Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9785results about "Treatment with anaerobic digestion processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

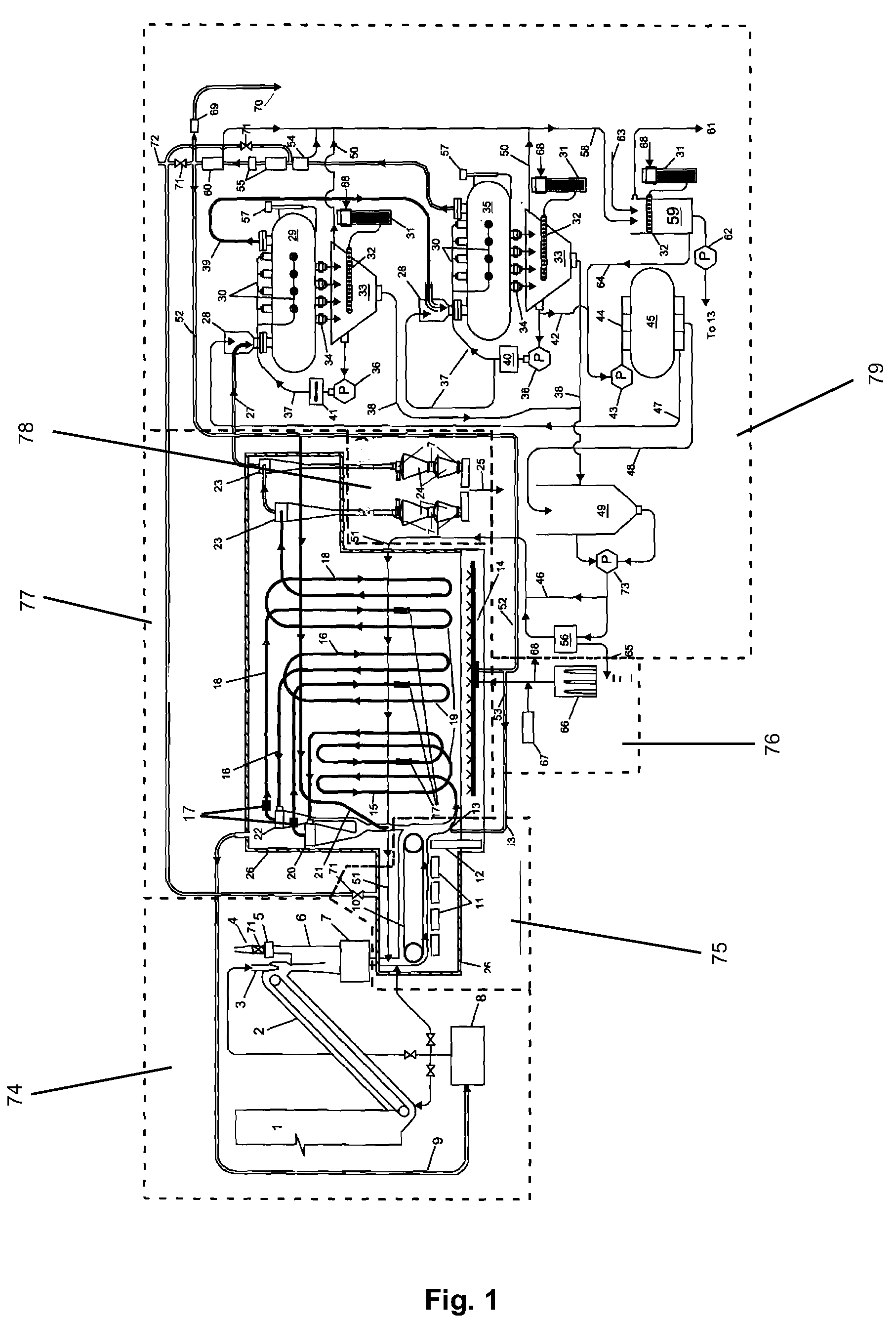

Method for processing lignocellulosic material

InactiveUS6555350B2High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseWater flow

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process, involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

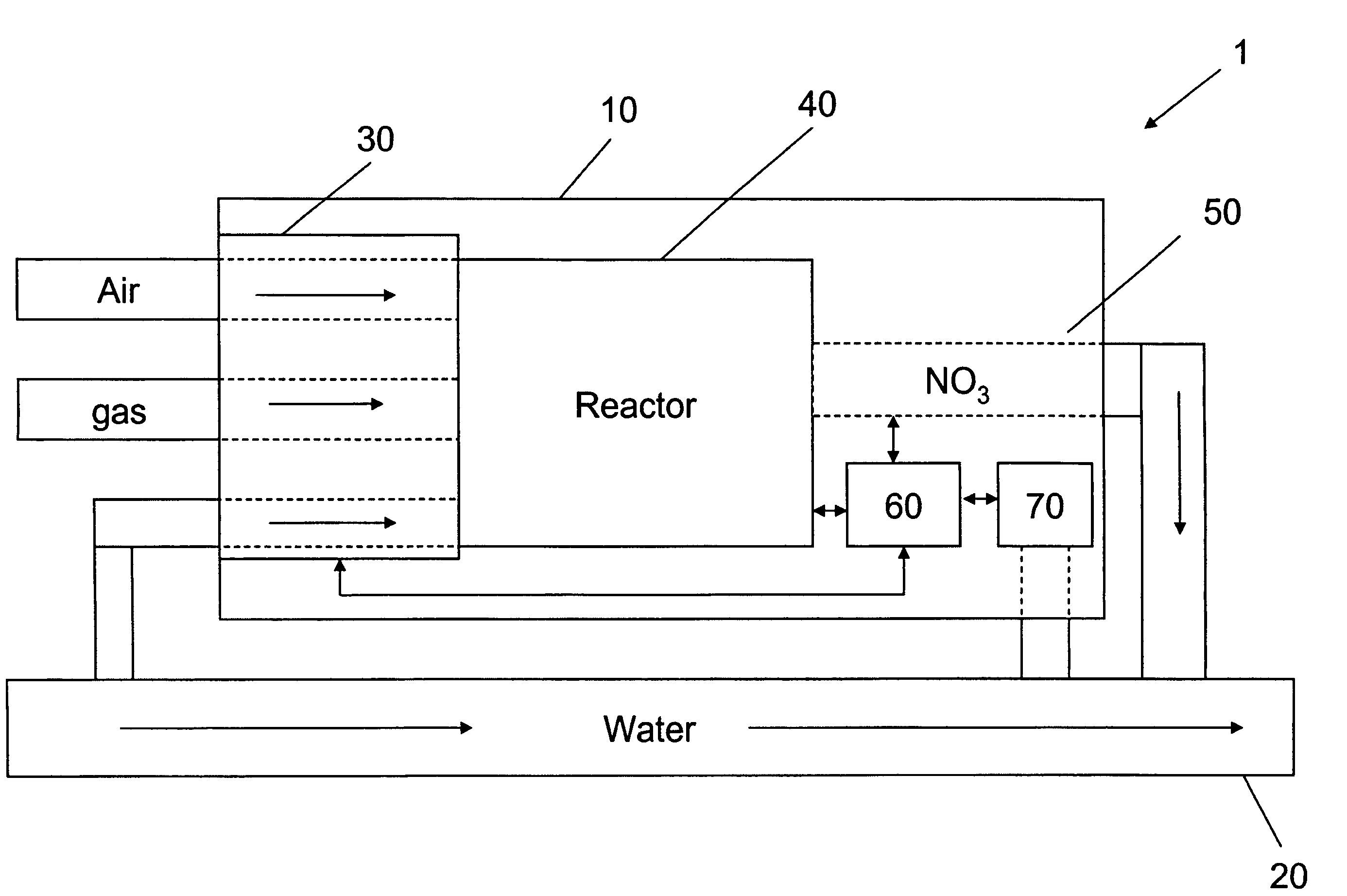

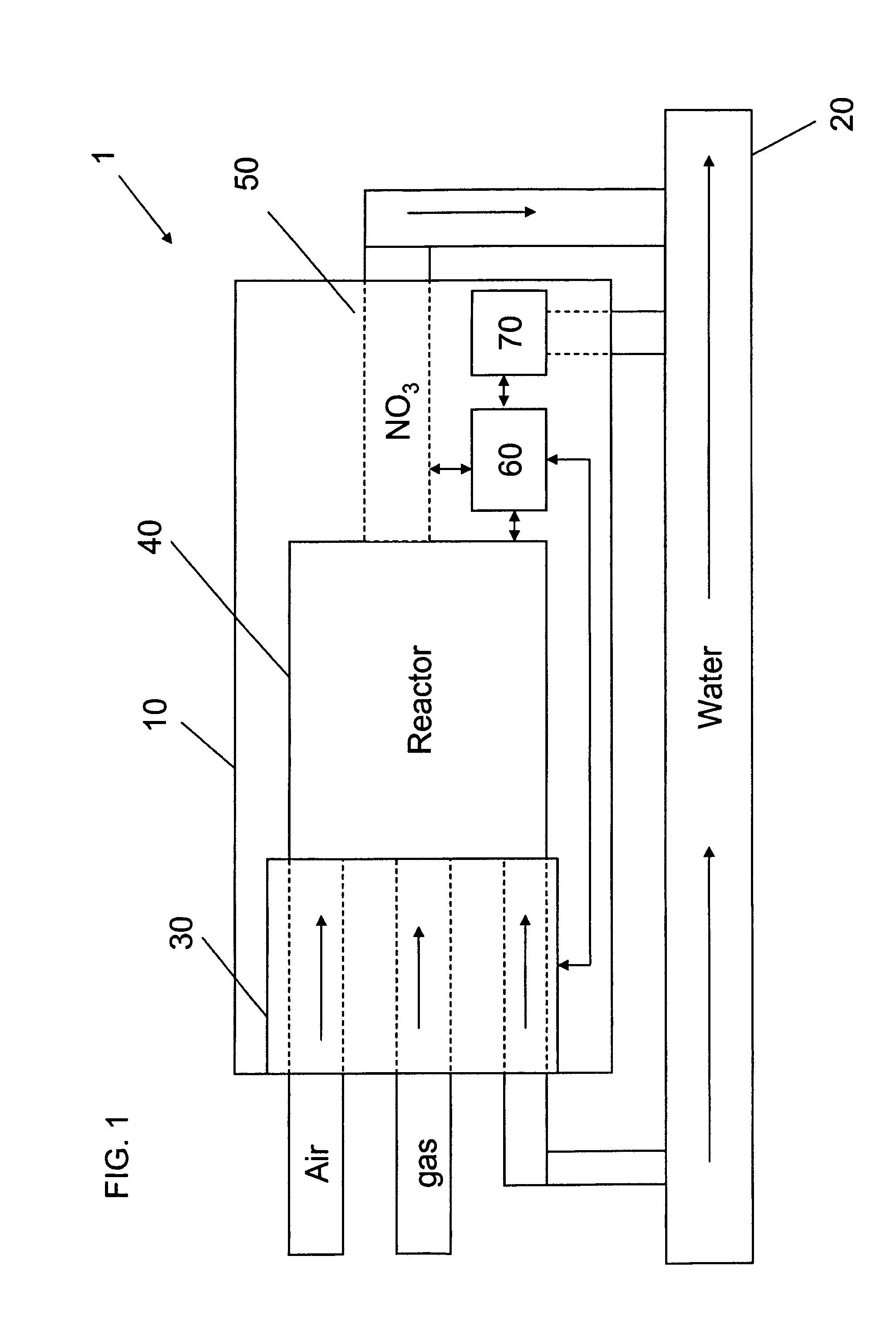

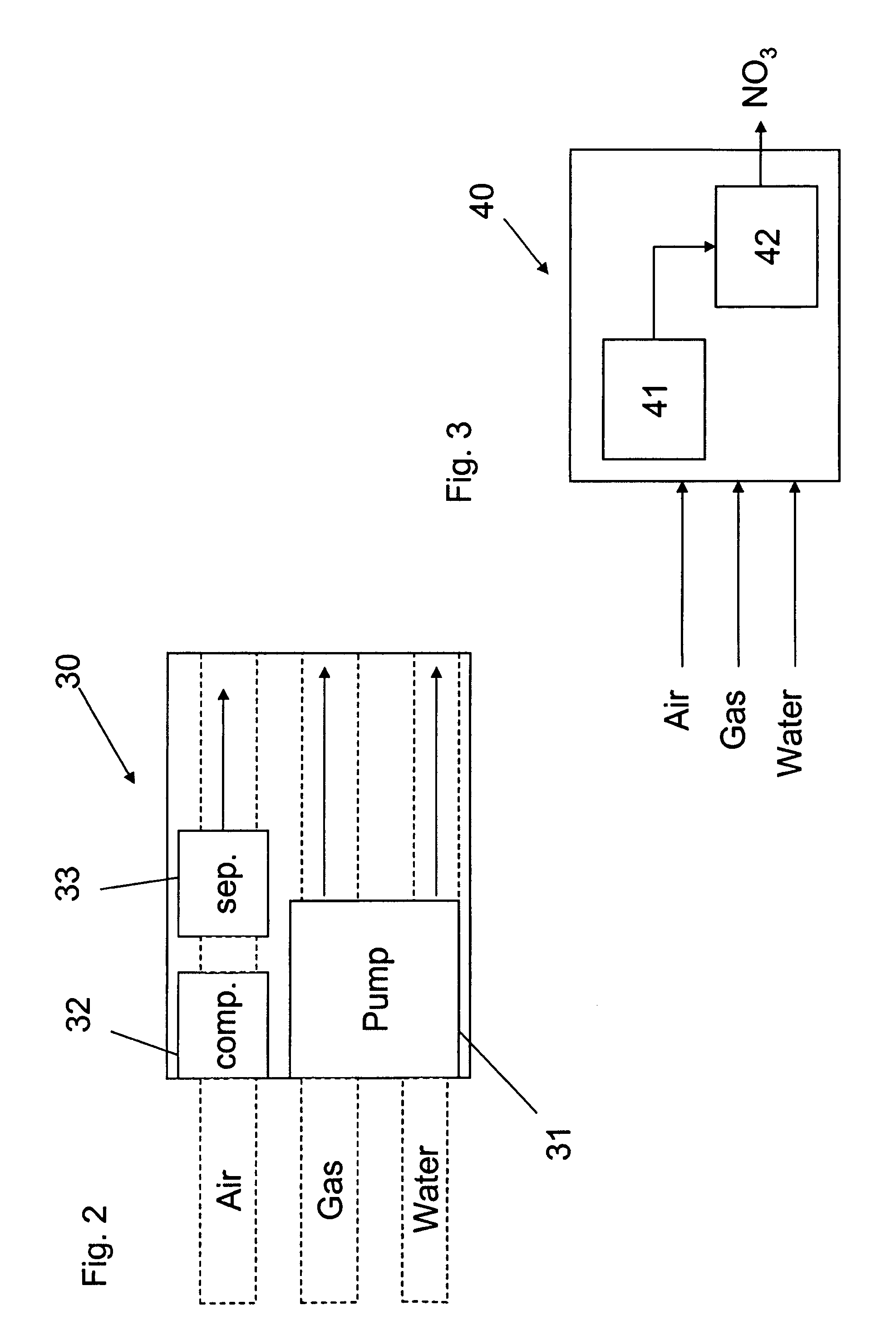

Apparatus for on-site production of nitrate ions

InactiveUS7514058B1Enhanced overall recoveryWater treatment parameter controlWater treatment compoundsMicrobial enhanced oil recoverySulfate-reducing bacteria

An apparatus and method produces nitrate ions on-site from water, natural gas and air extracted in proximity to the apparatus. The apparatus generates nitrate ions and brings the nitrate ions into contact with an aqueous system. Hydrogen sulfide present in the aqueous system is removed and the production of hydrogen sulfide by sulfate-reducing bacteria (SRB) is eliminated by introducing into the system nitrate ions, whereby denitrifying microorganisms, using nitrate, outcompete the sulfate-reducing bacteria for the available carbon nutrients, thus preventing the SRB from producing hydrogen sulfide. Nitrate ions generated by the apparatus and added to the aqueous system which contains the denitrifying microorganisms can enhance oil recovery by means of microbial enhanced oil recovery mechanisms.

Owner:NITRA GEN LLC

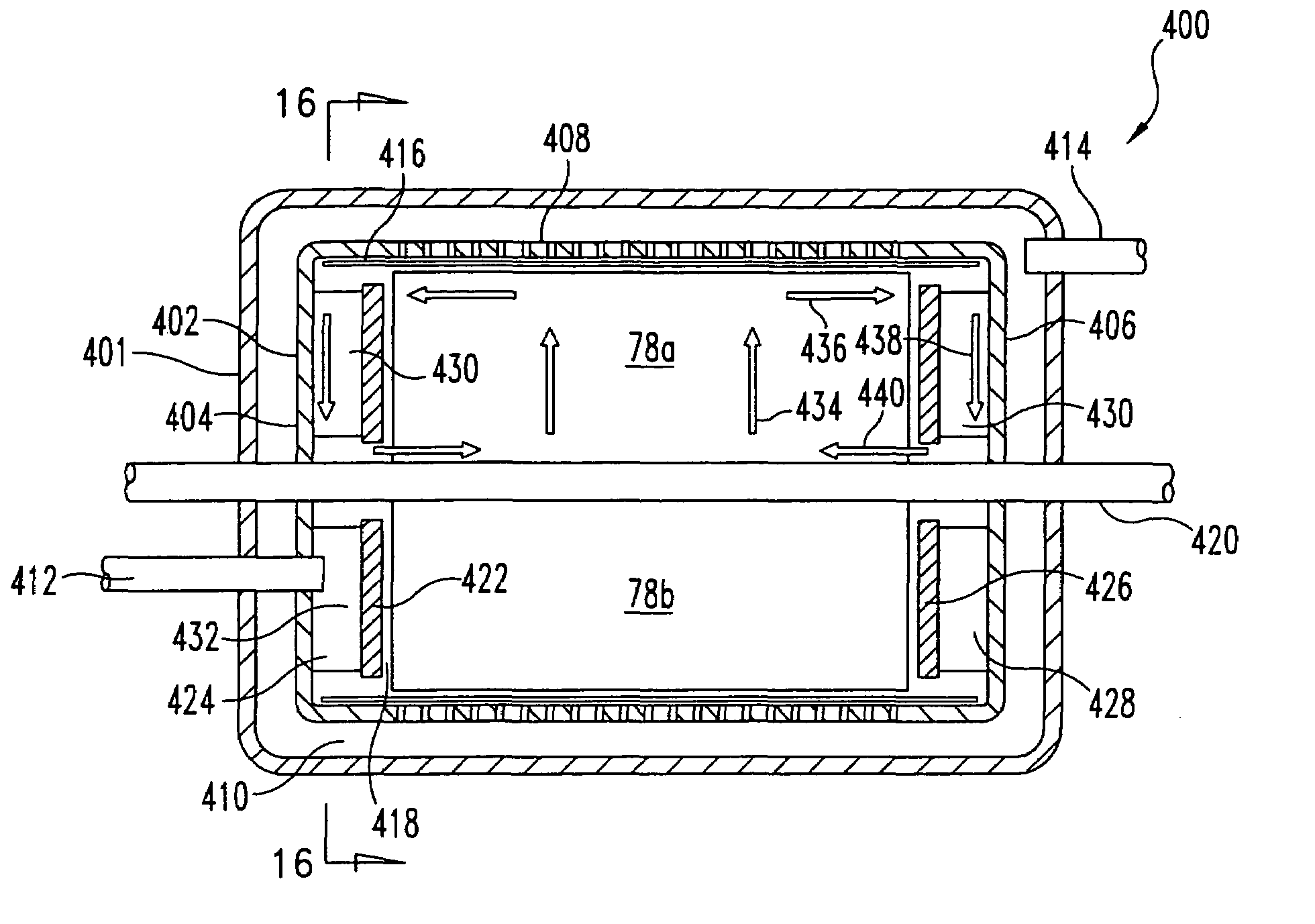

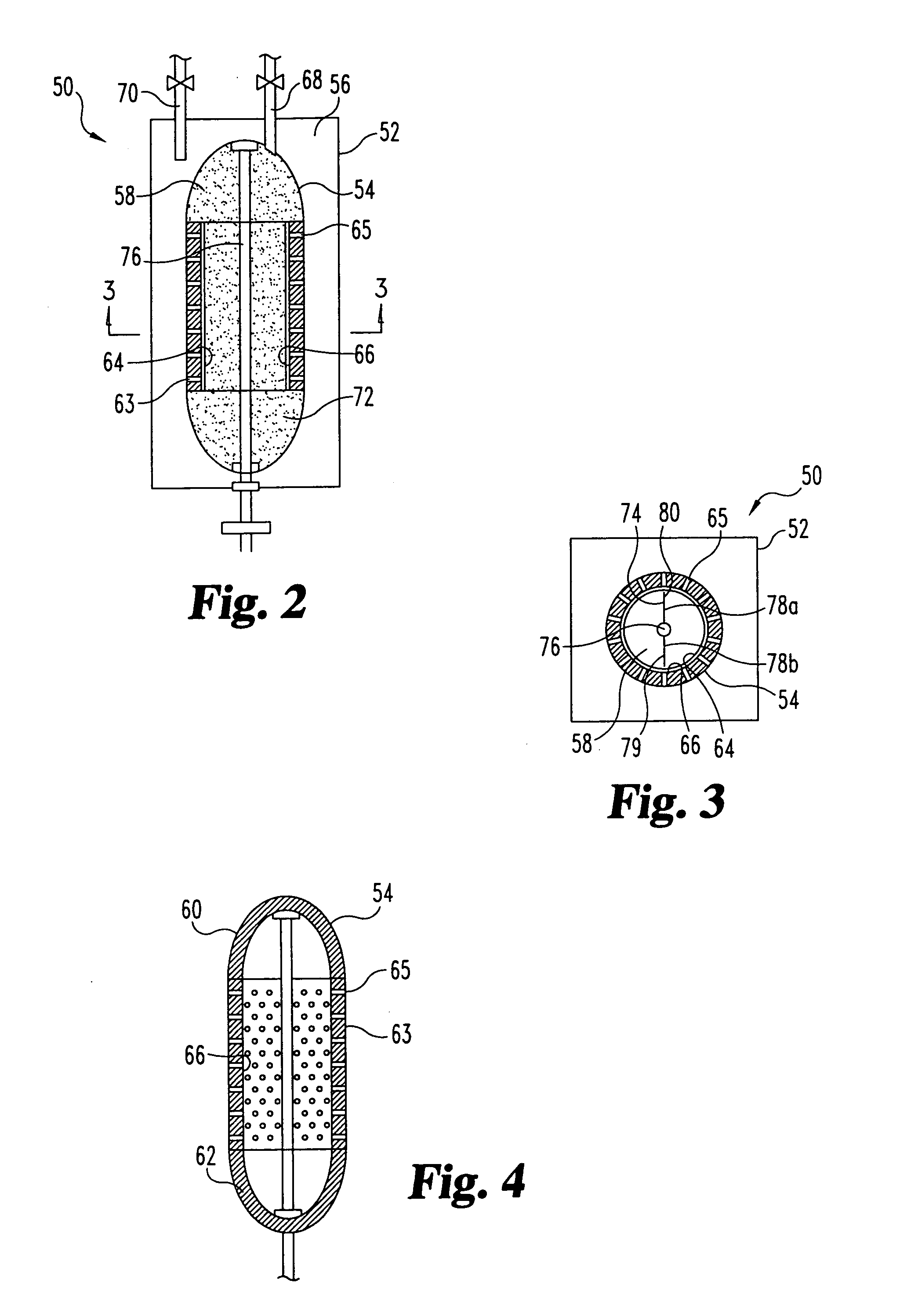

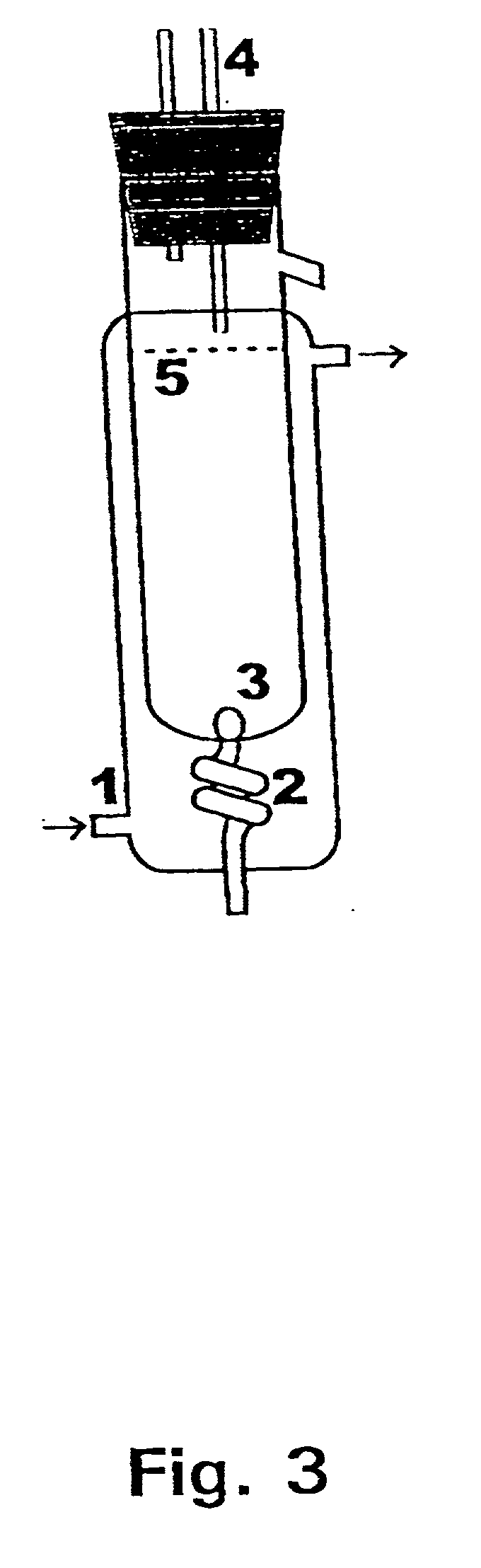

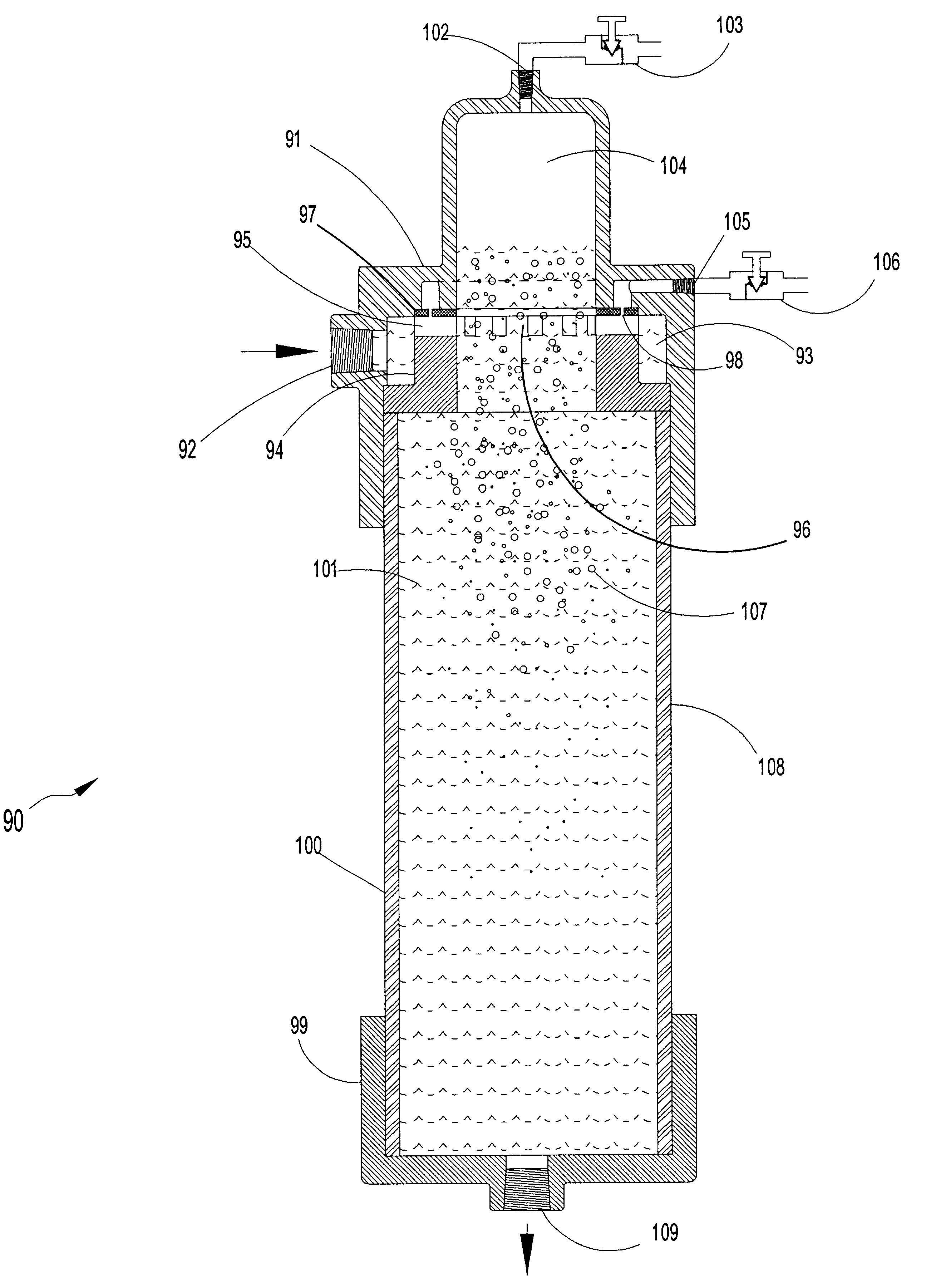

Sorbent reactor for extracorporeal blood treatment systems, peritoneal dialysis systems, and other body fluid treatment systems

InactiveUS7169303B2Facilitate homogeneous suspensionReduce probabilitySolvent extractionHaemofiltrationFluid balancePeritoneal dialysis

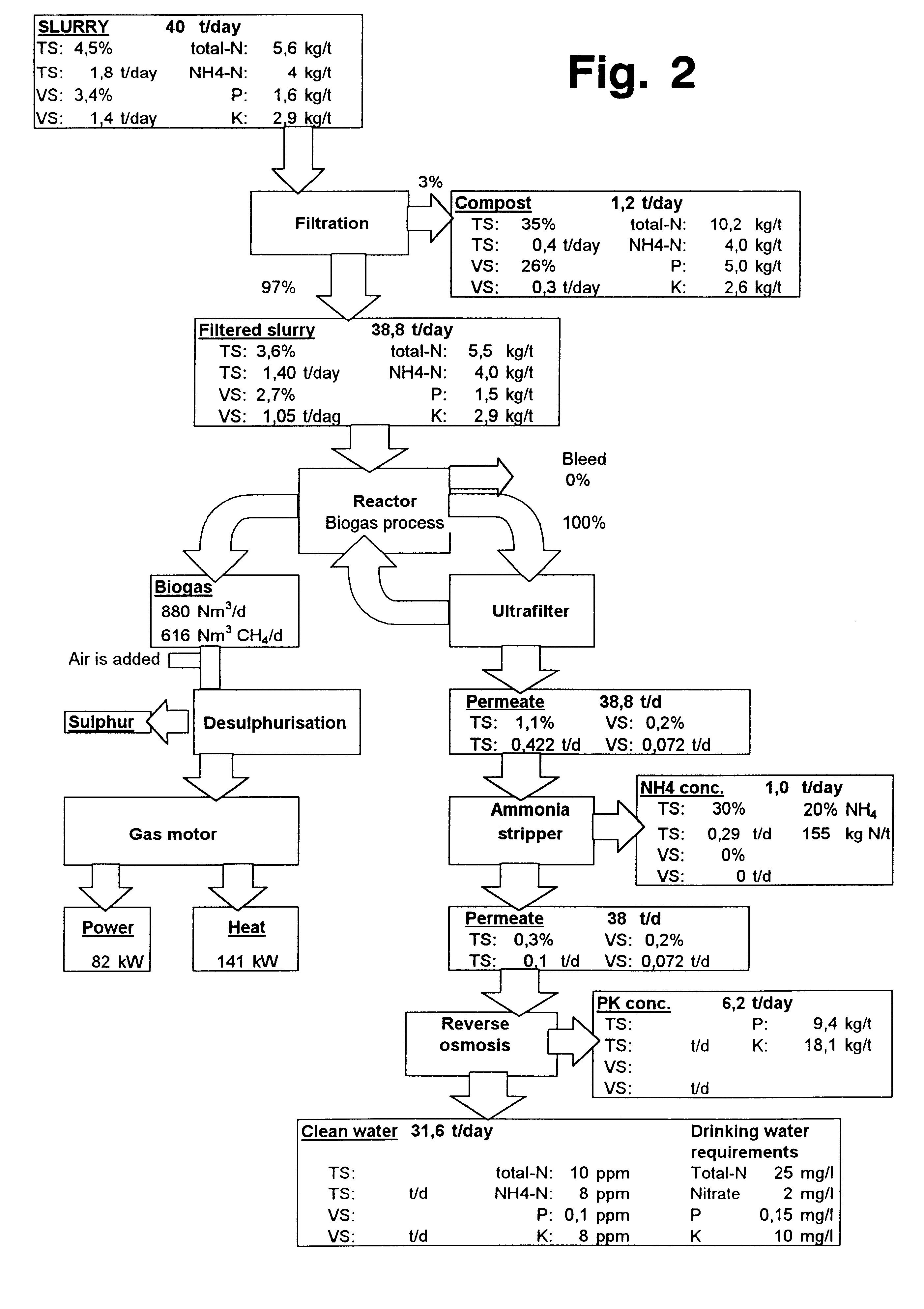

Systems and methods for extracorporeal processing of blood or other body fluid for the treatment of conditions, such as sepsis, autoimmune disease, or toxemia related to kidney failure, liver failure, or drug overdose are provided. In an extracorporeal treatment system, a fraction of a body fluid is passed into a treatment fluid, at least a portion of which is then passed through a sorbent suspension reactor for treatment by a sorbent suspension. The treatment fluid circuit can be maintained at a fixed volume, which enables accurate fluid balance between the patient and the extracorporeal circuit. Some or all of the treatment fluid, optionally also containing nutrients and / or therapeutic agents, is returned to the patient. In a peritoneal dialysis system, dialysate is passed into a patient's peritoneal cavity, recovered from the cavity, passed through a sorbent suspension reactor in accordance with the invention, and returned to the cavity.

