Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3709 results about "Polymethyl methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

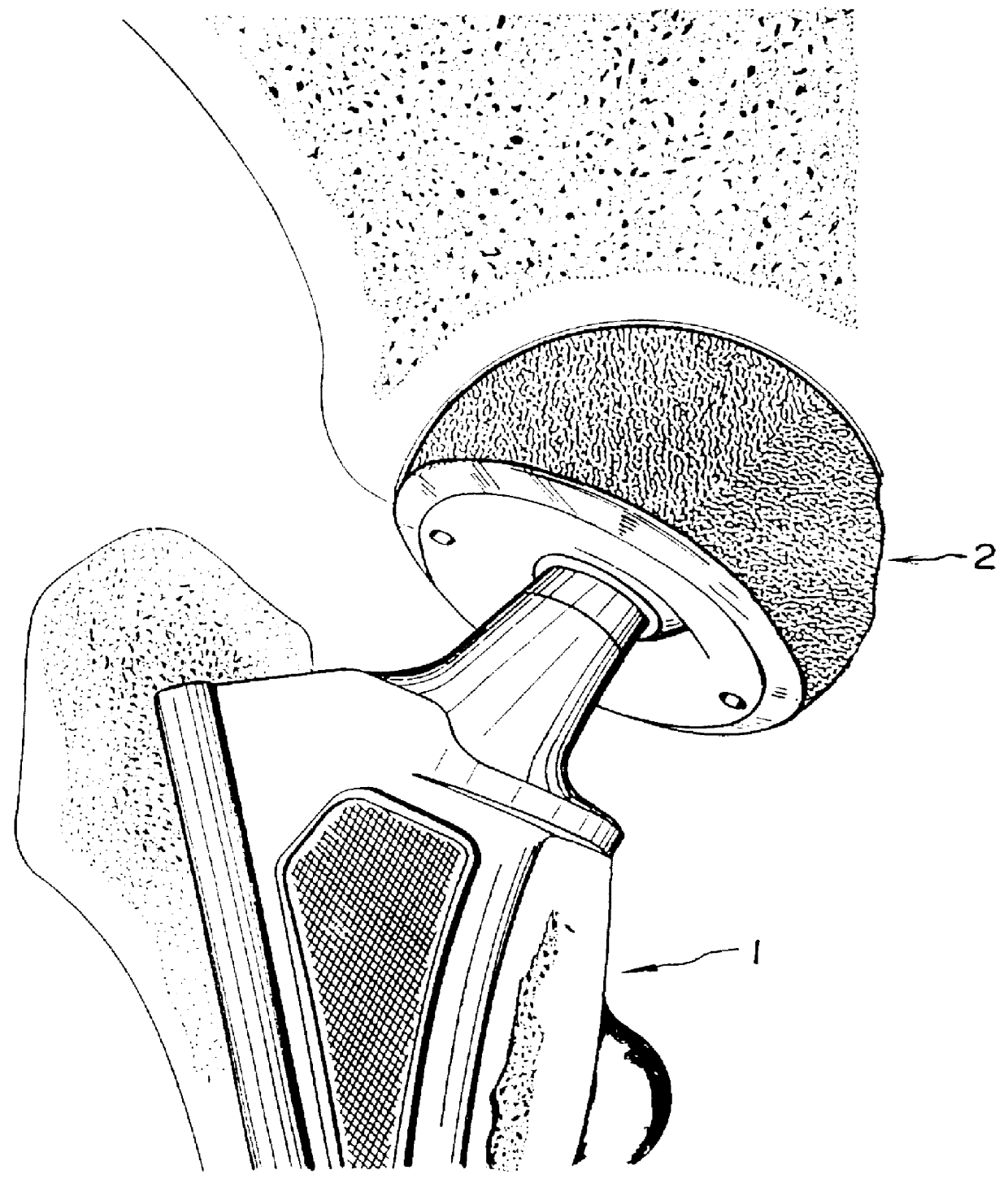

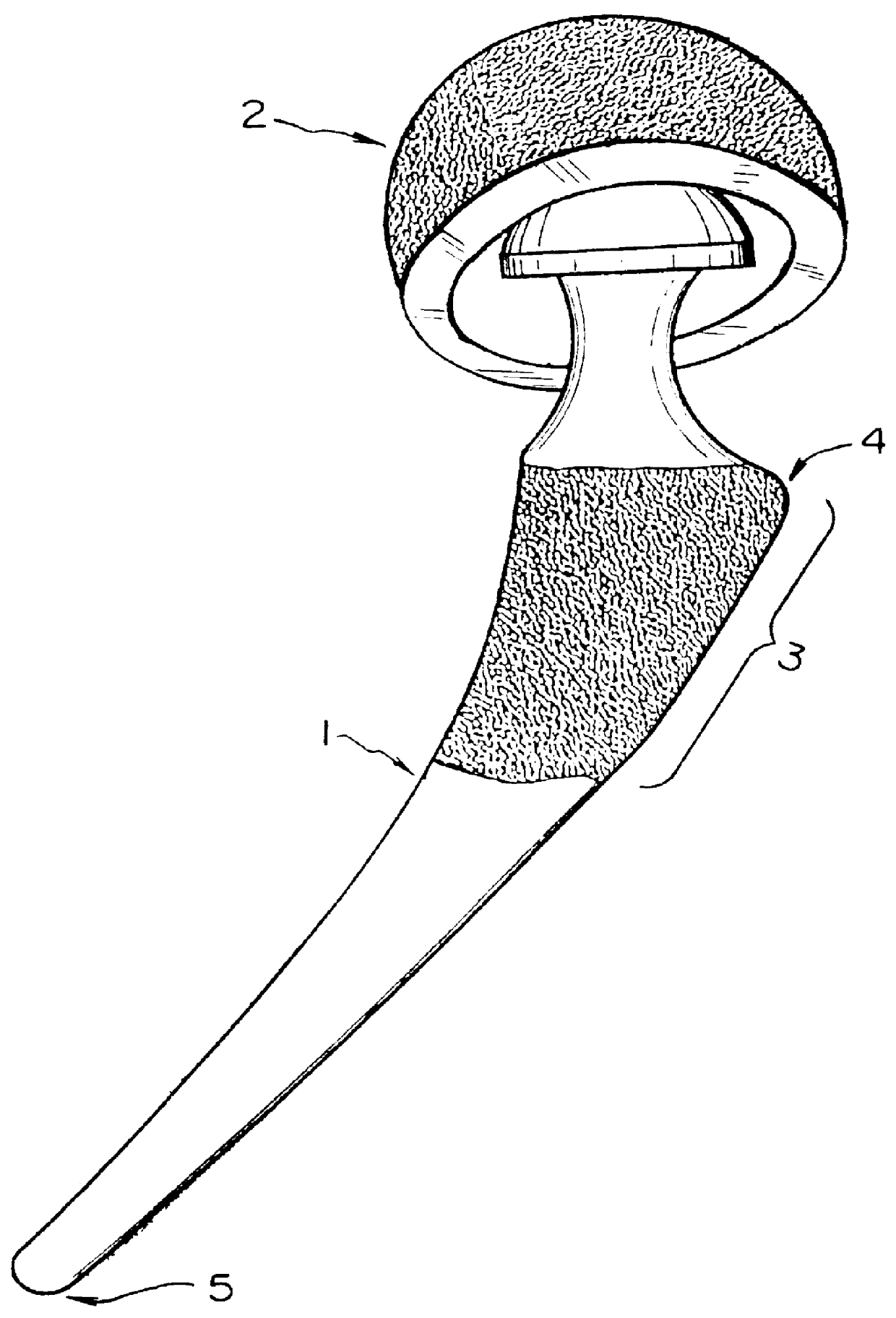

Orthopedic implant system

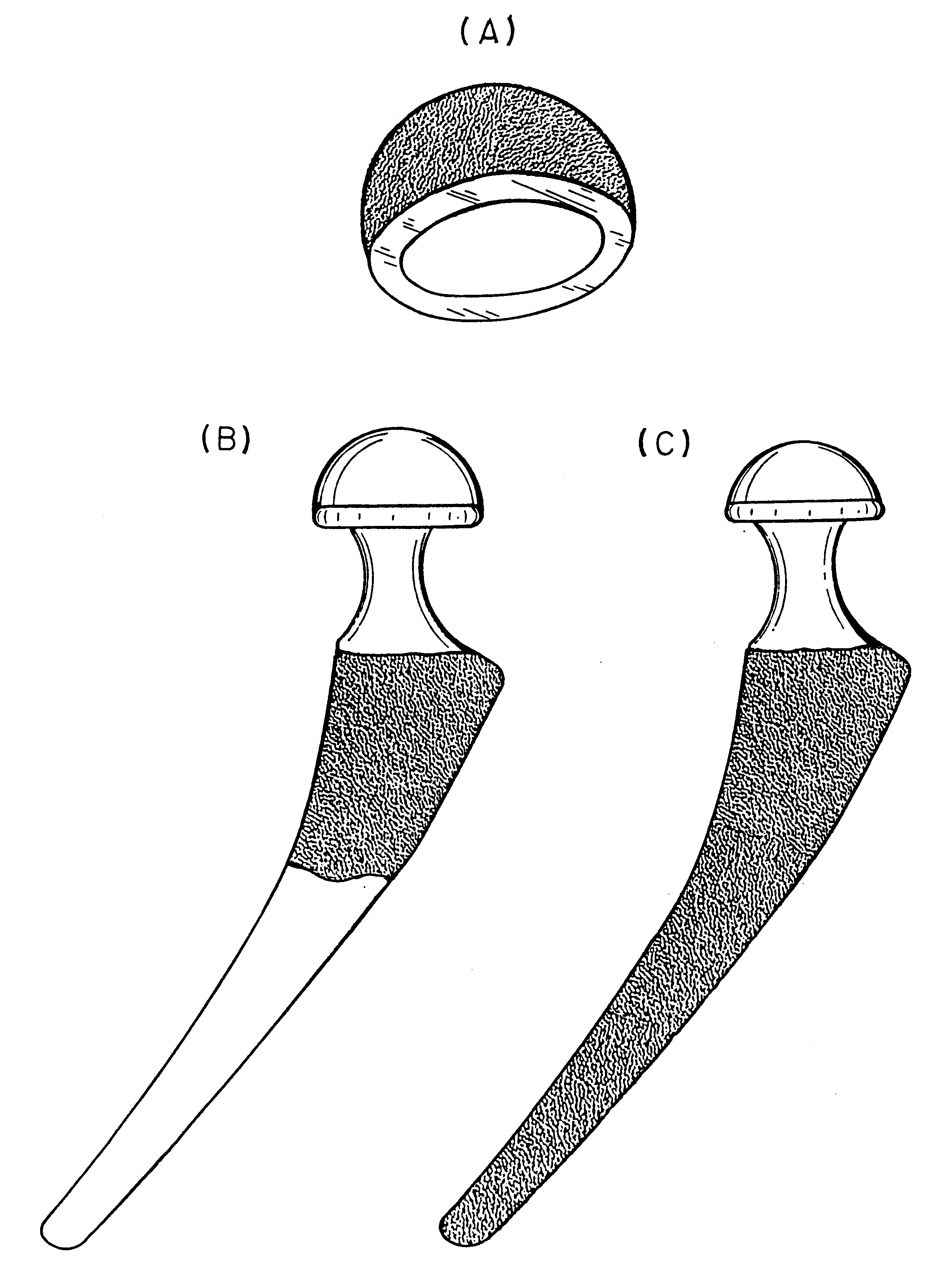

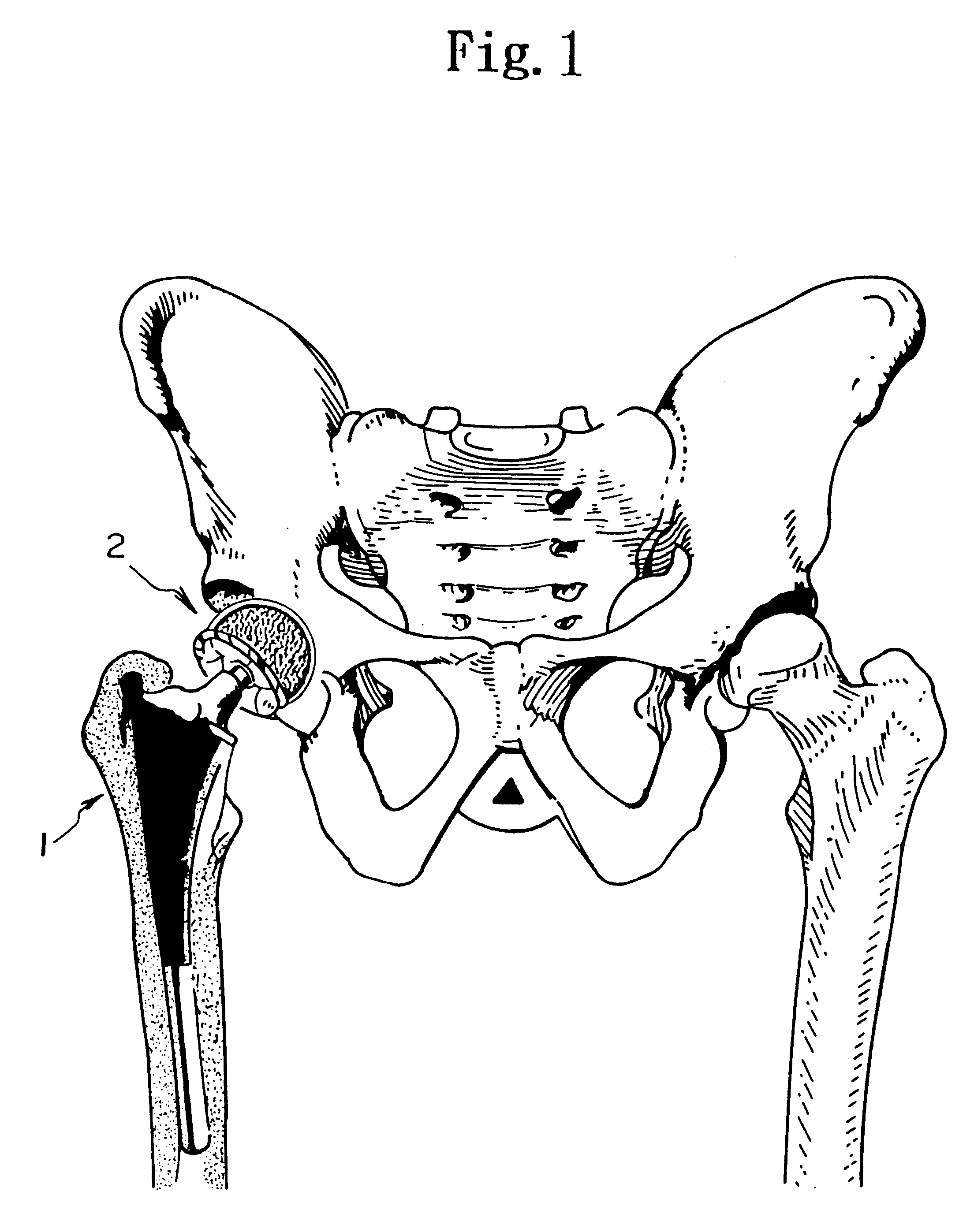

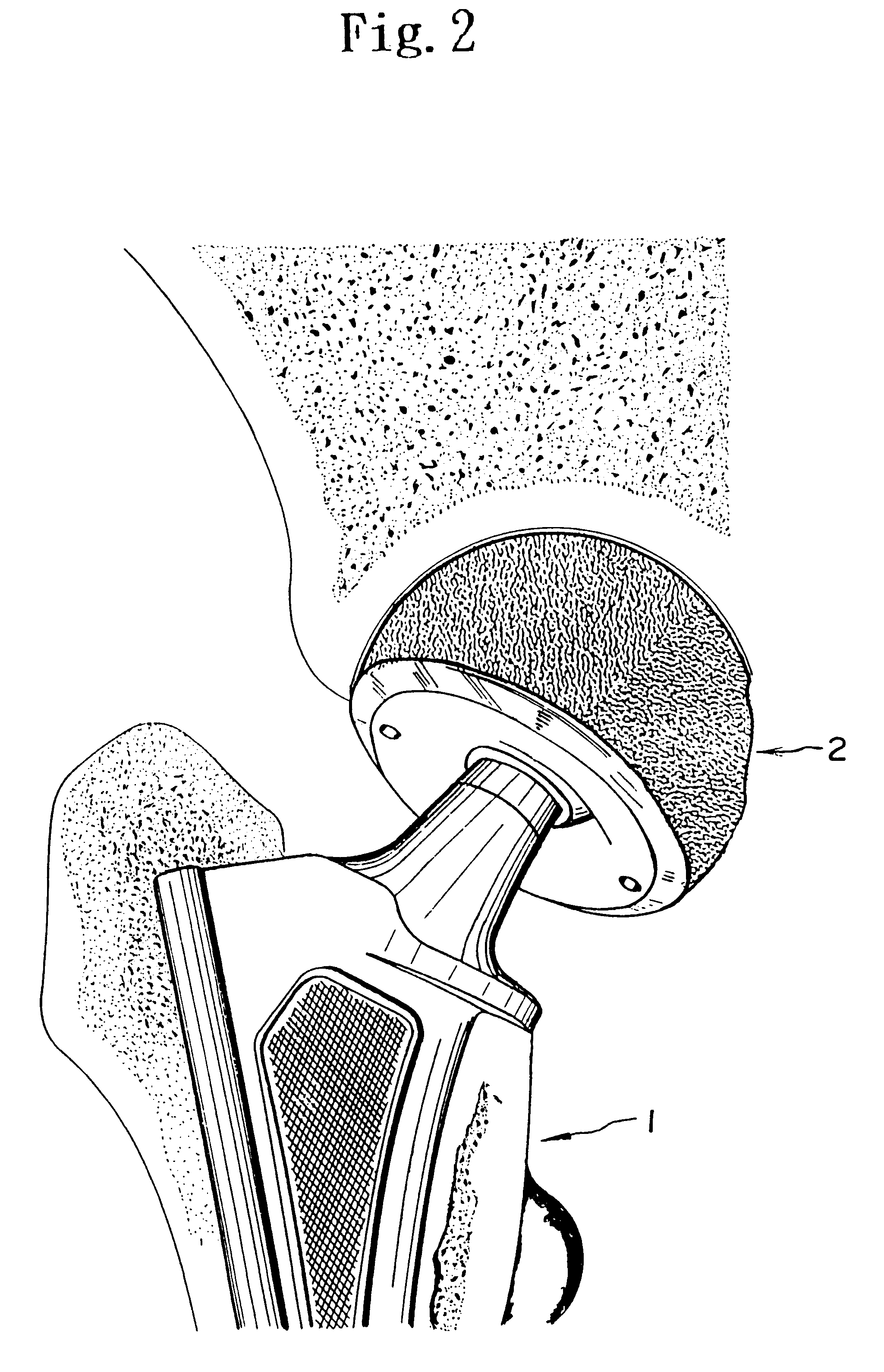

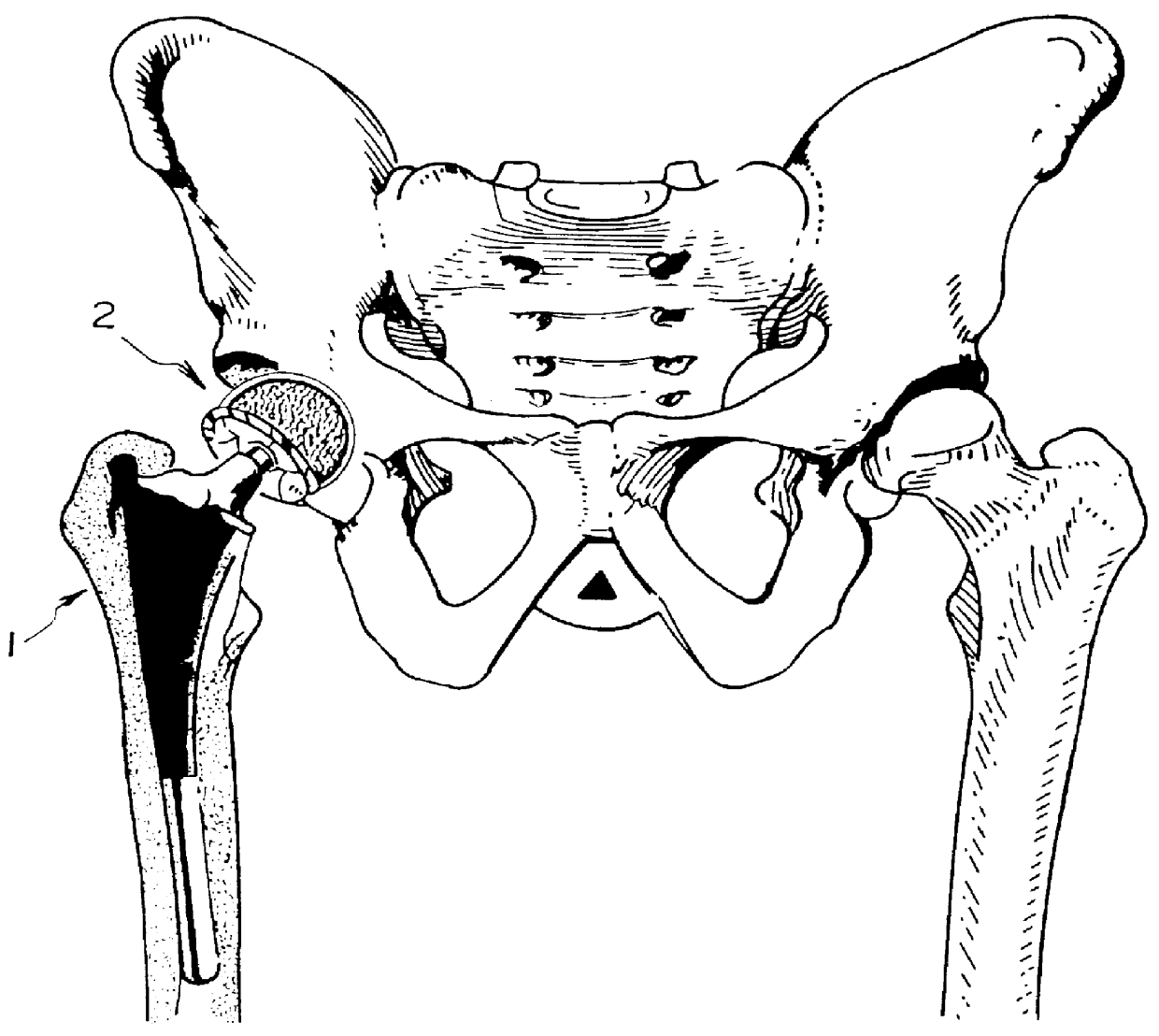

InactiveUS6312473B1Easy to fixAvoid excessive temperatureSurgical adhesivesBone implantFemoral stemPolymethyl methacrylate

It is an object of the present invention to provide an improved orthopedic implant system with satisfied biological, mechanical and morphological compatibilities.Solid metal femoral stem and solid metal acetabular head are covered with diffusion-bonded foamed-shaped sheet made of commercially pure titanium or titanium alloy(s). The open-cells in said foamed metal sheet are impregnated with biocompatible polymethyl methacrylate resin cement, which is reinforced with selected oxides including alumina, magnesia, zirconia, or a combination of these oxides along with an application of a small amount of a metal primer agent.

