Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5740 results about "Varnish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Varnish is a clear transparent hard protective finish or film. Varnish has little or no color and has no added pigment as opposed to paint or wood stain which contains pigment. However, some varnish products are marketed as a combined stain and varnish. Varnish is primarily used in wood finishing applications where the natural tones and grains in the wood are intended to be visible. It is applied over wood stains as a final step to achieve a film for gloss and protection. Varnish finishes are usually glossy but may be designed to produce satin or semi-gloss sheens by the addition of "flatting" agents.

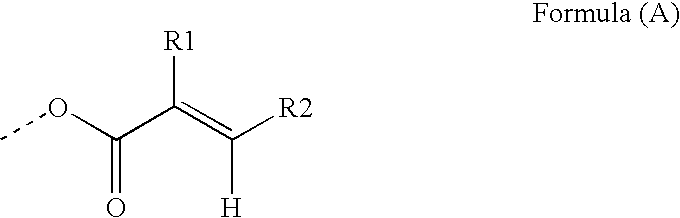

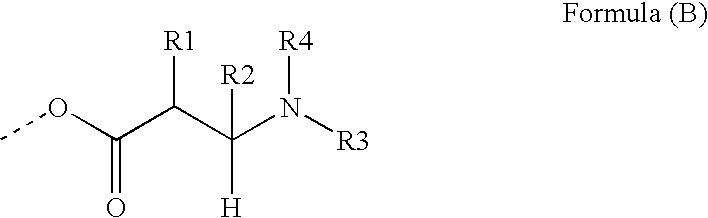

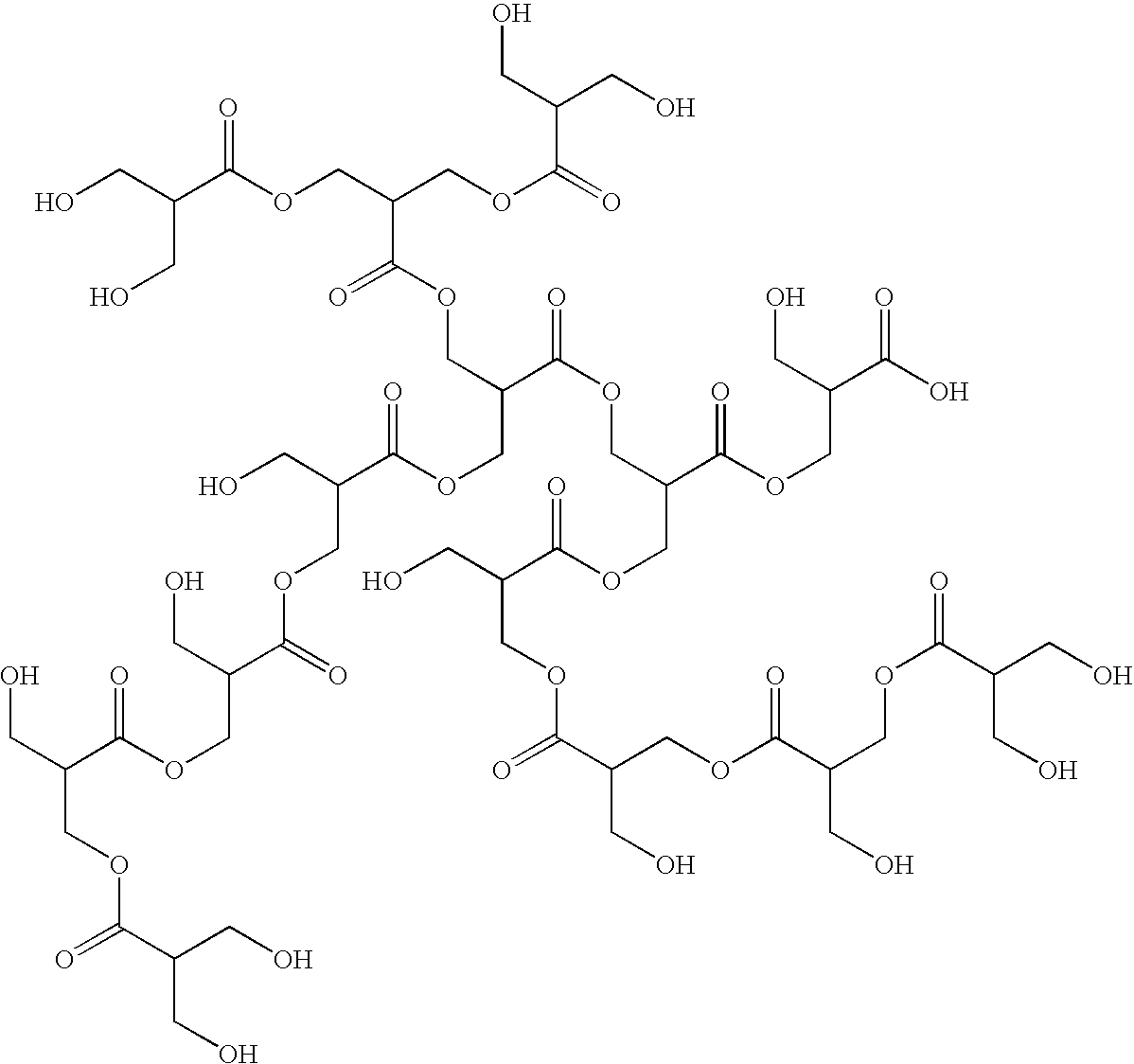

Novel radiation curable compositions

Radiation curable compositions with a polymeric co-initiator are disclosed comprising a dendritic polymer core with at least one co-initiating functional group as an end group. The dendritic polymeric core is preferably a hyperbranched polymer. Industrial applications include varnishes, lacquers and printing inks. The polymeric co-initiator is especially useful in radiation curable inkjet ink.

Owner:AGFA NV

Film coating composition for whitening teeth

PCT No. PCT / CN97 / 00004 Sec. 371 Date Sep. 17, 1998 Sec. 102(e) Date Sep. 17, 1998 PCT Filed Jan. 20, 1997 PCT Pub. No. WO97 / 25968 PCT Pub. Date Jul. 24, 1997The invention relates to a tooth-whitening varnish composition, comprising 6-20% of carbamide peroxide, 2-9% of film forming agent and 77-88% of volatile organic solvent, based on the total weight of the composition. The volatile organic solvent is selected from ether, ethylacetate, ethyl alcohol, or acetone. The film forming agent is artificial or natural material selected from cellulose, polyvinyl, butyral, coumarone resin or shellac. The composition can rapidly form films on dry tooth surfaces, and a remarkable tooth-whitening effect can be obtained.

Owner:IVOCLAR VIVADENT INC

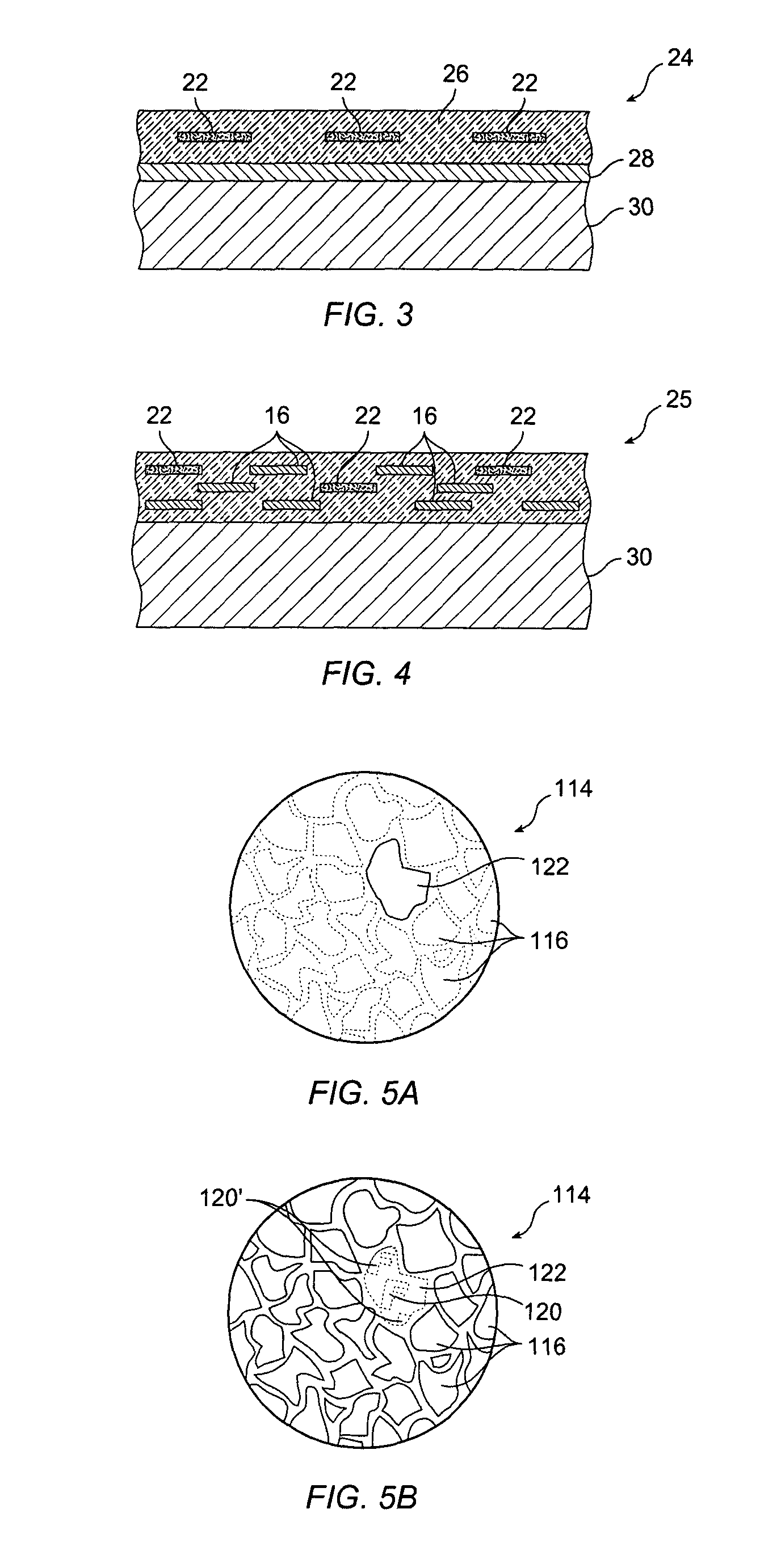

Provision of frames or borders around opaque flakes for covert security applications

InactiveUS20060035080A1Reduce concentrationPigment preparation by PVD/CVD methodsPencil leadsEngineeringMagnification

Opaque flakes, such as pigment or bright flake used in paints and inks, have a selected shape and / or other indicia to provide a covert security feature to an object. In some embodiments the composition includes base pigment, and the opaque covert flakes match the visual characteristics of the base pigment. In another embodiment, opaque covert flakes are mixed in the carrier with base pigment at a concentration sufficient to avoid changing the appearance of the composition. In another embodiment, opaque covert flakes are mixed in a clear or tinted varnish base that can be applied over an existing security feature. Shaped opaque covert flakes are not readily detectable by causal observation, but in some embodiments are easily seen at 50× magnification. In manufacturing the flakes a sheet of embossed frames are provided having symbols or indicia within; upon removing a coating from the sheet the coating material tends to break along frame lines and the resulting flakes are substantially uniform in size.

Owner:VIAVI SOLUTIONS INC

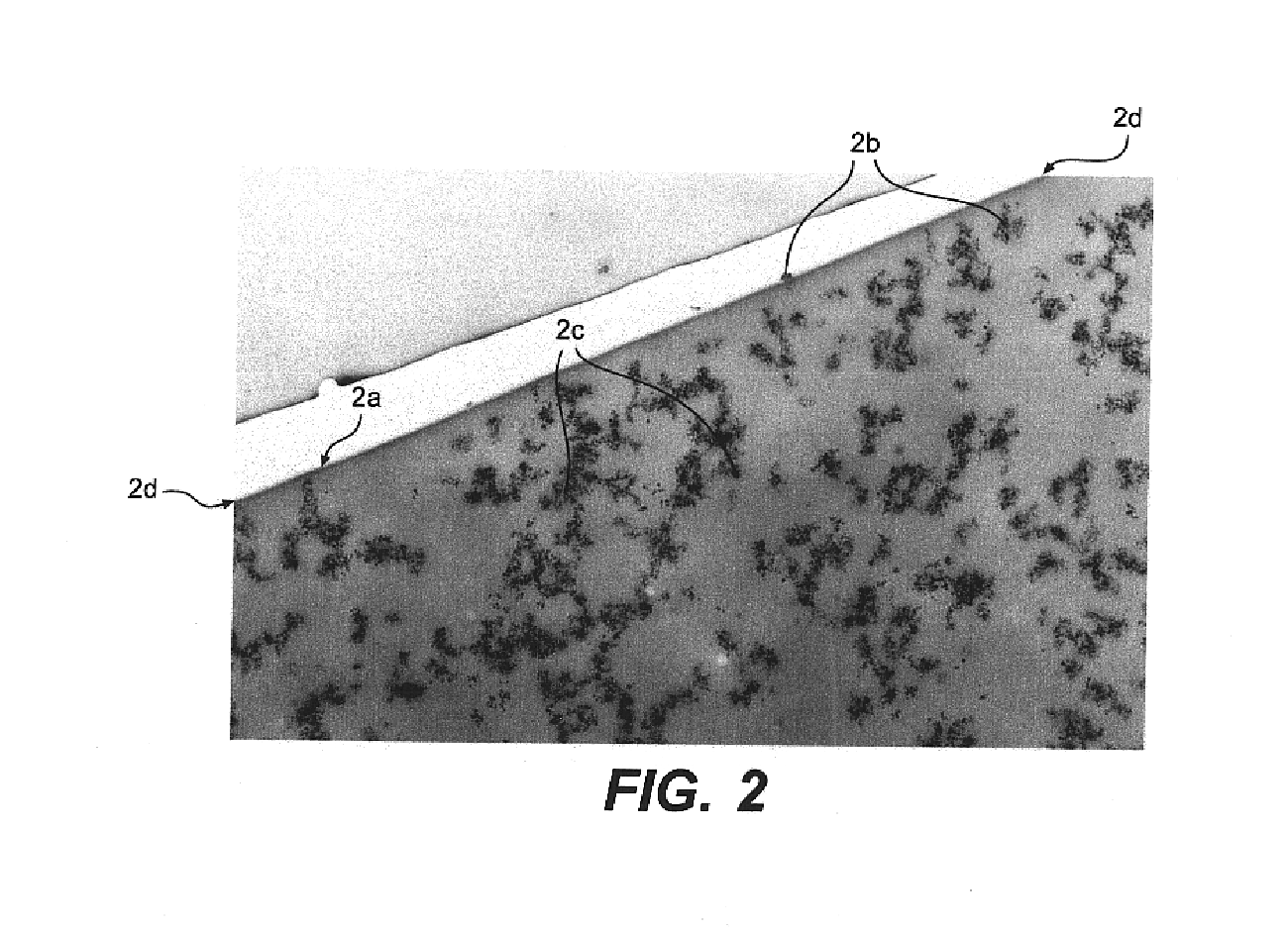

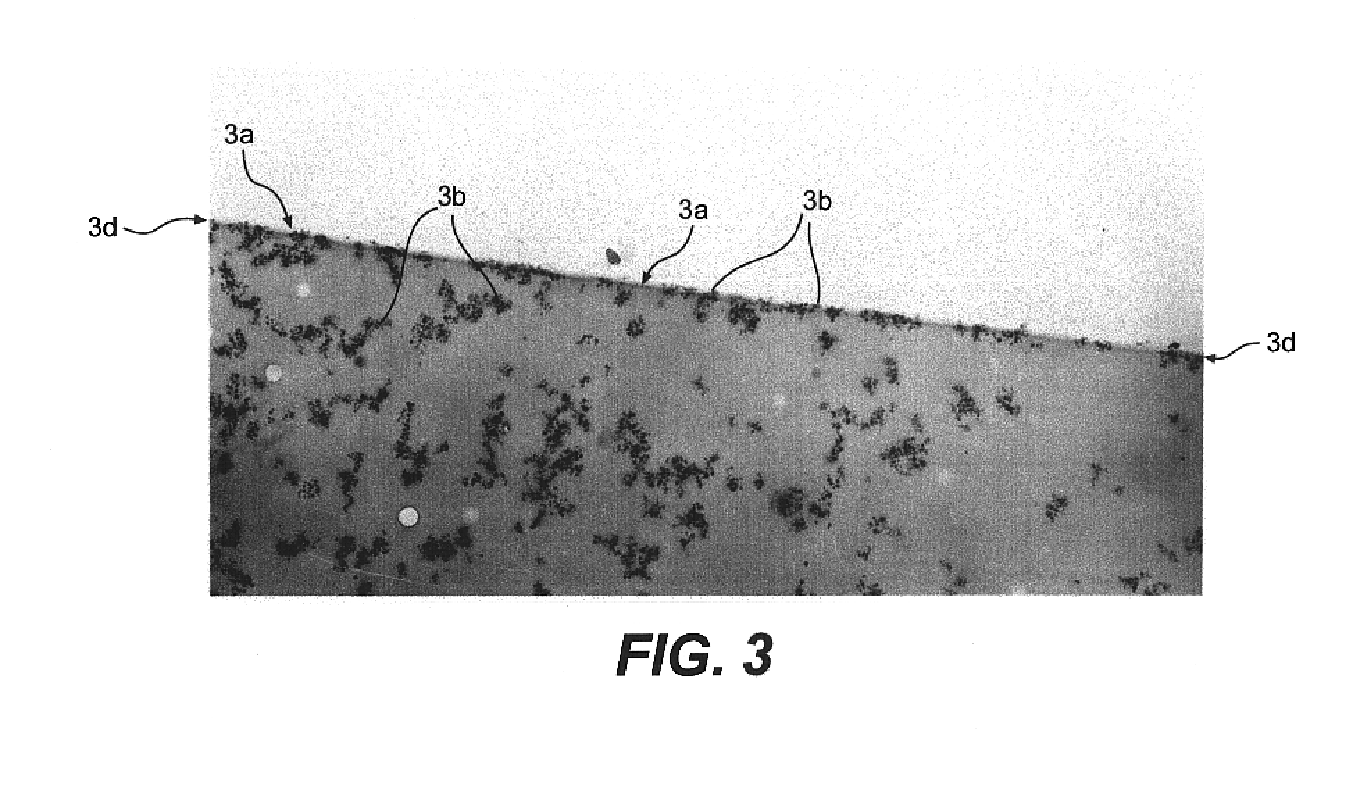

Coating compositions having improved scratch resistance, coated substrates and methods related thereto

InactiveUS7005472B2Improve scratch resistanceGood lookingMaterial nanotechnologyNanostructure manufacturePolymer sciencePolymer chemistry

