Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19234 results about "Methacrylic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methacrylic acid, abbreviated MAA, is an organic compound. This colorless, viscous liquid is a carboxylic acid with an acrid unpleasant odor. It is soluble in warm water and miscible with most organic solvents. Methacrylic acid is produced industrially on a large scale as a precursor to its esters, especially methyl methacrylate (MMA) and poly(methyl methacrylate) (PMMA). MAA occurs naturally in small amounts in the oil of Roman chamomile.

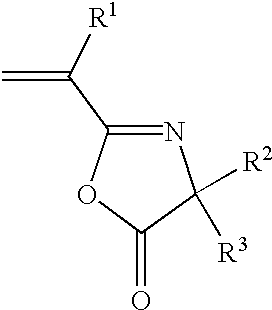

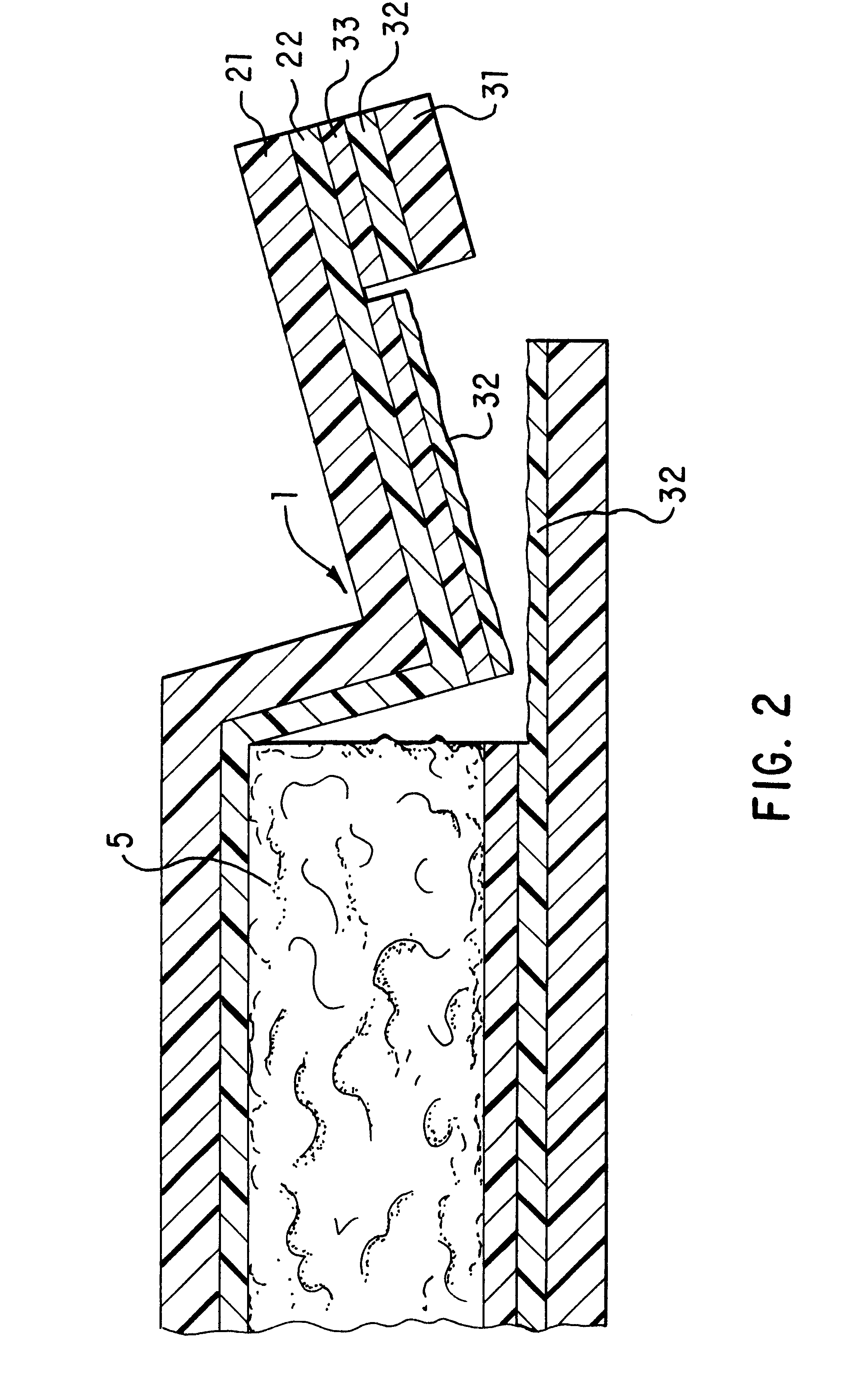

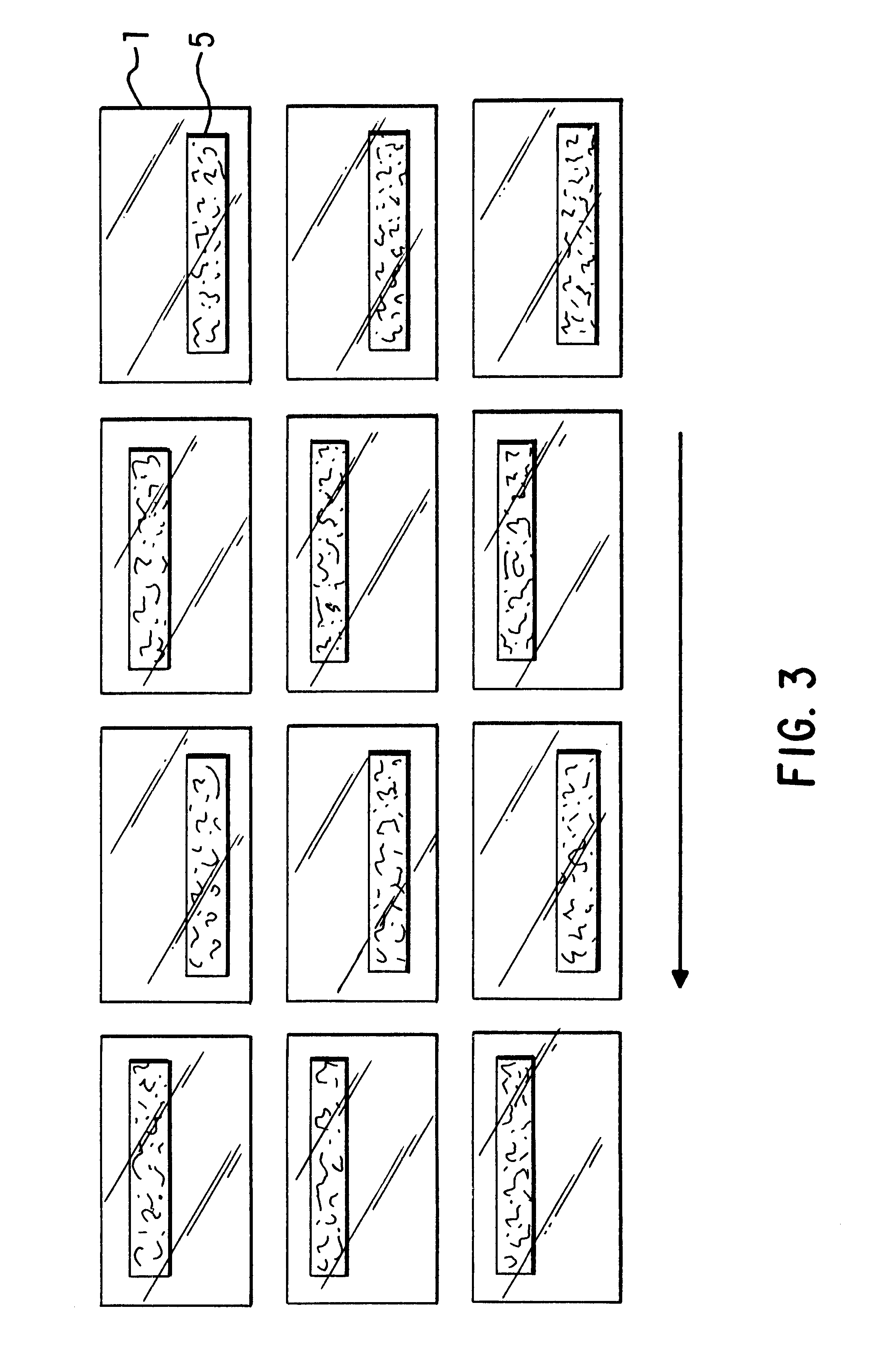

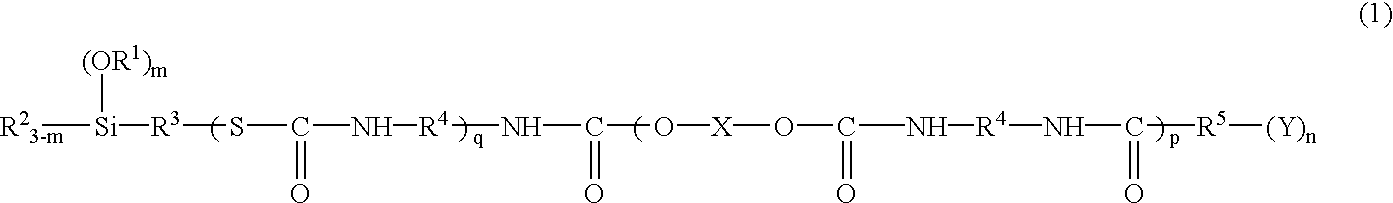

Photoresist cross-linker and photoresist composition comprising the same

InactiveUS6368773B1Enhance the imageAdequate resultOrganic chemistryPhotosensitive materialsCarboxylic acidKetone

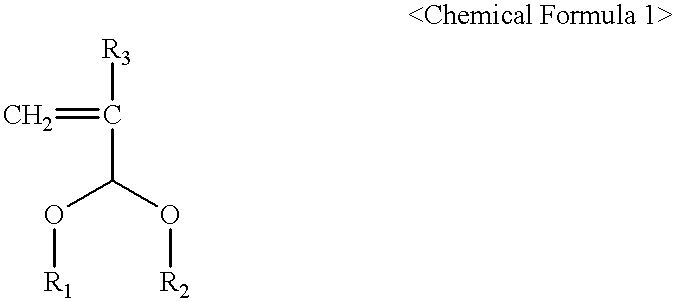

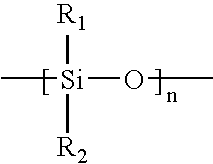

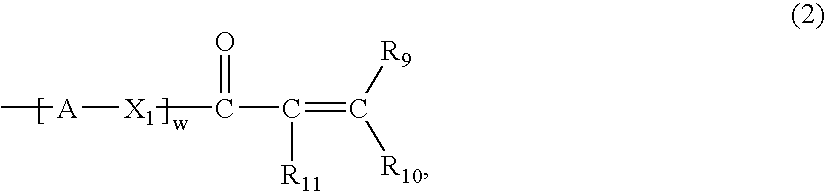

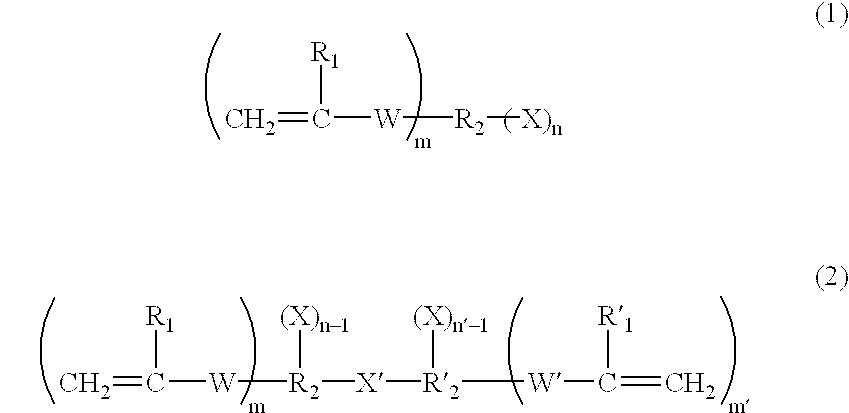

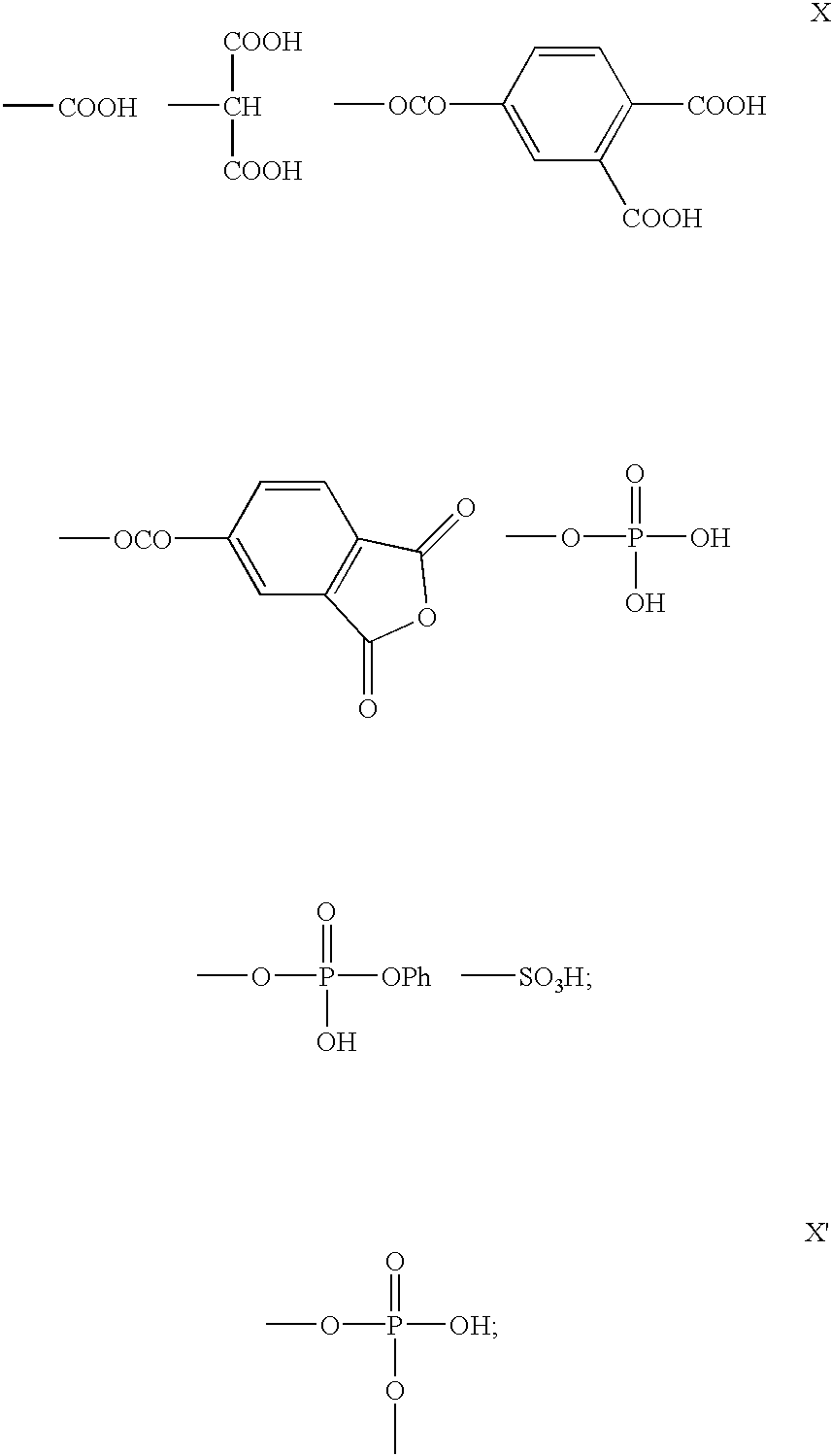

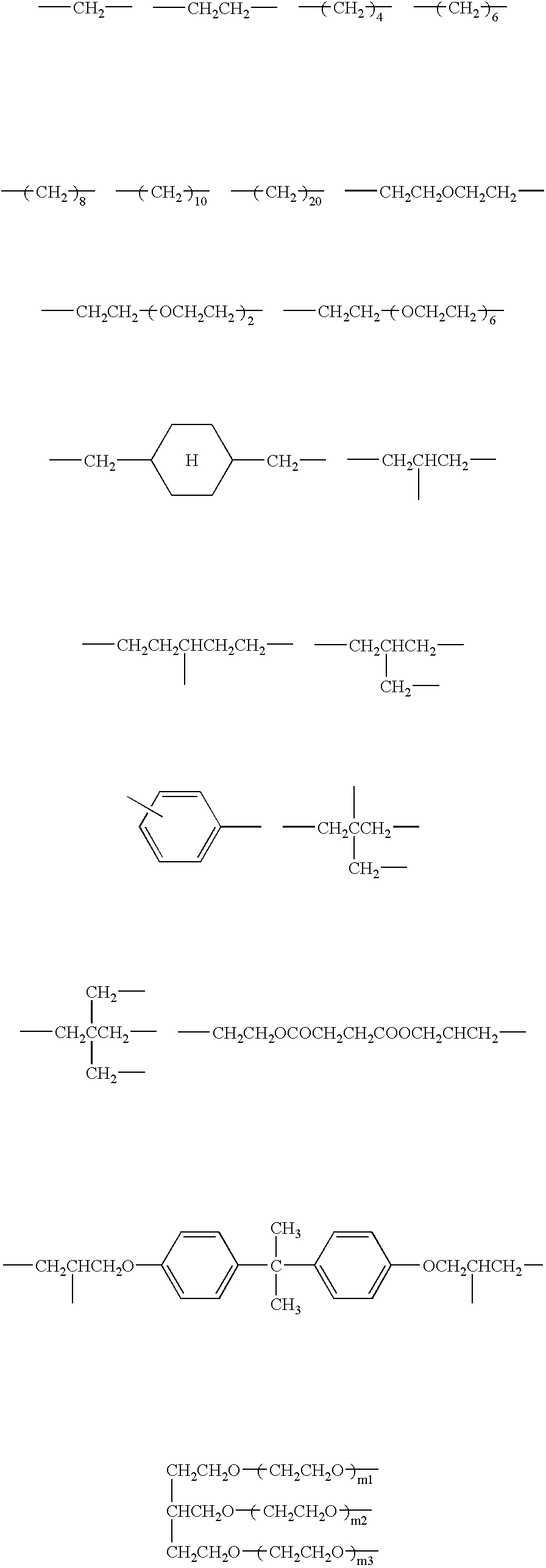

The present invention relates to a cross-linker for photoresist compositions which is suitable for a photolithography process using KrF (248 mn), ArF (193 mn), E-beam, ion beam or EUV light sources. Preferred cross-linkers, according to the present invention, comprise a copolymer of (i) a compound represented by following Chemical Formula 1 and / or (ii) one or more compound(s) selected from the group consisting of acrylic acid, methacrylic acid and maleic anhydride. ##STR1## wherein, R.sub.1 and R.sub.2 individually represent straight or branched C.sub.1-10 alkyl, straight or branched C.sub.1-10 ester, straight or branched C.sub.1-10 ketone, straight or branched C.sub.1-10 carboxylic acid, straight or branched C.sub.1-10 acetal, straight or branched C.sub.1-10 alkyl including at least one hydroxyl group, straight or branched C.sub.1-10 ester including at least one hydroxyl group, straight or branched C.sub.1-10 ketone including at least one hydroxyl group, straight or branched C.sub.1-10 carboxylic acid including at least one hydroxyl group, and straight or branched C.sub.1-10 acetal including at least one hydroxyl group; and R.sub.3 represents hydrogen or methyl.

