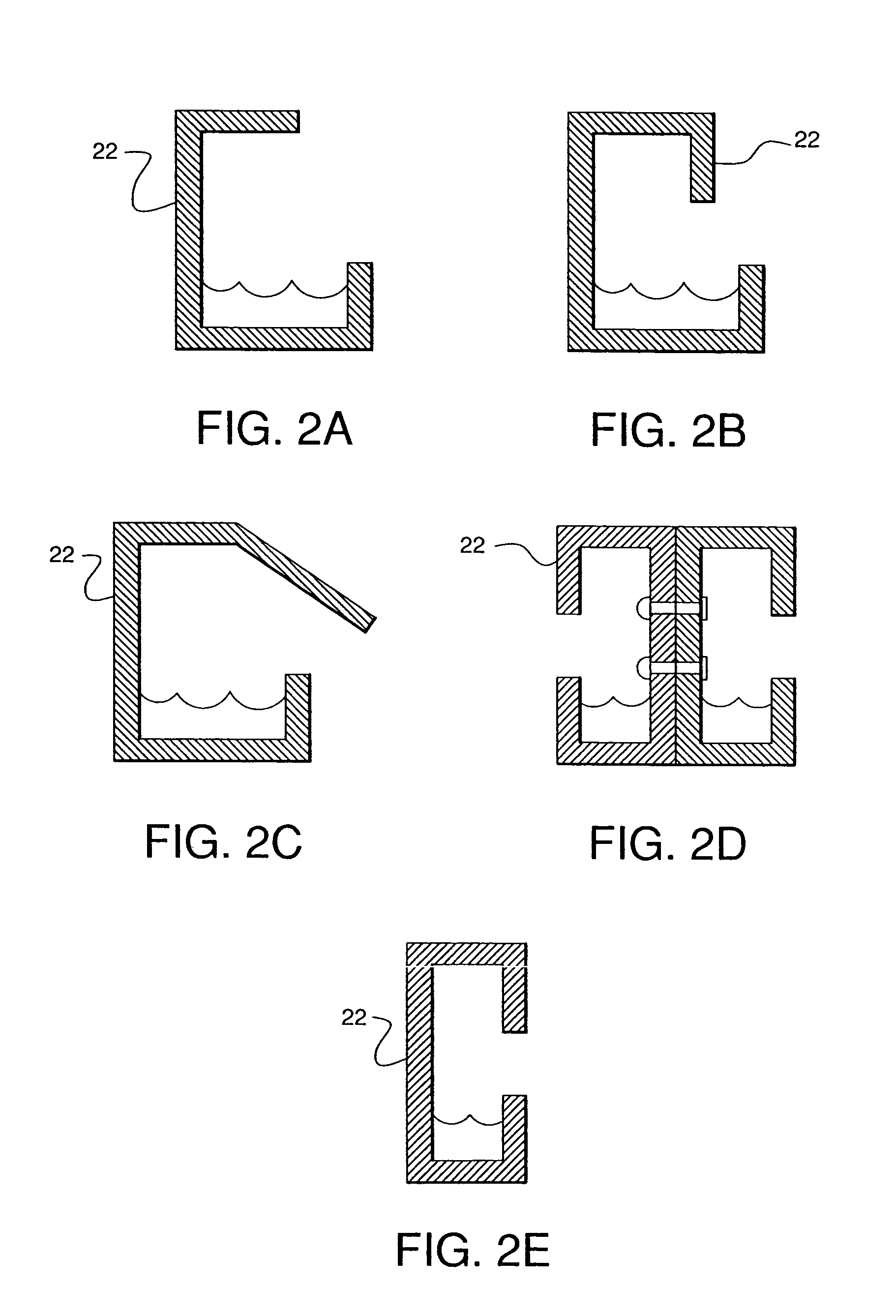

Underwater enclosure apparatus and method for constructing the same

InactiveUS20060159523A1Low curing temperatureMore temperaturePipe laying and repairNon-magnetic metal hullsRadial stressHydrostatic pressure

Apparatus for providing an enclosure, for example as a housing or to provide buoyancy, at underwater locations is disclosed comprising an inner shell and an outer shell, with a structural filler disposed between the two. The shells are prepared from fibre-reinforced plastic, with the fibres being oriented to provide resistance to both longitudinal and radial stresses induced in the apparatus by the hydrostatic pressure. The filler may be a structural filler comprising structural members extending between the inner and outer shells and occupying less than 60% of the volume of the cavity between the two shells. Alternatively, the filler may be a substantially void-free structural filler, such as a polyester resin. Methods of fabricating the apparatus are disclosed. In addition, a method of deballasting a buoyancy module is disclosed, in which the ballast, for example water, is withdrawn from the module by means of reduced pressure. Apparatus for deballasting is also disclosed.

Owner:COOPER CAMERON CORP

Stripping apparatus and process

ActiveUS7332132B2Install UnityCatalytic crackingSynthetic resin layered productsSolid particleMechanical engineering

Owner:UOP LLC

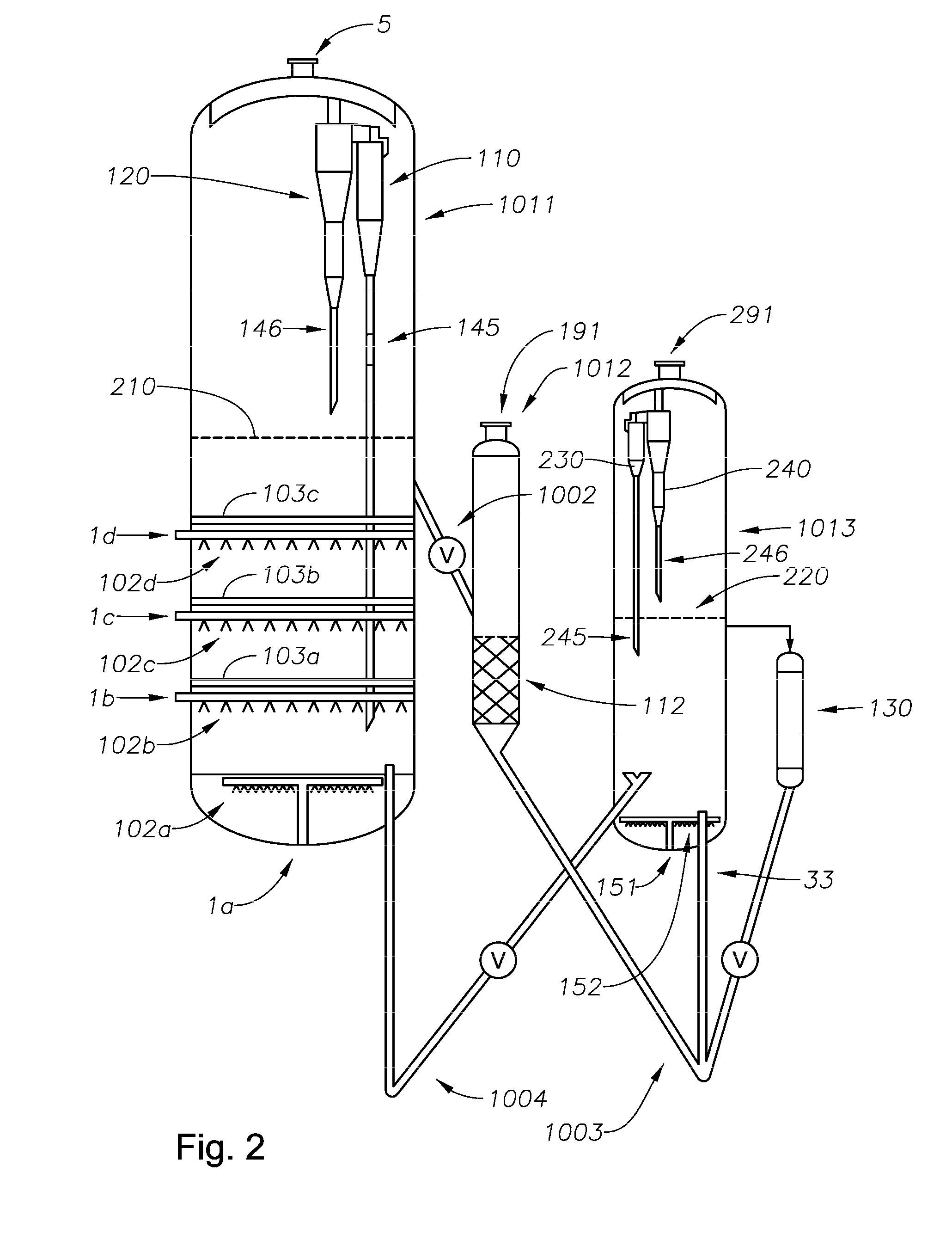

Fluid Bed Reactor with Staged Baffles

The invention relates to a process of alkylating aromatic hydrocarbons, and more particularly a process of making paraxylene by alkylation of benzene and / or toluene with methanol and / or dimethyl ether, and to an apparatus for carrying out said process, the improvement comprising staged injection of one of the reactants, with the stages separated by structured packing so as to minimize at least one of gas phase back-mixing, by-pass phenomena, and gas bubble size.

Owner:EXXONMOBIL CHEM PAT INC

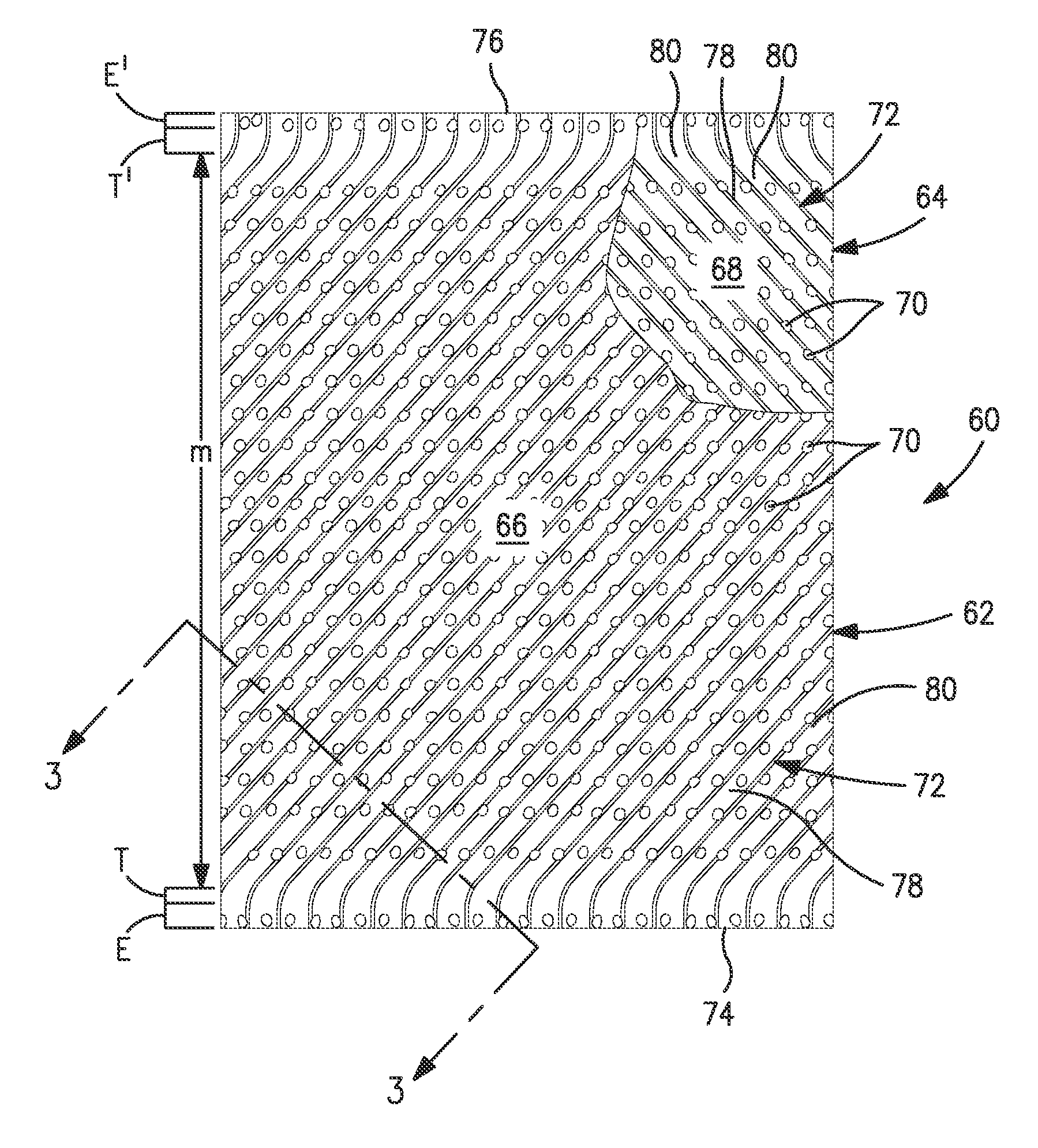

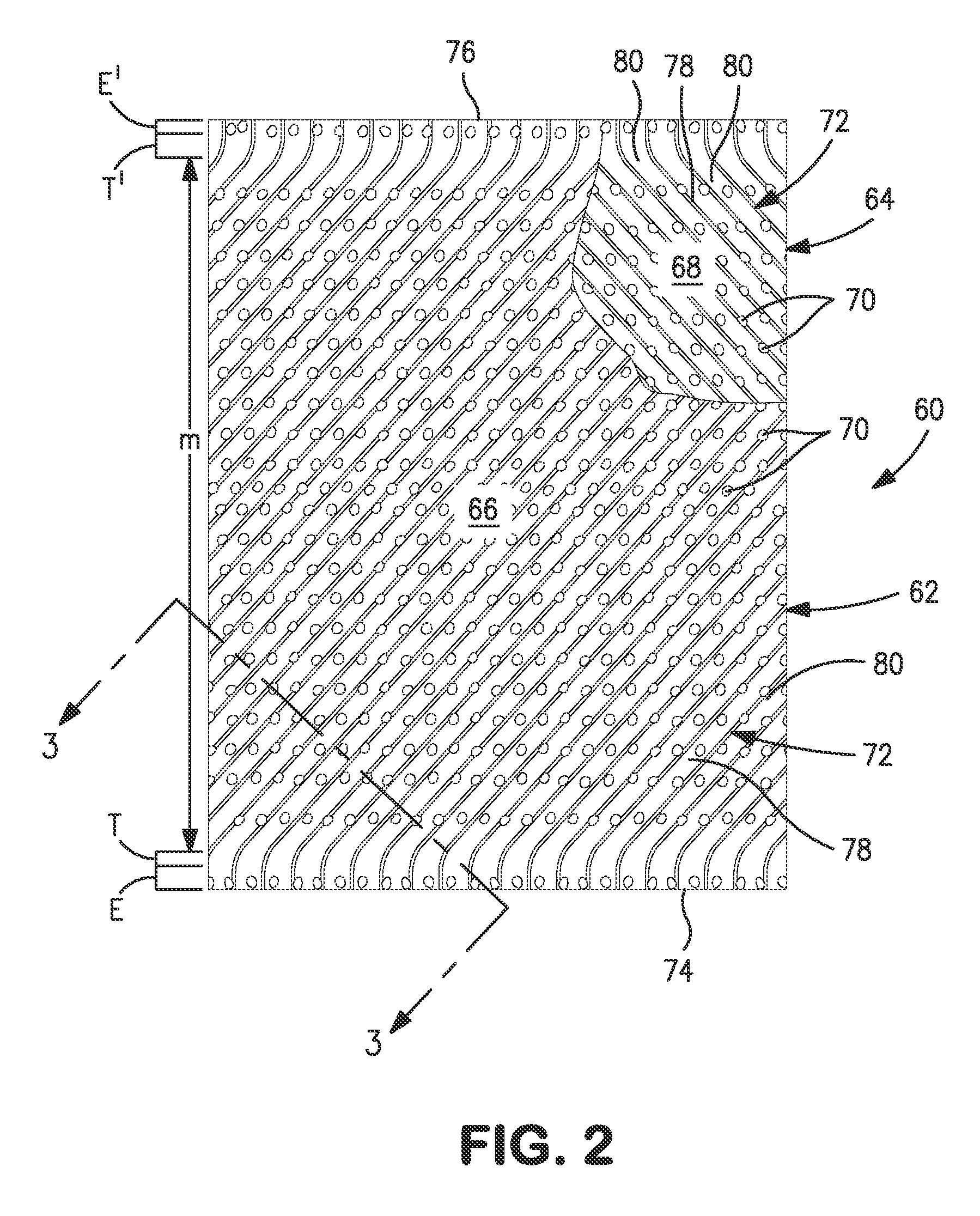

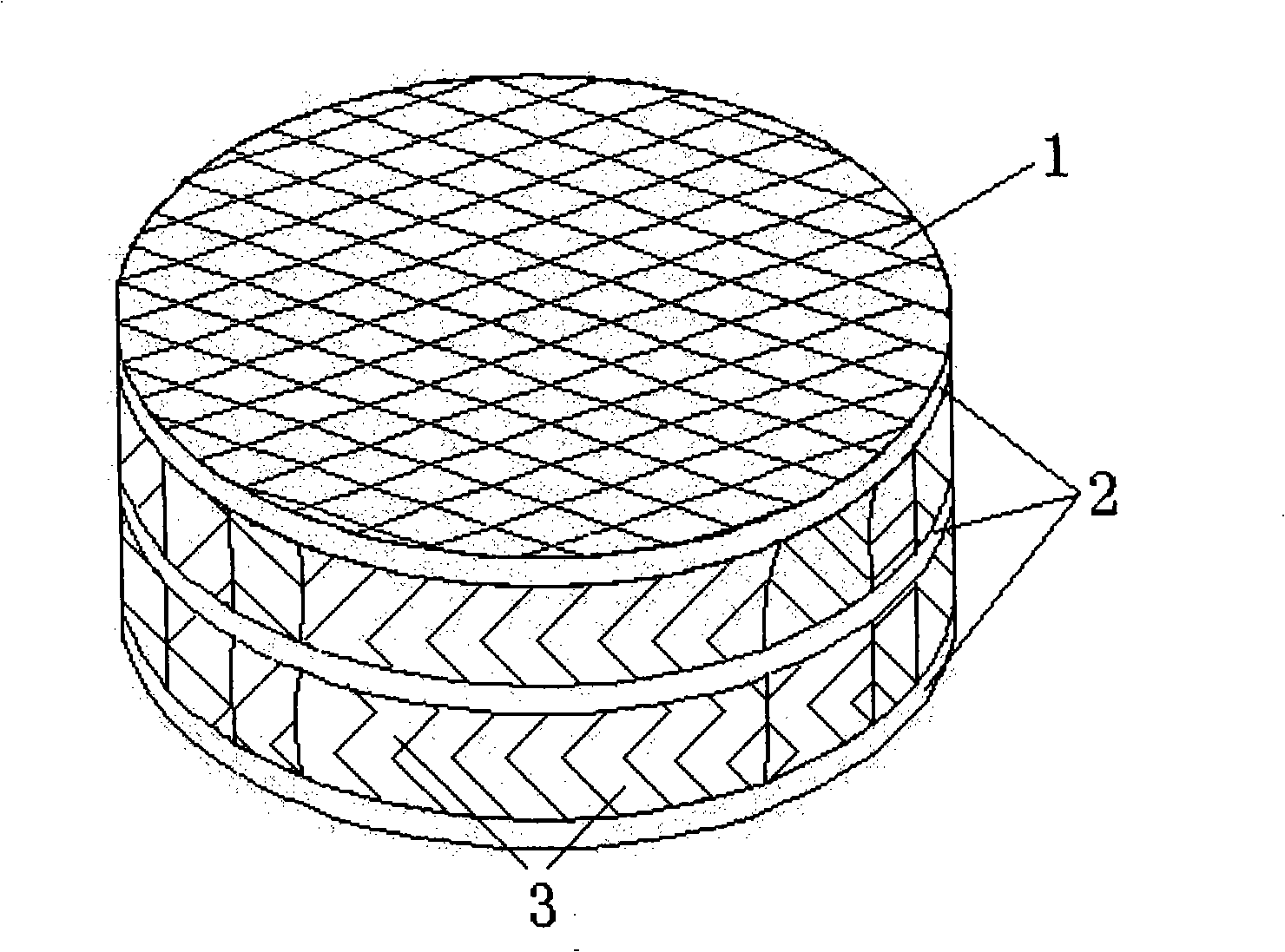

Structured Packing

InactiveUS20130233016A1Avoid mixingReduce mass transfer efficiencySolidificationLiquefactionEngineeringStructured packing

An apparatus for a heat transfer or mass transfer process, comprising a column or divided column having at least one pair of converging walls or wall portions and, within at least a region of the column or divided column bounded by at least one pair of converging walls or wall portions, a structured packing having a corrugation angle of at least about 50°; a method of heat and / or mass transfer applicable to the apparatus; and a method of installation of structured packing into a relevant apparatus.

