Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Faster processing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supercritical fluid-assisted deposition of materials on semiconductor substrates

InactiveUS20040023453A1Faster processing timeReduce processing costsSemiconductor/solid-state device detailsSolid-state devicesChemistryVapor phase

Supercritical fluid-assisted deposition of materials on substrates, such as semiconductor substrates for integrated circuit device manufacture. The deposition is effected using a supercritical fluid-based composition containing the precursor(s) of the material to be deposited on the substrate surface. Such approach permits use of precursors that otherwise would be wholly unsuitable for deposition applications, as lacking requisite volatility and transport characteristics for vapor phase deposition processes.

Owner:ADVANCED TECH MATERIALS INC

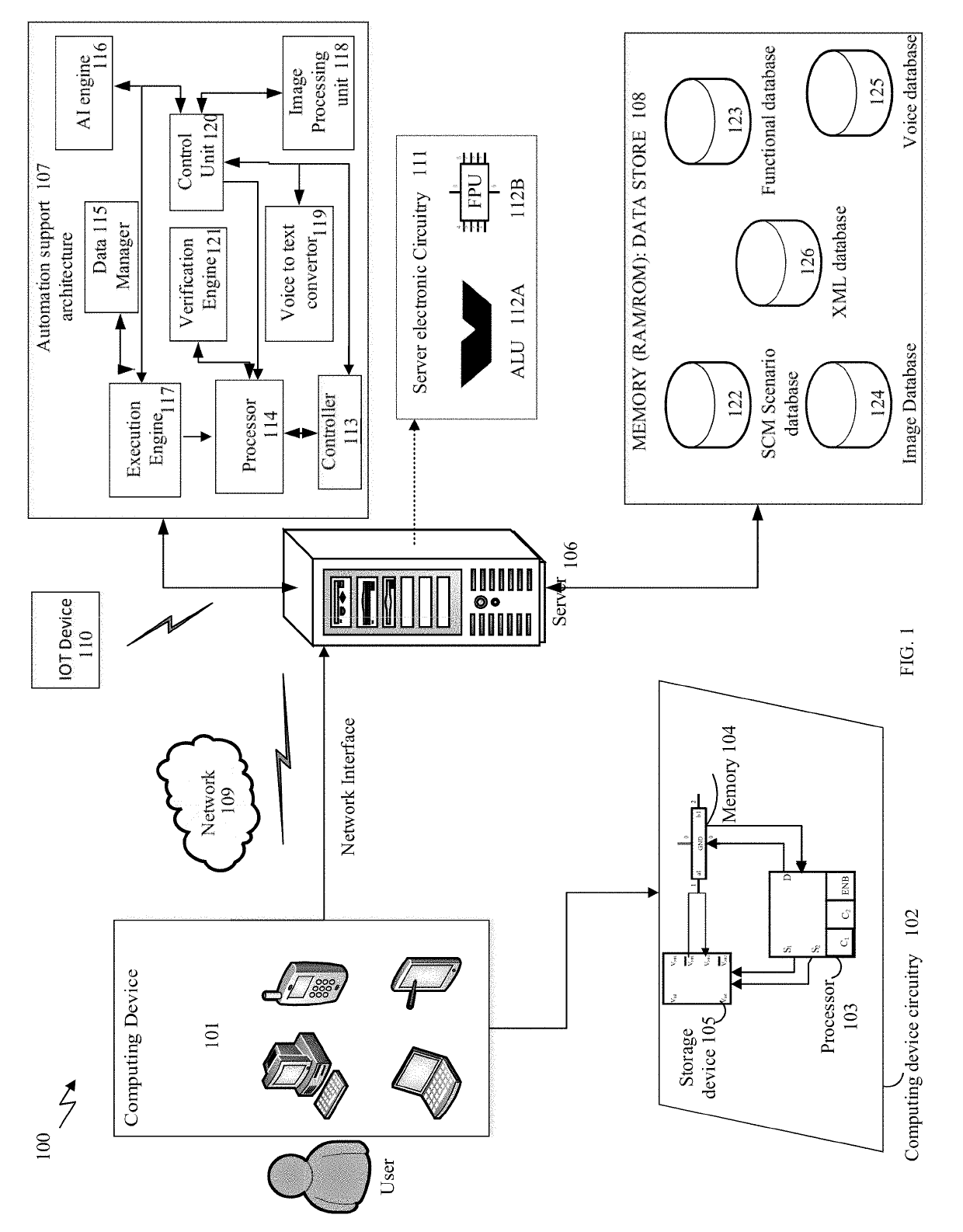

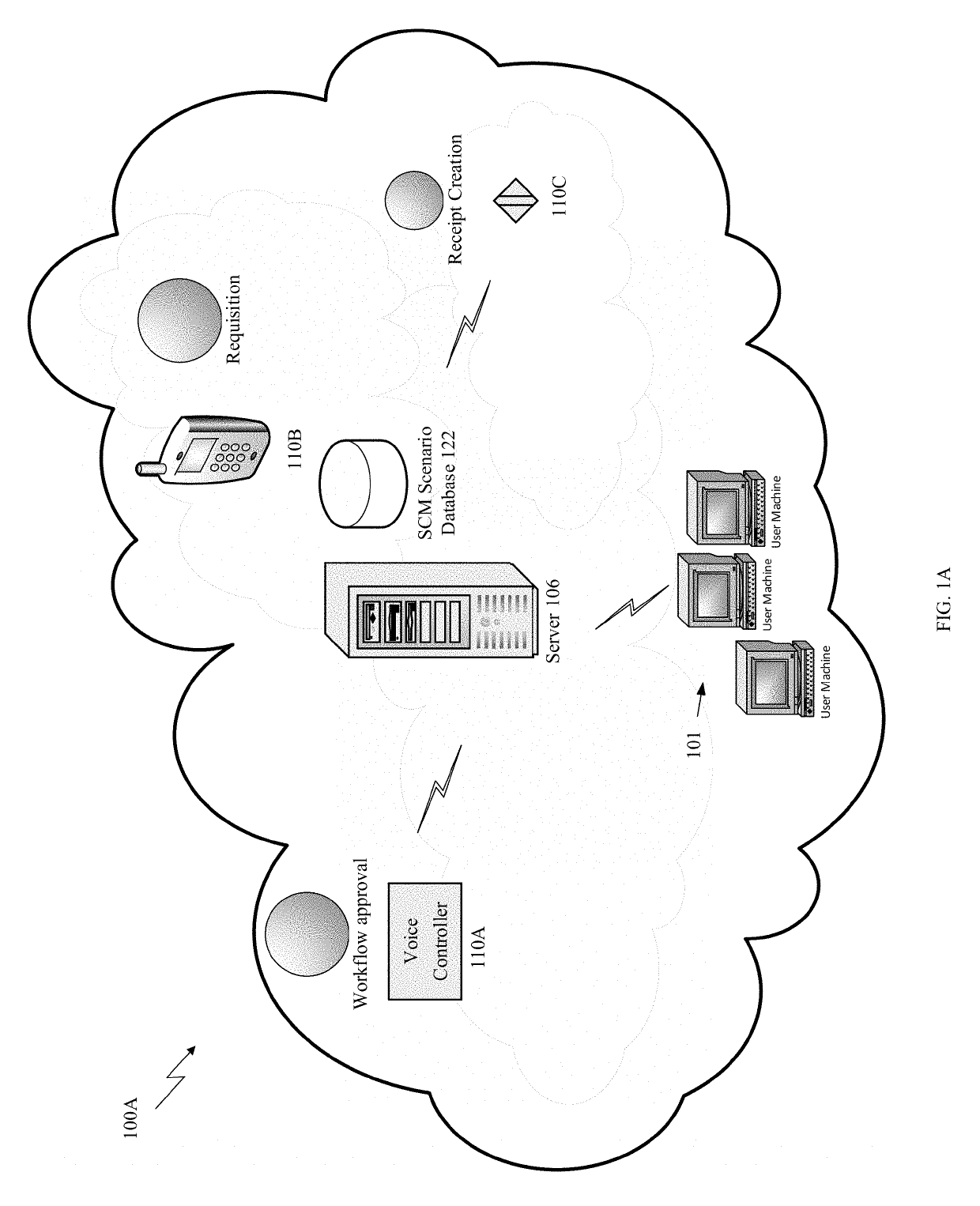

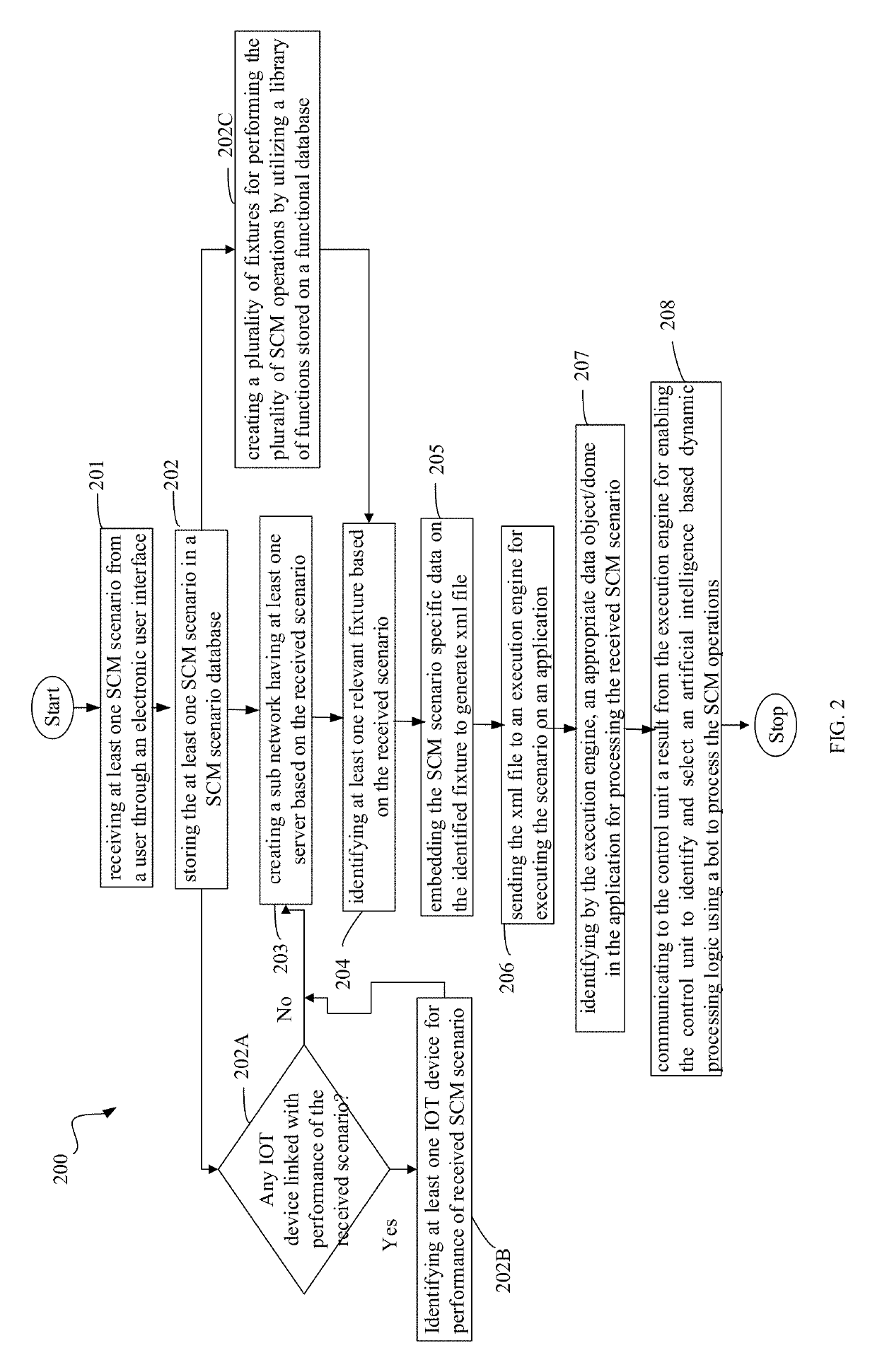

Robotic process automation for supply chain management operations

ActiveUS10324457B2Reduce processing timeMinimize process stepProgramme-controlled manipulatorArtificial lifeComputer scienceAutomation

Owner:GLOBAL EPROCURE

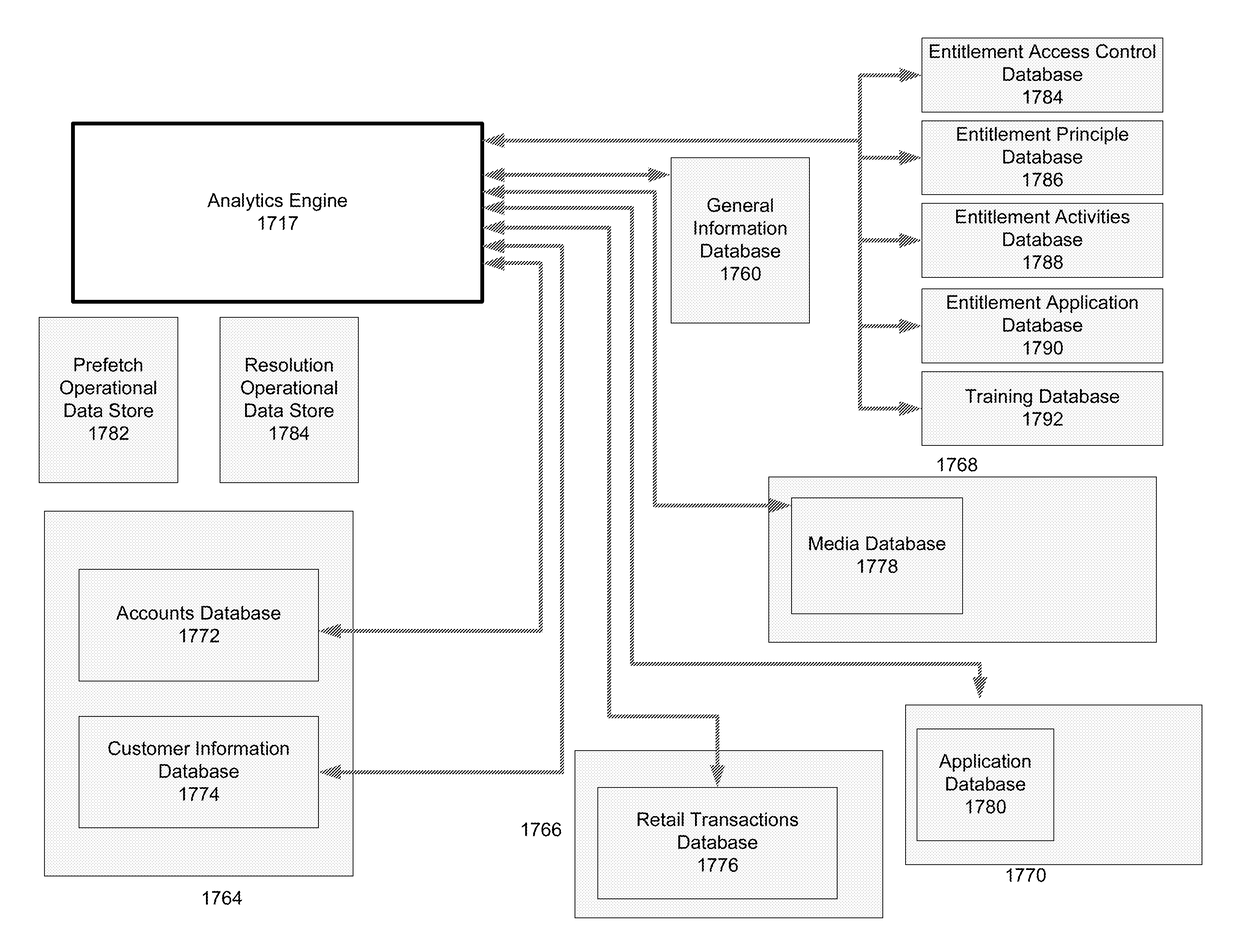

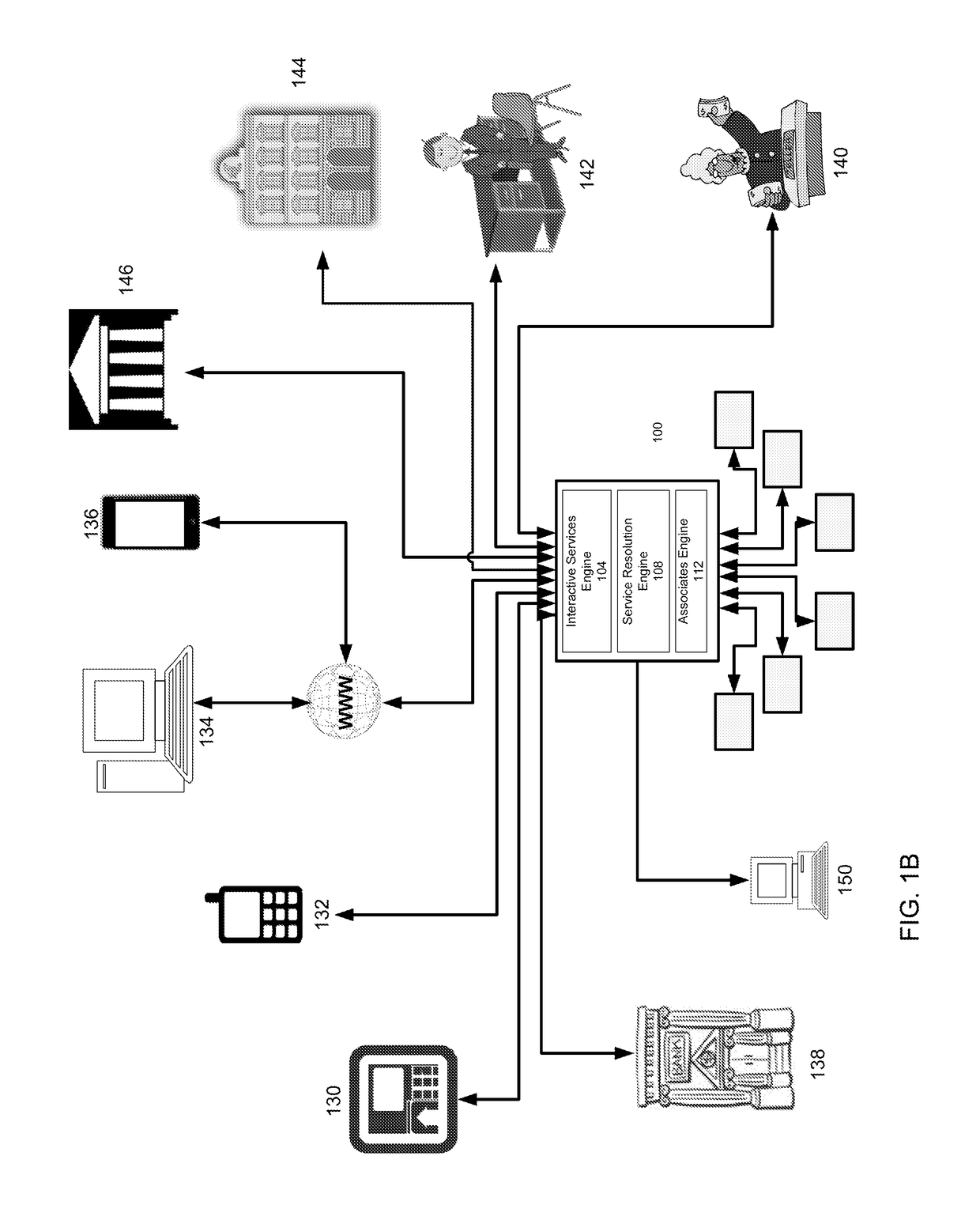

Enterprise fulfillment system with dynamic prefetching, secured data access, system monitoring, and performance optimization capabilities

ActiveUS9990636B1Increase efficiency and speedImprove efficiencyOffice automationBuying/selling/leasing transactionsApplication softwareWorkflow

Systems and methods for providing services to customers in response to customer requests received through one or more channels are disclosed. The present invention provides for a central fulfillment hub in which all requests from banking customers may be processed by applying a library of policies to systematically resolve the customer requests or engage resources necessary to resolve such requests. In addition, the system may provide security mechanisms to secure access to resources, including applications and data, based on applications, assigned user roles or user, activities, and access control configurations. Further, the system may dynamically allocate employees across teams based on system demand and provide secured access to the resources accordingly. In addition, the system includes an analytics engine that can dynamically modify the workflows, rules and other parameters of the system during operations in order to optimize system performance.

