Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

627 results about "Bituminous concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature-adjusted and modified recycled ascon composition for reusing 100% of waste ascon for road pavement, and method for manufacturing same

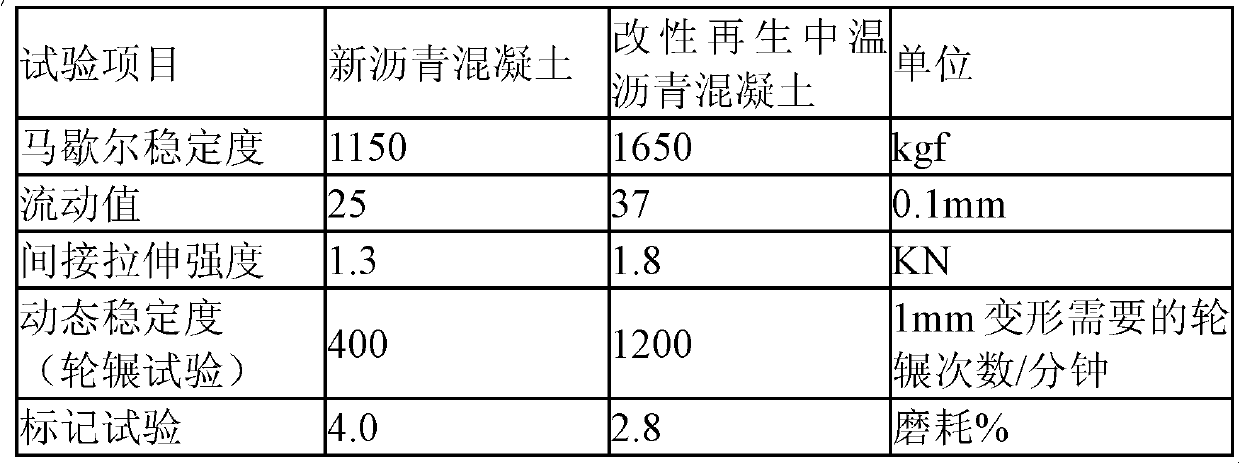

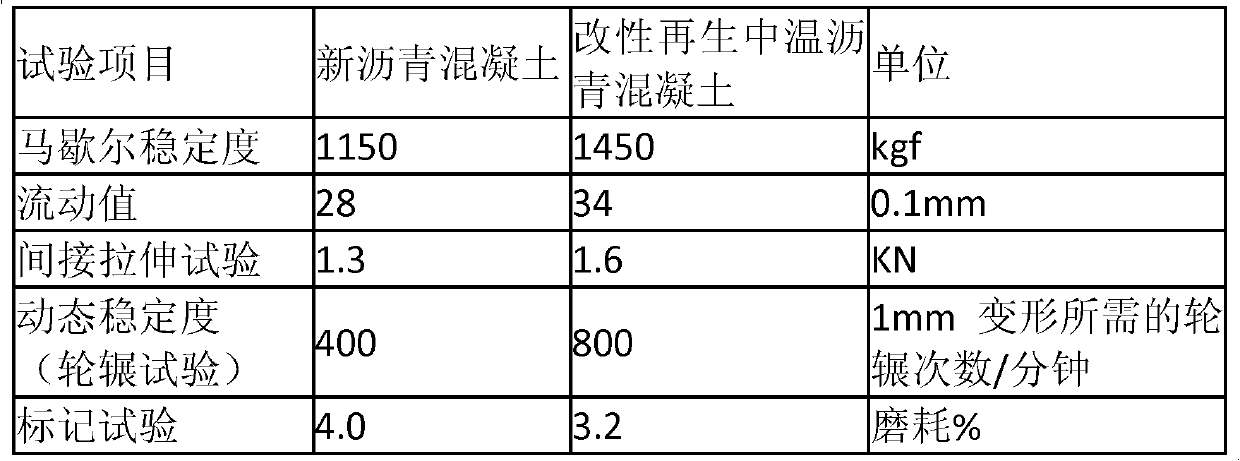

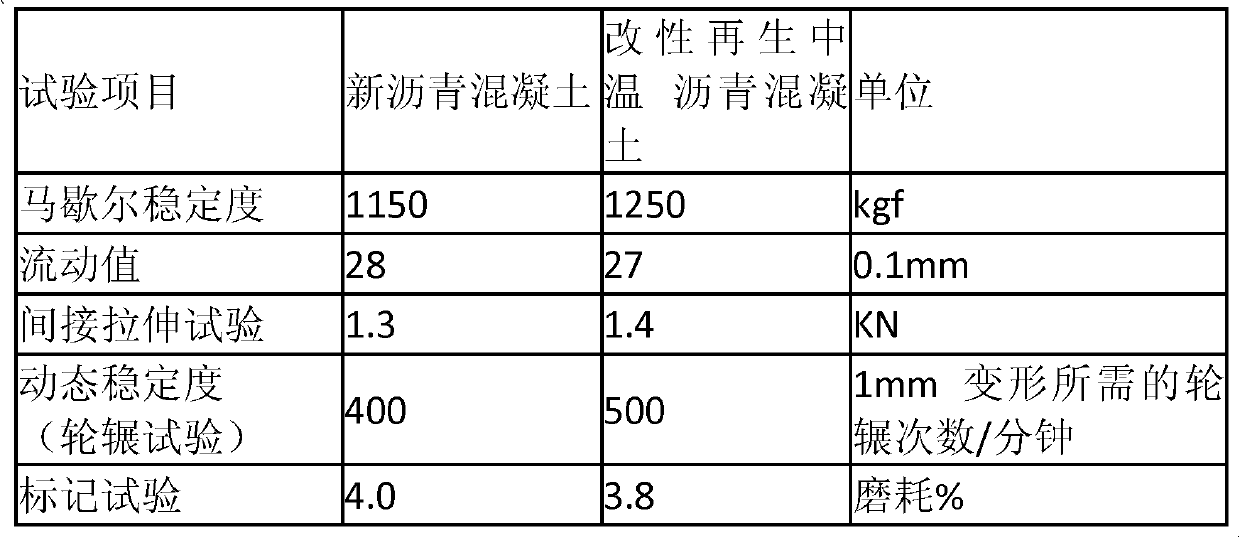

InactiveCN102448907AImprove qualityLow production temperatureIn situ pavingsSolid waste managementCost savingsParticle-size distribution

Provided is a temperature-adjusted and modified recycled ASCON composition for reusing 100% of waste ASCON for road pavement, and a method for manufacturing same, wherein the composition is used in asphalt pavement as a material for the wearing course, surface course, binder course, and base course, and the method comprises: feeding 100 wt % of waste ASCON aggregate having up to a 53 mm particle size distribution into a mixer via a feeding inlet for new aggregate; adding 0.1 to 20 wt % of a recycling modifier and 0.1 to 20 wt % of a temperature-adjusting additive to the waste ASCON via the feeding via the inlet for new aggregate; and homogeneously mixing said materials at 5 to 180 DEG C for 0.5 to 3 minutes. The recycling modifier improves the physical properties of recycled ASCON, while the temperature-adjusting additive adjusts the temperatures for producing and constructing recycled ASCON. The present invention may provide economic, social and technological conveniences by improving the overall recycling technology of waste ASCON. The conveniences may be achieved by virtue of: cost-saving in production by using only waste ASCON without any new materials; saving waste disposal costs; preventing the destruction of nature to obtain aggregate; reducing the consumption of new asphalt; preventing environmental pollution through the reuse of waste products; preventing the early occurrence of plastic deformation and fatigue cracks due to improving the quality of the recycling modifier; economic benefits from the prolonged lifespan of road pavement; the possibility of being used as a material for the wearing course and surface course of major roadways; saving energy in the production and construction of recycled ASCON by adding the temperature-adjusting additive; and reducing greenhouse gas emissions.

Owner:许政道

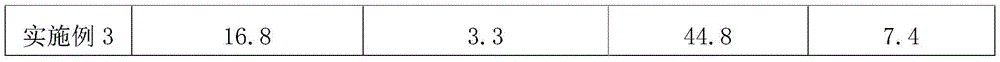

Robust control method for asphalt mixing plant batching error

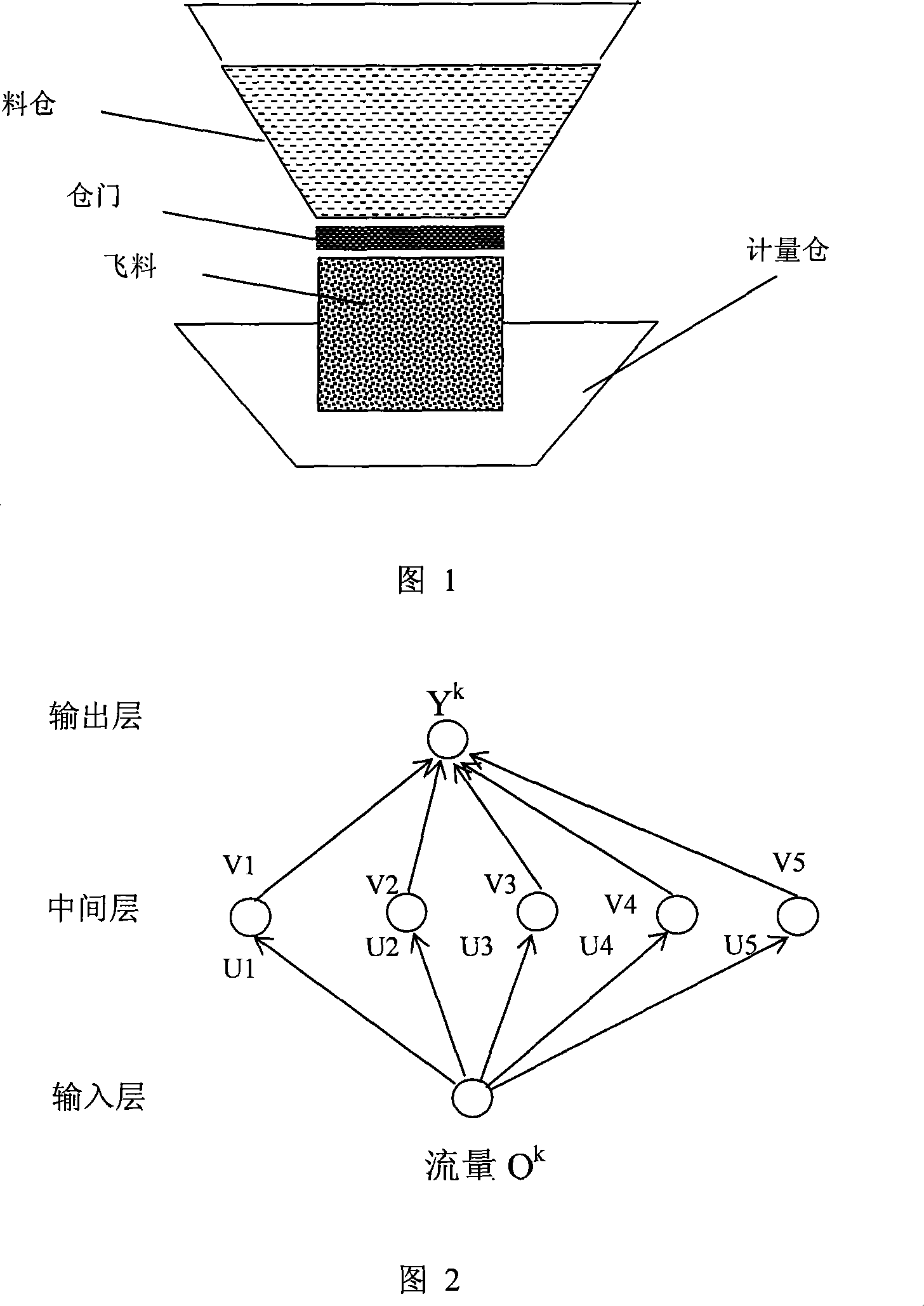

InactiveCN101226377AImprove batching accuracyImprove control effectMixing operation control apparatusRoads maintainenceProcess dynamicsArtificial neural network model

The invention discloses a robust control method of burden error of pitch concrete stirring device, which comprises first building an input / output artificial neutral network model of three-layer structure, while the input layer has one neuron, the middle layer has five neurons and the output layer has one neuron, processing dynamic prediction and learning. The invention builds the non-linear model of flux and fly ash amount to be compared with a linear model of fixed parameters via continuous learning and adjustment, to adapt the change of external parameters, thereby effectively controlling the burden error of pitch mixture stirring device, reaching +-2% burden error as maximum and improving the burden accuracy of pitch mixture stirring device.

Owner:NANJING UNIV OF SCI & TECH +1

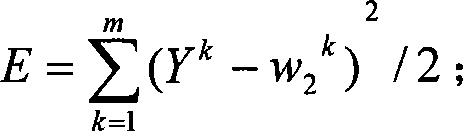

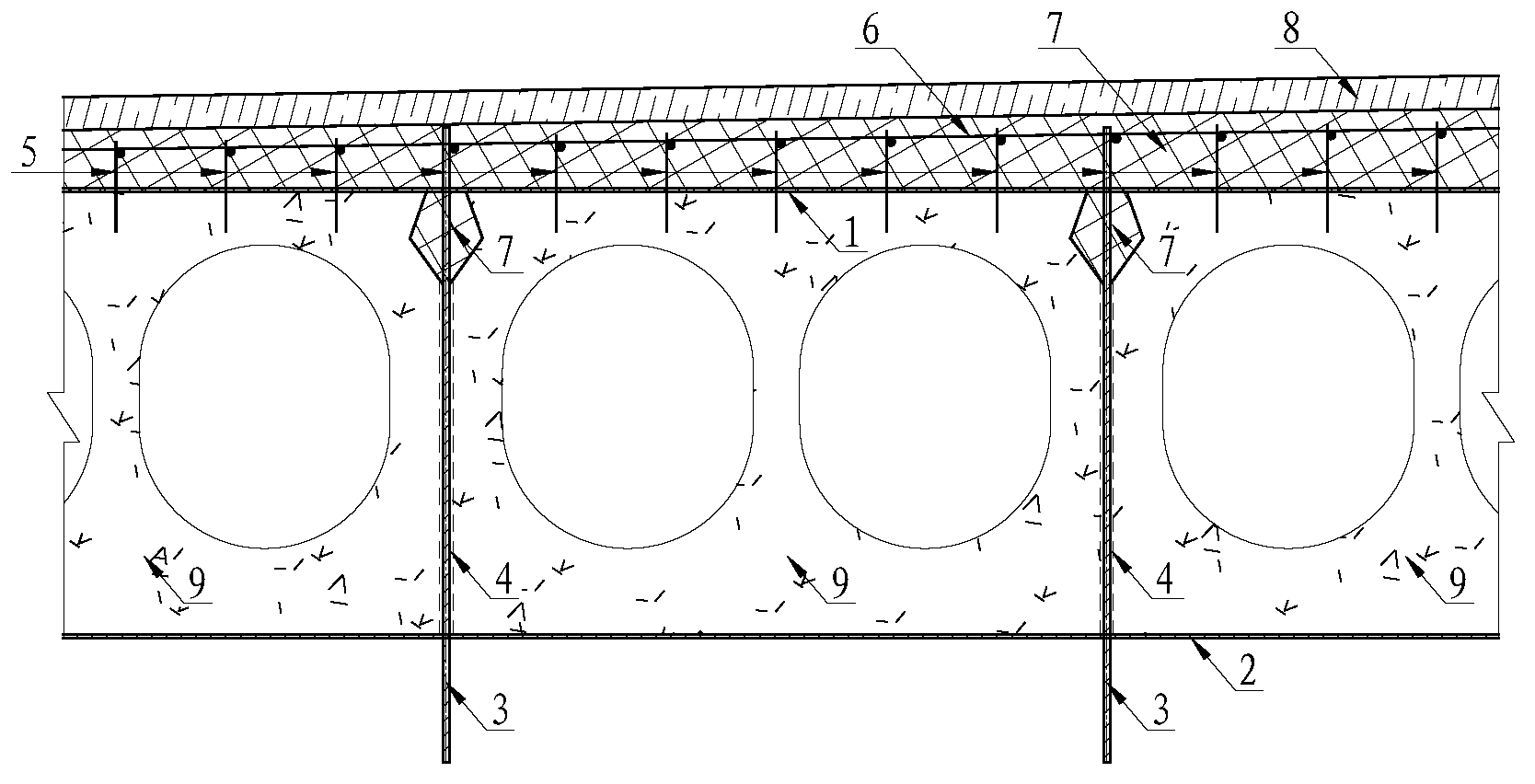

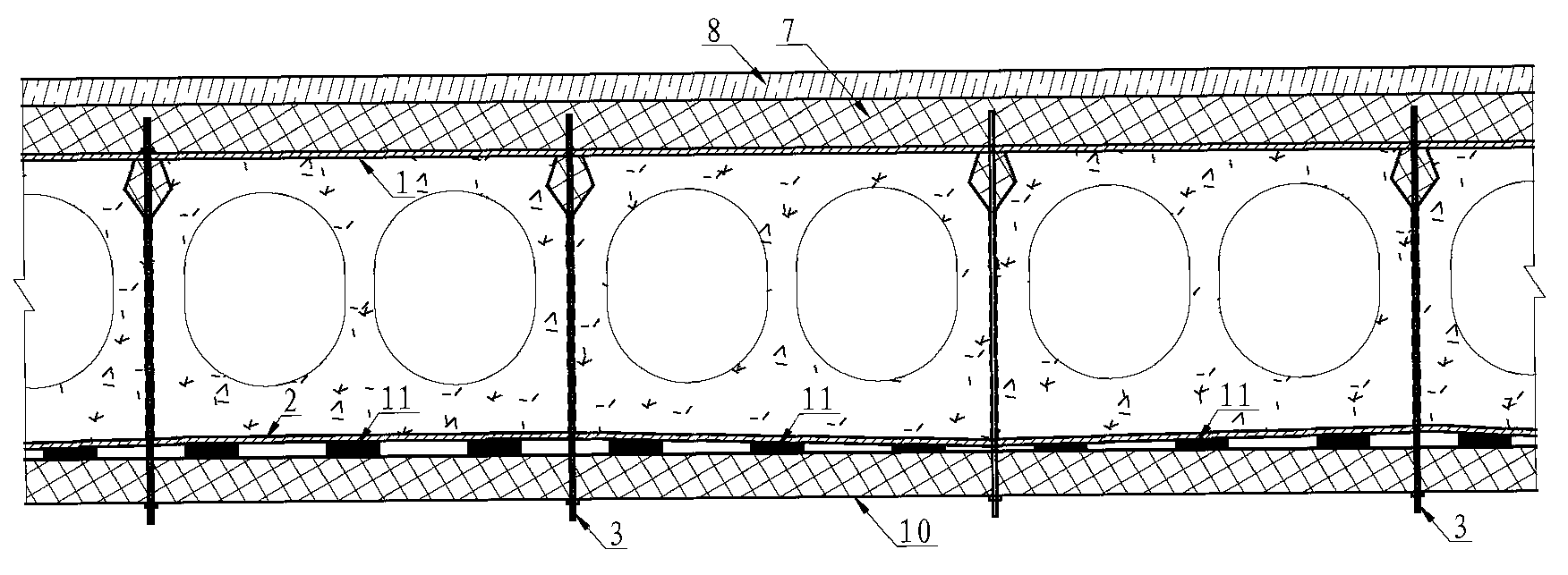

Single plate force-bearing reinforcing method of hollow slab bridge

InactiveCN103061271AAvoid destructionImprove reliabilityBridge erection/assemblyBridge strengtheningWhole bodyBridge deck

The invention relates to a single plate force-bearing reinforcing method of a hollow slab bridge. The single plate force-bearing reinforcing method includes that the original bridge deck pavement is shoveled, hinge joint concrete is removed, defects and cracks of the original hollow slab bridge beam body are processed, strip-shaped steel plates are transversely pasted on the upper surface and the lower surface of the hollow slab bridge in the longitudinal bridge direction at certain intervals, split screws penetrate through drilled holes at the hinge joint position, a counter-force frame is arranged, a wedge-shaped block is embedded between the counter-force frame and the steel plates, and the steel plates are pressurized and pasted in sealing mode and then are positioned and fixed; the counter-force frame is demounted after sticky steel glue is cured; cavities in beam joints are subjected to pressure grouting, shear reinforcements are placed into the top surface of a hollow slab, a reinforcement mesh is reconstructed, and the bridge deck reinforcement mesh and the implanted reinforcements are connected in binding or point welding mode to form a whole body; steel fiber reinforced concrete is poured and waterproof coatings are sprayed; and bituminous concrete is paved. The single plate force-bearing reinforcing method improves transverse load distribution, steel plate pasting reliability and bridge integral force-bearing performance on the premise of preventing hollow slab beam body damage, not changing a structural force-bearing system and not interrupting the traffic.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