Owner:AIR PROD & CHEM INC

Divided wall exchange column

A divided wall exchange column includes a dividing wall strengthened by stiffening members and / or a double wall design to better withstand pressure differentials and minimize temperature differentials. When a double wall is used, cost of manufacture and installation is minimized by reducing the manufacturing tolerances required while providing a design robust in construction, installation, and operation. When structured packing is used, the stiffening members, combined with positioning the layers of packing at preferred angles relative to the dividing wall, result in minimal interference with the heat and / or mass transfer process while minimizing the complexity of manufacture and construction of the packing. Further, by positioning the top layer of structured packing at other preferred angles relative to the dividing wall, a simplified liquid distributor design may be used in the divided wall exchange column while the layers below may still be orientated as described above with all the associated benefits.

Owner:AIR PROD & CHEM INC

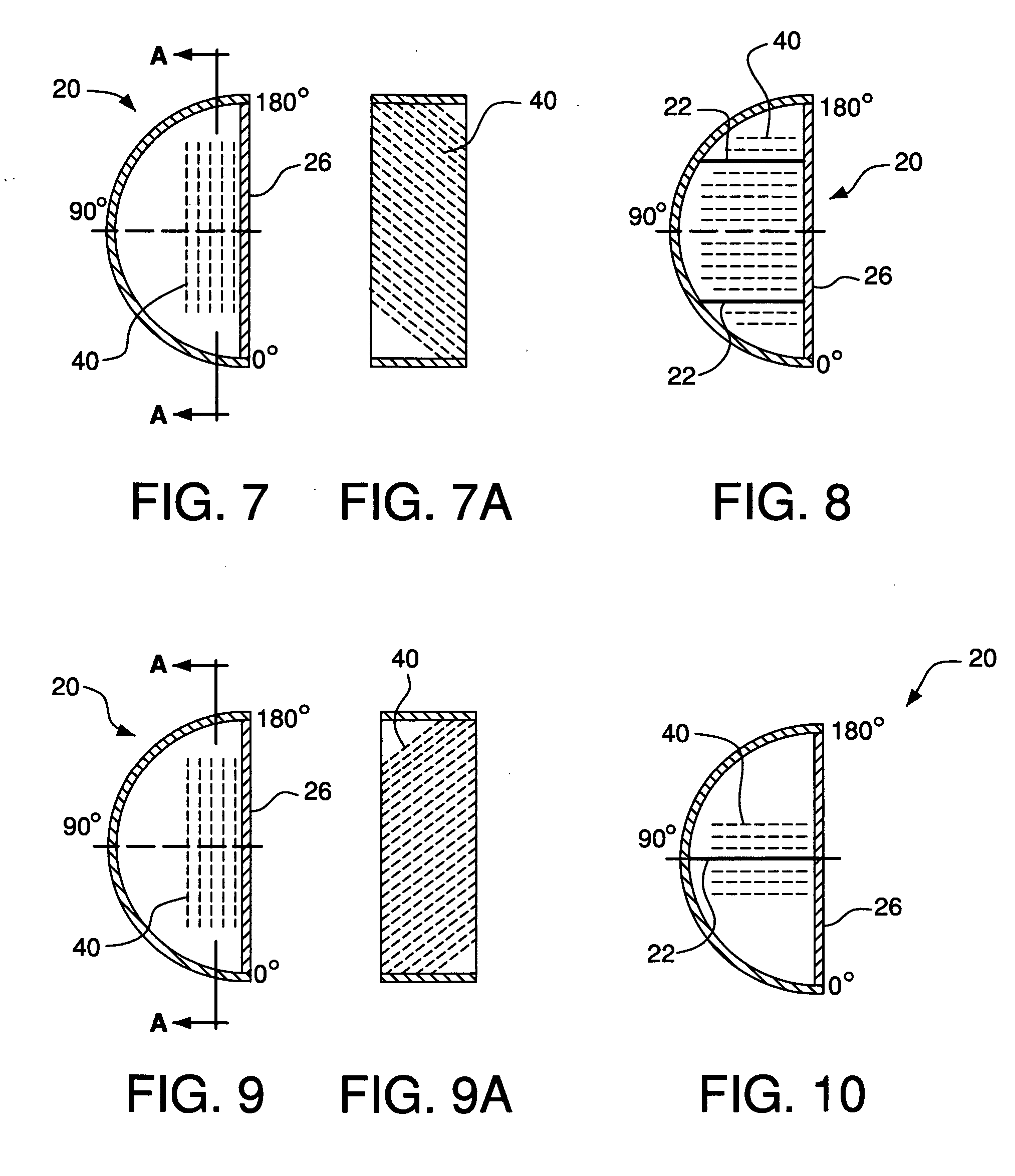

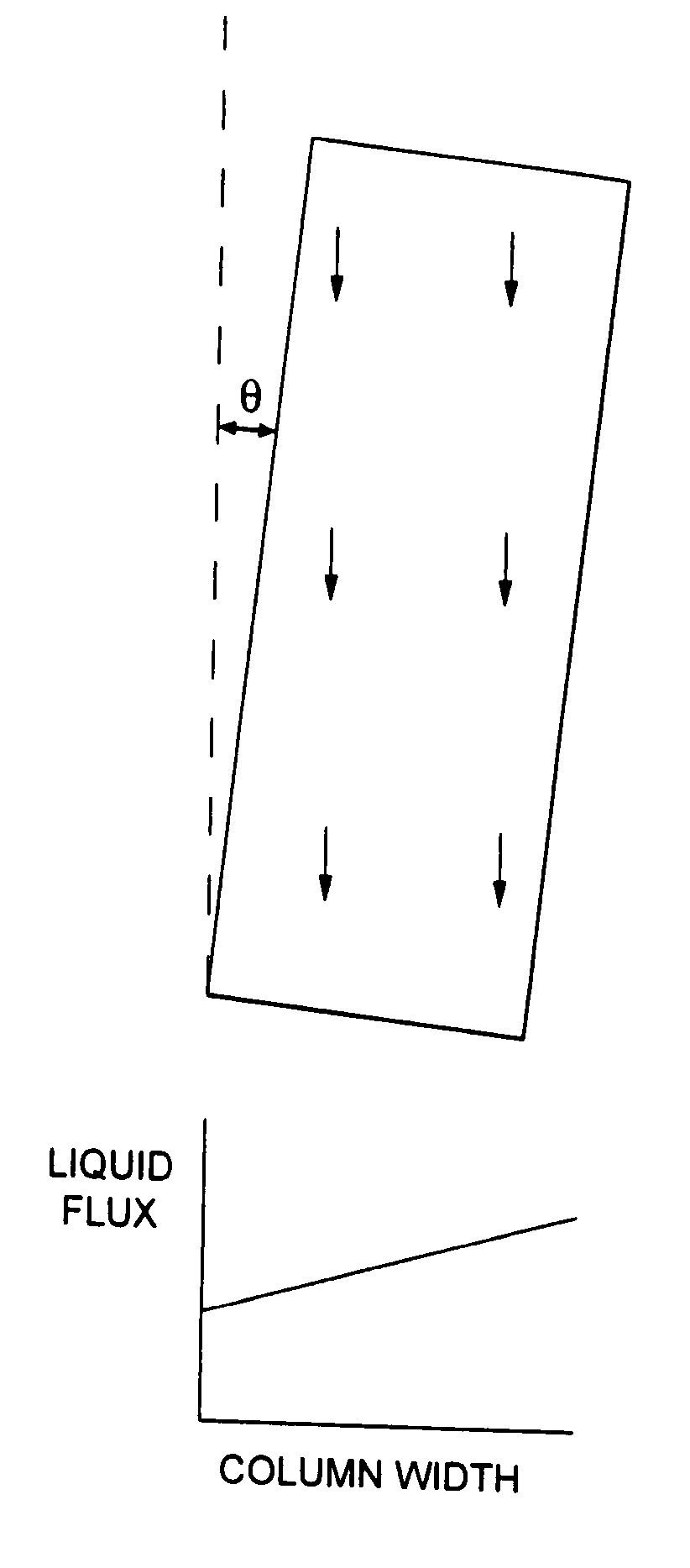

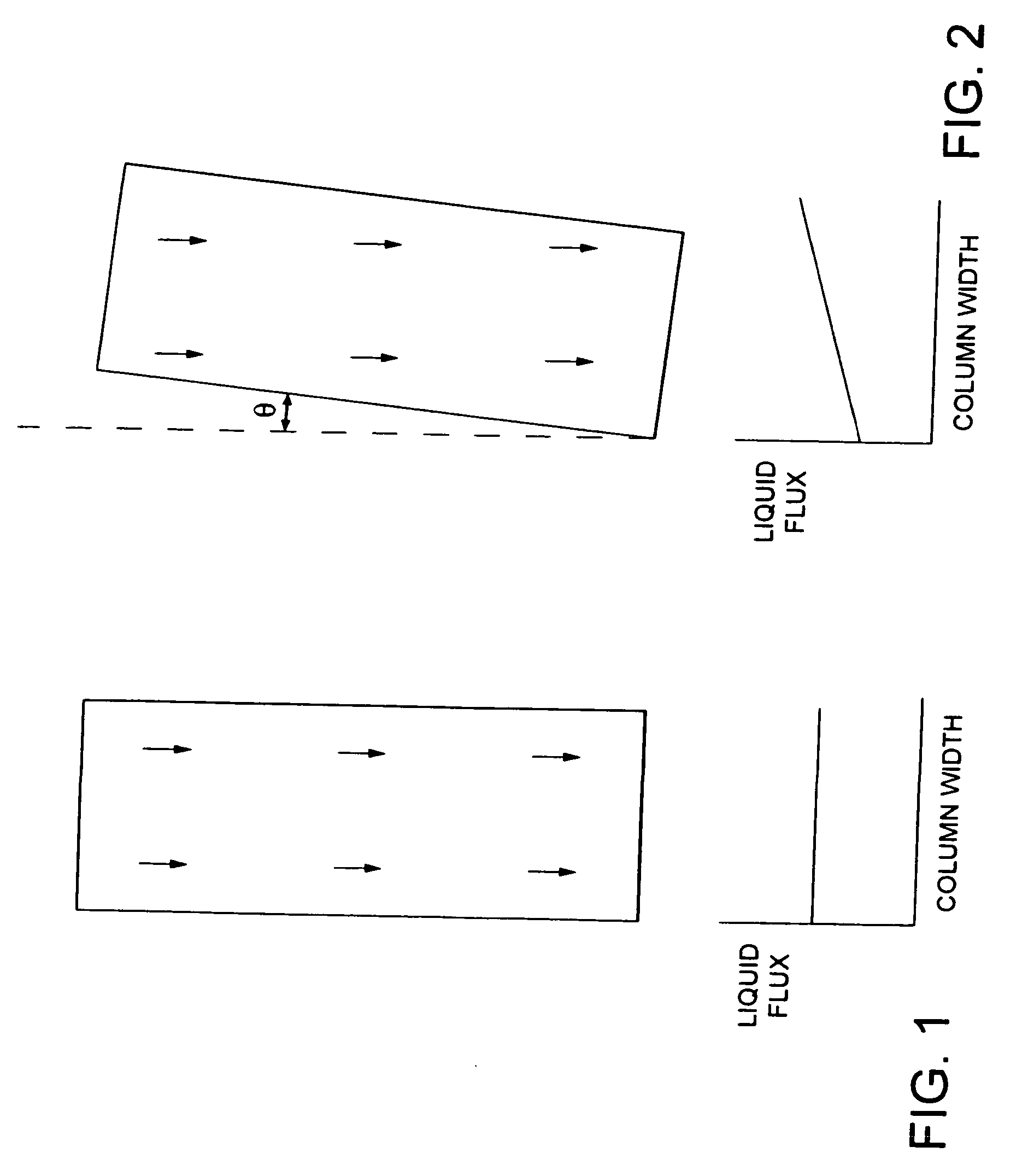

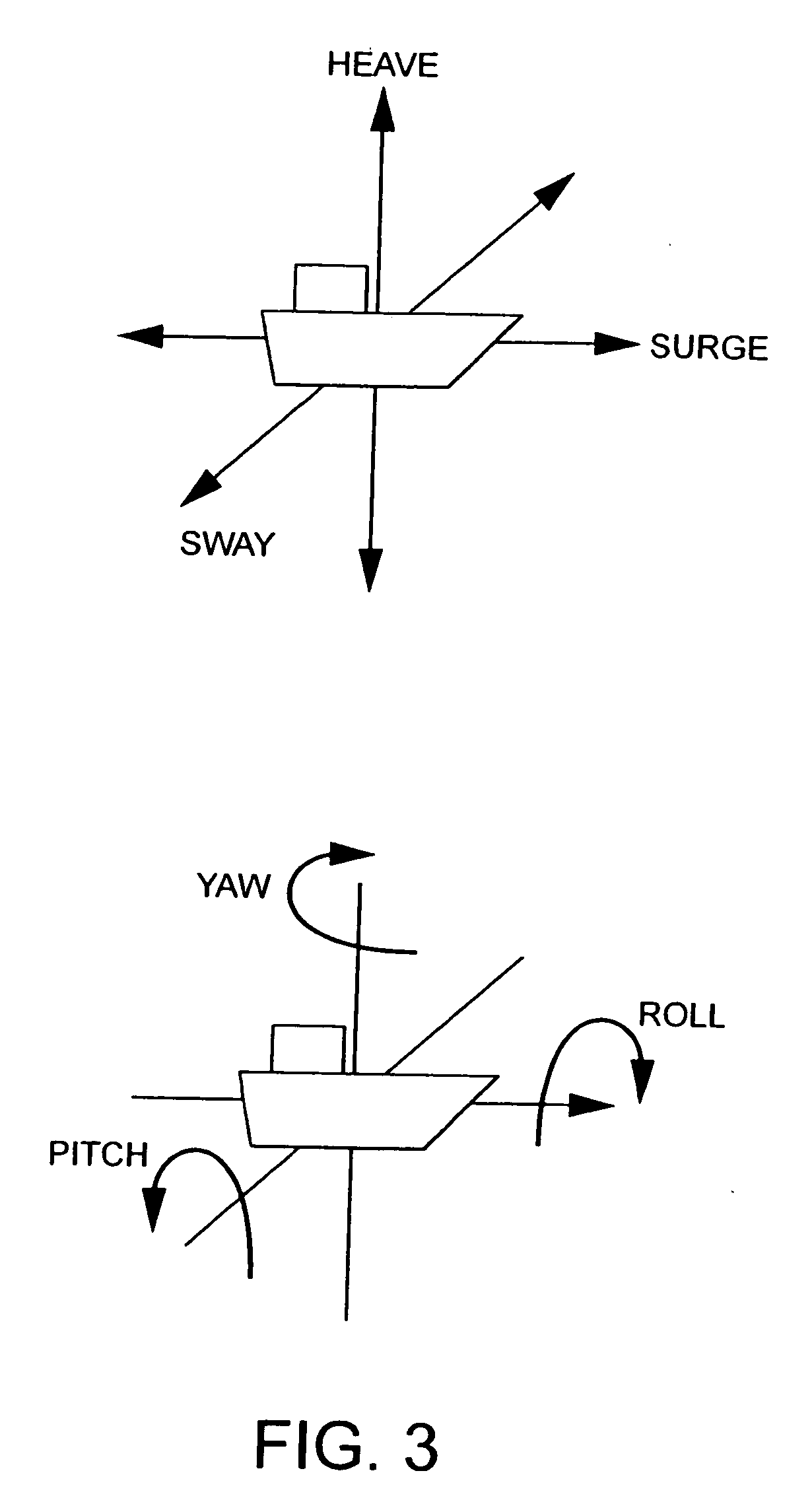

Structured packing and use thereof

At least one section of structured packing characterised in that: (a) the length of said section is from about 1 m to about 6 m; and (b) the specific surface area of the structured packing of said section is greater than 500 m2 / m3, is used in a vapour / liquid contact column operating in locations where environmental conditions adversely affect steady state operation of said column to reduce maldistribution of liquid in said column under motion. The structured packing section has particular application offshore on a buoyant platform where tilt of the column out of vertical alignment due to the rolling motion of the platform can significantly affect the efficiency of the column.

