Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

285 results about "Laser quenching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

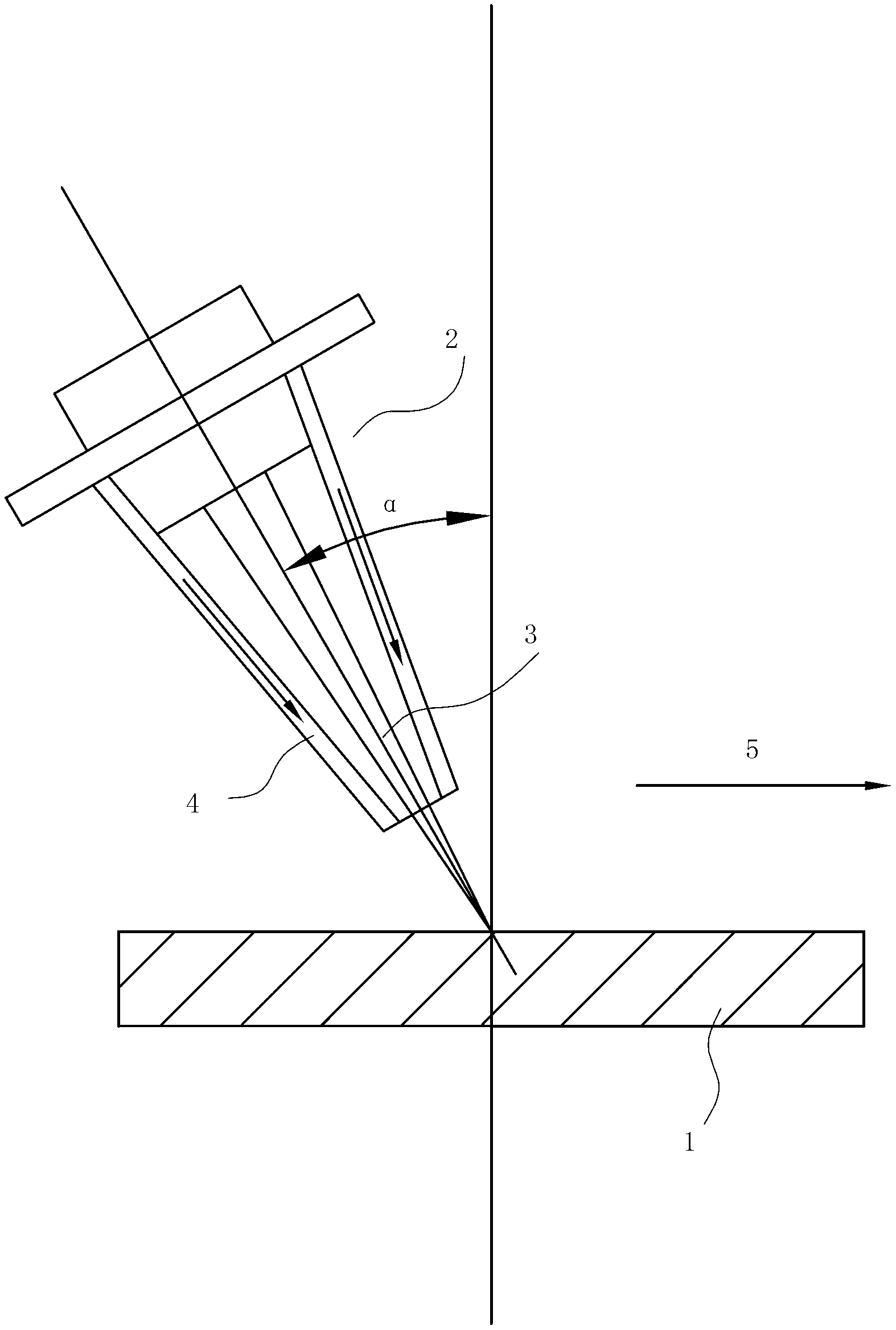

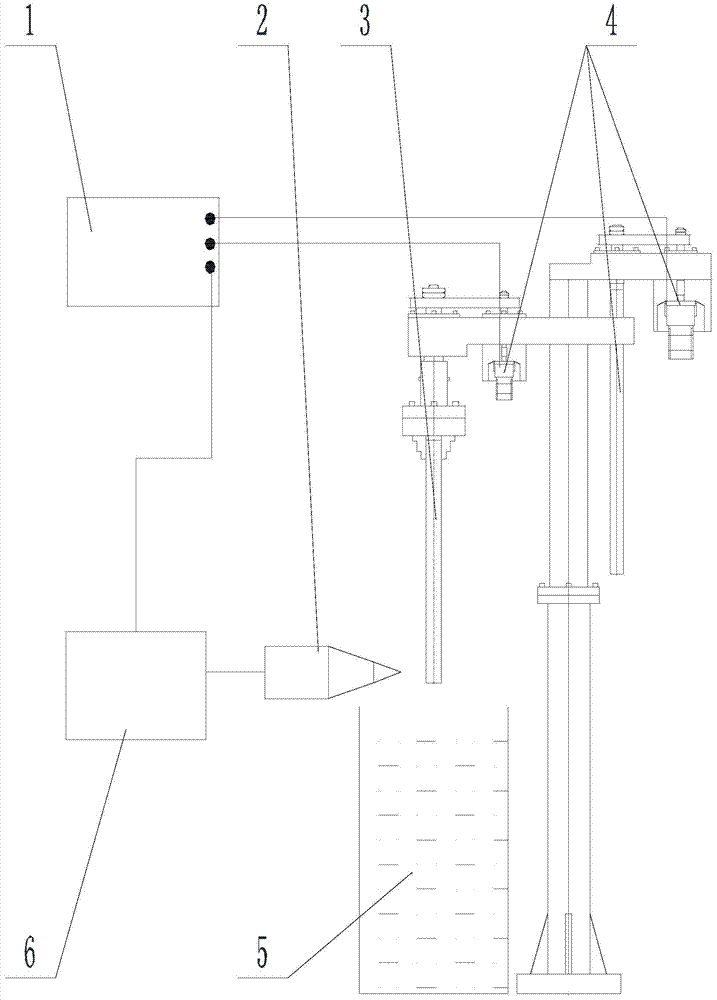

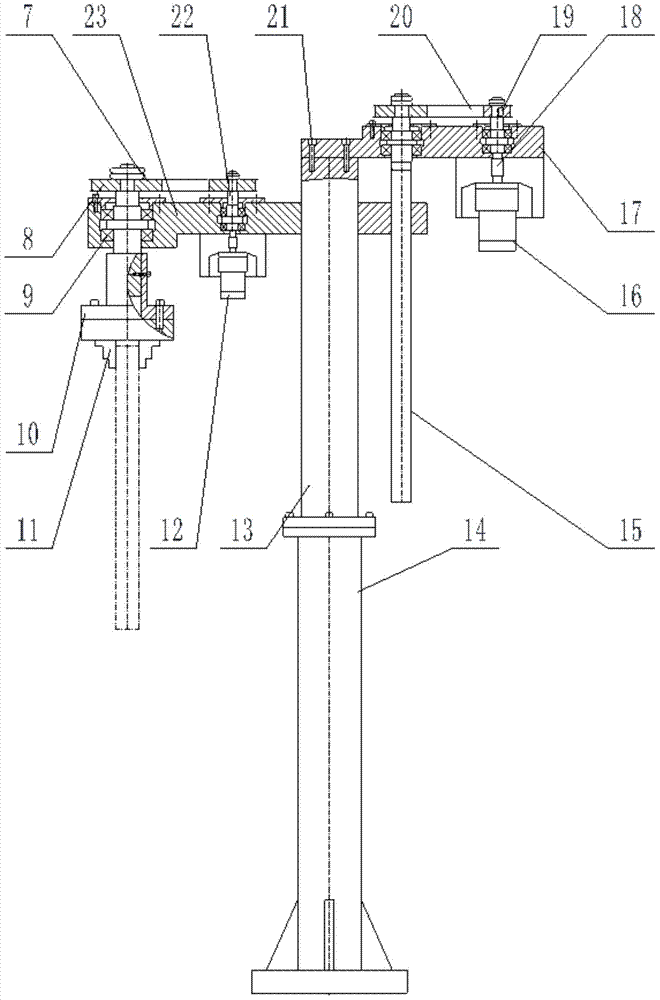

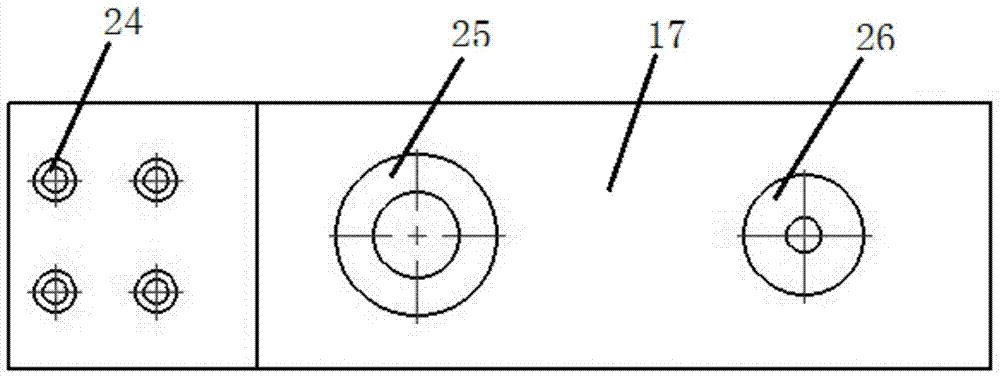

Multi-irradiation laser quenching method and device

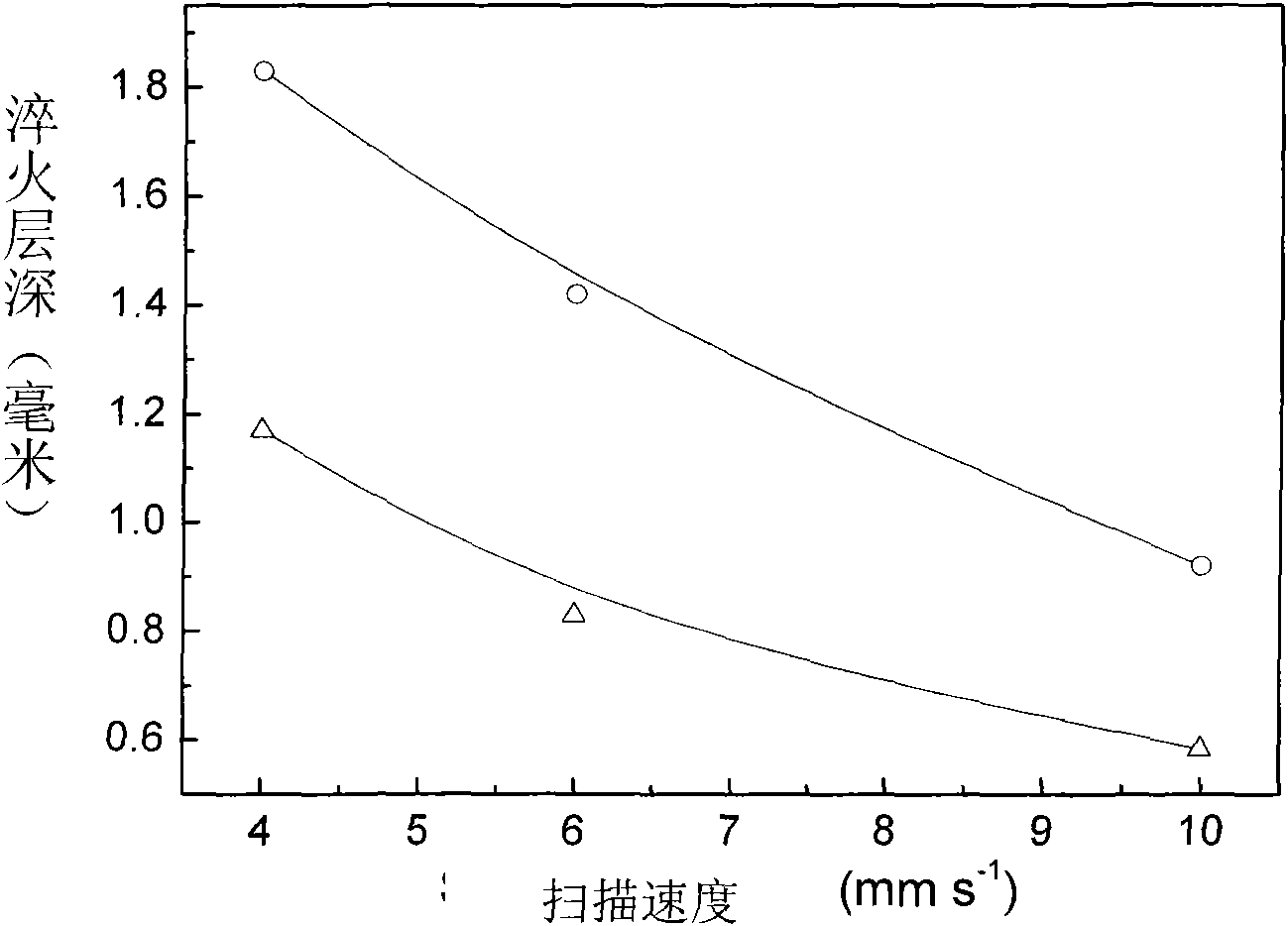

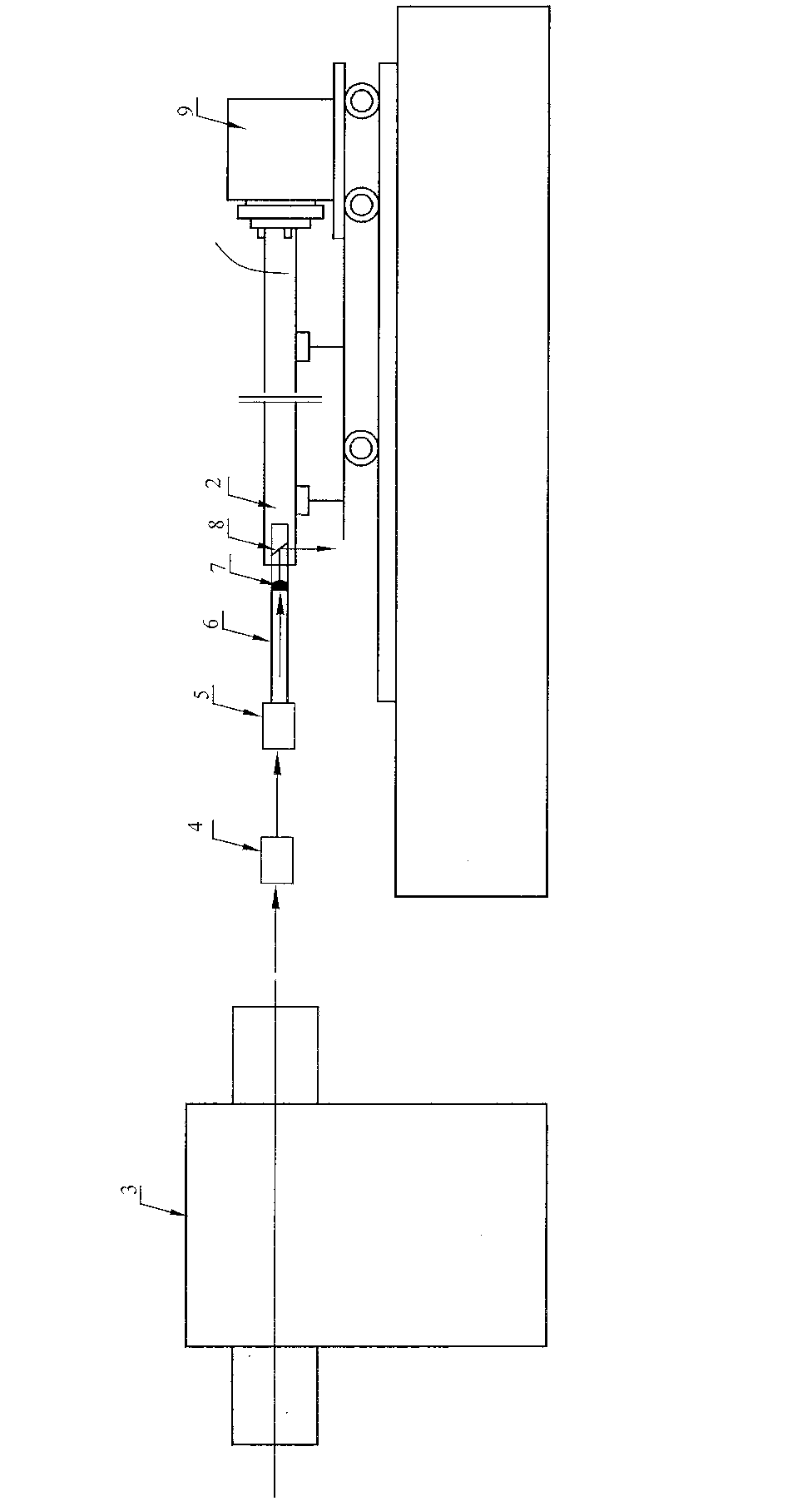

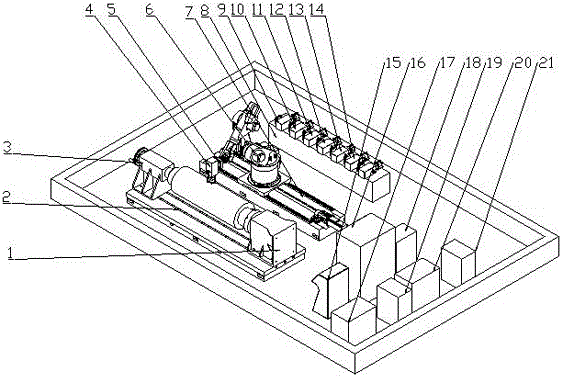

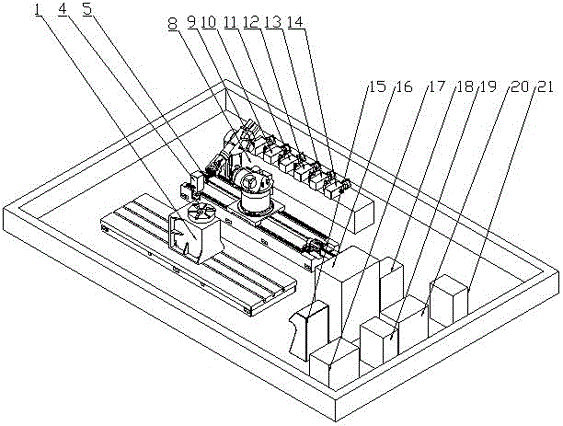

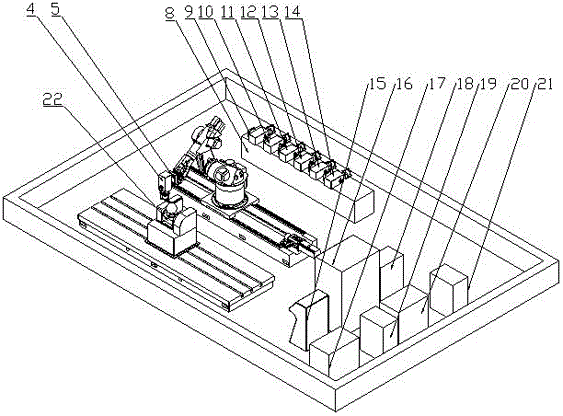

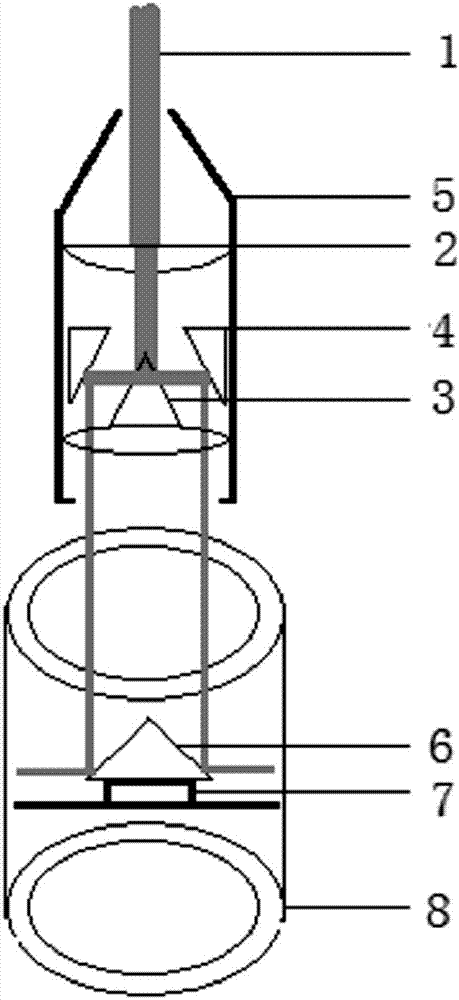

The invention discloses a laser quenching method and device. According to the method, single heating in the conventional laser quenching technology is changed into multi-irradiation heating, or even high-frequency multi-irradiation heating by combining multi-irradiation heating with a quick scanning function of a rotating mirror; the heat conduction process caused by input of laser energy is injected into the surface of a workpiece within short heating time in a multi-stacking mode, so that the accumulation of the laser energy absorbed by a metal base body is increased, and the accumulation of the heat conduction depth is also increased. The device comprises a laser device, a control system, a light guide system, a mechanical motion device and a laser processing head. Even if technical parameters adopt high laser power, and when the scanning speed is high, and an irradiation interval exists, the surface temperature of the metal is always controlled to be below a melting point, and heat can be effectively and continuously expanded from the surface of the workpiece into the workpiece; and therefore, on the premise that the surface of the metal is prevented from being melted, the depth of an austenitizing region on the surface of the workpiece is increased, and the laser quenching efficiency is obviously improved.

