Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

924 results about "Aluminum coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

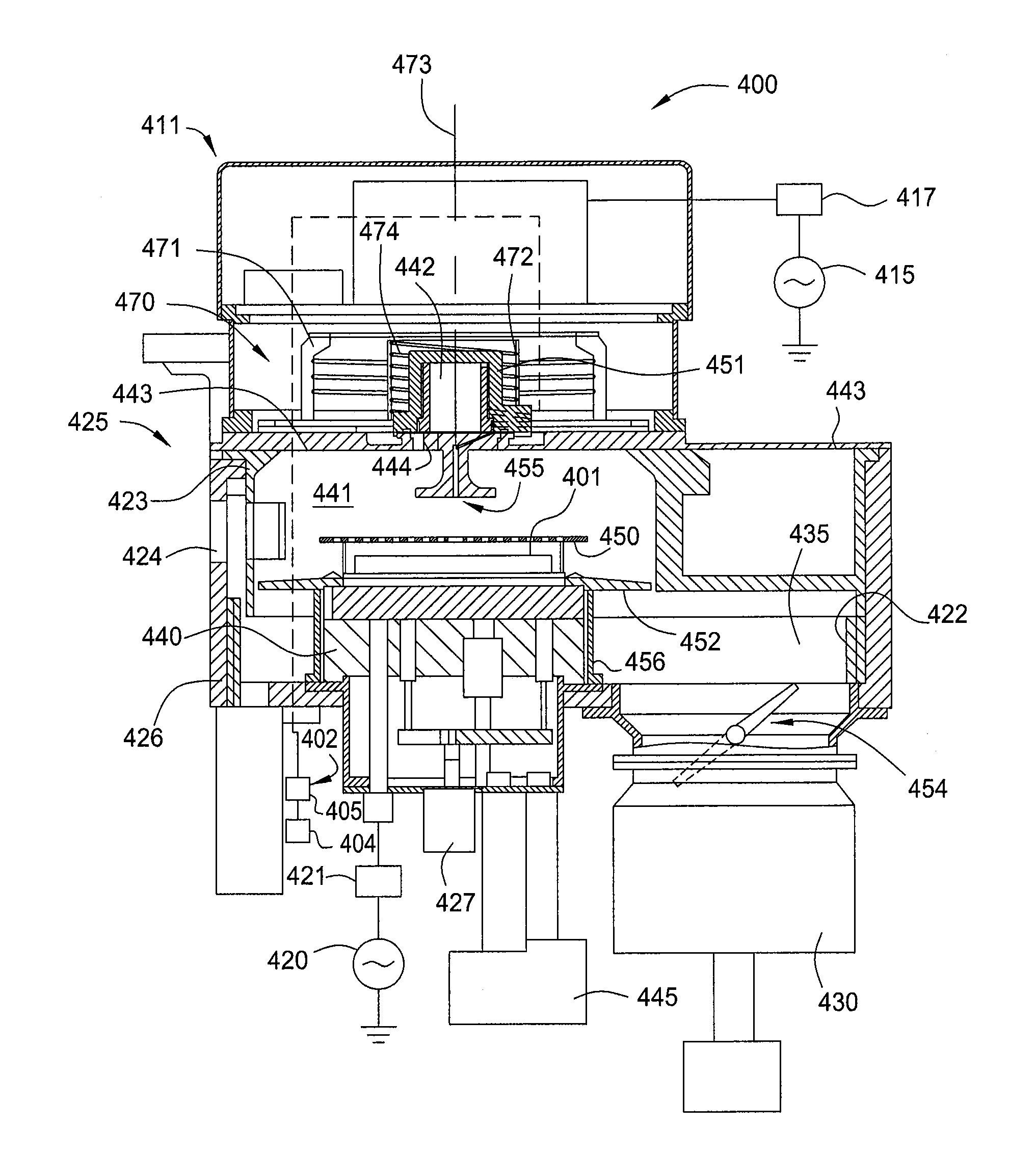

Apparatus for producing metal coated polymers

InactiveUS6106627AHigh breakdown strengthAvoid depositionRadiation applicationsVacuum evaporation coatingCross-linkBreakdown strength

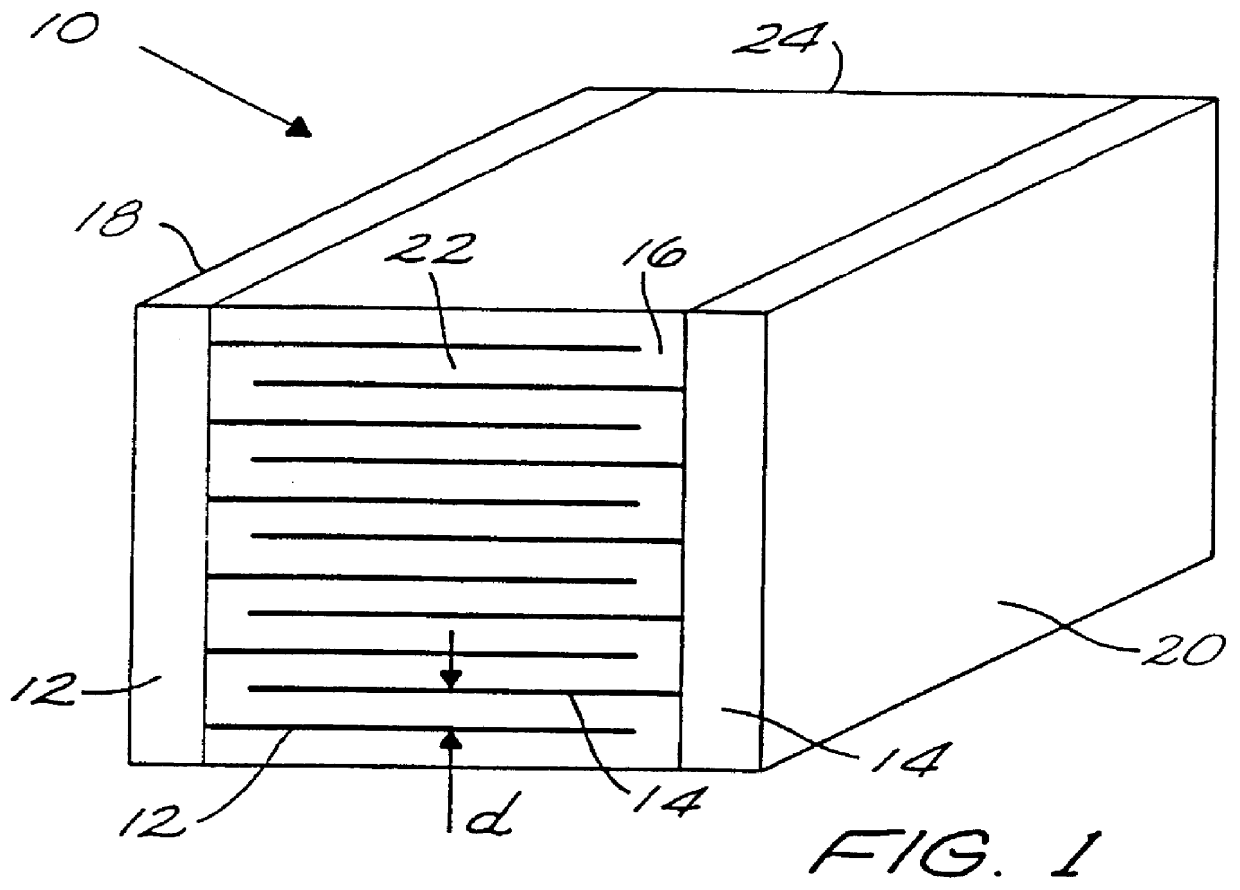

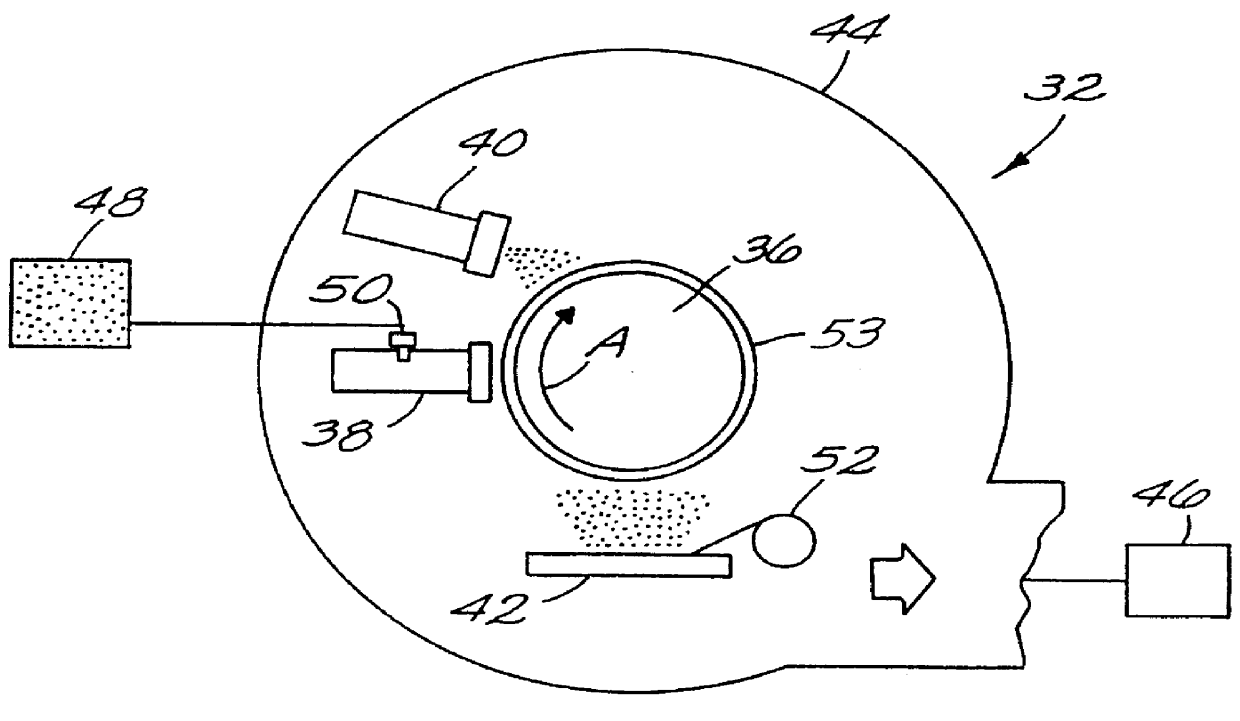

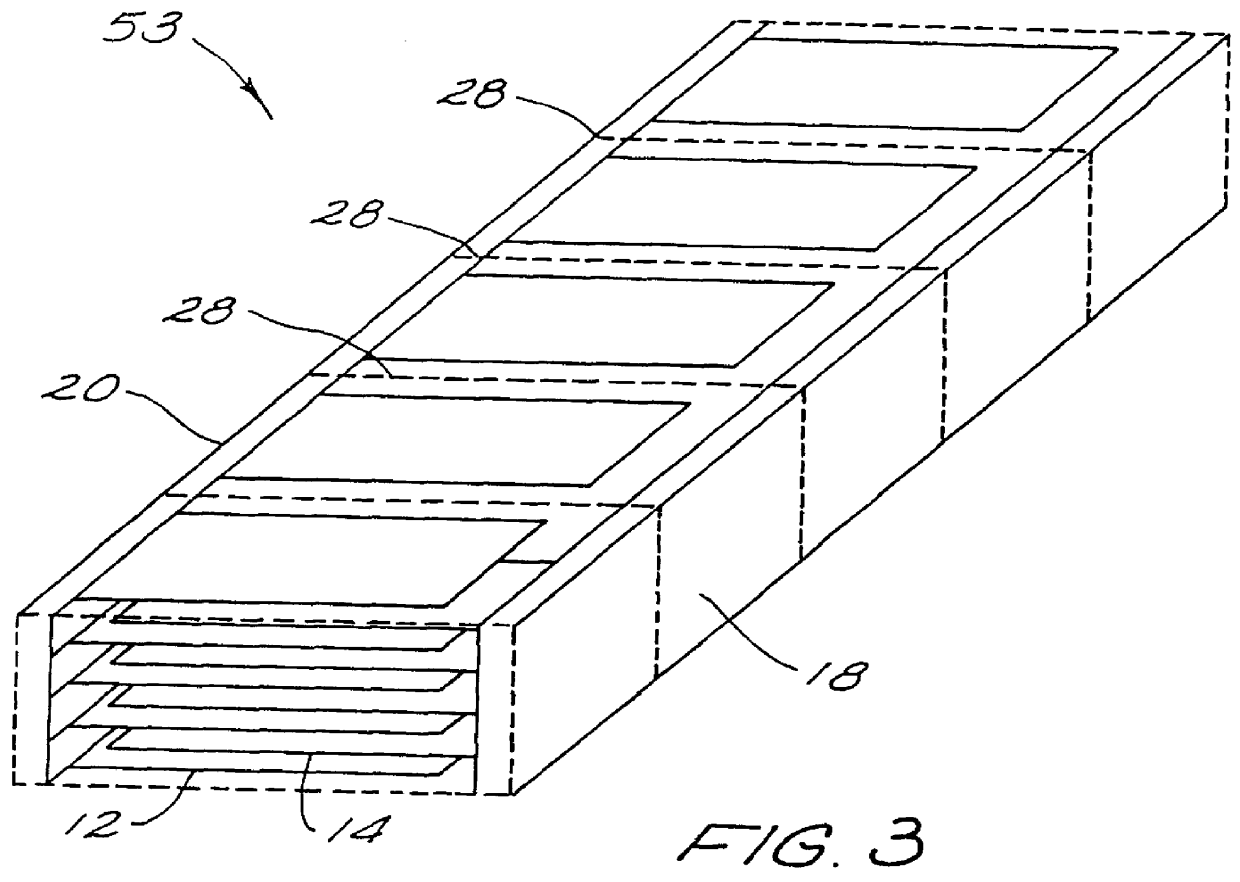

A method of improving the breakdown strength of polymer multi-layer (PML) capacitors is provided and of providing a window in food packaging is provided. The method comprises patterning the aluminum coating, either by selective removal of deposited aluminum or by preventing deposition of the aluminum on selected areas of the underlying polymer film. Apparatus is also provided for patterning metal deposition on polymer films comprising masking for defining regions in which metal is deposited. The apparatus comprises: (a) a rotating drum; (b) a monomer evaporator for depositing a monomer film on the rotating drum; (c) a radiation curing element for curing the monomer film to form a cross-linked polymer film; and (d) a resistive evaporator for depositing a metal film on the cross-linked polymer film. The foregoing elements are enclosed in a vacuum chamber. The masking comprising one of the following: (e1) a web mask provided with openings for depositing the metal film therethrough, the web mask including a portion adapted for positioning between the resistive evaporator for depositing the metal film on the cross-linked polymer film and the rotating drum; or (e2) a rotating element for transferring liquid from a source to the rotating drum, the rotating element adapted to transfer the liquid to the rotating drum after the monomer evaporator for depositing the polymer film and before the resistive evaporator for depositing the metal film.