Owner:AIR PROD & CHEM INC

Structured packing and method

ActiveUS9295925B2Lower resistanceReduce the average velocitySolidificationLiquefactionInternal pressureAcute angle

A structured packing formed of a plurality of corrugated, rectangular sheets and a method relating to the use thereof. End regions of the corrugations are provided with straight, parallel corrugations extending inwardly from opposed edges of the sheets and a right angles thereto to reduce pressure drop at the interfaces between packing layers and thereby increase hydraulic capacity. Contact is promoted between descending liquid and ascending vapor phases within a main region of the corrugations that have straight, parallel sections of the corrugations oriented at an acute angle to the opposed edges. Transition regions having arcuate sections of the corrugations connect corrugations within the main and end regions to reduce internal pressure drop within the structured packing and thereby further reduce pressure drop at the interfaces and further increase the hydraulic capacity.

Owner:PRAXAIR TECH INC

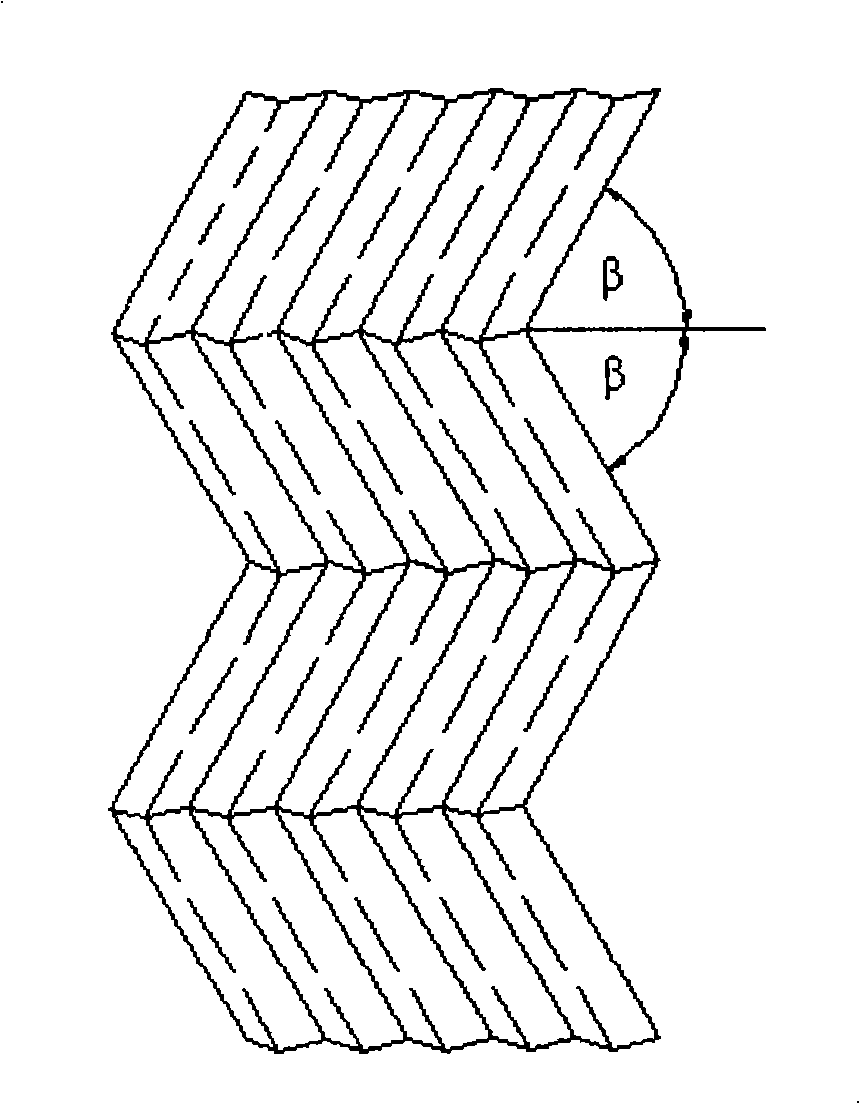

Strong-effect regular packing without wall flow

InactiveCN101347716AExtended stayConducive to redistributionChemical/physical/physico-chemical processesAngle alphaStructured packing

The invention discloses a high-performance non wall flow corrugated structured packing which is composed of corrugated silk screens or corrugated plates and a strap or other fastening pieces; the corrugated cross section of the corrugated plate takes a shape of a triangle or a circular arc, a plurality of short zigzag channels are connected along opposite direction to form one corrugated plate, a 'fold line'-shaped corrugated channel is formed by combination, thus a liquid channel can integrally deflect along a vertical and downward trend, the included angle Alpha between the corrugated plate and the longitudinal center line of the packing is 0-60 degrees. The high-performance non wall flow corrugated structured packing has the advantages that: when the fluid on a packing box flows downwards through the 'fold line'-shaped corrugated channel, the flow direction can be repeatedly changed for a plurality of times in one corrugated plate, thus prolonging the staying time of the fluid; the channel is short, narrow and zigzag, which can facilitate redistribution of fluid; even if local packing is staggered between trays, the caused impact can be effectively relieved due to flow deflection and rapid redistribution in the short channel, therefore, the corrugated structured packing can effectively solve the problems of wall flow, bias flow, etc.

Owner:NANJING UNIV

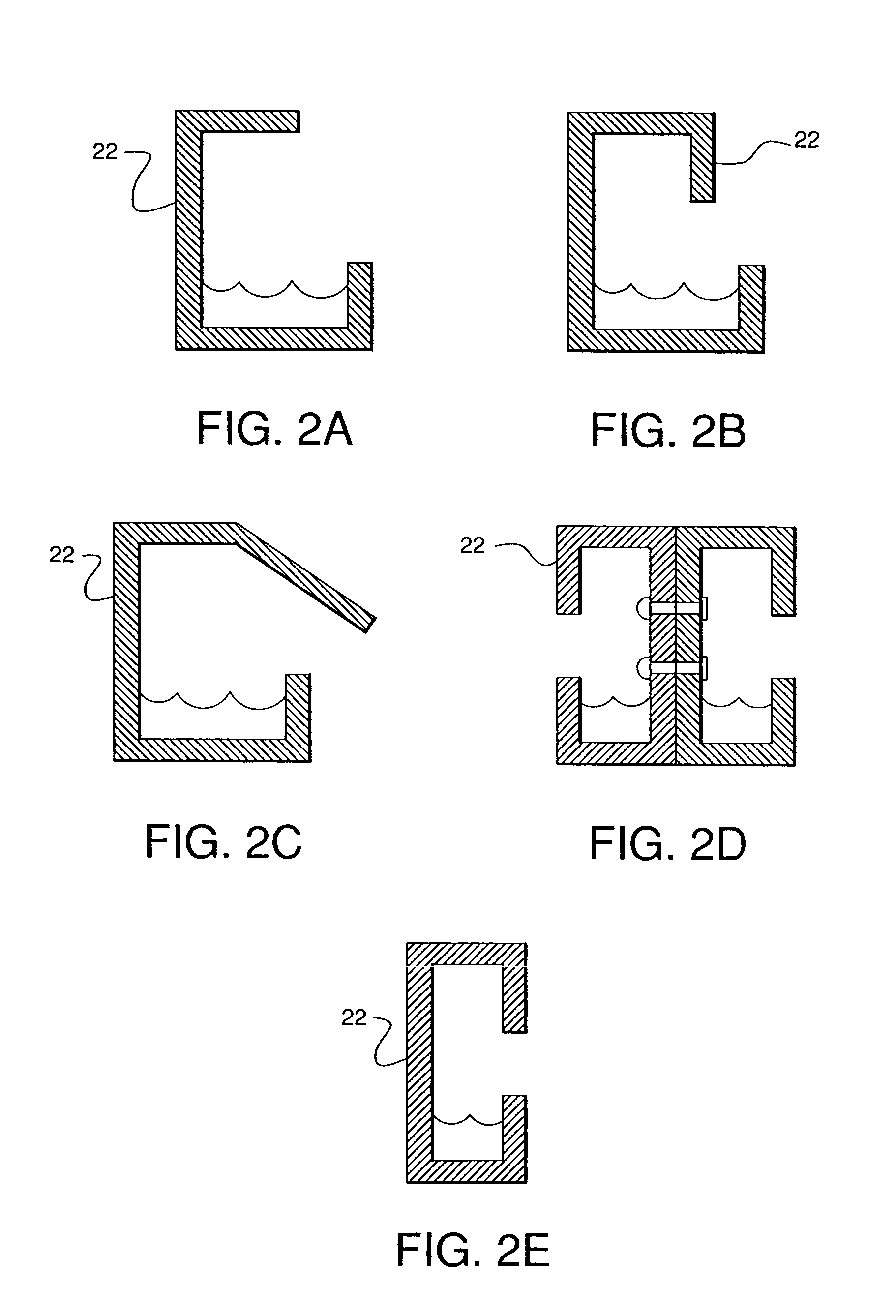

Wall-flow redistributor for packed columns

An apparatus for collecting and redistributing a flow of a liquid descending in an exchange column containing a layer of structured packing and having a longitudinal axis, a cross-sectional area, and an inner wall having an inner perimeter, includes: a wall-flow collector located above the layer of structured packing, the wall-flow collector having an outer perimeter adjacent the inner perimeter of the inner wall and being adapted to collect at least a portion of the liquid descending on or near the inner wall of the exchange column; a transmission means for transmitting at least a portion of the collected liquid collected by the wall-flow collector toward the longitudinal axis a substantial distance across the cross-sectional area of the exchange column; and a dispensing means for dispensing at least a portion of the portion of the collected liquid from the transmission means to the layer of structured packing.

Owner:AIR PROD & CHEM INC

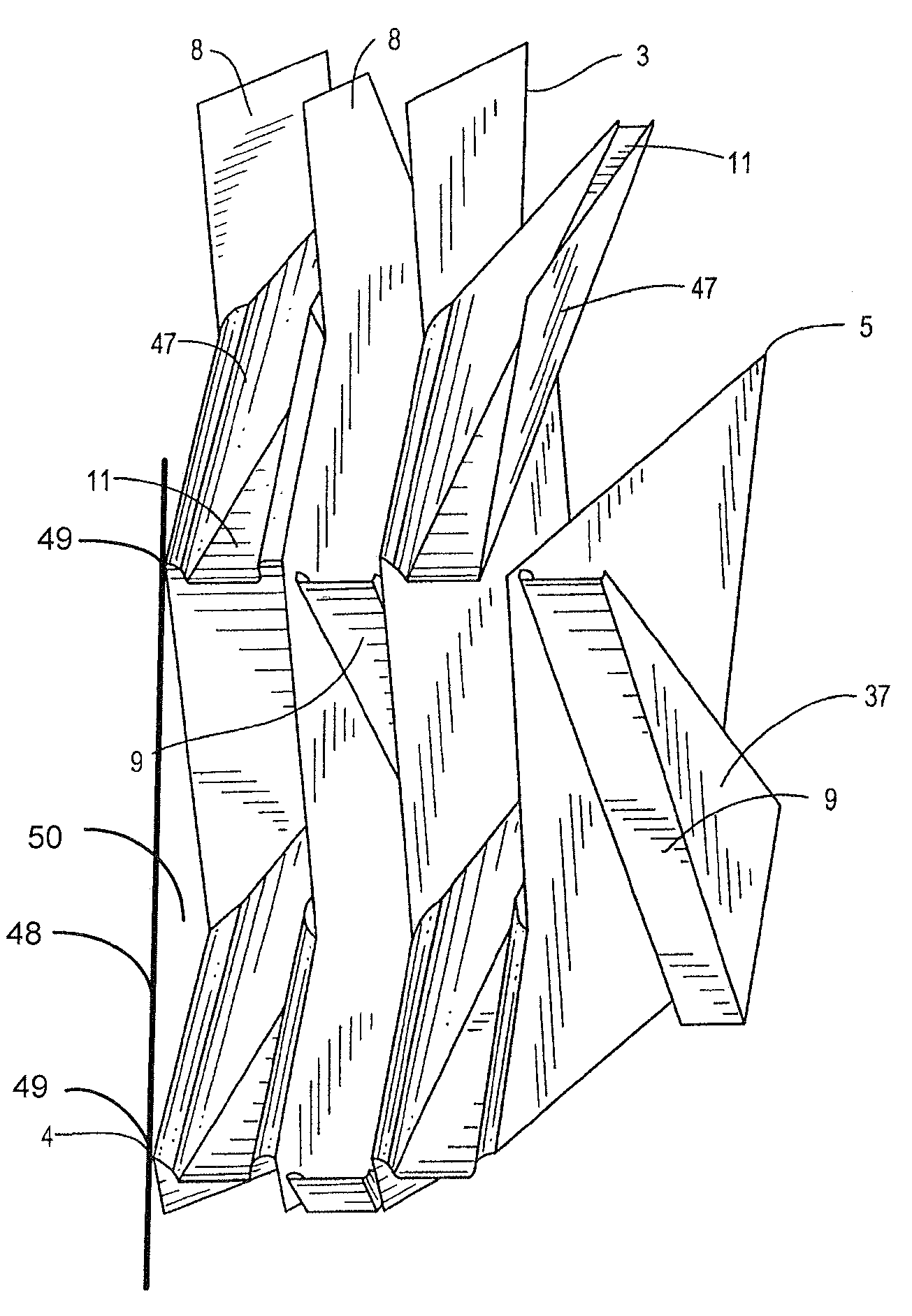

Structured packing for a reactor

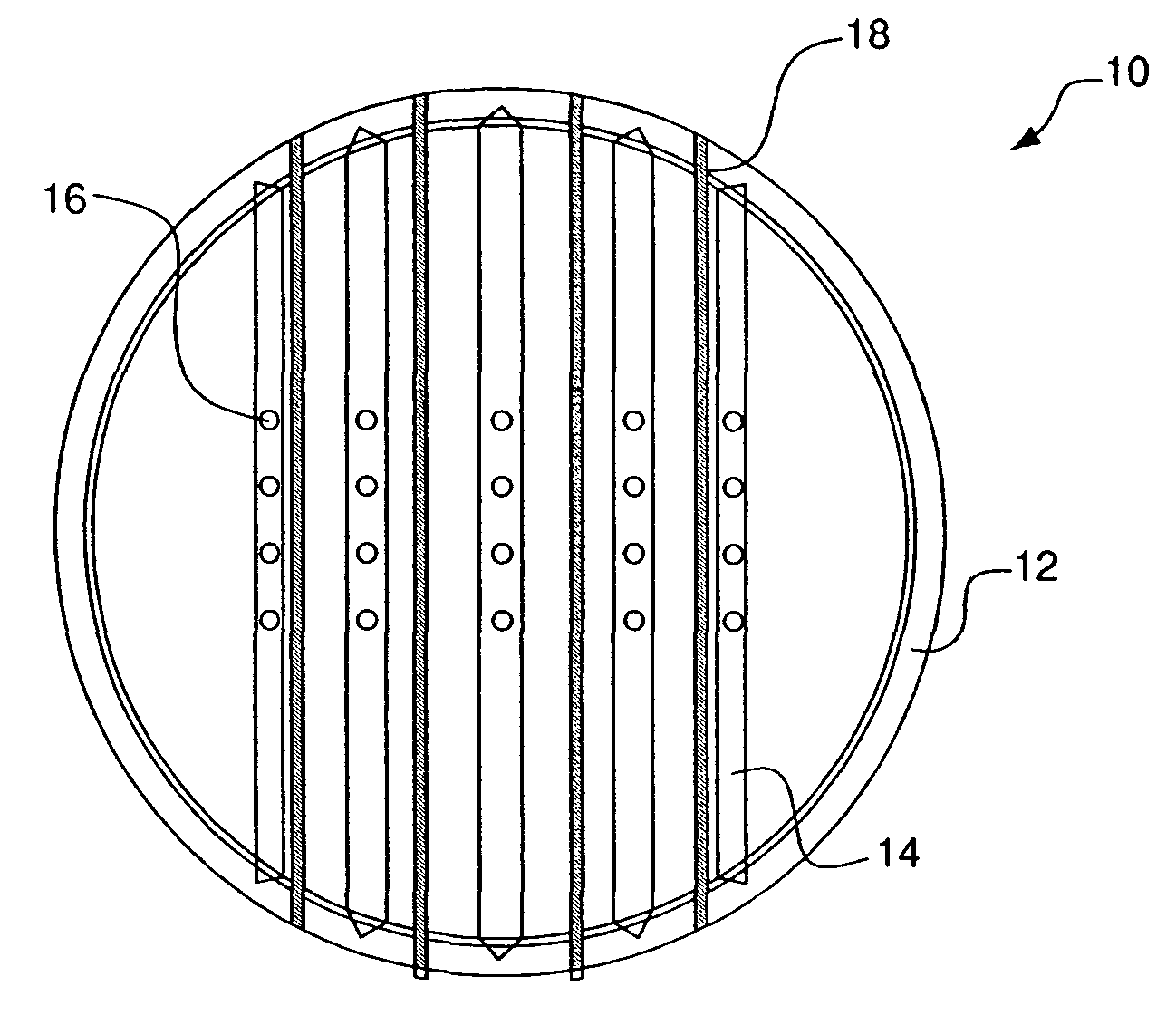

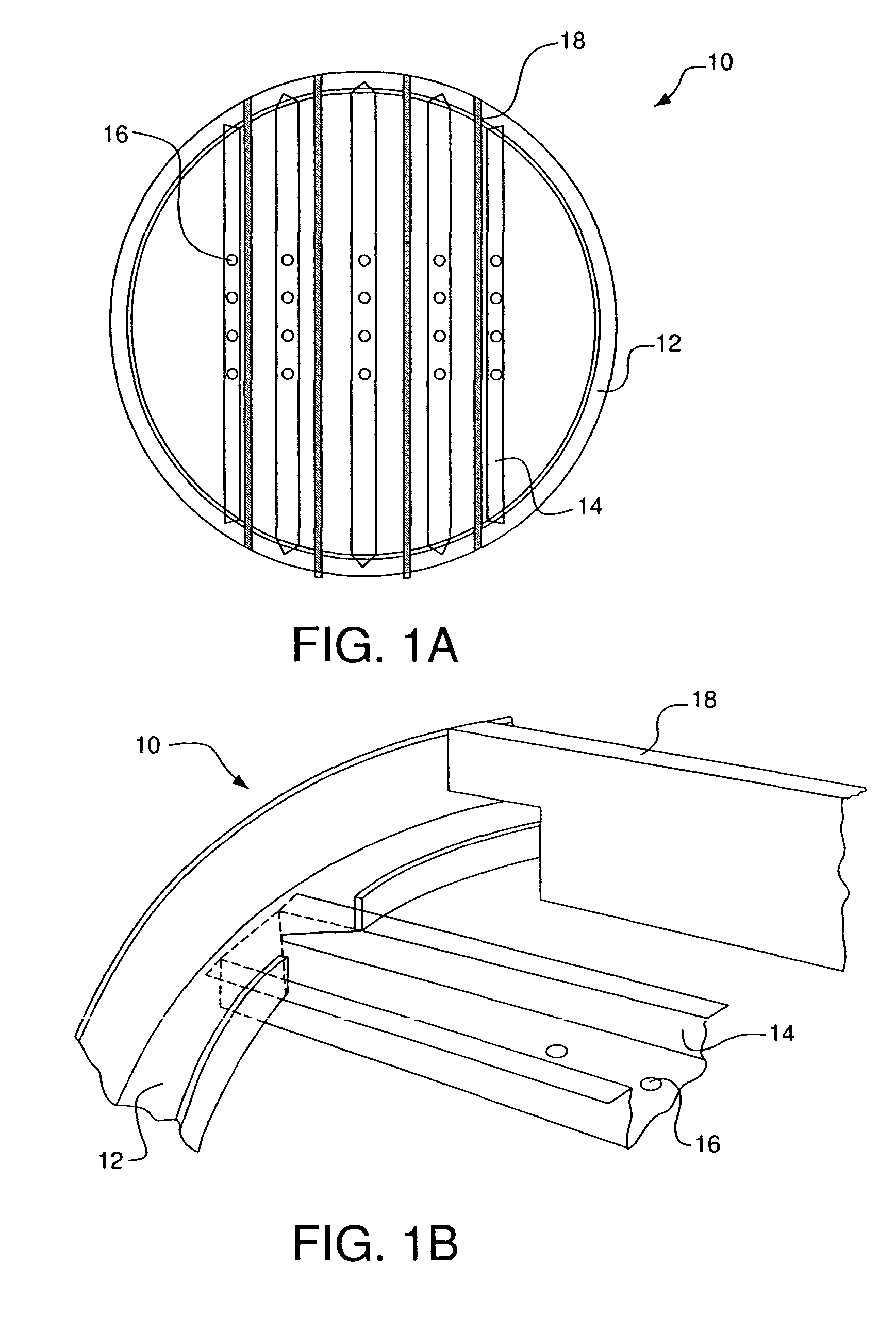

ActiveUS8235361B2Increase geometric surface area and heat transfer coefficientIncrease pressureCarburetting airPhysical/chemical process catalystsNuclear engineeringMetal sheet

A structured packing for a reactor is formed from a metal sheet to promote heat and mass transfer near the wall of the reactor. The structured packing causes lateral flow of fluids flowing through the packing such that jet impingement of at least one reactor wall is promoted. The packing may be used in a cylindrical, annular or plate-type reactor, e.g., a catalytic reactor, or a heat exchanger.