Owner:JPMORGAN CHASE BANK NA

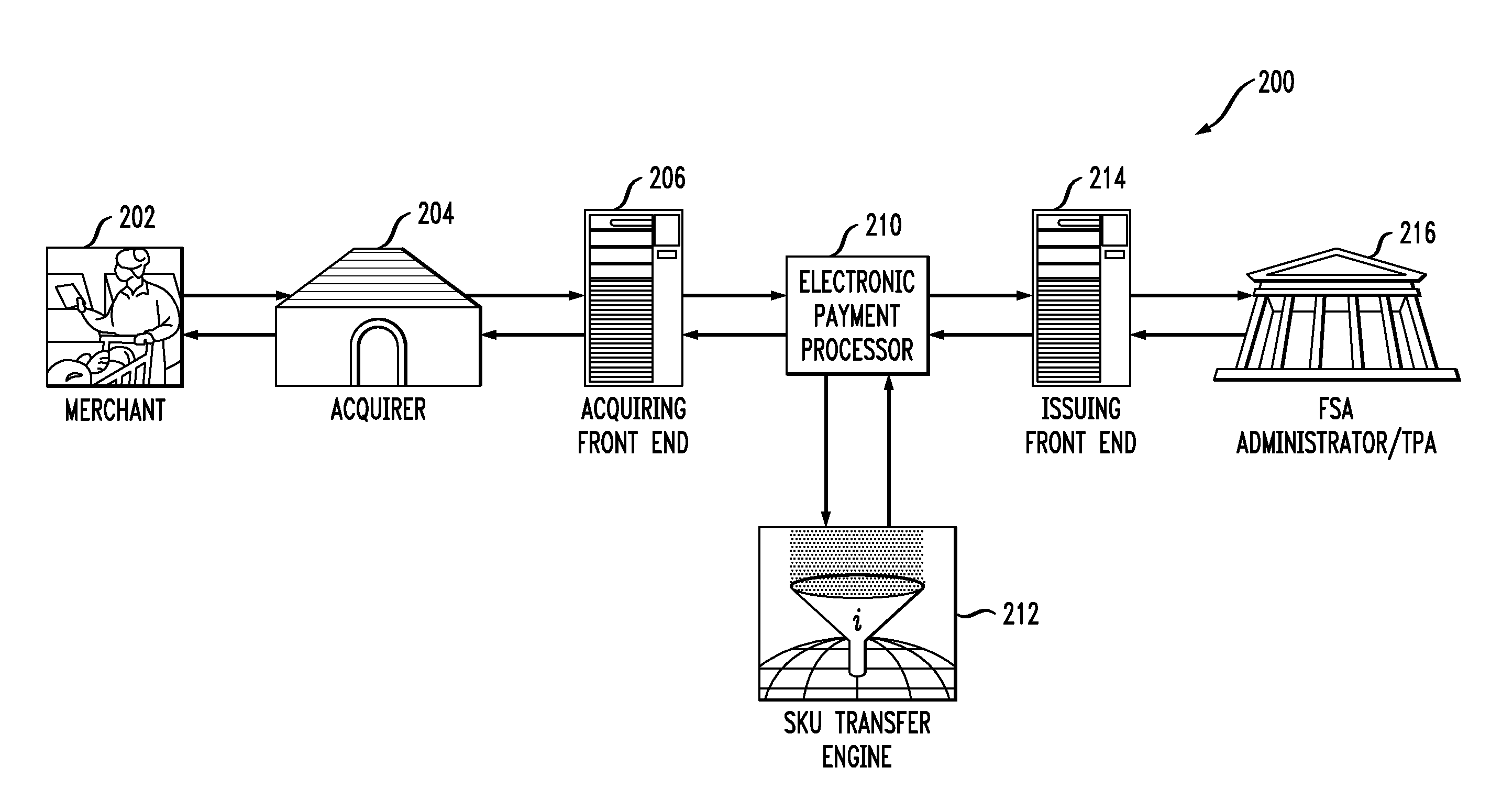

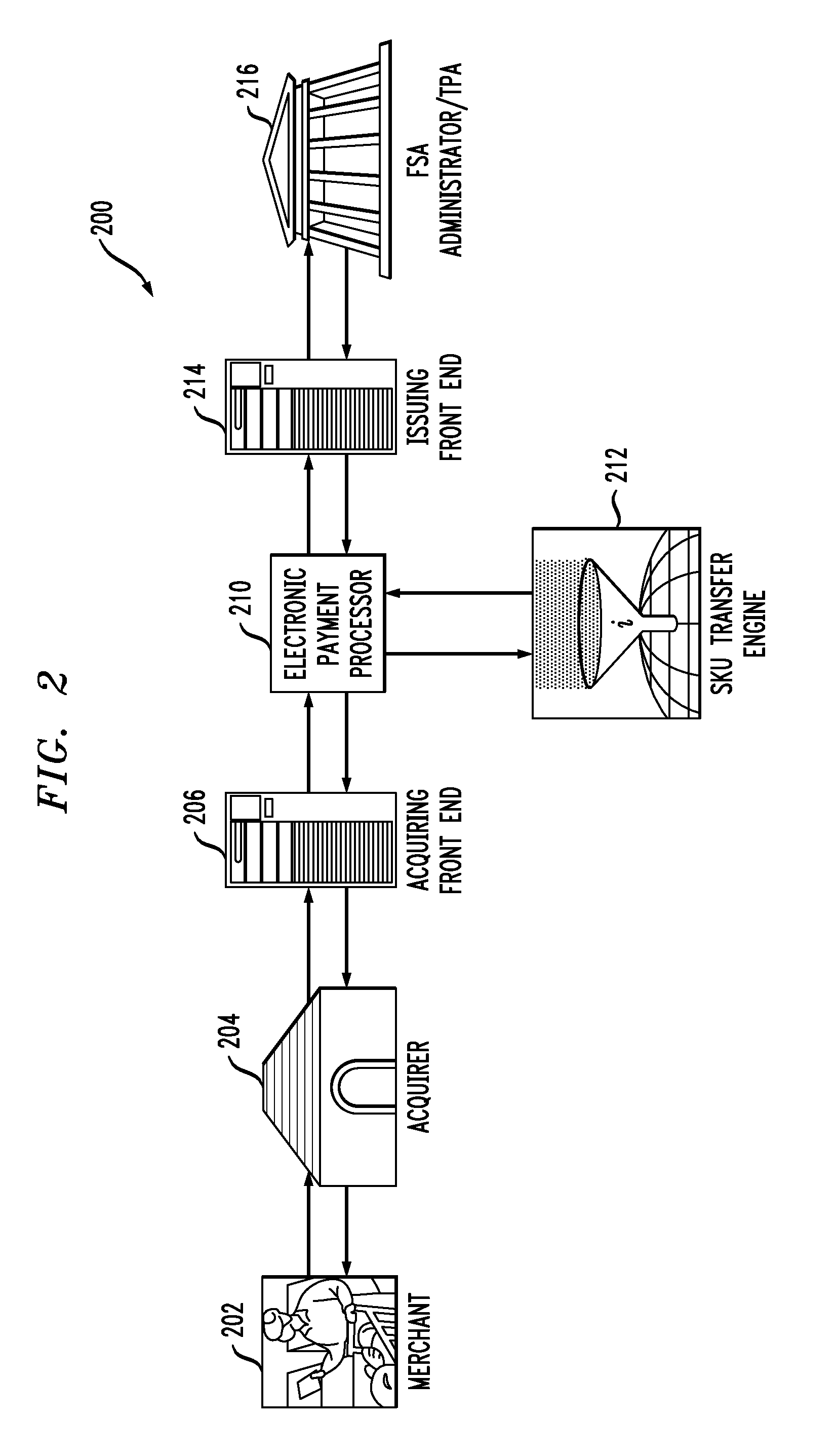

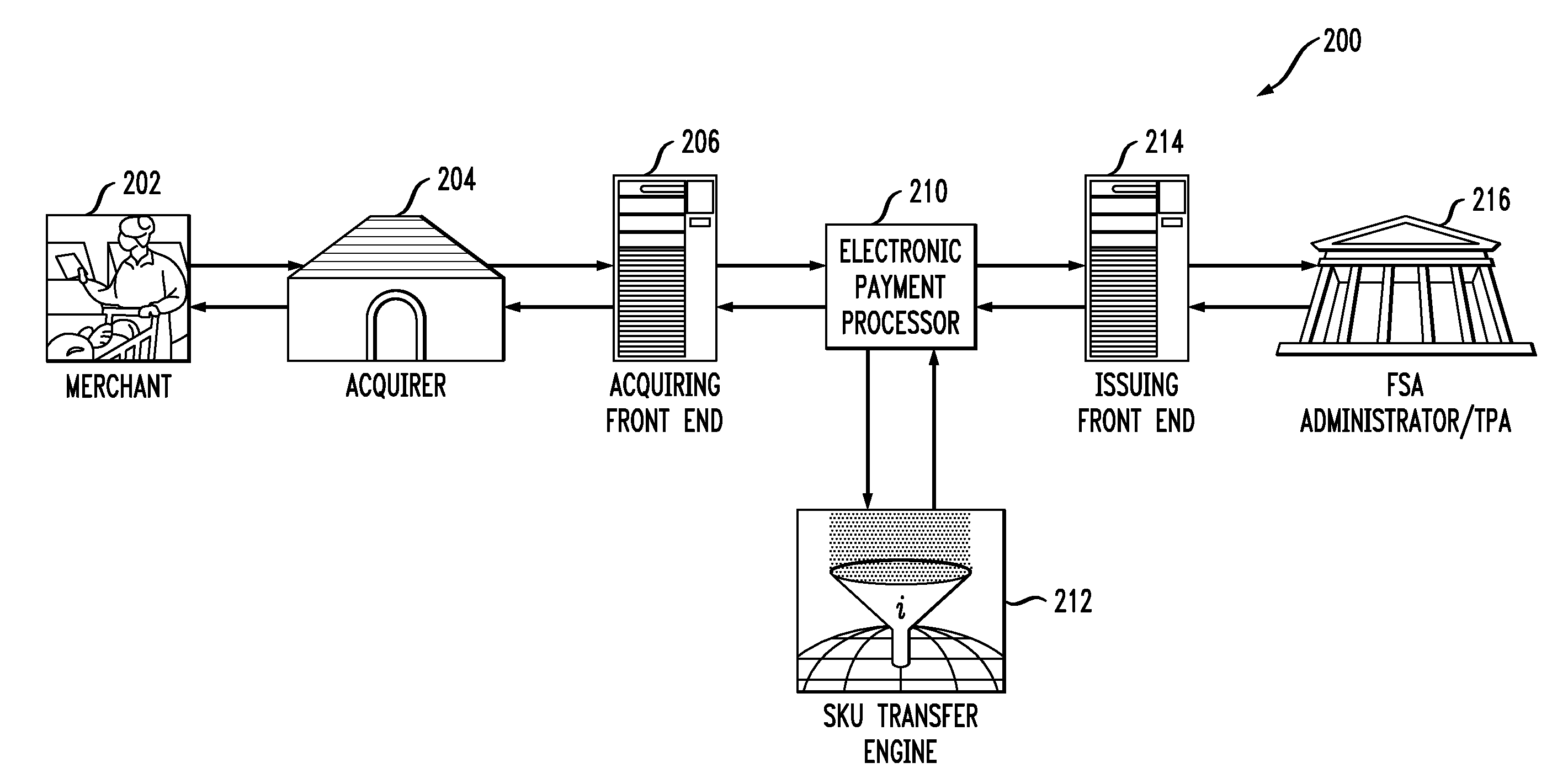

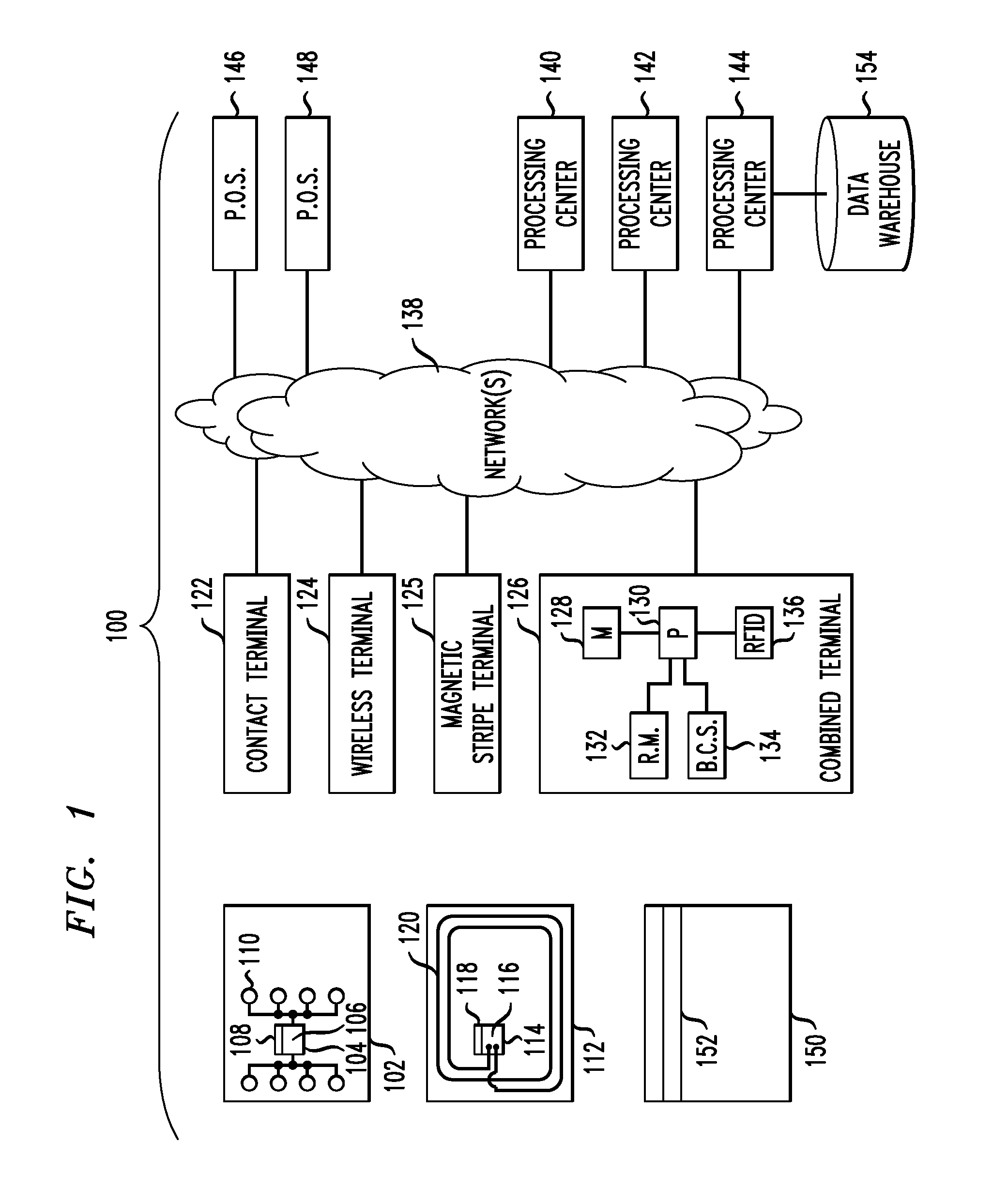

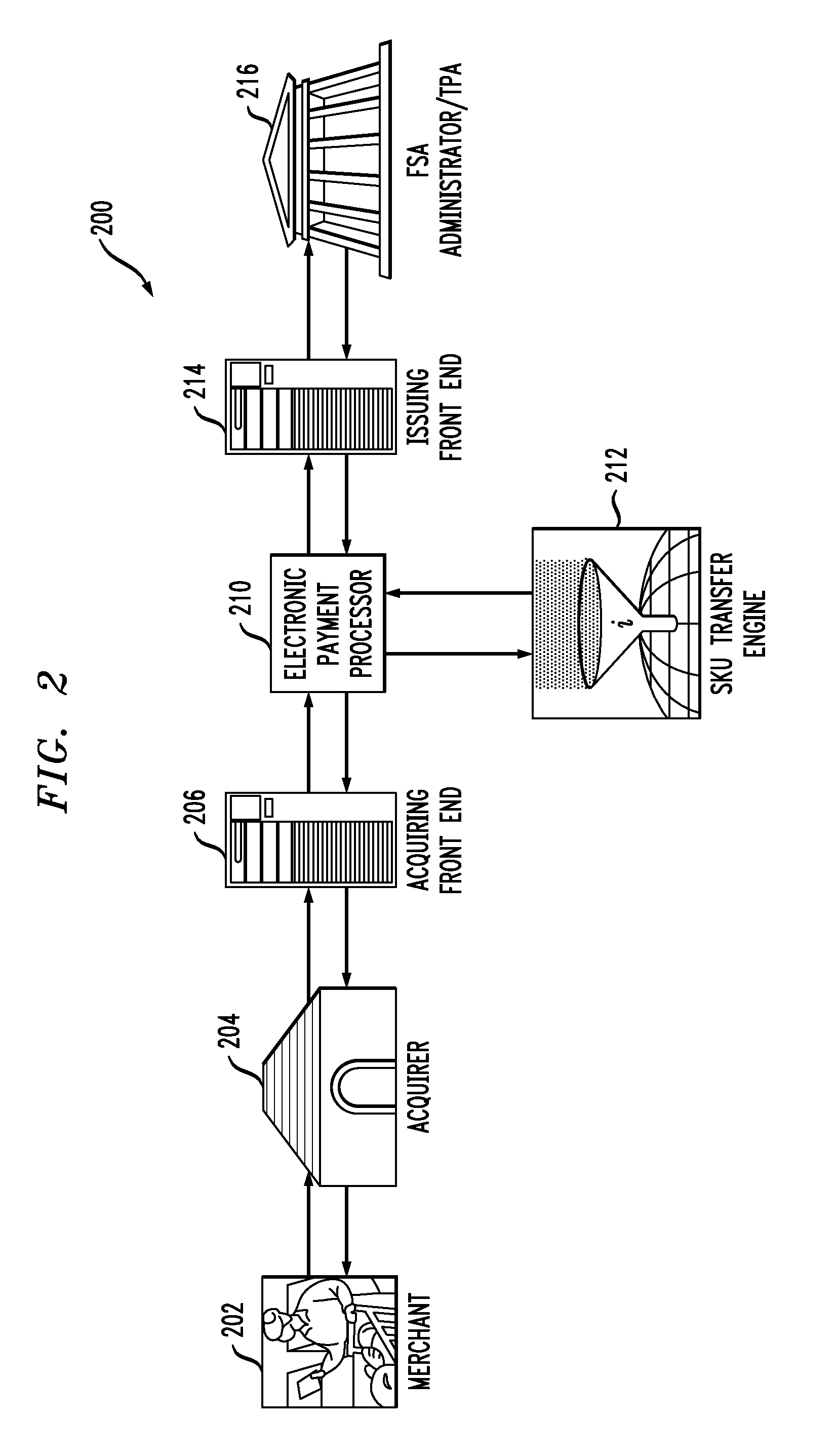

Method and system for enabling item-level approval of payment card

ActiveUS7628319B2Reduce decreaseFaster processing timeComplete banking machinesFinanceThird partyIndividual item

Owner:MASTERCARD INT INC

Method and System for Enabling Item-Level Approval of Payment Card

ActiveUS20080011820A1Reduce decreaseFaster processing timeComplete banking machinesFinanceIndividual itemThird party

A method includes the steps of facilitating obtaining indicia identifying individual items to be purchased at a point of interaction, in conjunction with an inbound authorization request; facilitating translation of the indicia into a form understandable by a third party transaction approver, to obtain translated indicia; and facilitating transfer of the translated indicia to the third patty transaction approver for item-by-item validation on the individual items The transfer of the translated indicia is in conjunction with an outbound authorization request. A system implementing the method can make use of an inventive transfer engine.

Owner:MASTERCARD INT INC

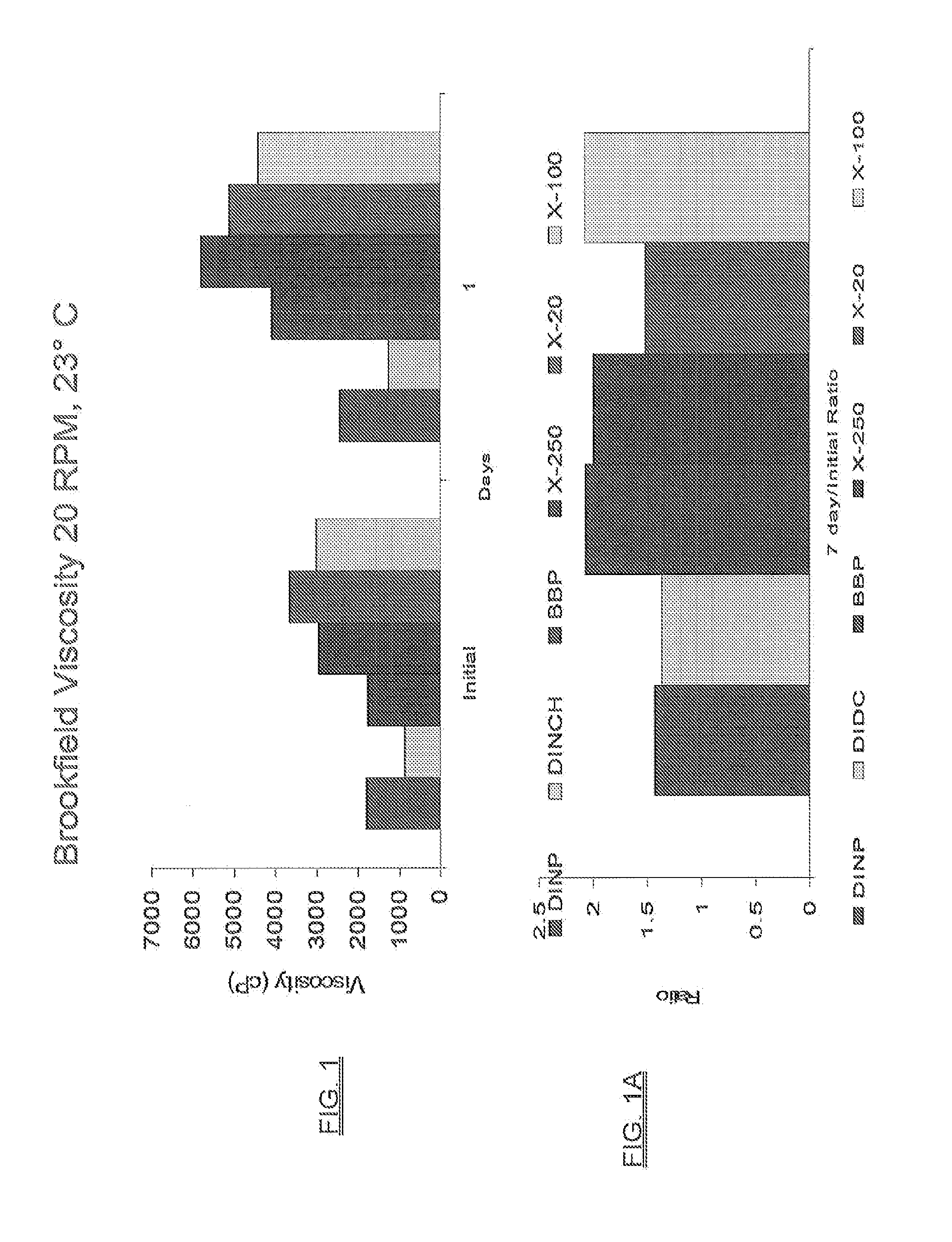

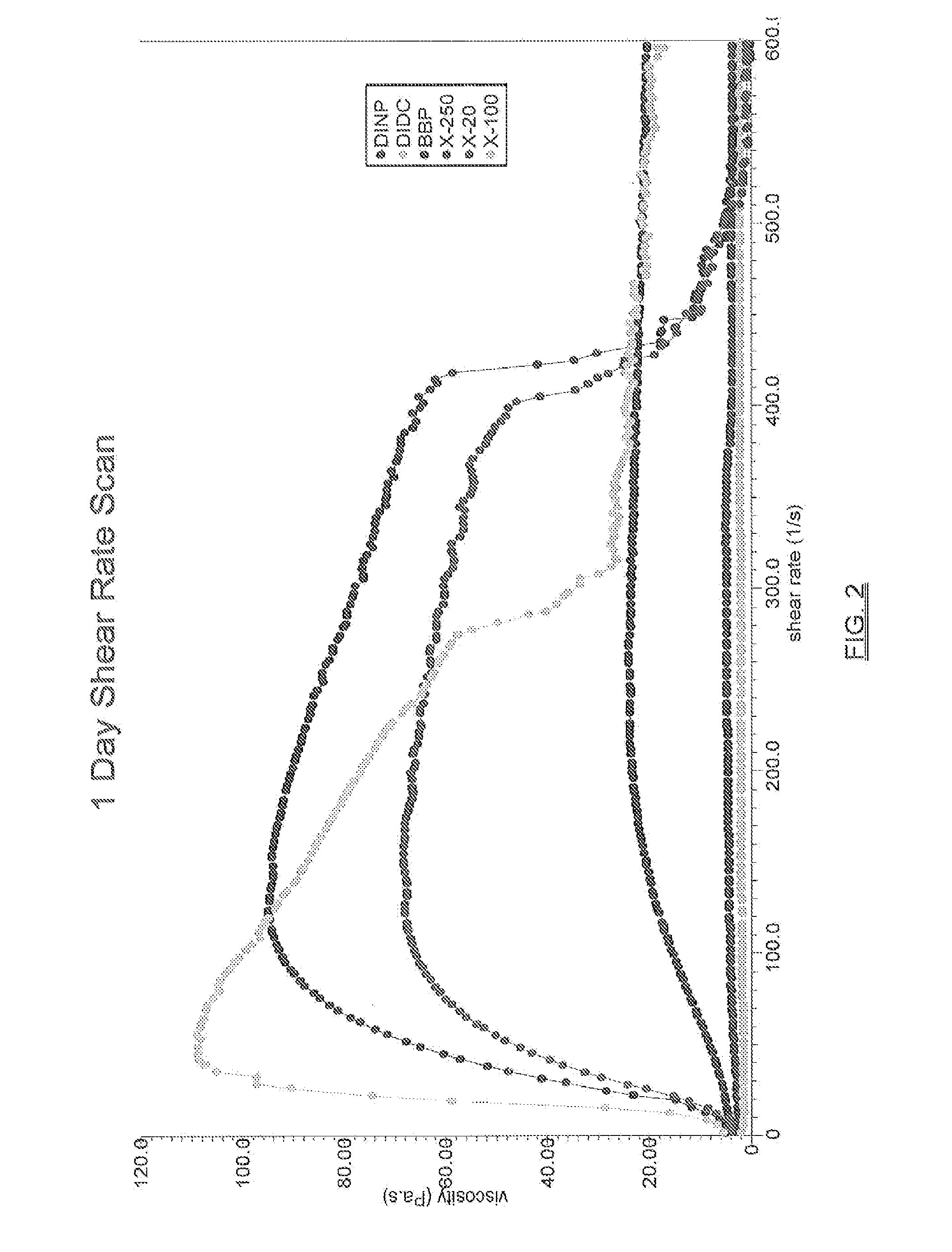

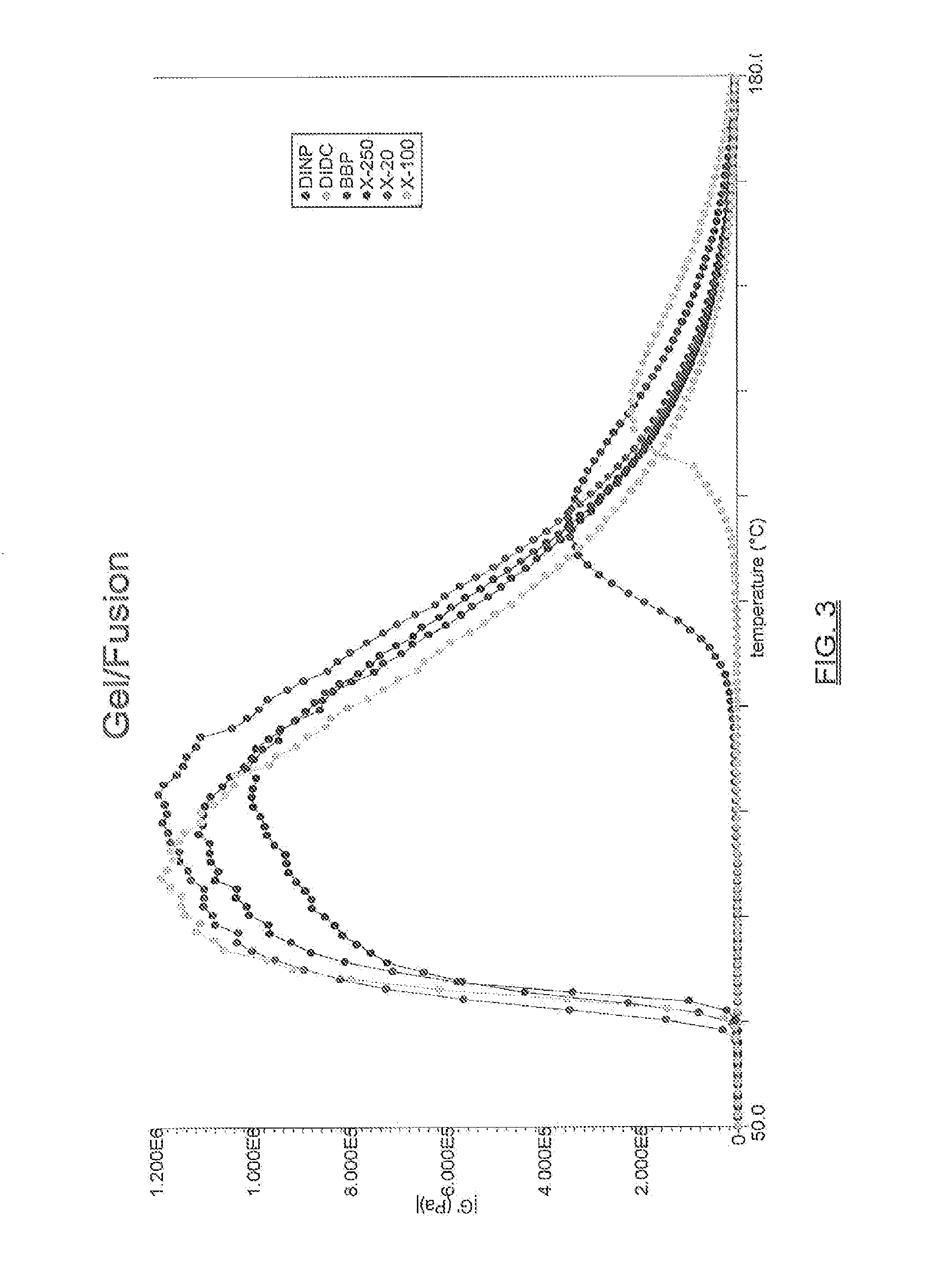

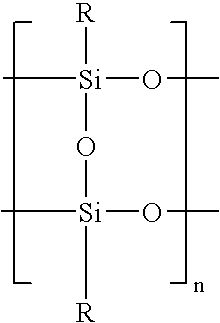

Blends of dibenzoate plasticizers

ActiveUS20130274396A1Efficient Tg suppressionFaster processing timeNon-macromolecular adhesive additivesInksElastomerAdhesive

Plasticizer blends comprise a triblend of diethylene glycol dibenzoate, dipropylene glycol dibenzoate, and 1,2-propylene glycol dibenzoate, in specified ratios, useful in combination with a multitude of thermoplastic polymers, thermosetting polymers, and elastomeric polymers and numerous applications, including but not limited to plastisols, adhesives, sealants, caulks, architectural coatings, industrial coatings, OEM coatings, inks, overprint varnishes, polishes, and the like. The advantages rendered by the use of the triblend depend on the type of polymer and application in which it is utilized and include among other advantages higher solvating power and lower processing time, low VOC's, reduced plasticizer freeze point, improved gelation and fusion characteristics, higher tensile strength, superior stain and extraction resistance, and improved rheology over traditional diblends of diethylene glycol dibenzoate and dipropylene glycol dibenzoate.

Owner:EMERALD KALAMA CHEM

Longest-edge refinement and derefinement system and method for automatic mesh generation

InactiveUS6266062B1Optimize data structureFaster processing time3D-image rendering3D modellingAlgorithmTheoretical computer science

A method, mesh data structure and apparatus is disclosed for producing an improved / refined / derefined mesh of finite elements for a three-dimensional object showing boundaries and faces. The improvement / refinement method repeatedly searching, for consecutive sets of active target elements to be refined or improved, an associated submesh and set of terminal edges, the searching process not modifying the mesh data structure; then according to the point insertion method chosen, selection of the point or the points to be inserted between the midpoints of the terminal edges modified by some boundary considerations; inserting the selected point or points in the initial mesh; and then proceeding to the succeeding set of active target elements until an user-defined stopping criterion is achieved.The derefinement method, for each target vertex finding an associated set of neighbor vertices to be derefined; then eliminating each said vertex according an appropriate order such that the derefinement of said vertex allows to re-obtain a previous terminal edge whose bisection produced said vertex. The method, mesh data structure and apparatus of this invention allowing the parallel scaleable refinement / derefinement of the mesh by locally modifying sets of neighbor elements sharing the common longest-edge.

