Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

944results about How to "Uniform grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

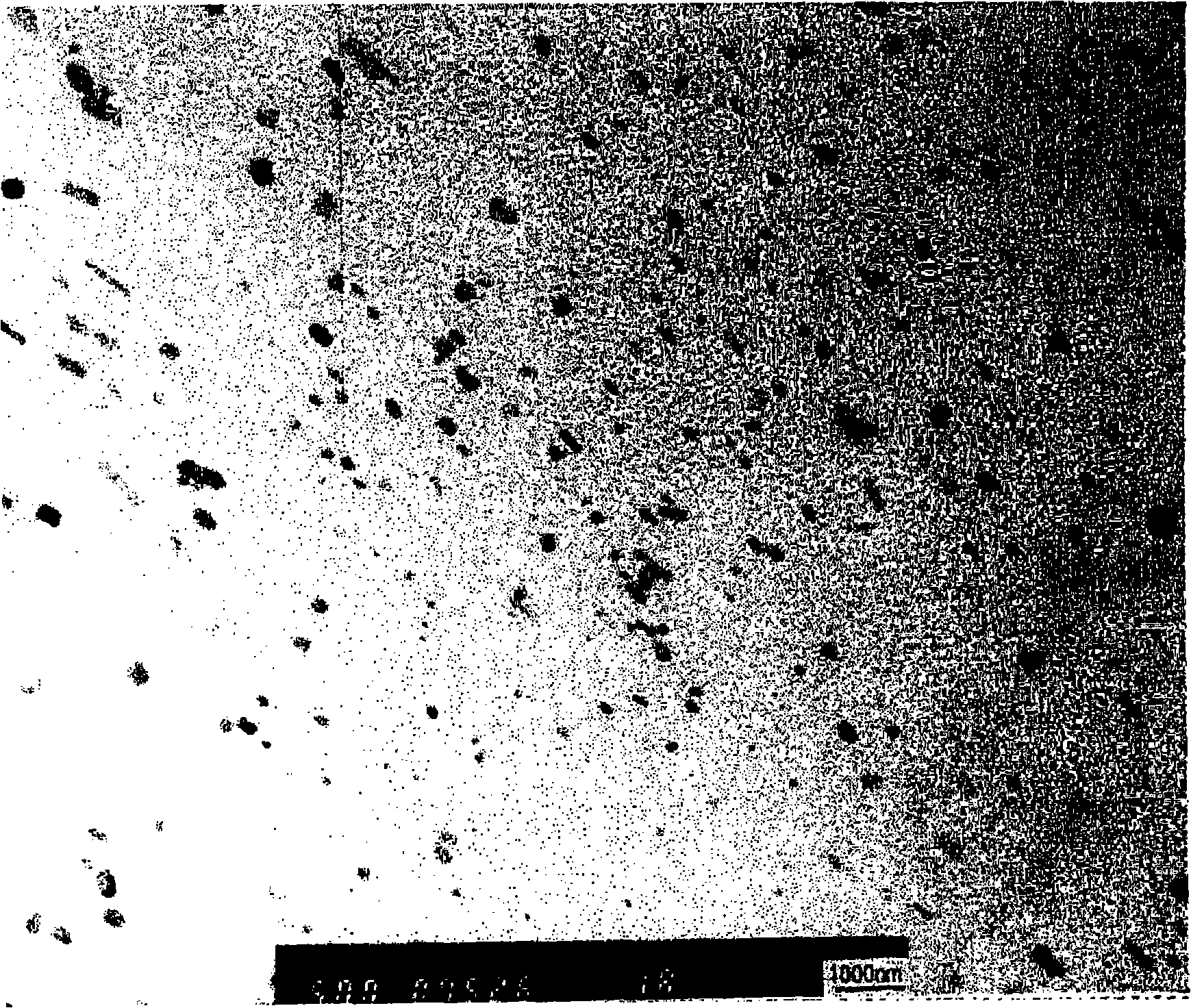

Preparation method of hydrocracking catalyst

ActiveCN103055923AUnlimited capacityGood dispersionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveDispersity

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, and then adding the acidic mixed solution A, the alkaline solution B and CO2 to a reaction tank filled with clear water in parallel to prepare gel; and then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering, drying and forming the mixture, and then washing, drying and roasting the product, thus preparing the hydrocracking catalyst. The method has the beneficial effects that a clean preparation method is adopted, so not only can the catalyst be easily formed and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased and the dispersity of metals in the catalyst can be improved, thus the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the catalyst prepared by the method can be used for a single-section hydrocracking process of a non-refining section or a one-section serial hydrocracking process of a refining section.

Owner:CHINA PETROLEUM & CHEM CORP +1

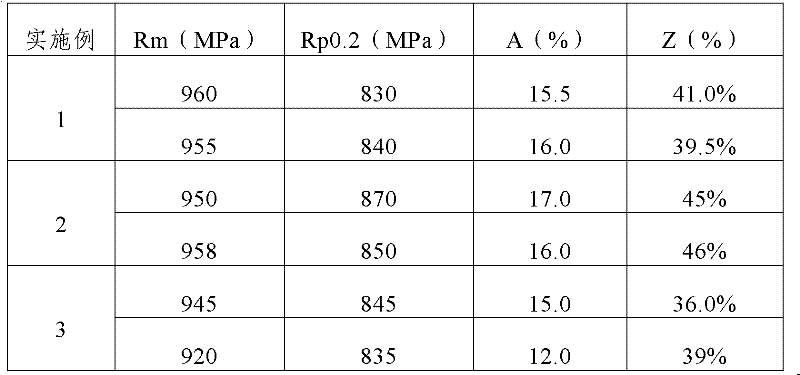

Processing method for TC4 titanium alloy large-sized bar

The invention discloses a processing method for a TC4 titanium alloy large-sized bar. The method comprises the following steps of: cogging and forging TC4 titanium alloy ingots for 2 to 3 heating times to obtain forging billets; 2, upsetting the forging billets repeatedly and performing drawing-out forging for 2 to 3 heating times; 3, upsetting the forging billets subjected to forging repeatedly and performing drawing-out forging for 3 to 5 heating times; and 4, performing chamfering round forging on the forging billets subjected to forging for 2 heating times to obtain the TC4 titanium alloy large-sized bar with the diameter of 200 to 400 mm and length of not less than 2,500 mm. The TC4 titanium alloy bar processed by the method has uniform and fine grains, few internal defects and high safety and accords with the domestic advanced level of the like products. In the processed TC4 titanium alloy bar, the room-temperature tensile strength is 920 to 960 MPa; the yield strength is 830 to 870 MPa; the elongation percentage is not less than 12 percent; the contraction ratio of the cross section is not less than 36 percent; flaw detection clutter reflects small signals; and the flaw detection level is high.

Owner:WESTERN TITANIUM TECH

Ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and making method thereof

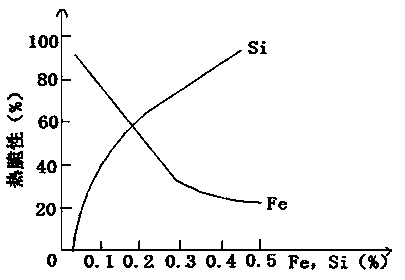

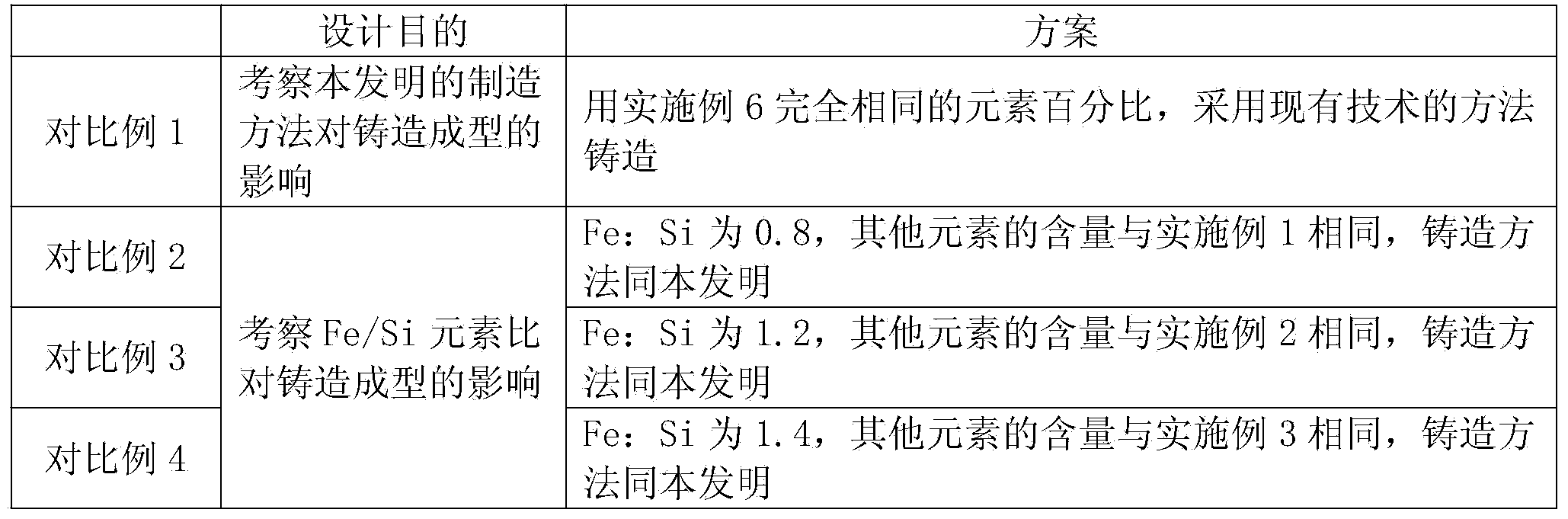

The invention discloses an ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and a making method thereof, and belongs to the aluminum alloy making field. The flat cast ingot comprises, by mass, 2.0-2.4% of Cu, 1.95-2.5% of Mg, 5.5-9.0% of Zn, 0.08-0.15% of Zr, 0.0003-0.0015% of Be, below 0.06% of Ti, below 0.04% of Cr, below 0.10% of Mn, 0.085% or less of Si, 0.14% or less of Fe, and the balance Al and inevitable elements, wherein the content of each of the inevitable elements is lower than 0.05%, the total amount of the inevitable elements is lower than 0.15%, and a content ratio of Fe to Si is not less than 1.6. The making method disclosed in the invention improves traditional making methods, and does not need pure aluminum bottoming, and the flat cast ingot made in the invention has the advantages of large size, high strength, no cracks, and high casting success rate.

Owner:广西南南铝加工有限公司

Method for producing the red pigment of ferric oxide from ferrous sulphate of byproduct abolished by titanium white

InactiveCN1415665AProlong hydrolysis timeReduce manufacturing costPigmenting treatmentAmmonium sulfateFertilizer

A process for preparing iron oxide red pigment from ferrous sulfate as the by-product of titanium oxide includes such steps as reducing iron scale at 50-70 deg.c, hydrolyzing for 6-10 hr, flocculating, deposition, refining heptahydrated ferrous sulfate, neutralizing with ammonia to generate crystal seeds, and neutralizing with ammonia while oxidizing with air to obtain target product. Its by-product, solution of ammonium sulfate, can be used for preparing composite fertilizer.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

