Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

707 results about "Work hardening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Work hardening, also known as strain hardening, is the strengthening of a metal or polymer by plastic deformation. Work hardening may be desirable, undesirable, or inconsequential, depending on the context.

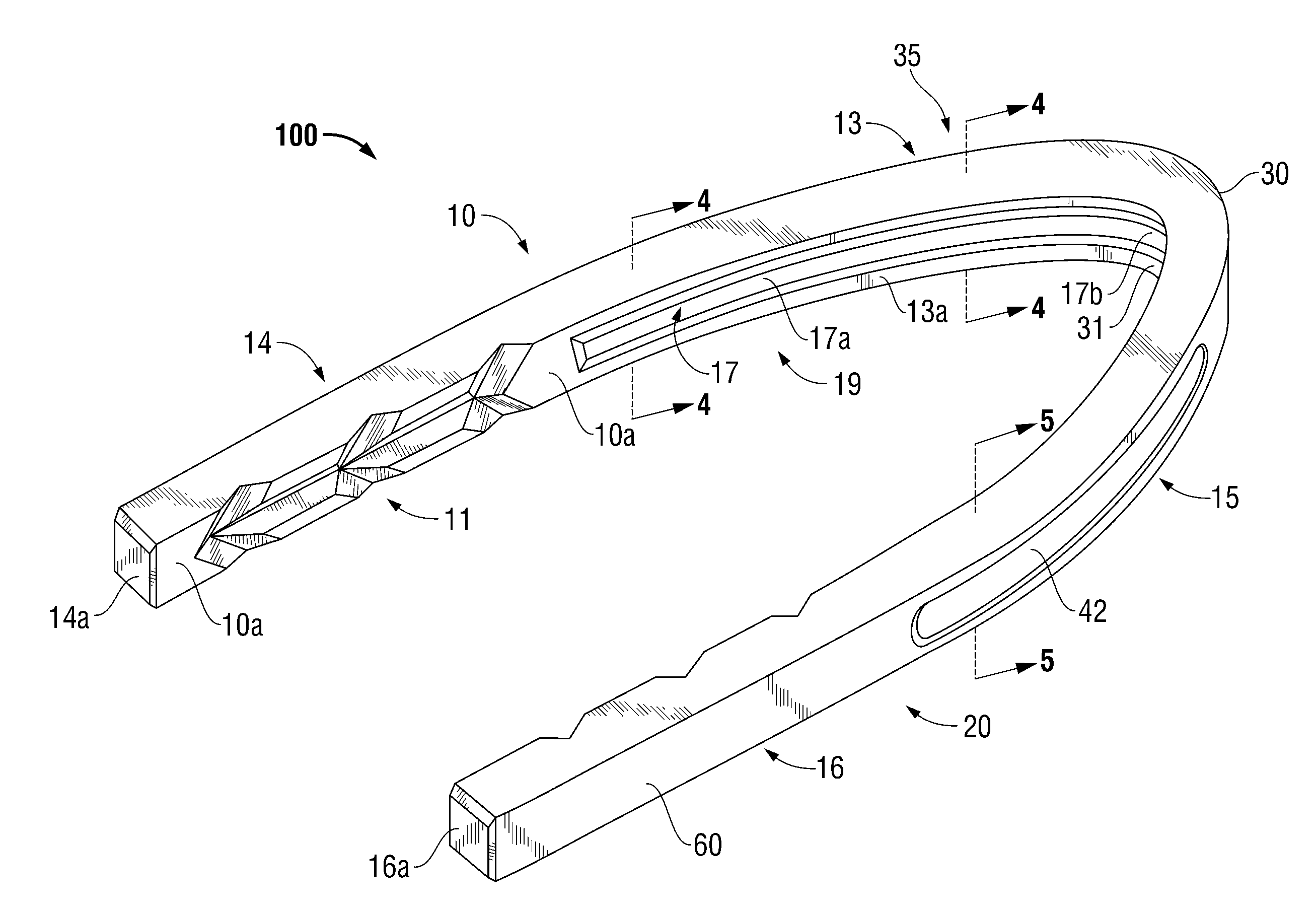

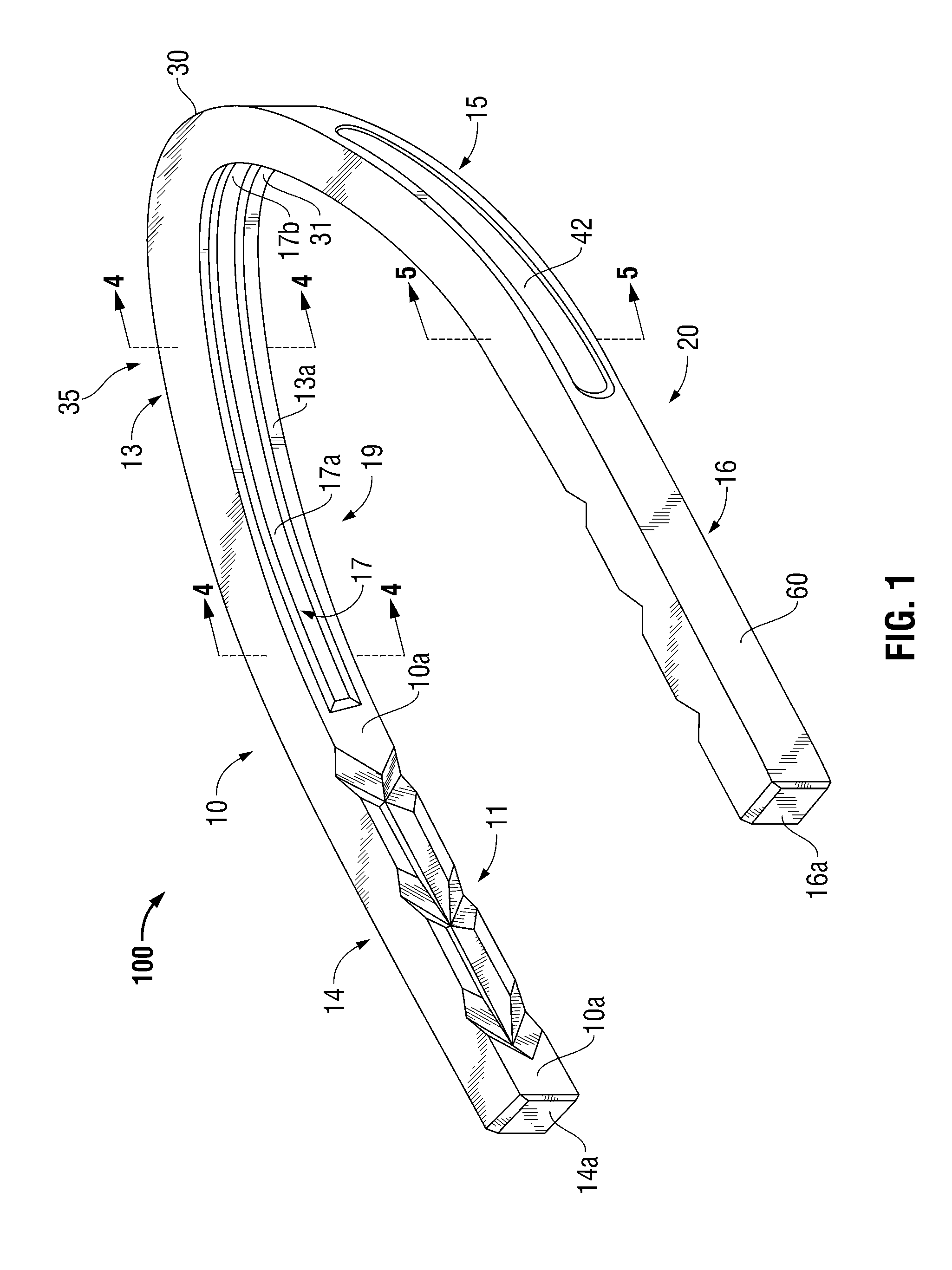

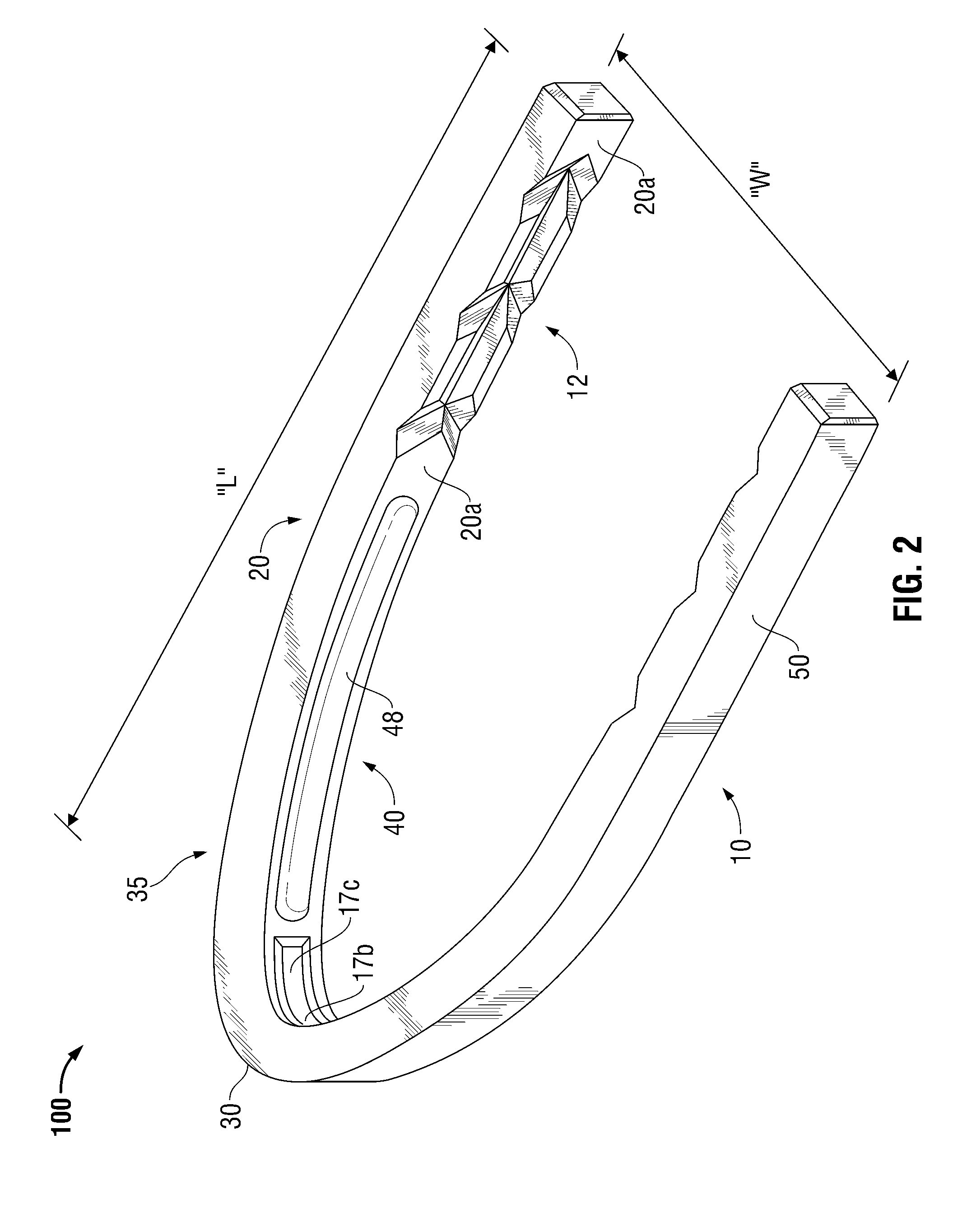

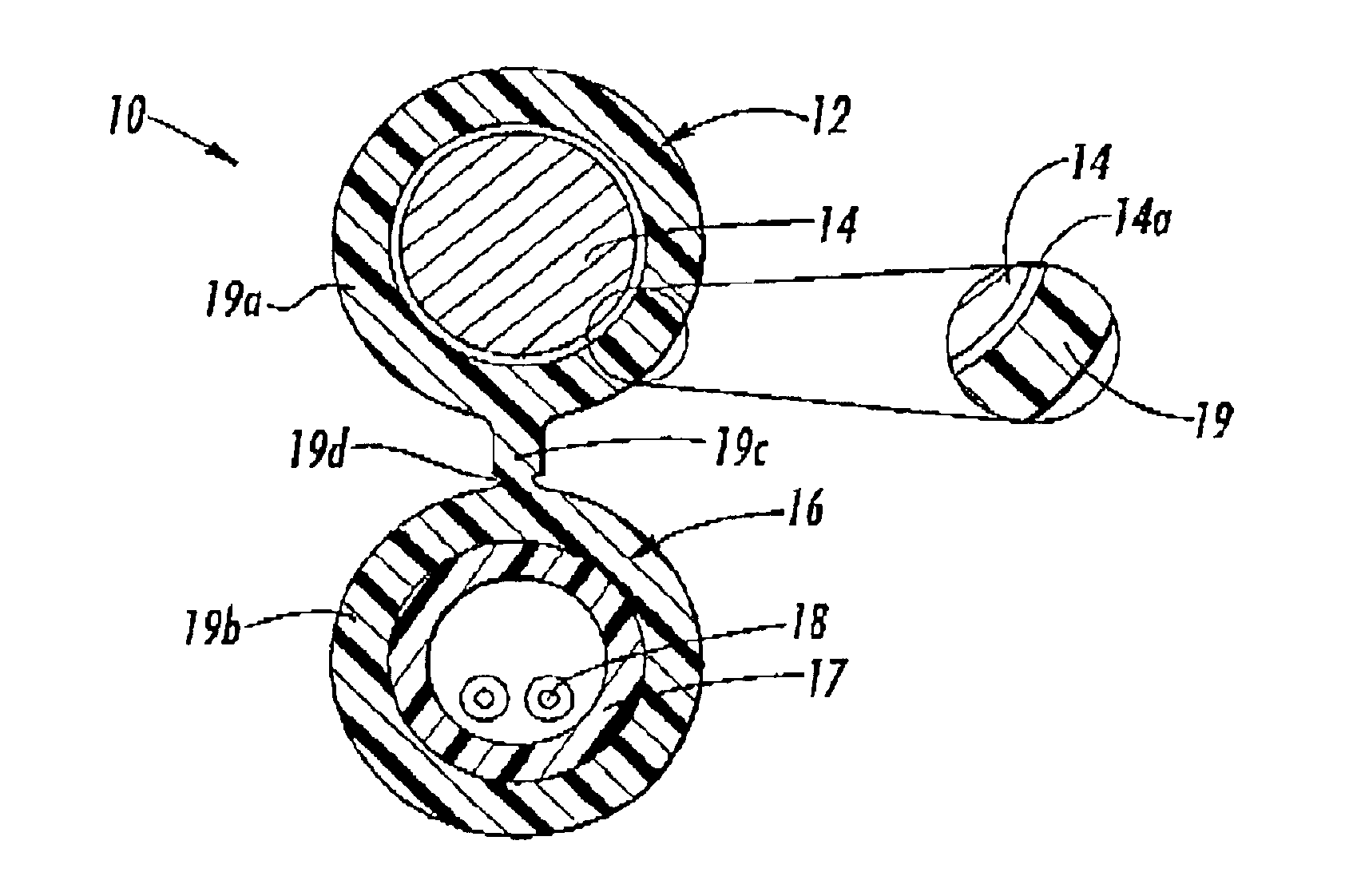

Surgical hemostatic clip including work-hardened, movement-inhibiting structure and method of manufacturing same

InactiveUS20110295290A1Enhance clip retentionMetal working apparatusWound clampsSurgical ClipsGeneral surgery

Owner:TYCO HEALTHCARE GRP LP

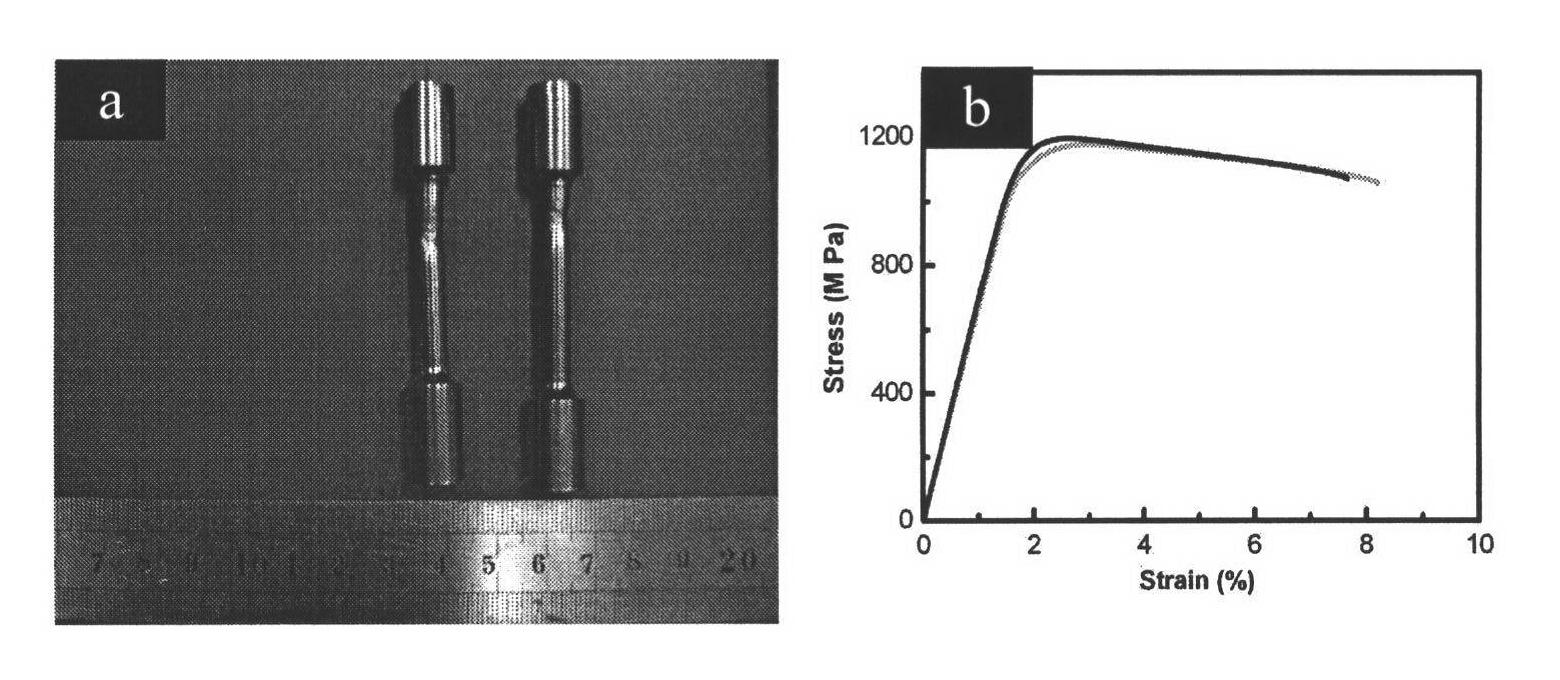

Method for manufacturing titanium alloy wire with enhanced properties

A method for producing reinforced titanium alloy wire, comprising forming a billet of titanium alloy with grains of a precipitated discontinuous reinforcement material such as TiB and / or TiC. The billet may be formed by the hot consolidation of a titanium alloy powder formed by gas atomization. The billet is then hot formed to reduce it to rod or coil form. The rod or coil is then subjected to successive cold drawing operations to form a reinforced titanium alloy wire of reduced diameter. The cold drawing includes periodic annealing operations under low oxygen conditions to relieve work hardening and to recrystallize the reinforcement material grains to reduce the size thereof.

Owner:FMW COMPOSITE SYST

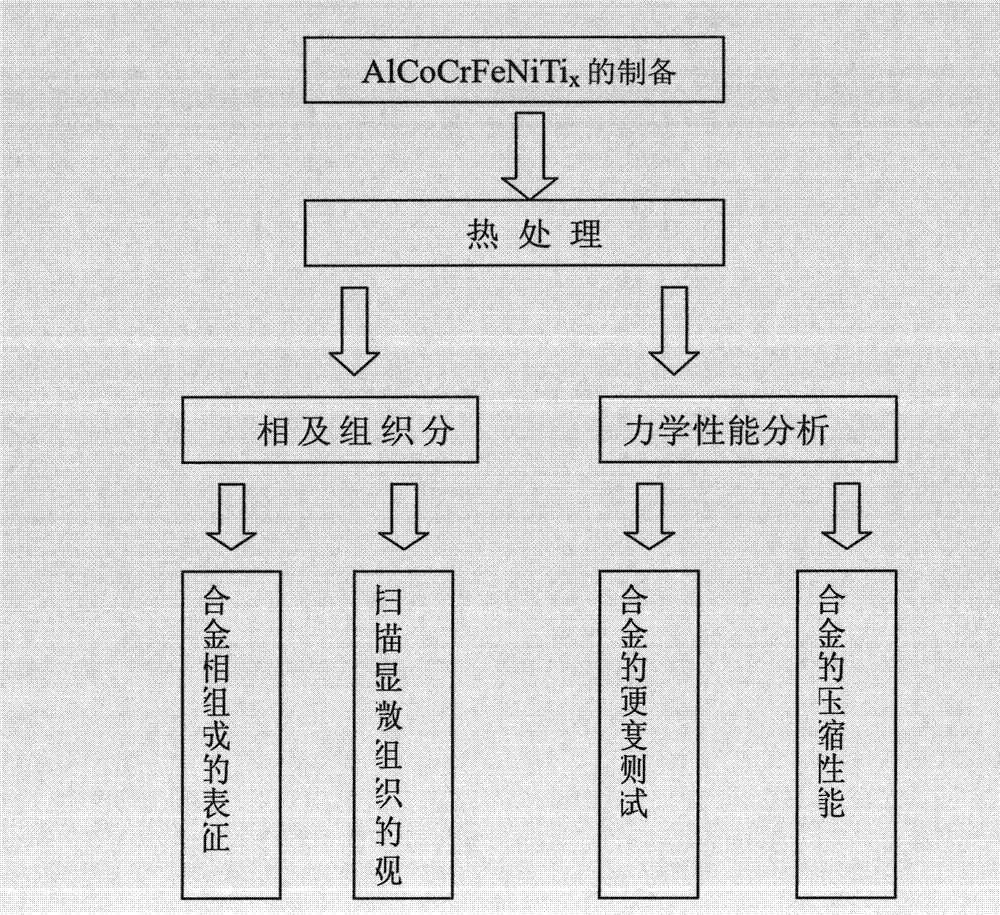

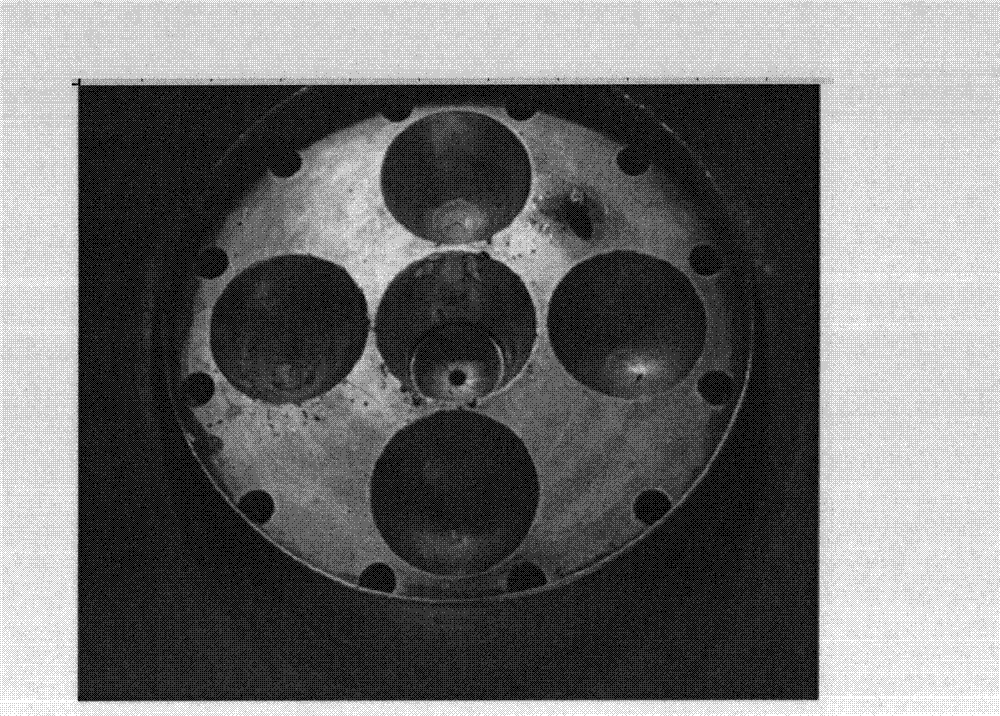

AlCoCrFeNiTix high-entropy alloy material and method for preparing same

The invention relates to a high-entropy alloy material and a method for preparing the same. The component of the high-entropy alloy material is AlCoCrFeNiTix, wherein x represents a molar ratio, and the value range is between 0.1-0.4. The method for preparing the material comprises: preparing raw materials, adopting the alloy smelting raw materials including Al, Co, Cr, Fe, Ni and Ti, and accurately weighing and proportioning according to the molar ratio; then, purifying oxide on a metal surface; putting the prepared raw materials into a tank in a water-cooling copper-formed mold smelting pool, vacuumizing, filling argon, controlling smelting current to be at about 250 ampere and smelting time for 30-60 seconds, turning an alloy block after alloys are fully mixed, putting an alloy ingot into a tank of a water-cooling copper-formed mold, regulating the smelting current, opening a suction casting air suction valve after the alloys are uniformly smelted, utilizing the negative pressure in a pump for suction casting, and taking out the alloy ingot after an alloy mould is cooled. Compared with the conventional crystalline state alloy, the high-entropy alloy material has relative high thermal stability, hardness, yield strength, breaking tenacity, plastic deformation and work hardening capacity.

Owner:TAIYUAN UNIV OF TECH

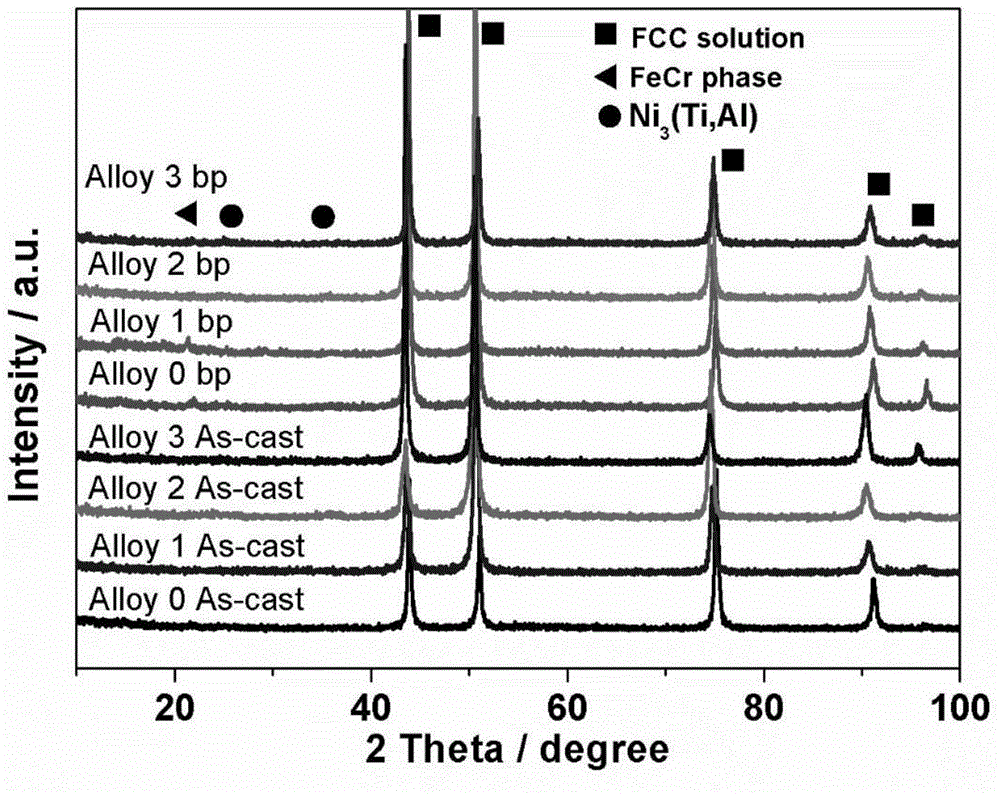

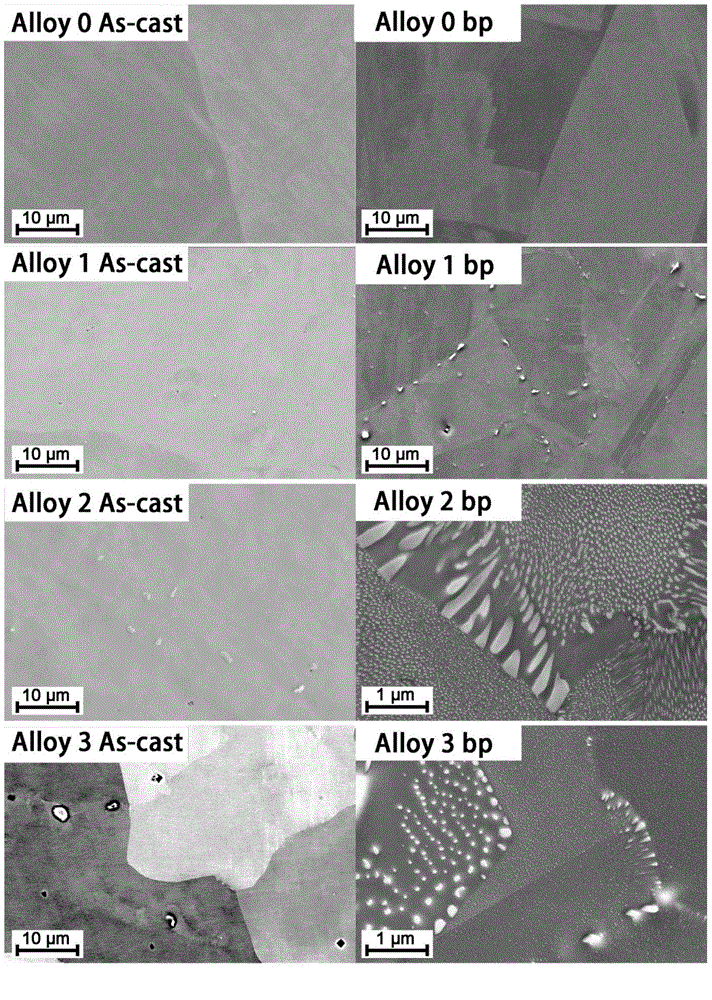

High-entropy alloy with dispersion nano-sized precipitate strengthening effect and preparing method thereof

ActiveCN104694808AWide range of ingredientsControl mechanical propertiesElectric arc furnaceHigh entropy alloys

The invention discloses high-entropy alloy with the dispersion nano-sized precipitate strengthening effect and a preparing method thereof. The method comprises the steps of removing oxidized skin of a metal material, and then conducting weighing and burdening accurately according to a ratio; conducing smelting in an electric-arc furnace in an argon shield atmosphere of titanium absorbed oxygen to obtain an initial high-entropy alloy ingot, and conducting cold rolling, wherein rolling reduction is 20-50%; placing the ingot in a heat treatment furnace with a temperature ranging from 900 DEG C to 1000 DEG C for heat preservation for 0.5-2 hours, and conducting quenching; placing the ingot in a heat treatment furnace with a temperature ranging from 700 DEG C to 800 DEG C for heat preservation for 2-18 hours, and conducting quenching. By means of precipitation strength, on the premise that high plasticity is kept, yield strength and tensile strength are improved greatly. The room-temperature tensile strength of (FeCoNiCr)94Ti2Al4 in the final state reaches 1094 MPa, plastic elongation is 35%, work hardening effect is remarkable, comprehensive room-temperature mechanical property is prominent, high-temperature tensile strength can reach 400 MPa at the temperature of 800 DEG C and strain rate of 10<-3>, steady creep rate is smaller than or equal to 10<-8> under the stress of 100 MPa and at the temperature of 750 DEG C, and high-temperature tensile strength and creep mechanical property are excellent.

