Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1239results about How to "Short synthesis time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

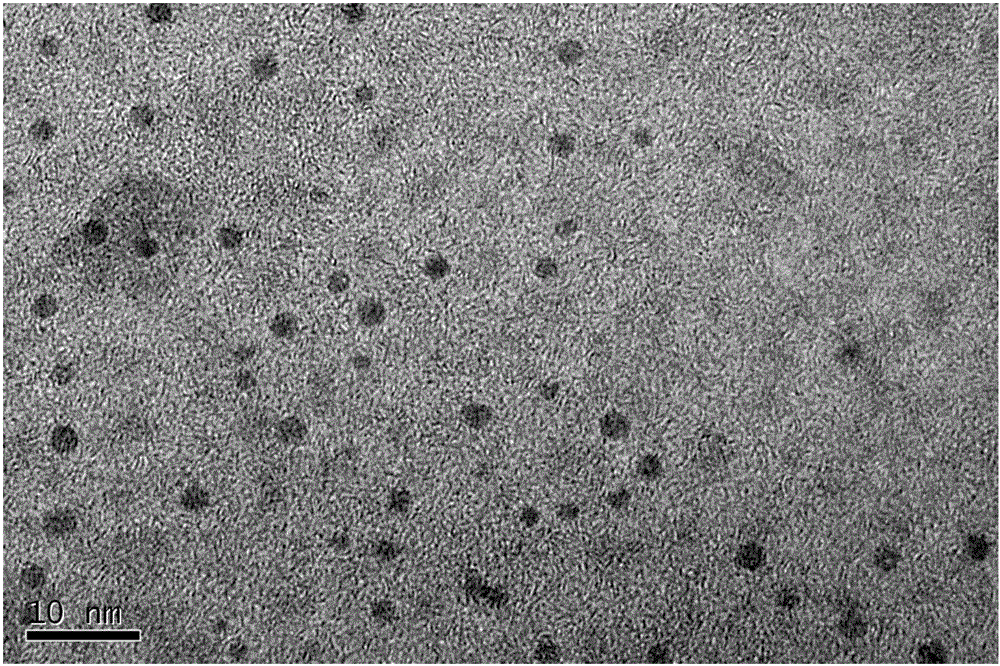

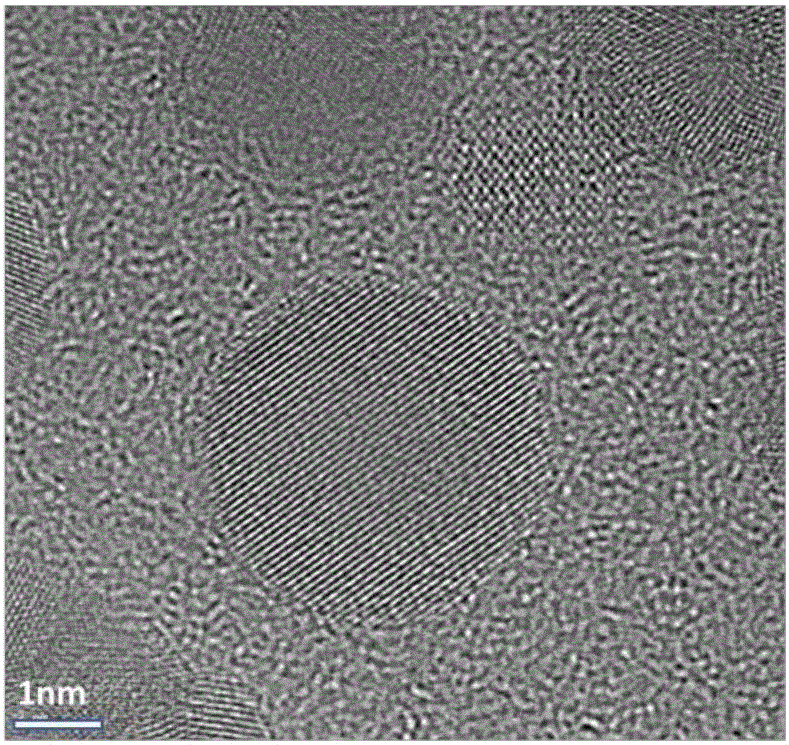

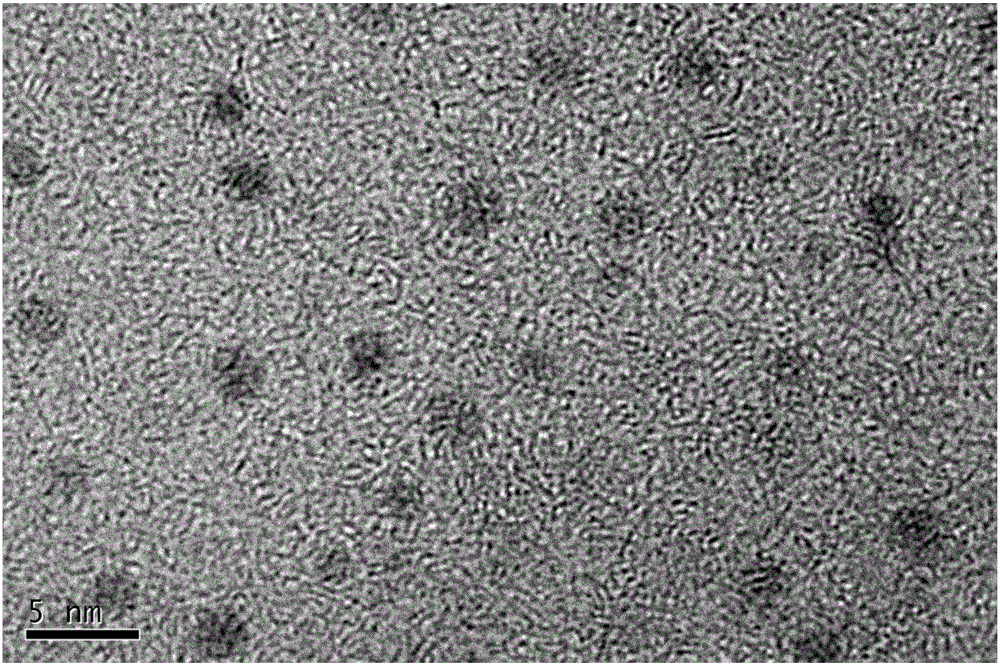

Nitrogen, phosphorus and sulphur doping or co-doping carbon dot and batch controllable preparing method and application thereof

InactiveCN104987863ASimple processShort synthesis timeNanoopticsFluorescence/phosphorescenceAir atmosphereSilica gel

The invention provides a nitrogen, phosphorus and sulphur doping or co-doping carbon dot and a batch controllable preparing method and application thereof. The method comprises the steps that a carbon source, a nitrogen source, a phosphorus source and a sulphur source are evenly mixed, and a mixture is obtained, wherein the molar ratio of C to N to P to S in the mixture is 1 to 0-0.8 to 0-0.4 to 0-0.4, and the contents of N, P and S are prevented from being zero at the same time; in the air, the mixture is heated to be fused, the reaction is carried out for 3 min to 60 min, natural cooling is carried out till the indoor temperature is reached, a reaction product is separated by a silicagel column, raw materials which do not react are removed, and the nitrogen, phosphorus and sulphur doping or co-doping carbon dot is obtained. According to the method, the technology is simple, the compound time is short, batch producing can be achieved, the doping amount can be adjusted and controlled accurately, the fluorescence color of the prepared carbon dot ranges from blue to green, the application can be achieved on bioluminescence marking and cell imaging aspects, and the good economic benefit and the application prospect are achieved.

Owner:XI AN JIAOTONG UNIV

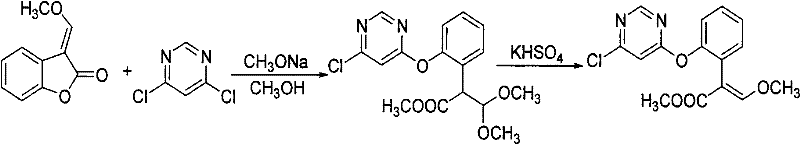

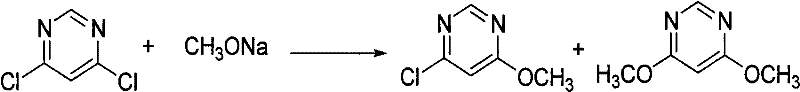

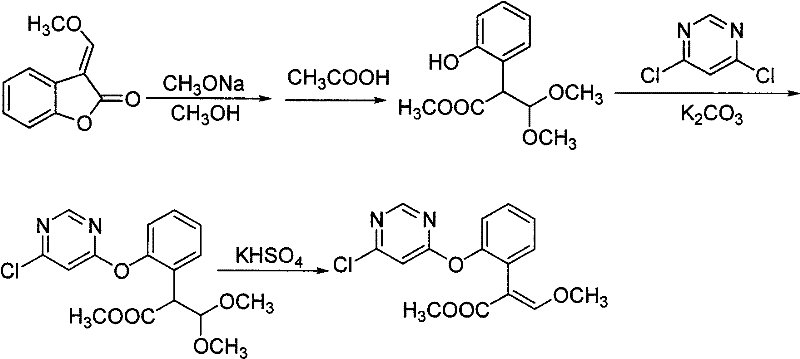

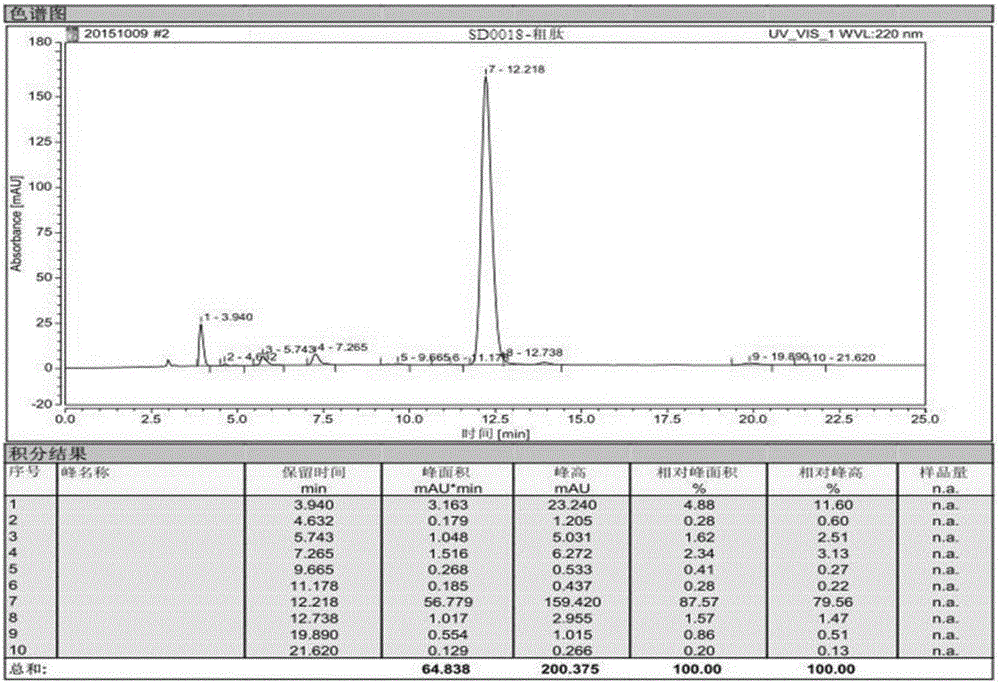

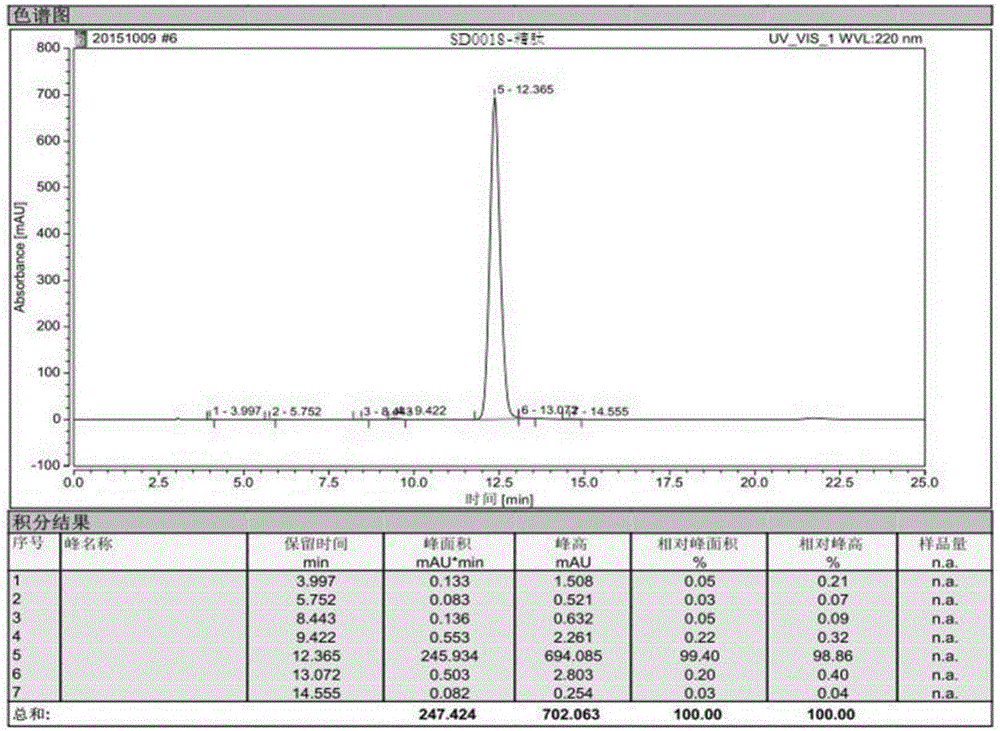

Synthetic method of azoxystrobin and special intermediate for synthesis

The invention relates to a synthetic process of a chemical substance, and particularly relates to a synthetic method for synthesizing (E)-2-[2-(6-chloro pyrimidine-4-yloxy)phenyl]-3-methoxy methacrylate and azoxystrobin; the method comprises the following steps: mixing a raw material of 3-(alpha-methoxy)methylene benzofuran-2-(3H)-ketone and potassium carbonate in a toluene solvent, cooling to 0-10 DEG C, adding sodium methoxide, reacting for 0.4-0.6 hours; adding 4,6-dichloropyrimidine and a catalyst of DABCO, reacting for 1-2 hours, filtering to remove inorganic salts, washing the filtrate with water, performing distillation to recover toluene; adding a catalyst of potassium bisulfate into the distillation residues of the above reaction, heating to 132-145 DEG C in a reduced-pressure condition for reaction; directly adding salicylonitrile to synthesize azoxystrobin or performing toluene dissolution, water washing, solvent recovery, recrystallization and filtration to obtain an intermediate. The production and synthesis of (E)-2-[2-(6-chloro pyrimidine-4-yloxy)phenyl]-3-methoxy methacrylate by the production process of the invention has high yield, and simple operations, and the used raw materials and processes are routine reagents and methods.

Owner:CHONGQING UNISPLENDOUR CHEM

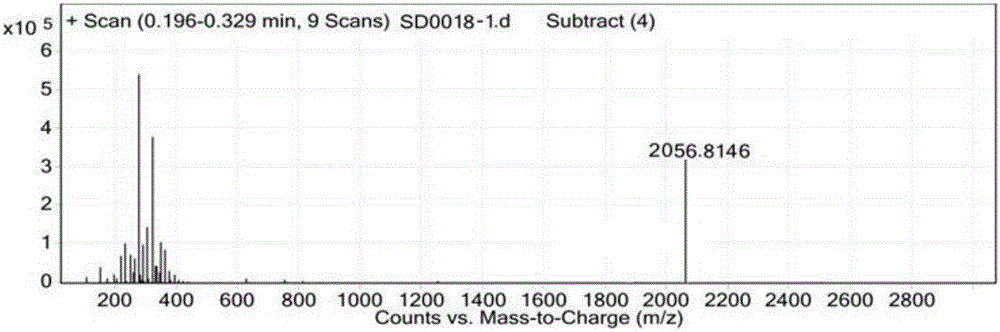

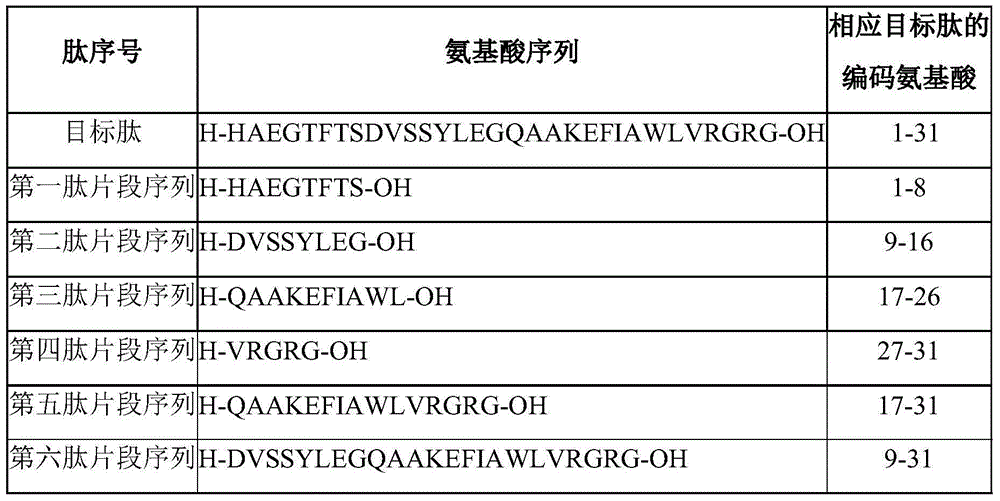

Synthesis method of semaglutide

ActiveCN106749613ALow costReduce the number of generatedPeptide preparation methodsBulk chemical productionSynthesis methodsPeptide sequence

The invention relates to a synthesis method of semaglutide. According to the method, a semaglutide product is synthesized by adopting a solid-liquid phase combination method, and three fragments are simultaneously synthesized in a synthesis manner of 16+6+9 fragments, and therefore, the synthesis time of the product is greatly shortened; moreover, by step-by-step analysis on synthesis factors of His-Ala-Glu-Gly-Thr-Phe-Thr-Ser-Asp-Val-Ser-Ser-Tyr-Leu-Glu-Gly, Gln-Ala-Ala-N6-[N-(17-carboxy-1-oxoheptadecyl-L-gama-glutamyl [2-(2-aminoethoxy) ethoxy] acetyl [2-(2-aminoethoxy) ethoxy] acetyl]-Lys-Glu-Phe, Ile-Ala-Trp-Leu-Val-Arg-Gly-Arg-Gly-OH and the like, the difficulty in synthesis of a peptide sequence in solid-phase synthesis is reduced, the problem of batch amplification in the solid-phase synthesis is solved, and the synthesis efficiency is improved; and as liquid-phase fragment synthesis is adopted, the purification difficulty is effectively reduced, and the production cost is greatly lowered. The synthesis method disclosed by the invention has the advantages that the synthesis time can be shortened by 40%, the cost of materials is lowered, the generation quantities of deletion peptide and hybrid peptide are decreased, and the synthesis method is suitable for industrial large-scale production.

