Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3138 results about "Flash evaporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

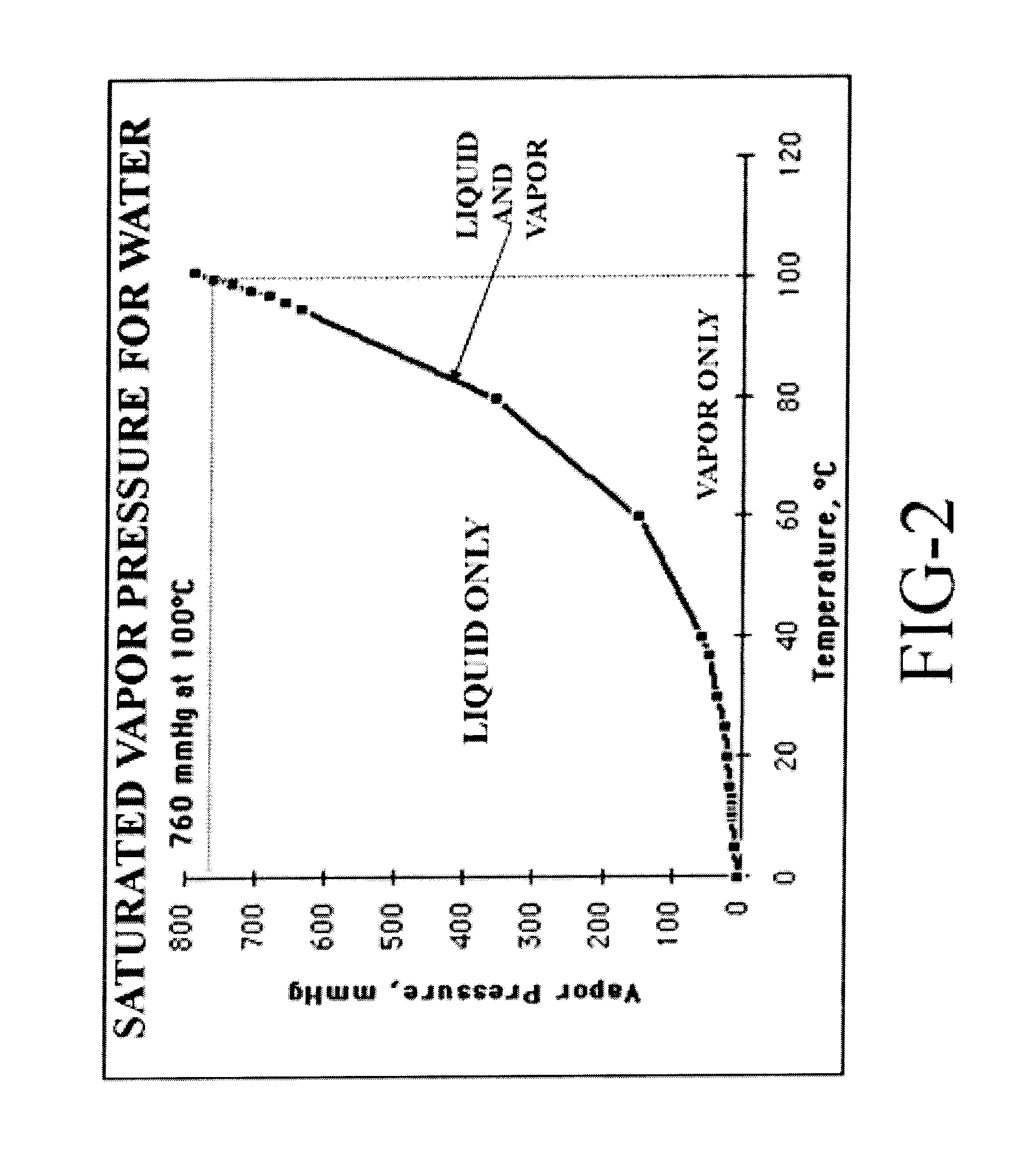

Flash (or partial) evaporation is the partial vapor that occurs when a saturated liquid stream undergoes a reduction in pressure by passing through a throttling valve or other throttling device. This process is one of the simplest unit operations. If the throttling valve or device is located at the entry into a pressure vessel so that the flash evaporation occurs within the vessel, then the vessel is often referred to as a flash drum.

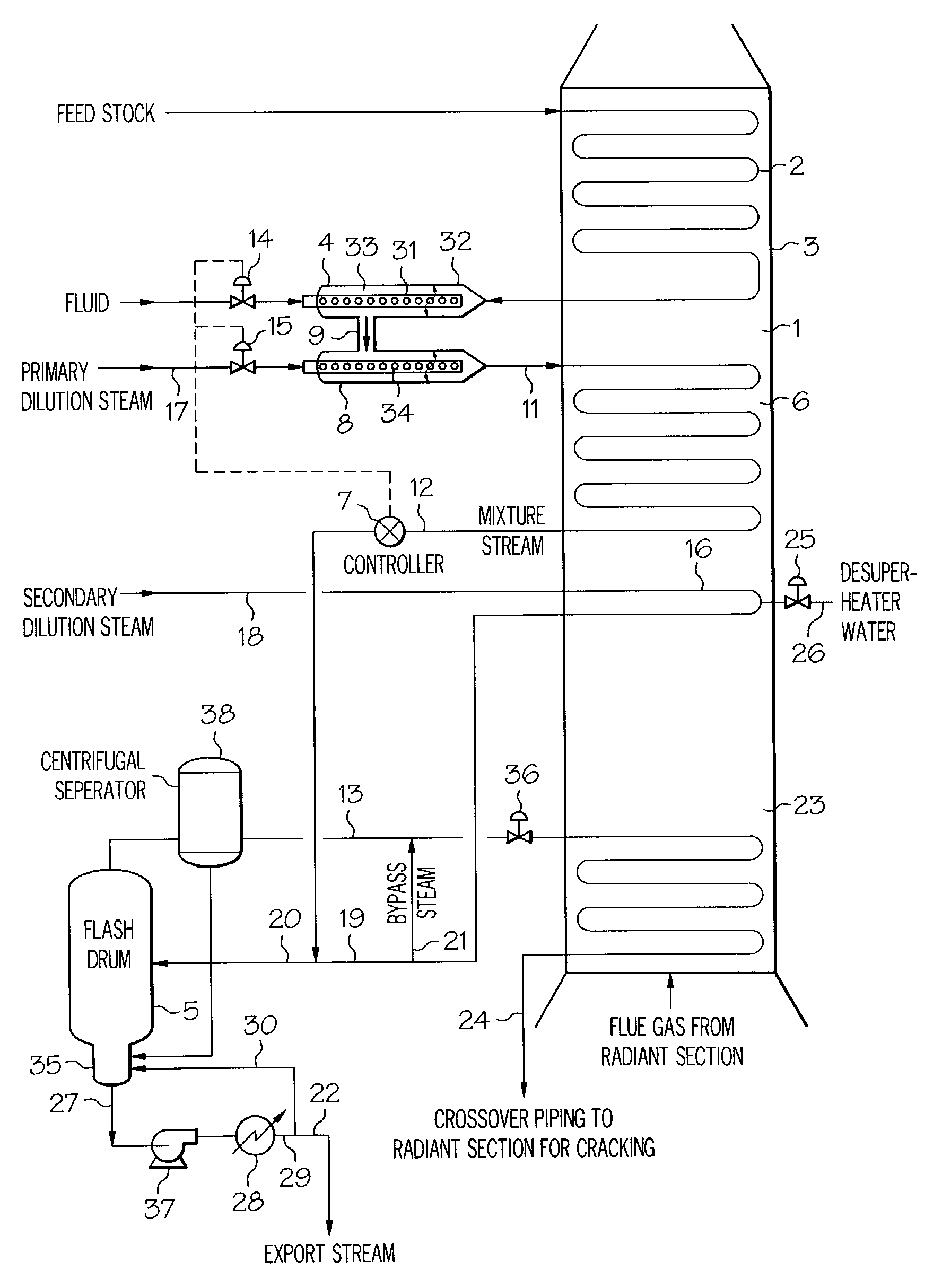

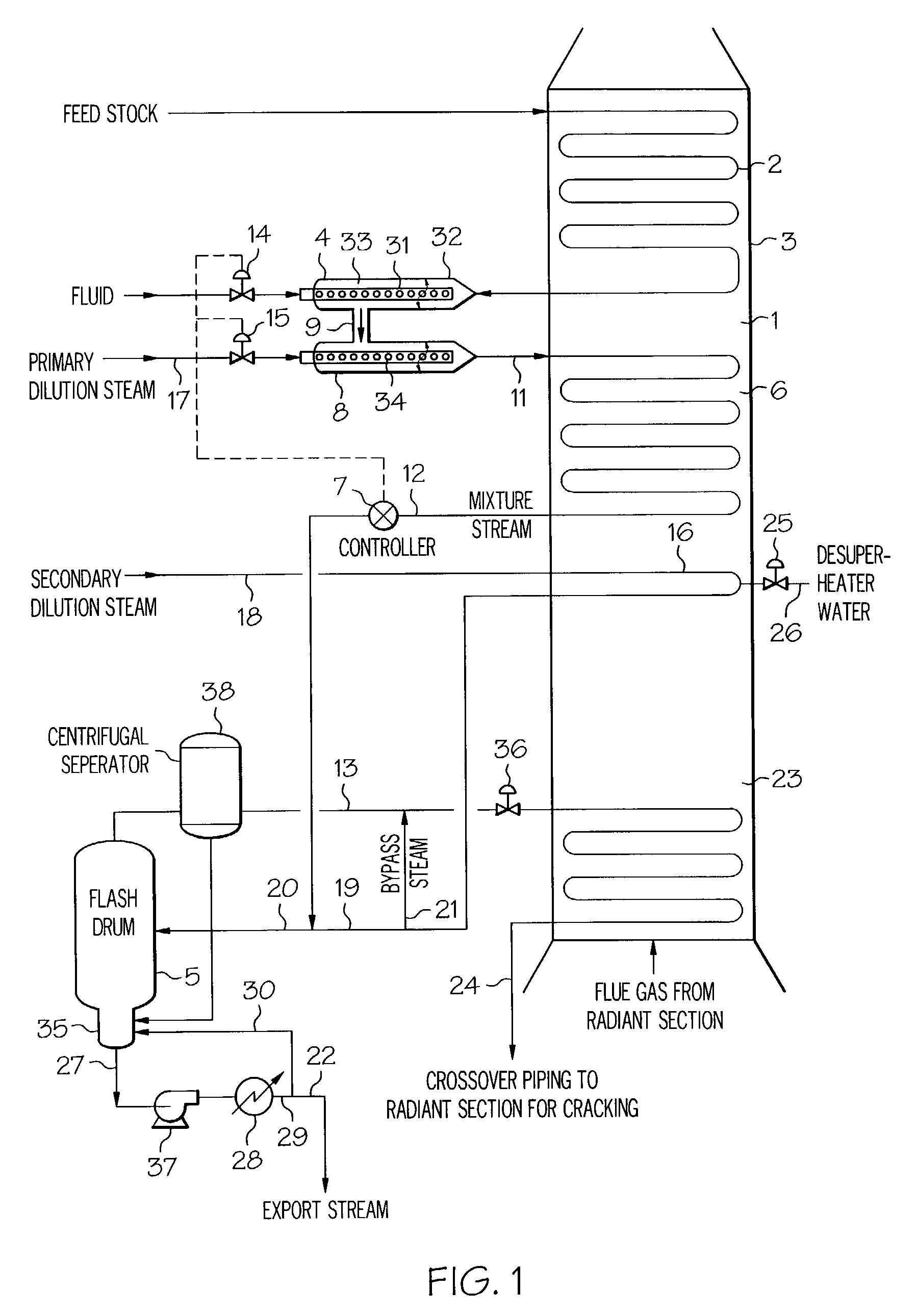

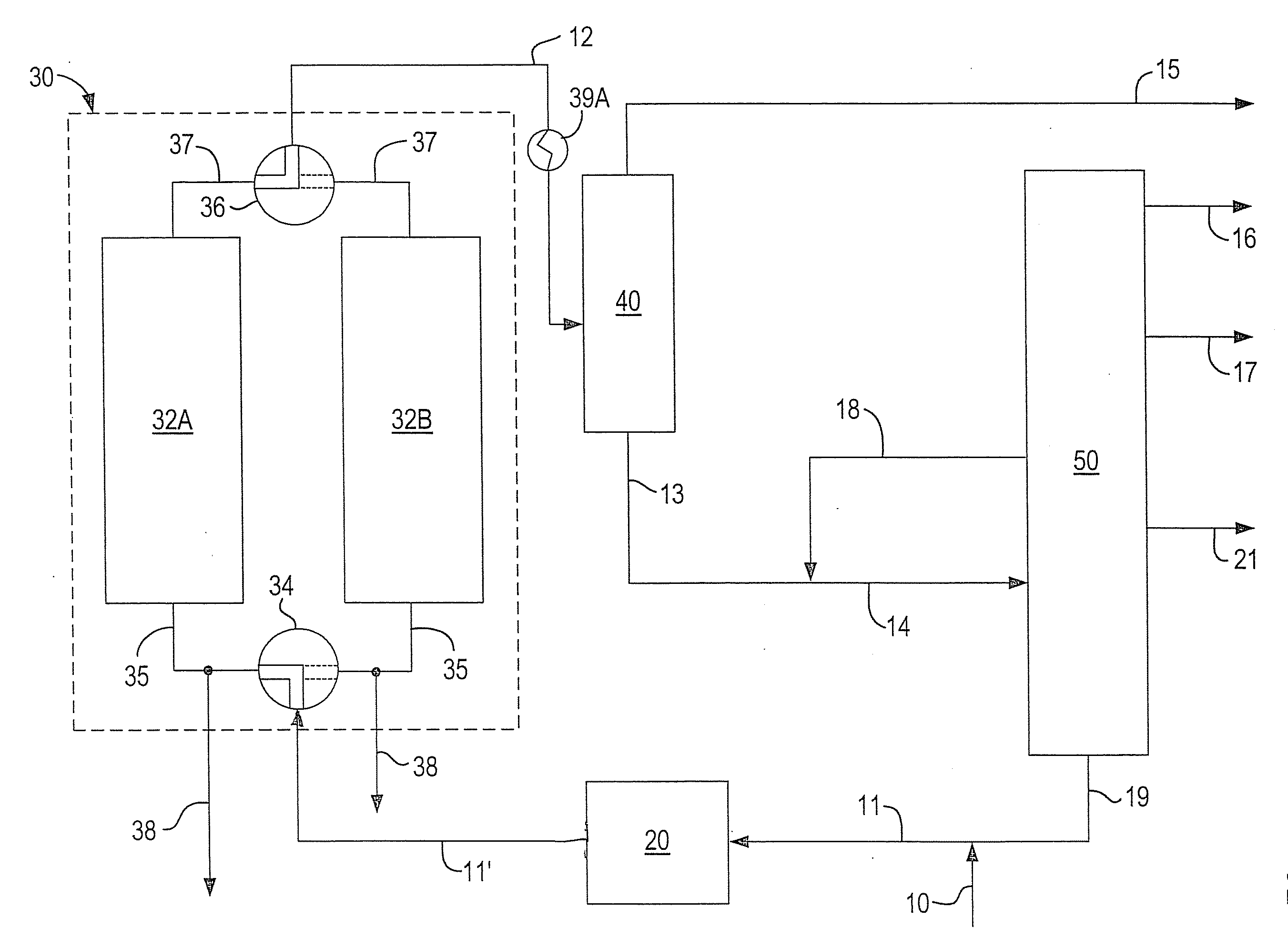

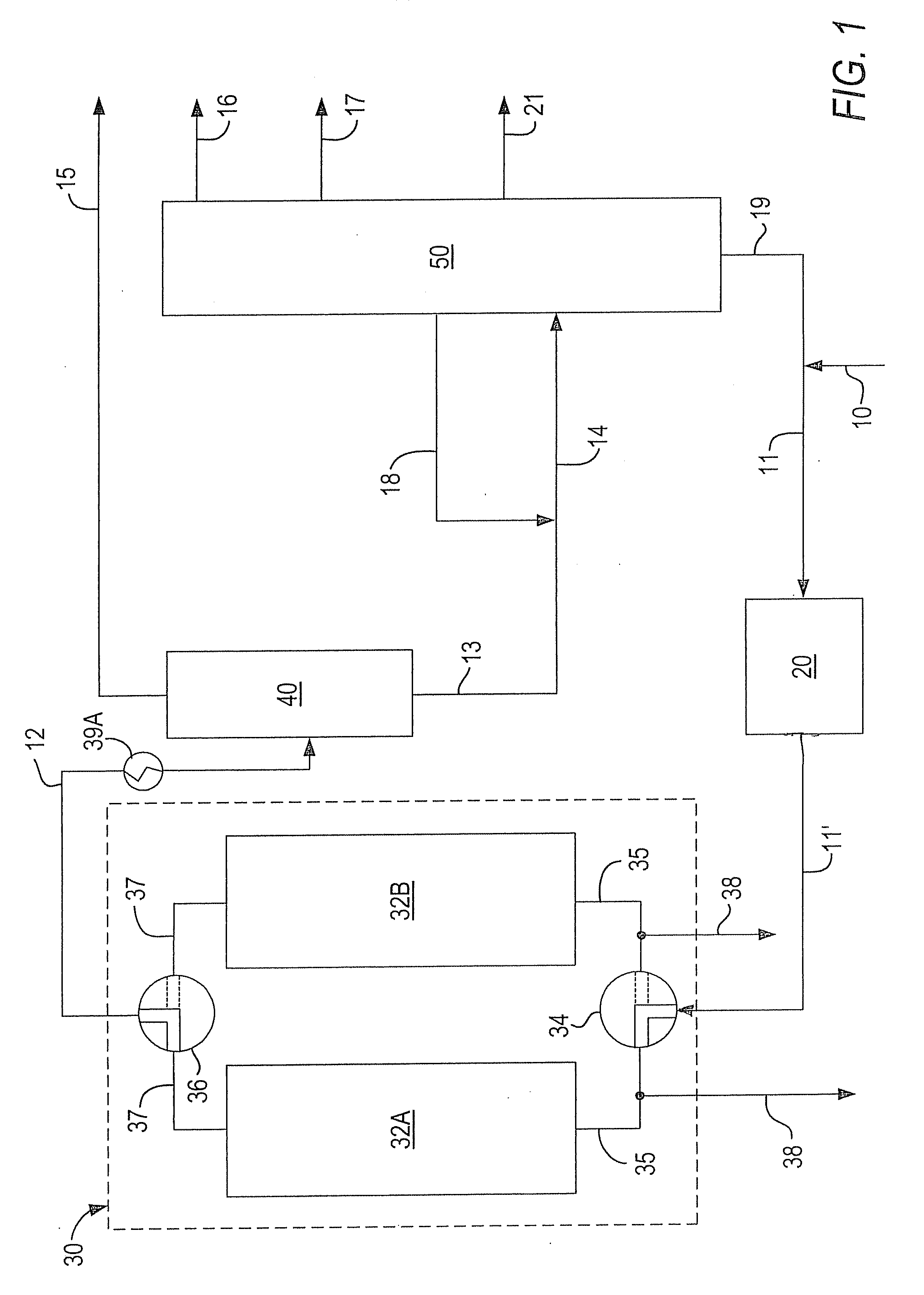

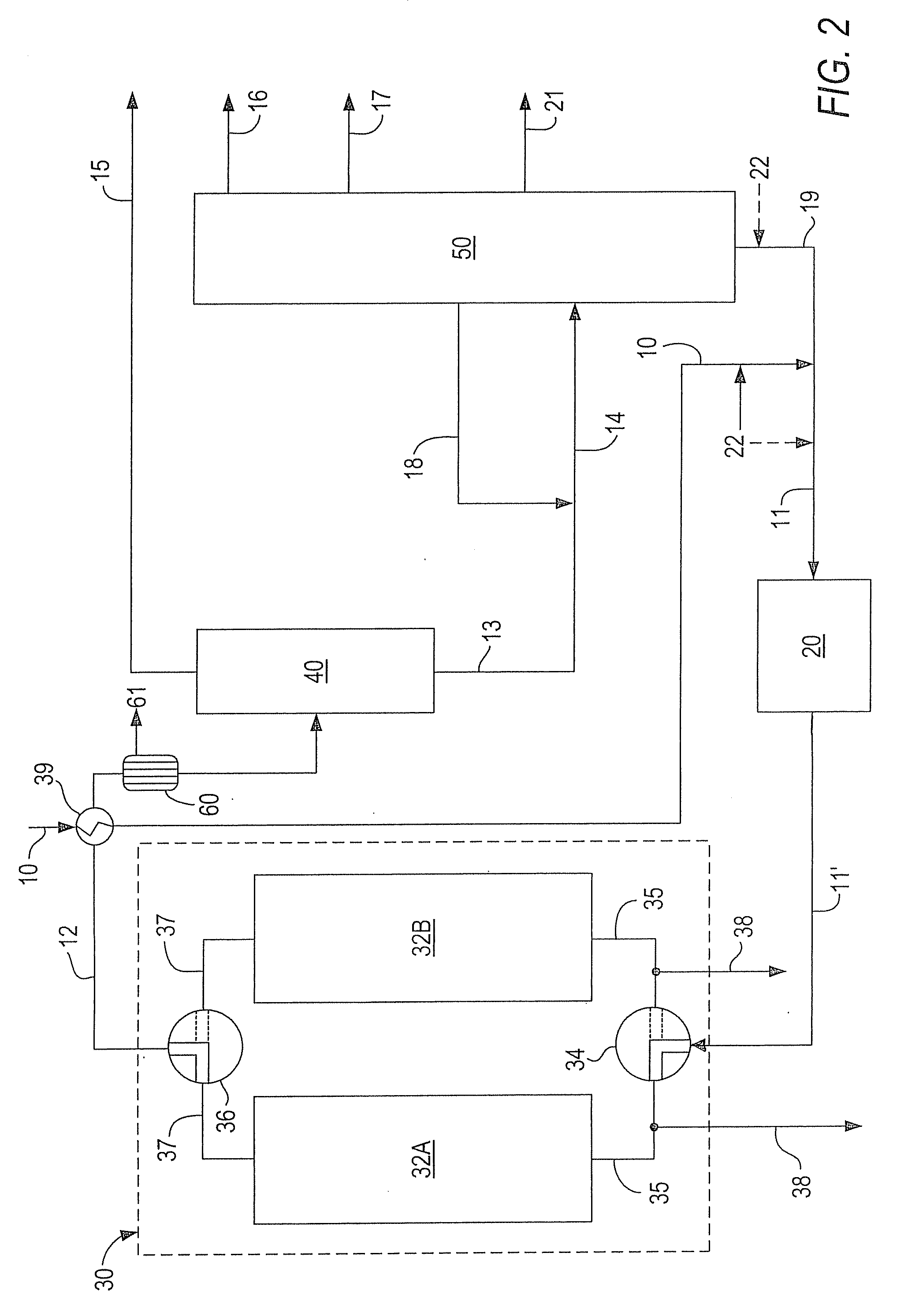

Process for steam cracking heavy hydrocarbon feedstocks

A process for feeding or cracking heavy hydrocarbon feedstock containing non-volatile hydrocarbons comprising: heating the heavy hydrocarbon feedstock, mixing the heavy hydrocarbon feedstock with a fluid and / or a primary dilution steam stream to form a mixture, flashing the mixture to form a vapor phase and a liquid phase, and varying the amount of the fluid and / or the primary dilution steam stream mixed with the heavy hydrocarbon feedstock in accordance with at least one selected operating parameter of the process, such as the temperature of the flash stream before entering the flash drum.

Owner:EXXONMOBIL CHEM PAT INC

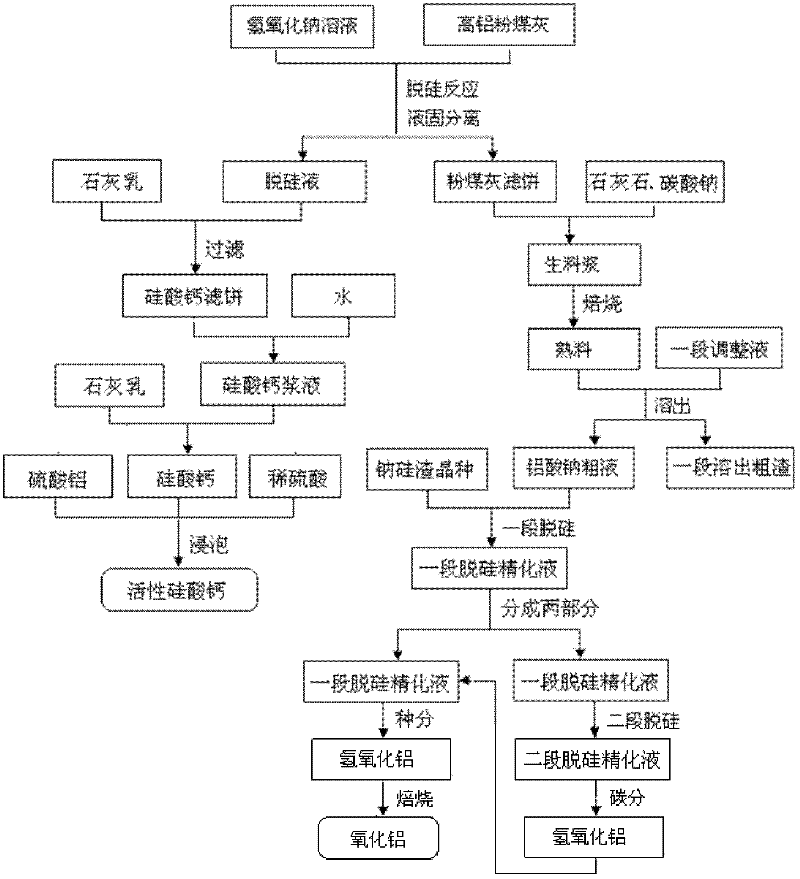

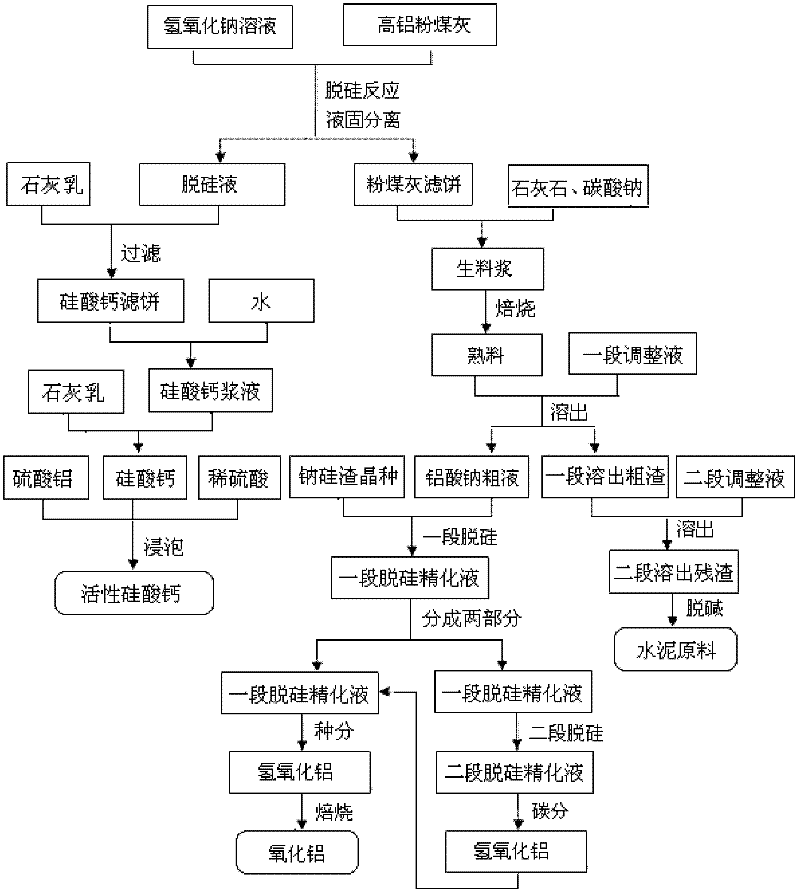

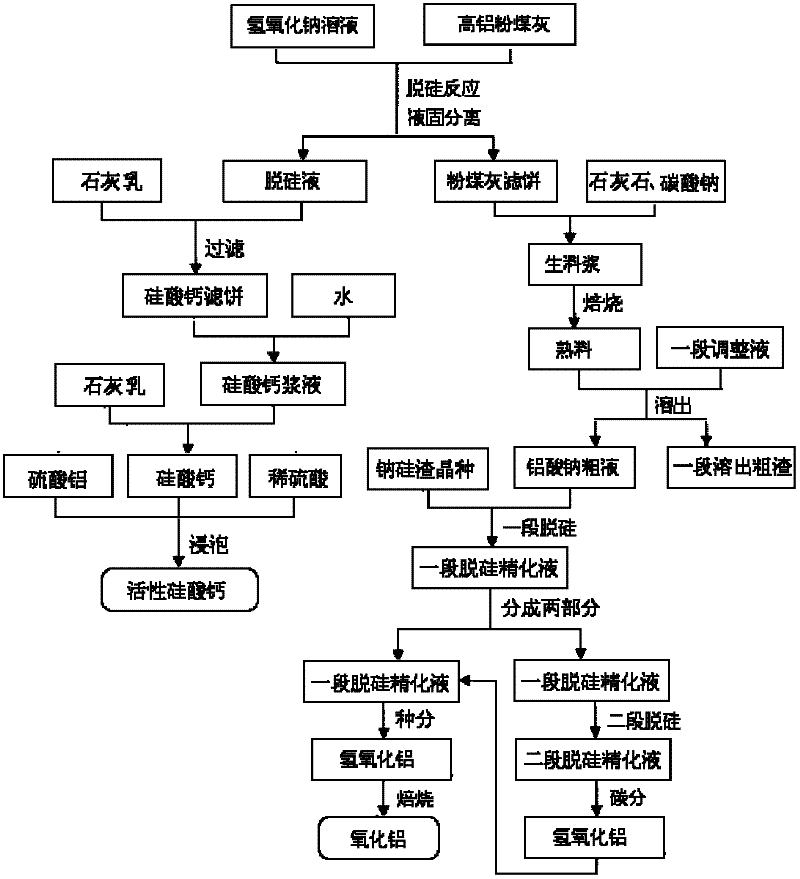

Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

ActiveCN102249253AExtraction is effective and cheapIncrease Al-Si RatioAlkaline-earth metal silicatesAluminium oxide/hydroxide preparationCalcium silicateSodium aluminate