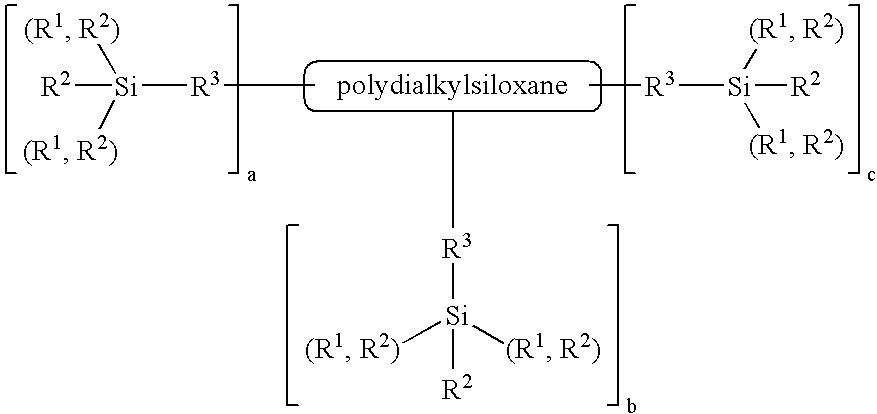

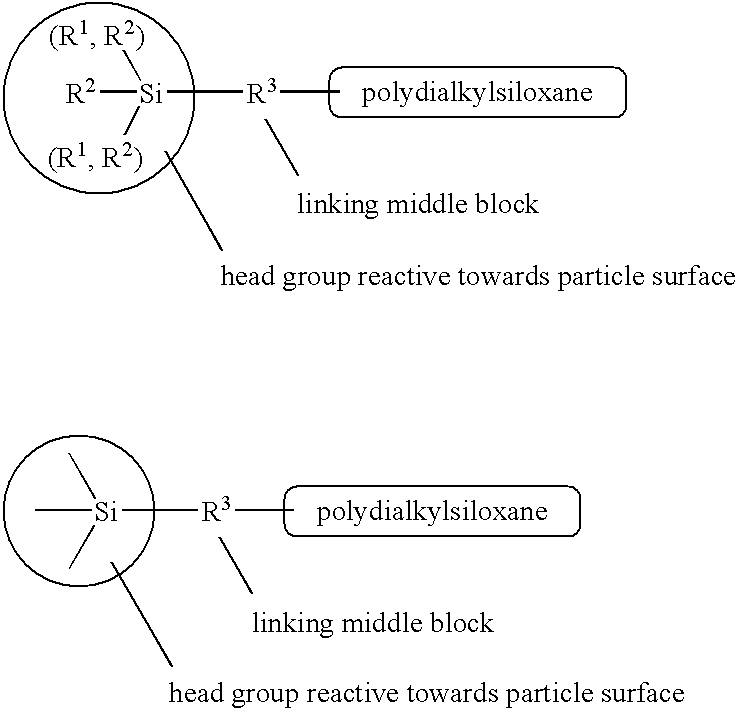

Coating compositions are provided which are formed from components comprising (a) at least one polysiloxane comprising at least one reactive functional group; (b) at least one reactant comprising at least one functional group that is reactive with at least one functional group selected from the at least one reactive functional group of the at least one polysiloxane and at least one functional group of at least one reactant; and (c) a plurality of particles, wherein each component is different, and wherein the at least one reactive functional group of the at least one polysiloxane and the at least one functional group of the at least one reactant are substantially nonreactive with the particles. A multi-component composite coating composition formed from a basecoat and a topcoat deposited from the curable coating composition also is provided. The multi-component composite coating compositions of the invention provide highly scratch resistant color-plus-clearcoatings capable of retaining scratch resistance after weathering.

Owner:PPG IND OHIO INC

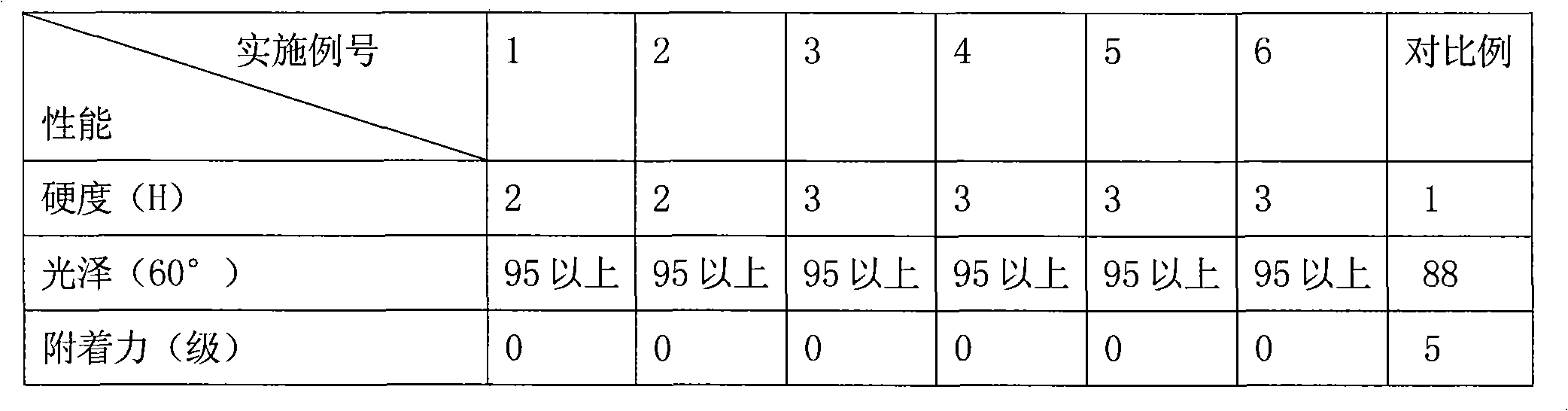

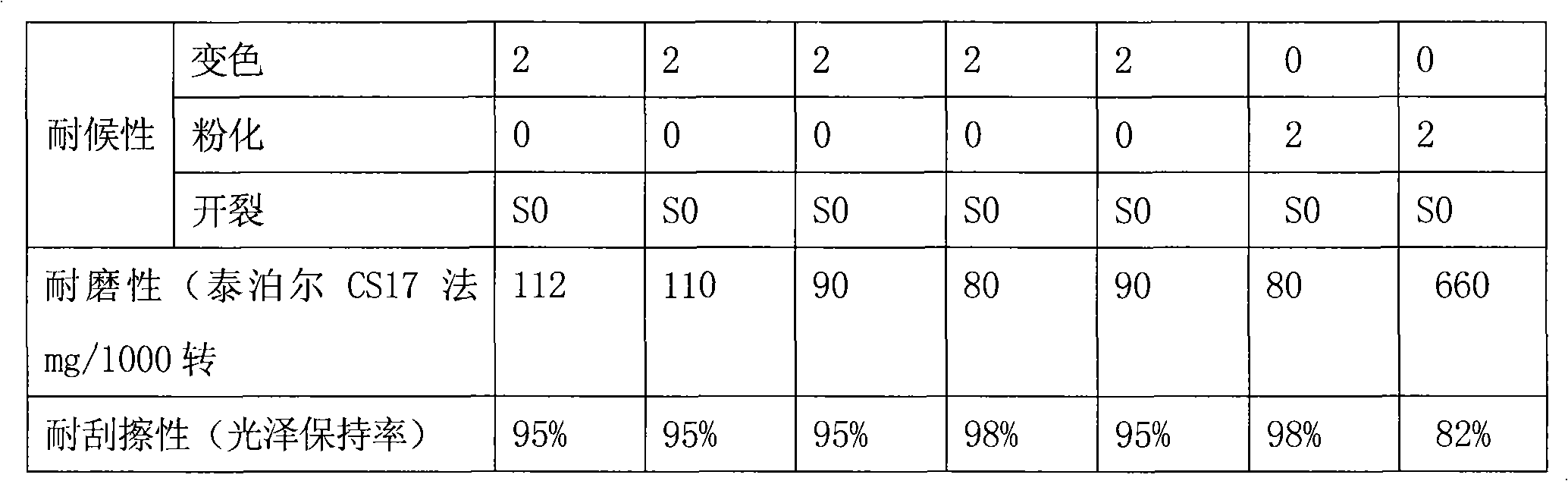

UV curing color decorative coating

InactiveCN101407651ASolve the problem of deep curingAvoid pollutionMulticolor effect coatingsPolyesterUltraviolet

The invention relates to an ultraviolet curing color decorative coating, the components of the coating and the parts by weight thereof are as follows: 5 to 25 parts of epoxy acrylate prepolymer, 5 to 30 parts of polyurethane acrylate prepolymer, 2 to 10 parts of polyester acrylate prepolymer, 15 to 70 parts of acrylate monomer, 1 to 10 parts of photoinitiator, 1 to 35 parts of pigment, 0.5 to 10 parts of dispersant and 0.1 to 2 parts of auxiliary agent, the acrylate monomer is a mixture of the monomer with bifunctionality and the monomer with high functionality, wherein, the mixture ratio of the monomer with high bifunctionality to the monomer with bifunctionality is 1: 0.3 to 8. Compared with an ultraviolet curing transparent varnish, the ultraviolet curing color decorative coating has stronger decorative effect and almost the same curing speed, paint film hardness, adhesion, paint film gloss, and the like; and compared with a traditional solvent based colored paint, the ultraviolet curing color decorative coating does not contain volatile organic solvent, thereby avoiding the pollution and greatly improving the production efficiency. The ultraviolet curing color decorative coating is applicable to the decoration of plastics, wood materials, metals and other base materials.

Owner:BAODING LUCKY POLYMER MATERIAL TECH DEV +1

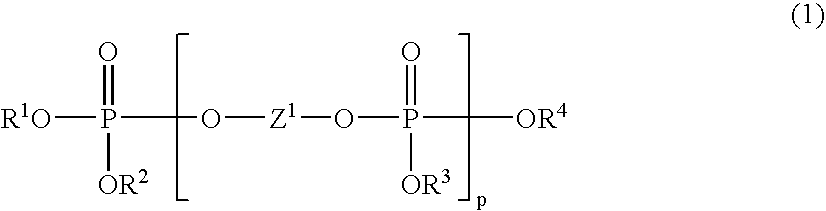

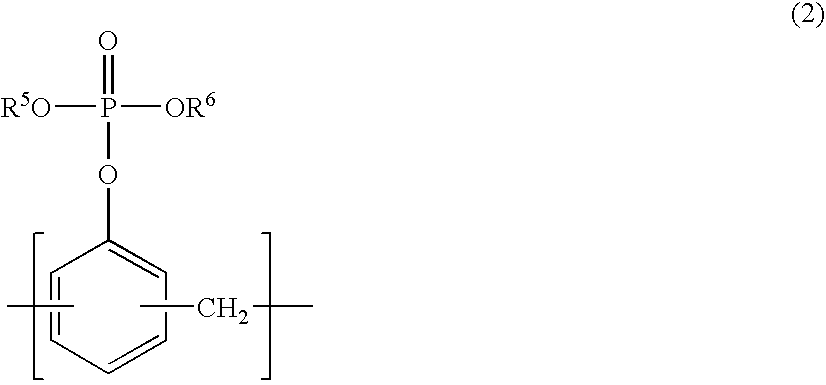

Flame-retardant resin composition

A flame-retardant resin composition comprises 10 to 300 parts by weight of a flame retardant (B) and 1 to 200 parts by weight of an inorganic filler (C) (a glass fiber and / or a glass flake), relative to 100 parts by weight of a base resin (A). The flame retardant (B) comprises a polyphenylene oxide-series resin and / or a polyphenylene sulfide-series resin (B1), a phosphoric ester (B2), and a nitrogen-containing cyclic compound (B3) (for example, a polyphosphate of an amino group-containing triazine compound). The inorganic filler (C) has been treated with a surface-treatment agent or sizing agent containing a novolak epoxy resin. Such a resin composition is useful for obtaining a shaped article which has been inhibited from dripping and to which flame retardancy is highly imparted.

Owner:POLYPLASTICS CO LTD

Paint of aqueous epoxy resin and its preparation method

A water epoxy resin paint is composed of the epoxy resin emulsion prepared from epoxy resin through emulsifying, and the solidifying agent prepared from polyvinylpolyamine through terminating, addition and salting. Said paint is prepared by proportional mixing both components together. Its advantages are high stability and antiwear nature, high film hardness and high durability.