Owner:HEMOCLEANSE TECH

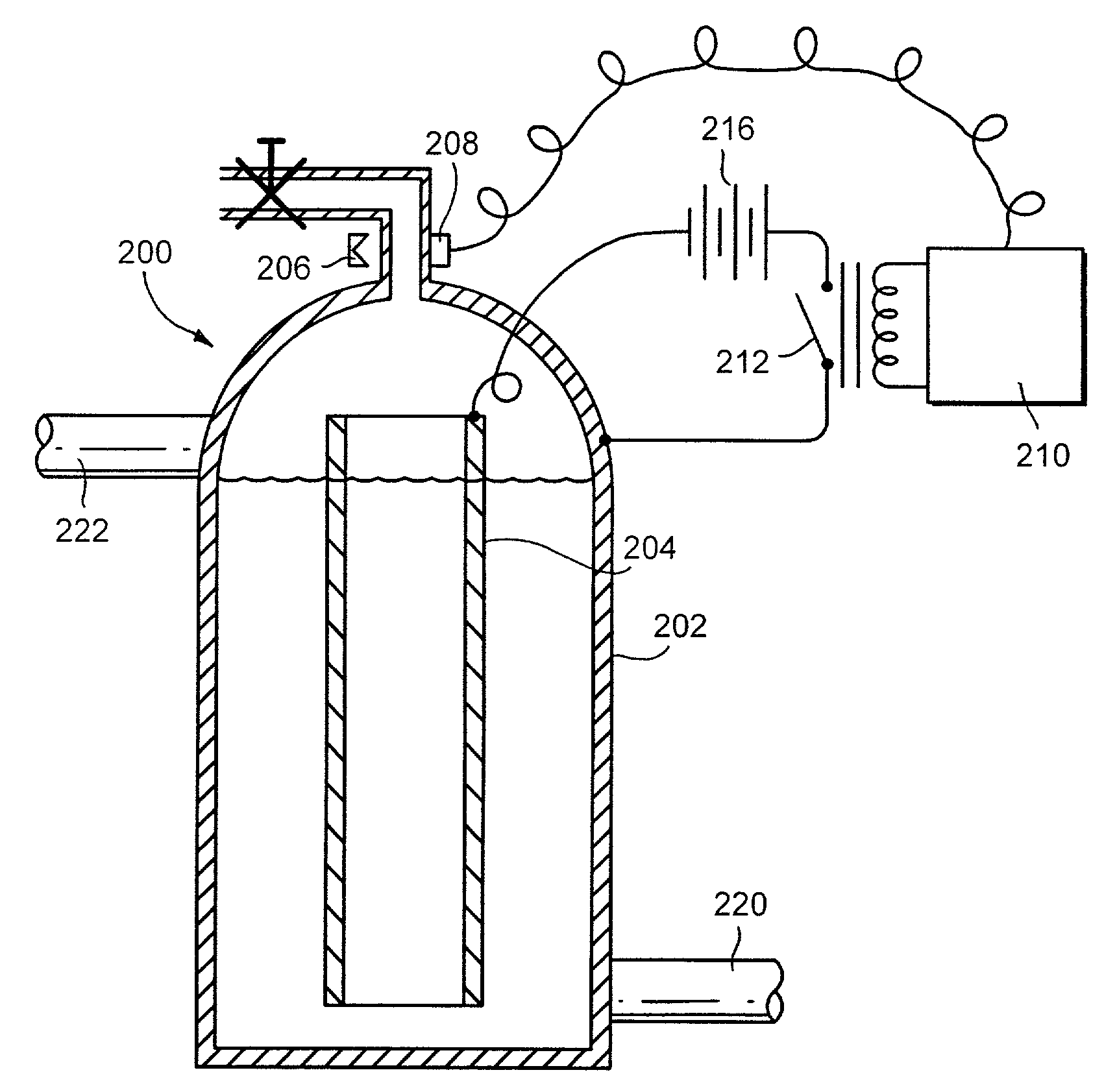

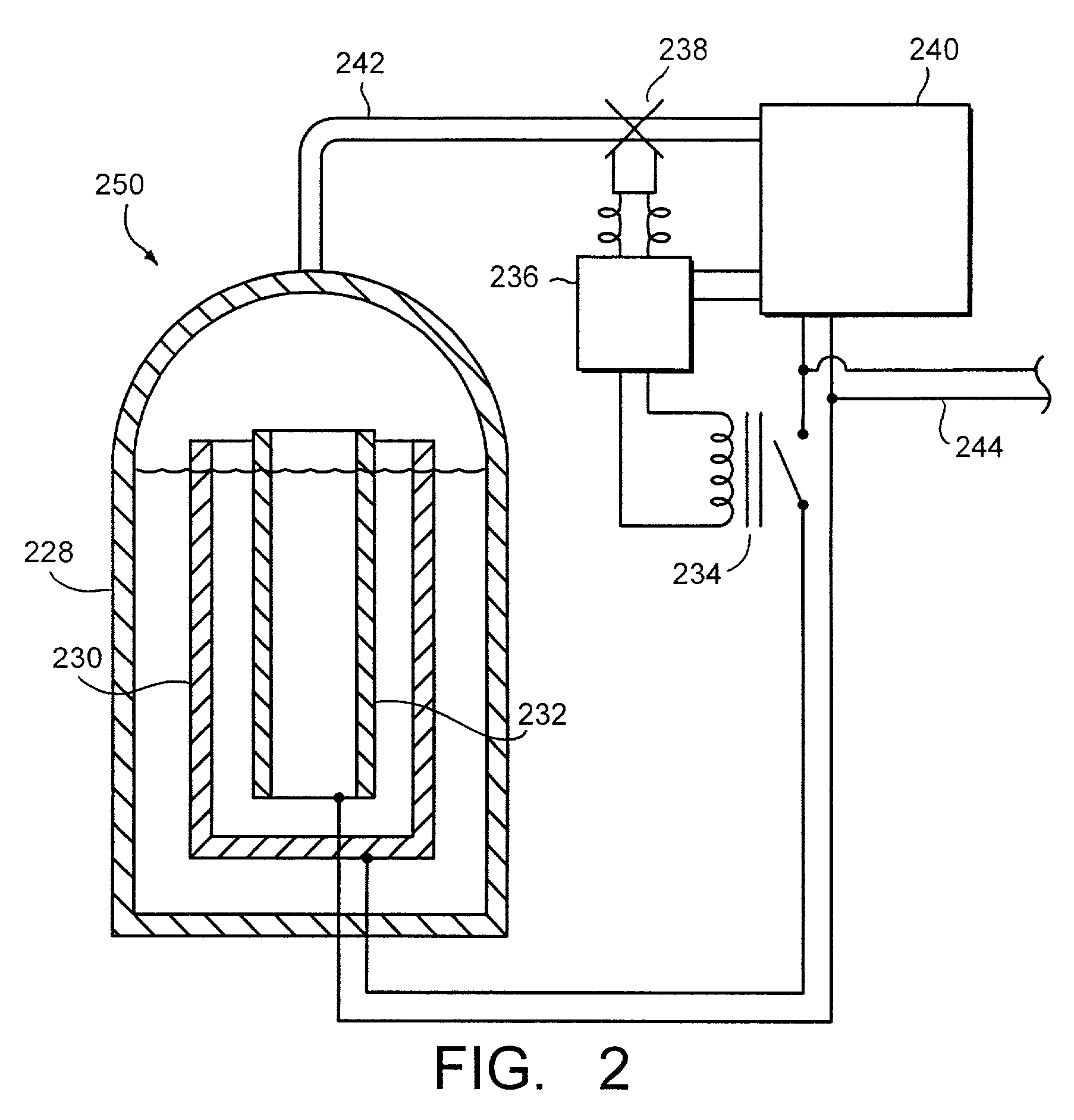

Method and apparatus for sustainable energy and materials

A process for the production of hydrogen from anaerobically decomposed organic materials by applying an electric potential to the anaerobically decomposed organic materials, including landfill materials and sewage, to form hydrogen, and for decreasing the time required to treat these anaerobically decomposed organic materials. The organic materials decompose to volatile acids such as acetic acid, which may be hydrolyzed by electric current to form hydrogen. The process may be continuously run in sewage digestion tanks with the continuous feed of sewage, at landfill sites, or at any site having a supply of anaerobically decomposed or decomposable organic materials.

Owner:MCALISTER TECH LLC +1

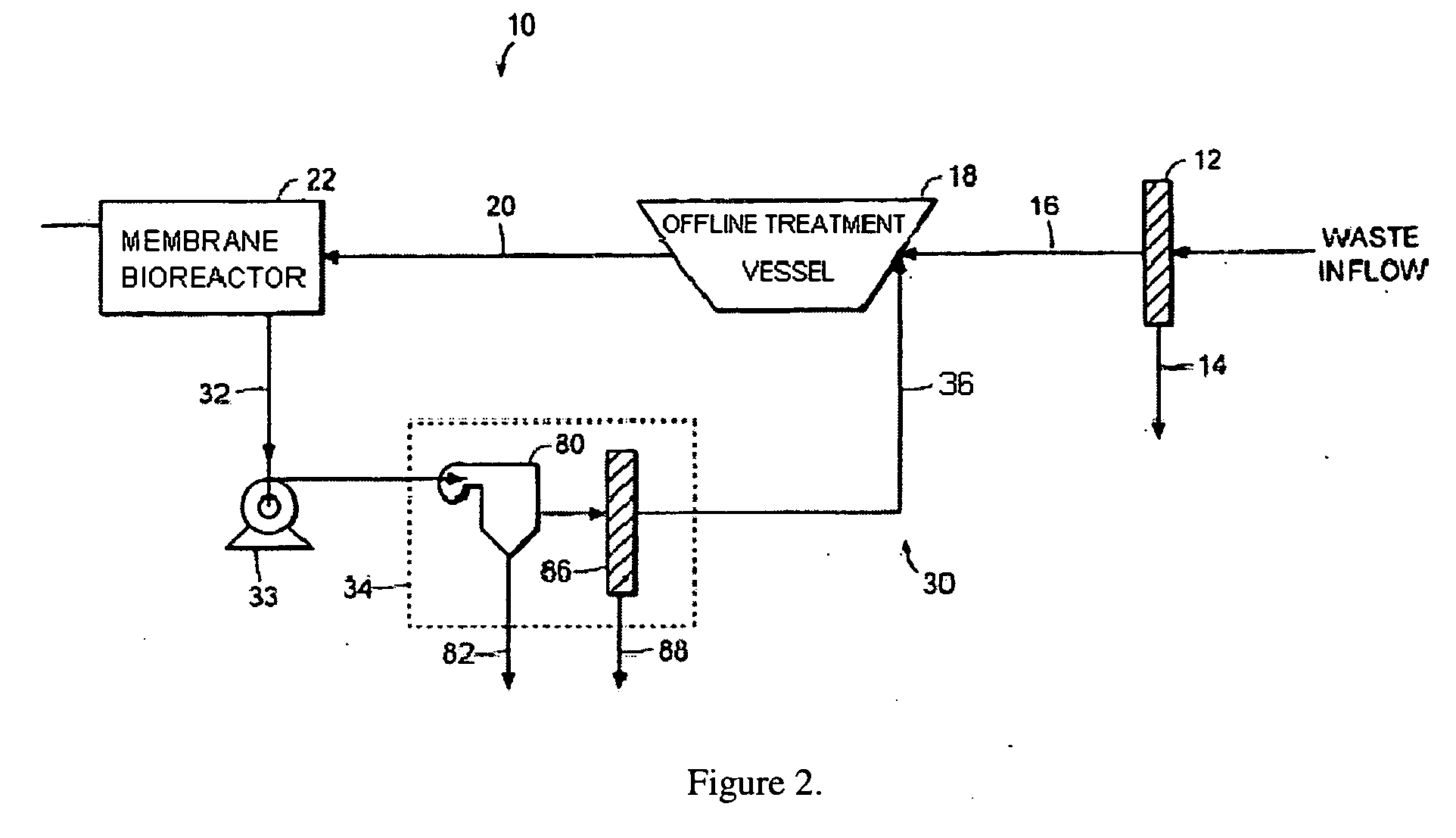

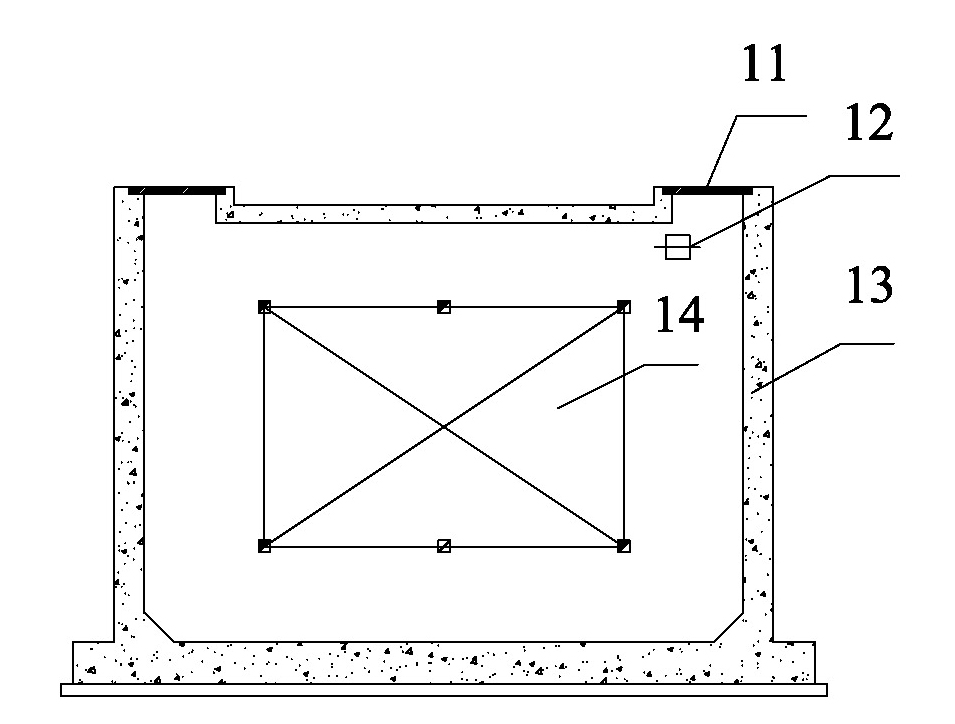

Filtration apparatus comprising a membrane bioreactor and a treatment vessel for digesting organic materials

InactiveUS20060201876A1Low costReducing resourceWater/sewage treatment by centrifugal separationWater treatment parameter controlFiltrationMembrane bioreactor

The invention relates to a membrane bioreactor process combined with an advanced biological sludge digestion process that provides significant improvements in sludge digestion by reducing the costs and resources required for disposing of digested sludge. The offline treatment vessel is used to solubilize the organic material by operating in a very low oxygen environment. Digested process fluid is transferred back to the membrane bioreactor. The processes and apparatus substantially reduce the production of waste sludge.

Owner:EVOQUA WATER TECH LLC

Method and plant for the treatment of liquid organic waste

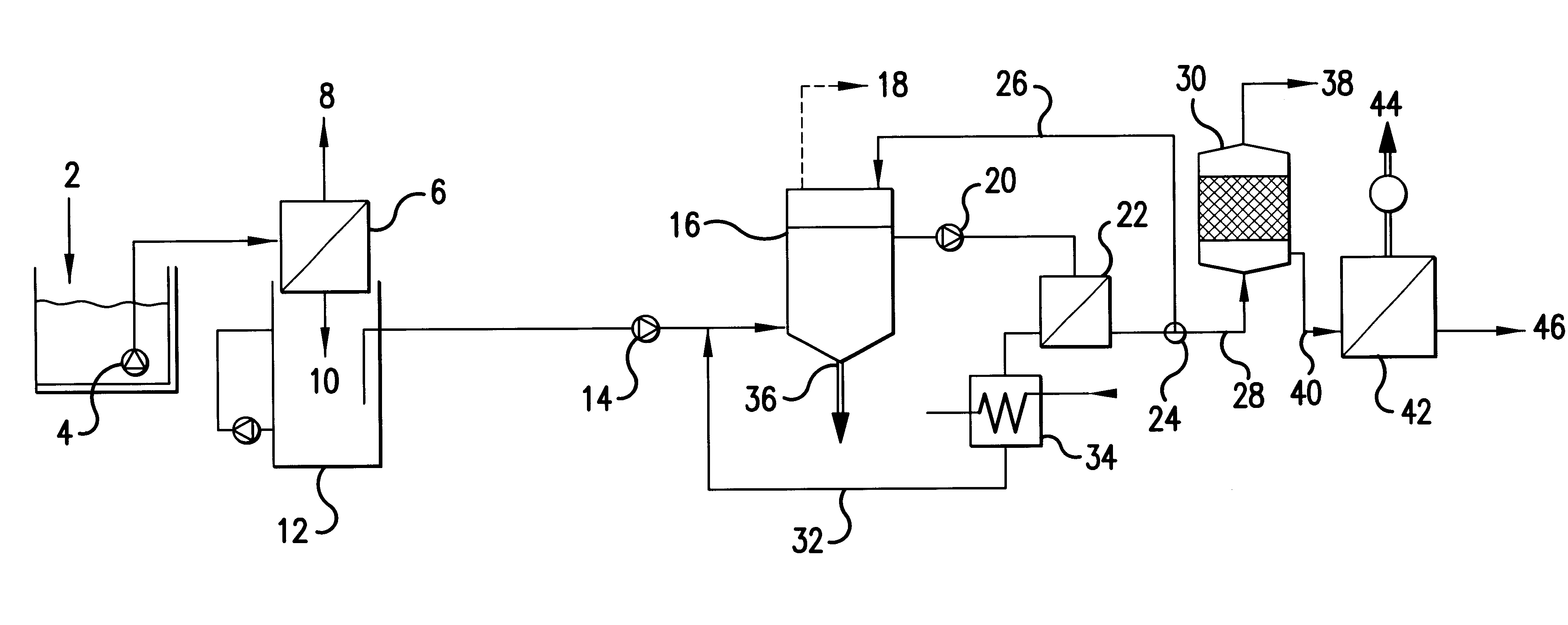

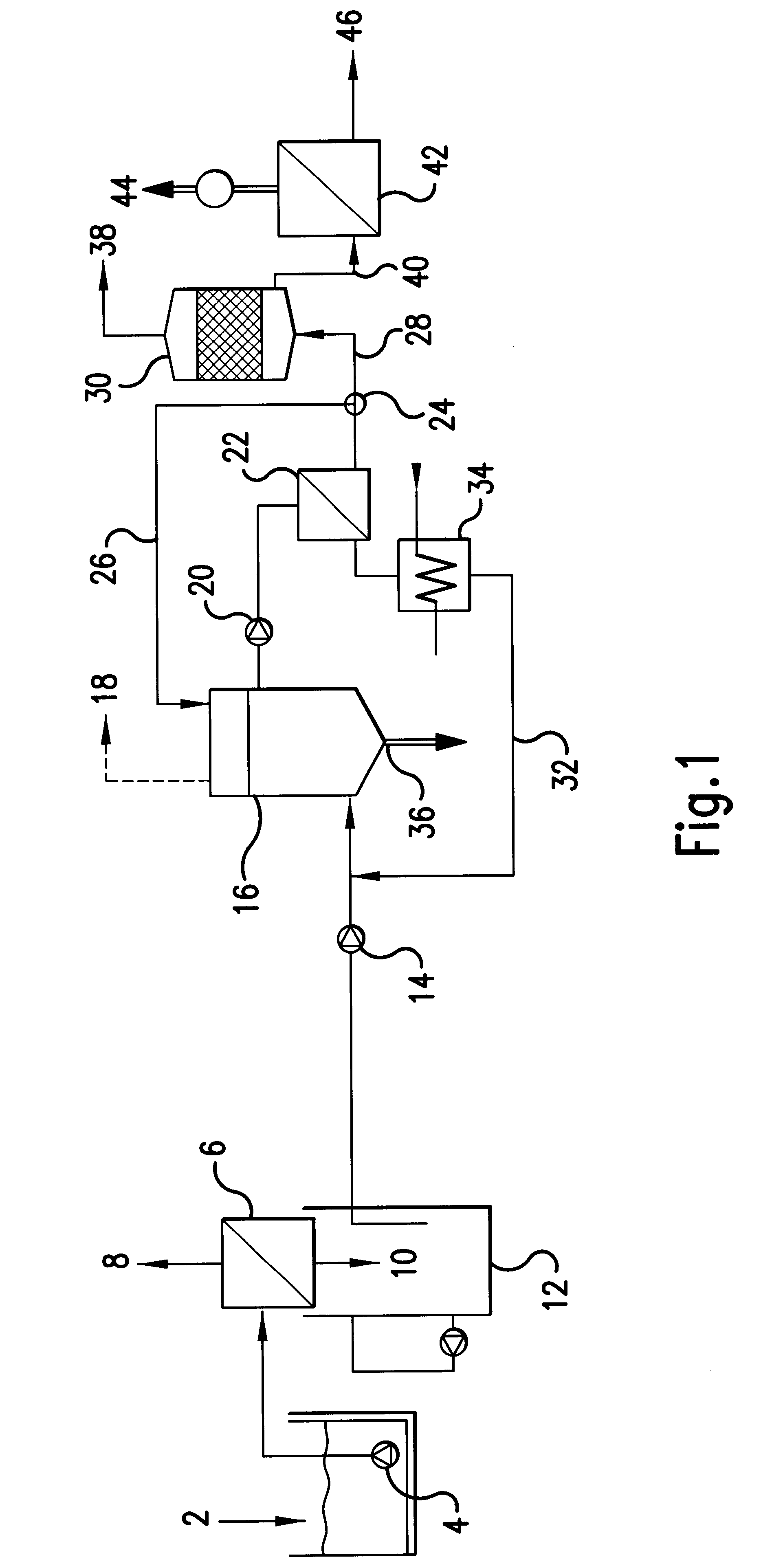

InactiveUS6368849B1Increase profitReduce environmental impactBioreactor/fermenter combinationsBio-organic fraction processingFiberUltrafiltration

A method and plant for the treatment of an organic waste material in liquid form, e.g. liquid manure from livestock, the method comprising filtering fibres and particles from the liquid, subjecting the liquid to anaerobic fermentation in a biogas reactor, separating a substantially sterile and particle-free permeate stream from the biogas reactor, e.g. using ultrafiltration, subjecting the permeate stream to treatment with an ammonia stripper at an elevated temperature and preferably at reduced pressure to remove substantially all ammonia and carbon dioxide and to result in an ammonia fraction and a nutrient salt fraction, and separating the nutrient salt fraction into a fertiliser concentrate fraction and a water fraction, e.g. using reverse osmosis. The end products of the method are clean water, ammonia concentrate, fertiliser concentrate containing salts of P and K, compost and high-quality biogas with a high methane content.

Owner:GR BIOTECH

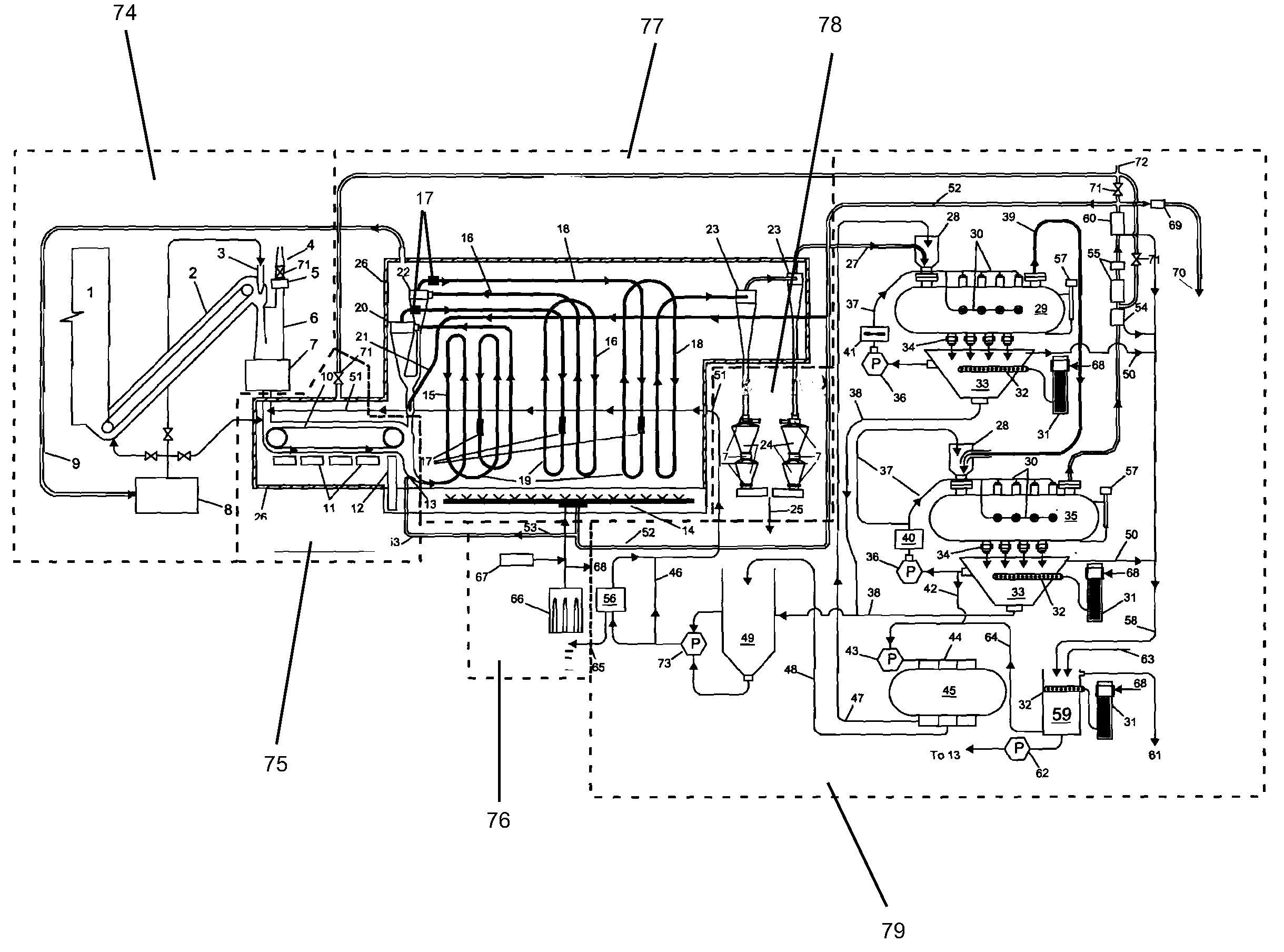

Method for processing lignocellulosic material

InactiveUS20020192774A1High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseEnvironmental engineering

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process. involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

