Steel deck composite pavement structure laying grid type shear connectors

A technology for connecting parts and steel bridge decks, which is applied to the coagulation pavement, bridges, bridge parts and other directions laid on site, can solve the problems of rutting, wrapping, low tensile, shearing and compressive strength, etc. The effect of convenience, economy and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

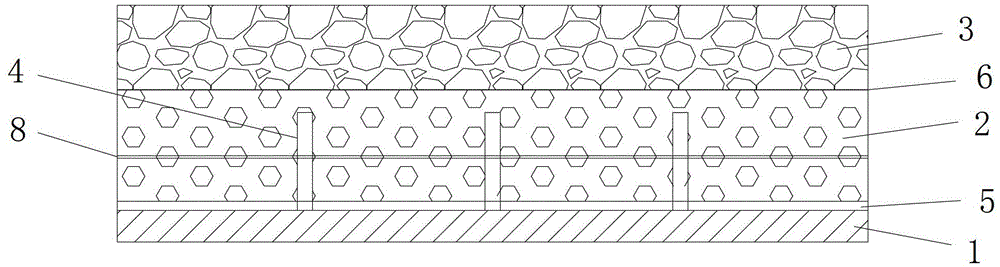

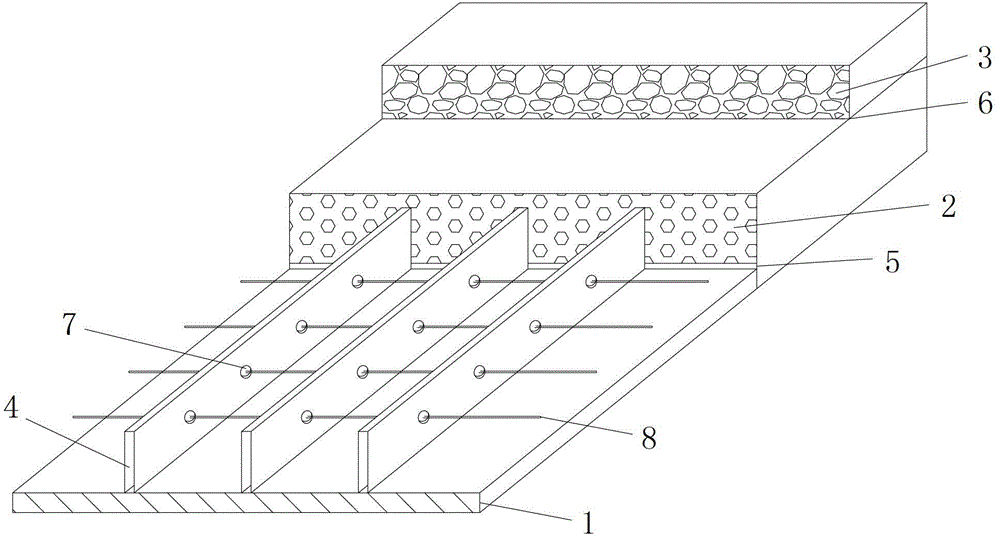

[0029] Such as figure 1 , figure 2 As shown, the present invention comprises a steel bridge deck 1, a lightweight concrete lower layer 2 laid on the steel bridge deck 1 and an asphalt concrete upper layer 3 laid on the lightweight concrete lower layer 2, and the lightweight concrete lower layer 2 A waterproof bonding layer 6 is arranged between the asphalt concrete upper layer 3 . The lower layer 2 of the lightweight concrete is provided with grid-type shear connectors, and the grid-type shear connectors include a plurality of longitudinal connectors arranged in the direction of the longitudinal bridge and a plurality of transverse connectors arranged in the direction of the bridge. Connecting parts, the plurality of longitudinal connecting parts are connected as a whole through a plurality of horizontal connecting parts. A plurality of the longitudinal connecting elements are arranged in parallel, a plurality of the transverse connecting elements are arranged in parallel, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com