Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

752results about How to "Improve internal quantum efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

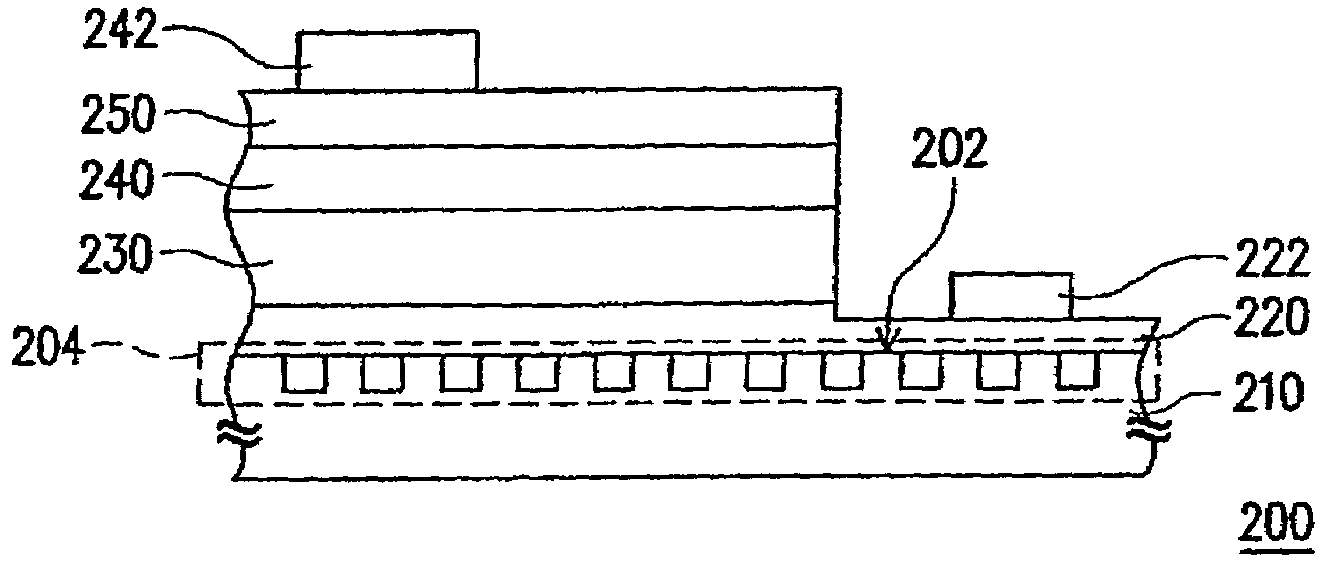

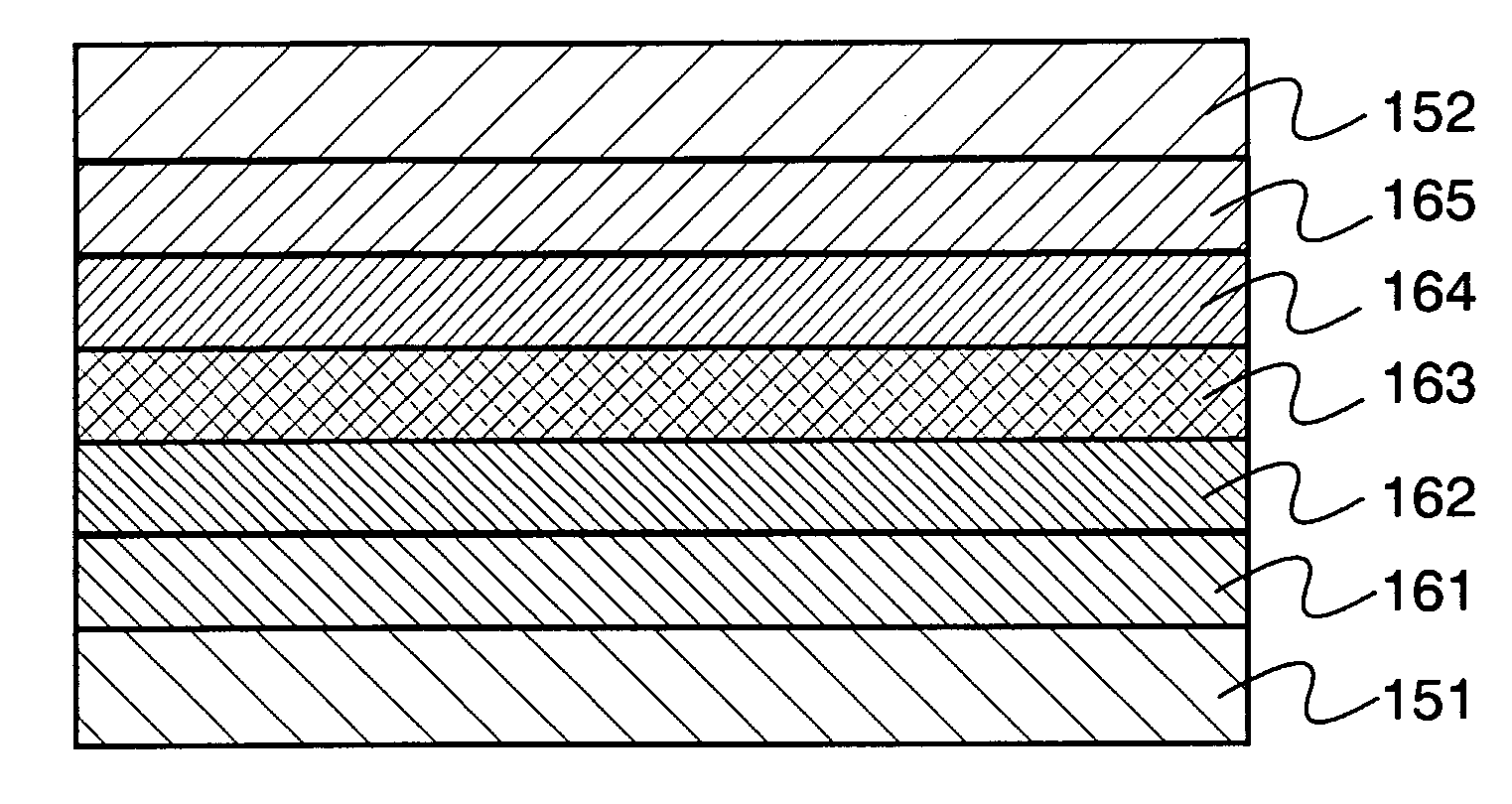

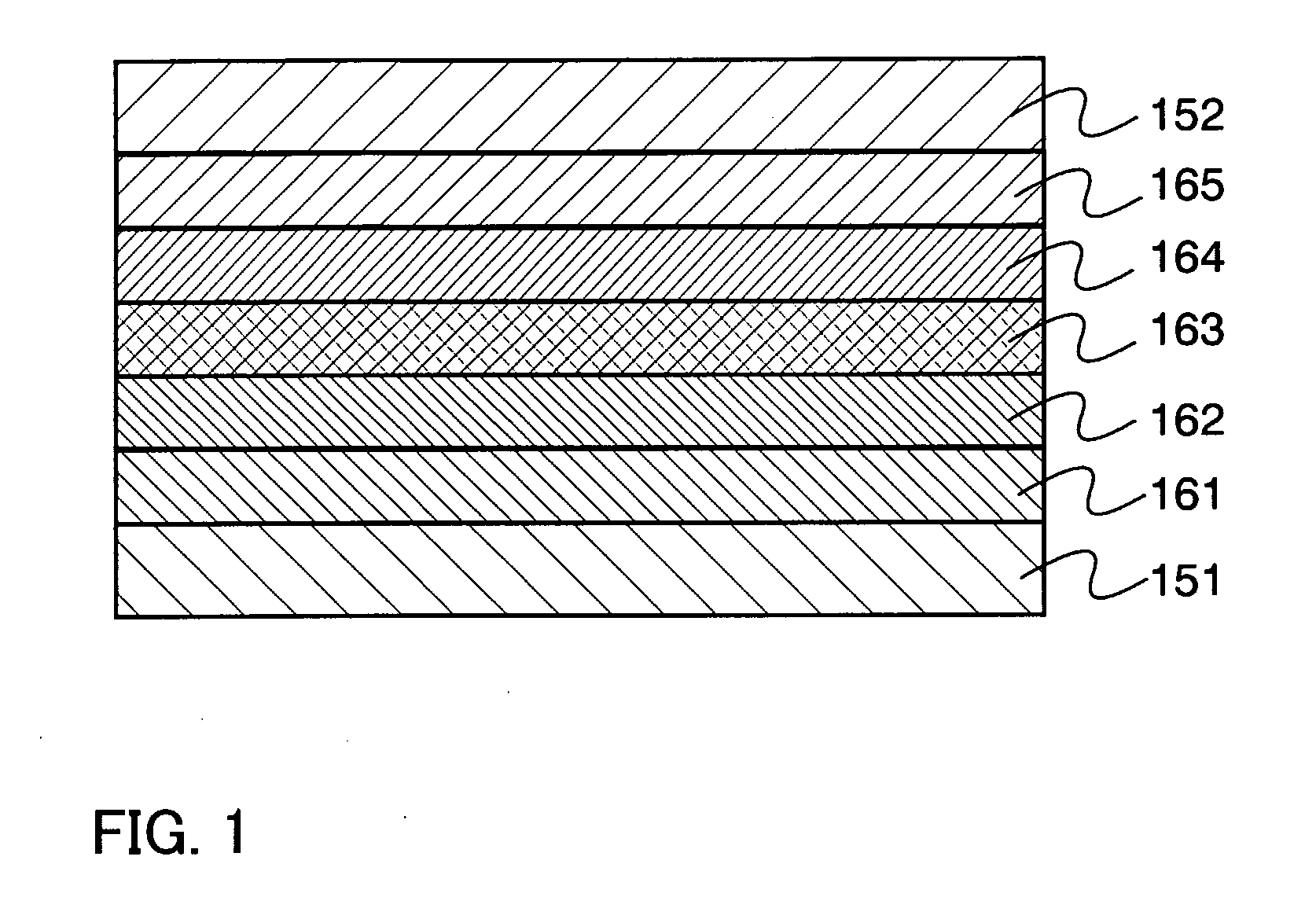

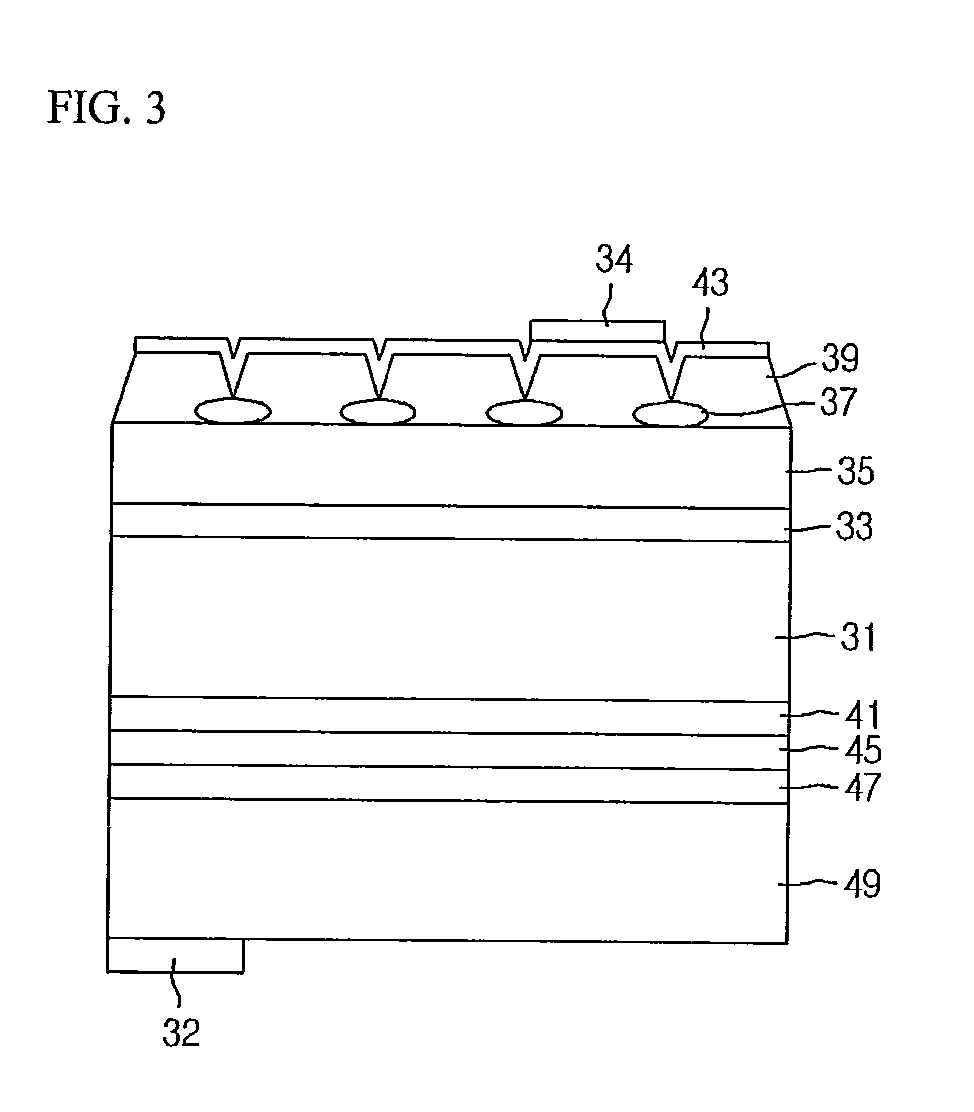

Semiconductor optoelectronic device and method of fabricating the same

ActiveUS20080095492A1Reducing internal lossImprove internal quantum efficiencyNanoopticsSemiconductor lasersQuantum wellOpto electronic