Owner:SIGMA LAB OF ARIZONE

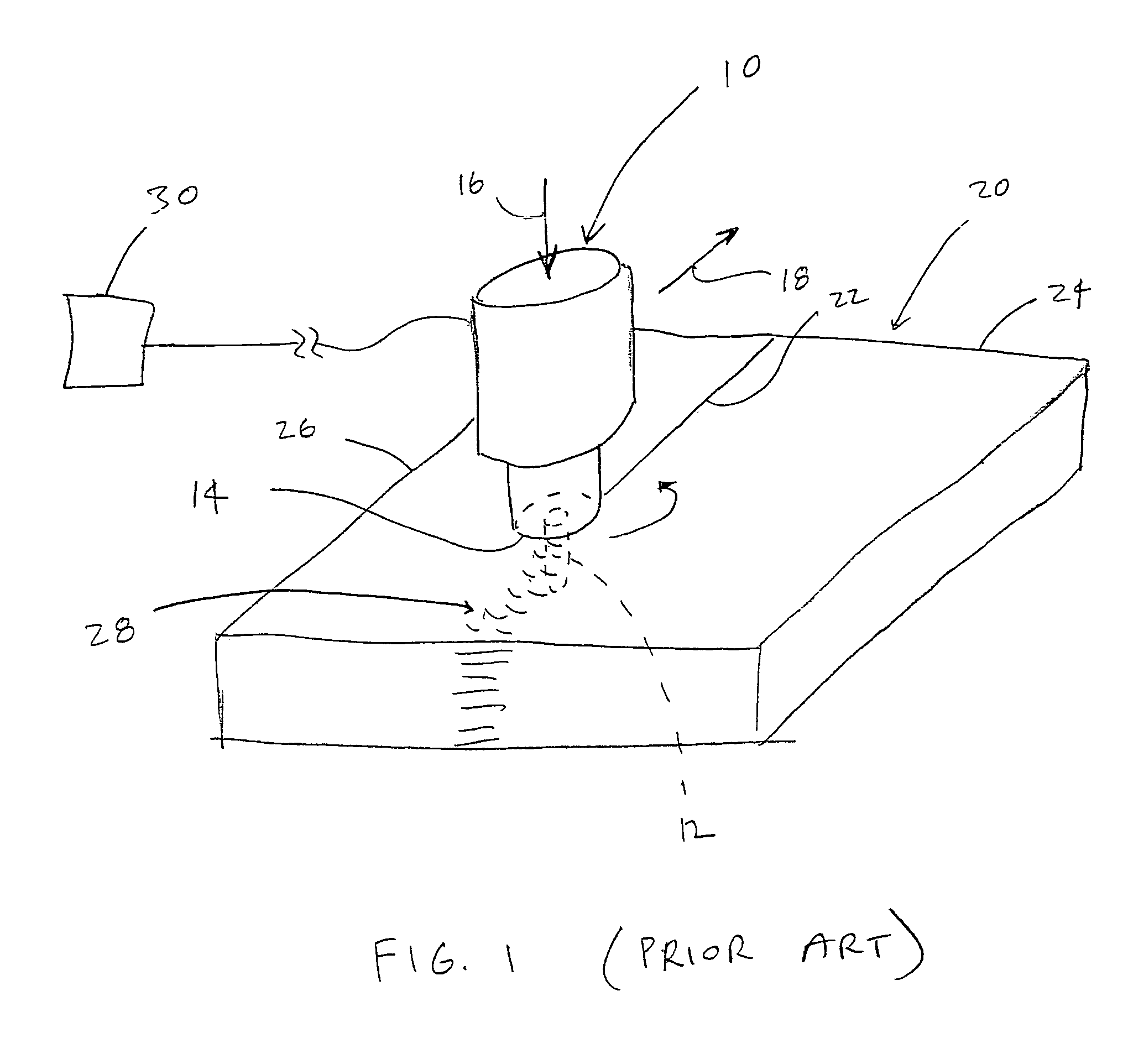

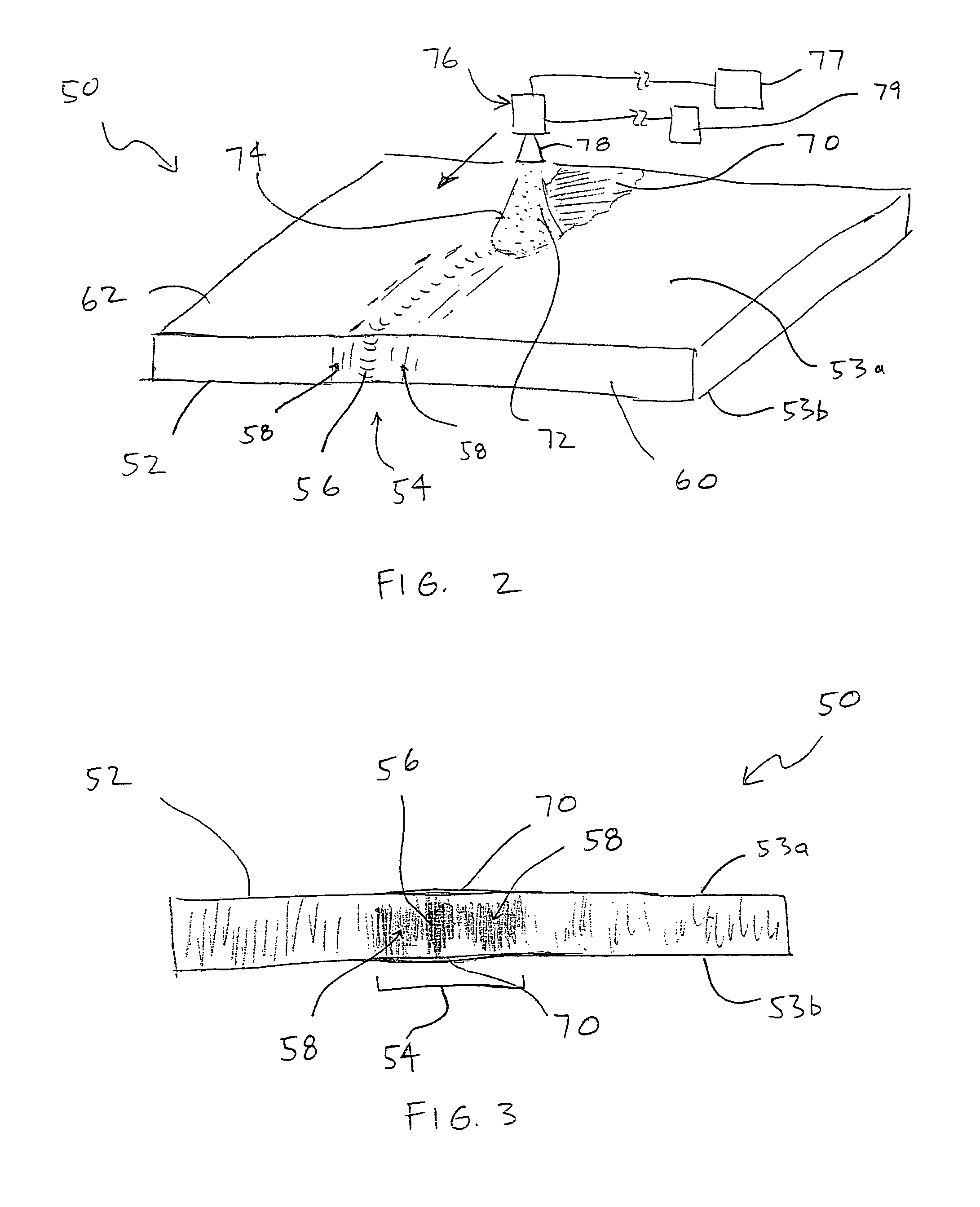

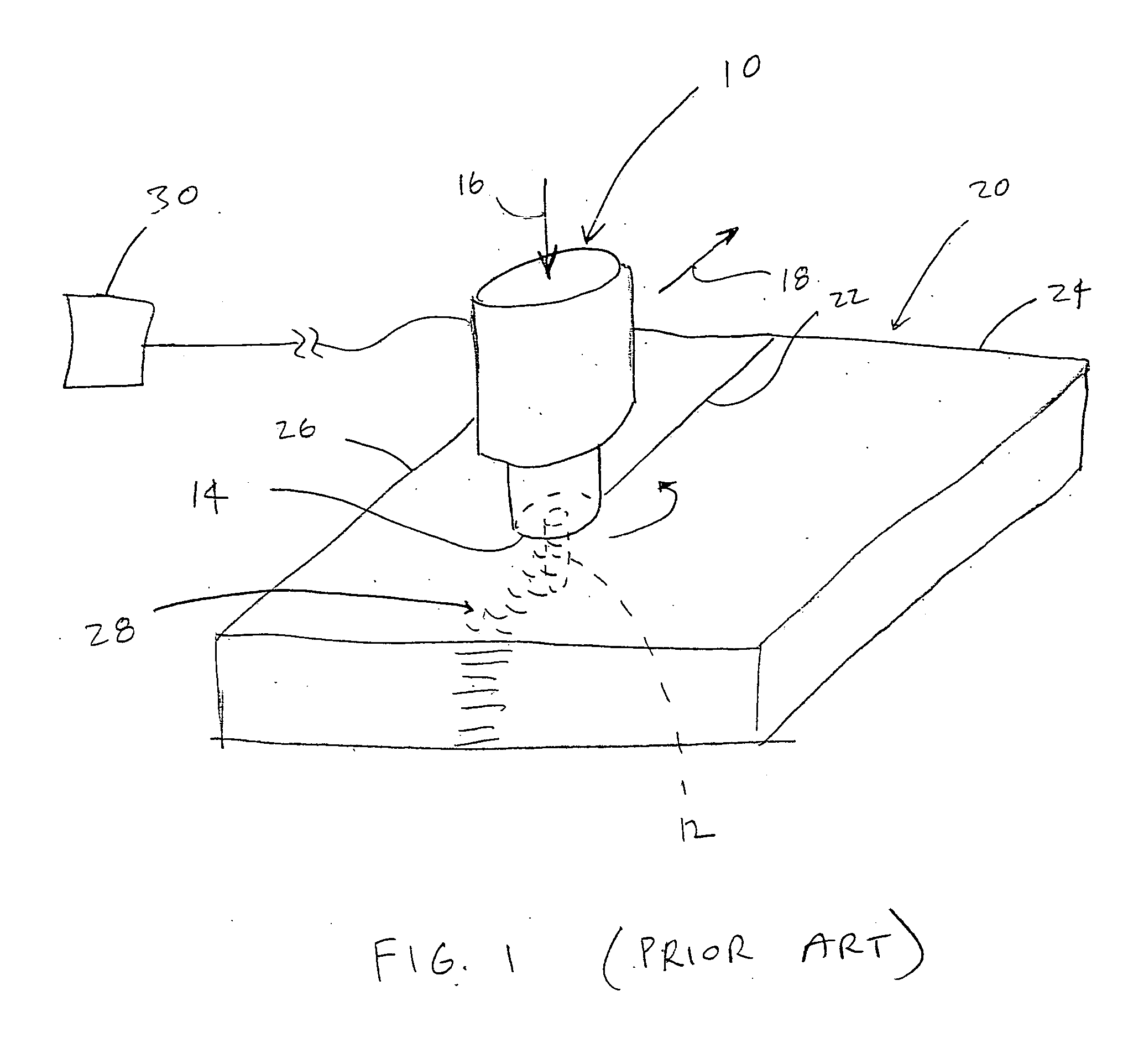

Aluminum coating for the corrosion protection of welds

ActiveUS7066375B2Improve corrosion resistanceSoldering apparatusPretreated surfacesFriction weldingHeat-affected zone

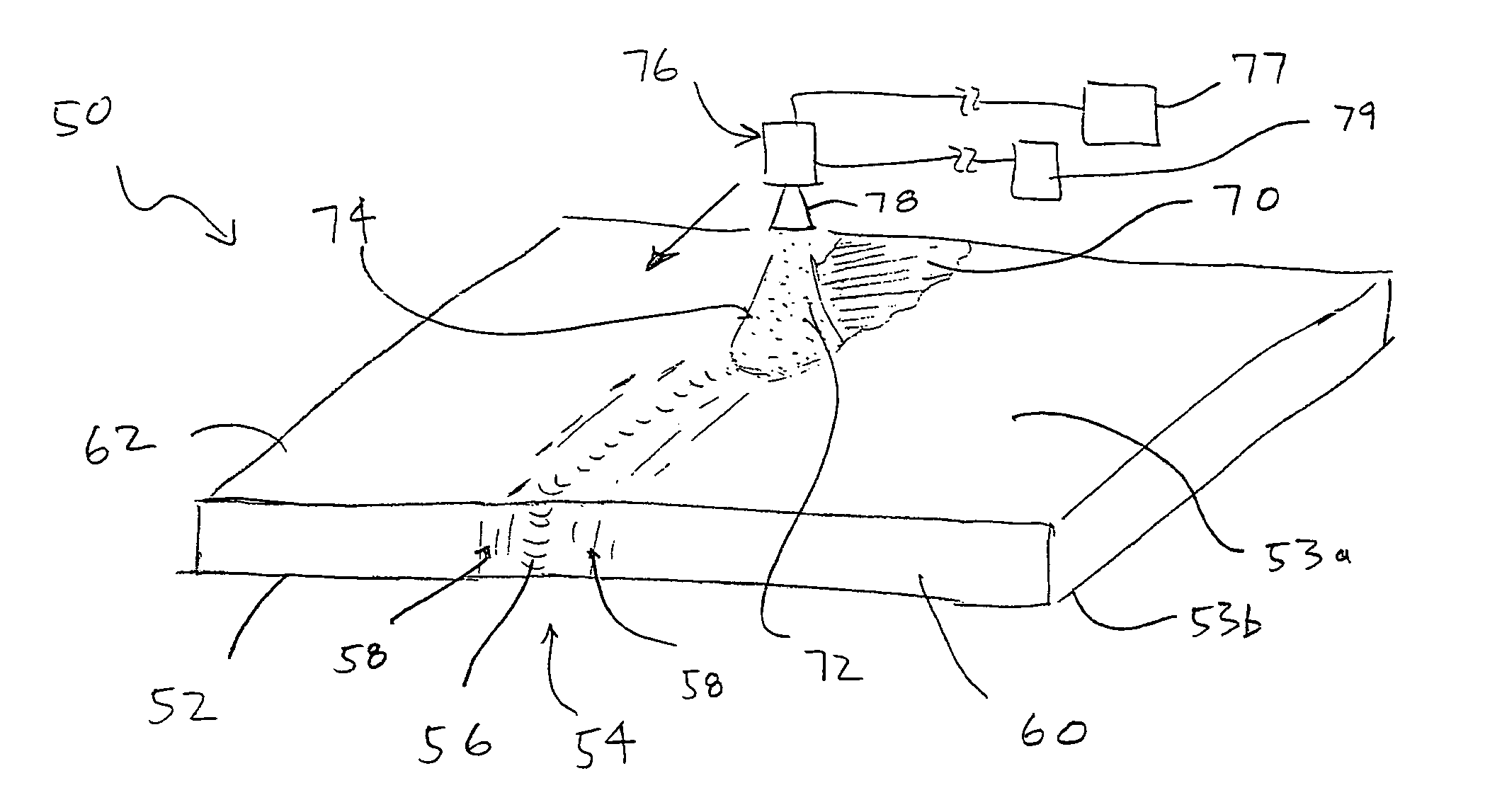

A method for coating and an associated assembly including such a coating are provided. The assembly includes a workpiece defining a weld portion, such as a friction weld joint and a heat affected zone. A coating is disposed on the weld portion to at least partially cover the weld portion, thereby providing enhanced corrosion resistance to the workpiece.

Owner:THE BOEING CO

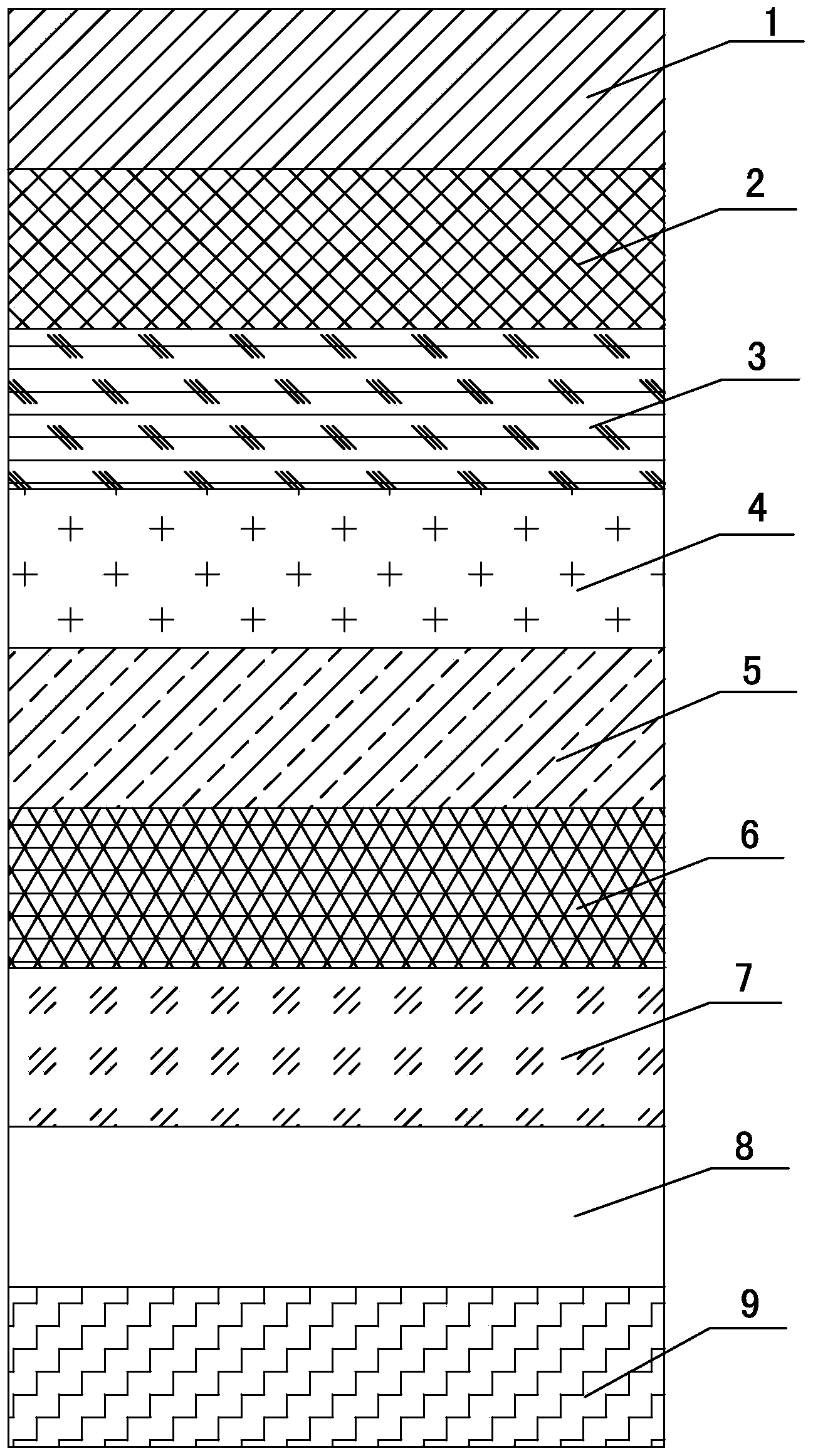

Positive electrode current collector and preparation method and application thereof

ActiveCN107123812AIncrease energy densityReduce thicknessFinal product manufactureElectrode carriers/collectorsEvaporationAluminum metal