Owner:WUHAN HIVALUE INTELASER LTD

Laser hardening ossifying technique of railway high speed heavy rail

The invention relates to a railway high-speed heavy rail laser quenching hardening process, which comprises that: first, gasoline or alcohol decontamination solvents are used to remove the oil and rust on a steel rail surface, and the sand paper polishing on steel surface is carried out in order to evenly spray an absorbing light coating; second, an absorbing light coating SiO2 mixed with a bonding agent is uniformly coated on the steel surface with a spray gun or a brush , in order to increase the absorption rate of metal surface to CO2 Laser. The proportion between the coating and adhesivs is of 80g to 100g of SiO2 and 500ml to 600ml of alcohol and 15 ml of paint flakes. The pre-coated thickness is of 0.02mm to 0.05 mm; third, an integral-round spot is changed to a rectangular spot through a broadband integral mirror technology, and the bandwidth sizes for length and width are of 30 mm is multiplied by 1mm; fourth, a DL-HL-10000 type CO2 laser is used to fast scan the steel rail surface to realize rapid heating and cooling on the surface of the steel rail. By adoption the laser quenching strength method, the invention is capable of replacing the high-alloy material with the common railway steel rail material, thereby reducing the steel rail cost; the invention is capable of repairing the failure rail, thus reducing the material waste, and bringing greater economic benefits.

Owner:鞍山大陆激光技术有限公司

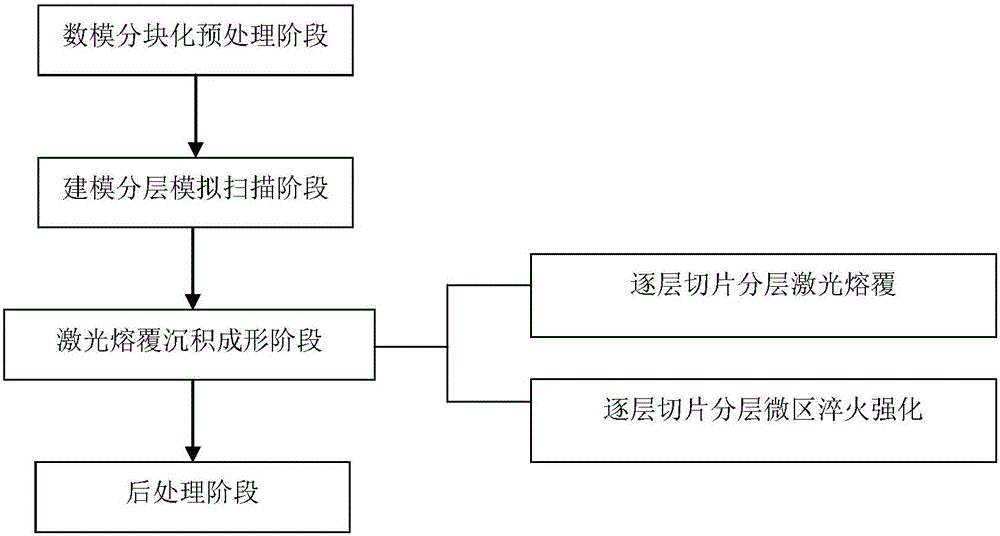

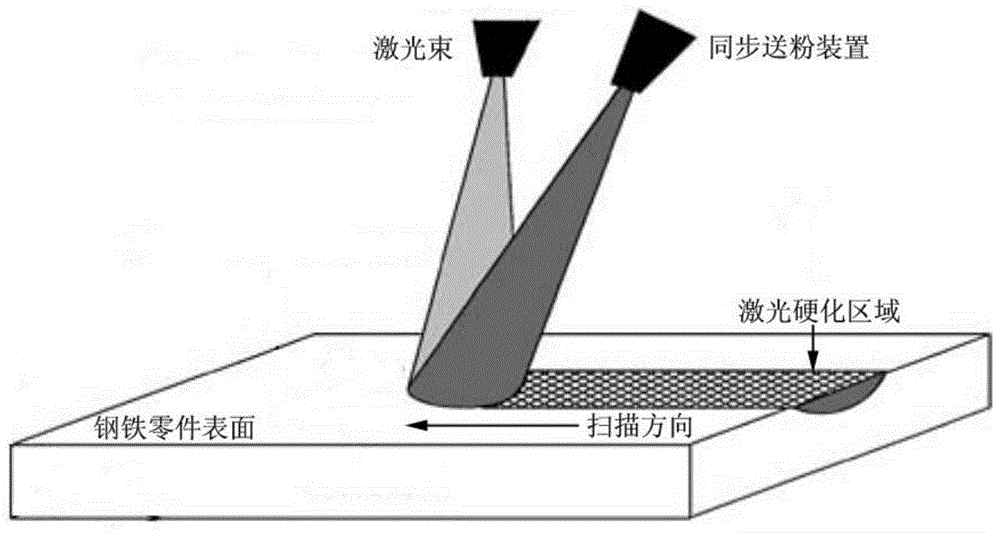

Metal die 3D printing laser micro-region treating method

ActiveCN105935771AReasonable designShort timeAdditive manufacturing apparatusIncreasing energy efficiencyLaser quenchingOptoelectronics

The invention relates to a metal die 3D printing laser micro-region treating method. The method comprises the following steps of 1, a digital-analog blocking pretreatment stage; 2, a modeling layered scanning stage; 3, a laser cladding deposition forming stage, wherein in the stage, after laser cladding deposition is carried out on a first layer slice, secondary laser surface reinforcing treatment is carried out micro-regions in layers of the first layer slice, layered laser cladding deposition on a second layer slice and secondary laser surface reinforcing and quenching treatment on micro-regions in the second layer slice are carried out after secondary laser quenching surface treatment on the micro-regions of the first layer slice is completed, layered laser cladding forming of all slices is completed in this way, and a metal die forming piece is formed; 4, a posttreatment stage, wherein heat treatment, polishing and machining treatment are included in the stage. The metal die 3D printing laser micro-region treating method has the advantages that the design is reasonable, operation is convenient, and the metal die forming piece is reliable in mechanical performance, short in machining and manufacturing operation time, capable of effectively relieving the labor intensity of operation workers and lowering machining cost and the like.

Owner:四川三阳激光增材制造技术有限公司

Laser quenching hardening treatment method for cutter and die cutting edge

InactiveCN1580296AShort heating timeReduce distortionFurnace typesHeat treatment furnacesLaser quenchingLight beam

The invention relates to method of cutter and mould cutting edge laser quenching treatment of hardness, belonging to mechanical workout. Concrete steps as follow: a. put one front of cutting edge being dealt up on the surface of machine tool desk; b. wipe laser heat treatment light absorbed paint equally between the dealing surface with a distance of 10-15mm and parallel with the cutting edge; c. change laser beam focus dealing surface, put light beam center with a distance of cutting edge 2.6-3.7mm; d. laser beam scan and heat on the dealing surface in the direction of paralleling cutting edge. Short heatup time, little distortion, simple process, convenient practice, easy operation.

Owner:FAW GROUP

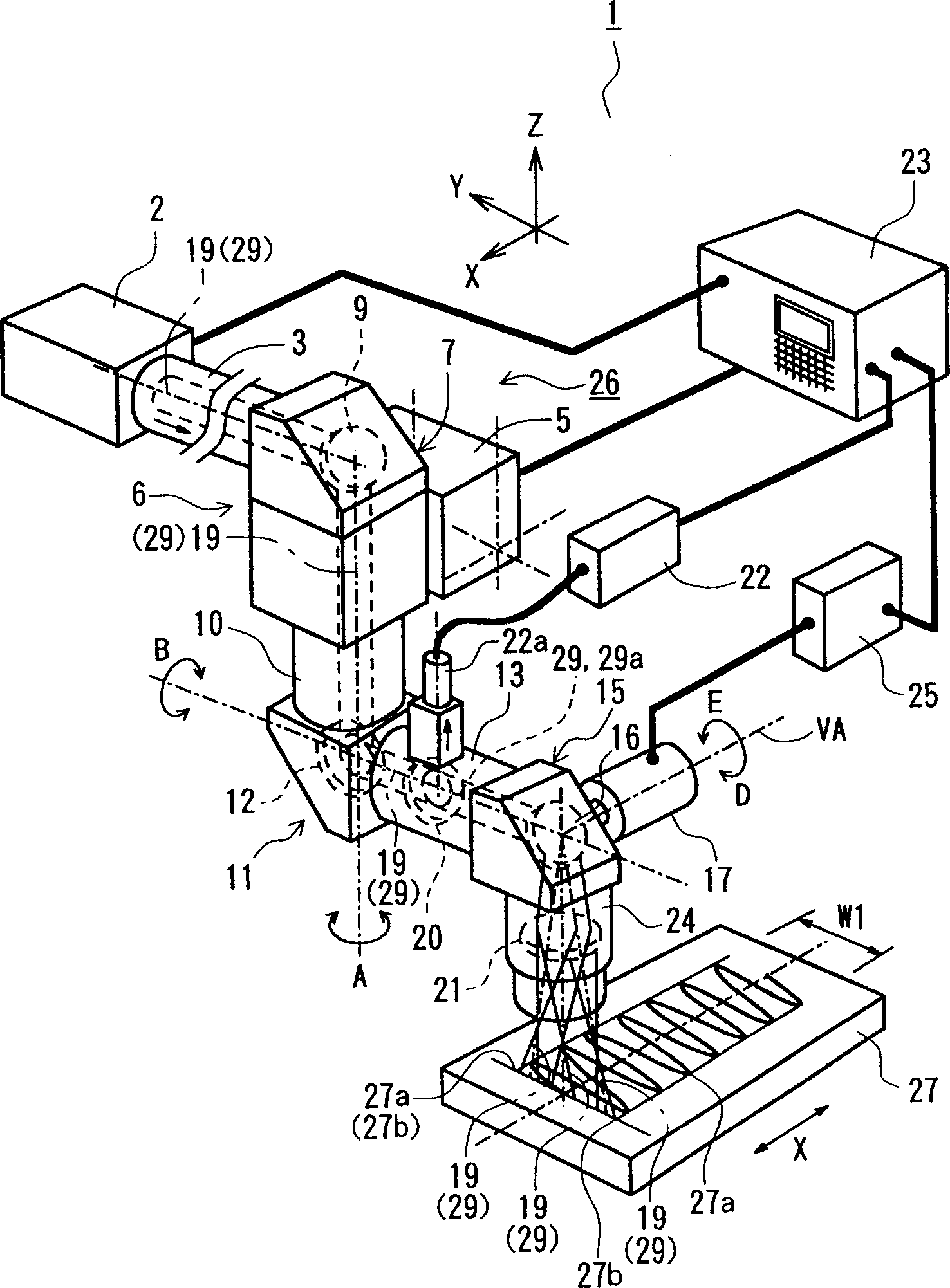

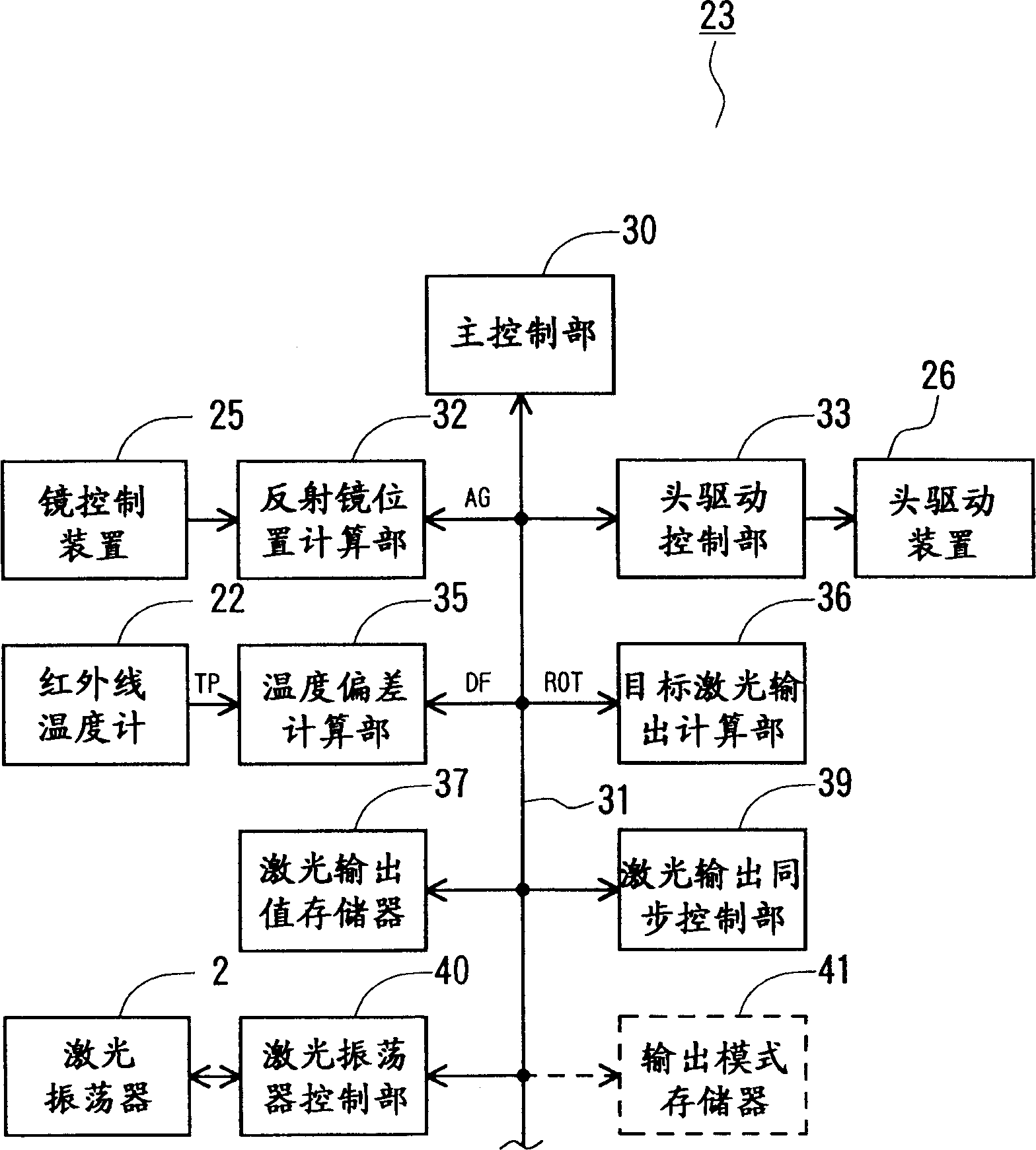

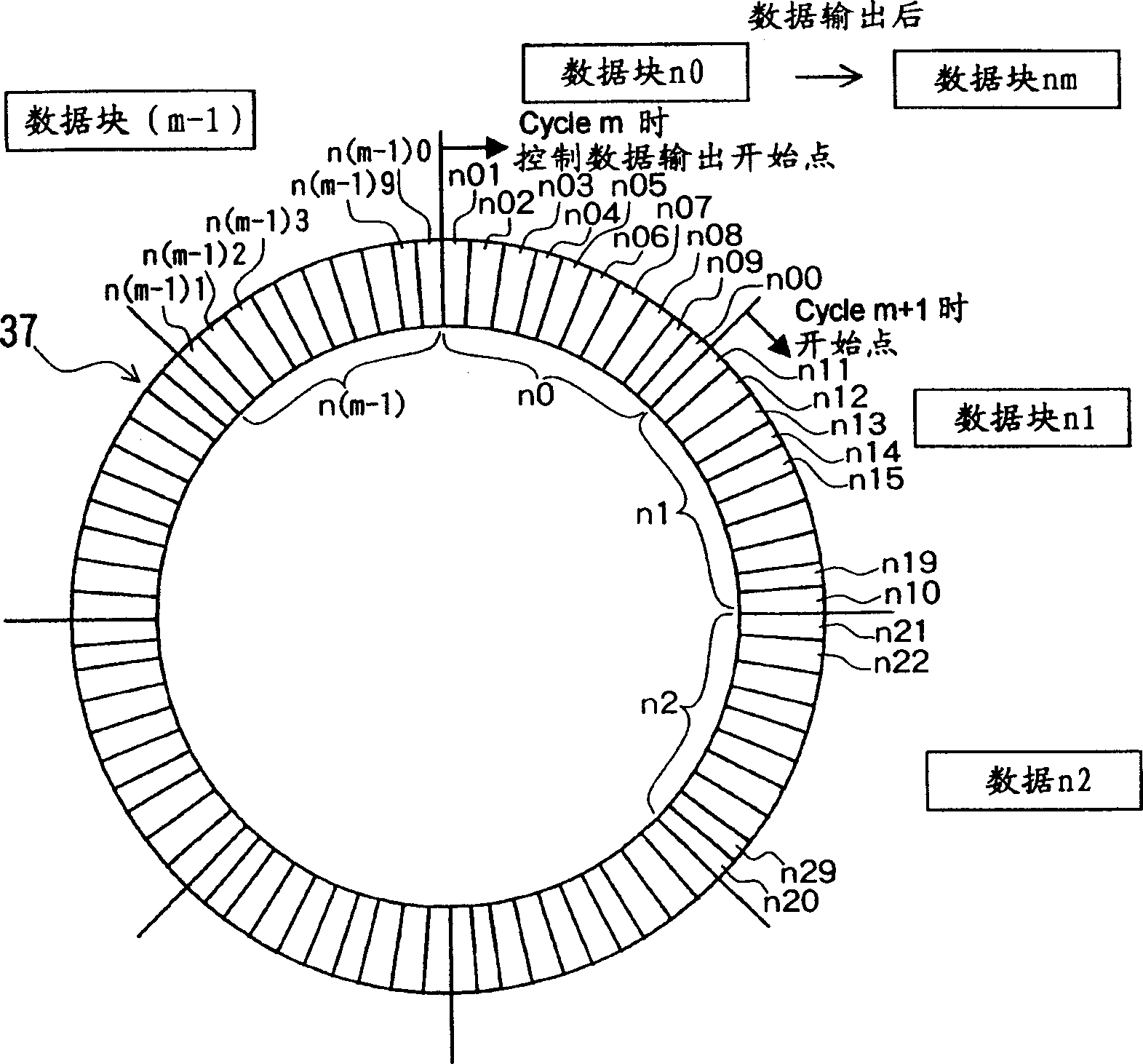

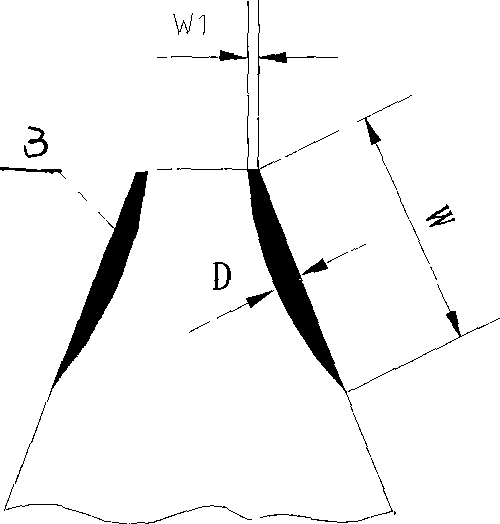

Laser quench controlling method and laser quencher

InactiveCN1417354AHeat treatment process controlLaser beam welding apparatusLaser quenchingVolumetric Mass Density

