Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

505 results about "Glass composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

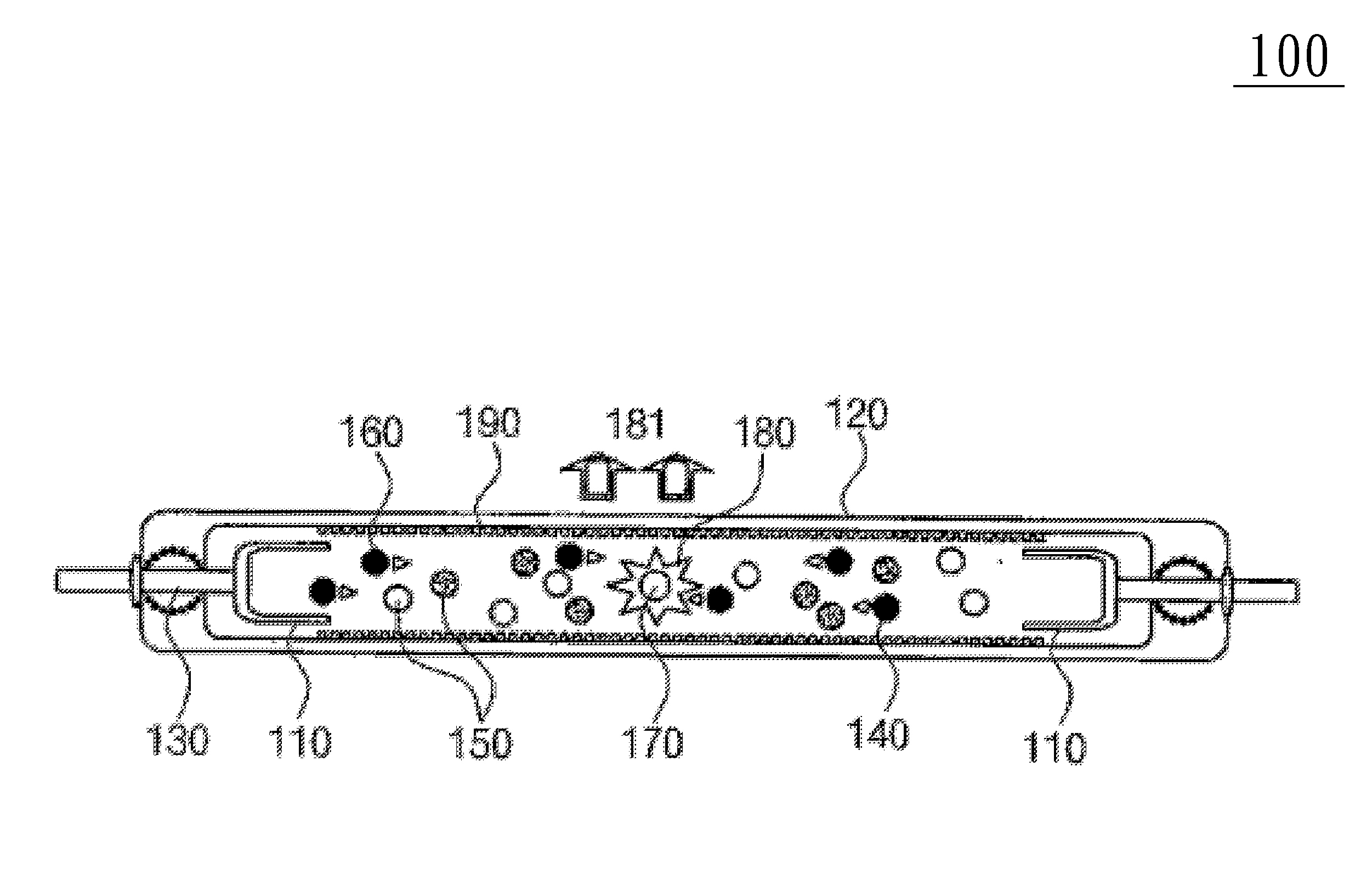

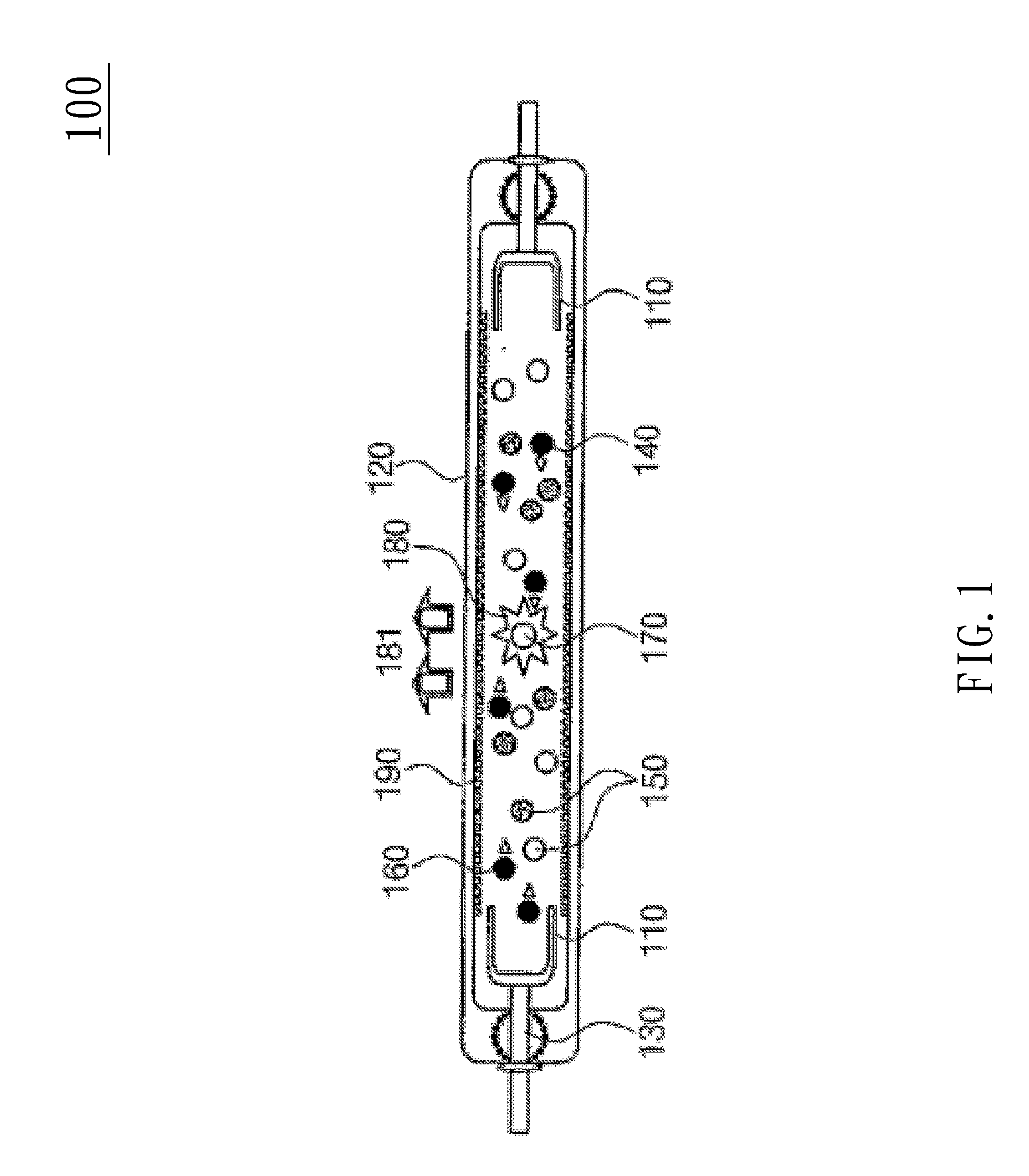

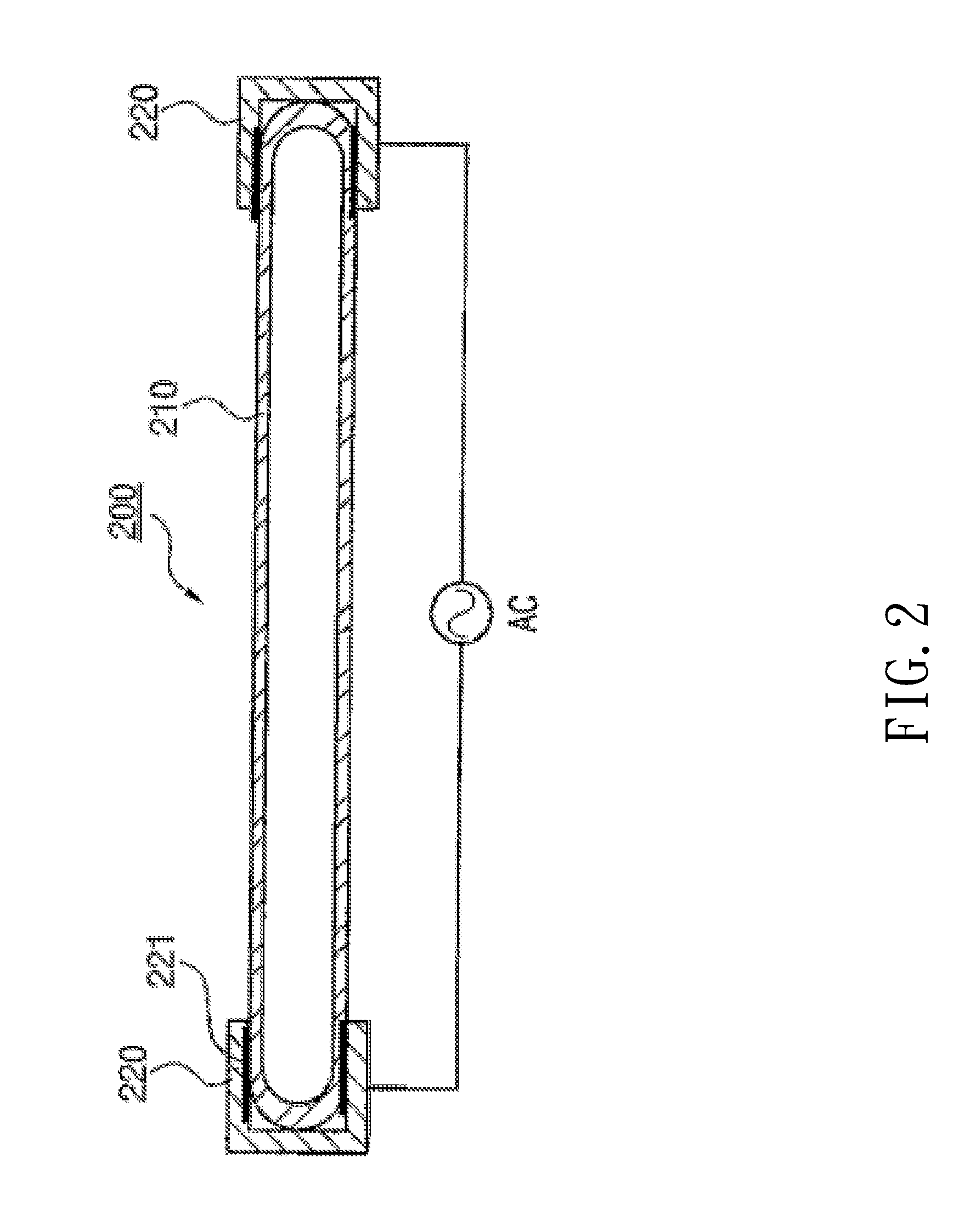

Ceramic-glass composite electrode and fluorescent lamp having the same

InactiveUS20120212121A1Low costSimple structureDischarge tube luminescnet screensLamp detailsGlass compositesAdhesive

The present invention provides a ceramic-glass composite electrode and a fluorescent lamp having the same. The ceramic-glass composite electrode according to the present invention is a ceramic-glass composite, which is disposed at the ends of a glass tube of the fluorescent lamp. A stopper is disposed at the end of the glass tube for pushing against the ceramic-glass composite electrode and limiting the position of the ceramic-glass composite electrode slipped on the glass tube. Thereby, flowing of adhesives into the glass tube is avoided when the adhesives are used for gluing the glass tube and the ceramic-glass composite electrode, and hence extending the lifetime of the fluorescent lamp.

Owner:SANTOMA

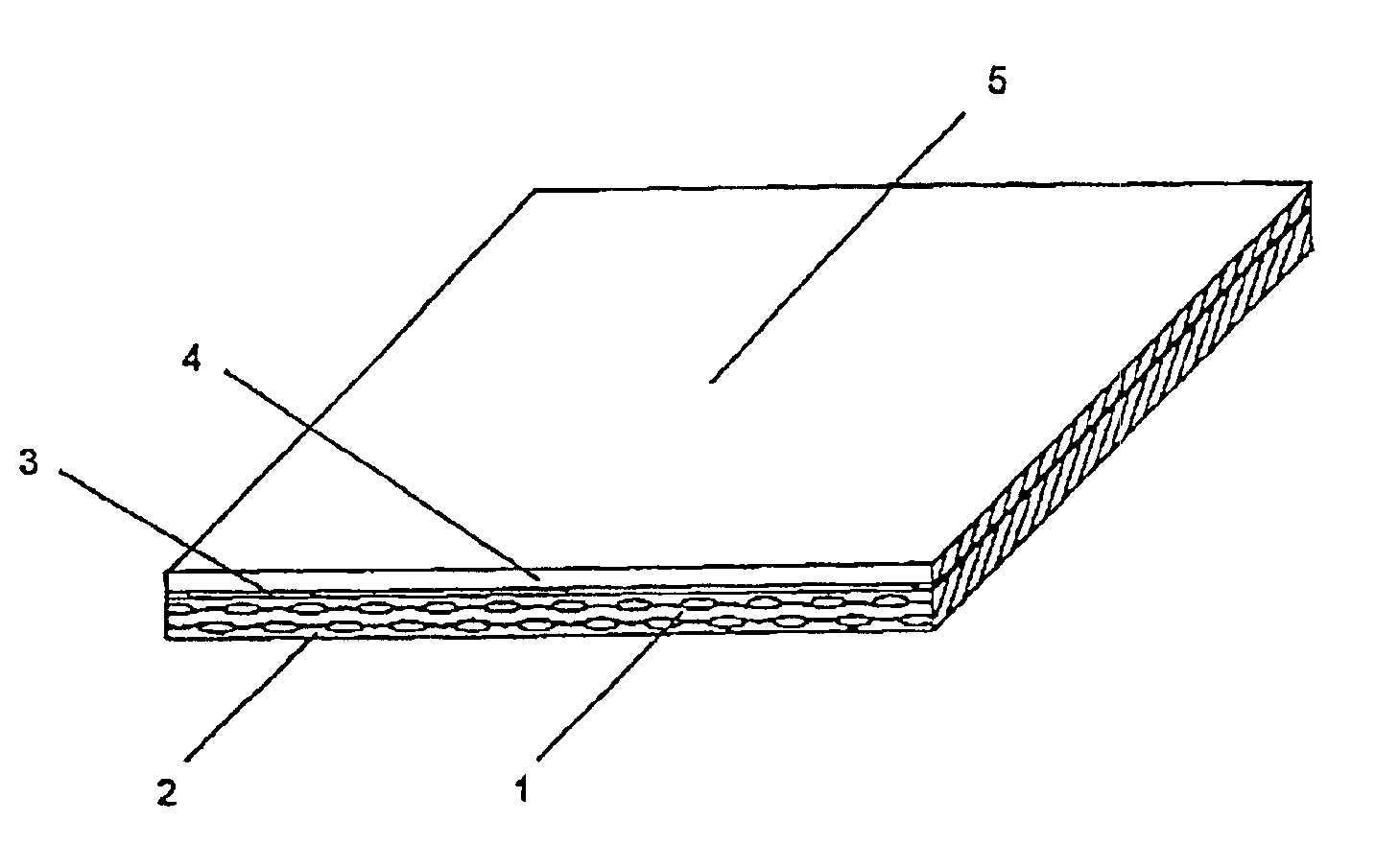

High-Strength Film Laminates Having Layers Of Plasticizer-Containing Polyvinyl (N)Acetal and Plasticizer-Containing Polyvinyl (Iso)Acetal

ActiveUS20130022824A1Improve mechanical propertiesHigh plasticizer compatibilitySynthetic resin layered productsGlass/slag layered productsArchitectural glassGlass composites

The invention relates to film laminates, formed from at least three layers A, B and C, each layer containing at least one plasticizer and at least one polyvinyl acetal, wherein, at least one of the layers A, B or C contains at least one polyvinyl (iso)acetal having a mean degree of polymerisation of less than 3000, 10 to 25% by weight of polyvinyl alcohol groups and a proportion 50 to 80% by weight of polyvinyl (iso)acetal groups, and wherein layer B has a plasticizer content of less than 32% by weight. The film laminates can be used for the production of glass / film laminate / glass composites for motor vehicles, aircraft, ships, architectural glazings, façade components, or for the production of photovoltaic modules.

Owner:KURARAY EURO GMBH

Amorphous metals and composites as mirrors and mirror assemblies

ActiveUS20130139964A1Reduce mirror costRobust scratch resistanceMolten spray coatingMirrorsGlass compositesOptical surface

Owner:CALIFORNIA INST OF TECH

High-strength film laminates having layers of plasticizer-containing polyvinyl (N)acetal and plasticizer-containing polyvinyl (ISO)acetal

ActiveUS8597792B2Improve mechanical propertiesGood compatibilitySynthetic resin layered productsGlass/slag layered productsArchitectural glassGlass composites

The invention relates to film laminates, formed from at least three layers A, B and C, each layer containing at least one plasticizer and at least one polyvinyl acetal, wherein, at least one of the layers A, B or C contains at least one polyvinyl (iso)acetal having a mean degree of polymerization of less than 3000, 10 to 25% by weight of polyvinyl alcohol groups and a proportion 50 to 80% by weight of polyvinyl (iso)acetal groups, and wherein layer B has a plasticizer content of less than 32% by weight. The film laminates can be used for the production of glass / film laminate / glass composites for motor vehicles, aircraft, ships, architectural glazings, façade components, or for the production of photovoltaic modules.

Owner:KURARAY EURO GMBH

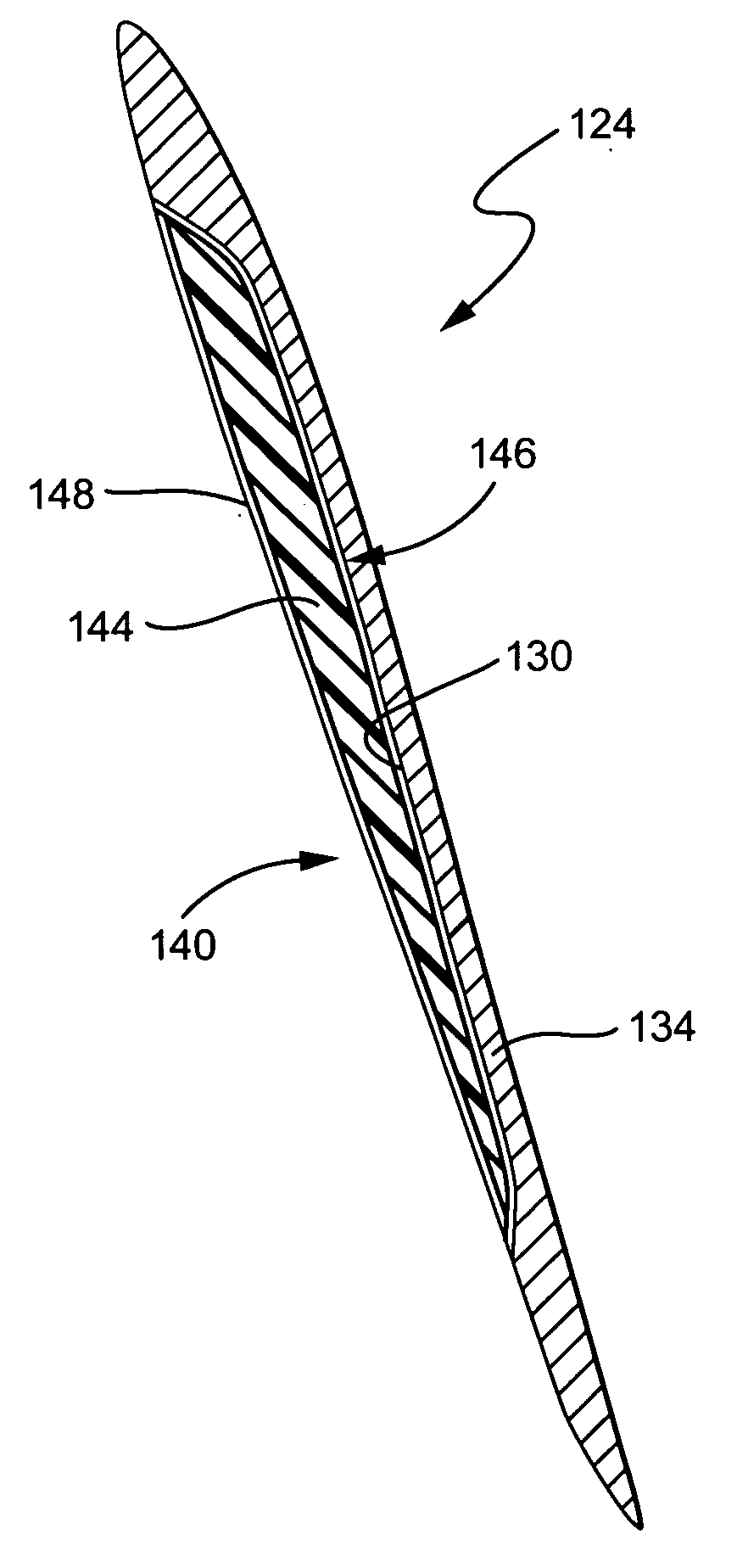

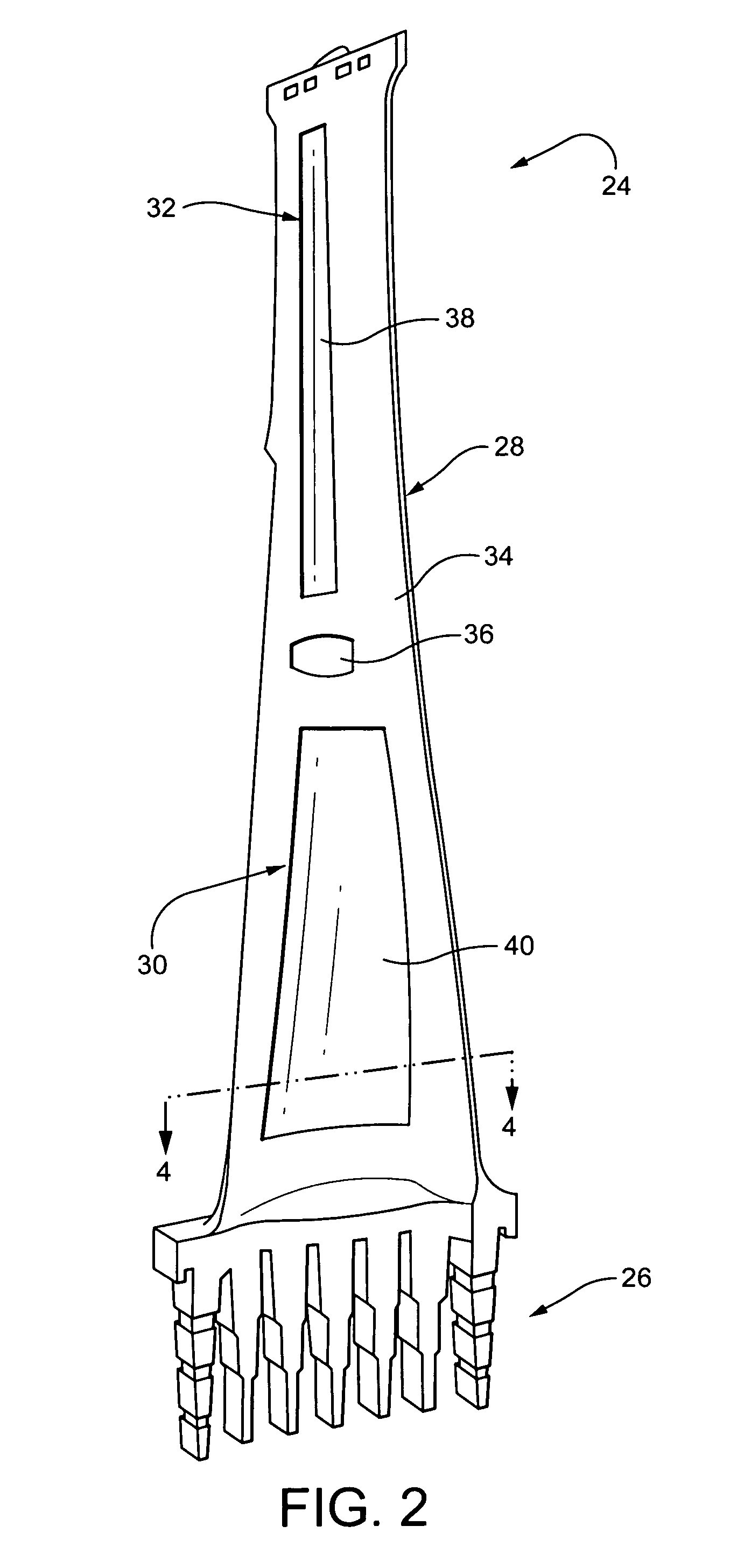

Hybrid blade for a steam turbine

To address certain deficiencies of carbon fiber material as a filler in a hybrid blade, a glass composite layer is provided as a barrier layer between a carbon fiber resin filler and the metallic main body of the blade. The glass composite layer also advantageously provides a gradient in thermal expansion between the carbon fiber composite and the body of the blade (steel) to reduce interfacial residual stress.

