Supercritical fluid-assisted deposition of materials on semiconductor substrates

a technology of supercritical fluid and semiconductor substrate, which is applied in the direction of liquid/solution decomposition chemical coating, chemical vapor deposition coating, coating, etc., can solve the problems of limited cvd process for film deposition, high particle level, and low thermal stability of many chemical species

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

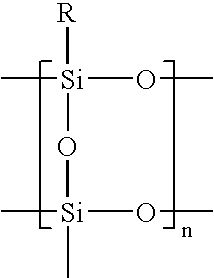

Image

Examples

Embodiment Construction

[0030] Supercritical fluids are formed under conditions at which the density of the liquid phase equals the density of the gaseous phase of the substance. For example, carbon dioxide (CO2), which is a gas at standard temperature and pressure, undergoes a transition from liquid to SCF above a critical point, corresponding to Tc≧31.1° C. and pc≧73.8 atm. Once formed, the density of the SCF can be varied from liquid-like to gaseous-like, yielding different solvation abilities, by varying the pressure and temperature. Supercritical fluids have a solubility and diffusibility approaching that of the liquid and gaseous phase, respectively. Additionally, the surface tension of SCFs is negligible.

[0031] Because of its readily manufactured character, ability to be recycled, lack of toxicity and negligible environmental effects, supercritical CO2 is a preferred SCF in the broad practice of the present invention, although the invention may be practiced with any suitable SCF species, with the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com