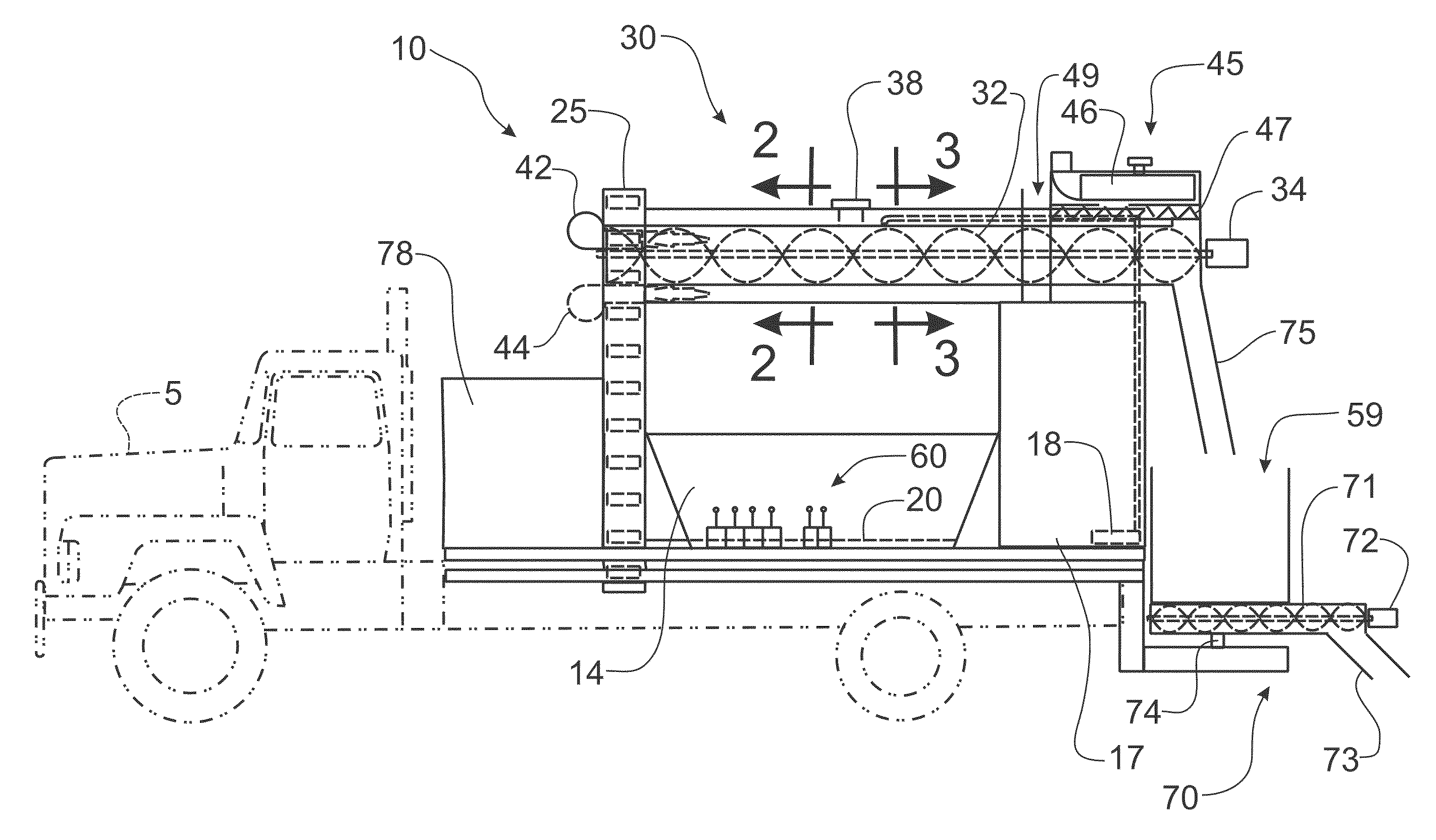

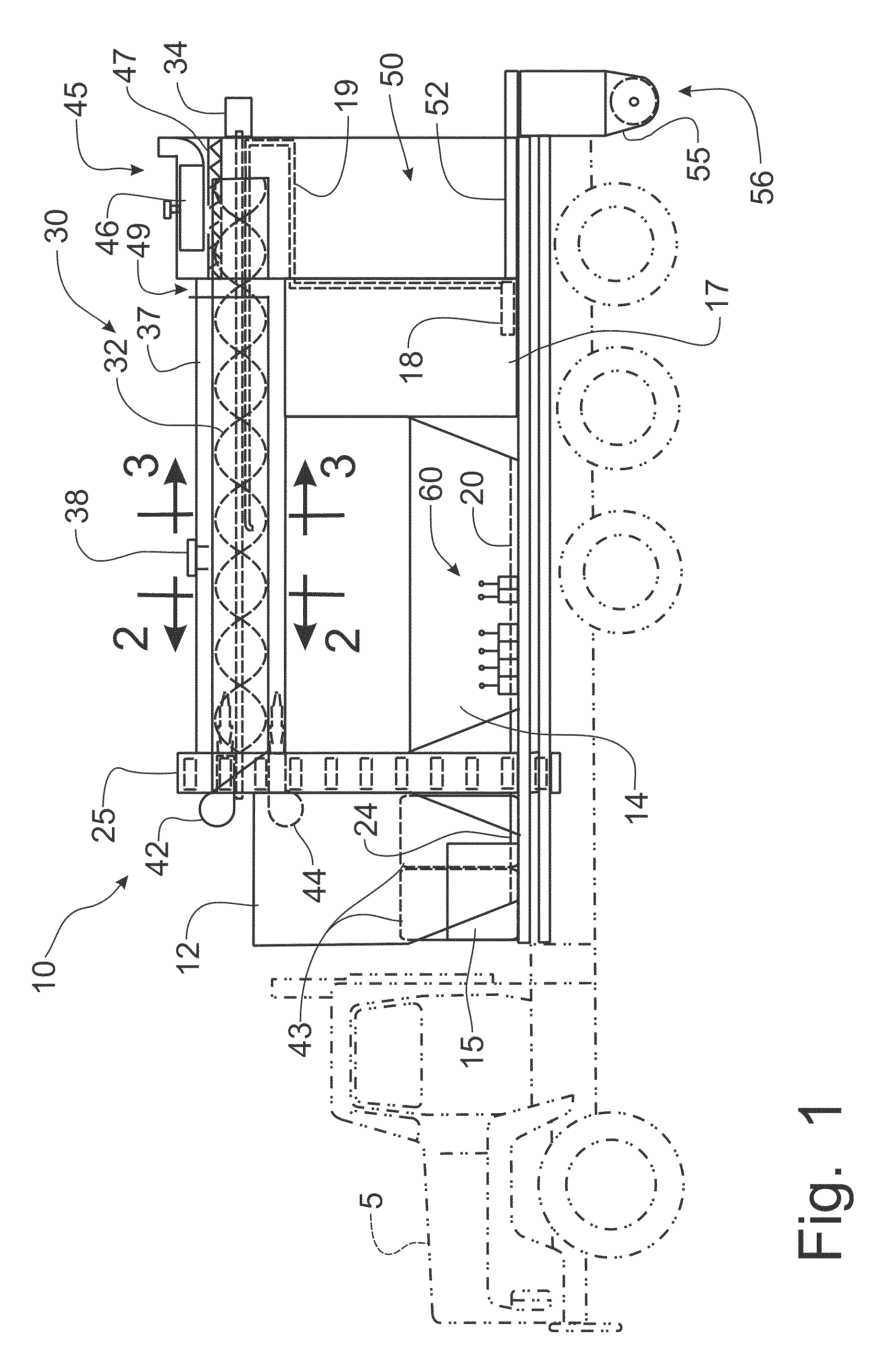

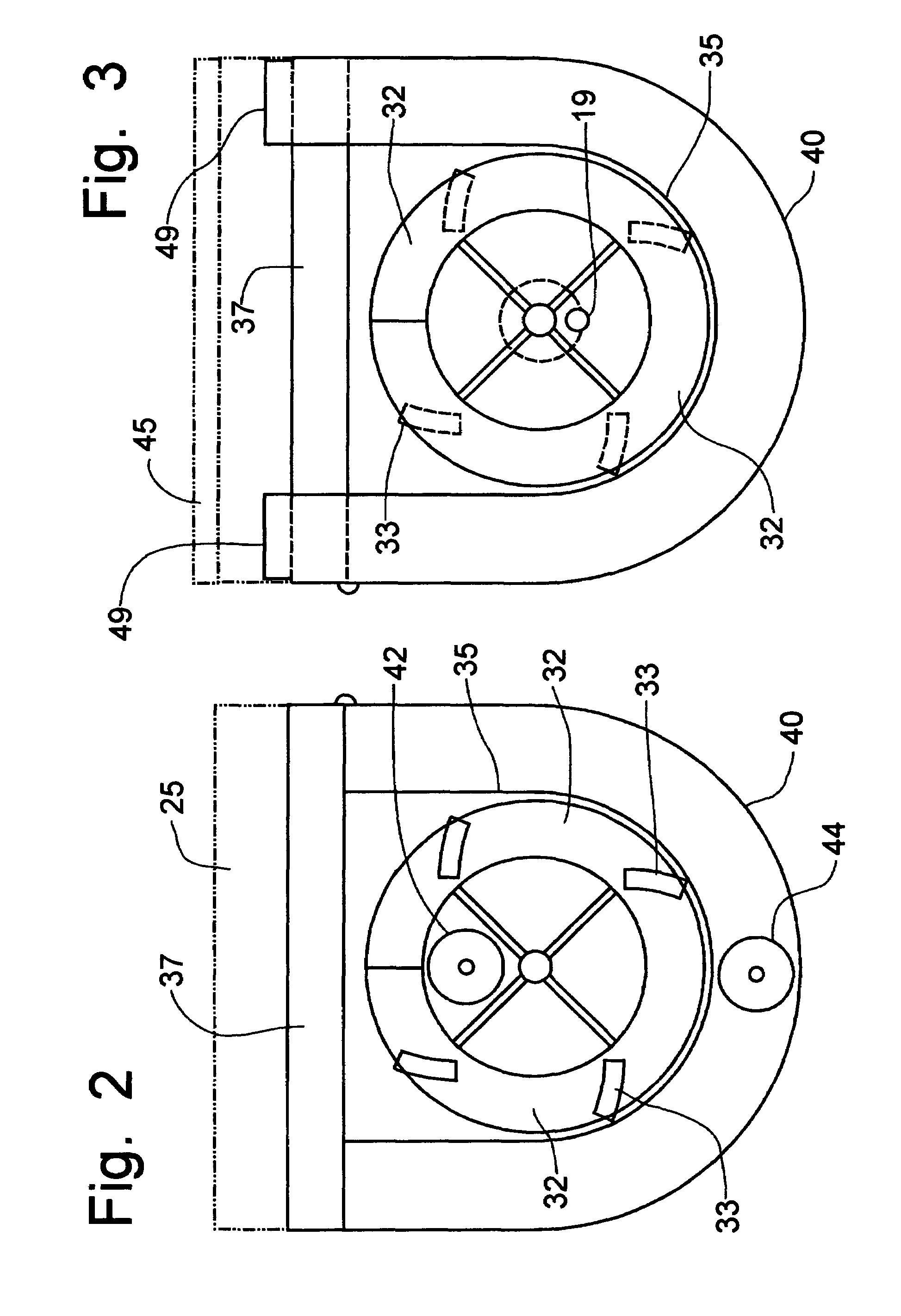

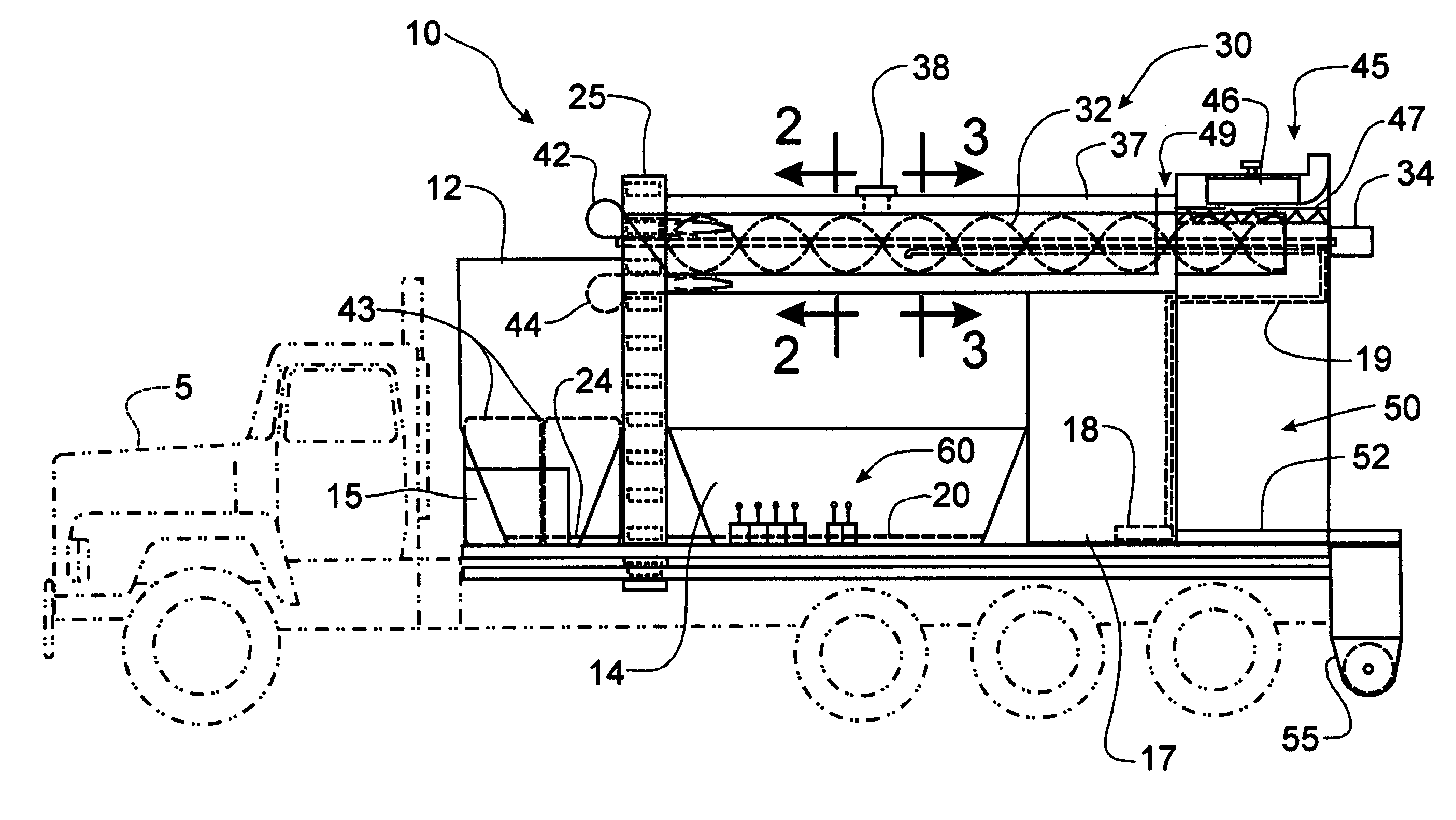

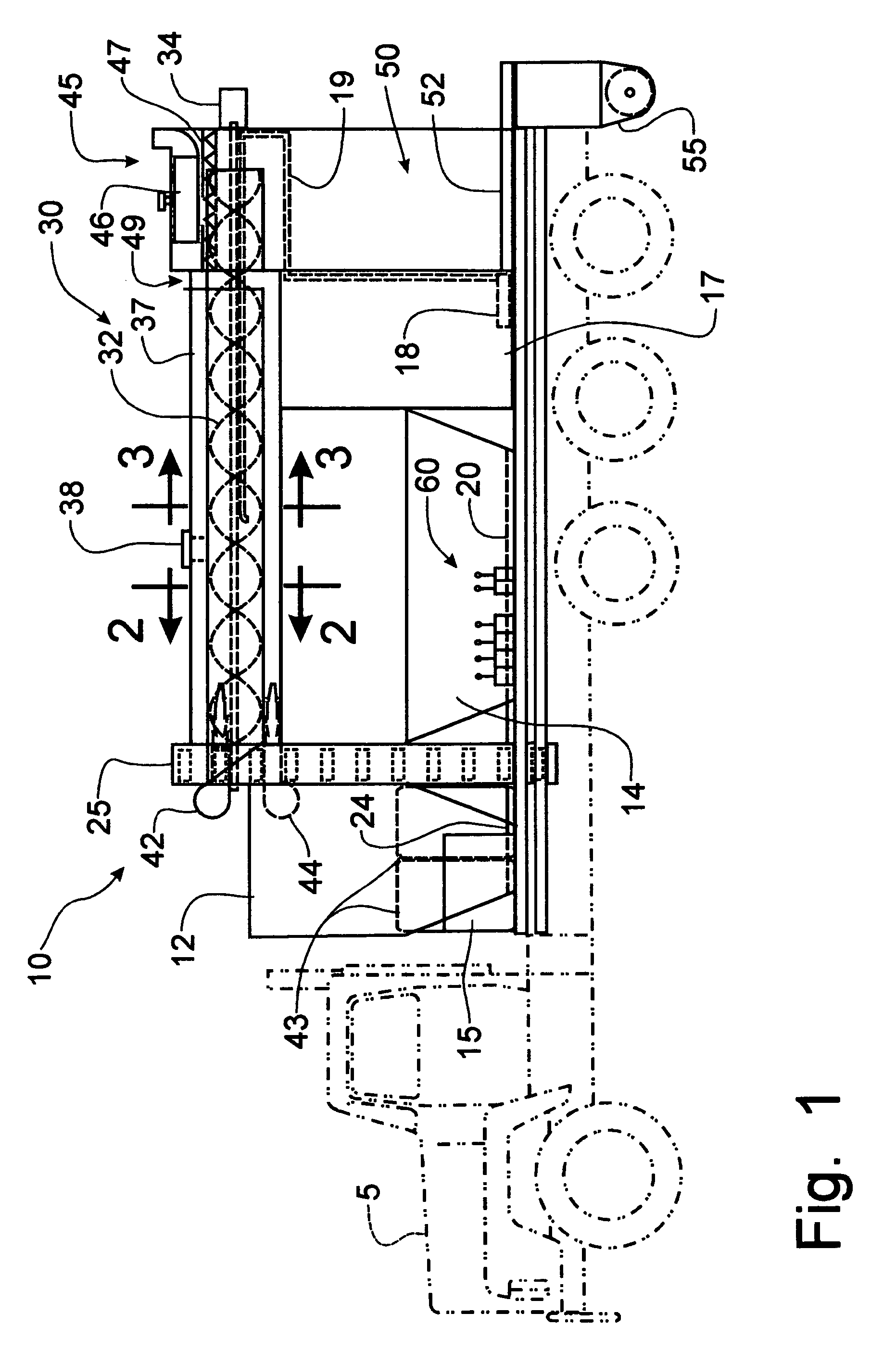

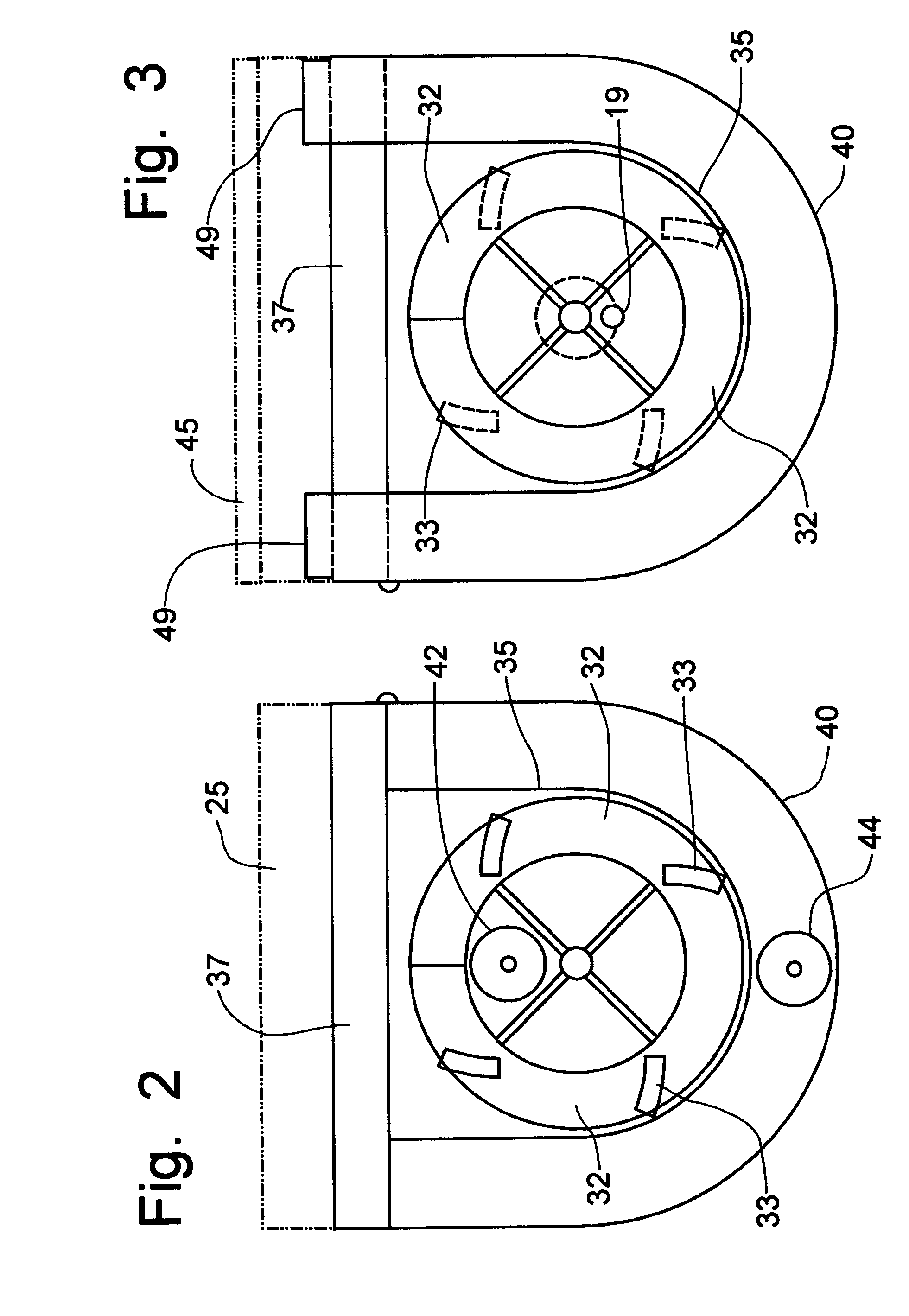

Mobile asphalt production machine

A mobile asphalt production machine mixes bituminous concrete at the job site through a mixing auger mechanism mounted in an insulated housing. Propane burners provide heat within the mixing auger mechanism and within the insulated housing to produce a hot-mix bituminous concrete in large or small batches. The components of the asphalt mixture are stored in separate bins that can be re-filled at the job site to provide a continuous supply of asphalt. Hot liquid bitumen is added to heated aggregate within the mixing auger mechanism. Recycled asphalt can be added through a port in the mixing auger for incorporation into the mixture. Controls permit the rate of flow of each individual component to be selectively varied in order to change the recipe for the mixture and to provide calibration of the component, while a master control will maintain the pre-established flow rates through a variable speed of operation.

