Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118 results about "Resin cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

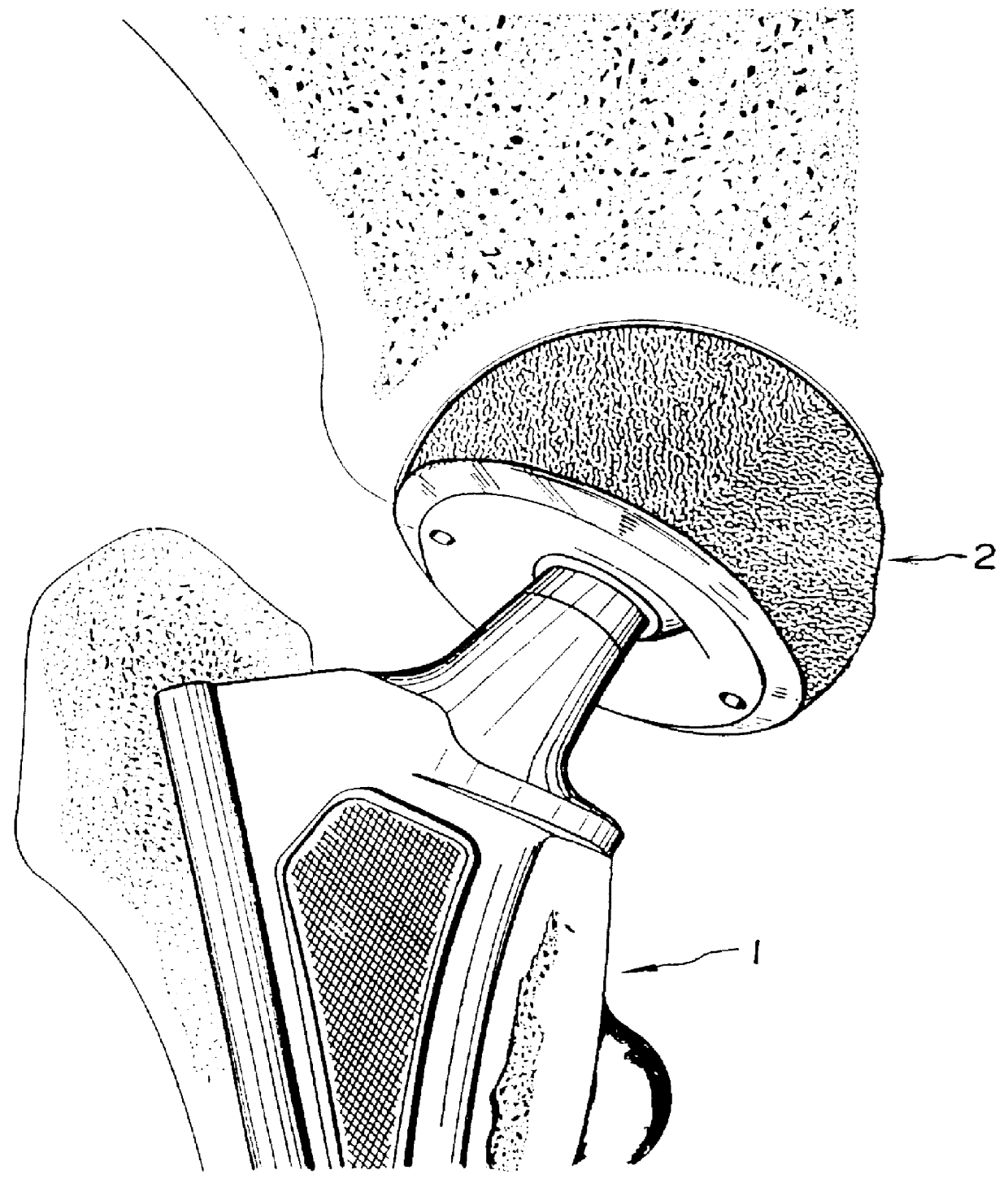

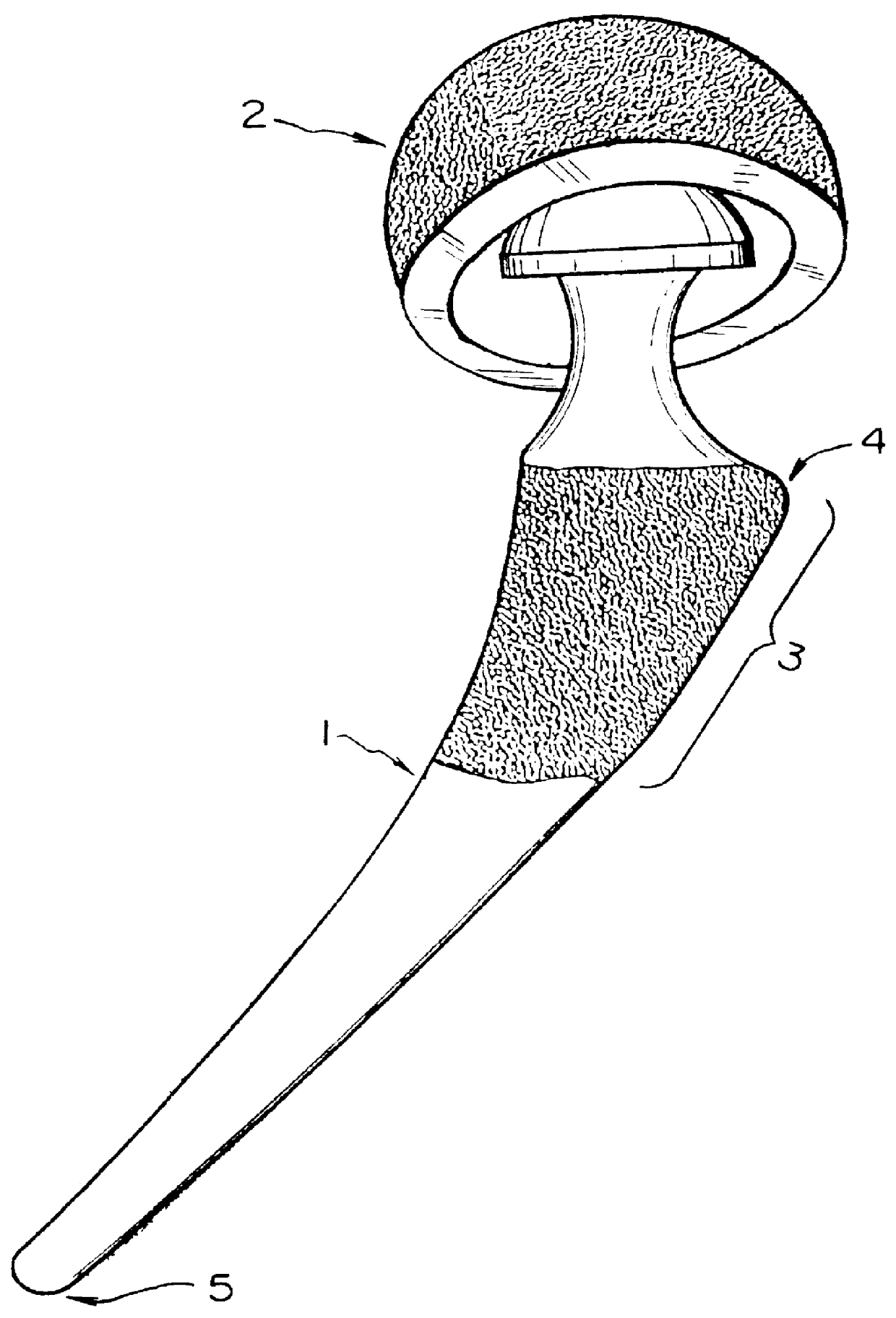

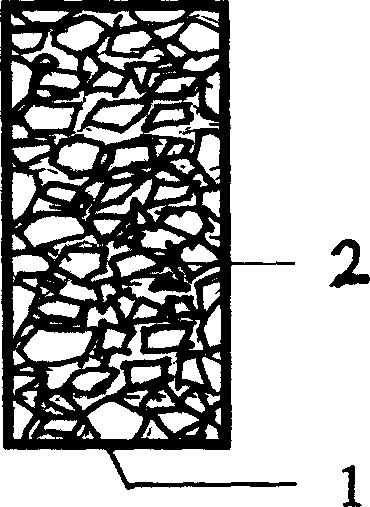

Orthopedic implant system

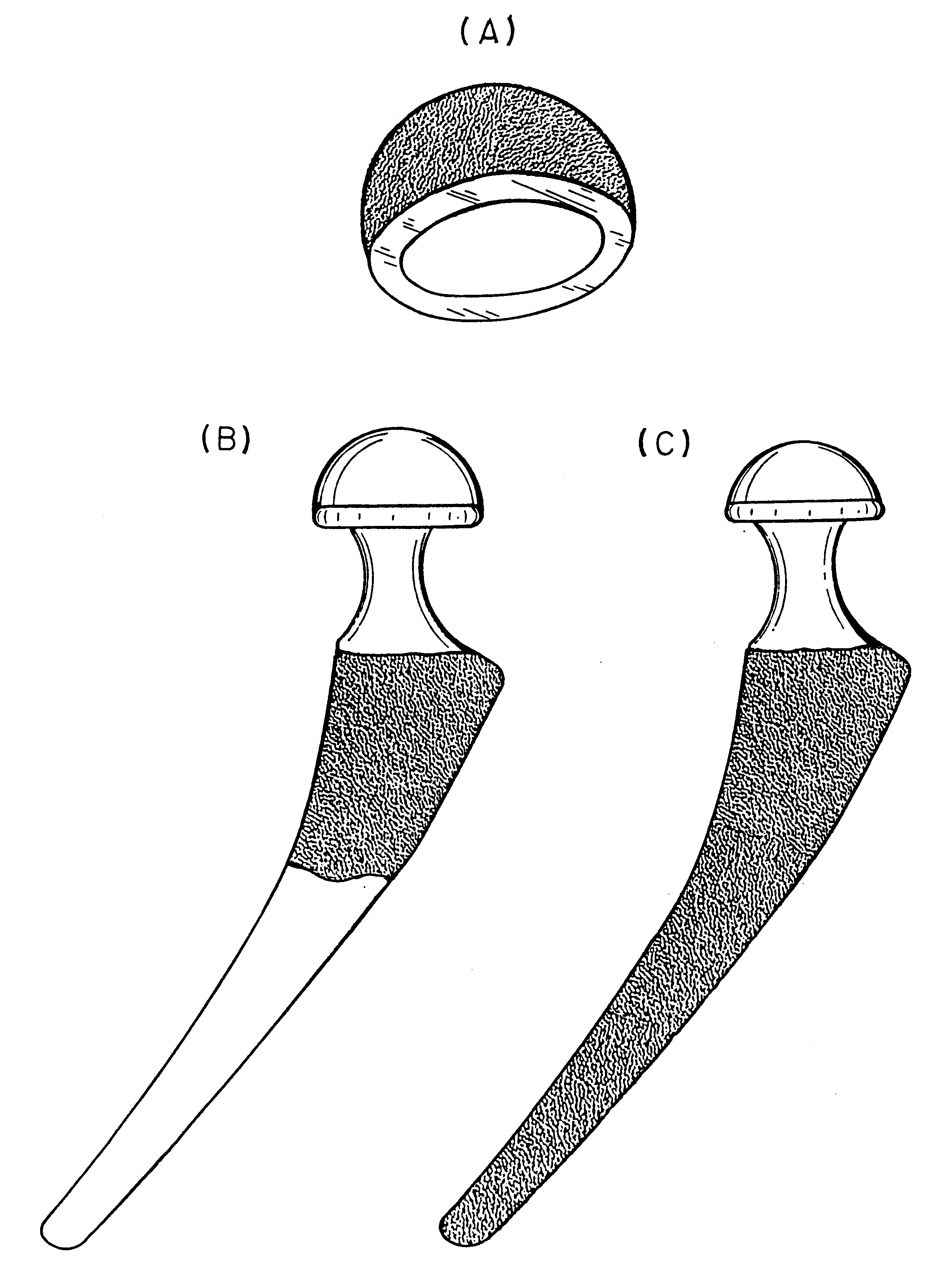

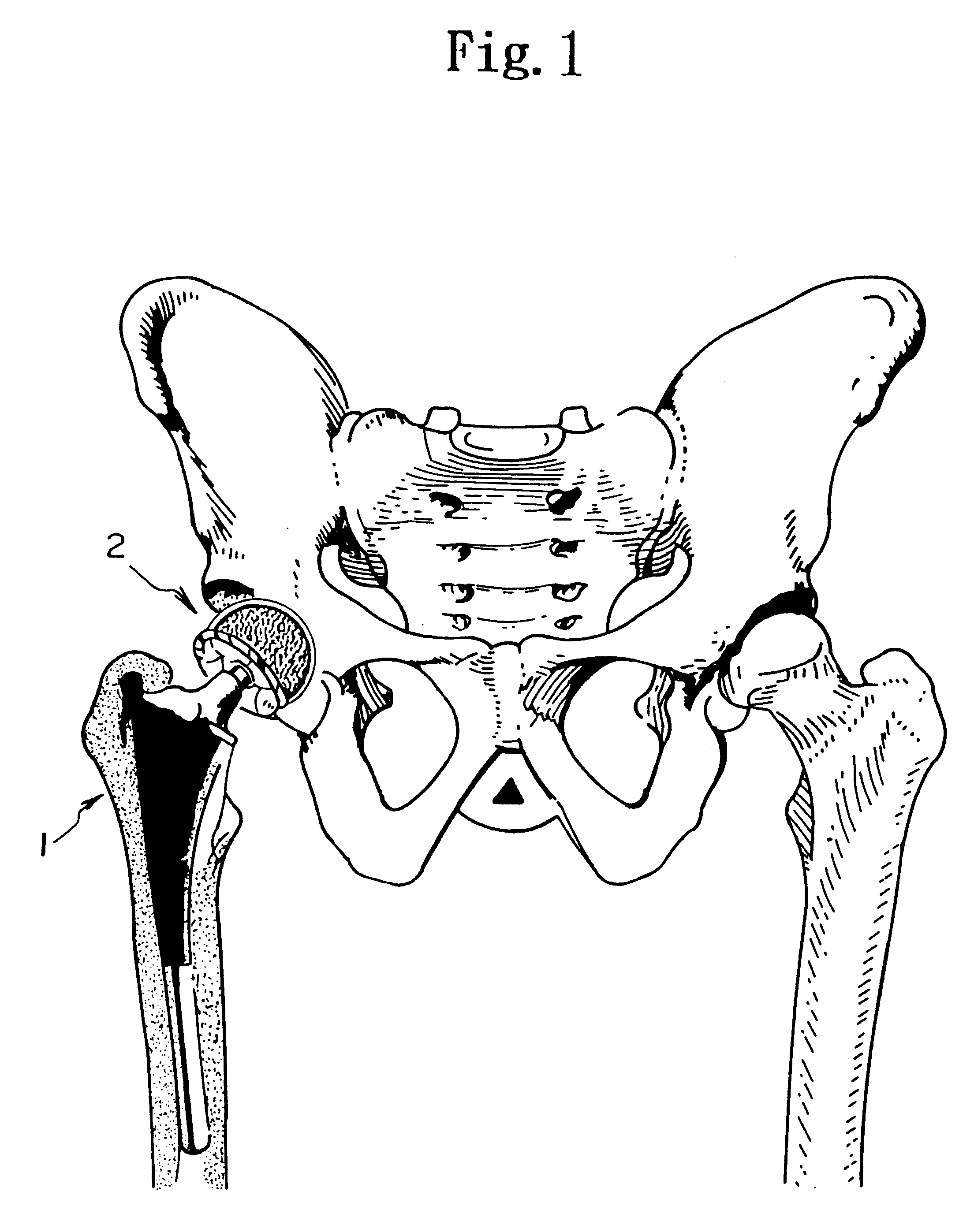

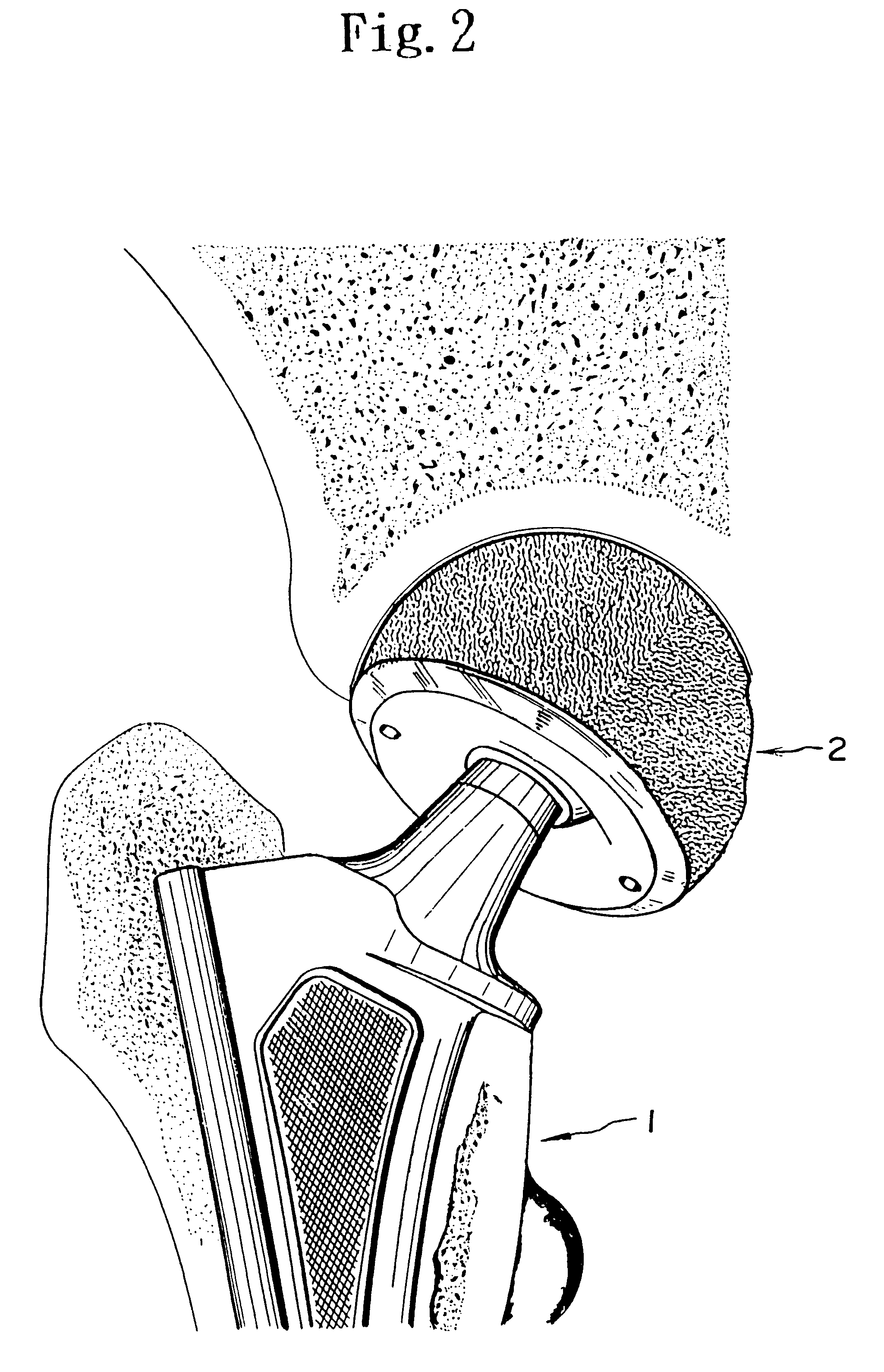

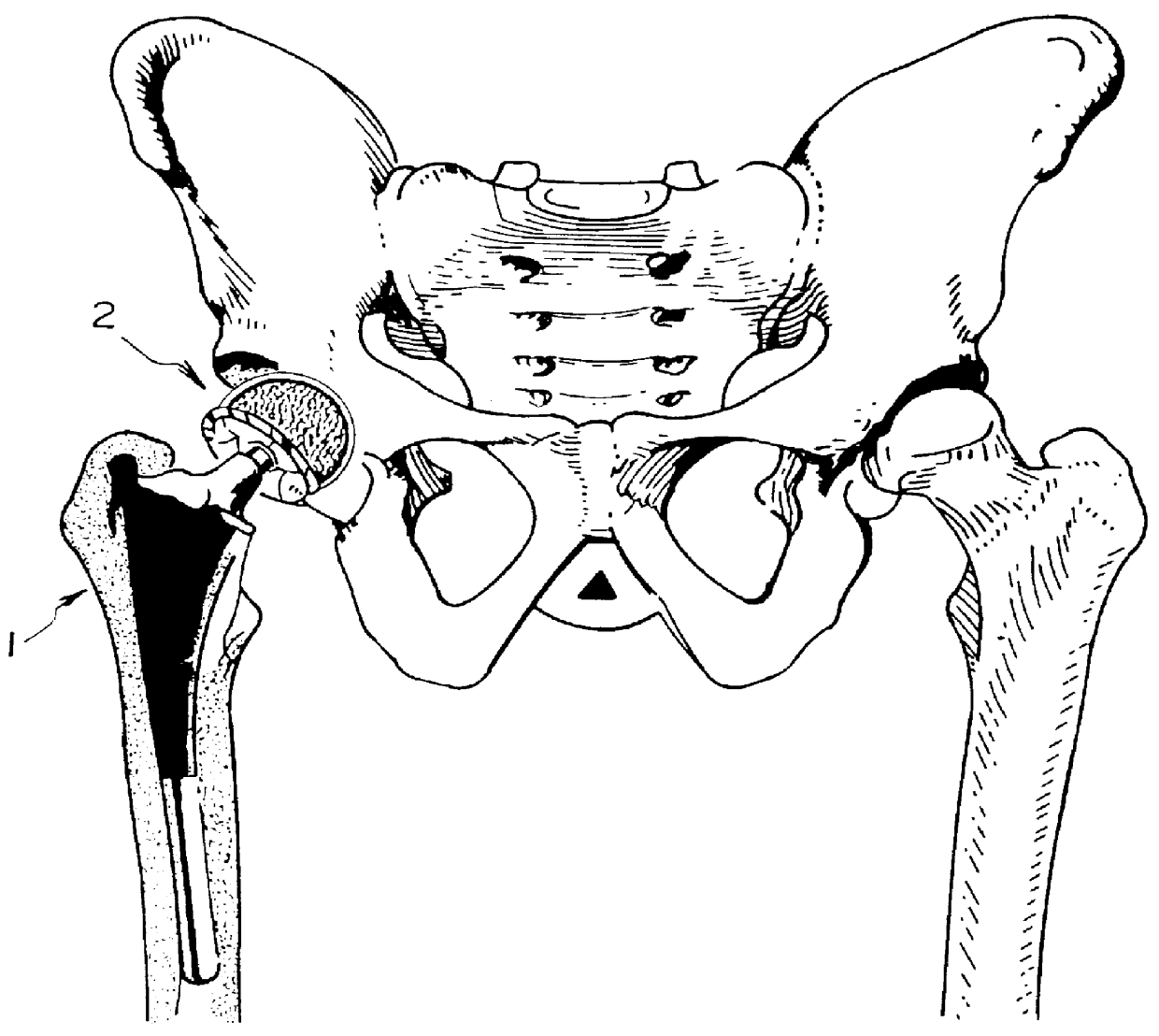

InactiveUS6312473B1Easy to fixAvoid excessive temperatureSurgical adhesivesBone implantFemoral stemPolymethyl methacrylate

It is an object of the present invention to provide an improved orthopedic implant system with satisfied biological, mechanical and morphological compatibilities.Solid metal femoral stem and solid metal acetabular head are covered with diffusion-bonded foamed-shaped sheet made of commercially pure titanium or titanium alloy(s). The open-cells in said foamed metal sheet are impregnated with biocompatible polymethyl methacrylate resin cement, which is reinforced with selected oxides including alumina, magnesia, zirconia, or a combination of these oxides along with an application of a small amount of a metal primer agent.

