Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35266 results about "Liquid phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid phase (plural liquid phases) (physics) One of the three fundamental structural phases of matter in which the thermal mobility of molecules or atoms is comparable with the cohesiveness, having them connected but fluid in a mass.

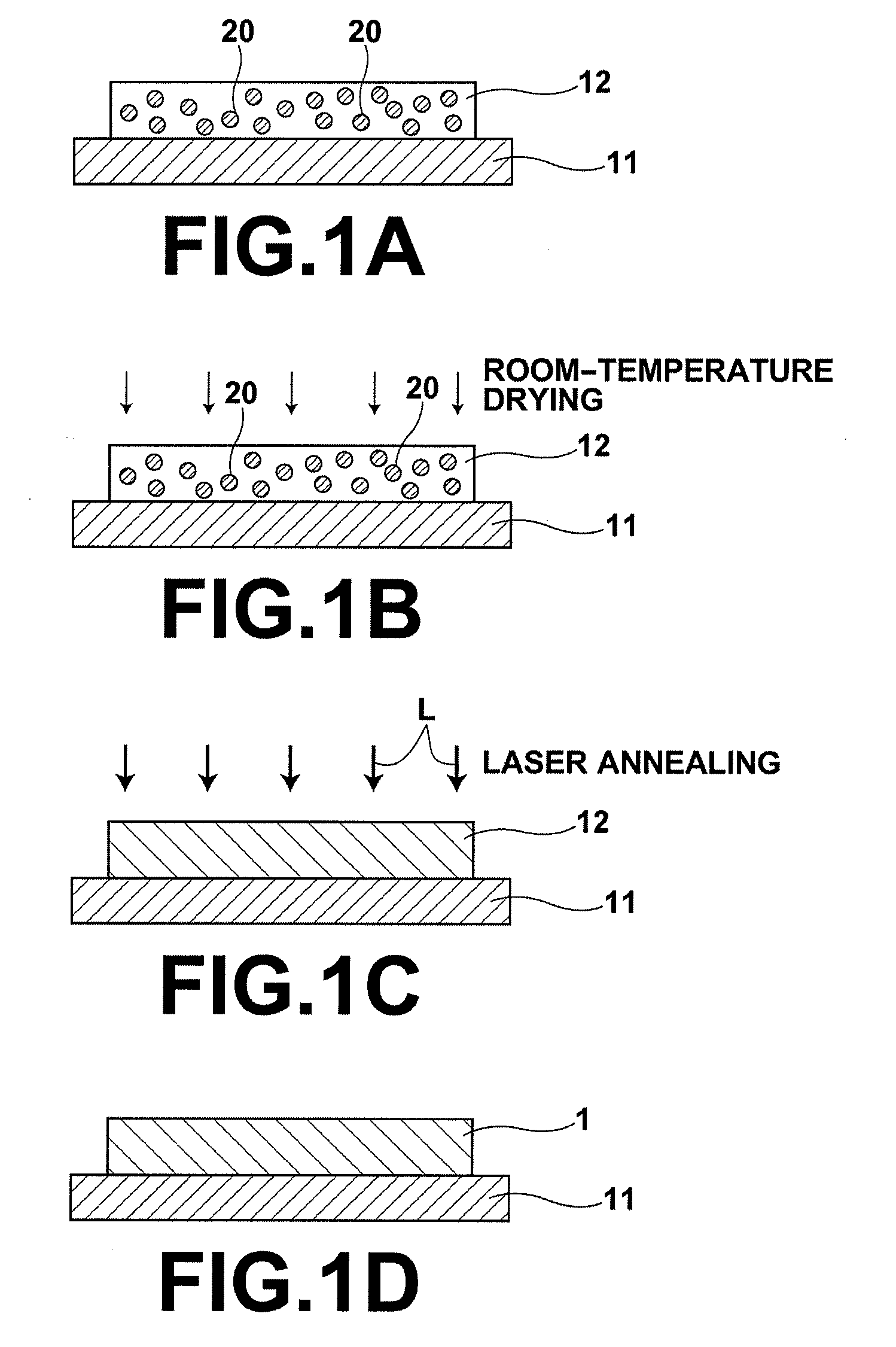

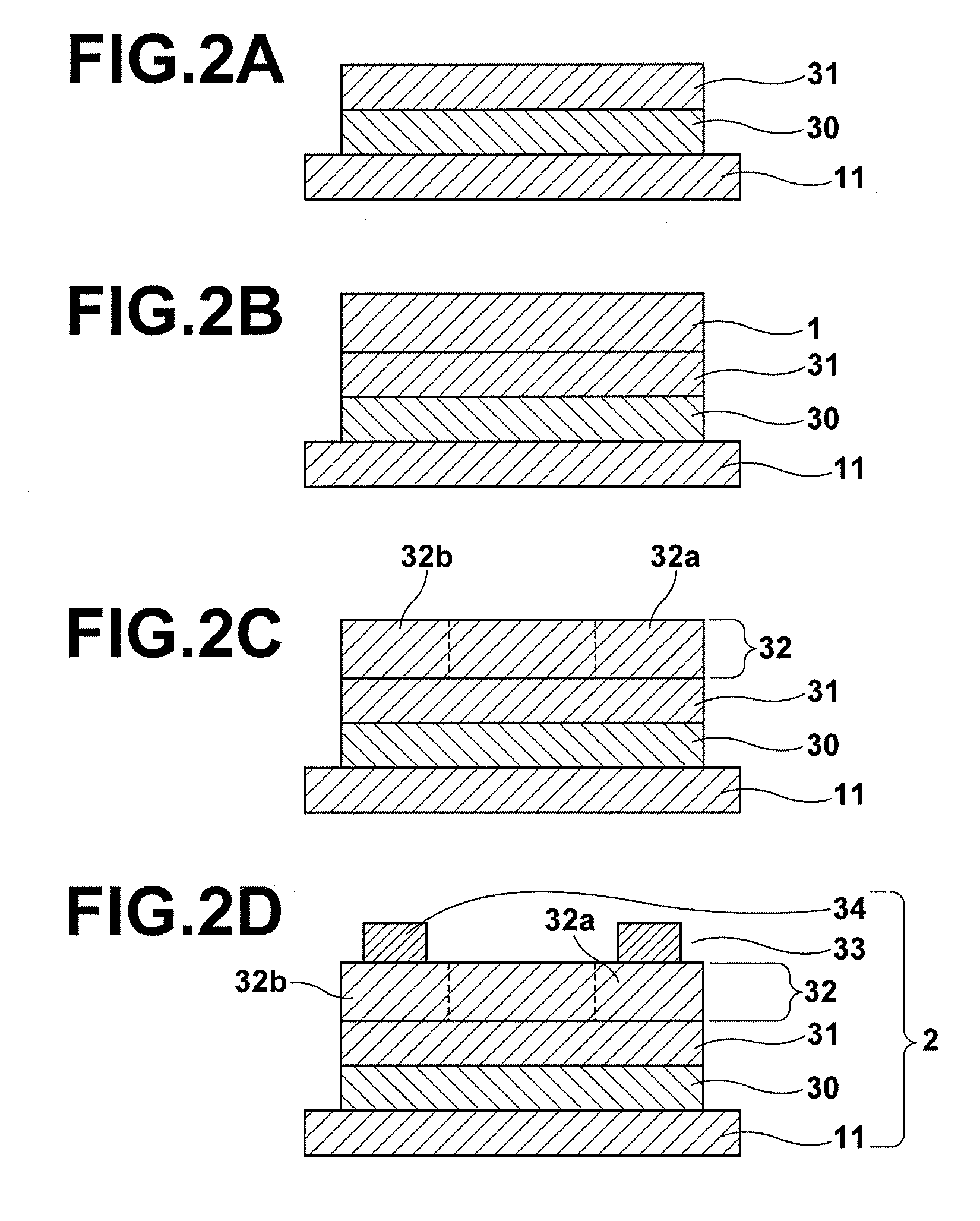

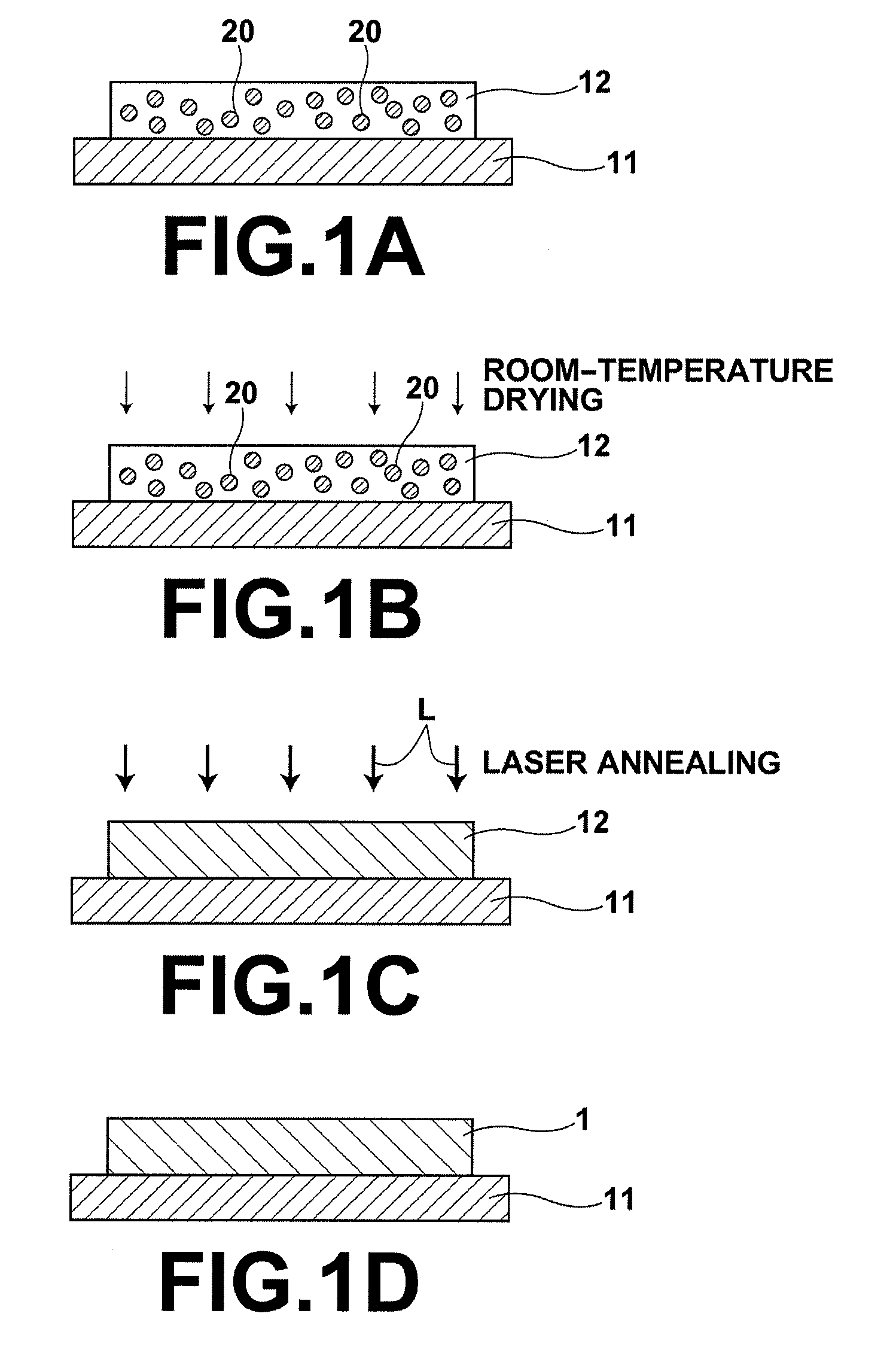

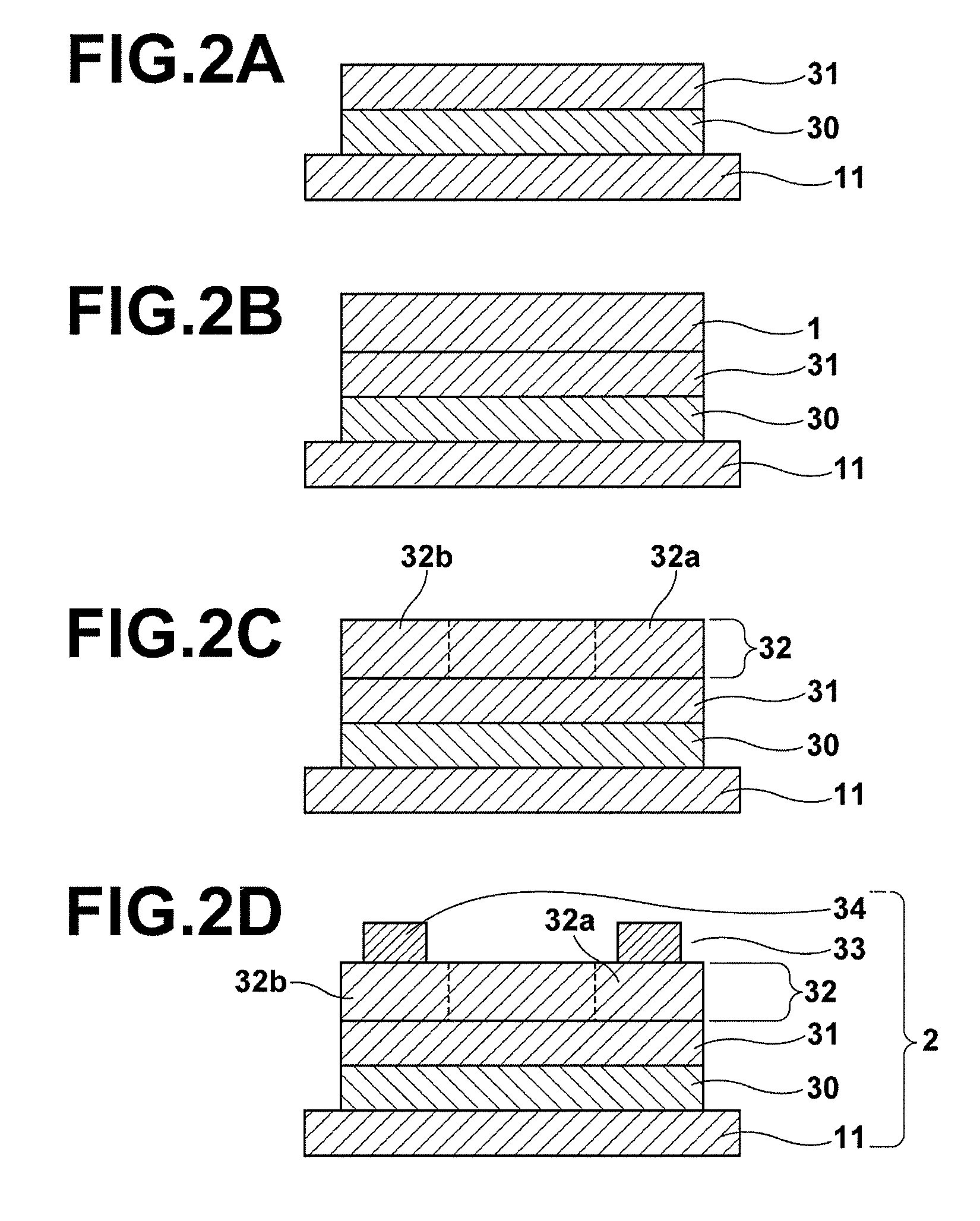

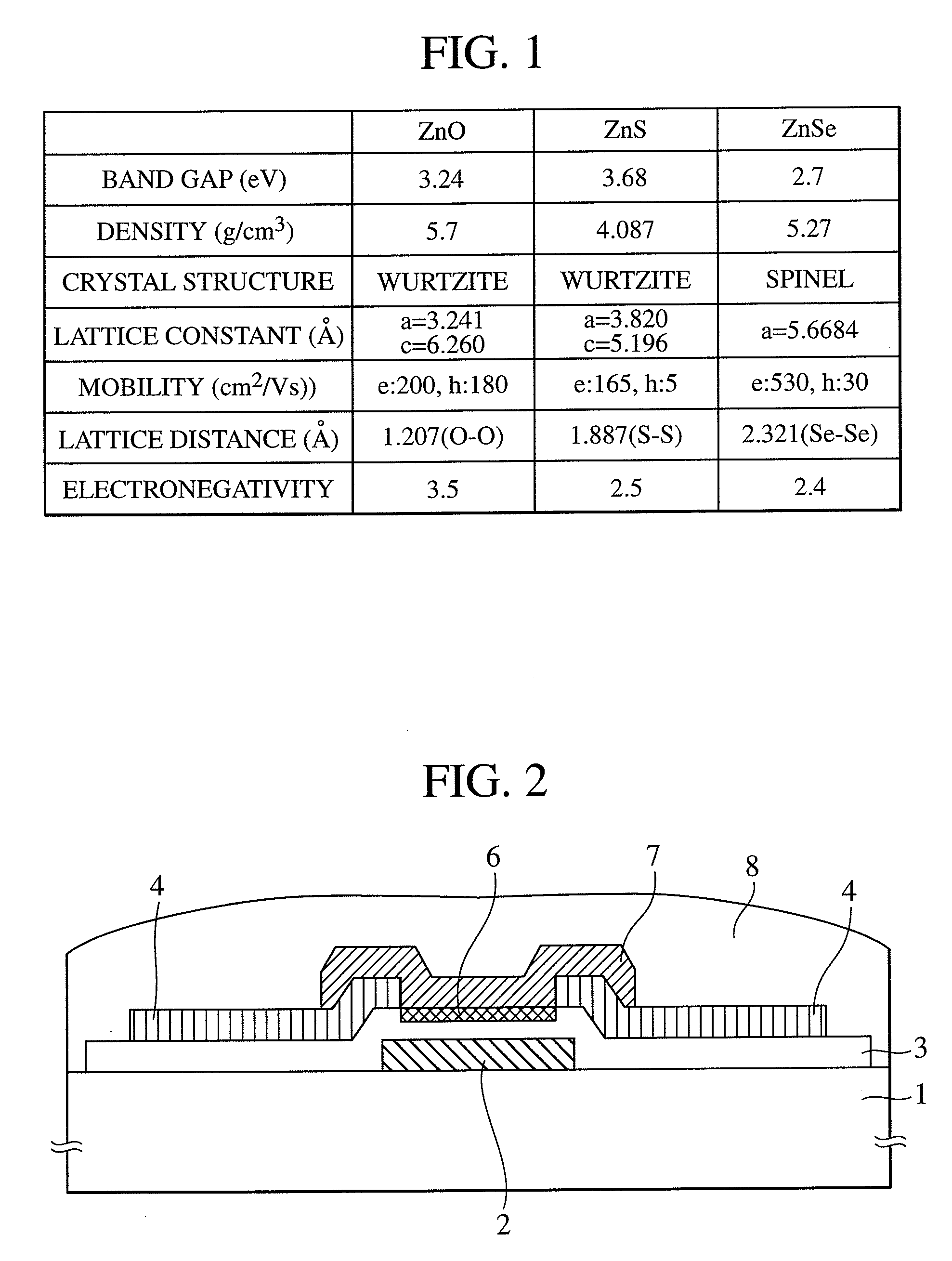

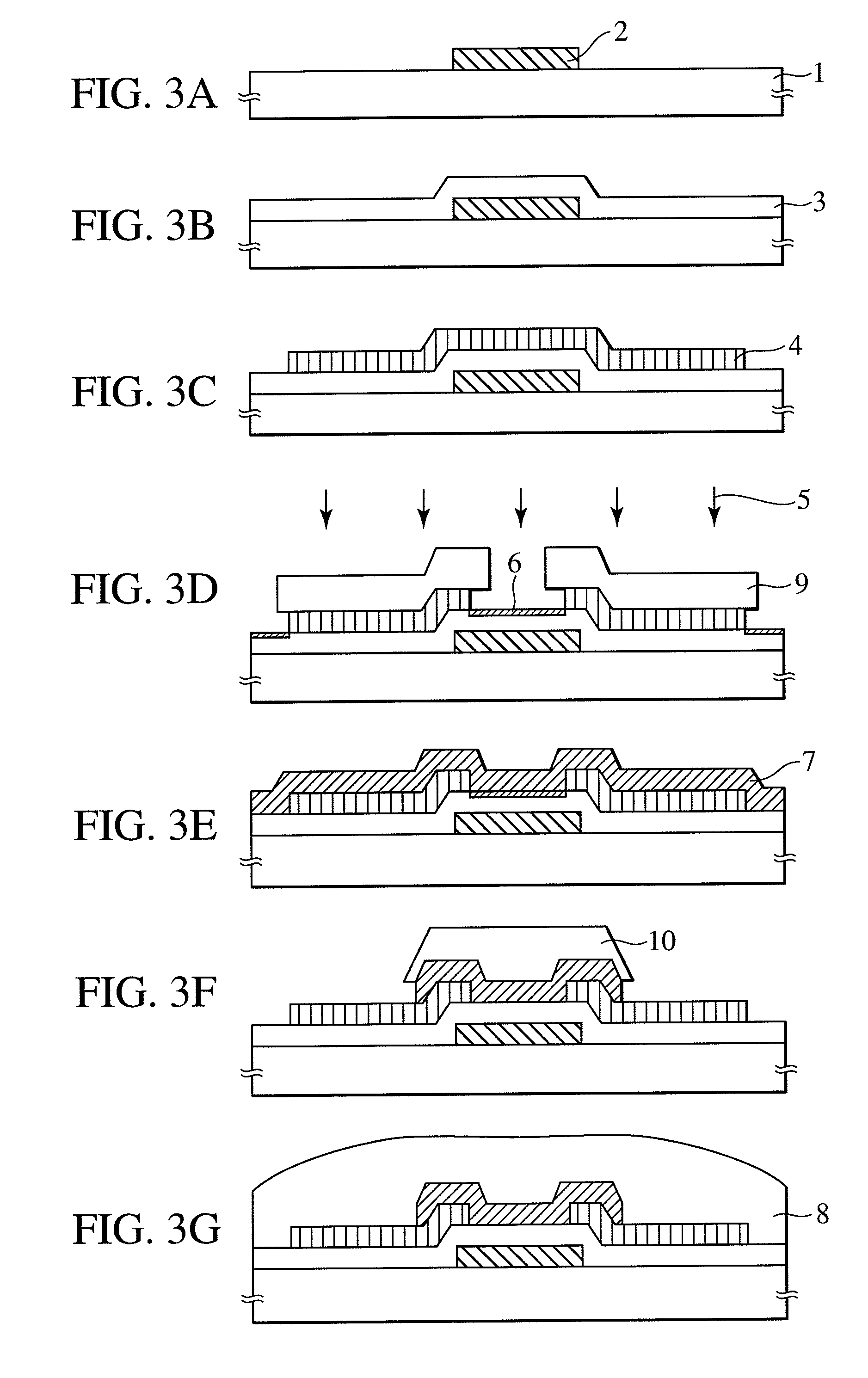

Process for producing oriented inorganic crystalline film, and semiconductor device using the oriented inorganic crystalline film

ActiveUS20090152506A1Orientation can be controlledLow costFrom gel stateFrom solid stateOrganic solventDevice material

In a process for producing an oriented inorganic crystalline film, a non-monocrystalline film containing inorganic crystalline particles is formed on a substrate by a liquid phase technique using a raw-material solution which contains a raw material and an organic solvent, where the inorganic crystalline particles have a layered crystal structure and are contained in the raw material. Then, the non-monocrystalline film is crystallized by heating the non-monocrystalline film to a temperature equal to or higher than the crystallization temperature of the non-monocrystalline film so that part of the inorganic crystalline particles act as crystal nuclei.

Owner:FUJIFILM CORP

Laundry multi-compartment pouch composition

InactiveUS20090011970A1Improve bleaching effectEasy to useDetergent materialsDetergent compounding agentsSolid componentWater soluble

This invention relates to a laundry pouch made from a water-soluble film and having at least two compartments, containing a solid component and a liquid component, wherein the solid phase contains a peroxide source and the liquid phase contains bleach activator. The present invention also relates to a method for treating laundry by placing the pouch, according to the present invention, in the drum of the washing machine.

Owner:THE PROCTER & GAMBLE COMPANY

Process for producing oriented inorganic crystalline film, and semiconductor device using the oriented inorganic crystalline film

ActiveUS8202365B2Orientation can be controlledLow costFrom gel stateFrom solid stateOrganic solventCrystal structure

In a process for producing an oriented inorganic crystalline film, a non-monocrystalline film containing inorganic crystalline particles is formed on a substrate by a liquid phase technique using a raw-material solution which contains a raw material and an organic solvent, where the inorganic crystalline particles have a layered crystal structure and are contained in the raw material. Then, the non-monocrystalline film is crystallized by heating the non-monocrystalline film to a temperature equal to or higher than the crystallization temperature of the non-monocrystalline film so that part of the inorganic crystalline particles act as crystal nuclei.