Owner:ZIMMERMAN HAROLD M

Composite modified asphalt and preparation method thereof

ActiveCN103232717AGood compatibilityHigh temperature and low temperature performanceBuilding insulationsEpoxyBridge deck

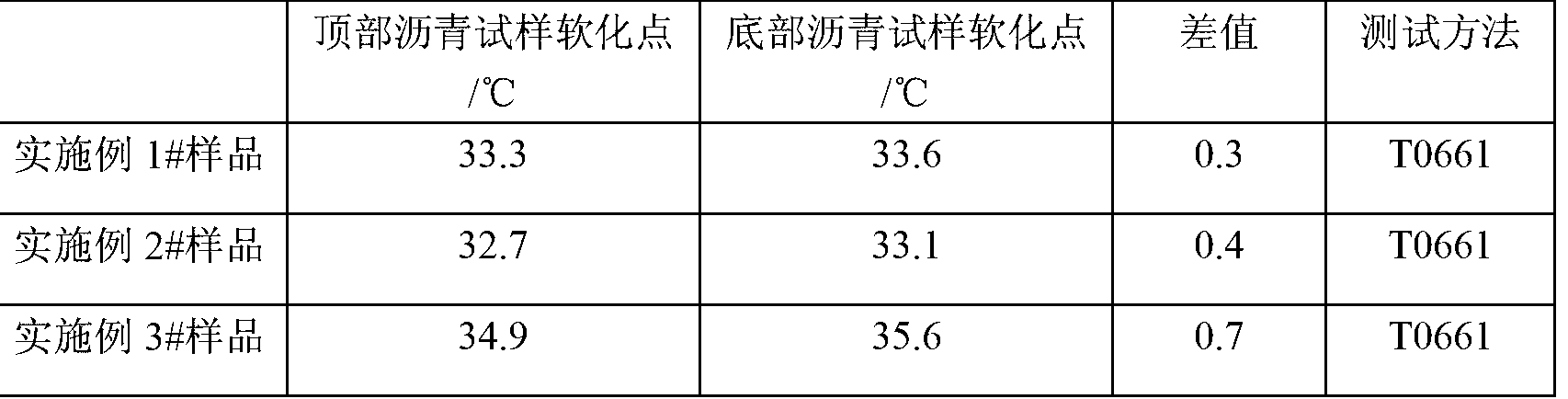

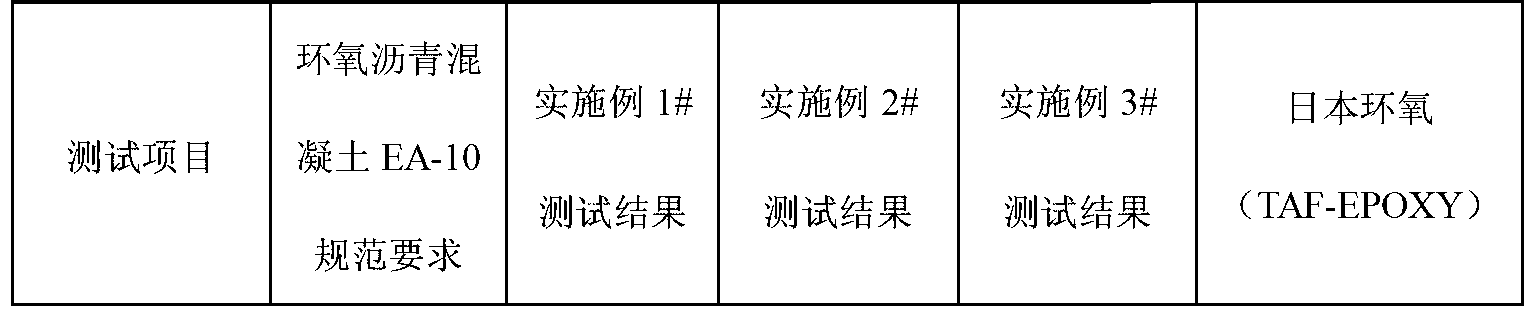

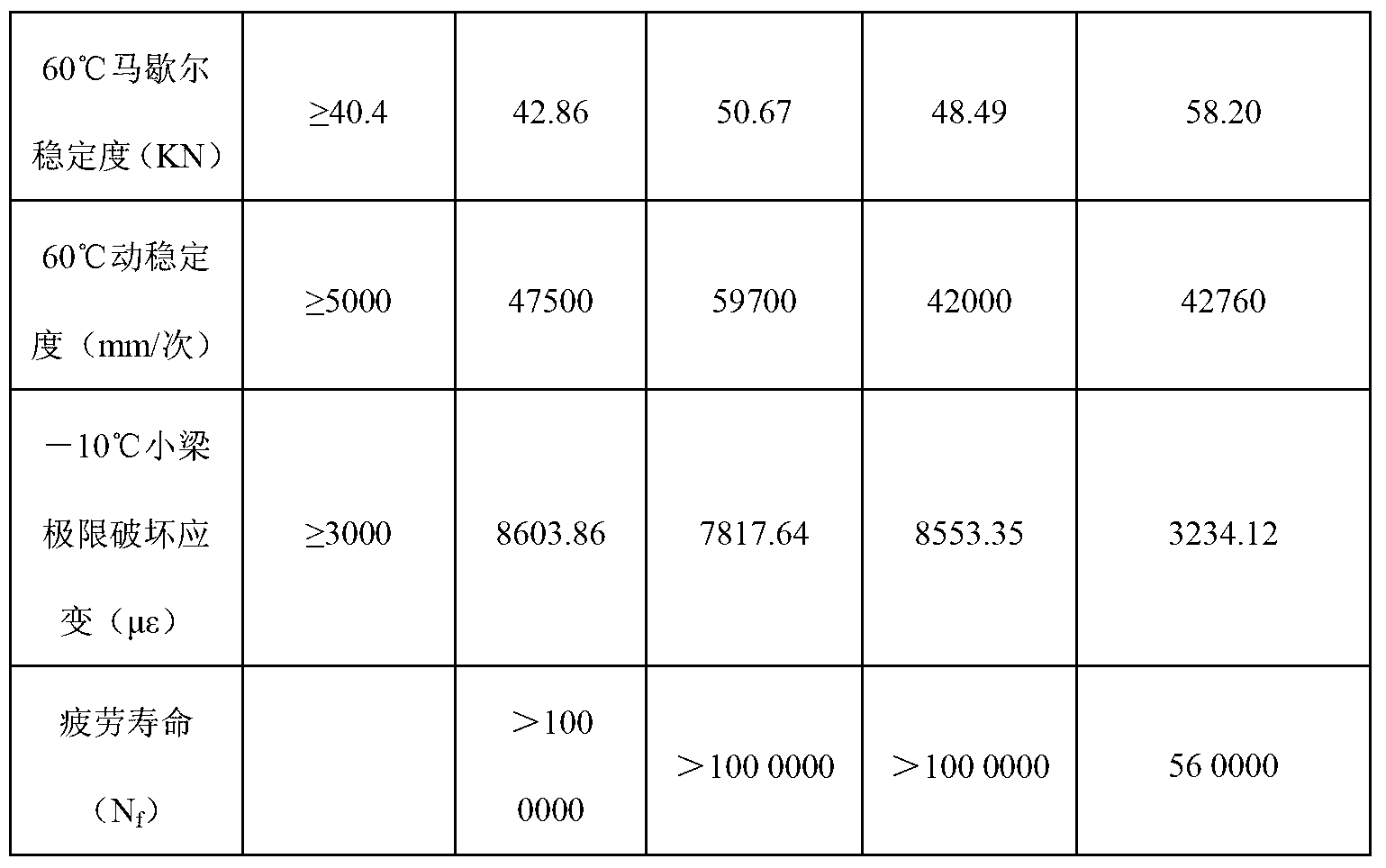

The invention relates to composite modified asphalt. The composite modified asphalt is prepared from the following raw materials in percentage by weight: 23.1-45.5% of polyurethane modified epoxy resin, 5-10% of compatibilizer, 5-10% of plasticizer, 5-10% of curing agent and 40-60% of road petroleum asphalt, wherein the polyurethane modified epoxy resin is terminal-amino polyurethane modified epoxy resin, terminal-isocyanato polyurethane modified epoxy resin or imidazolyl-terminal-capped polyurethane modified epoxy resin, the compatibilizer is naphthalene oil, asphalt tar or a mixture of naphthalene oil and asphalt tar, the plasticizer is dioctyl phthalate, dibutyl phthalate or a mixture of dioctyl phthalate and dibutyl phthalate, the curing agent is a modified aromatic amine curing agent, and the road petroleum asphalt is 70# petroleum asphalt, 90# petroleum asphalt or 110# petroleum asphalt. The road performance of concrete adopting the polyurethane epoxy resin composite modified asphalt further meets the requirements of technical specifications and surpasses that of the similar imported product Japan Epoxy, so that the composite modified asphalt can be widely applied to the construction of steel bridge deck pavement, and has great significance in opening a market for domestic epoxy asphalt materials.

Owner:重庆市智翔铺道技术工程有限公司

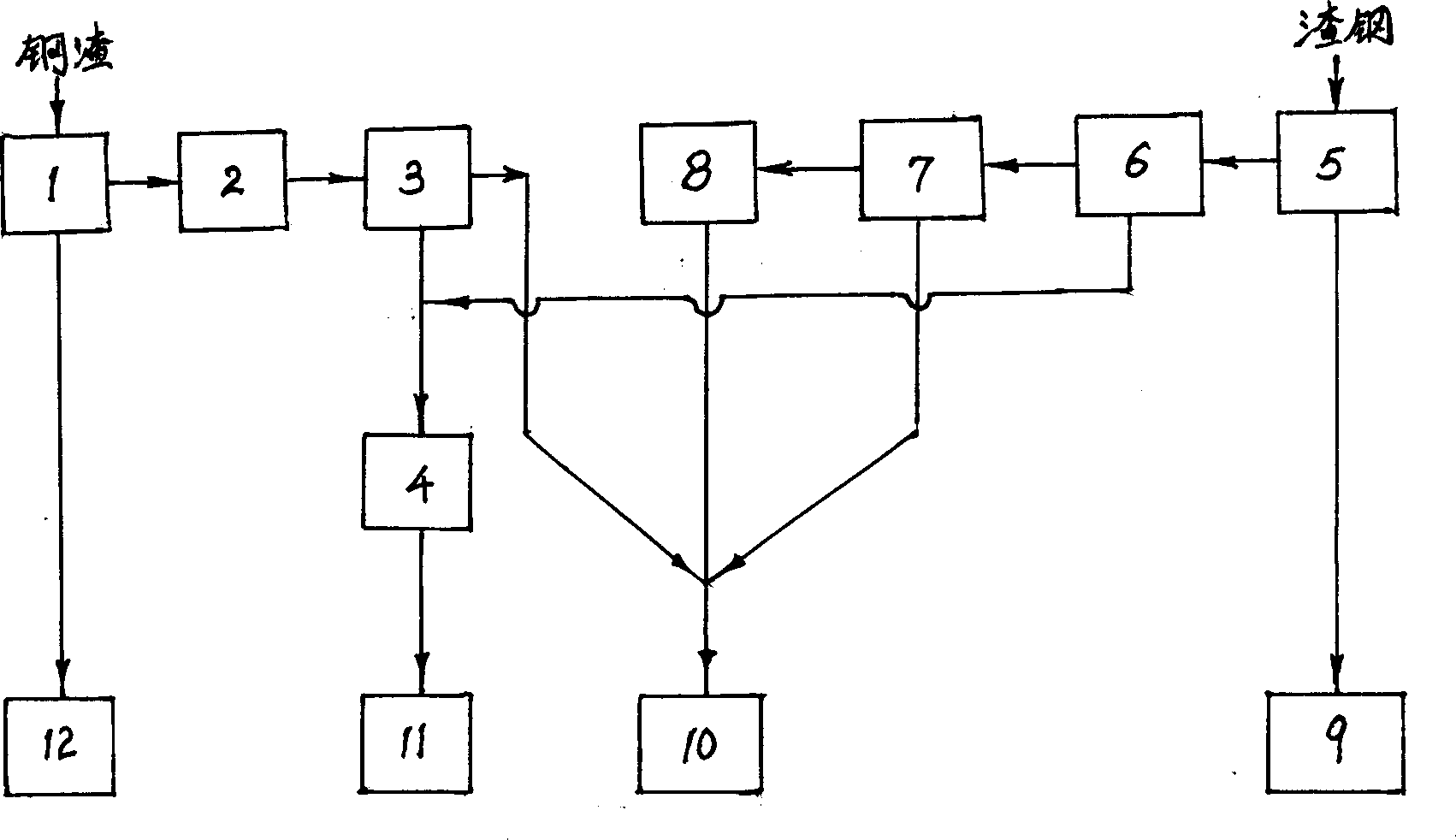

Process for treating steel slag

InactiveCN1390795AIncrease added valueSolve the pollution of the environmentRecycling and recovery technologiesProcess efficiency improvementIron powderSlag

A process for reclaiming the steel slags includes such steps as preparing steel slags and residual steel as raw material, sieving, ball grinding, magnetic separating, and wind classifying to obtain 4 products: high-quality waste steel used for smelting steel, refined iron powder used for smelting iron, micro slag powder used as high-activity additive of concrete, and steel slag aggregate used for slag-asphalt-concrte pavement of highway.

Owner:北京科美隆科技发展有限公司

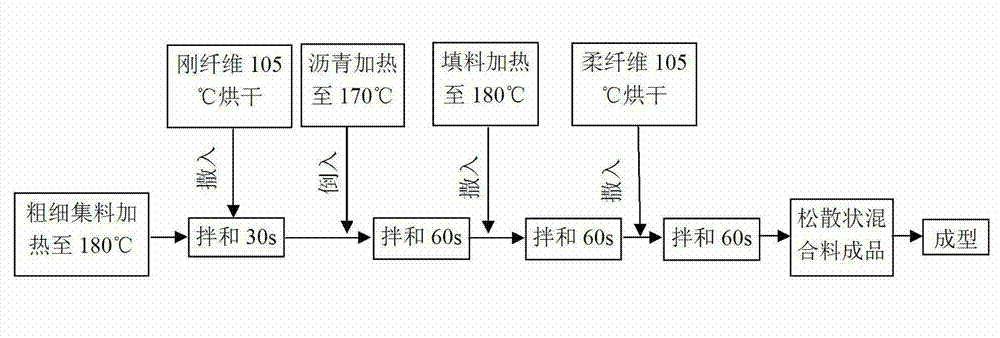

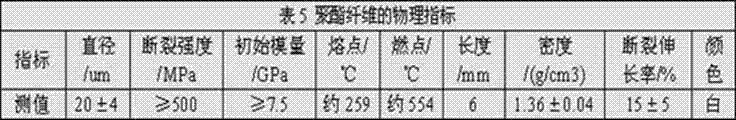

Crack self-healing bituminous concrete and preparation method thereof

The invention relates to a crack self-healing bituminous concrete and a preparation method thereof. The bituminous concrete comprises coarse aggregate, fine aggregate, fillers, pitch, rigid fiber and flexible fiber, wherein the mixing amount of the rigid fiber is 0.50-2.5wt.% of the total amount of the coarse aggregate, the fine aggregate, the fillers and the pitch, and the mixing amount of the flexible fiber is 0.10-0.35wt.% of the total amount of the coarse aggregate, the fine aggregate, the fillers and the pitch. The preparation method of the concrete comprises the steps of weighing dried aggregates, placing the aggregates in a material containing disk, mixing the aggregates uniformly, preheating in a drying oven to the temperature of 180 DEG C, and heating the fillers separately to the temperature of 180 DEG C; preheating the pitch to the temperature ranging between 160 DEG C and 175 DEG C; drying the rigid fiber and the flexible fiber respectively for backup use according to the requirement; and firstly mixing the rigid fiber into the mixed aggregate with blending, then blending the aggregate and the liquid pitch, then blending with the fillers, then blending with the flexible fiber, and finally forming the bituminous concrete. According to the bituminous concrete and the preparation method, the low-temperature cracks of bituminous pavements are reduced to the minimum and can be healed spontaneously, early-stage cracking is avoided effectively, the service life of the bituminous pavements is prolonged, and the project implementation is convenient.