Owner:ZONEFLOW REACTOR TECH

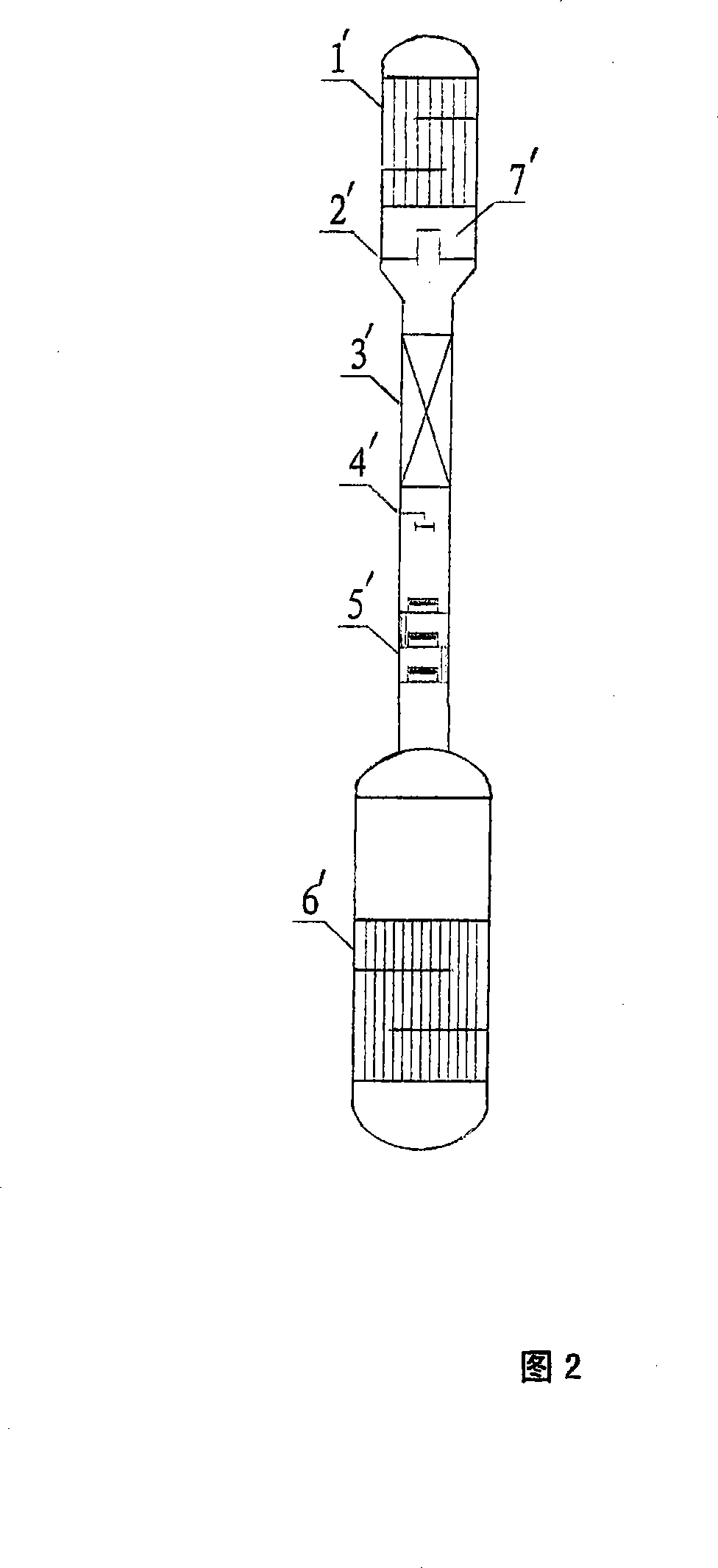

Process and apparatus for separation of stable isotope compound

Stable isotope atoms present in the form of stable isotope compounds, for example, 13C present in the form of 13CO, are separated by distillation using a distillation column packed orderly with a formed packing, and preferably by distillation using a distillation column packed with a "promoting-fluid-dispersion type" structured packing.

Owner:NIPPON SANSO CORP

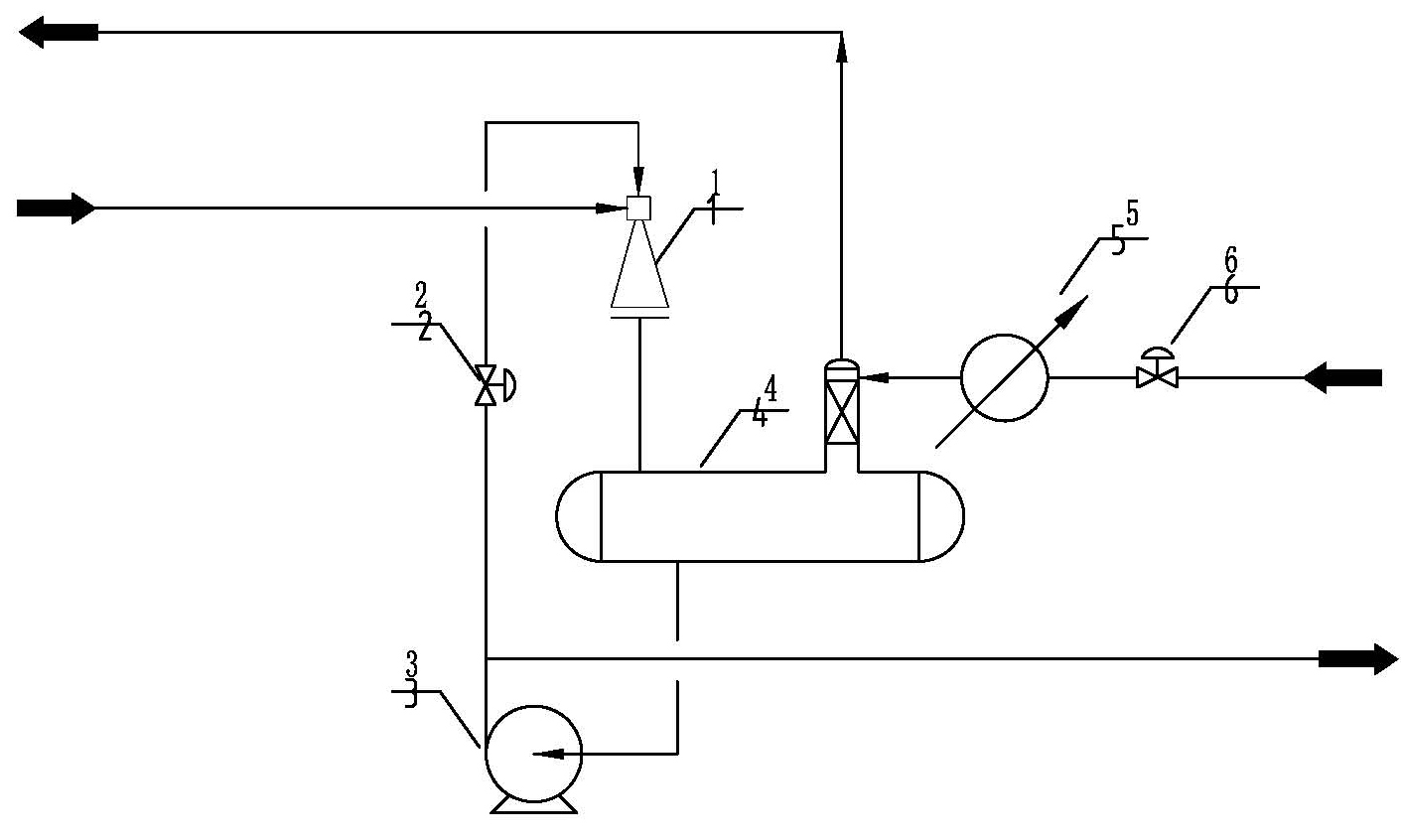

Improved method for producing food grade liquid carbon dioxide product and distillation and purification tower

The invention relates to a method for producing carbon dioxide and in particular discloses a method for producing a food grade liquid carbon dioxide product. The method comprises the following steps of: (1) compressing; (2) dealkylating; (3) purifying; (4) liquefying; and (5) performing distillation and purification, wherein flashing gas rises and passes through structured packing of a lower corrugated plate, structured packing of an upper corrugated plate, tube pass of a lower heat exchanger and tube pass of an upper heat exchanger, and finally, the flashing gas becomes a gas mixture containing a little uncooled carbon dioxide gas and lots of methane, ethylene and oxygen and is exhausted from the top of the distillation and purification tower. By the method, the yield of the food grade liquid carbon dioxide product is improved.

