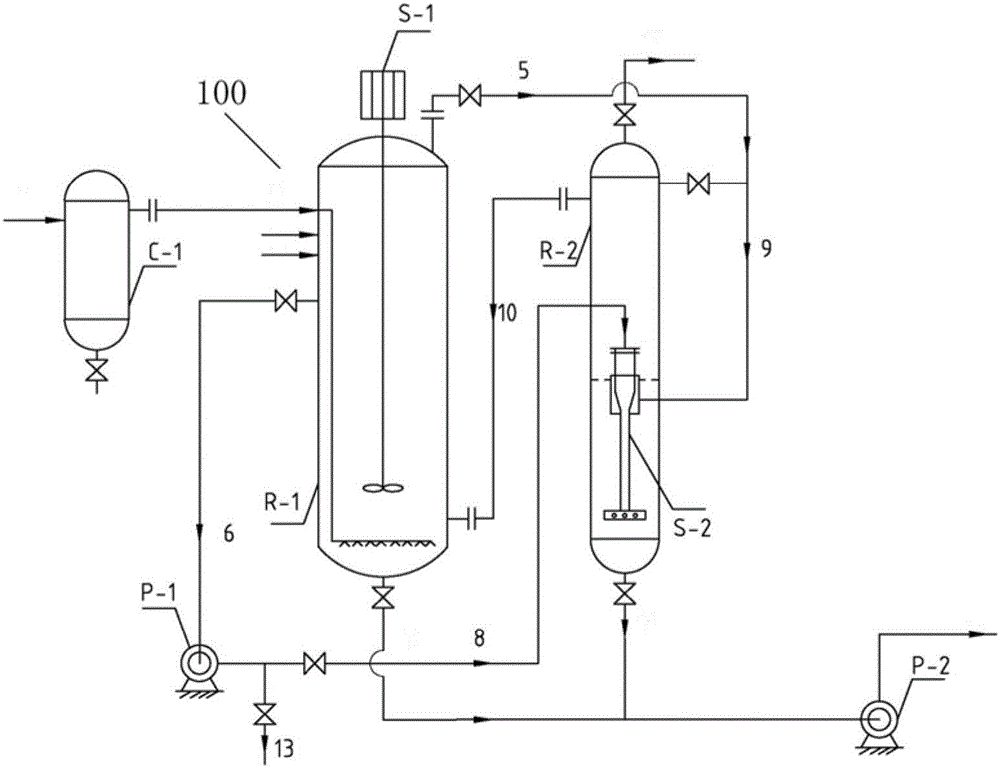

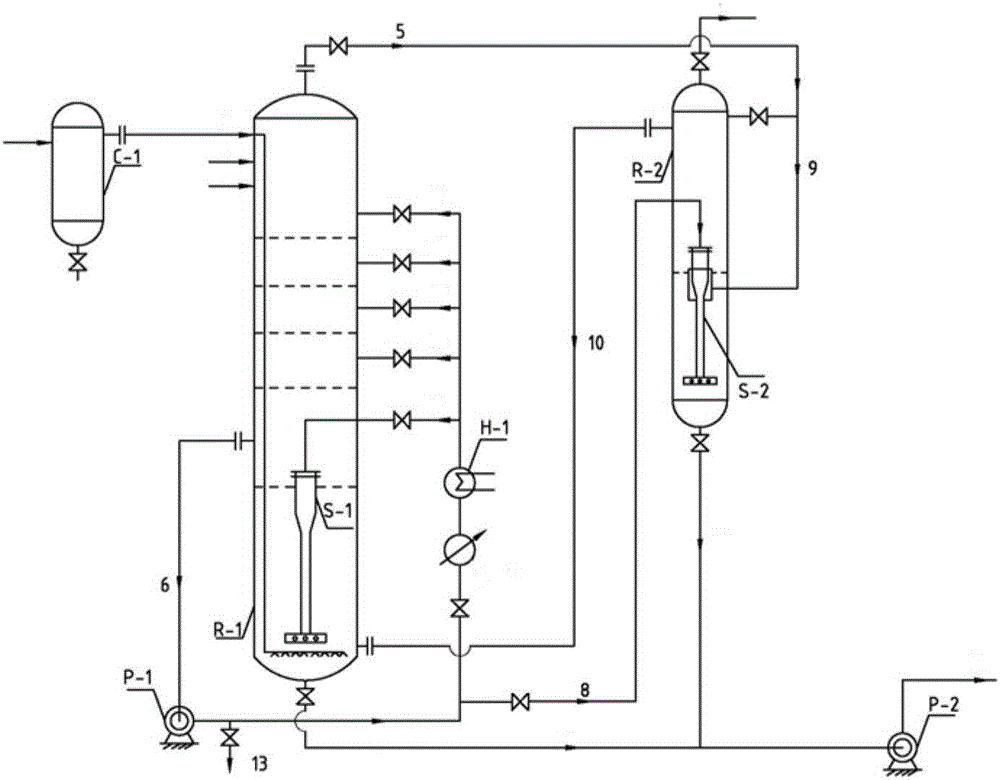

Device and technique for producing cyclohexane by benzene hydrogenation

A technology of benzene hydrogenation and cyclohexane, applied in the field of chemistry, can solve the problems of high maintenance cost, large bubble diameter, long reaction time, etc., and achieve the effects of high mass transfer efficiency, high reaction rate and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The volume is 1M 3 50kg / h normal temperature benzene and catalyst are added to the reactor R-1, and fresh hydrogen with a temperature of 100°C and a pressure of 0.3MPa is added to the reactor R-1 through the buffer tank C-1; Motor S-1 and heat exchanger H-1 are mixed and heated to a temperature of 210°C and a pressure of 1.5MPa. When the pressure of the reactor R-1 reaches the set value of 1.5MPa, slowly open the gas phase outlet valve at the top of the reactor R-1 to control the tail gas flow at the set value of 2m 3 / h, to maintain the pressure required for the reaction, the tail gas enters the gas phase inlet of the bubble breaker S-2 through the pipeline 5. After the reaction, the 25kg / h mainly containing the product cyclohexane, a small amount of intermediate products and unreacted benzene is transported to the liquid phase inlet of the bubble breaker S-2 through the pipeline 6 through the pump P-1.

[0067] The superfine bubble generator R-2 communicates with th...

Embodiment 2

[0069] The volume is 2.5M 3 Add 100kg / h normal temperature benzene and catalyst into the reactor R-1, add fresh hydrogen with a temperature of 120°C and a pressure of 0.5MPa into the reactor R-1 through the buffer tank C-1; open the reactor R-1 Motor S-1 and heat exchanger H-1 are mixed