Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

438results about How to "Reduce the amount of feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

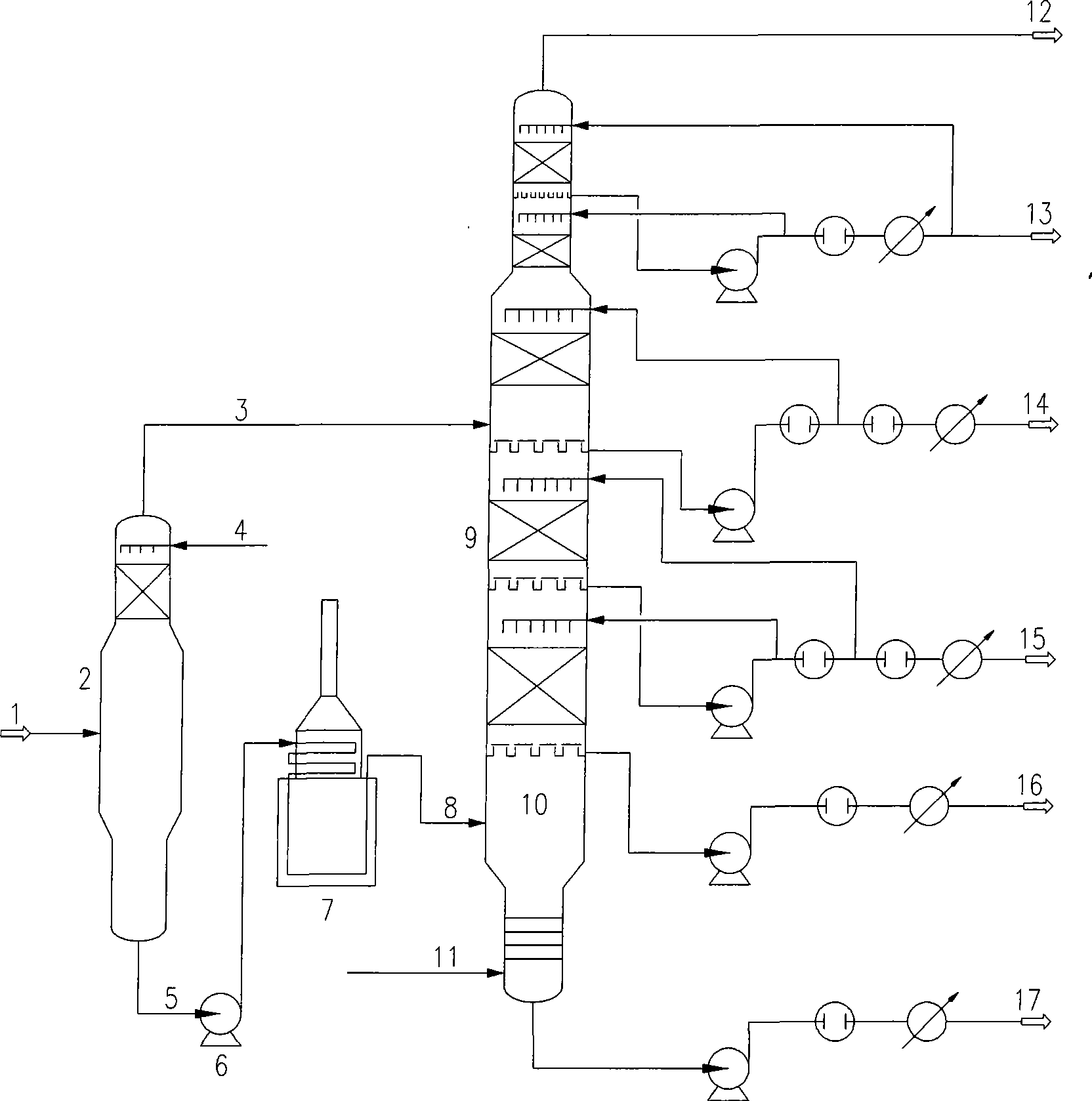

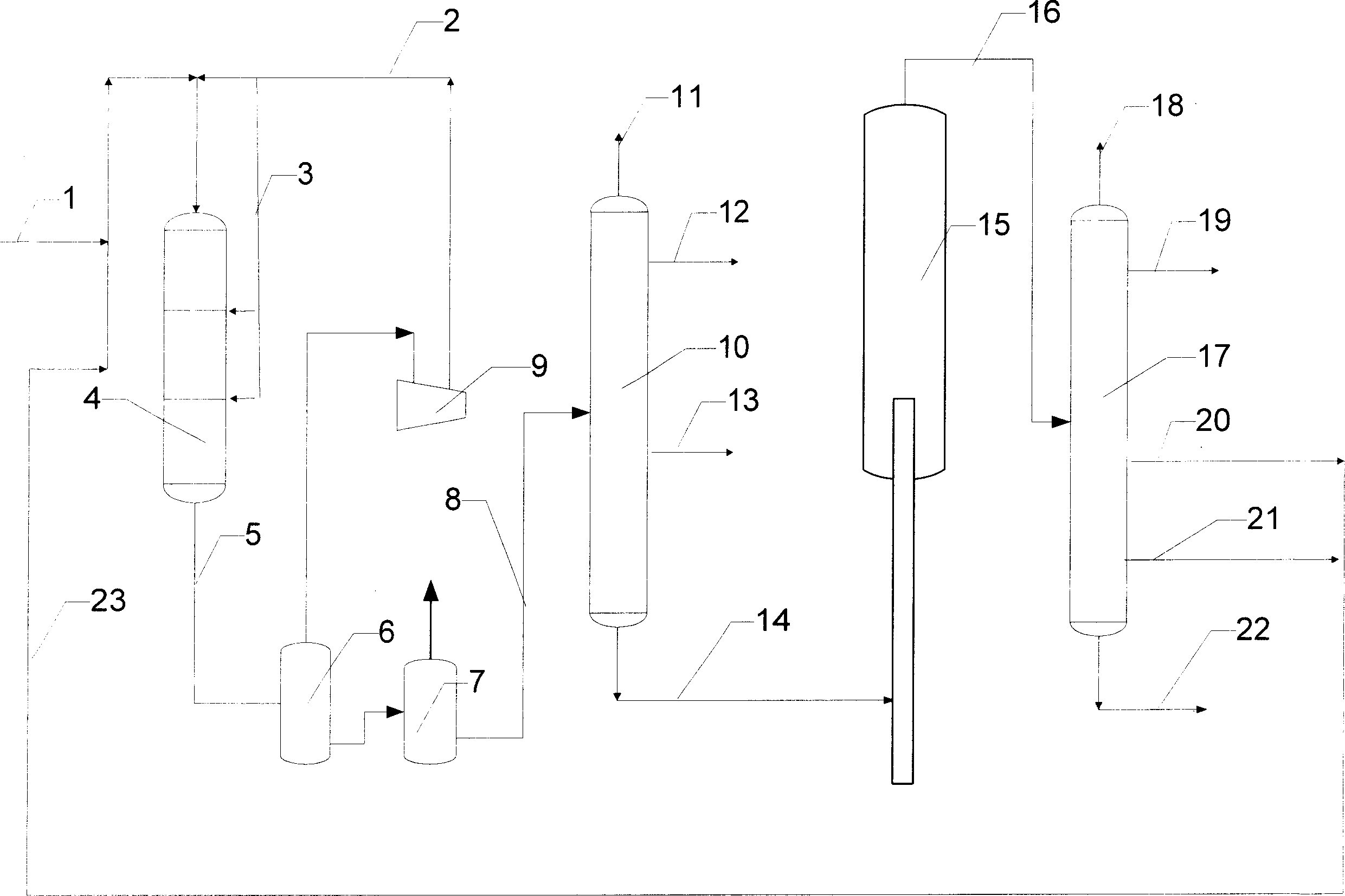

Atmospheric vacuum distillation method and apparatus with vacuum flash vaporizer

InactiveCN101376068AReduce the amount of feedEasy to handleVacuum distillation separationVacuum distillationVaporizationPulp and paper industry

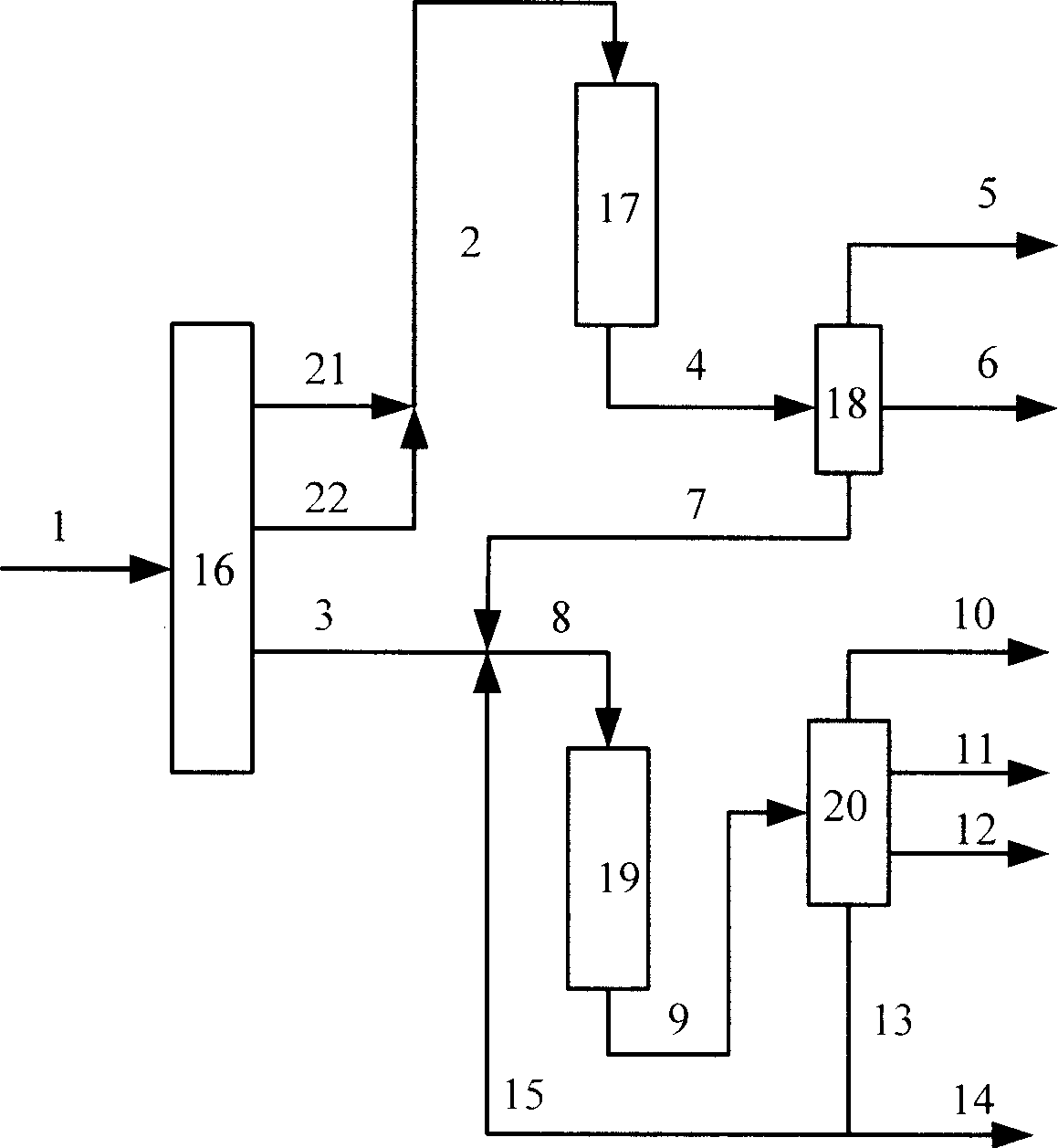

The invention relates to an atmospheric and vacuum distillation device with a vacuum flash tower and a method thereof. The atmospheric and vacuum distillation device with a vacuum flash tower is characterized in that the vacuum flash tower arranged in front of a vacuum furnace is connected with the vacuum furnace and a vacuum tower through a pump and a pipeline. Constant bottom oil (1) is introduced into the vacuum flash tower (2)at first, and the operation pressure at the top part of the vacuum flash tower is higher than the operation pressure at the top part of the vacuum tower (9) by10 to 200mmHg; Flash cap gas (3) is introduced into the upper part or the lower part of an outlet for a side product which is similar to Flash cap gas fraction; flash bottom oil (5) is introduced into the vacuum furnace (7) through a flash bottom oil pump (6); when the flash bottom oil is heated to 350 to 430 degrees, air-liquid mixing vacuum tower feed material is obtained through partial vaporization and is introduced into a flash evaporation segment (10) of the vacuum tower through a transfer line (8); and products with different fractions are drawn from the side of the vacuum tower and vacuum residue is drawn from the bottom of the vacuum tower. Through adding the vacuum flash tower to improve the working process of the atmospheric and vacuum distillation device, the invention achieves the advantages of increasing treatment capacity, increasing vacuum distillation yield, and reducing energy consumption.