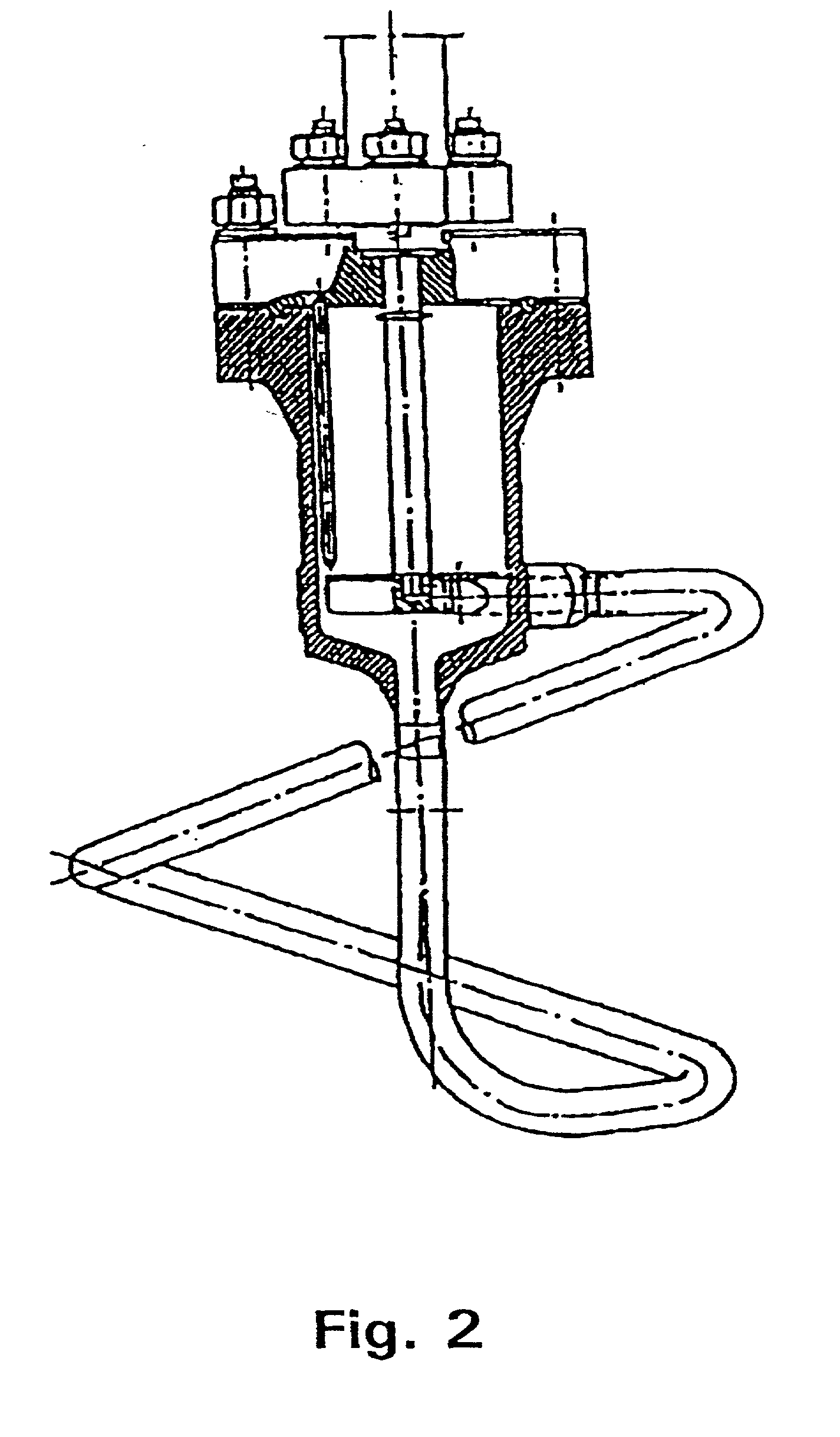

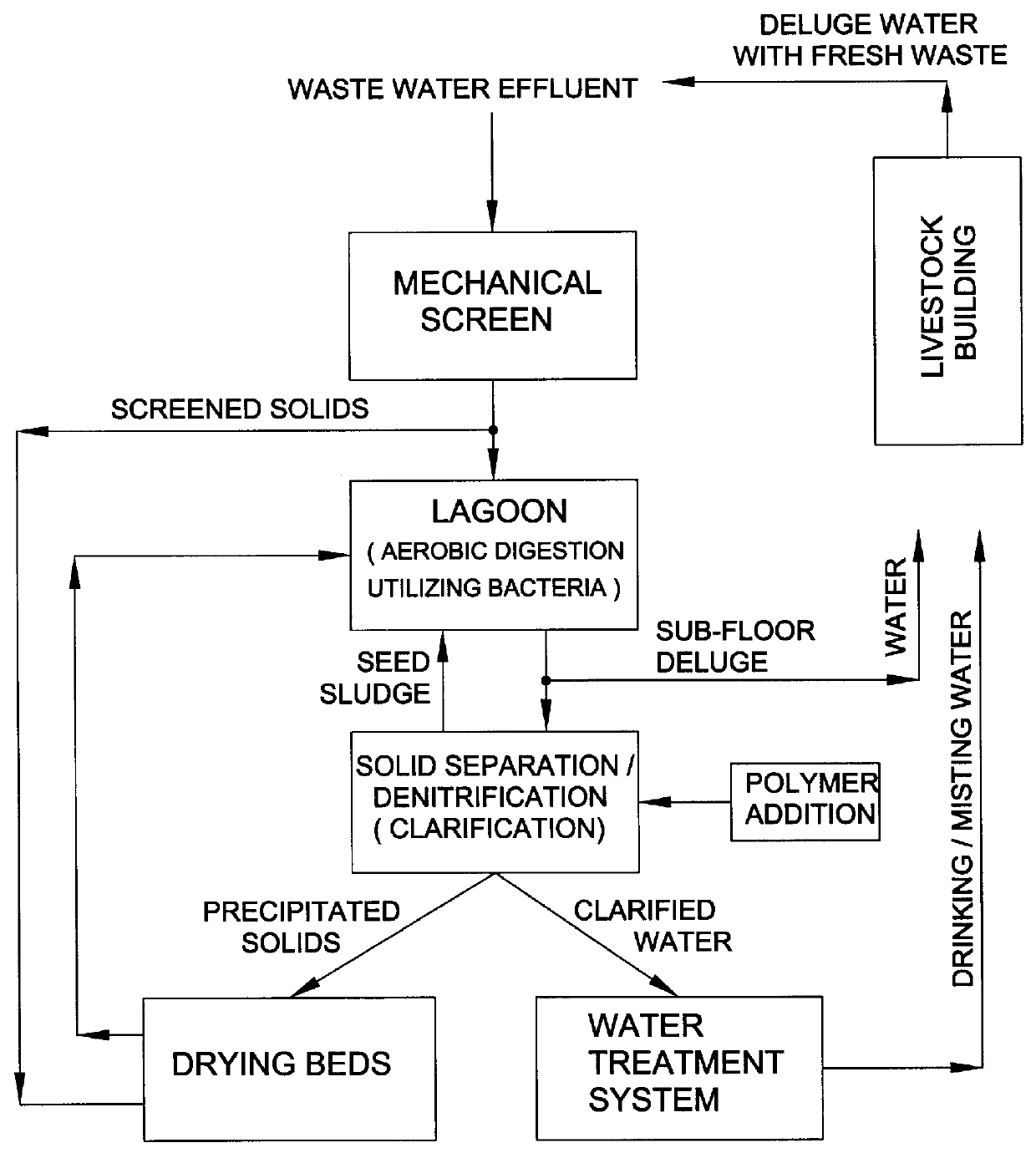

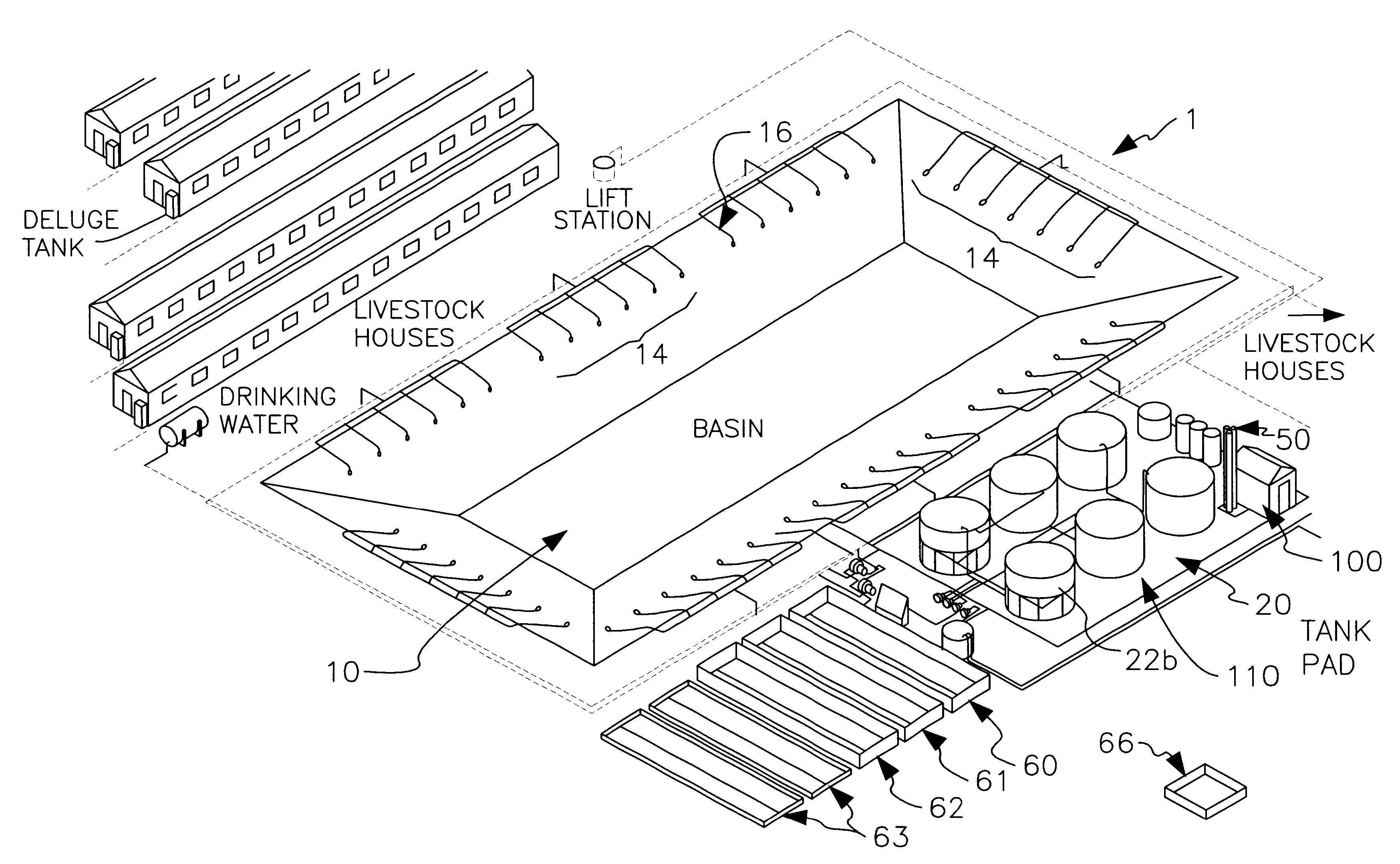

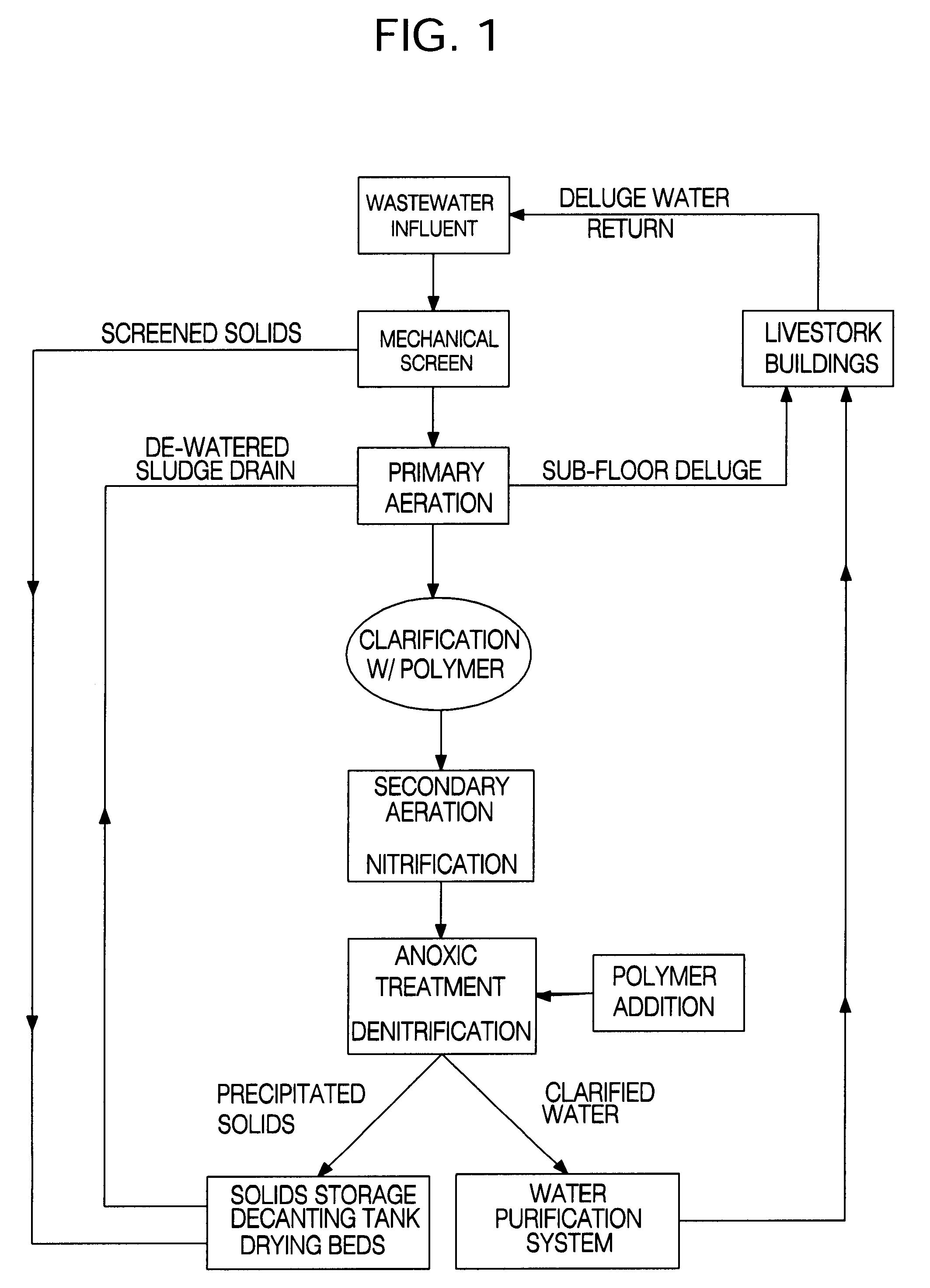

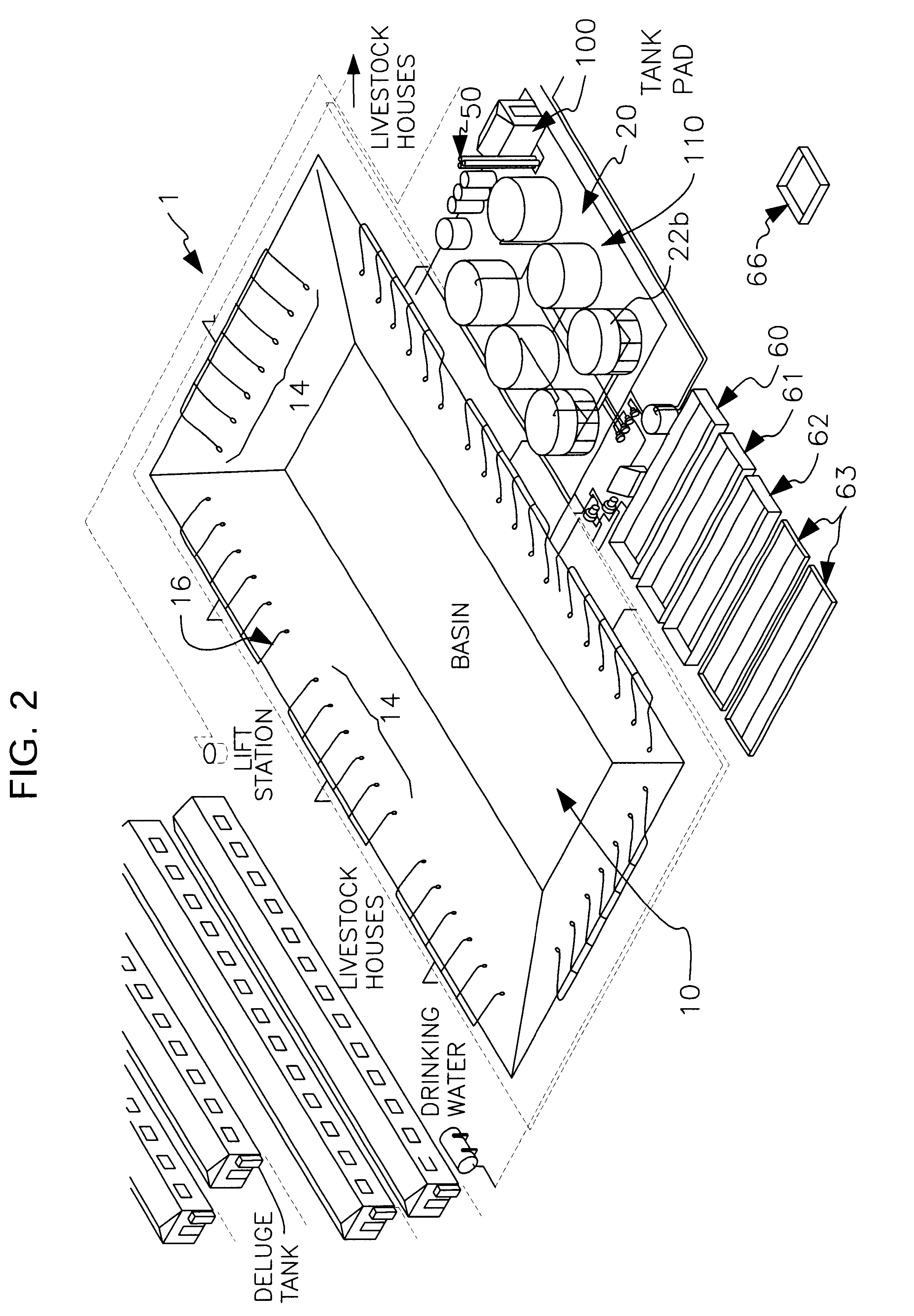

Apparatus and method for purification of agricultural animal waste

InactiveUS6039874AEffective treatment of wastewaterReducing fertilizer nutrientTreatment using aerobic processesOther chemical processesAbove groundFiltration

An apparatus and method for treating and reusing the wastewater discharged from agricultural animal farms. The apparatus and method of the present invention is designed to be a zero discharge system in which no wastewater will be discharged or spray irrigated. The wastewater effluent is first passed through a mechanical screen were bulk solids are separated and partially de-watered. The screened effluent is then directed to a primary plastic-lined earthen lagoon where it undergoes aerobic digestion utilizing specially selected bacteria. After treatment in the primary lagoon, the wastewater effluent is used to wash the floors of the hog houses or undergoes a purification phase including solids separation / denitrification, filtration and sterilization. The solids separation / denitrification phase (clarification) preferably takes place in an anoxic environment in preferably above-ground tanks where suspended solids removal will occur as well as denitrification for nitrate reduction. The clarification process may be facilitated through use of polymer addition. The majority of solids will be sent to a plurality of drying beds for de-watering and subsequent removal.

Owner:AGRIMOND USA CORP

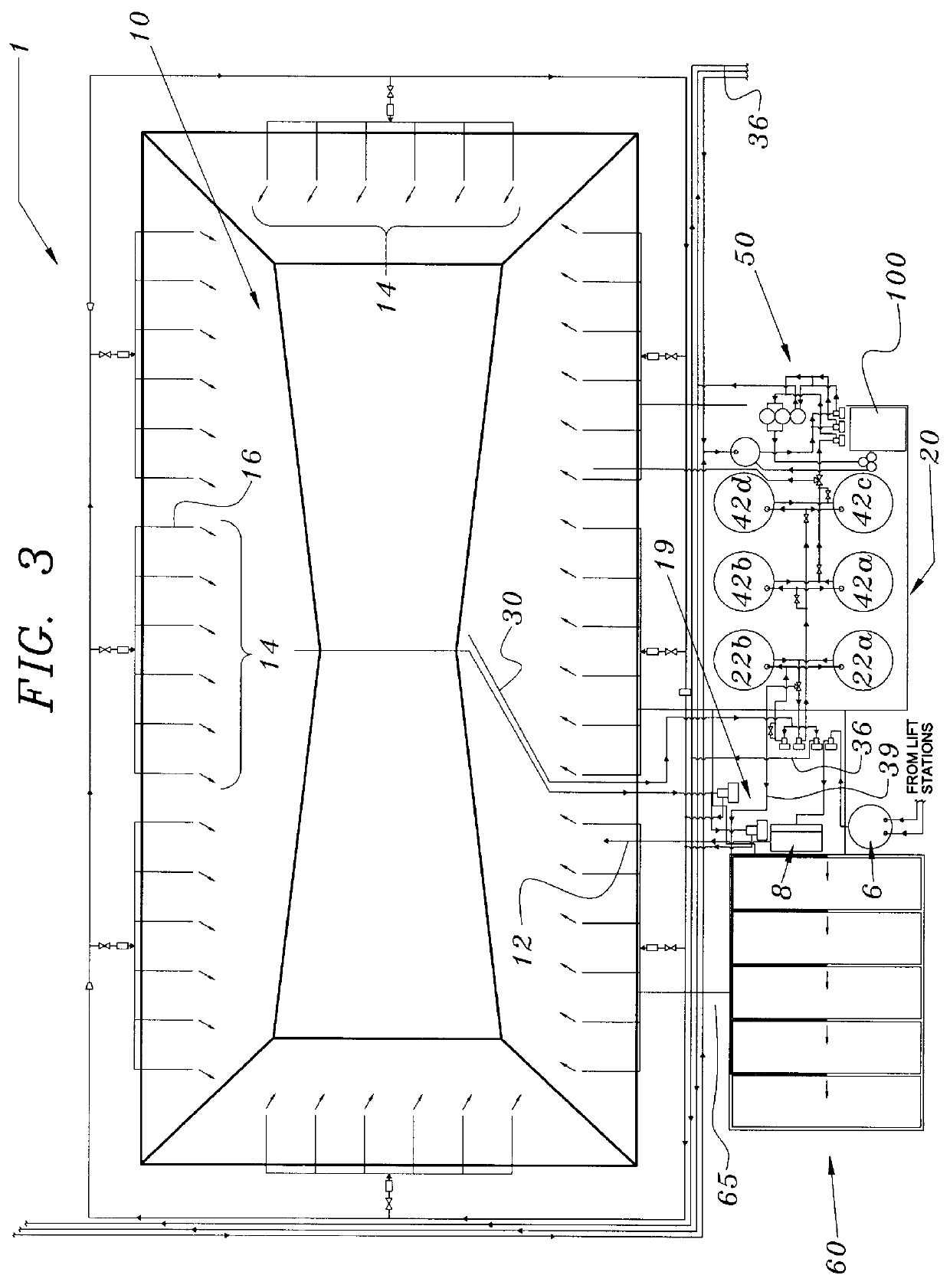

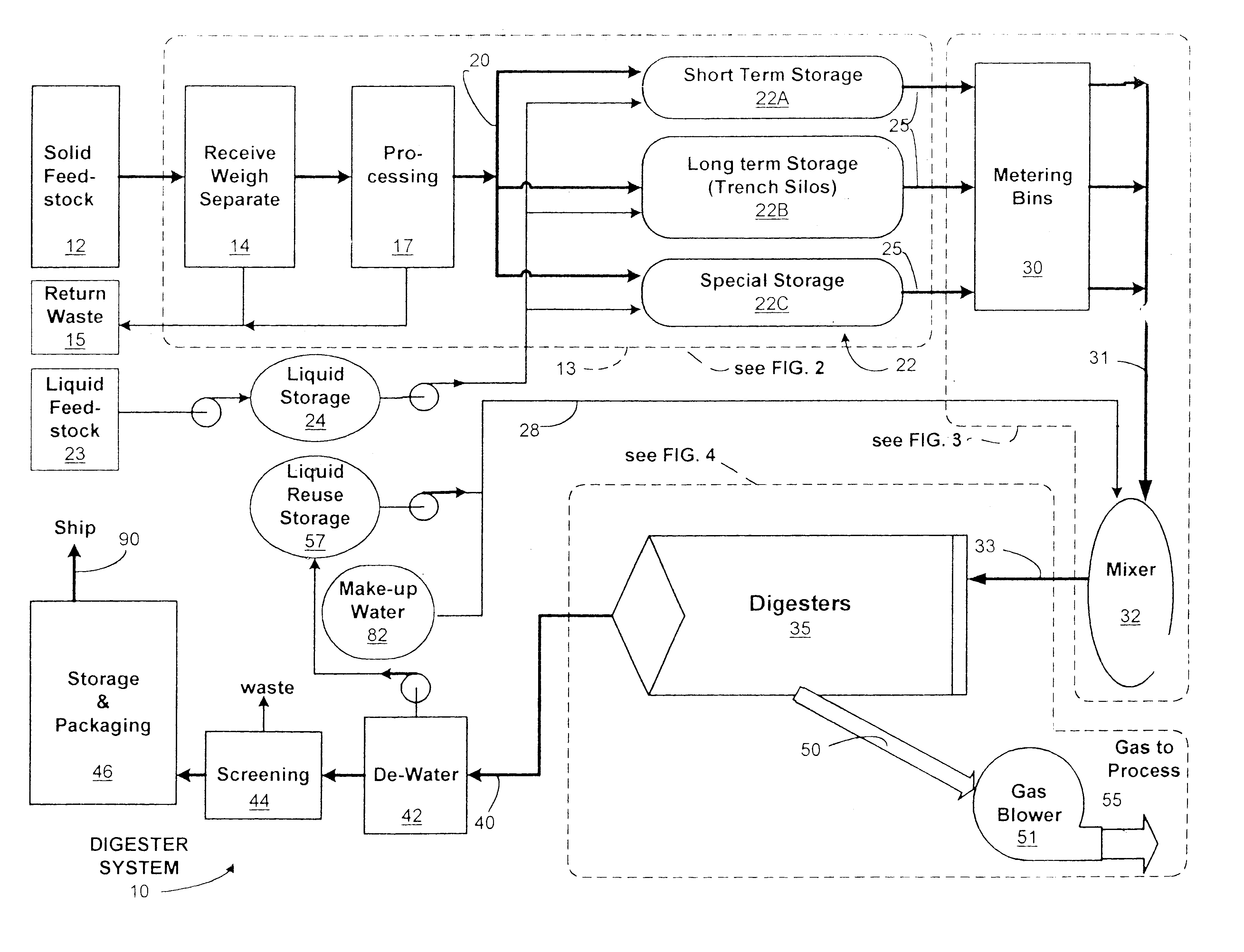

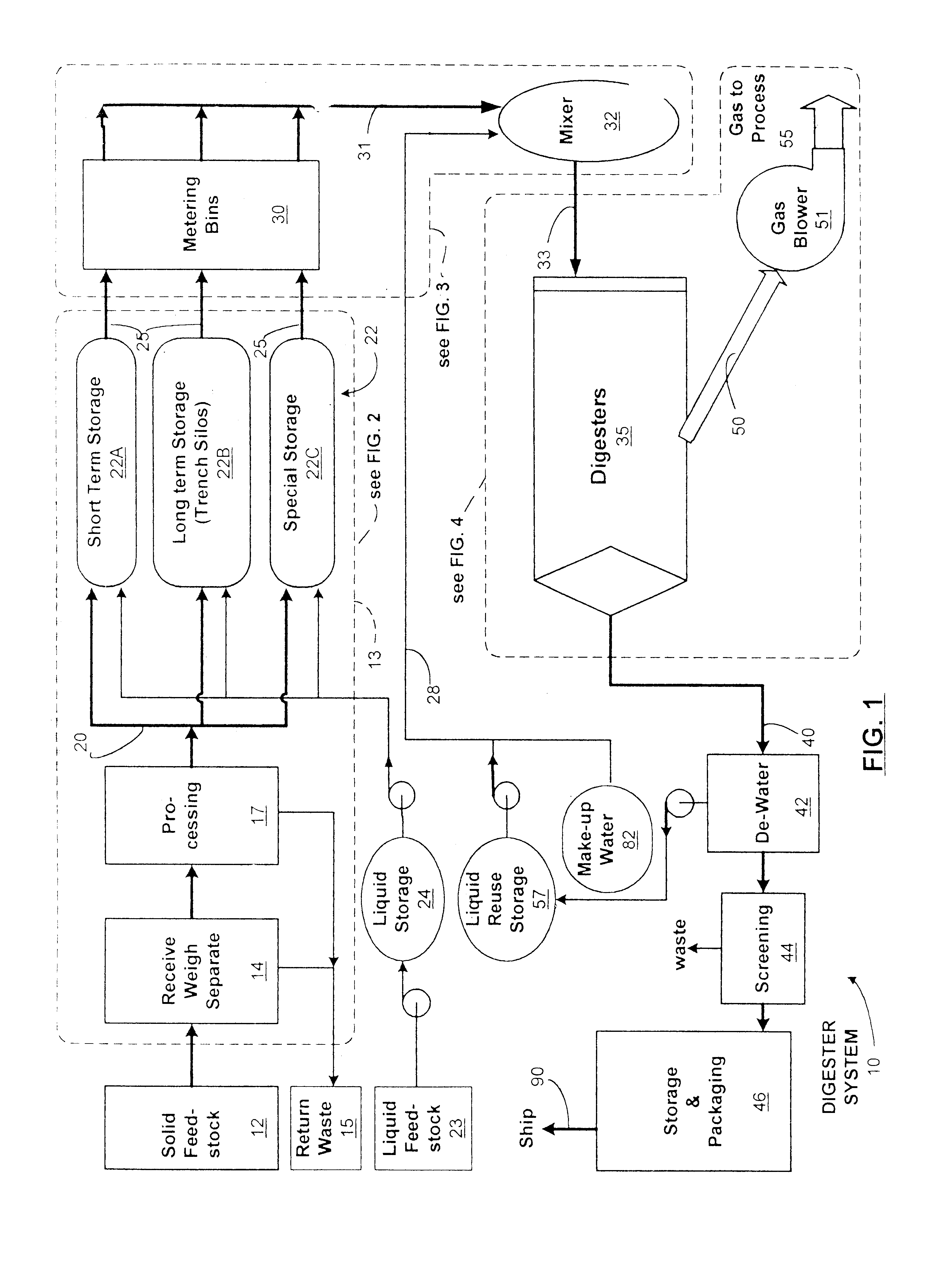

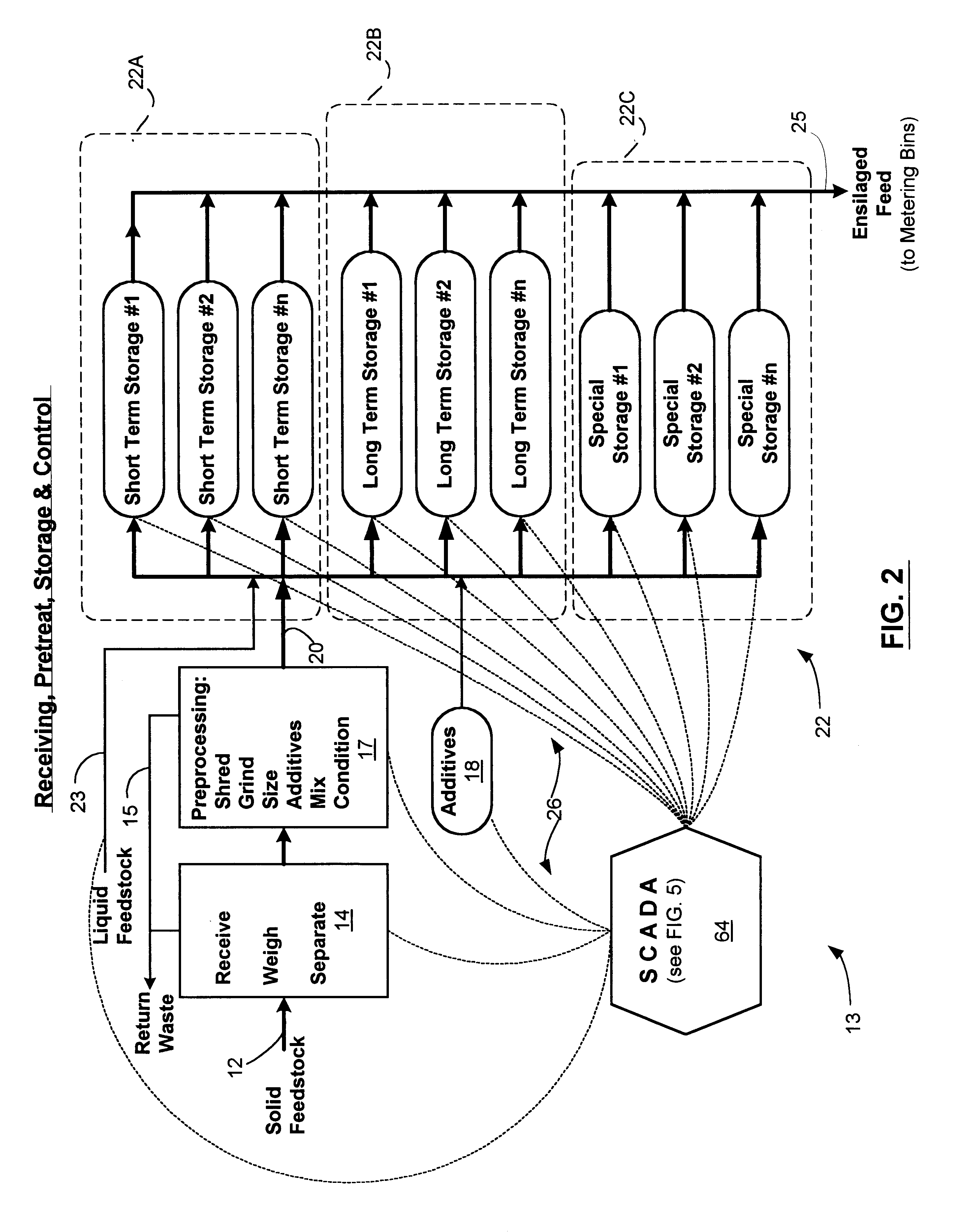

Anaerobic digester system

InactiveUS6296766B1Easy to monitorEasy to controlData processing applicationsBiological treatment regulationGrowth plantEnvironmental engineering

A method for an anaerobic digester system is provided that employs a cumulative data base to better monitor and control the anaerobic process, as compared with conventional anaerobic digester systems. The method includes the storing and ensiling of a feedstock, preferably a biomass, to form a digester feed material, which then processed by a digester. The process evolves a biogas and forms a digested material. The process is monitored, to collect a plurality of digester data from all stages of the process. These individual points or elements of the data are telemetered to a cumulative data base for storage and eventual retrieval and the cumulative data base is mined to compile predictive, feed forward controls and construct feedstock correlations between the metabolic activity within the digesters and an analysis of the feedstocks into the digesters. The method further includes the production of a high quality plant growth media from the digested mash, and recovery of the biogas generated within the digester. The biogas is collected with the aid of a biogas recovery system. The biogas is predominantly methane, and the anaerobic digester system is preferably operated to maximize the quantity and quality of methane generated.

Owner:TECHN INFORMATION

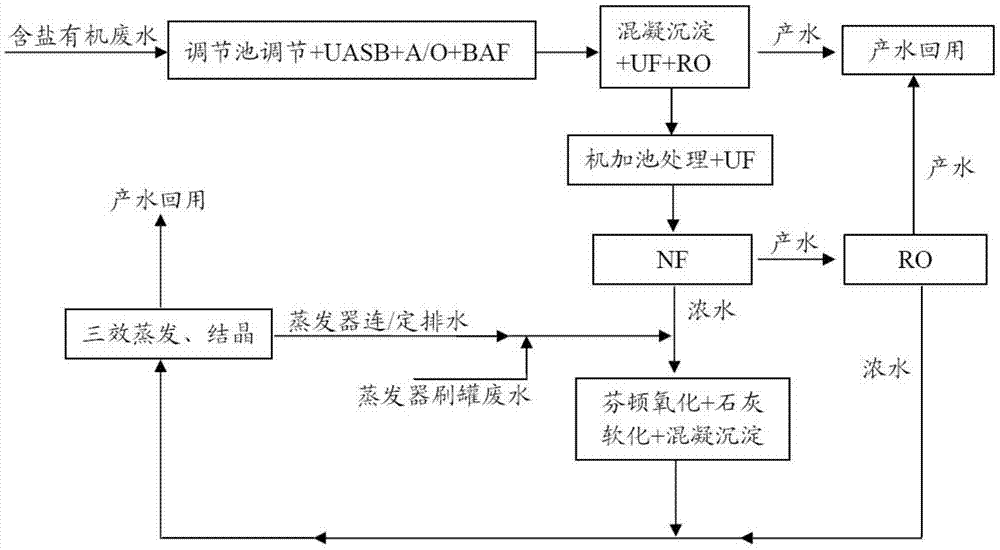

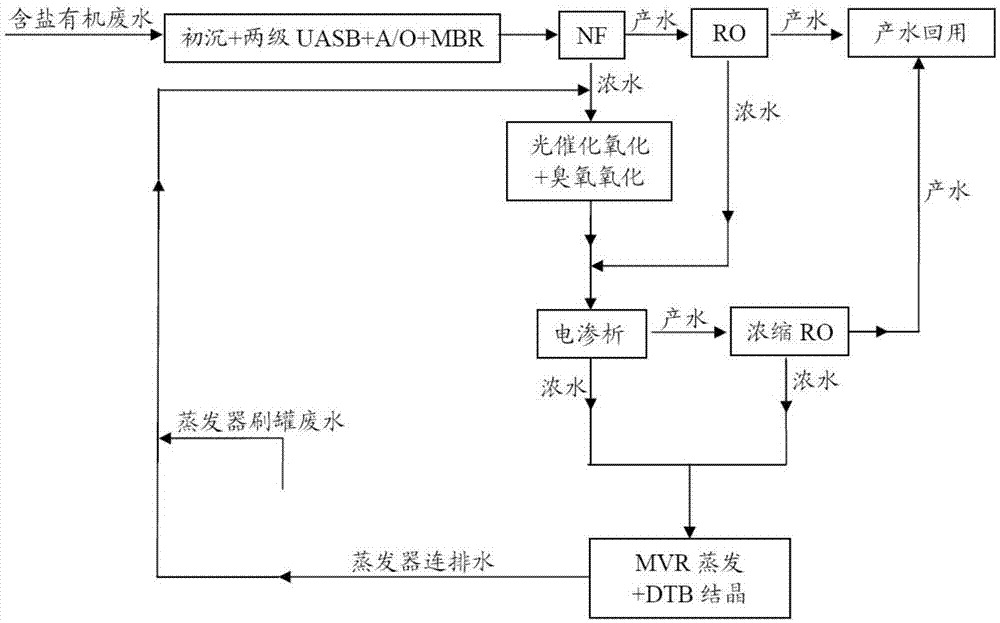

Zero-discharge treatment method of salt-containing organic wastewater

InactiveCN105439395AEasy to handleEfficient reuseTreatment using aerobic processesTreatment involving filtrationEvaporationOrganic matter

The invention provides a zero-discharge treatment method of salt-containing organic wastewater. The method comprises the following steps that biochemical treatment and filtering treatment are performed on wastewater; then, membrane concentration is performed; pure-water-producing high-organic-matter-content membrane concentration concentrated water and optional low-organic-matter-content membrane concentration concentrated water are obtained; the high-organic-matter-content membrane concentration concentrated water is used for high-grade oxidation treatment; high-grade oxidation produced water is used for regulation treatment to obtain high-grade oxidation outlet water; the obtained high-grade oxidation outlet water is subjected to evaporation treatment; or the obtained high-grade oxidation outlet water and the low-organic-matter-content membrane concentration concentrated water are mixed under the condition that the low-organic-matter-content membrane concentration concentrated water exists in the step, and then, the evaporation treatment is carried out; external discharge concentration liquid of an evaporator and / or high-salt-content high-organic-matter-content wastewater discharged during the tank brushing of the evaporator are conveyed back into a high-grade oxidation treatment unit; after the liquid is mixed with the high-organic-matter-content membrane concentration concentrated water, the high-grade oxidation treatment is carried out. The wastewater treatment method is stable and reliable; the long-period and stable operation of an evaporation system can be ensured; the zero discharge of the industrial wastewater is realized.

Owner:DATANG INT CHEM TECH RESINST

Aerobic treatment of liquids to remove nutrients and control odors

InactiveUS6398959B1Effective treatment of wastewaterReduce nutrientsTreatment using aerobic processesWaste water treatment from animal husbandrySludgeWastewater

The present invention is drawn to a unique apparatus and method for treating and reusing the wastewater discharged from agricultural animal farms. The apparatus and method of the present invention may be readily-sized and configured depending upon the amount and constituent(s) of the wastewater to be treated. In a first embodiment, the apparatus and method of the present invention is designed to be a zero discharge system in which no wastewater will be discharged or land applied. In use, the apparatus and method of the first embodiment may actually require addition of make-up water during periods of low rainfall to make up water losses due to evaporation and drift. It is contemplated that the only byproduct of the apparatus and method of the first embodiment may be a beneficial sludge if a sufficient number of installations are operated. In a second embodiment, the apparatus and method of the present invention provides a treatment system capable of reducing the nutrient loading in a step-wise fashion so that the wastewater can be used from different steps of treatment in order to apply the varying nutrient loads required by crops on a seasonal basis.