Owner:UNIV OF SCI & TECH BEIJING

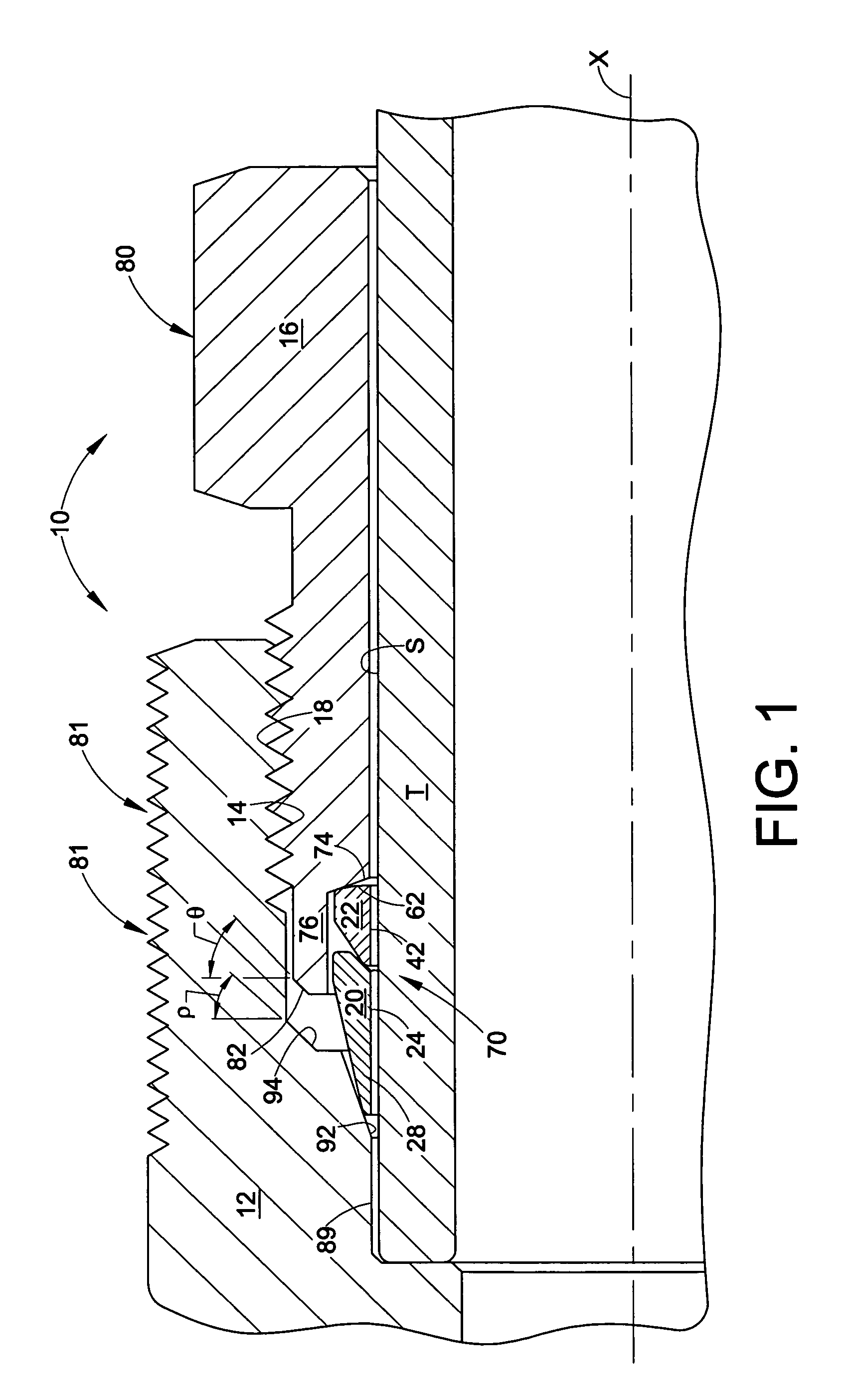

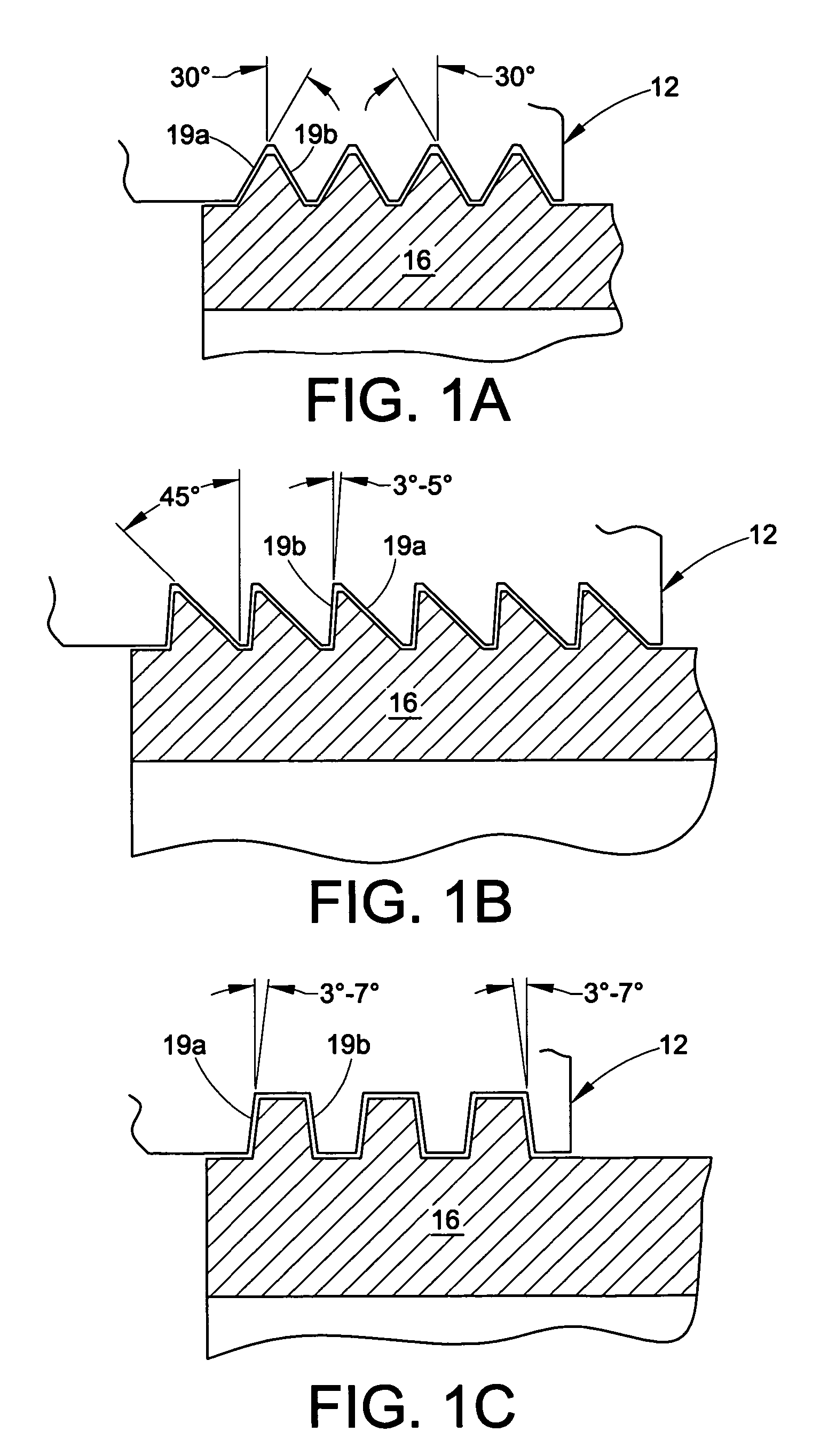

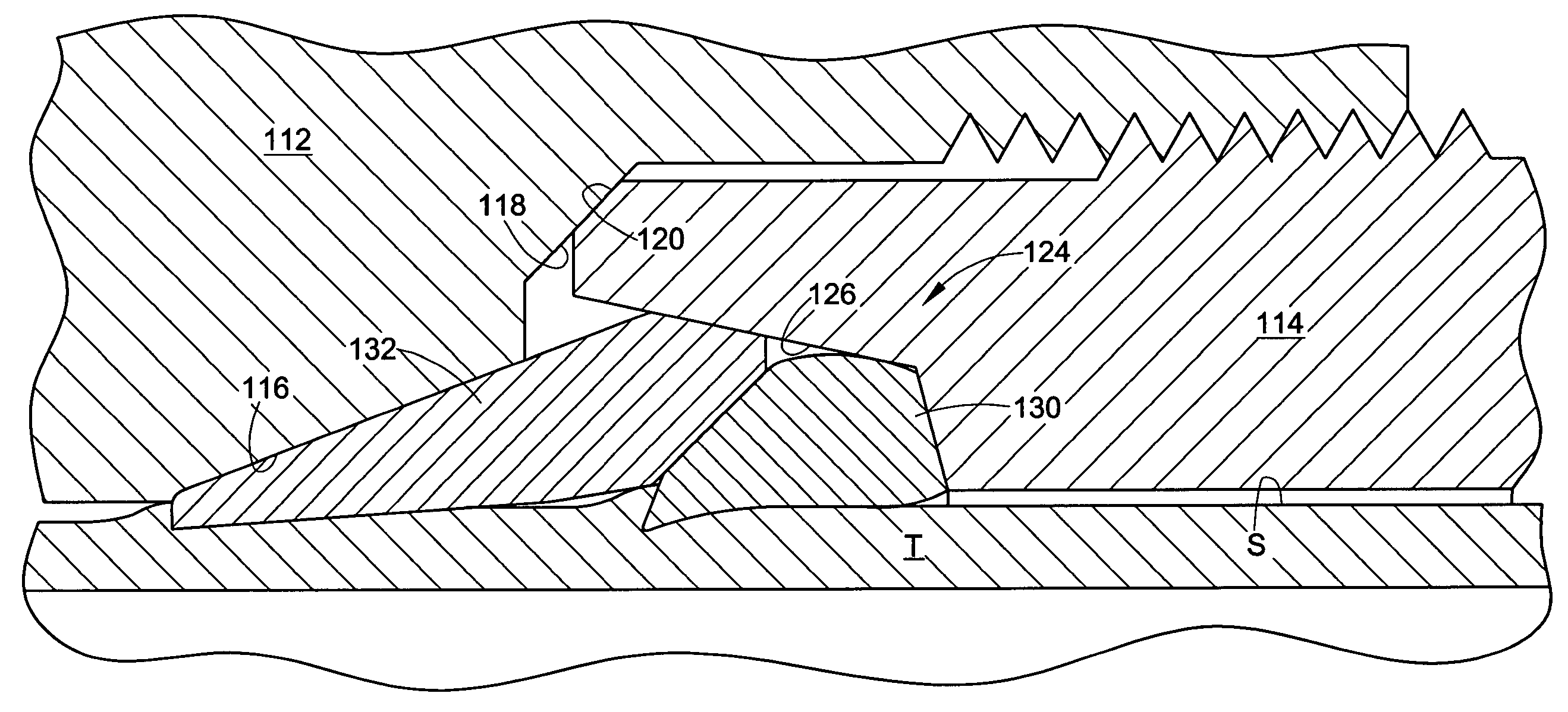

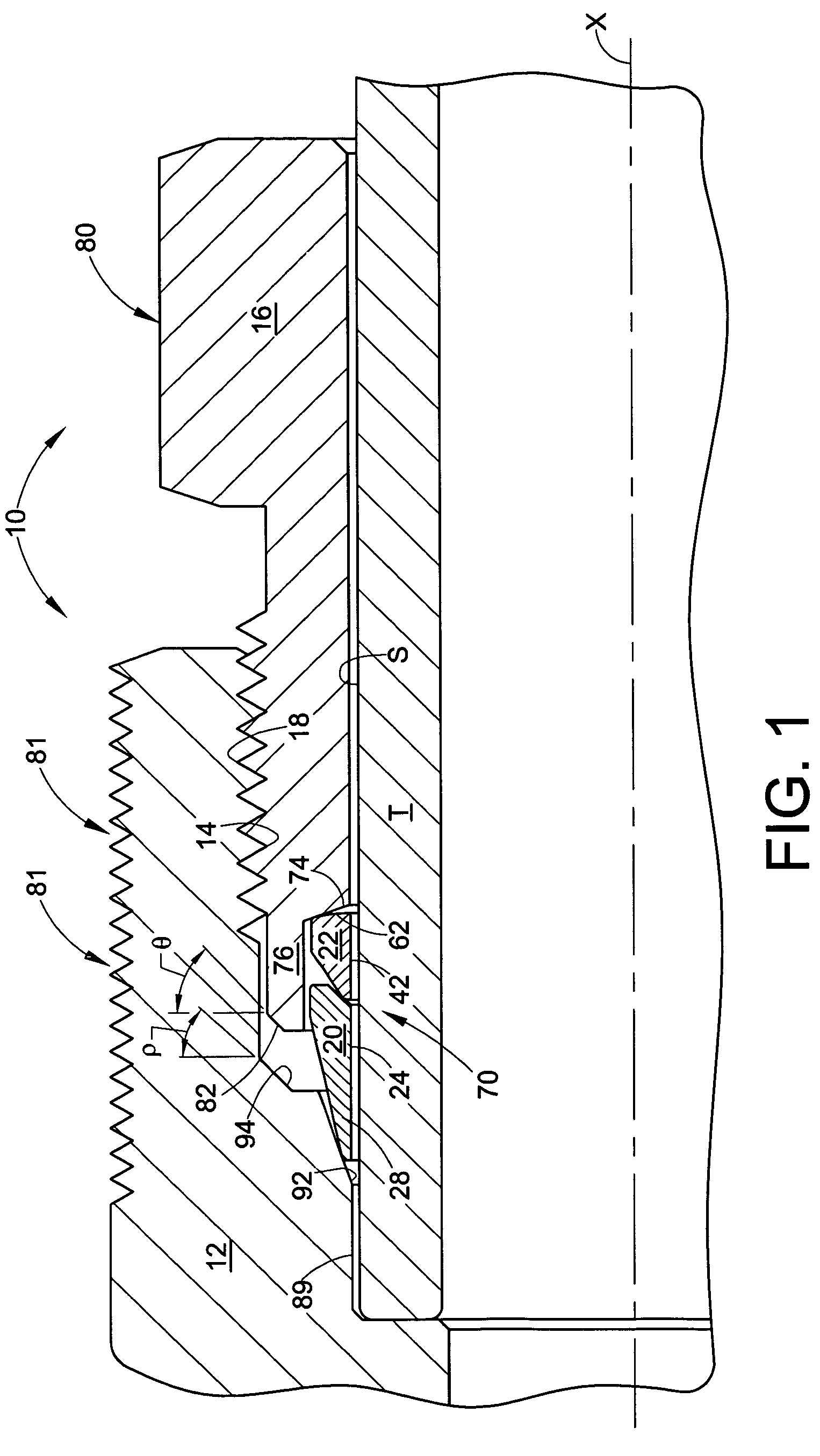

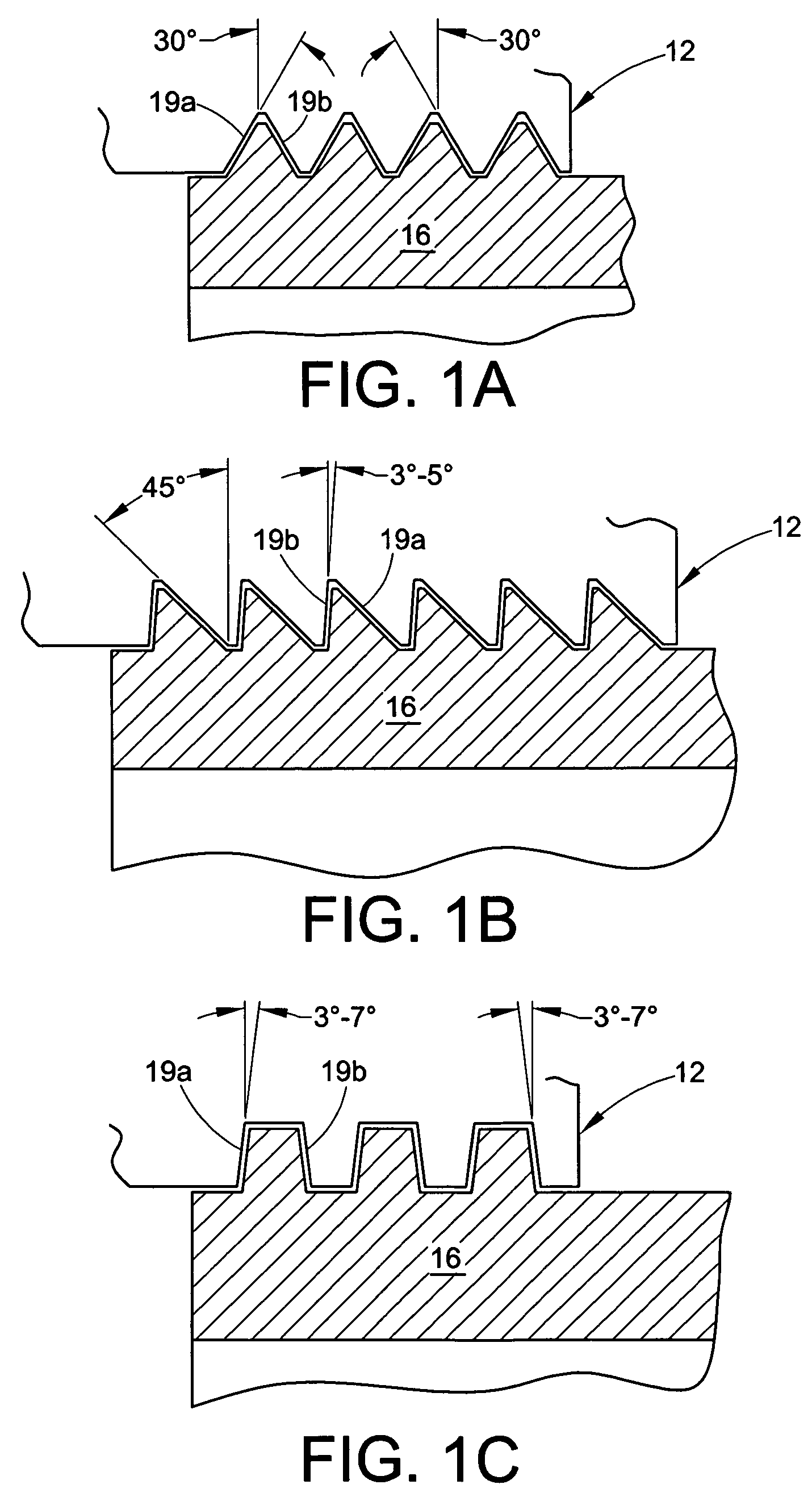

Fitting for tube and pipe

ActiveUS20050242582A1Shorten the lengthSecure retentionSleeve/socket jointsFluid pressure sealed jointsEngineeringHigh pressure

A fitting for a tube or pipe capable of functioning a high pressures having a first fitting component adapted to receive the conduit end; a conduit gripping device such as a ferrule or ferrules and a second fitting component that can be joined to the first fitting component to cause the conduit gripping device to grip the conduit and seal when assembled. In one aspect of the invention, the first fitting component is constructed from a material that is softer than the material used to construct the second fitting component. An additional aspect of the invention include a retaining portion on the second fitting component that constrains the tube gripping device against pressure. The retaining portion can also be configured to retain the tube gripping device to the second fitting component prior to installation and in a finger-tight condition. A further aspect of the invention includes a first fitting component in which an exterior portion of the component is work hardened radially outward from the tube gripping device. The fitting may optionally be provided with a structure to effect the pull-up by torque functionality.

Owner:SWAGELOK CO

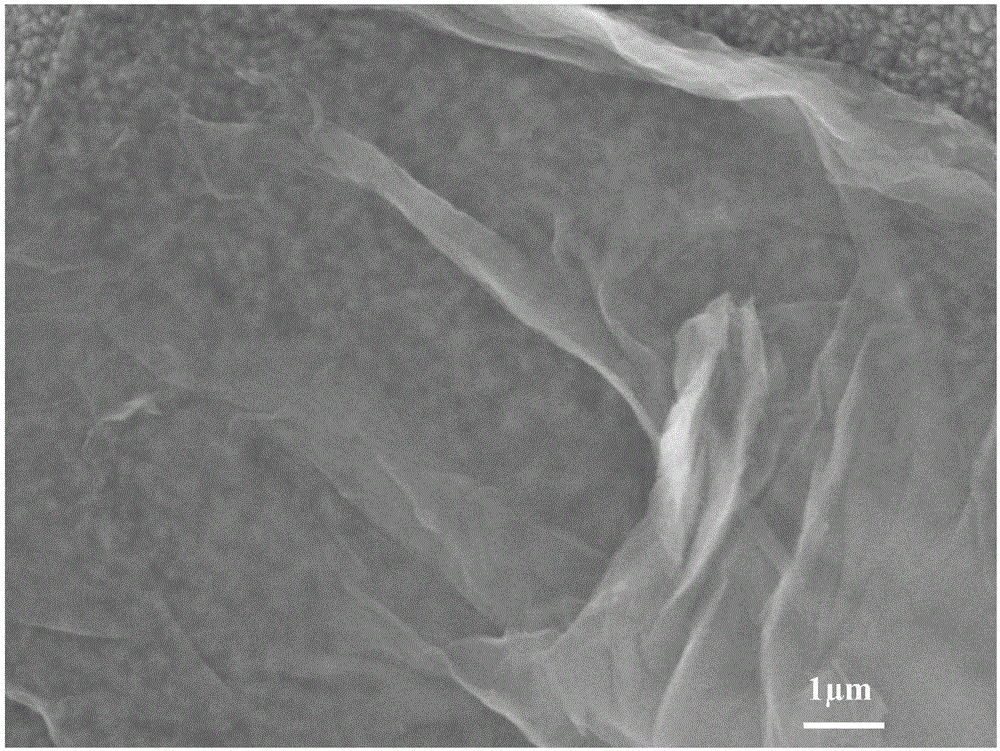

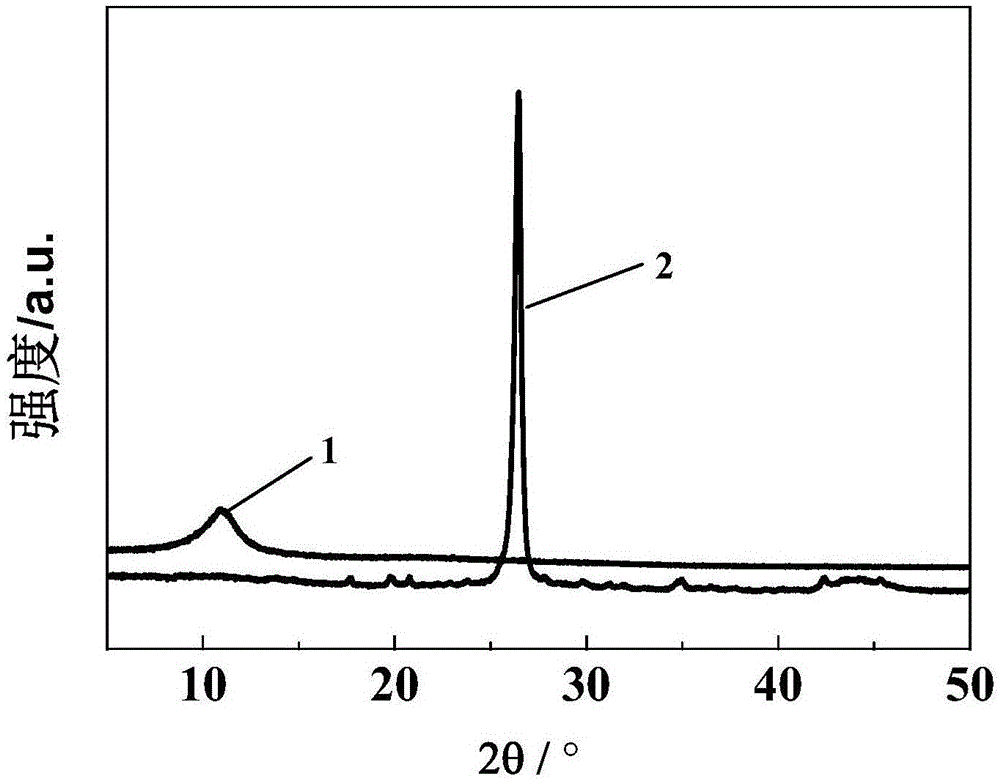

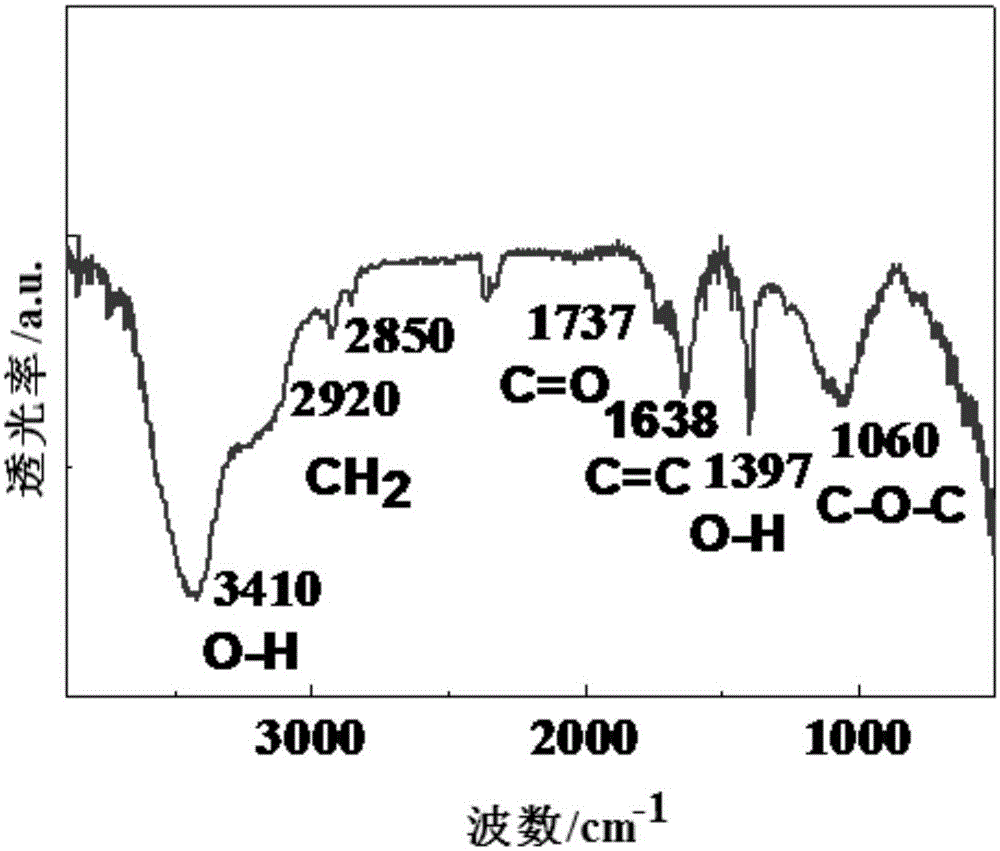

Method for preparing grapheme reinforced aluminum matrix composite material

The invention relates to a method for preparing a grapheme reinforced aluminum matrix composite material. The method aims at solving the technical problems that in an existing method for preparing the grapheme reinforced aluminum matrix composite material, the grapheme dispersibility is poor, and agglomeration is prone to happening. The method includes the steps that (1) oxidized grapheme is prepared; (2) surface modification on aluminum powder is carried out; (3) oxidized grapheme-aluminum composite powder is prepared; and (4) the grapheme reinforced aluminum matrix composite material is prepared. An electrostatic self-assembly method is adopted in the method, so that graphene is evenly dispersed in an aluminum matrix to enable the graphene to be more evenly dispersed, phenomena of damage to graphene size and work hardening generated on the aluminum matrix during ball-milling treatment are avoided, and graphene agglomeration is prevented; in addition, the mechanical property of the composite material is obviously improved; and compared with a pure aluminum material, the strength of extension is improved by 10%-20%, and the hardness is improved by 10%-30%.