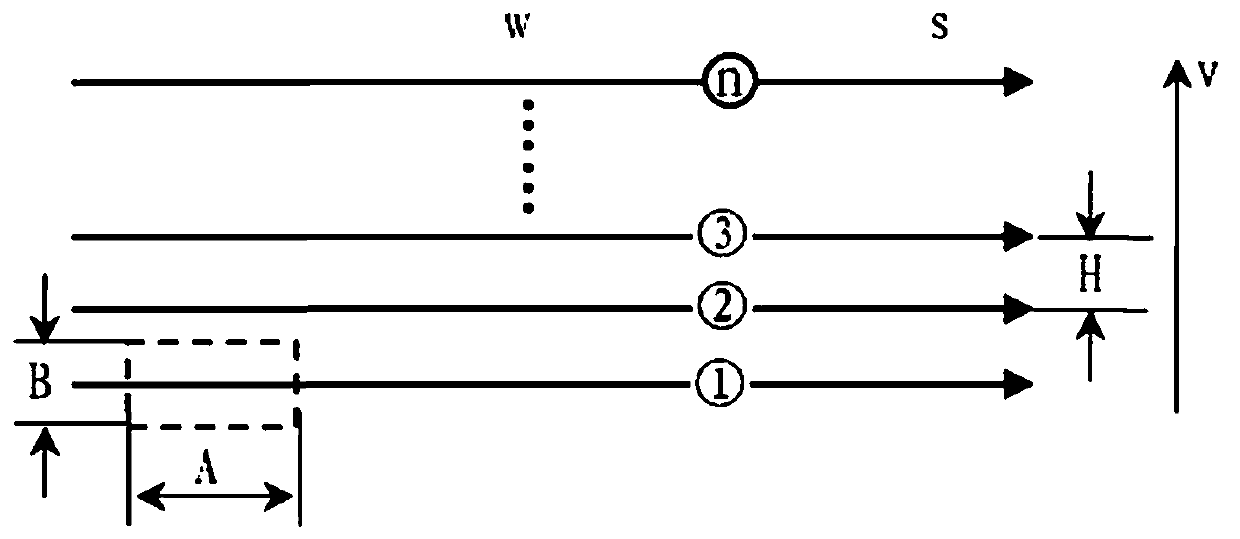

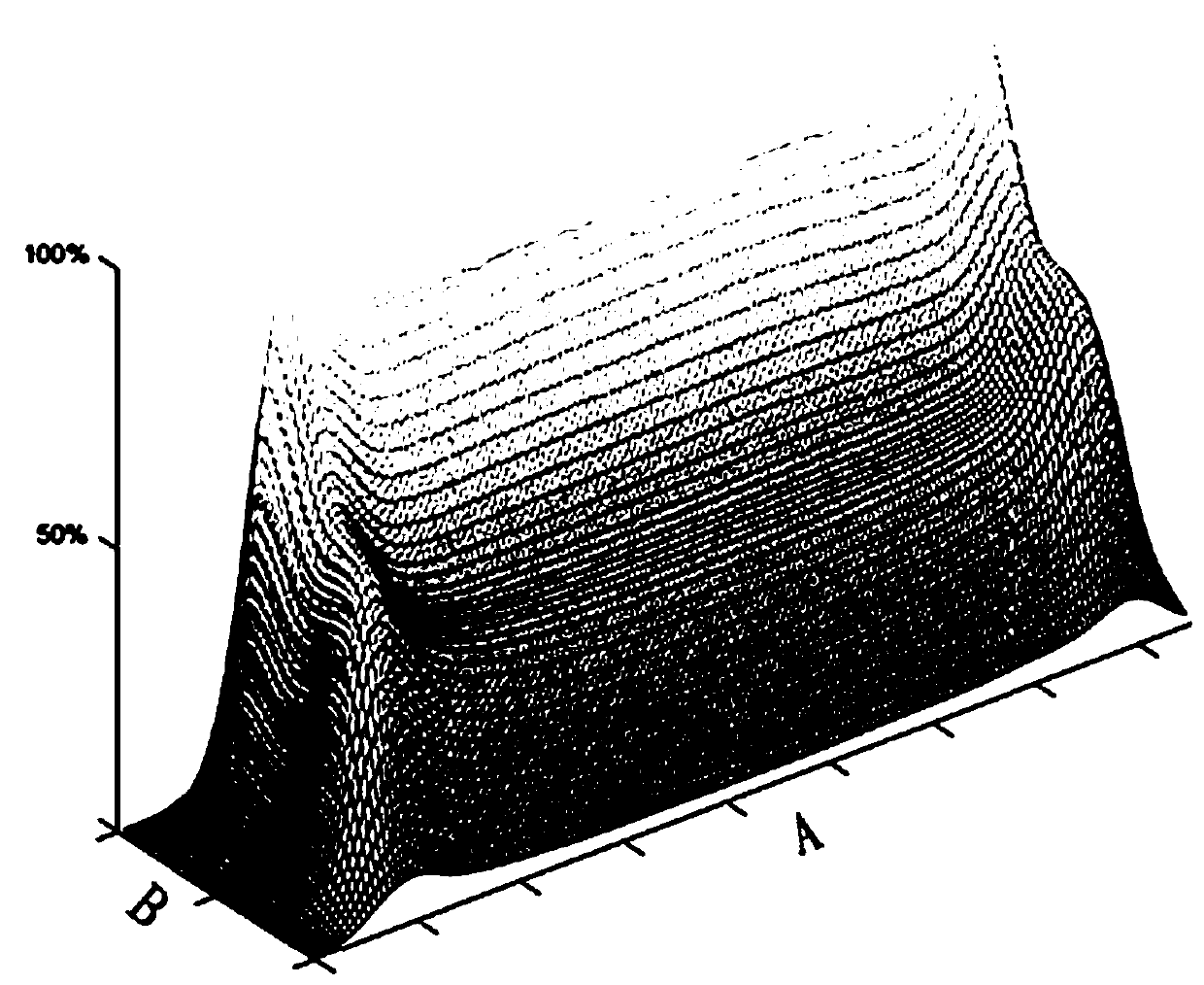

In hardening with laser beam by irradiating laser beam. 29 on a workpiece 27, oscillating the laser beam so as to heat a workpiece with a hardening width W1, laser beam output in both end portions (times (1), (5), (6), (10) of FIG 4, for instance) of amplitude of the laser beam is made lower than one of a center portion (times (3), (4), (7), (8) of FIG 4, for instance) of the amplitude. Relative moving velocity of the laser beam with respect to workpiece is decreased, and the quantity of giving energy of the laser beam in both end portions of the amplitude where the density of giving energy of laser beam is high is decreased so as to equalize quantity of aiming energy in the whole hardening cycle. By doing so, a proper hardening action is possible.

Owner:YAMAZAKI MAZAK KK

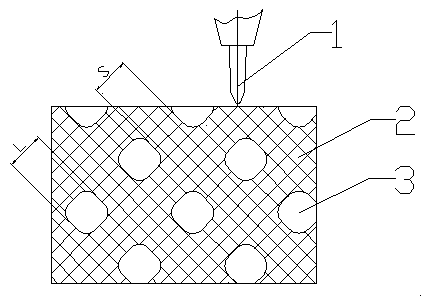

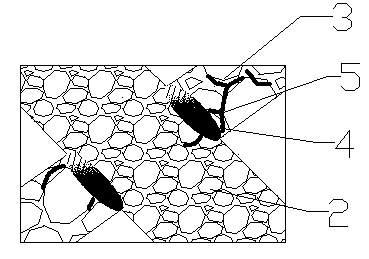

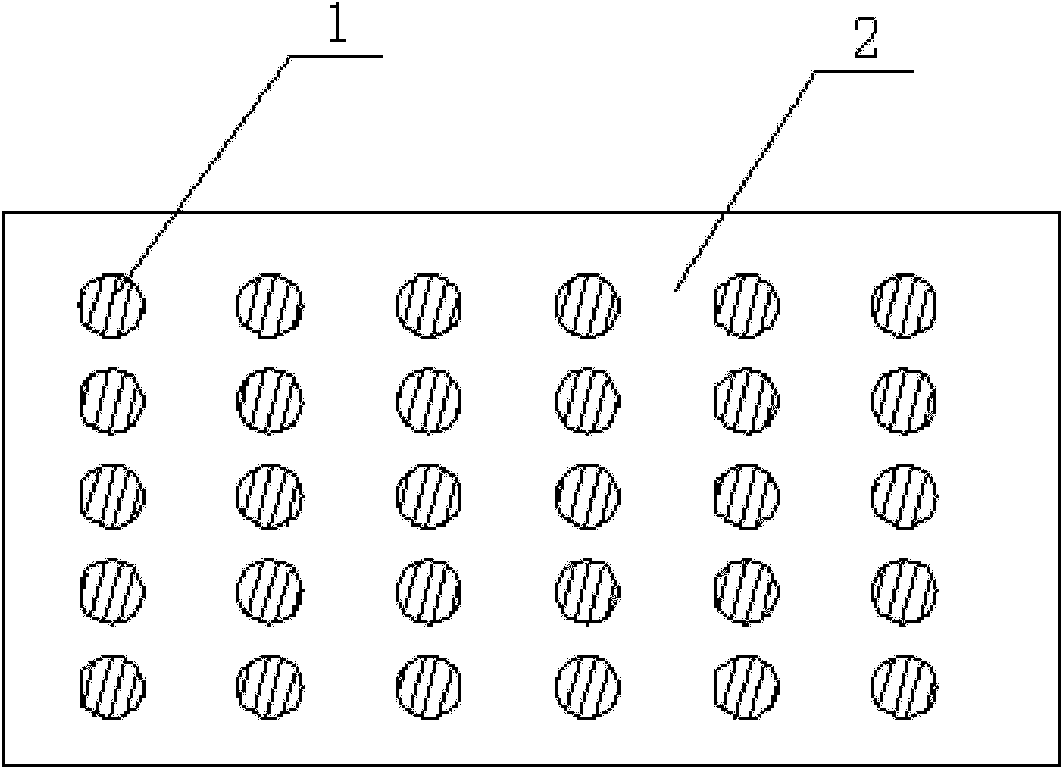

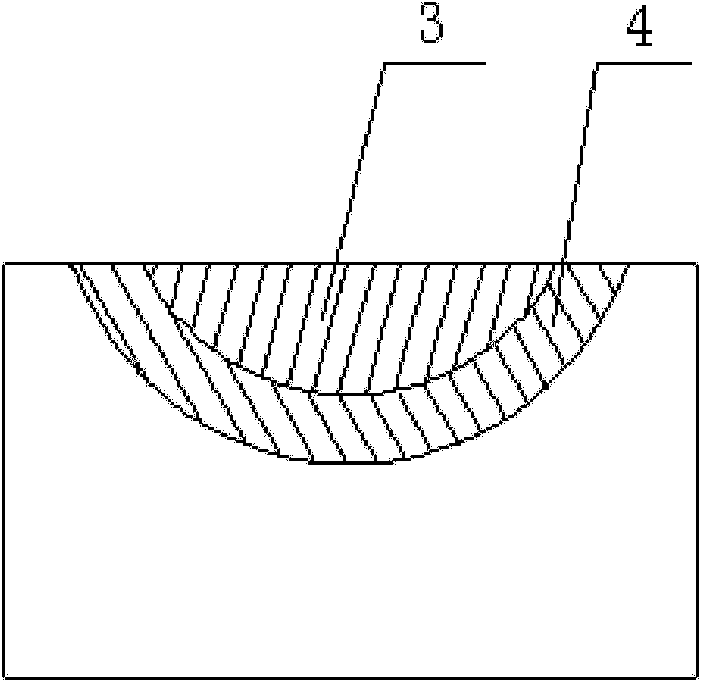

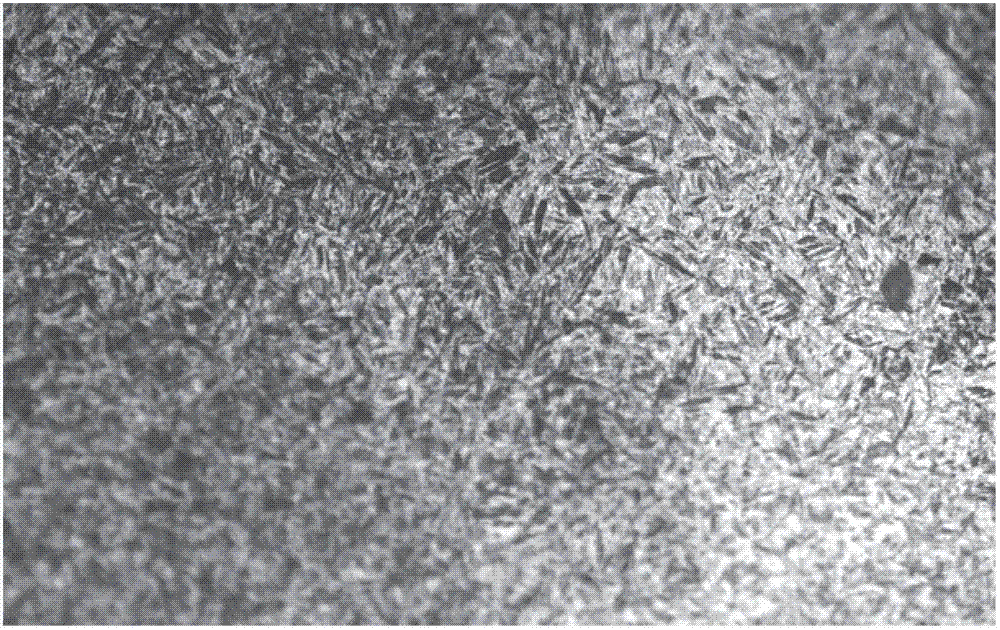

Workpiece surface intensifying method by laser micro processing

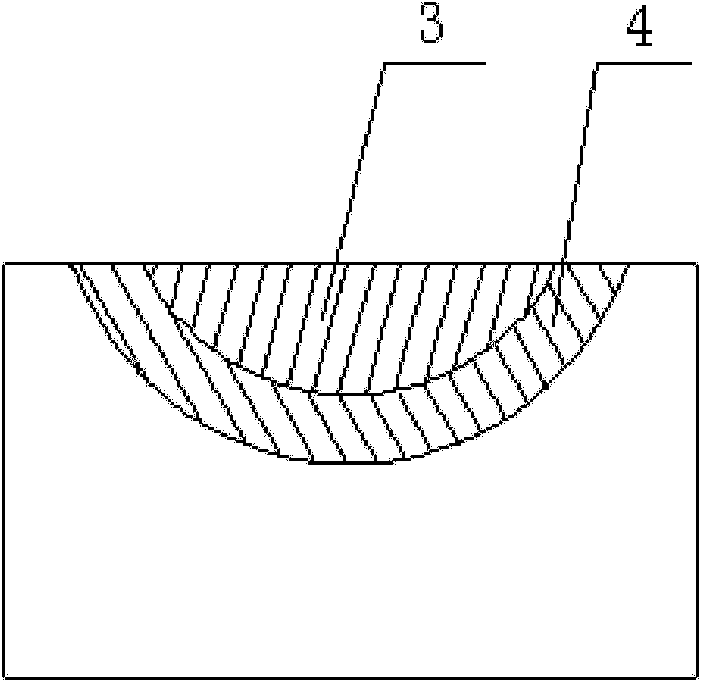

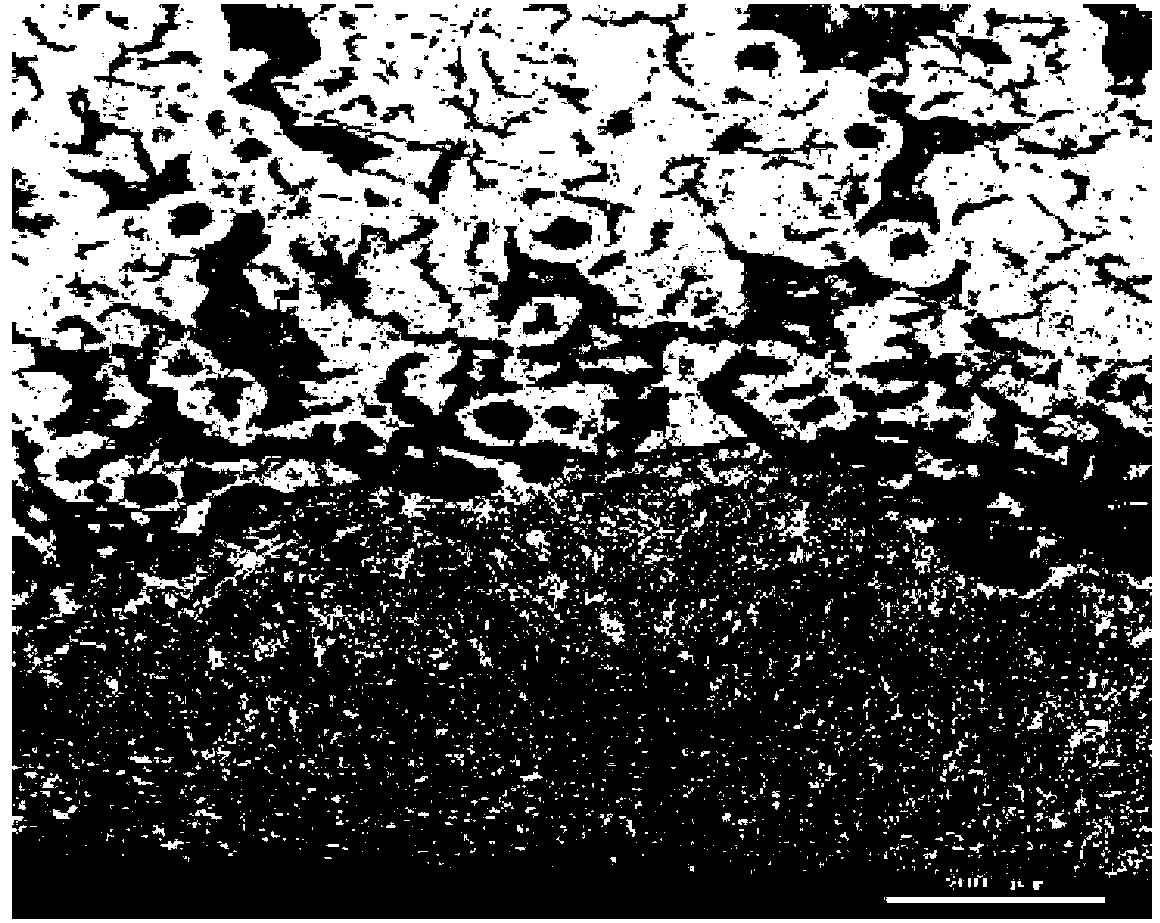

The invention relates to a method for intensifying the surface of a workpiece by lasers. The surface of the workpiece is subjected to integral laser quenching, and thus the crystalline grains of the workpiece are refined to a certain extent; the surface of the workpiece is subjected to partial laser grid intensification, the hardness of an intensification region is improved further, and the crystalline grains are refined further; the crystalline grains on the intensified surface of the workpiece is refined, so that the workpiece material is in isotropy, and the large interface causes dislocation to avoid piling up; during the service life of the workpiece, not only is the stress concentration alleviated greatly, but also the fatigue crack growth is hindered, and the plasticization is intensified. Additionally, the crystalline grain size in a non-intensified region is greater than the average crystalline grain size in an intensified region, the dislocation distribution is random, and the crystalline grain arrangement of the non-intensified region is widely different from the compact crystalline grain arrangement in the intensified region, so that a crack interference fringe is formed between the non-intensified region and the intensified region, and a fatigue crack can be effectively prevented from growing.

Owner:JIANGSU UNIV

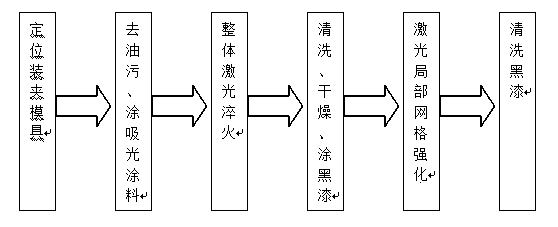

Surface laser quenching process of car panel die

InactiveCN101665862AExtend your lifeTo achieve the purpose of quenchingFurnace typesHeat treatment furnacesChemical industryLaser quenching

A laser quenching process of a car panel die surface comprises the steps of: firstly coating a coating on the surface of a die; then utilizing the laser emitted by a CO2 laser device to scan the surface of the die coated with the coating; and finally eliminating the coating on the surface of the die. The laser quenching process of the car panel die surface is characterized in that the painting ofthe coating comprises 60-70% by weight of Al2O3 particles, 10-22% by weight of ZrO2 particles and 12-20% by weight of SiO2 particles, which are then evenly dispersed by water with 20-50 percent of thepainting weight and finally coated on the surface of the die. The laser quenching process can replace processes such as the traditional high-frequency / medium-frequency quenching, flame surface quenching and the like, obtains a hardening layer with the depth of a millimeter level, has high and even hardness for the hardening layer and good process repeatability, leads the workpiece to keep a highpressure stress state, can be widely applied in the fields of metallurgy, chemical industry and heavy machinery equipment and the like, and significantly prolongs the service life of the workpiece.

Owner:武汉武钢华工激光大型装备有限公司

Metal laser deep-layer quenching process

InactiveCN1603425AAvoid deformationSolve the problem of shallow depthLaser quenchingLaser processing

One kind of metal laser deep layer quenching craft, through must process the area surface spreading alloy extinction coating after the metal, according to processes the area choice certain facula the light beam to carry on laser processing, simultaneously, blows the metal surface laser partial with the certain current capacity gas sphere of action, and with the liquid cooling laser sphere of action periphery, causes the metal hardening level quenching depth to achieve 0.7~~3mm. The invention has solved the metal induction heating time deformation, enhanced the metal skin hardness, simultaneously has solved an ordinary laser quenching hardening depth shallower problem.

Owner:ZHEJIANG UNIV OF TECH

Method and apparatus for laser quenching

ActiveUS20160076115A1Add depthIncrease productivityFurnace typesHeat treatment furnacesSingle scanMaterials science