Owner:FUJIFILM CORP

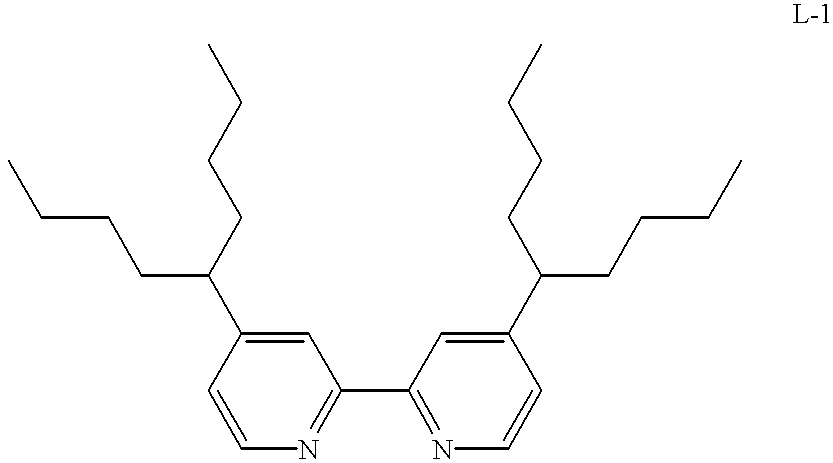

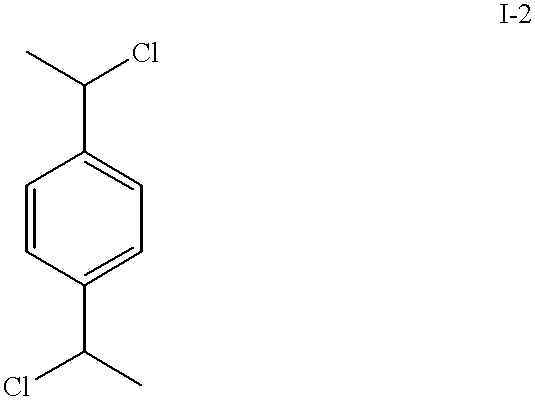

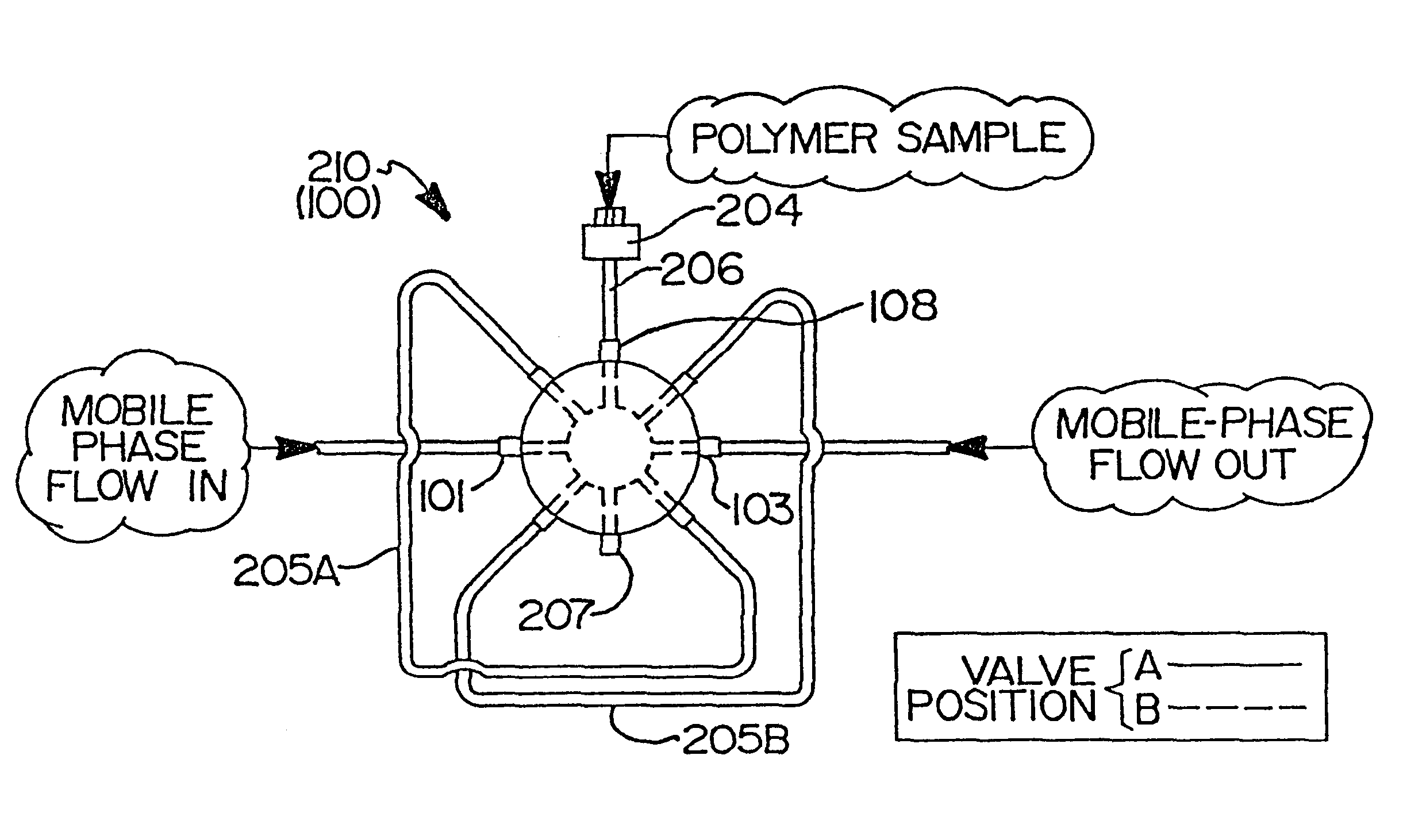

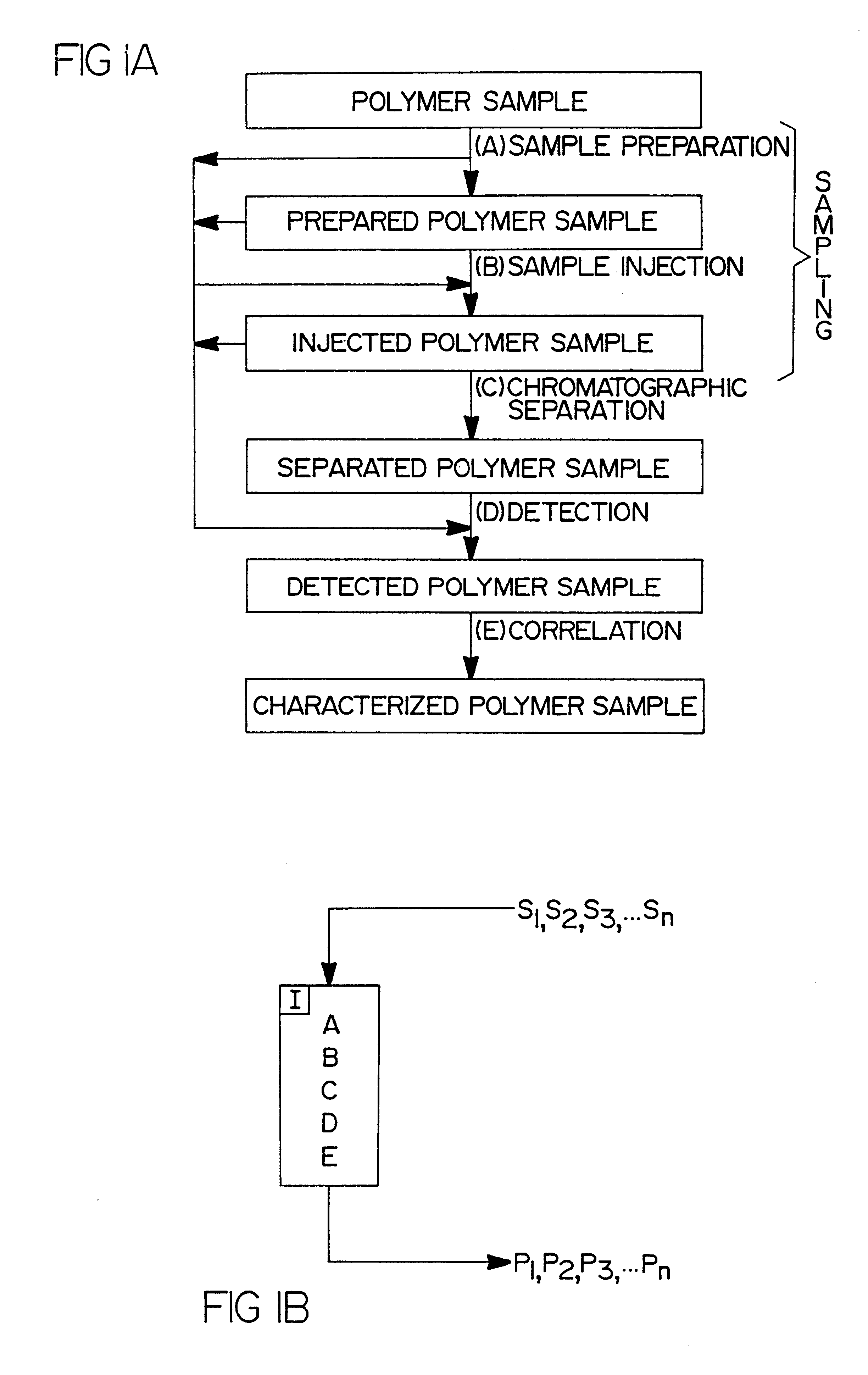

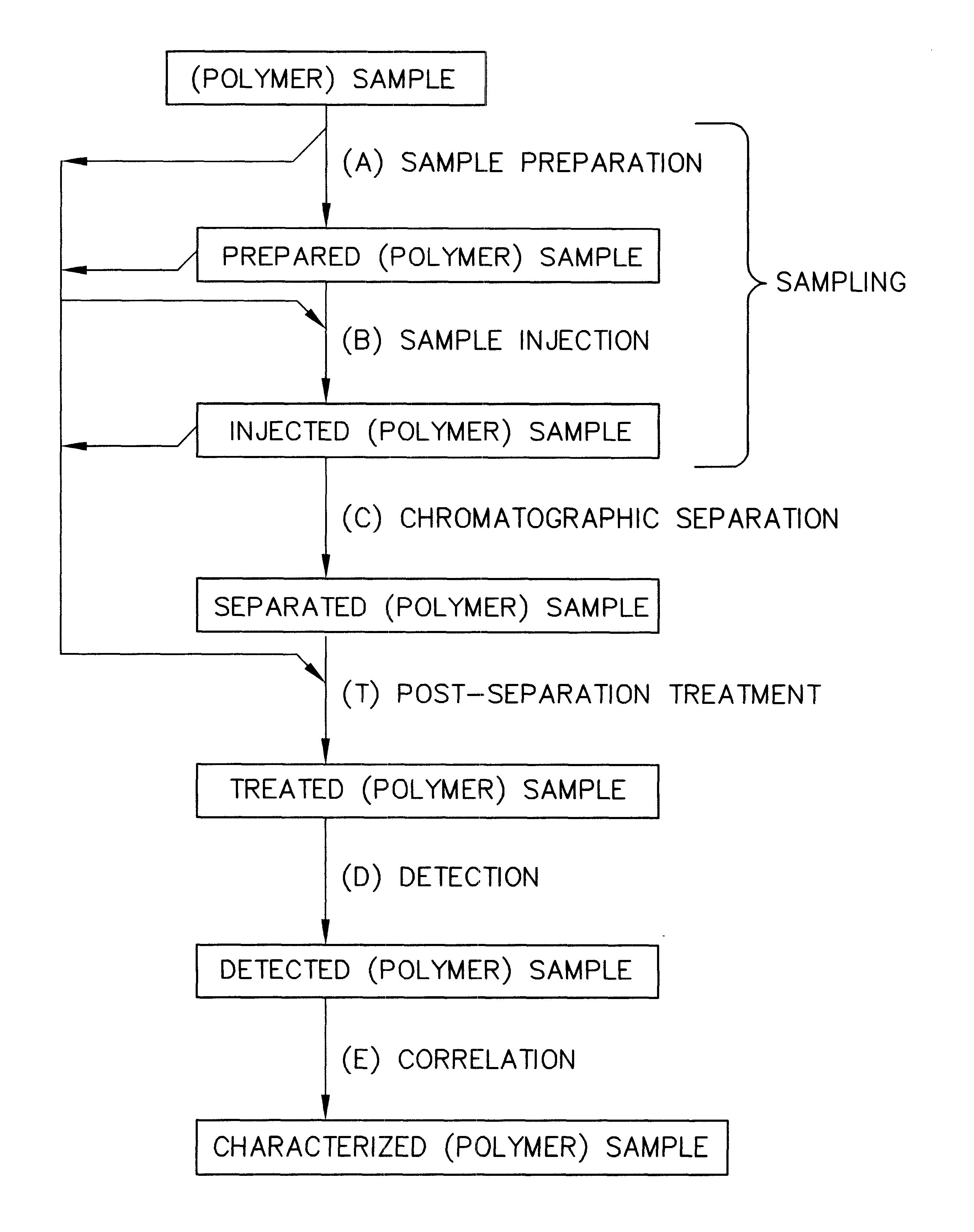

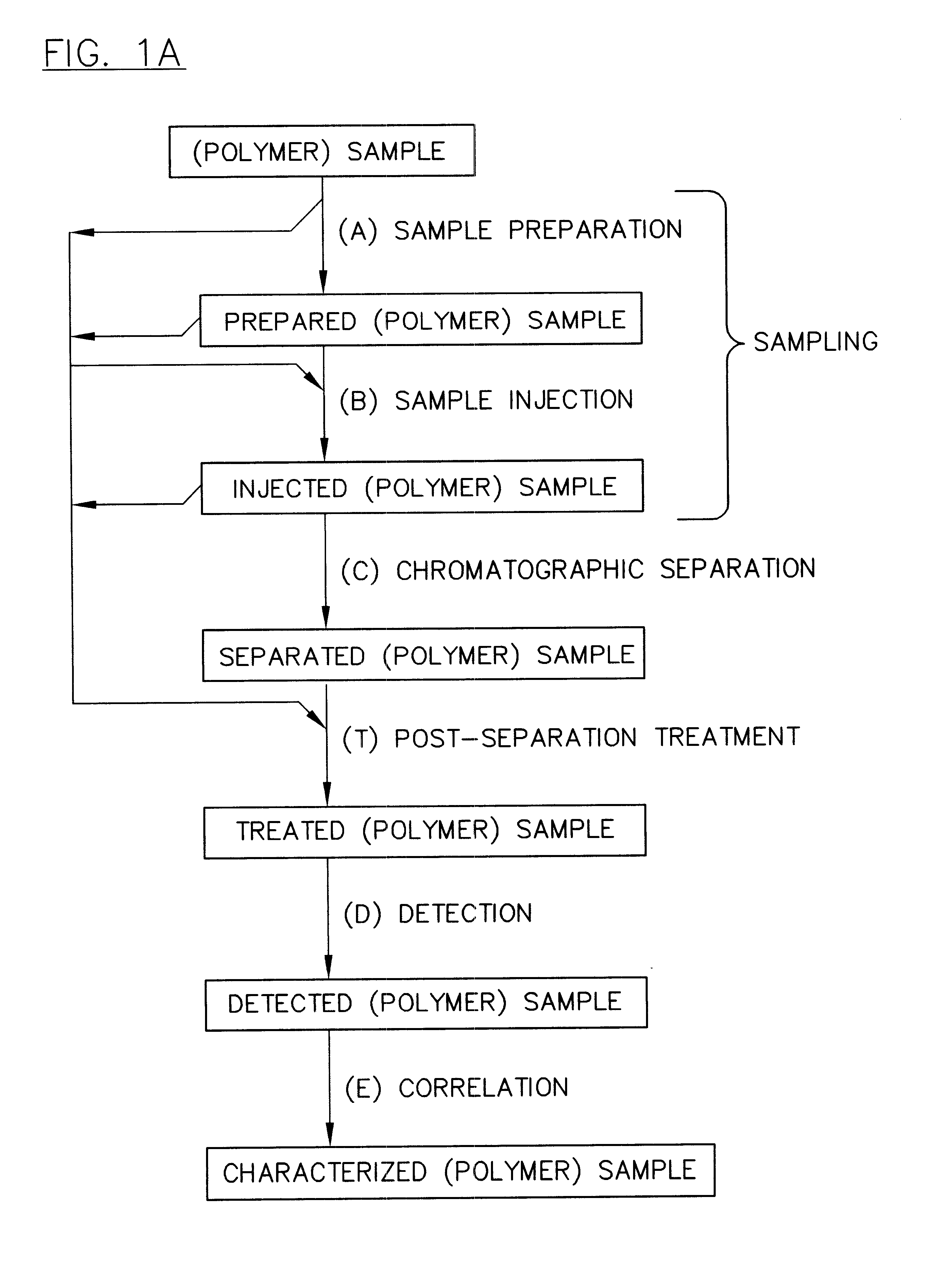

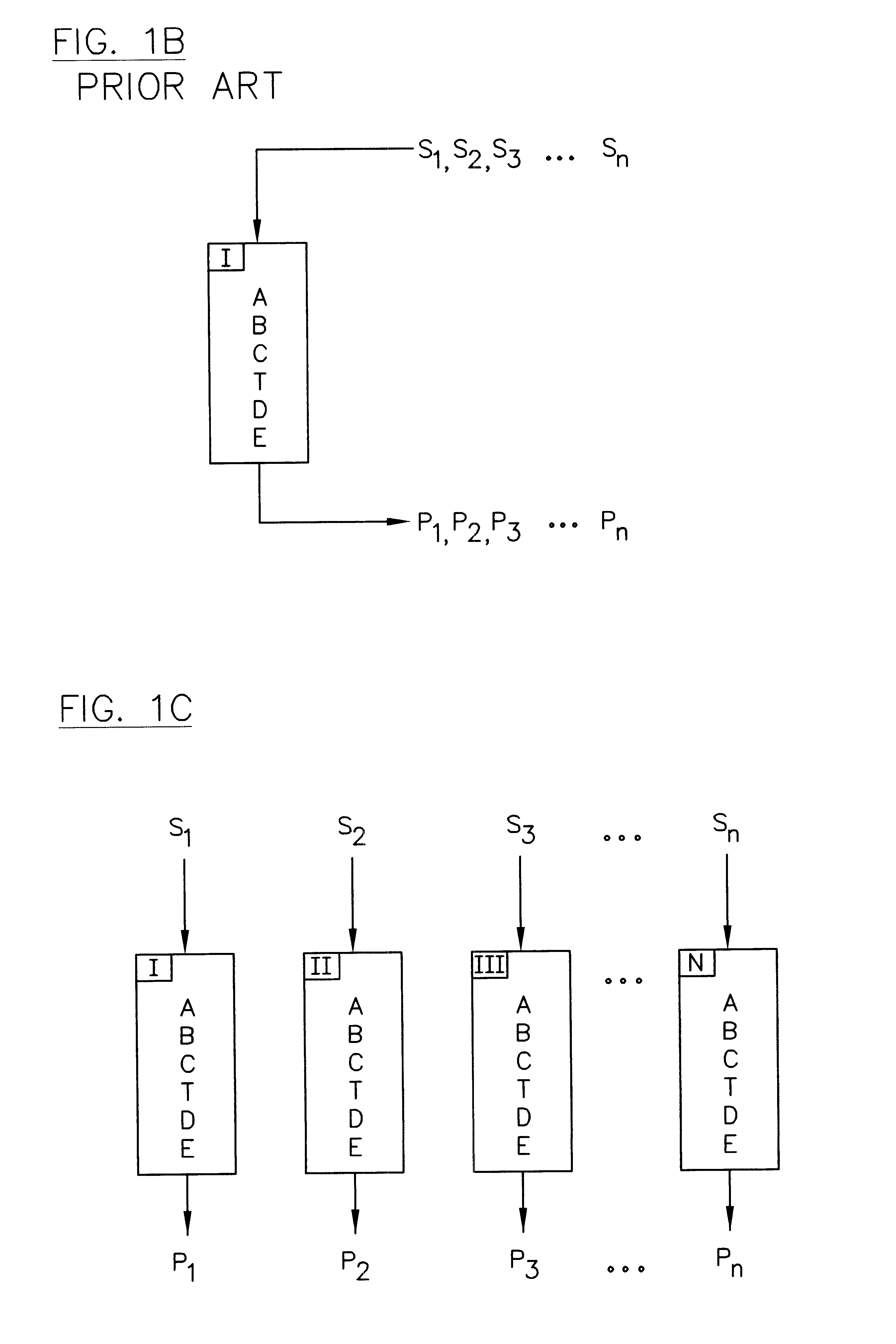

Flow-injection analysis and variable-flow light-scattering methods and apparatus for characterizing polymers

InactiveUS6175409B1Avoid backlogImprove throughputSequential/parallel process reactionsSamplingFlow injection analysisPolymer

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. The described methods, systems, and devices have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

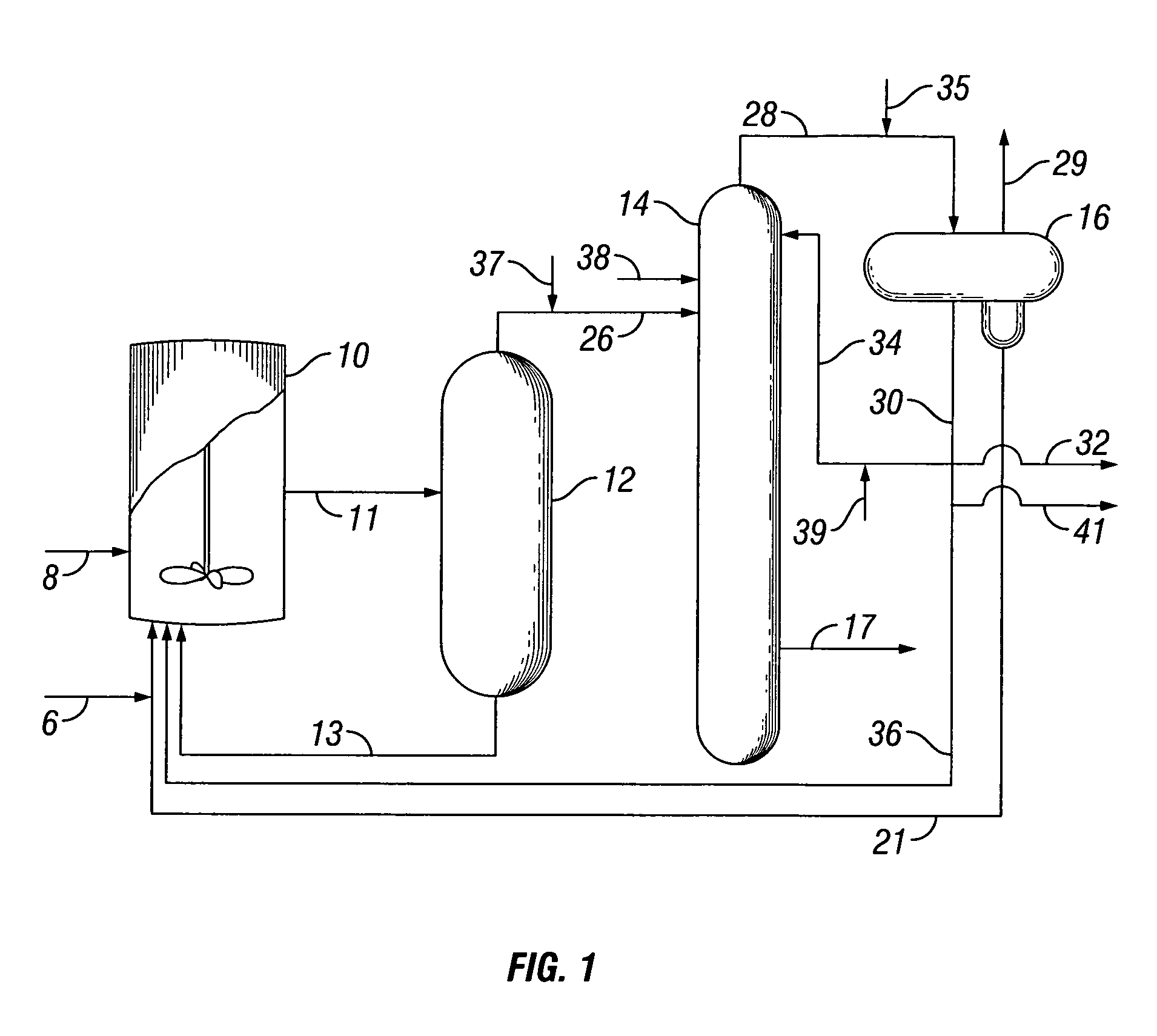

Process for producing acetic acid

ActiveUS7208624B2Easy to separateFacilitate phase separationOrganic compound preparationCarboxylic preparation from carbon monoxide reactionMethyl acetateFormate Esters

An improved process is disclosed for producing acetic acid, including the following steps: reacting a carbonylatable reactant such as methanol, methyl acetate, methyl formate or dimethyl ether with carbon monoxide in a reaction medium containing water, methyl iodide, and a catalyst to produce a reaction product that contains acetic acid; separating the reaction product to provide a volatile phase containing acetic acid, water, and methyl iodide and a less volatile phase; distilling the volatile phase to produce a purified acetic acid product and a first overhead containing water, methyl acetate, and methyl iodide; phase separating the first overhead to provide a first liquid phase containing water and a second liquid phase containing methyl iodide; and adding dimethyl ether to the process in an amount effective to enhance separation of the first overhead to form the first and second liquid phases.

Owner:CELANESE INT CORP

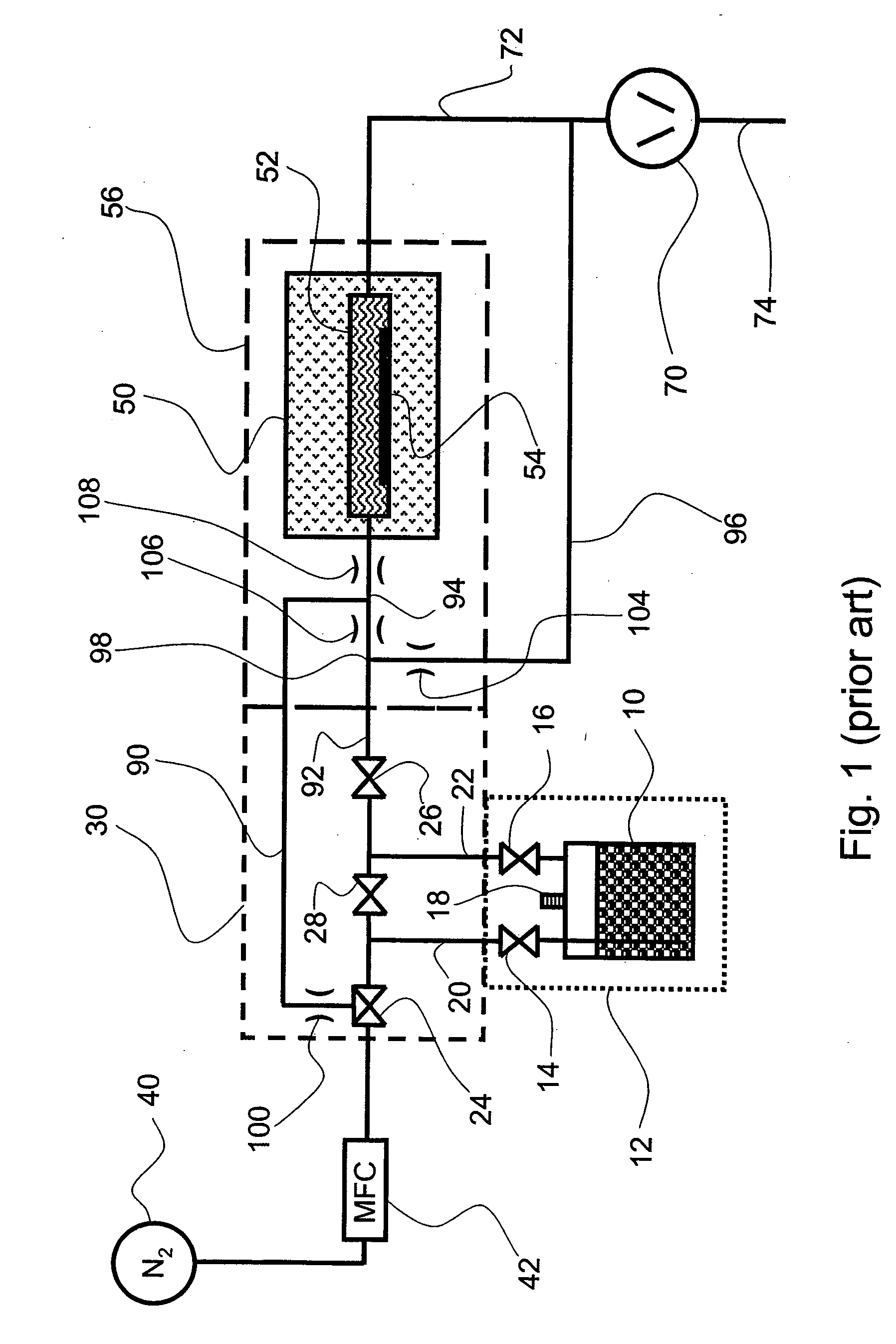

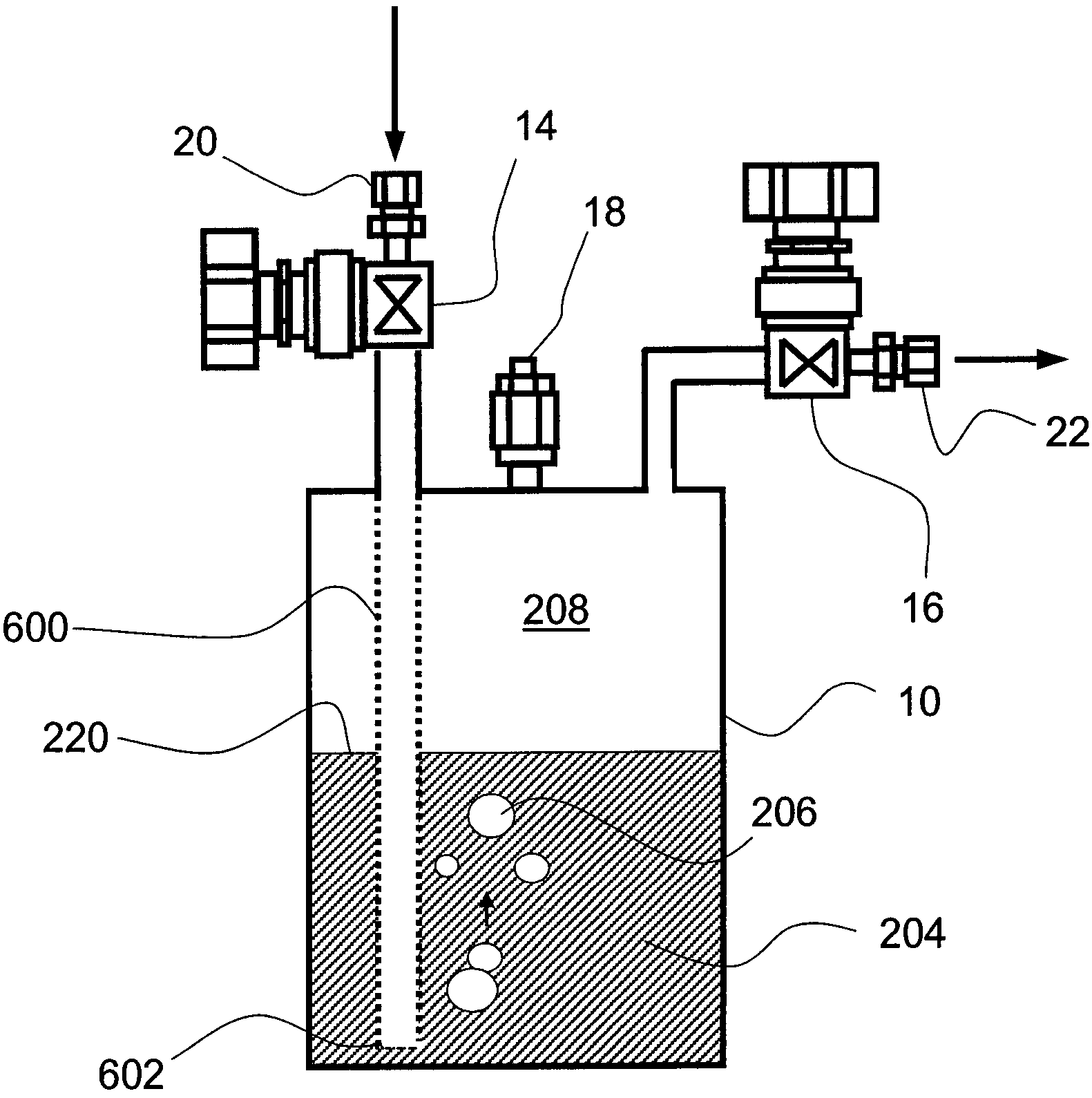

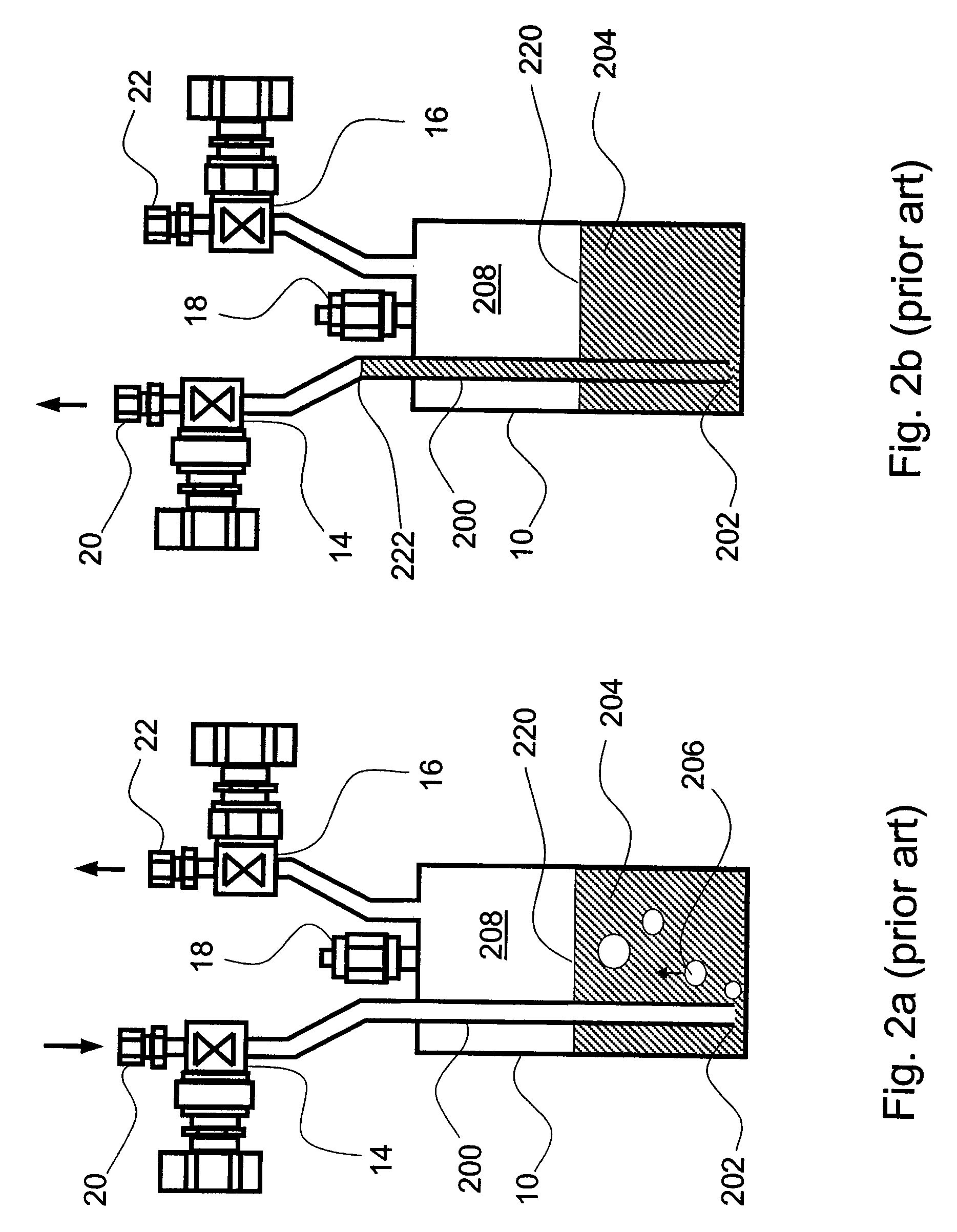

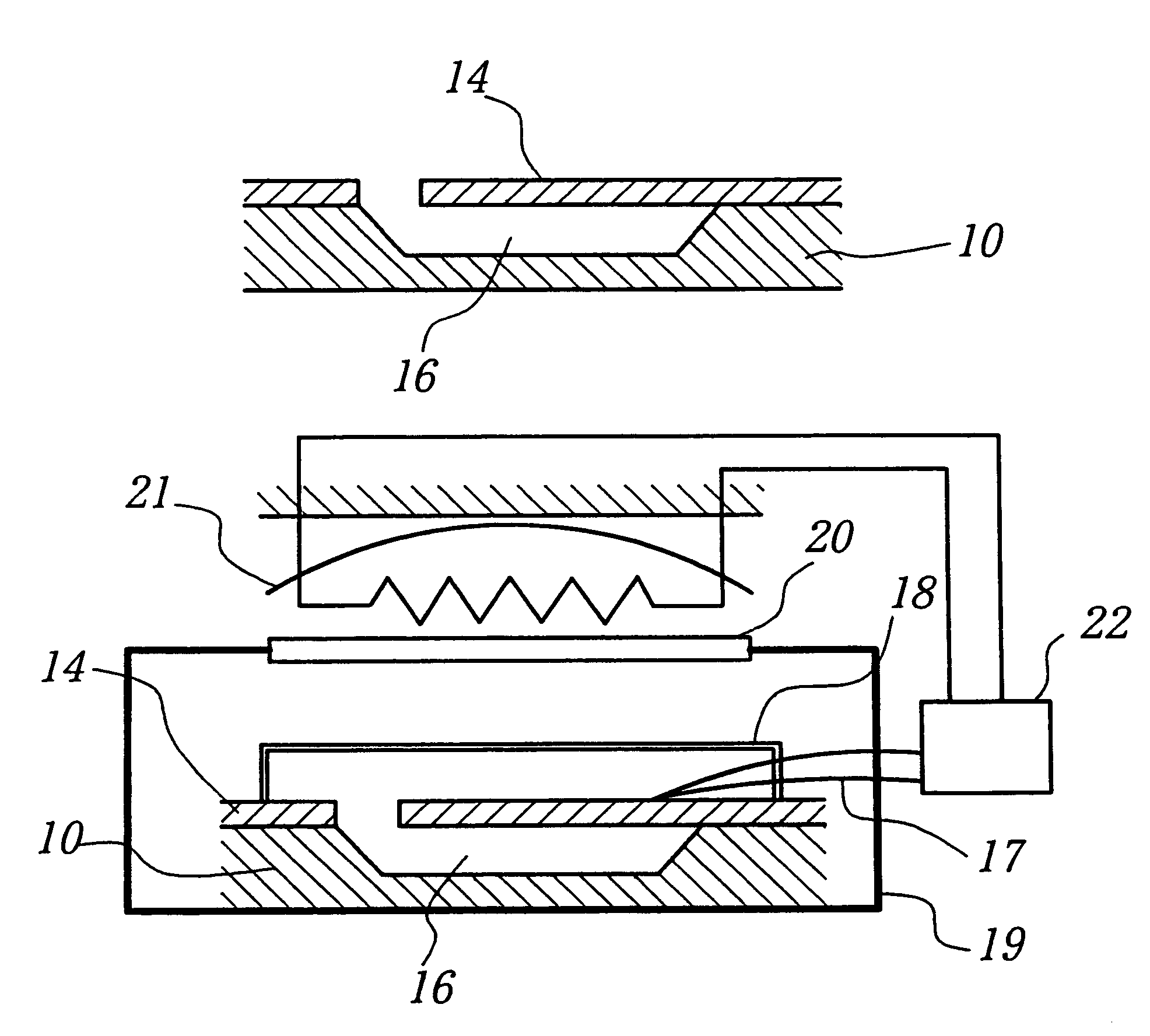

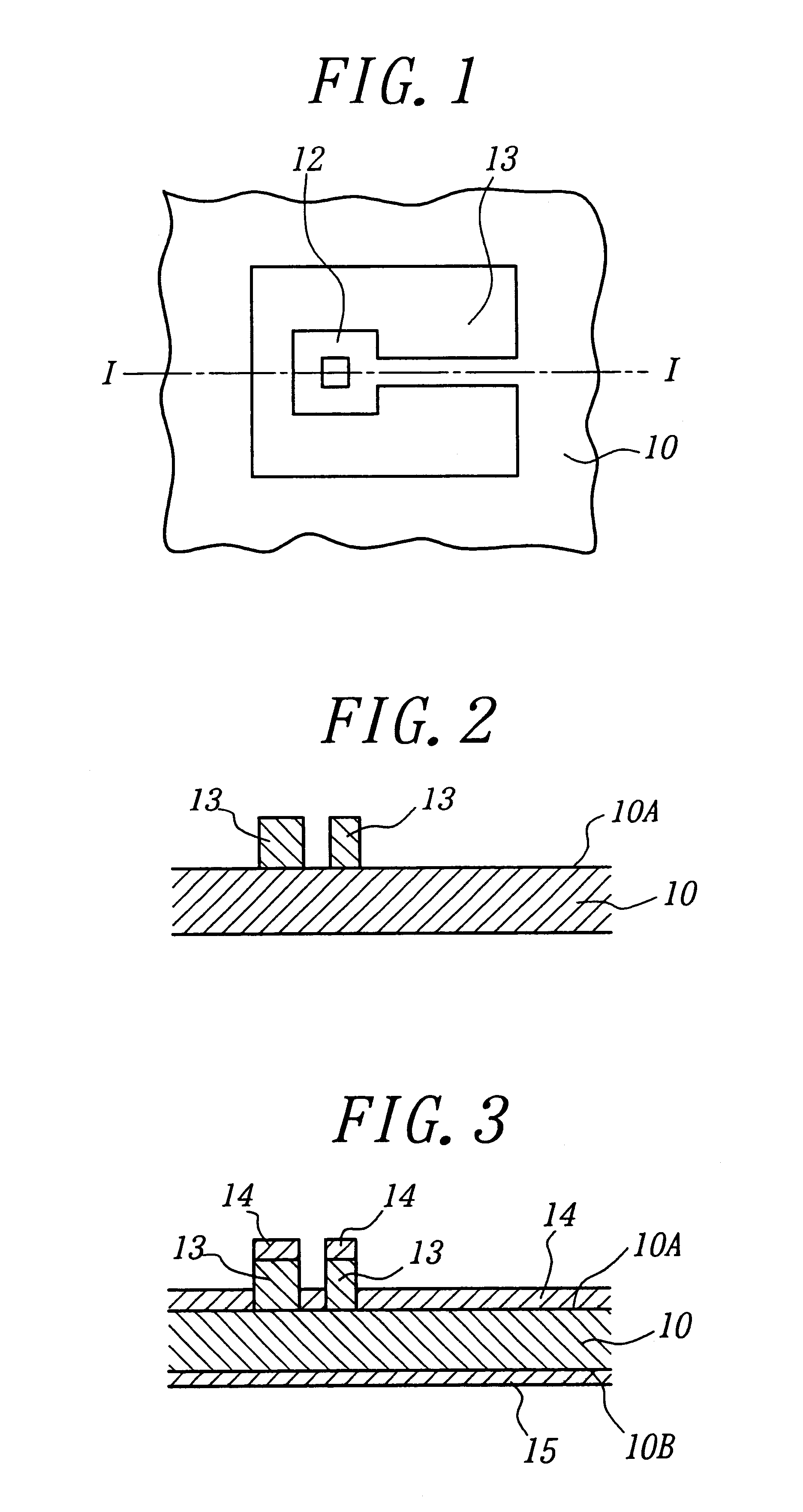

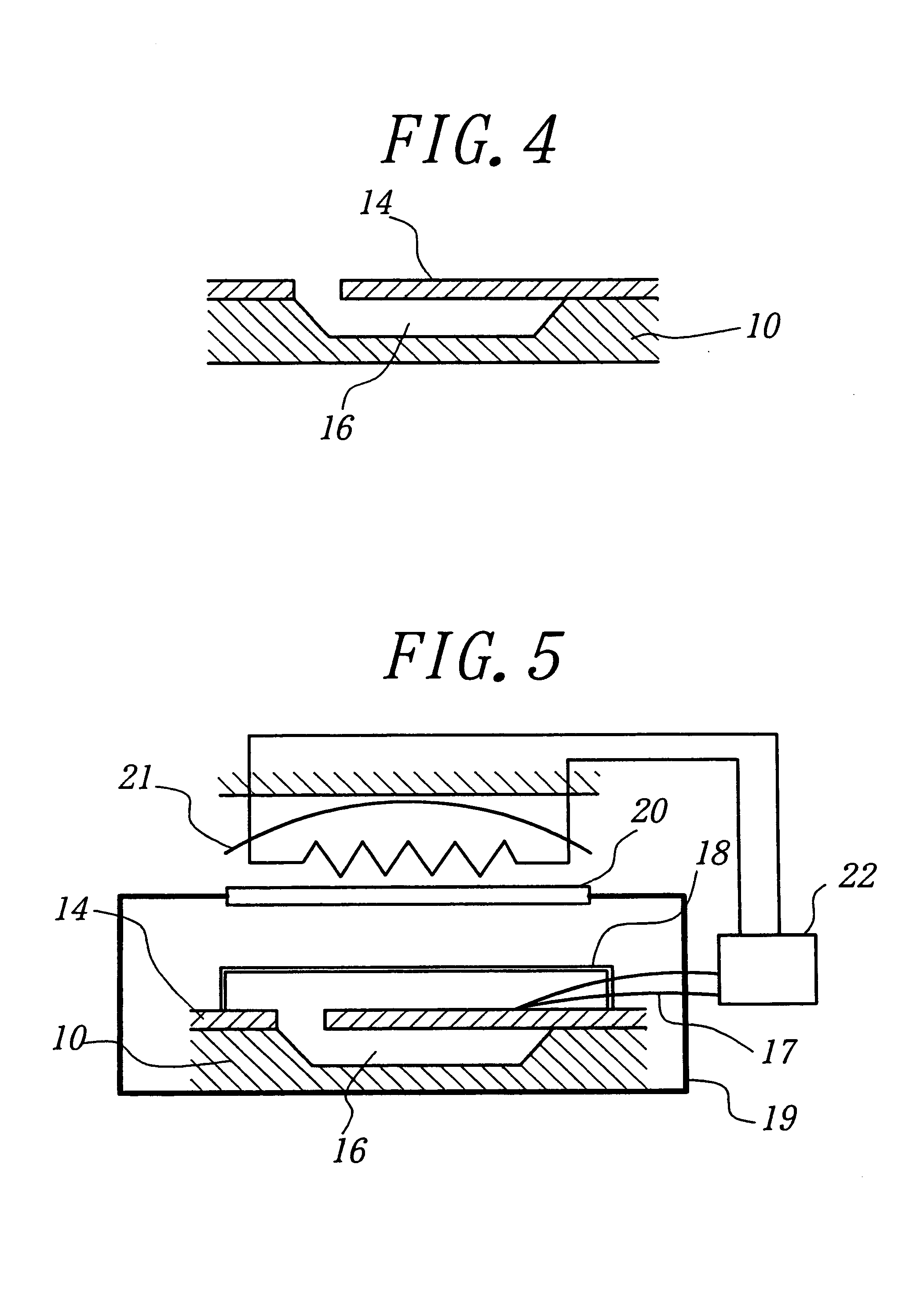

Safe liquid source containers

ActiveUS20050066893A1Excessive pressure increaseEncouraging capillary migrationCarburetting airMixing methodsPorous membraneEngineering