Owner:HARBIN UNIV OF SCI & TECH

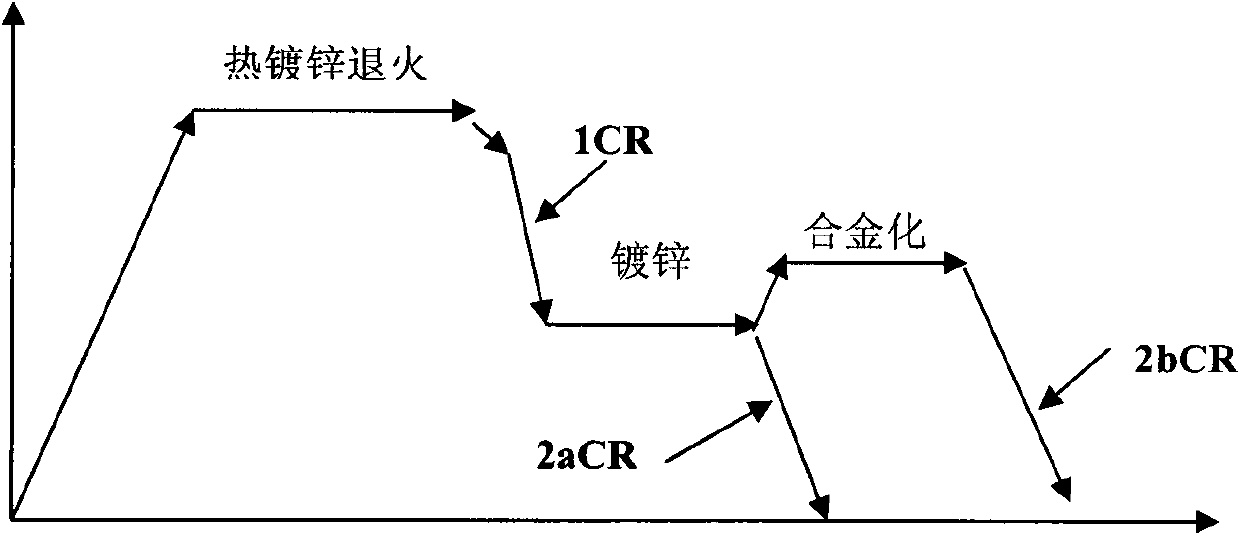

Cold-rolled galvanized duplex steel and manufacturing method thereof

ActiveCN102021482APlatability EliminationHigh strengthHot-dipping/immersion processesManufacturing convertersHigh rateOxygen

The invention relates to a cold-rolled galvanized duplex steel, wherein the substrate thereof comprises the following components by weight percentage: 0.08 to 0.18 wt.% of C, 0.50 to 1.50 wt.% of Si, 1.50 to 2.5 wt.% of Mn, 0.10 to 1.0 wt.% of Cr, 0.02 to 0.5 wt.% of Mo, 0.005 to 0.05 wt.% of Nb, 0.005 to 0.05 wt.% of Ti, 0.002 to 0.05 wt.% of T.Al, less than or equal to 0.02 wt.% of P, less thanor equal to 0.01 wt.% of S and less than or equal to 0.006 wt.% of N, and the balance of Fe. The manufacturing method thereof comprises the steps of: smelting in an oxygen top-blown convertor, refining in a heating steel ladle, continuously casting into a slab, and then conventionally hot rolling, pickling tandem rolling, galvanizing and annealing, wherein the critical annealing temperature is between 760 and 840 DEG C; the annealing is finished in the two-phase area of ferrite and austenite; 1CR section cooling has a cooling speed of 1 to 40 DEG C / S from the annealing temperature to the zincpool, putting the substrate into the zinc pool having a temperature of 450 to 465 DEG C so as to galvanize; and 2a CR section cooling has a cooling speed more than 3 DEG C / S. The steel of the invention has the advantages of high tensile strength, low yield ratio, capable of being press formed, excellent matching between strength and toughness, high rate of initially work-hardening and being free from yield extending.

Owner:BAOSHAN IRON & STEEL CO LTD

Aluminium-magnesium alloy plate or extrusion

A high strength Al-Mg alloy in plate or extrusion form having significantly improved strength in both soft and work-hardened tempers as compared with AA5083 is provided. The materials have ductility, pitting, stress and exfoliation corrosion resistances equivalent to those of the AA5083. The materials have improved long term stress and exfoliation corrosion resistances at temperatures above 80° C. The composition is 5-6% Mg, >0.6-1.2% Mn, 0.4-1.5% Zn, 0.05-0.25% Zr, up to 0.3% Cr, up to 0.2% Ti, up to 0.5% each Fe and Si, up to 0.4% each Cu and Ag, remainder Al and inevitable impurities. Manufacture of plate of this alloy is by homogenizing an ingot, hot rolling the ingot into plate in the range 400-530° C., cold rolling the plate with or without inter-annealing, final and optionally inter-annealing of the cold rolled material at temperatures in the range 200-550° C.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

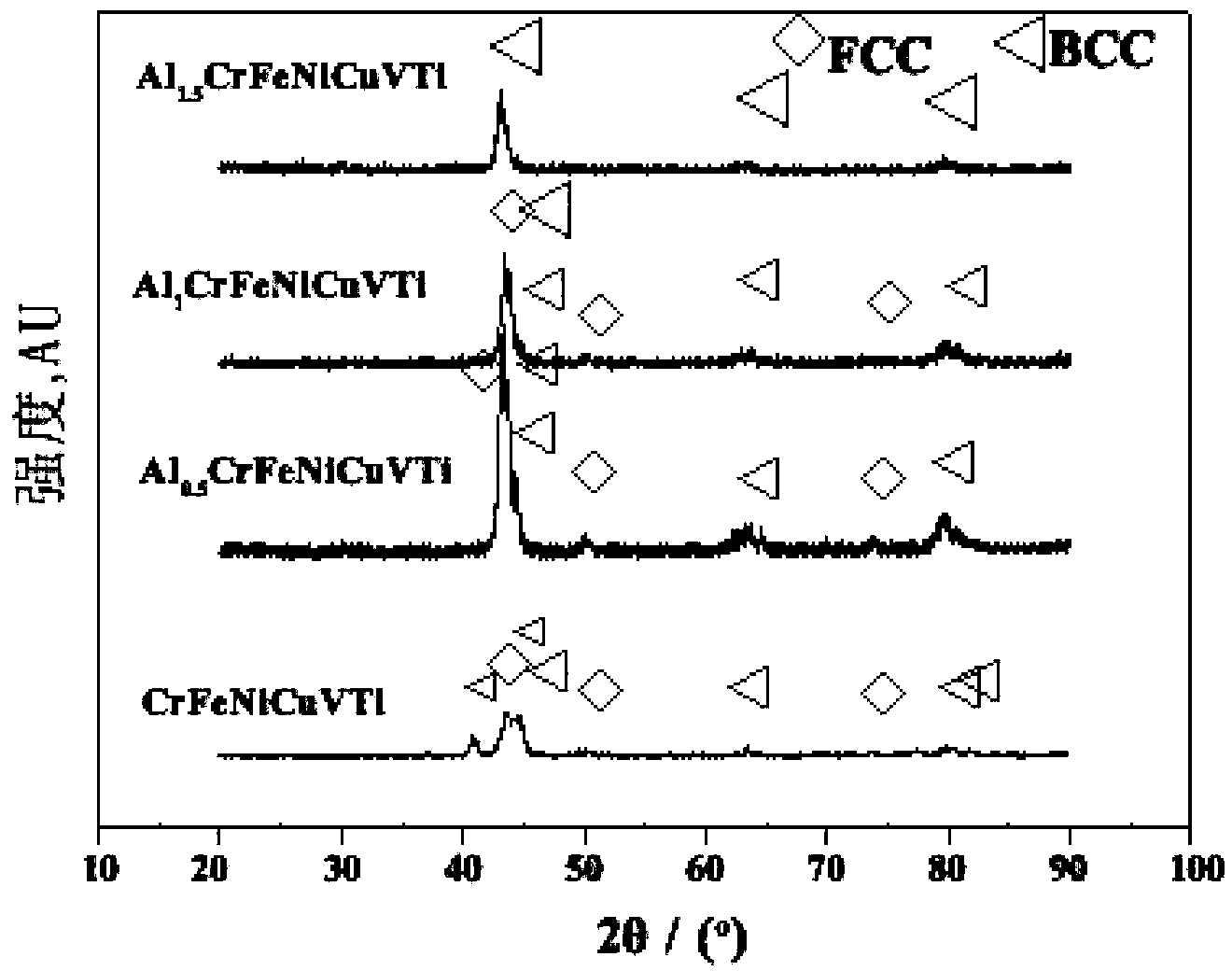

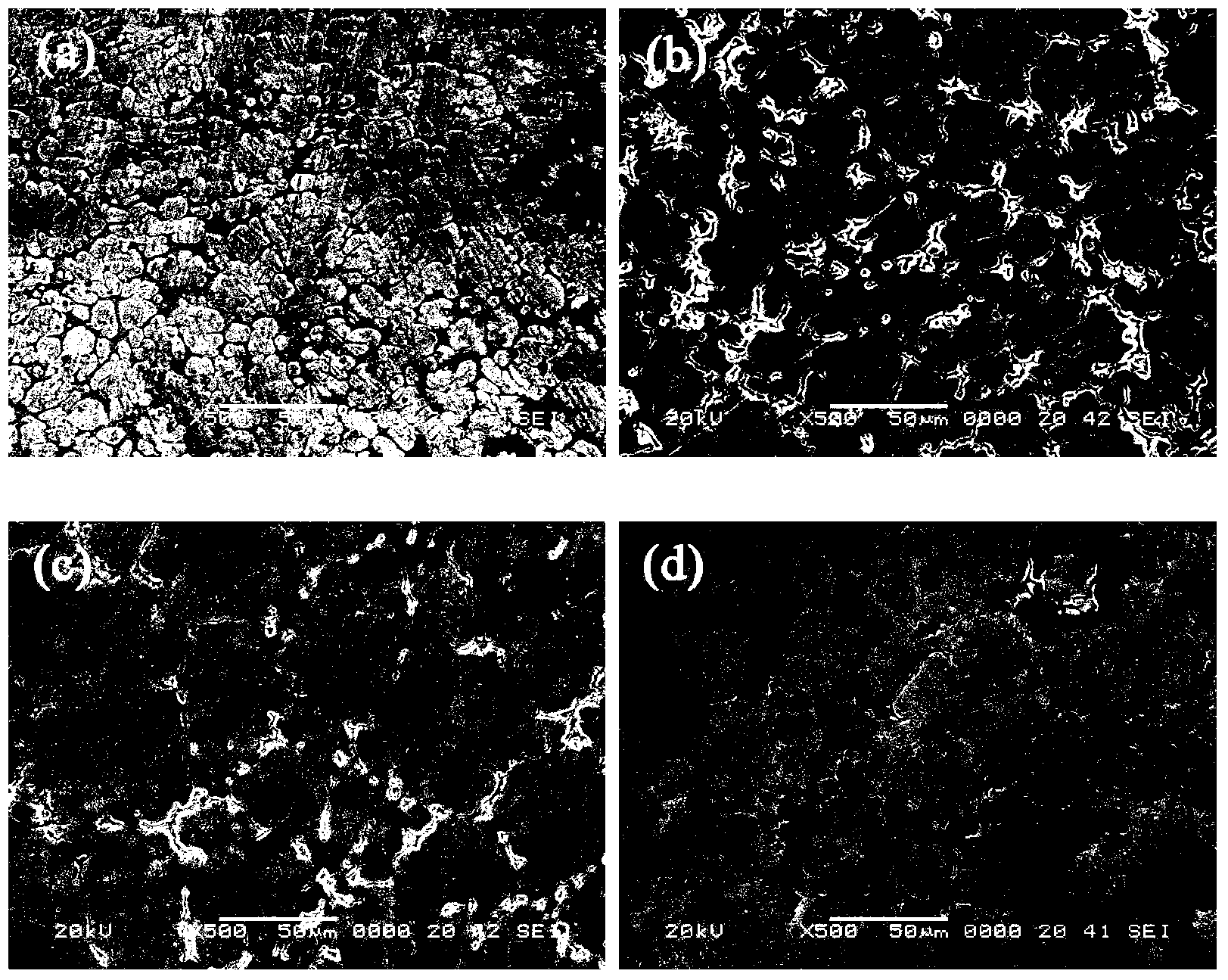

AlxCrFeNiCuVTi high-entropy alloy material and preparation method thereof

The invention relates to an AlxCrFeNiCuVTi high-entropy alloy material and a preparation method thereof. The high-entropy alloy comprises a component of AlxCrFeNiCuVTi, wherein x is a molar ratio, and the value range of x is 0.5-1.5. The preparation method of the alloy material comprises the following steps of: putting raw materials into a solution including acetone and ethanol, cleaning for 23-30 minutes by using an ultrasonic oscillator, and then drying in a 50DEG C drying oven for 6 hours; weighing alloys according to a molar ratio, and putting the alloys into a water-cooling copper crucible; when the air pressure in a furnace body reaches 3*10<-3>Pa, introducing high-purity argon to clean for 3-5 times; introducing high-purity argon to ensure that the air pressure in a furnace chamber is kept to be 0.8-0.9 atmospheric pressure, and then electrifying, wherein the smelting striking current is 30-40A, the current after stabilization is 90A, the time for smelting the alloys once is 10 seconds, and a sample needs to be smelted for 5 times repeatedly; and when the components of a smelted sample are uniformly cooled, taking the alloy out of the furnace. Compared with a conventional crystal alloy, the AlxCrFeNiCuVTi high-entropy alloy material has higher hardness, strength, high temperature stability, corrosion resistance and work hardening capacity.

Owner:梧州漓佳铜棒有限公司

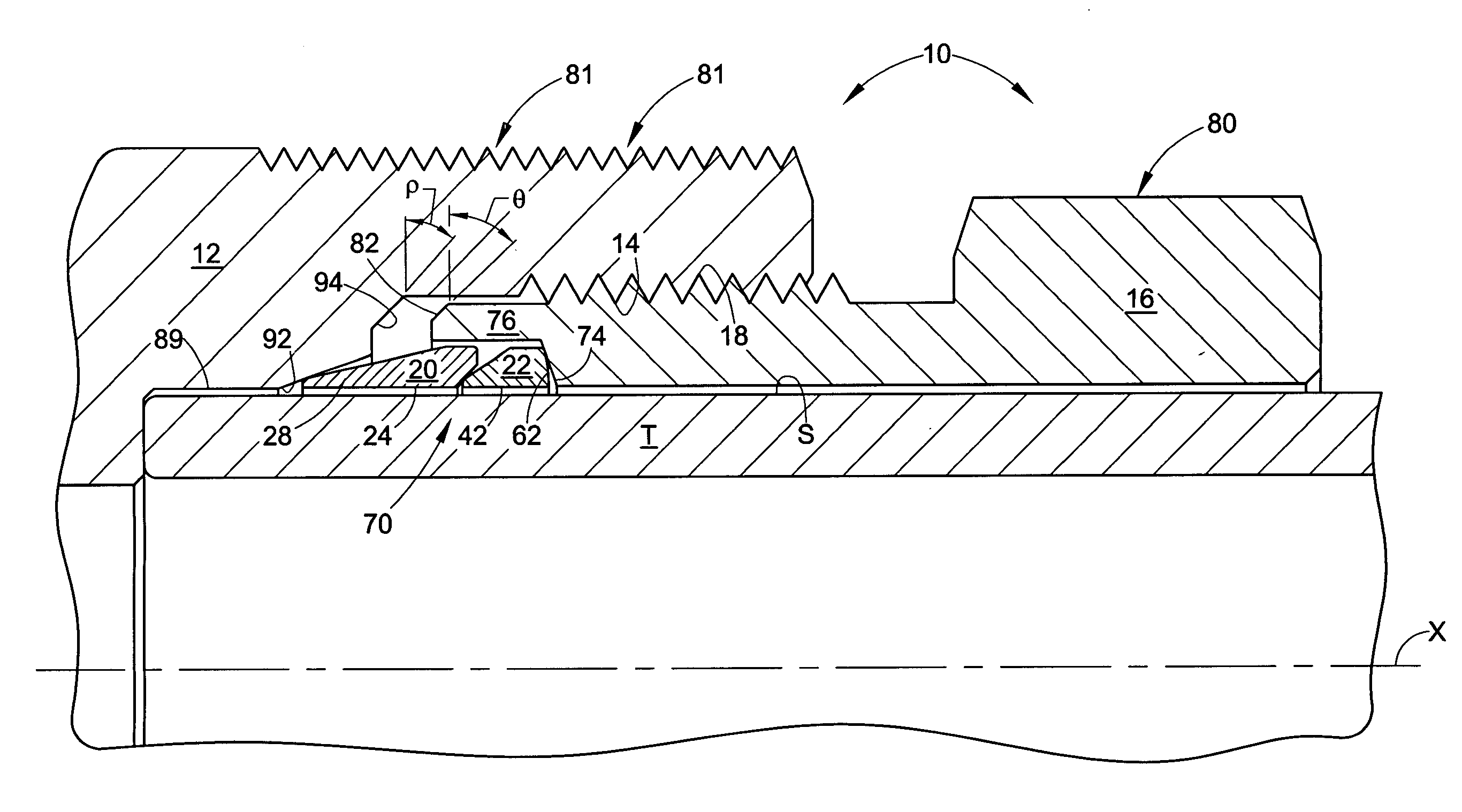

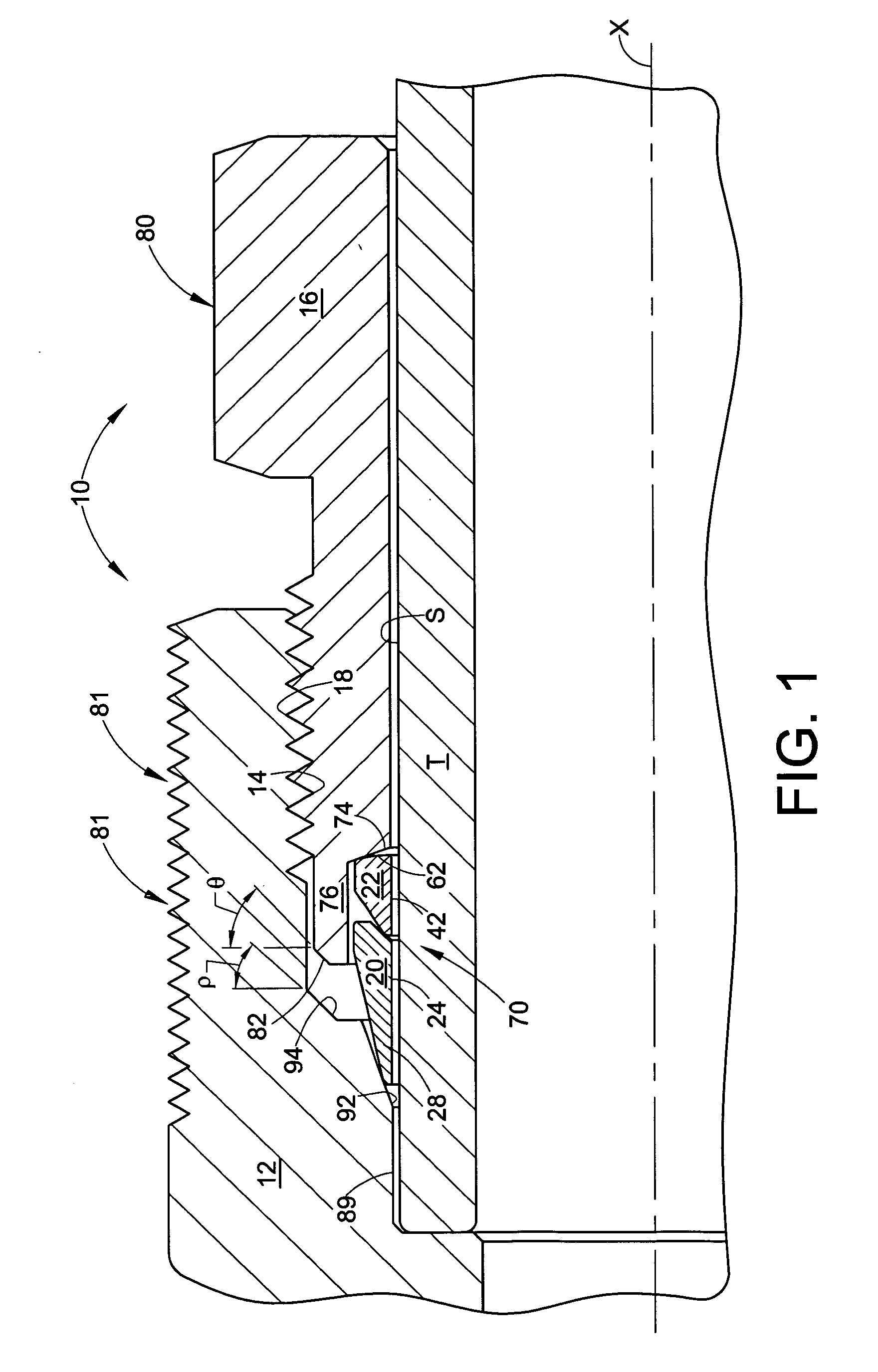

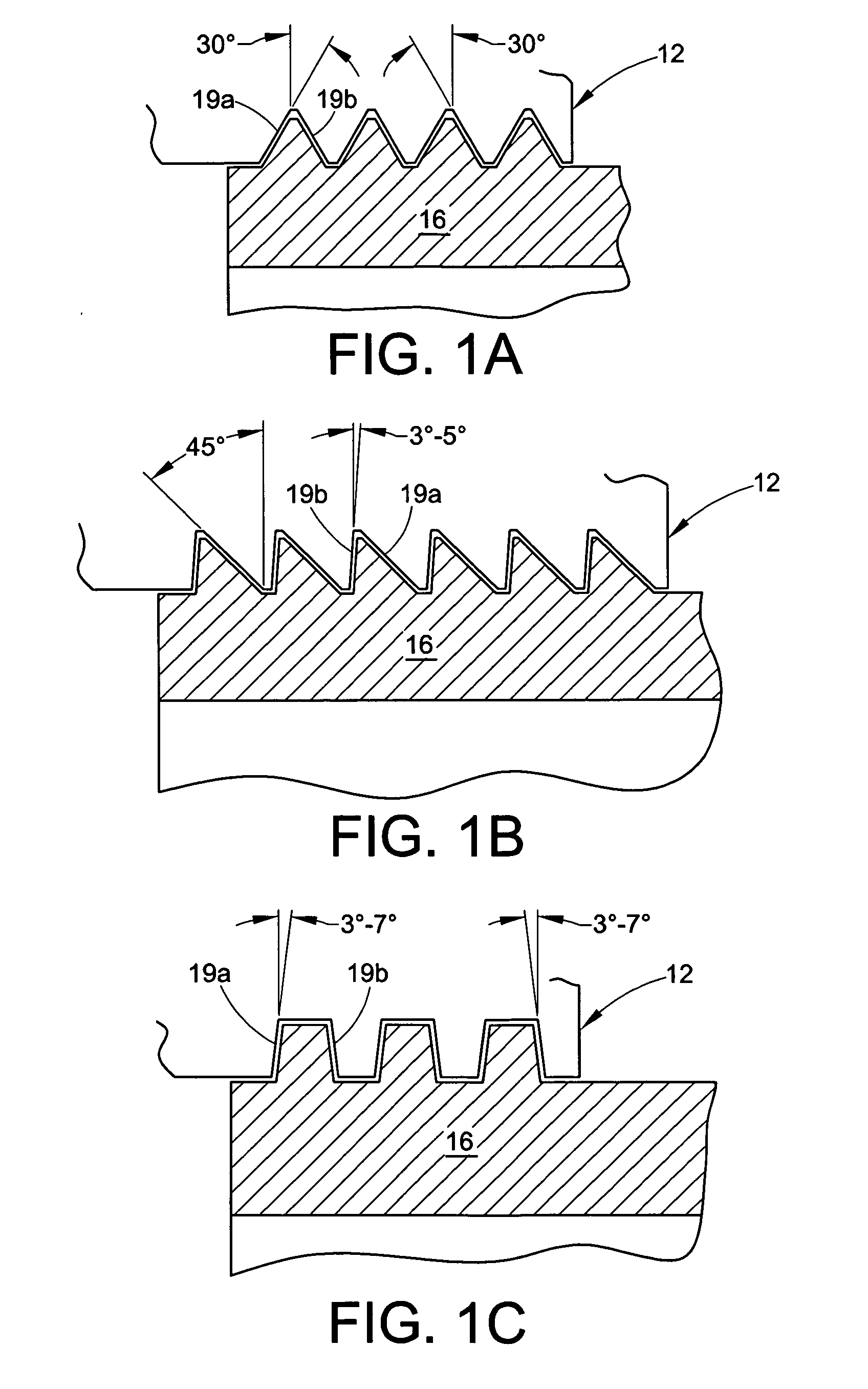

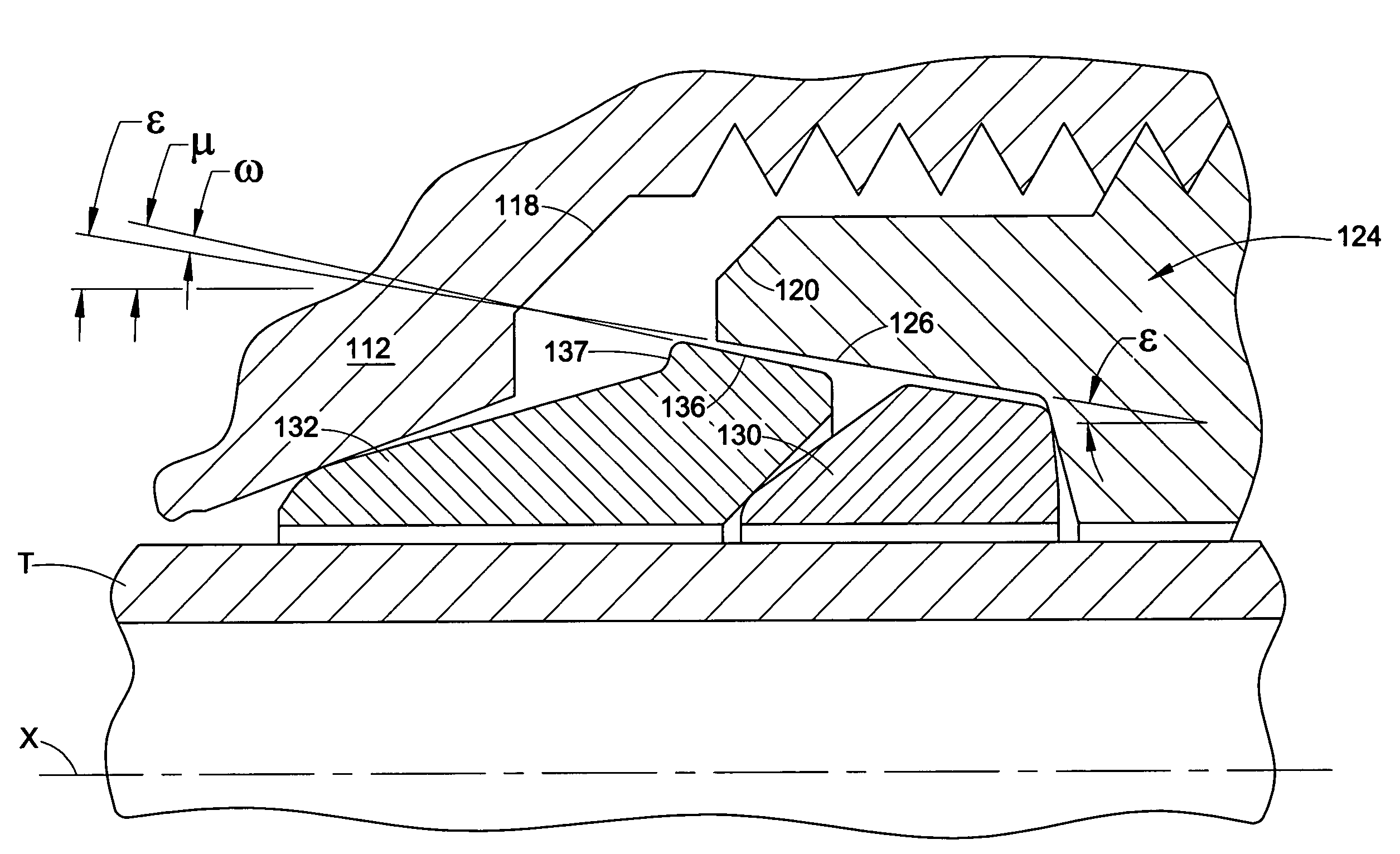

Fitting for tube and pipe with cartridge

ActiveUS7497483B2Secure retentionShorten the lengthSleeve/socket jointsFluid pressure sealed jointsCatheterHigh pressure

A fitting for a tube or pipe capable of functioning a high pressures having a first fitting component adapted to receive the conduit end; a conduit gripping device such as a ferrule or ferrules and a second fitting component that can be joined to the first fitting component to cause the conduit gripping device to grip the conduit and seal when assembled. In one aspect of the invention, the first fitting component is constructed from a material that is softer than the material used to construct the second fitting component. An additional aspect of the invention include a retaining portion on the second fitting component that constrains the tube gripping device against pressure. The retaining portion can also be configured to retain the tube gripping device to the second fitting component prior to installation and in a finger-tight condition. A further aspect of the invention includes a first fitting component in which an exterior portion of the component is work hardened radially outward from the tube gripping device. The fitting may optionally be provided with a structure to effect the pull-up by torque functionality.

