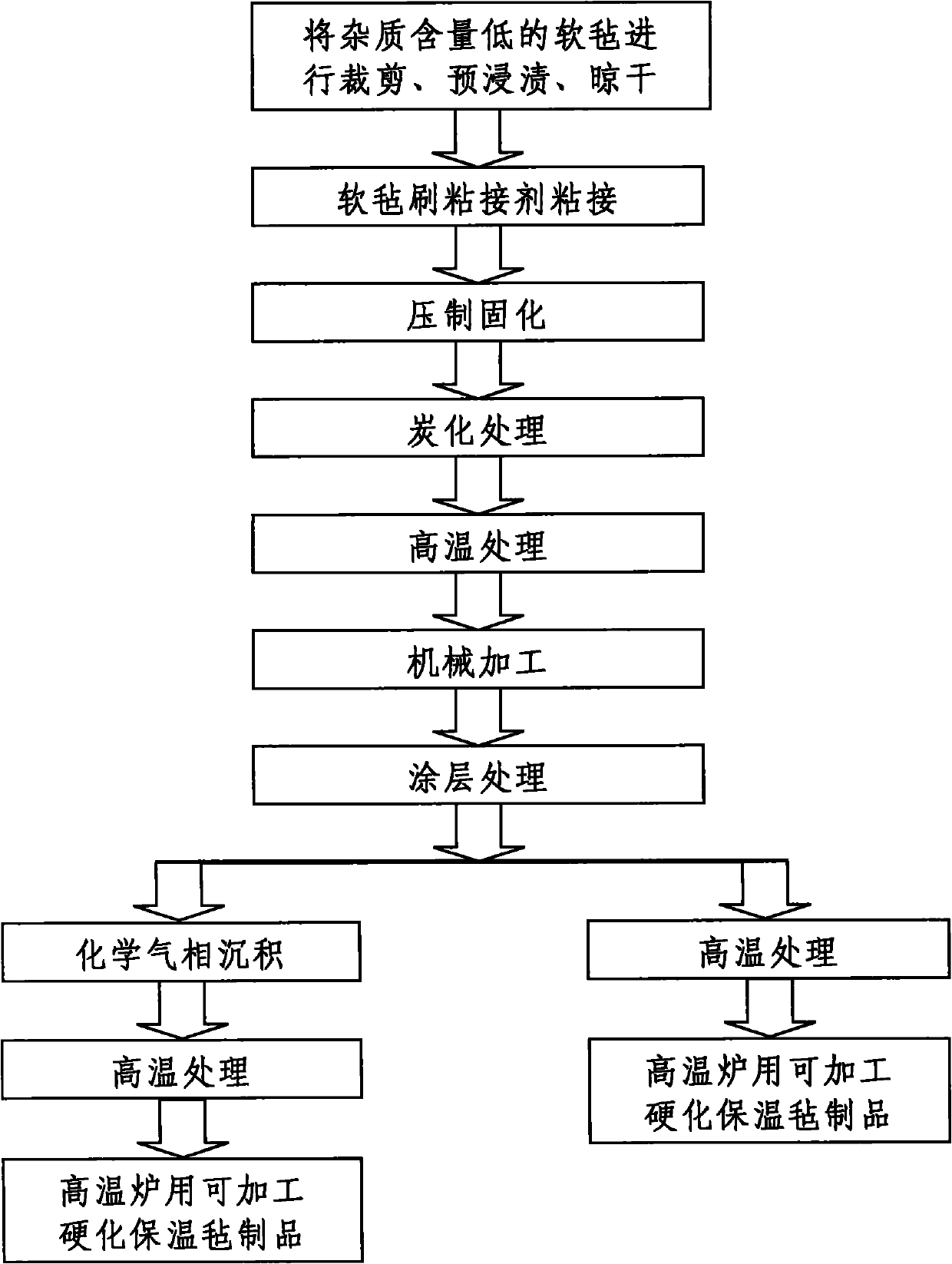

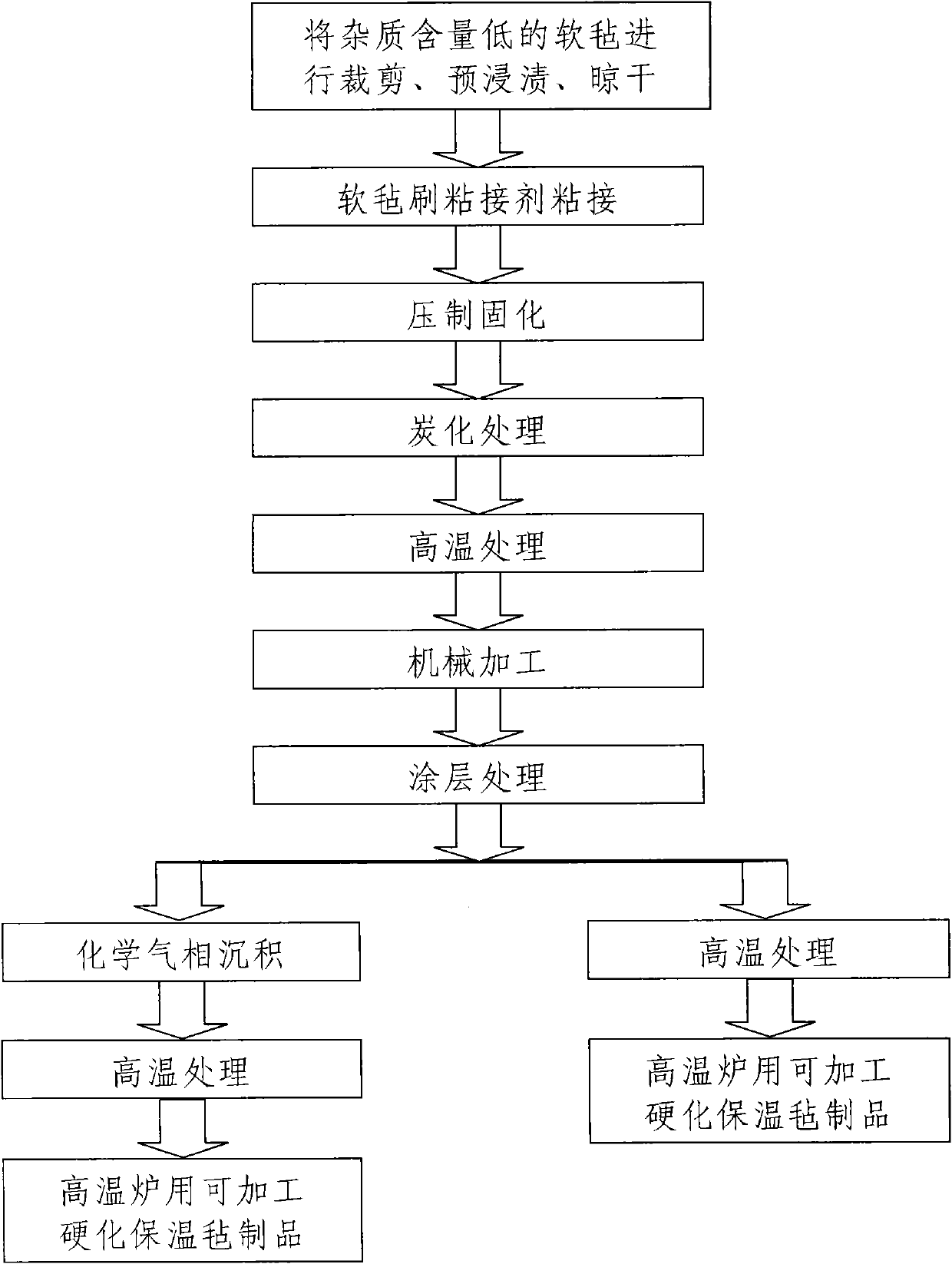

Method for preparing work hardening insulation quilt for high temperature furnace

A technology of work hardening and thermal insulation felt, which is applied in the field of thermal field material accessories for high temperature furnaces, can solve the problems of low mechanical strength of foamed carbon and poor product machinability, and achieves enhanced machinability and reduced chemical vapor infiltration densification process. , the effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Adopt polyacrylonitrile-based carbon felt with an ash content of 1800ppm, cut the polyacrylonitrile-based carbon felt to a width of 200mm, and pre-impregnate with a mixed glue of alcohol and aminophenol-formaldehyde resin with a mass ratio of 2:1, impregnate The amount of agent used is to submerge the soft felt; then dry the pre-impregnated soft felt for 5 hours;

[0028] (2) brush bonding agent on the soft felt after drying to bond soft felt, and bonding agent is the mixture of phenolic resin and graphite powder that mass ratio is 10: 0.5;

[0029] (3) Press and solidify the bonded soft felt at a temperature of 140° C. and a pressure of 0.01 MPa to obtain a semi-finished product;

[0030] (4) The semi-finished product is placed in a carbonization furnace, and the temperature is raised to 700°C under the condition of a heating rate of 5°C / h for carbonization treatment;

[0031] (5) Place the carbonized product in a high-temperature heat treatment furnace, and heat ...

Embodiment 2

[0036] The preparation process of this embodiment is the same as that of Example 1, except that the mass ratio of the coating material used is phenolic resin: alcohol: graphite powder = 2: 1: 1, and the thermal conductivity of the machinable hardening insulation felt is It is 0.47W / m·K, and the ash content is 600ppm.

Embodiment 3

[0038] The preparation process of this embodiment is the same as that of Example 1, except that the mass ratio of the coating material used is phenolic resin: alcohol: graphite powder = 10: 5: 1, and the thermal conductivity of the processed hardening insulation felt is It is 0.40W / m·K, and the ash content is 1100ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com