and heated to a temperature of 250°C and a pressure of 2.0MPa. When the pressure of the reactor R-1 reaches the set value of 2.0MPa, slowly open the gas phase outlet valve at the top of the reactor R-1 to control the tail gas flow at the set value of 4m 3 / h, to maintain the pressure required for the reaction, the tail gas enters the gas phase inlet of the bubble breaker S-2 through the pipeline 5. After the reaction, the 25kg / h mainly containing the product cyclohexane, a small amount of intermediate products and unreacted benzene is transported to the liquid phase inlet of the bubble breaker S-2 through the pipeline 6 through the pump P-1.

[0070] The superfine bubble generator R-2 communi...

Embodiment 3

[0072] Reactor R-1 has a tower diameter of 800mm and a tower height of 4.5m. There are five layers of sieve plates with an opening rate of 60%. The jet circulator S-3 is fixed in the center of the first layer of sieve plates. The distance between the plates is 0.4m, and there is a circulation outlet above the first sieve plate. Add 100kg / h normal temperature benzene and catalyst to reactor R-1, and add fresh hydrogen with a temperature of 100°C and a pressure of 0.3MPa into reactor R-1 through buffer tank C-1; the operation in reactor R-1 The temperature is set to 140°C and the pressure is set to 1.2MPa. When the liquid level in the reactor R-1 exceeds the circulation outlet, the pump P-1 is turned on to transport the reaction feed liquid to the jet circulator S-3 and a circulating liquid phase inlet, wherein the circulating liquid phase inlet is arranged in the tangential direction of the tower wall, and the circulating liquid phase enters the reactor R-1 in the tangential di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com