Owner:AGRIMOND USA CORP

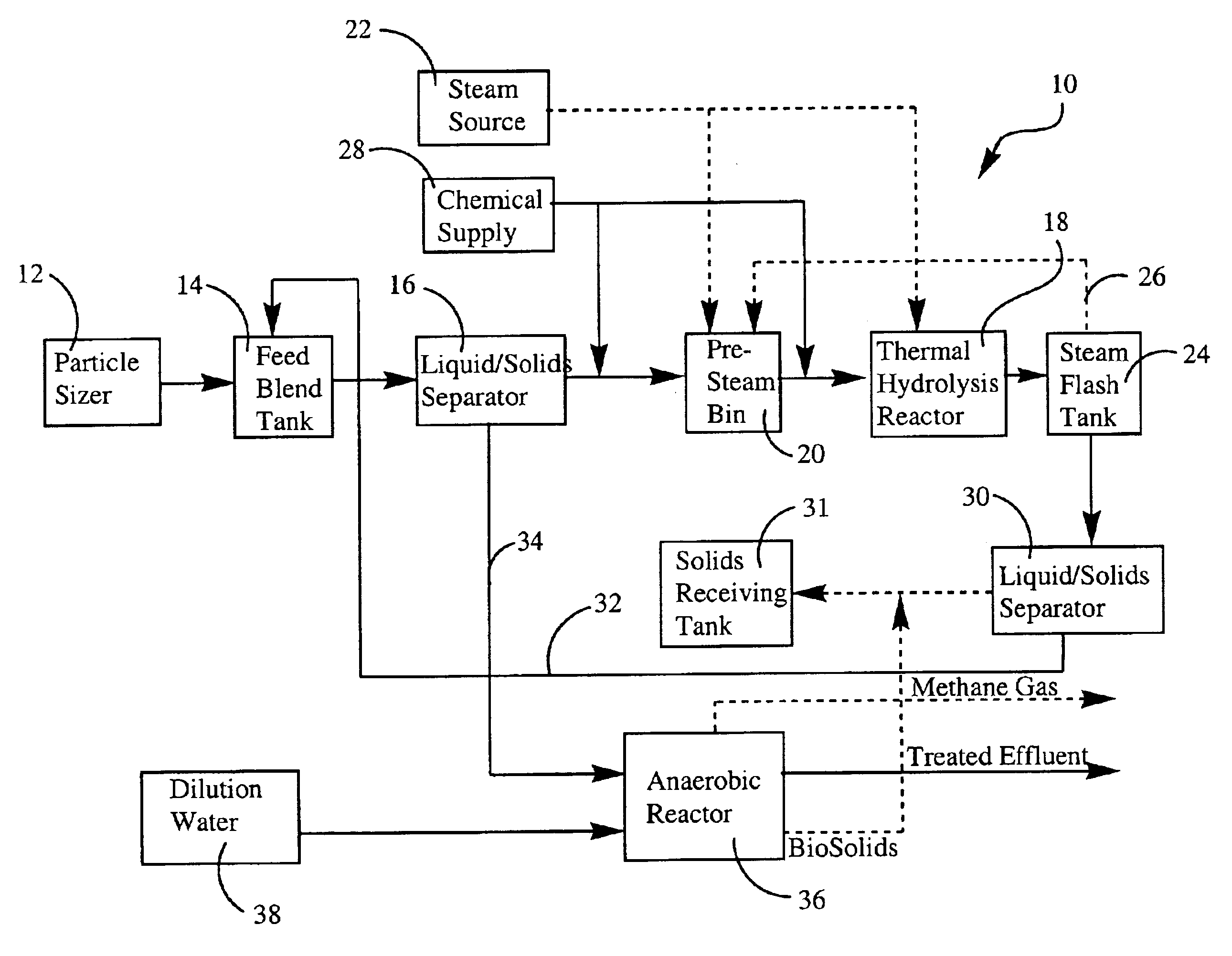

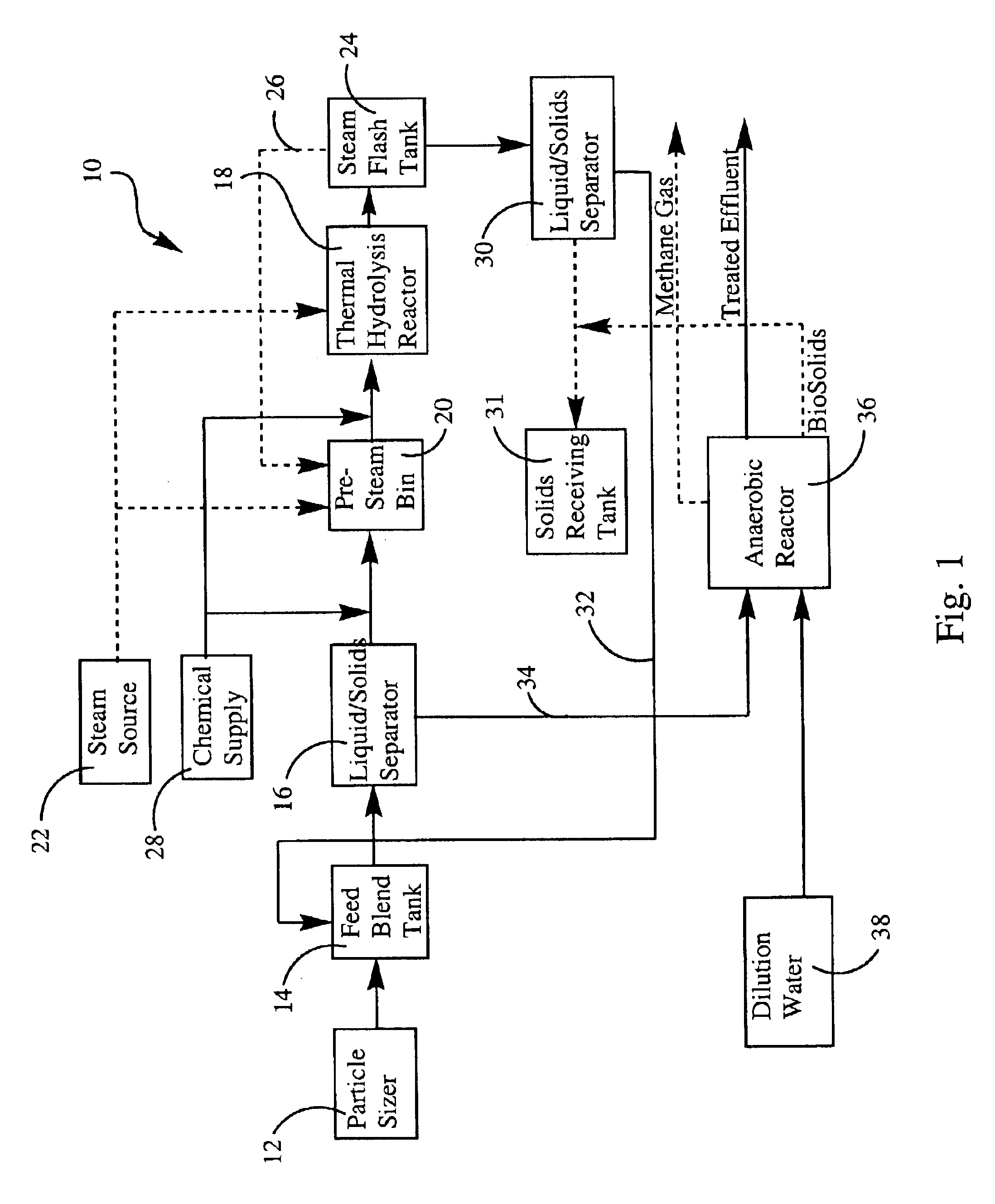

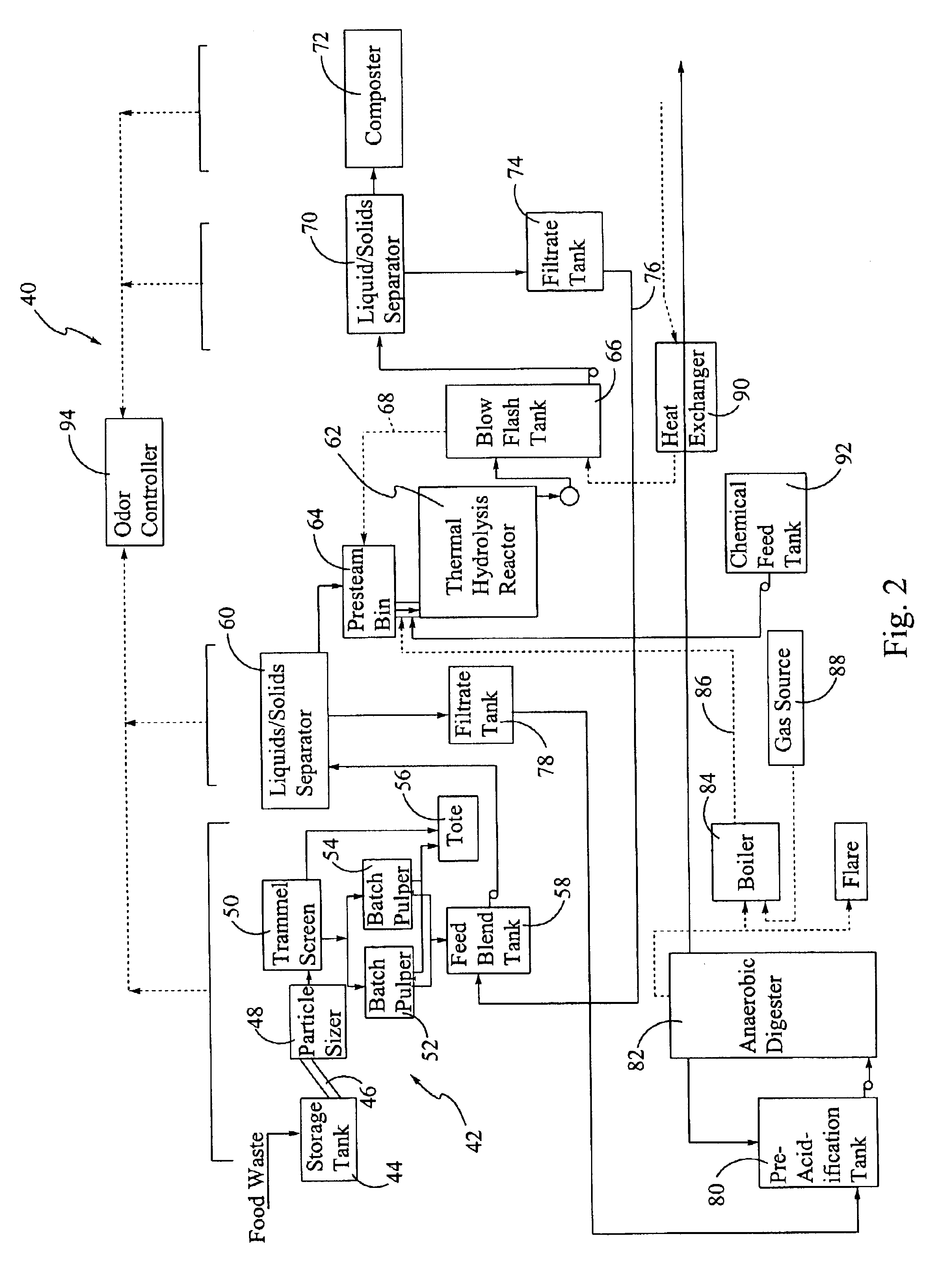

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS6905600B2Lower the volumeSaving in volume requirementBio-organic fraction processingBiological substance pretreatmentsPotassium hydroxideSaturated water vapor

A method for treating particulate biodegradable organic waste includes sizing the waste and adding a base prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The base is preferably potassium hydroxide (KOH) at a concentration of about 1%. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

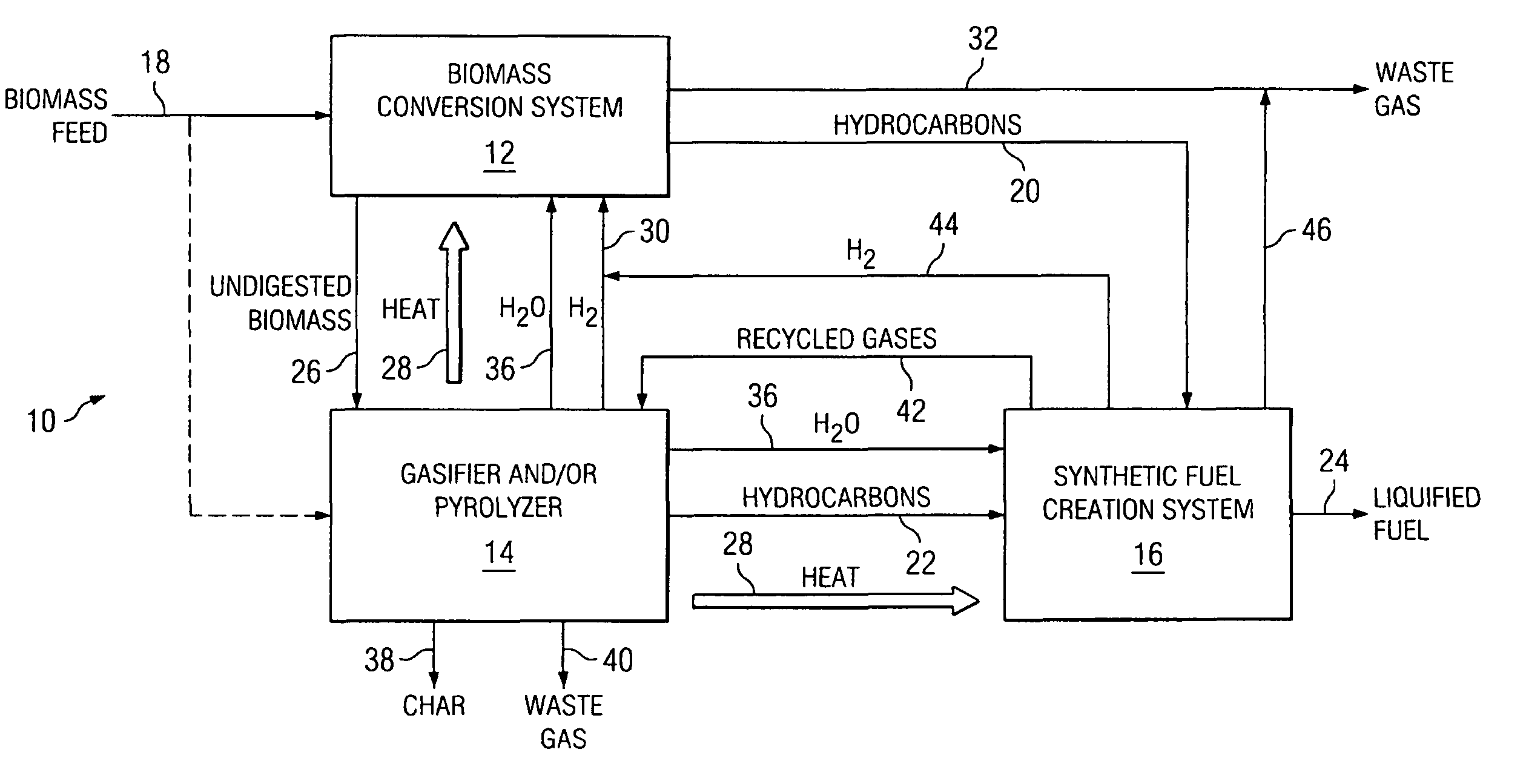

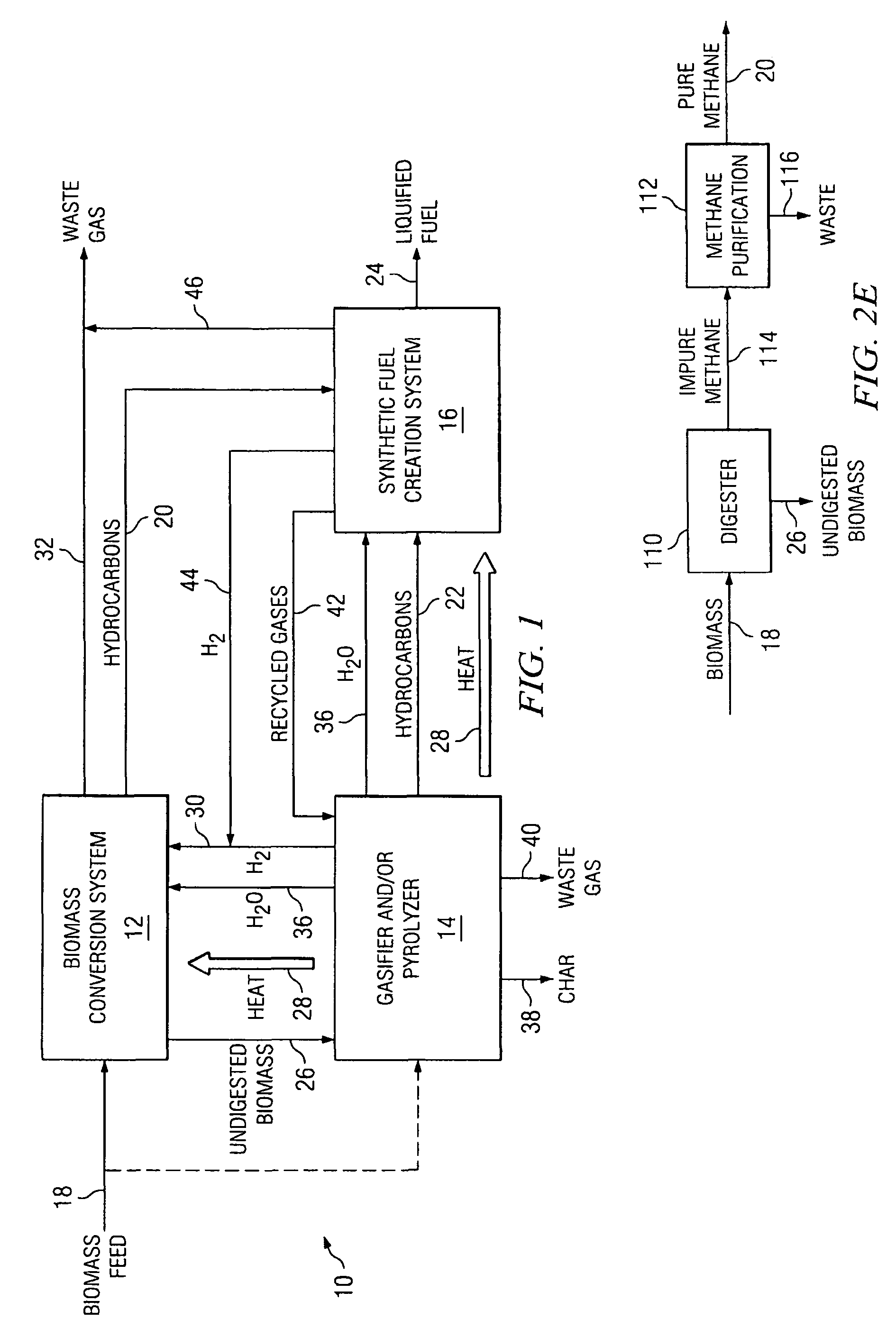

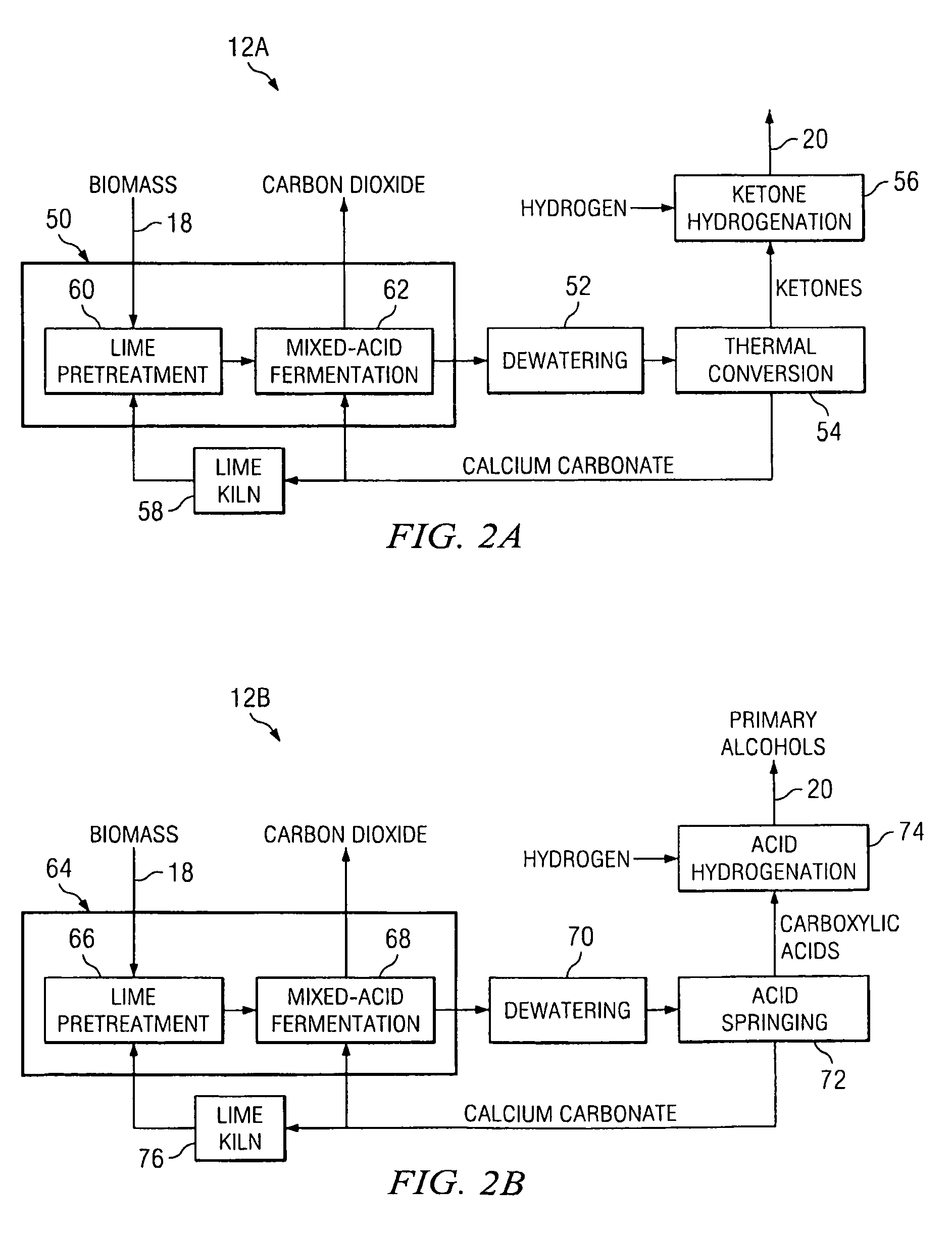

Integrated biofuel production system

InactiveUS8153850B2Improve efficiencyIncrease energy densityGas production bioreactorsWaste based fuelThermal energySystem integration

According to an embodiment, a biomass conversion subsystem produces methane and / or alcohol and residual biomass. A pyrolysis or a gasification subsystem is used to produce thermal energy and / or process gasses. The thermal energy may be stored thermal energy in the form of a pyrolysis oil. A fuel conversion subsystem produces liquid hydrocarbon fuels from the methane and / or alcohol using thermal energy and / or process gasses produced by the gasification or pyrolysis subsystem. Because the biomass production system integrates the residual products from biomass conversion and the residual thermal energy from pyrolysis or gasification, the overall efficiency of the integrated biomass production system is greatly enhanced.

Owner:TEXAS A&M UNIVERSITY

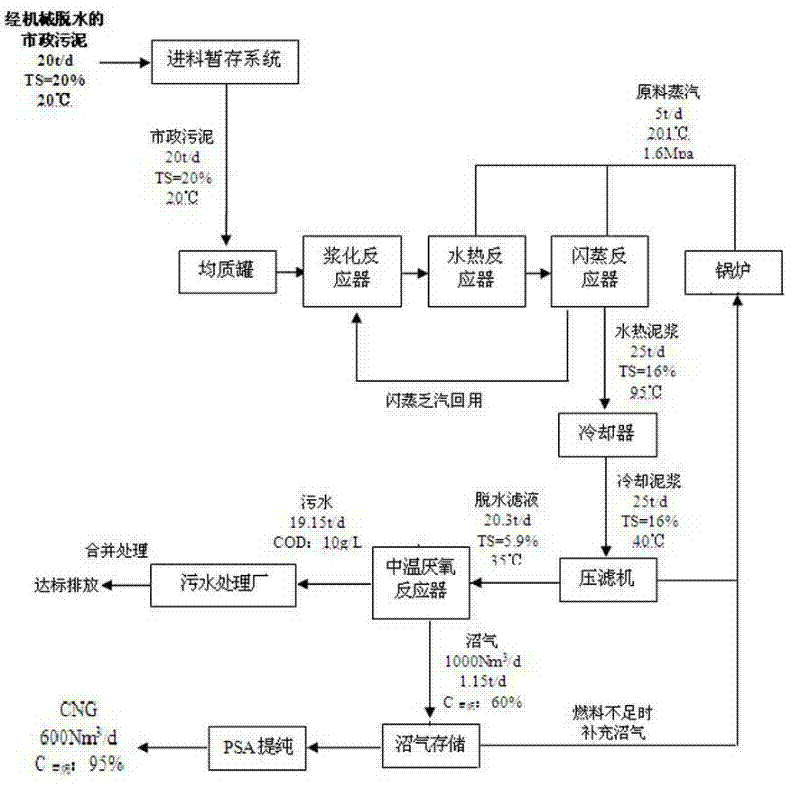

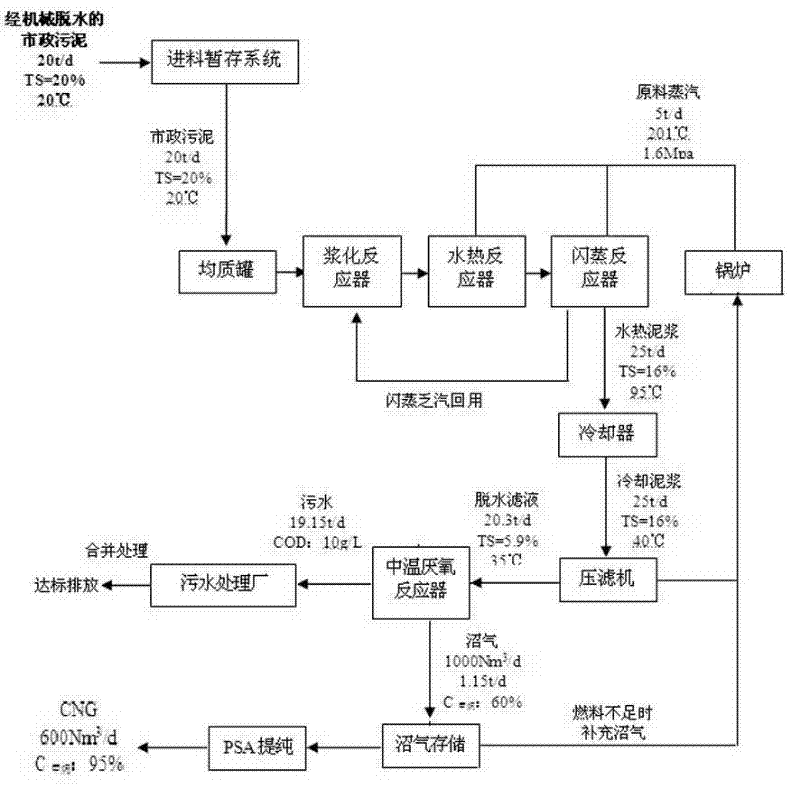

Sludge treatment process based on hydrothermal modification technology

InactiveCN102381820AAdvanced technologyHighlight energy savingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAnaerobic reactorHigh pressure

The invention relates to a sludge treatment process based on a hydrothermal modification technology. The sludge treatment process is carried out by comprising the following steps of: (1) temporarily storing the sludge which is subjected to mechanical dehydration and has the water content of 70-85% to a pretreatment unit and deodorizing the sludge; (2) introducing to a homogeneous device, fully mixing and homogenizing, introducing the homogenized sludge to a slurrying device, introducing the slurried sludge to a hydrothermal reactor for hydrothermal reaction, and introducing the hydrothermal sludge to a flash evaporator for decompression and flash evaporation; (3) cooling to 35-45 DEG C by using a cooler, then introducing to a high-pressure diaphragm pressure filter for pressure filtering and dehydration to obtain a dehydrated mud cake with the solid content of 35-45% and dehydrated filtrate; (4) introducing the dehydrated filtrate to an intermediate temperature anaerobic reactor, wherein the residence time is for 5.5-7.5d, the inlet water temperature is controlled below 40 DEG C, and the anaerobic reaction temperature is 30-40 DEG C; and (5) preparing a biomass fuel rod by using the dehydrated mud cake, and introducing the biomass fuel rod to a boiler to provide steam for the hydrothermal reactor and the flash evaporator. The sludge treatment process has the advantages of goodtreatment effect, obvious volume reduction effect, high harmless degree, recycling of methane, good economic benefit and the like.

Owner:FUZHOU DEV ZONE SANSHUI ENVIRONMENTAL PROTECTION TECH

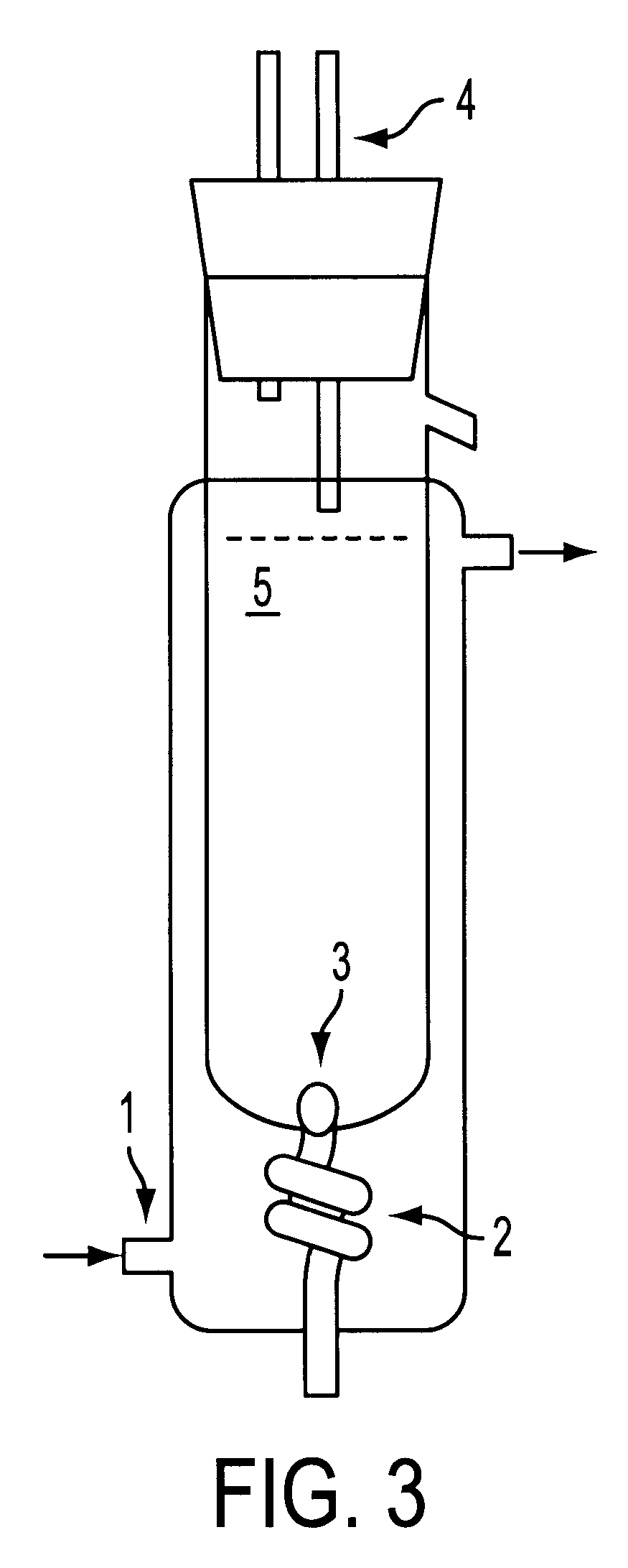

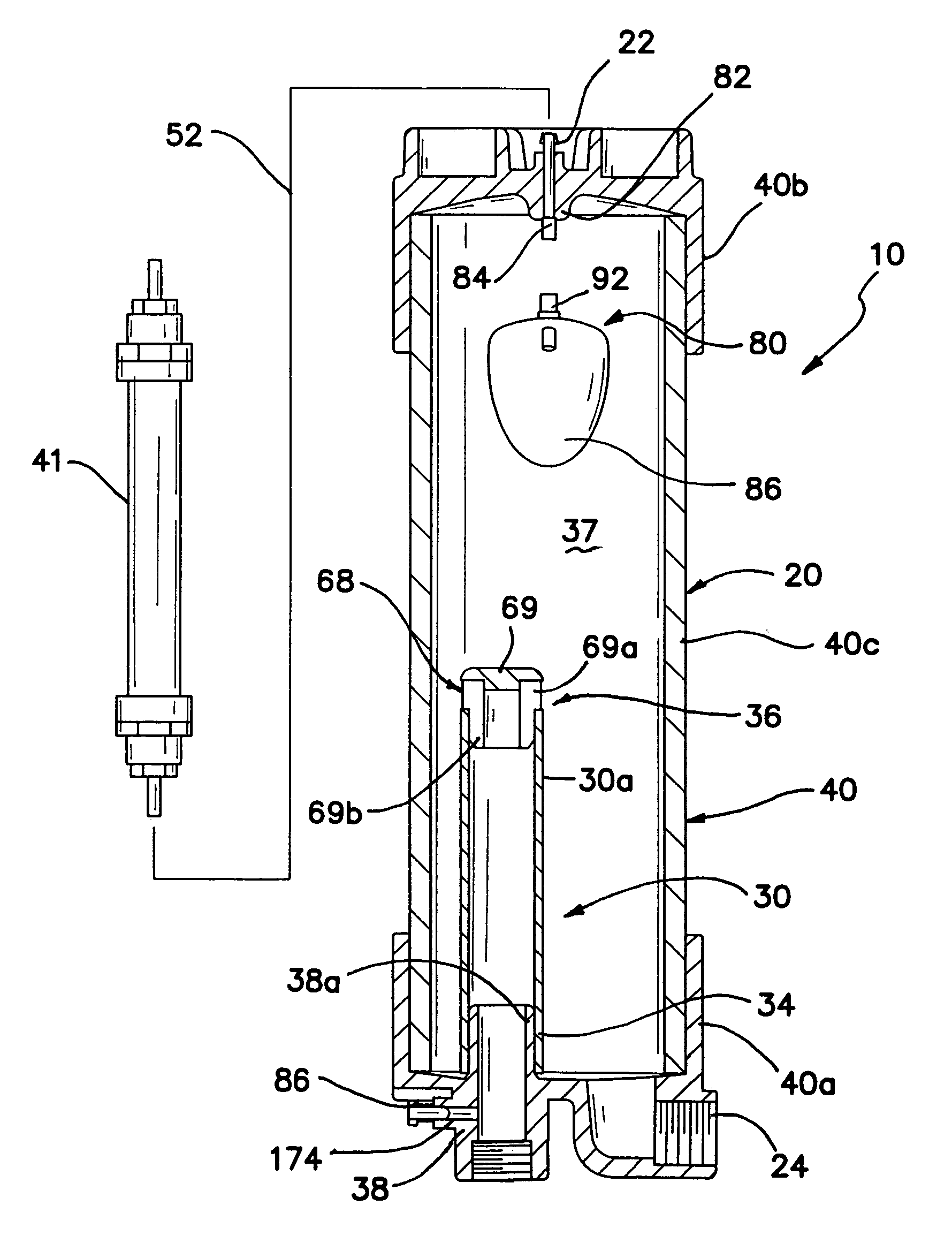

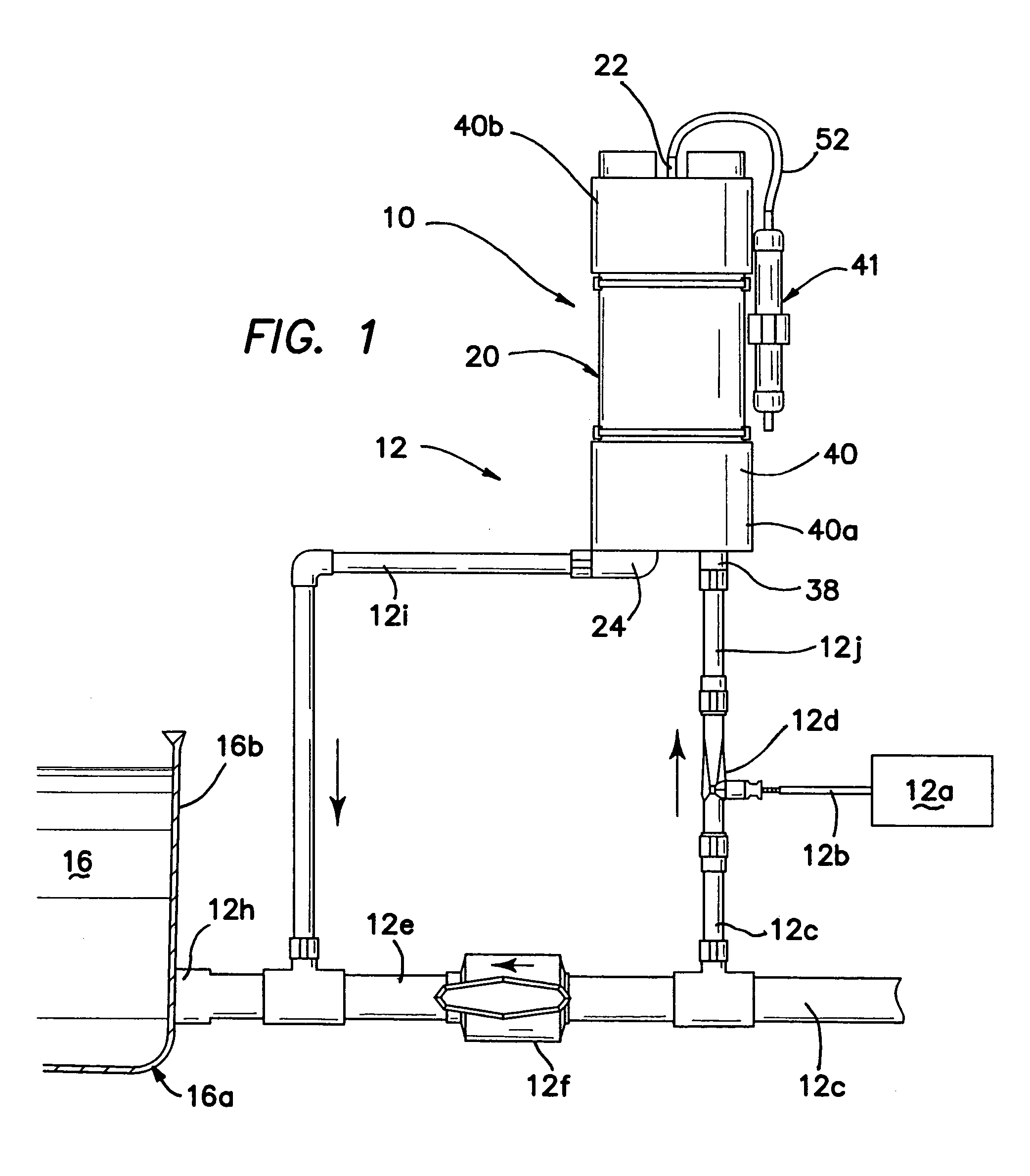

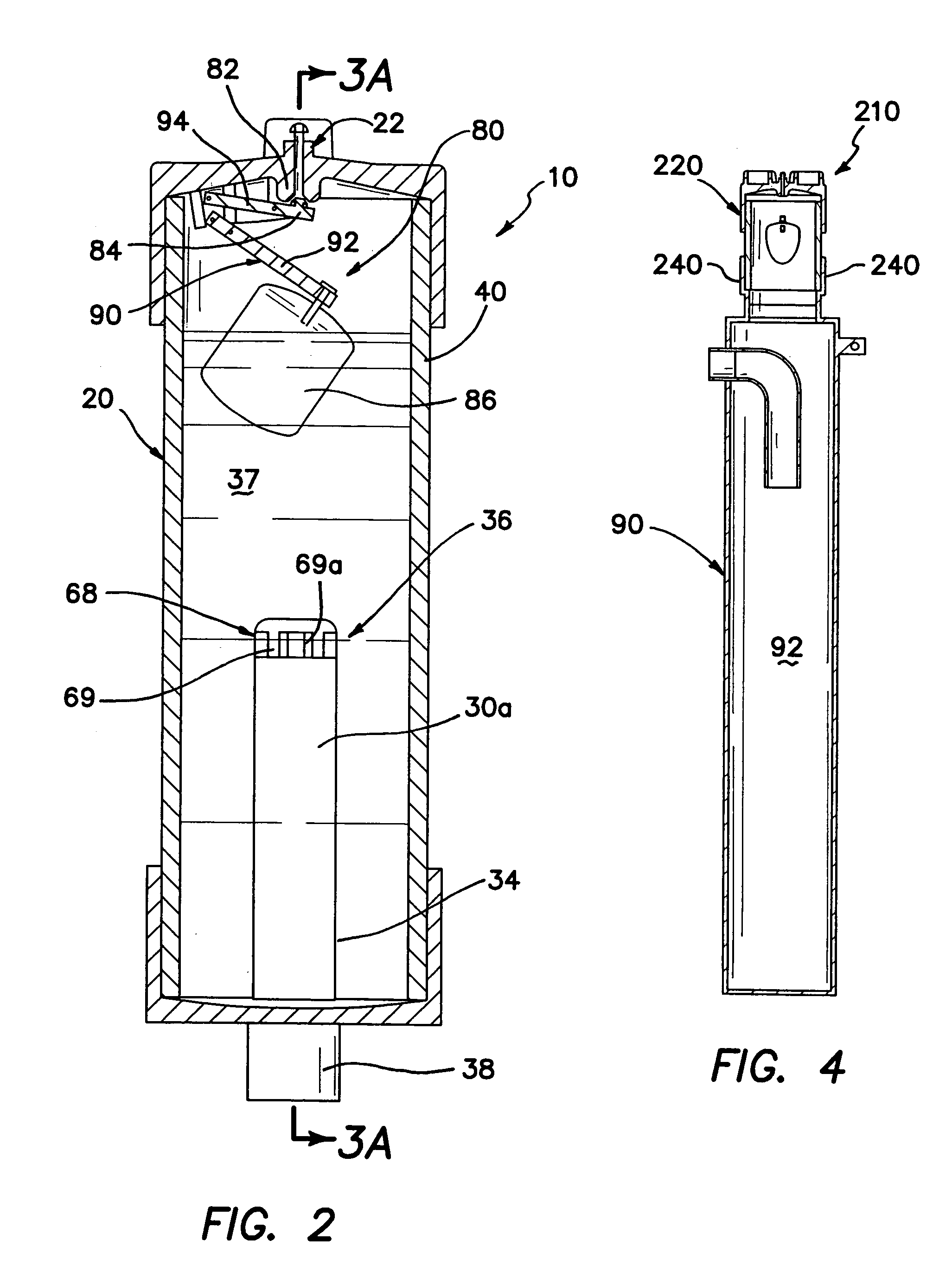

Water ozonation mixing and degassing system

ActiveUS7022225B1Straightforward in constructionEasy to useOther chemical processesDispersed particle separationLiquid waterExhaust fumes