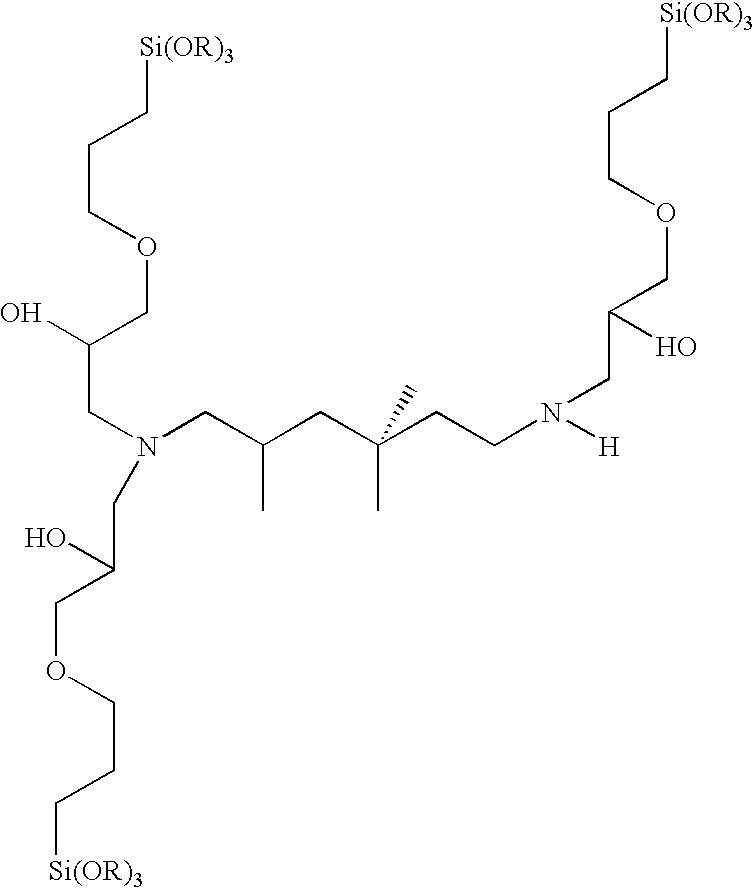

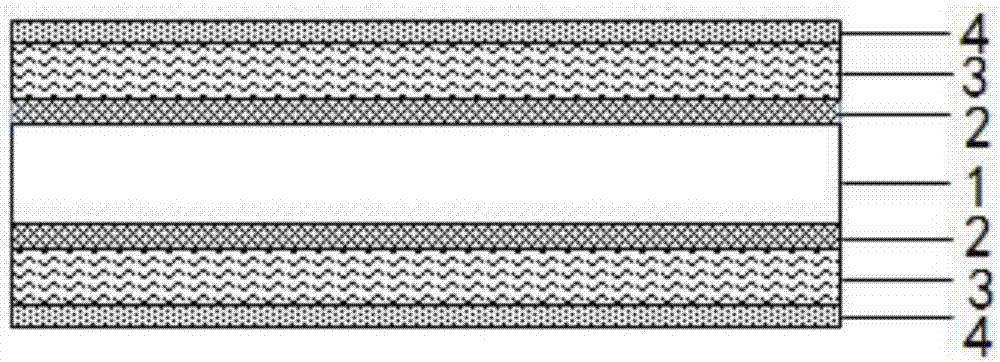

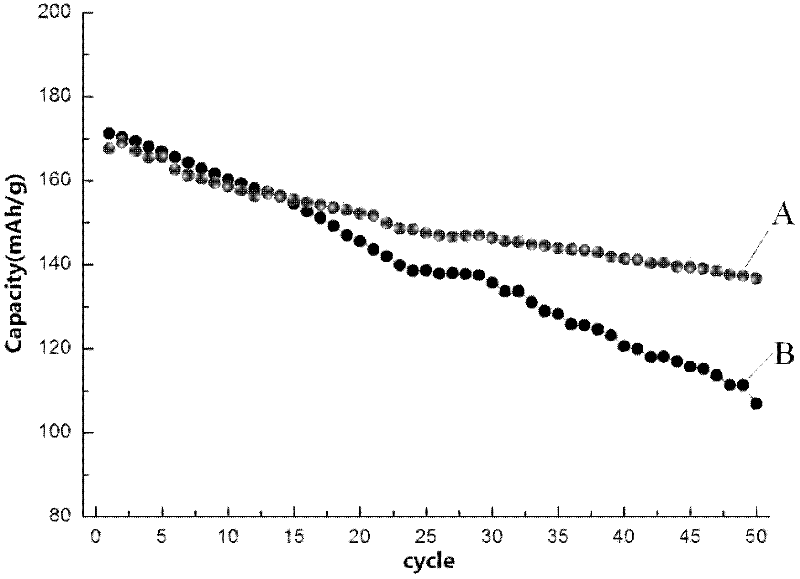

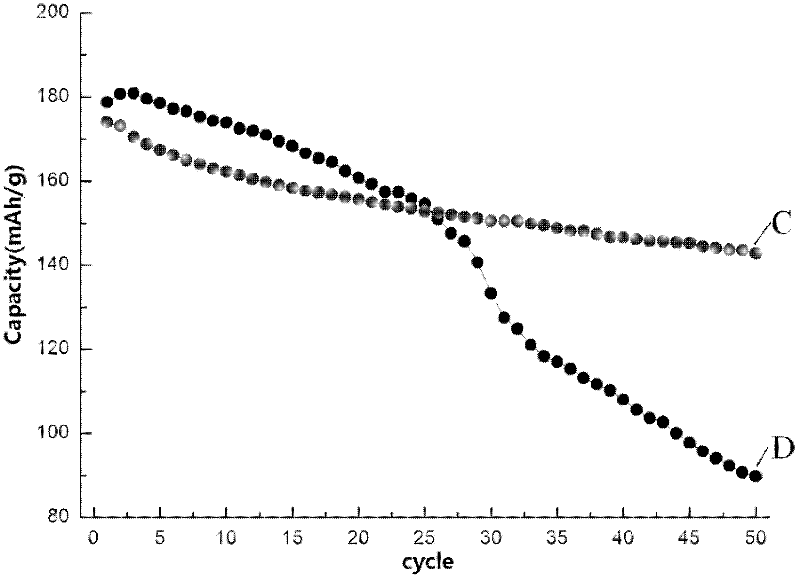

The invention discloses a positive electrode current collector and a preparation method and an application thereof. The positive electrode current collector is of a multilayered structure and comprises a plastic thin film, wherein the upper and lower surfaces of the plastic thin film are coated with a bonding force enhancement layer, an aluminum metal coating layer and an anti-oxidization layer in sequence. The preparation method comprises the steps of coating the bonding force enhancement layer, the aluminum metal coating layer and the anti-oxidization layer through an evaporation film-coating process in sequence. The application of the positive electrode current collector mainly refers to an application in a lithium ion battery. By virtue of the positive electrode current collector, light weight of the battery can be realized, energy density can be improved, the aluminum coating layer does not fall off easily, and easy oxidization can be avoided.

Owner:CONTEMPORARY AMPEREX TECH CO +1

Preparation method of lithium-ion battery cathode material coated aluminum

InactiveCN102299299ACoating process conditions are easy to controlImprove high temperature stabilityCell electrodesNickel saltElectrical battery

The invention relates to a method for preparing aluminum-coated anode materials of lithium-ion batteries, which is characterized in that: firstly, soluble nickel salts, cobalt salts, and manganese salts are formulated into salt solutions, and then mixed with ammonia-water-mixed sodium hydroxide or potassium hydroxide solutions React to form precursor particles, wash and dry; add water to the dried precursor particles to prepare a flowable slurry, stir, and add trivalent aluminum salt solution and sodium hydroxide or potassium hydroxide solution dropwise to the slurry at the same time , to obtain the precursor of nickel hydroxide cobalt manganese coated with aluminum; then mix the precursor with lithium source, and then sinter to obtain the positive electrode material of lithium ion battery coated with aluminum. The present invention has the following obvious advantages: raw materials are easy to obtain; coated The process conditions are easy to control, and it is easy to obtain a relatively uniform coating body; the prepared positive electrode material can make the lithium ion battery have superior high temperature stability and better cycle characteristics.

Owner:深圳市天骄科技开发有限公司

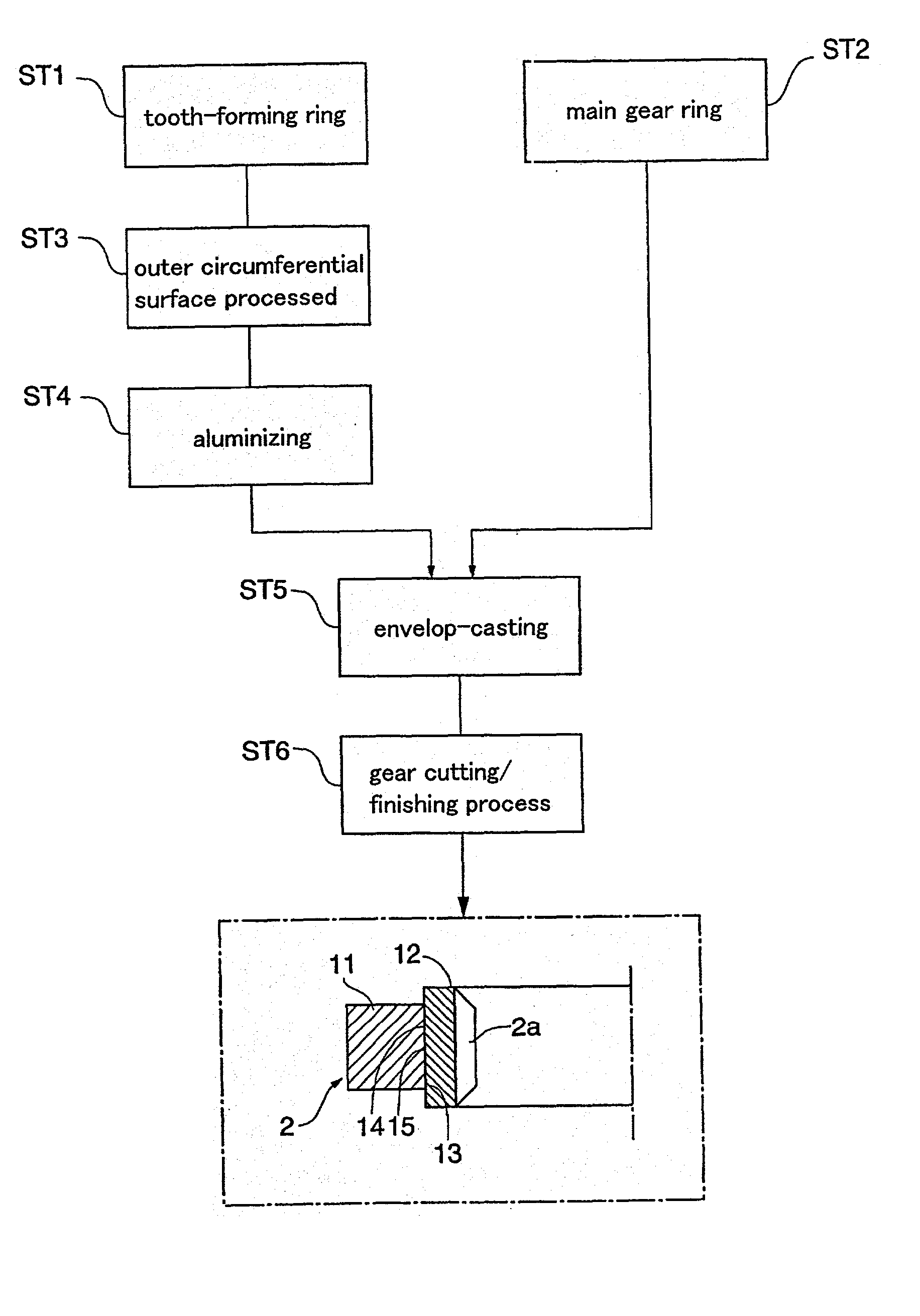

Method of manufacturing a rigid internal gear of a wave gear device

InactiveUS20020184766A1Increase pressureForming accuratelyToothed gearingsGear wheelsCopperAluminum coating

A rigid internal gear 2 of the wave gear device is composed by integrating a tooth-forming ring 12 formed with internal teeth, and a main gear ring 11 into a single body. The tooth-forming ring 12 is manufactured from a ferrous or copper material that has superior strength and abrasion resistance, while the main gear ring 11 is manufactured from a lightweight material, such as an aluminum alloy. The outer circumferential surface of the tooth-forming ring 12 is aluminized to form a dispersed aluminum coating 15, before the tooth-forming ring 12 is cast within the main gear ring 11 so as to integrate the main gear ring 11 and the tooth-forming ring 12. Both parts are reliably integrated so that a large amount of torque can be transmitted, whereby realizing a rigid internal gear that is lighter than conventional models.

Owner:HARMONIC DRIVE SYST IND CO LTD

Method for preparing Al-Al2O3 composite coating on surface of magnesium alloy

InactiveCN101831652AEasy to recycleHigh bonding strengthAnodisationSuperimposed coating processAluminum coatingCorrosion

The invention relates to a method for preparing an Al-Al2O3 composite coating on the surface of magnesium alloy, belonging to the technical field of metal surface treatment. The Al / Al2O3 composite coating prepared on the surface of the magnesium alloy by a calorization-oxidation method has high corrosion resistance and rigidity. The method comprises the following main steps of: firstly, coating an aluminum coating to the magnesium alloy, and then electrochemically oxidizing the aluminum coating to form an aluminum oxide film layer having extremely high corrosion resistance and rigidity, wherein a cold spraying method or a molten-salt aluminum electroplating method is used in the preparation process of the aluminum coating of the magnesium alloy, and common anodic oxidization and plasma anodic oxidization are used for the oxidation of the aluminum coating. By coating the aluminum coating to the surface of the magnesium alloy to carry out calorization treatment and then carrying out electrochemical anodic oxidization, the invention enhances the comprehensive protective performance of the surface of the magnesium alloy, and the Al / Al2O3 composite coating prepared on the surface of the magnesium alloy has the advantages of large bonding strength, high rigidity, good corrosion resistance and the like, thereby being the ideal protective coating for the magnesium alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

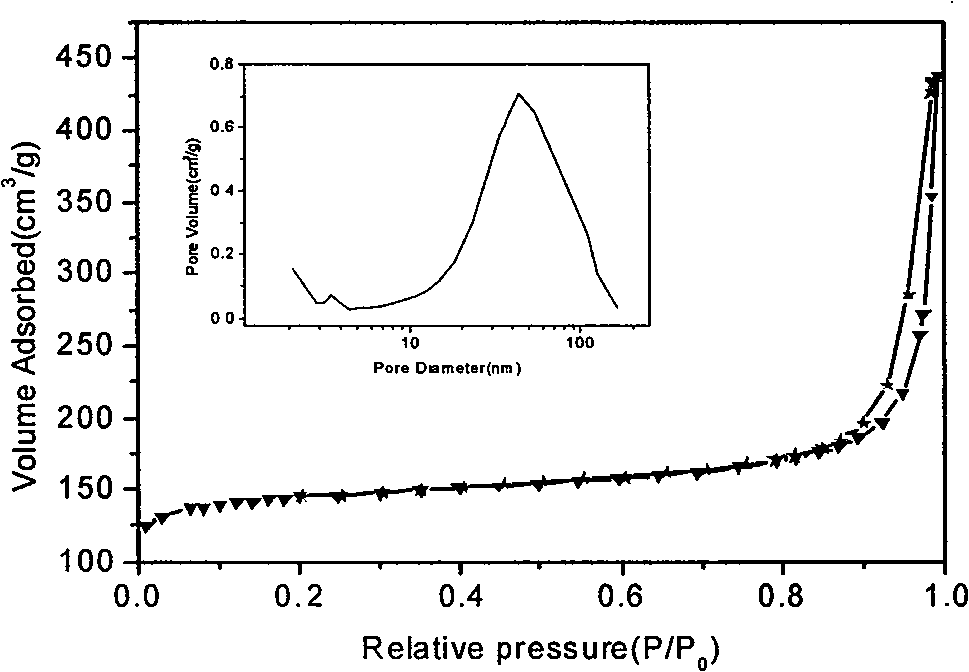

Method for preparing multi-level porous channel beta zeolite

InactiveCN101538049ATake advantage ofAdjustable mesoporosityMolecular-sieve and base-exchange compoundsDiffusion resistancePorous carbon

The invention provides a method for preparing multi-level porous channel beta zeolite, and belongs to the technical field of preparation and application of the zeolite. The method is characterized in that: carbon grains which are generated under restriction of the sequent meso-porous channels are taken as a hard mold board, and added with a small molecular organic ammonium soft mold board to convert the meso-porous silicon-aluminum coating the carbon grain into the meso-porous beta zeolite in situ, and the meso-porous beta zeolite is calcined to remove the soft and hard mold boards so as to obtain the multi-level porous channel containing beta zeolite. Compared with the zeolite obtained by directly taking the meso-porous carbon as the mold board, the multi-level porous channel beta zeolite synthesized by the method does not need to remove the meso-porous silicon-aluminum first and then introduce the silicon-aluminum species synthesizing the zeolite, thereby reducing complicated working procedures as well as saving raw materials. The method has the advantages of greatly lowering diffusional resistance, reducing secondary reaction, and having better catalytic property and huge potential application values in fields such as petrochemical industry, fine chemical industry, and the like.

Owner:TAIYUAN UNIV OF TECH

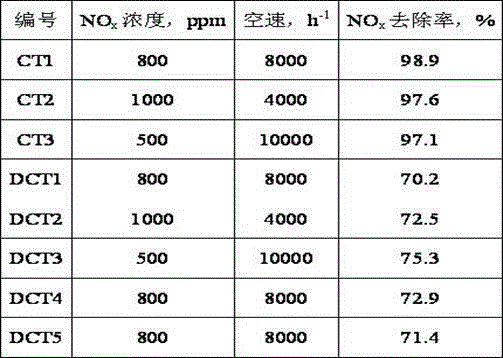

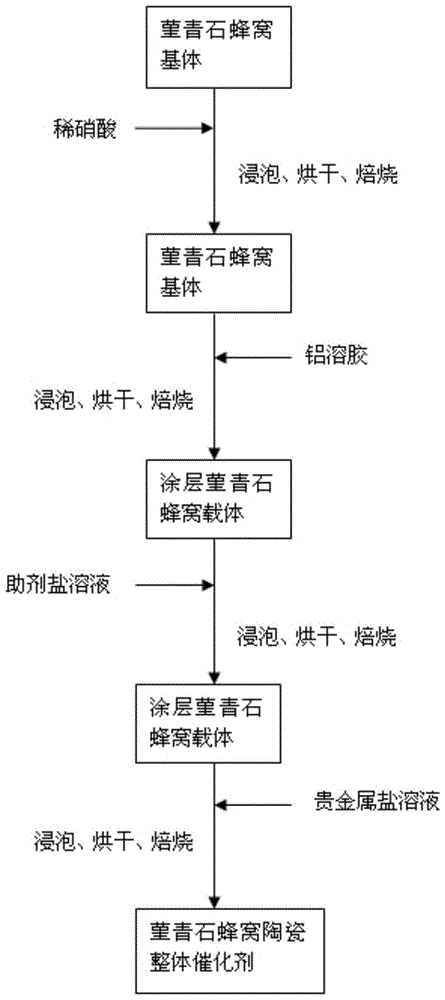

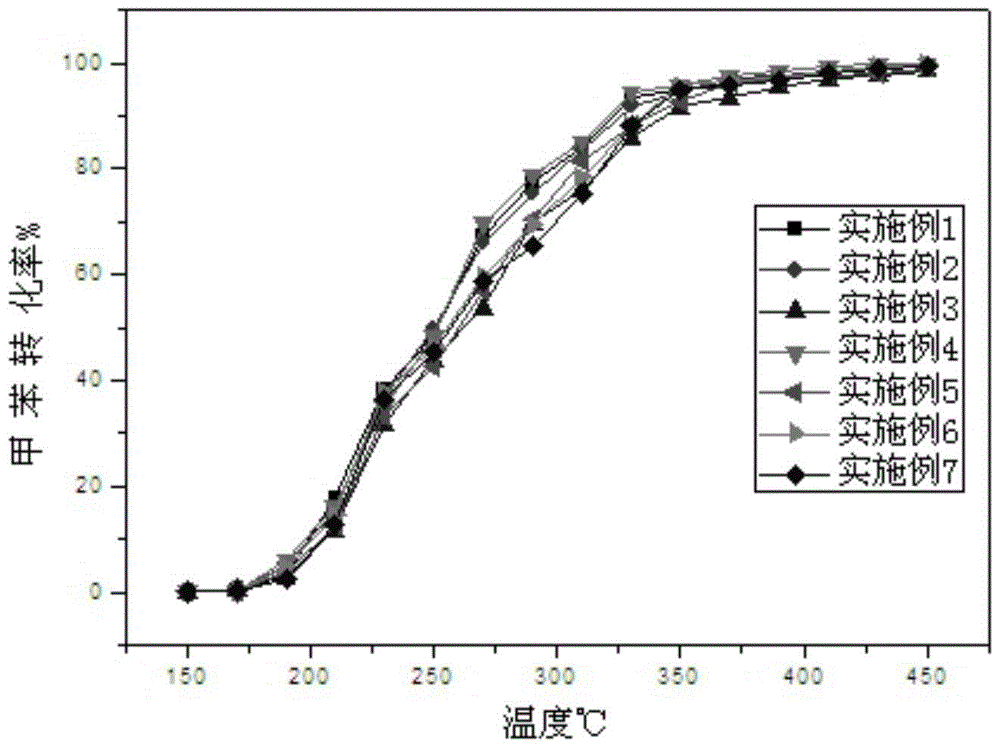

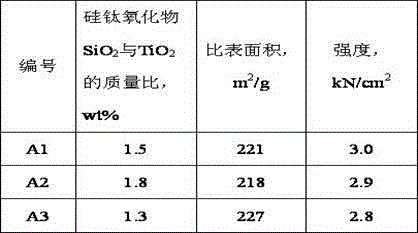

Denitration catalyst and preparation method thereof

ActiveCN104415780ASimple structureLarge specific surface areaMolecular sieve catalystsDispersed particle separationPtru catalystReaction temperature