The invention provides a method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash. The method comprises the following steps that: the high-alumina fly ash firstly reacts with a sodium hydroxide solution to carry out pre-desilication to obtain a liquid-phase desiliconized solution and a solid-phase desiliconized fly ash; lime cream is added to the liquid-phase desiliconized solution to carry out a causticization reaction, the resulting solid phase is active calcium silicate which is prepared through carrying out filter pressing, flash evaporation and drying to obtain the finished product; limestone and a sodium carbonate solution are added to the desiliconized fly ash to blend qualified raw slurry, then the blend qualified raw slurry is subjected to baking into the clinker, the liquid phase generated from dissolution of the clinker is a crude solution of sodium aluminate; the crude solution of the sodium aluminate is subjected to processes of first-stage deep desilication, second-stage deep desilication, carbonation, seed precipitation, baking and the like to obtain the metallurgical grade aluminum oxide meeting requirements. According to the present invention, the defects in the prior art are overcome; purposes of less material flow and small amount of slaggling are achieved; energy consumption, material consumption and production cost are relative low; extraction rate of the aluminum oxide is high; the calcium silicate with high added value is co-produced; the method provided by the present invention can be widely applicable for the field of chemical engineering.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

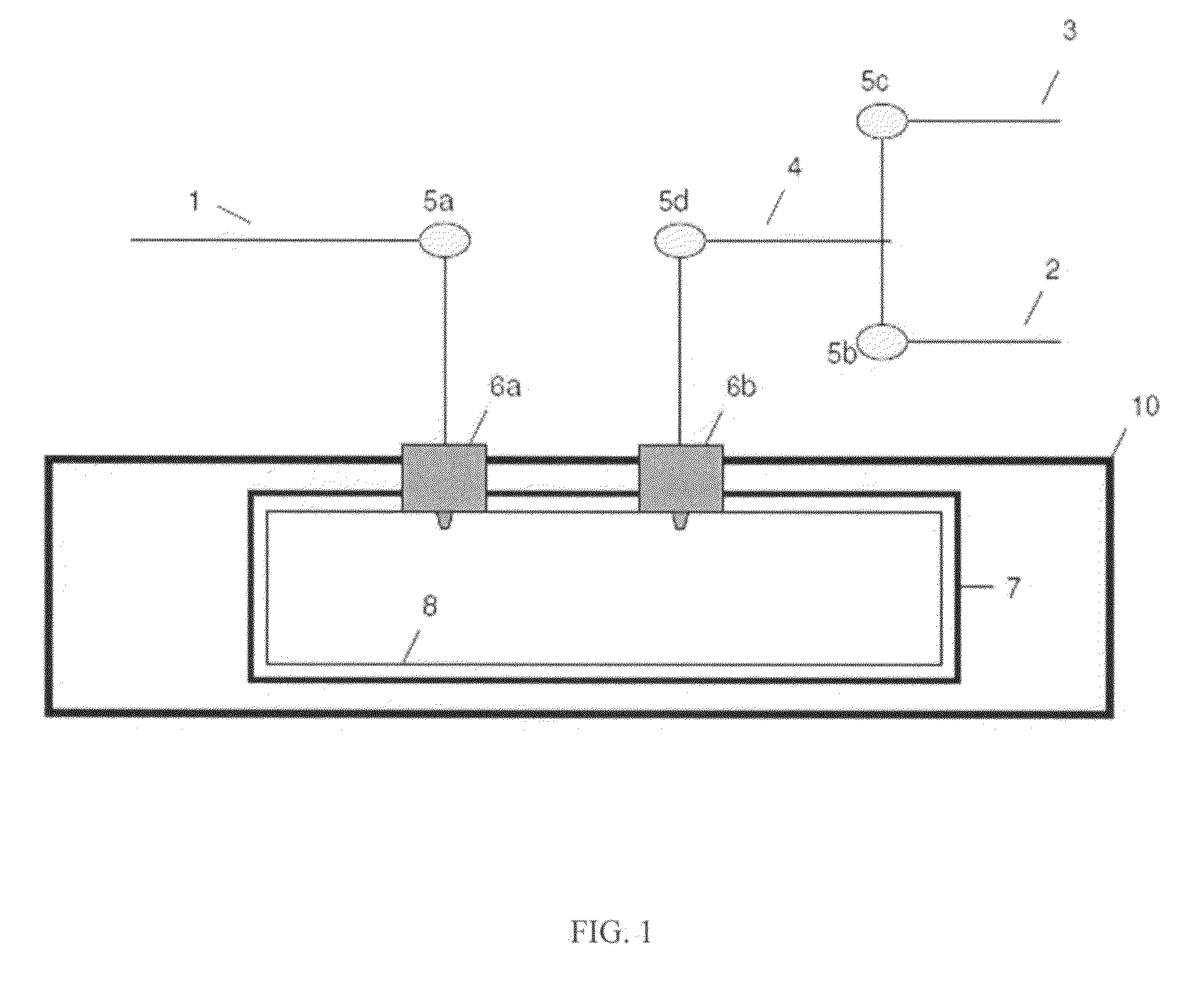

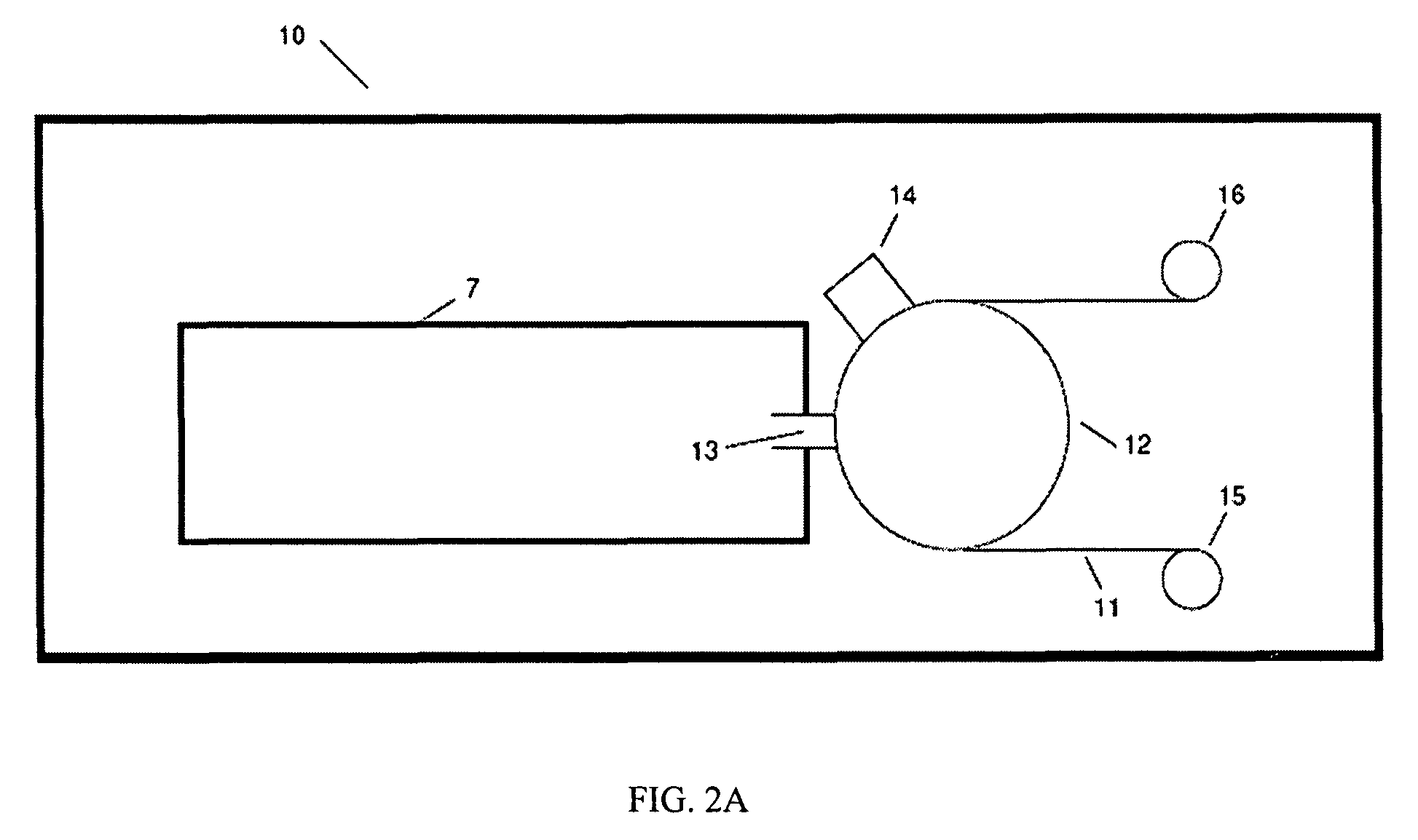

Co-flash evaporation of polymerizable monomers and non-polymerizable carrier solvent/salt mixtures/solutions

The present invention relates generally to methods for supplying one or more vapors, under reduced pressure, to an environment. The vapor may comprise at least one polymerizable component. In some cases, at least two components may be combined to form the vapor. The components may be provided as separate vapor streams, which may be combined and homogenized. Methods of the invention may also be useful in the deposition of materials on the surface of a substrate. In some cases, the material may form a layer, such as a polymer layer, on the surface of a substrate. The present invention may be useful in applications that require the formation of homogeneous films on the surface of a substrate.

Owner:SION POWER CORP

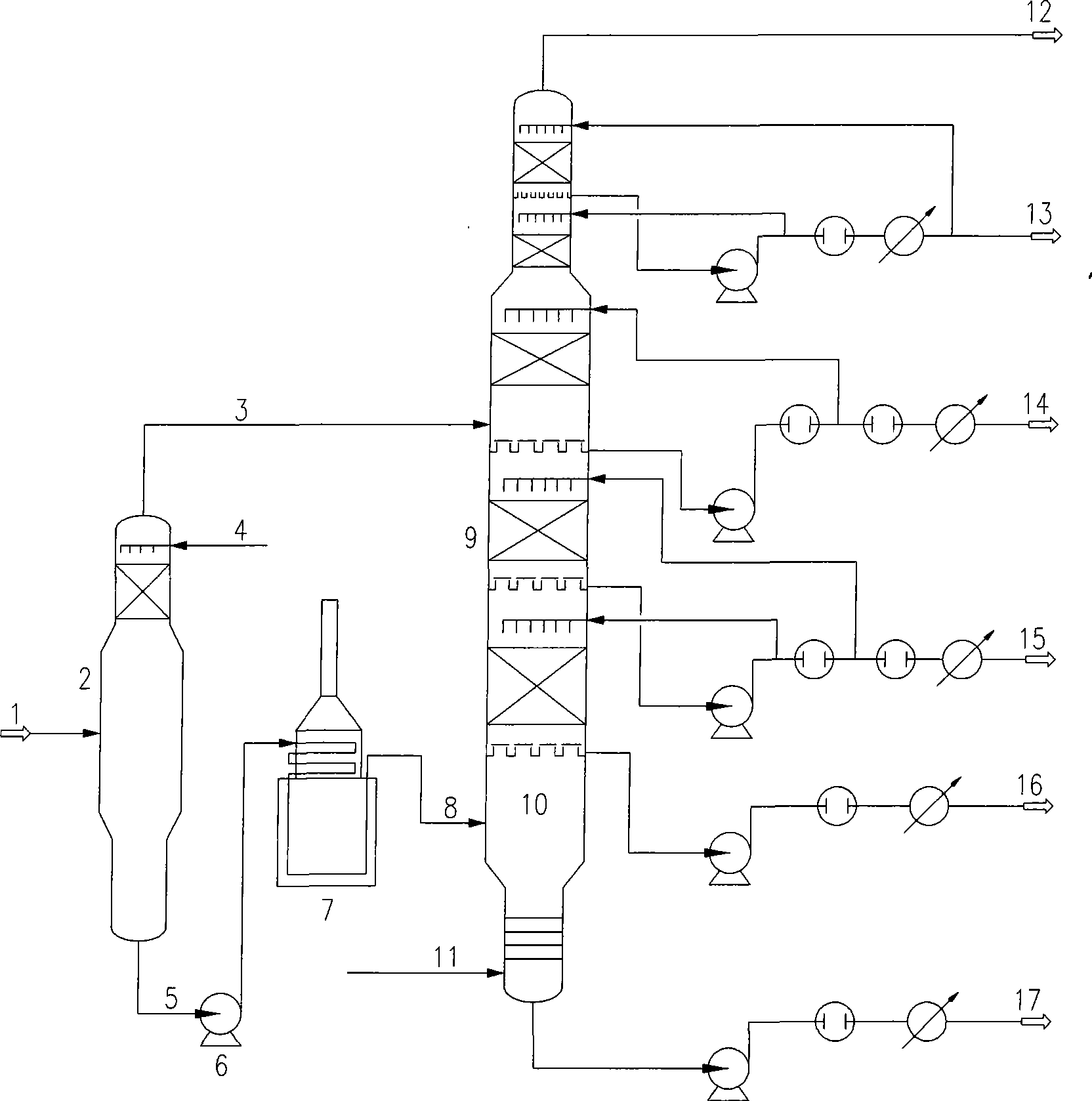

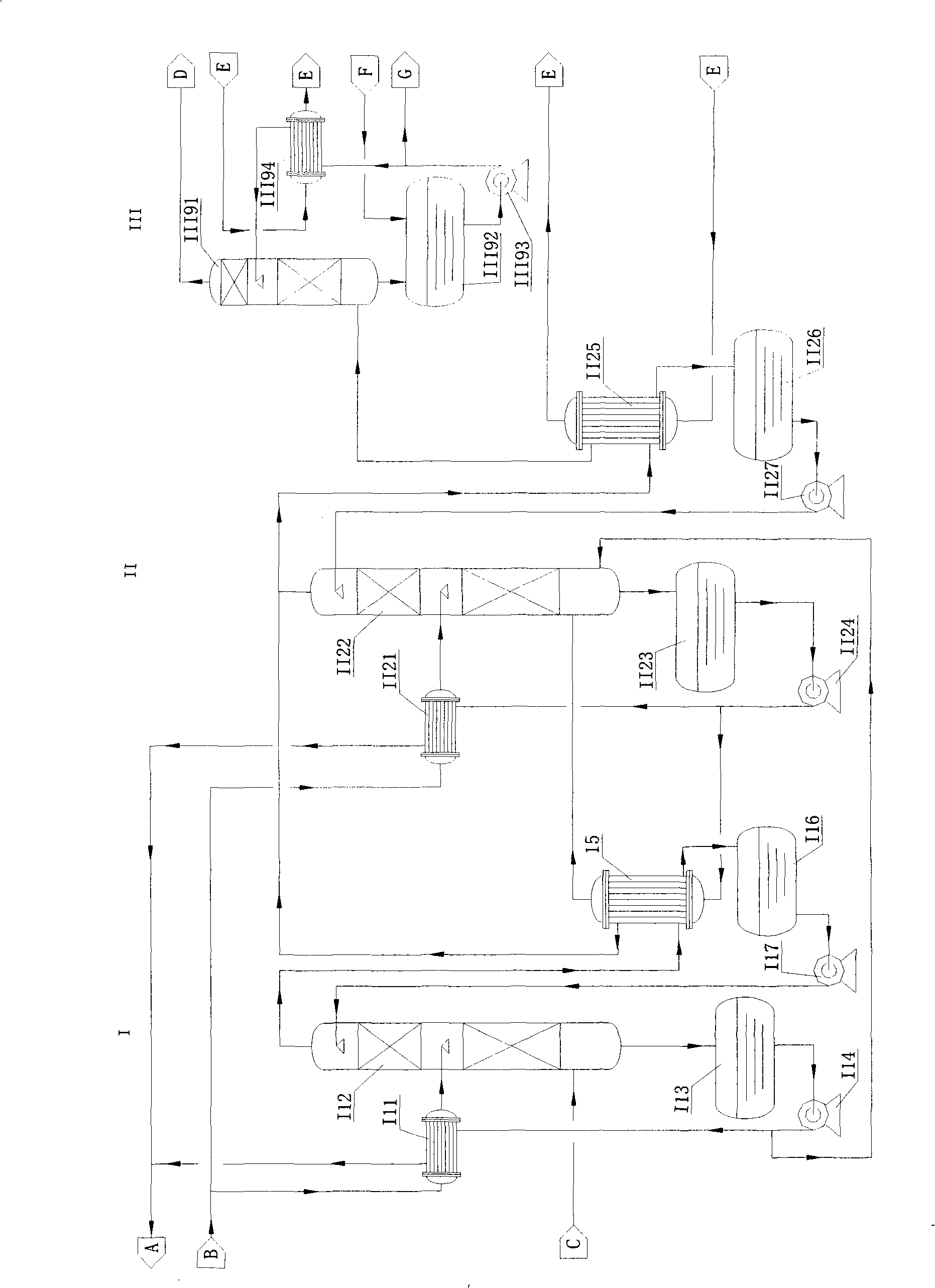

Atmospheric vacuum distillation method and apparatus with vacuum flash vaporizer

InactiveCN101376068AReduce the amount of feedEasy to handleVacuum distillation separationVacuum distillationVaporizationPulp and paper industry

The invention relates to an atmospheric and vacuum distillation device with a vacuum flash tower and a method thereof. The atmospheric and vacuum distillation device with a vacuum flash tower is characterized in that the vacuum flash tower arranged in front of a vacuum furnace is connected with the vacuum furnace and a vacuum tower through a pump and a pipeline. Constant bottom oil (1) is introduced into the vacuum flash tower (2)at first, and the operation pressure at the top part of the vacuum flash tower is higher than the operation pressure at the top part of the vacuum tower (9) by10 to 200mmHg; Flash cap gas (3) is introduced into the upper part or the lower part of an outlet for a side product which is similar to Flash cap gas fraction; flash bottom oil (5) is introduced into the vacuum furnace (7) through a flash bottom oil pump (6); when the flash bottom oil is heated to 350 to 430 degrees, air-liquid mixing vacuum tower feed material is obtained through partial vaporization and is introduced into a flash evaporation segment (10) of the vacuum tower through a transfer line (8); and products with different fractions are drawn from the side of the vacuum tower and vacuum residue is drawn from the bottom of the vacuum tower. Through adding the vacuum flash tower to improve the working process of the atmospheric and vacuum distillation device, the invention achieves the advantages of increasing treatment capacity, increasing vacuum distillation yield, and reducing energy consumption.

Owner:TIANJIN UNIV +2

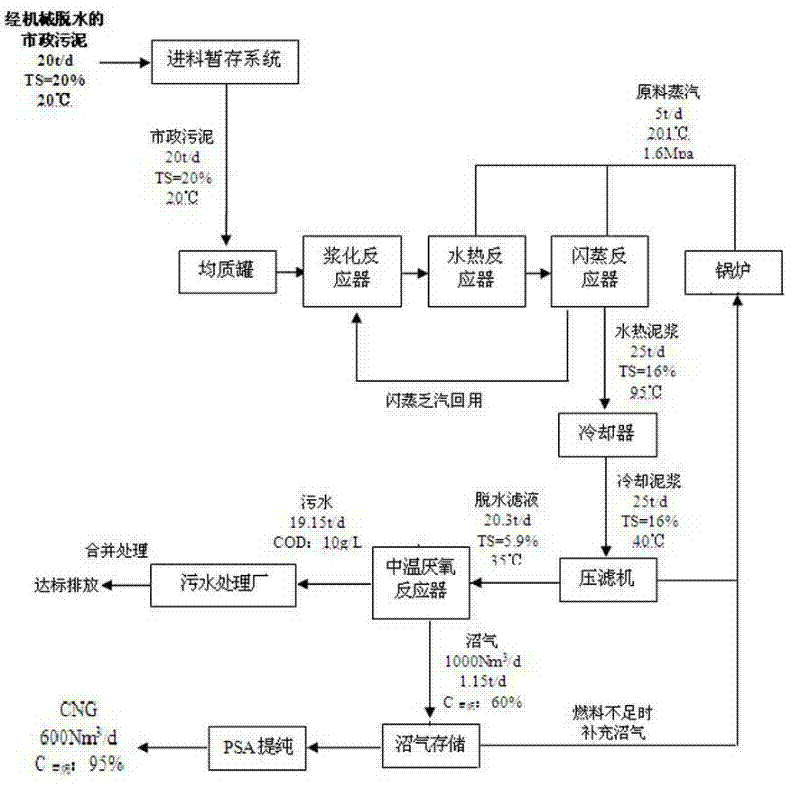

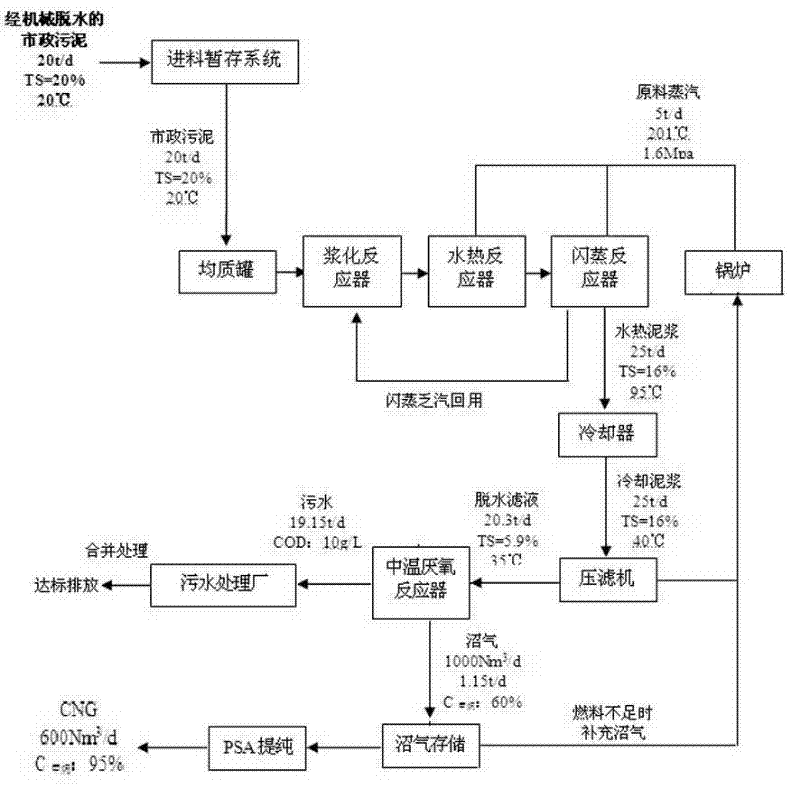

Sludge treatment process based on hydrothermal modification technology

InactiveCN102381820AAdvanced technologyHighlight energy savingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAnaerobic reactorHigh pressure

The invention relates to a sludge treatment process based on a hydrothermal modification technology. The sludge treatment process is carried out by comprising the following steps of: (1) temporarily storing the sludge which is subjected to mechanical dehydration and has the water content of 70-85% to a pretreatment unit and deodorizing the sludge; (2) introducing to a homogeneous device, fully mixing and homogenizing, introducing the homogenized sludge to a slurrying device, introducing the slurried sludge to a hydrothermal reactor for hydrothermal reaction, and introducing the hydrothermal sludge to a flash evaporator for decompression and flash evaporation; (3) cooling to 35-45 DEG C by using a cooler, then introducing to a high-pressure diaphragm pressure filter for pressure filtering and dehydration to obtain a dehydrated mud cake with the solid content of 35-45% and dehydrated filtrate; (4) introducing the dehydrated filtrate to an intermediate temperature anaerobic reactor, wherein the residence time is for 5.5-7.5d, the inlet water temperature is controlled below 40 DEG C, and the anaerobic reaction temperature is 30-40 DEG C; and (5) preparing a biomass fuel rod by using the dehydrated mud cake, and introducing the biomass fuel rod to a boiler to provide steam for the hydrothermal reactor and the flash evaporator. The sludge treatment process has the advantages of goodtreatment effect, obvious volume reduction effect, high harmless degree, recycling of methane, good economic benefit and the like.