Owner:SWAGELOK CO

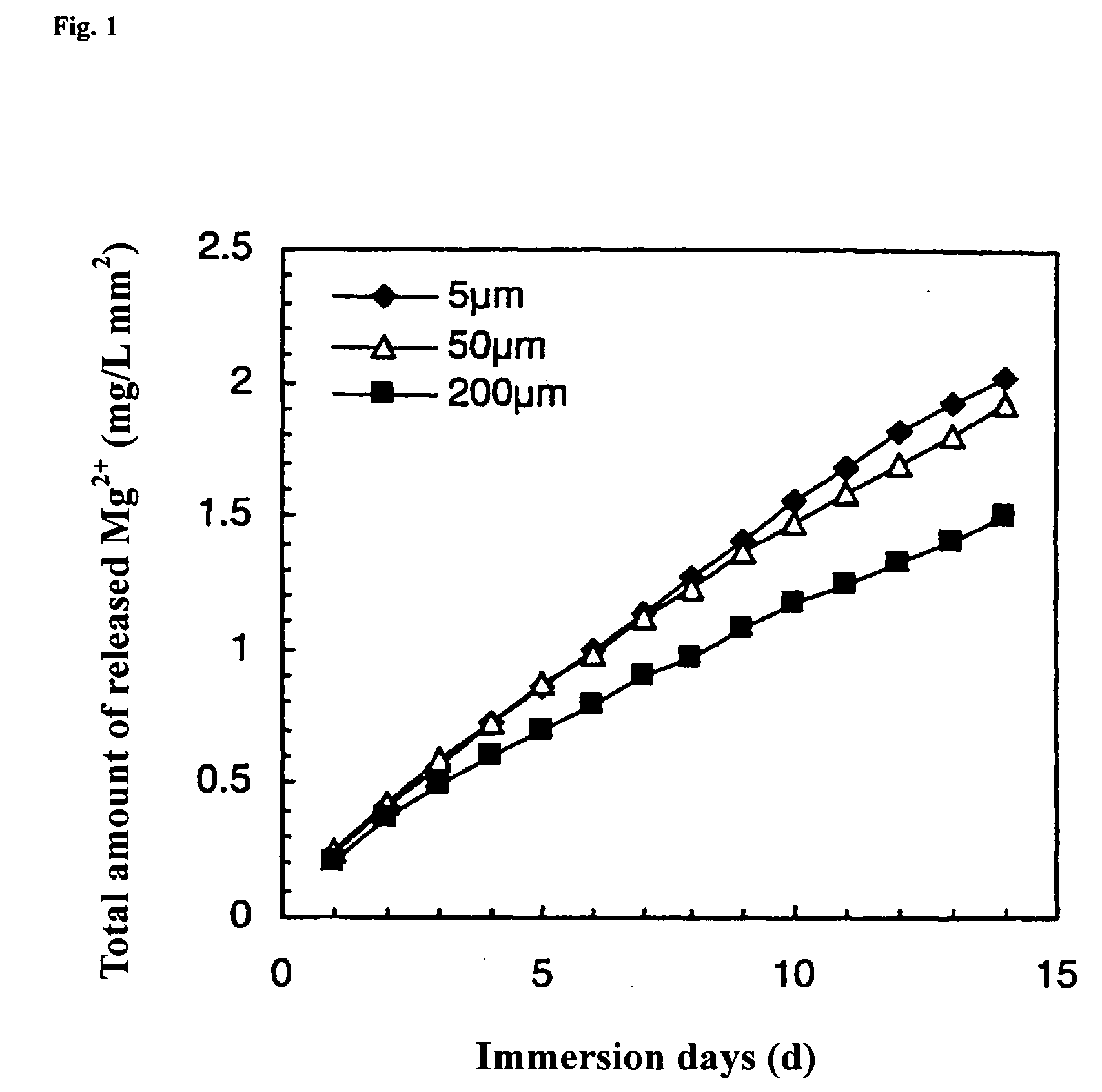

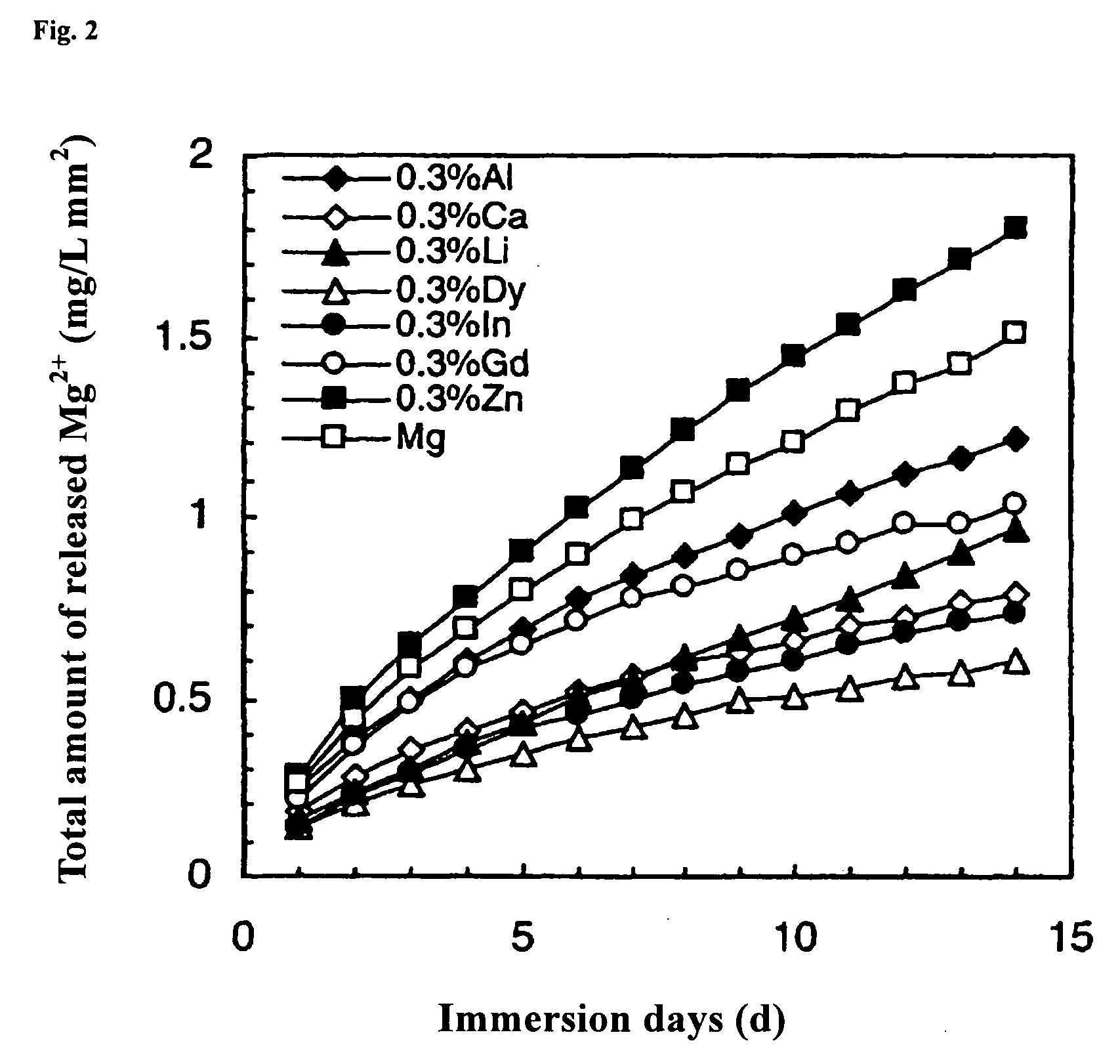

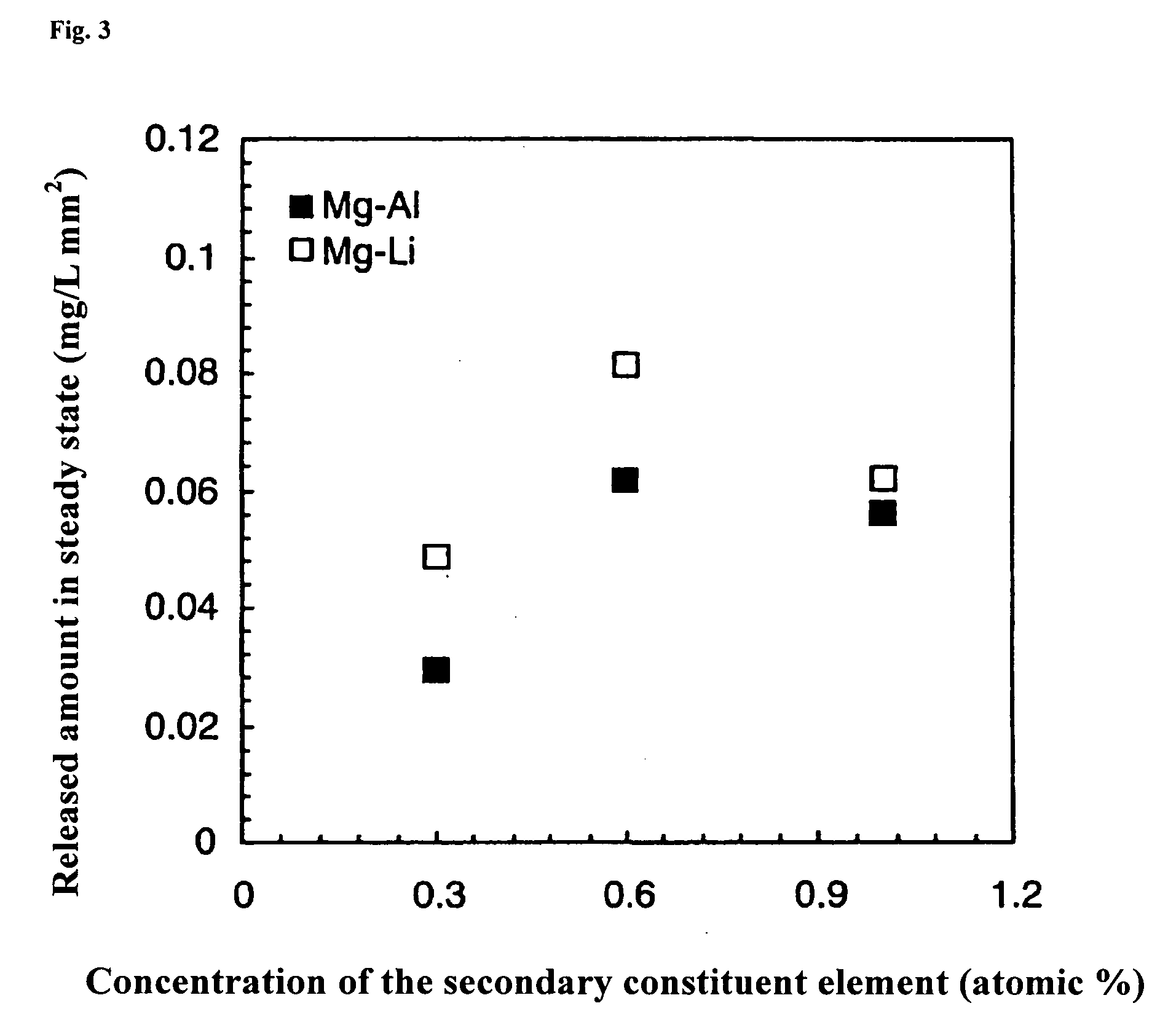

Magnesium-Based Biodegradable Metallic Material

ActiveUS20090171452A1Possibility of degradationAnalysis using chemical indicatorsSurgeryMetallic materialsImplanted device

As a novel biodegradable metallic material the degradation speed of which in vivo can be controlled over a broad scope while achieving desired mechanical properties such as strength, work hardening and ductility without restricting the shape of an implant device, it is intended to provide a magnesium-based biodegradable metallic material which comprises Mg containing Mg as the major composition and having a concentration of inevitable impurities equal to or less than 0.05 atomic %, is free from precipitates or intermetallic compounds, and has an average grain size being regulated to equal to or less than ¼ of the minimum part of the material.

Owner:NAT INST FOR MATERIALS SCI

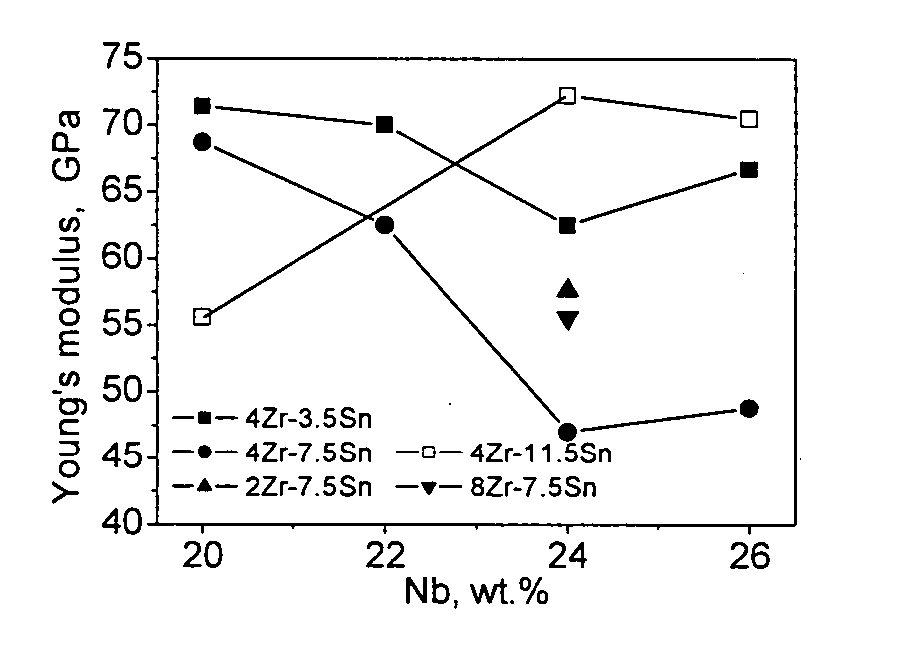

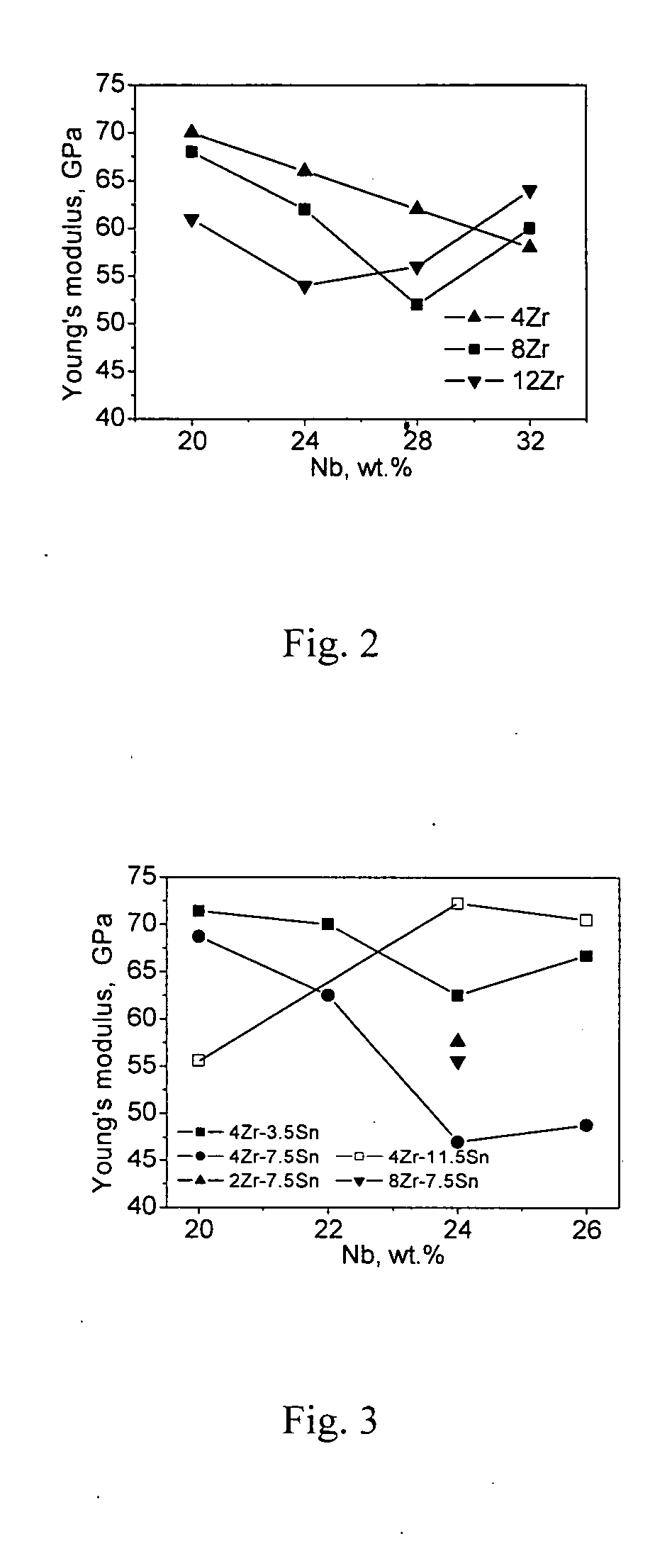

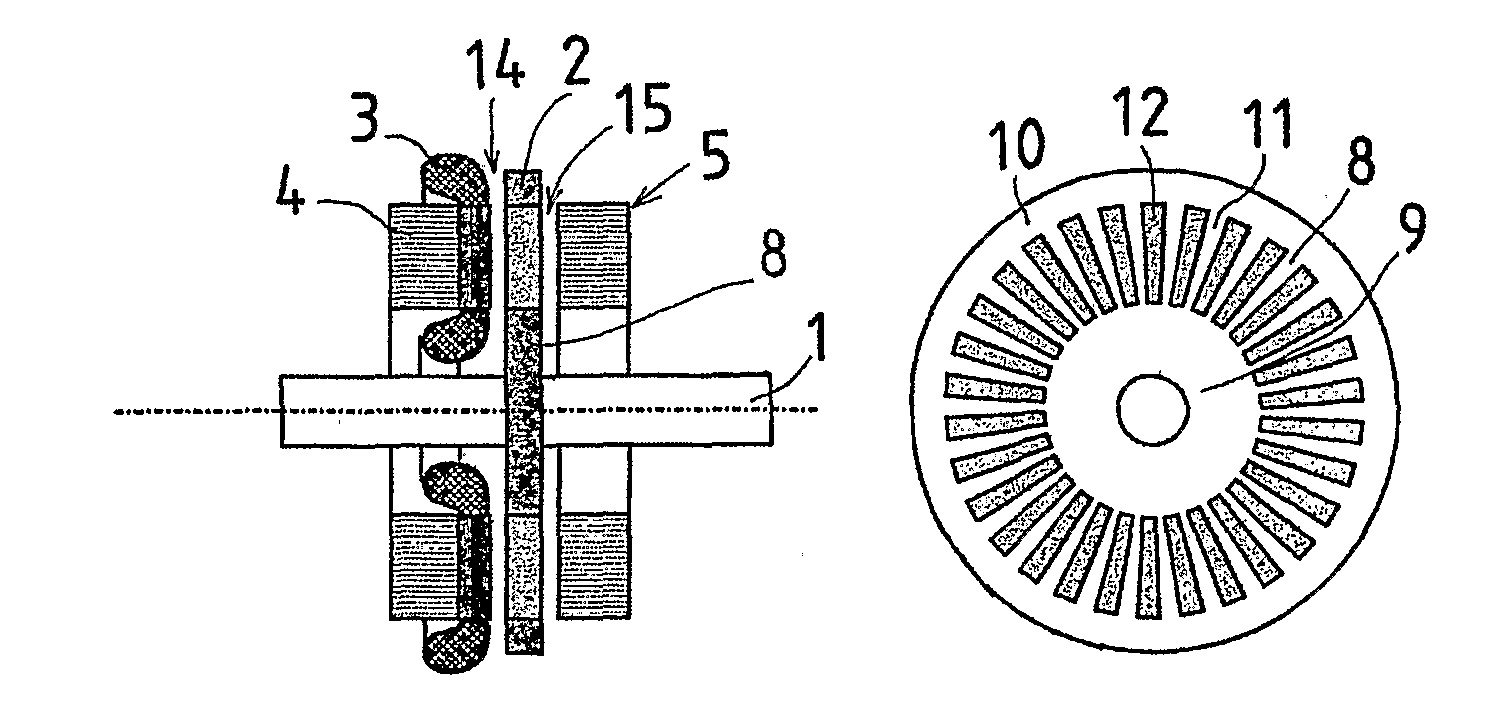

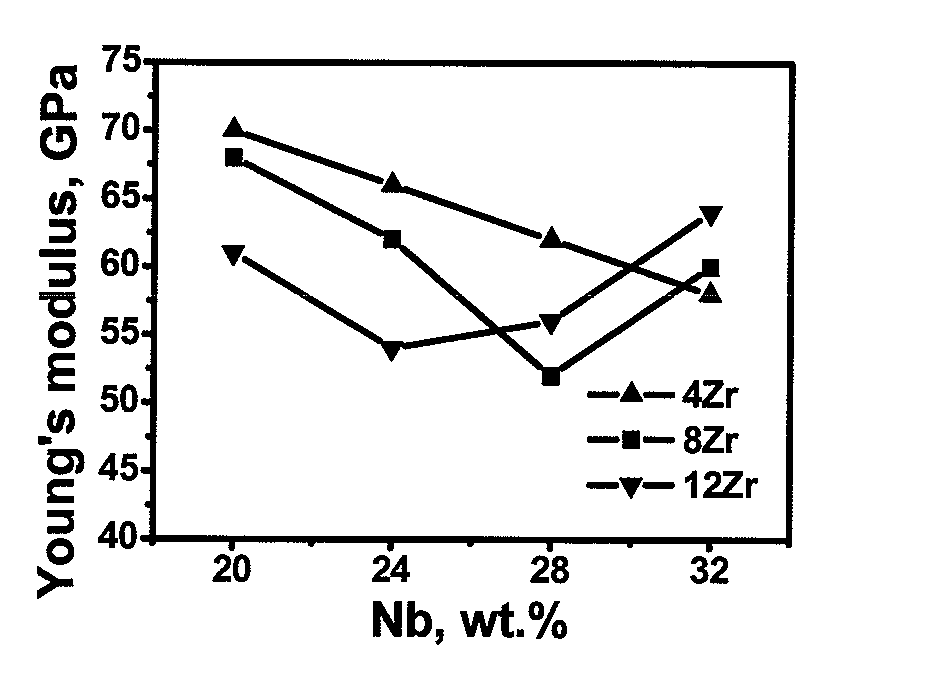

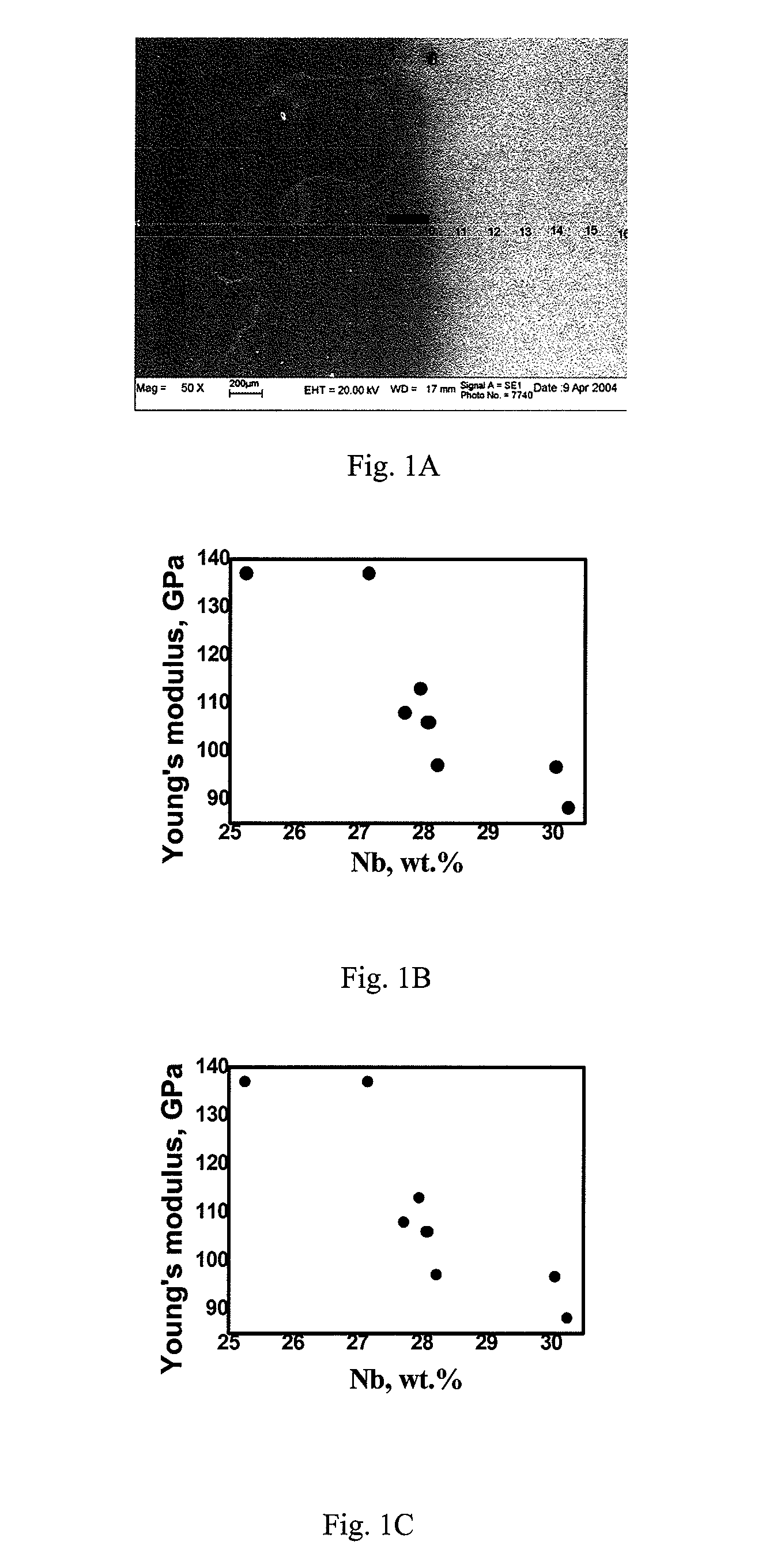

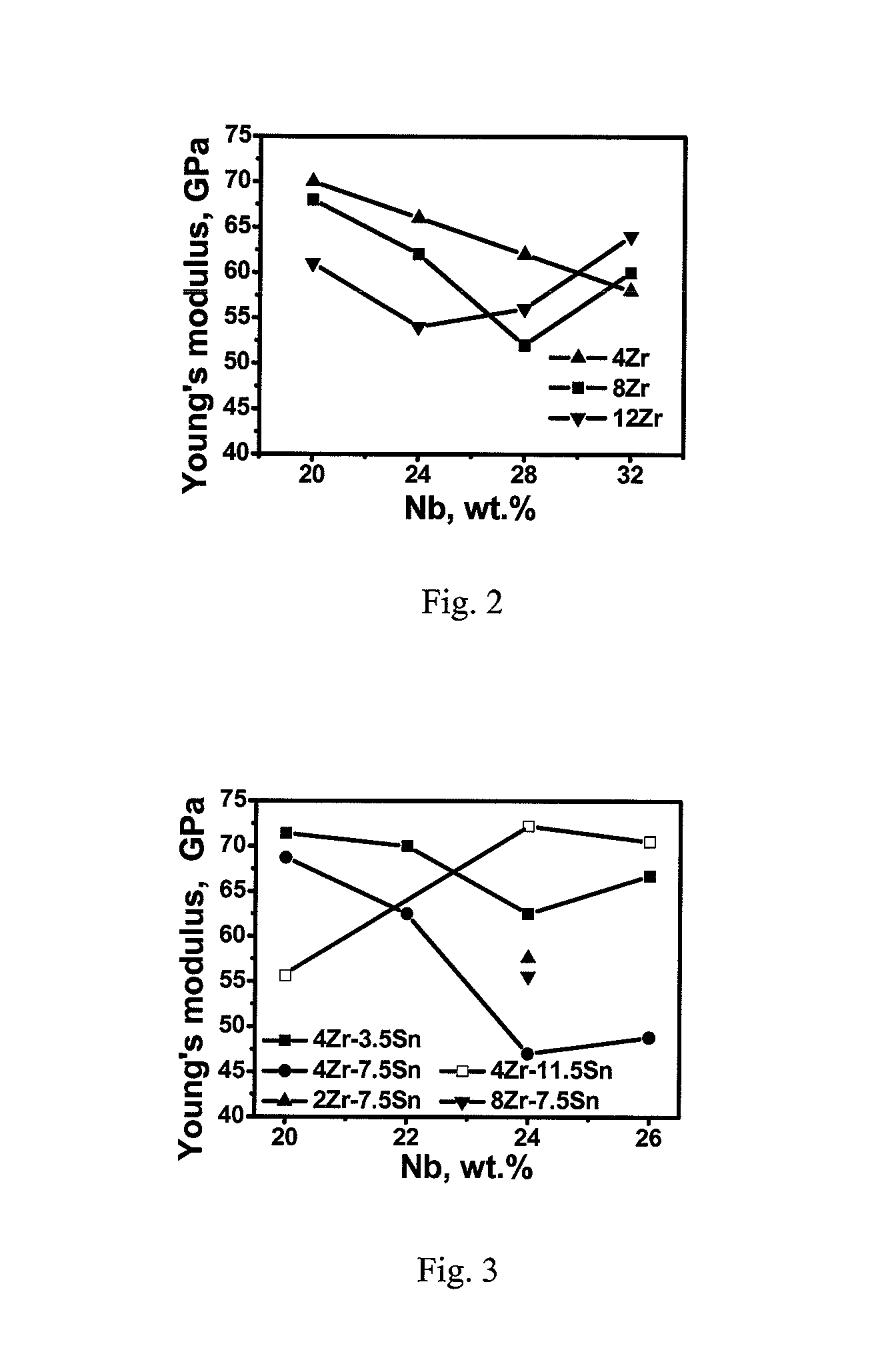

Titanium alloy with extra-low modulus and superelasticity and its producing method and processing thereof

