Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

612results about How to "No scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

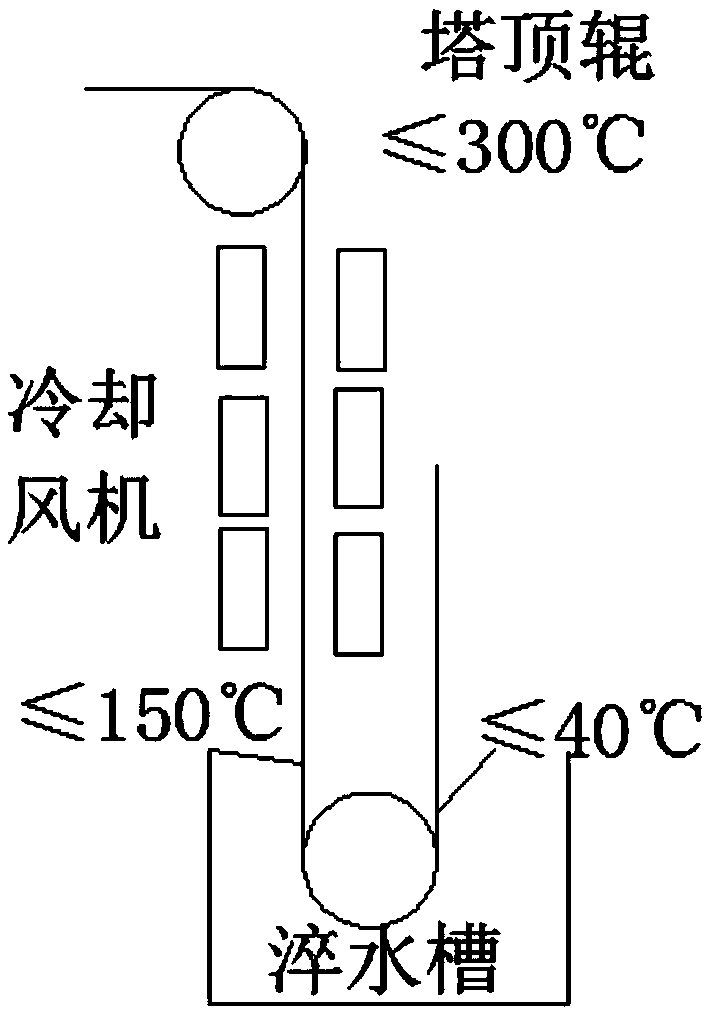

Production process of aluminum alloy section

The invention discloses a production process of an aluminum alloy section. The aluminum alloy section having a smooth surface and high compactness is produced through the process steps such as aluminum alloy cast rod preparation, hot extrusion and molding, on-line quenching, stretch rolling, saw cutting, artificial aging, finished product saw cutting, packaging and the like. By strictly controlling the preheating temperature of the whole process, the aluminum alloy section produced through quenching and stretch rolling has no scratch, no bubble, no extrusion streak and no corrosion spot on the surface, has a smooth and level surface, and is high in ductility, strength and internal compactness.

Owner:HENAN HUILONG ALUMINUM IND

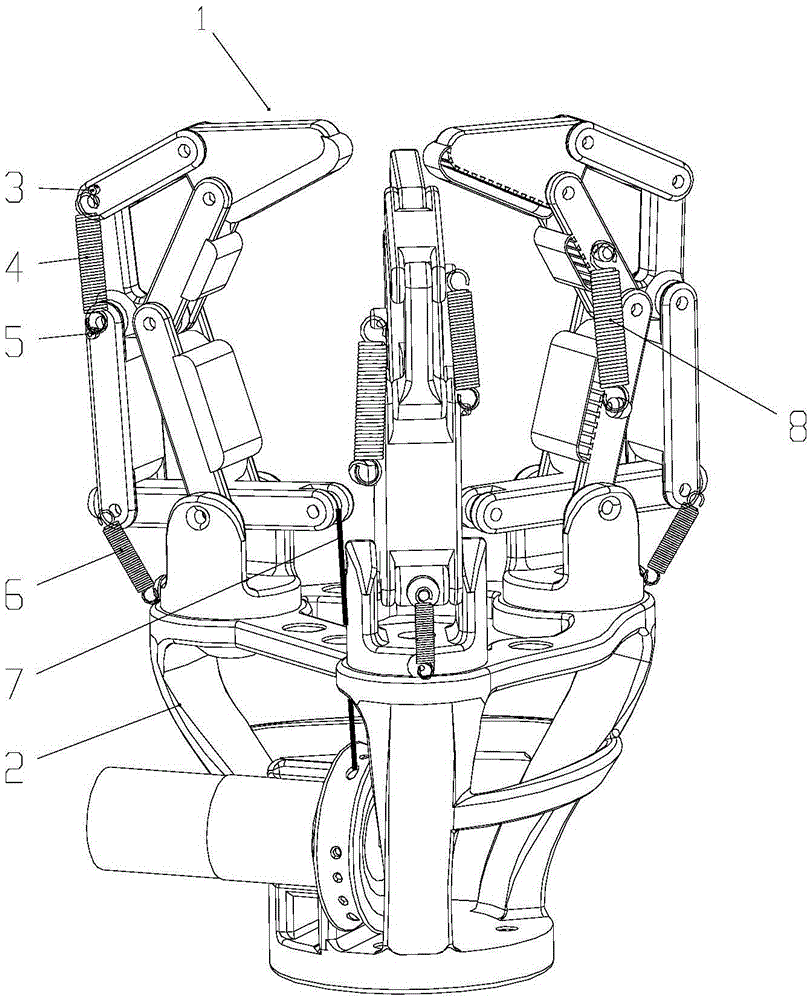

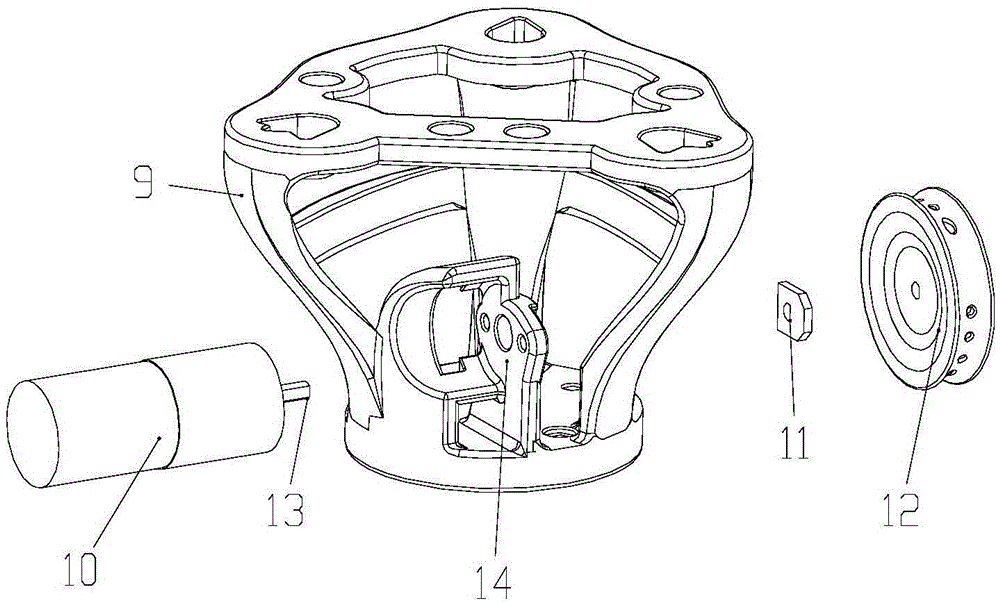

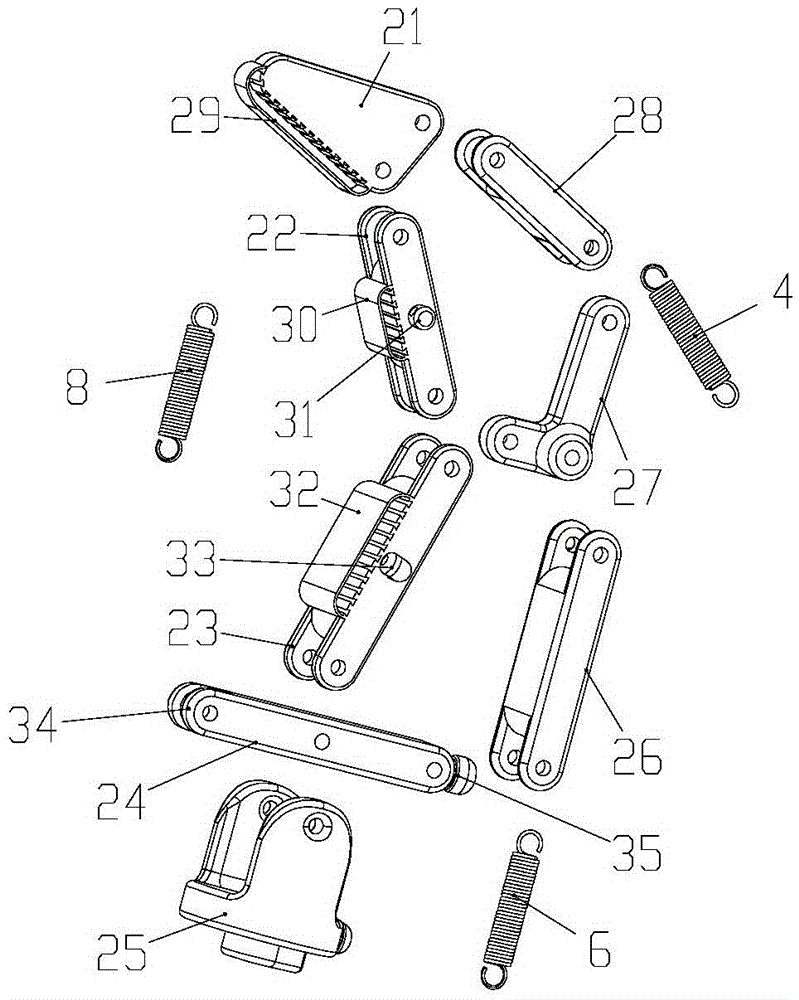

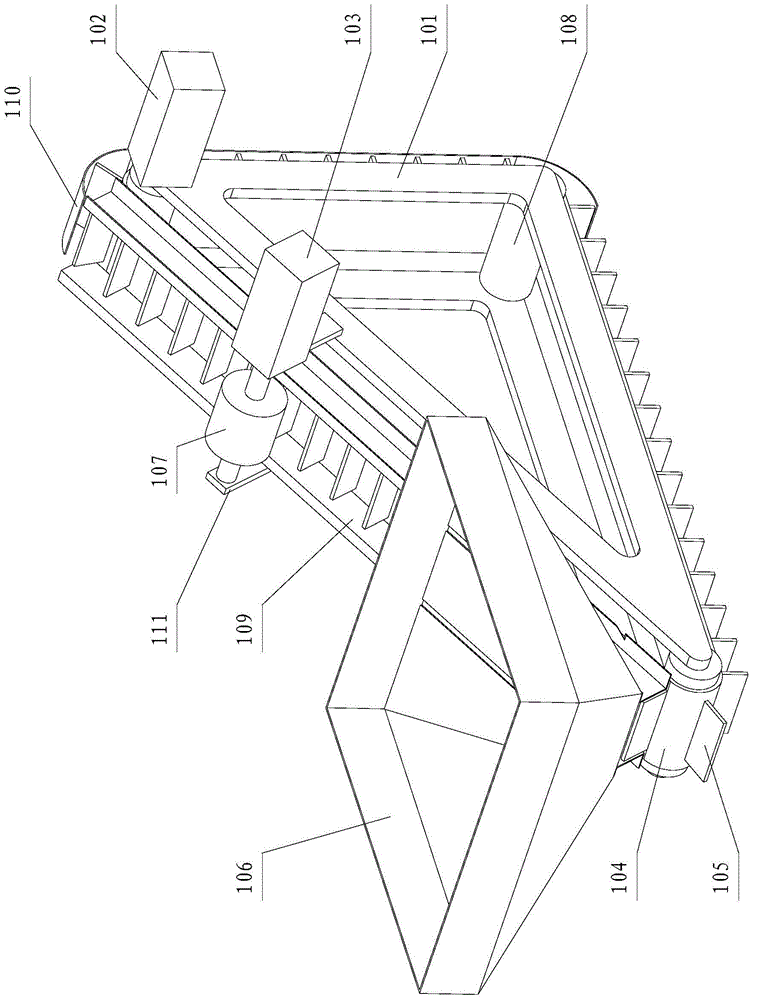

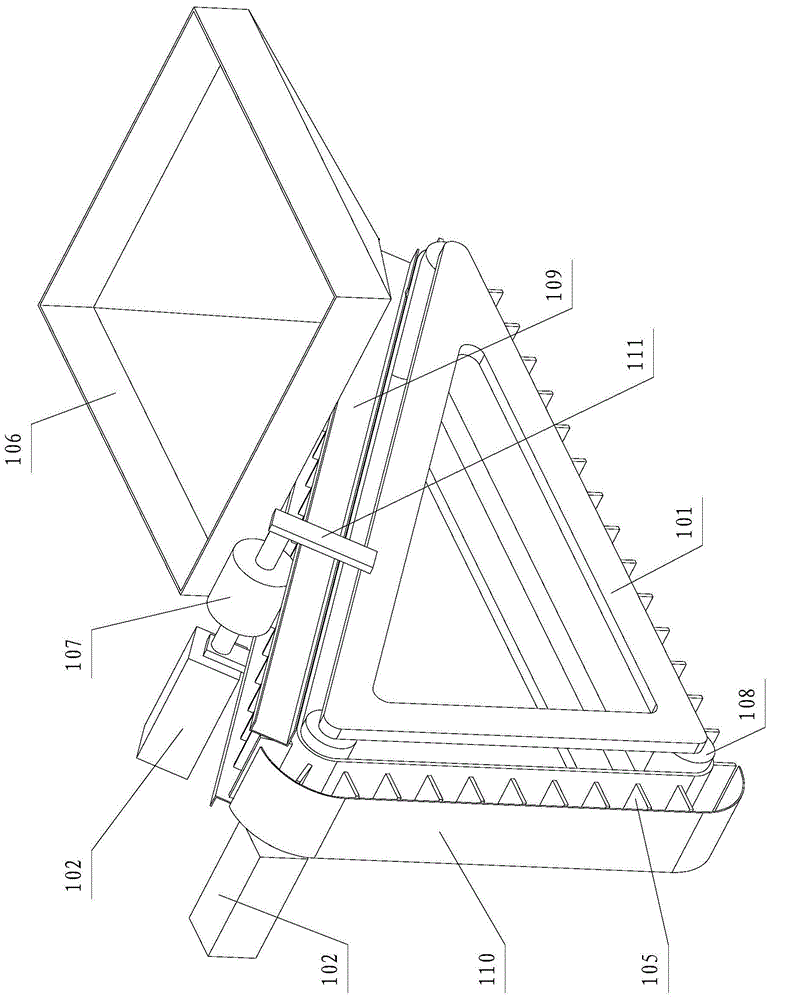

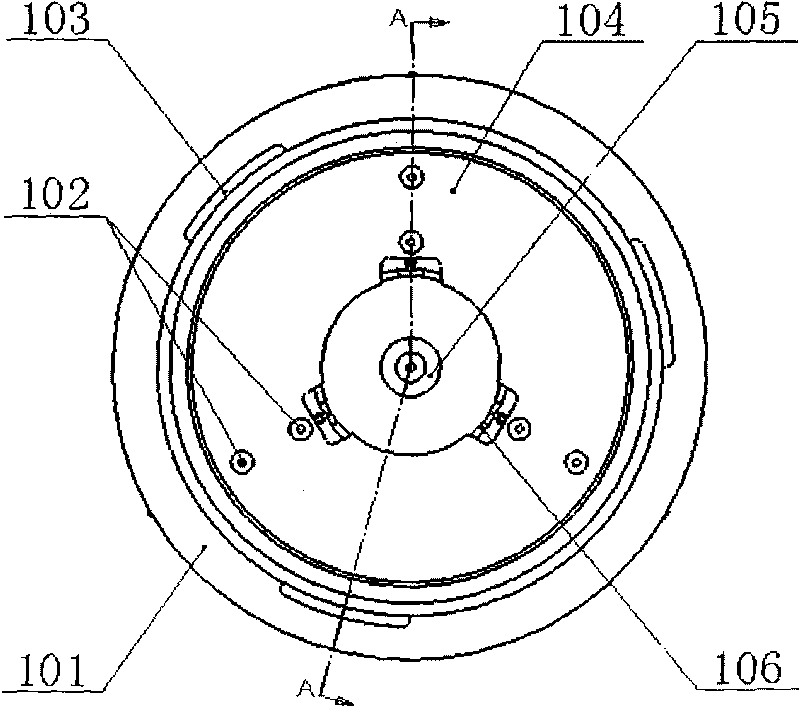

Flexible self-adaption under-actuated robot hand

ActiveCN105563513AGuaranteed crawlGuaranteed crawling workProgramme-controlled manipulatorGripping headsRobot handWinch

The invention relates to a hand, in particular to a flexible self-adaption under-actuated robot hand. The flexible self-adaption under-actuated robot hand comprises fingers and a wrist; the wrist includes a skeleton, a direct-current motor, a potentiometer and a winch; the direct-current motor is fixedly connected to a motor mounting surface of the skeleton; the potentiometer is fixedly connected to a potentiometer mounting surface of the skeleton by penetrating through an output shaft of the motor; the winch is fixedly connected to the tail end of the output shaft of the motor; multiple fingers are provided; and the fingers are embedded in clamping grooves of the skeleton or multiple clamping grooves through convex blocks of rotating bodies. The flexible self-adaption under-actuated robot hand is assembled at the tail end of an industrial robot for assisting mechanical assembly or mechanical manufacturing process and finishing automatic workpiece loading / unloading; and the fingers can flexibly adapt to geometric shapes of products, and realize automatic adjustment according to the geometric shapes of workpieces to realize stable grabbing.