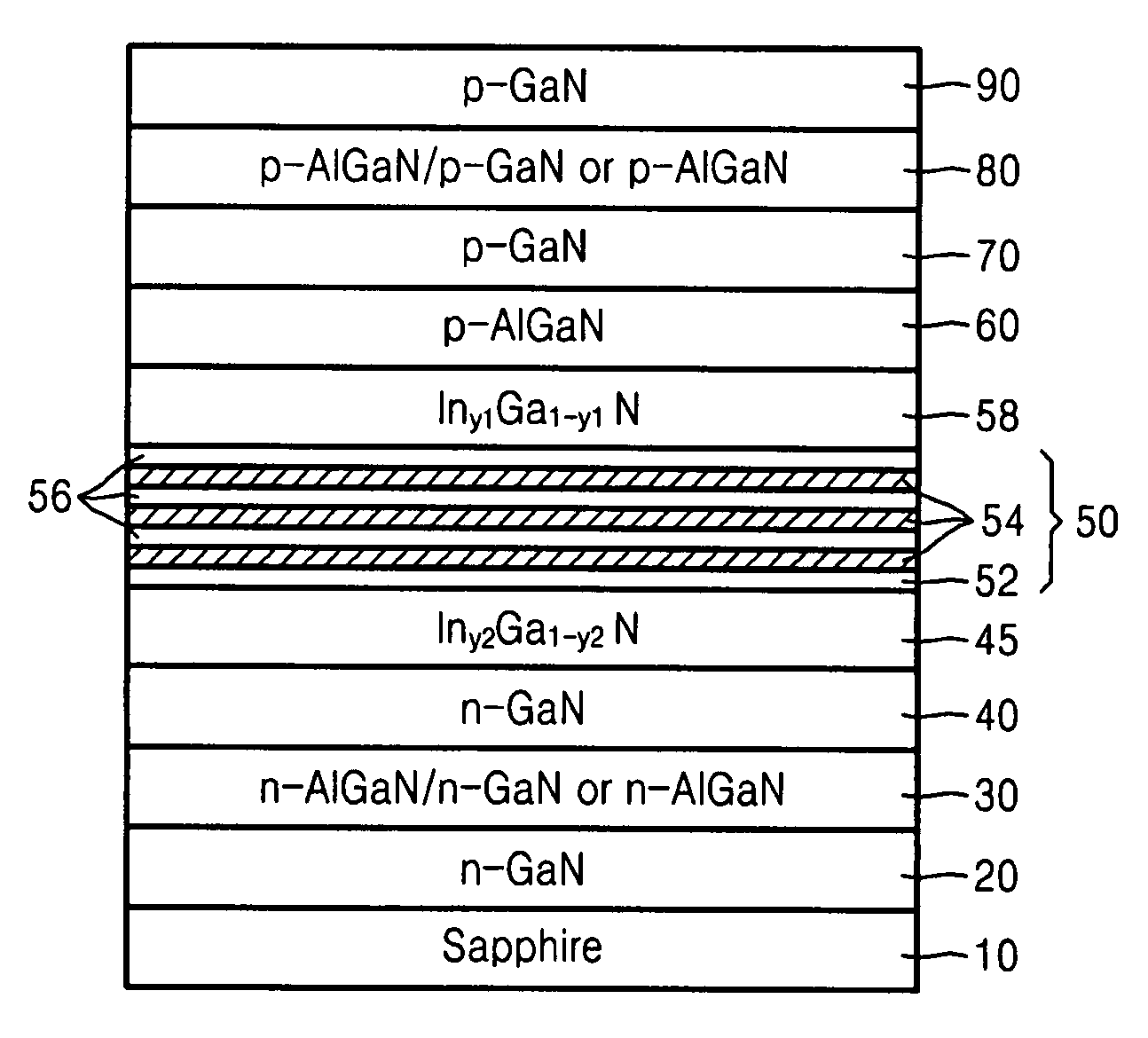

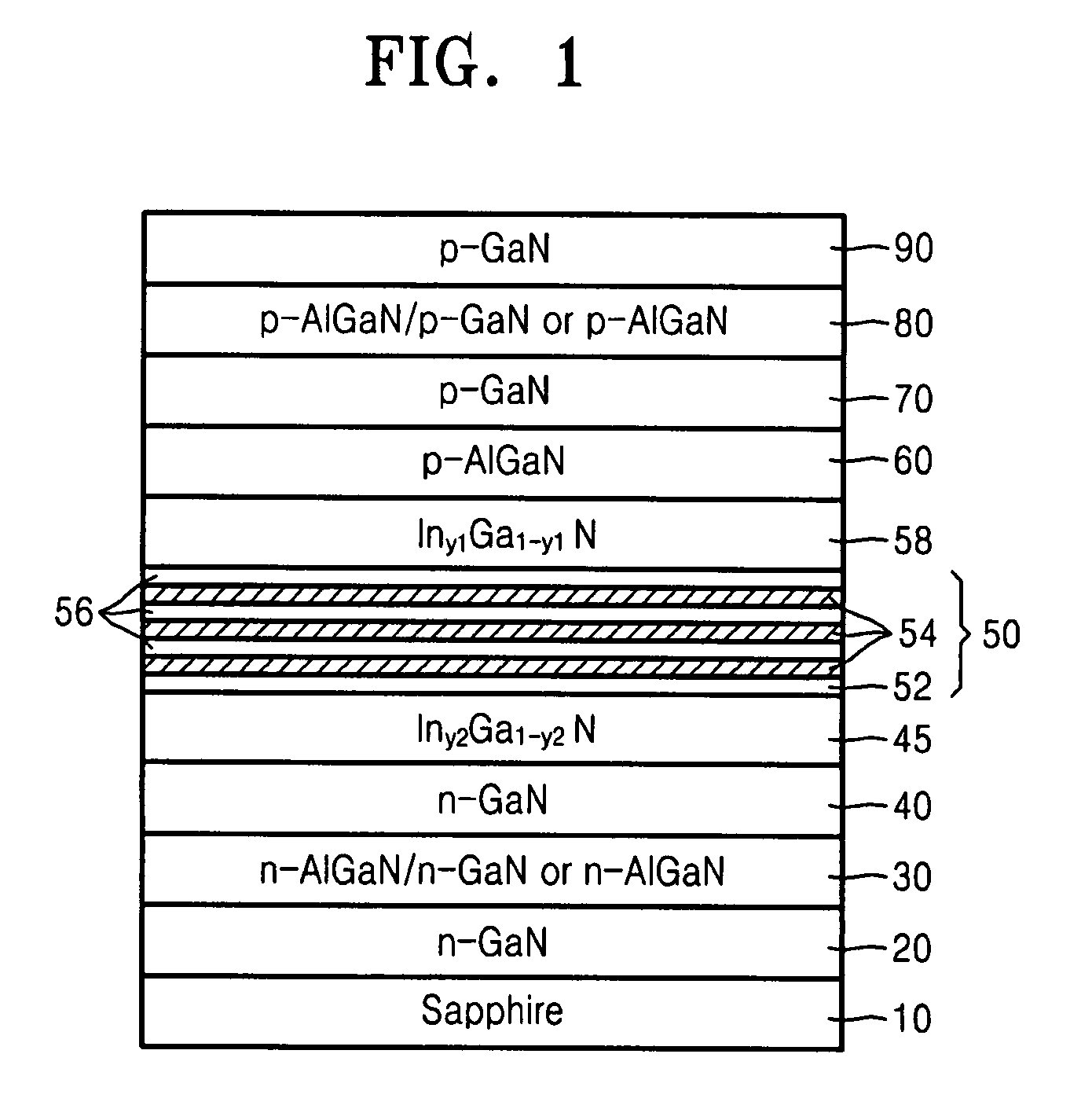

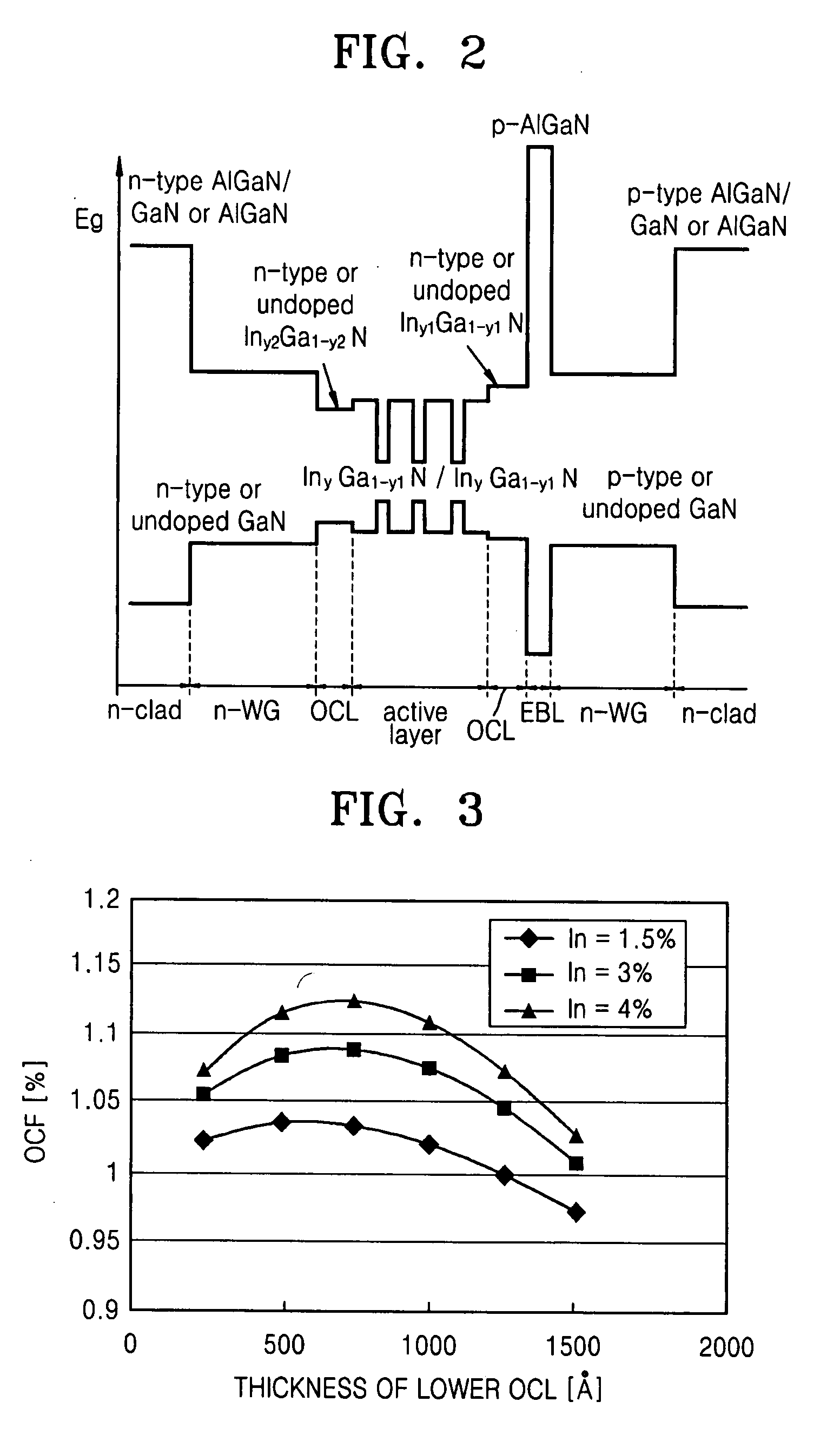

Provided is a semiconductor opto-electronic device that may comprise an active layer including a quantum well and a barrier layer on a substrate, upper and lower waveguide layers on and underneath the active layer, respectively, and upper and lower clad layers on and underneath the upper and lower waveguide layers, respectively. The semiconductor opto-electronic device may further comprise an upper optical confinement layer (OCL) between the active layer and the upper waveguide layer and having an energy gap smaller than the energy gap of the upper waveguide layer and equal to or larger than the energy gap of the barrier layer, and a lower OCL between the active layer and the lower waveguide layer and having an energy gap smaller than the energy gap of the lower waveguide layer and equal to or smaller than the energy gap of the barrier layer. Also provided is a method of fabricating the semiconductor opto-electronic device.