Owner:FUZHOU DEV ZONE SANSHUI ENVIRONMENTAL PROTECTION TECH

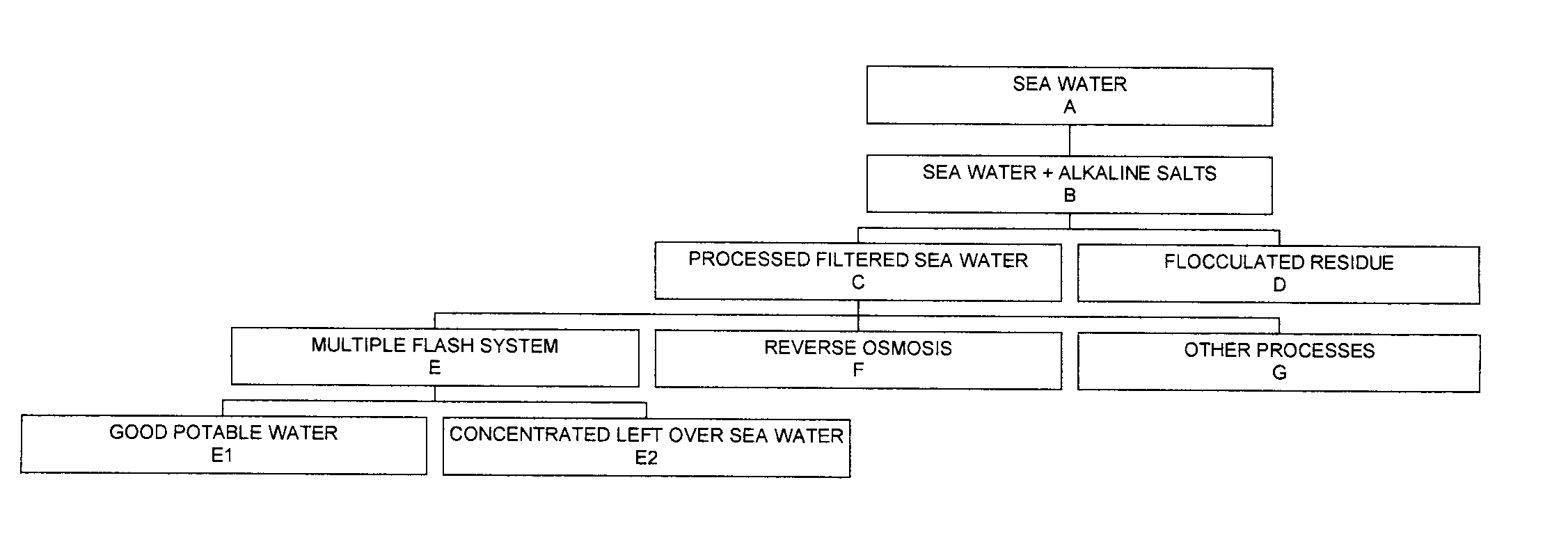

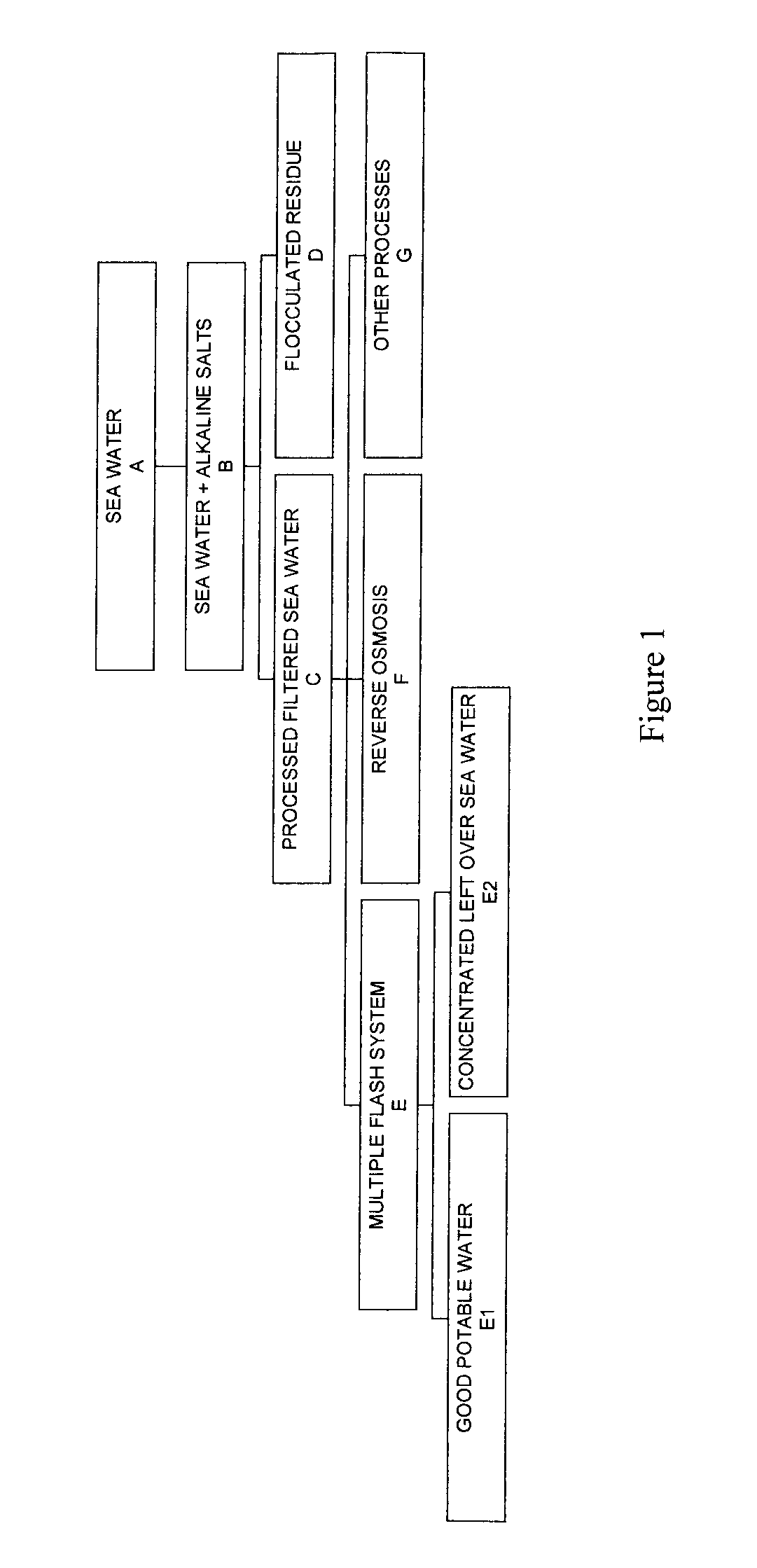

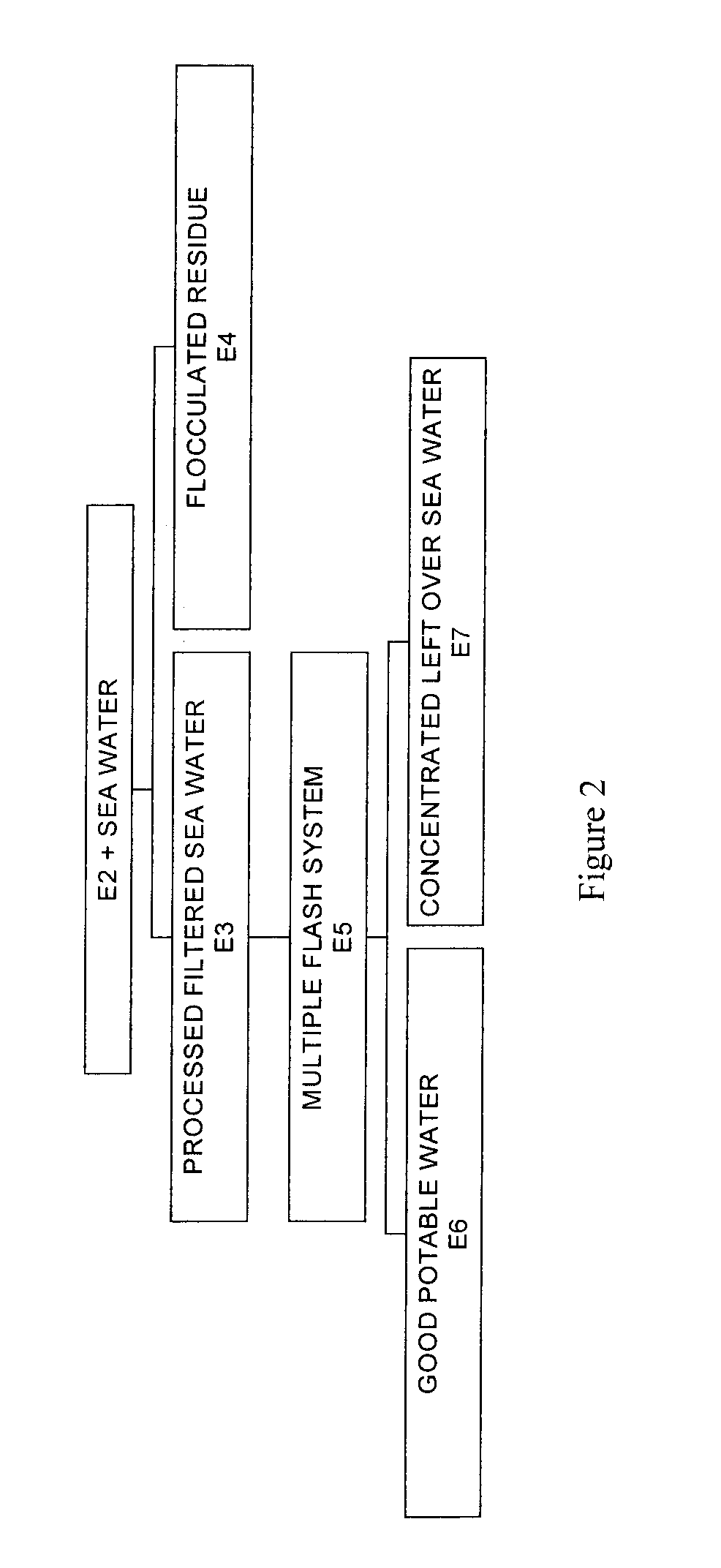

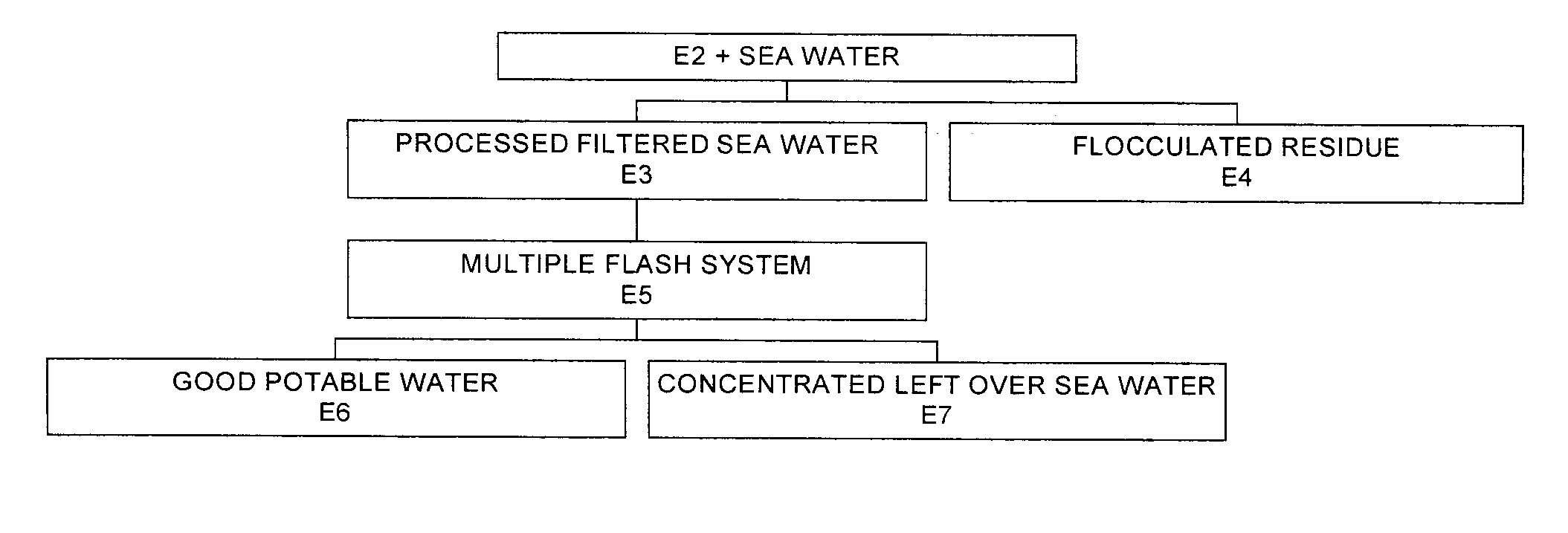

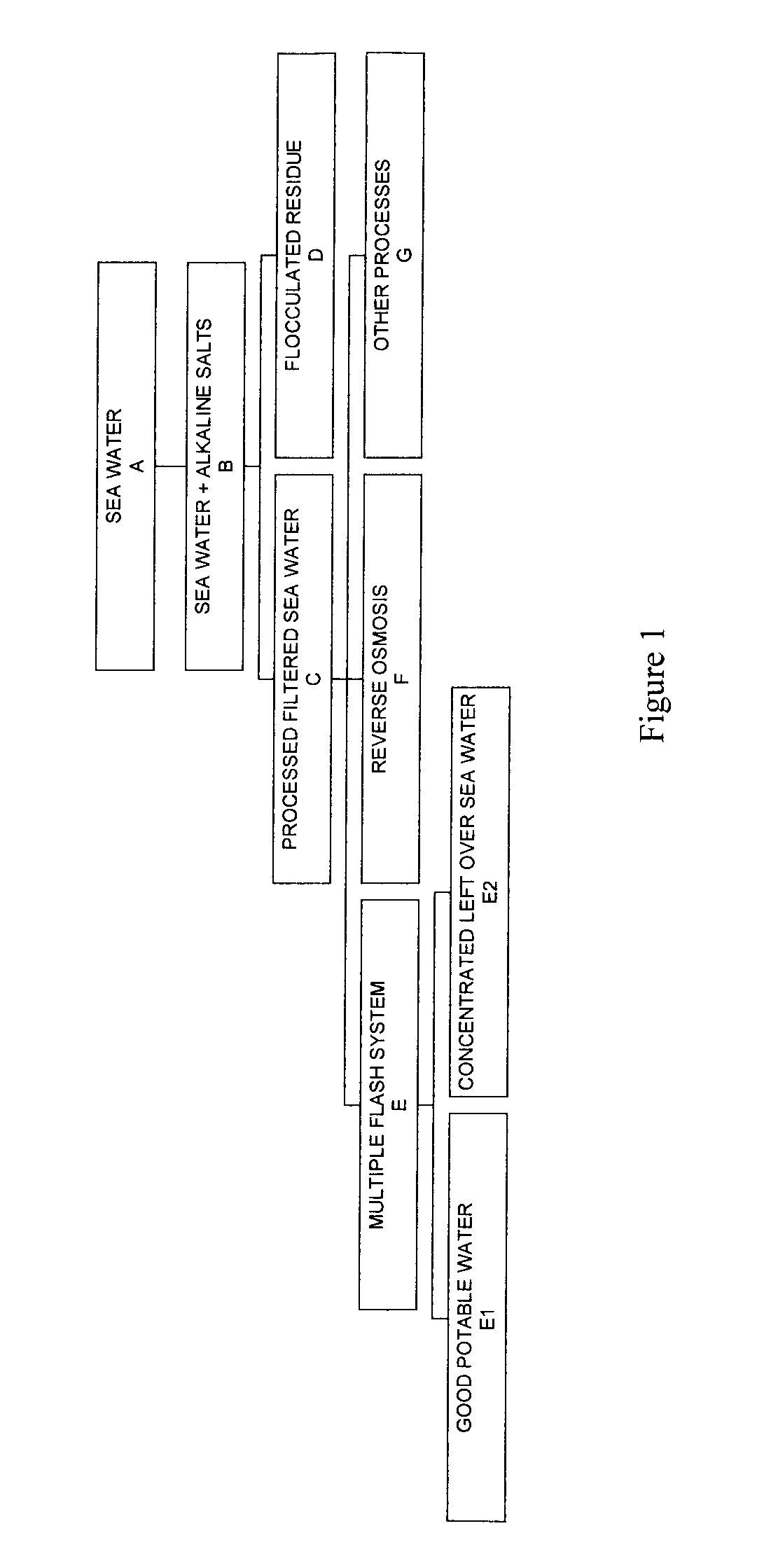

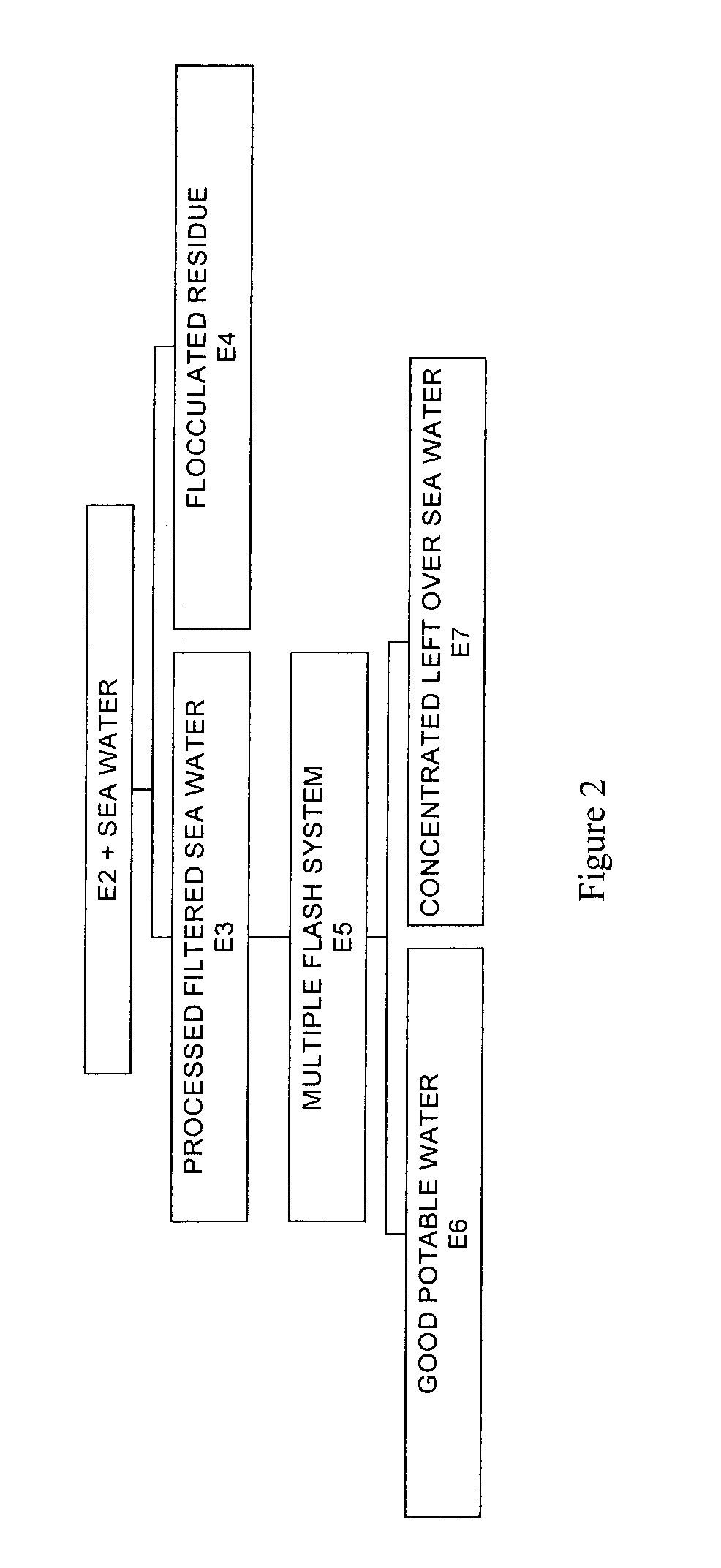

Process for pre-treating and desalinating sea water

ActiveUS20050098499A1Reduce maintenanceExtend equipment lifeGeneral water supply conservationSeawater treatmentCalcium bicarbonatePotassium hydroxide

Water containing dissolved salts, such as calcium sulfate, calcium chloride, magnesium sulfate, magnesium chloride, sodium carbonate, sodium chloride, sodium sulfate, calcium bicarbonate, and mixtures thereof, is treated to reduce the concentration of those salts. About 0.1 to about 60 g / L of sodium hydroxide, sodium carbonate, potassium hydroxide, potassium carbonate, calcium hydroxide, calcium carbonate, aluminum hydroxide, aluminum sulfate, aluminum potassium sulfate, and mixtures thereof is added to the water, whereby a precipitate forms in the water. The precipitate is separated from said water and the water is desalinated using reverse osmosis, flash evaporation, or another method. The process is preferably performed by first adding calcium oxide or calcium hydroxide, separating the precipitate that forms, then adding sodium hydroxide and sodium carbonate to form a second precipitate.

Owner:HUSSAIN MOHAMMED AZAM

Process for pre-treating and desalinating sea water

ActiveUS7198722B2Extend equipment lifeReduce maintenanceGeneral water supply conservationSeawater treatmentCalcium bicarbonateReverse osmosis

Owner:HUSSAIN MOHAMMED AZAM

Bulk depositing synthesis process of isotactic polybutylene-1

The present invention is bulk depositing synthesis process of isotactic polybutylene-1, and belongs to the field of polymer technology. The powdered isotactic polybutylene-1 product is obtained through bulk depositing polymerization of butylene-1 as the monomer and reactant medium at 0-70 deg.c in the presence of supported titanium catalyst, and the subsequent flash evaporation to eliminate unpolymerized monomer. The catalyst system may have organic aluminum AlR3 as co-catalyst, added electron donor compound, and hydrogen as molecular weight regulator. The polymerization reaction is performed in a polymerizing kettle with stirring screw belt. The present invention has simple technological process, high efficiency and low cost, and the prepared isotactic polybutylene-1 has high stereoregularity degree, crystallization degree higher than 60 %, and smelting point of 127.5 deg.c.

Owner:SHANDONG ORIENT HONGYE CHEM +1

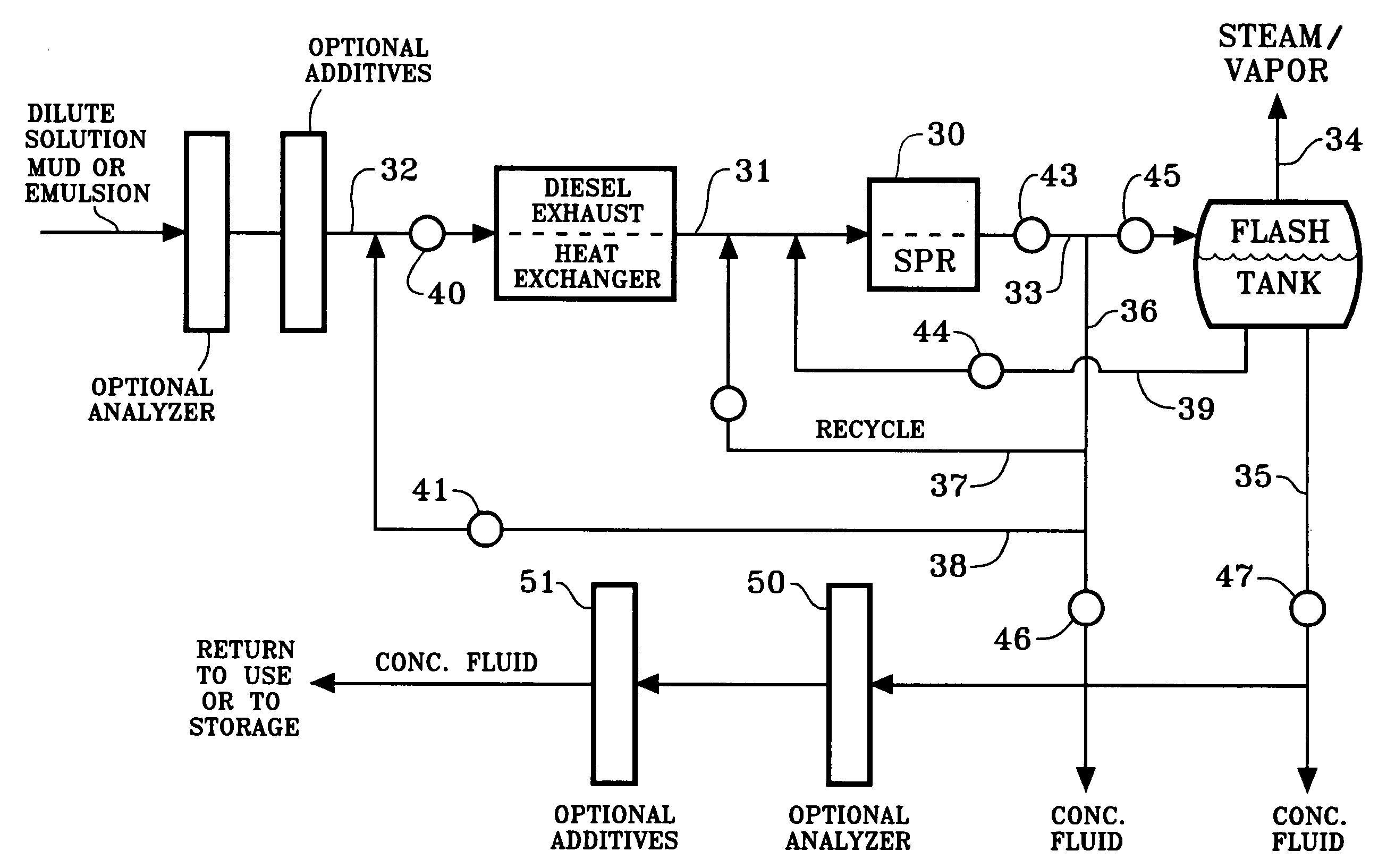

Conserving components of fluids

InactiveUS7201225B2Efficient designSurveyWater/sewage treatment by irradiationProcess engineeringComponents of crude oil

A cavitation device is used to heat, concentrate and recycle or otherwise reuse dilute and other oil well fluids, brines and muds, and solution mining fluids, all of which commonly contain ingredients worthy of conservation. The cavitation device is powered by a Diesel engine whose exhaust may be used to heat the incoming fluid, and the product of the cavitation device is directed to a flash tank.

Owner:TOTAL SEPARATION SOLUTIONS

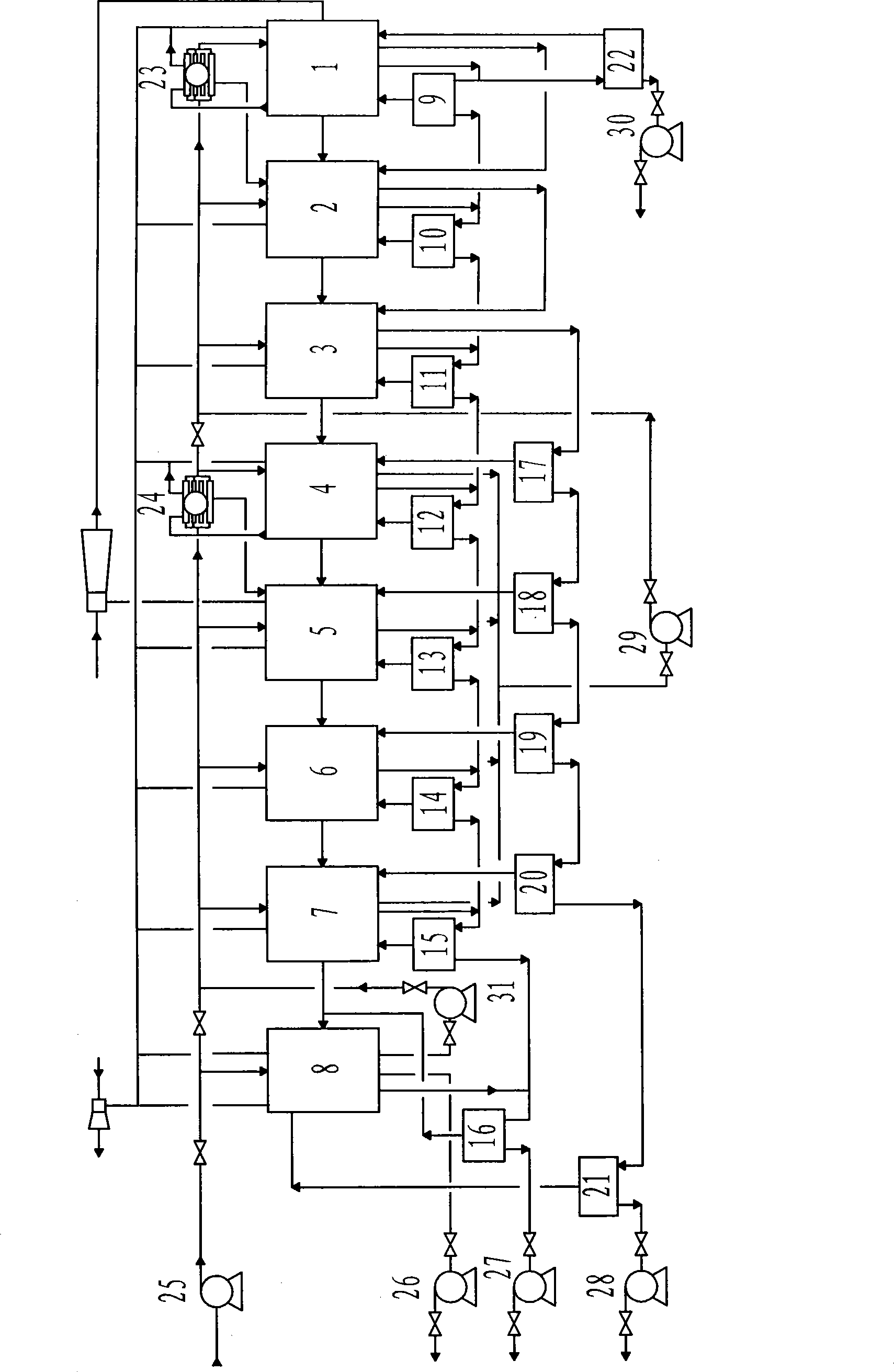

Ammonia nitrogen waste water discharge-reducing and ammonia nitrogen resource utilizing device and method

InactiveCN101264948AReduce consumptionWater/sewage treatment by degassingAfter treatmentResource utilization

The invention relates to a device for ammonia nitrogen wastewater discharge reduction and ammonia nitrogen resource utilization and a method thereof, and belongs to the field of wastewater discharge reduction. The conventional steam blow-off method has high unit energy consumption (250-300 Kg steam / ton wastewater) in ammonia nitrogen wastewater treatment, thus resulting in very high ammonia nitrogen wastewater treatment cost. The inventive device comprises at least two stages of ammonia nitrogen stripping step and ammonia nitrogen reutilization step. The ammonia nitrogen wastewater to be treated is respectively fed into each stage of ammonia nitrogen stripping step, and the removal of ammonia nitrogen in wastewater is realized in ammonia nitrogen stripping tower and the resource utilization is realized in the ammonia nitrogen reutilization step. Except for the first stage of the ammonia nitrogen stripping tower requiring steam introduction, the steam required on other stages of ammonia nitrogen stripping tower is obtained by vaporization of a part of the tower bottom liquid in each tower by using the heat released via condensation of a part of steam in the upper stage tower and flash evaporation of the tower bottom liquid in the upper stage tower, so as to remarkably reduce steam consumption. The inventive device and method have the advantages of high ammonia nitrogen content wastewater treatment, low ammonia nitrogen content in wastewater after treatment, low steam consumption, and low treatment cost.