Owner:华粹智能装备有限公司

Aluminum alloy material and production method of cast-rolling stock of decorative strip of same

The invention relates to a 3004 aluminum alloy material and a production method of a cast-rolling stock of a decorative strip of the 3004 aluminum alloy material. The compositions of the aluminum alloy material comprise smaller than or equal to 0.25 percent of Si, 0.20 to 0.60 percent of Fe, 0.10 to 0.15 percent of Cu, 1.0 to 1.20 percent of Mn, 0.85 to 1.25 percent of Mg, smaller than or equal to 0.05 percent of Ti, and the remaining amount of Al. The production method comprises the steps of smelting, refining, on-line degassing, grain refinement, filtration, cast rolling, and the like; during the smelting, 50 percent to 60 percent of electrolytic aluminum liquid and the rest of aluminum alloy waste materials are mixed and smelted; the compositions except Mg are added to the mixture; and after the steps of powder injection refining, slag skimming, magnesium ingot adding, furnace turning-down and refining are conducted, the stock of the strip is cast-rolled. A product of the production method has even and steady chemical compositions and can satisfy the mechanical property requirements of subsequent rolling, so that the yield of subsequent rolling is increased; by using the aluminum alloy waste materials as raw materials, the raw materials are saved; by directly adding the electrolytic aluminum liquid, gas loss in the melting process is reduced, and burning loss in the waste material melting process can also be decreased; and by using a cast-rolling manner to replace a hot-rolling manner, the process is simplified and the production cost is greatly reduced.