Owner:RIVARA MARIA CECILIA

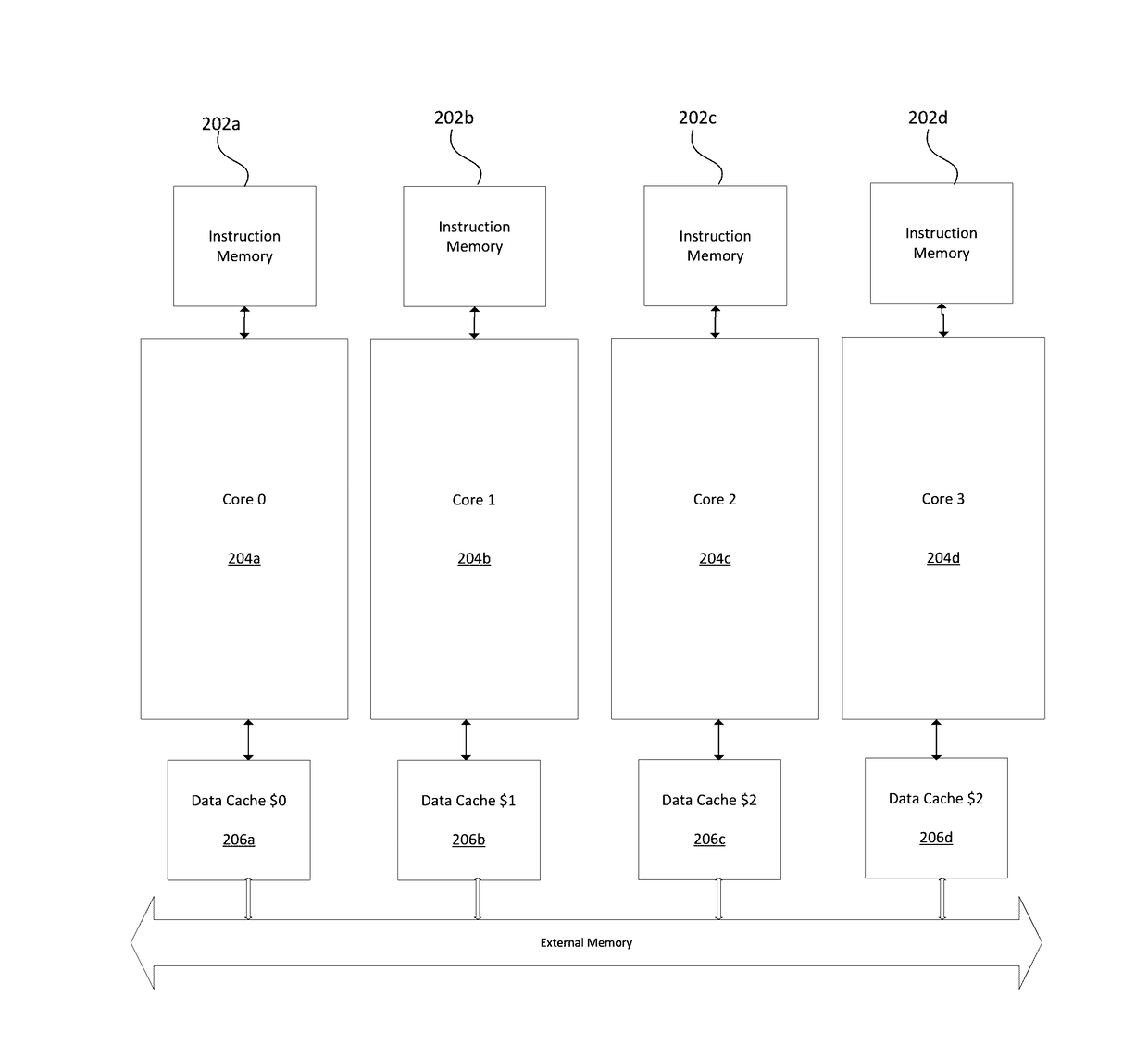

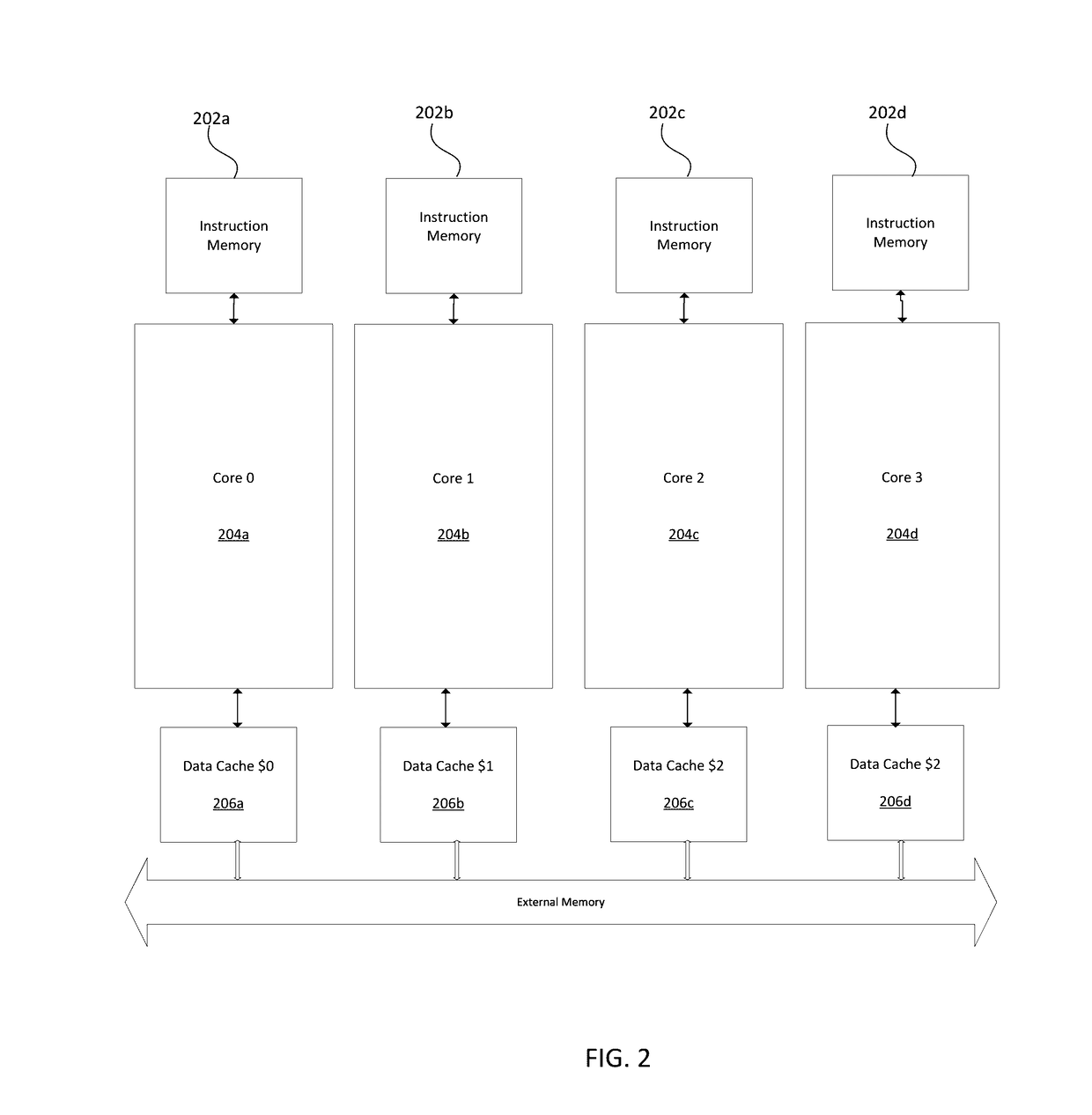

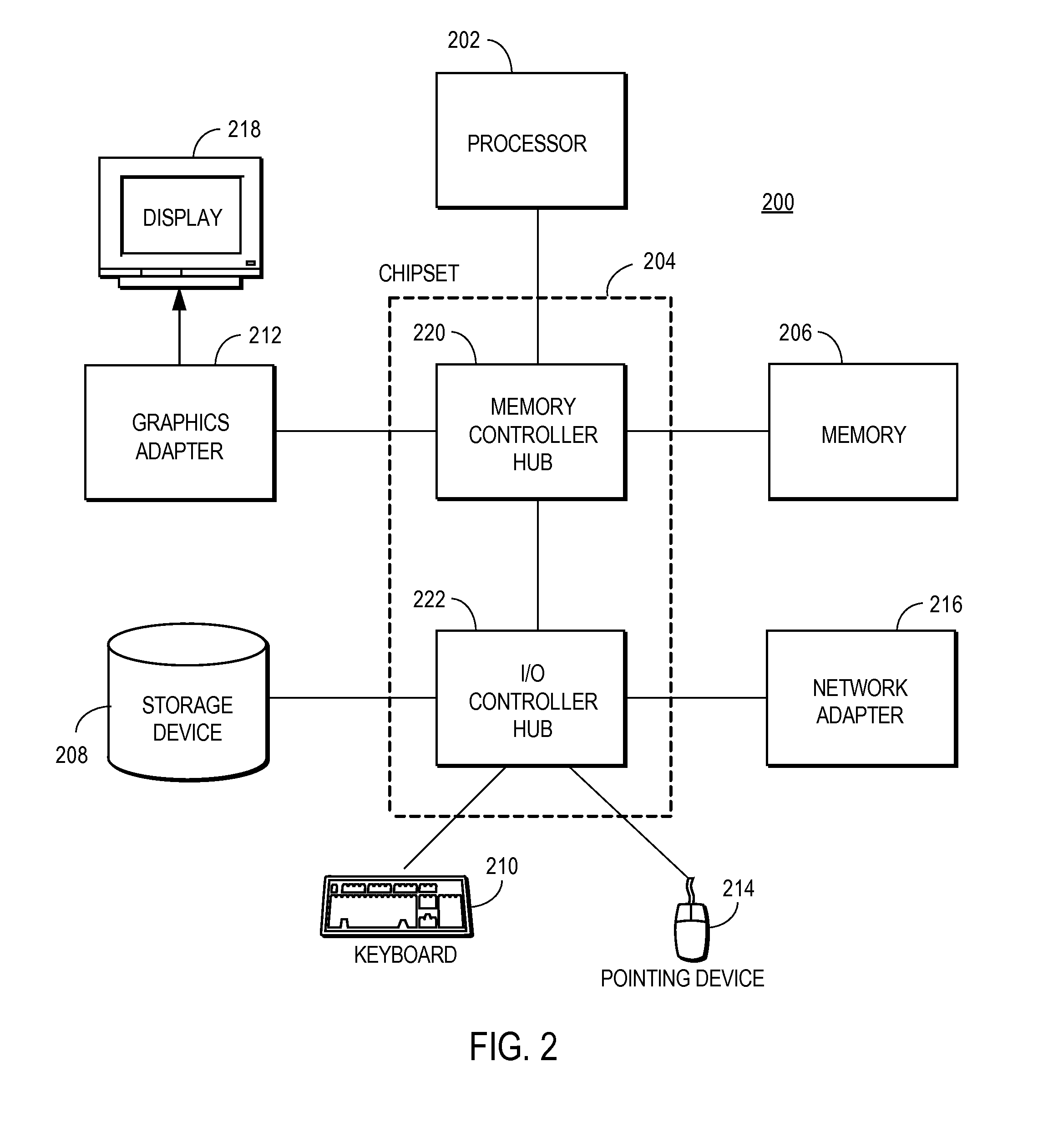

System on chip with image processing capabilities

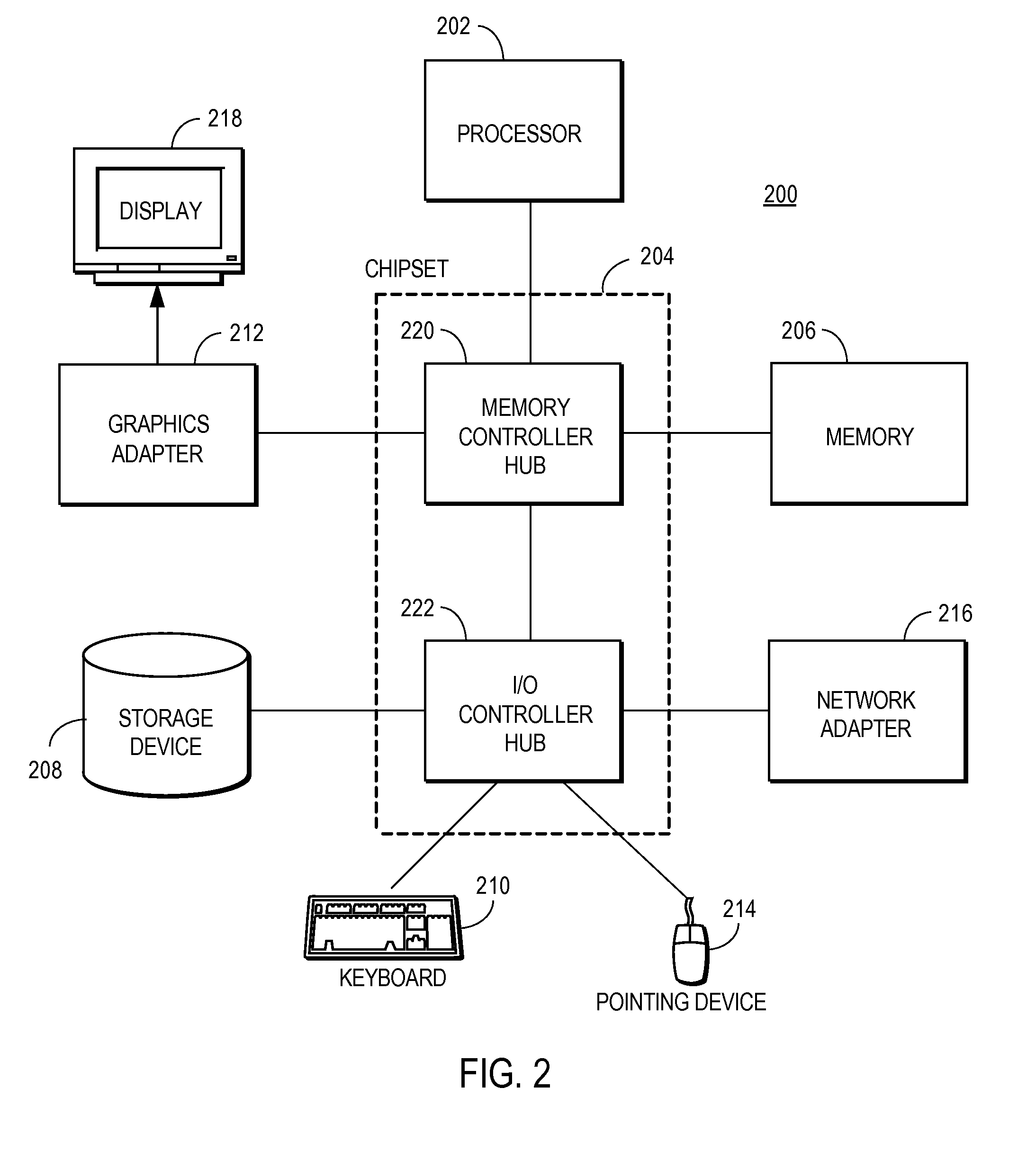

ActiveUS20170103022A1Faster processing timeReduce in quantityMemory architecture accessing/allocationRegister arrangementsProcessing coreImaging processing

A multi-core processor configured to improve processing performance in certain computing contexts is provided. The multi-core processor includes multiple processing cores that implement barrel threading to execute multiple instruction threads in parallel while ensuring that the effects of an idle instruction or thread upon the performance of the processor is minimized. The multiple cores can also share a common data cache, thereby minimizing the need for expensive and complex mechanisms to mitigate inter-cache coherency issues. The barrel-threading can minimize the latency impacts associated with a shared data cache. In some examples, the multi-core processor can also include a serial processor configured to execute single threaded programming code that may not yield satisfactory performance in a processing environment that employs barrel threading.

Owner:MOBILEYE VISION TECH LTD

Supercritical fluid-assisted deposition of materials on semiconductor substrates

InactiveUS7119418B2Faster processing timeReduce processing costsSemiconductor/solid-state device detailsSolid-state devicesGas phaseDeposition process

Supercritical fluid-assisted deposition of materials on substrates, such as semiconductor substrates for integrated circuit device manufacture. The deposition is effected using a supercritical fluid-based composition containing the precursor(s) of the material to be deposited on the substrate surface. Such approach permits use of precursors that otherwise would be wholly unsuitable for deposition applications, as lacking requisite volatility and transport characteristics for vapor phase deposition processes.

Owner:ADVANCED TECH MATERIALS INC

Process for Fabricating Optical Waveguides

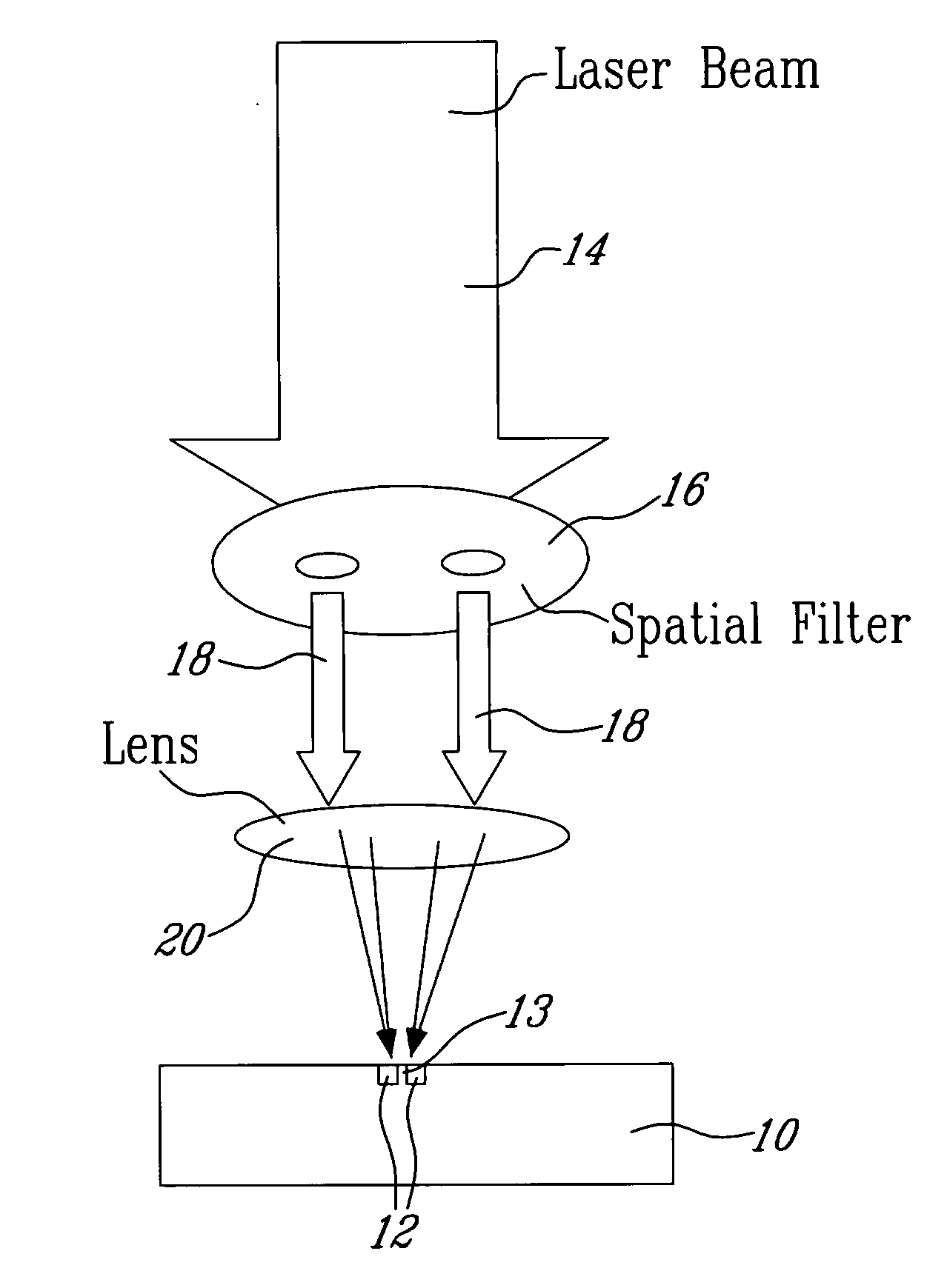

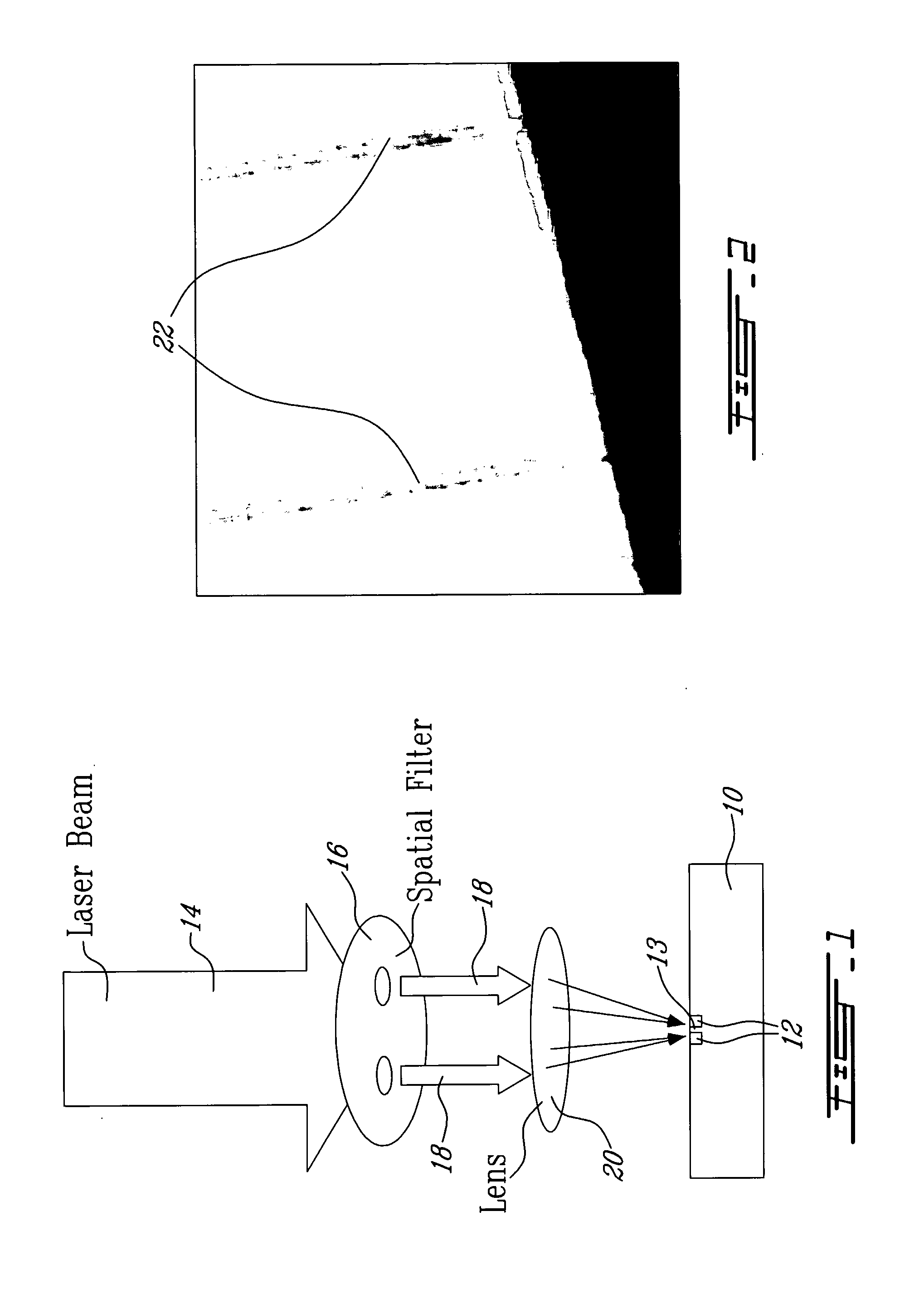

InactiveUS20080264910A1Speed up the processEasy to integrateWelding/soldering/cutting articlesOptical waveguide light guideDielectric substratePhotonics

A one step process for fabricating planar optical waveguides comprises using a laser to cut at least two channels in a substantially planar surface of a piece of dielectric material defining a waveguide there between. The shape and size of the resulting guide can be adjusting by selecting an appropriate combination of laser beam spatial profile, of its power and of the exposure time. A combination of heating and writing lasers can also be used to fabricate waveguides in a dielectric substrate, wherein the heating laser heats the substrate with a relatively broad focused spot, the power of the heating laser being controlled to raise the temperature heating the substrate just below the substrate's threshold temperature at which it begins to absorb electro-magnetic radiation, the writing laser, which yields a spot size smaller than the heating laser then melts the substrate within the focal spot of the heating laser. Compare to processes from the prior art, a waveguide fabrication process according to the present invention results in lower cost, faster processing time and applicability to a wider range of materials. The present process is particularly suited for the mass production of inexpensive photonic devices.

Owner:CORP DE LECOLE POLYTECHNIQUE DE MONTREAL

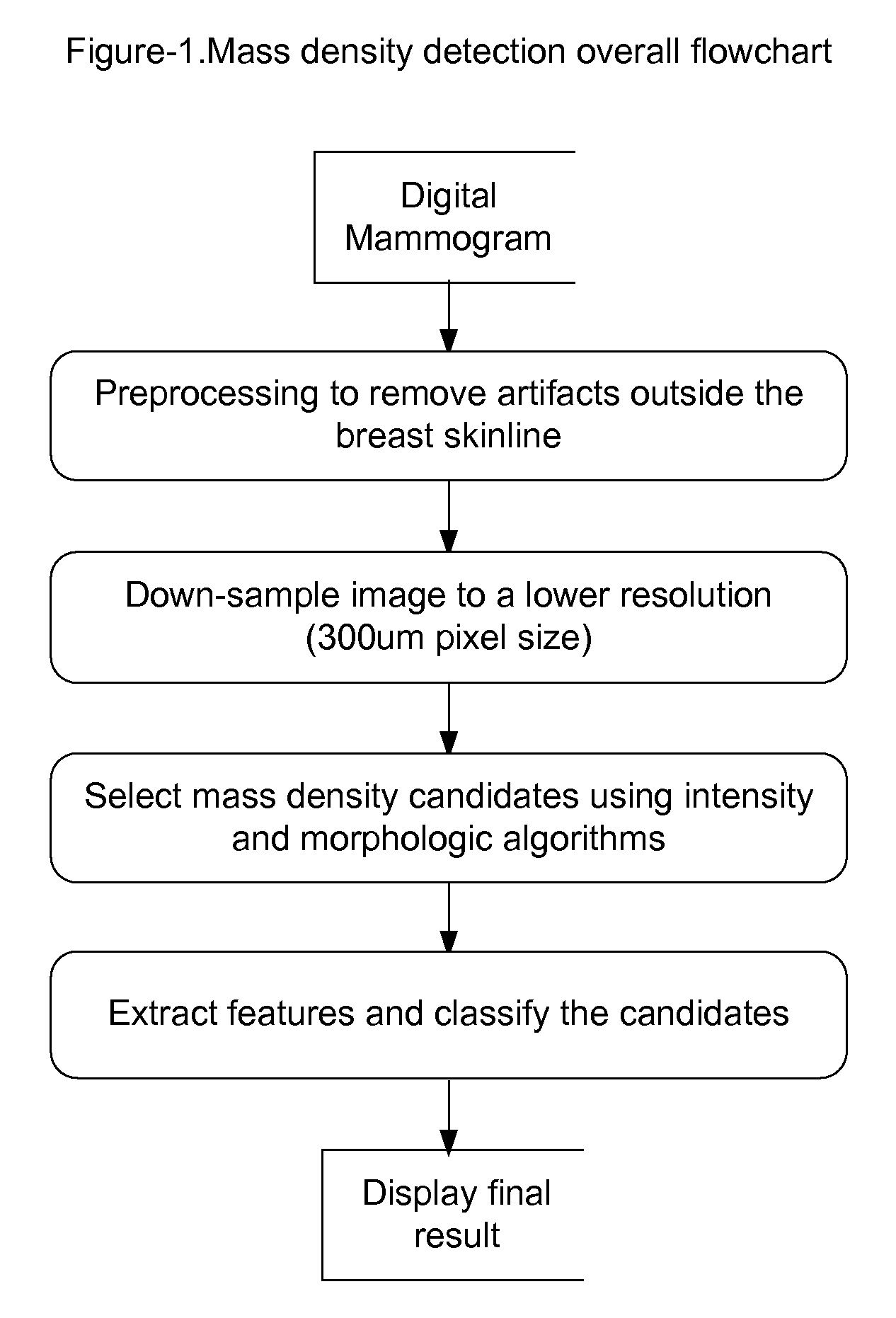

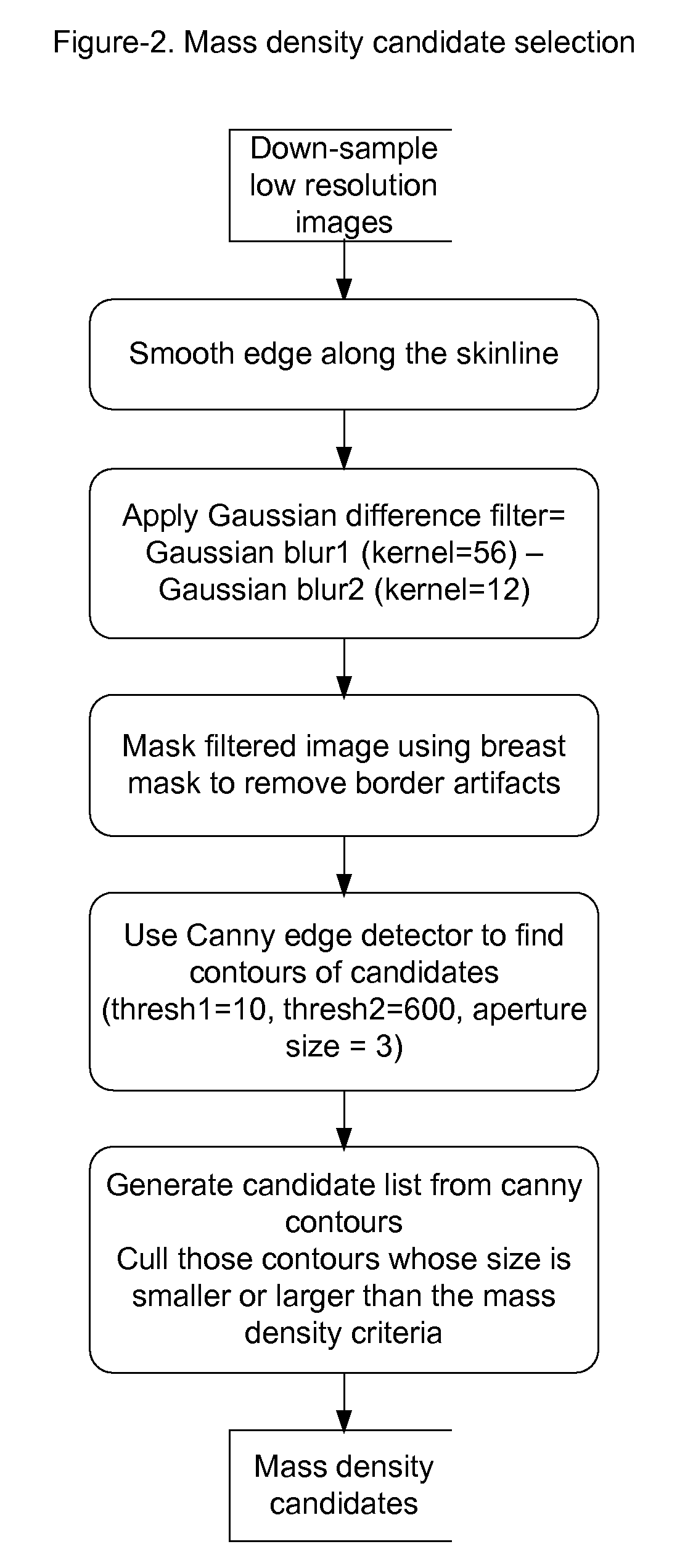

Algorithms for selecting mass density candidates from digital mammograms

ActiveUS20080267470A1High sensitivityFaster processing timeImage enhancementImage analysisTomosynthesisSonification

The present invention provides a method for selecting mass density candidates from mammograms for computer-aided lesion detection, review and diagnosis. The method has two steps: a Gaussian difference filter to enhance the intensity and a Canny detector to find potential mass density contours. For circumscribed masses, an additional Hough circle detector is used. This invention makes use of both intensity and morphology information and only processes each image at a single gray-level, so both sensitivity and processing time are improved. The selection algorithm can be also used to select mass candidates from ultrasound images, from 3D tomosynthesis mammography images and from breast MRI images.

Owner:THREE PALM SOFTWARE

Supercritical fluid-assisted deposition of materials on semiconductor substrates

InactiveUS20060178006A1Faster processing timeReduce processing costsSolid-state devicesSemiconductor/solid-state device manufacturingGas phaseDeposition process

Supercritical fluid-assisted deposition of materials on substrates, such as semiconductor substrates for integrated circuit device manufacture. The deposition is effected using a supercritical fluid-based composition containing the precursor(s) of the material to be deposited on the substrate surface. Such approach permits use of precursors that otherwise would be wholly unsuitable for deposition applications, as lacking requisite volatility and transport characteristics for vapor phase deposition processes.