Owner:TONGJI UNIV

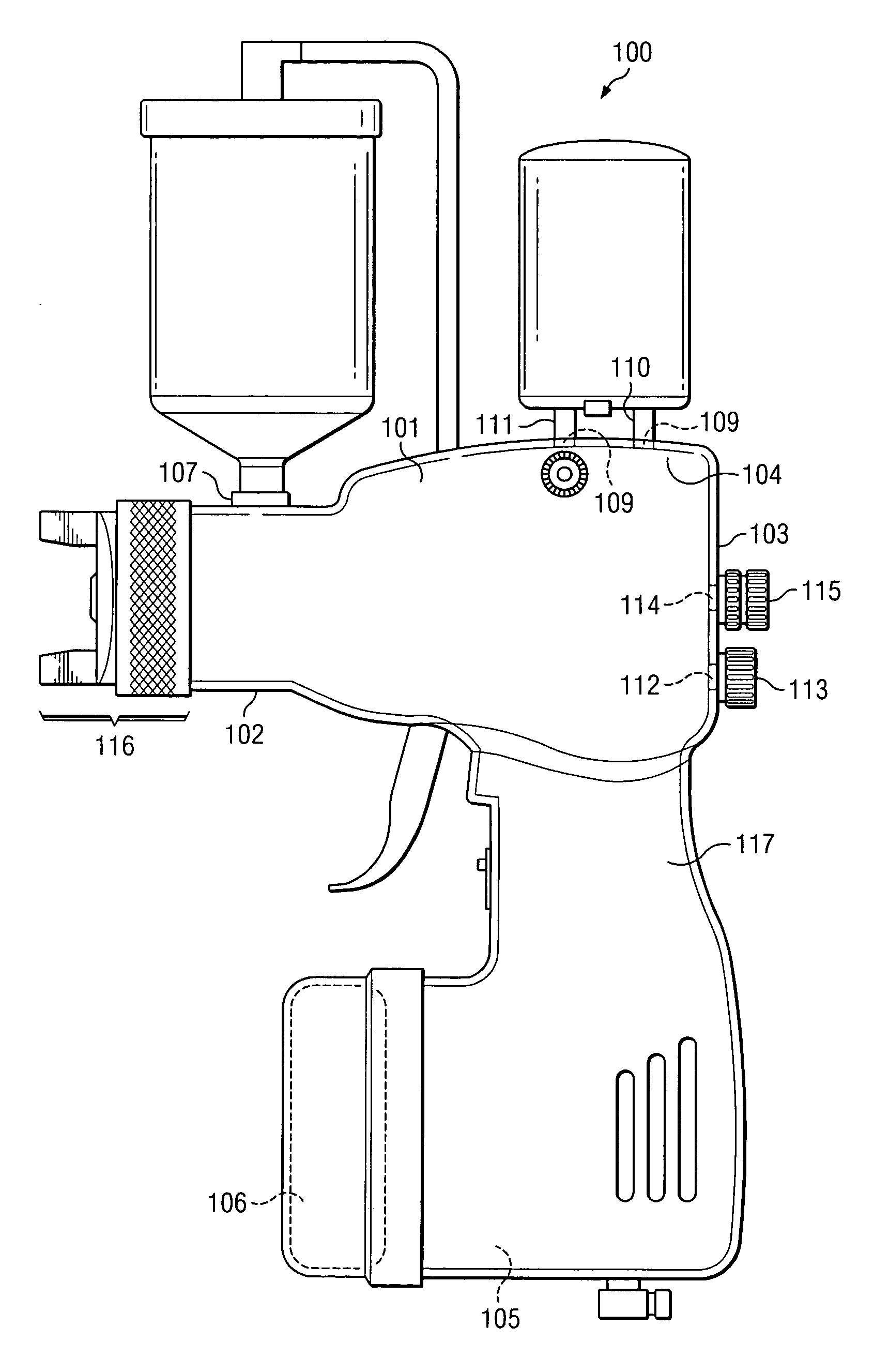

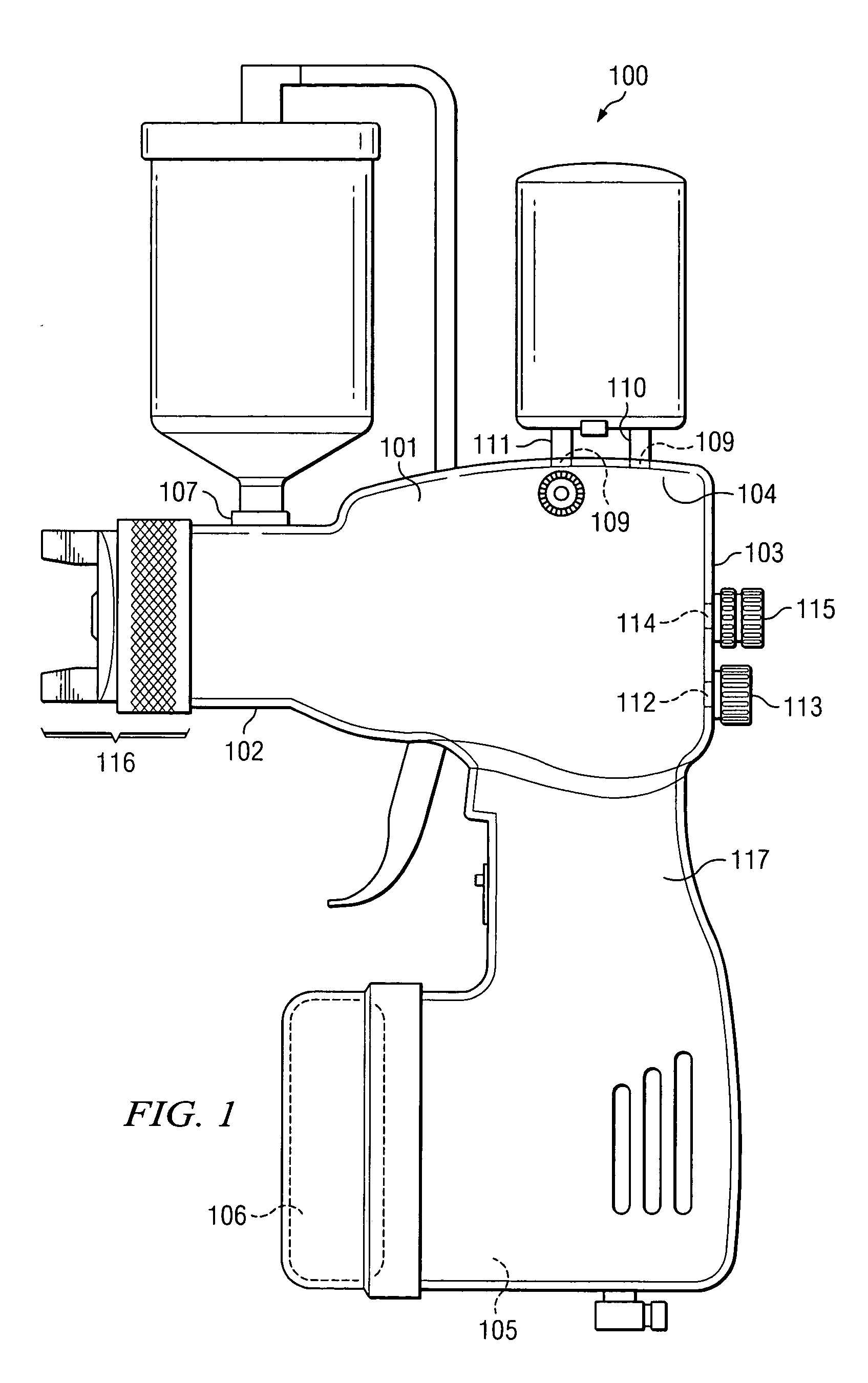

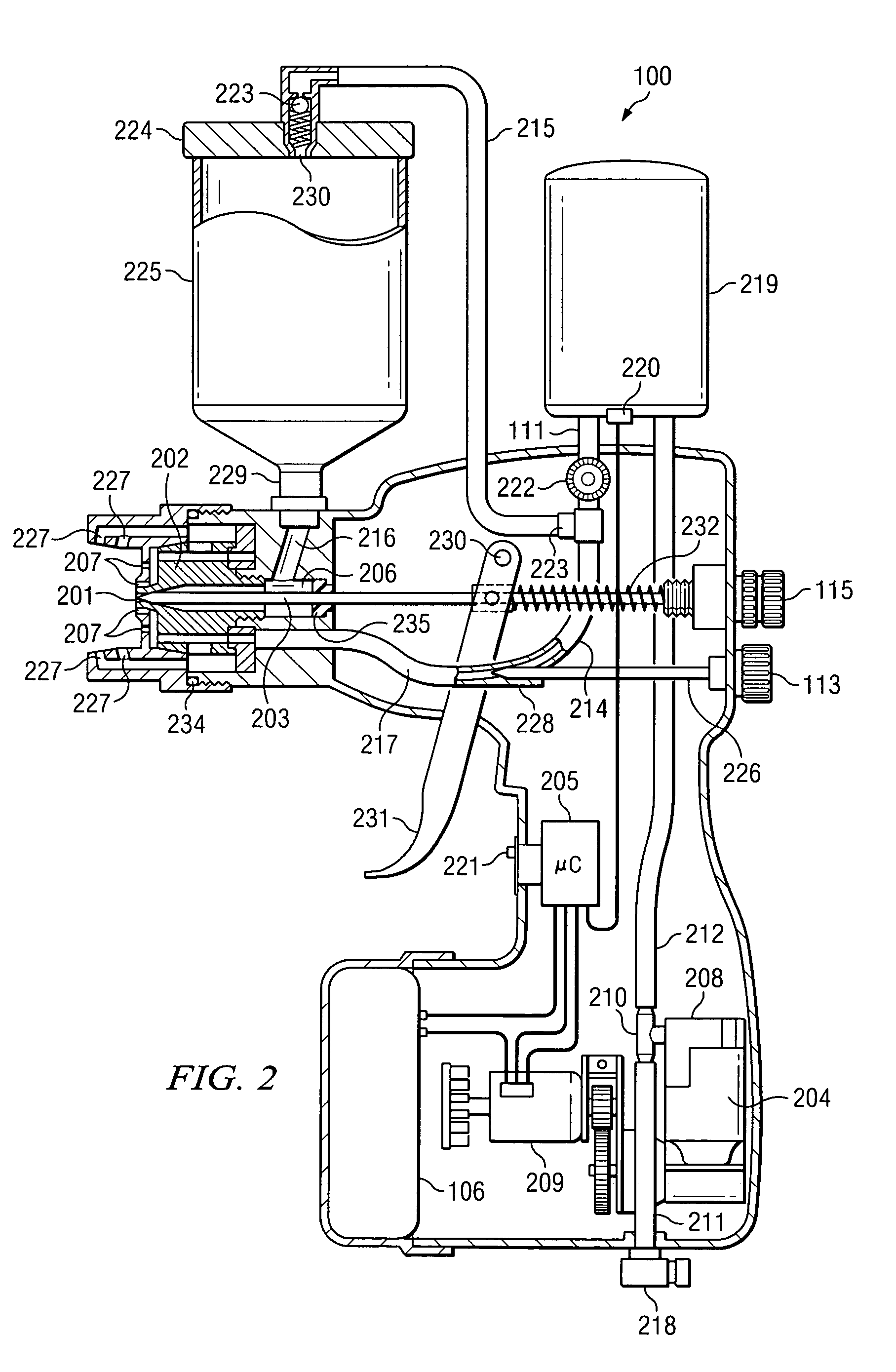

Cordless, self-contained, handheld spray gun

What is disclosed is a self contained, cordless, handheld spray gun (100). The spray gun (100) comprises a fluid container (225) in intercommunication with at least one fluid nozzle orifice (201) and a source of pressurized gas (204) in intercommunication with at least one gas nozzle orifice 207 and one fan nozzle orifice (227). The spray gun (100) is actuated by pulling a trigger (231) that opens at least one valve (202) so that the fluid, such as paint, primer, stain, varnish, sealant or the like, can flow to a fluid chamber (206), atomized, and sprayed through a fluid nozzle orifice (201) out onto the article to be painted.

Owner:JUST A SIMPLE THING

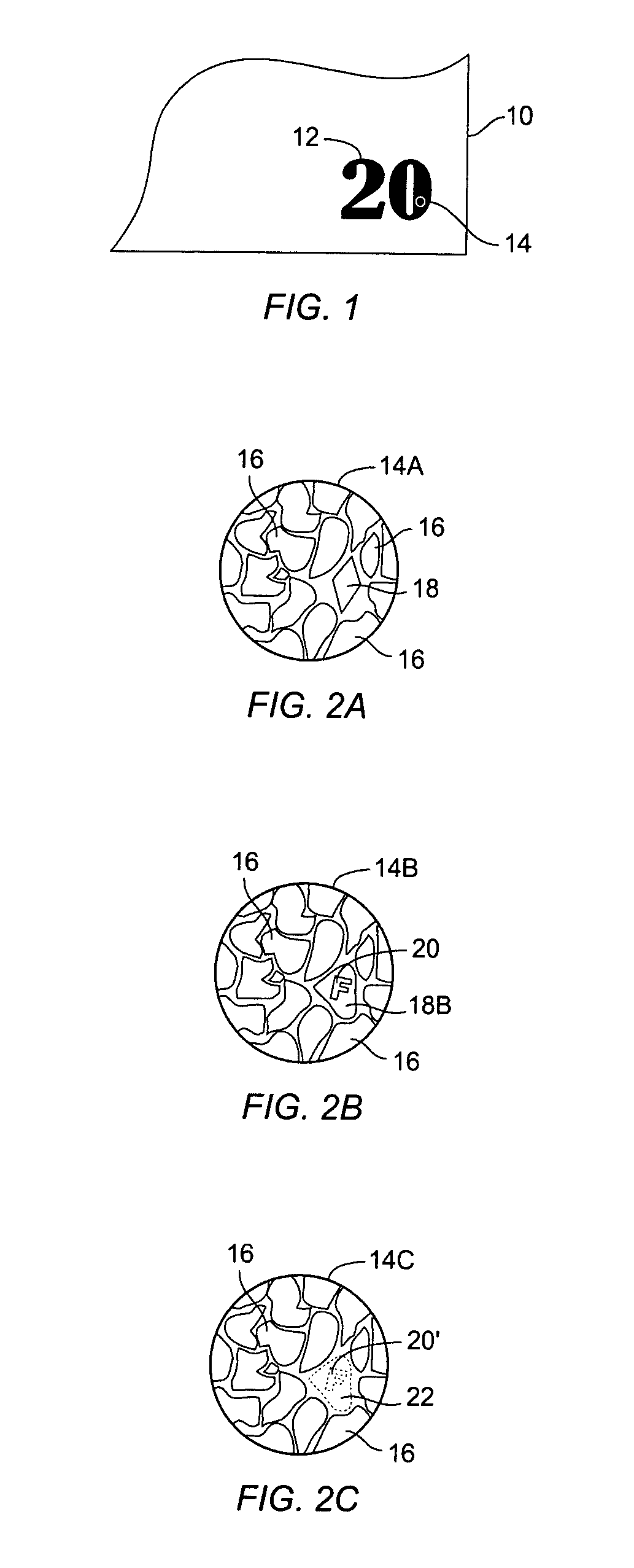

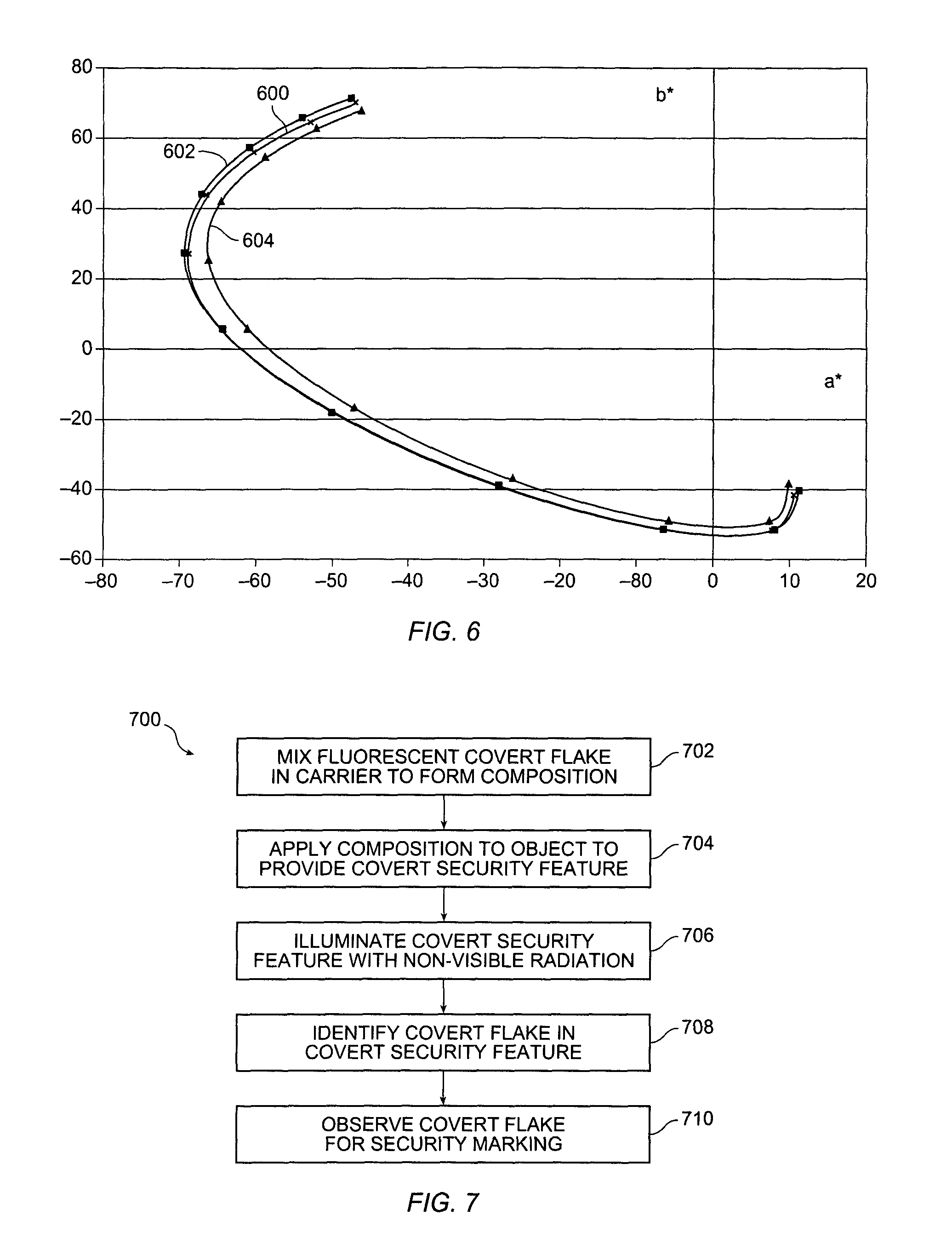

Flake for covert security applications

Covert flakes having one or more symbols and / or a selected shape are used in a composition, such as ink or paint, to provide a covert security feature to an object. In some embodiments the composition includes base pigment, and the covert flakes are covert pigment flakes that match the visual characteristics of the base pigment. In another embodiment, clear covert flakes are mixed in the carrier with base pigment. In another embodiment, clear covert flakes are mixed in a varnish base to provide a clear composition that can be applied over an existing security feature or elsewhere. The composition is used to print a field on the object, such as a stock certificate or bank note, for example. The covert flakes are not readily detectable by causal observation under visible light. In one embodiment, illuminating the covert security feature with ultraviolet light causes a covert flake to fluoresce and allows the observer to identify the location of the covert flake so that cover indicia may be observed. In a particular embodiment, a covert flake having one or more symbols is located using non-visible radiation, and then observed under visible light to read the symbol(s) on the covert flake.

Owner:VIAVI SOLUTIONS INC

Water epoxy paint for ground floor and its mfg. process and construction technology

The invention relates to a water epoxy ground floor coating and its making method and constructing process, where one component is low-molecular weight liquid-state epoxy resin assorted with active diluter in a proper proportion, and the other component is a dispersoid with hydrophilic curing agent as the principal thing, containing water-borne curing agent, water, acid-resistant wearable color filler, various auxiliaries, etc. and its producing method is simple and mainly includes mechanical dispersing and mixing; it does need to clean paint-covered surface as used on humid basal surface; the paint film has excellent properties of oily products and unilateral permeability. It uses water as dispersing medium, has no VOC, safe and environmental-protection.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Ultraviolet light cured printing ink

The invention discloses the ultra-violet light solidified printing ink. The ultra-violet light solidified printing ink hasn't volatile organic solvent, avoiding the pollution and improving the durability and flexible. The invention uses the national standard GB / T 1731-93 to test, and the baseboard uses soft PVC film. The invention uses national standard GB / T 1766-95 to test durability, and uses GB / T 1865-97 to test printing ink. The flexible is 1mm, the discoloration is 2 grade, the efflorescence is 0 grade, and the cracking is 0 grade.

Owner:SHANGHAI HUAMING HI TECH GRP

Coated Metal Product, Method to Produce It and Use of the Method

InactiveUS20090181262A1High quality finishResistant to damageDecorative surface effectsPretreated surfacesLacquerMetallic substrate

Owner:SANDVIK INTELLECTUAL PROPERTY AB

High-performance organic-inorganic resin coating material with hybrid acrylic ester and production thereof

InactiveCN1746236AEasy to prepareHigh hardnessLiquid surface applicatorsCoatingsCross-linkResin coating

A high-performance organic-inorganic hybrid acrylate resin coating material and its production are disclosed. The process is carried out by taking inorganic nanometer oxidant collosol containing hydroxyl group and alkoxy as curing agent, reacting with acrylate resin containing functional group, cross-linking and curing to obtain inorganic-organic hybrid coating. It achieves higher hardness, better thermal stability, abrasive and scraping-resistances and ultraviolet shielding characteristic. It can be used for surface protective ornament of car, metal, building, leather and fabric.

Owner:FUDAN UNIV

Environment-friendly rust inhibiting primer

InactiveCN101899248AHarmless to healthGood resolvabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyOrganic solvent

The invention discloses environment-friendly rust inhibiting primer. The rust inhibiting primer comprises the following components in parts by weight: 20 to 50 parts of hydroxyl resin, 5 to 30 parts of amino resin, 2 to 8 parts of epoxy resin, 2 to 10 parts of coalescent, 8 to 20 parts of pigment, 2 to 30 parts of inorganic filler, 5 to 25 parts of organic solvent, 0.01 to 1.0 part of flatting agent, 0.05 to 3.0 parts of conductivity improver, 0.2 to 4 parts of dispersing agent, and 0.2 to 3.0 parts of coupling agent. The primer has good redissolution resistance, can perform 'wet on wet' spraying with undercoat and varnish, namely 'three spraying-one bake' to produce a film after a workpiece is sprayed by primer, undercoat and varnish in turn and is treated by baking once, and the performance of the film is equivalent to the conventional 'three spraying-three bake' process. The heavy metal content of the rust inhibiting primer can achieve the requirement of related laws and regulations, and is harmless to human health.