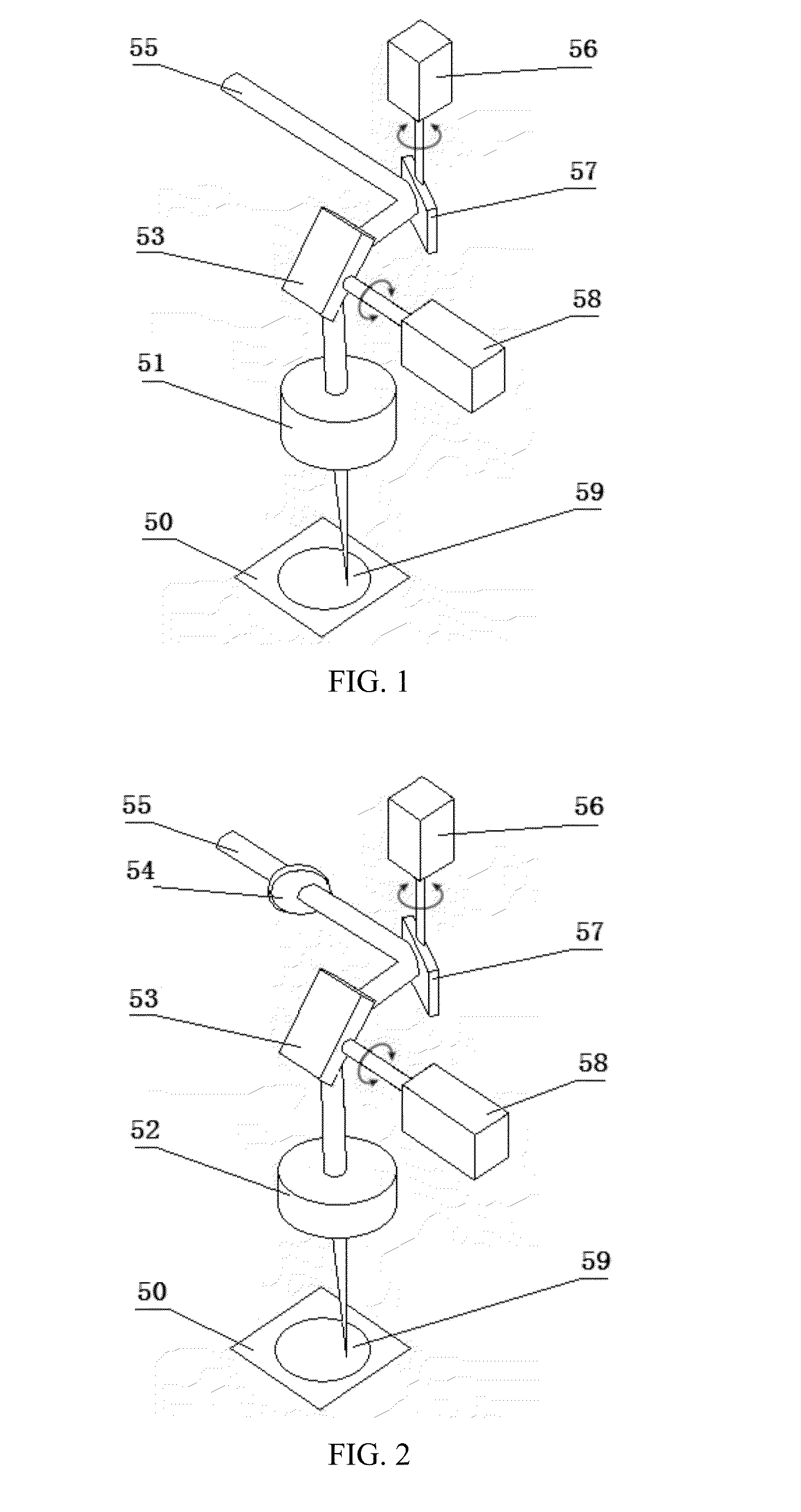

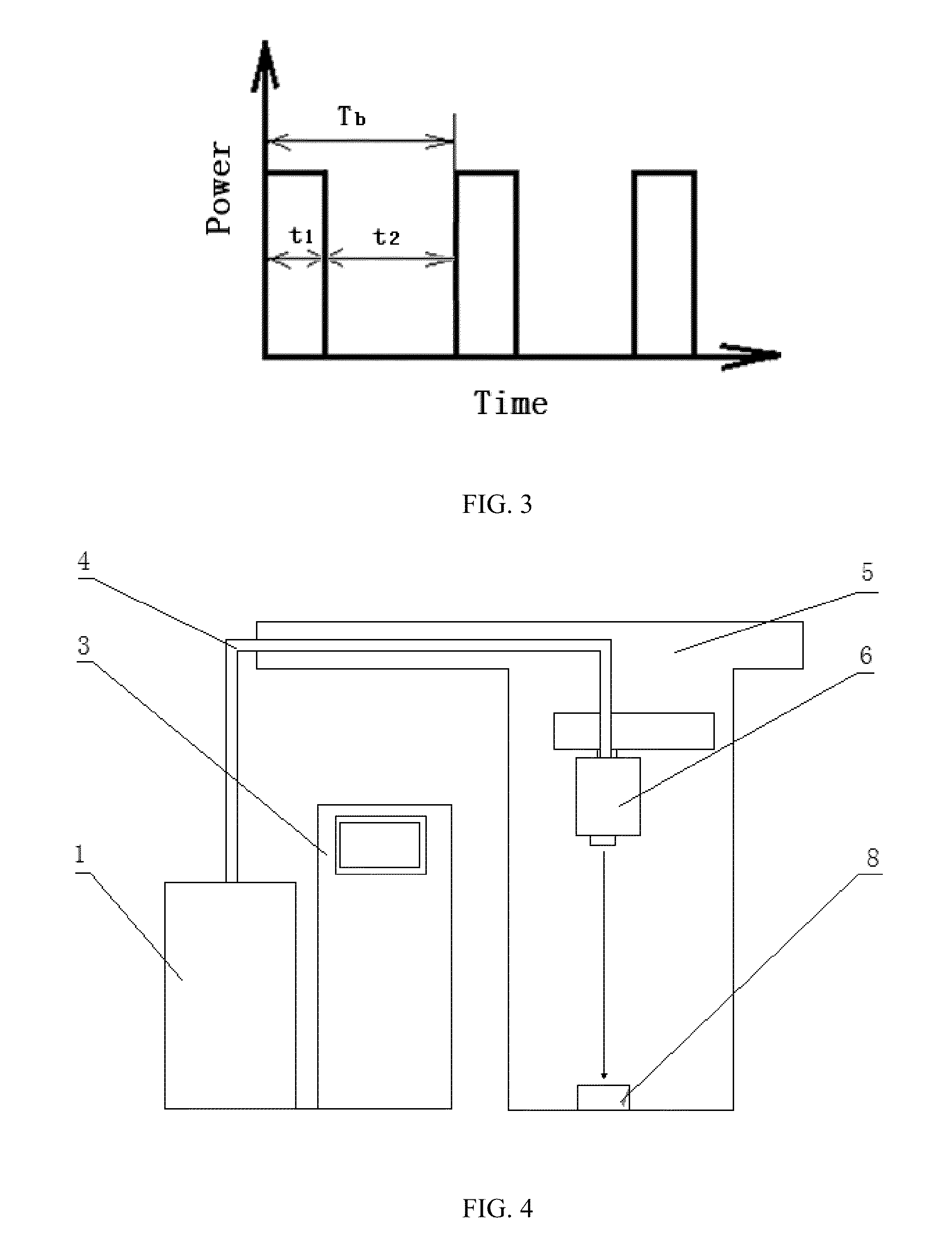

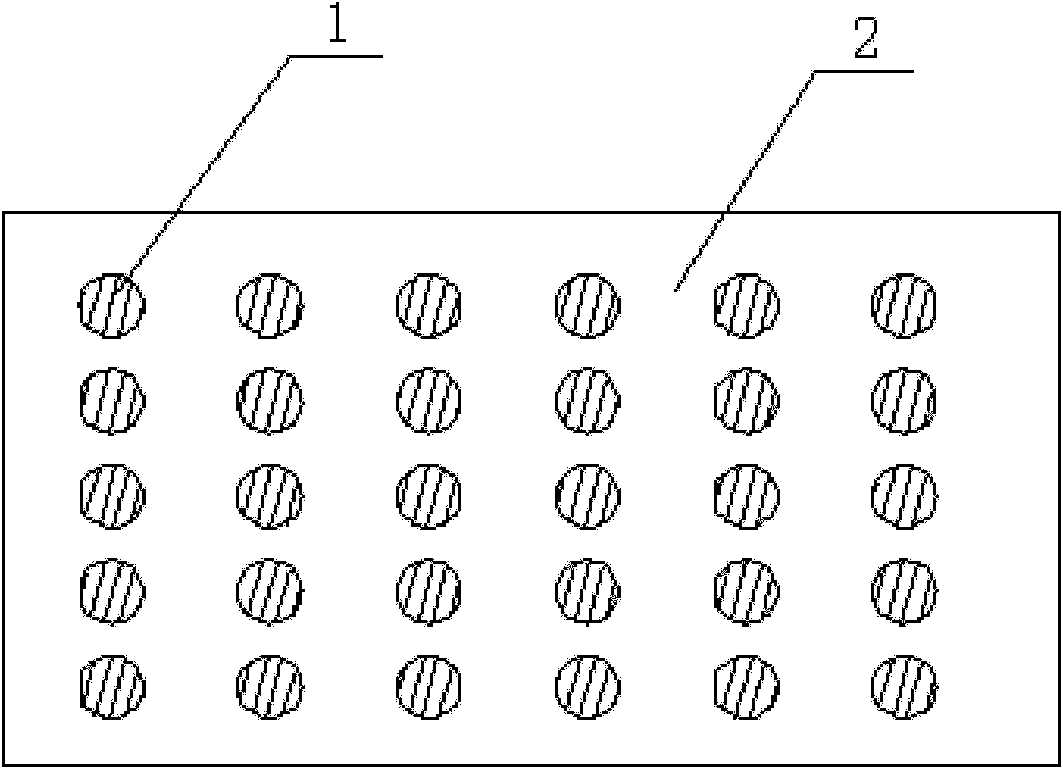

Provided are a method and an apparatus for laser quenching. The method takes the advantage of a high jumping speed of a scanning galvanometer, and adopts the method of heating on multiple or even high frequency repeated scans instead of on a single scan in prior art for laser quenching, wherein the laser energy is fed into the surface of a workpiece by way of short time and multiple superimposed heating, cumulatively, the laser energy absorbed by the metal base is increased and the depth of thermal conduction is improved also. The apparatus includes a laser, a control system, a light guiding system, a mechanical motion device and a scanning galvanometer. Therefore, even though the used laser power is relative high, the surface temperature of a metal object can be always restricted below its melting point and the heat can be conducted from the surface to the internal of a workpiece by thermal conduction constantly and effectively as a result of high scanning speed and the introduce of time interval at scanning, so that melting in the metal surface can be avoided, and the depth of the austenitizing region in the surface of the workpiece and the productivity of laser quenching can be significantly improved.

Owner:WUHAN HIVALUE INTELASER LTD

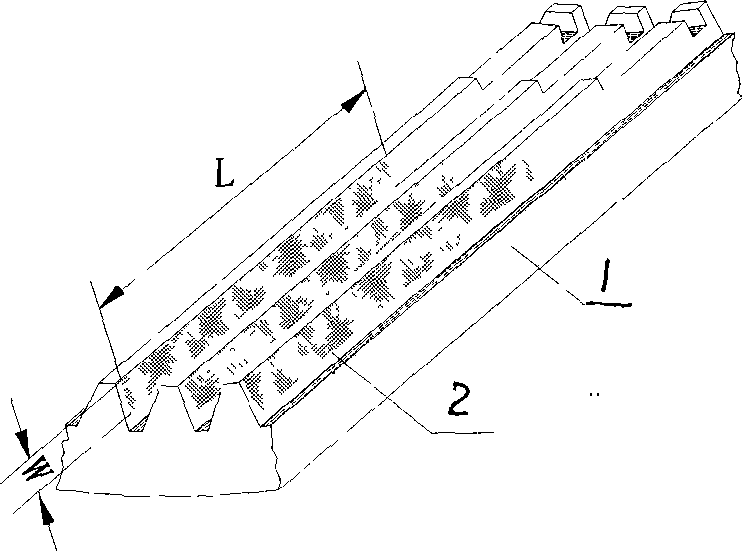

Off-line laser quenching process for surface strengthening treatment of steel rail

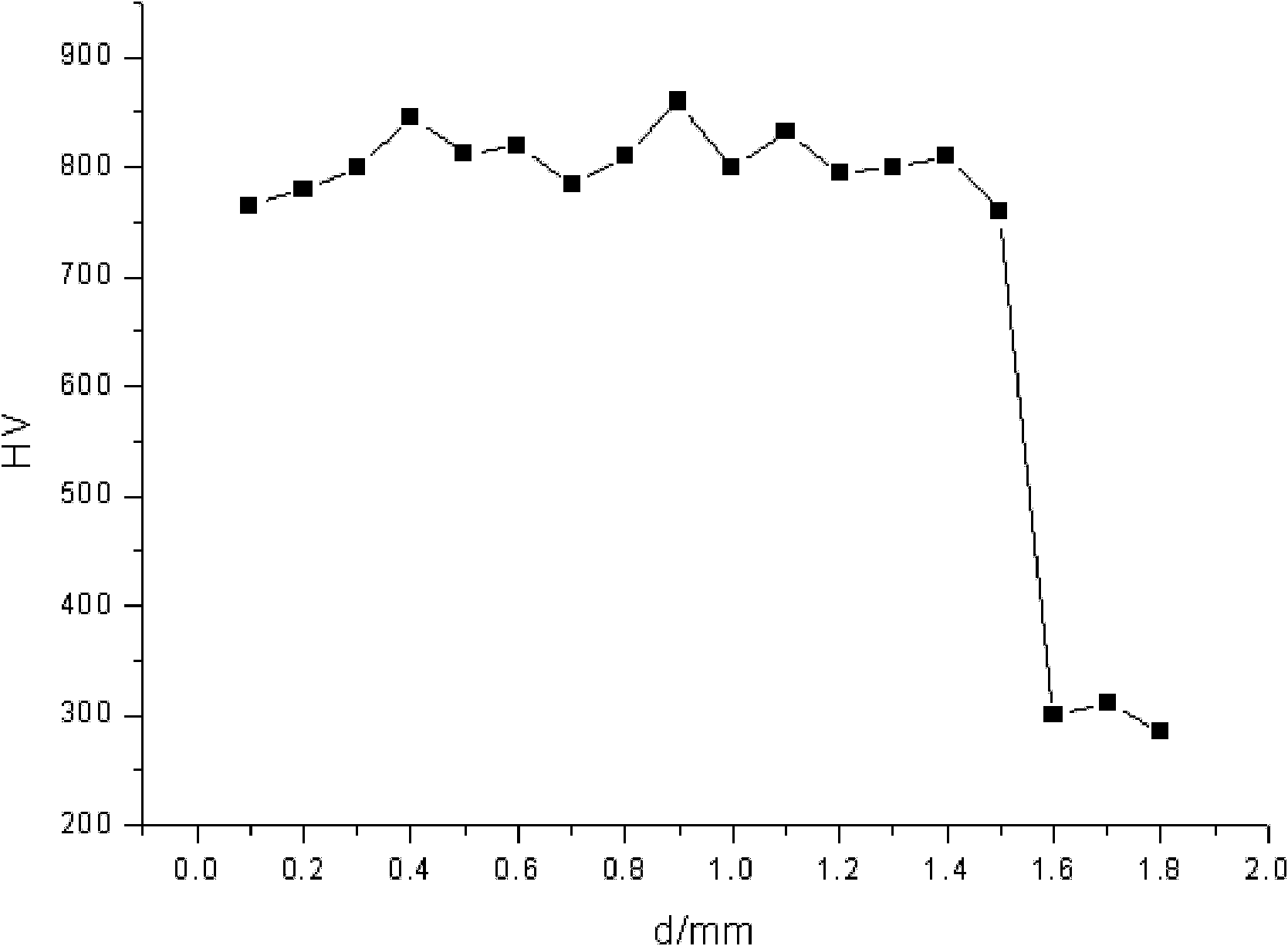

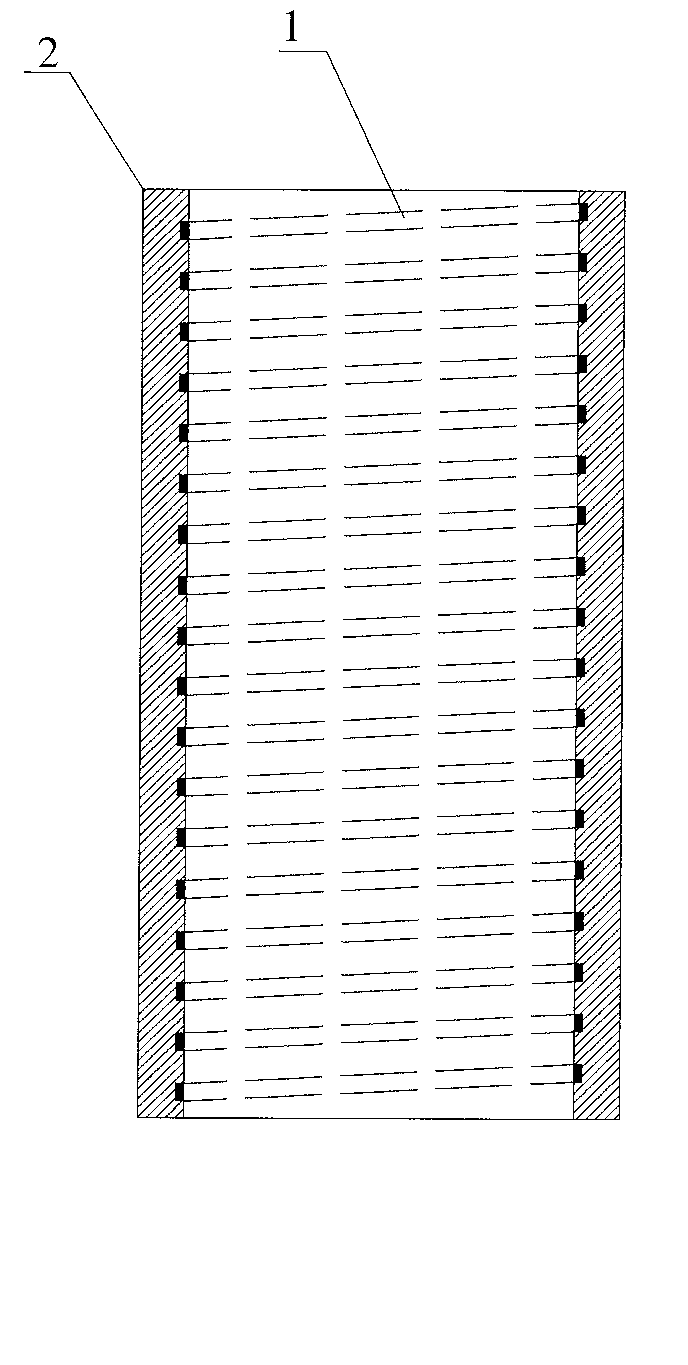

InactiveCN102121064AImprove absorption efficiencyExtended service lifeFurnace typesRailway track constructionLaser quenchingHardness

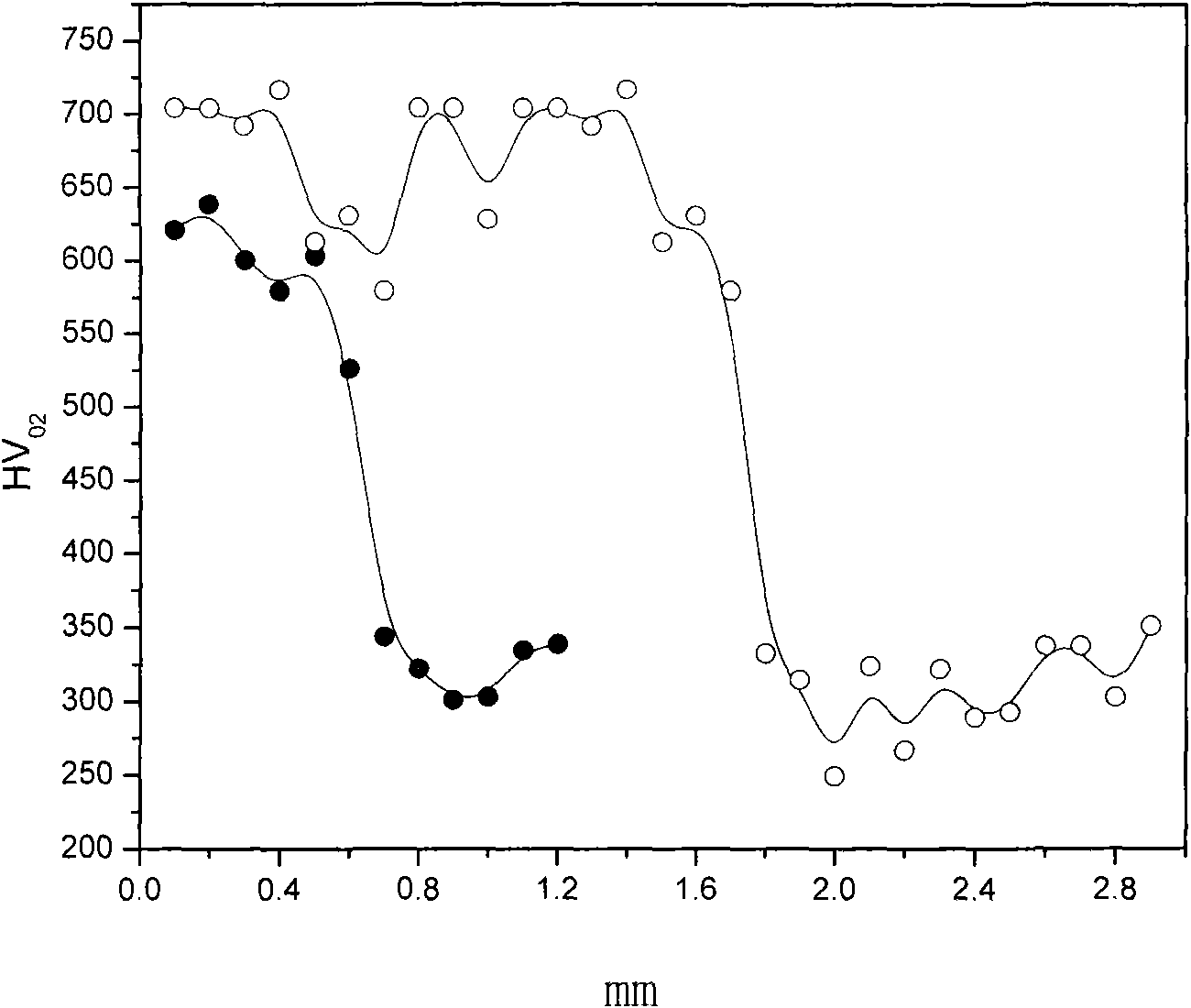

The invention discloses an off-line laser quenching process for surface strengthening treatment of a steel rail. The process comprises the following steps of: coating a layer of light absorption coating on the surface of the steel rail, then moving the steel rail, and scanning the surface of the steel rail by using pulse laser along the length direction at a certain speed to obtain latticed tissues, namely fine martensitic laser quenching points on the surface of the steel rail, wherein the area of the laser quenching points is 50 to 80 percent of the area of the surface of the steel rail, and the highest depth of the quenching points is 0.4 to 1.0 millimeter. In the off-line laser quenching process, the latticed quenching points can be formed on the surface of the steel rail, the quenching point tissues are martensitic tissues, the depth of the quenching layer is 0.4 to 1.0 millimeter, the hardness is more than HV700, and the fine martensite of the laser quenching points has high hardness and abrasion resistance. The toughness of the steel rail is reserved for pearlite in an untreated area, and the complex phase tissues of the martensite and the pearlite have good toughness and can remarkably prolong the service life of the steel rail.