Owner:SINOPEP ALLSINO BIOPHARMACEUTICAL CO LTD

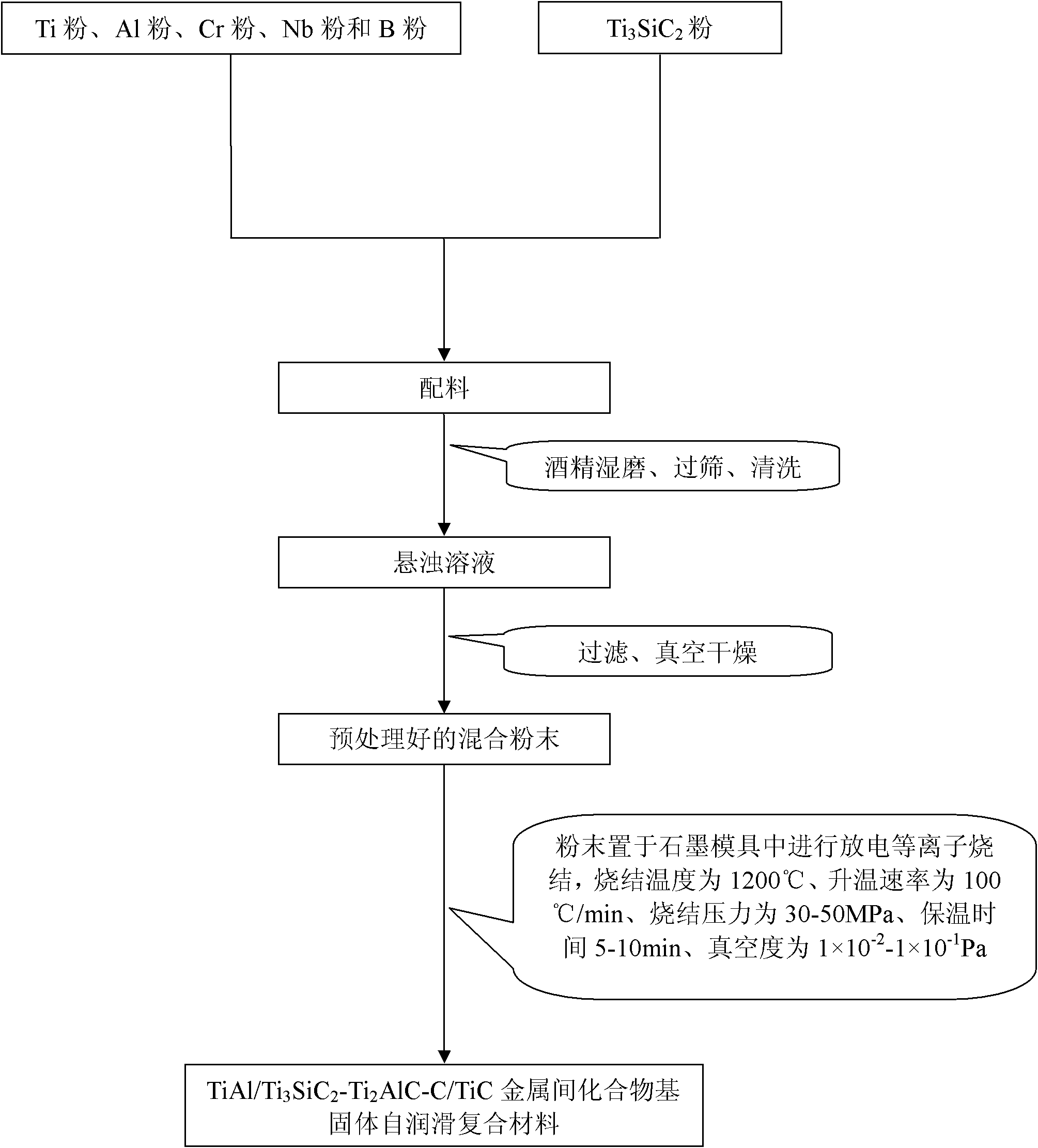

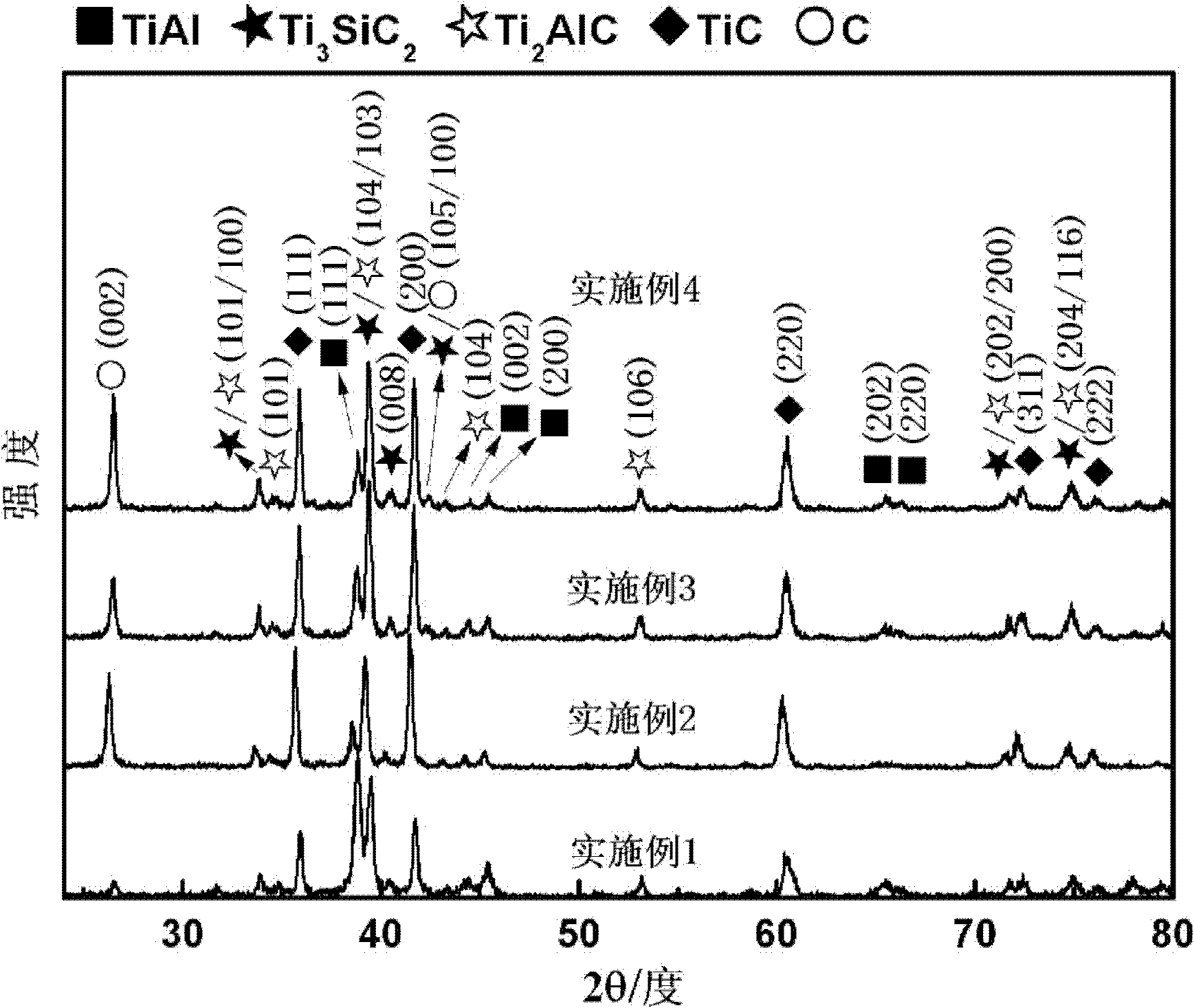

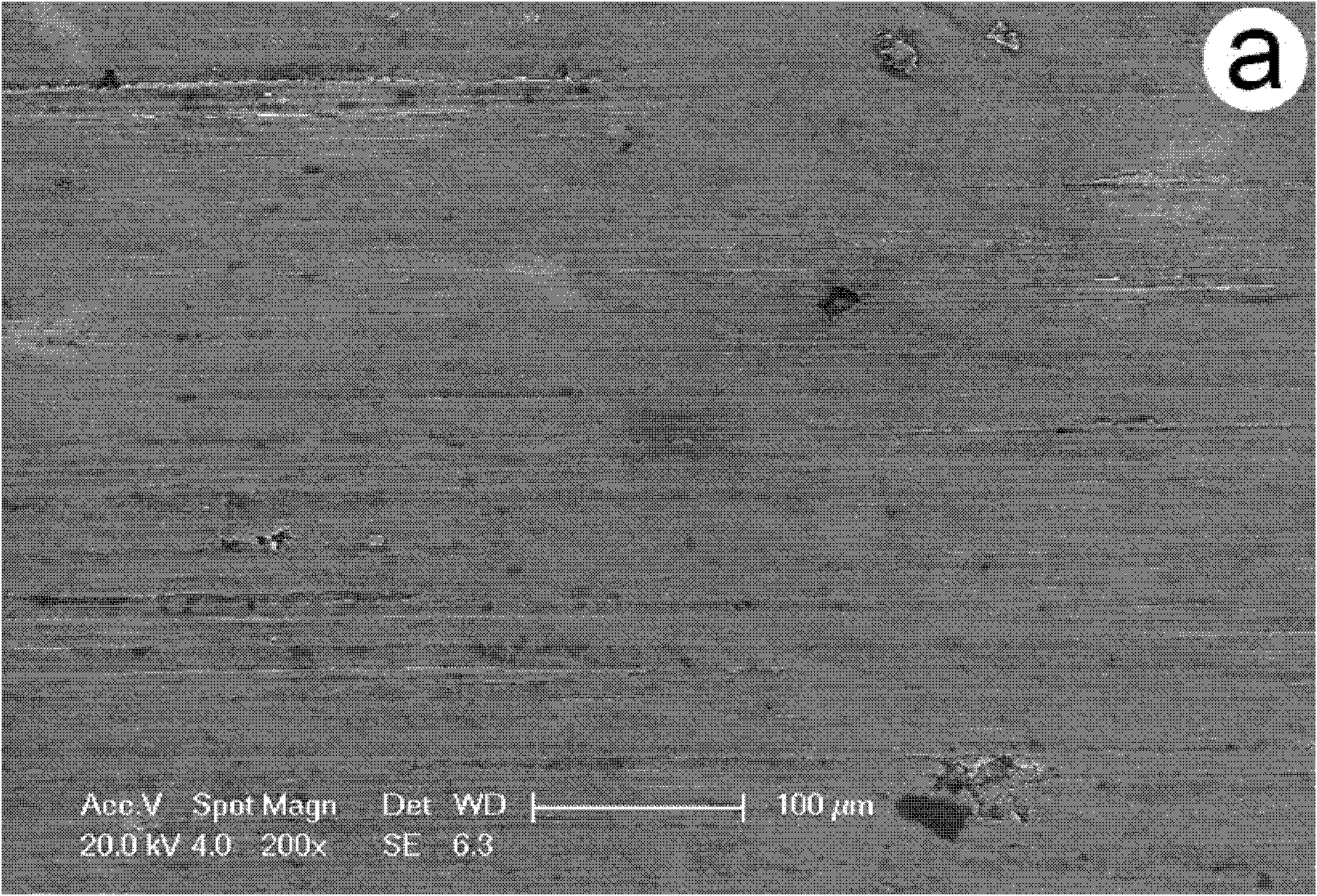

TiAl intermetallic compound-based solid seif-lubricating composite material and preparation method thereof

The invention relates to a TiAl intermetallic compound-based solid seif-lubricating composite material which comprises Ti3SiC2, Ti2AlC and C which are used as the ternary composite lubricating phase and TiC which is used as the reinforced phase, and a preparation method thereof. The TiAl intermetallic compound-based solid seif-lubricating composite material is characterized in that the material is prepared from Ti powder, Al powder, Cr powder, Nb powder, B powder and Ti3SiC2 powder, wherein the molar ratio of Ti, Al, Cr, Nb and B is 48:47:2:2:1 and the dosage of the Ti3SiC2 powder is 5-20wt.% of the total weight of the Ti powder, Al powder, Cr powder, Nb powder and B powder. The TiAl / Ti3SiC2-Ti2AlC-C / TiC intermetallic compound-based solid seif-lubricating composite material synthesized by the method is novel in component design (the intermetallic compound matrix, the composite lubricating phase and the reinforced phase), high in density, good in tribological properties, stable in technological parameters, fast and simple in preparation process and easy in operation and the method is suitable to be used to prepare the high performance TiAl intermetallic compound-based solid seif-lubricating composite material.

Owner:WUHAN UNIV OF TECH

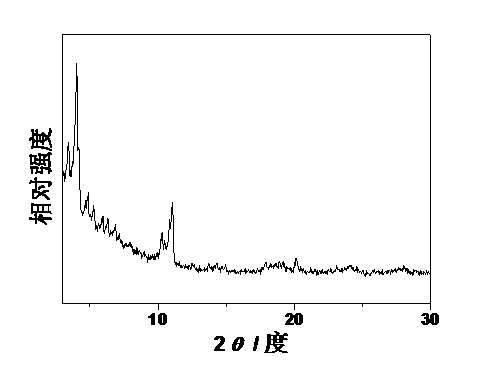

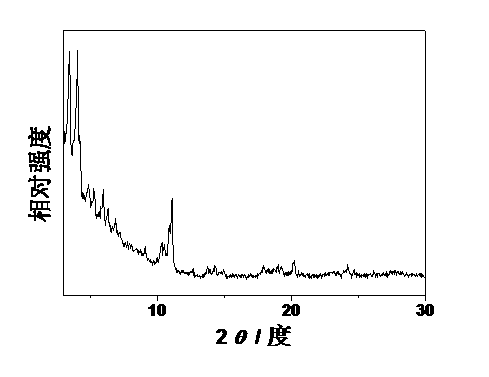

Method of synthesizing mesoporous carbon material

The invention discloses a synthesizing method of dielectric carbon material through hard moulding method, which is characterized by the following: sintering the composition of silica / molder or saccharose directly; removing silica to obtain dielectric carbon; shortening the synthesizing time with high sequence; fitting for manufacturing.