Containers for providing vapor phase reactant from liquid sources include bubbler designs and designs in which carrier gas flows over the liquid surface. Among the bubbler arrangements, a bypass conductance is provided to release excess pressure from the gas volume inside the container, or an enlarged bubbler tube is provided with a volume sufficient to accommodate all possible liquid backflow without having the liquid exit the container. Among the overflow designs, flow dividers provide a tortuous path for the gas to increase the time exposure of carrier gas packets to the evaporating liquid surface. The flow dividers can be microporous to encourage capillary action, thereby increasing the evaporating surface. The tortuous gas flow path can be separated from the liquid phase by a breathable semi-porous membrane that permits vapor phase reactant to pass through but prohibits liquid from passing in the other direction.

Owner:ASM INTERNATIONAL

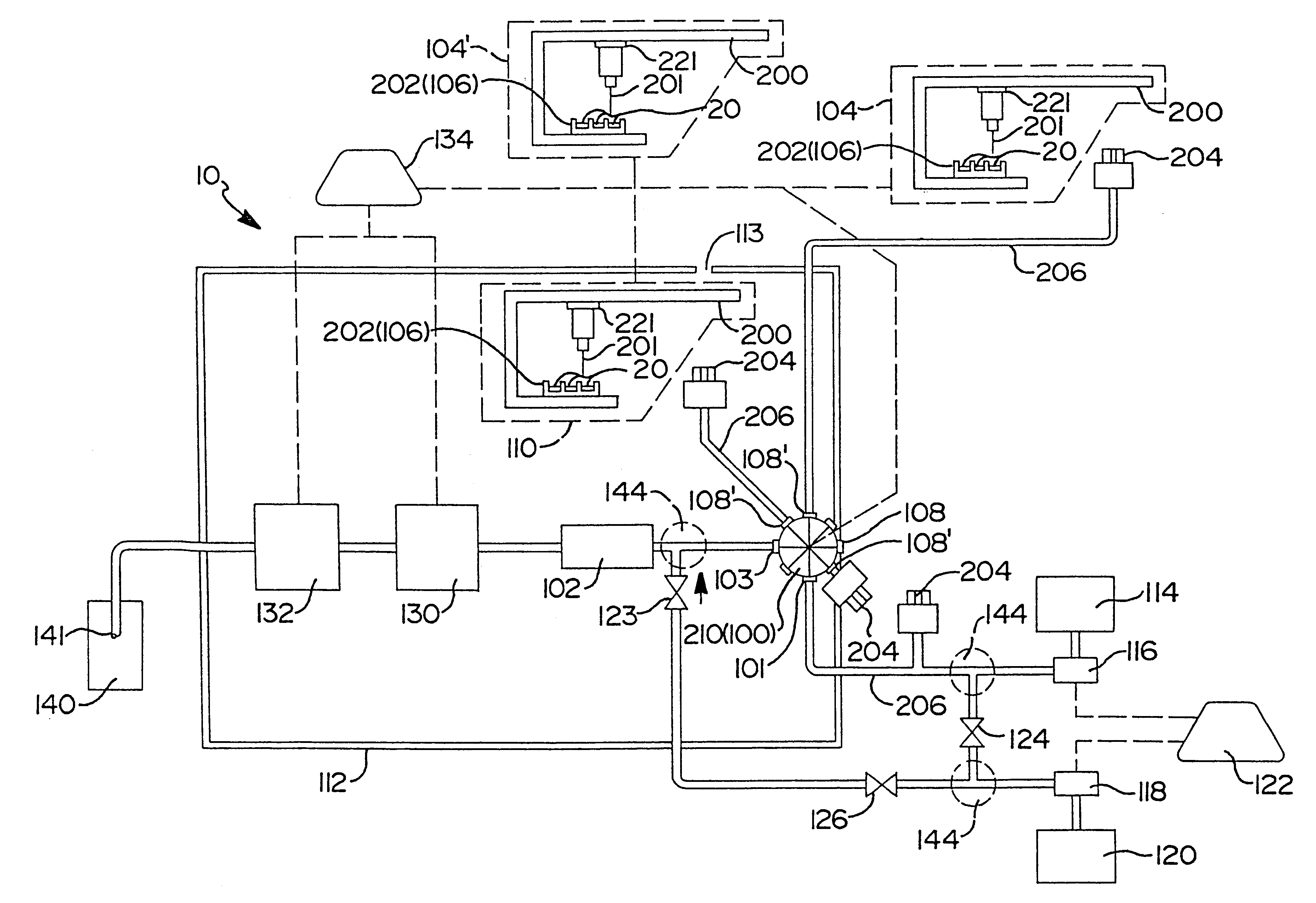

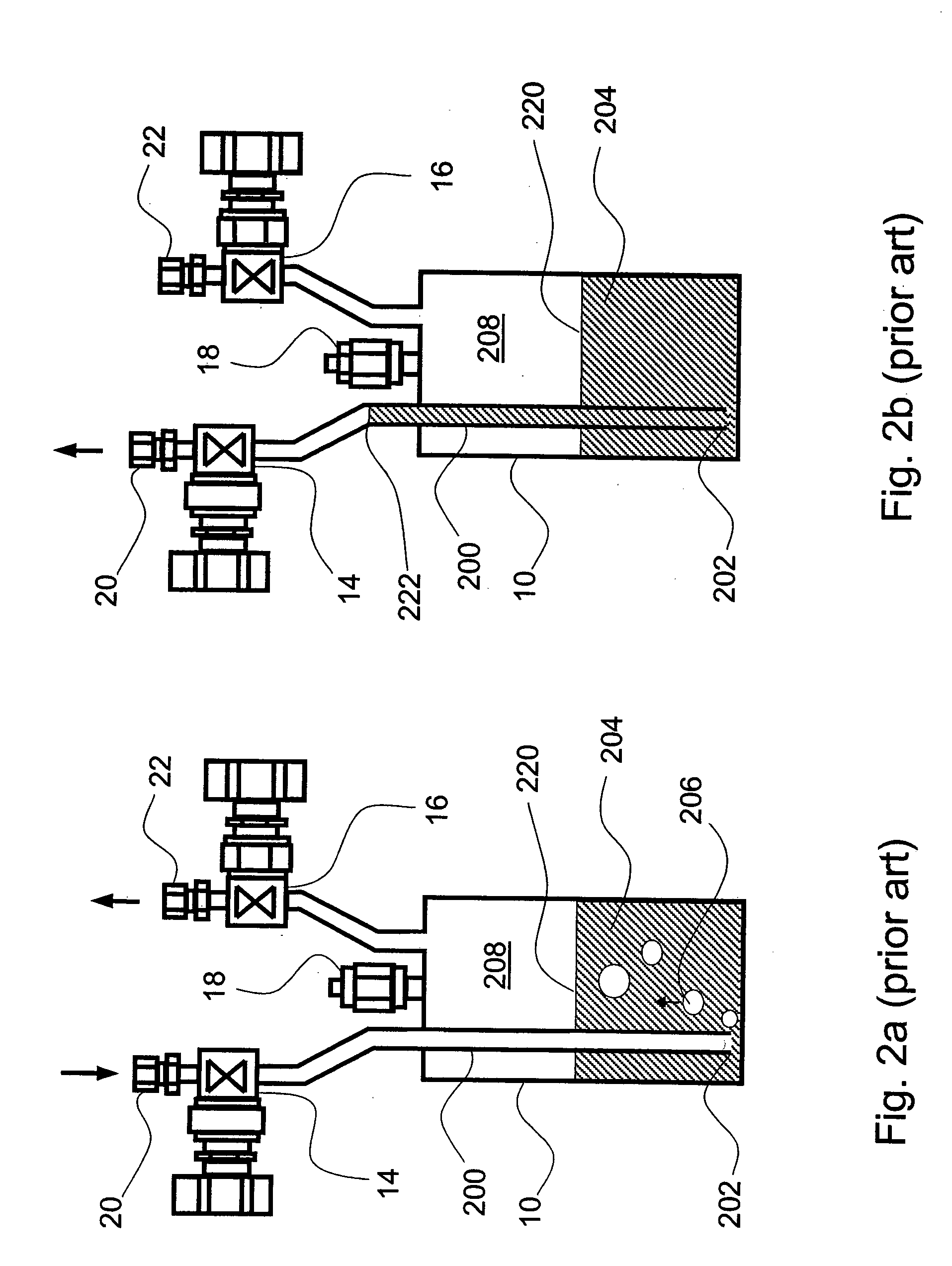

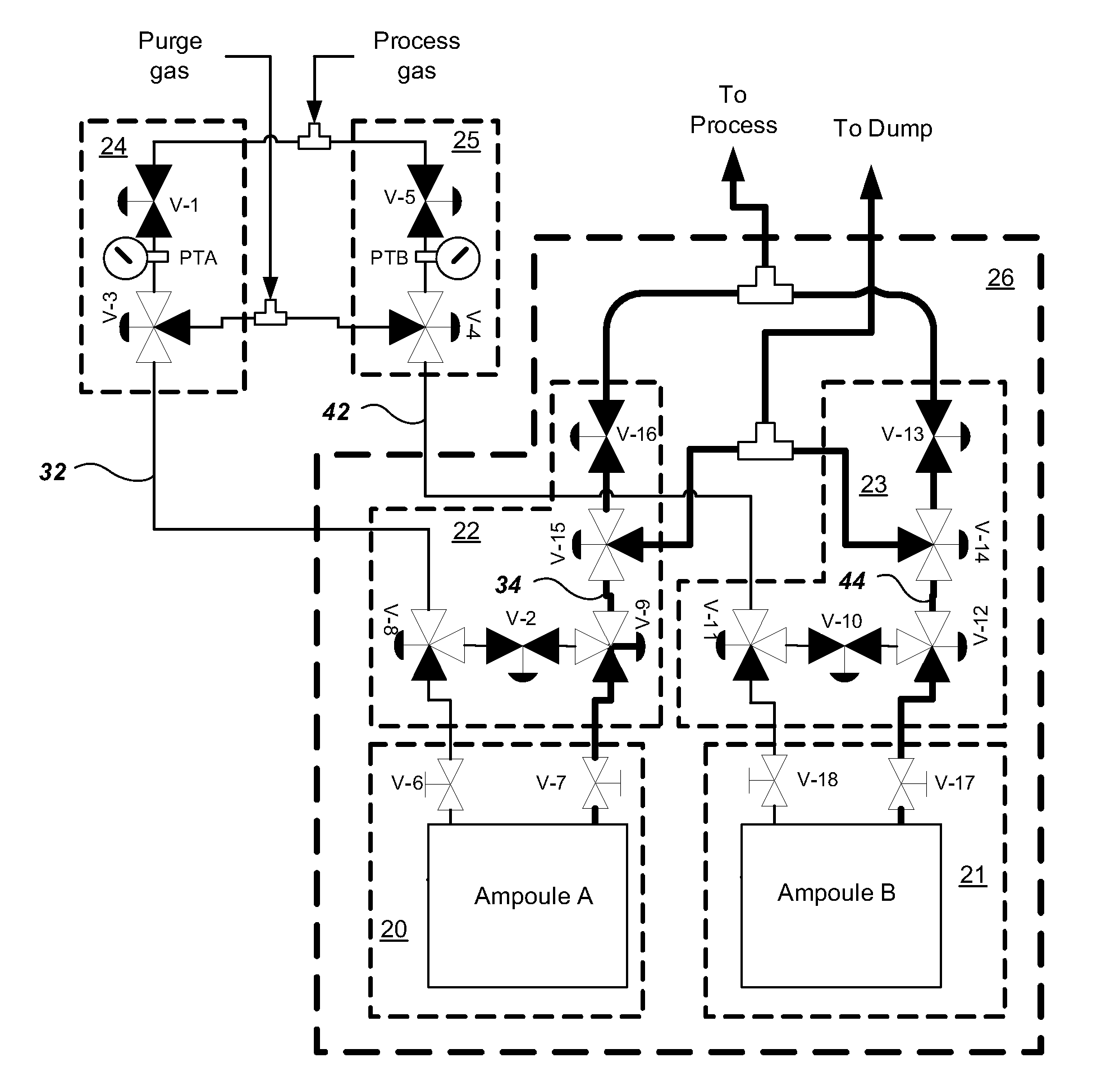

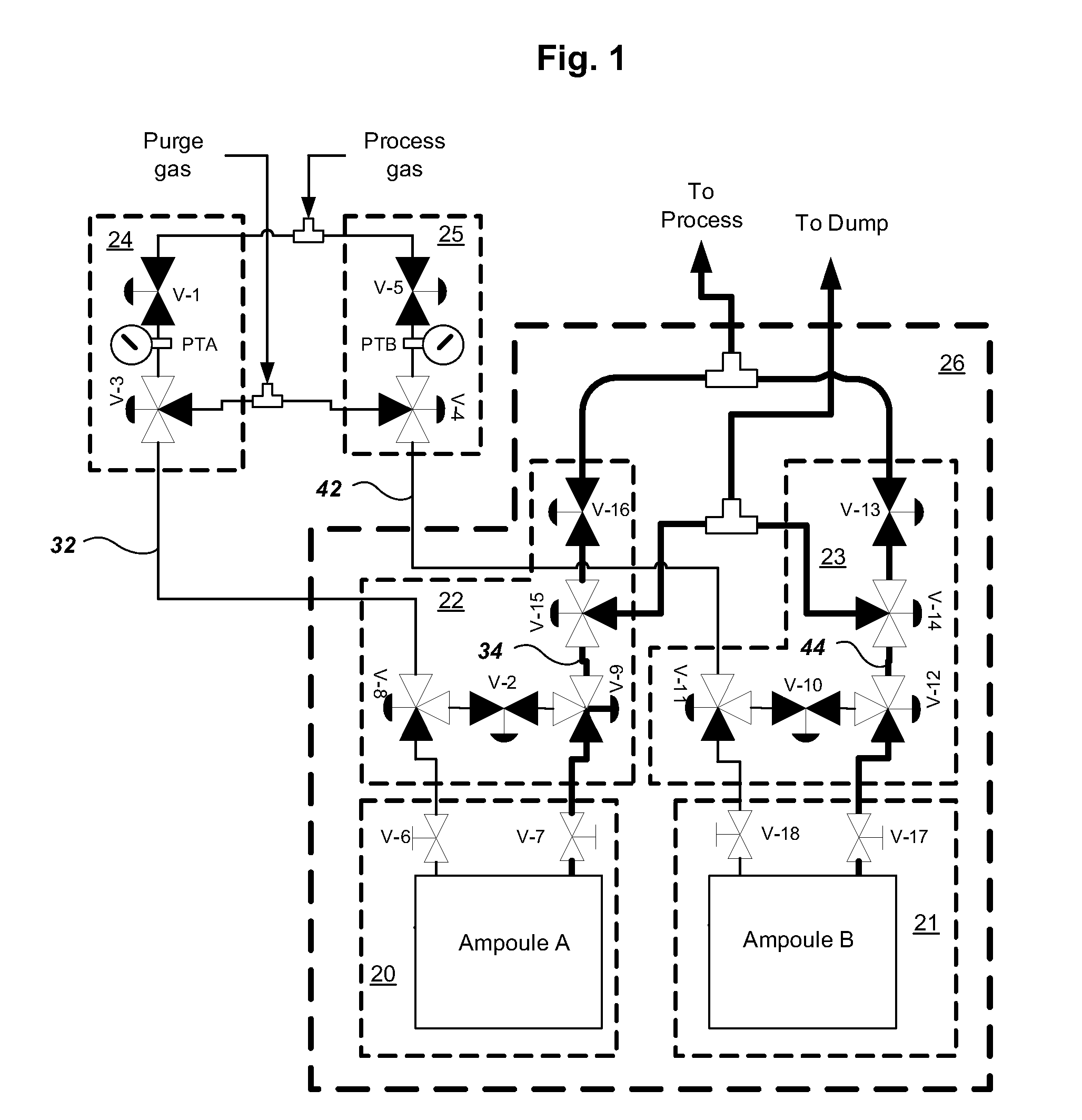

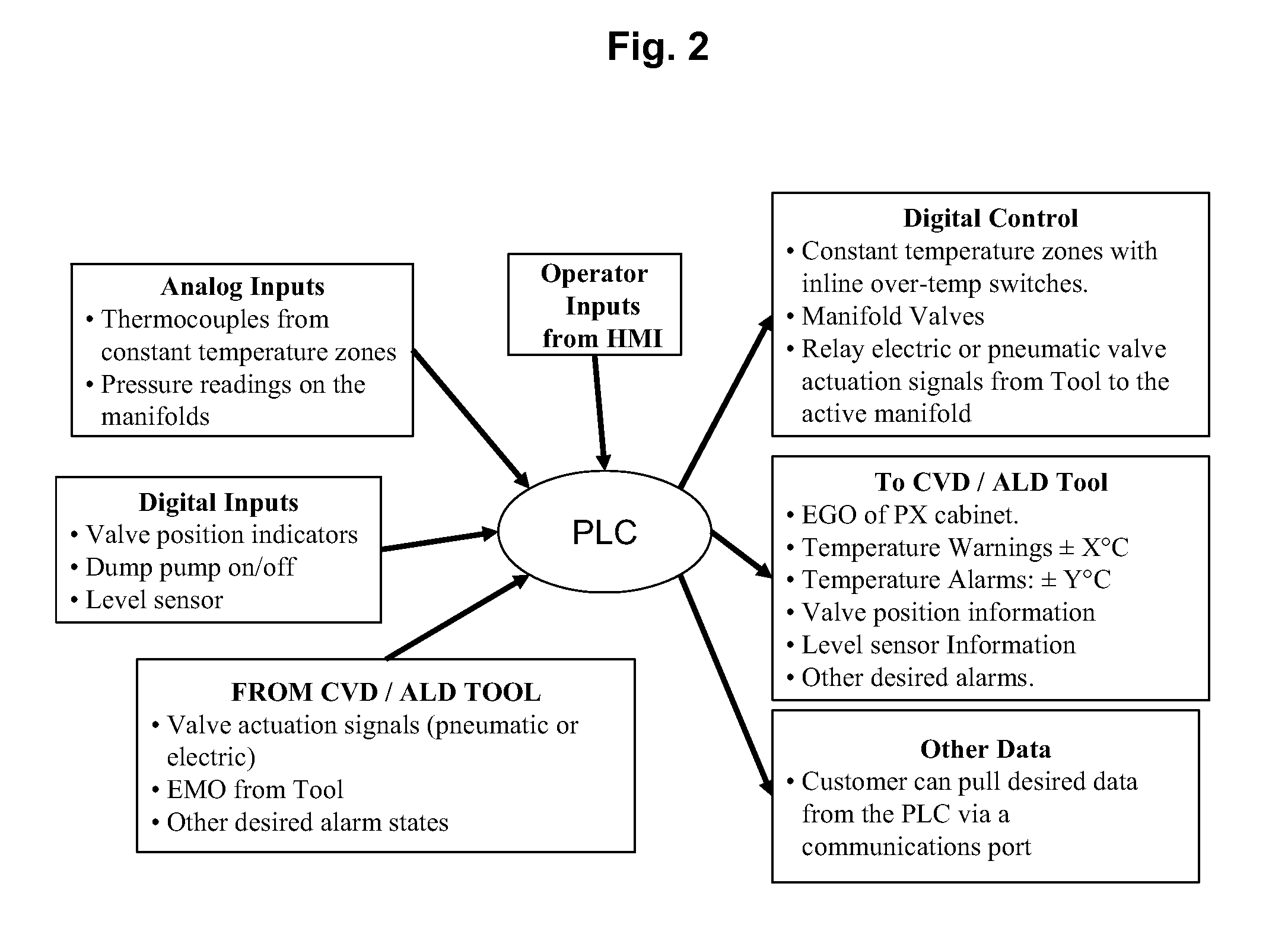

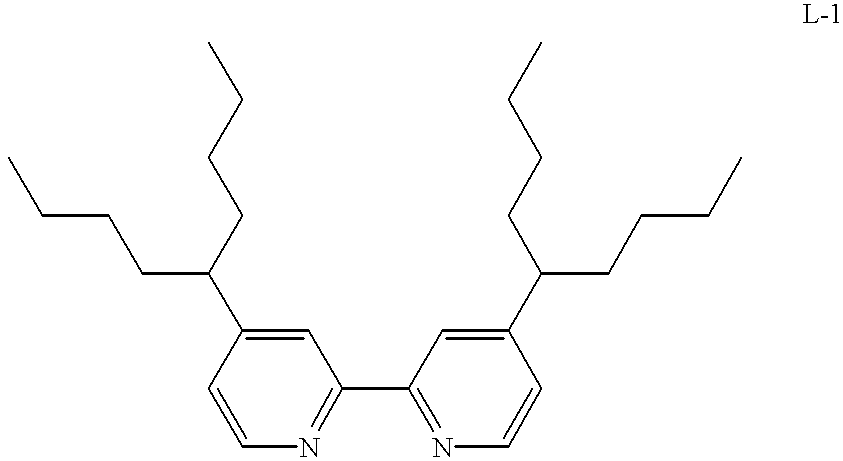

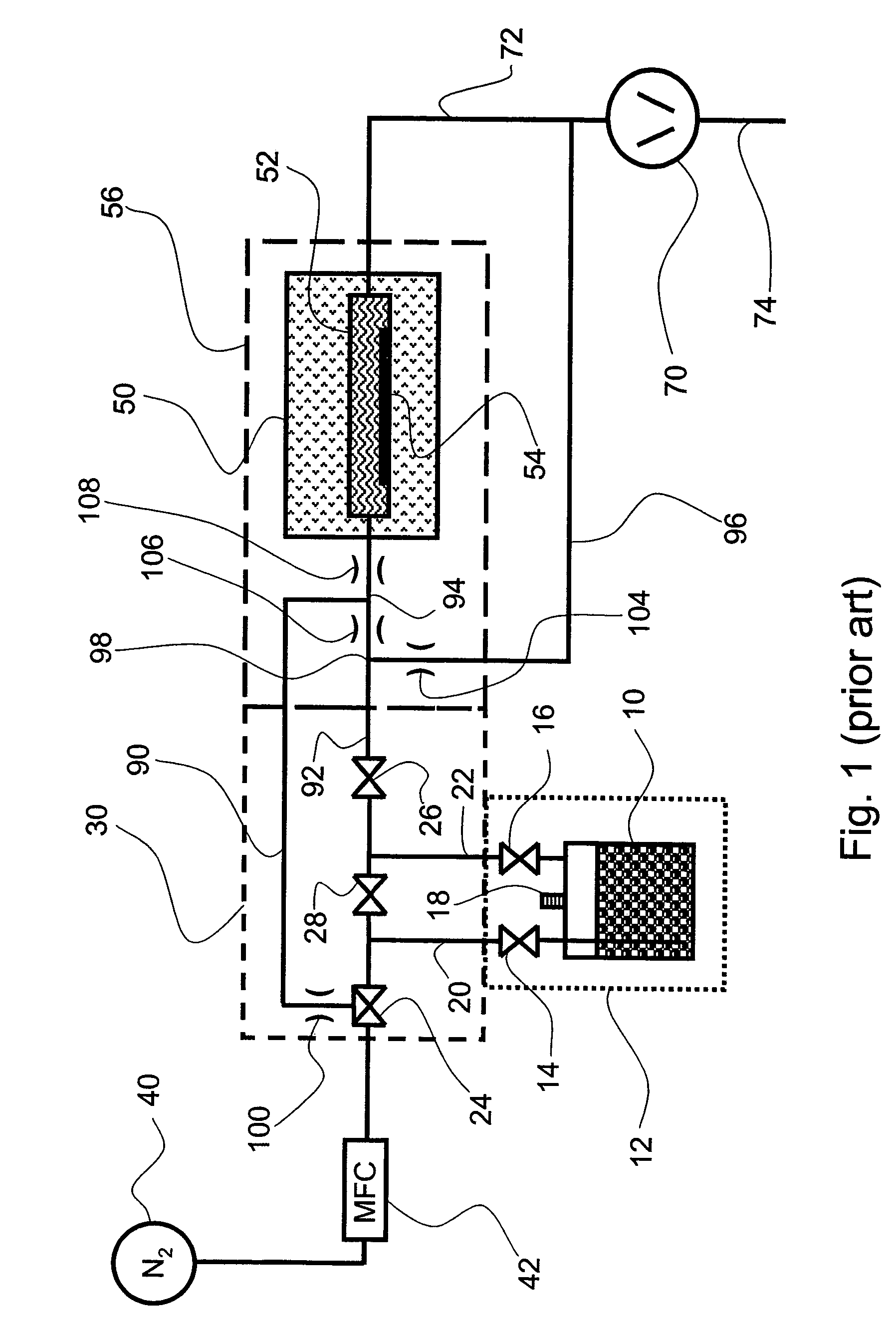

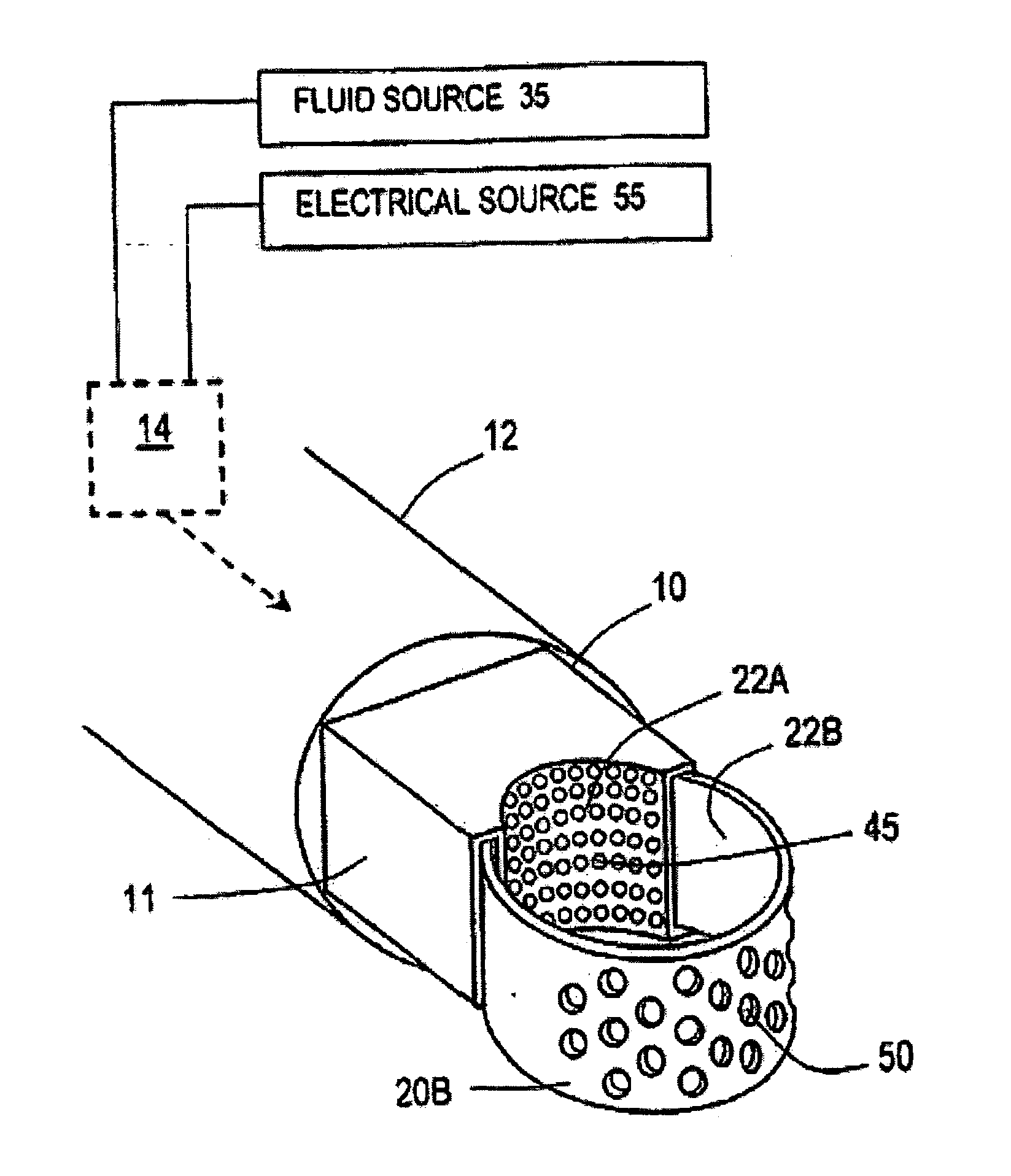

Multiple ampoule delivery systems

InactiveUS20090211525A1Easy to useReduce wasteLiquid surface applicatorsPipeline systemsSemiconductor materialsDelivery system

This invention relates to an integrated vapor or liquid phase reagent dispensing apparatus having a plurality of vessels and a plurality of carrier or inert gas feed / vapor or liquid phase reagent delivery manifolds, that may be used for continuously dispensing vapor or liquid phase reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

High-temperature characterization of polymers

InactiveUS6260407B1Avoid backlogImprove throughputSequential/parallel process reactionsComponent separationElutionChromatography column

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. In preferred high-temperature embodiments, the polymer sample is maintained at a temperature of not less than about 75° C. during sample preparation, loading into a liquid chromatography or flow-injection analysis system, injection into a mobile phase of a liquid chromatography or flow-injection analysis system, and / or elution from chromatographic column. The described methods, systems, and device have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

Safe liquid source containers

ActiveUS7156380B2Encouraging capillary migrationFine surfaceCarburetting airMixing methodsPorous membraneProduct gas

Containers for providing vapor phase reactant from liquid sources include bubbler designs and designs in which carrier gas flows over the liquid surface. Among the bubbler arrangements, a bypass conductance is provided to release excess pressure from the gas volume inside the container, or an enlarged bubbler tube is provided with a volume sufficient to accommodate all possible liquid backflow without having the liquid exit the container. Among the overflow designs, flow dividers provide a tortuous path for the gas to increase the time exposure of carrier gas packets to the evaporating liquid surface. The flow dividers can be microporous to encourage capillary action, thereby increasing the evaporating surface. The tortuous gas flow path can be separated from the liquid phase by a breathable semi-porous membrane that permits vapor phase reactant to pass through but prohibits liquid from passing in the other direction.