Owner:沁阳市鼎建建设发展有限公司

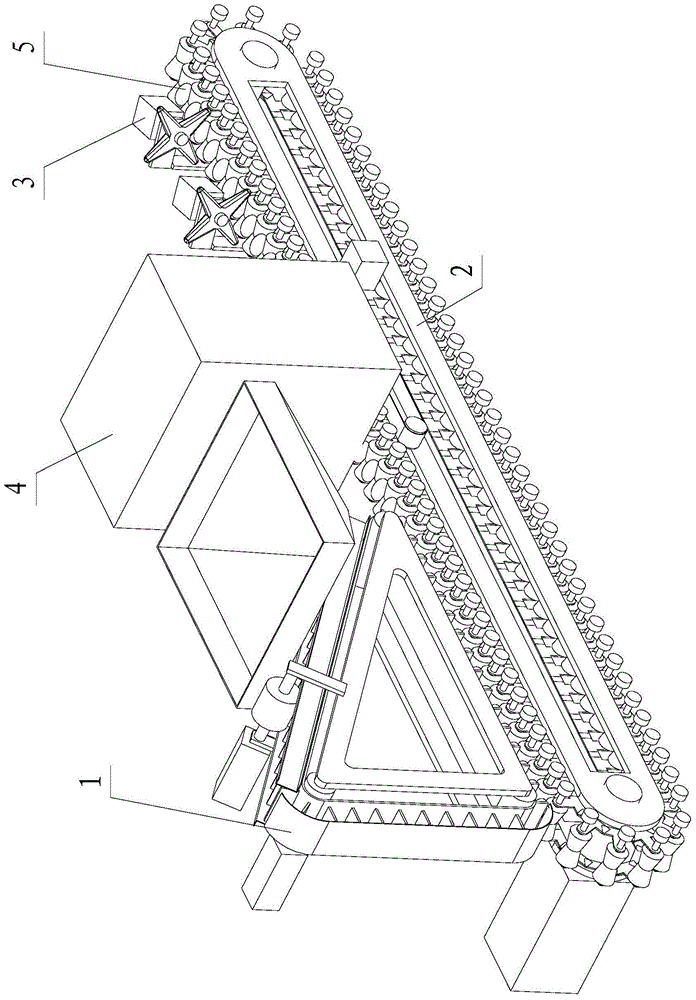

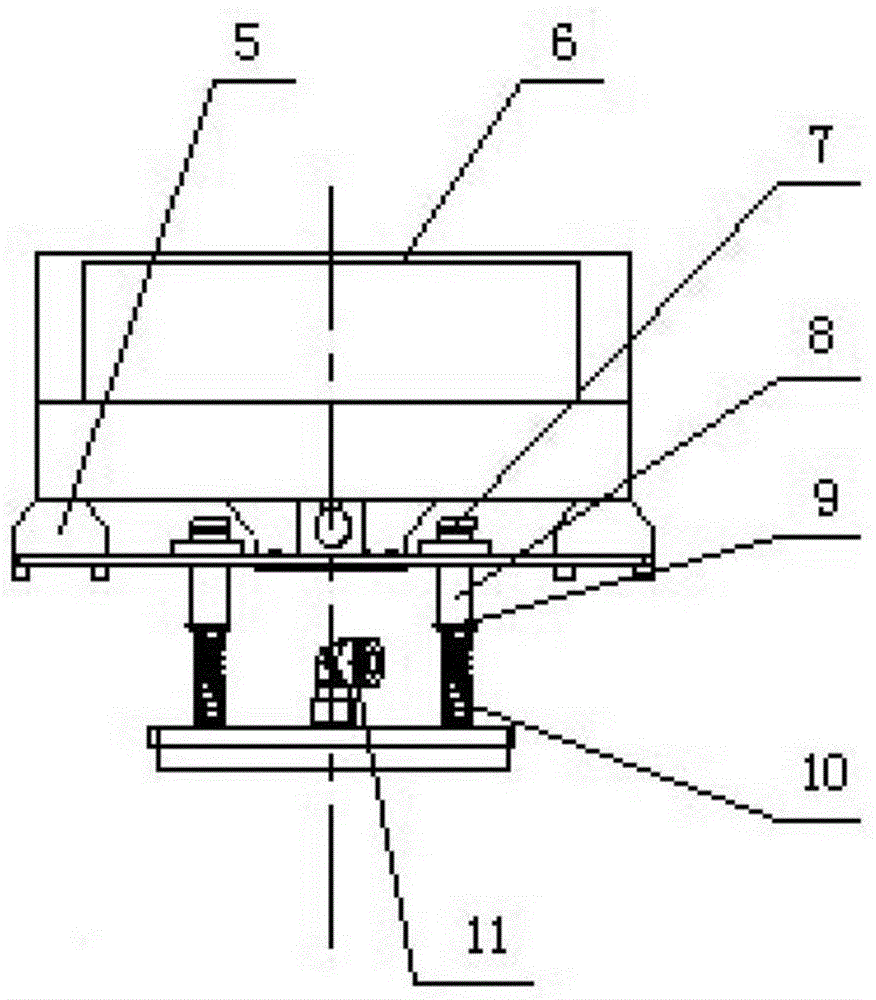

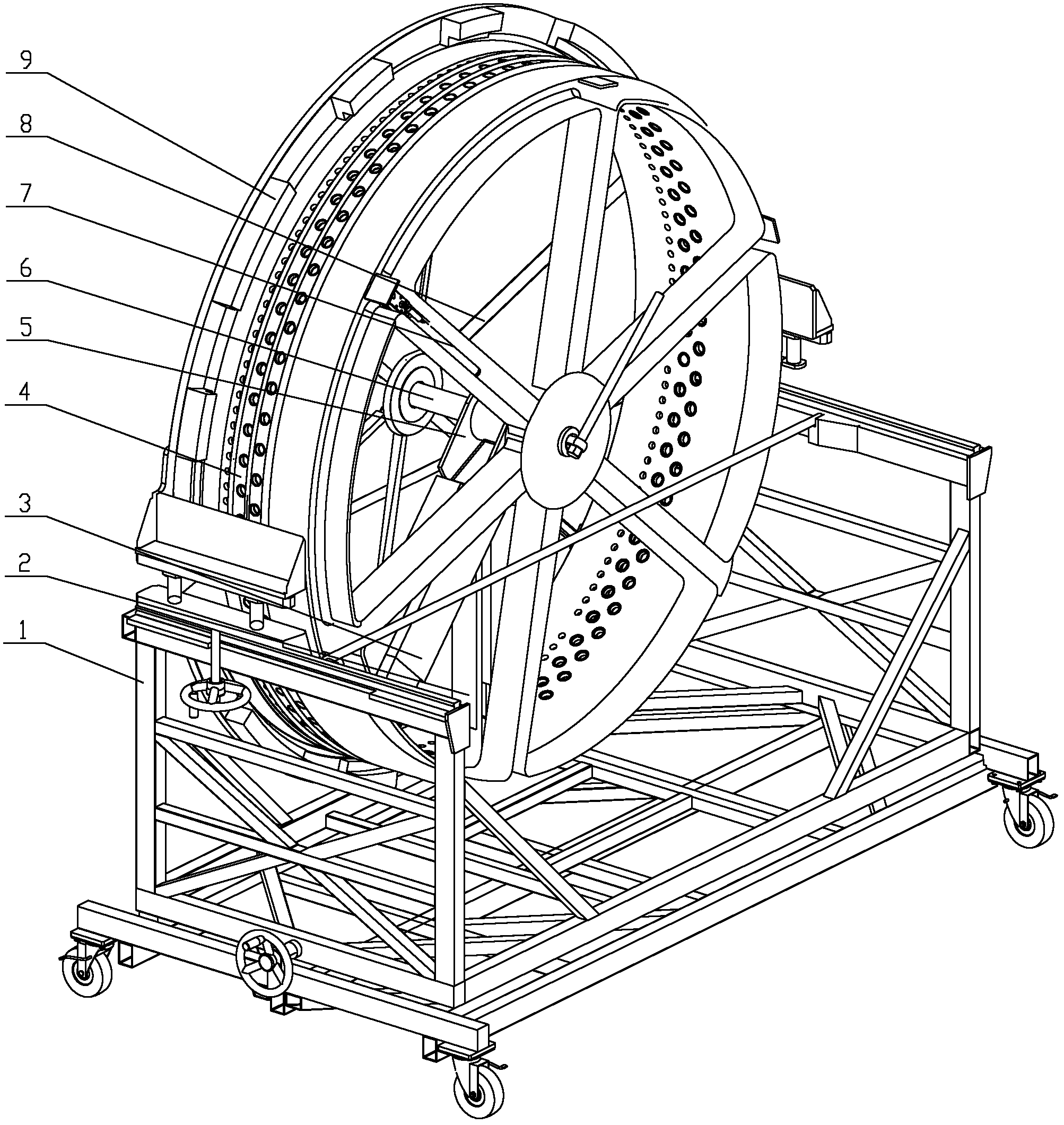

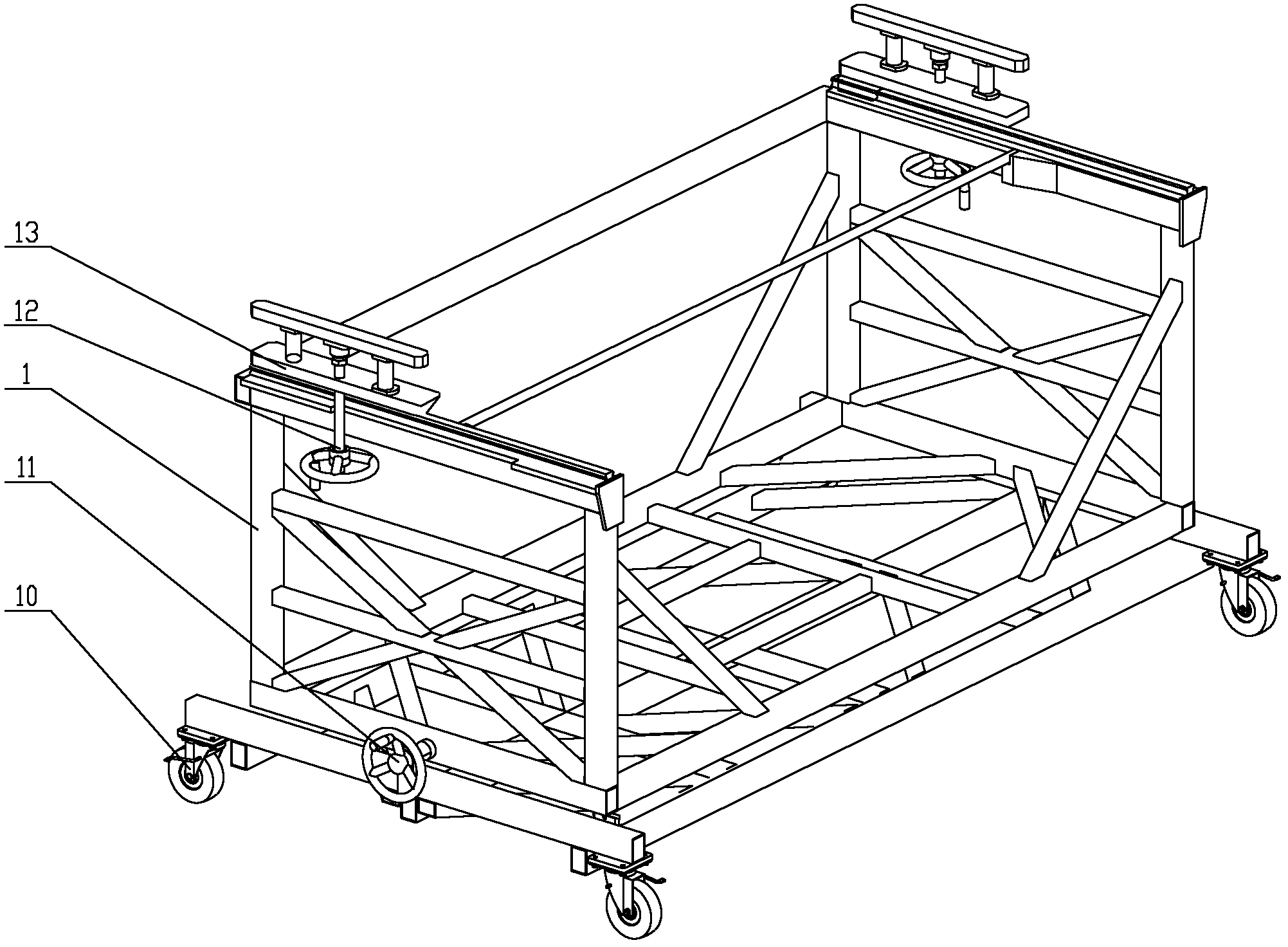

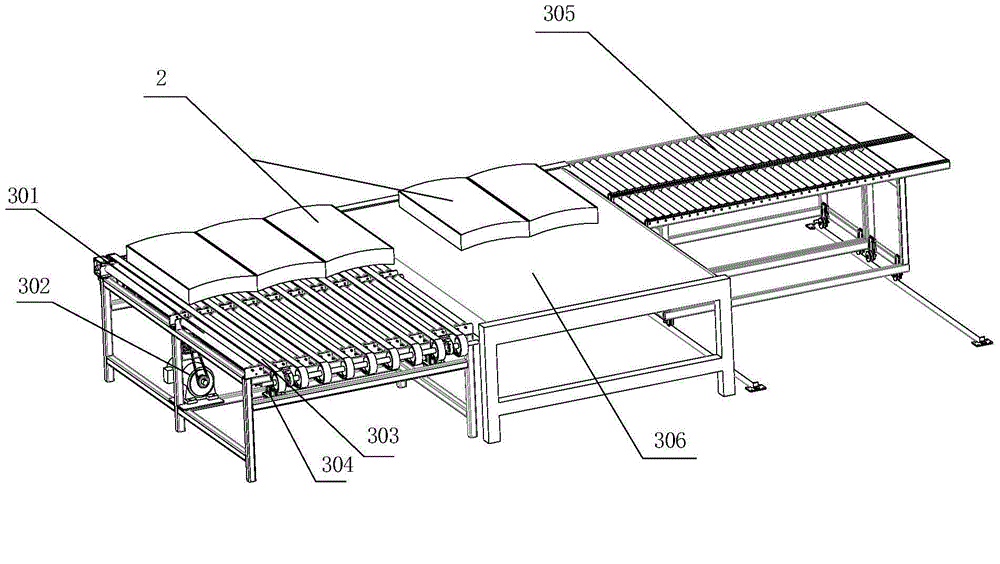

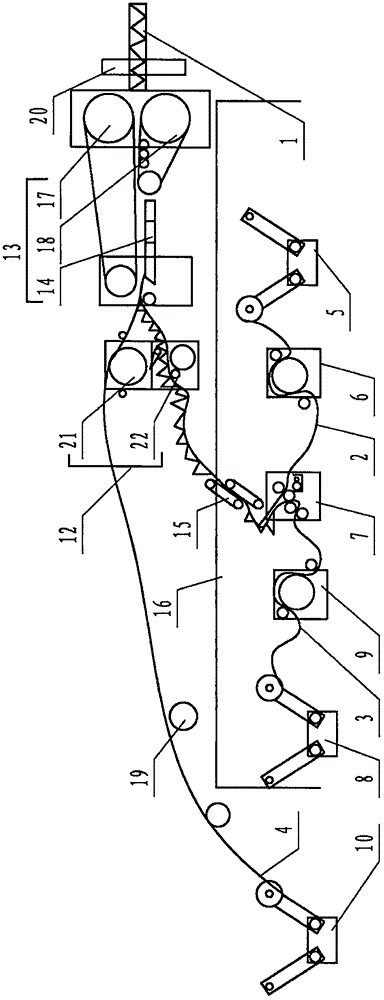

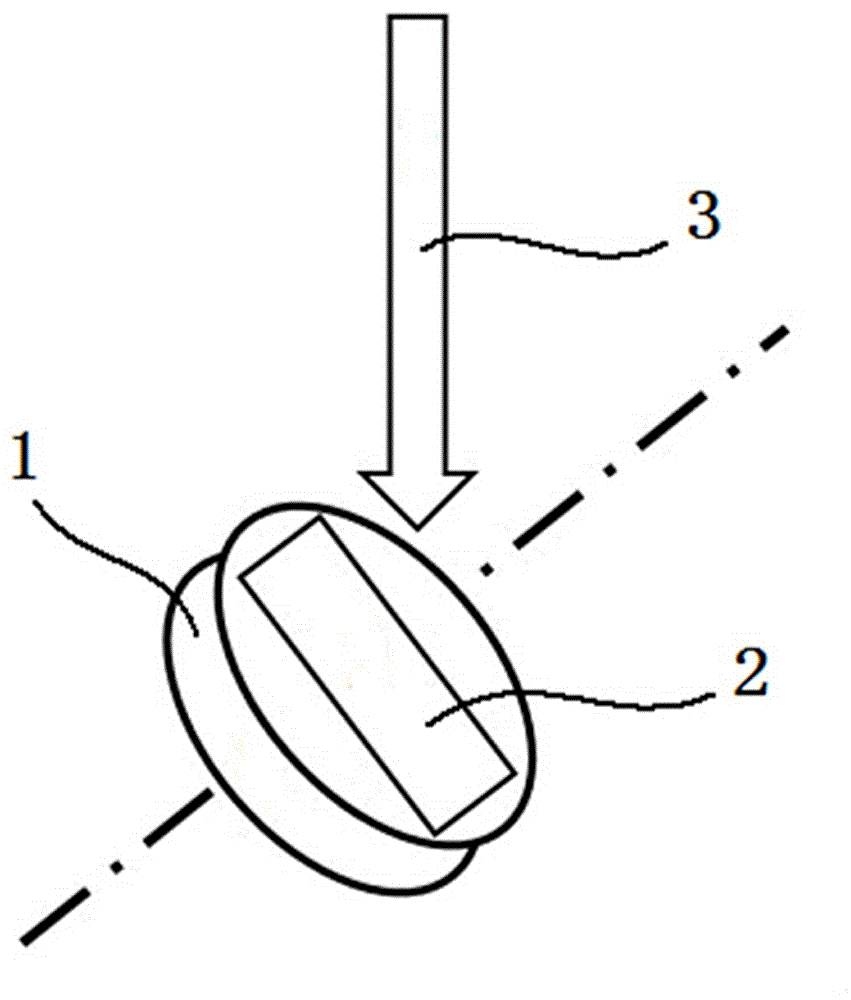

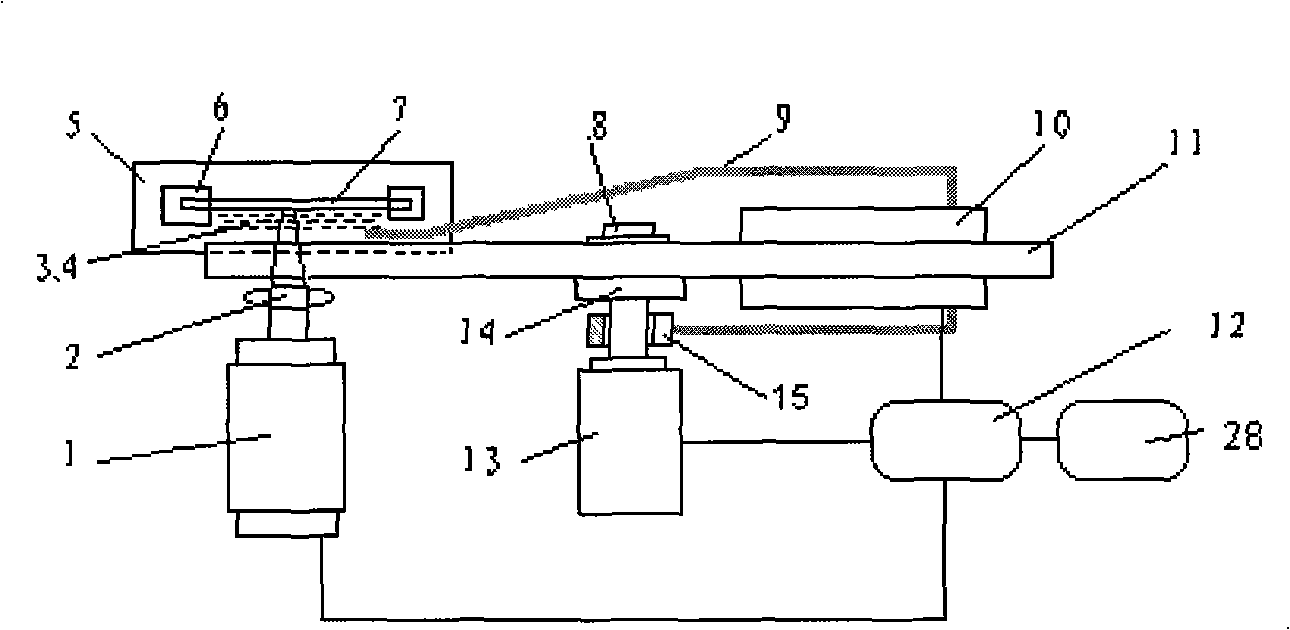

Appearance on-line vision detection and classification system of red dates

ActiveCN104646308ASuitable for visual inspectionImprove detection efficiencyConveyorsSortingEngineeringVisual perception

The invention relates to food detection equipment and particularly provides an appearance on-line vision detection and classification system of red dates, which includes: a sequencing apparatus, a roller conveyor belt apparatus, an on-line detection apparatus and a reject and classification apparatus. The sequencing apparatus, the on-line detection apparatus and the reject and classification apparatus are arranged on the roller conveyor belt apparatus in a conveying direction successively. Red dates are fed into a bucket of the sequencing apparatus and are sequenced thereby so that the red dates fall on the roller conveyor belt apparatus orderly. The on-line detection apparatus detects and classifies the red dates and the reject and classification apparatus rejects and classifies red dates of which the appearance has defects. The system can tidily sequencing the red dates, can automatically detect the appearance of the red dates by means of the on-line detection apparatus and can reject unqualified red dates and classify qualified red dates. The system can solve problems of large consumption of labor intensity, low detection efficiency and low accuracy in the manual appearance detection of the red dates well.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Enhanced scratch resistant coatings using inorganic fillers

InactiveUS6844374B2Improve scratch resistanceNo scratchesImpression capsOrganic chemistryInorganic fillerCoating

The invention provides organic coatings with improved scratch resistance. More particularly, the present invention relates to the use of inorganic filler materials of a defined type and particle size which can be added to curable organic coatings to improve the scratch resistance of the coating without a negative impact on the physical and performance properties or application parameters of the original coating material.