Owner:ZHENGZHOU UNIV

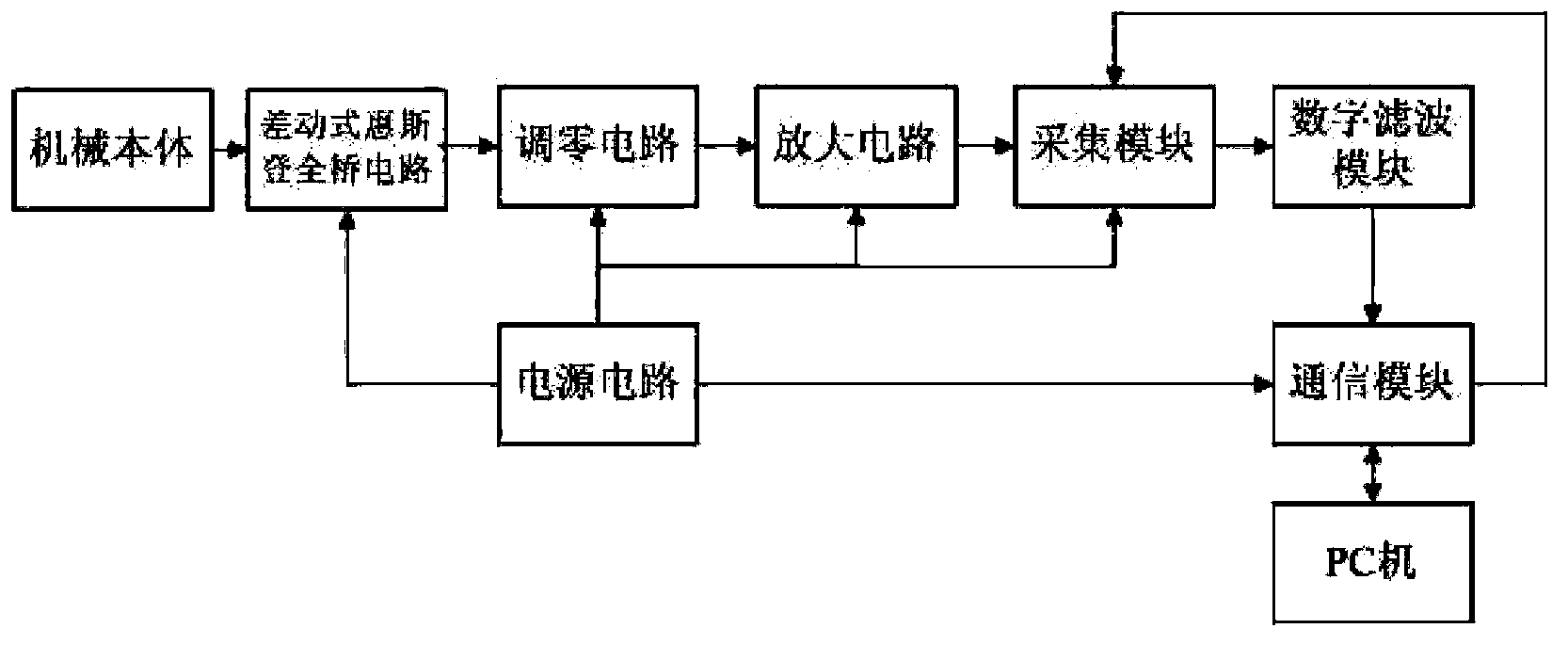

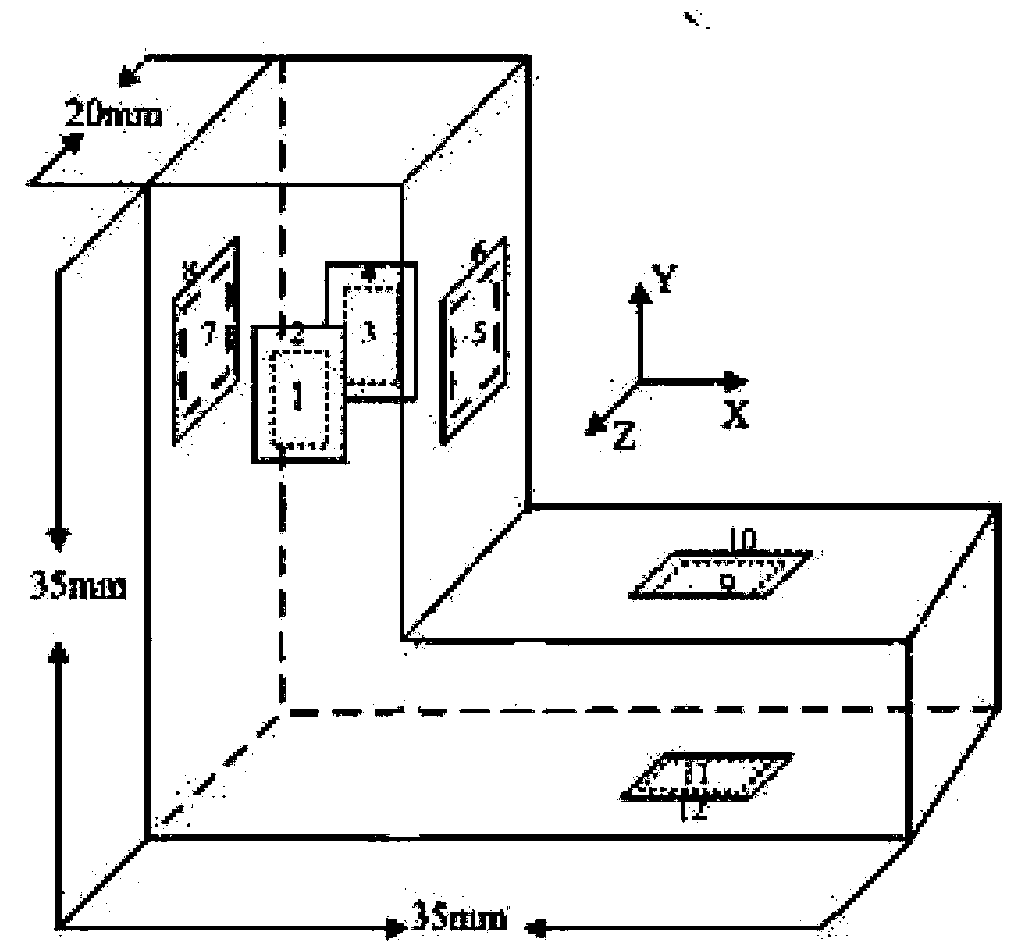

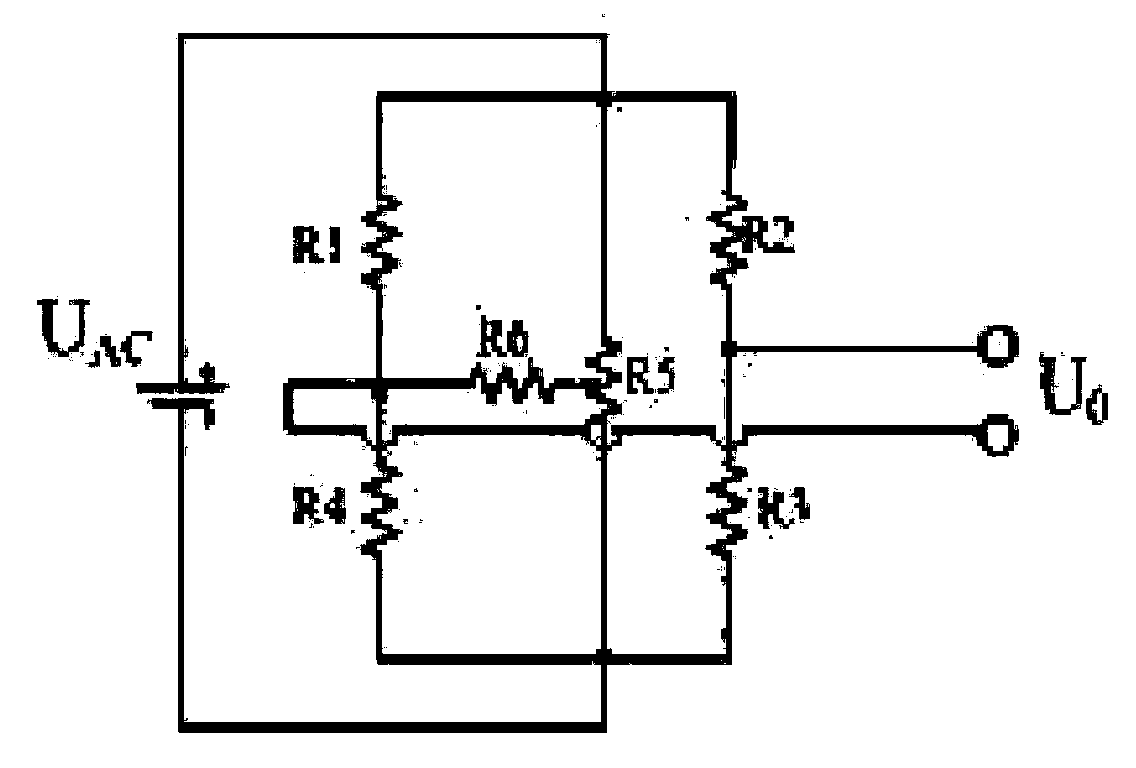

Novel three dimensional stress measuring sensor

InactiveCN103398807ASimple structureEasy to processForce measurementElectrical resistance and conductanceElastomer

The invention relates to a novel three dimensional stress measuring sensor, which comprises a machine body and hardware circuits, wherein the machine body is composed of a metal hollow elastic body and resistance strain gages, and is buried in bituminous concrete, the resistance strain gages are in three groups, the three groups are used for measuring the component of the applied stress in X, Y, and Z directions respectively, each group has four resistance strain gages, and when stress is applied on the metal hollow elastic body, two resistance strain gages are pulled and two are pressed in each group, and strain symbols are opposite; the hardware circuits comprise differential type Wheatstone full bridge circuits, zero setting circuits, an amplifying circuit, an acquisition module, a digital filtering module, a communicating module, and a power supply circuit; the three groups of the strain gages make up the three differential type Wheatstone full bridge circuits respectively, and each differential type Wheatstone full bridge circuit is in external connection with a zero setting circuit; outputs of the three groups of the each differential type wheatstone full bridge circuits are communicated with a PC machine through the amplifying circuit, the acquisition module, the digital filtering module, the communication module.

Owner:中交一公局土木工程建筑研究院有限公司

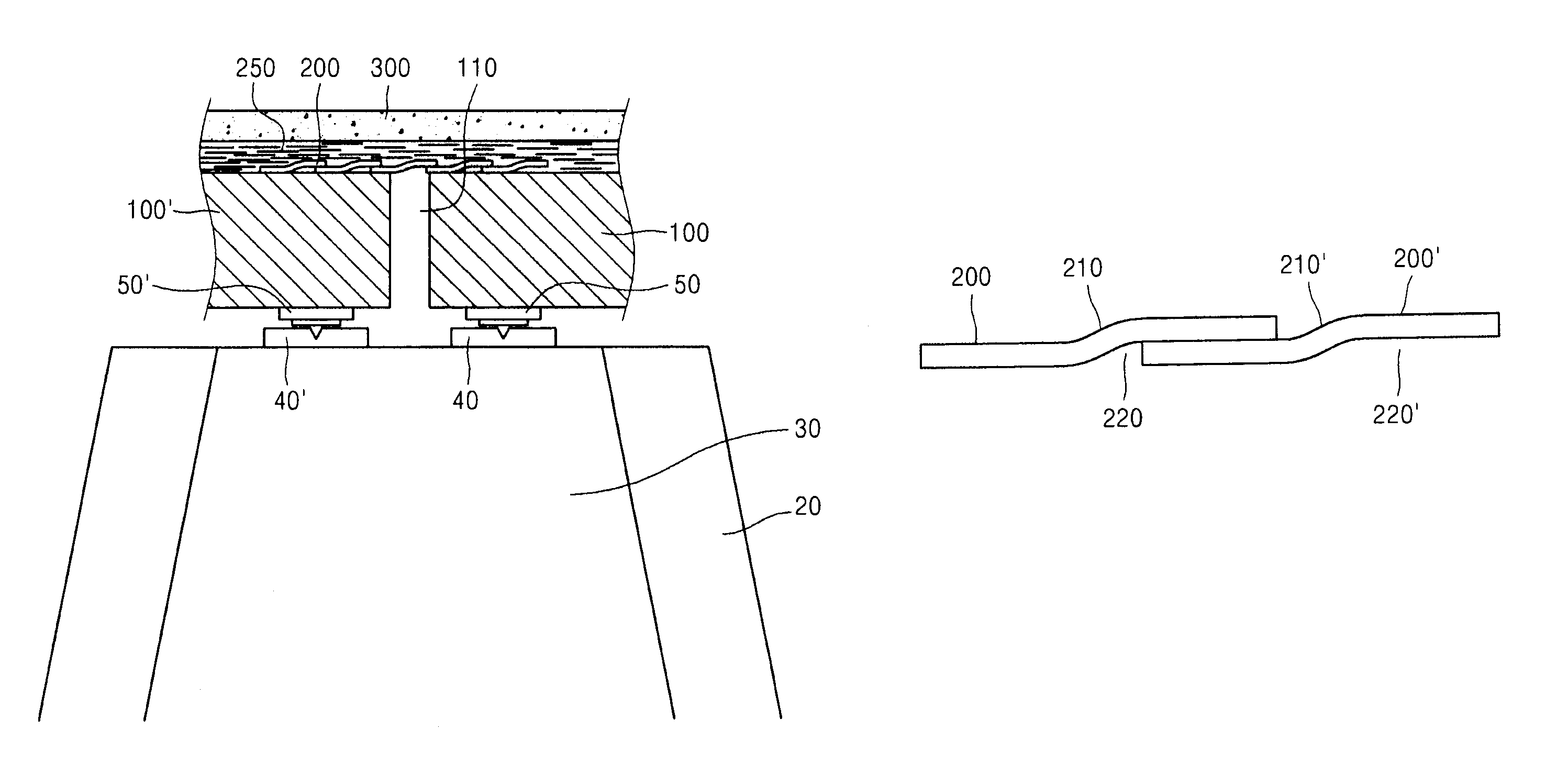

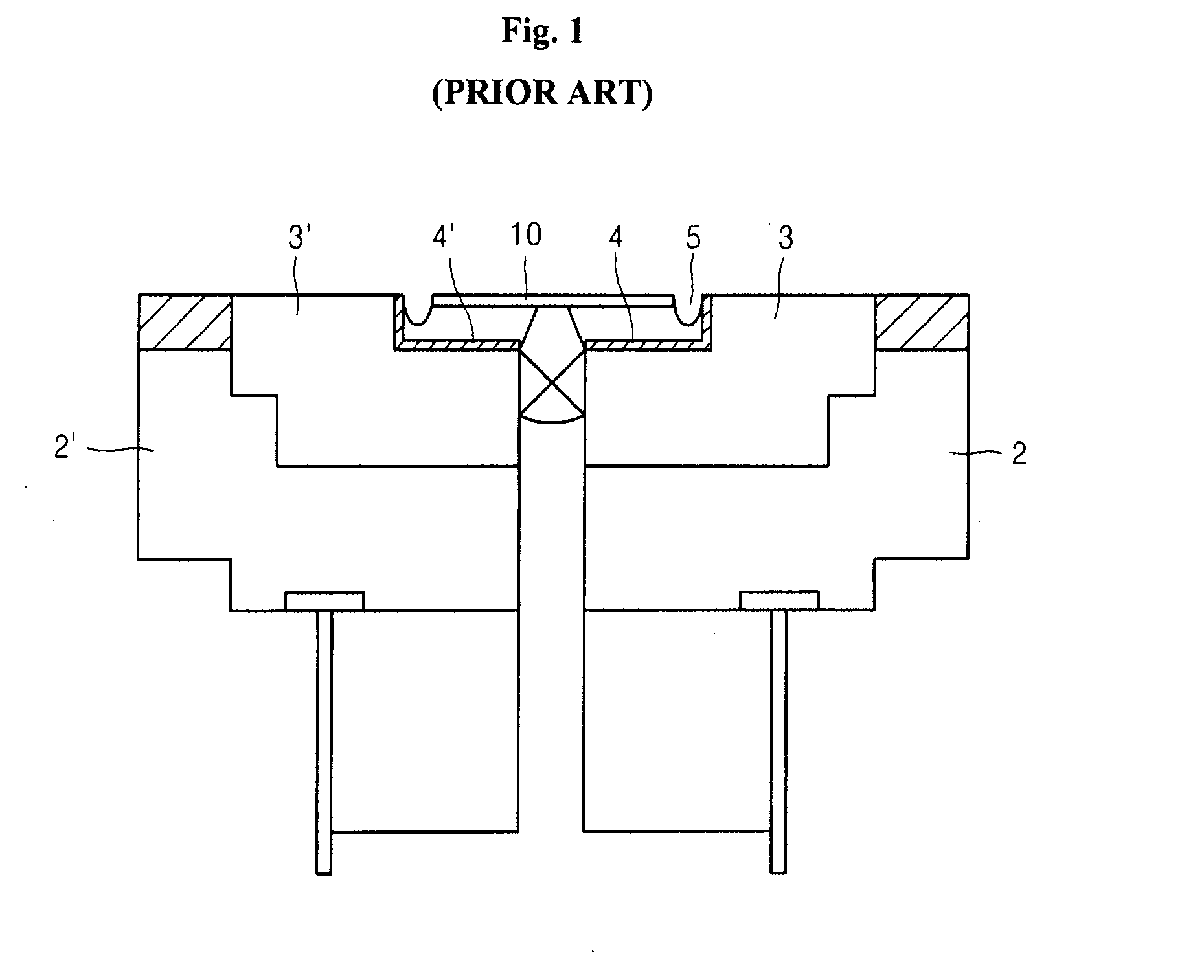

Anti-expansion joint bridge constructed through detailed survey for bridge

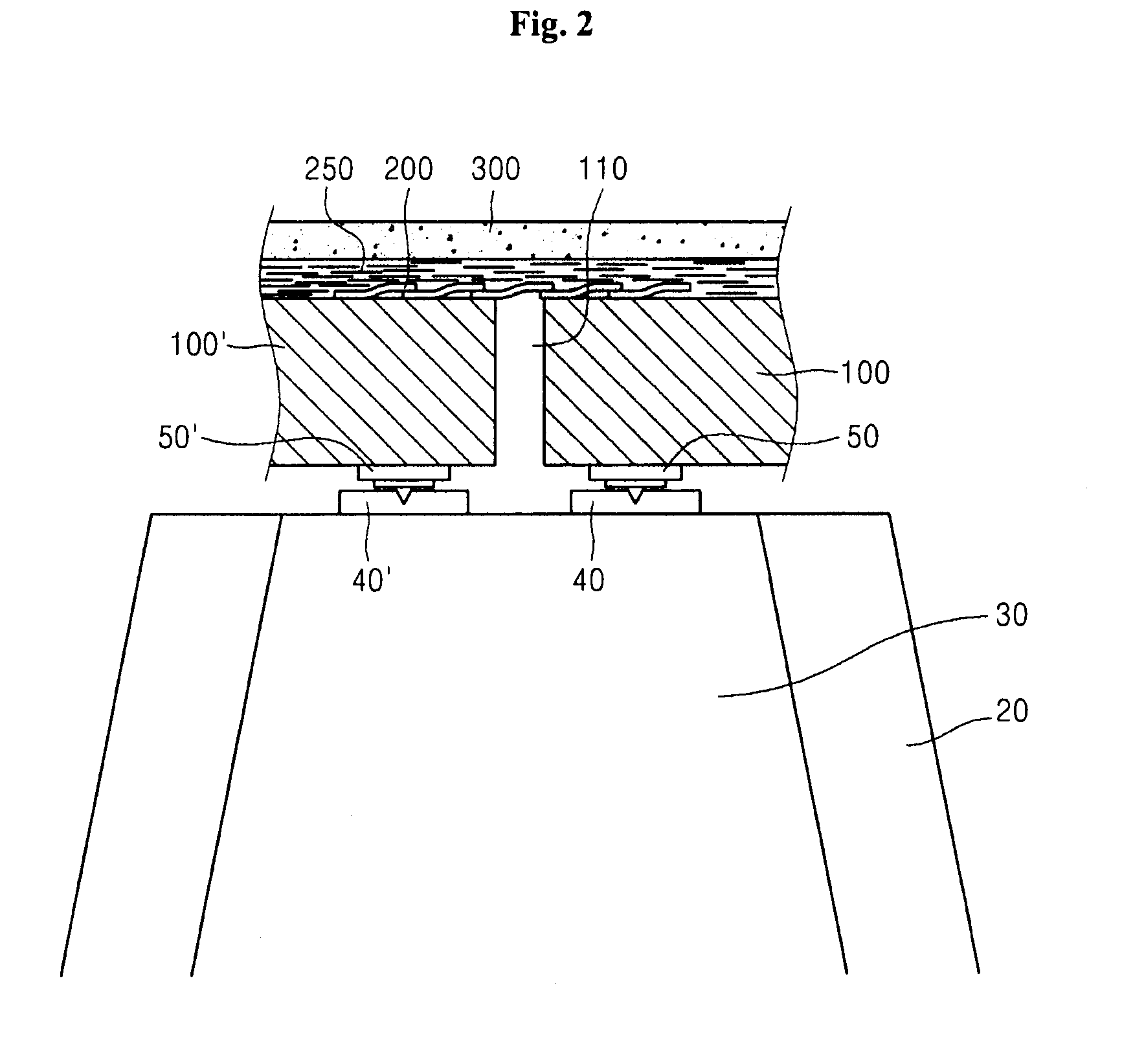

InactiveUS8171590B2Reduce frictionAvoid noisePaving detailsBridge structural detailsFloor slabSlide plate

Disclosed herein is an anti-expansion joint bridge which eliminates an expansion joint structure from an upper structure thereof, and includes a plurality of slidable steel plates to cover a space between girders or floor slabs expanding and contracting on piers and asphalt concrete pavement on the steel plates, so that expansion and contraction of the girders occurring on the piers is prevented from affecting the pavement, thereby ensuring smooth travel of vehicles thereon. The anti-expansion joint bridge includes a pair of expandable / contractible girders separated from each other while constituting an upper structure of the bridge, a plurality of sliding plates overlapping each other on the girders while covering a gap between the girders, and an ascon part covering the pair of girders together with the sliding plates.

Owner:KIM EUN JOO

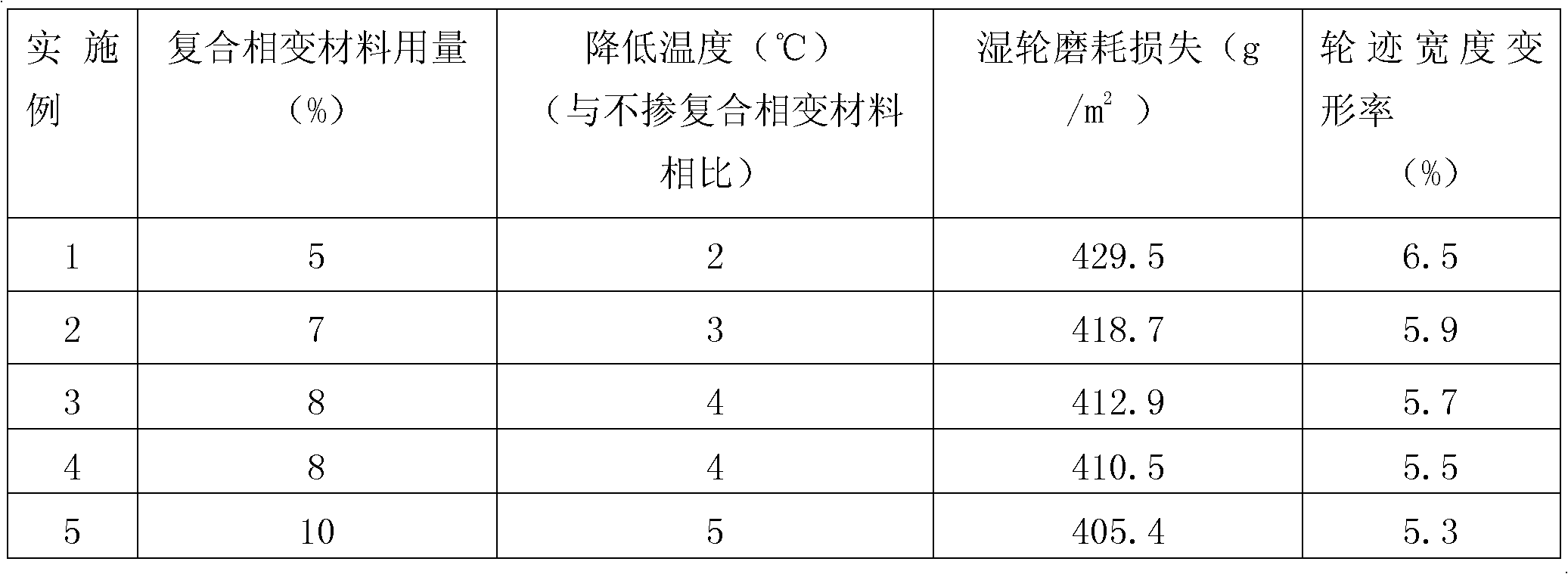

Self temperature adjustment cold mixing bituminous concrete and preparation method thereof

The invention belongs to the technical of bituminous pavement maintenance materials, and particularly relates top a cold mixing bituminous concrete and a preparation method thereof. The self temperature adjustment cold mixing bituminous concrete is characterized by being prepared from the following raw mateirals in percentage by weight: 70-80 percent for the aggregate, 1-3 percent for the filler, 5-10 percent for the composite phase change material, 8-10 percent for water and 6-8 percent for the modified emulsified asphalt. The composite phase change material is made of wax and expanded graphite composited together, the mass ratio of the expanded graphite and the wax is 1:8-9, the phase change temperature of the composite phase change material is 40-50 DEG C, and the phase change heat is 150-160kJ / kg. The process is simple, the cost is low and implementation is easy. The concrete has the function of reducing pavement temperature.