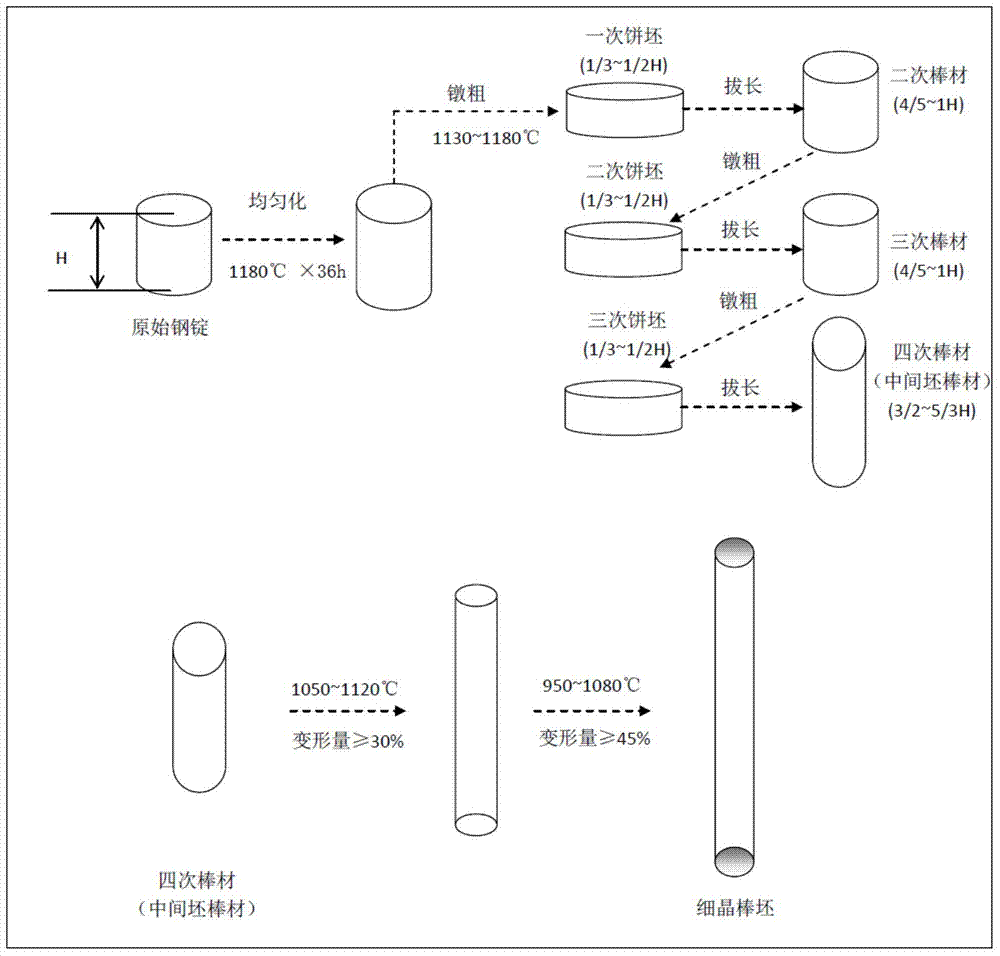

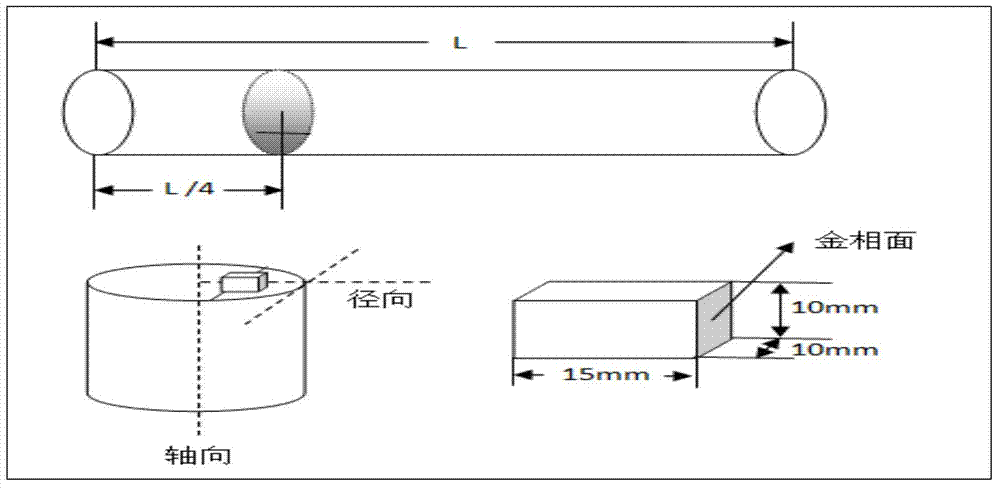

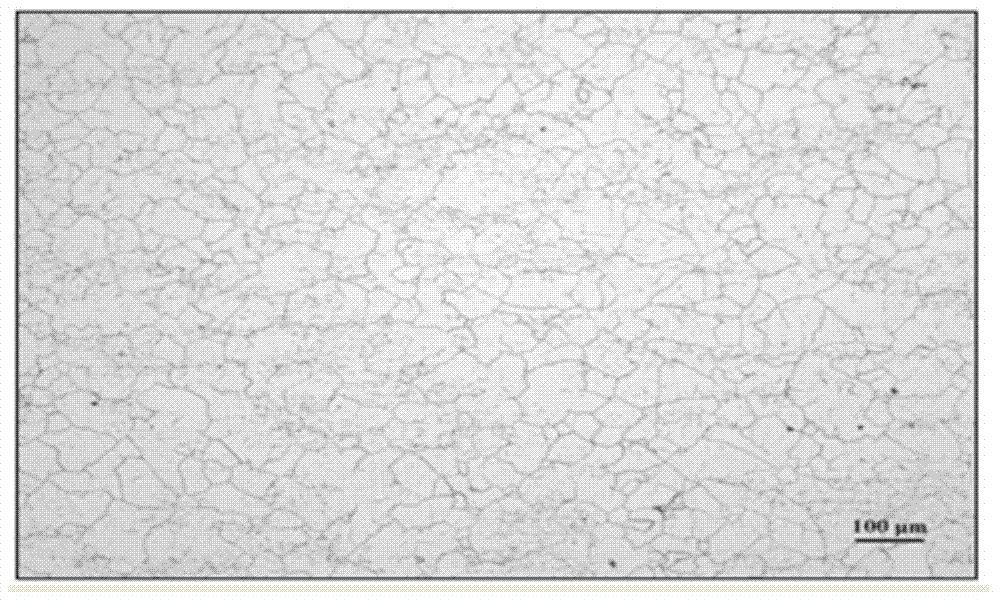

Fine-grain forging method for large-size GH690 nickel-based alloy bar billet

The invention discloses a fine-grain forging method for a large-size GH690 nickel-based alloy bar billet, and belongs to the technical field of forging. By using the composite technology of ingot billet homogenization and classified forging for preparing the GH690 nickel-based alloy bar billet, the grains of the bar billet for forging can be uniform and fine, thus meeting fine-grain structure homogeneity control requirements on final large-size alloy forgings; classified repeated upsetting-stretching cogging is performed on the basis of controlling a deformation temperature and the deformation amount of each heating number, the forgings are formed by hot upsetting by virtue of end part lubrication and horizontal restrain technologies, and rapidly cooled to eliminate grain coarsening caused by deformation heat effect, and finally, the forging structures with uniform carbides and fine grains are obtained.

Owner:CENT IRON & STEEL RES INST

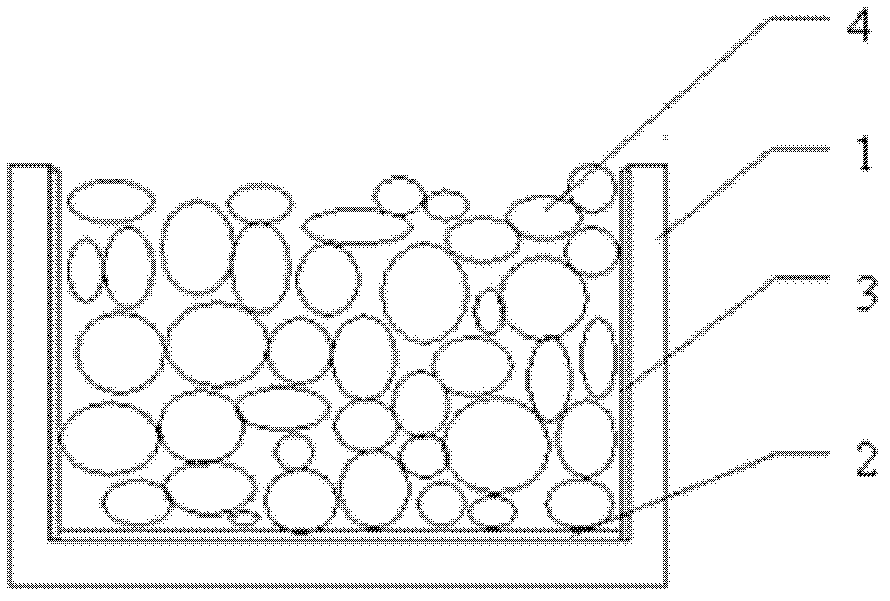

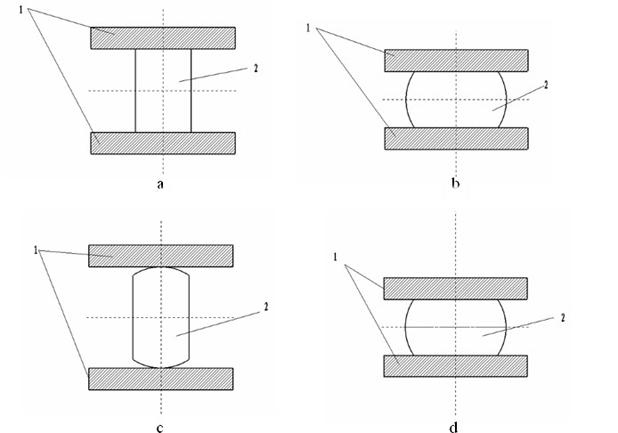

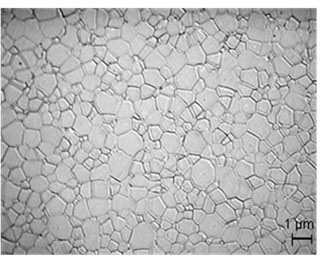

Polycrystalline silicon ingot, preparation method of polycrystalline silicon ingot, polycrystalline silicon slice and crucible for polycrystalline silicon ingot casting

ActiveCN102776561APromote nucleationUniform grainPolycrystalline material growthSingle crystal growth detailsMolten stateCrucible

The invention provides a preparation method of a polycrystalline silicon ingot. The preparation method comprises the following steps that a core source is arranged at the bottom of a crucible, and a core source layer is formed; silicon materials in a molten state are arranged on the core source layer; and the temperature in the crucible is controlled to gradually rise in a direction vertical to the upward direction form the bottom of the crucible, the temperature gradient is formed, the silicon materials in the molten state form core crystallization by utilizing the core source, and the polycrystalline silicon ingot is prepared. The invention also provides high-quality polycrystalline silicon ingot obtained by the preparation method, a polycrystalline silicon slice obtained through the preparation of the polycrystalline silicon ingot and the crucible for polycrystalline silicon ingot casting. The polycrystalline silicon ingot prepared by the preparation method has the advantages that the crystalline size is uniform and regular, the dislocation density is low, and in addition, no obvious pine-tree crystals or twin crystals exist.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