Owner:ASM INTERNATIONAL

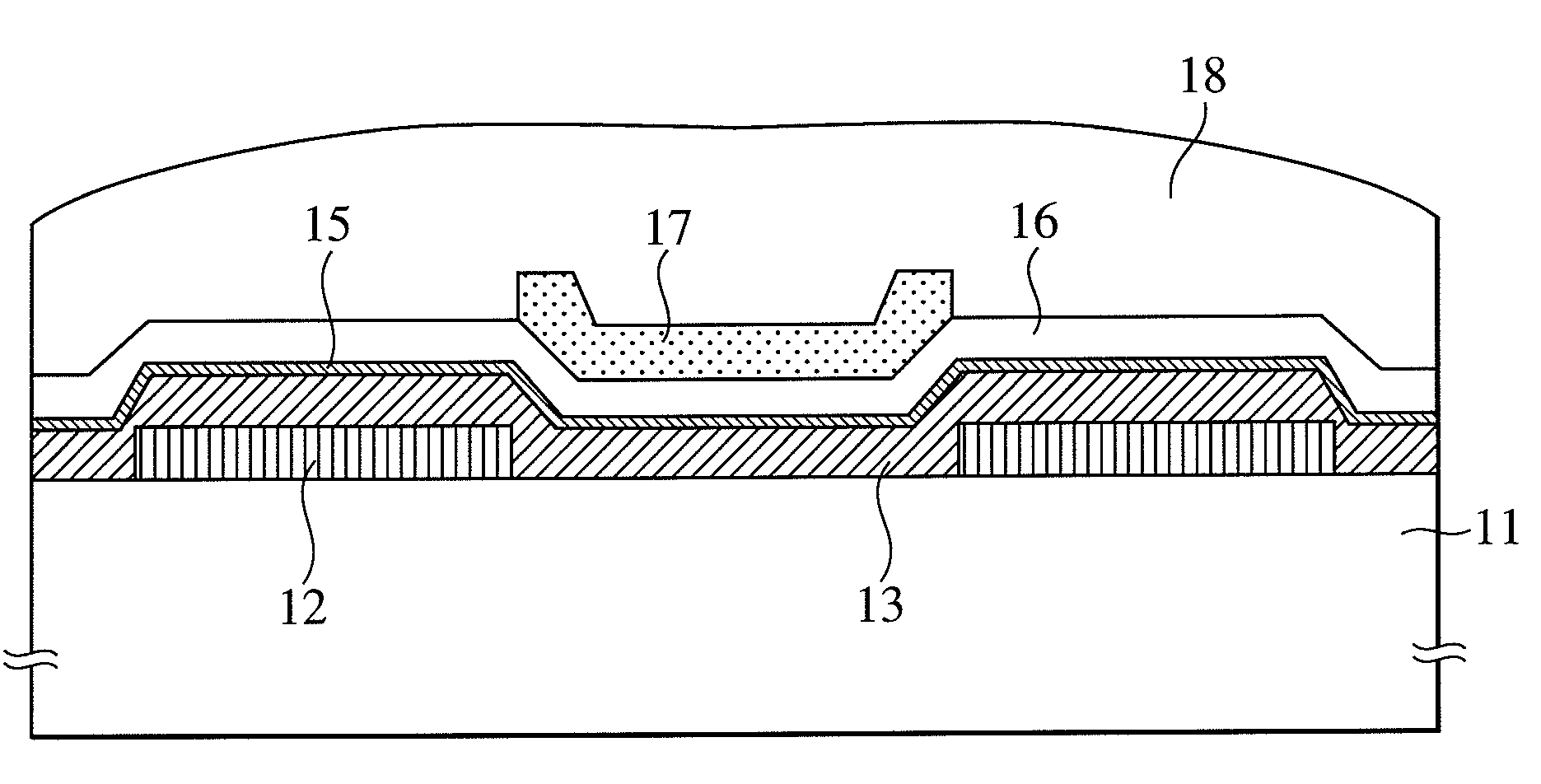

Oxide semiconductor device and surface treatment method of oxide semiconductor

InactiveUS20090166616A1Effectively suppressing the threshold potential shift and occurrence of leak currentPhysical property is lessSolid-state devicesSemiconductor/solid-state device manufacturingGas phaseThreshold potential

Oxygen defects formed at the boundary between the zinc oxide type oxide semiconductor and the gate insulator are terminated by a surface treatment using sulfur or selenium as an oxygen group element or a compound thereof, the oxygen group element scarcely occurring physical property value change. Sulfur or selenium atoms effectively substitute oxygen defects to prevent occurrence of electron supplemental sites by merely applying a gas phase or liquid phase treatment to an oxide semiconductor or gate insulator with no remarkable change on the manufacturing process. As a result, this can attain the suppression of the threshold potential shift and the leak current in the characteristics of a thin film transistor.