Owner:HYUNDAI ELECTRONICS IND CO LTD

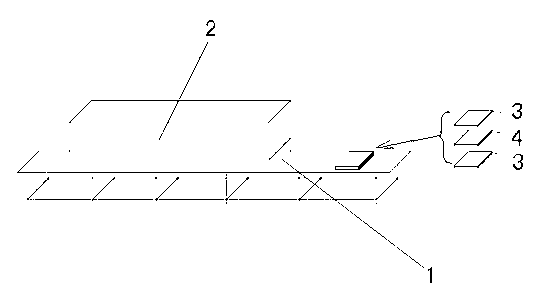

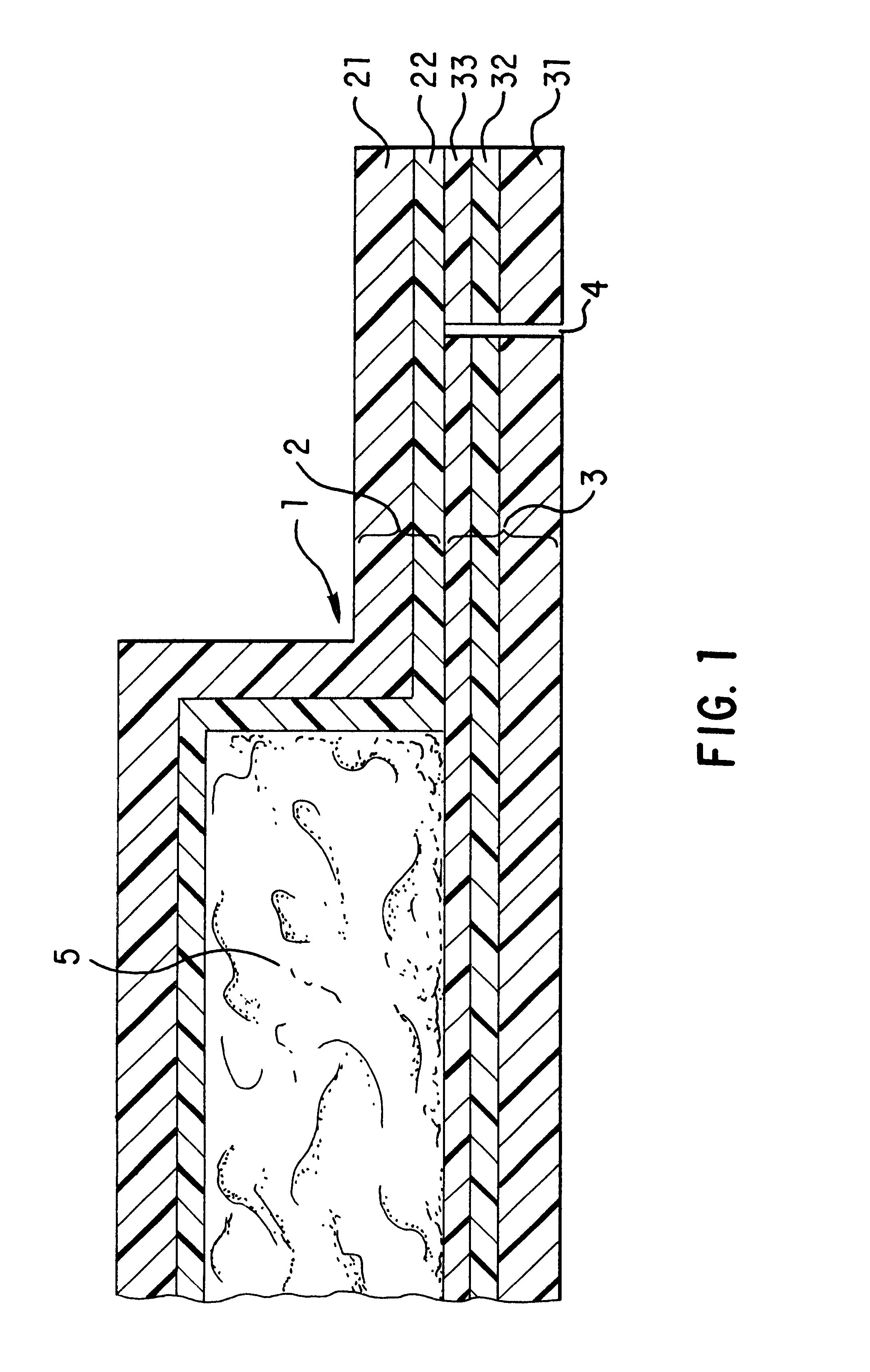

Biocompatible crosslinked coating and crosslinkable coating polymer composition for forming such a coating