Owner:LORD CORP

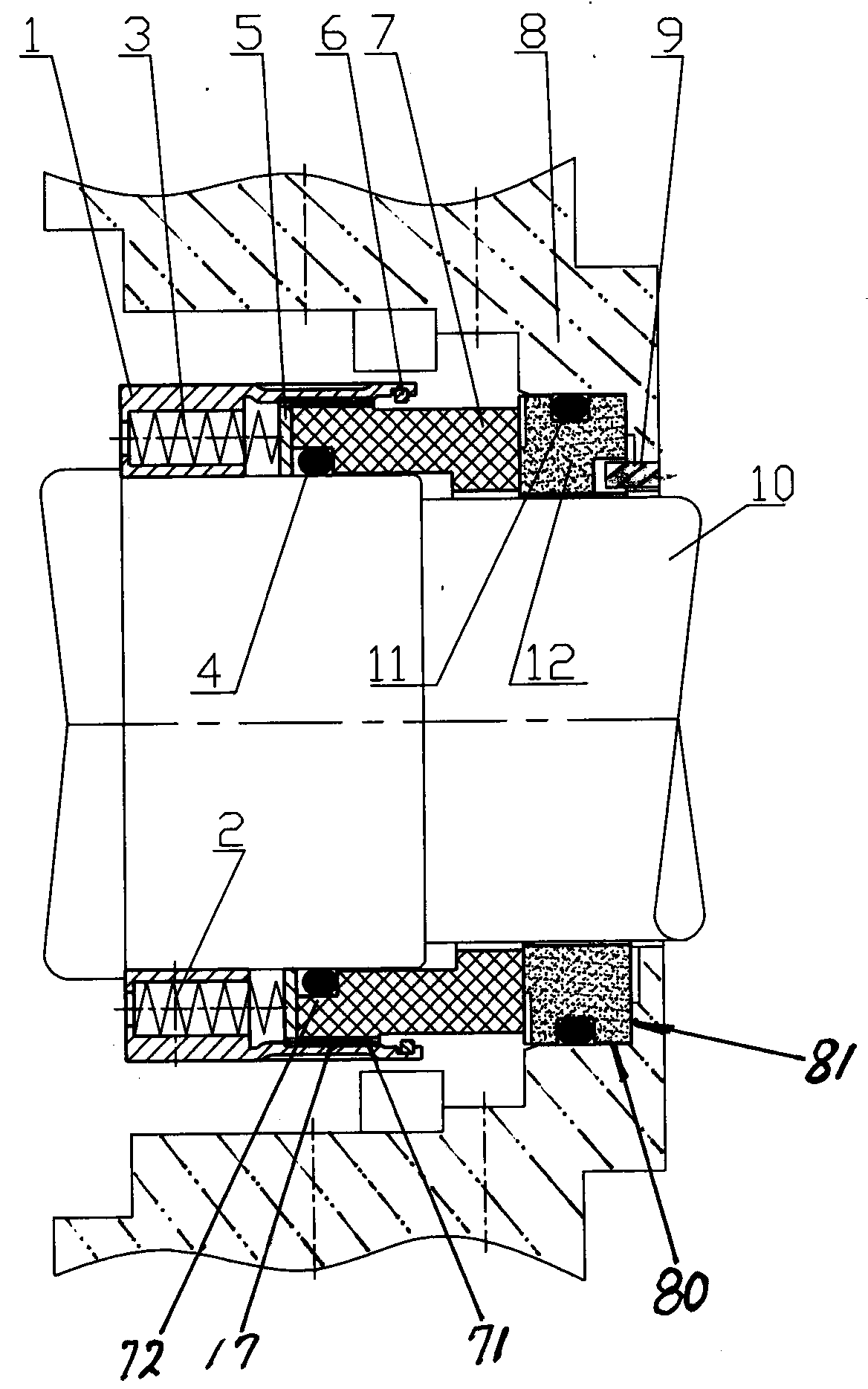

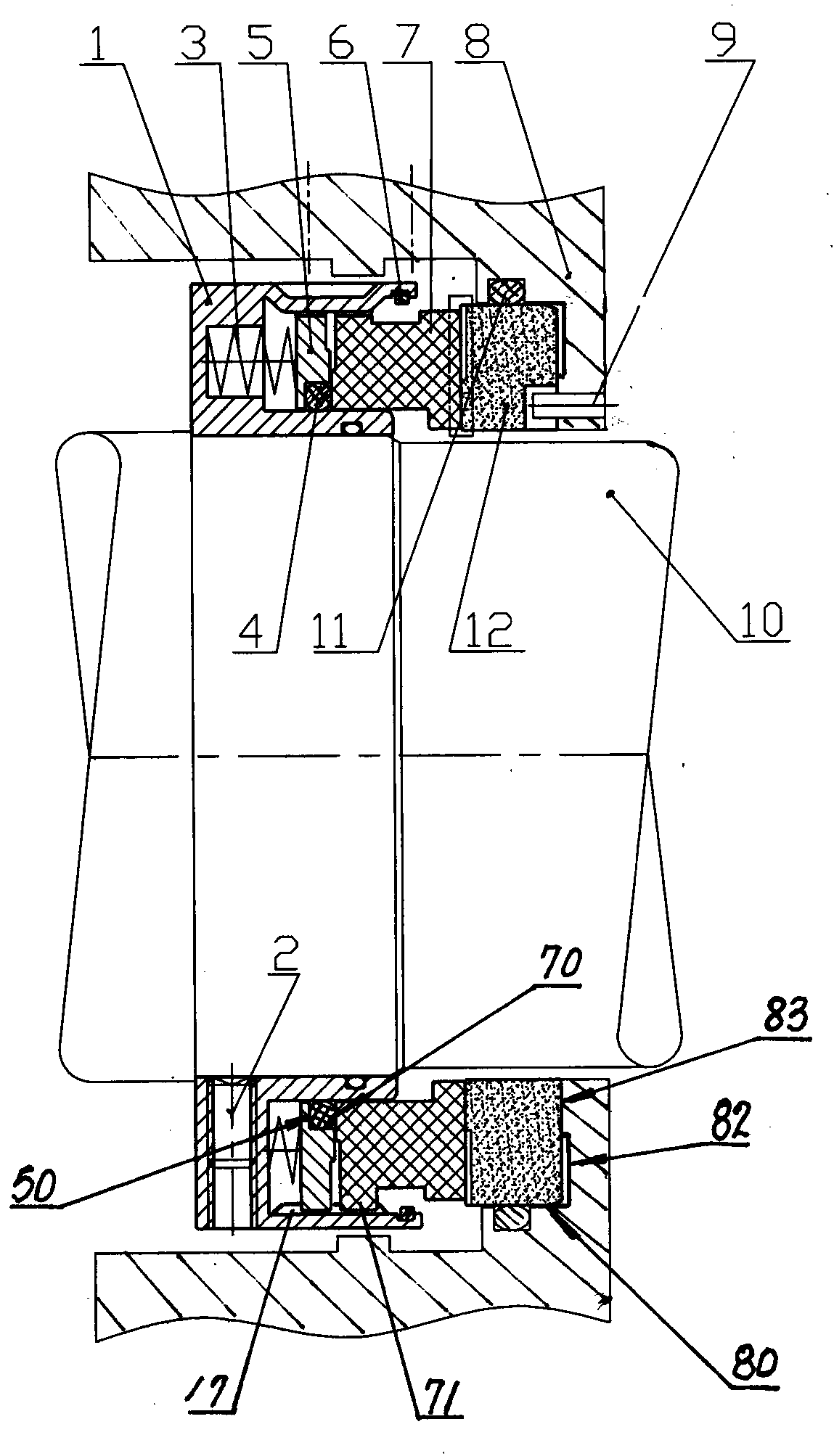

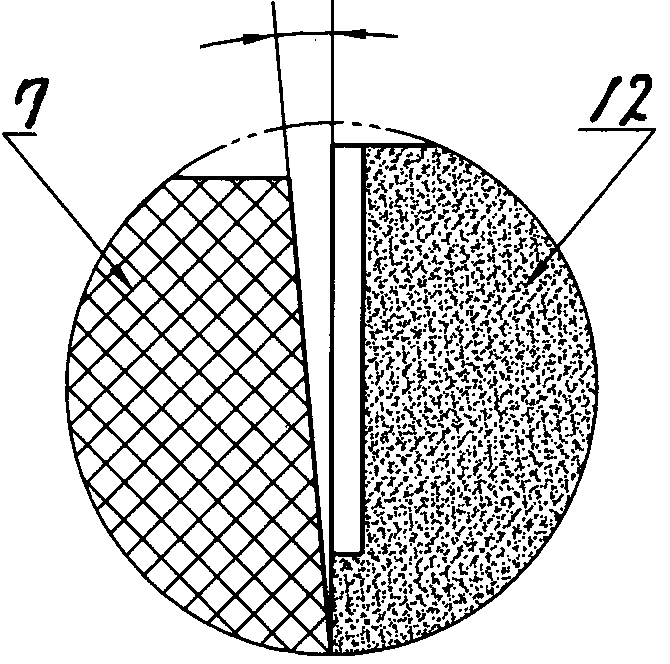

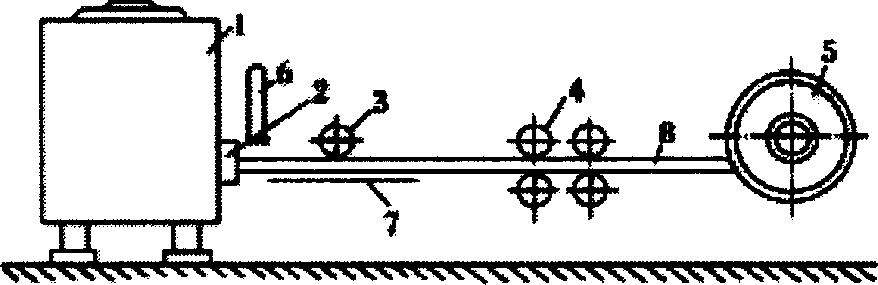

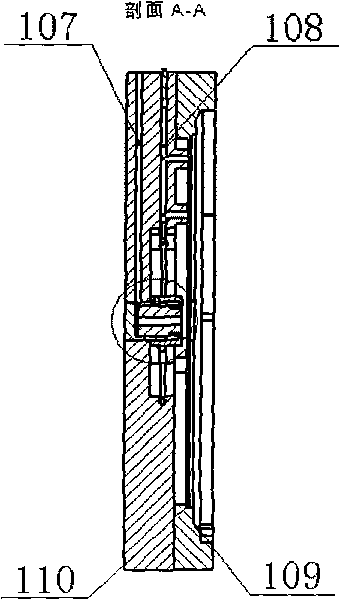

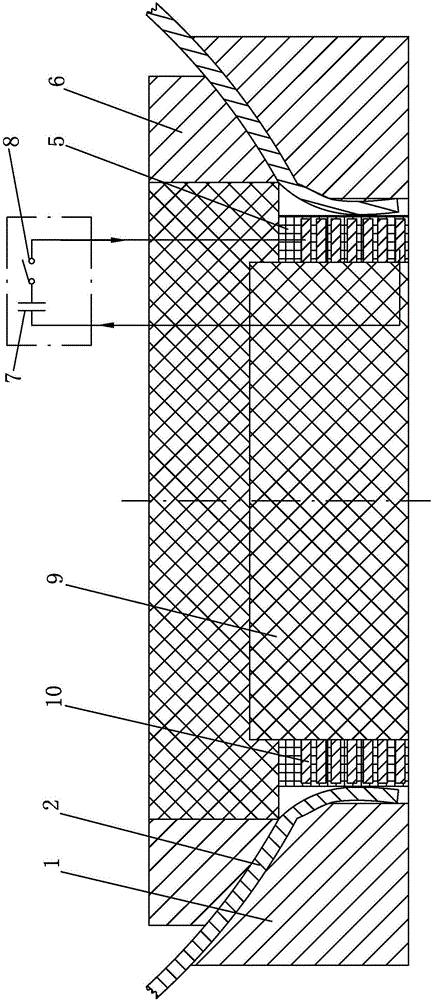

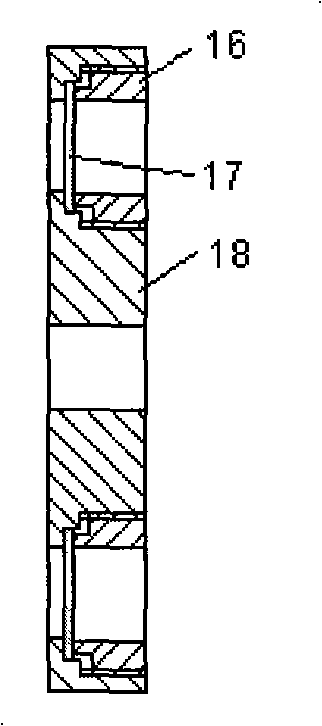

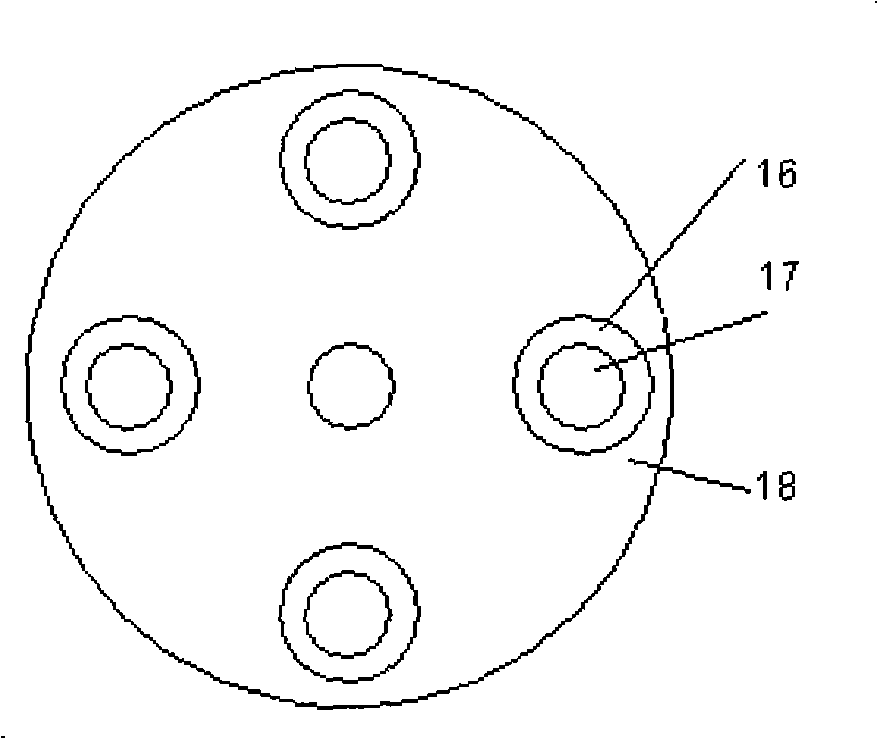

Mechanical dry gas sealing device for pumps

ActiveCN103486268AReduce frictional resistanceGood followabilityEngine sealsInterference resistanceEngineering

The invention discloses a mechanical dry gas sealing device for pumps. The mechanical dry gas sealing device comprises a movable ring component and a fixed ring component, wherein the movable ring component comprises a spring box (1), a stopper screw (2), a spring (3), a sealing ring (4), a pushing ring (5), a snap spring (6) and a movable ring (7), and the fixed ring component comprises a fixed ring (12), an anti-rotating pin (9), a sealing ring (11) and a gland (8). The mechanical dry gas sealing device is characterized in that the sliding sealing ring (4) is mounted in a seam allowance groove (50) on the inner diameter of the front end of the pushing ring (5), the pushing ring (5) is in close fit with the rear end face (70) of the movable ring (7), and compression rate of the O-shaped sliding sealing ring (4) ranges from 2% to 5%. A sealing end face of the movable ring (7) of a compensation ring is a conical surface. A boss (83) is arranged on the inner diameter of a vertical end face (82) mounting a seam allowance groove (80) of the fixed ring (12) and is matched with the inner diameter of the inner end face of the fixed ring (12) in a support manner. An end face of the compensation ring of the mechanical dry gas sealing device is good in adherence. Besides, the mechanical dry gas sealing device is stable to run, high in interference resistance, good in sealing performance and suitable for diversified working conditions.

Owner:DANDONG COLOSSUS GROUP

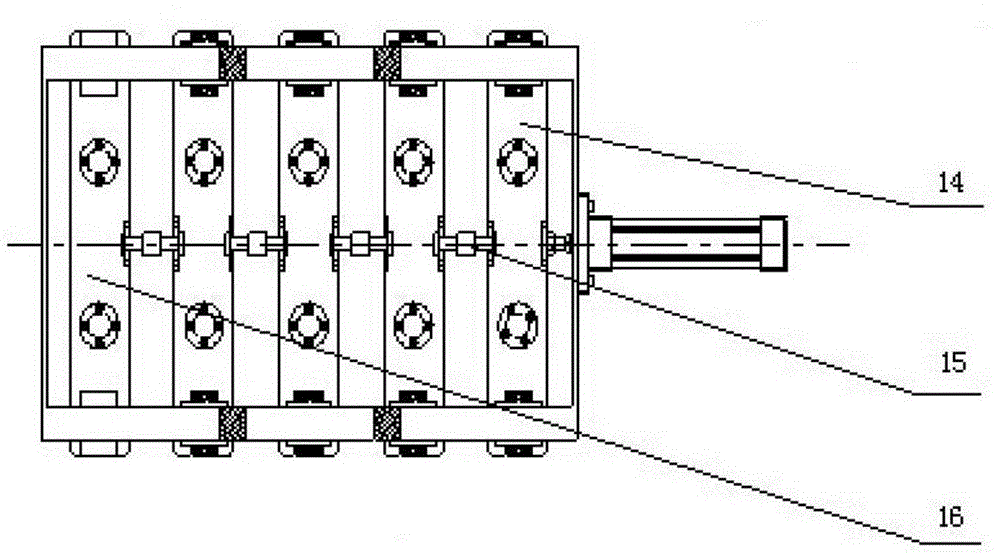

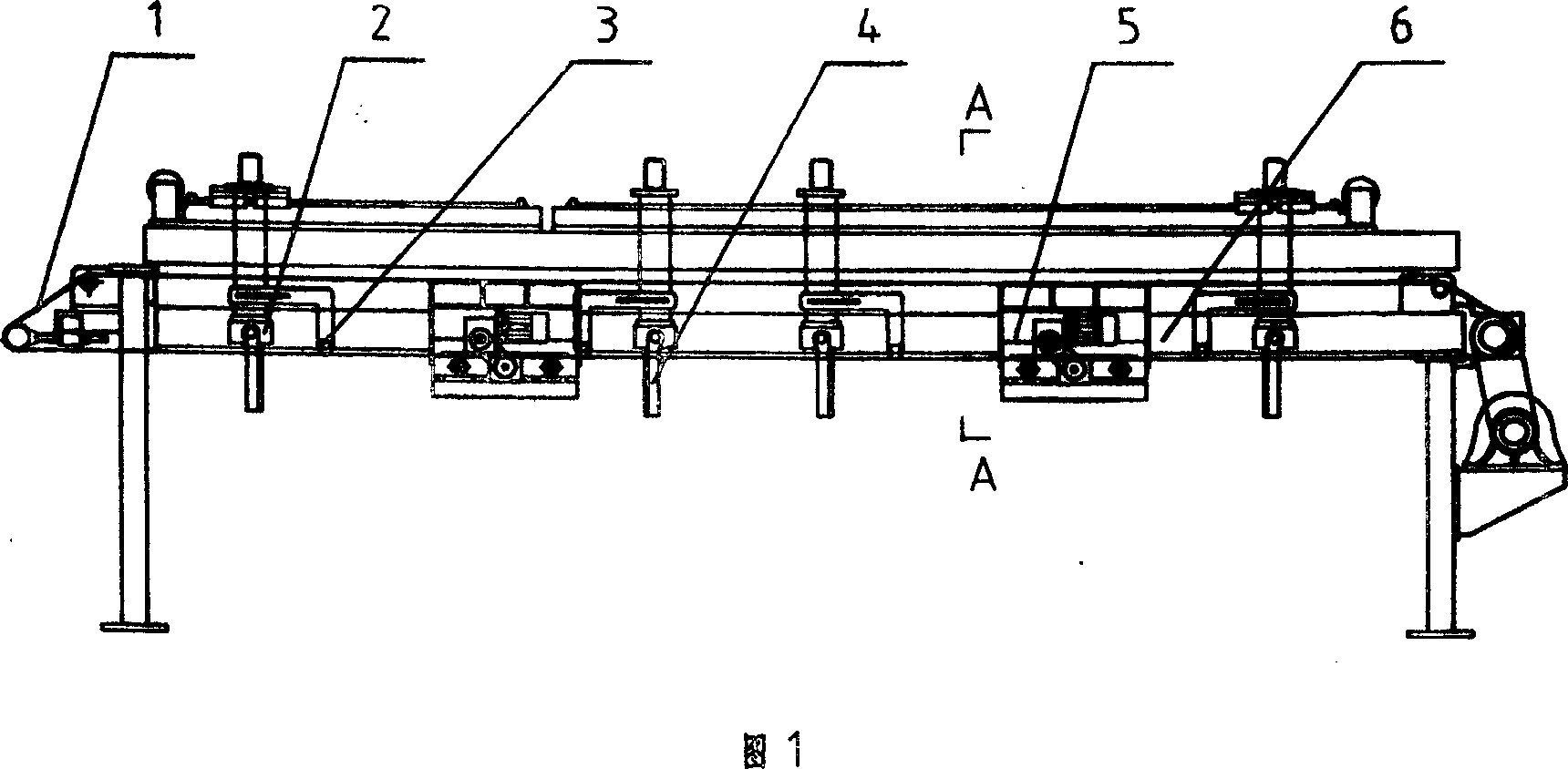

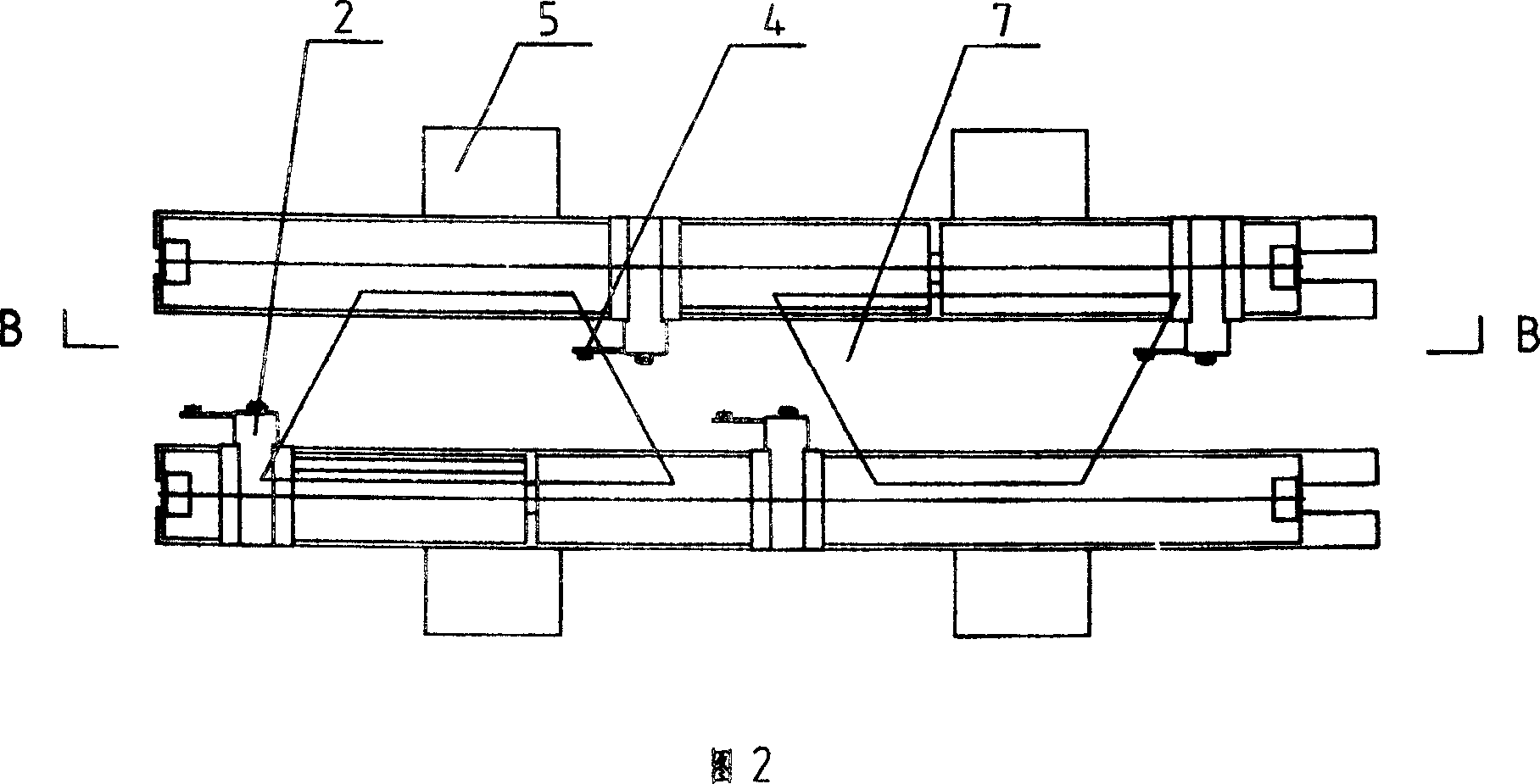

Sucker type stacking manipulator capable of remaining gap

InactiveCN104476553AIntegrity guaranteedNo scratchesGripping headsStacking articlesEngineeringManipulator

The invention discloses a sucker type stacking manipulator capable of remaining a gap. The sucker type stacking manipulator capable of remaining the gap comprises a lead rail bracket, and linear lead rails are symmetrically arranged at two sides of the downside of the lead rail bracket; the linear lead rails are provided with slide blocks, and the slide blocks are connected with mobile mounting plates; a fixing block is arranged at the left end of the lead rail bracket, and the fixing block is connected with a fixed mounting plate; a drive cylinder is arranged at the right end of the lead rail bracket, and a drive cylinder piston rod is connected with the rightmost mobile mounting plate; the fixing mounting plate is connected with the adjacent mobile mounting plate through a spacing shaft, and the mobile mounting plates are connected through spacing shafts; each of the mobile mounting plates and fixed mounting plate is provided with a linear bearing, guide shafts enter the linear bearings, and ends of the guide shafts are connected with a sucker bottom plate; a vacuum joint is arranged at the middle of the sucker bottom plate; a sucker is pasted at the lower surface of the sucker bottom plate. The sucker type stacking manipulator capable of remaining the gap has advantages that the structure is simple, the operation is facilitated, there is no scratch on the surface of a workpiece, and the stacking is compact and regular.

Owner:CHANGZHOU INST OF ADVANCED MFG TECH

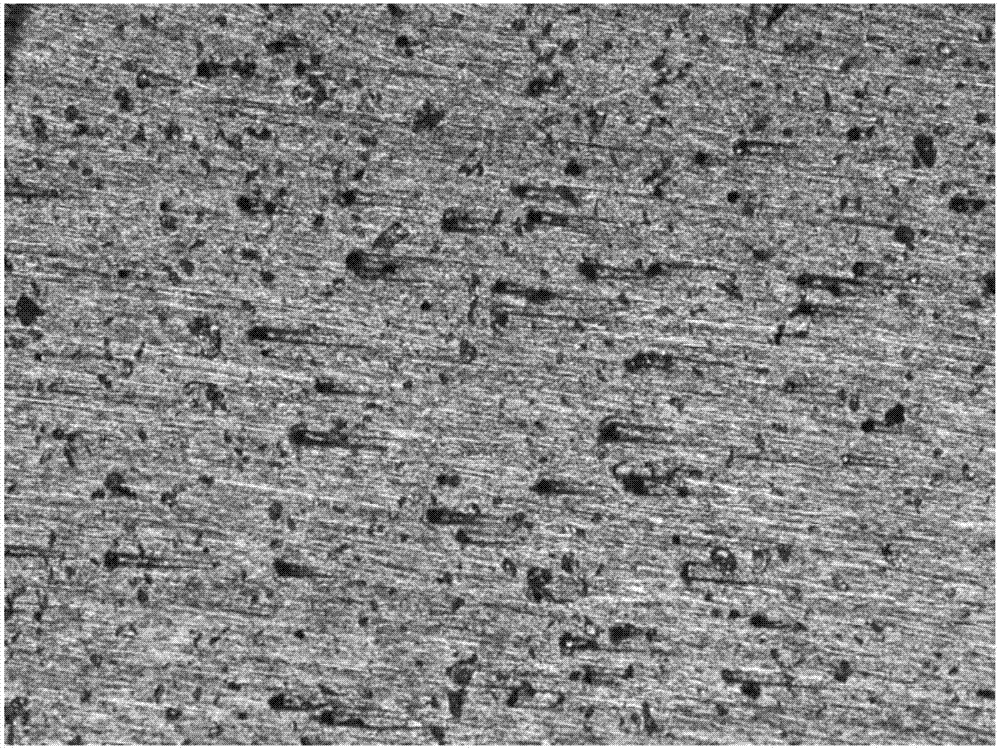

Pure-nickel metallographic etchant and corroding method using same

ActiveCN104878389AFast corrosionEfficient CorrosionPreparing sample for investigationAcetic acidDistilled water

The invention provides pure-nickel metallographic etchant and a corroding method using the same. The pure-nickel metallographic etchant is prepared by mixing distilled water, 65-68% concentrated nitric acid and 99.5% glacial acetic acid. The corroding method using the pure-nickel metallographic etchant includes: preparing a pure-nickel sample, using the etchant to perform metallographic surface corrosion, observing with a metallographic microscope, and analyzing a metallographic structure through metallographic structure morphology and crystal boundary observation. The pure-nickel metallographic etchant has the advantages that the glacial acetic acid is added according to strict proportion and appropriate amount and acid-water mixture is added, the corroded metallographic sample is allowed to have the clear metallographic structure, the etchant can fast and effectively erode the metallographic structure of the sample, the clear metallographic structure of the pure-nickel metallographic sample can be observed after corrosion, and evident boundary and contrast exist among different phases.