Owner:GENERAL ELECTRIC CO

Low boron containing microfiberglass filtration media

InactiveUS6933252B2Enhanced filtration performance characteristicSmall toleranceFibre treatmentSynthetic resin layered productsAir filtrationFiber

The present invention provides nonwoven glass composites formed from an essentially boron free glass wool and an essentially boron free chopped glass fiber, used as a reinforcing material. The nonwoven glass composites are suitable for air filtration apparatus and can be used in the semiconductor industry where the elimination of boron from clean rooms is of importance.

Owner:HOLLINGSWORTH VOSE

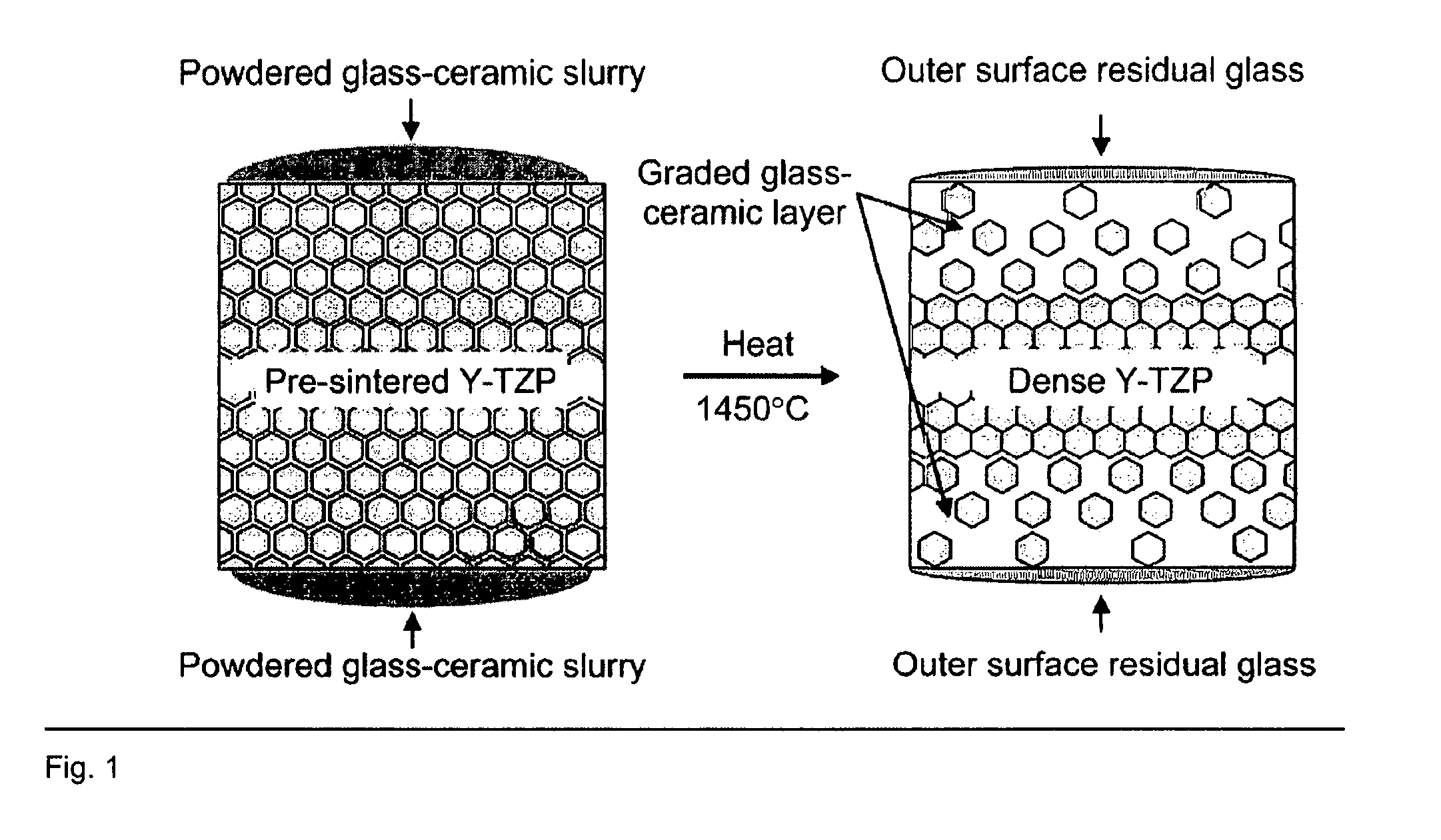

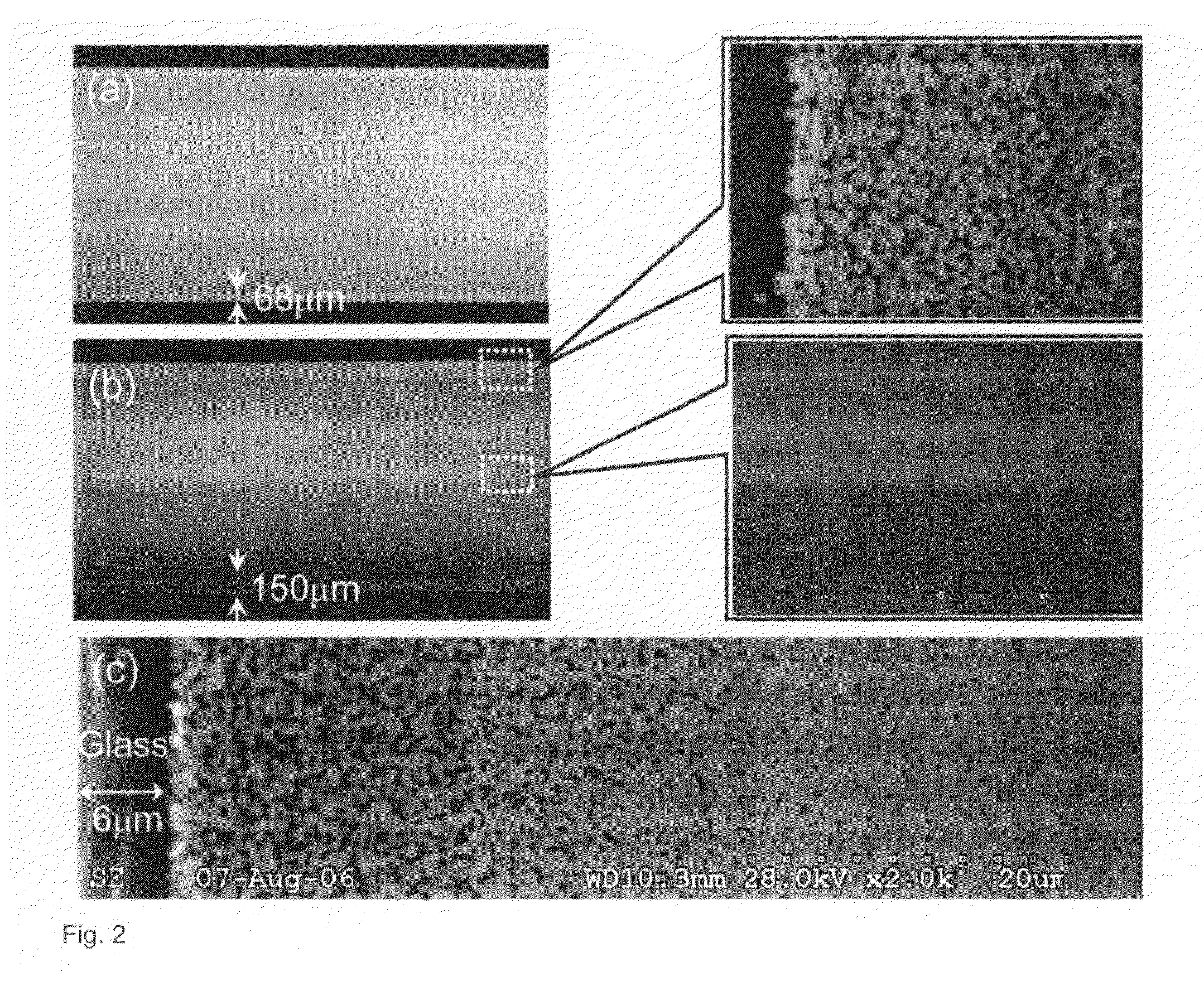

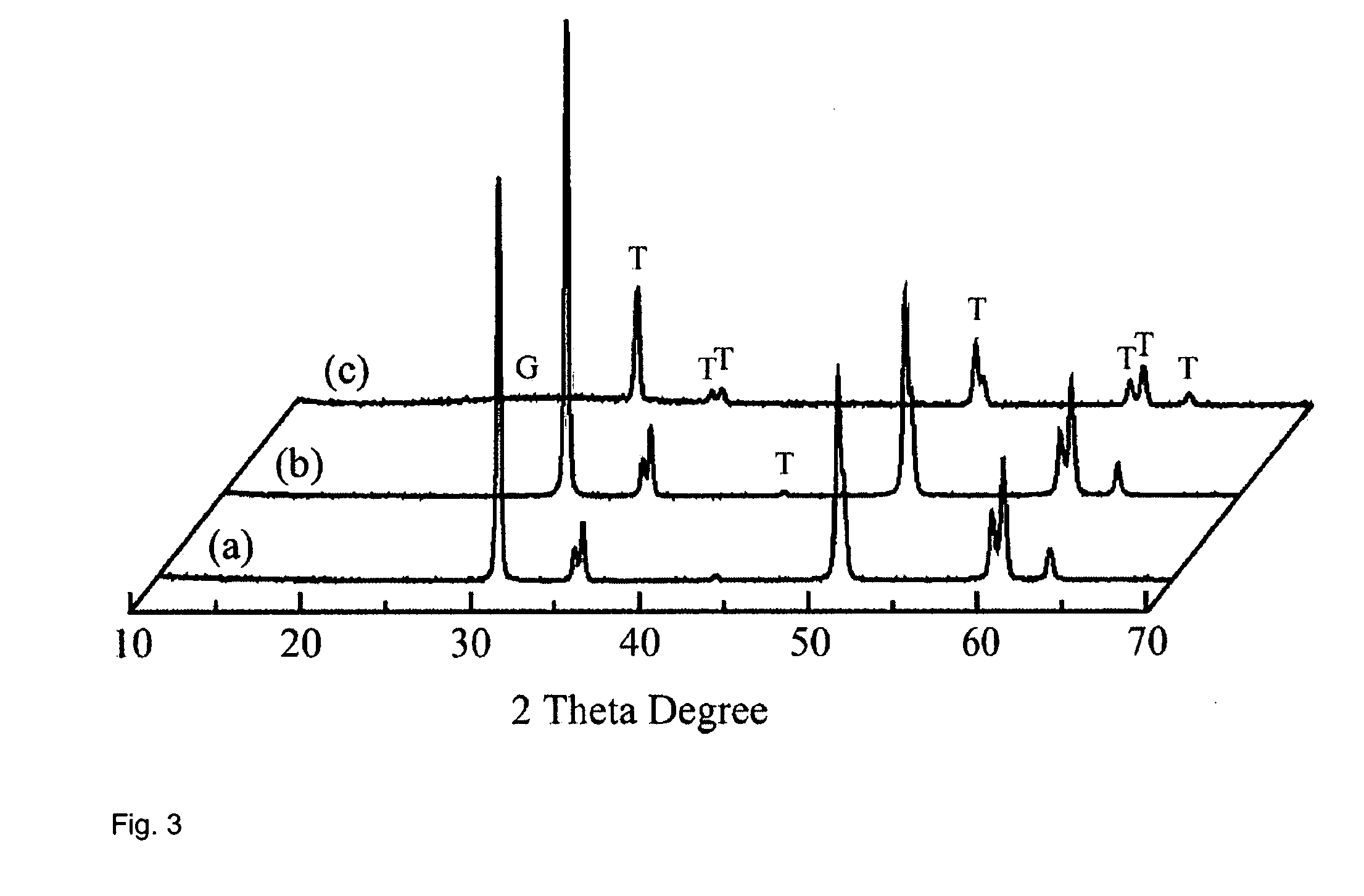

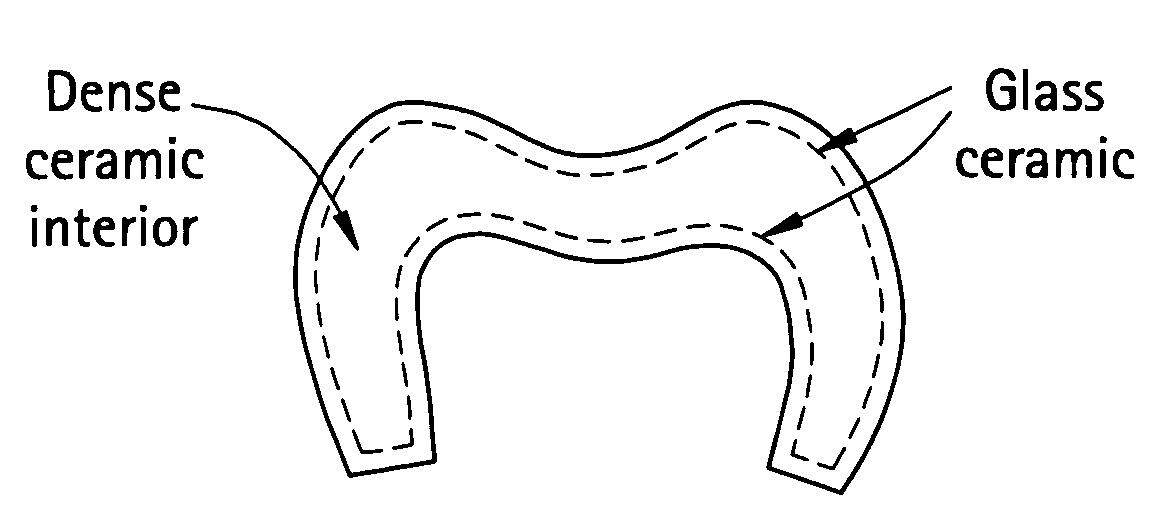

Graded glass/zirconia/glass structures for damage resistant ceramic dental and orthopedic prostheses

The present invention provides a functionally graded glass / ceramic / glass sandwich system for use in damage resistant, ceramic and orthopedic prosthesis. The functionally graded glass / substrate / glass composite structure comprises an outer residual glass layer, a graded glass-ceramic layer, and a dense interior ceramic. The functionally graded glass / substrate / glass composite structure may further comprise a veneer on an exterior surface. The present invention also provides a method for preparing a functionally graded glass / ceramic / glass sandwich system. A powdered glass-ceramic composition is applied to the accessible surfaces of a presintered zirconia substrate to thereby substantially cover the substrate surfaces. The glass of the composition has a CTE similar to that of the substrate material. The glass-ceramic composition is infiltrated into and densifies the substrate by heating the assembly to at least the sintering temperature of the substrate.

Owner:NEW YORK UNIV

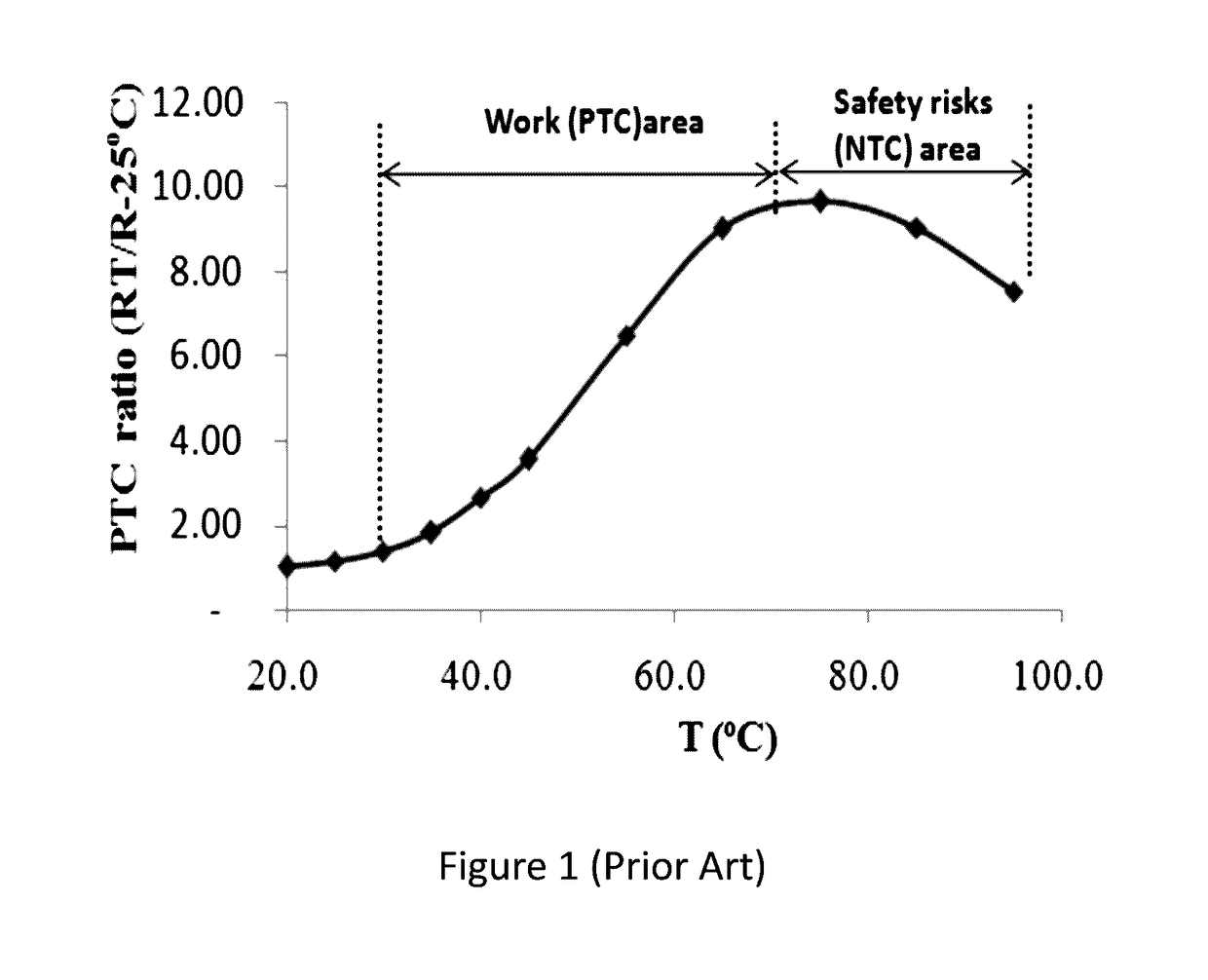

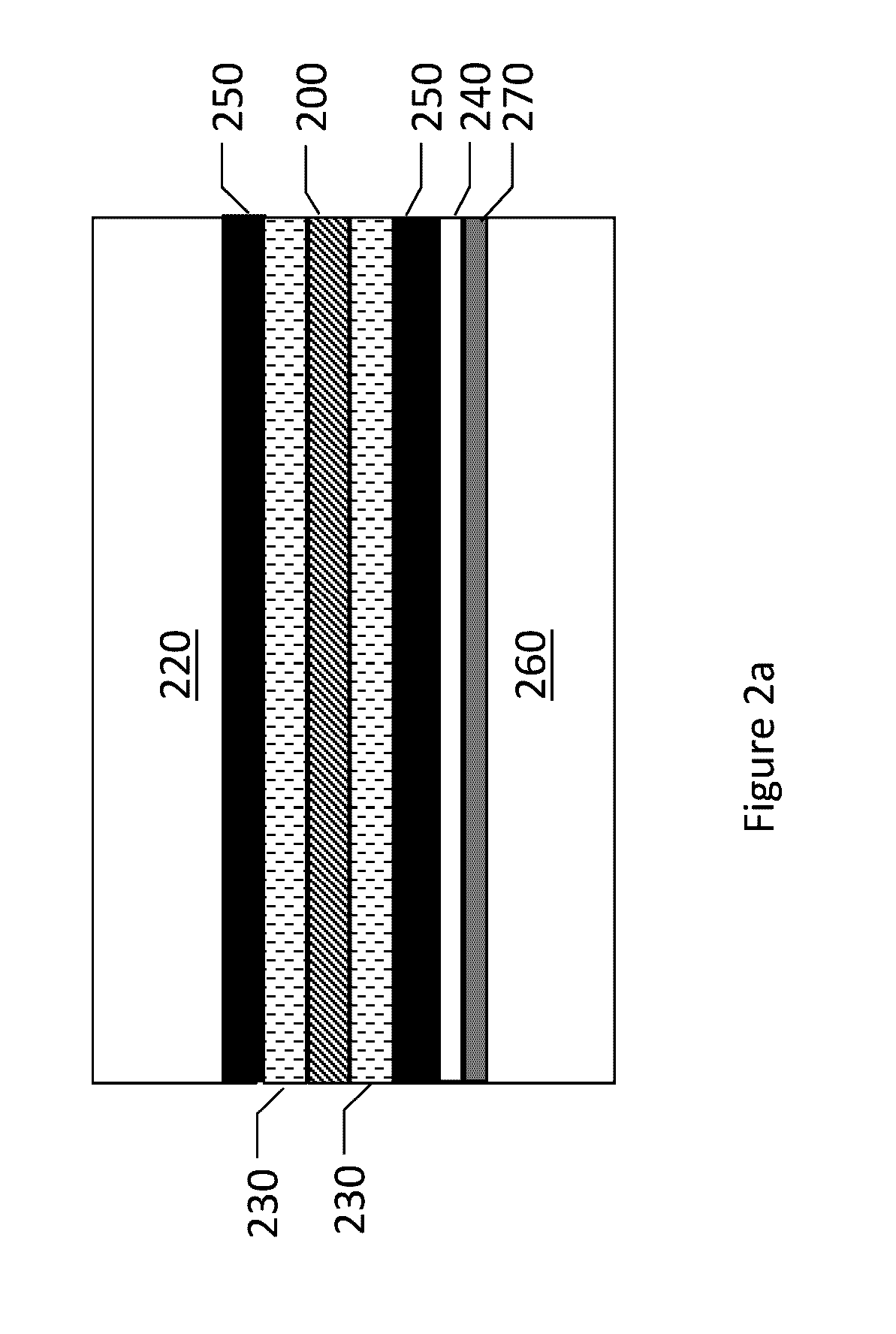

Electrically conductive PTC ink with double switching temperatures and applications thereof in flexible double-switching heaters

ActiveUS20170158898A1Eliminate the effects ofHigh PTC characteristicLighting and heating apparatusIce productionPolyesterCarbon composites

A double-switching heater includes a double-switching PTC ink deposited on a substrate to form one or more resistors. The double-switching PTC ink has a first resin that provides a first PTC effect at a first temperature range and a second resin that provides a second PTC effect at a second temperature range, where the second temperature range is higher than the first temperature range. The substrate may be a flexible substrate or a rigid substrate, and may bedeformable to generate a three-dimensional structure. The substrate may be: polyester, polyimide, polyamide, polypropylene, thermoplastic polyurethane, fiberglass, cement board, carbon composite materials, polyethylene terephthalate, polyethylene, aluminum, steel, glass composite, molded plastic, high-density polyethylene or styrene ethylene butylene styrene.