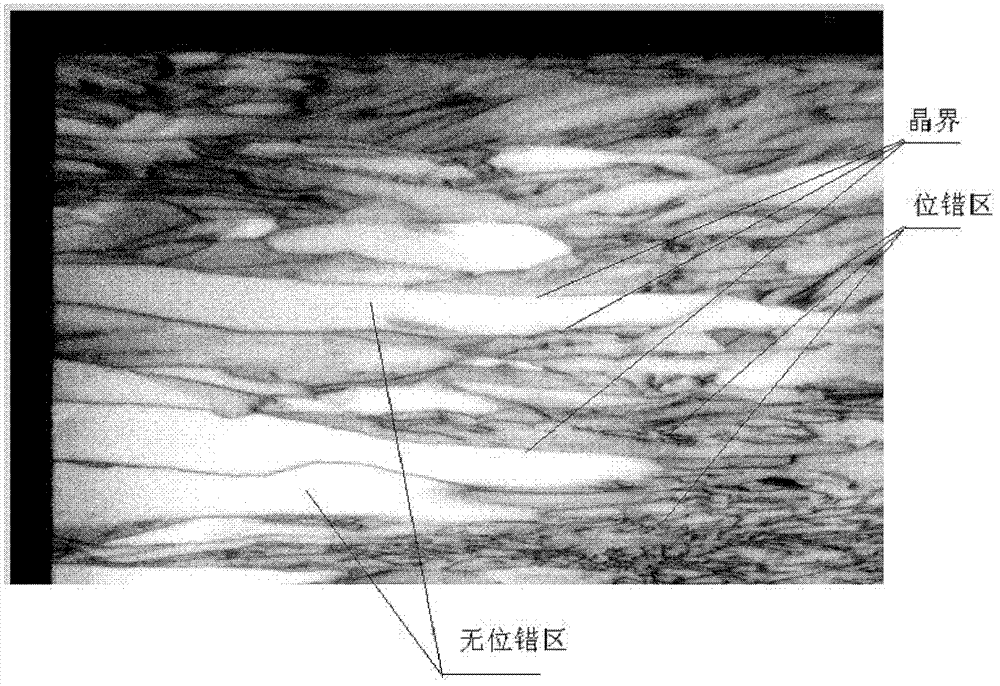

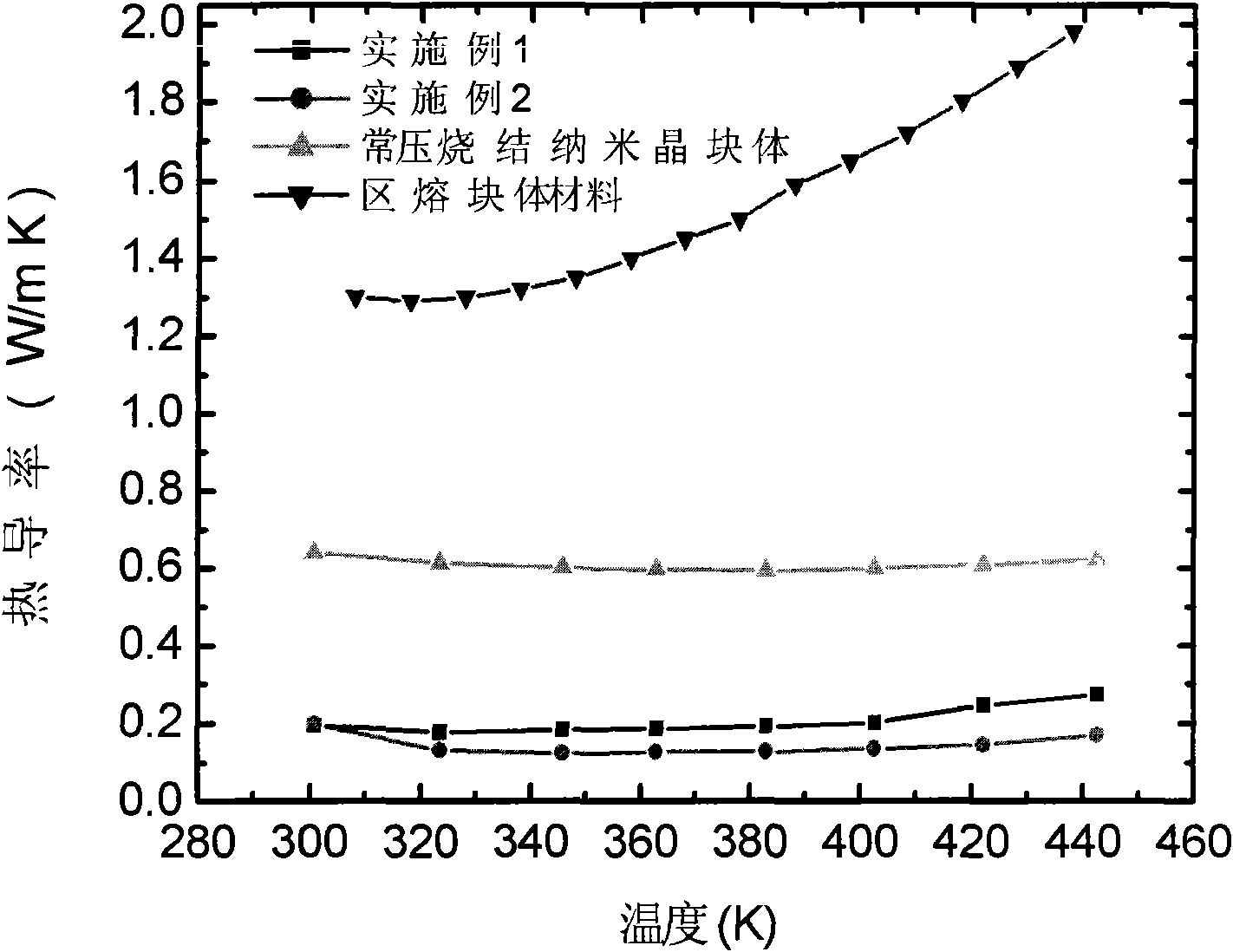

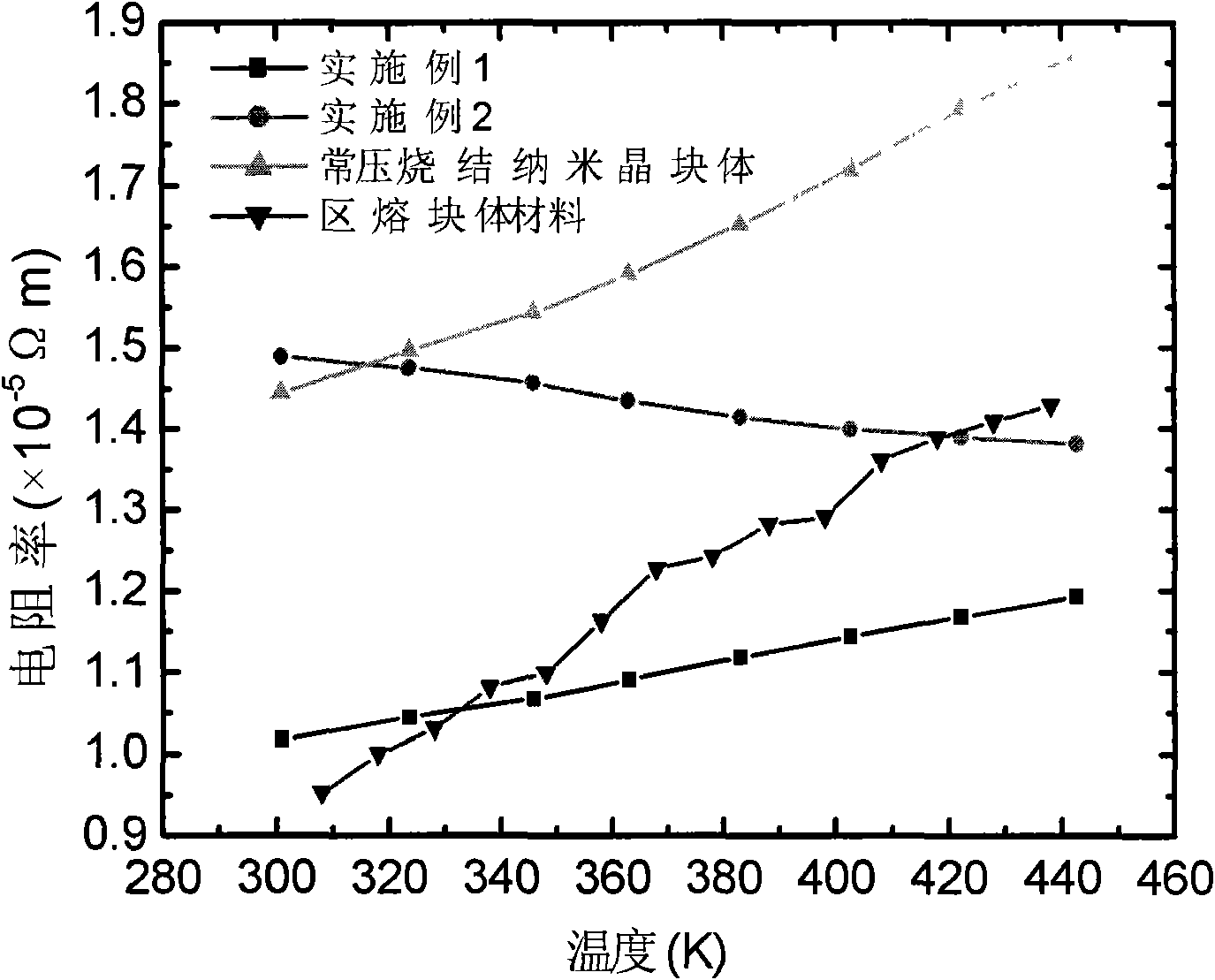

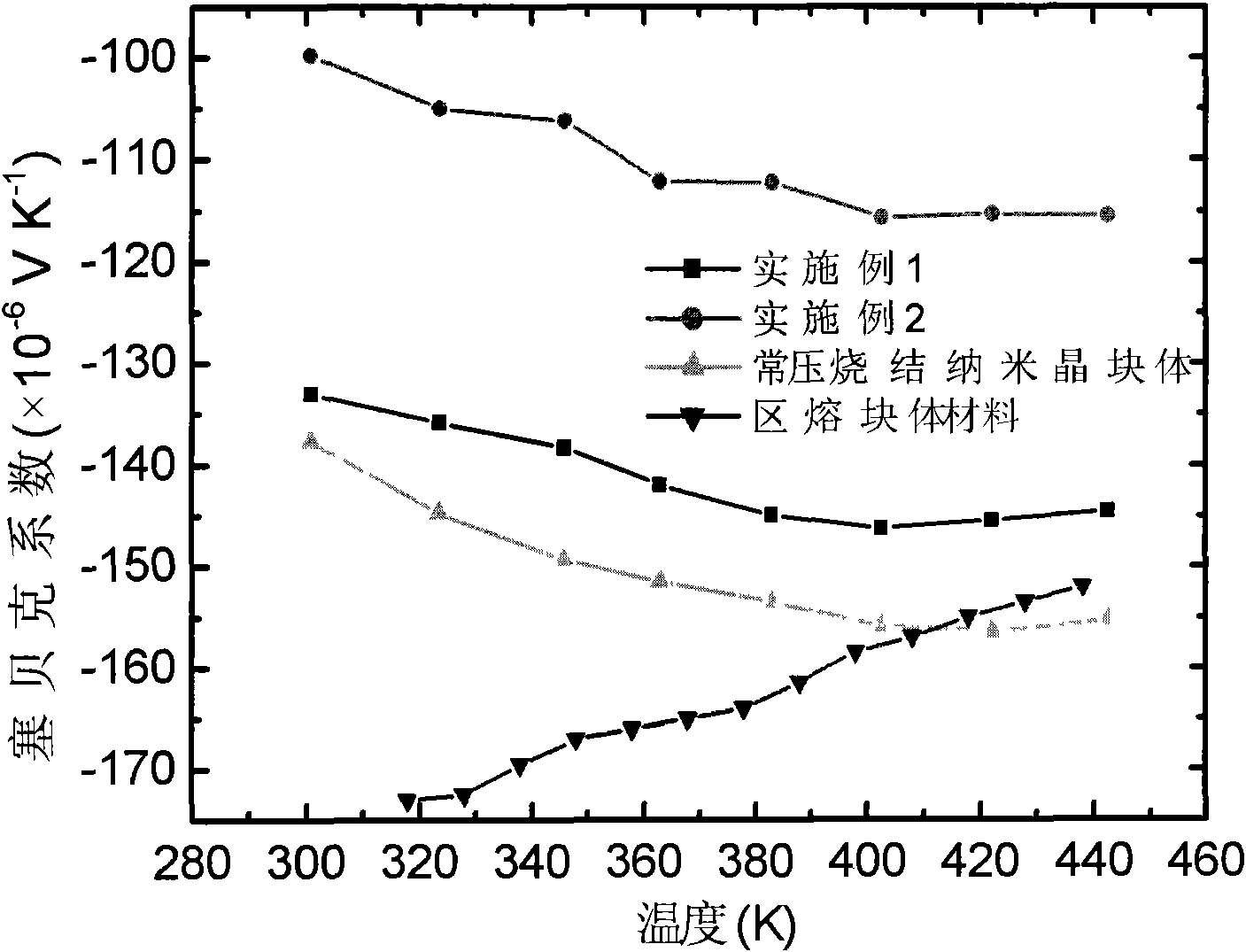

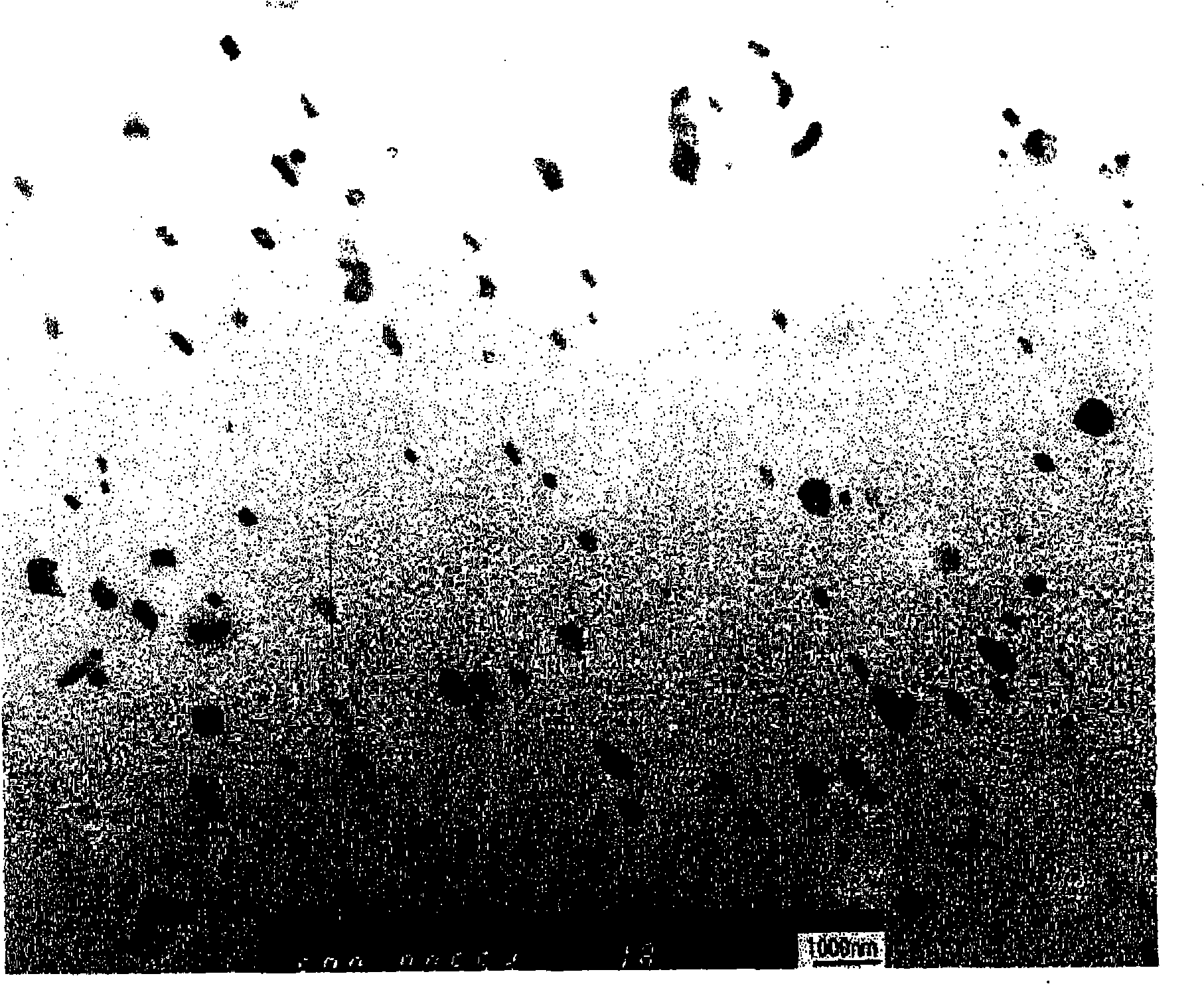

High-pressure sintering preparation method of high-densification high-performance nano crystal block thermoelectric material

InactiveCN101549405ASimple processSimple stepsMaterial nanotechnologyThermoelectric device manufacture/treatmentThermoelectric materialsCondensed matter physics

The invention discloses a high-pressure sintering preparation method of high-densification high-performance nano crystal block thermoelectric material, characterized in that: (1) preparing nano crystal alloy powder using a ball milling method, with crystal grain size of 5nm-30nm; (2) preparing nano crystal block thermoelectric material using the high-pressure sintering technique, at pressure range of 0.8GPa-6GPa and sintering temperature range of 0.25-0.8T[melting point] for sintering time range of 10-120 minutes and the relative density of the obtained nano crystal block thermoelectric material is 90-100% and the average grain size is 10-50 nm. The technique is simple and the zero dimension thermoelectricity Q-value (ZT) is above 2.0. The prearation method increase the density of the nano crystal block thermoelectric material on the basis of ensuring the material with high thermoelectricity with good industrialization foreground.

Owner:YANSHAN UNIV

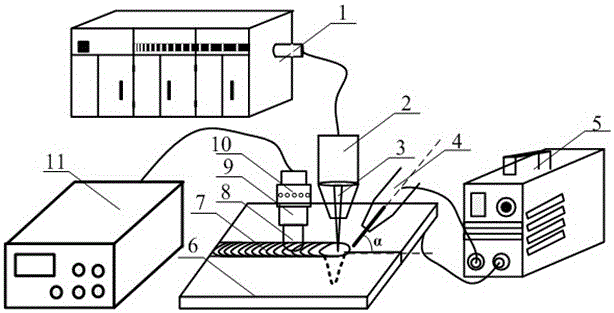

Ultrasonic assistec laser electric arc composite welding method of aluminum alloy

InactiveCN105710537AEfficient weldingPromote escapeWelding/soldering/cutting articlesLaser beam welding apparatusCavitationWelding residual stress

The invention relates to an ultrasonic assisted laser electric arc composite welding method of an aluminum alloy. On the basis of carrying out a welding scheme by combining TIG electric arc welding and laser welding, ultrasonic vibration pressure is introduced into a welding seam, wherein a designed vibration head is in direct contact with the welding seam, so that ultrasonic resources can be more sufficiently utilized, and gas in the welding seam can be rapidly escaped; most of gas in the welding seam is removed so that welding seam gas pore defects are reduced or avoided; tissue crystal grains of the welding seam are remarkably refined by utilizing cavitation effect and acoustic streaming effect caused by the fact that ultrasonic waves are transmitted in liquid, and furthermore, tissue alloy elements of the welding seam are more uniform, segregation is reduced, the strength and corrosion resistance performance of the welding seam are improved, and the performance of a welding connector is improved; and welding residual stress is effectively eliminated or reduced and the strength and corrosion resistance performance of the connector are enhanced, so that the efficient welding of the aluminum alloy is realized.

Owner:北京隆源自动成型系统有限公司

Method for preparing superhigh-purity aluminum fine grain high-orientation target

InactiveCN102002653AIncrease the total deformationEliminate deformation inhomogeneitiesVacuum evaporation coatingSputtering coatingAluminiumInternal stress

The invention relates to the field of alloy materials, in particular to a method for preparing superhigh-purity aluminum fine grain high-orientation target, which comprises: performing uniform annealing of superhigh-purity aluminum ingots at a high temperature of 500 to 630 DEG C to eliminate casting internal stress and refine cast structure; performing multi-pass multi-directional forging of superhigh-purity aluminum ingots at 150 to 300 DEG C to obtain high-strain refined superhigh-purity aluminum grains on the premise of no change in the shape of the ingots; placing the multi-directionally forged workpiece in ice water to cool the workpiece to 0 to 5 DEG C and performing cold rolling, wherein the pass compression amount is controlled to be 5 to 30 percent, and through the inter-pass cooling by ice water of the plate, the temperature rise in the plate rolling process is controlled and the crystallization of the plate is inhibited; and performing low-temperature annealing at 50 to 250 DEG C. The method can be used to produce targets which have a thickness of 5 to 25 millimeters, an average grain size f of 200 micrometers and a (200) direction-based grain orientation, and while the targets operate at 200 DEG C, the structure of the targets is stable.