Owner:OSHIDA YOSHIKI

Orthopedic implant system

InactiveUS6066176AStrong interlocking fixationEasy to fixSurgical adhesivesBone implantPolymethyl methacrylateFemoral stem

It is an object of the present invention to provide an improved orthopedic implant system with satisfied biological, mechanical and morphological compatibilities. Solid metal femoral stem (entirely or partially) and solid metal acetabular head (entirely or partially) are covered with diffusion-bonded foamed-shaped sheet made of commercially pure titanium or titanium alloy(s). The open-cells in said foamed metal sheet are impregnated with biocompatible polymethyl methacrylate resin cement, which is reinforced with selected oxides (e.g., alumina, magnesia, zirconia, or a combination of these oxides) along with an application of a small amount of a metal primer agent.

Owner:OSHIDA YOSHIKI

Dental self-curing resin cement compositions

InactiveUS20050049326A1Physical improvementImprove mechanical propertiesImpression capsTeeth fillingMethacrylateAntioxidant

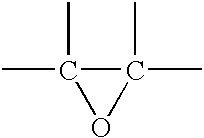

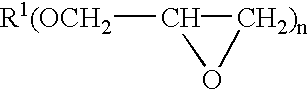

The present invention refers to dental self-curing resin compositions having enhanced mechanical and physical properties. In particular, the present invention relates to dental self-curing resin compositions consisting of (i) a Paste A composition containing the multifunctional prepolymer mixture of 2,2-bis-[4-(2-hydroxy-3-methacryloxypropoxy)phenyl]propane (“Bis-GMA”) and multifunctional prepolymer formed by substituting hydrogen atoms in hydroxyl group with methacrylate groups in the Bis-GMA molecules, and further containing a diluent, an adhesive monomer, a polymerization initiator, a polymerization inhibitor, a light stabilizer, an antioxidant, an inorganic pigment and an inorganic filler; and ii) a Paste B composition containing the same prepolymer mixture in the Paste A composition, and further containing a diluent, an adhesive monomer, a reductant, a polymerization inhibitor, a light stabilizer, an antioxidant, an inorganic pigment and an inorganic filler. The composition according to the present invention has better physical and mechanical properties than that of conventional compositions and is an ointment-ointment system able to be conveniently used.

Owner:KOREA INST OF SCI & TECH +1

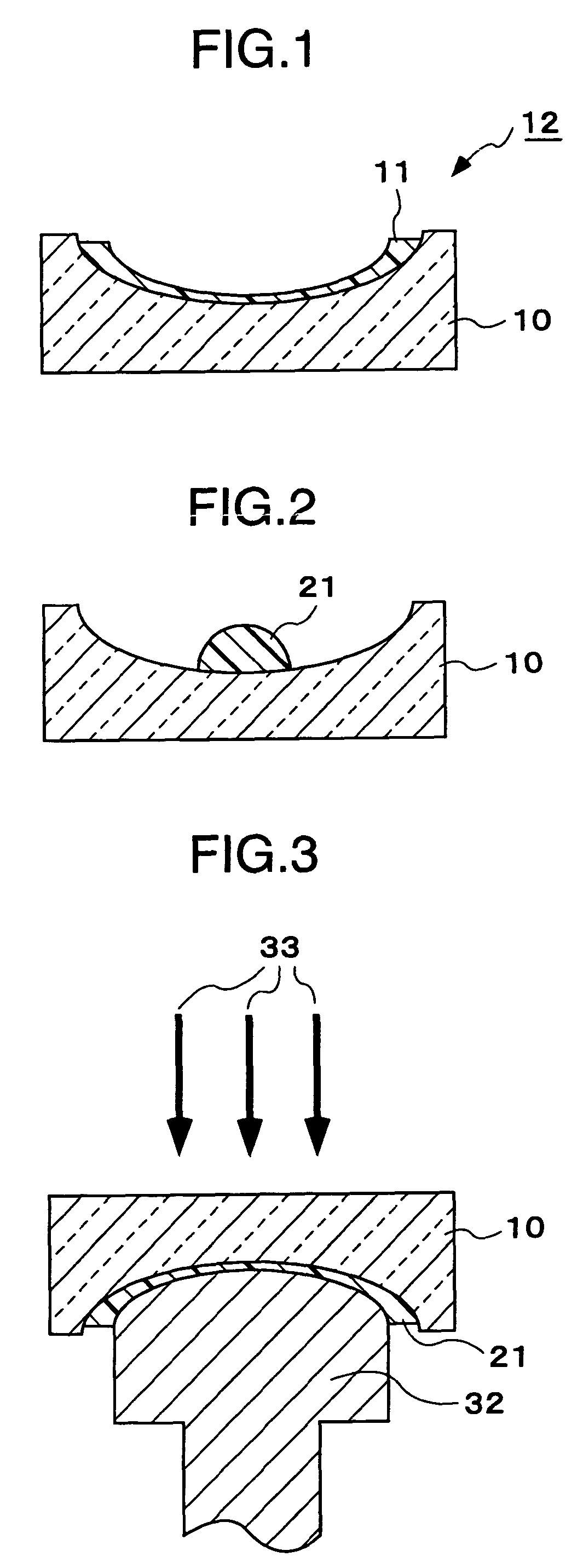

Resin-bond type optical element, production method therefor and optical article

InactiveUS7070862B1Good molding effectHigh refractive indexSynthetic resin layered productsOptical articlesTransmittanceRefractive index

This invention provides a resin-cemented optical element comprising a base member and a resin layer formed on the surface of the base member and comprising a cured product of a photosensitive resin composition, and the resin layer has (1) a refractive index of 1.55 or more, (2) a visible-light inner transmittance of 95% or more in a 100 μm thick area, (3) a rate of hygroscopic dimensional change of 0.4% or less, (4) a durometer hardness of HDD 70 or more, (5) a gel percentage of 95% or more, (6) a glass transition temperature of 95° C. or above or (7) a rate of shrinkage on curing of 7% or less; and a production process for the element and an optical article having the element.

Owner:NIKON CORP

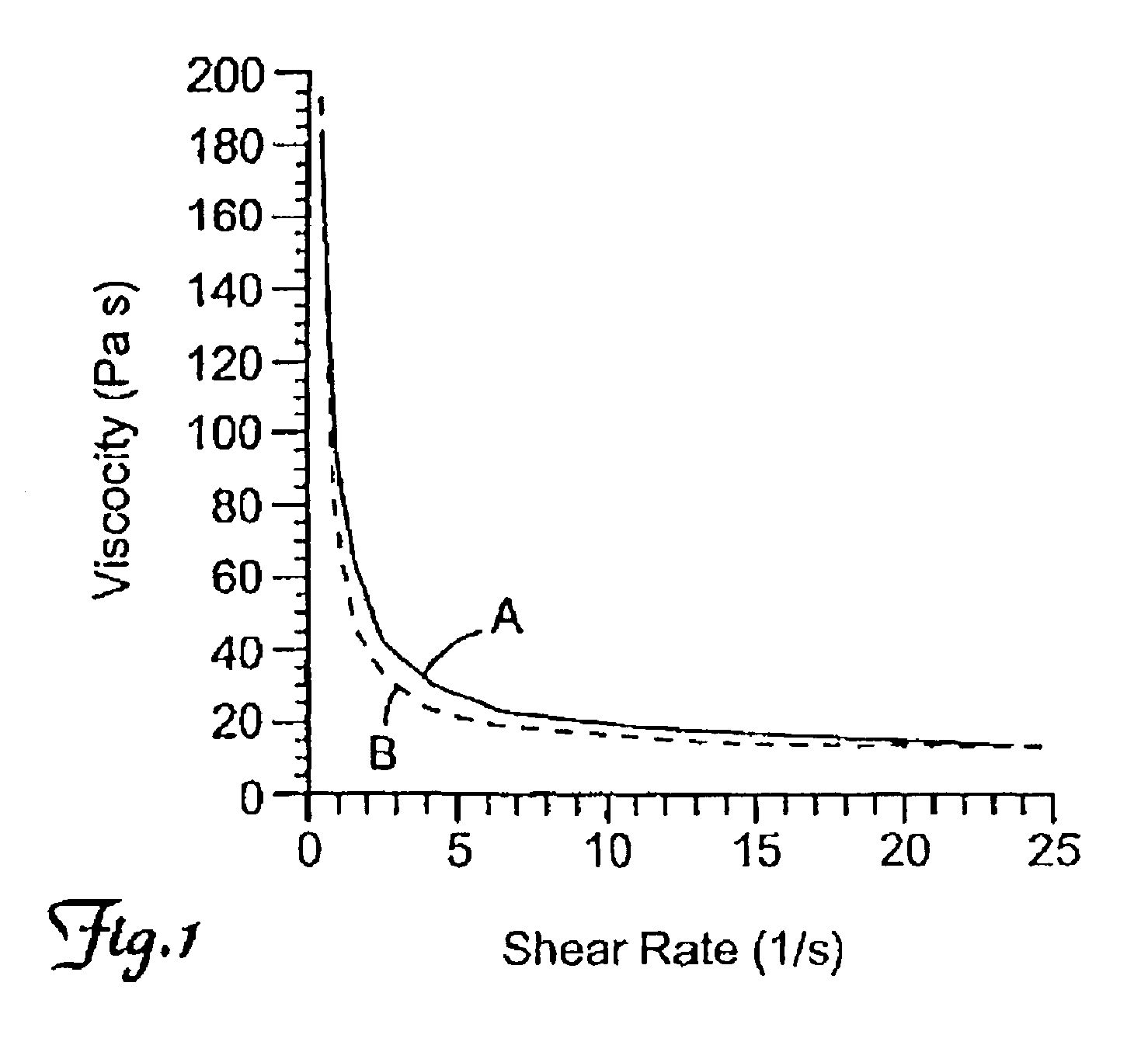

Dental resin cements having improved handling properties

Dental resin cement materials having unique handling properties are provided that comprise a) filler, b) polymerizable resin, and c) a polymeric handling modifier that is dispersed in the polymerizable resin at 25° C. and that has a molecular weight of between about 500 and 100,000. Components a) b) and c) are present in an amount effective to achieve a Viscosity vs Shear Rate Curve that fits a power law model of F(x)=AxB. The correlation value of the material to this curve is greater than 0.85 for both the increasing and decreasing shear rate curves, and the value of B is less than about −0.01.Resin cements are also provided that comprise acid functionality and water, but which do not comprise an acid reactive filler. Such cements may be self etching, thereby avoiding the need to carry out a separate acid etch step.