Owner:LMS CONSULTING GRP LLC

Film laminates having damping properties containing a sub-layer made of plasticizer-containing polyvinyl (iso)acetal

InactiveUS8920930B2Good compatibilityImprove sound insulationSynthetic resin layered productsGlass/slag layered productsTO-18Glass composites

Film laminates are formed from at least three layers A, B and C, each containing at least one plasticizer and at least one polyvinyl acetal, wherein two outer layers A and C each contain at least one identical or different polyvinyl acetal having a proportion of polyvinyl alcohol groups of 18.5 to 23% by weight, at least one inner layer B contains a polyvinyl acetal having a proportion of polyvinyl alcohol groups of 12 to 18% by weight, and at least one of the layers A, B or C contains at least one polyvinyl (iso)acetal. The film laminates can be used for the production of glass / film laminate / glass composites for motor vehicles, aircraft, ships, architectural glazings, façade components, or for the production of photovoltaic modules.

Owner:KURARAY EURO GMBH

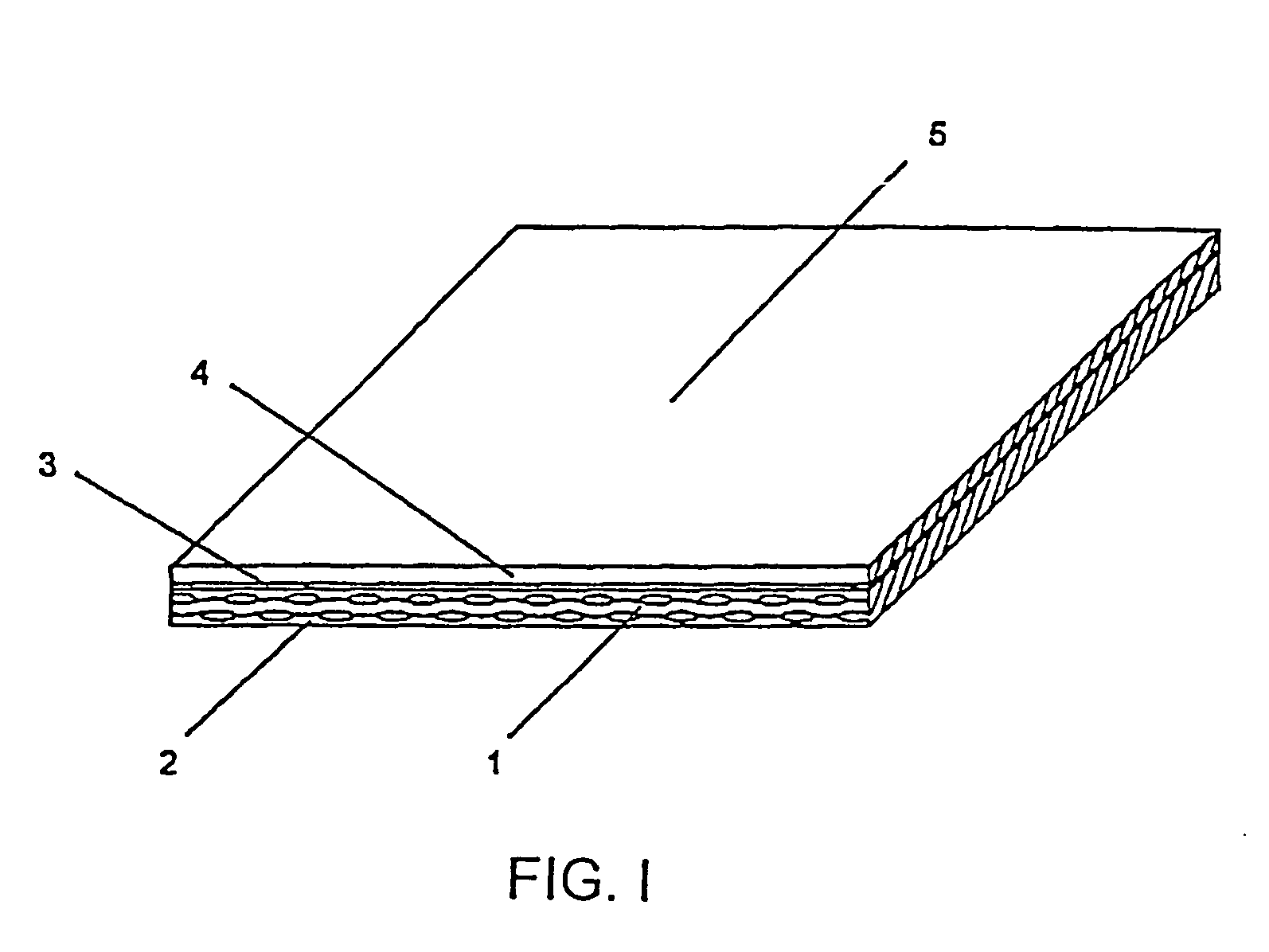

Non-curling reinforced composite membranes with differing opposed faces, methods for producing and their use in varied applications

InactiveUS20050170722A1Improve performanceConveyorsSynthetic resin layered productsGlass compositesIndependent function

A double-faced PTFE-silicone rubber reinforced composite with curling tendency controlled is achieved by coating one side of a balanced PTFE / glass composite with liquid silicone rubber. Each face of the composite can perform independent functions in a single application, thereby optimizing performance.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

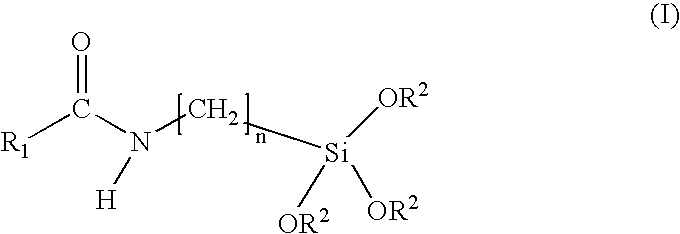

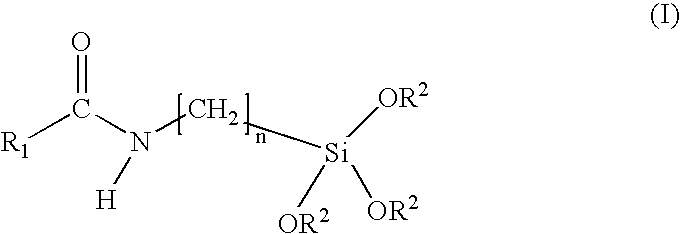

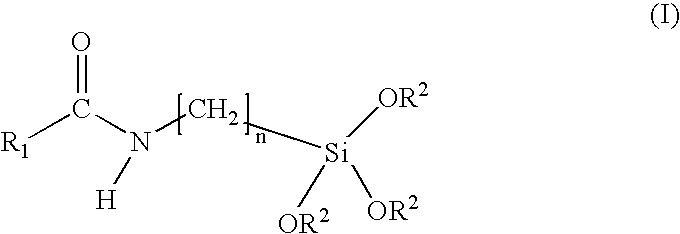

Thermoplastic polyurethanes and use thereof

InactiveUS20060135728A1Glass/slag layered productsPhotovoltaic energy generationGlass compositesPolymer science

The present invention relates to thermoplastic polyurethane molding compositions. These thermoplastic polyurethanes exhibit good adhesion to glass due to the presence of the required silanes. This invention also relates to the production of glass composites and solar cell modules from these novel thermoplastic polyurethanes.

Owner:BAYER MATERIALSCIENCE AG

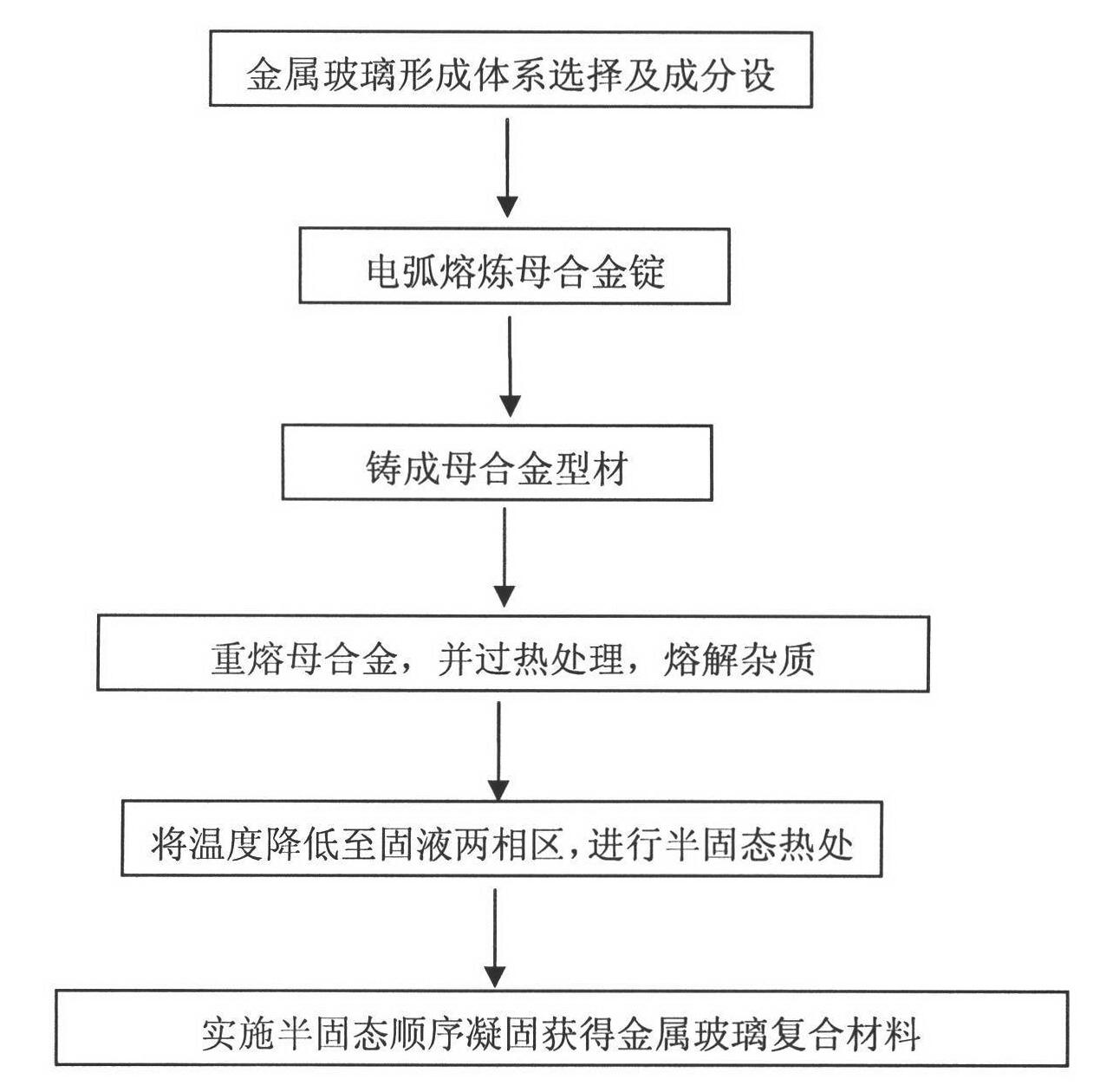

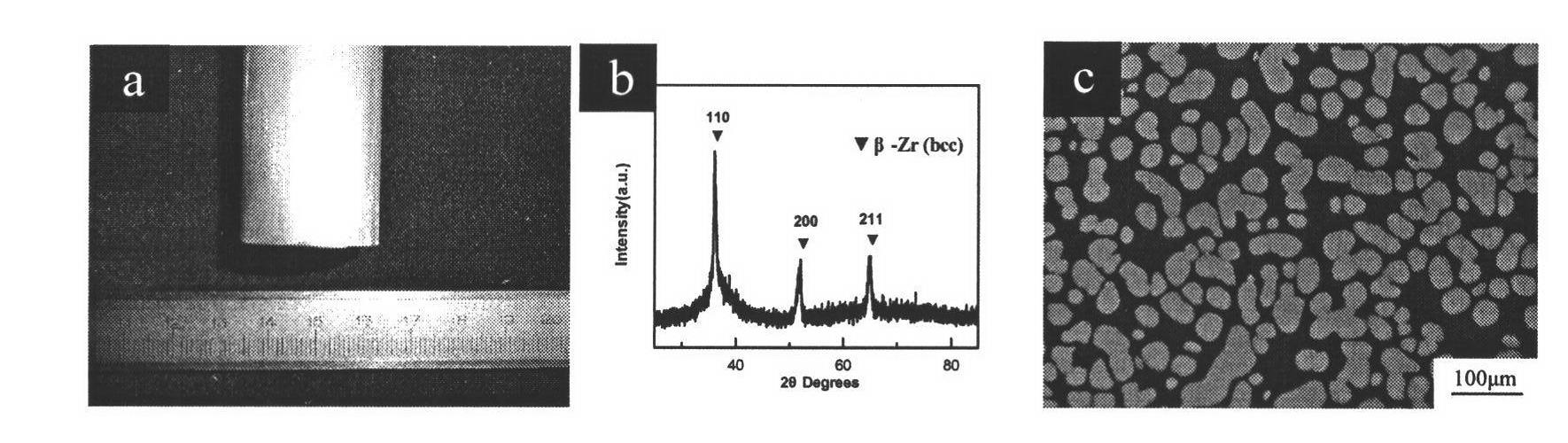

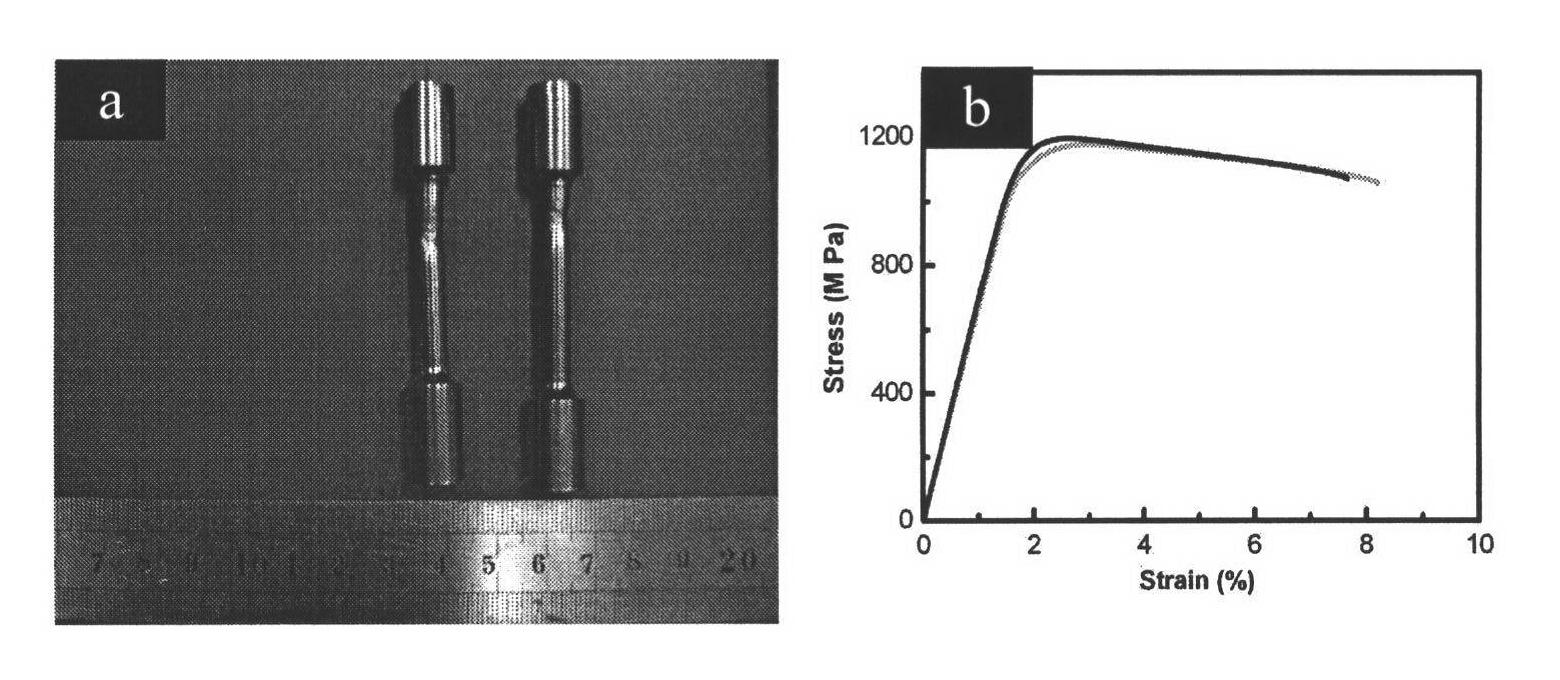

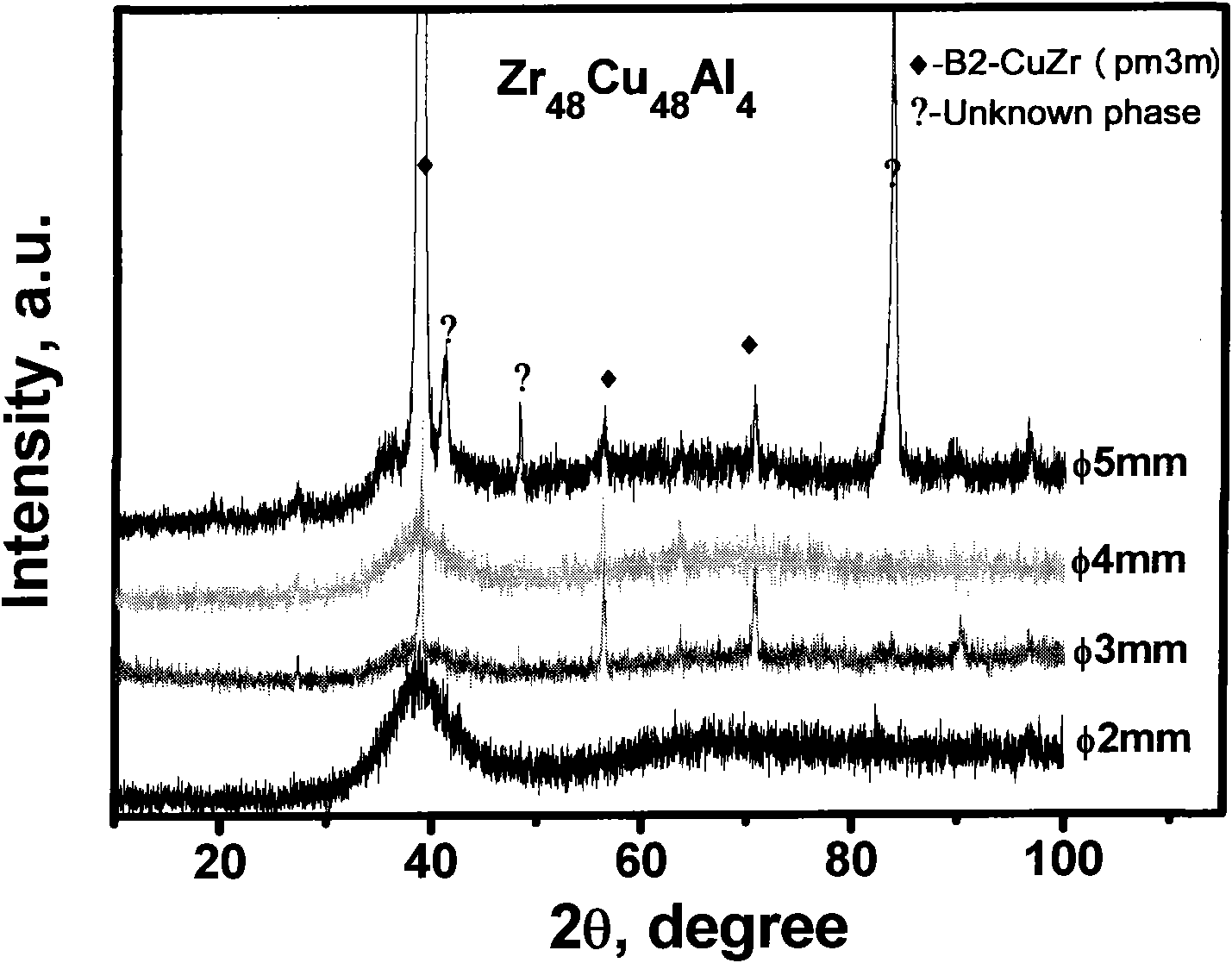

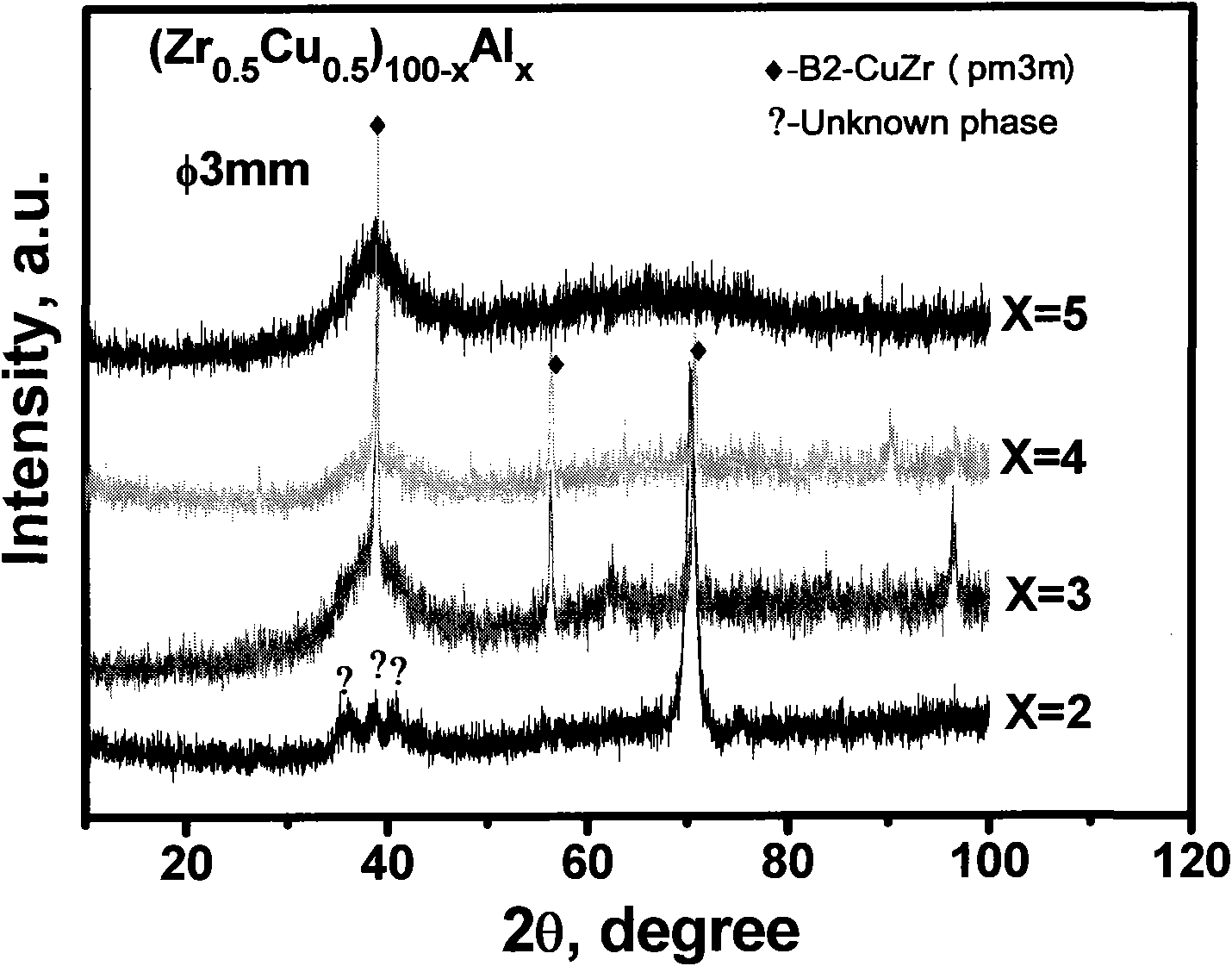

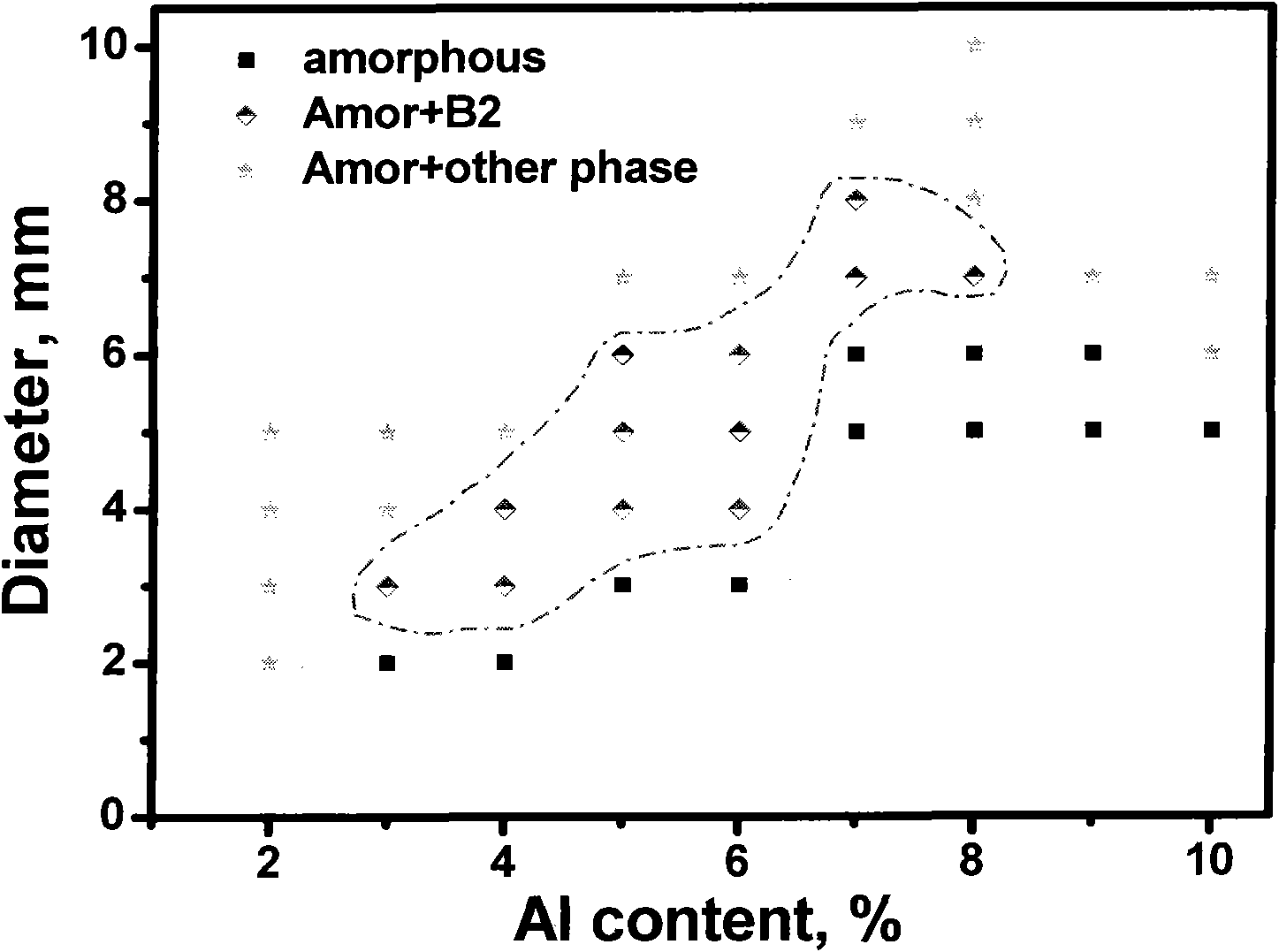

Large-size metallic glass composite material with tensile ductility and preparation method thereof