Owner:OSHIDA YOSHIKI

Polymer powders for SIB processes

A process of selective inhibition of bonding (SIB) to produce three-dimensional objects is used to obtain high-quality moldings. High-quality moldings can be produced by using pulverulent materials which have a median particle size of from 10 to 200 μm in which at least one polymer or copolymer selected from polyester, polyvinyl chloride, polyacetal, polypropylene, polyethylene, polystyrene, polycarbonate, polymethyl methacrylate (PMMA), PMMI, ionomer, polyamides, copolyester, copolyamides, terpolymers, or ABS, or a mixture of these, is present.

Owner:EVONIK DEGUSSA GMBH

Orthopedic implant system

InactiveUS6066176AStrong interlocking fixationEasy to fixSurgical adhesivesBone implantPolymethyl methacrylateFemoral stem

It is an object of the present invention to provide an improved orthopedic implant system with satisfied biological, mechanical and morphological compatibilities. Solid metal femoral stem (entirely or partially) and solid metal acetabular head (entirely or partially) are covered with diffusion-bonded foamed-shaped sheet made of commercially pure titanium or titanium alloy(s). The open-cells in said foamed metal sheet are impregnated with biocompatible polymethyl methacrylate resin cement, which is reinforced with selected oxides (e.g., alumina, magnesia, zirconia, or a combination of these oxides) along with an application of a small amount of a metal primer agent.

Owner:OSHIDA YOSHIKI

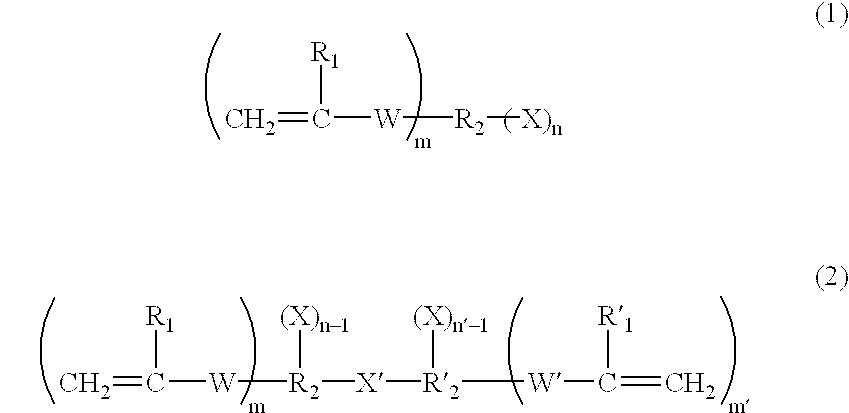

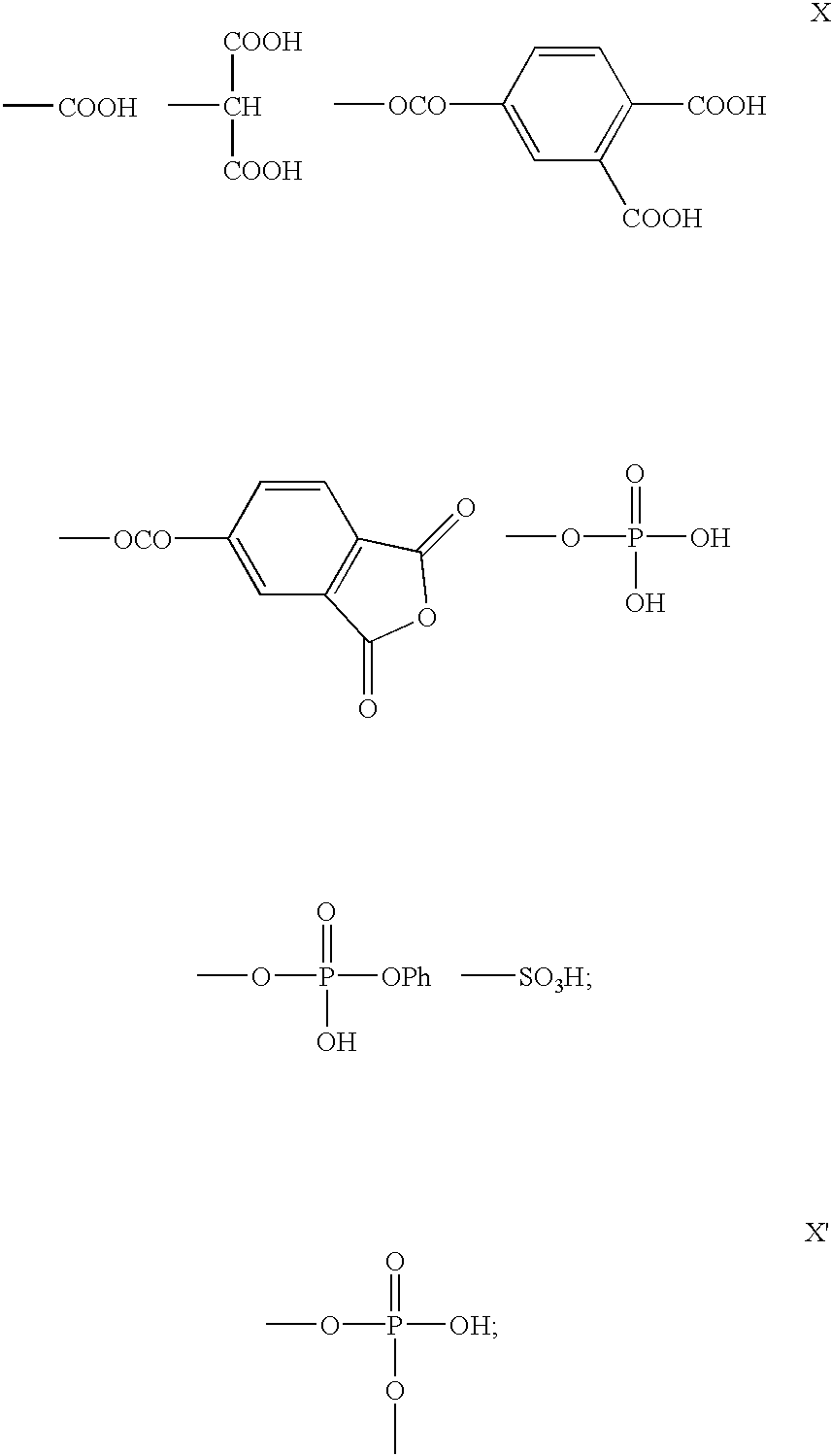

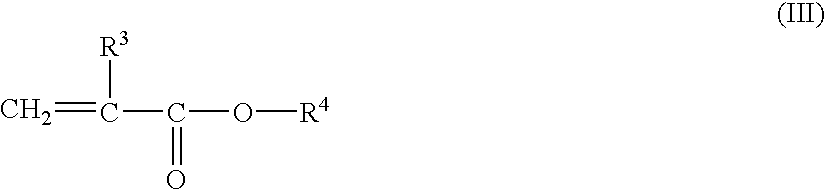

Dental adhesive composition

This invention discloses a dental adhesive composition comprising (A) a polymerizable monomer comprising an acidic-group containing polymerizable monomer such as 11-methacryloyloxy-1,1-undecane dicarboxylic acid, (B) a mixed filler of a spherical filler substantially consisting of a non-crosslinking polymethyl methacrylate and a spherical filler substantially consisting of a non-crosslinking polyethyl methacrylate; and (C) a polymerization initiator; and a dental adhesive kit comprising the above dental adhesive composition in combination with a dental primer comprising (D) an acidic-group containing polymerizable monomer, (E) an aryl borate, (F) an organosulfinic acid salt and (G) water. The dental adhesive composition exhibits good operability and improved adhesion performance.

Owner:TOKUYAMA DENTAL CORP +1

Silver nanowire-based transparent conductive thin film and preparation method thereof

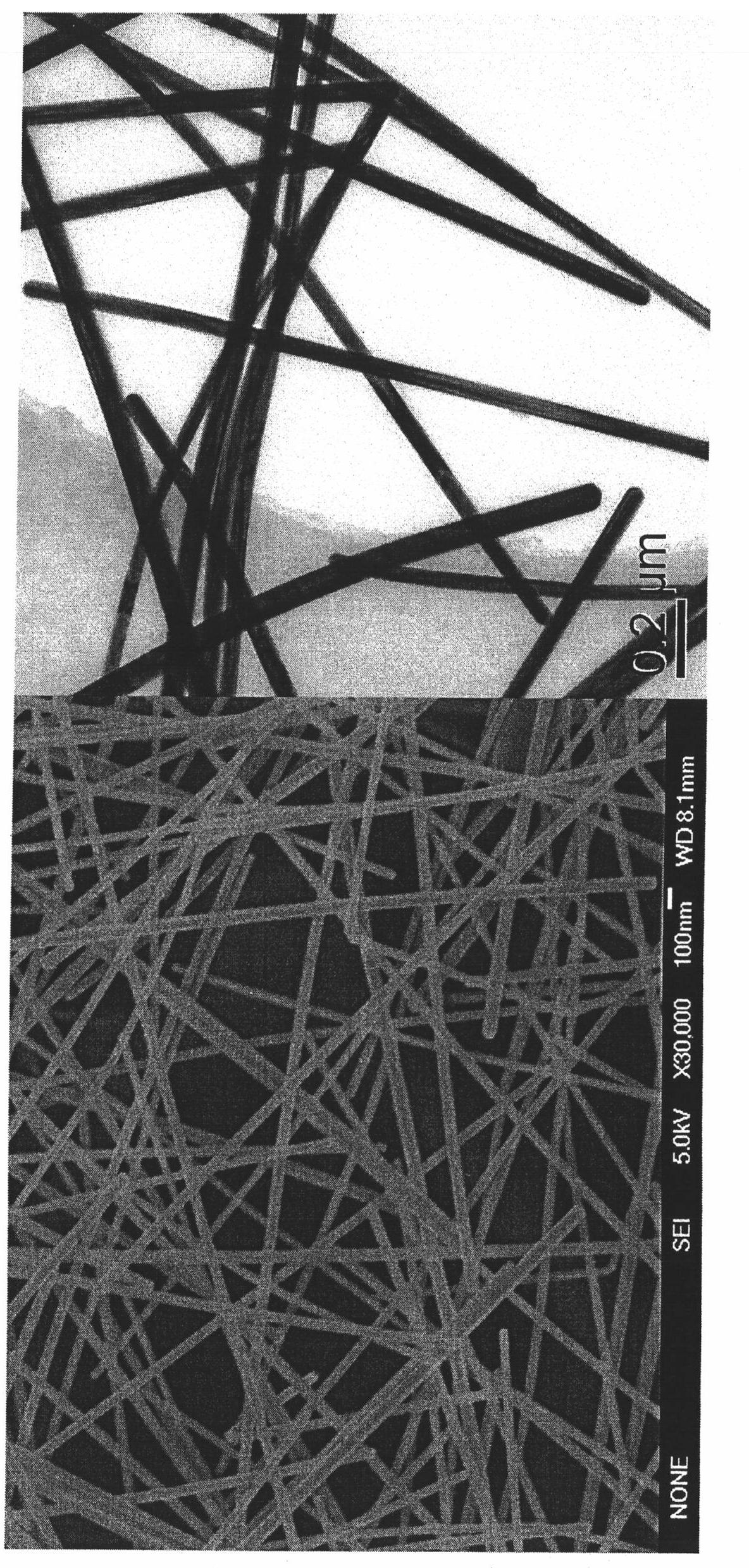

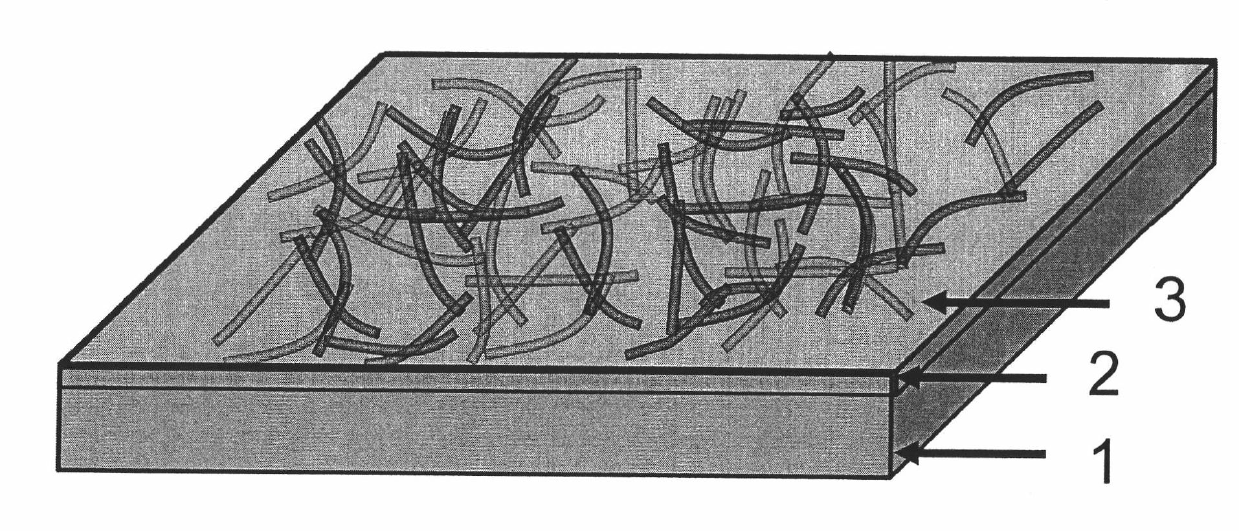

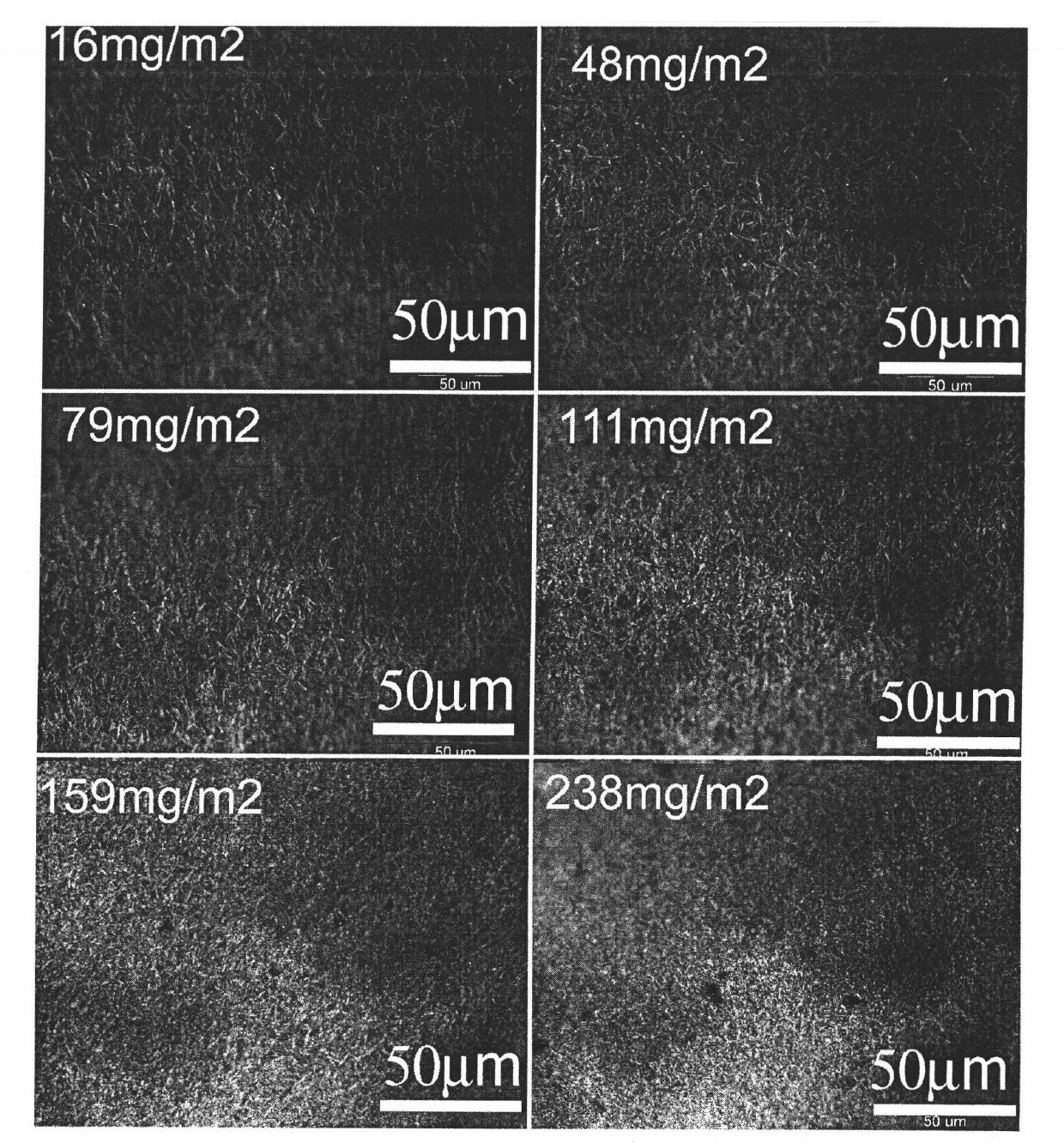

InactiveCN102087886AReduce roughnessReduce transmittanceConductive layers on insulating-supportsIndividual molecule manipulationPolyvinyl alcoholPolymethyl methacrylate

The invention provides a silver nanowire-based transparent conductive thin film and a preparation method thereof. The preparation method is characterized by comprising the following steps of: forming a uniform adhesive layer on a substrate by organic polymer fluid; and forming a silver nanowire conductive layer on the adhesive layer, wherein silver nanowires can be firmly adhered to the adhesive layer. Through the adhesive layer, the firmness and the reliability of the silver nanowire transparent conductive thin film are greatly improved, the problem of easiness of falling of the silver nanowires is solved, and the selection range of the substrate is expanded. If the adhesive layer is formed by polyvinyl alcohol on a polymethyl methacrylate (PMMA) substrate, the visible light transmittance reaches 84 percent when square resistance is 130.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

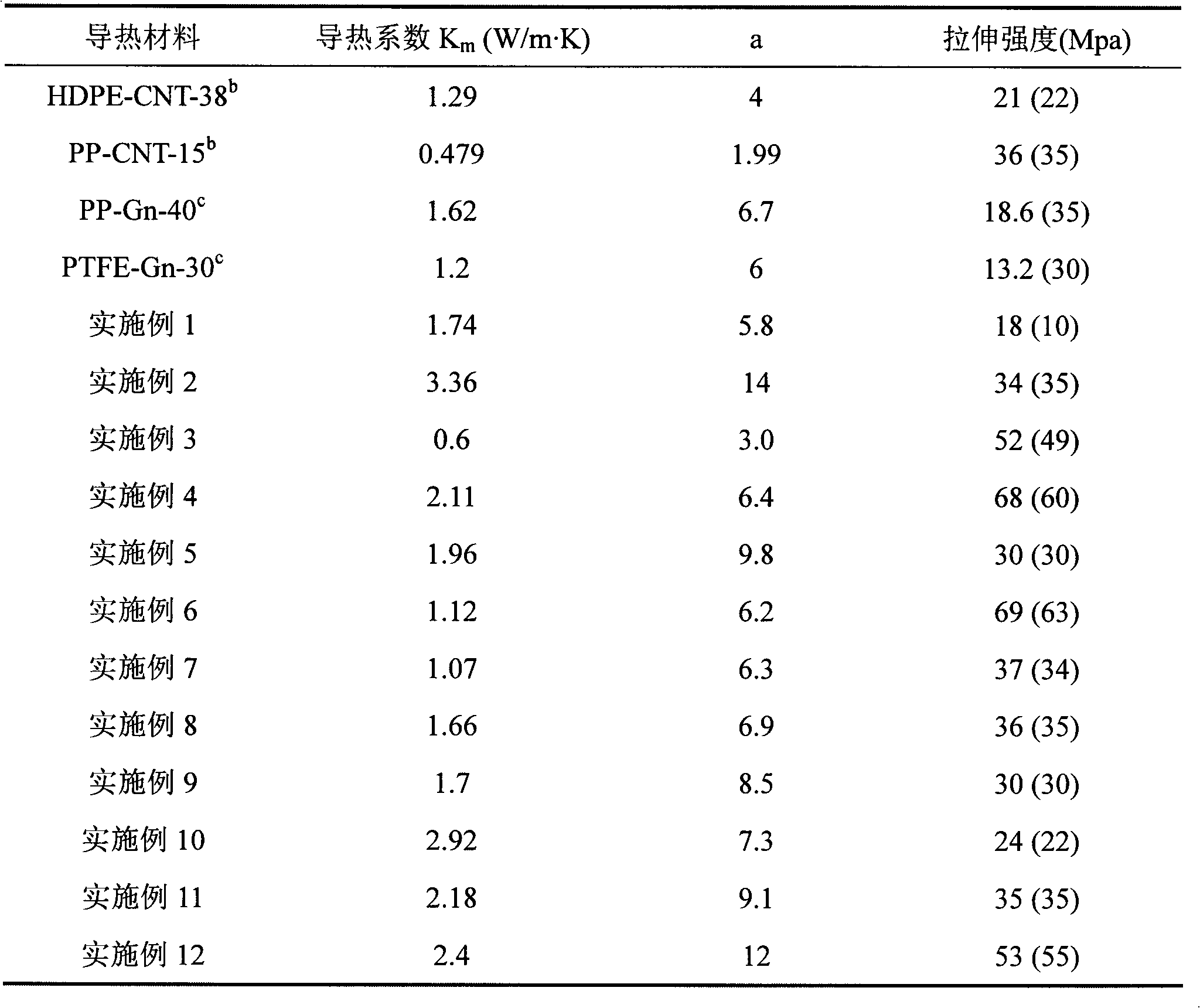

High-heat-conductivity composite material and preparation method thereof

InactiveCN102040761AImprove thermal conductivitySmall amount of thermally conductive fillerFiberCarbon fibers

The invention discloses a high-heat-conductivity composite material and a preparation method thereof. The preparation method comprises the following steps: evenly mixing fibrous heat-conduction filler and high-heat-conductivity filler graphene in a mass ratio of 1:1-1:200 with thermoplastic polymer, dispersing for 0.5-24 hours, granulating to obtain high-heat-conductivity composite grains, and putting the grains in a die to carry out hot molding at 170-280 DEG C under the pressure of 10-18 MPa. The thermoplastic polymer is any one of polyethylene, polypropylene, polyvinylidene fluoride, polytetrafluoroethylene, polyperfluoroalkoxy ester, nylon, polymethyl methacrylate, polycarbonate and polyvinyl chloride. The fibrous heat-conduction filler is carbon fiber or carbon nanotube, and the high-heat-conductivity filler accounts for 5-35 wt% of the high-heat-conductivity composite material. The high-heat-conductivity composite material has the advantages of excellent heat-conduction property, low consumption of heat-conduction filler, favorable mechanical properties, simple preparation technique and low cost.

Owner:SOUTH CHINA UNIV OF TECH

Special plastic/acrylonitrile butadiene styrene (PC/ABS) alloy for notebook computer shell

ActiveCN101974218AExcellent surface hardnessImprove scratch resistanceGlass fiberPolymethyl methacrylate

The invention discloses a special plastic / acrylonitrile butadiene styrene (PC / ABS) alloy for a notebook computer shell. The formula comprises the following materials in parts by weight: 30-80 parts of polycarbonate, 5-65 parts of acrylonitrile-butadiene-styrene copolymer, 5-15 parts of compatilizer, 1-15 parts of flame retardant agent, 3-20 parts of filler, 1-10 parts of hardness modifier, 0.5-5 parts of anti-falling agent and 0-1 part of auxiliary agent. By adopting specific high-molecular polymers of polymethyl methacrylate (PMMA), ultrahigh-molecular polysiloxane and the like, the special PC / ABS alloy selects mineral fillers of specific-size mica, glass fiber and the like to carry out rematching therewith and generates synergistic effect, thus obviously improving the surface hardness and scraping resistance of the material and simultaneously having no influence on the other performances of the material. The PC / ABS alloy material has excellent impact resistance, surface scraping resistance and flame retardance, can meet the requirements of plastic for the notebook computer shell and has considerable promotion and application values.