Owner:BEIJING UNIV OF CHEM TECH

Process for delayed coking of whole crude oil

ActiveUS20120298552A1Enhance thermal cracking reactionReduce coke yieldThermal non-catalytic crackingCatalytic crackingNaphthaFractionating column

An improved delayed coking process utilizing a coking unit and a coking unit product fractionating column which includes the steps of:heating a mixture of a fresh whole crude oil feedstream and the bottoms from the coking unit product fractionator in a furnace to a coking temperature in the range of 480° C. to 530° C. / 896° F. to 986° F.;introducing the heated mixed whole crude oil and bottoms feedstream directly into the delayed coking unit;optionally passing the vaporized liquid and gaseous coking unit product stream into a flash unit;recovering a light product gas stream that includes H2S, NH3 and C1 to C4 hydrocarbons from the flash unit;transferring the bottoms from the flash unit to the coking unit product fractionating column;recovering as separate side streams from the fractionating column naphtha, light gas oil and heavy gas oil;recycling a portion of the heavy gas oil by introducing it into the fractionating column optionally with the bottoms from the flash unit;mixing the fractionating column bottoms with the whole crude oil feedstream to form the mixed feedstream; andintroducing the mixed whole crude oil and fractionating column bottoms feedstream into the furnace.

Owner:SAUDI ARABIAN OIL CO

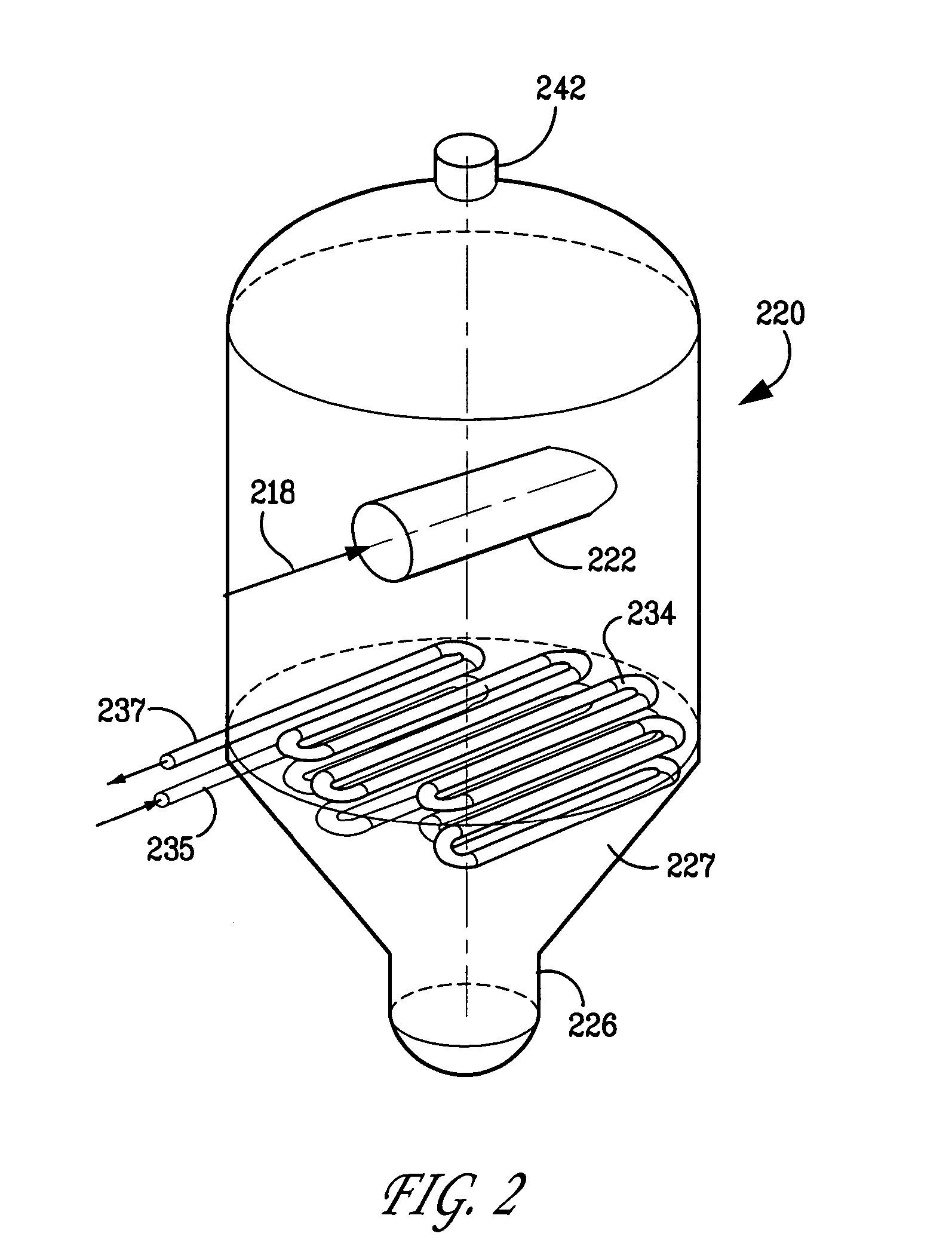

Methods for co-flash evaporation of polymerizable monomers and non-polymerizable carrier solvent/salt mixtures/solutions

Methods for supplying one or more vapors, under reduced pressure, to an environment are provided. The vapor may comprise at least one polymerizable component. In some cases, at least two components may be combined to form the vapor. The components may be provided as separate vapor streams, which may be combined and homogenized. Methods of the invention may also be useful in the deposition of materials on the surface of a substrate. In some cases, the material may form a layer, such as a polymer layer, on the surface of a substrate. The present invention may be useful in applications that require the formation of homogeneous films on the surface of a substrate.

Owner:SION POWER CORP

Flash evaporation-plasma coating deposition method

The present invention provides a method for the formation of an organic coating on a substrate. The method includes: providing a substrate in a vacuum; providing at least one vaporized organic material comprising at least one component from at least one source, wherein the vaporized organic material is capable of condensing in a vacuum of less than about 130 Pa; providing a plasma from at least one source other than the source of the vaporized organic material; directing the vaporized organic material and the plasma toward the substrate; and causing the vaporized organic material to condense and polymerize on the substrate in the presence of the plasma to form an organic coating.

Owner:3M INNOVATIVE PROPERTIES CO

Biochar base soil modifier and preparation method thereof

ActiveCN102660291AReduce leaching wasteGood sustained release effectAgriculture tools and machinesOrganic fertilisersDecompositionCarbonization

The invention discloses a biochar base soil modifier and a preparation method thereof. The biochar base soil modifier comprises the following components in percentage by weight: 95.5-98.5% of biomass carbon black and 1.5-4.5% of probiotics agent. Agricultural waste serves as a biomass raw material to carry out low-temperature carbonization to form the porous biomass carbon black; beneficial microorganism is enlarged and cultivated and is fermented into probiotics liquid; after mixing, solid and liquid separation, flash evaporation and drying are carried out to obtain the probiotics agent; the beneficial microorganism is selected from one or more of paenibacillus polymyxa, trichoderma strains, nitrogen-fixing bacteria, rhizobium, phosphate solubilizing bacteria, potassium bacteria, cellulose decomposition bacteria, antibiotic generation bacteria and photosynthetic bacteria. The biochar base soil modifier disclosed by the invention adopts the microporous biomass carbon which has strong adsorption capability and good light absorption and temperature-increasing effect. The probiotics agent has a high survival rate and can be stored for a long time at the normal temperature, the fertilizer synergy action is obvious, and the soil borne disease can be effectively prevented and cured.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