Owner:SAMSUNG ELECTRONICS CO LTD

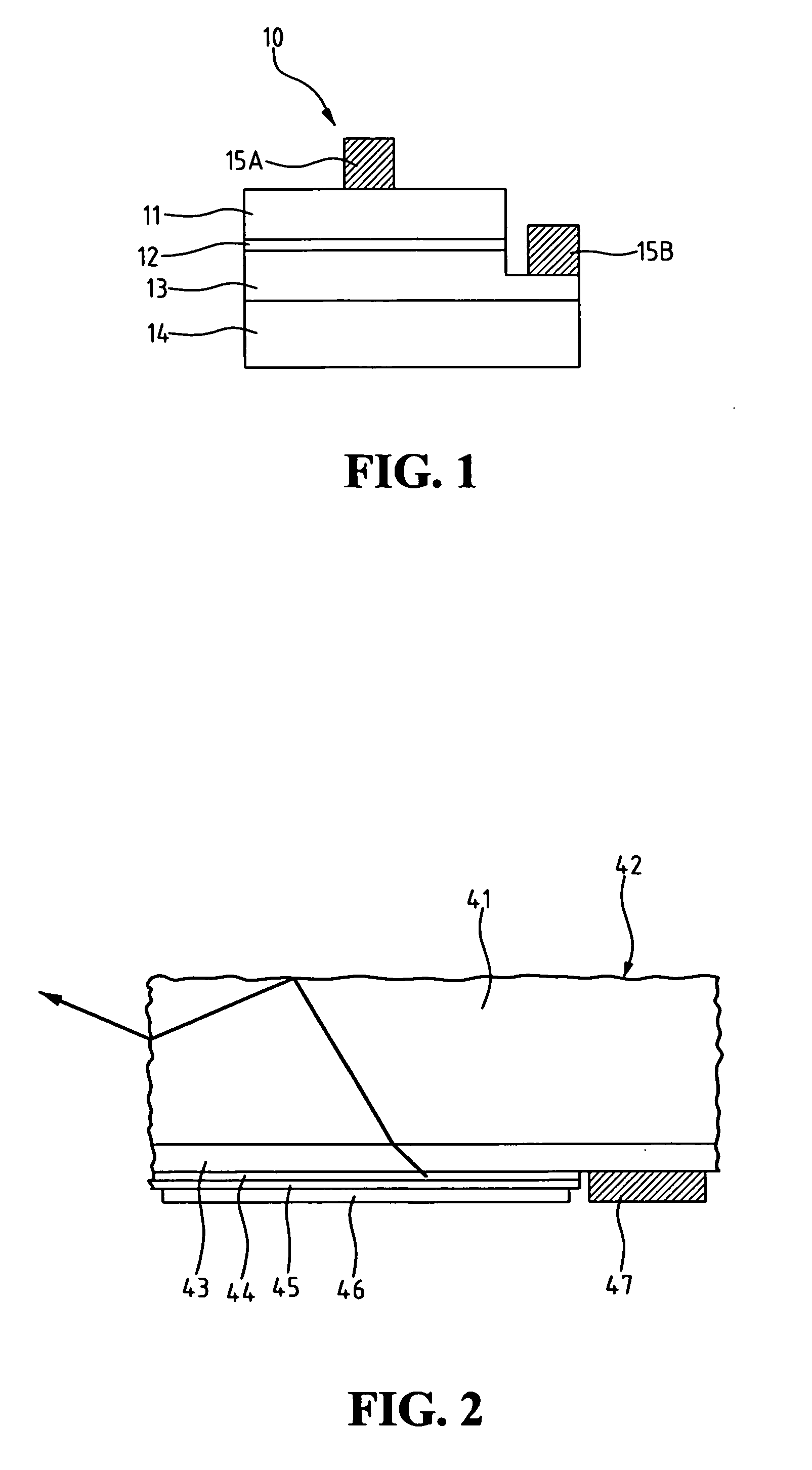

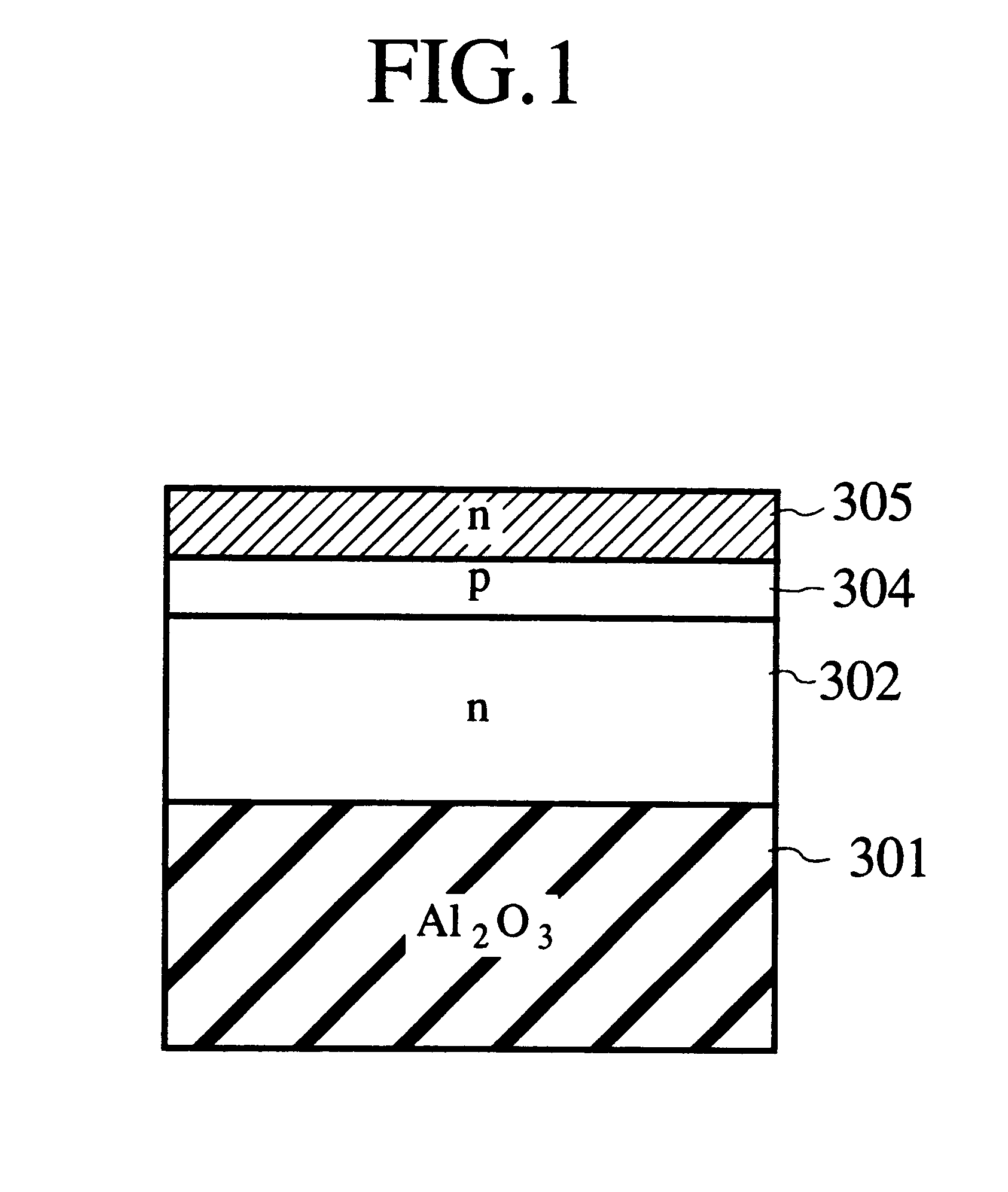

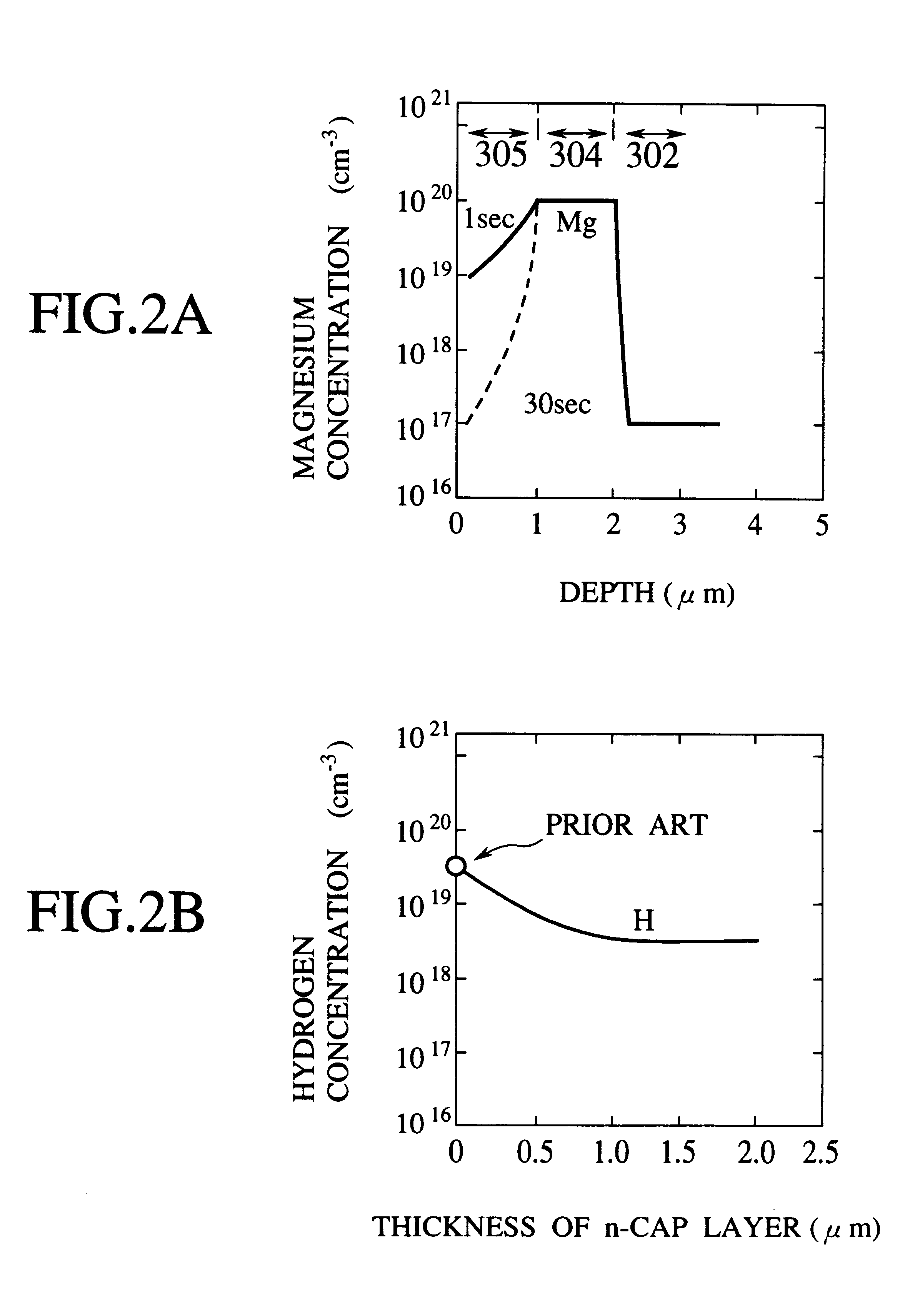

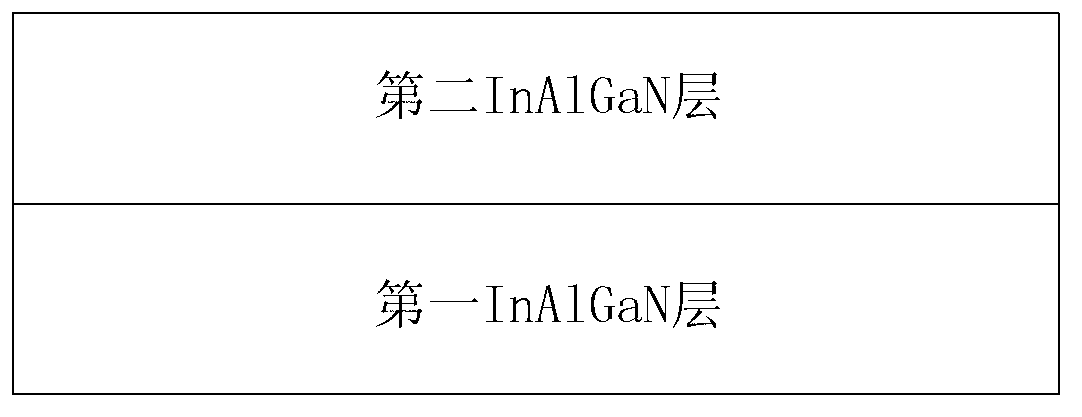

GaN based optoelectronic device and method for manufacturing the same

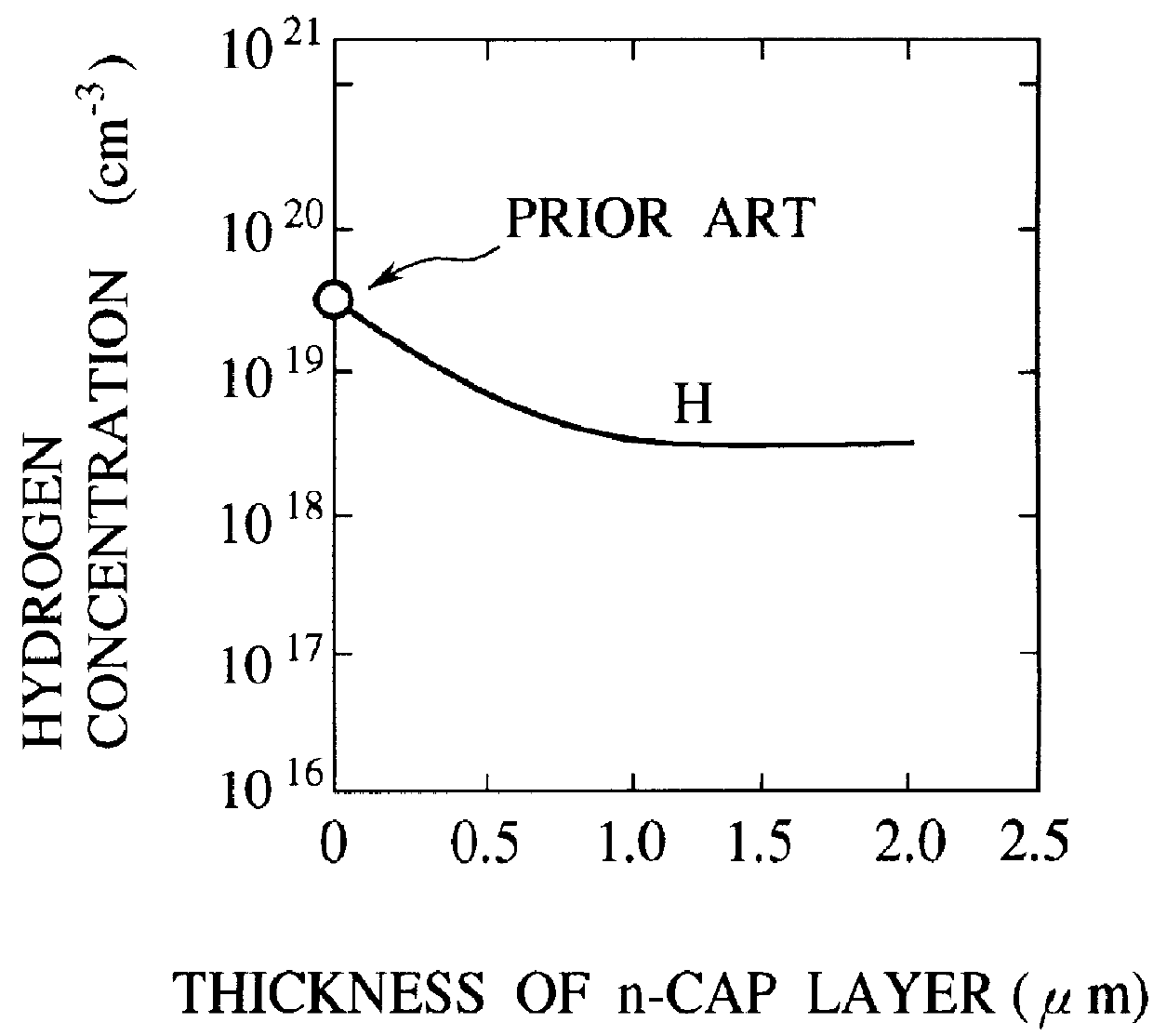

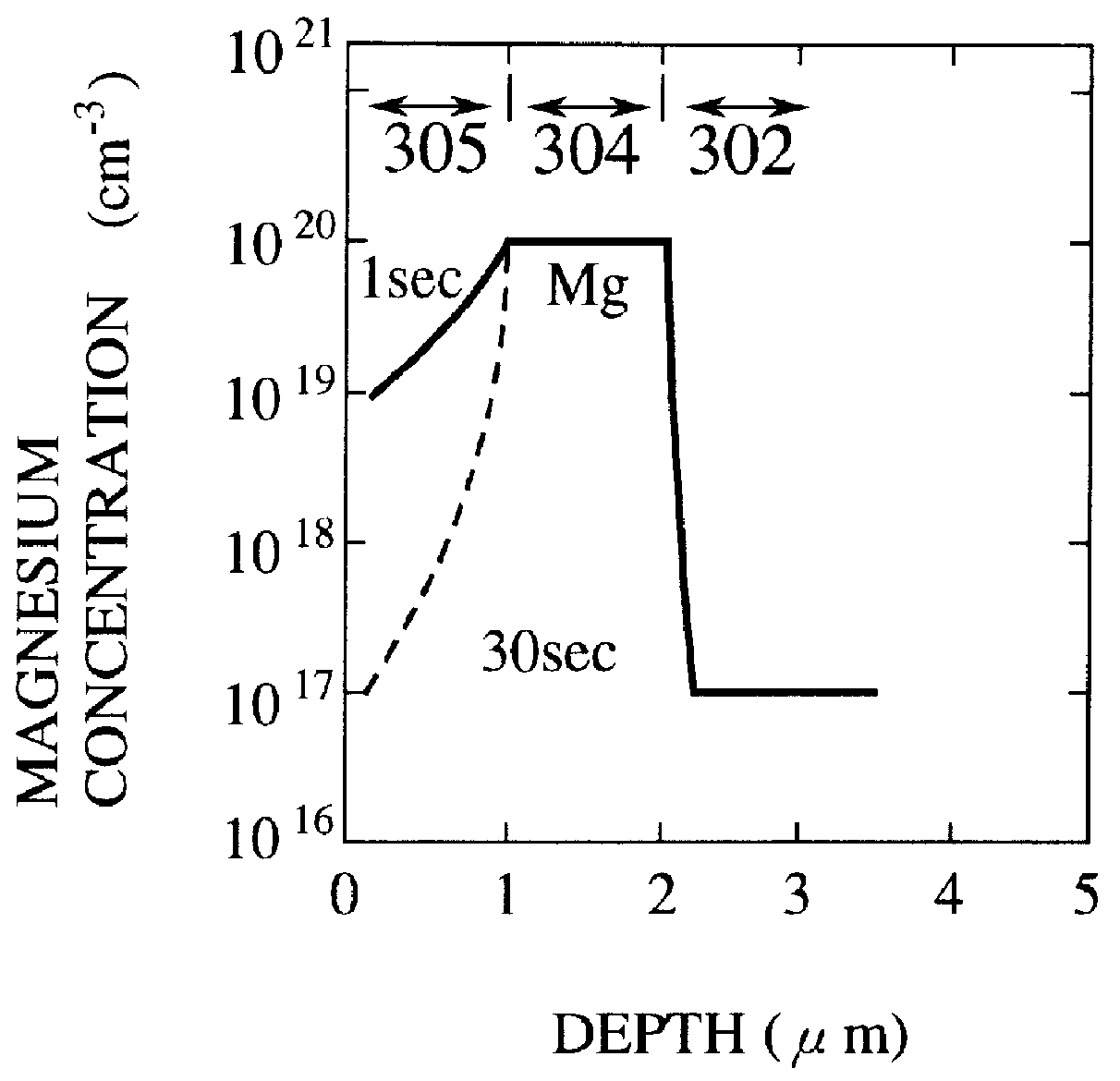

InactiveUS6020602AImprove extraction efficiencyImprove luminous performanceLaser detailsLaser active region structureCharge carrierAcceptor impurity

An n-cap layer is formed on a top surface of p-type clad layers, the p-type clad layer is a top layer of a stacked structure having a pn-junction for emitting carriers into light-emitting region of a GaN based light-emitting device, thus increasing the activation ratio of acceptor impurities in the p-type clad layers. The n-cap layer is used also as a current blocking layer, thereby constructing a current-blocked structure. The n-cap layer should preferably be made of InuAlvGa1-u-vN (0<u, v<1) deposited as thick as 1.0 micron or more. The present invention will easily provide a high luminous efficiency GaN based semiconductor light-emitting device without using any complicated processes such as electron-beam irradiation or thermal annealing.

Owner:KK TOSHIBA

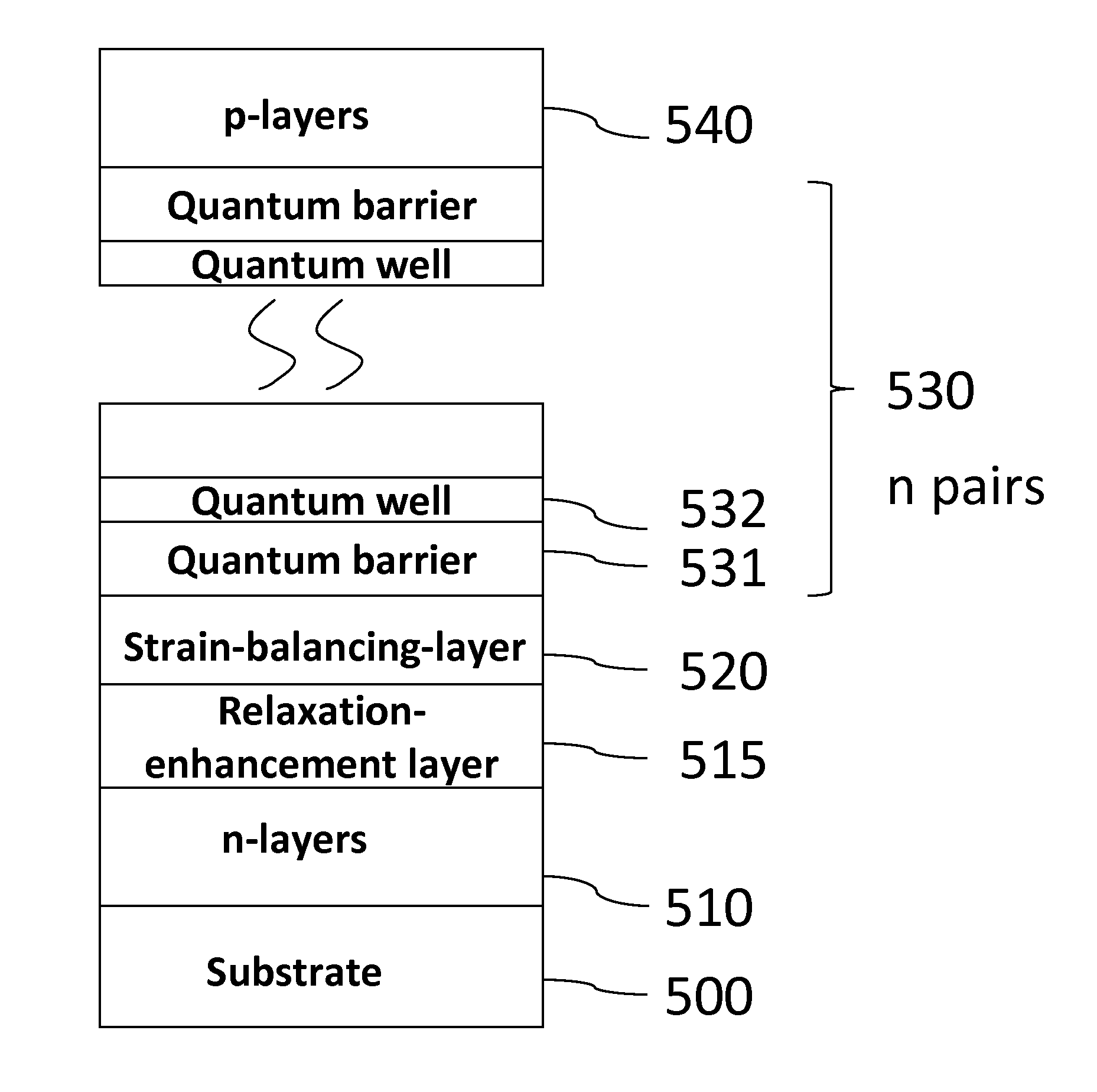

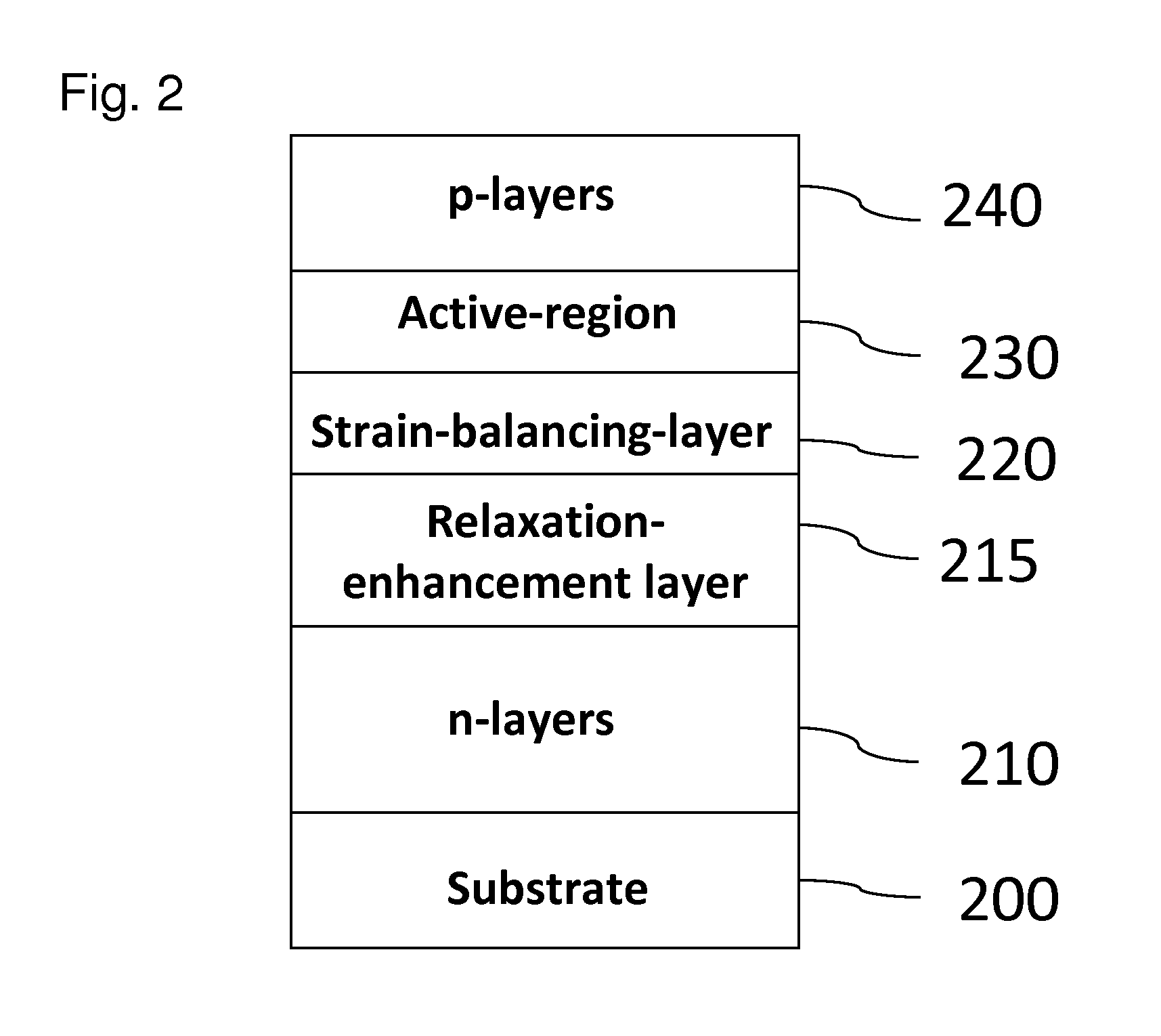

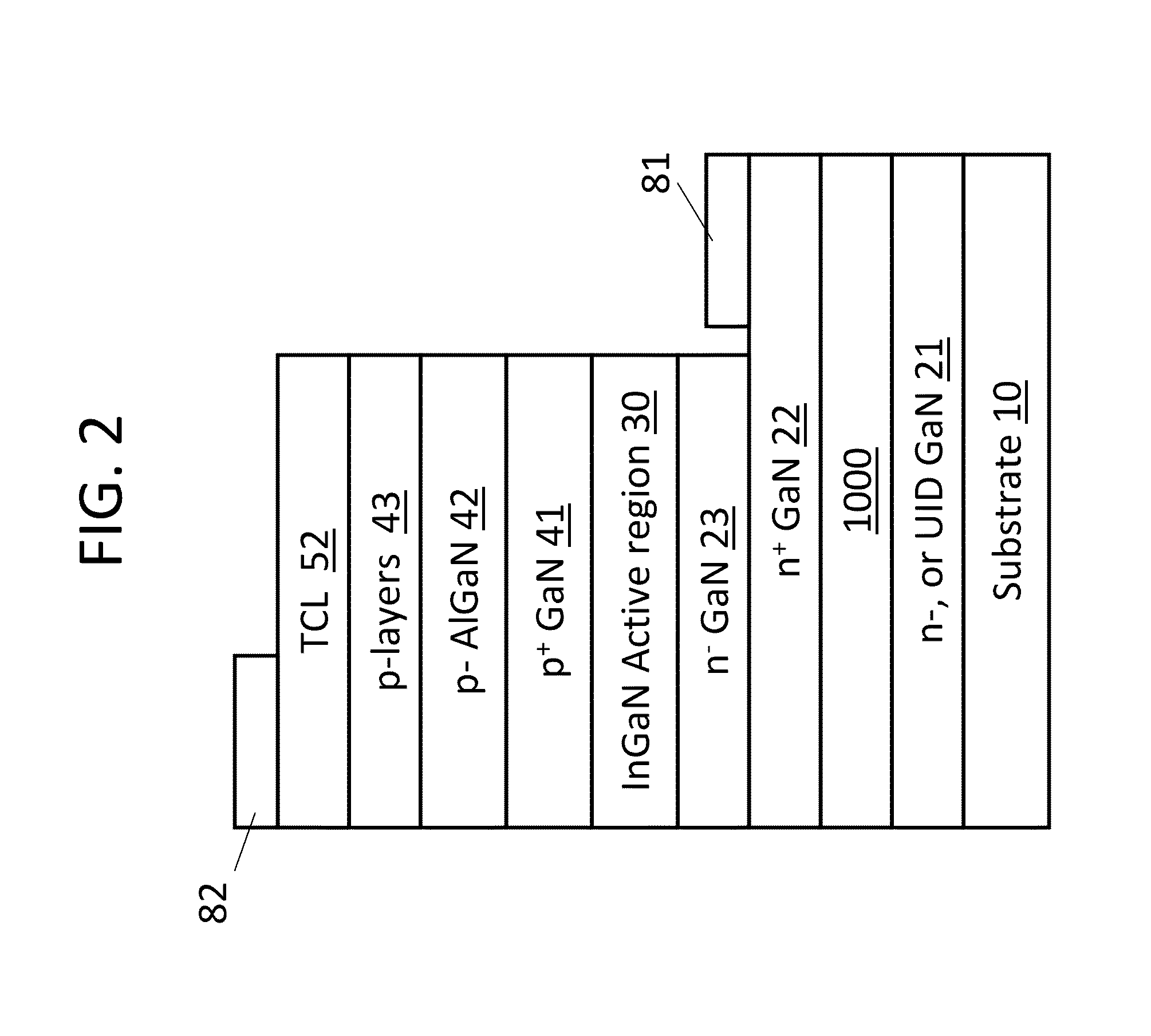

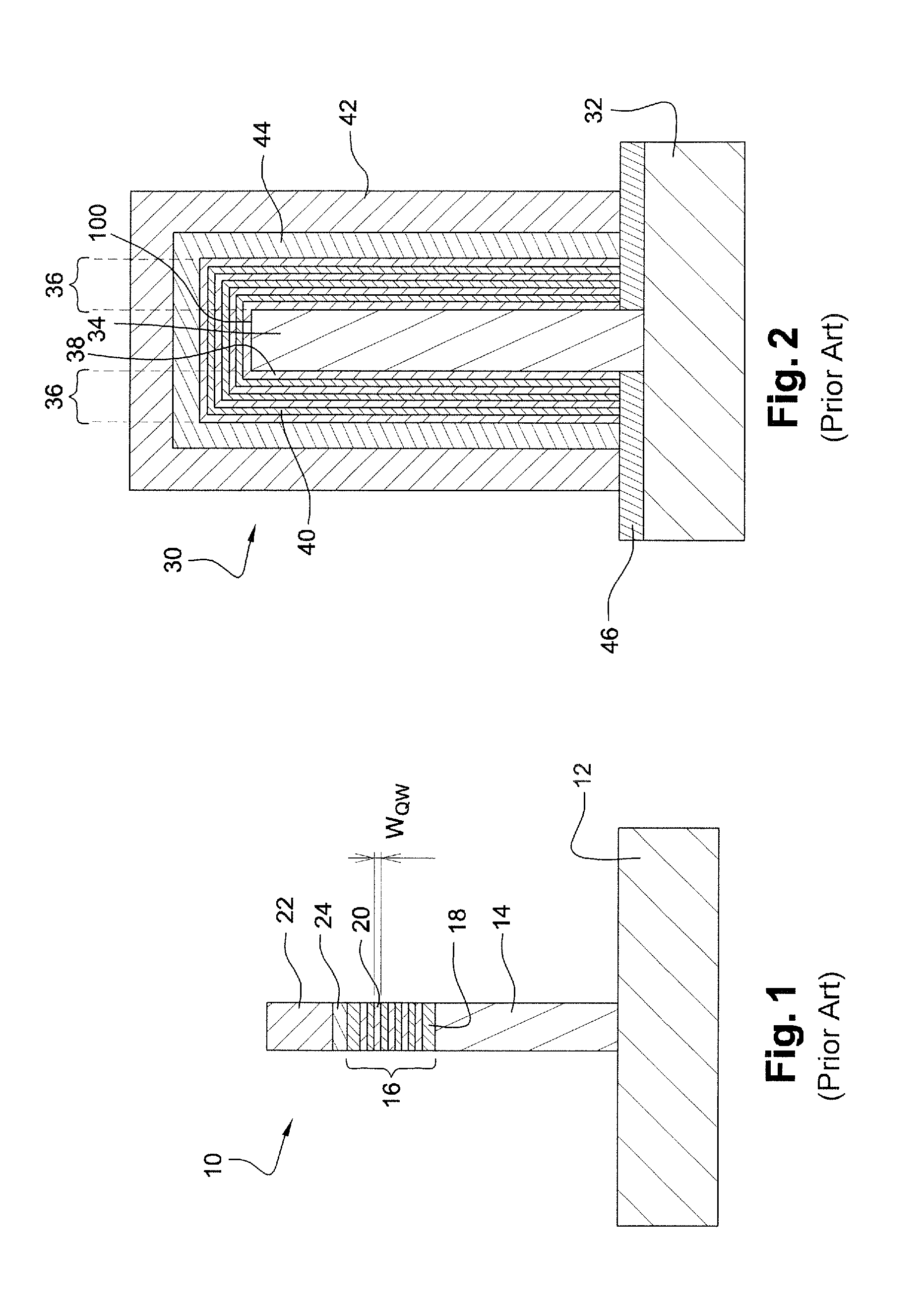

Strain balanced light emitting devices

InactiveUS20100187496A1Improve performanceIncrease flexibilitySemiconductor/solid-state device manufacturingSemiconductor devicesLattice constantLight emitting device