Owner:大河宝利材料科技(苏州)有限公司

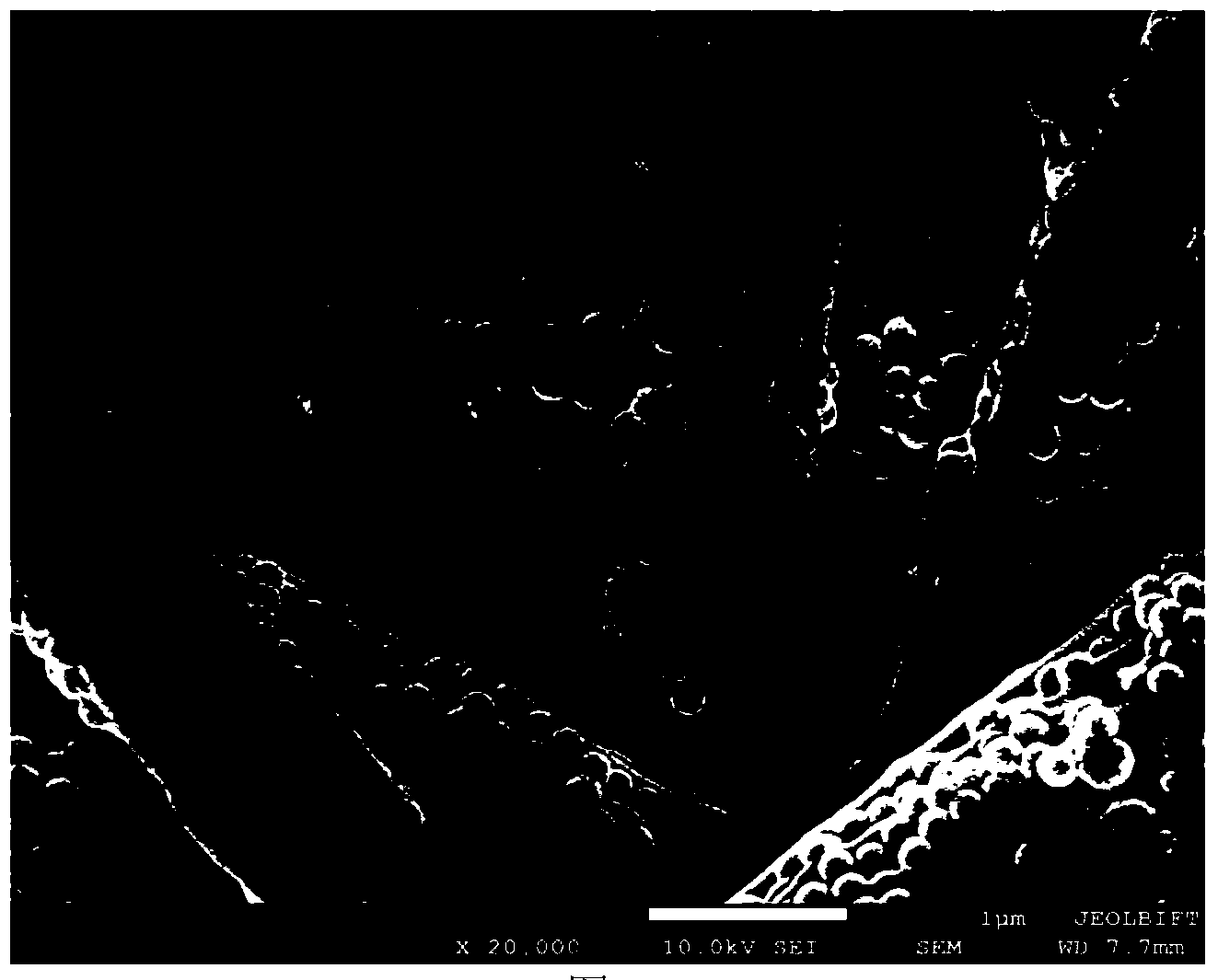

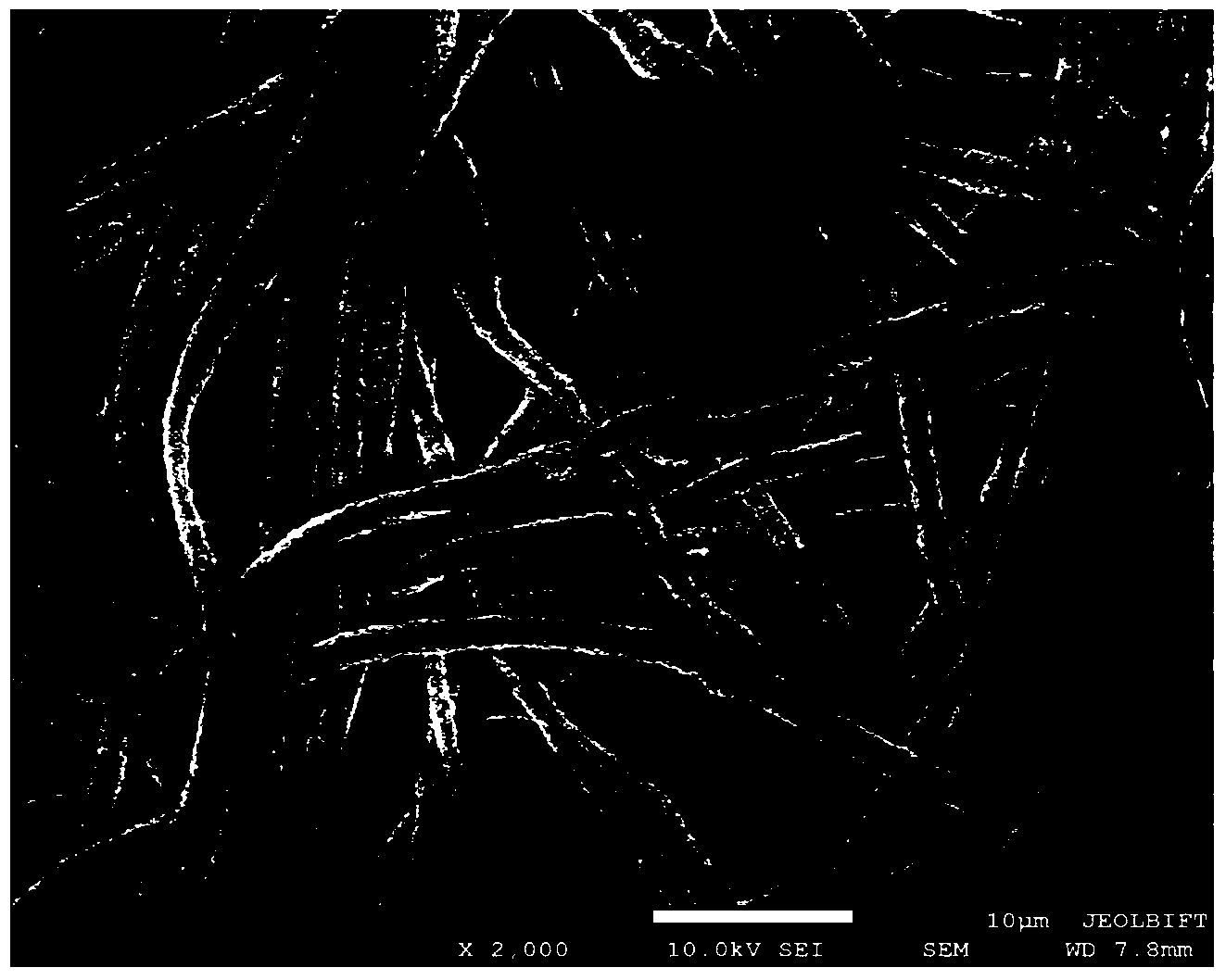

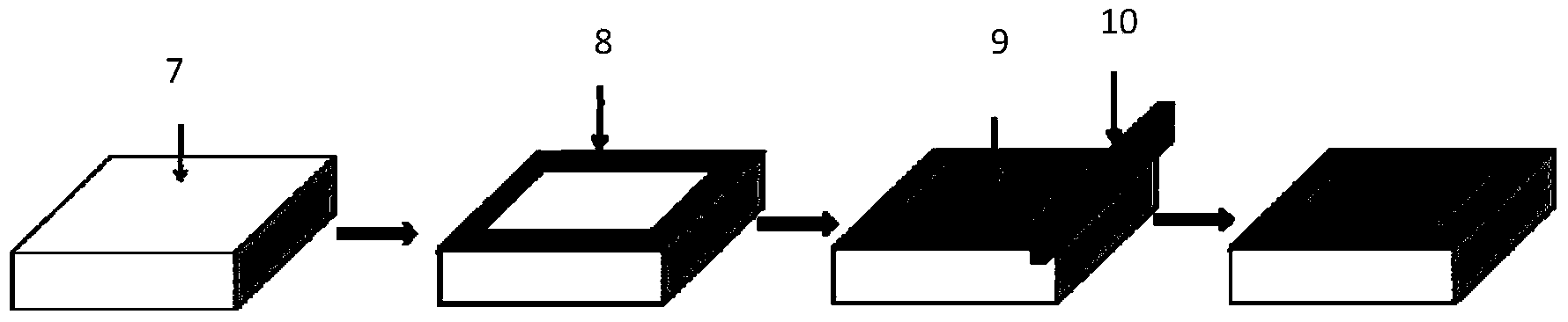

High-quality transfer method of graphene prepared by chemical vapor deposition method

The invention relates to a high-quality transfer method of graphene prepared by a chemical vapor deposition method. The method comprises the following steps: a, spinning a polymethylmethacrylate (PMMA) thin layer having even thickness on the surface of graphene prepared on a copper foil substrate with the chemical vapor deposition method; b, dissolving the copper foil; c, laminating; and d, and removing PMMA. By using the method provided by the invention, graphene can be stably, reliably and high-quality transferred, and the impurities in graphene are less, thereby ensuring the completeness and good property of prepared graphene not to be damaged and meeting the requirement of researching and applying graphene. After the method provided by the invention is adopted, complete and less-impurity-containing graphene can be stably, reliably and high-quality transferred, and thus a reliable guarantee for representation, research and application of graphene is provided.

Owner:SOUTHEAST UNIV

Polymer blend for matte injection moulded parts

The invention relates to a polymer mixture, comprising a) a polymer matrix which is composed of a (meth)acrylate(co)polymer or of a mixture of (meth)acrylate(co)polymers with a Vicat softening point VSP (ISO 306-B50) of at least 104° C. and / or of a (meth)acrylimide(co)polymer, b) an impact modifier which is based on crosslinked poly(meth)acrylates and which does not have covalent bonding to the polymer matrix a), c) from 1 to 15% by weight of plastics particles composed of crosslinked polymers based on polymethyl methacrylate, on polystyrene and / or on polysilicones. The polymer mixture can be used to obtain injection mouldings with matt surfaces and Vicat softening points VSPs (ISO 306-B50) of at least 90° C.

Owner:EVONIK ROEHM GMBH

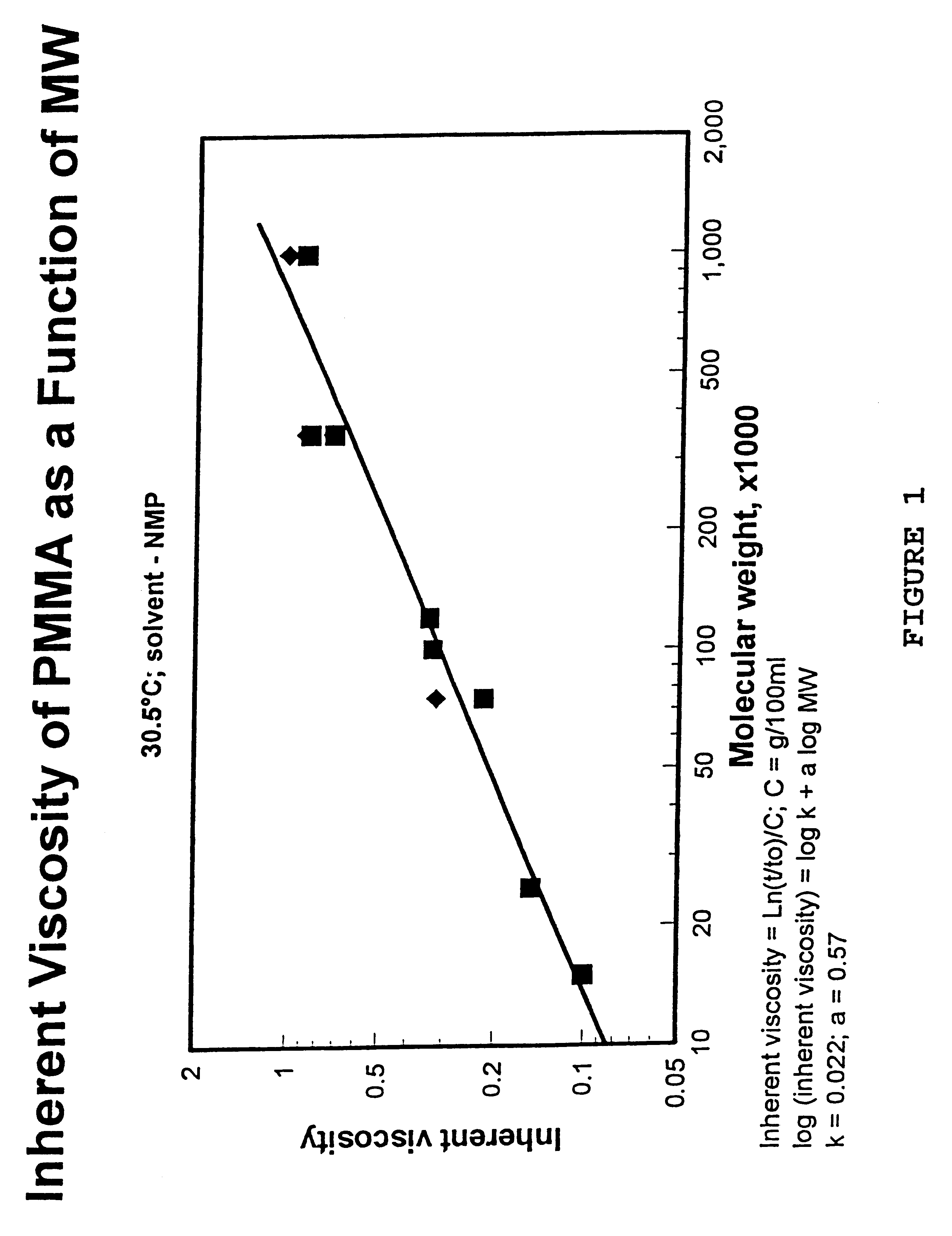

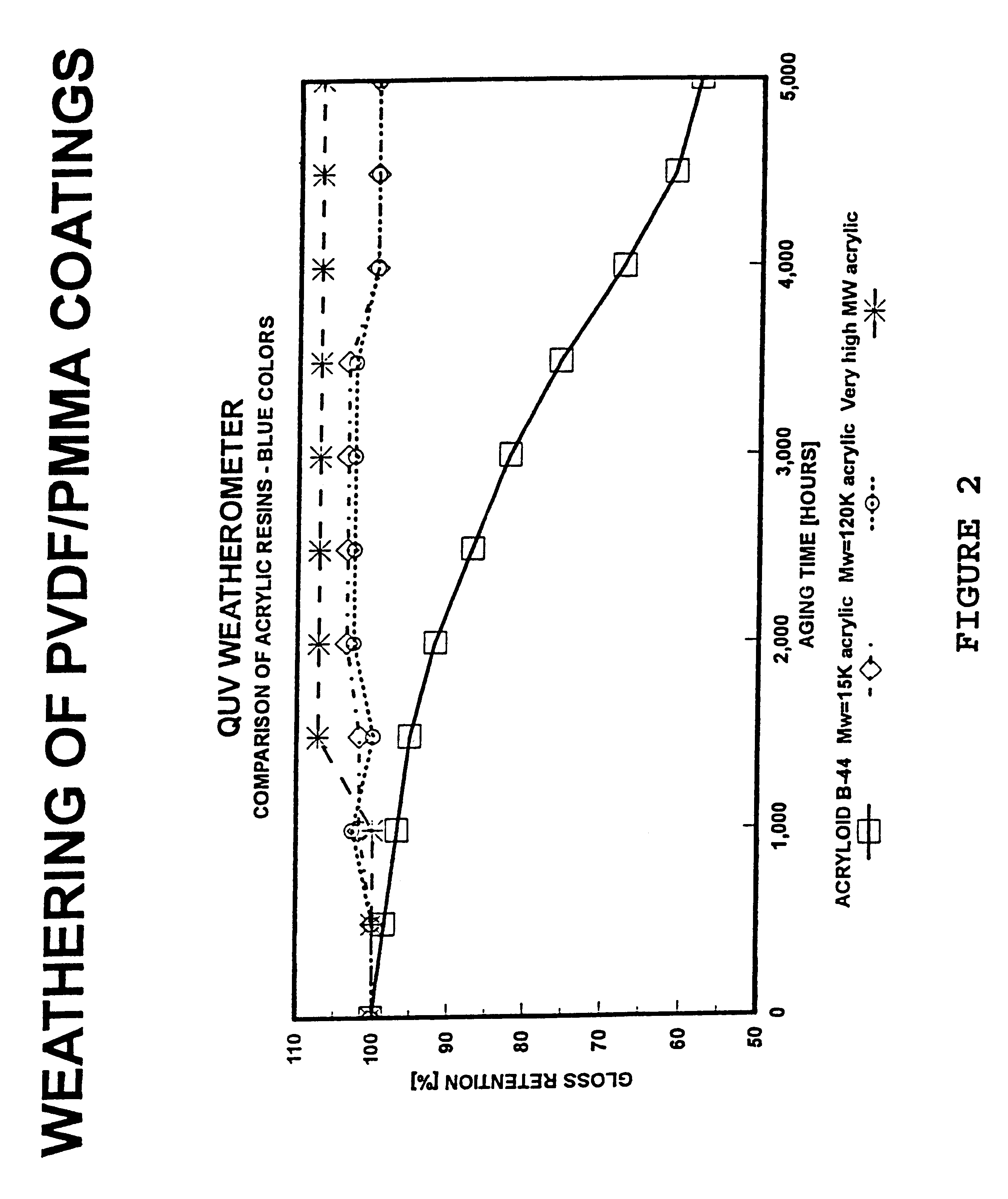

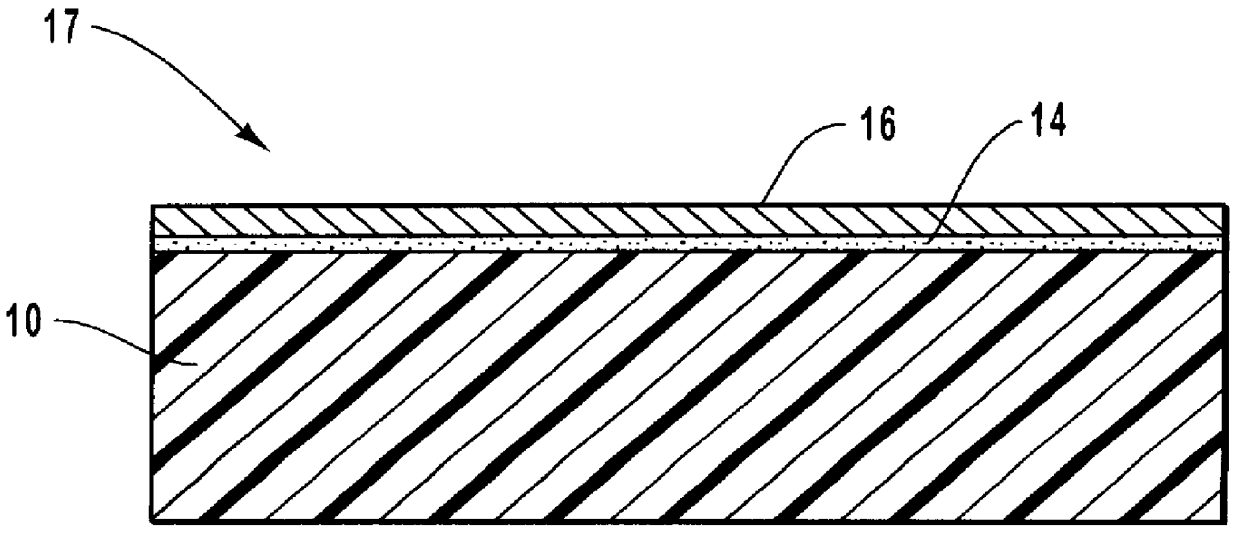

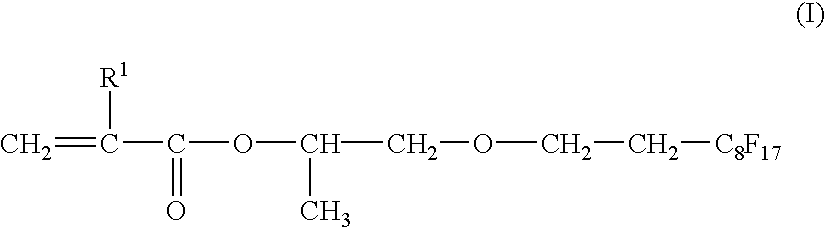

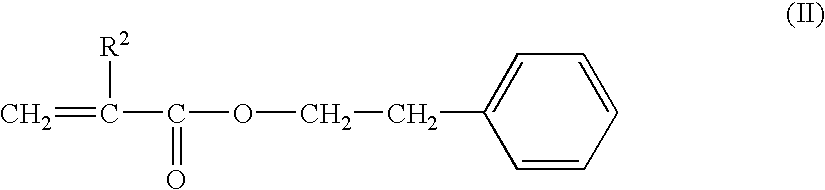

Polyvinylidene fluoride weather resistant coating compositions including polymethyl methacrylate

InactiveUS6362271B1Improve adhesionReduce the shrinkage of the polyvinylidene fluorideMixing methodsCoatingsMethacrylatePolymethyl methacrylate

A weather resistant coating composition comprising a miscible polymer blend of highly crystalline polyvinylidene fluoride polymer and polyalkyl methacrylate, such as PVDF and PMMA. The miscible blend comprises from about 50 weight percent to about 90 weight percent polymer comprising polyvinylidene fluoride and from about 10 weight percent to about 50 weight percent polyalkyl methacrylate. The polyalkyl methacrylate having a molecular weight within the range of about 25,000 grams per mole to about 200,000 grams per mole. The crystallinity of the polyvinylidene fluoride polymer is about 20% to about 70%. The weather resistant coating has excellent and unexpected physical characteristics, including solvent resistance and gloss retention.