The invention discloses a denitration catalyst and a preparation method thereof, the catalyst takes pretreated cordierite honeycomb ceramics as a matrix, a silicon-aluminum coating, a composite coating and an active component are coated on the surface of the matrix, by measuring gross weight of the catalyst, the catalyst contains 80-90wt% of cordierite honeycomb ceramics, 2-9wt% of silicon-aluminium coating, 3-10wt% of composite coating, and 0.01-15wt% of active component, wherein the active component can be Mn and Fe; by measuring gross weight of the silicon-aluminum coating, the silicon-aluminum coating comprises 10-50wt% of silica, and 50-90wt% of alumina; by measuring gross weight of the composite coating, the composite coating contains 40-80wt% of titanium dioxide, 5-35wt% of ZSM-5 molecular sieve, and 10-40wt% of auxiliary agent; wherein the auxiliary agent is selected from one or more of cerium oxide, zirconia or lanthana. The denitration catalyst has the advantages of large coating load capacity, high firmness, good poison-resistance performance and activity, and wide reaction temperature window; and the preparation method is simple and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

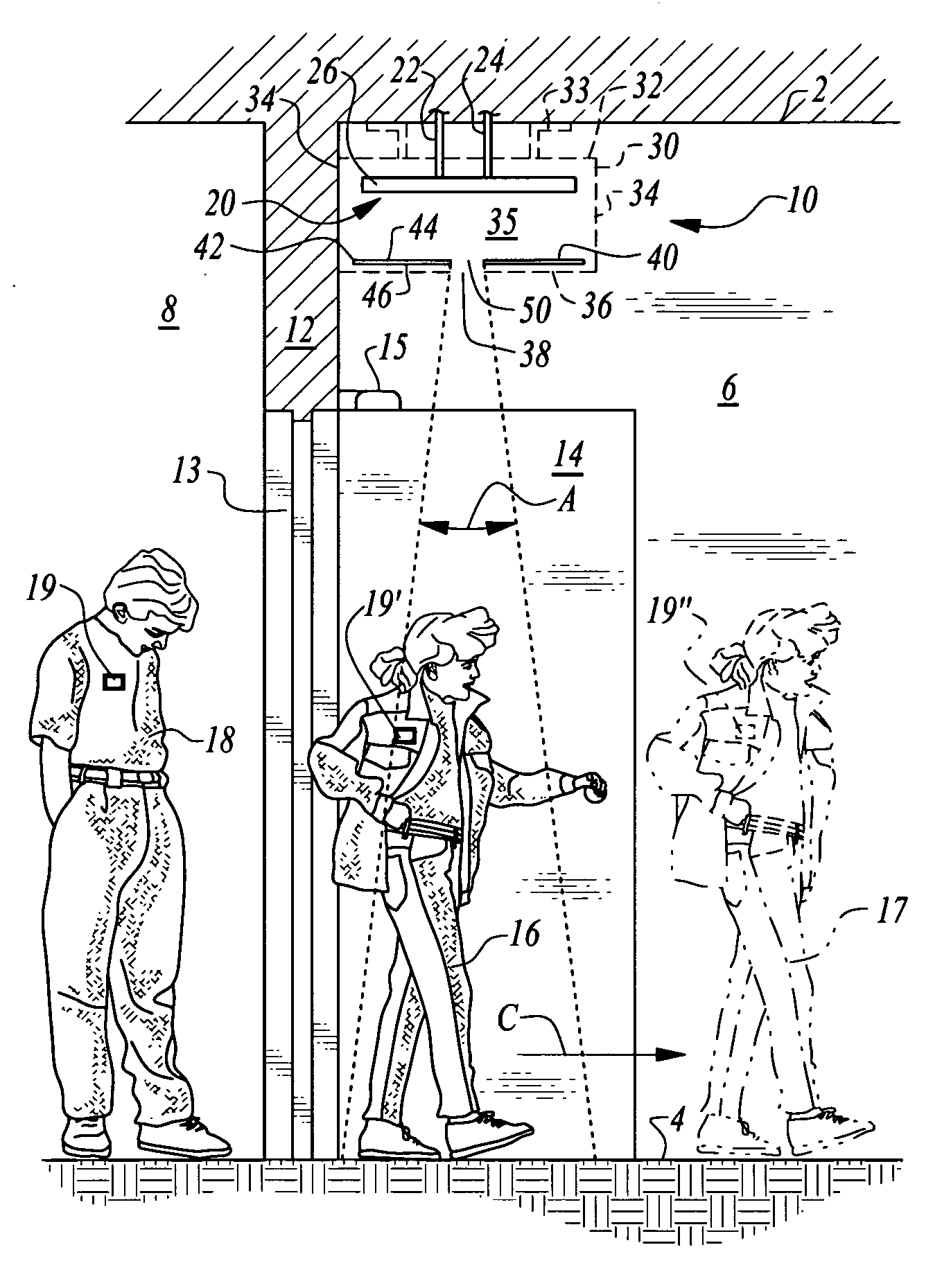

RFID transceiver sensitivity focusing system

InactiveUS20080185540A1Reduce sensitivityAccurate detectionMeasurement devicesShieldingRf fieldTransceiver

Shielding of a particular material and geometry is interposed between a radio frequency identification (“RFID”) antenna transceiver and a zone to be monitored by the antenna. The shielding has an aperture therein that to some extent defines a degree of focusing of the radio frequency (“RF”) field associated with the antenna. RFID tags having appropriate RFID circuitry are only detected by the antenna when they pass within the focused RF field. The shielding is formed of a thin metalized plastic material, such as film used in forming anti-static material for storage of sensitive electronics. One particular formulation is primarily polyethylene film with an aluminum coating or layer thereon.

Owner:INCOM CORP

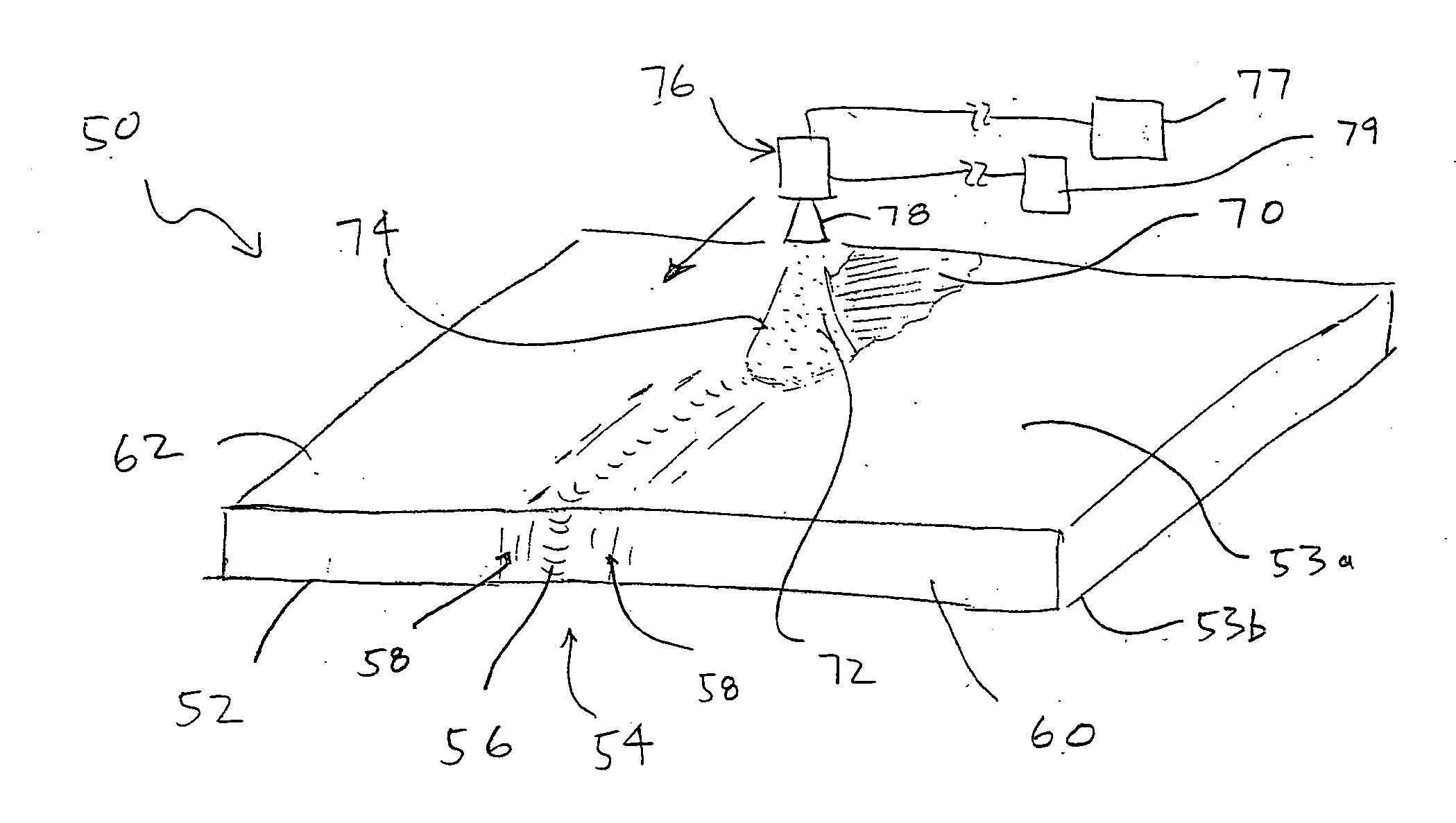

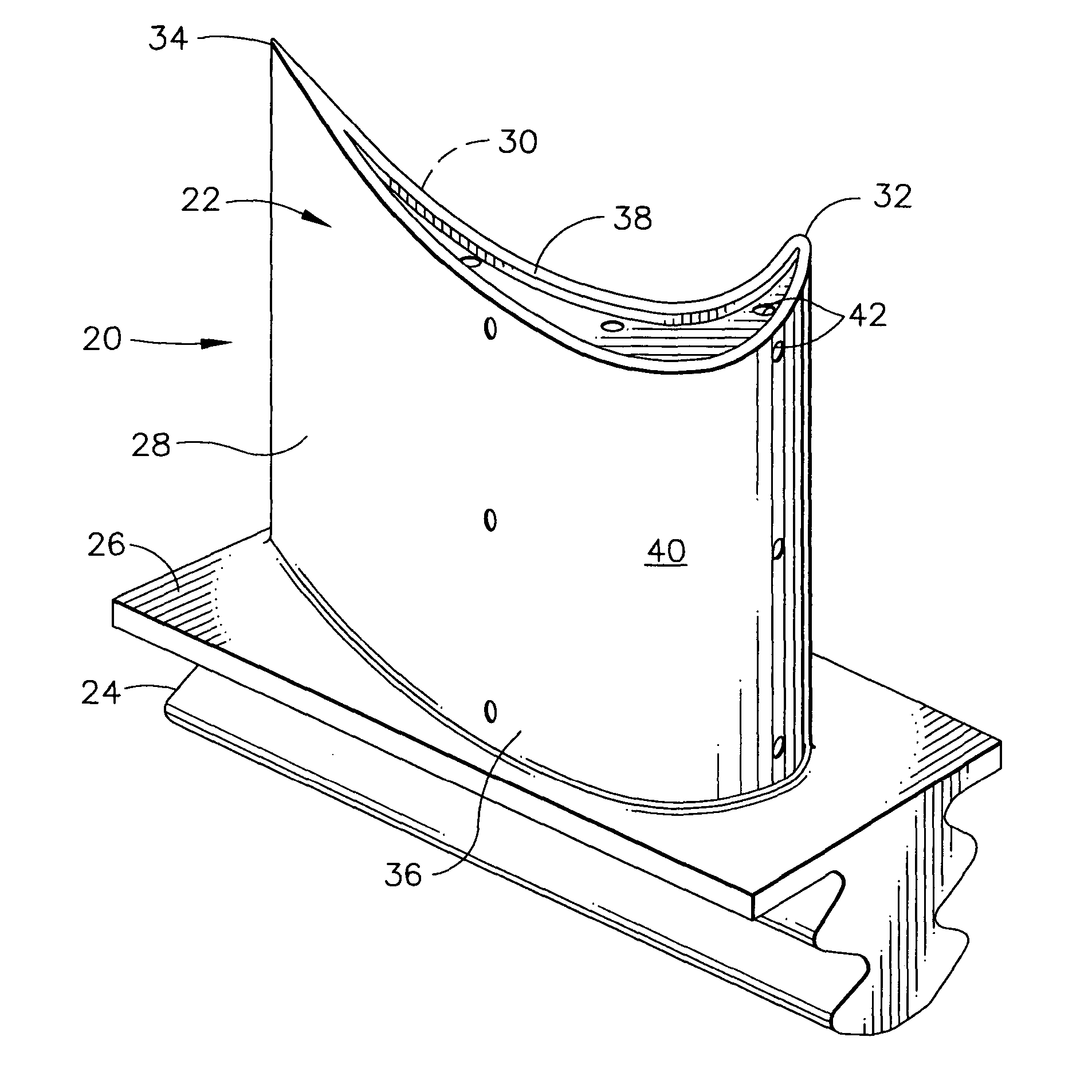

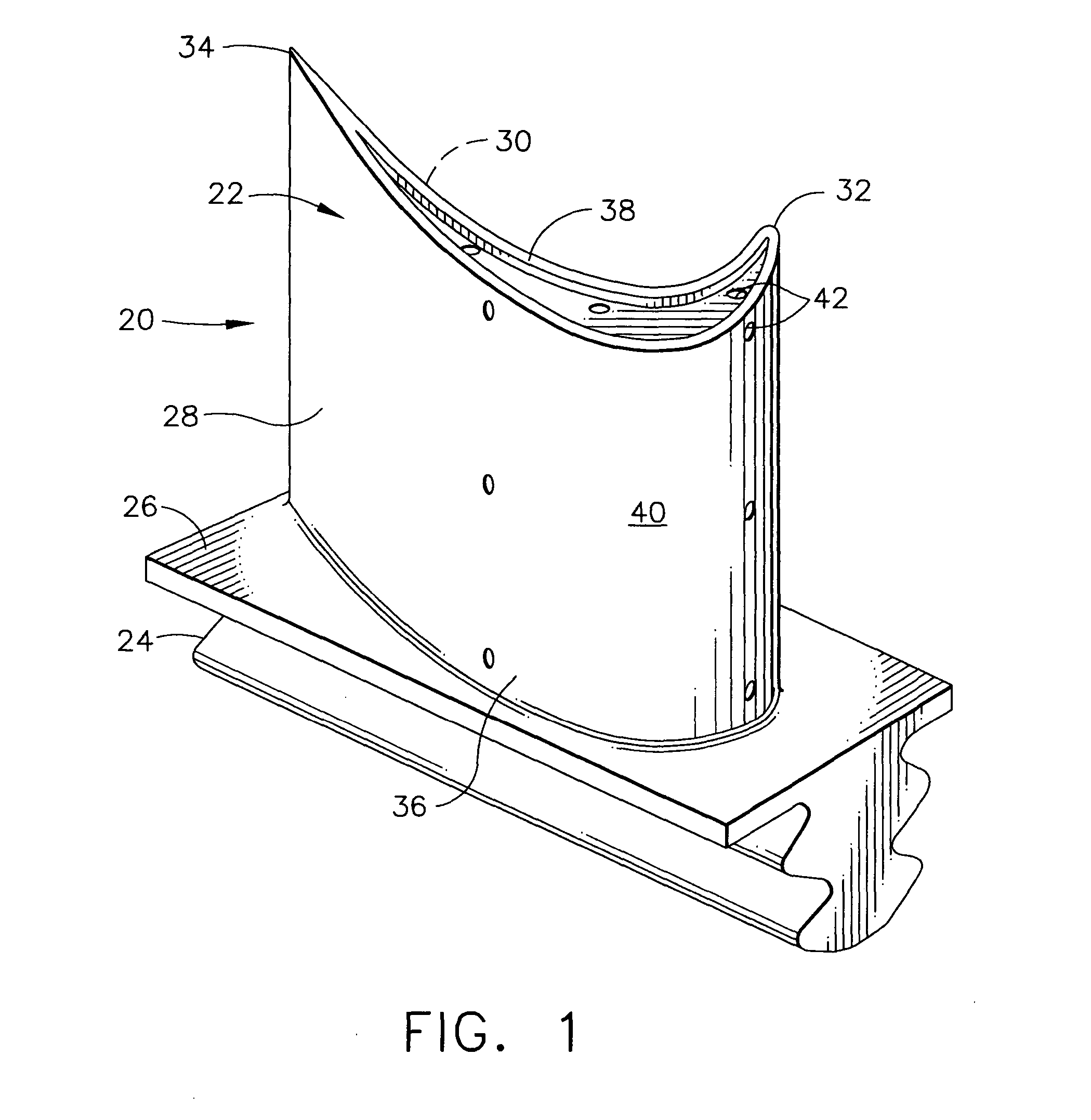

Aluminum coating for the corrosion protection of welds

ActiveUS20050242158A1Improve corrosion resistanceSoldering apparatusPretreated surfacesHeat-affected zoneAluminum coating

A method for coating and an associated assembly including such a coating are provided. The assembly includes a workpiece defining a weld portion, such as a friction weld joint and a heat affected zone. A coating is disposed on the weld portion to at least partially cover the weld portion, thereby providing enhanced corrosion resistance to the workpiece.