Owner:JIANGMEN PAINT FACTORY

Surface-modified nanoparticles, their preparation and use

ActiveUS20060204528A1Suitable for preparationEasy to measureCosmetic preparationsMaterial nanotechnologyNanoparticleVarnish

Owner:BYK CHEM GMBH

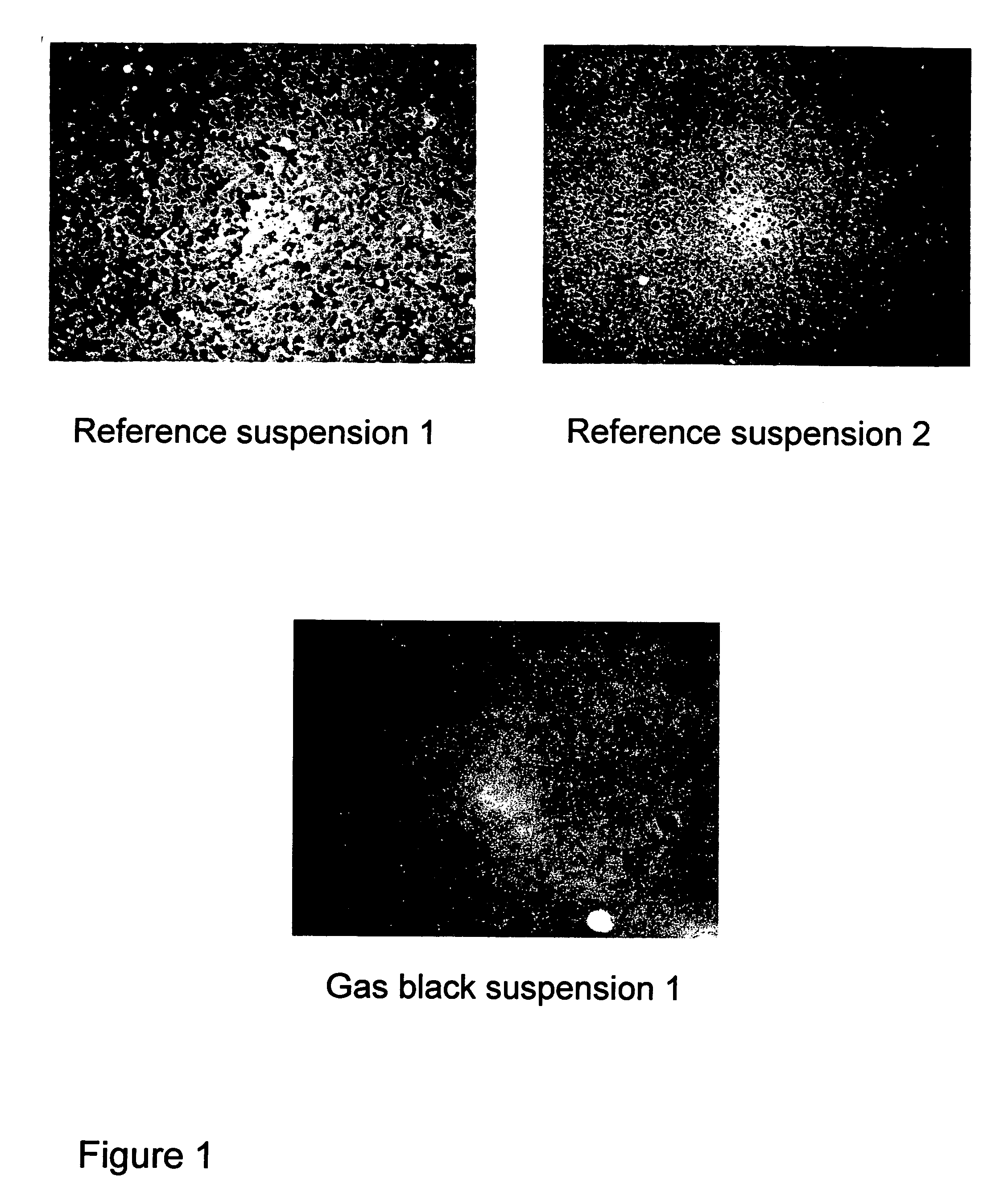

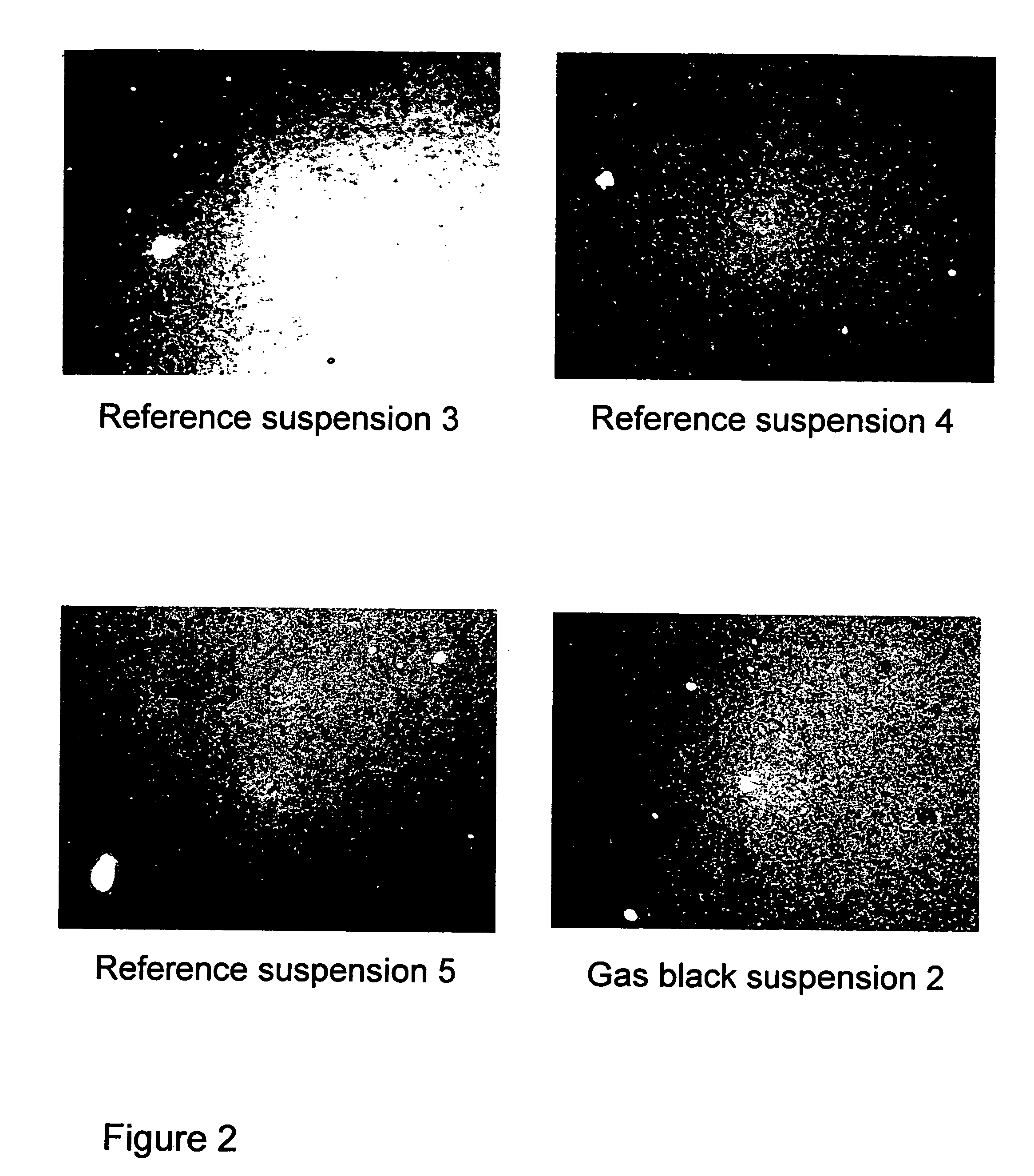

Aqueous, colloidal, freeze-resistant and storage-stable gas black suspension

InactiveUS20040087707A1Low viscosityImprove suspension stabilityDuplicating/marking methodsSpecial tyresZeta potentialLacquer

Aqueous, colloidal, freeze-resistant and storage-stable gas black suspension are disclosed containing 2-30 wt. % gas black, 0-40 wt. % carbon black, a dispersion-supporting additive, a biocide and water and having a zeta potential of less than -10 mV, a surface tension of greater than 50 mN / m and an average particle size of less than 200 nm. The aqueous, colloidal, freeze-resistant and storage-stable gas black suspension is produced by dispersing the gas black and the carbon black in water together with the dispersion-supporting additive and biocide. Inks, ink-jet inks, lacquers and printing inks can be made from these suspensions.

Owner:EVONIK DEGUSSA GMBH

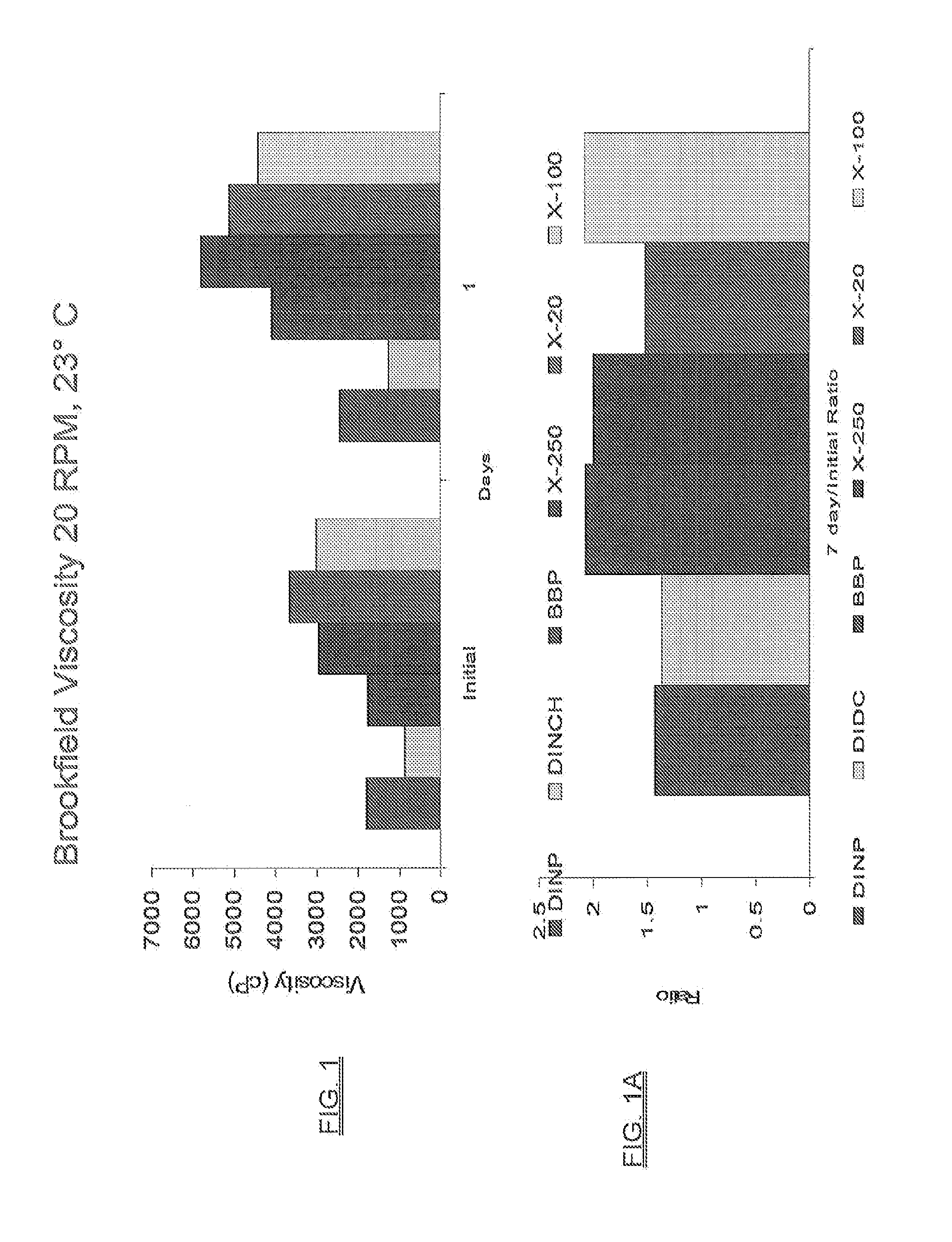

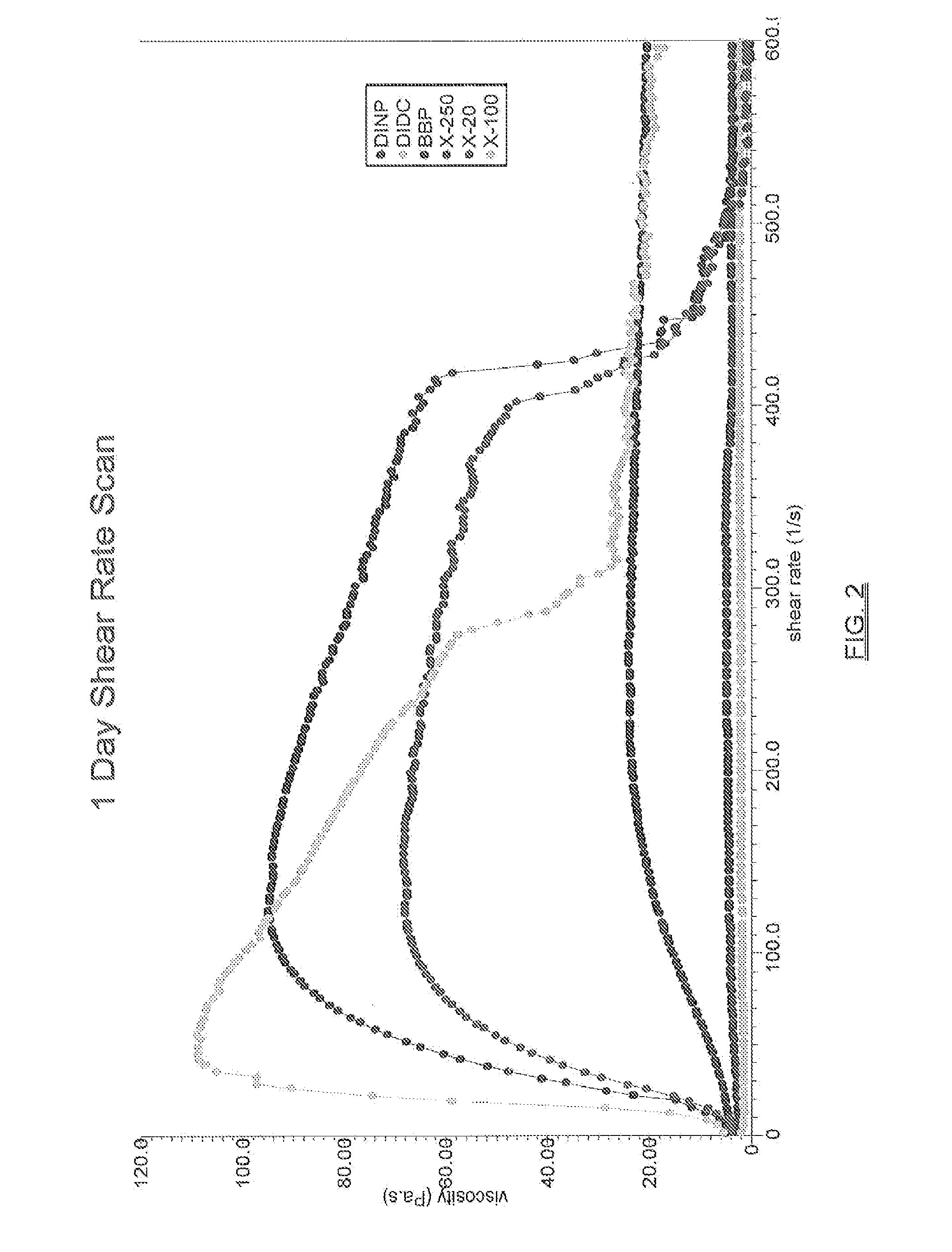

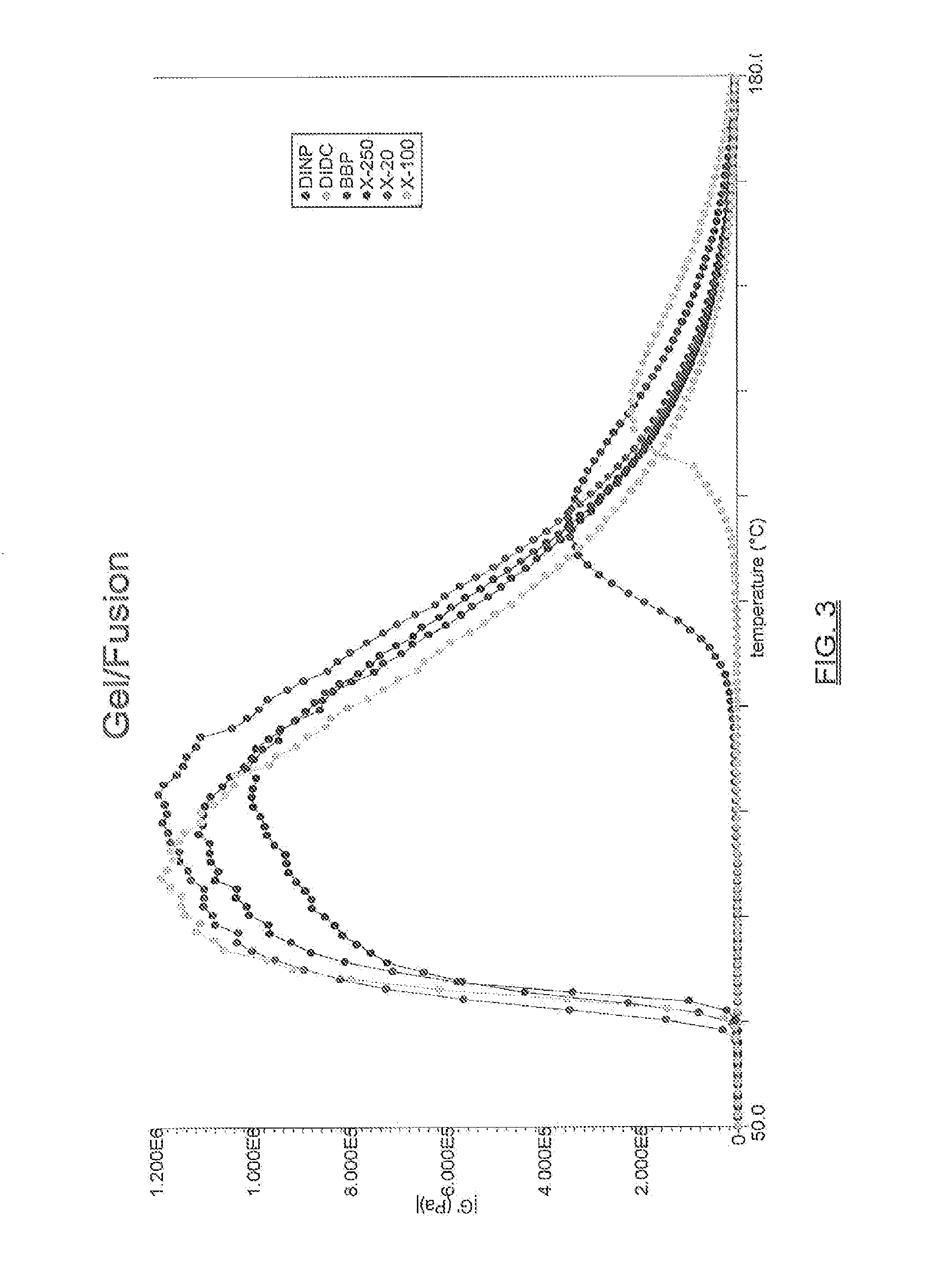

Blends of dibenzoate plasticizers

ActiveUS20130274396A1Efficient Tg suppressionFaster processing timeNon-macromolecular adhesive additivesInksElastomerAdhesive

Plasticizer blends comprise a triblend of diethylene glycol dibenzoate, dipropylene glycol dibenzoate, and 1,2-propylene glycol dibenzoate, in specified ratios, useful in combination with a multitude of thermoplastic polymers, thermosetting polymers, and elastomeric polymers and numerous applications, including but not limited to plastisols, adhesives, sealants, caulks, architectural coatings, industrial coatings, OEM coatings, inks, overprint varnishes, polishes, and the like. The advantages rendered by the use of the triblend depend on the type of polymer and application in which it is utilized and include among other advantages higher solvating power and lower processing time, low VOC's, reduced plasticizer freeze point, improved gelation and fusion characteristics, higher tensile strength, superior stain and extraction resistance, and improved rheology over traditional diblends of diethylene glycol dibenzoate and dipropylene glycol dibenzoate.