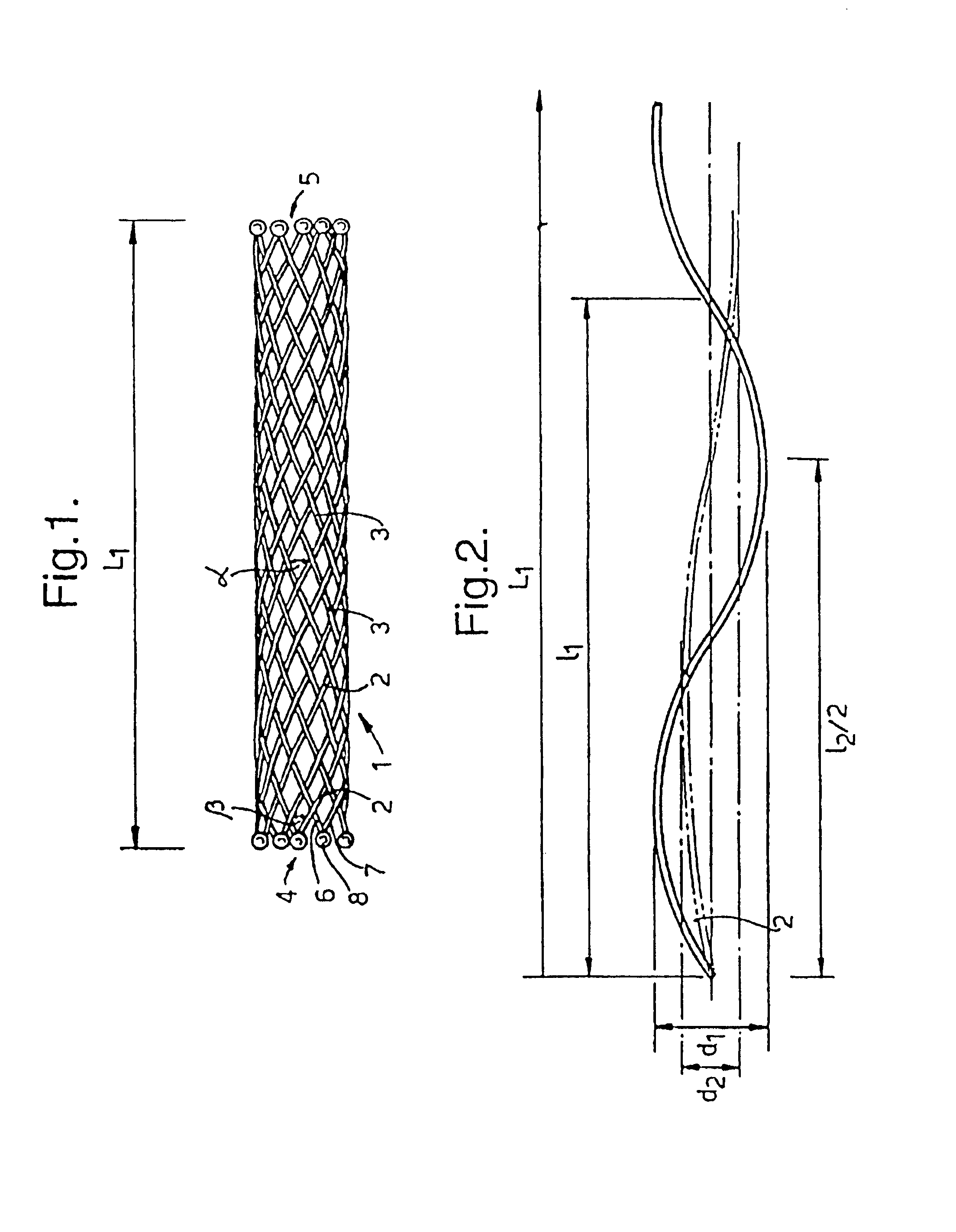

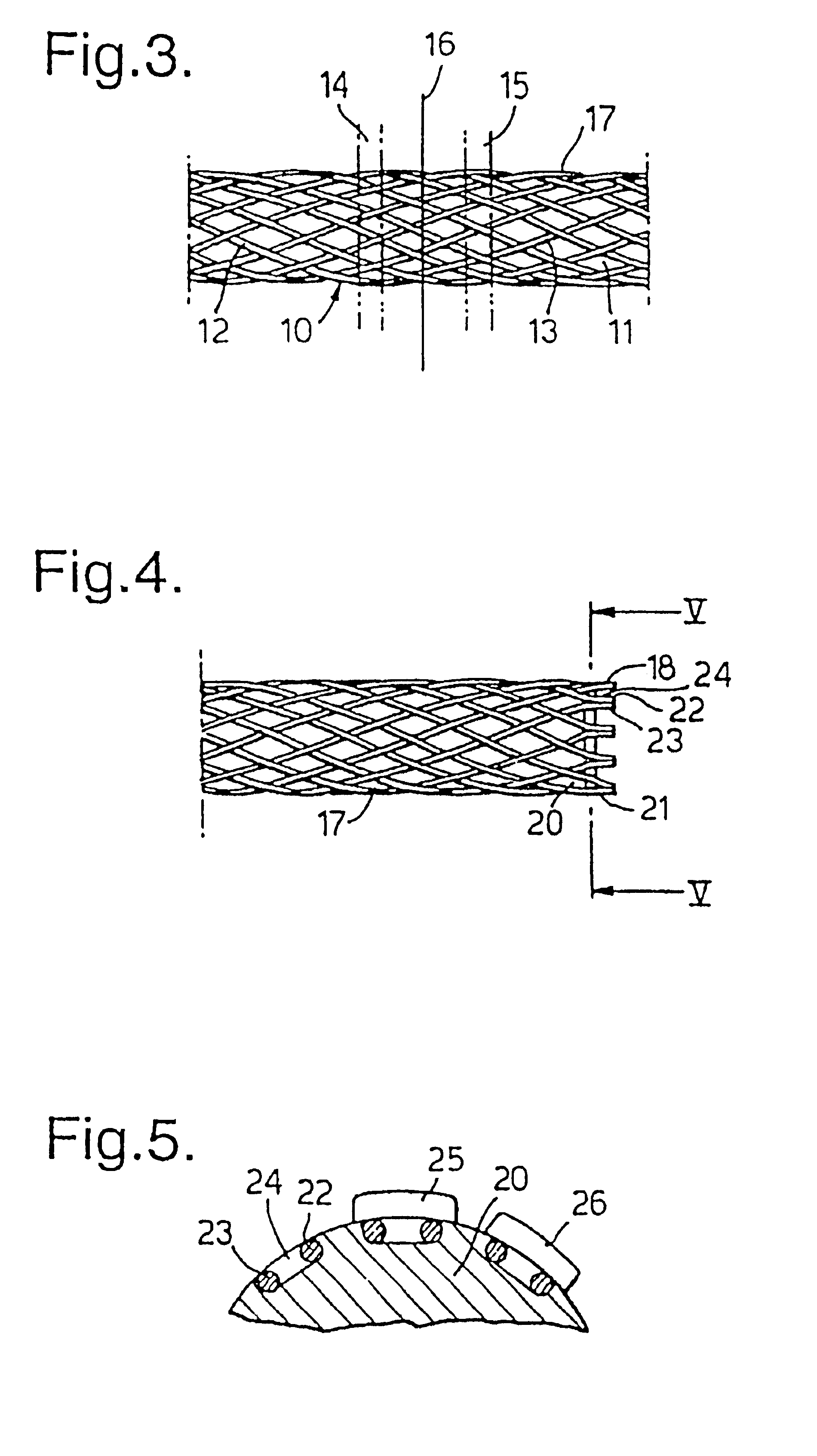

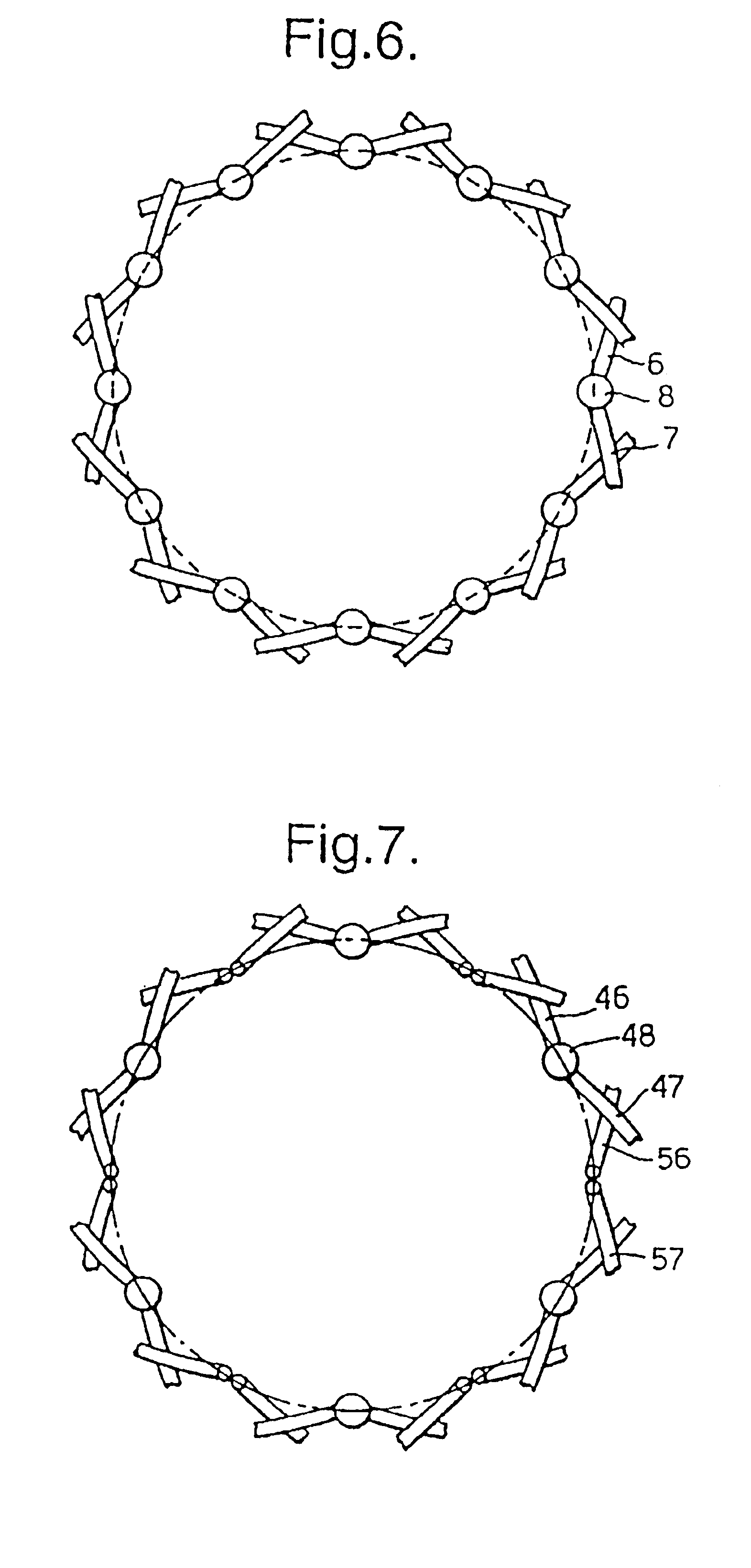

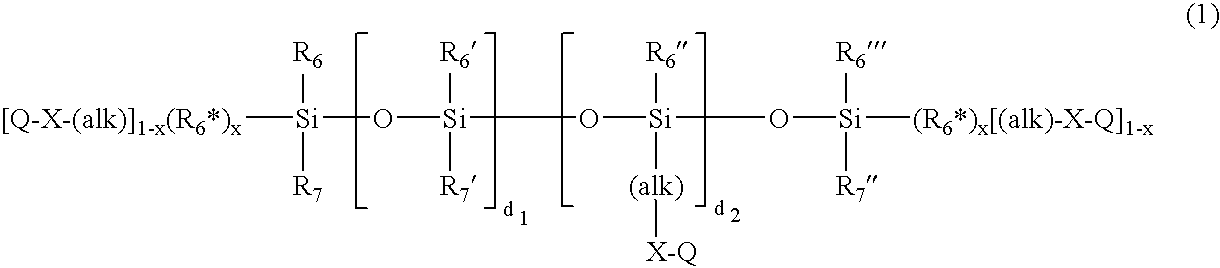

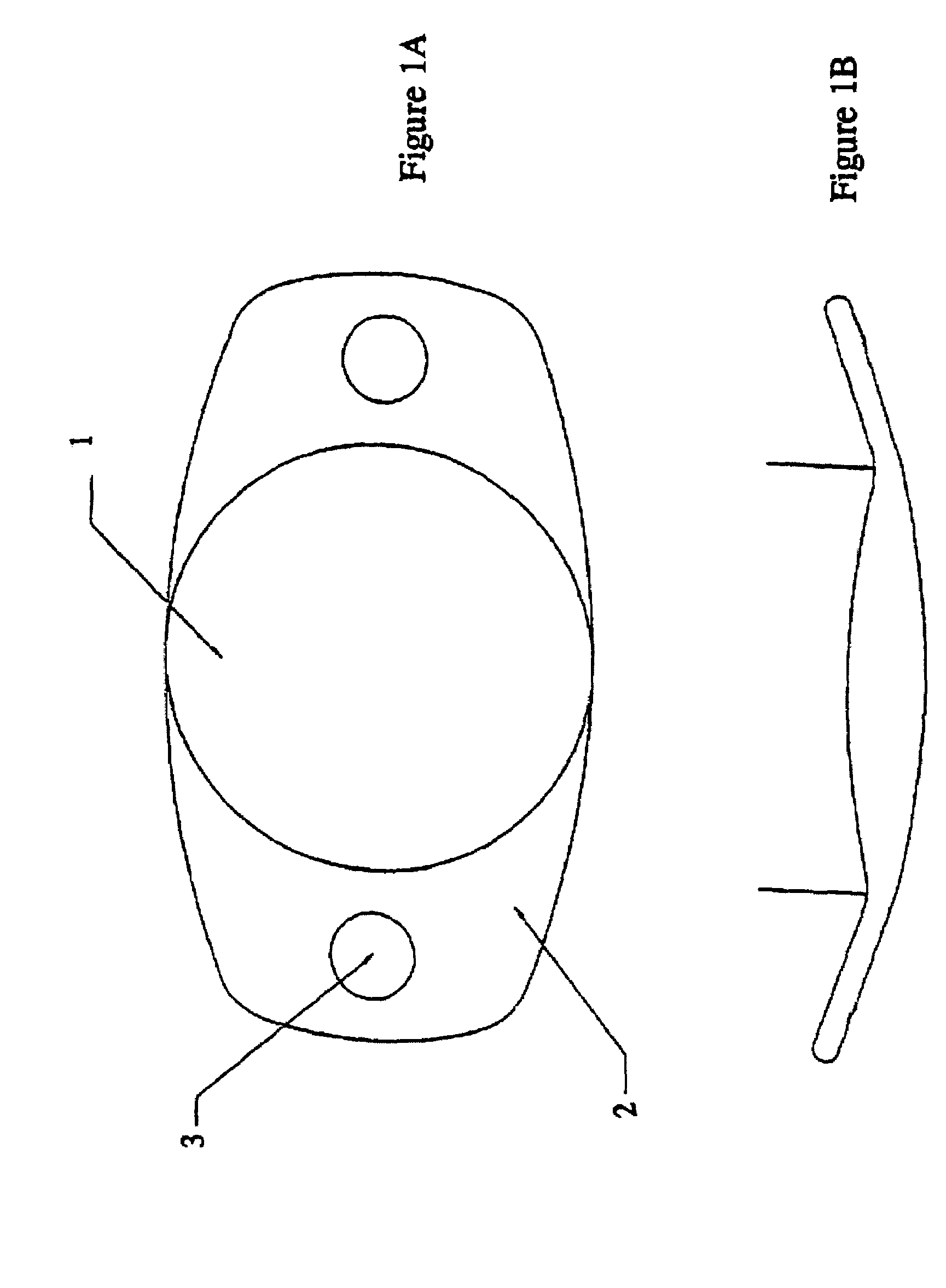

A braided stent (1) for transluminal implantation in body lumens is self-expanding and has a radial expanded configuration in which the angle α between filaments is acute. Some or all of filaments (6,7) are welded together in pairs at each end (4,5) of the stent to provide beads (8), thereby strengthening the stent and assisting its deployment from a delivery device. The stent is preferably completely coated using a biocompatible polymeric coating, said polymer preferably having pendant phosphoryl choline groups. A method of making the stent by braiding and welding is described as well as a delivery device for deploying the device.The present invention provides a biocompatible crosslinked coating and a crosslinkable coating polymer composition for forming such a coating. The biocompatible crosslinked coating may be formed by curing a polymer of 23 mole % (methacryloyloxy ethyl)-2-(trimethylammonium ethyl) phosphate inner salt, 47 mole % lauryl methacrylate, 5 mole % γtrimethoxysilyl propyl methacrylate and 25 mole % of hydroxy propyl methacrylate. The crosslinkable coating polymer may include 23 mole % (methacryloyloxy ethyl)-2-(trimethylammonium ethyl) phosphate inner salt, 47 mole % lauryl methacrylate, 5 mole % γtrimethoxysilyl propyl methacrylate and 25 mole % of hydroxy propyl methacrylate.<?insert-end id="INS-S-00001" ?>

Owner:BIOCOMPATIBLES UK LTD

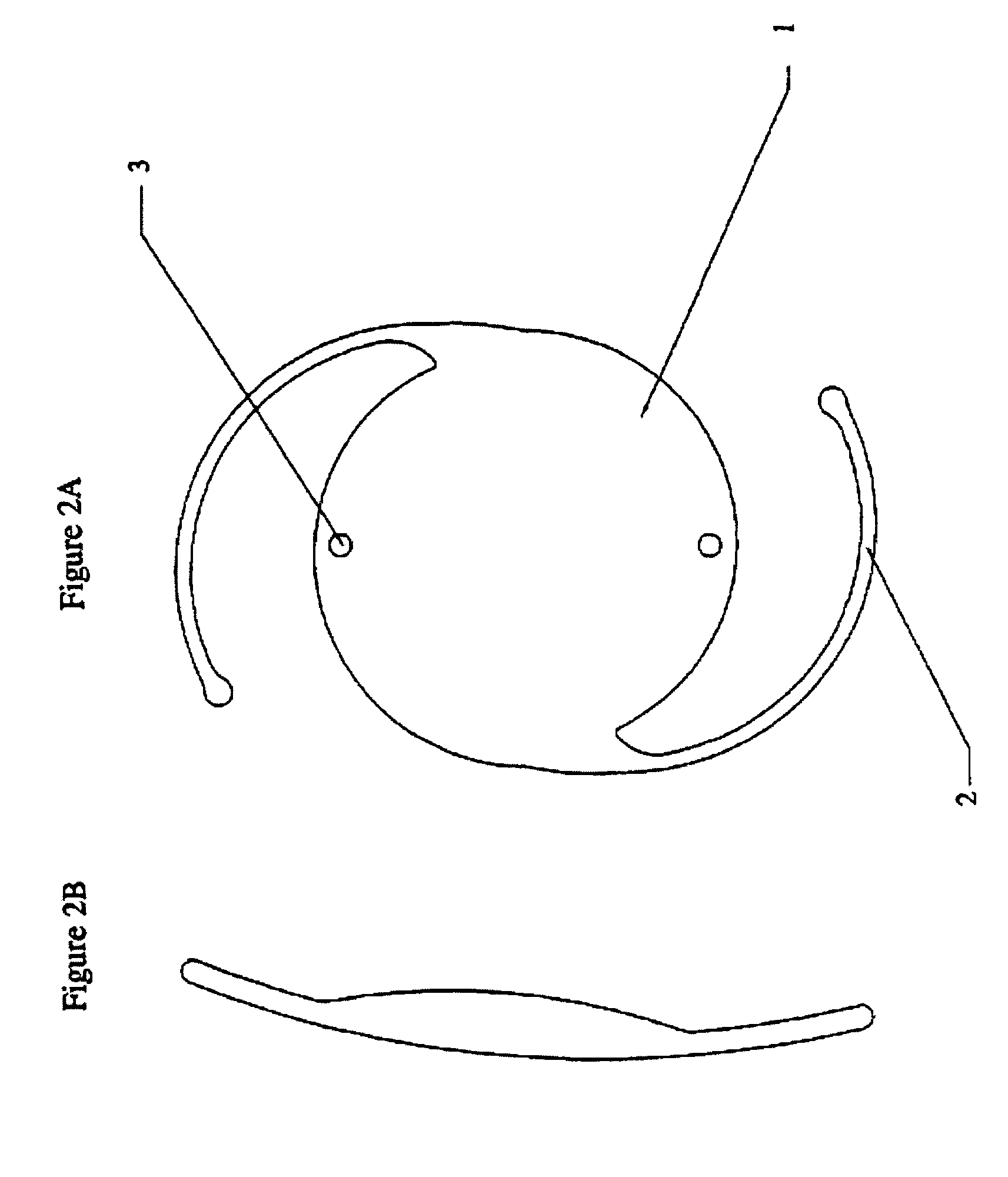

Novel Polymers

ActiveUS20080015315A1Sufficient amountReduce the amount requiredOrganic compound preparationCarboxylic acid esters preparationHydrophilic monomerPolymer science

The invention relates to novel crosslinkable copolymers which are obtainable by (a) copolymerizing at least two different hydrophilic monomers selected from the group consisting of N,N-dimethyl acrylamide (DMA), 2-hydroxyethyl acrylate (HEA), glycidyl methacrylate (GMA), N-vinylpyrrolidone (NVP), acrylic acid (AA) and a C1-C4-alkoxy polyethylene glycol (meth)acrylate having a weight average molecular weight of from 200 to 1500, and at least one crosslinker comprising two or more ethylenically unsaturated double bonds in the presence of a chain transfer agent having a functional group; and (b) reacting one or more functional groups of the resulting copolymer with an organic compound having an ethylenically unsaturated group.

Owner:ALCON INC

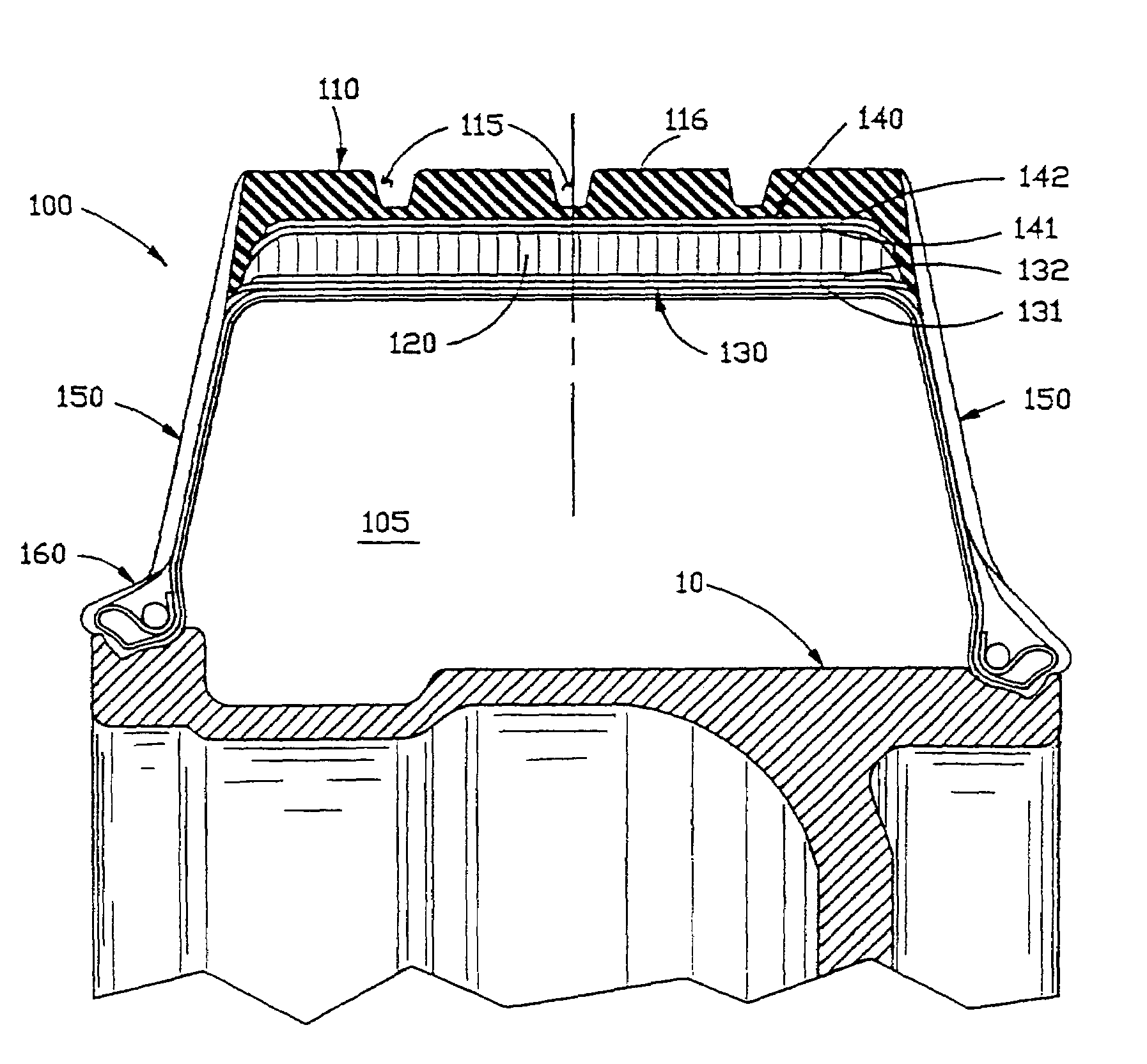

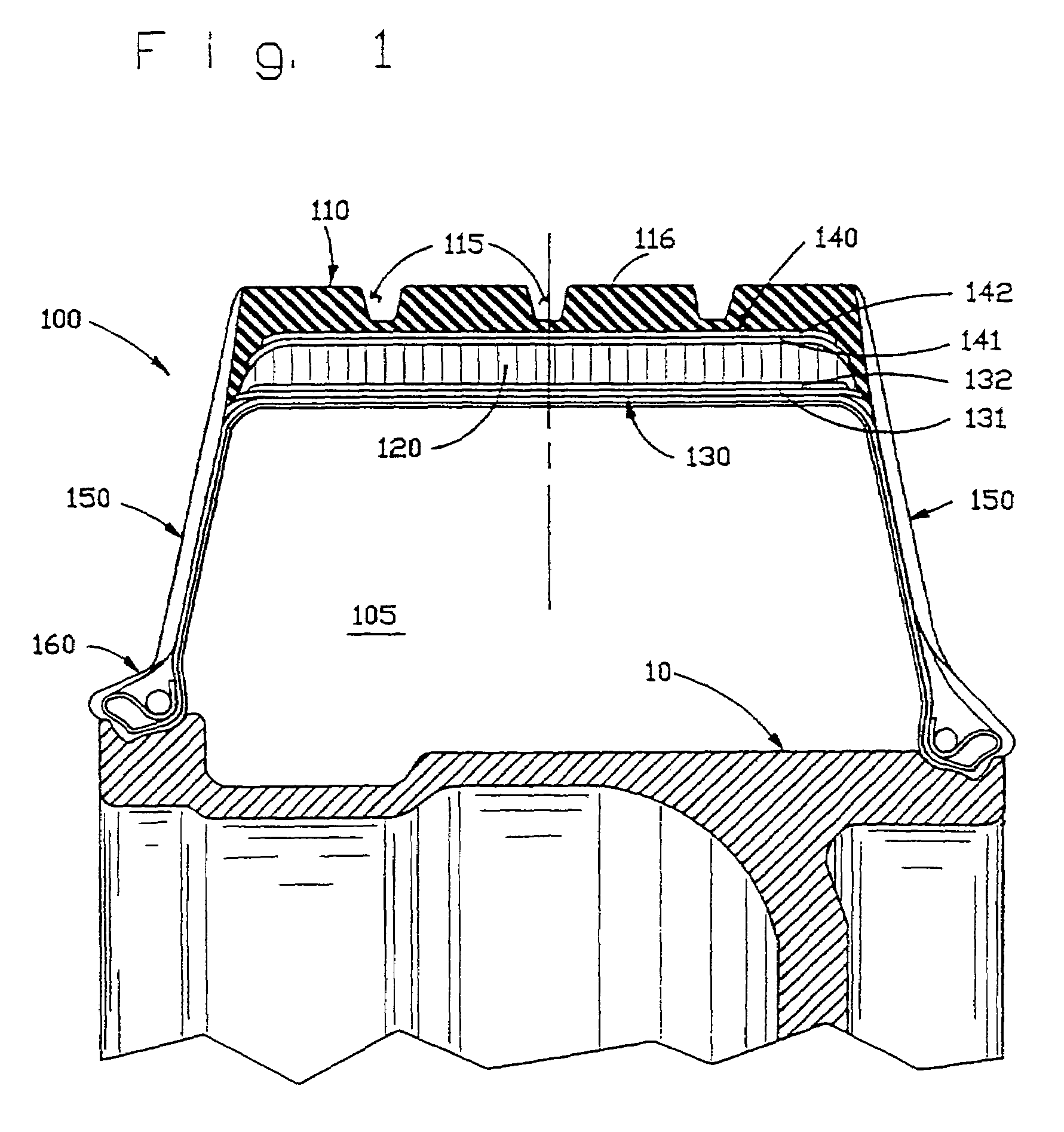

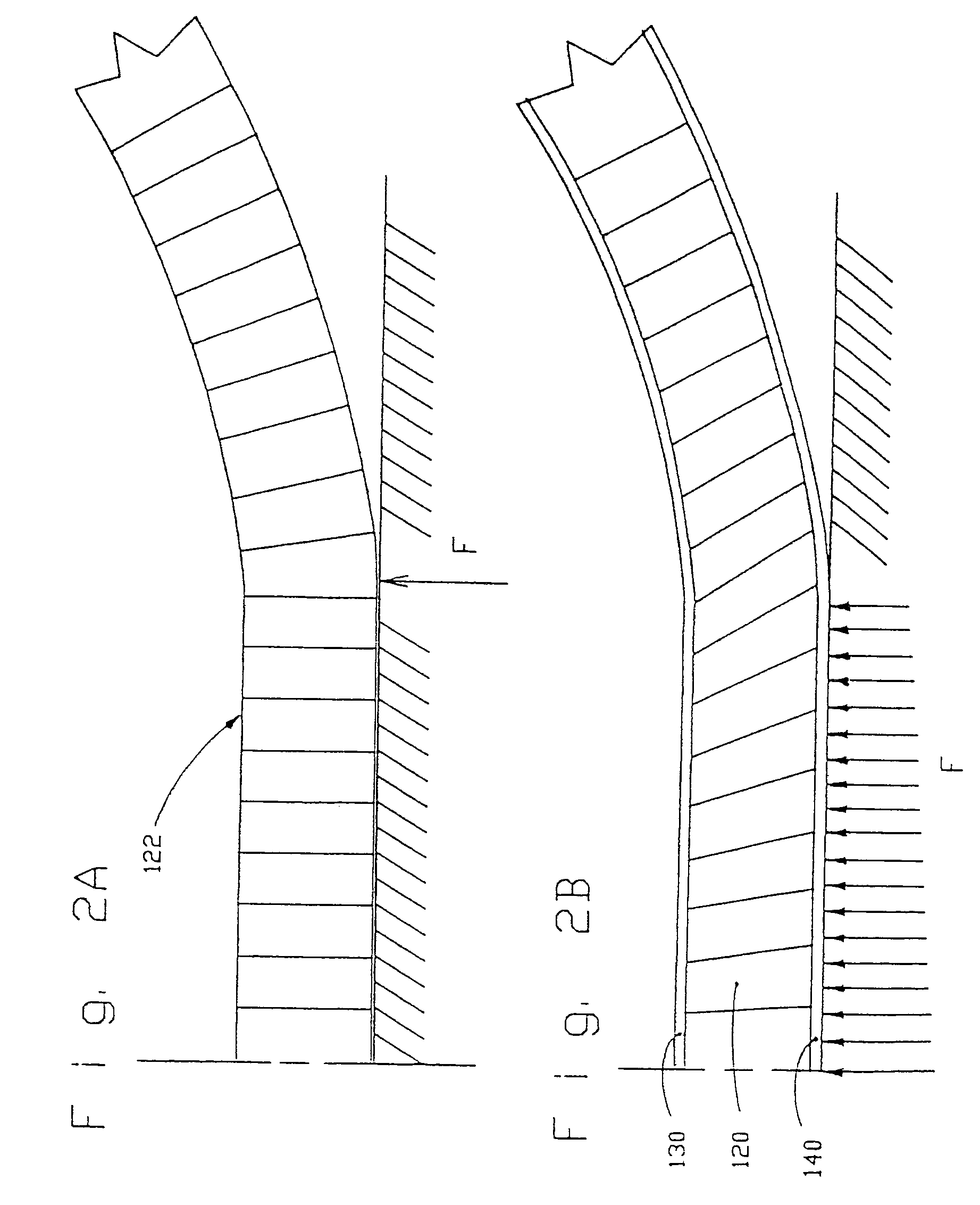

Structurally supported resilient tire and materials

The invention comprises an improved non-pneumatic tire, and particularly a shear layer for a non-pneumatic tire wherein the shear layer comprises an elastomeric composition that includes a metal salt of a carboxylic acid. The shear layer preferably comprises a dienic elastomeric composition that includes a metal salt of a carboxylic acid. In one embodiment of the invention, the metal salt of the carboxylic acid is zinc diacrylate or zinc dimethacrylate. In one embodiment of the invention, the metal salt of the carboxylic acid is zinc diacrylate or zinc dimethacrylate, and a peroxide curative agent is employed.