A strain balanced active-region design is disclosed for optoelectronic devices such as light-emitting diodes (LEDs) and laser diodes (LDs) for better device performance. Lying below the active-region, a lattice-constant tailored strain-balancing layer provides lattice template for the active-region, enabling balanced strain within the active-region for the purposes of 1) growing thick, multiple-layer active-region with reduced defects, or 2) engineering polarization fields within the active-region for enhanced performance. The strain-balancing layer in general enlarges active-region design and growth windows. In some embodiments of the present invention, the strain-balancing layer is made of quaternary InxAlyGa1-x-yN (0≦x≦1, 0≦y≦1, x+y≦1), whose lattice-constant is tailored to exert opposite strains in adjoining layers within the active-region. A relaxation-enhancement layer can be provided beneath the strain-balancing layer for enhancing the relaxation of the strain-balancing layer.

Owner:ZHEJIANG INVENLUX TECH

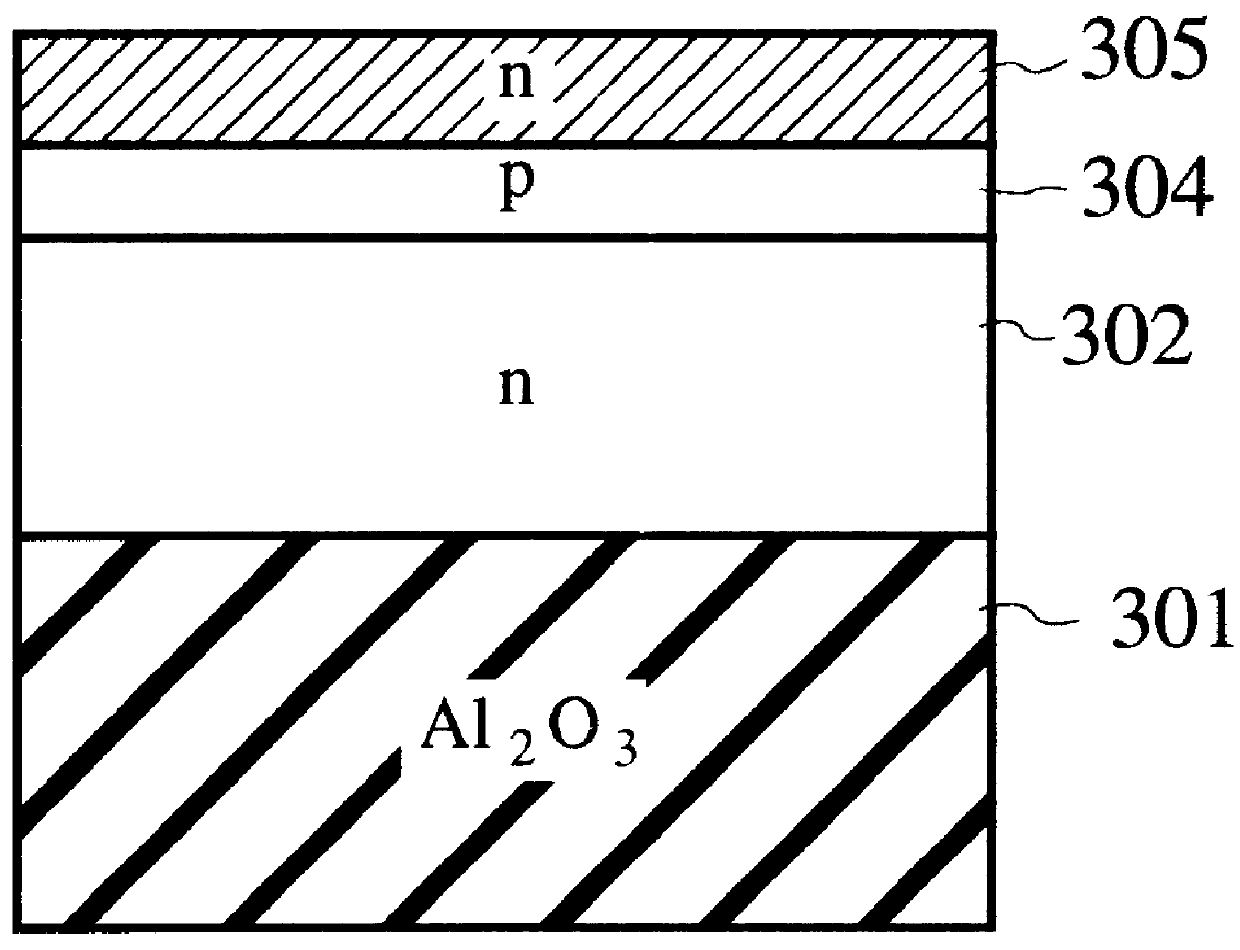

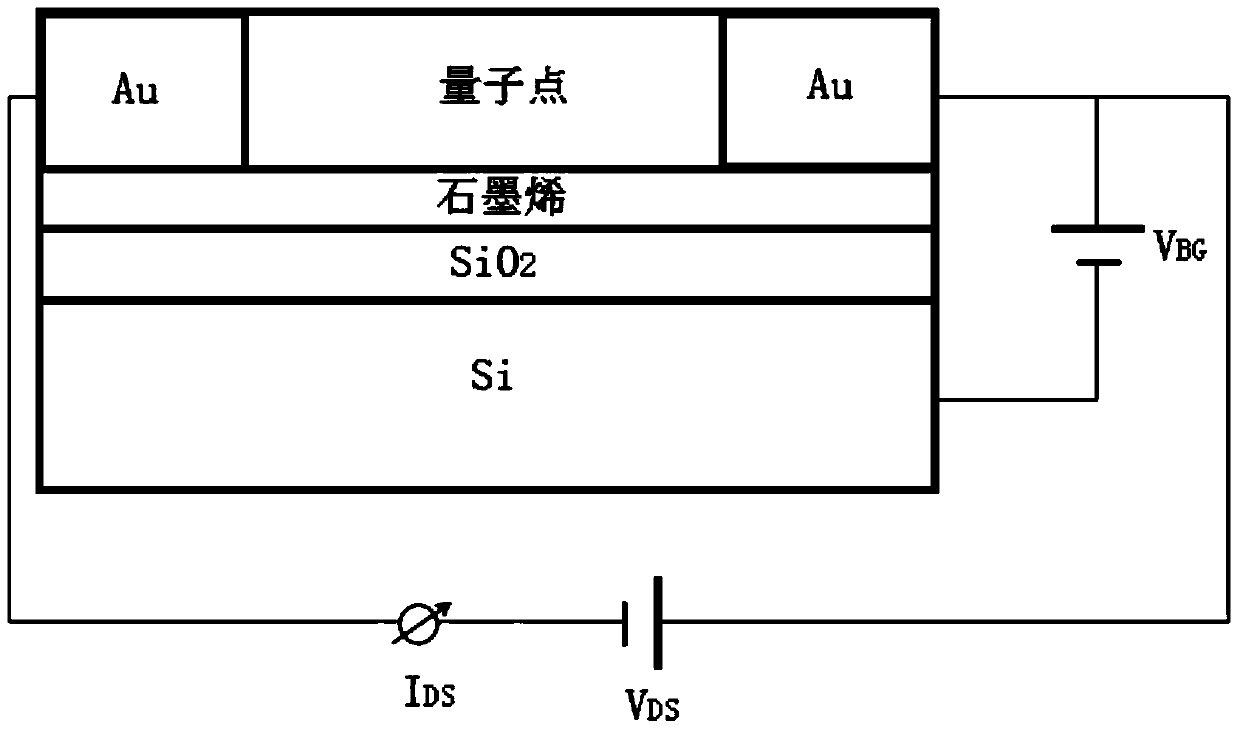

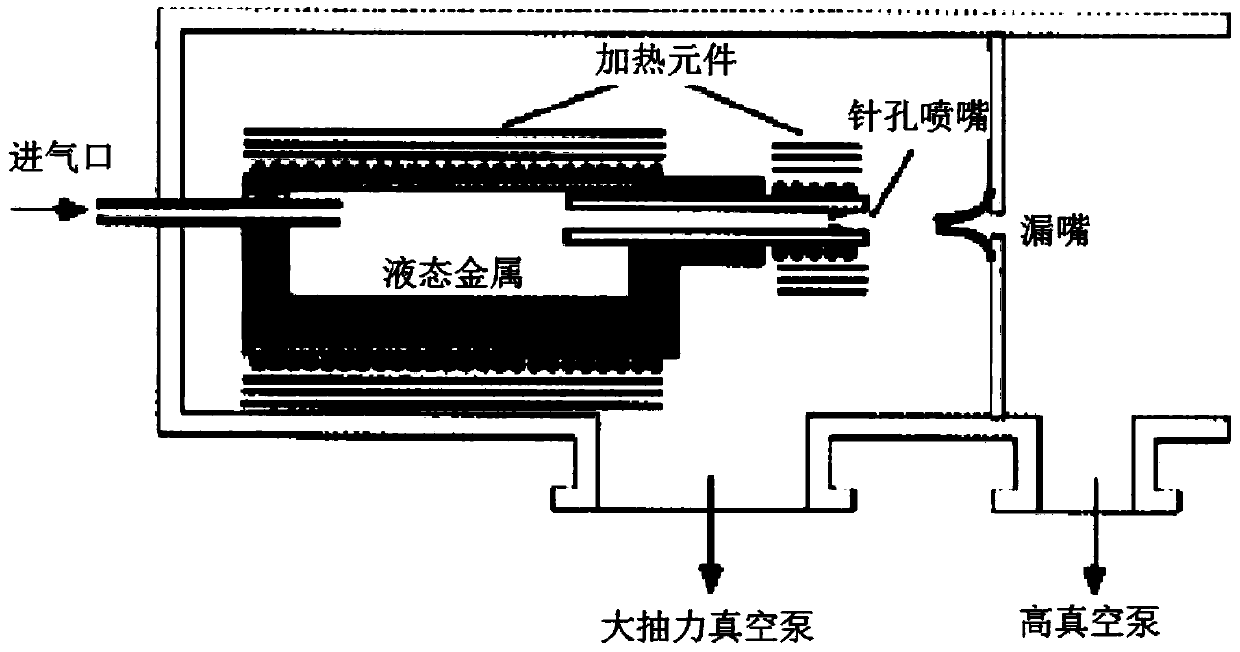

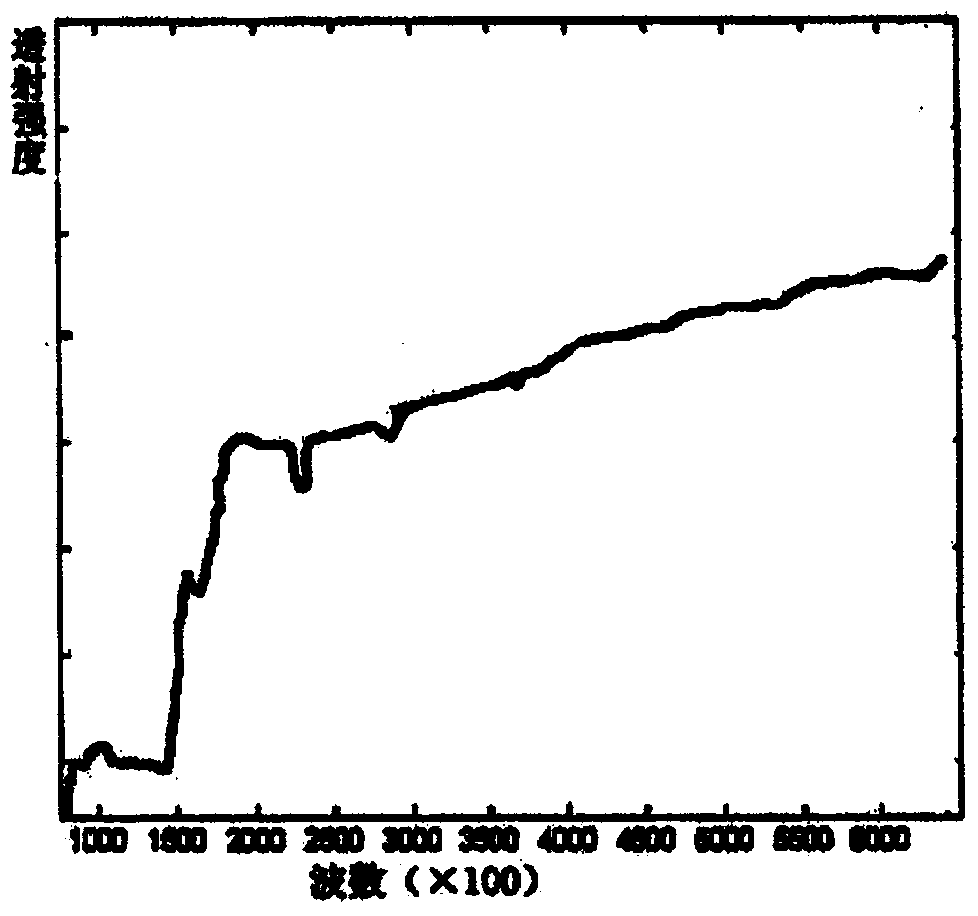

Graphene medium-far infrared detector and preparing method thereof

InactiveCN103633183AHigh infrared light absorptionReduce gainFinal product manufactureSemiconductor devicesOxide semiconductorCMOS

The invention discloses a graphene medium-far infrared detector and a preparing method thereof. The infrared detector comprises a layer of graphene film of which the basic unit is a graphene infrared photoelectric transistor using a colloid quantum dot layer as an optical control top gate. The graphene medium-far infrared probe overcomes the problems of lower absorption rate of graphene to light, and the electricity adjustability of graphene channels is kept, so the graphene medium-far infrared detector can be both optically and electrically bias-controlled. The transistor has ultrahigh infrared absorption rate, inner quantum efficiency, gain and very low noise level and different colloid quantum dot layer materials can be selected according to the difference of detected infrared wavelength ranges. The graphene medium-far infrared detector is easily compatible with the existing silica-based CMOS (complementary metal-oxide-semiconductor transistor) integrated circuit technology, and can realize the large-scale sensor array production with low cost. The successful preparation of the graphene medium-far infrared detector lays a basis for the research on high-performance graphene-based infrared focal plane array sensors.