Owner:NORTHEASTERN UNIV

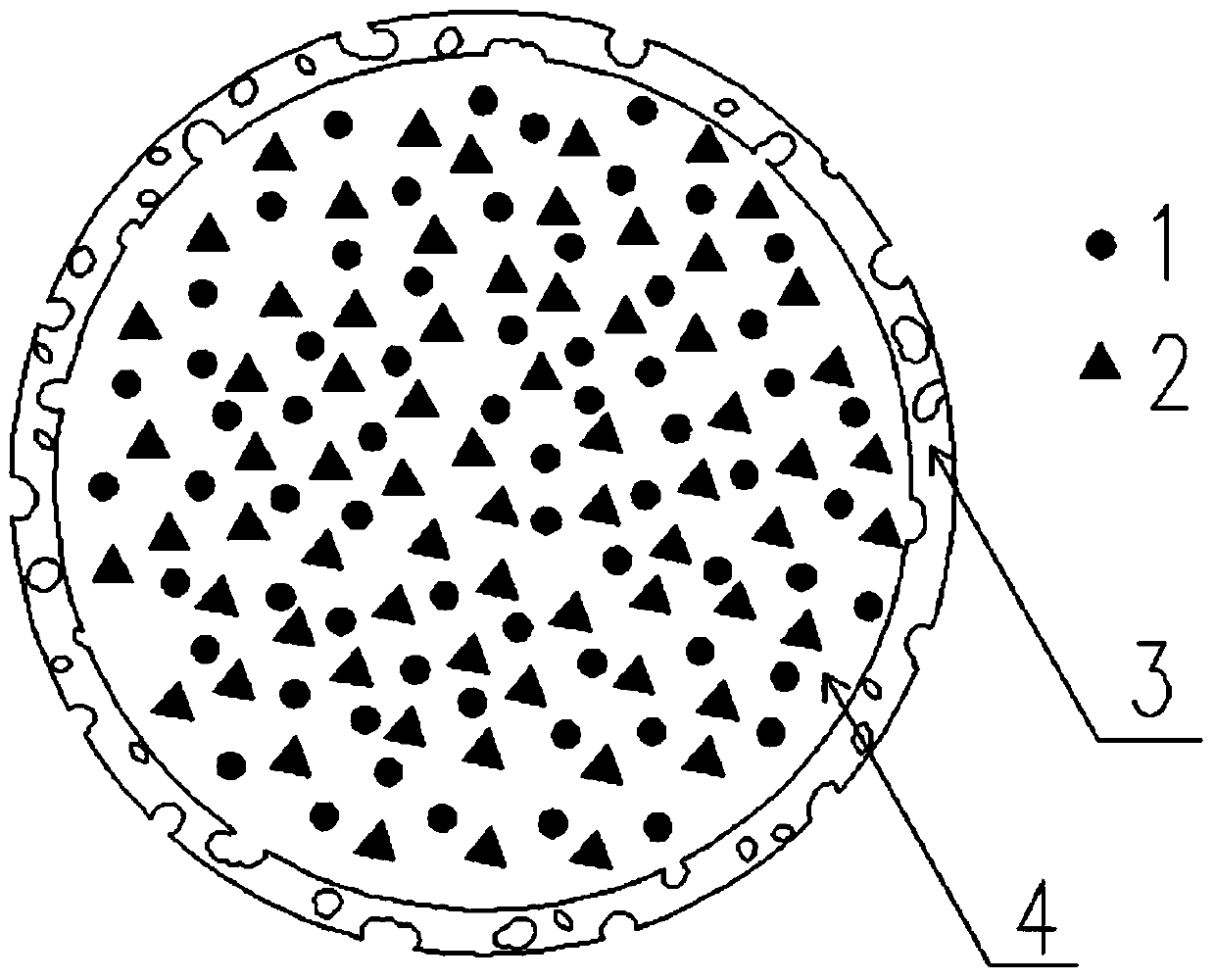

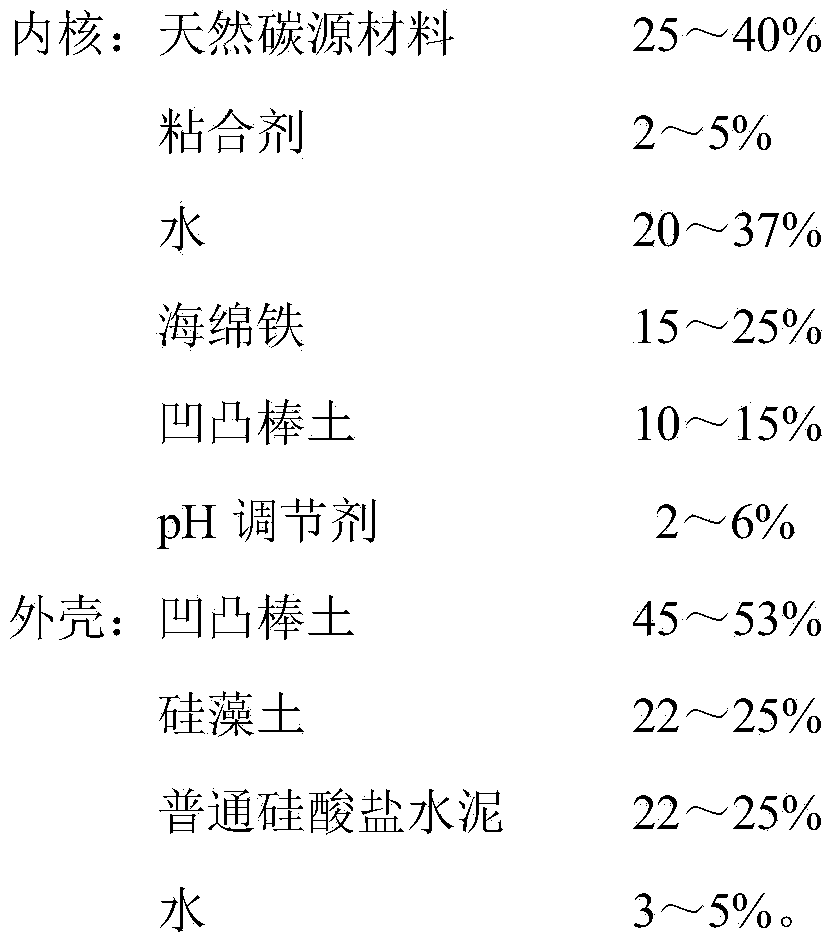

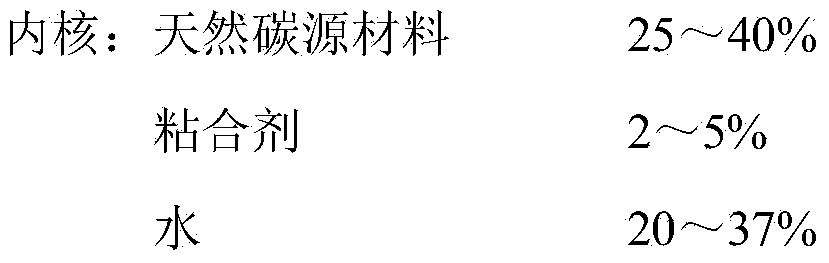

Carbon-iron microbattery slow-release carbon source filler and preparation method thereof

InactiveCN103723824AEliminate ChromaImprove biodegradabilityTreatment with anaerobic digestion processesAdhesivePortland cement

The invention discloses a carbon-iron microbattery slow-release carbon source filler and a preparation method thereof, belonging to the field of restoration of underground water pollution. The carbon-iron microbattery slow-release carbon source filler is composed of an inner core and an outer shell, wherein the inner core is made from organic carbon source mixed materials, and the outer shell is prepared from cement and high-permeability raw materials. The inner core is prepared from the following components in percentage by mass: 25-40% of natural carbon source material, 2-5% of adhesive, 20-37% of water, 15-25% of spongy iron, 10-15% of attapulgite and 2-6% of pH regulator; and the outer shell is prepared from the following components in percentage by mass: 45-53% of attapulgite, 22-25% of kieselguhr, 22-25% of ordinary Portland cement and 3-5% of water. By using the filler and method, the particle strength of the inner core can be enhanced to 70-105N / particle, and the thickness of the slow-release outer shell is lowered to 1-1.5 mm, so that the carbon-iron can be uniformly distributed in the material.

Owner:NANJING UNIV

Neodymium iron boron magnetic materials and preparation method of the same

The invention discloses neodymium iron boron magnetic materials and a preparation method of the neodymium iron boron magnetic materials. The neodymium iron boron magnetic materials comprise, by weight, 27-34.5 % of neodymium (Nd), 4.5-5.75 % of praseodymium (Pr), 0.45-0.575 of gadolinium (Gd), 2-4% of boron (B), 0.08-0.16 % of niobium (Nb), 0.01-0.02 % of hafnium (Hf), 0.01-0.02 % of wolfram (W) and 0.045-0.0575 % of scandium (Sc), and the rest is ferrum (Fe). The neodymium iron boron magnetic materials have uniform textures and strong structures, and can not only improve tenacity performance of the materials but also improve magnetic performance to some extent. The preparation method of the neodymium iron boron magnetic materials fully utilizes praseodymium-neodymium waste materials to directly produce raw materials for alloy, is flexible in composition proportion, qualified in quality control, capable of reducing cost and simple in technology, and fully utilizes waste powder materials with high oxygen content.

Owner:江苏澳芯微电子有限公司

Aluminum alloy material and production method of cast-rolling stock of decorative strip of same

The invention relates to a 3004 aluminum alloy material and a production method of a cast-rolling stock of a decorative strip of the 3004 aluminum alloy material. The compositions of the aluminum alloy material comprise smaller than or equal to 0.25 percent of Si, 0.20 to 0.60 percent of Fe, 0.10 to 0.15 percent of Cu, 1.0 to 1.20 percent of Mn, 0.85 to 1.25 percent of Mg, smaller than or equal to 0.05 percent of Ti, and the remaining amount of Al. The production method comprises the steps of smelting, refining, on-line degassing, grain refinement, filtration, cast rolling, and the like; during the smelting, 50 percent to 60 percent of electrolytic aluminum liquid and the rest of aluminum alloy waste materials are mixed and smelted; the compositions except Mg are added to the mixture; and after the steps of powder injection refining, slag skimming, magnesium ingot adding, furnace turning-down and refining are conducted, the stock of the strip is cast-rolled. A product of the production method has even and steady chemical compositions and can satisfy the mechanical property requirements of subsequent rolling, so that the yield of subsequent rolling is increased; by using the aluminum alloy waste materials as raw materials, the raw materials are saved; by directly adding the electrolytic aluminum liquid, gas loss in the melting process is reduced, and burning loss in the waste material melting process can also be decreased; and by using a cast-rolling manner to replace a hot-rolling manner, the process is simplified and the production cost is greatly reduced.