Owner:JINCHUAN GROUP LIMITED

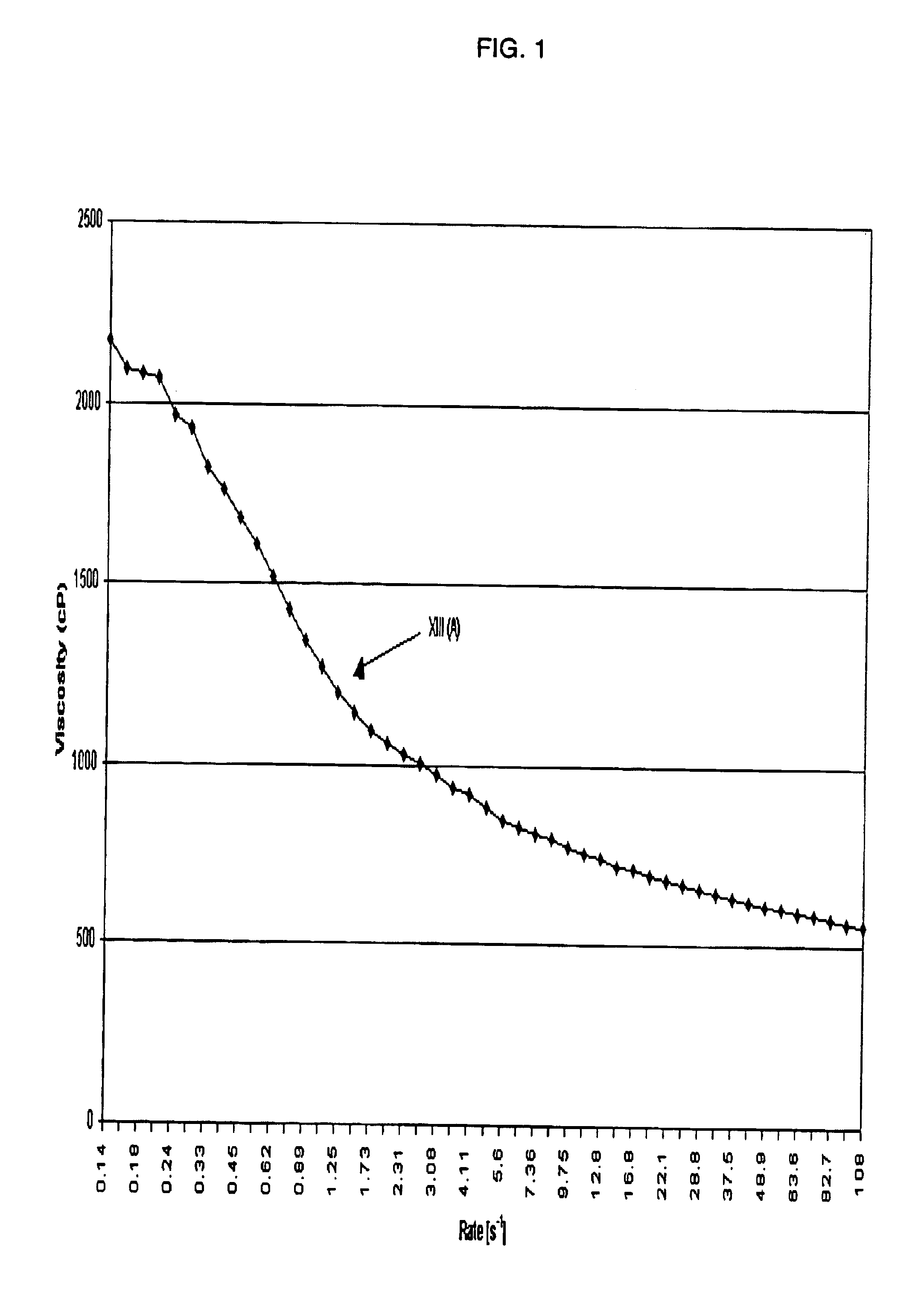

Low viscosity scratch resistant coatings using texturizing and inorganic fillers

InactiveUS6852768B2Improve scratch resistanceNo scratchesImpression capsOrganic chemistryMicrometerShear rate

The invention provides curable organic coatings with improved scratch resistance. More particularly, the present invention relates to a combination of inorganic filler having a 50th percentile particle diameter of from about 3 to about 9 micrometers comprised of aluminum oxide, silicon dioxide, ceramic spheres or mixtures thereof, and particles having a 50th percentile particle diameter of from about 10 to about 150 micrometers. The liquid coatings have a viscosity before curing of from about 100 cps (mPa-s) to about 70,000 cps (mPa-s) at a shear rate of 0.15 s−1. The use of inorganic filler materials of the defined type and particle size are combined with the curable organic coating to improve the scratch resistance of the coating without a negative impact on the physical and performance properties or application parameters of the original coating material. The present invention also provides organic coatings comprising texture-producing particles which provide the coating with texture after the coating has been cured.

Owner:LORD CORP

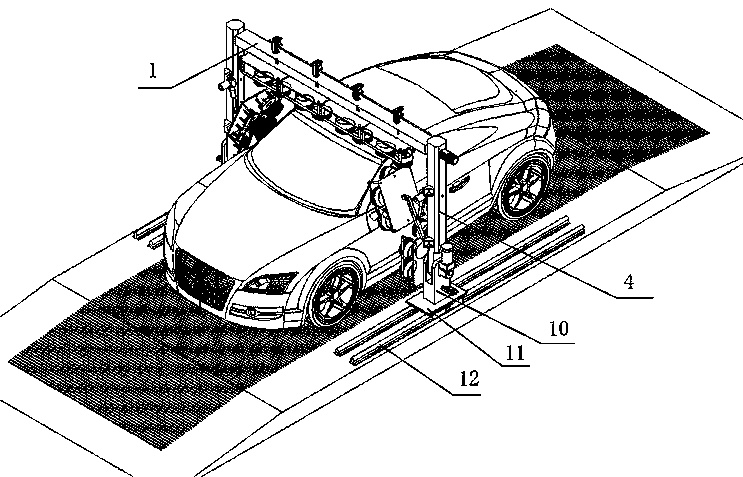

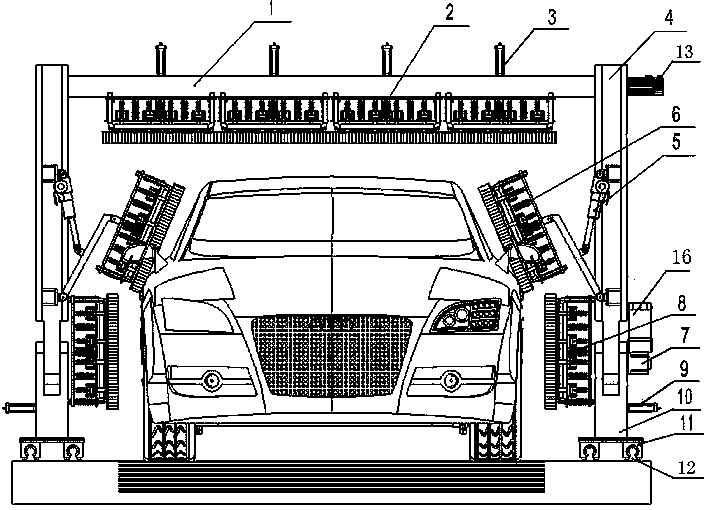

Gantry swing arm type automatic vehicle cleaning mechanism

PendingCN107685717AReduce volumeImprove cleanlinessCleaning apparatus for vehicle exteriorsStructural engineeringControl theory

The invention discloses a gantry swing arm type automatic vehicle cleaning mechanism which comprises fixing guide rails, movable sliders, swing arm supports, gantry swing arms and a gantry transversebeam. The fixing guide rails are arranged on the ground, the movable sliders can slide on the fixing guide rails in the front-back directions, the swing arm supports are fixed onto the movable sliders, the gantry swing arms are arranged on the swing arm supports and are connected with the swing arm supports by connecting shafts, and the gantry transverse beam is arranged on the two gantry swing arms and is connected with the gantry swing arms by shafts; bottom electric push rods are arranged on the swing arm supports, and bottom cleaning devices are arranged at the front ends of the bottom electric push rods. The gantry swing arm type automatic vehicle cleaning mechanism has the advantages that the gantry swing arm type automatic vehicle cleaning mechanism is of a gantry structure, two side arms of a gantry can swing, accordingly, the gantry swing arm type automatic vehicle cleaning mechanism can be easily matched with vehicle shapes, and vehicles can be efficiently automatically cleaned in a high-quality manner; the gantry swing arm type automatic vehicle cleaning mechanism is small in occupied area, simple in integral structure and quite suitable for popularization and utilization.

Owner:HEBEI BOYI GONGJI SCI & TECH DEV CO LTD

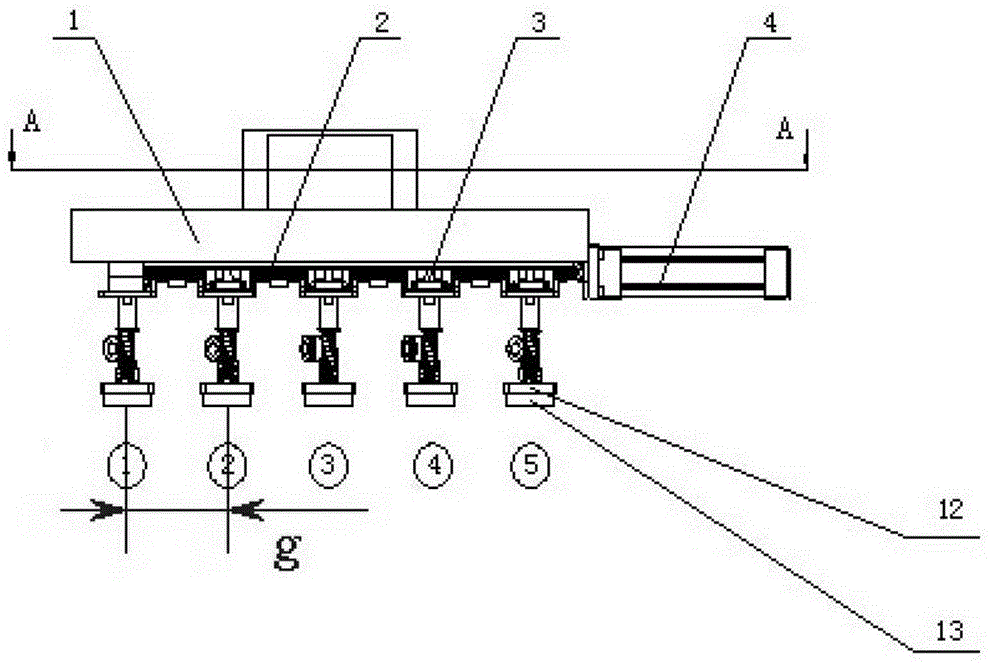

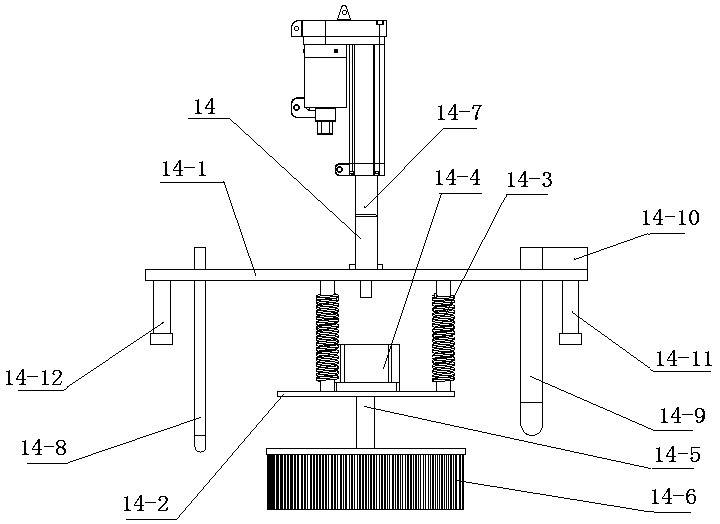

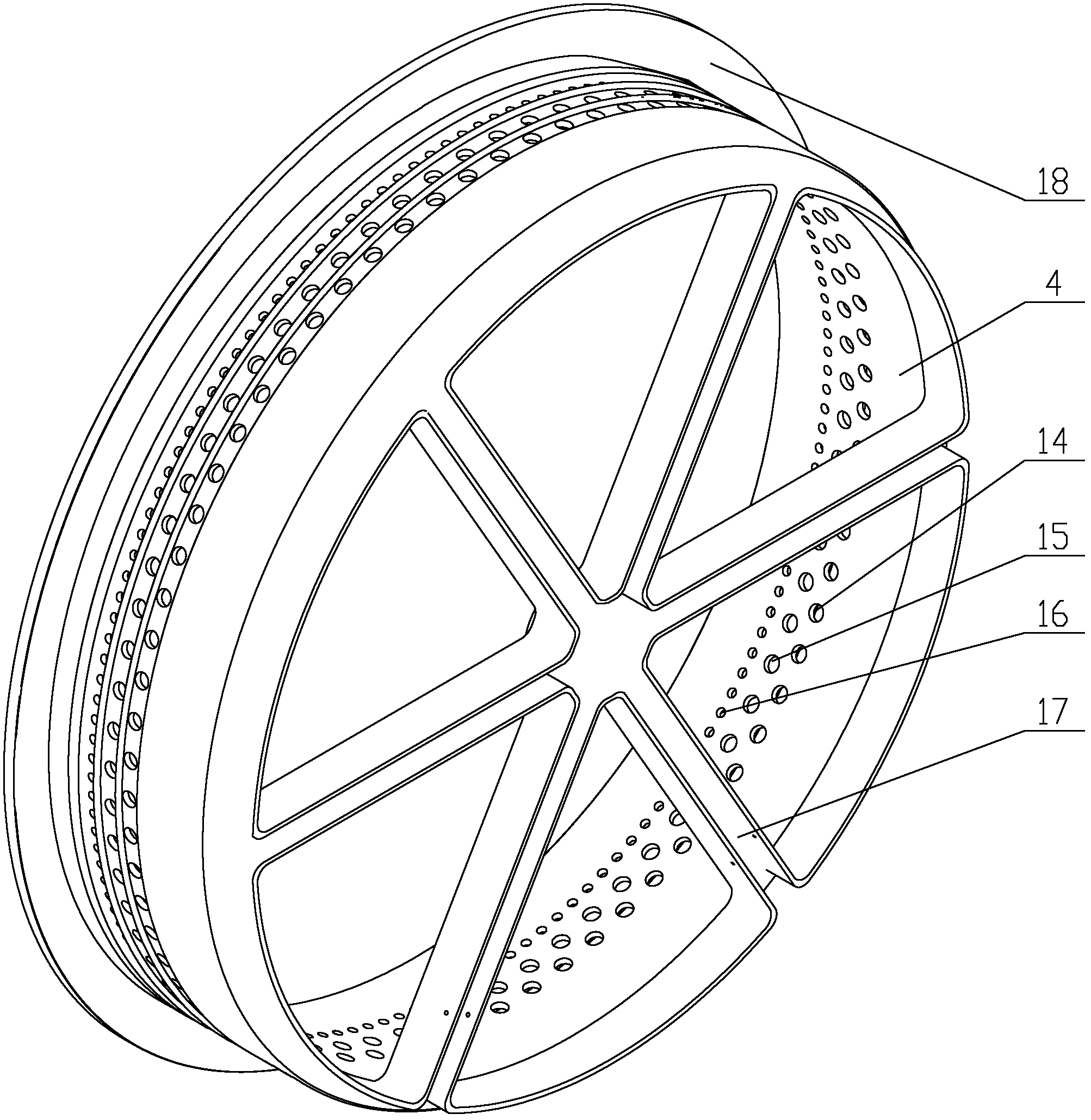

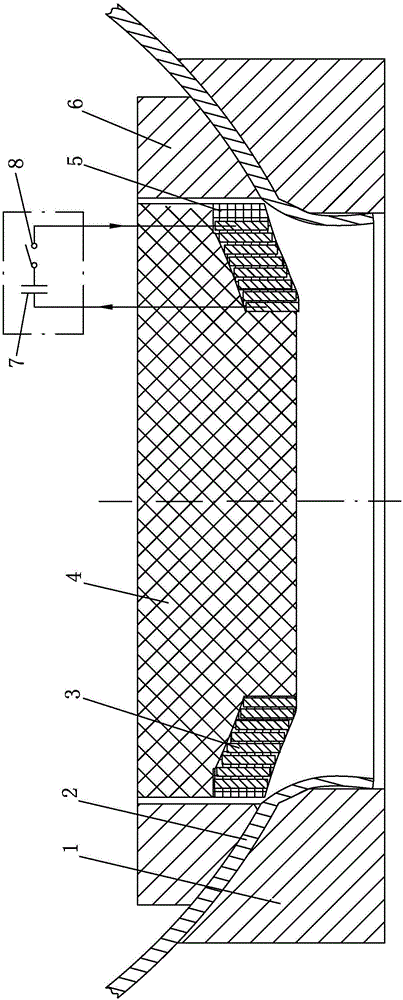

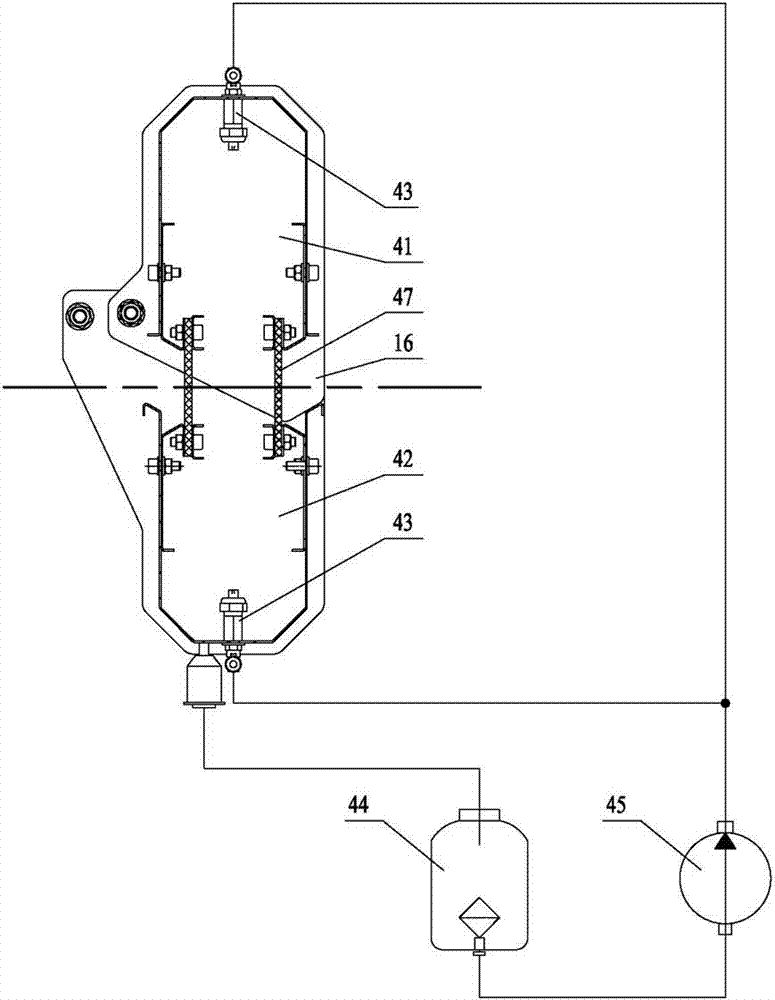

Radial automatic drilling device for large-size compound cylinder

The invention provides a device which has a simple structure and can be used for automatically drilling a large-size compound cylinder in batches along a radial direction aiming at the problems of difficulty in tool setting and low drilling efficiency in the process of drilling the large-size compound cylinder along the radial direction. A processing mode of processing from inner to outer is adopted in the drilling device, thereby avoiding the fiber tearing and layering on the inner wall of a cylinder made of compound materials. By using a double-power head for drilling, first and second rows of holes can be processed at the same time. In order to change a drilling position, a drilling unit is rotated without moving the large-size compound cylinder, thereby widening the processing range. And meanwhile, a drilling device bracket is designed for storing and mounting the drilling device and avoiding the rubbing between the drilling device and the inner wall of the cylinder.