Owner:WUHAN UNIV OF TECH

Bituminous concrete material capable of reducing adhesion of snow ice on road surface and preparation method thereof

ActiveCN102173656AImprove hydrophobicityReduce crystallizationBuilding insulationsRoad surfaceSilicon rubber

The invention provides a bituminous concrete road surface material capable of reducing adhesion of snow ice on a bituminous road surface and a preparation method thereof, relating to bituminous road surfaces such as a freeway, a ramp, an overhead, a bridge surface and the like. The bituminous concrete road surface material comprises the following components: 107 organic silicon rubber modified bitumen, ore aggregate and ore powder. The preparation method comprises the following steps: firstly, preparing a 107 organic silicon rubber modified bitumen cement material; and then preparing an organic silicon rubber modified bituminous mixture. By utilizing a high hydrophobic bitumen film which is formed by organic silicon rubber with low surface energy on the surface of the aggregate and insidethe gap of the aggregate, the adhesion of the snow ice on the road surface is reduced, thus the snow ice is easy to eradicate.

Owner:ZHEJIANG JIAOGONG HIGHWAY MANTAINANCE

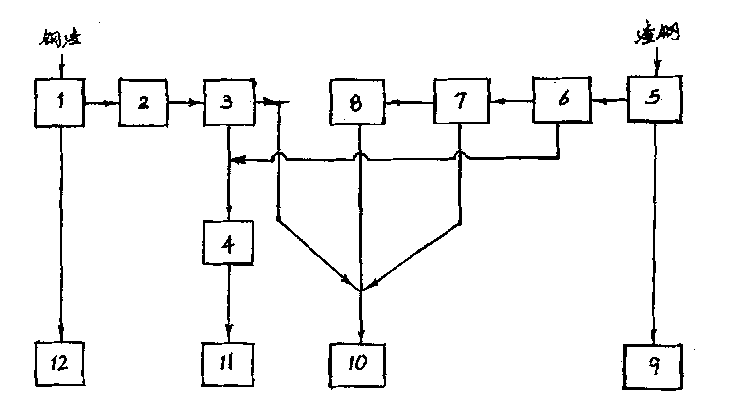

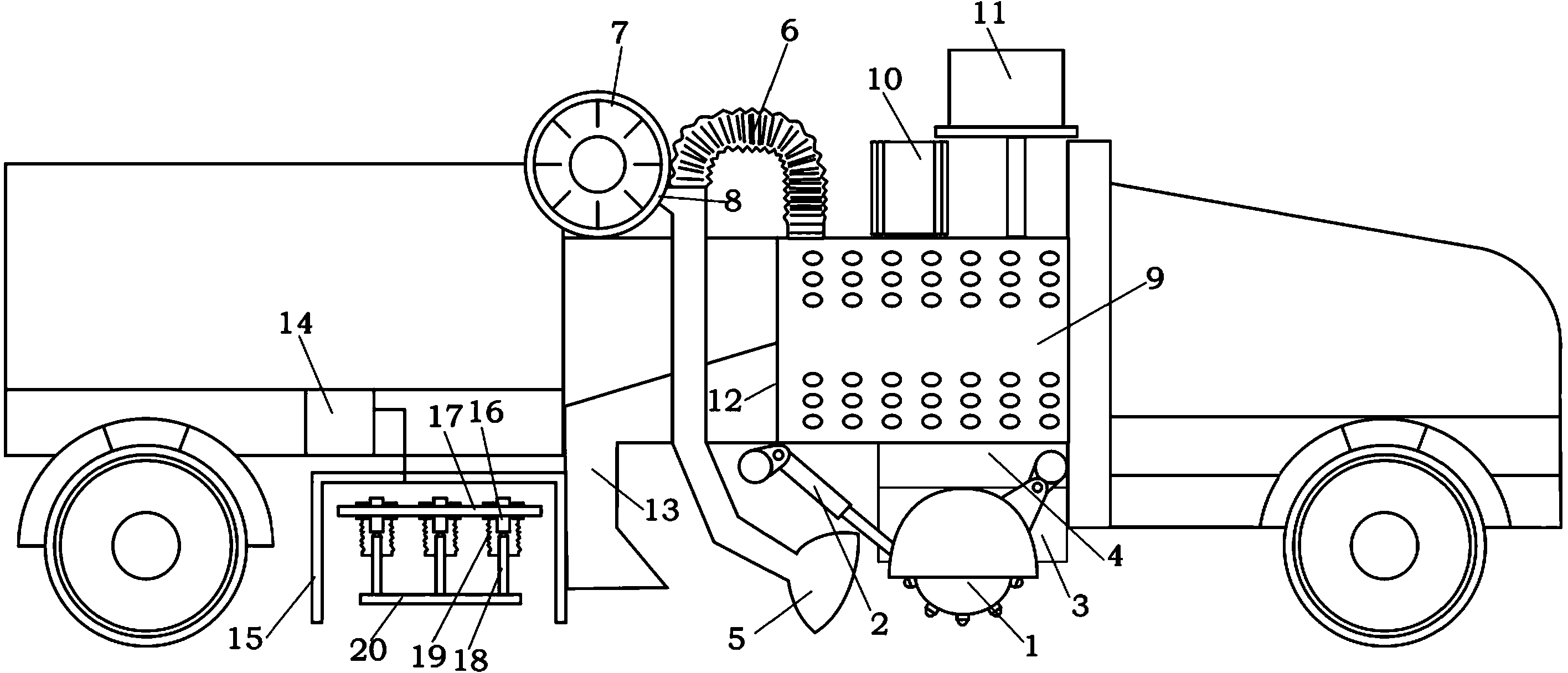

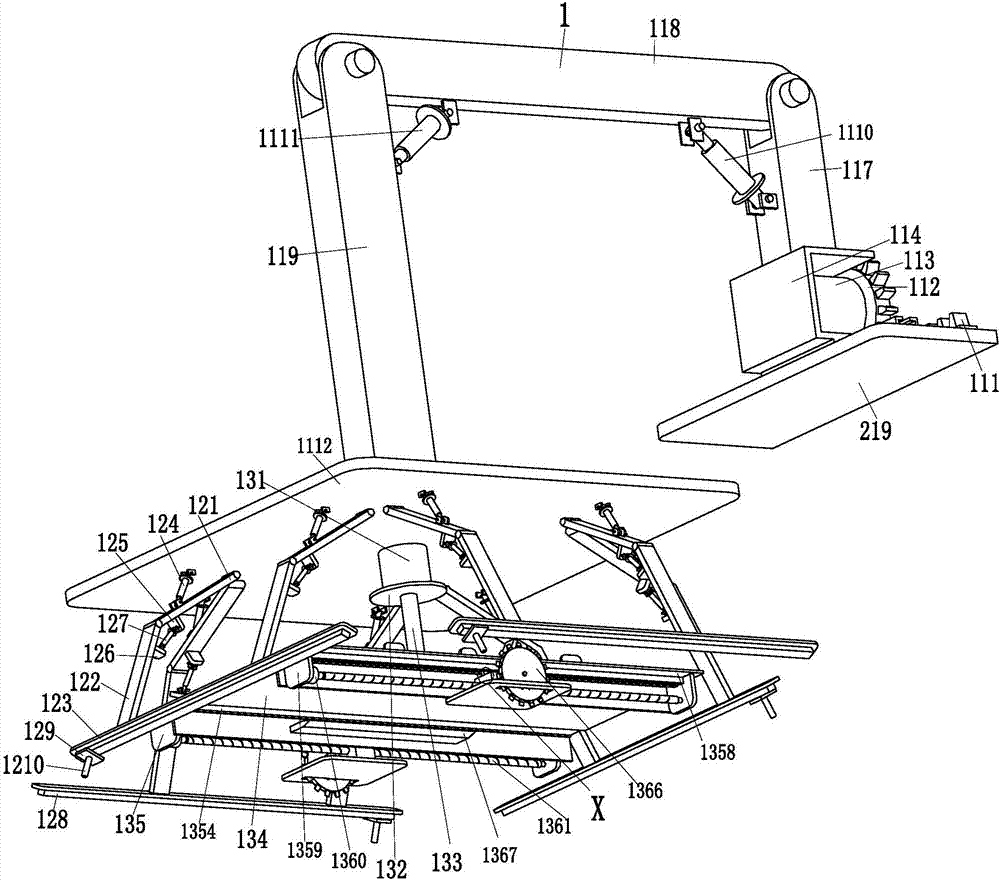

Bituminous pavement digging-milling-repairing integrated system device

ActiveCN103643623AImprove maintenance qualityExtended service lifeRoads maintainenceMicrowavePavement maintenance

The invention relates to a bituminous pavement digging-milling-repairing integrated system device comprising a car body, wherein a digging-milling part, a crushed return material part, a microwave stirring and blanking part and a compaction part are sequentially arranged in front and back of the car body; the digging-milling part is used for carrying out digging-milling treatment on a bituminous damaged part of a pavement; the crushed return material part is used for collecting dug and milled bituminous concrete waste; the microwave stirring and blanking part is used for treating the collected dug and milled bituminous concrete waste and blanking to a digging-milling area again; the compaction part is used for carrying out compaction treatment on a dropped material and complementary bituminous concrete. According to the bituminous pavement digging-milling-repairing integrated system device, digging-milling, recycling regeneration, padding and repairing parts are integrated into a whole, dug and milled waste is recycled to be added with appropriate emulsified asphalt to heat to reuse, and the bituminous pavement digging-milling-repairing integrated system device is high in environmental protection and high in working efficiency. The bituminous pavement digging-milling-repairing integrated system device is small in number of transmission links, compact in structure and high in space utilization. By utilizing the bituminous pavement digging-milling-repairing integrated system device, the operation efficiency of pavement maintenance is effectively improved, the labor intensity is lightened, the off-time of each process is effectively shortened, the compaction uniformity of a reworked material of the bituminous concrete is improved, the pavement maintenance quality is improved and service life is prolonged.

Owner:中部华科建设集团有限公司

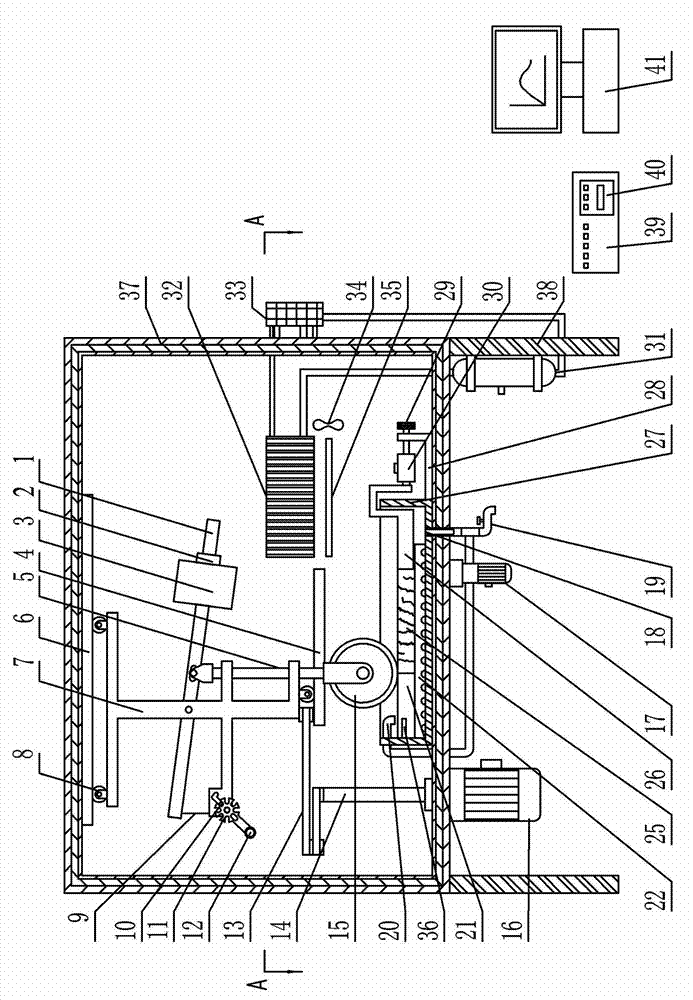

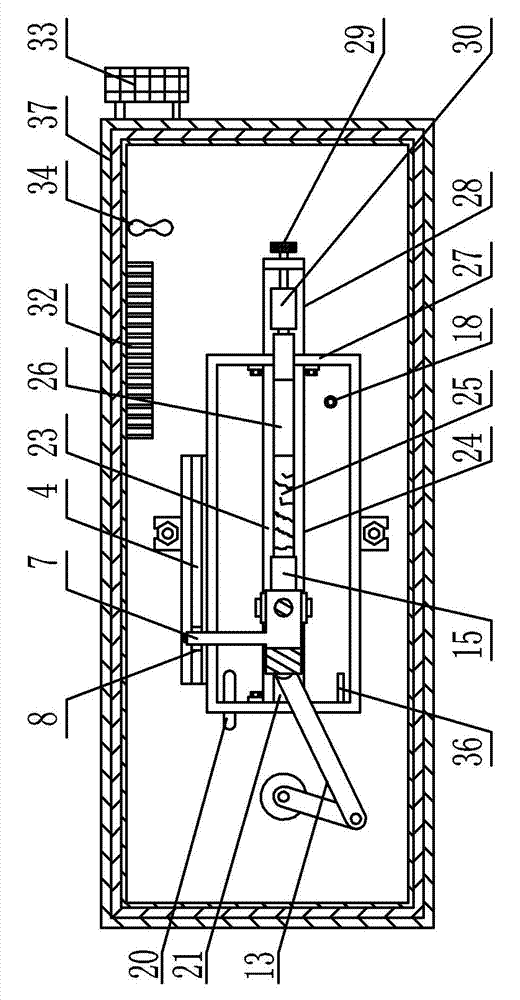

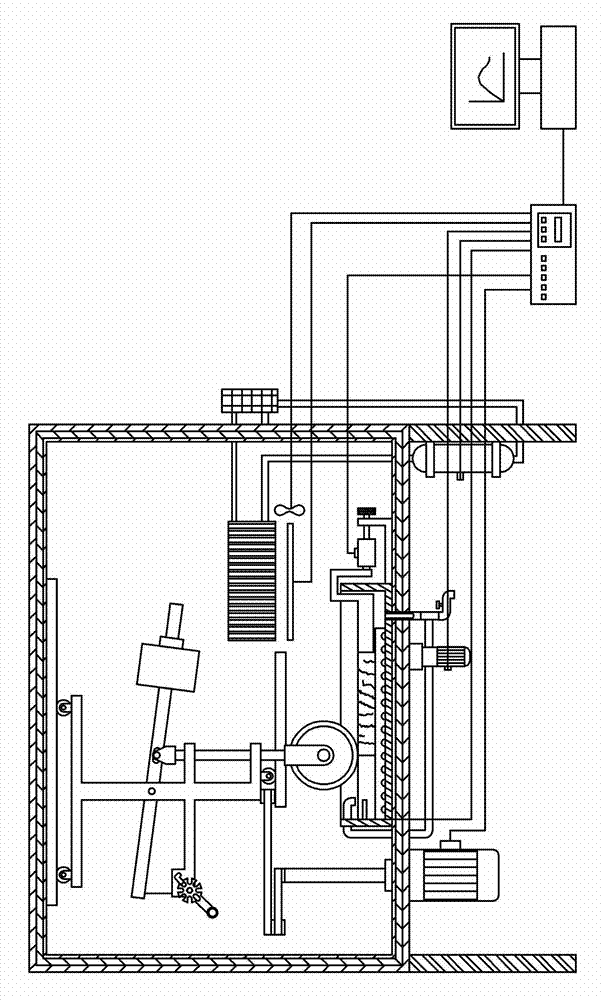

Simulation tester for self healing of asphalt concrete cracks

A simulation tester for self healing of asphalt concrete cracks comprises a main frame, a test control and data collection system, an environment simulation box, a rigidity water tank, a test piece, a test piece limit clamp, a wheel load simulation device, a test piece healing force application device, a loading frame horizontal reciprocating moving mechanism, a temperature environment control device and a water circulation system simulating humidity environment. The main frame is provided with the environment simulation box which is at least composed of an inner rigidity layer, an outer rigidity layer and a middle heat insulation layer. The rigidity water tank is installed on the bottom wall in the middle in the environment simulation box, the test piece and the test piece limit clamp are installed in the rigidity water tank, the wheel load simulation device is arranged vertically above one side of the test piece and contains test wheels in rolling fit with the corresponding test piece, a test piece healing force application and test device is arranged horizontally on the other side of the test piece, the wheel load simulation device contains a loading frame which is provided with the loading frame horizontal reciprocating moving mechanism, and the water circulation system simulating humidity environment is arranged under the rigidity water tank. The simulation tester is high in automation degree, accurate in control, capable of simulating and researching self healing actions of the asphalt concrete cracks under various work conditions, convenient to operate, safe and reliable.

Owner:ZHENGZHOU UNIV +1

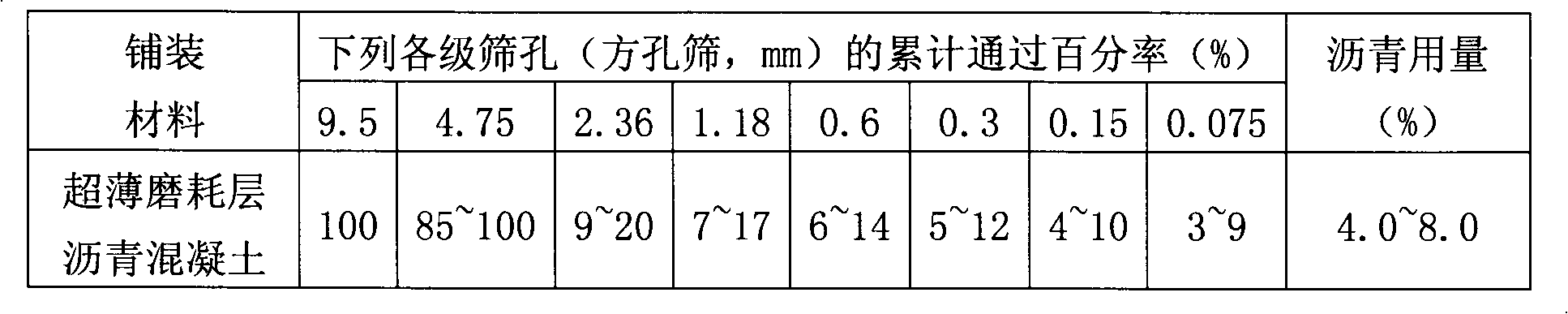

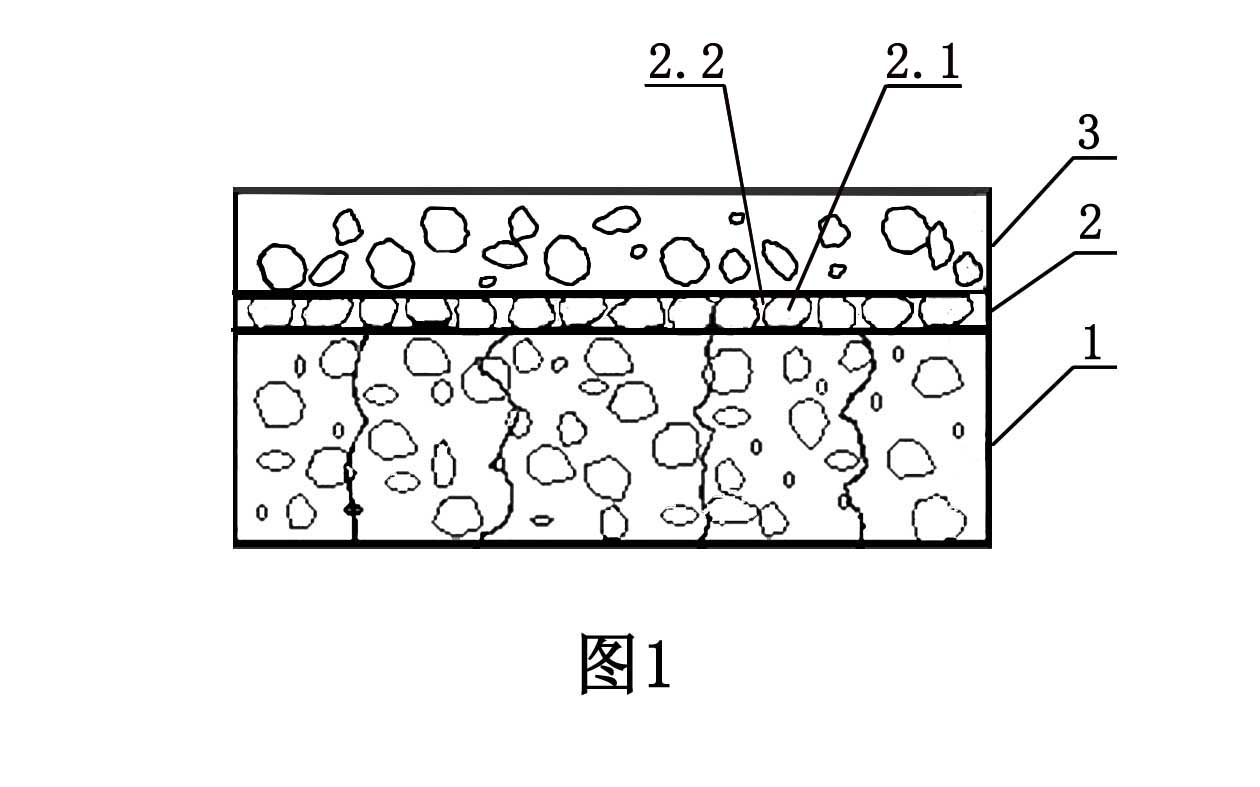

Ultra-thin wearing layer bituminous concrete material for paving bridge deck and preparation method thereof

The invention discloses an ultra-thin wearing layer bituminous concrete material for paving a bridge deck. The material consists of an epoxy asphalt binder and an aggregate in a weight ratio of 4-8:100, wherein the ratio of an epoxy resin to a curing agent-added substrate asphalt is 10-25:100; and the aggregate is prepared from the following raw materials in part by weight: 1,200 to 1,000 parts of basalt aggregate and 1,000 parts of mineral filler. The preparation method comprises the following steps of: 1), based on the weight ratio, blending and uniformly mixing the epoxy resin heated to 75 to 85 DEG C and the curing agent-added substrate asphalt heated to 120 to 130 DEG C to prepare the epoxy asphalt binder, wherein the blending ratio is 10-25:100; and 2), adding the prepared epoxy asphalt binder into the basalt aggregate pre-heated to 110 to 130 DEG C, stirring the mixture for at least 20 seconds in a stirring pot, adding the mineral filler into the stirring pot, stirring again for at least 40 seconds, and obtaining the ultra-thin wearing layer bituminous concrete material for paving the bridge deck.