Owner:沁阳市鼎建建设发展有限公司

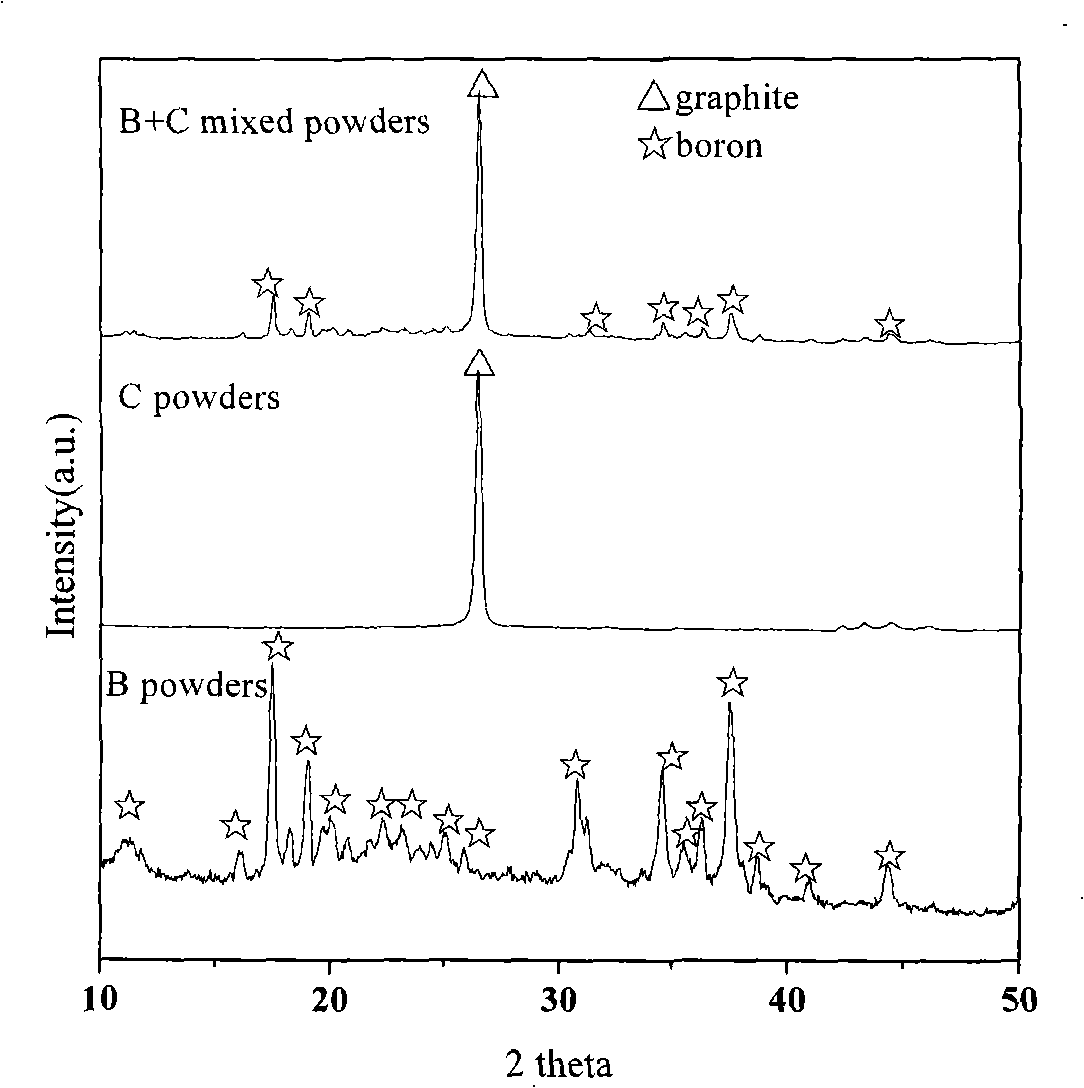

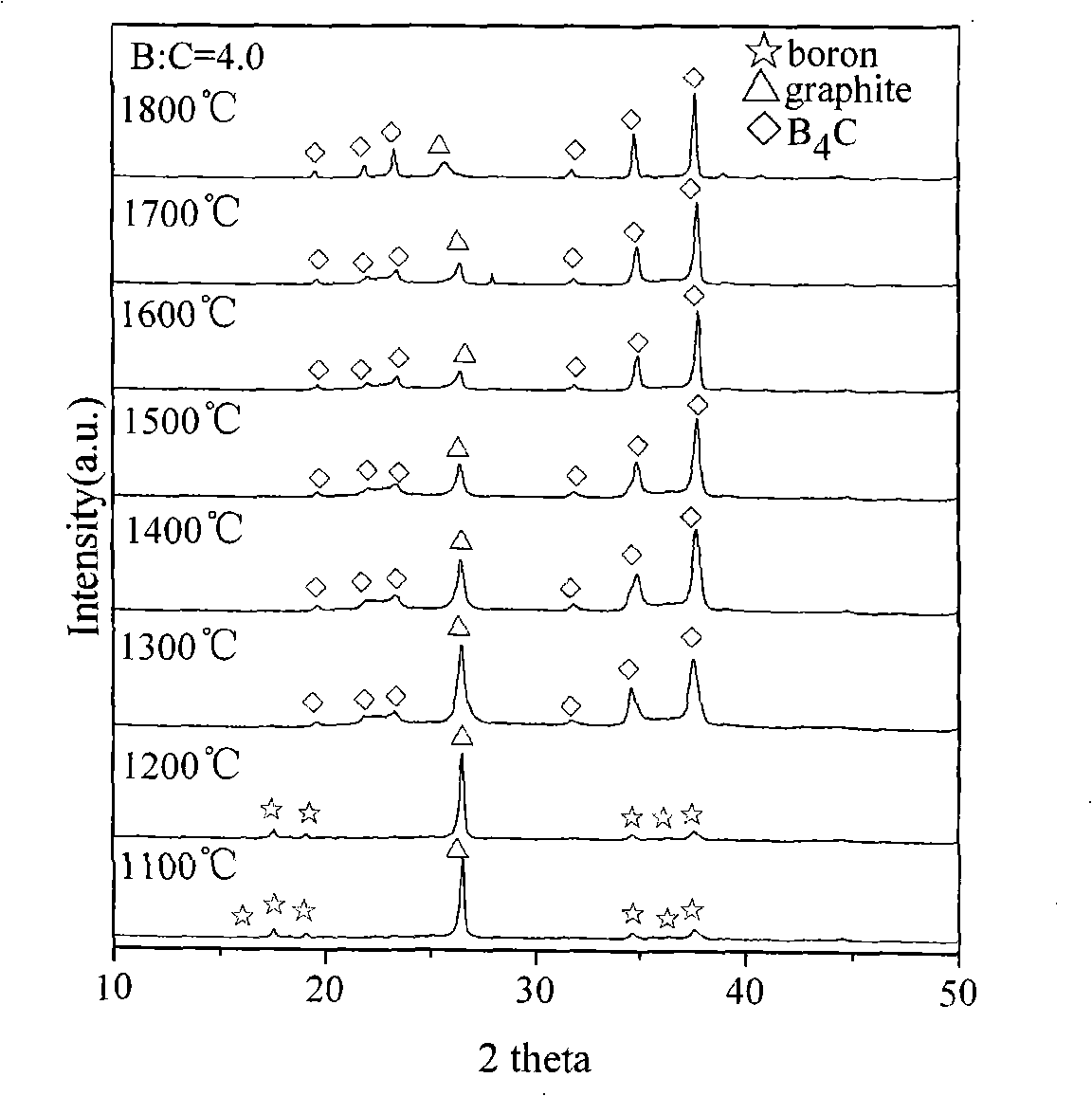

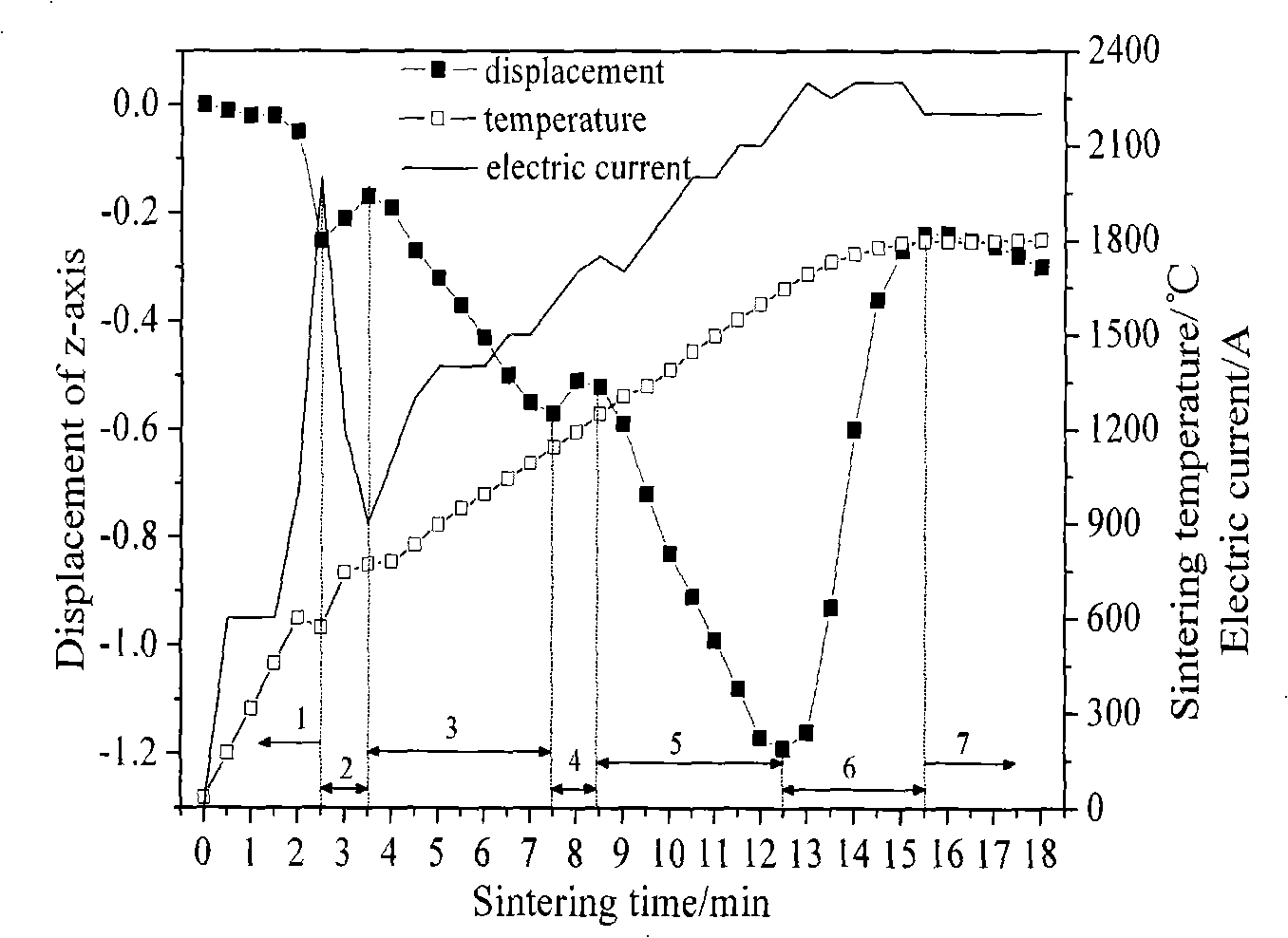

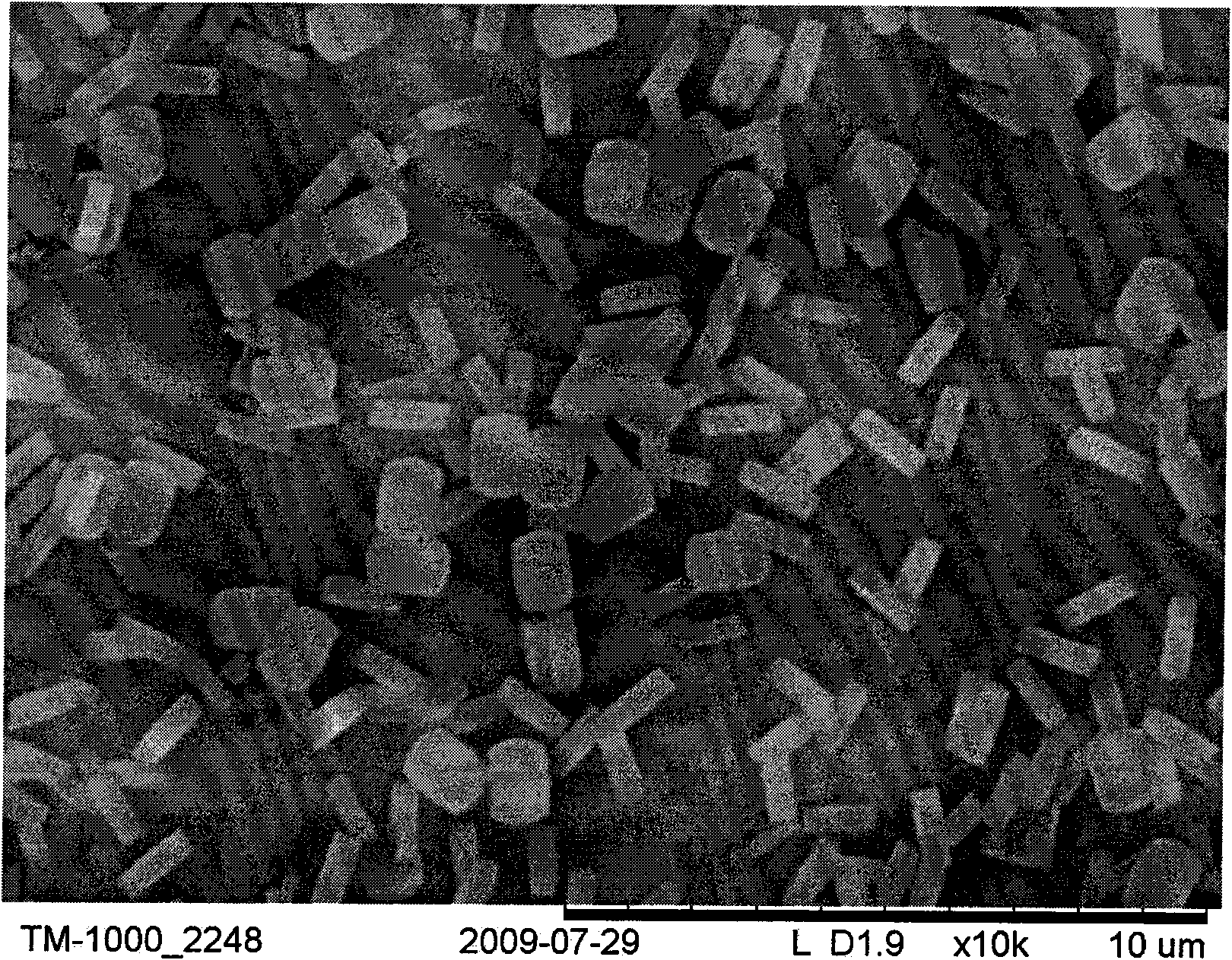

Method for preparing boron carbide ceramic

The present invention relates to a preparation method of boron carbide ceramics. In particular, the preparation method comprises the following steps: first, boron powder and carbon powder are weighed and mixed with the molar ratio of boron and carbon equal to 0.5 to 22.5; secondly, the powder prepared in the first step is arranged in a die and transmitted to discharging plasma sintering equipment for sintering, and the temperature is raised to be between 1300 and 2200 DEG C under the vacuum conditions; thirdly, the die is taken out from the discharging plasma sintering equipment and cooled to be at the room temperature; then the die is drawn away and thus the final product is prepared. In the preparation method, the direct synthesis and densification of boron carbide are completed in one step; the powder is sintered under the vacuum conditions; and the prepared boron carbide ceramics has the advantages of high purity, variety in the ratio of boron and carbon, and high hardness.

Owner:WUHAN UNIV OF TECH

Method for producing the yellow pigment of ferric oxide from ferrous sulphate of byproduct abolished by titanium white

InactiveCN1415666AHigh recovery rateAchieve the purpose of separationPigmenting treatmentFerric oxide yellowTitanium oxide

A process for preparing iron oxide yield pigment from ferrous sulfate as the by-product of titanium oxide includes such steps as reducing iron scale at 50-70 deg.c, hydrolyzing for 6-10 hr, flocculating, deposition, refining ferrous sulfate, neutralizing with ammonia to generate crystal seeds, and neutralizing with ammonia while oxidizing with air to obtain target product. Its by-product, solution of ammonium sulfate, can be used for preparing composite fertilizer.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

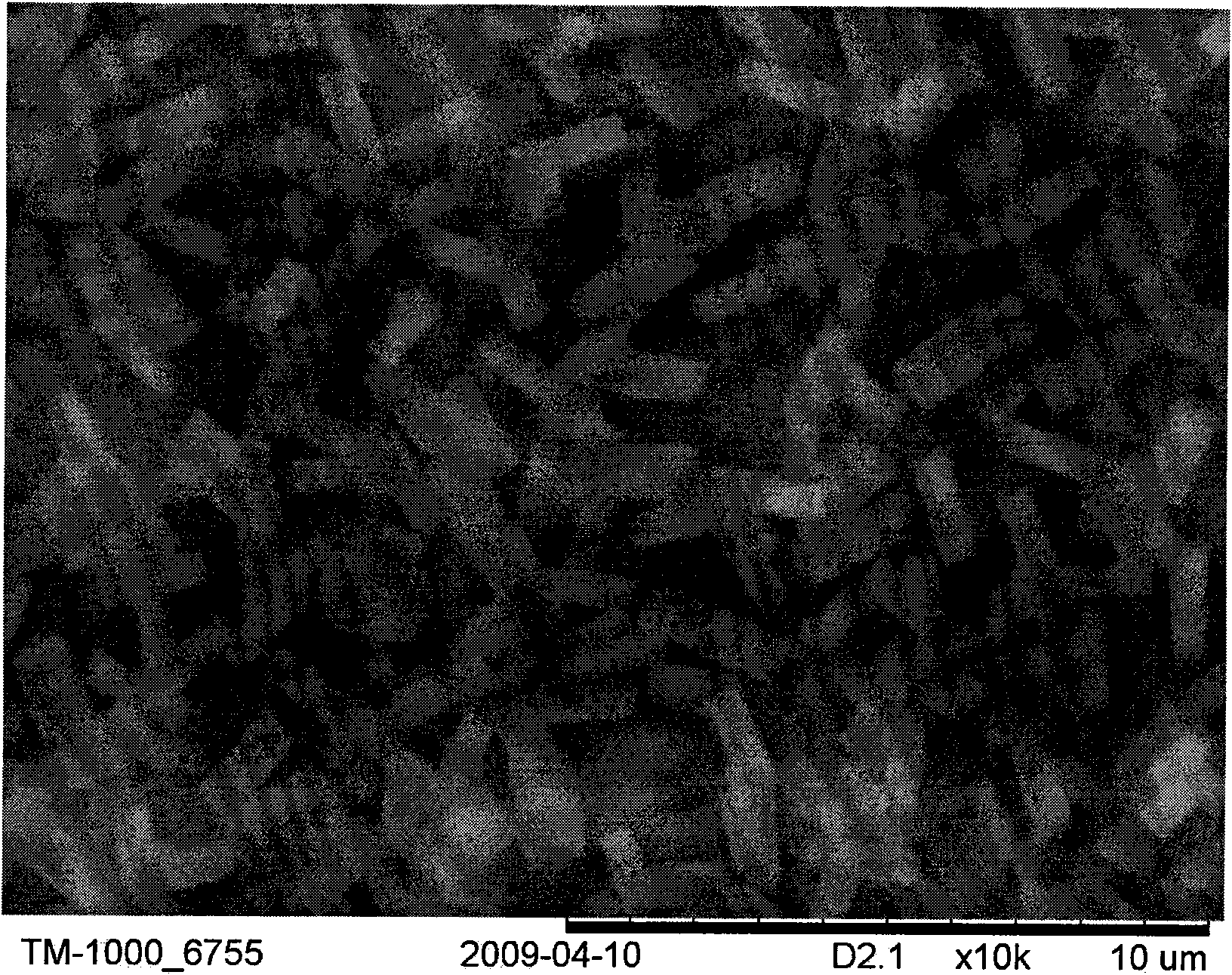

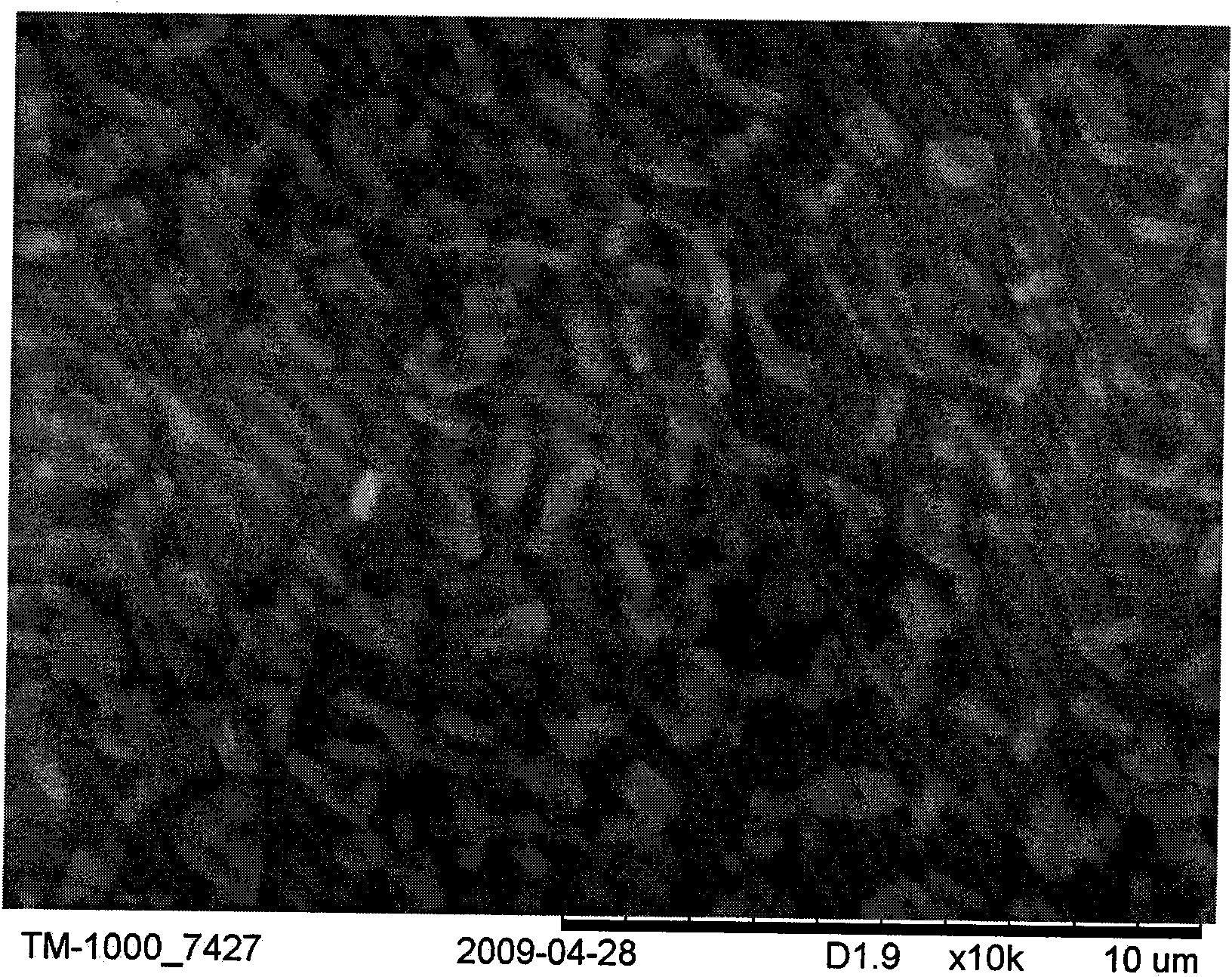

Method for synthesizing oriented MFI type molecular sieve membrane by means of microwave heating

InactiveCN101643218AUniform grainShort synthesis timeCrystalline aluminosilicate zeolitesMolecular sieveTime range

The invention discloses a method for synthesizing an oriented MFI type molecular sieve membrane by means of microwave heating. The method comprises the following steps of: 1) preparation of molecularsieve synthetic fluid, wherein the synthetic fluid consists of tetraethoxysilane, tetrapropylammonium hydroxide and water, which follow a mol ratio of 1:0.2-0.6:100-250; 2) stirring the synthetic fluid at the room temperature for 1-4 h, adding support body, carrying out aging for a time ranging from 10 min to 50 h in the condition of the room temperature or heating, or carrying out aging first fora time ranging from 10 min to 50 h in the condition of the room temperature or heating and then adding the support body, and synthesizing a molecular sieve membrane by means of microwave heating, wherein the synthesis temperature is 100-200 DEG C and the synthesis time is 10-30 min; and 3) washing and drying and finally obtaining the oriented MFI type molecular sieve membrane from the support body. The MFI type molecular sieve membrane synthesized with the method is b-axis oriented and has good synthetic repetition. The microwave heating greatly accelerates the nucleation and crystallizationspeed of the molecular sieve, remarkably reduces the molecular sieve membrane synthesis time and the energy consumption and is helpful for cost reduction.