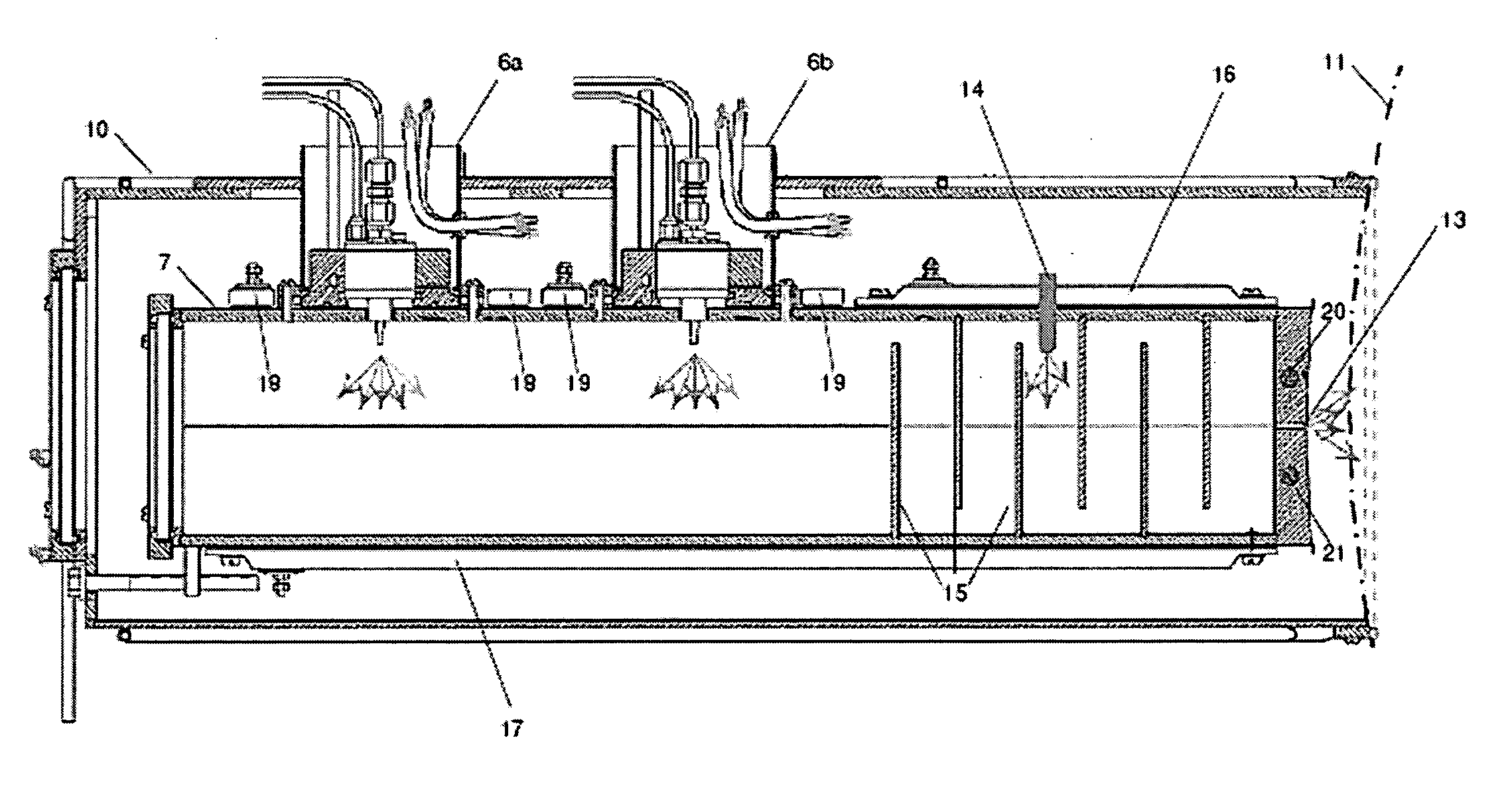

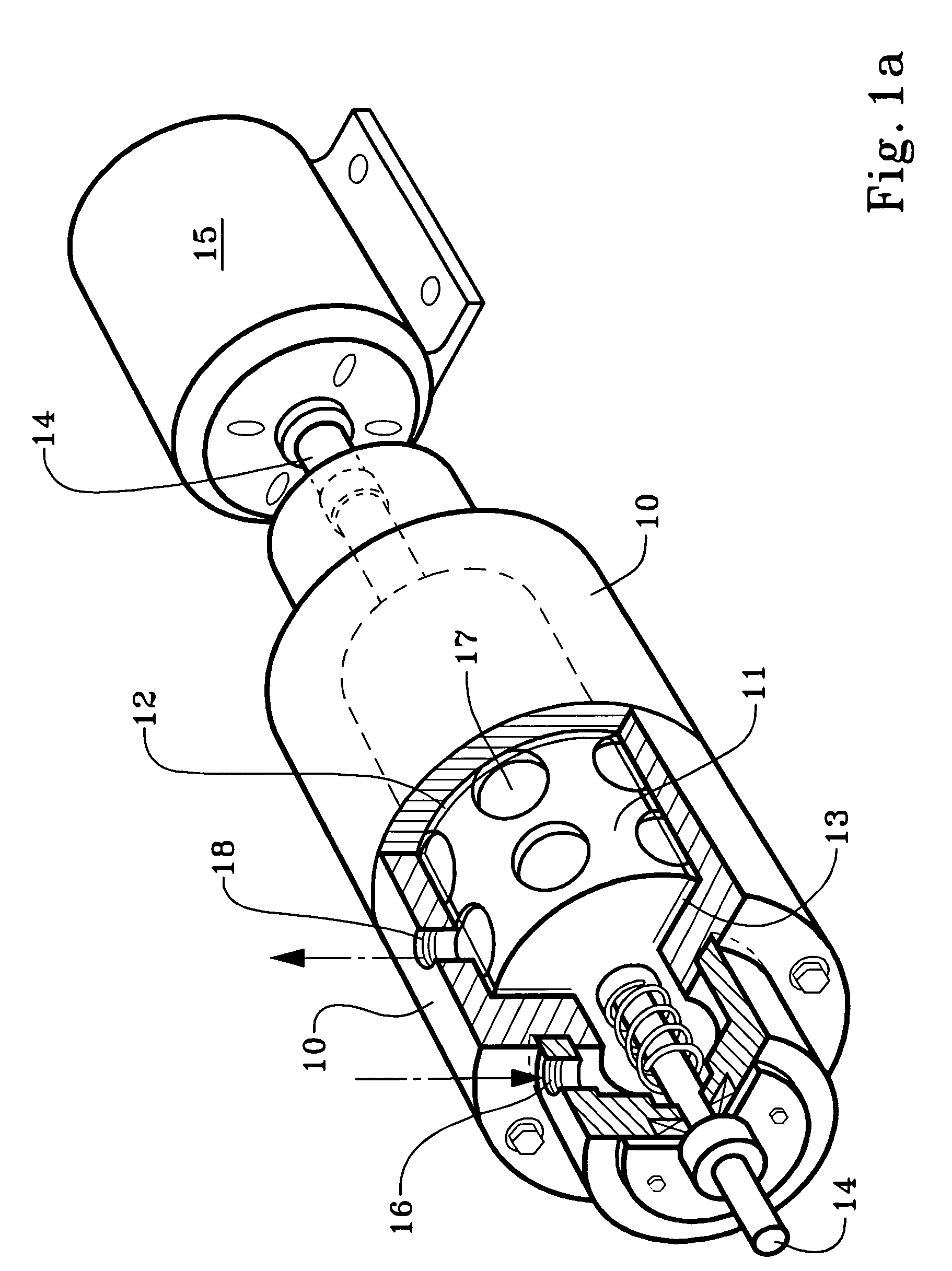

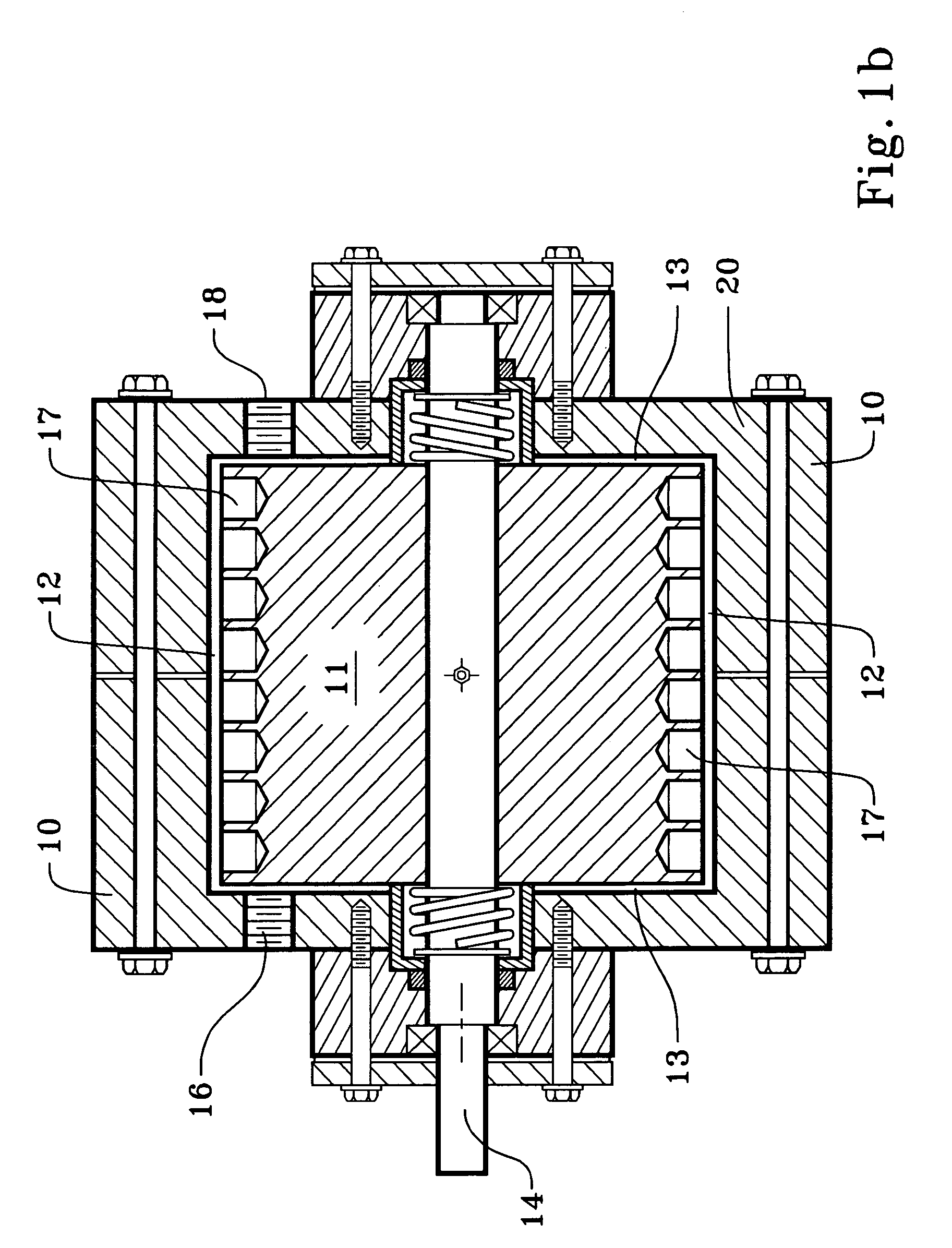

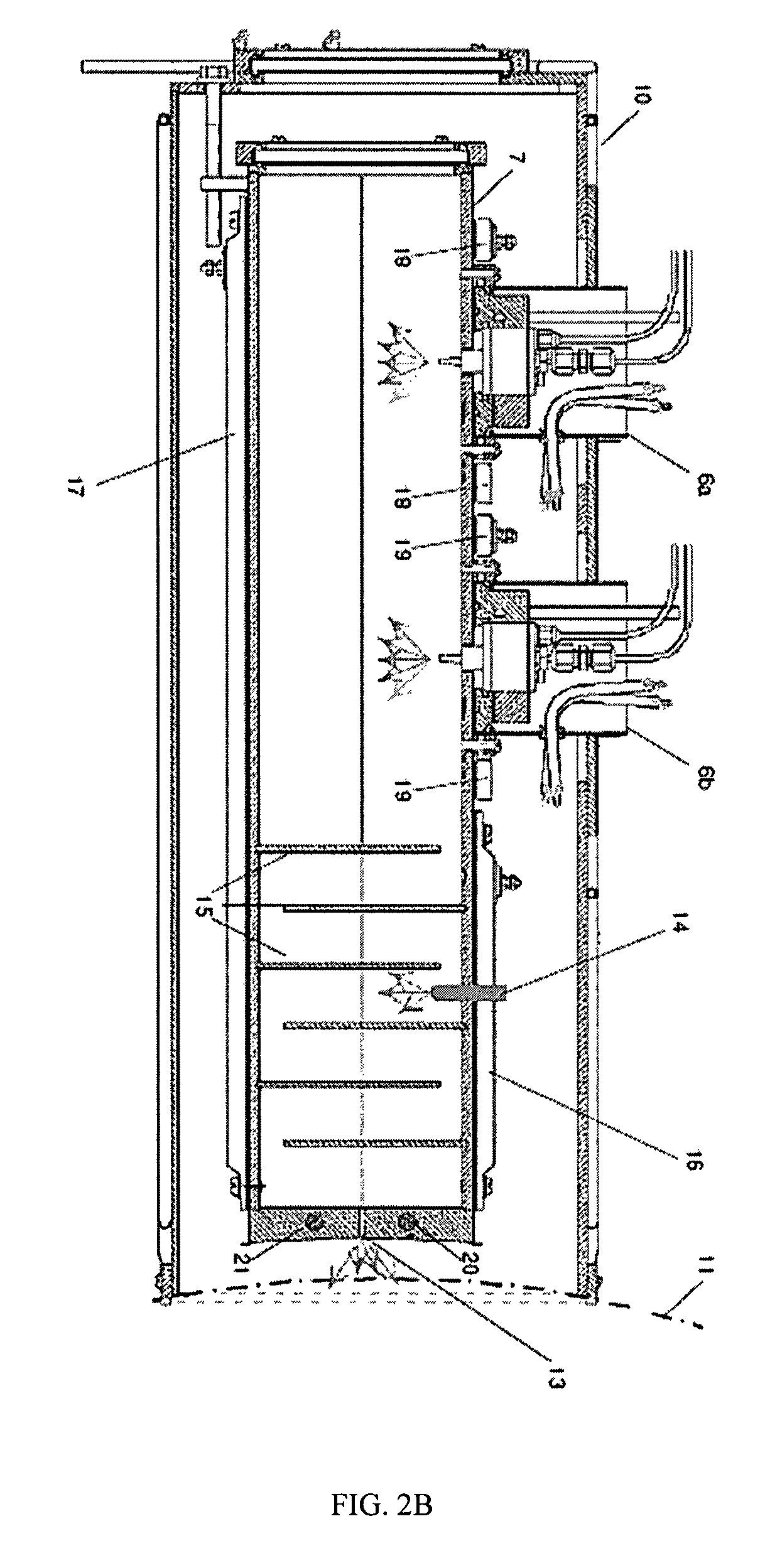

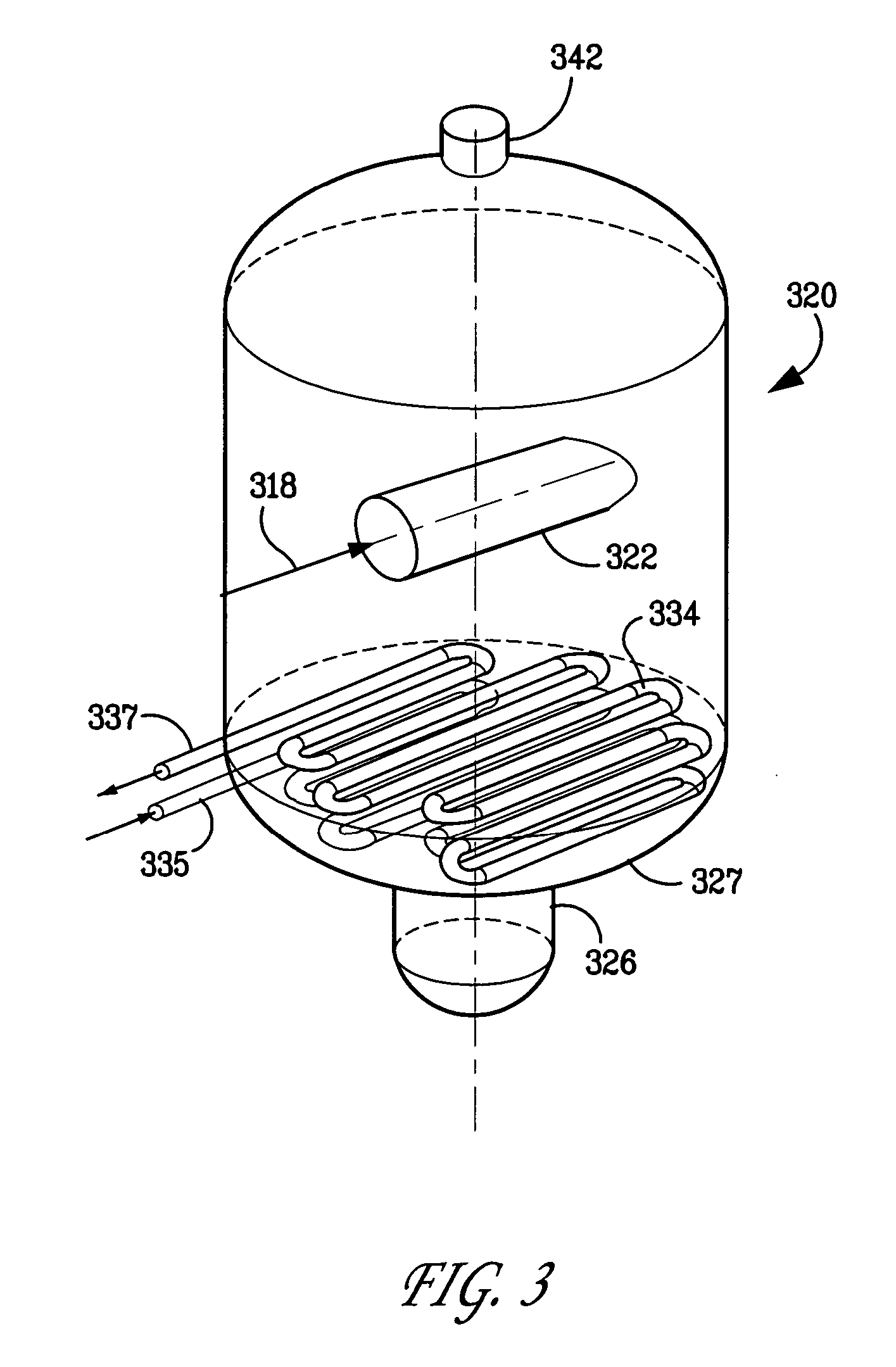

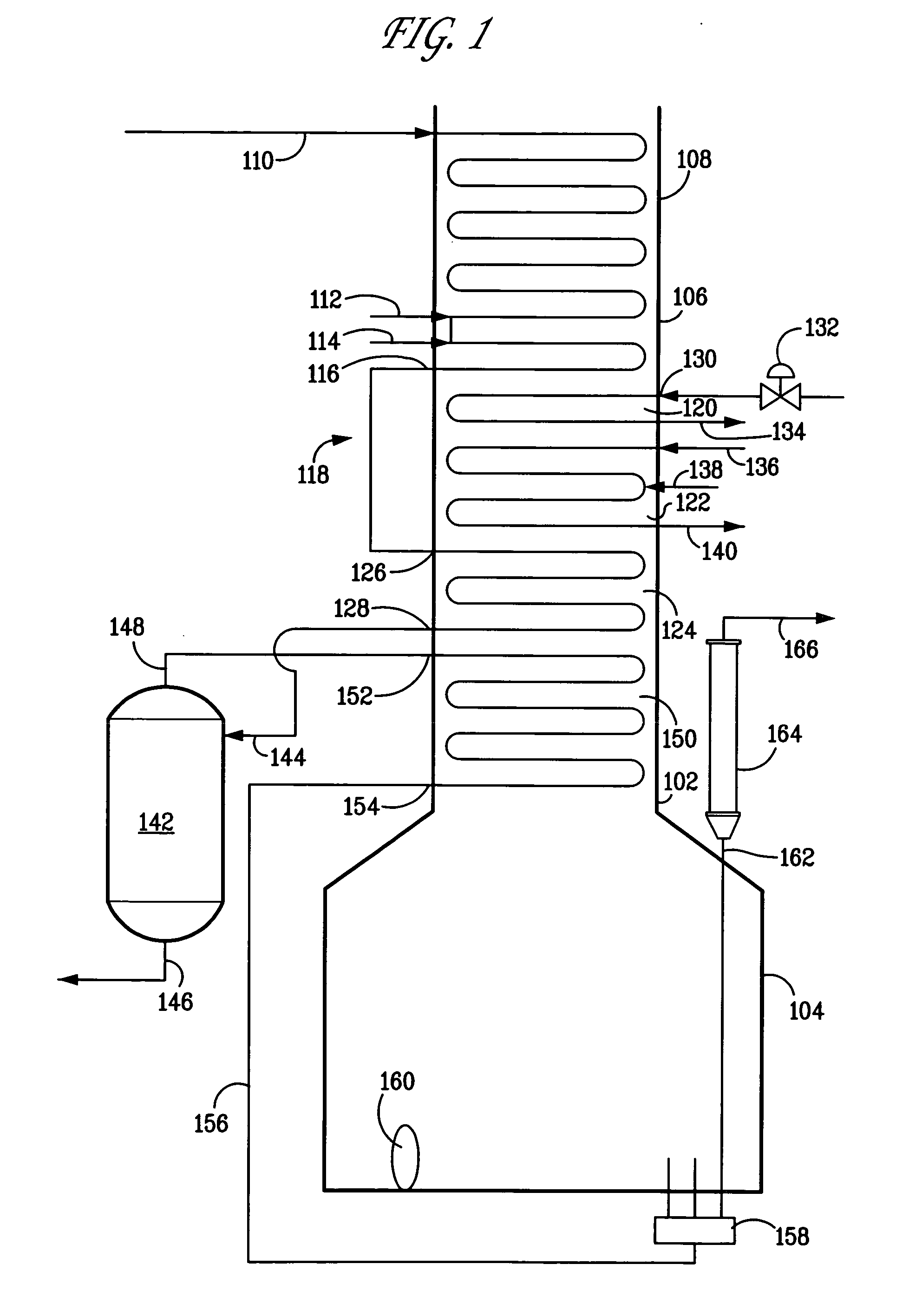

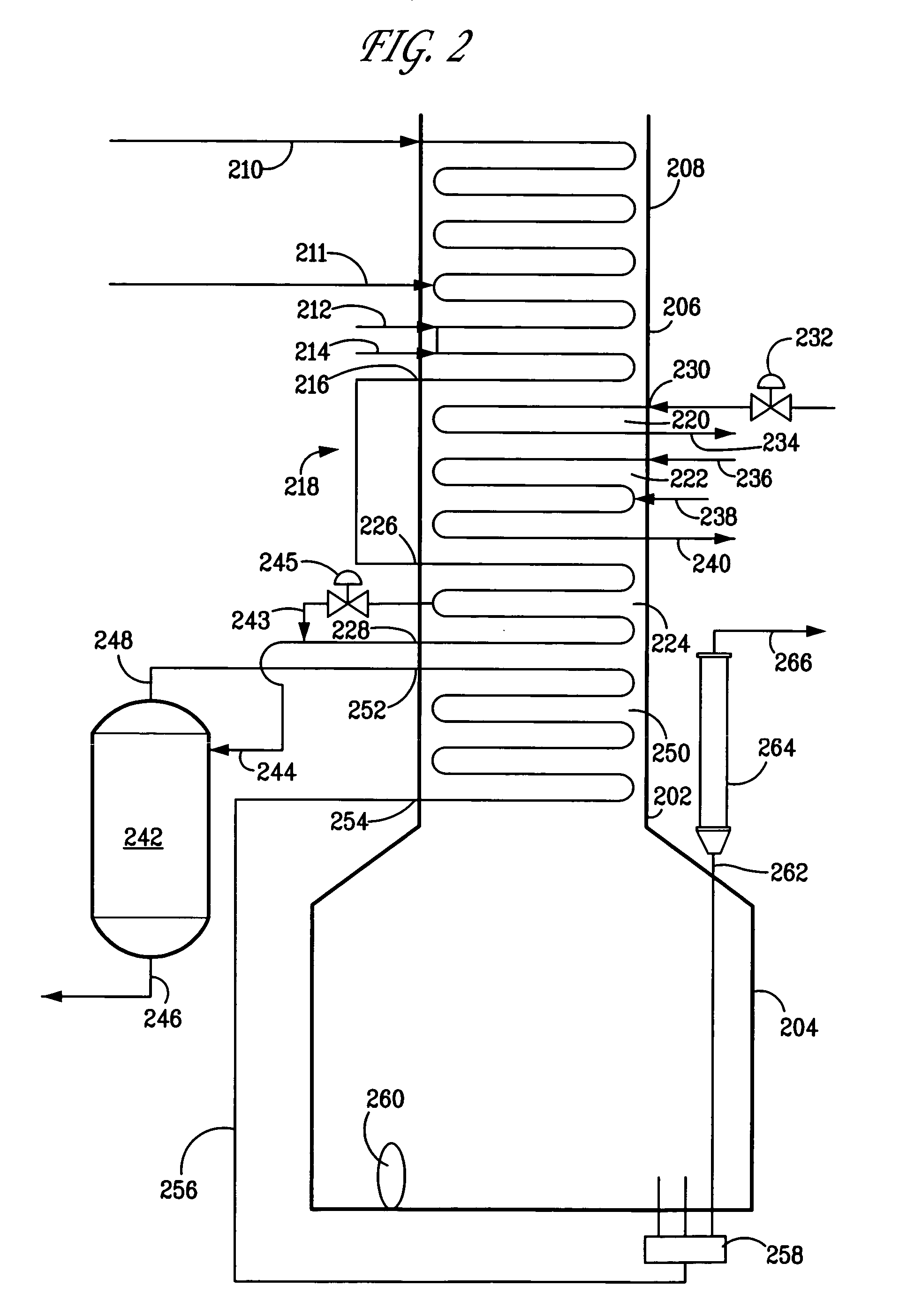

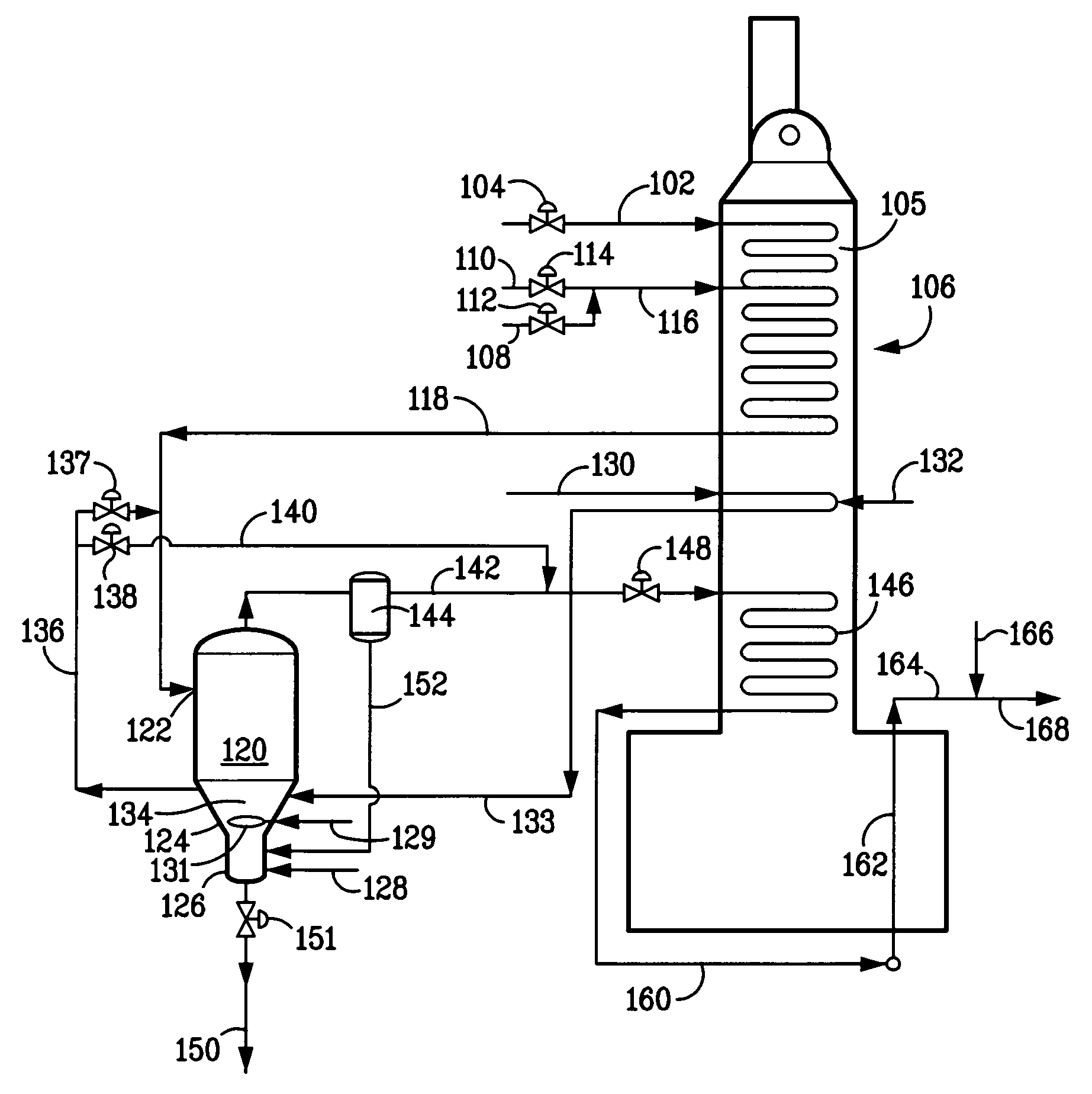

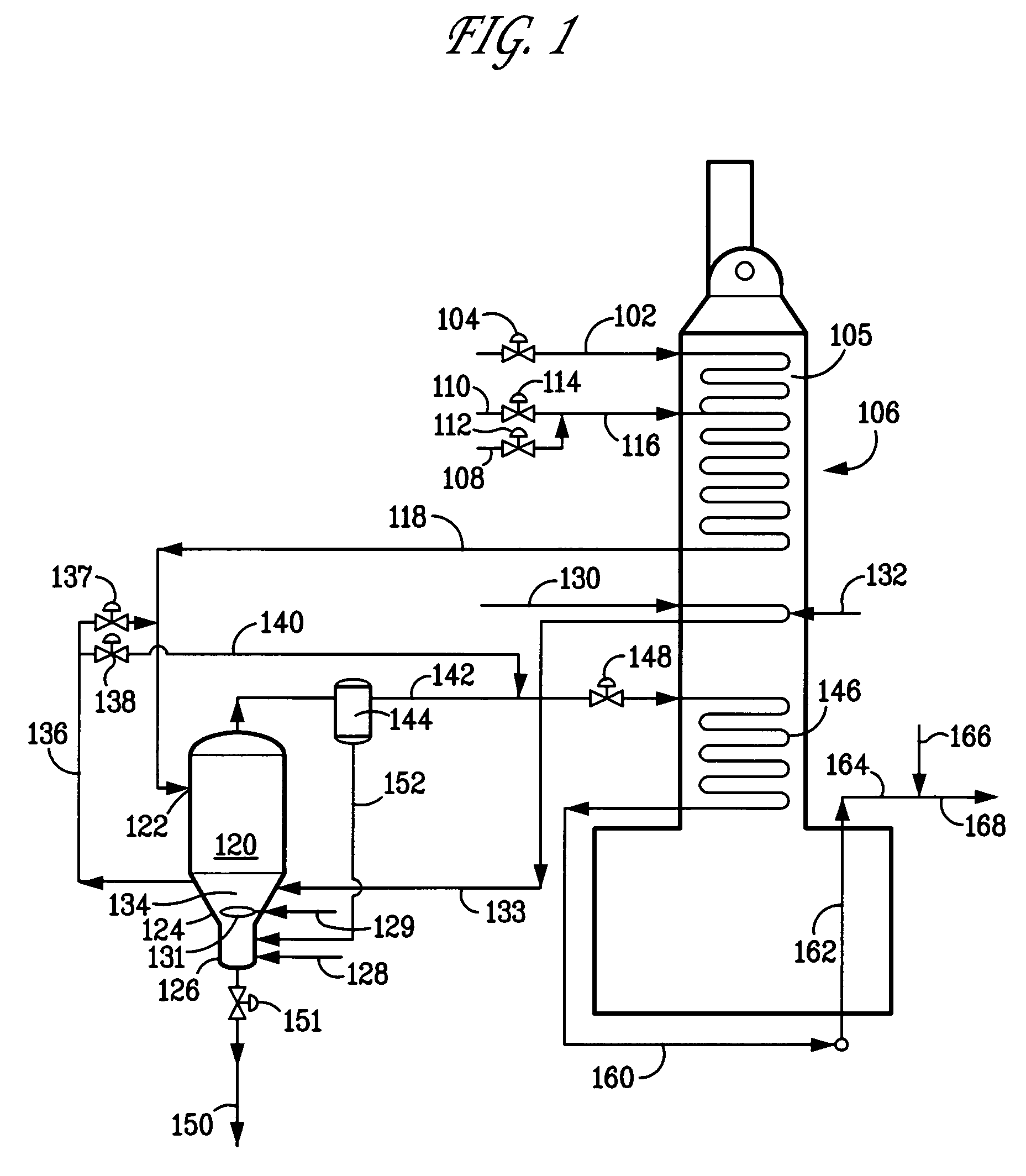

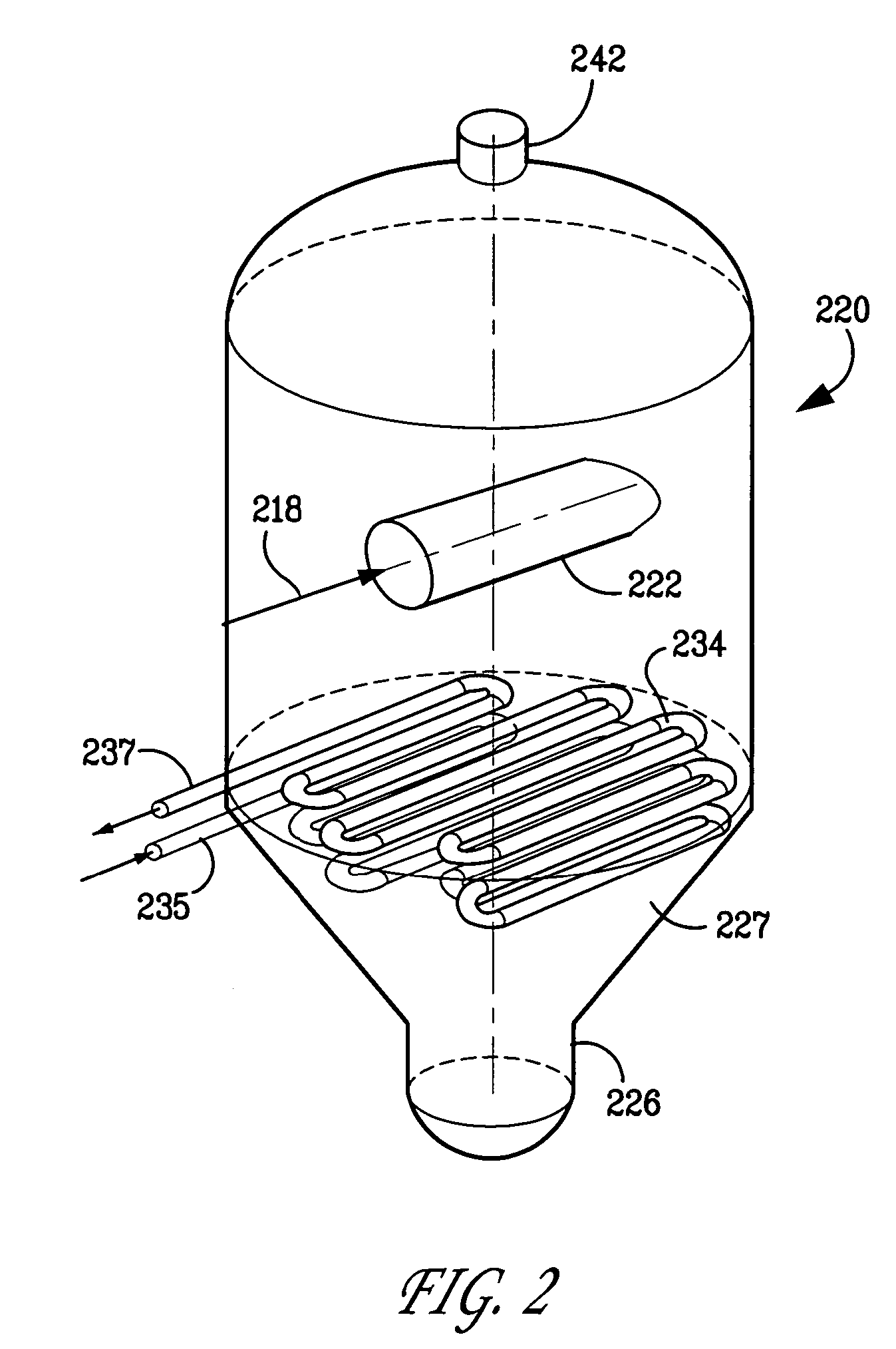

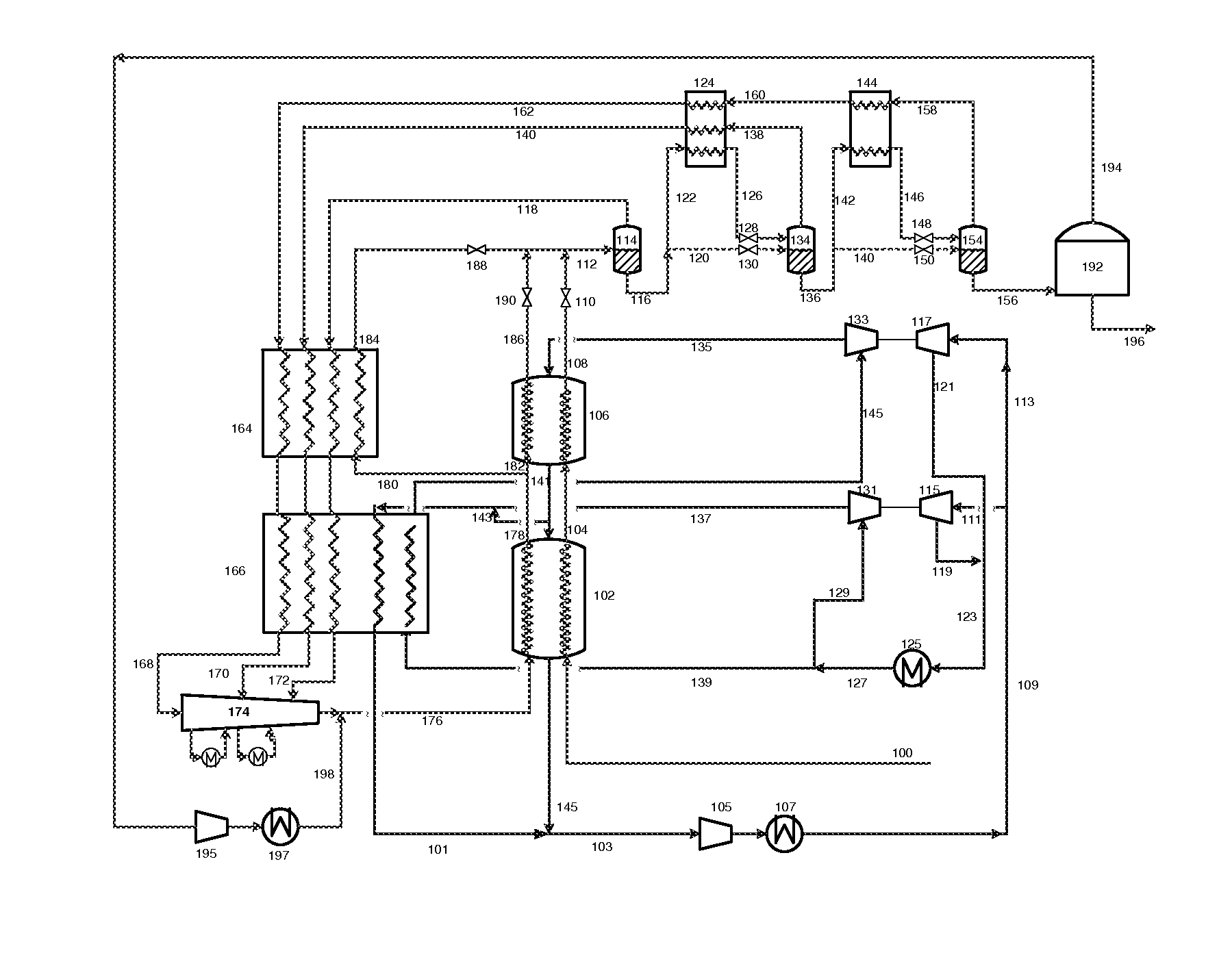

Process and apparatus for cracking hydrocarbon feedstock containing resid to improve vapor yield from vapor/liquid separation

ActiveUS20060089519A1Avoid excessive diameterReduce condensationThermal non-catalytic crackingHydrocarbonsGas phaseDiluent

A process for cracking hydrocarbon feedstock containing resid comprising: heating the feedstock, mixing the heated feedstock with a fluid and / or a primary dilution steam stream to form a mixture, flashing the mixture to form a vapor phase and a liquid phase which collect as bottoms and removing the liquid phase, separating and cracking the vapor phase, and cooling the product effluent. The process comprises at least two of the following conditions: (1) maintaining the bottoms under conditions to effect at least partial visbreaking; (2) reducing or eliminating partial vapor condensation during flashing by adding a heated vaporous diluent to dilute and superheat the vapor; (3) partially condensing the vapor within said flash / separation vessel by contacting with a condenser; (4) decoking internal surfaces and associated piping of the flash / separation vessel with air and steam; (5) utilizing a flash / separation vessel having an annular, inverted L-shaped baffle; and (6) regulating temperature in furnace tube banks used for heating by utilizing a desuperheater and / or an economizer. An apparatus for carrying out the process is also provided.