Owner:TIANJIN UNIV +2

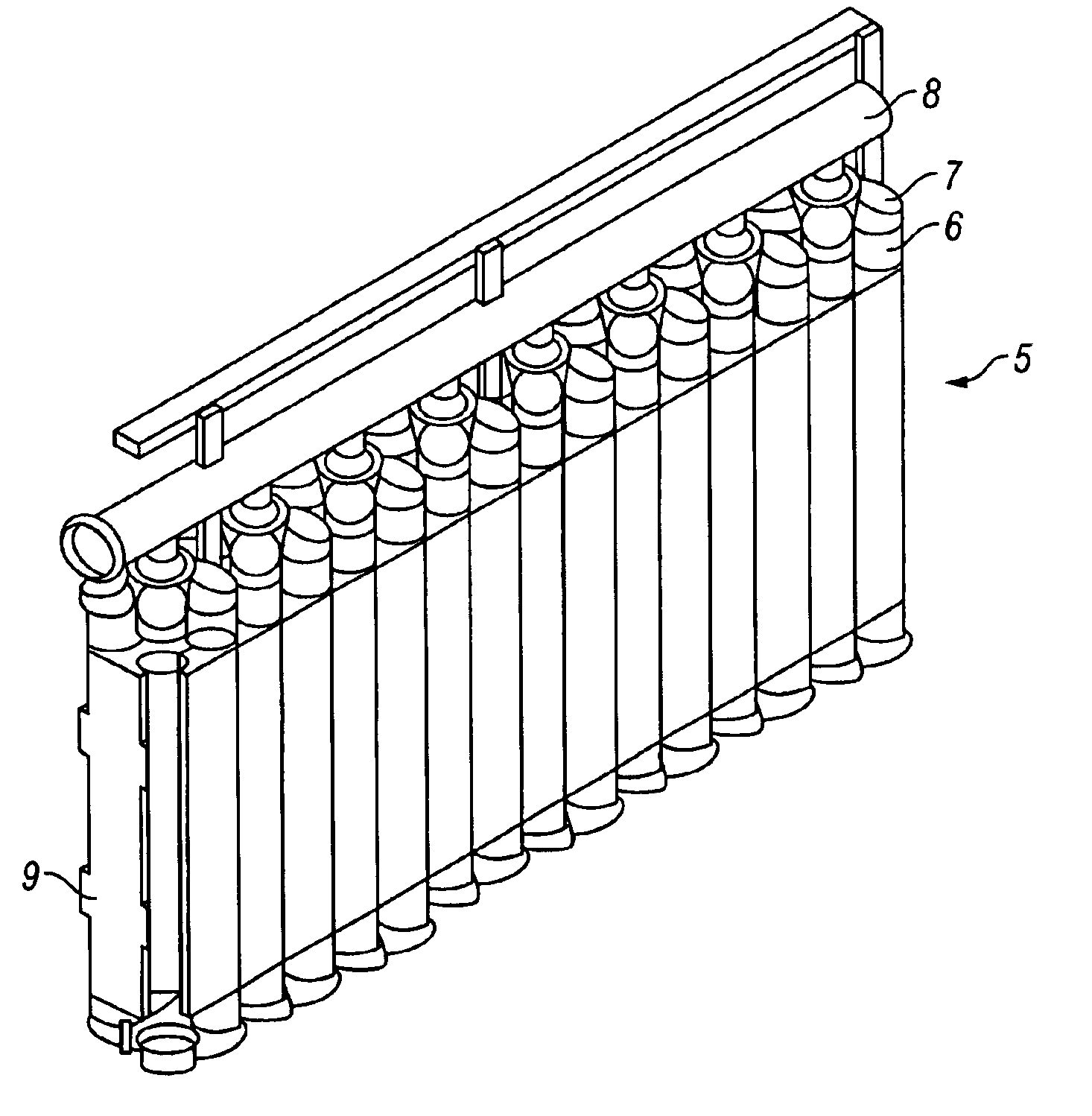

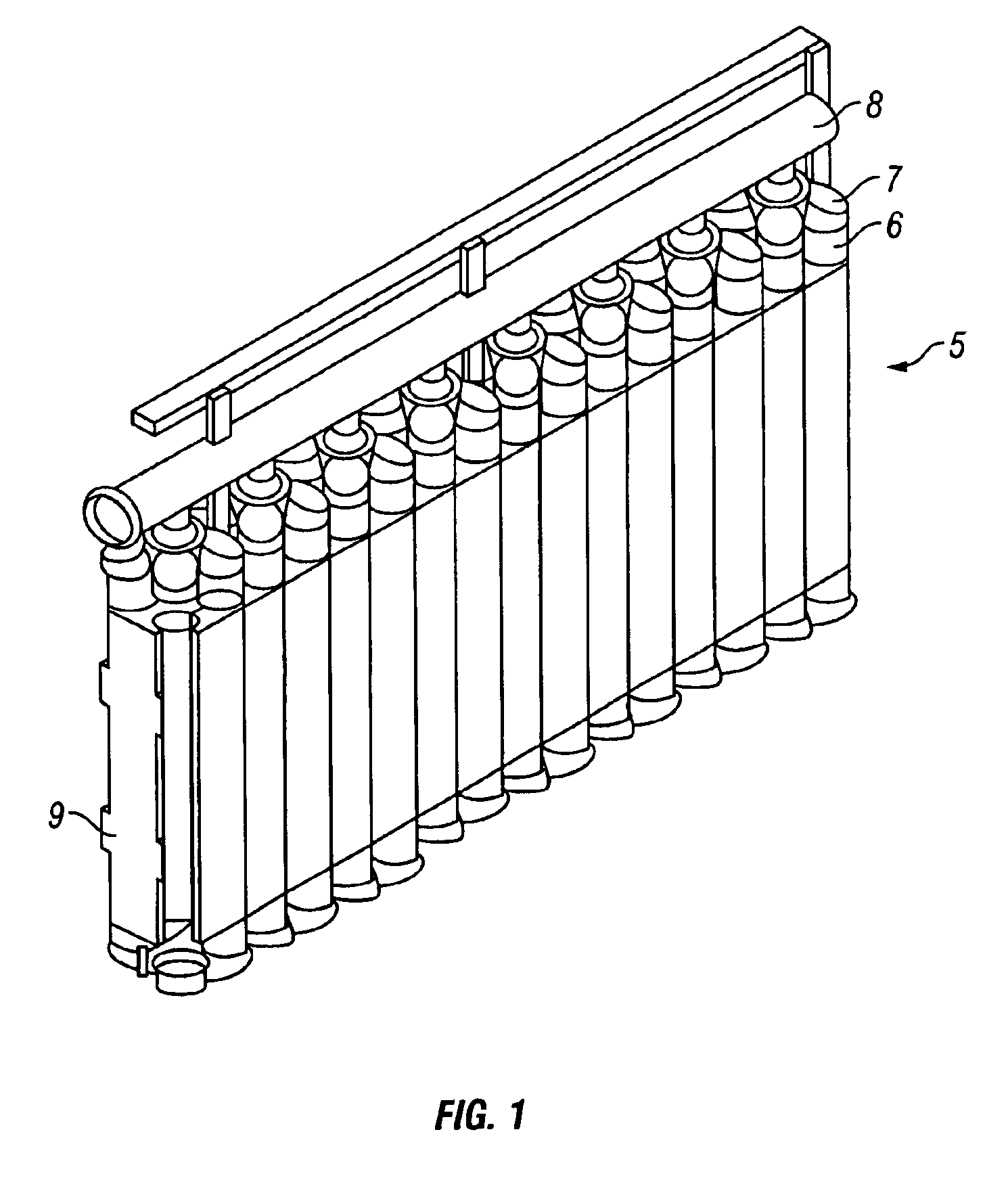

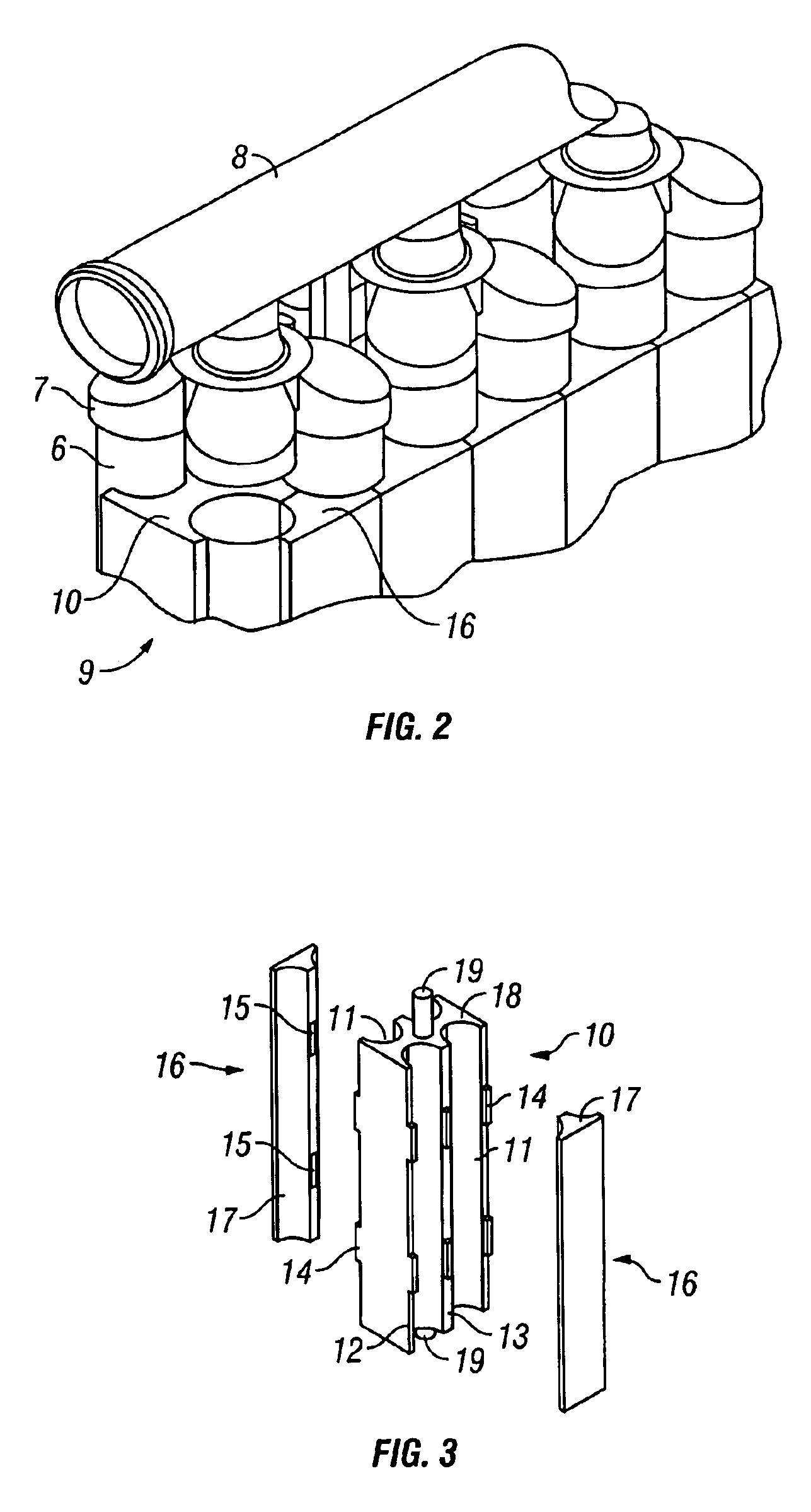

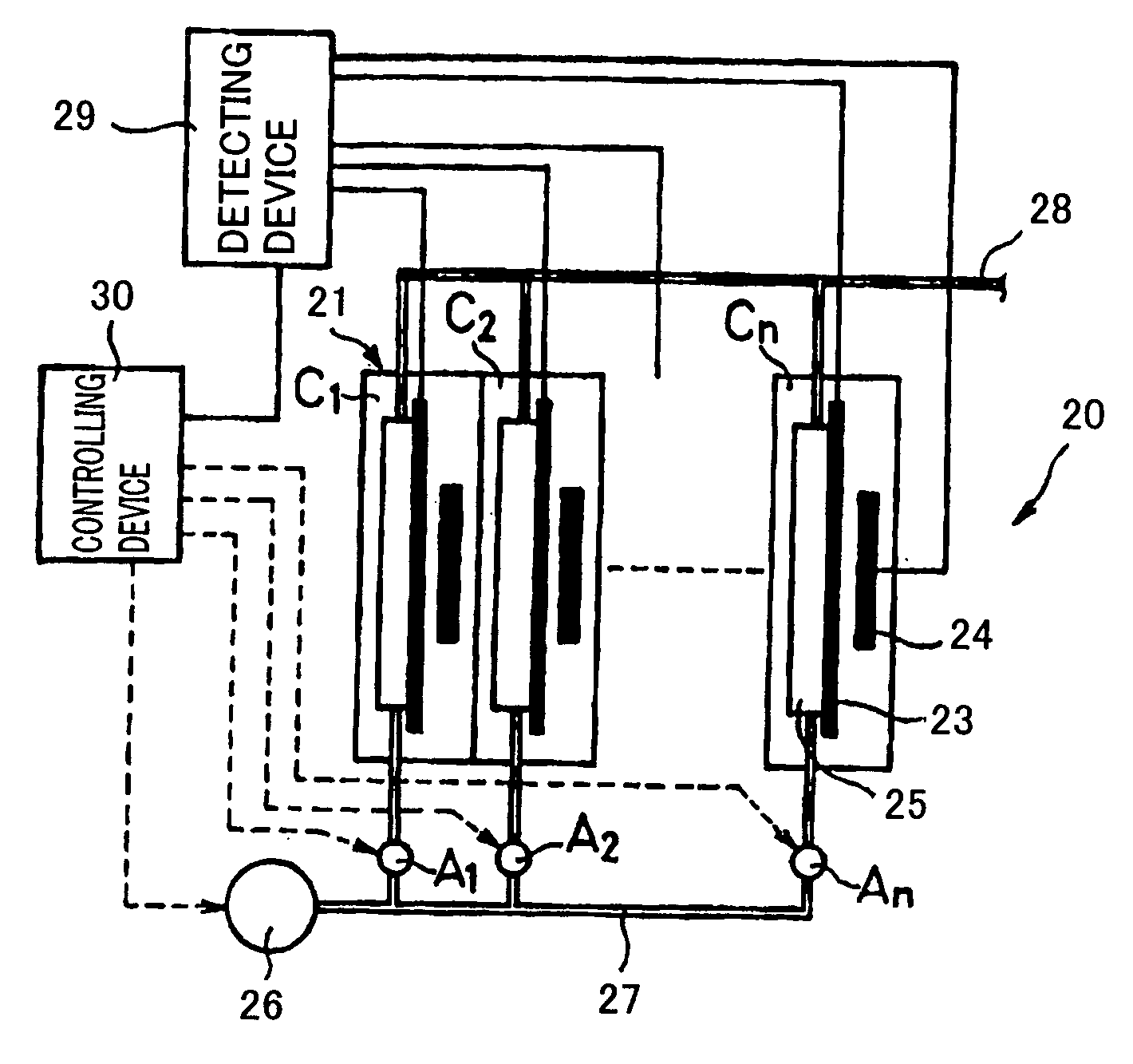

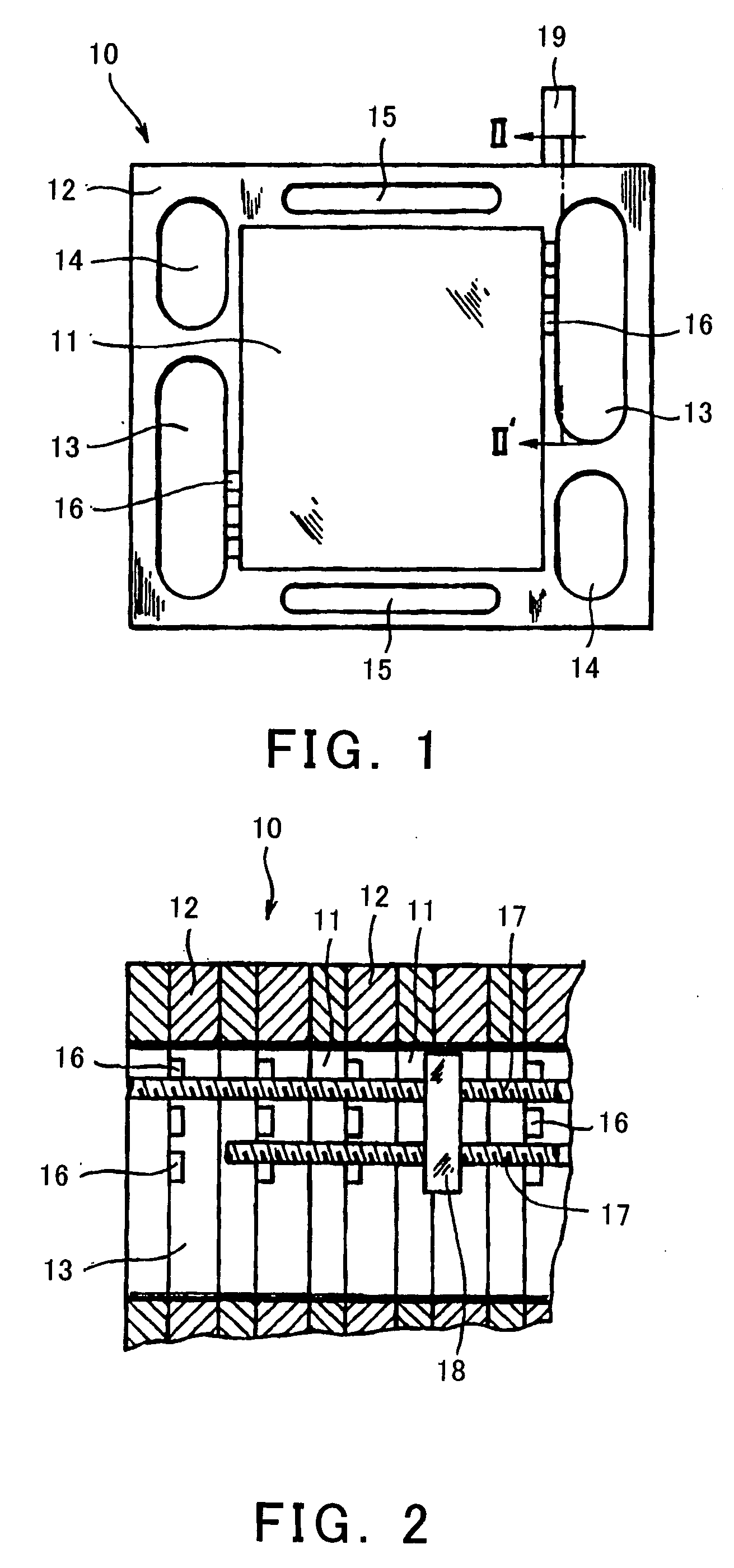

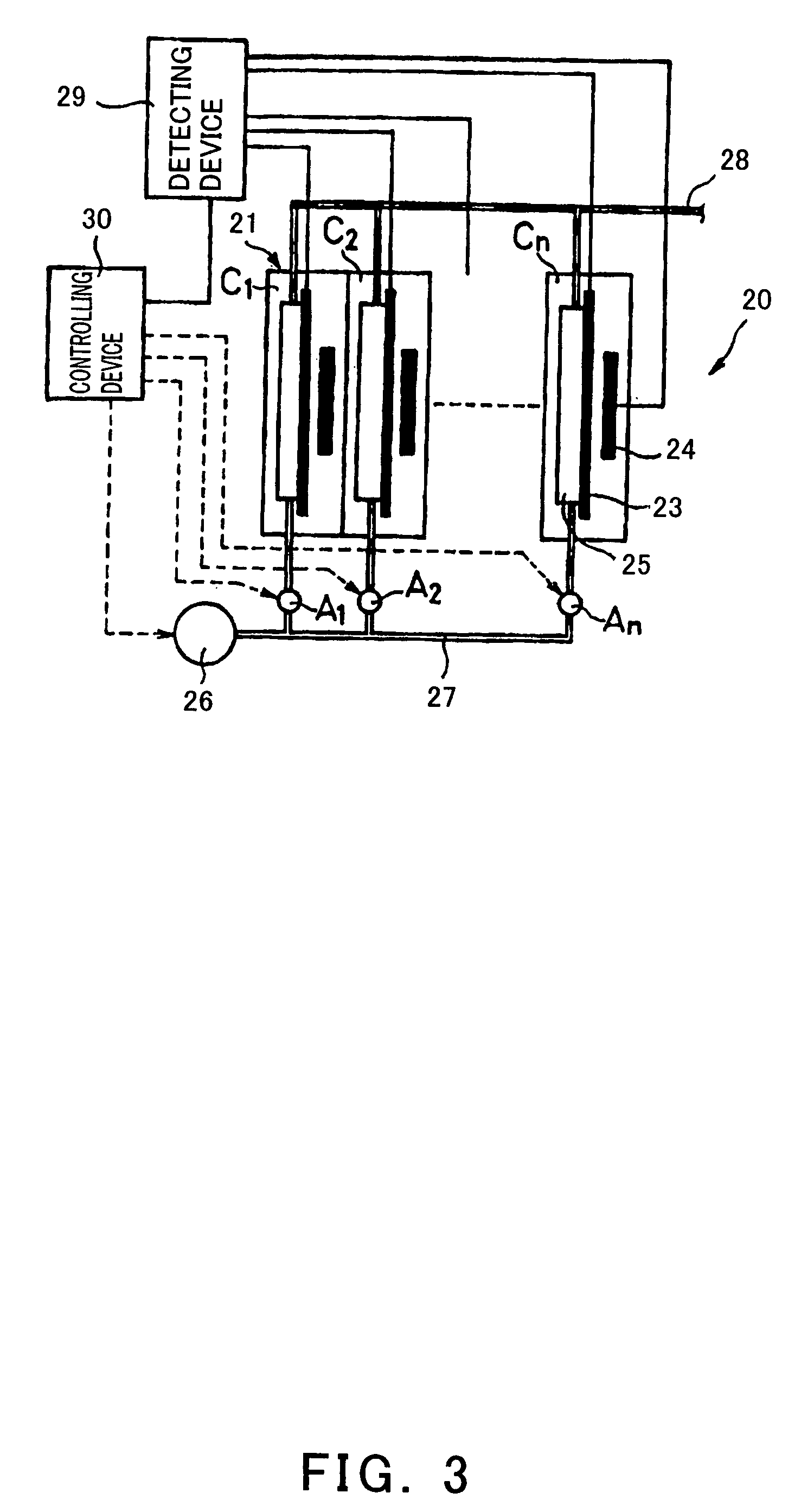

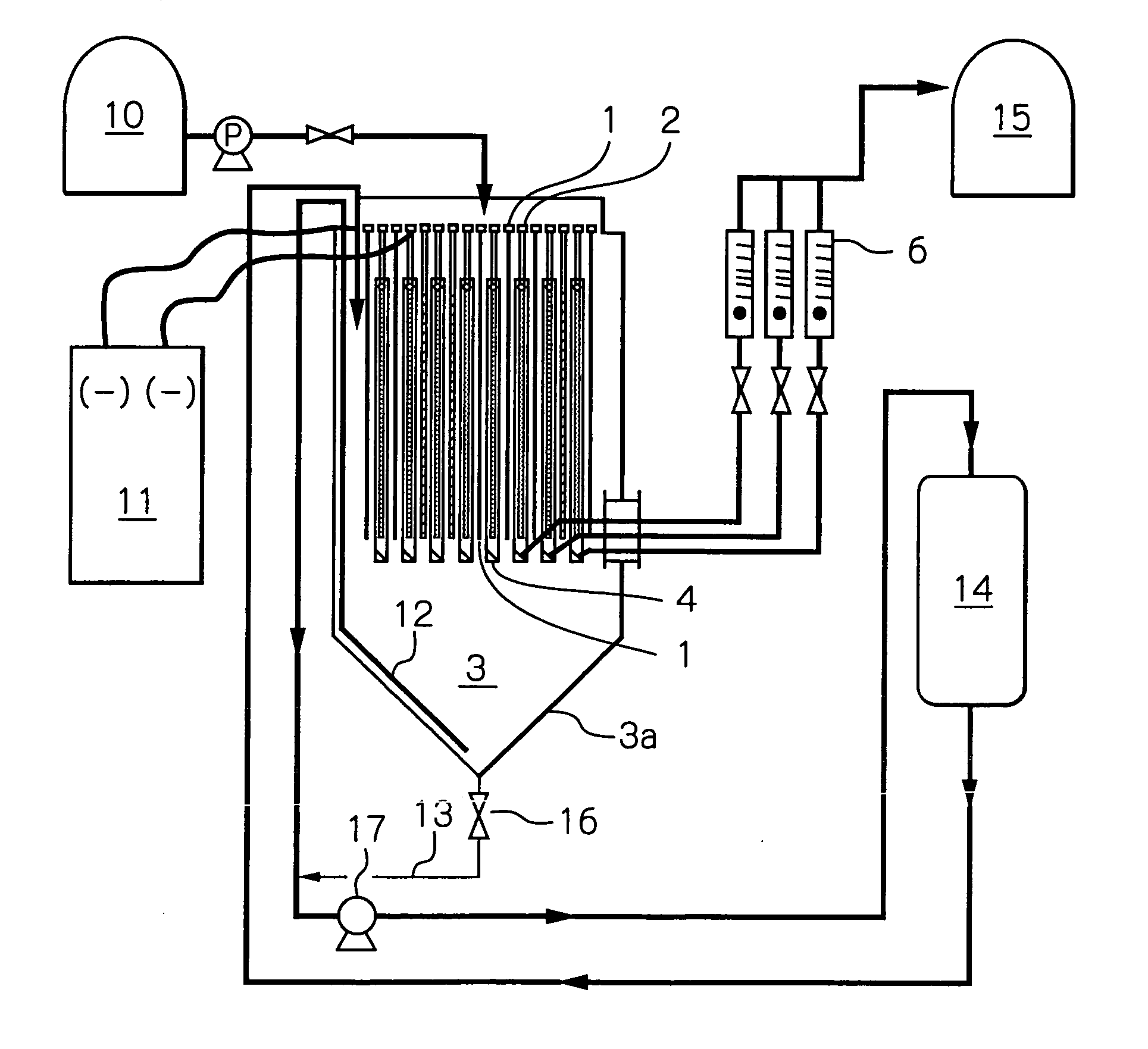

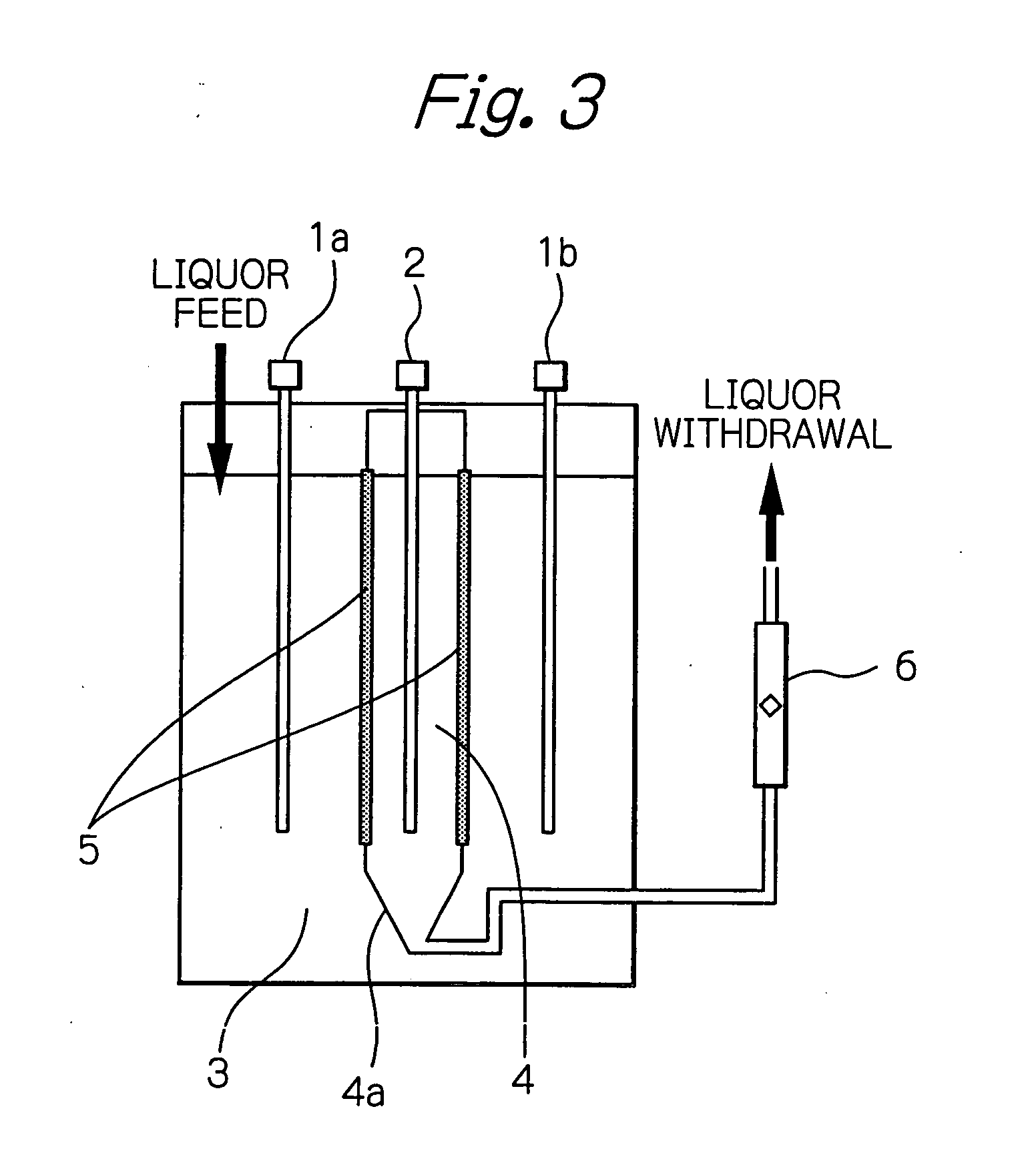

Membrane filtration system

InactiveUS6872305B2Reduce feed volumeSimplicity and costMembranesUltrafiltrationPorous membraneChemistry

A method and apparatus for reducing volume of feed liquid required in a porous membrane filtration system having a number of porous membranes (6) submersed in a volume of feed liquid to be filtered is provided, the method comprising the step of providing filler elements (9) within said volume of feed liquid to be filtered.

Owner:EVOQUA WATER TECH

Method of operation fuel cell system and fuel cell system

InactiveUS20040137292A1Feeding amount of the oxygen-containing gas on the oxygen electrode isIncrease the amount of feedFuel cells groupingFuel cell auxillariesFuel cellsAutomotive engineering

Owner:PANASONIC CORP

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

Momordica grosvenori extractive with at least 40 percent grosvenor momordica glycoside and preparation method thereof

InactiveCN101200753AReduce the amount of feedShorten the production cycleFermentationFood preparationSocial benefitsEnzymatic hydrolysis

The invention provides a milk white fructus momordicae extract, fructus momordicae glycoside V and fructus momordicae glycoside of which are respectively larger than or equal to 40 percent and 98 percent. The invention also discloses a preparation method of the extract. Using fresh fructus momordicae as the raw material, the invention is obtained through the water extraction, the concentration, the enzymatic hydrolysis, the macroporous adsorption resin refining, the ion exchange resin decoloration, the concentration and the spray drying. The invention is characterized in that the process parameters of the steps which are suitable for the industrial production are found, the yield and the quality of the fructus momordicae extraction are all obviously improved, and obvious economic benefits and social benefits are obtained.