An apparatus and system for mixing and separating ozonated water is provided. The apparatus is especially useful as a component of a system for cycling sanitizing ozonated water to a body of water such as a pool, spa or pond. The apparatus generally includes a separating vessel including a mixing tower, preferably located substantially entirely within the separating vessel and including a diffuser element for enhancing mixing of ozonated water without increasing turbulence in the separating vessel. Preferably, the apparatus includes a seal mechanism that substantially prevents liquid water from escaping the separating vessel with vented off-gas. The invention further provides an ozone destruct assembly including a condensate collection portion, and may also include a return line for passing a treated off-gas into the body of water.

Owner:CUSTOM MOLDED PROD

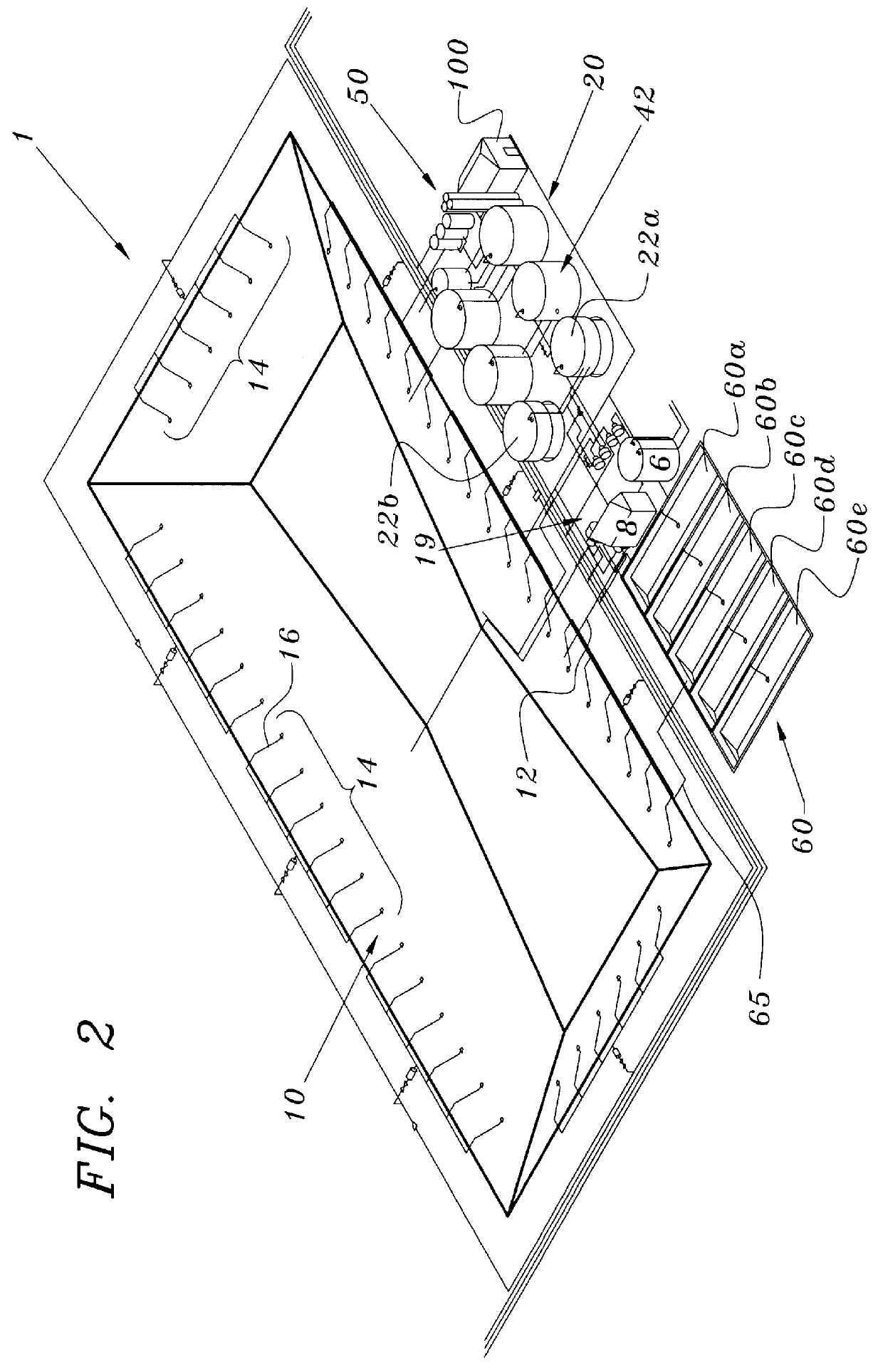

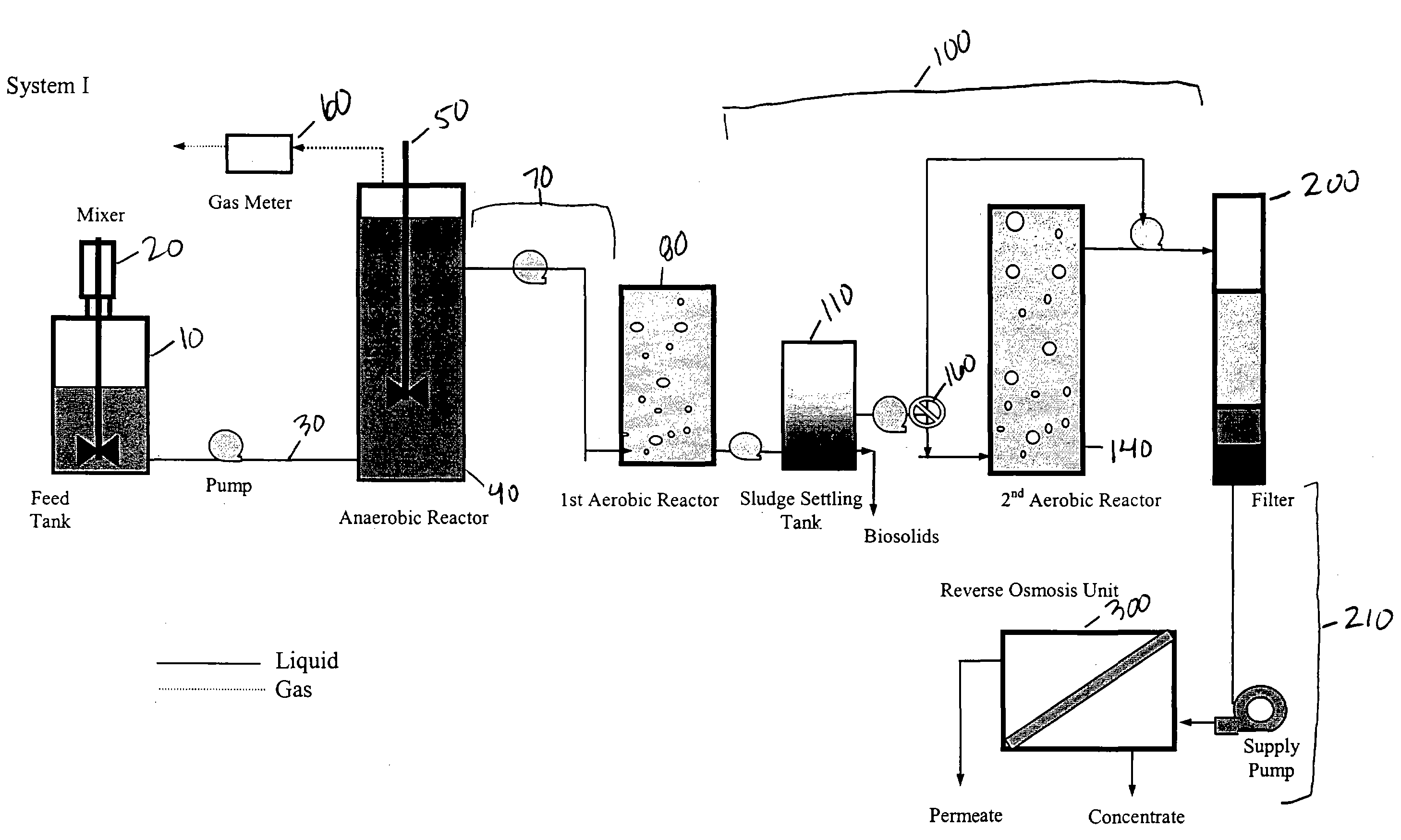

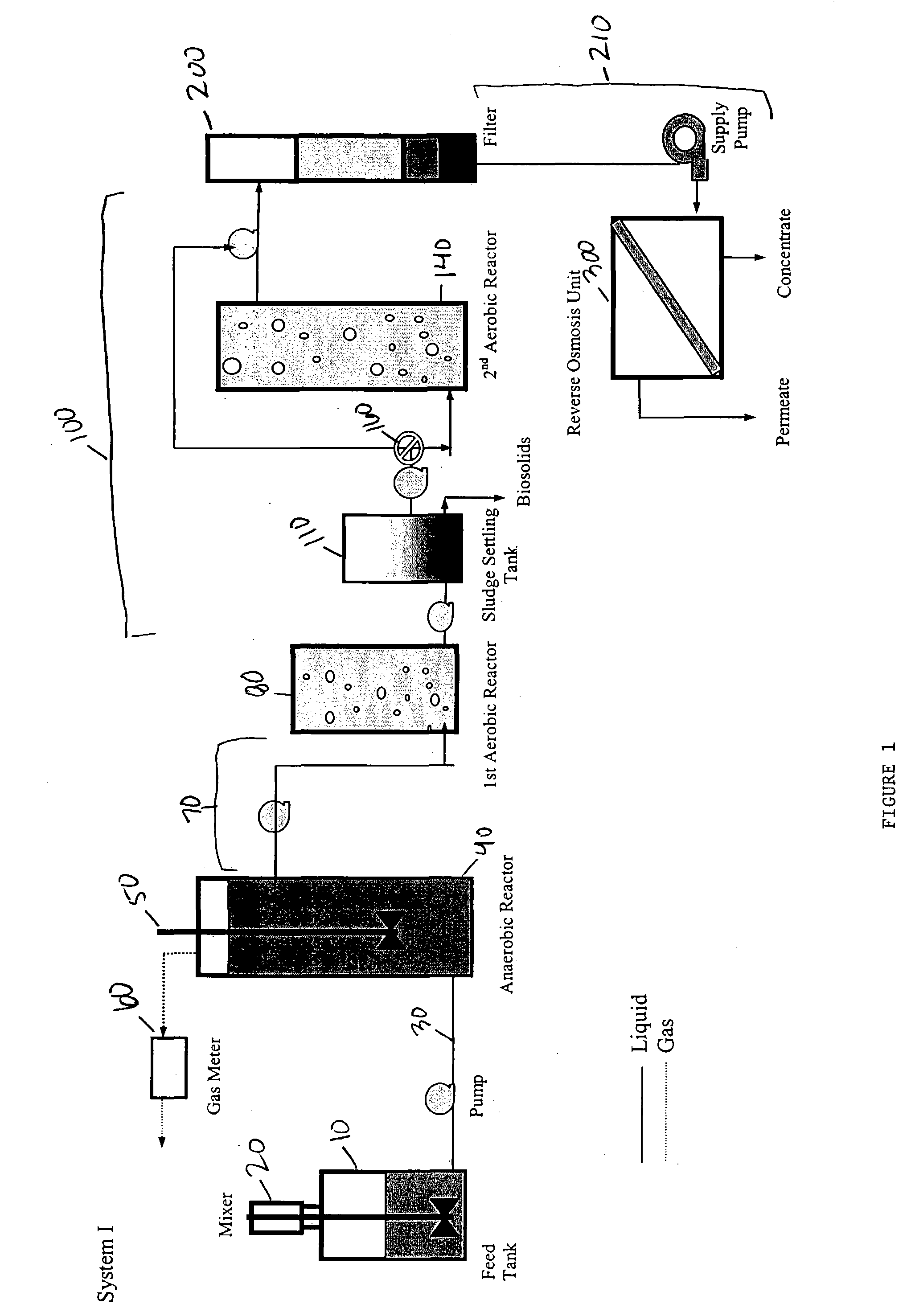

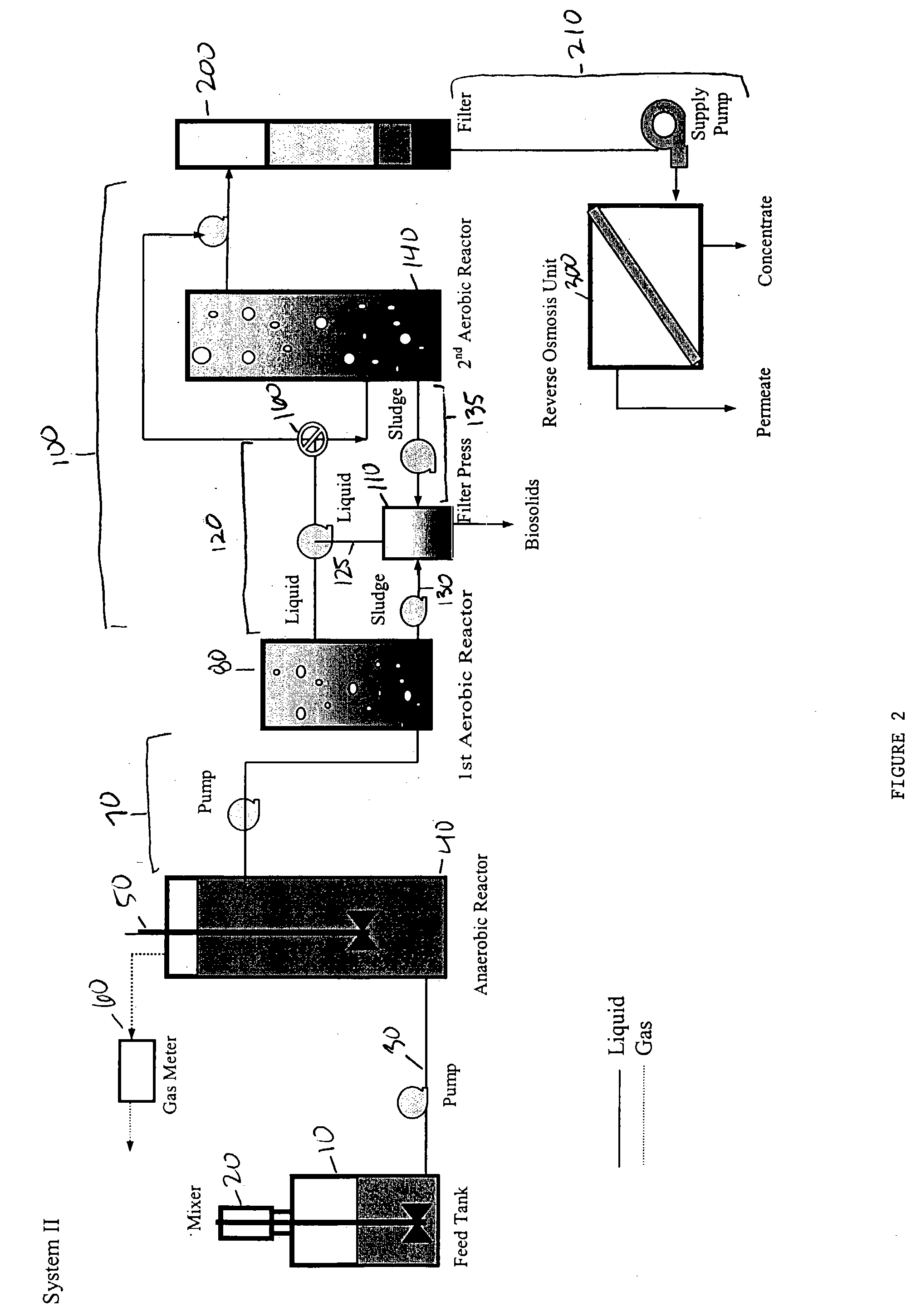

Treatment of swine wastewater by biological and membrane separation technologies

InactiveUS20050035059A1Bio-organic fraction processingWaste water treatment from animal husbandryFiltrationSeparation technology

The present invention provides an integrated system for treatment of biodegradable waste, including sewage sludge, forestry waste, food waste, agricultural waste, municipal waste, and the like. The integrated system comprises an anaerobic reactor, at least one aerobic reactor, a filtration device, and a desalinization device.

Owner:RGT UNIV OF CALIFORNIA

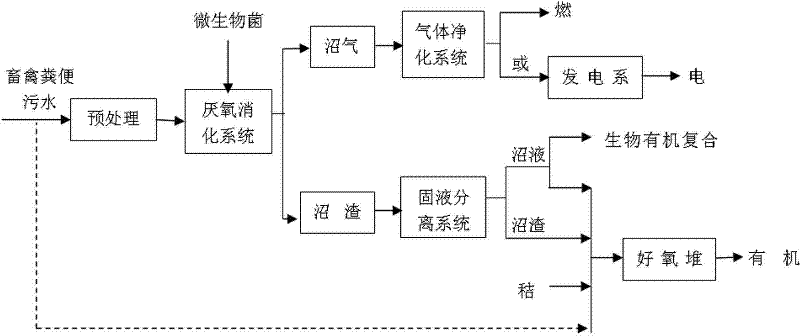

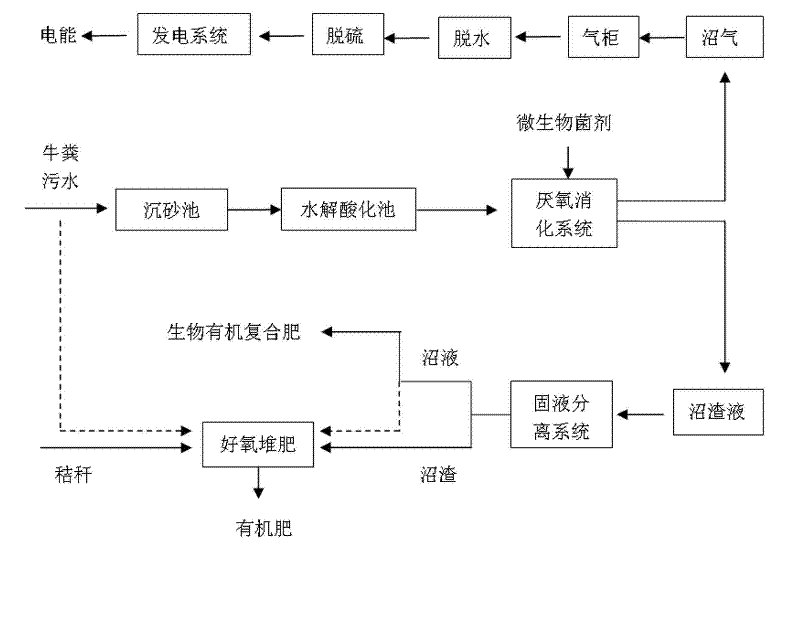

Method for comprehensively recycling fecal sewage of large-scale livestock and poultry farms and farmland crop straws

InactiveCN102173507AOvercome the problem of insufficient productionIncrease gas productionBio-organic fraction processingWaste based fuelFecesSlurry

The invention relates to a method for comprehensively recycling the fecal sewage of large-scale livestock and poultry farms and farmland crop straws, which comprises the following steps of: (1) performing anaerobic digestion, namely regulating the solid content of the fecal sewage of livestock and poultry to be between 5 and 10 percent, adding anaerobic digestion inocula, and performing the anaerobic digestion to generate methane; (2) performing energy utilization on the methane, namely purifying the methane obtained in the step (1) to be used as fuel gas or allowing the purified methane to be used for power generation to perform energy utilization; (3) performing solid-liquid separation, namely performing the solid-liquid separation on biogas residues and biogas slurry which are obtainedin the step (1) to obtain the biogas slurry and the biogas residues of which the moisture content is about 60 percent; (4) preparing a biological organic compound fertilizer from the biogas slurry, and mixing the biogas residues and part of biogas slurry with the straws and part of excrement to perform aerobic compost; and (5) mixing and performing the aerobic compost, namely mixing part of biogas slurry obtained in the step (3) and the crushed straws, regulating the moisture content of the mixture to be between 50 and 60 percent, and performing the aerobic compost. In the method, clean resources are recovered by the anaerobic digestion, and the biogas slurry is used for producing the biological organic compound fertilizer with a high additional value.