Owner:MICHELIN RECH & TECH SA

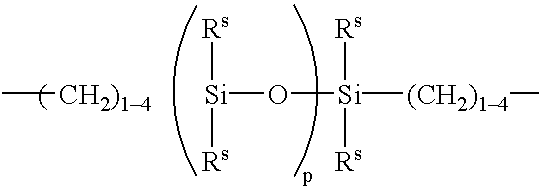

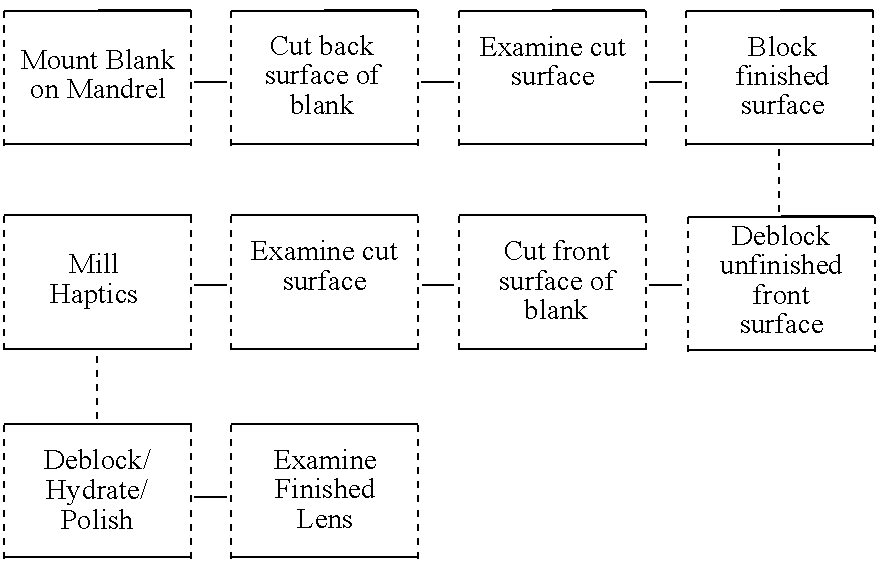

Hydrogel from polysiloxane-containing urethane prepolymer, tris (trimethylsiloxy) silylpropyl methacrylate, and a hydrophilic comonomer

A polyurethane based prepolymer is provided and useful in biomedical devices which provides high oxygen permeability and superior physical properties. A hydrogel is produced from a comonomer mixture containing a polysiloxane-containing urethane prepolymer, tris(trimethylsiloxy)-silylpropyl methacrylate and a hydrophilic comonomer. The hydrogel is especially useful for biomedical materials such as contact lenses and implants.

Owner:BAUSCH & LOMB INC

Gel pad and UV-curving production method thereof

The invention relates to a gel pad and a uv-curing production method thereof. This invention, including the gel bag, is characterized in that the gel bag is filled with gel which is prepared from gel monomers, a cross-linking agent and a photoinitiatorandwater prepared from the UV curving. The gel consists of monomers, cross-linking agents, cross-linking agents, photo initiators and water. The said monomer are two or more than two of an acrylic acid alkali metal salt, ester generated by methacrylic acid ,acrylamide ,methacrylamide and AMPS(2-acrylamide-2-methyl-propanesulfonic acid ). The said cross-linking agent is a non-conjugated double bond compound which is polyol(glycerol )N,N'-methylene bisacrylamide. The said photoinitiator is a cracking type initiator or a photosensitive initiator or a cationic initiator. The advantages of the method are that the production process is simple, the gel solidification is fast and the gel pad produced is flattened.

Owner:朱雪兵

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

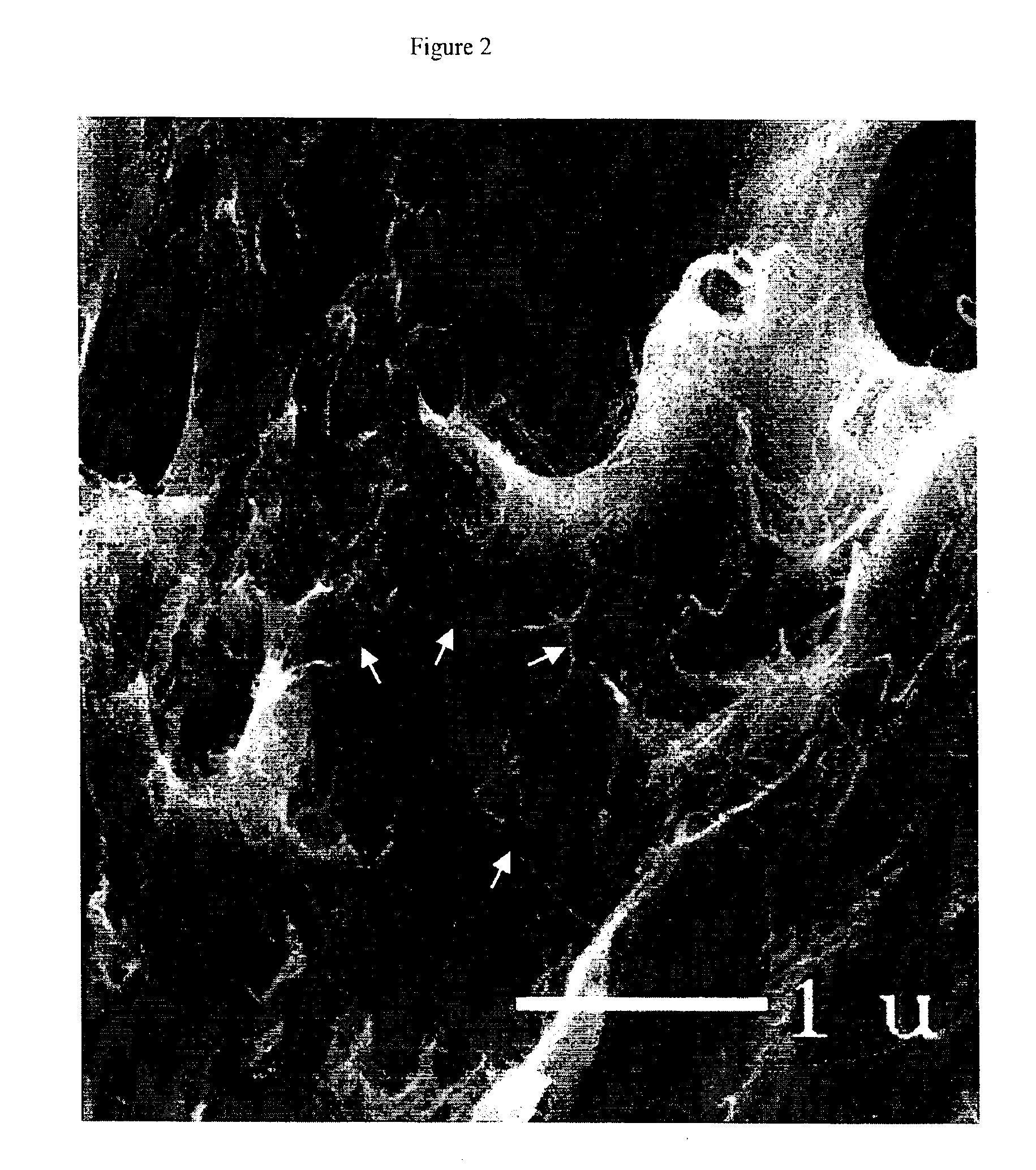

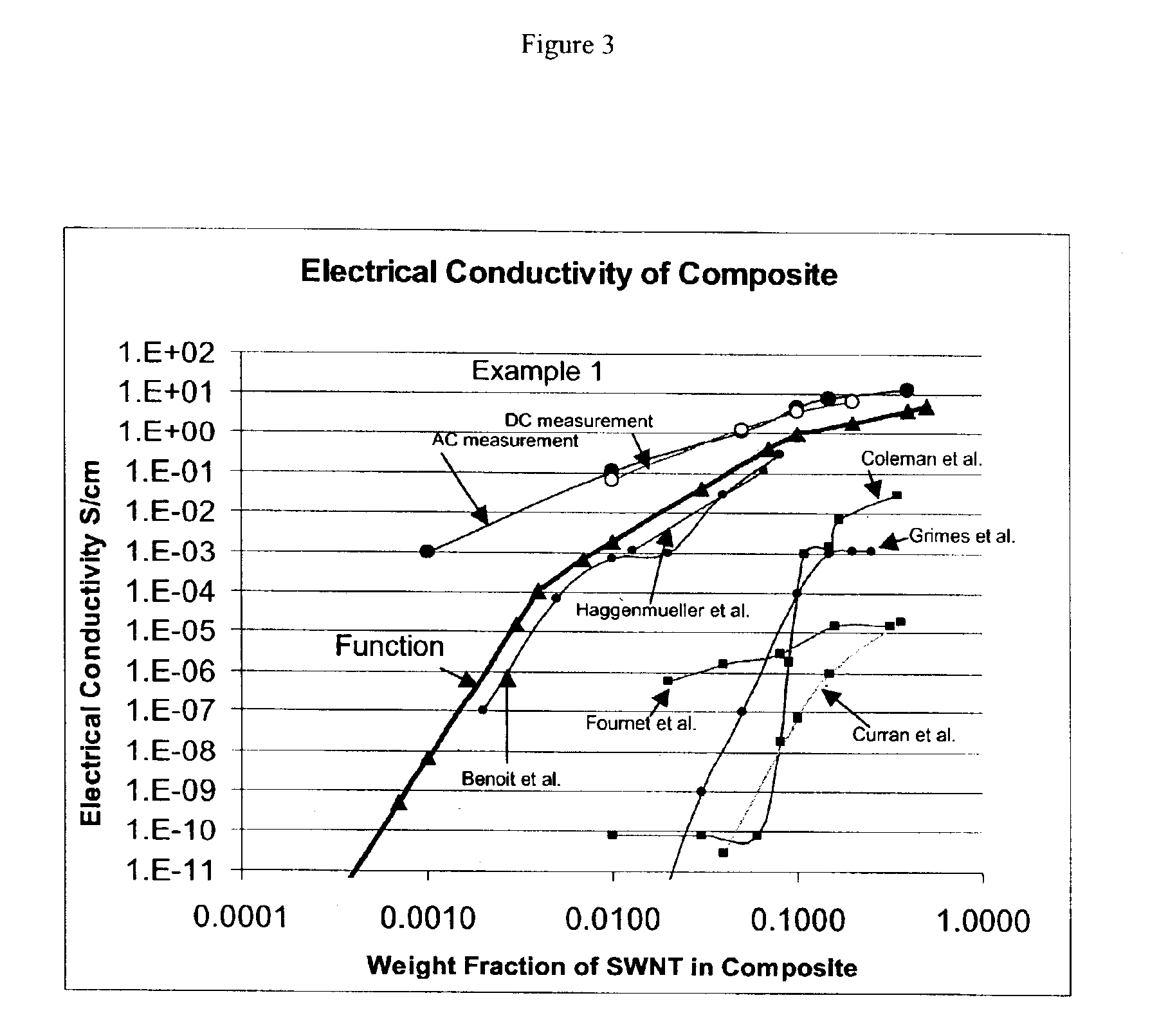

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

Materials for making hydrophobic intraocular lens

Owner:BENZ RES & DEV

Liquid inks comprising a stable organosol

InactiveUS20020128349A1Good dispersionAvoid resistanceDuplicating/marking methodsInksMethacrylateDispersion stability

A liquid ink comprises (a) a carrier liquid having a Kauri-Butanol number less than 30; (b) a graft copolymer comprising a (co)polymeric steric stabilizer covalently bonded to a thermoplastic (co)polymeric core that is insoluble in the carrier liquid; and (c) a colorant, wherein the steric stabilizer comprises units derived from 3,3,5-trimethylcyclohexyl methacrylate, and the thermoplastic (co)polymeric core comprising units derived from at least a polymerizable monomer selected from the group consisting of (meth)acrylates having aliphatic amino radicals, nitrogen-containing heterocyclic vinyl monomers, N-vinyl substituted ring-like amide monomers, aromatic substituted ethylene monomers containing amino radicals, and nitrogen-containing vinylether monomers. The organosol provides improved liquid electrophotographic and electrographic ink compositions with improved dispersion stability, chargeability, and blocking resistance so that improved print quality or ink transfer performance are obtained.

Owner:S PRINTING SOLUTION CO LTD

Pharmaceutical dosage form with multiple coatings for reduced impact of coating fractures

InactiveUS6893662B2Reduce the impactReduce impactPowder deliveryOrganic active ingredientsOral medicationActive agent

The present invention relates to a pharmaceutical composition in a solid unit dosage form for oral administration in a human or lower animal comprising: a. a safe and effective amount of a therapeutically active agent; b. an inner coating layer selected from the group consisting of poly(methacrylic acid, methyl methacrylate) 1:2, poly(methacrylic acid, methyl methacrylate) 1:1, and mixtures thereof; and c. an outer coating layer comprising an enteric polymer or film coating material; wherein the inner coating layer is not the same as the outer coating layer; wherein if the inner coating layer is poly(methacrylic acid, methyl methacrylate) 1:1 then the outer coating layer is not poly(methacrylic acid, methyl methacrylate) 1:2 or is not a mixture of poly(methacrylic acid, methyl methacrylate) 1:1 and poly(methacrylic acid, methyl methacrylate) 1:2; and wherein the inner coating layer and the outer coating layer do not contain any therapeutically active agent. This invention further relates to a method of maintaining the desired site of delivery of a therapeutic agent in the gastrointestinal tract by administering the above compositions to a human or lower animal.