InactiveCN102181809ARealize one-step moldingUniform Work Hardening AbilityGlass compositesWork hardening

The invention discloses a large-size metallic glass composite material with tensile ductility and a preparation method thereof. A composition expression of the metallic glass composite material is ZraTibMcCudNieBef (atom percent), wherein M is one of Nb, V or Hf, a is not less than 10 and not more than 70, b is not less than 10 and not more than 70, c is not less than 4 and not more than 20, d isnot less than 2 and not more than 20, e is not less than 0 and not more than 15, f is not less than 5 and not more than 22.5, and a+b+c+d+e+f is equal to 100. The preparation method is called after semi-solid progressive solidification method, which comprises the following steps of: smelting master alloy ingots and casting into master alloy profiles; putting the master alloy profiles into a crucible and heating until the profiles are completely melted, and performing the overheating processing to dissolve impurity phases; reducing the temperature to a solid-liquid two-phase region; performingsemi-solid processing, and controlling the shape and the size of a precipitated solid solution phase; and then performing the semi-solid progressive solidification to form the large-size metallic glass composite material with tensile ductility. By adopting the method, the homogeneous and defect-free large-size (30 mm) metallic glass composite material is prepared, and the composite material has remarkable work hardening capacity and excellent tensile strength and ductility.

Owner:NANJING UNIV OF SCI & TECH

Nucleated glass composite material and process for preparing same

InactiveCN1433985AThe level of artistic aesthetics has improvedReduce manufacturing costGlass compositesSurface layer

The present invention relates to a nucleated glass composite material and its preparation method. Said composite material is formed from surface layer nucleated glass and base material. Its surface layer bucleated glass includes ZnO 10-40% (wt%), SiO2, Al2O3, CaO, MgO, Na2O+K2O, Li2O, BaO and ZrO2, and its base material is ceramic or nucleated glass layer. Said nucleated glass is made up by following steps: preparing surface layer nucleated glass granulated raw material, preparing base material, combining them and making them into semi-finished product, edge grinding, scrapping, coarse grinding, polishing, edge grindnig, chamferring and drying, and the pattern of the obtained nucleated glass copmosite material can be various forms of ball, chrysanthemum flower, slag flow, flower cluster, flowing lines, flame and radiation, etc.

Owner:戴长禄 +1

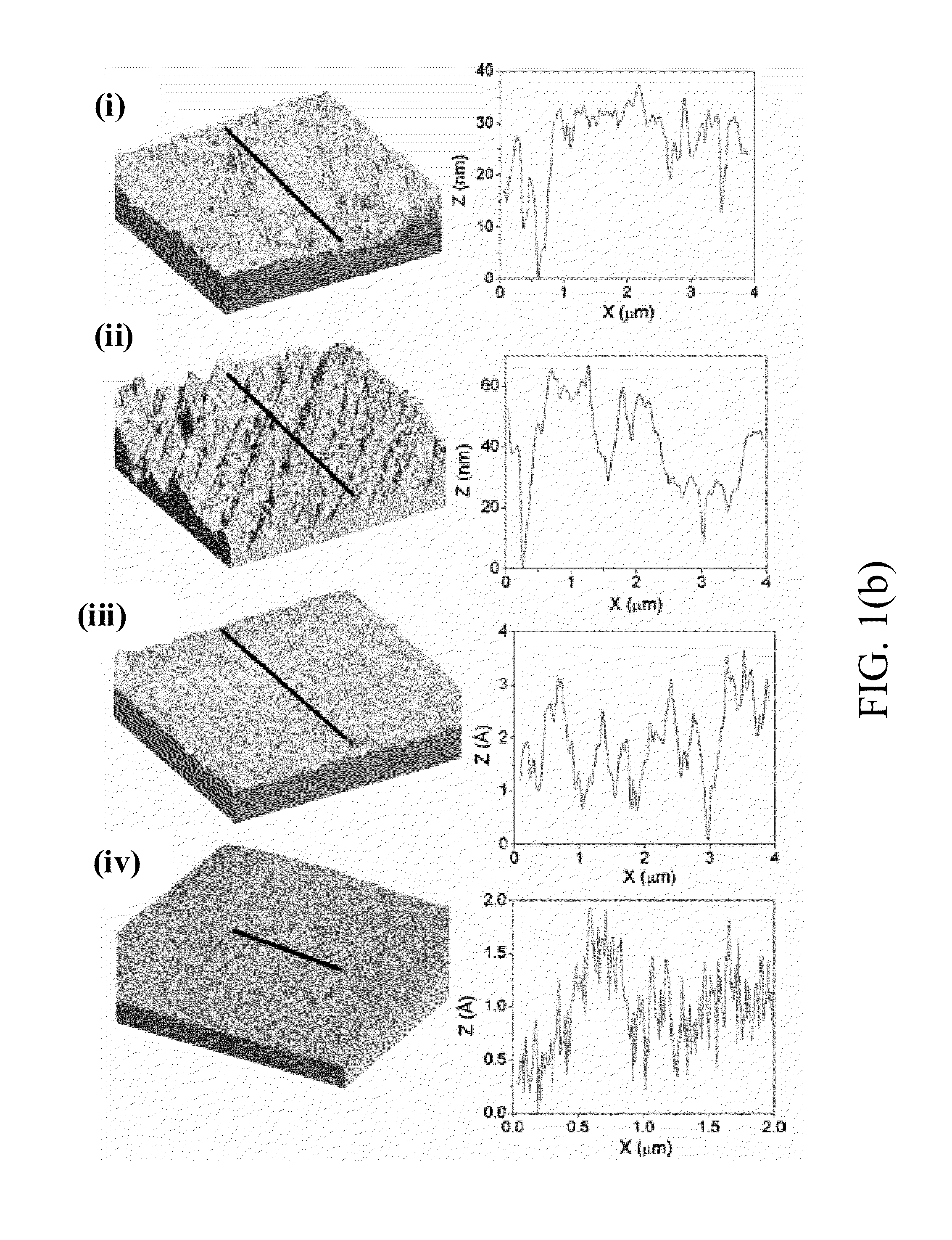

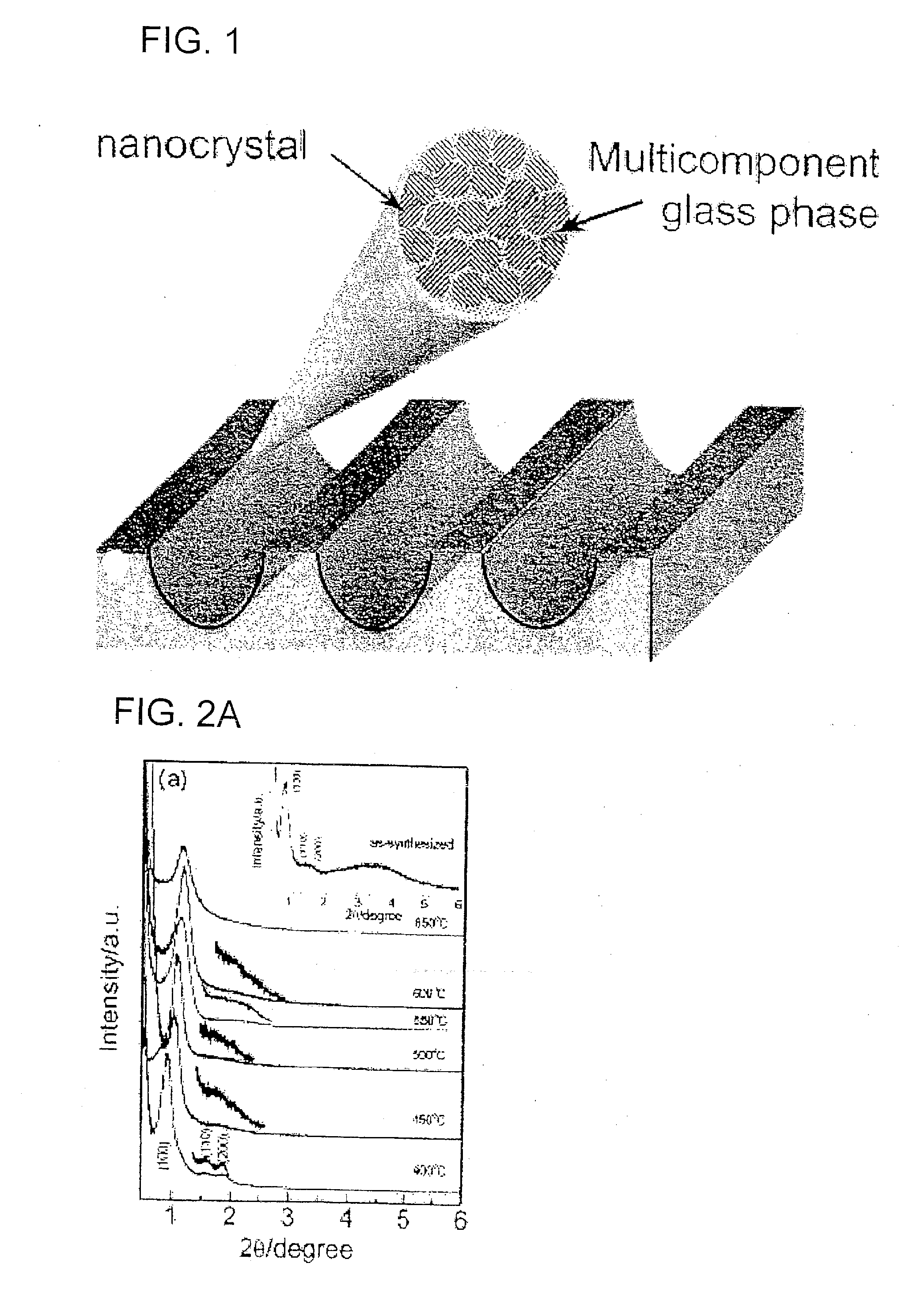

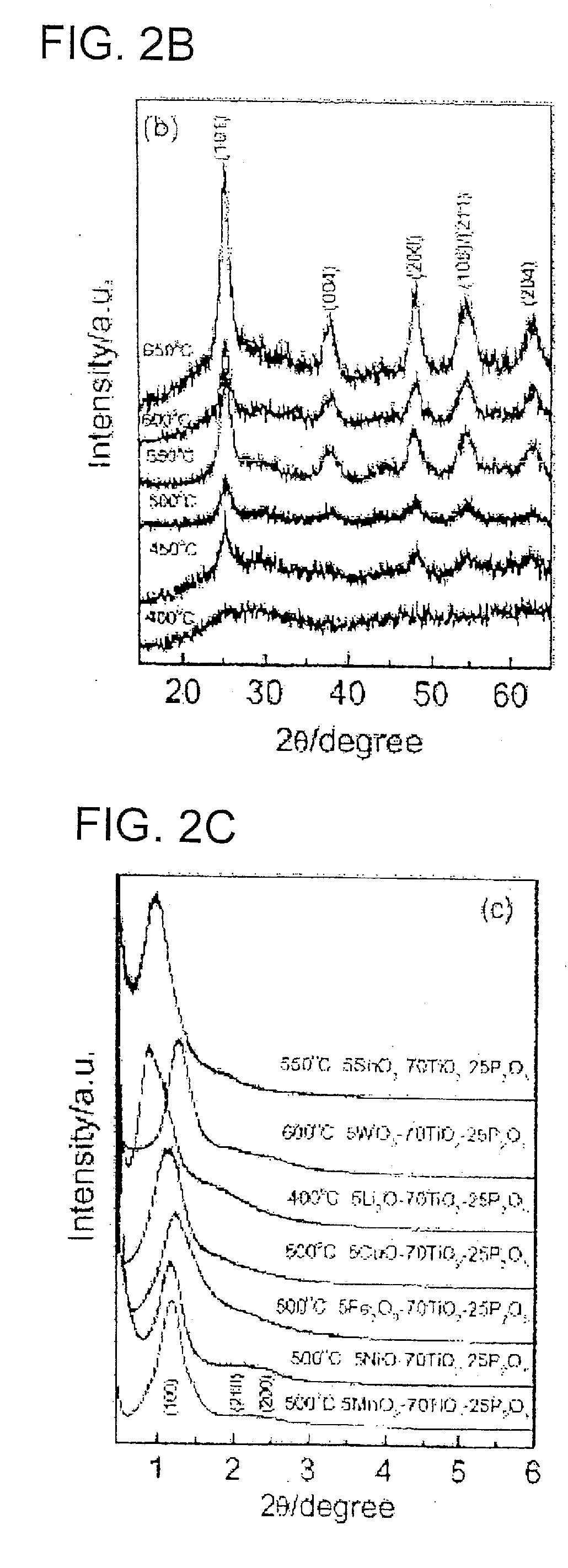

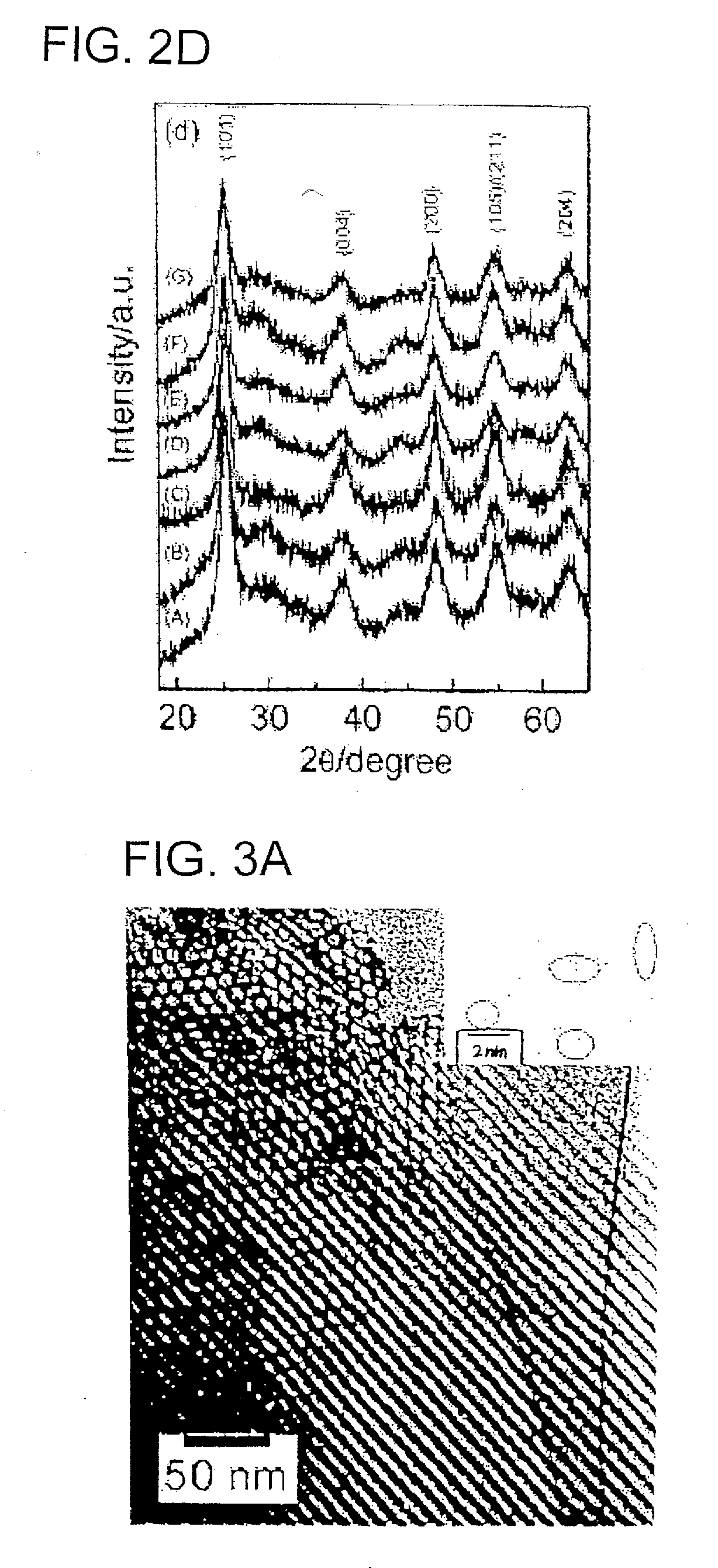

Nanocrystal oxide/glass composite mesoporous powder or thin film, process for producing the same, and utilizing the powder or thin film, various devices, secondary battery and lithium storing device

InactiveUS20070027015A1Simple methodLarge capacityPhosphorus oxidesMaterial nanotechnologyGlass compositesManufacturing technology

The present invention aims to realize (1) manufacture of a mesoporous composite powder or thin film composed of nanocrystalline metal oxide-glass having a three-dimensional structure with a large specific surface area, (2) construction of a porous structure framework with nanocrystalline metal oxide crystal and a slight amount of glass phase (SiO2 or P2O5, B2O3), (3) control of crystal growth of metal oxide with a slight amount of glass phase (SiO2 or P2O5, B2O3), (4) simplification of the manufacturing process, and (5) use thereof in manufacture of a lithium intercalation electric device, photocatalytic device, solar battery and energy storage device. Provided are a nanocrystal oxide-glass mesoporous composite powder or thin film having a three-dimensional structure with regularly arranged mesopores, and a secondary battery comprising the same.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Non-curling reinforced composite membranes with differing opposed faces, methods for producing and their use in varied applications

InactiveUS6930063B2Improve performanceConveyorsSynthetic resin layered productsGlass compositesPolymer science

A double-faced PTFE-silicone rubber reinforced composite with curling tendency controlled is achieved by coating one side of a balanced PTFE / glass composite with liquid silicone rubber. Each face of the composite can perform independent functions in a single application, thereby optimizing performance.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

Polyurethane-water glass composite grouting material as well as preparation method and application thereof

InactiveCN103756291AImprove flame retardant performanceImprove antistatic performanceGlass compositesAntistatic agent

The invention discloses a polyurethane-water glass composite grouting material as well as a preparation method and an application thereof. The polyurethane-water glass composite grouting material comprises a component A and a component B in a weight ratio of 1:1-1:2, wherein the component A comprises the following components in percentage by weight: 72%-83% of polyurethane prepolymer, 5%-15% of plasticizer, 5%-10% of flame retardant and 2%-3% of surfactant, and the component B comprises the following components in percentage by weight: 99.2%-99.5% of water glass and 0.5%-0.8% of antistatic agent. The obtained composite grouting material has low slurry toxicity and relatively good compressive strength, is dense in jet-grouted solid and does not foam when being wet; and the flame retardancy and the anti-static performance of the composite grouting material meets the requirements of national coal industrial standards MT113-1995; and the polyurethane-water glass composite grouting material can be used for reinforcing coal seams of coal mines.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