Owner:SOLVAY SOLEXIS

Polymeric optical substrate method of treatment

InactiveUS6156394AImprove adhesionHigh hardnessVacuum evaporation coatingSputtering coatingPretreatment methodOptical coating

A pretreatment method for use in manufacturing an improved optical component comprises (i) providing a polymeric optical substrate; and (ii) exposing the polymeric optical substrate to electromagnetic energy having a wavelength of about 30 nm to about 350 nm. The exposure of the polymeric optical substrate to the electromagnetic energy substantially improves adhesion between the substrate and an optical coating deposited onto the substrate following pretreatment. The invention addresses the significant need for coated plastic optics by providing a method to achieve reliable adhesion of optical coatings placed on polymeric optical substrates. Specifically, this invention enables improved adhesion for even highly curved or shaped parts which have been historically more difficult to coat. The pretreatment method is particularly useful for molded substrates such as molded polymethylmethacrylate.

Owner:JDS UNIPHASE CORP

Intraocular lenses and process for the producing molded-in type intraocular lenses

Owner:HOYA HEALTHCARE CORP

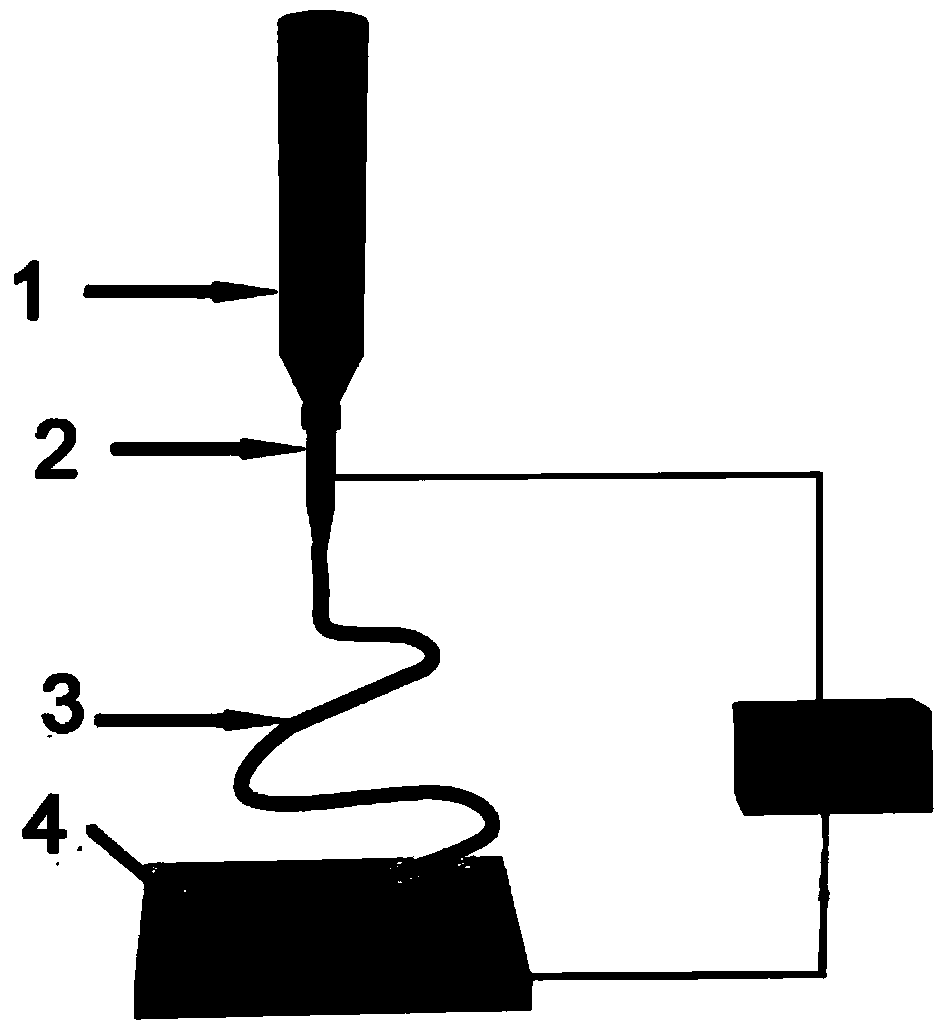

Efficient oil and water separation composite fiber film and preparation method thereof

InactiveCN103866492ASelf-supportingRealize multiple reuseFilament/thread formingNon-woven fabricsFiberHydrophobic polymer

The invention discloses an efficiency oil and water separation composition fiber film and a preparation method thereof, and belongs to the field of functional nanometer fiber materials. Hydrophobic polymers such as polyurethane, polystyrene and polymethyl methacrylate or polycaprolactone are used as the main raw materials of the fiber film, the main raw materials are dissolved in an organic solvent to form a polymer solution, hydrophobic nanometer particles are added into the polymer solution in the preparation process, after the mixture is evenly mixed, electro-spinning is conducted on the mixed solution by means of the electrostatic spinning method, and then a fiber film material which is formed by micro-nanometer composite structures and is in the shape of non-woven fabric is obtained. The electro-spun fiber film of the micro-nanometer structure has super-hydrophobic / super-oleophylic property in the air and excellent oil adsorption performance, and the contact angle to oil is nearly zero. The efficient oil and water separation composite fiber film is simple in preparation method, low in energy consumption, high in efficiency, high in oil and water separation speed, and capable of being widely used in the fields such as oily water efficient purification.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Alumina carrier with composite pore structure and preparation method thereof

ActiveCN102614934AExtend your lifeHigh selectivityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPolymer scienceMicrosphere

The invention discloses a preparation method of an alumina carrier with a composite pore structure, which comprises the steps of mixing and roasting an aluminum-contained compound and a composite template, wherein the composite template comprises a mesoporous template selected from at least one of a polyethylene glycol-polypropylene glycol-polyethylene glycol triblock polymer, polyethylene glycol, dodecylamine, hexadecyl trimethyl ammonium bromide, lauric acid, stearic acid and fatty alcohol polyoxyethylene ether and a macroporous particulate template selected from polystyrene microspheres with the particle size of greater than 50nm, polymethyl methacrylate microspheres, biomaterial particles, asphalt particles or heavy oil residues; and the weight ratio of the mesoporous template to the macroporous particulate template to the aluminum-contained compound (by alumina) is 0.1-2:0.1-0.7:1. The invention also discloses the alumina carrier simultaneously having mesoporous tunnels and macroporous tunnels prepared through the method, wherein mesopores account for 40-90% of the total pore volume, and macropores account for 10-60% of the total pore volume.

Owner:CHINA PETROLEUM & CHEM CORP

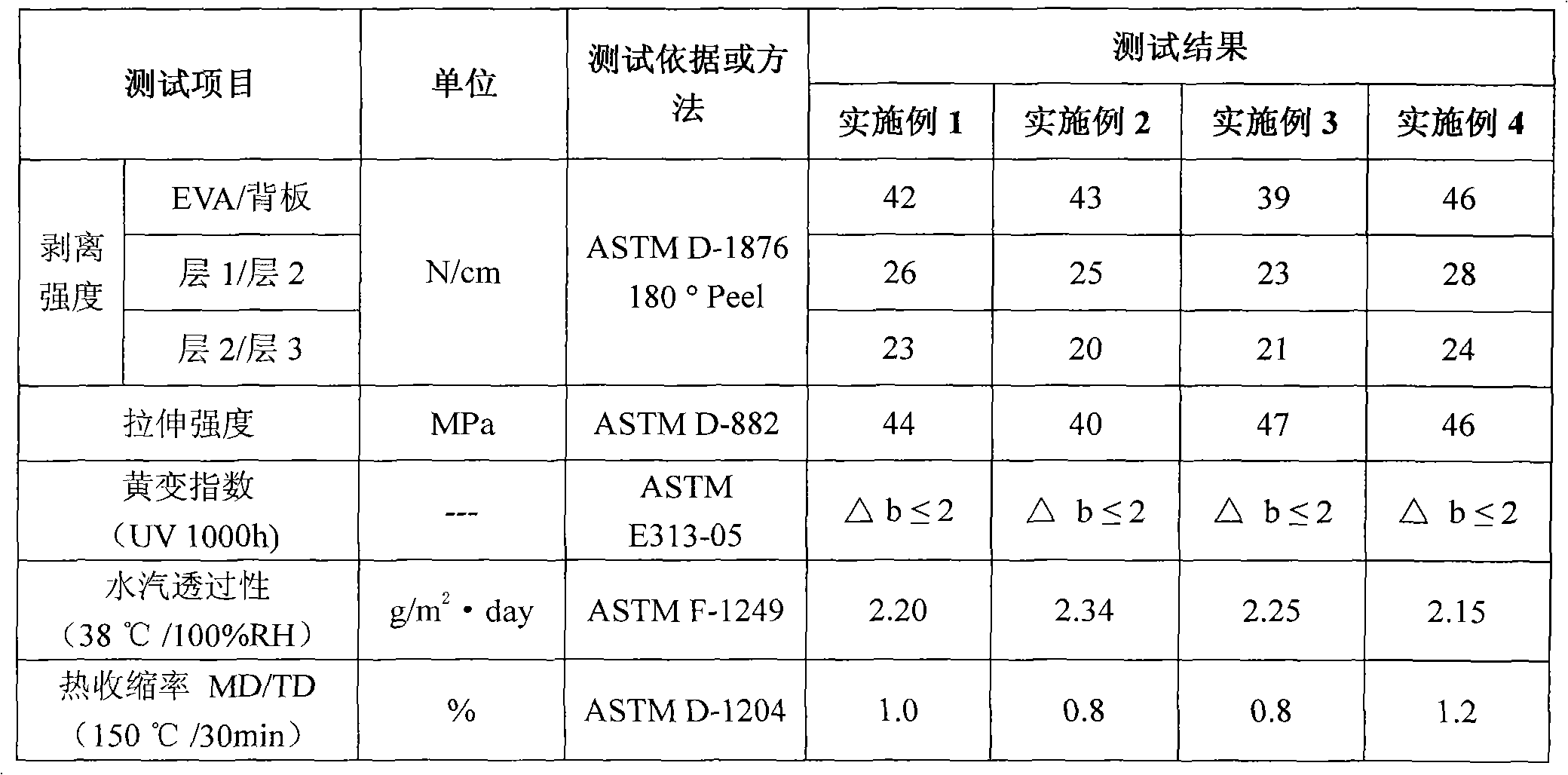

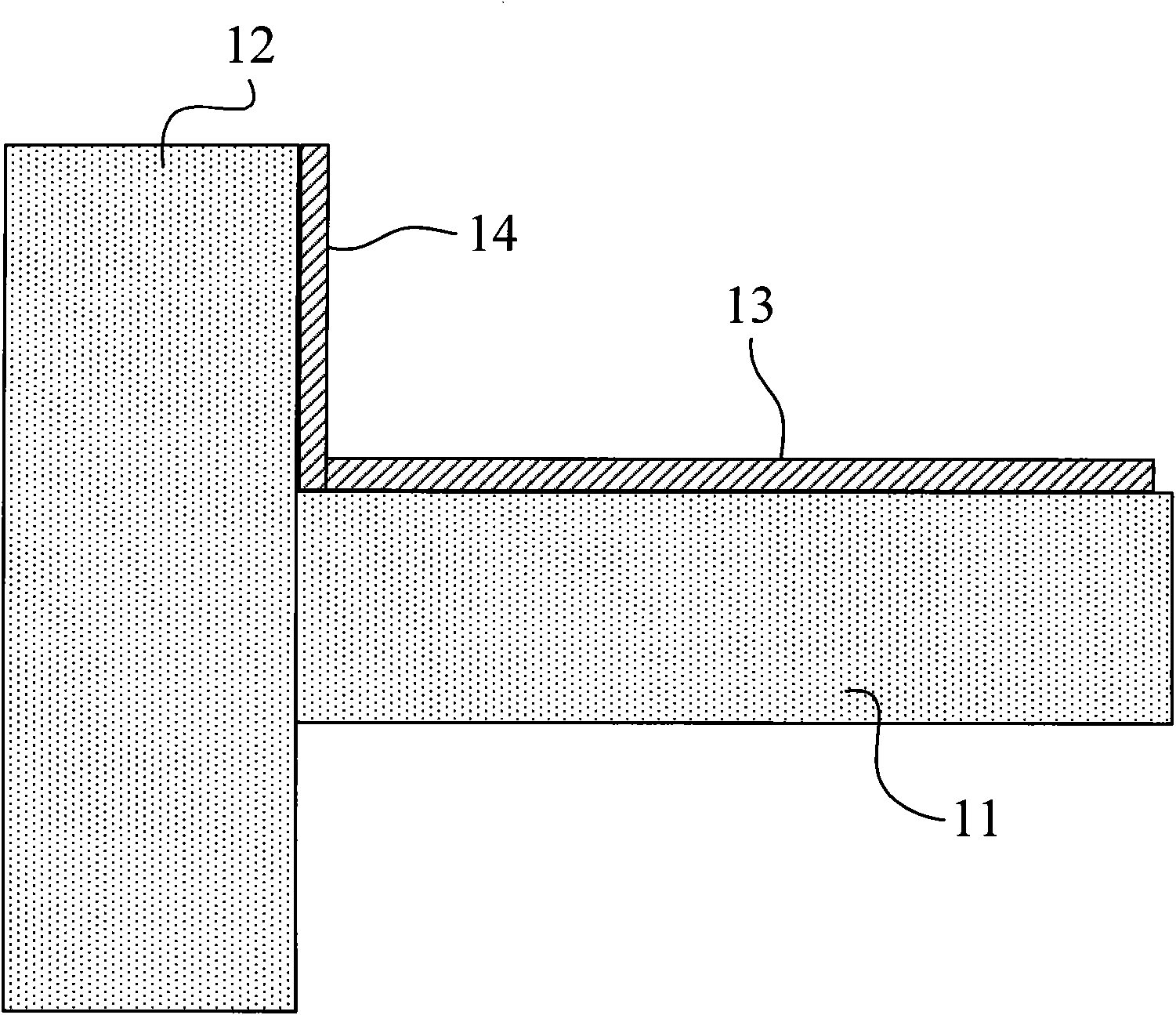

Back panel of solar cell and preparation method thereof

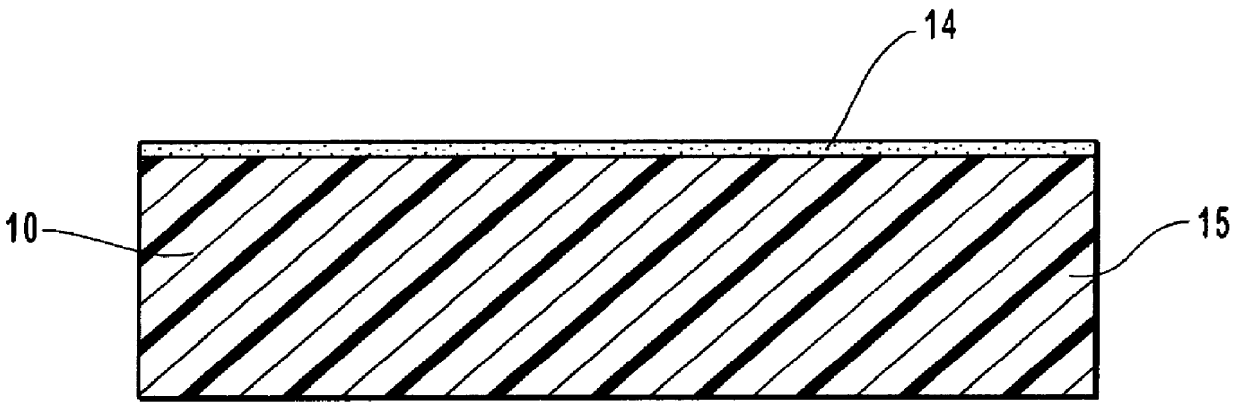

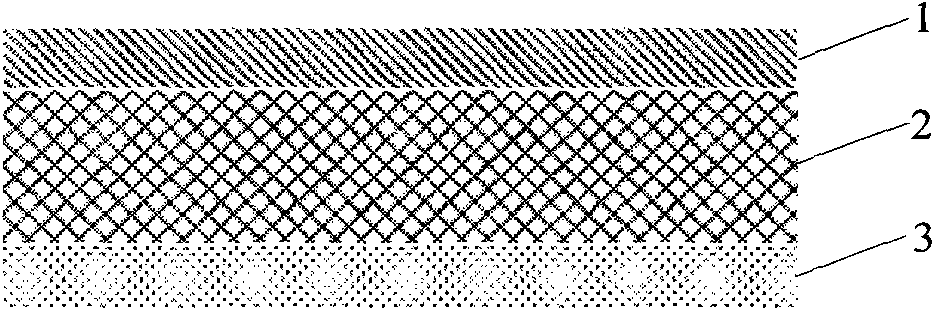

ActiveCN102157591AExtended service lifeMeet the requirementsFinal product manufactureSynthetic resin layered productsComposite filmPolyethylene terephthalate glycol

The invention relates to a back panel of a solar cell and a preparation method thereof. The solar back panel is provided with three polymer film layers from top to bottom, namely an adhesive weatherable layer, an adhesive reinforcing layer and an adhesive moisture-retarding layer, wherein the adhesive weatherable layer is a PVDF(polyvinylidene fluoride) / EVA (ethylene vinyl acetate) alloy layer, the adhesive reinforcing layer is a PET (polyethylene terephthalate) / PMMA (polymethyl methacrylate) alloy layer, and the adhesive moisture-retarding layer is a PVDF / PVB (polyvinyl butyral) alloy layer. In the preparation method, a multi-layer melting and co-extrusion method is adopted for realizing interface-free fusion of the three film layers, and a composite film can achieve good dimensional stability by online high-temperature shaping. The structure of the back panel of the solar cell only comprises the three layers, an adhesive layer does not need to be used, the preparation process is simple, the steps of sizing and hot-pressing are omitted, and the production efficiency is high; and simultaneously, the back panel has excellent performances and is in line with the packaging requirements of the solar cell.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

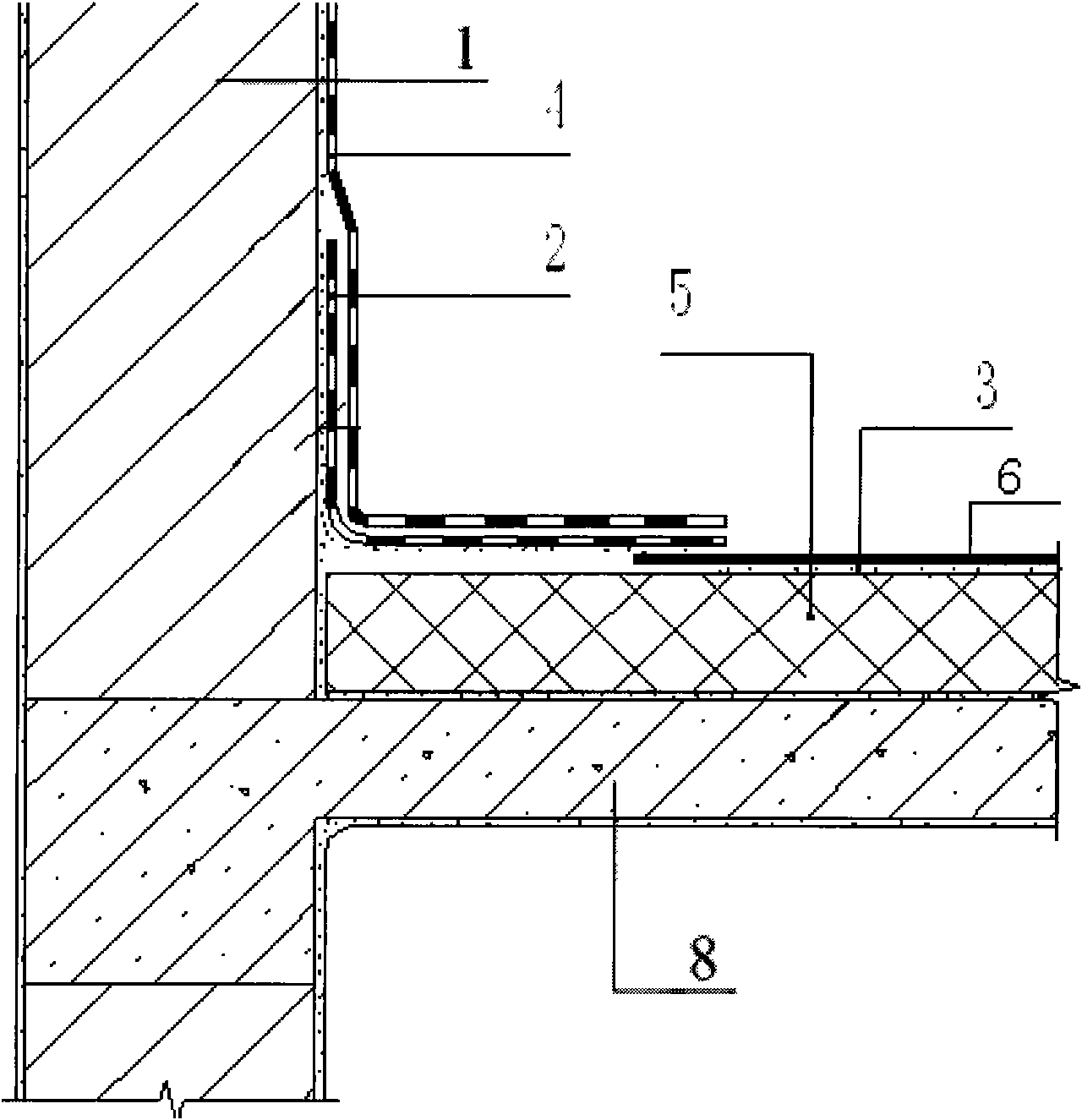

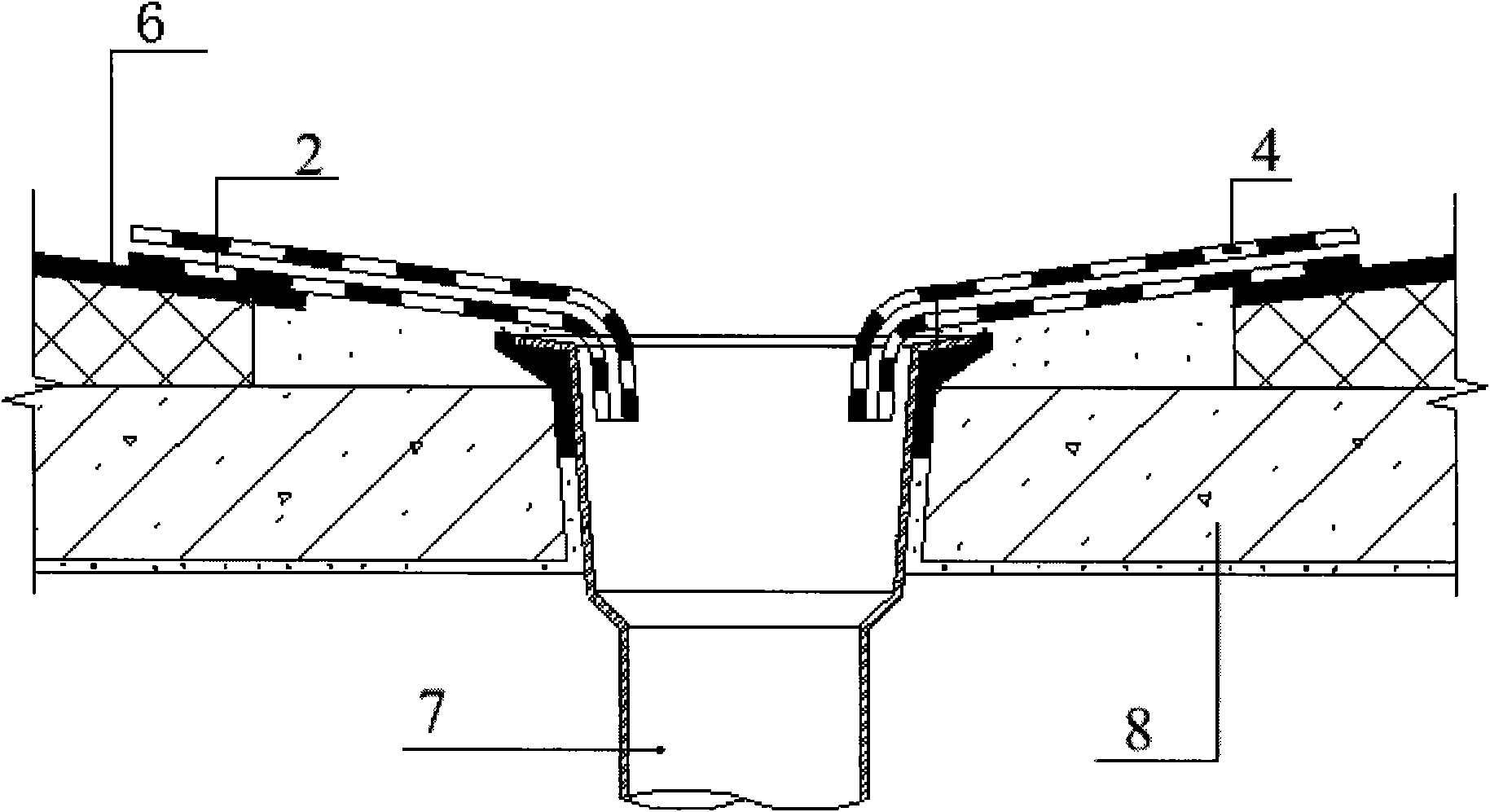

Waterproof structure and manufacturing method thereof

The invention relates to a waterproof structure and a manufacturing method thereof. The waterproof structure is used for waterproofing of detail joints on roofing and comprises a waterproof coiled material layer and a waterproof coating layer which is arranged on the position of the detail joints and is overlapped and struck with the waterproof coiled material layer, wherein the inside of the waterproof coating layer can comprise a reinforcing layer made of polyester or nylon non-woven fabrics or textile fabrics; and the material of the waterproof coating layer is exposed polyurea waterproof paint or modified waterproof paint thereof, exposed polyurethane waterproof paint or modified waterproof paint thereof, exposed polymethyl methacrylate waterproof paint or modified waterproof paint thereof or exposed polystyrene-ethylene-butadiene-styrene or modified waterproof paint thereof. Because the waterproof coating layer of the waterproof structure has large bonding force, strong capability to resist stretching and high elasticity, when the detail joints on the roofing are deformed because of gusty condition or other reasons, the waterproof coating layer is not destroyed and still has excellent waterproof effect.