Owner:武汉武钢华工激光大型装备有限公司

Machine tool guide rail broad band laser-quenching technique

The present invention provides a machine tool guide rail broad band laser quenching process, which includes: A. Gasoline or alcohol is used to remove oil stain or rust on the surface of a steel rail, then sand paper is used to polish the surface of the guide rail to remove the oil stain further, so that a light absorbing coat can be applied evenly; B. A spraying gun or a brush can be used to apply the SiO2 light absorbing dope well proportioned with adhering agent mixture on the surface of the guide rail evenly, to improve the absorbing rate of the SiO2 laser by the metal surface; the prescription of the dope and the adhering agent is 80-100gSiO2 plus 500-600ml alcohol plus 15ml paint flake, and the pre-coating thickness is 0.02-0.05mm; C. An air-dry coat; D. A 3-6KW crosscurrent CO2 laser is used to scan the guide rail arranged on a laser numerical control machine at a speed of 250-800mm / min, to heat and cool the SO2 coat on the surface of the guide rail rapidly. The present invention has the advantages that the quenching rigidity is high, the workpiece distortion is small, the quenching medium is not needed, and the work efficiency is high, oxygenation and pollution cannot be produced.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

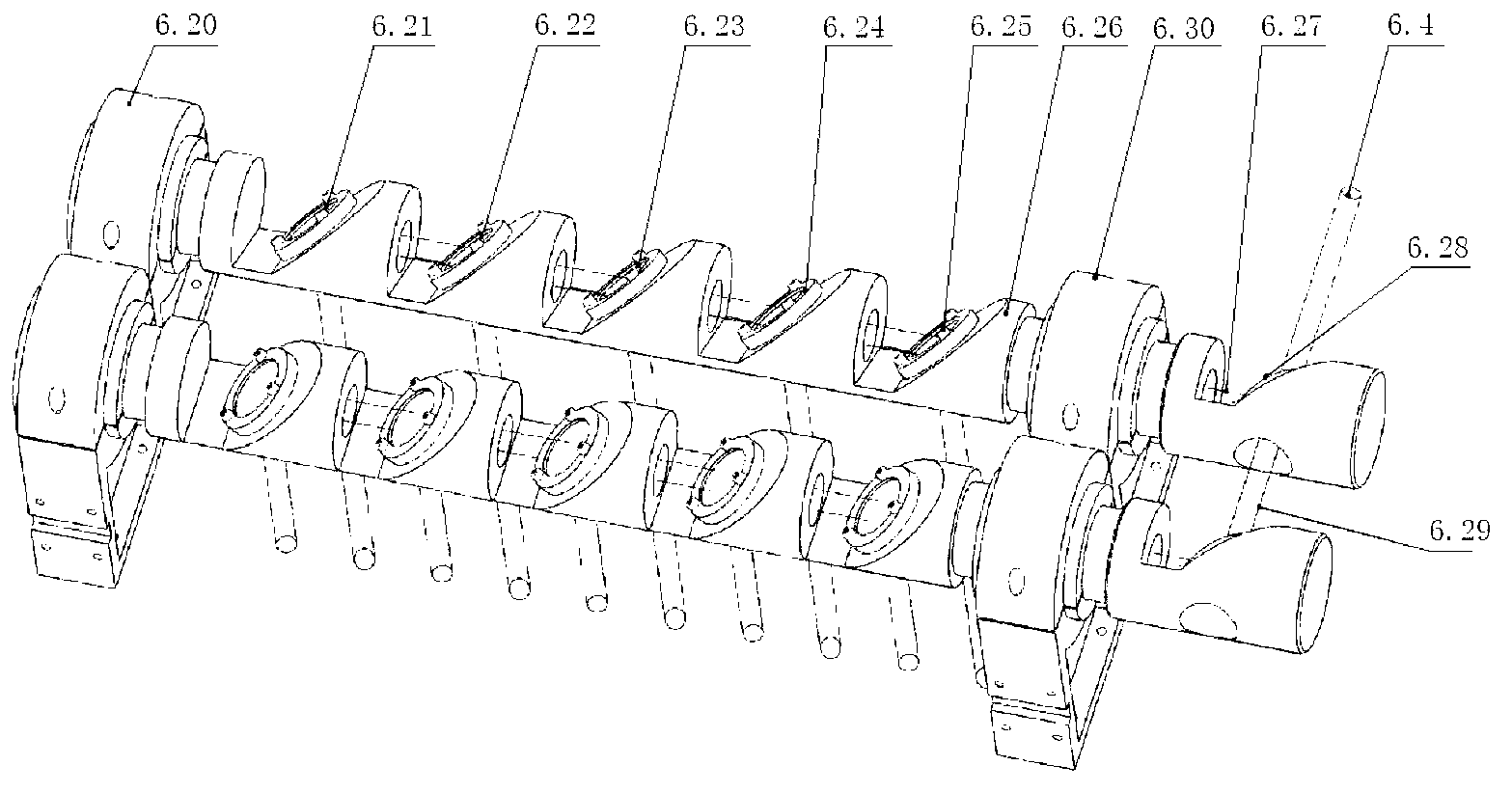

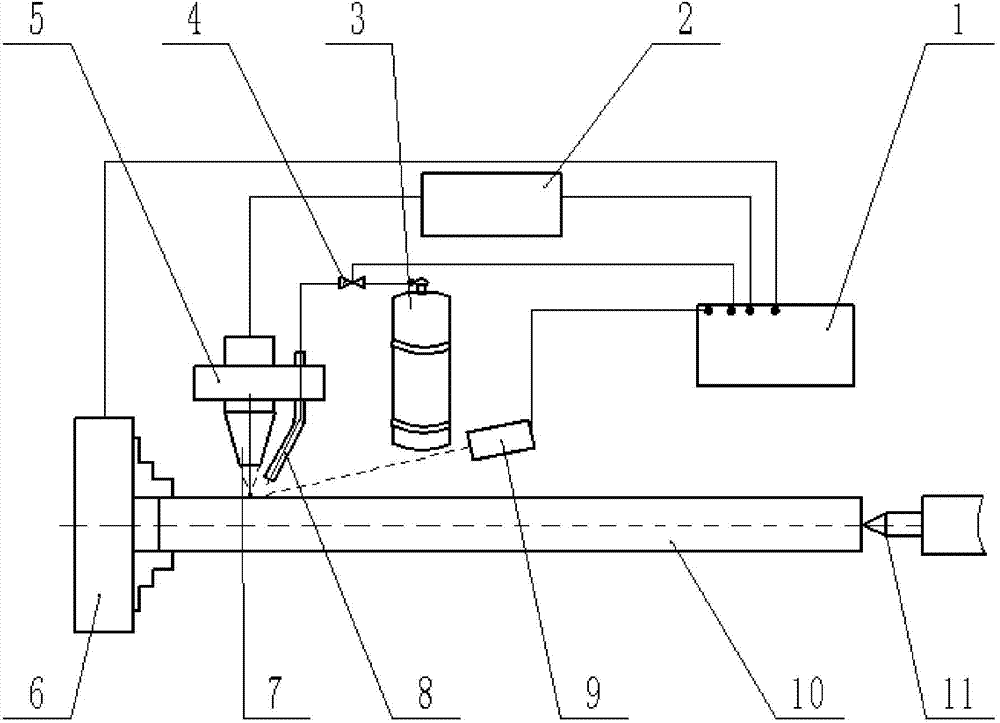

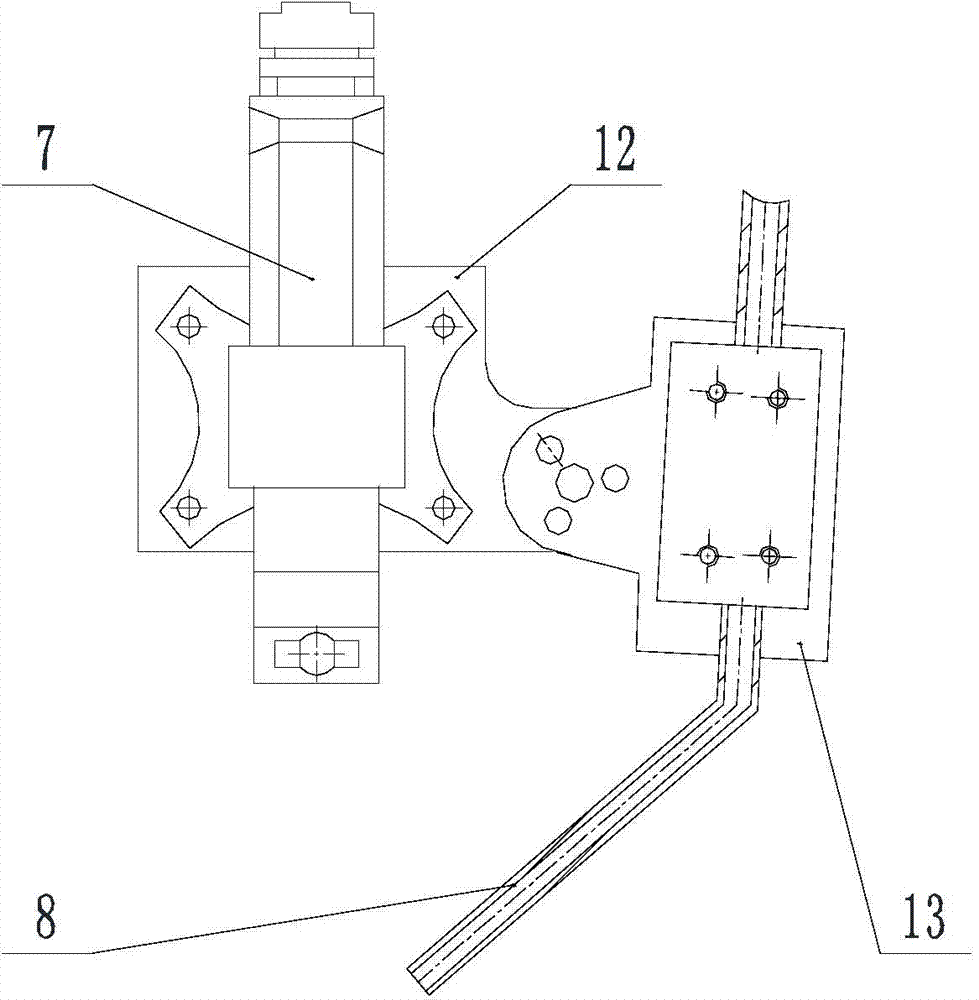

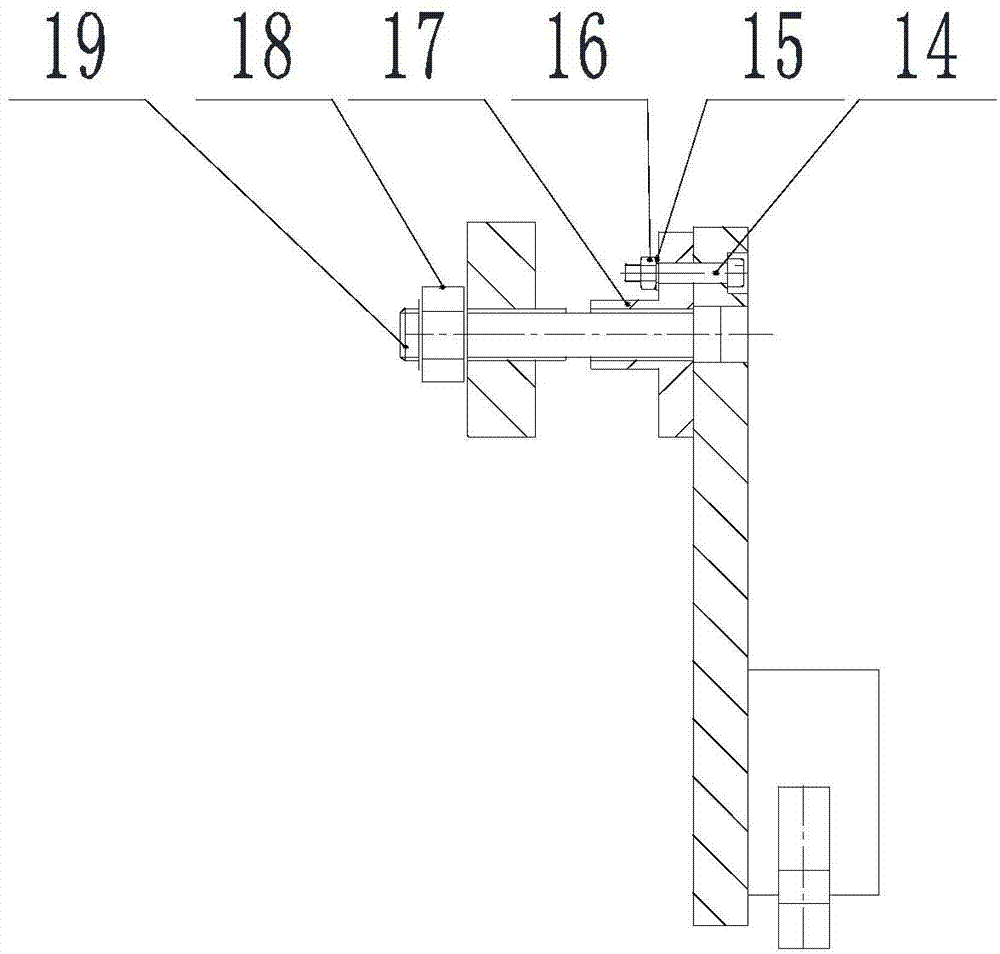

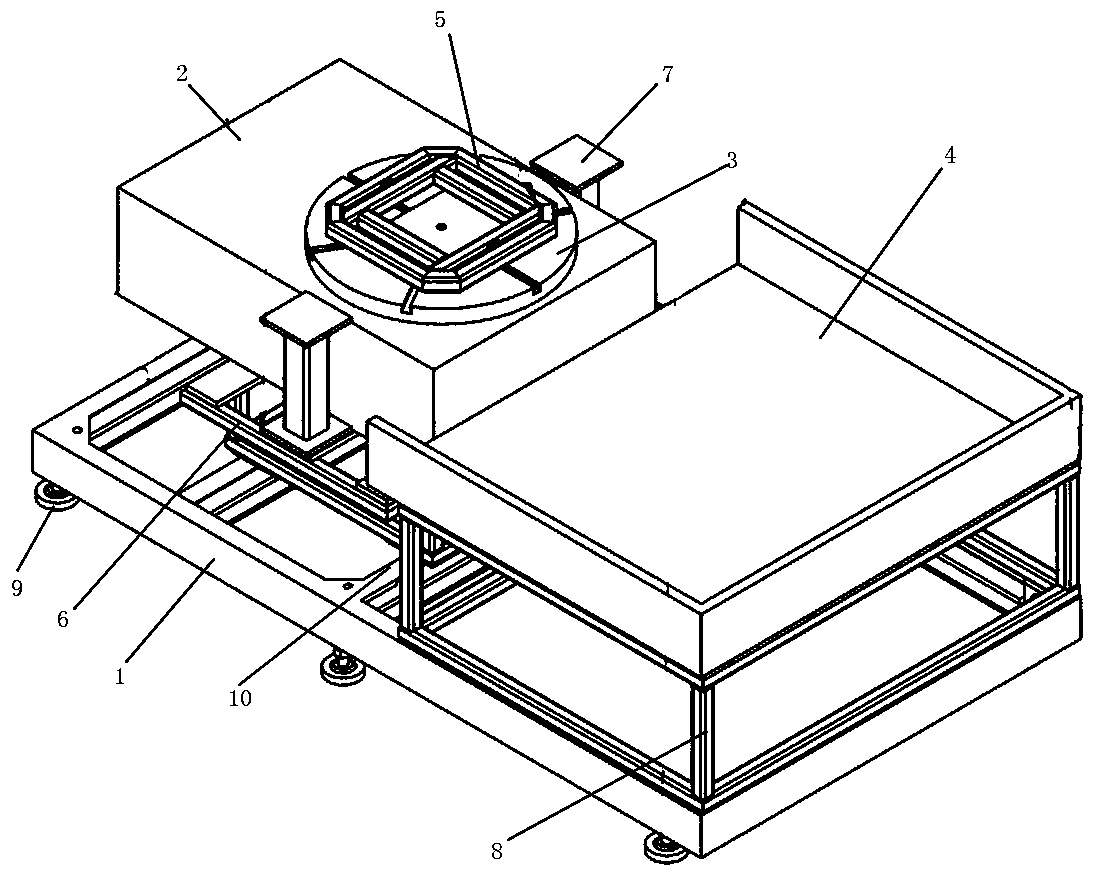

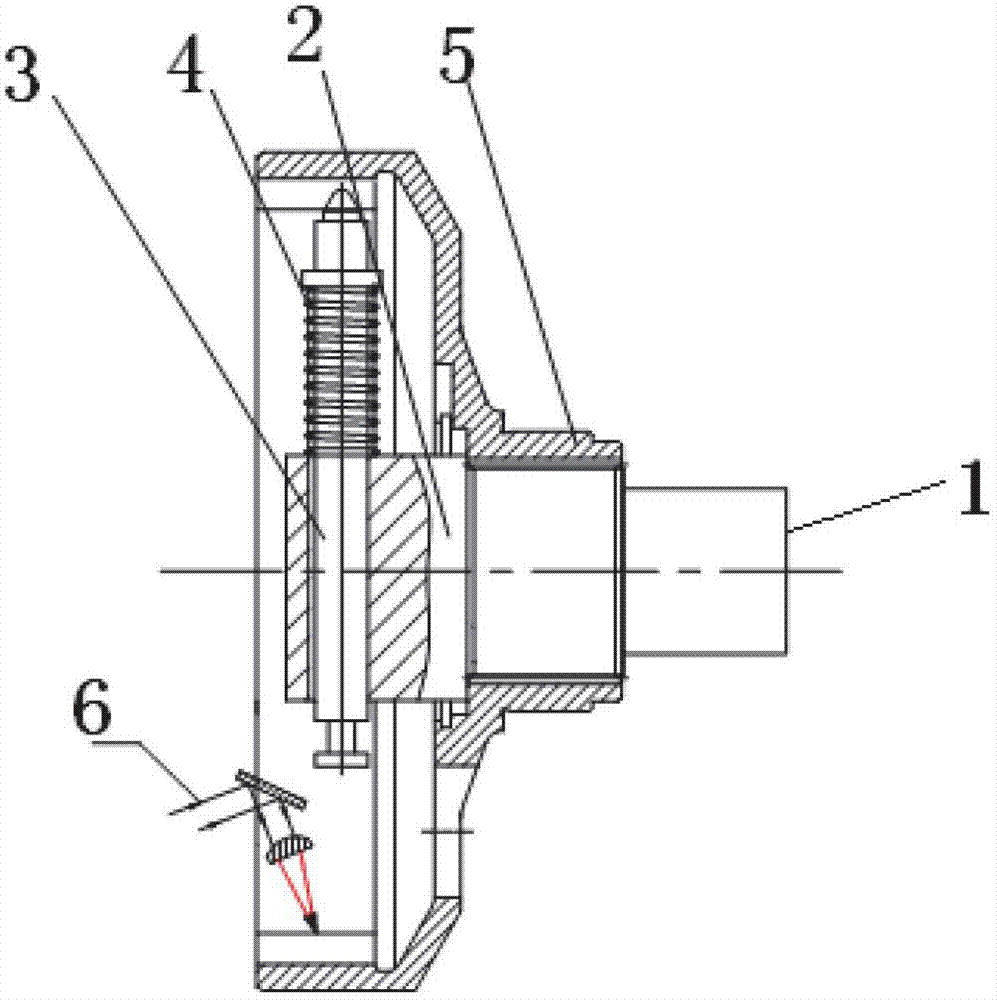

Quick quenching device and method for shaft parts

InactiveCN104775011ATemperature monitoringWon't soften the problemFurnace typesHeat treatment furnacesLaser quenchingLiquid nitrogen cooling

The invention discloses a quick quenching device and method for shaft parts. The quick quenching device for shaft parts is provided with a temperature monitoring device, a laser device, a liquid nitrogen cooling system, a workpiece clamp and a connecting plate assembly, wherein the connecting plate assembly is provided with a manipulator connecting plate, a connecting component and a spray nozzle connecting plate, a laser head is installed on the manipulator connecting plate, and a liquid nitrogen spray nozzle is installed on the spray nozzle connecting plate and is connected with a liquid nitrogen cooling system control valve through an air delivery pipe. The workpiece clamp is arranged under the connecting plate assembly and is provided with a chuck, a tip and a control system for controlling rotation of the chuck, and a workpiece is arranged between the chuck and the tip. The temperature monitoring device is arranged on one side of the connecting plate assembly and is used for monitoring the temperature of a laser quenching zone on the workpiece. By the adoption of the quick quenching device and method for shaft parts, the automation degree of surface laser strengthening of large shafts can be improved, working efficiency can be improved, shaft surface strengthening and near-net shaping can be also achieved, additional machining is not needed basically, and working procedures and cost are saved.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

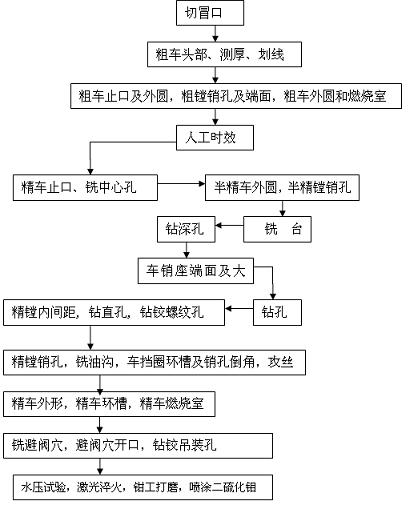

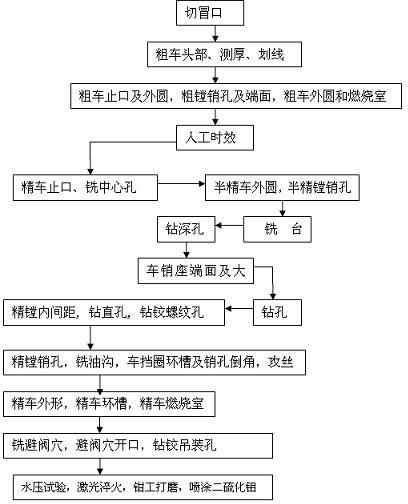

Processing technology for whole spherical iron piston

InactiveCN102213313AImprove machining accuracyRigorous processPlungersTrunk pistonsCombustion chamberLaser quenching

The invention discloses a processing technology for whole spherical iron piston, and the method comprises the following steps: step a, cutting a riser; step b, carrying out rough turning on a head, measuring the thickness and marking off; step c, carrying out rough turning on a spigot and an excircle, carrying out heavy boring on a pin hole and an end face, and carrying out rough turning on the excircle and a combustion chamber; step d, carrying out precipitation heat treatment; step e, carrying out finish turning on the spigot and milling a center hole; step f, carrying out semi-finish turning on the excircle, and carrying out semi-finish boring on the pin hole; step g, milling a table face; step h, drilling a deep hole; step i, turning a seat end face and turning a macropore; step j, drilling a hole; step k, carrying out finish boring on an internal space, drilling a straight hole and drilling a hinge screwed hole; step l, carrying out finish boring on the pin hole, milling an oil gallery, chamfering an vehicle shield ring groove and the pin hole, and tapping; step m, carrying out finish turning on appearance, carrying out finish turning on the ring groove and carrying out finish turning on the combustor chamber; step n, milling an avoided valve hole, opening the avoided valve hole, and drilling a hinge hoisting hole; step o, carrying out a hydrostatic test, laser quenching and fitter polishing, and spraying molybdenum disulfide. The processing technology for the whole spherical iron piston in the invention has the advantages of high process precision, rigorous process flow and superior processed product quality.