Owner:DALIAN UNIV OF TECH

Lubricant for drawing spring steel wire

ActiveCN103897787AConsistent colorSignificant change in softening pointLubricant compositionSide effectBorax

The invention provides a lubricant for drawing a spring steel wire. The lubricant for drawing the spring steel wire comprises the following components in percentage by weight: 40-60% of calcium stearate, 35-55% of softening point regulator and 5%-8% of extreme pressure additive, wherein the softening point regulator is one or more selected from calcium hydroxide, titanium dioxide, zinc oxide, sodium carbonate, sodium silicate, borax and paraffin. The lubricant is characterized in that the softening point of the lubricant changes obviously in a drawing process, and in the viscosity-temperature change of the lubricant, the lubricant is brought into a mold during drawing, and therefore, the requirements of the drawing process can be met. The lubricant has the advantages that the protection capacity of the lubricant on the surface of the steel wire is further improved, the subsequent heat treatment is not affected after drawing, no toxic or side effects are produced, a stable lubricating film can be formed on the surface of the steel wire under severe wire drawing conditions, and the wire drawing process is stabilized and the surface of the steel wire is protected against scratch.

Owner:GUANGZHOU ORSA WIRE SCI & TECH

Production method of a soft-light glazed brick

The invention discloses a production method of a soft-light glazed brick. The production method comprises steps as follows: (1), preparing a soft-light glazed brick green body with a conventional method; (2), preparing priming glaze and surface glaze of the soft-light glazed brick; (3), applying the priming glaze; (4), performing drying; (5), applying the surface glaze; (6), performing drying and sintering; (7), performing polish treatment; (8), performing selection, packaging and warehousing. The production method has the beneficial effects as follows: the problem of high probability of severe scratching and pollution absorption of soft-light treatment of an existing glazed brick is solved, and the production method of the soft-light glazed brick is better.

Owner:GUANGXI UNIV

Polishing disk for polishing crystal glass

InactiveCN102120315AExtended service lifeHydrophilicAbrasion apparatusWater solubleHigh wear resistance

The invention relates to a polishing disk for polishing crystal glass. In the polishing disk for polishing crystal glass, a polishing layer comprises the following components in percentage by mass: 5 to 60 percent of grinding material, 10 to 60 percent of unsaturated resin with water swelling property, 0.5 to 5 percent of curing agent, 0.1 to 30 percent of water soluble additive and 0.05 to 8 percent of functional regulating additive, wherein the total mass percentage of the components is 100 percent. The grinding material may be diamond, carborundum and aluminum oxide. The polishing disk solves the problem that the diamond, carborundum, aluminum oxide and the like, which are harder than workpieces, cannot be used as a grinding material on the polishing disk, and has the advantages of high processing efficiency, high wear resistance and long service life.

Owner:ZHEJIANG PUJIANG MINRUI PRECISION MACHINERY TECH

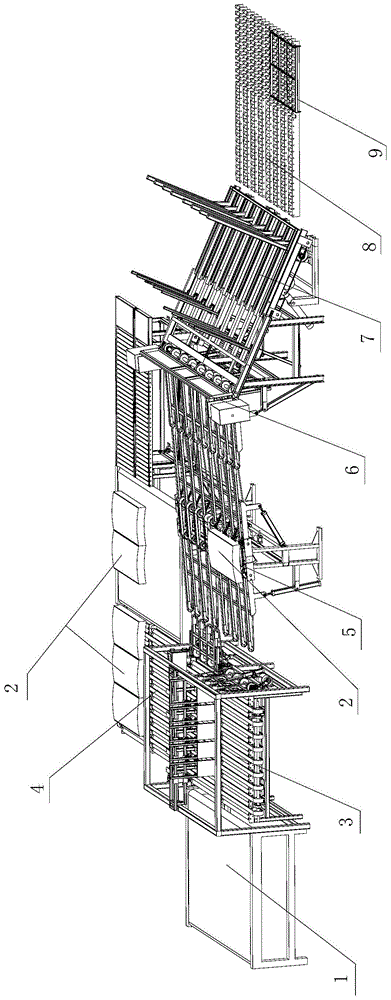

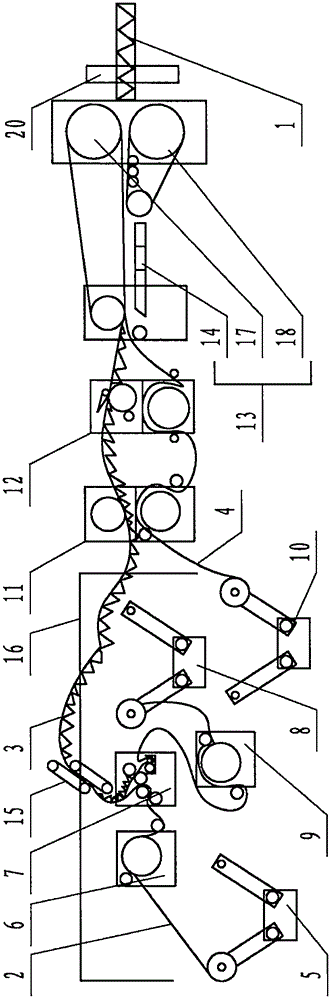

Corrugated paperboard turning and stacking discharging production line and control method thereof

InactiveCN104944195ASimple structureEasy to operatePile receiversArticle deliveryProduction linePaperboard

The invention discloses a corrugated paperboard turning and stacking discharging production line and a control method thereof. The production line comprises a paperboard separating and pushing device, an interlock-type turning device, a temporary storing and moving device, a stacking righting device and a paperboard stack conveying device which are sequentially connected with one another. Corrugated paperboards of the discharging production line are conveyed to the interlock-type turning device through a conveyor belt, every two corrugated paperboards are stacked through the interlock-type turning device, the stacked corrugated paperboard units are conveyed to the temporary storing and moving device which erects each corrugated paperboard unit, after multiple corrugated paperboard units are stacked into a group, the temporary storing and moving device conveys the corrugated paperboard unit groups to the stacking righting device which turns the corrugated paperboard unit groups by 90 degrees and conveys the corrugated paperboard unit groups to the paperboard stack conveying device, paperboard stack trays are arranged in the paperboard stack conveying device, and the corrugated paperboard unit groups are placed in the paperboard stack trays. The corrugated paperboard turning and stacking discharging production line and the control method thereof have the advantages of being simple in structure, easy to operate and high in automation degree.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +2

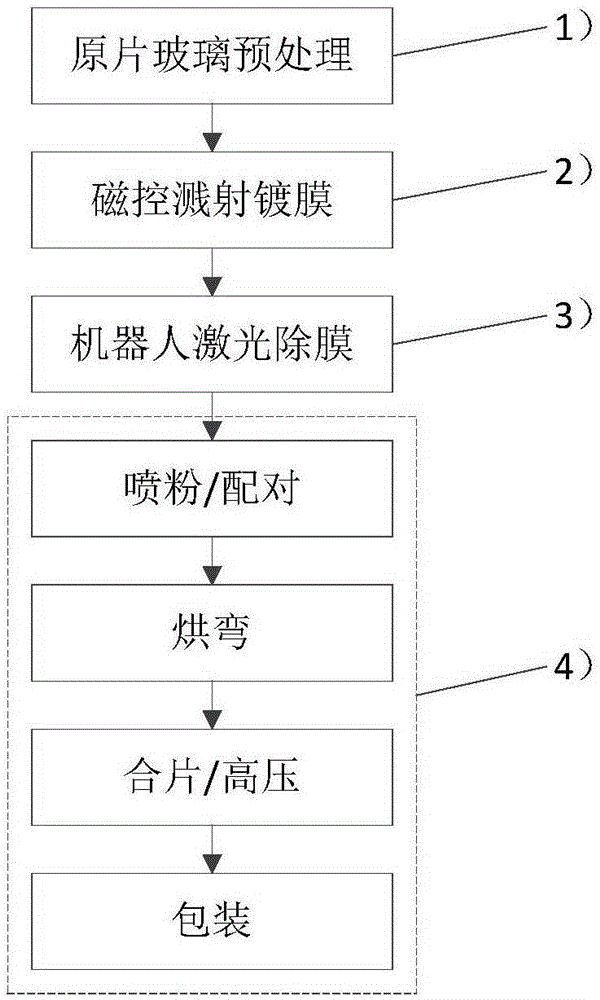

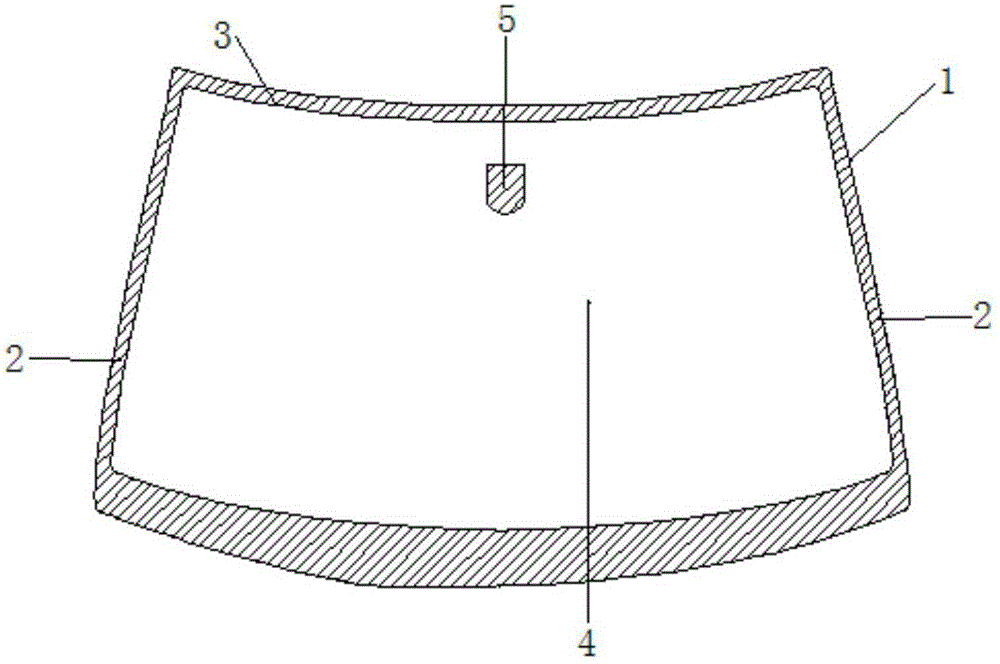

Manufacturing method of low-emissivity coated laminated glass capable of removing film in peripheral area and being bent by drying

The invention relates to a manufacturing method of low-emissivity coated laminated glass capable of removing a film in the peripheral area and being bent by fire drying. The manufacturing method comprises the following steps of firstly, pretreating a raw glass sheet: performing slicing, sheet loading, cutting, edging, washing and drying treatment on the raw glass sheet to obtain an automotive-grade raw glass sheet; secondly, coating a film: coating a low-emissivity film layer on the surface of the automotive-grade raw glass sheet by using magnetron sputtering coating equipment; thirdly, removing the film: using robot arms to control a laser for instantly evaporating a low-emissivity film layer material in an area which does not need coating, of the automotive-grade raw glass sheet; fourthly performing posttreatment: performing drying, powder spraying, pairing, fire drying-bending, laminating, and high-pressure and packaging treatment on the automotive-grade raw glass sheet to obtain the low-emissivity coated laminated glass capable of removing the film in the peripheral area and being bent by fire drying. Compared with the prior art, the manufacturing method disclosed by the invention has the advantages that the uniformity in coating is realized, an electromagnetic wave signal is enabled to pass through, a low-emissivity function is guaranteed, and a glass double-image is small in area; the manufacturing method is suitable for preparing coated glass in automobile windscreen and skylight laminated glass.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

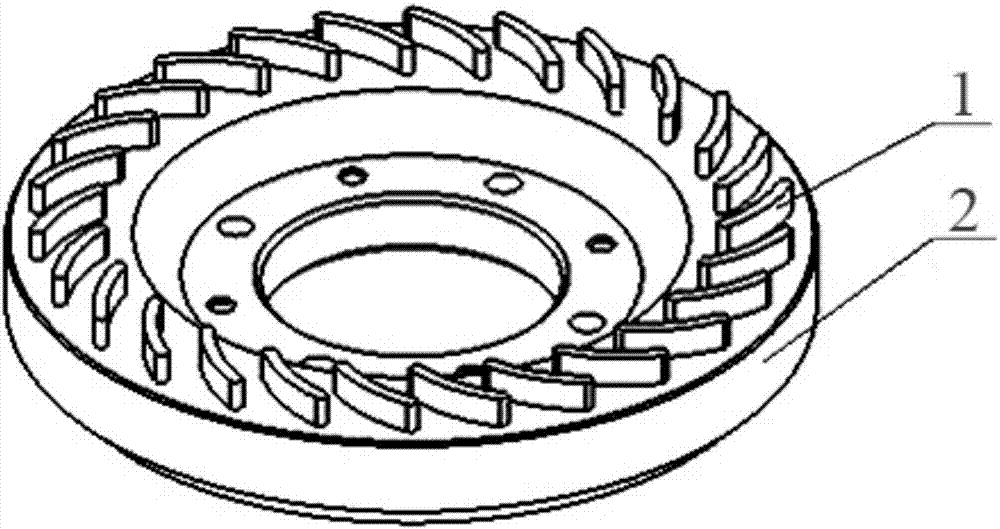

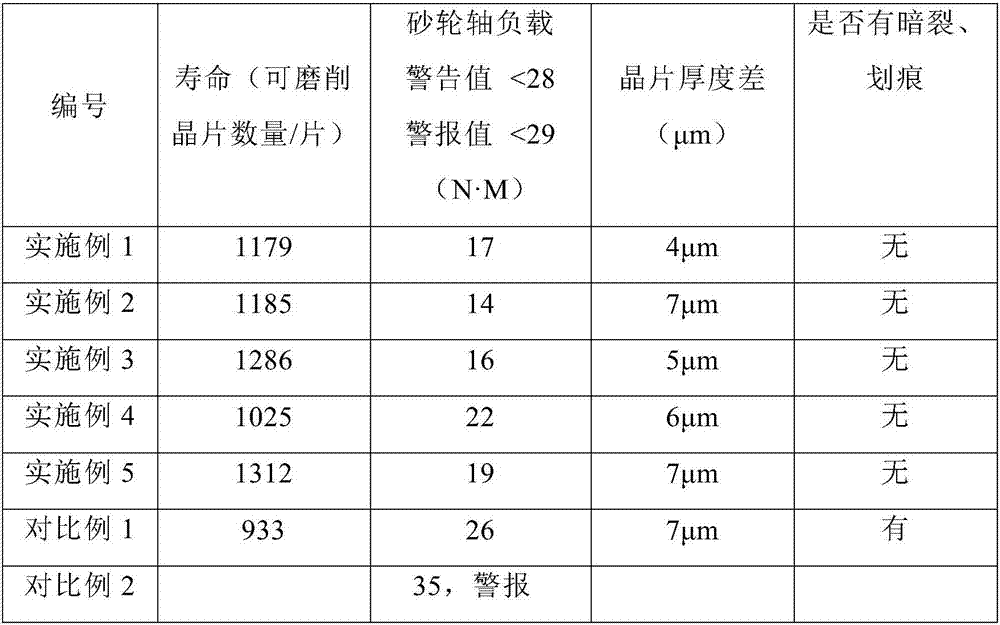

Metallic bond, diamond grinding wheel prepared through bond and preparation method of diamond grinding wheel

The invention relates to a metallic bond, a diamond grinding wheel prepared through the bond and a preparation method of the diamond grinding wheel. The metallic bond comprises, by weight percent, 95%-99% of copper-tin prealloyed powder, 0.5%-3% of graphite powder and 0.5%-2% of nanometer alpha-Al2O3. The copper-tin prealloyed powder, the graphite powder, the nanometer alpha-Al2O3 and diamond are taken according to a certain proportion, procedures of burdening and material mixing, pelletizing, compression, sintering and aftertreatment are carried out in sequence, and tool bits can be prepared. The multiple tool bits are arranged on a matrix at equal distance in the circumferential direction, the cambered surfaces of the tool bits are perpendicular to the matrix, and the diamond grinding wheel is prepared. The above tool bits are uniform in ingredient and good in density, diamond distribution is uniform, and the control effect of the metallic bond on the diamond is good. The grinding wheel has the beneficial effects of being good in ground workpiece surface quality, free of dark cracks and scratches, sharp in grinding and long in service life, facilitating large-scale production and the like and is especially suitable for producing sapphire wafers with the thinning thickness ranging from 100 micrometers to 700 micrometers.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

Grinding liquid for sapphire substrate and preparation method of grinding liquid

InactiveCN102643613AEvenly dispersedGood chemical stabilityPolishing compositions with abrasivesSurface roughnessProcessing cost

The invention relates to a grinding procedure of a sapphire crystal, belonging to the field of a process technology of a crystal material. The invention provides grinding liquid for a high-quality sapphire substrate. The grinding liquid is prepared from diamond micropowder, auxiliary grinding powder, de-ionized water, glycerol and an additive. The grinding liquid prepared by the method is uniform in dispersion and good in chemical stability; the grinding liquid prepared by the method provided by the invention is used for grinding the sapphire crystal so that the grinding efficiency is improved on the precondition that the surface quality of the substrate is guaranteed and the processing cost is effectively reduced. The sapphire substrate grinded by the grinding liquid disclosed by the invention has the advantages of low surface roughness, good flatness, no obvious scratches and easiness for washing, and meets the requirements of industrial production.