Owner:北京森聚柯高分子材料有限公司 +1

Polylactic acid-containing resin composition and product molded therefrom

InactiveUS20090018237A1Satisfactory in durabilityMeet heat resistanceCoatingsHeat resistanceRefractive index

A polylactic acid-containing resin composition is provided which comprises 100 parts by mass of a resin containing 20 to 98 mass % of polymethyl methacrylate and 80 to 2 mass % of polylactic acid, and 1 to 100 parts by mass of an impact resistance improving material. The impact resistance improving material is a polymeric material comprising an acrylic monomer unit. The impact resistance improving material has a refractive index of 1.402 to 1.542. The resin composition is excellent in heat resistance, moldability, durability, transparency and impact resistance.

Owner:UNITIKA LTD

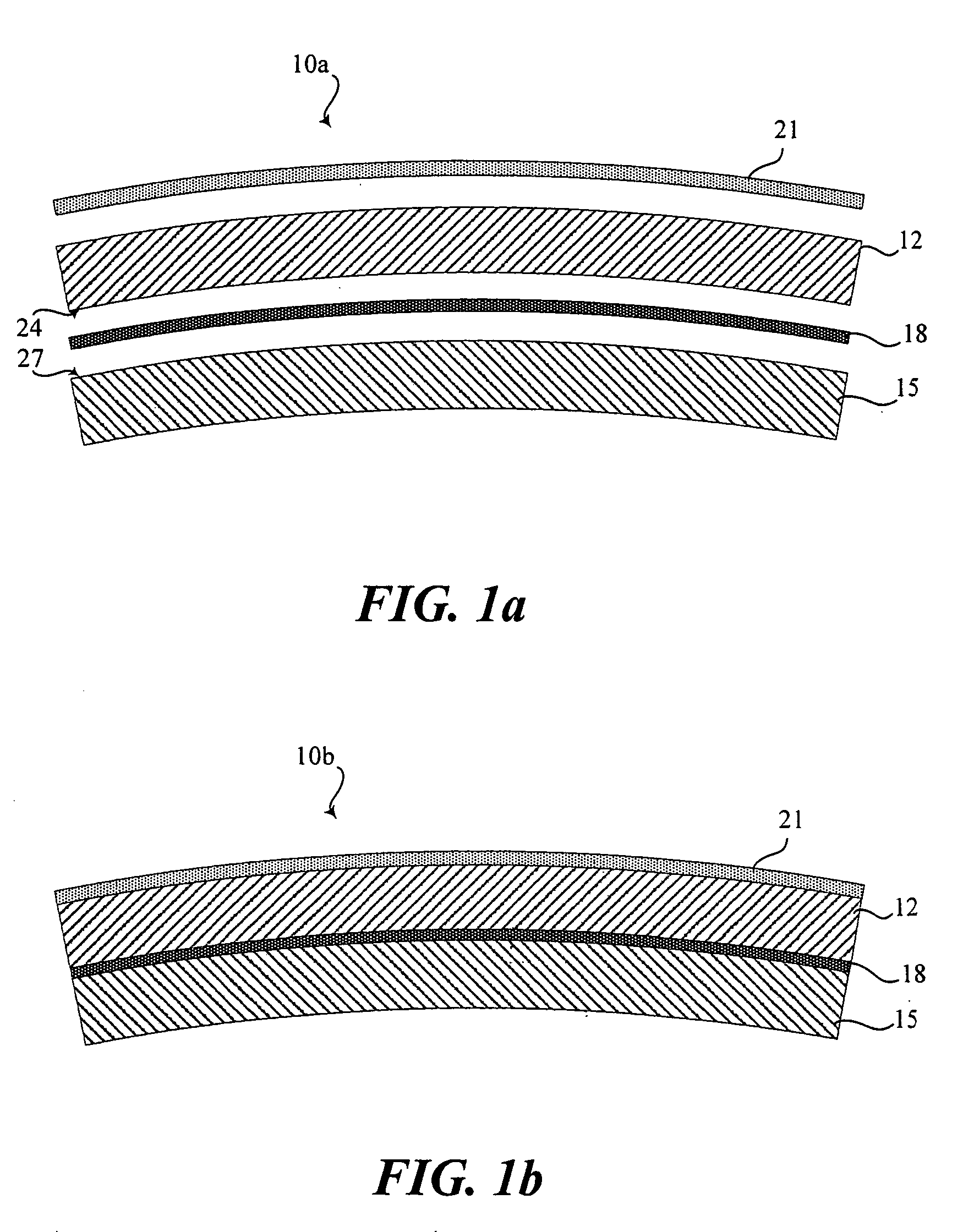

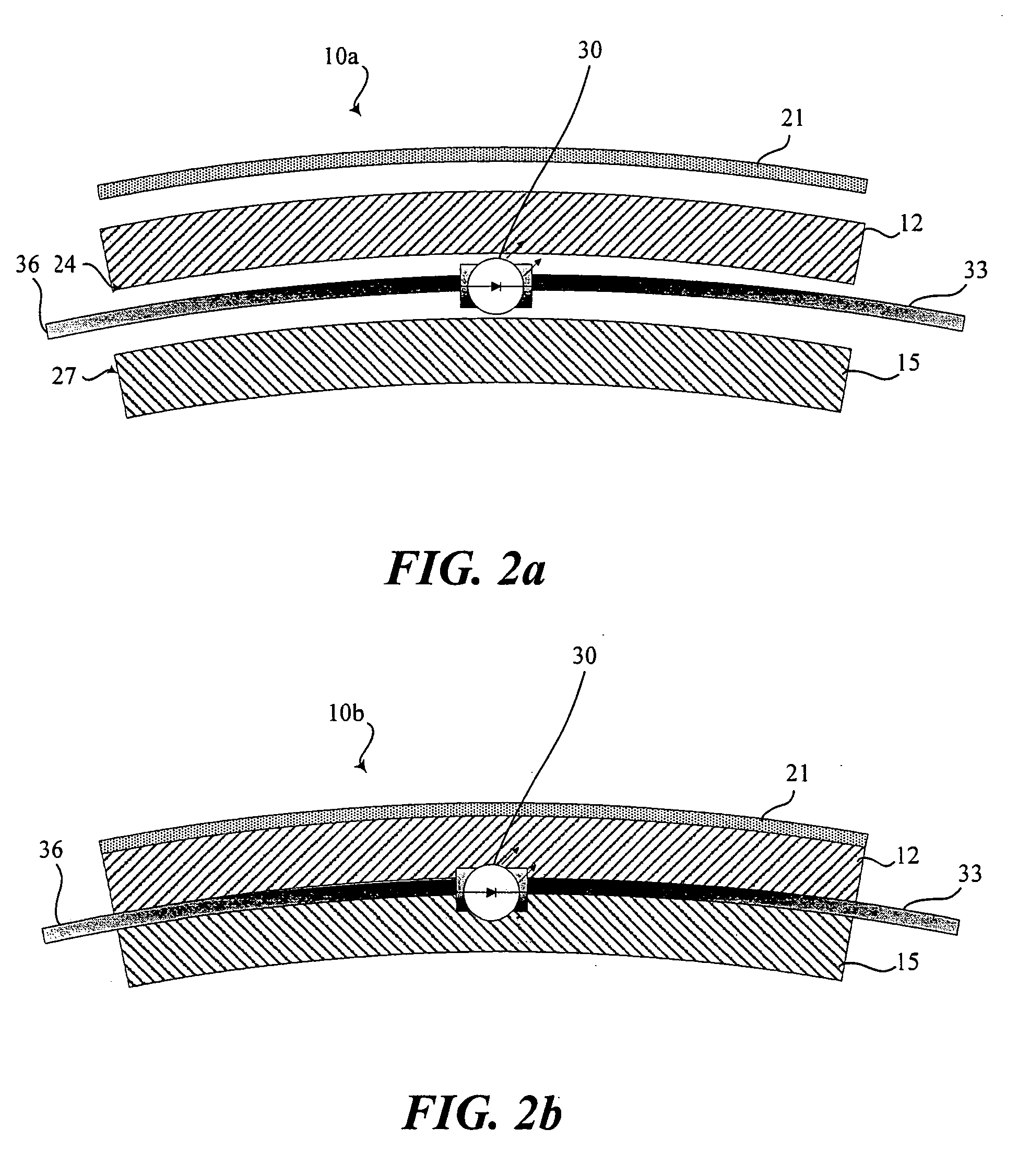

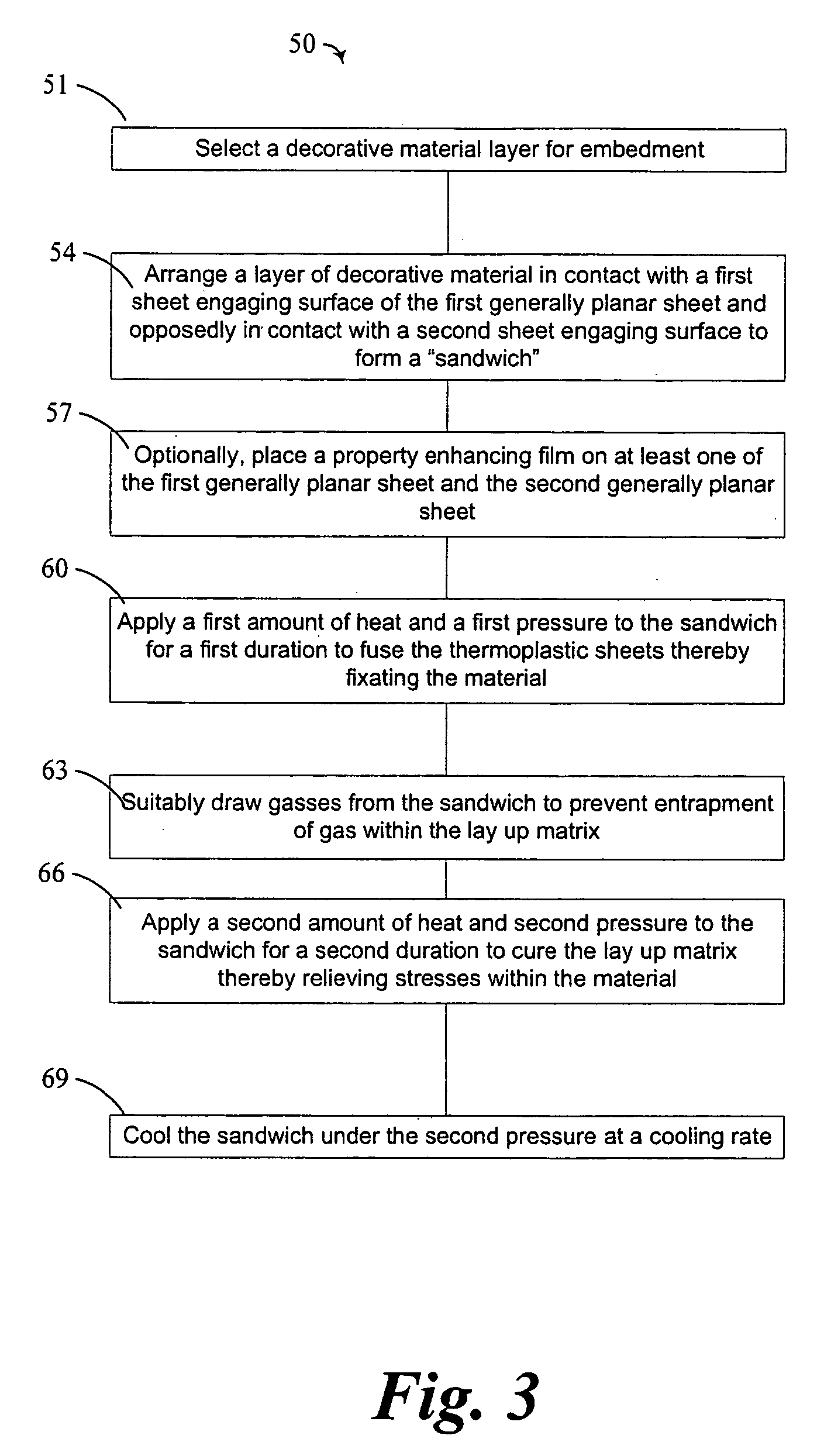

Solid surface products

A bullet resistant, non-porous unitary solid surface structure. The structure includes a first non-porous unitary material, a decorative material, and a second non-porous unitary material. The second non-porous unitary material is fused to the first non-porous unitary material in opposed relation relative to the decorative material. The fused materials produce a bullet resistant structure. The first and second non-porous unitary materials include at least one of acrylic, cross-linked acrylic, polymethyl methacrylate, polycarbonate, polyvinyl chloride, polyethylene, polypropylene, polyester, nylon, polyurethane, polystyrene, fluoropolymers, acrylonitrile-butadiene-styrene, polylactic acid, and cellulosics.

Owner:LUMICOR

Preparation method for patterned graphene membrane

InactiveCN102653454ANo damageEasy to operateMaterial nanotechnologyGraphenePolymethyl methacrylateCvd graphene

The invention provides a preparation method for a patterned graphene membrane. The preparation method comprises the following steps of: firstly coating photoresist or PMMA (polymethyl methacrylate) on a substrate; carrying out patterning process on the substrate; removing the photoresist or PMMA of the area required to form a grapheme pattern; then coating graphene oxide solution on the substrate to form a membrane; carrying out reduction on the obtained substrate in hydrazine steam; processing the graphene oxide into graphene to obtain the graphene membrane; finally immersing the obtained substrate in acetone or photoresist stripping solution; and removing the photoresist or PMMA and the graphene membrane on the photoresist or PMMA to obtain the patterned graphene membrane. With the preparation method disclosed by the invention, the patterned photoresist or PMMA is simply formed on the substrate so as to prepare the patterned graphene membrane. The method is simple to operate and low in cost, can be used on a large scale, does not damage the substrates and is suitable for various substrates, and the application of the solution method in preparing the graphene is expanded.

Owner:BOE TECH GRP CO LTD

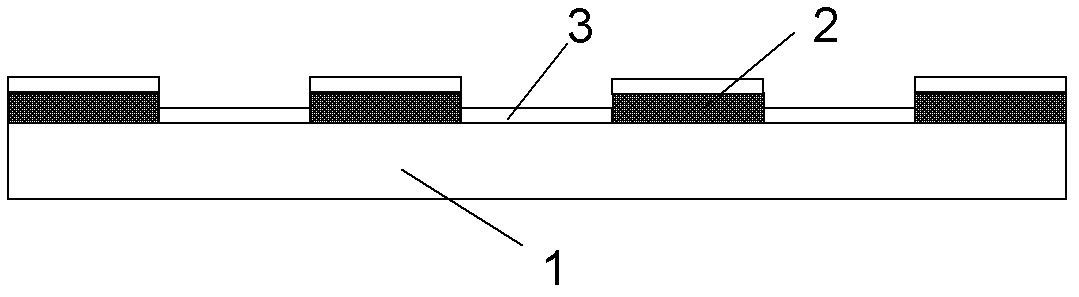

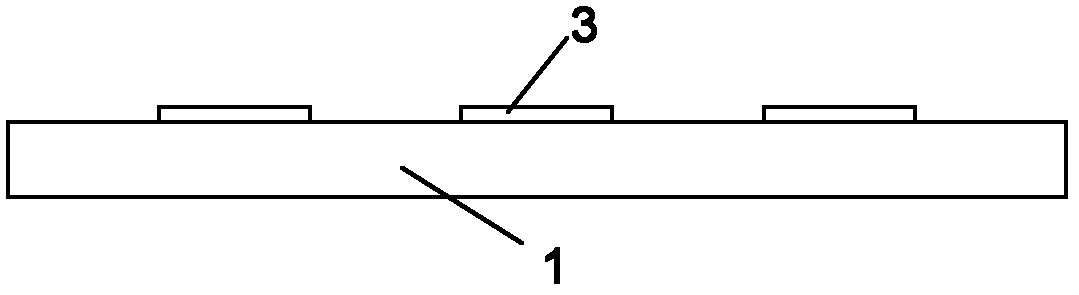

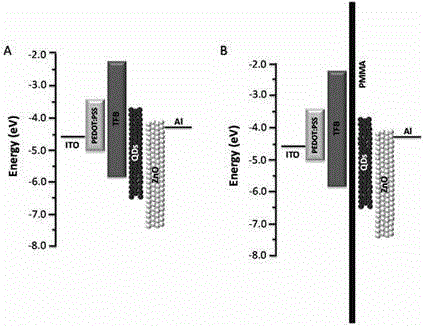

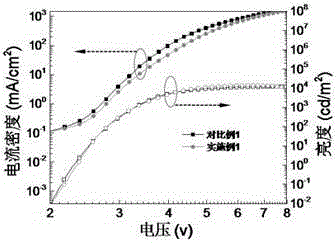

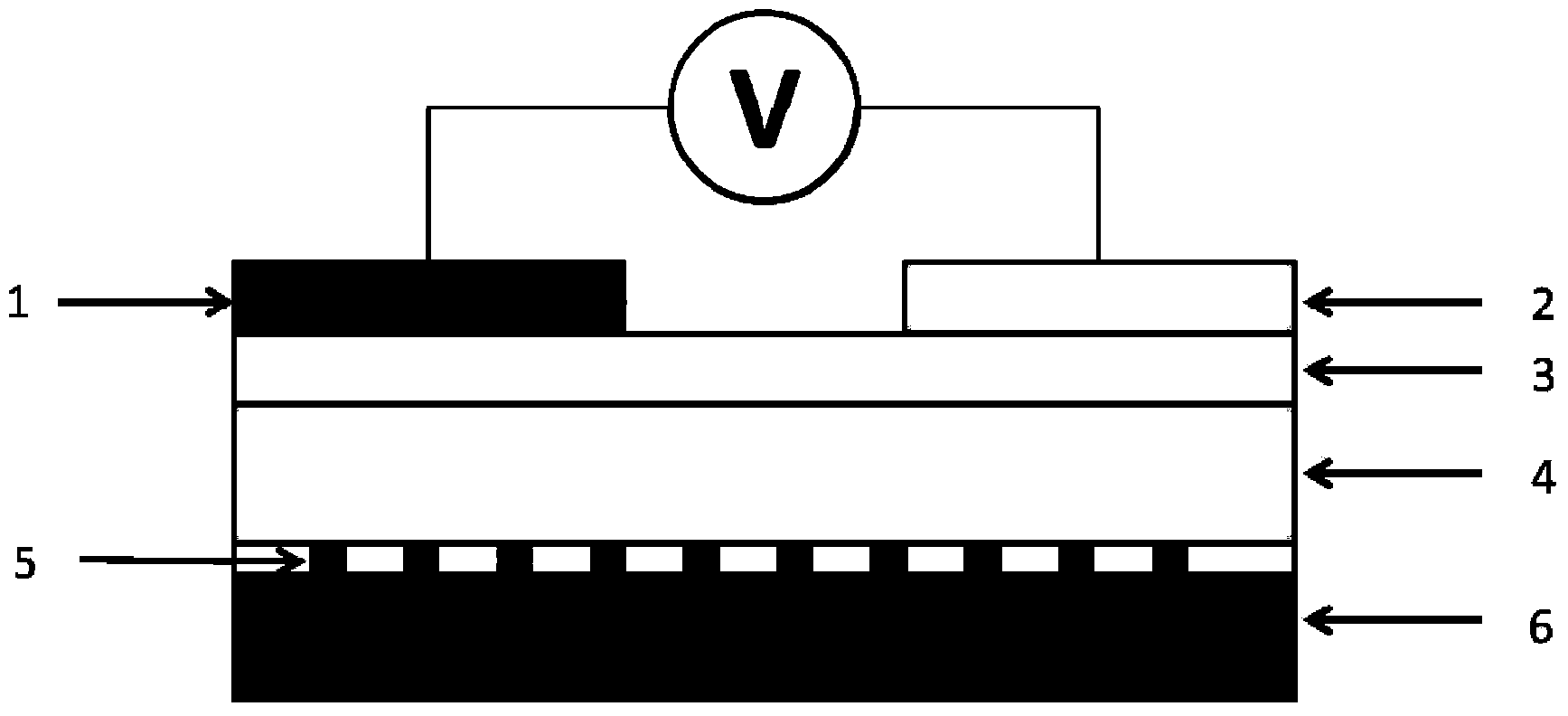

Novel quantum dot luminescent device

ActiveCN105261707ALow costImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingPolymethyl methacrylateSilicon oxide

The invention belongs to the field of electroluminescent devices and particularly relates to a novel quantum dot luminescent device. The novel quantum dot luminescent device comprises an ITO anode, a hole injection layer, a hole transmission layer, a quantum dot luminescent layer, an electron transmission layer, an Al cathode and an insulating layer, wherein the insulating layer is arranged between the hole transmission layer and the quantum dot luminescent layer. The material of the insulating layer can be one or more of polymethyl methacrylate, calcium oxide, aluminum oxide, silicon oxide or gallium oxide and the like. Through the arrangement of the insulating layer, on one hand, injection of holes and electrons is effectively balanced; and on the other hand, the electric neutrality of quantum dots is ensured, so that the luminescence property of a blue-green quantum dot light-emitting diode is improved.