Owner:3M INNOVATIVE PROPERTIES CO

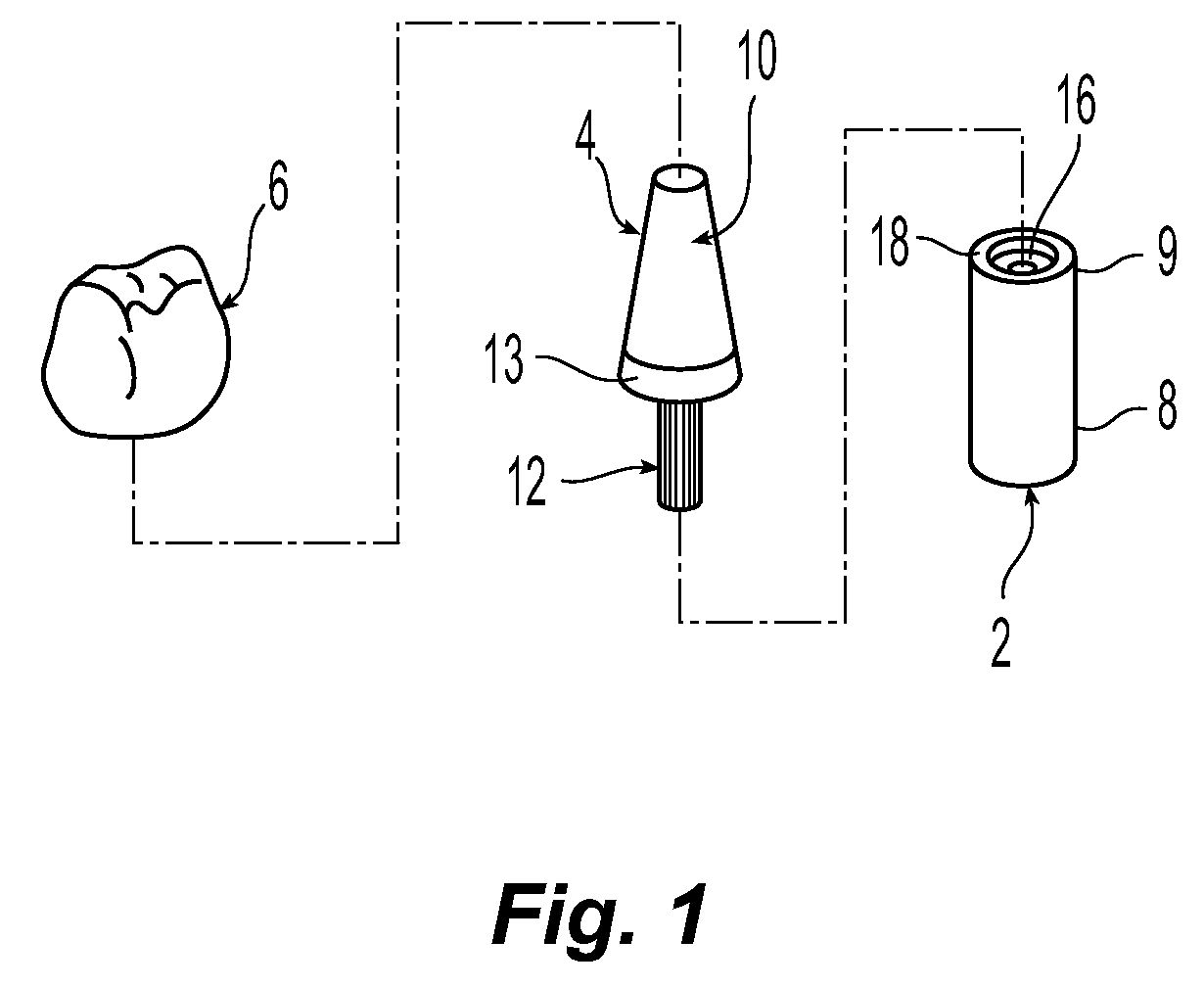

Universal dental implant system

A dental abutment is disclosed for use with a replacement tooth prosthesis. The abutment has a projection that fits generically within the fastener recess of an implant fixture pre-fitted within the patient's jawbone. The projection comprises a solid core surrounded by a plurality of fibers oriented parallel to the core. Resin cement is used to fix the abutment within the implant fixture. Downward pressure pushes the fibers out into intimate contact with the inner surfaces of the fastener recess. The abutment may be a polymer resin, metal, or a combination thereof. The abutment may also have a series of calibrated projections configured to engage corresponding projections of a pre-formed replacement tooth prosthesis to enable quick and precisely aligned installation of the prosthesis. The prosthesis may be a curable resin that is formed or molded in-situ, or it may be pre-manufactured. An installation method and a multi-piece kit are also provided.

Owner:ROSENBERG JEFFREY M

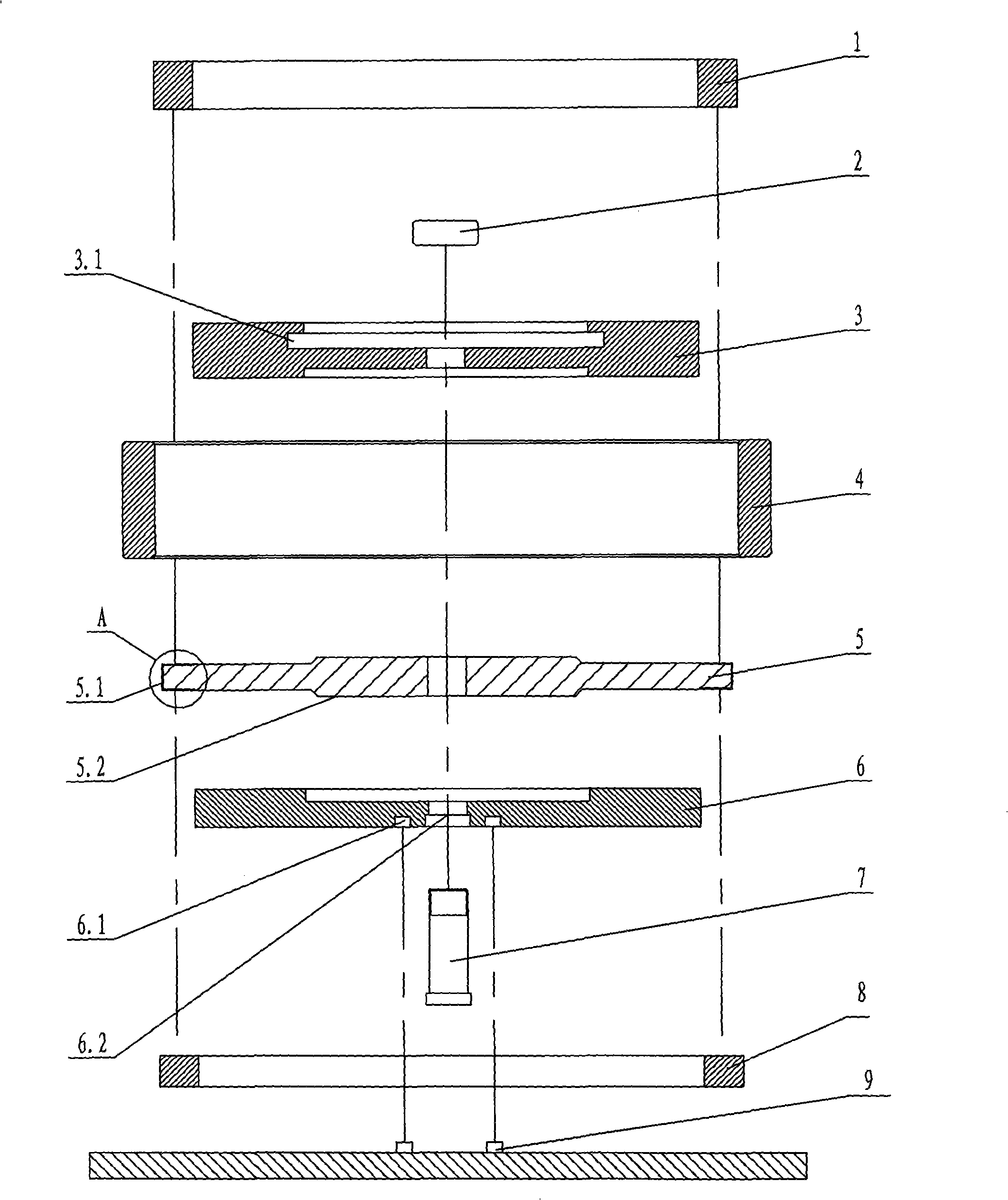

Boron-containing radioactive spent resin cement solidification method

InactiveCN101456715AImprove processing efficiencySolid waste managementPressurized water reactorPortland cement

The invention discloses a method for cement solidification of a boron-containing radioactive waste resin, which belongs to the technical field of cement solidification of the boron-containing radioactive waste resin of a pressurized water reactor nuclear power station. The method comprises the following steps: the boron-containing radioactive waste resin of the pressurized water reactor nuclear power station, ordinary Portland cement, a water reducing agent, zeolite, lime and water are taken as raw materials, the mixture ratio of the raw materials comprises that the boron-containing radioactive waste resin of the pressurized water reactor nuclear power station: the ordinary Portland cement: the water reducing agent: the zeolite: the lime: the water is equal to 300-500L: 800-1,000kg: 4-5kg: 40-50kg: 25-30kg: 90-110kg, and the raw materials are weighed; and the materials are added into a C1 solidification barrel with a volume of 1 cubic meter and are stirred evenly to obtain a cement solidification body. The adoption of each solidification drum with the volume of 1 cubic meter can solidify 300 to 500L of radioactive resin, and remarkably improve the treatment efficiency of boron-containing radioactive waste resins of pressurized water reactors.

Owner:TSINGHUA UNIV

Hybrid nanocomposite material used for buildings and preparation method thereof

InactiveCN102936113AGood dispersionGood network distributionCeramic shaping apparatusWater basedFiber

The invention relates to a material used for buildings and a production method of the material. The hybrid nanocomposite material used for buildings provided in the invention includes the following components by weight: 100 parts of cement, 10-30 parts of water-based resin, 0.01-45 parts of a water-based resin curing agent, 25-50 parts of water, 0.5-2 parts of a super plasticizer, 0.1-5 parts of a nano-fiber, 0.1-5 parts of a nano-fiber dispersing agent, 0.01-3 parts of a thickening stabilizer, and 0.02-0.2 part of a foam inhibitor. With the method provided in the invention, the nano-fiber can realize good dispersion and network distribution in a water-based resin system and a subsequent resin / cement hybrid matrix, and can form a compact reticular cemented structure together with hardening resin and cement, thus improving the dynamic shock resistance and dynamic vibration damping performance of the hybrid composite material.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Resin cement cubic boron nitride grinding wheel and preparation method thereof

ActiveCN101332587AExtend your lifeIncrease grinding ratioBonded abrasive wheelsMetal working apparatusPass rateBoron nitride

The invention relates to a resinoid wedding agent cubic boron nitride grinding wheel and a manufacturing method thereof, the resinoid wedding agent cubic boron nitride grinding wheel comprises a grinding wheel matrix and a grinding layer, the grinding layer is arranged on the external wall of the grinding wheel matrix and peripheries of an upper end face and a lower end face; the grinding layer includes 12-40% of cubic boron nitride (nickel plating), 25-50% of Dialok939p resin, 1-10% of villaumite grinding aid, 1-10% of a solid lubricant filler, 10-30% of a powder filler with high thermal conductivity and 1-15% of oxide filler by volume percentage of the grinding layer. A specially designed hot pressing dies and separately batch feeding method are adopted, which causes the pressed products to have homogeneous structure and consistent density; the formula of the grinding wheel is simple, and the designed die has the advantages of simple and reasonable structure, easy die filling and die release, the product obtained has high once-pass rate, homogeneous structure and consistent density; the grinding wheel has good grinding performance and long service life, can perform peripheral grinding and end face grinding, and is equivalent to three grinding wheels with the same specification, the matrix and making cost are saved, production cost is reduced, the product value is improved.

Owner:广东奔朗新材料股份有限公司

Ultra-slow resin anchoring agent

ActiveCN101412603AMeet special requirements such as long construction time and high strength requirementsFirming agentCompressive strength

The invention discloses a super-slow resin anchoring agent. Unsaturated polyester resin is adopted; one or a plurality of tertiary amine accelerant, quinhydrone, naphthaquinone or other polymerization inhibiting stabilizer with similar functions, and other chemical assistant and filler are added in resin production or later process to be mixed into resin cement; initiator (solidifying agent) is one or a plurality of dibenzoyl peroxide or other similar peroxide, pasty or powdered solidifying agent diluted by water, stone powder or other inert materials; and the mixture is packaged into scrolls by a diplopore film bag or packaged by a barrel or other packaging modes. In the formulation, the super-slow resin anchoring agent produced through fine adjustment, which has gelling time of between 10 and 180 minutes and compressive strength not less than 40MPa, so the super-slow resin anchoring agent can meet special requirements of long engineering construction, high strength requirement, and the like.