Owner:CHANGZHOU TONGTAI PHOTOELECTRIC

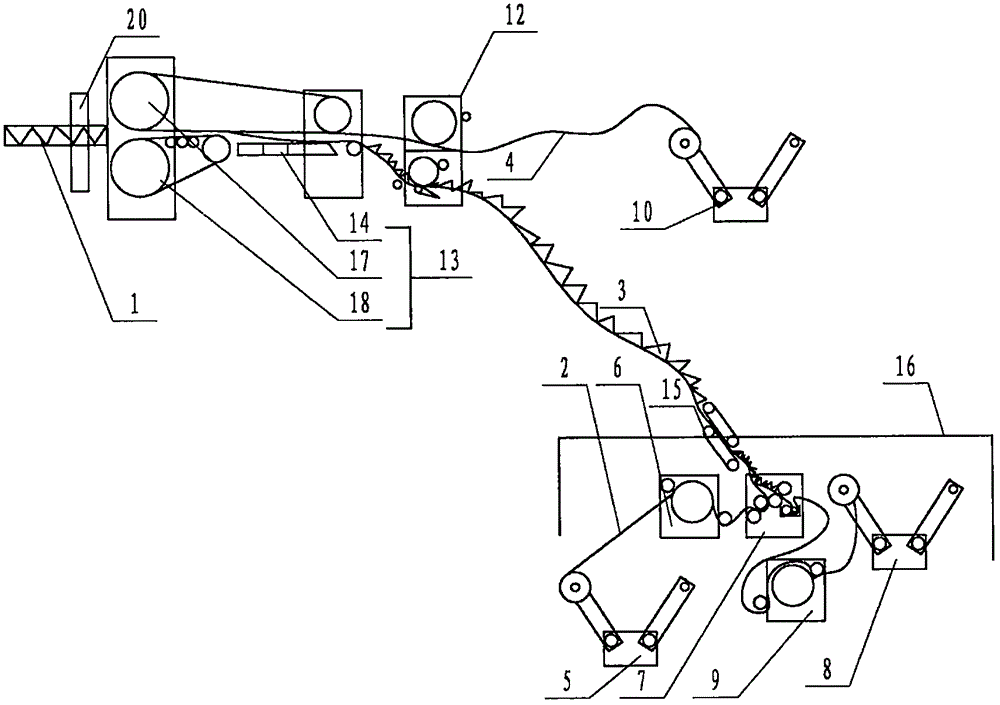

Improved corrugated board production line and production process thereof

InactiveCN105881982ASave secondary warm-upLow costMechanical working/deformationPaper/cardboard layered productsProduction linePulp and paper industry

The invention relates to an improved corrugated board production line which comprises an inner body paper rack used for placing corrugated inner paper of the corrugated board, an inner paper preheating cylinder used for heating the corrugated inner paper, a corrugated body paper rack used for placing the corrugated paper, a corrugated paper preheating cylinder used for heating the corrugated paper, a corrugating machine used for corrugating the corrugated paper and adhering the corrugated inner paper and the corrugated paper, a surface body paper rack used for placing corrugated surface paper, a pasting machine used for gluing the to-be-adhered upper surface of the corrugated paper, and a double-faced machine used for adhering the to-be-adhered upper surface of the corrugated paper and the lower surface of the corrugated surface paper. The improved corrugated board production line disclosed by the invention is compact in structure, reasonable in design and convenient to use, has the capacities of saving energy, reducing consumption, optimizing the process and lowering the cost, and is suitable for large-scale popularization.

Owner:周景勇

Hot spraying aluminium-zinc alloy wire rod and method for making same

The invention relates to a heat spraying aluminium zinc alloy wire rod composition and its preparing process, wherein the constituents (by weight percentage) of the wire rod include Al 54-56%, 0.004%<=M<=1.08%, impurity whose total amount is less than 1%, and balancing Zn, M is any one or the combination of RE, Mg, Ti or B.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

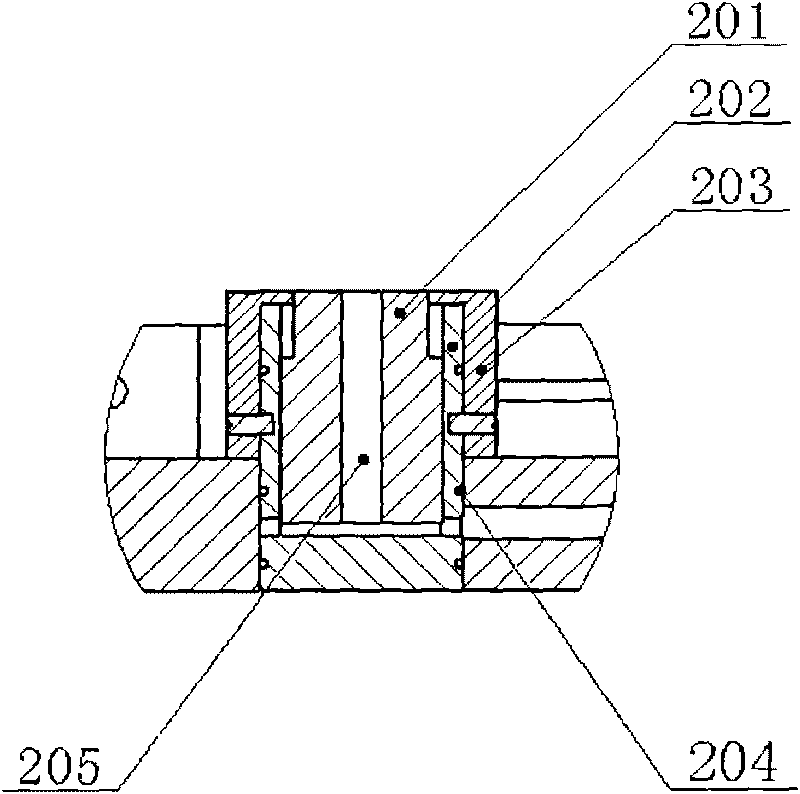

Silicon slice positioning and loading device of chemical mechanical polishing equipment

InactiveCN101704218APrecise positioningNo scratchesGrinding machine componentsSemiconductor/solid-state device manufacturingEngineeringSilicon

The invention provides a silicon slice positioning and loading device of chemical mechanical polishing equipment, which relates to the technical field of the chemical mechanical polishing equipment. The silicon slice positioning and loading device comprises a loading base plate, wherein a loading guide ring is fixed on the loading base plate and is internally provided with a first incline chamfer and a second incline chamfer; and a water pressure nozzle is arranged on the loading base plate, and a gap is arranged between the water pressure nozzle and a silicon slice arranged on the second incline chamfer. By adopting the device, the silicon slice can be precisely positioned, smoothly loaded and unloaded so as to be convenient for normally polishing; meanwhile, the silicon slice can not be scraped in the whole process, thereby being beneficial to improving the processing quality and the processing efficiency of the silicon slice.

Owner:THE 45TH RES INST OF CETC

Magnetic pulse flanged hole method for shells

The invention relates to shell flanged hole part forming methods, in particular to a magnetic pulse flanged hole forming method for shells. The method aims at solving the problems that in the flanged hole manufacturing process of an existing steel die hole flanging method, the technology is complex, the production efficiency is low, and the production cycle is long. The method comprises the steps that firstly, the shape of a flanged hole coil bobbin is designed according to a curved surface shell with pre-manufactured holes; secondly, the curved surface shell with the pre-manufactured holes is arranged on a flanged hole forming female die, an edge pressing ring is arranged on the inner surface of the curved surface shell in the periphery direction, a hole flanging coil matched with the hole flanging deforming area is wound on the flanged hole coil bobbin, covers the hole flanging deforming area and is attached to the hole flanging deforming area, one end of a capacitor set is connected with one terminal of the hole flanging coil, the other end of the capacitor set is connected with one end of a gap switch, the other end of the gap switch is connected with the other terminal of the hole flanging coil, and the capacitor set is charged to reach the preset voltage value; thirdly, magnetic pulse flanged hole forming is carried out; fourthly, flanged holes are corrected. The method is used for forming flanged hole parts of shells.

Owner:HARBIN INST OF TECH +1

High-surface-quality aluminum coating steel plate and production method thereof

ActiveCN108754312AImprove surface qualityNo scratchesHot-dipping/immersion processesHigh surfaceAluminum coating

The invention provides a high-surface-quality aluminum coating steel plate and a production method thereof. The high-surface-quality aluminum coating steel plate and the production method thereof comprises a substrate and a coating layer; the substrate contains C larger than or equal to 0.0010% and less than or equal to 0.25%, Si larger than or equal to 0.010% and less than or equal to 0.60%, Mn larger than or equal to 0.06% and less than or equal to 2.0%, P less than or equal to 0.015%, S less than or equal to 0.025%, 0.030% to 0.055% of Als, N less than or equal to 0.0050%, Ti less than or equal to 0.10%, Nb less than or equal to 0.10%, Cr less than or equal to 0.15%, B less than or equal to 0.0035%, and the balance Fe and inevitable impurities. The coating layer contains 7% to 11% of Si, 1.0% to 3.0% of Fe, 0.05% to 0.20% of La, 0.05% to 0.2% of Ti, and the balance Al and inevitable impurities. Compared with the prior art, the aluminum coating silicon steel plate produced by the method is high in surface quality, no obvious aluminum flowers are seen, and the surface quality reaches more than FC grade.

Owner:MAANSHAN IRON & STEEL CO LTD

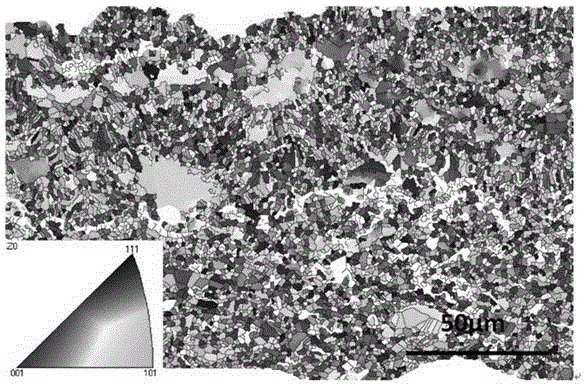

Preparation method for electron back scattered diffraction test sample of zirconium oxide thermal barrier coating

InactiveCN104089801ANo pollution in the processNo residual shear stressPreparing sample for investigationPollutionElectron

The invention relates to a preparation method for an electron back scattered diffraction test sample of a zirconium oxide thermal barrier coating. The preparation method comprises the steps of a. performing surface treatment on the electron back scattered diffraction test sample of the zirconium oxide thermal barrier coating; b. fixing the electron back scattered diffraction test sample of the zirconium oxide thermal barrier coating on a sample table of an argon ion beam grinder, and adjusting the center of the electron back scattered diffraction test sample of the zirconium oxide thermal barrier coating; c. vacuumizing to form a pressure being 1*10<-5>-1*10<-3>Pa, adjusting an inclination angle of the sample table for three times, wherein the inclination angle of the sample table is adjusted to be 60-85 degrees each time, and performing argon ion beam grinding on the electron back scattered diffraction test sample of the zirconium oxide thermal barrier coating; and d. resetting the inclination angle of the electron back scattered diffraction test sample of the zirconium oxide thermal barrier coating to zero degree, and performing spray-plating on the electron back scattered diffraction test sample of the zirconium oxide thermal barrier coating. The preparation method has the characteristics of no shear stress residue, no grinding material pollution, no scratches, low injury to the test sample and the like; a kikuchi band is relatively high in definition; the calibration rate of an electronic diffraction pattern is over 95 percent.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH +1

Sheel metal stacker

ActiveCN101045505APrecise positioningRealize blankingPile receiversArticle deliveryInductorEngineering

A plate stacking machine for the shaped plates is composed of a moving, locating and plate lowering system consisting of machine frame, parallel two longitudinal beams, driver unit, controller, conveying belt, electromagnetic suction block, and automatic locating block, an automatic lifting-lowering platform, coaxial two horizontal stop blocks under the plate inlets and perpendicular to longitudinal beam, another two stop blocks on said longitudinal beams, and an inductor between said another two stop blocks and connected electrically to said controller.

Owner:JIANGSU YAWEI MACHINE TOOL

Glass detergent

InactiveCN104371837AImprove protectionQuick removalInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCelluloseGlycerol

The invention relates to a glass detergent which is prepared from the following raw materials in parts by weight: 6-10 parts of silica sol, 5-10 parts of nonylphenol polyethenoxy ether, 5-10 parts of sodium polyacrylate, 3-6 parts of ethanol, 7-10 parts of aluminum sol, 4-9 parts of jasmine oil, 2-6 parts of Chinese honeylocust gum, 1-5 parts of sodium silicate, 2-8 parts of sodium thiosulfate, 3-6 parts of hydrochloric acid, 1-4 parts of titanium dioxide, 5-8 parts of hydroxymethyl cellulose, 3-8 parts of fatty alcohol polyethenoxy ether and 4-7 parts of glycerol. The glass detergent can quickly remove stains, can not generate scratches, has favorable protective action on glass, and has longer service time.