The patent provides the titanium alloy with extra-low modulus and superelasticity containing 20˜35 wt. % niobium, 2˜15 wt. % zirconium, balanced titanium and other unavoidable impurity elements. The advantages of the invention alloy are shown as follows: The invention titanium alloy has superior cold processing capacity and low work hardening rate; It can be severely deformed by cold rolling and cold drawing; It has superelasticity, shape memory effect, damping capacity, low modulus, high strength, good corrosion resistance and high biocompatibility; The invention titanium alloy can be made into nano-size materials by cold deformation and extra high strength can be achieved by heat treatment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

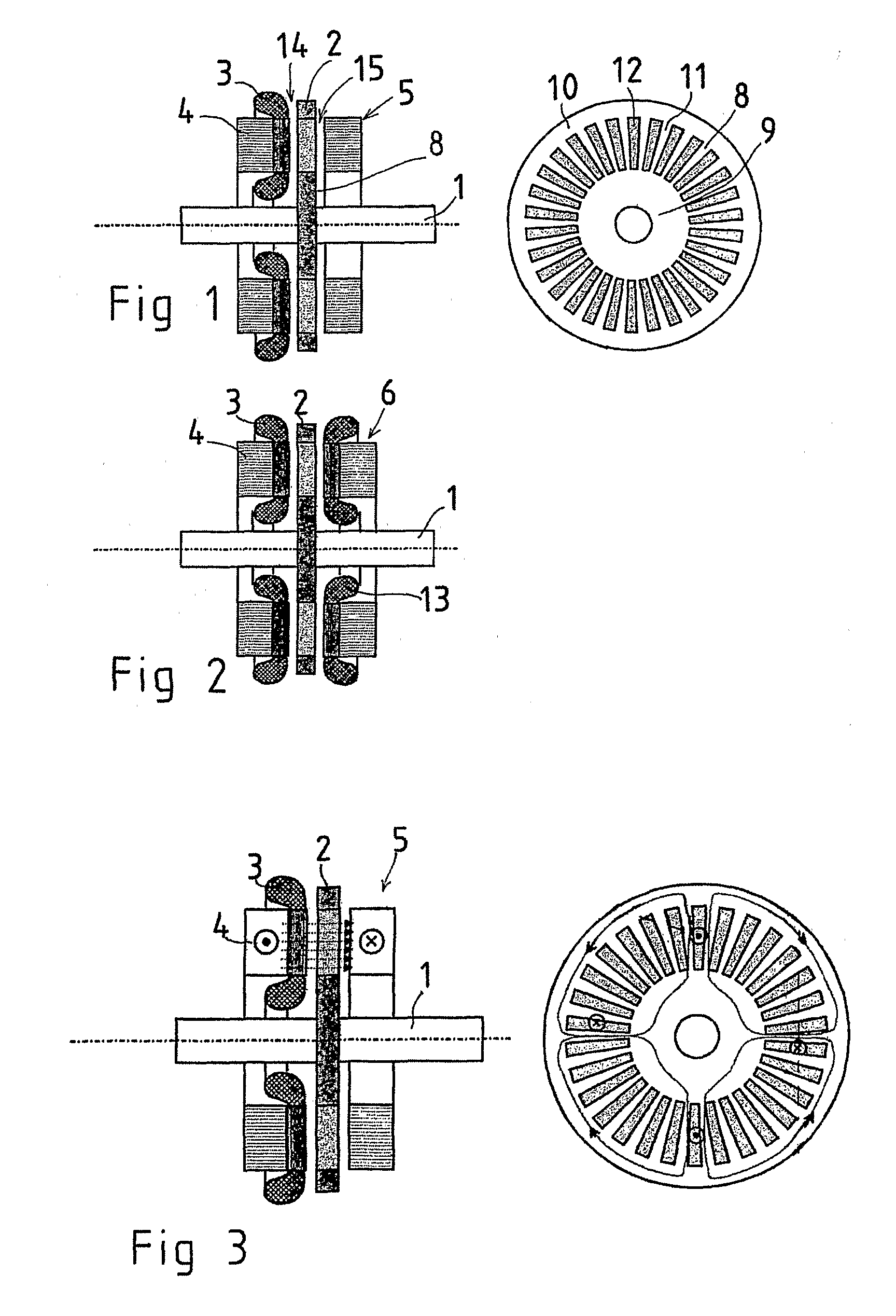

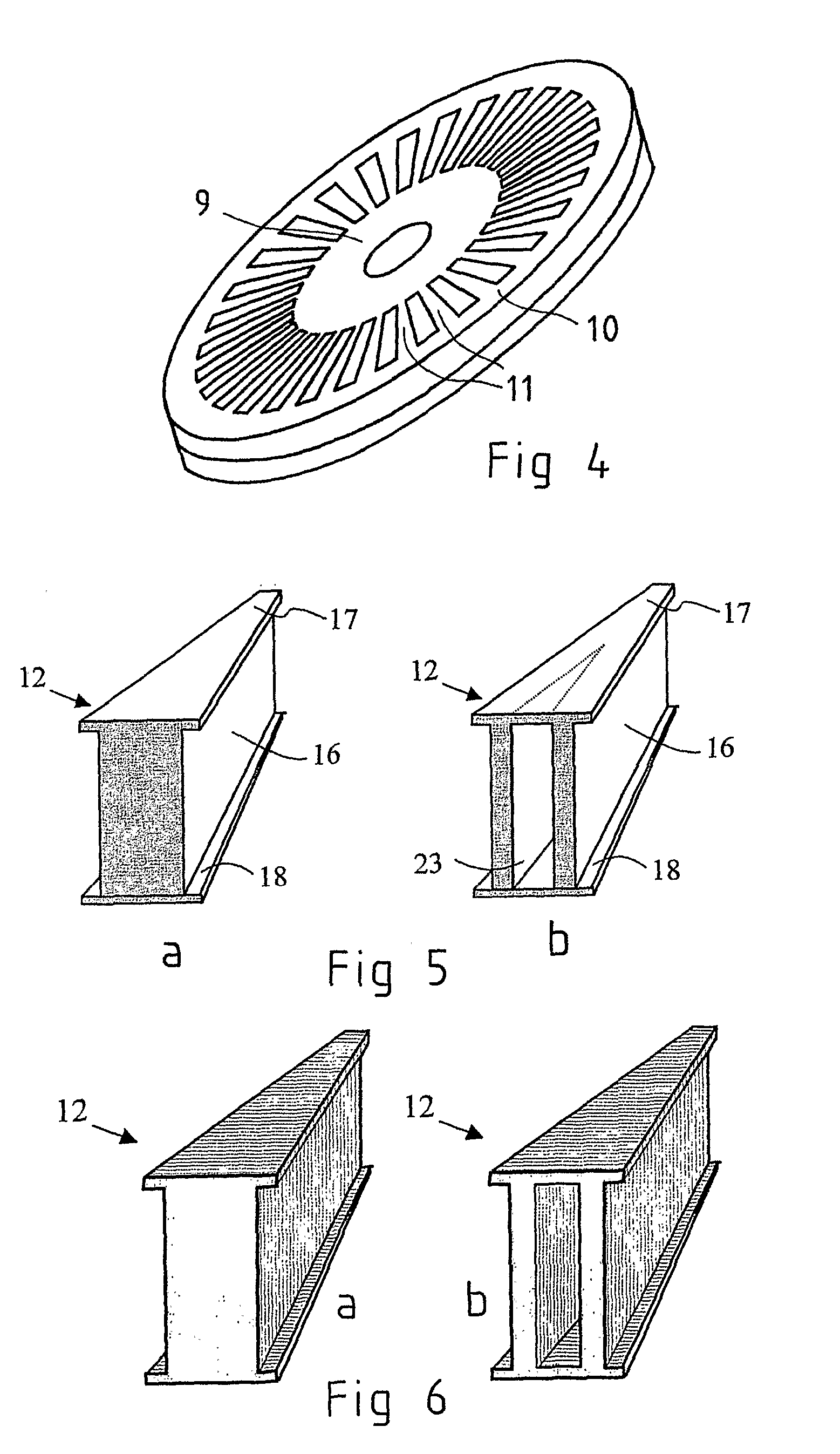

Axial Flux Induction Electric Machine

InactiveUS20080001488A1Easy to with power toolIncrease speedSynchronous generatorsWindingsAxial fluxWork hardening

The invention relates to an axial flux induction electrical machine comprising a frame, a shaft (1) bearing-mounted to the frame, a disc-like rotor (2) supported to the shaft, a stator (4) comprising a stator winding (3) and supported by the frame on the first side of the rotor in axial direction. The disc-like rotor (2) comprises a non-ferromagnetic rotor frame (8) fabricated of a material with high electrical conductivity and comprising a uniform inner periphery (9) and an outer periphery (10) and conductor bars (11) fabricated of the same material and galvanically connecting the peripheries (11), the conductor bars together with the inner and outer peripheries forming in addition to the rotor frame also the cage winding of the rotor. In addition, between the inner periphery and the outer periphery there is a plurality of ferromagnetic pieces (12) extending through the frame plate and being spaced apart from each other at an appropriate distance so that the radial conductor bars are appropriately located between the pieces. According to the invention, the disc-like rotor frame (8) comprises at least one circular plate machined of work-hardened metal sheet.

Owner:AXCO MOTORS OY

Fitting for tube and pipe with cartridge

ActiveUS20060138774A1Shorten the lengthSecure retentionSleeve/socket jointsFluid pressure sealed jointsCatheterHigh pressure

A fitting for a tube or pipe capable of functioning a high pressures having a first fitting component adapted to receive the conduit end; a conduit gripping device such as a ferrule or ferrules and a second fitting component that can be joined to the first fitting component to cause the conduit gripping device to grip the conduit and seal when assembled. In one aspect of the invention, the first fitting component is constructed from a material that is softer than the material used to construct the second fitting component. An additional aspect of the invention include a retaining portion on the second fitting component that constrains the tube gripping device against pressure. The retaining portion can also be configured to retain the tube gripping device to the second fitting component prior to installation and in a finger-tight condition. A further aspect of the invention includes a first fitting component in which an exterior portion of the component is work hardened radially outward from the tube gripping device. The fitting may optionally be provided with a structure to effect the pull-up by torque functionality.

Owner:SWAGELOK CO

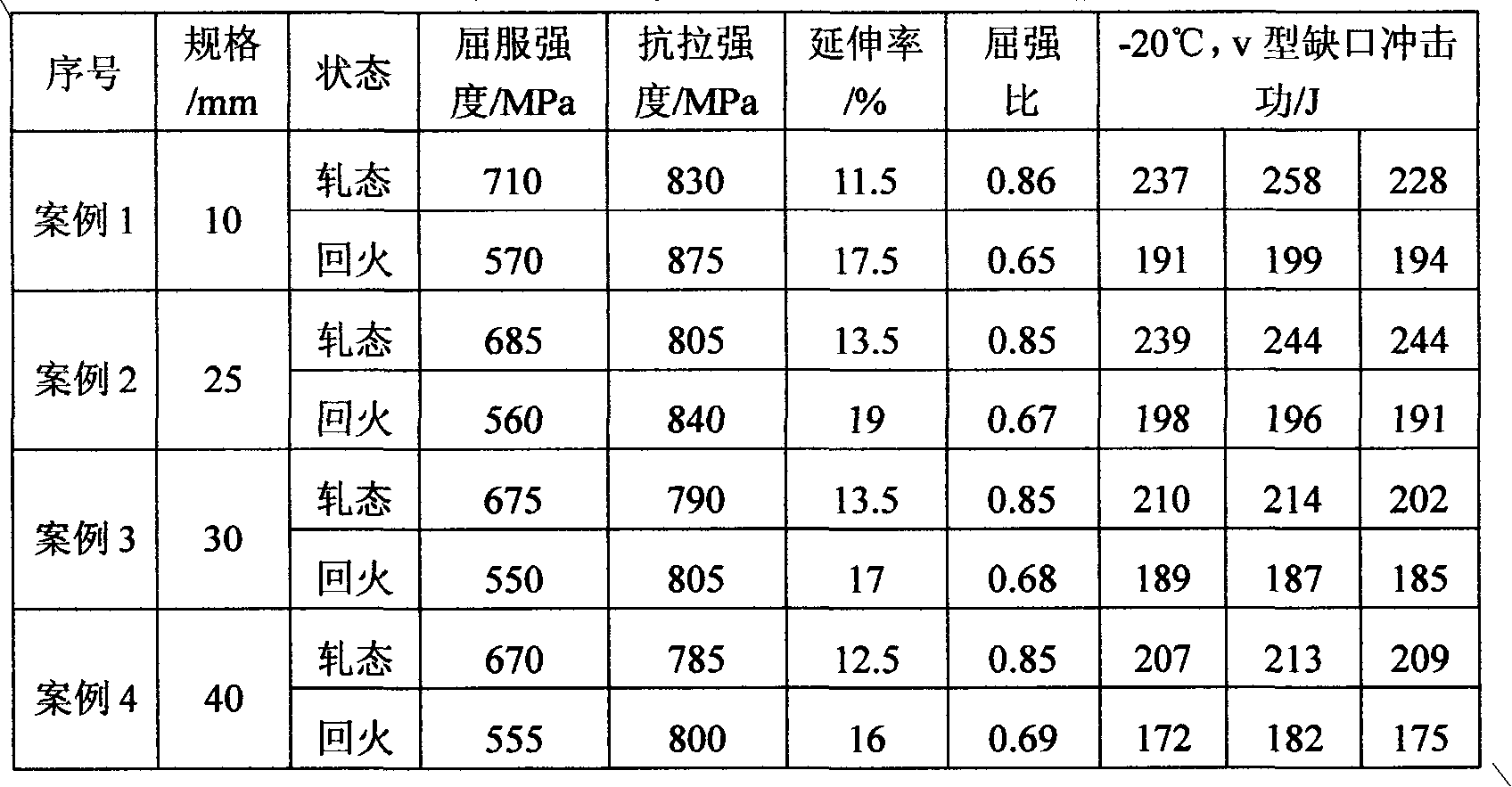

800 MPa-grade low-yield-ratio structural steel plate and production method thereof

ActiveCN102011068AGood welding performanceGood low temperature impact propertiesYield ratioHeat treated

The method relates to an 800 MPa-grade low-yield-ratio structural steel plate and a production method thereof. The steel comprises the chemical components in percentage by weight: 0.045 to 0.075 percent of C, 0.30 to 0.55 percent of Si, 1.55 to 1.95 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.0025 percent of S, 0.012 to 0.035 percent of Al, 0.15 to 0.25 percent of Cr, 0.15 to 0.3 percent of Mo, 0.2 to 0.4 percent of Cu, 0.2 to 0.4 percent of Ni, 0.008 to 0.04 percent of Nb, 0.008 to 0.04 percent of V, 0.008 to 0.03 percent of Ti, 0.0008 to 0.0015 percent of B, and the balance of Fe and inevitable impurities. The steel is subjected to RH vacuum treatment, ladle furnace (LF) external refining, full protection casting, a thermo mechanical control process (TMCP), and tempering heat treatment to form the steel plate with low yield ratio, high strength and high work hardening rate. The steel plate has the thickness specification of between 10 and 40 mm, the yield strength of more than or equal to 550MPa, the tensile strength of more than or equal to 800 MPa and the yield ratio of less than 0.70, and has excellent low temperature compact performance, cold forming performance and welding performance.

Owner:SHOUGANG CORPORATION

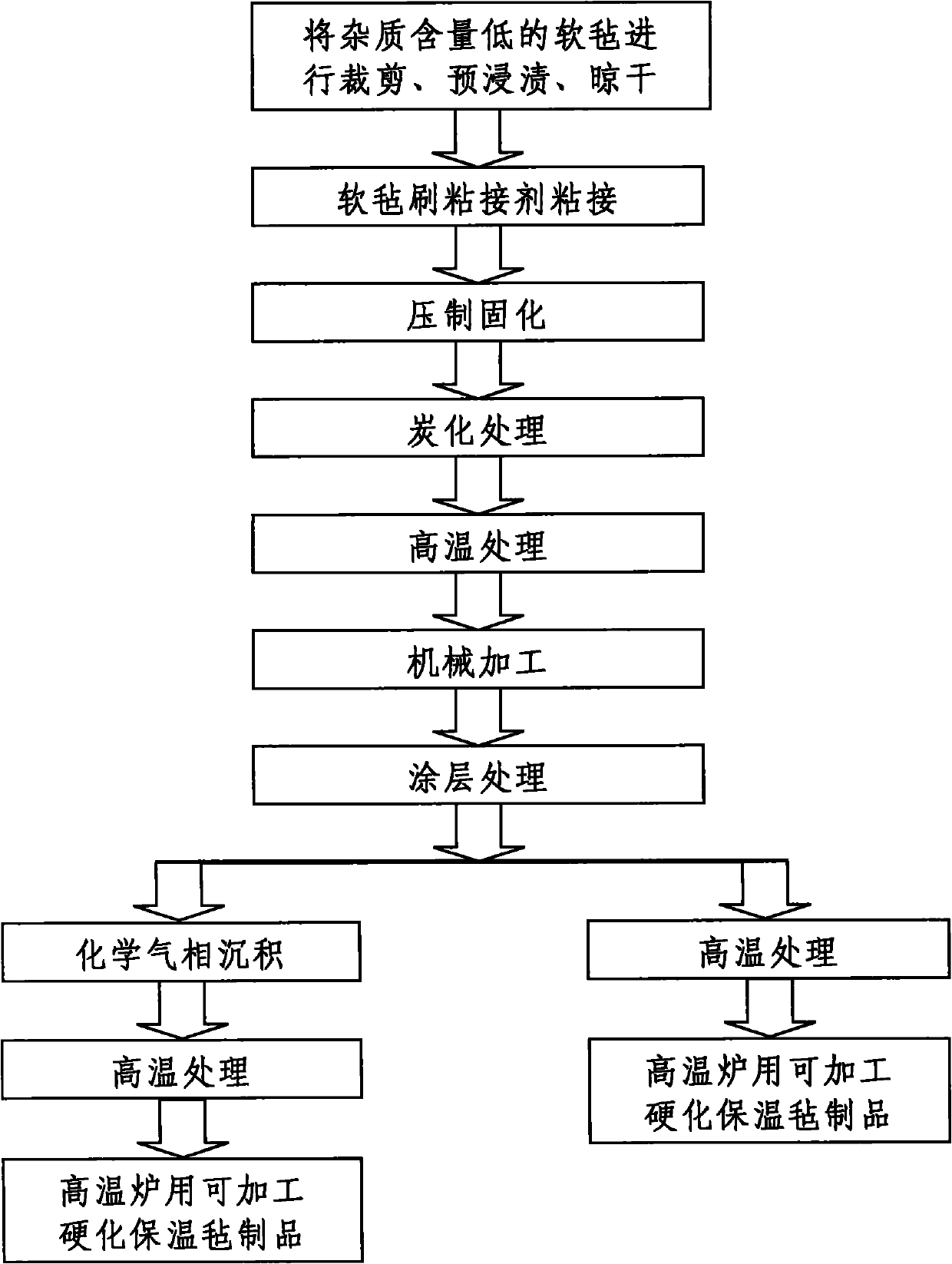

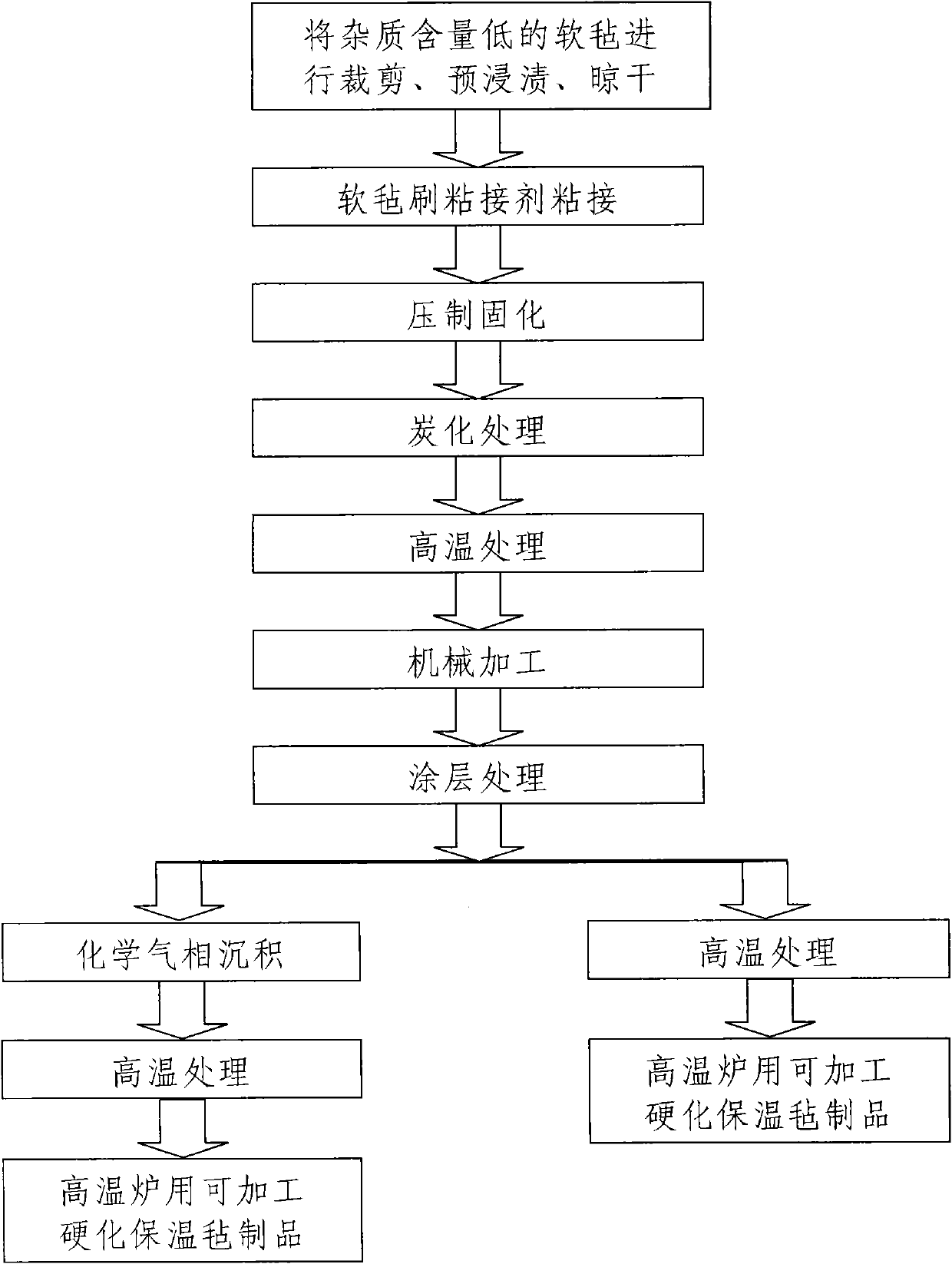

Method for preparing work hardening insulation quilt for high temperature furnace

The invention relates to a method for preparing a work hardening insulation quilt for a high temperature furnace, which comprises the following steps of: 1, cutting, pre-impregnating and airing a soft quilt; 2, adhering the soft quilt by using an adhesive; 3, pressing and curing for forming; 4, performing carbonization treatment; 5, performing high temperature treatment; 6, machining; 7, performing coating treatment; and 8, performing chemical vapor deposition treatment and high temperature treatment, or directly performing high temperature treatment to obtain the work hardening insulation quilt for the high temperature furnace. The method has the advantages of simple technological process and suitability for mass production; and the prepared work hardening insulation quilt has the heat conductivity of less than or equal to 0.5W / m.K, the ash content of less than or equal to 2,000ppm, high mechanical properties and high-temperature dimensional stability and excellent processability, does not generate volatile matters when used in the high temperature furnace, cannot pollute the product, and has important significance for prolonging the service life of the insulation quilt in the high temperature furnace.

Owner:XIAN CHAOMA SCI TECH

Fitting for tube and pipe

ActiveUS7695027B2Secure retentionShorten the lengthSleeve/socket jointsFluid pressure sealed jointsEngineeringHigh pressure

A fitting for a tube or pipe capable of functioning a high pressures having a first fitting component adapted to receive the conduit end; a conduit gripping device such as a ferrule or ferrules and a second fitting component that can be joined to the first fitting component to cause the conduit gripping device to grip the conduit and seal when assembled. In one aspect of the invention, the first fitting component is constructed from a material that is softer than the material used to construct the second fitting component. An additional aspect of the invention include a retaining portion on the second fitting component that constrains the tube gripping device against pressure. The retaining portion can also be configured to retain the tube gripping device to the second fitting component prior to installation and in a finger-tight condition. A further aspect of the invention includes a first fitting component in which an exterior portion of the component is work hardened radially outward from the tube gripping device. The fitting may optionally be provided with a structure to effect the pull-up by torque functionality.