Owner:GUILIN HUITONG BIOTECH

Hydrogenation purifying combined process for Fischer-Tropsch synthetic substance

A kind of combined technology method to hydrogenate and improve quality of the product from Fishcher-Tropsch synthesis process, condensate and synthetic wax can be gained by natural isolation of the product from Fishcher-Tropsch synthesis process, and the condensate will contact with hydrogen and hydrofining catalyst, then the tail oil produced by the isolation of the hydrofining reactant liquor will contact with the synthetic wax, hydrogen, and hydrocracking and isocracking catalyst, the middle oil fraction product can be gained after the isolation of the hydrocracking reactant liquor at last. The yield of the diesel oil is more than 80% by the method, the cetane number will be more than 80, and sulfur, nitrogen and aromatic hydrocarbon can barely found in the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

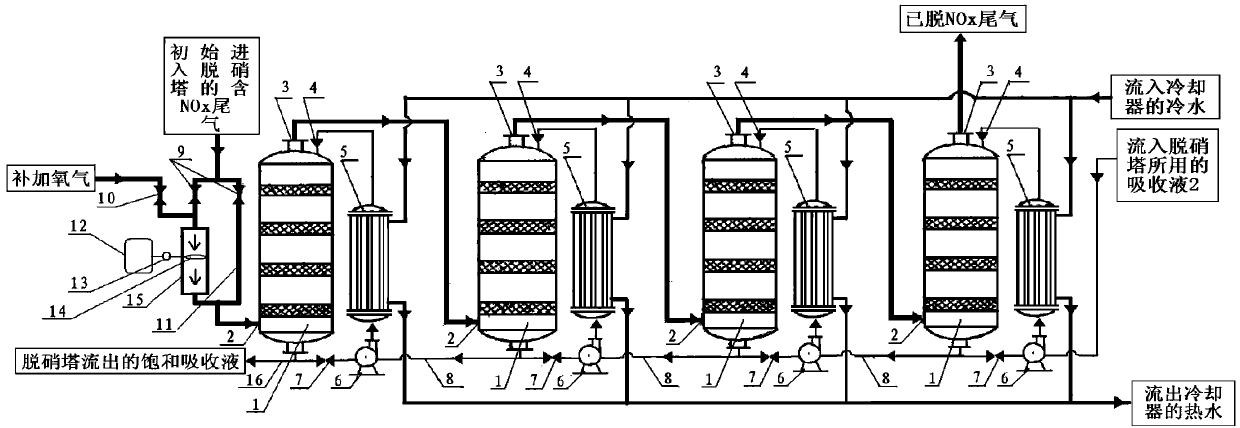

Desulfurization and denitrification method for tail gas, used equipment and product application thereof

InactiveCN105080307AReduce material costsLow costOther chemical processesDispersed particle separationCorrosion preventionChemistry

The present invention discloses a desulfurization and denitrification method for tail gas, used equipment and product application thereof. According to the method provided by the present invention, an oxidative catalyst is not used in a desulfurization column or a denitration column, or a small amount of the oxidative catalyst with a simplified formula added is used outside the desulfurization column and the denitration column, so that the cost is reduced significantly. The oxidative catalyst is not used in the desulfurization column or the denitration column to avoid the severe corrosion of the desulfurization column and denitration column texture by the material, so that the texture cost of the desulfurization column and the denitration column is reduced significantly; The volume of the processed material is small: only 30%-10% of the material in volume in the desulfurization column and the denitration column, and the cost for equipment corrosion prevention is lowered, so that a small amount of the oxidative catalyst used and a simplified formula can be facilitated.

Owner:陈汇宏 +2

Method for production of porous material

InactiveUS6166097AExcels in abilityExcels in of propertyWater/sewage treatment by centrifugal separationTransportation and packagingWastewaterImpurity

A method for producing a porous material by forming a water-in-oil type high internal phase emulsion, which method is characterized by causing waste water generated during the process of production to be put to reuse. The waste water is preferred to be reused after the removal of impurities or the adjustment of pH. According to this invention, the waste water can be reused up to 50 repetitions, with the result that the amount of feed water and the amount of waste water will be decreased. Incidentally, by adjusting the pH of the water-in-oil type high internal phase emulsion after the reaction thereof in the range of 4-9, it is made possible to continue the reuse of waste water and, at the same time, lower the stimulating property of the produced porous material.

Owner:NIPPON SHOKUBAI CO LTD

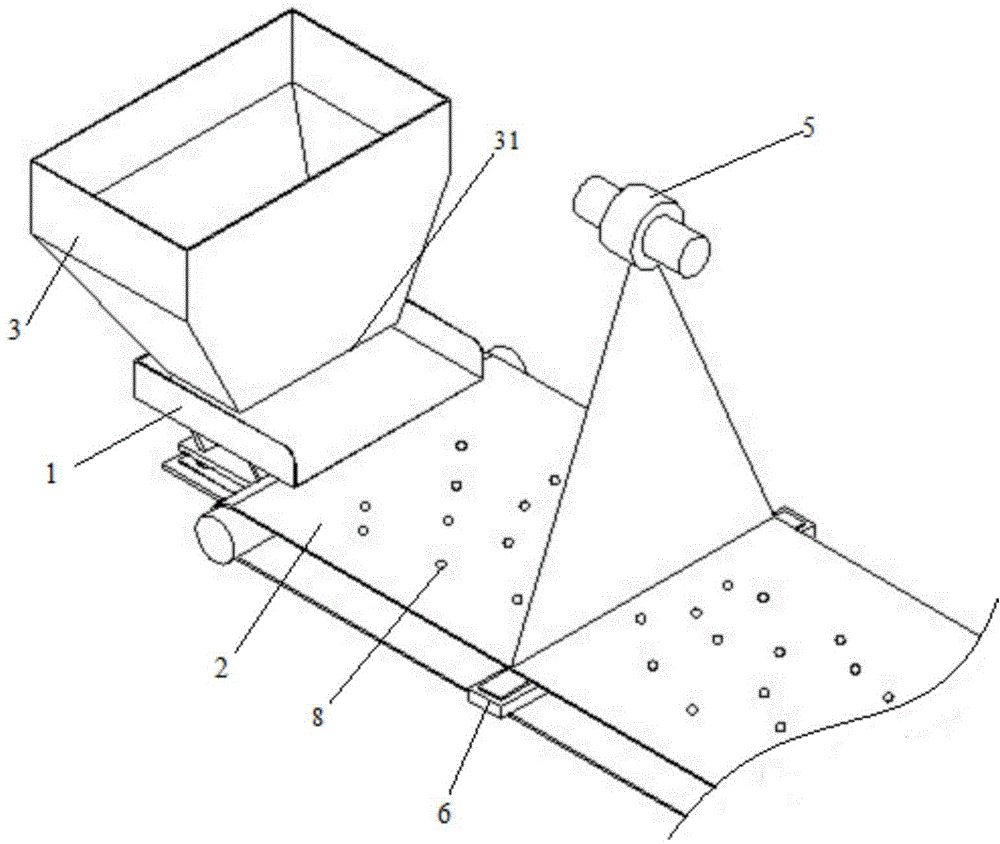

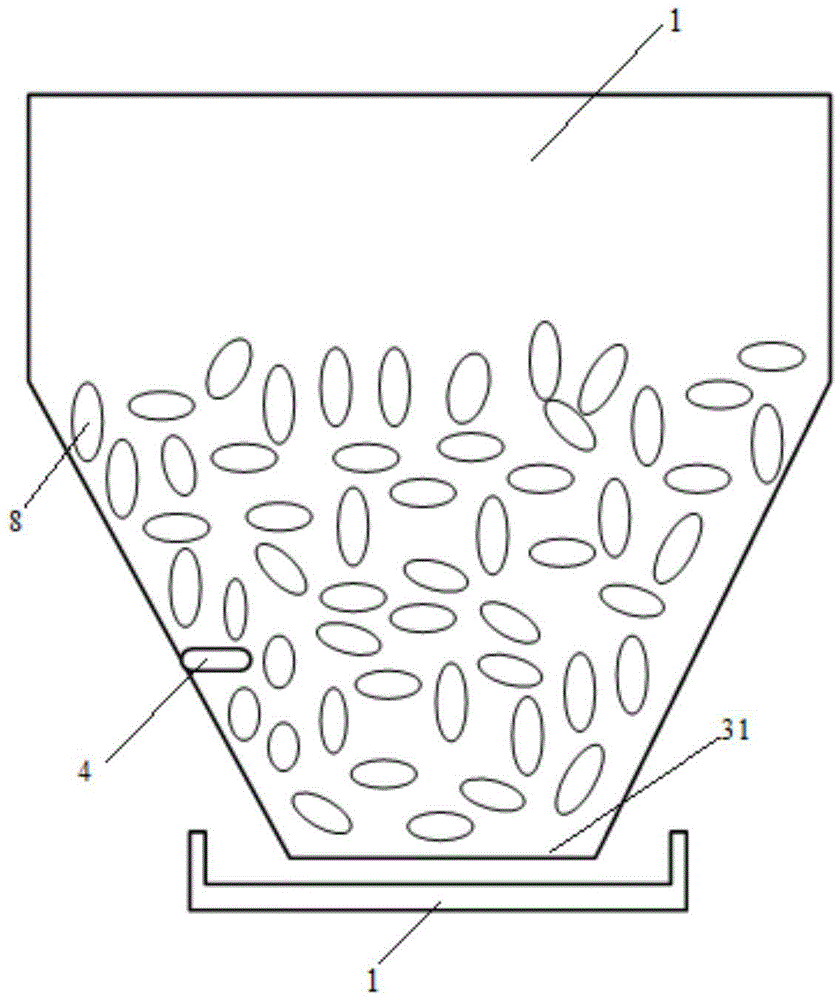

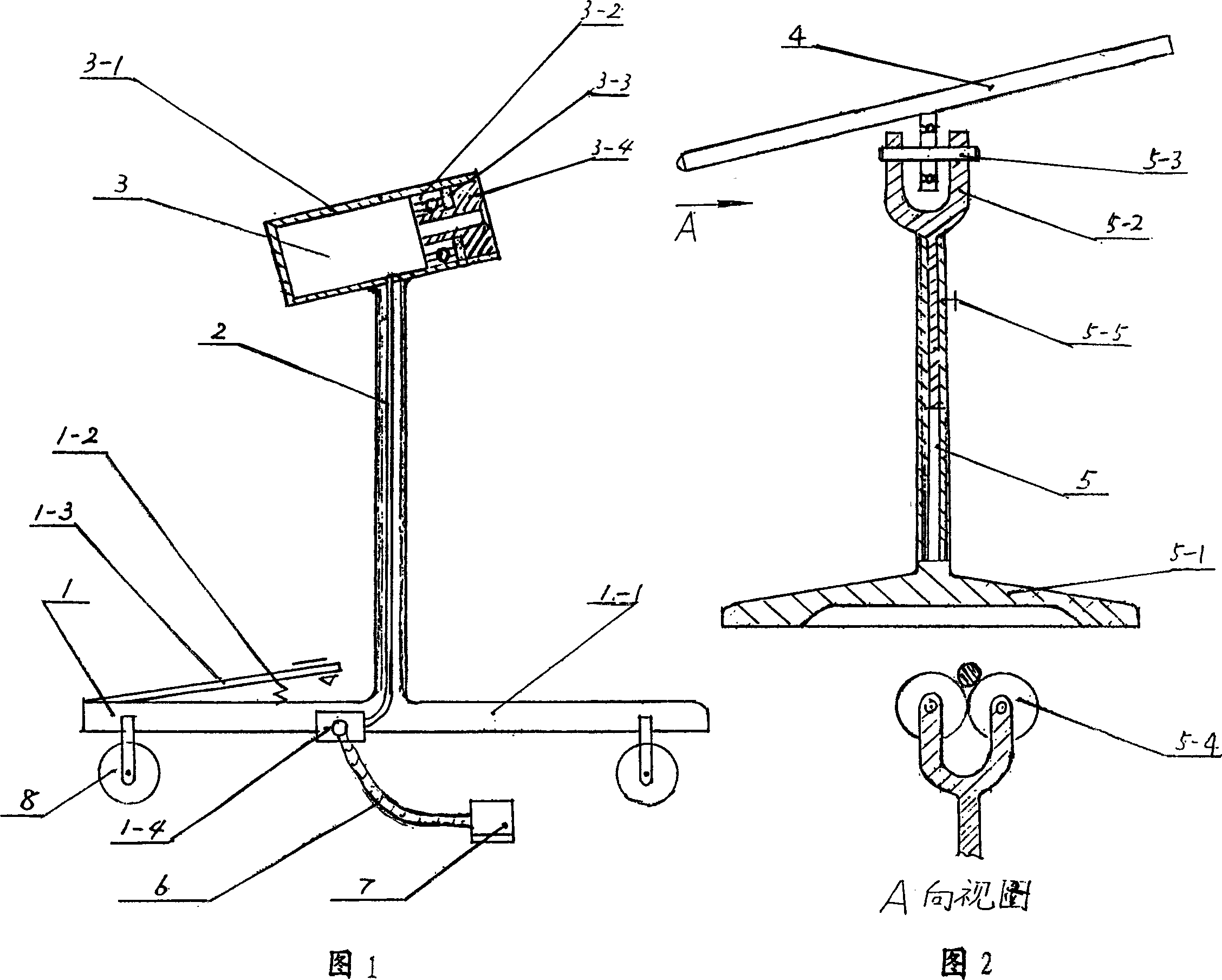

Automatic feeding adjustment module and method, device and bulk foreign body detection mechanism thereof

ActiveCN104085667ASpread evenlyReduce the amount of vibrationConveyor partsMaterial analysis by transmitting radiationForeign matterEngineering

The invention provides an automatic feeding adjustment module and a method, device and bulk foreign body detection mechanism of the automatic feeding adjustment module. A discharging port of a hopper is located above a conveying belt, and materials are evenly laid on the conveying belt through vibration of a vibrator. A first sensor detects the material level of the materials in the hopper. Rays are emitted from a radiation source to the materials on the conveying belt, and a second sensor collects the rays which penetrate through the conveying belt and the materials. A processor forms a corresponding target image according to the rays collected by the second sensor, in addition, when the material level is not smaller than a first preset material level value, the vibrator is turned on, and data analysis thread is started, wherein the duty ratio R of the target image is calculated, the vibration magnitude of the vibrator is increased if the duty ratio R is smaller than a first preset duty ratio threshold, the vibration magnitude of the vibrator is decreased if the duty ratio R is larger than a second preset duty ratio threshold, or else, the current vibration magnitude of the vibrator is kept unchanged, and the second preset duty ratio threshold is larger than the first preset duty ratio threshold.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH

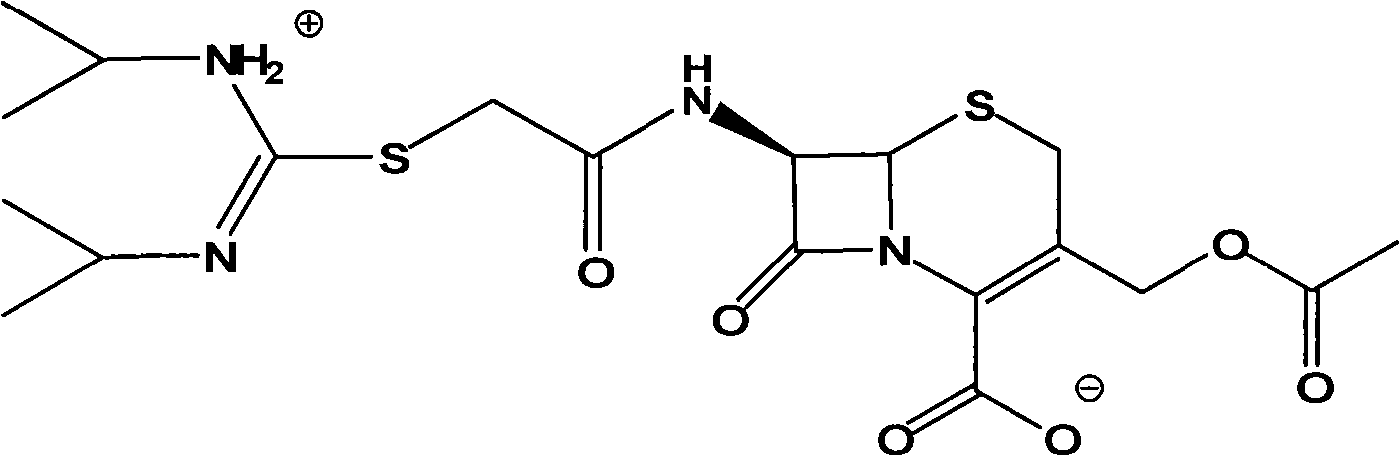

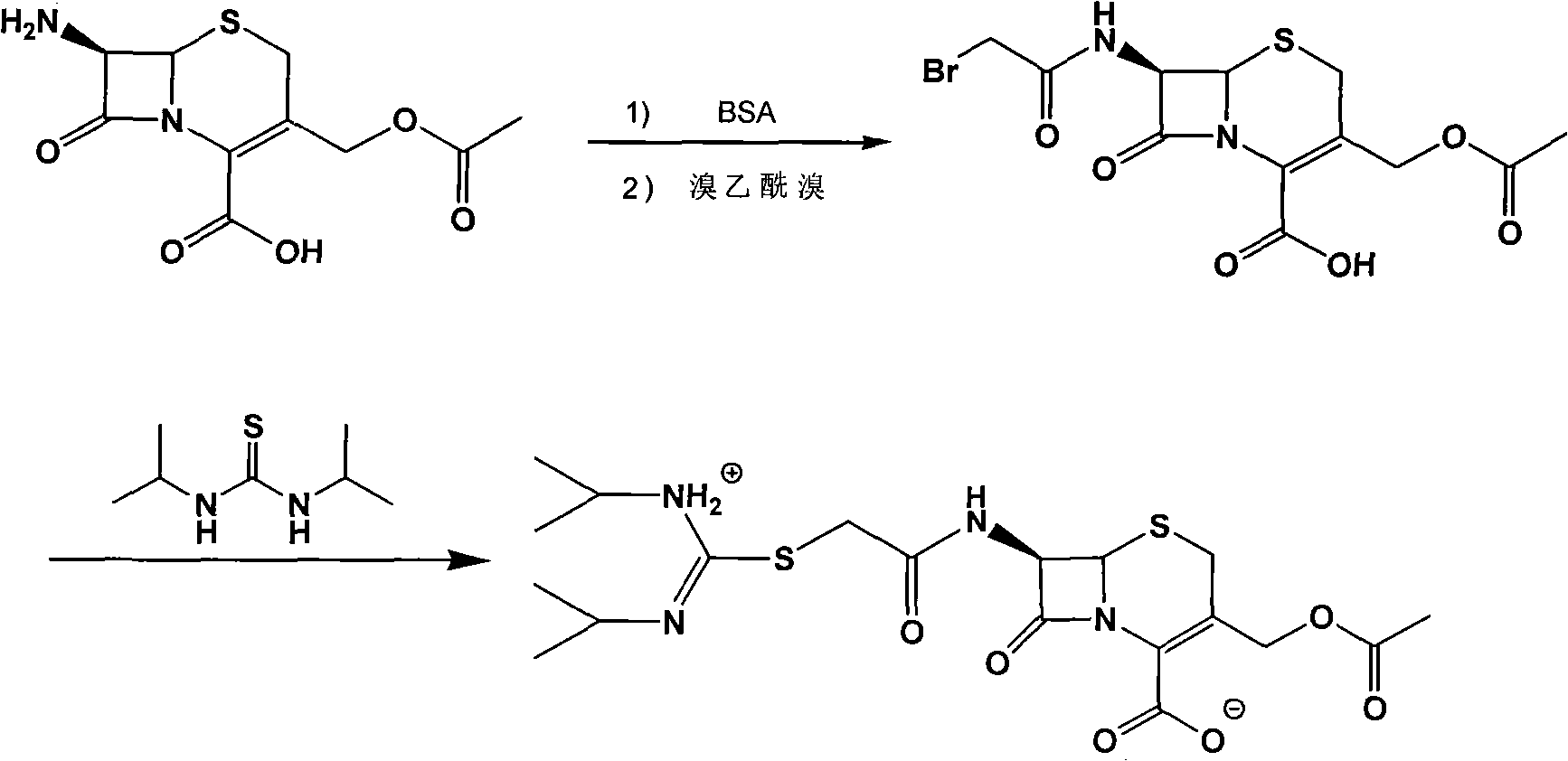

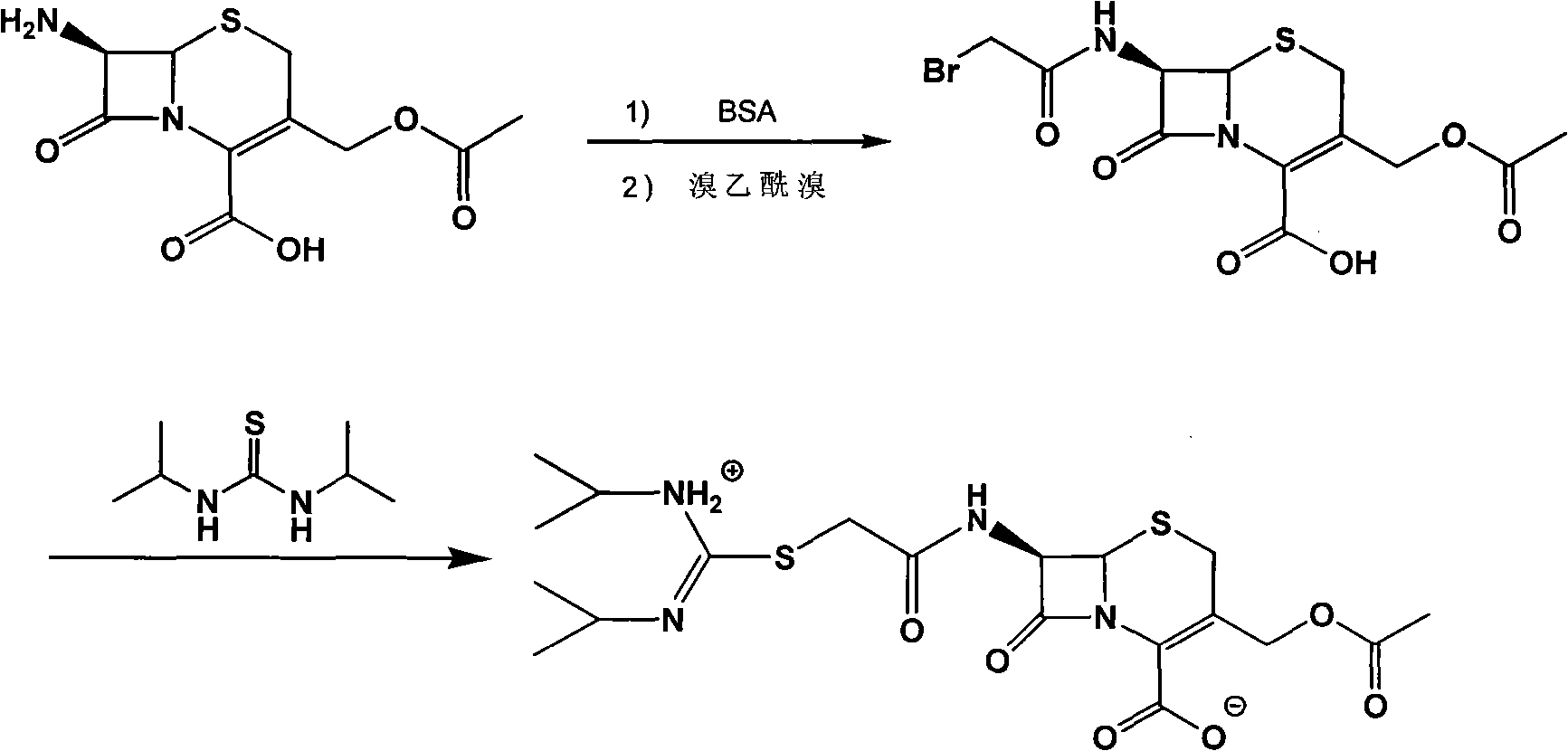

Preparation method of cefathiamidine

The invention relates to a preparation method of cefathiamidine, which comprises the following steps: (1) preparing cefathiamidine acid, performing silanization of 7-AC by BSA at room temperature, reacting with bromoacetyl bromide at zero DEG C, processing and separating out solid, filtering and drying to obtain high-purity cefathiamidine acid; (2) adding alkaline reagent to the cefathiamidine acid, reacting with N, N'-diisopropyl thiourea, adding slightly soluble solvent and separating out coarse cefathiamidine; and (3) dissolving the coarse cefathiamidine in a proper solvent, regulating the pH value of the solution to be between 4 and 5.5, adding the lightly soluble solvent until the solution is turbid, controlling the stirring speed, continuing slowly dripping the slightly soluble solvent, separating out the product, separating and drying to obtain the cefathiamidine. The method has the advantages of few steps, simple process, high purity and easy implementation.

Owner:INST OF MATERIA MEDICA AN INST OF THE CHINESE ACAD OF MEDICAL SCI

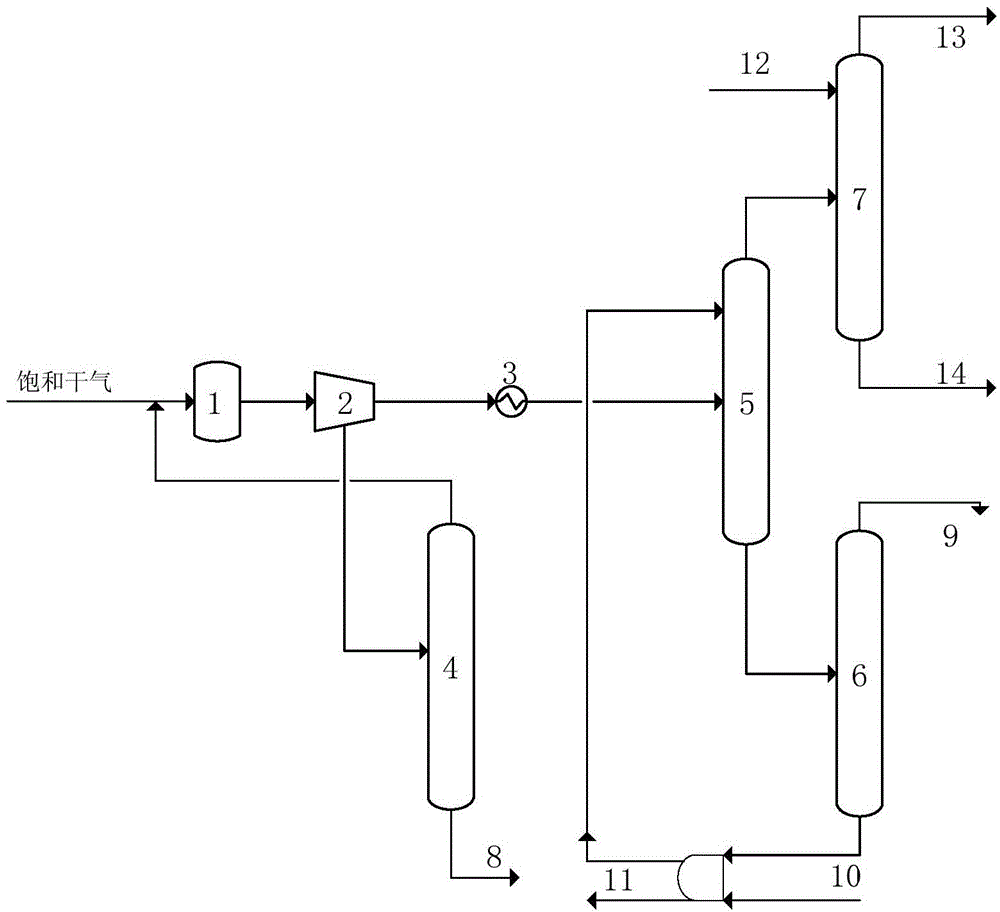

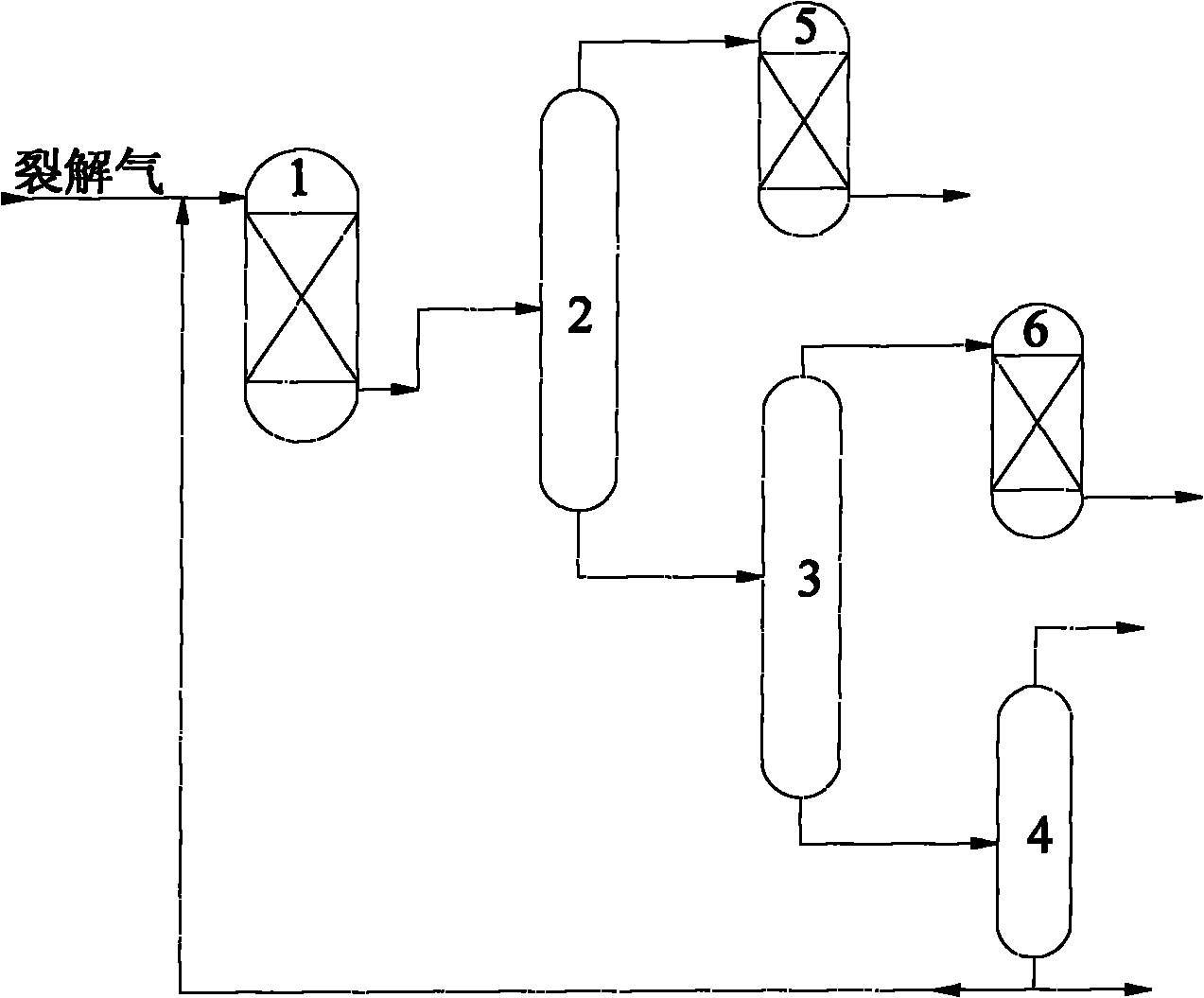

Refinery saturated dry gas recovery system and recovery method

ActiveCN104560194AReduce the amount of feedReduce circulationGaseous mixture working upRecovery methodPressure rise