Owner:HITACHI LTD

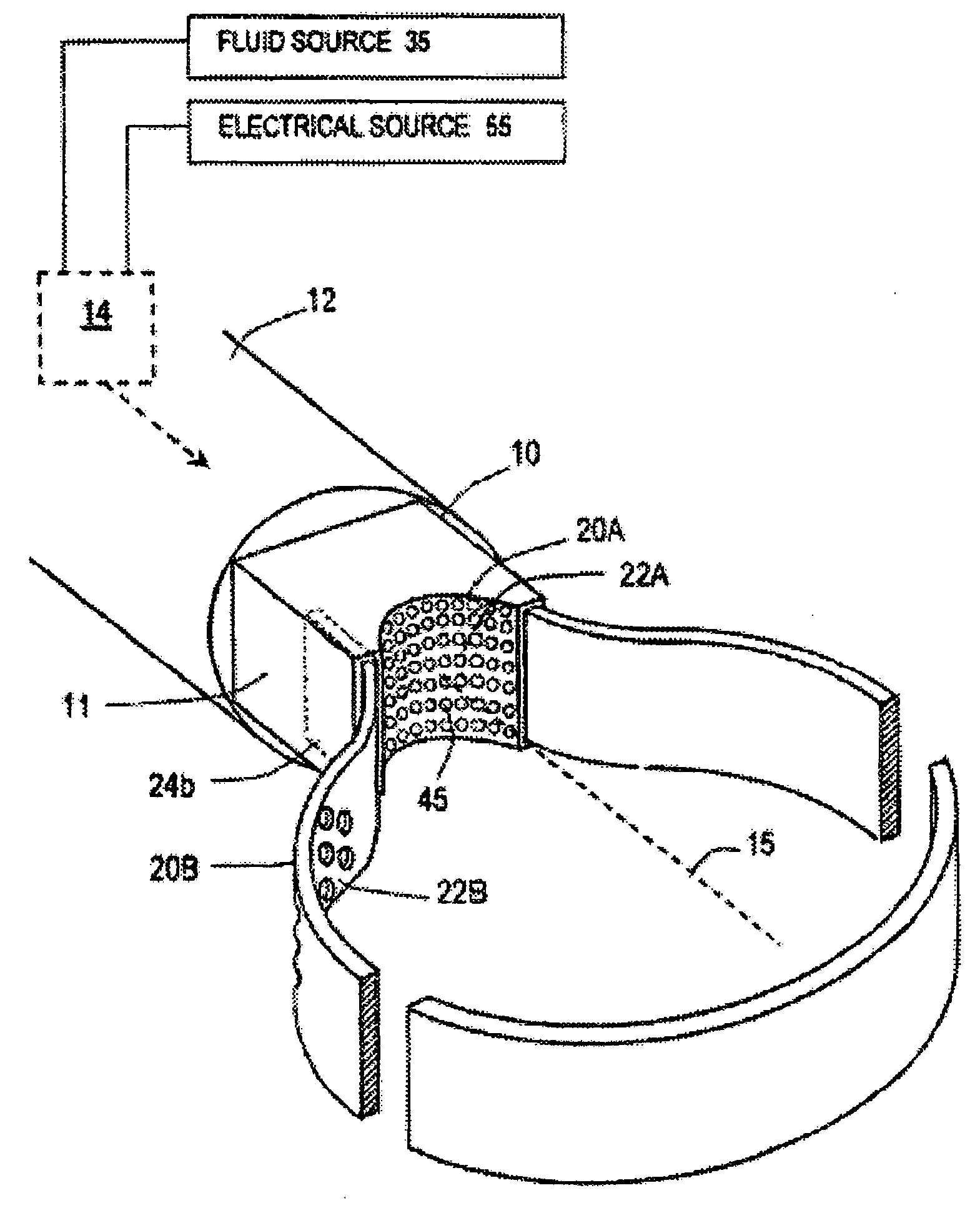

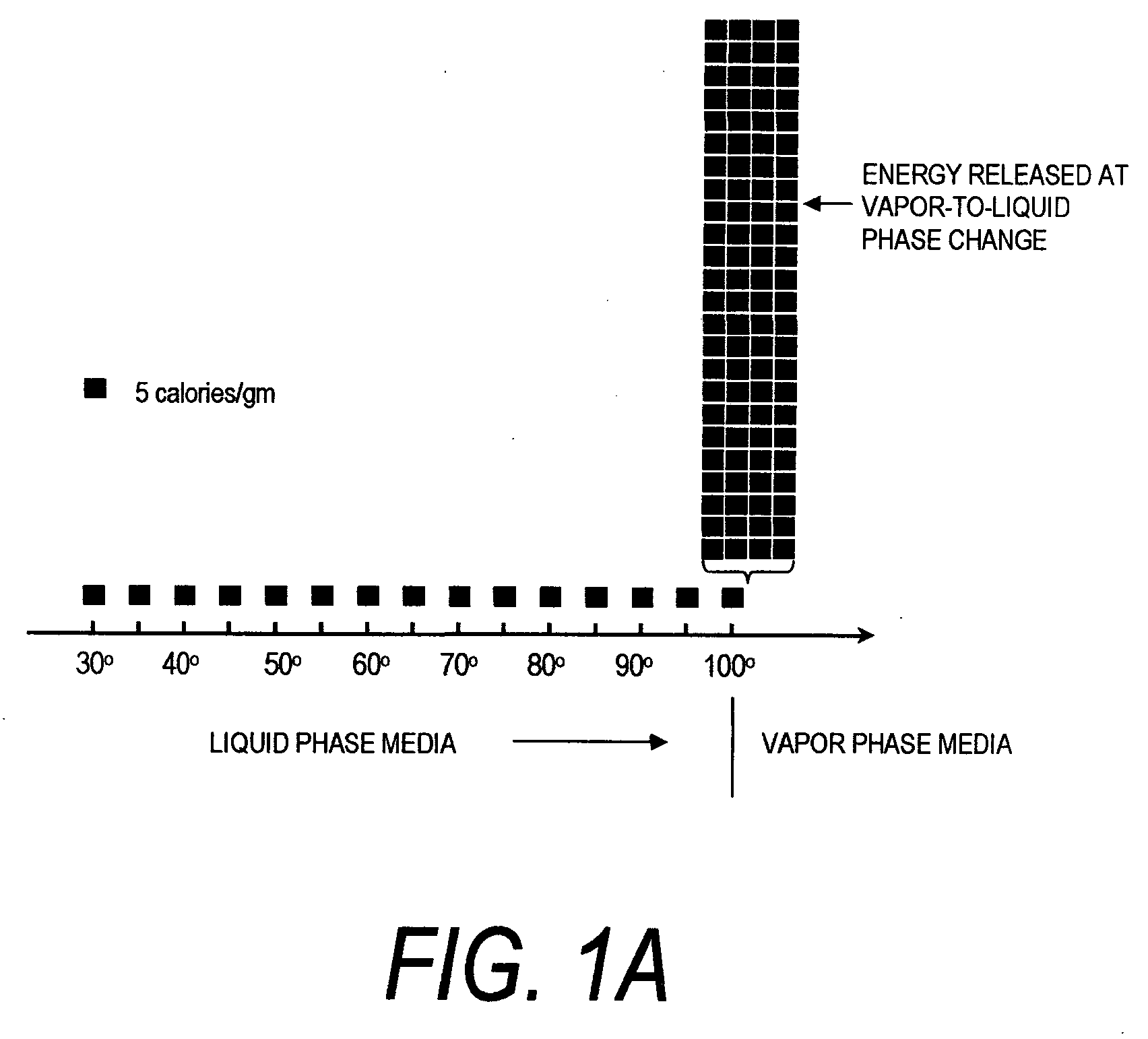

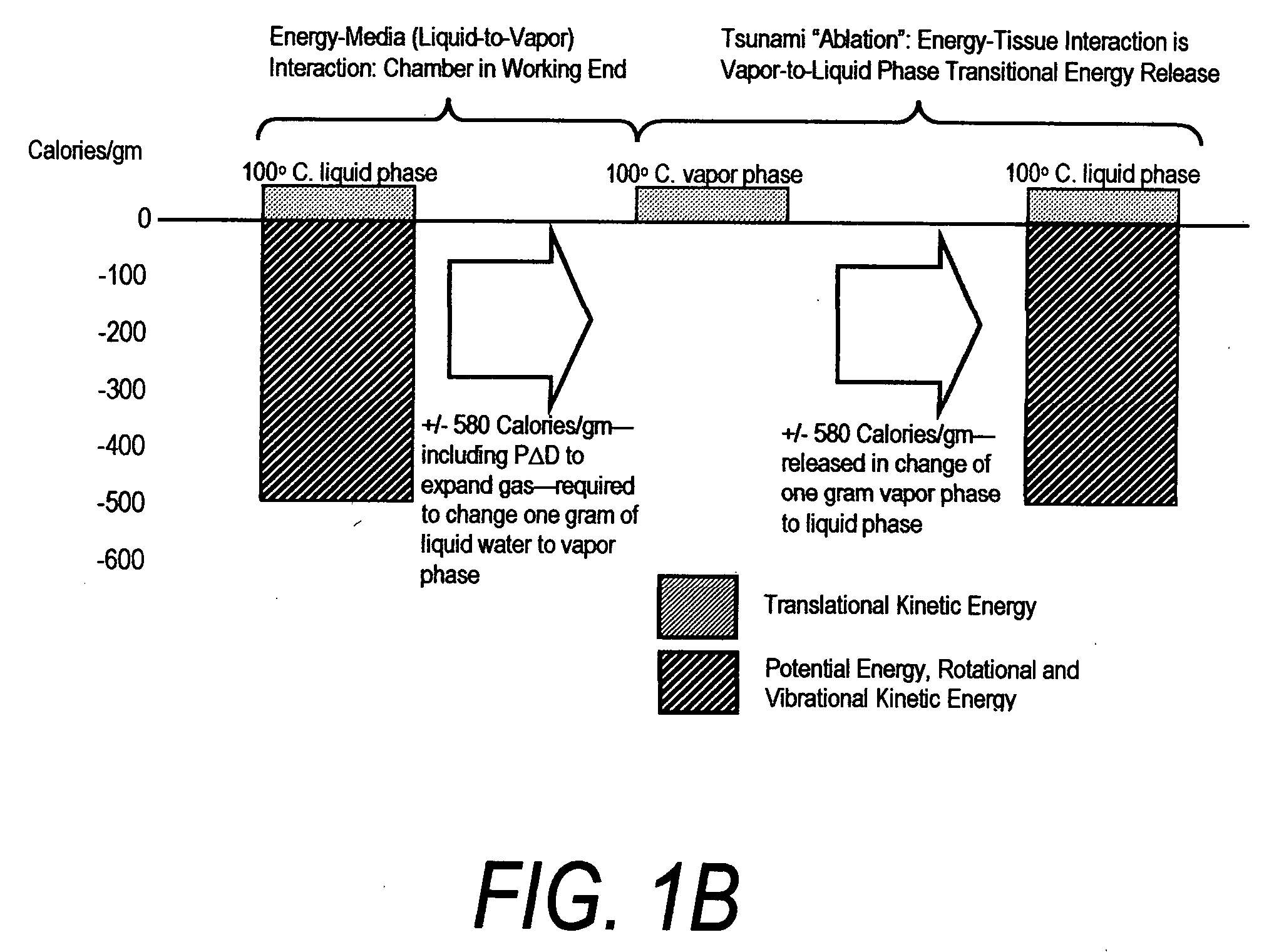

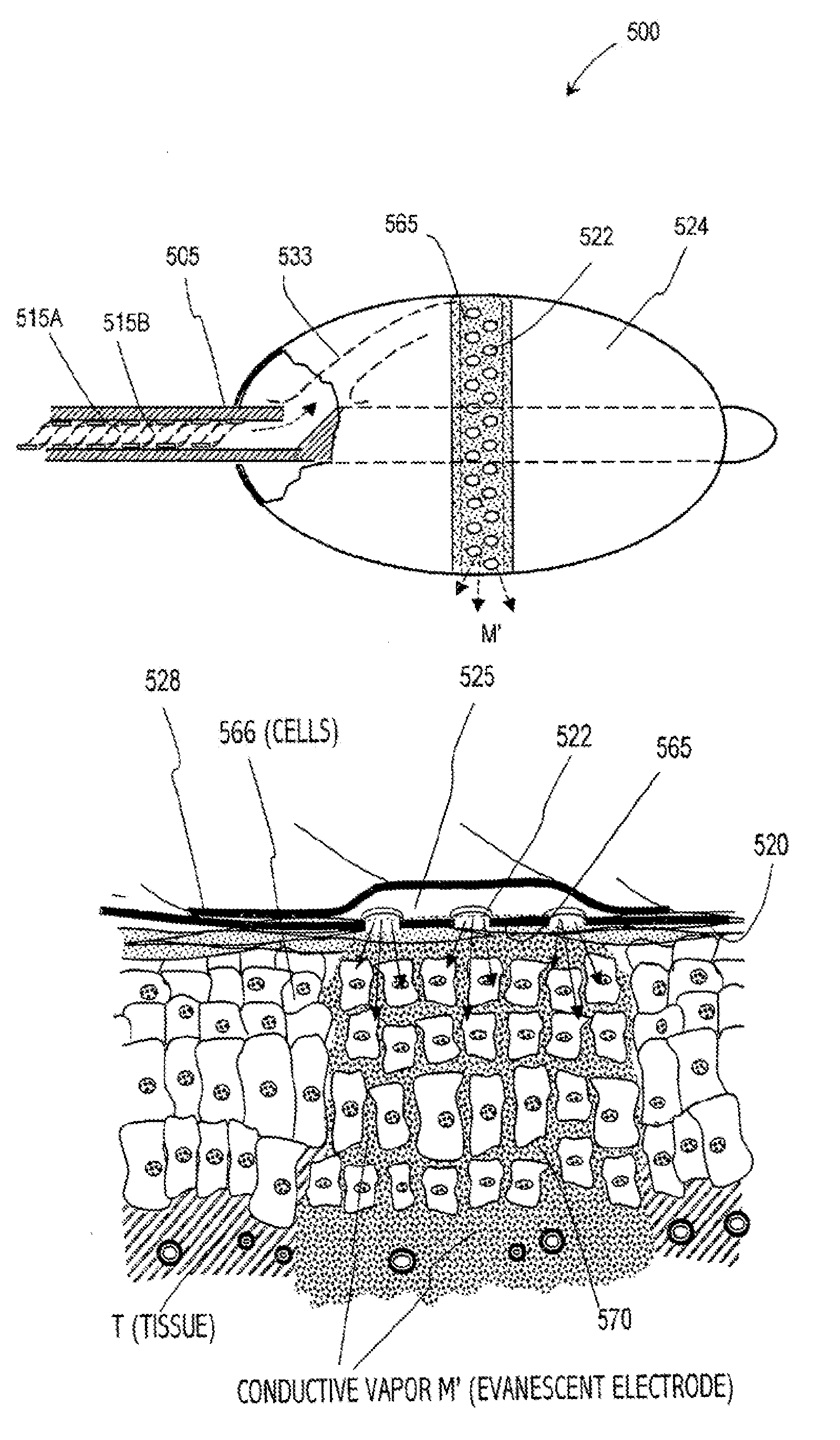

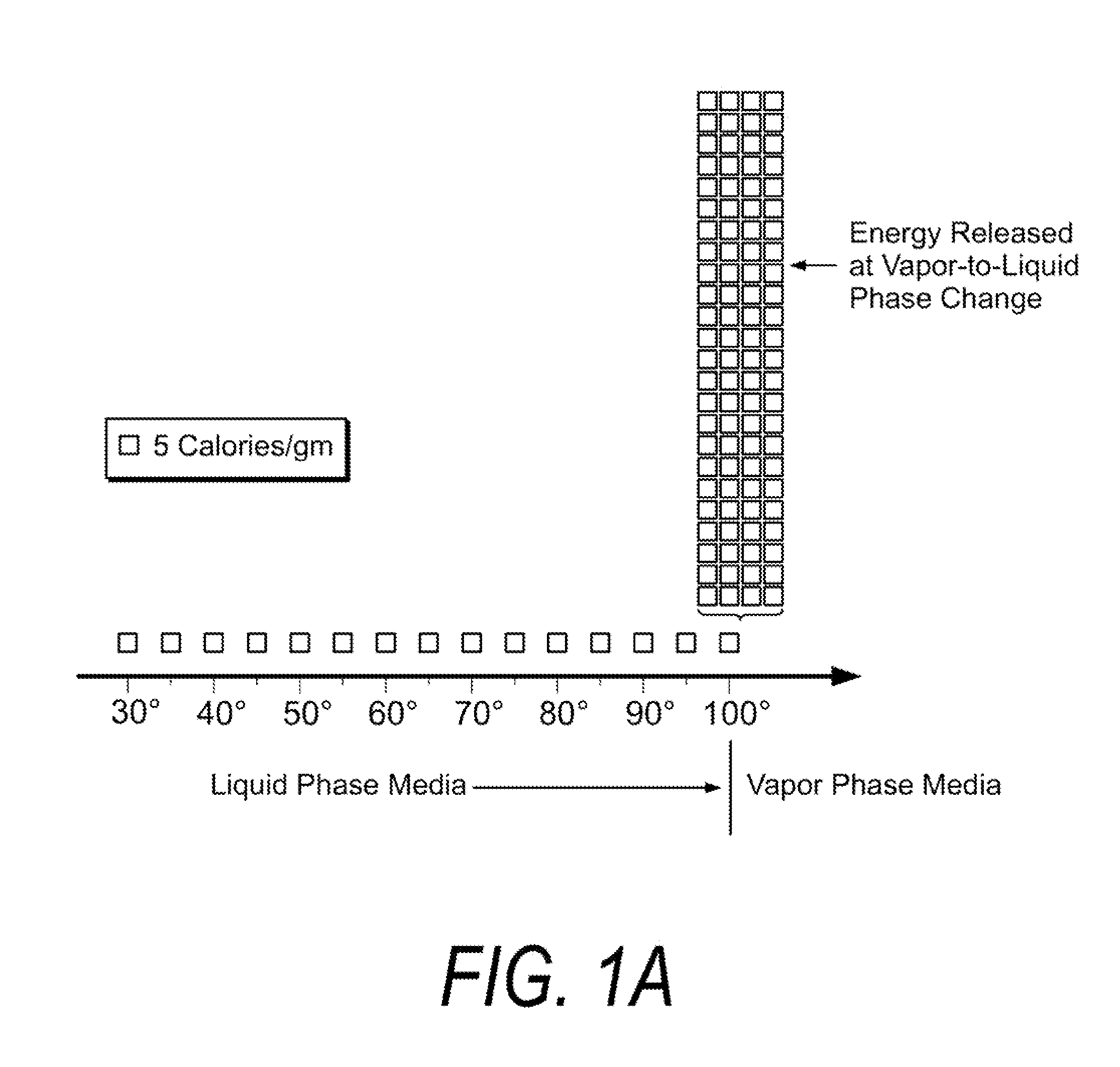

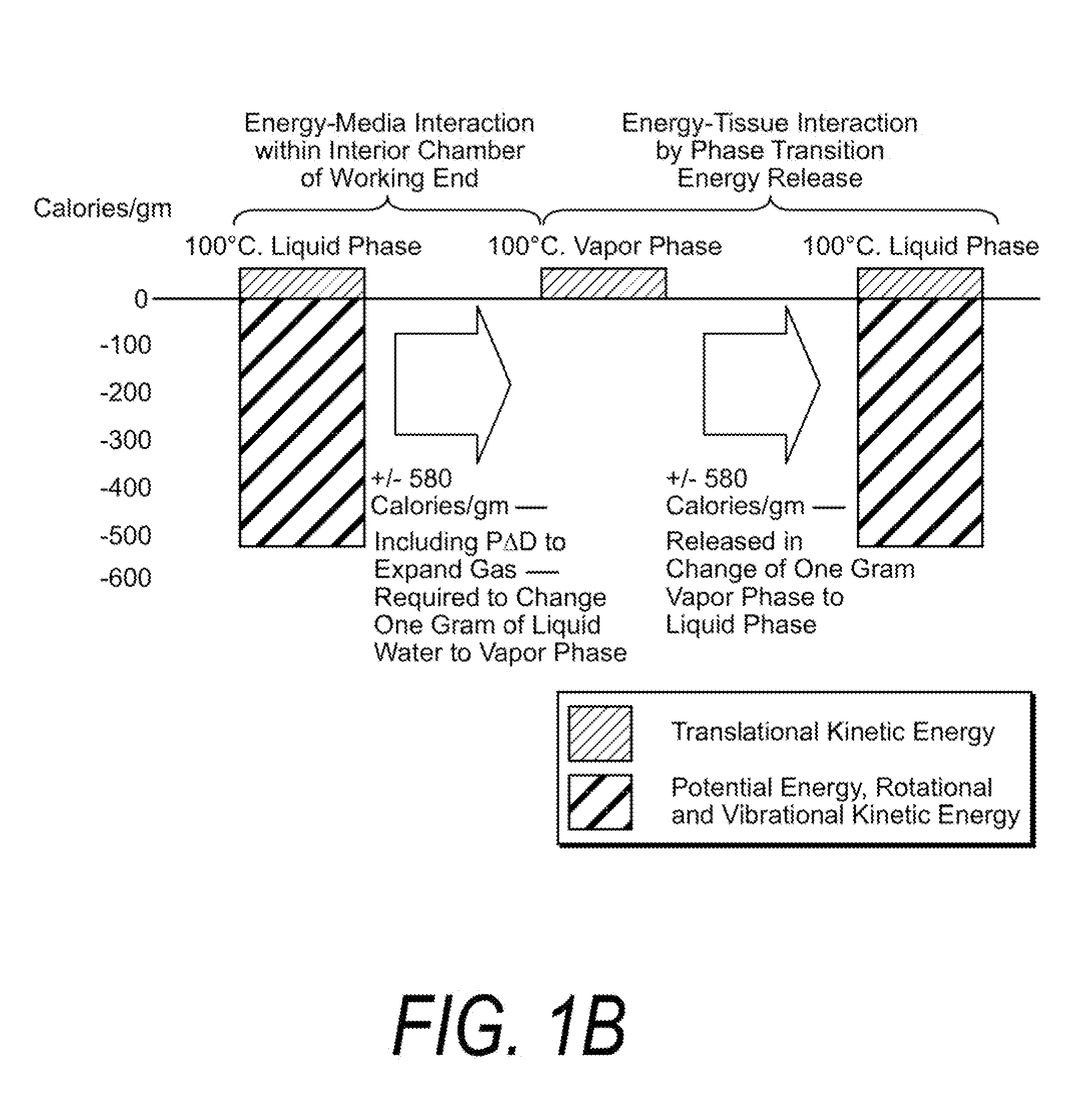

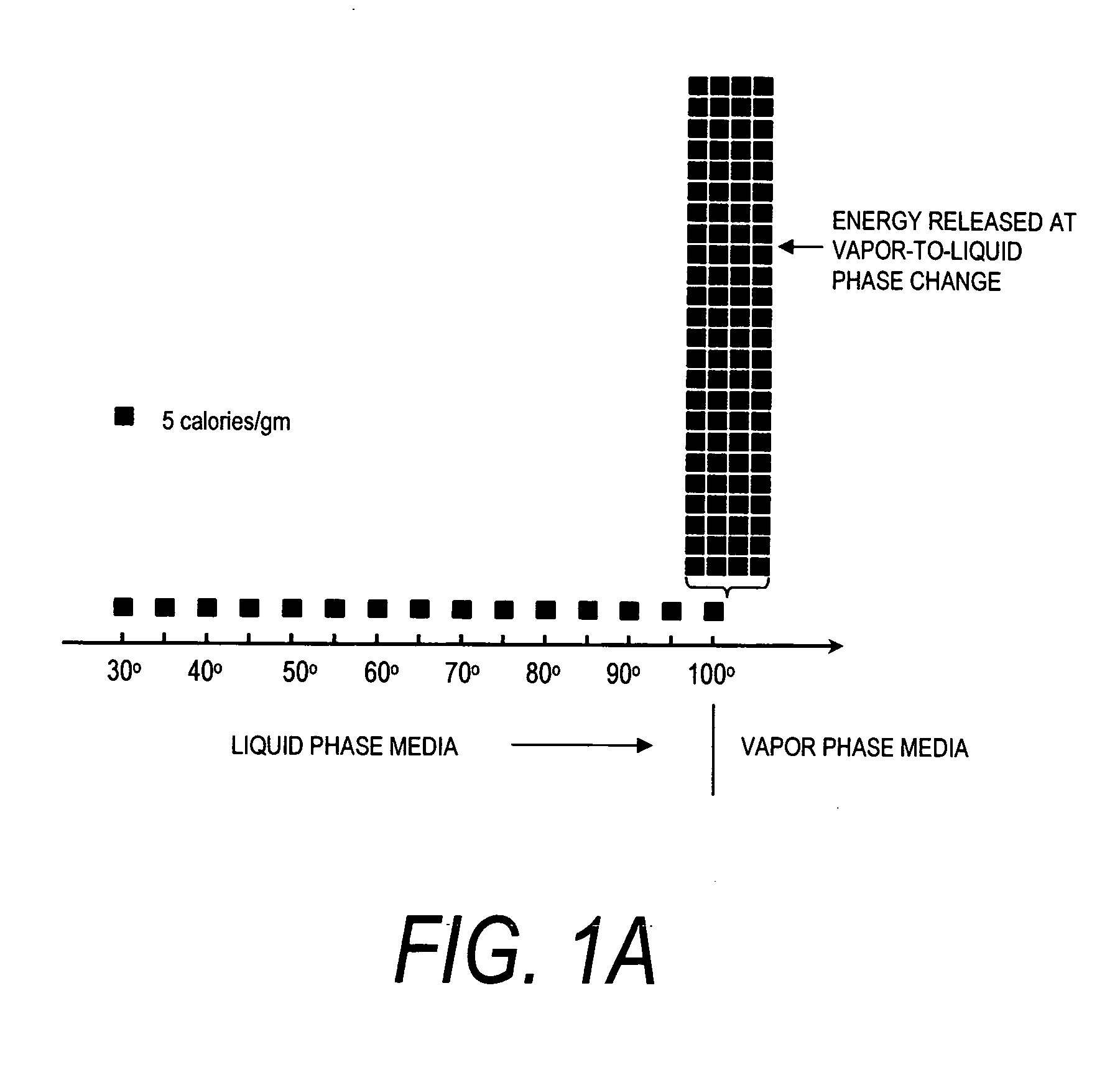

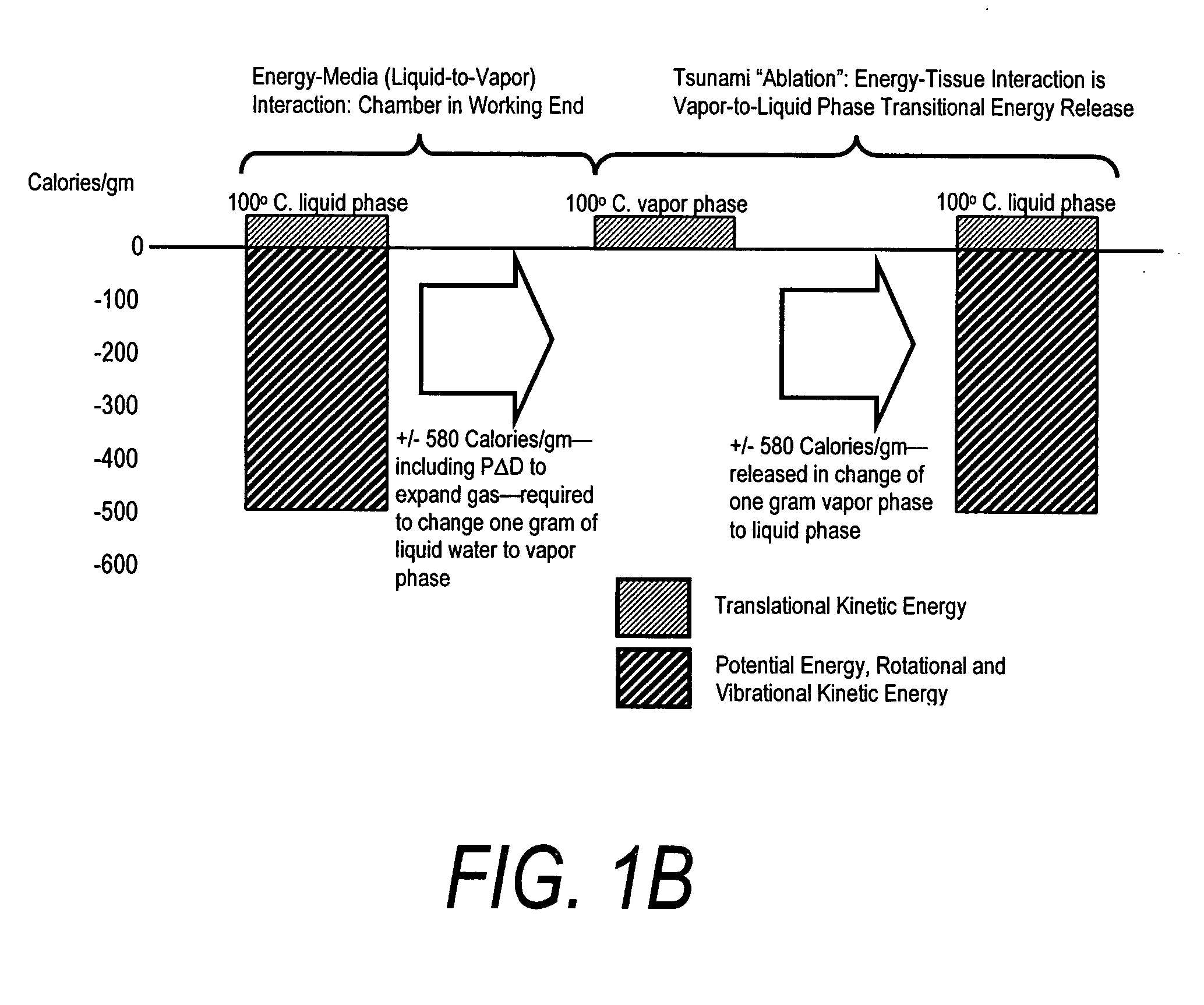

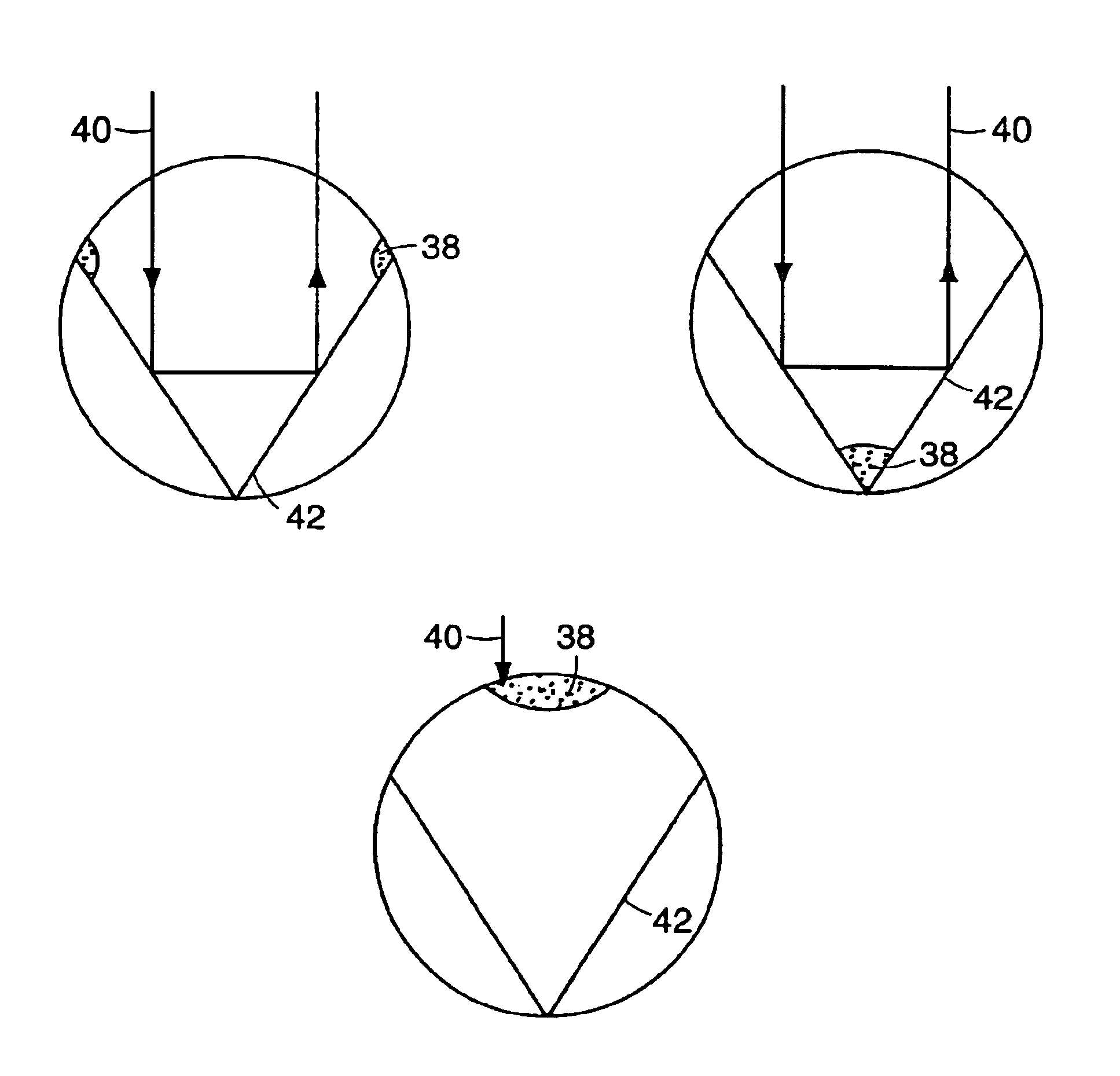

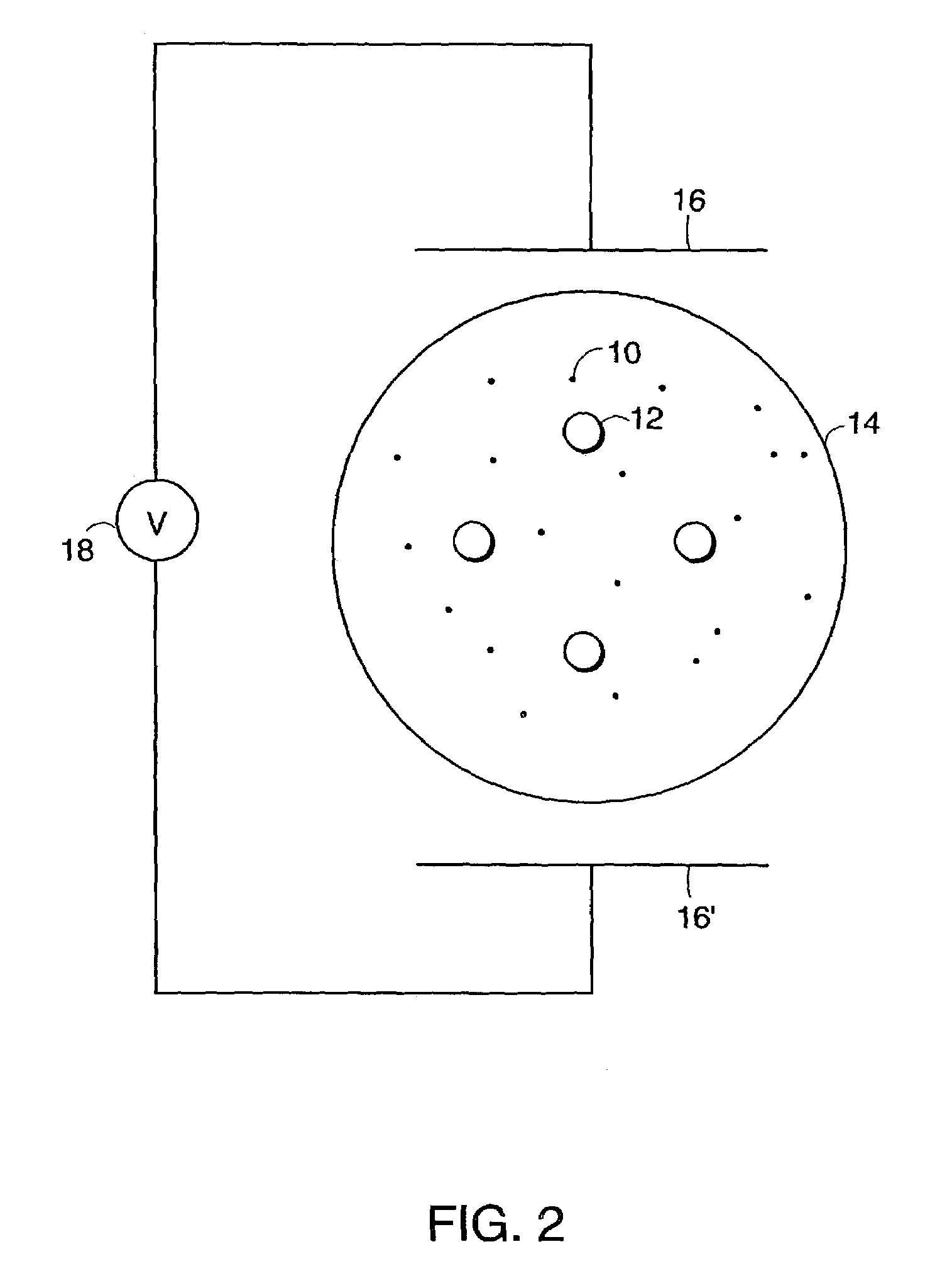

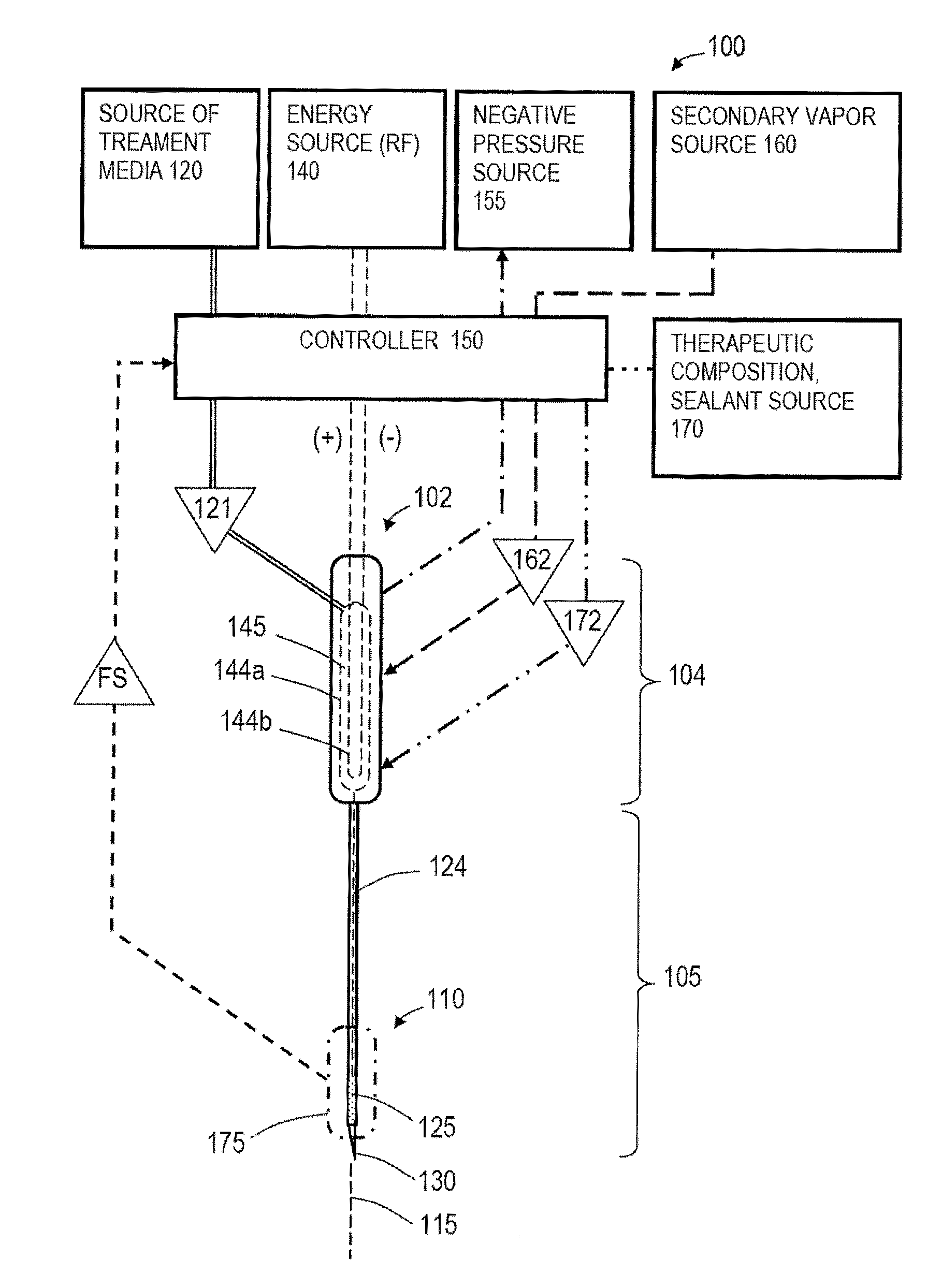

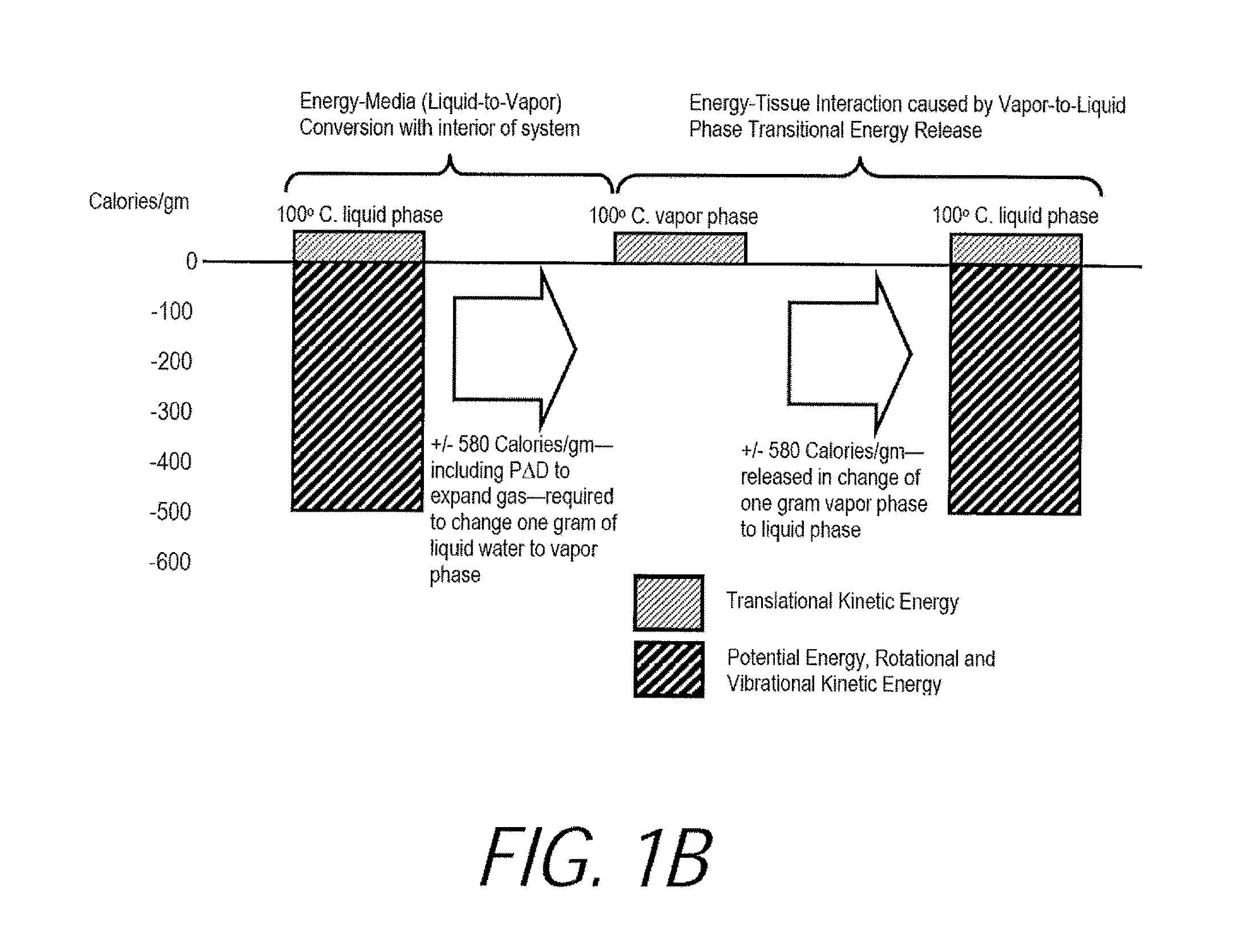

Medical instrument and method of use

ActiveUS20060224154A1Prevents desiccationPrevents escharSurgical instruments for heatingTherapeutic coolingThermal energyGas phase

An instrument for thermally-mediated therapies in targeted tissue volumes or for volumetric removal of tissue. In one embodiment, the instrument has an interior chamber that includes a diffuser structure for diffusing a biocompatible conductive fluid that is introduced under high pressure. The interior chamber further includes surfaces of opposing polarity electrodes for vaporizing the small cross-section diffused fluid flows created within a diffuser structure. In one embodiment, the diffuser structure includes a negative temperature coefficient of resistance material between the opposing polarity surfaces. The NTCR structure can self-adjust the lengths of current paths between the opposing polarities to insure complete vaporization of the volume of flow of conductive fluid. The non-ionized vapor phase media is ejected from a working surface of the instrument and a controlled vapor-to-liquid phase change in an interface with tissue applies thermal energy substantially equal to the heat of vaporization to ablate tissue. In another embodiment, the instrument provides voltage means for converting the non-ionized vapor phase media into an ionized media or plasma for applying energy to body structure.

Owner:TSUNAMI MEDTECH

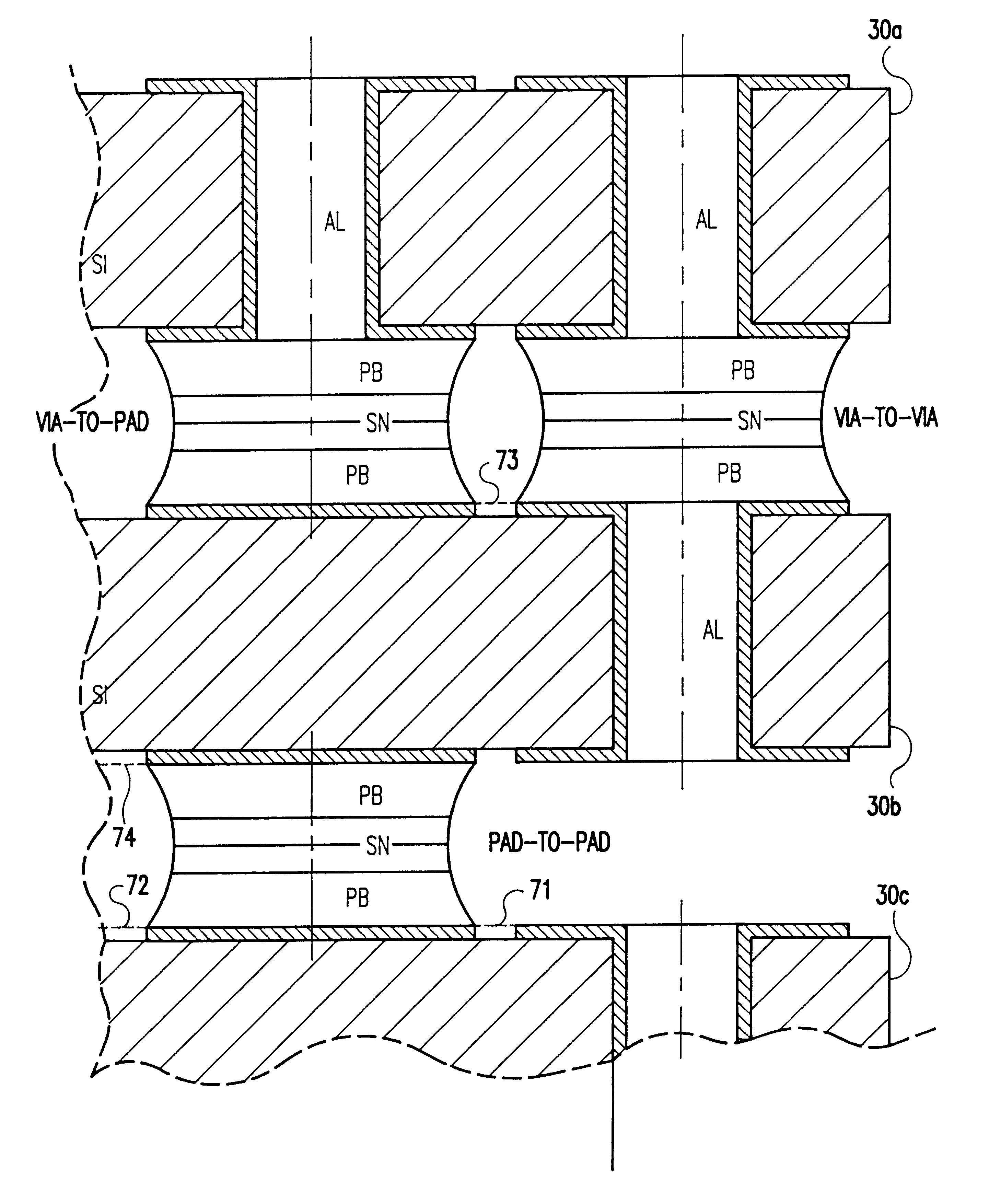

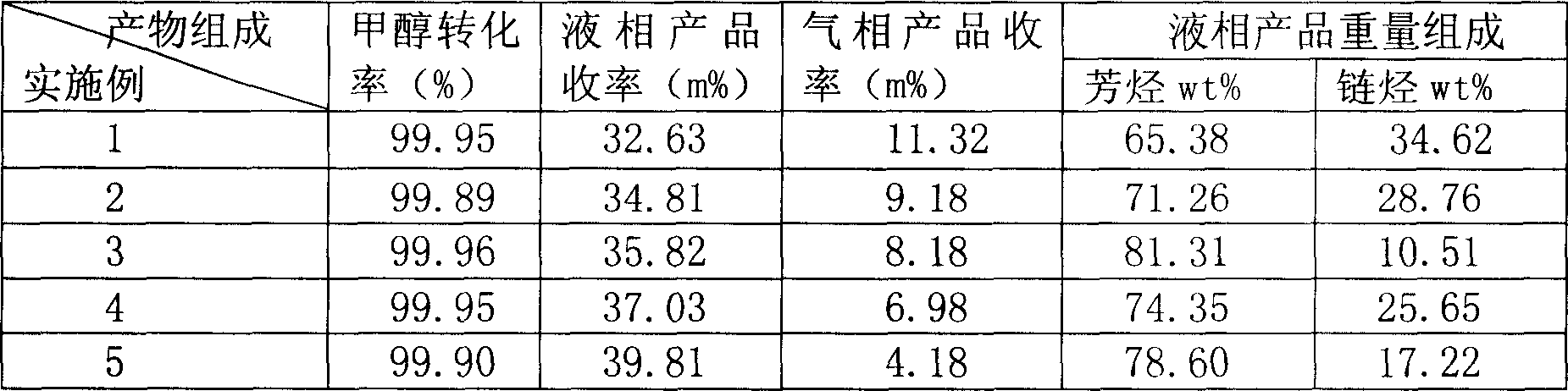

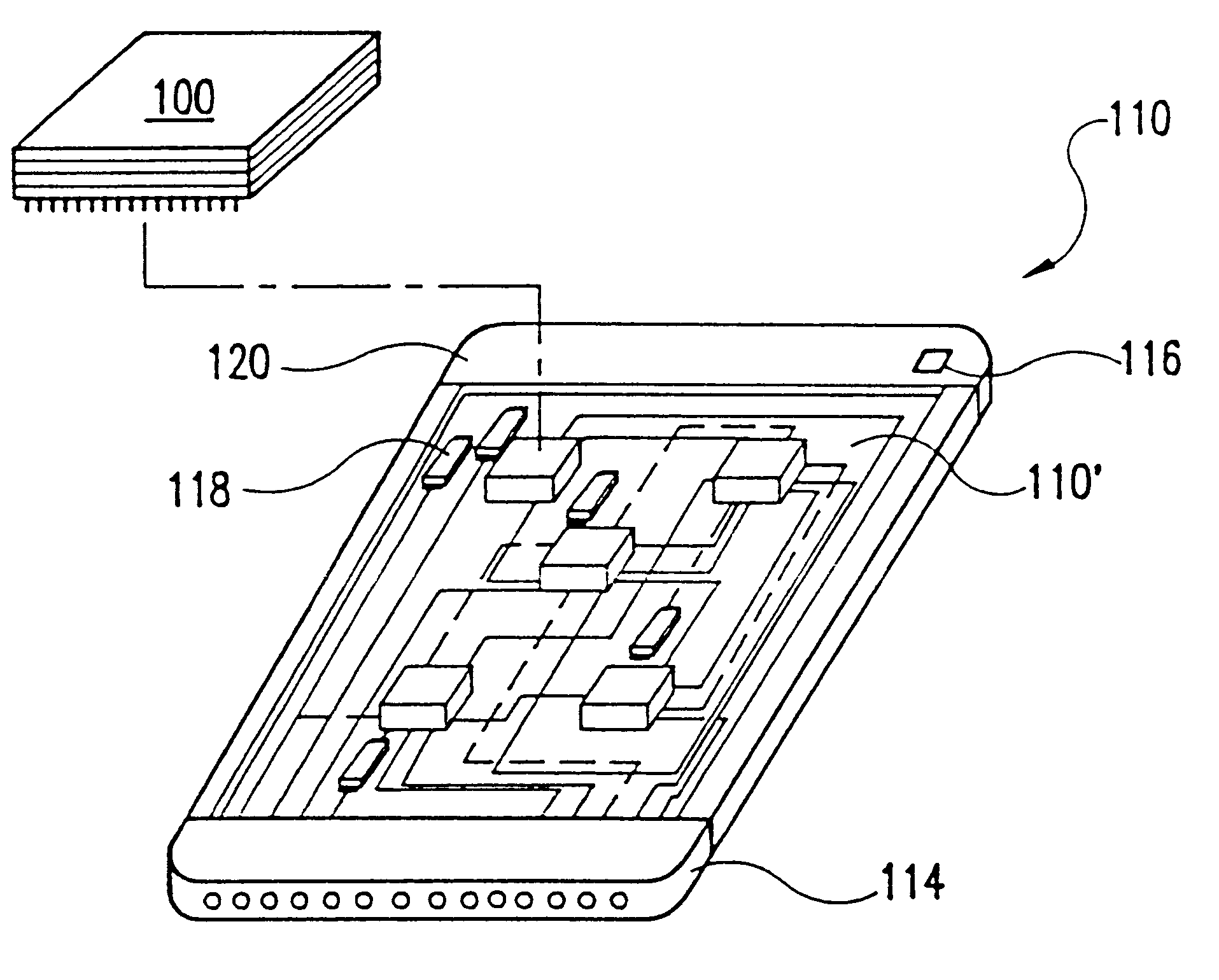

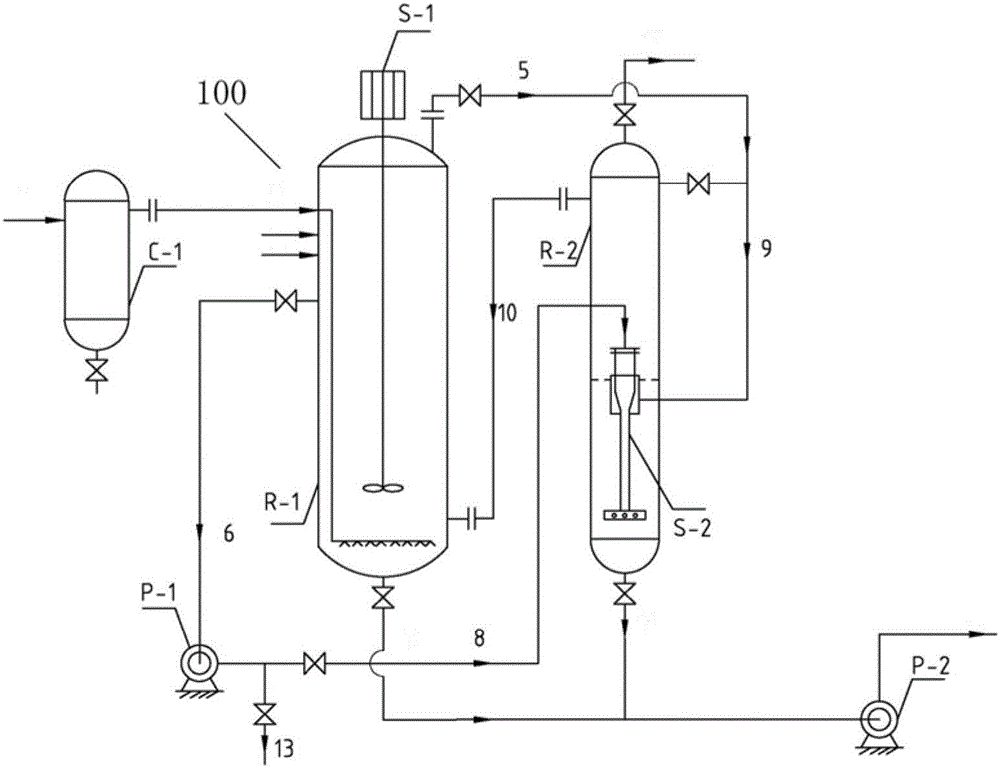

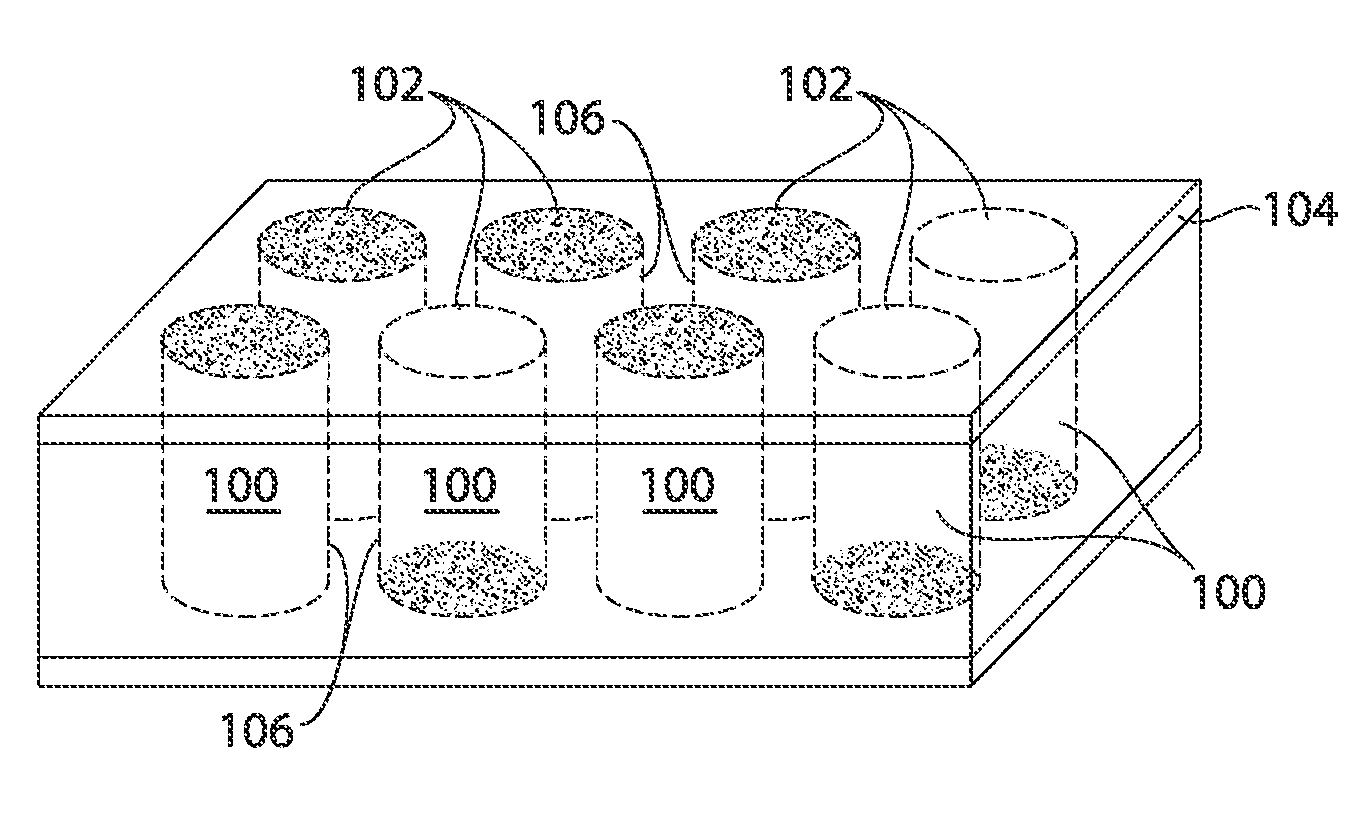

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6236115B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal expansion

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:INT BUSINESS MASCH CORP

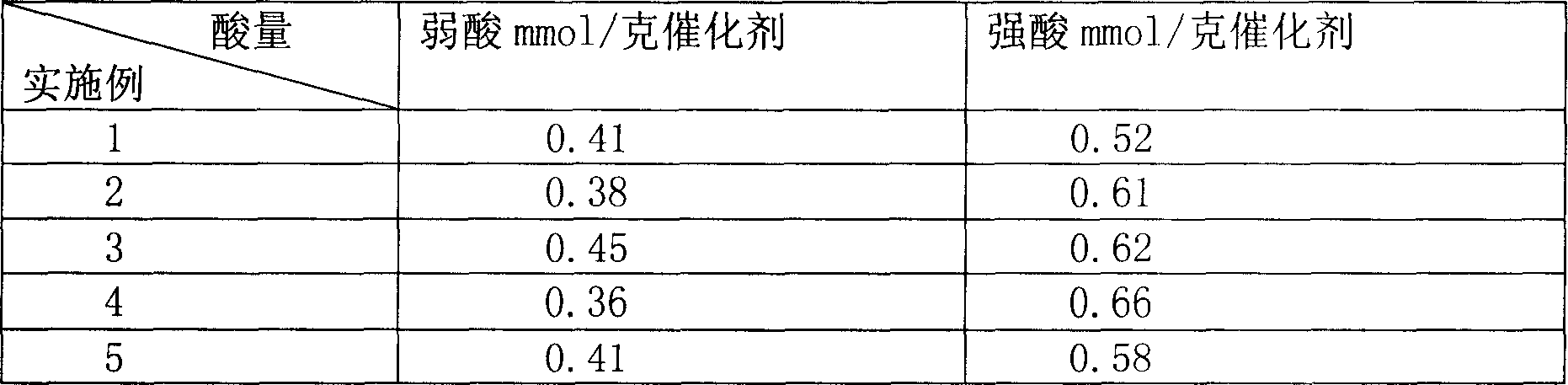

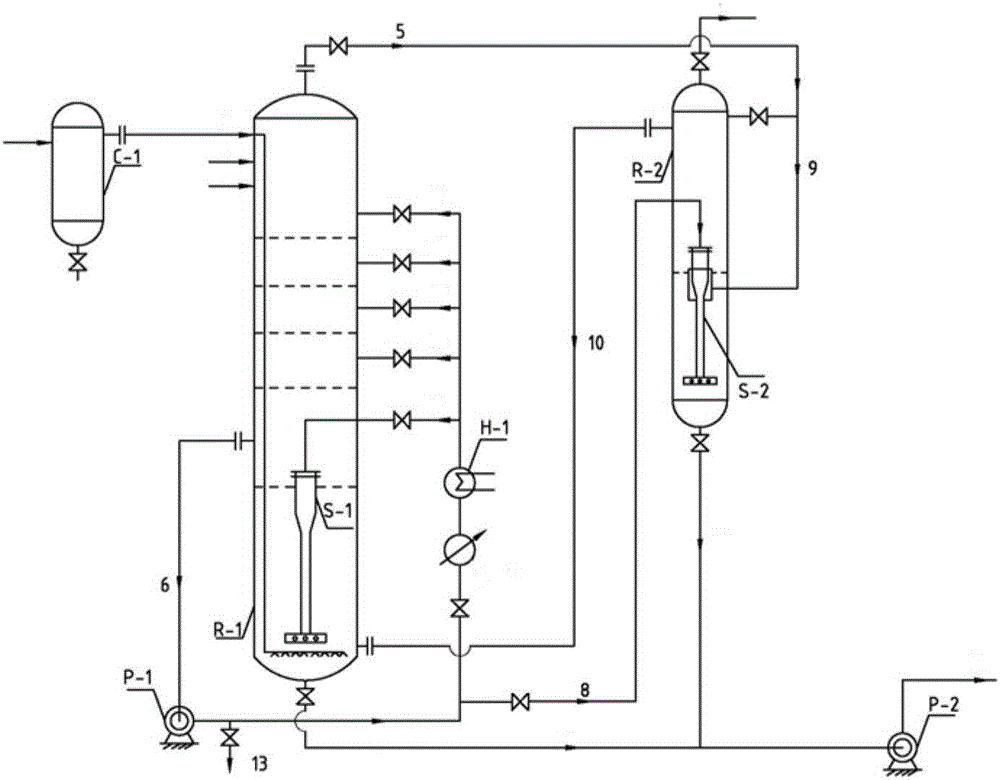

Process of methanol conversion for preparing arene and catalyst and catalyst preparation method

InactiveCN1880288AHigh selectivityHigh flexibility in process operationMolecular sieve catalystsHydrocarbonsGas phaseAromatic hydrocarbon

This invention relates to a process for transforming methanol to aromatic hydrocarbons, comprising: use methanol as raw material, with modified ZSM-5 molecular sieve as catalyst, under conditions of operation pressure 0.1-5.0Mpa, operation temperature 300-460Deg C, raw material liquid air speed 0.1-6.0h-1, transformed to products with aromatic hydrocarbons as main components; separate the gas-phase products lower carbon hydrocarbons from the liquid-phase C5+ hydrocarbons by cooling separation; the liquid-phase C5+ hydrocarbons then can be separated to be aromatic hydrocarbons and non-aromatic hydrocarbons by extracting separation. This invention is characterized of high total selectivity of aromatic hydrocarbons and flexible process operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

Indirect calibration of polymer characterization systems

InactiveUS6294388B1Avoid backlogImprove throughputIon-exchange process apparatusSamplingPolymer characterizationFlow injection analysis

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. The described methods, systems, and devices have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

Parallel high-performance liquid chromatography with post-separation treatment

InactiveUS6436292B1High sample throughputEasy to findIon-exchange process apparatusSamplingChromatographic separationCombinatorial synthesis

High-performance liquid chromatography (HPLC) methods and systems are disclosed that combine parallel chromatographic separation of a plurality of samples with a detection technique that involves post-separation treatment of the plurality of samples to enhance one or more properties of the sample or of a component thereof, followed by detection of the one or more enhanced properties. Selective, tunable detection schemes are achievable, and are particularly advantageous as applied in connection with combinatorial chemistry, combinatorial material science and more particularly, combinatorial synthesis and screening of polymeric materials.