Owner:HUNAN KAIMEITE GASES

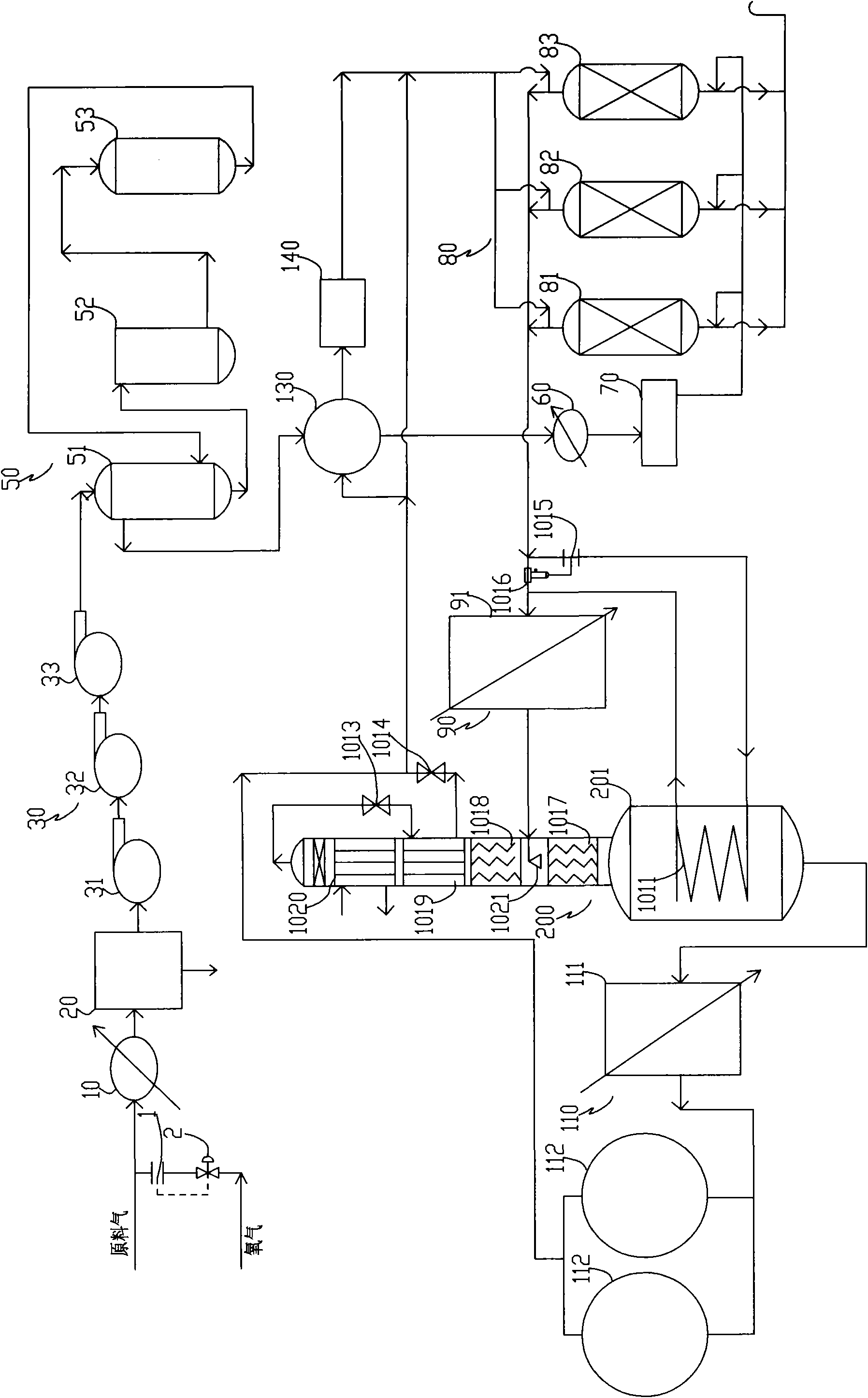

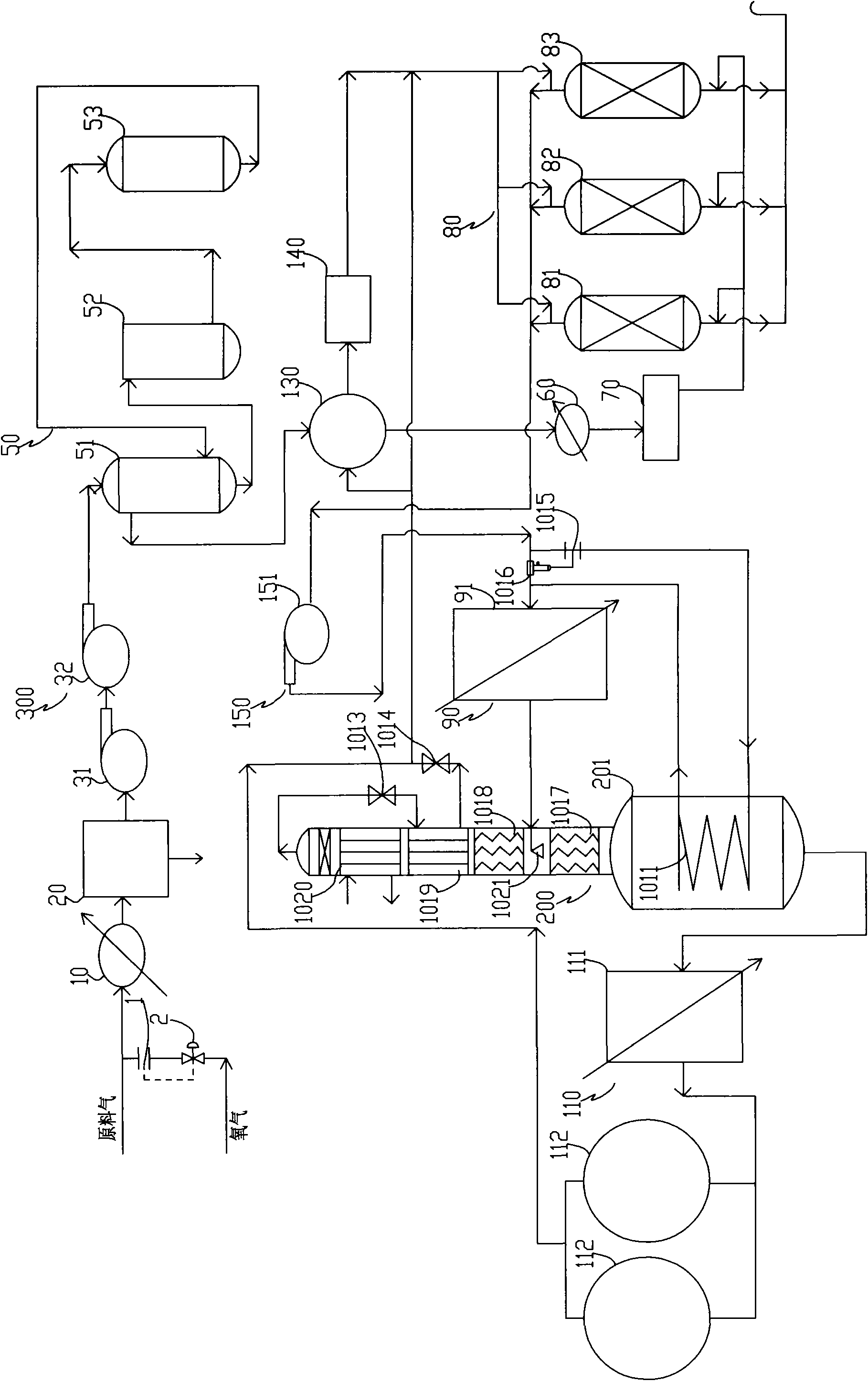

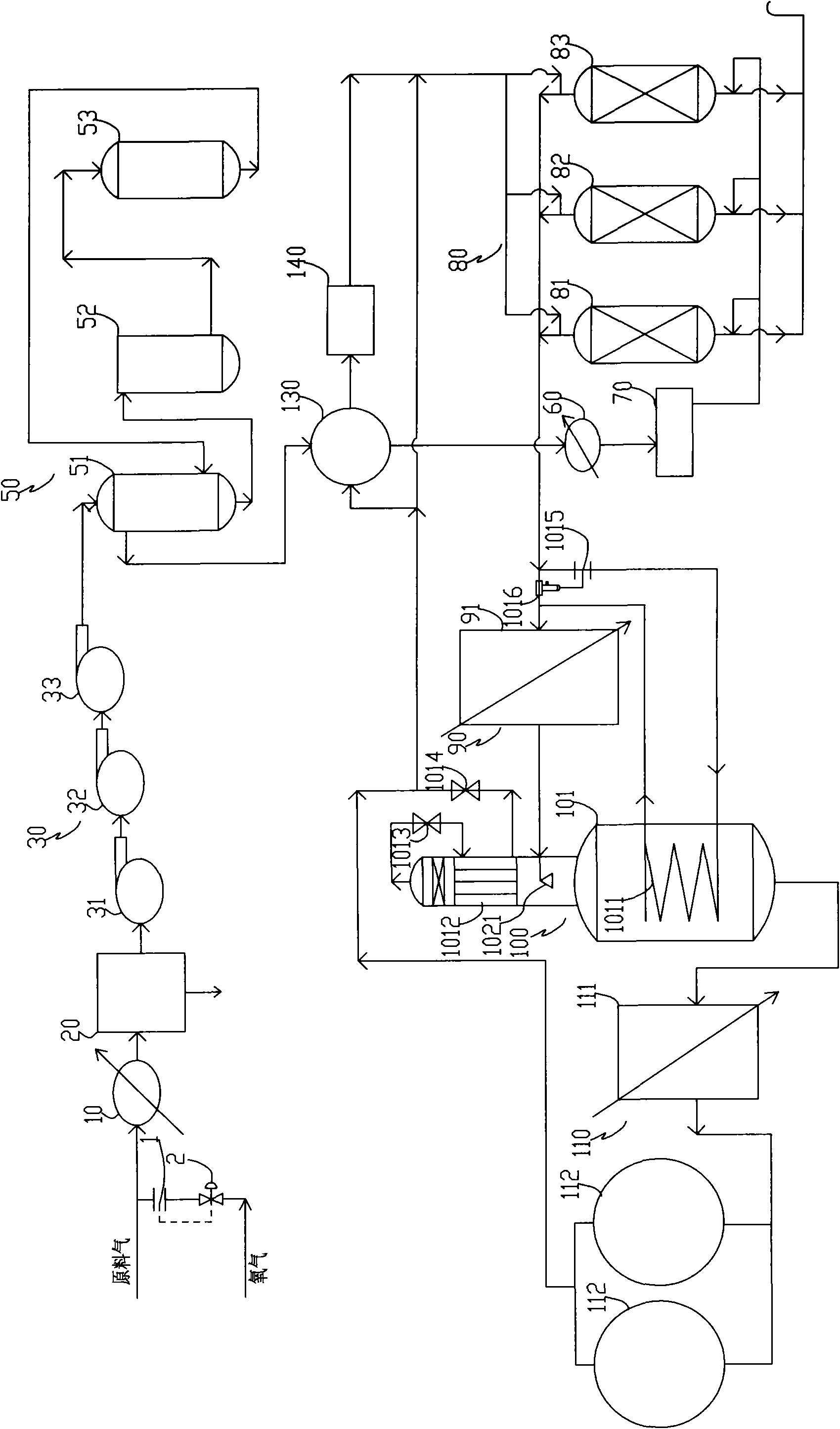

Fluid bed reactor with staged baffles

The invention relates to a process of alkylating aromatic hydrocarbons, and more particularly a process of making paraxylene by alkylation of benzene and / or toluene with methanol and / or dimethyl ether, and to an apparatus for carrying out said process, the improvement comprising staged injection of one of the reactants, with the stages separated by structured packing so as to minimize at least one of gas phase back-mixing, by-pass phenomena, and gas bubble size.

Owner:EXXONMOBIL CHEM PAT INC

Vapor-liquid contactor, cryogenic air separation unit and method of gas separation

InactiveUS6560990B2Increased pressure lossIncrease flow resistanceCarburetting airSolidificationVapor liquidProduct gas

In an vapor-liquid contactor 4a for flowing down a liquid along the surface of a packing and contacting said liquid with the vapor while ascending the vapor, the improvement being characterized in that said packing is a non-promoting-fluid-dispersion type structured packing A1, A2 in which various types of thin sheets or tubes for determining the flow direction of the above liquid or vapor is laminated and