Owner:APTALIS PHARMA

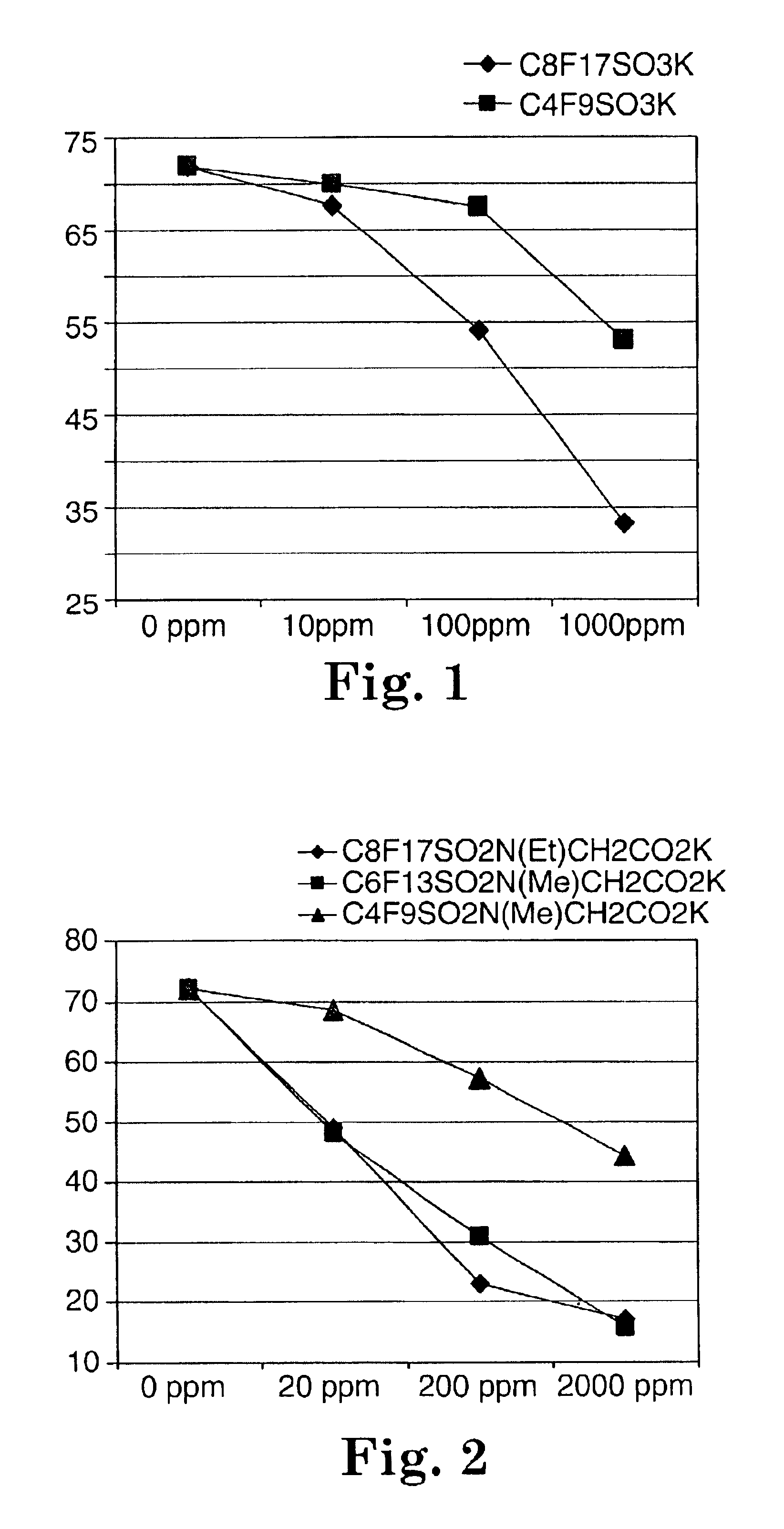

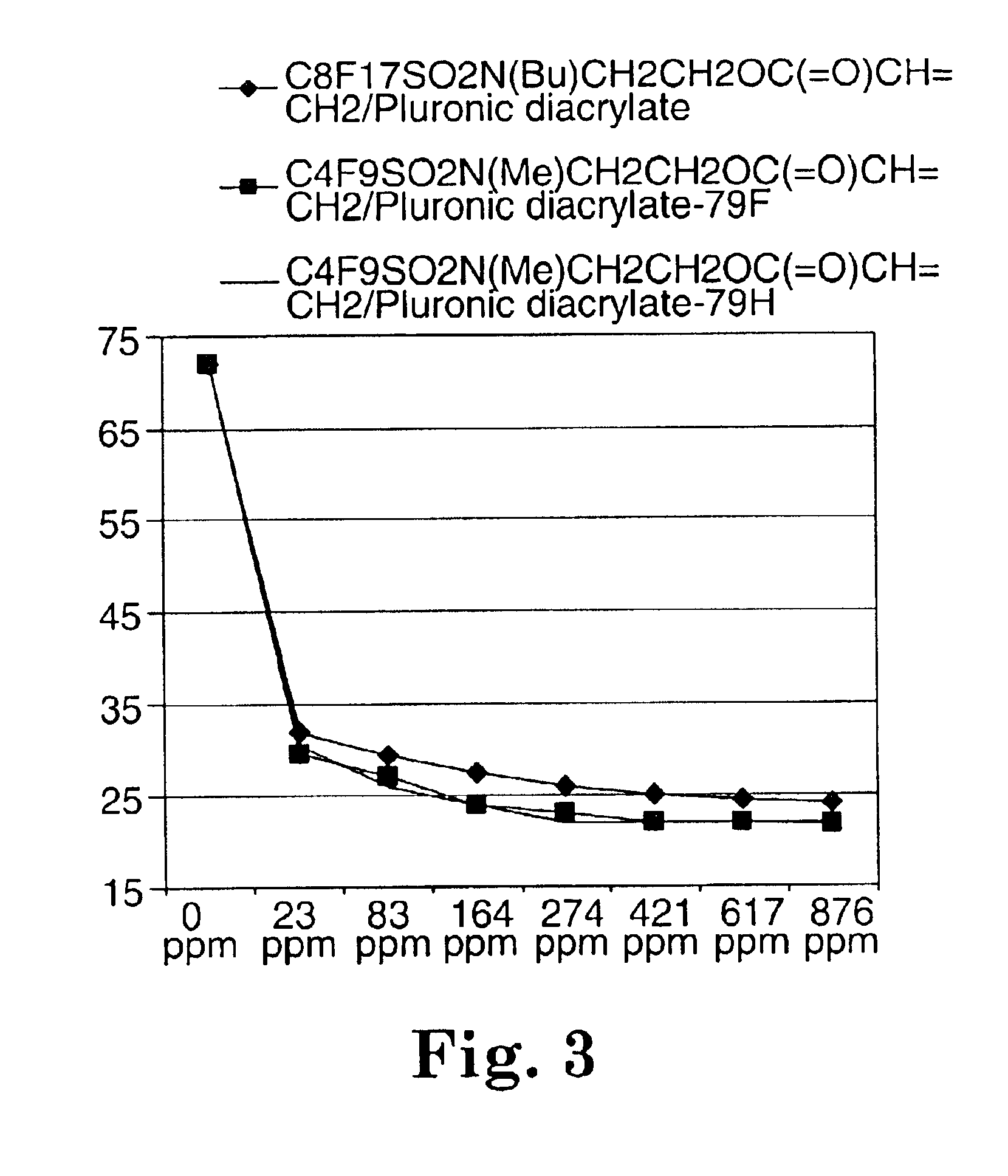

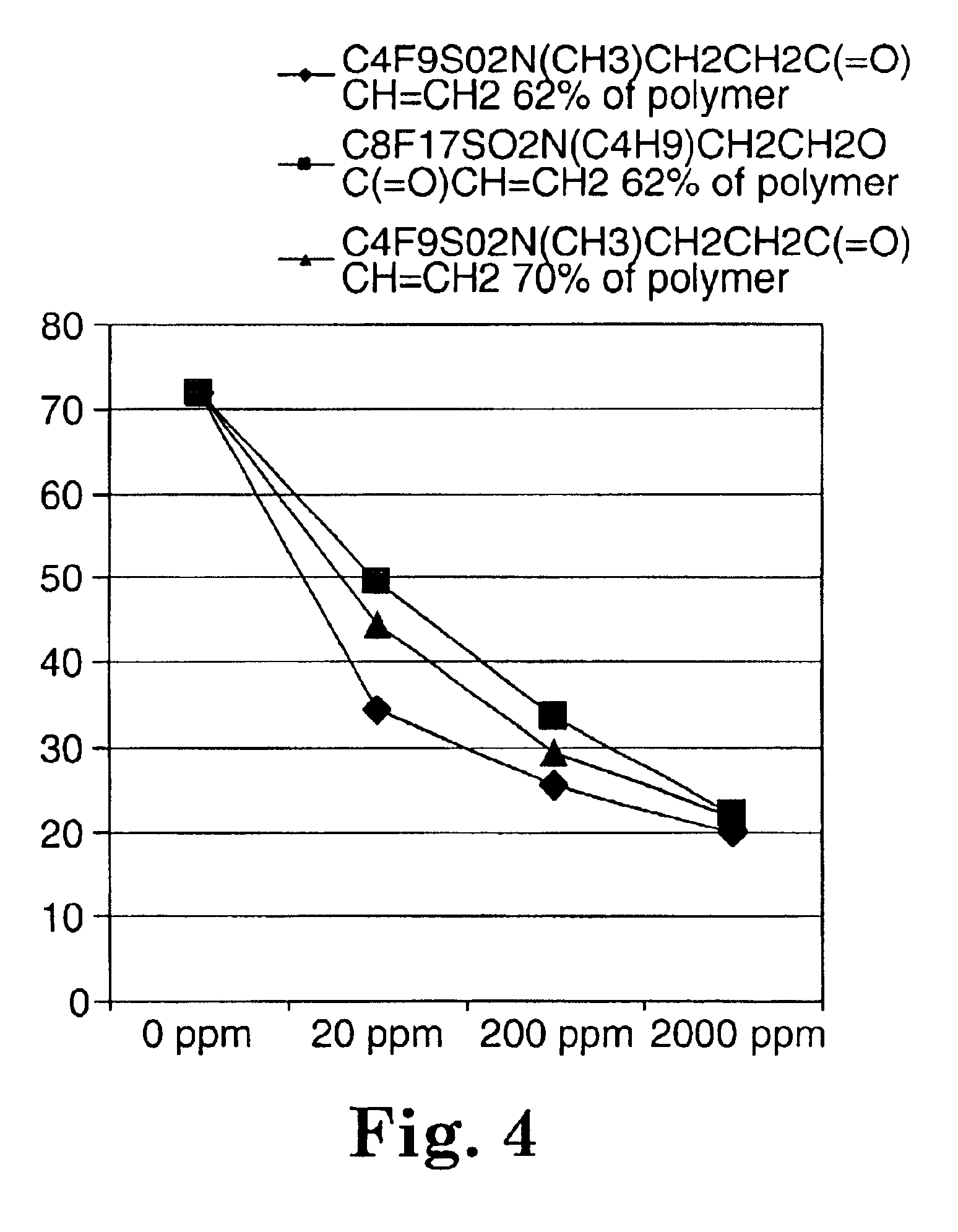

Fluorochemical sulfonamide surfactants

InactiveUS6852781B2High yieldLow costNon-macromolecular adhesive additivesPhotosensitive materialsSide chainSulfonyl fluoride

Described are fluorochemical surfactants derived from nonafluorobutanesulfonyl fluoride that contain polyalkyleneoxy side chains and may be copolymerized with acrylic acid or methacrylic acid to form polyacrylates or polymethacrylates. The surfactants surprisingly lower the surface tension of water and other liquids in the same or similar low values achieved by premier surfactants such as those derived from perfluorooctane sulfonyl fluoride.

Owner:3M INNOVATIVE PROPERTIES CO

Pigment ink jet ink composition

An ink jet ink composition comprising an aqueous media and a pigment dispersion comprising a pigment and a polymeric dispersant wherein said polymeric dispersant is a copolymer comprising at least a hydrophobic methacrylate or acrylate monomer containing an aliphatic chain having greater than or equal to 12 carbons; and a hydrophilic methacrylic or acrylic acid monomer; wherein said copolymer comprises at least 10% by weight of the methacrylate or acrylate monomer and at least 5% by weight of the methacrylic or acrylic acid monomer; and wherein the copolymer comprises, in total, 20 to 95 weight % of hydrophobic monomer.

Owner:EASTMAN KODAK CO

Sensor system

InactiveUS7964390B2Bioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteSensor system

A sensor probe suited for implanting into the skin of a person includes a sensor body which may be formed from a polymer which includes 2-hydroxyethyl methacrylate (HEMA). A sensing system is supported by the body. The sensing system exhibits a detectable change when the probe is exposed to the analyte in the fluid. The sensing system may include an enzyme capable of catalyzing a reaction of the analyte to form a reaction product and a dye system which absorbs in the infrared region of the spectrum in response to the reaction product.

Owner:CASE WESTERN RESERVE UNIV

Dental adhesive composition

This invention discloses a dental adhesive composition comprising (A) a polymerizable monomer comprising an acidic-group containing polymerizable monomer such as 11-methacryloyloxy-1,1-undecane dicarboxylic acid, (B) a mixed filler of a spherical filler substantially consisting of a non-crosslinking polymethyl methacrylate and a spherical filler substantially consisting of a non-crosslinking polyethyl methacrylate; and (C) a polymerization initiator; and a dental adhesive kit comprising the above dental adhesive composition in combination with a dental primer comprising (D) an acidic-group containing polymerizable monomer, (E) an aryl borate, (F) an organosulfinic acid salt and (G) water. The dental adhesive composition exhibits good operability and improved adhesion performance.

Owner:TOKUYAMA DENTAL CORP +1

Ternary polymer blend, the film containing it, and the easy-to-open package made therewith

InactiveUS6476137B1Easy opening strengthImprove the immunitySynthetic resin layered productsPackagingPolymer sciencePolybutylene

Object of the present invention is an extrudable blend comprising (i) a copolymer of ethylene and acrylic acid or methacrylic acid (ii) a modified EVA copolymer and (iii) a polybutylene. Included are the films comprising said blend in the sealant layer or in a layer directly adhered to the sealant layer, and the easy-to-open packages obtained therefrom.