Owner:EMERALD KALAMA CHEM

Fluorine-silicon modified self-crosslinking acrylic ester emulsion and preparation thereof

InactiveCN101348595ASimple preparation processReaction conditions are easy to controlCoatingsPolymeric surfacePolymer science

The invention provides a fluorine-silicon modified self-crosslinking acrylic ester emulsion and a preparation method thereof, belonging to the technical field of polymer synthesis. The emulsion is a product formed by organosilicon monomers, fluoride-containing acrylic monomers, (methyl) acrylic monomers and self-crosslinking monomers through core-shell emulsion polymerization. The preparation method adopts a core-shell emulsion polymerization method, thereby ensuring that the fluoride-containing acrylic monomers tend to surface polymerization, and fluorine atoms tend to polymer surface in emulsion film forming process; moreover, the monomers capable of self-crosslinking is added to a shell layer, so as to utilize the crosslinking of the monomers to fixedly limit the migration of the fluorine atoms towards the inside of latex particles, as well as the swing of chains, thereby ensuring that the performances of the fluoride-containing emulsion are completely embodied. The preparation method improves the water resistance, stain resistance, solvent resistance, weather resistance and other comprehensive performances of the emulsion. The fluorine-silicon modified self-crosslinking acrylic ester emulsion prepared through the preparation method can be widely applied to high-grade building paint, industrial paint and wooden ware varnish. Moreover, the preparation method has the characteristics of simple manufacturing process, easy reaction condition control, good emulsion stability and environment-friendly property.

Owner:PEKING UNIV +1

Water epoxy resin coating and preparing process thereof

InactiveCN1752163AEvenly dispersedImprove performanceEmulsion paintsEpoxy resin coatingsEpoxyEmulsion

A water epoxy resin paint is prepared from one of low-molecular liquid epoxy resin, the ether solution of epoxy resin and epoxy resin emulsion, and the solidifying agent prepared from polyvinylpolyamine through terminating, addition and salting. Its advantages are high hardness, adhesion and resistance to water and corrosion.

Owner:TONGJI UNIV

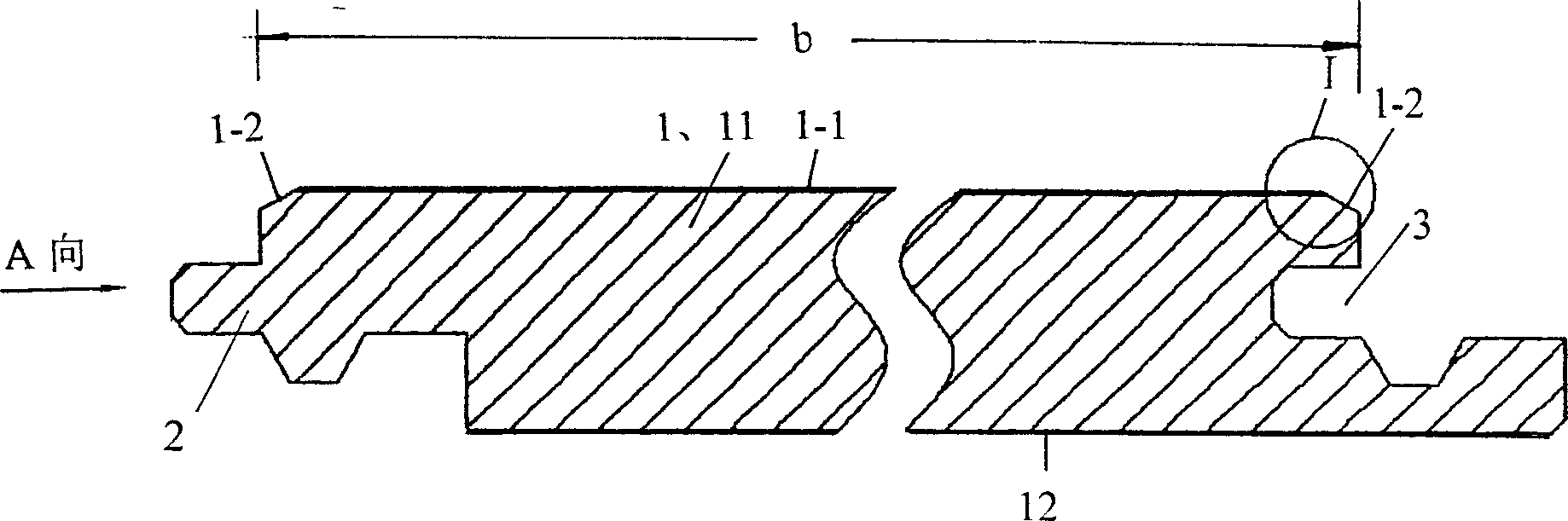

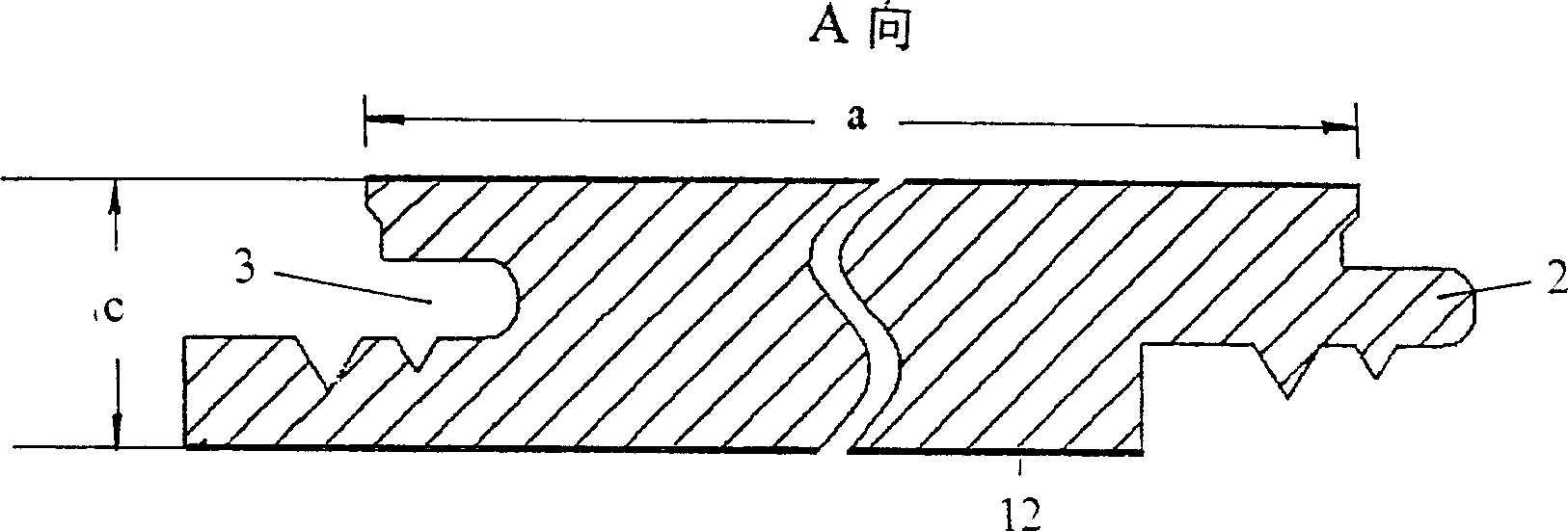

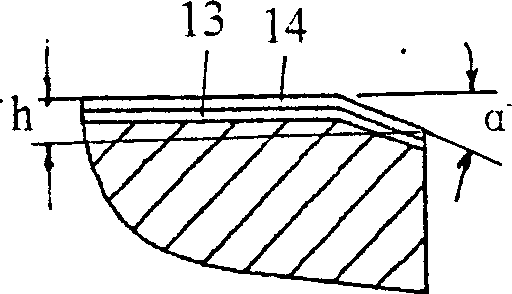

Stiffened timber floor and the manufacturing method thereof

InactiveCN1485184ALow priceExtended service lifeWood working apparatusWood layered productsSolid woodPulp and paper industry

An intensified wood floor board and its manufacturing method. One measure is, the upper surface of the floor mainbody is composed of the walking plane and inclined planes of the two sides of the walking plane; the upper surface of fiberboard has a paper layer with wood texture and a durable paper layer in sequence; by pressing mold, balanced paper layer, fiberboard, the paper layer with wood texture and a durable paper layer are adhered with each other. The second measure is, the upper surface of the floor mainbody is composed of the walking plane parallel to the base surface and inclined planes of the two sides of the walking plane, the upper surface of the upper surface of the fiberboard has a paper layer with wood texture and a durable paper layer in sequence; by bonding, the inclinedplanes on two sides are adhered with the paper layers with wood texture; resin varnish is coated on the paper layers with wood texture. due to inclined planes of two sides of the upper surface of floor mainbody, it is convenient to pave floor board. The floor board is durable, inexpensive and could use for a long time.

Owner:葛跃进

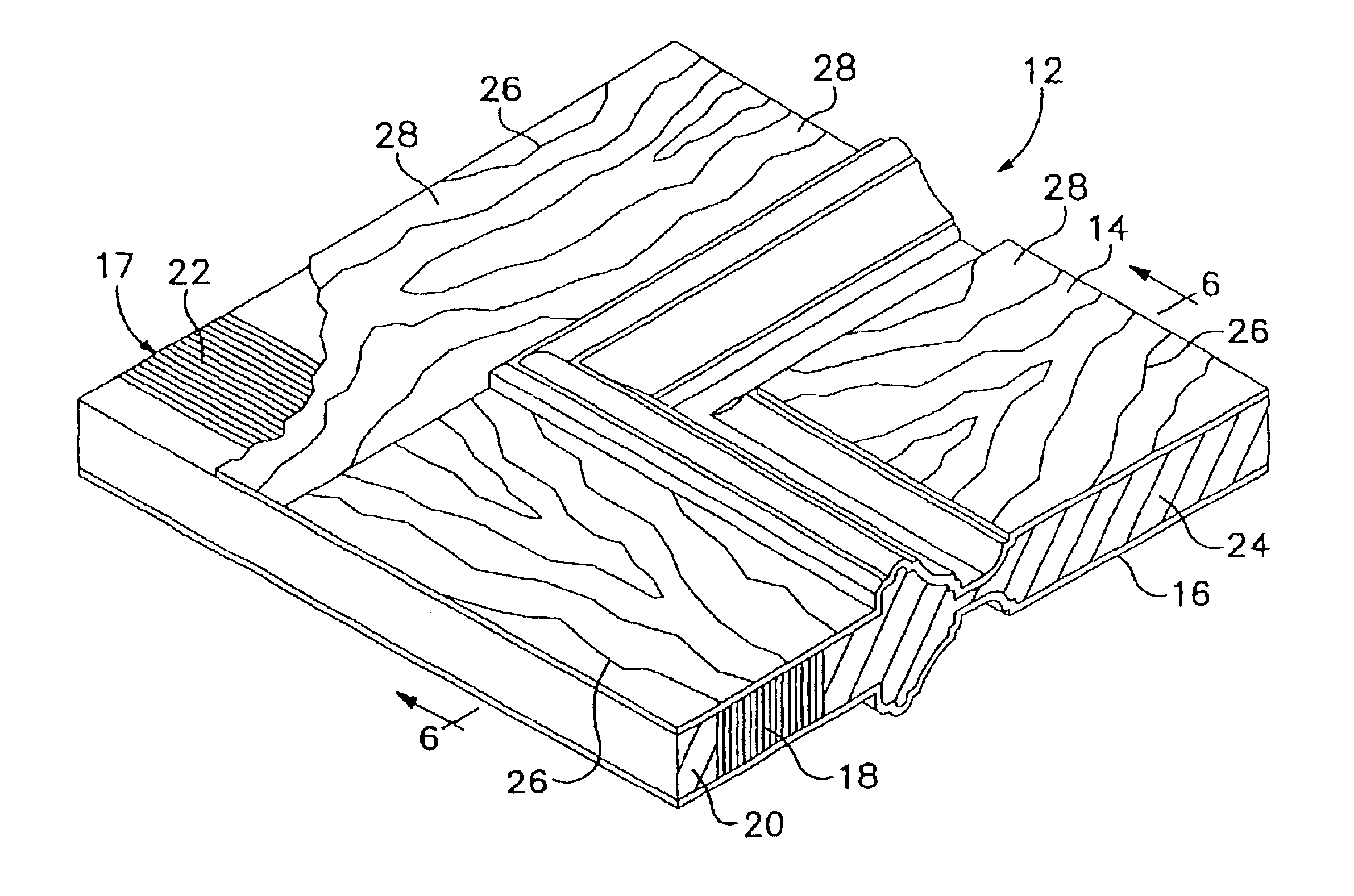

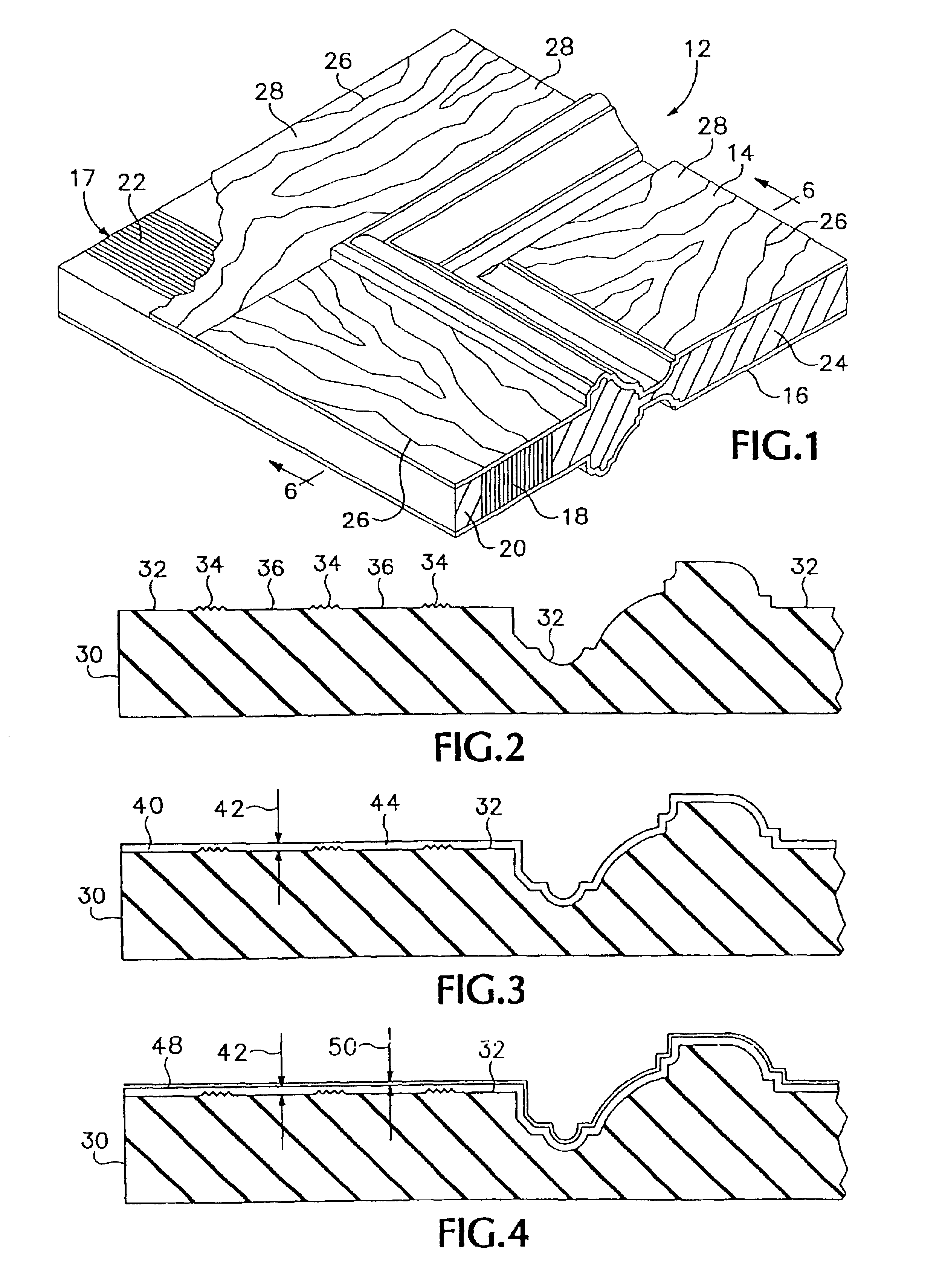

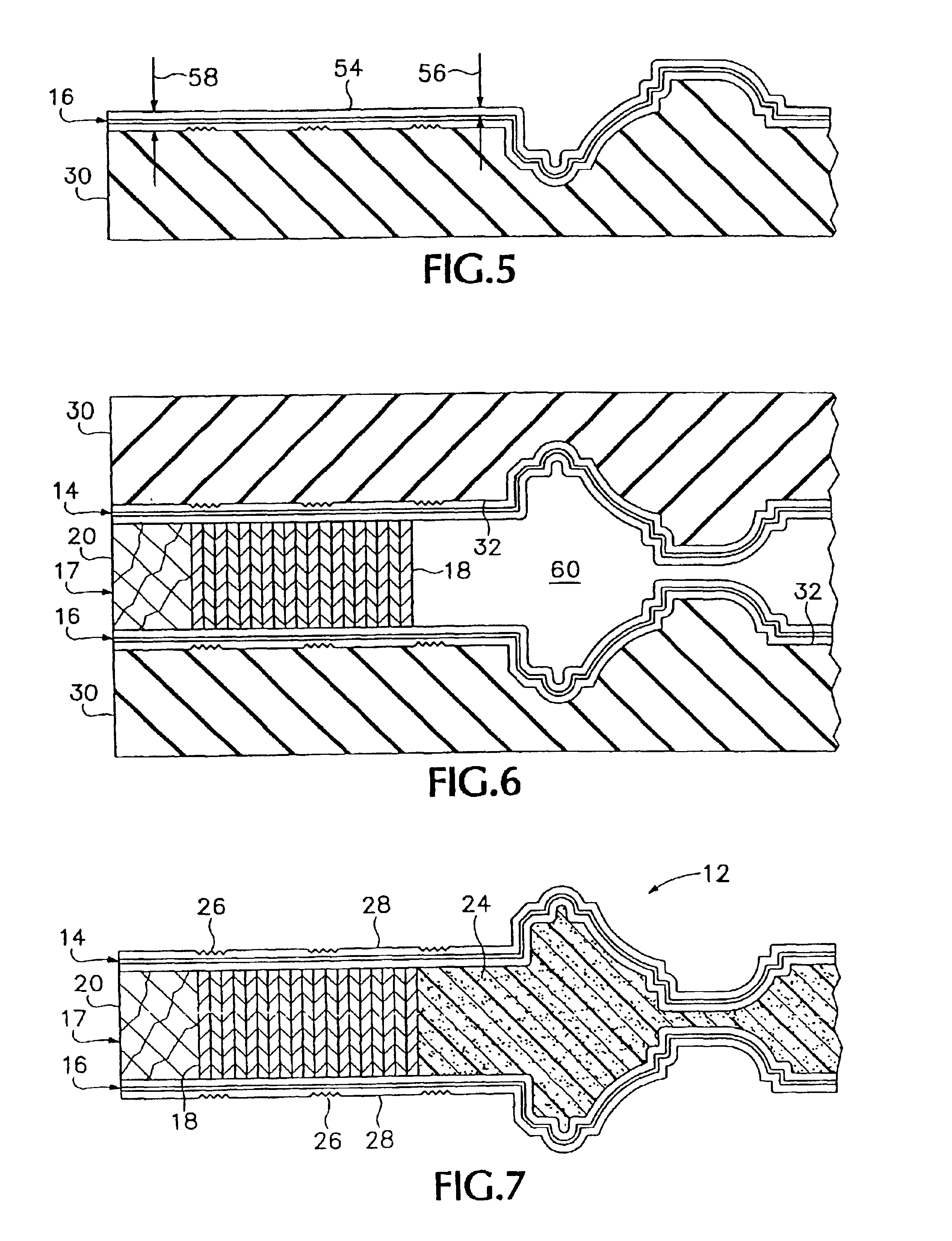

Articles of composite structure having appearance of wood

A door or other entryway component of synthetic resin composite construction and closely resembling the appearance of stained real wood. Skin portions of doors and other structures have a surface layer of clear gel coat resin molded to include the texture of a wood grain surface. A subsurface layer adjacent the clear gel coat layer is of pigmented gel coat resin. A structural support layer of the skin is of reinforced resin. Skins of a door or similar article are mounted on frames, and dense micro porous resin foam is provided between the skins to form a solid structure such as a door. Moldings retaining glass panels in openings defined in the door or similar structure are attached to the skins by adhesively fastening the moldings to the skins. Fasteners mounted in the moldings so that there are no plugged holes in the exterior surfaces of the moldings are used to locate the moldings properly with respect to the skins by inserting the fasteners into predrilled holes in the skins. The assembled doors and other structures can be finished by staining and coating with a finish system such as a urethane varnish to provide an appearance closely resembling real wood.