Owner:QINGDAO ZHIGU INNOVATION TECH

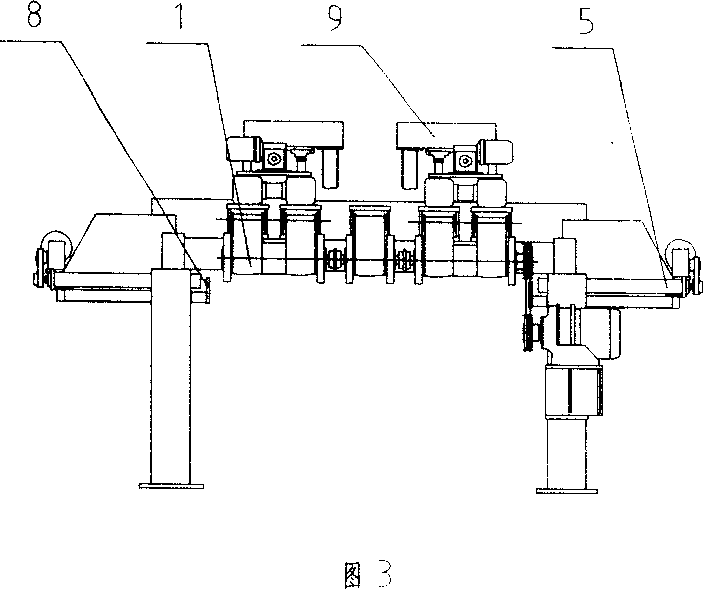

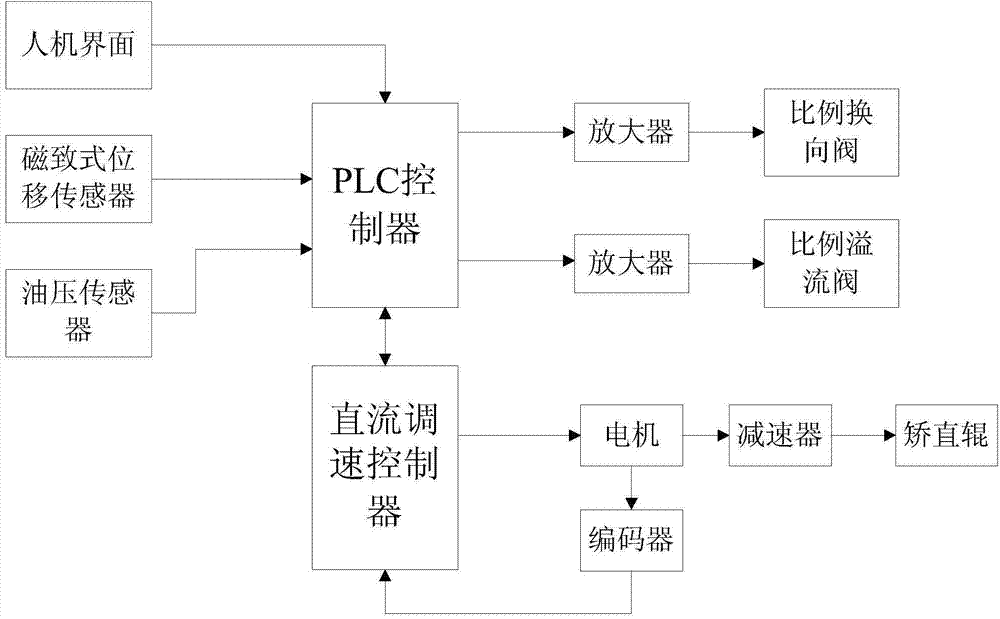

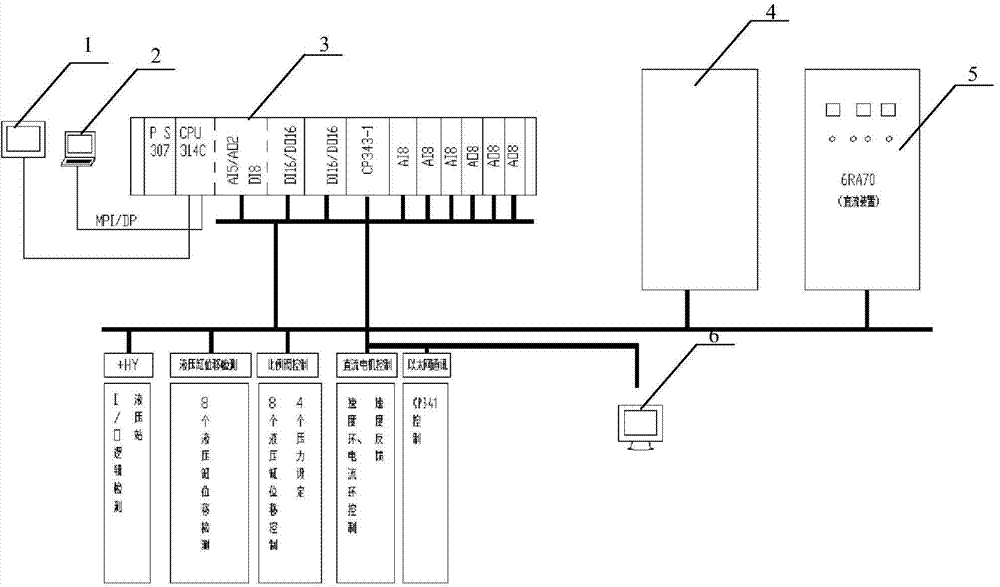

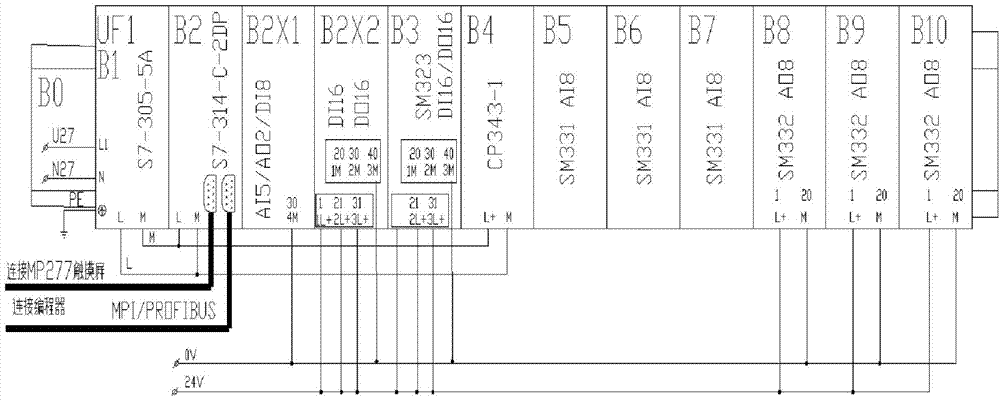

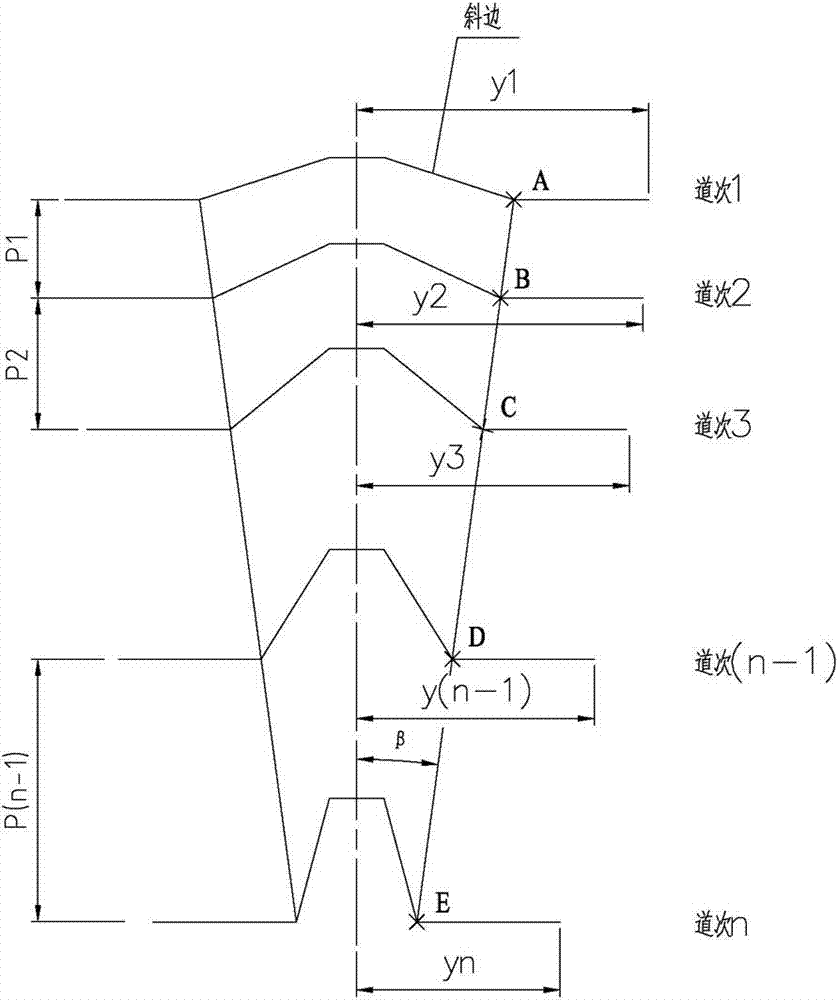

Automatic control system and method for high-precision straightening machine

ActiveCN104117554AEnsure consistencyNo dead zoneProgramme control in sequence/logic controllersPistonAutomatic control

The invention relates to an automatic control system and method for a high-precision straightening machine and belongs to the field of automatic control. Through the automatic control system and method, the straightness (curvature) reaches over 0.3 mm / m according to the straightening precision of the high-precision straightening machine; a hardware structure and a software method of the automatic control system for the high-precision straightening machine are designed considering closed-loop control of oil source pressure and oil cylinder piston displacement of a hydraulic system of the high-precision straightening machine, continuous detection of straightening operation process data, stepless speed regulation control for calibrating transmission of all sets of straightening rollers and the like, the international advanced level of three-dimensional rotation straightening under high-precision automatic control is reached, consistency of roller gap precision in the straightening process, stability of evenly distributed and balanced straightening force and reliability of nonlinear variable gain automatic compensation can be guaranteed, the straightness is improved to 0.2 mm / m from 0.3 mm / m according to the straightening precision of the high-precision straightening machine, and the straightening target that straightened materials have no blind area or tiny crack or scratch or oval or bounce is achieved.

Owner:辽宁银捷装备科技股份有限公司

Laser eyeglass protection method and apparatus based on laser composite life-prolonging technique

InactiveCN101402156AEasy to cleanNo scratchesMetallic material coating processesLaser beam welding apparatusLaser processingControl system

The invention relates to the technical field of laser processing and lasers, in particular to a protection method and a protection device for a lens of a laser compounded life-prolonging laser for a heat-resistant part. A protection disk which is orderly connected with a servomotor, a frame, a control system, a protective cover, and a protection glass cleaning device is arranged between the lens of the laser and a test specimen to protect the lens; during a pulse interval of laser shock, the servomotor drives the protection disk to rotate with certain angle; during the continuous laser action of laser cladding and quenching, the servomotor drives the protection disk to continuously rotate, so a polluted position of the protection disk is away from a laser working position; the position of the protection disk which is quickly cleaned by the protection glass cleaning device moves to the laser working position and prepares for continuous laser work; at the same time, the protection glass cleaning device cleans and dries the polluted position of the protection disk. The protection device has the advantages that the protection device has a simple structure and low cost, simplifies the cleaning process of the lens, has no scratches on protection glass, and is convenient to realize multi-point continuous shock and long laser cladding and quenching.

Owner:江苏宏大特种钢机械厂有限公司 +1

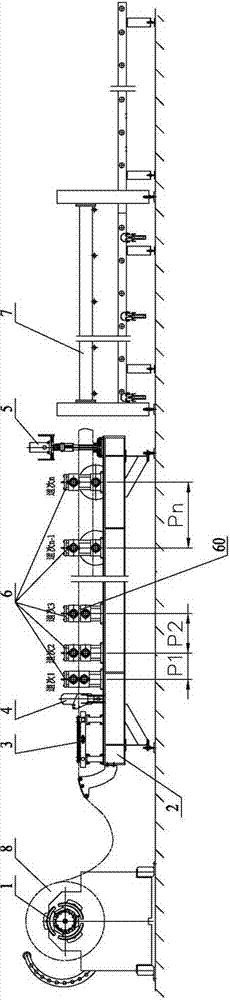

Cold-bending forming machine for high corrugated steel floor deck

The invention relates to a cold-bending forming machine for a high corrugated steel floor deck. The cold-bending forming machine for the high corrugated steel floor deck comprises an automatic uncoiler, a machine frame, a guiding device, a lubricating device, a cold-bending forming roller set, a hydraulic cutting device and a stacking machine, wherein the automatic uncoiler is arranged at one side of the machine frame, and the stacking machine is arranged at the other side of the machine frame. The guiding device, the lubricating device, the cold-bending forming roller set and the hydraulic cutting device are sequentially installed on the machine frame, and the guiding device is arranged at one side of the automatic uncoiler. The cold-bending forming roller set comprises a plurality of rolls, and the rolls are unequally distributed at intervals. The cold-bending forming machine for the high corrugated steel floor deck has the advantages of being high in forming speed, applicable to cold rolling galvanized steel sheets or color plates with the rolling thickness of 0.7-1.5 mm and the yield strength of 230-350 MPa, or applicable to the construction steel floor deck with the rolling corrugated height of 120-220 mm and the substrate developed width of 900-1500 mm. By means of the cold-bending forming machine for the high corrugate steel floor deck, the coating or the plating of the rolled tubular products is not scratched, no visible bag-shaped wave, thus the forming quality of the products is enabled to be good.

Owner:绍兴仕马特机械制造有限公司

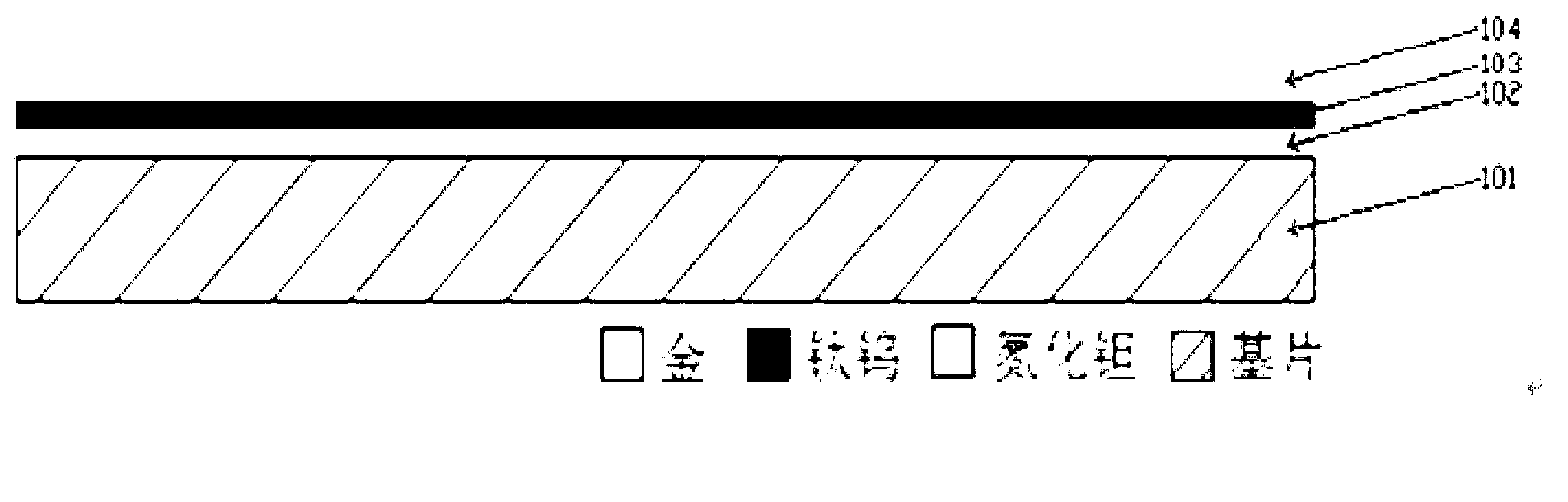

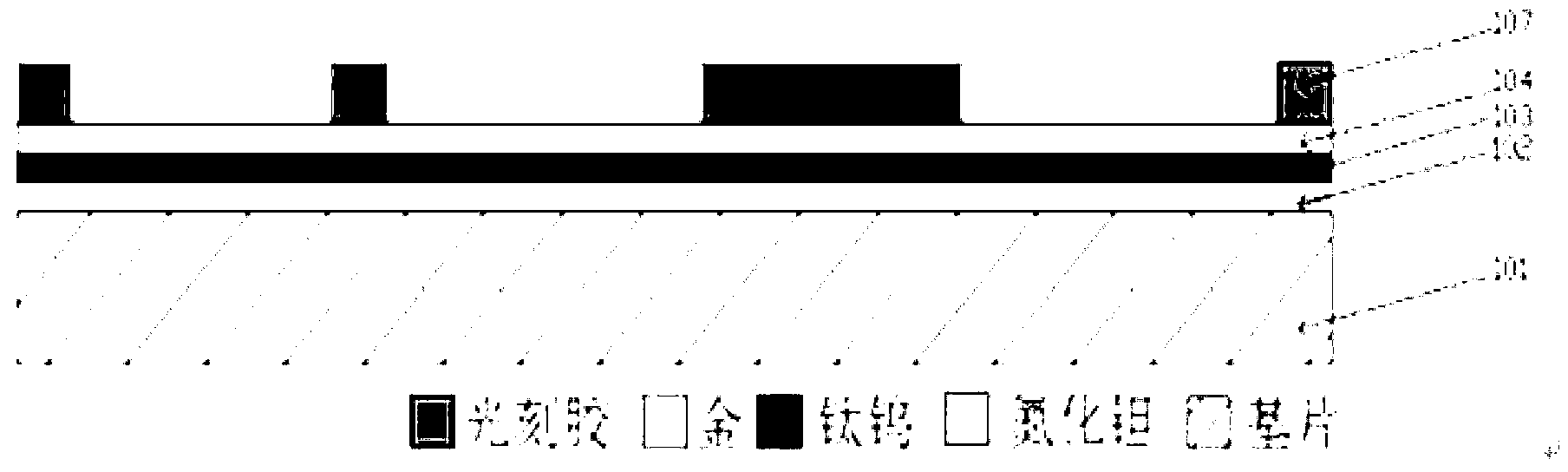

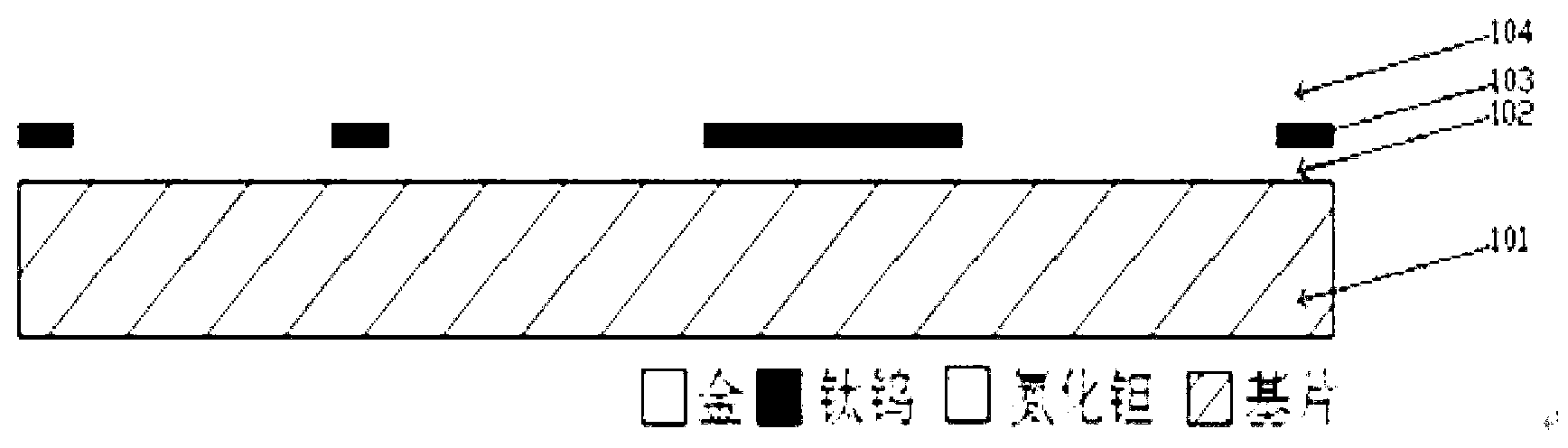

Thin film hybrid integrated circuit electroplating method

InactiveCN103236415AEasy to operateHigh precisionSemiconductor/solid-state device manufacturingEnvironmental resistanceComposite film

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com