Owner:CRYOVAC INC

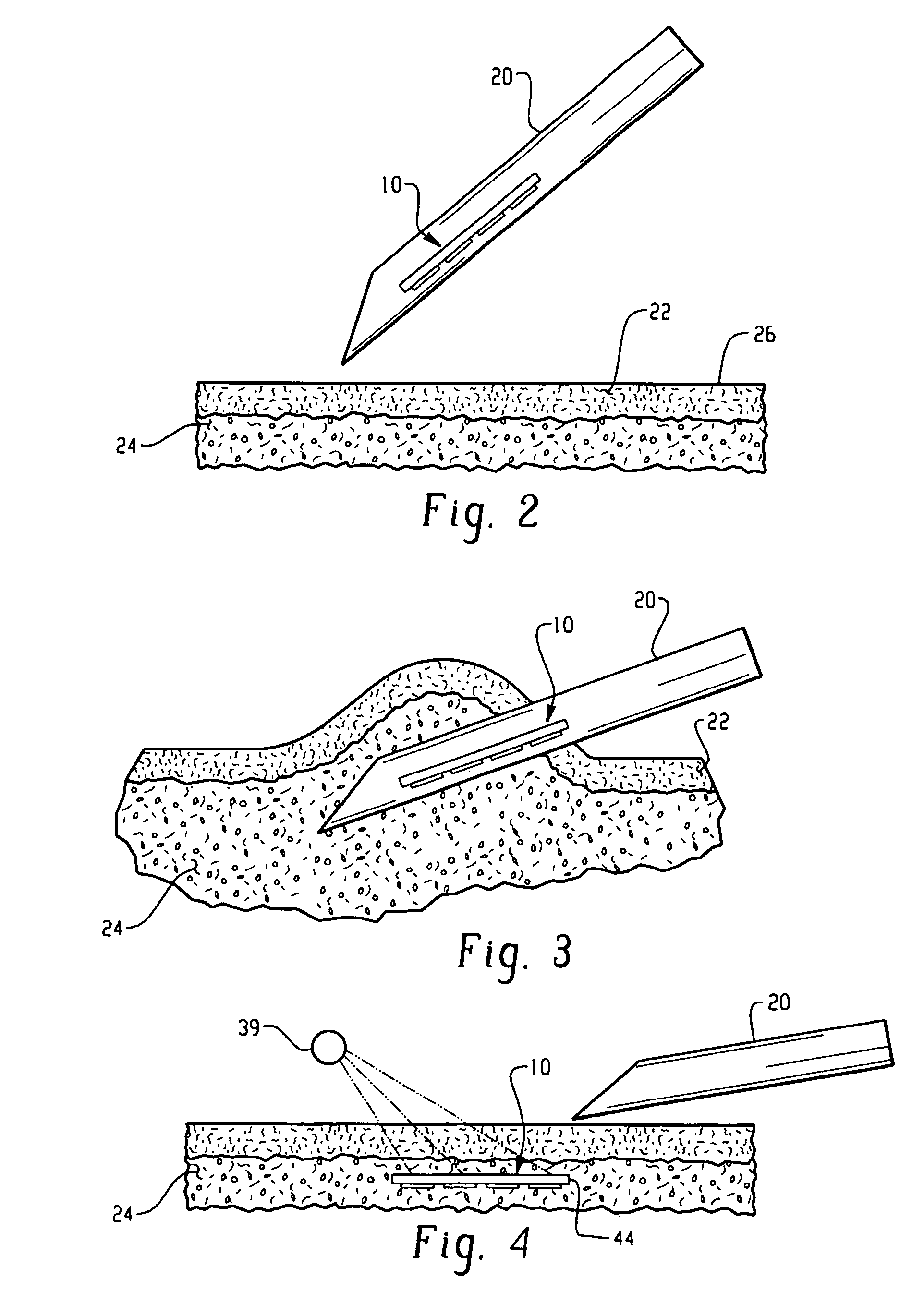

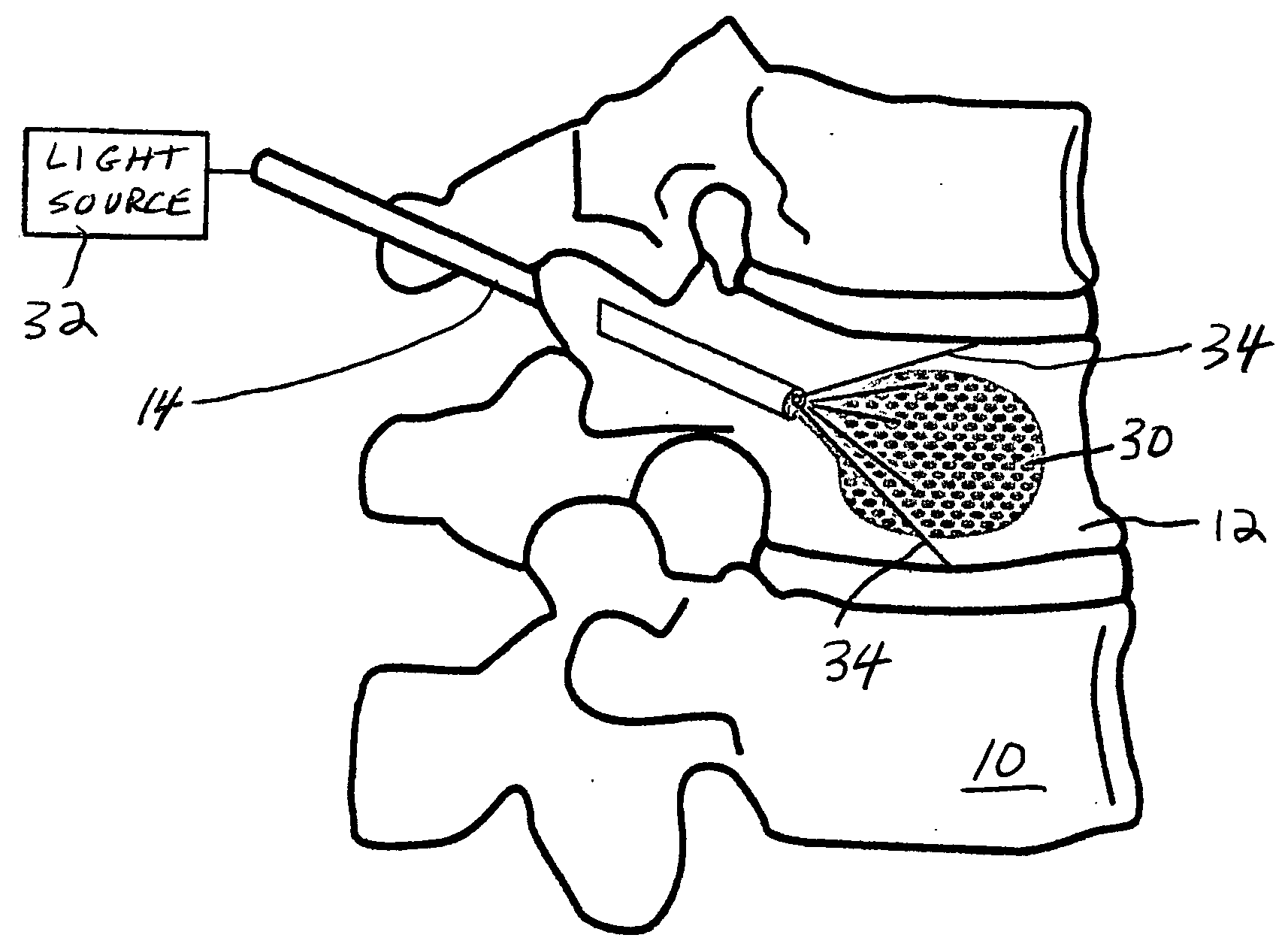

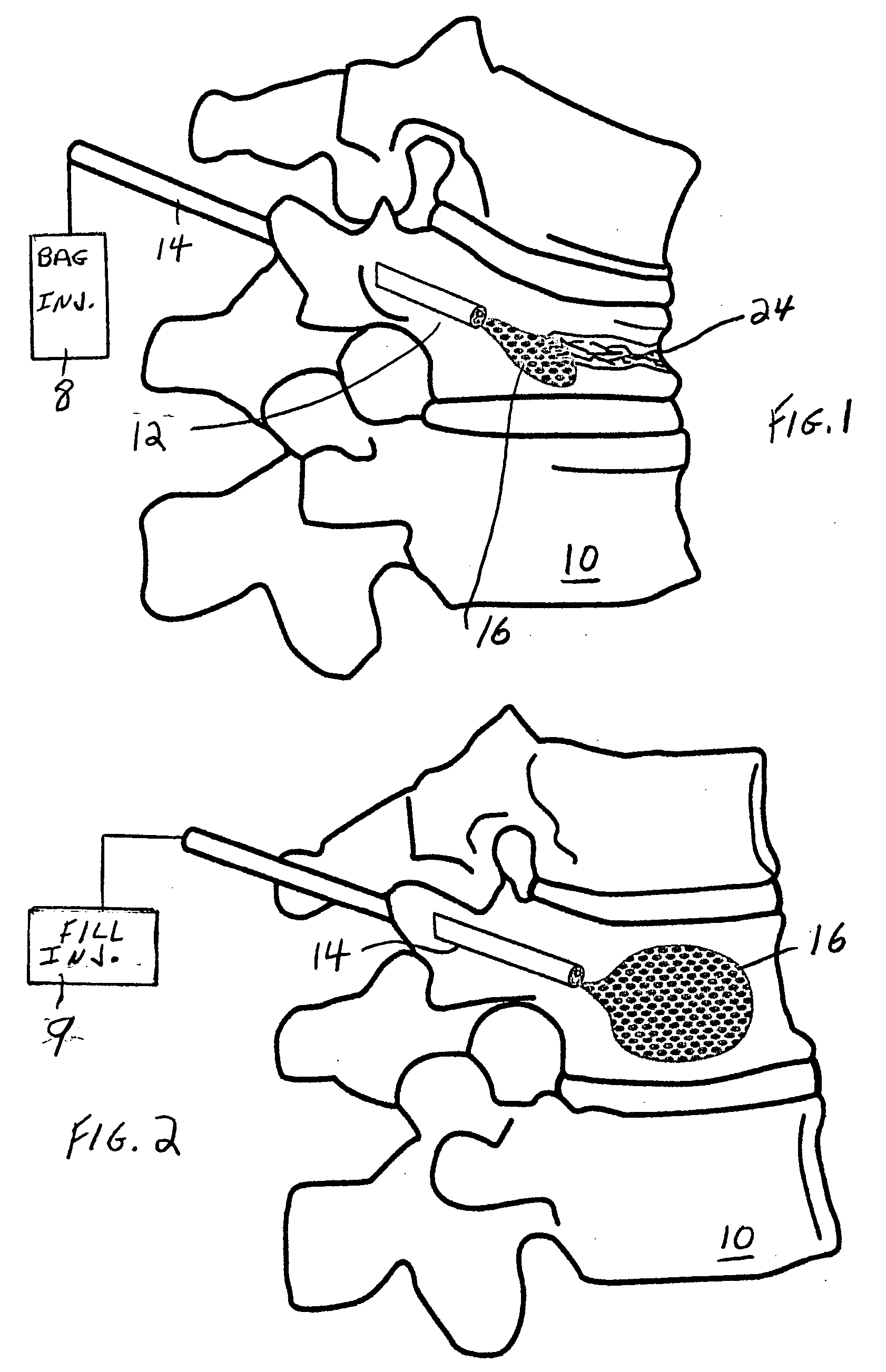

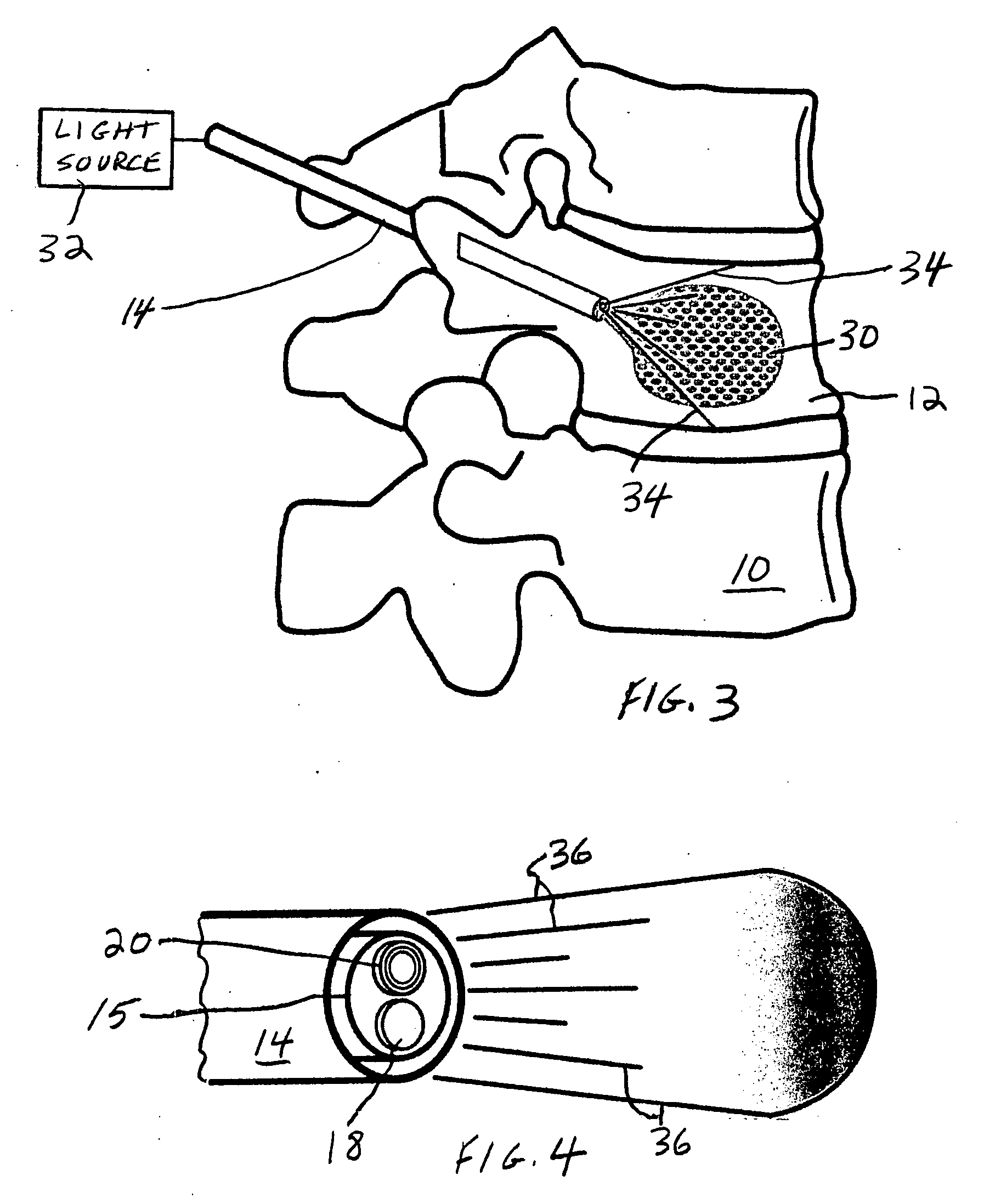

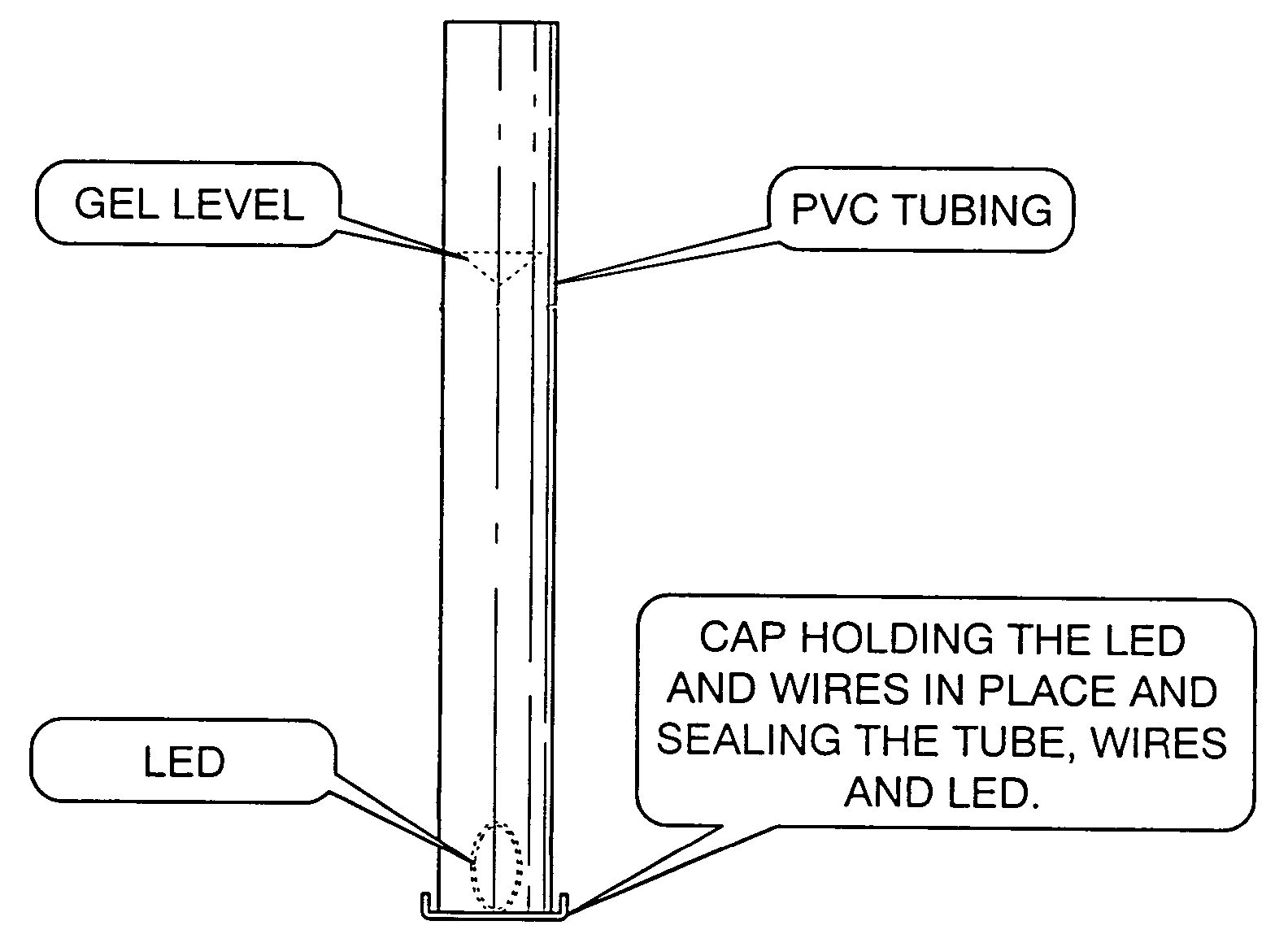

Spinal fill for disk surgery

The invention is based on the use of polyisobutylmethacrylate instead of PMMA as an adhesive or spinal fill material for treating diseases of the spine. Polyisobutylmethacrylate has several advantages over PMMA, mainly less heat is developed during the in situ polymerization process. When using any spinal adhesive of fill material that is light activated, a tube can be used to transmit activating light to the light-activated adhesive or spinal polymerizable fill material at the surgical site. In addition, a mesh bag comprising optical fibers or similar light transmitting material can be employed to receive the injected light-activated fill, with the mesh bag, irradiated externally, for directing the light via the bag to the polymerizable fill.

Owner:ELLIQUENCE

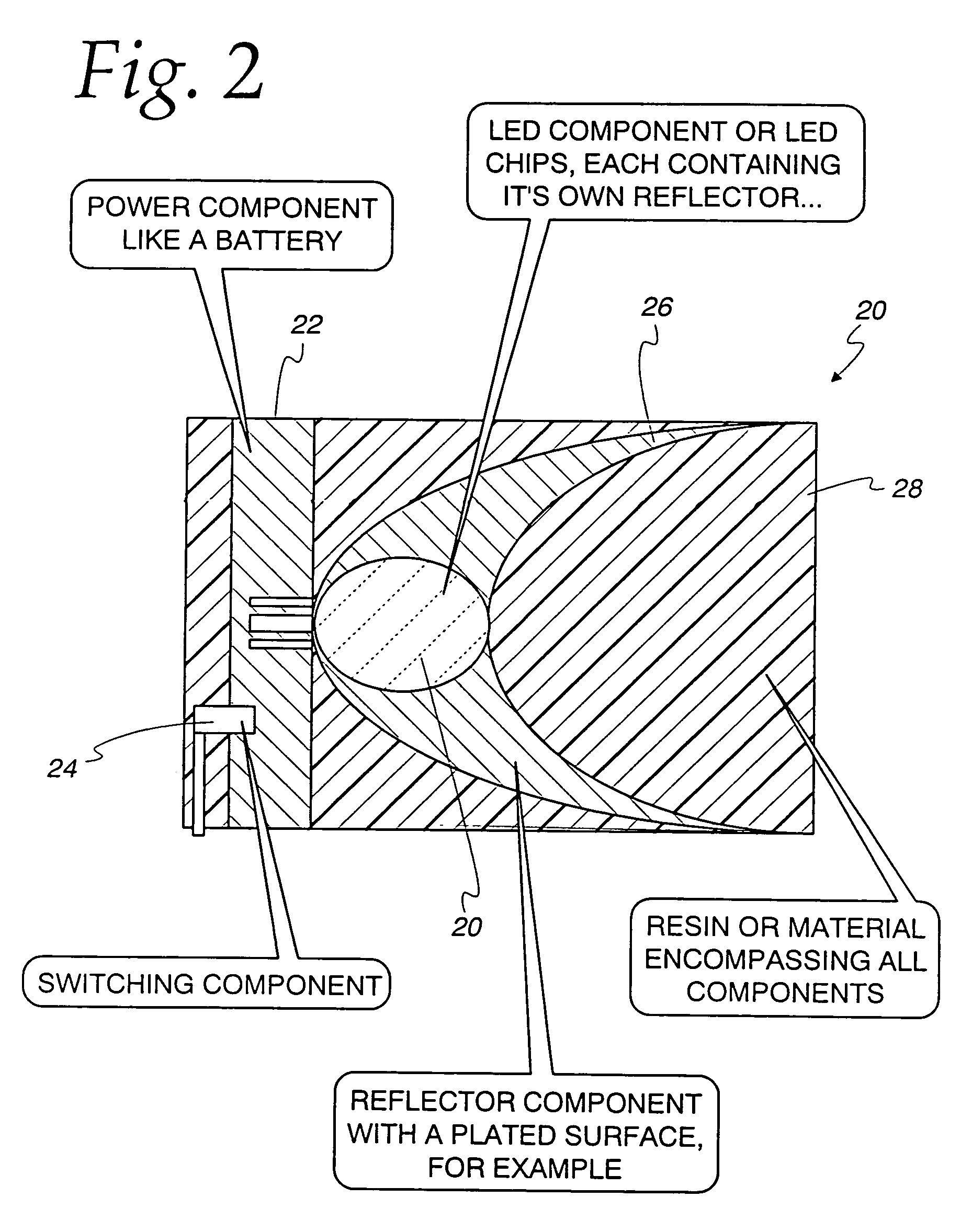

Light emitting medium and illumination system

Owner:ZARIAN JAMES ROUBEN +1

Use of a Partially Neutralized, Anionic (Meth)Acrylate Copolymer as a Coating for the Production of a Medicament Releasing Active Substance at Reduced Ph Values

(EN) The invention relates to the use of a partially neutralized, anionic (meth)acrylate copolymer comprising radically polymerized units of 25 to 95 percent by weight of C1 to C4 alkyl esters of acrylic or methacrylic acid and 5 to 75 percent by weight of (meth)acrylate monomers with an anionic group, at least 4 percent of which are neutralized by means of a base, for producing a medicament that is provided with an active substance-containing core and is coated with the partially neutralized, anionic (meth)acrylate copolymer. Said medicament releases at least 30 percent of the active substance contained therein in 30 minutes at a pH at which the active substance is sufficiently soluble and stable and at which the corresponding medicament that is coated with the non-neutralized anionic (meth)acrylate polymer releases less than 10 percent of the active substance contained therein.

Owner:EVONIK OPERATIONS GMBH

Radiation-curable metal particles and curable resin compositions comprising these particles

InactiveUS6521677B2High refractive indexHigh hardnessMaterial nanotechnologyConductive materialPolymer scienceMeth-

Provided is a liquid curable resin composition which can produce transparent cured products with a high refractive index, high hardness, and superior abrasion resistance, and which can be suitably used as a coating material. The liquid curable resin composition comprises: (A) a poly-functional (meth)acrylic compound having at least three (meth) acryloyl groups in the molecule; (B) a reaction product obtained by the reaction of a compound having a polymerizable unsaturated group and alkoxysilyl group in the molecule and particles metal oxide, the metals being preferably selected from the group consisting of zirconium, antimony, zinc, tin, cerium, and titanium; and (C) a radiation polymerization initiator.

Owner:JSR CORPORATIOON

Injection molding method for neutral and acidic-group containing (meth)acrylate copolymers

InactiveUS20020160042A1Reduce contentOrganic dyesPharmaceutical non-active ingredientsMeth-Additive ingredient