Owner:FREESLATE

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6187678B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesThermal expansionPrism

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:IBM CORP

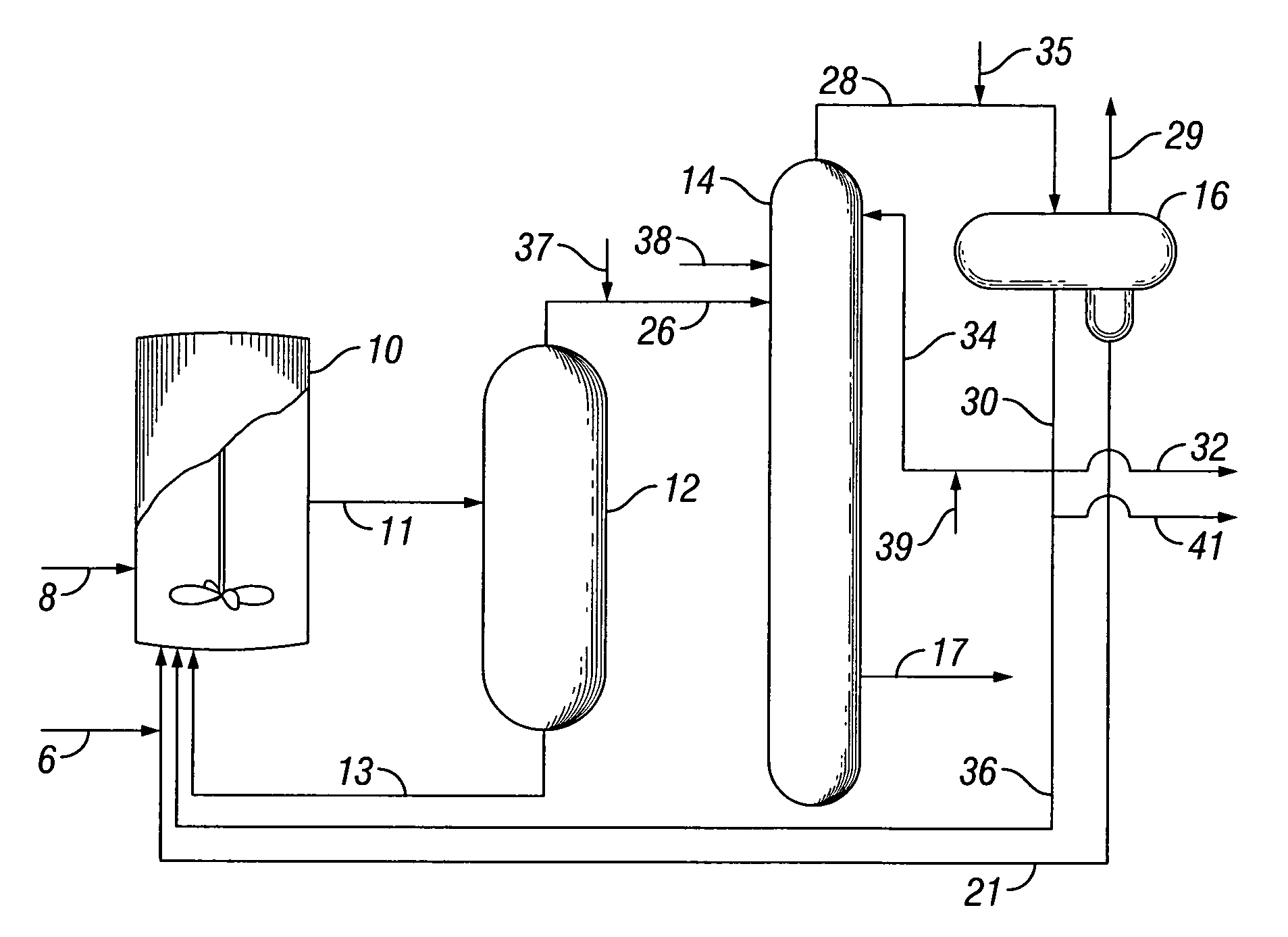

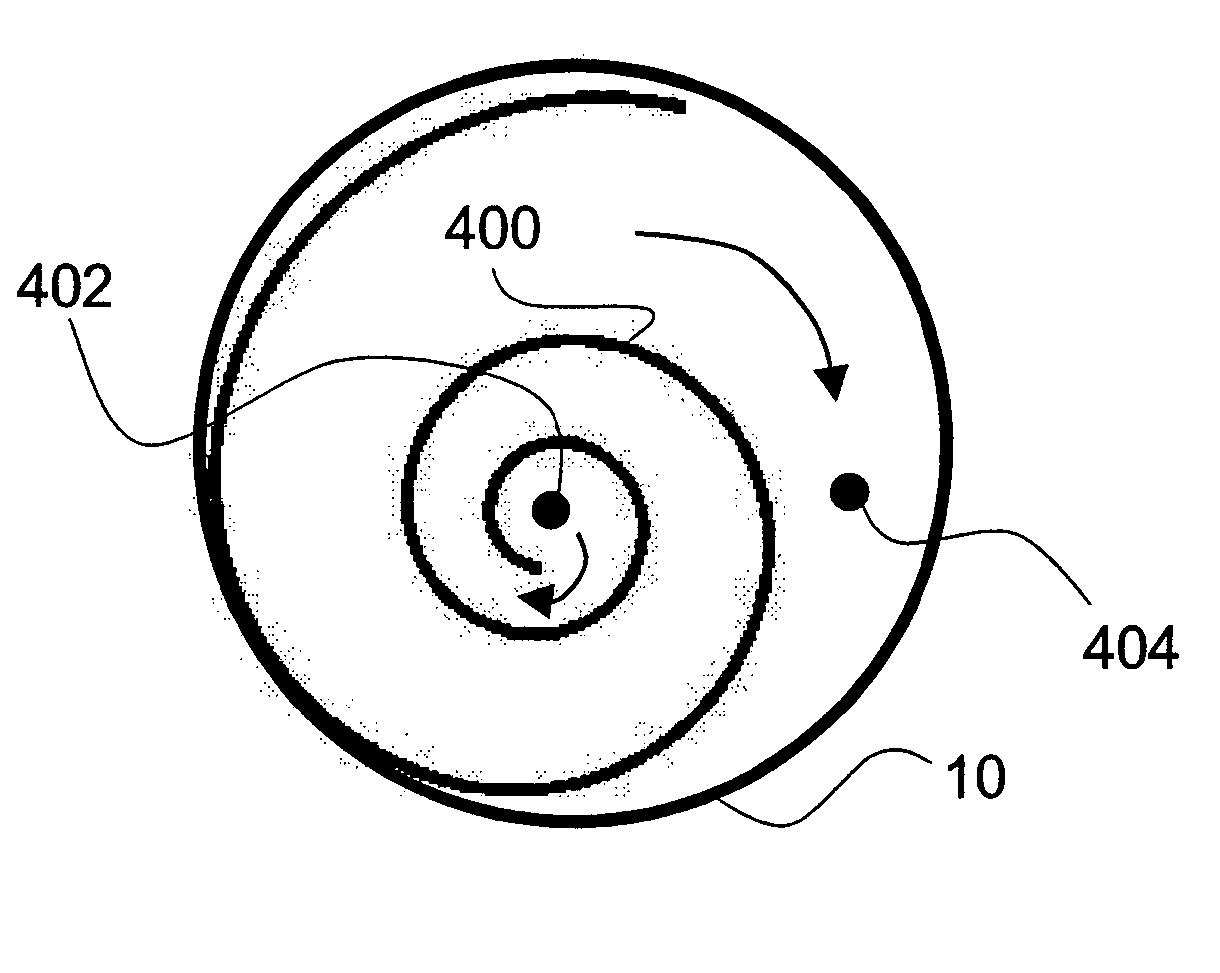

Device and technique for producing cyclohexane by benzene hydrogenation

ActiveCN106187660AImprove mass transfer efficiencyIncrease reaction rateHydrocarbon by hydrogenationBenzeneGas phase

The invention discloses a device and technique for producing cyclohexane by benzene hydrogenation. The device for producing cyclohexane by benzene hydrogenation comprises a reactor, a superfine bubble generator and a bubble breaker, wherein the reactor is provided with a first containing cavity; the wall of the first containing cavity is provided with a feed port, a circulation discharge port, a circulation return port and a gas phase outlet; the superfine bubble generator is provided with a second containing cavity; the wall of the second containing cavity is provided with a return port and a gas phase outlet; the return port of the superfine bubble generator communicates with the circulation return port of the reactor; the bubble breaker is arranged in the second containing cavity; the bubble breaker is provided with a gas phase inlet and a liquid phase inlet which communicates with the circulation discharge port of the reactor; and the gas phase inlet of the bubble breaker communicates with the gas phase outlet of the reactor. The device disclosed by the embodiment of the invention has the advantages of high mass transfer efficiency, high reaction rate, short reaction time, low material consumption and energy consumption, simple structure, low manufacturing cost and low maintenance cost.

Owner:NANJING UNIV

Thin film-structure and a method for producing the same

InactiveUS6759261B2Increase productivityGood reproducibilityLiquid-phase epitaxial-layer growthElectrical measurement instrument detailsRoom temperatureCooling down

A thin film made of an amorphous material having supercooled liquid phase region is formed on a substrate. Then, the thin film is heated to a temperature within the supercooled liquid phase region and is deformed by its weight, mechanical external force, electrostatic external force or the like, thereby to form a thin film-structure. Thereafter, the thin film-structure is cooled down to room temperature, which results in the prevention of the thin film's deformation.

Owner:TOKYO INST OF TECH

Medical instruments and techniques for thermally-mediated therapies

InactiveUS7674259B2Thermal ablation rapidly and efficientlyPrevents desiccationDiagnosticsSurgical instruments for heatingThermal energyGas phase

A surgical instrument for thermally-mediated therapies in targeted tissue volumes and for causing thermal effects in polymer tissue-contacting members. In one embodiment, the instrument has a working end with an interior chamber that is supplied with a biocompatible liquid. An energy source causes a liquid-to-vapor phase change within the interior of the instrument. The vapor phase media then is ejected from the working surface of the instrument, and a controlled vapor-to-liquid phase change in an interface with tissue applies thermal energy substantially equal to the heat of vaporization to ablate tissue. The vapor-to-liquid phase transitions, or internal energy releases, can be provided about thin-film flexible structures for engaging body lumens and cavities. An exemplary embodiment can be used for shrinking, sealing, welding or creating lesions in tissue—while causing limited collateral thermal damage and while totally eliminating electrical current flow in the engaged tissue.

Owner:TSUNAMI MEDTECH

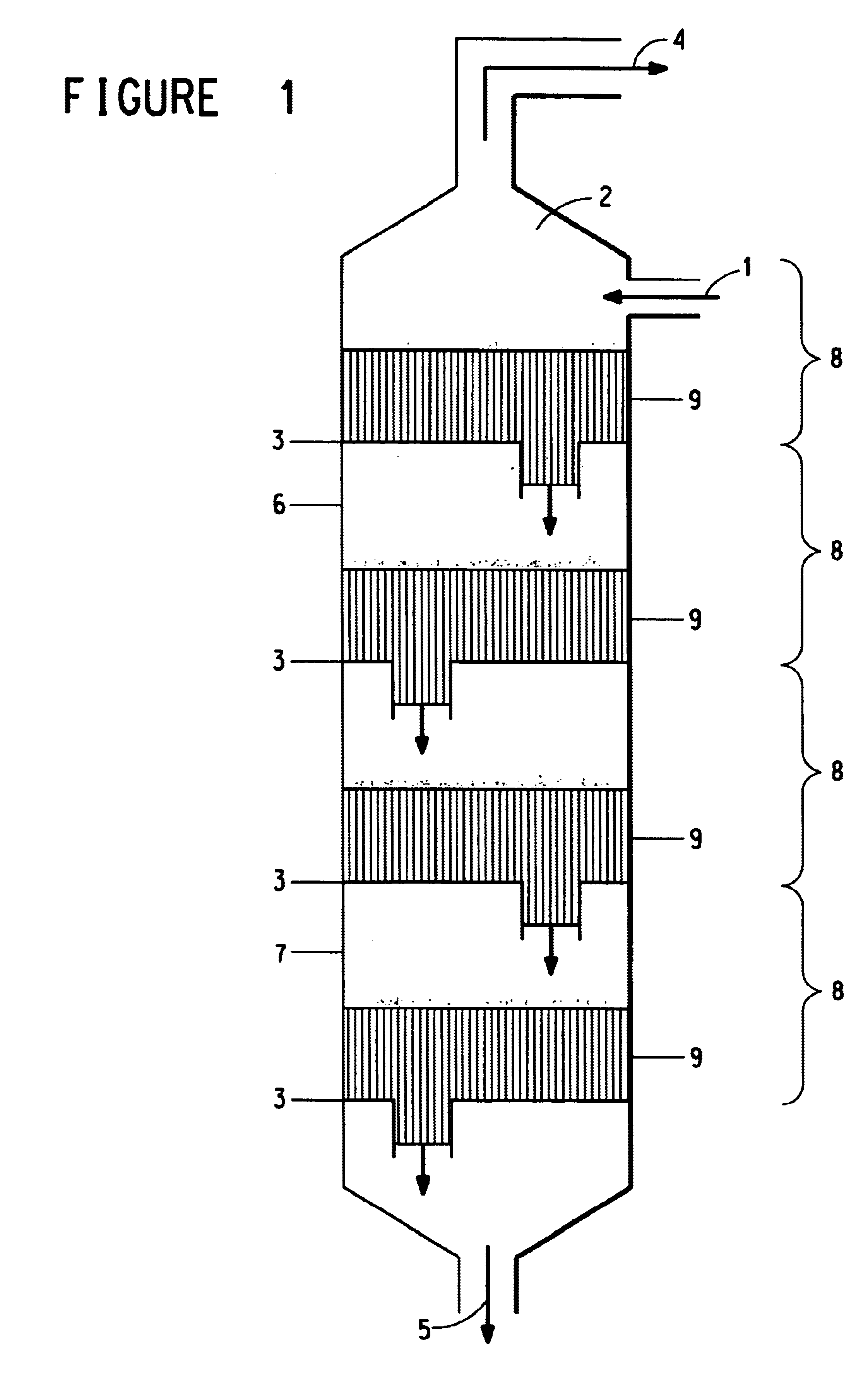

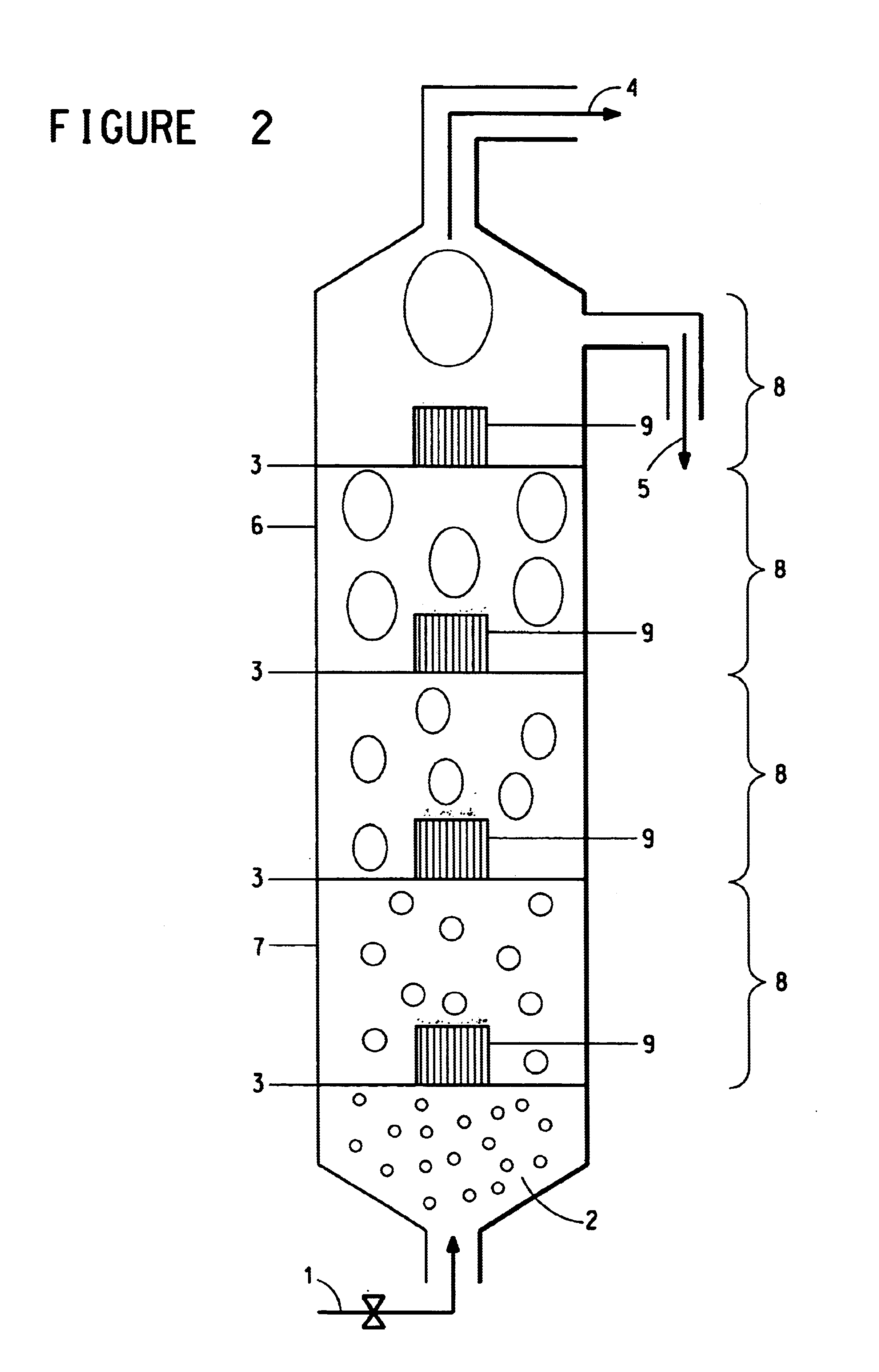

Continuous process for the preparation of polytrimethylene ether glycol

InactiveUS6720459B2Liquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationGas phaseEther

The invention is a continuous process for the preparation of polytrimethylene ether glycol from 1,3-propanediol reactant. In addition, the invention is directed to a continuous multi-stage process comprising reacting at least one reactant in a liquid phase in an up-flow column reactor, and forming a gas or vapor phase by-product wherein the gas or vapor phase by-product is continuously removed at the top and at least one intermediate stage.