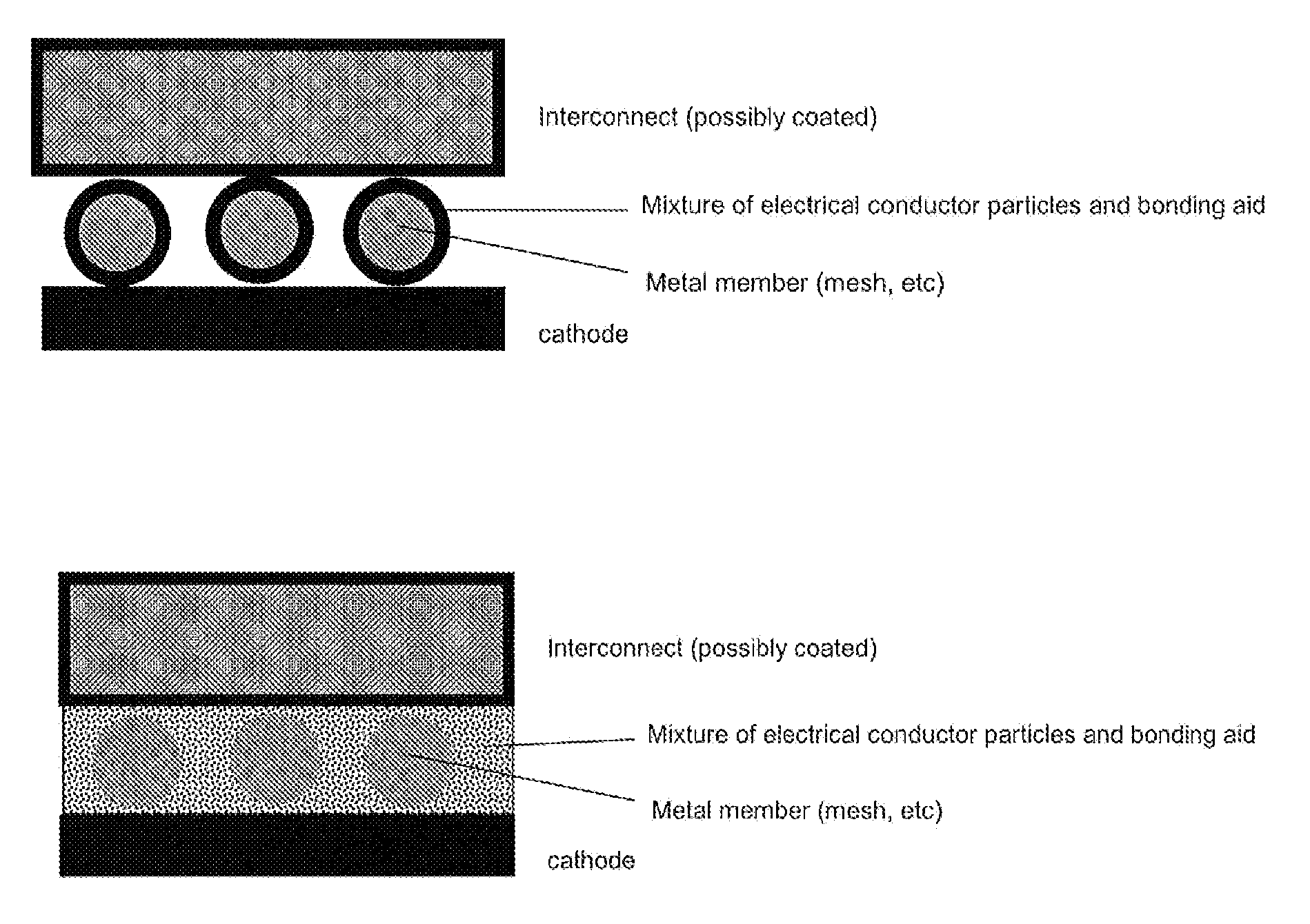

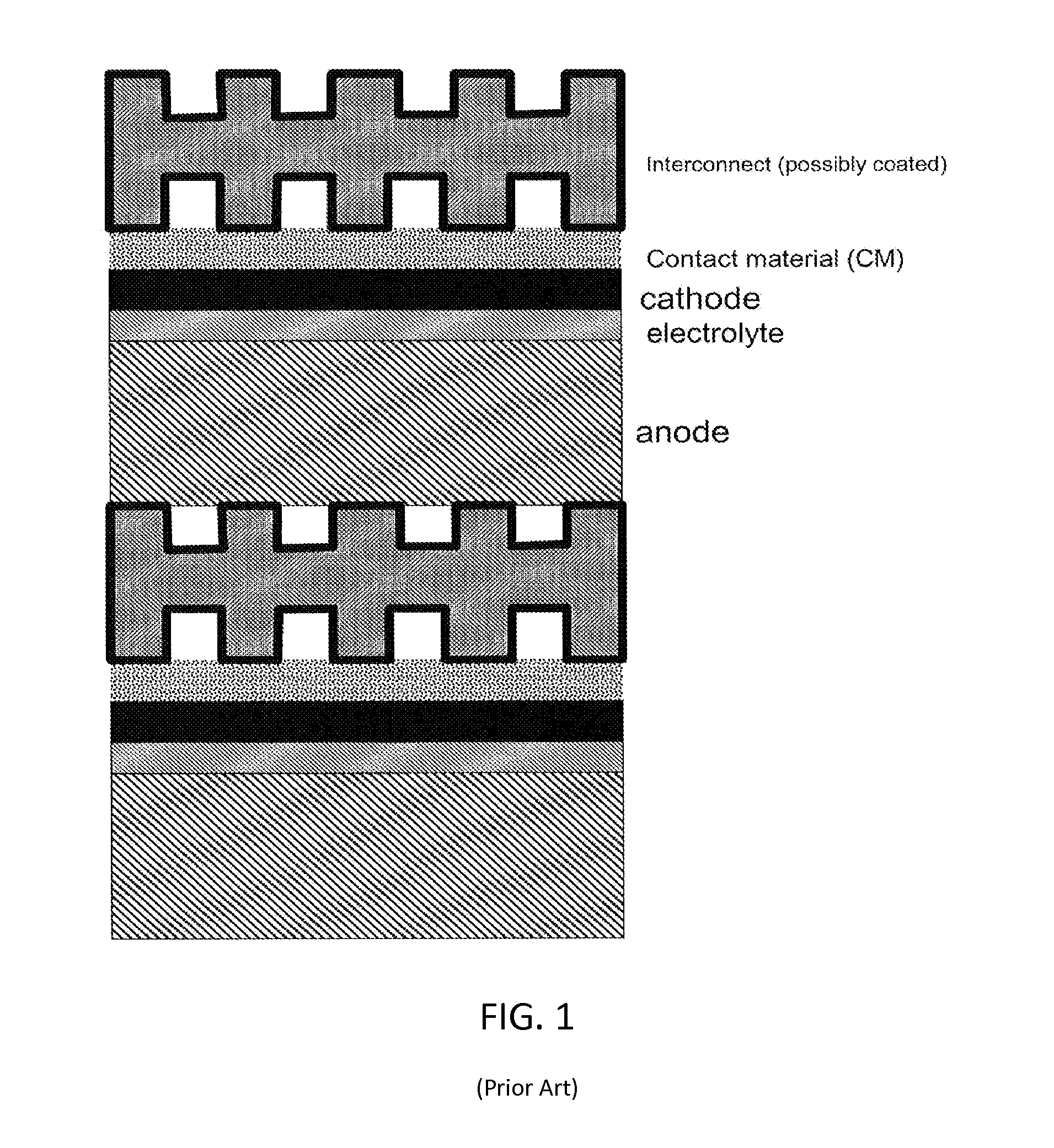

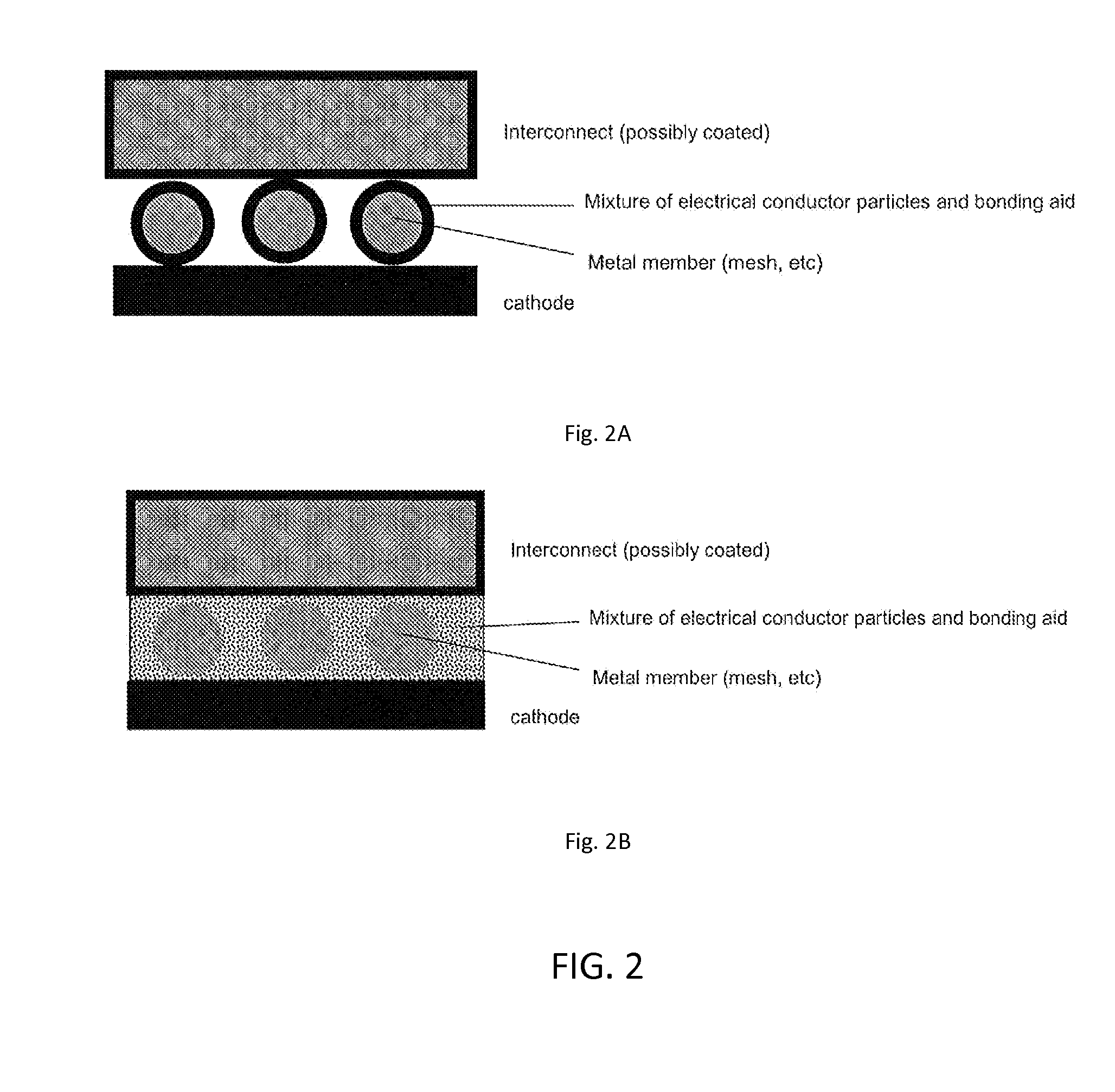

Electrical Contact Material in High-Temperature Electrochemical Devices

InactiveUS20120258241A1Reduce conductivityCell electrodesConductive materialElectricityGlass composites

The feasibility of adding glass to conventional SOFC cathode contact materials in order to improve bonding to adjacent materials in the cell stack is assessed. A variety of candidate glass compositions were added to LSM and SSC. The important properties of the resulting composites, including conductivity, sintering behavior, CTE, and adhesion to LSCF and MCO-coated 441 stainless steel were used as screening parameters. The most promising CCM / glass composites were coated onto MCO-coated 441 stainless steel substrates and subjected to ASR testing at 800° C. In all cases, ASR is found to be acceptable. Indeed, addition of glass is found to improve bonding of the CCM layer without sacrificing acceptable conductivity.

Owner:RGT UNIV OF CALIFORNIA

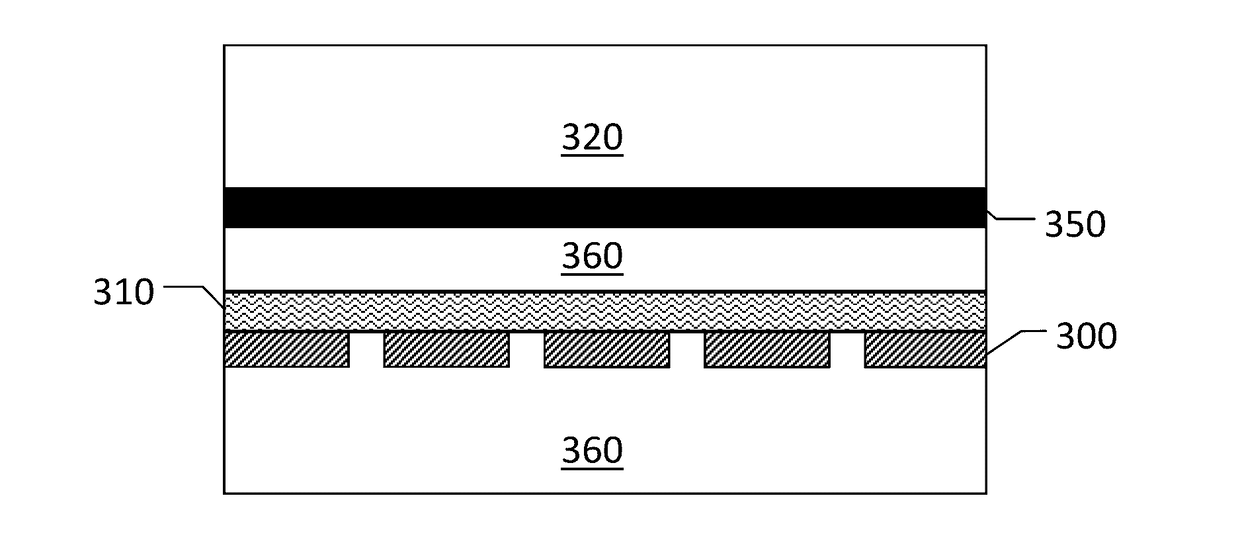

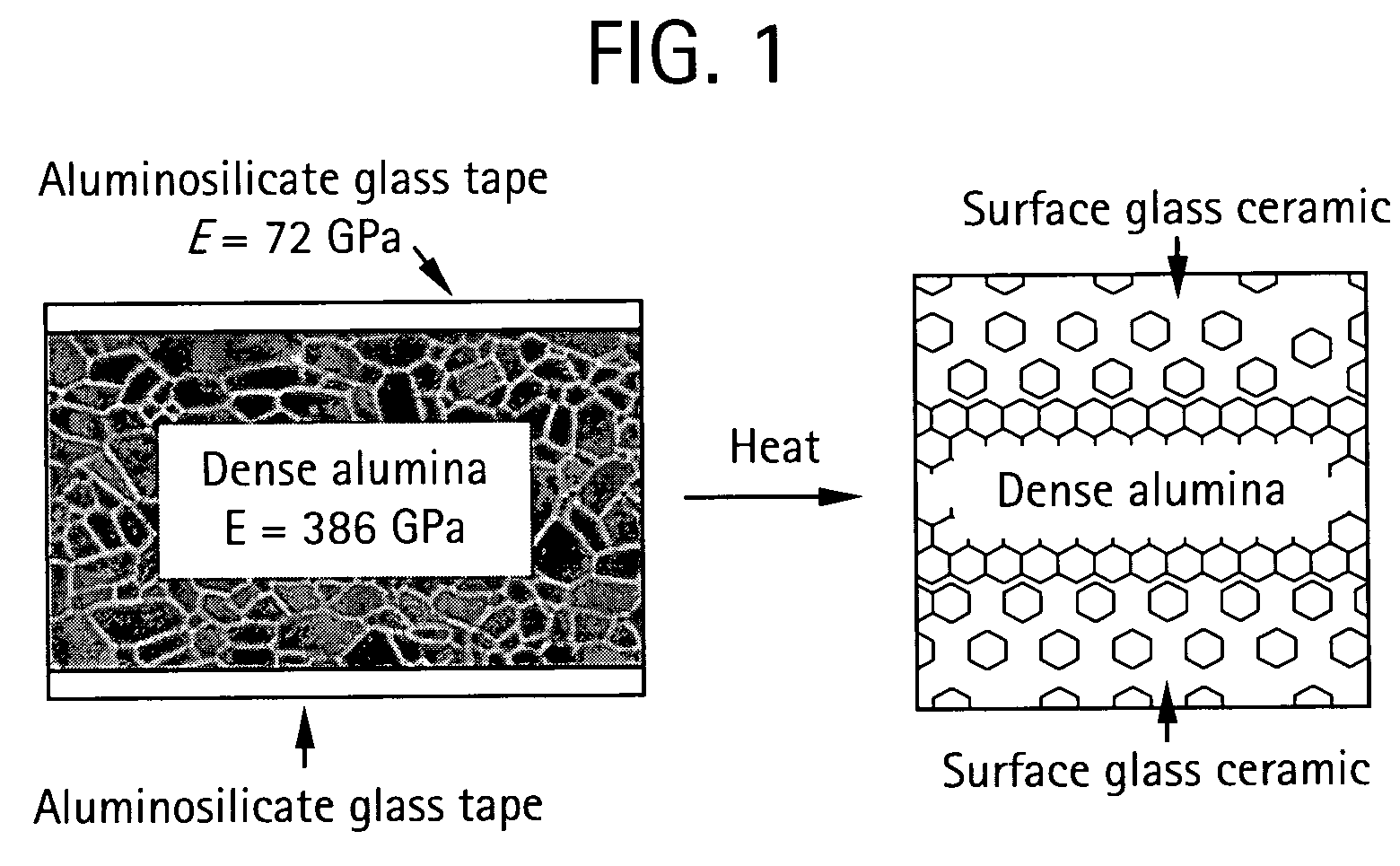

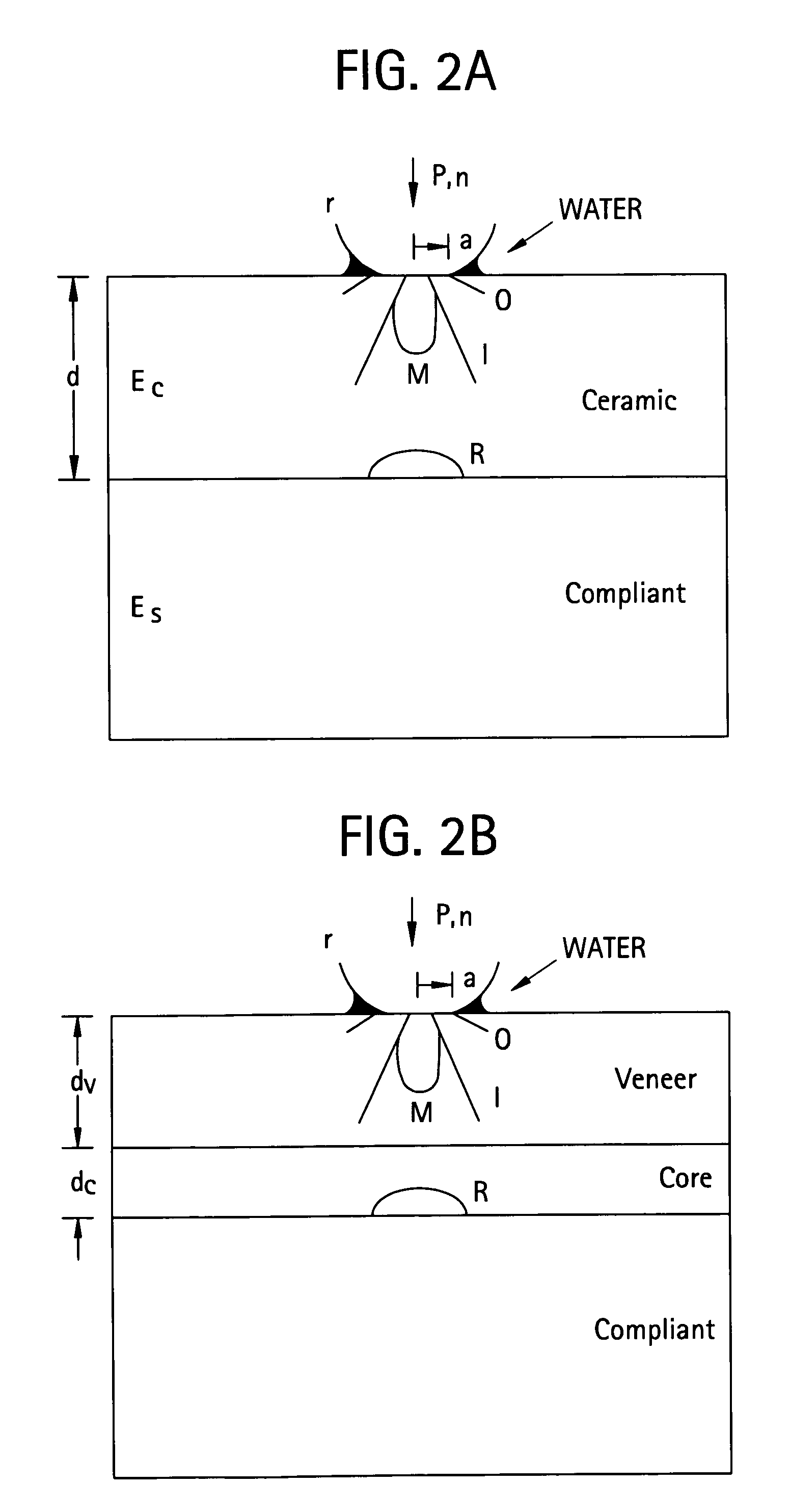

Graded glass/ceramic/glass structures for damage resistant ceramic dental and orthopedic prostheses

InactiveUS20080213727A1Minimizes problemFracture can be problematicDental implantsArtificial teethGlass compositesMetallurgy

The present invention provides a functionally graded glass / ceramic / glass sandwich system especially useful in damage resistant, ceramic dental and orthopedic prosthesis. The functionally graded glass / substrate / glass composite structure comprises an outer (aesthetic) residual glass layer, a graded glass-ceramic layer, and a dense interior ceramic. The functionally graded glass / substrate / glass composite structure may further comprise a veneer on an exterior surface. The present invention also provides a method for preparing a functionally graded glass / ceramic / glass sandwich system. A powdered glass-ceramic composition or a glass tape is applied to the accessible surfaces of a dense alumina substrate to thereby substantially cover the substrate surfaces. The glass of the composition has a CTE similar to that of the substrate material. The glass-ceramic composition is infiltrated into the dense substrate by heating the assembly to temperatures 50-700° C. below the sintering temperature of the substrate.

Owner:NEW YORK UNIV

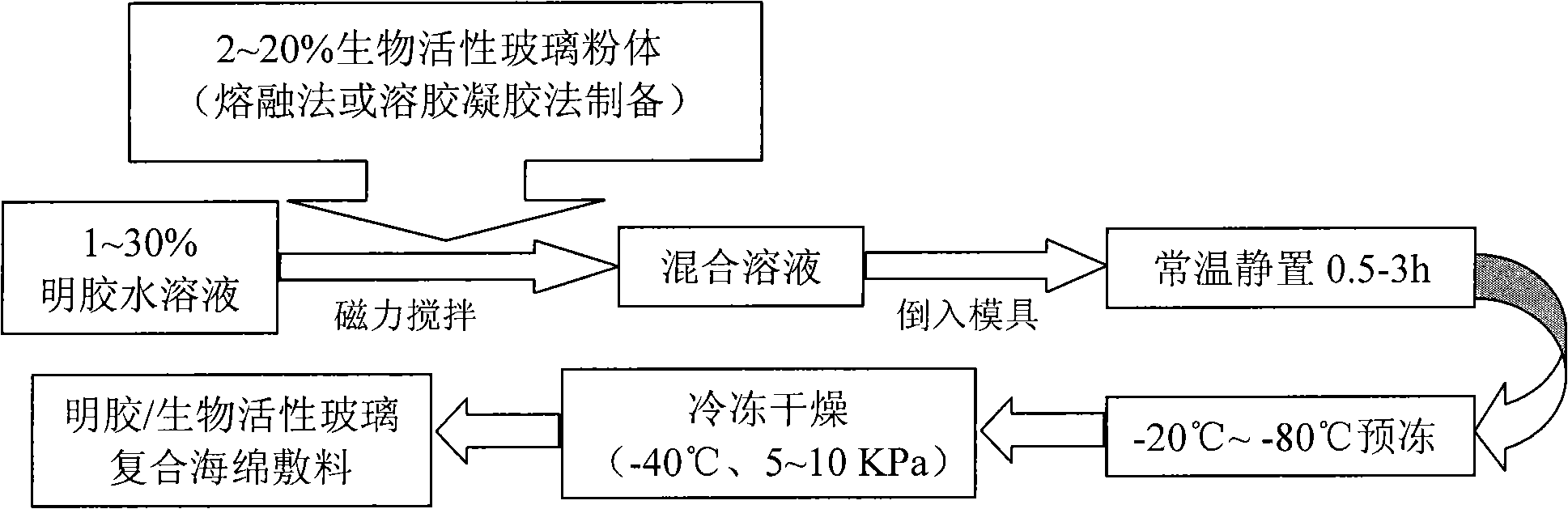

Gelatine/biological activity glass composite sponge dressing and preparation thereof

The present invention relates to a gelatin / biological activity glass compounded sponge dressing and a preparation method thereof, belonging to the biomaterial field. The dressing is characterized in that a solution of a content of between 1 and 30 percent is prepared with gelatin as the raw material; the biological activity glass powder with a weight percentage of between 2 and 20 percent, prepared by the fusion method or the sol-gel method, is put into the solution; and then a mixed solution is obtained by magnetic stirring. The mixed solution is poured into a mould, the liquid layer is up to between 1 and 8 mm, the mixed solution is kept stand for 0.5 to 3 h, and then the prefreezing temperature is controlled between 20 DEG C below zero and 80 DEG C below zero; the lyophilization is controlled to be carried out at a temperature of 40 DEG C below zero and a pressure of between 5 and 10 KPa. The section of the present invention is of a double layer composite structure with a thickness of between 0.5 and 5 mm, wherein, the upper layer is a loose porous layer, and the lower layer is a dense powder layer, the thickness of the powder layer being up to between 0.1 and 2.0 mm. The double layer sponge dressing is flexible, which can be used as a parenchyma wound restoring material. Particularly, the double sponge dressing is suitable for any one of parenchyma ulcers of cervix erosions, oral ulcers, bedsores, sinuses, fat liquescency wounds, venereal disease ulcers, hemorrhoids, diabetes ulcers, etc. and the long-term erosions thereof.