Owner:SOUTHEAST UNIV

Hot-distribution rubber bituminous pavement and construction method thereof

InactiveCN101982610AImprove adhesionAvoid enteringIn situ pavingsSolid waste managementInter layerChipseal

The invention discloses hot-distribution rubber bituminous pavement and a construction method thereof. The construction method comprises the following steps: 1, cleaning a lower bearing layer; 2, preparing rubber asphalt; 3, distributing the rubber asphalt, namely, uniformly distributing a rubber asphalt layer on the lower bearing layer, wherein the distribution amount of the rubber asphalt is 2.2 to 2.6 kg / m<2>, and the distribution temperature is 180 to 190 DEG C; 4, distributing broken stone with an amount which is 60 to 70 percent based on the distribution area of the rubber asphalt, wherein the distribution temperature of the broken stone is not lower than 80 DEG C; and 5, rolling and forming, namely, rolling and forming a rubber asphalt waterproof adhesive layer by a rubber-tire pavement roller following a broken stone distribution vehicle, wherein the rubber-wire pavement roller rolls the pavement once to twice back and forth. The construction method of the invention can enhance the inter-layer adhesive performance, prevent water penetration, effectively absorb and eliminate inter-layer stress and reduce reflection cracks caused by the conventional bituminous pavement, and can be applied to the projects of building and rebuilding bituminous pavement, pavement of bituminous concrete bridge floor, bituminous overlaying of cement concrete pavement and the like.

Owner:BEIJING ROAD & BRIDGE CONSTR GROUP +2

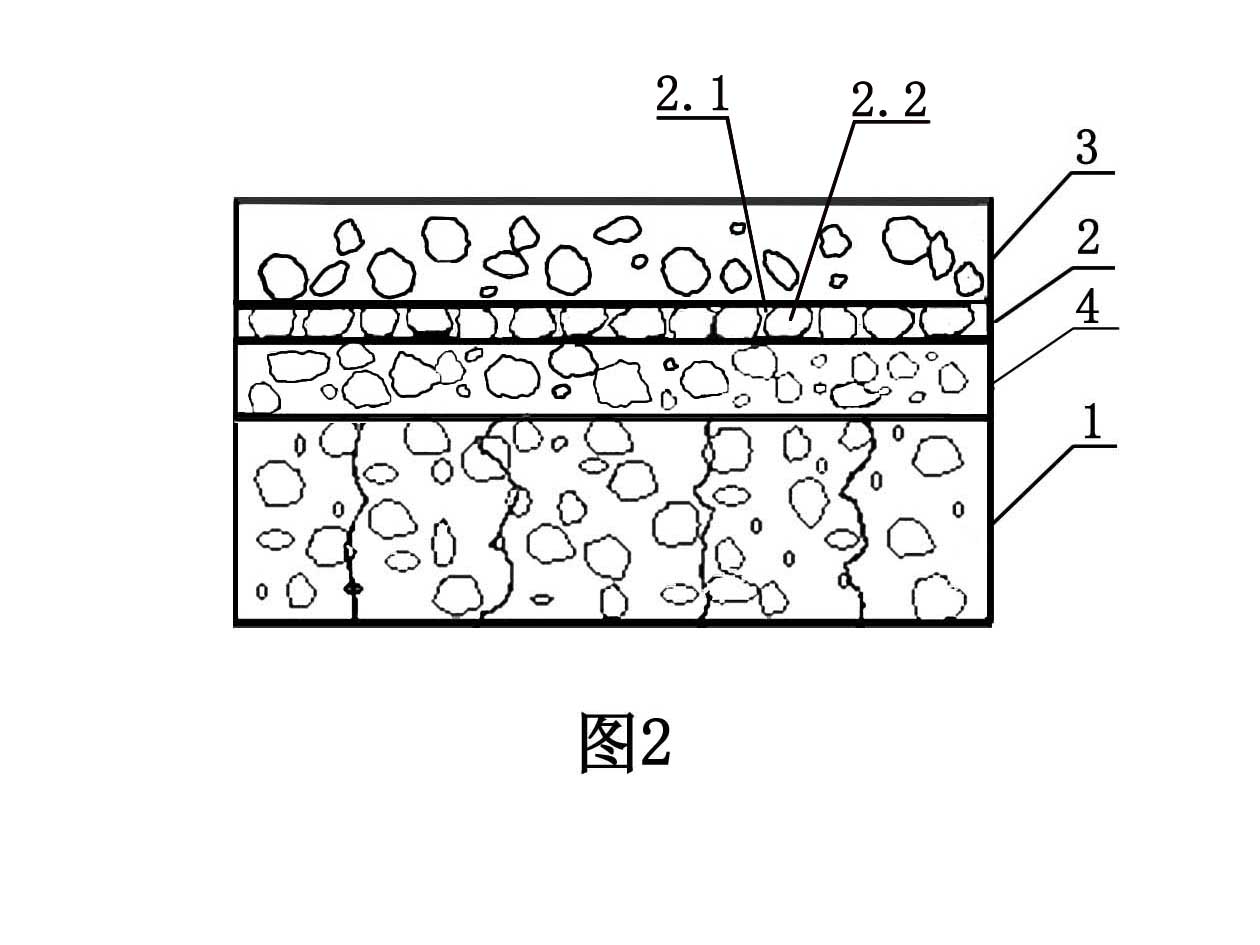

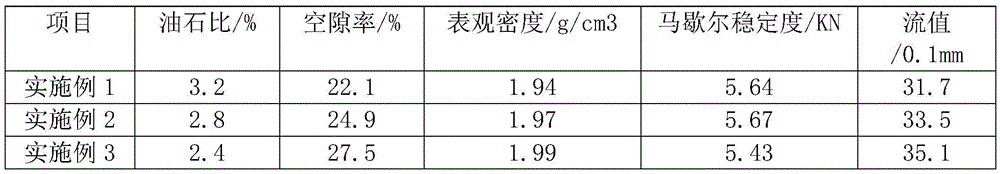

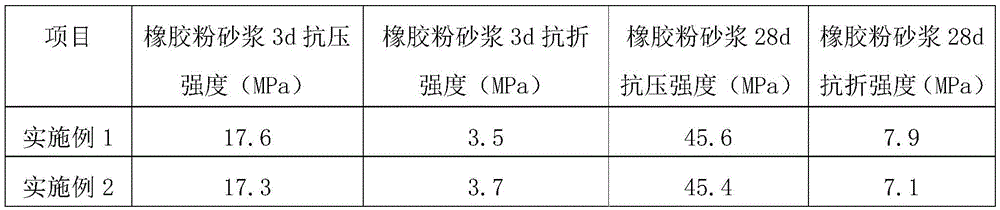

Semi-flexible composite pavement structure and preparation method thereof

The invention provides a semi-flexible composite pavement structure and a preparation method thereof. The semi-flexible composite pavement structure comprises components in percentage by weight as follows: 70%-80% of a macro-porous asphalt mixture matrix and 20%-30% of rubber powder cement mortar; the macro-porous asphalt mixture matrix is prepared firstly, then the rubber powder cement mortar is prepared, the rubber powder cement mortar is poured into a mixture gap of the macro-porous asphalt mixture matrix finally, and a product can be utilized after maintenance. According to the semi-flexible composite pavement structure, the defects of asphalt pavements and cement concrete pavements in China at present are overcome, rigidity of the cement concrete pavements and the flexibility of the asphalt pavements are integrated, the respective advantages of rigid and flexible pavement structures can be sufficiently played, the respective defects of the rigid and flexible pavement structures are overcome, and the semi-flexible composite pavement structure is a novel pavement structure with better pavement performance and higher cost performance.

Owner:广西交通职业技术学院

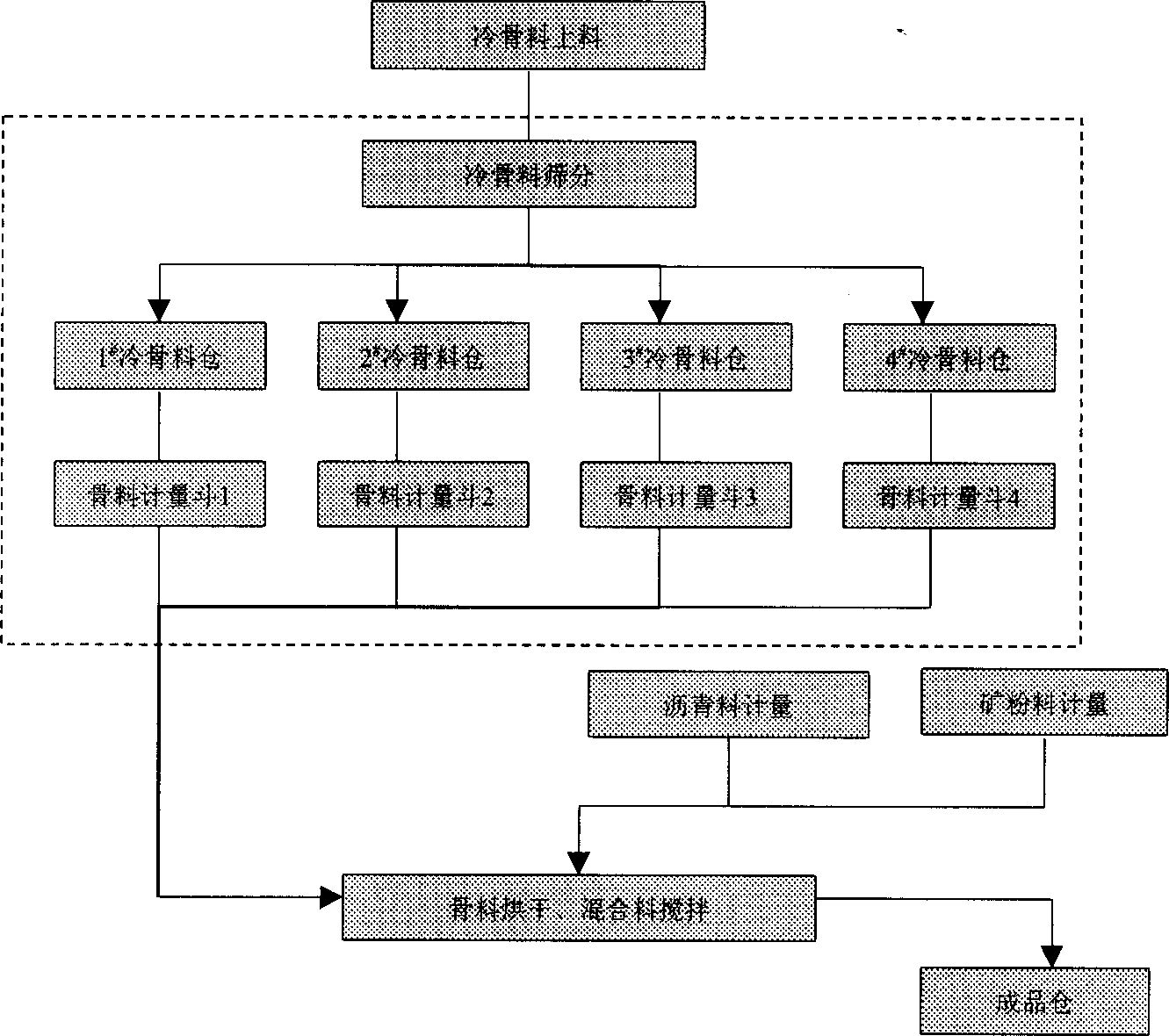

Cold aggregate batching treatment method and device for continuous bituminous concrete mixing equipment

InactiveCN1371791AQuality improvementReasonable gradationSievingScreeningSurface constructionRoad surface

The present invention relates to a cold aggregate batching treatment method for continuous-stirring equipment of bituminous concrete for highroad surface construction and asphalt parement regeneration engineering, and is characterized by that before the cold aggregate is continuously metered, firstly, said cold aggregate is passed through sieving machine to implement pregradation, then continuously metered by means of metering device then fed into continuous bituminous concrete stirring equipment and its next stoving procedure.

Owner:袁国琴

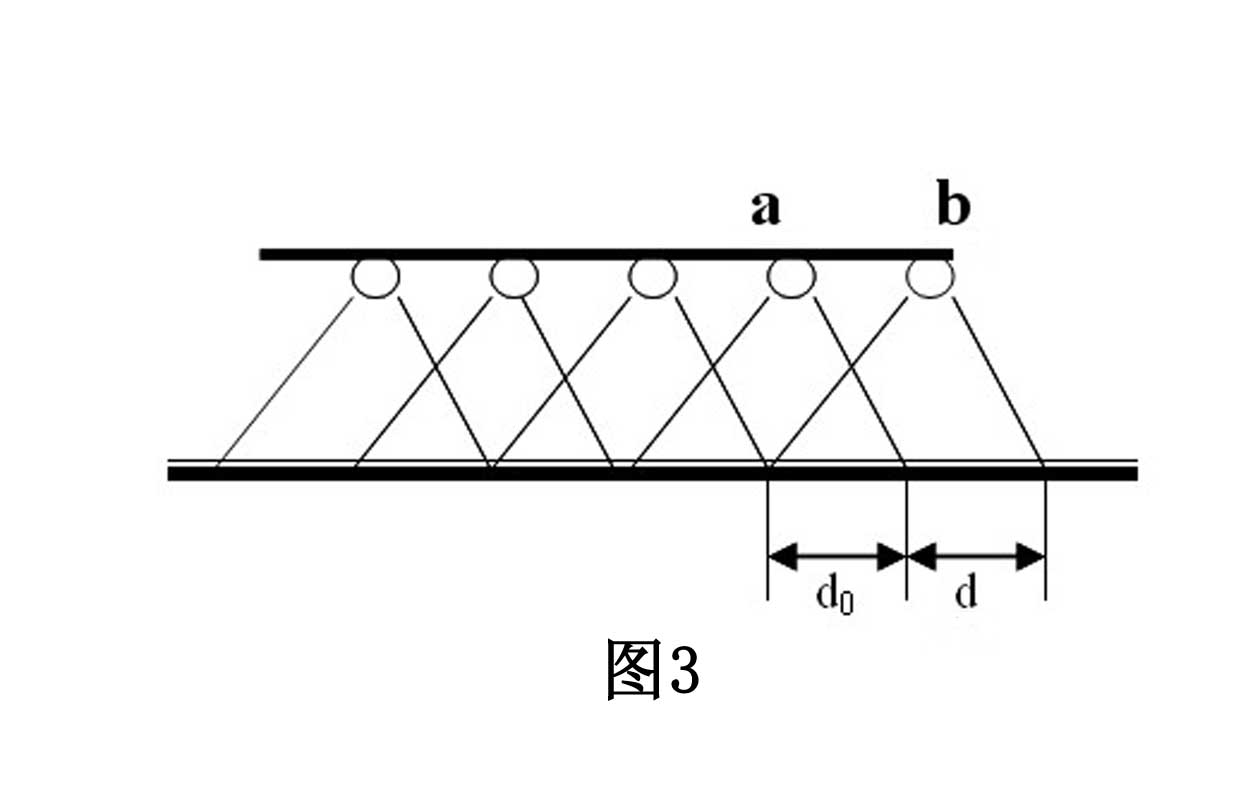

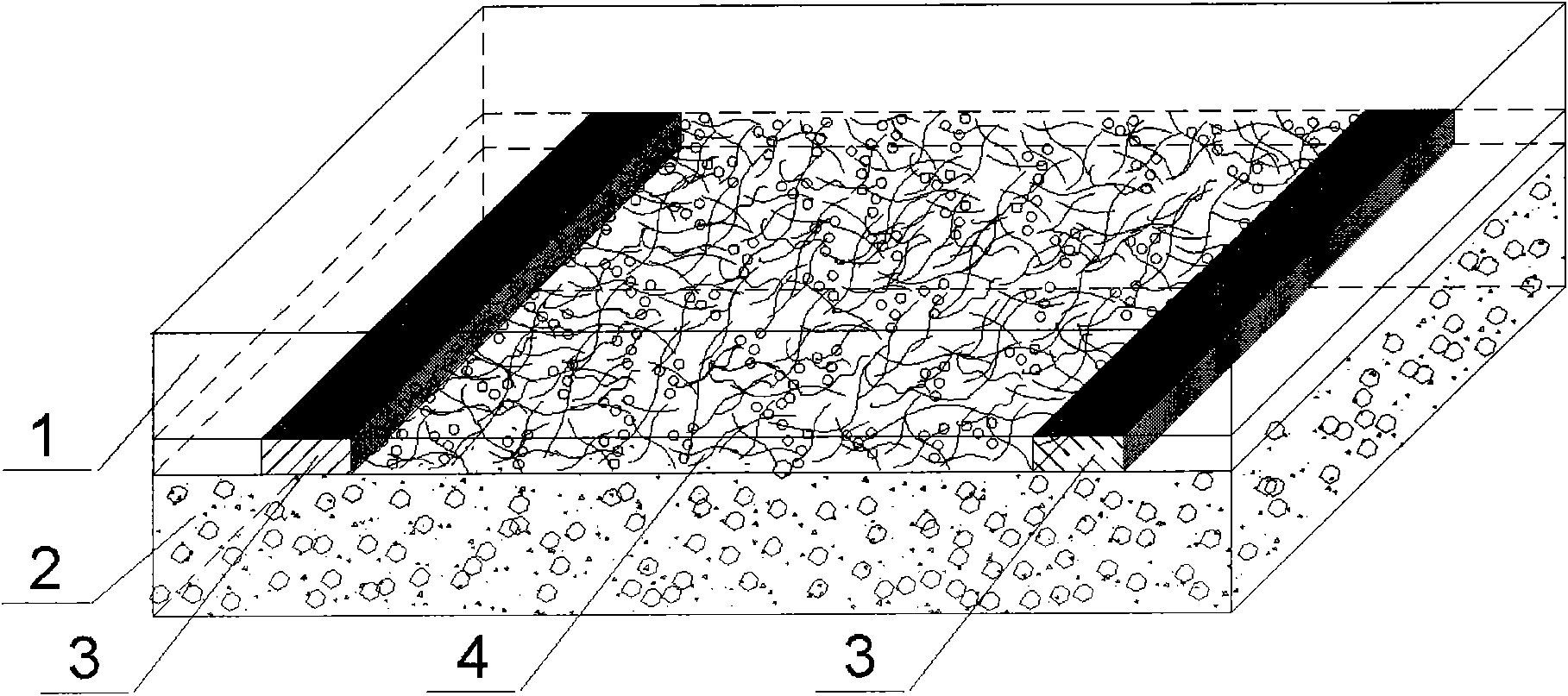

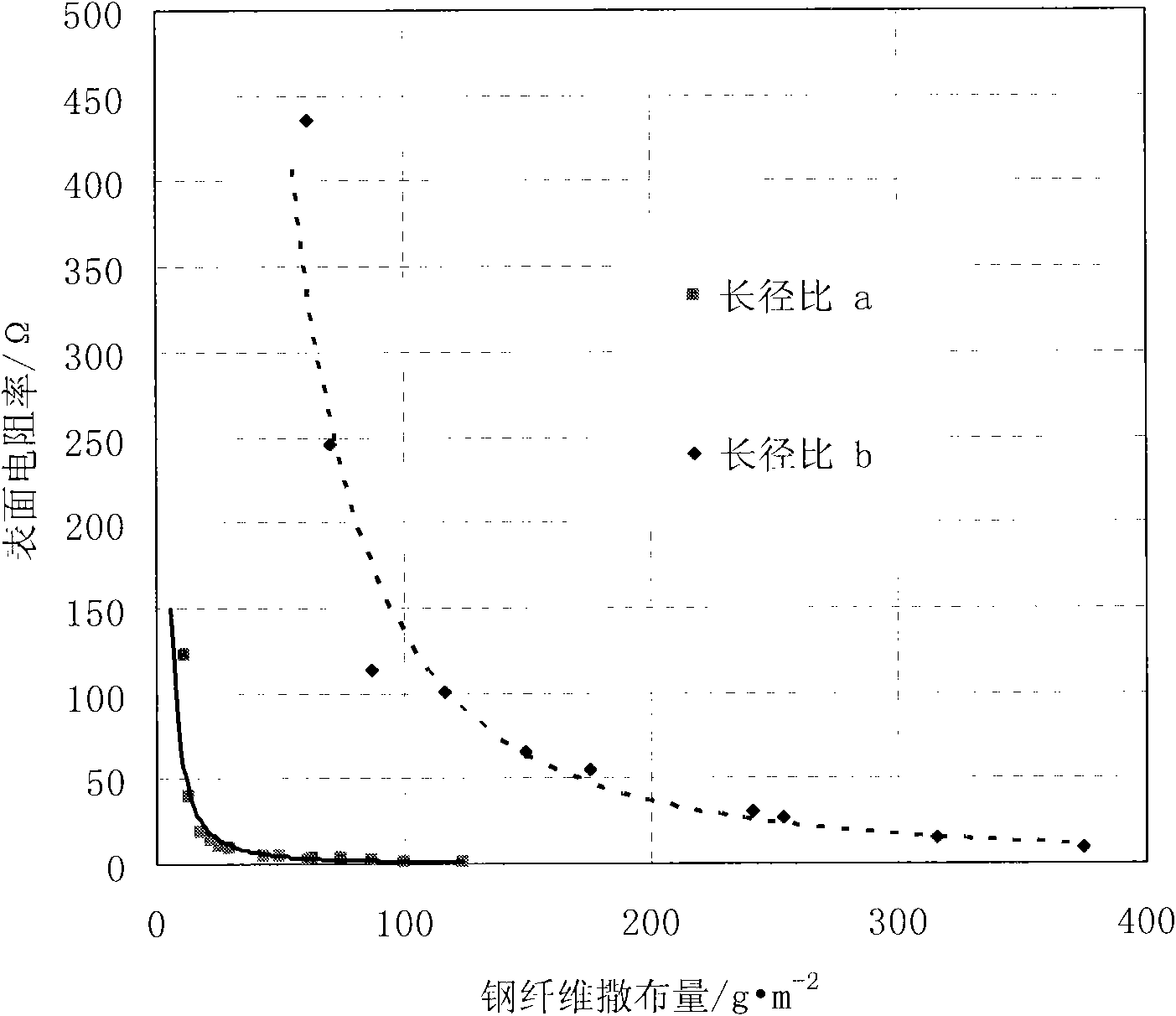

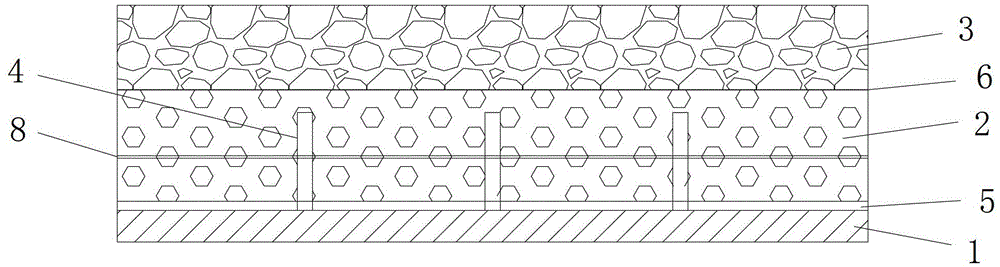

Layered steel fiber conductive bituminous concrete

ActiveCN101806028ALow costImprove conductivityIn situ pavingsPaving detailsCrack resistanceMetallurgy