Owner:THE BOEING CO

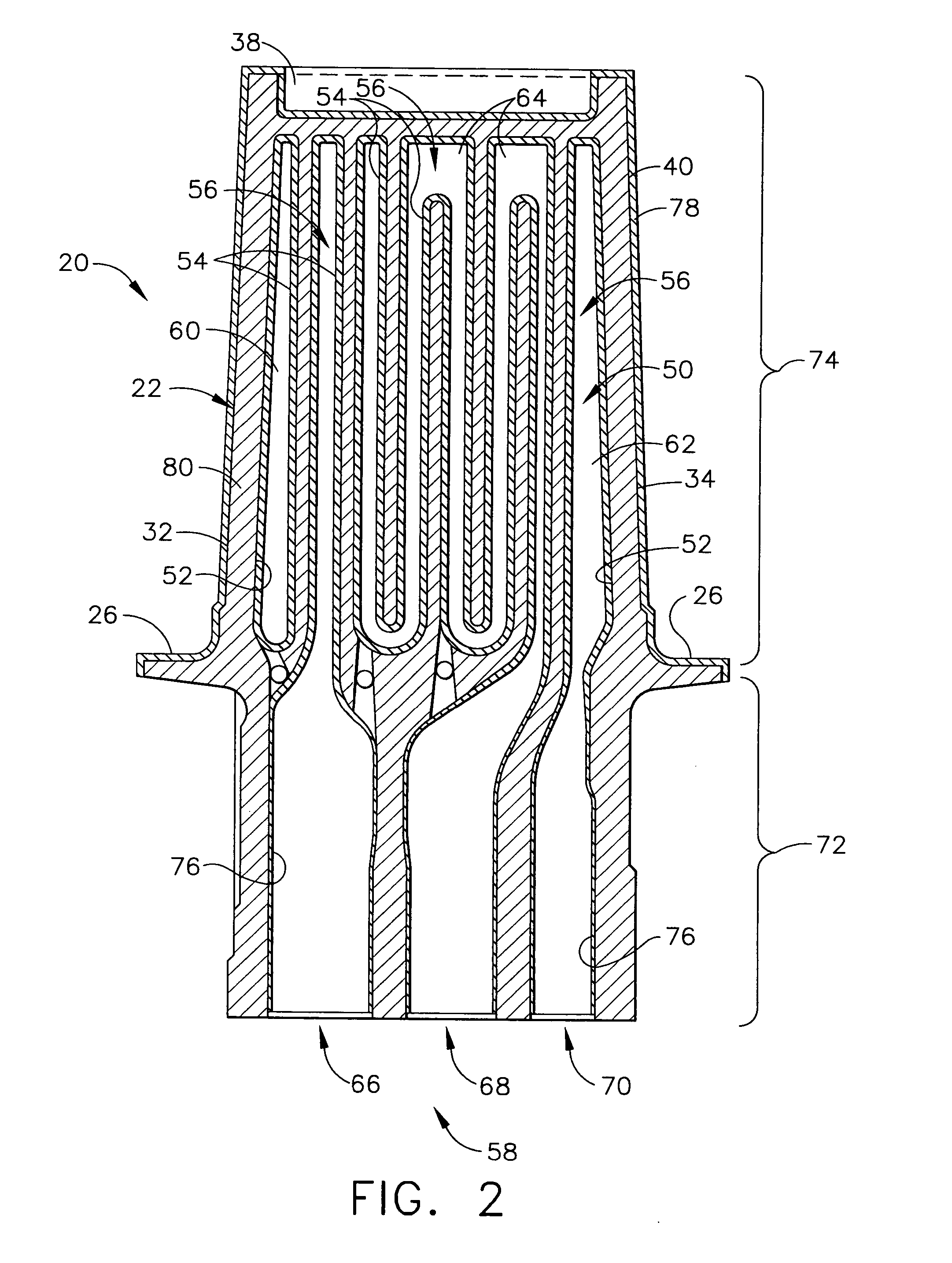

Aluminide coating of turbine engine component

A method for forming an aluminide coating on a turbine engine component having an external surface and an internal cavity defined by an internal surface that is connected to the external surface by at least one hole. The method is conducted in a vapor coating container having a hollow interior coating chamber, and includes the steps of loading the coating chamber with the component to be coated; flowing a tri-alkyl aluminum coating gas into the loaded coating chamber at a specified temperature, pressure, and time to deposit an aluminum coating on the external and internal surfaces of the component; and heating the component in a nonoxidizing atmosphere at a specified temperature and time to form an aluminide coating on the external and internal surfaces. The coated component is typically then maintained at an elevated temperature in the presence of oxygen to form an oxide coating on the external and internal surfaces of the component. In one embodiment, the turbine engine component is a turbine engine blade having an external surface and an internal cooling cavity having an internal surface that is connected to the external surface by cooling holes.

Owner:GENERAL ELECTRIC CO

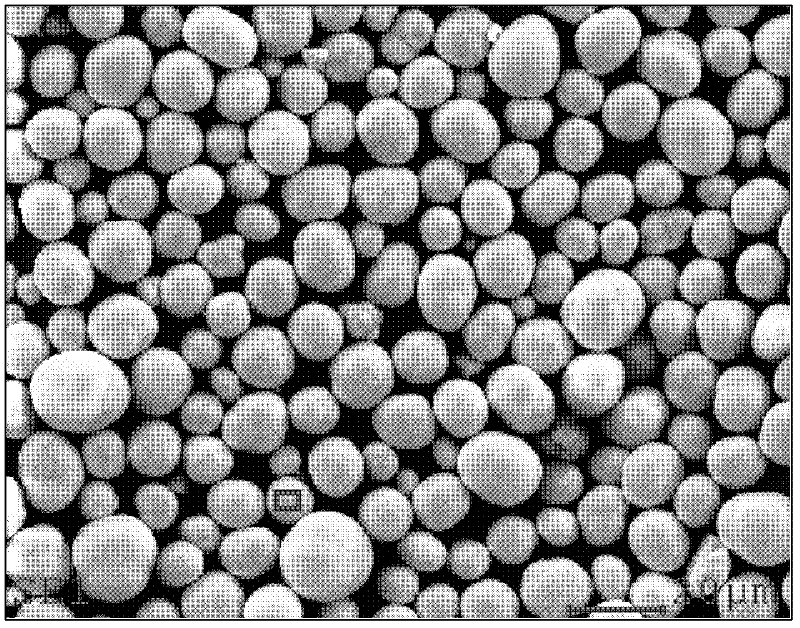

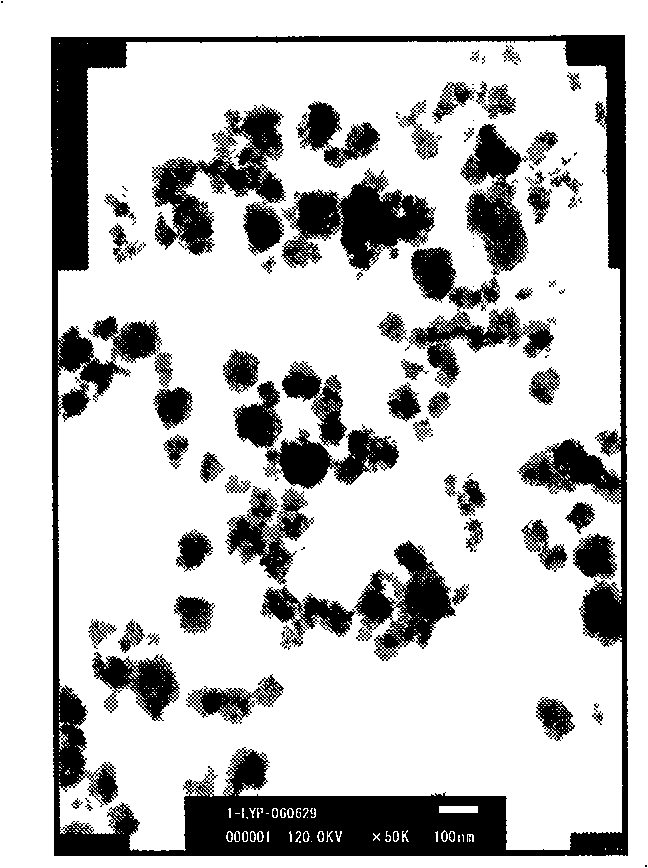

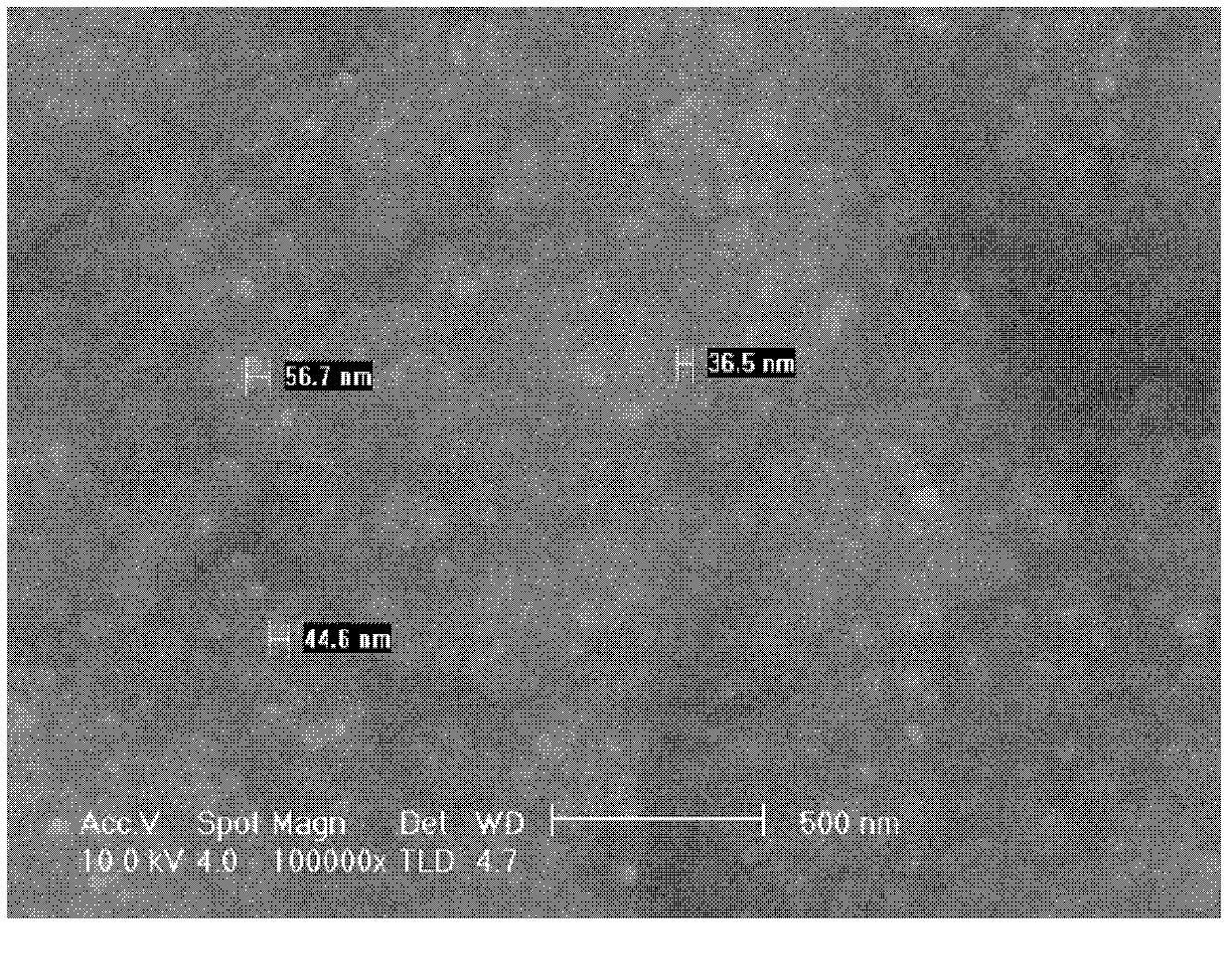

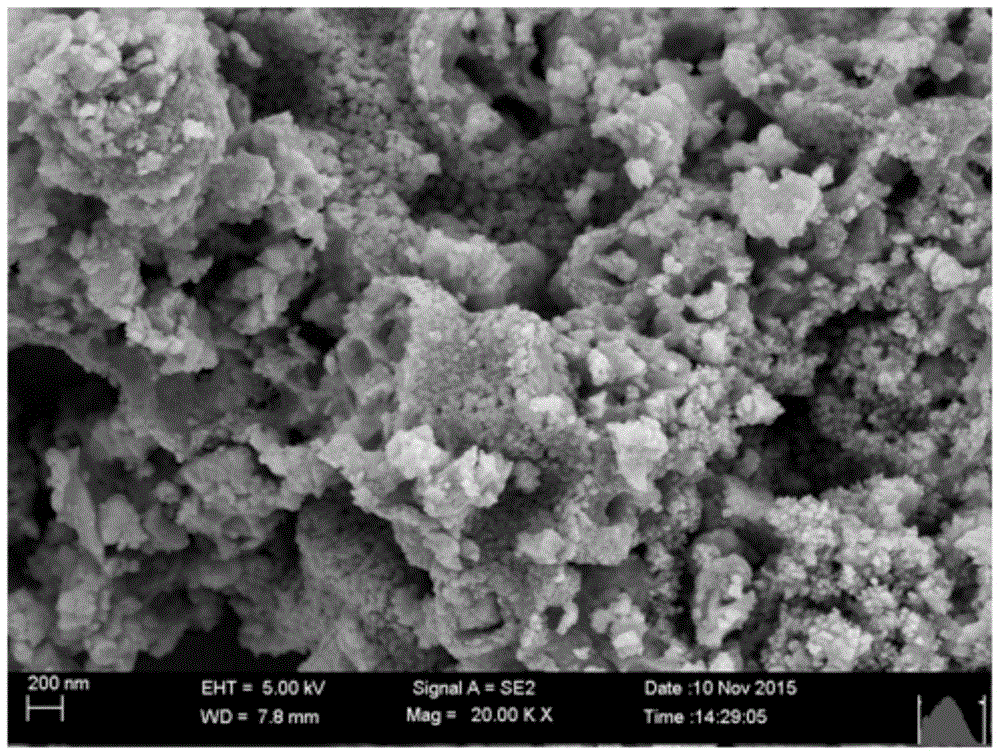

Method for preparing nanometer aluminum or nanometer aluminum coating in low-temperature electro-deposition form by using ion liquid/additive system

ActiveCN102888630AHigh purityWide variety of sourcesMaterial nanotechnologyElectrochemical windowIonic liquid

The invention designs a method for preparing nanometer aluminum or nanometer aluminum coating in an electro-deposition form by using an ion liquid / additive system. The method is characterized in that: ion liquid and anhydrous aluminum trichloride are mixed into a low-temperature electrolyte and suitable additives are added for preparing the ion liquid / additive system. A processed substrate is taken as a deposition cathode; the direct current electro-deposition is adopted for preparing the nanometer aluminum or nanometer aluminum coating; and the size of the aluminum grains is adjusted according to requirements. According to the method, the problems of high cost and small output of the present technology for producing the nanometer aluminum are solved; the adopted ion liquid is conventional ion liquid and is characterized by wide source, low cost, high conductivity, wide electrochemical window and being non-volatile and environment-friendly; the suitable additives are used, so that the high-quality nanometer aluminum or nanometer aluminum coating obtained in the conventional ion liquid is realized; the obtained aluminum deposited coating is compact, smooth and flat; a nanometer material can be obtained by using the ion liquid / additive system at lower temperature; the reaction is easy to control; the energy consumption is low; the obtained nanometer aluminum is high in quality and high in current efficiency; the size of the nanometer aluminum can be effectively controlled by adjusting the dosage and formula of the additives; the process is simple; the cost is low; and the application prospect is better.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of titanium dioxide for color masterbatch

InactiveCN105419404AHigh whitenessGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentDispersityHigh concentration

The invention relates to a preparation method of titanium dioxide for a color masterbatch. The preparation method comprises the following steps: a) preparing TiO2 slurry; b) silicon coating: diluting the TiO2 slurry obtained in step a to 300g / L to 450g / L, regulating pH of the slurry to 8 to 11, adding dispersing agent, feeding steam to heat to 60 to 90 DEG C, adding a silicon-containing compound under agitation, maintaining the pH of the slurry to be 8 to 10 to enable the surfaces of TiO2 particles to be coated with silicon oxide layers; c) aluminum coating: adding an aluminum oxide compound into the slurry obtained in step b, performing hydrolysis to form water-containing aluminum oxide layers on the surfaces of the silicon oxide layers, and maintaining the pH of the slurry to be 4 to 10 and temperature to be 40 to 60 DEG C; d) drying; e) crushing. The whiteness of the titanium dioxide obtained by adopting the preparation method provided by the invention is high, the dispersity is good, the newly formed interfacial surface energy is reduced through coating treatment, the titanium dioxide is prevented from being coagulated again during processing of the color masterbatch, especially high-concentration masterbatch, and thus not only can the amount of the used titanium dioxide be reduced, but also the rheological property of the color masterbatch can be improved.

Owner:NINGBO XINFU TITANIUM DIOXIDE

High water dispersity titanium dioxide and coating method thereof

ActiveCN101235223ASimple stepsReduce manufacturing costInorganic pigment treatmentDispersityChemical industry

The invention relates to titanium dioxide with high water dispersibility and a coating process, belonging to the chemical industry field, which solves the technical problem that titanium dioxide which is produced by a current process has lower dispersibility. The coating process of titanium dioxide with high water dispersibility of the invention comprises the steps of beating, silicon coating, aluminum coating, scouring, drying and disintegrating and the like, wherein sodium aluminate solution is used to conduct coating in the aluminum coating step, and sodium silicate solution is used to conduct coating in the silicon coating step, wherein the molar ratio of sodium aluminate solution usage which is calculated with A1 2 O3 and sodium silicate usage which is calculated with SiO 2 is 1:4. The process of the invention can be used to prepare titanium dioxide with high water dispersibility, which has widespread application prospect, and the Haegeman index of titanium dioxide which is prepared can reach over 7.0 in emulsion paint.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Stripping solution for sintered neodymium-iron-boron surface aluminum coating

The invention discloses stripping solution for a sintered neodymium-iron-boron surface aluminum coating. The stripping solution comprises sodium hydroxide serving as a corroding agent, sodium carbonate serving as an auxiliary salt, a complexing agent capable of promoting the dissolution of metallic aluminum, a corrosion inhibitor for retarding the corrosion of a matrix, and a surfactant for uniformly dissolving an aluminum coating. Compared with the prior art, the stripping solution for the sintered neodymium-iron-boron surface aluminum coating has the advantages of quickly and uniformly stripping the sintered neodymium-iron-boron surface aluminum coating and simultaneously reducing the damage to the sintered neodymium-iron-boron matrix due to the reasonable design of components and content of the stripping solution; and besides, the stripping solution has the characteristics of low production cost, high stability and long service cycle.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +4