Owner:EXXONMOBIL CHEM PAT INC

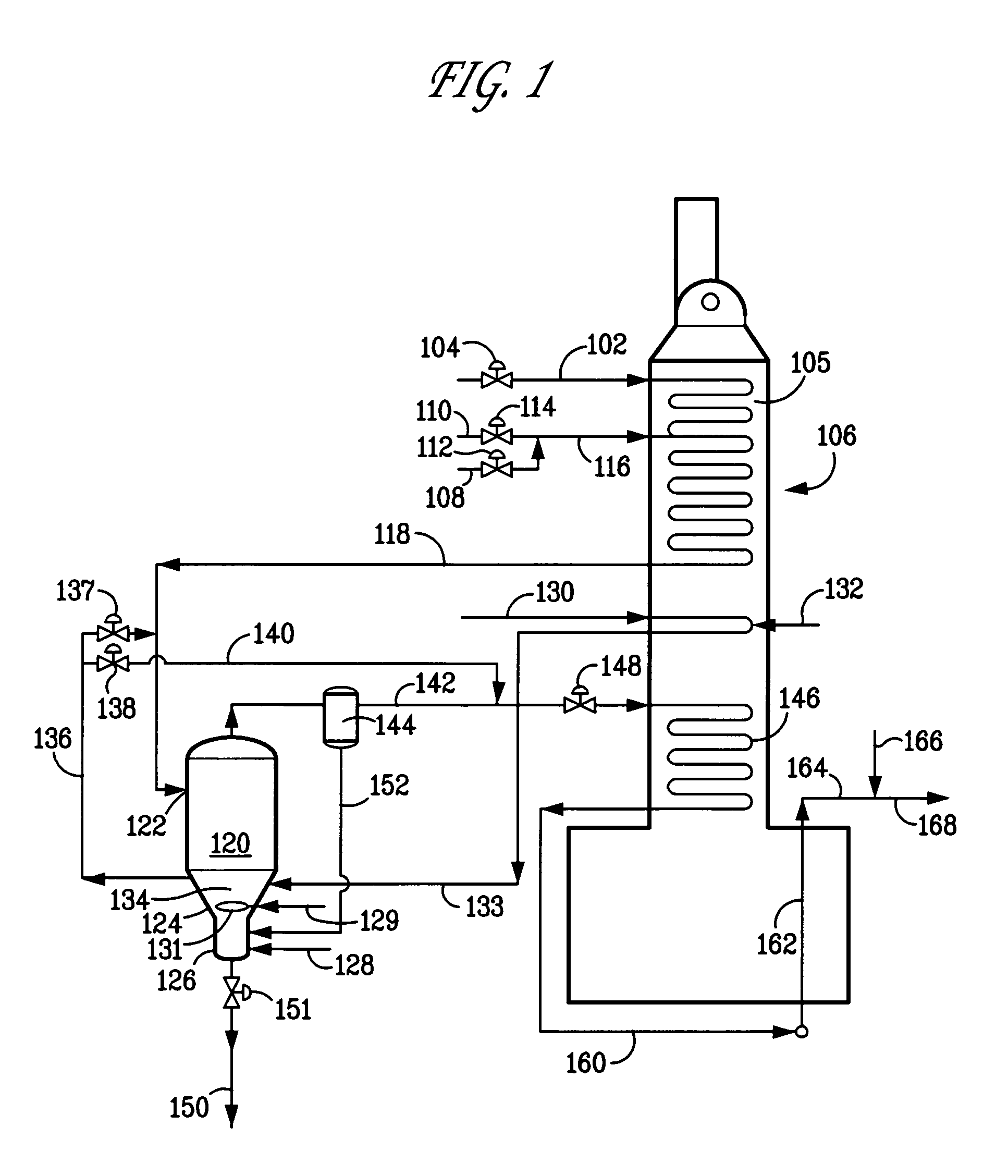

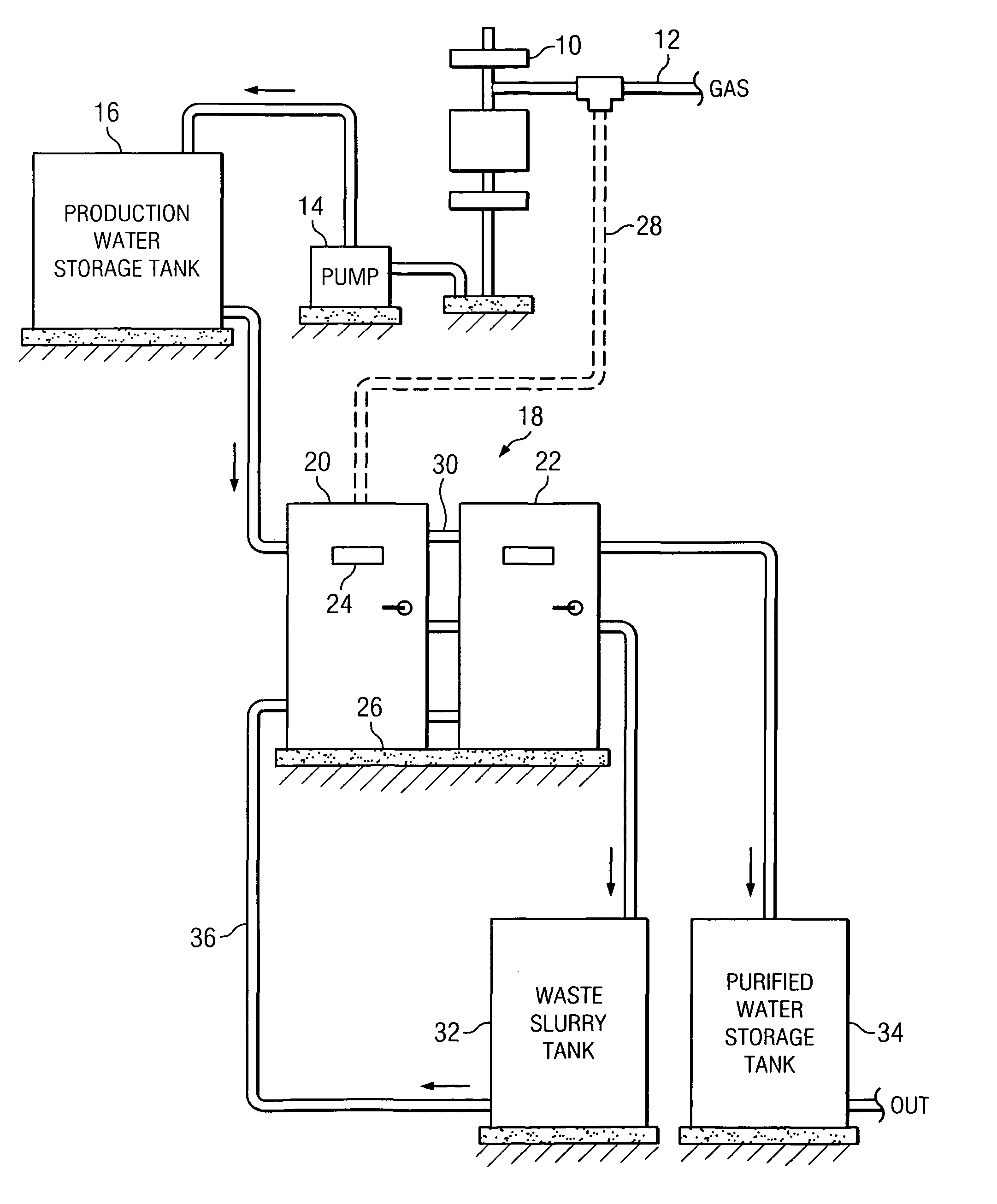

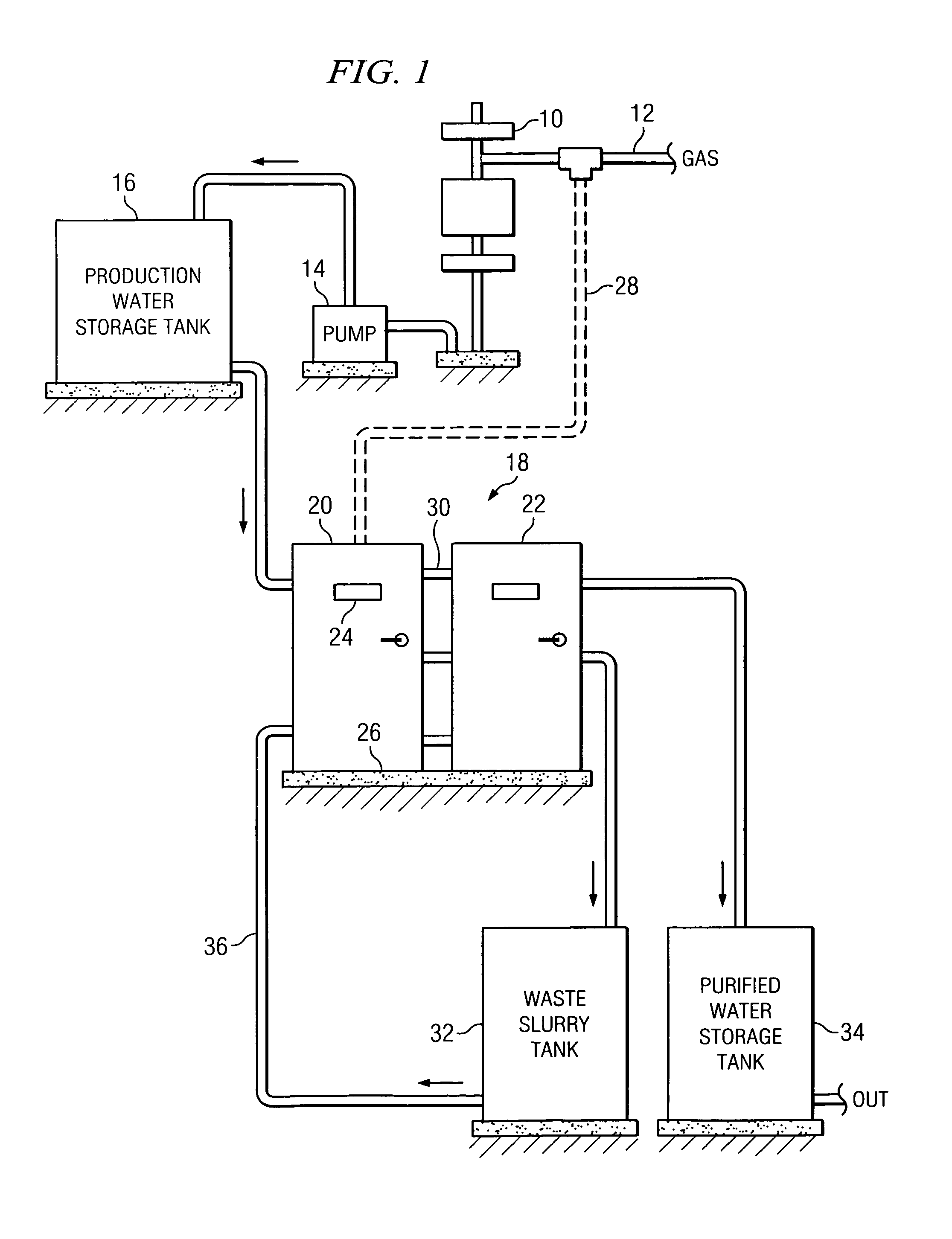

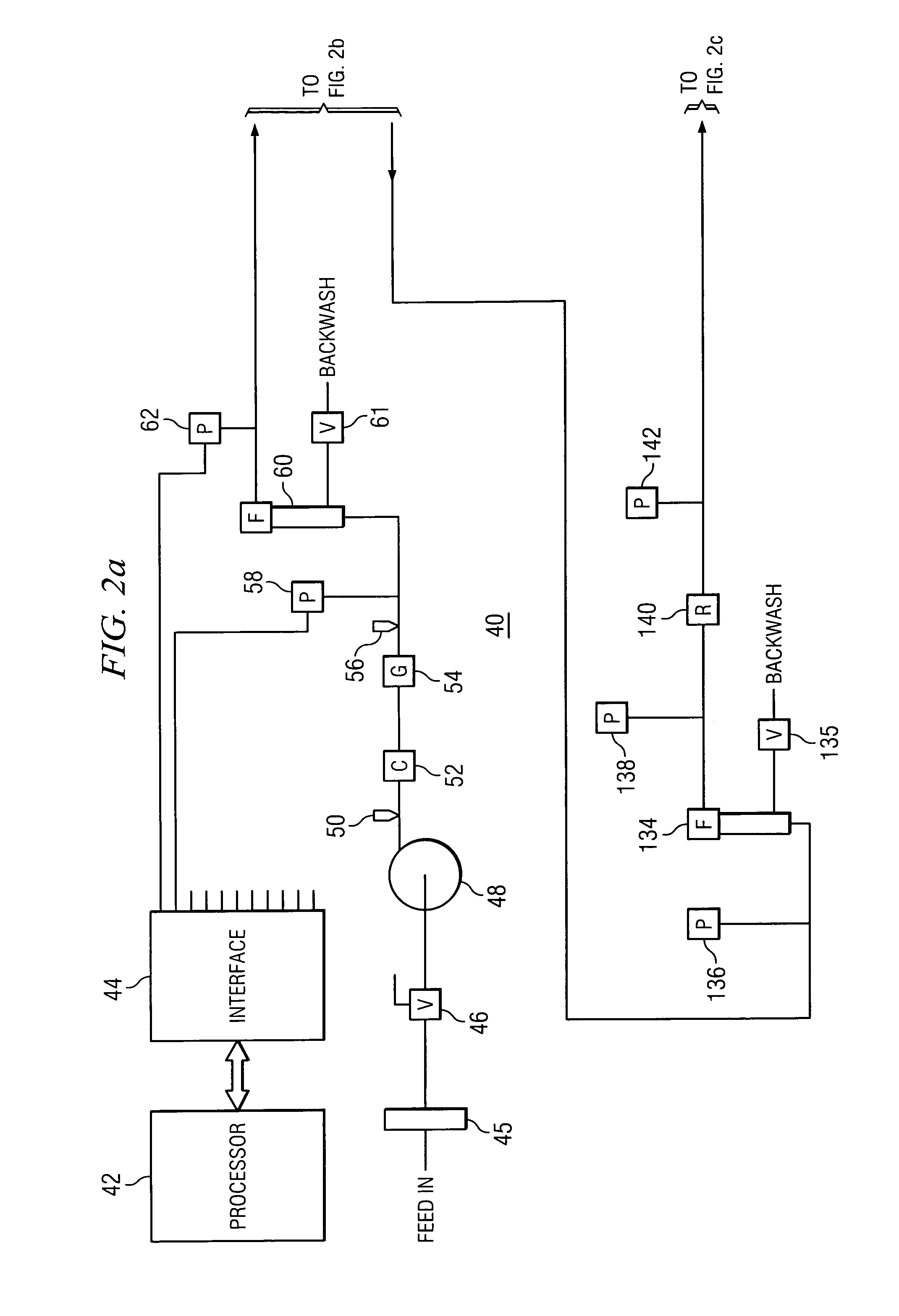

Method and apparatus for purifying water

ActiveUS8097128B1Improve efficiencyImprove throughputLiquid degasificationAuxillariesThermal energyInternal combustion engine

An efficient flash evaporation water purification system located at a hydrocarbon well site. An internal combustion engine uses hydrocarbon fuel from the well and drives a pump to pressurize production water from the well. The engine also generates thermal energy used to preheat the production water. An electrical generator is also driven by the engine to produce electrical power for the water purification system, as well as produce AC power for off-site consumers.

Owner:SHERRY RAYMOND C

Process and equipment for preparing adipic acid by catalyzing air and oxidizing cyclohexane

InactiveCN101337879AImprove conversion rateHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCyclohexanoneBoiling point

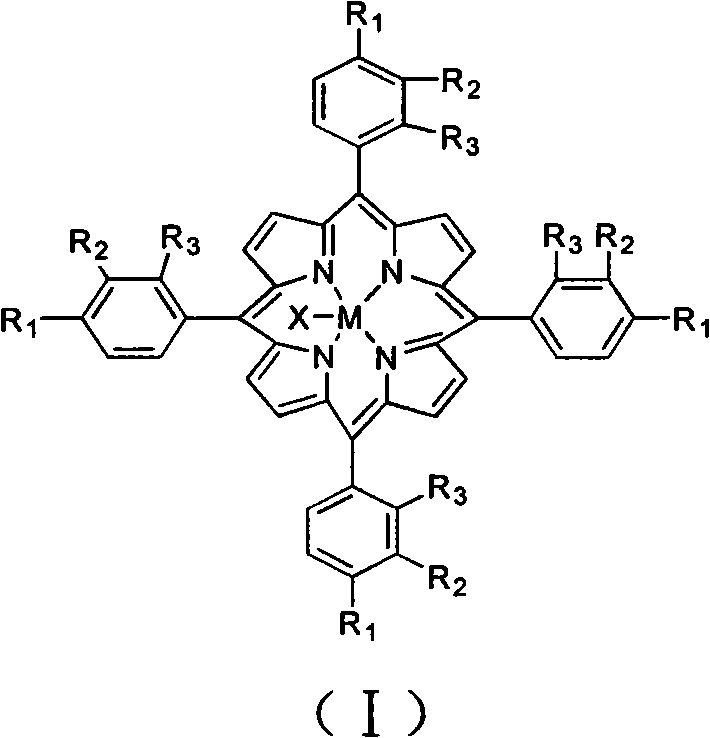

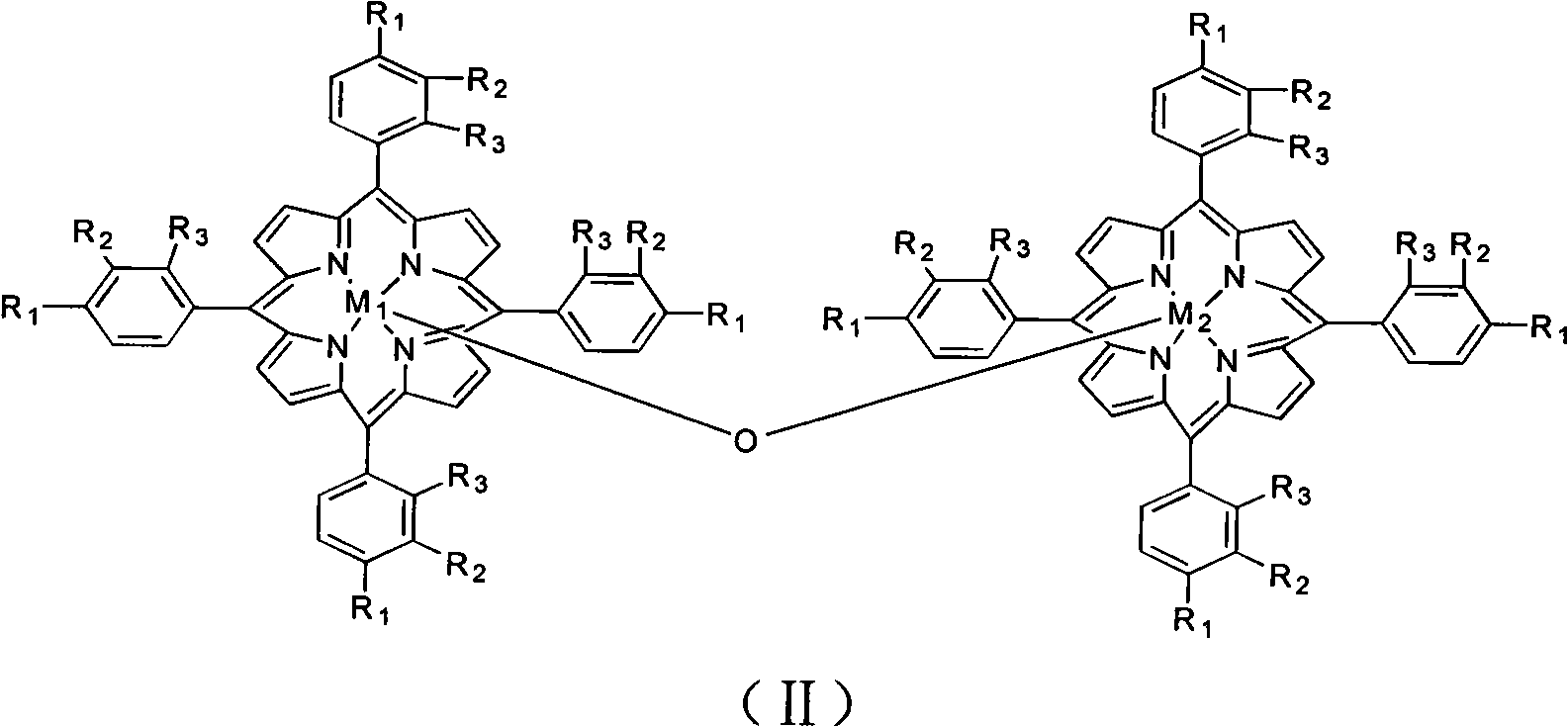

The invention discloses a process and a plant for preparing adipic acid by catalytically aerobically oxidizing cyclohexane. The process comprises the following steps: dissolving 1 to 50 PPM of a catalyst including single metalloporphyrin or mu-oxo bimetallic porphyrin or a mixture of single metalloporphyrin, mu-oxo bimetallic porphyrin and transition metal salt or oxide in cyclohexane; introducing 5 to 12 atm of air or oxygen-rich or oxygen-poor air into a multi-stage oxidation reactor with a gas distributor; controlling the reaction temperature at 140 to 160 DEG C; oxidizing cyclohexane for 45 to 120 min; feeding the mixture of the oxidation reaction into a flash separator to carry out flash evaporation at the temperature of 78 to 155 DEG C and under the pressure of 0.1 to 1.0 atm, so that the low-boiling-point products such as cyclohexane, cyclohexanol and cyclohexanone change to gas and are separated from adipic acid with the content above 80%; continuously circularly oxidizing the low-boiling-point products to separate and purify the high-boiling-point oxidation product; and purifying and separating by the existing technique to obtain fine adipic acid product. The process can directly prepare adipic acid by aerobically oxidizing cyclohexane, wherein the conversion rate of cyclohexane is up to 95%, and the yield of adipic acid is up to 70%.

Owner:HUNAN UNIV

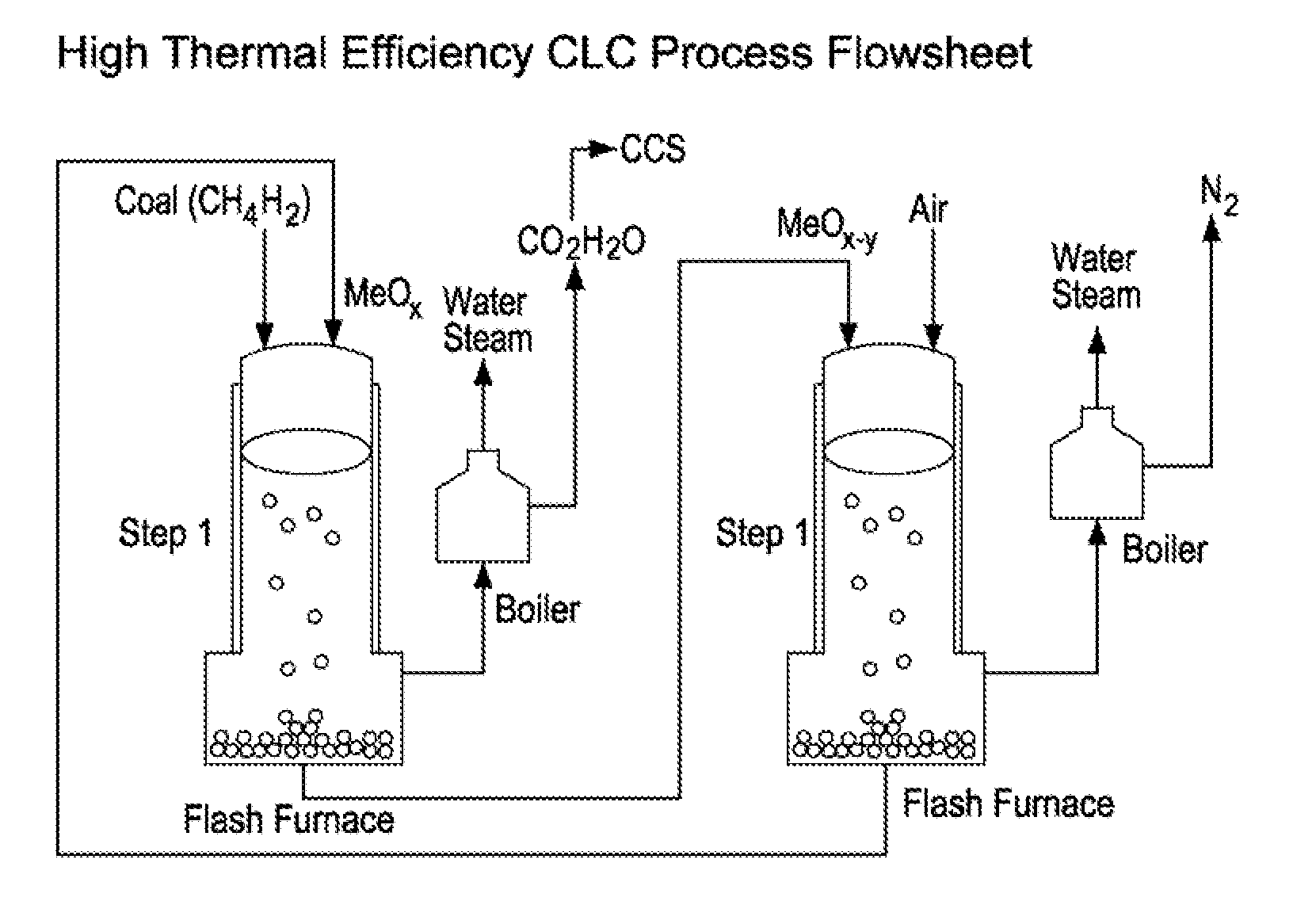

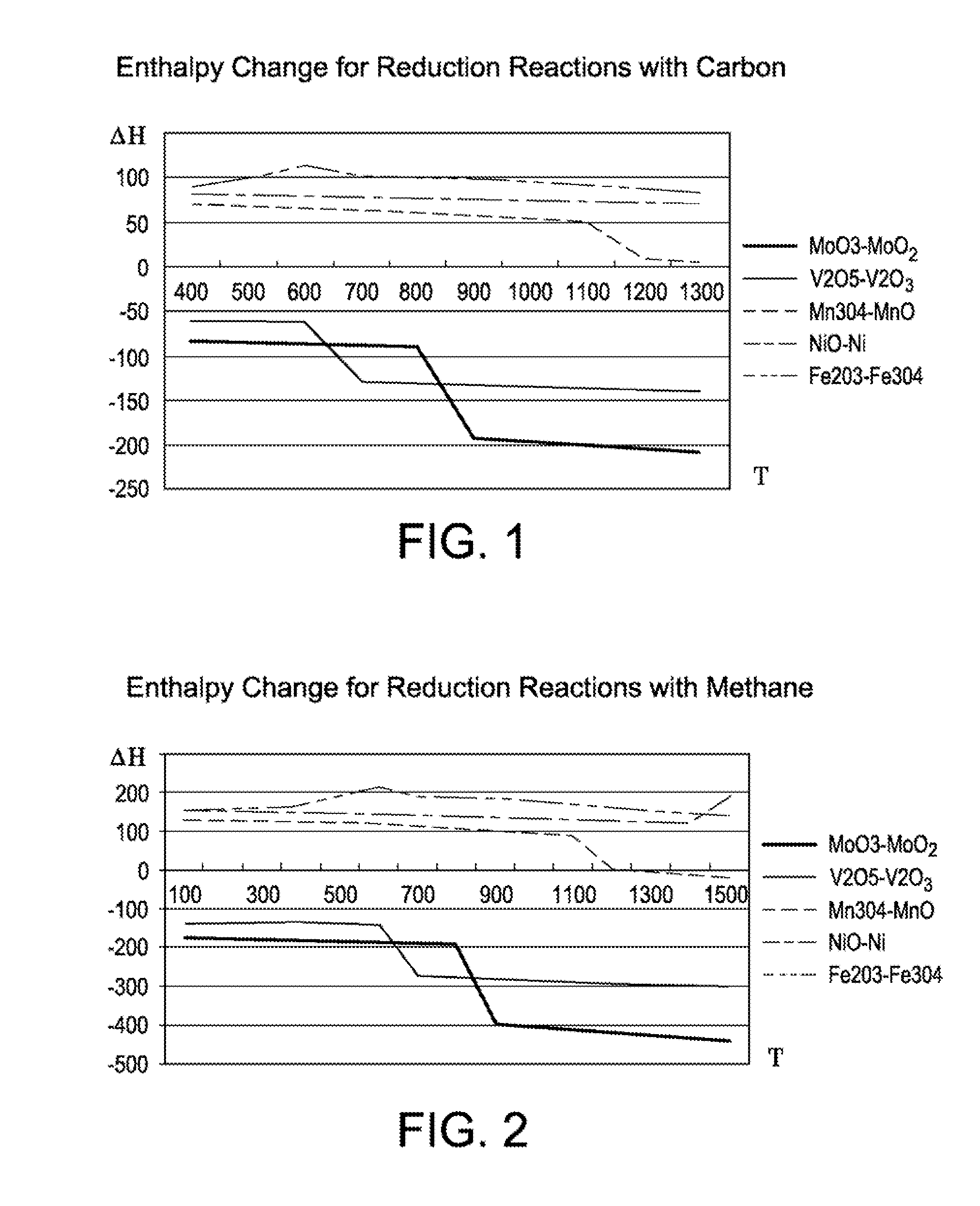

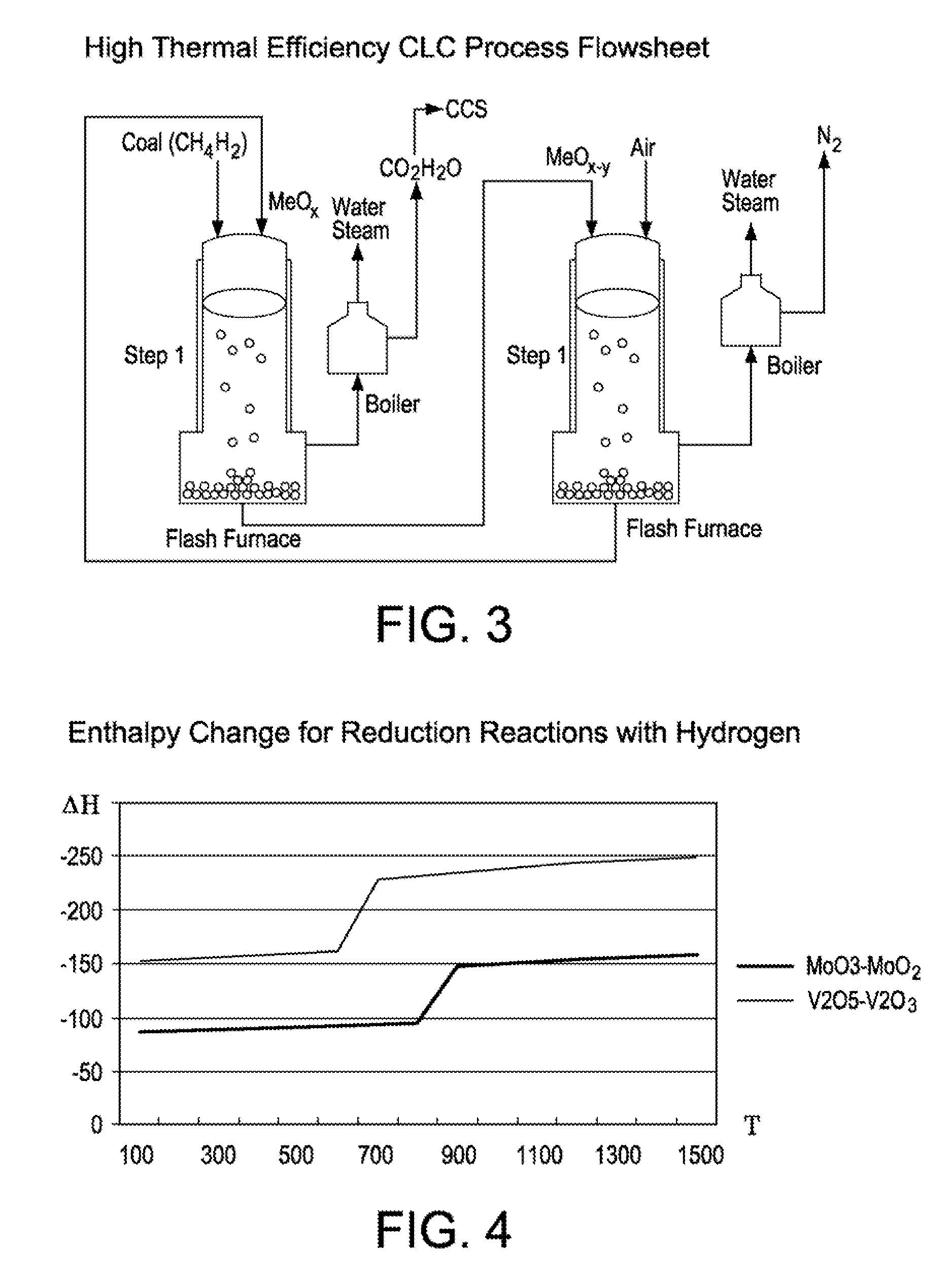

Process and apparatus for high energy efficiency chemical looping combustion

InactiveUS20110094226A1Liquid carbonaceous fuelsDirect carbon-dioxide mitigationHigh energyChemical measurement

Process and apparatus are provided for a high energy efficiency chemical combustion process. The process provides two reaction steps, both of which are exothermic. First, a reduced oxygen carrier is contacted with oxygen in a reactor to form an oxidized oxygen carrier, such as metal oxide or metal suboxide, and then the oxidized oxygen carrier is fed to a second reactor and combusted with a fuel. The reaction produces the reduced oxygen carrier and carbon dioxide. The reduced oxygen carrier from the second reactor is recycled back to said first reactor. Carbon monoxide can also be produced during the process depending on stoichiometric amounts of the reactants. Though the process can be performed in various types of reactor systems, one preferred embodiment is the flash furnace with the production of fly ash during combustion. The process is highly efficient and produces a large amount of usable work.