Owner:江苏加德绿色能源有限公司

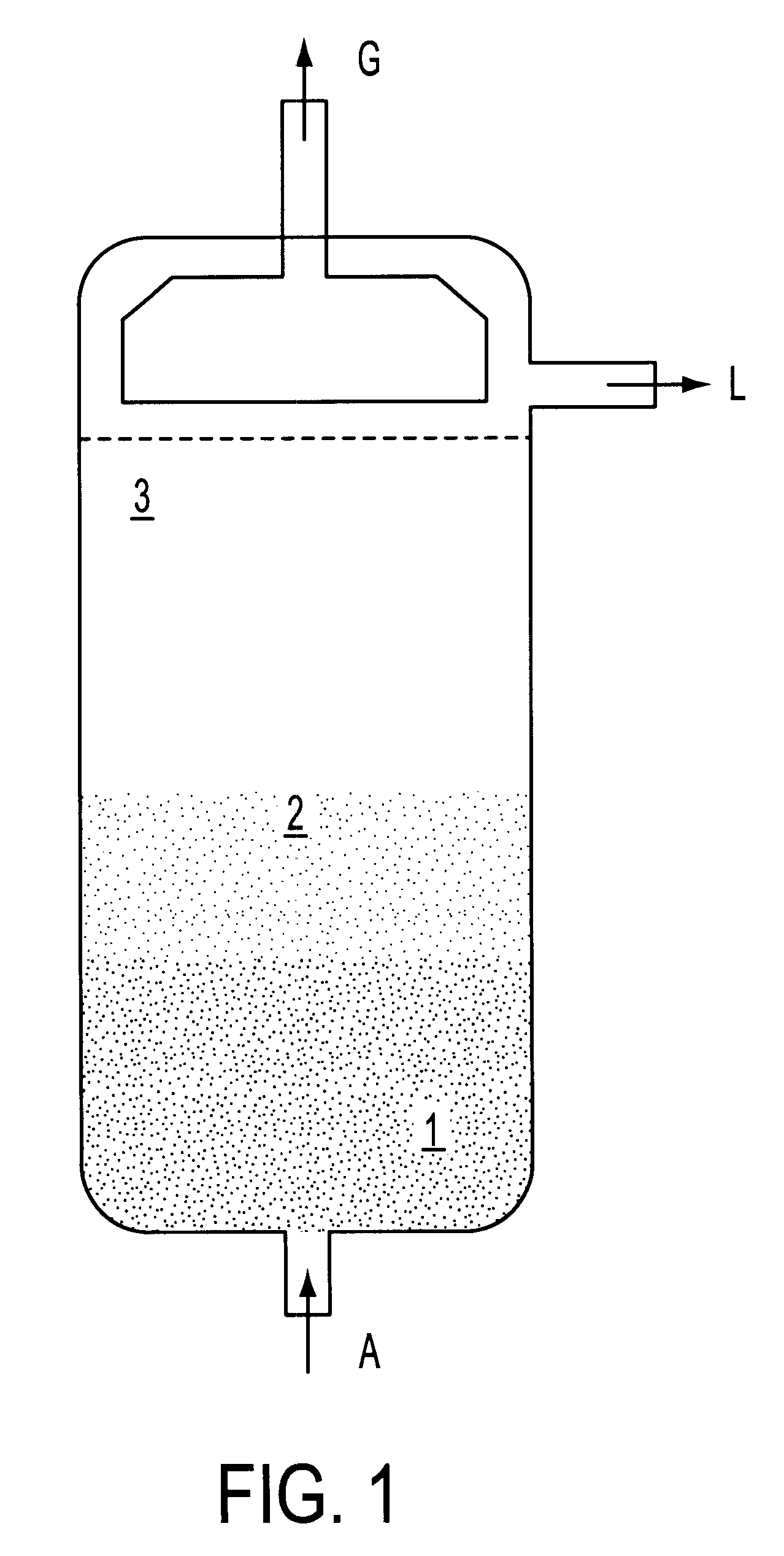

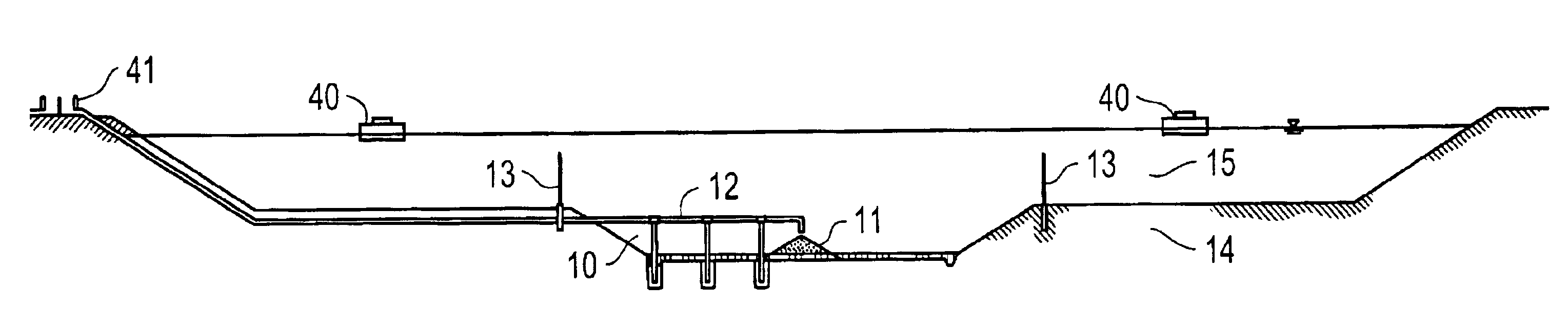

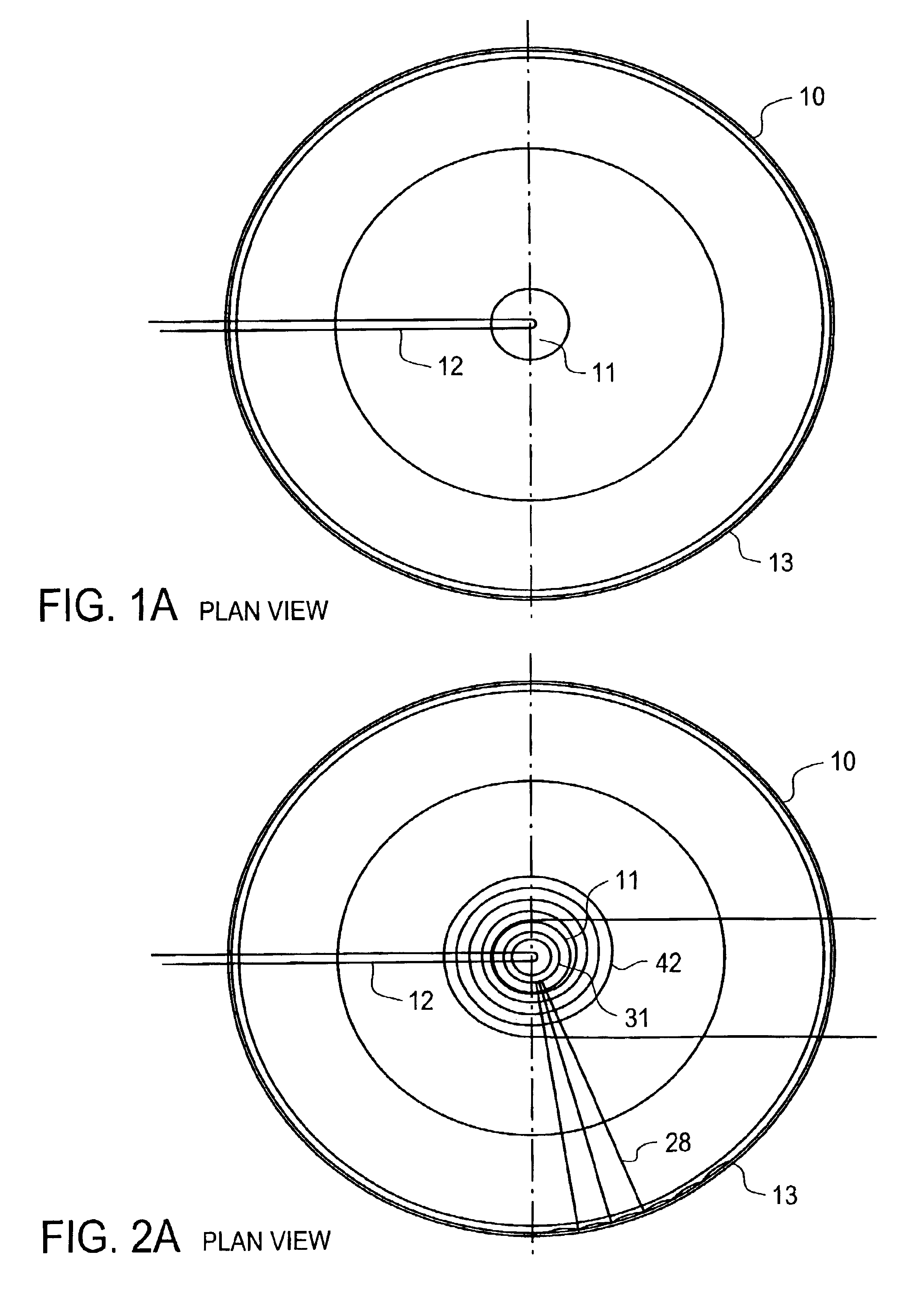

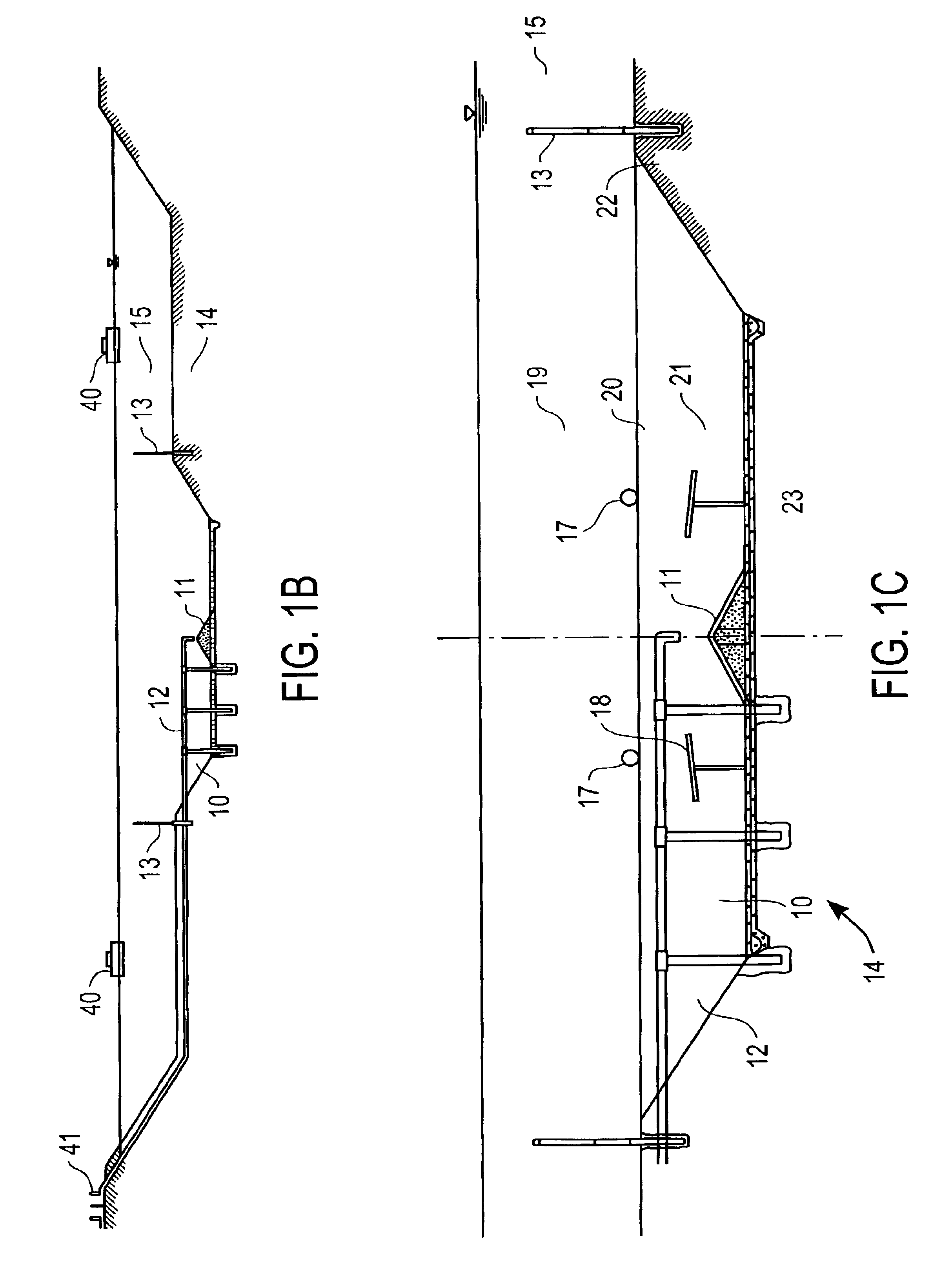

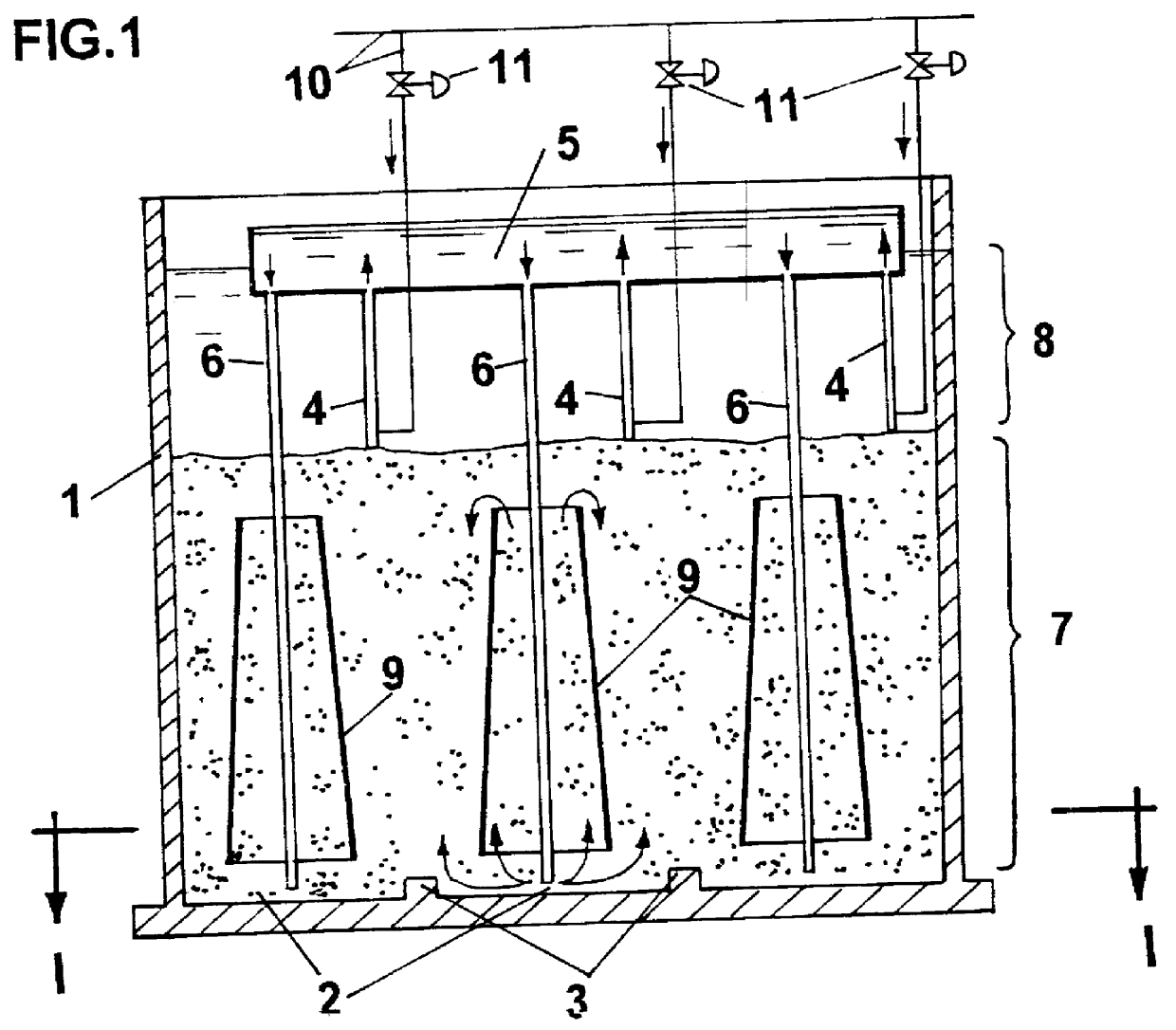

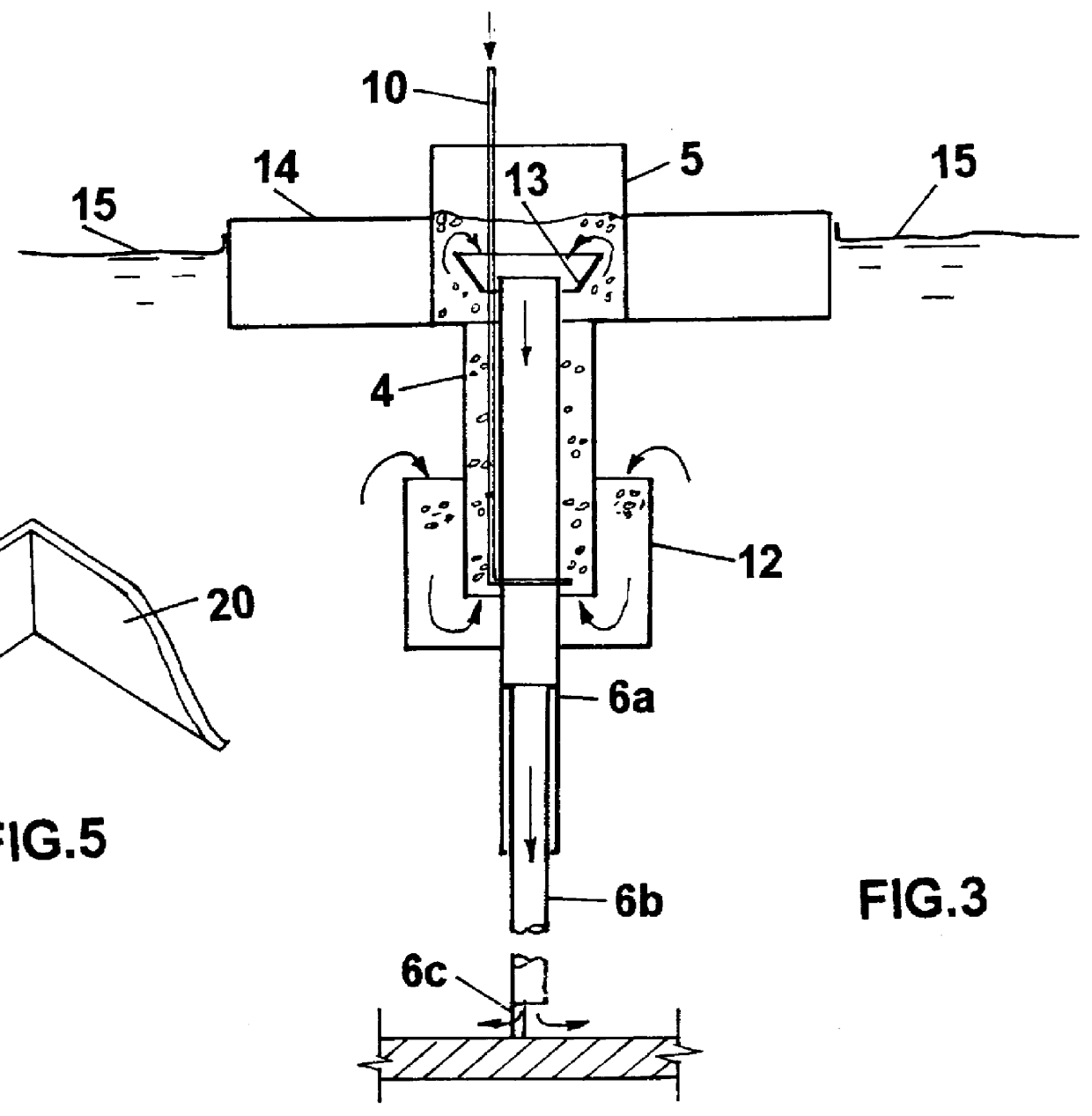

Apparatus to establish and optimize sedimentation and methane fermentation in primary wastewater ponds

InactiveUS6923906B2Raise the pHIncreases the rate of die-away of pathogenic bacteriaLiquid degasificationMixing methodsSludgeIncrease ph

Owner:GREEN FRANKLIN BAILEY +2

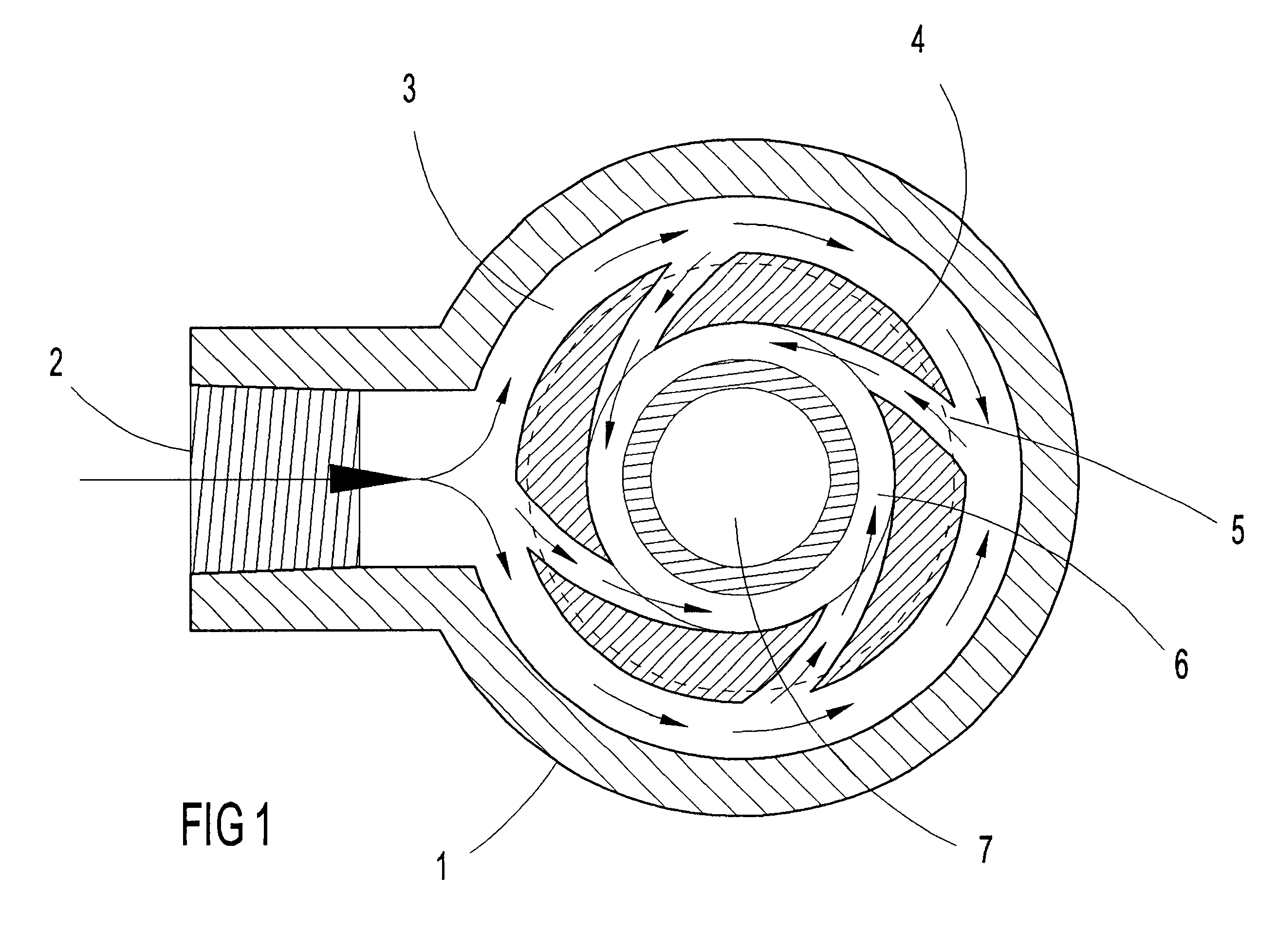

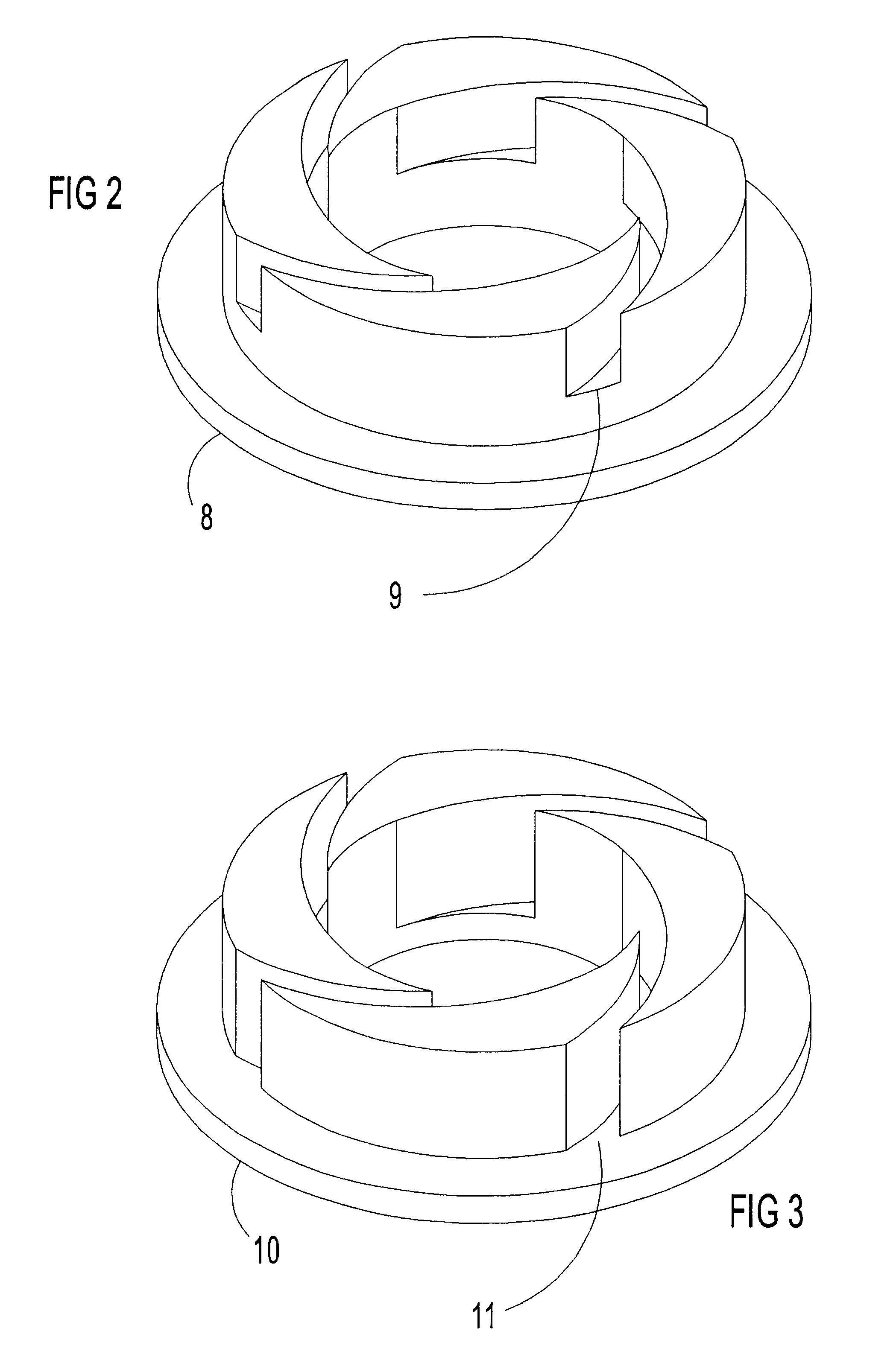

Apparatus for mixing fluids

InactiveUS6669843B2Eliminate needLiquid separation auxillary apparatusSpace heating and ventilationGas passingSolid particle

Owner:HYDROTREAT

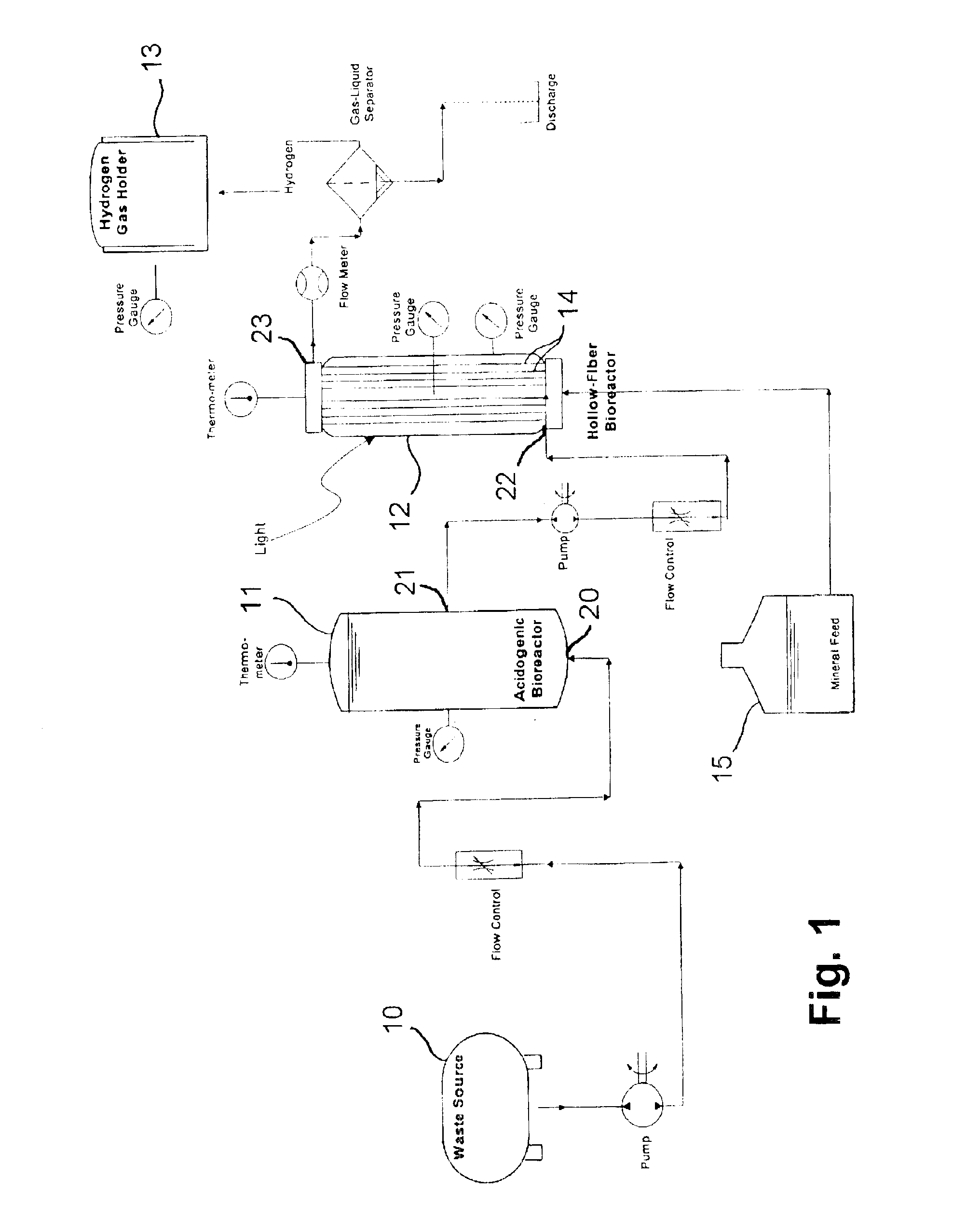

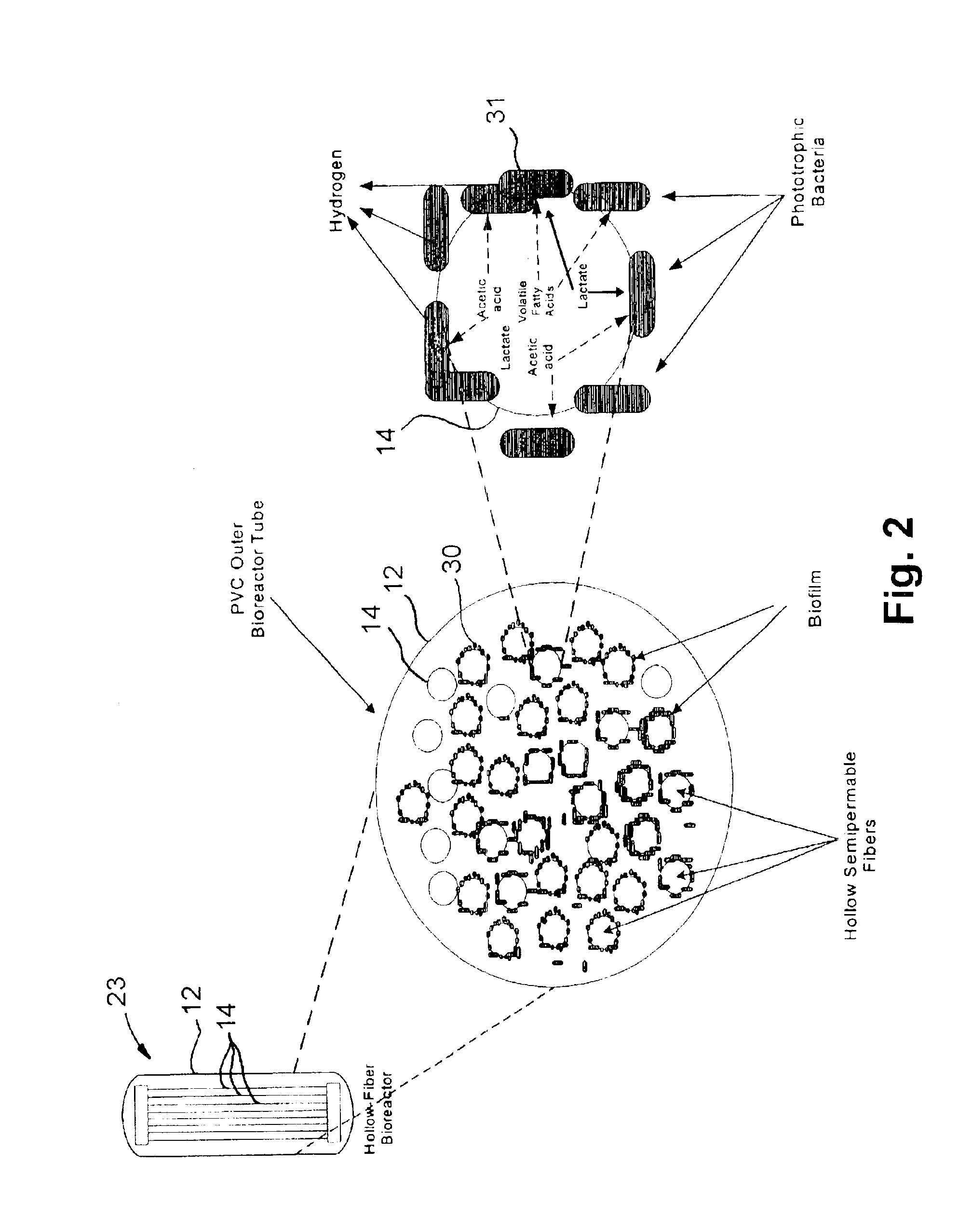

Method and apparatus for hydrogen production from organic wastes and manure

InactiveUS6887692B2Good characterBioreactor/fermenter combinationsBiological substance pretreatmentsFiberHollow fibre