Owner:EAST CHINA NORMAL UNIVERSITY

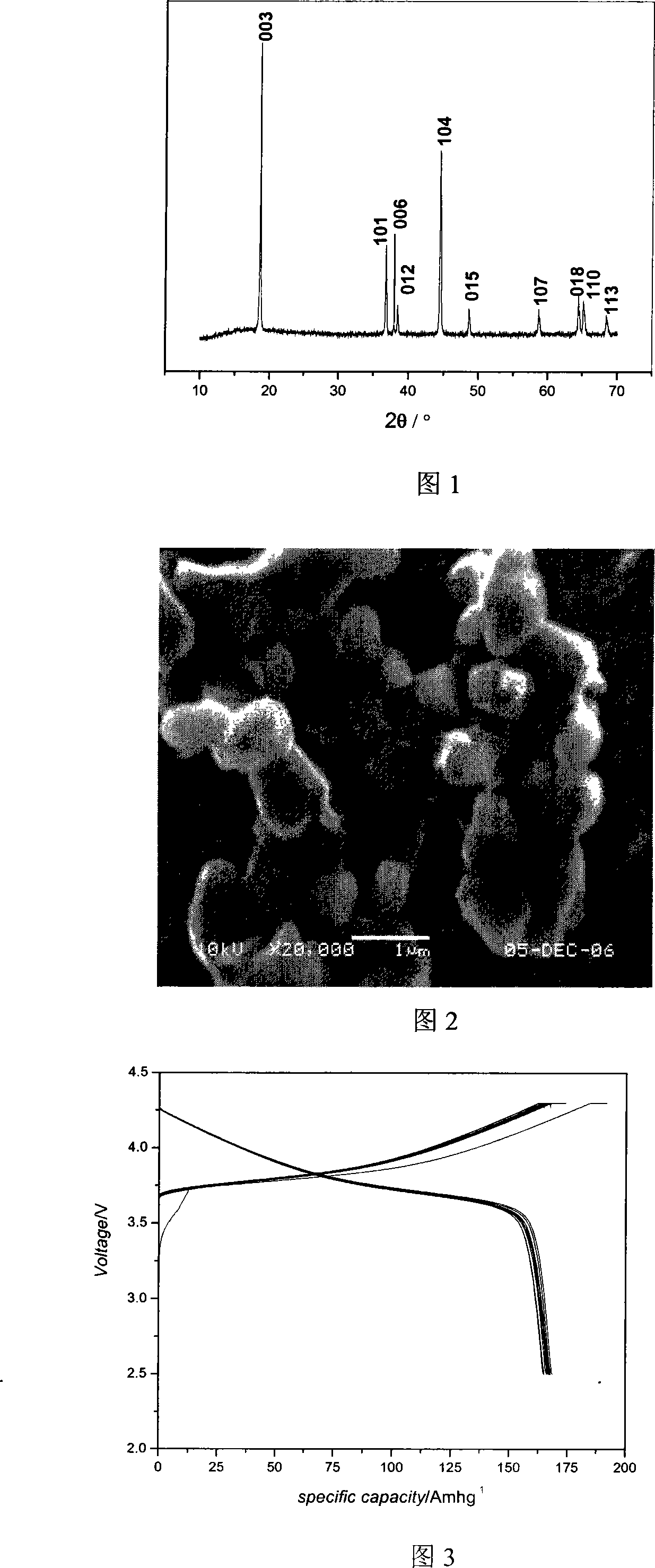

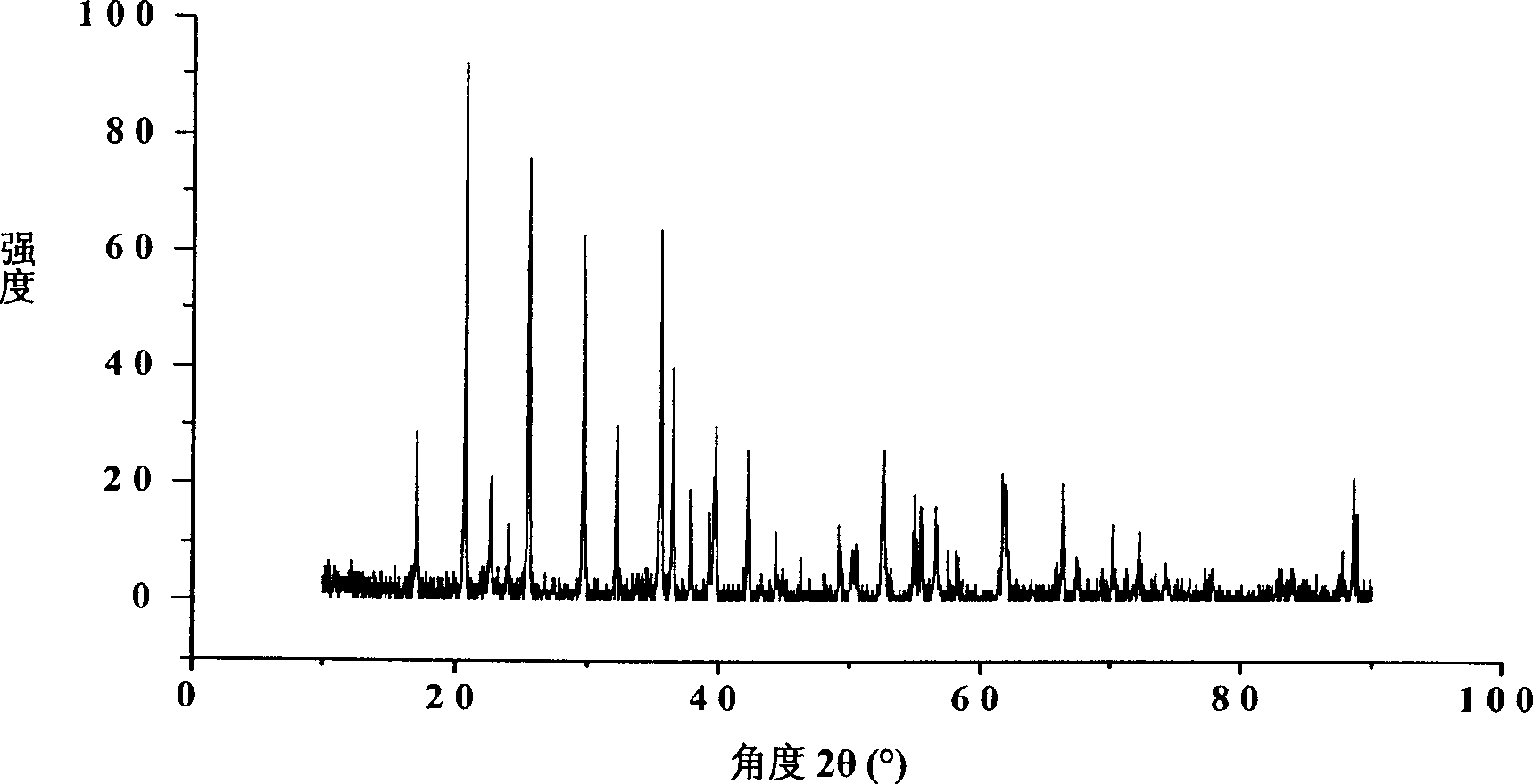

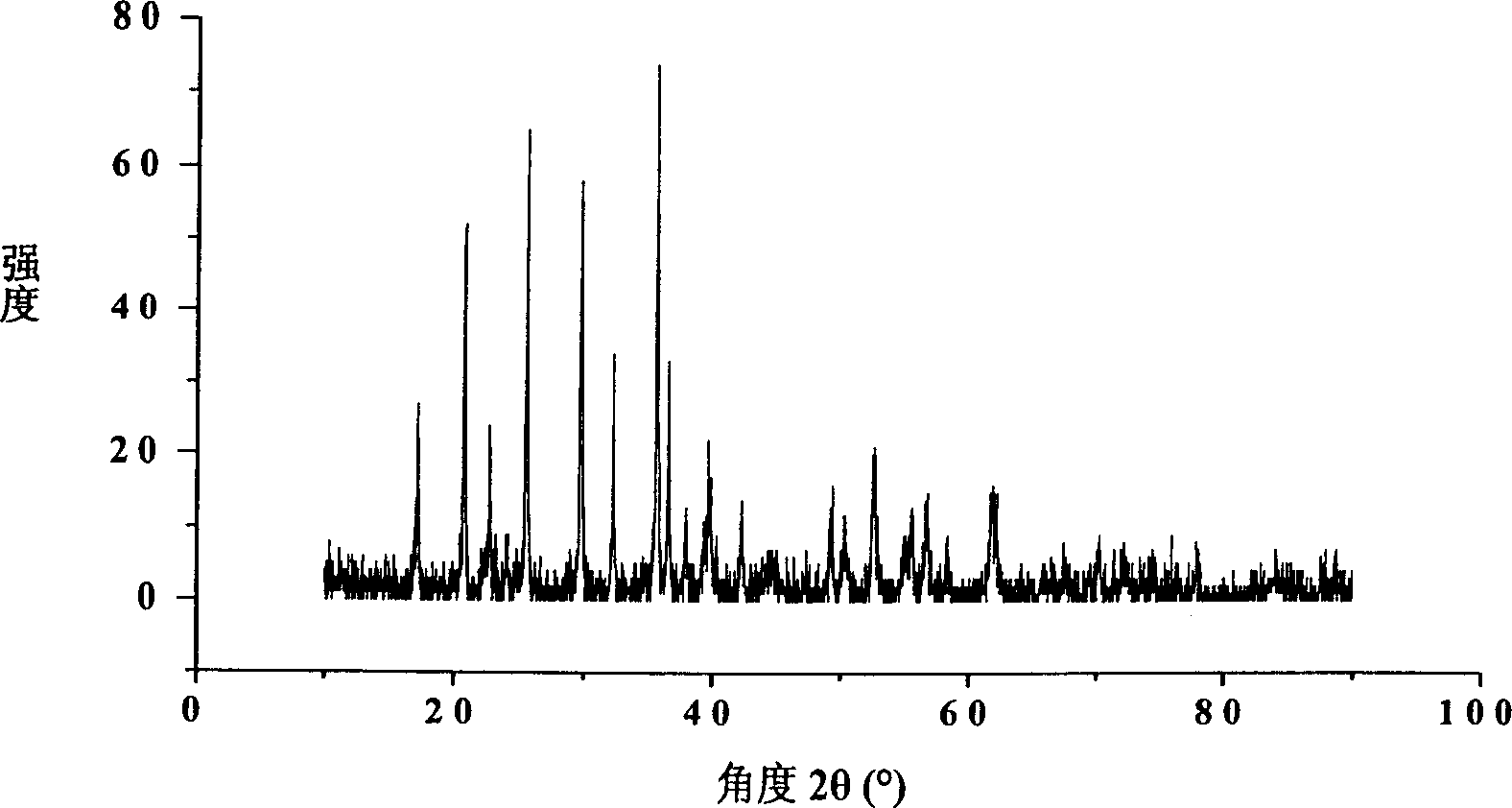

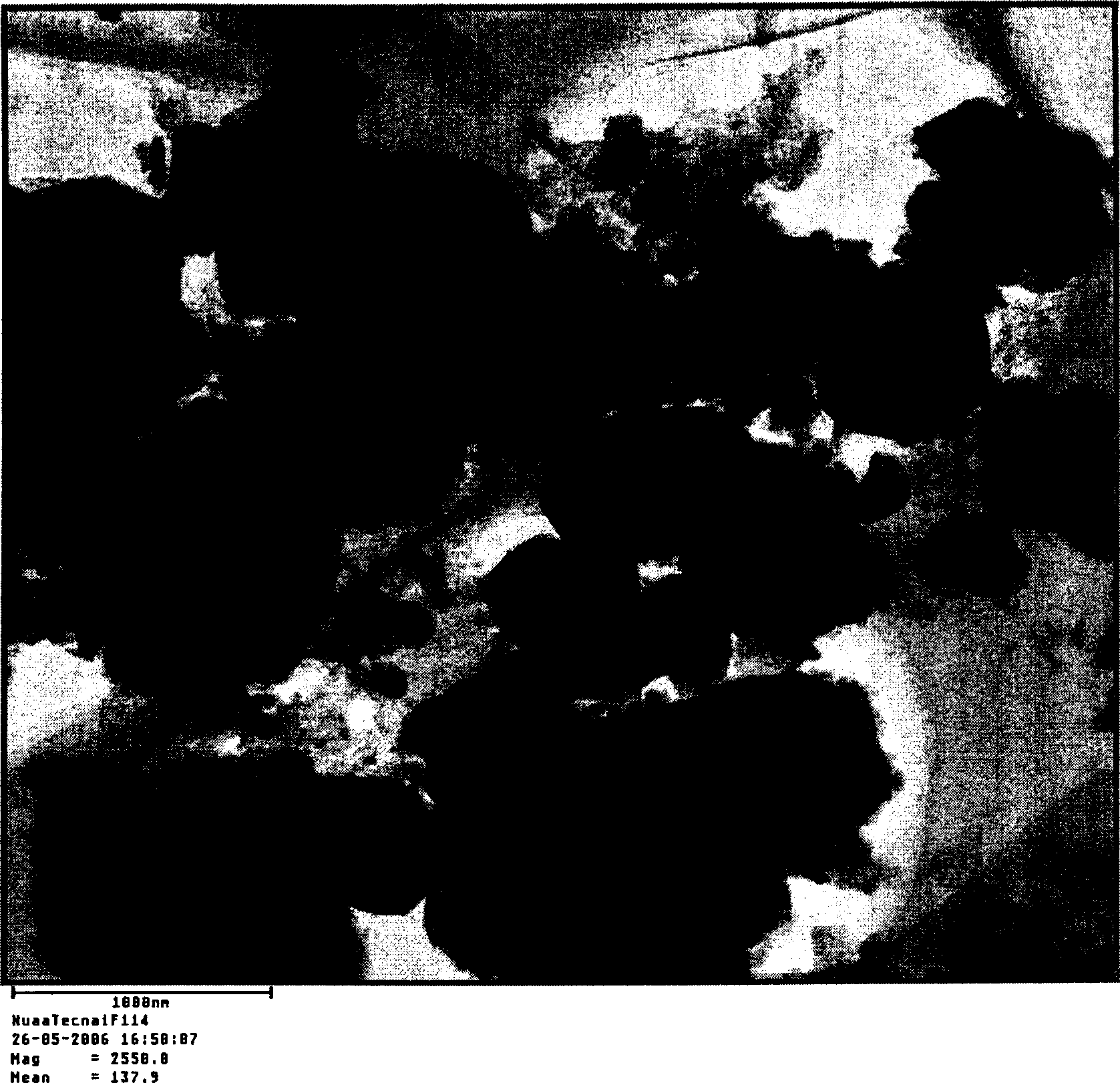

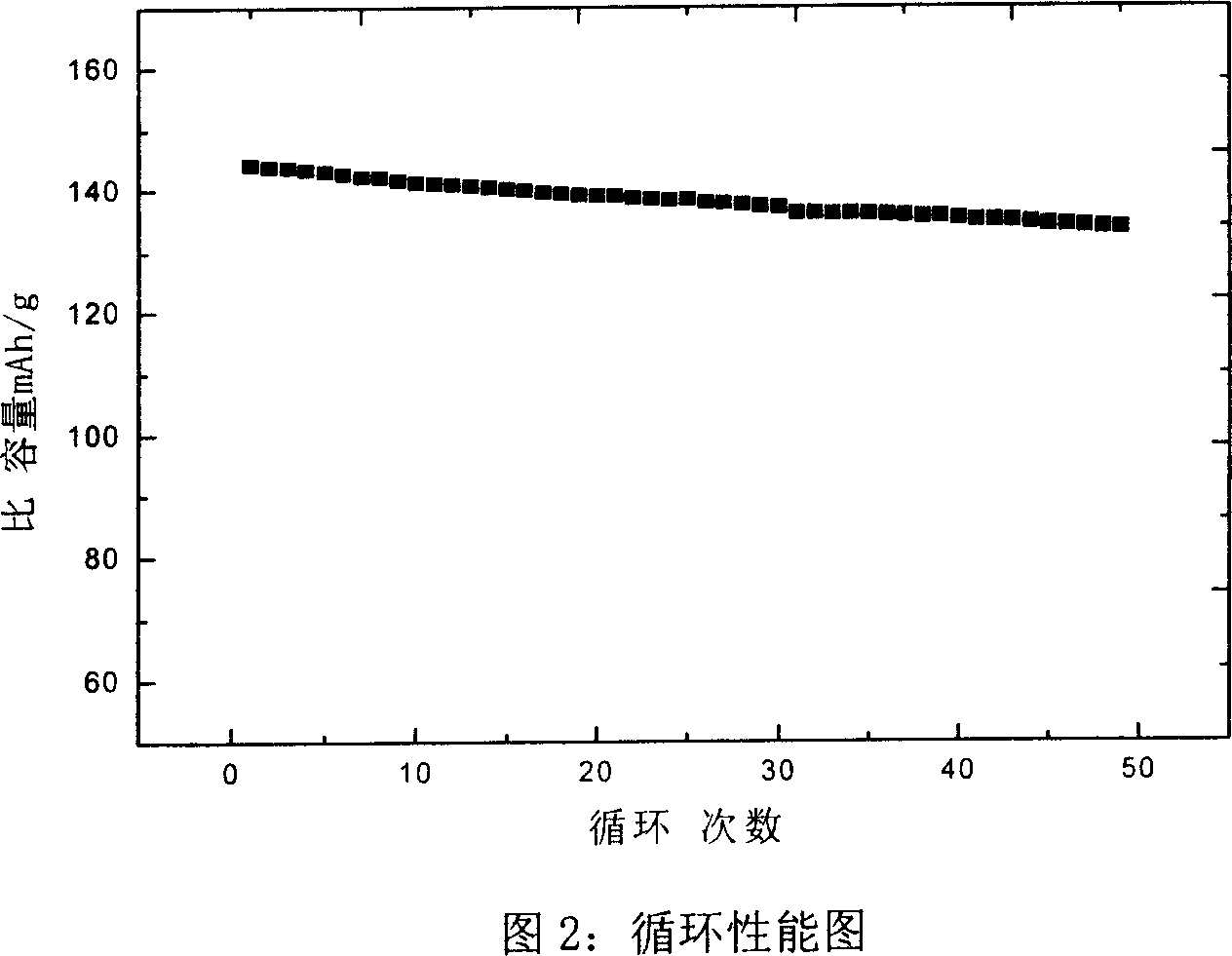

Coprecipitation-combustion synthesis method for lithium nickel cobalt manganate

InactiveCN101215011AGood chemical stabilityEliminate ingredient lossCell electrodesNickel compoundsSynthesis methodsManganate

The invention discloses a process of coprecipitation-combustion synthesis of nickel cobalt manganese lithium carbonate. (1) Utilizing acetate or nitrate of nickel, cobalt, and manganese as transition metal source and ammonia as complexing agent and utilizing H2C2O4, (NH4)3C2O4, (NH4)2CO3 or NH4HCO3 as precipitator, compound carbonate contained Ni-Co-Mn or oxalate precursors is synthesized by coprecipitation method. (2) Directly drying the compound carbonate containing Ni-Co-Mn or the suspension liquid of the oxalate and adding lithium nitrate or lithium acetate or a small quantity of water or ethanol to adjust into rheological phase. (3) Laying the materials in rheological phase in an electric stove to perform burning synthesis reaction, wherein the electric stove heats the materials in rheological phase at temperature of 400-600DEG C and then keeps constant temperature. (4) Temper drawing the reaction product with temperature of 600-1200DEG C, and anode active materials of lithium ion battery LiNixCoyMn1-x-yO2 is obtained. The invention has the advantages of simple technique, easy operation, saving water and energy and environment-friendliness, further, the synthetic material is provided with the shape of sphere or near-sphere, high specific capacity and fine cycle performance.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Production of cryogenic direct-welding polyurethane envelope without pinhole

InactiveCN101029203AReduce direct soldering temperatureImprove adhesionPolyurea/polyurethane coatingsEngineeringPolyurethane

A low-temperature straight-welding polyurethane wire enamel without pin hole is carried out by preparing hydroxide radical component, preparing enclosed component and formulating wire enamel. It can be used for extended or bended zero pin hole below 340degree.

Owner:DANYANG STAR CHEM

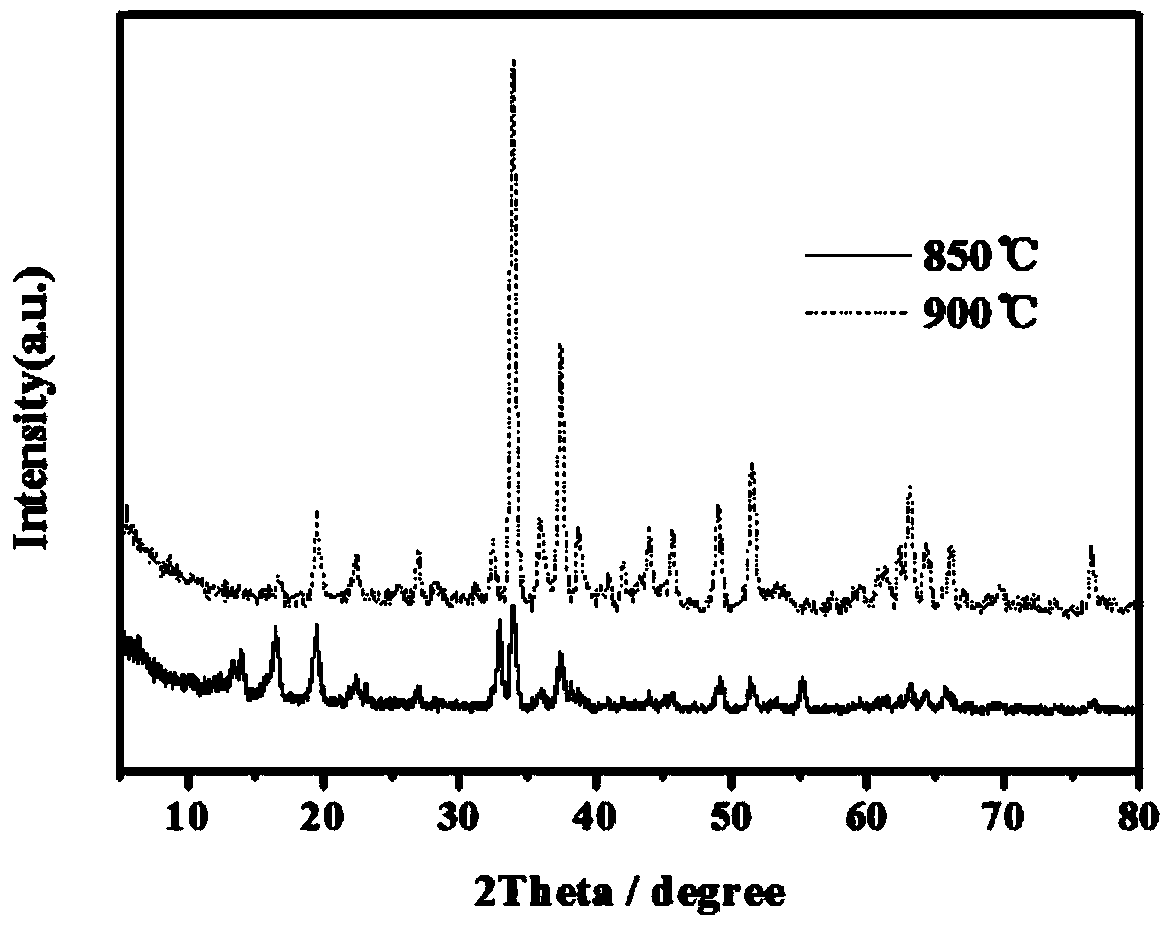

High-temperature solid-phase synthesis method of one-dimensional nano-sodion cell anode material NaxMnO2

InactiveCN103594707AUniform shapeEasy to shapeNon-aqueous electrolyte accumulatorsCell electrodesManganeseEvaporation

The invention discloses a high-temperature solid-phase synthesis method of a one-dimensional nano-sodion cell anode material NaxMnO2. The high-temperature solid-phase synthesis method comprises the following steps of 1, dissolving a sodium salt and a manganese salt in water according to a mole ratio of sodium to manganese of 0.44-0.56 to obtain a solution I, 2, dissolving citric acid in water to obtain a solution II, wherein a mole ratio of citric acid to the total metal ions is in a range 0.5-1, 3, dropwisely adding the solution I into the solution II and carrying out stirring for 10-60min, 4, carrying out heating evaporation on the mixed solution at a temperature of 60-90 DEG C to remove a solvent, heating the residues at a temperature of 120 DEG C for 6-24h, cooling the heated residues to a temperature of 10-30 DEG C, and grinding the cooled residues into powder, 5, heating the powder at a temperature of 350-500 DEG C for 3-10h, cooling the powder to a temperature of 10-30 DEG C, and grinding the cooled powder into fine powder, and 6, heating the fine powder at a temperature of 800-950 DEG C for 10-45h, and carrying out cooling to obtain the one-dimensional nano-sodion cell anode material NaxMnO2. The high-temperature solid-phase synthesis method has short synthesis time and a high yield in unit time. The one-dimensional nano-sodion cell anode material NaxMnO2 has uniform, dispersive, thin and long product morphology and good electrochemical properties (of a specific discharge capacity of 114mA.h / g at 0.1C charging-discharging multiplying power).