arranged in the perpendicular direction, and said contactor includes at least one fluid distribution unit E1, E2 formed of a rough distribution part C1, C2 to distribute the liquid roughly and a minute distribution part B1, B2 to distribute the liquid minutely and equally.

Owner:NIPPON SANSO CORP

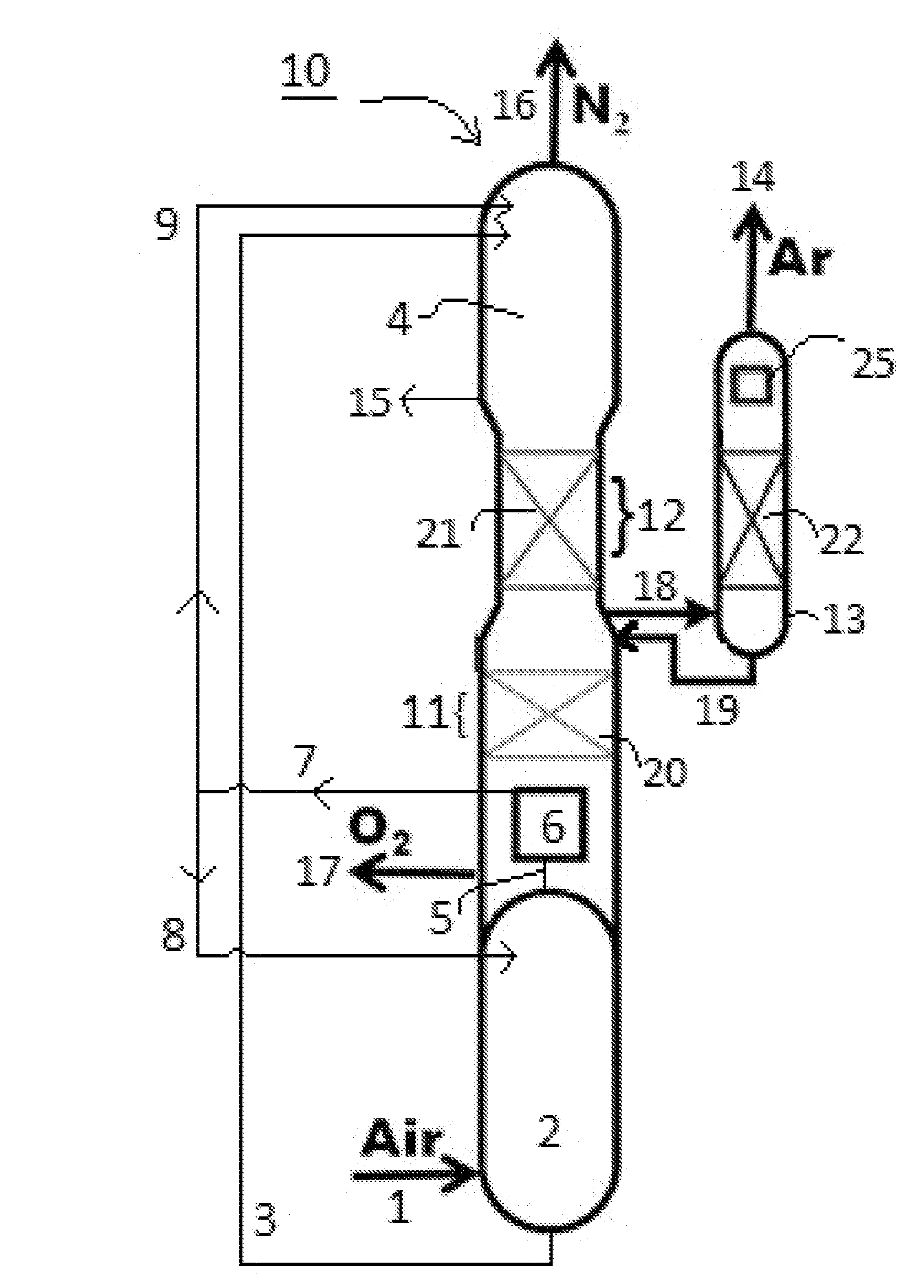

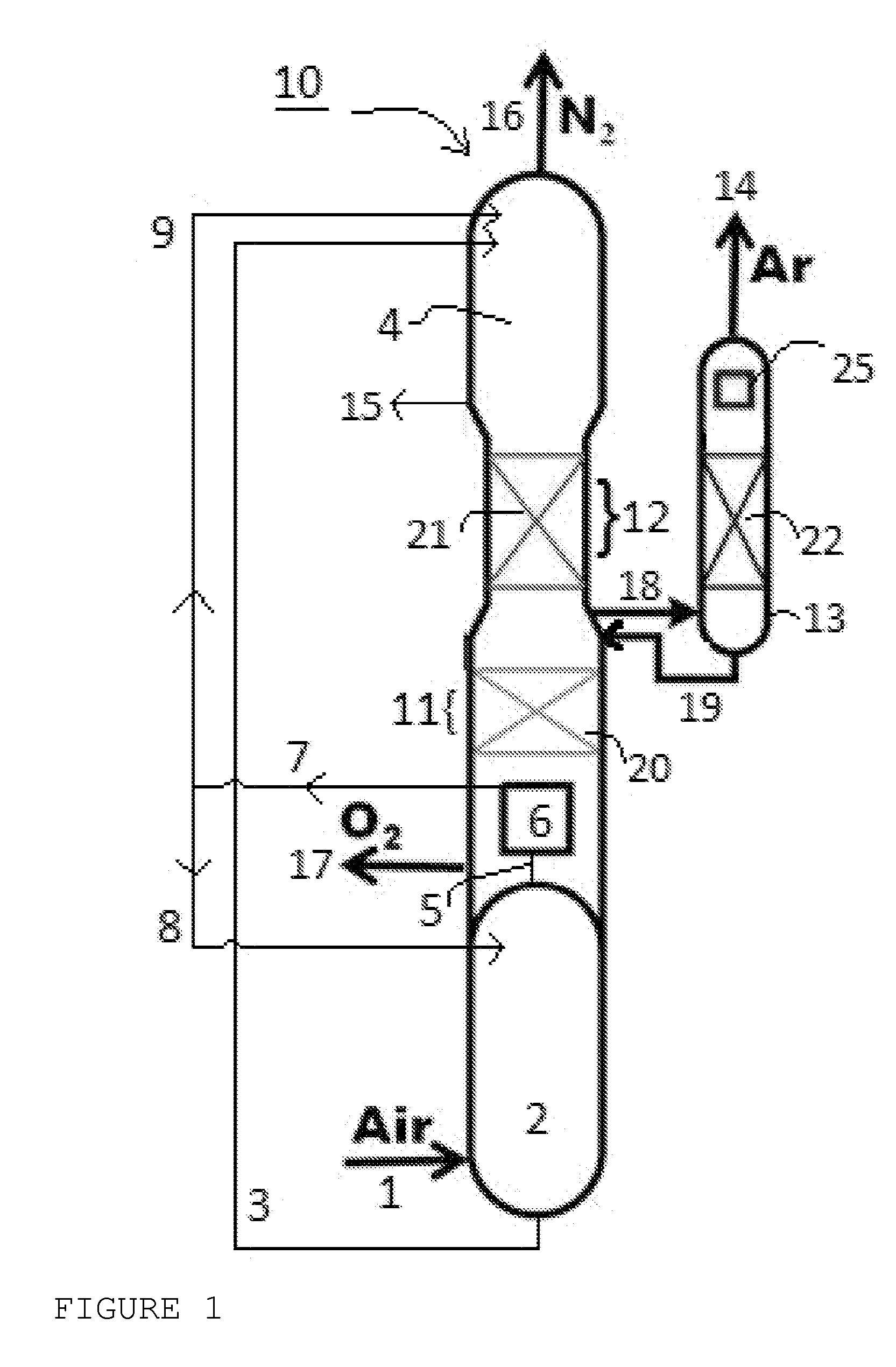

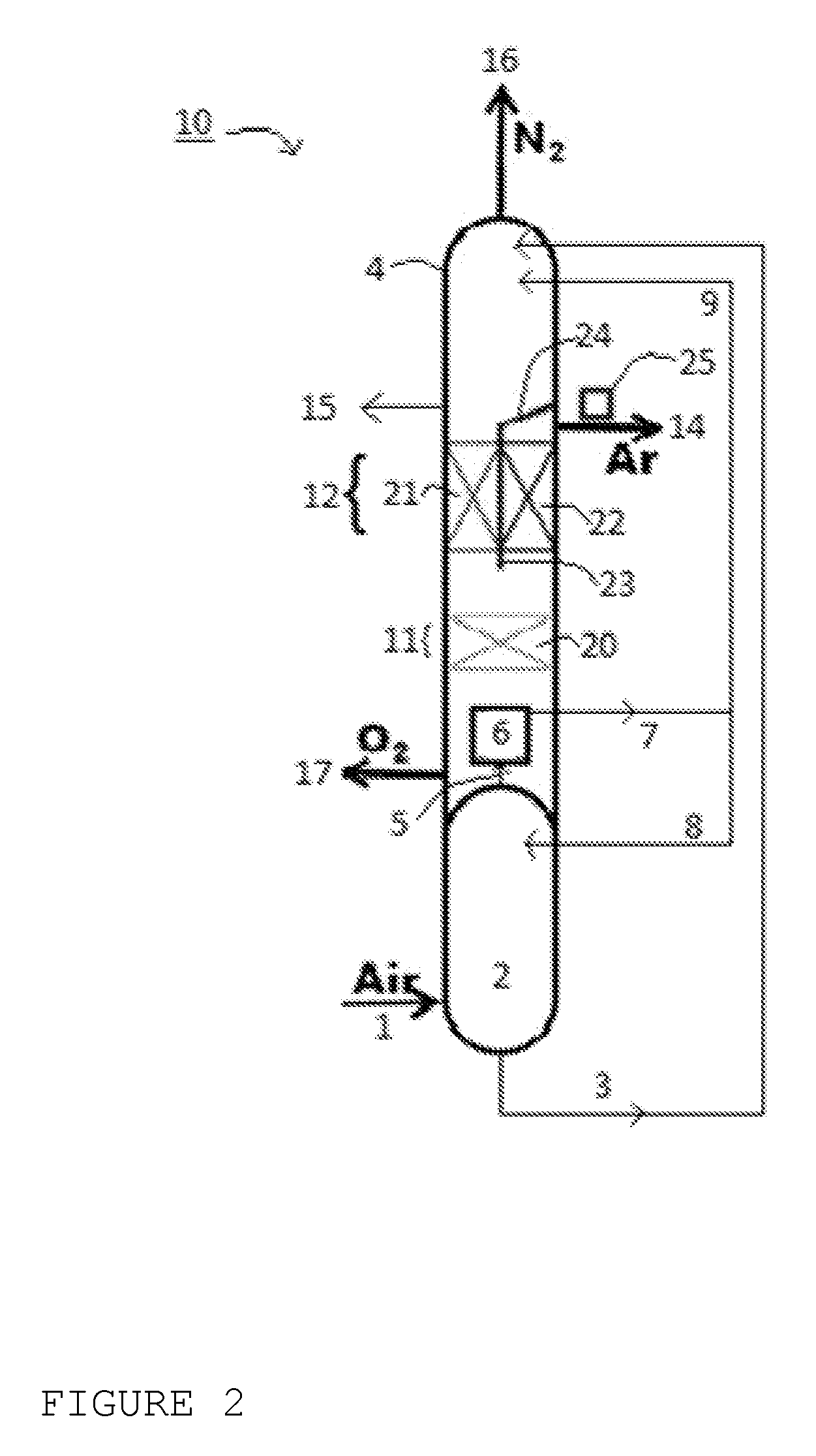

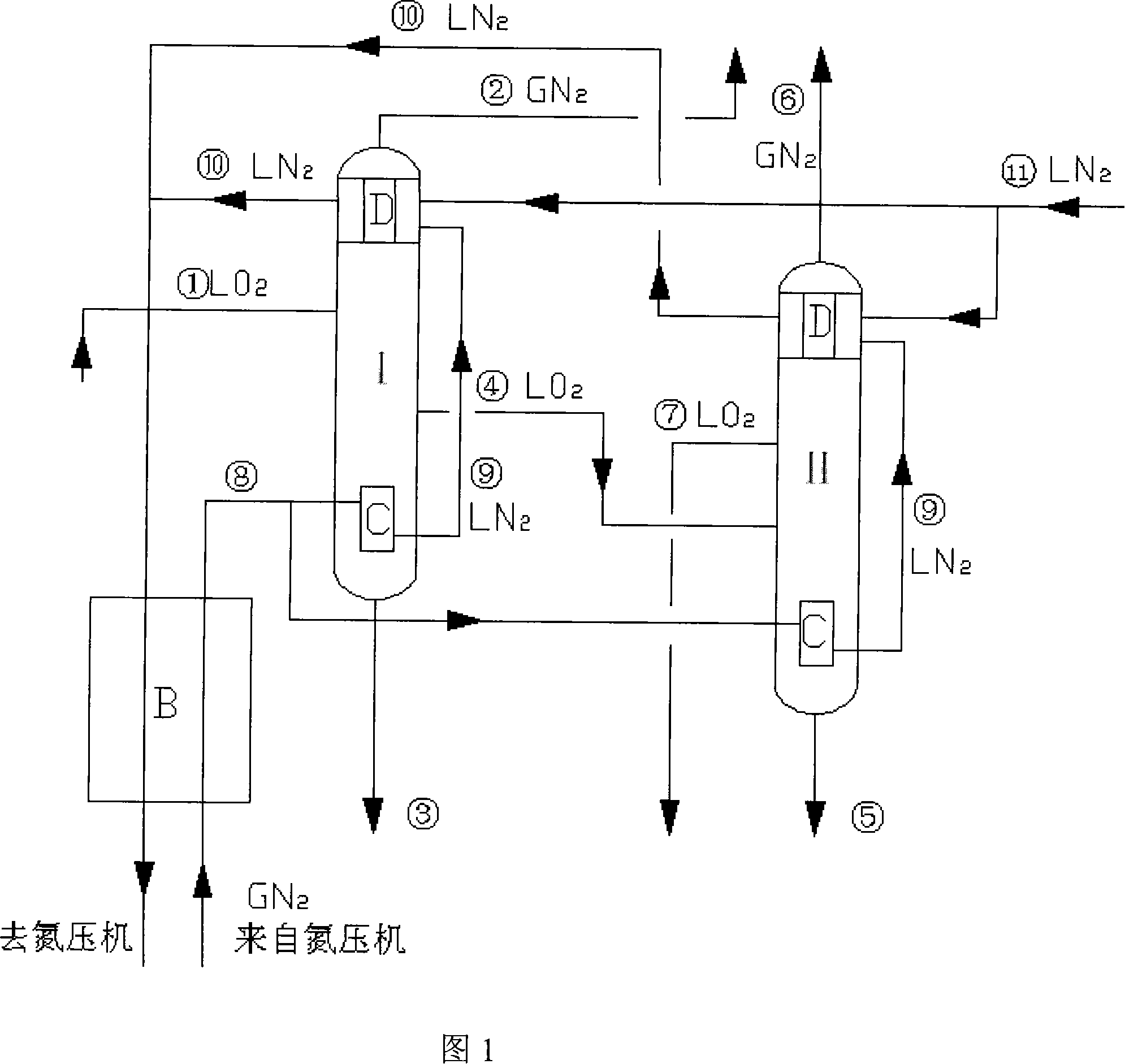

Method for preparing high purity oxygen by double-tower low temperature rectification

InactiveCN101148252AChange the reflux ratioLower the altitudeSolidificationLiquefactionOxygen contentTower

The present invention provides double tower low temperature rectification process of preparing high purity oxygen. Industrial liquid oxygen material with oxygen content of 99.6 % is low temperature rectified in two structured packing towers to obtain electronic industry level high purity oxygen of oxygen content not lower than 99.9998 % and impurity contents including N2 not more than 0.5 ppm, CH4 not more than 0.1 ppm, H2O not more than 0.1 ppm, and Ar not more than 0.5 ppm. The process of preparing high purity oxygen has best utilization of energy, low cold loss, low power consumption and low cost, and is suitable for industrial production.