Owner:DALIAN BINCHENG PISTON MFG

Online laser quenching process for strengthening steel rail surface

InactiveCN102121217AImprove absorption efficiencyExtended service lifeRailway track constructionLaser quenchingMartensite

The invention provides an online laser quenching process for strengthening a steel rail surface, comprising the following steps: coating a light absorbing coating layer on the steel rail surface; scanning the steel rail surface by a pulse semiconductor laser in the length direction at a certain speed; and obtaining laser quenching points of which the tissues arranged in a grid shape are fine martensite on the steel rail surface, wherein the area of the laser quenching points is 50-80% of the that of the steel rail surface, and the largest depth of the quenching points is 0.6-1.5 mm. In the invention, the composite phase tissue consisting of the martensite and pearlite has good toughness and ensures that the service life of a steel rail is obviously prolonged; simultaneously, the laser quenching process is conveniently adjusted, does not need a quenching medium, does not need tempering and ensures small deformation of a work piece; and the semiconductor laser is small in volume, and convenient to push, so online laser quenching treatment can be carried out on the steel rail surface.

Owner:武汉武钢华工激光大型装备有限公司

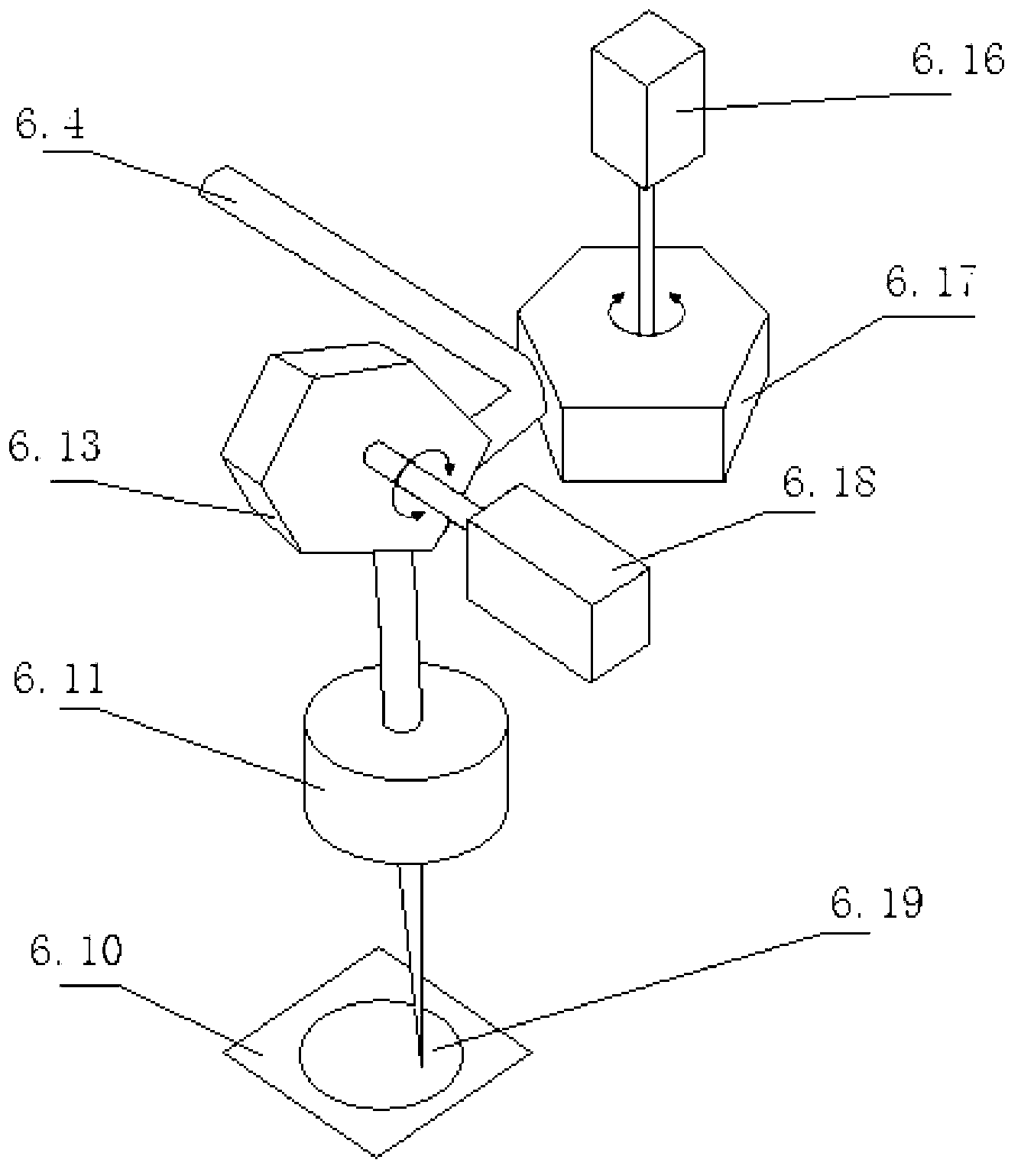

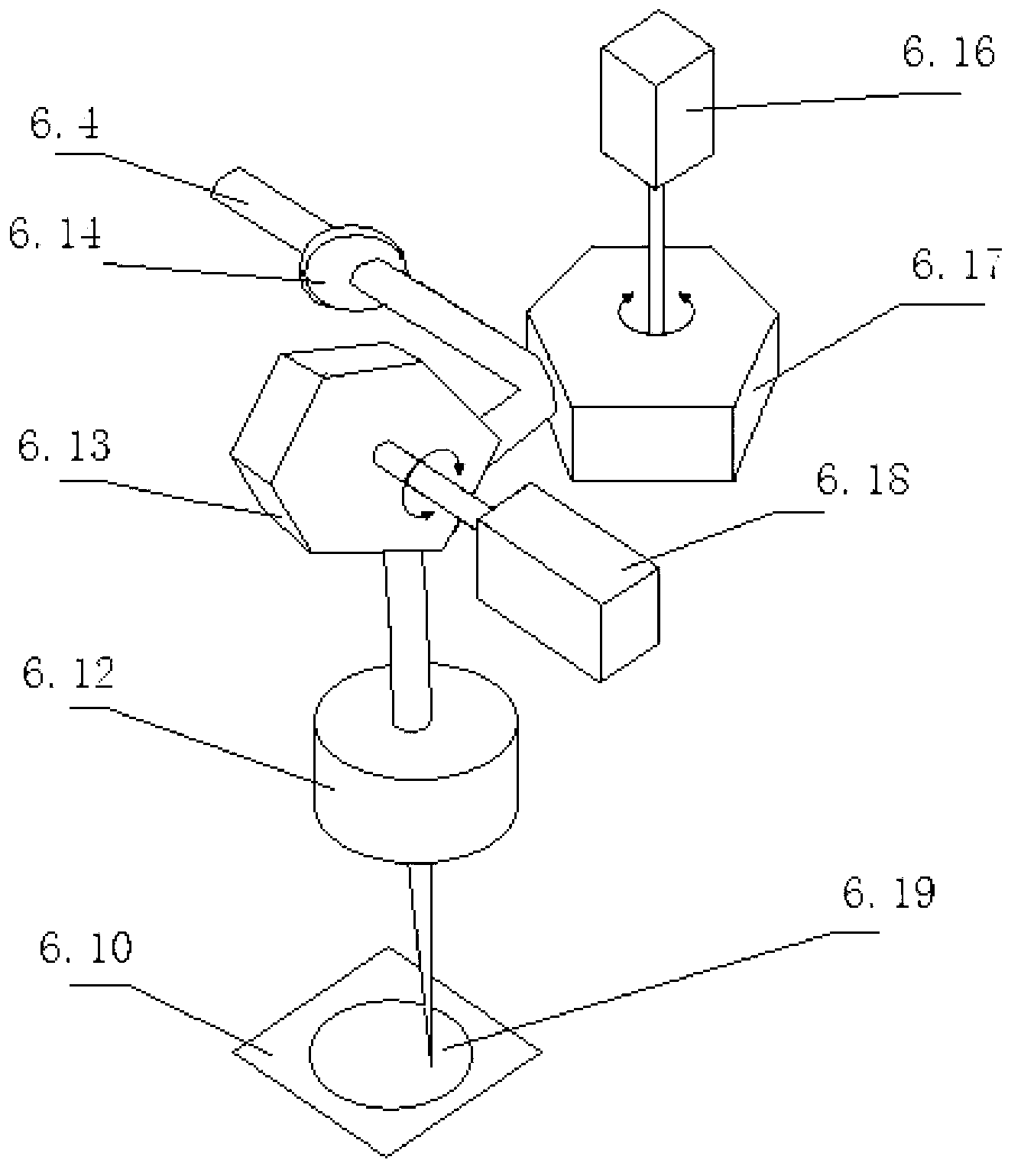

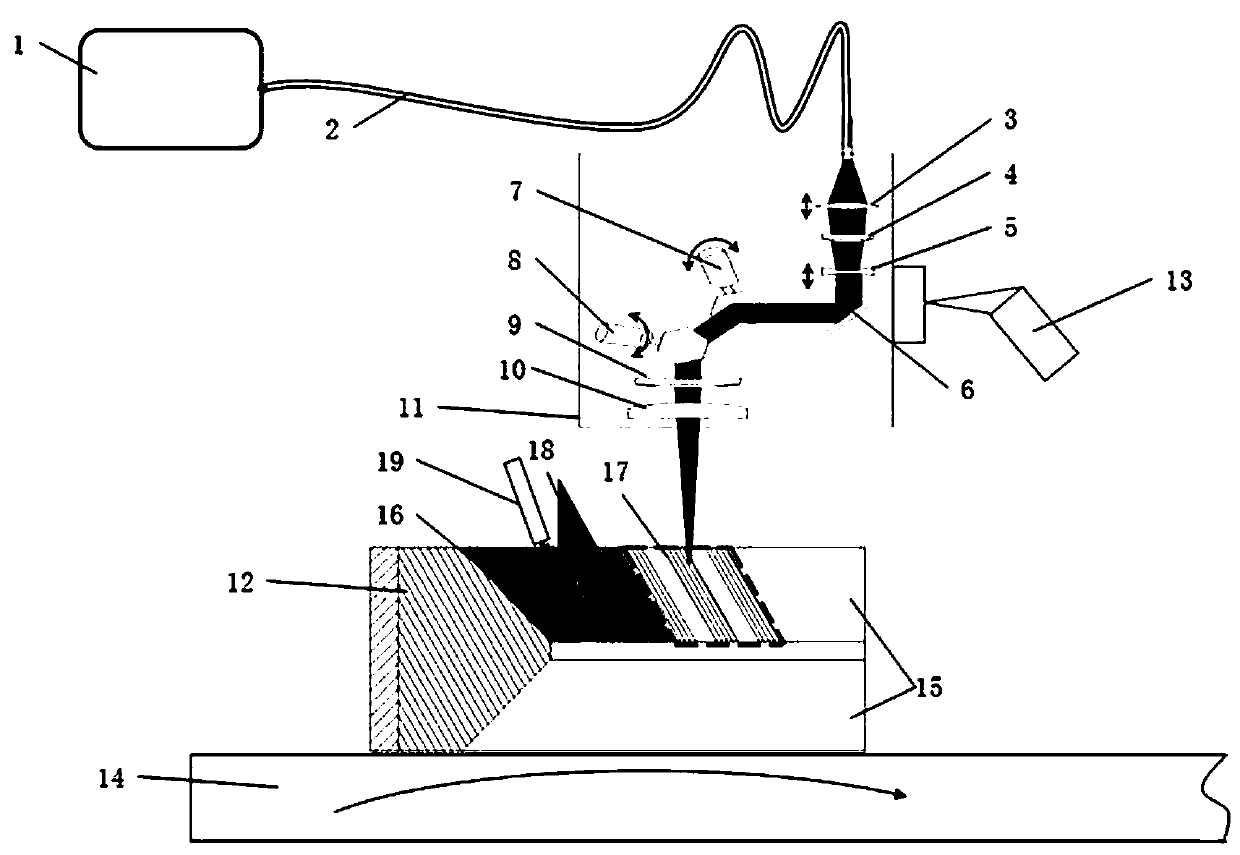

Laser-cladded oil well pipe subjected to multicomponent cementation compound treatment and production process and device

ActiveCN103114292AImprove wear resistanceImprove corrosion resistanceDrilling rodsSolid state diffusion coatingLaser quenchingLight guide

The invention discloses a laser-cladded oil well pipe subjected to multicomponent cementation compound treatment and a production process and device. A laser cladded heat treatment layer is arranged on a surface multicomponent cementation compound layer of the oil well pipe. The production process comprises the following steps of: step 1. machining a thread structure; step 2. carrying out quenching and tempering treatment; step 3. carrying out polishing treatment; step 4. pre-heating; step 5. carrying out salt bath nitriding treatment; step 6. carrying out salt bath oxidization treatment; step 7. removing salt and washing; step 8. carrying out polishing treatment; step 9. carrying out the salt bath oxidization treatment for the second time; step 10, removing the salt and washing for the second time; step 11. carrying out laser quenching treatment; and step 12. carrying out oil immersing treatment. A device for laser quenching heat treatment is formed by a CO2 laser device, a power meter, an optical shutter, a light guide system, a focusing lens, a reflection lens and a worktable; and the device has the beneficial effects that the service life of the oil well pipe is greatly improved, the cost is low and the benefits are obvious.

Owner:梅河口市弘业无缝钢管有限公司

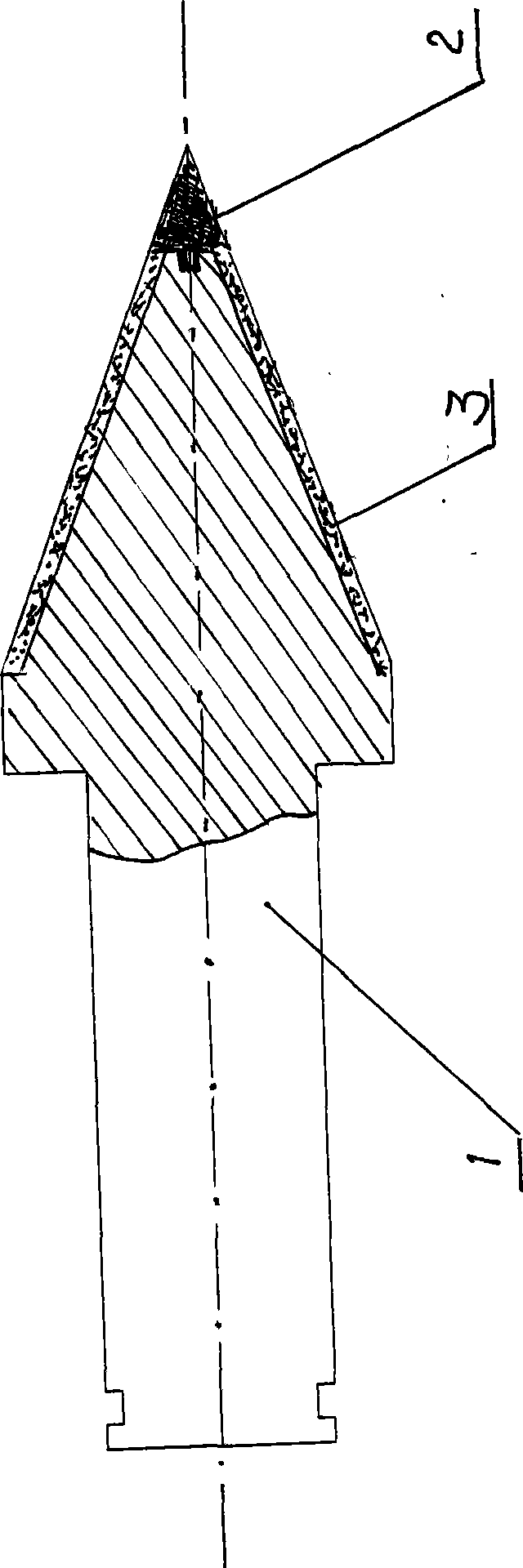

Antiwear laser strengthened pick and its processing method

InactiveCN101392649AUniform thicknessUniform hardness distributionFurnace typesMetallic material coating processesLaser quenchingHardness

The invention discloses an antiwear laser strengthening cutting pick for a coal mining unit and a processing method thereof. The conical surface of a body of the cutting pick is provided with a laser strengthening layer. The processing method for the antiwear laser strengthening layer comprises the following steps: a laser energy beam is utilized to perform laser cladding, surface alloying or laser quenching strengthening to the conical surface of the cutting pick, thereby improving the hardness and the wear resisting property of the conical position on the end part of the cutting pick, prolonging the wear rate, effectively protecting a hard alloy tool bit, and prolonging the service life of the cutting pick.

Owner:SHANDONG ENERGY HEAVY EQUIP MFG GRP CO LTD

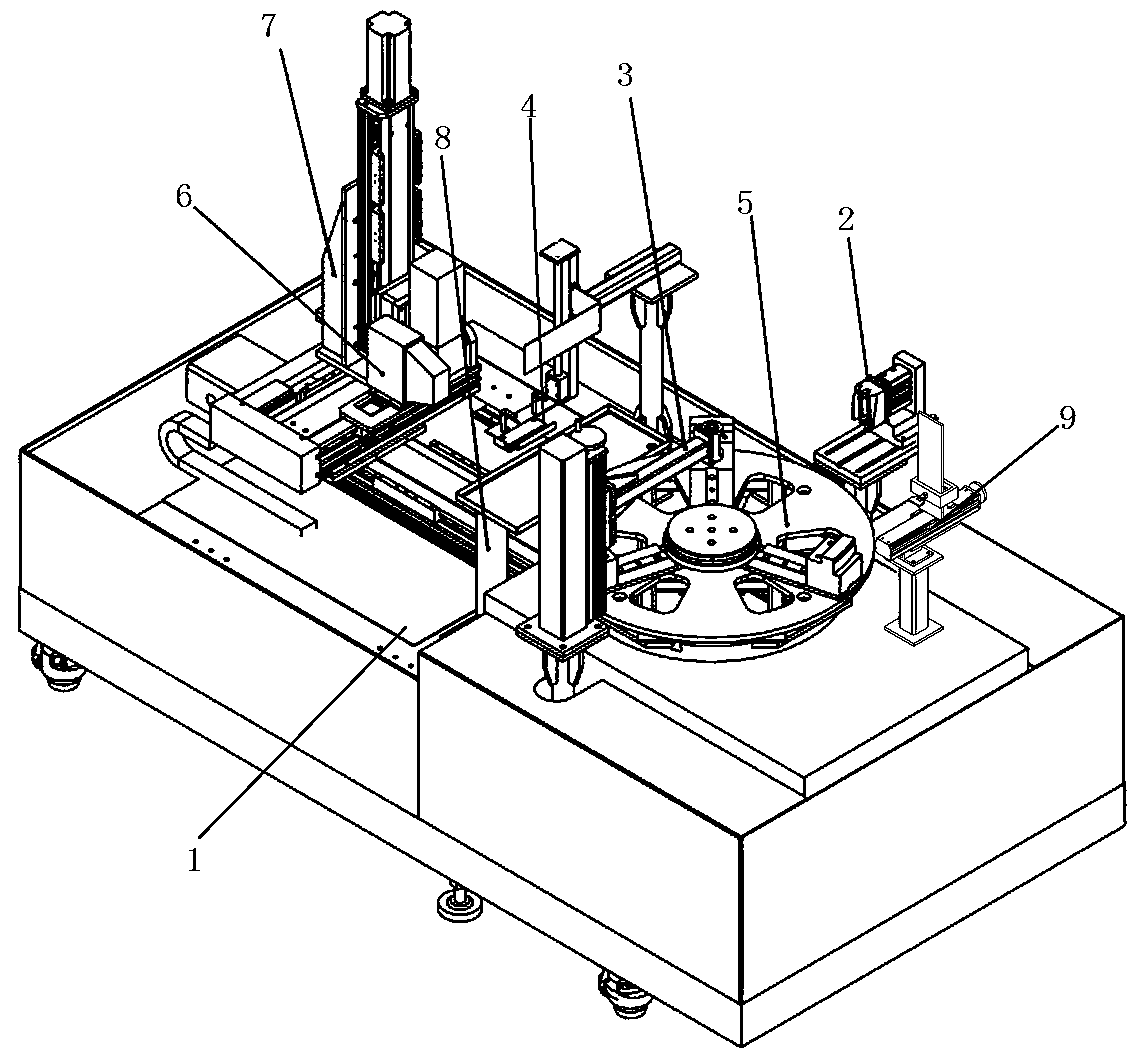

Laser quenching machine for gear

PendingCN109929980APrecise positioningEasy to assemble and disassembleFurnace typesHeat treatment furnacesRotary stageLaser quenching

The invention discloses a laser quenching machine for a gear. The machine comprises a quenching platform, a gear mounting turntable, a laser head, a gear positioning mechanism, a centre mechanism, a laser head moving device, a cooling mechanism, a cooling liquid recovering mechanism and a sweeping mechanism, wherein the quenching platform comprises a base, a four-axis rotating platform and a laserhead mounting platform; the gear positioning mechanism is used in match with the gear mounting turntable and comprises a positioning head, a positioning cylinder and a positioning frame; the centre mechanism is used in match with the gear mounting turntable and comprises a vertical supporting column and a centre lead screw transmission mechanism; the laser head moving device comprises an up-downmoving mechanism, a forward-backward moving mechanism and a leftward-rightward moving mechanism; the cooling mechanism comprises a cooling liquid spray head, a solenoid valve, a spraying head liftingstructure and a water baffle; the cooling liquid recovering mechanism comprises a cooling liquid recovering groove; and the sweeping mechanism comprises an air port, an up-down moving mechanism and aforward-backward moving mechanism. The machine is capable of sweeping gear teeth with different diameter and thickness, so that the quenching efficiency, the quenching effect and the product quality are ensured; and the applicable scope is wide.