Owner:SOUTHWEST UNIVERSITY

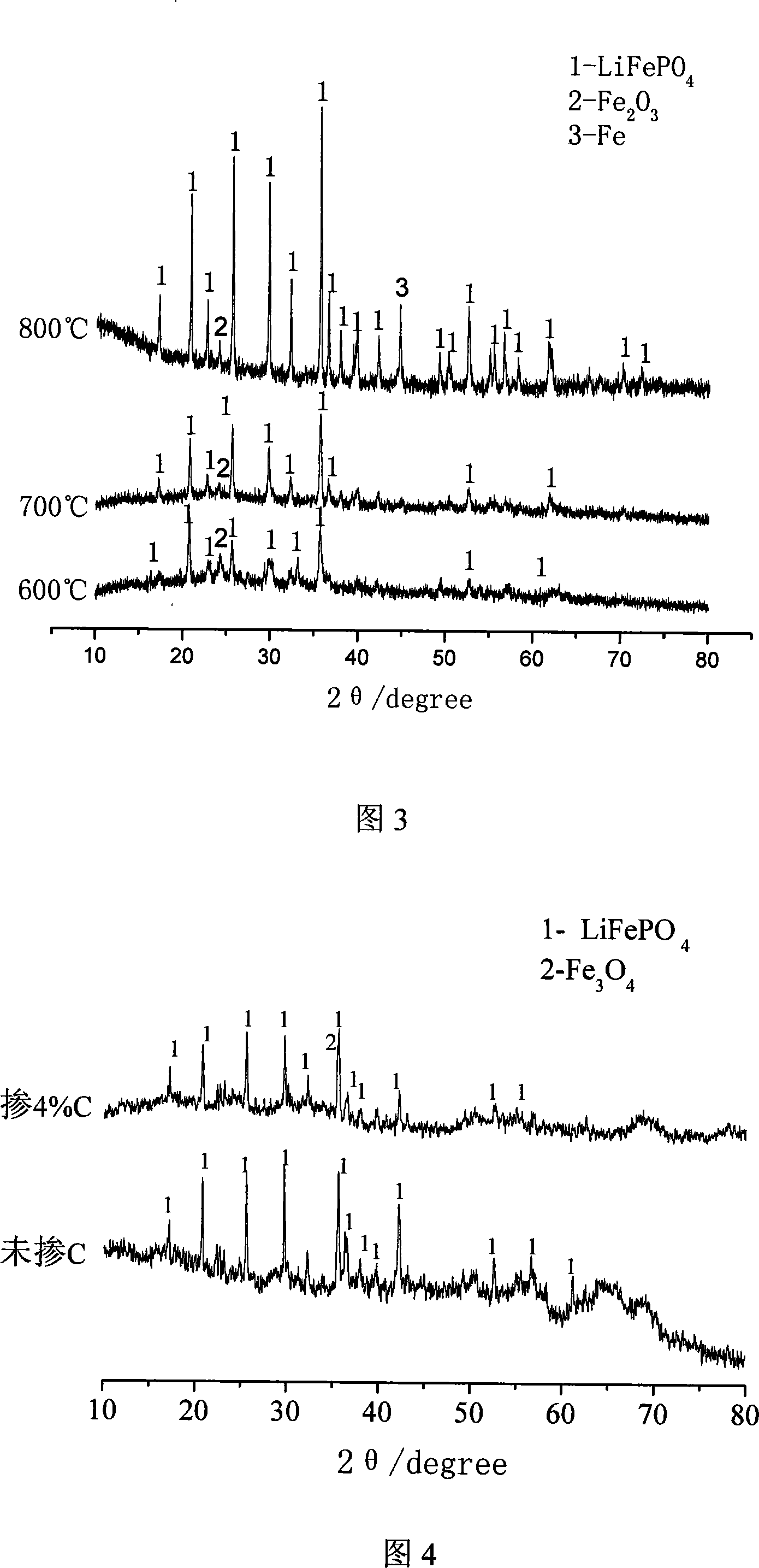

Microwave synthesis method for carbon coated iron phosphate of ion battery composite anode material

InactiveCN1911792AImprove conductivityReduce polarizationCell electrodesPhosphorus compoundsPhosphateSynthesis methods

The microwave synthesis process of carbon coated lithium iron phosphate as the composite positive electrode material for lithium ion cell includes the following steps: mixing material of lithium salt, organic ferrite, phosphate radical containing material and organic carbon source as coating material in the stoichiometric ratio of Li, Fe, P and C of 1 to 1 to 1 to 0.2-2 via ball milling with ethanol or acetone as dispersant for 3-6 hr; drying the mixture; tabletting; setting into alumina crucible together with active carbon and heating in microwave oven for 5-12 min. The lithium salt material may be inorganic Li2CO3 or LiOH, or organic lithium acetate, lithium lactate, lithium oxalate, lithium citrate or lithium formate; and the phosphate radical containing material may be (NH4)2HPO4 or (NH4)H2PO4.

Owner:NANJING UNIV

High density ultrafine composite ferric lithium phosphate anode material and preparation method

ActiveCN1907844AChemical composition is easy to controlEasy to dopeCell electrodesPhosphorus compoundsIron saltsOrganic compound

This invention belongs to battery field, which relates to ultra-micro compound lithium iron phosphate cathode material with high density and its fabrication method. Said cathode material is prepared by mixing iron salt, lithium salt and phosphates at a P / Li / Fe ratio of 1-1.1:1-1.1:1-1.1, adding conductive additives containing dopant element and carbon-bearing organic compound, adding organic acid as carrier, adjusting pH, controlling solution temperature in reactor to form sol, separating the sol to obtain nano-precursor and placing it into micorwave oven under protection of inert gas, and obtaining the final product. It is easy to control the chemical component, phase composition and particle size distribution. The conductive additive can be well-distributed. The method also has the advantages of short reaction time, low energy consumption during synthesis process and low cost. The obtained composite has high purity and good compatibility with electrolyte, excellent conductive property and charge and discharge property with large current, and good structure stability,thermal stability and cycle performance.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

Synthetic resin adhesive for E0/E1 level shaving board

InactiveCN101348699AHigh bonding strengthReduce releaseAldehyde/ketone condensation polymer adhesivesHigh concentrationPolyvinyl alcohol

The invention discloses a synthetic resin adhesive for an E0 / E1 grade flakeboard, which is melamine modified urea-formaldehyde resin; formaldehyde with the concentration of 48 percent in mass percentage is adopted as a raw material; the adhesive comprises the following reaction materials in percentage by mass: 4.0 to 5.0 percent of melamine, 43.0 to 45.0 percent of urea, 48.0 to 51.0 percent of formaldehyde, 1.00 to 1.10 percent of addition agent, 0.20 to 0.22 percent of polyvinyl alcohol and proper acid and alkali; the total molar ratio is between 1.08 and 1.11; and the materials are reacted and synthesized, thereby preparing the adhesive. The high-concentration formaldehyde is adopted as the raw material; the adhesive has excellent bonding strength, proper curing time, good storage stability and the free formaldehyde content of between 0.06 and 0.08 percent; with the adhesive, the E1 and E0 flakeboard with excellent quality can be stably produced; and the adhesive has the advantages of low adhesive application amount, strong process adaptability, rapid curing, etc.

Owner:DARE TECH

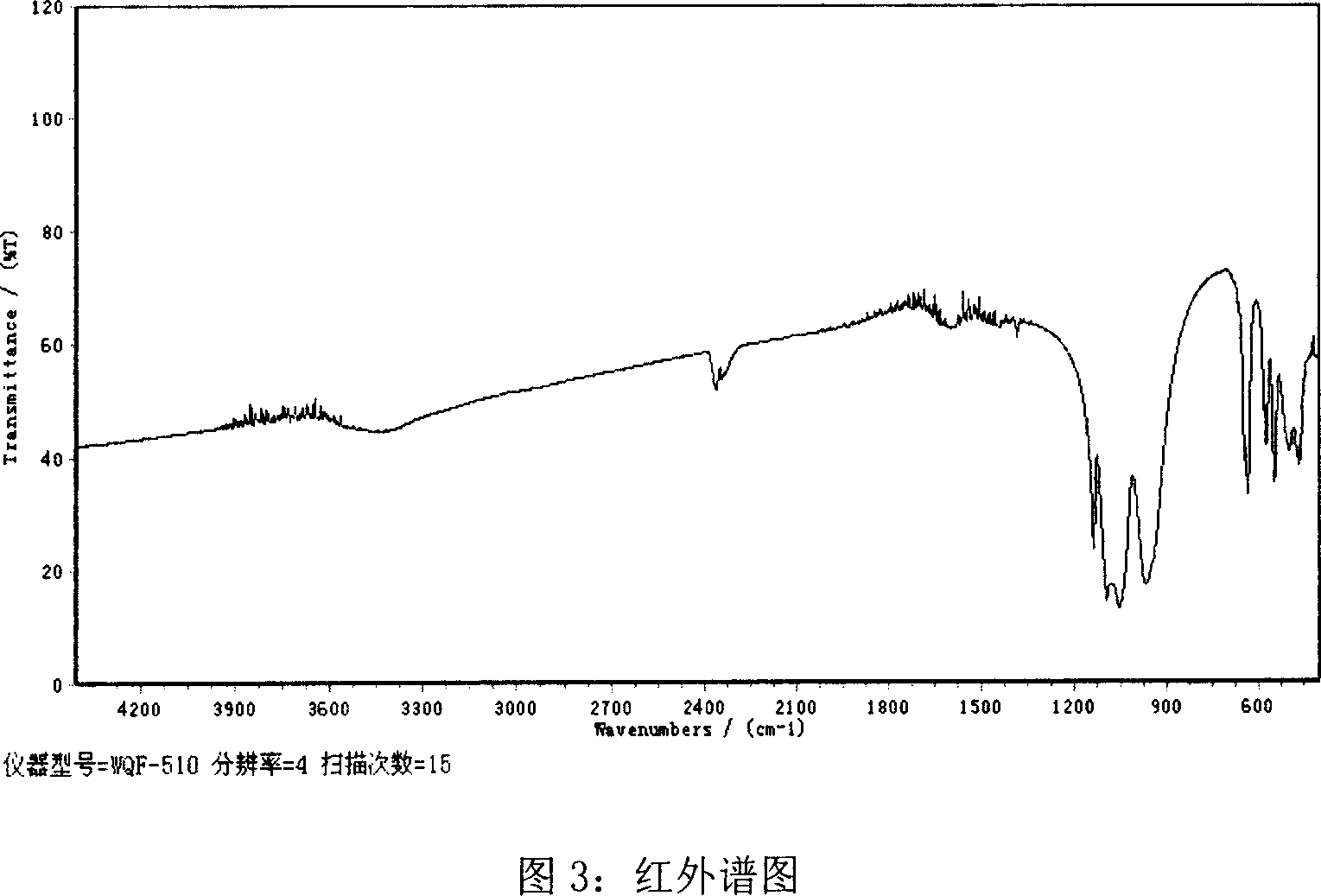

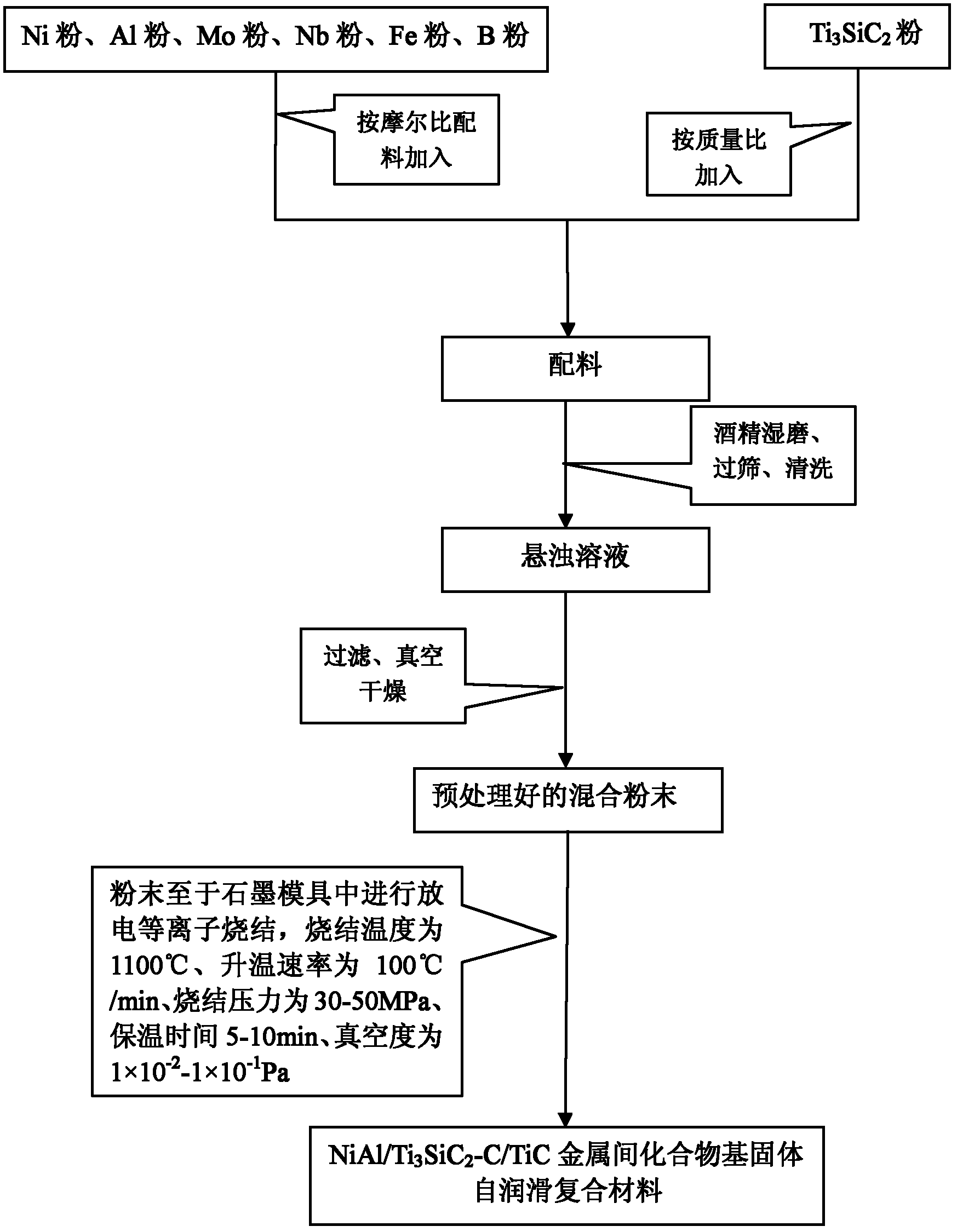

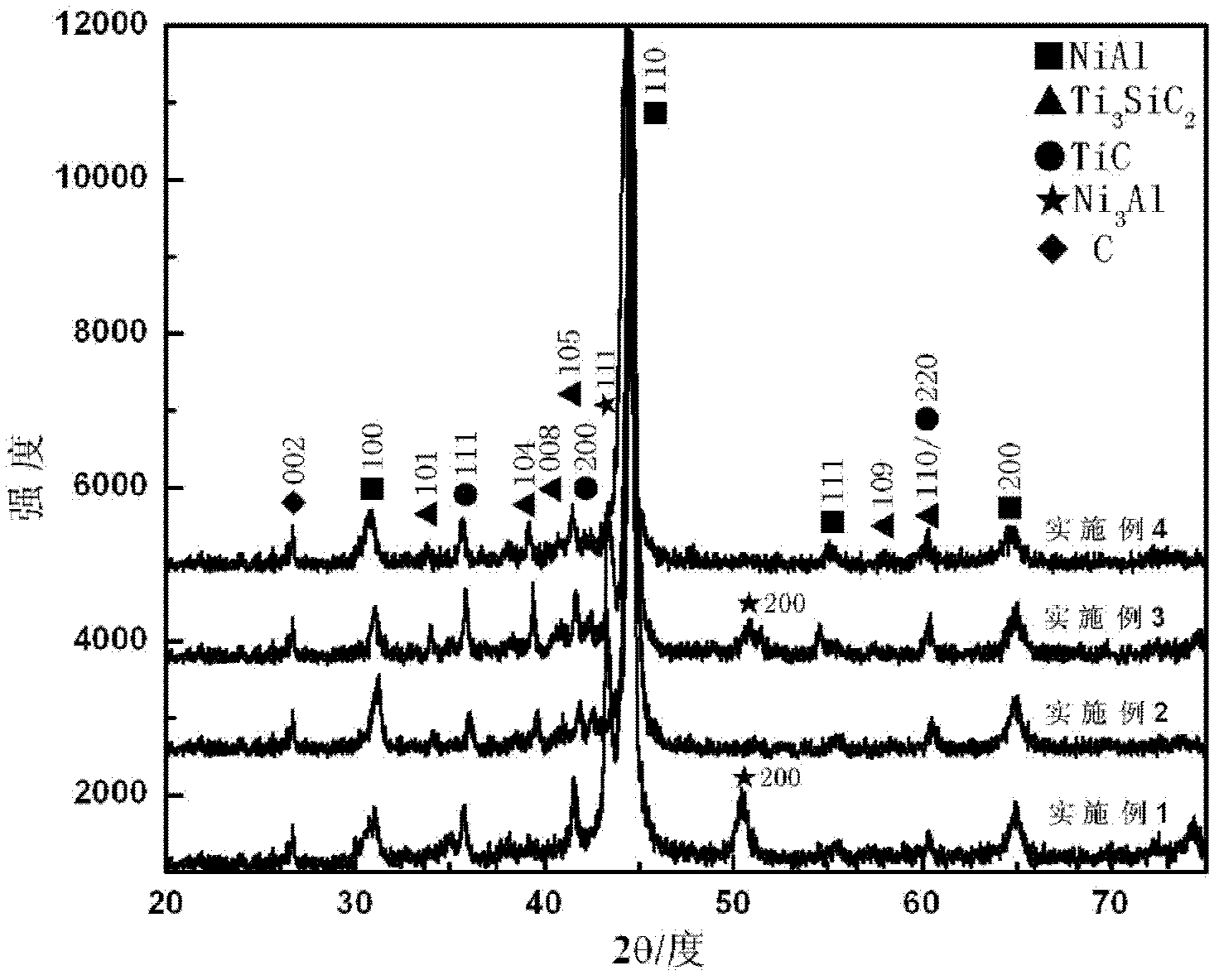

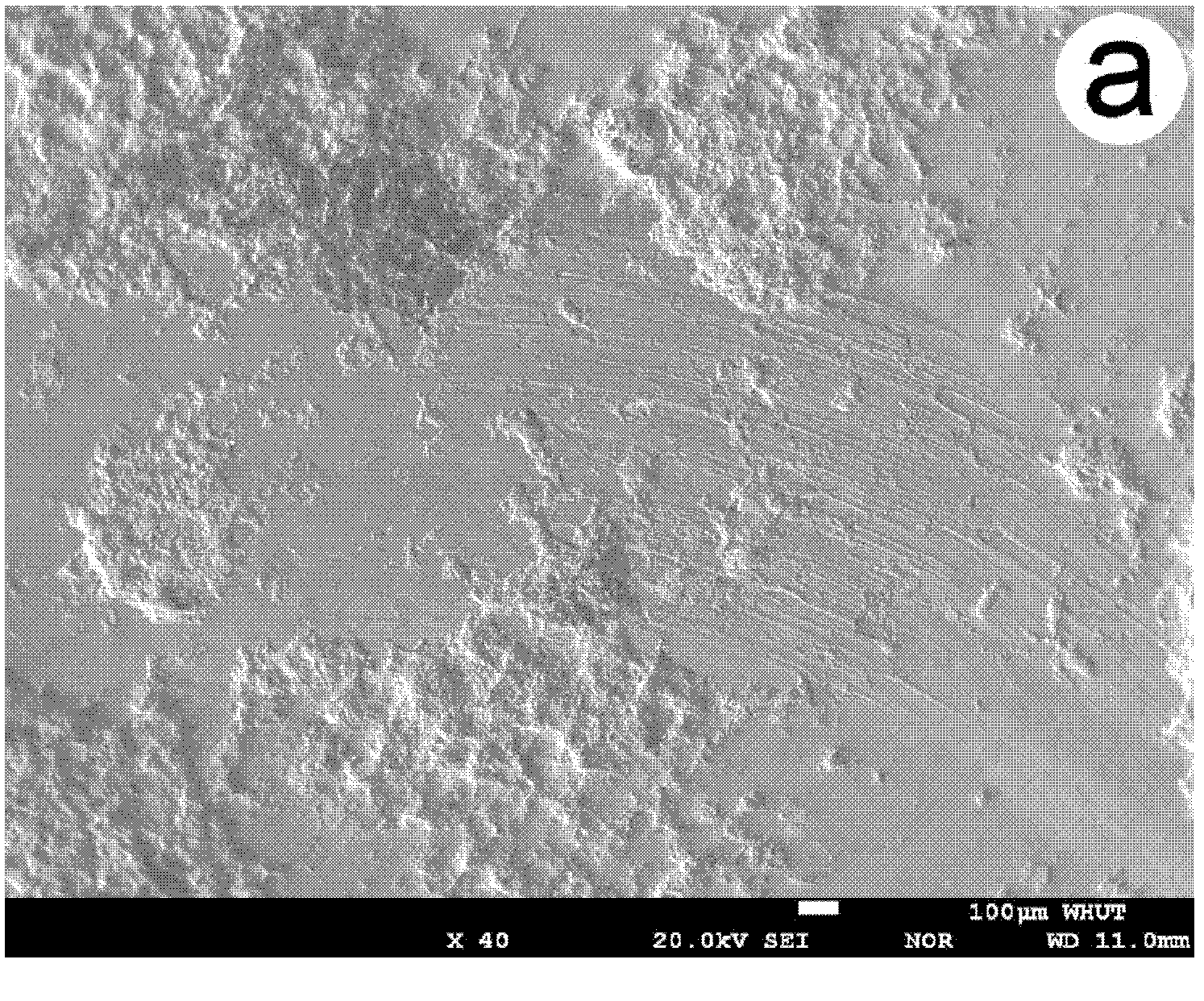

NiAl intermetallic base solid self-lubricating composite material and preparation method thereof

The invention relates to a preparation method of a NiAl intermetallic base solid self-lubricating composite material containing Ti3SiC2 and C binary composite lubrication phase and wild phase TiC. The NiAl intermetallic base solid self-lubricating composite material is prepared from Ni powder, Al powder, Mo powder, Nb powder, Fe powder, B powder and Ti3SiC2 powder, wherein the molar ratio of Ni: Al: Mo: Nb: Fe: B=48: 50: 1: 1: 0.5: 0.02, and the addition quantity of the Ti3SiC2 powder is 5-20 weight percent of the total weight of the Ni powder, the Al powder, the Mo powder, the Nb powder, theFe powder and the B powder. The NiAl / Ti3SiC2-C / TiC intermetallic base solid self-lubricating composite material synthesized by the method has novel component design (intermetallic matrix+ composite lubrication phase+ wild phase), high density, good tribological properties and stable technological parameters. The preparation process is fast and simple, and the method is easily operated and is suitable for preparing NiAl intermetallic base solid self-lubricating composite materials with high performance.