Owner:GAS TECH INST

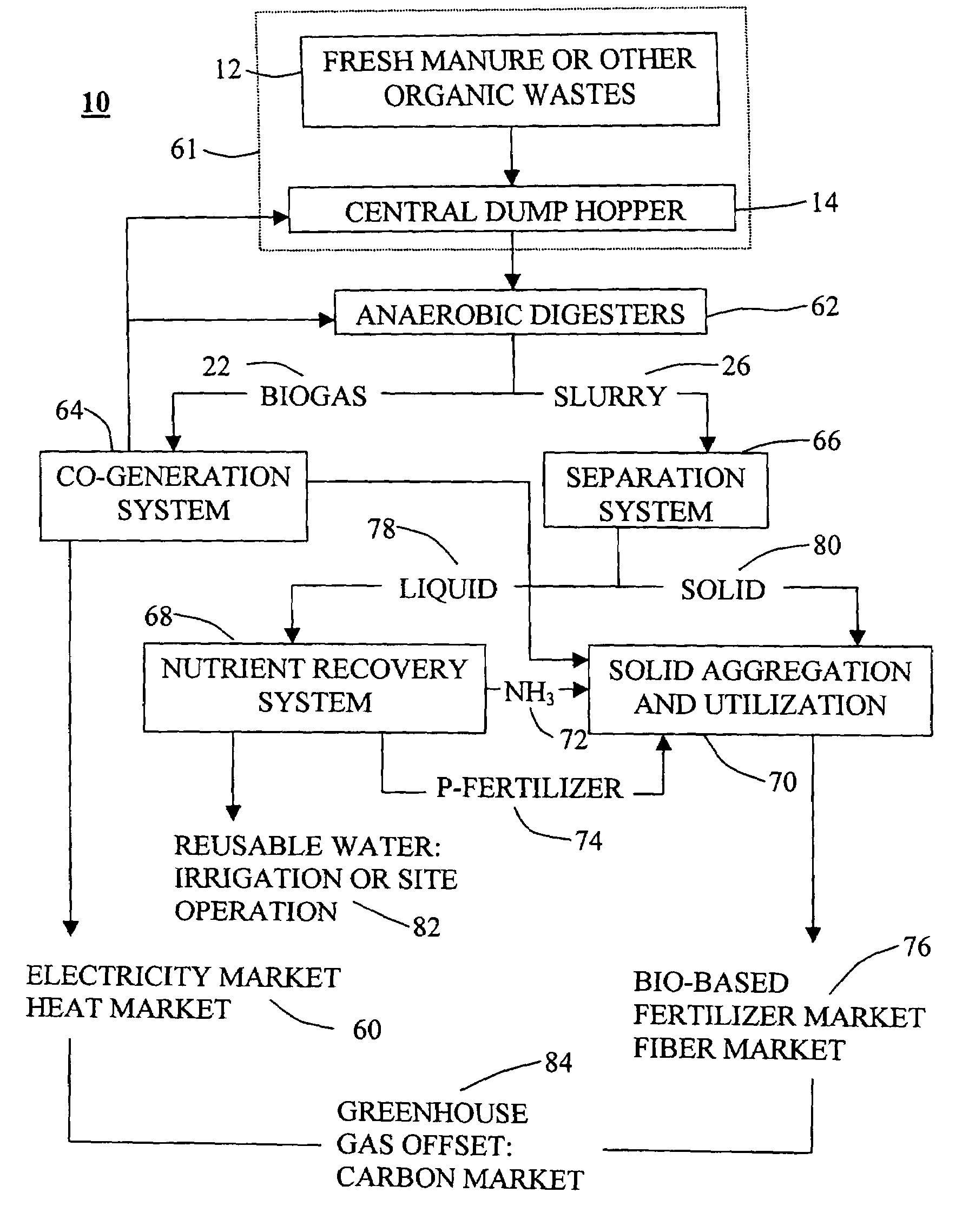

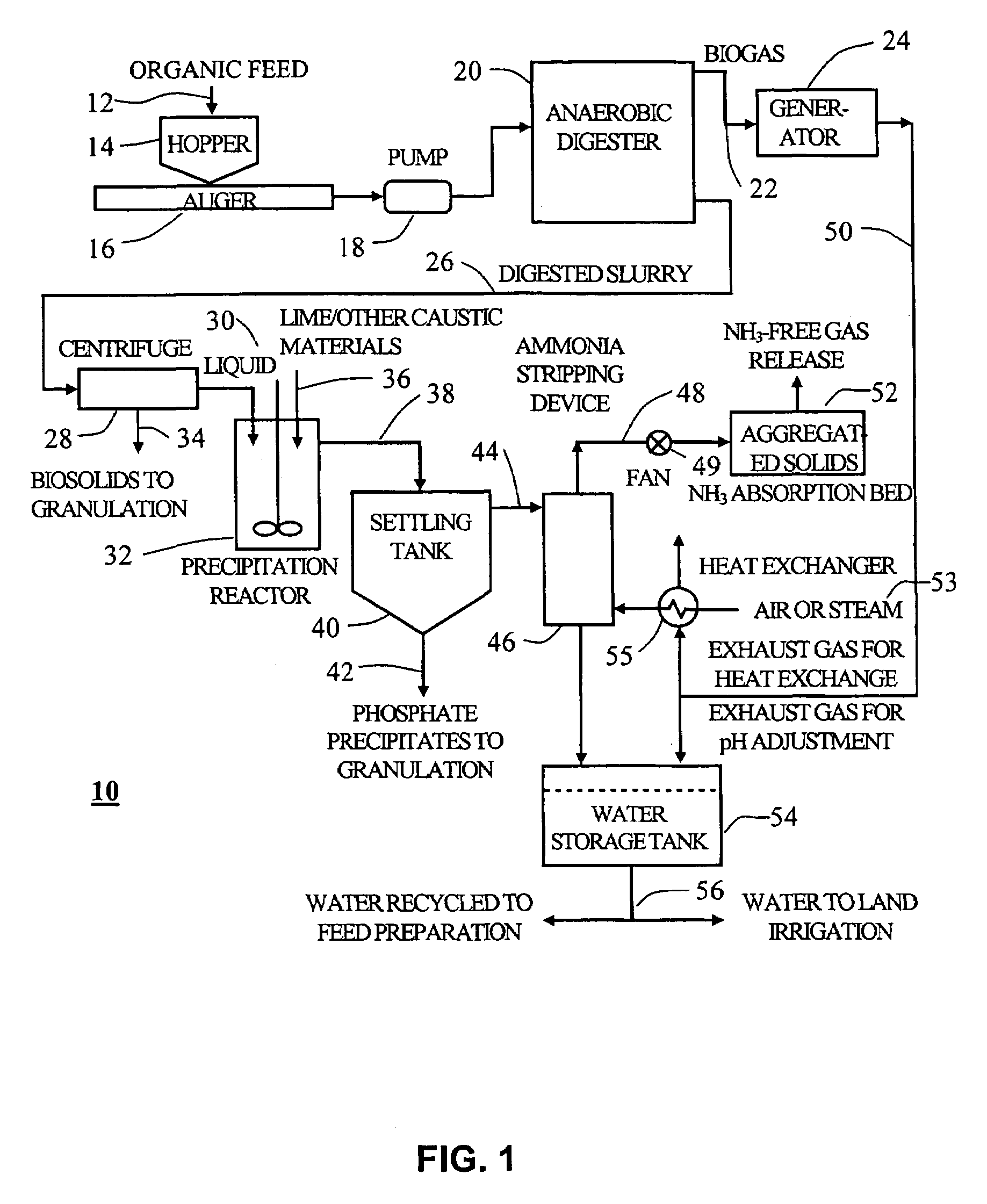

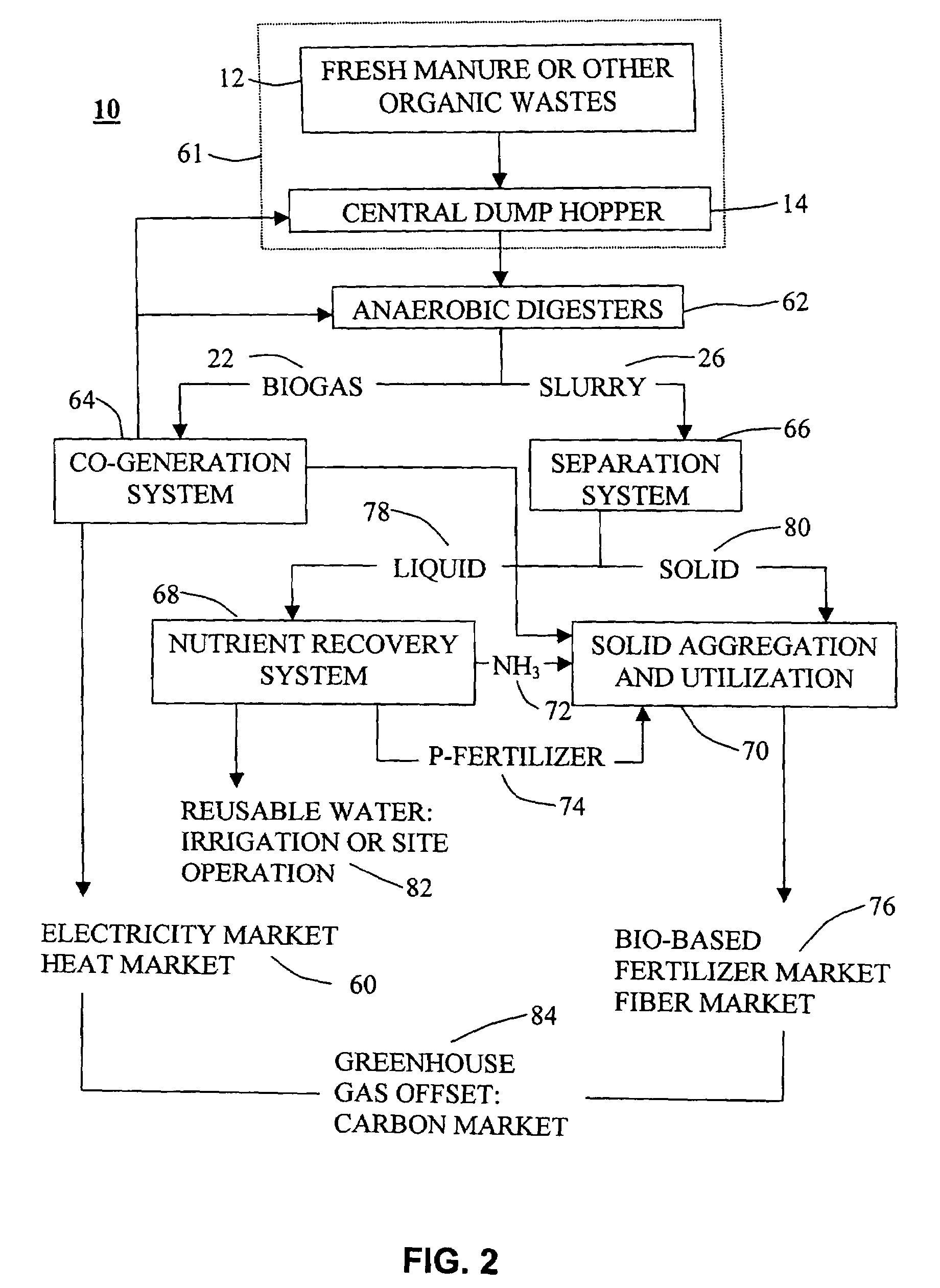

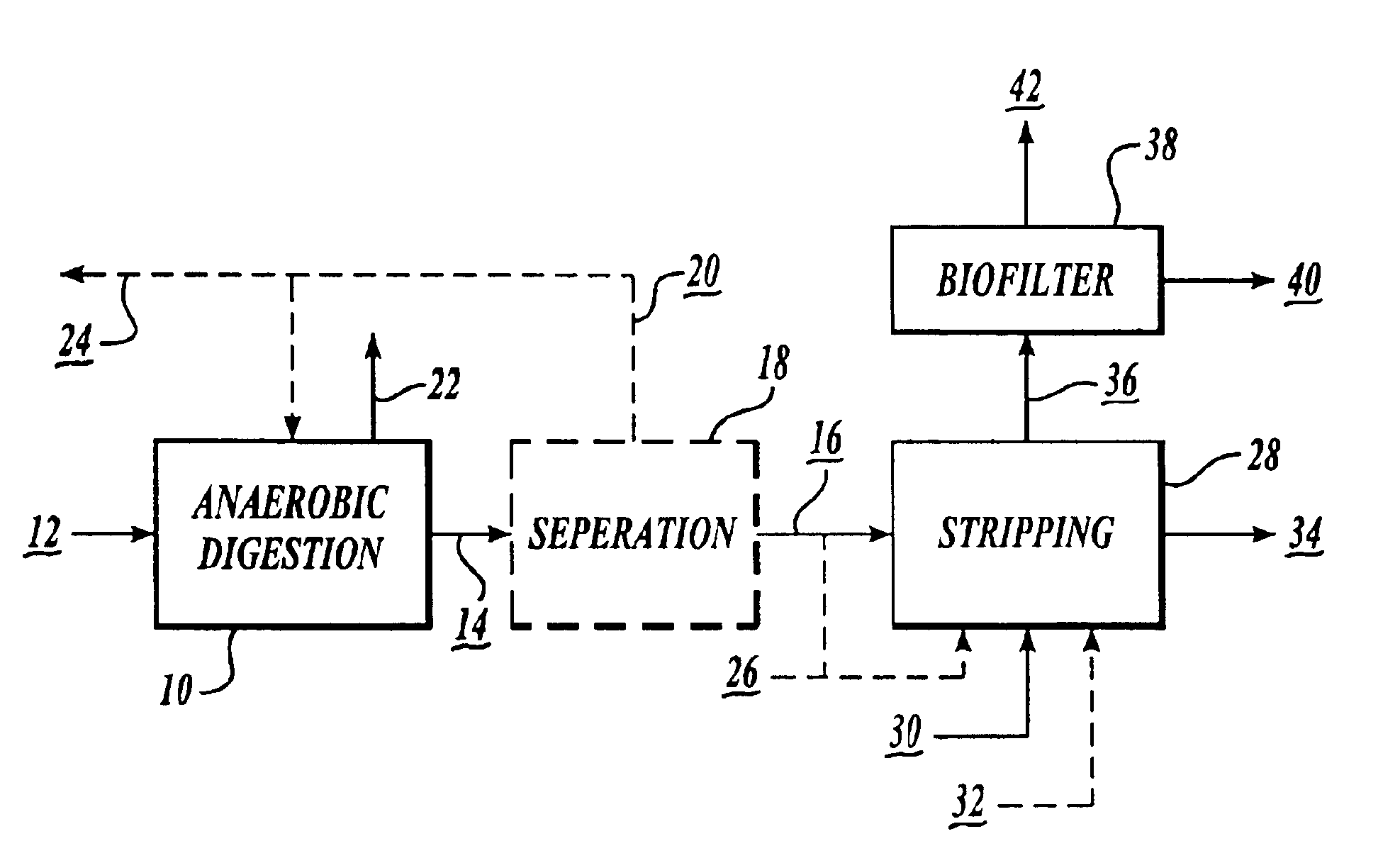

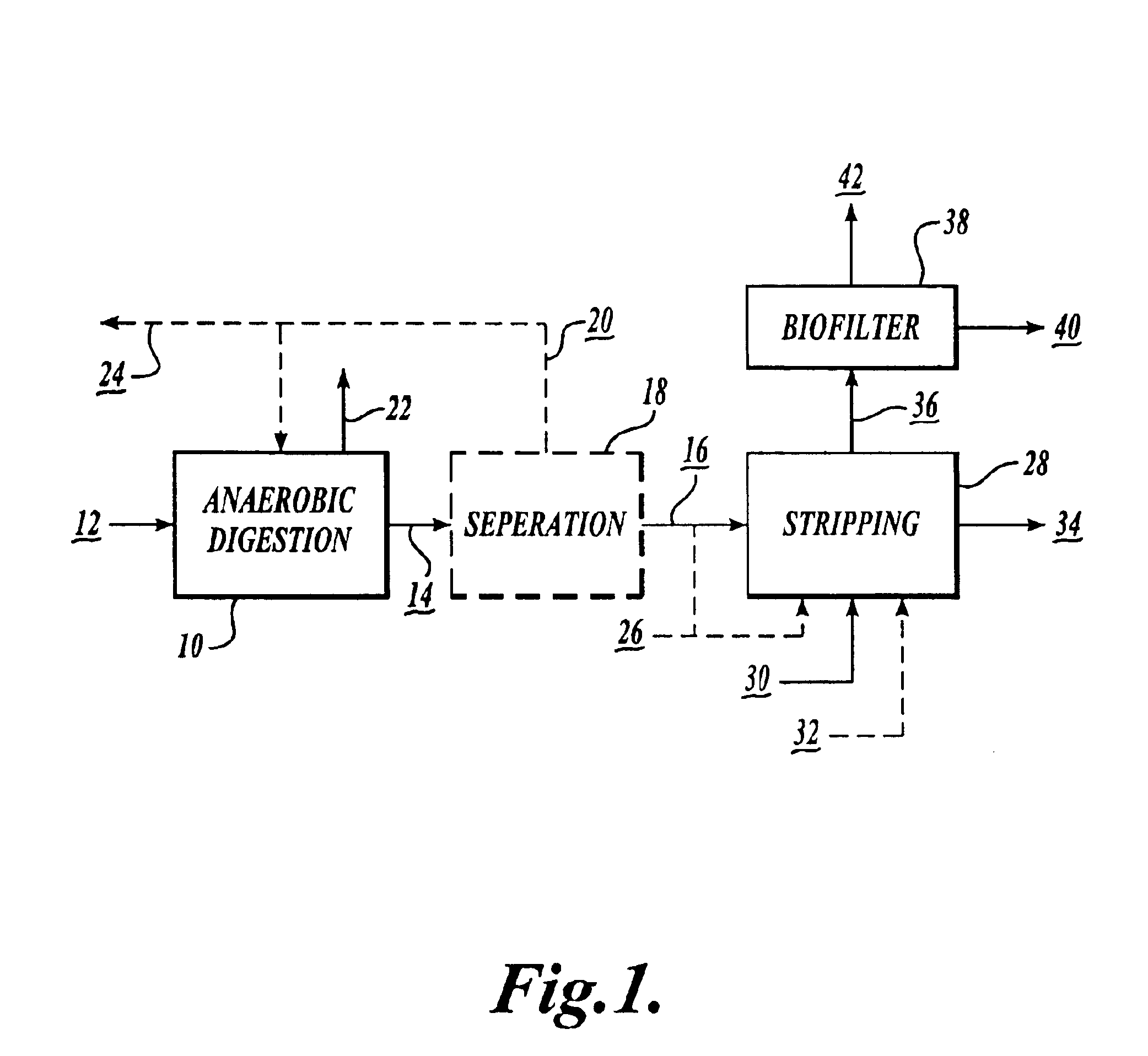

Process for removal and recovery of nutrients from digested manure or other organic wastes

InactiveUS7014768B2Eliminate the effects ofIncrease temperatureBioreactor/fermenter combinationsBio-organic fraction processingCogenerationNitrogen gas

A process for removal and recovery of nutrients and recycling of water from digested manure or other organic wastes. A first step involves separating waste from an anaerobic digester into digested liquids, digested solids, and biogas. A second step involves precipitating solids from the digested liquids. A third step involves stripping ammonia from the digested liquids. A fourth step involves injecting an exhaust stream of carbon dioxide drawn from the co-generator into the digested liquids to reduce the pH and raise the temperature of the digested liquid. A fifth step involves recycling the digested liquids back to the anaerobic digester for use in diluting in coming solid wastes. A sixth step involves passing the excess ammonia stripped from the digested liquid through the digested solids to recover nitrogen through aborption with the resultant digested solids being usable as a biofertilizer with a high nitrogen content. A seventh step involves capturing the biogas for use in a co-generation system.

Owner:HIGHMARK RENEWABLES RES PARTNERSHIP

Ecological greenbelt treatment process and system for treating rural domestic sewage

ActiveCN101948214AEasy to handleLess investmentTreatment using aerobic processesWaste based fuelConstructed wetlandReclaimed water

The invention relates to an ecological greenbelt treatment process for treating rural domestic sewage, which mainly comprises the steps of: (1) anaerobic pretreatment: performing anaerobic hydrolysis pretreatment to domestic sewage; (2) artificial wetland treatment: performing artificial wetland treatment to pretreated domestic sewage; and (3) shallow ecological pond aerobic biotreatment: further performing shallow ecological pond aerobic biotreatment to outlet water treated by the artificial wetland, degrading and converting organic matters and nutrients entering the pond, and recycling purified sewage as a regenerated water resource. The invention adopts an ecological greenbelt treatment system comprising the anaerobic pretreatment, the artificial wetland and the shallow ecological pond to treat the rural domestic sewage, and has the characteristics of good treatment effect, recycling on site, low investment, low system operating cost, simple maintenance, obvious ecological benefit and the like.

Owner:浙江博世华环保科技有限公司

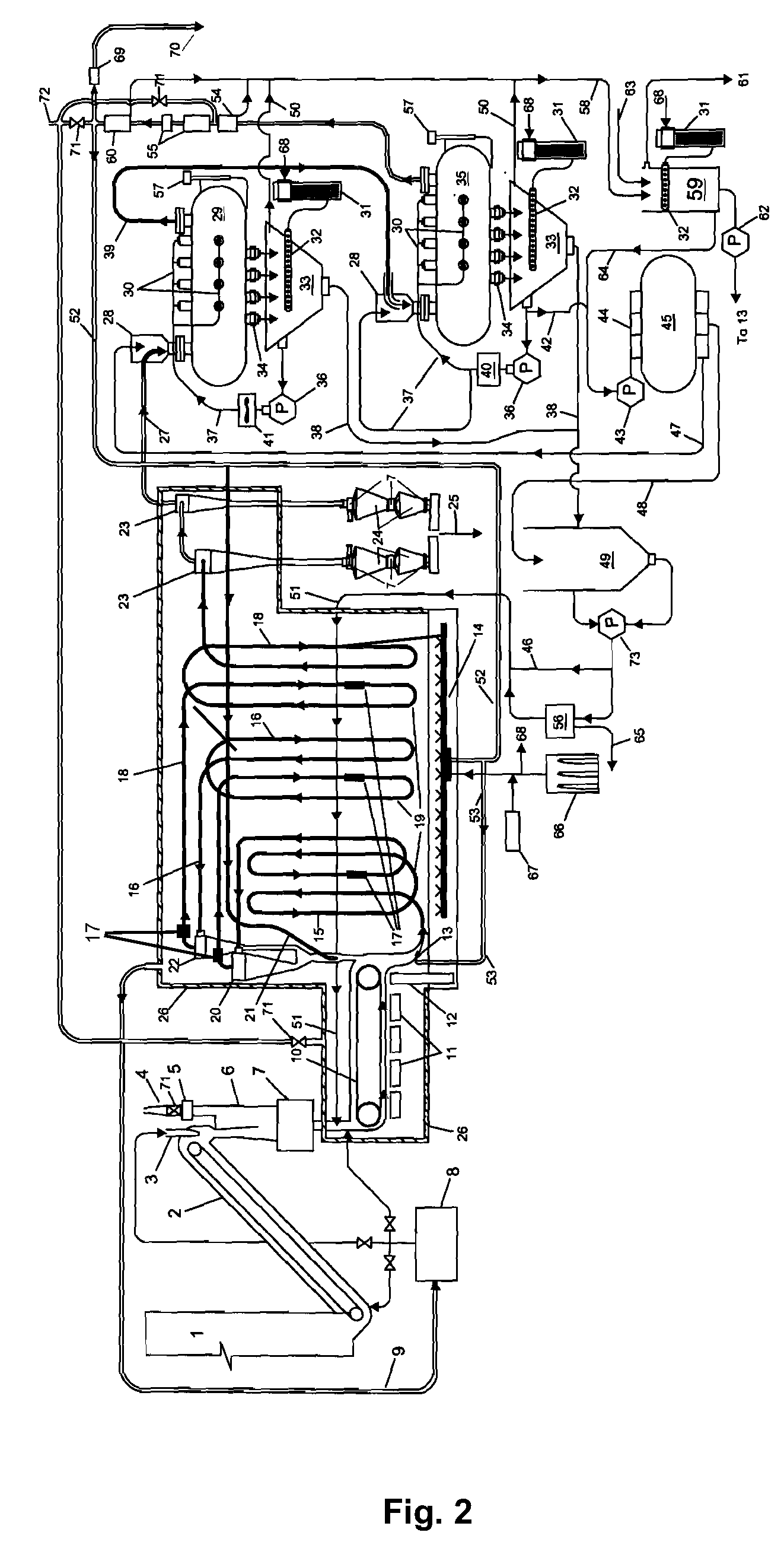

Methods and Apparatus for Solid Carbonaceous Materials Synthesis Gas Generation

Methods and apparatus may permit the generation of consistent output synthesis gas from highly variable input feedstock solids carbonaceous materials. A stoichiometric objectivistic chemic environment may be established to stoichiometrically control carbon content in a solid carbonaceous materials gasifier system. Processing of carbonaceous materials may include dominative pyrolytic decomposition and multiple coil carbonaceous reformation. Dynamically adjustable process determinative parameters may be utilized to refine processing, including process utilization of negatively electrostatically enhanced water species, process utilization of flue gas (9), and adjustment of process flow rate characteristics. Recycling may be employed for internal reuse of process materials, including recycled negatively electrostatically enhanced water species, recycled flue gas (9), and recycled contaminants. Synthesis gas generation may involve predetermining a desired synthesis gas for output and creating high yields of such a predetermined desired synthesis gas.

Owner:THERMOTEK

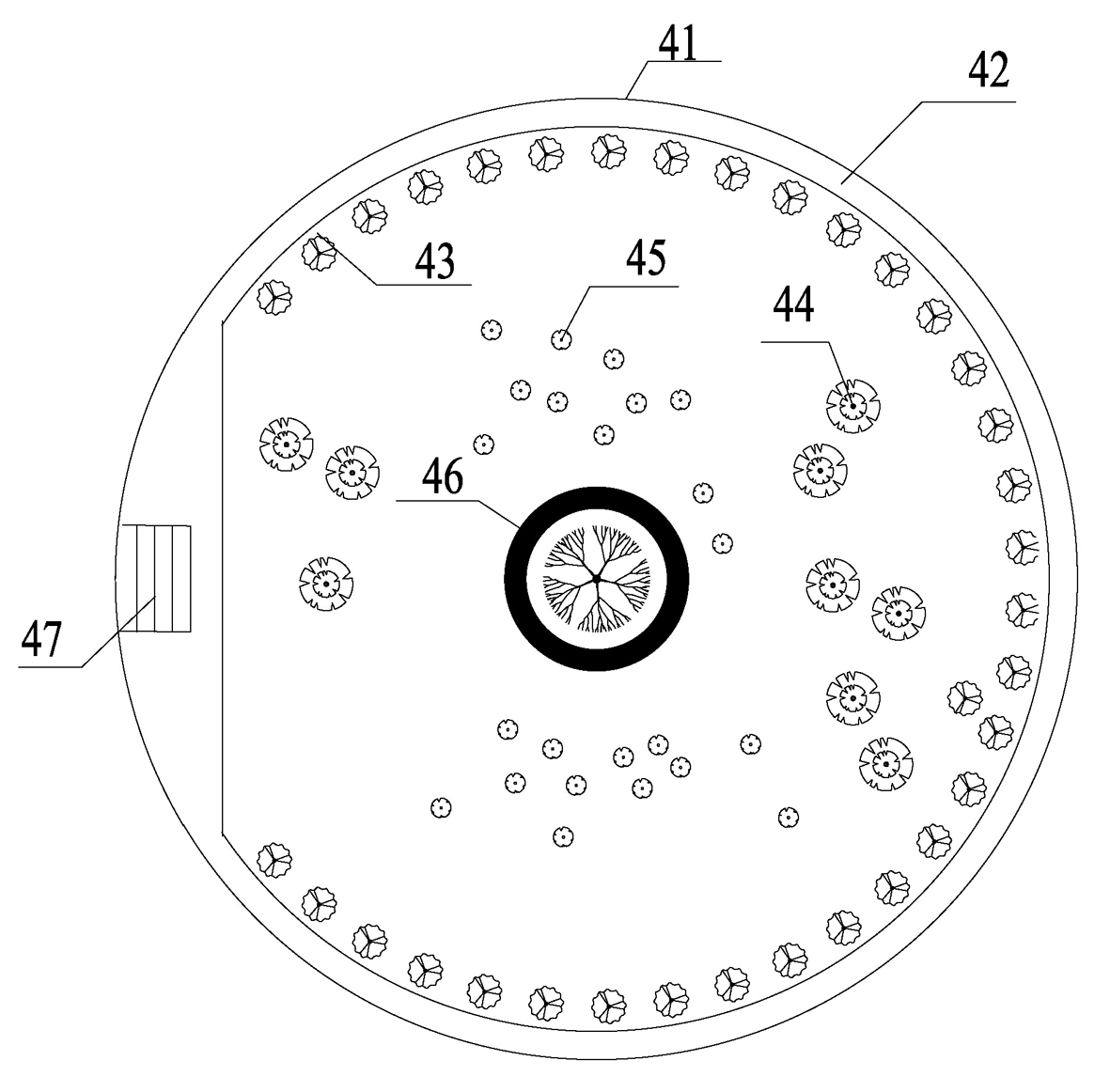

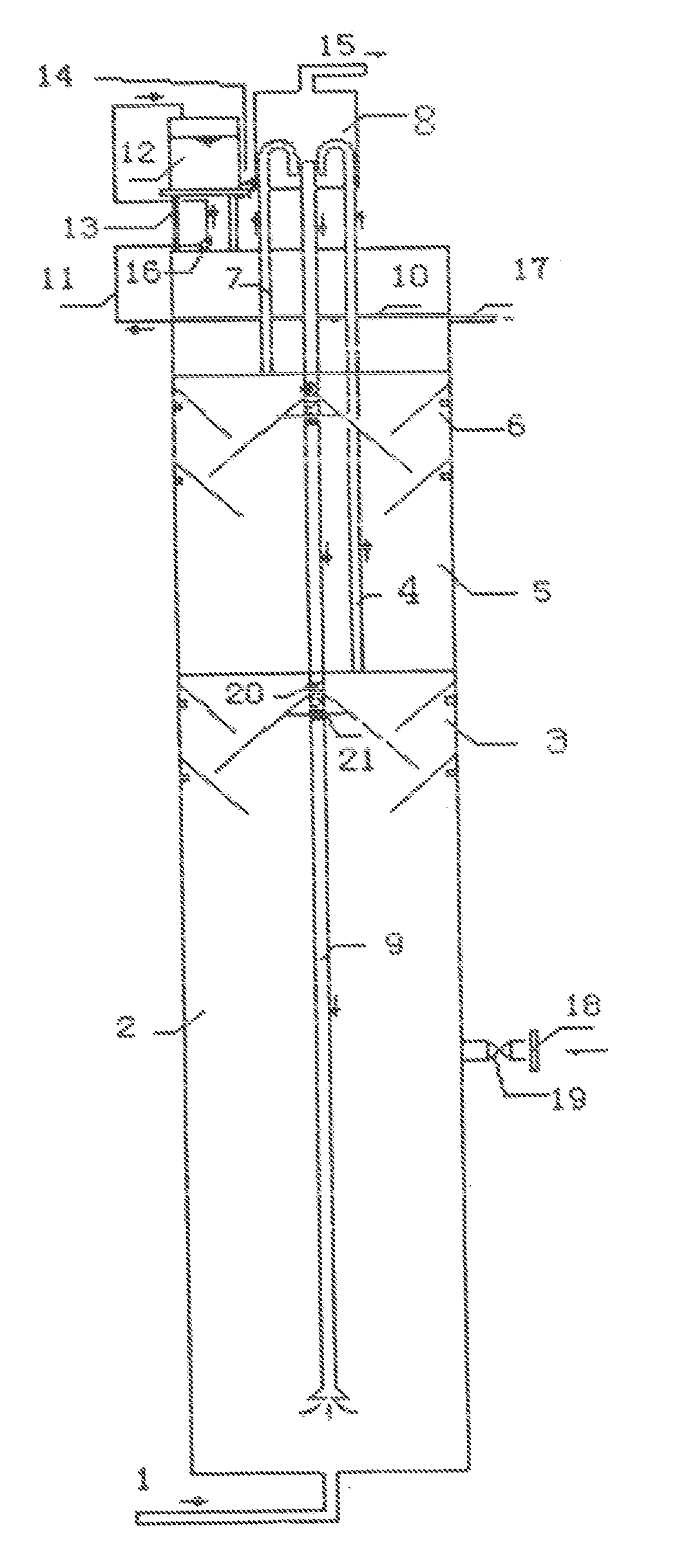

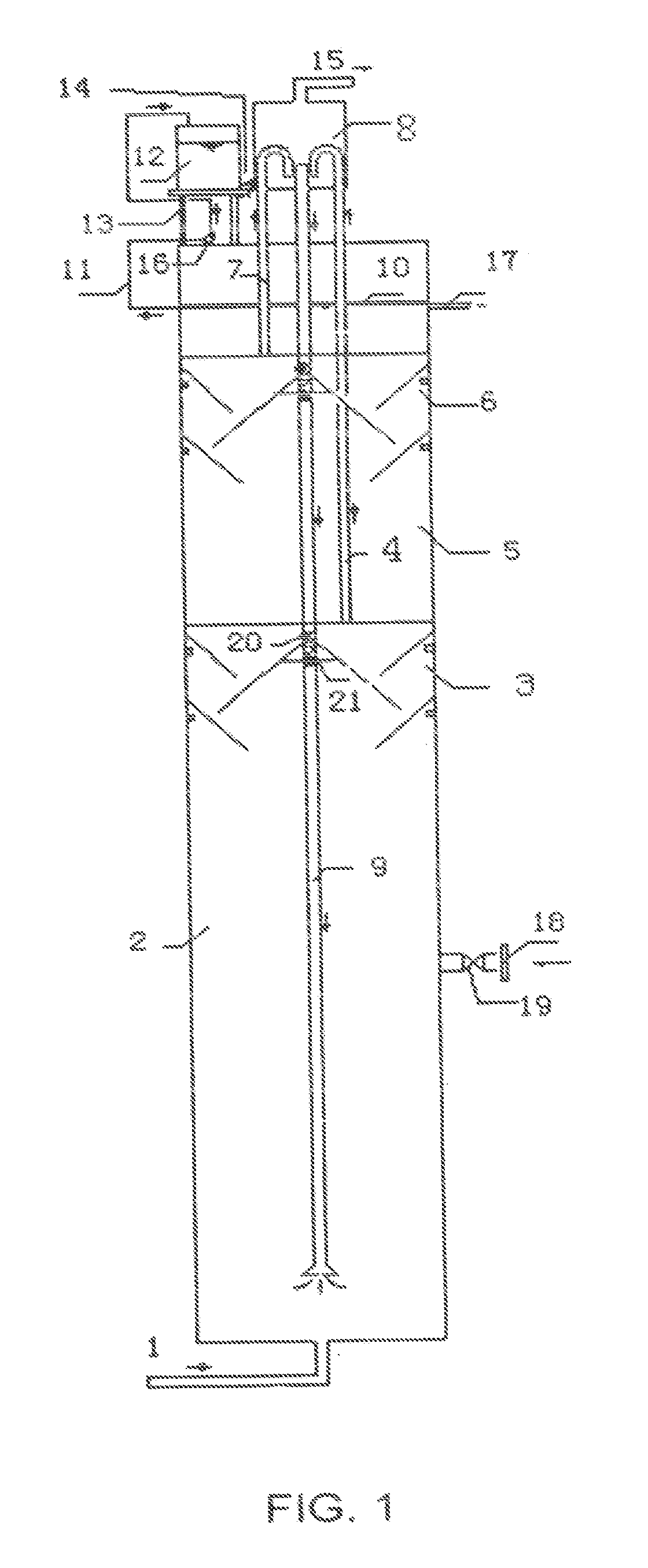

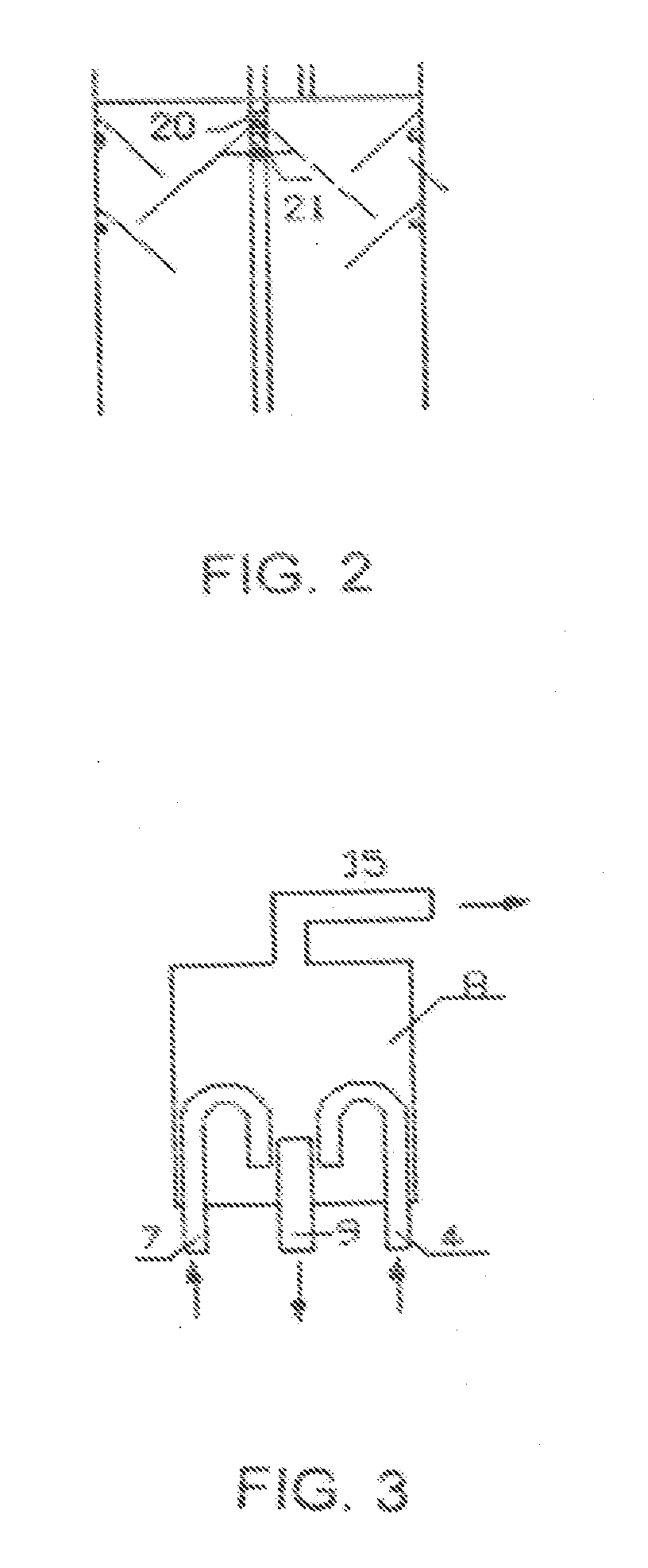

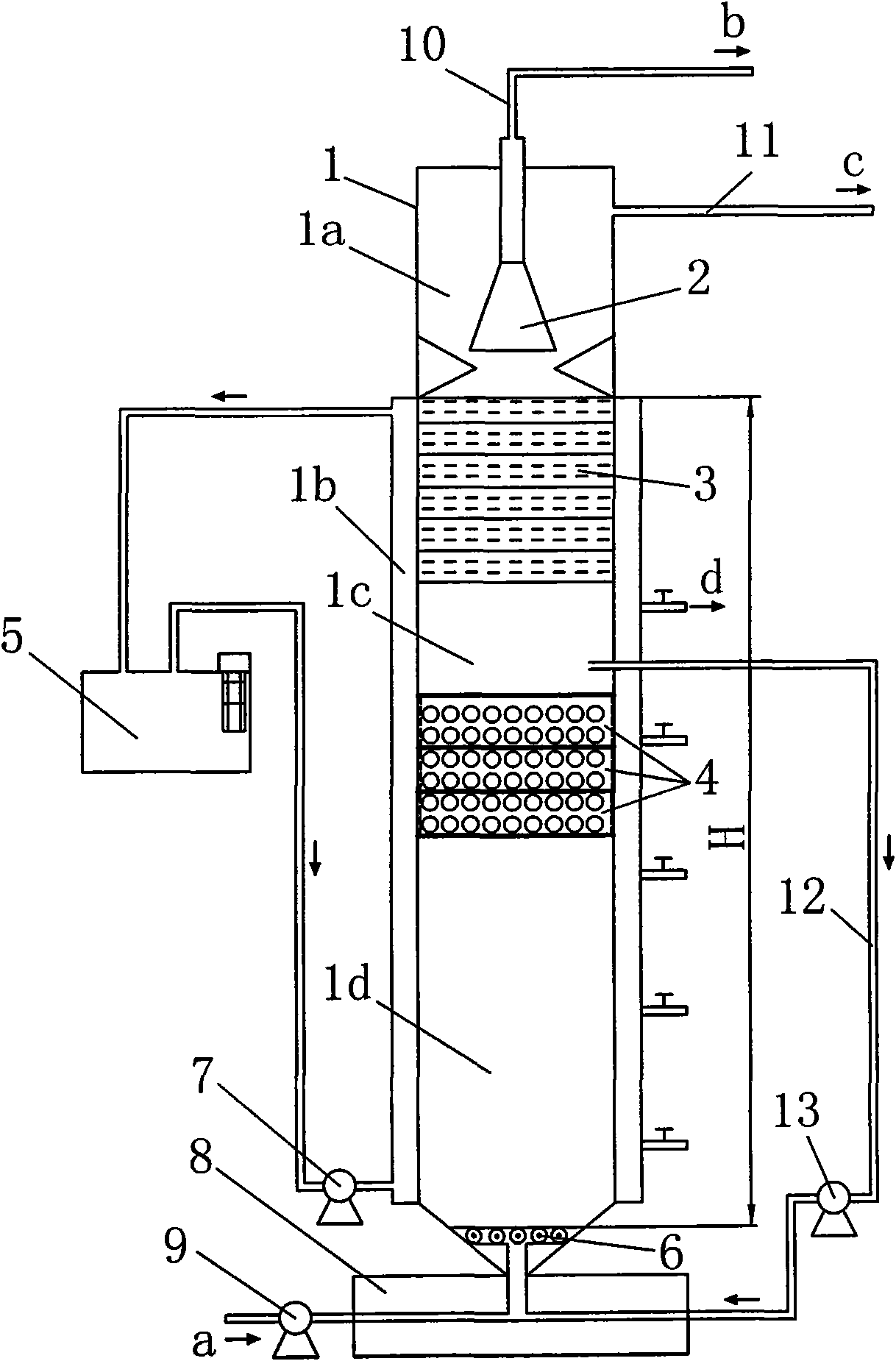

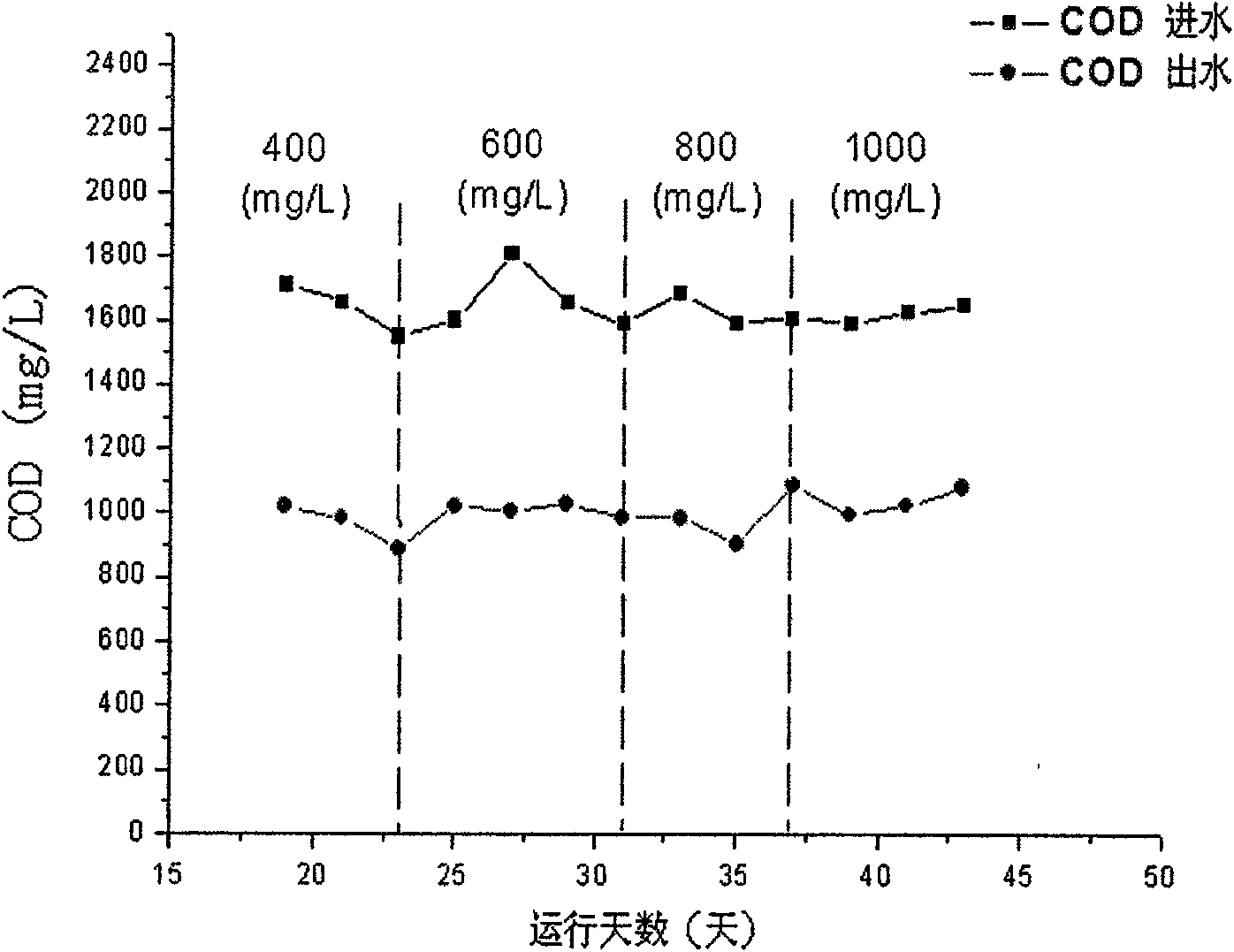

Up-flow Multi-stage Anaerobic Reactor (UMAR)

ActiveUS20080277328A1Improved and modified structureImproved and modified and processLiquid degasificationWaste based fuelHigh concentrationLow load

The present invention discloses an Up-flow Multi-stage Anaerobic Reactor (UMAR) used for treatment of medium / high concentration organic wastewater. The stated UMAR with forced internal circulation, improved phase separator and added sludge inlet overcomes the disadvantages of a lower load, a longer hydraulic retention time and a larger dimension in traditional anaerobic reactors. The forced internal circulation increases capacity and cycles of internal circulation thus increased efficiency of contaminant removal. The fast jetting is avoided and efficiency of gas / liquid separation is increased by an improved bending outlet of up flow pipe. The simplified sludge addition and usage are obtained by a sludge inlet. The load of UMAR in this invention can reach about 30 kgCOD / (m3d) for treatment of medium / high concentration of organic wastewater from pulp and paper process and similar wastewater, being about four times of load and capacity of traditional Up-flow Anaerobic Sludge Bed (UASB) reactors.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

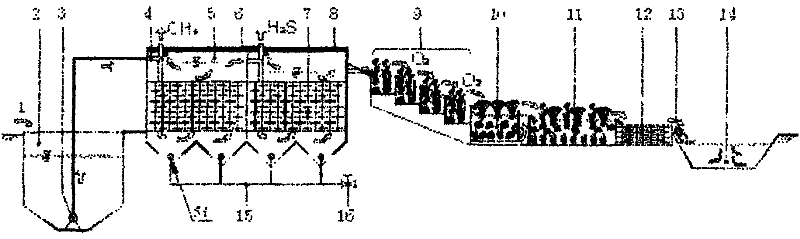

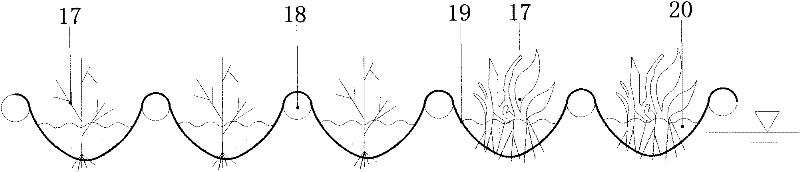

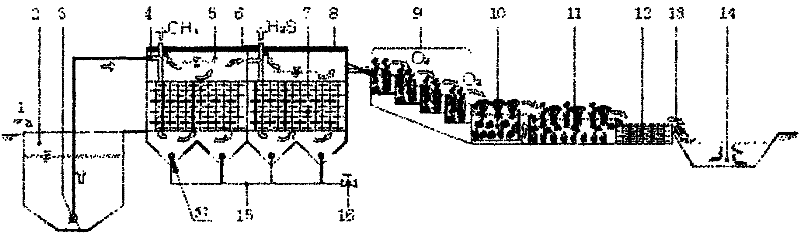

Novel technology for treating domestic sewage in rural area

ActiveCN102219332AIncrease economic benefitsLess investmentWaste based fuelTreatment with anaerobic digestion processesRural areaNitrogen

The invention discloses a system and method for treating domestic sewage in a rural area, which belongs to the technical field of environment-friendly sewage treatment. The domestic sewage enters an aerated grit chamber also serving as an adjusting tank for carrying out appropriate grit setting and adjusting, so that a part of inorganic pollutants is removed; the sewage is conveyed to a concentration type two-stage anaerobic reaction tank through a lifting water pump, suspended matters in the sewage are filtered and intercepted when the sewage passes through a concentration filter layer; contaminated gases, such as CH4, H2S and the like generated in the concentration type two-stage anaerobic reaction tank are discharged through a gas port; a part of concentration liquid is discharged out of the system through a concentration bottom sediment drainage pipe by opening a valve regularly; supernatant fluid from a water outlet of the concentration type two-stage anaerobic reaction tank enters a ladder plunge type wetland, a non-medium wetland, an economic income type wetland, a bacteria filter and a fishpond in turn; and nitrogen and phosphorus eutrophic pollutants in water are filtered, intercepted, adsorbed, decomposed, absorbed and precipitated by rootstocks of aquatic plants and the like. Therefore, according to the novel technology disclosed by the invention, the purpose of water purification can be achieved through regular harvest.