The invention discloses a refinery saturated dry gas recovery system and a recovery method. The system comprises an absorption tower, a desorption tower, a reabsorber, a compressor and a heat exchanger, wherein the system is provided with a condensate stripper; a condensate outlet of the compressor is connected with the condensate stripper, and the top of the condensate stripper is connected with an inlet of the compressor. The method comprises the steps of during the pressure rising of refinery saturated dry gas, delivering an interstage condensate to the condensate stripper, and recovering stripped hydrocarbon as one of products. According to the refinery saturated dry gas recovery system and the recovery method, the products are all delivered to an ethylene unit cracking furnace, an acidic gas removal device, a deoxidation device, a dryer and the like are not required, the investment is reduced, the energy consumption is low, the flow is simple, and the recovery rate is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

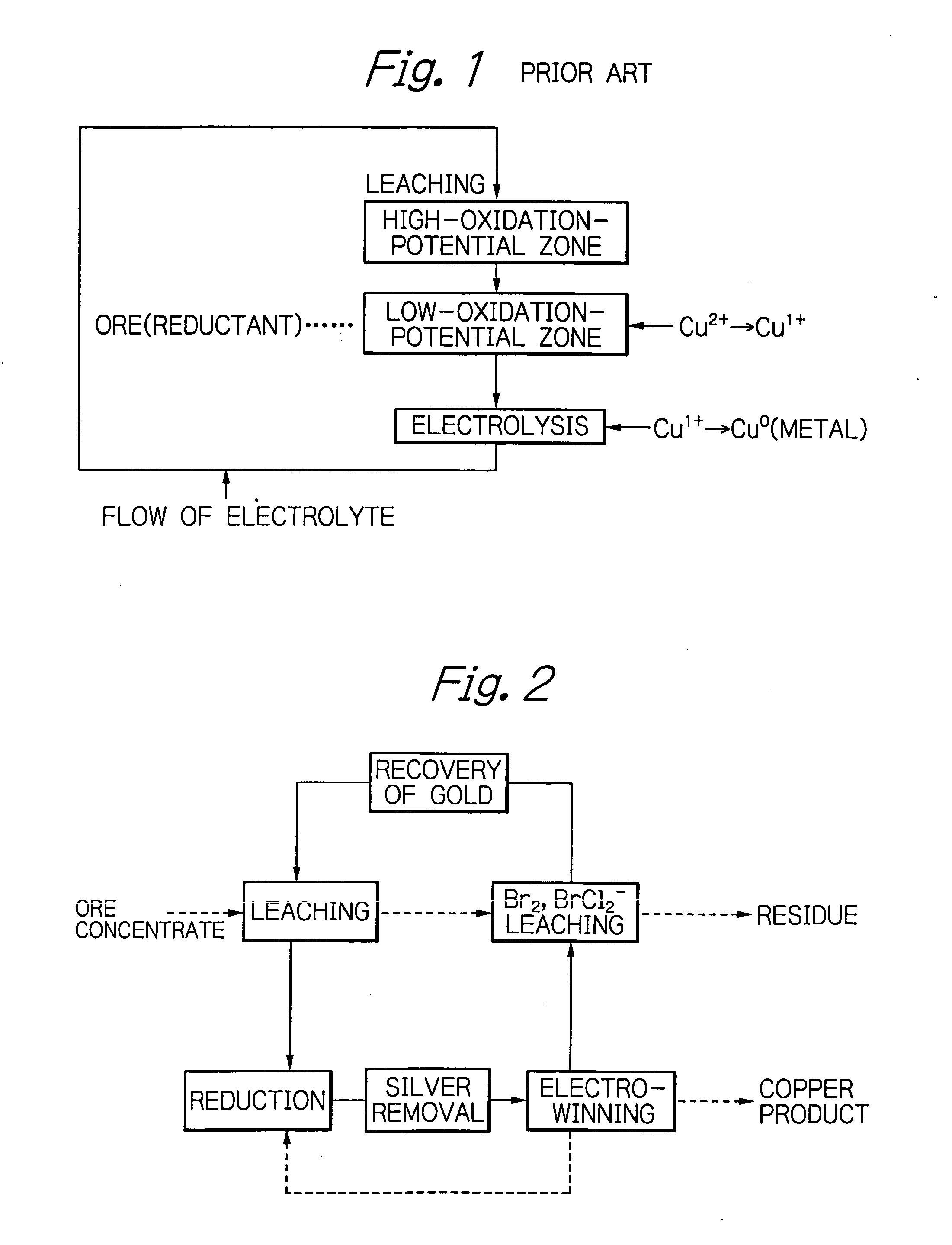

Electrolytic method in diaphragm-type cell

InactiveUS20050067299A1Improve leaching efficiencyReduce reaction efficiencyPhotography auxillary processesElectrolysis componentsPregnant leach solutionChloride electrolytes

In a metal-winning method, copper ore or copper-ore concentrates is effectively hydraulically leached in a chloride leach liquor and the resultant leached liquor is diaphragm-electrolyzed. A chloride electrolyte containing Br− ions and the leached metals is subjected to a diaphragm-electrolysis in an electrolytic cell comprising an anode compartment (4) and a cathode compartment (3). A portion of the electrolyte in the anode compartment (4) is withdrawn from below an anode (2) of the anode compartment (4) and is returned to the leaching step so as to increase the oxidation potential of the chloride leach liquor.

Owner:JX NIPPON MINING& METALS CORP +1

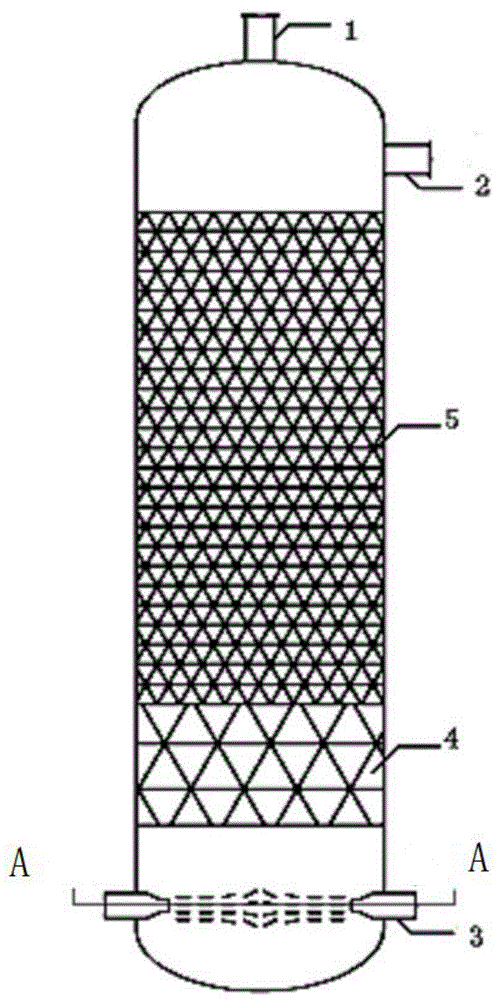

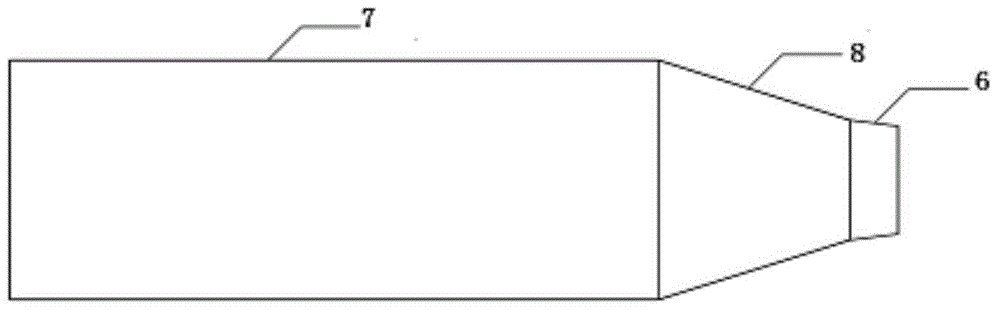

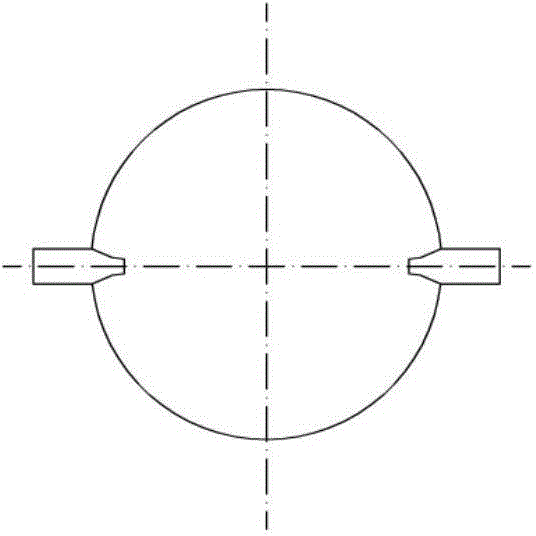

Reactor and method for preparing epoxypropane by reactor

ActiveCN104907009AIntensified interphase mixingHigh selectivityOrganic chemistryChemical/physical processesSpray nozzleFixed bed

The invention discloses a reactor. The middle of the reactor is filled with an epoxidation catalyst, the top wall of the reactor is provided with a gas outlet, the upper side wall of the reactor is provided with a liquid outlet, the lower side wall of the reactor is provided with one or two groups of injectors, each group of the injectors comprises two injectors symmetrically distributed on the same plane, the injector comprises a jet pipe and a nozzle connected to the jet pipe, the nozzle is frustoconical, the diameter of one end of the nozzle connected to the jet pipe is greater than that of the other end, the nozzle stretches into a fixed bed reactor, the jet pipe comprises two sections, the section of the jet pipe far away from the nozzle is cylindrical, the other section is frustoconical, and the diameter of one end of the jet pipe far away from the nozzle is greater than the diameter of one end of the jet pipe connected to the nozzle. The invention discloses a method for preparing epoxypropane by the reactor and a reaction system composed of the reactors connected in series. The reactor realizes reactant high-speed clashing mixing, improves reactant mixing effects, improves heat and mass transfer effects and improves a cumene hydroperoxide conversion rate and epoxypropane selectivity.

Owner:HONGBAOLI GRP CO LTD +1

Novel Microbial Biomass Based Feed Products

ActiveUS20190000124A1Relieve pressureReduce the amount of feedBioreactor/fermenter combinationsBiological substance pretreatmentsOxygenBiological materials

Aquafeed, animal feed, and other food products, as well as nutritional and pharmaceutical compounds, chemicals and biomaterials are important commodities that can be produced at commercial scale by fermentation of microorganisms. The present invention provides a method for producing these valuable multi-carbon compounds from simple gas feedstocks, such as carbon dioxide, hydrogen and oxygen, by cultivating a consortium of microbial cells specially selected for this purpose in an aqueous culture medium. In addition to exploiting inexpensive feedstocks, such as waste industrial gas for this cultivation, the platform described herein also provides the advantage of removing carbon dioxide and other waste gases from industrial emissions, which would otherwise contribute to global climate change. Furthermore, the cultivation of a microbial consortium can provide highly nutritious components to a feed blend that might not be available from a monoculture.

Owner:OAKBIO INC

Method for preparing sulfonated polystyrene (strongly acid type) cation exchange resin

InactiveCN102040694AWide range of usesEfficiently catalyzes the synthesis ofChlorosulfuric acidReaction temperature

The invention relates to a method for preparing sulfonated polystyrene (strongly acid type) cation exchange resin by taking chlorosulfonic acid as a sulfonating agent. The method has the following characteristics: 1. the advantages of low reaction temperature, short time, less dosage, high sulfonation degree, cost saving, environmental protection and the like can be achieved since chlorosulfonic acid is used as a sulfonating agent; and 2. the sulfonation degree of the resin prepared by using chlorosulfonic acid as a sulfonating agent is controllable in the range of 0.01-95%.

Owner:NANJING UNIV OF TECH

Selective hydrogenation method of highly unsaturated hydrocarbons in cracking gas

ActiveCN101818077AFully expected effectGood choiceGaseous mixture working upUnsaturated hydrocarbonAlkyne

The invention discloses a selective hydrogenation method of cracking gas, belongs to the technical field of selective hydrogenation of unsaturated hydrocarbons, aims at solving the problem that the prior art does not have higher conversion rate for both acetylene and alkynes and dienes containing more carbon atoms and provides a method for carrying out selective hydrogenation on the C2-C10 highlyunsaturated hydrocarbons (alkynes and dienes) on the upstream side of a front dethanizer of an olefin production device with the adoption of acting liquid phase flow of substrate flow of the dethanizer, which is characterized by loading a non-noble metal catalyst in an upper layer in a reactor for carrying out the hydrogenation on the alkynes and the dienes of C3 and above, and loading a noble metal catalyst in a lower layer for carrying out the selective hydrogenation on the acetylene. The method can carry out the hydrogenation on the alkynes and the dienes in the cracking gas as far as possible, simultaneously fully play the role of the liquid phase flow of the mixed phase hydrogenation reactor, reduce the feed rate entering into the front dethanizer, reduce the energy consumption and the equipment investment and be conductive to improving the selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combined flocculant

InactiveCN103241817AReduce manufacturing costReduce the amount of feedWater/sewage treatment by flocculation/precipitationMetasilicatePotassium ferrate

The invention discloses a combined flocculant composed of the following components in parts by weight: 5-10 parts of polymeric aluminum calcium chloride, 10-20 parts of aluminum trichloride, 10-20 parts of ferric citrate, 5-8 parts of polysulfide ferric chloride, 6-9 parts of polymeric ferric metasilicate, 2-3 parts of potassium ferrate, 5-10 parts of polyaluminum chloride, 10-15 parts of soluble coatings and 3-5 parts of flocculant activating components, wherein the flocculant activating components are selected from one or a combination of two from porous perlite micro powder and coal ash micro powder, and the particle size of the porous perlite micro powder is 200-300. The combined flocculant is good in humidity resistance, favorable in quality stability, long in quality guarantee period, high in adaptability for the natural environment and convenient to use.

Owner:CHUZHOU YOULIN TECH DEV

Technique for fabricating color decorative glass sheet

InactiveCN1539771AEasy to removeFast operationGlass blowing apparatusGlass productionGlass ballUltimate tensile strength

A process for preparing decorative color sheet includes proportionally mixing quartz sand, flux, coloring agent and borax, high-temp smelting, blowing glass ball by a blowing mechanism, cooling and cutting. Its advantages are high toughness and strength, high productivity, and high of finished products.