Owner:ZHEJIANG UNIV

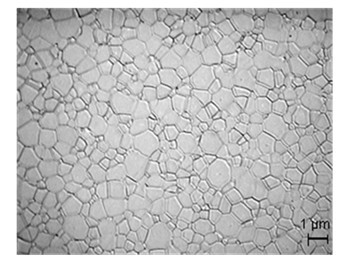

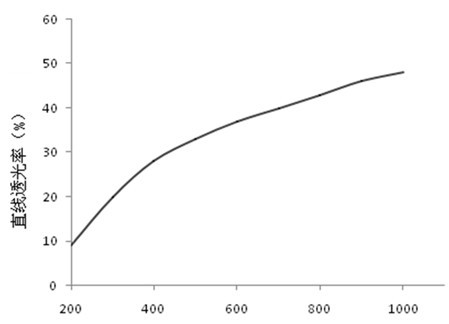

Fine-crystal transparent alumina ceramic material and preparation method

InactiveCN102627450ABreak through the phenomenon that the bending strength is less than 300MPaUniform grainHydrogen atmosphereMicrometer

The invention discloses a fine-crystal transparent alumina ceramic material and a preparation method. A formula of the material comprises the following constituents by weight percentage: 99.6-99.98% of Al2O3 and 0.02-0.4% of MgO, ZrO2 and La2O3. The particle size of the ceramic is at the range of 0.8 micrometer to 1.5 micrometer, and the linear light transmission at the 640-nanometer position is larger than 37%. High-purity alumina powder is used to be formed by cold isostatic compaction and sintered at hydrogen atmosphere, and temperature rises to 1,300 DEG C, then decreases to 1,150 DEG C and is preserved. By means of the method, the fine-crystal transparent alumina ceramic material is high in compactness, excellent in mechanical property, high linear transmission and suitable for ceramic metal halide lamp tubes, key components of semiconductor devices, high temperature observation and the like.

Owner:SUZHOU KEY MATERIALS TECH

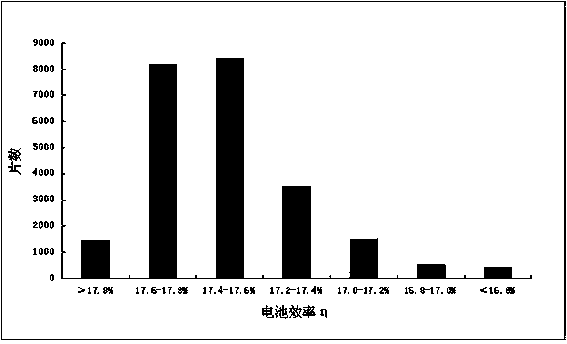

Preparation method of polycrystalline silicon

ActiveCN103469293AEasy to operateGuaranteed not to be completely meltedPolycrystalline material growthFrom frozen solutionsThermal insulationPhysical chemistry

The invention discloses a preparation method of polycrystalline silicon. The preparation method of the polycrystalline silicon comprises the following steps: firstly carrying out pre-treatment on a quartz crucible, then paving a crystalline silicon chip material layer at the bottom of the quartz crucible, then placing silicon and mother alloy into the quartz crucible, charging, vacuumizing, and heating to melt silicon; after melting is finished, controlling the temperature of a heater to be 1540-1570 DEG C, lifting a thermal insulation cage until aperture a is 5-20mm, and controlling temperature TC2 to be no more than 1425 DEG C until broken polycrystals at the bottom are just molten, performing a temperature-fall period, and slowly opening the thermal insulation cage while slowly cooling in gradient; finally growing crystals, so that the polycrystalline silicon containing massive twin crystals is formed. A polycrystalline silicon slice prepared by adopting the preparation method is uniform in grain size, the battery efficiency is 0.2-0.3% higher than that of common polycrystalline silicon, the average battery efficiency of the whole silicon slice is more than 17.5%, and ratio of the silicon slice with the efficiency more than 17.4% is more than 65.0%.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

Preparation method of tubular niobium target for magnetron sputtering

The invention discloses a preparation method of a tubular niobium target for magnetron sputtering. The method comprises the following steps of: forging a niobium casting ingot into a cylindrical niobium blank; drilling a through hole at the center of the cylindrical niobium blank to obtain a tubular niobium blank, and then uniformly coating anti-oxidization coatings on the surfaces of the inner and outer walls of the tubular niobium blank; extruding the tubular niobium blank coated with the anti-oxidization coatings to obtain a niobium tube blank; sequentially carrying out sand spraying, acid washing and machining on the niobium tube blank to obtain a semi-finished product of the tubular niobium target; and carrying out vacuum heat treatment on the semi-finished product of the tubular niobium target to obtain the tubular niobium target for the magnetron sputtering. The tubular niobium target prepared by the method disclosed by the invention has a good structure property; and crystal grains along the wall thickness direction of the target are uniform and can reach the grade of 4-6, the size of the crystal grains is not more than 100 mu m, and the re-crystallization rate of the grains is not less than 90%, so that the uniform consistency of a coating film in the magnetron sputtering is guaranteed.

Owner:西安方科新材料科技有限公司

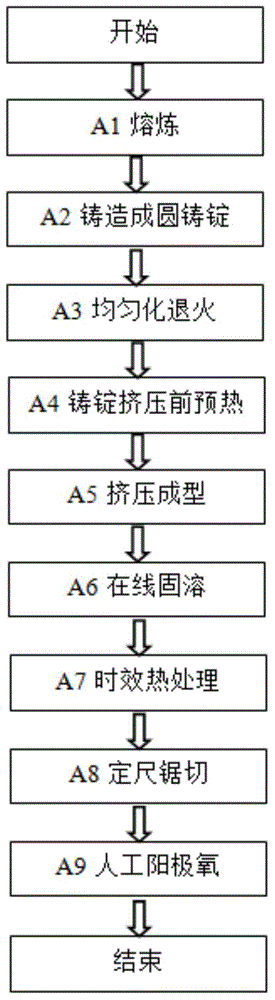

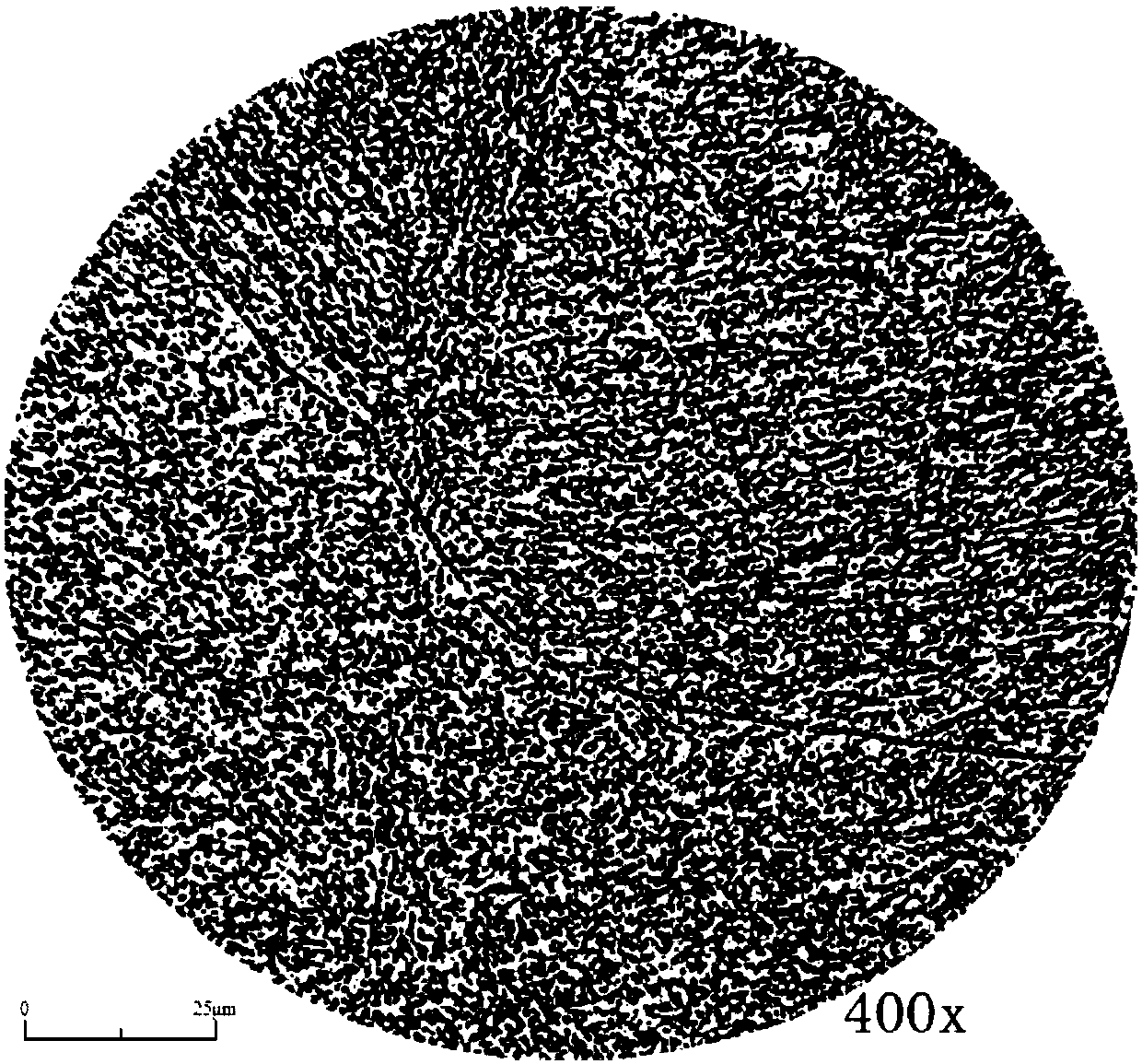

7XXX aluminum alloy

The invention relates to 7XXX aluminum alloy. The 7XXX aluminum alloy comprises the following components by weight percent: 6.6 to 7.6 percent of zinc, 1.25 to 1.80 percent of magnesium, 0.18 to 0.44 percent of copper, less than or equal to 0.06 percent of silicon, less than or equal to 0.16 percent of iron, , less than or equal to 0.03 percent of manganese, less than or equal to 0.03 percent of chromium, less than or equal to 0.02 percent of germanium, less than or equal to 0.02 percent of vanadium, less than or equal to 0.03 percent of titanium, less than or equal to 0.02 percent of zirconium, and less than or equal to 0.03 percent of total weight of manganese and chromium, less than or equal to 0.03 percent of each rest impurity element, less than or equal to 0.10 percent of total weight of rest impurity elements, and the balance of aluminum. On the basis of experiment, the material strength is improved by re-designing the mass fraction and a ratio of Zn to Mg; by re-designing the mass fraction of Cu, the alloy has excellent corrosion resistance, and the oxidation different color problem of silver white can be solved. By strictly controlling the weight percent of the impurity elements such as Mn and Cr, the crystal grains of the alloy material are uniform. Compared with the existing disclosed Al-Zn alloy system, the alloy has better comprehensive performance, and an oxidized membrane formed by oxidizing the material by virtue of anode is more delicate and beautiful.

Owner:TAISHAN CITY KAM KIU ALUMINUM EXTRUSION

Manufacturing technology of hot work die steel forge piece

ActiveCN107686878AReduce contentOligodendrite segregationMetal-working apparatusSolution treatmentManufacturing technology

The invention relates to a manufacturing technology of a hot work die steel forge piece. The manufacturing technology comprises the steps including forging, high-temperature normalization, high-temperature tempering, ultrafine solution treatment, spheroidizing and sampling inspection. Through the procedures and related heat treatment, chemical components in the hot work die steel forge piece tendto be consistent, the structure inheritance is effectively cut off, and accordingly the purposes of refining grains and homogenizing structures are achieved. After spheroidizing, a spherical pearlitewith fine-particle-shaped carbide evenly distributed on a ferrite base body is obtained. An excellent organization structure is provided for final heat treatment.

Owner:山西同航特钢有限公司

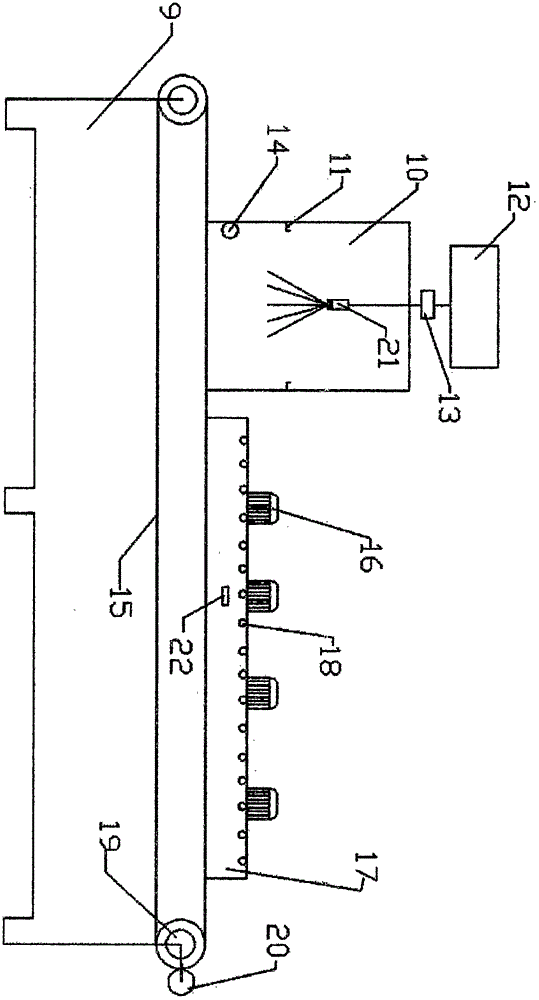

Method for directly casting and rolling aluminum plate base for PS plate with electrolytic aluminium liquid

ActiveCN101318288AQuality assuranceQuality improvementTemperature control deviceMetal rolling arrangementsSocial benefitsFiltration

The invention relates to a method for cast-rolling to produce aluminum substrates used in PS plates directly by electrolytic aluminum liquid; the main steps are as follows: electrolyzing the aluminum liquid under the high temperature, smelter hearth, adjusting element compositions, refining, conducting the furnace, adjusting the temperature to 740 DEG C to 750 DEG C, adding Al-Ti-B refiners to carry out the grain refinement, degassing, filtering, cast-rolling coils of strip, cool rolling, stretch bending and straightening, and producing finished products; various steps of the invention are synthesized to optimize technique parameters; the prepared aluminum substrates used in the PS plates is high in tensile strength and elongation, and the quality of the prepared aluminum substrates are better than that of similar products, thus omitting the remelting process when aluminum ingots are used, saving resources, reducing the production cost and increasing the economic and social benefits.