Owner:SWAGELOK CO

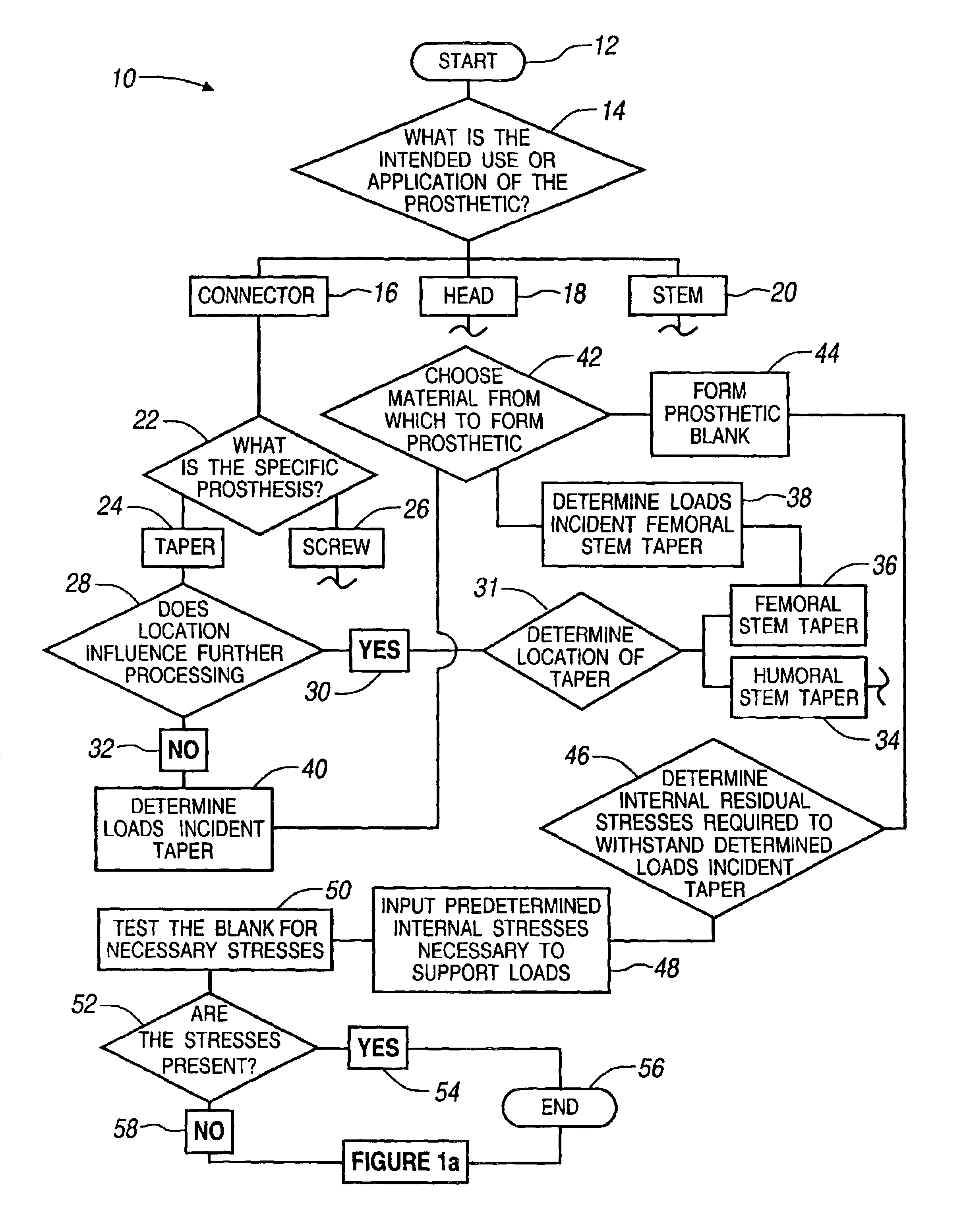

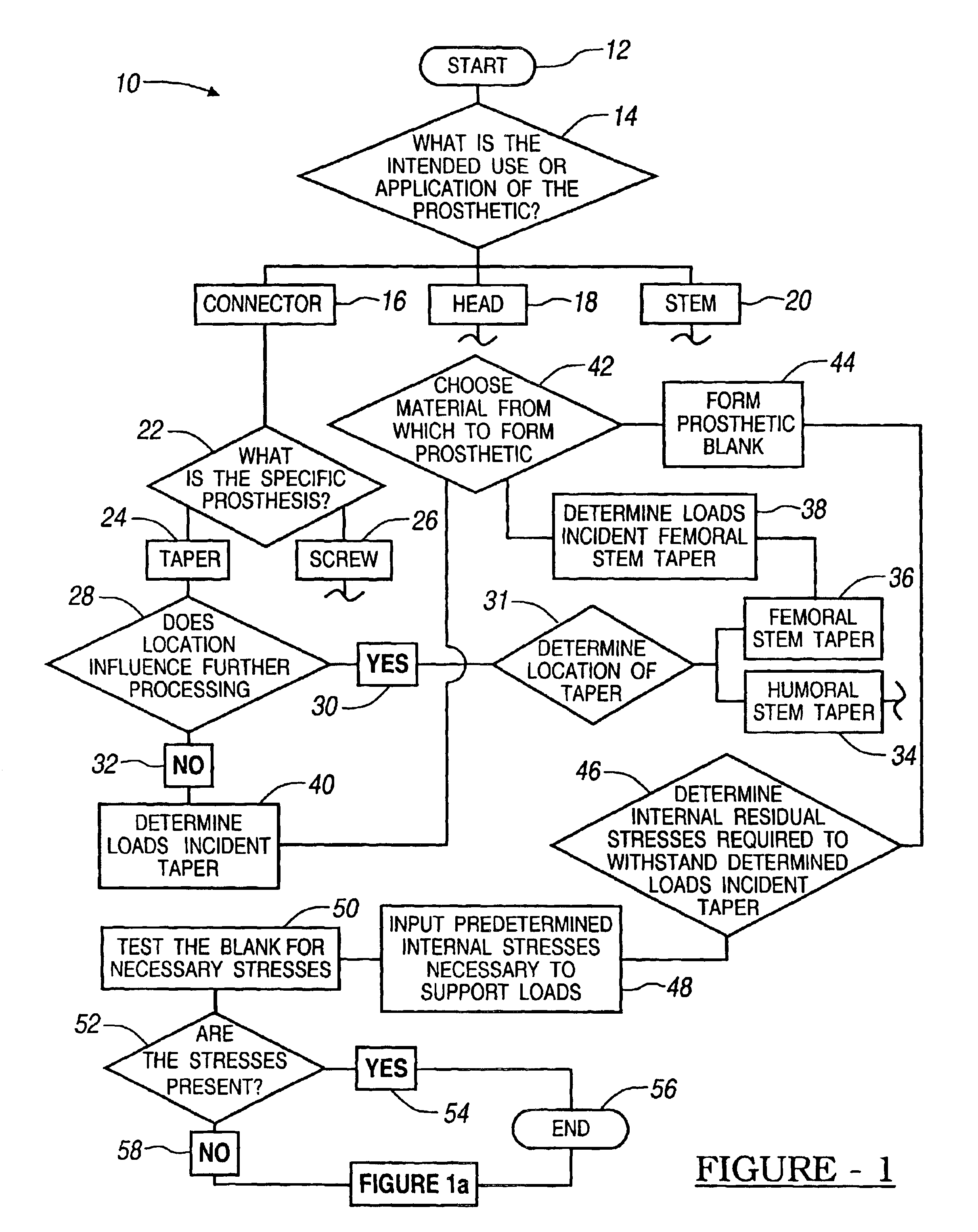

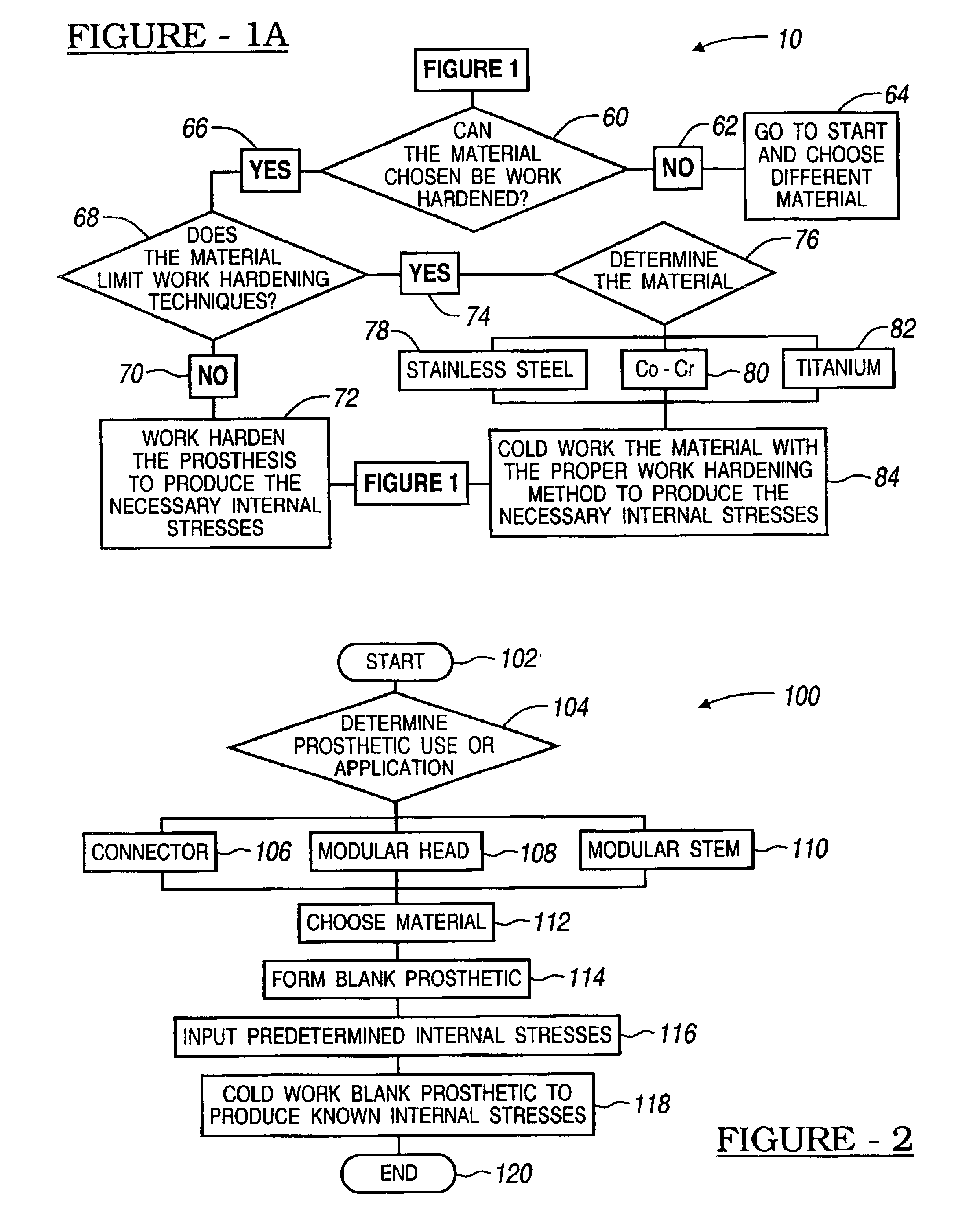

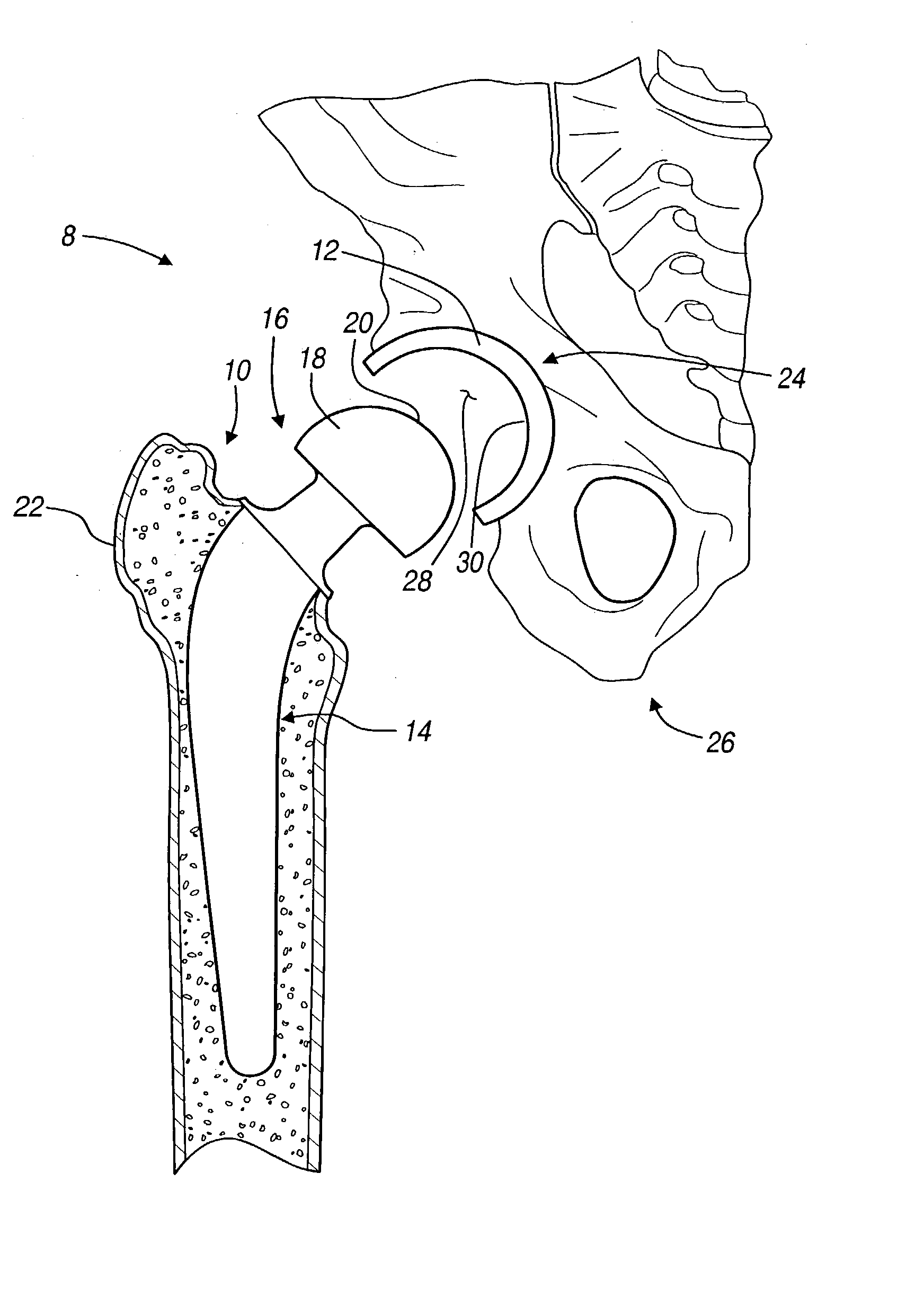

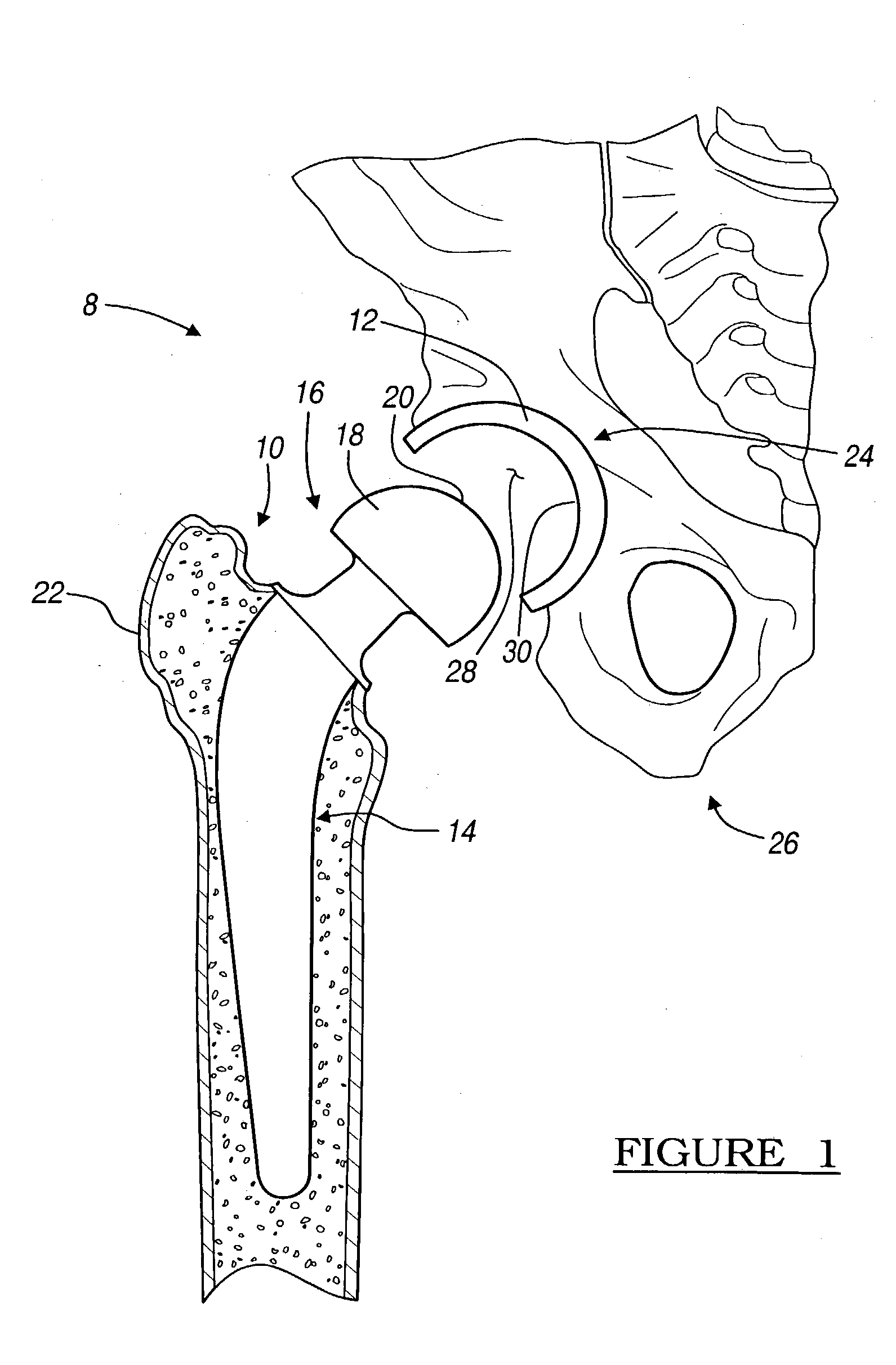

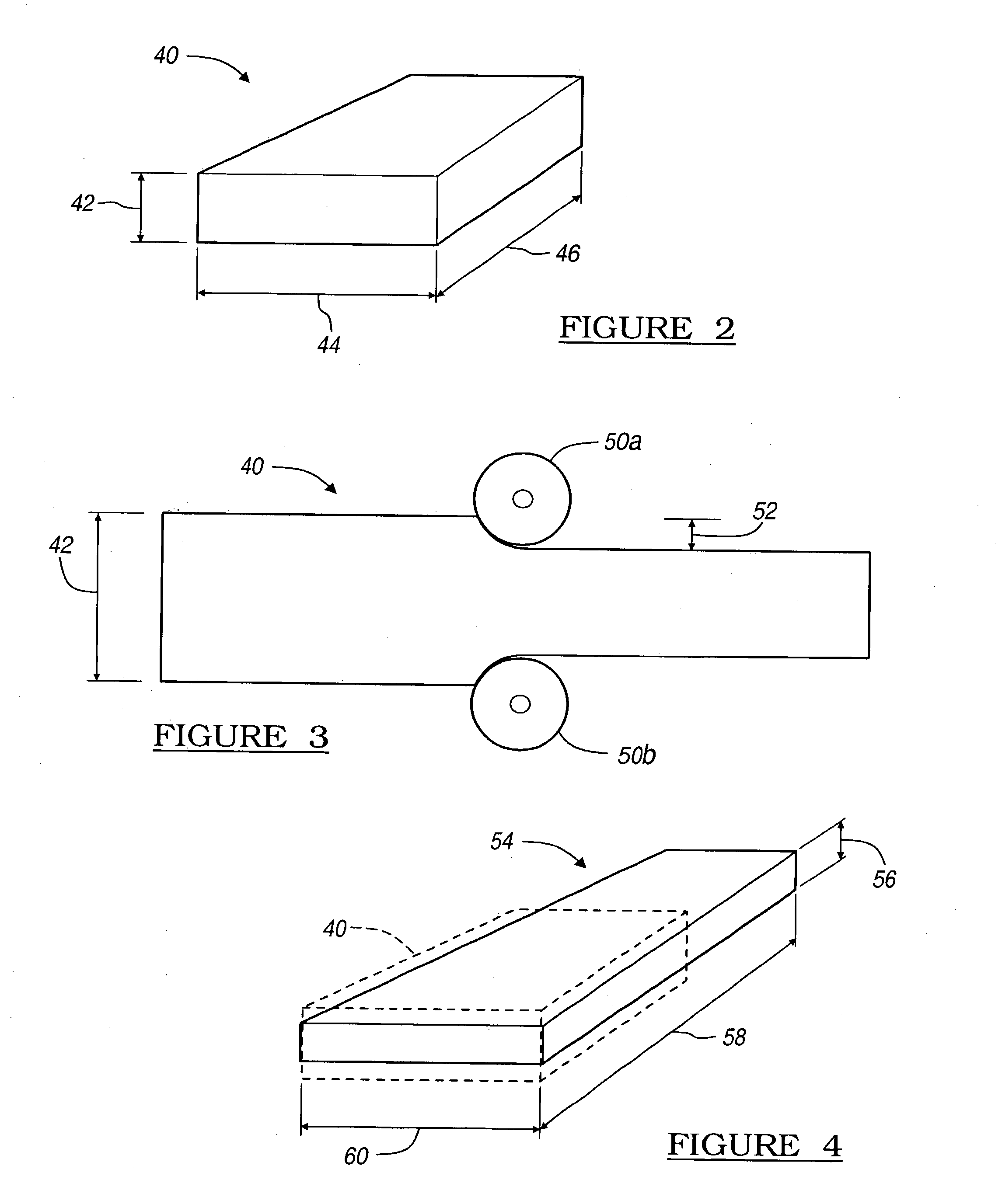

Method for controlling residual stress in prosthetics

InactiveUS6911100B1High strengthParticular longevityMeasurement/indication equipmentsJoint implantsProsthesisUltimate tensile strength

A method for producing predetermined internal stresses in a prosthetic device for implantation. The method includes first determining internal stresses which are preferred in prosthetics to instill a particular strength and longevity to the prosthetic. In particular, internal stresses may be used to increase the strength of smaller prosthetic devices. Additionally, once the preferred internal stresses are determined, the internal stresses can be cold worked into subsequent prosthetic devices to instill the same characteristics. Once parts are manufactured, internal stresses can be measured to validate manufacturing process and serve as verification for quality control purposes. Producing prosthetic devices, including predetermined internal stresses through work hardening the prosthetic devices, is described.

Owner:BIOMET MFG CORP

High hardness and toughness low alloy abrasion resistant steel and use thereof

The invention discloses high-hardness-ductility low alloy abrasion-resistant steel with high hardness, good ductility, high work hardening capacity, favorable comprehensive mechanical property and hardenability. In the invention, as Nb, B and rear-earth elements are added, the high-hardness-ductility low alloy abrasion-resistant steel can be ensured to have better hardenability, better ductility, high initial hardness, high work hardening capacity and better abrasion-resistant performance, thereby enlarging the application of materials. The invention is suitable for preparing wearing parts, in particular to parts used for impacting wearing working conditions.

Owner:韶关韶瑞铸钢有限公司

High-strength hot-dip galvanized steel sheet and high-strength alloyed hot-dip galvanized steel sheet excellent in mechanical cutting property, and manufacturing method thereof

ActiveUS20140287263A1High densityImprove work hardening abilityHot-dipping/immersion processesFurnace typesSheet steelSurface layer

There is provided a high-strength hot-dip galvanized steel sheet and the like excellent in mechanical cutting property, which are capable of obtaining high ductility while ensuring high strength with maximum tensile strength of 900 MPa or more. The high-strength hot-dip galvanized steel sheet has a sheet thickness of 0.6 to 5.0 mm and has a plating layer on a surface of a steel sheet with component compositions being set in appropriate ranges, in which the steel sheet structure contains a 40 to 90% ferrite phase and a 3% or more retained austenite phase by volume fraction. In the retained austenite phase, a solid solution carbon amount is 0.70 to 1.00%, an average grain diameter is 2.0 μm or less, an average distance between grains is 0.1 to 5.0 μm, a thickness of a decarburized layer in a steel sheet surface layer portion is 0.01 to 10.0 μm, an average grain diameter of oxides contained in the steel, sheet surface layer portion is 30 to 120 nm and an average density thereof is 1.0×1012 oxides / m2 or more, and moreover, a work hardening coefficient (n value) during a 3 to 7% plastic deformation is 0.080 or more on average.

Owner:NIPPON STEEL CORP

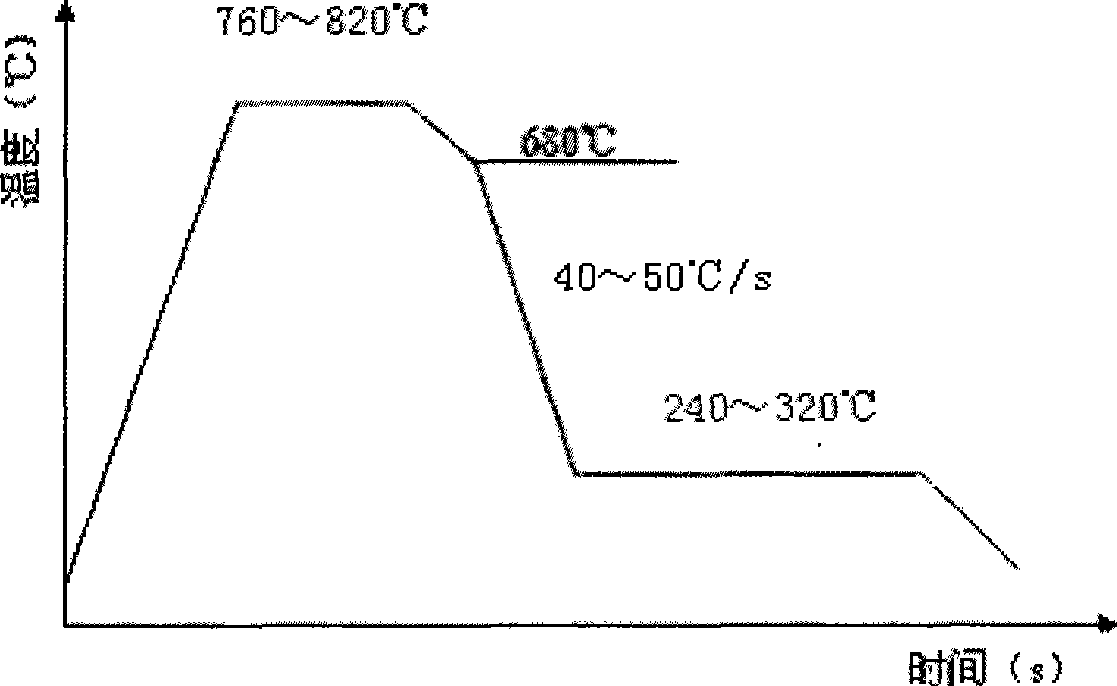

Cold rolled dual-phase sheet steel with 1000MPa grade tensile strength and preparation method thereof

A cold-rolled biphase steel plate with 1000 MPa of tensile strength and a production method thereof belong to the technical field of high-intensity cold-rolled biphase steel. The steel plate comprises the following chemical components by mass percentages: 0.14%-0.21% of C, 0.40%-0.90% of Si, 1.5%-2.1% of Mn, 0.01%-0.05% of Nb, less than 0.02% of P, less than 0.01% of S, and Fe and inevitable impurities. The production method is as follows: a billet is treated by the conventional hot rolling, pickling, cold rolling and continuous annealing, the annealing temperature is 760-820 DEG C and is kept for 70-120s, the fast cooling speed is 40-50 DEG C per second, the aging temperature is 240-320 DEG C and the aging time is 180-300s. The cold-rolled biphase steel plate has the advantages of high tensile strength, low tensile ratio, high initial work hardening rate, no yield elongation which avoids wrinkles on the formed parts. The cold-rolled biphase steel plate has a biphase organization with fine grain ferrite and martensite, wherein, the volume fraction of the martensite is 30%-40% and the average grain size of the ferrite is 2mum.