Owner:XIDIAN UNIV

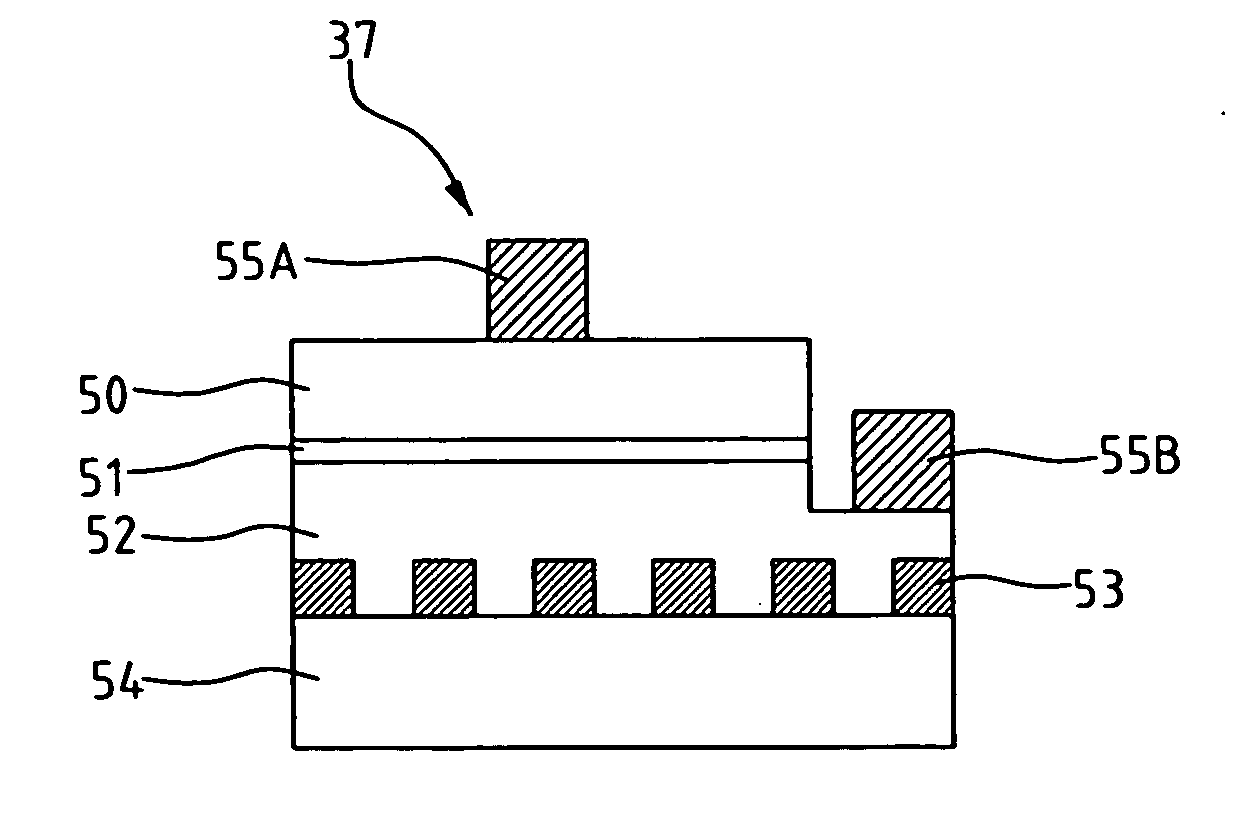

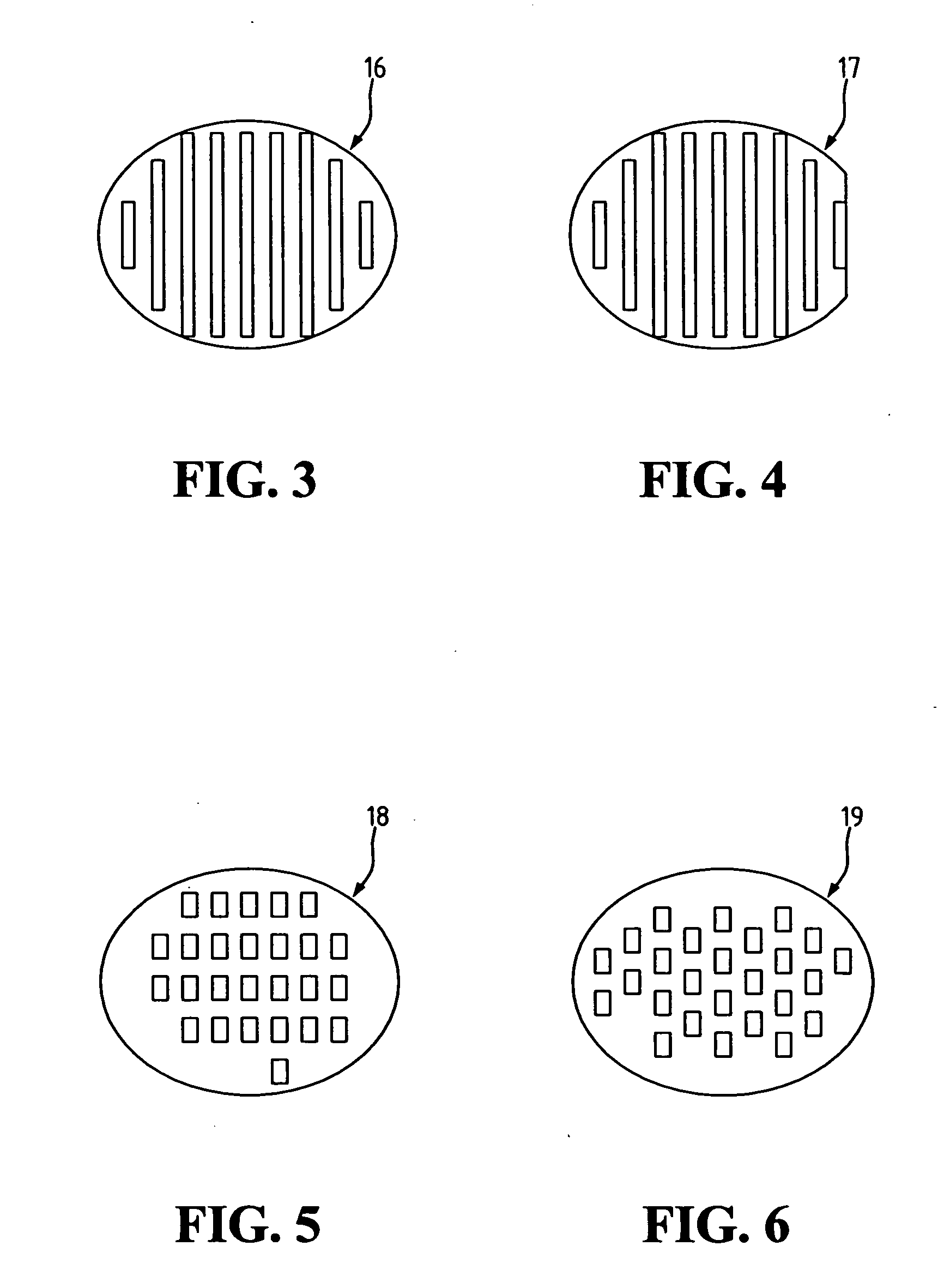

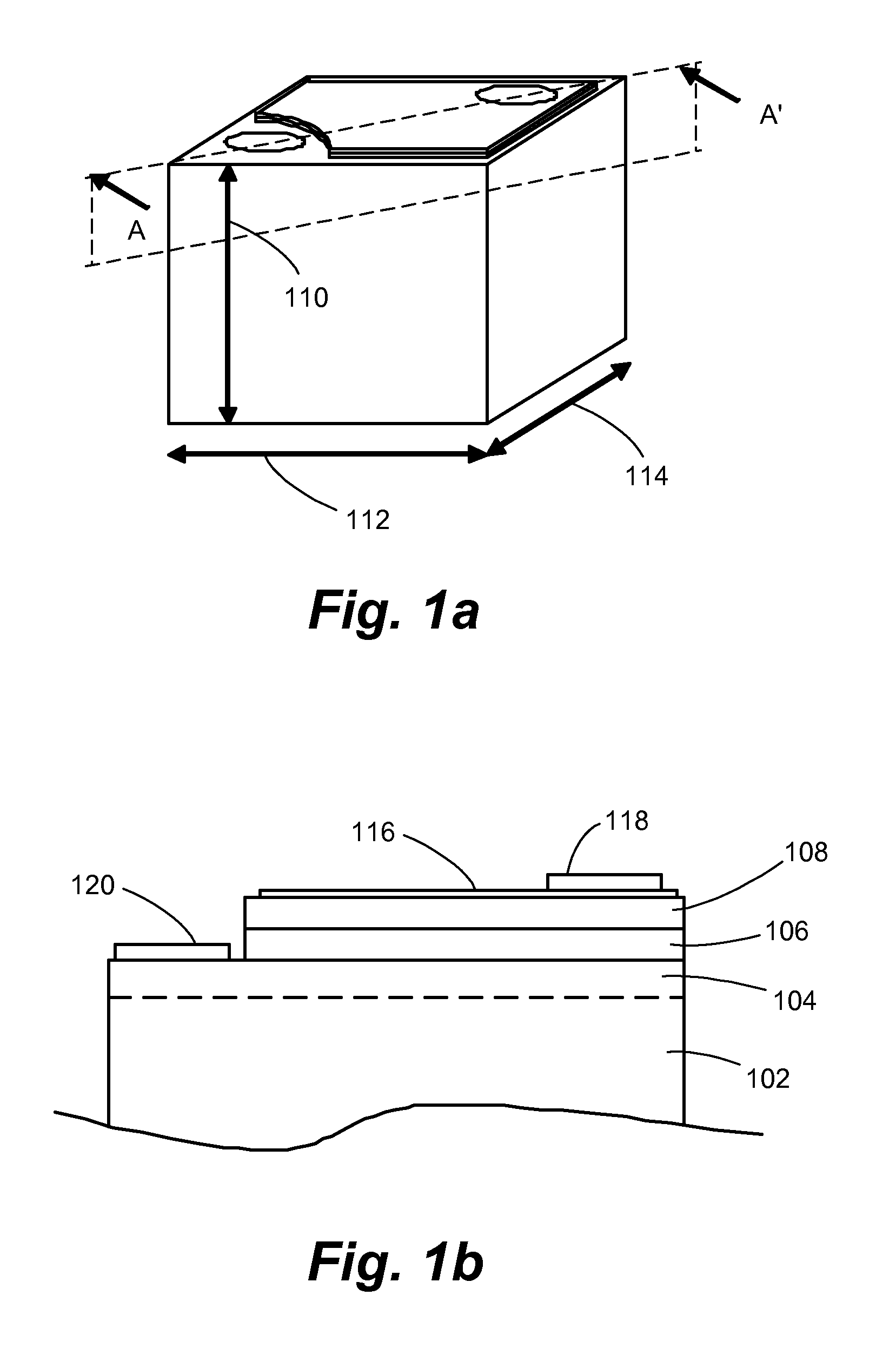

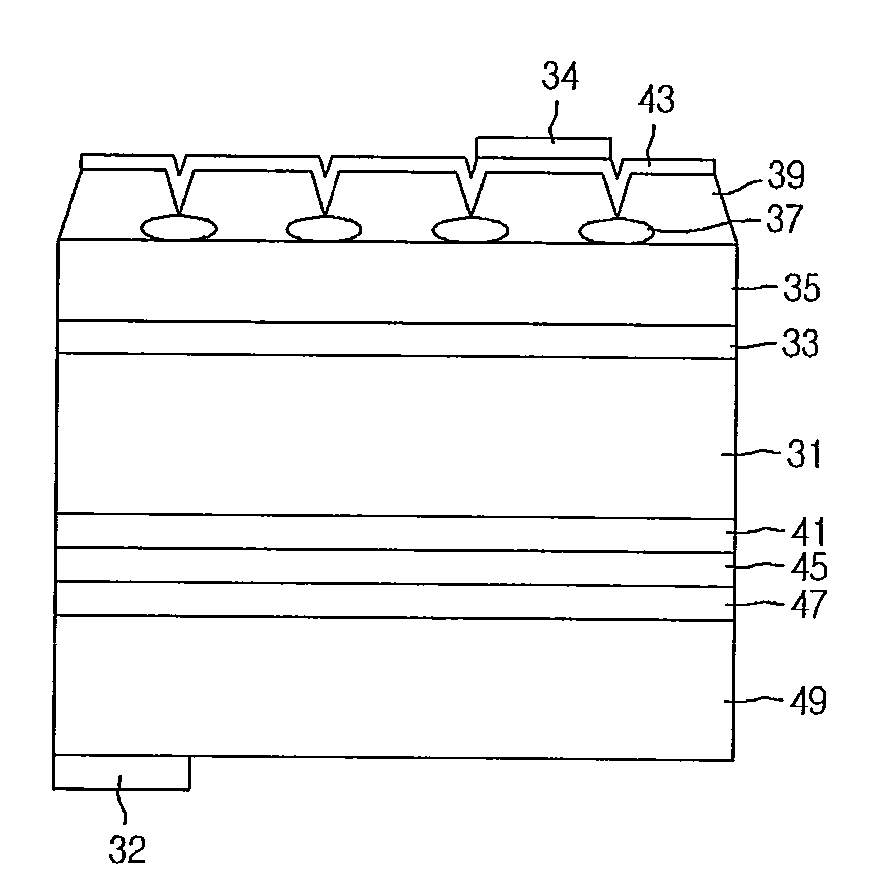

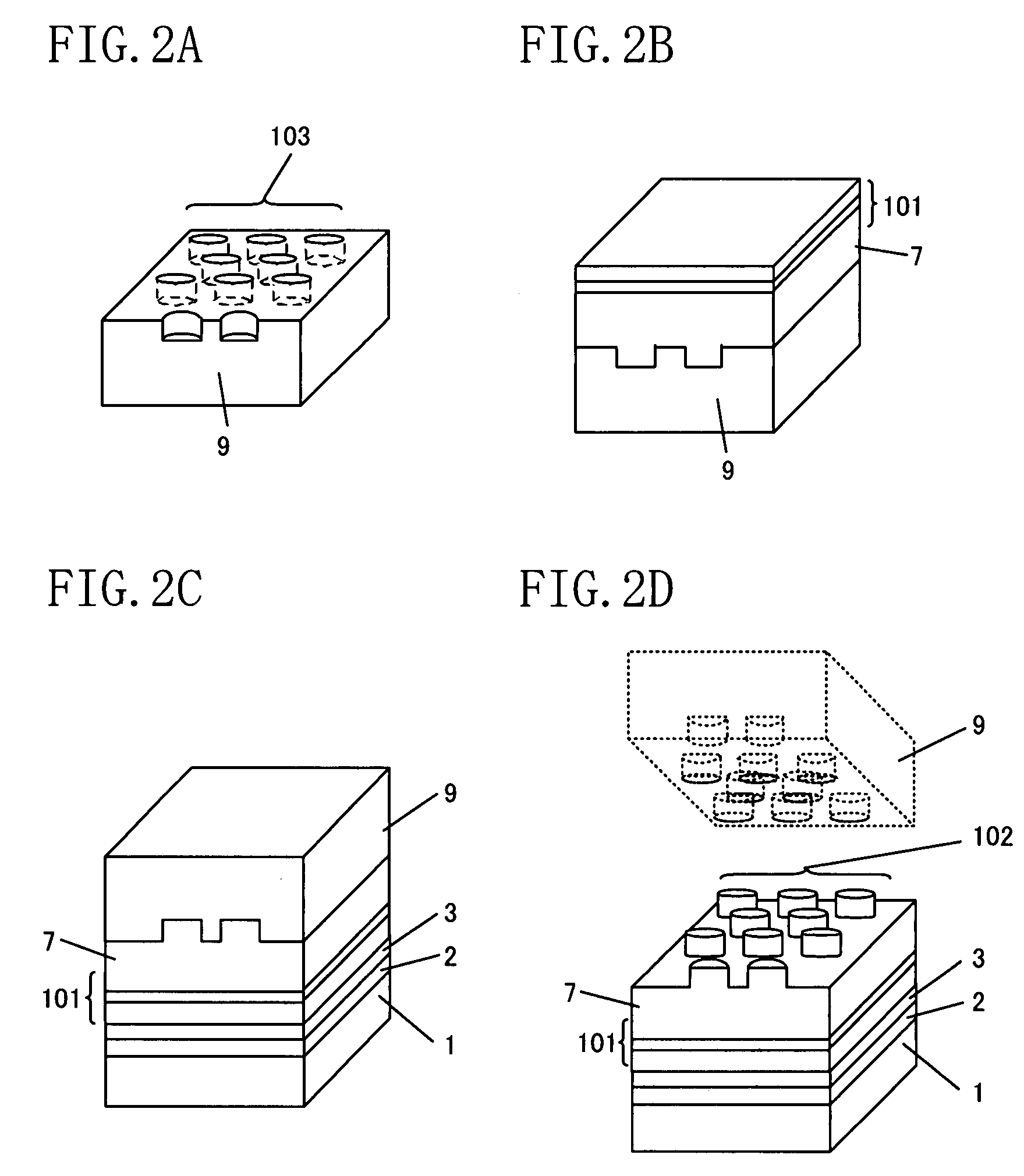

Light emitting diode structure having photonic crystals

ActiveUS7173289B1Improve epitaxy qualitySurface lightSolid-state devicesSemiconductor devicesPhotonic crystalPhotonics

A light emitting diode (LED) structure includes a substrate with a surface and cylindrical photonic crystals, a first type doping semiconductor layer, a first electrode, a light emitting layer, a second type doping semiconductor layer and a second electrode. The first type doping semiconductor layer is formed on the substrate to cover the photonic crystals. The light emitting layer, the second type doping semiconductor layer and the second electrode are sequentially formed on a portion of the first type doping semiconductor layer. The first electrode is formed on the other portion of the first type doping semiconductor layer without being covered by the light emitting layer. Because the substrate with photonic crystals can improve the epitaxial quality of the first type doping semiconductor layer and increase the energy of the light forwardly emitting out of the LED, the light emitting efficiency of the LED is effectively enhanced.

Owner:FORMOSA EPITAXY INCORPORATION +1

High performance nitride-based light-emitting diodes

InactiveUS20050145872A1Improve external quantum efficiencyReduce defectsSemiconductor devicesChemical solutionRefractive index

A nitride-based light-emitting diode is provided, including a substrate having a light extraction layer grown on the substrate, and a nitride semiconductor epitaxy layer grown on the light extraction layer. The external quantum efficiency is improved by changing the traveling path of the emitted light and by matching the refraction index between the light extraction layer and the substrate. Also, a high power nitride-based light-emitting diode having a sacrificial layer is disclosed. A sacrificial layer is used for growing a light-emitting structure, and a binding layer made of two or more metals or alloys is used to bind the grown light-emitting structure and a substrate with high thermoconductivity. The sacrificial layer is later entirely etched away with a chemical solution used in a chemical etching process, and the nitrogen epitaxy structure is placed on the substrate with high thermoconductivity so that the diode can operate at high electrical current to improve external quantum efficiency.

Owner:FORMOSA EPITAXY INCORPORATION

Organometallic Complex, and Light-Emitting Element, Light-Emitting Device and Electronic- Device Using the Organometallic Complex

InactiveUS20090015143A1Improve recombination efficiencyEffective lightingGroup 5/15 element organic compoundsSolid-state devicesHydrogenHalogen

It is an object of the present invention to provide an organometallic complex which can increase recombination efficiency of electrons and holes. One aspect of the present invention is an organometallic complex having a structure represented by a general formula (1), wherein each of R1 and R2 is any of a halogen group, a —CF3 group, a cyano group, and an alkoxycarbonyl group, each of R3 and R4 is any of hydrogen and an alkyl group having 1 to 4 carbon atoms, and M is an element that belongs to Group 9 or 10 of the periodic table.

Owner:SEMICON ENERGY LAB CO LTD

Epitaxial structure and growing method for improving gallium nitride (GaN) based light-emitting diode (LED) lighting efficiency

InactiveCN103066174AImprove crystal qualityStress reliefSemiconductor devicesPotential wellEffect light

The invention discloses an epitaxial structure and a growing method for improving gallium nitride (GaN) based light-emitting diode (LED) lighting efficiency. The order of the epitaxial structure from bottom to up is that a substrate, a low-temperature GaN buffer layer, a GaN non-doping layer, a N-shaped GaN layer, a multiple quantum well (MQW) structure, a multiple quantum well active layer, a low-temperature P-shaped GaN layer, a P-shaped aluminum (AL) GaN layer, a high-temperature P-shaped GaN layer and a P-shaped contact layer, wherein the order of the multiple quantum well active layer from bottom to up comprises a InyGa1-yN potential well layer, a InN layer and a barrier layer in sequence. The growing method of the multiple quantum well active layer structure is that by inserting the InN layer and a low-temperature annealing step in the growing process of a InyGa1 potential well layer and a GaN barrier layer, so that the composition of In quantum dot in the barrier layer is advanced and crystalline quality of the quantum well is improved, therefore, gallium nitride based LED lighting efficiency is improved.

Owner:合肥彩虹蓝光科技有限公司

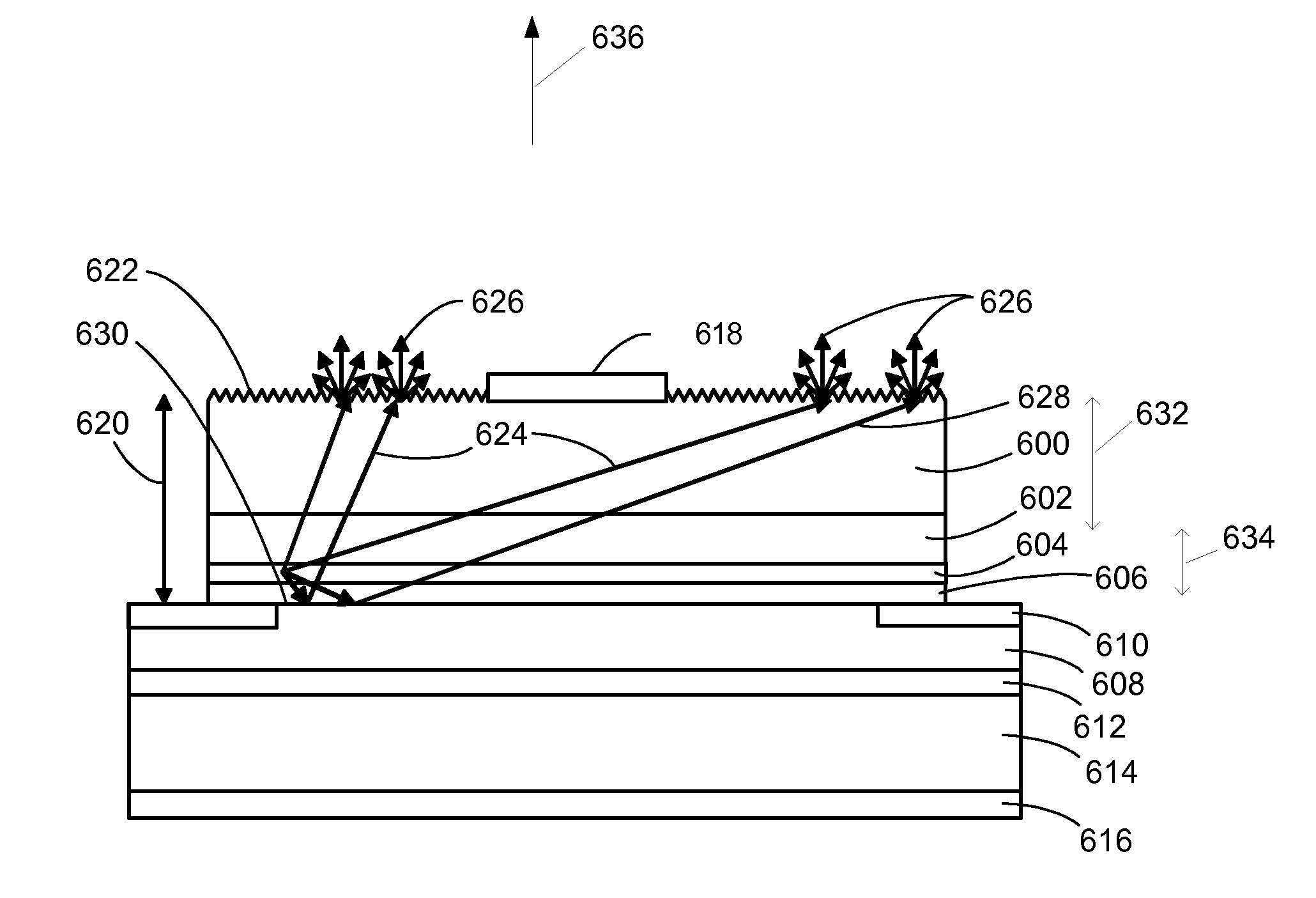

Light output enhanced gallium nitride based thin light emitting diode

InactiveUS20090141502A1Internal reinforcementReduce reabsorptionSemiconductor/solid-state device manufacturingGlobesMicrometerAlloy

A gallium nitride (GaN) based light emitting device, wherein the device comprises a first surface and a second surface, and the first surface and second surface are separated by a thickness of less than 100 micrometers, and preferably less than 20 micrometers. The first surface may be roughened or textured. A silver or silver alloy may be deposited on the second surface. The second surface of the device may be bonded to a permanent substrate.