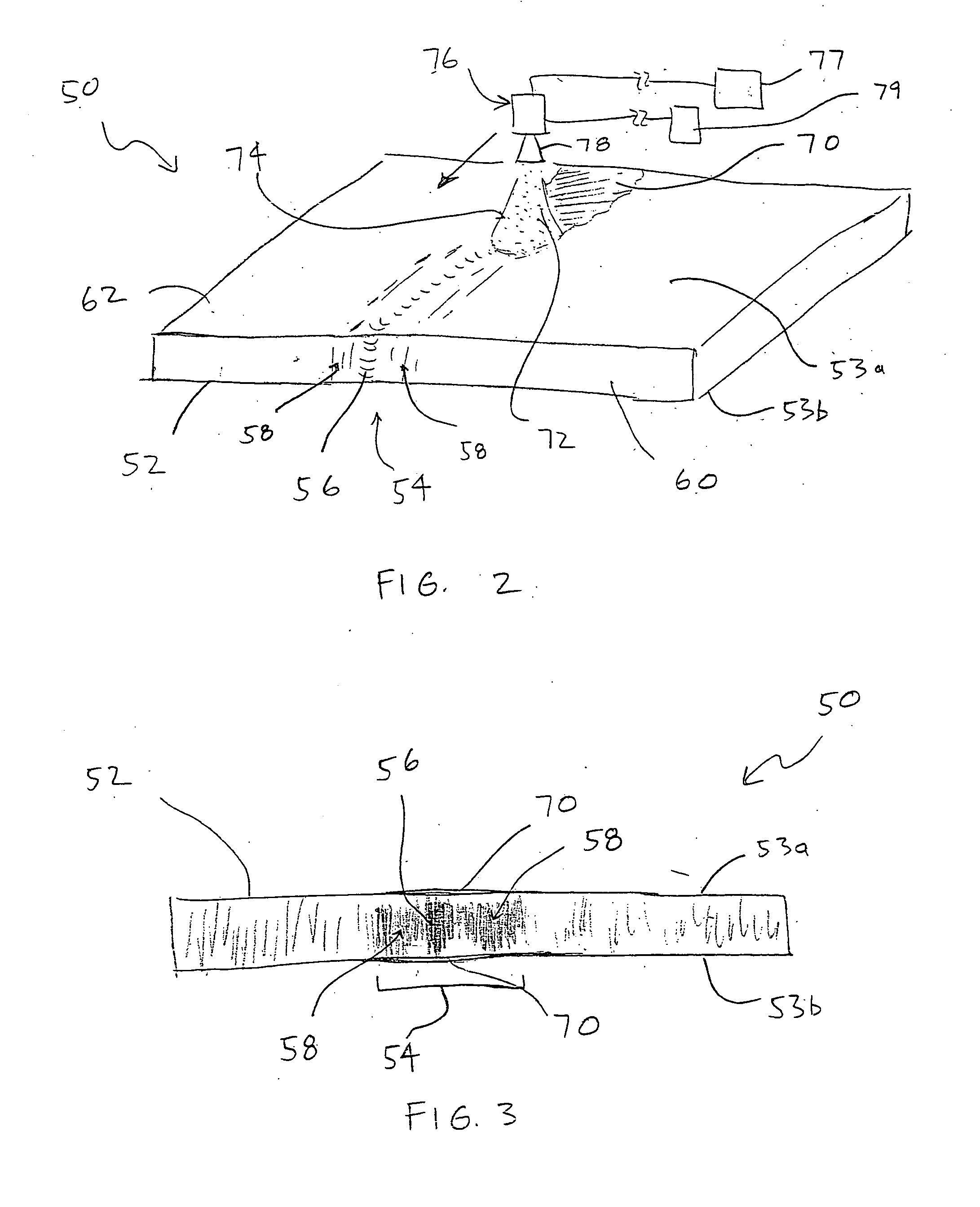

Preparation method of composite high-speed steel wear-resistant layer on aluminum alloy surface

InactiveCN102284786AUniform mosaicImprove wear resistanceMolten spray coatingNon-electric welding apparatusThermal sprayingHardness

The invention relates to a method for preparing a composite high-speed steel wear-resistant layer on the surface of an aluminum alloy. First, a high-speed steel coating with a thickness of 0.2 mm to 1.5 mm is thermally sprayed on the surface of an aluminum alloy, and then the thermally sprayed high-speed steel is processed by friction stir processing. The coating is evenly inlaid and fused in the aluminum alloy surface layer to form a good wear-resistant layer, and a metallurgical bond is formed between the coating and the substrate. In the invention, the thermal spraying coating is evenly inlaid and fused in the surface layer of the aluminum alloy through friction stirring processing to form a good wear-resistant layer, and a metallurgical bond is formed between the coating and the substrate. The hardness of the wear-resistant layer of the high-speed steel obtained by the invention is greater than 520HV, and the bonding strength is greater than 70MPa.

Owner:HUBEI UNIV OF TECH

Stripping apparatus and method for removal of coating on metal surfaces

ActiveUS20050241679A1Easily and quickly stripVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

A coating is stripped off a work piece by applying a chromous and aluminiforous coat directly on the work piece and stripping the work piece with an alkaline solution containing a strong oxidant. A single-compartment system can be used, which includes a spray chamber including a circulatory spray-cycle system; a support for holding the work piece; and a media container connected to the spray chamber via a media circulation system.

Owner:UNAXIS BALZERS LTD +1

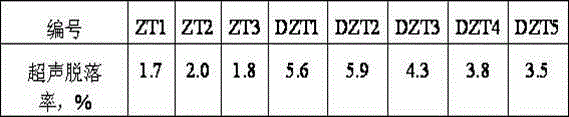

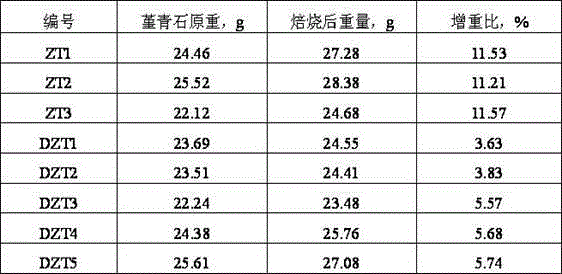

Catalyst for low-temperature catalytic combustion of volatile aromatic hydrocarbon organic matters and method for preparing catalyst

InactiveCN105709734AImprove bindingNot easy to fall offCatalyst activation/preparationIncinerator apparatusRare earthCordierite

The invention relates to a chemical catalyst preparation technology, and aims to provide a catalyst for low-temperature catalytic combustion of volatile aromatic hydrocarbons and a preparation method thereof. The catalyst is based on cordierite honeycomb ceramics, and the surface of the base body is sequentially provided with an aluminum coating, an additive coating and an active component layer from the inside to the outside; based on the total amount of the catalyst, the catalyst contains 85-90 wt% of the cordierite honeycomb ceramics, 8-12 wt% of the aluminum coating, 1-5 wt% of the auxiliary coating, and 0.05-0.5 wt% of the active component layer; wherein, the composition of the aluminum coating is alumina; the composition of the auxiliary coating is a rare earth metal oxide; The constituents of the active component layer are noble metals. The preparation process of the invention is simple, the preparation raw materials are easy to obtain, the specific surface area is large, the cost is low, and the catalytic combustion reaction of benzene series such as toluene has high catalytic activity; the active component has strong binding force with the matrix, and is not easy to fall off and crack It can still maintain high activity under high space velocity airflow and thermal shock.

Owner:ZHEJIANG UNIV

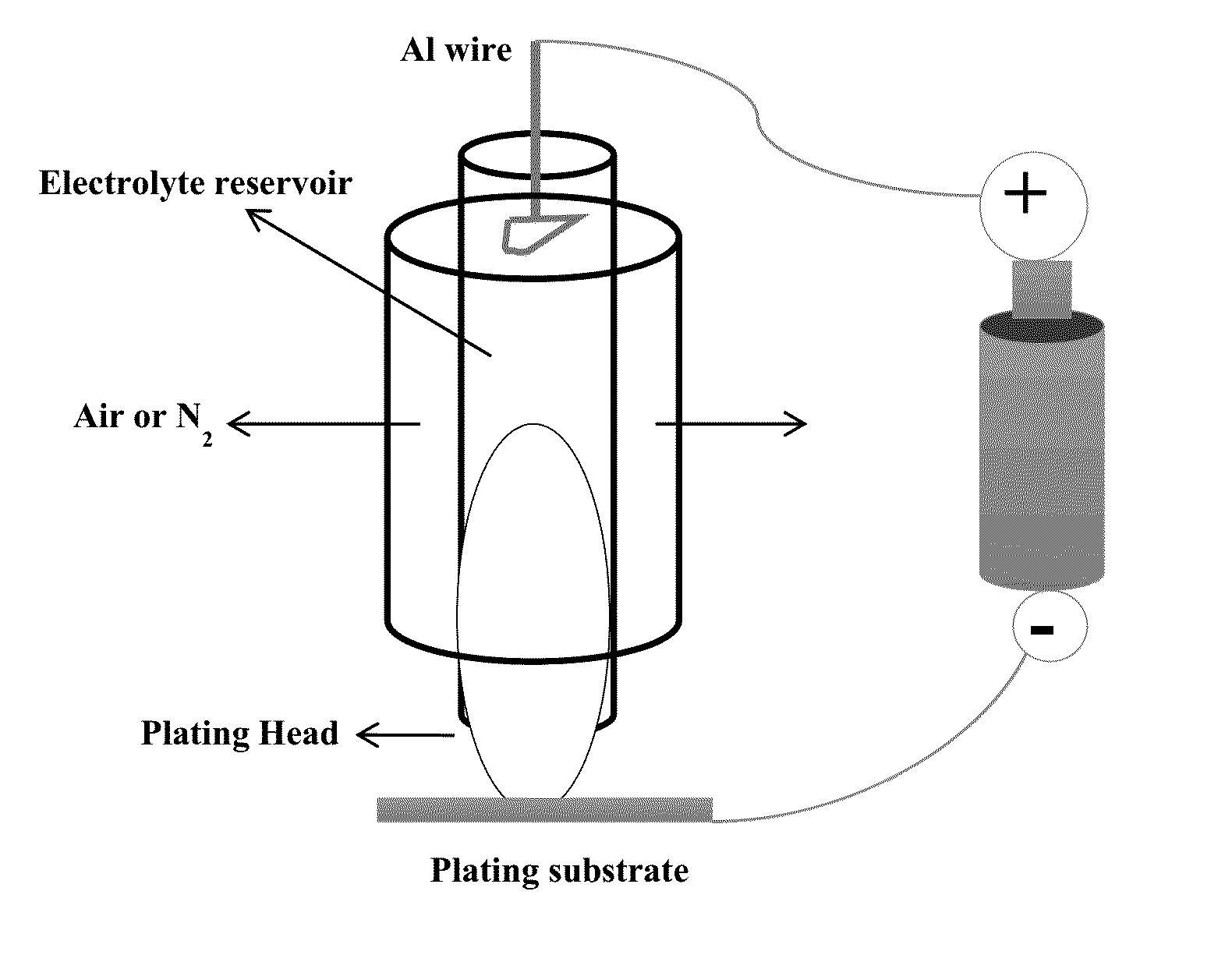

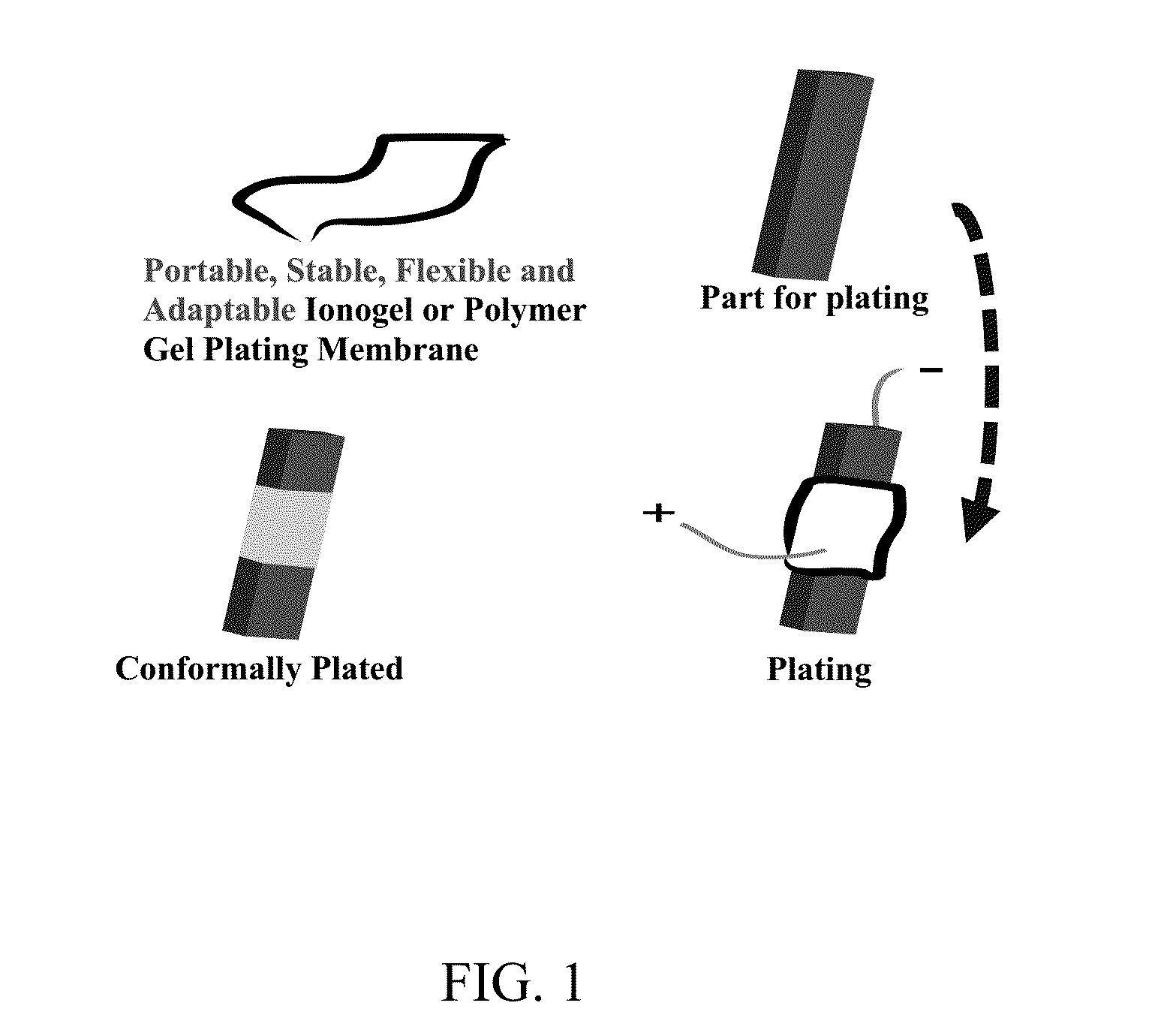

Aluminum deposition devices and their use in spot electroplating of aluminum

A method for spot electroplating aluminum onto a metallic substrate without submersion or dipping of the metallic substrate in an electroplating bath, the method comprising: (i) spot coating said metallic substrate with an aluminum ion-containing electrolyte contained within a protective structure possessing at least one aperture, and releasing said electrolyte from said at least one aperture onto said metallic substrate to form a coating of said electrolyte thereon, wherein said electrolyte is in contact with an anode; and (ii) applying a voltage potential between the anode and metallic substrate polarized as cathode when the aluminum ion-containing electrolyte is released from said aperture and forms a coating on the metallic substrate, to produce a coating of aluminum on the substrate. Devices, such as brush and ball pen plating devices, for achieving the above-described method are also described.

Owner:UT BATTELLE LLC +1

Method for electroplating inorganic molten salt on surface of magnesium and magnesium alloy with aluminum

The invention relates to a method for electroplating inorganic molten salt on surface of magnesium and magnesium alloy with aluminum, which belongs to the technical field of metal surface treatment. The method comprises a step of preplating a zinc layer as a substrate and a step of electroplating inorganic molten salt with aluminum. The step of preplating the zinc layer as the substrate comprises a step of immersion-plating the zinc layer and a step of electroplating the zinc layer. The step of electroplating the zinc layer is performed in an inorganic molten salt system, wherein anhydrous aluminum chloride is main salt, and sodium chloride, potassium chloride or a mixture of the two is a main complexing agent. An aluminum coating obtained by the method is complete, dense, uniform and bright, is firmly combined with a matrix, can be individually used as a protective layer, and can be prepared into a surface functional layer with better corrosion resistance, better wear resistance and high hardness through subsequent treatment. The whole process of the method has the advantages of simple process, cheap equipment, friendliness to environment, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-firmness honeycomb ceramic carrier and preparation method thereof

ActiveCN104549529ALarge specific surface areaImprove bindingCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsCordieriteSilicon oxide

The invention discloses a high-firmness honeycomb ceramic carrier and a preparation method thereof. Cordierite honeycomb ceramic is used as a base body; an aluminum oxide coating layer and a composite coating layer are arranged on the surface of the base body in sequence; by the total weight of the honeycomb ceramic carrier, the honeycomb ceramic carrier contains 85-95 percent of cordierite honeycomb ceramic, 2-7 percent of the aluminum oxide coating layer and 3-8 percent of the composite coating layer; by the total weight of the composite coating layer, the composite coating layer contains 40-80 percent of titanium dioxide, 5-35 percent of silicon dioxide, 1-10 percent of aluminum oxide and 10-40 percent of an auxiliary. The preparation method comprises the following steps: (1) immersing the cordierite honeycomb ceramic base body subjected to acid treatment into alumina sol for treatment, taking out the cordierite honeycomb ceramic base body, blowing away residual liquid, and drying and roasting to obtain the cordierite honeycomb ceramic base body loaded with the aluminum oxide coating layer; (2) soaking the carrier obtained by the step (1) in composite coating layer slurry for treatment, taking out the carrier, blowing away the residual liquid, and drying and roasting to obtain a final product. The coating layer load of the honeycomb ceramic carrier is large, the firmness is high, and the preparation technology is simple; the mechanical strength of the base body is not damaged; the high-firmness honeycomb ceramic carrier is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Colorful holographic numerical code information thermoprint foil and preparation method thereof

ActiveCN103862907ASolve the problem of color printingAchieve the perfect combinationPattern printingThermographyPrinting inkDigital printing