Owner:上海硅健生物材料有限公司

Lithium disilicate glass-ceramics composite material using ZrO2 as reinforcing phase and method for making same

InactiveCN101139170AGuaranteed densificationGood mechanical propertiesGlass particleMechanical property

The present invention relates to a lithium disilicate glass-ceramic composite material with ZrO2 as the reinforcing phase and thepreparation method, which solve the problems that the production cycle is long, the cost is high, the products can be easily formed and the mechanical properties of the lithium disilicate glass-ceramic is lower. The present invention is composed of the lithium disilicate base glass and zirconia powders. The preparation method goes in that the ball milling is carried out according to the components of the original glass; the desiccated raw materials are placed in a corundum crucible so as to be melted under high temperature; the glass solution is poured into the distilled water to go into water quenching so as to be changed into 1 to 2mm glass particles; the ball milling is applied to the glass particles after going into the water quenching so as to obtain the glass powders; the lithium disilicate glass powder is taken to be mixed with the zirconia powders and the ball milling is applied to the lithium disilicate glass powder and the zirconia powders with the alcohol as the medium; the vacuum heating-press sintering is implemented and then the lithium disilicate glass-ceramic composite material with ZrO2 as the reinforcing phase is prepared. The present invention is uneasily deformed, has short production cycle and low cost and has excellent bending strength and fracture toughness indexes.

Owner:HARBIN INST OF TECH

Porous ceramic-microcrystalline glass composite insulation decorative plate and preparation method thereof

InactiveCN102942383AImprove insulation effectImprove waterproof performanceCeramicwareSlurryGlass particle

The invention discloses a porous ceramic-microcrystalline glass composite insulation decorative plate and a preparation method thereof. The porous ceramic comprises ceramic tile raw material, additive, pore forming agent and foaming agent, and the microcrystalline glass comprises SiO2, CaO, ZnO, Al2O3, Na2O, K2O, etc. The preparation method comprises the following steps: firstly uniformly mixing ceramic tile raw material, additive, pore forming agent and foaming agent, and conducting ball milling to obtain an ultrafine powder slurry; then granulating, drying, and conducting compression molding; drying the green ware body and then sintering in a roller kiln or a shuttle kiln; then, melting quartz sand, limestone, soda ash and other minerals or chemical raw materials to obtain a glass melt, carrying out water quenching on the glass melt to obtain glass particles; screening the dried glass particles and then classifying, paving on the surface of a porous ceramic plate, then pushing into a crystallization kiln to sinter, crystallize, anneal and cool the glass particles to form a microcrystalline glass layer; in the process, simultaneously compounding the microcrystalline glass with the porous ceramic plate to form the porous ceramic-microcrystalline glass composite insulation decorative plate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

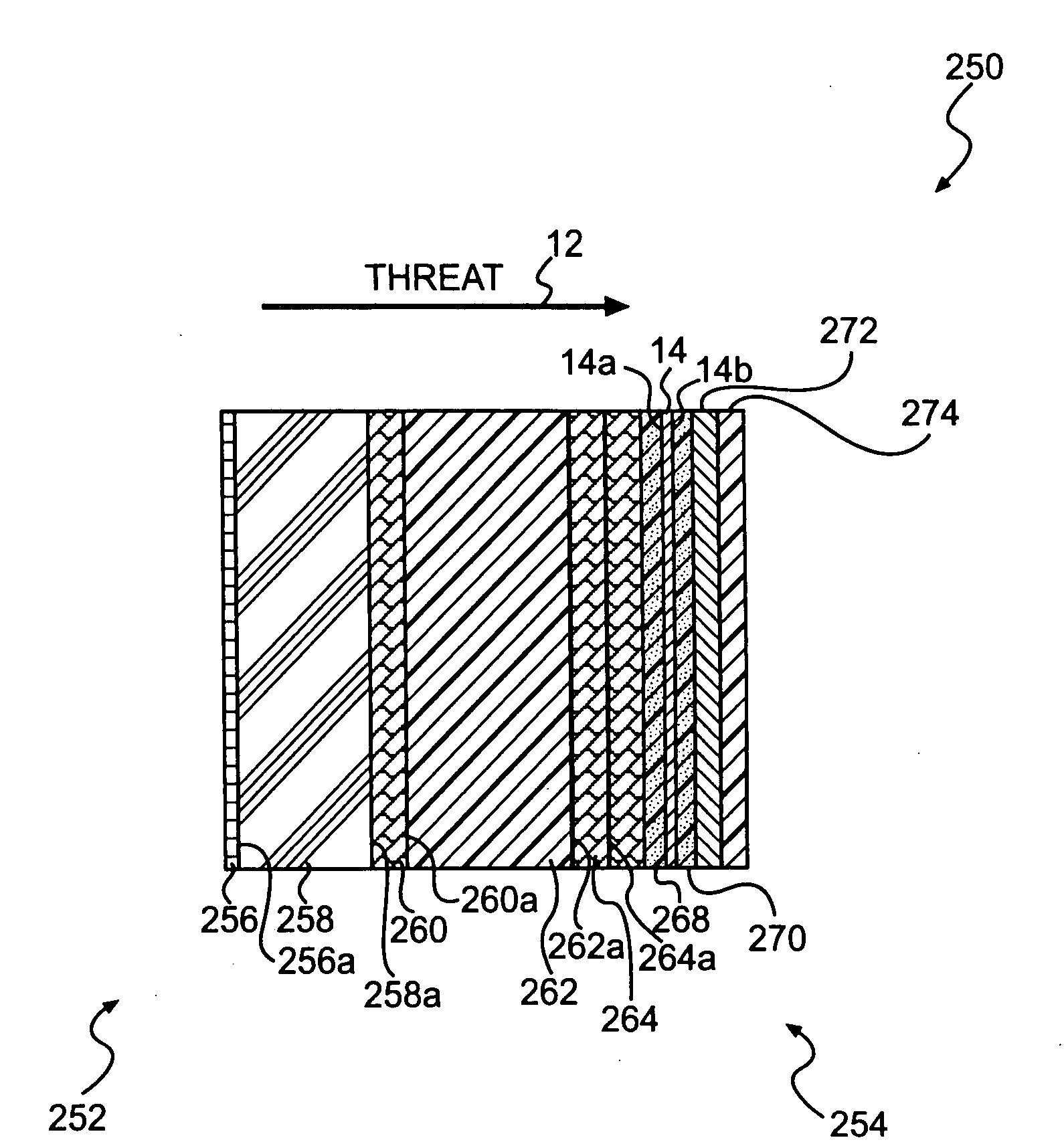

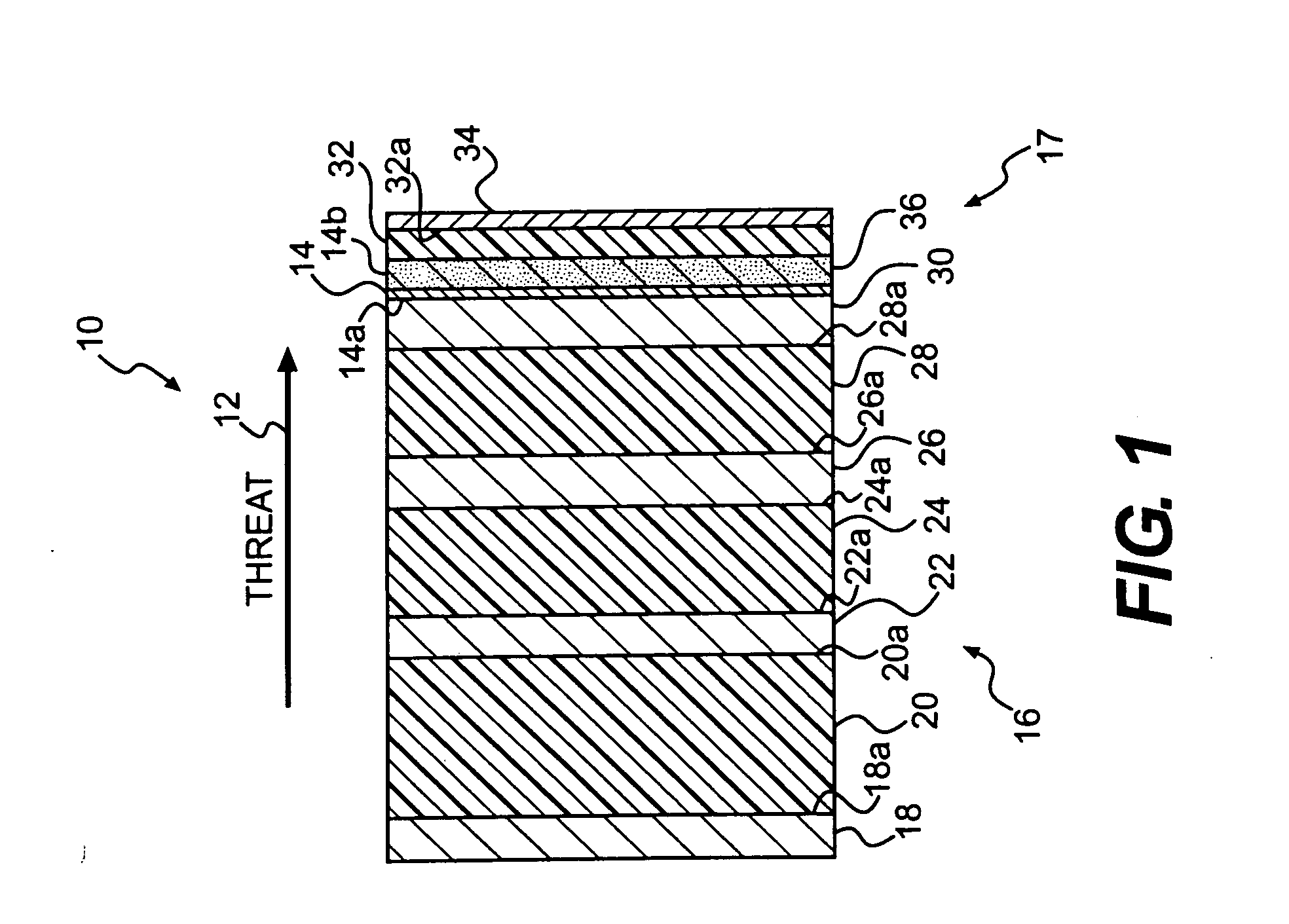

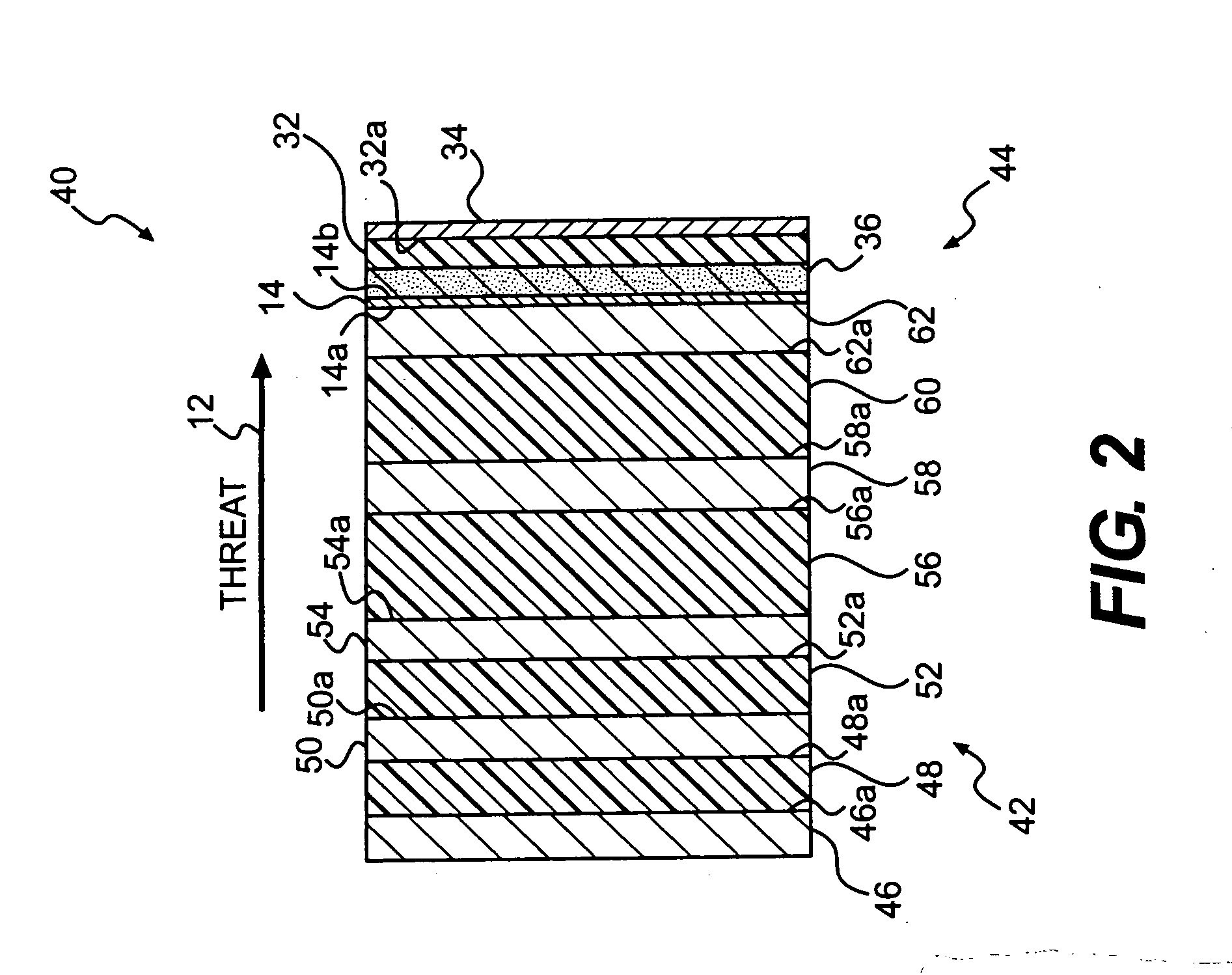

Apparatus for defeating high energy projectiles

The disclosed armor system for protecting a vehicle from high energy projectiles includes a leading layer, relative to the projectile trajectory, positioned exterior to the hull; a first plurality of sheet-like layers of a low density material positioned between the leading layer and the hull; and a second plurality of sheet-like high strength metal layers positioned between the leading layer and the hull. The individual ones of the first plurality of high strength metal layers are positioned alternating with, and to the rear of, individual ones of the second plurality of low density material layers. The leading layer can be one of a sheet-like metal layer, a metalicized grid layer, and the outer-most layer of the first plurality of low density materials layers. The materials of the high strength metal layers may be selected from high strength steel and high strength aluminum, and the materials of the low density material may be selected from low density polypropylene composites and R-Glass composites.

Owner:FORCE PROTECTION TECH

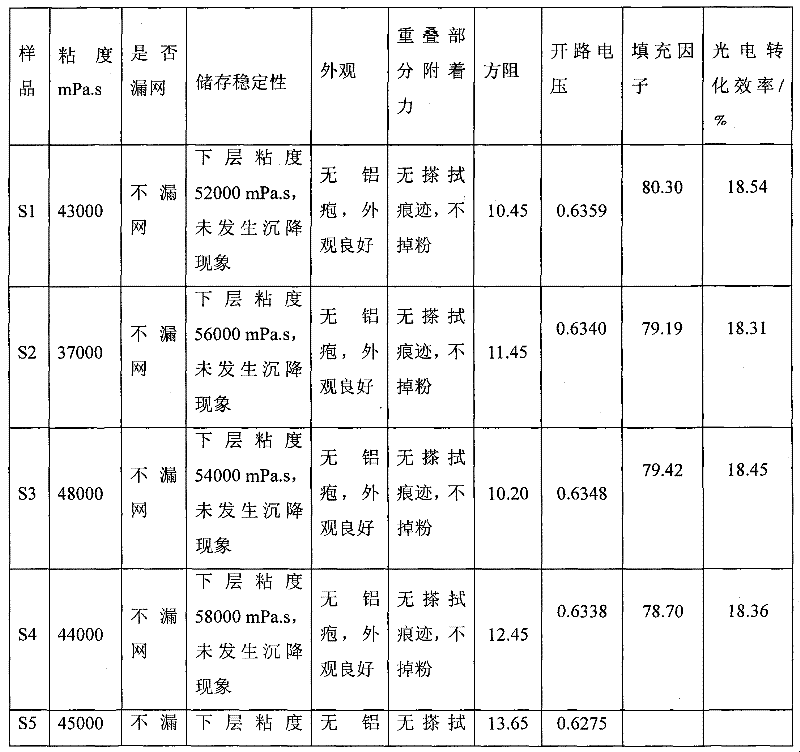

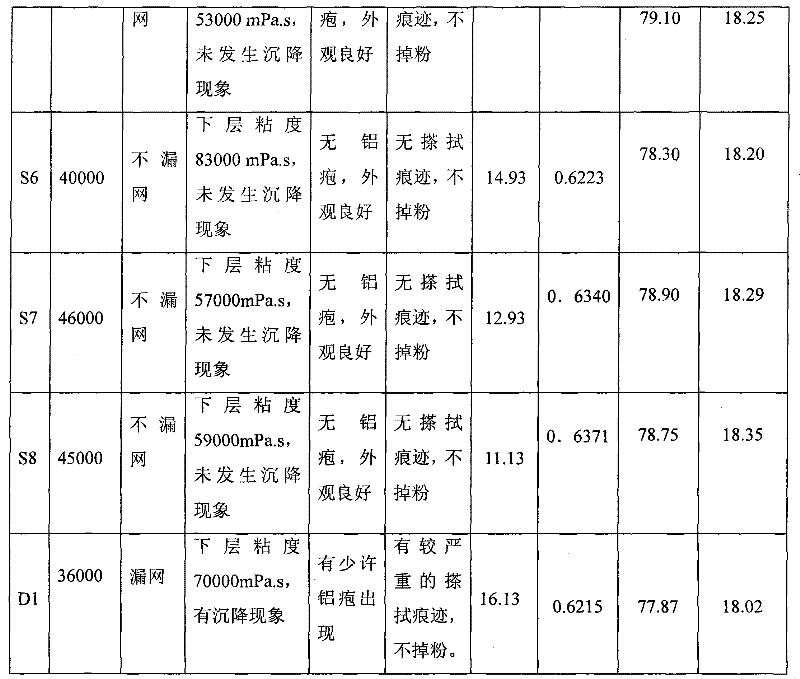

Conductive paste for solar cell and preparation method thereof

ActiveCN102479568AImprove rheologyEasy constructionNon-conductive material with dispersed conductive materialCable/conductor manufactureOpen-circuit voltageSedimentation

The invention provides a conductive paste and a preparation method thereof. The conductive paste comprises aluminum powder, an inorganic binding agent, an organic carrier and metal-glass composite powder, wherein the metal-glass composite powder is of nano-particles and a core-shell structure, glass is used as a core material, and metal is used as a shell material. The conductive paste disclosed by the invention is good in storage stability and less prone to sedimentation and agglomeration, and the conductive paste is less prone to leakage from a screen during screen printing; after sintering, an aluminum film is smooth in surface and grey white, and has no aluminum vesicles or aluminum beads; and furthermore, the part in contact and superimposition with a back silver electrode, of the aluminum film is wiped by a non-dust cloth, and wiping traces and powder dropping can be avoided. The series resistance of the produced solar cell is reduced obviously, a filling factor is increased obviously, and the average photoelectric conversion efficiency of a monocrystalline silicon cell piece can be above 18.20%. Simultaneously, the conductive paste disclosed by the invention is good in construction performance, a film layer formed after sintering is compact, the sintering thickness is uniform, the bending of a silicon chip is small, the sheet resistance is small and the open circuit voltage (Voc) of the formed cell is high.

Owner:BYD CO LTD

Method for preparing microcrystalline glass composite material containing alumina

InactiveCN101565323AImprove uniformityReduce manufacturing costAluminium oxides/hydroxidesFiberGlass composites

The invention relates to a method for preparing a microcrystalline glass composite material containing alumina, which comprises the following steps: adopting boehmite sol to prepare a microcrystalline glass precursor containing the alumina; performing heat treatment on the precursor at a temperature of around 500 DEG C; mixing amorphous microcrystalline glass powder containing the alumina after the heat treatment with a solvent and a binding agent to prepare slurry; and preparing the unidirectional carbon fiber reinforced microcrystalline glass composite material containing the alumina by adopting the prior art of slurry soaking and hot pressed sintering. Compared with the unidirectional carbon fiber reinforced microcrystalline glass composite material containing the alumina, which is prepared through slurry soaking and hot pressed sintering by founding glass first and then preparing matrix powder, the microcrystalline glass composite material containing the alumina has the characteristics of low energy consumption, simple process, good evenness of basic components, low firing temperature and the like.