Owner:JELD-WEN

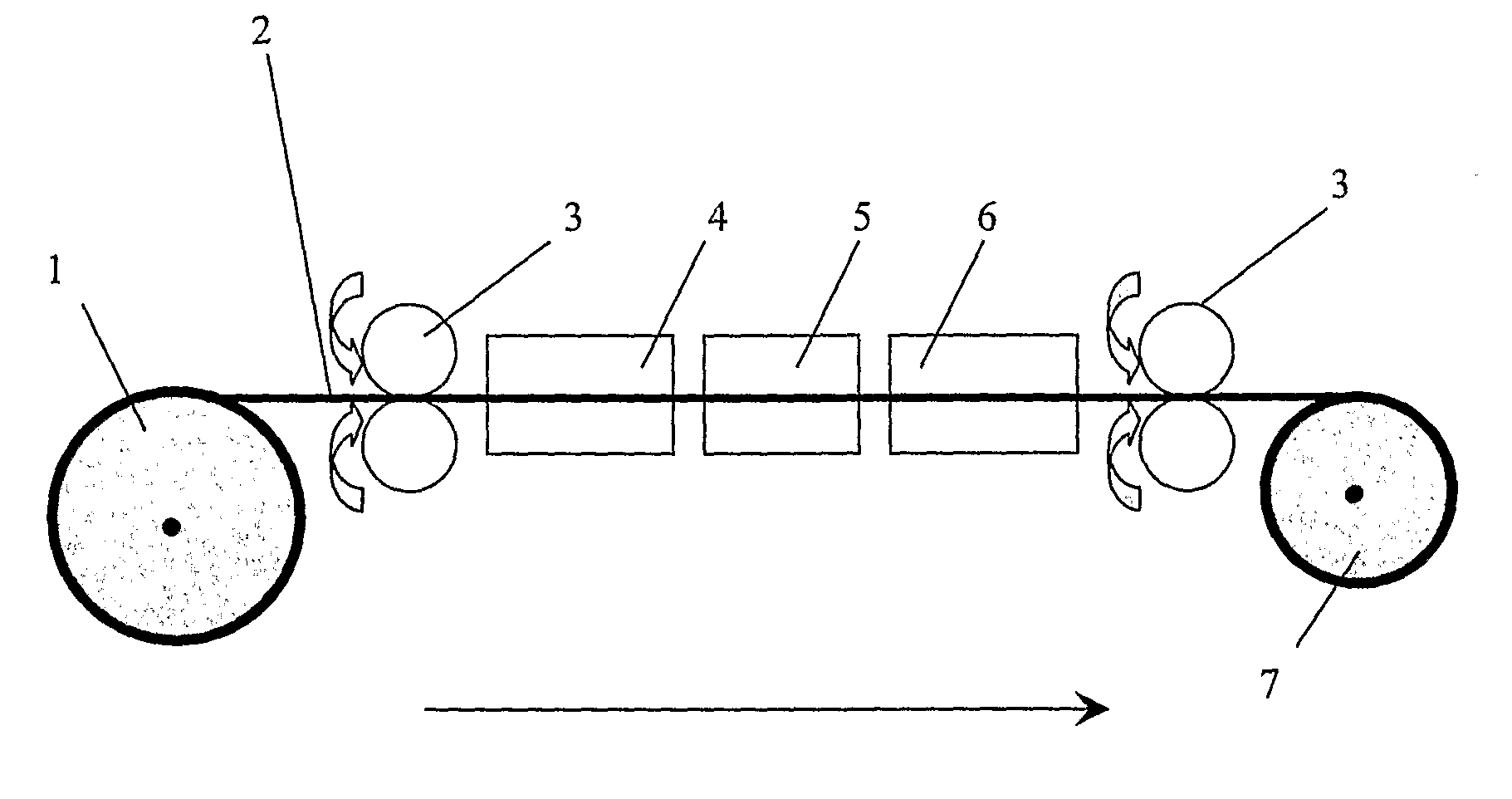

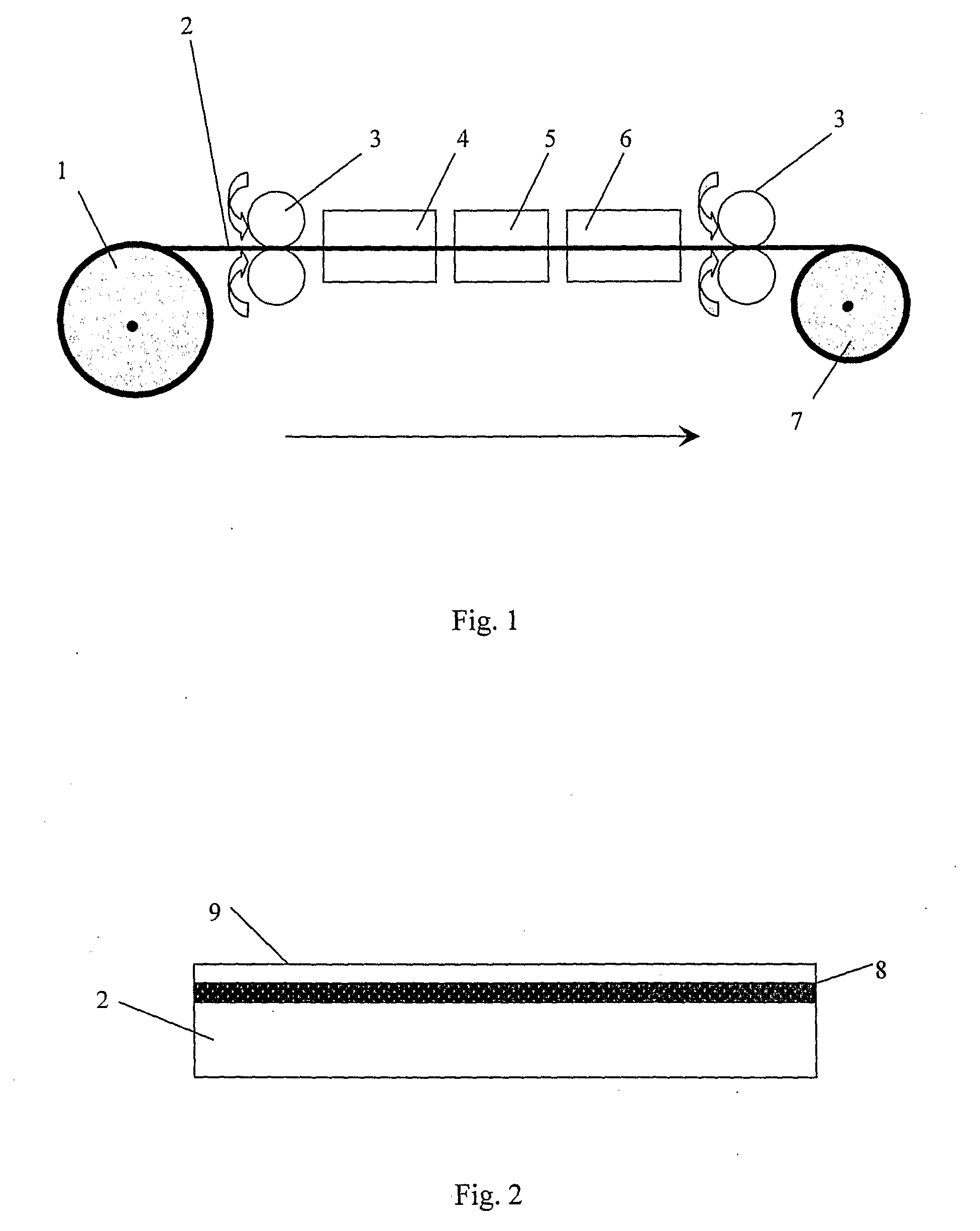

Energy-saving coating process

ActiveCN101574689AReduce investmentReduced footprintPretreated surfacesElectrophoretic coatingsLacquerCoating system

The invention relates to an energy-saving coating process which is characterized by comprising the following steps: carrying out surface treatment before painting; coating cathodic electrophoretic priming; drying priming paint, keeping the workpiece temperature to be 160 DEG C to 180 DEG C for 20 min and cooling;, sanding the priming and scouring; spraying PVC car bottom and sealing welding line;airing for 20 min; floating coat spray coating; airing for 7 to 15 min; coating finishing coat spray or spraying metal base paint; airing for 10 min; spraying finishing varnish; airing for7 to 15 min;and drying coated film; keeping workpiece temperature to be 140 DEG C to 150 DEG C for 20 min and cooling. PVC glue and a plurality of layers of coating adopt the energy-saving process technology with wet-on-wet coating, so that drying devices on the coating line are saved. Compared with a traditional three-coating coating system, the invention simplifies the coating process, reduces coating device investment and occupation area, saves heating energy of the coating line, reduces the product coating cost, and enhances the market competitiveness of car products.

Owner:CHINA FIRST AUTOMOBILE

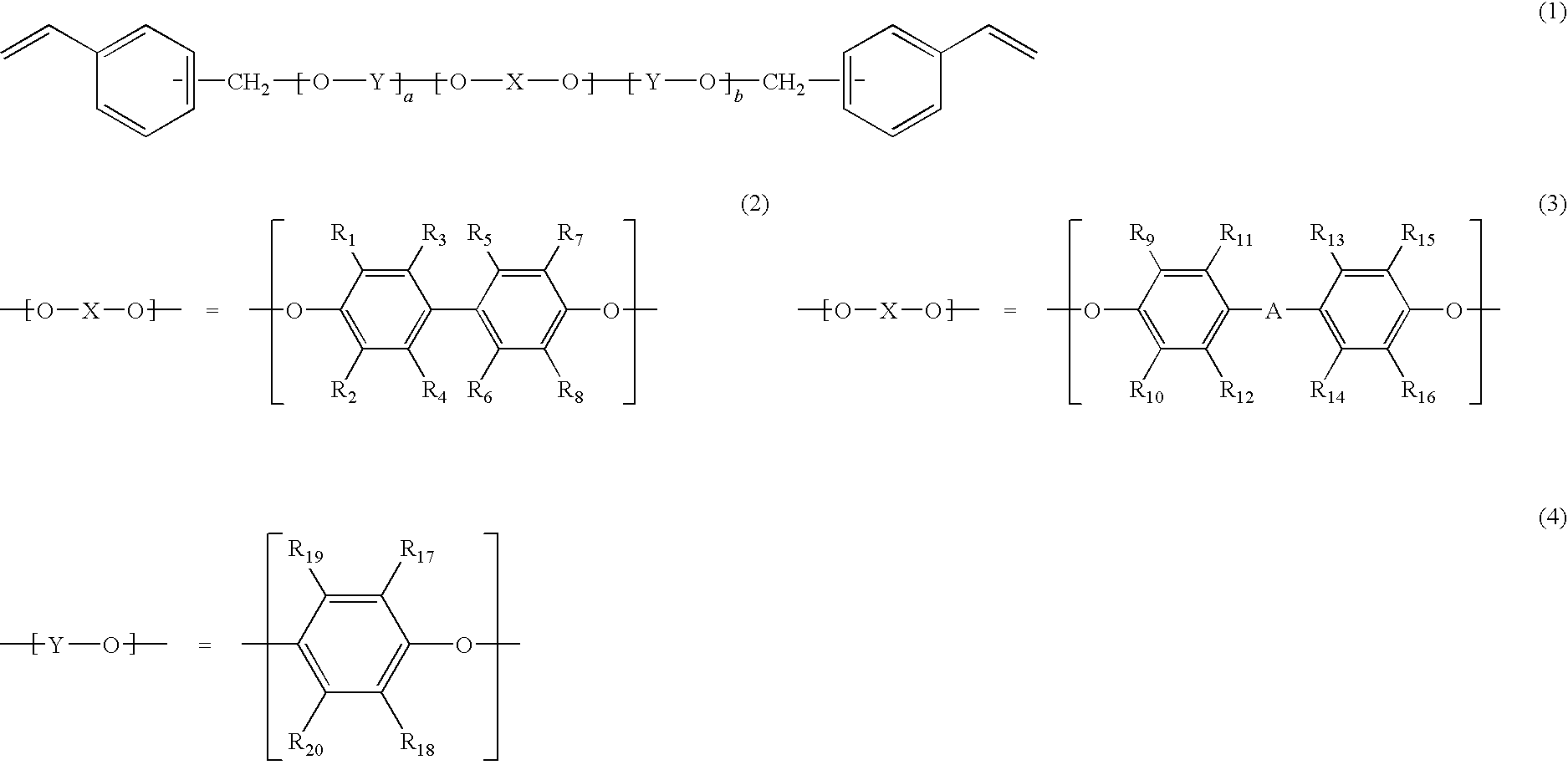

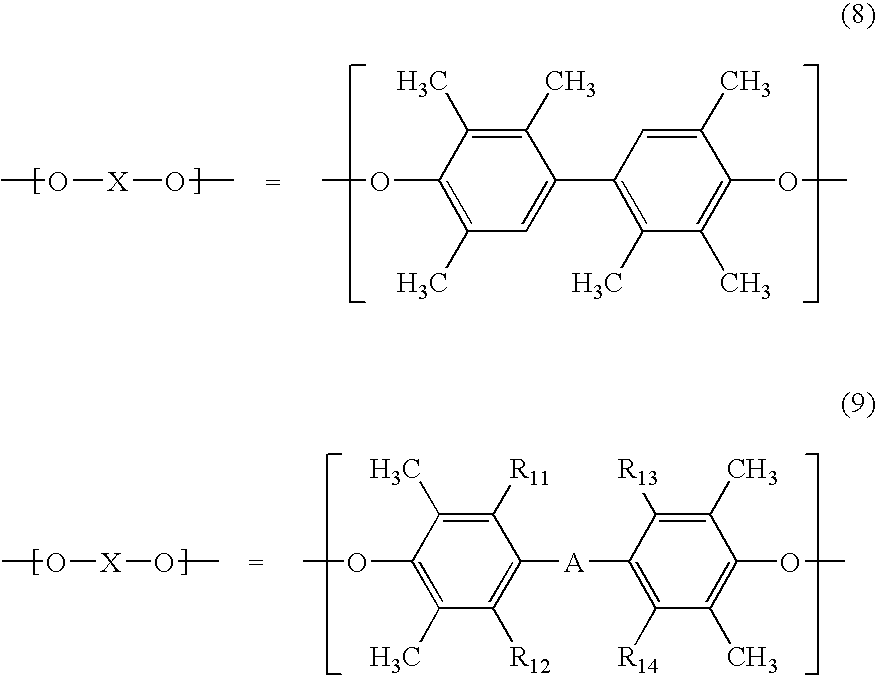

Resin composition, prepreg and their uses

ActiveUS20090203279A1Extended shelf lifeSuitable materialSynthetic resin layered productsWoven fabricsOligomerMetal foil

A vinyl-compound-based resin composition containing a terminal vinyl compound (a) of a bifunctional phenylene ether oligomer having a polyphenylene ether skeleton, a specific maleimide compound (b), a naphthol aralkyl type cyanate ester resin (c) and a naphthalene-skeleton-modified novolak type epoxy resin (d) for a high-multilayer and high-frequency printed wiring board, which resin composition is excellent in varnish shelf life at low temperature and does not show a decrease in multilayer moldability, heat resistance after moisture absorption, electrical characteristics and peel strength even in a winter period and for a long period of time, and a prepreg, a metal-foil-clad laminate and a resin sheet each of which uses the above resin composition.