Owner:许昌县华伟玻璃制品有限责任公司

Bait feeding method for baby grey sea horses

ActiveCN103444612AImprove feeding efficiencyExtended feeding timePisciculture and aquariaFisheryZoology

The invention provides a bait feeding method for baby grey sea horses. The method is conducted under the condition of a cultivation system and a cultivation environment and is characterized in that bait of different specifications is fed according to baby grey sea horse growing requirements in a cultivation period; newly hatched artemia strengthened through highly unsaturated fat acid is fed before the baby grey sea horses are 4 centimeters in height, and feeding density is 10-12 pieces per milliliter; when the baby grey sea horses are 4-4.5 centimeters in height, 4-5-day old artemia is fed, the artemia is strengthened by highly unsaturated fat acid before feeding, the feeding density is 5-6 pieces per milliliter; when the baby grey sea horses are 5.5-6 centimeters in height, 5-7-day old artemia is fed, the artemia is strengthened by highly unsaturated fat acid before feeding, and the feeding density is 5-6 pieces per milliliter; when the baby grey sea horses are more than 6.5 centimeters in height, adult artemia is fed, the artemia is strengthened by highly unsaturated fat acid before feeding, and the feeding density is 3-4 pieces per milliliter; feeding is conducted twice a day according to the bait feeding method, and excrement and dead bait are siphoned four times a day.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Method for preparing ofloxacin

ActiveCN101648960AFew reaction stepsShort reaction timeOrganic chemistryOrganic solventCarboxylic acid

The invention discloses a method for preparing ofloxacin. The invention aims to provide a method for preparing ofloxacin, which has short production period, less pollution, high raw material utilization rate, yield and purity, and simple and convenient operation. The method comprises the following steps: preparing 9,10-difluoro-2,3-dihydro-3-methyl-7-O-7H-pyridino[1,2,2-de]-[1,4]- benzoxazinyl-6-carboxylic acid by tetrafluorobenzoyl chloride as a raw material through a compounding method; and reacting with alkali in an organic solvent to obtain the ofloxacin. The invention has the advantages that the tetrafluorobenzoyl chloride reacts with 3-(2-R1-2-R2-4- methylimidazole alkyl) acrylic ester, the product is directly hydrolyzed during post processing and then is carried out the ring close;the reaction step is reduced, the reaction time is shortened, and the yield is as high as 85-90 percent. Organic or inorganic alkali is added in preparation, thereby reducing the feed content of methyl piperazine, reducing the reaction cost and having high yield.

Owner:CHENGDA PHARM CO LTD

Abiduoer granular formulation

ActiveCN1868470AReduce the amount of feedLow costOrganic active ingredientsAntiviralsAdhesiveUmifenovir

An Abiduoer particle is proportionally prepared from Abiduoer hydrochloride, excipient, suspending aid, adhesive and solvent.

Owner:SICHUAN BAILI PHARM CO LTD

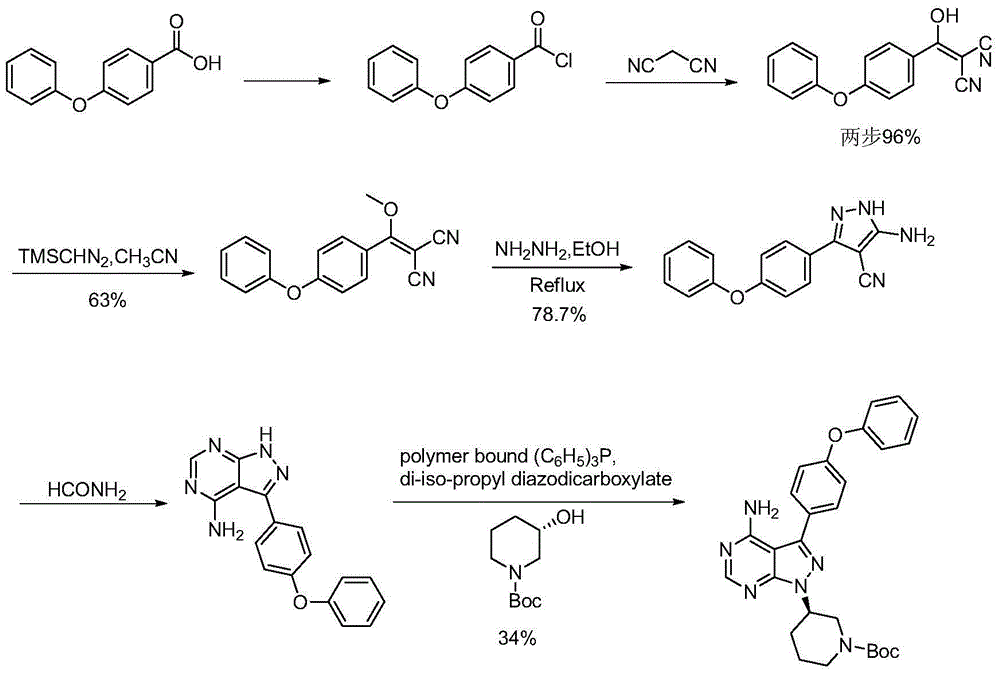

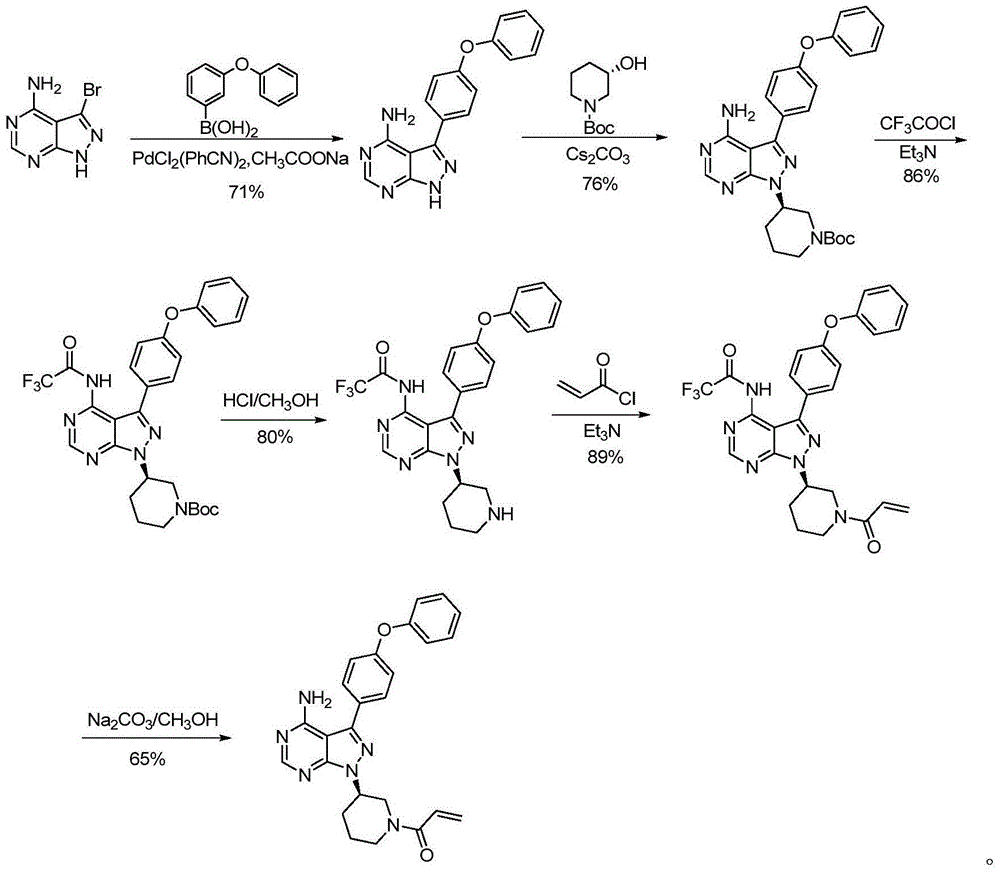

Preparation method for ibrutinib

InactiveCN105985343AHigh product yield and purityImprove conversion rateOrganic chemistryBulk chemical productionCombinatorial chemistryMitsunobu reaction

The invention specifically relates to a preparation method for ibrutinib, belonging to the field of pharmaceutical chemistry. The preparation method comprises the following steps: reacting a compound as shown in a formula 1 which is described in the specification with a compound as shown in a formula 2 which is described in the specification in the presence of a Mitsunobu reaction reagent so as to obtain a compound as shown in a formula 3 which is described in the specification, and removing protective groups of the compound as shown in the formula 3 in the presence of acid so as to produce a compound as shown in a formula 4 which is described in the specification; subjecting the compound as shown in the formula 4 and a compound as shown in a formula 5 which is described in the specification to a Suzuki coupling reaction in the presence of a catalyst so as to produce a compound as shown in a formula 6 which is described in the specification; and reacting the compound as shown in the formula 6 with acryloyl chloride in the presence of alkali so as to produce ibrutinib. The method has the advantages of high yield of each step, easy purification of the product, high product purity and good industrial production prospects.

Owner:SHANGHAI DUDE MEDICAL SCI & TECH CO LTD +1

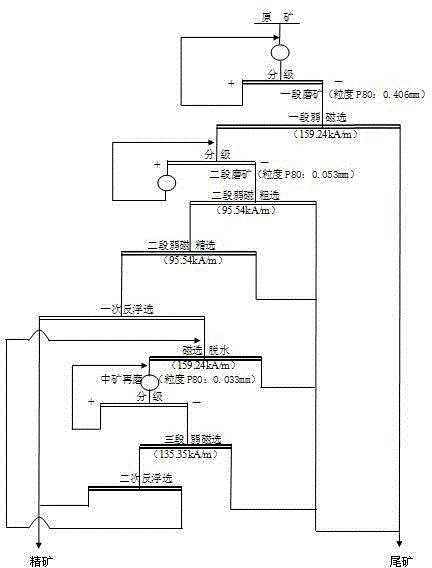

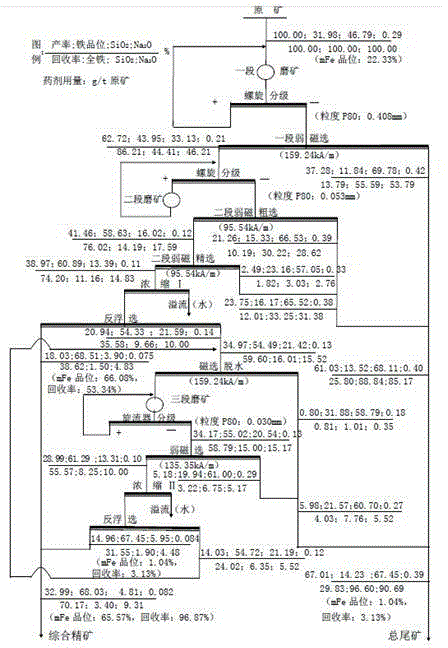

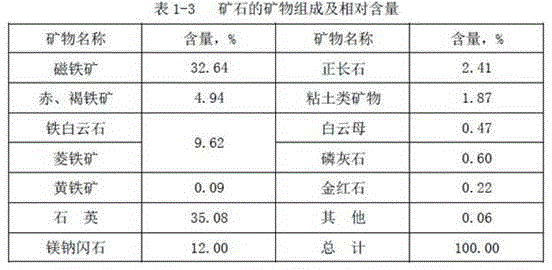

New mineral separation method suitable for separation of hard-separation micro-fine particle magnetic iron ores

InactiveCN104826728ASolve the bottleneck problem of development and utilizationHuge market potentialFlotationWet separationSingle stageThree stage

The invention discloses a new mineral separation method suitable for separation of hard-separation micro-fine particle magnetic iron ores. The new mineral separation method adopts a process comprising the steps of carrying out two-stage grinding on raw ores, carrying out low-intensity magnetic separation, obtaining ore concentrate through reverse flotation and single-stage roughing, regrinding middlings, carrying out the low-intensity magnetic separation and carrying out the reverse flotation; two-stage low-intensity magnetic separation ore concentrate is obtained through the process by adopting a method comprising the steps of stage grinding and stage low-intensity magnetic separation tailings discarding; qualified iron ore concentrate can be obtained in advance by carrying out a cationic collector reverse flotation technology on the two-stage low-intensity magnetic separation ore concentrate under the situation that the granularity is roughened; a regrinding and low-intensity magnetic separation technology is carried out on reverse flotation middlings, the cationic collector reverse flotation technology is carried out on three-stage low-intensity magnetic separation ore concentrate, and thus the iron concentrate grade is increased. According to the new mineral separation method disclosed by the invention, ore concentrate is obtained in advance as the reverse flotation is carried out by independently adopting a cationic collector under the situation that a depressor DF is not added, adding points of medicament are reduced, the manual operation difficulty is reduced, and the cost of mineral separation medicament is reduced; since the ore concentrate is obtained in advance through the reverse flotation, three-stage ball milling material amount is reduced, the ore grinding cost is greatly reduced, and the effect of extracting iron and reducing the energy can be achieved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Method for synthesizing glutathione by enzymatic catalysis

ActiveCN106086126AHigh synthesis efficiencyShort synthesis timePeptidesFermentationATP regenerationGlutamic acid

The present invention discloses a method for synthesizing glutathione by enzymatic catalysis, comprising the following steps: S1, mixing Upsilon-glutamylcysteine synthetase liquid and glutathione synthetase liquid to obtain mixed liquid A, mixing the mixed liquid A with acetate kinase to obtain mixed liquid B; S2, adding an immobilized carrier in the mixed liquid B, stirring for immobilizing, and filtering to obtain an immobilized enzyme; S3, blending glutamic acid, L-cysteine, glycine, magnesium sulfate, ATP (adenosine triphosphate) and acetyl phosphate into a reaction liquid, adding the immobilized enzyme, and stirring for reacting; S4, after reacting, filtering the reaction liquid, and extracting and refining filtrate to obtain the glutathione. The method of the invention has high synthetic efficiency, the production content of the reaction liquid is higher than 10 g / L, and substrate conversion rate reaches higher than 90%; by introducing acetate kinase to construct an ATP regeneration and coupling system, ATP charge is greatly reduced and production cost is significantly reduced; the immobilized enzyme is reusable and highly stable.