Owner:HARBIN INST OF TECH AT WEIHAI

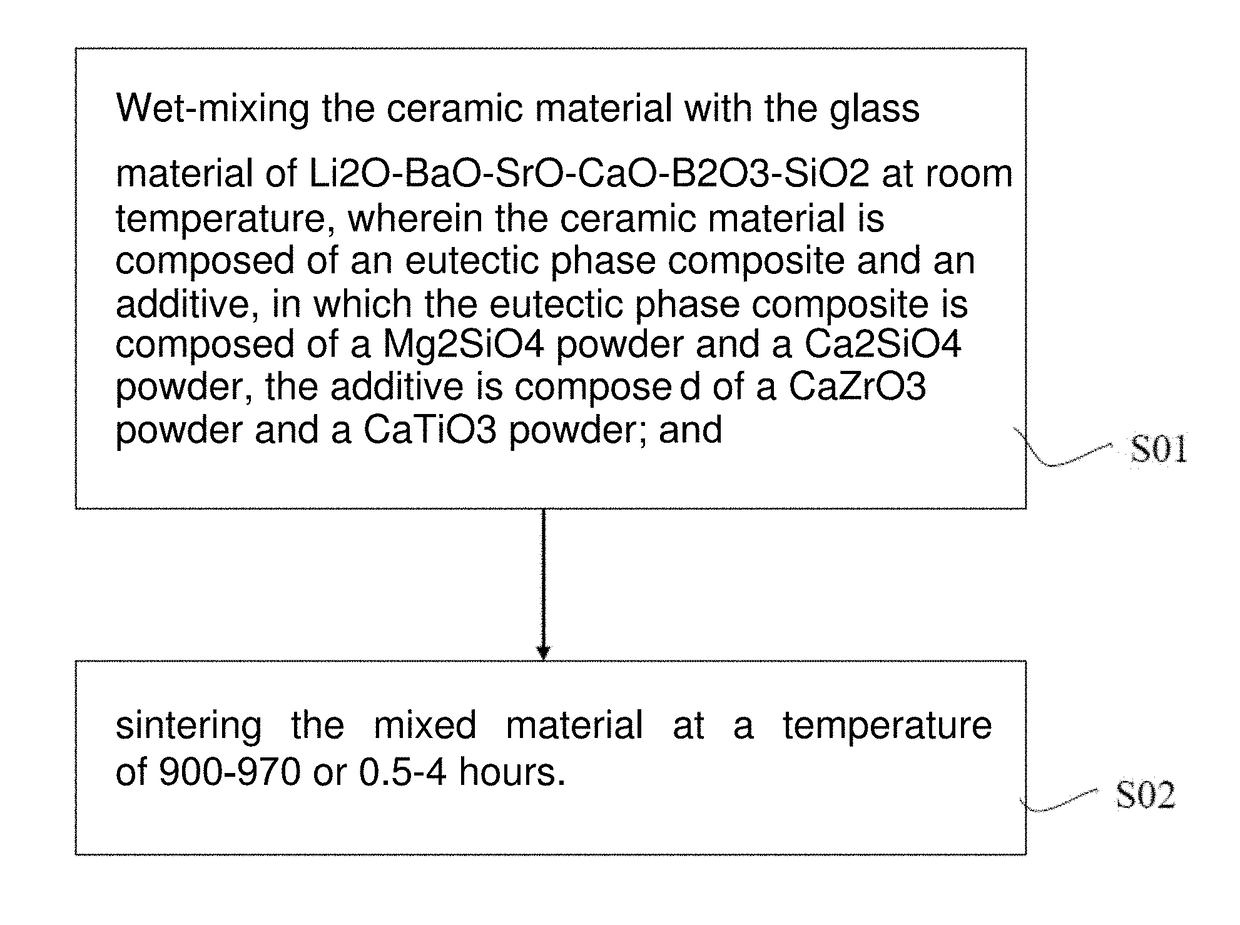

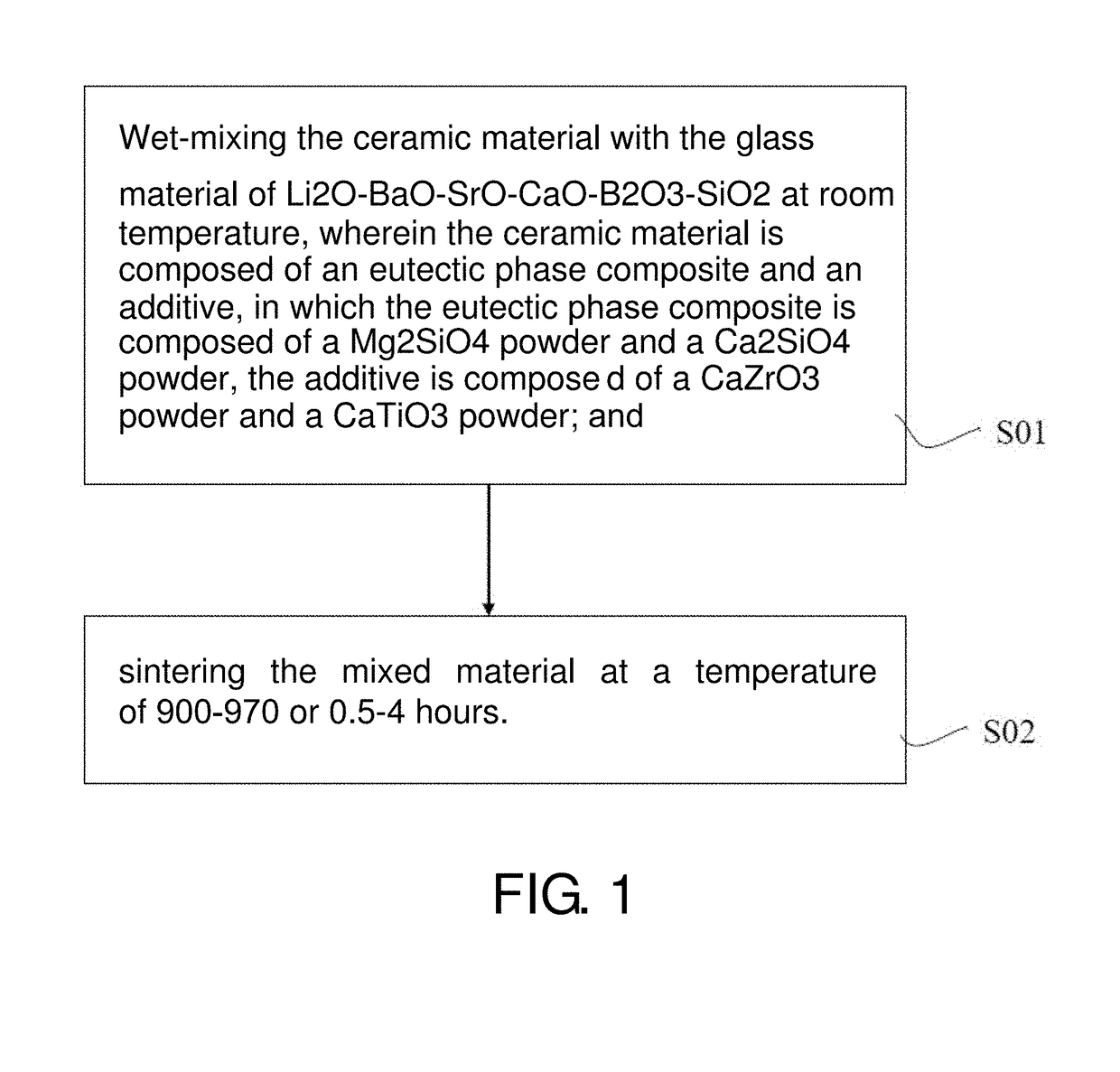

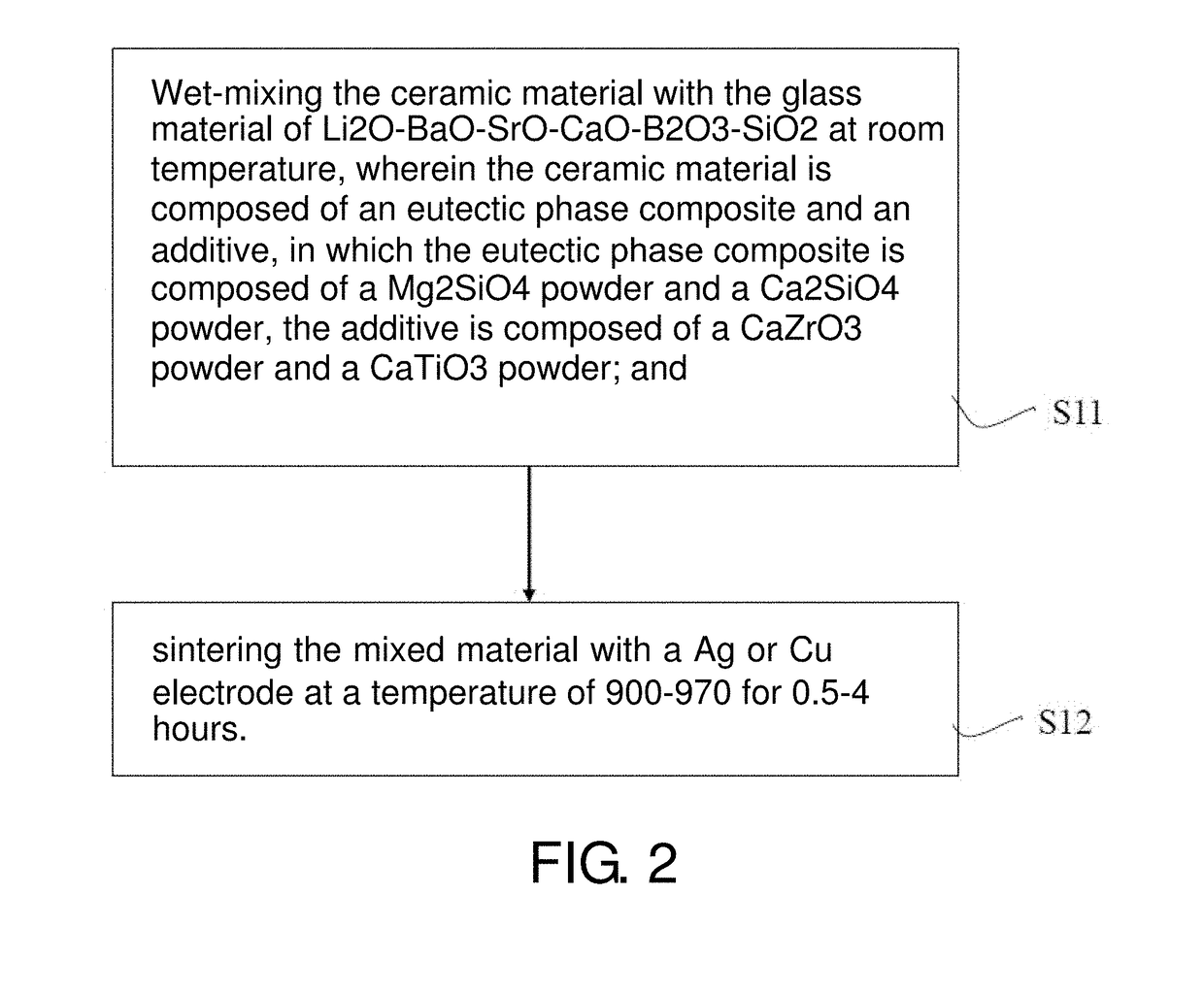

Low-temperature co-fired microwave dielectric ceramic material and preparation method thereof

InactiveUS20170334785A1Maintain good propertiesLow dielectric constantCeramicsWaveguide type devicesGlass compositesDielectric loss

A low-temperature, high stability co-fired microwave dielectric composite of ceramic and glass, including 85-99 wt % microwave dielectric ceramic of formula [1-y-z[(1−x)Mg2SiO4−xCa2SiO4]−yCaTiO3−zCaZrO3, wherein 0.2≦x≦0.7,0.05≦y≦0.3 and 0.02≦z≦0.15], and 1 to 15 wt % with Li2O—BaO—SrO—CaO—B2O3—SiO2 glass respectively made at a low sintering temperature of ceramic for co-firing with Ag or Cu electrode, employing eutectic phase of ceramic oxides to reduce its melting temperature, a low melting-point glass material with high chemical stability as a sintering aid added to oxides and raw material powders of Li2O, BaO, SrO, CaO, B2O3 and SiO2, obtained by combining and melting the ingredients in the temperature range between 1000 to 1300° C., quenching and crashing, and then adding it to the main ceramic oxides to form the final composition. This ceramic / glass composite material may be co-fired with an Ag and Cu electrode at 900° C.-970° C. for 0.5-4 hours in a protective atmosphere. After sintering, this dielectric material possesses efficacious microwave dielectric properties, dielectric constant between middle-K to low-K at 8−15, high quality factors, low dielectric loss, low temperature-capacitance coefficient and superior chemical stability suitable for manufacture of multilayer ceramic devices.

Owner:WALSIN TECHNOLOGY CORPORATION

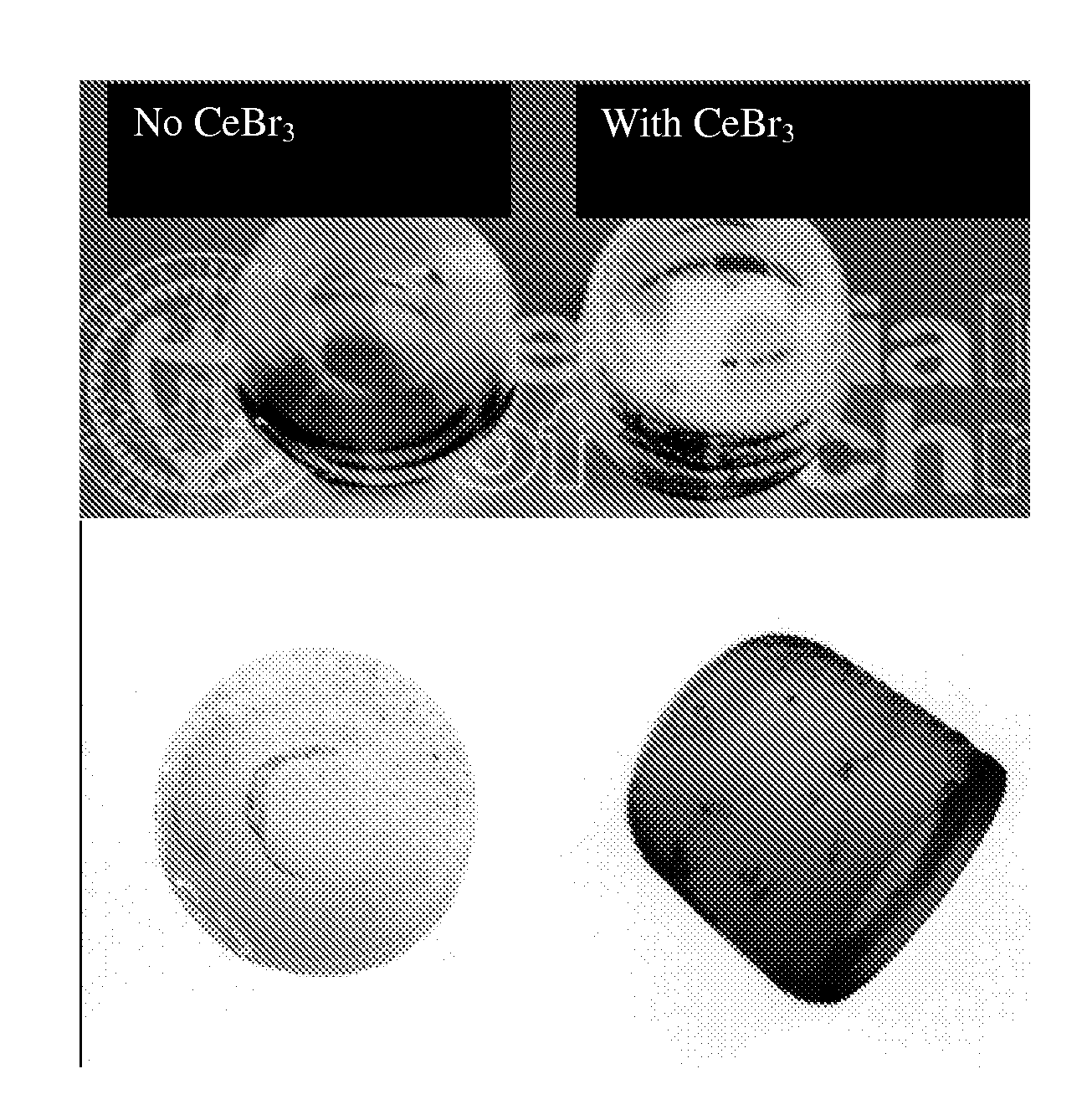

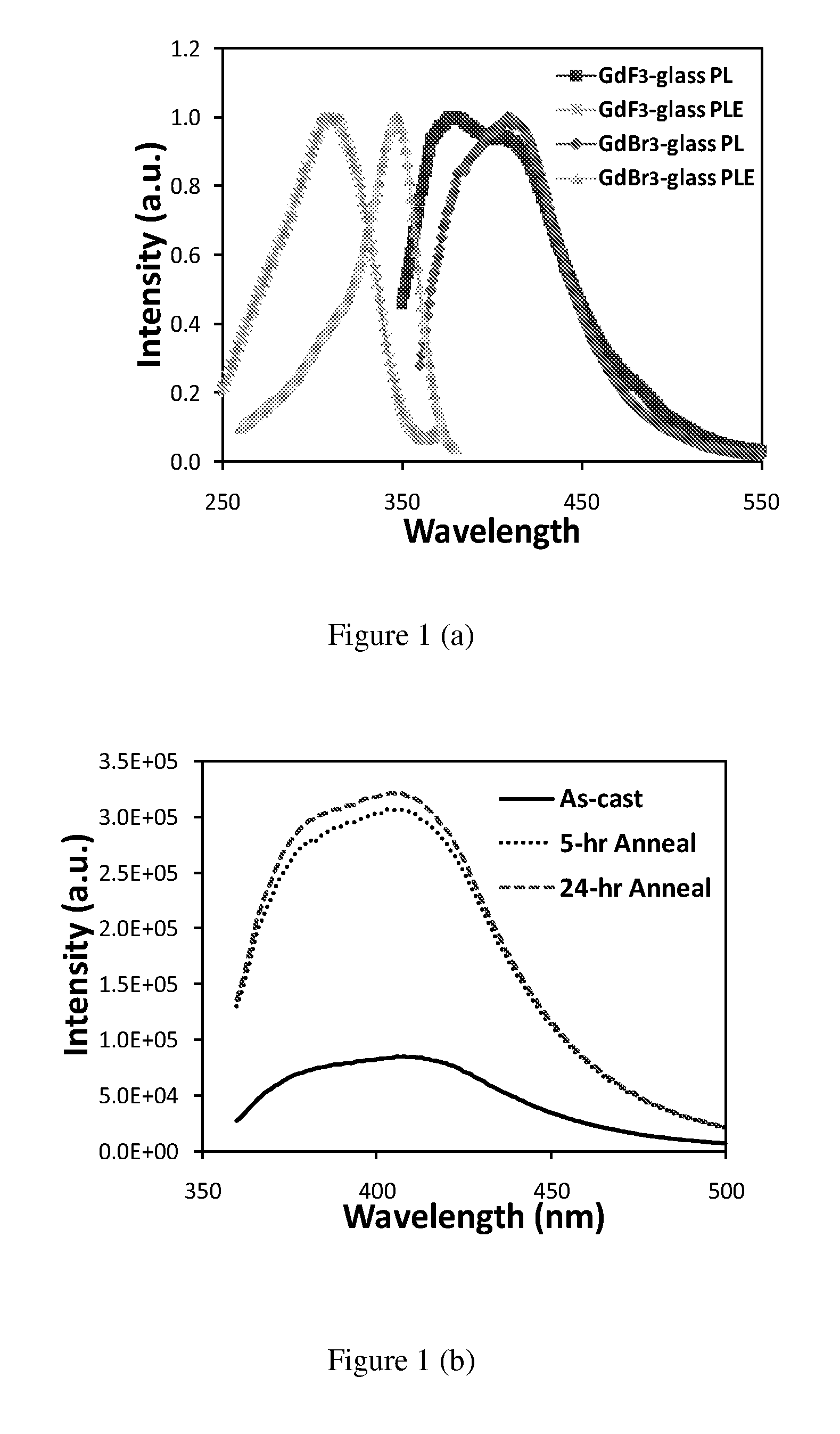

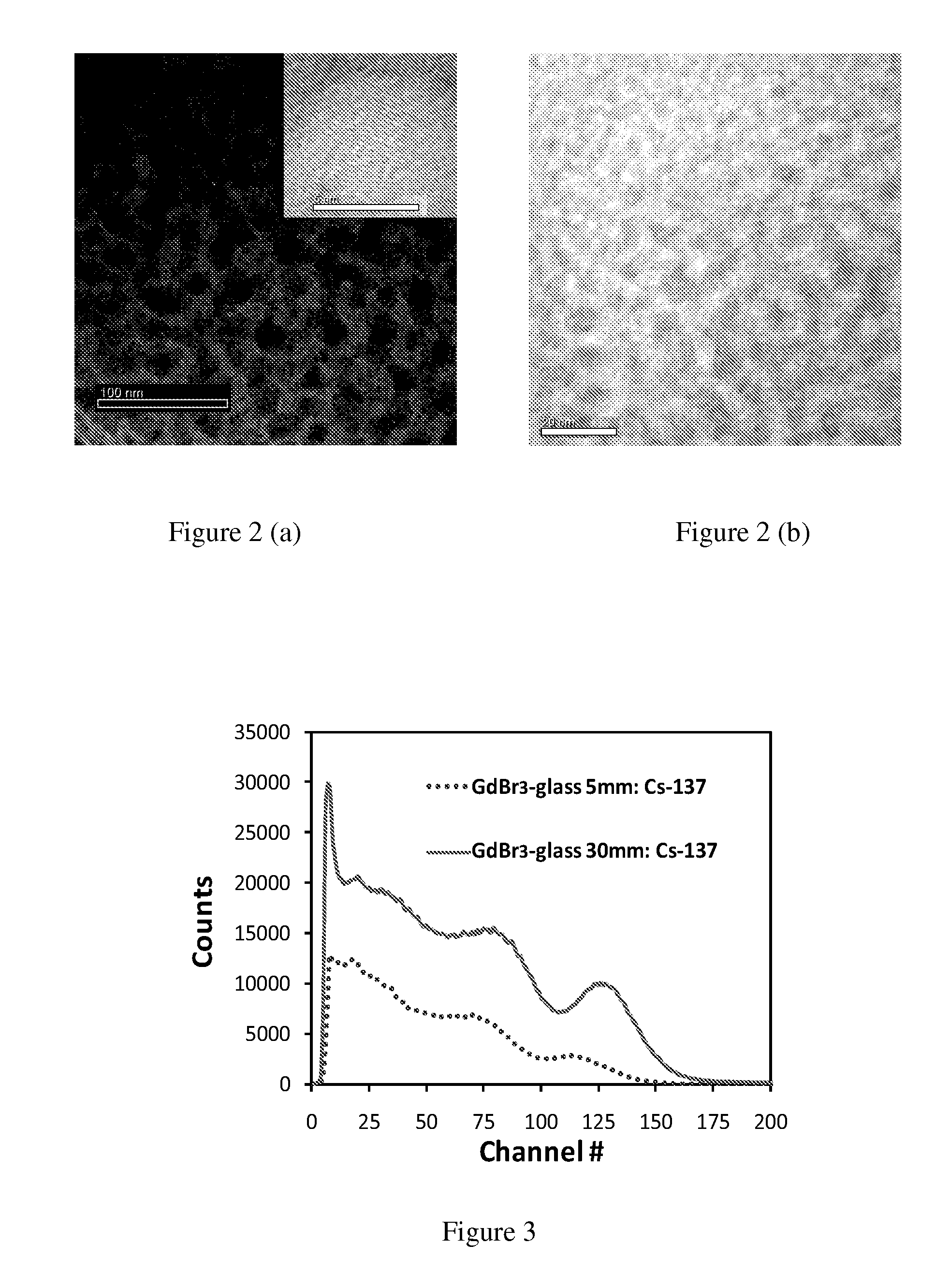

Transparent glass scintillators, methods of making same and devices using same

ActiveUS20140166889A1Measurement with scintillation detectorsPhotometryNuclear radiationGlass composites

Compositions and methods are described for transparent glass composite having nanoparticles therein that scintillate in the presence of nuclear radiation, particularly gamma rays, but also x-rays, alpha particles, beta particles, and neutrons. The transparent glass composites can be prepared by a melt / cool process to produce the transparent glass composite. The wavelength of light emitted by the transparent glass composite can be tailored based on the materials used to make the glass composite. A detector that utilizes the transparent glass composite can measure nuclear radiation from numerous sources.

Owner:GEORGIA TECH RES CORP

Bulk metal glass composite material with stretching plasticity and work hardening capacity

The invention relates to a bulk metal glass composite material with stretching plasticity and work hardening capacity. A crystal phase capable of producing phase change is generated in the metal glass during deforming by alloy component control and cooling speed adjustment, and the crystal phase is deformed to produce the phase change so as to prepare the composite material. The bulk metal glass composite material with the stretching plasticity and work hardening capacity is prepared by taking common pure metal elements as main components, mixing the materials according to an atomic percentage expressed by an alloy component expression, and smelting and suction casting. The bulk metal glass composite material contains 10 to 60 volume percent of crystals. The bulk metal glass composite material of the invention can undergo the phase change during deforming, has higher strength and compression plasticity, particularly has higher stretching plasticity and work hardening capacity, and can meet the requirement of practical engineering application; therefore, the composite material has quite broad engineering application prospect.