Owner:UNIV OF SCI & TECH BEIJING +1

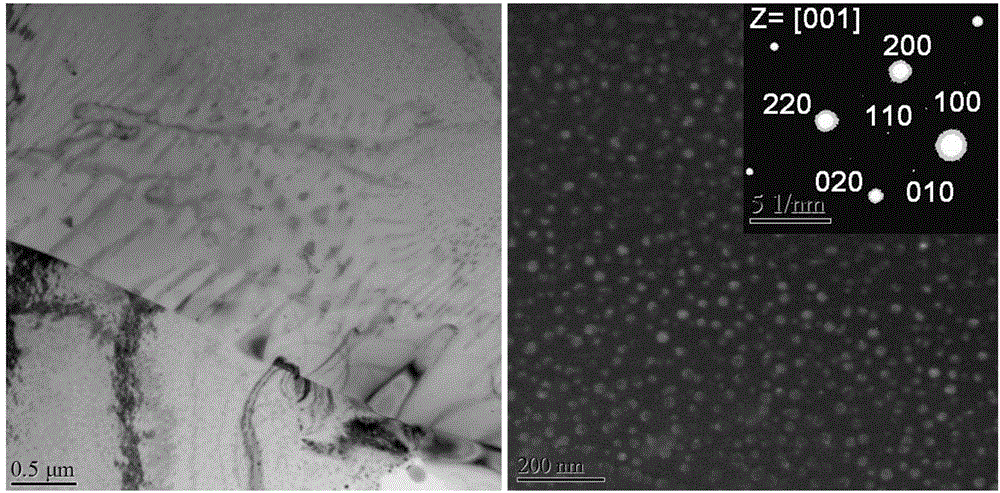

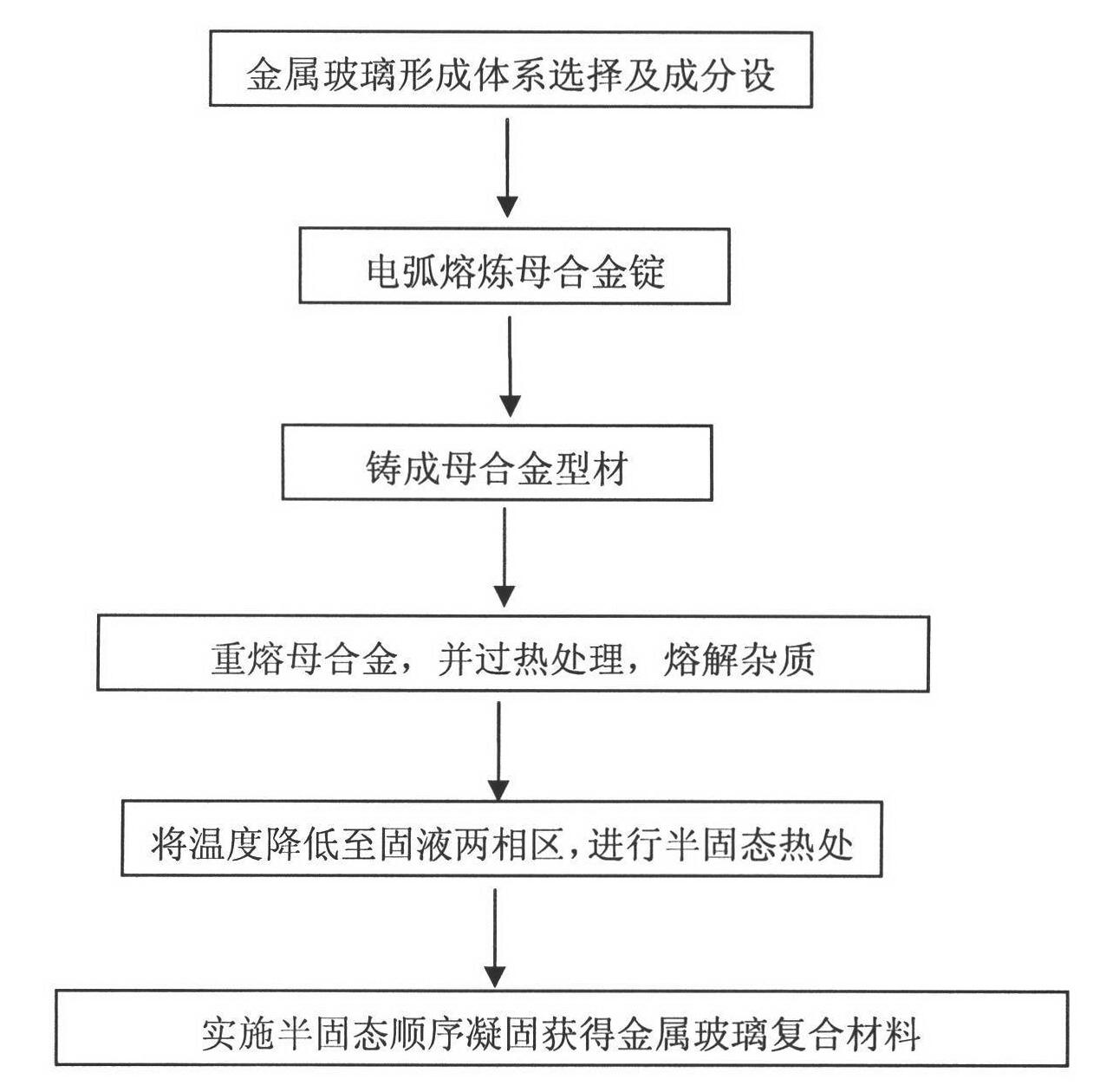

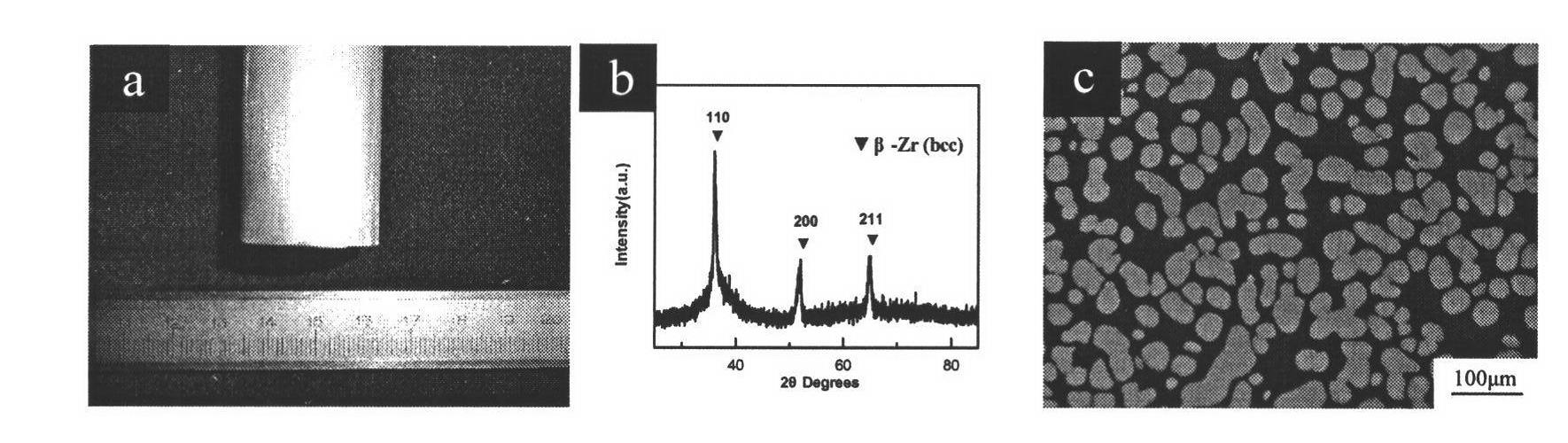

Large-size metallic glass composite material with tensile ductility and preparation method thereof

InactiveCN102181809ARealize one-step moldingUniform Work Hardening AbilityGlass compositesWork hardening

The invention discloses a large-size metallic glass composite material with tensile ductility and a preparation method thereof. A composition expression of the metallic glass composite material is ZraTibMcCudNieBef (atom percent), wherein M is one of Nb, V or Hf, a is not less than 10 and not more than 70, b is not less than 10 and not more than 70, c is not less than 4 and not more than 20, d isnot less than 2 and not more than 20, e is not less than 0 and not more than 15, f is not less than 5 and not more than 22.5, and a+b+c+d+e+f is equal to 100. The preparation method is called after semi-solid progressive solidification method, which comprises the following steps of: smelting master alloy ingots and casting into master alloy profiles; putting the master alloy profiles into a crucible and heating until the profiles are completely melted, and performing the overheating processing to dissolve impurity phases; reducing the temperature to a solid-liquid two-phase region; performingsemi-solid processing, and controlling the shape and the size of a precipitated solid solution phase; and then performing the semi-solid progressive solidification to form the large-size metallic glass composite material with tensile ductility. By adopting the method, the homogeneous and defect-free large-size (30 mm) metallic glass composite material is prepared, and the composite material has remarkable work hardening capacity and excellent tensile strength and ductility.

Owner:NANJING UNIV OF SCI & TECH

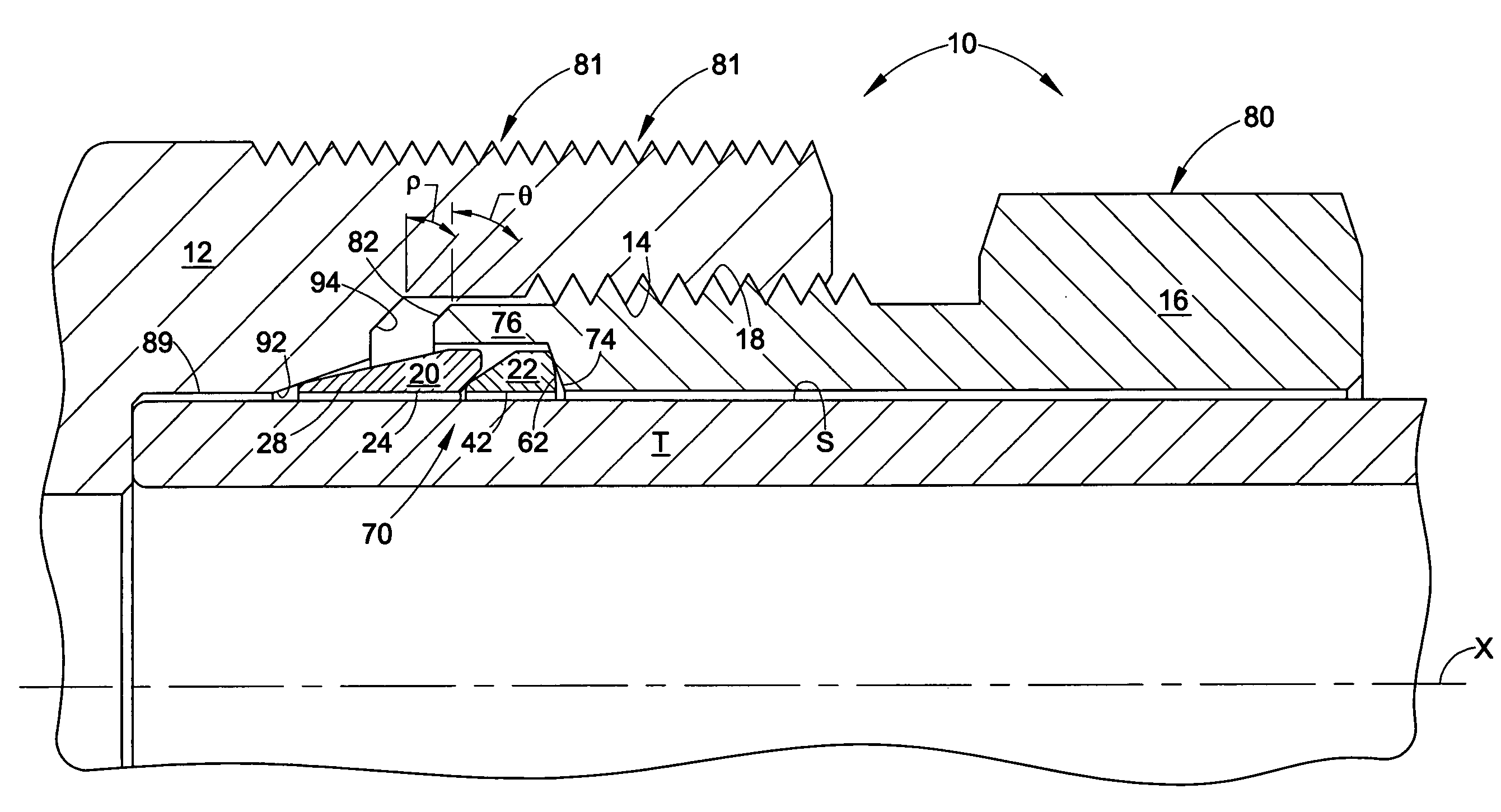

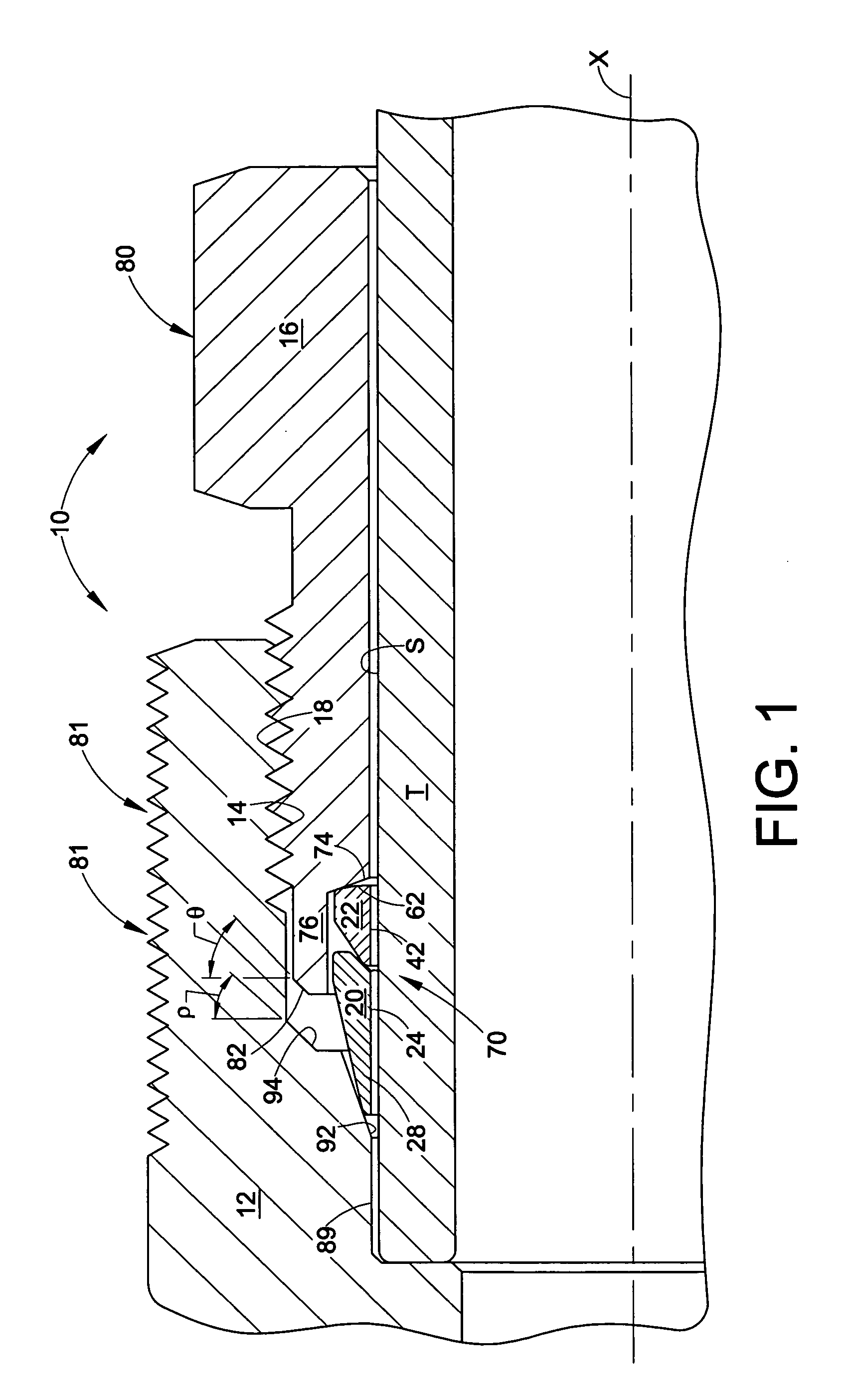

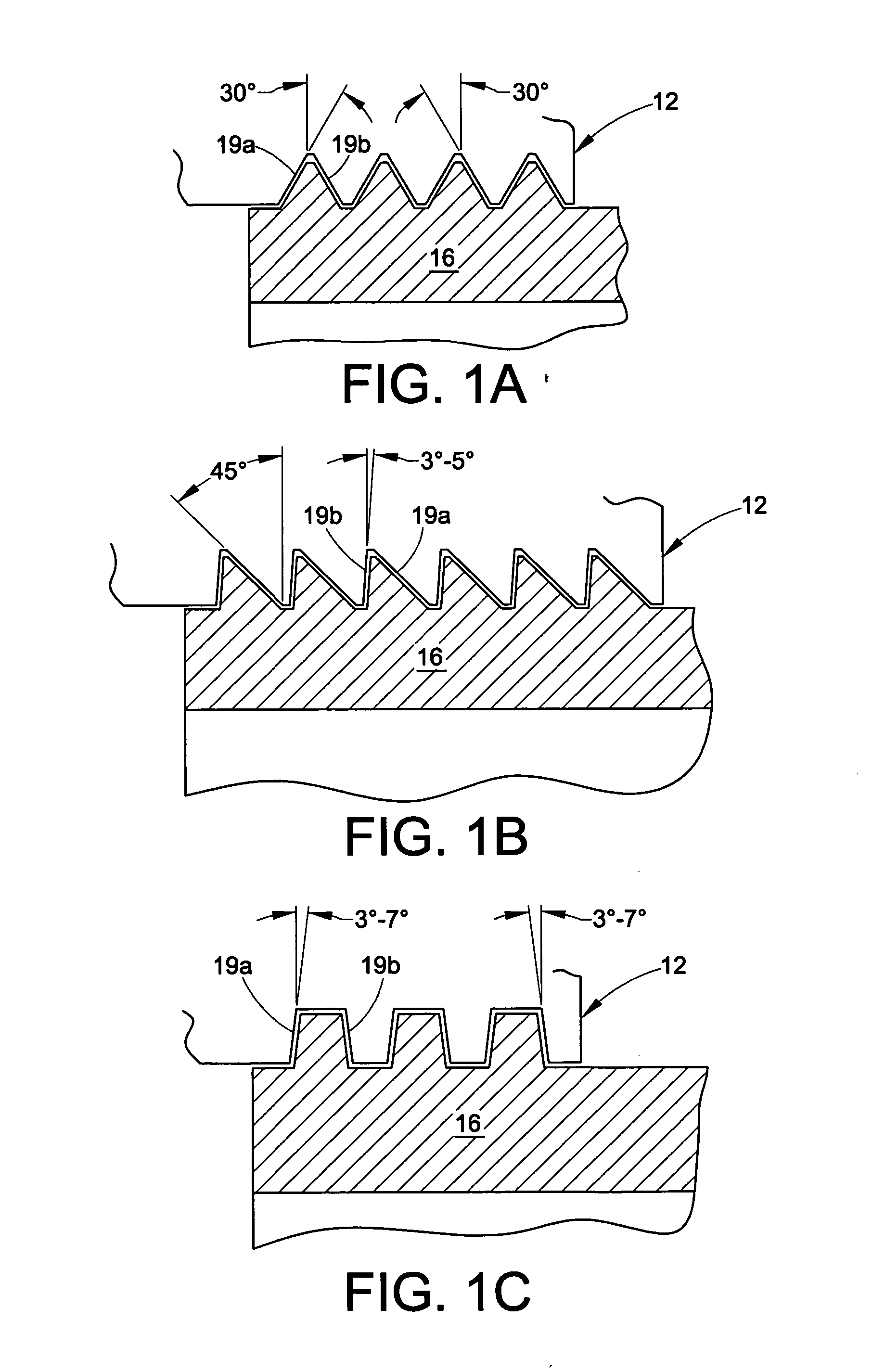

Wear surface for metal-on-metal articulation

InactiveUS20040148033A1Extend your lifeReduce wear debrisBone implantJoint implantsProsthesisSacroiliac joint

A work hardened articulating surface for anatomical prosthetics. Articulating surfaces of prosthetics are work hardened to decrease the wear and increase the longevity of the prosthetic after implantation. The articulating surface can be hardened in any number of ways, for example the articulating surface can be formed from stock material that has been work hardened throughout or the articulating surface can be work hardened prior to final finishing of the prosthetic component. Regardless, the hardened articulating surface reduces wear after implantation while eliminating the need for a separate bearing component.

Owner:BIOMET MFG CORP

Medium alloy abrasion resistant steel and use thereof

The invention discloses medium alloy abrasion-resistant steel with high hardness, good impact ductility, high work hardening capacity, favorable comprehensive mechanical property and hardenability. In the invention, as boron element and rear-earth elements are added, the medium alloy abrasion-resistant steel can be ensured to have better hardenability, better ductility, high initial hardness, high work hardening capacity and better abrasion-resistant performance, thereby enlarging the application of materials. The invention is suitable for preparing wearing parts, in particular to parts used for impacting wearing working conditions.

Owner:JINAN UNIVERSITY

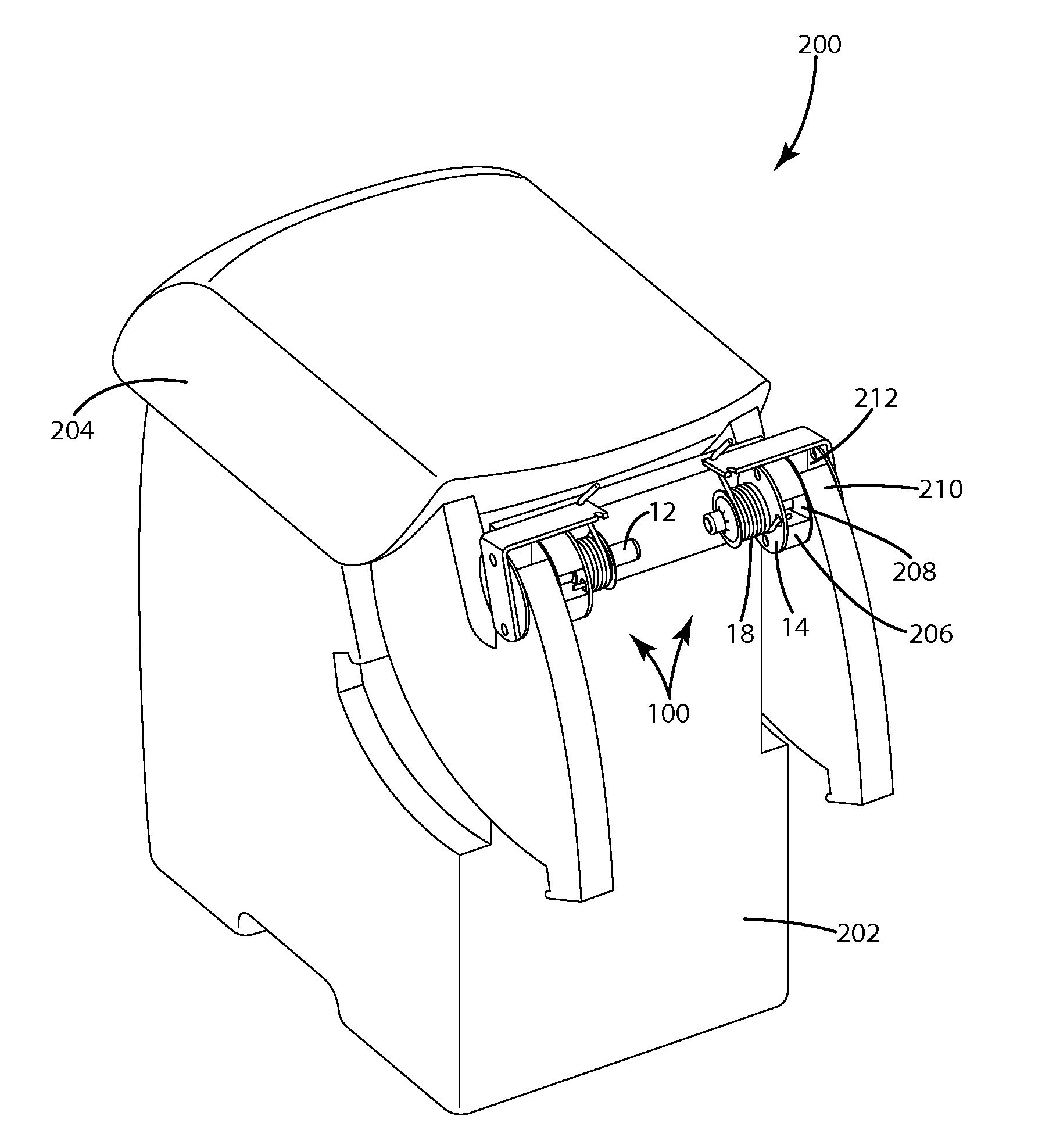

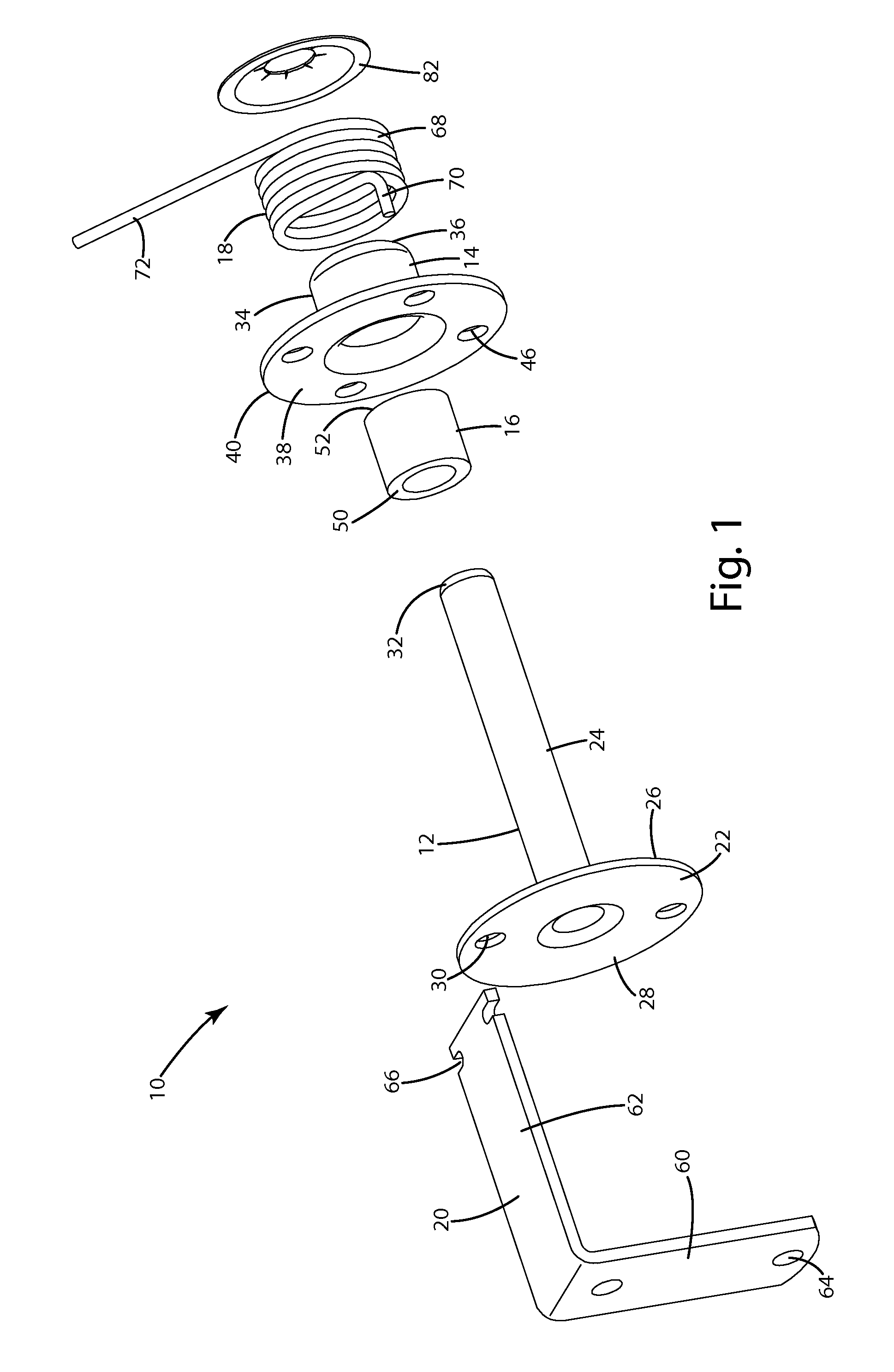

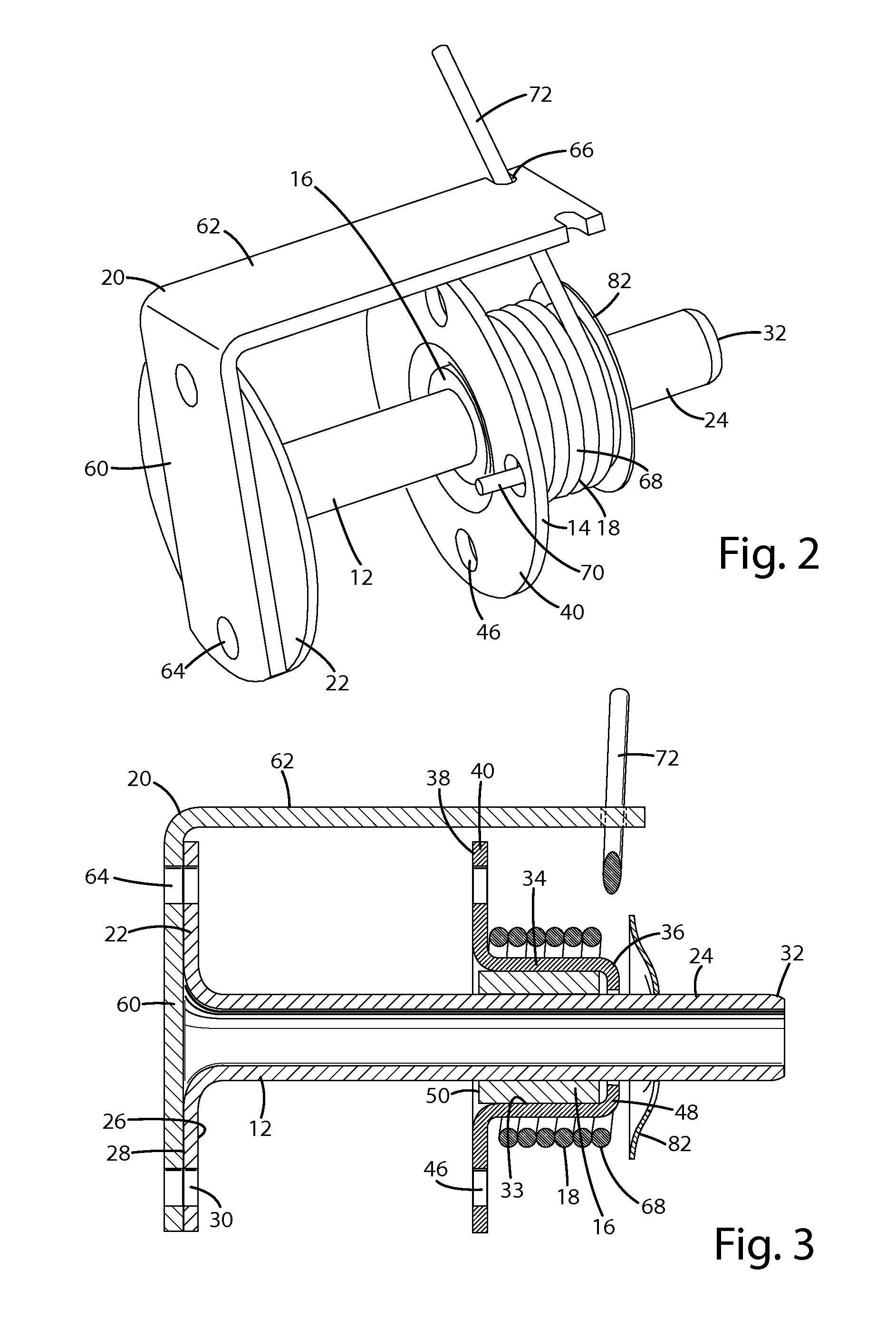

Torque assembly and method of manufacture

A torque assembly includes a spindle, a cap mounted on the spindle for rotation about the spindle, and a work-hardened, plastic sleeve inserted between the cap and the spindle for constant rotation of the sleeve and cap with respect to the spindle. The torque assembly may be installed onto a hinged object and fixed object with movement along a single axis. The torque assembly may be formed by: (a) providing a spindle having a base and a rod extending from the base; (b) providing a cap member with an annular section defining an inner diameter; (c) providing an annular plastic sleeve having an inner diameter and an outer diameter; (d) work-hardening the sleeve for a predetermined time period; (e) changing the inner diameter of the sleeve; and (f) inserting the spindle rod through the inner diameter of the sleeve.