Owner:KAIPING GENUINE BIOCHEM PHARMA

Power generation system capable of realizing complementation between solar energy and biomass energy

InactiveCN104179647AEfficient use ofReduce lossesFrom solar energyMachines/enginesAir preheaterThermal energy

The invention discloses a power generation system capable of realizing complementation between solar energy and biomass energy. The power generation system comprises a slot type solar heat collection sub-system, a biomass after-burning sub-system and a power generation sub-system, wherein the slot type solar heat collection sub-system comprises a solar heat collection field, an oil-water heat exchanger and a heat conduction oil pump, and is used for receiving and gathering solar radiation energy; supplied water is heated up to a certain temperature or is heated until becoming steam by the oil-water heat exchanger; waste heat of heat conduction oil is used for replacing part or all high-pressure cylinder extract air of a steam turbine for heating the low-temperature supplied water; the biomass after-burning sub-system comprises a biomass boiler, a superheater, a reheater and an air pre-heater, and is used for generating high-temperature flue gas and heating products at an outlet of the oil-water heat exchanger and steam at an outlet of a high-pressure cylinder into high-temperature and high-pressure steam; the power generation sub-system comprises the steam turbine and a generator set, and is used for converting received thermal energy into electric energy and outputting the electric energy. After the power generation system capable of realizing complementation between solar energy and biomass energy is adopted, the problem that a slot type solar single thermal power generation system is low in main steam parameter can be solved, the dosage of biomass is reduced, and the biomass resource collection, transportation and storage costs can be lowered.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

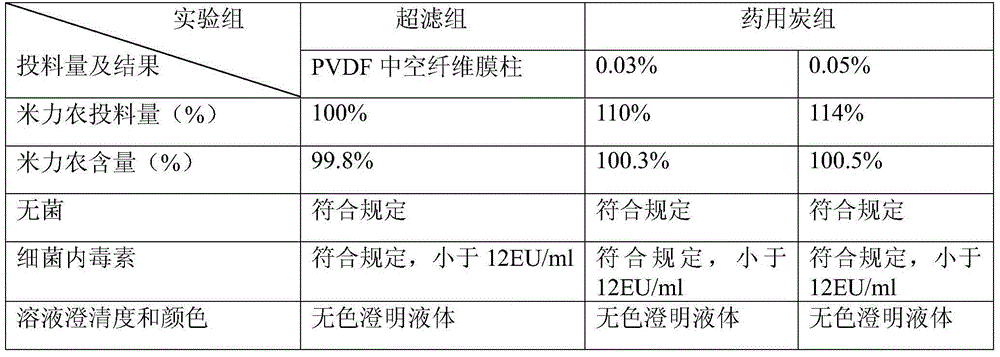

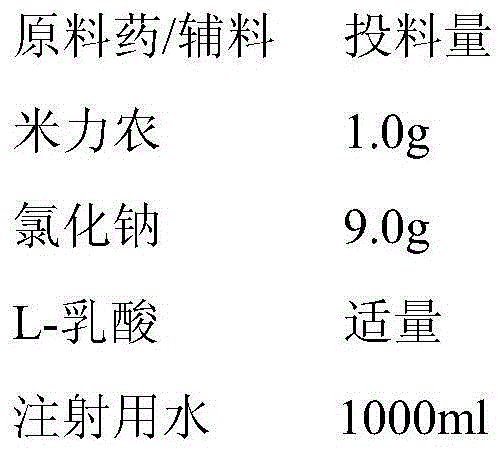

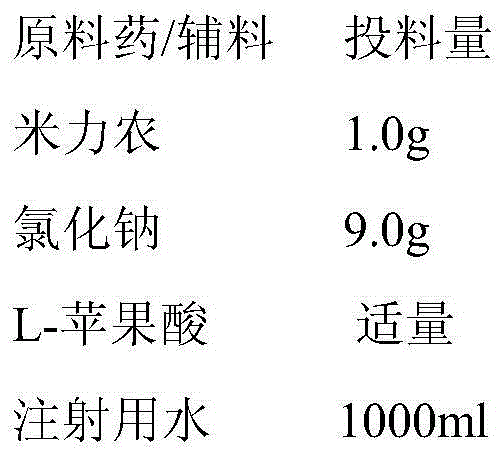

Milrinone pharmaceutical composition and preparation method thereof

InactiveCN105663034AReduce the amount of feedLarge adsorption capacityOrganic active ingredientsPharmaceutical delivery mechanismMilrinoneFiltration

The invention discloses a milrinone pharmaceutical composition. Either L-lactic acid or L-malic acid is used as a cosolvent and a pH value regulator, and an ultra-filtration method is adopted for filtering. The milrinone pharmaceutical composition provided by the invention can improve hyperchloremia caused by excessive Cl- and the like generated from the adoption of inorganic acid and can improve metabolic disorders and even acidosis caused by D-lactic acid or lactic acid. The process for preparing the milrinone pharmaceutical composition provided by the invention is simple to operate and is capable of improving medication safety.

Owner:YANGZIJIANG PHARMA GROUP SHANGHAI HAINI PHARMA

Machining method for utilizing radial forging machine for producing multi-step cold-rolled work roller blank

ActiveCN108672625AReduce manufacturing costReduce blank process weightForging hammersFurnace typesSurface cleaningWater cooling

The invention discloses a machining method for utilizing a radial forging machine for producing a multi-step cold-rolled work roller blank, and belongs to the technical field of metallurgical machinemanufacturing. After electric furnace smelting, LF furnace refining and VD vacuum treatment, fire cutting, annealing, surface shot blasting, coal gas baking and electroslag remelting are conducted tomanufacture an MC6B multi-step cold-rolled work roller blank electroslag ingot; then, annealing and surface cleaning are conducted, and the gas furnace heating heat preservation time is larger than orequal to 24 h; then, arc upsetting plate upsetting, first-time furnace returning heating, upper flattening, lower V-shaped anvil drawing-out, second-time furnace returning heating and radial forgingmachine forging are conducted to manufacture an MC6B multi-step cold-rolled work blank roller blank; and finally, hot saw cutting, normalizing after water cooling, two-segment type spheroidizing annealing and nondestructive inspection checking are conducted, and the radial forging machine is utilized for producing the multi-step cold-rolled work roller blank. According to the machining method, forge piece allowance of a produced roller blank forge piece is small, the machining time is shortened, accordingly, the forge piece technology weight is reduced, and the manufacturing cost is saved.

Owner:建龙北满特殊钢有限责任公司

Organic/inorganic compound type flocculant

InactiveCN103241818AWide variety of sourcesReduce manufacturing costWater/sewage treatment by flocculation/precipitationCelluloseInorganic compound

The invention discloses an organic / inorganic compound type flocculant which consists of the following components in parts by weight: 10-20 parts of aluminum potassium sulfate, 10-15 parts of ferric citrate, 3-5 parts of ferrate, 5-10 parts of polyaluminum chloride, 10-15 parts of mixture of polyacrylamide, gelatin and soluble cellulose, 3-5 parts of flocculant activation component, 5-10 parts of dicyanodiamine, 5-10 parts of formaldehyde and 15-25 parts of polycalcium aluminum chloride sulfate. The flocculant disclosed by the invention has the advantages of wide source of raw materials, low production cost, small investment, good flocculation excitation effect and low flocculation treatment cost, remarkably reduces the water content of waste residues, and greatly improves the removal rate of suspended solids.

Owner:CHUZHOU YOULIN TECH DEV

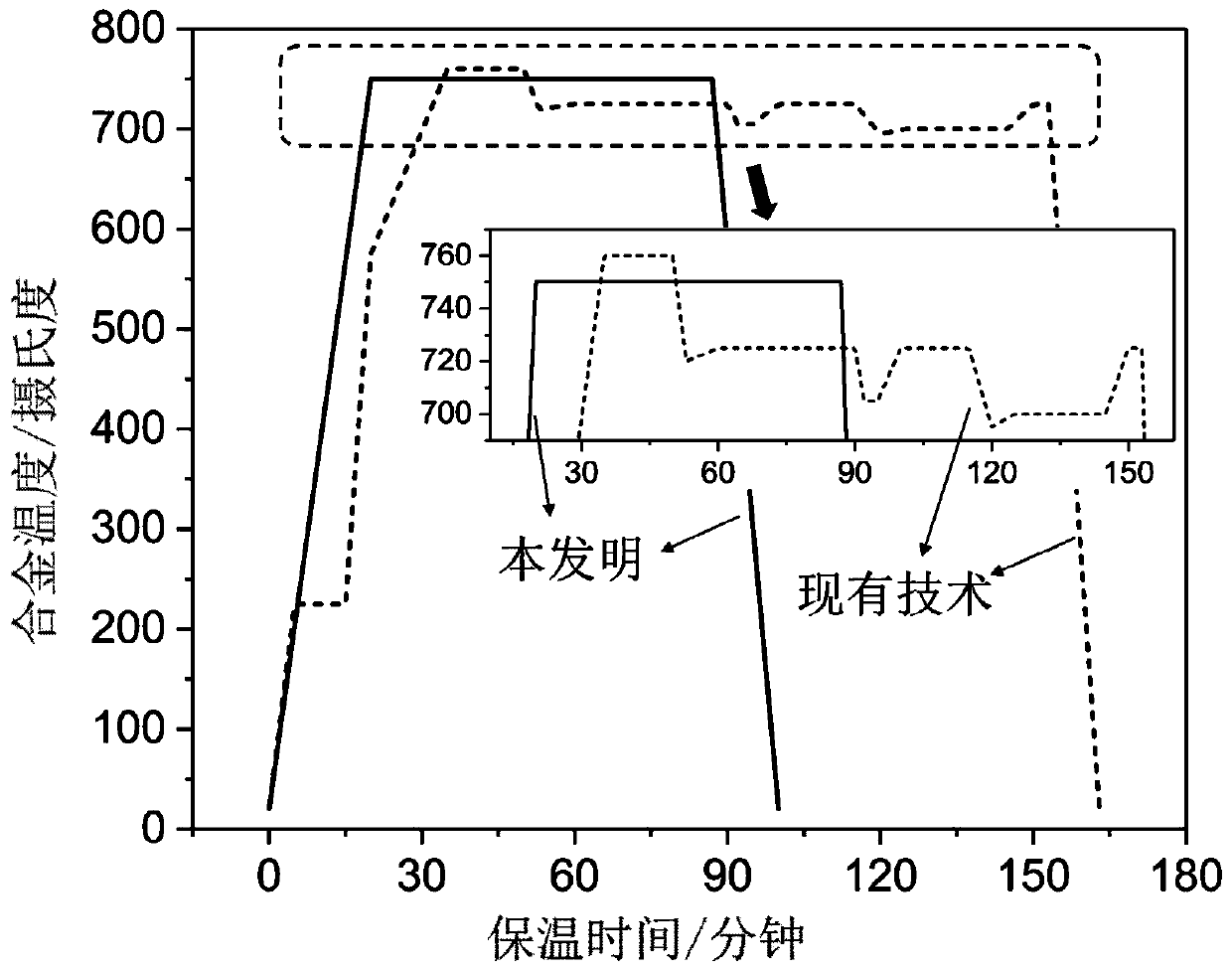

Hypereutectic cast aluminum-silicon alloy modification method

The invention discloses a hypereutectic cast aluminum-silicon alloy modification method. The method comprises the following steps that material preparation is prepared with the following elements of,by mass, 6.000%-12.600% of Si, 0.001%-0.150% of Sr, 0.020%-0.122% of La or RE, 0.001%-0.150% of B, and the balance Al, wherein the mass ratio of the Sr to the B is not larger than 1.351, the mass ratio of the La to the B or the RE to the B is within 1-5, then smelting and casting are conducted through the processes of melting, refining and degassing, feeding and heat preservation casting to obtainan aluminum-silicon alloy, wherein the modification grade is 4-6 grades, and the modification period is 2-3 hours. According to the method disclosed, the total feeding amount of the Sr, the La and the B is reduced by 62.3%-72.5%, the sum of the mass fractions of the modified elements is only 0.022%-0.237%, that the production time is shortened by 37.5%-52.0%, and only reaches 60-100 minutes, andthe method has extremely high economic value.

Owner:SHANGHAI UNIV

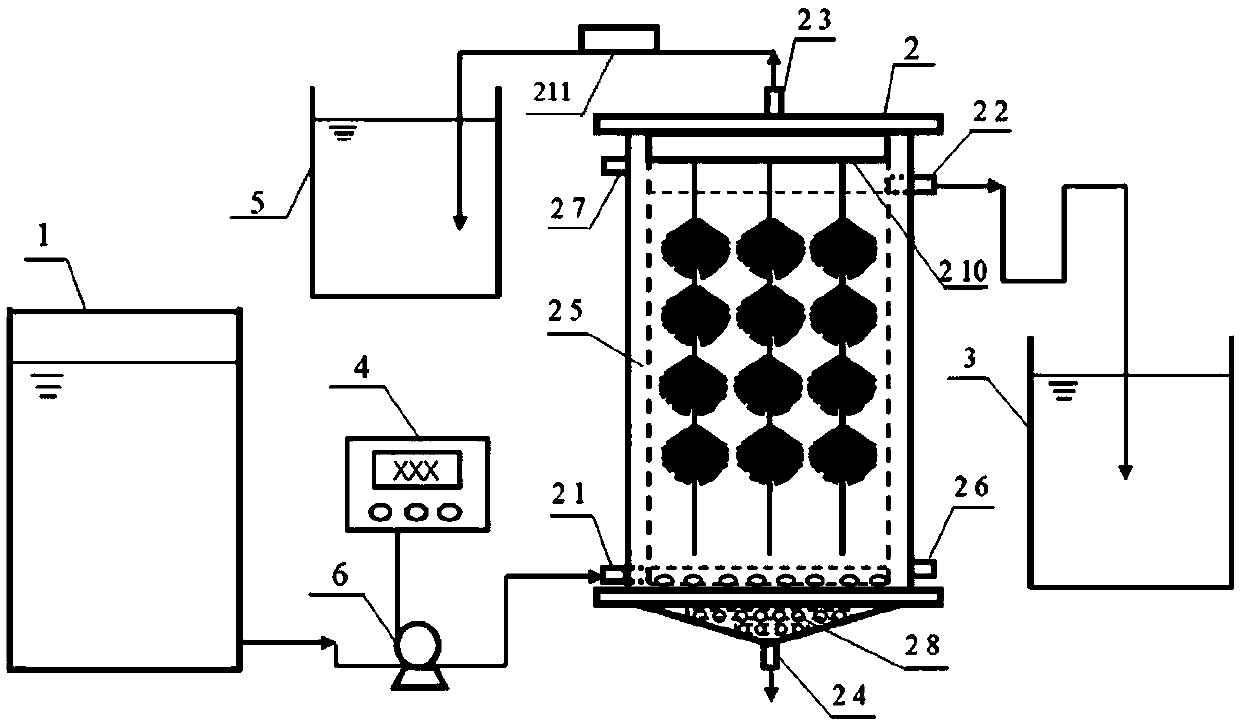

Method and device for enriching anaerobic ammonium oxidizing bacteria based on modified basalt fiber filler

ActiveCN109593685AShort generation cycleSave matrix feedBioreactor/fermenter combinationsBiological substance pretreatmentsSludgeSewage

The invention discloses a method and a device for enriching anaerobic ammonium oxidizing bacteria based on modified basalt fiber filler, and belongs to the technical field of sewage biological treatment. The method is characterized by comprising the following steps: S1, starting a system, mixing nitrified sludge with anaerobic ammonium oxidized sludge, then adding the mixed sludge into a reactor filled with modified basalt fibers, and mixing the sludge thoroughly; S2, in an initial stage of culturing, sending matrix raw water into the reactor; at the same time, turning on circulating water forcircular flow; and S3, in a logarithmic growth phase, controlling the water inlet speed of the raw water matrix for continuous rapid enrichment culturing of the anaerobic ammonium oxidizing bacteria.By adopting the method for enriching the anaerobic ammonium oxidizing bacteria provided by the invention, the generation cycle of the anaerobic ammonium oxidizing bacteria can be effectively shortened, high-activity proliferation in a short time can be realized, effective enrichment culturing of the anaerobic ammonium oxidizing bacteria can be implemented, and a foundation is laid for the engineering application of the novel biological denitrification technology.

Owner:江苏艾特克环境工程设计研究院有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com