Owner:登电集团铝加工有限公司

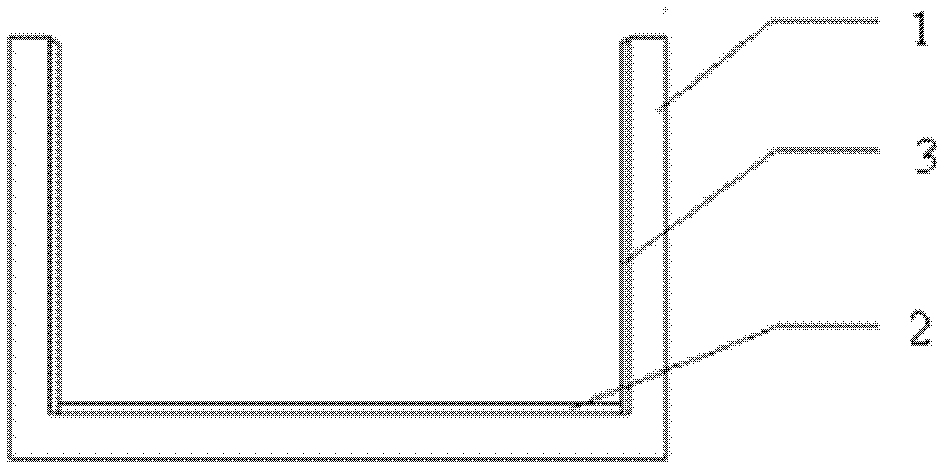

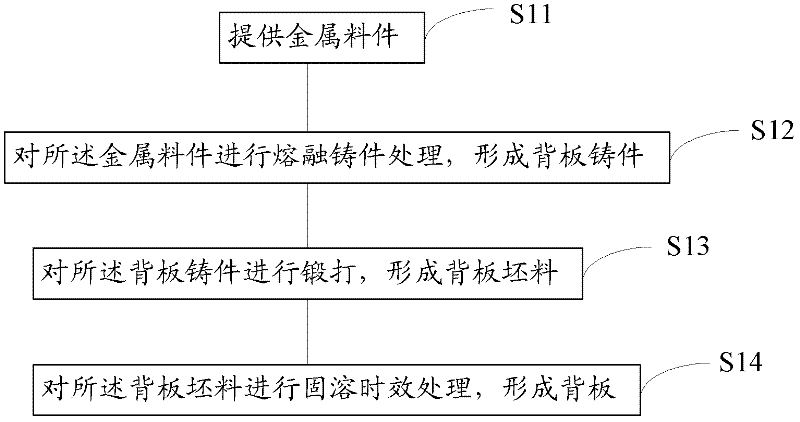

Backboard fabricating method

ActiveCN102534518AUniform grain refinementAvoid distortionVacuum evaporation coatingSputtering coatingSiliconDistortion

The invention discloses a backboard fabricating method, comprising the following steps of: providing a backboard casting piece; forging the backboard casting piece at a temperature of 800-1000 DEG C so as to form a backboard blank; and processing the backboard blank so as to form a backboard. According to the backboard fabricating method disclosed by the invention, the backboard with a finer and more uniform inner organization structure can be obtained, so that the backboard is prevented from distortion and deformation. On one hand, a deviation between each part of a target and a silicon wafer substrate is reduced, and the quality of a coating film is improved; and on the other hand, the service life of a sputtering target assembly is prolonged.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

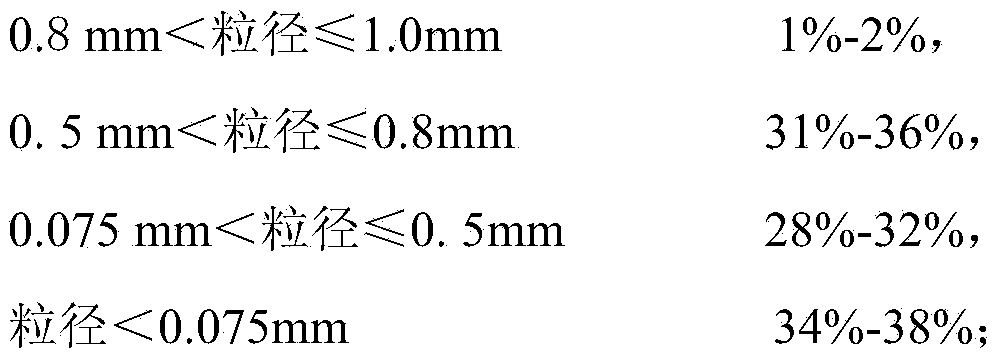

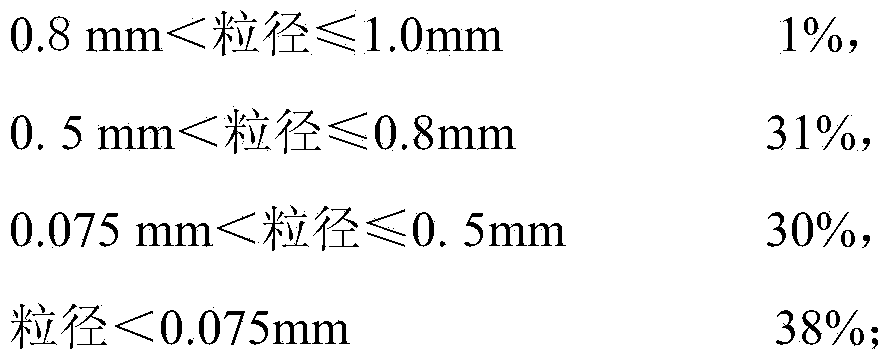

Graphite material for continuous casting mold and preparation method thereof

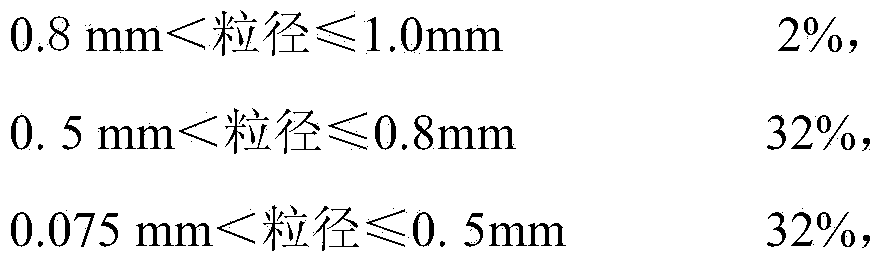

The invention relates to a preparation method of a graphite material for a continuous casting mold. The preparation method comprises the following steps: crushing, screening and burdening calcined coke, adding mid-temperature pitch, and carrying out mixing, molding, primary roasting, primary dipping, secondary roasting, secondary dipping, third roasting and graphitizing to obtain the product, wherein the particle size range and the content of the calcined coke are that the calcined coke with the particle size which is smaller than or equal to 1.0mm and greater than 0.8mm accounts for 1-2%; the calcined coke with the particle size which is smaller than or equal to 0.8mm and greater than 0.5mm accounts for 31-36%; the calcined coke with the particle size which is greater than 0.075mm and smaller than or equal to 0.5mm accounts for 28-32%; the calcined coke with the particle size which is smaller than 0.075mm accounts for 34-38%; the mixing is divided into dry blending and wet blending; the wet blending comprises the following processes: firstly heating the mid-temperature pitch to 180-230 DEG C, carrying out heat preservation and stirring for 30-60 minutes, and then adding the mid-temperature pitch to aggregate twice to knead, wherein the kneading temperature is 140-150 DEG C.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

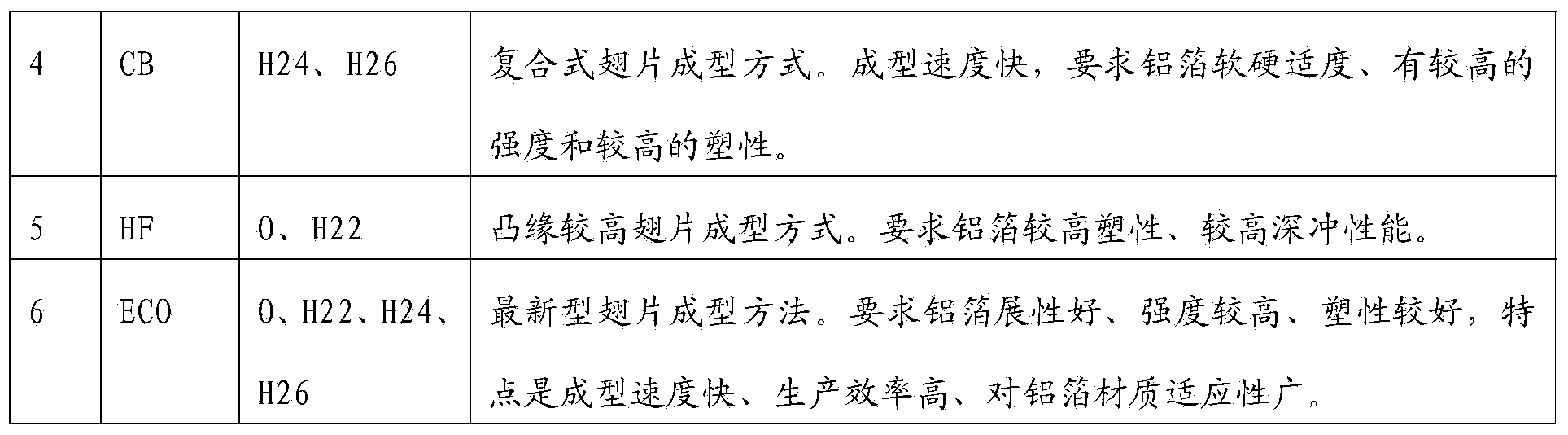

Novel aluminum alloy and method for manufacturing aluminum foil with high deep-drawing performance by continuous cast-rolling

InactiveCN104060132AIncreased recrystallization temperature rangeHigh strengthMaterials processingPre treatment

The invention relates to the field of processing and manufacturing of metal materials and particularly relates to a novel aluminum alloy and a method for manufacturing an aluminum foil with high deep-drawing performance by continuous cast-rolling. The novel aluminum alloy contains the following components in percentage by mass: 0.1-0.3% of Si, 1.0-1.5% of Fe, 0.3-0.6% of Mn, not greater than 0.05% of Ti and the balance of Al. According to the novel aluminum alloy and the method for manufacturing the aluminum foil with high deep-drawing performance by continuous cast-rolling, which are provided by the invention, cast-rolled aluminum coils are pre-processed by increasing the content of Mn and Fe in a blank and optimizing a continuous cast-rolling process, so that defects that the aluminum foil produced by the cast-rolling blank is low in plasticity and insufficient in deep-drawing performances are overcome; the produced aluminum foil can achieve and can even exceed performances of the hot-rolled blank aluminum foil, and can solve a universality problem of the fin aluminum foil and a thinning problem of the deep-drawing aluminum foil very well.

Owner:山东邹平长城能源科技有限公司

Cold-rolled aluminum alloy sheet for bottle can with excellent neck part formability and process for producing the cold-rolled aluminum alloy sheet

Owner:KOBE STEEL LTD

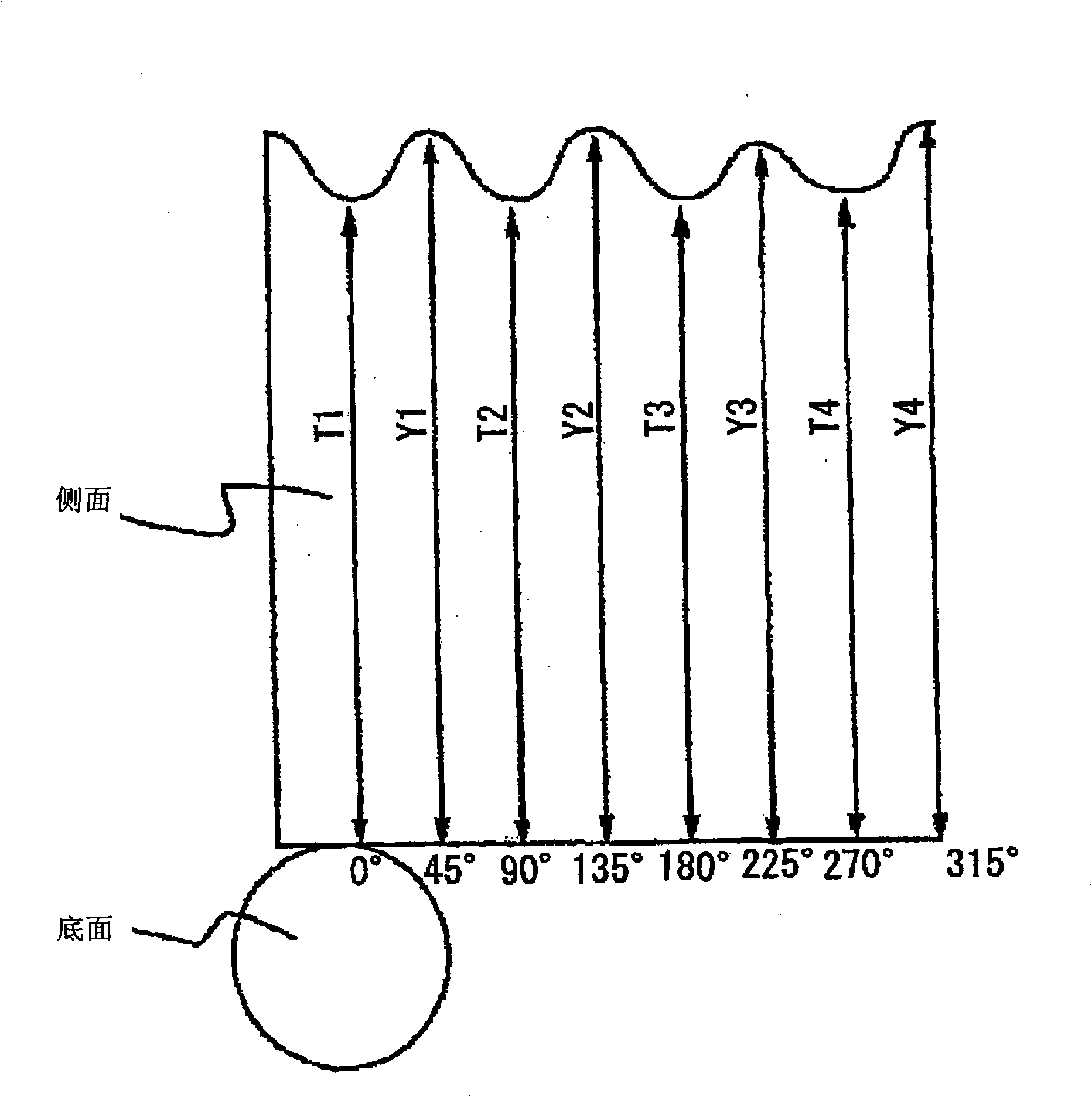

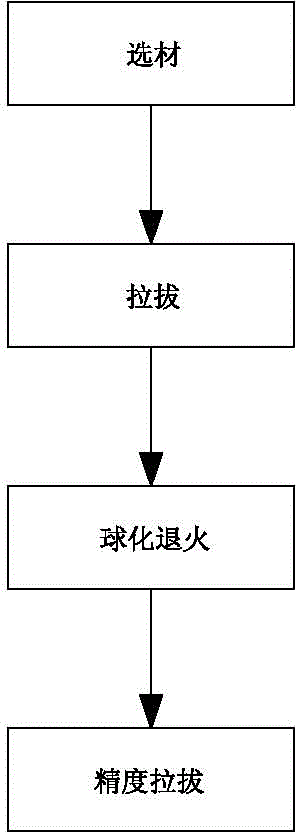

Process for producing high-nodularity fastener wire rod

The invention discloses a process for producing a high-nodularity fastener wire rod. The process comprises the following steps: (1) selecting materials, namely selecting a steel wire with the model of SWRCH22A; (2) drawing, namely drawing the steel wire by adopting a drawing machine, wherein the compression rate is more than or equal to 50 percent; (3) performing spheroidizing annealing, namely lifting the steel wire into an atmosphere protection furnace, adding a protective atmosphere into the atmosphere protection furnace, heating the steel wire to a temperature which is 20-30 DEG C higher than the austenite transformation temperature, preserving the heat for 4-6 hours, slowly cooling to a temperature which is 20-30 DEG C lower than the austenite transformation temperature at a rate of 10 DEG C per hour, preserving the heat for 3-4 hours, and performing furnace cooling until the product is discharged out of the furnace; and (4) performing precision drawing, namely drawing the steel wire again by adopting the drawing machine, wherein the compression rate is less than or equal to 10 percent. The treated steel wire has the grain size of more than or equal to 10 grades, the grains are uniform, the nodulizing grade is more than or equal to 5, the nodulizing rate is high, the pearlite is uniform in distribution, and the wire rod does not have abnormal tissues, has high plastic deformation capacity and is suitable for subsequent plastic forming, and the wire rod with excellent size and surface is obtained.