Owner:RGT UNIV OF CALIFORNIA

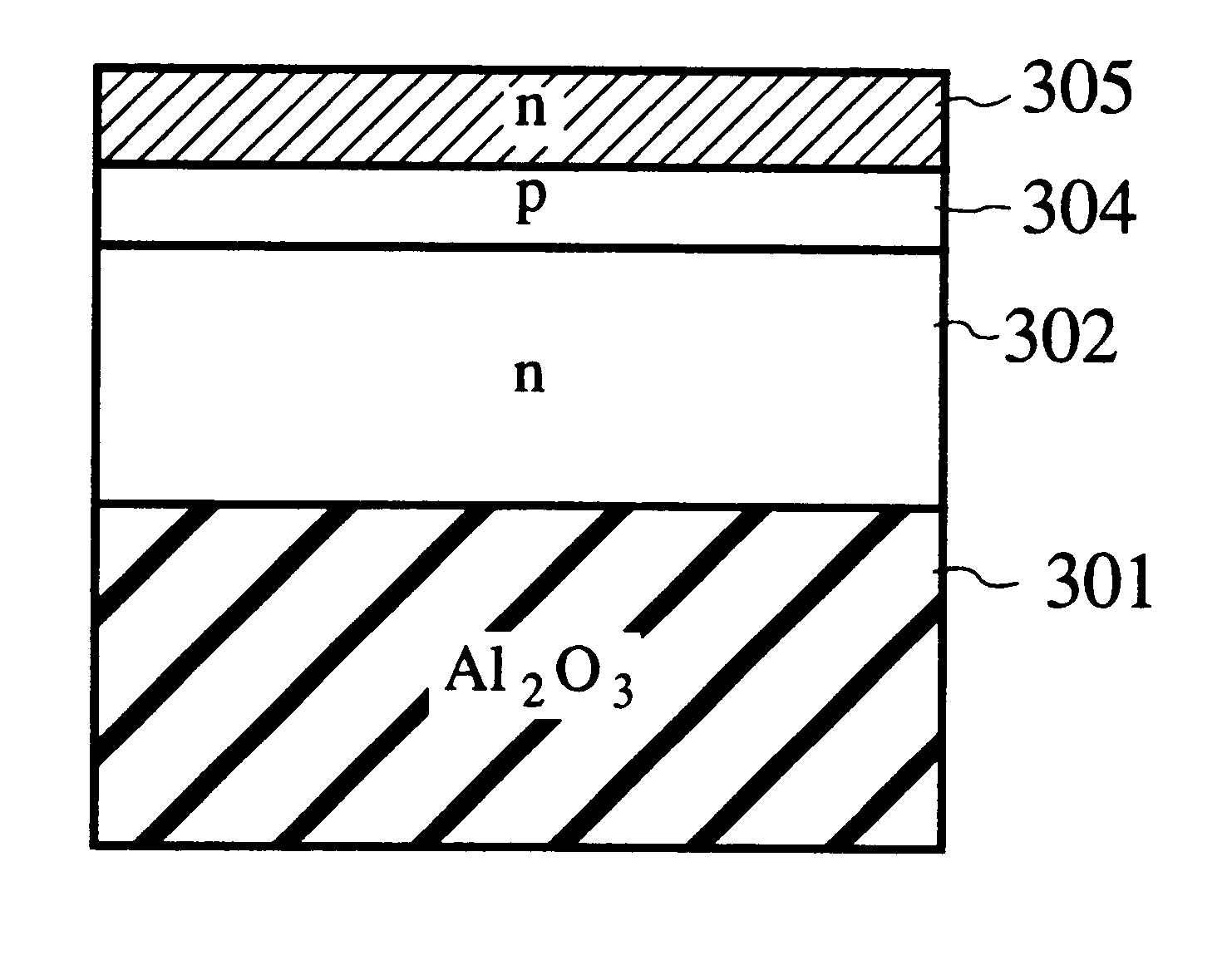

GaN based optoelectronic device and method for manufacturing the same

InactiveUS6221684B1Improve extraction efficiencyImprove luminous performanceLaser active region structureSemiconductor/solid-state device manufacturingCharge carrierAcceptor impurity

An n-cap layer is formed on a top surface of p-type clad layers, the p-type clad layer is a top layer of a stacked structure having a pn-junction for emitting carriers into light-emitting region of a GaN based light-emitting device, thus increasing the activation ratio of acceptor impurities in the p-type clad layers. The n-cap layer is used also as a current blocking layer, thereby constructing a current-blocked structure. The n-cap layer should preferably be made of InuAlvGa1-u-vN (0<u, v<1) deposited as thick as 1.0 micron or more. The present invention will easily provide a high luminous efficiency GaN based semiconductor light-emitting device without using any complicated processes such as electron-beam irradiation or thermal annealing.

Owner:KK TOSHIBA

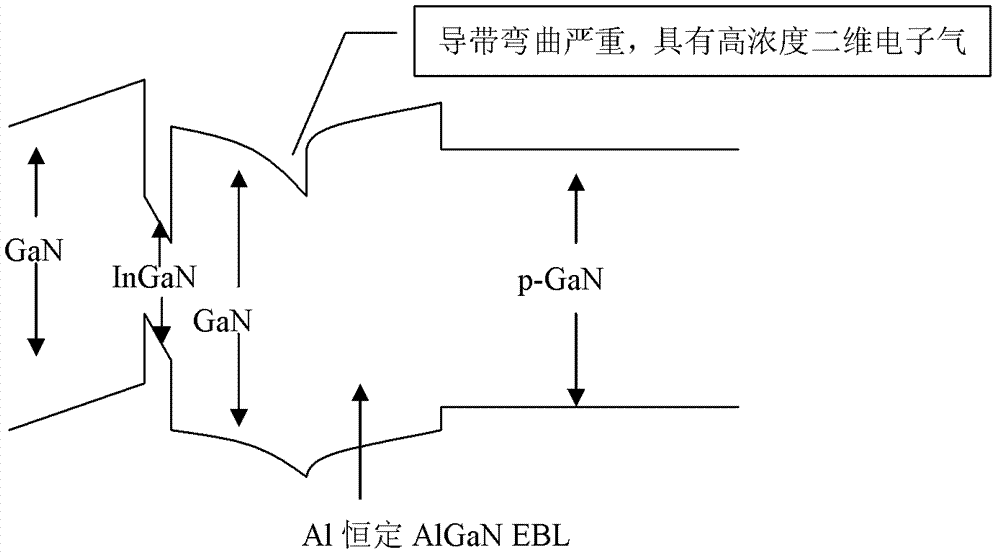

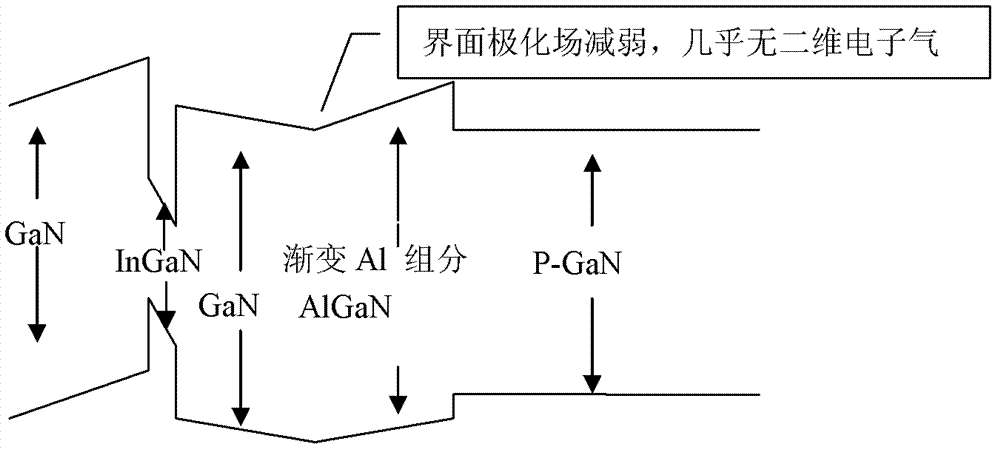

LED structure with aluminum-component-gradient electron blocking layer

InactiveCN102820394AAvoid defectsLess bendingSemiconductor devicesUltrasound attenuationQuantum efficiency

The invention relates to an LED structure with an aluminum-component-gradient electron blocking layer. Low-Al-component AlxGa1-xN is arranged on one side, which is in contract with an outer GaN barrier of a multiple-quantum well layer, of the aluminum-component-gradient electron blocking layer, the x is greater than or equal to 0 and smaller than or equal to 0.1, high-Al-component AlyGa1-yN is arranged on one side, which is in contact with a p-GaN layer, of the aluminum-component-gradient electron blocking layer, the y is greater than 0.1 and is smaller than or equal to 0.4, and the quantity of Al components in the middle of the aluminum-component-gradient electron blocking layer is gradually increased linearly. The low-Al-component AlGaN is arranged on one side, which is in contact with the GaN barrier, of the electron blocking layer, so that the density of polarization charges between interfaces of the electron blocking layer and the GaN barrier are effectively reduced, and a polarization field is weakened. Accordingly, the concentration of two-dimensional electron gas of the interfaces is greatly reduced, leakage current is decreased, the internal quantum efficiency of a device is improved in general, and the problem of attenuation of the quantum efficiency is solved.

Owner:JIANGSU YONGDING COMM

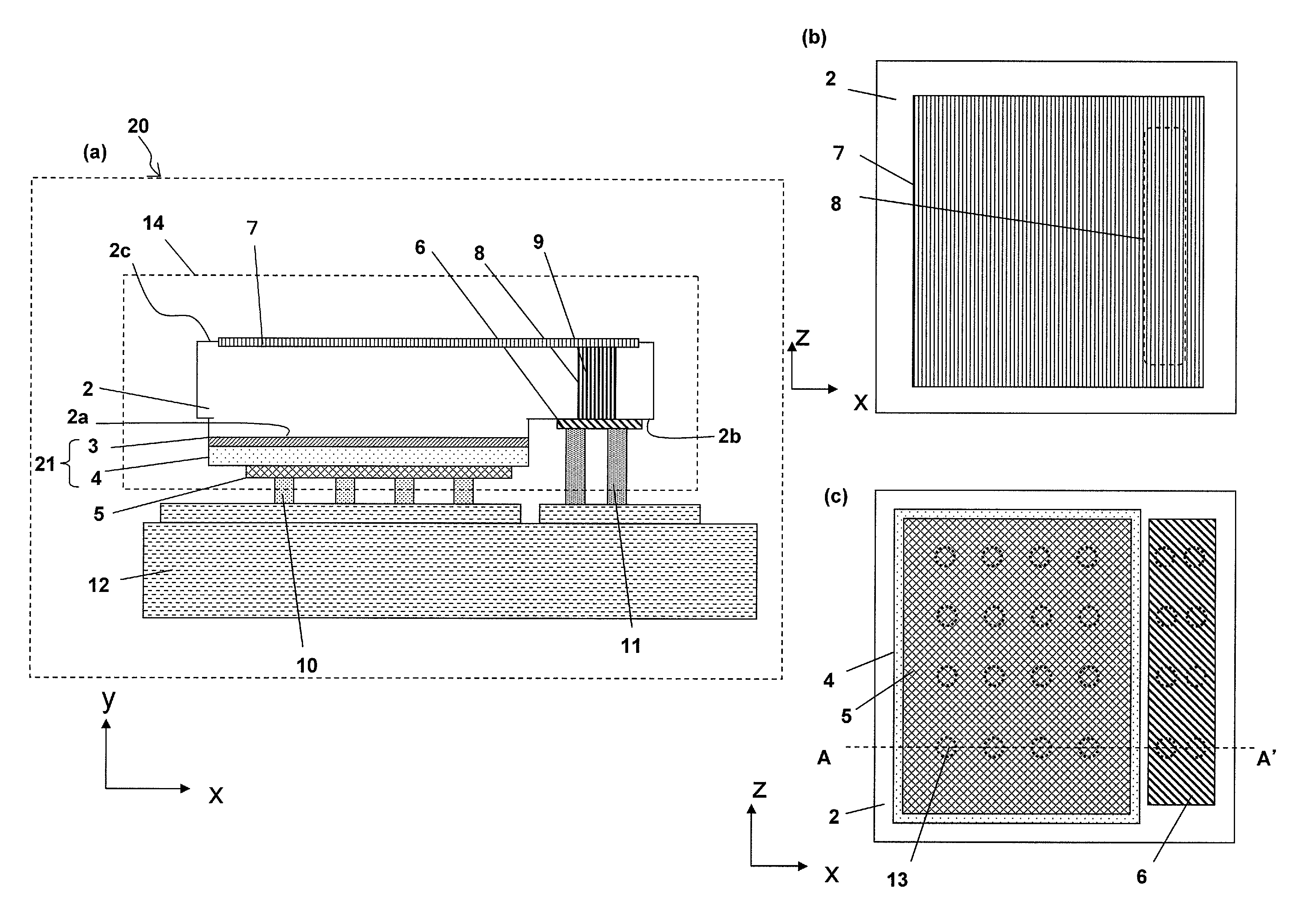

Light-emitting diode

InactiveUS20120113656A1Probability decreaseImproved power efficiencyLighting support devicesLight fasteningsGallium nitrideSurface electrode

A light-emitting diode element includes: an n-type conductive layer 2 being made of a gallium nitride-based compound, a principal surface being an m-plane; a semiconductor multilayer structure 21 provided on a first region 2a of the principal surface of the n-type conductive layer 2, the semiconductor multilayer structure 21 including a p-type conductive layer 4 and an active layer 3; a p-electrode 5 provided on the p-type conductive layer 4; a conductor portion 9 provided on a second region 2b of the principal surface of the n-type conductive layer 2, the conductor portion 9 being in contact with an inner wall of a through hole 8; and an n-type front surface electrode 6 provided on the second region 2b of the principal surface of the n-type conductive layer 2, the n-type front surface electrode 6 being in contact with the conductor portion 9.