Owner:XU CHONGYING +2

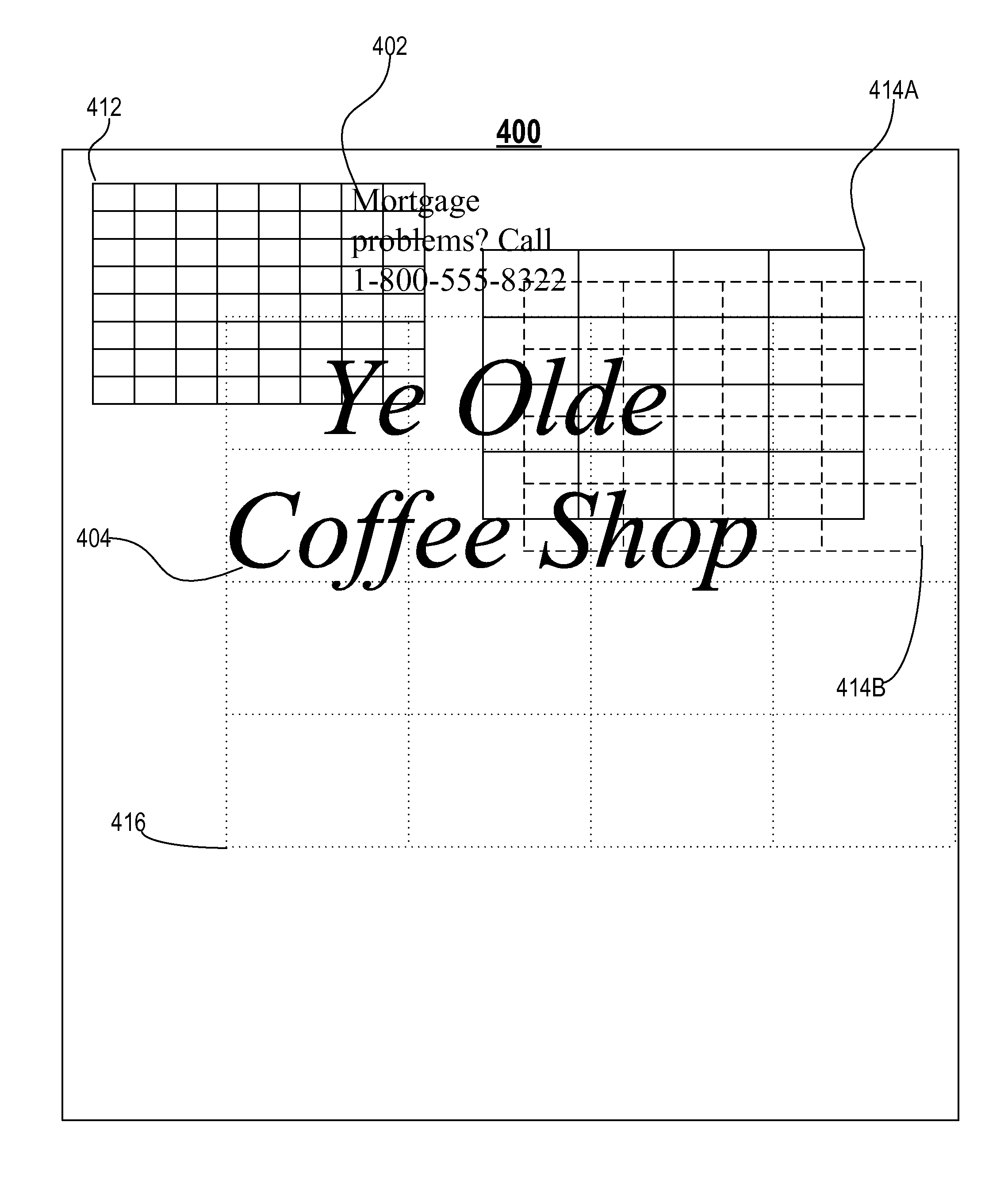

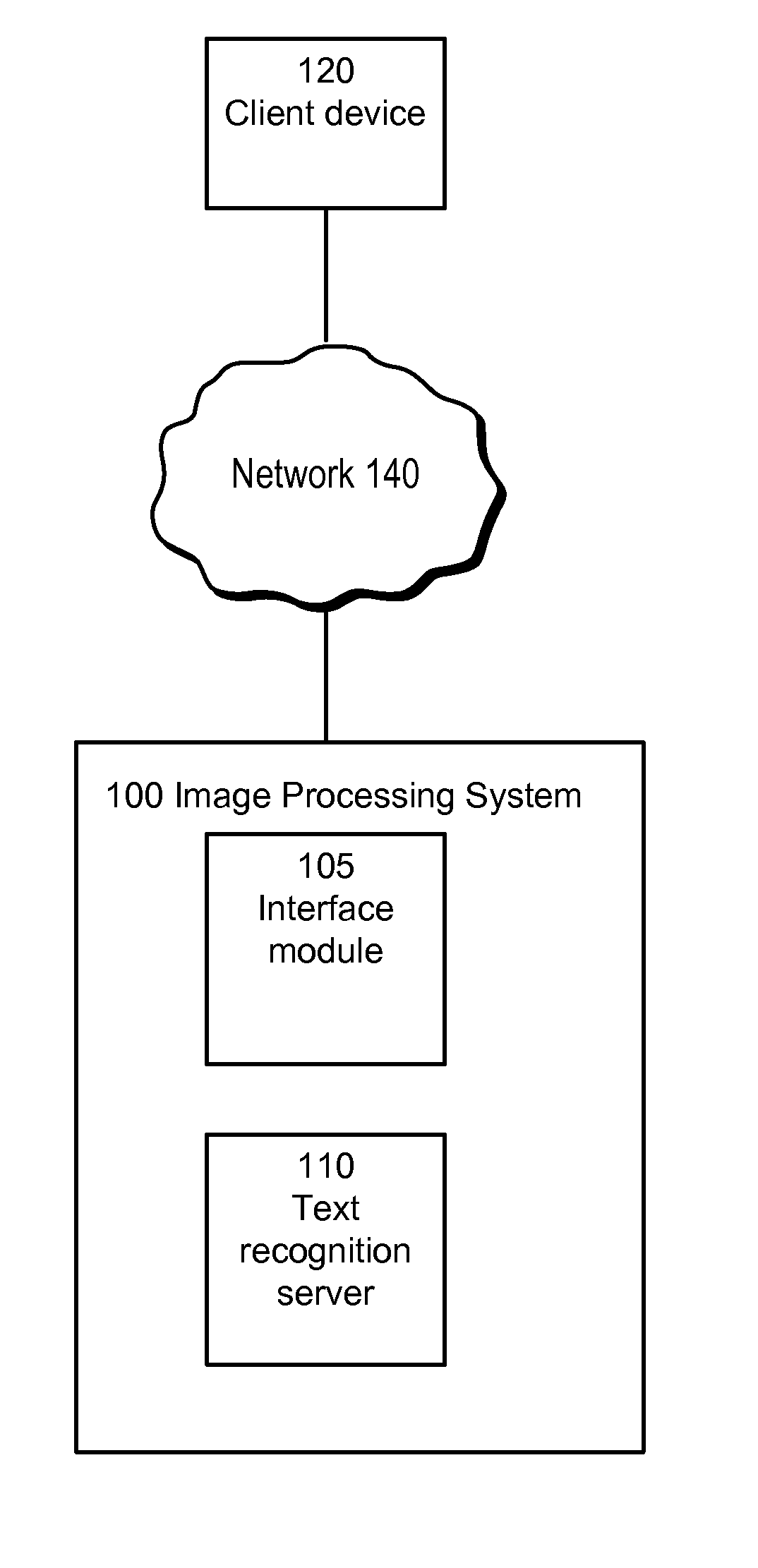

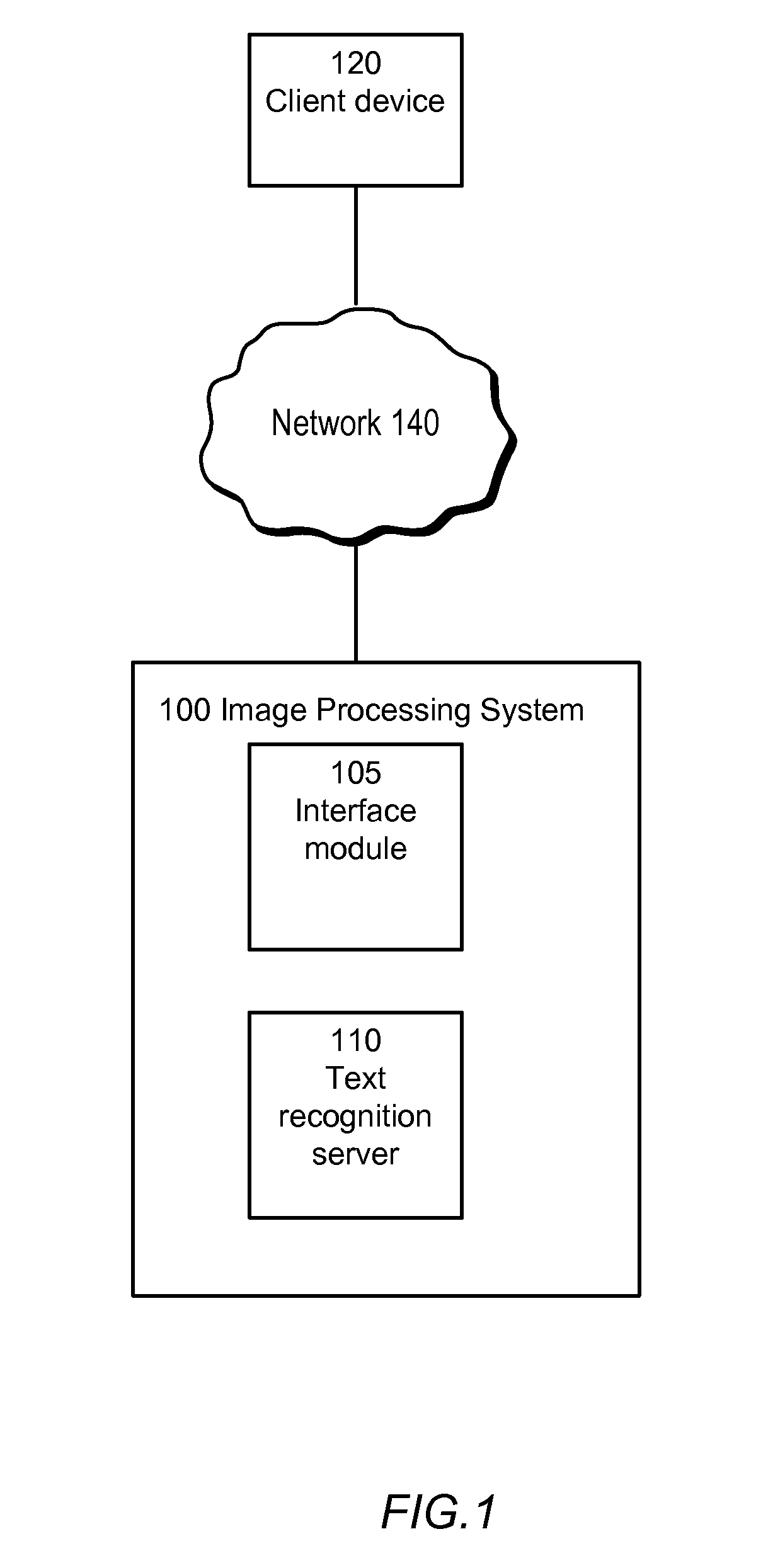

Text recognition for textually sparse images

A text recognition server is configured to recognize text in a sparse text image. Specifically, given an image, the server specifies a plurality of “patches” (blocks of pixels within the image). The system applies a text detection algorithm to the patches to determine a number of the patches that contain text. This application of the text detection algorithm is used both to estimate the orientation of the image and to determine whether the image is textually sparse or textually dense. If the image is determined to be textually sparse, textual patches are identified and grouped into text regions, each of which is then separately processed by an OCR algorithm, and the recognized text for each region is combined into a result for the image as a whole.

Owner:GOOGLE LLC

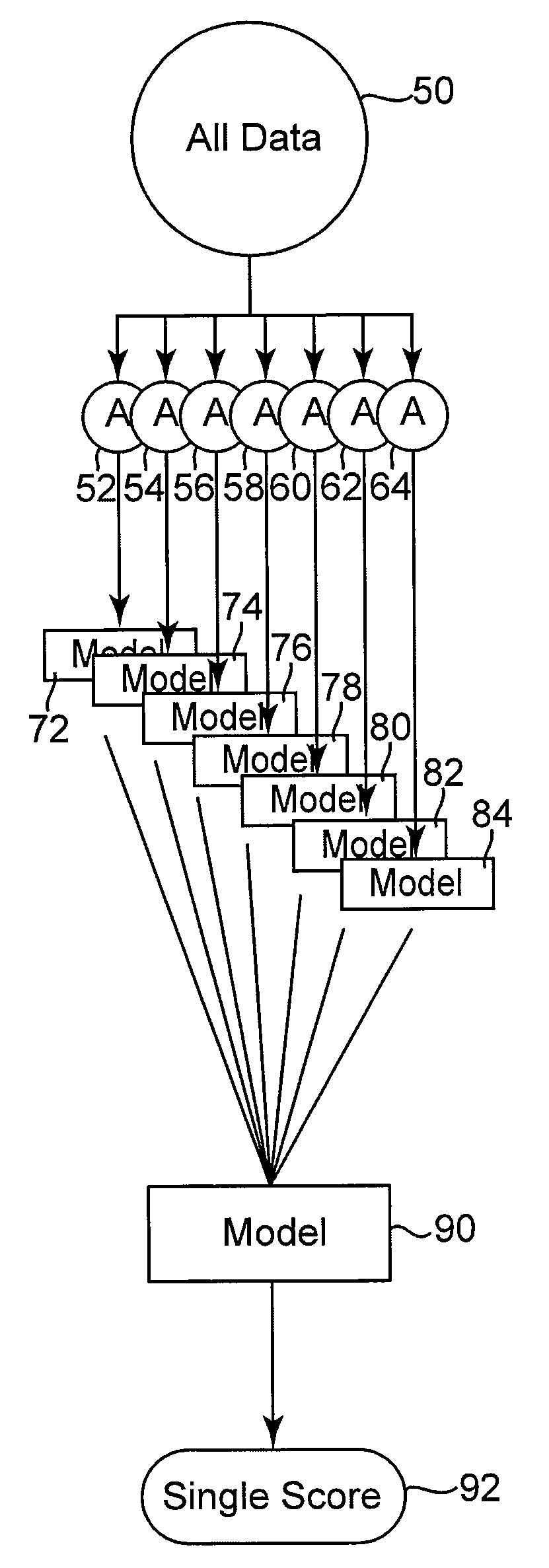

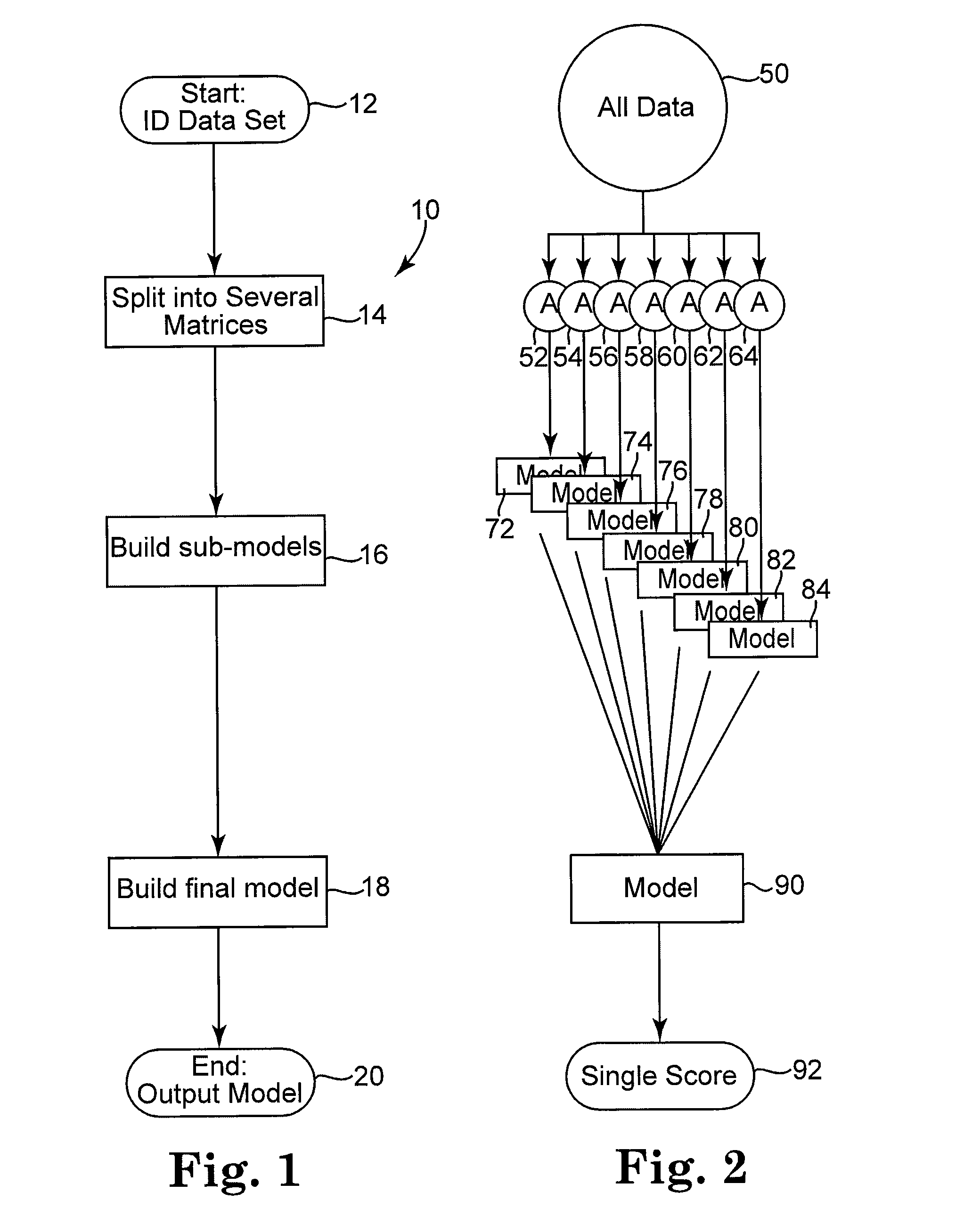

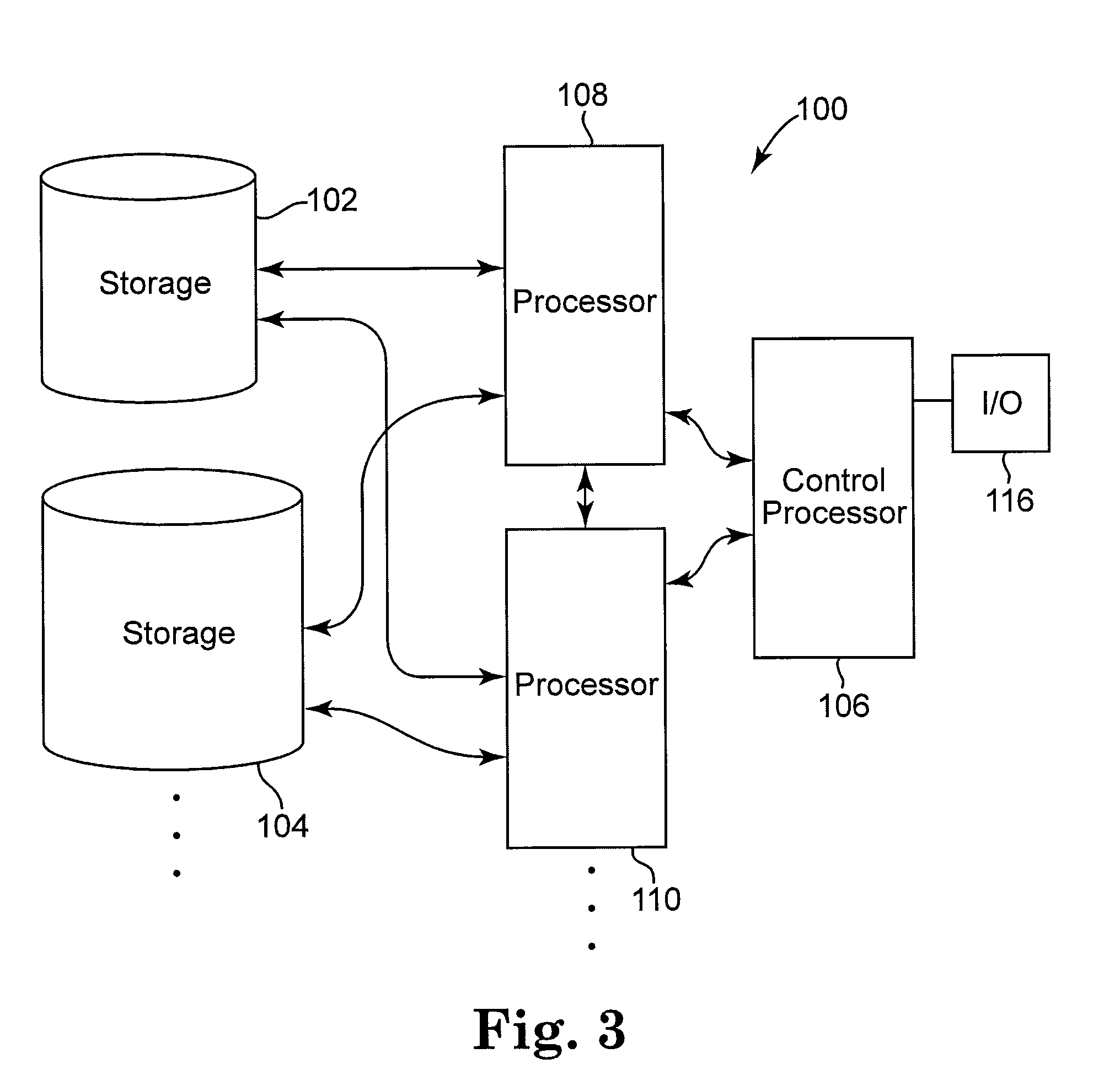

Segmented modeling of large data sets

InactiveUS20090018982A1Utilize processing powerImprove efficiencyDigital computer detailsMachine learningData setProbable Case

To provide efficient and effective modeling of data set, the data set is initially separated into several subsets which can then be processed independently. The subsets themselves are chosen to have some internal commonality, thus providing effective independent tools where possible. This commonality may include correlation between variables or interaction amongst the variables in the subset. Once separated, each subset is independently modeled, creating a subset model having predictive qualities related to the data subset. Next, the subset models themselves are aggregated to generate a overall final model. This final model is predictive of outcomes based upon all data in the data set, thus providing a more robust stable model.

Owner:IS TECH

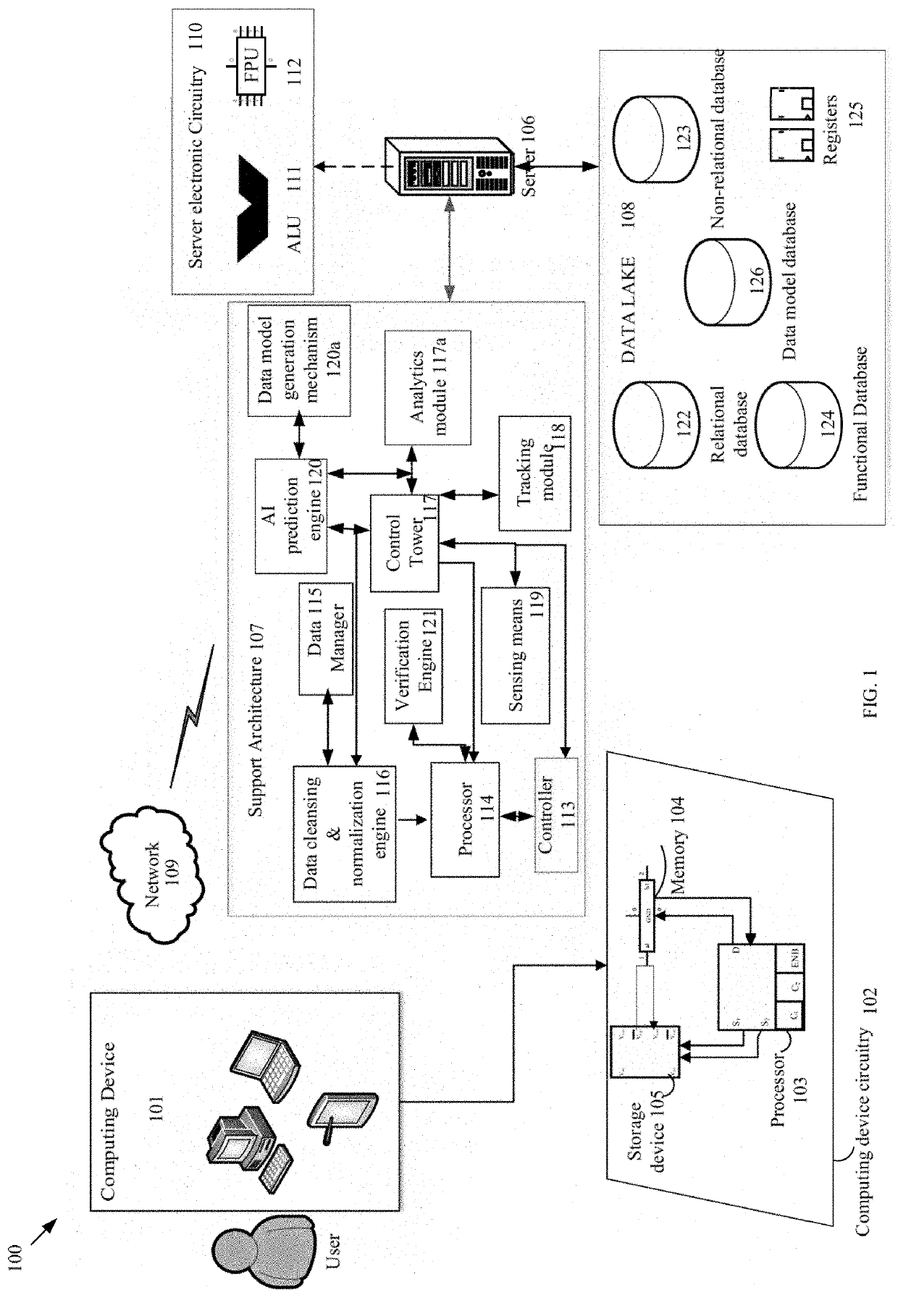

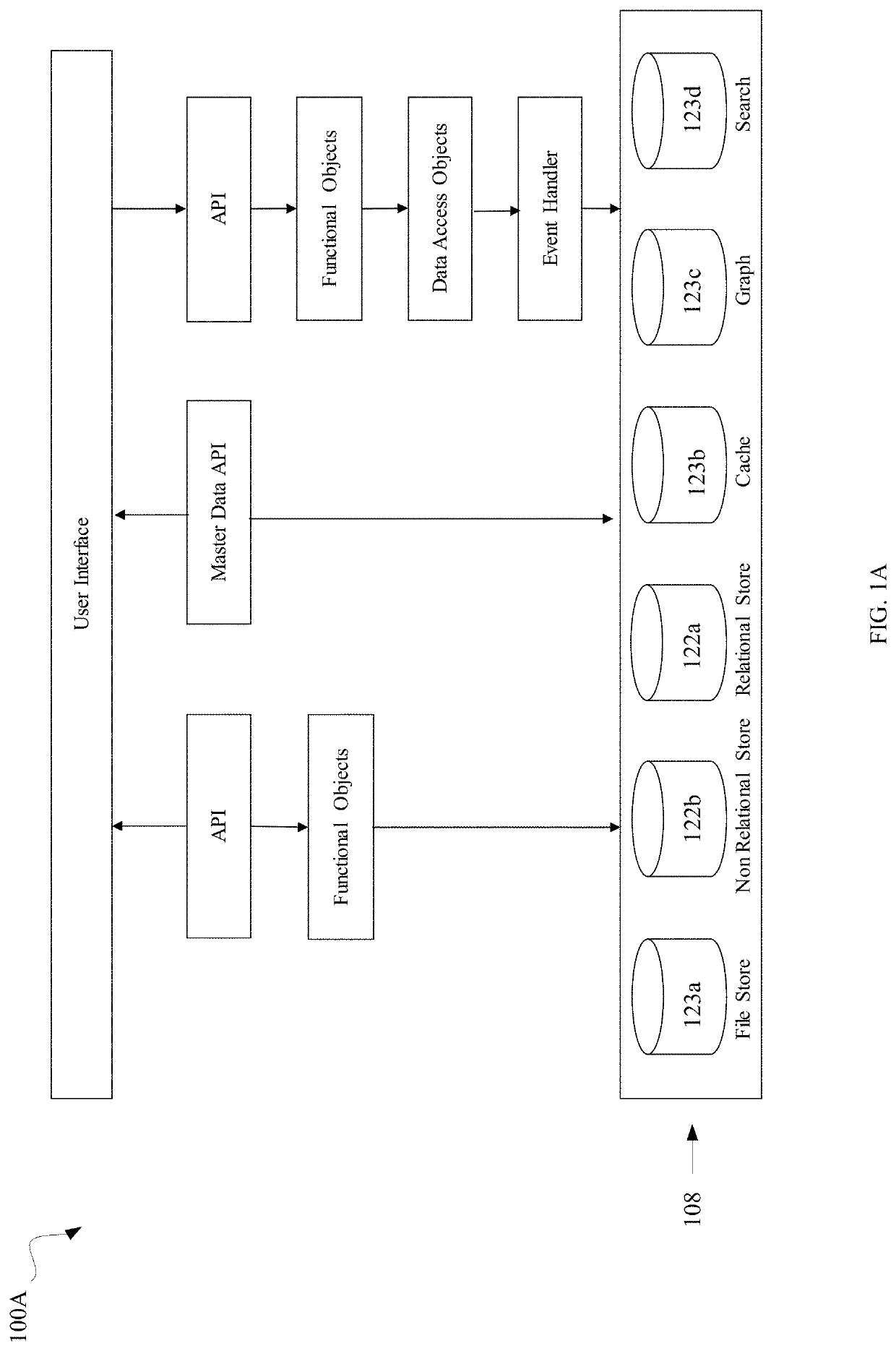

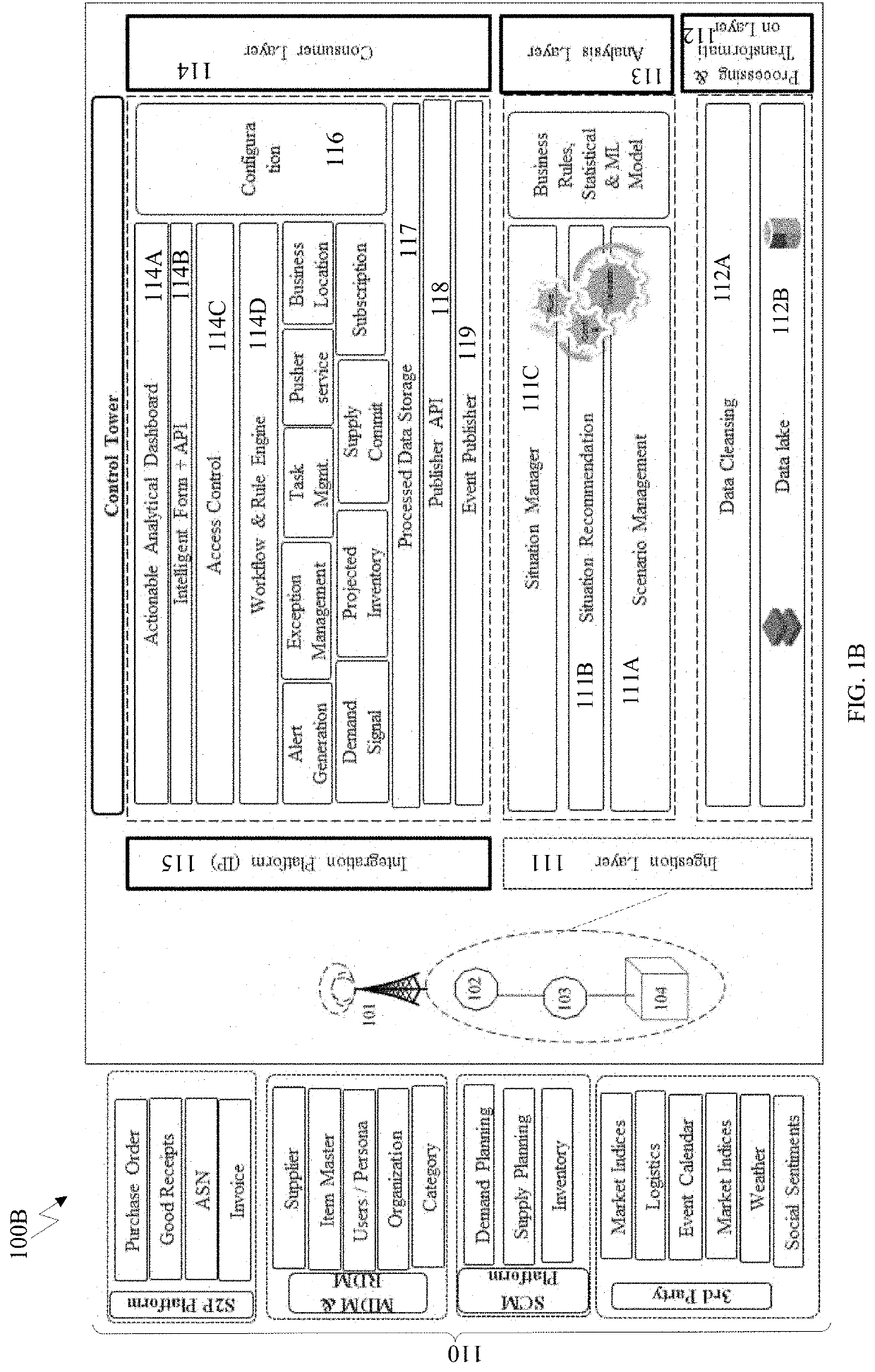

Self-driven system & method for operating enterprise and supply chain applications

PendingUS20200279200A1Fast and accurate resultImprove it predictive capabilityProgramme controlCharacter and pattern recognitionMultiple applicationsEnterprise application

The present invention provides self-driven AI based system and method for operating one or more applications including enterprise application and supply chain management applications. The system includes centralized data lake for storing data received from plurality of distinct sources, a control tower configured for sensing change in attribute of the received data and determining impact of the change on plurality of functions of EA and SCM applications.

Owner:NB VENTURES INC

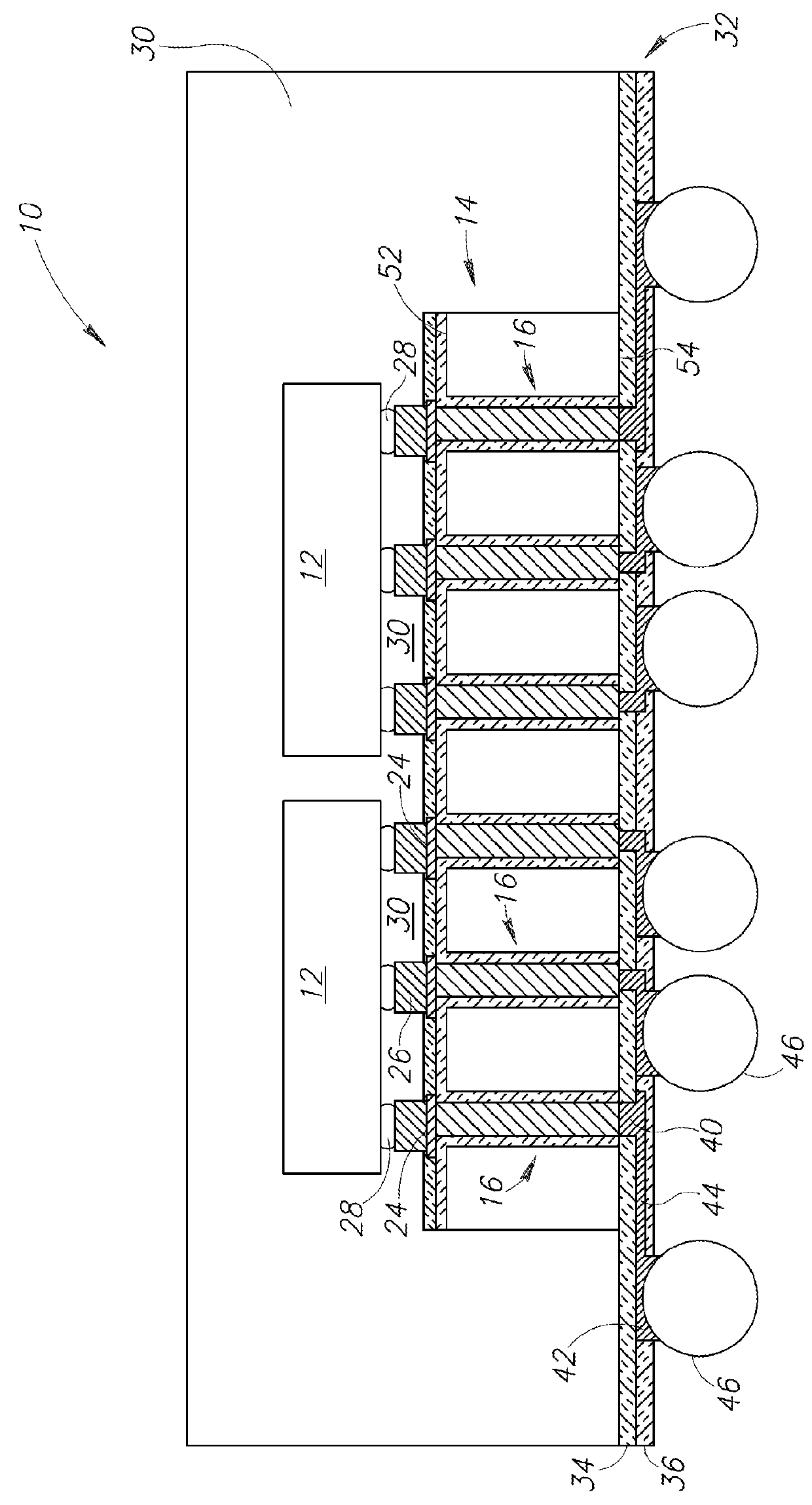

System-in-packages and methods for forming same

ActiveUS9252030B1Faster processing timeLow costSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipInterposer

One or more embodiments are directed to a system-in-package (SiP) that includes a plurality of semiconductor chips and an interposer that that are molded in an encapsulation layer together. That is, a single processing step may be used to encapsulate the semiconductor chips and the interposer in the encapsulation layer. Furthermore, prior to setting or curing, the encapsulation layer is able to flow between the semiconductor chips and the interposer to provide further mechanical support for the semiconductor chips. Thus, the process for forming the SiP is reduced, resulting in a faster processing time and a lower cost. Additionally, one or more embodiments described herein reduce or eliminate warpage of the interposer.