Owner:WUHAN UNIV OF TECH

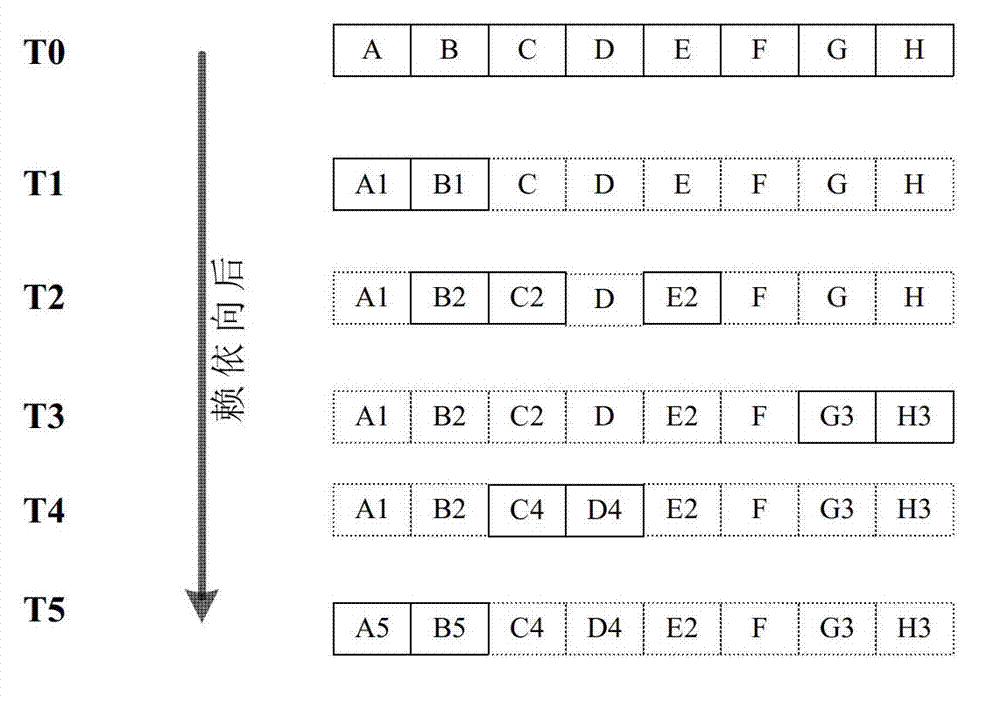

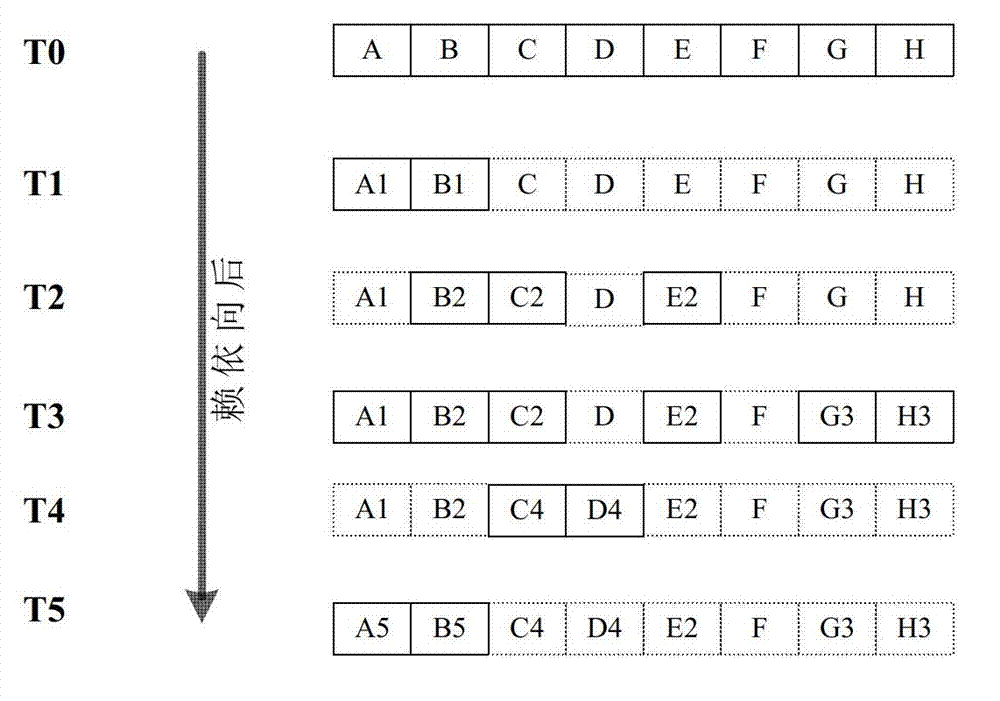

Data backup method and related device

ActiveCN103049353AShort synthesis timeImprove efficiencyRedundant operation error correctionData recoveryBackup

An embodiment of the invention discloses a data backup method and a related device to improve efficiency in recovering data to near time points. The method in the embodiment includes: acquiring information of a variable data block which is a data block changed relative to a front backup; storing data corresponding to the variable data block in a backup server, and enabling an omnidirectional image generated in first-time backup to point at all updated data blocks, wherein the first-time backup is an omnidirectional backup; and directing a first backup set to the omnidirectional image, wherein the first backup set is a backup set corresponding to the current backup.

Owner:CHENGDU HUAWEI TECH

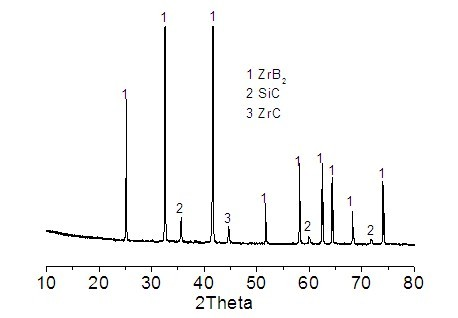

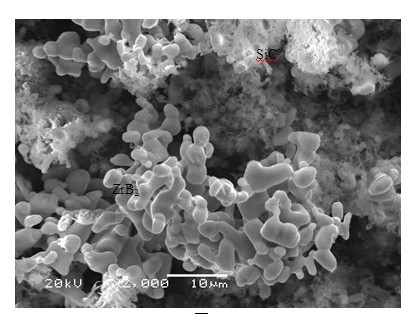

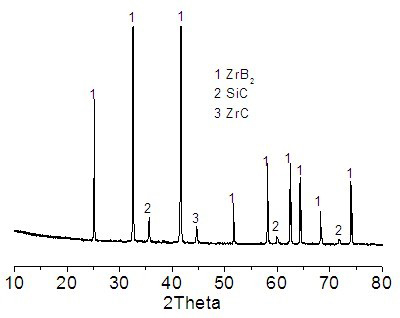

ZrB2-SiC composite powder and preparation method thereof

InactiveCN102320850AFix issues with restricted usageSynthesis temperature is lowUltra-high-temperature ceramicsRefractory

The invention discloses ZrB2-SiC composite powder and a preparation method thereof. According to the invention, zircon sand, a boron raw material and a carbon raw material are adopted as main materials. The main materials are mixed, grinded, and are heated under a temperature of 1350 to 1480 DEG C, such that the powder is obtained. The powder comprises components of, by weight: 37 to 63% of ZrSiO4, 16 to 32% of B2O3, and 20 to 28% of C, wherein the boron raw material is calculated according to the amount of B2O3, and the carbon raw material is calculated according to the amount of C element. According to the invention, natural zircon sand with a relatively low price is used as a raw material for producing high-grade ZrB2-SiC. The advantages of ZrB2 and SiC are combined. Mutual complement of advantages can be realized when ZrB2 and SiC are used in the field of high-temperature materials. ZrB2-SiC provides relatively high thermal conductivity, excellent thermal shock resistance and corrosion resistance. When ZrB2-SiC is introduced into the composite powder, high-temperature mechanical properties, oxidative stabilities and corrosion resistances of ultra-high temperature ceramics and refractory materials can be improved.

Owner:ZHENGZHOU UNIV

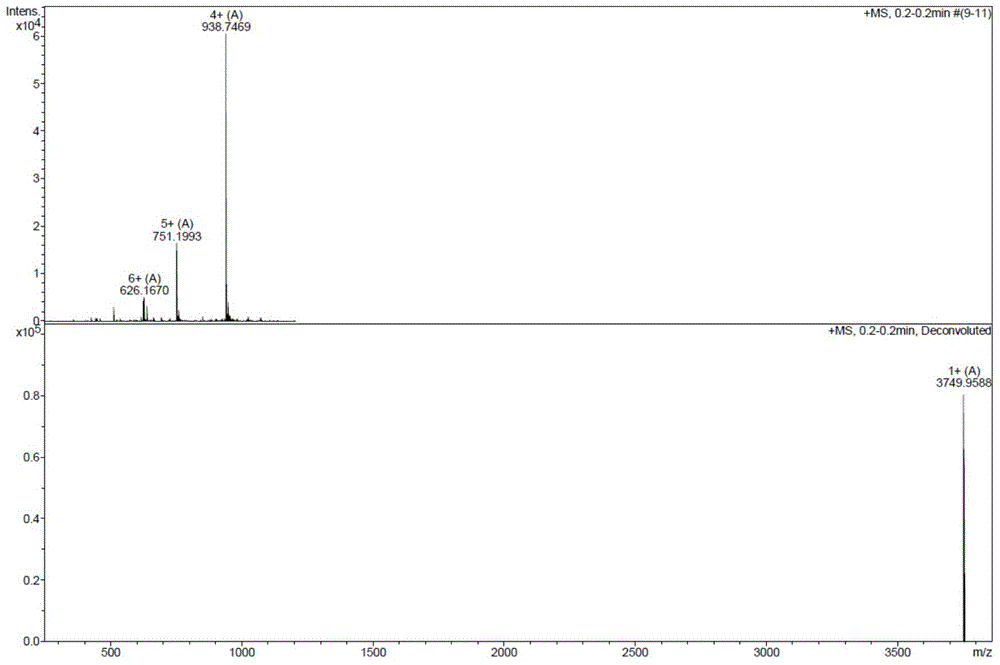

Method for preparing liraglutide by convergent synthesis

ActiveCN104650219AHigh purityHigh yieldPeptide preparation methodsBulk chemical productionSide chainPeptide fragment

The invention discloses a method for preparing liraglutide by convergent synthesis. The method comprises the steps of performing solid phase synthesis to obtain four side chain protected peptide fragment sequences, gradually coupling the peptide fragments in a solution system to obtain an all-protected liraglutide straight chain polypeptide, removing the side chain protection of the 20th Lys, performing modification to form all-protected liraglutide, then cracking to remove protecting groups to obtain a crude liraglutide peptide, purifying and exchanging salt to obtain liraglutide; wherein in the four peptide fragment sequences, the first peptide fragment sequence is 1st to 8th amino acids in the liraglutide sequence, the second peptide fragment sequence is 9th to 16th amino acids in the liraglutide sequence, the third peptide fragment sequence is 17th to 26th amino acids in the liraglutide sequence, and the fourth peptide fragment sequence is 27th to 31st amino acids in the liraglutide sequence. By adopting the method, the yield is improved, and the synthesis cost is greatly reduced; and the method is favorable for large-scale and industrialized production.

Owner:LANZHOU UNIVERSITY

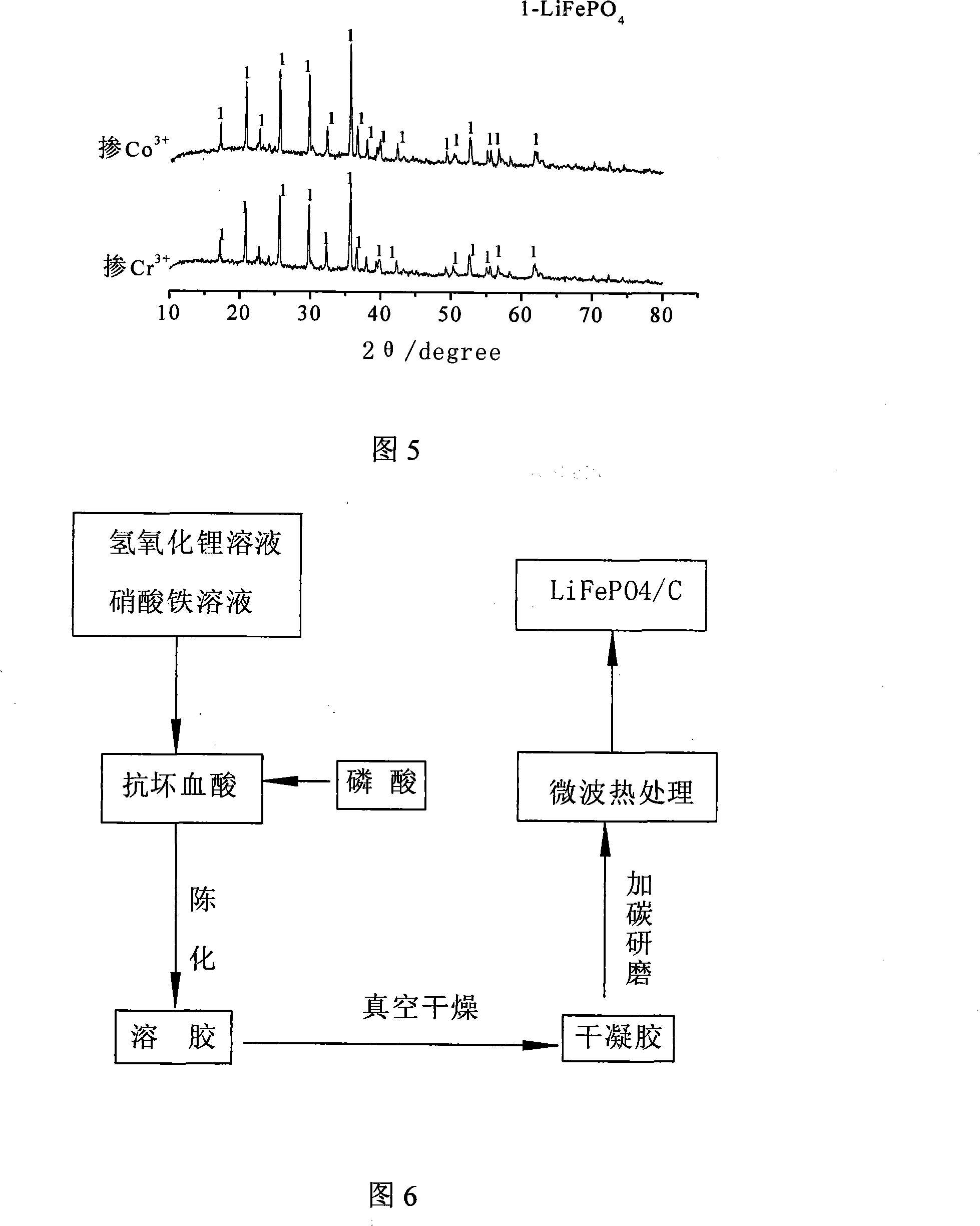

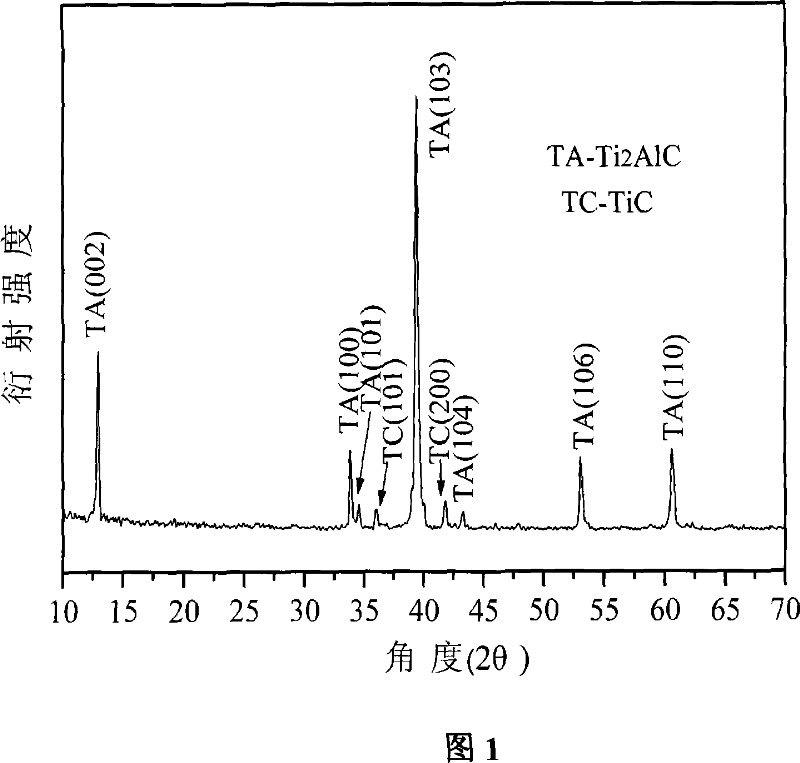

Method for producing high performance lithium ion battery anode material LiFePO4/C

InactiveCN101179124AIncrease the cell volumeIncreased Diffusion ChannelElectrode manufacturing processesPhosphorus compoundsHigh rateCharge discharge

The invention relates to a preparation method for making lithium ion battery cathode materials of LiFePO4 / C by using the reducing agent and inorganic salts of iron source, phosphorus source, lithium source, carbon source and so on as raw materials. Adopt the combining method of sol-gel and microwave treatment and prepare ultrafine particles of LiFePO4 and carbon coat the particles at the same time. On this basis, change the property of LiFePO4 / C by metal doping of Cr3 plus , Co3 plus . By processing with industrial microwave oven of high power, the invention shortens processing time greatly, increases the yield remarkably, reduces material cost and energy loss, simplifies the processes, improves the efficiency of industrial production of lithium ion battery and is convenient for implementation in industry. Take it as cathode materials of lithium ion battery with high-rate discharge. The invention raises conductivity of lithium iron phosphate and at the same time improves charge discharge capacity and cycle numbers by carbon coating and metal element doping.