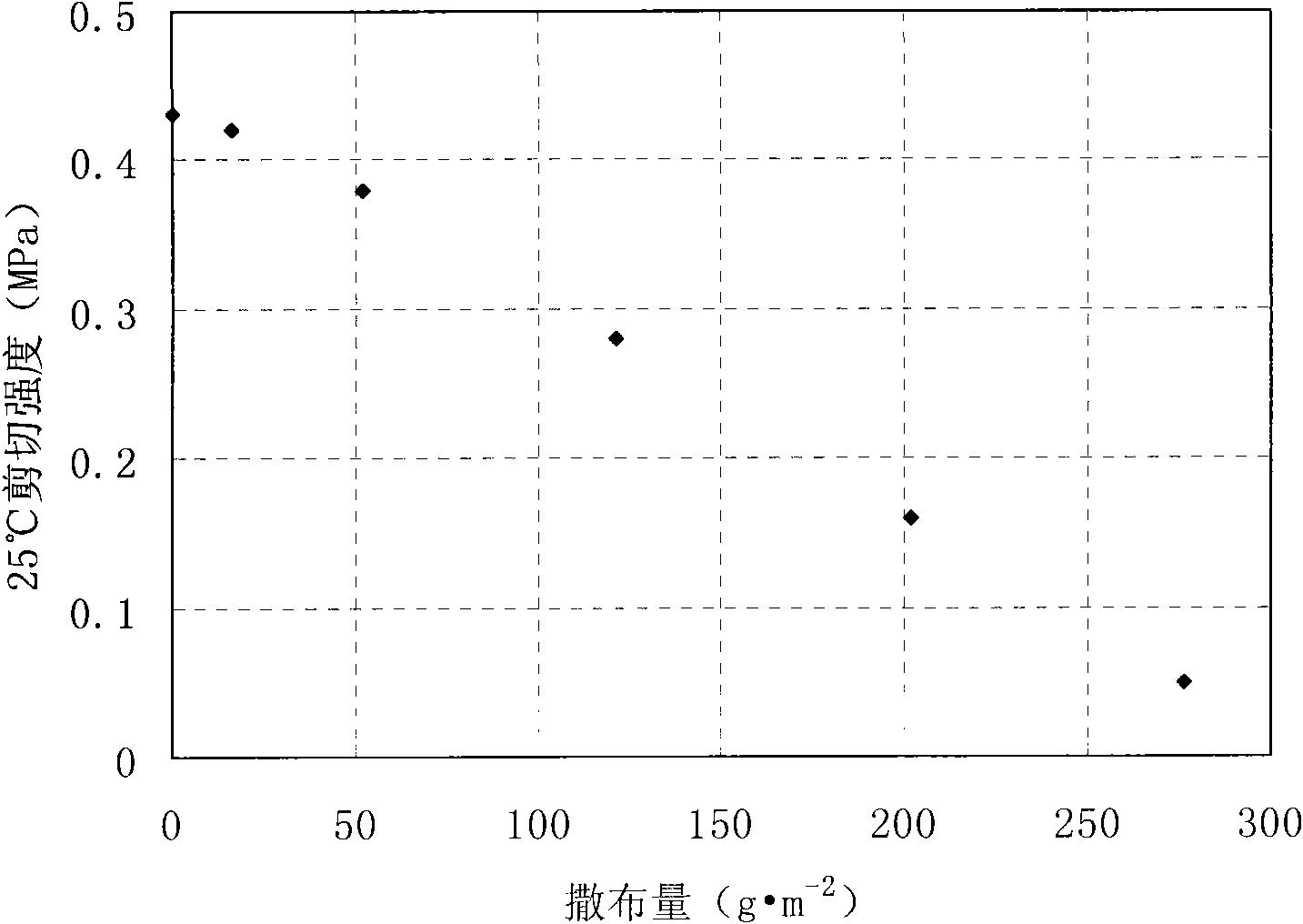

The invention relates to a steel fiber bituminous concrete, in particular to a layered steel fiber conductive bituminous concrete. The layered steel fiber conductive bituminous concrete is characterized by comprising a bituminous concrete pavement, a steel fiber layer and a lower bearing layer which are sequentially arranged from top to bottom, wherein electrodes are embedded in the steel fiber layer; the steel fiber layer consists of steel fiber and conductive emulsified asphalt and is uniformly paved on the surface of the lower bearing layer with a spreading method, the conductive emulsified asphalt is sprayed on the steel fiber, the spreading amount of the steel fiber is 170-330g / m<2>, and the spraying amount of the emulsified asphalt is 0.6-0.81g / m<2>. The invention has the characteristics of low cost of construction, simple and convenient construction, easy control of quality and favorable conductive performance, and meanwhile, the high-temperature stability and the low-temperature crack resistance are improved. The layered steel fiber conductive bituminous concrete is applied to deicing and snow melting of bituminous pavements and self-healing or heat repairing of the diseases of bituminous pavements.

Owner:武汉理工大产业集团有限公司

Method for preparing bituminous concrete pavement anti-rutting agent from directly-liquefied coal residue

The invention discloses a method for preparing a bituminous concrete pavement anti-rutting agent from directly-liquefied coal residue, comprising the following steps: respectively crushing directly-liquefied coal residue, petroleum asphalt and polyethylene into lump materials with the grain diameter smaller than 5mm; fully mixing the following components by weight percent: 30-55% of the directly-liquefied coal residue, 5-10% of the petroleum asphalt, 33-64.5% of the polyethylene and 0.5-2% of polyethylene wax; and adding the mixed raw materials in a screw extruder, mixing in the temperature range of 120-240 DEG C, and extruding the mixed materials into strip anti-rutting agent; and cooling the extruded and formed strip anti-rutting agent by utilizing a normal temperature water cooling tank, and adopting a plastic pelletizer for cutting to obtain the anti-rutting agent in a solid grain state with the grain diameter of 2-5mm. The anti-rutting agent in the invention can obviously improve the anti-rutting performance of bituminous pavement, has low cost, and can realize the purposes of waste recycling, energy conservation and emission reduction.

Owner:CHANGAN UNIV

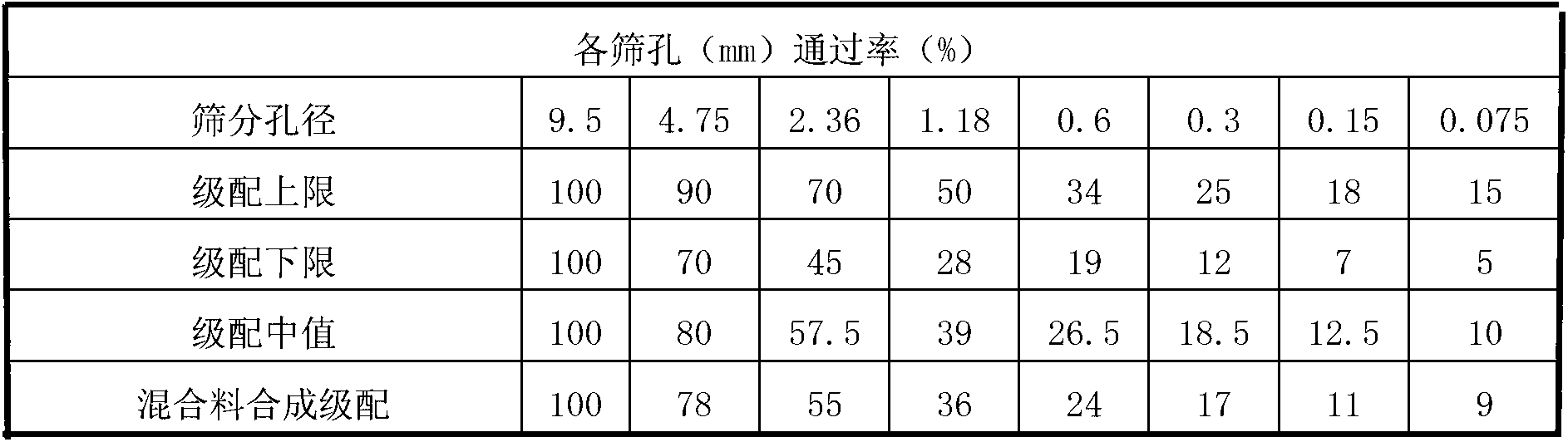

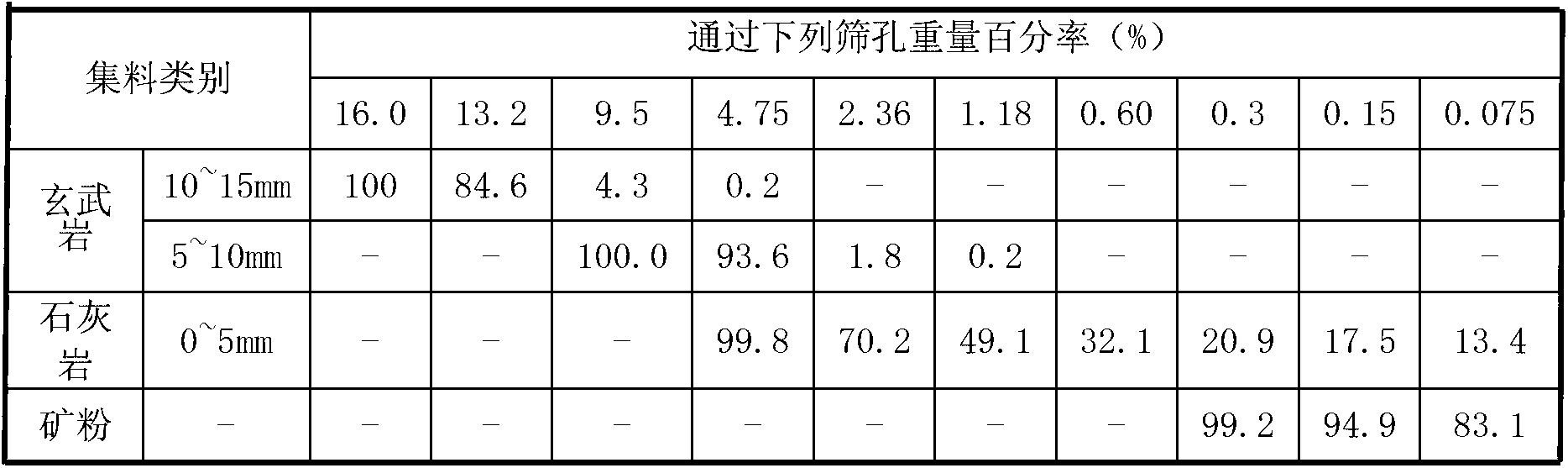

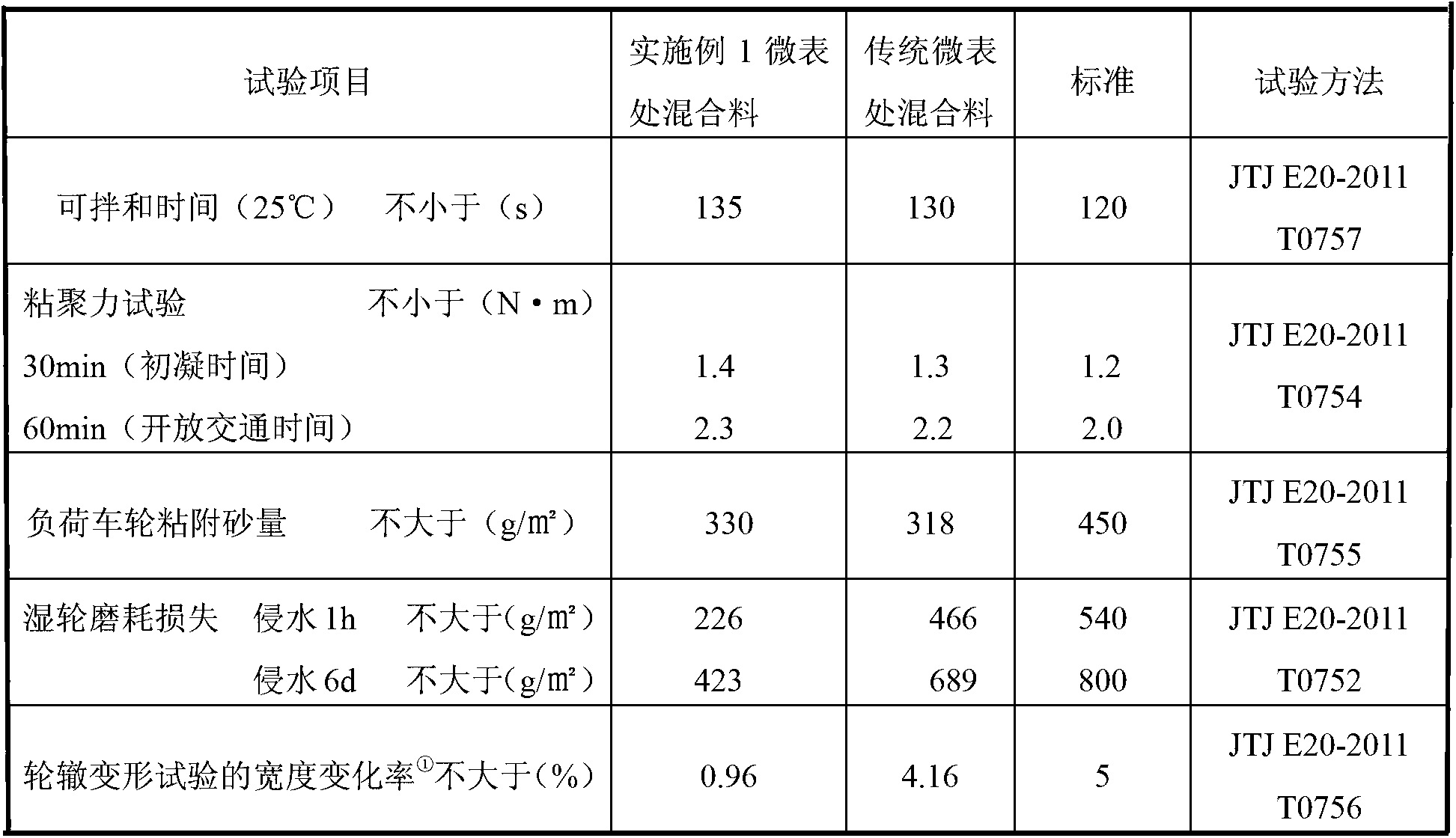

Micro-surfacing mixture

InactiveCN103073232AOvercome high temperature stabilityOvercoming poor low temperature crack resistancePolymer scienceBitumen emulsion

Owner:重庆市智翔铺道技术工程有限公司

Bituminous pavement automatic repairing device for bituminous concrete road

InactiveCN107489087ANo manual operationReduce labor intensityRoads maintainenceRoad surfaceUltimate tensile strength

The present invention relates to an asphalt pavement automatic repair equipment for asphalt concrete roads, comprising a cutting device, a material conveying and rolling moving device, a crushing device and a grabbing device, and the cutting device is installed on the upper end of the conveying and rolling moving device On the front side of the conveyor, a crushing device is installed on the right side of the upper end of the material conveying rolling mobile device, and a grabbing device is installed on the upper left side of the material conveying rolling mobile device. The present invention can solve the problem that in the process of repairing the ground on the existing asphalt road, the waste materials are dug away manually and then grouted and rolled. There are deviations in the manual marking and cutting of the staff, and there are safety hazards at the same time. The construction personnel shatter the ground with the help of tools At the same time, the dead corner areas on the four sides cannot be completely shattered, and the surrounding small areas cannot be fully excavated. People use existing tools to grout the construction area and then use rolling props to roll the ground. The work is labor intensive and efficient. Low-level problems can realize the automatic repair function of asphalt pavement.