Owner:DONGGUAN KELEE STEEL WIRE

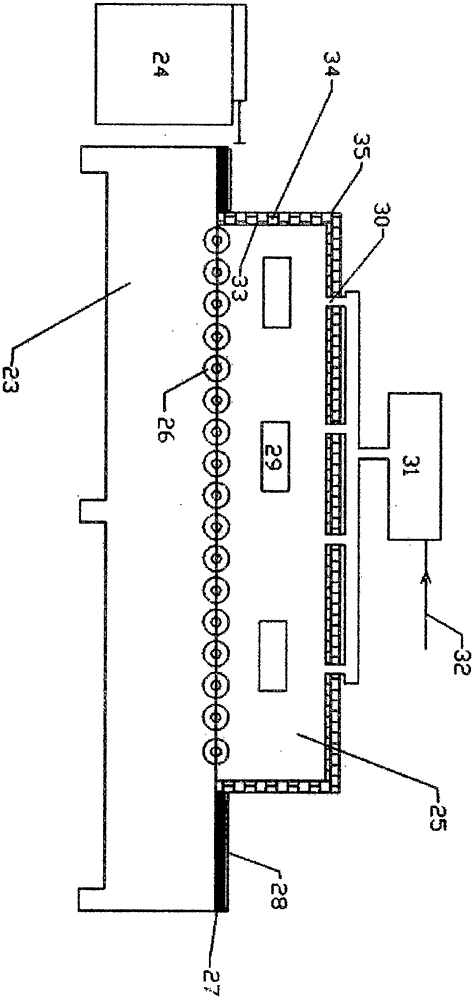

High-strength ceramic substrate and preparation method and production line thereof

InactiveCN105881700AHigh strengthHigh mechanical strengthCeramic shaping plantsProduction linePlasticizer

The invention discloses a high-strength ceramic substrate. The high-strength ceramic substrate is composed of ceramic powder, binders, dispersing agents, plasticizers and solvents, wherein the weight ratio of the ceramic powder to the binders to the dispersing agents to the plasticizers and to the solvents is 1 to 0.08-0.15 to 0.01-0.03 to 0.03-0.06 to 0.5-0.8; the ceramic powder is composed of alumina powder and zirconium oxide powder, and the content of the zirconium oxide powder accounts for 3-30% in the ceramic powder by weight. The invention further discloses a preparation method and a production line of the ceramic substrate. The ceramic substrate is excellent in mechanical strength, high in bending strength, good in heat conduction characteristic, high in stability at high temperature and capable of being machined into various complex shapes. The preparation method is simple, the number of processes is small, and the obtained substrate is uniform and compact in structure, high in bending strength, smooth in surface and low in cost. The production line is simple, small in occupied space and suitable for industrial application.

Owner:SINOCERAM TECH (ZHENGZHOU) CO LTD

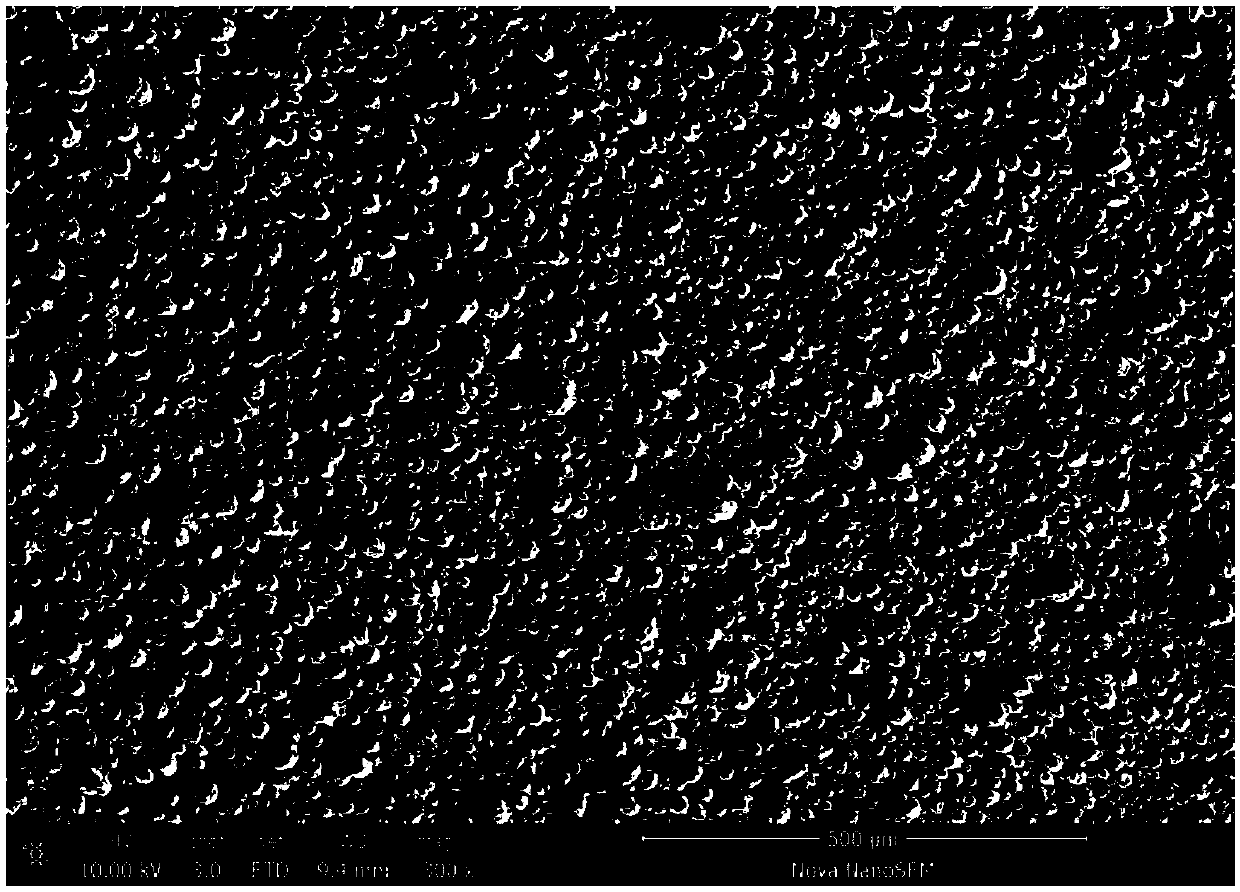

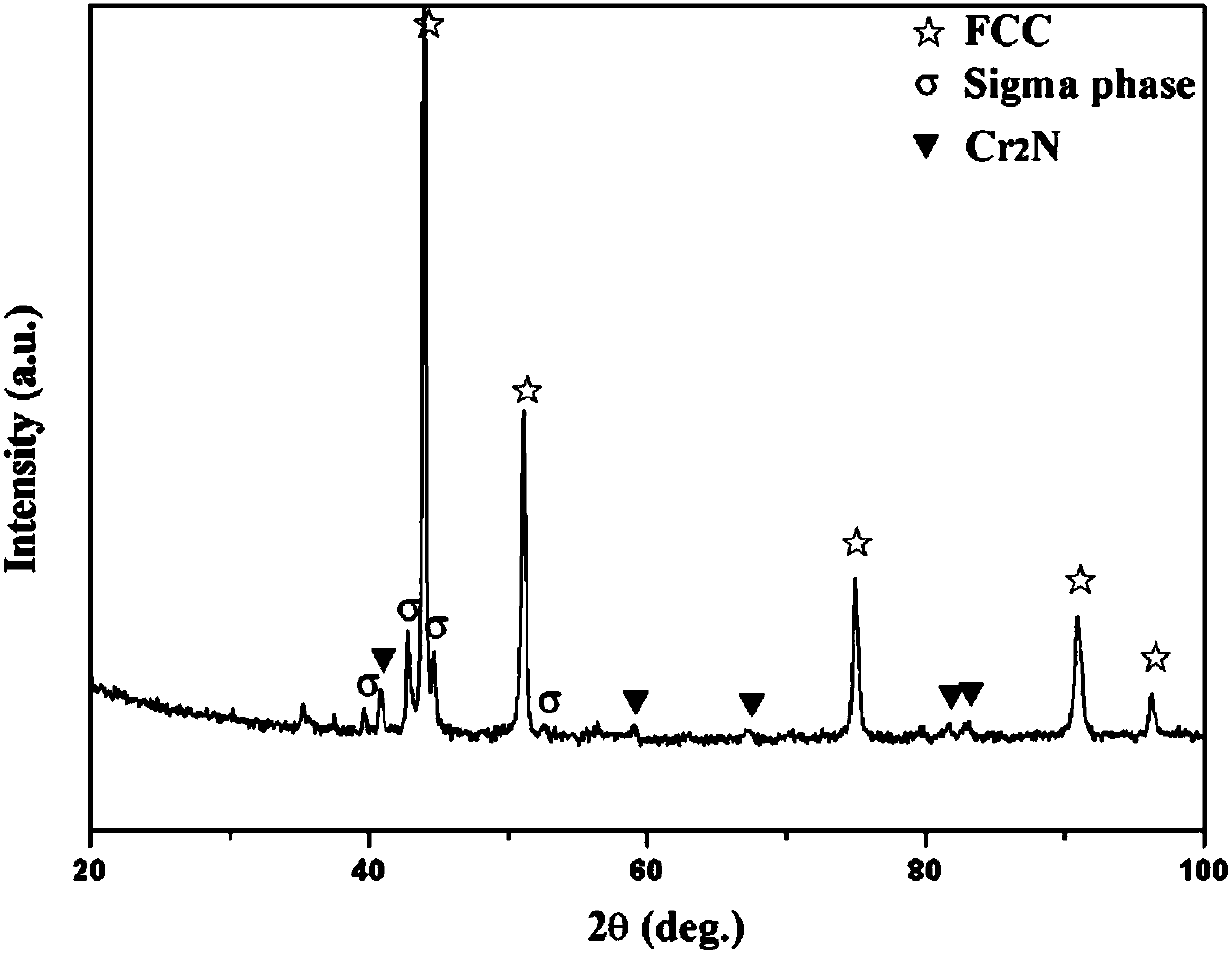

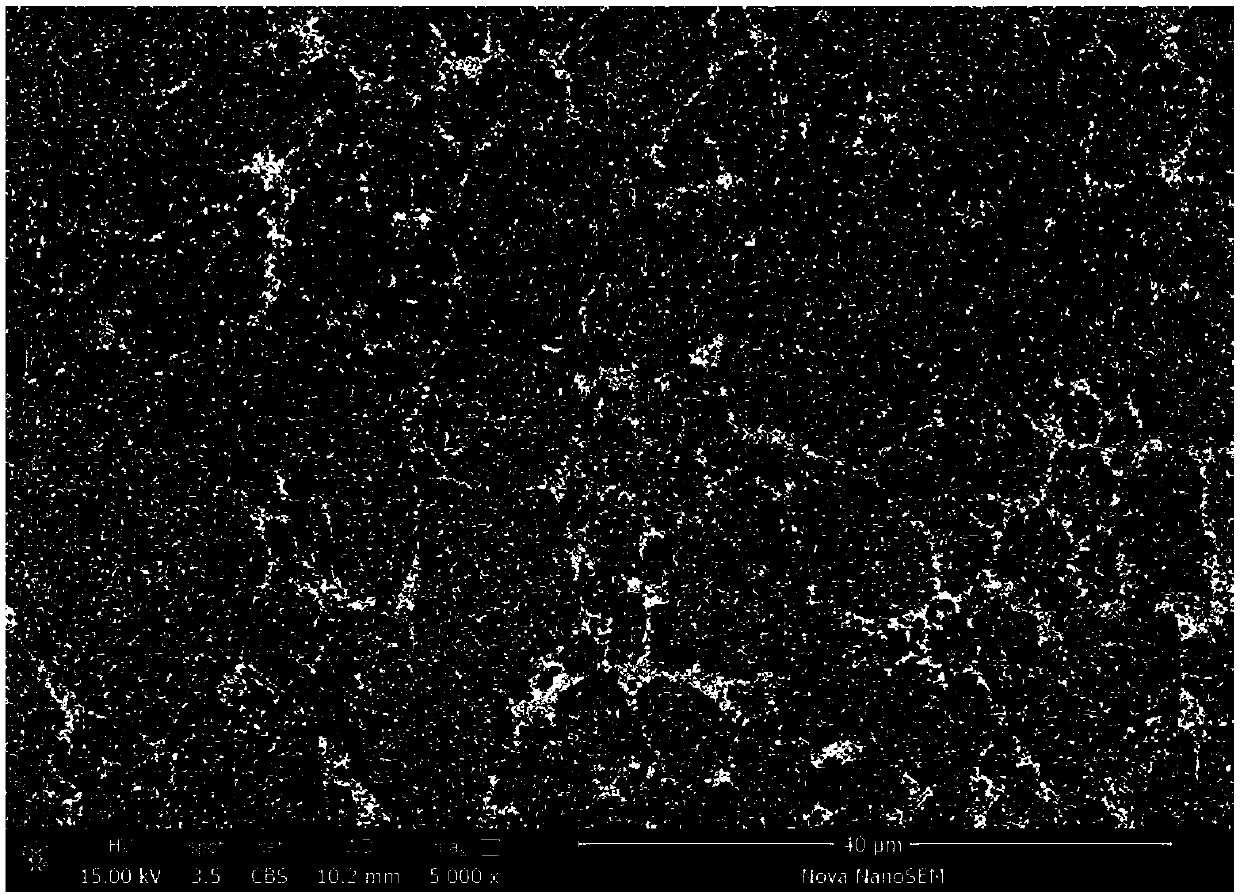

High-entropy alloy and method for preparing high-entropy alloy block through powder metallurgy method

A powder metallurgy high-entropy alloy comprises, by atomic percentage, 5-35% of iron, 5-35% of cobalt, 5-35% of chromium, 5-35% of nickel, 5-35% of manganese and 0.1-5% of nitrogen. A preparation method of the powder metallurgy high-entropy alloy includes the steps that high-entropy alloy powder is prepared, the high-entropy alloy powder is matched, after being mixed uniformly, the high-entropy alloy powder is placed in a ball mill to be subjected to ball milling, the particle shape of the high-entropy alloy powder after being subjected to ball milling is in the shape of a sphere uniform in particle size or a similar sphere, and the particle size range is 20-30 microns; and the high-entropy alloy powder after being subjected to ball milling is placed in a high-strength graphite mold to besubjected to vacuum hot pressing sintering, and finally furnace cooling is performed. The high-entropy alloy uniform in structure and fine in grain is obtained in a powder metallurgy method, and therefore the performance of the alloy is improved.

Owner:FUJIAN UNIV OF TECH

Nickel-based high-temperature alloy bar and preparation method thereof

The invention provides a nickel-based high-temperature alloy bar and a preparation method thereof. The nickel-based high-temperature alloy bar comprises the following steps of S1, vacuum smelting; S2,forging; S3, hot rolling; S4, solid solution treatment; and S5, machining. On a basis of optimizing alloying element components, a relationship between strength and toughness of an alloy is coordinated, so that high strength and high toughness of the nickel-based high-temperature alloy are achieved. By adopting advanced vacuum smelting process and electroslag remelting process, the obtained alloycomponents are uniform in tissue, and a high purity precision alloy ingot is obtained. The alloy bar which is relatively high in thermoplasticity is prepared by way of hot forging, hot rolling and solid solution treatment. Compared with a conventional 718 high-temperature alloy bar, the nickel-based high-temperature alloy bar is more excellent in mechanical property, and hardness and wear resistance of the bar are improved well.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

Zero trans fat acid corn oil and refining process thereof

ActiveCN103005013AShort growing timeUniform grainFatty-oils/fats refiningEdible oils/fatsChemistryChemical synthesis

The invention provides zero trans fat acid corn oil and a refining process thereof. The appropriate processing of corn oil is achieved through the processes of alkali refining, dewaxing, decolorizing, deodorizing and packing of crude corn oil to produce the zero trans fat acid corn oil. The refining process is characterized in that the corn oil is decolorized after being dewaxed, and the decolorized corn oil is deodorized, wherein the dewaxing procedure adopts a corn oil tubular continuous dewaxing technology, and the deodorizing procedure adopts a dual-temperature and dual-tower deodorizing technology. The zero trans fat acid corn oil has the advantages that the trans fat acid content is less than or equal to 0.3%, the Vitamin E content is larger than or equal to 1,000 mg / kg, the phytosterol content is larger than or equal to 10,000 mg / kg, any chemical synthesis antioxidants and nutrition enhancers are not added, and the corn oil is more nutritious and safer and is beneficial to long-term health of people.

Owner:SHANDONG SANXING CORN IND SCI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com