Owner:DUPONT CA +1

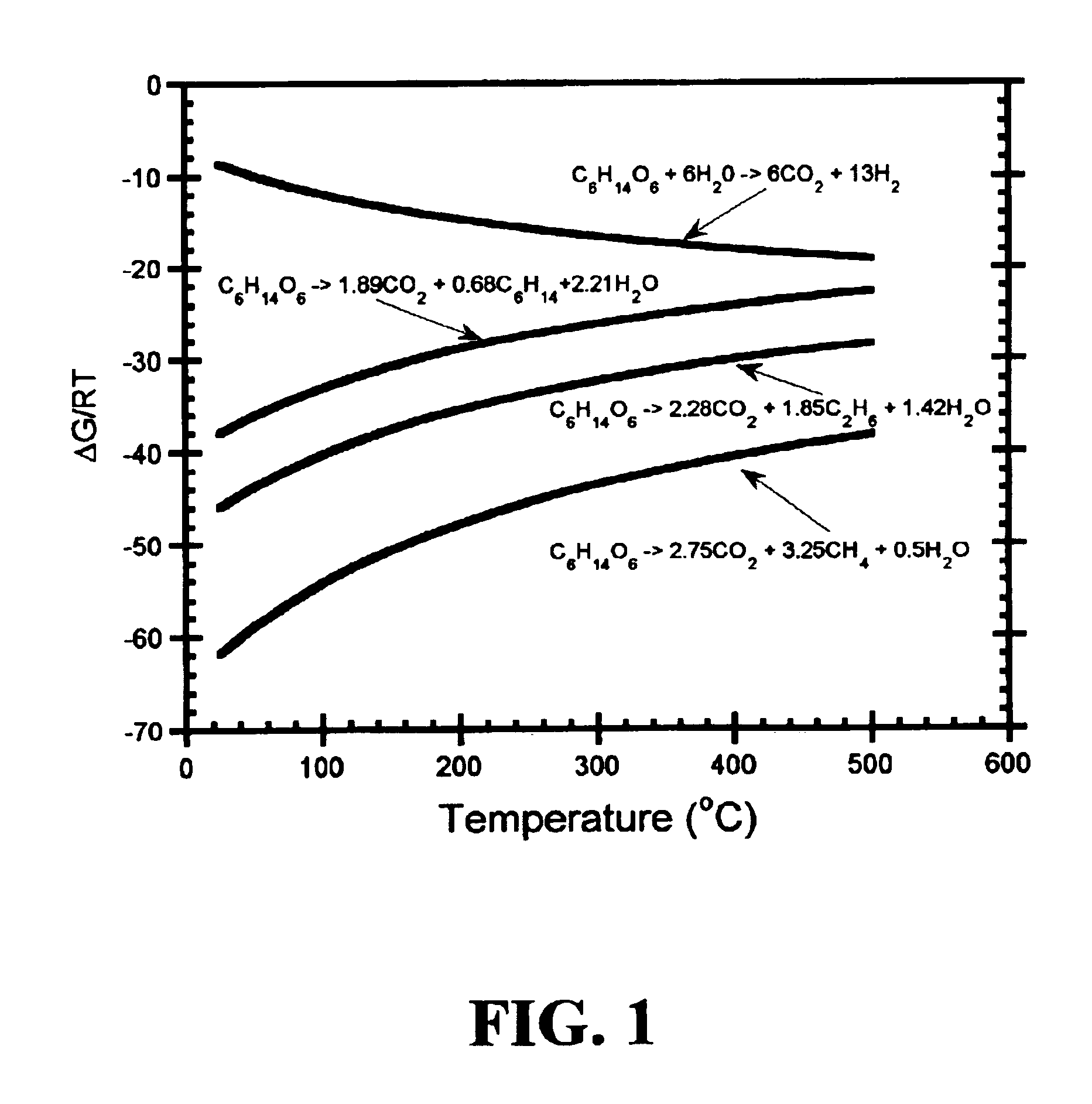

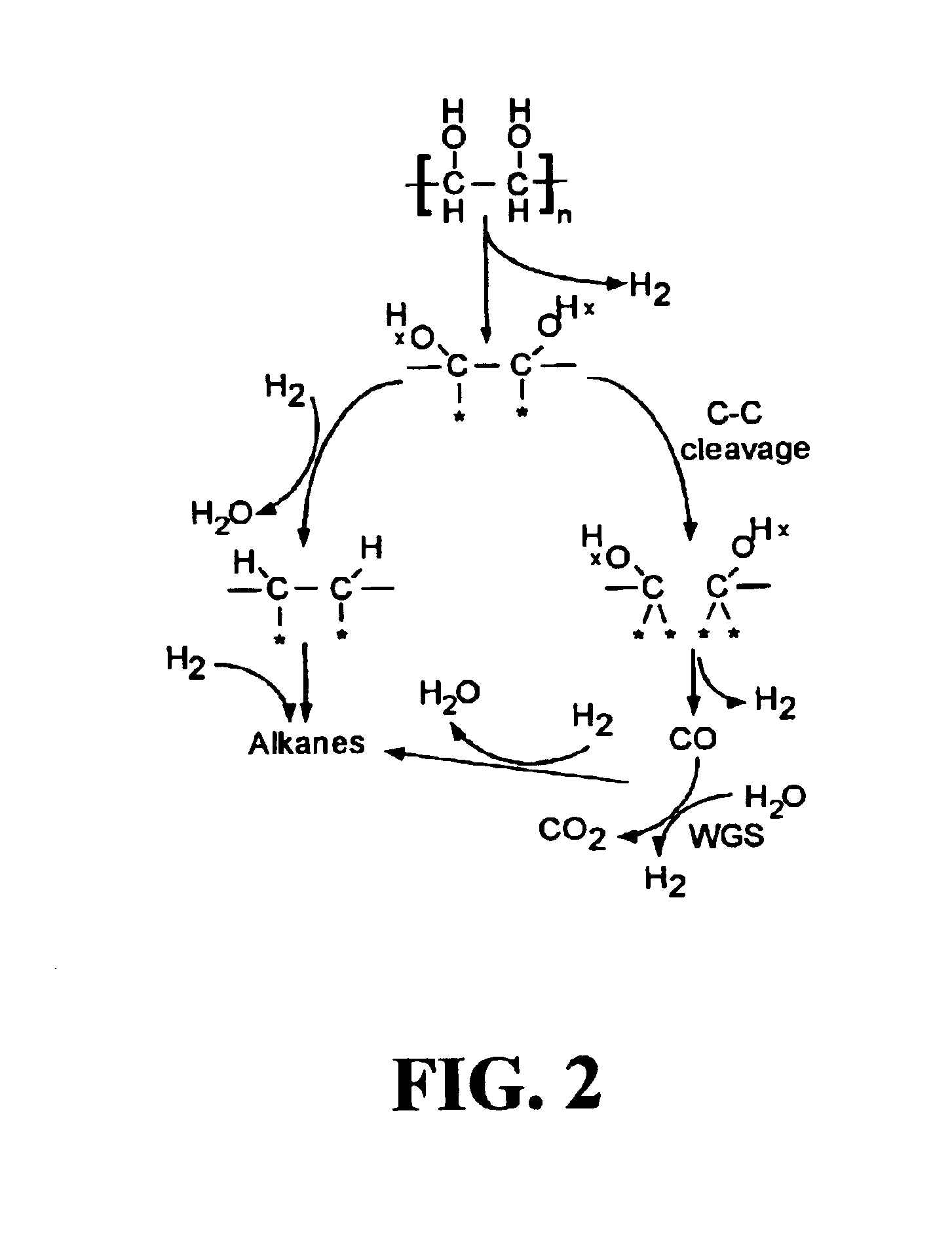

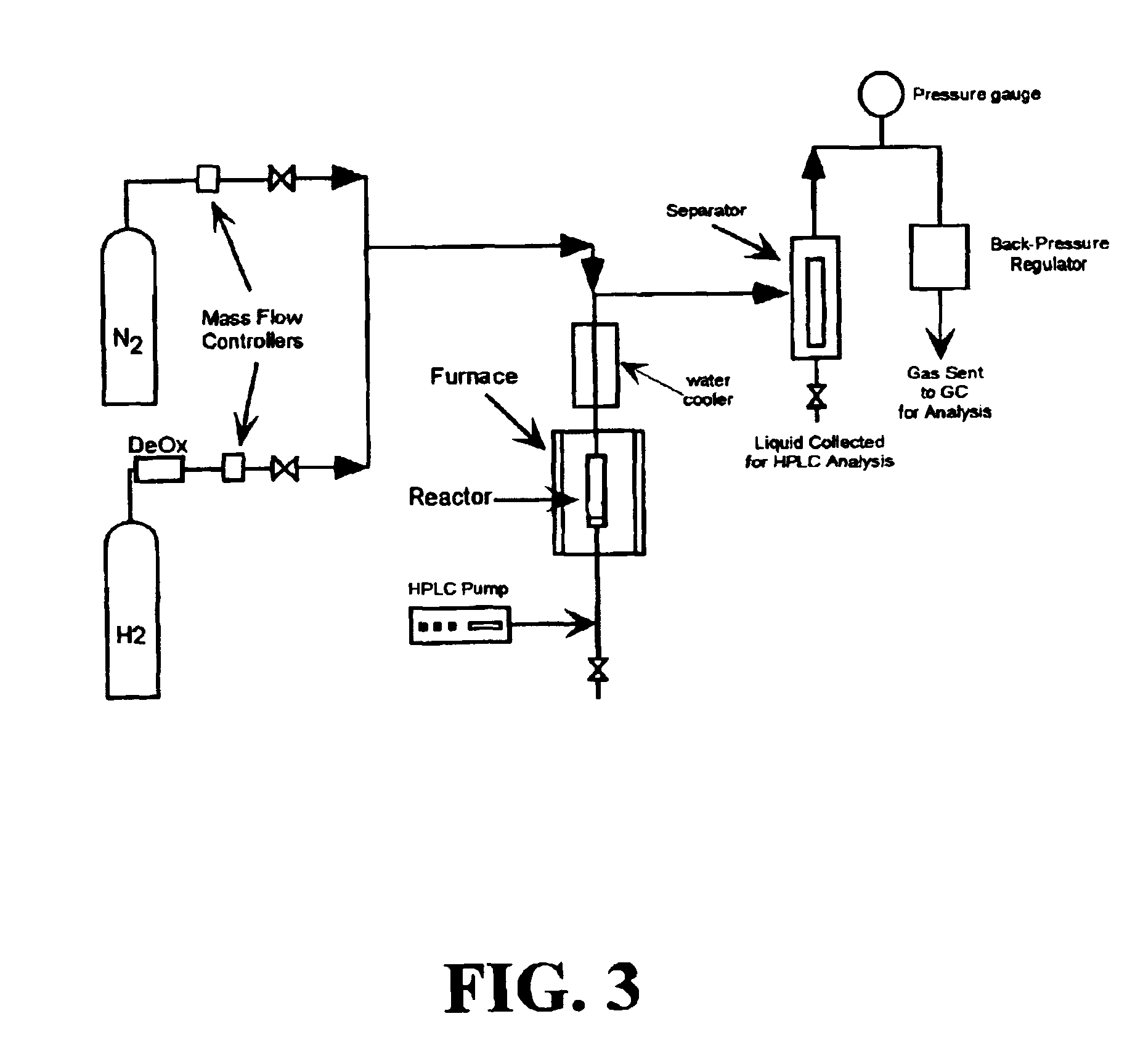

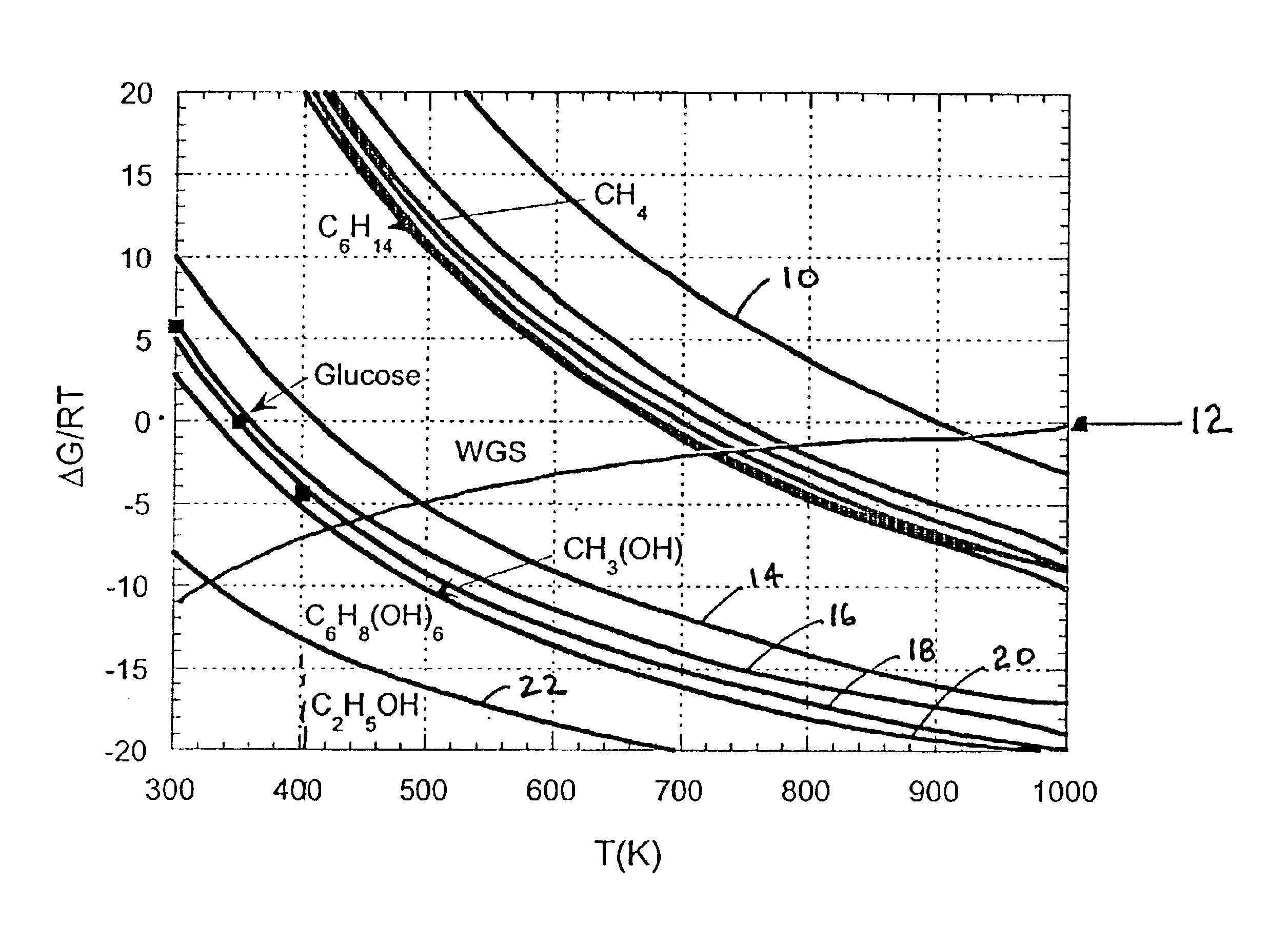

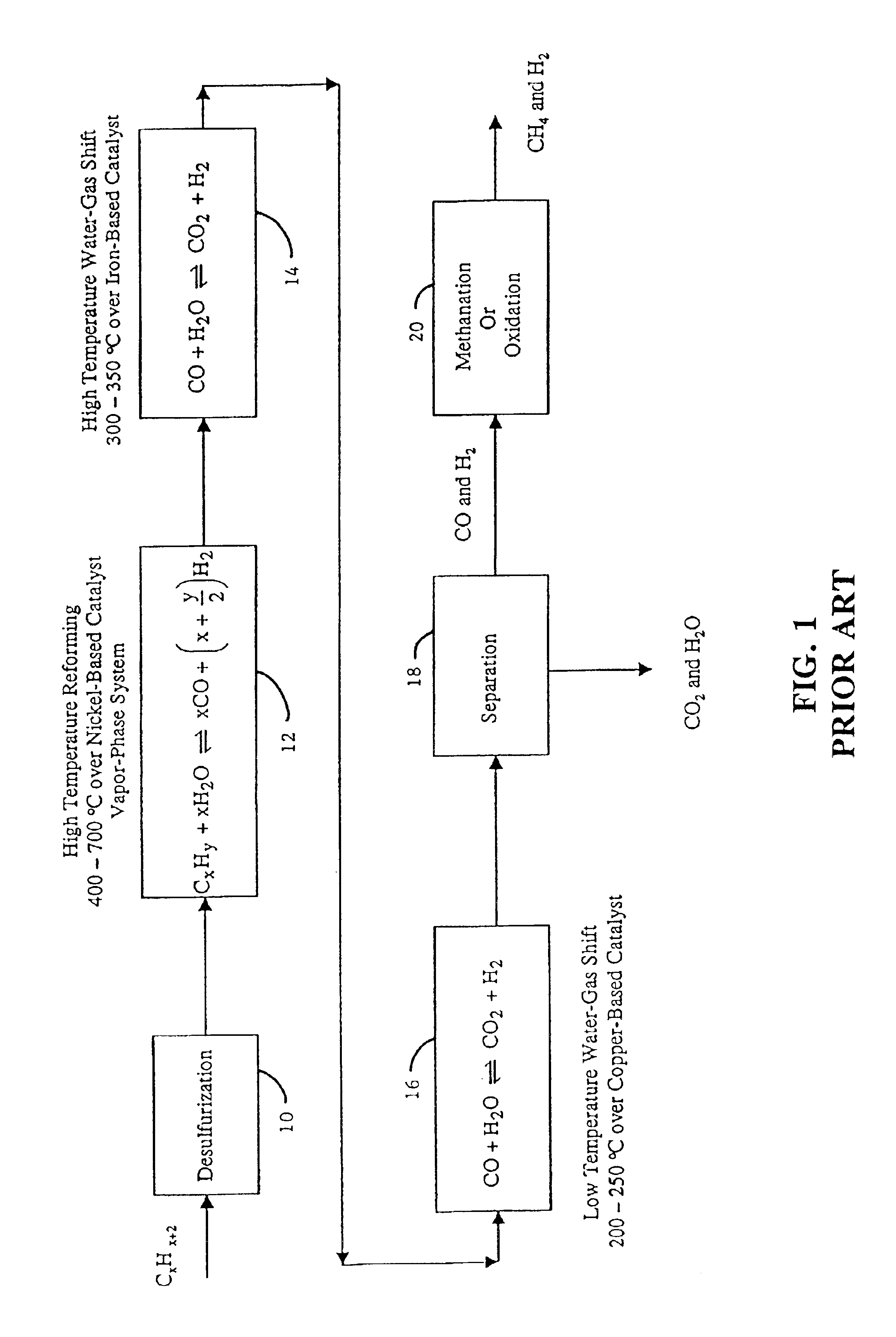

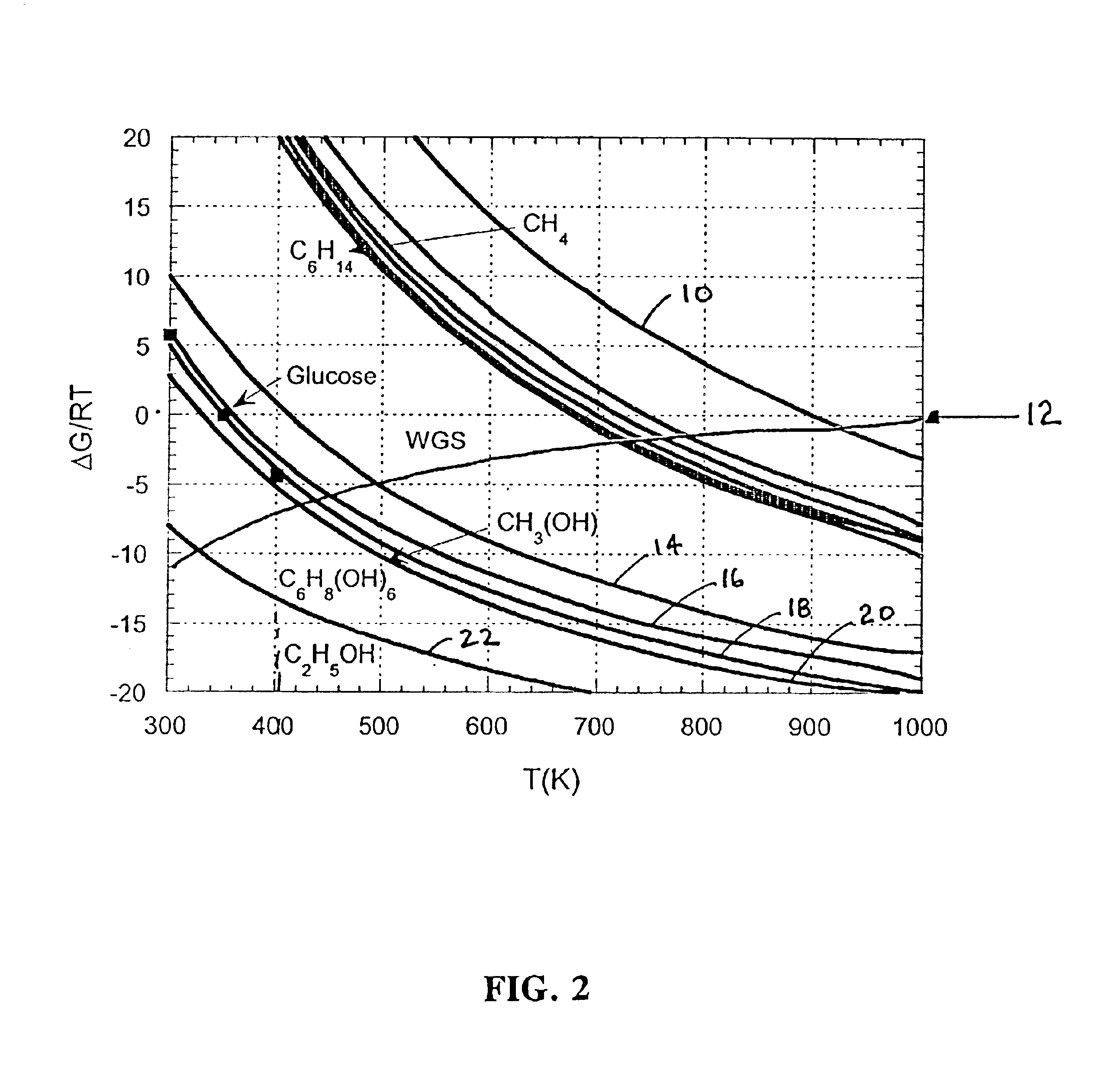

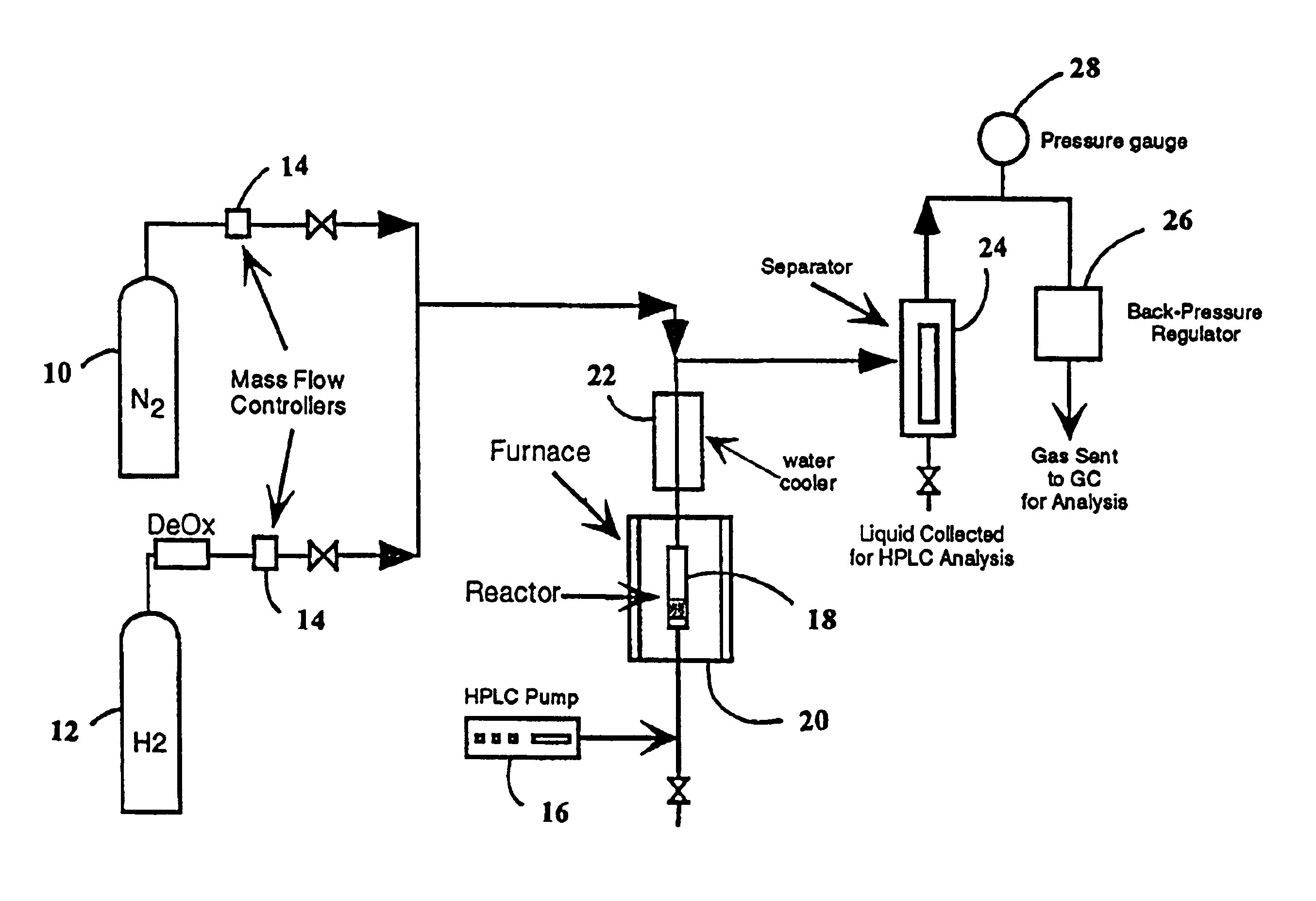

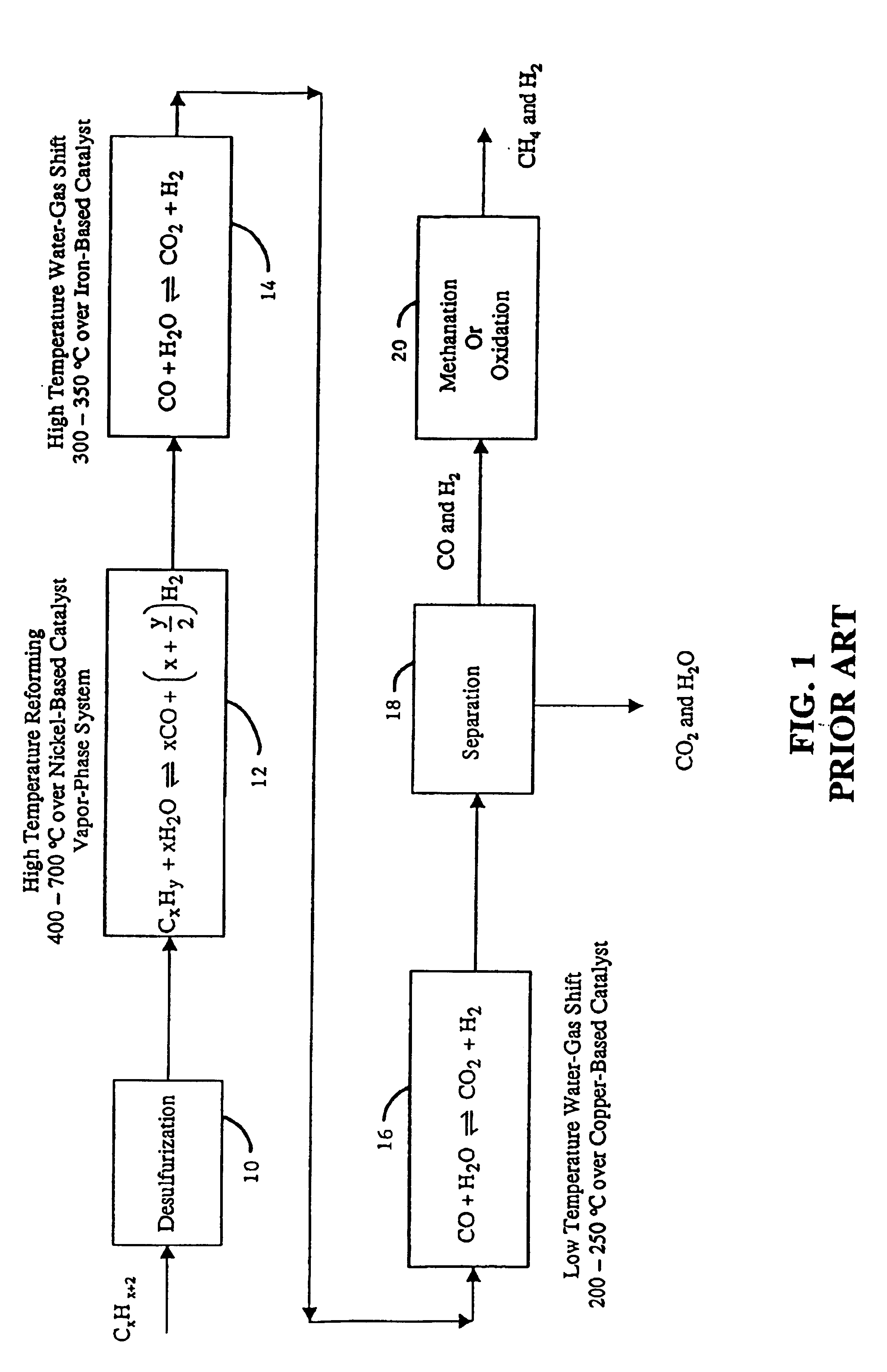

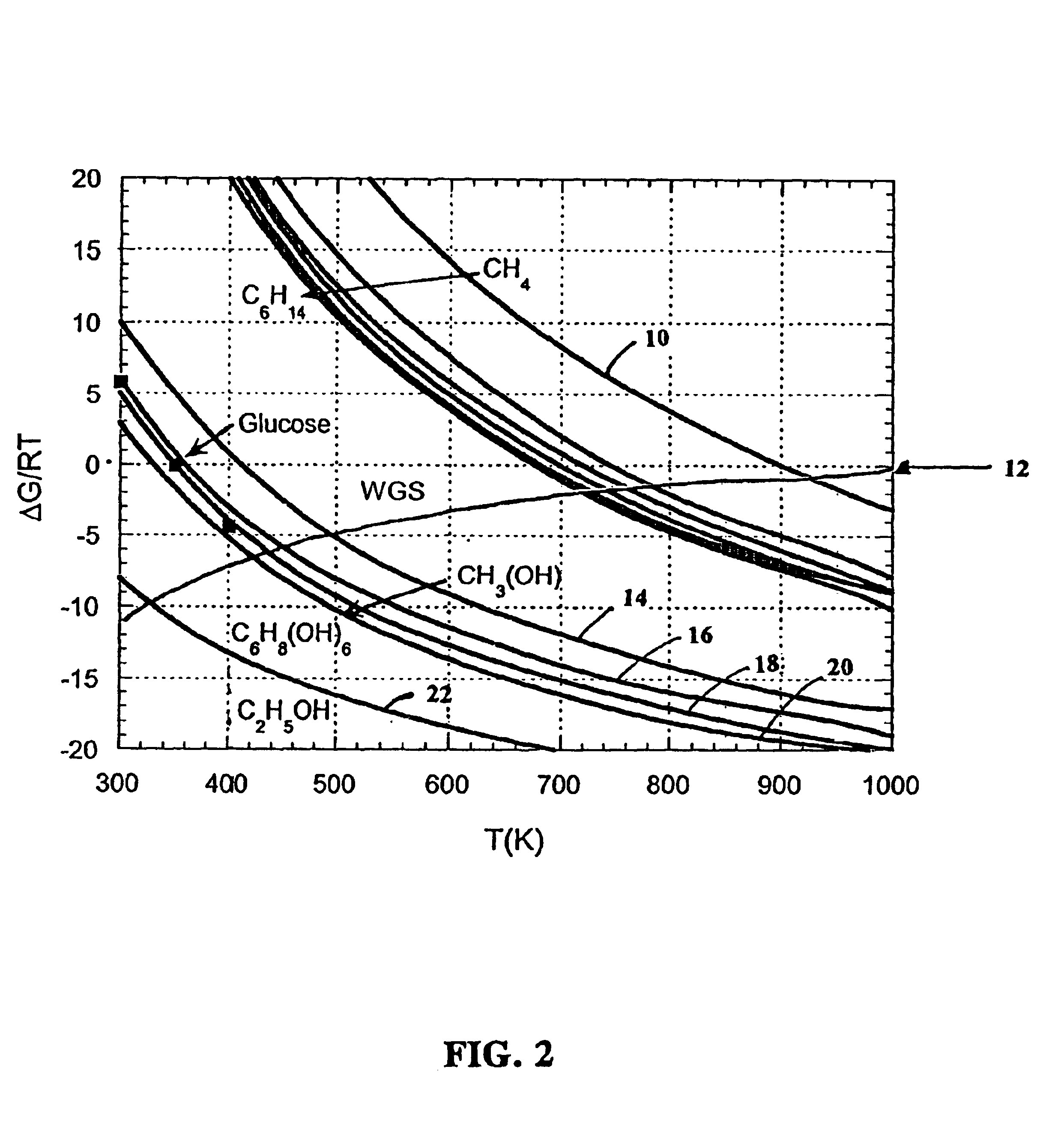

Low-temperature hydrocarbon production from oxygenated hydrocarbons

Disclosed is a method of producing hydrocarbons from oxygenated hydrocarbon reactants, such as glycerol, glucose, or sorbitol. The method can take place in the vapor phase or in the condensed liquid phase (preferably in the condensed liquid phase). The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon having at least two carbon atoms, in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. These metals are supported on supports that exhibit acidity or the reaction is conducted under liquid-phase conditions at acidic pHs. The disclosed method allows the production of hydrocarbon by the liquid-phase reaction of water with biomass-derived oxygenated compounds.

Owner:WISCONSIN ALUMNI RES FOUND

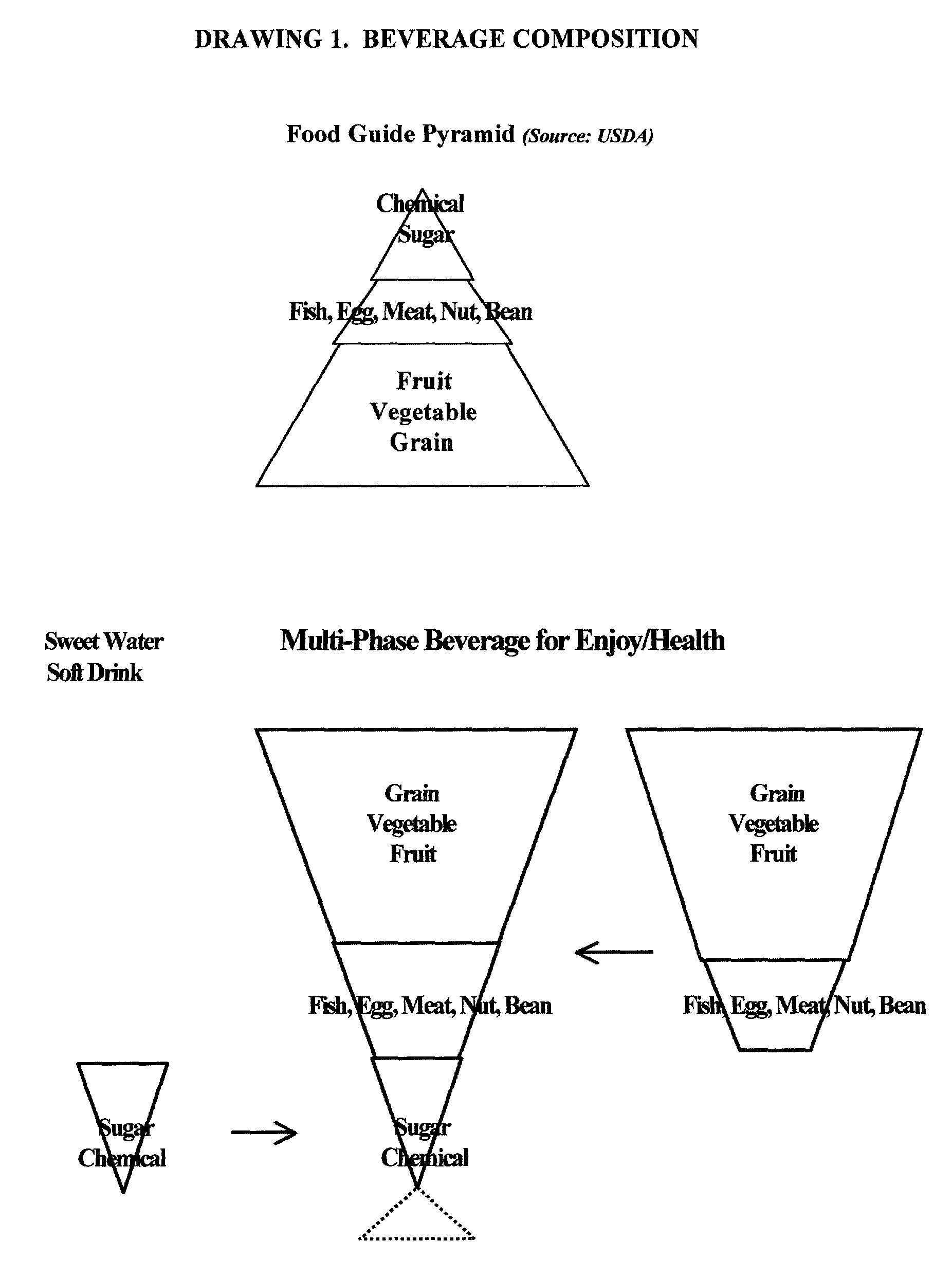

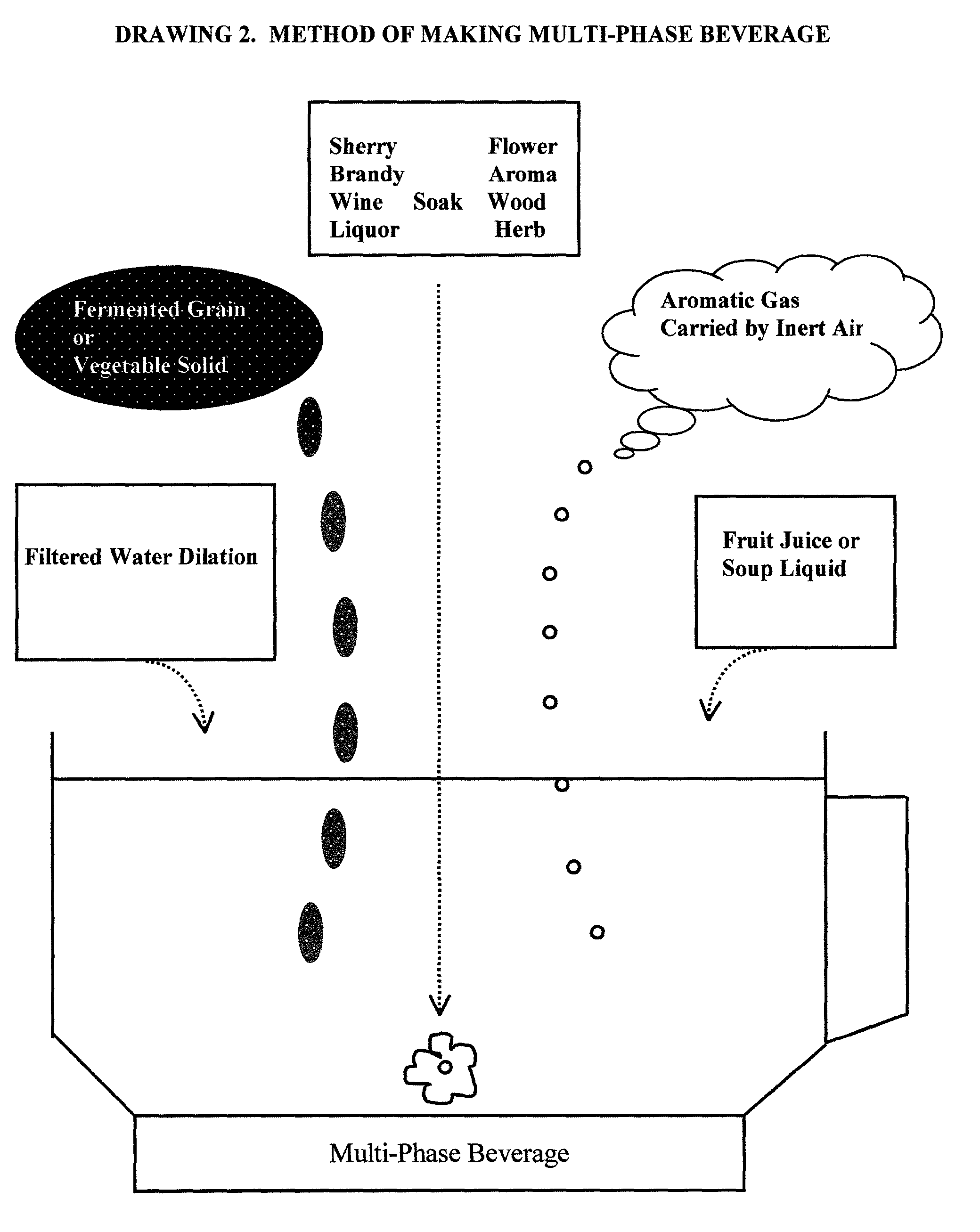

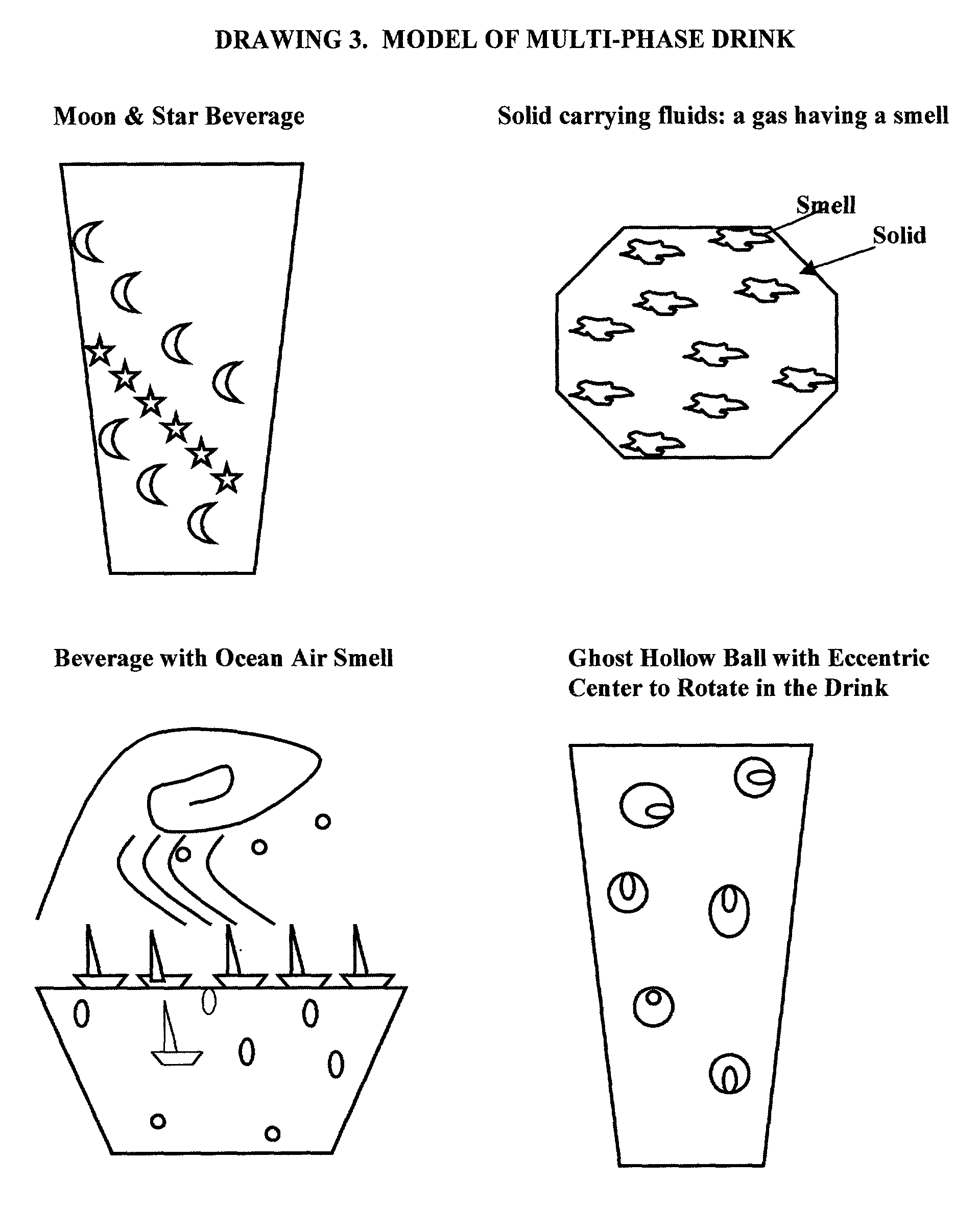

Multi-phase food & beverage

A method of making, combining, and using a balanced multi-phase food mixture and a multi-phase beverage made thereof is incorporated into carbonated herb beverage, aerated tea, fast fermented grain drink, amino acid flavored beverage, alcohol soaked cocktail drink, and aerated vegetable beverage. The liquid phase comprises total small molecular mineral and sugar up to 350 mOsm, pH 3.5-7.8, sweetener up to 7 wt %, alcohol up to 3 wt %, protein up to 30 wt %, fiber 20-37 gram per 2000 calories, at least 30% of calories are derived from complex carbohydrate, and up to 5% by volume gas, which will release a meaningful smell when being consumed. The solid phase includes at least 10% by weight plant mix, complex carbohydrate, protein, fat, and a combination thereof The beverage is natural and balanced referred to physiological body composition for normalizing body composition and fluid metabolism toward optimal body fitness with increased sensory experience and satiety.