Owner:MITSUBISHI GAS CHEM CO INC

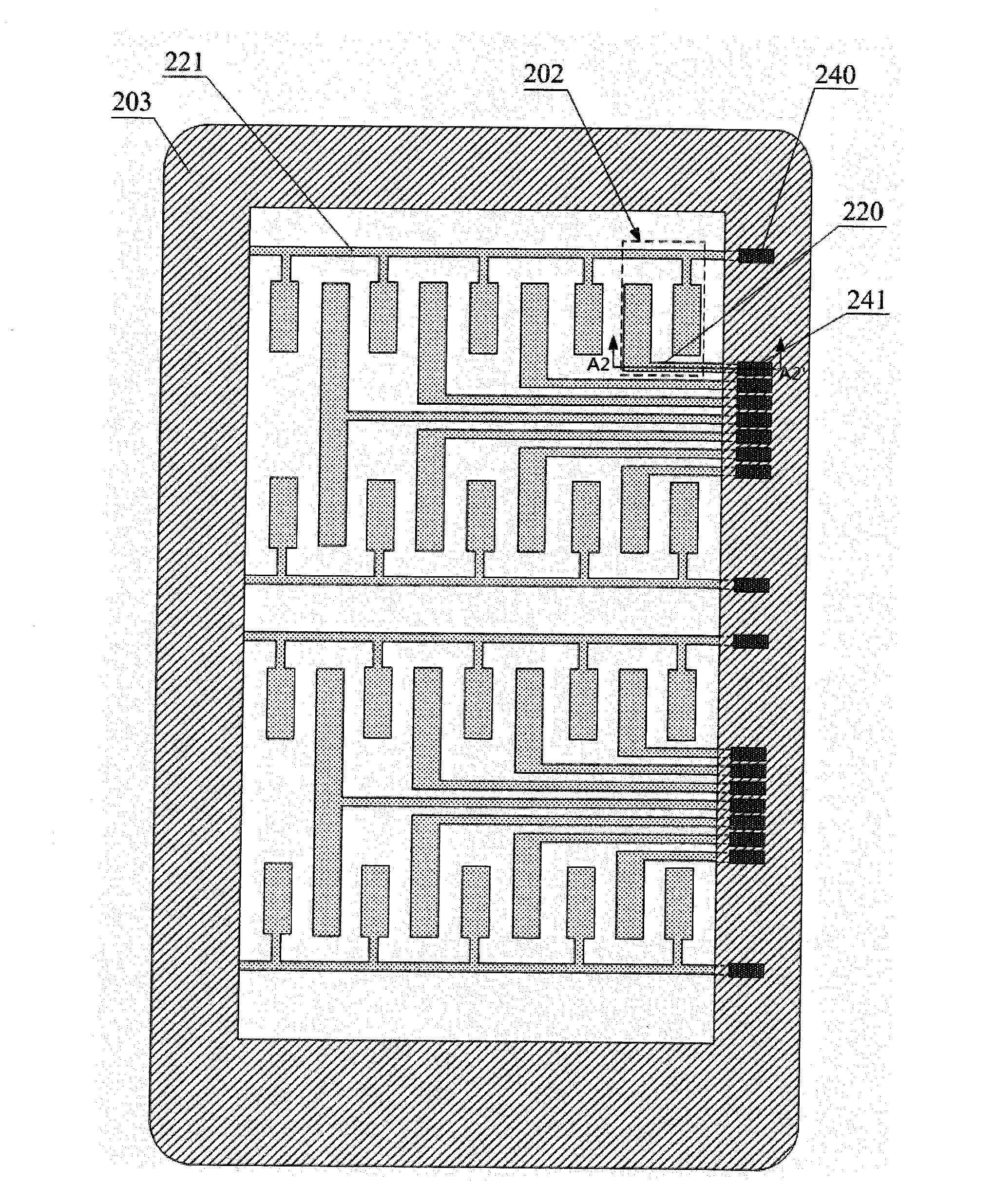

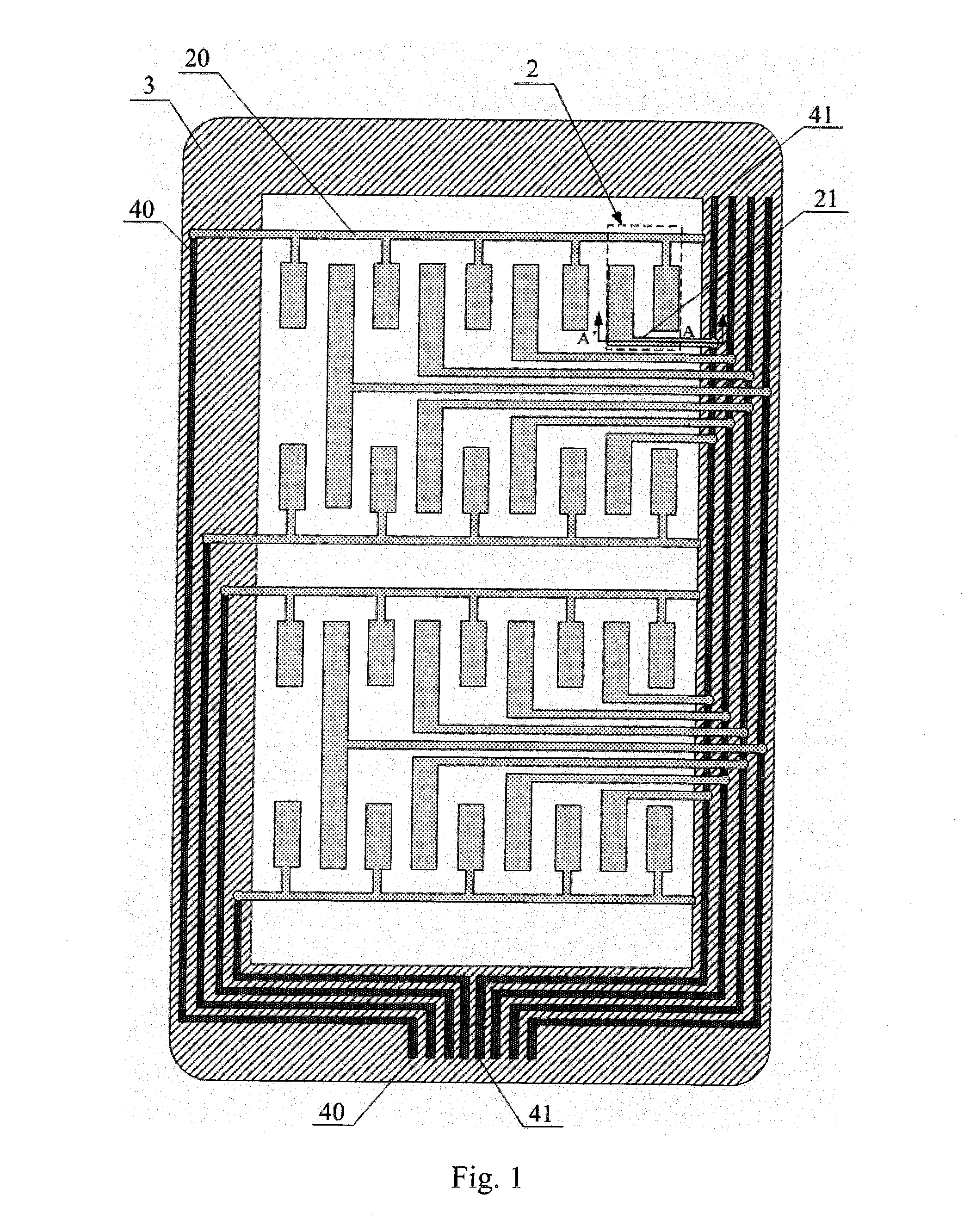

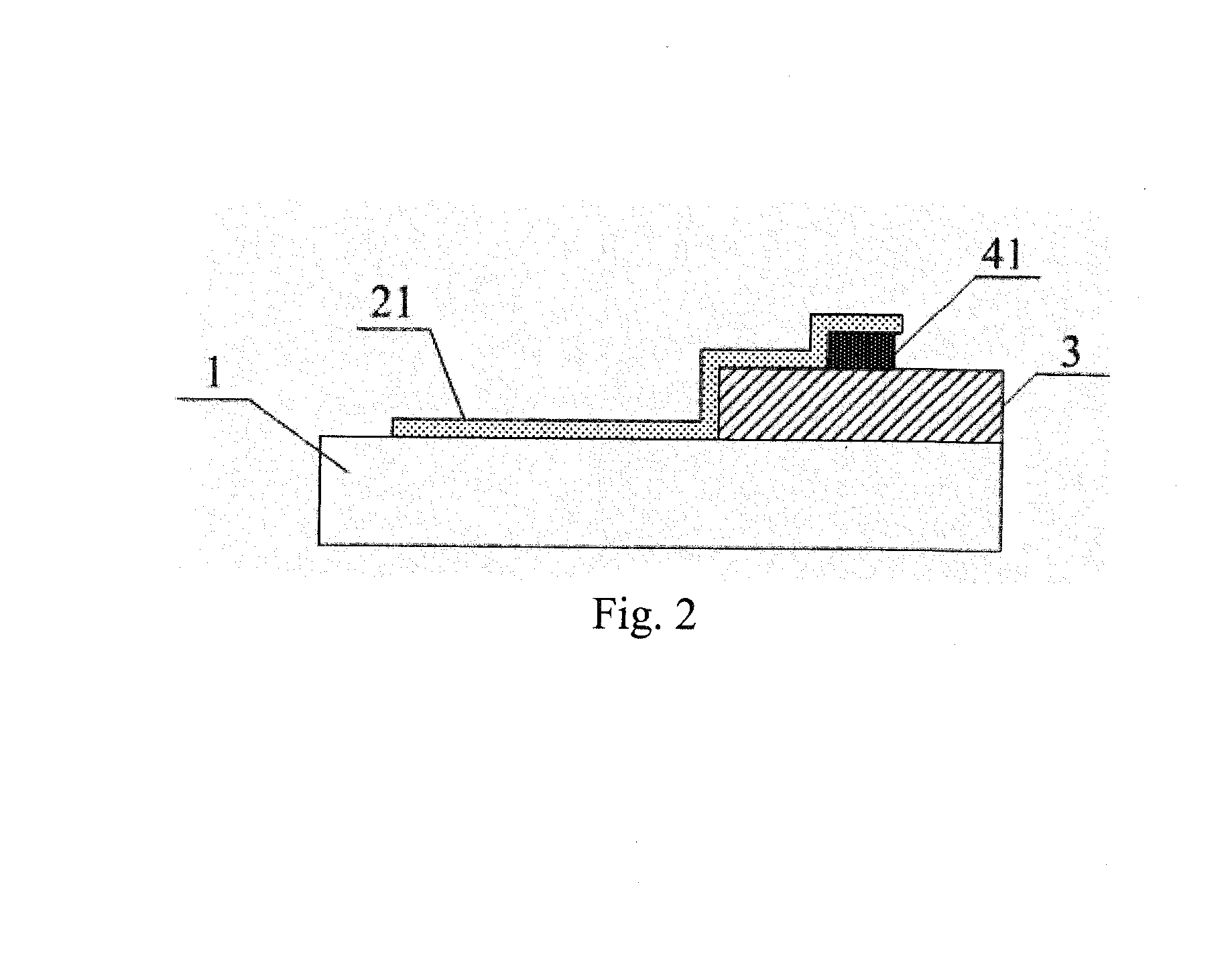

One glass solution capacitive touch screen and manufacturing method thereof

ActiveUS20160124546A1Improve reliabilitySimple structureElectric switchesSelector switchesResistElectrical conductor

Owner:FUJIAN KECHUANG PHOTOELECTRIC

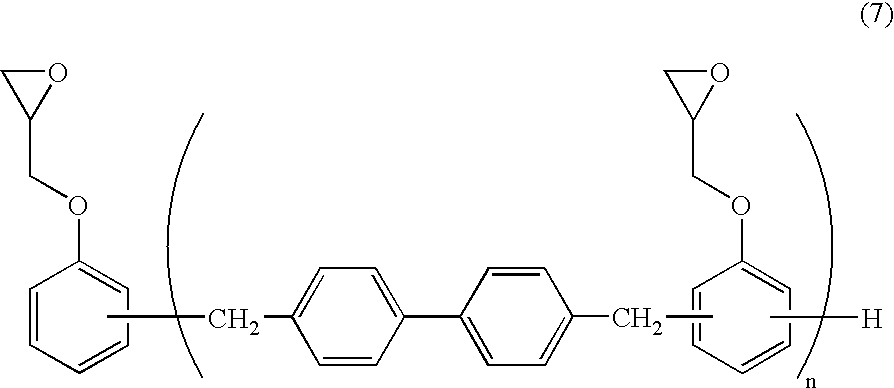

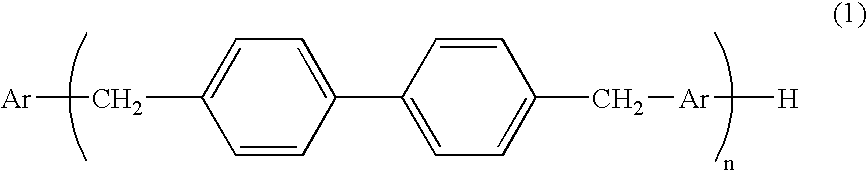

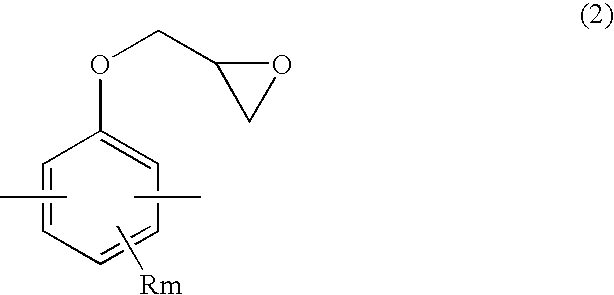

Epoxy Resin, Hardenable Resin Composition Containing the Same and Use Thereof

It is an object of the present invention, with respect to a phenol aralkyl type epoxy resin, to suppress any crystal precipitation, improve the quality manageability and operation efficiency at composition production and enhance the properties, including heat resistance, thereof. It is also intended to provide a resin composition that even when stored in the form of a varnish for a prolonged period of time, is resistant to crystal precipitation, excelling in storage stability and operation efficiency, and that gives a hardening product of low dielectric constant and low dielectric tangent excelling in heat resistance, water resistance and flame retardance.There is provided an epoxy resin characterized by comprising a phenol aralkyl type epoxy resin in which a content (an area % measured by gel permeation chromatography) of a bifunctional compound is 20% or less, and provided a resin composition obtained therefrom.