Owner:HENAN UNIVERSITY

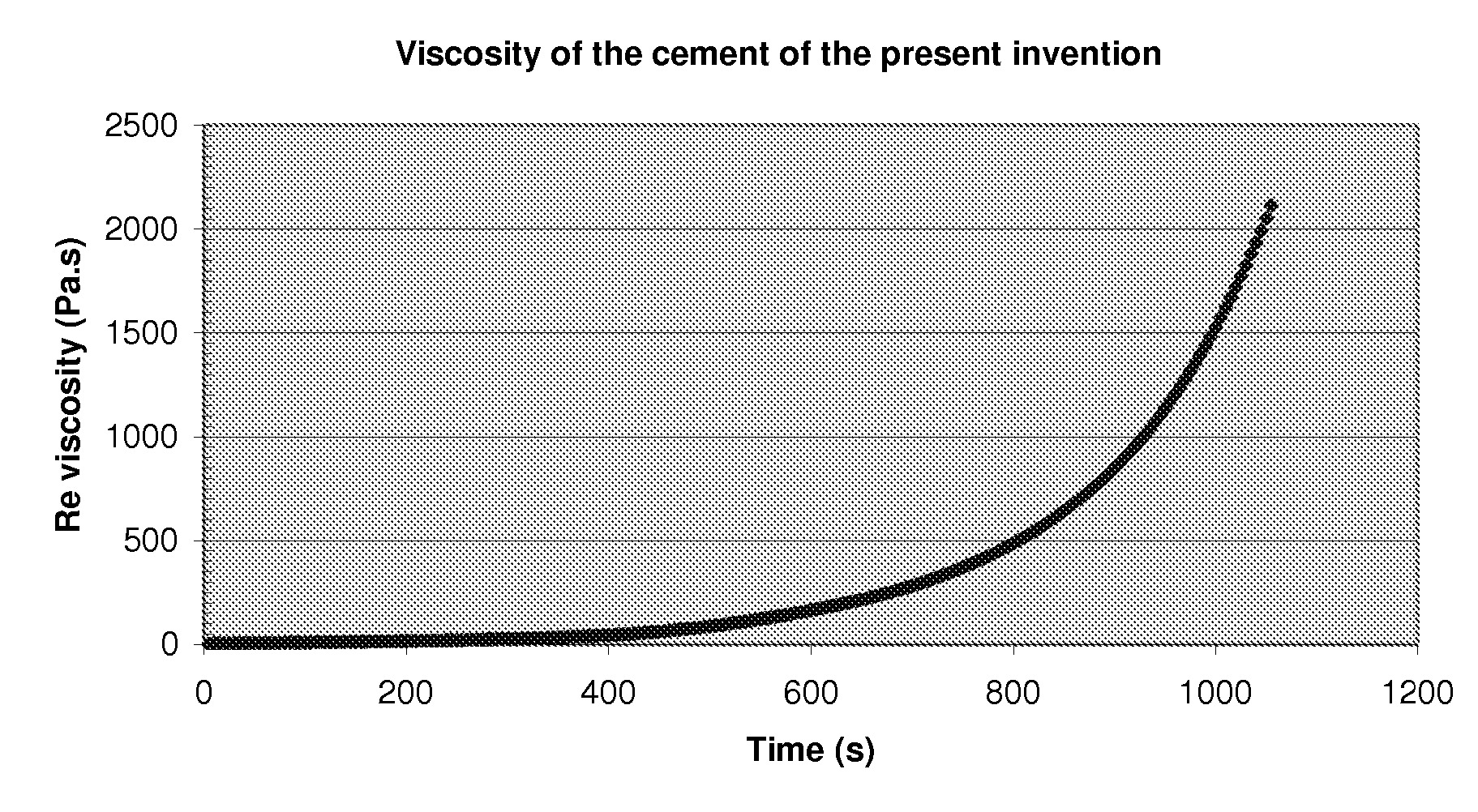

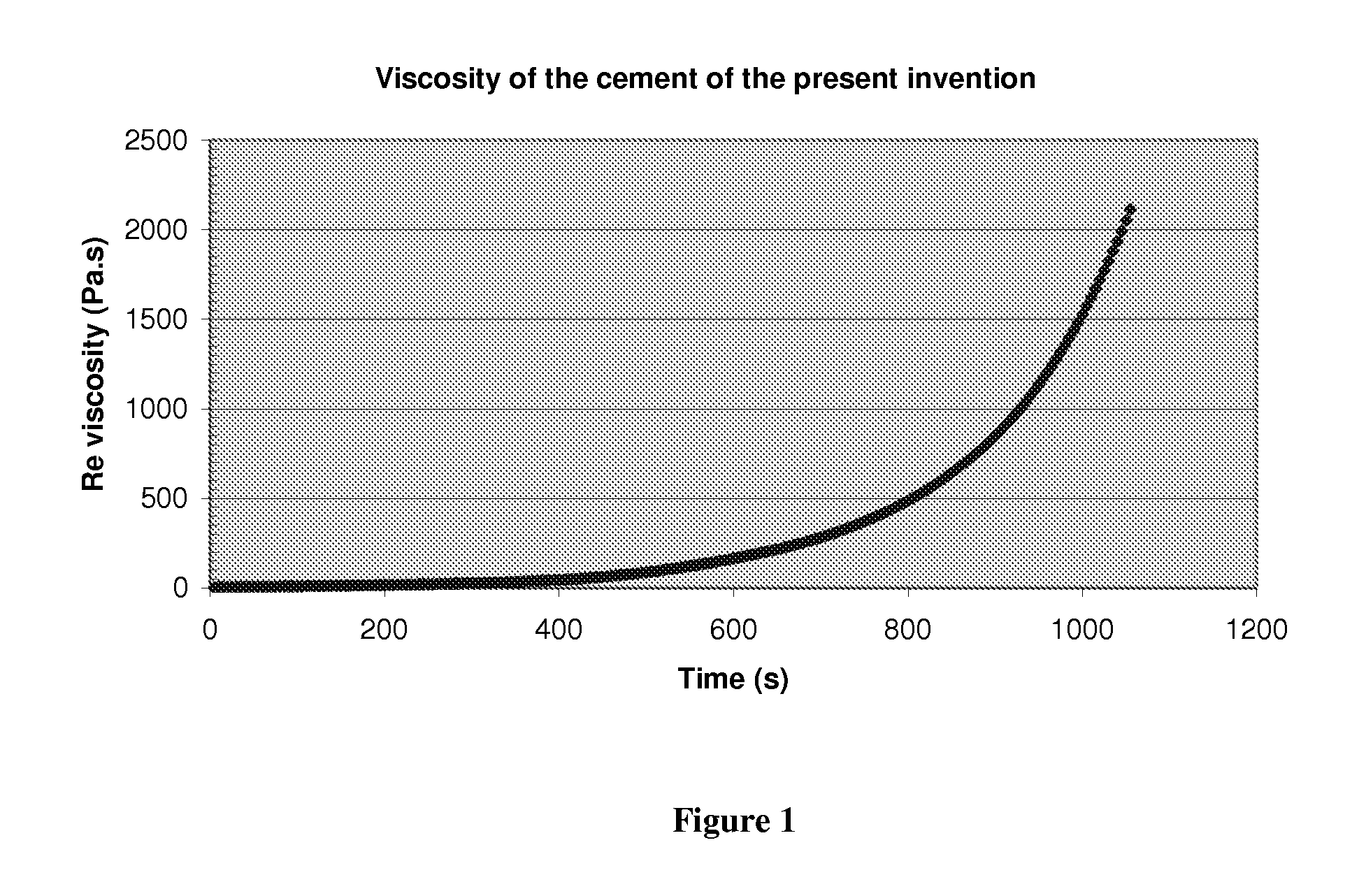

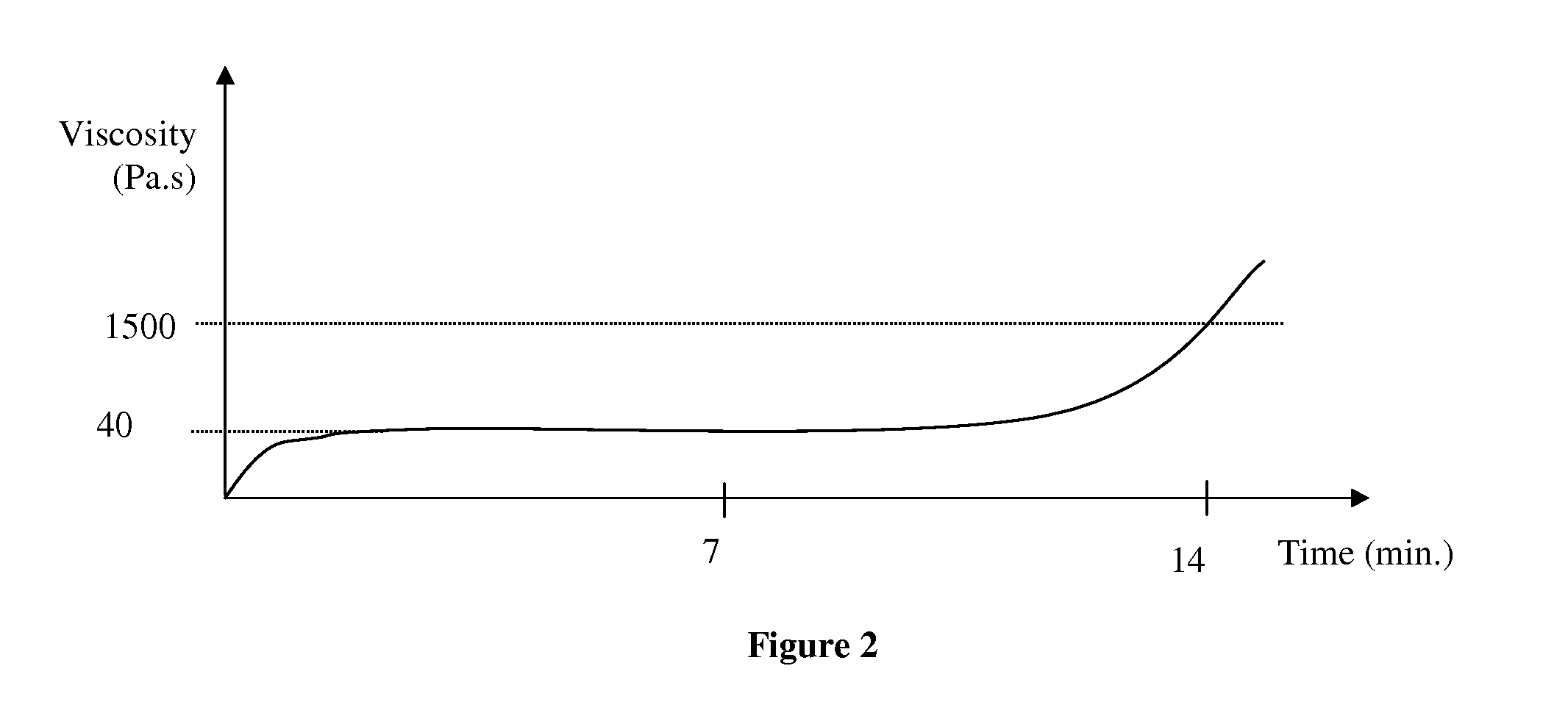

Polymer cement for percutaneous vertebroplasty and methods of using and making same

The invention provides a fluid cement for medical use for bone reconstruction, in particular for filling the vertebral body, and a binary composition which is intended for the preparation of such a cement. The invention also provides a device for conditioning the binary composition, and a method of preparing a bone cement from a binary composition. The fluid cement according to the invention comprises: a) approximately 60% to 85% by weight of a polymer comprising a polymethylmethacrylate and a methylmethacrylate monomer and b) approximately from 15 to 40% by weight of a radio-opaque composition. Preferably, the radio-opaque composition comprises a radio-opacifier, such as barium sulfate and zirconium dioxide, in a mixture with a calcium phosphate, for example apatite hydroxide.

Owner:TEKNIMED SAS

Dental adhesive composition

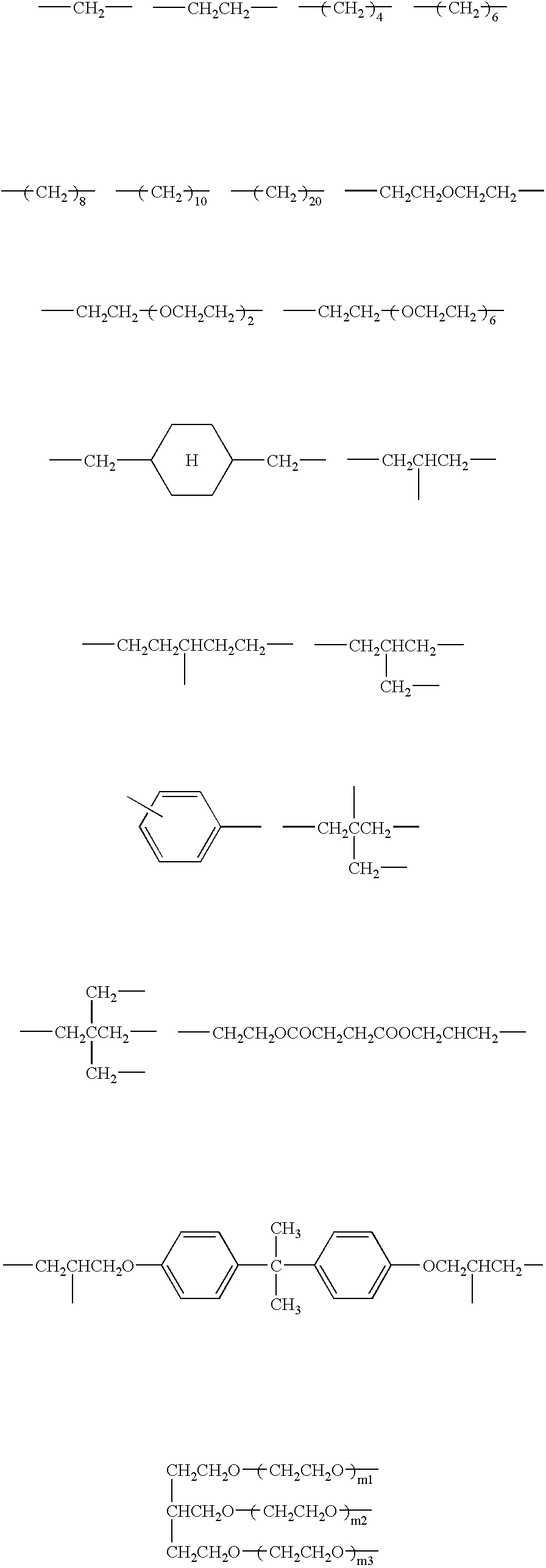

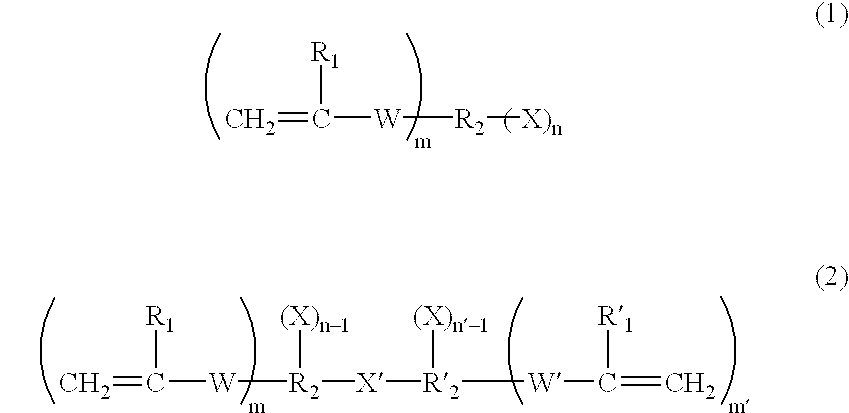

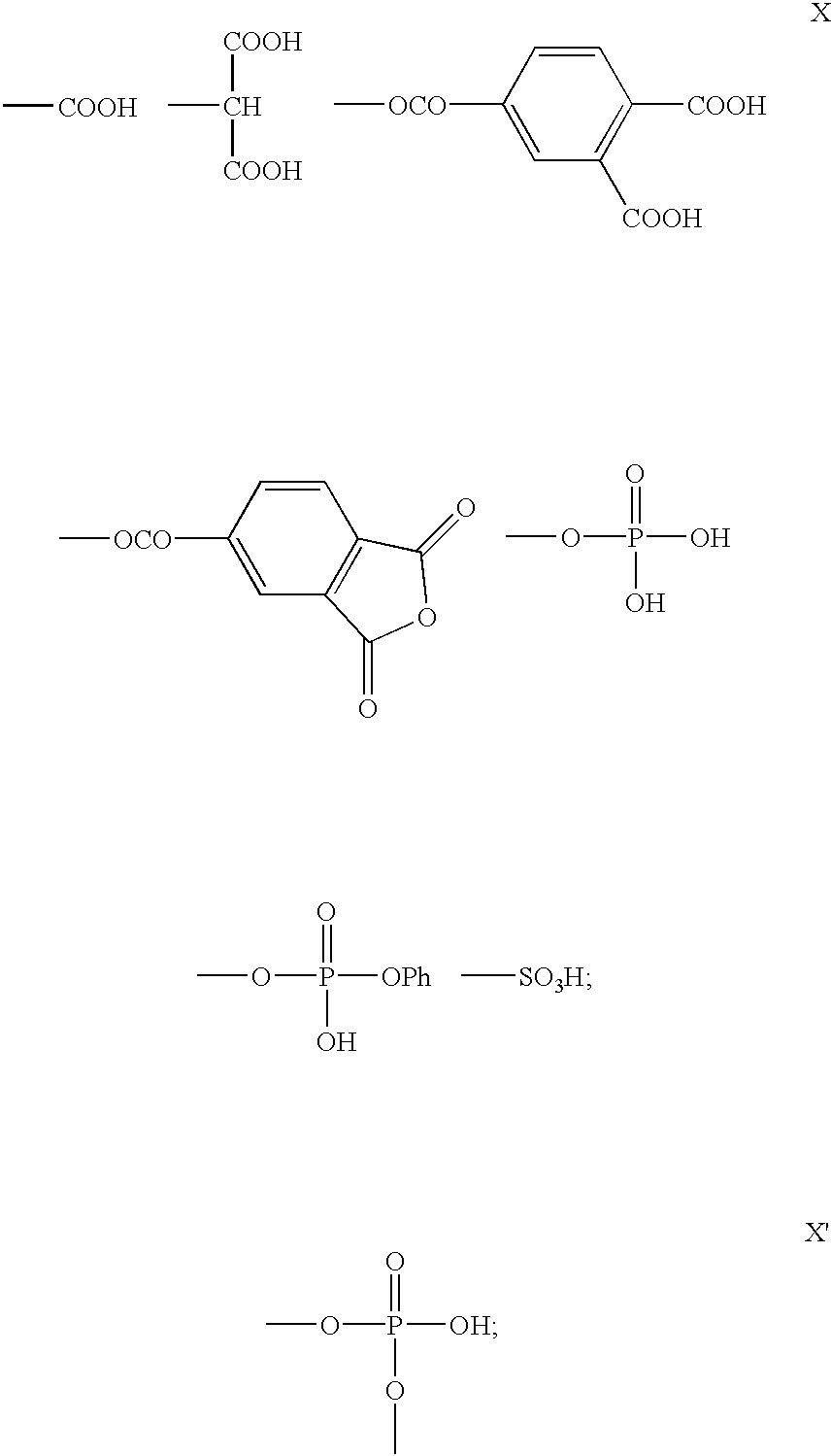

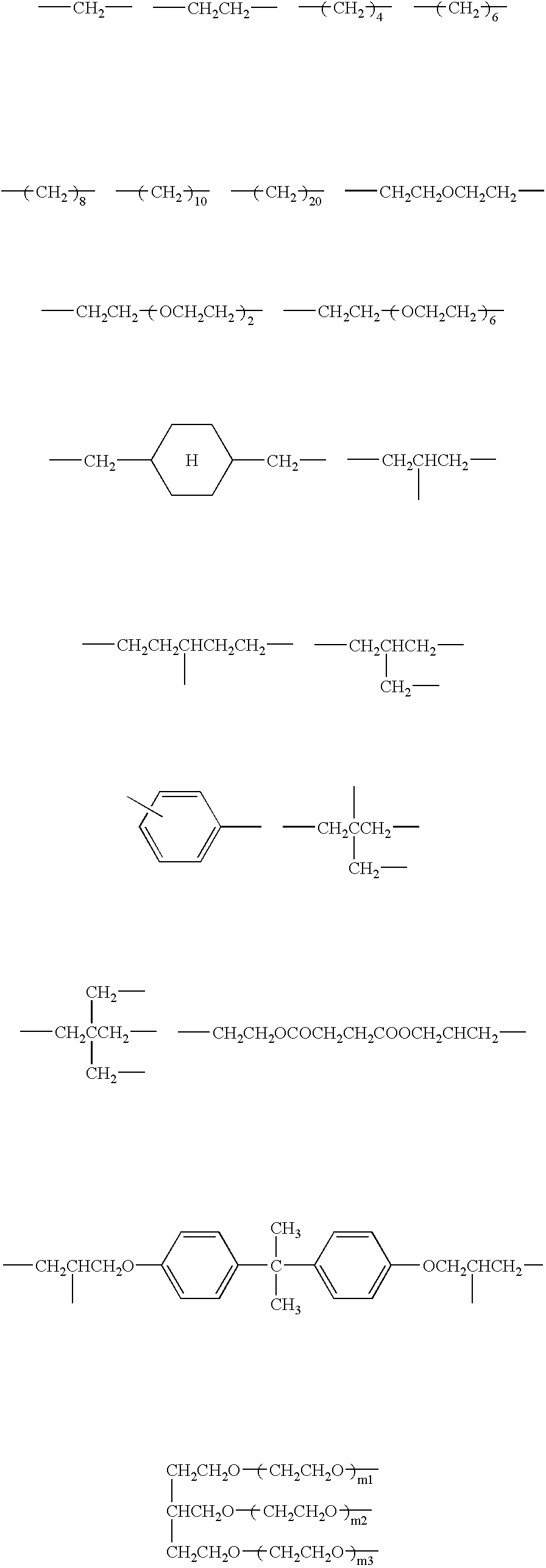

InactiveUS20030050359A1Short working hoursOptimize working timeImpression capsTeeth fillingArylAdhesive

This invention discloses a dental adhesive composition comprising (A) a polymerizable monomer comprising an acidic-group containing polymerizable monomer such as 11-methacryloyloxy-1,1-undecane dicarboxylic acid, (B) a mixed filler of a spherical filler substantially consisting of a non-crosslinking polymethyl methacrylate and a spherical filler substantially consisting of a non-crosslinking polyethyl methacrylate; and (C) a polymerization initiator; and a dental adhesive kit comprising the above dental adhesive composition in combination with a dental primer comprising (D) an acidic-group containing polymerizable monomer, (E) an aryl borate, (F) an organosulfinic acid salt and (G) water. The dental adhesive composition exhibits good operability and improved adhesion performance.