Owner:丁建丽

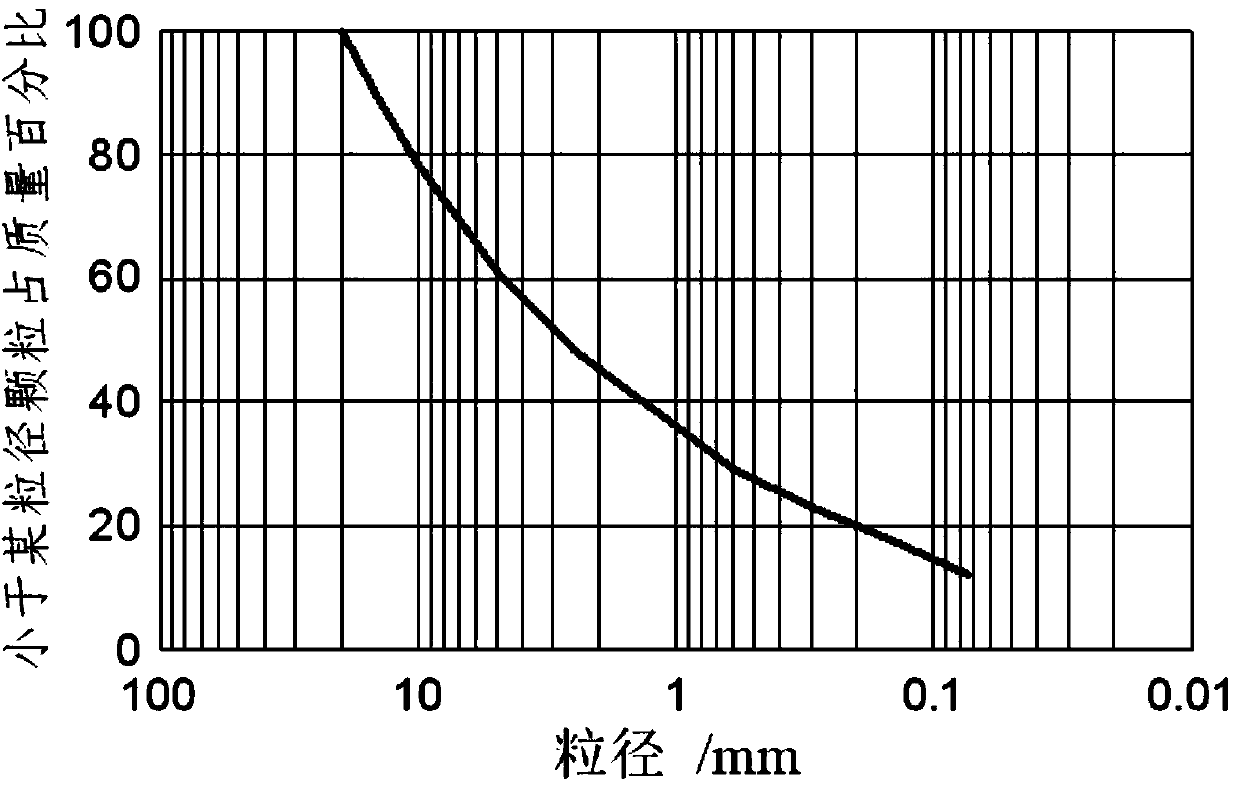

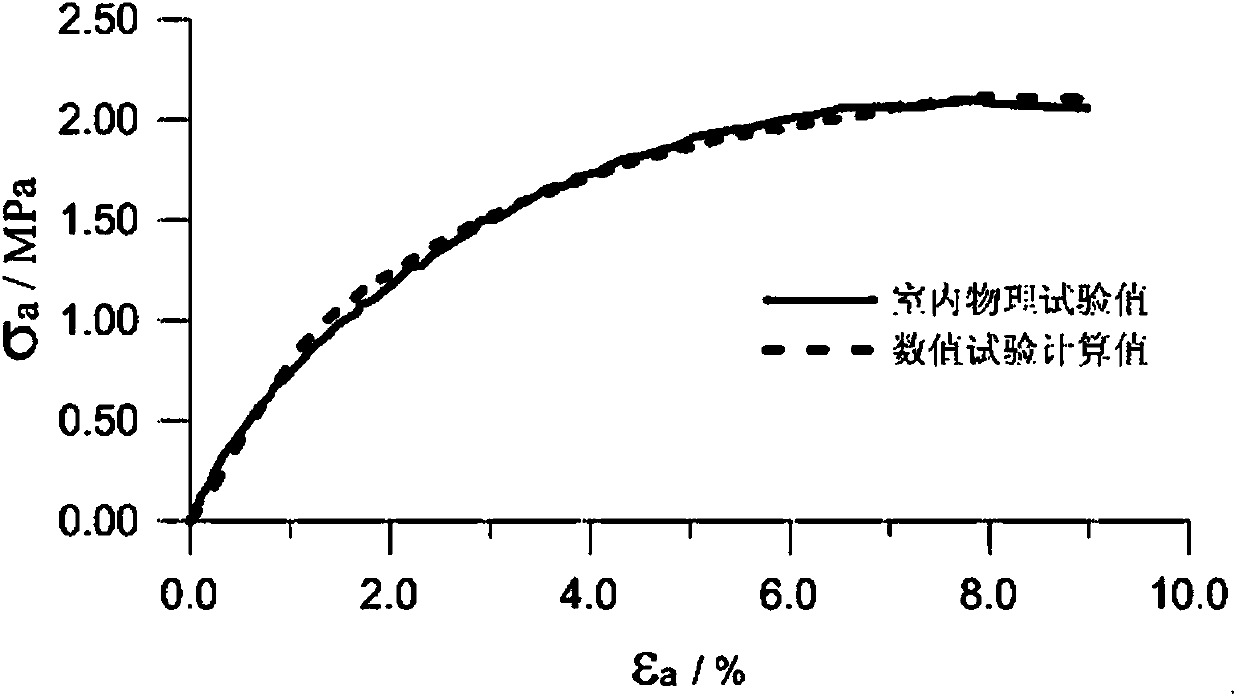

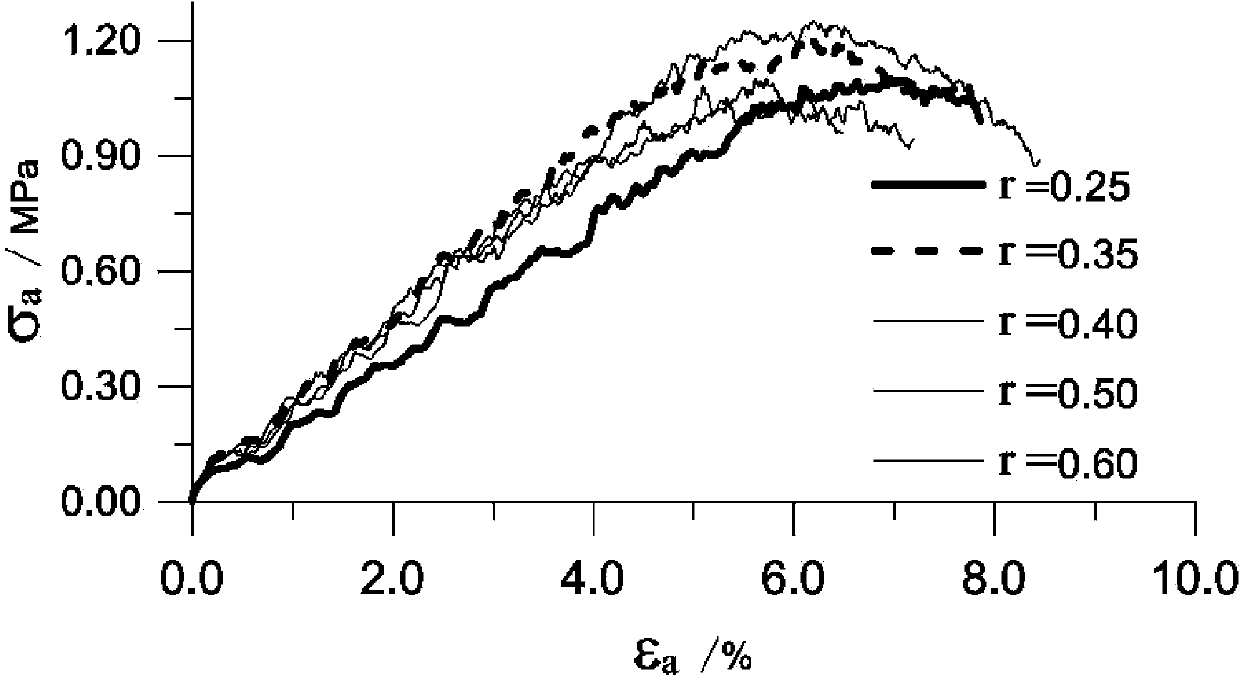

Method for building numerical simulation model of hydraulic engineering asphalt concrete

InactiveCN103605841AObjectively evaluate the quality of on-site constructionSmall discreteSpecial data processing applicationsTest sampleArchitectural engineering

The invention discloses a method for building a numerical simulation model of hydraulic engineering asphalt concrete. The method includes steps of 1, manufacturing hydraulic engineering asphalt concrete test samples with a required mixture ratio, and actually measuring stress-strain curves of the various hydraulic engineering asphalt concrete test samples; 2, acquiring internal microstructures of the hydraulic engineering asphalt concrete test samples and building an initial numerical simulation model corresponding to the hydraulic engineering asphalt concrete test samples according to the internal microstructures; 3, using the stress-strain curves obtained in the step 1 as targets to adjust microcosmic parameters of the initial numerical simulation model by an optimization inversion process, enabling actually measured stress-strain curves to be matched with the stress-strain curves which are acquired by means of computation by the aid of the numerical simulation model so as to obtain the numerical simulation model of the hydraulic engineering asphalt concrete with the mixture ratio. The invention further discloses a method for determining the optimal mixture ratio of the hydraulic engineering asphalt concrete and a method for evaluating the construction quality of the hydraulic engineering asphalt concrete.

Owner:HOHAI UNIV

Fire-retardant modified asphalt material and preparing method

InactiveCN101024727AImprove flame retardant performanceGood high and low temperature performanceBuilding insulationsEmulsionCrack resistance

The invention relates to a inflaming retarding modification pitch material that includes ground substance pitch, rubber modification agent and inflaming retarding modification agent. It adopts high speed shear mixing emulsion machine to make inflaming retarding modification pitch material that includes the following steps: dehydrating for 30min at 110 degree centigrade, heating to 175 degree centigrade, adding SBS, cutting for 10min, and adding inflaming modification agent and cutting for 5min. The invention has the advantages of high temperature stability, low temperature crack resistance, good covering ability to stone, and good anti-aging and excellent inflaming retarding ability.

Owner:重庆市智翔铺道技术工程有限公司

Municipal road and construction method thereof

ActiveCN108867220AImprove compactnessGuaranteed compaction densityIn situ pavingsClimate change adaptationRoad engineeringBituminous concrete

The invention discloses a construction method for a municipal road, and belongs to the field of the road engineering. A technical scheme is that the construction method comprises the following steps:positioning and paying off, excavating a roadbed groove, backfilling the roadbed groove, paving and bedding, laying a cement stabilization layer, spraying emulsified asphalt, laying a modified asphaltconcrete pavement, processing a construction joint, and maintaining the road. The invention further provides the municipal road obtained by the above construction method. The provided municipal roadhas the advantages of small interspaces between various layers, uniform sedimentation, and less generated cracks.

Owner:四川先舟建设工程有限公司

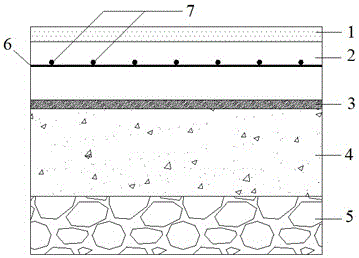

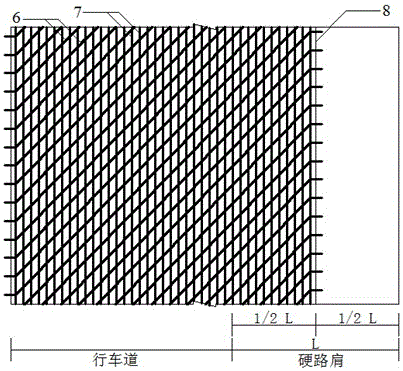

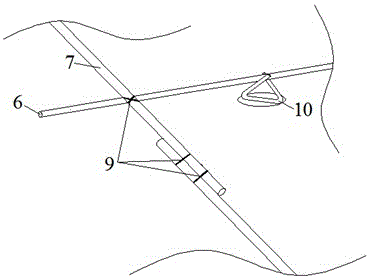

Cement concrete pavement structure provided with continuous steel bars

ActiveCN104988823AReduce maintenance and repair costsGood driving comfortPaving reinforcementsIn situ pavingsRoller-compacted concreteCrushed stone

The invention discloses a cement concrete pavement structure provided with continuous steel bars. The pavement structure comprises a base layer. Roller compacted concrete is adopted in the base layer. A broken stone hardcore is laid below the base layer. Cement concrete surface layers are laid on the base layer. The cement concrete surface layers include the upper surface layer and the lower surface layer. Rubber cement concrete is adopted in the upper surface layer. A transverse induction kerf is arranged on the edge of the upper surface layer on the left side of the driving direction. The continuous transverse steel bars, the continuous longitudinal steel bars and a slidable support are arranged at the portion, within the range of a carriageway and one half of the width (L) of a hardened verge, of the lower surface layer. Plain concrete is formed at the portion, within the other half of the width (L) of the hardened verge, of the lower surface layer. A longitudinal joint is arranged at the portion one half of the width of the hardened verge. A bituminous concrete anti-scouring layer is arranged between the base layer and the surface layers. The pavement structure can solve the problems of existing cement concrete pavements and continuous reinforced concrete pavement structures and can be widely applied to high-grade highways, tunnel pavements and the like on the heavy-duty traffic condition.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Structure of felting bridge floor made from steel box girder in large span

InactiveCN1563588AMeet the loadMeet temperature requirementsBridge structural detailsLong spanBituminous concrete

This invention is a structure of long span steel beam and its pave method. It is especially use to pave the bridge directly with the different nature steel plate on the bridge surface. This structure is: the higher layer is epoxy pitch cement, lower layer is pouring pitch cement, on the steel beam bridge surface is water-proof layer, on the layer is lower binding layer, on the lower binding layer is pouring pitch cement layer, on the layer, is higher binding layer, on the layer is epoxy pitch cement. The steps of pavement are: a) Sprinkling water-proof layer on the cleaned and anti-corroded steel bridge surface plate; b) Sprinkling lower binding layer; c) Spread out the mixture pitch materials on; d) Sprinkling higher binding layer; e) Spread out higher layer of epoxy pitch cement; f) When the degree of solidify intensity of epoxy pitch cement reach to 85%, the natural maintained for the steel bridge surface sprinkling are finished.

Owner:SOUTHEAST UNIV

Mobile asphalt production machine

A mobile asphalt production machine mixes bituminous concrete at the job site through a mixing auger mechanism mounted in an insulated housing. Propane burners provide heat within the mixing auger mechanism and within the insulated housing to produce a hot-mix bituminous concrete in large or small batches. The components of the asphalt mixture are stored in separate bins that can be re-filled at the job site to provide a continuous supply of asphalt. Hot liquid bitumen is added to heated aggregate within the mixing auger mechanism. Recycled asphalt can be added through a port in the mixing auger for incorporation into the mixture. Controls permit the rate of flow of each individual component to be selectively varied in order to change the recipe for the mixture and to provide calibration of the component, while a master control will maintain the pre-established flow rates through a variable speed of operation.

Owner:ZIMMERMAN HAROLD M

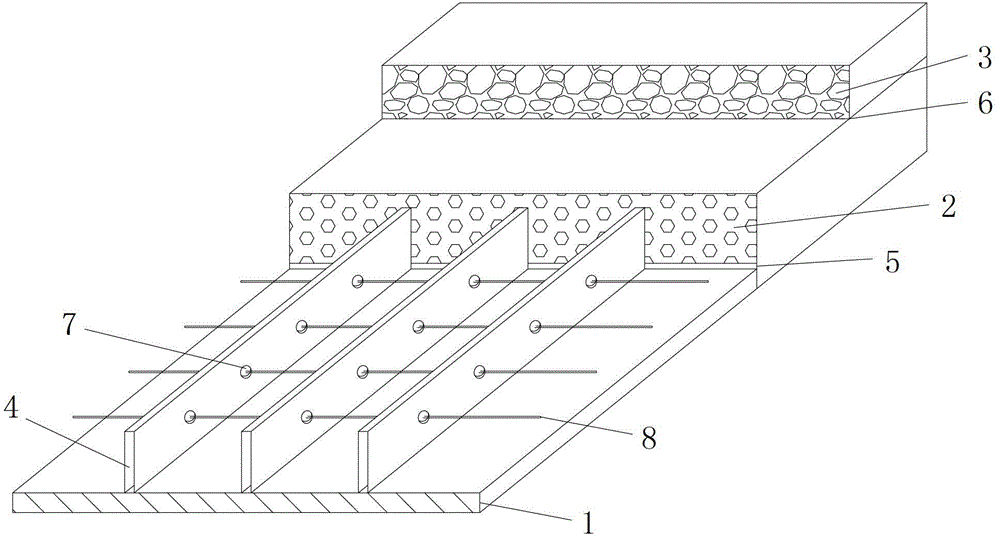

Steel deck composite pavement structure laying grid type shear connectors

InactiveCN102979037ASimple structureReasonable designPaving reinforcementsIn situ pavingsSheet steelSurface layer

The invention discloses a steel deck composite pavement structure laying grid type shear connectors. The steel deck composite pavement structure comprises a steel deck plate, a lightweight concrete lower surface layer laid on the steel deck plate and an asphalt concrete upper surface layer laid on the lightweight concrete lower surface layer, wherein a waterproof bonding layer is arranged between the lightweight concrete lower surface layer and the asphalt concrete upper surface layer; the grid type shear connectors are laid in the lightweight concrete lower surface layer, the grid type shear connectors comprise multiple longitudinal connectors which are laid in the longitudinal direction of a bridge and multiple transverse connectors which are laid in the transverse direction of the bridge, and the multiple longitudinal connectors are connected into a whole through the multiple transverse connectors; the longitudinal connectors are of long strip-shaped steel plates fixed on the steel desk plate and the transverse connectors are of steel bar bundles; and a plurality of holes are formed at the middle parts of the long strip-shaped steel plates from the front to the back. The steel deck composite pavement structure disclosed by the invention has the advantages of simple structure, reasonable design, simplicity and convenience in construction and good stress performance, and can solve the problems that an asphalt surface layer of the existing steel desk pavement structure is prone to rutting, slippage delamination, upheaval and the like.

Owner:CHANGAN UNIV

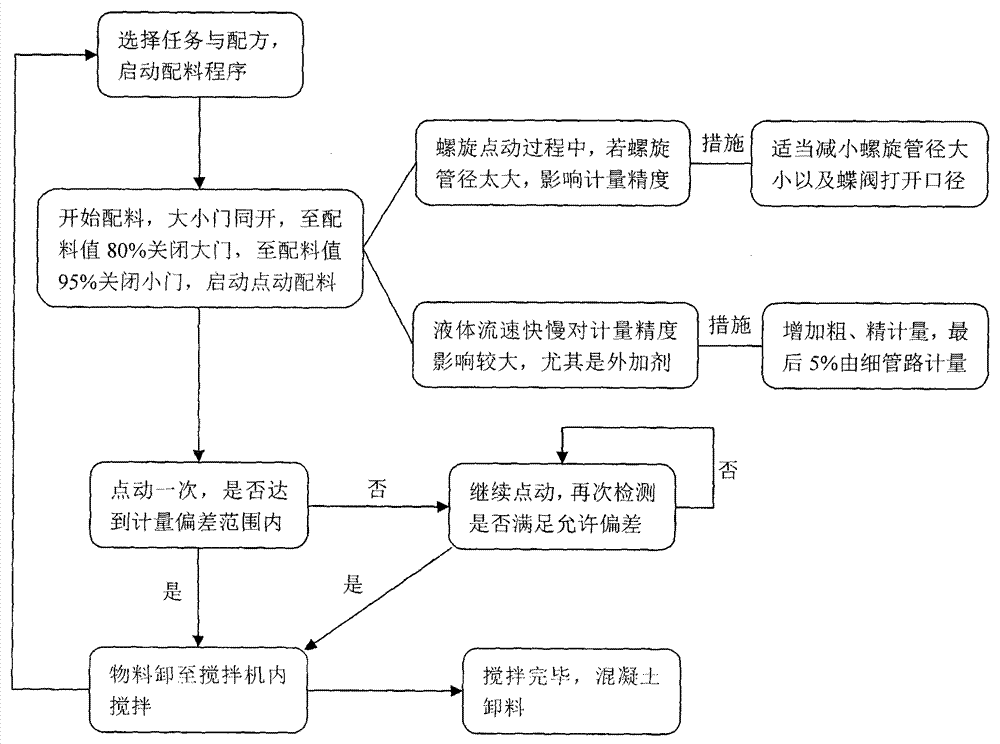

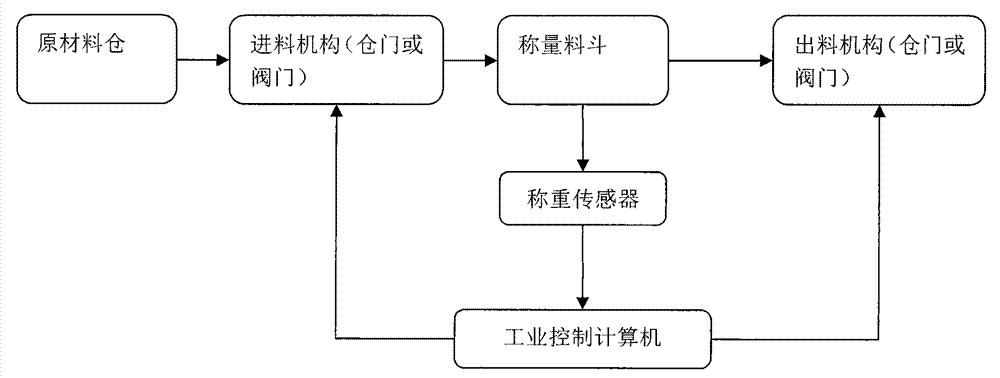

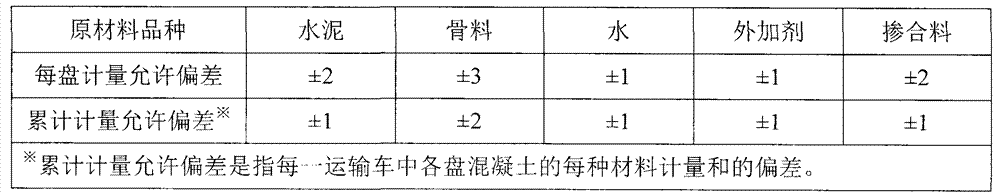

Dynamic control system and method for batching accuracy of concrete mixing plant

ActiveCN104260207AHigh precisionImprove stabilityMixing operation control apparatusIngredients proportioning apparatusAutomatic controlCycle control

The invention belongs to the technical field of concrete engineering and relates to a dynamic control system and method for the batching accuracy of a concrete mixing plant. The dynamic control system comprises a batching device, a weighing sensor, a batching instrument (namely a PLC) and an industrial control computer. According to the control system, dynamic weighing data which is acquired in real time is compared with an expected batching set value (namely a proportioning parameter), the unloading quantity is controlled in a stepped manner by the batching device by virtue of a rough weighing-fine weighing two-stage batching method, and the accurate batching is finished by carrying out inching control and automatically correcting real-time fall by virtue of a cycle control algorithm. The dynamic control system has the outstanding advantages of high batching accuracy and good stability and thus can be applied to concrete and bituminous concrete mixing plants in the field of civil engineering, the real-time automatic control can be realized, the automation degree of the mixing plants can be improved, the batching accuracy and reliability are improved, and the production quality of concrete is guaranteed.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Snow-melting and ice-breaking magnetic iron ore bituminous concrete surface layer and construction method thereof

InactiveCN101748673AIncreased durabilityImprove securityIn situ pavingsSolid waste managementSurface layerMicrowave

The invention relates to a snow-melting and ice-breaking magnetic iron ore bituminous concrete surface layer which comprises the following components by weight part: 100 of aggregate, 2-6 of mineral powder and 2-6 of asphalt, wherein the aggregate is formed by proportioning the following components by weight part: 10-75 of magnetic iron ore aggregate and 25-90 of common aggregate. The construction method comprises the following steps of prior pavement treatment, tack coat oil application, mixing and pavement, compaction and quality test to pave the magnetic iron ore bituminous concrete surface layer with a thickness of 2-6 cm. Through test, the magnetic iron ore bituminous concrete surface layer indicates that various road performance indexes of a structure layer completely conform to the standard requirements issued by the Ministry of Communications, and the microwave heat radiation capacity of the structure layer is strong. The magnetic iron ore bituminous concrete surface layer has the advantages of good road property, simple and convenient construction, low cost, safety, environment protection and the like and can be widely applied to bridges, airport roads, municipal roads, expressways and the like and quickly emit heat to melt sown and break ice under the microwave action.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com