Owner:ORCHARD MATERIAL TECH

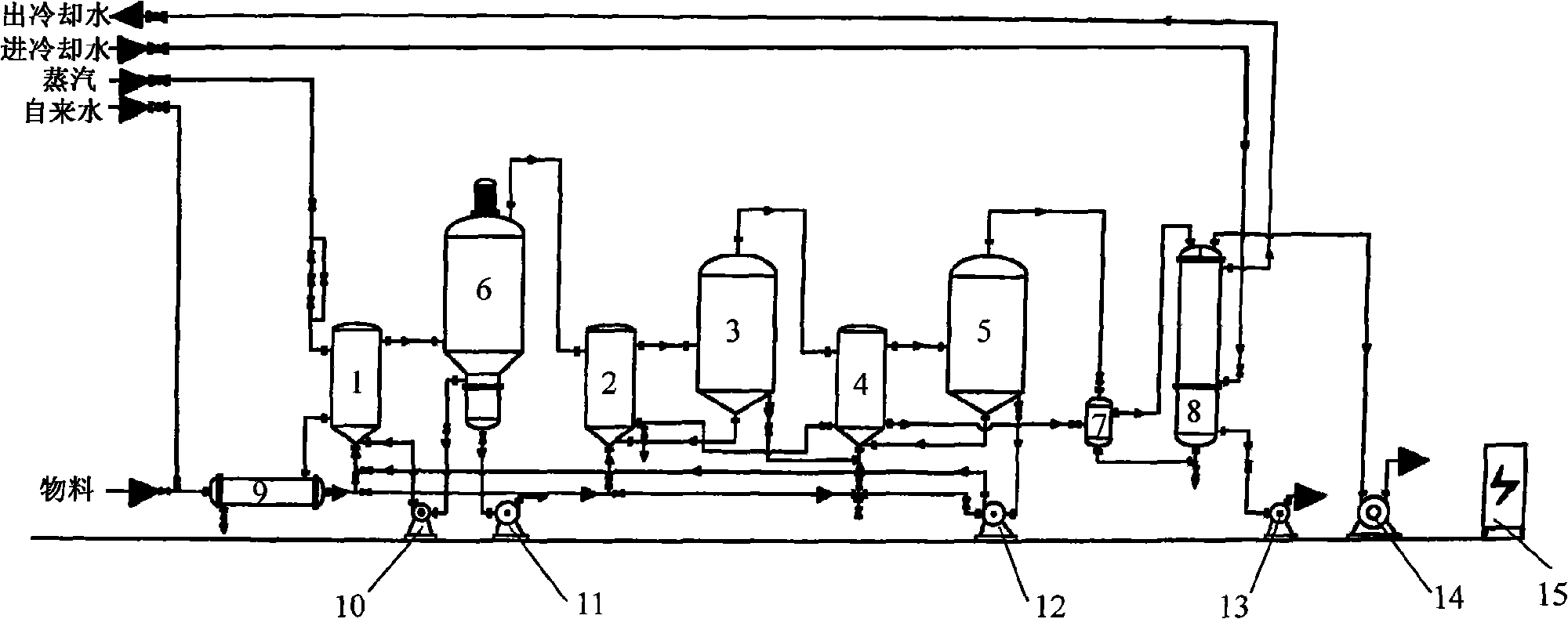

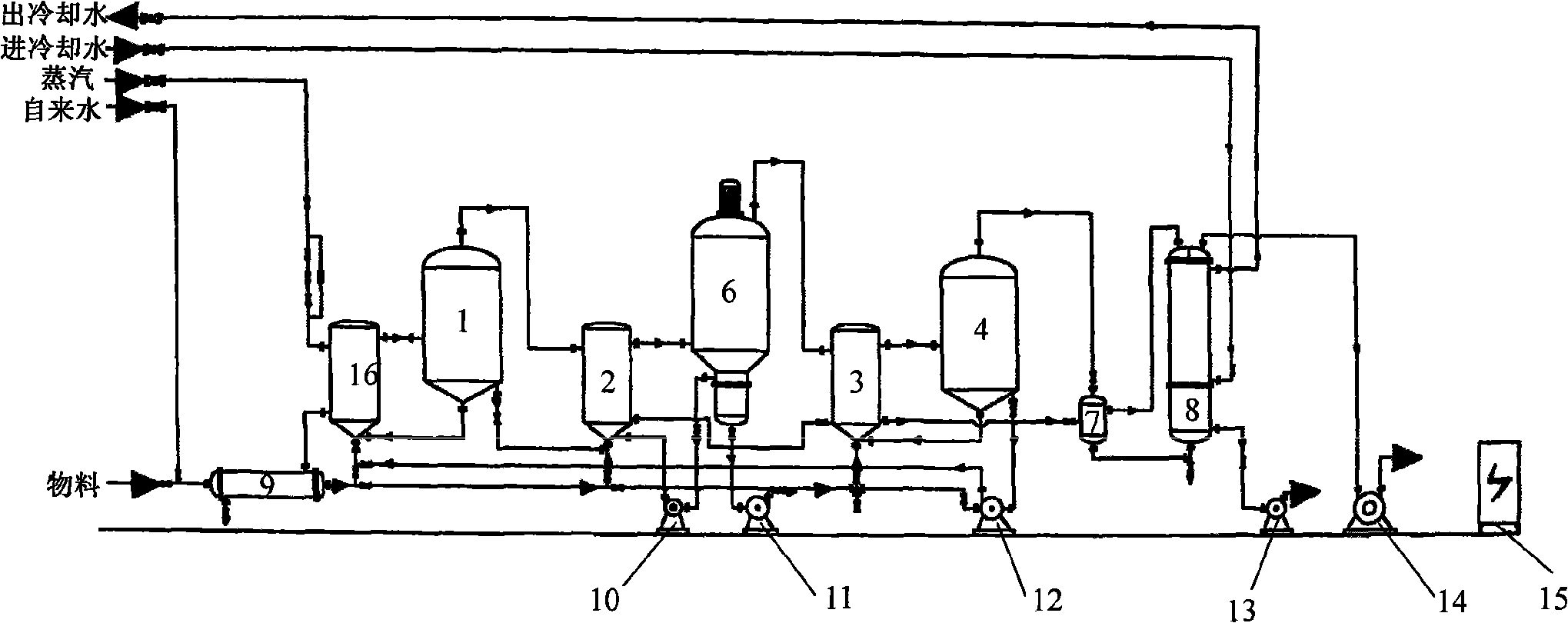

Multifunctional multiple-effect automatic continuous evaporative crystallization technique and crystallization device

InactiveCN101306260AEasy to separateReduce manufacturing costSolution crystallizationMultiple-effect evaporationOrganic solventEconomic benefits

The invention relates to an evaporative crystallization process, in particular to the multifunctional multi-effect automatic continuous evaporative crystallization process and a crystallization device. The process preheats unsaturated water solution or organic solution of materials and carries out the continuous evaporation to the material liquid by a multi-effect evaporator, the temperature of the multi-effect evaporator is gradually reduced and the vacuum degree is gradually increased; when the concentration of the material liquid achieves the saturation, the material liquid enters a crystallizer for the flash evaporation crystallization, and products after the crystallization are subjected to the solid-liquid separation in a centrifuge; the unsaturated solution after the centrifugalization is sent back to the device for the further evaporation crystallization, and the evaporated water or the organic solvent is recycled for use after cooling, thereby realizing the continuous production. The evaporative crystallization process can greatly reduce the labor use and improve the productivity, thereby directly bringing economic benefits to enterprises which use the device and simultaneously reducing the national energy consumption.

Owner:项公浩

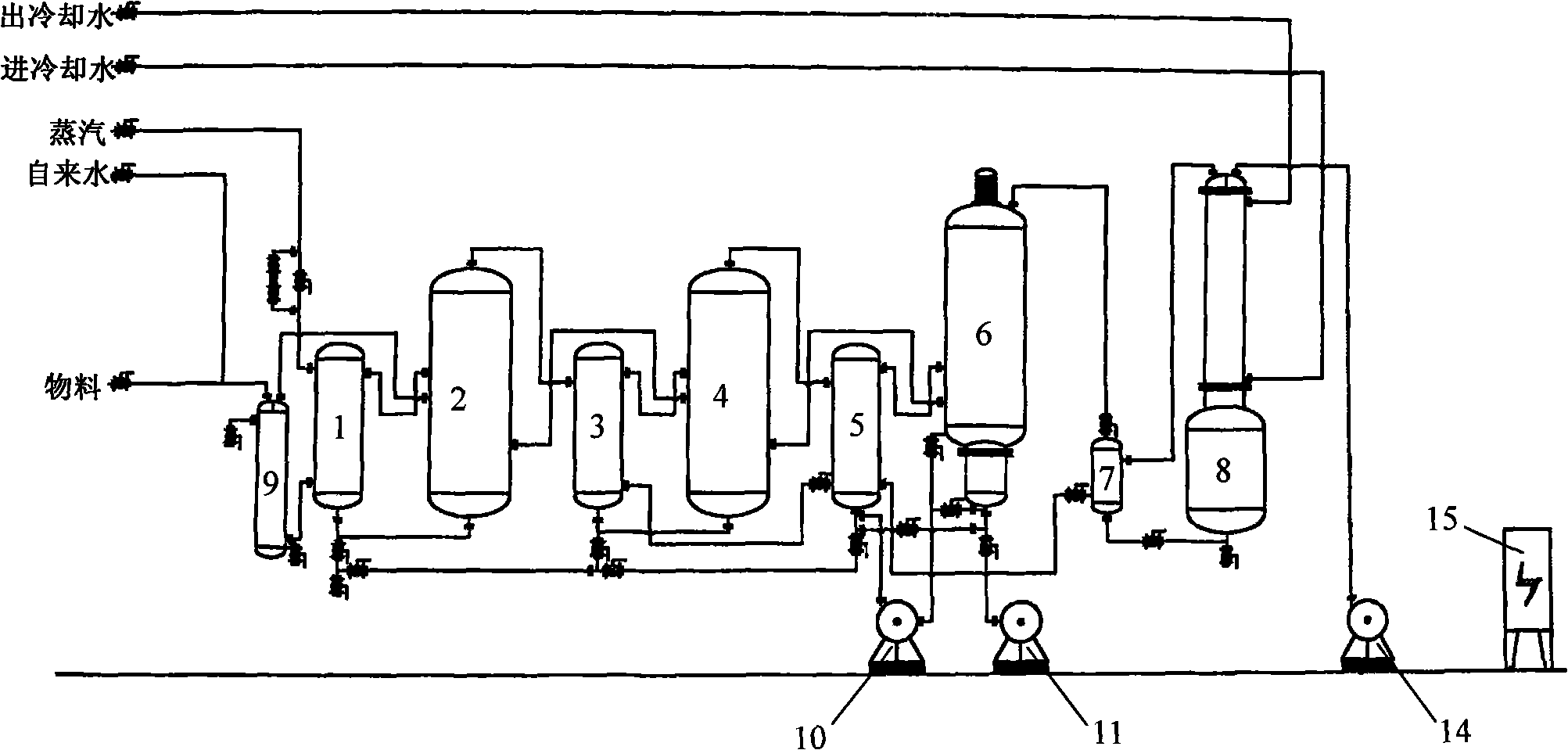

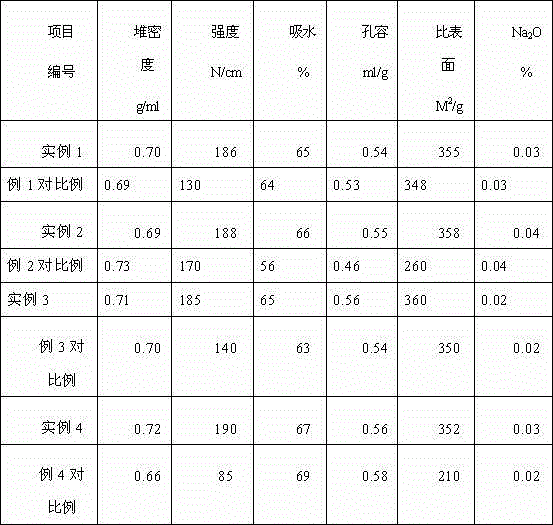

Preparation method of large-pore-volume and high-strength aluminum oxide of catalyst for preparing ethylene from ethanol

ActiveCN104084182AHigh viscosityHigh strengthPhysical/chemical process catalystsHydrocarbon from oxygen organic compoundsFluidized bedMixed materials

The invention discloses a preparation method of large-pore-volume and high-strength aluminum oxide of a catalyst for preparing ethylene from ethanol. The preparation method is characterized by comprising the following steps: (1) drying and crushing aluminum hydroxide trihydrate, and carrying out flash evaporation on aluminum hydroxide trihydrate for rapid dehydration; (2) adequately mixing raw powder and a pore-enlarging agent in a mixing machine so as to obtain a mixed material; (3) adding the mixed material into a kneading machine, and kneading; (4) adding the kneaded material into a strip extruder, and extruding the kneaded material to obtain a strip material; (5) adding the cut strip material into a drying room, and carrying out forced curing; (6) adding the cured strip material into an activating oven, and roasting the strip material; (7) washing the roasted strip material in a washing tank; and (8) adding the washed strip material into the activating oven, and roasting the strip material again. The preparation method has the beneficial effects that by improving the process flow and selecting the pore-enlarging agent, the physical and chemical properties of the catalyst for preparing ethylene from ethanol are greatly improved, and the conversion rate and selectivity of process for preparing ethylene from ethanol are increased; the catalyst can resist the repeated scouring of a fluidized bed, so that the service life of the catalyst is greatly prolonged.

Owner:温州精晶氧化铝有限公司 +1

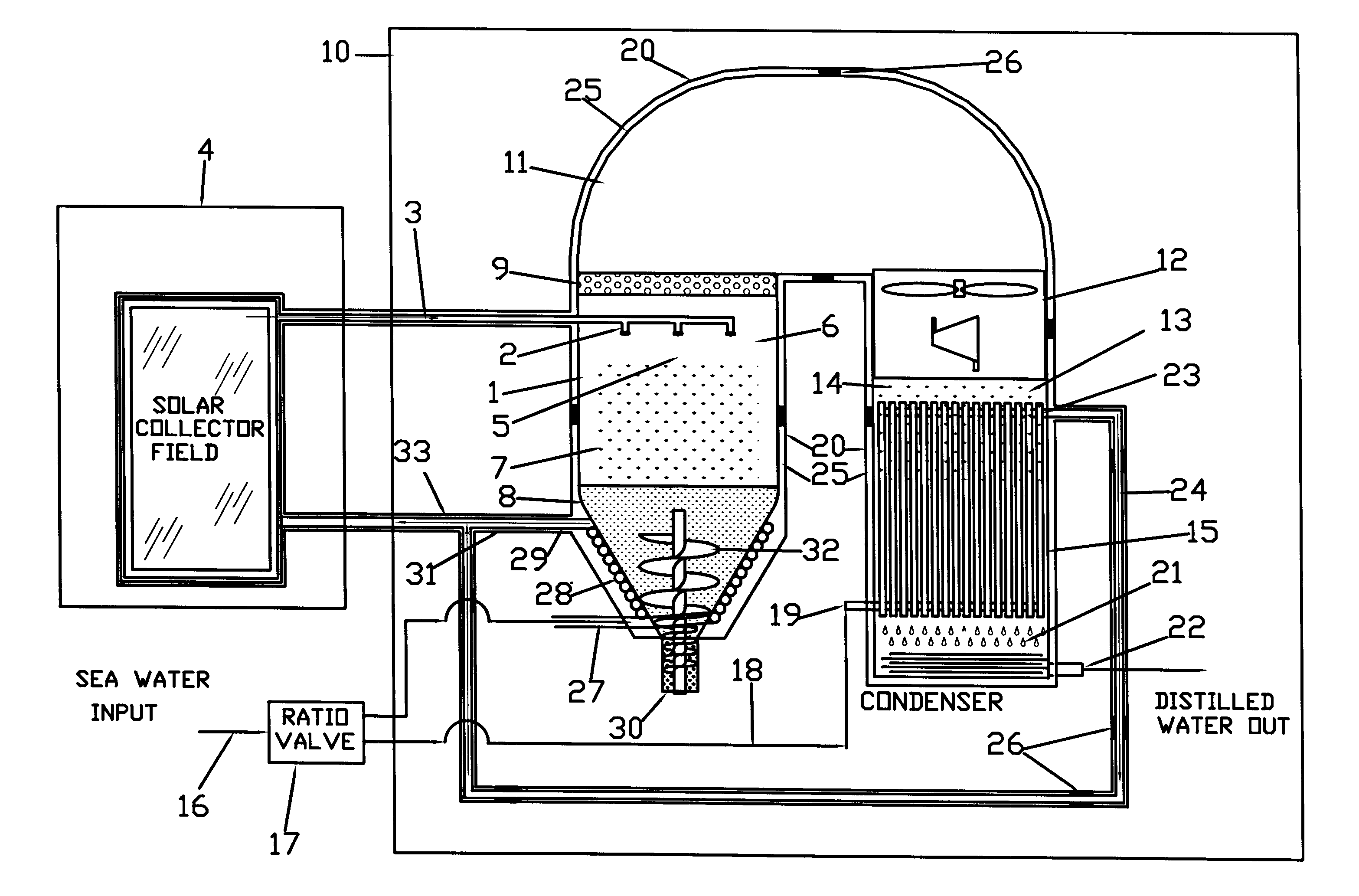

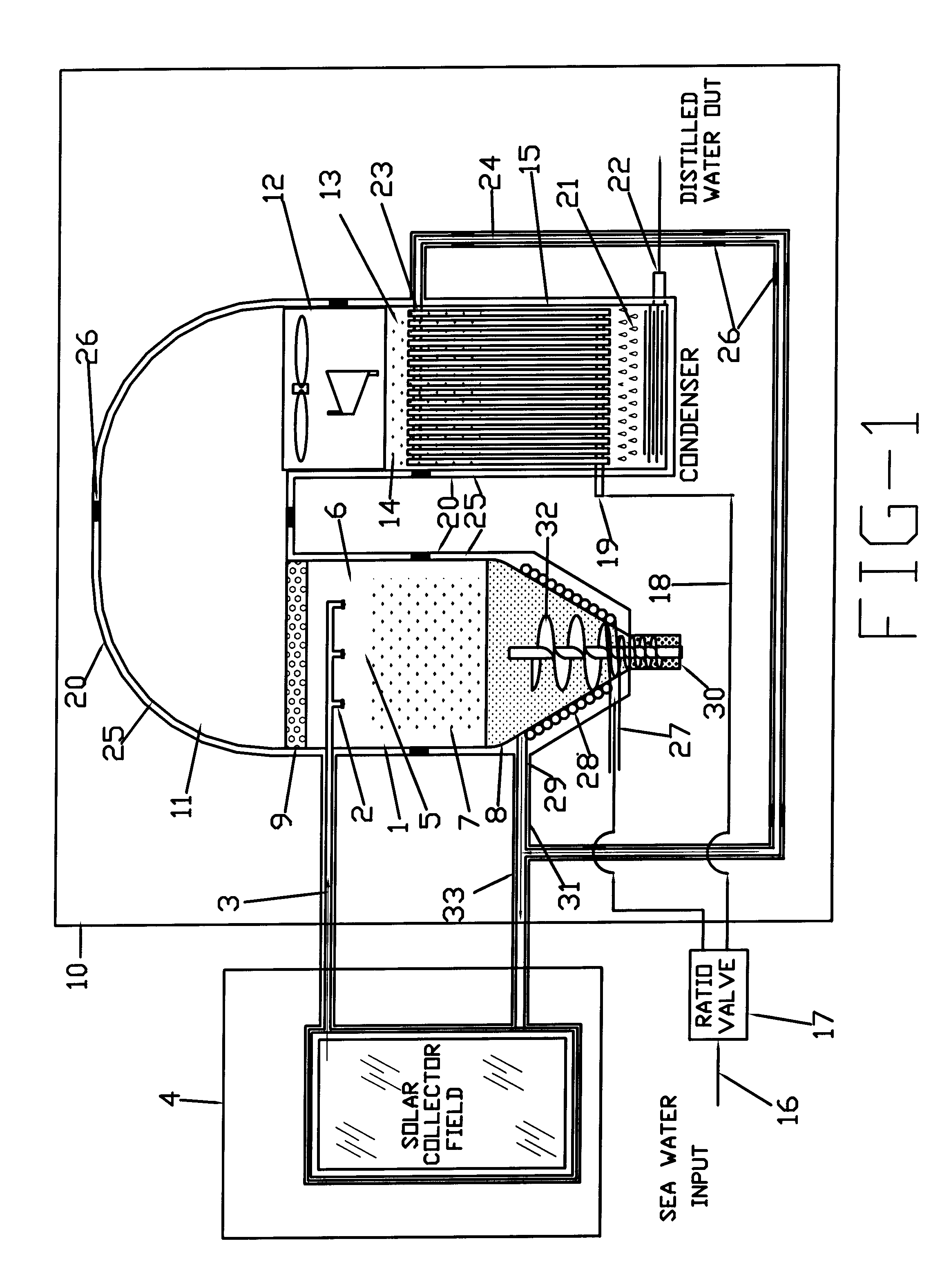

Large scale insulated desalination system

ActiveUS20120085635A1Improve distillation efficiencyLower energy requirementsGeneral water supply conservationAuxillariesDistillationBrackish water

An apparatus and method for the distillation of ocean and brackish water that includes insulation means for preventing heat from escaping to the atmosphere is disclosed. The insulation means comprises a second wall surrounding the basic assemblies of a desalination system in which the space between the second wall and basic assemblies is under low partial vacuum and is partially or totally filled with an insulation material for structural support. The system provides a means for flash evaporation of heated input water and condensing the resultant vapors into pure distilled water. A means for recapturing and using the heat of condensation as well as heat from the salt byproduct to preheat the input contaminated water is also disclosed.

