Off-line laser quenching process for surface strengthening treatment of steel rail

A laser quenching and surface treatment technology, used in heat treatment furnaces, heat treatment equipment, rails, etc., can solve the problems of reducing the toughness of the rails, prone to cracking, etc., and achieve the effects of small deformation of the workpiece, improved absorption efficiency, and improved wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

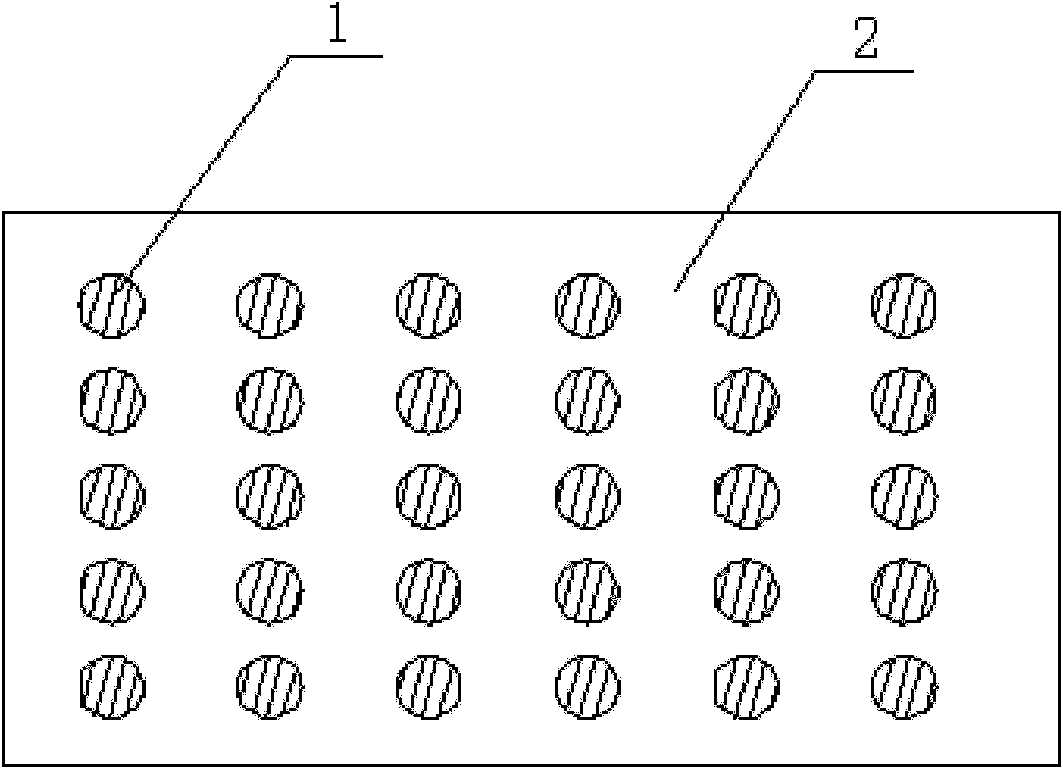

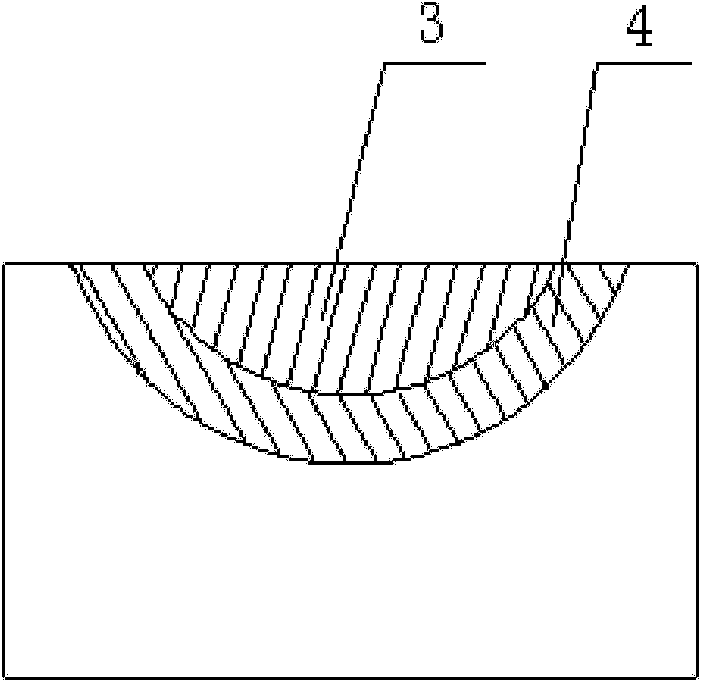

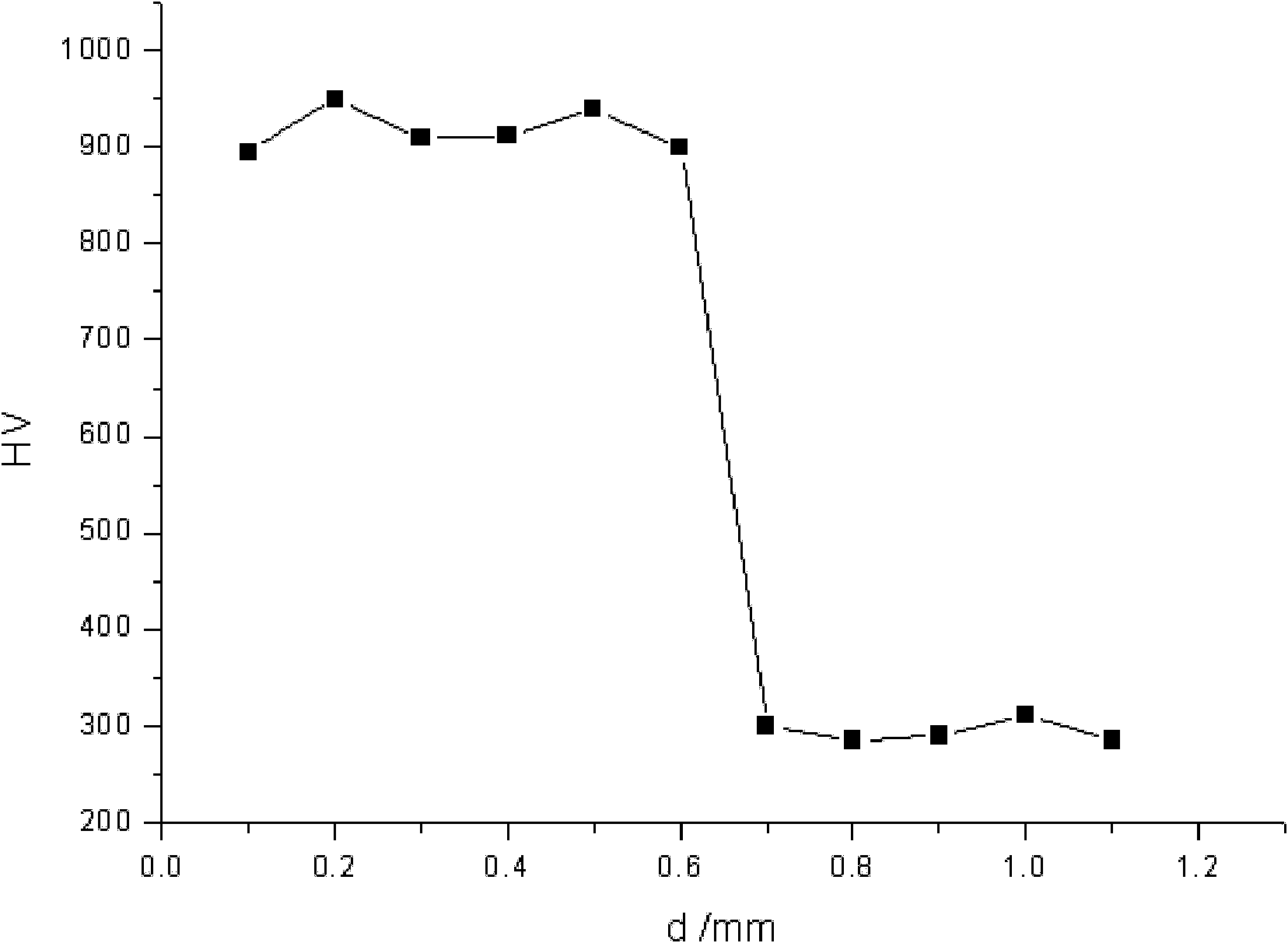

[0027] First, use sandpaper to polish the surface of the rail to remove oxides and dirt such as rust on the surface of the rail, and then use alcohol to further remove the oil on the surface of the rail to facilitate the absorption of the light-absorbing coating. Then the mass fraction is 60% Al 2 o 3 Particles, ZrO with a mass fraction of 20% 2 Particles and SiO with a mass fraction of 20% 2 The particles are mixed with water to obtain a light-absorbing paint. The Al 2 o 3 Particles, ZrO 2 Particles and SiO 2 Particles are submicron particles with a particle size of less than 1 micron. Then spray a layer of light-absorbing paint on the surface of the cleaned U71Mn rail with a spray gun to form a spray coating with a thickness of 0.01 mm. Finally, the rail is driven by the traction device to move at a speed of 10mm / s along the long axis on the cantilever laser processing machine tool. The machine tool is a five-coordinate four-linkage structure, and the laser is fixed ...

Embodiment 2