Owner:STMICROELECTRONICS INT NV

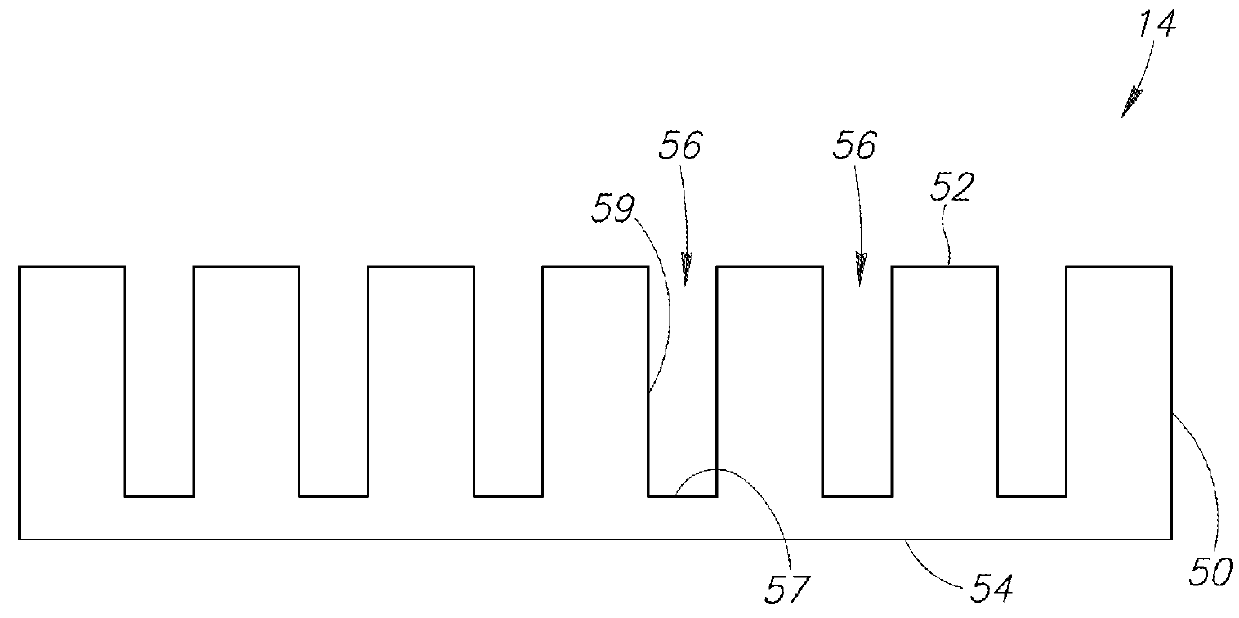

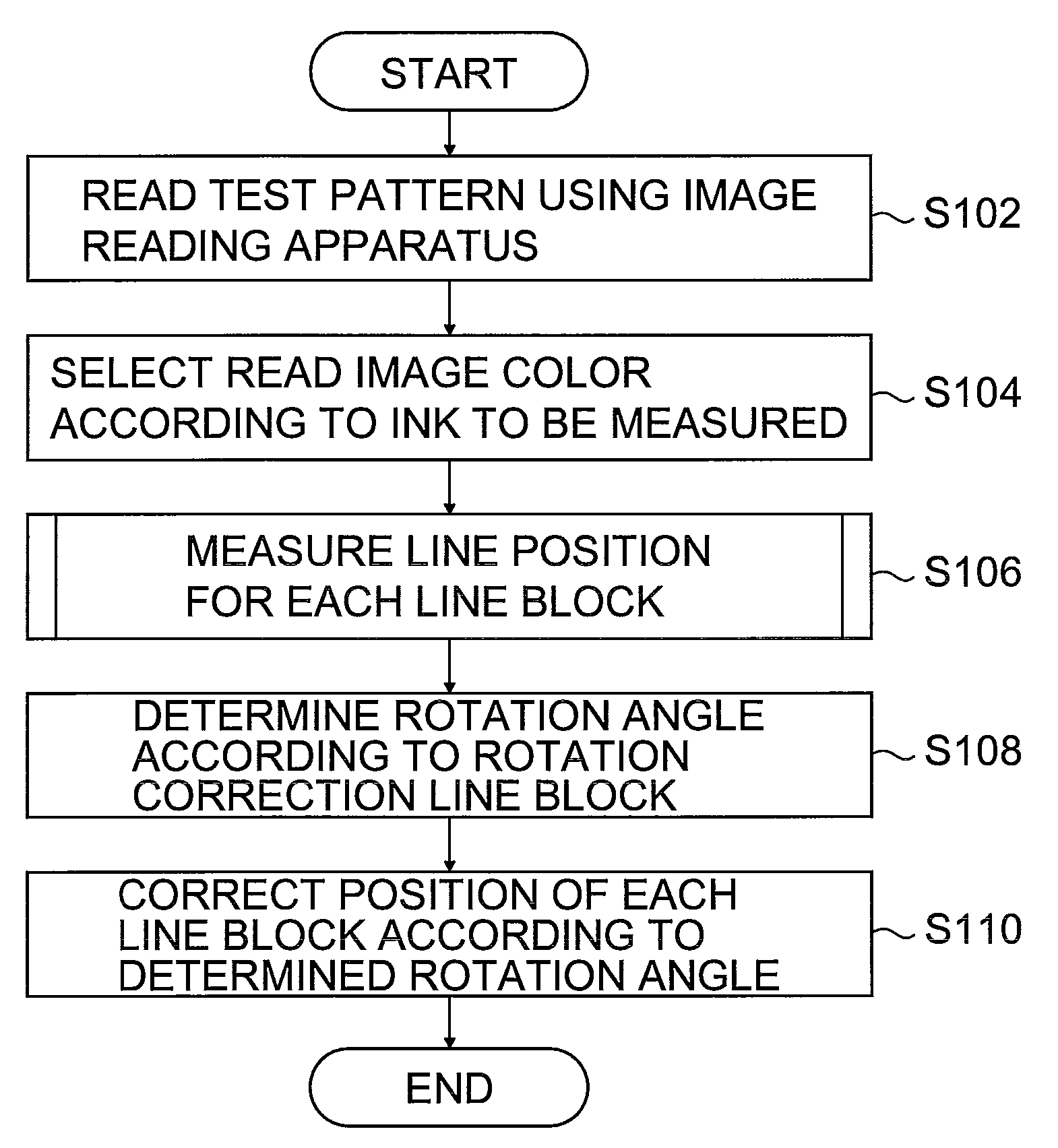

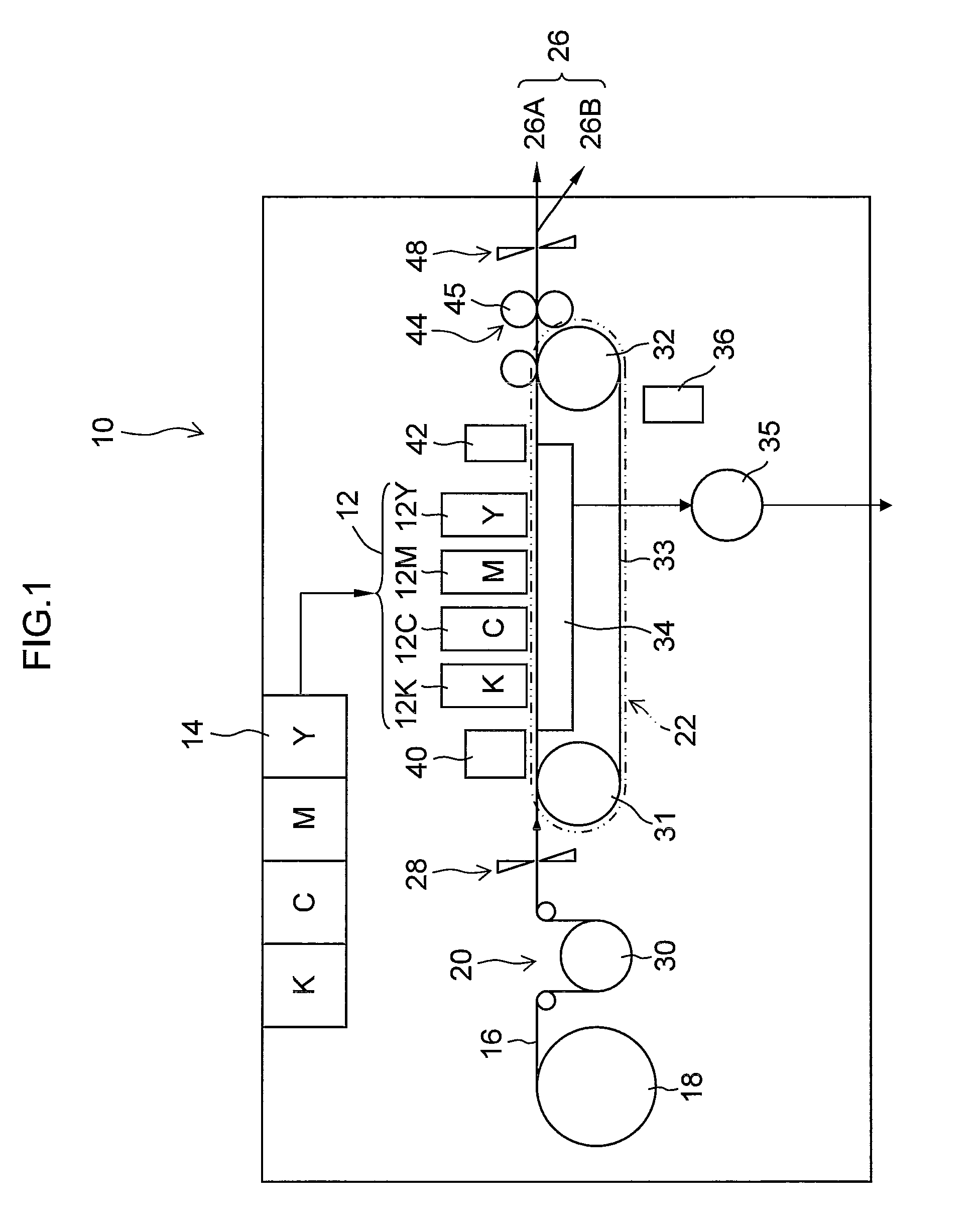

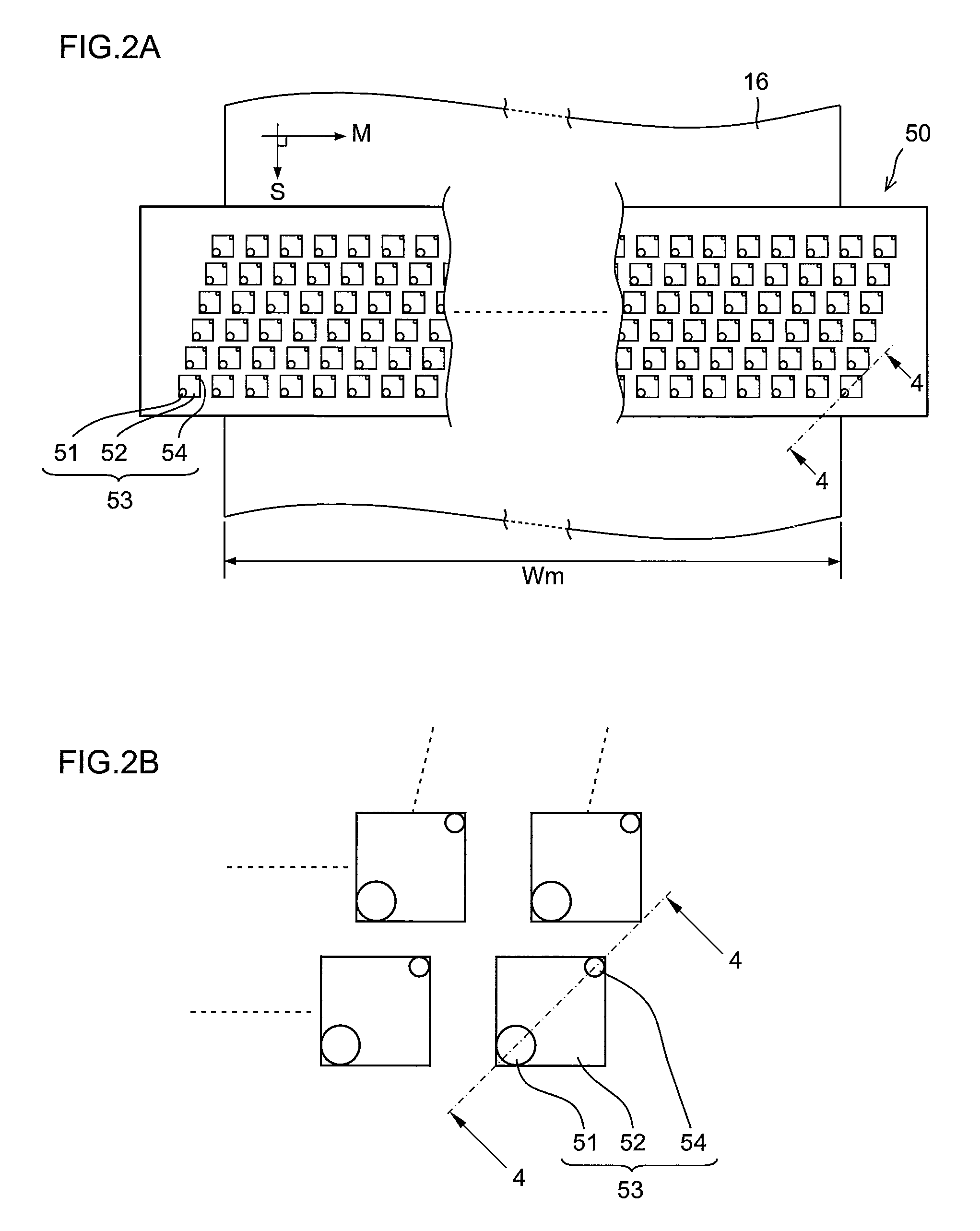

Dot position measurement method, dot position measurement apparatus, and computer readable medium

InactiveUS20100079518A1Reduced measurement timeReduce resolutionOther printing apparatusLocation determinationImaging data

A dot position measurement method includes: a line pattern formation step of recording dots continuously by a plurality of recording elements of a recording head while performing relative movement between the recording head and a recording medium in such a manner that a measurement line pattern including a plurality of lines of rows of the dots respectively corresponding to the plurality of recording elements is formed on the recording medium; a reading step of reading the measurement line pattern formed on the recording medium with an image reading apparatus in a state where a longitudinal direction of the plurality of lines of the measurement line pattern are directed to a sub-scanning direction of the image reading apparatus and a reading resolution in the sub-scanning direction of the image reading apparatus is lower than a reading resolution in a main scanning direction of the image reading apparatus in such a manner that an electronic image data indicating a read image of the measurement line pattern is acquired; a region allocating step of allocating a plurality of averaging regions where an image signal on the read image is averaged in terms of the sub-scanning direction, to different positions in terms of the sub-scanning direction of each of line blocks, each line block including the lines arranged in the main scanning direction; an average profile image forming step of averaging the image signal in terms of the sub-scanning direction in each of the plurality of averaging regions that have been allocated to the different positions and creating average profile images for positions in terms of the main scanning direction; an edge position determination step of determining positions of both edges of each of the lines according to the average profile images; an averaging region position determination step of determining positions of the lines in the plurality of averaging regions according to the positions of the both edges determined in the edge position determination step; and a line block position determination step of determining positions of the lines in the line blocks according to the positions of the lines in the plurality of averaging regions determined according to the average profile images corresponding to the plurality averaging regions respectively.

Owner:FUJIFILM CORP

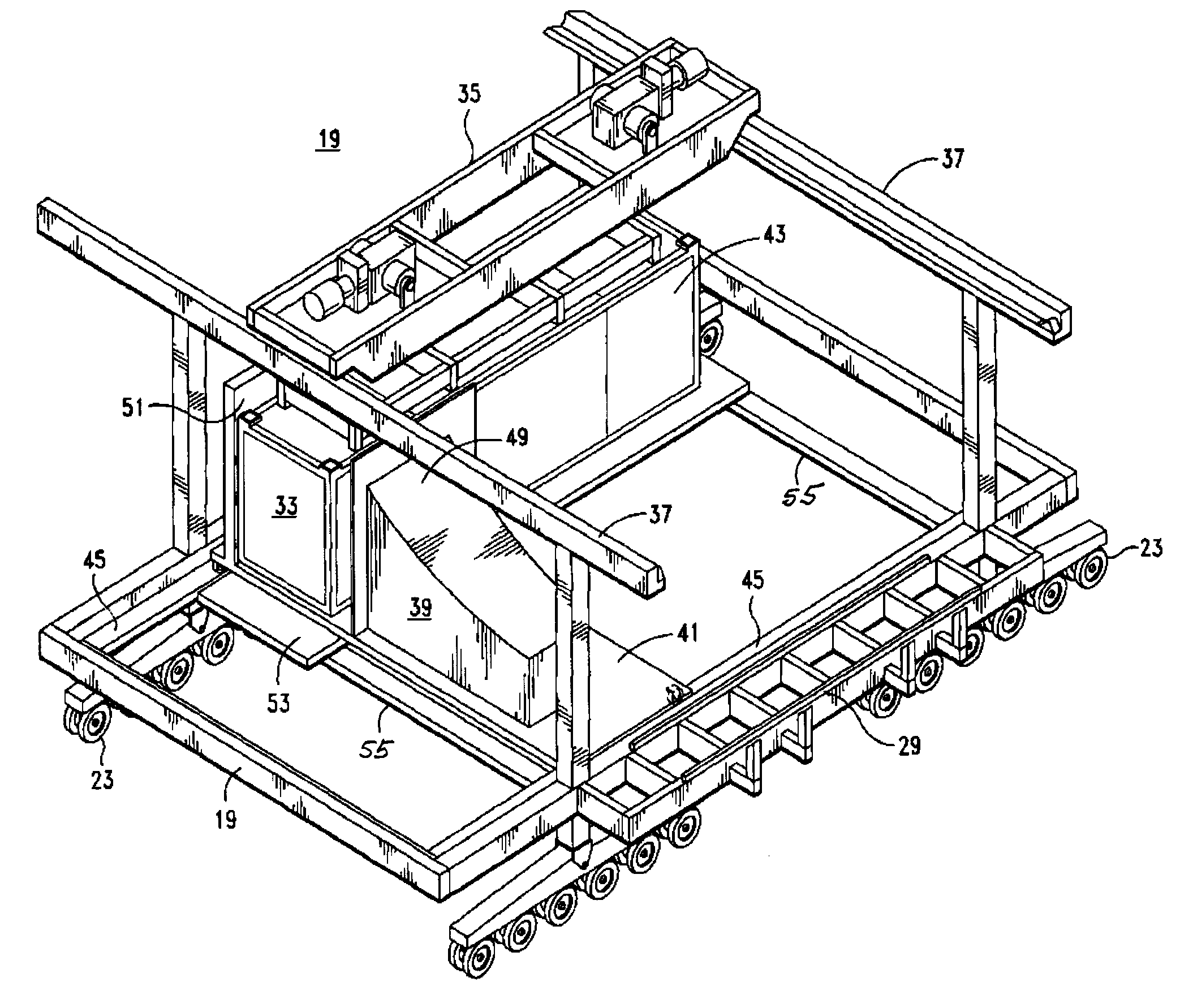

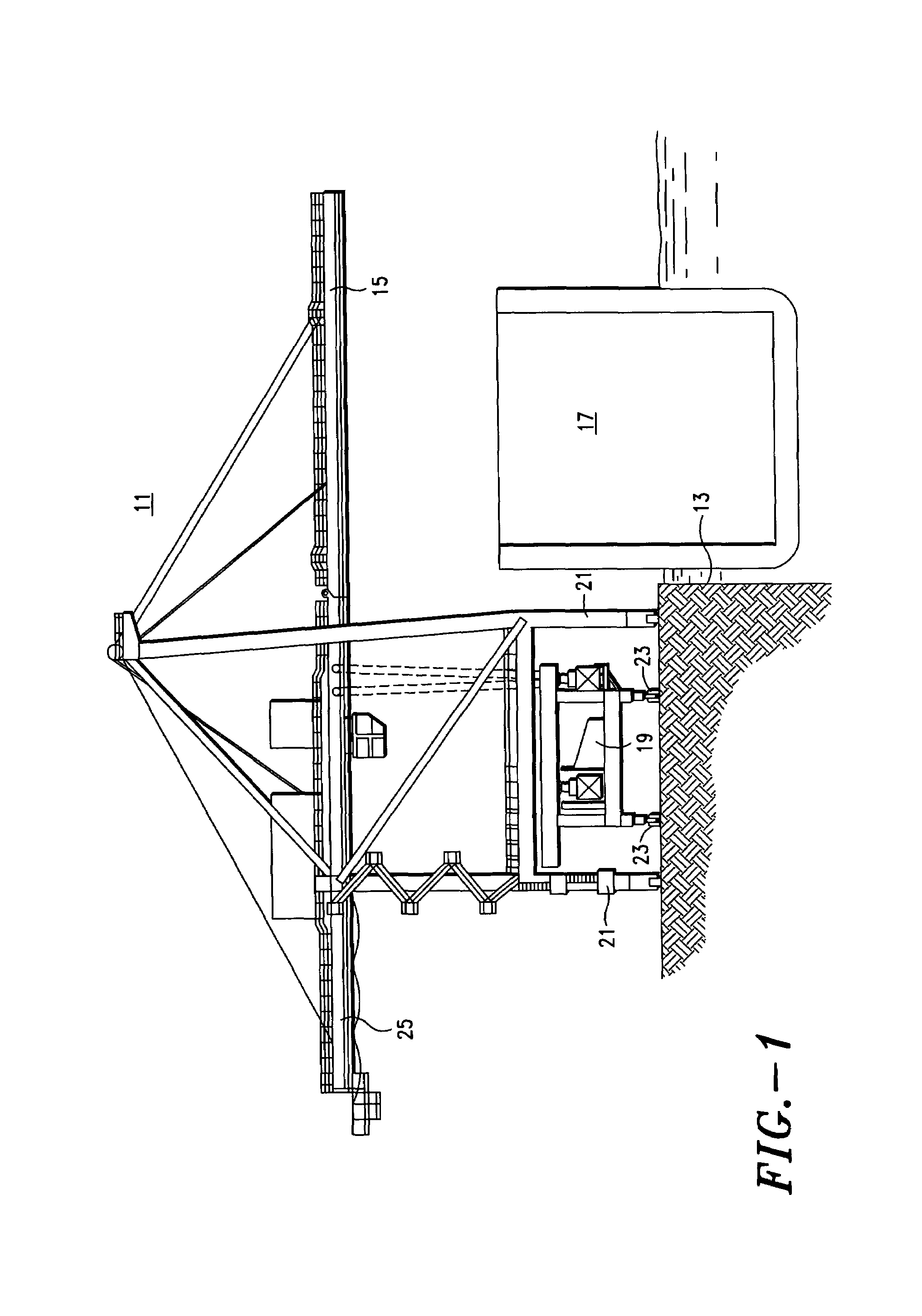

Mobile cargo container scanning buffer crane

InactiveUS7677857B2Easy to integrateFaster processing timeCargo handling apparatusBase supporting structuresEngineeringOverhead crane

A mobile cargo container handling buffer crane having a bridge crane mounted thereon for transferring cargo containers between a ship and land transportation with an intermediate transfer position at which a suspended container can be noninvasively inspected by a longitudinally reciprocating container traversing nonintrusive inspection apparatus.

Owner:PACECO

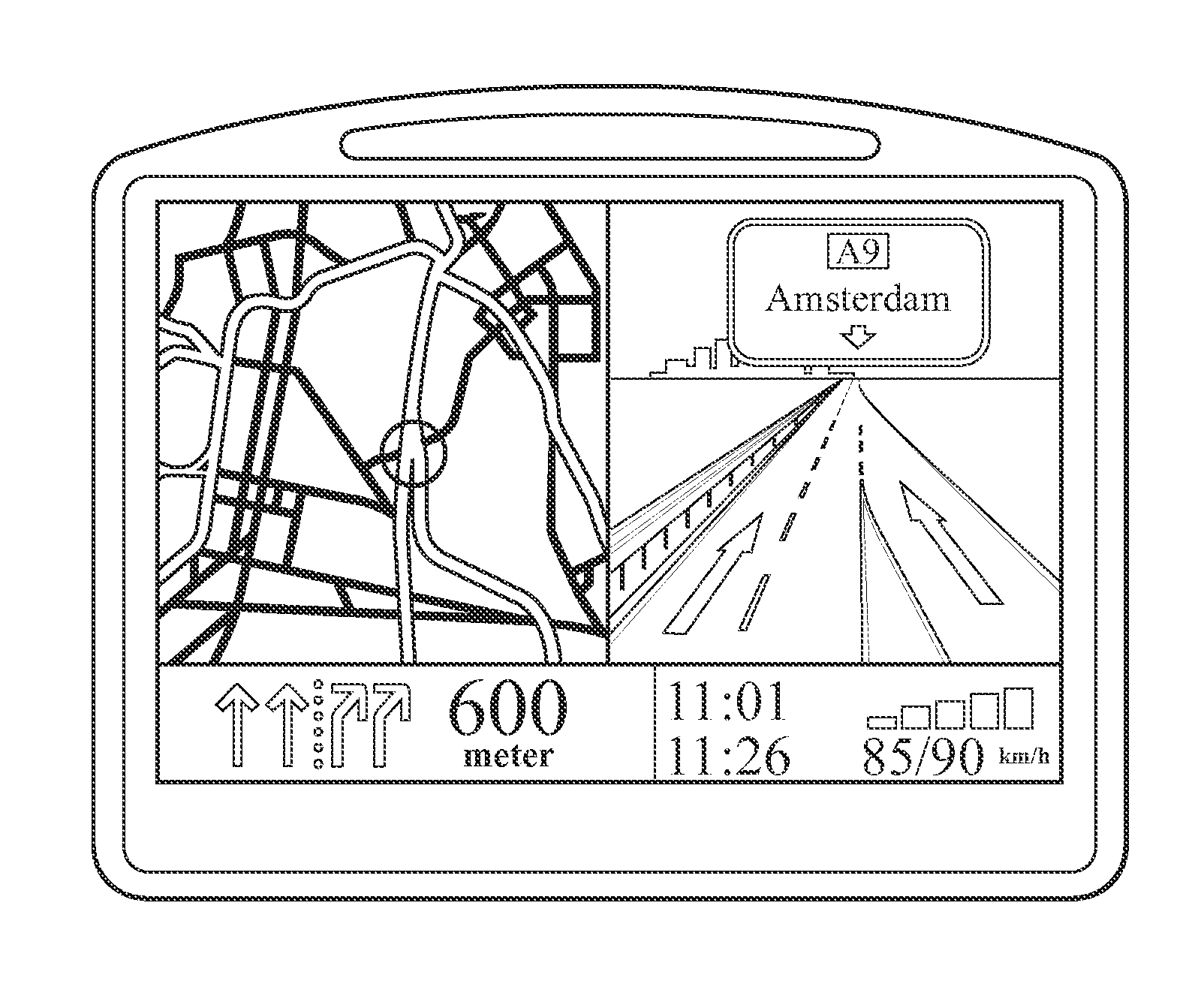

Seamless network generation

ActiveUS20140163875A1Faster processing timeAccelerate computationInstruments for road network navigationRoad vehicles traffic controlNetwork generationTechnical standard

A system and method for generating a seamless road network of a large geographical area includes a plurality of GPS probe traces extending across a geographical area. The probe traces are divided into sub-sets base on criteria, such as accuracy. A plurality of threads simultaneously employ the sub-sets traces to generate an independent network of the entire geographical area. The networks generated using sub-sets having a high accuracy are preferred over networks generating using sub-sets having a lower accuracy. The independent networks are combined to form a seamless networks of road segments.