Owner:WUHAN HUAXING IND & TECH +1

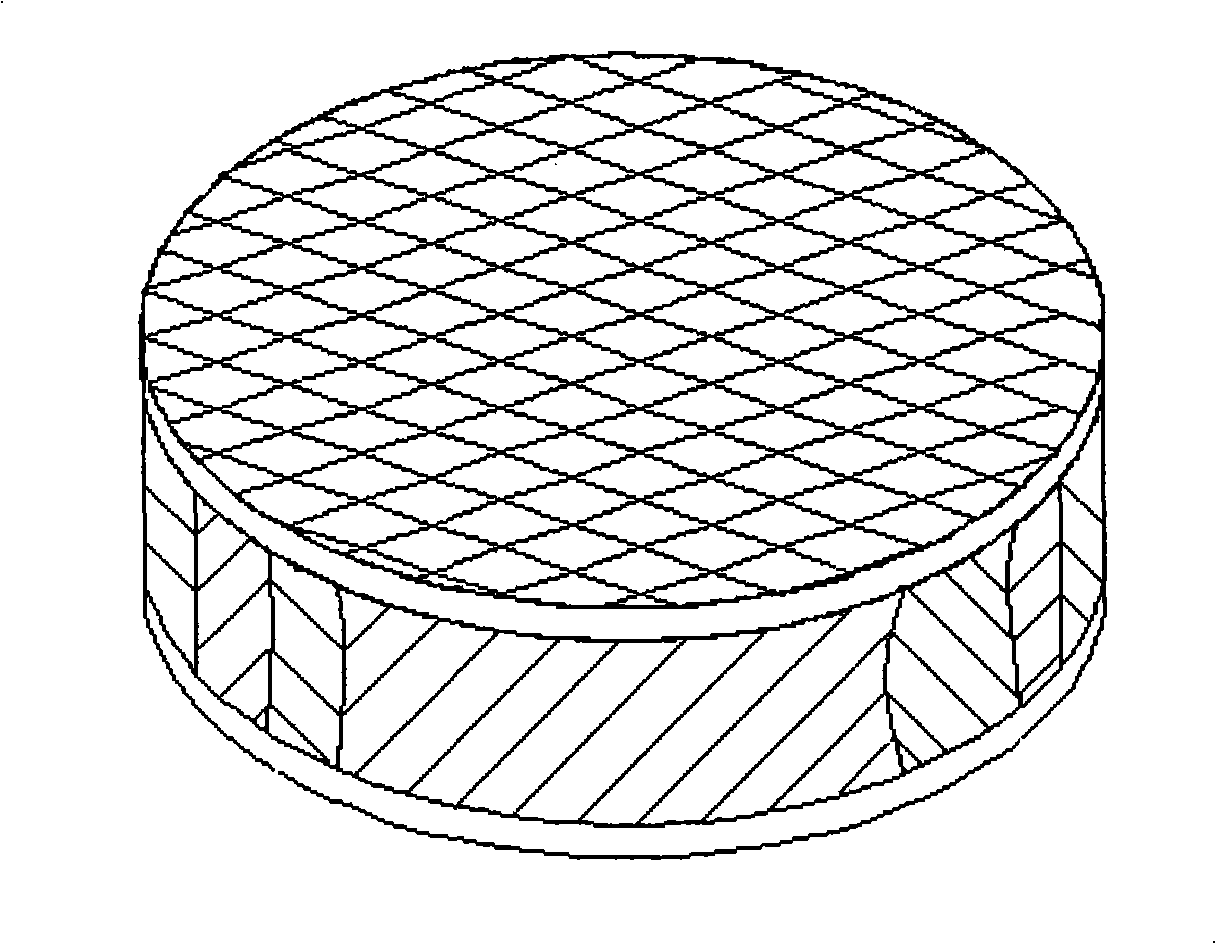

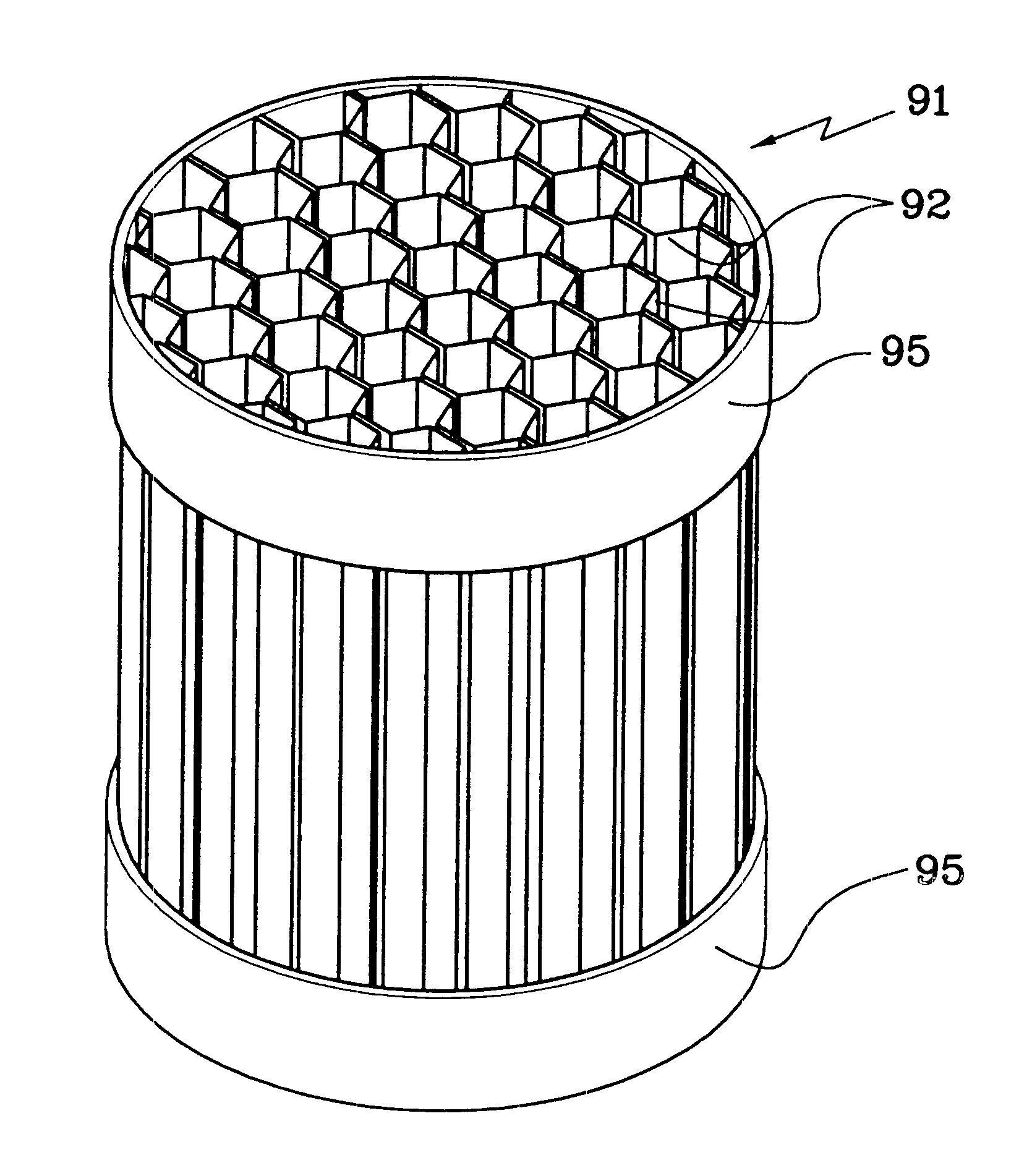

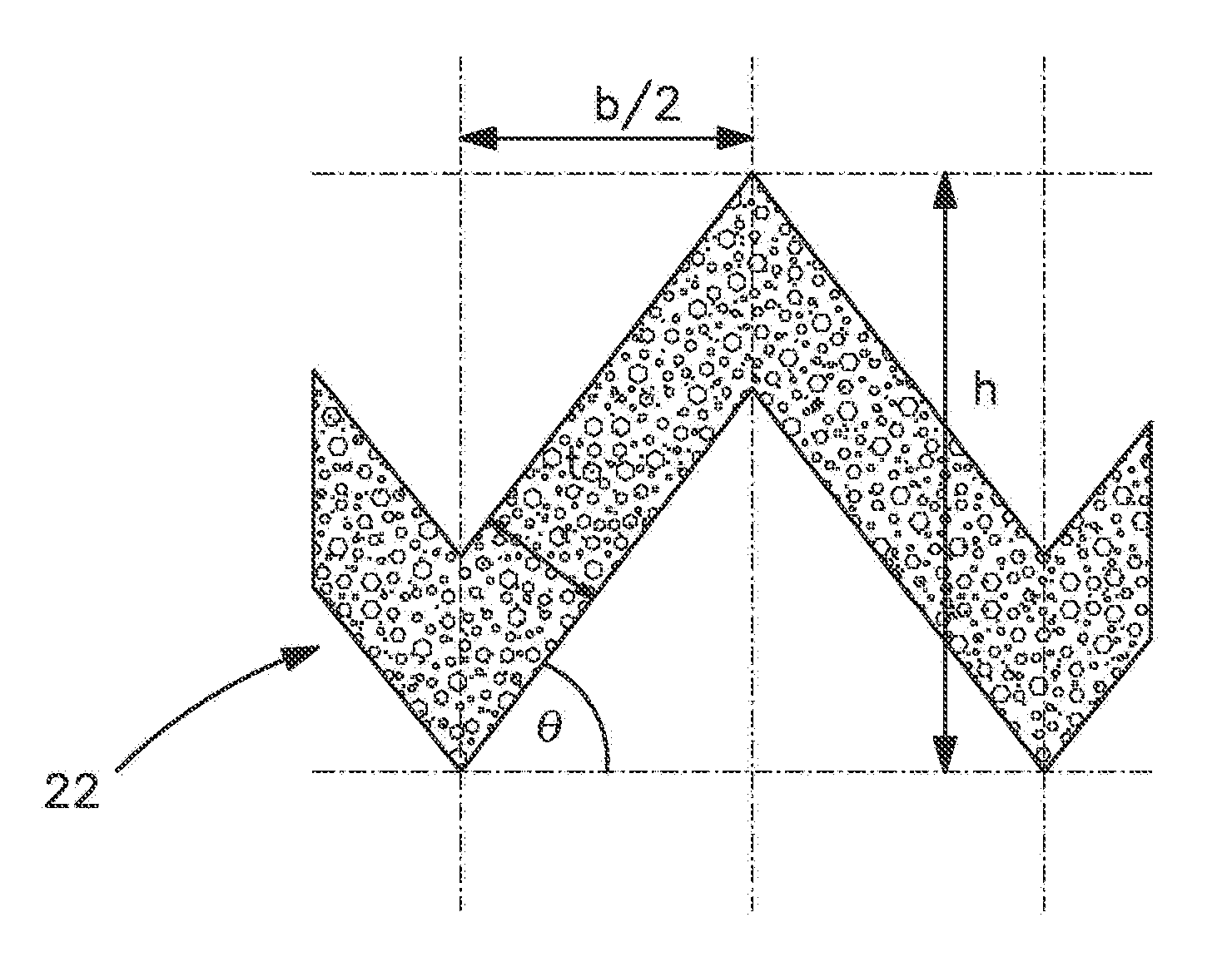

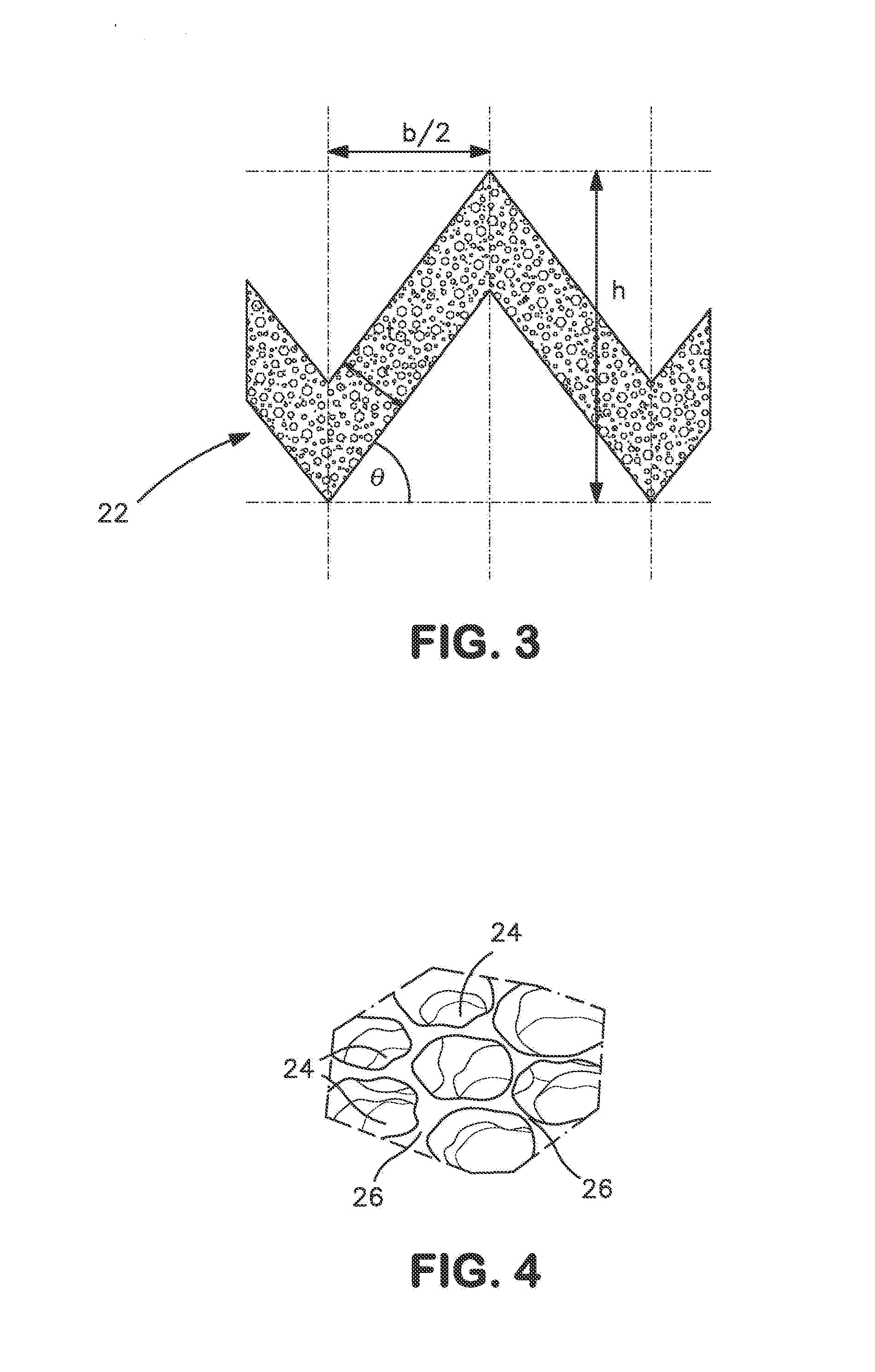

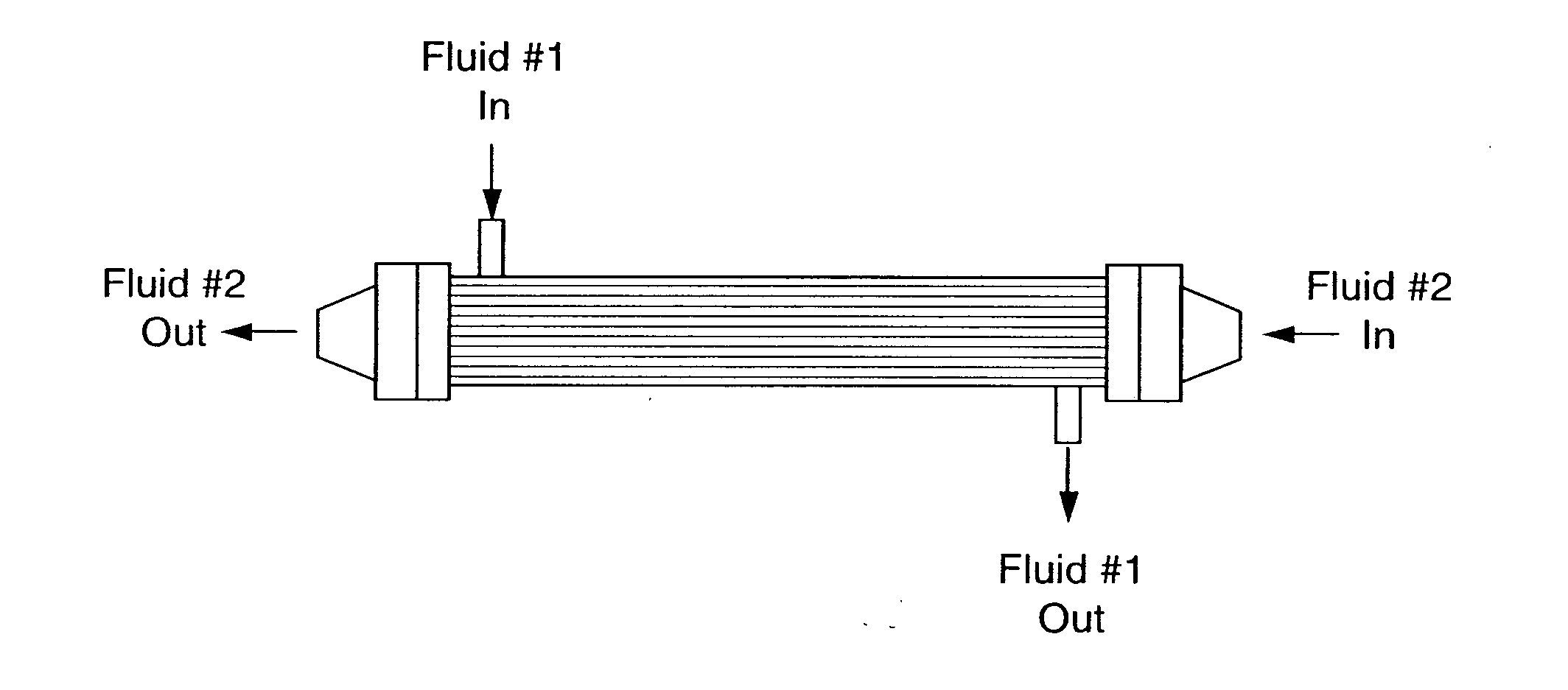

Distillation method and structured packing

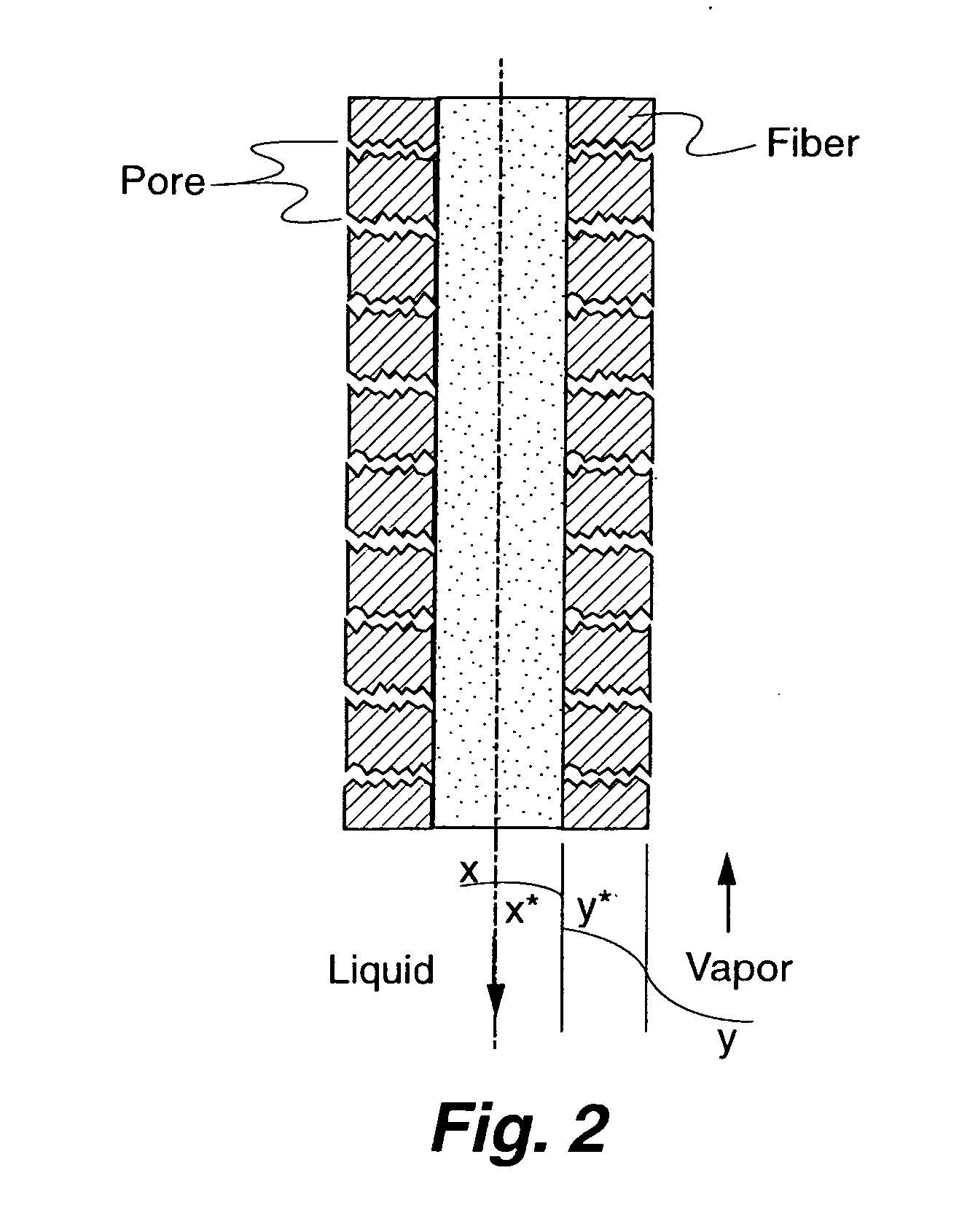

A method of conducting a distillation process and a cross-corrugated structured packing for use in such a process in which ascending vapor phases and descending liquid phases are contacted in such packing. The cross-corrugated structured packing contains corrugated sheets fabricated of an open cell foam-like material. The liquid phase produces a liquid film descending along struts forming cells of the material and the vapor phase ascends within the cross-corrugated structured packing and enters the cells and contacts the liquid film. The cross-corrugated structured packing is configured such that a superficial velocity at which ambient air would flow through the cross-corrugated structured packing at a pressure drop of 0.3″ wc / ft is no greater than 20 times a reference superficial velocity at which the ambient air would flow through the foam-like material making up the corrugated sheets at the same pressure drop to ensure that vapor enters the cells of the foam-like material.

Owner:PRAXAIR TECH INC

Porous membrane materials as structured packing for distillation

The present invention includes an apparatus and method for use of distillation packing material made from a non-selective meso / microporous membrane that separates light hydrocarbon mixtures.

Owner:LOS ALAMOS NATIONAL SECURITY

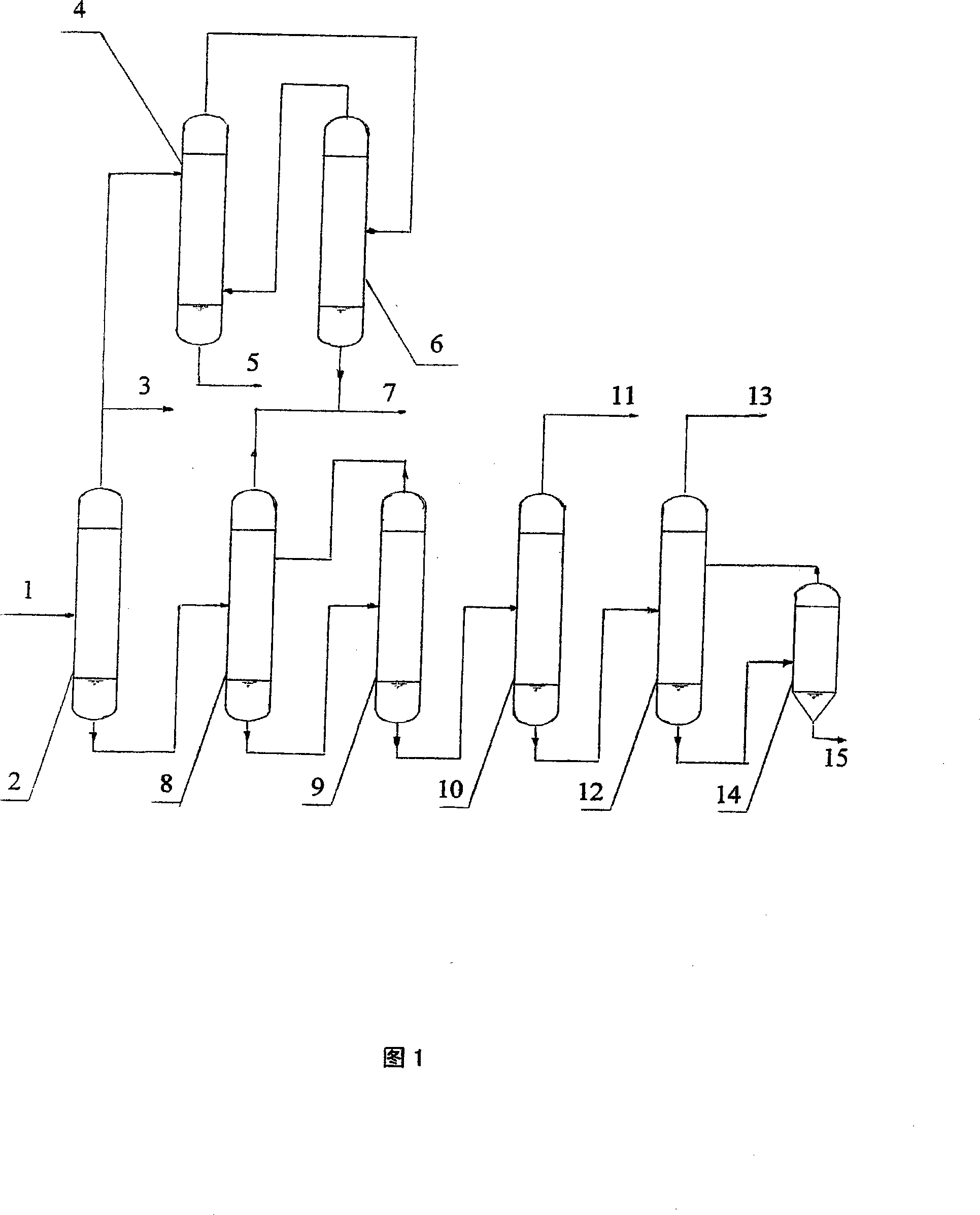

Method for separating catechol/hydroquinone from phenol hydroxylation reaction solution

ActiveCN101225025AImprove liquidityAvoid carbonizationOrganic chemistryOrganic compound preparationReboilerHydroquinone products

The invention discloses a method of separating catechol / hydroquinone in phenol hydroxylation reaction solution, which is characterized in that: phenol and hydrogen peroxide are reacted under catalyst action to produce reaction solution comprising water, phenol, catechol, hydroquinone and tar; vacuum rectification dehydration, de-phenol, catechol separating, hydroquinone separating and tar removing are made upon the reaction solution to prepare the catechol and the hydroquinone product; thermal medium oil independent circulation stepwise condensation / heat mode is adopted for the distillation system separating the catechol and the hydroquinone; vertical sieve plate is adopted for stripping section of the distillation tower; high-efficiency structured packing is adopted for the distillation section; embedded type structure in the tower is adopted for the condenser and the reboiler of the distillation tower. The method of separating catechol / hydroquinone in phenol hydroxylation reaction solution has the advantages of solving the problems of difficultly liquefying the catechol and the hydroquinone for the condenser at the top part of the distillation tower and easily causing material condensing or gasifying due to small difference value between the boiling point and the freezing point during vacuum rectifying for the catechol and the hydroquinone, prolonging production period, lowering unit consumption of product and reaching more than 99% for product purity of the catechol and the hydroquinone.