Owner:ZHAO IRIS GINRON

Medical instruments and techniques for treating pulmonary disorders

ActiveUS20080132826A1Enhance tissue remodelingReducing lung volumeMedical devicesFluid jet surgical cuttersThermal energyDisease

A surgical instrument for delivering energy to lung tissue, for example to cause lung volume reduction. In one embodiment, an elongated catheter has a handle portion that includes an interior chamber that is supplied with a biocompatible liquid media under pressure. An energy source delivers energy to the media to cause a liquid-to-vapor phase change within the interior chamber and ejects a flow of vapor media from the working end of the catheter. The delivery of energy and the flow of vapor are controlled by a computer controller to cause a selected pressure and selected volume of vapor to propagate to the extremities of the airways. Contemporaneously, the vapor undergoes a vapor-to-liquid phase transition which delivers a large amount of energy to airway tissue. The thermal energy delivered is equivalent to the heat of vaporization of the fluid media, which shrinks and collapses the treated airways. The treated tissue is the maintained in a collapsed state by means of aspiration for a short interval to enhance tissue remodeling. Thereafter, the patient's wound healing response causes fibrosis and further remodeling to cause permanent lung volume reduction.

Owner:TSUNAMI MEDTECH

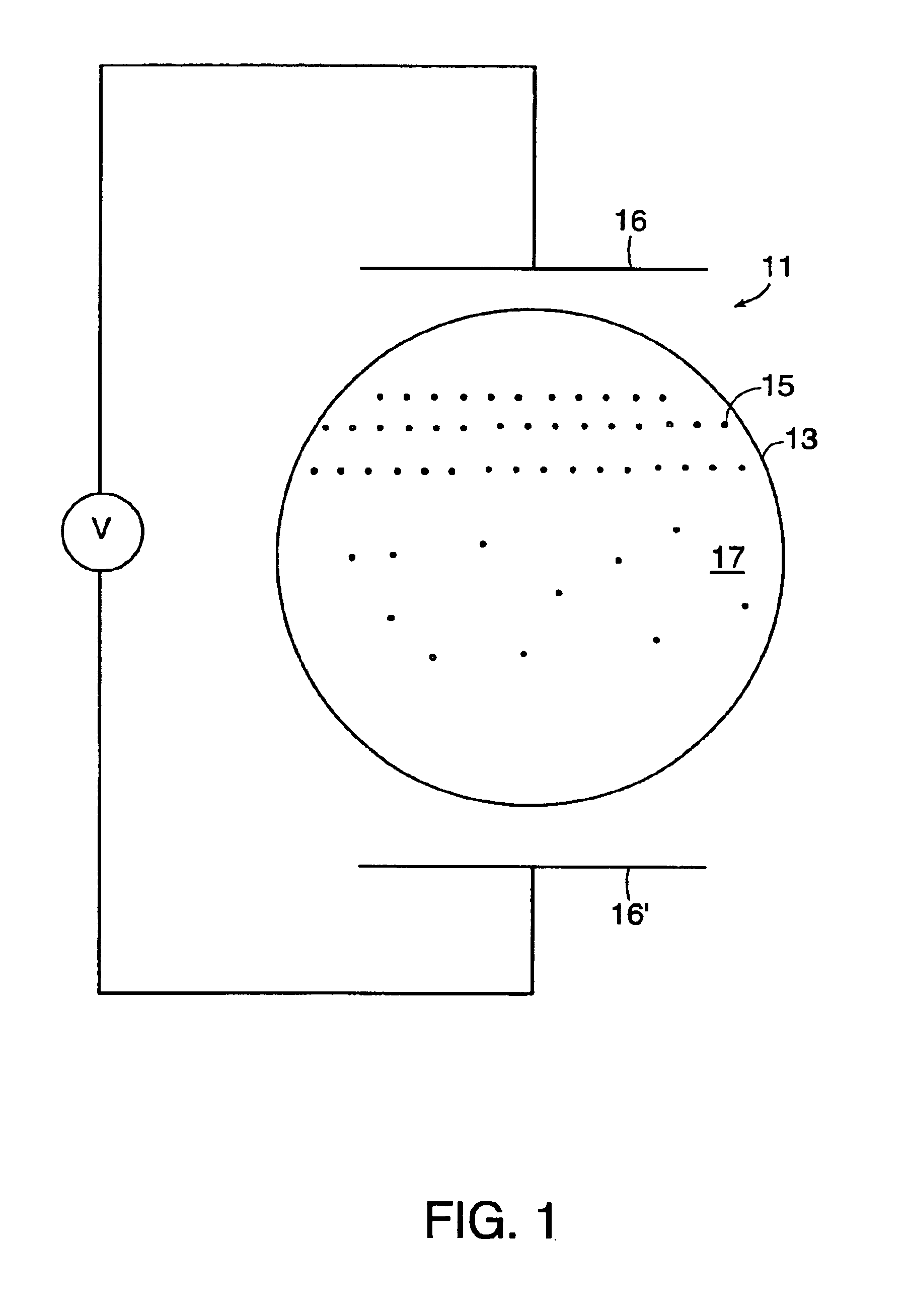

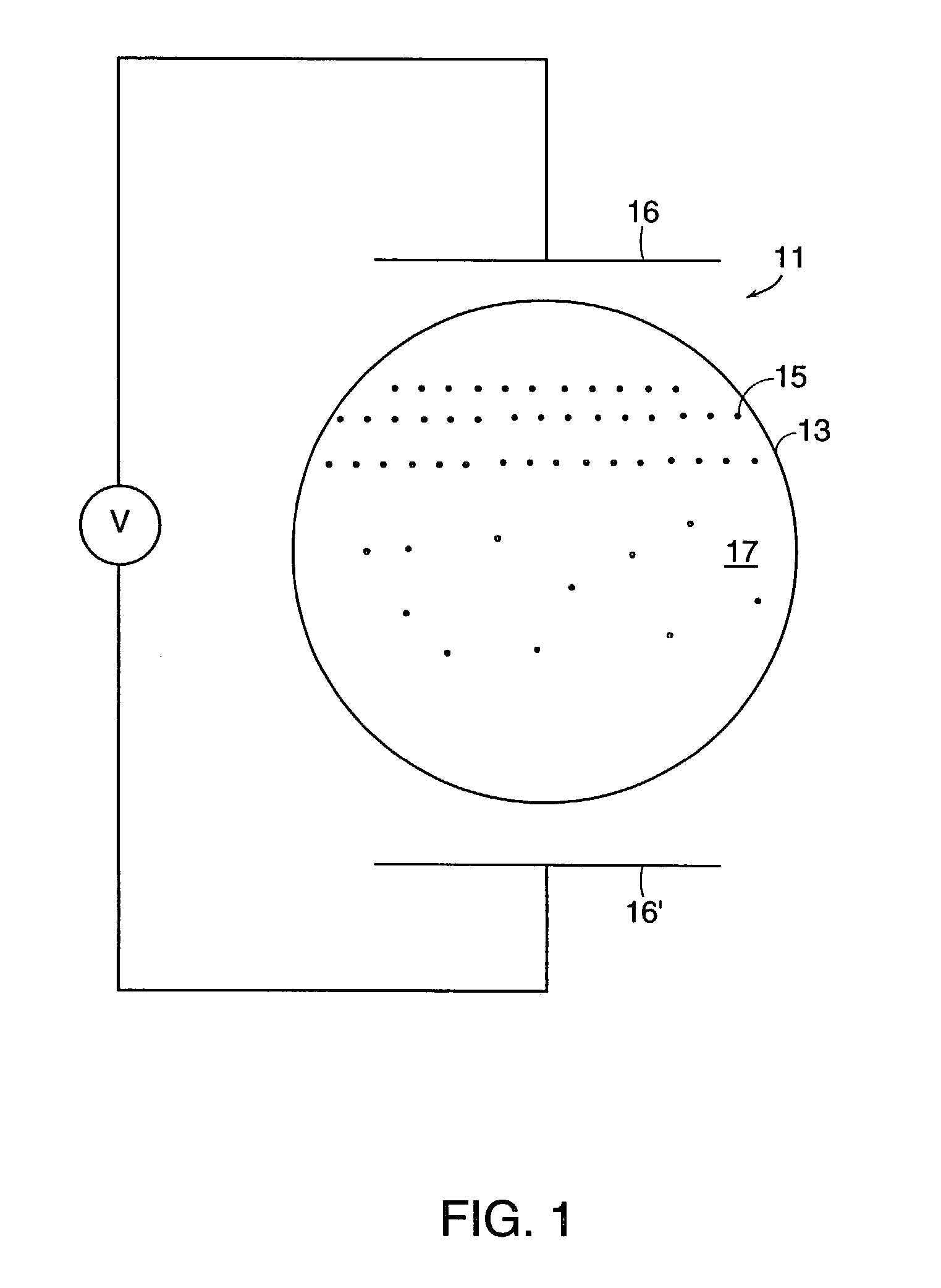

Retroreflective electrophoretic displays and materials for making the same

InactiveUS7071913B2High level controlDisorientingMechanical clocksStatic indicating devicesCelluloseOptical property

Disclosed herein are novel electrophoretic displays and materials useful in fabricating such displays. In particular, novel encapsulated displays are disclosed. Particles encapsulated therein are dispersed within a suspending, or electrophoretic, fluid. This fluid may be a mixture of two or more fluids or may be a single fluid. The displays may further comprise particles dispersed in a suspending fluid, wherein the particles contain a liquid. In either case, the suspending fluid may have a density or refractive index substantially matched to that of the particles dispersed therein. Finally, also disclosed herein are electro-osmotic displays. These displays comprise at least one capsule containing either a cellulosic or gel-like internal phase and a liquid phase, or containing two or more immiscible fluids. Application of electric fields to any of the electrophoretic displays described herein affects an optical property of the display.

Owner:E INK CORPORATION

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS6964757B2Reduce riskWeaken energyHydrogen productionHydrogen/synthetic gas productionSteam reformingAlkane

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as methanol, glycerol, sugars (e.g. glucose and xylose), or sugar alcohols (e.g. sorbitol). The method takes place in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

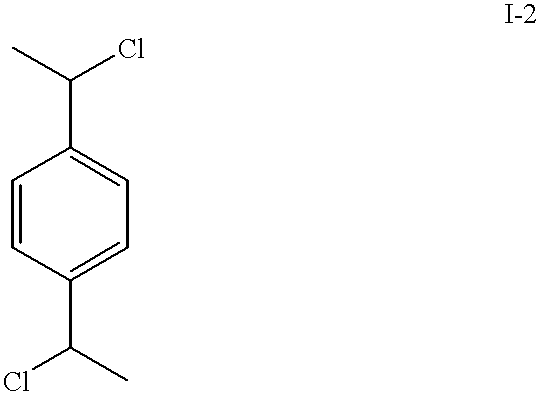

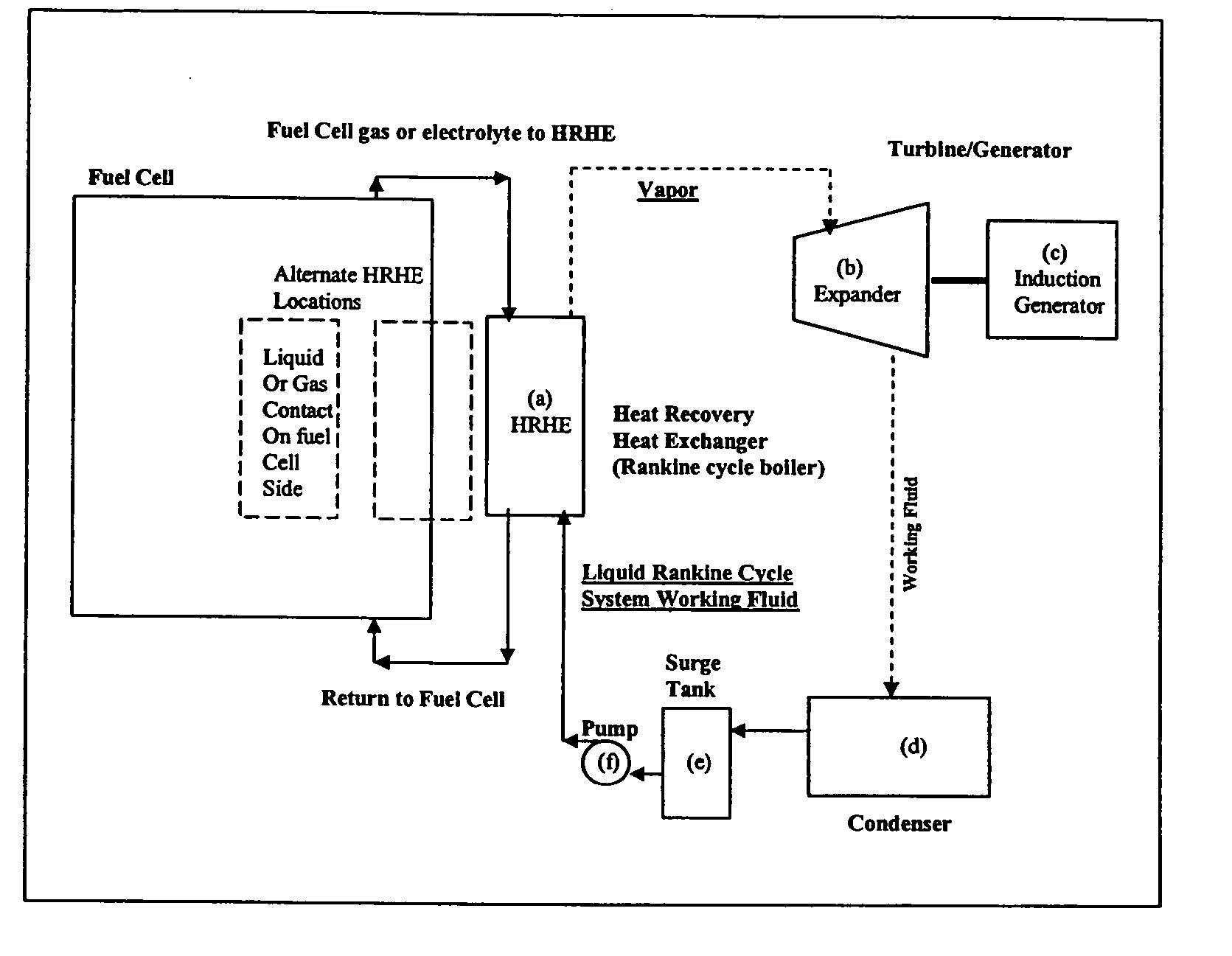

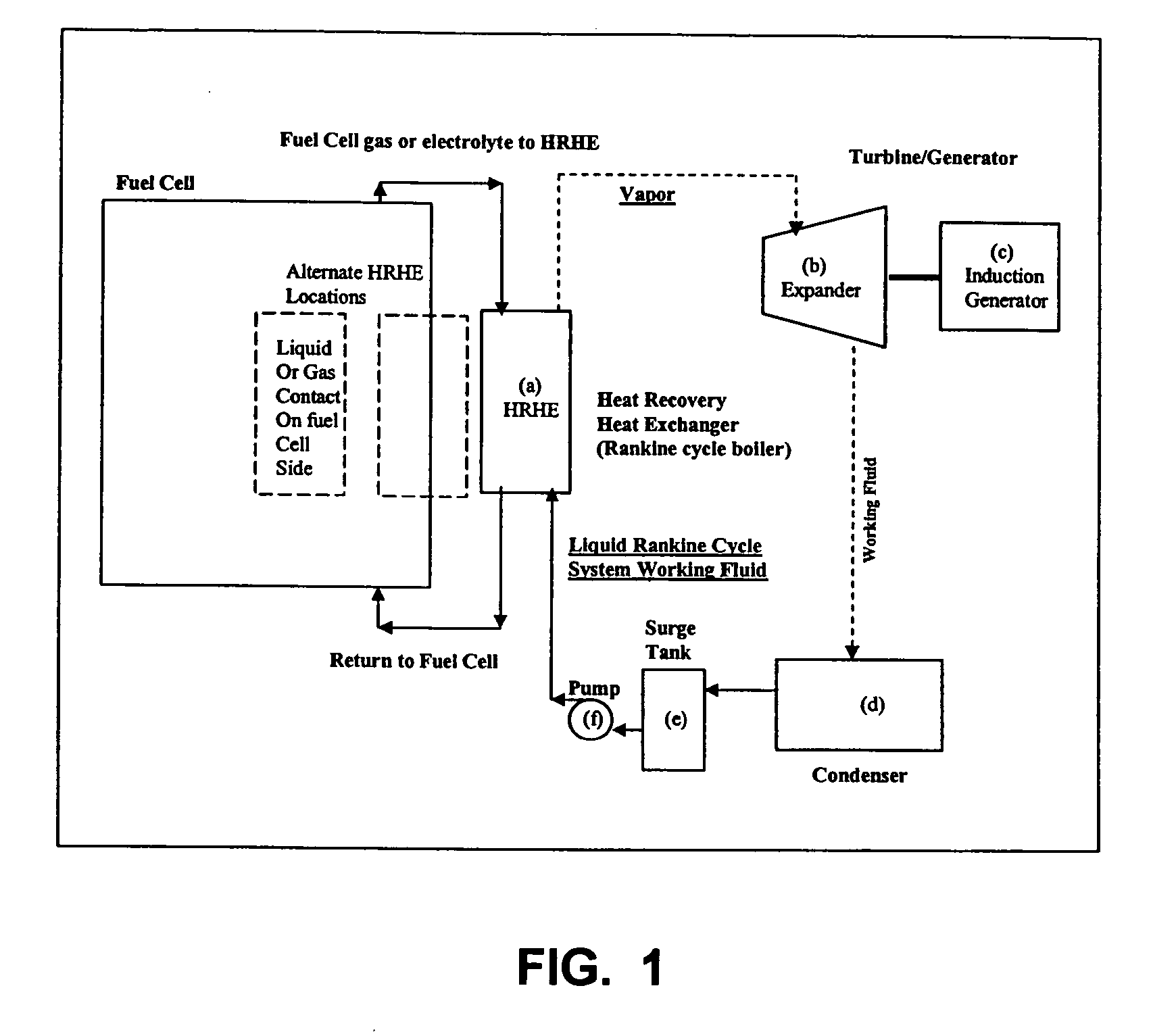

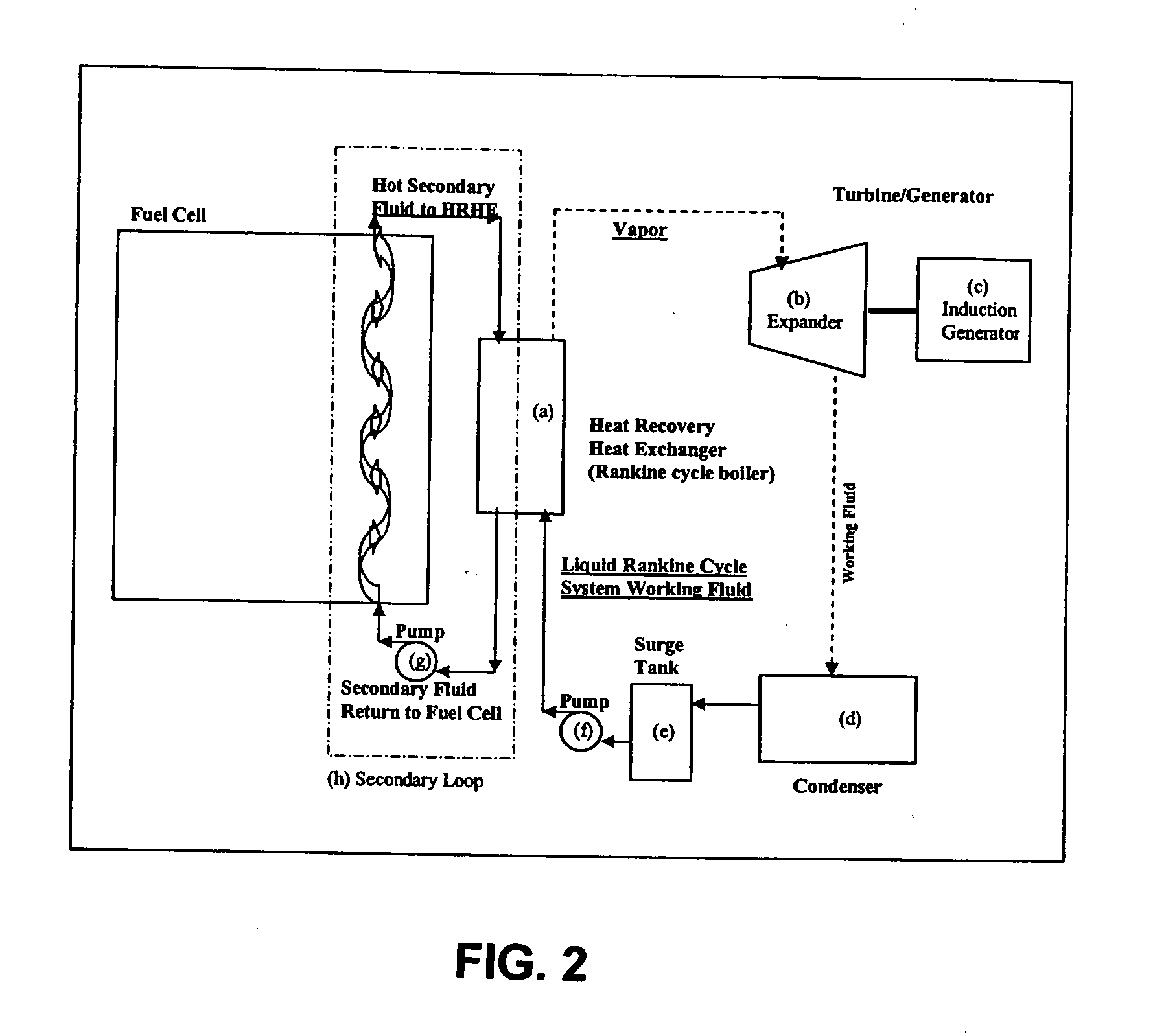

Working fluids for thermal energy conversion of waste heat from fuel cells using rankine cycle systems

A process for recovering waste heat which comprises: (a) passing a liquid phase working fluid through a heat exchanger in communication with a process which produces the waste heat; (b) removing a vapor phase working fluid from the heat exchanger; (c) passing the vapor phase working fluid to an expander, wherein the waste heat is converted into mechanical energy; and (d) passing the vapor phase working fluid from the expander to a condenser, wherein the vapor phase working fluid is condensed to the liquid phase working fluid. The preferred working fluid is an organic Rankine cycle system working fluid comprising compounds having the following general structure: where x, y, z, and m are each selected from the group consisting of: fluorine, hydrogen, Rf, and R, wherein R and Rf are each an alkyl, aryl, or alkylaryl of 1 to 6 carbon atoms, and wherein Rf is partially or fully fluorinated.

Owner:HONEYWELL INT INC

Non-spherical cavity electrophoretic displays and methods and materials for making the same

InactiveUS7109968B2High level controlEasy to chargeStatic indicating devicesNanoinformaticsCelluloseOptical property

Disclosed herein are novel electrophoretic displays and materials useful in fabricating such displays. In particular, novel encapsulated displays are disclosed. Particles encapsulated therein are dispersed within a suspending, or electrophoretic, fluid. This fluid may be a mixture of two or more fluids or may be a single fluid. The displays may further comprise particles dispersed in a suspending fluid, wherein the particles contain a liquid. In either case, the suspending fluid may have a density or refractive index substantially matched to that of the particles dispersed therein. Finally, also disclosed herein are electro-osmotic displays. These displays comprise at least one capsule containing either a cellulosic or gel-like internal phase and a liquid phase, or containing two or more immiscible fluids. Application of electric fields to any of the electrophoretic displays described herein affects an optical property of the display.

Owner:E INK CORPORATION

Medical system and method of use

InactiveUS20110077628A1Simple methodWithout the potential of carbonizing tissueSurgical instruments for heatingTherapeutic coolingThermal energyGas phase

An instrument and method for tissue thermotherapy including an inductive heating means to generate a vapor phase media that is used for interstitial, intraluminal, intracavity or topical tissue treatment. In one method, the vapor phase media is propagated from a probe outlet to provide a controlled vapor-to-liquid phase change in an interface with tissue to thereby apply ablative thermal energy delivery.

Owner:TSUNAMI MEDTECH

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS6964758B2High energy costWeaken energyHydrogen productionHydrogen/synthetic gas productionSteam reformingAlkane

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as glycerol, glucose, or sorbitol. The method can take place in the vapor phase or in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon having at least two carbon atoms, in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIII transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

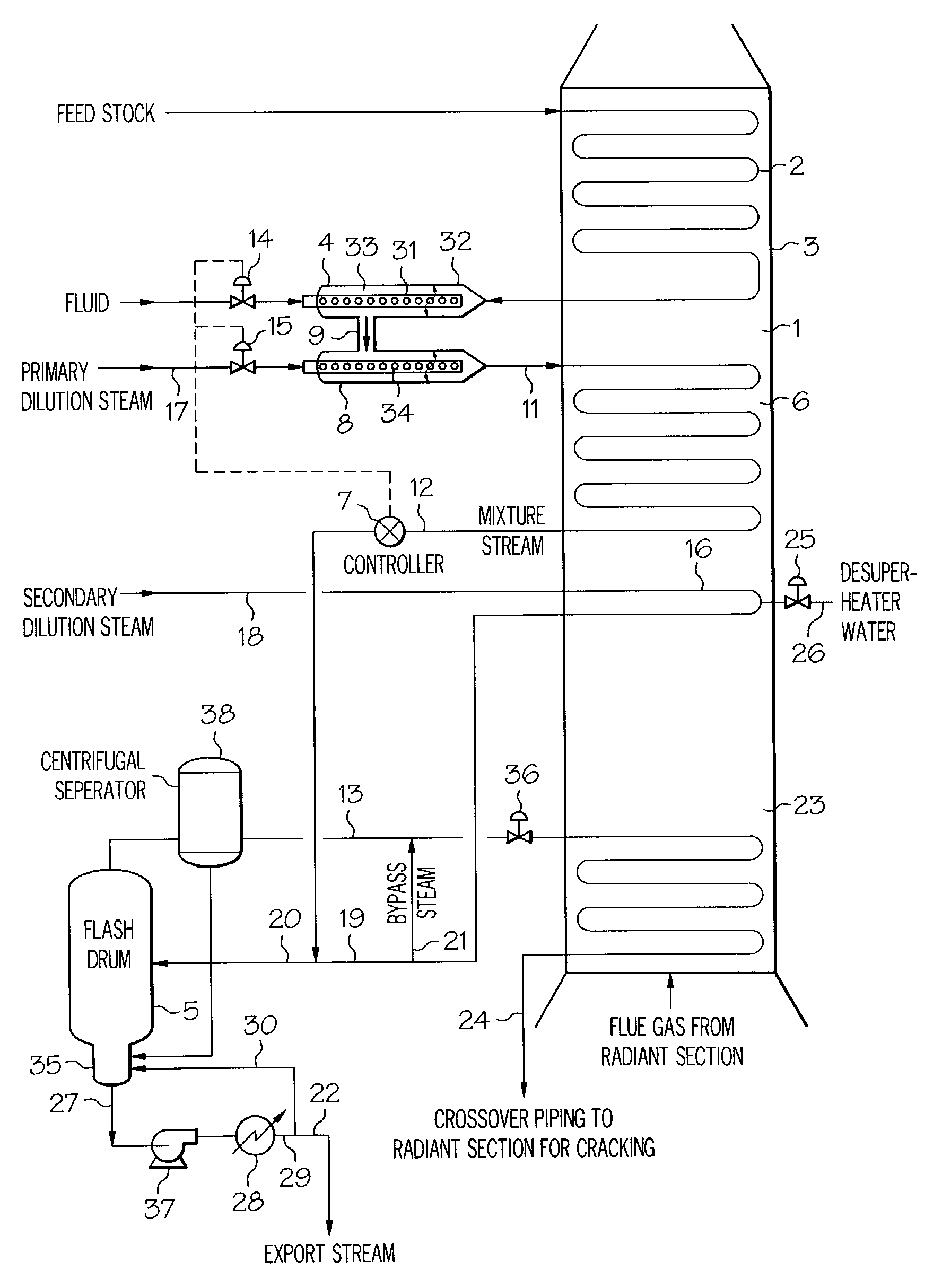

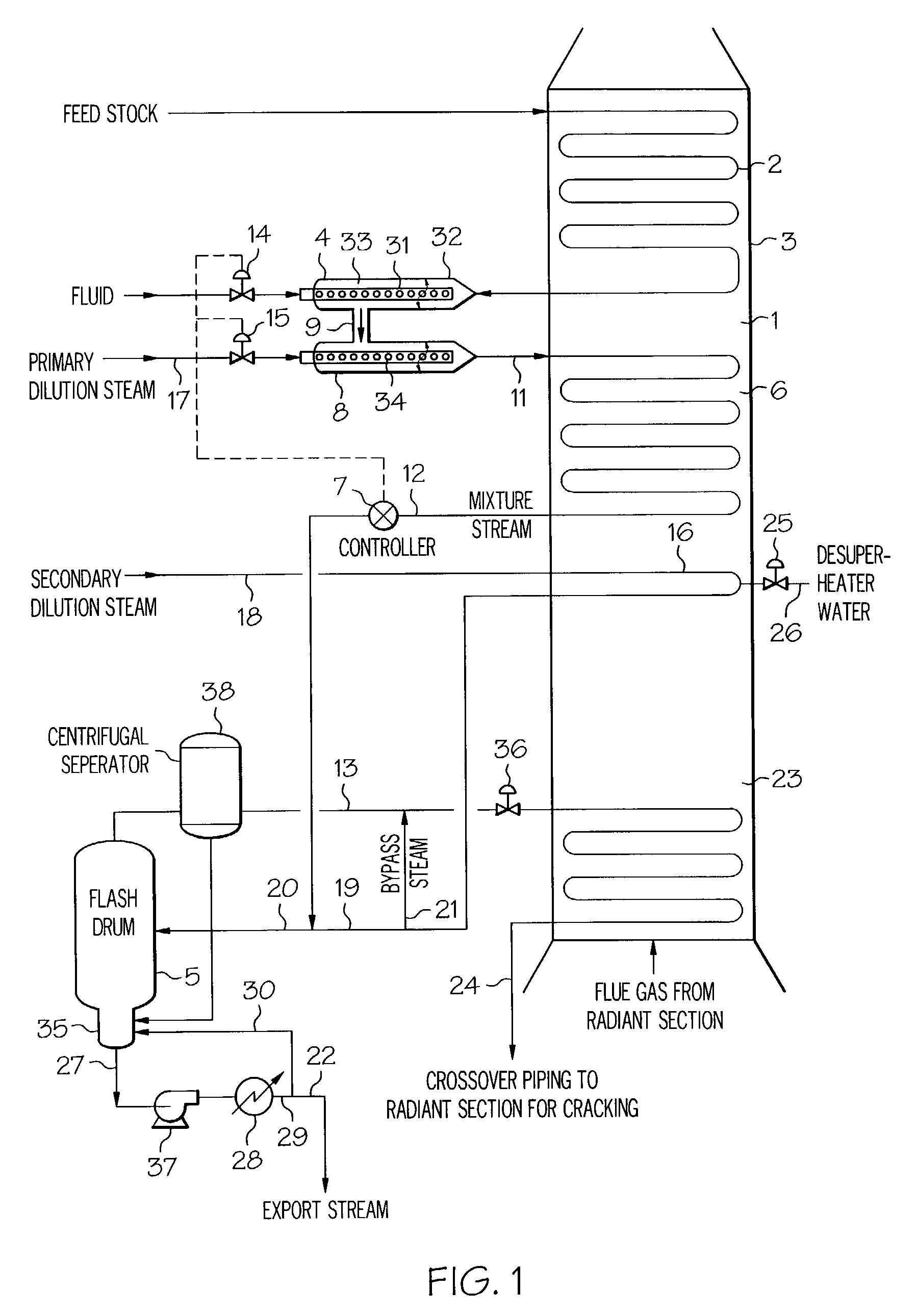

Process for steam cracking heavy hydrocarbon feedstocks

A process for feeding or cracking heavy hydrocarbon feedstock containing non-volatile hydrocarbons comprising: heating the heavy hydrocarbon feedstock, mixing the heavy hydrocarbon feedstock with a fluid and / or a primary dilution steam stream to form a mixture, flashing the mixture to form a vapor phase and a liquid phase, and varying the amount of the fluid and / or the primary dilution steam stream mixed with the heavy hydrocarbon feedstock in accordance with at least one selected operating parameter of the process, such as the temperature of the flash stream before entering the flash drum.

Owner:EXXONMOBIL CHEM PAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com