Owner:UNIV OF SCI & TECH BEIJING

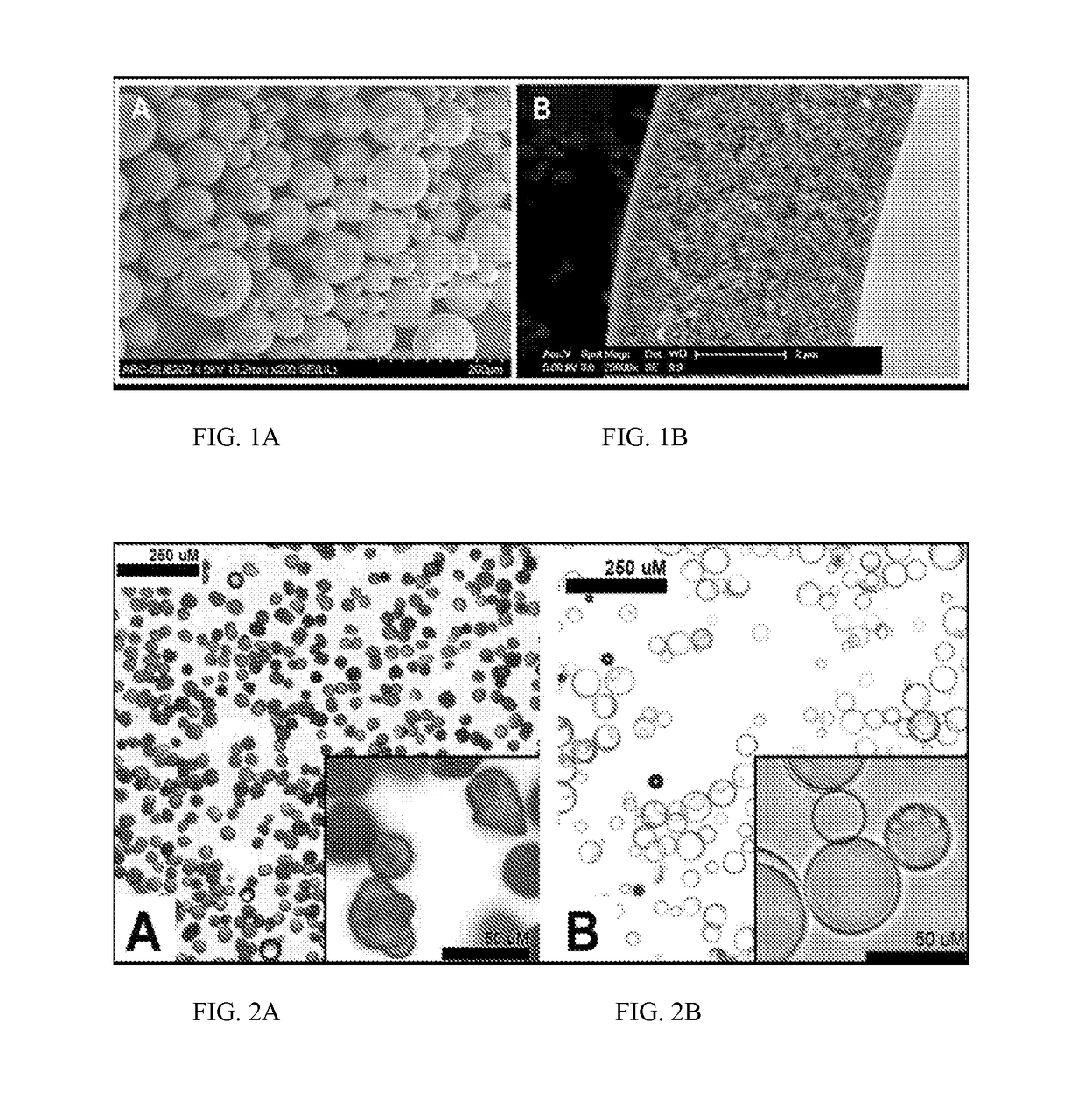

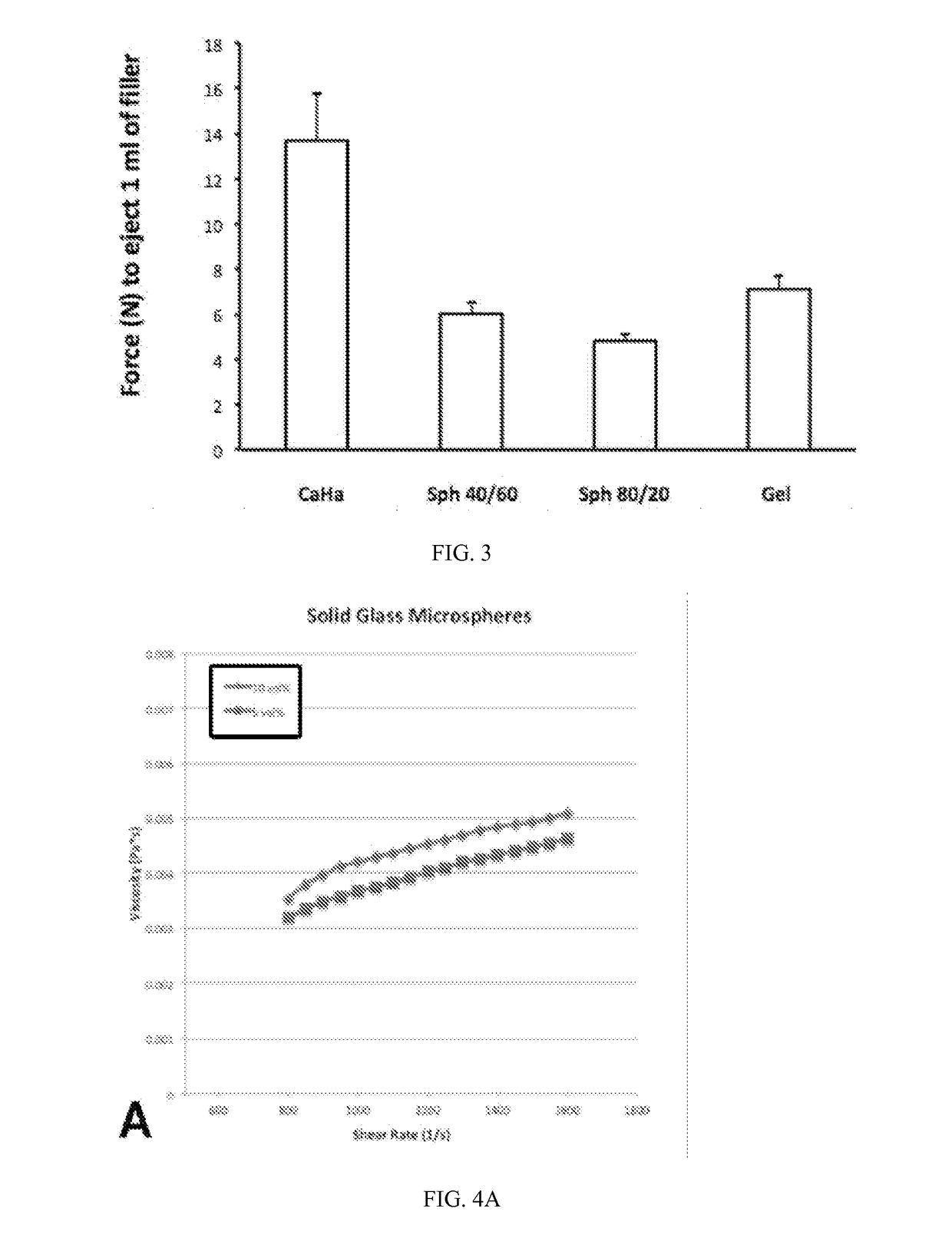

Glass Composites for Tissue Augmentation, Biomedical and Cosmetic Applications

ActiveUS20170354755A1Controlled and reduced viscosityReduces and inhibits and prevents immunological reactionPigmenting treatmentCosmetic preparationsGlass compositesMicrosphere

Compositions and methods for glass composites suitable for tissue augmentation, biomedical, and cosmetic applications are provided. The glass microsphere component of the composites are biologically inert, non-reactive and act as a nearly permanent tissue filler. One embodiment provides a tissue augmentation composite containing an effective amount of solid glass microspheres, hollow glass microspheres, porous wall hollow glass microspheres, or combinations thereof with a suitable biocompatible matrix to serve as a bulking agent when injected into a patient. The compositions can be used for soft or hard tissue augmentation as well as delivery of cargos on demand.

Owner:AUGUSTA UNIV RES INST INC +1

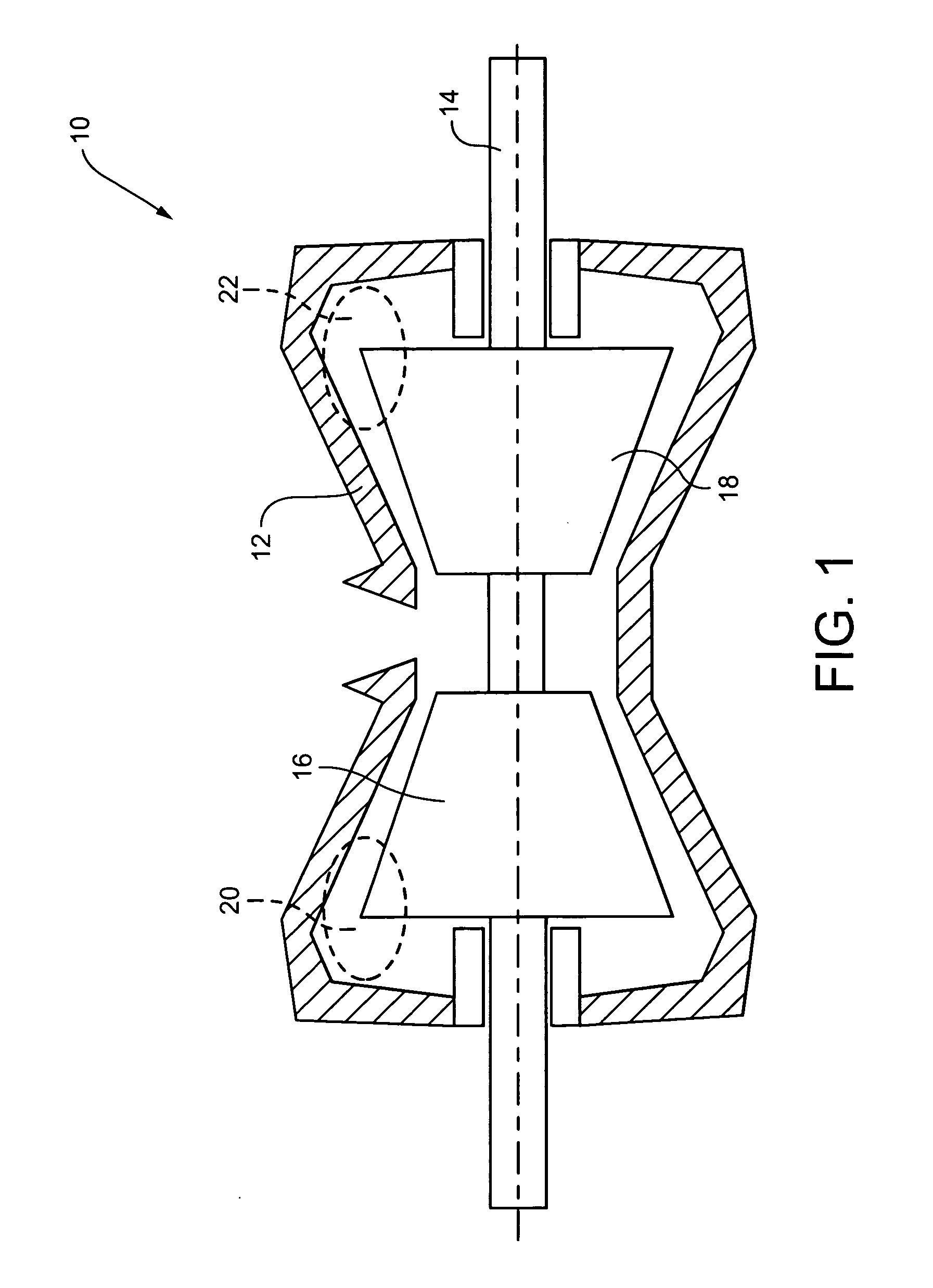

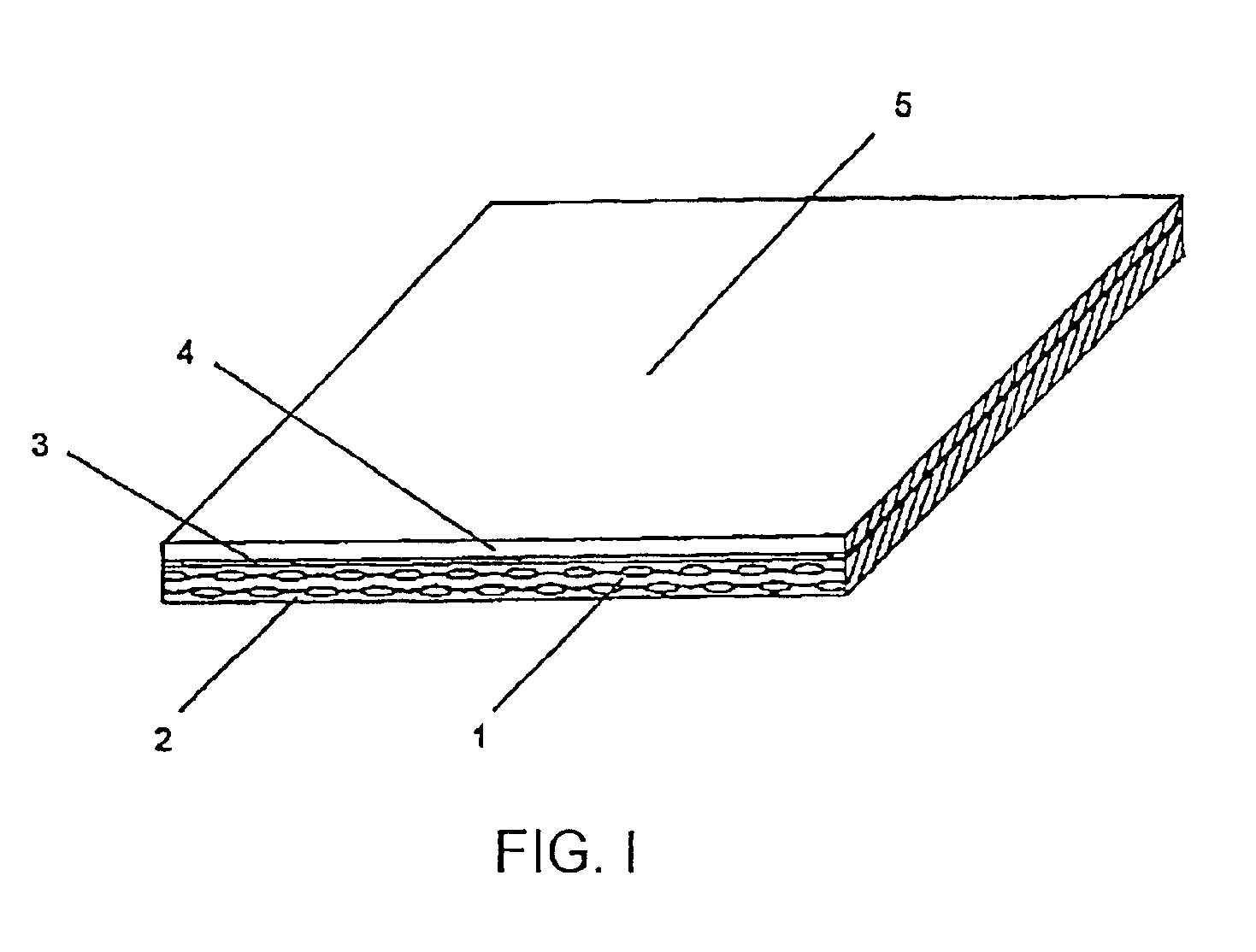

Lightweight Blast Mitigating Composite Panel

ActiveUS20110041679A1Improve adhesionAbility to disperse/distribute localized blast loadSynthetic resin layered productsMilitary adjustmentFiberGlass composites

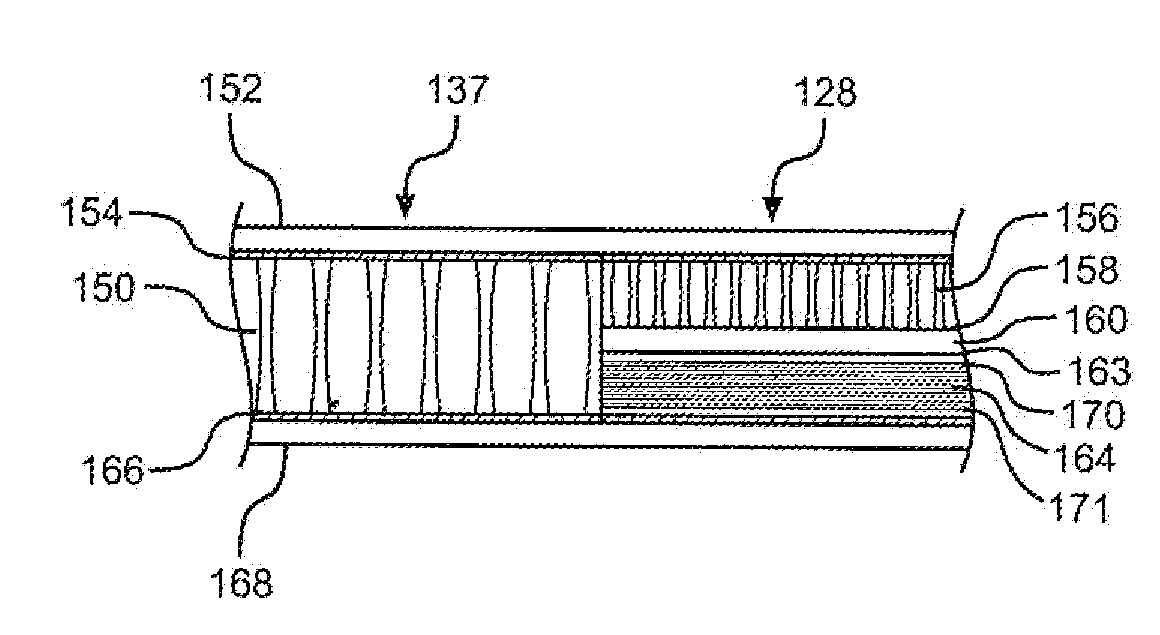

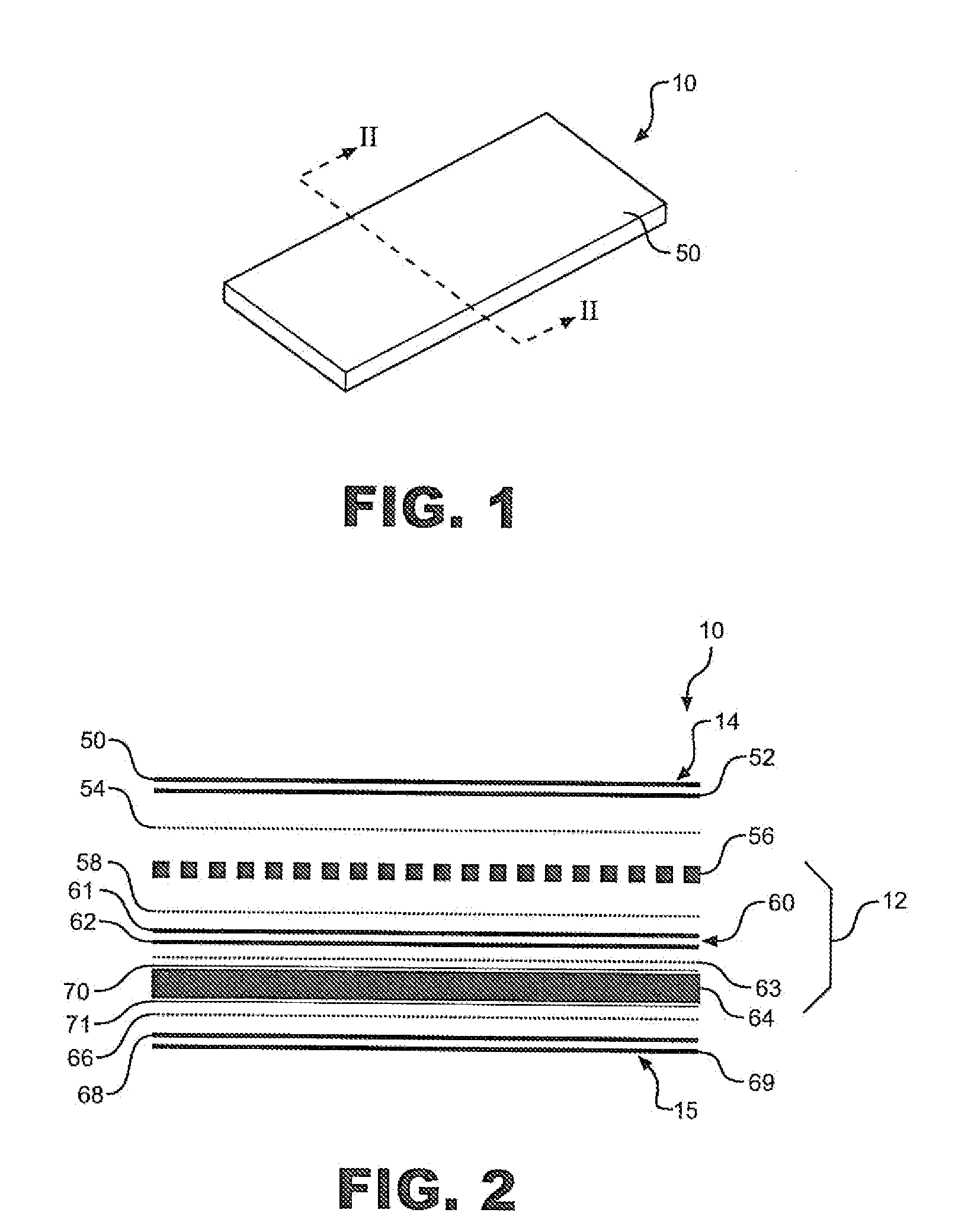

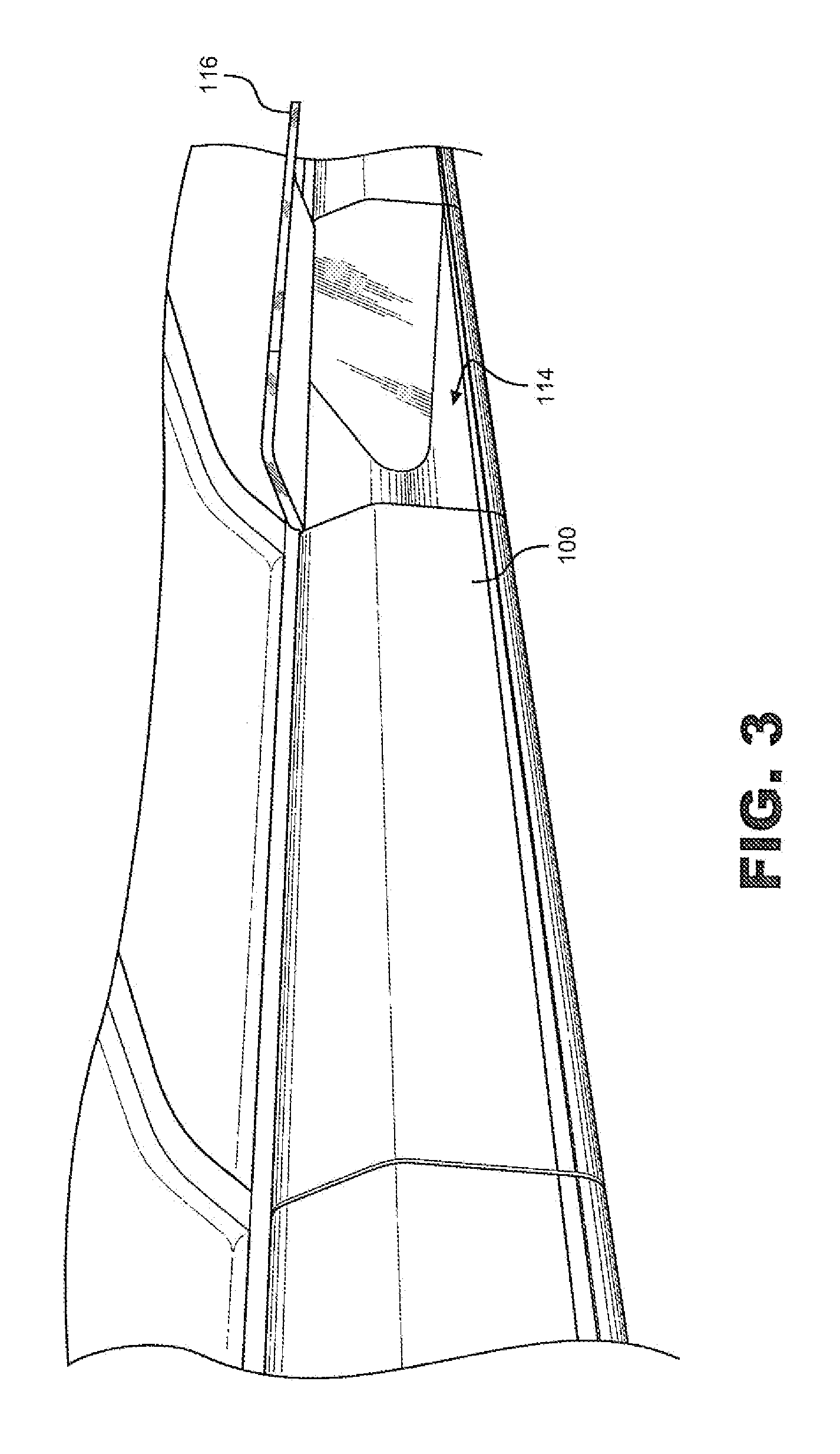

Lightweight blast mitigating composite panels (10) include a first glass composite shell (14; 152), an intermediate, preferably honeycomb layer (56; 156), a reinforcing layer (60; 160), an ultra high molecular weight polyethylene fiber (UHMWPE) layer (64; 164) and a second glass composite shell (15; 168) adhered together with fire resistant adhesive layers (54; 58, 63, 66; 154, 158, 163, 166). The UHMWPE layer (64; 164) includes top and bottom coatings (70, 71) of fire resistant thermoset plastic preferably in the form of a paste. The panels (10) have use in a wide range of applications including in a blast mitigating overhead storage bin (100). The storage bin (100) includes a main body portion (133) defining a storage area formed from composite unarmored and armored panel segments (137, 138; 128-132). The unarmored and armored panel segments (137, 138; 128-132) share first and second shells (14, 15) to form an integral main body portion, with the armored panel segments (128-132) providing blast protection between the storage area and a wall (125) of an airplane cabin (120).

Owner:BATTELLE MEMORIAL INST

Low fluorescence nylon/glass composites for micro-analytical diagnostic applications

InactiveUS6734012B2Minimizes in detectionMinimizes participationBioreactor/fermenter combinationsBiological substance pretreatmentsGlass compositesMicroscope slide

An improved combination non-luminescent microporous membrane and solid support for use in micro-analytical diagnostic applications is disclosed. Specifically, composite microarray non-luminescent slides having a microporous membrane effectively attached by covalent bonding through a surface treatment to a substrate that prepares the substrate to sufficiently, covalently bond to the non-luminescent microporous membrane formed by a phase inversion process such that the combination produced thereby is useful in microarray applications and wherein the porous non-luminescent nylon composite microarray slides are covalently bonded to a solid base member, such as, for example, a glass or Mylar microscope slide, such that the combination produced thereby is useful in microarray applications. Apparatus and methods for fabricating lithe non-luminescent composite microarray slides are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com