Electrochemical aluminum for stamping gold on ultraviolet (UV) glazing oil surface and preparation method thereof

A technology of anodized aluminum and aluminized layer, which is applied in the printing field, can solve the problems of insufficient hot stamping and weak hot stamping, and achieve the effects of high stamping efficiency, clear edges of graphics and text, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below through specific examples, but the present invention is not limited to these examples.

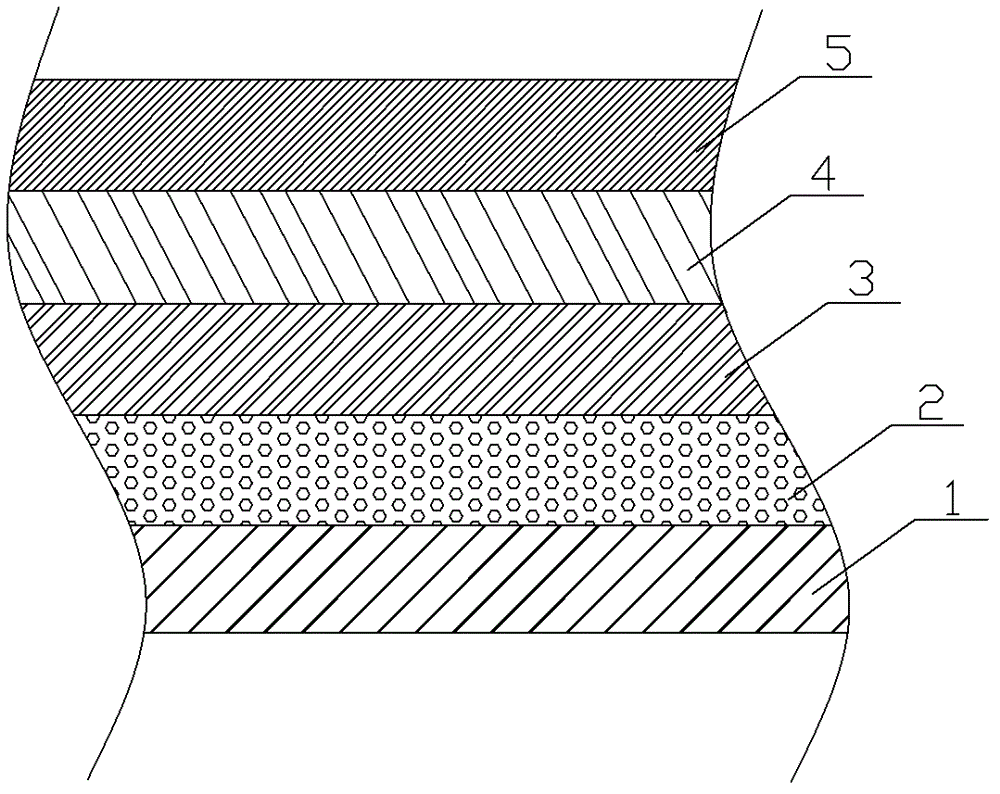

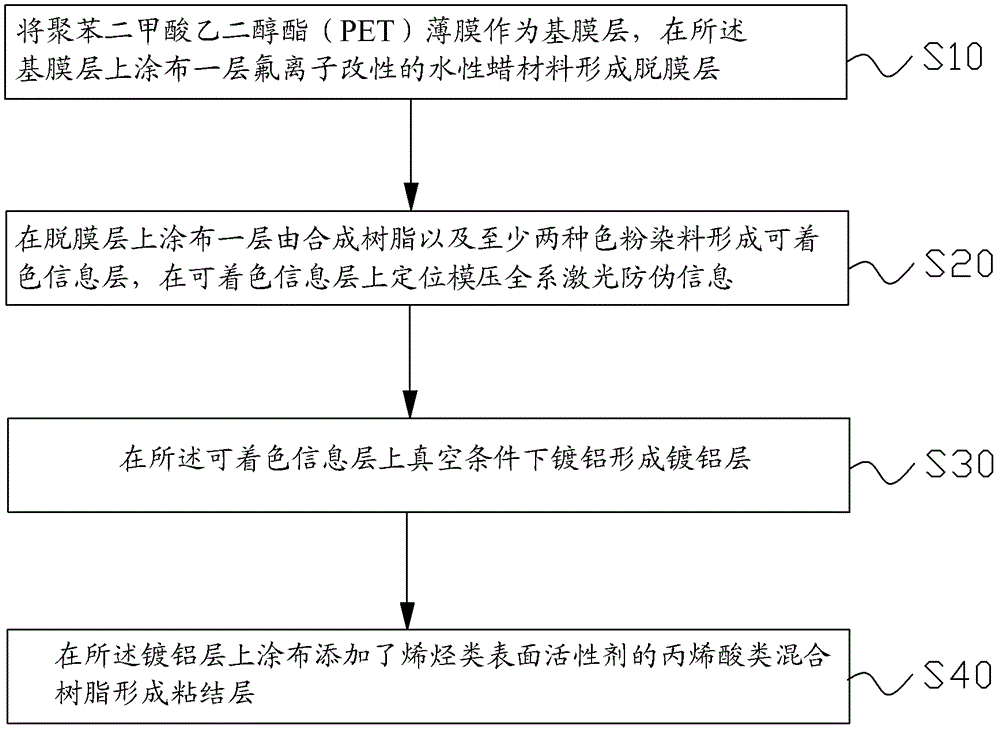

[0012] Such as figure 1 As shown, the embodiment of the present invention provides an anodized aluminum that can be hot stamped on the surface of UV varnish, including a base film layer 1, a release layer 2, a colorable information layer 3, an aluminum plating layer 4, and an adhesive layer 5.

[0013] Among them, the base film layer 1 is a 12-18μm thick polyethylene phthalate (PET) film as the various layers (release layer 2, colorable information layer 3, aluminized layer 4 and adhesive layer 5) The attached and finished coating and molding carrier substrate not only has high strength and stretch resistance, it can ensure that the size of the hologram text will not be affected by the size change during the coating process; it also has high heat resistance , The characteristics of high toughness can ensure that it will not be damaged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com