Owner:五莲县计量检测服务中心

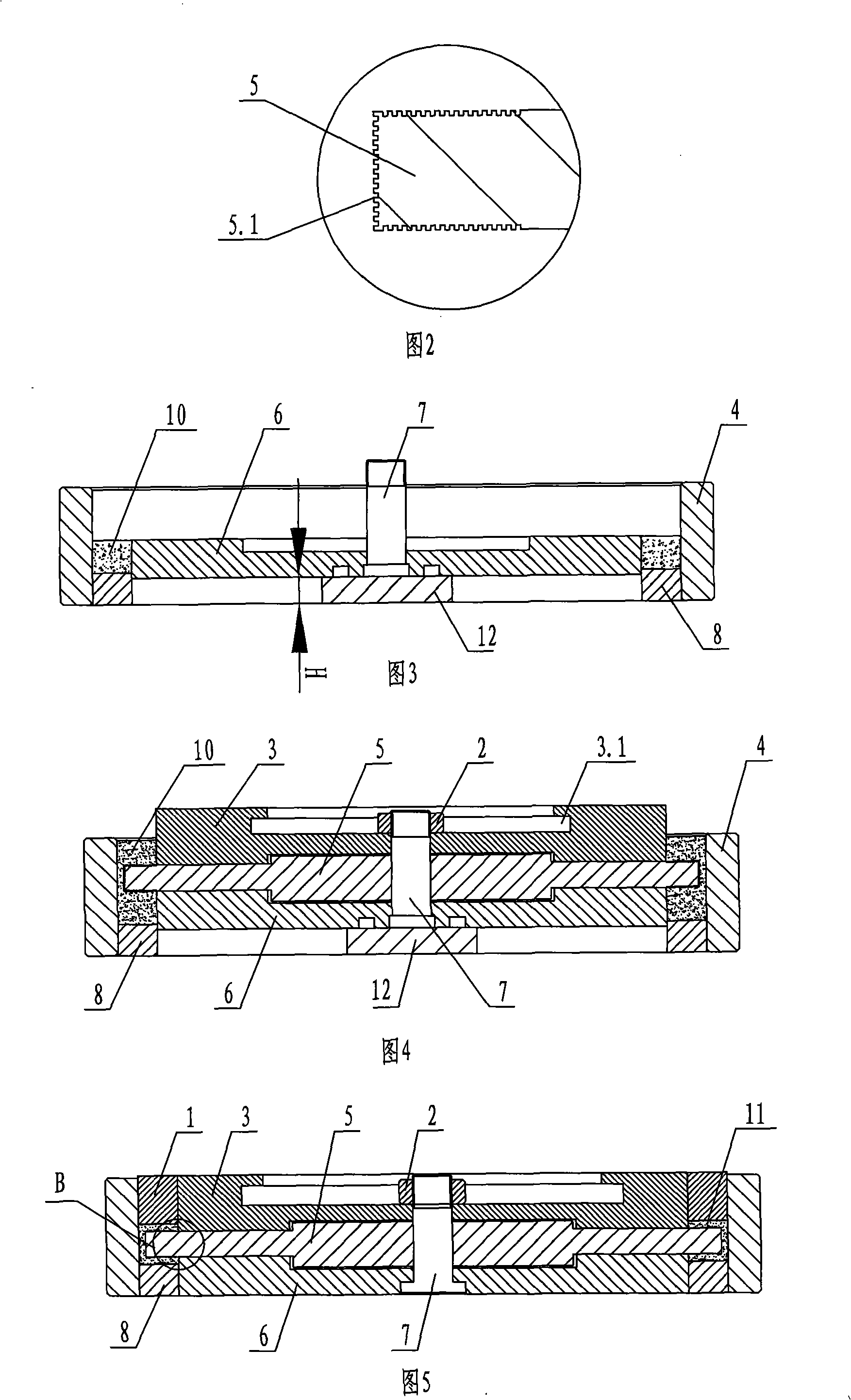

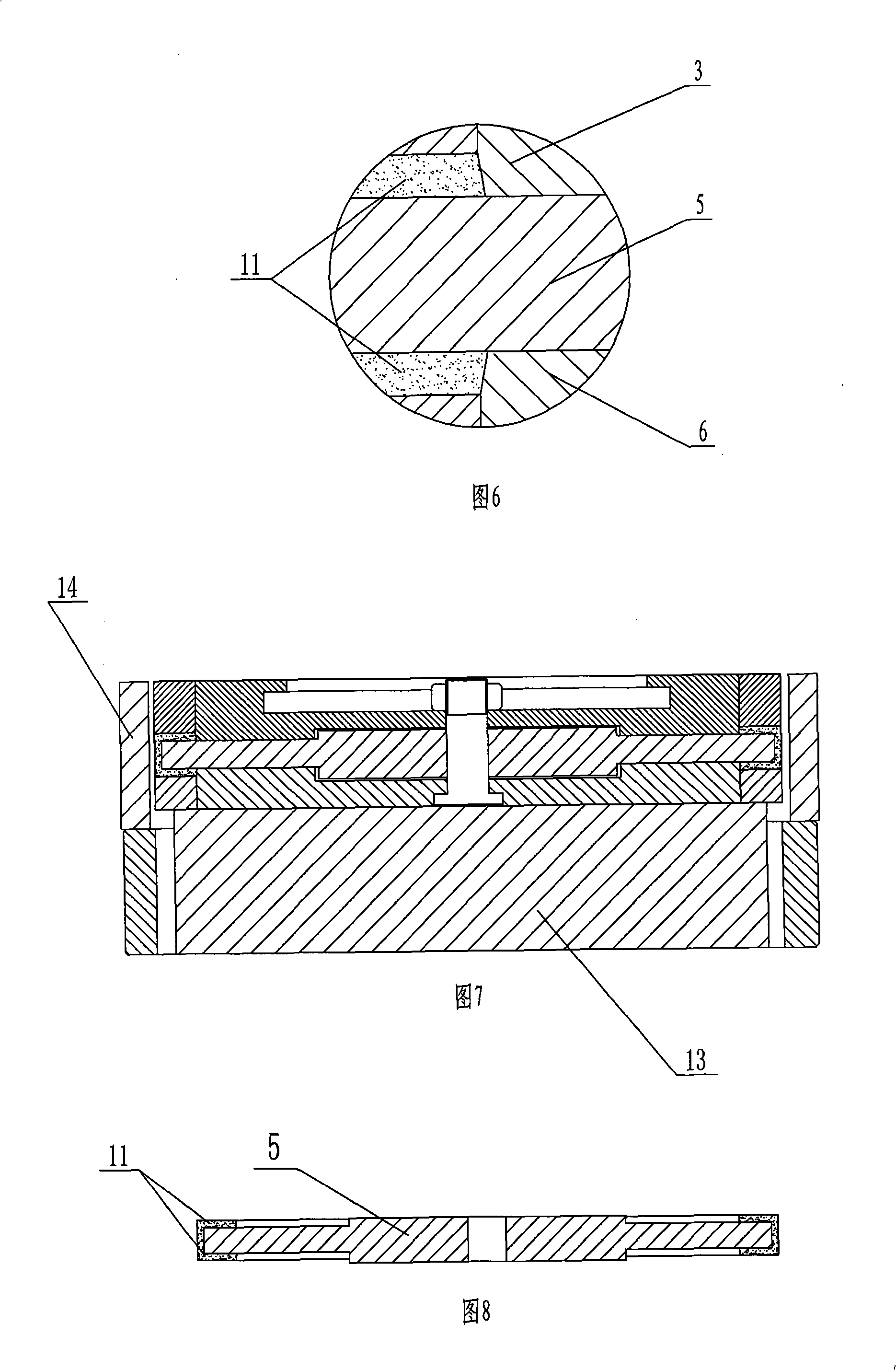

Artificial core containing controllable and movable fluid, and manufacturing method of artificial core

InactiveCN104390825AOvercoming the problem of poor simulation accuracyPrecise pore distributionPreparing sample for investigationEpoxySilicic acid

The invention relates to an artificial core containing controllable and movable fluid, and a manufacturing method of the artificial core. The manufacturing method mainly comprises the following steps: firstly, evenly stirring quartz sand, traditional epoxy resin cement and sub-nanoscale powder cement, wherein the median particle diameter of the sub-nanoscale powder cement is within the range from 0.7 to 1.0mu m, and the sub-nanoscale powder cement is formed by tricalcium silicate, dicalcium silicate, tricalcium aluminate and crystallized calcium sulfate according to the mass ratio of (0.20-0.25) to (0.30-0.35) to (0.25-0.35) to (0.20-0.30); putting the mixture into a cylindrical steel mould, pressurizing, and drying at high temperature to obtain the artificial core. Due to the change of proportions of two types of mixtures, the artificial core has better similarity with the natural core in the macroscopic aspects such as porosity and permeability, and the distribution proportion of the movable fluid is changed within the specific range on the basis that different levels of pores in the artificial core reach the specific proportion; furthermore, the artificial core is higher in accuracy, thus meeting the experimental demands such as oil field three-mining chemical flooding optimization, and microscopic use law.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Dental Composite Resin Cement, Dental Primer and Dental Adhesive Kit Containing Them

ActiveUS20090048366A1Improve adhesionRich in hydrophilicityImpression capsOther chemical processesResin cementMaterials science

The present invention provides a dental resin cement which is excellent in a mechanical strength, workability and storage stability, and a dental primer which significantly improves adhesiveness of the dental resin cement both to enamel and dentin of a tooth. According to the present invention, a salt of barbituric acid is used as a polymerization initiator in the dual-cure two-paste type dental resin cement being excellent in workability and storage stability to improve the storage stability, and a primer containing barbituric acid and amine is applied to a surface of a tooth to significantly improve adhesiveness of the dental resin cement both to enamel and dentin of teeth.

Owner:SHOFU INC

Dental composite resin cement, dental primer and dental adhesive kit containing them

ActiveUS7879924B2Improve adhesionRich in hydrophilicityImpression capsOther chemical processesTooth enamelDentin

The present invention provides a dental resin cement which is excellent in a mechanical strength, workability and storage stability, and a dental primer which significantly improves adhesiveness of the dental resin cement both to enamel and dentin of a tooth. According to the present invention, a salt of barbituric acid is used as a polymerization initiator in the dual-cure two-paste type dental resin cement being excellent in workability and storage stability to improve the storage stability, and a primer containing barbituric acid and amine is applied to a surface of a tooth to significantly improve adhesiveness of the dental resin cement both to enamel and dentin of teeth.

Owner:SHOFU INC

Method for solidifying radioactive waste resin cement

ActiveCN102034560AImprove impact resistanceAvoid surface crackingRadioactive decontaminationBreaking strengthFiber

The invention discloses a method for solidifying radioactive waste resin cement, and belongs to the technical field of radioactive waste treatment. The method for solidifying the radioactive waste resin cement by a dura fiber comprises the following steps of: mixing the dura fiber, zeolite, cement, dehydrated radioactive waste resin and water uniformly, pouring the mixture into a test die and curing to obtain a cement solidified body. The dura fiber is 0.1 to 0.5 mass percent of a mixture of the zeolite and the cement; and the mass ratio of the cement to the dehydrated radioactive waste resin to the water is 1 to (0.3-0.5) to 0.35. The shock resistance of the obtained cement solidified body is enhanced obviously, the surface has no crack, and the performance indexes all meet the requirement of the national standard. The compression strength of the solidified body for 28 days is more than 11.5 MPa, and the breaking strength of the solidified body is more than 3.1 MPa.