Owner:上海欧保环境科技有限公司

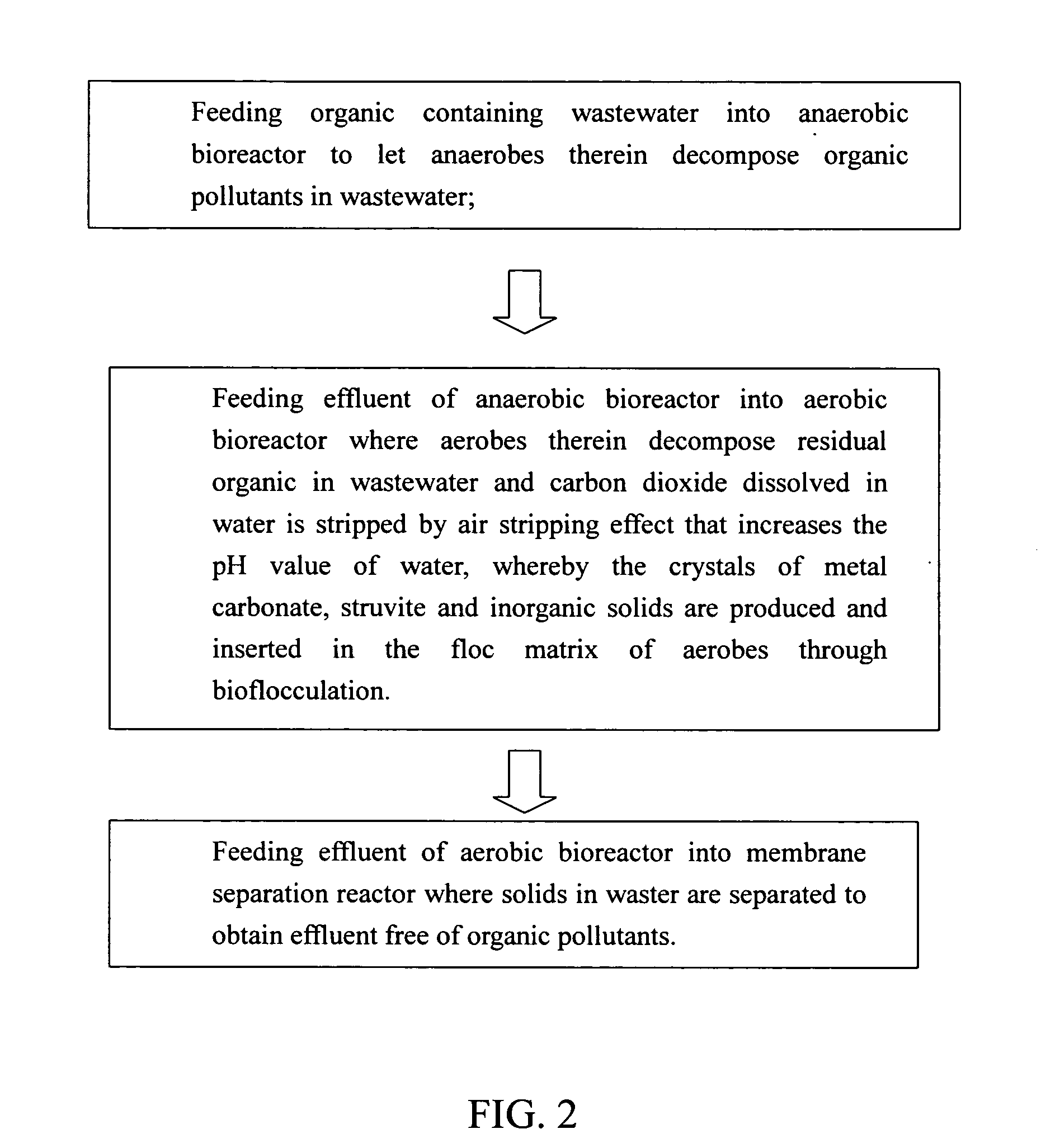

Method and system for treating wastewater containing organic compounds

ActiveUS20050109694A1Reduce inhibitionImprove abilitiesLiquid degasificationTreatment using aerobic processesSimple Organic CompoundsWater treatment system

A system for treating wastewater containing organic compounds is provided, comprising an anaerobic bioreactor, an aerobic bioreactor disposed rearwardly of the anaerobic bioreactor, and a membrane separation reactor disposed rearwardly of the aerobic bioreactor. The system is capable of removing organic pollutants in wastewater through biological treatment process and separating solid from the liquid ones by using a membrane. By employing the system for treating wastewater containing organic pollutants, organic pollutants can be effectively eliminated and the problem of scaling and fouling on the surface of the membrane prevented, thus achieving the objectives of lowering cost and improving efficiency.

Owner:IND TECH RES INST

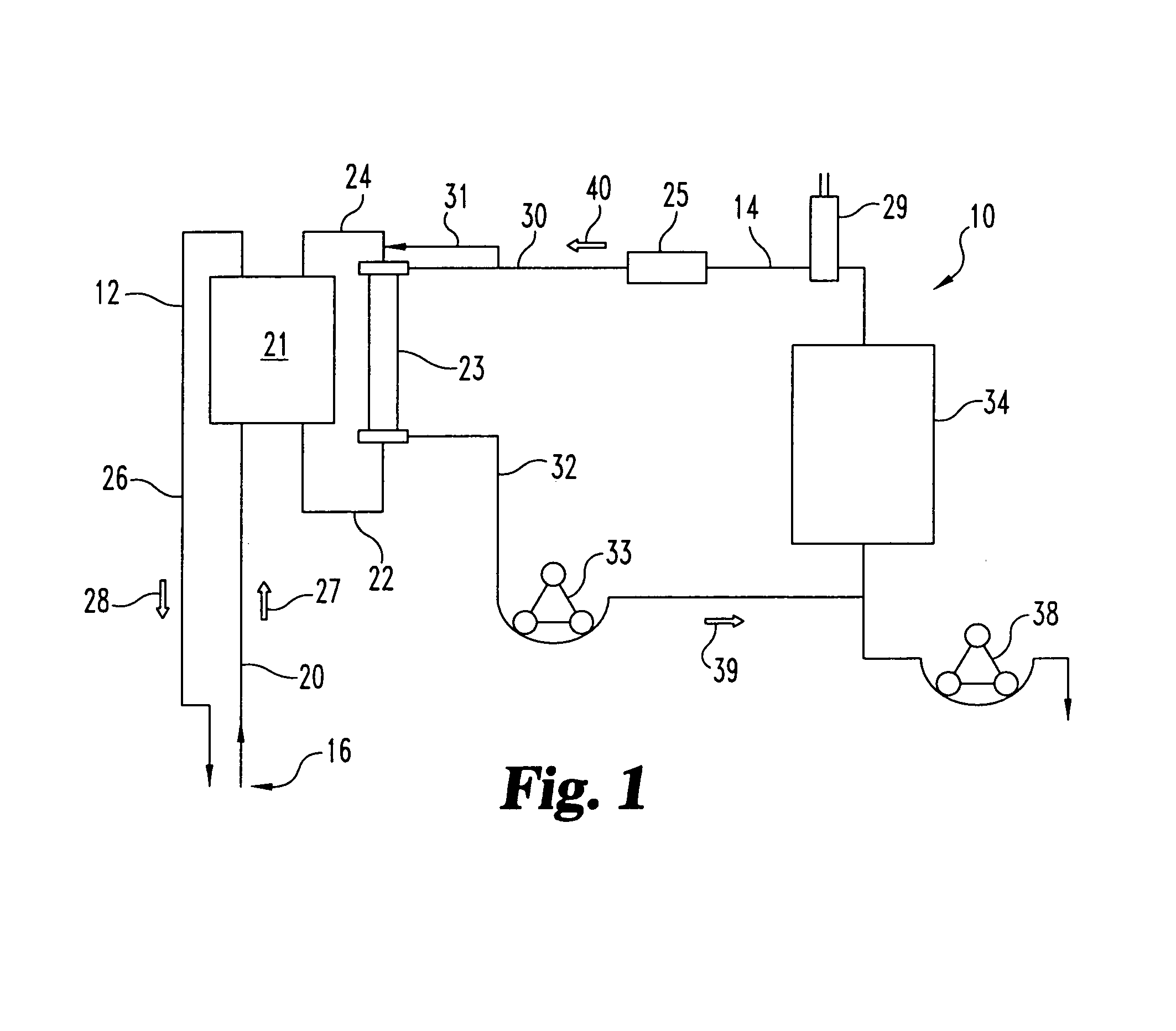

Nitrogen recovery system and method

InactiveUS6866779B1Less greenhouse gasGood health benefitsBio-organic fraction processingCyanogen compoundsLiquid wasteNitrate

A process for the recovery of nitrogen from anaerobically digested liquid waste and for the collection of the nitrogen as nitrate compounds that can be used to produce fertilizer and compost, includes stripping ammonia from anaerobically digested liquid waste, and converting the ammonia into nitrates via nitrification.

Owner:ENVIRONMENTAL ENERGY & ENG

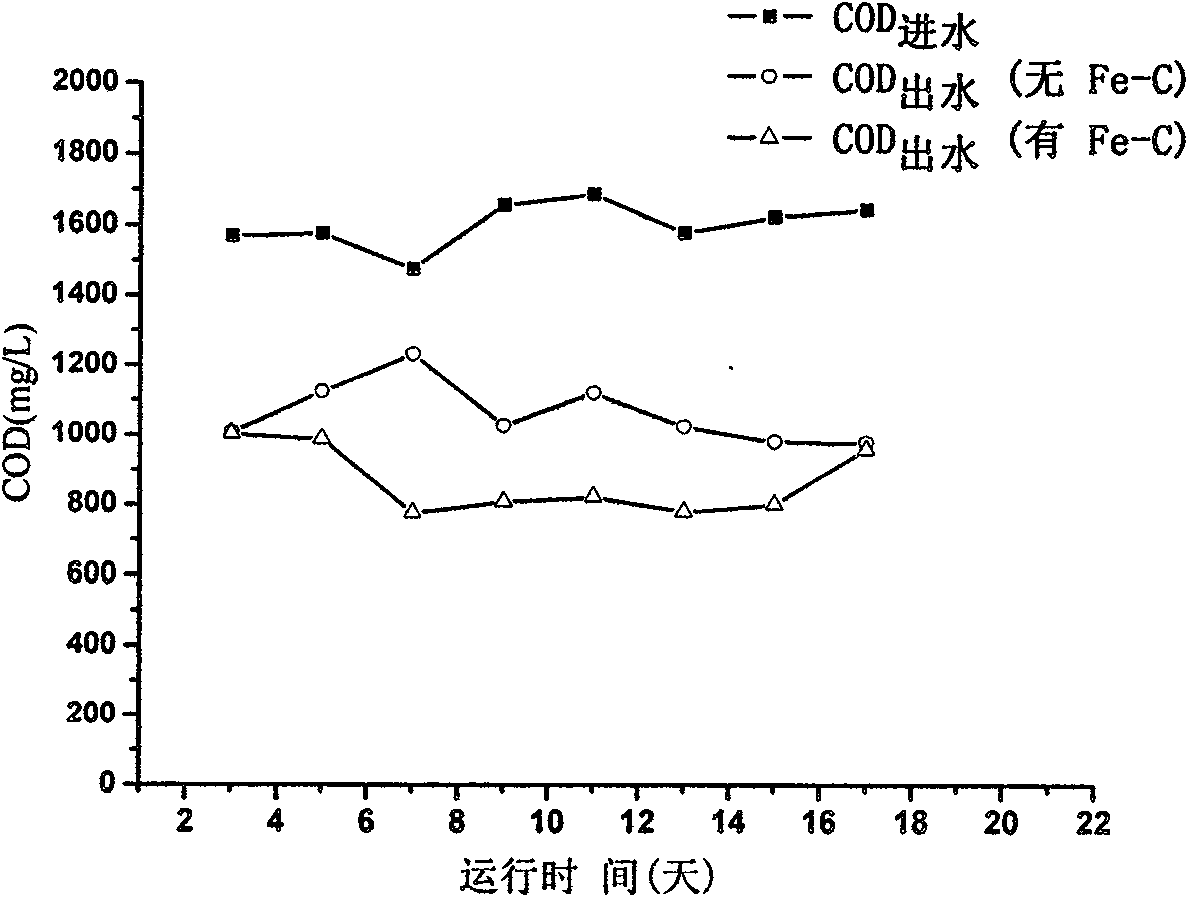

Anaerobic zero-valent iron sewage treatment method

ActiveCN101624250AImprove responseAvoid formingWaste based fuelTreatment with anaerobic digestion processesAnaerobic reactorDyeing wastewater

The invention relates to an anaerobic zero-valent iron sewage treatment method, belonging to the sewage treatment technical field. The anaerobic zero-valent iron sewage treatment places zero-valent iron in an anaerobic reactor and utilizes the environmental conditions of the anaerobic isolated air to largely reduce the formation rate of the rust of zero-valent iron and avoid the formation of hardening; meanwhile, the method uses the reducing action of metal iron to increase the anaerobic reductive atmosphere, balance the pH and increase the effect of the anaerobic organism. A circulating pump is adopted for sewage backflow so as to increase the overflow load of an iron / activated carbon layer and the reaction effect of zero-valent iron, improve the fluidization effect of sludge to increase the anaerobic process efficiency. In a sewage treatment system, ferrous iron contained in the discharged sewage is oxidized to Fe(OH)3 with the air and the coagulation generated in the process can further purify the sewage. Long-term experiment research shows that the decolorizing rate of the sewage treatment method for dye wastewater can teach 85%-95%, the COD can be reduced by more than 50% and the biodegradability can be increased to more than 0.3.

Owner:DALIAN UNIV OF TECH

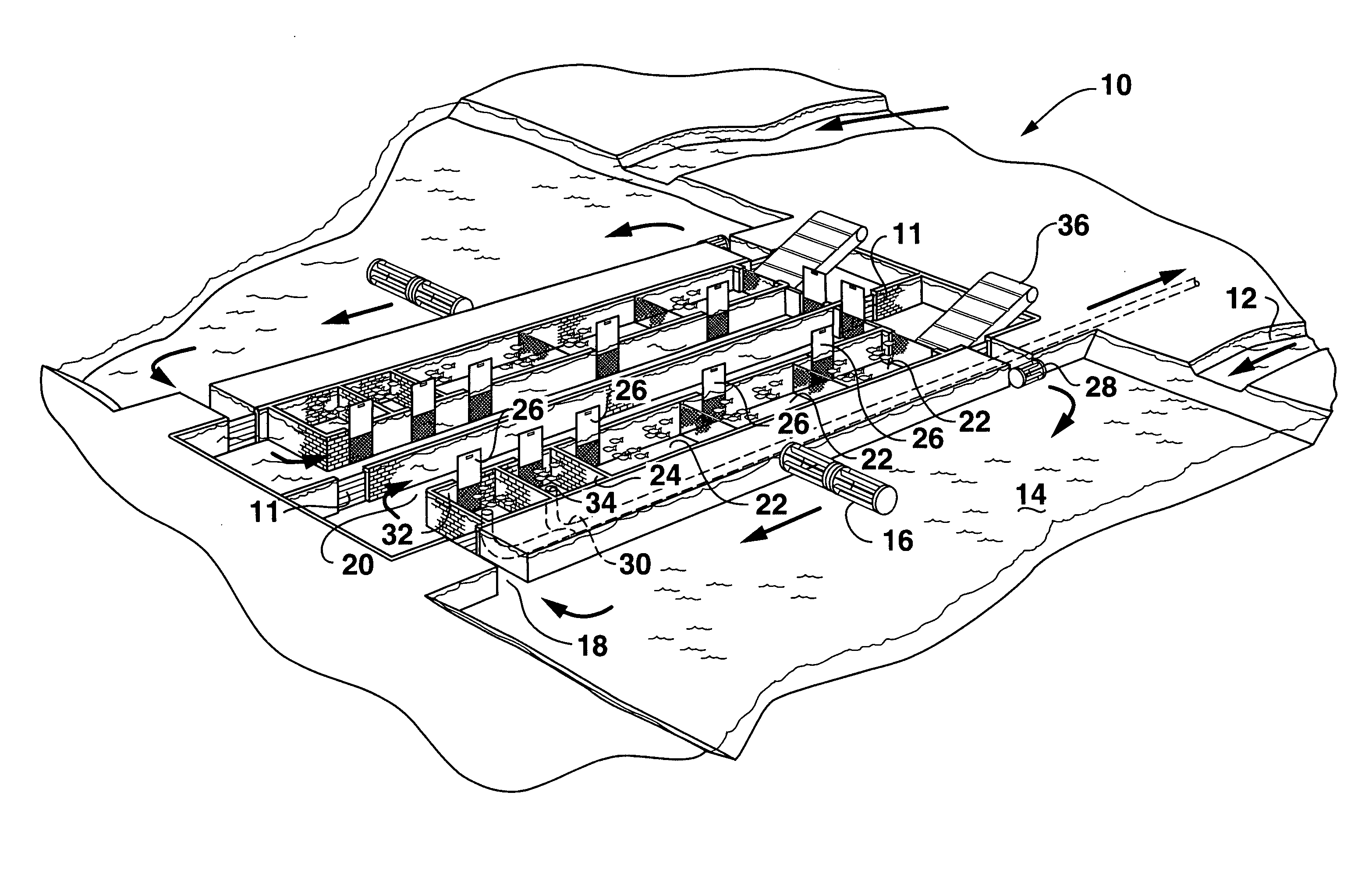

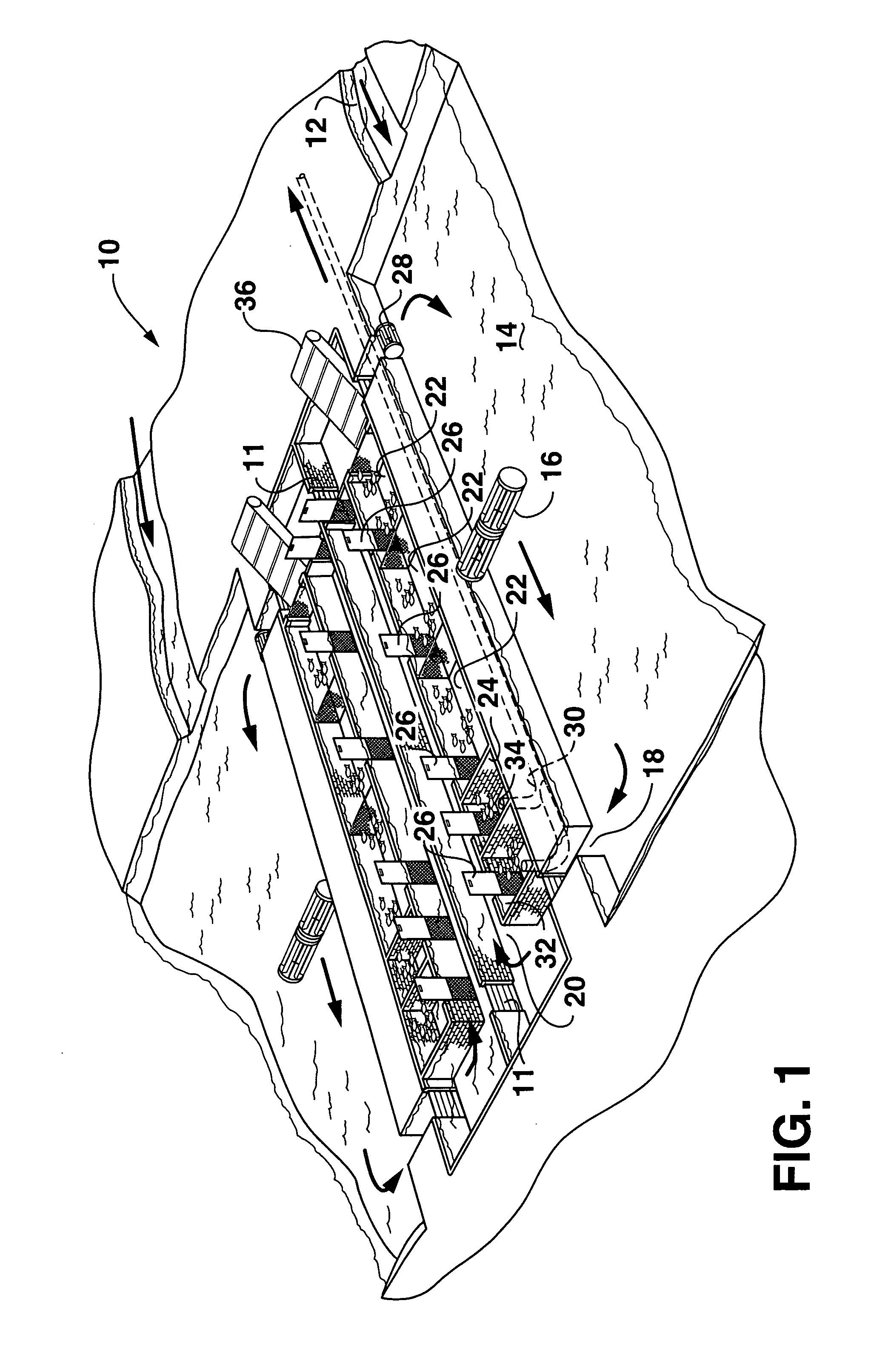

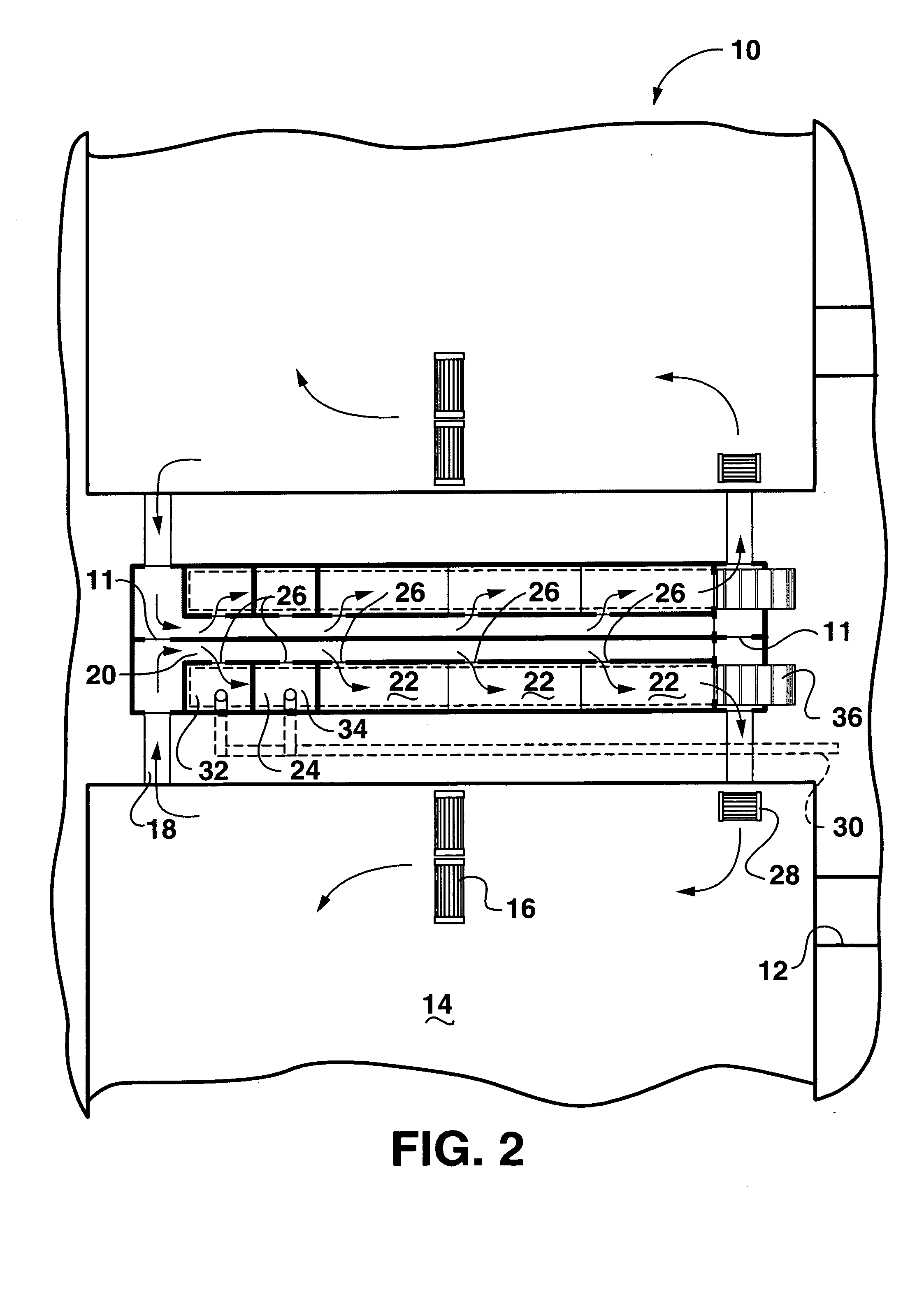

Controlled eutrophication system and process

InactiveUS20050115893A1Improve productivityReduce investmentWater cleaningTreatment using aerobic processesEutrophicationWater source

A controlled eutrophication system and process are disclosed. The system includes the combination of a partitioned aquaculture system in conjunction with an anaerobic digester. Wastewater containing pollutants, such as nitrogen and phosphorus, are fed to the partitioned aquaculture system. Algae within the system converts the pollutants into algal biomass. Fish populations, in turn, control the algal populations. The fish populations may then be periodically harvested for human or animal consumption. A polishing chamber is contained in the system in which aquatic organisms remove substantial amounts of the algae from batch fed additions of water. The water is then discharged to an external water source containing virtually no pollutants. In one embodiment, the biomass excreted by the aquatic organisms in the system are collected and fed to a digester. In the digester, the biomass is converted to a hydrocarbon gas and collected for its fuel value, while the liquid fraction is collected for its fertilizer value.

Owner:CLEMSON UNIV RES FOUND

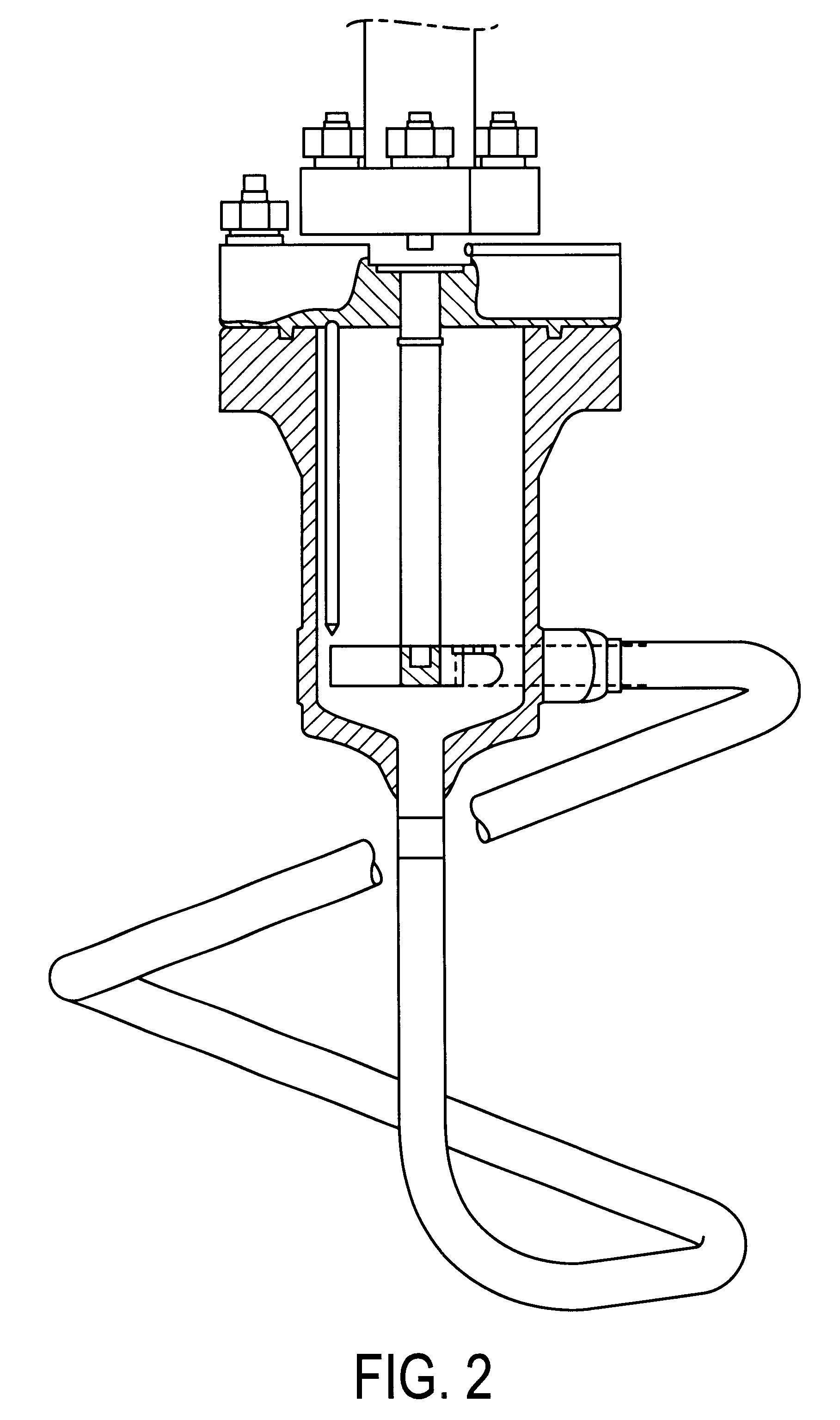

Method and apparatus for fluidization of particulate bed materials

InactiveUS6048459ATreatment using aerobic processesSolid sorbent liquid separationParticulatesOrganismal Process

A method for fluidization of a particulate bed material in a fluidized bed reactor with an upflow of fliud being treated, wherein a step of recycling said treated fluid is provided and further comprising the steps of (a) uniformly collecting at least a portion of the fluid above the fluidized bed and lifting this fluid by at least one gaslift having an intake above the bed, and (b) recycling the lifted fluid under the bed via at least one downcomer positioned within the bed. An generic apparatus for conducting the method steps in a variety of applications is also provided. The fluidized bed reactor can be used for chemical, physical chemical, biological processes, and combinations thereof in the chemical processing, food, environmental and other industries.

Owner:MOCKBA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com