Owner:江苏君明高新科技有限公司

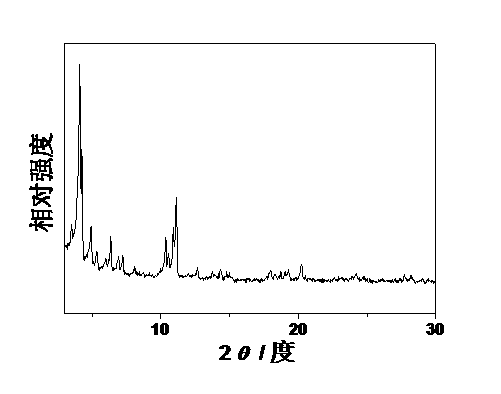

High-purity Ti2AlC powder material and preparing method thereof

The present invention discloses a high pure Ti2AlC powder material and a preparation method of the same. The powder material comprises Ti powder, TiC powder, Al powder and active carbon powder, wherein the mol ratio of which is n(Ti):n(TiC):n(Al):n(C)=(1.15~1.95):(0.5~0.95):1:(0.15~0.95). The preparation method comprises the steps of: feed weighing according to compounding ratio; mixing the raw material powder evenly; tabletting the mixed raw material and putting into the chamber of the microwave sintering device, and sintering in the presence of argon gas; obtaining the powder material after natural cooling. The powder material of the present invention has high purity and small crystal grain. The preparation process has simple raw material, adequately uses the characteristics of microwave sintering technology and the advantages of self-propagating reaction, and has a short synthesis time; besides the Ti2AlC powder material has a high purity, is adapted to industrial production. The application of the material is greatly improved.

Owner:WUHAN UNIV OF TECH

Preparation method of MIL-100(Fe) packaged phosphotungstic heteropolyacid catalyst

ActiveCN103191786ALess prone to elution and lossEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsWater basedPtru catalyst

The invention discloses a preparation method of an MIL-100(Fe) packaged phosphotungstic heteropolyacid catalyst. The preparation method comprises the steps of: adding raw materials for synthesizing phosphotungstic heteropolyacid into a certain amount of deionized water based on certain proportion; subsequently adding a certain amount of an iron source, mixing and stirring, further adding a certain amount of an organic ligand, mixing, stirring, adding a certain amount of an acid solution, and mixing and stirring; mixing, stirring and reacting for 5-20 hours under normal pressure at 80-95 DEG C; and filtering the obtained solid, washing for 10-20 hours at 60-80 DEG C by using absolute ethyl alcohol, subsequently treating for 10-15 hours at 60-80 DEG C by using a 30-60mmol / L ammonium fluoride solution, sufficiently washing by using deionized water, and finally drying for 5-10 hours at 100-200 DEG C so as to obtain the MIL-100(Fe) packaged phosphotungstic heteropolyacid catalyst. The method is temperate in synthesis condition, low in synthesis energy consumption and high in catalyst synthesis yield.

Owner:日照经济技术开发区客商服务有限公司

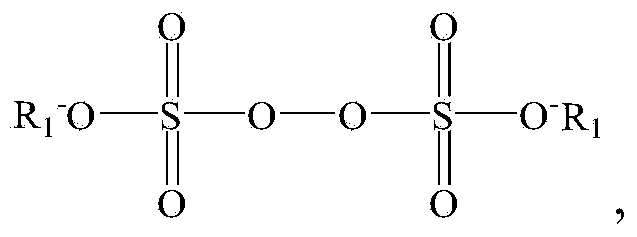

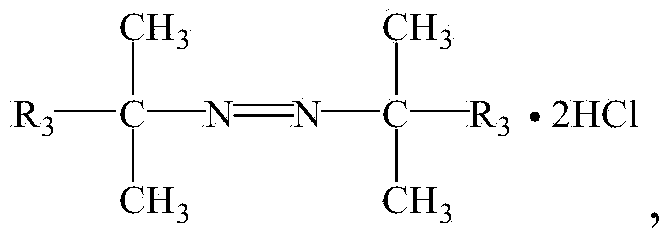

Method for preparing polycarboxylic acid grafted copolymer superplasticizer

The invention discloses a method for preparing a polycarboxylic acid grafted copolymer superplasticizer. In the method, the preparation is implemented at the low temperature of 5-30 DEG C; a used initiating system is a complex initiating system which adopts the combination of one initiator I and various reducers R, or one reducer R and various initiators I or various initiators I and various reducers R, wherein the initiator (s) I is (are) selected from hydrogen peroxide, persulfate salt LS2O8 and a water-soluble azo initiator W, and the reducer (s) R is (are) selected from ascorbic acid and certain kinds of inorganic salt. The preparation method is simple, excellent in repetition stability and low in cost, does not require heating, and avoids toxicity and pollution; the prepared superplasticizer is high in water-reducing rate, and excellent in adaptability and slump-retaining capability, thereby being suitable for popularization and application.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for rapid synthesis of aluminum orthophosphate salt polyalcohol

InactiveCN101172596AProduction Method AdvantagesShort synthesis timePhosphorus compoundsMicrowave ovenPhosphoric acid

The invention discloses a method for rapidly synthesizing aluminum phosphate salt polymeric compound. The method is characterized in that the mixture of phosphoric acid and aluminum hydroxide reacts and the mixture is synthesized under microwave condition. The method comprises the following steps: the phosphoric acid and the aluminum hydroxide are added with water to be mixed and stirred uniformly according to mol ratio; the mixture after being stirred uniformly is put into a microwave oven, and the defrosting and heating mode is selected to radiate the mixture; 750 W is selected to heat the mixture; white aluminum tripolyphosphate powder is gotten through hydrating, drying and grinding. The aluminum tripolyphosphate powder product is put into the microwave oven again to be radiated with 900 W power, and aluminum metaphosphate powder is gotten. The method integrates the reaction and polymerization of the prior art, reduces the composition time, saves the energy and the equipment, and improves the production efficiency. Because of the penetrating action of the microwave, the composition is not limited by the material quantity, and the synthetic ratio of the aluminum tripolyphosphate and the aluminum metaphosphate is improved. Related equipment can be adopted during the industrial production to realize continuous scale production.

Owner:GUANGXI UNIV FOR NATITIES

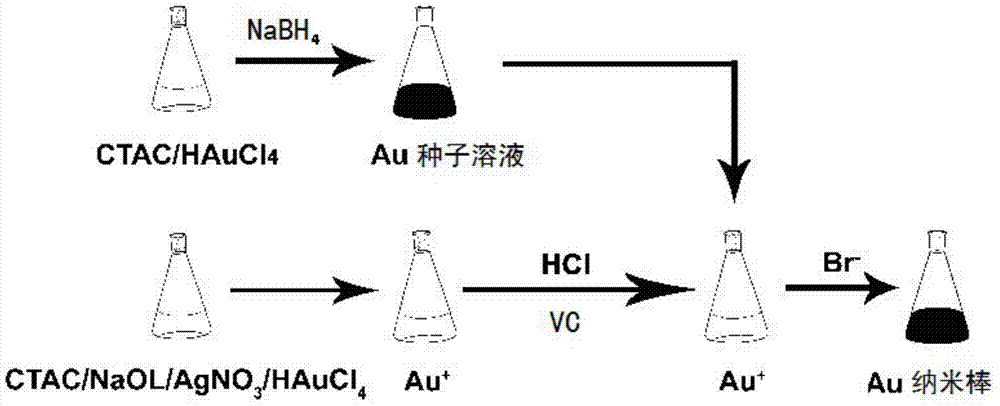

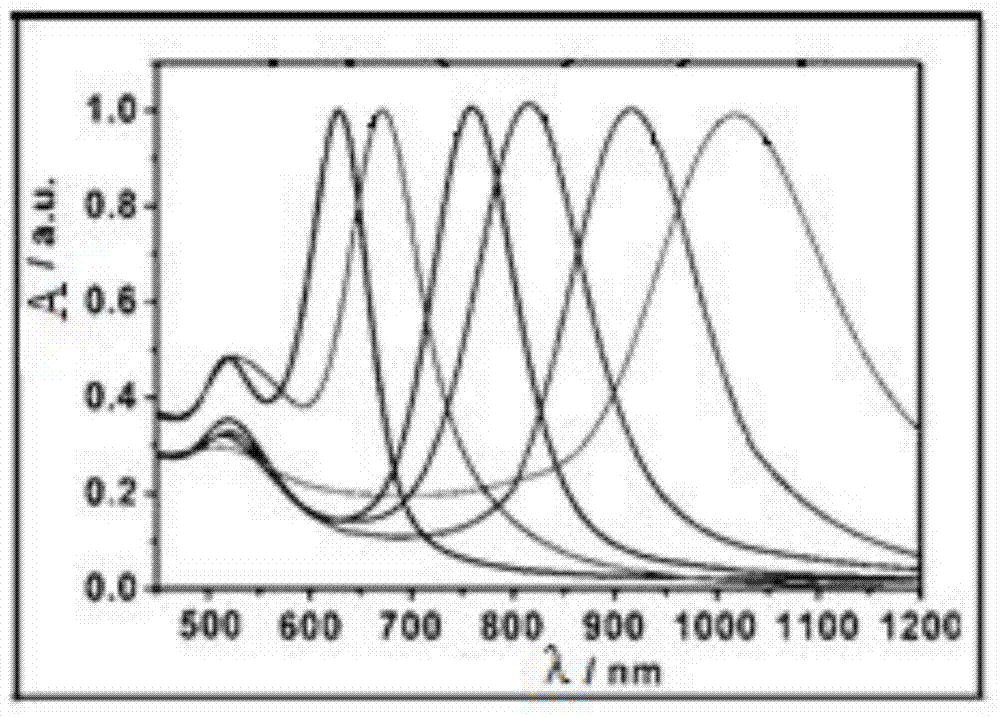

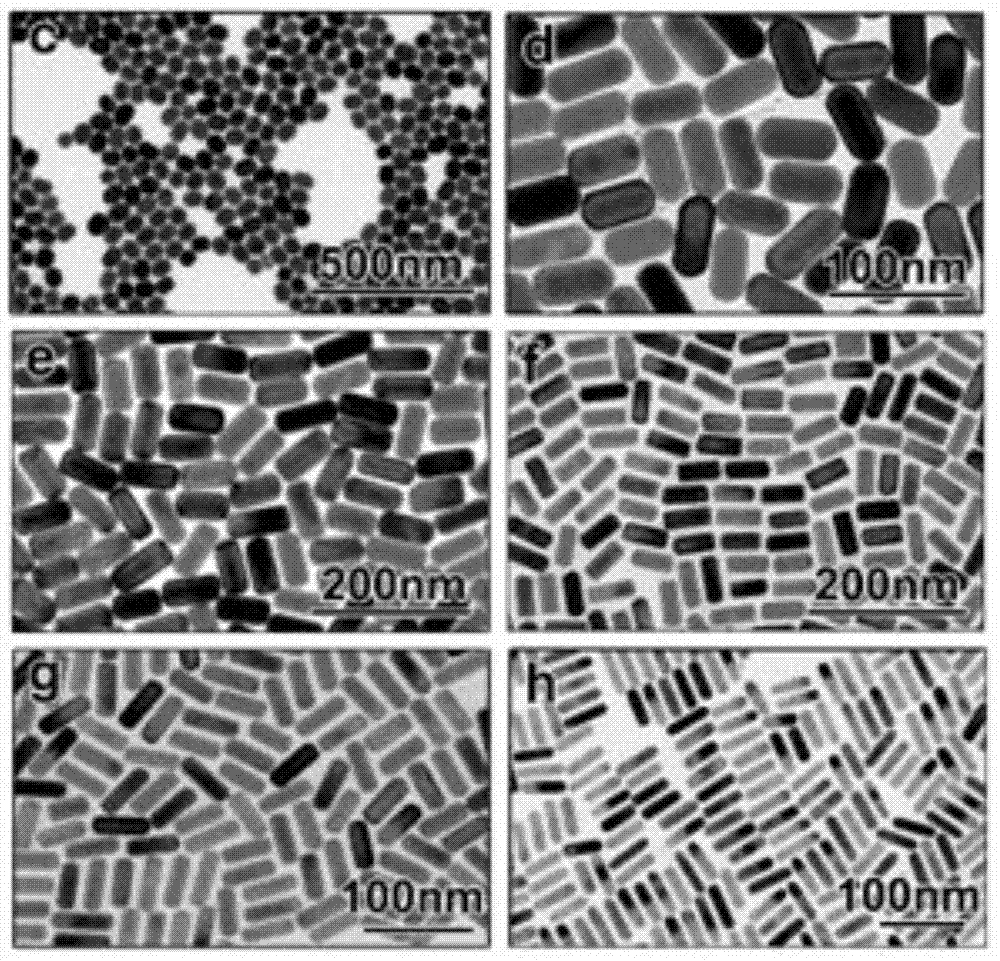

Method for rapidly preparing gold nanorod

The invention discloses a method for rapidly preparing a gold nanorod, which belongs to the technical field of a nano material, and solves the problem that the existing gold nanorod seed induction growth method is long in consumed time. The method is characterized in that cationic surface active agent chloride quaternary ammonium salt is used as a protective agent, gold seeds which are obtained by reducing sodium borohydride through the reducing agent sodium oleate, ascorbic acid are added into a chloroauric acid solution under the assistant effect of ions and silver ions to obtain gold nanorods. According to the method, the synthesis of the gold nanorods can be completed in 15 minutes, so that not only can the synthesis time of the gold nanorods be greatly shortened and a material base be provided for the real application of the gold nanorods, but also the yield of the gold nanorods is high, and fewer spherical particles exist.

Owner:SUZHOU UNIV

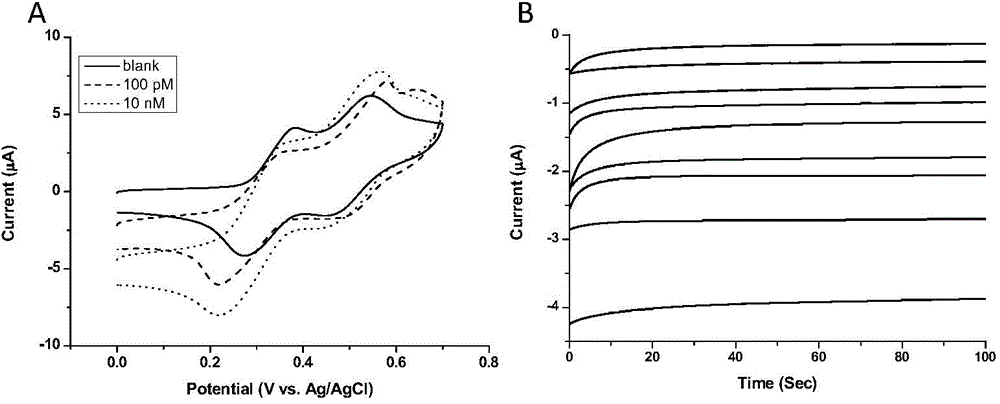

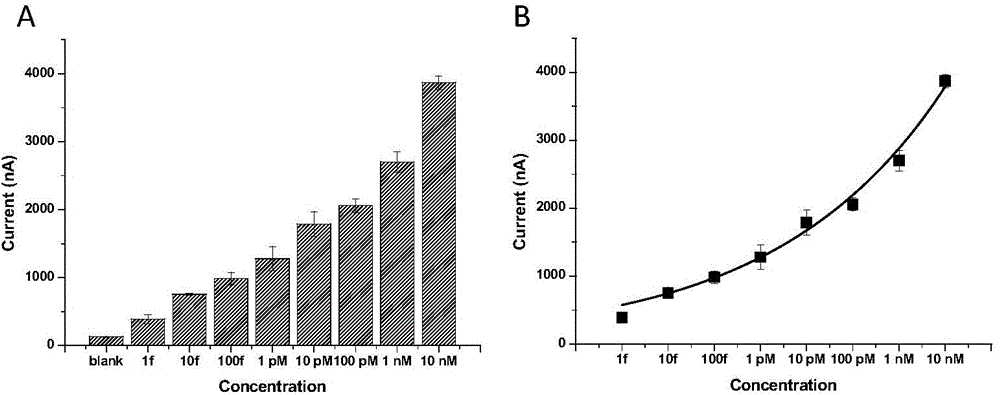

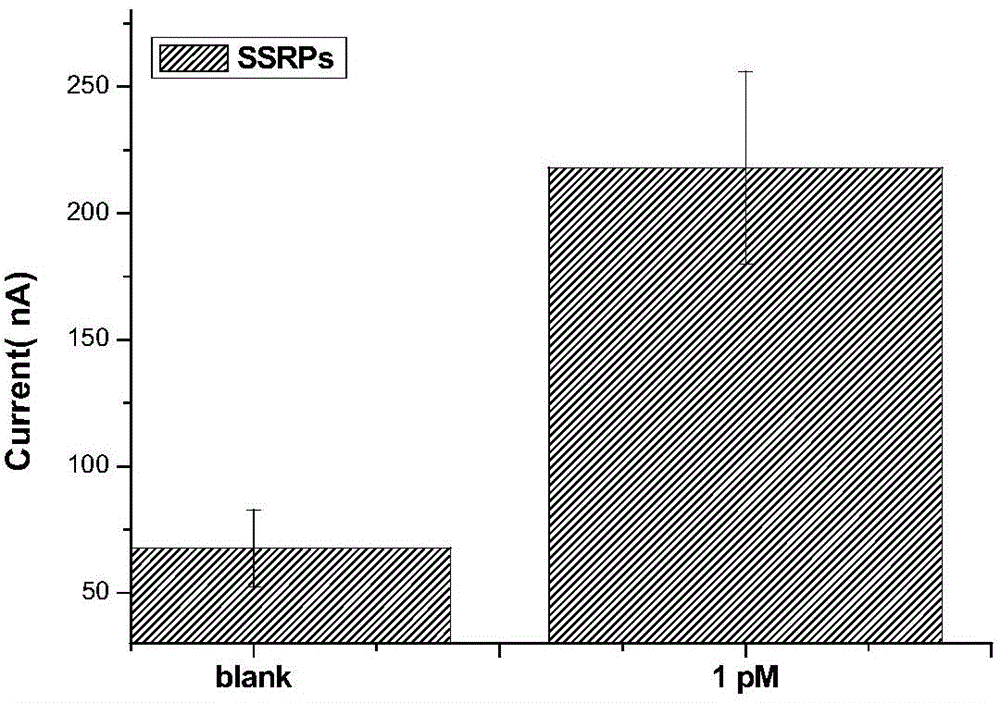

DNA tetrahedral nano-structure signal probe and application thereof

InactiveCN104651491AShort synthesis timeSimple methodMicrobiological testing/measurementMaterial electrochemical variablesNano structuringDna recognition

The invention provides a DNA tetrahedral nano-structure signal probe. The signal probe is a DNA signal probe having a tetrahedral base, wherein the signal probe is formed by self-assembling single-stranded DNA of a DNA recognition sequence extending from 5' end and single-stranded DNA of three chains with 5' ends modified with labeled molecule; the DNA recognition sequence extends from a vertex of the tetrahedral structure, the DNA recognition sequence is complementarily combined with to-be-detected target DNA or miRNA, and other three vertexes, due to the labeled molecules, are specifically combined with modified signaling modules, so as to achieve multi-signal amplification. The signal probe disclosed by the invention greatly improves the sensitivity of the target DNA or miRNA subjected to electrochemical detection, and a limit of detection can be as low as 1fM.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