Owner:TSINGHUA UNIV

Repair reinforcing structure of steel bridge deck and repair reinforcing method of repair reinforcing structure

ActiveCN102505641AReduce stress amplitudeImprove fatigue lifeBridge structural detailsBridge erection/assemblyEpoxySheet steel

The invention discloses a repair reinforcing structure of a steel bridge deck and a repair reinforcing method of the repair reinforcing structure. The repair reinforcing structure comprises the steel bridge deck, and is characterized in that the upper surface of the steel bridge deck is welded with a plurality of longitudinal steel ribs and a plurality of transverse steel ribs, the longitudinal steel ribs and the transverse steel ribs are mutually staggered to form a gridding supporting structure, crushed aggregates are filled in rectangular grooves of the gridding supporting structure, steel cover plates are arranged above the rectangular grooves and are fixedly welded with the longitudinal steel ribs and the transverse steel ribs, the adjacent steel cover plates are connected in a welded manner, epoxy resin cement paste is filled in a gap between the steel bridge deck and each steel cover plate and gaps among the crushed aggregates, and a cold-mixing resin bituminous concrete bridge deck paving layer is paved on the steel cover plates. The repair reinforcing structure of the steel bridge deck has the advantages that the repair reinforcing structure of the steel bridge deck is reliable in quality, convenient in construction, relatively low in comprehensive manufacturing cost and convenient in repair.

Owner:宁波天意钢桥面铺装工程有限公司

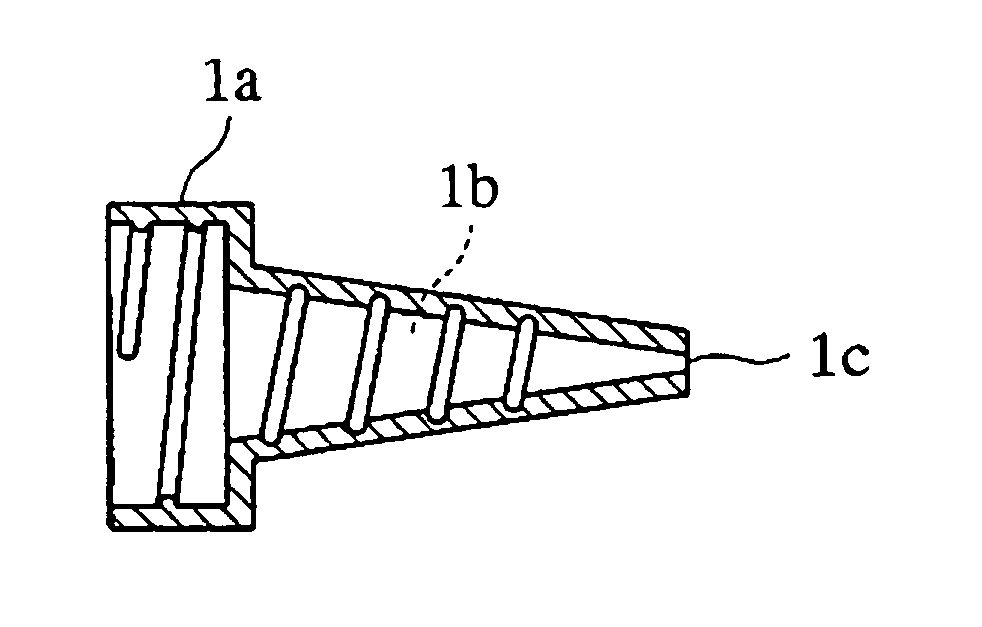

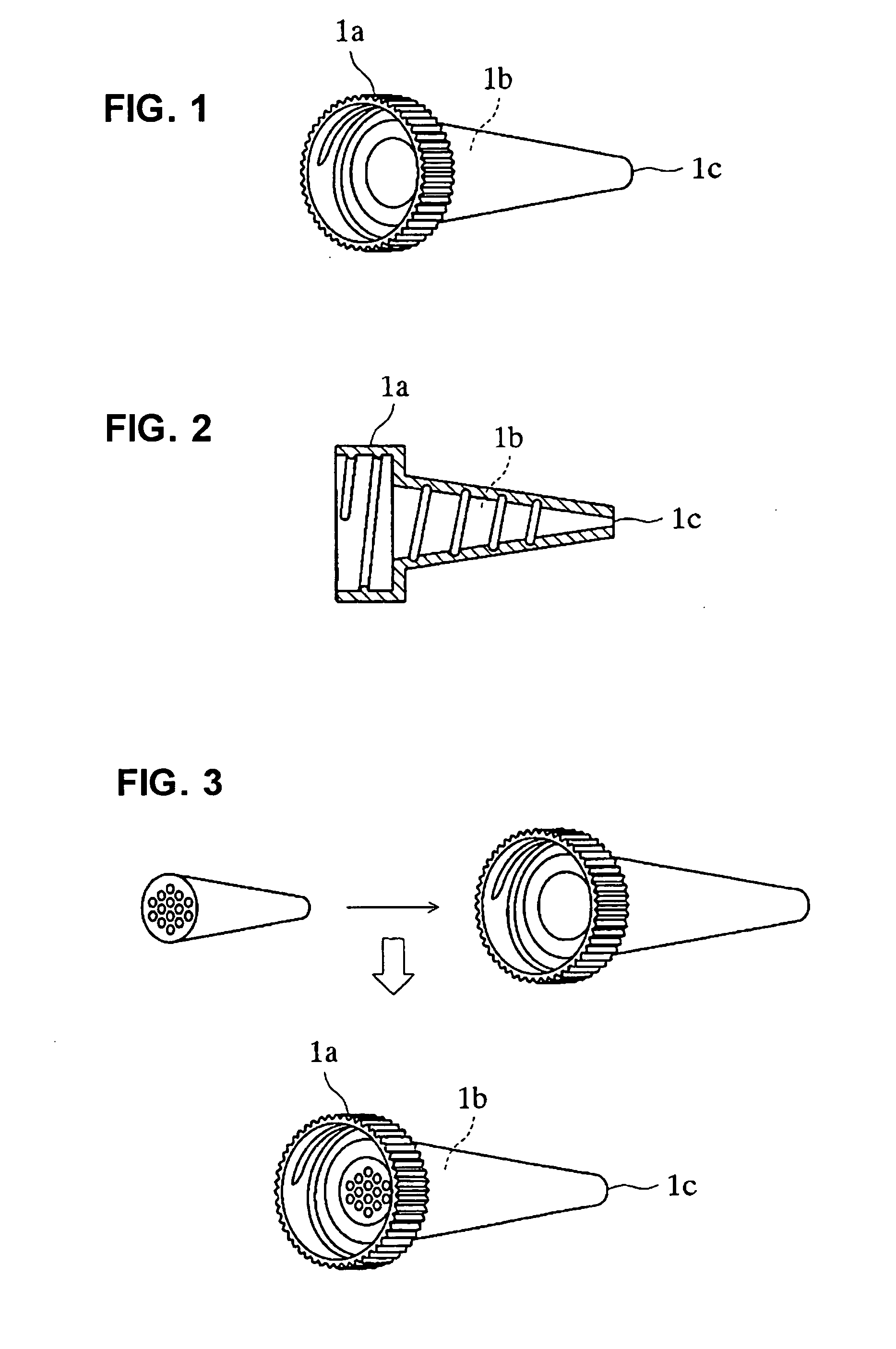

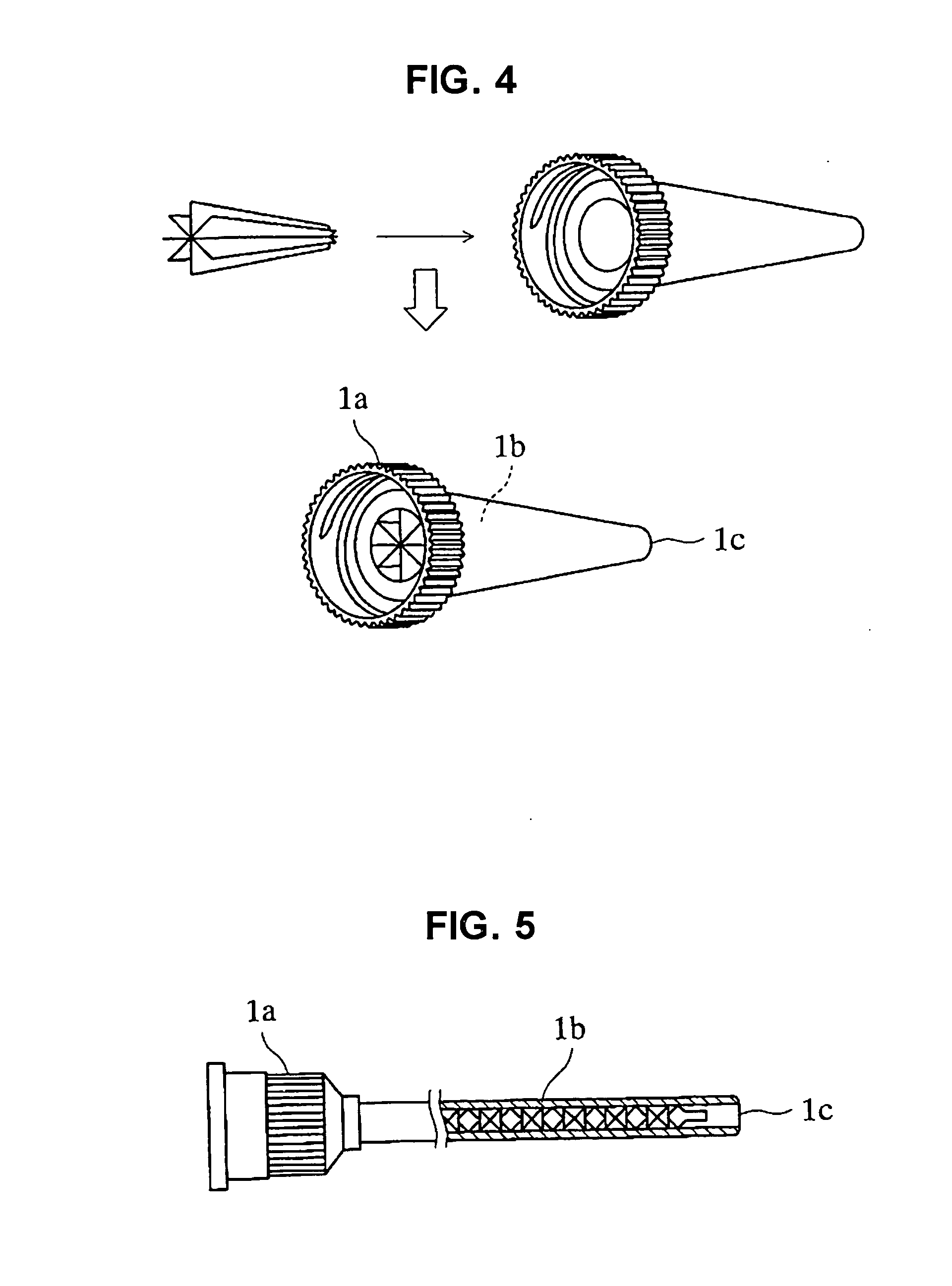

Nozzle for dental composition

InactiveUS20070031779A1Good storage stabilityReduce the number of partsLiquid surface applicatorsAmalgam presses/mixersGlass ionomersResin cement

To separate a catalyst for polymerizing a monomer contained in a liquid or paste dental composition containing at least a monomer, such as a dental resin cement, an autopolymerizing dental resin or a resin-reinforced dental glass ionomer cement, from the liquid or paste dental composition to thereby improve storage stability of the dental composition and reduce number of division of the dental composition, an extrusion nozzle for a dental composition mounted on one end of an extruder for extruding a liquid or paste dental composition containing at least a monomer, the extrusion nozzle contains a catalyst for polymerizing the monomer contained in the dental composition during extrusion, and the catalyst is attached to an inner wall of an extruding channel of the extrusion nozzle.