Owner:FLO ONICS LLC

Use of steam cracked tar

ActiveUS20070163921A1Catalytic crackingWorking-up pitch/asphalt/bitumen by chemical meansTarPulp and paper industry

Owner:EXXONMOBIL CHEM PAT INC

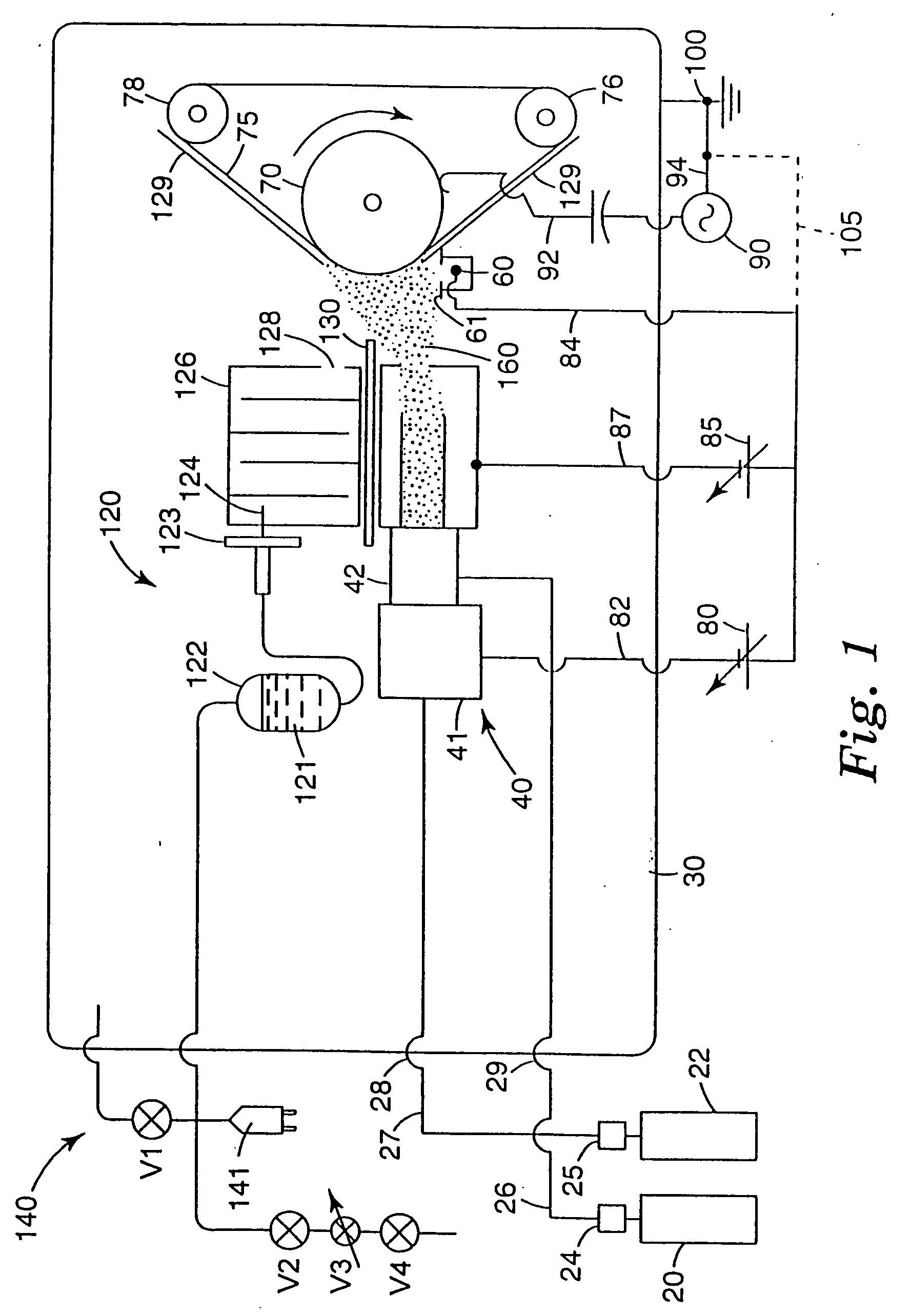

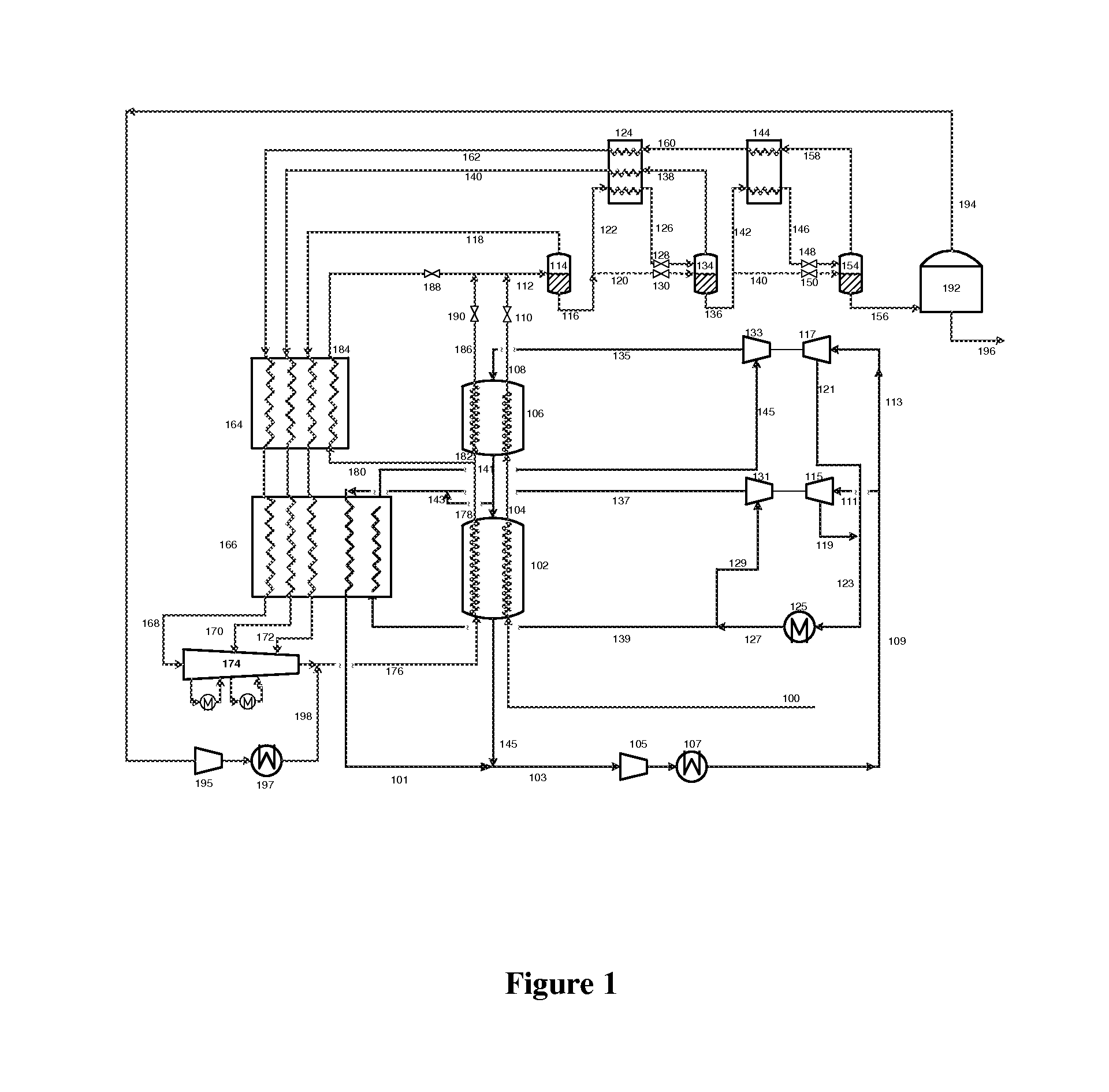

Apparatus and process for controlling temperature of heated feed directed to a flash drum whose overhead provides feed for cracking

InactiveUS20050261536A1Great heat contentThermal non-catalytic crackingHydrocarbon oil cracking processVapor liquidTemperature control

An apparatus and process are provided for cracking hydrocarbonaceous feed, wherein the temperature of heated effluent directed to a vapor / liquid separator, e.g., flash drum, whose overhead is subsequently cracked, can be controlled within a range sufficient so the heated effluent is partially liquid, say, from about 260 to about 540° C. (500 to 1000° F.). This permits processing of a variety of feeds containing resid with greatly differing volatilities, e.g., atmospheric resid and crude at higher temperature and dirty liquid condensates, at lower temperatures. The temperature can be lowered as needed by: i) providing one or more additional downstream feed inlets to a convection section, ii) increasing the ratio of water / steam mixture added to the hydrocarbonaceous feed, iii) using a high pressure boiler feed water economizer to remove heat, iv) heating high pressure steam to remove heat, v) bypassing an intermediate portion of the convection section used, e.g., preheat rows of tube banks, and / or vi) reducing excess oxygen content of the flue gas providing convection heat.

Owner:EXXONMOBIL CHEM PAT INC

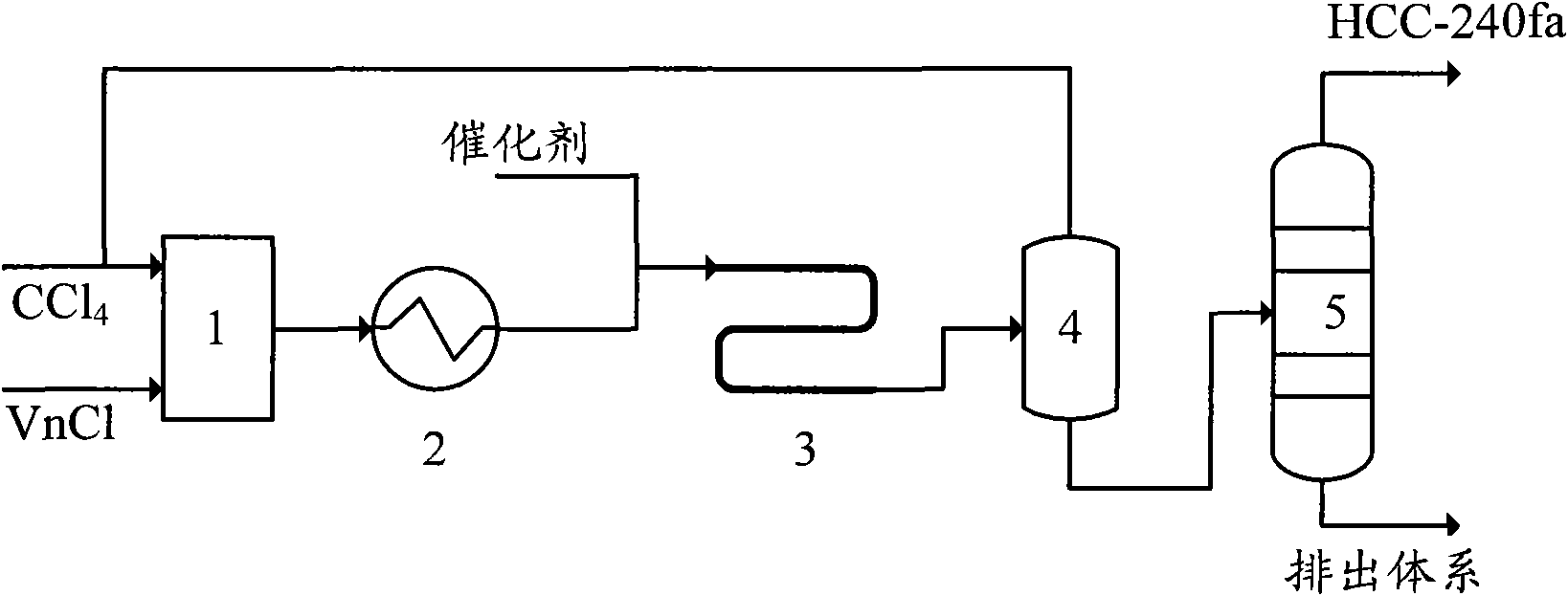

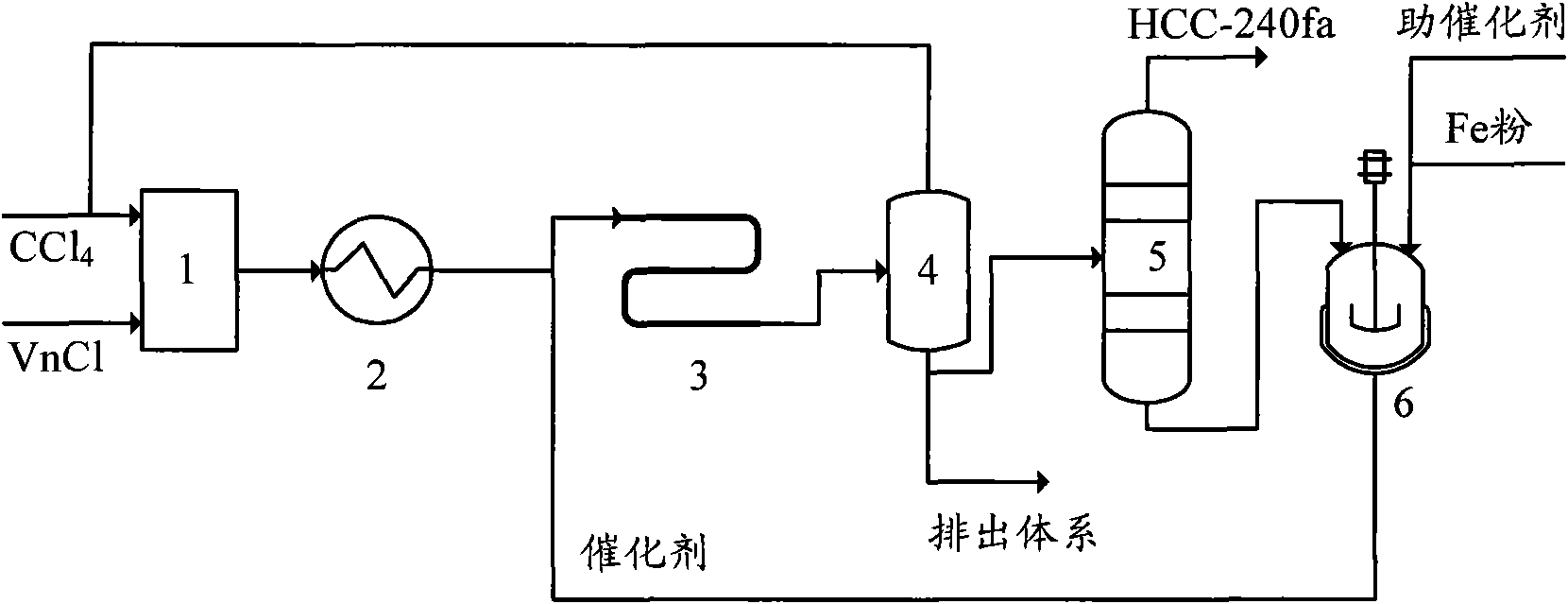

Production method of 1,1,1,3,3-pentachloropropane

InactiveCN101913980AEasy to transportAccurate measurementOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingReaction temperatureSilicon tetrachloride

The invention provides a production method of 1,1,1,3,3-pentachloropropane (HCC-240fa). The 1,1,1,3,3-pentachloropropane is synthesized by continuously reacting the materials of carbon tetrachloride and chloroethylene in a tubular reactor. The method comprises the steps of firstly mixing the carbon tetrachloride with the chloroethylene and preheating the mixture to a reaction temperature, then introducing the mixture together with a catalyst into the tubular reactor for telomeric reaction, removing the unreacted carbon tetrachloride and chloroethylene through flash evaporation, and then further distilling to obtain the HCC-240fa, wherein the unreacted carbon tetrachloride and chloroethylene are recycled and the catalyst is recycled after being subjected to the activating treatment. The invention adopts the liquid as the activated system and uses the tubular reactor for reaction, thereby ensuring simple and convenient operation as well as continuous production.

Owner:XIAN MODERN CHEM RES INST

Process and apparatus for cracking hydrocarbon feedstock containing resid to improve vapor yield from vapor/liquid separation

A process for cracking hydrocarbon feedstock containing resid comprising: heating the feedstock, mixing the heated feedstock with a fluid and / or a primary dilution steam stream to form a mixture, flashing the mixture to form a vapor phase and a liquid phase which collect as bottoms and removing the liquid phase, separating and cracking the vapor phase, and cooling the product effluent. The process comprises at least two of the following conditions: (1) maintaining the bottoms under conditions to effect at least partial visbreaking; (2) reducing or eliminating partial vapor condensation during flashing by adding a heated vaporous diluent to dilute and superheat the vapor; (3) partially condensing the vapor within said flash / separation vessel by contacting with a condenser; (4) decoking internal surfaces and associated piping of the flash / separation vessel with air and steam; (5) utilizing a flash / separation vessel having an annular, inverted L-shaped baffle; and (6) regulating temperature in furnace tube banks used for heating by utilizing a desuperheater and / or an economizer. An apparatus for carrying out the process is also provided.

Owner:EXXONMOBIL CHEM PAT INC

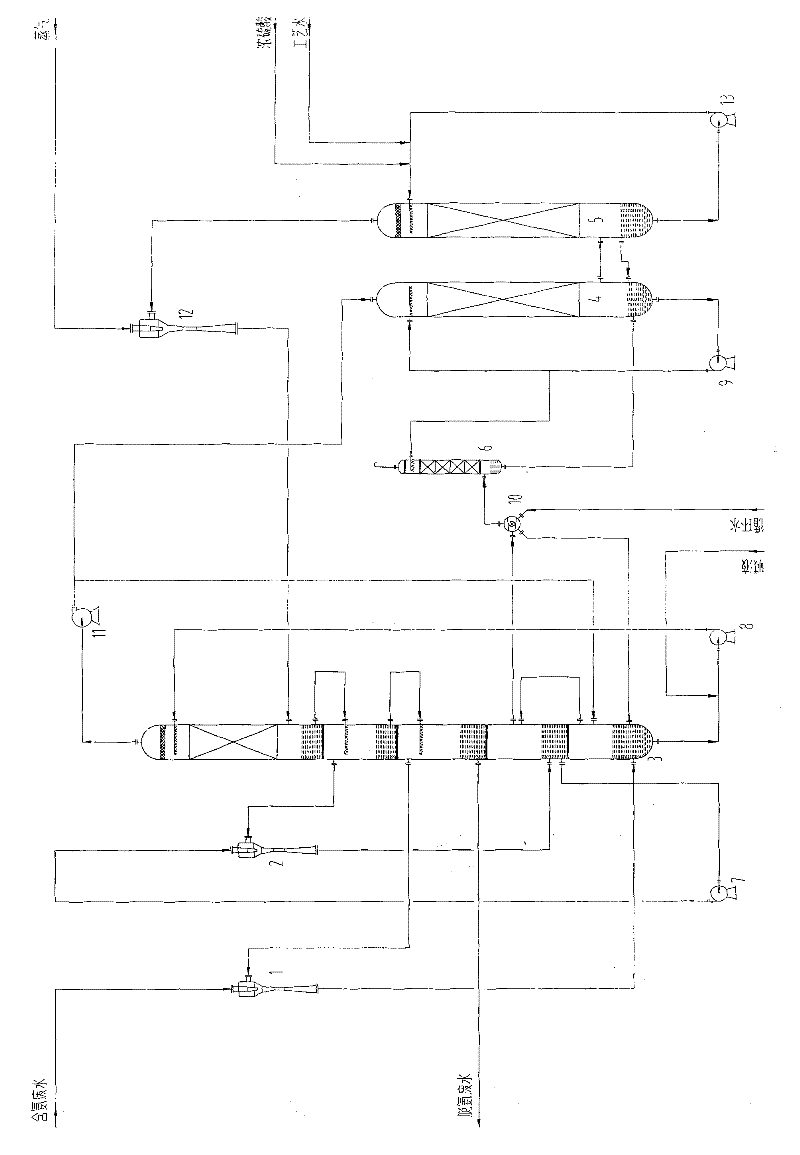

Low temperature multiple-effect distillation seawater desalination system and process flow thereof

InactiveCN101462780AImprove desalination efficiencyImprove efficiencyGeneral water supply conservationSeawater treatmentSaline waterDistillation

The invention discloses a low-temperature multieffect seawater distillation desalting system. The system comprises a plurality of multi-effect evaporator sets; each evaporator set is at least provided with a heater for preheating feeding seawater; an effect intermediate pump is arranged between two adjacent multi-effect evaporators; and one end of a condenser is connected with a raw material water pump, and the other end of the condenser is connected with the last evaporator set of the plurality of the multi-effect evaporator sets. The invention also discloses a process flow for utilizing the low-temperature multieffect seawater distillation desalting system to desalt seawater; the evaporators of the low-temperature multi-effect seawater distillation desalting system are divided into a plurality of sets; each set feeds in parallel; simultaneously, the front of the feeding seawater of the highest-temperature effect evaporator of each set is provided with a heater; residual strong brine of the front evaporator set is collected and beaten to the next evaporator set through the effect intermediate pump, and so on; a product water and strong brine flow in a ladder shape in a series of flash tanks and are gradually subjected to flash evaporation and cooling; steam obtained through flash evaporation enters the evaporator; and finally, the product of the cooled water and the strong brine are pumped out through a corresponding water pump respectively.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Preparation method of citric acid fermentation solution

ActiveCN101555497ASimple processReduce manufacturing costMicroorganism based processesFermentationNitrogen sourceCitric acid fermentation

The invention discloses a preparation method of a citric acid fermentation solution, which comprises the steps of: (1) mixing dry corn powder with water to form paste, adding amylase into the paste and then heating the paste, conducting spraying liquefaction by one time on the paste at the temperature ranging from 92 DEG C to 98 DEG C and then flash evaporation by one time, lowering the temperature to 88 DEG C to 90 DEG C and maintaining the liquefaction for 90min to 120min to obtain liquefied solution; (2) taking 5 percent to 15 percent of the liquefied solution obtained in the step (1), putting the liquefied solution into a seed tank, adding a nitrogen source, heating and sterilizing, maintaining for 20min to 30min, then lowering the temperature to 36 DEG C, and inoculating the obtained mixture into aspergillus niger strains for strain culture; (3) taking 5 percent to 15 percent of the liquefied solution obtained in the step (1), putting the liquefied solution into a fermenter; (4) taking the rest of the liquefied solution obtained in the step (1) for solid-liquid separation to obtain liquefaction clear liquid, putting the obtained liquefaction clear liquid into the fermenter, adding a nitrogen source, raising the temperature to 80 DEG C to 90 DEG C by heating, sterilizing, maintaining for 5min to 10min, lower the temperature to 38 DEG C, and leading the substances in the seed tank obtained in the step (2) into the fermenter; and (5) conducting solid-liquid separation to obtain the citric acid fermentation solution after ferment. The preparation method has the advantages of simple technique and low production cost.

Owner:COFCO BIOTECHNOLOGY CO LTD

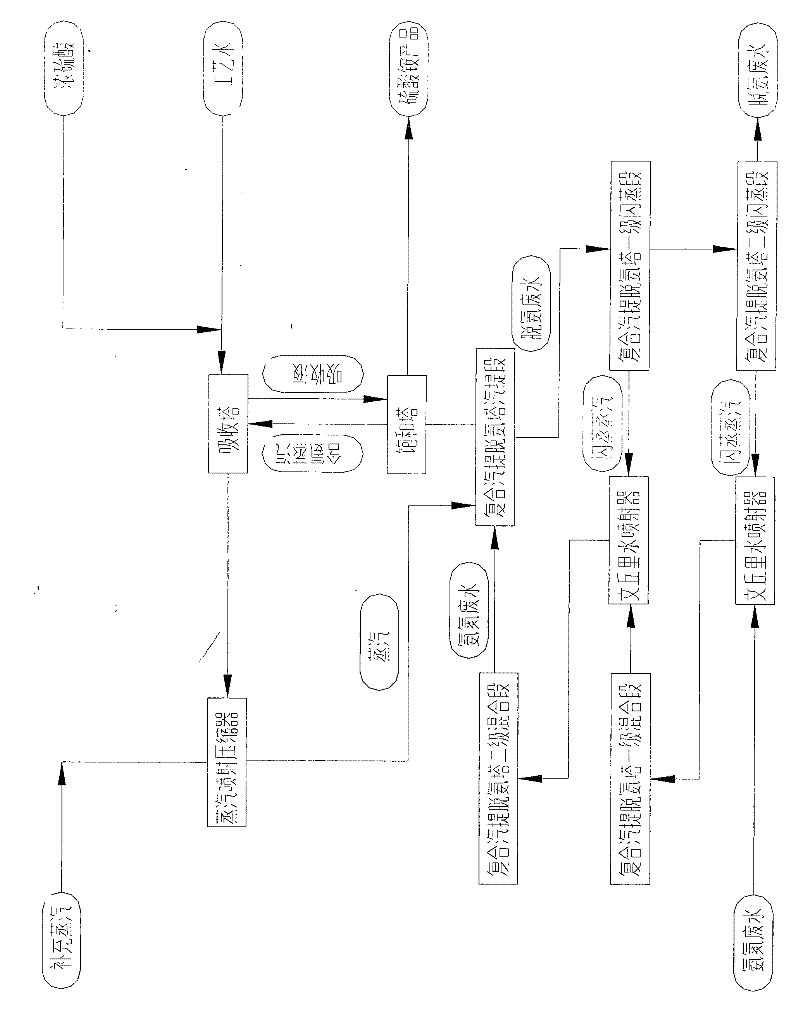

Stripping ammonia-removing method based on flash evaporation and heat pump technologies

ActiveCN102190341ARealize heat exchangeAvoid badWater contaminantsWater/sewage treatment by degassingAbsorption columnDirect heating

The invention relates to a stripping ammonia-removing method based on flash evaporation and heat pump technologies. The method comprises the following steps of: absorbing steam which is obtained after stripping ammonia removal and rich in ammonia nitrogen with an absorption column, pressurizing the purified steam with a heat pump set for recycling, carrying out flash evaporation on wastewater subjected to ammonia-removing process with a vacuum flash evaporation set composed of a Venturi and a liquid ring vacuum pump, and directly heating for pretreating wastewater with high ammonia nitrogen content. Compared with the traditional process with high ammonia-removing steam consumption and high operation cost, the method disclosed by the invention has prominent effects in energy saving and consumption reducing, and has broad market application prospect and high application potential in the treatment of wastewater containing ammonia nitrogen.

Owner:CHINA PETROLEUM & CHEM CORP +3

Integrated Methane Refrigeration System for Liquefying Natural Gas

Described herein is a method and system for liquefying a natural gas feed stream to produce an LNG product. The natural gas feed stream is liquefied, by indirect heat exchange with a gaseous methane or natural gas refrigerant circulating in a gaseous expander cycle, to produce a first LNG stream. The first LNG stream is expanded, and the resulting vapor and liquid phases are separated to produce a first flash gas stream and a second LNG stream. The second LNG stream is then expanded, with the resulting vapor and liquid phases being separated to produce the second flash gas stream and a third LNG stream, all or a portion of which forms the LNG product. Refrigeration is recovered from the second flash gas by using said stream to sub-cool the second LNG stream or a supplementary LNG stream.

Owner:AIR PROD & CHEM INC

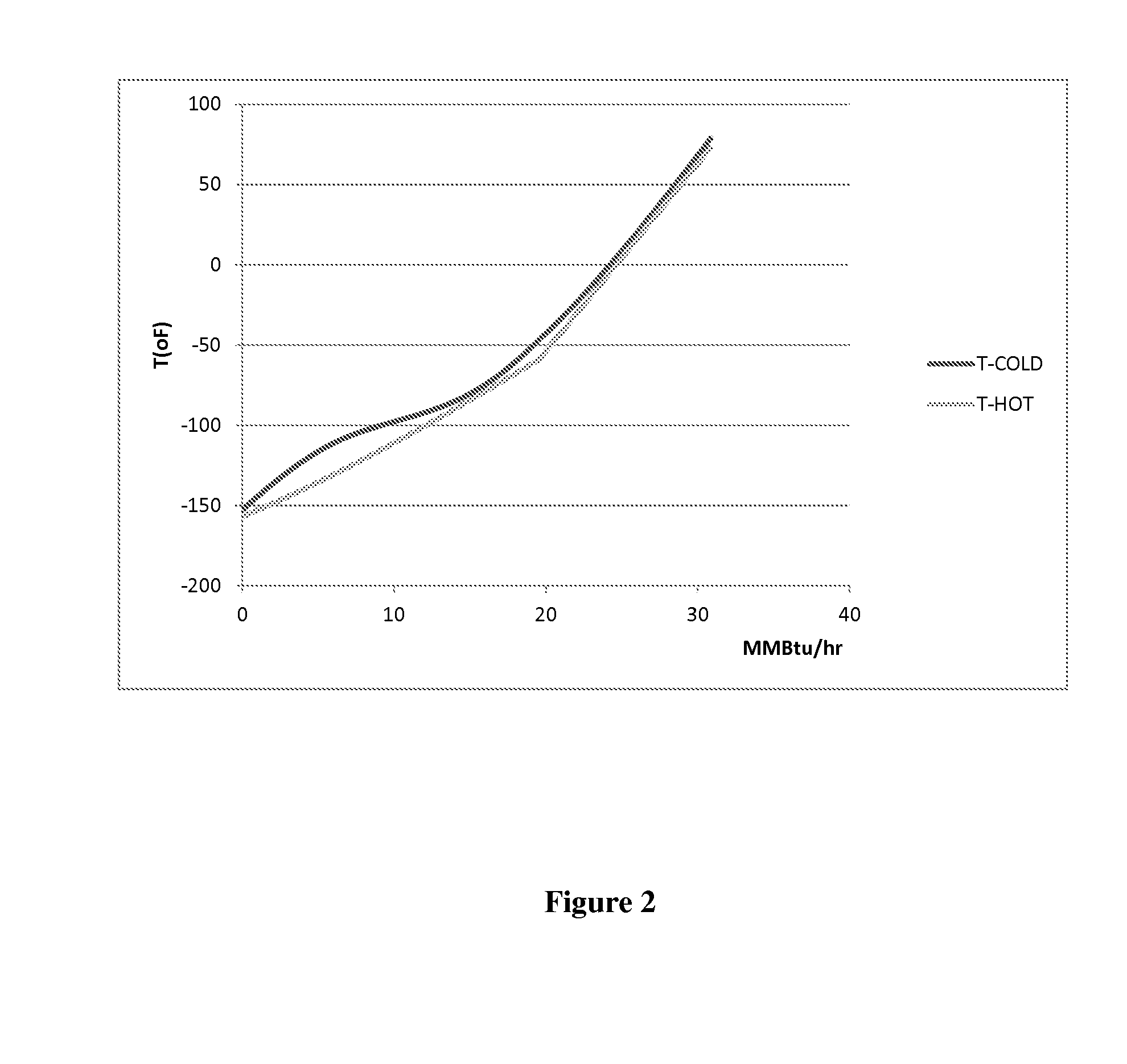

Method for producing purified dialkyl-furan-2,5-dicarboxylate vapor

Disclosed is a process to produce a purified vapor comprising dialkyl-furan-2,5-dicarboxylate (DAFD). Furan-2,5-dicarboxylic acid (FDCA) and an alcohol in an esterification zone to generate a crude diester stream containing dialkyl furan dicarboxylate (DAFD), unreacted alcohol, 5-(alkoxycarbonyl)furan-2-carboxylic acid (ACFC), and alkyl furan-2-carboxylate (AFC). The crude diester stream is fed to a flash evaporation zone to produce a vapor alcohol composition and a first liquid DAFD rich composition. At least a portion of the remaining alcohol can be separated from the first liquid DAFD rich composition to produce a second alcohol vapor and a second liquid DAFD rich composition, followed by separating AFC from the second liquid DAFD rich composition to product an AFC vapor and a partially purified DAFD rich composition, followed by separating a portion of the DAFD from the partially purified DAFD rich composition to produce a purified DAFD vapor.

Owner:EASTMAN CHEM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com