Owner:TOKUYAMA DENTAL CORP +1

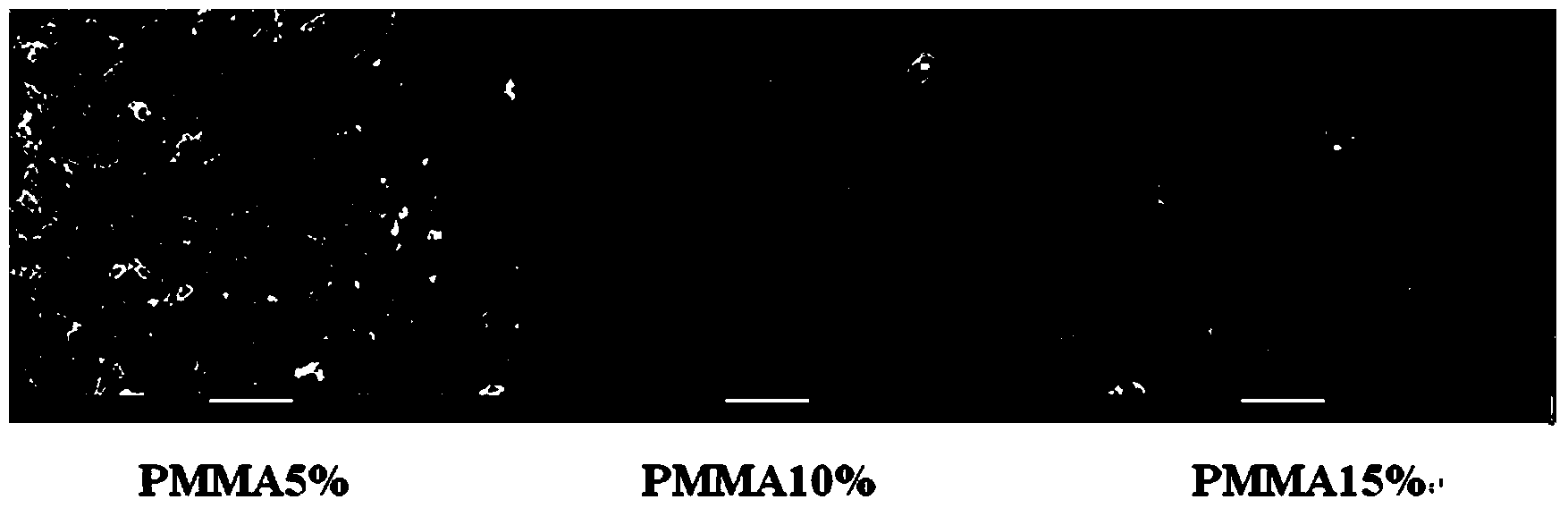

YSZ (Yttria Stabilization Zirconia)-based mixed potential type NO2 sensor with high-efficiency three-phase boundary and preparation method thereof

InactiveCN103954670AIncreased sensitivitySimple processMaterial analysis by electric/magnetic meansReactive sitePolymethyl methacrylate

The invention discloses a porous YSZ (Yttria Stabilization Zirconia) substrate-based mixed potential type NO2 sensor with a high-efficiency three-phase boundary and a preparation method thereof, belonging to the technical field of gas sensors. The sensor sequentially consists of an Al2O3 ceramic plate provided with a Pt heating electrode, the porous YSZ substrate of which one side is provided with a pore-forming surface, a Pt reference electrode and an NiO sensitive electrode, wherein the reference electrode and the sensitive electrode are both of strip-shaped structures and are symmetrically arranged close to the edge on the pore-forming surface of the porous YSZ substrate; the porous YSZ substrate is prepared by steps of blade-coating of a layer of a YSZ sizing agent added with pore forming agents on the YSZ substrate, low-temperature degreasing and high-temperature sintering, and is of a double-layer structure of which the surface is rough and porous. The pore forming agents have three types, including PMMA (Polymethyl Methacrylate), graphite and starch, and the doping ratios of the three types of pore forming agents are all 5% to 15%. By increasing the reaction area and active sites of the three-phase boundary of the mixed potential type NO2 sensor, the sensitivity of the sensor is improved.

Owner:JILIN UNIV

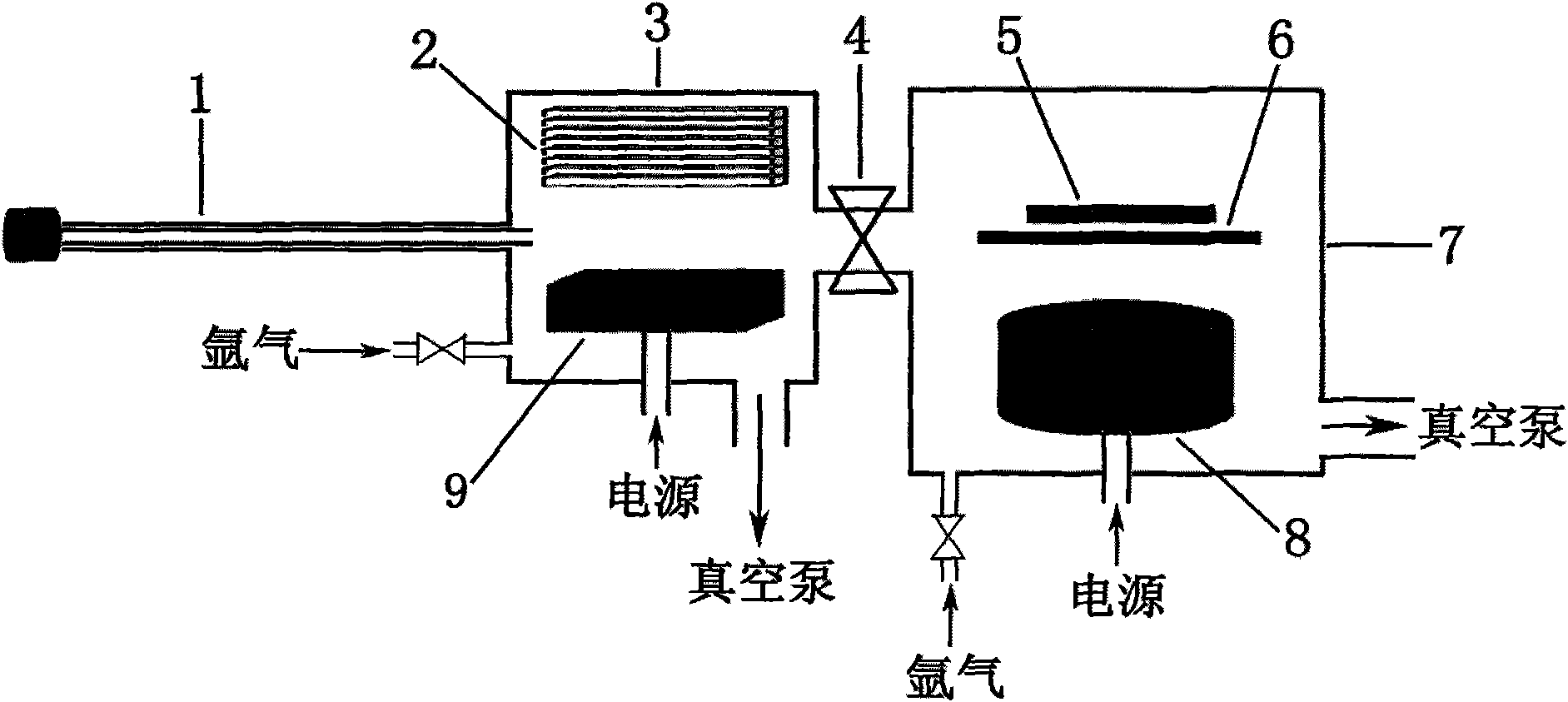

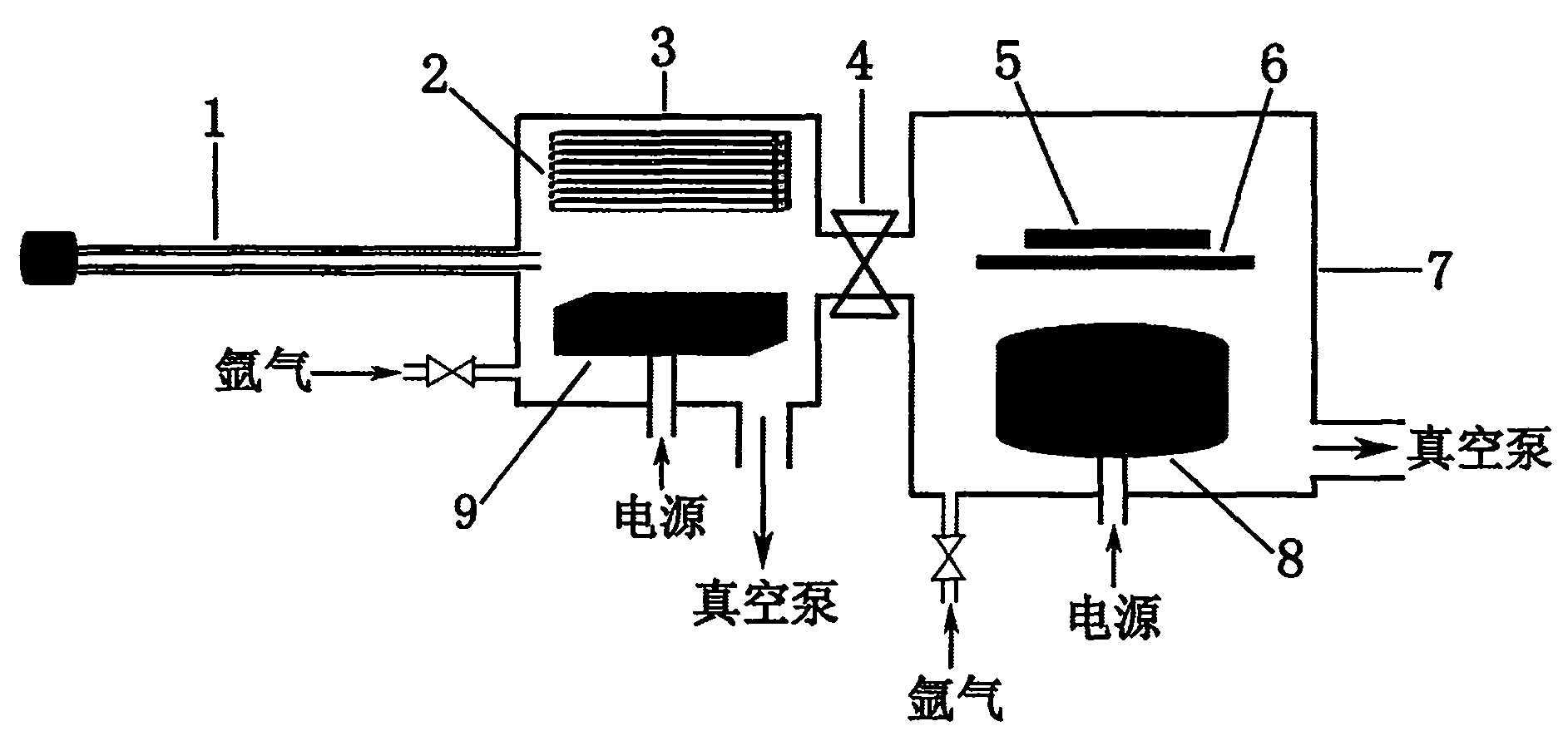

Method for depositing metal or hard ornament film on plastic substrate

InactiveCN101985738AImprove bindingAvoid strippingVacuum evaporation coatingSputtering coatingIridiumRadio frequency magnetron sputtering

The invention relates to a method for depositing a metal or hard ornament film on a plastic substrate. In the method, the metal or hard ornament film is prepared on the surface of a plastic substrate material by using a radio frequency magnetron sputtering technology, and good binding force exists between the prepared ornament film and the substrate. The plastic substrate material comprises ABS plastic (terpolymer of acrylonitrile-butadiene-styrene), PMMA (polymethyl methacrylate) organic glass, PE (poly ethylene) plastics, PP (polypropylene) plastics and the like. The metal ornament film comprises chromium, nickel, titanium, aluminum, aurum, silver, iridium or alloys and the like, and the hard ornament film comprises metal nitrides, carbon compounds, oxides, diamonds and the like. The method has the advantages of simple operation, no pollution and low cost, and the prepared film is good in adhesive force.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

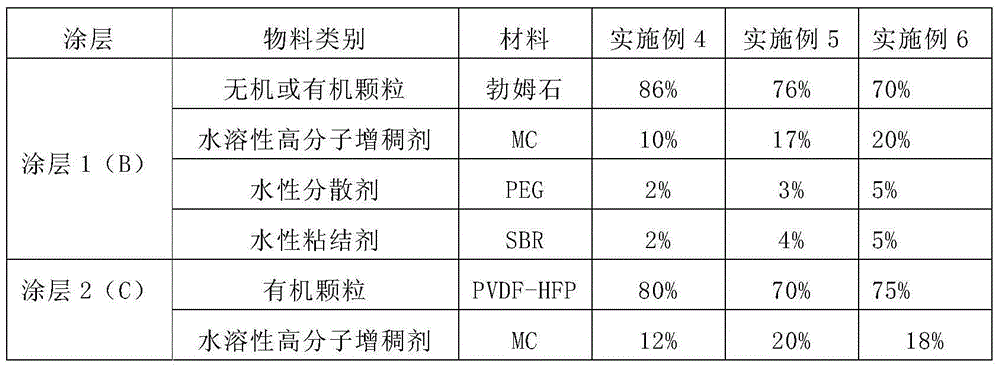

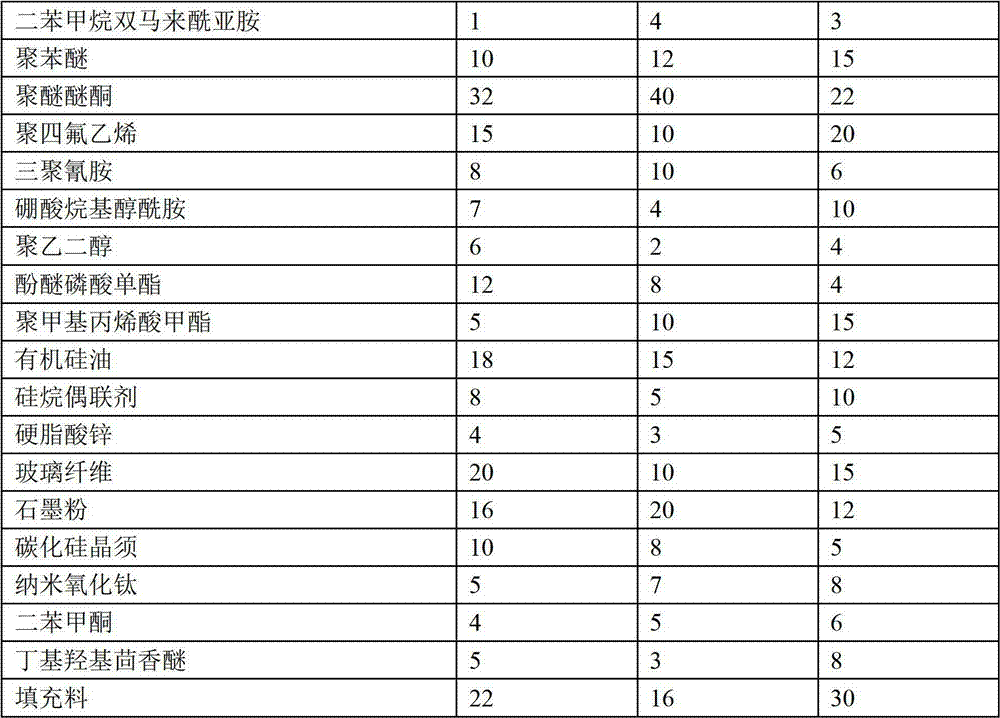

Water-based multi-layer membrane for lithium ion battery

InactiveCN104868081ACell seperators/membranes/diaphragms/spacersSecondary cellsWater basedElectrical battery

The invention provides a water-based multi-layer membrane for a lithium ion battery. The water-based multi-layer membrane comprises a polymer membrane substrate (A), an inorganic or organic particle coating (B) coating one or two sides of the polymer membrane substrate (A), and an organic particle coating (C) coating the inorganic or organic particle coating (B), wherein the inorganic or organic particle coating (B) is formed by a composition which comprises 15-70wt% of inorganic or organic particles and 30-85wt% of water; the inorganic or organic particles are selected from aluminum oxide, silica, barium sulfate, boehmite or polyimide; the organic particle coating (C) is formed by a composition which comprises 5-30wt% of organic particles and 70-95wt% of water; and the organic particles are selected from polyvinylidene fluoride-hexafluoropropylene, polyacrylonitrile, polyoxyethylene or polymethyl methacrylate.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

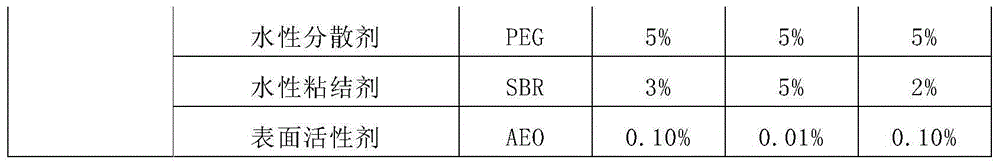

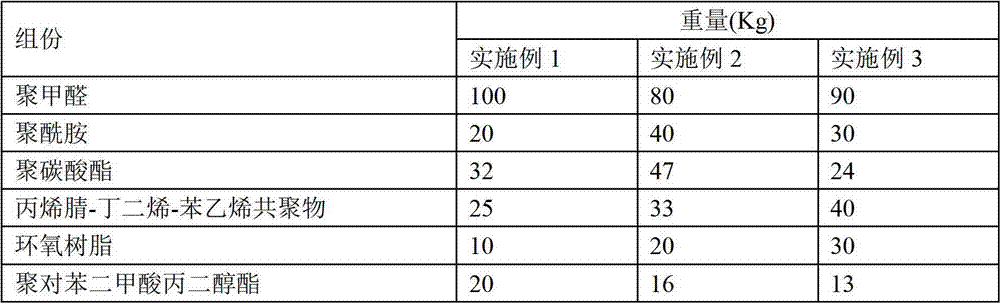

Engineering plastic with high wearing resistance

InactiveCN102875956AGood mechanical propertiesReduce wear ratePolyethylene glycolPolymethyl methacrylate

The invention provides an engineering plastic with high wearing resistance. The engineering plastic is made from the following raw materials by weight: 80-100 parts of polyformaldehyde, 20-40 parts of polyamide, 20-50 parts of polycarbonate, 25-40 parts of acrylonitrile-butadiene-styrene copolymer, 10-30 parts of epoxy resin, 12-20 parts of polytrimethylene terephthalate, 1-5 parts of diphenylmethane bismaleimide, 10-15 parts of polyphenyl ether, 20-40 parts of polyether-ether-ketone, 10-20 parts of polytetrafluoroethylene, 5-10 parts of melamine, 4-12 parts of boric acid alkanolamide, 2-6 parts of polyethylene glycol, 4-12 parts of phenolic ether phosphomonoester, 5-15 parts of polymethyl methacrylate, 10-20 parts of organic silicone oil, 5-10 parts of silane coupling agent, 3-5 parts of zinc stearate, 10-20 parts of glass fibre, 12-20 parts of graphite, 5-10 parts of silicon carbide whisker, 5-8 parts of nanometre titanium oxide, 4-6 parts of diphenyl ketone, 3-8 parts of butylated hydroxyanisole and 15-30 parts of filler. The engineering plastic provided by the invention has a good wear-resisting property.

Owner:SUZHOU YUNYUAN NETWORK TECH

Modified porous materials and methods of creating interconnected porosity in materials