[0030] After polishing the surface of the rail with sandpaper to remove oxides and dirt such as rust on the surface of the rail, alcohol is used to further remove the oil on the surface of the rail to facilitate the absorption of the light-absorbing coating. Then the mass fraction is 70% Al 2 o 3 Particles, ZrO with a mass fraction of 18% 2 Particles and SiO with a mass fraction of 12% 2 The particles are mixed with water to obtain a light-absorbing paint. The Al 2 o 3 Particles, ZrO 2 Particles and SiO 2Particles are submicron particles with a particle size of less than 1 micron. Then apply a layer of light-absorbing paint on the surface of the cleaned U75V rail with a brush to form a spray coating with a thickness of 0.01mm. Finally, the rail is driven by the traction device to move at a speed of 8 mm / s along the long axis on the cantilever laser processing machine tool. The machine tool is a five-coordinate four-linkage structure, and the laser is fixed and incident...

Embodiment 3

[0033] After polishing the surface of the rail with sandpaper to remove rust and other oxides and dirt on the surface of the rail, use alcohol to further remove the oil on the surface of the rail to facilitate the absorption of the light-absorbing coating. Then the mass fraction is 70% Al 2 o 3 Particles, ZrO with a mass fraction of 18% 2 Particles and SiO with a mass fraction of 12% 2 The particles are mixed with water to obtain a light-absorbing paint. The Al 2 o 3 Particles, ZrO 2 Particles and SiO 2 Particles are submicron particles with a particle size of less than 1 micron. Then spray a layer of light-absorbing paint on the surface of the cleaned U71Mn rail with a spray gun to form a spray coating with a thickness of 0.1mm. Finally, the rail is driven by the traction device to move at a speed of 14mm / s along the long axis on the cantilever laser processing machine tool. The machine tool is a five-coordinate four-linkage structure, and the laser is fixed and incid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com