Owner:VENTURESOURCE SOLUTIONS

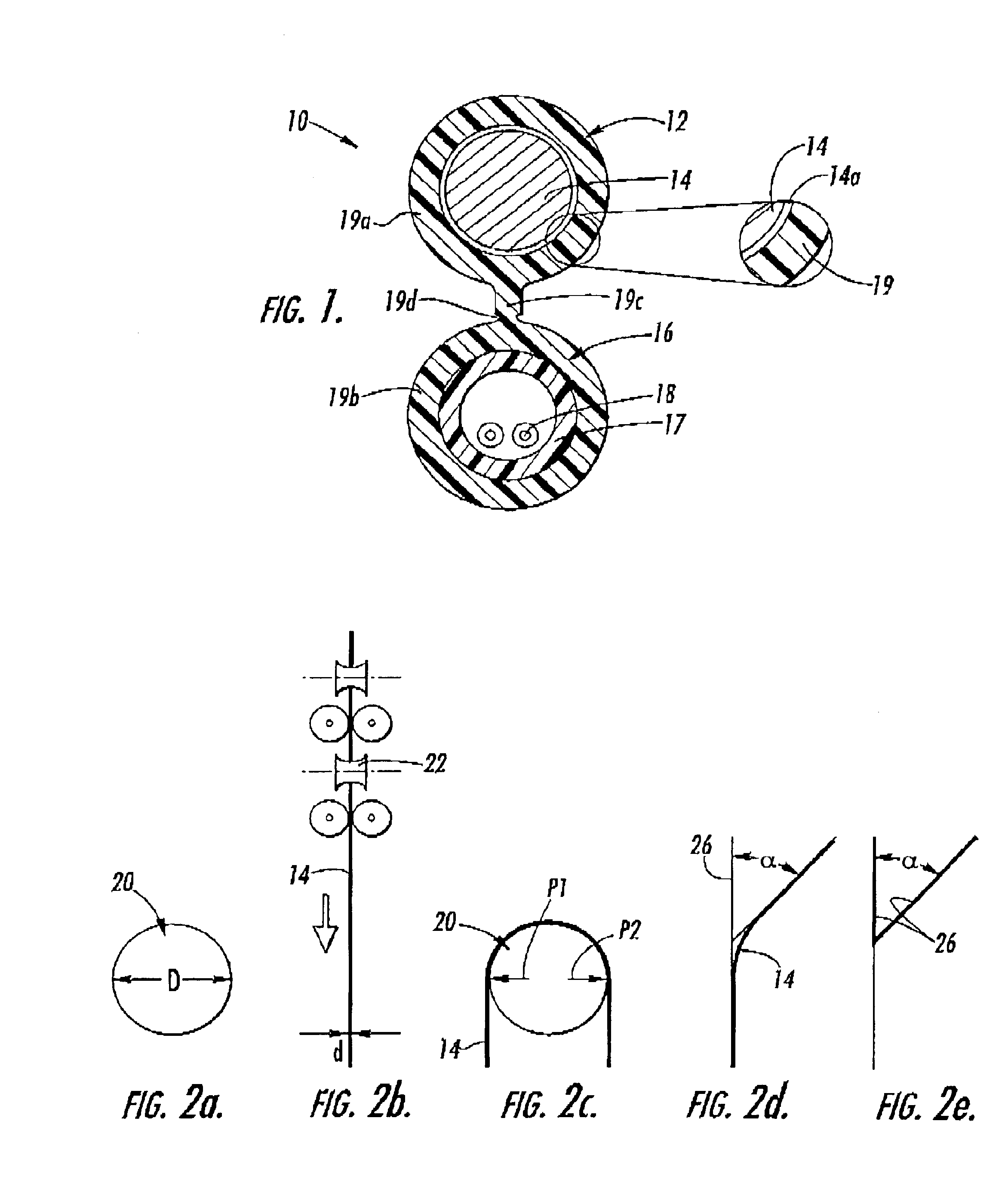

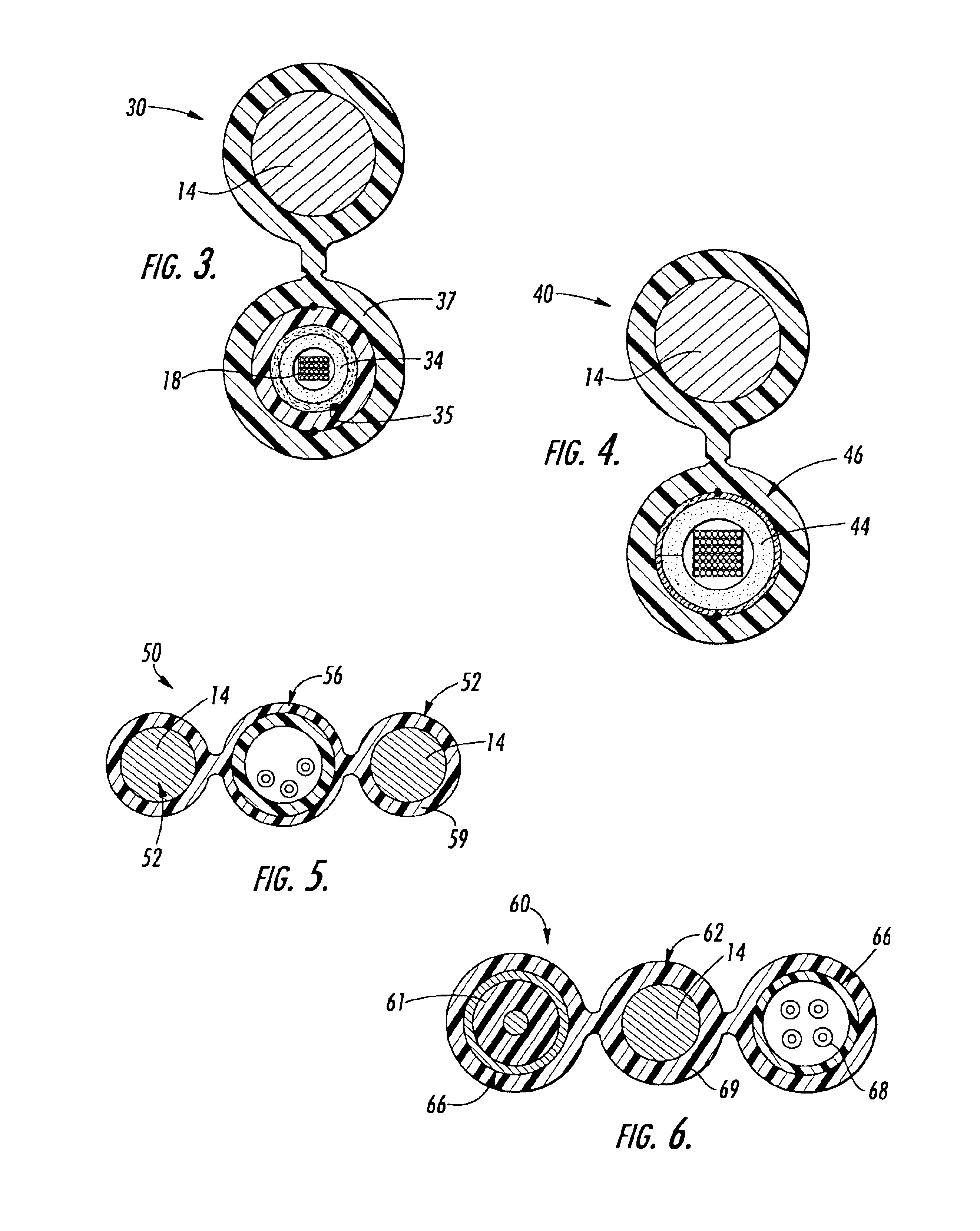

Fiber optic cable having a strength member

InactiveUS6928217B2Relieve pressureTelevision system detailsColor television detailsFiberEngineering

A fiber optic cable includes at least one optical waveguide, at least one strength member, and a jacket. The at least one strength member is a material having an average residual angle in the range of about 30 degrees to about 65 degrees during a bending test using a mandrel having a wire ratio (D / d) of about 200. The strength member is suitable, if necessary, for self-attaching to studs, hooks, or the like by bending it therearound and is also suitable for hardware such as P-clamps or other grips. In other embodiments, strength member 14 is annealed to relieve work hardening. Preferred embodiments use a steel strength member with a carbon content between about 0.30 percent to about 0.75 percent. Additionally, a coating may be applied to the strength member for environmental / corrosion protection or conductivity.

Owner:CORNING OPTICAL COMM LLC

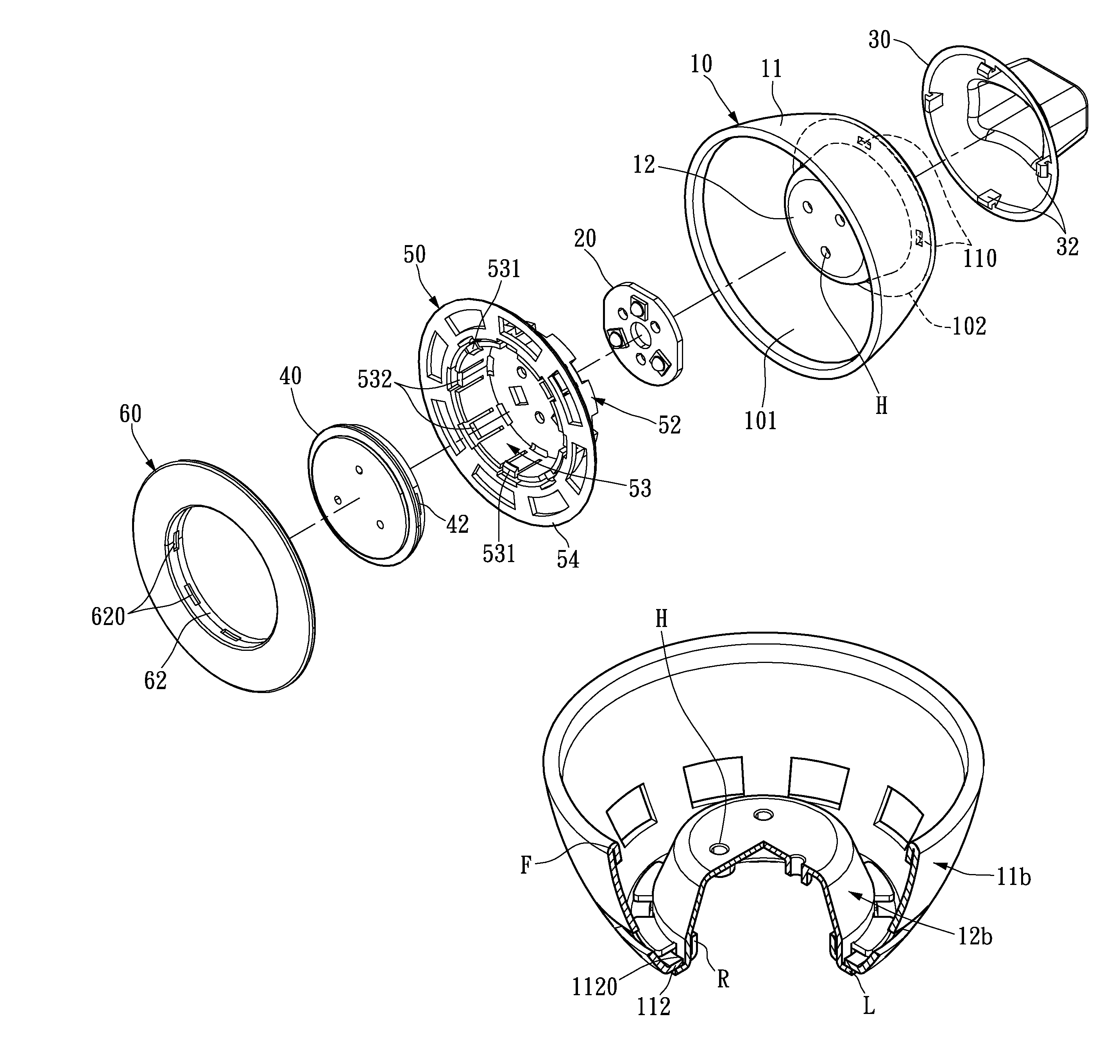

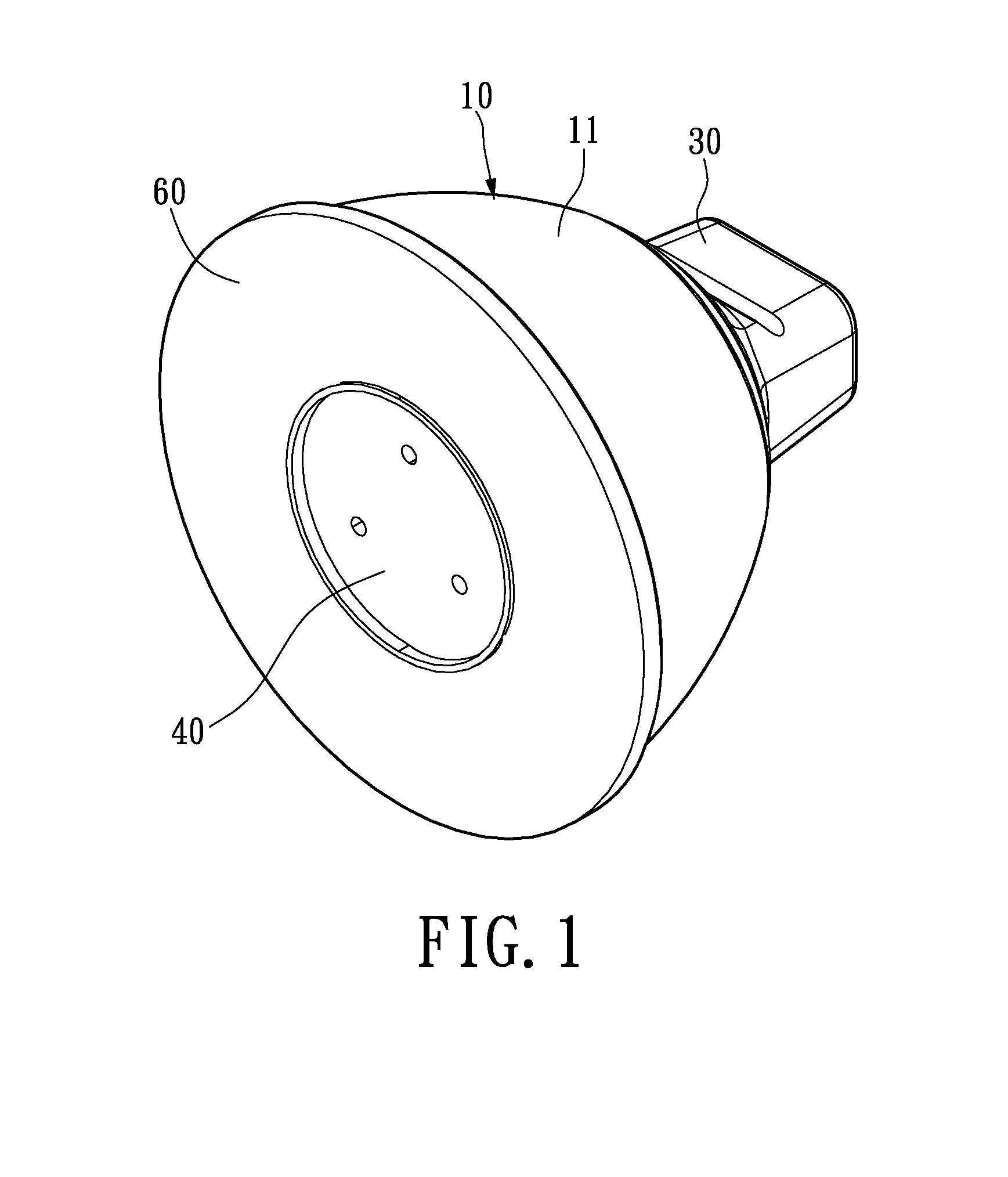

LED lamp

InactiveUS8388197B1Improve efficiencyLight weightPoint-like light sourceLighting heating/cooling arrangementsEngineeringLamp shell

The instant disclosure relates to a lamp having a heat dissipating lamp shell particularly suitable for housing solid state light sources. The lamp comprises a lamp shell of stamping construction and a light source unit. The lamp shell comprises an outer pot portion and an inner tray portion substantially concentrically coupled to the outer pot portion. Externally, the lamp shell forms a substantial portion of the lamp. The light source unit comprises a light module disposed on the inner tray portion of the lamp shell, a controller placed at the rear portion of the lamp shell, and an electrical connecter arranged exposedly from the rear of the lamp. The lamp shell of stamping construction is beneficially characterized by the light weight and strong structural integrity, which attribute to the work hardening property of the stamping process.

Owner:COOLER MASTER DEVELOPMENT CORP

Titanium alloy with extra-low modulus and superelasticity and its producing method and processing thereof

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

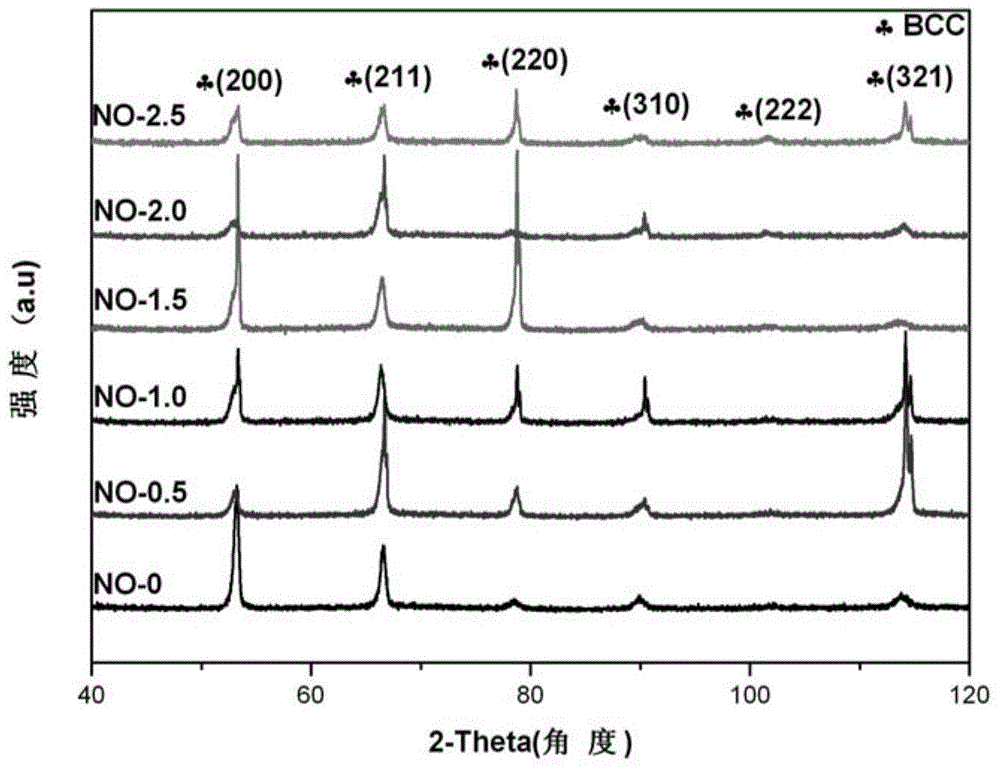

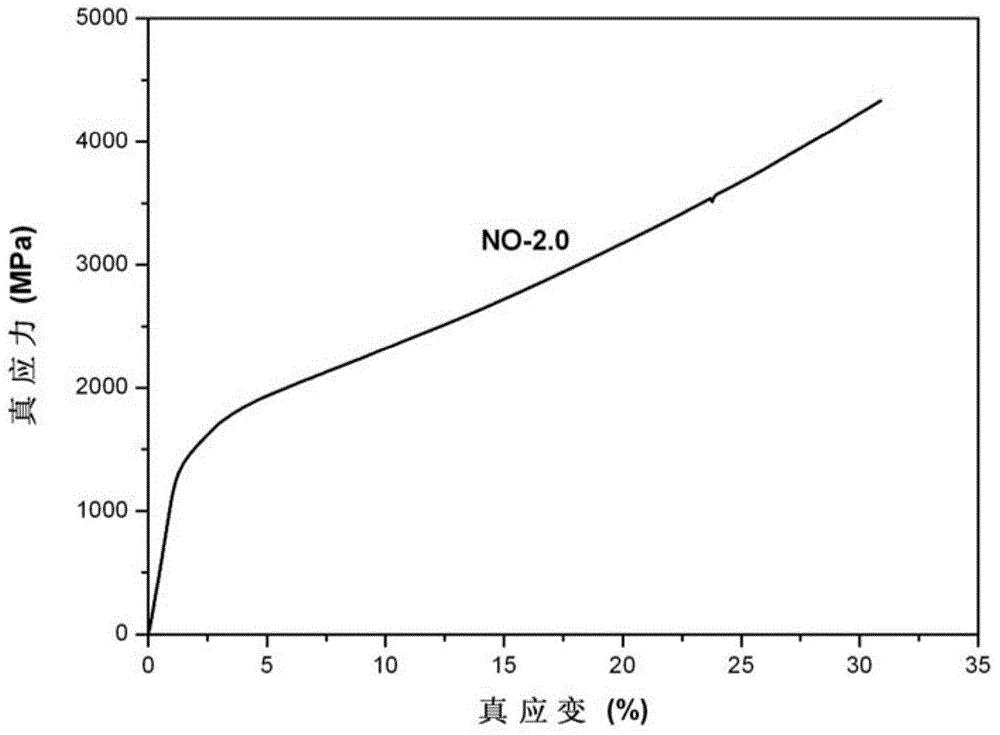

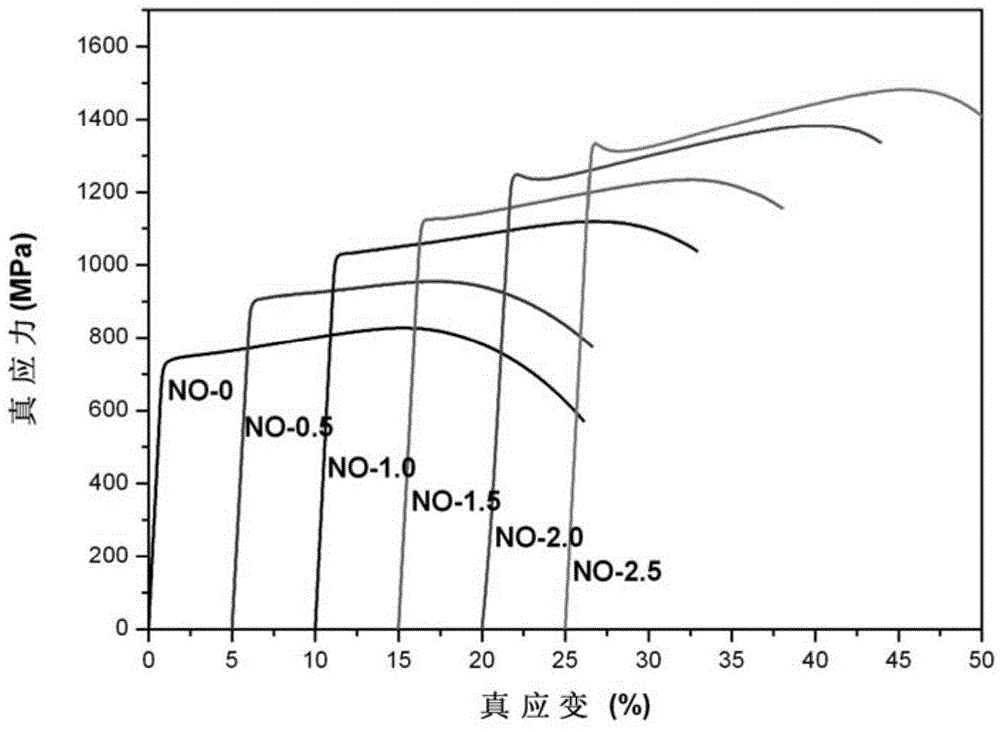

TiZrHfNb based high-entropy alloy with nitrogen and oxygen alloyed together and preparation method thereof

ActiveCN105671404AWide range of ingredientsWide range of preparation conditionsHigh entropy alloysOxygen

The invention relates to TiZrHfNb based high-entropy alloy with nitrogen and oxygen alloyed together and a preparation method thereof. Particularly, the tensile strength and tensile ductility of the alloy are remarkably improved by simultaneously microalloying N and O elements. The preparation method includes the following steps that metal raw materials of Ti, Zr, Hf and Nb are accurately weighed according to the molar ratios after oxide skin is removed; other added elements are accurately weighed according to the molar ratios after oxide skin is removed and the elements are washed with alcohol; the N element is added in the form of nitride, and the O element is added in the form of oxide; and target alloy is smelted in a nonconsumable vacuum arc furnace or cold crucible shower furnace, and the alloy is obtained through vacuum suction casting or casting equipment. The tensile property of the high-entropy alloy is improved remarkably by simultaneously adding the N and O elements, the tensile strength of (TiZrHfNb)97.5(NO)2.5 based high-entropy alloy reaches 1300 MPa, meanwhile, the tensile ductility exceeds 15%, the work-hardening rate is low, and the comprehensive tensile property is excellent.

Owner:UNIV OF SCI & TECH BEIJING

Aircraft structural member made of an Al-Cu-Mg alloy

ActiveUS7294213B2Improve propertiesIncrease costThin material handlingMetal layered productsAlloyDissolution

The invention relates to a work-hardened product, particularly a rolled, extruded or forged product, made of an alloy with the following composition (% by weight):Cu 3.8-4.3; Mg 1.25-1.45; Mn 0.2-0.5; Zn 0.4-1.3; Fe<0.15; Si<0.15; Zr≦0.05; Ag<0.01,other elements <0.05 each and <0.15 total, remainder Al treated by dissolution, quenching and cold strain-hardening, with a permanent deformation of between 0.5% and 15%, and preferably between 1.5% and 3.5%. Cold strain-hardening can be achieved by controlled tension and / or cold transformation, for example rolling, die forging or drawing. This cladded metal plate type product is a suitable element to be used as aircraft fuselage skin.

Owner:CONSTELLIUM ISSOIRE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com