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

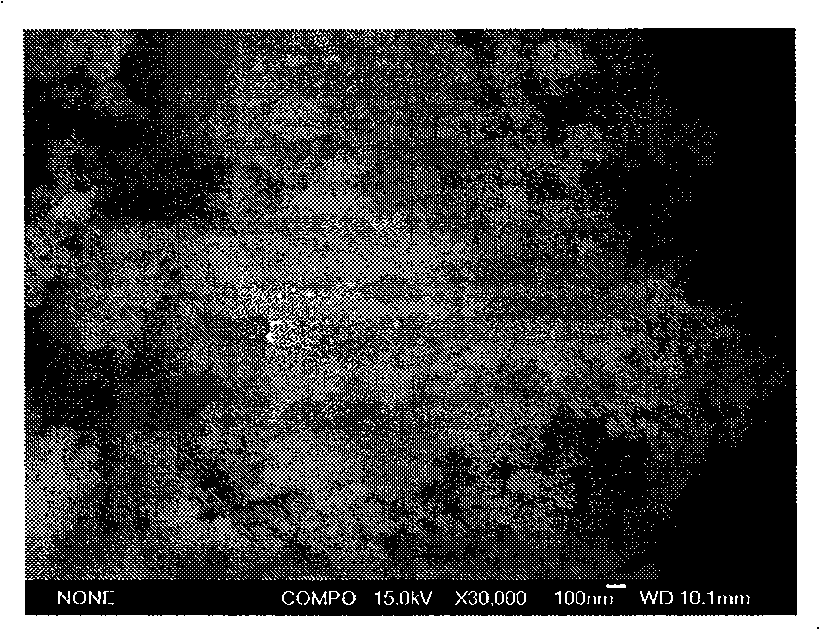

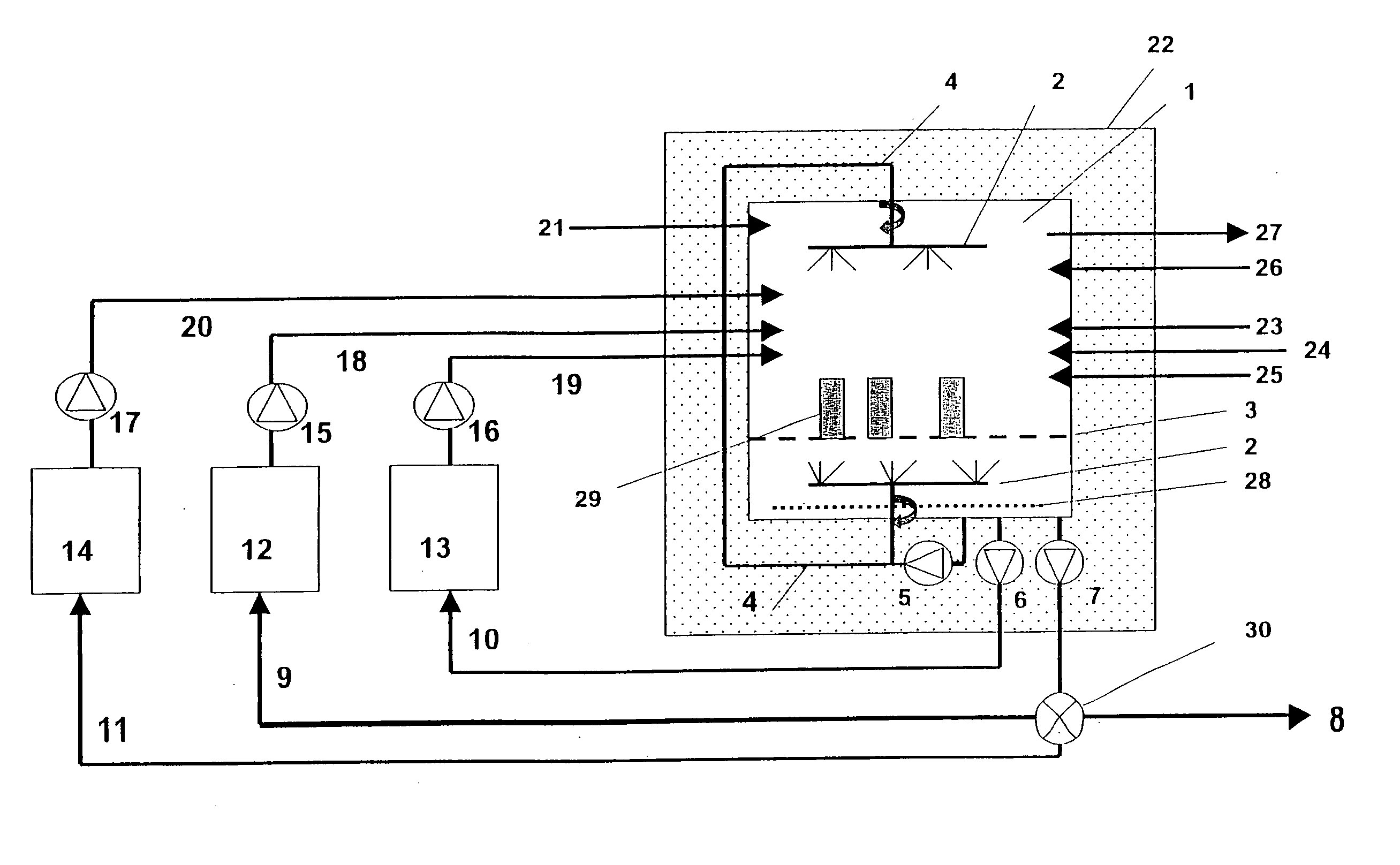

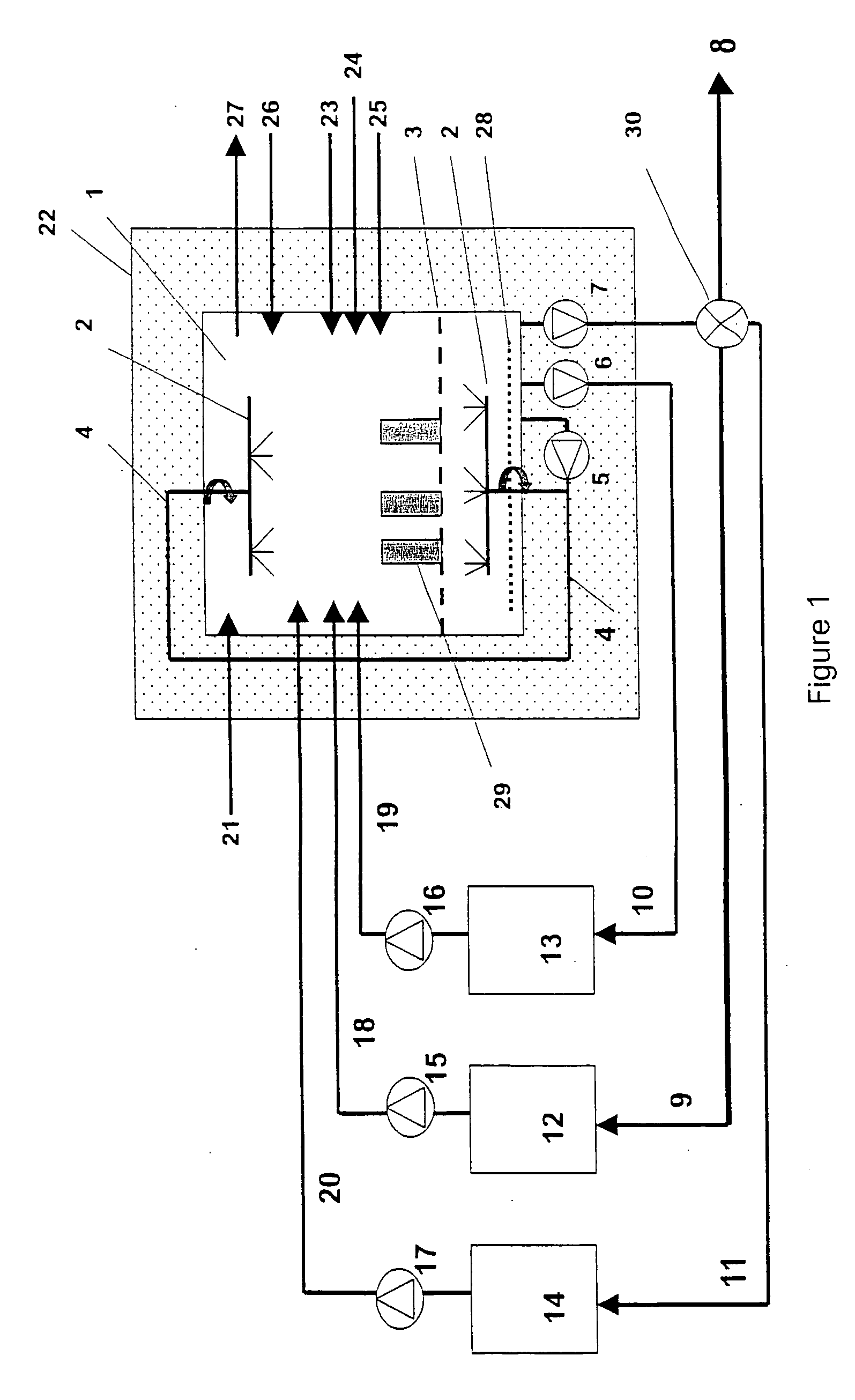

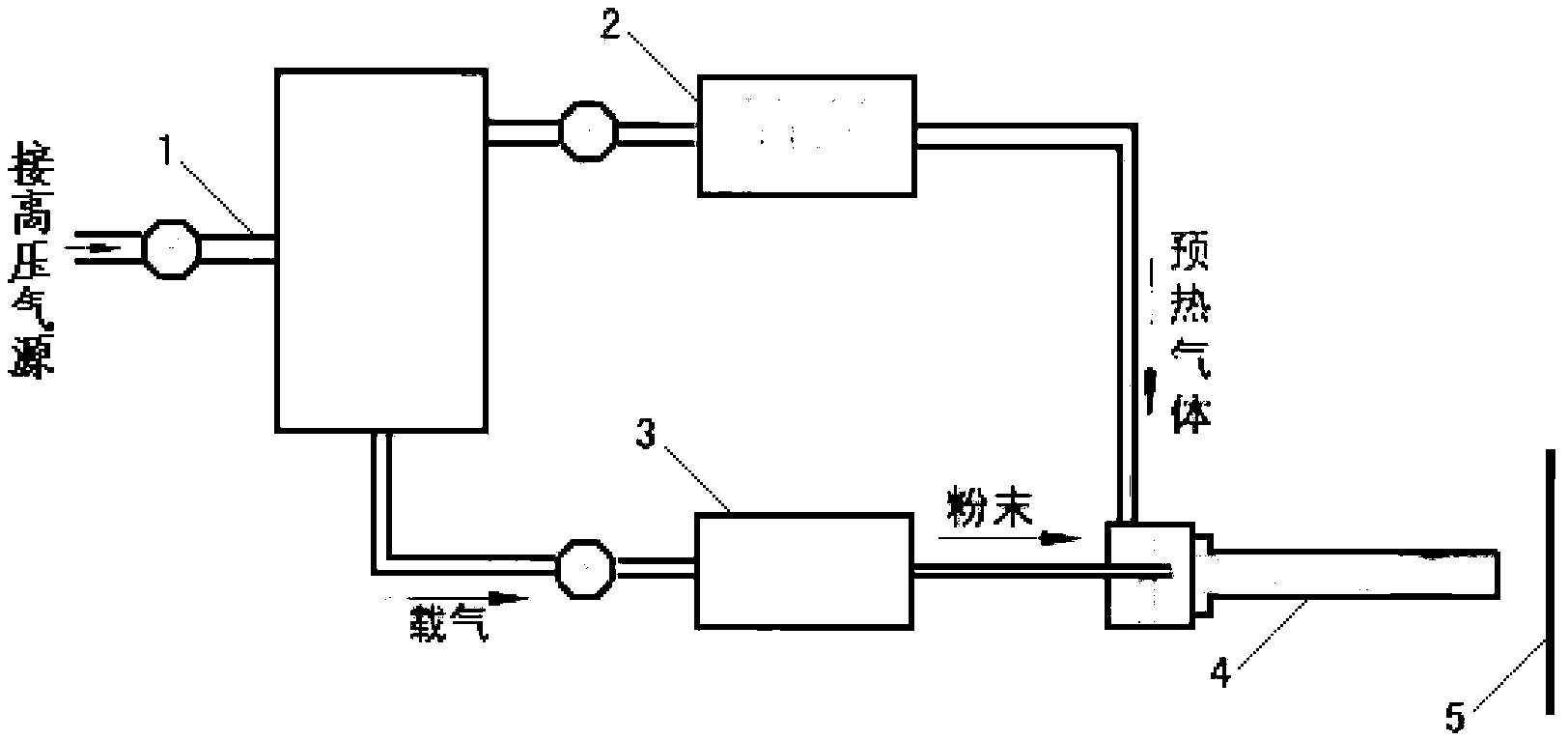

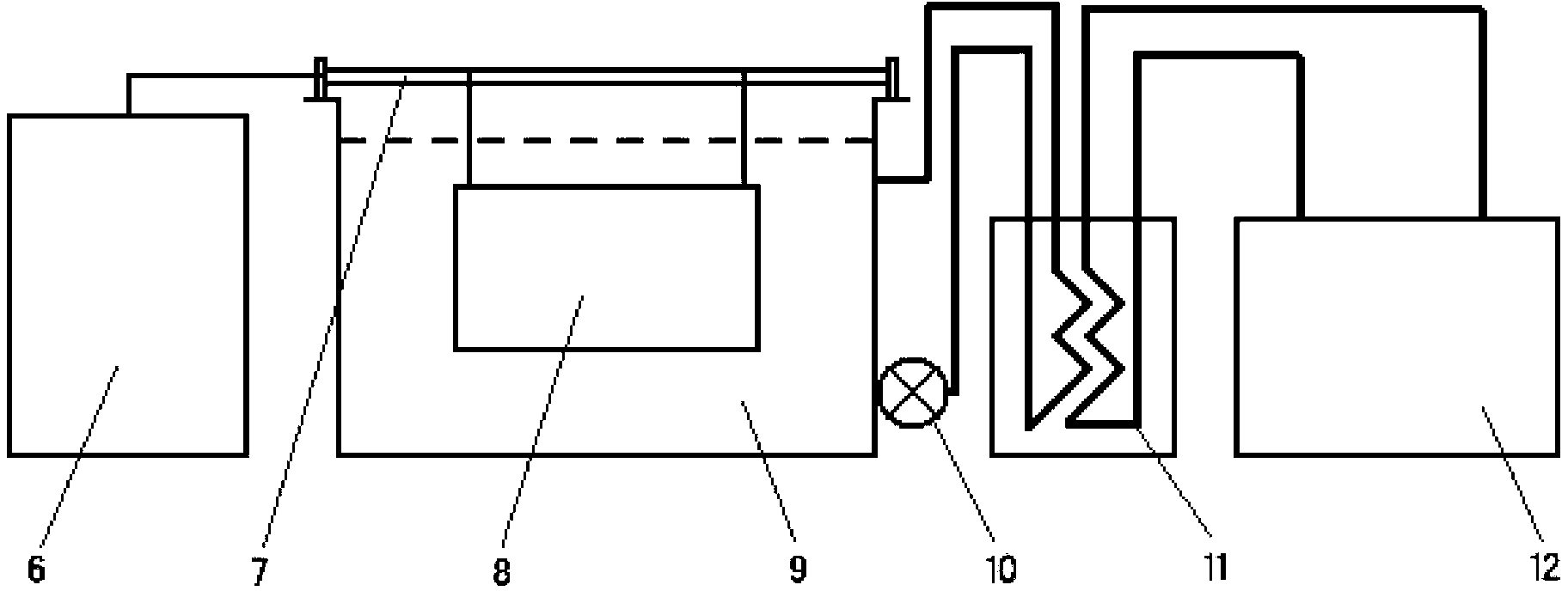

Aluminum-particle-based method for preparing coating by cold spray deposition

InactiveCN102154639AImprove deposition efficiencyImprove corrosion resistancePressure inorganic powder coatingAbrasive blastingThermal spraying

The invention discloses an aluminum-particle-based method for preparing a coating by cold spray deposition in the technical field of metal material coatings. Helium is used as a working gas and a carrier gas, and high-purity aluminum powder is sprayed onto a matrix subjected to iron silicate particle blasting treatment by using a spray gun to realize coating preparation. Various defects in the prior art, particularly in the thermal spraying aluminum coating preparation process are overcome, risks of small-size particles in storage and cold spray processes are overcome, and the cost of aluminum powder particle deposition is effectively reduced.