Owner:TOMTOM GERMANY

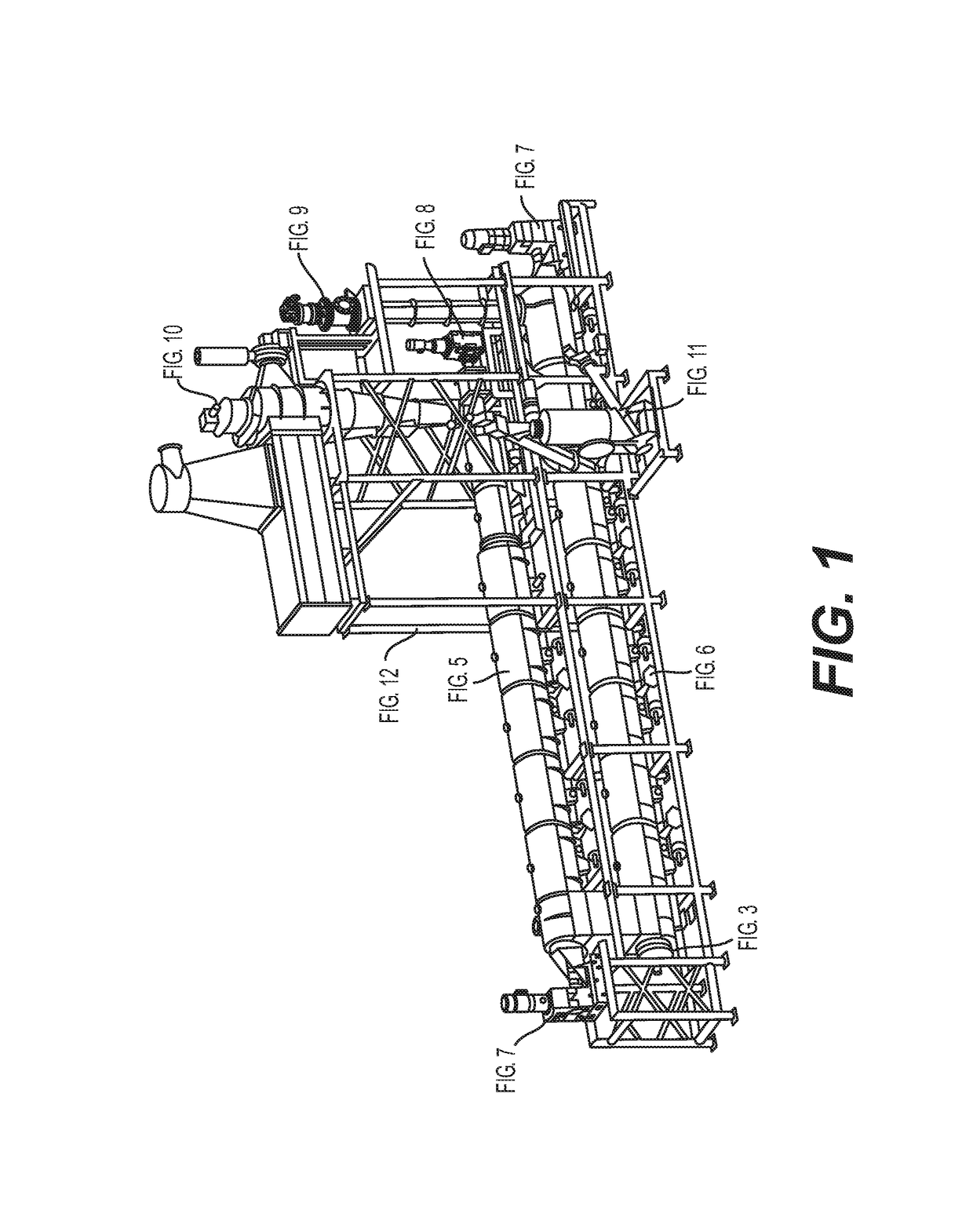

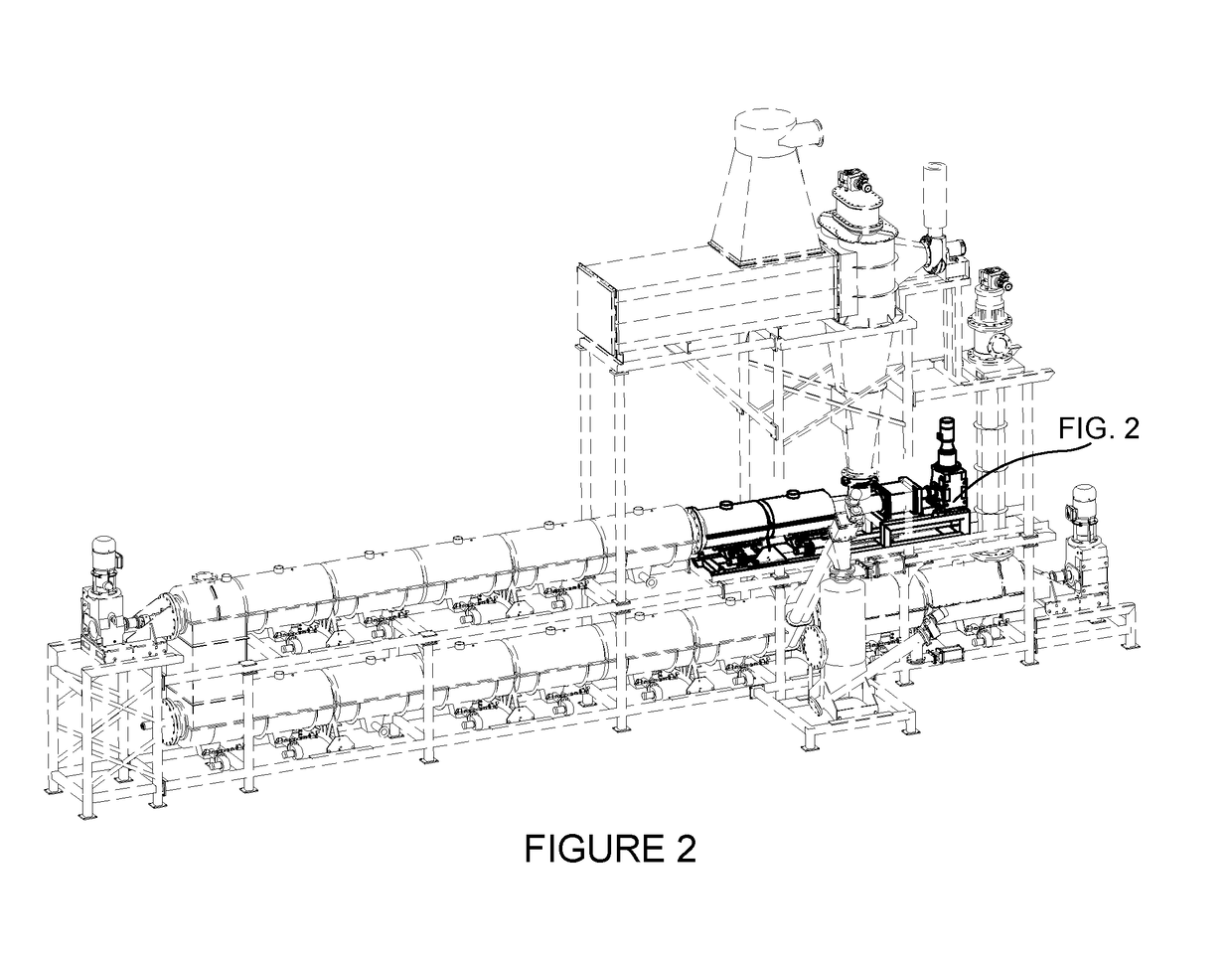

Heated airlock feeder unit

A Heated Airlock Feeder is disclosed. The Heated Airlock Feeder allows for the continuous feeding of solid, shredded plastic into a reactor tube surrounded by clamshell burner boxes. Inside of the reactor tube, two augers, one with right hand flights and one with left hand flights are welded to smooth augers to create two continuous augers that push solid plastic material, liquid plastic material and molten plastic material through two small holes. As the plastic is in its molten state while being forced through the two small holes, an airlock is formed preventing air form entering the system. As the solid, shredded plastic is fed into the system, an airlock is formed allowing for the continuous feeding of the system. The clamshell burner boxes allow for convection and radiant heat allowing for even, continuous heat.

Owner:GOLDEN RENEWABLE ENERGY LLC

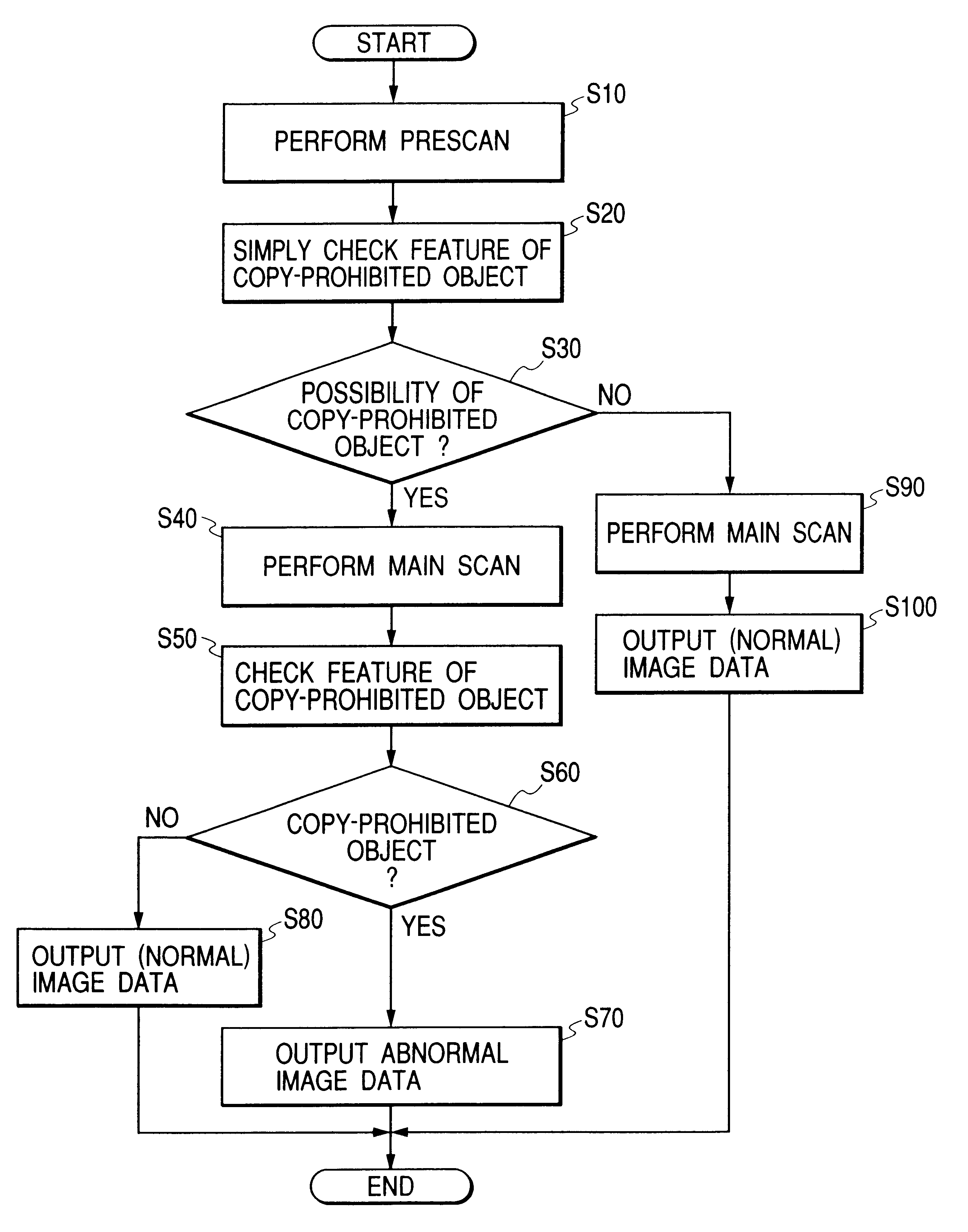

Image processing method, apparatus, and medium storing program for checking for copy-prohibited objects

InactiveUS6839146B1Faster processing timeEffective functionDigitally marking record carriersDigital computer detailsImage InspectionHigh density

A configuration is provided in which whether or not an article to be copied by a scanner is a copy-prohibited article such as a bill can be judged in a relatively short period of time. First, a copy object is prescanned by a scanner and read in rough pixel density, and with respect to the image, whether or not a copy object is a copy-prohibited article is checked. After completion of checking, main scanning is carried out to obtain a desired image of high density. As the result of the checking, the possibility that a copy object is a copy-prohibited article is examined, and when the possibility is low, said image of high density is output, and when the possibility is high, the image is checked again. As the result of checking, the possibility that a copy object is a copy-prohibited article is examined, and when the possibility is high, processing that the image is totally coated is carried out to output an unnormal image, and when the possibility is low, a normal image is output.

Owner:CANON KK

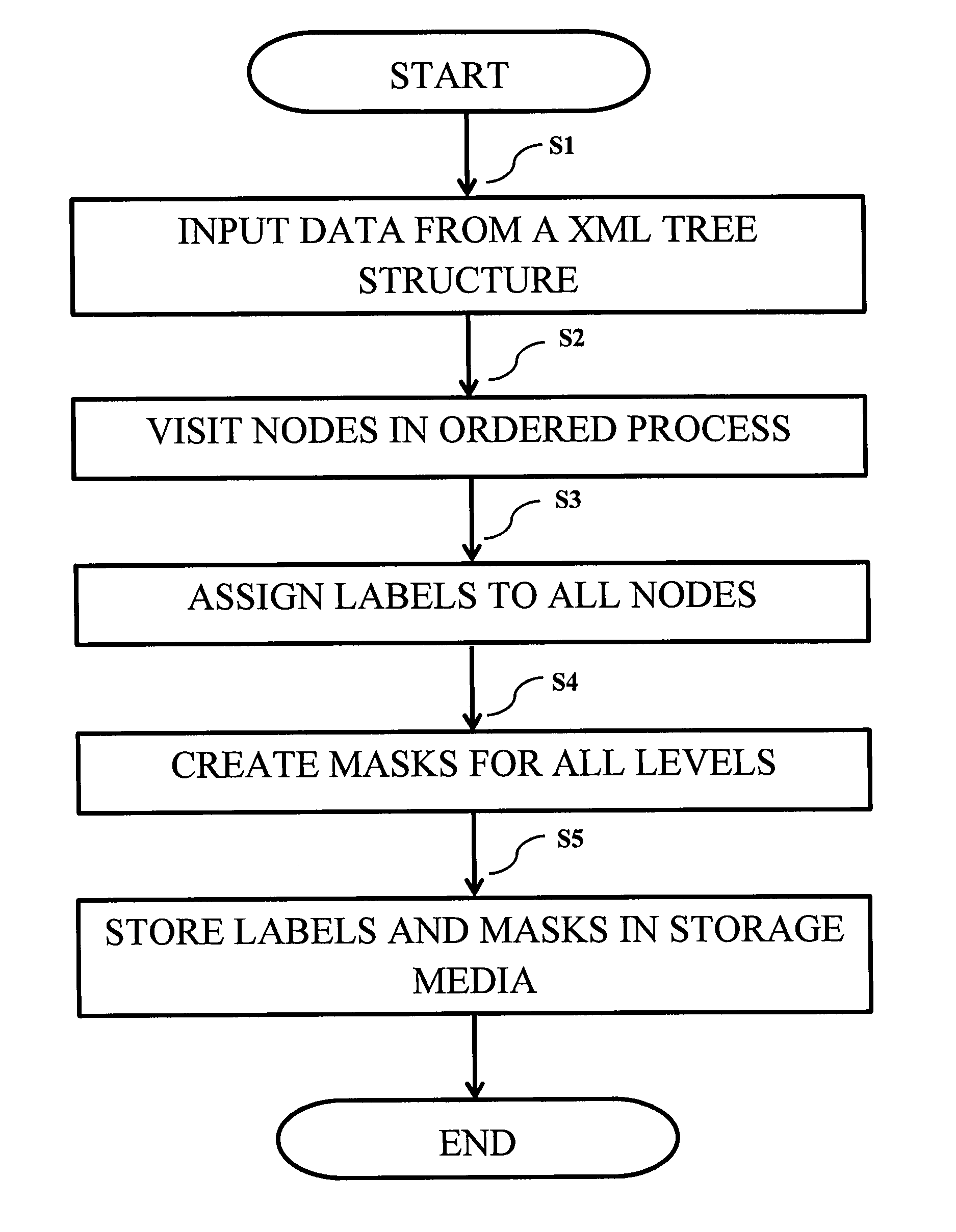

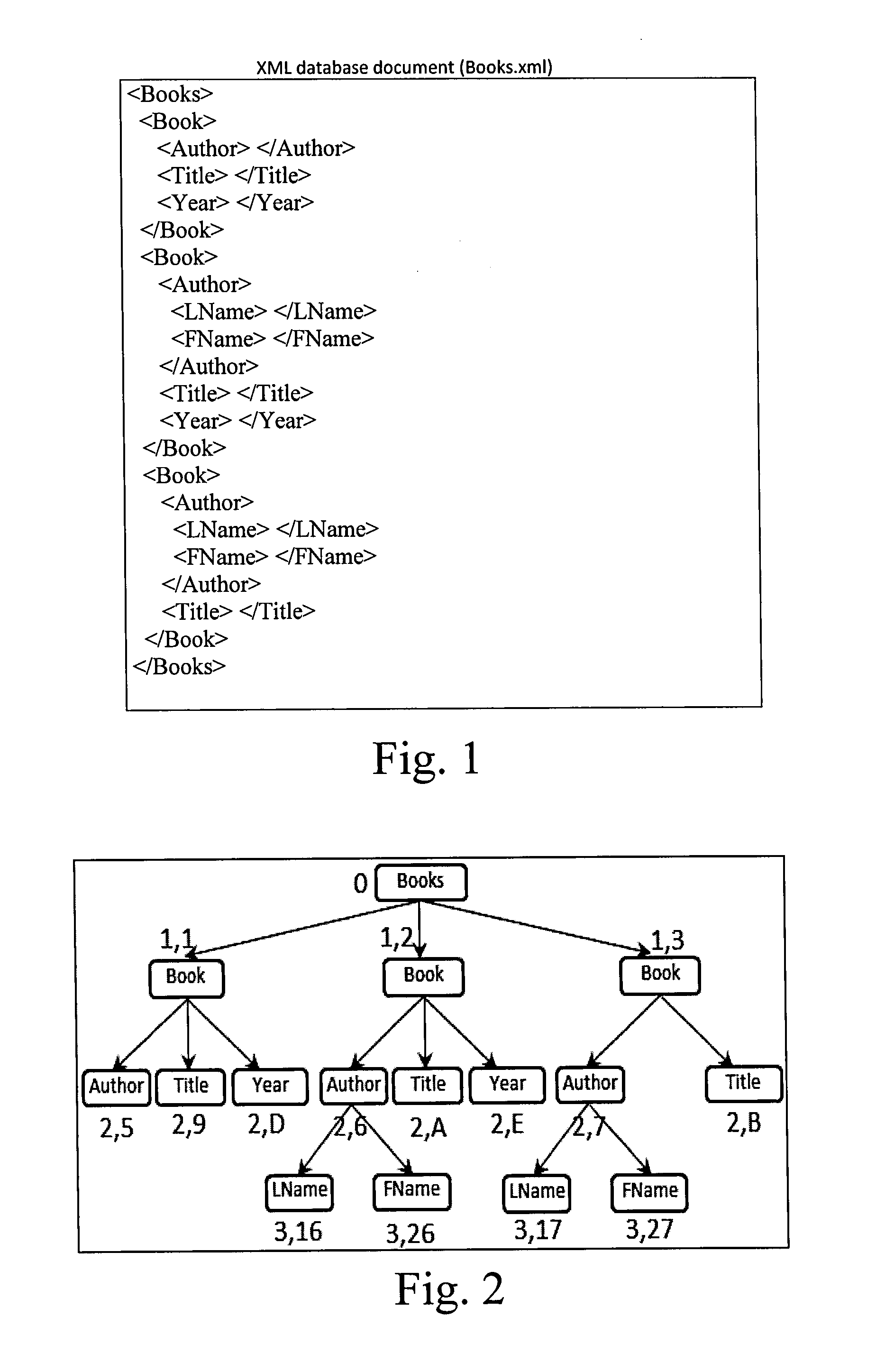

XML node labeling and querying using logical operators

InactiveUS20150213150A1Less storage requirementGuaranteed effective sizeWeb data indexingDigital data processing detailsLevel orderTheoretical computer science

A method includes labeling XML document and determining the relationship between the nodes in the document by inputting data from a XML tree structure, visiting the nodes of the XML document by breath-first traversal in level order, assigning a label to each node in the form of <Level, Number>, where the level is the level where the node exists and the number is a unique identifying number generated by using a masking technique, creating a mask for each level, and storing the label and mask created for each level in the memory. The method further includes determining the relationship between nodes by using logical operators.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

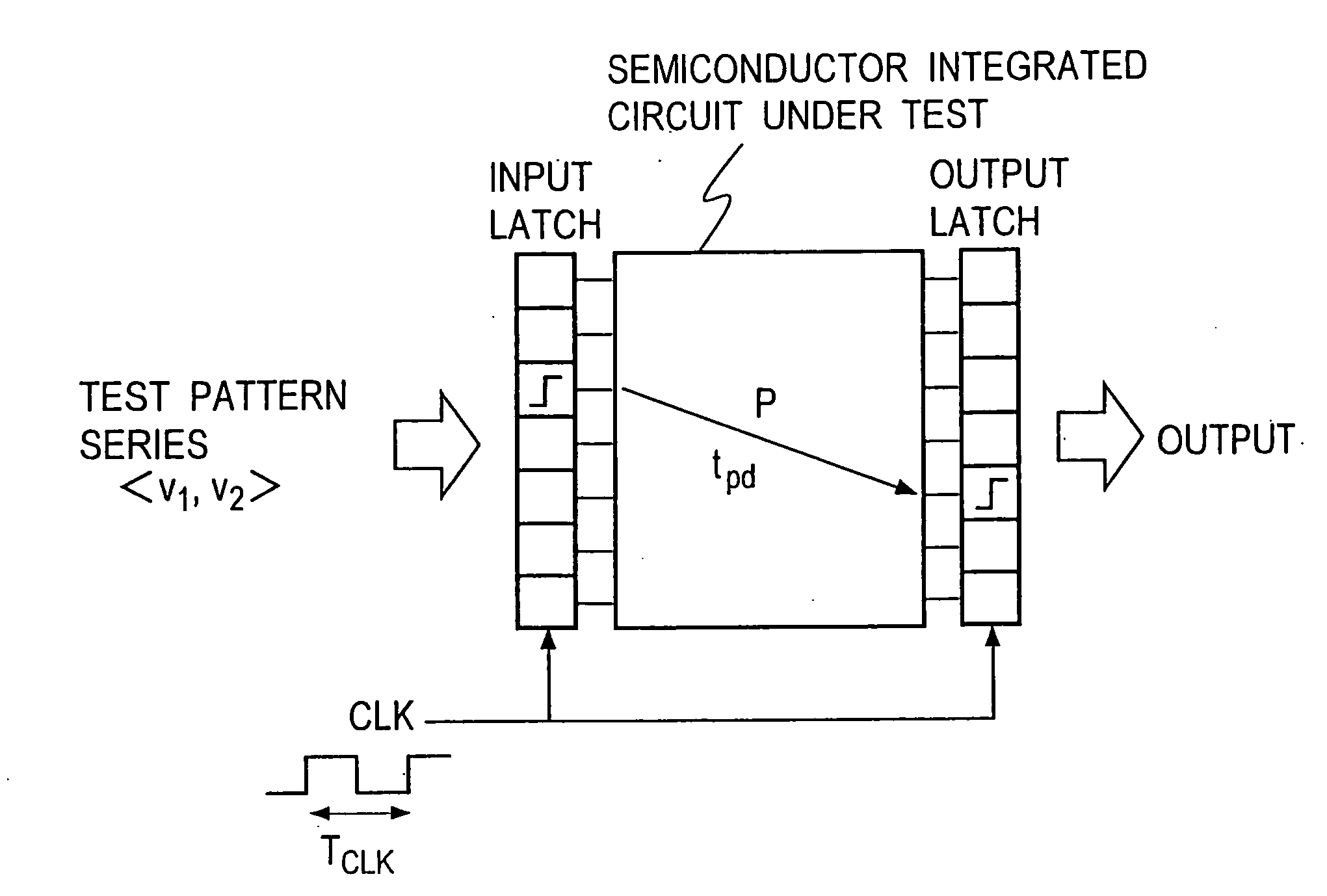

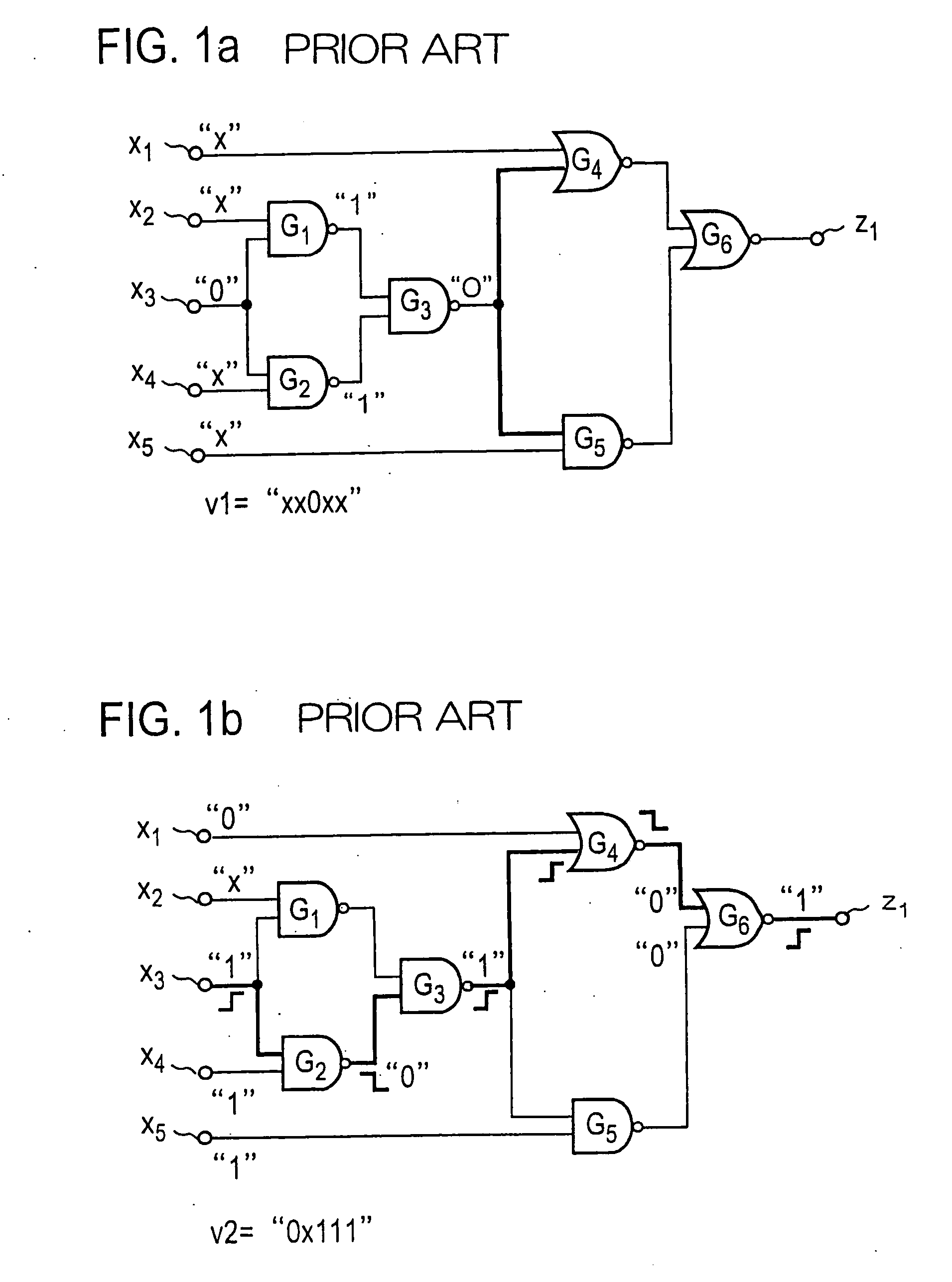

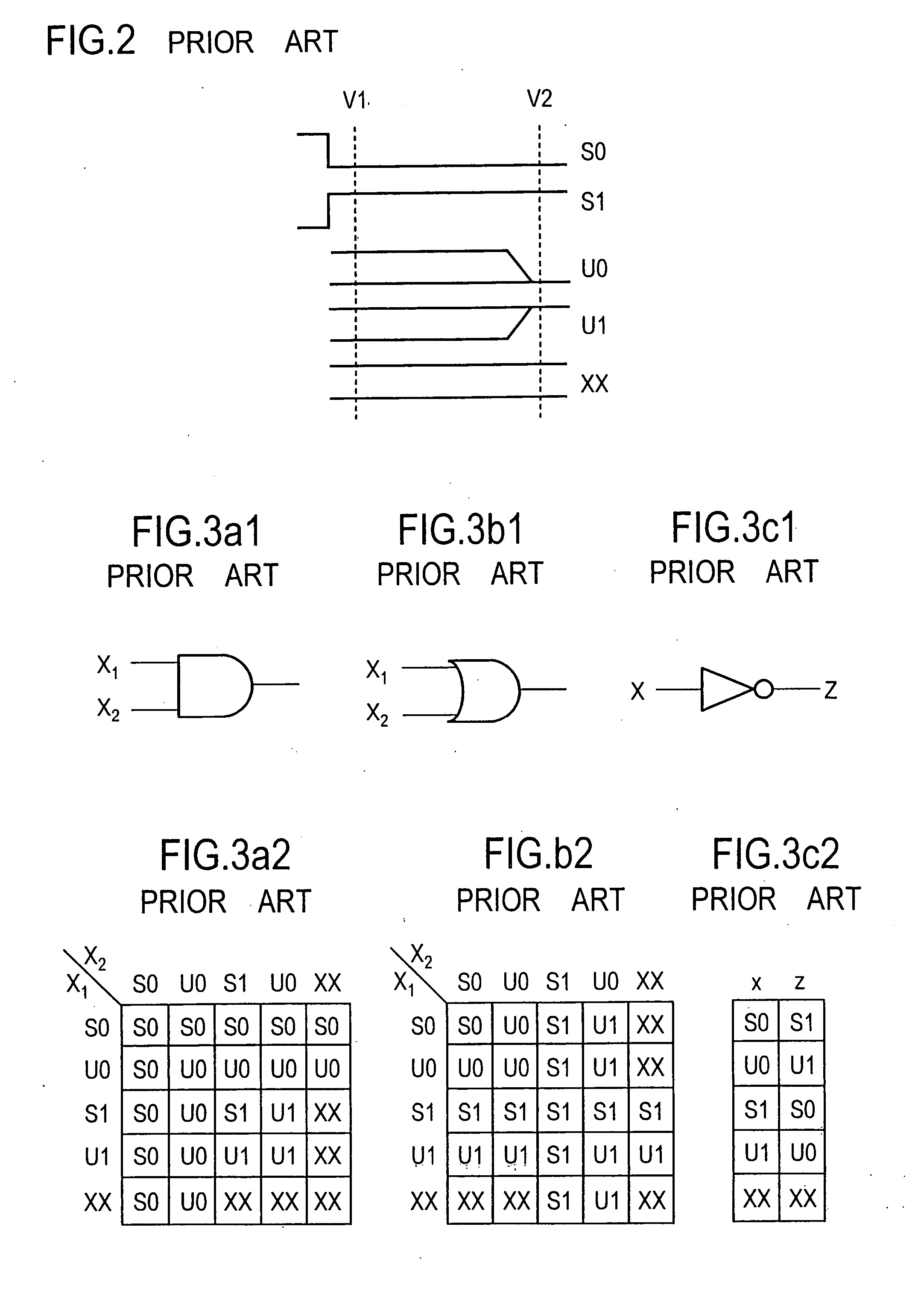

Generating test patterns used in testing semiconductor integrated circuit

InactiveUS20060041810A1Quick buildFaster processing timeDigital circuit testingError detection/correctionPattern sequenceInit

A test pattern sequence which is used to test a delay fault or an open fault which accompanies a delay occurring in an IC is easily and rapidly generated. A list of locations such as logic gates and signal lines within the circuit where a fault is likely to occur is prepared (101). One of the faults is selected, and an initialization test pattern v1 which establishes an initial value for activating the fault at the location of a fault is determined by the implication operation (103), and a propagation test pattern v2 which causes a stuck-at fault to be propagated to a following gate is determined by the implication operation (105). A sequence formed by v1 and v2 is registered with a test pattern list (107), and the described operations are repeated until there remains no unprocessed fault in the fault list.