Owner:PANASONIC CORP

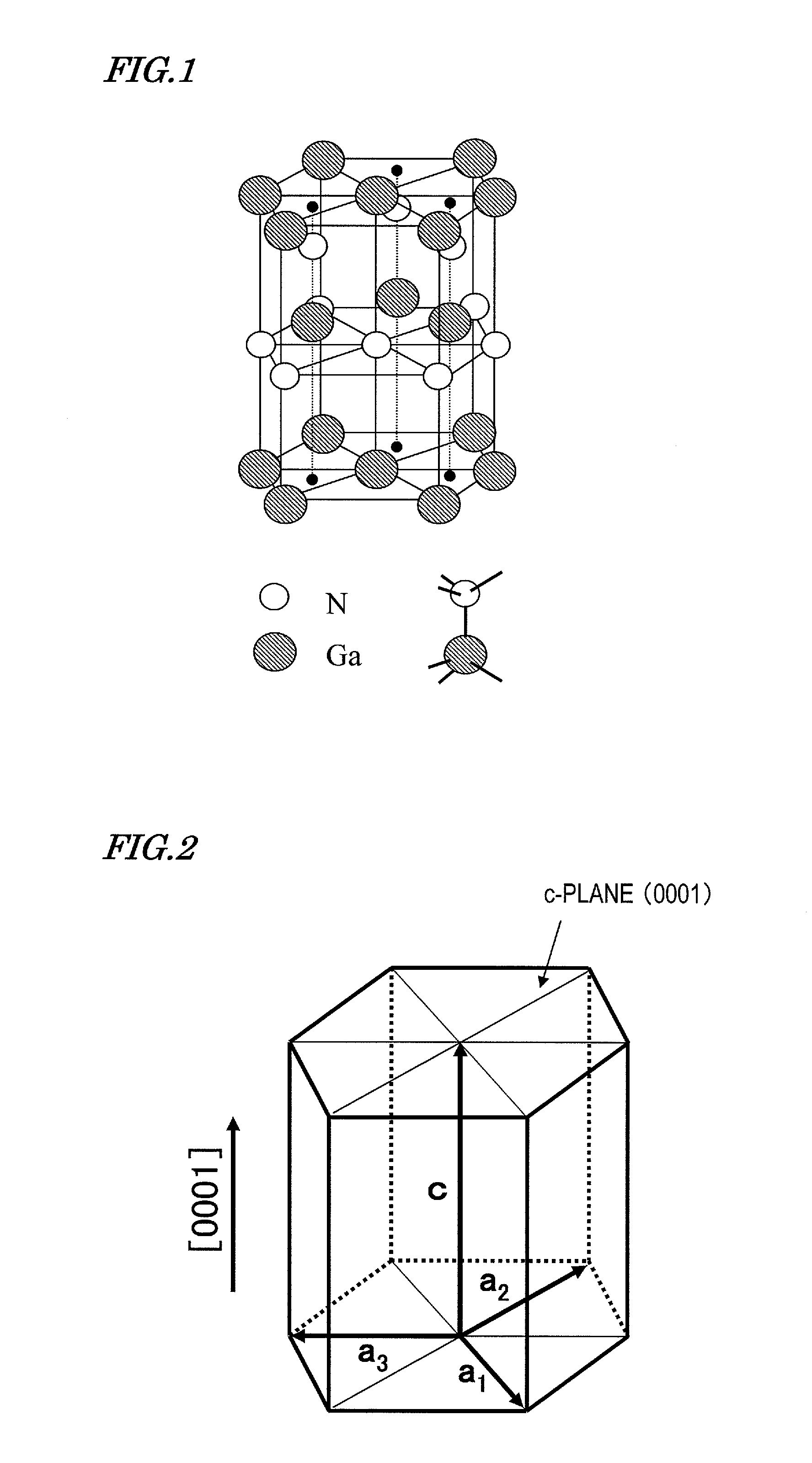

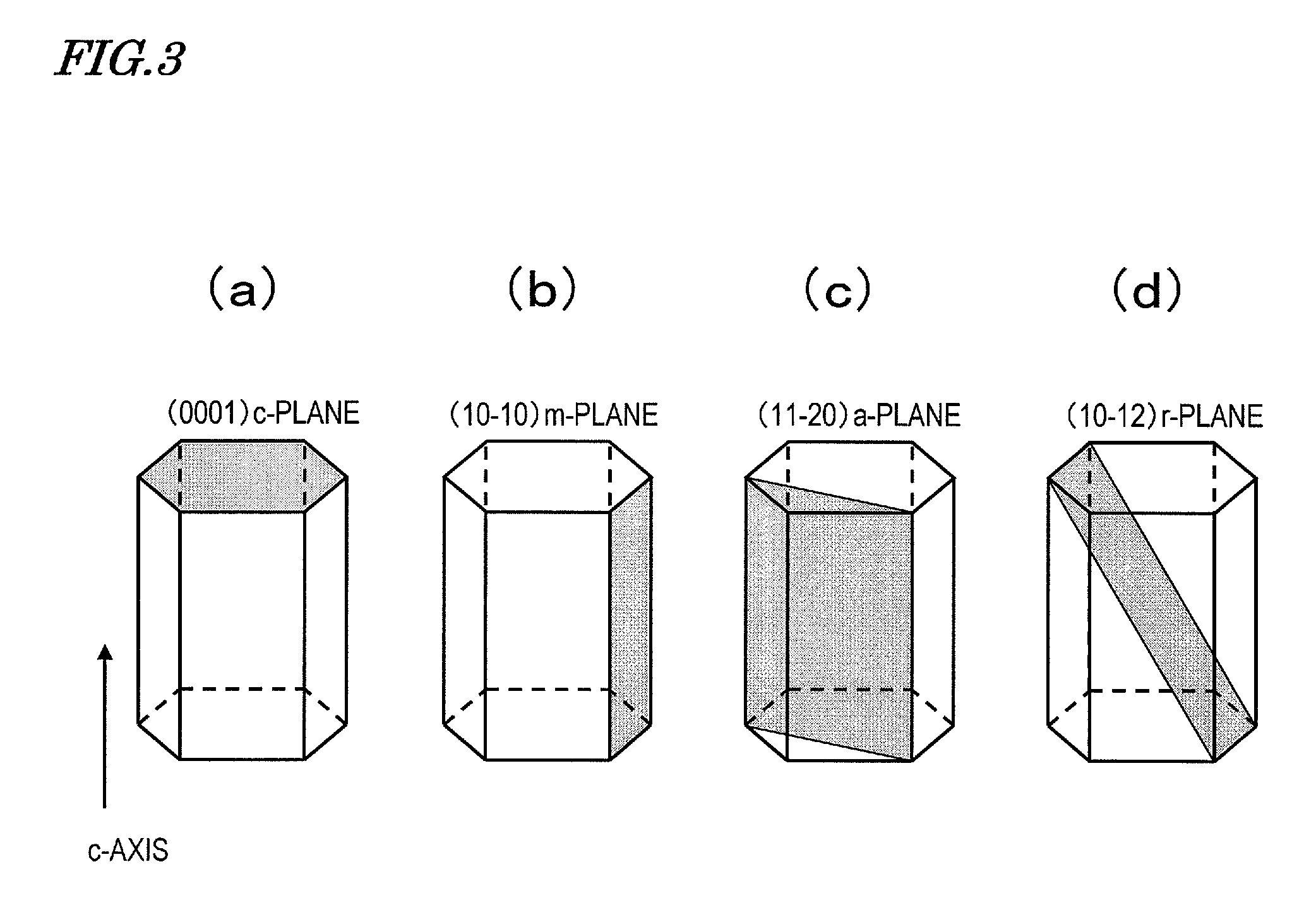

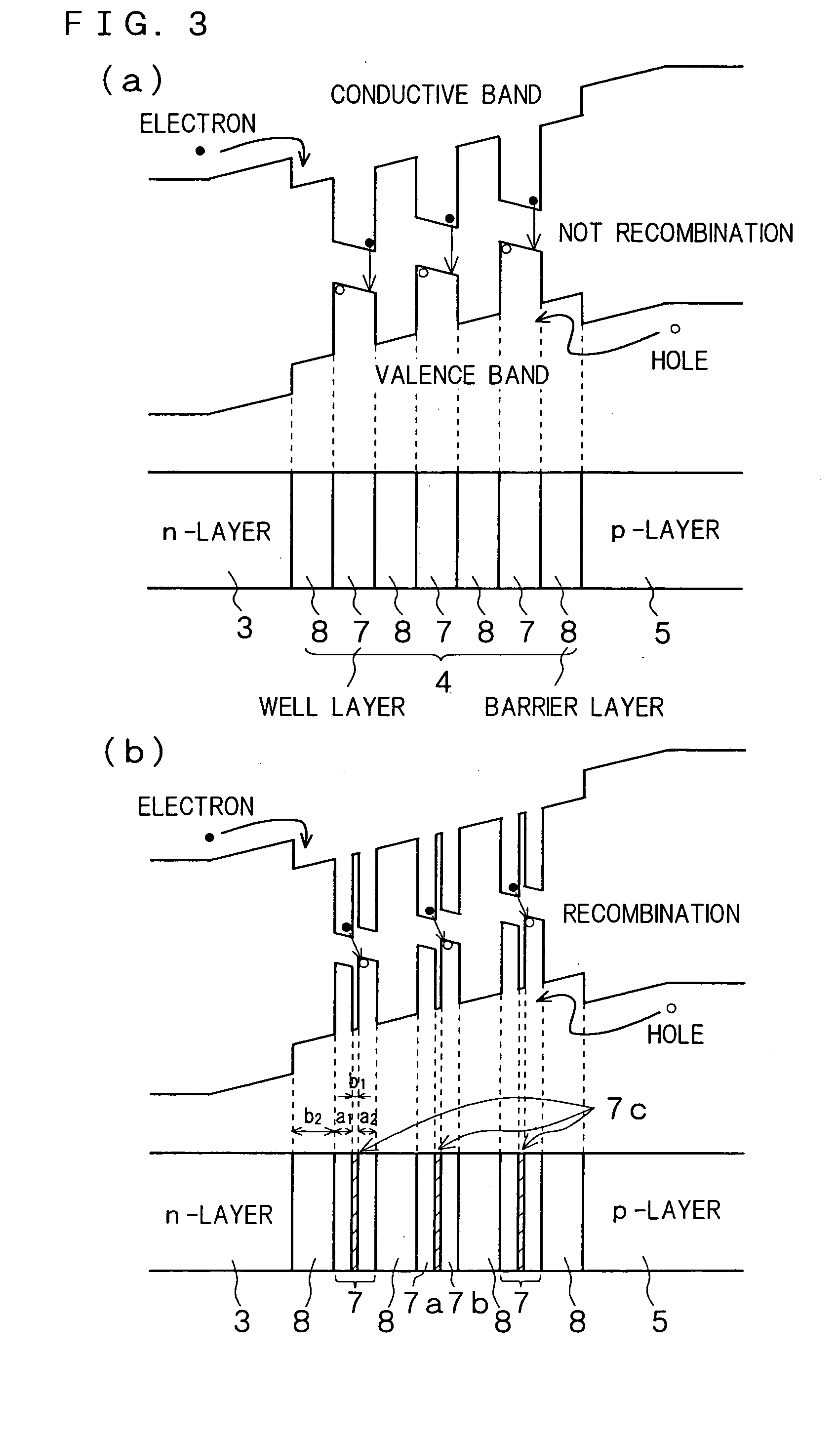

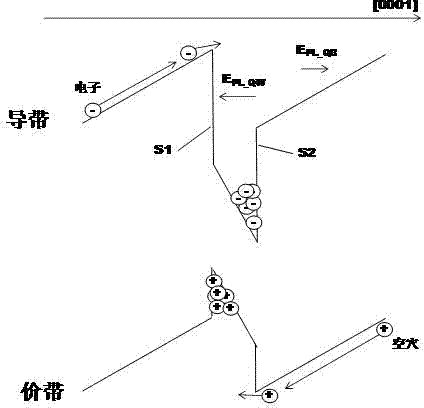

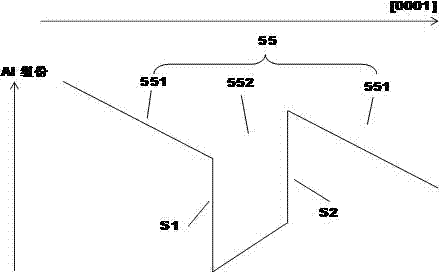

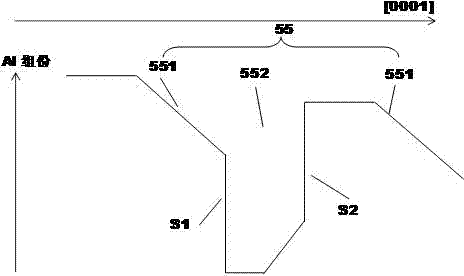

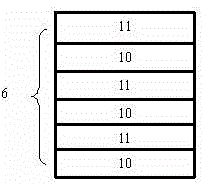

Nitride Semiconductor Light Emitting Device

InactiveUS20090166668A1Large band gap energyImprove efficiencySolid-state devicesNanoopticsQuantum efficiencyRecombination radiation

There is provided a nitride semiconductor light emitting device having high internal quantum efficiency by accelerating recombination radiation while employing a multiple quantum well structure in which each of well layers has a relatively large thickness. The nitride semiconductor light emitting device is provided with a nitride semiconductor lamination portion (6) provided on a substrate (1). The nitride semiconductor lamination portion (6) includes at least an active layer (4) in which a light emitting portion is formed. And the active layer is constituted with a multiple quantum well structure formed by laminating well layers (7) made of InxGa1-xN (0<x≦1), and barrier layers (8) made of AlyInzGa1-y-zN (0≦y<1, 0≦z<1, 0≦y+z<1, z<x) alternately. In addition, one of the well layers is divided at least into a first well layer (7a) and a second well layer (7b) by a thin film barrier layer (7c) made of AlvInwGa1-v-wN (0≦v<1, 0≦w<1, 0≦v+w<1, w<x), and the thin film barrier layer is formed so as to have a thickness of one atomic layer or more and 20 Angstroms or less.