Owner:SHANGHAI JIAO TONG UNIV

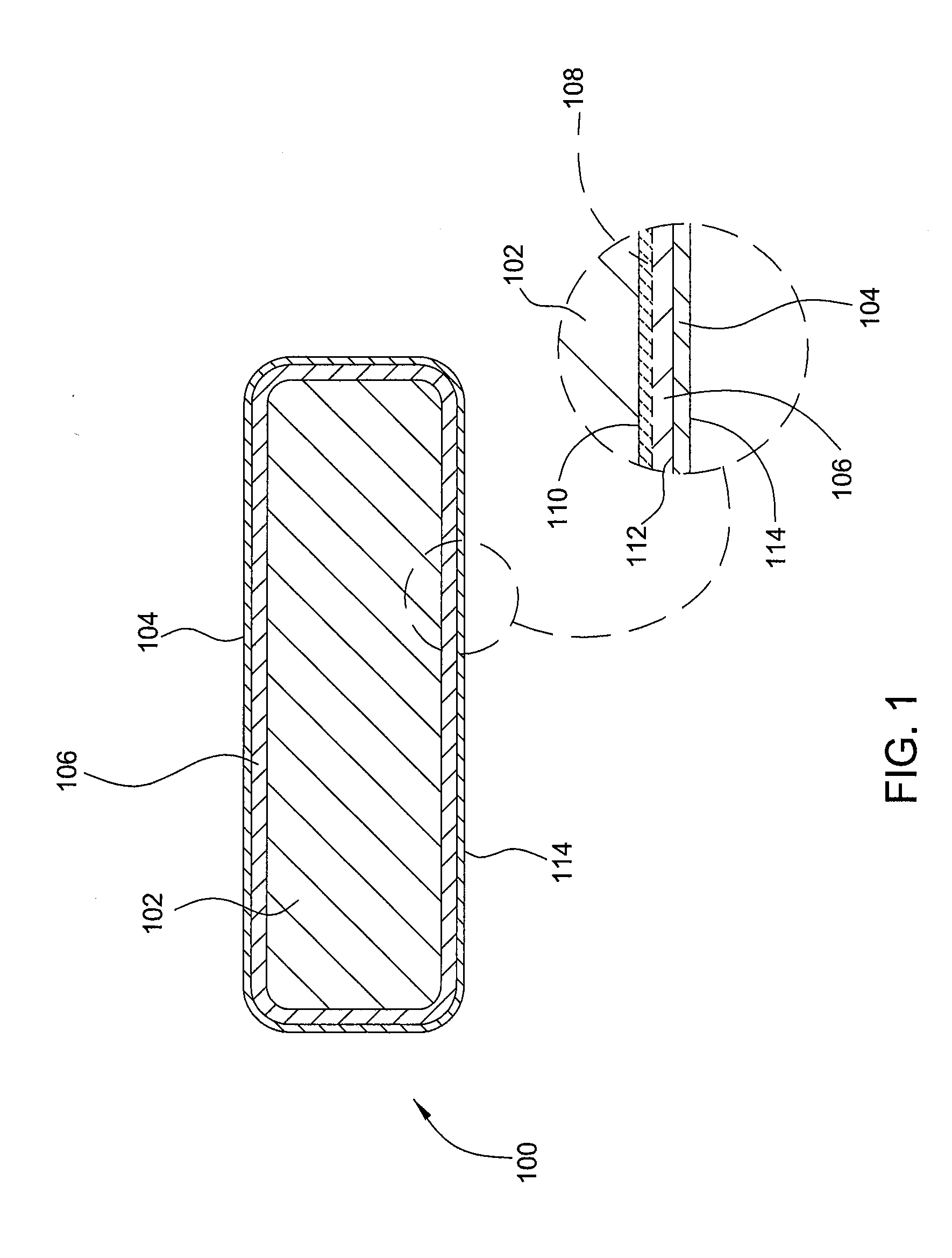

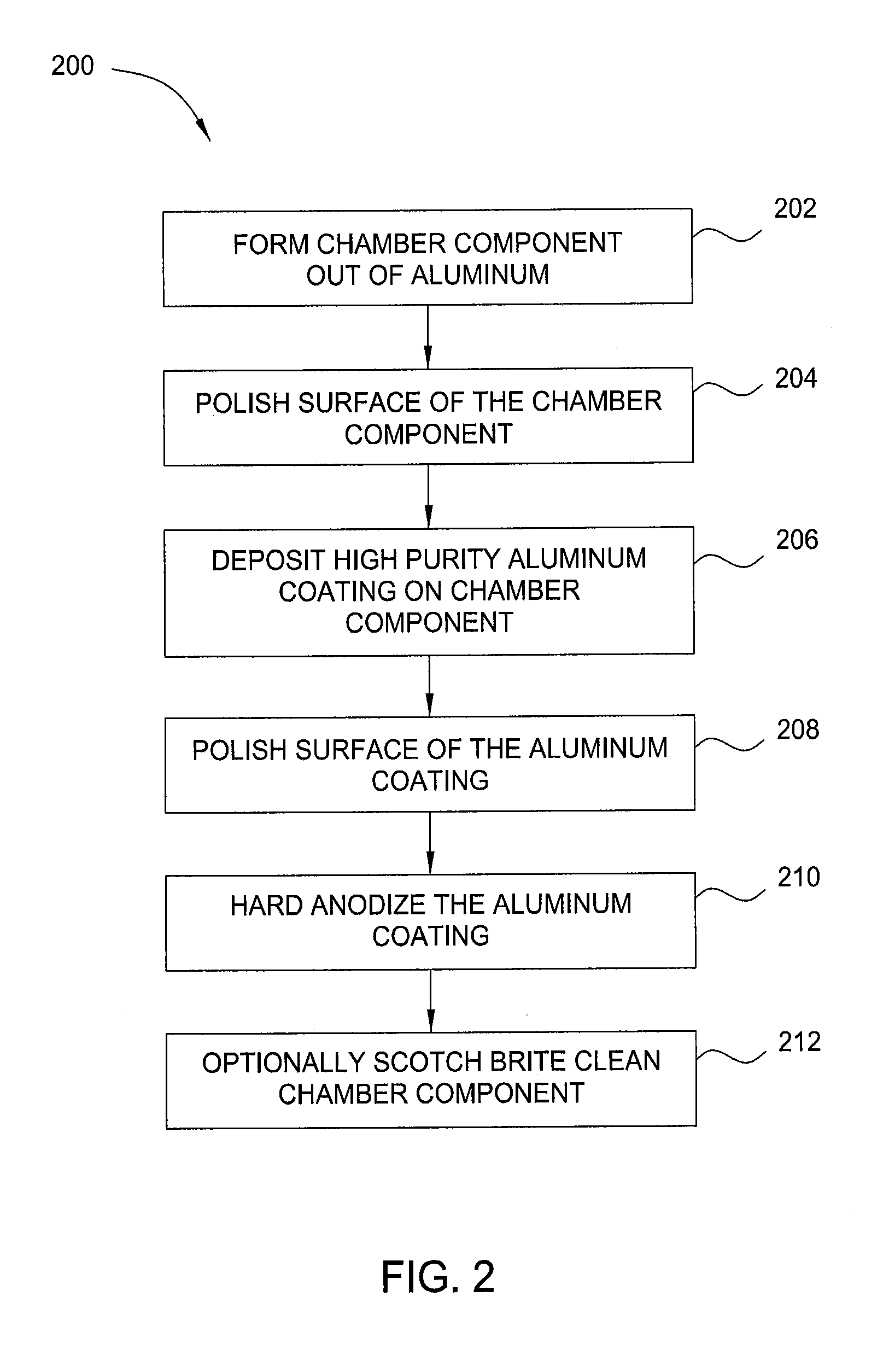

High purity aluminum coating hard anodization

The disclosure relates to a chamber component or a method for fabricating a chamber component for use in a plasma processing chamber apparatus. The chamber component includes a polished high purity aluminum coating and a hard anodized coating that is resistive to the plasma processing environment.

Owner:APPLIED MATERIALS INC

Electrochemical aluminum for stamping gold on ultraviolet (UV) glazing oil surface and preparation method thereof

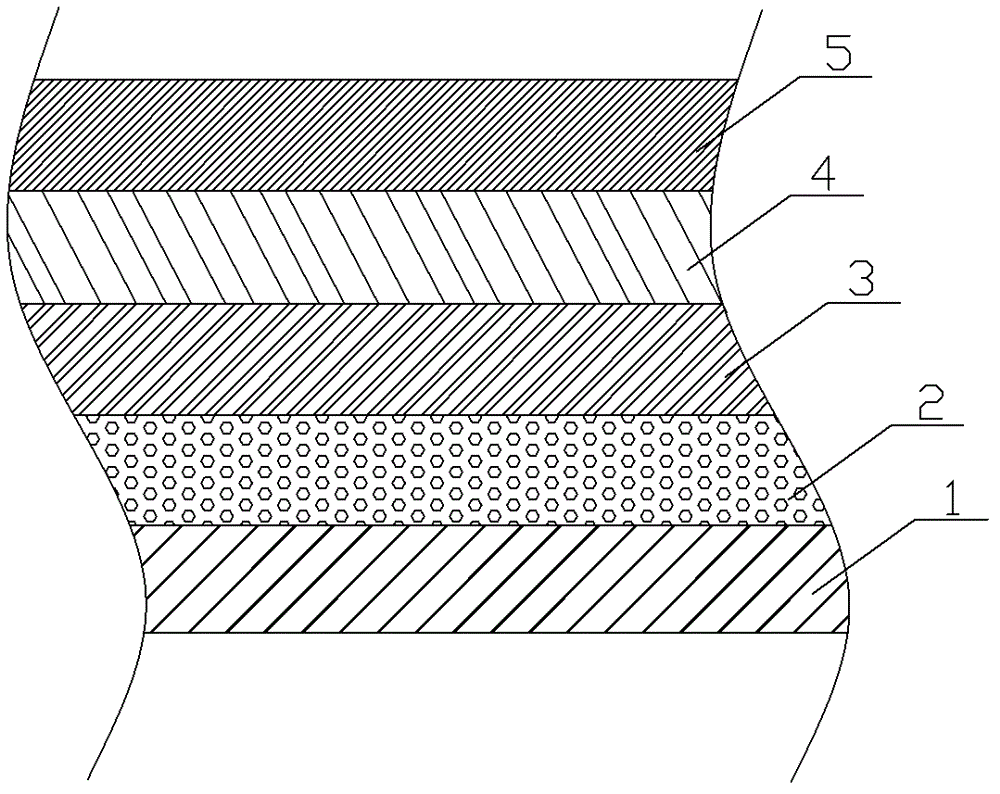

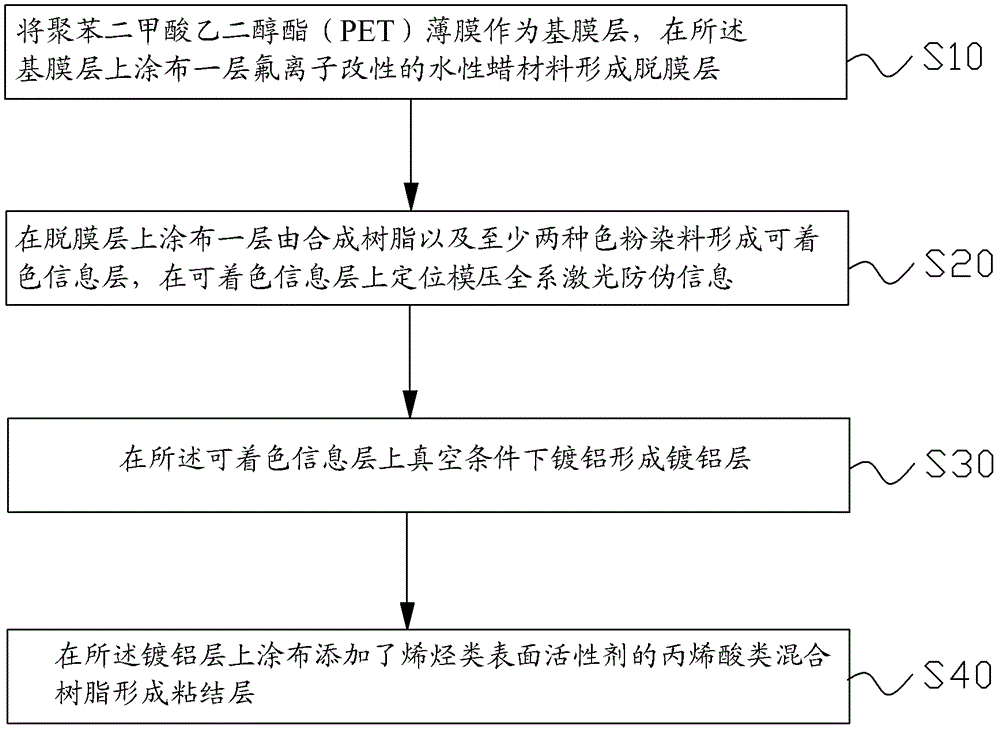

ActiveCN102795015AImprove performanceImprove bronzing efficiencySynthetic resin layered productsThermographyInformation layerPolyethylene terephthalate glycol

The embodiment of the invention provides electrochemical aluminum for stamping gold on an ultraviolet (UV) glazing oil surface. The electrochemical aluminum comprises a base film layer, a stripping layer, a colorable information layer, an aluminum coating and a bonding layer; the base film layer 1 is made of a polyethylene terephthalate film; the stripping layer is positioned on the base film layer and made of a fluorine-containing water-based wax material prepared by an emulsified paraffin method; the colorable information layer is positioned on the stripping layer and prepared from synthetic resin and at least two toner dyes; full series laser anti-counterfeiting information is positioned and die-pressed on the colorable information layer; and the bonding layer is positioned on the aluminum coating and prepared from acrylic mixed resin added with olefin surfactant. The embodiment of the invention also provides a preparation method for the electrochemical aluminum for stamping the gold on the UV glazing oil surface. According to the embodiment, an electrochemical aluminum god stamping material prepared from a special stripping agent and adhesive at a low temperature is excellent in performance and suitable for most printed materials of which the surfaces are provided with UV glazing oil.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

Glass door body

InactiveCN101824953AEasy to processReduce processing stepsDomestic cooling apparatusLighting and heating apparatusEngineeringAluminum coating

The invention discloses a glass door body, which comprises an outer door plate, an inner door plate, and a door frame. The outer door plate is made of glass; an aluminum coating is arranged on the inner side of the outer glass plate; the door frame is adhered to the aluminum coating of the outer glass plate through binders; and the inner door plate is adhered on the inner side of the door frame through binders. The hidden binding structure of the door frame and the glass panel is adopted, and the glass plate is adhered to the door frame, so the door body structure is stable and reliable and the difficulty in controlling the door frame assembly quality is reduced. The whole door body is fine and beautiful, top-grade and fashionable, and caters to the consuming taste of the new trend group for pursuing the quality of life. The glass door body is applied to refrigerators and cocktail cabinets, and can be also widely applied to sterilized cupboards and other household appliances.

Owner:广东安博基业电器有限公司

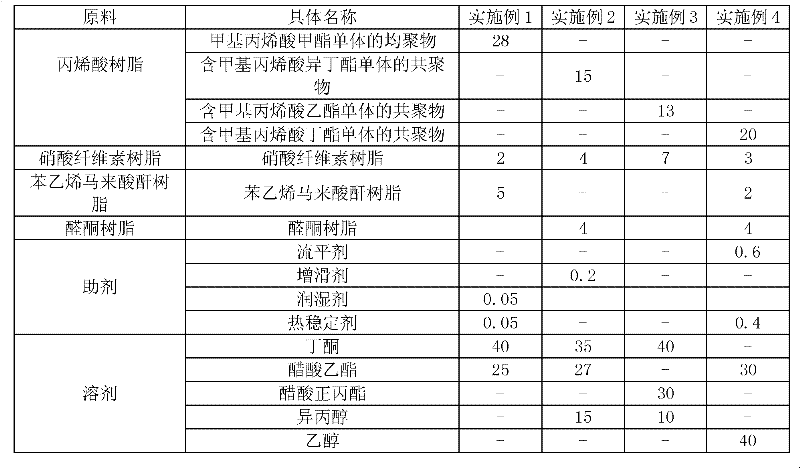

Laser electrolytic aluminum coating composition and preparation method thereof

The invention discloses a laser electrolytic aluminum coating composition and a preparation method thereof. The laser electrolytic aluminum coating comprises the following components by weight percent: 13-28% of acrylic resin, 2-7% of nitrocellulose resin, 0-5% of styrene maleic anhydride resin, 0-4% of aldehyde ketone resin, 0-1% of auxiliary agent and 65-80% of solvent. The preparation method comprises the steps of: putting the solvent into a reaction kettle, and heating to 40-70 DEG C when stirring; putting the nitrocellulose resin into the reaction kettle, and stirring; sequentially putting the rest resins into the reaction kettle, and further stirring; after all the resins which are put into the reaction kettle are completely dissolved, putting the auxiliary agent into the reaction kettle, and cooling after dispersing to obtain the laser electrolytic aluminum coating. Compared with the prior art, the laser electrolytic aluminum coating disclosed by the invention is environment-friendly, low in cost, good in application adaptability and excellent in performance.

Owner:SHANGHAI WEIKAI CHEM +1

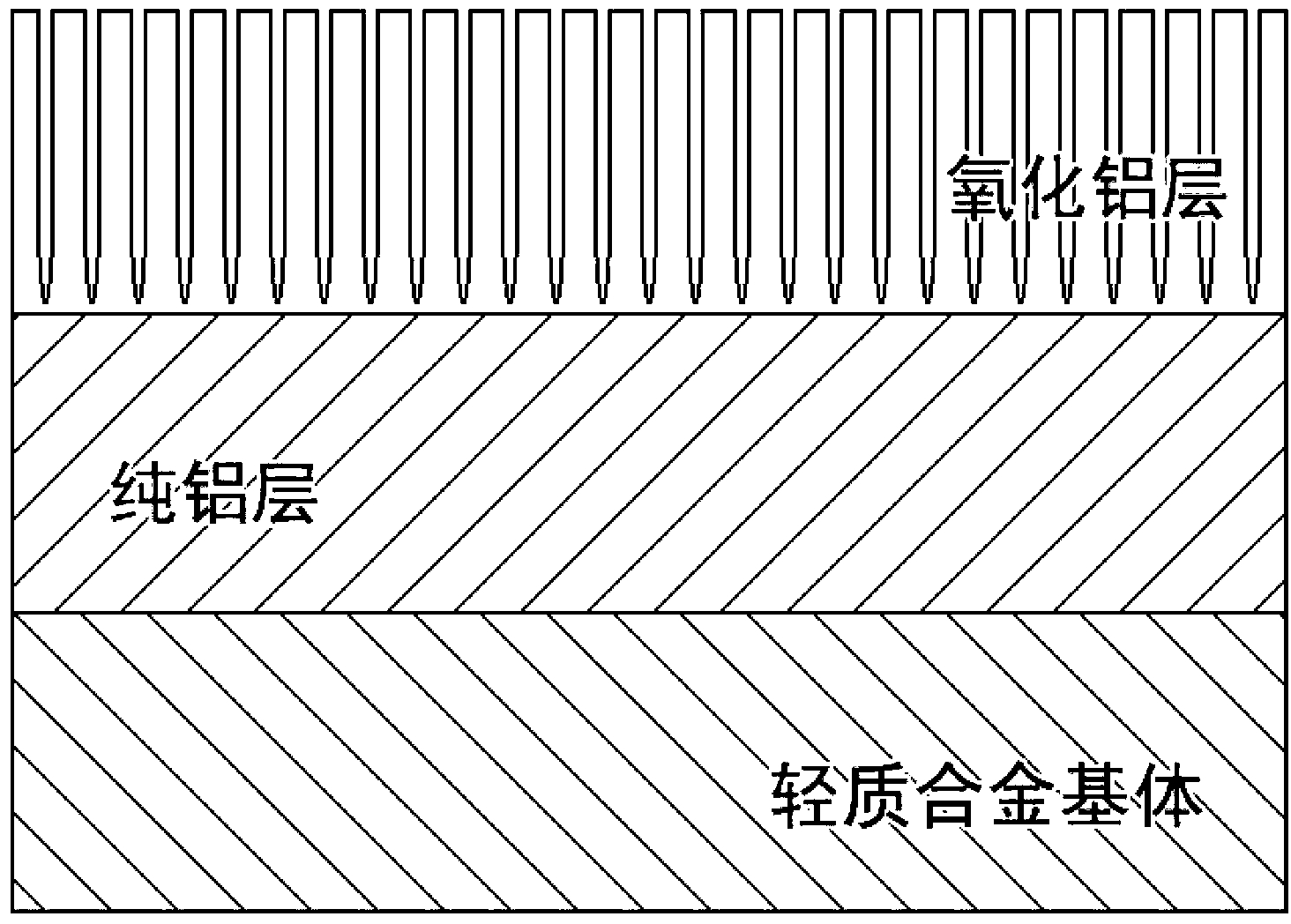

Method for preparing surface protecting coating layer of light weight alloy

InactiveCN103215589AImprove performanceImprove corrosion resistanceAnodisationSuperimposed coating processSurface layerTitanium alloy

The invention relates to the field of surface coating protection and particularly relates to a method for preparing a surface protecting coating layer of a light weight alloy. The method comprises the steps of: firstly, preparing a pure aluminum coating layer on the surface of the light weight alloy in a cold spraying way by adopting pure Al or ultra-pure Al powder, wherein the pure aluminum coating layer serves as a bottom layer of the protecting layer; and secondly, performing surface polishing and anodic oxidizing on the pure aluminum coating layer to prepare an aluminum oxide thin film on the surface of the pure aluminum coating layer, wherein the aluminum oxide thin film serves as a surface layer of the protecting coating layer. After anodic oxidization, the aluminum oxide thin film with excellent properties can be generated on the surface of the pure aluminum coating layer, and the corrosion resistance of the thin film is far better than that of another aluminum oxide thin film which is formed after anodizing an aluminum alloy; and the coating layer is especially suitable to large-scale integrated circuit equipment, so that the equipment is maintained to be ultra-clean under the environments with strong corrosion and plasma compact. The light weight alloy is a magnesium alloy, a magnesium alloy or an aluminum alloy. The method is applicable to the magnesium alloy, the magnesium alloy and the aluminum alloy, and is capable of enhancing the corrosion resistance of the magnesium alloy, the magnesium alloy and the aluminum alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aeroengine case seam allowance size repairing method

The invention relates to an aeroengine case seam allowance size repairing method. The porosity and hardness of a coating and the content of oxides in the coating can be effectively adjusted by controlling the plasma spraying power and the heating process of spraying powder during flying, and heat stress of the coating is reduced. The hardness and thermal expansion coefficient of the prepared nickel-aluminum coating are equivalent with those of a case, the bonding strength of the coating is far higher than the stress strength of a case seam allowance under the given working condition, and the use working condition of the aeroengine case can be met.

Owner:HARBIN DONGAN ENGINE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com