Owner:杭州智钒激光科技有限公司

Laser melting quenching process capable of greatly increasing RuT300 surface hardness

The invention relates to a laser melting quenching process capable of greatly increasing the RuT300 surface hardness. The laser melting quenching process is characterized by comprising the following steps of carrying out flattening treatment and surface pretreatment on the surface of a to-be-treated RuT300 workpiece, setting the included angle of the transmitting direction of a laser beam and the normal of the treated surface of the workpiece at 0-45 DEG, carrying out laser melting quenching and carrying out liquid penetrant test immediately after the workpiece is cooled to the room temperature after the laser melting quenching. Compared with the prior art, the process disclosed by the invention has advantages that the operation is simple, the efficiency is high and the corresponding surface blackening treatment is not needed, so that the processing efficiency is increased; the workpiece deformation is little, so that the application of high-precision parts or dies can be satisfied; and the repeatability is good, the crater crack problem is well solved and a laser quenching zone with no crack or air hole on the surface is obtained, so that the surface fatigue resistance of the parts can be greatly increased and the service life of the parts is prolonged.

Owner:北方材料科学与工程研究院有限公司 +1

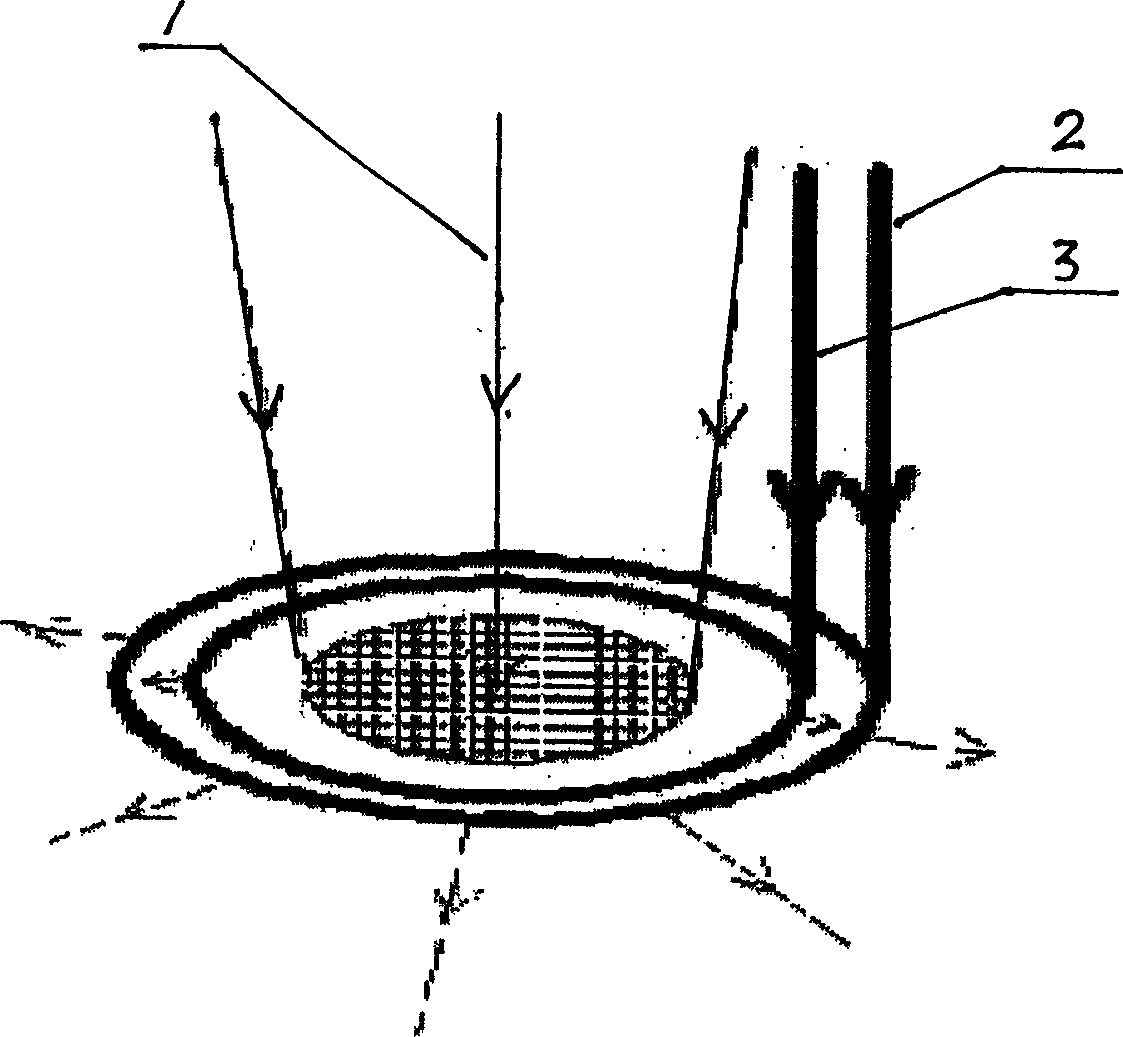

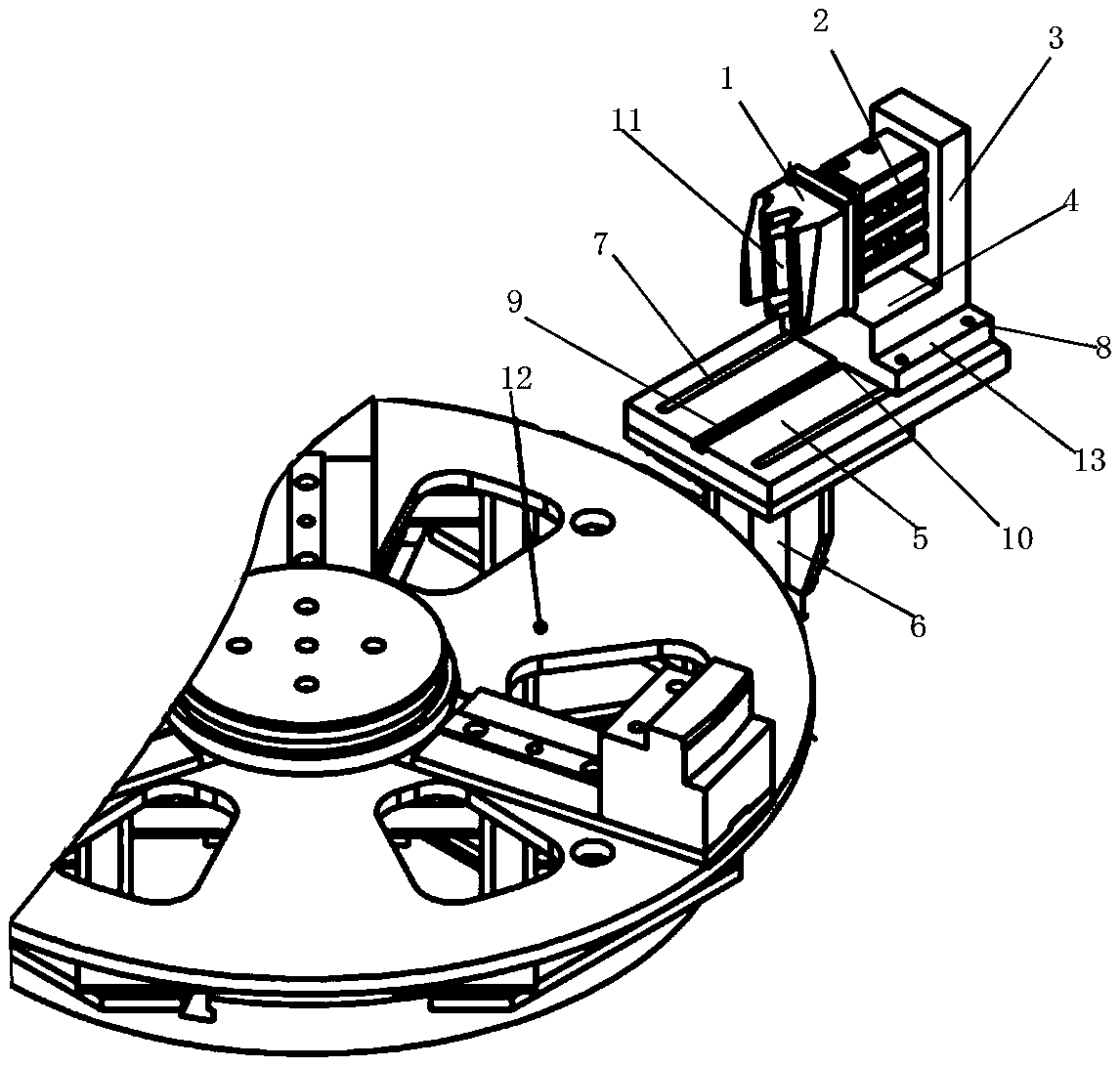

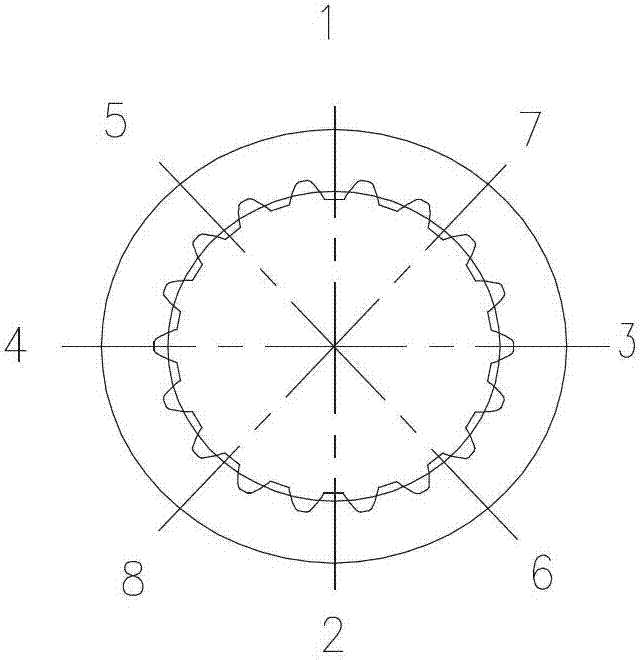

Tooth ring tooth surface laser induration processing method

ActiveCN101368226ASmall quenching deformationMeet hardening technical requirementsLaser quenchingLight guide

The invention relates to a laser hardening treatment method for a gear surface of a gear ring, which is characterized the in that: laser hardening treatment methods for the two side surfaces of each gear of the gear ring (1) and the top of the gear thereof are the same; the processing method thereof is described as follows: 1) the gear ring is arranged in the clamp of a rotary working platform; the direction of the length of the gear is vertical to the surface of the rotary working platform; 2) the upper end of the gear ring is provided with a light shielding ring; 3) the laser hardening treatment parameters, such as a laser power, a laser beam scanning speed, the focus of a focus lamp, are reasonably matched; 4) the center of a light guide cylinder deviates from the center of the gear ring; 5) the layer beam enters into the processing surface of the gear side of the gear ring; 6) a guide head moves up and down to match the periodic rotating of the rotary platform with small angle and scale division; or the light guide head moves up and down and rotates to form a laser hardening zone at the processing surface; 7) a primary switch is blocked by light to finish laser hardening treatment on all the gear surface of the gear ring (1). The rigidity and the wear-resistance when the two side gear surfaces of each gear of the gear ring are engaged with the gear surface of a planet gear are improved; simultaneously, as the self-owned characteristics of laser quenching, the quenching deformation of the gear ring is very small which completely meets the technical demands for design and production.

Owner:CHINA FIRST AUTOMOBILE

Manufacturing method of strengthened valve tappet

ActiveCN104862694AImprove surface strengthImprove surface wear resistanceMetallic material coating processesLaser quenchingHardness

The invention provides a manufacturing method of a strengthened valve tappet. The method comprises the following steps that the bottom face of the valve tappet is cleaned, and phosphating is carried out on the cleaned bottom face of the valve tappet; laser heat treatment is carried out on the phosphated bottom face of the valve tappet to obtain the strengthened valve tappet; and the laser heat treatment is laser quenching treatment or laser remelting treatment or laser fusion covering treatment. The laser surface modification technology that is the laser quenching method or the laser remelting method or the laser fusion covering method is adopted to strengthen the bottom working face of the valve tappet, and parameter adjustment in the laser surface modification technology is adjusted, so that the hardness and the wear resistance of the treated valve tappet are greatly improved.

Owner:WEICHAI POWER CO LTD

Laser quenching treatment method and quenched workpiece

ActiveCN105331778AHigh hardnessHigh strengthMetallic material coating processesLaser quenchingLaser scanning

The invention relates to a laser quenching treatment method and a quenched workpiece, and belongs to the technical field of heat treatment. The laser quenching treatment method comprises the following steps: a tempered and blued workpiece is quenched by laser; and the laser quenching treatment has the power of 550-650 w, the laser scanning speed of 1.2-1.8 m / min, the focal distance of 300 mm and the defocusing amount of 30-40 mm. The workpiece treated by the laser quenching treatment method has no fusing phenomenon on the surface; and the metal surface hardness can reach above HV700.

Owner:PINGGAO GRP +1

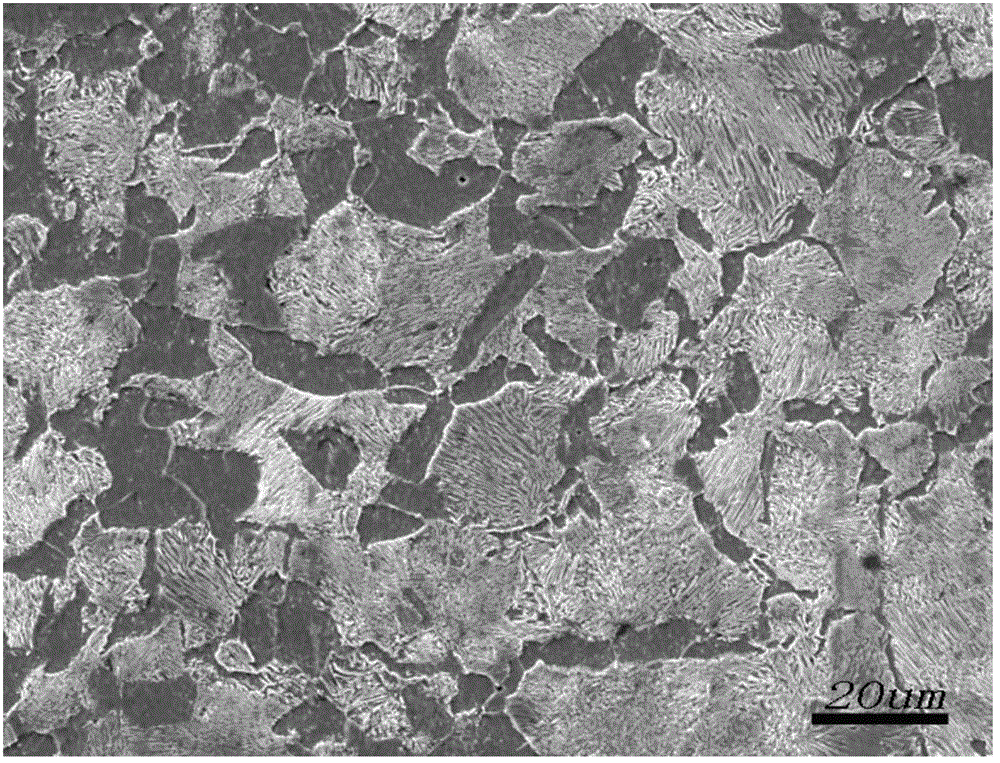

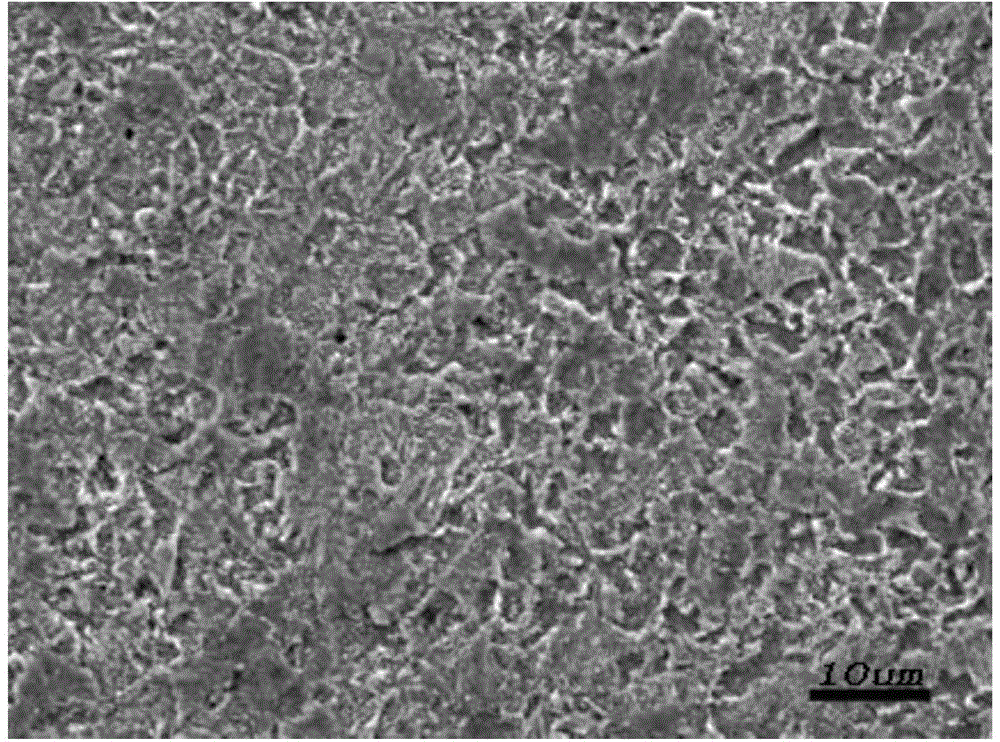

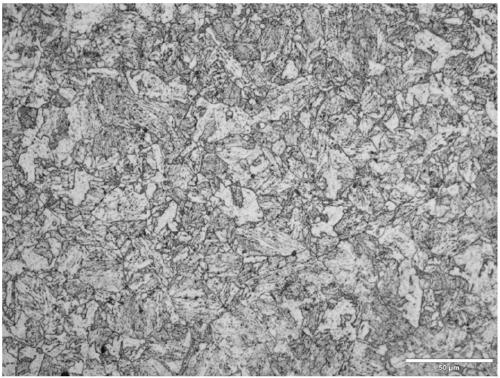

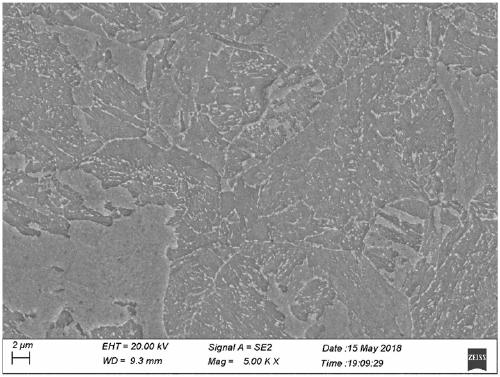

Surface modification method of axles of high-speed trains

InactiveCN109022744AHigh hardnessImprove wear resistanceFurnace typesHeat treatment furnacesLaser quenchingLight spot

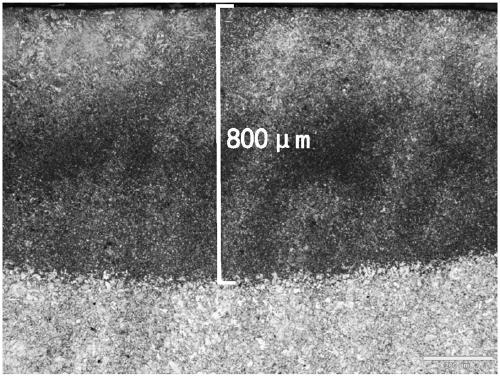

The invention relates to the field of production and manufacturing of axles of high-speed trains, in particular to a surface modification method of axles of high-speed trains. Through laser quenching,the surfaces of the axles are transformed into a mixed structure of granular bainites and martensites. After quenching, the depth of a surface abrasion-resistance layer can reach 100 [mu]m to 800 [mu]m, the surface Rockwell hardness can reach 70-85 HR15N, and the microhardness of an axle cross-section quenching layer can reach 390-550 HV. According to the technological parameters of laser quenching, laser quenching power is 1200 W-2500 W, the light-spot scanning rate is 20-60 mm / s, the light-spot diameter is 4 mm, light-spot spacing is 2-4 mm, and the light-spot height is 60-80 mm. Accordingto the surface modification method of the axles of the high-speed trains, laser heating is adopted, so that the surfaces of the axles of the high-speed trains are quickly enabled to reach the austenitizing temperature, and a certain cooling speed is maintained by controlling the gas flow rate; and the mixed structure of the granular bainites and the martensites is formed on the surfaces of the axles, so that a role in improving the surface hardness and abrasion resistance is played.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