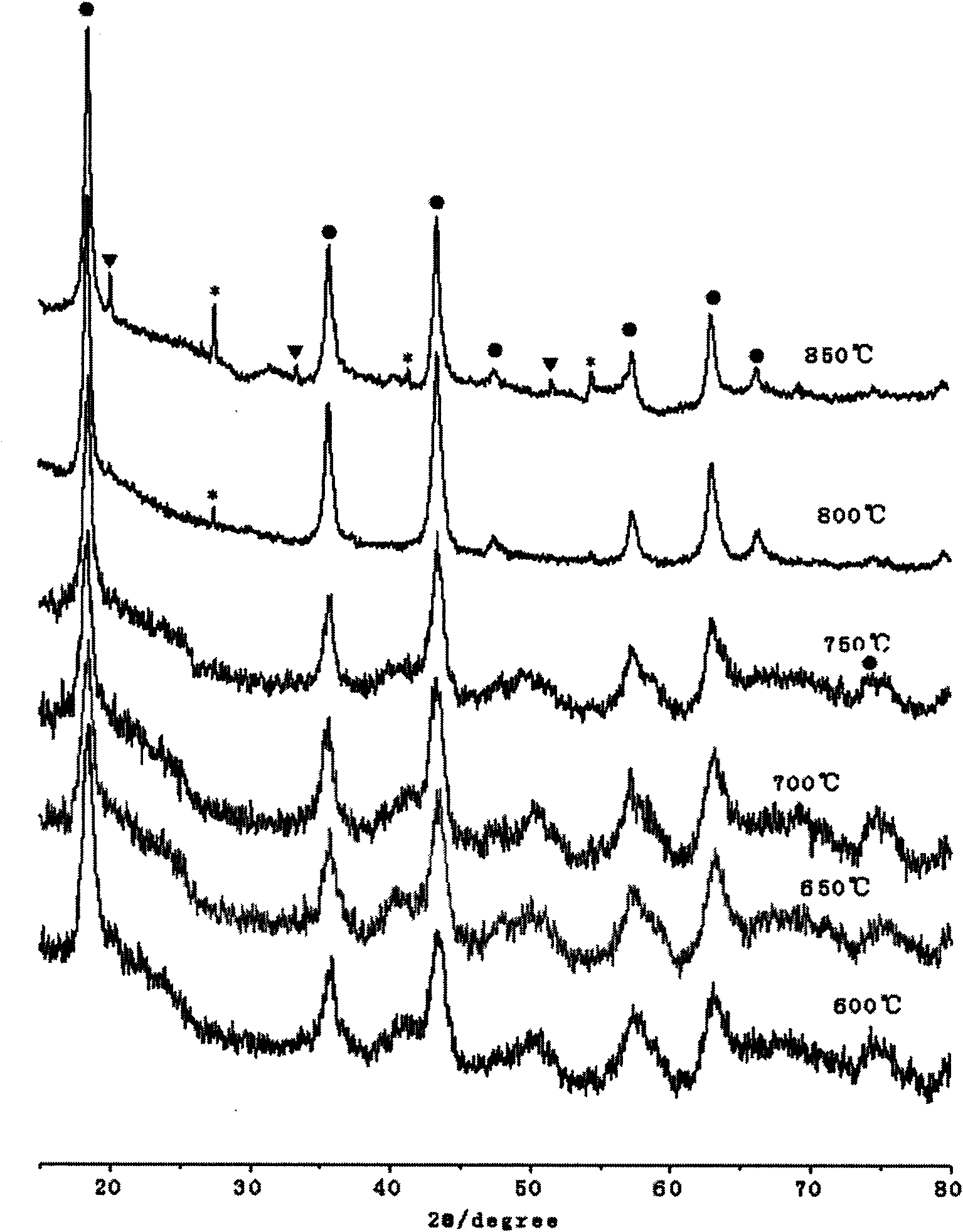

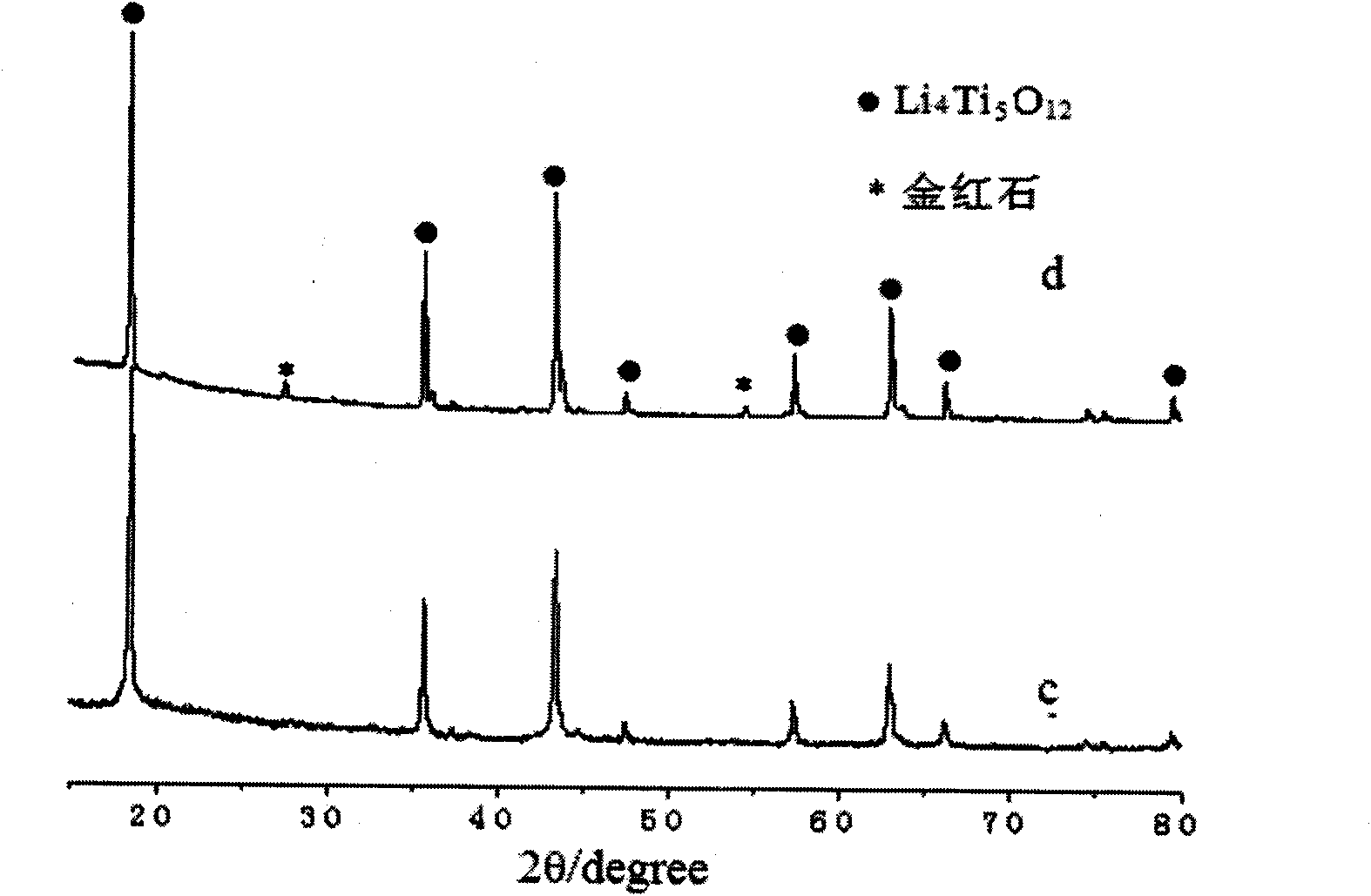

Method for preparing spinel lithium titanate of cathode material of lithium ion battery

InactiveCN101593830ALow costReduce energy consumptionElectrode manufacturing processesCombined methodMicroparticle

The invention relates to a method for preparing a cathode material Li4Ti5O12 of a high-performance lithium ion battery. The method comprises the following steps of: adopting the combined method of sol-gel and microwave treatment to prepare micro powder of nano-class Li4Ti5O12, and simultaneously modifying Li4Ti5O12 by carbon doping and metallic doping. The method utilizes the sol-gel method to effectively control chemical composition, phase composition and powder size of the Li4Ti5O12, thereby improving the uniformity and the electric conductivity of the Li4Ti5O12; simultaneously by utilizing the characteristics of the microwave technique of quick temperature rise, even heating and conglobation resistance, the high-power industrial microwave oven is used for treatment, so that the treatment time of the Li4Ti5O12 is greatly shortened, the yield is greatly improved, and the cost and the energy consumption of the material are reduced, the process is simplified, the efficiency on the industrialized production of the lithium ion battery is improved, and the industrialized application is easily achieved; and by doping carbon and metallic elements, the electric conductivity of lithium iron phosphate is greatly improved, and the charging and discharging capacities and the cycle index of the lithium iron phosphate are simultaneously and effectively increased.