Owner:ADVANTEST CORP

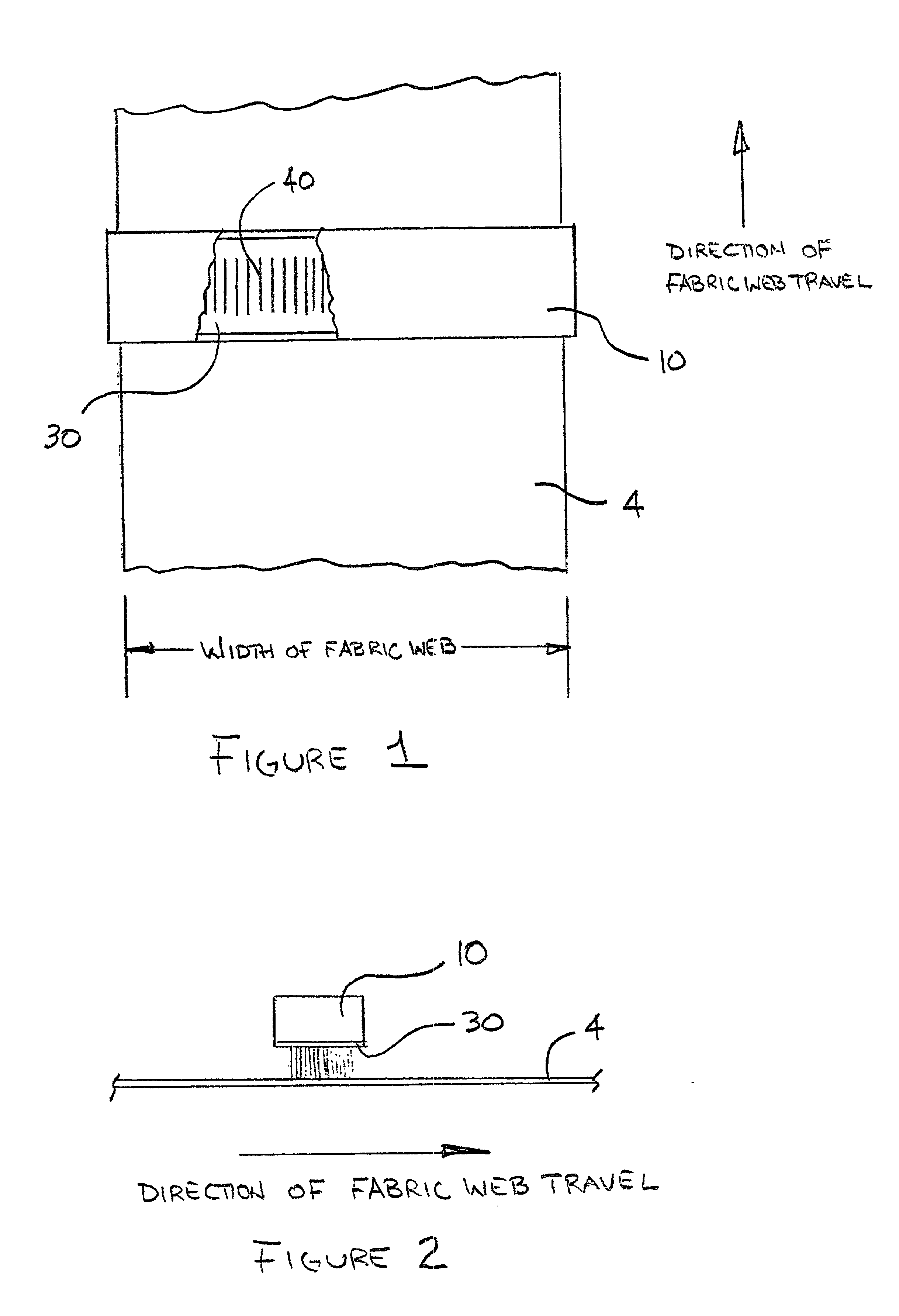

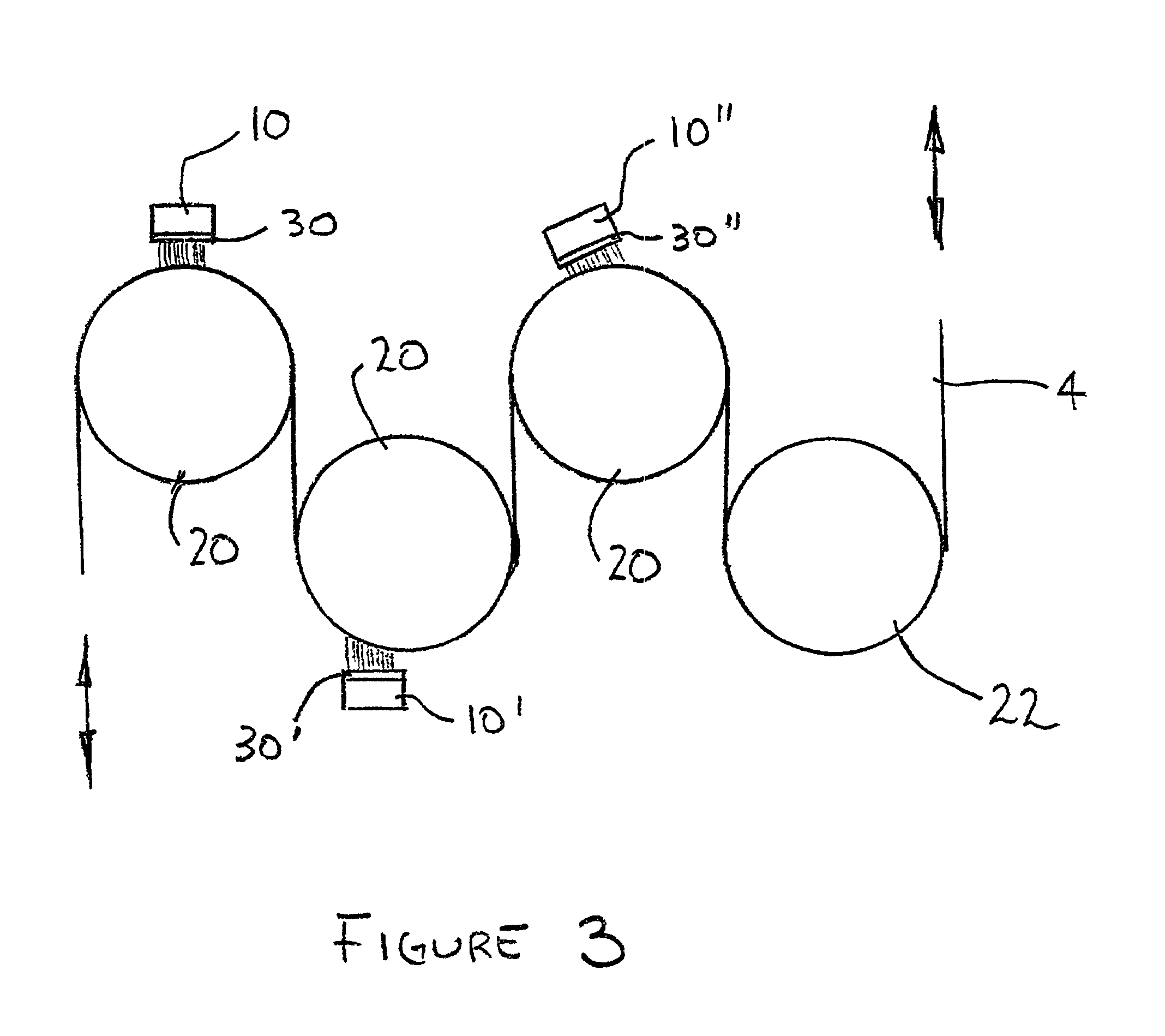

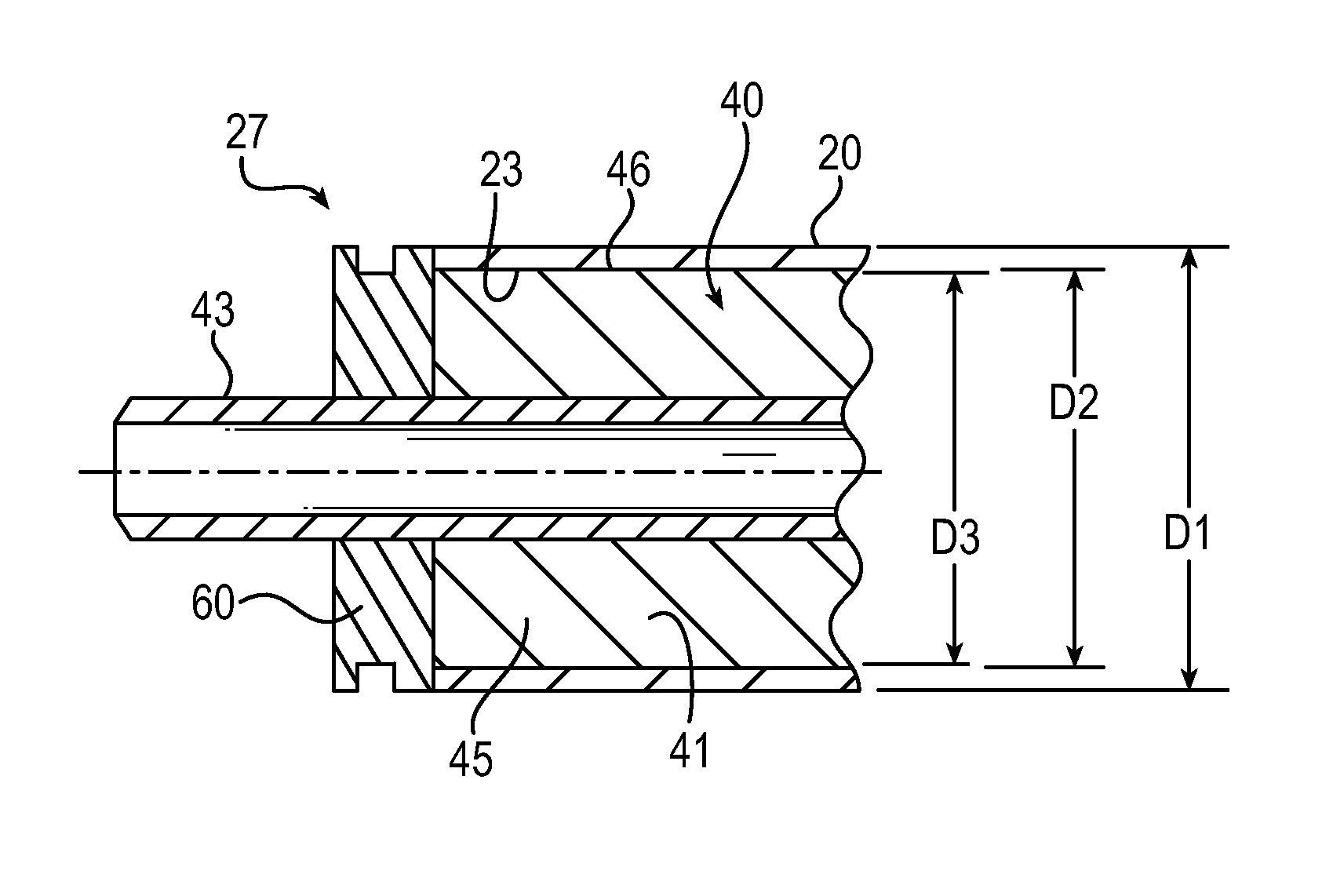

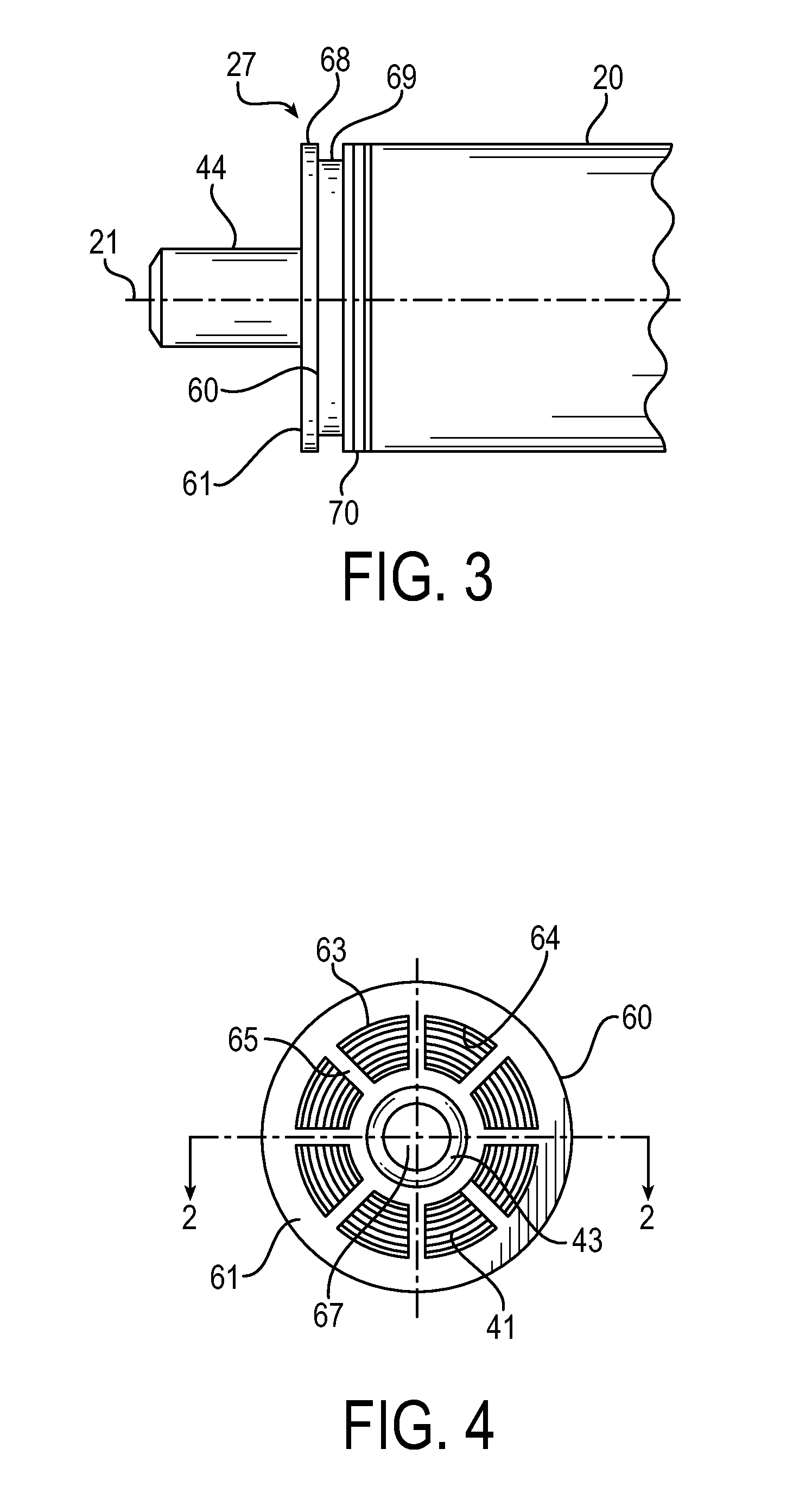

Method for hydroenhancing fabrics using a shaped orifice

InactiveUS6694581B2Improve energy efficiencyReduce in quantityPattern makingDrying machines with progressive movementsFiltrationEngineering

A method for hydroenhancing fabrics is described. The method uses the force of pressurized liquid passing through elongated orifices and impinging on the fabric. The pressurized liquid exits in a coherent or columnar fashion from elongated orifices that are generally rectangular or linear in shape. The elongated orifices can be arranged so as to produce various effects on a web of fabric, including striping, graduated shading and seer-suckering. The elongated orifices also facilitate the hydroenhancement of high-warp-count fabrics without streak or moire effects. Liquid filtration can be relaxed without clogging the orifices, because the elongated orifices permit larger solid objects to pass. The use of elongated orifices also enhances the energy efficiency of the hydroenhancement process.

Owner:TEXTILE ENHANCEMENTS INT

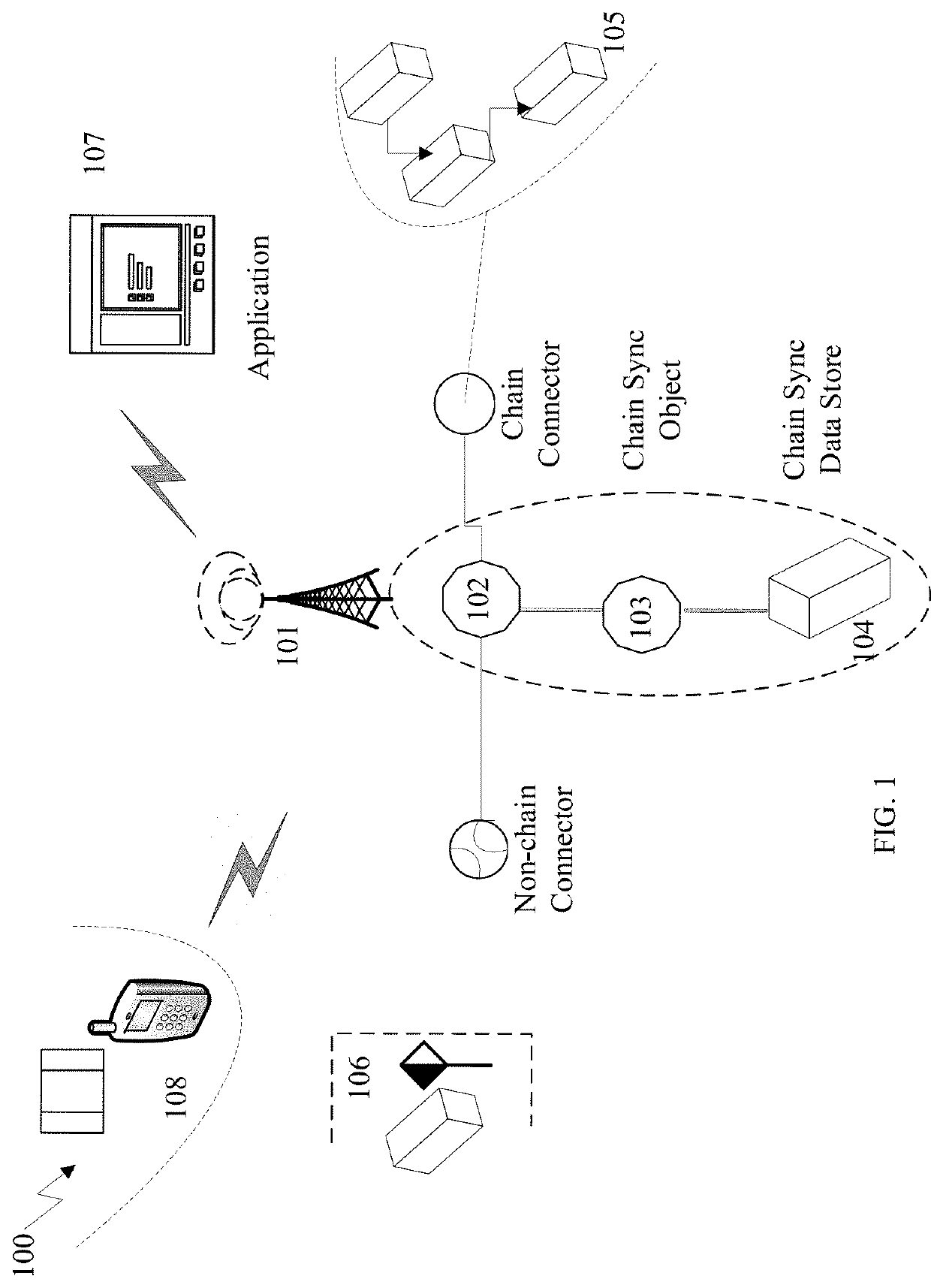

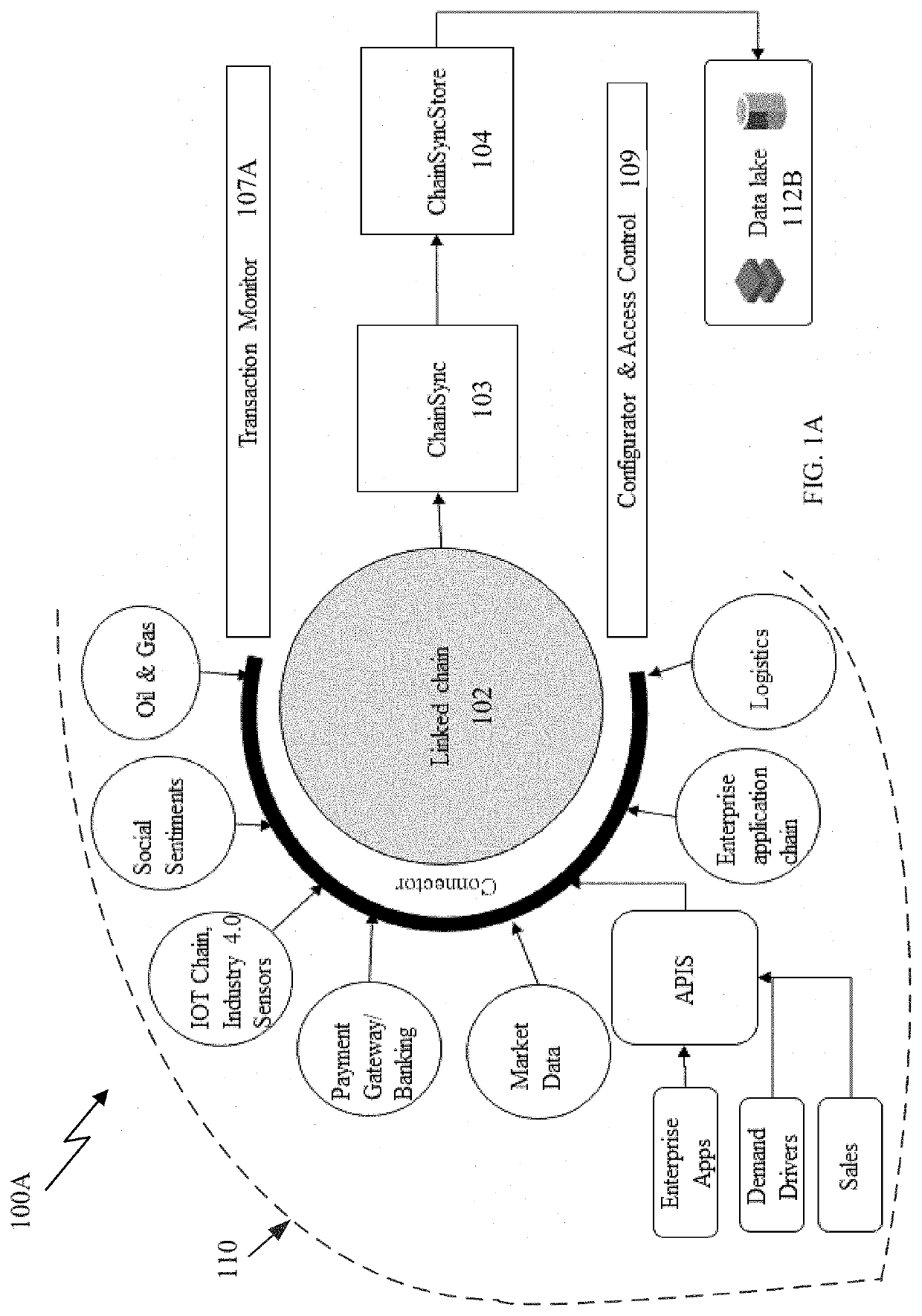

Linkedchain, control tower and blockchain for enterprise applications

PendingUS20210201236A1Correction errorAccurate flowCryptography processingDatabase distribution/replicationSoftware engineeringMechanical engineering

The present invention provides linkedchain, control tower and blockchain for one or more enterprise applications. The system includes a linked chain within a control tower configured to connect with blockchain and non-blockchain based entity systems.

Owner:NB VENTURES INC DBA GEP

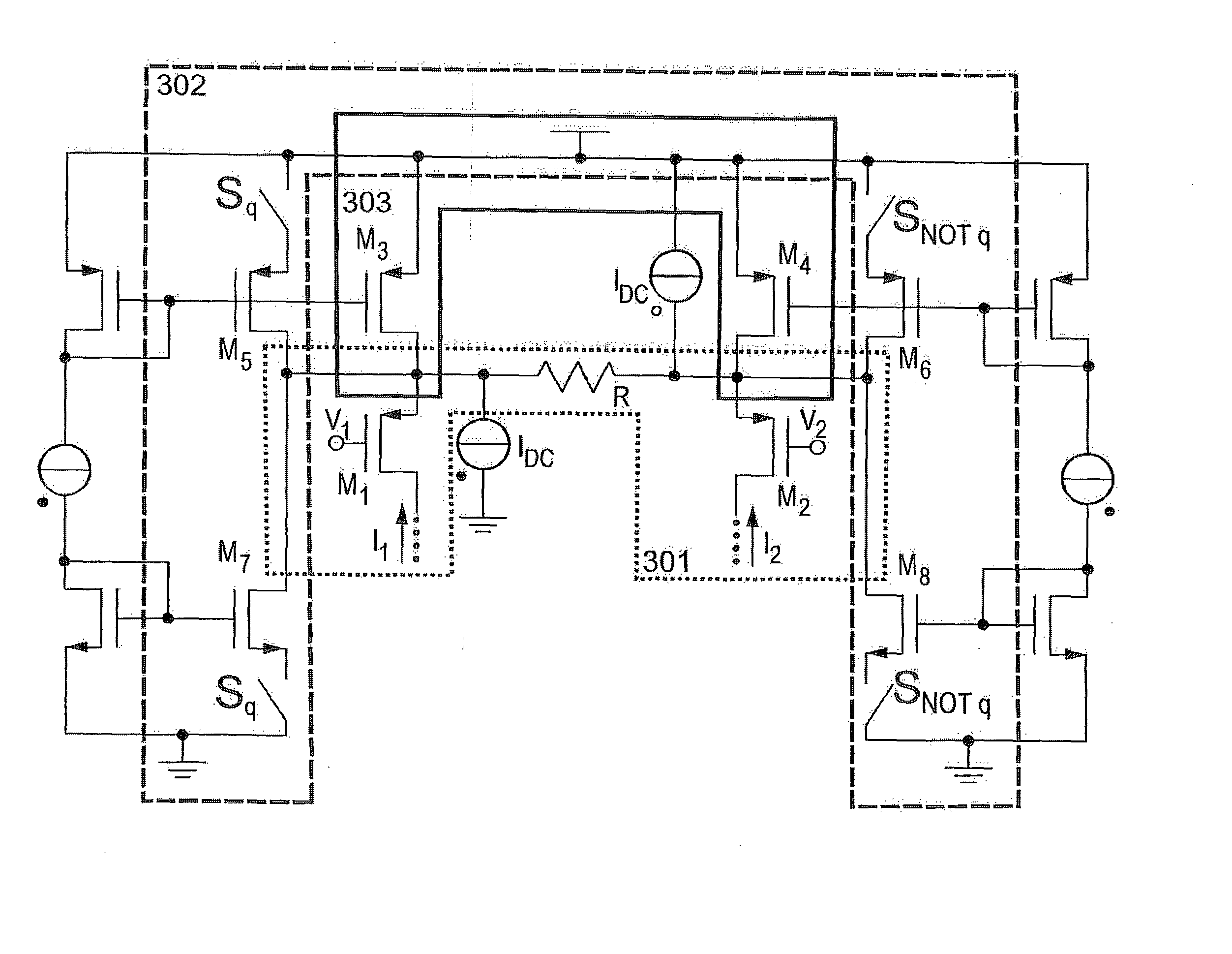

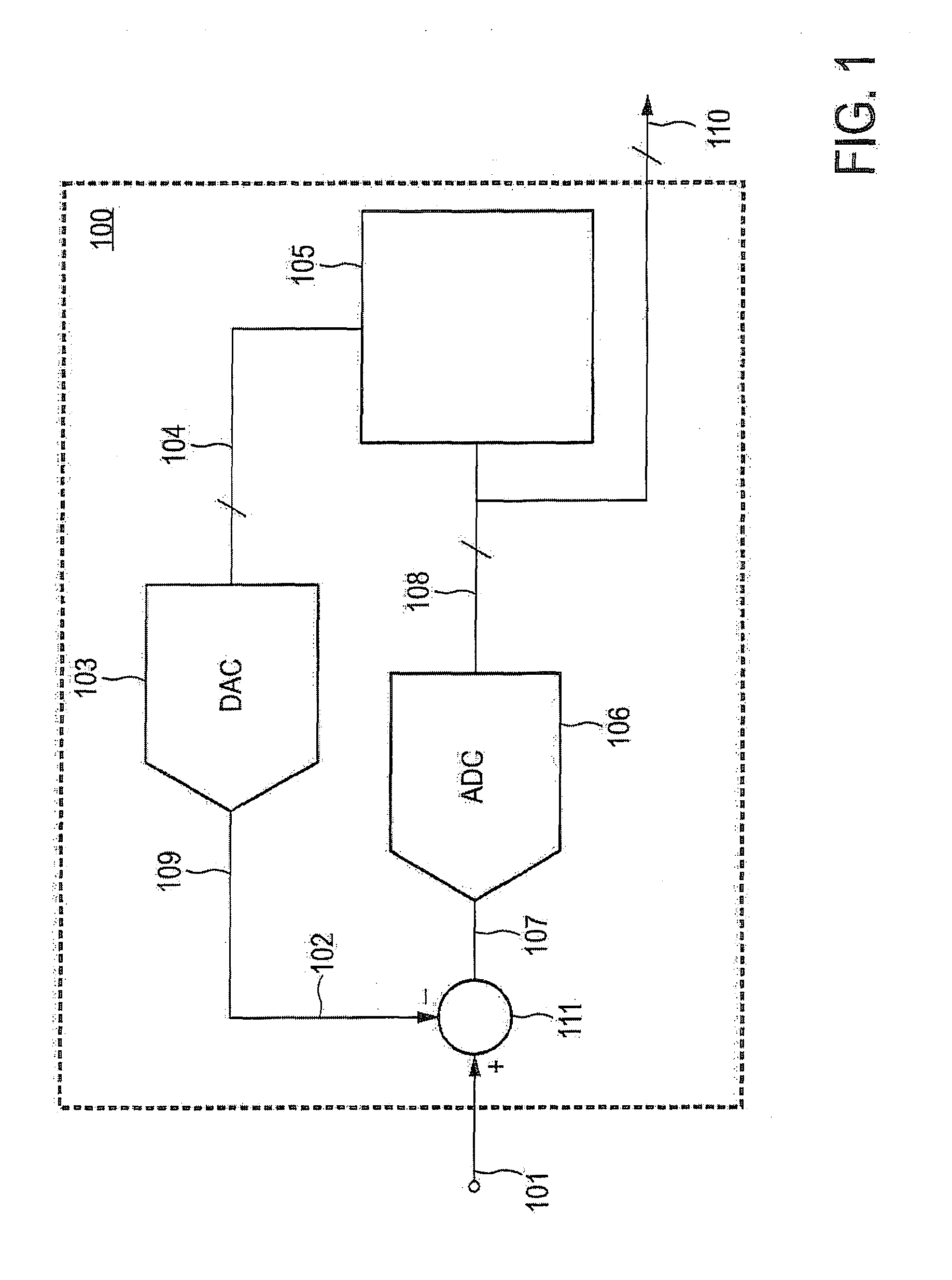

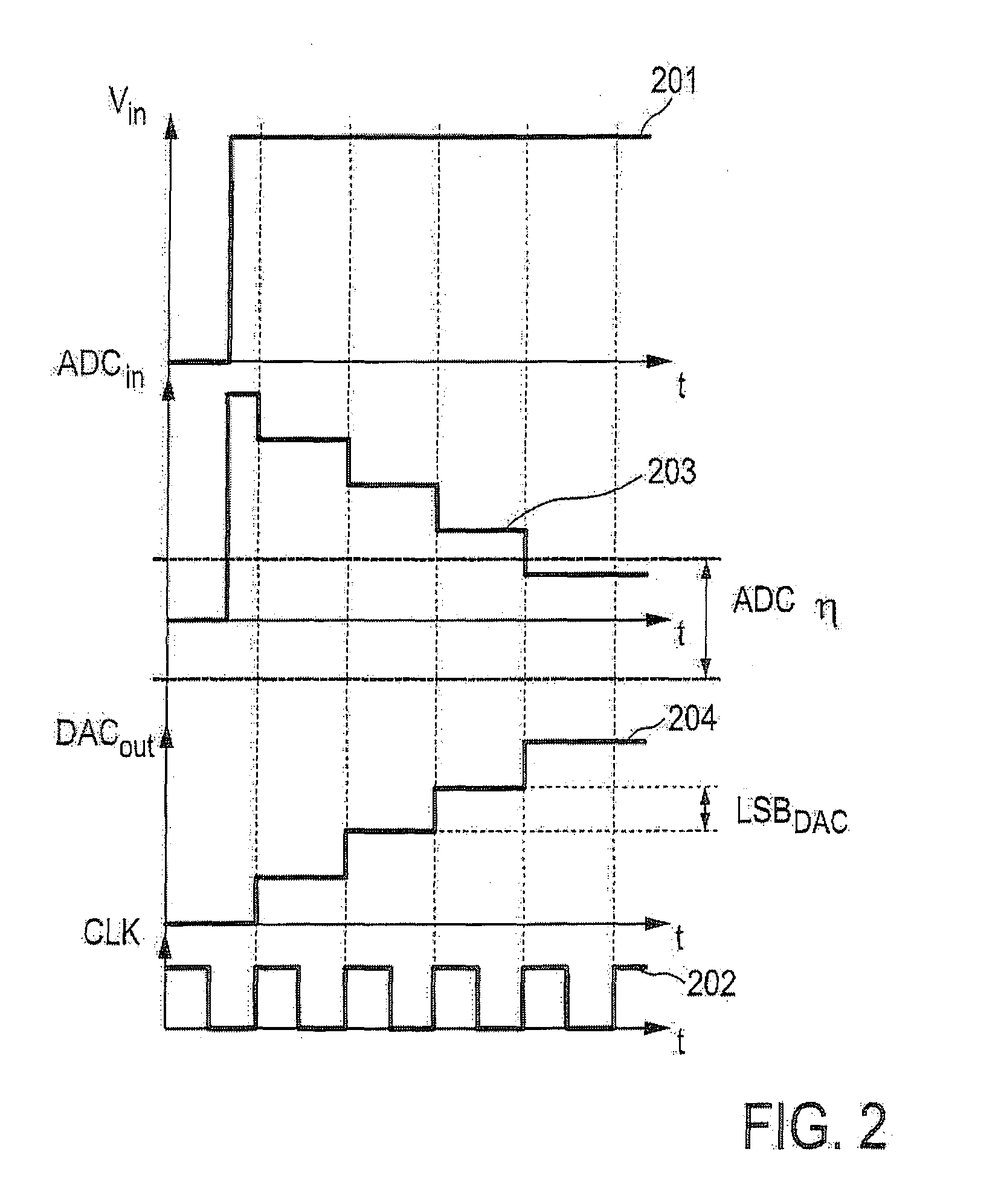

Automatic common-mode rejection calibration

ActiveUS20100201551A1Improve balanceImproved CMRRElectric signal transmission systemsAnalogue conversionDigital analog converterOperation point

The present invention relates to a circuit and a method for automatic common-mode rejection calibration in a differential conversion system and unbalance compensation for balancing the operation point of a circuit in the signal path and for enhancing the common-mode rejection. The circuit for automatic common-mode rejection calibration in a differential conversion system comprises an analog input stage for an analog input signal (101), an analog-digital-converter (106) for converting an analog signal (107) into its digital representation (108), a digital block (105) arranged to adapt said digital representation (108) of a portion of a DC offset of said analog input signal (101) in accordance with whether said analog input signal (101) is in a predetermined input range of said analog-digital-converter (106), and a digital-analog-converter (103) arranged in a feedback path (102) from said digital block (105) to subtraction means (111) of said analog input stage for converting a digital signal (104) into an analog output signal (109), wherein said analog output signal (109) is subtracted from said analog input signal (101) resulting in said analog signal (107).