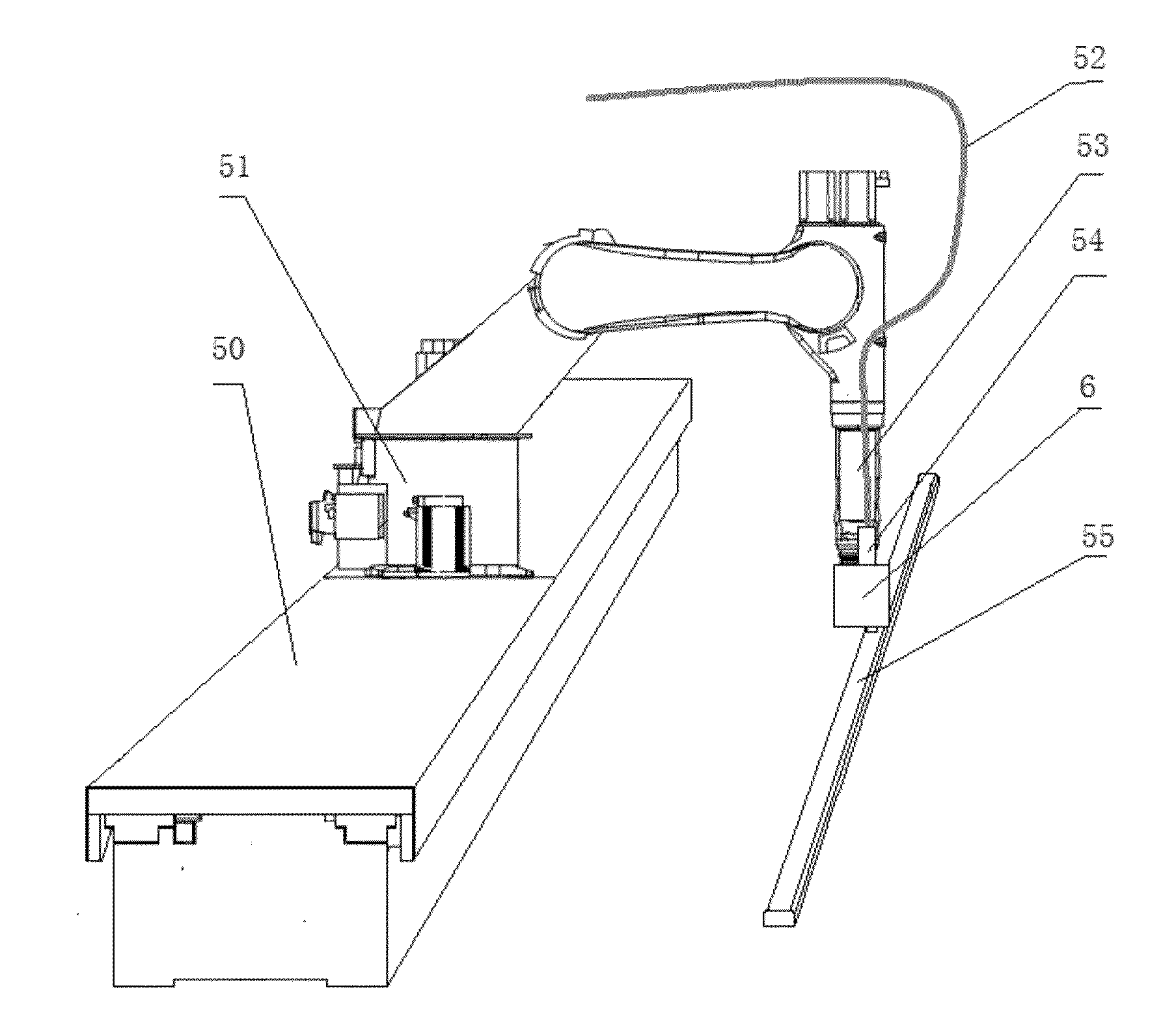

High-precision flexible laser processing system

ActiveCN106624350AQuick Auto SwitchQuick switchLaser beam welding apparatusLaser-hybrid weldingLaser processing

The invention discloses a high-precision flexible laser processing system. The high-precision flexible laser processing system can achieve up to seven types of 3D laser processing on the surfaces of various workpieces. The types of laser processing comprise laser cladding, laser welding, laser quenching, laser cutting, laser hybrid welding, laser micro-processing and laser cleaning. The high-precision flexible laser processing system is composed of a laser system, a mechanical motion forming system, a laser head base system, a control system and an auxiliary system. According to the flexible laser processing system, laser heads are installed on a robot arm in the mechanical motion forming system through a fast switch, the fast switch can be matched with a laser head base for use so that the laser heads can be switched quickly and automatically, and thus the functions of the high-precision flexible laser processing system can be switched rapidly.

Owner:NANTONG UNIVERSITY

Inner bore laser quenching head and quenching method

ActiveCN104294011AChange the quenching methodIncrease productivityFurnace typesHeat treatment furnacesLaser quenchingLaser beams

The invention provides an inner bore laser quenching head and a quenching method. After passing through a collimation lens, a laser beam passes through a full-reflection lens and a full-reflection focusing lens to form a ring-shaped laser beam; the ring-shaped laser beam enters into an inner bore part to be quenched; and through a second full-reflection lens in the inner bore part, the ring-shaped laser beam is irradiated on the inner wall of the inner bore part so as to achieve the aim of simultaneously carrying out laser quenching on the circumference of the inner wall of the inner bore part. Inner bore movement equipment 7 is consistent with an outer laser quenching head in the aspect of movement.

Owner:SHENYANG POLYTECHNIC UNIV

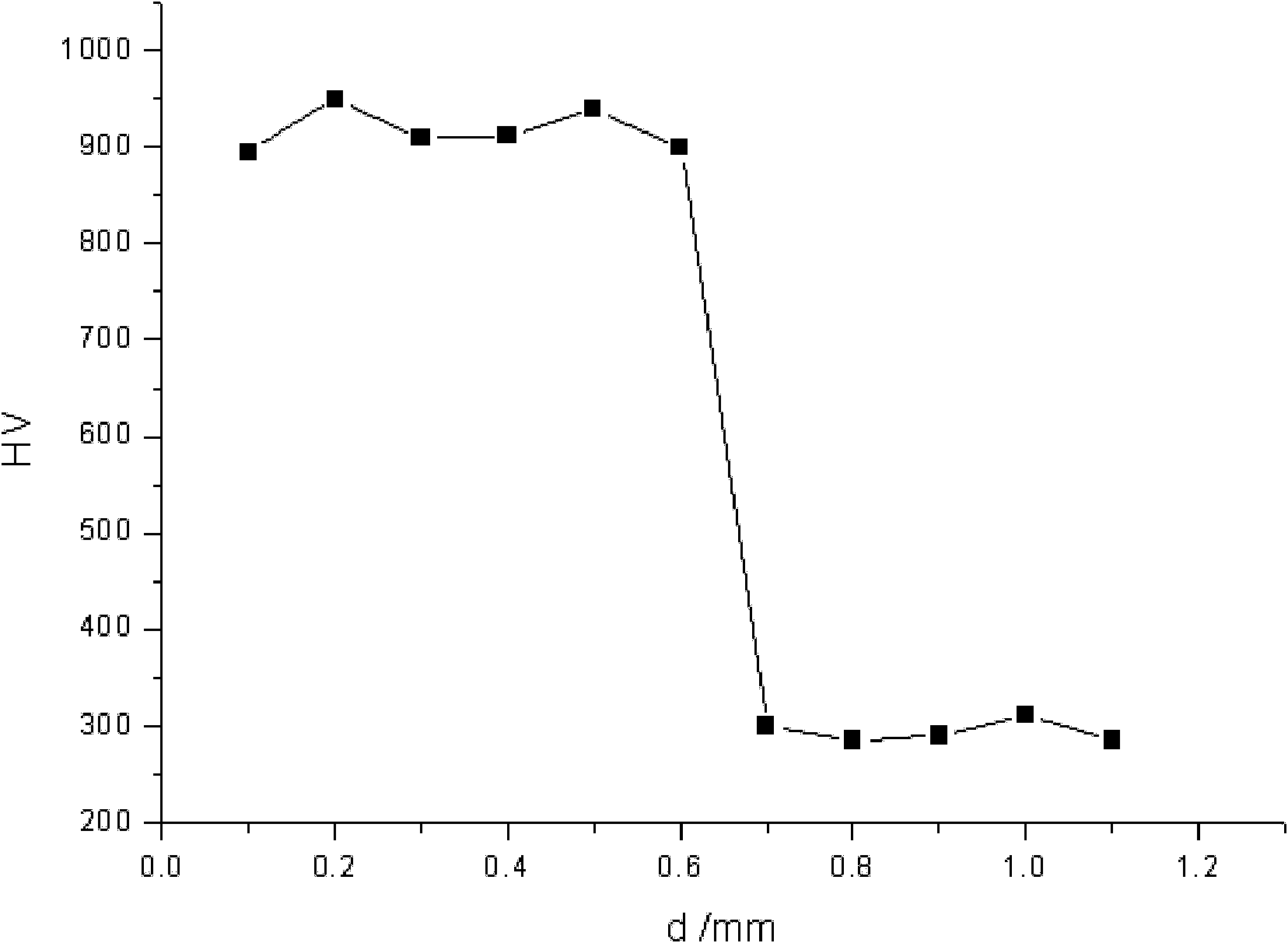

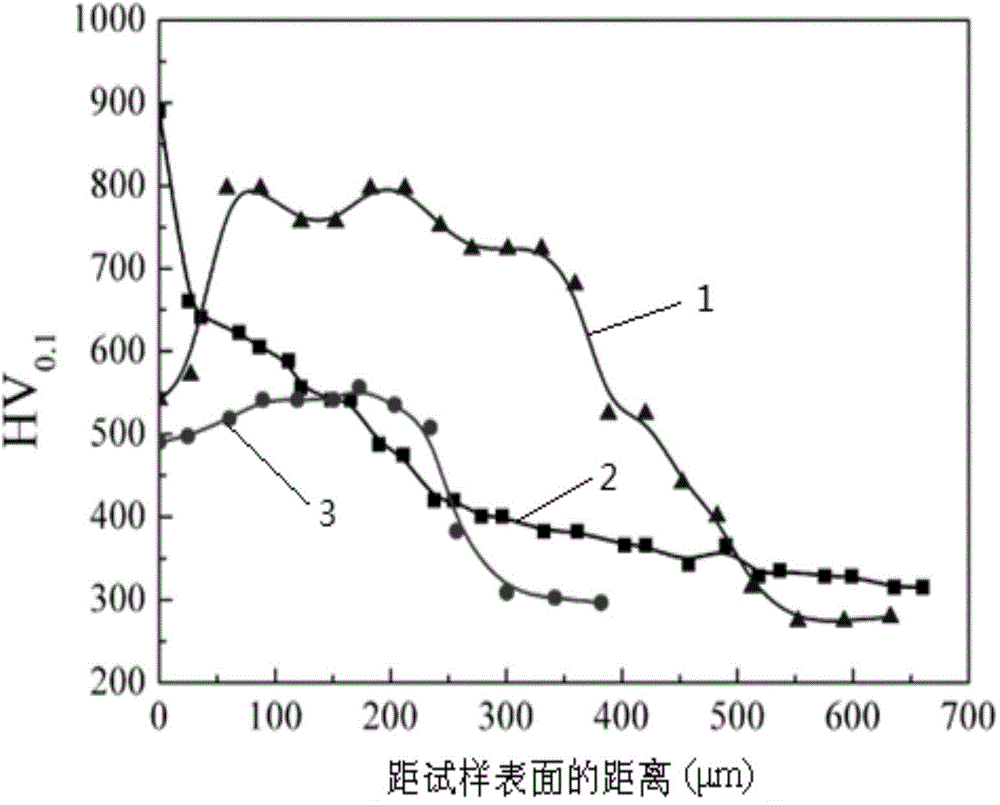

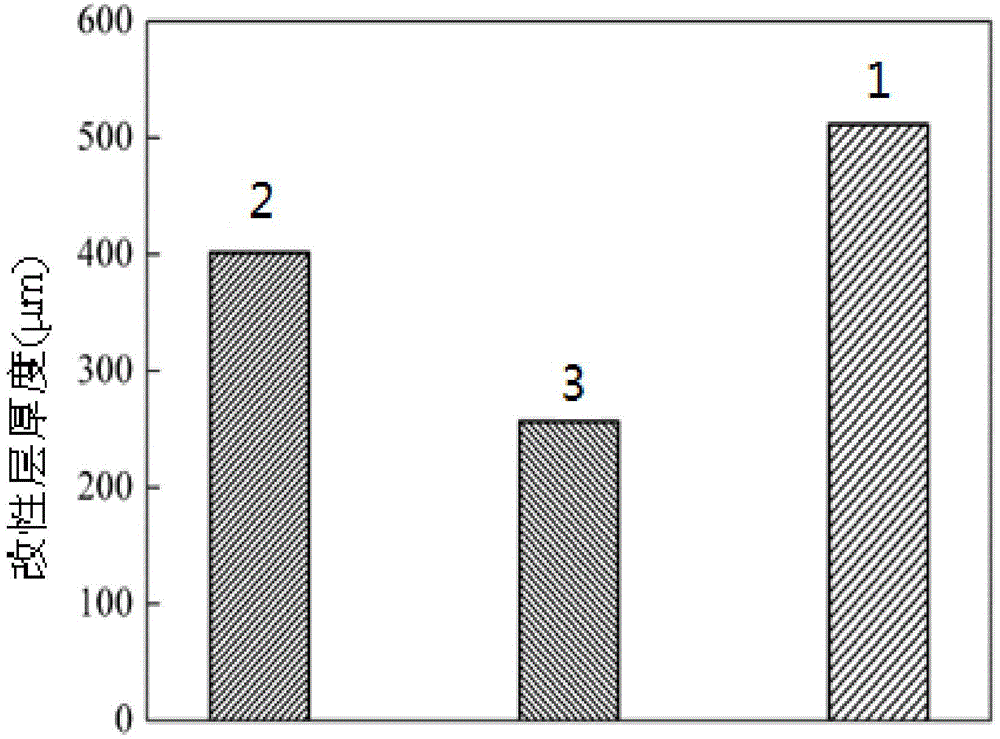

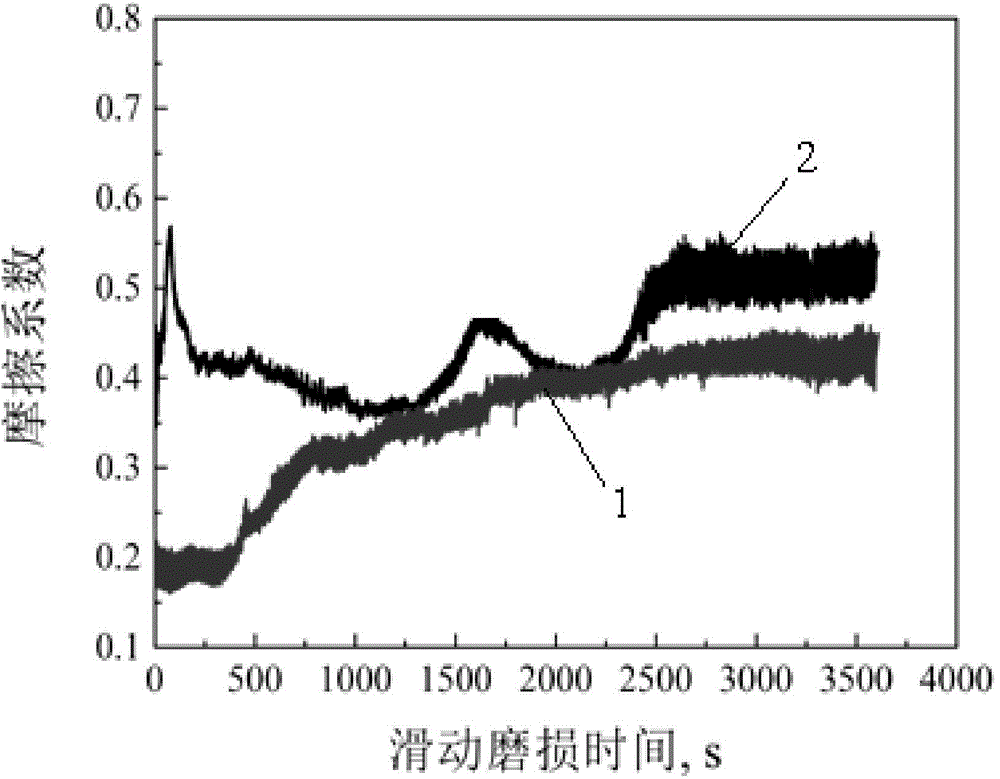

Composite modification method used for multiplying thickness and hardness of steel nitriding layers or rapid heating quenching hardened layers

InactiveCN104962856AImprove metallographic structureImprove mechanical propertiesSolid state diffusion coatingLaser quenchingHardness

The invention discloses a composite modification method used for multiplying thickness and hardness of steel nitriding layers or rapid heating quenching hardened layers, and belongs to the field of steel modification method. The composite modification method is used for solving a problem that hardened layers with both high hardness and high thickness can not be prepared via conventional steel surface treatment method. The composite modification method comprises steps of pretreatment, nitriding, and laser quenching.

Owner:HARBIN INST OF TECH

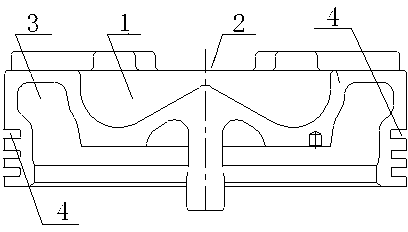

Piston crown structure

InactiveCN103016198AExtended service lifeExcellent surface hardnessMachines/enginesPistonsLaser quenchingCombustion chamber

The invention discloses a piston crown structure comprises a combustion chamber (1), valve avoidance holes (2), an inner cavity (3) and piston ring grooves (4), wherein the combustion chamber (1) is arranged at the upper part of the piston crown; the valve avoidance holes (2) are uniformly distributed on the circumference of the piston crown; the inner cavity (3) is formed in the inner side of the piston crown; the piston ring grooves (4) are formed in the outer cylindrical surface of the piston crown. According to the invention, the piston ring grooves adopt laser quenching to improve the surface hardness of the ring grooves and prolongs the service life of the piston, and can be suitable for occasions under abominable working environments.

Owner:DALIAN BINCHENG PISTON MFG

Thin-wall gear ring type part quenching method for keeping accuracy level

InactiveCN102808077AReduce deformationShorten the timeFurnace typesHeat treatment furnacesLaser quenchingHigh energy laser beam

The invention relates to a thin-wall gear ring type part quenching method for keeping the accuracy level. The method comprises the following steps of: performing coarse and fine machining on a thin-wall gear ring type part of steel for nitriding medium carbon according to a process specified cutting amount in a machining process; destressing and tempering respectively; uniformly coating a surface to be reinforced with a coating material; scanning the surface of a workpiece by using high energy laser beams to obtain a uniform-surface martensite structure; sequentially and gradually heating the surface to be hardened of the part by adopting a symmetric equant gradient heating way; and comparing two thermal treatment processes including a tool positioning and laser quenching process and a nitriding process to obtain a martensite structure with surface compression stress through laser quenching, so that the fatigue resistance of the surface of the part is improved remarkably. The method meets the requirement of product performance; and meanwhile, the symmetric equant gradient heating way is adopted, so that part deformation is reduced, part machining procedures can be reduced on the basis of not lowering the machining accuracy level, and the requirement of product performance is met.

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

Bar hot shear blade laser-quenching manufacturing process

InactiveCN102094111AImprove productivityImprove the rate of successFurnace typesHeat treatment furnacesLaser quenchingEngineering

The invention discloses a bar hot shear blade laser-quenching manufacturing process. The process is characterized by comprising the following steps of: (1) removing greasy dirt and rust from the surface of the shear blade, and polishing the surface of the shear blade to ensure that a light absorption coating can be sprayed conveniently and uniformly; (2) uniformly coating a SiO2 light absorption coating on the surface of the shear blade to improve the CO2 laser absorption rate of the metal surface; (3) air-drying the coating; and (4) quickly scanning the surface of the shear blade on which the light absorption coating is coated by using a DL-HL-5000 type CO2 laser to quickly heat and cool the surface of the shear blade, wherein the process parameters are that: laser power is 2.5 to 4.5kW, round light spots are changed into rectangular light spots by a broadband integral mirror technology, the bandwidth size is that length*width is equal to 10mm*1mm, lap width is 0.5 to 1mm, and scanning speed V is equal to 200 to 1,000mm / min. An appropriate laser-quenching process is selected, good metallurgical bonding of a hard gold layer and a shear blade matrix is realized.

Owner:BEIJING DALU TIANRUI LASER ENG TECHCO

Laser quenching equipment and use method

InactiveCN104775010ARapid coolingSpeed up coolingFurnace typesHeat treatment furnacesLaser quenchingProgrammable logic controller

The invention discloses laser quenching equipment and a use method. The equipment comprises a programmable logic controller, a laser, a laser head, a motion mechanism for driving a workpiece to move and a cooling liquid tank. The motion mechanism is provided with a base and a guide rod, a fixed plate is arranged on the guide rod, a motor II and a lead screw are arranged on the fixed plate, and the motor II drives the lead screw to rotate through a belt II. A connecting plate is arranged on the guide rod, a guide hole is formed in the connecting plate, the connecting plate is arranged on the guide rod in a sleeving mode through the guide hole, a screw hole matched with the lead screw is formed in one side of the connecting plate, a motor I and a connecting assembly are arranged on the other side of the connecting plate, the workpiece is arranged at the lower end of the connecting assembly, and the motor I acts on the connecting assembly through a belt I to drive the workpiece to rotate. The motor I, the motor II and the laser are in wire connection with the programmable logic controller. According to the equipment, the stability of the quality of the workpiece is ensured after laser quenching, the advantages of being high in automation degree and improving work efficiency are achieved, no additional processing exists almost, and procedures and cost are saved.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Bearing surface laser quenching device and method based on distributed three-dimensional light beam scanning

ActiveCN109593919AQuality improvementRapid quenchingFurnace typesHeat treatment furnacesLaser quenchingLight beam

The invention discloses a bearing surface laser quenching device and method based on distributed three-dimensional light beam scanning, and belongs to the field of metal material surface laser quenching. A laser device, a laser transmission optical fiber, a laser machining head and a robot arm are included. Laser beams emitted by the laser device sequentially pass through the laser transmission optical fiber and the laser machining head to arrive at the surface of a bearing roller bed, and the robot arm carries the laser machining head. The robot arm controls the light beam focus of the lasermachining head to correspond to the laser quenching initial position of the bearing roller bed. The device further comprises a partition plate, a cooling medium nozzle and a transposition machine. Asthe transposition machine drives a bearing workpiece to rotate at the constant speed, the position and the posture of the laser machining head are kept unchangeable, the laser machining head is constantly aligned with the surface of the bearing roller bed, and high-speed scanning is conducted on the whole bearing roller bed along with rotation of the bearing workpiece. The problem about 5-8 MW wind turbine generator large main shaft bearing roller bed surface softened belts is solved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com