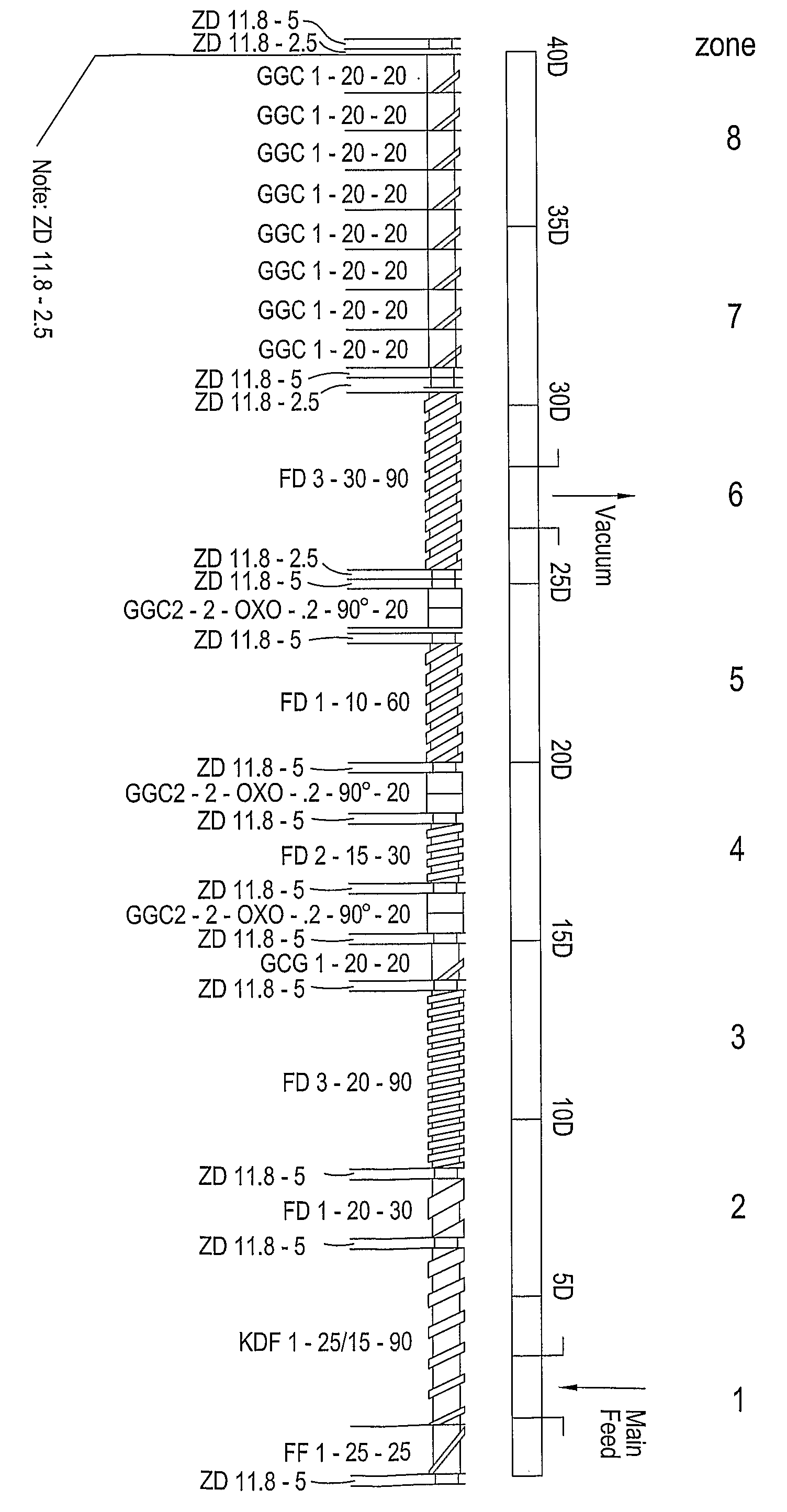

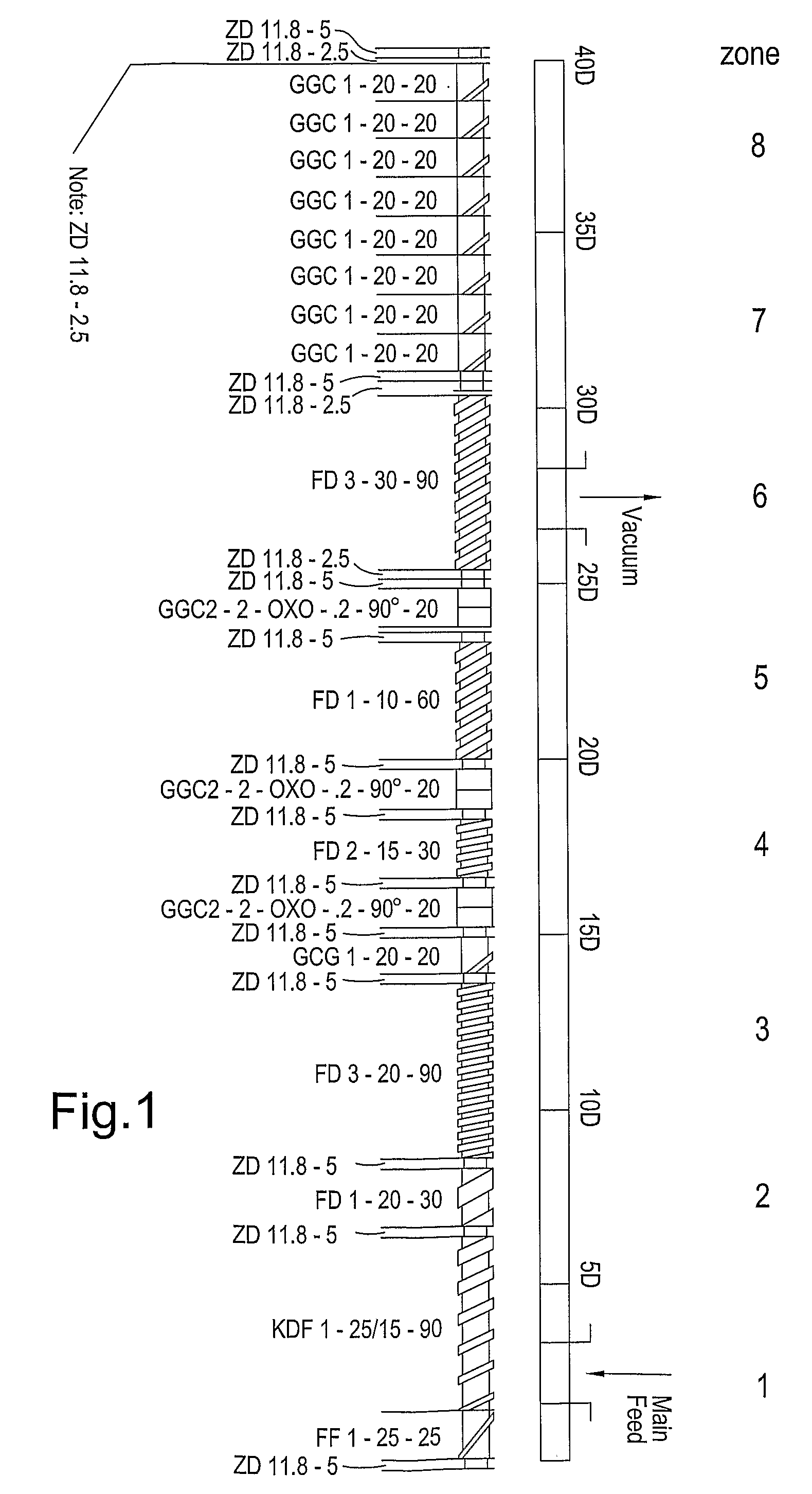

The invention relates to a process for producing mouldings by injection moulding, the steps in the process being A) Melting a mixture made from a) a (meth)acrylate copolymer composed of from 40 to 100% by weight of free-radical-polymerized C1-C4-alkyl esters of acrylic or methacrylic acid and from 0 to 60% by weight of (meth)acrylate monomers having an anionic group in the alkyl radical, where the copolymer comprises b) from 0.1 to 3% by weight of a release agent, and, where appropriate, the mixture may comprise c) from 0 to 50% by weight of a drier, d) from 0 to 30% by weight of a plasticizer, e) from 0 to 100% by weight of additives or auxiliaries, f) from 0 to 100% by weight of an active pharmaceutical ingredient, g) from 0 to 20% by weight of another polymer or copolymer, where the amounts given for components b) to g) are based on the (meth)acrylate copolymer a) and the mixture prior to melting has a content of more than 0.5% by weight of low-boiling constituents with vapour pressure of at least 1.9 bar at 120° C., B) Devolatilizing the mixture in the thermoplastic state at temperatures of at least 120° C., thereby lowering to not more than 0.5% by weight the content of the low-boiling constituents with vapour pressure of at least 1.9 bar at 120° C., C) Injecting the molten and devolatilized mixture into the mould cavity of an injection mould, the temperature of the mould cavity being below the glass transition temperature of the (meth)acrylate copolymer by at least 10° C., cooling the molten mixture, and removing the resultant moulding from the mould.

Owner:PFIZER INC +1

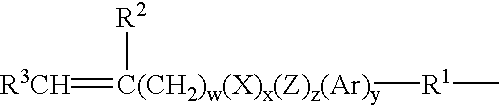

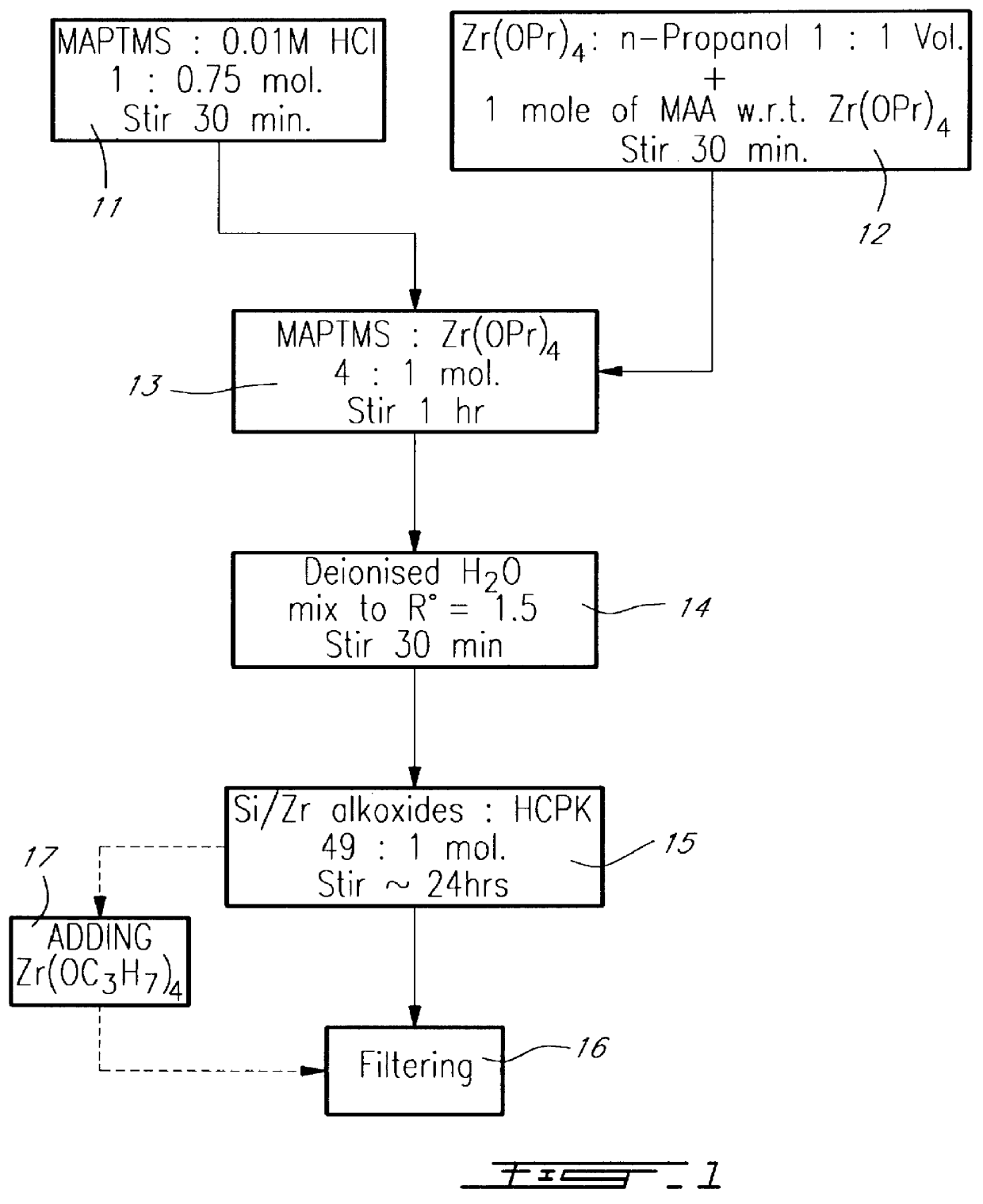

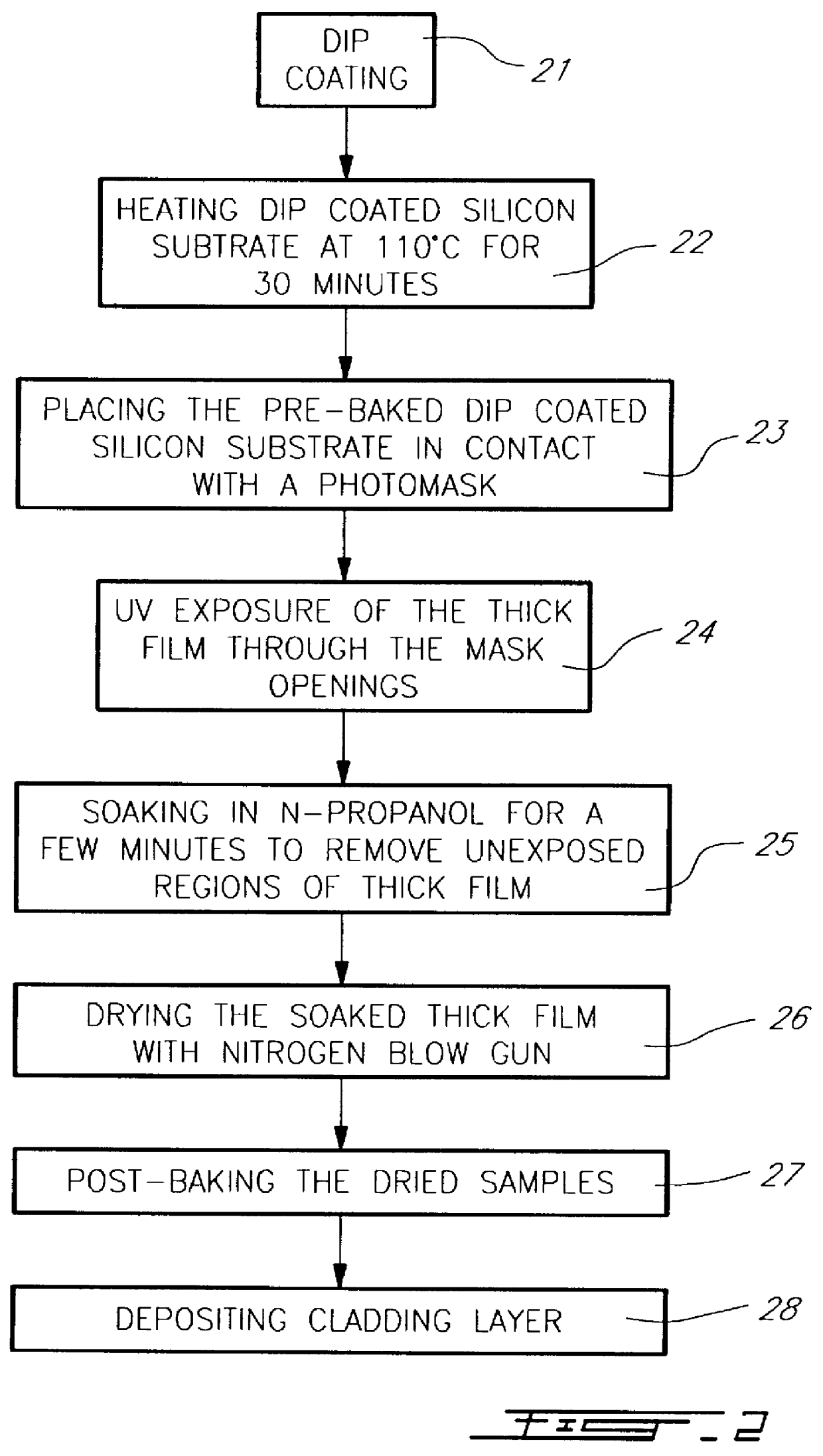

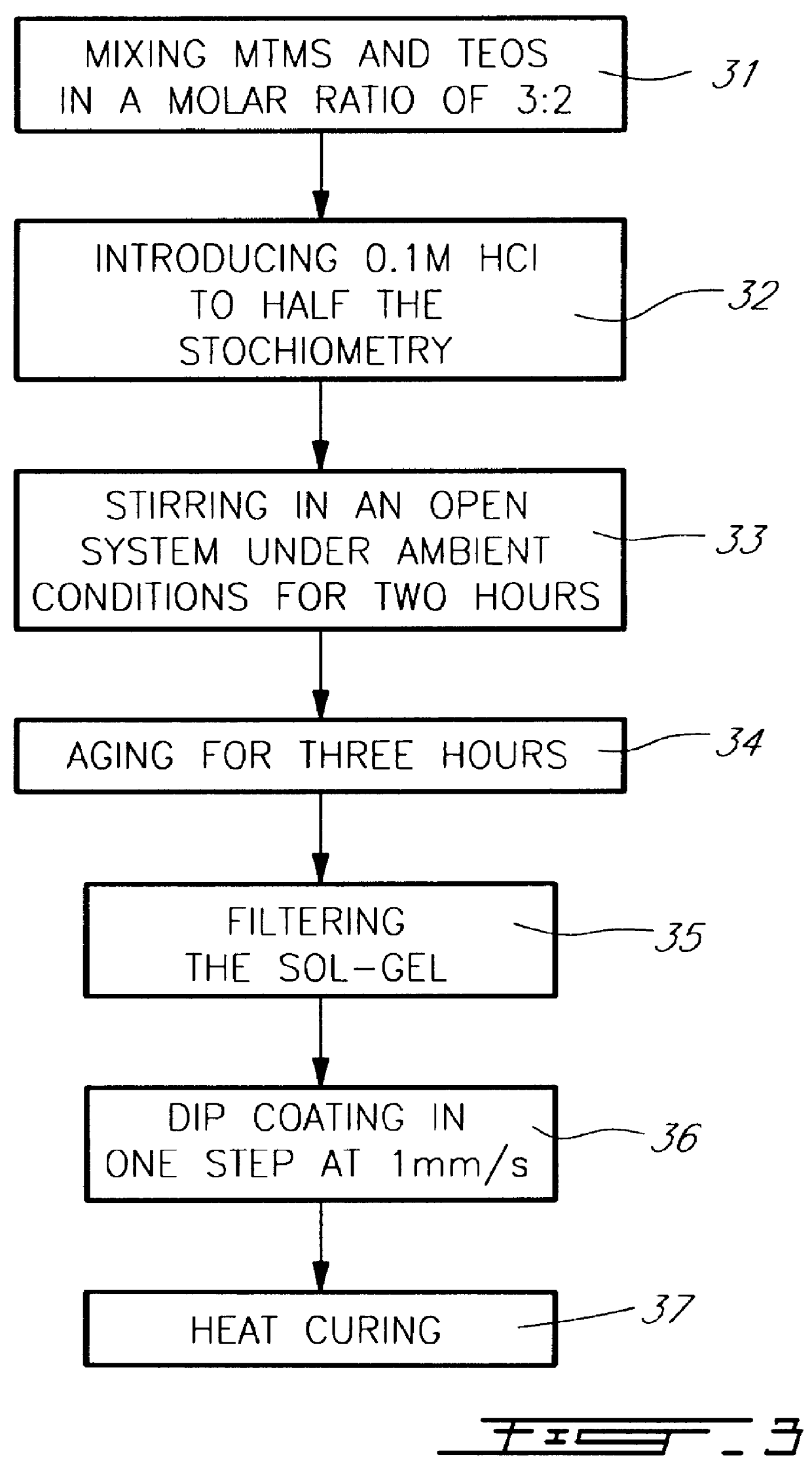

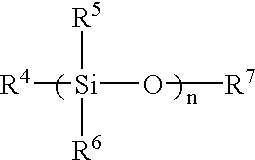

Solvent-assisted lithographic process using photosensitive sol-gel derived glass for depositing ridge waveguides on silicon

InactiveUS6054253ARapid thermal annealingSimple wayPhotomechanical apparatusOriginals for photomechanical treatmentRidge waveguidesSolvent

The process for fabricating a ridge waveguide on a substrate uses a photosensitive sol-gel glass material prepared, according to a first embodiment, by mixing methacryloxypropyltrimethoxysilane (H2C=C(CH3)CO2(CH2)3Si(OCH3)3) and methacrylic acid (H2C=C(CH3)COOH) or, according to a second embodiment, by mixing methacryloxypropyltrimethoxysilane (H2C=C(CH3)CO2(CH2)3Si(OCH3)3) with bis(s-butoxy)aluminoxytriethoxysilane. A thick film of photosensitive sol-gel glass material is first dip coated on at least a portion of the substrate. A photomask is applied to the film of photosensitive sol-gel glass material, and this sol-gel material is exposed to ultraviolet radiation through the opening(s) of the photomask to render a portion of the film insoluble to a given solvent and thereby imprint the ridge waveguide in that film. The thick film is then soaked in this solvent, for example n-propanol to dissolve the unexposed portion of the sol-gel film and leave on the substrate the exposed film portion and therefore the ridge waveguide. The ridge waveguide is heat cured and the heat cured ridge waveguide is covered with a cladding layer.