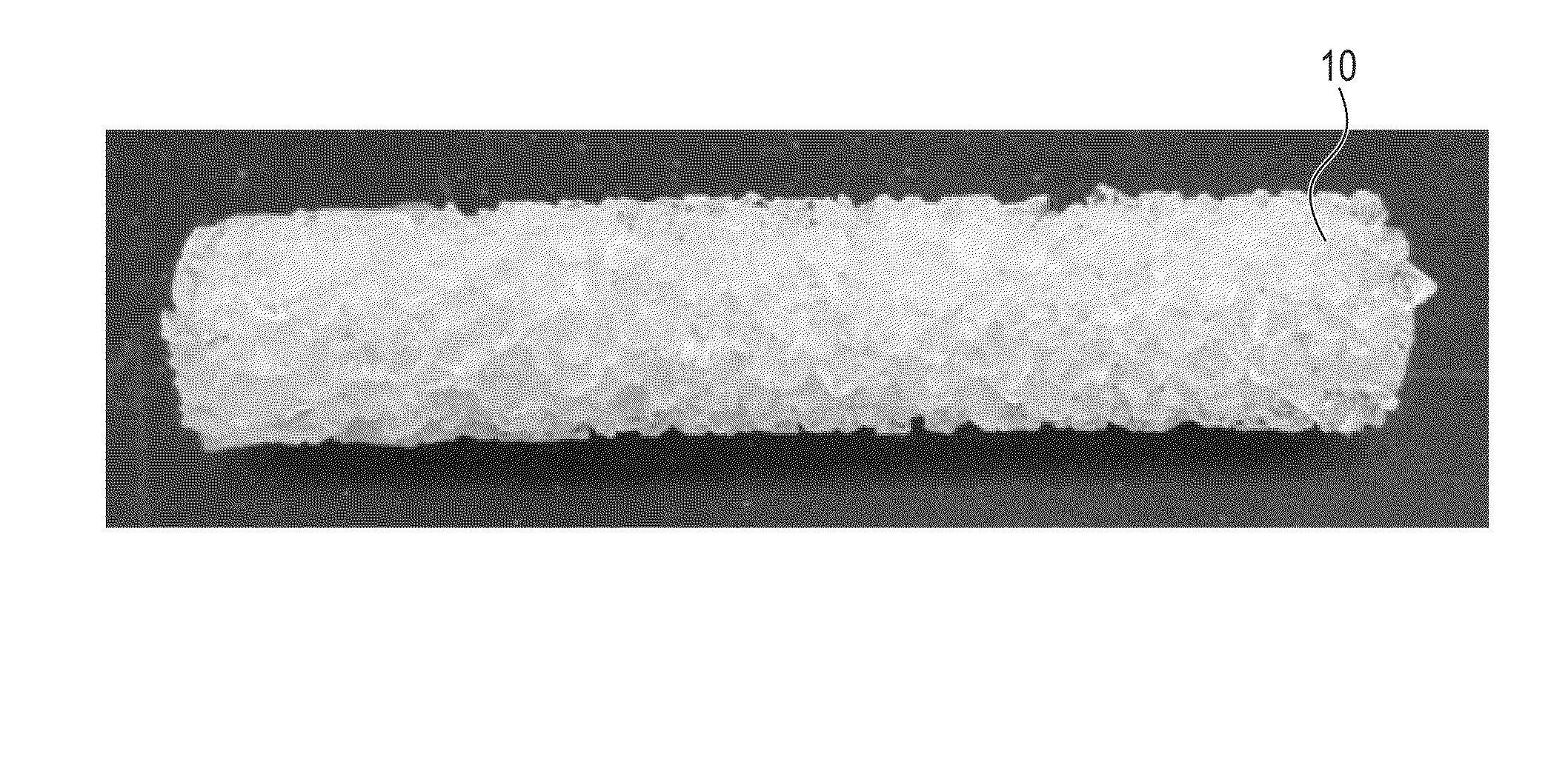

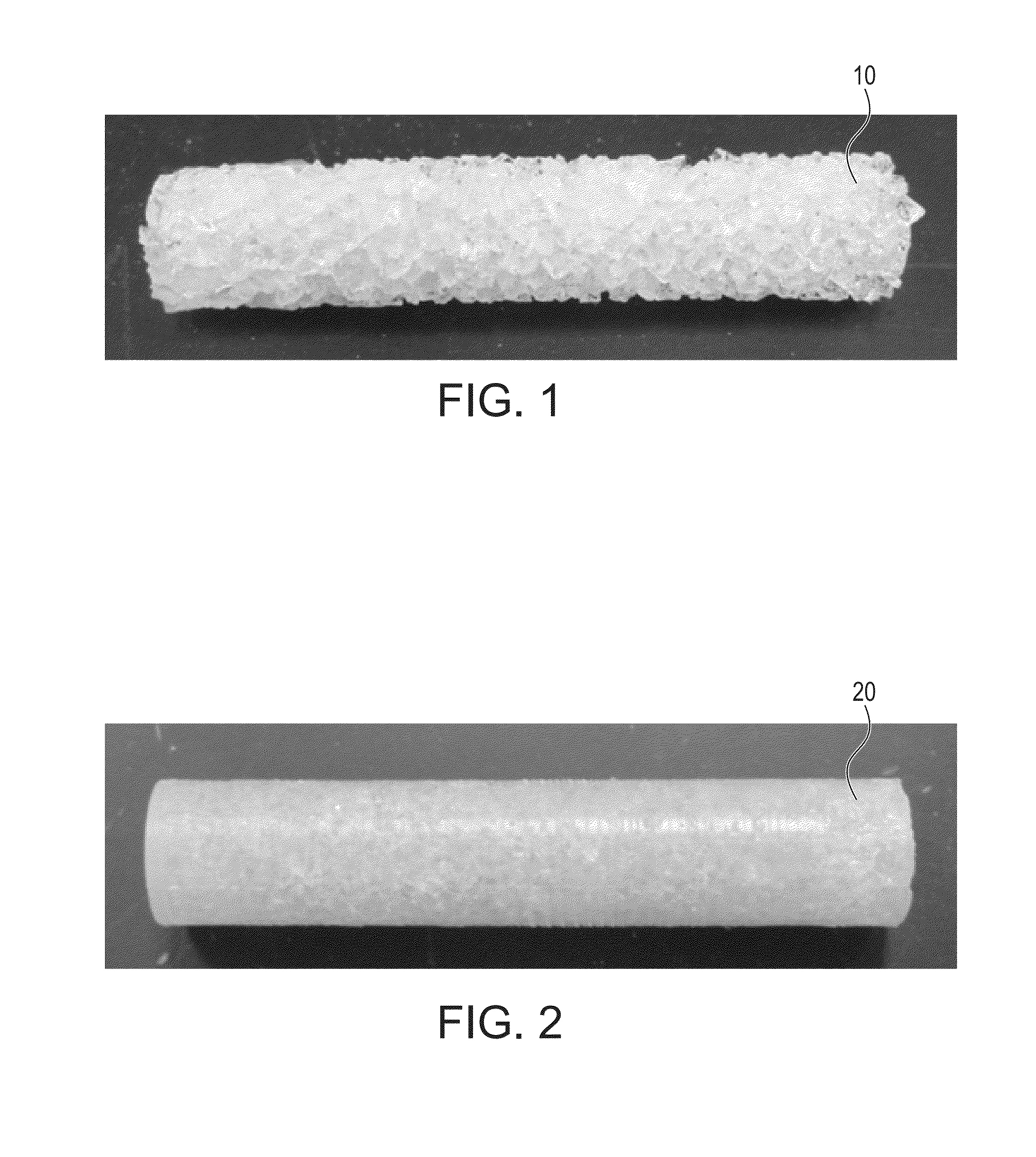

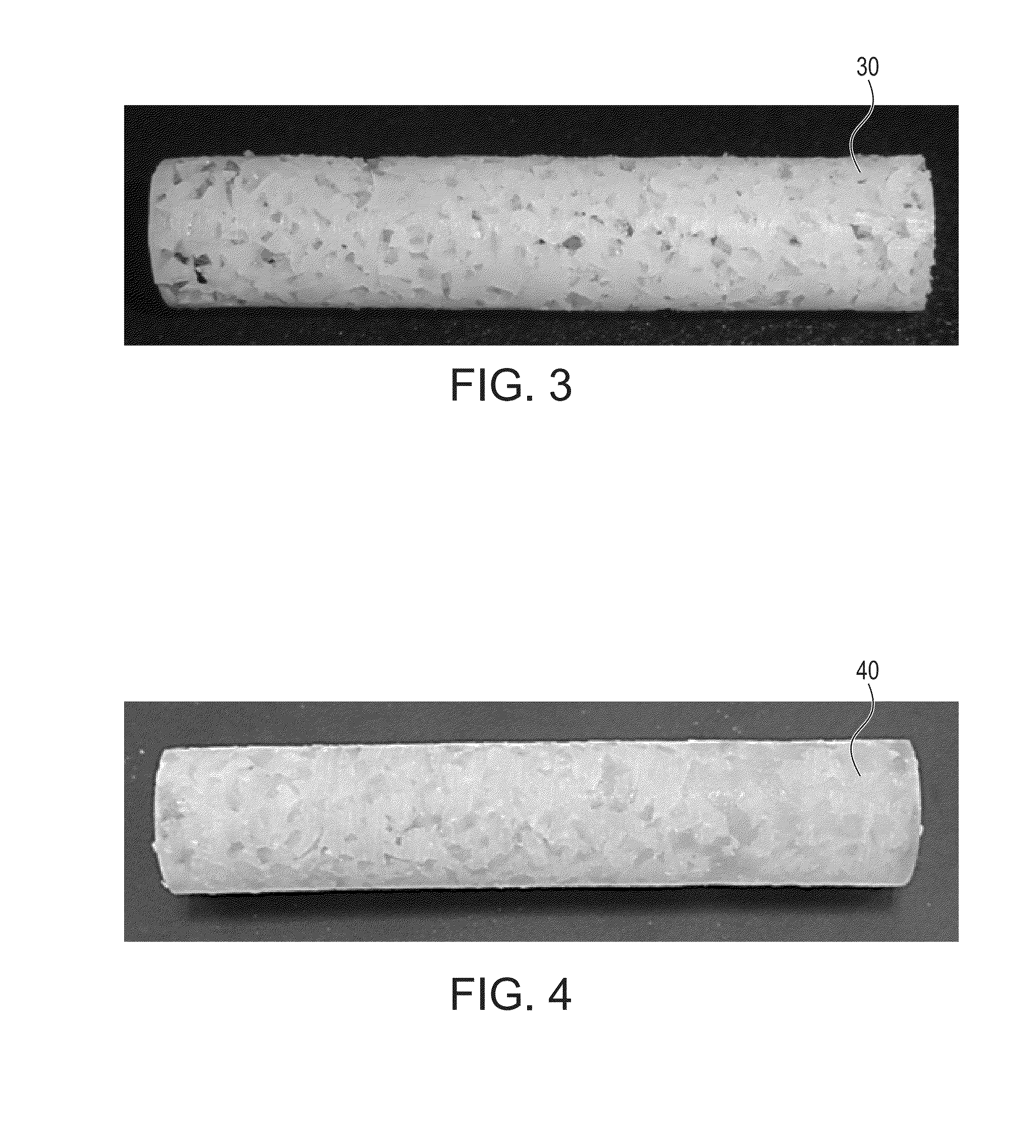

ActiveUS20140243439A1Solve Porosity InsufficiencyHigh mechanical strengthSurgeryAbsorbent padsSuture anchorsInterference screws

Techniques, mixtures and improved porous materials (interconnected porous constructs) that are capable of maintaining a sufficient porosity while conferring improved mechanical and physical strength to the final construct. A sacrificial construct (for example, a sacrificial material such as polymethyl methacrylate (PMMA)) is used to obtain an inverse porosity of the construct it was molded into. The process provides a less porous end material that may be used as an arthroplasty device or surgical implant (for example, an interference screw of suture anchor) among many other applications. The process employs a sacrificial material to reduce the porosity of the final construct to about 35%.

Owner:ARTHREX

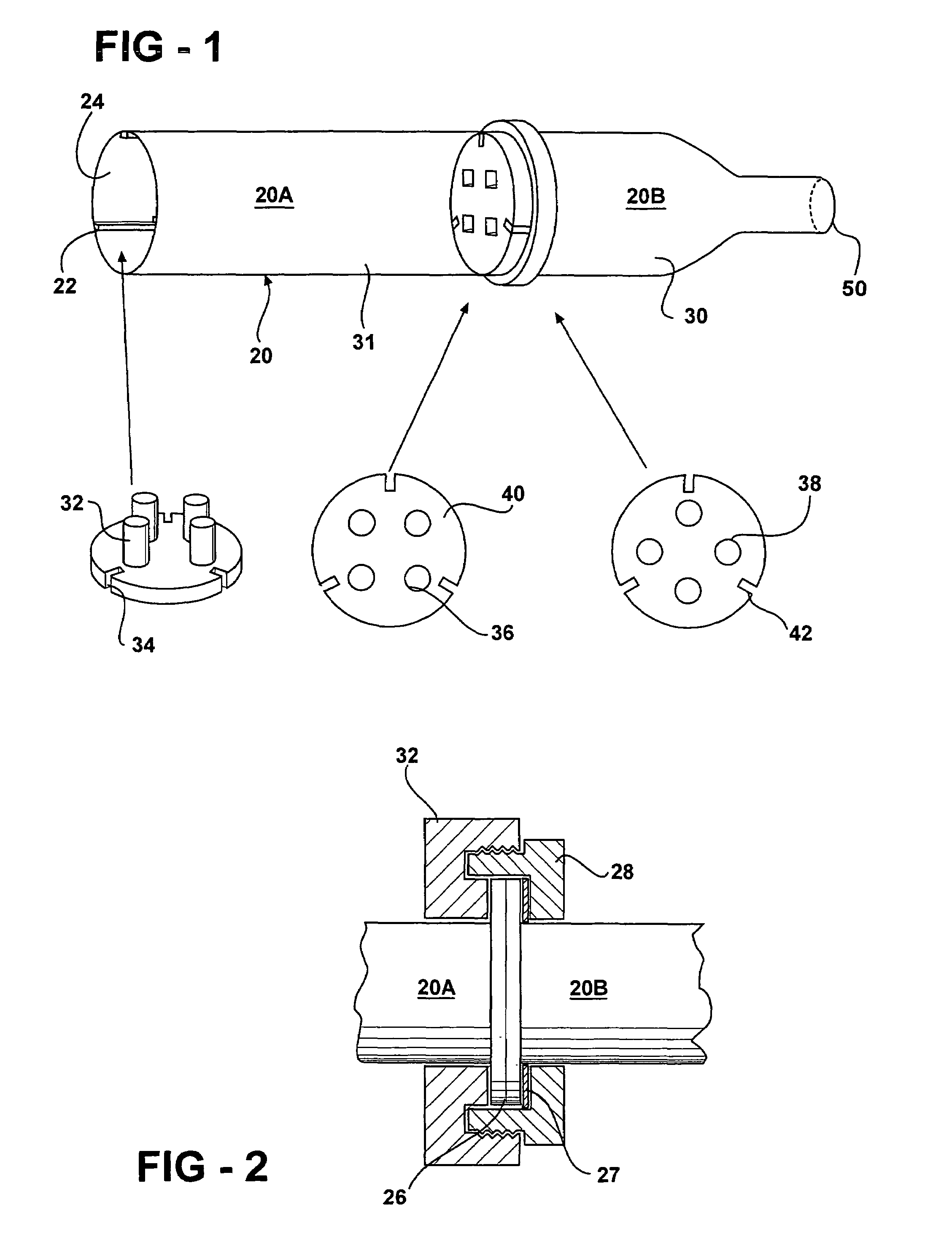

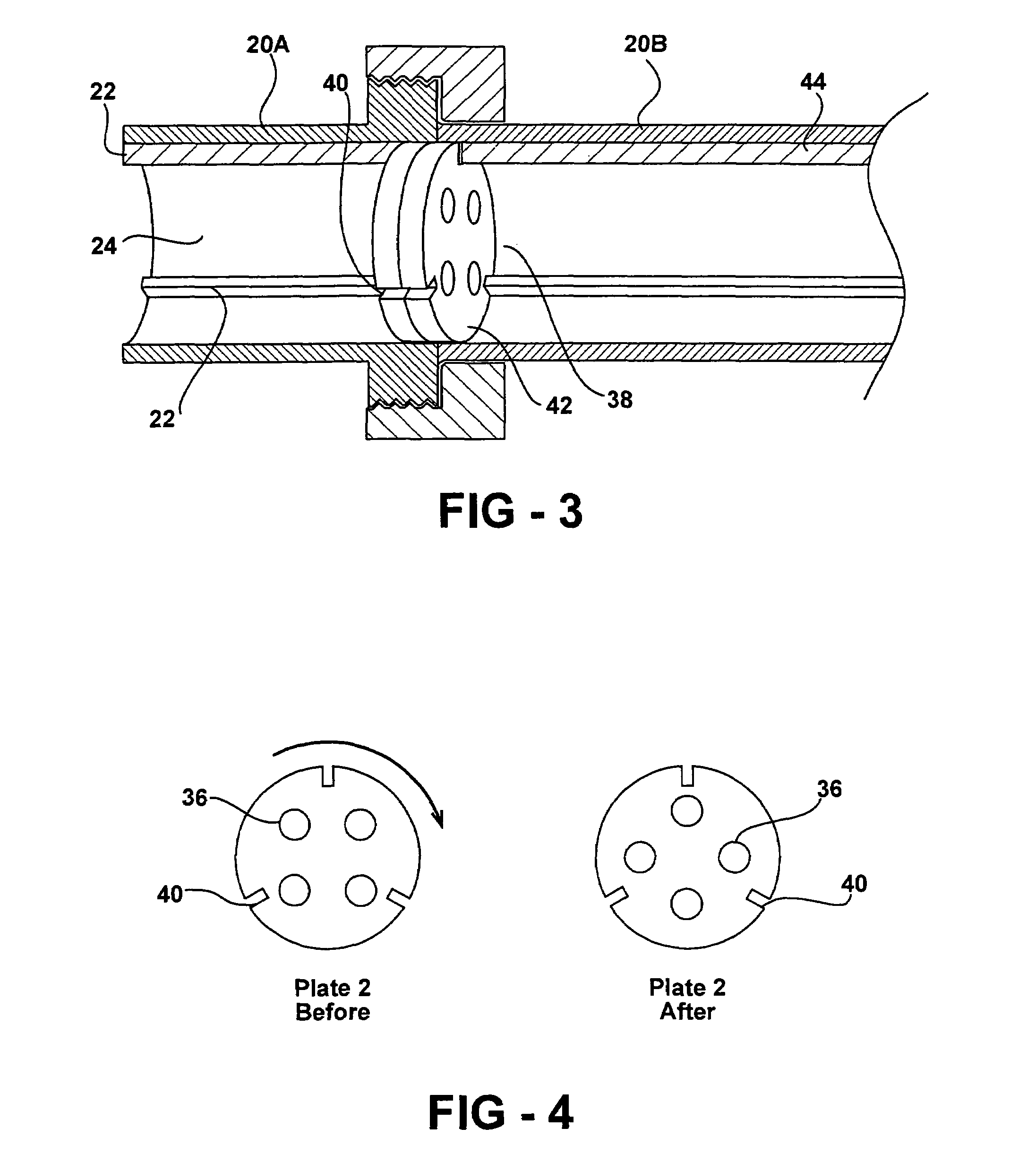

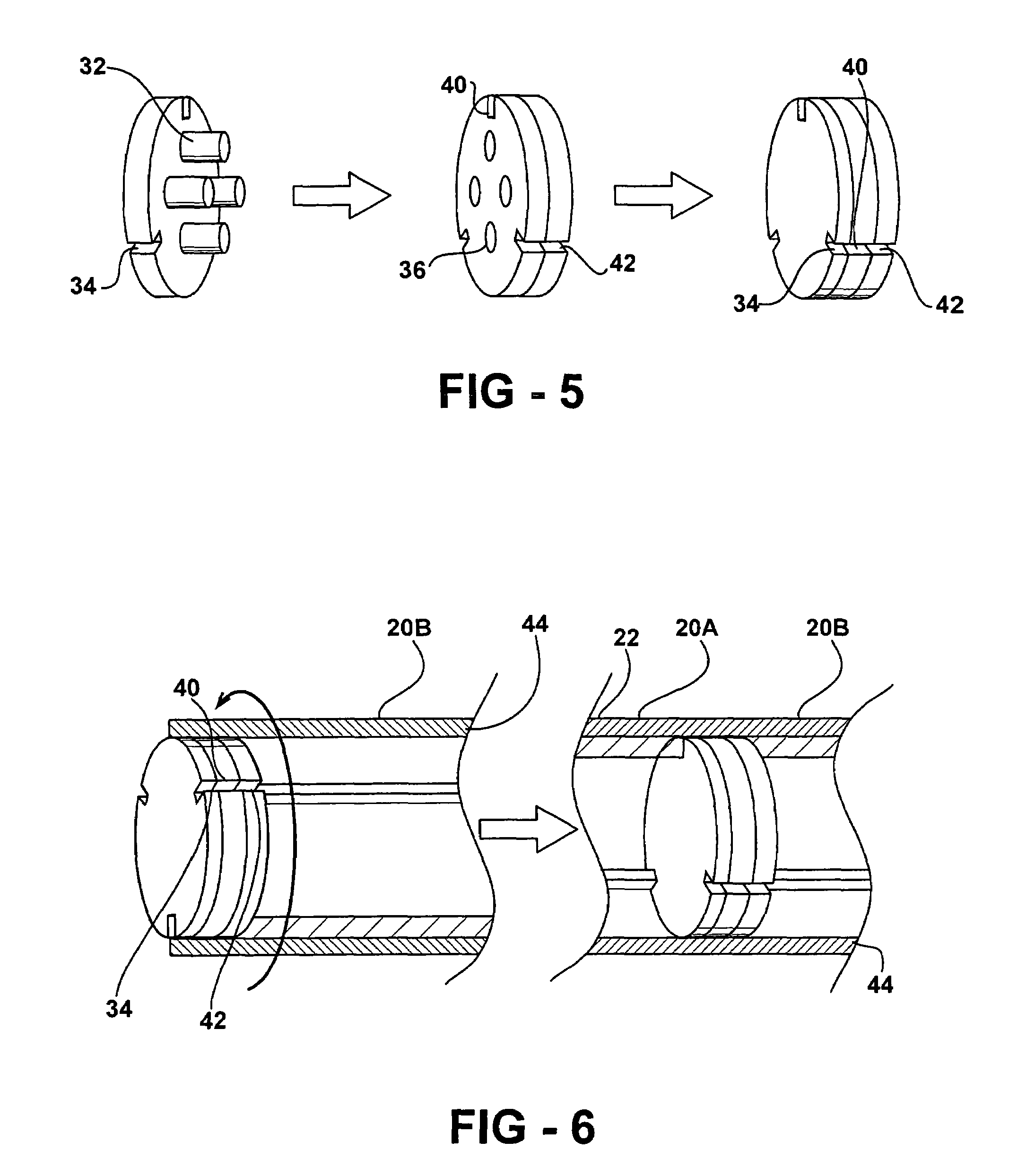

Bone cement and a system for mixing and delivery thereof

A bone cement formulation stored as a solid component pack having 0.3 to 20 solid component pack weight percent of an elastomer and a polymer bead core having a polyacrylate terminated surface. The second component pack is a liquid component pack including an acrylate monomer. An alternate solid component pack includes 3 to 25 solid component pack weight percent of a polyacrylate and a rubber toughened polymethyl methacrylate. A cement mixing and delivering system according to the present invention includes a tube having an exit nozzle and an aperture. An end plate is adapted to seal against the interior of the tube aperture and the end plate has a plurality of needles protruding therefrom into the tube. A rotatable and slidable divider is received within the tube intermediate between the end plate and the exit nozzle. The divider includes at least two plates. Each of the plates has a plurality of apertures that upon alignment the needles of the first plate are urged through the apertures of the at least two divider plates.

Owner:UAB RES FOUND

Method for preparing graphene/copper composite material by in-situ catalysis of solid carbon source on surfaces of copper powders

The present invention relates to a method for preparing a graphene / copper composite material by in-situ catalysis of a solid carbon source on surfaces of copper powders. The method comprises the steps of: adding steel balls, the copper powders and polymethyl methacrylate at the mass ratio of 150: 10: (0.1-0.3) into a ball milling tank, and filling argon as protective atmosphere after vacuum pumping; after ball milling, preparing cooper-polymethyl methacrylate powders which are uniformly dispersed; performing reduction treatment in a tubular furnace to catalyze the polymethyl methacrylate into graphene, and obtaining graphene / copper composite powders with graphene in-situ growth; and then preparing a graphene copper-based composite material block. Tensile property of the graphene reinforced copper-based composite material prepared by the method is better than tensile property of that prepared by a traditional adding method, that is a method of adding reduction-oxidation graphene or graphene sheets. Reinforcement of a cooper-based material is achieved, and high-strength copper materials have a better application prospect on electronic devices.

Owner:TIANJIN UNIV

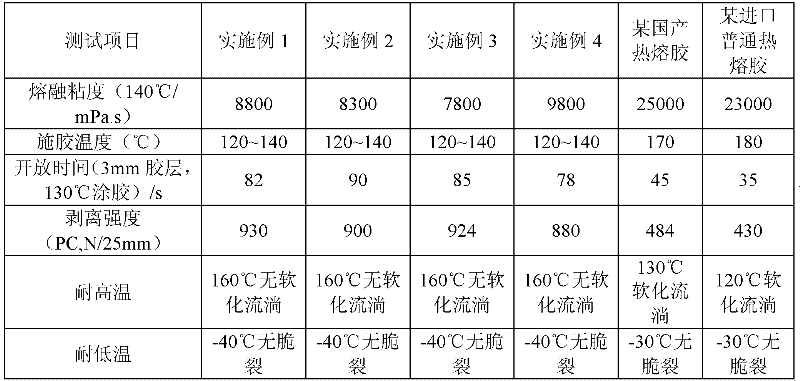

Polyurethane hot-melt adhesive for bonding and preparation method thereof

ActiveCN102585753AExcellent peelabilityEasy to apply glueNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to a polyurethane hot-melt adhesive for bonding and a preparation method thereof, belonging to the technical field of preparation of automobile hot-melt adhesives. The preparation method comprises the following steps of: firstly, feeding high-crystalline polyester glycol, polyester polyol and tackifying resin into a reactor, heating, dehydrating at vacuum while stirring, andthen cooling; secondly, preheating diisocyanate, adding the preheated diisocyanate to the reactor to uniformly stir and carrying out prepolymerization reaction; after the prepolymerization is finished, sequentially adding weighed catalyst, antioxidant, coupling agent, viscosity stabilizer and grey paste under nitrogen circulation, and stirring till being mixed uniformly; discharging in the nitrogen protection condition, sealing and packaging so as to obtain the product, that is, the polyurethane hot-melt adhesive for bonding automobile lights. The hot-melt adhesive prepared by adopting the preparation method disclosed by the invention can be used for bonding a plurality of base materials such as PP (Polypropylene), PBT (polybutylece terephthalate), ABS (Acrylonitrile Butadiene Styrene), PMMA (polymethyl methacrylate), PC (Poly Carbonate) and inorganic glass.

Owner:WUXI WANLI ADHESION MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com