Owner:NXP BV

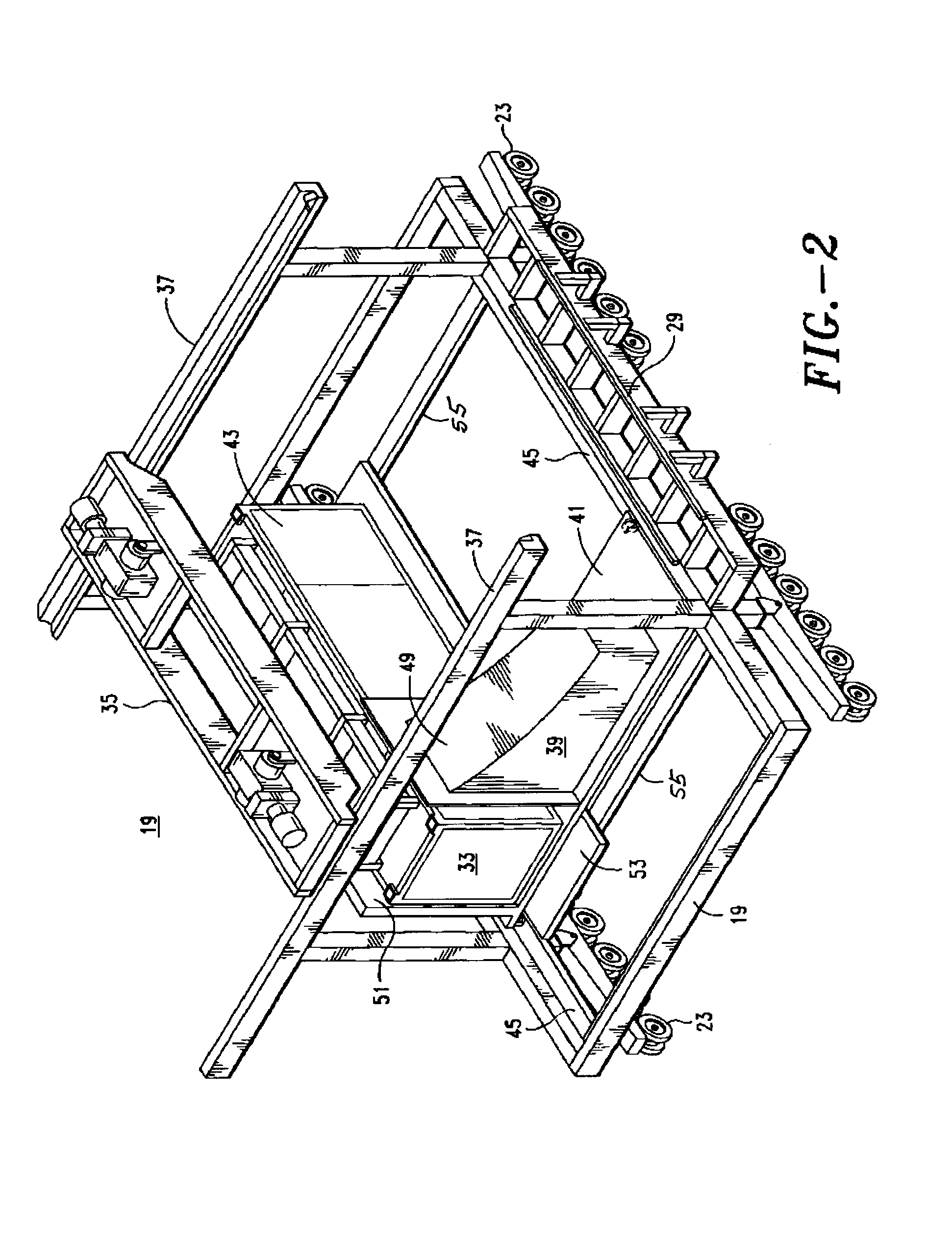

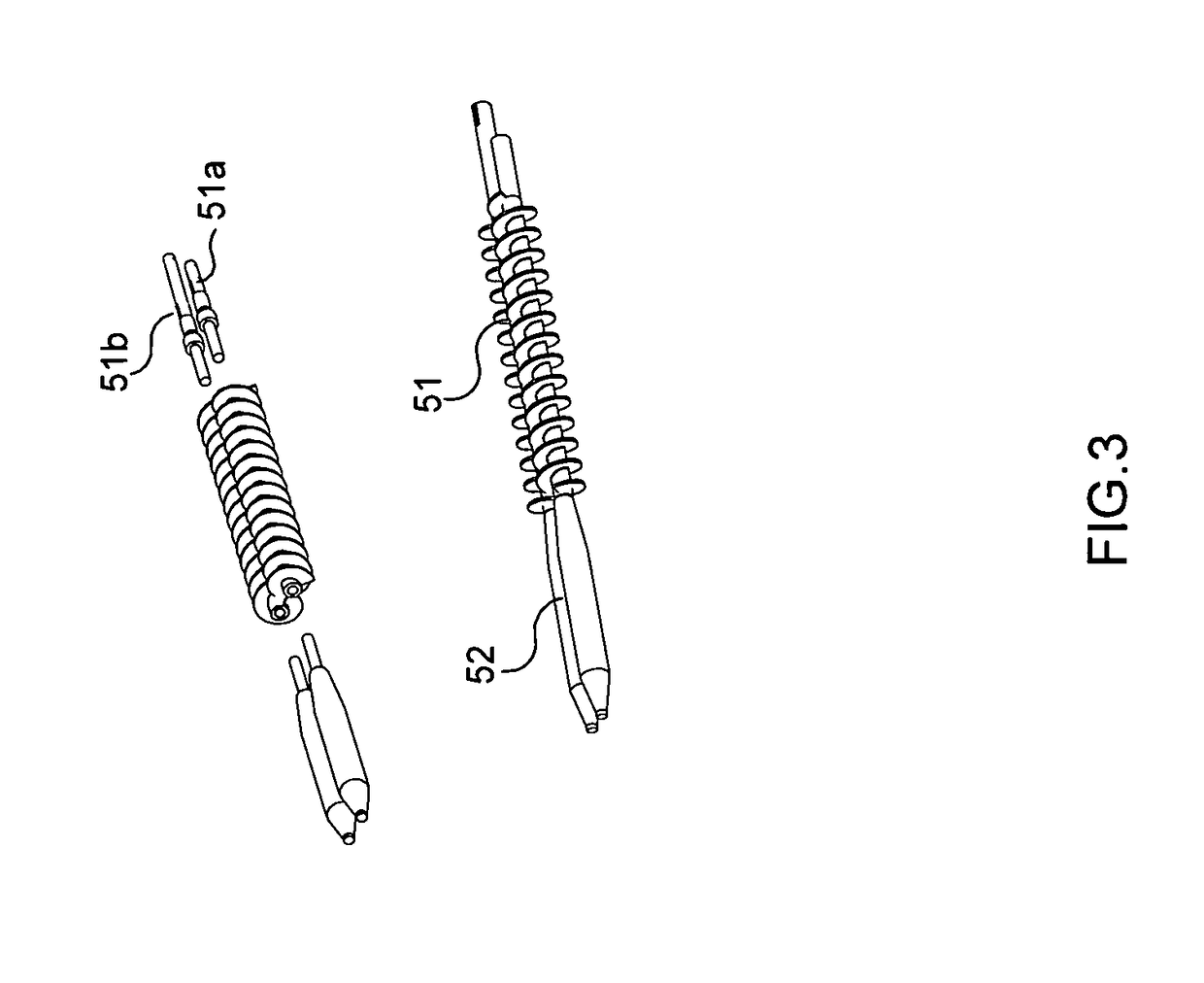

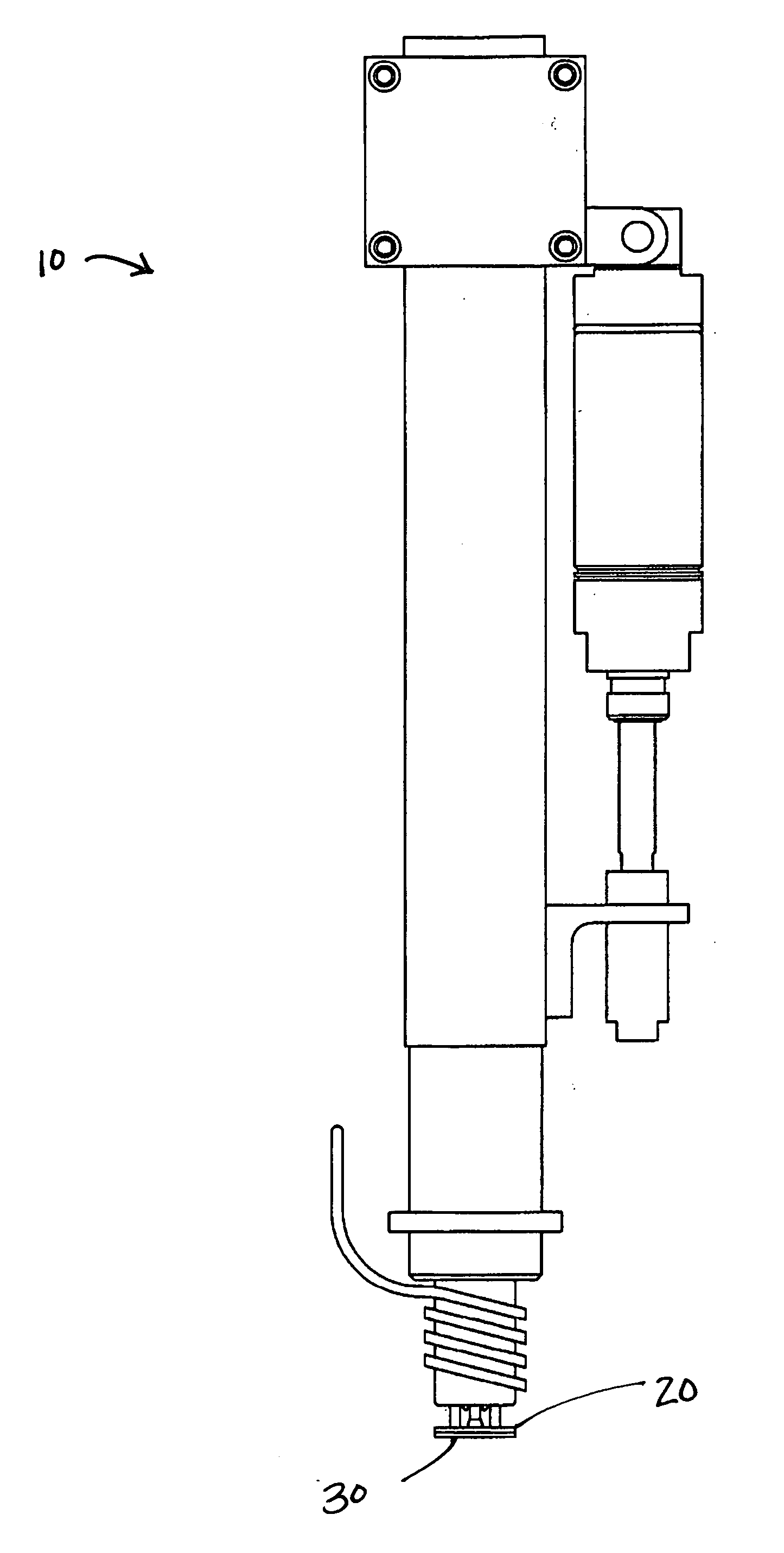

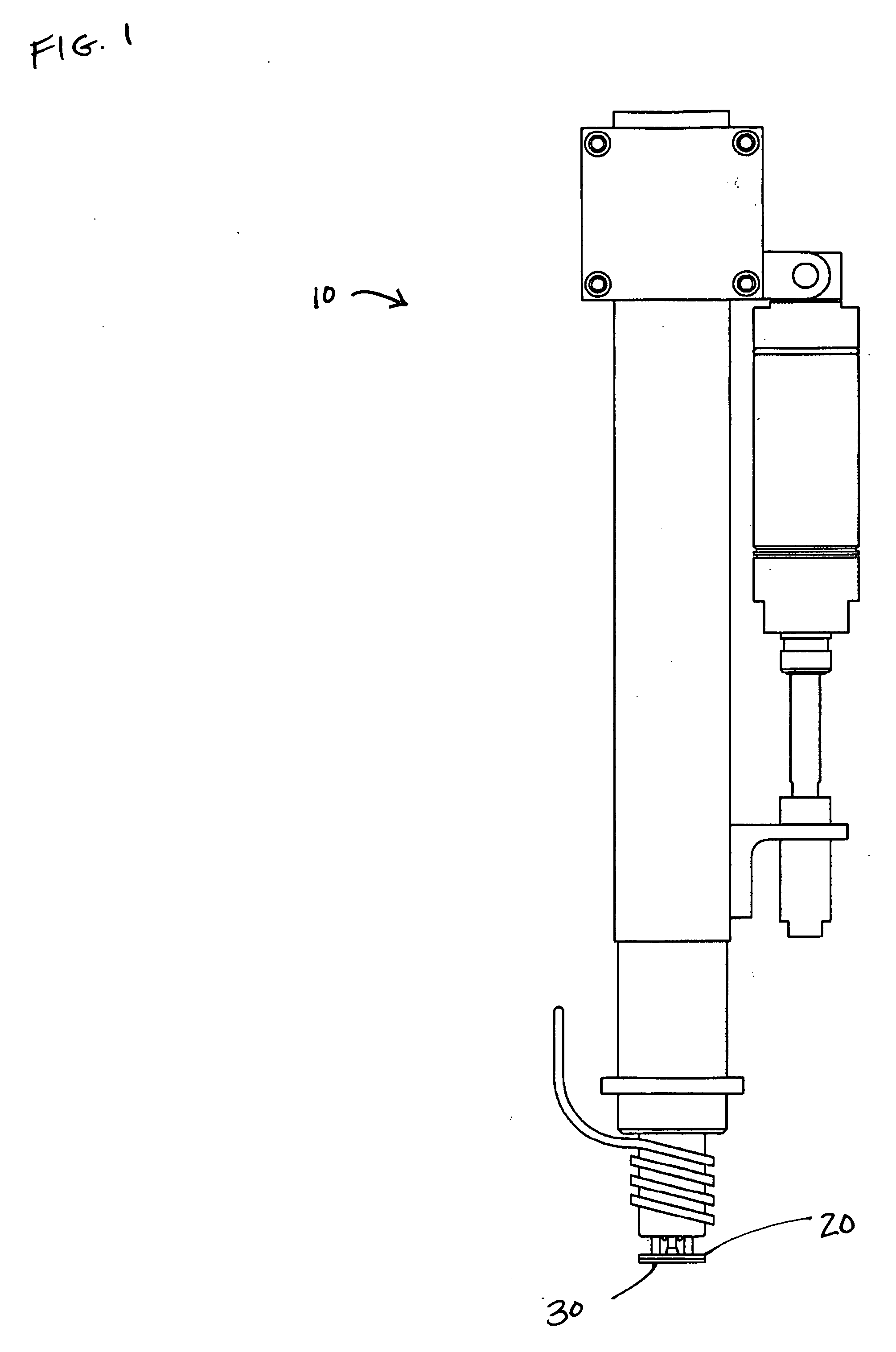

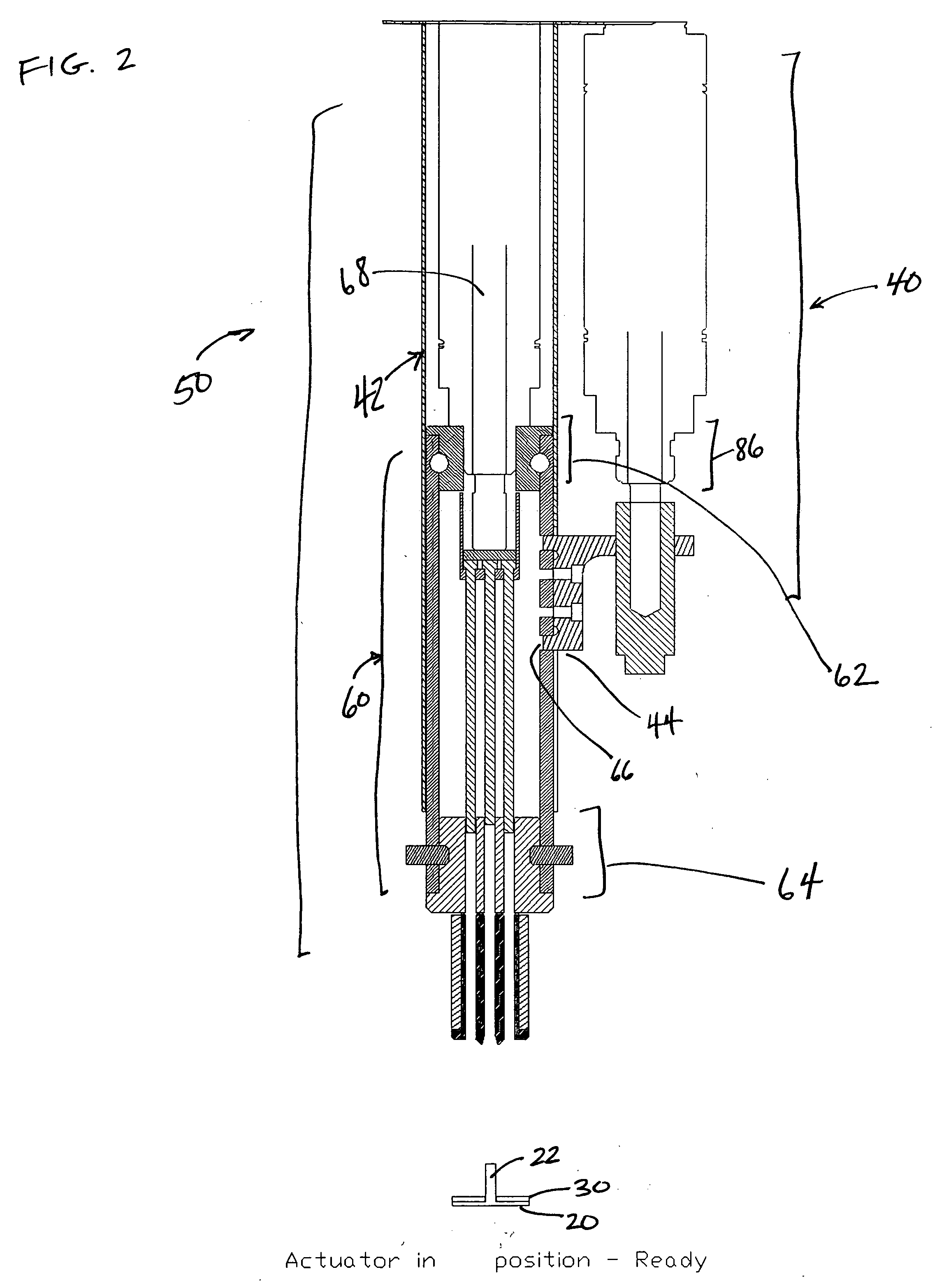

Positive displacement heatstake apparatus and method thereof

A heat staking method and apparatus for deforming thermoplastic parts and joining thermoplastic and dissimilar material parts to form an assembly is featured.

Owner:NORTHPOINTE

Text recognition for textually sparse images

A text recognition server is configured to recognize text in a sparse text image. Specifically, given an image, the server specifies a plurality of “patches” (blocks of pixels within the image). The system applies a text detection algorithm to the patches to determine a number of the patches that contain text. This application of the text detection algorithm is used both to estimate the orientation of the image and to determine whether the image is textually sparse or textually dense. If the image is determined to be textually sparse, textual patches are identified and grouped into text regions, each of which is then separately processed by an OCR algorithm, and the recognized text for each region is combined into a result for the image as a whole.

Owner:GOOGLE LLC

Encapsulating outer shell for membrane elements

InactiveUS20150290589A1Faster processing timeReduce labor costsMembranesReverse osmosisReverse osmosisEngineering

A reverse-osmosis separator module includes a pre-formed shell housing having a longitudinal axis extending between opposite ends and defining an inner chamber. A reverse-osmosis separator element is telescopically disposed in the inner chamber, and includes a permeate tube extending along the longitudinal axis and a membrane construction spirally wound around the permeate tube. An end cap is located at each end of the pre-formed shell housing.

Owner:PARKER HANNIFIN CORP

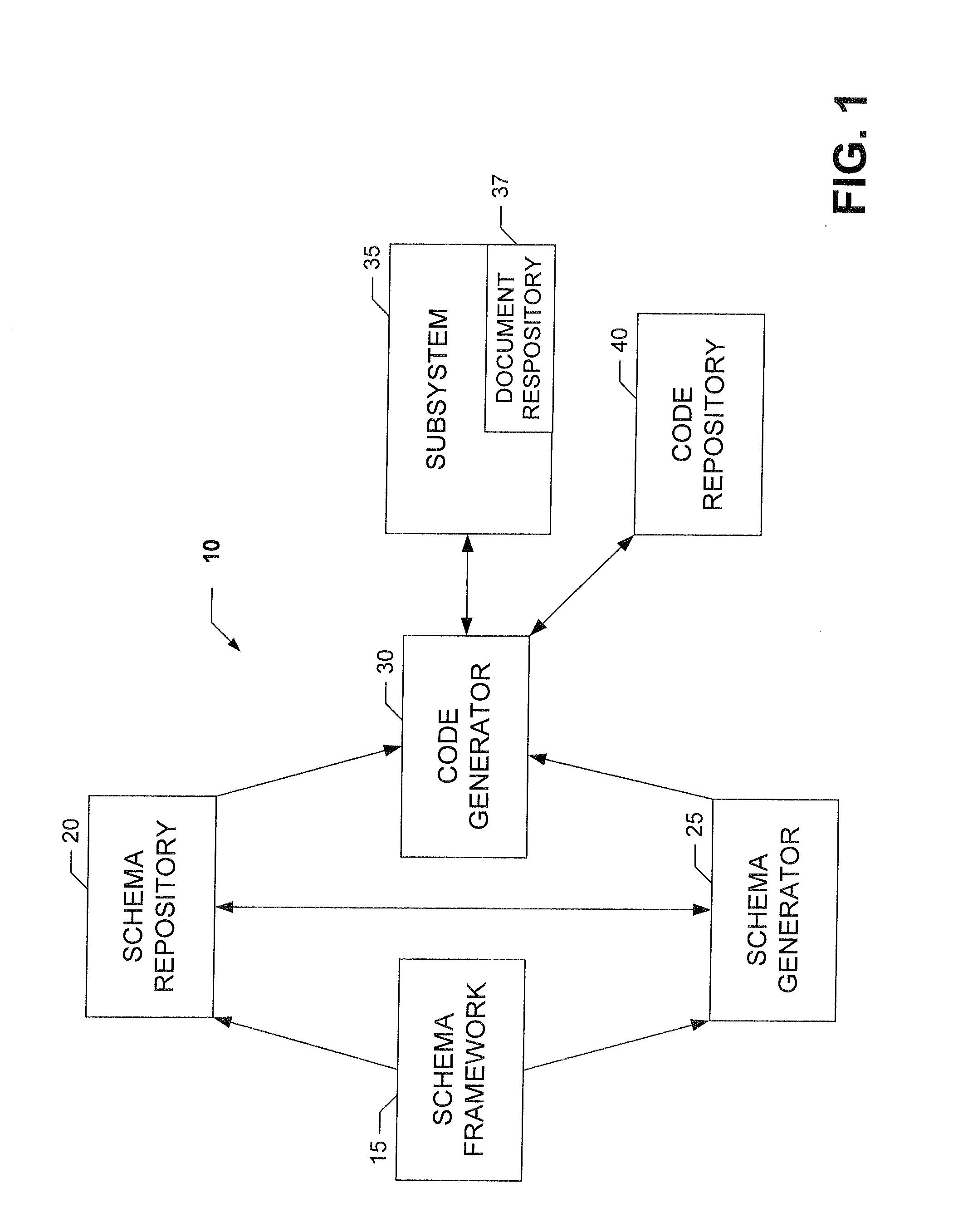

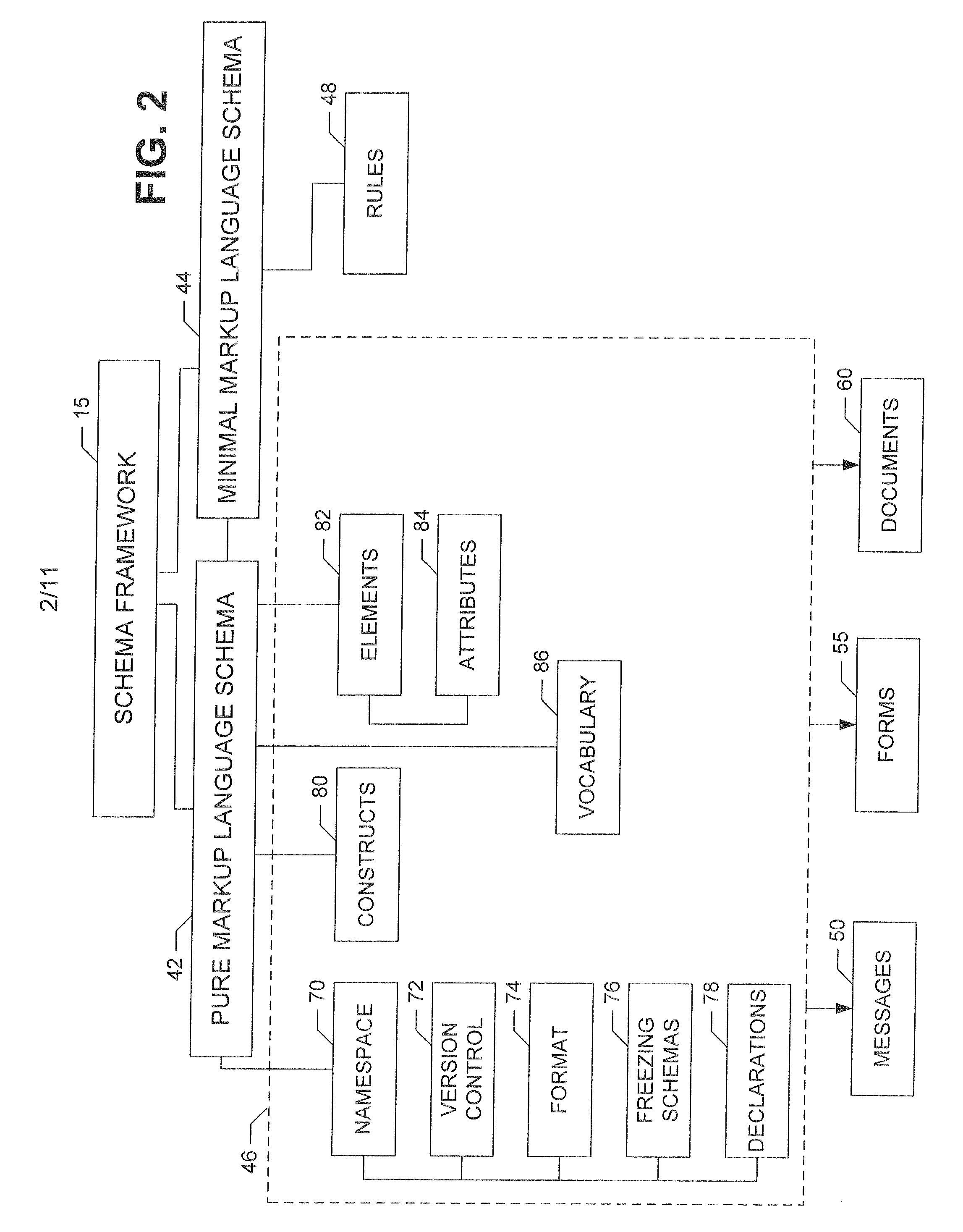

Automated system and method for creating minimal markup language schemas for a framework of markup language schemas

InactiveUS20090044101A1Rapid transmission timeReduce space volumeSpecific program execution arrangementsSpecial data processing applicationsArchival storageXML

A system for creating and realizing efficiencies in markup language (e.g., XML) schema, markup language instances, and code-generated code. A schema generator receives a markup language schema as input and automatically generates a minimal markup language schema. The minimal markup language schema, and instances conforming to it, are forwards and backwards compatible with the original markup language schema and instances. A code generator receives a markup language schema as input and generates code that can both generate and consume instances conforming to the original markup language schema or the minimal markup language schema. Accordingly, smaller markup language schemas and instances result in increased processing speed, faster transmission time, and reduced archival storage space.

Owner:WTVIII

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com