Owner:SHANGHAI HUAYI NEW MATERIAL

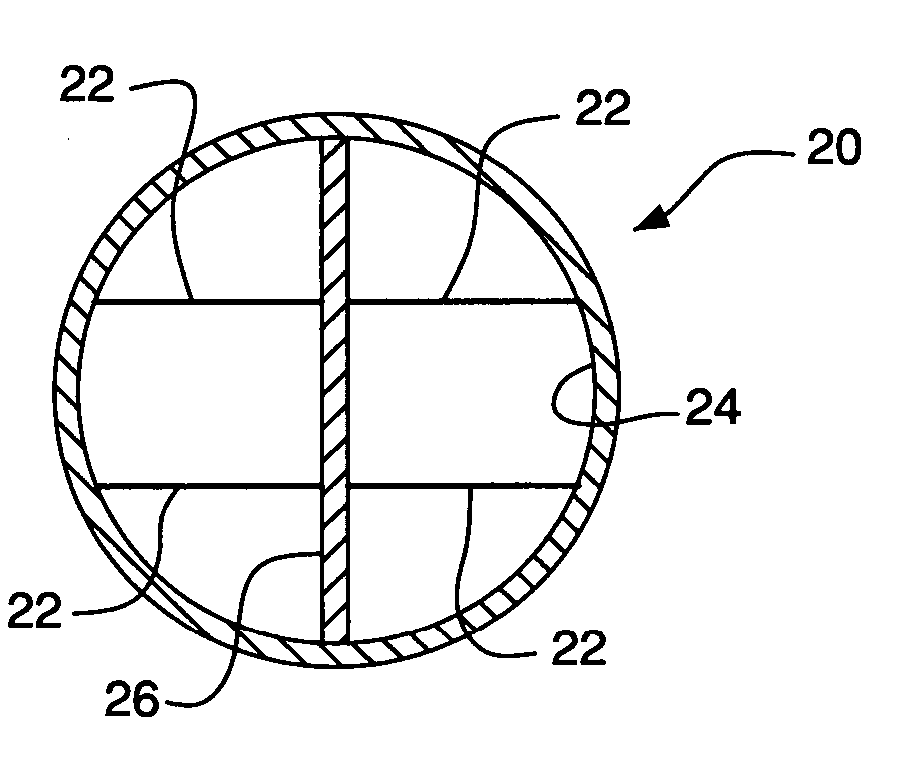

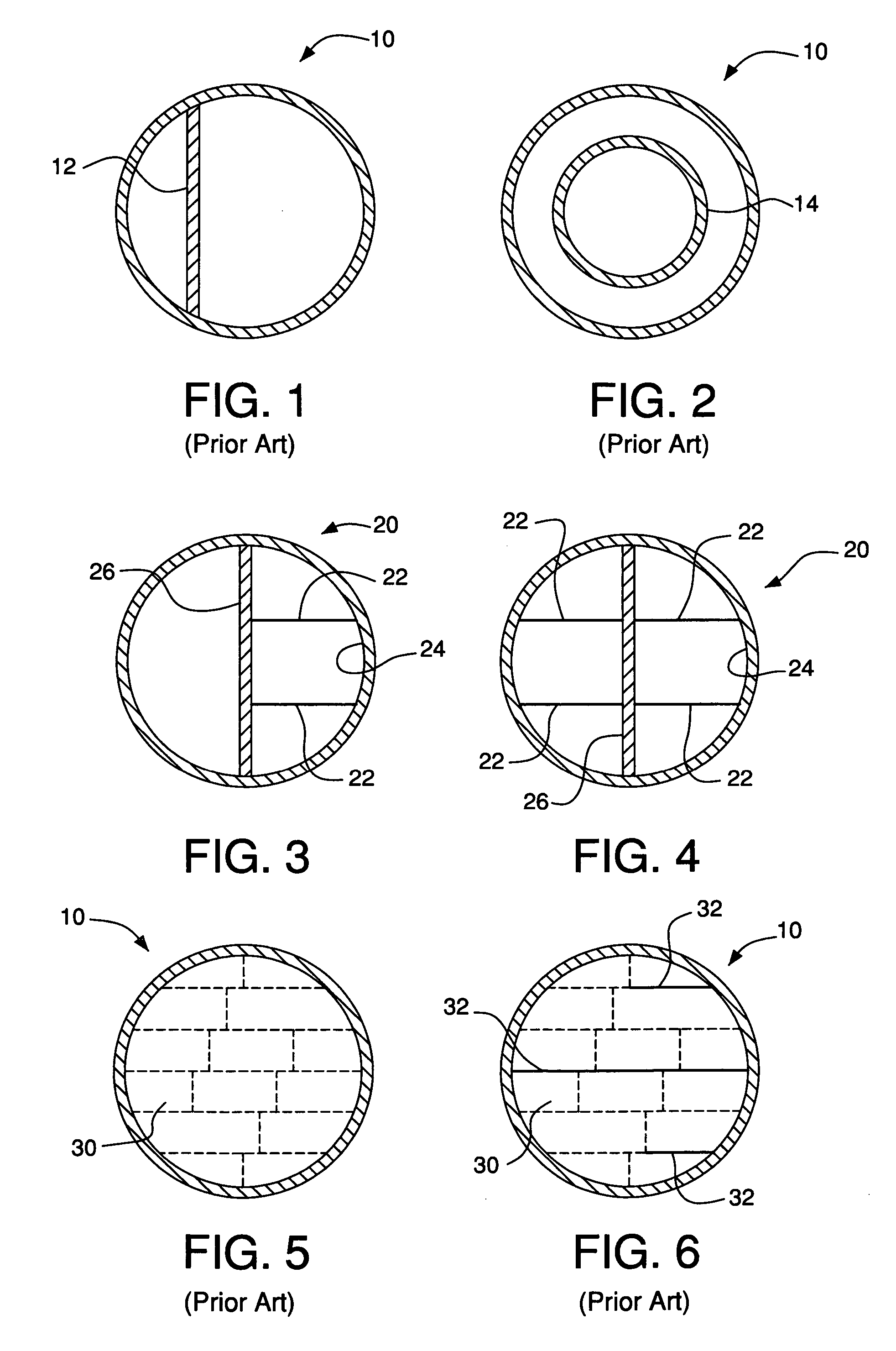

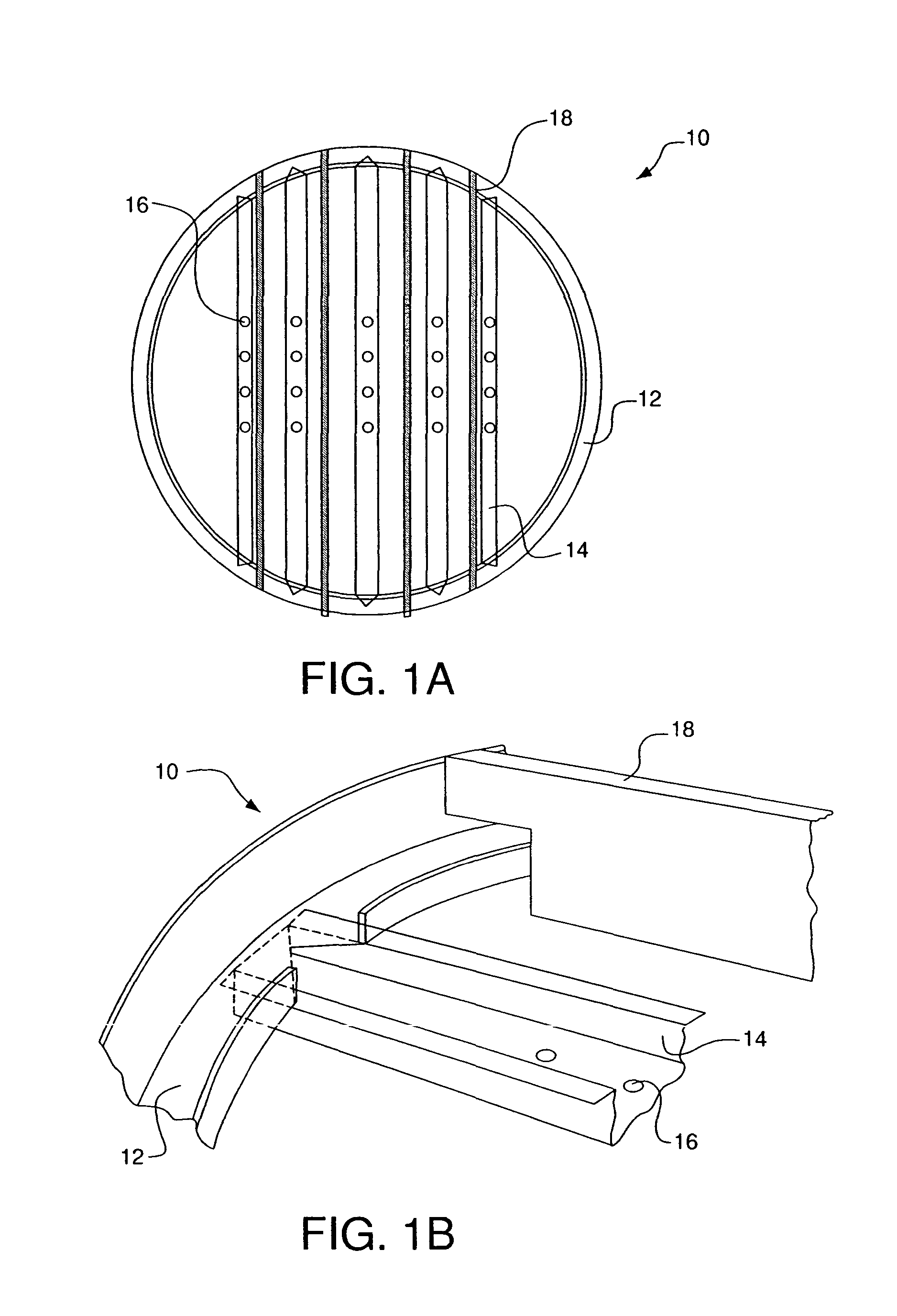

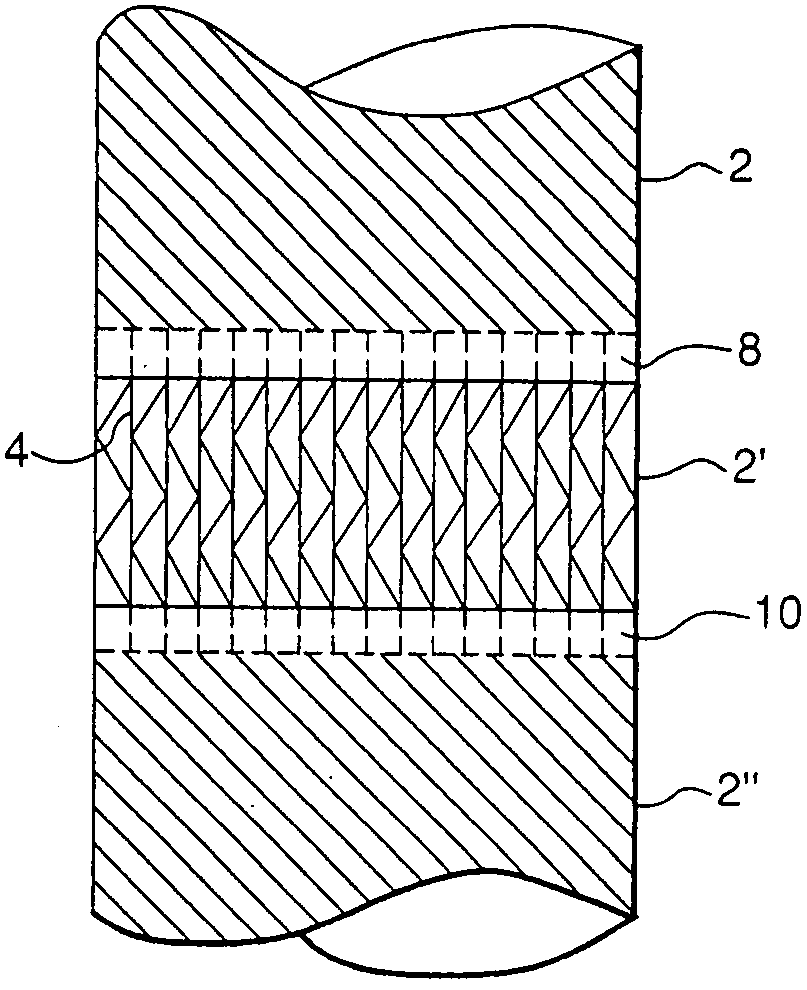

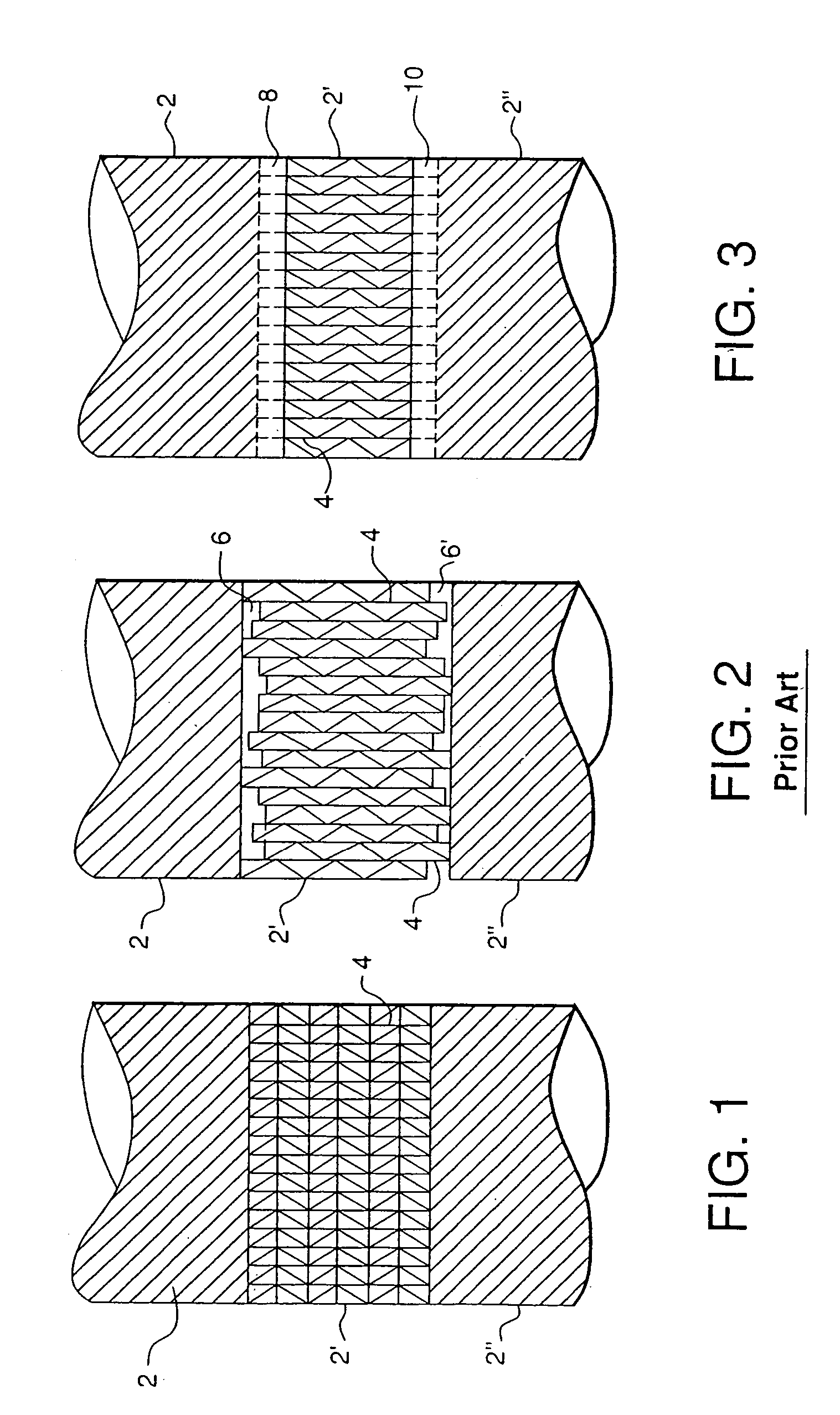

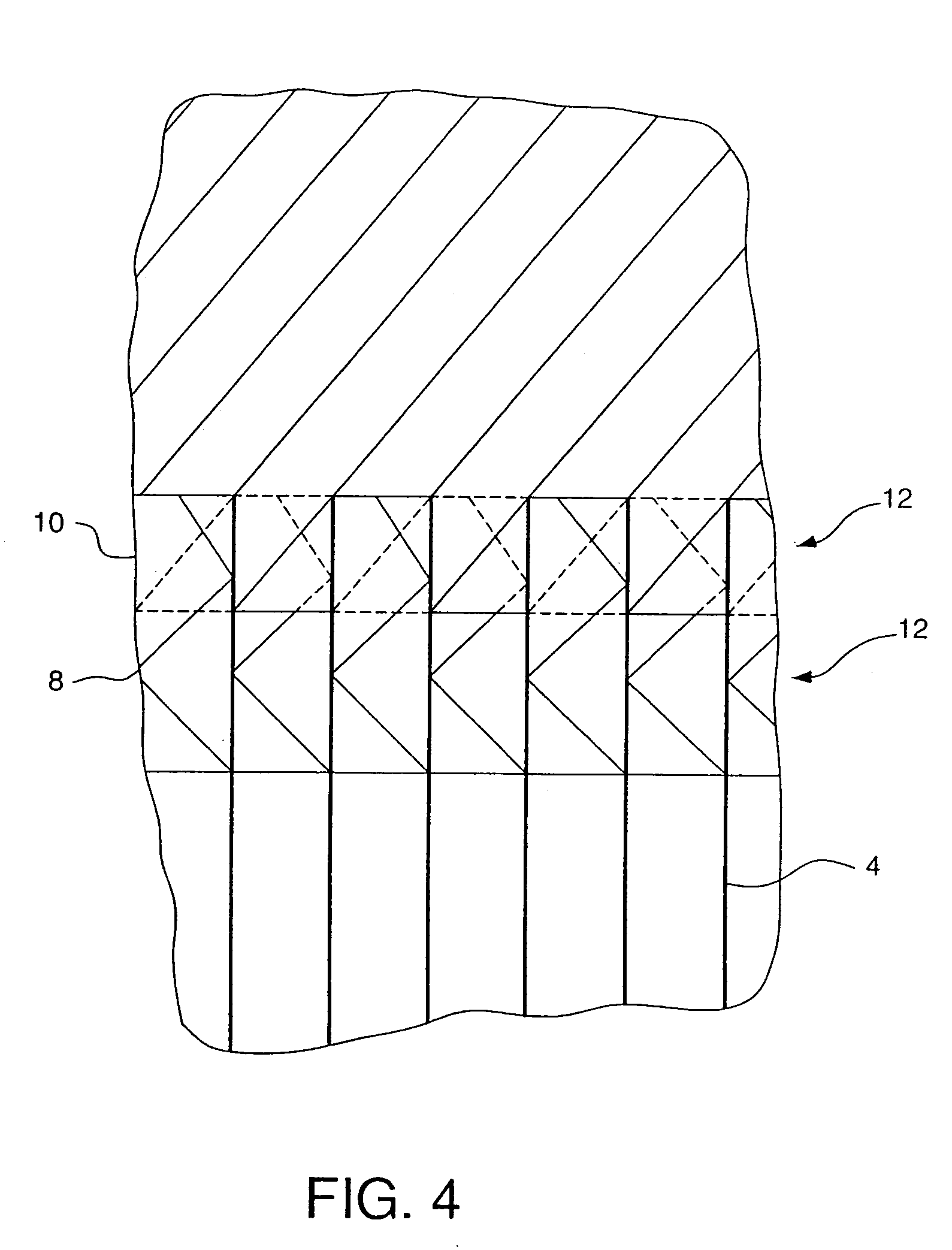

Structured packing with increased capacity

A structured packing element has at least one edge adapted to intermesh with an edge of at least one other structured packing element. The structured packing elements may be used in a packed section in an exchange column which includes: a first layer of structured packing including a first structured packing element having an upper edge adapted to intermesh with a generally vertically adjacent lower edge of a second structured packing element; and a second layer of structured packing located above the first layer of structured packing, the second layer including the second structured packing element having the lower edge adapted to intermesh with the generally vertically adjacent upper edge of the first structured packing element. The upper edge of the first structured packing element intermeshes with the lower edge of the second structured packing element.

Owner:AIR PROD & CHEM INC

Fractionating tower for separating acrylic aldehyde from 3-hydroxypropionaldehyde solution

ActiveCN101033180AEasy to cleanSpeed up contactCarbonyl compound separation/purificationEngineeringTower

This invention provides a rectifying tower for separating and hydrate acrolein to prepare non-reacted acrolein in a 3-lactic aldehyde reacted product, the top of the tower applies a new vertical seeve plate and the lower part applies a parallel flow jet filling tower plate and the rectifying section applies structured packing, which can increase the separation ability of towers to reduce pressure drop of the tower and operation temperature, reduce aggregation trend and reduction and aggregation trend of 3-hydroxide propaldehyde so as to reduce the loss of acrolein in the top tower.

Owner:SHANGHAI HUAYI NEW MATERIAL

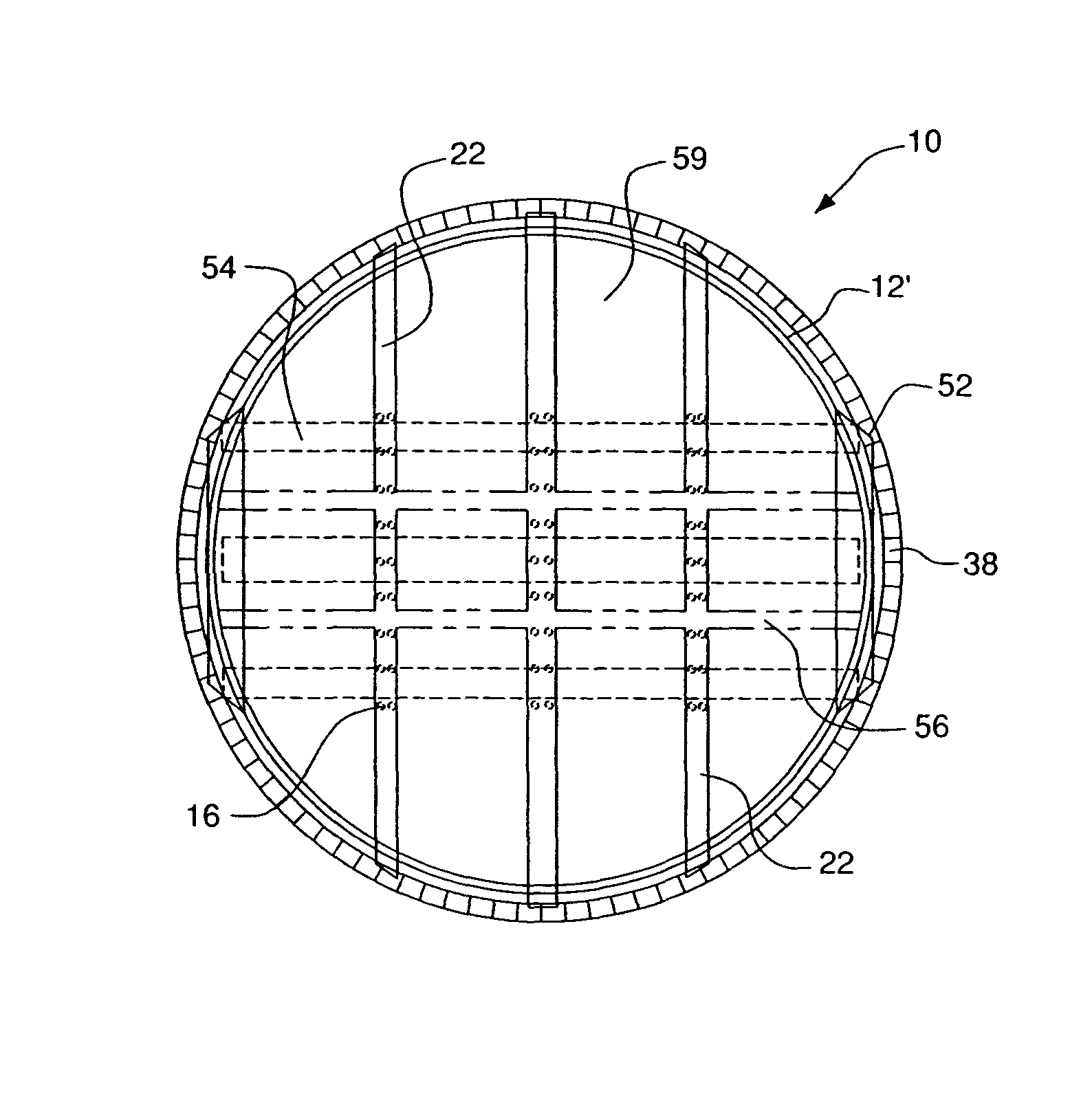

Wall-flow redistributor for packed columns

An apparatus for collecting and redistributing a flow of a liquid descending in an exchange column containing a layer of structured packing and having a longitudinal axis, a cross-sectional area, and an inner wall having an inner perimeter, includes: a wall-flow collector located above the layer of structured packing, the wall-flow collector having an outer perimeter adjacent the inner perimeter of the inner wall and being adapted to collect at least a portion of the liquid descending on or near the inner wall of the exchange column; a transmission means for transmitting at least a portion of the collected liquid collected by the wall-flow collector toward the longitudinal axis a substantial distance across the cross-sectional area of the exchange column; and a dispensing means for dispensing at least a portion of the portion of the collected liquid from the transmission means to the layer of structured packing.

Owner:AIR PROD & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com