Owner:GC CORP

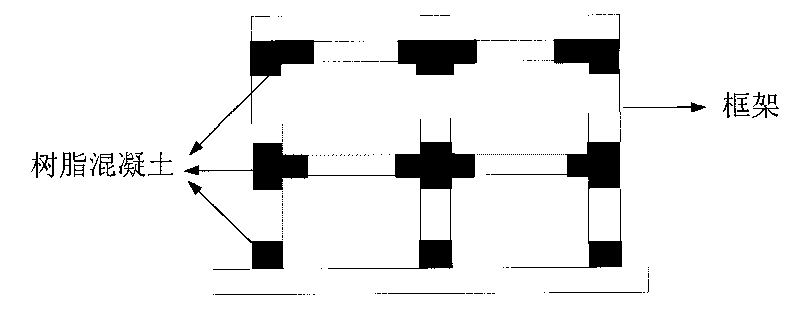

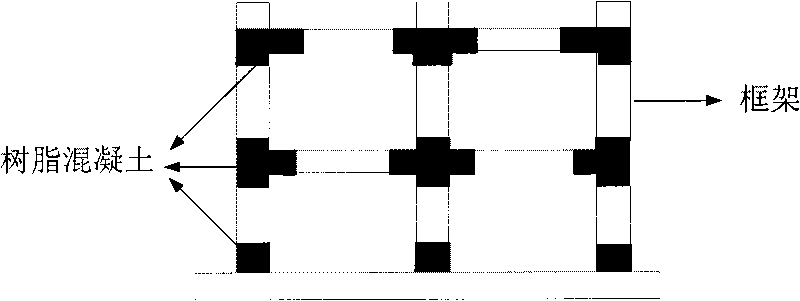

Method for making shock-resistant and energy-dissipating framework by mixing resin concrete and reinforced concrete

InactiveCN101718113AEffective seismic response reductionLow initial construction costShock proofingRebarPlastic hinge

The invention relates to a method for making a shock-resistant and energy-dissipating framework by mixing resin concrete and reinforced concrete, which comprises the following six steps of: (1) reserving a position of the framework, at which a plastic hinge is possible to emerge, and pouring other parts of the framework according to an original construction design; (2) conserving the concrete poured in the framework for 14 days, carving burrs from the concrete around the reserved position, clearing gravels and dust off and cleaning the surface by acetone; (3) priming a layer with a thickness of 3 to 5mm by resin cement; (4) supporting a template at the reserved position; (5) preparing and pouring the resin concrete; and (6) standing and conserving the resin concrete framework over 10 DEG C for 72 hours and stripping a mold. Because the ultimate compression strain of the resin concrete is far greater than that of the ordinary concrete, the resin concrete is filled at an appropriate position in an ordinary reinforced concrete framework to form a mixed framework structure. Therefore, the framework can consume earthquake energy on the premise of not being damaged entirely. The method has a practical value in the technical field of civil engineering.

Owner:BEIHANG UNIV

Novel waterproof compound coal binder

InactiveCN103710065AImprove adhesionConvenient and cheap sourceSolid fuelsSodium BentoniteEconomic benefits

The invention discloses a novel waterproof compound coal binder mainly used for the molding production of industrial gasification briquette from pulverized anthracite. The binder comprises bentonite, starch, extraordinary resin, cement and an organic polymer material. The binder has the advantages of low consumption, simple preparation technology, low cost, no secondary pollution, and suitableness for various coals. Molded gasification briquette processed in the invention has high cold and hot strengths (a cold compression strength of 85-115kg / ball and a hot compression strength of 40-45kg / ball, has a strong binding power and a good waterproof property, so the binder has a good economic benefit and application prospect.

Owner:ZHENGZHOU UNIV

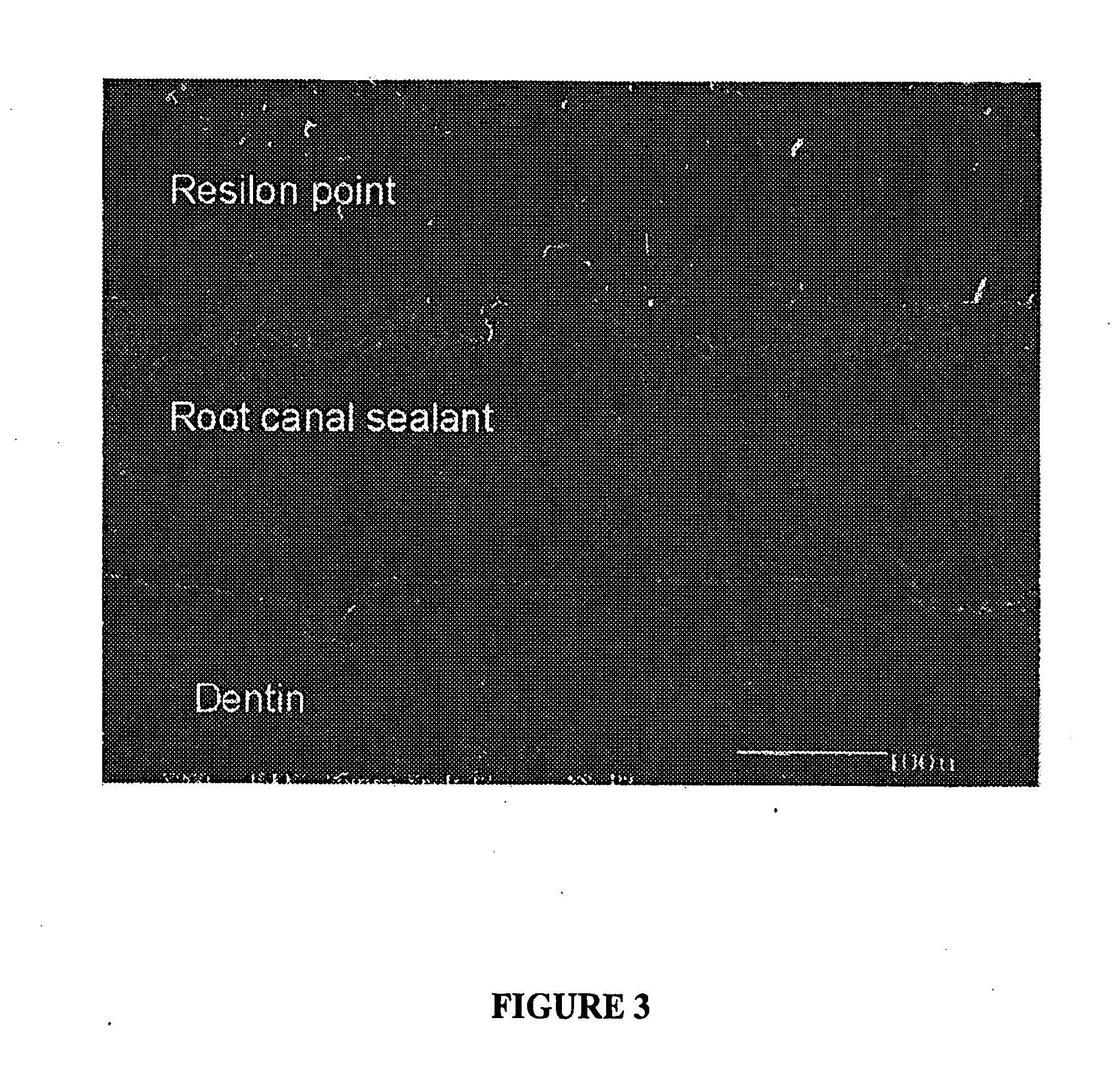

Endodontic procedure using self-adhesive resin cements and sealers or self etching adhesives and chemically bondable obturators

A method of filling and sealing a root canal during an endodontic procedure, the method comprising: a) filling the root canal with a combination comprising: i) an obturator composed at least in part of a chemically-bondable material; and ii) a self-etching adhesive or self-adhesive resin-based cement or sealer; and b) curing the combination to seal the root canal. Also disclosed is a kit for carrying out the method, the kit comprising: a) an obturator composed at least in part of a chemically-bondable material; and b) a self-adhesive resin-based cement or sealer.

Owner:HERAEUS KULZER

Macromolecule composite for manhole cover

InactiveCN1542051AImprove toughnessImprove impact resistanceArtificial islandsUnderwater structuresEpoxyToughness

The composite polymer material for manhole cover is one kind epoxy resin cemented concrete, and consists of epoxy resin fluid an in 10-20 wt% and compounded concrete B in 80-90 wt%. Manhole cover made of the material has high toughness and high shock strength, can prevent damage during transportation, construction and use. It is also anticorrosive, has no noise produced and may be colored.

Owner:东莞市东历复合材料有限公司

Fibre reinforced plastic and concrete composite arc structure and construction method

InactiveCN1609379AAccelerated corrosionImprove airtightnessArched structuresVaulted structuresPolyesterEngineering

The present invention relates to building member and its construction process and is especially composite arched structure of fiber reinforced plastic and concrete. The present invention proposes one kind of arced structure with laminated fiber reinforced plastic adhered to the surface of concrete and its construction process. The construction process includes forming concrete arch, milling surface with grinding wheel to eliminate floated surface mortar and roughen the surface, smearing epoxy resin-cement putty to flat the surface, painting primer with structural glue, coating with fiber fabric, soaking the fiber fabric with resin adhesive, covering with polyester film, extruding with scraper the excessive resin adhesive, curing and taking down the polyester film. The composite arched structure is corrosion resistant and durable, and has doubled bearing capacity and simple construction.

Owner:杨庆国 +3

Thermoplastic resin coated water-borne epoxy resin cement concrete crack self-repairing microcapsule and preparation method thereof

ActiveCN108483976AGood fluidity at room temperatureExtended service lifeMicroballoon preparationMicrocapsule preparationFirming agentResin cement

The invention belongs to the technical field of concrete and in particular relates to a thermoplastic resin coated water-borne epoxy resin cement concrete crack self-repairing microcapsule and a preparation method thereof. The microcapsule consists of water-borne epoxy resin microcapsule and a curing agent microcapsule, wherein the water-borne epoxy resin microcapsule consists of the following components in parts by weight: 30-55 parts of paraffin, 5-10 parts of a petroleum resin and 35-65 parts of a water-borne epoxy resin; the curing agent microcapsule consists of the following components inparts by weight: 35-60 parts of paraffin, 5-10 parts of a petroleum resin and 30-60 parts of a curing agent. In case of concrete cracks, the microcapsule is applied to an expanding crack, under the action of expansion force of the tip point of the crack, the wall of the microscopes can be easily broken, then the water-borne epoxy resin and the curing agent inside the microcapsule can flow out anddiffuse into the concrete crack, a curing reaction can be resulted, the crack can be then repaired, and thus the service life of concrete can be prolonged.

Owner:WUHAN UNIV OF TECH

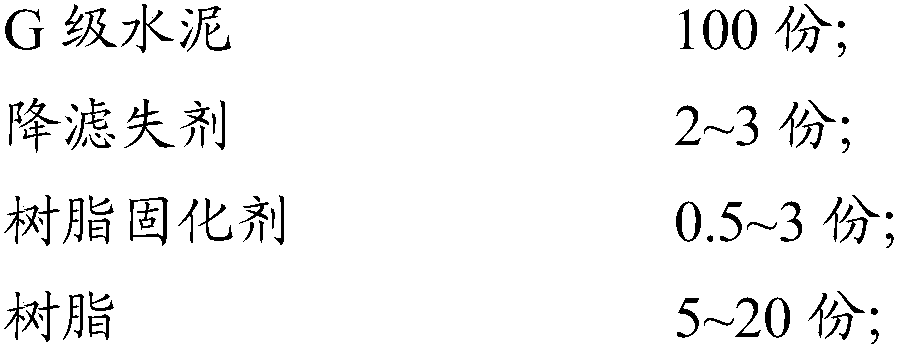

Anti-channeling well cementation resin cement paste and application thereof

InactiveCN108373297AImprove toughnessImprove cementing performanceDrilling compositionResin cementCement sheath

The invention provides an anti-channeling well cementation resin cement paste and application thereof. The anti-channeling well cementation resin cement paste comprises, by mass, 100 parts of G-gradecement, 2-3 parts of filtrate reducer, 0.5-3 parts of resin curing agent, 5-20 parts of resin, 0.5-1 part of dispersant, 0.5-1 part of retarder, 0-40 parts of weighting agent and 35-55 parts of water,wherein rein refers to one or multiple of water-soluble epoxy resin, organic silicon resin and phenolic resin. As the anti-channeling well cementation resin cement paste is added with the resin, toughness and cementing property of cement sheaths can be improved, and further, flow of formation fluid can be prevented effectively, and gas-channeling prevention effect can be improved. According to results of an embodiment of the invention, the viscosity of the anti-channeling well cementation resin cement paste is 190mPa.s, the cement paste has good flowability and its anti-channeling performancereaches up 18-22MPa / m.