Owner:ZHENGZHOU UNIV +1

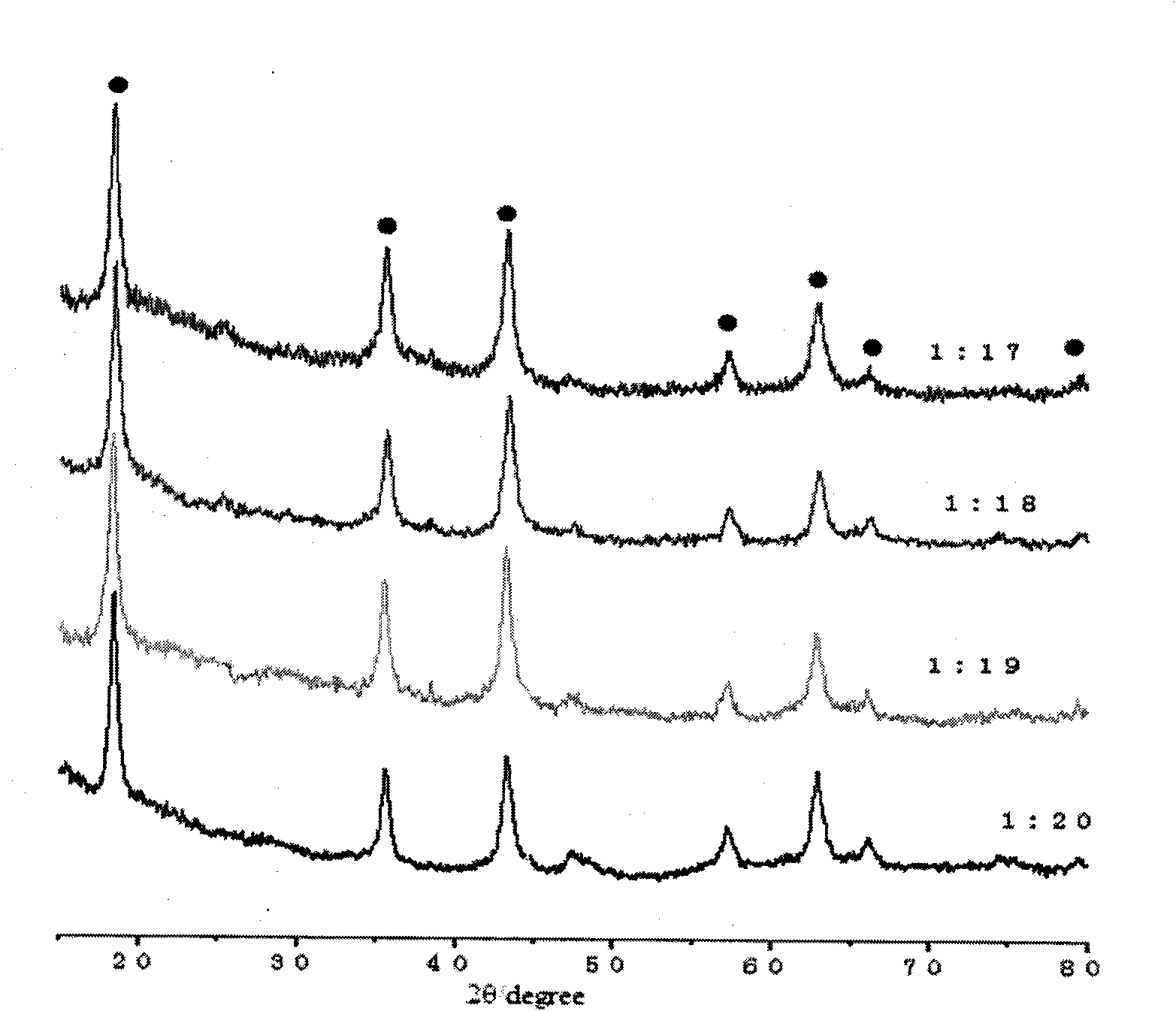

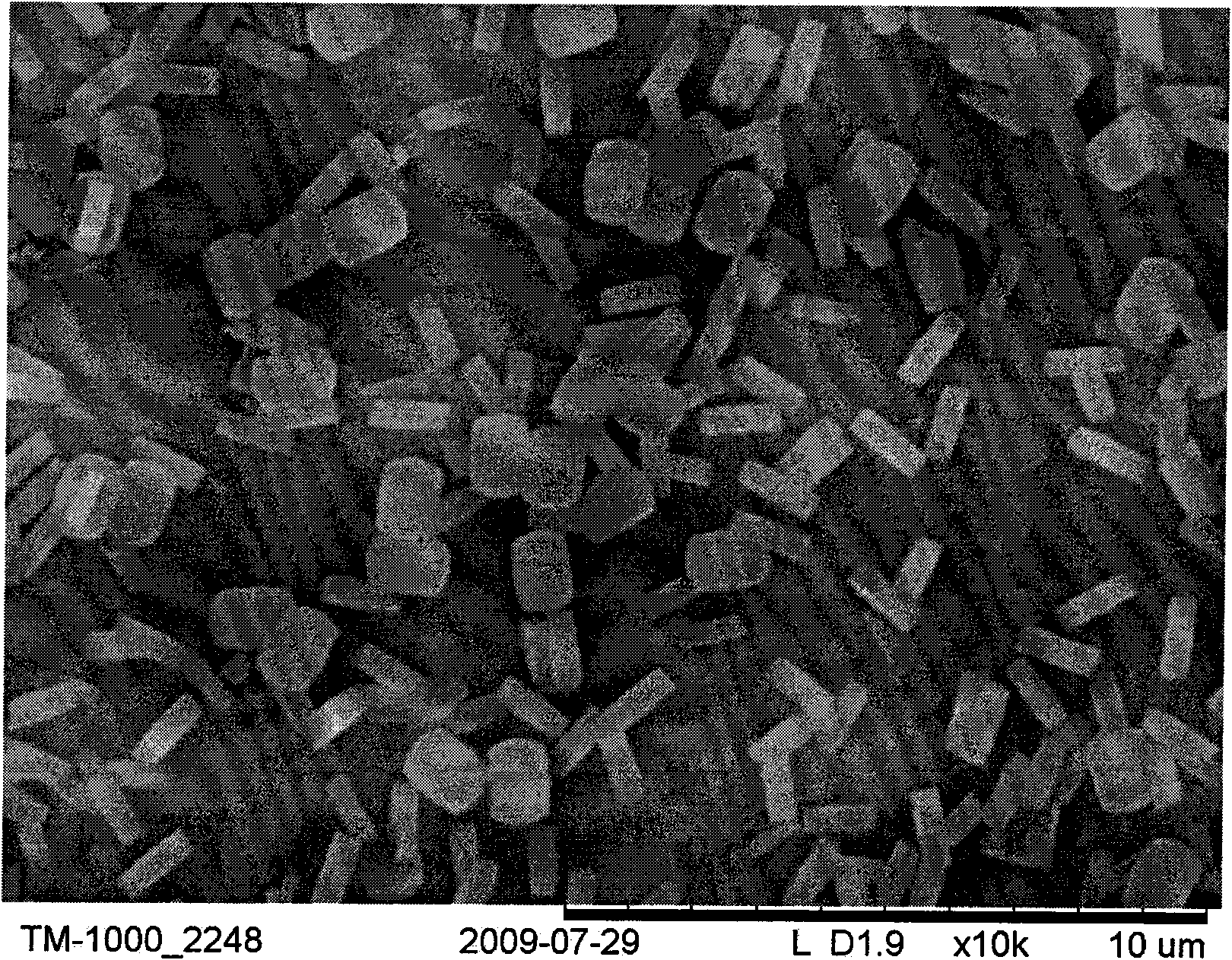

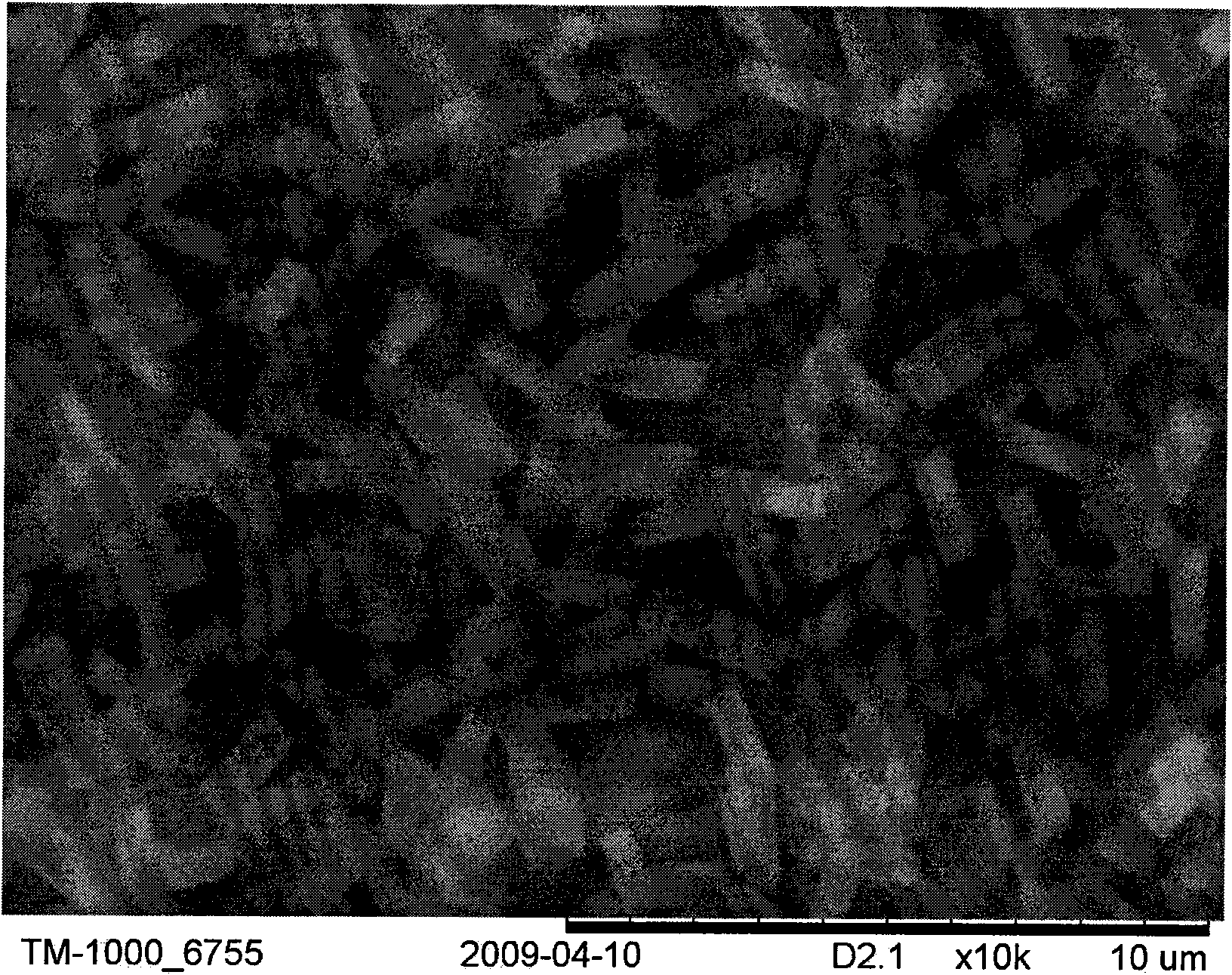

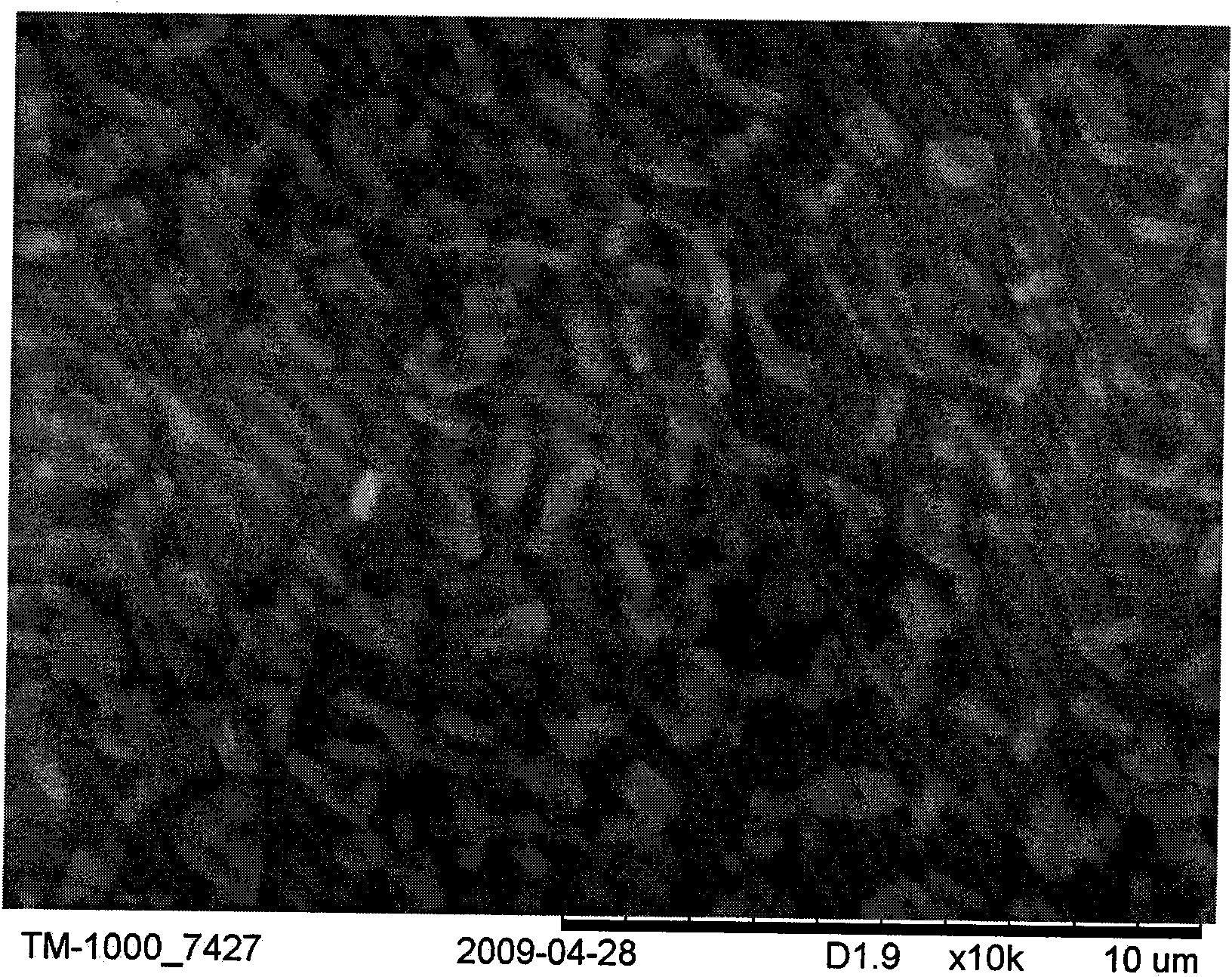

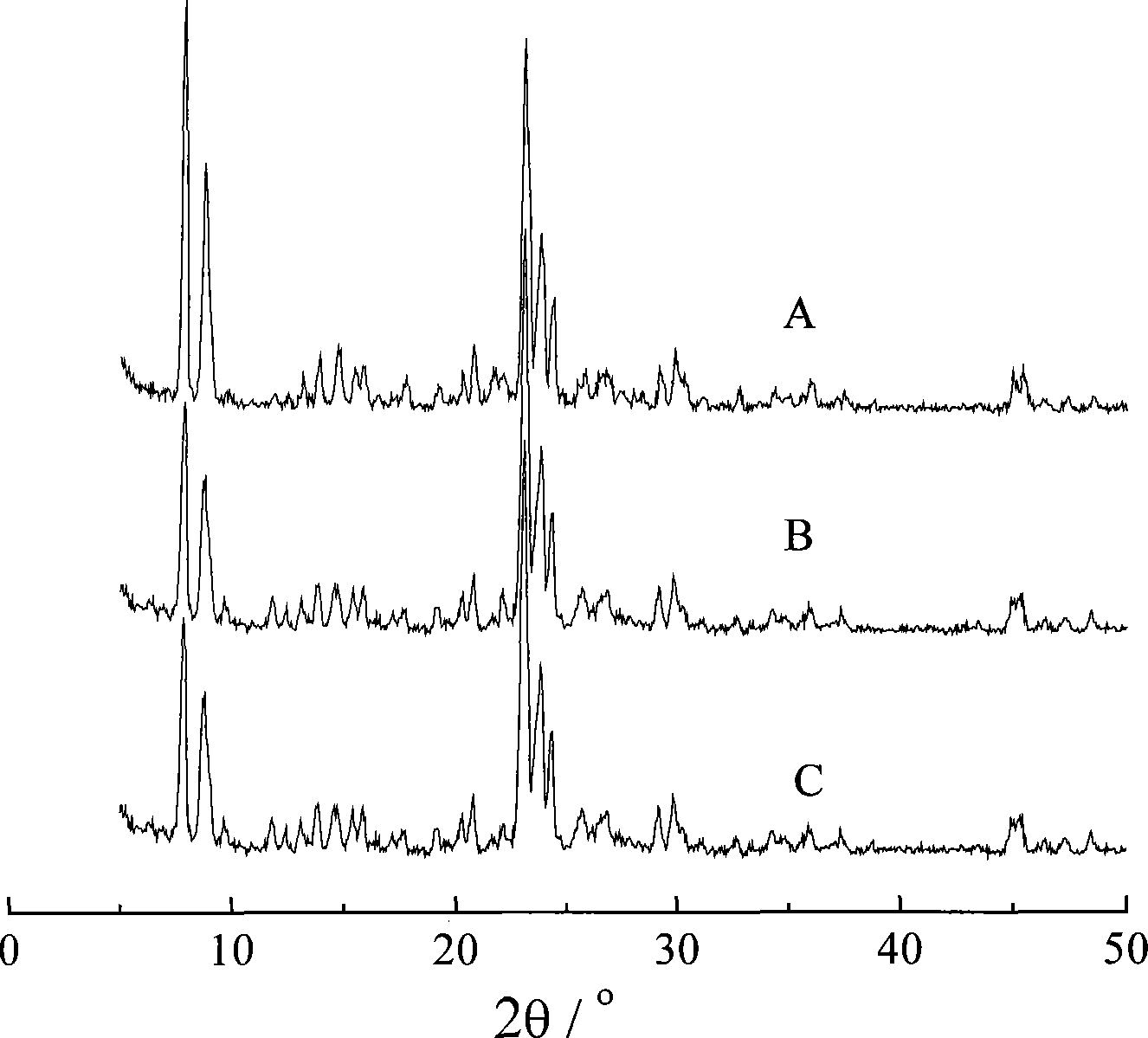

Method for synthesizing oriented MFI type molecular sieve membrane by means of microwave heating

InactiveCN101643218AUniform grainShort synthesis timeCrystalline aluminosilicate zeolitesMolecular sieveTime range

The invention discloses a method for synthesizing an oriented MFI type molecular sieve membrane by means of microwave heating. The method comprises the following steps of: 1) preparation of molecularsieve synthetic fluid, wherein the synthetic fluid consists of tetraethoxysilane, tetrapropylammonium hydroxide and water, which follow a mol ratio of 1:0.2-0.6:100-250; 2) stirring the synthetic fluid at the room temperature for 1-4 h, adding support body, carrying out aging for a time ranging from 10 min to 50 h in the condition of the room temperature or heating, or carrying out aging first fora time ranging from 10 min to 50 h in the condition of the room temperature or heating and then adding the support body, and synthesizing a molecular sieve membrane by means of microwave heating, wherein the synthesis temperature is 100-200 DEG C and the synthesis time is 10-30 min; and 3) washing and drying and finally obtaining the oriented MFI type molecular sieve membrane from the support body. The MFI type molecular sieve membrane synthesized with the method is b-axis oriented and has good synthetic repetition. The microwave heating greatly accelerates the nucleation and crystallizationspeed of the molecular sieve, remarkably reduces the molecular sieve membrane synthesis time and the energy consumption and is helpful for cost reduction.

Owner:ZHEJIANG UNIV

Process for producing fine grain ZSM-5 zeolite catalyst for methylbenzene selective dismutation

InactiveCN101244391ALess side effectsShort synthesis timeOrganic chemistryMolecular sieve catalystsAdhesiveIon exchange

The invention relates to method for preparing toluene selective disproportionate catalyst using small crystallite ZSM-5 zeolite, which comprises the steps as follows: mixing molecular weight siloxane and aluminum salt for hydrolysis reaction for 1 to 24 hours under acid conditions with the presence of a template; adjusting the pH value of the mixture using inorganic base; performing hydrothermal crystallization for 10 to 24 hours at 160 to 200 DEG C; preparing small crystallite ZSM-5 zeolite with the crystalline grain of 100 to 500nm; forming the small crystallite zeolite using adhesive; preparing hydrogenous zeolite through ion exchange; adopting tetraethyl orthosilicate chemical liquidoid silica deposition for modification, so as to obtain a shape selective catalyst with high activity, high selectivity to xylene and low side reaction. The catalyst has the advantages of simple reparation technology, low cost, high reactivity, and wide application prospect.

Owner:NANJING UNIV OF TECH

Combustion synthesis method of sub-micron titanium carbide nitride powder

InactiveCN1699284AHigh puritySmall granularityNitrogen compoundsTitanium compoundsSynthesis methodsAcid washing

Disclosed is a combustion synthesis method of sub-micron titanium carbide nitride powder which comprises proportioning base raw material and thinning agent, the base material includes titanium oxide 55-62%, magnesite powder 20-40%, carbon black 0-20%, the thinning agent is carbon azotized titanium powder, the weight of the thinning agent is 0-2.3 times of the base raw material. The preparation process comprises high temperature drying, ball grinding, mixing homogeneously, cooling down with circulating water, reacting at the presence of nitrogen, cooling down and acid-washing, water scrubbing, filtering and drying to obtain the end product.

Owner:HARBIN INST OF TECH

Auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process

The invention discloses auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process. The formula of raw materials required in the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process is as follows: the mole ratio of sodium sulfide to sodium hydroxide to santochlor to N-methyl-2-pyrrolidinone is 0.93-1.15 to 1.00-1.28 to 1.98-2.98 to 1.18 to 1.48. The industrial synthetic process mainly comprises the following steps: firstly, in a sodium hydrosulfide dehydration treatment stage, a pipeline filter is adopted to filtrate a sodium hydrosulfide solution to treat mechanical impurities in the solution, then a sodium hydroxide solution with the concentration 84 mol percent is added in the formula for chemical treatment on the sodium hydrosulfide; secondly, in the condensation polymerization stage, anaerobic deionized water is added to further appropriately adjust the molecular weight and molecular weight distribution coefficient of synthesized polyphenylene sulfide resin; thirdly, deionized water is adopted for repeatedly scrubbing for 3 to 6 times, and finally, the target product of the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process provided by the invention is obtained. The resin in the obtained product of the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process is low in polydispersity index and high in oxygen index, and has an excellent electrical insulation property.

Owner:周洪

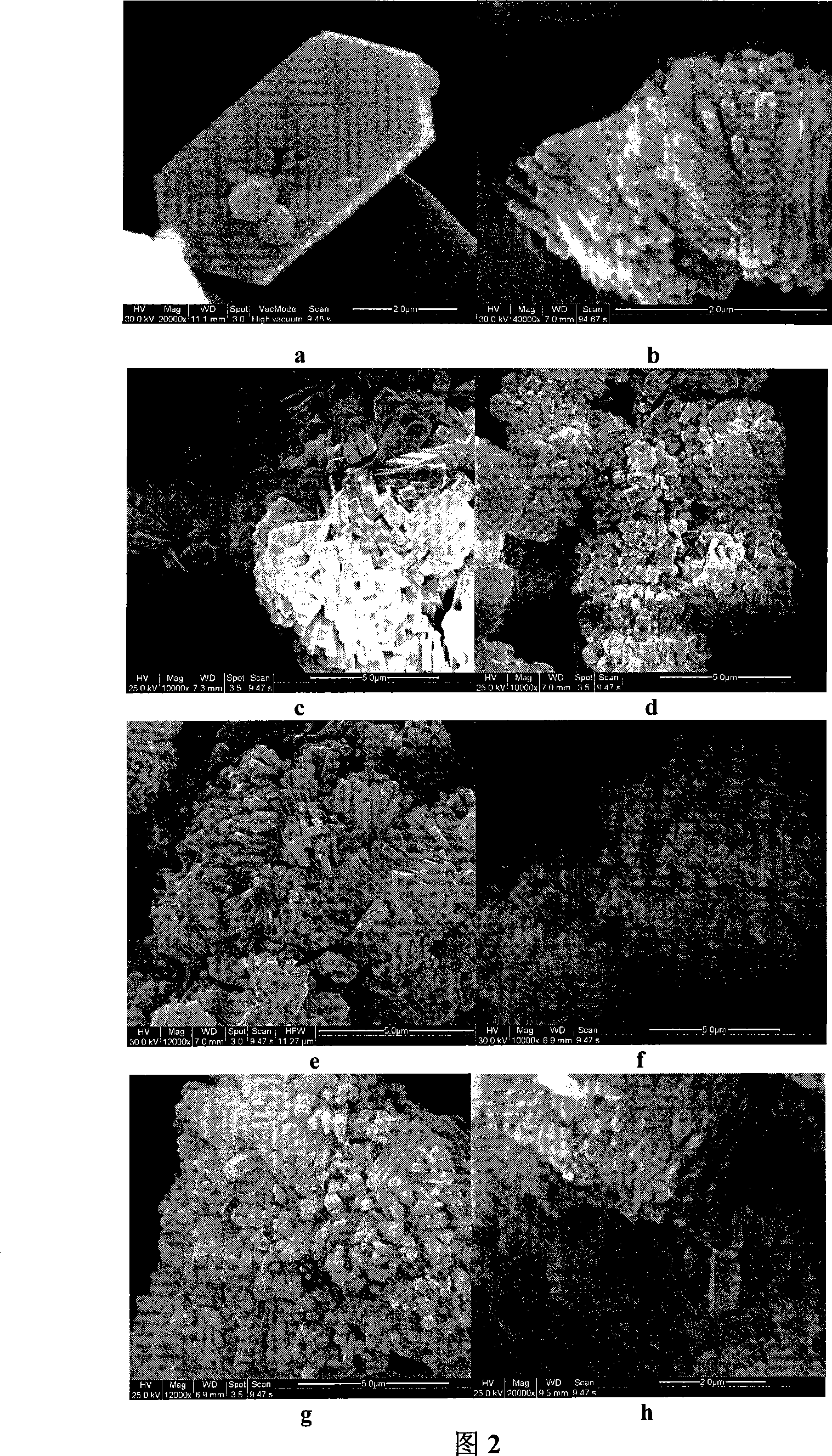

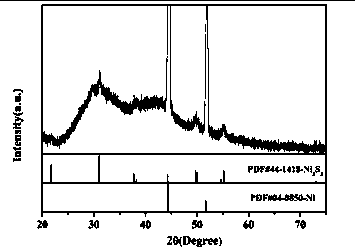

Synthesis method of vanadium-modified Ni3S2 electrocatalyst automatically assembled from rodlike shape into ball-flower shape

ActiveCN108325539ASynthesis temperature is lowShort synthesis timePhysical/chemical process catalystsElectrodesMicrowaveSulfur

The invention discloses a synthesis method of vanadium-modified Ni3S2 electrocatalyst automatically assembled from a rodlike shape into a ball-flower shape. The synthesis method comprises the following steps that clean foamed nickel is dipped into turbid liquid with the vanadium source concentration being 5-30 mM and the mole ratio of a vanadium source to a sulfur source being (1) to (0.5-12), a microwave solvent thermal reaction is conducted, and after the sufficient reaction is completed, the vanadium-modified Ni3S2 electrocatalyst material automatically assembled from the rodlike shape intothe ball-flower shape is obtained. The method is easy to operate, the reaction condition is mild, the consumed time is short, the prepared vanadium modified Ni3S2 product automatically assembled fromthe rodlike shape into the ball-flower shape is high in purity, and uniform in shape and size. In order to achieve the above purpose, the following technical scheme is adopted.

Owner:SHAANXI UNIV OF SCI & TECH

Fast synthesis process of strong acid-type ZSM-5 molecular sieve

InactiveCN1417121AShort synthesis timeStrong acidMolecular sieve catalystsPentasil aluminosilicate zeoliteStrong acidsSilicon

The fast synthesis process of strong acid-type ZSM-5 molecular sieve includes compounding solution A with silicon source, template agent and one half of deionized water in certain proportion; compounding solution B with aluminum source, inorganic acid and the other half of deionized water in certain proportion; adding dropwise solution B to solution A to prepare guiding agent; compounding solution C with silicon source, template agent and one half of deionized water in certain proportio; compounding solutio D with aluminium source, inorganic acid and the other half of deionized water in certain proportion; adding dropwise solution D to solution C and adding guiding agent in the amount of 5-10 vol% of total amount. The process has advantages of short synthesis period and storing acidity.

Owner:SYNFUELS CHINA TECH CO LTD

Polyesterimide enamelled wire paint capable of straightly soldering and method for preparing same

InactiveCN101338157AShort synthesis timeReduce energy consumptionPlastic/resin/waxes insulatorsCoatingsPolyesterLacquer

The invention discloses direct welding polyester imine enamel wire paint and a preparation method thereof. Firstly, polyester imine resin generates from monacid, aromatic dicarboxylic acid, 4-methacryoxypropyl, 4, 4'-diaminodiphenyl-methane, trihydric alcohol, triethanolamine, dihydric alcohol and monoethanolamine through the melt copolycondensation under the function of catalyst; secondly, modified etherifying amino resin is prepared from melamine, urea, benzoguanamine, 37 percent of formaldehyde, methanol, isopropanol and normal butyl alcohol through the hydroxymethylation and etherification; thirdly, modified etherified phenolic resin is prepared from technical xylenol, isopropylidene diphenol, boric acid, 37 percent of formaldehyde, methanol, isopropanol and normal butyl alcohol through the hydroxymethylation and etherification; finally, three products obtained through the three steps are mixed with mixed environmental solvent according to the quality ratio of 1-1.9 to 0.2-0.9 to 0.2-0.9 to 8 to obtain the direct welding polyester imine enamel wire paint. The enamel wire painted through the enamel wire paint of the invention can be welded directly under the condition of not higher than 400 DEG C and the stretch of the enamel wire paint or the fluting of zero pinhole can be realized.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com