Owner:NIPPON KAYAKU CO LTD

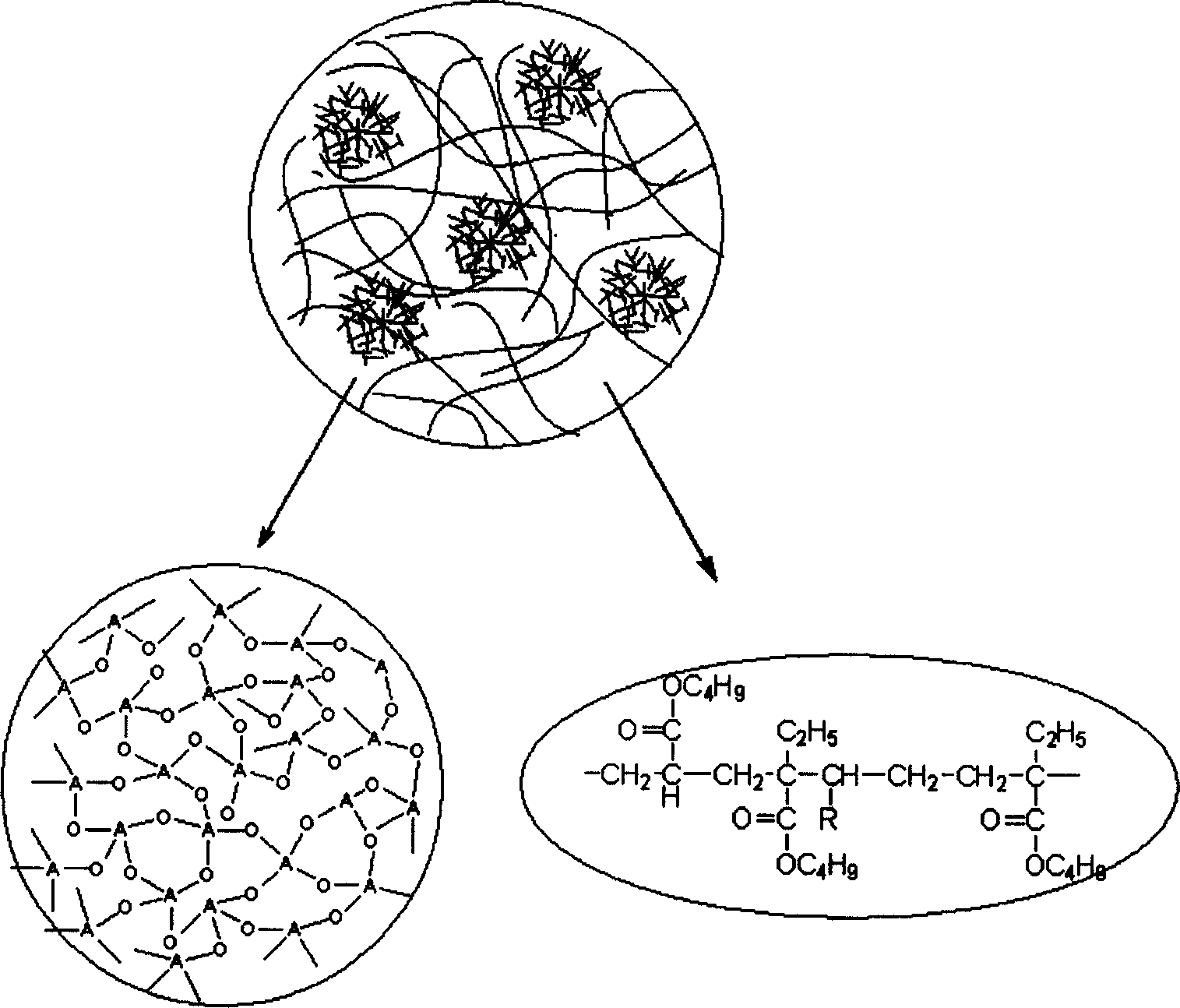

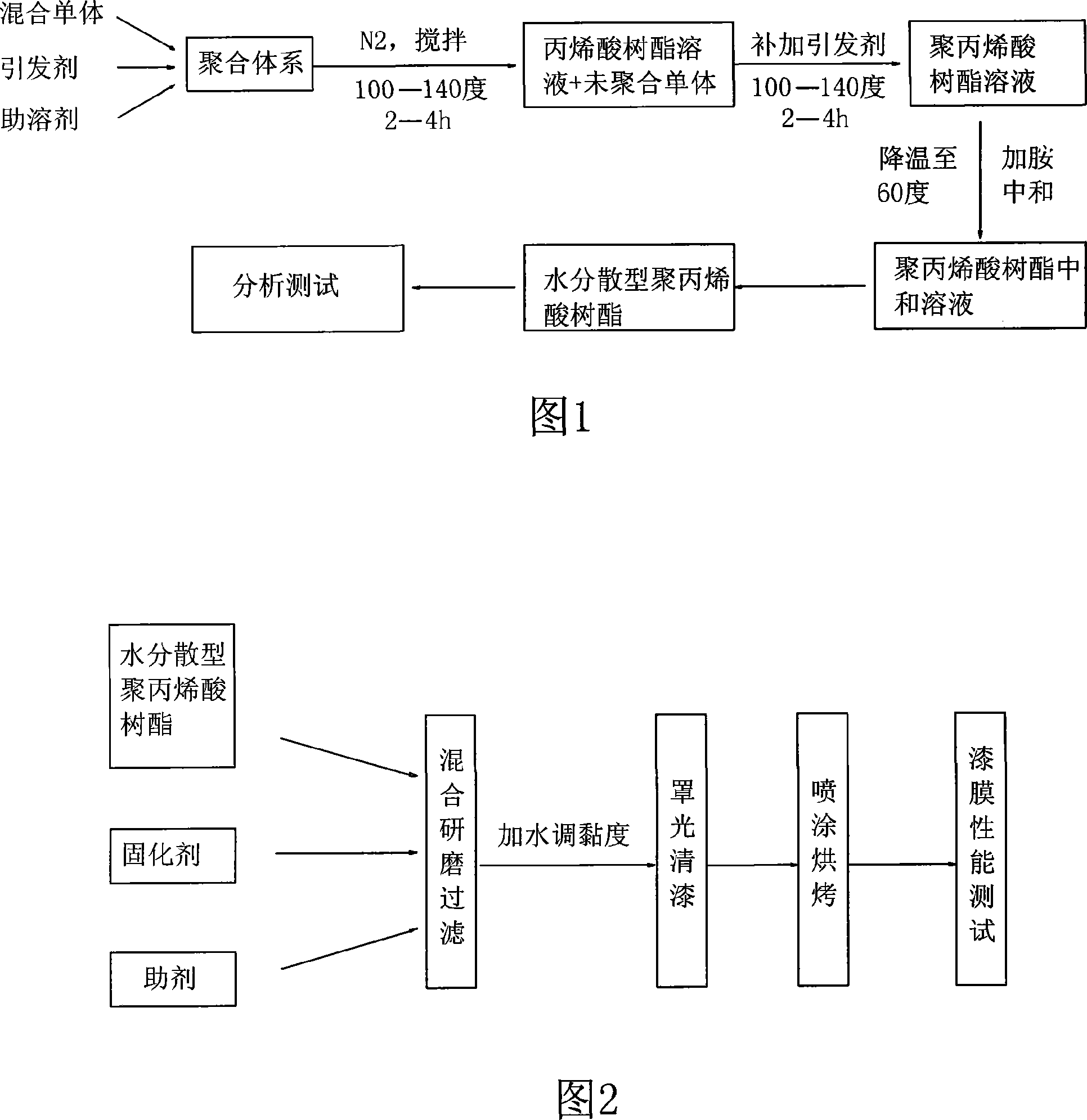

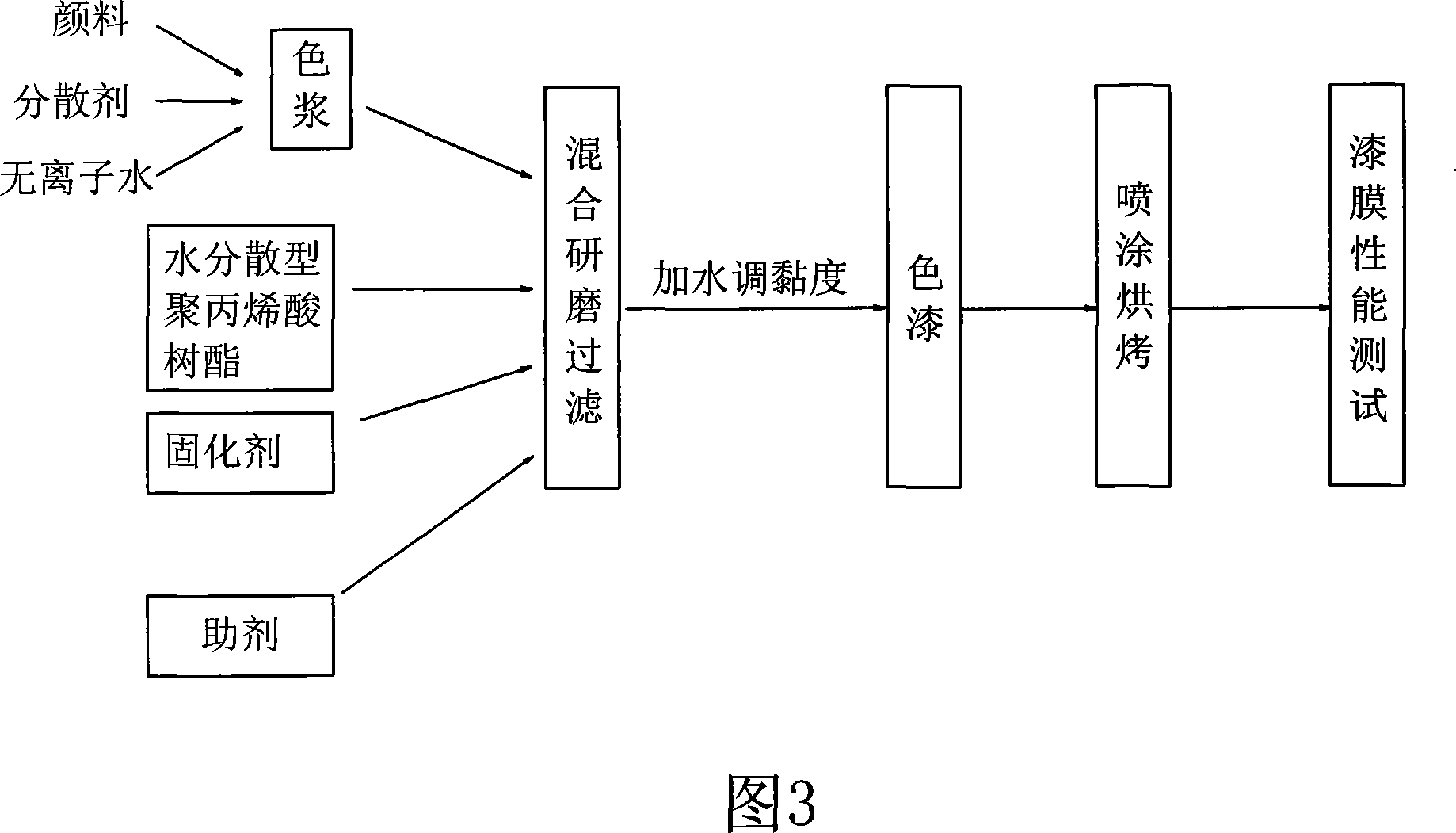

Preparation method for waterborne acrylic acid modified epoxy ester emulsion and its amino baking varnish

InactiveCN103467748AGood storage stabilityGood self-crosslinkingEpoxy resin coatingsEpoxyMethacrylate

The invention relates to a waterborne acrylic acid modified epoxy ester emulsion, the synthetic formula of which consists of the following components (by weight percentage): 12%-17% of epoxy resin; 14%-19% of unsaturated fatty acid; 4%-6% of a (methyl) acrylic ester or vinyl monomer; 2%-4% of methacrylic acid; 0.1%-0.5% of an initiator; 4%-6% of a cosolvent; 1.5%-2.5% of a neutralizing agent; and 45%-55% of deionized water. The waterborne epoxy ester amino baking varnish based on the waterborne acrylic acid modified epoxy ester emulsion involved in the invention adopts water as the diluent, takes the pigment and filler that both are free of harmful lead or chromium compound, has no risk of combustion, explosion, poisoning and environmental pollution, and is safe and environment friendly. The amino baking varnish can employ brush coating, spray coating, dip coating and other construction methods.

Owner:JIAXING QINGHE GAOLI INSULATION MATERIAL

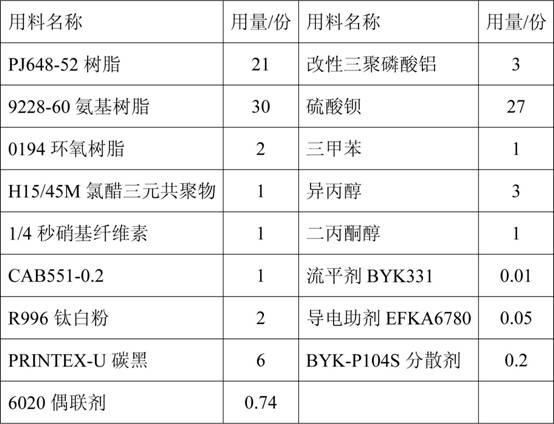

Automobile finishing varnish containing water dispersible acrylic ester and preparation method thereof

ActiveCN101081957AHigh glossHigh distinctness of imageLiquid surface applicatorsCoatingsWater dispersiblePolymer science

The present invention discloses water dispersed automobile finishing varnish of polyacrylate and its preparation process. The water dispersed automobile finishing varnish is mixture of water dispersed polyacrylate, water dispersed curing agent amino resin and closed polyisocyanate. The polyacrylate is water dispersoid prepared with the mixture of five components, and through the first radical initiator initiated polymerization in mixed solvent to obtain polyacrylate resin and the subsequent neutralization with neutralizer. The water dispersed automobile finishing varnish after being sprayed and cured forms varnish film possessing high glossiness, high brightness, high hardness, high impact resistance, high weather resistance, high compactness and fast adhesion to the base material.

Owner:GUANGDONG YATU CHEM +1

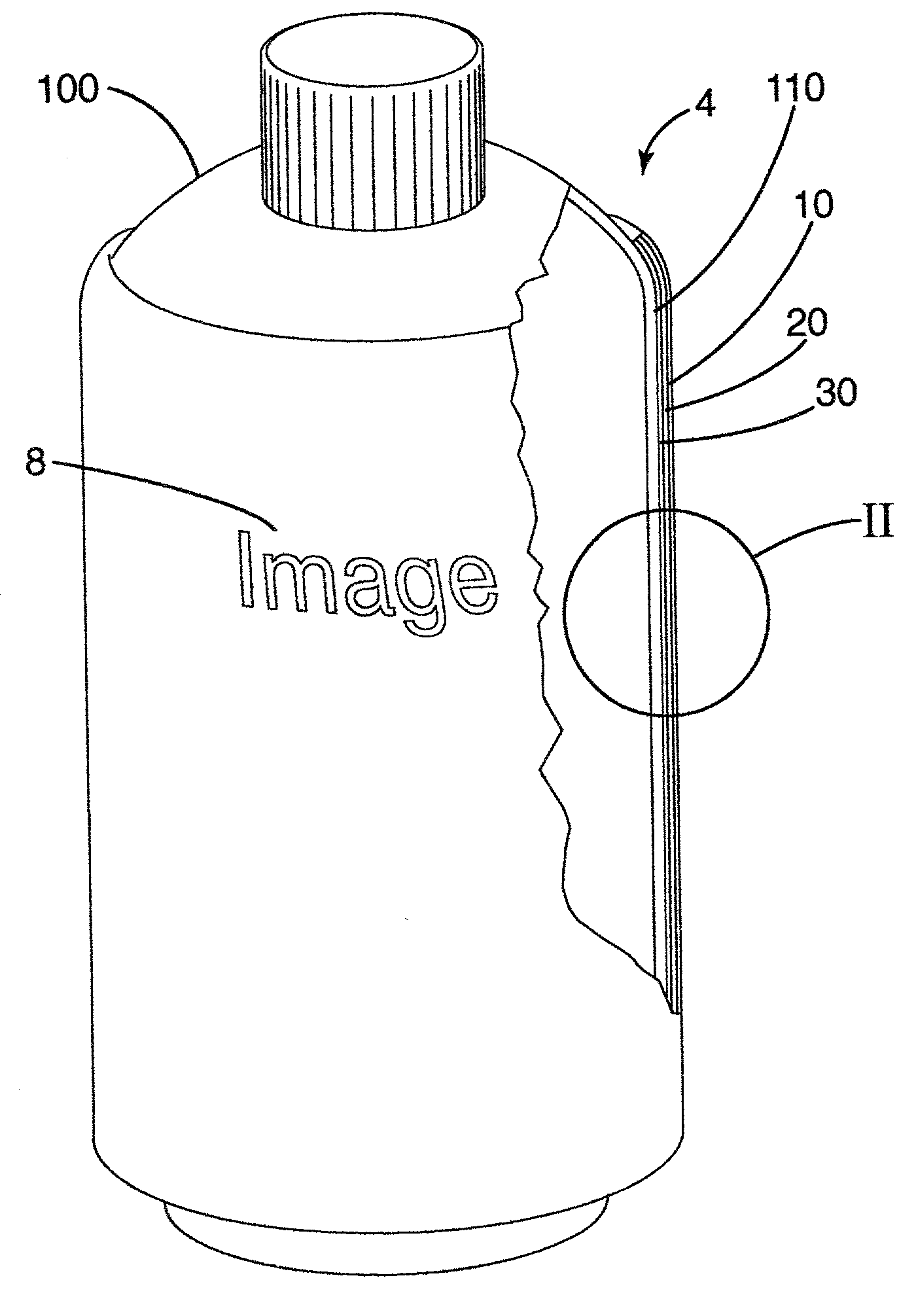

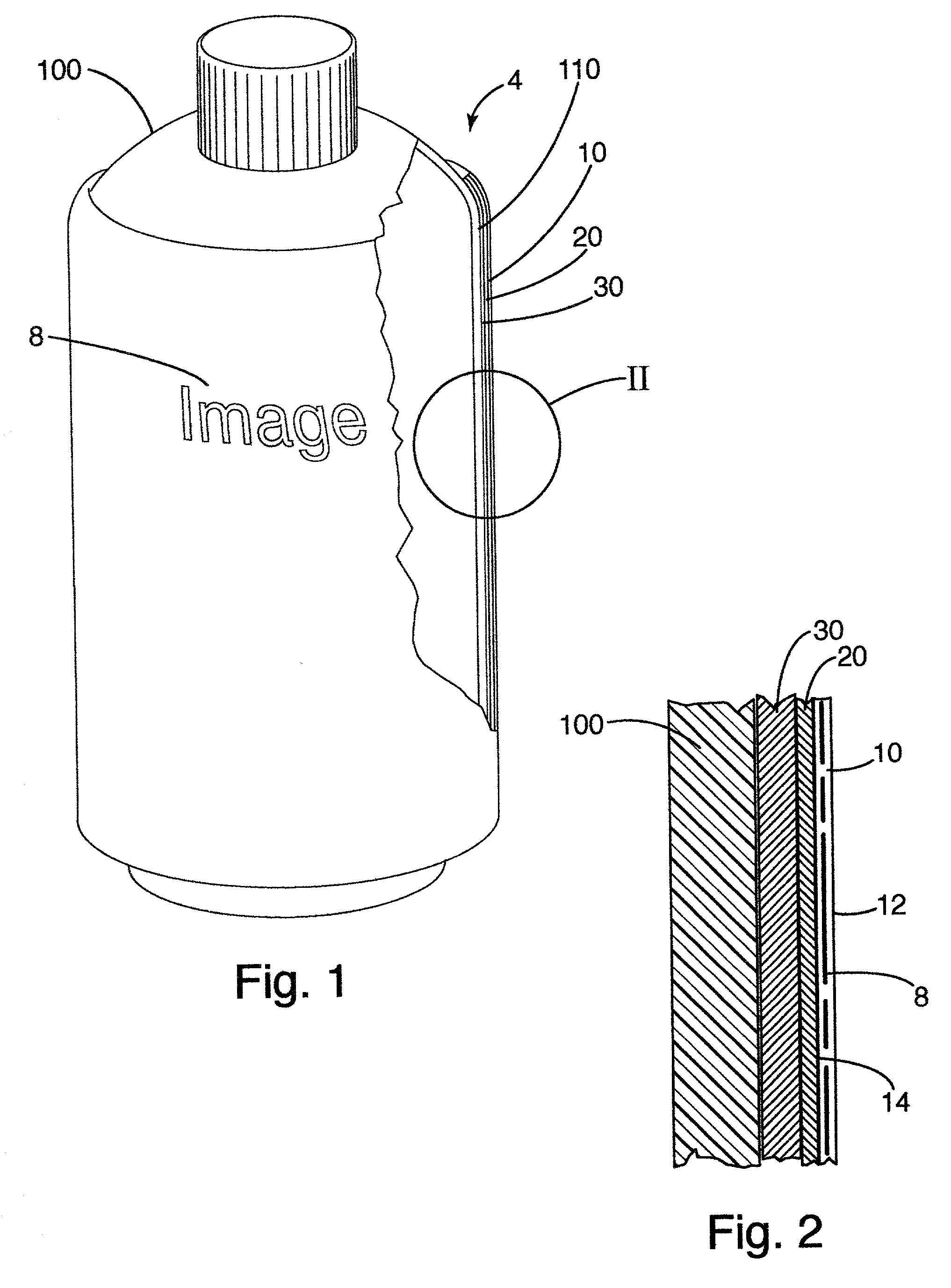

Metalized shrink label and related method of manufacture

InactiveUS20030021918A1Enhance image and graphic and overall appearanceEnhance image and graphicEnvelopes/bags making machineryLiquid surface applicatorsMetallic materialsThin membrane

A metalized shrink film for contoured containers and other articles and a process for manufacturing the same. A preferred metalized shrink film includes a heat-shrinkable film layer, a varnish disposed over the film on at least one side, and a metalized layer disposed over the varnish. The metalized layer is preferably viewable through the heat-shrinkable film layer. Preferably, the varnish is a clear and ultraviolet curable, and the heat-shrinkable film includes images or graphics. A preferred method of manufacturing the metalized shrink film includes: providing a heat-shrinkable film material; applying varnish over the film; and applying a metal material over the varnish and any regions of the film not covered by the varnish. Preferably, the heat shrink film is incorporated into a heat-shrinkable label or sleeve used on contoured containers, such as bottles. When the label or sleeve is shrunk over contours of the container, the metalized regions viewable through the film and the images or graphics on the film do not discolor or become cloudy near the contours.

Owner:UV COLOR +1

Phenol-formaldehyde novolac resin having low concentration of free phenol

ActiveUS20080280787A1Synthetic resin layered productsCellulosic plastic layered productsPHENOL LIQUIDShell molding

A phenol-formaldehyde novolac resin having a low concentration of free phenol prepared by distilling residual phenol from a molten novolac resin and replacing at least a portion of the phenol with a solvent having a volatility equal to or less than phenol. Such modified novolac resins are suitable for the production of resin coated molding sands for shell molding and sand cores, as well as for the production of resin coated proppants for use in oil and gas recovery operations.

Owner:GEORGIA PACIFIC CHEM LLC

High-fullness high-resolution environment protection polyureshane sublight uarnish

InactiveCN1483777AIncreased weight percentageReduce weightPolyurea/polyurethane coatingsKetoneSolvent

The present invention relates to a high-fullness high-distinctness environment-protecting type polyurethane matte varnish. Said varnish consists of the paint component, polyurethane solidifying agent component and diluting agent component according to the ratio of 1:0.5:0.6-0.8. The polyurethane solidifying agent component contains 50-70 wt% of tolylene diisocyanate trimer, and the rest is the affixture of 80% of tolylene diisocyanate and 20% of trimethylol propane, the paint component contains 15-25% of short oil soya alkyd resin whose solid content is 80%, 50-60% of modified saturated polyester resin, 0-5% of castor oil, 10-12% of aldehyde ketone resin whose solid content is 60%, 3-5% of flatting silica, 0.3-1.0% of teflon wax and 4%-10% of conventional adjuvant and solvent, and the diluting agent component contains 70-80% of butyl acetate, 10-20% of mixed diacid dimethyl ester and 10-15% of isophorone.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com