Owner:YANGTZE UNIVERSITY +1

Making method for inorganic proton exchange film fuel cell film pole

InactiveCN101034747ASolve the real problemNo toxic behaviorFinal product manufactureCell electrodesProtonSurface-active agents

The invention relates to an inorganic proton exchange membrane fuel cell membrane electrode preparation method. the preparation method, its characteristic lies in that it includes the following steps: 1) inorganic proton exchange membrane preparation: a) first prepares the heteropolyacid and the inorganic oxide compound forerunner body mix solution; b) the surface active agent solution preparation; c) inorganic proton conduction powder forerunner body preparation; d) inorganic proton exchange membrane preparation: The inorganic proton conduction powder forerunner body which step c) prepares sets in the culture dish, dry, high temperature burning, obtains the inorganic proton conduction powder, joins the thermoplastic resin cementing agent rmo-compression to prepare the inorganic proton exchange membrane; 2) inorganic proton exchange membrane-catalysis layer module preparation; 3) inorganic proton exchange membrane -catalysis layer module seal; 4) inorganic proton exchange membrane fuel cell membrane electrode preparation. The membrane electrode operating temperature of the method preparation is high (may be higher than 200 degree centigrade).

Owner:WUHAN UNIV OF TECH

Resin-cement composite non-sintered water-permeable floor tile

InactiveCN105330230AImprove the disadvantage that large holes are easily blocked by mudHigh strengthSolid waste managementCeramicwarePorositySilanes

The invention discloses a resin-cement composite non-sintered water-permeable floor tile. The resin-cement composite non-sintered water-permeable floor tile is prepared from, by weight, 50-53 parts of desert sand, 4-5 parts of thermoplasticity phenolic resin, 0.6-0.7 part of urotropin, 0.2-0.22 part of calcium stearate, an adequate amount of water, 42-45 parts of portland cement of which the mark number is 42.5, 155-160 parts of municipal waste incineration residues, 20-22 parts of black corundum, 1-1.2 parts of gamma-aminopropyl triethoxy silane, 5-6 parts of wood sawdust, 3-3.5 parts of waterborne polyurethane emulsion, 5-6 parts of flyash and 0.7-0.8 part of polycarboxylate superplasticizer. According to the resin-cement composite non-sintered water-permeable floor tile, the wood sawdust is added in surface materials, a porous structure is obtained through carbonization, the porosity of the surface materials is further increased, and the effects of sound absorption and noise reduction are improved; the water-permeable floor tile is made by adopting a sintering-free forming process, energy saving and consumption reducing are achieved, and the product is high in stability, compressive strength and coefficient of water permeability.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Resin cement for levelling cement concrete road surface

The invention relates to the field of road construction, in particular to resin cement for levelling cement concrete road surface. The resin cement for levelling cement concrete road surface overcomes the shortages of existing methods for levelling cement concrete road surface and especially solves the problem that common cement concrete has the disadvantages of low cement concrete bonding strength, slow strength development, long solidification time, long traffic hampering time and the like when common cement concrete is used for repairing road surface. The resin cement is prepared from 10-20% of epoxy resin, 0.2-0.5% of curing agent, 5-15% of polyving alcohol particle of which the particle size is 2-3cm, 3-10% of polyving alcohol powder of which the particle size is 70-80 meshes, 5-10% of 108 glue, 2-6% of asbestos fiber with 70-80 meshes, 0.5-2% of common silicate cement, 2-5% of sand and water. The resin cement has strong cohesive force with old road surface after solidifying, does not need to cut and chip damaged sites of the old road surface, has the characteristics of quick hardening, early strength, small contraction, small chromatic aberration with old concrete, strong cohesive force, abrasion resistance, endurance and convenient construction and is favourable for improving road surface repair quality and speed.

Owner:亢吉田

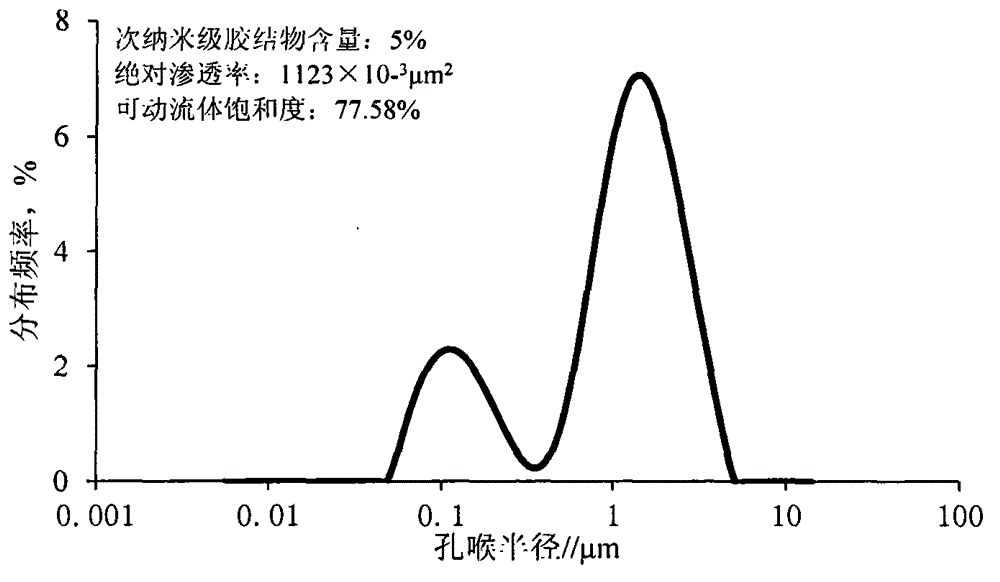

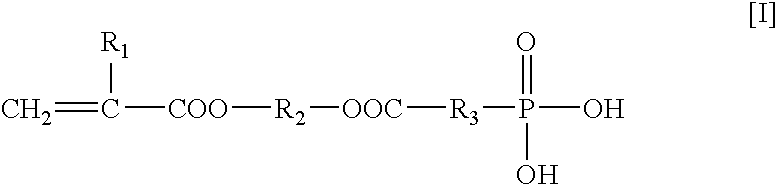

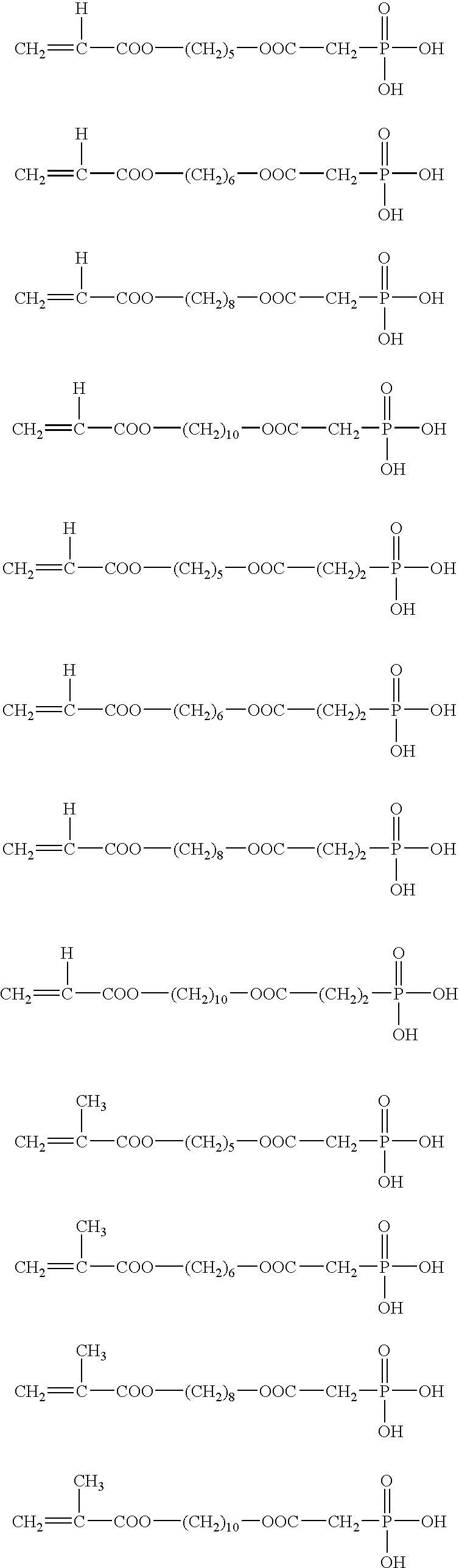

Two-paste type dental self-adhesive resin cement

ActiveUS8183306B2Strong adhesionHigh transparencyImpression capsDentistry preparationsPhosphoric Acid EstersResin-Based Composite

The present invention provides a dental self-adhesive resin cement having clinically-acceptable adherability for various adherends without pre-treatment with primers. Specifically, there is provided the dental self-adhesive composite resin cement comprising:(a) a radical polymerizable monomer,(b) a polymerizable monomer having a phosphonic acid group and / or a phosphoric acid ester group,(c) a polymerizable monomer having a dibasic acid carboxyl group,(d) a filler, and(e) a polymerization catalyst.

Owner:SHOFU INC

A method of solidifying radioactive waste resin using naalo2 coagulant cement

InactiveCN102276231AIncrease waste bag capacityHigh compressive strengthRadioactive wasteCompressive strength

The invention discloses a method for curing a radioactive waste resin by NaAlO2 coagulant cement, and belongs to the technical field of radioactive waste resin cement curing. The method comprises the following steps of mixing sulfoaluminate cement, a composite mineral additive, NaAlO2 and NaOH well, stirring the mixture and a radioactive waste resin in a stirring kettle, transferring the mixture obtained by the previous step into a mold and maintaining for curing. The method is utilized for curing a radioactive waste resin, improves a capacity and compressive strength of cured waste, and shortens coagulation time.

Owner:TSINGHUA UNIV

High-attitude-area dam upstream face antiseepage coating and construction method thereof

ActiveCN105350491AGood anti-seepageImprove adaptabilityMarine site engineeringEpoxy resin coatingsEpoxySurface layer

The invention discloses a high-attitude-area dam upstream face antiseepage coating and a construction method of the coating. The coating is characterized in that the coating is high-elasticity modified epoxy resin cement gum for a seamless common concrete surface, and the thickness is about 1mm; the antiseepage coating for a structural joint, a telescopic joint, a construction joint and other crack portions is composed of a bottom layer, a middle layer and a surface layer; and the bottom-layer coating is low-viscosity epoxy resin with the thickness being about 0.1 mm to 0.2 mm, the middle layer is toughening cloth with the thickness being 0.5 mm, and the surface layer coating is a nano-modified polyaspartate polyurea with the thickness ranging from 0.5 mmm to 1.0 mm. The antiseepage coating is economical and practical, has the good antiseepage performance, meanwhile has the good adaptation to the special severe environment of the high-attitude area and has the very important effect on the security service of the water conservancy project.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION +2

Resin anchoring agent realizing rapid loading under water and preparation method thereof

The invention relates to a resin anchoring agent realizing rapid loading under water. The resin anchoring agent is prepared by mixing epoxy resin cement gum and an organic amine curing agent according to a mass ratio of (2-4):1. By adopting the resin anchoring agent prepared in the invention, rapid curing can be implemented in an underwater environment during specific construction, and anchor rods, anchor ropes and the like can be firmly adhered in anchor eyes to bear enough load so as to achieve a good bottom swelling treatment effect and to provide a reliable anchoring material for rapid construction of a high-pretightening force grouting anchor rope.

Owner:CCTEG COAL MINING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com