Owner:MCGILL UNIV - THE ROYAL INSTION FOR THE ADVANCEMENT OF LEARNING

Silyl (METH) acrylate copolymers, processes for preparing the same, antifouling paint compositions containing the silyl (METH) acrylate copolymers, antifouling coating films formed from the antifouling paint compositions, antifouling methods using the antifouling paint compositions, and hulls or underwater structures coated with the antifouling coating films

InactiveUS6458878B1Improve antifouling performanceSuppressed hydrolysis rateAntifouling/underwater paintsPaints with biocidesMeth-Unsaturated monomer

Disclosed is a silyl (meth)acrylate copolymer which comprises 20 to 80% by weight of (a) silyl (meth)acrylate constituent units (I), 0.01 to 40% by weight of (b) acrylic unsaturated monomer constituent units (II) and 5 to 79.9% by weight of Ĉ unsaturated monomer constituent units other than the constituent units (a) and (b). Also disclosed is a process for preparing the silyl (meth)acrylate copolymer, an antifouling paint composition comprising the copolymer, a coating film formed from the paint composition, a hull with the coating film and an antifouling method using the paint composition.

Owner:CHUGOKU MARINE PAINTS

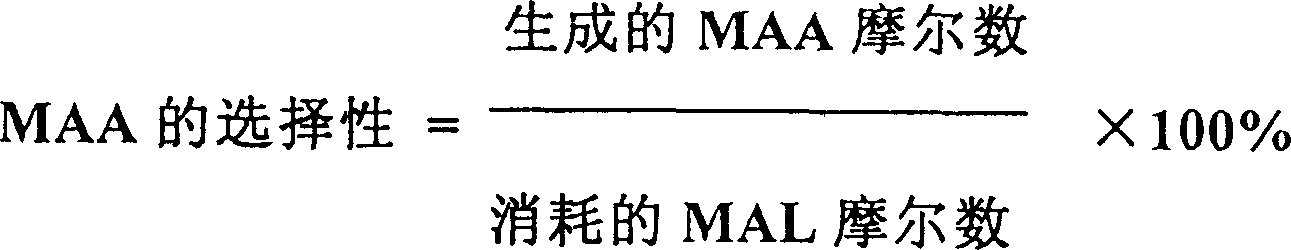

Catalyst for selectively oxidizing methyl acrylic aldehyde to synthesize methyl propenoic acid and its use

ActiveCN1647854AHigh reactivityHigh selectivityPhysical/chemical process catalystsOrganic compound preparationHeteropoly acidGas phase

The present invention provides catalyst for selectively oxidizing methyl acrolein to synthesize methylpropenoic acid and its usage in catalyzing gas phase oxidation of methyl acrolein to synthesize methylpropenoic acid. The catalyst is one heteropoly acid salt containing Mo, P, K, Sb, Cu, As, etc., and has high catalytic activity and stability, long service life, methyl acrolein converting rate higher than 85 % and methylpropenoic acid selectivity over 87 % in the presence of molecular oxygen and diluting gas.

Owner:SHANGHAI HUAYI NEW MATERIAL

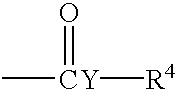

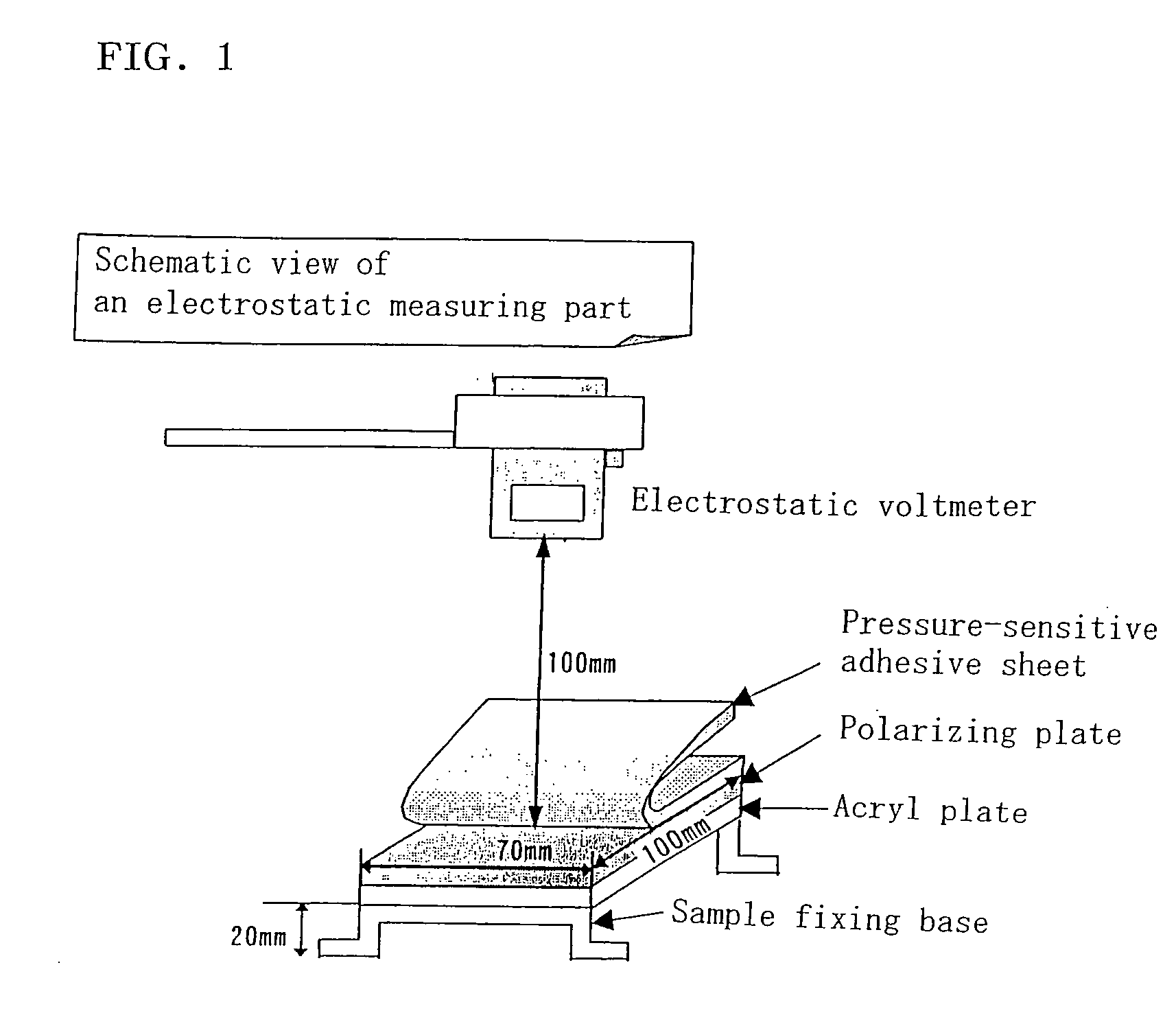

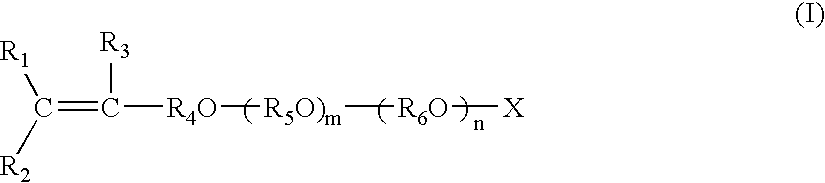

Pressure-sensitive adhesive compositions, pressure-sensitive adhesive sheets and surface protecting films

InactiveUS20060207722A1Optimize timingLow dyeabilityOrganic chemistryNon-macromolecular adhesive additivesCarbon numberHydrogen

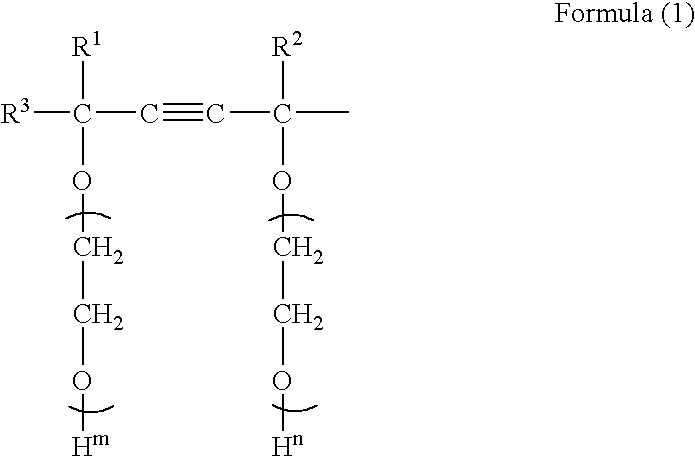

An object of the present invention is to provide an antistatic pressure-sensitive adhesive composition which is excellent in antistatic property and antistatic property with time of a non-electrification-prevented adherend (subject to be protected) upon peeling, and has reduced stainability in an adherend and is excellent in adhesion reliance, and electrification preventing pressure-sensitive adhesive sheets using the same. There is provided a pressure-sensitive adhesive composition comprising an ionic liquid, and a (meth)acryl-based polymer containing, as a monomer component, 0.01 to 20% by weight of a reactive surfactant shown by the following general formula (I) as a monomer unit. [in the formula (I), R1, R2, and R3 indicate likewise or differently hydrogen or the methyl group, R4 indicates an alkylene group of 0 to 30 in carbon number (further, 0 in carbon number means that there is no R4), R5 and R6 indicate likewise or differently alkylene groups of 1 to 30 in carbon number, m indicates the number of 0 to 50 (may not be an integer), n indicates the number of 0 to 100 (may not be an integer), m+n indicates the number of 1 to 150 (may not be an integer), and X indicates hydrogen or an anionic hydrophilic group]

Owner:NITTO DENKO CORP

Method for injection moulding moulded bodies consisting of (meth) acrylate copolymers

InactiveUS20040104501A1Reduce contentLittle reabsorptionPharmaceutical non-active ingredientsEndocrine system disorderPolymer scienceMeth-

The invention relates to a process for producing mouldings by injection moulding the steps in the process being a) melting and mixing of a (meth)acrylate copolymer composed of from 85 to 98% by weight of C1-C4-alkyl (meth)acrylates capable of free-radical polymerization and from 15 to 2% by weight of (meth)acrylate monomers having a quaternary ammonium group in the alkyl radical, with from 10 to 25% by weight of a plasticizer, and also from 10 to 50% by weight of a dryers [sic] and / or from 0.1 to 3% by weight of a release agent, and, where appropriate, with other conventional pharmaceutical additives or auxiliaries and / or with an active pharmaceutical ingredient, b) devolatilizing the mixture at temperatures of at least 120° C., thus reducing the content of the low-boiling constituents with a vapour pressure of at least 1.9 bar at 120° C. to not more than 0.5% by weight, and c) injecting the devolatilized mixture at a temperature of from 80 to 160° C. into the mould of an injection moulding system and removing the resultant moulding from the mould.

Owner:ROEHM GMBH & CO KG +1

Aqueous ink composition and method of manufacturing the same

InactiveUS20050004261A1Improve printing qualityReduce blurDuplicating/marking methodsInksMethacrylatePolymer science

An aqueous ink composition comprising: a pigment, having a particle diameter as determined by the light scattering method of no less than 20 nm and no more than 200 nm; and a water dispersible polymer, having a styrene-equivalent number average molecular weight of as determined by gel permeation chromatography no less than 5000 and no more than 200000, having a surface tension of no less than 20 mN / m and no more than 40 mN / m, and wherein the abovementioned pigment is a polymer-coated pigment that is coated with the abovementioned water dispersible polymer, is provided. The water-dispersible polymer may be a copolymer of monomers, mainly comprising acrylic acid and / or methacrylic acid and an acrylate and / or methacrylate. With this ink composition, the printing quality can be improved.

Owner:SEIKO EPSON CORP

Multiparticulates

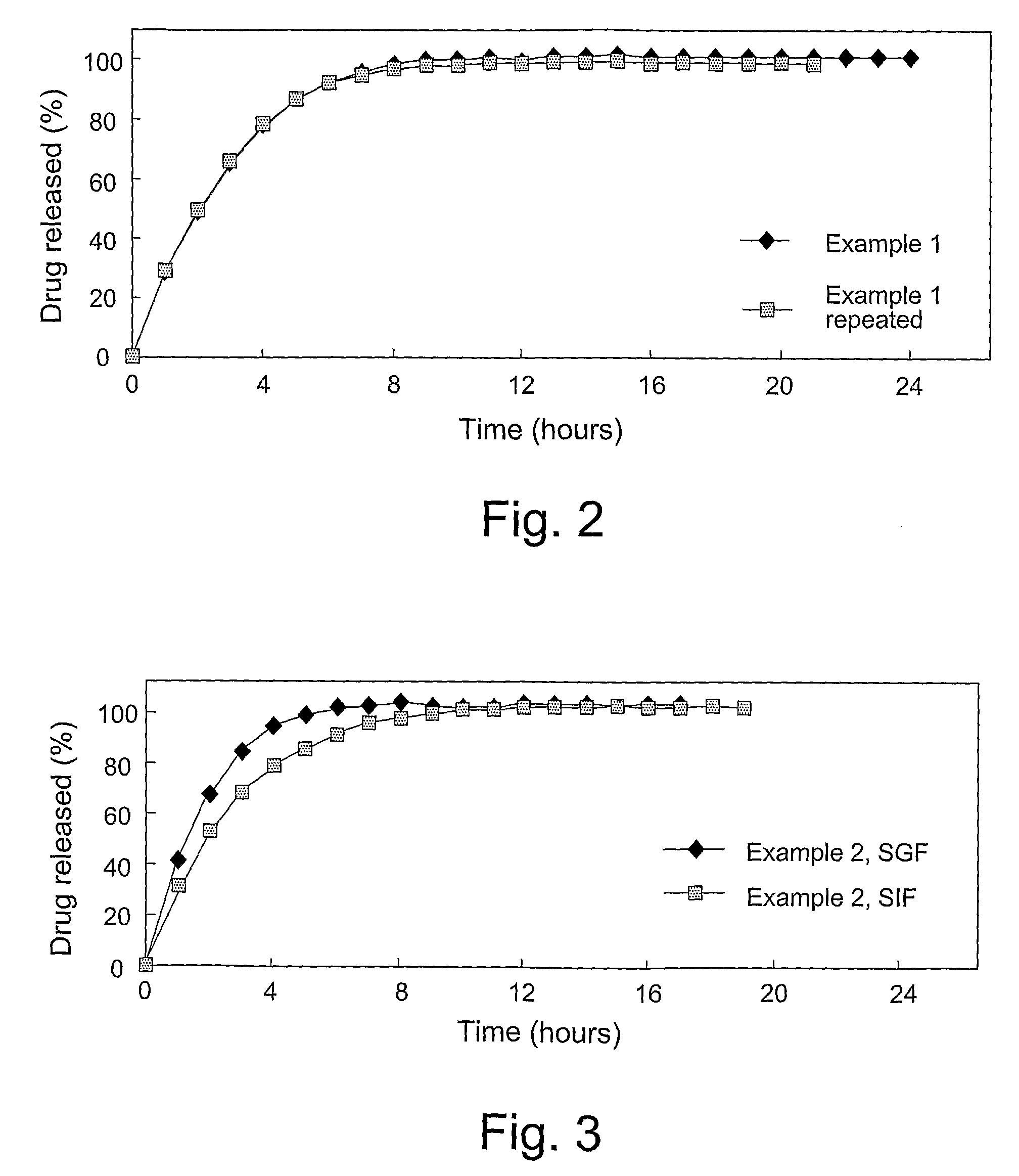

InactiveUS20080260815A1Reduce adhesionReduce the required powerOrganic active ingredientsPowder deliveryActive agentExcipient

Extrusion of a mix containing a pharmaceutically active agent can be achieved using a plasticising excipient in an amount sufficient to act as plasticiser and also act as lubricant, thereby avoiding the need for inclusion of a lubricant. The invention provides multiparticulates with controlled release properties, substantially free of lubricant. The present invention is preferably directed to extruded multiparticulates containing an opioid such as oxycodone, an ammonium methacrylate copolymer such as Eudragit® RSPO, a plasticising excipient such as preferably stearyl alcohol and a water permeability modifier such as preferably Eudragit® RLPO. The obtained multiparticulates show a release rate profile which is pH-independent.

Owner:EURO-CELTIQUE SA

Stiff-feel hair styling compositions

InactiveUS6214328B1Increase stiffnessOptimum hydrophiliclhydrophobic balanceCosmetic preparationsHair cosmeticsMeth-Dicarboxylic acid

A method for enhancing the performance of hair fixative resins in hair styling compositions by using selected polymers having certain compositions is disclosed. In particular, the present invention involves a method of improving the stiffness performance of hair fixative resins by using polymers containing 5-95% (C1-C10)alkyl (meth)acrylate, 0-70% hydroxyalkyl (meth)acrylate, 0-50% monocarboxylic acid monomer and 1-25% dicarboxylic acid monomer. The selected polymers are particularly useful in aqueous hair styling compositions containing low (80% or less) volatile organic compound (VOC) concentrations.

Owner:ROHM & HAAS CO

Water vapor permeable, pressure sensitive adhesive composition

InactiveUS6262329B1Improved pressure sensitive adhesive compositionSimple compositionAdhesive dressingsEster polymer adhesivesWater vaporPolymer chemistry

A water vapor permeable, pressure sensitive adhesive composition comprising a hydrophilic, all acrylic polymer system, free of additives and having enhanced water vapor transmission which contains a significant high amount of hydroxyalkyl acrylate / methacrylate. This adhesive composition is particularly useful in surgical or medical dressing applications.

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

Cationically polymerizable pigmented composition

InactiveUS6166100AGood dispersibilityMaintain good propertiesOrganic chemistryFilm/foil adhesivesEpoxyPolymer science

A cationically polymerizable pigmented composition comprising (A) a cationically polymerizable binder component containing at least one resin or compound selected from the group consisting of (A-1) a cationically polymerizable acrylic resin consisting of a copolymer of (a) a (meth) acrylic ester monomer having C6-31 aliphatic hydrocarbon group, (b) a polymerizable unsaturated monomer containing a polymerizable unsaturated group and at least one cationically polymerizable moiety selected from the group consisting of an epoxy group and an oxetane ring, and optionally (c) other polymerizable unsaturated monomer, and (A-2) a fatty acid-modified epoxy compound containing C6-32 aliphatic hydrocarbon group and epoxy group, (B) a cationic polymerization initiator initiating polymerization by irradiation or heating, and (C) a color pigment.

Owner:KANSAI PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com