Owner:ROHM CO LTD

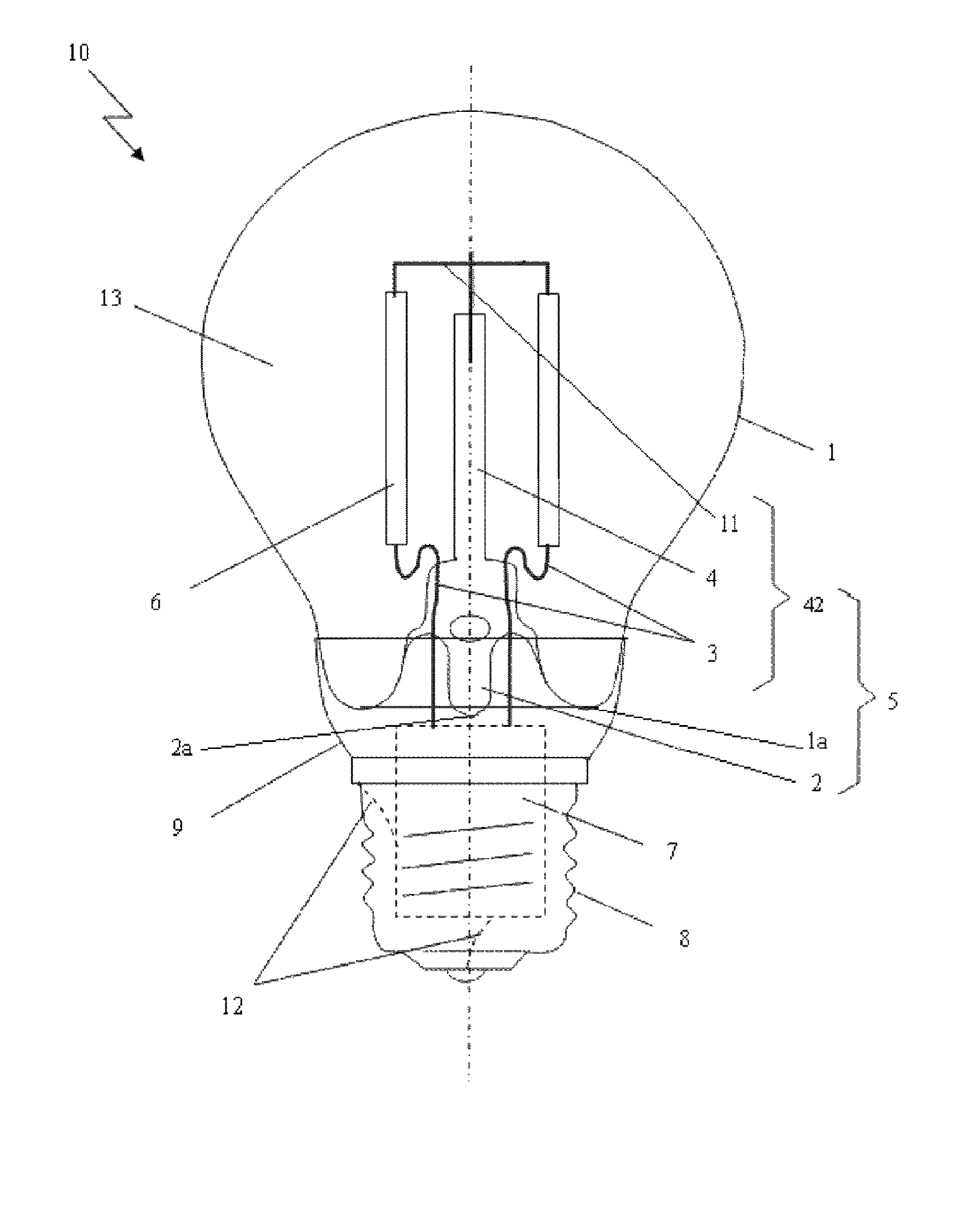

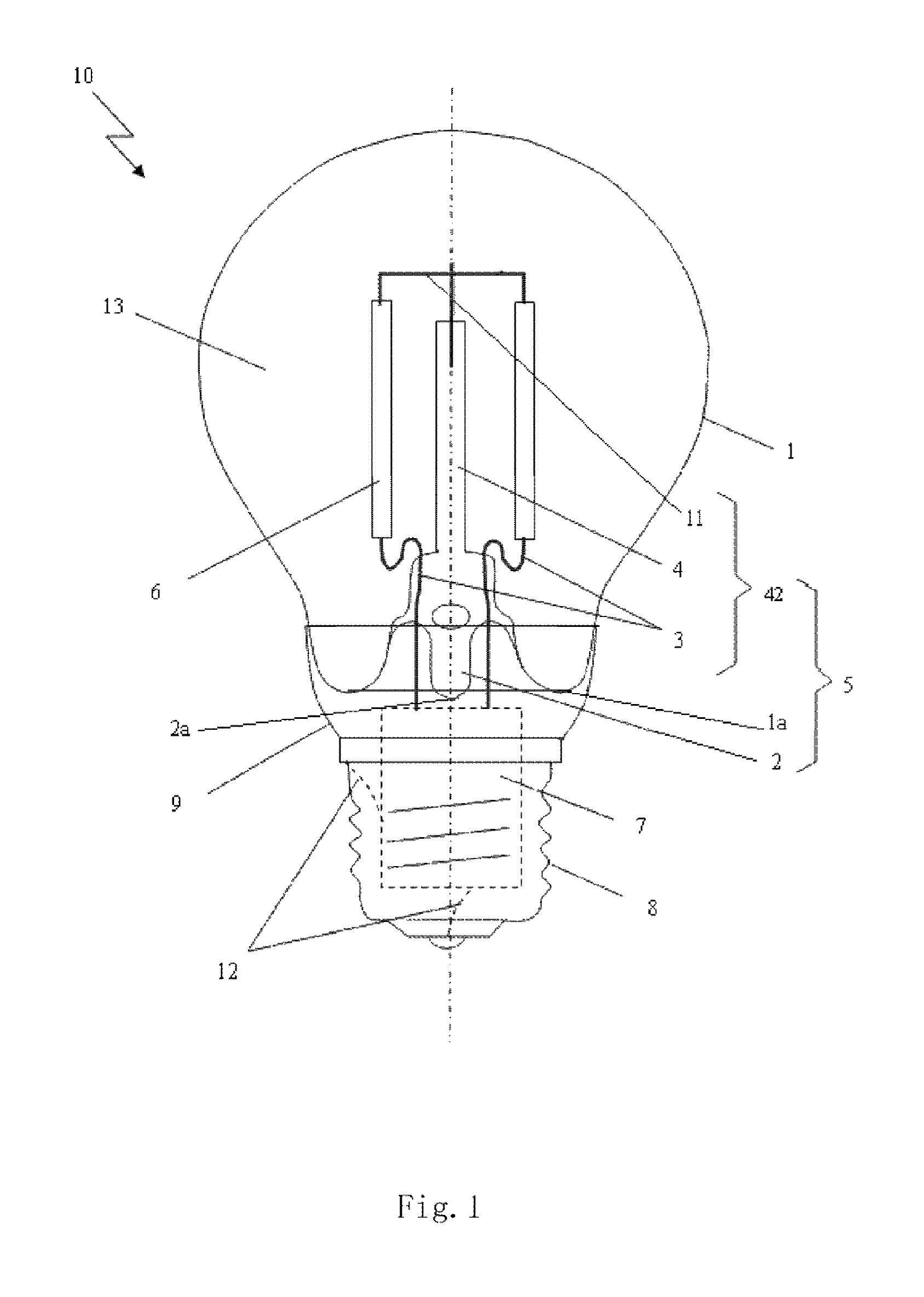

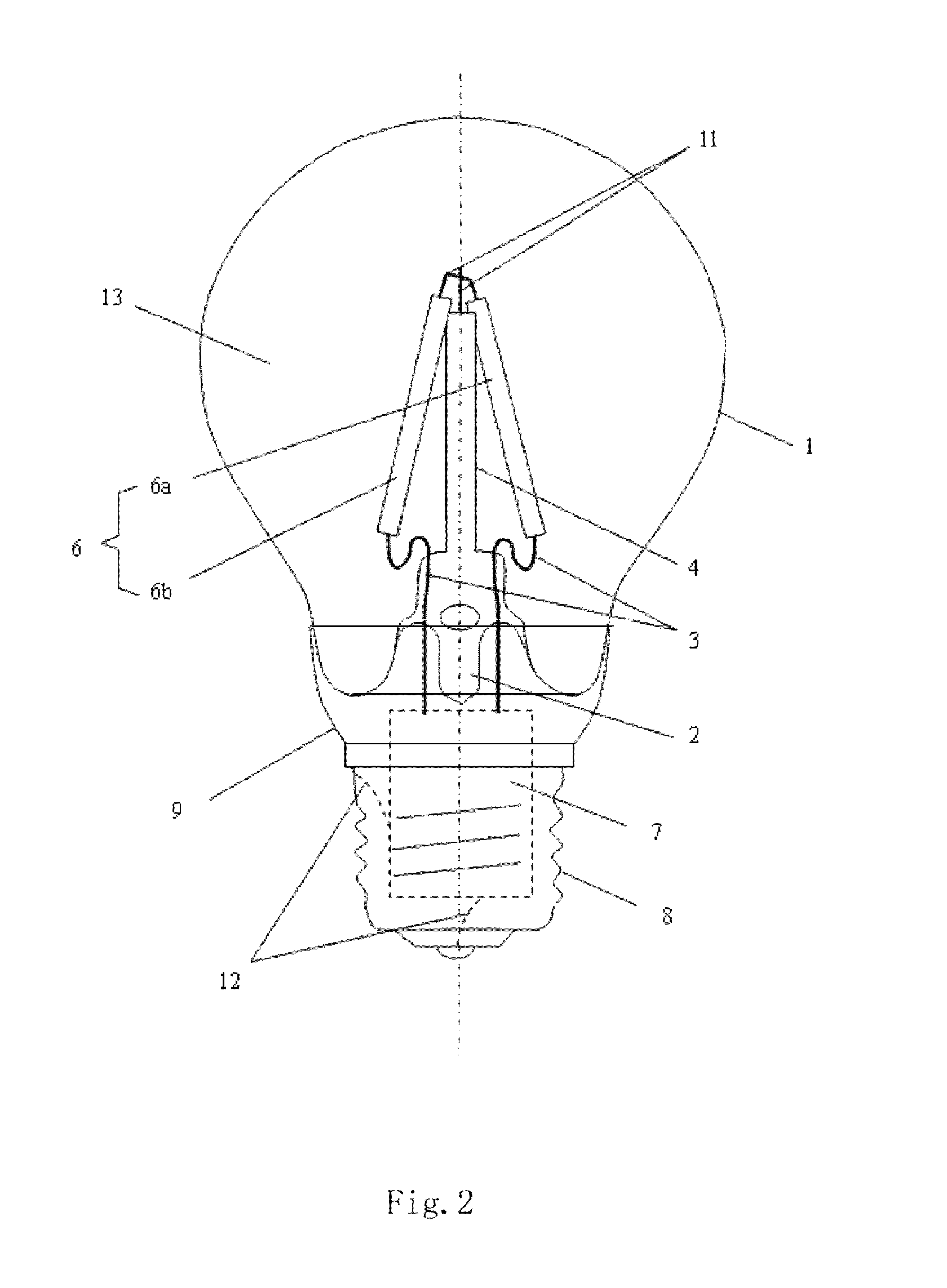

LED light bulb and LED light-emitting strip being capable of emitting 4TT light

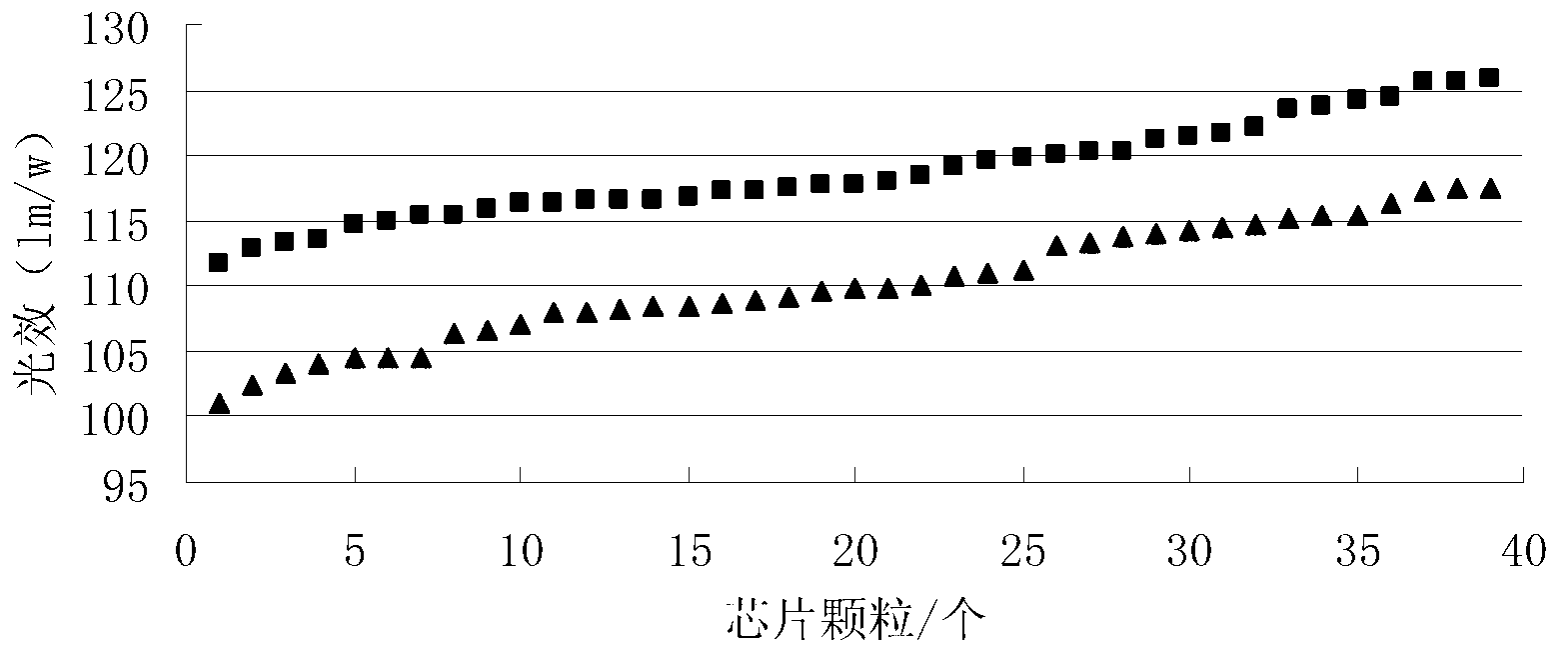

ActiveUS9261242B2Improve efficiencyImprove internal quantum efficiencyPoint-like light sourceElongate light sourcesElectricityEngineering

The present invention discloses a LED light bulb, comprising: a LED light bulb shell; a core column with an exhaust tube and a bracket; at least one LED light emitting strip with LED chips therein emitting 4π light; a driver; and an electrical connector, wherein the LED light bulb shell is vacuum sealed with the core column so as to form a vacuum sealed chamber, which is filled with a gas having a low coefficient of viscosity and a high coefficient of thermal conductivity, the bracket and the LED light emitting strips fixed on the bracket are housed in the vacuum sealed chamber, the LED light emitting strip is in turn electrically connected to the driver, the electrical connector, while the electrical connector is used to be electrically connected to an external power supply, so as to light the LED light emitting strips. In addition, the present invention also provides the LED light emitting strips with LED chips emitting 4π light, as used in the LED light bulb.

Owner:ZHEJIANG LEDISON OPTOELECTRONICS

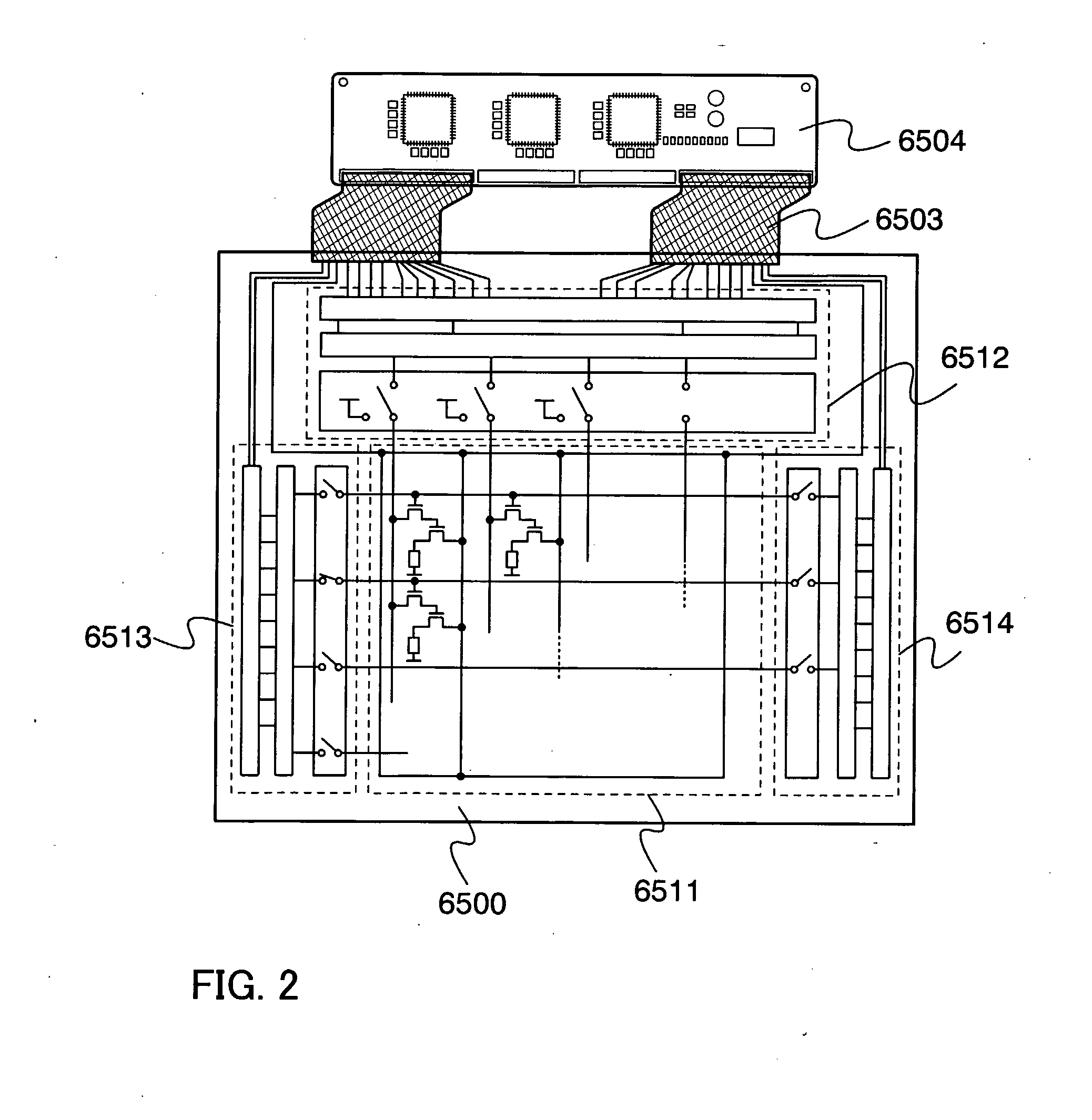

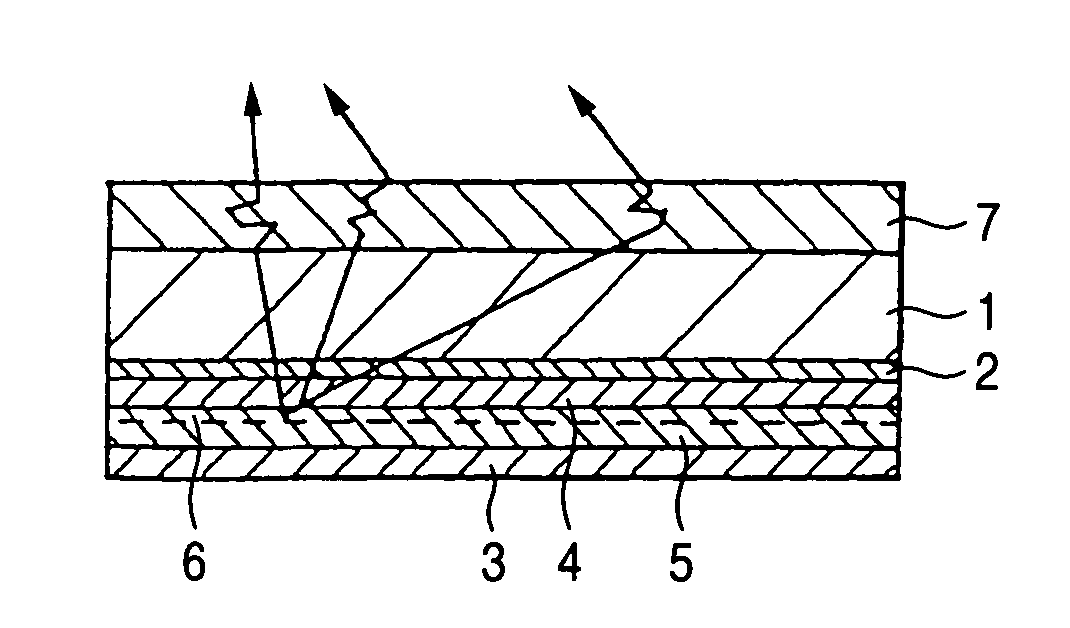

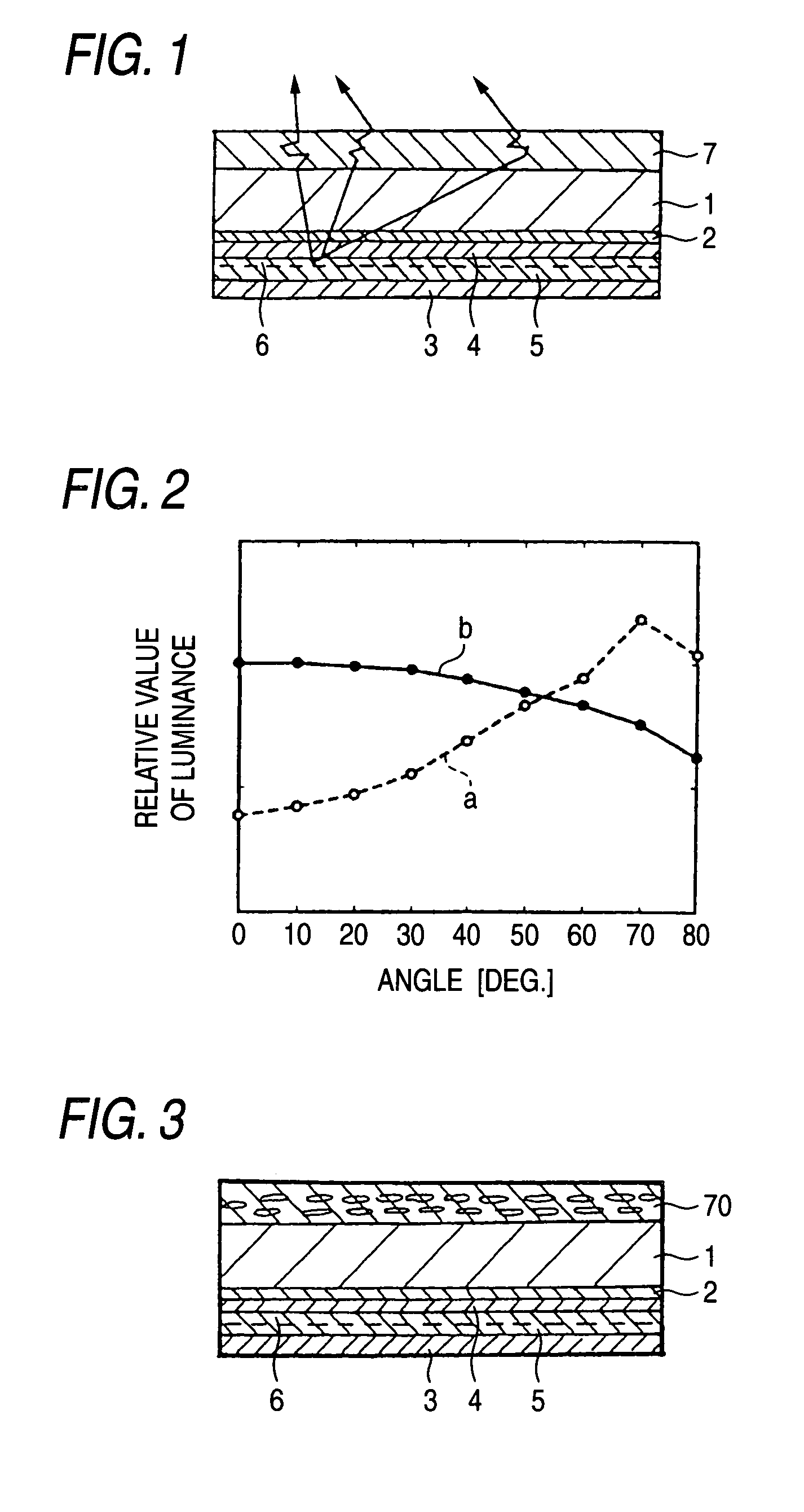

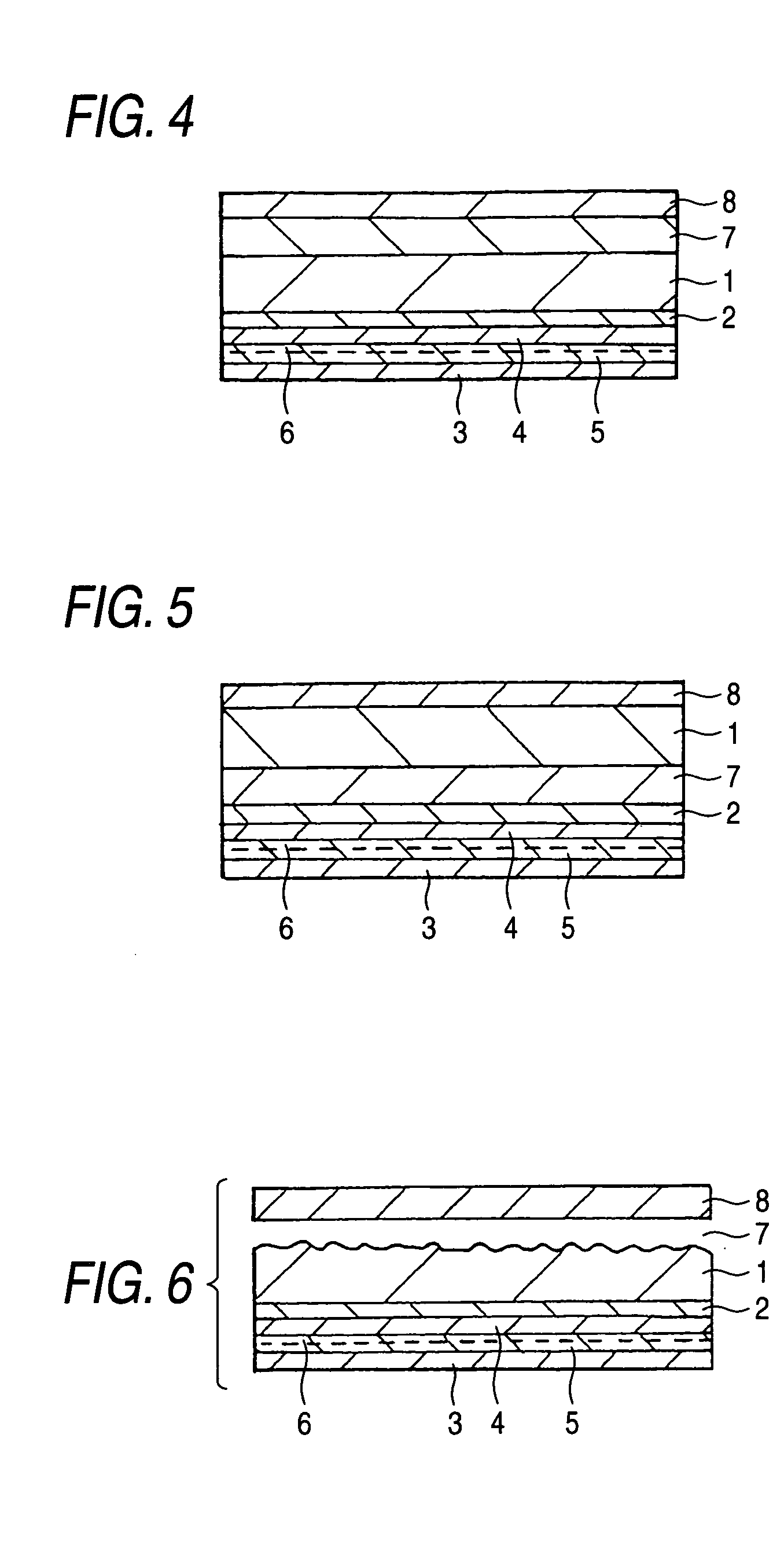

Organic electroluminescence cell, planar light source and display device

ActiveUS7109651B2Extend cell lifeTotal current dropIncadescent screens/filtersDischarge tube luminescnet screensOrganic layerDisplay device

An organic electroluminescence cell including at least one organic layer and a pair of electrodes, the organic layer including a light-emitting layer and sandwiched between the pair of electrodes, the pair of electrodes including a reflective electrode and a transparent electrode, the organic electroluminescence cell formed to satisfy the expression: B0<Bθ in which B0 is a frontal luminance value of luminescence radiated from a light extraction surface to an observer, and Bθ is a luminance value of the luminescence at an angle of from 50° to 70°, wherein a reflection / refraction angle disturbance region is provided so that the angle of reflection / refraction of the luminescence is disturbed while the luminescence is output from the light-emitting layer to the observer side through the transparent electrode.

Owner:NITTO DENKO CORP

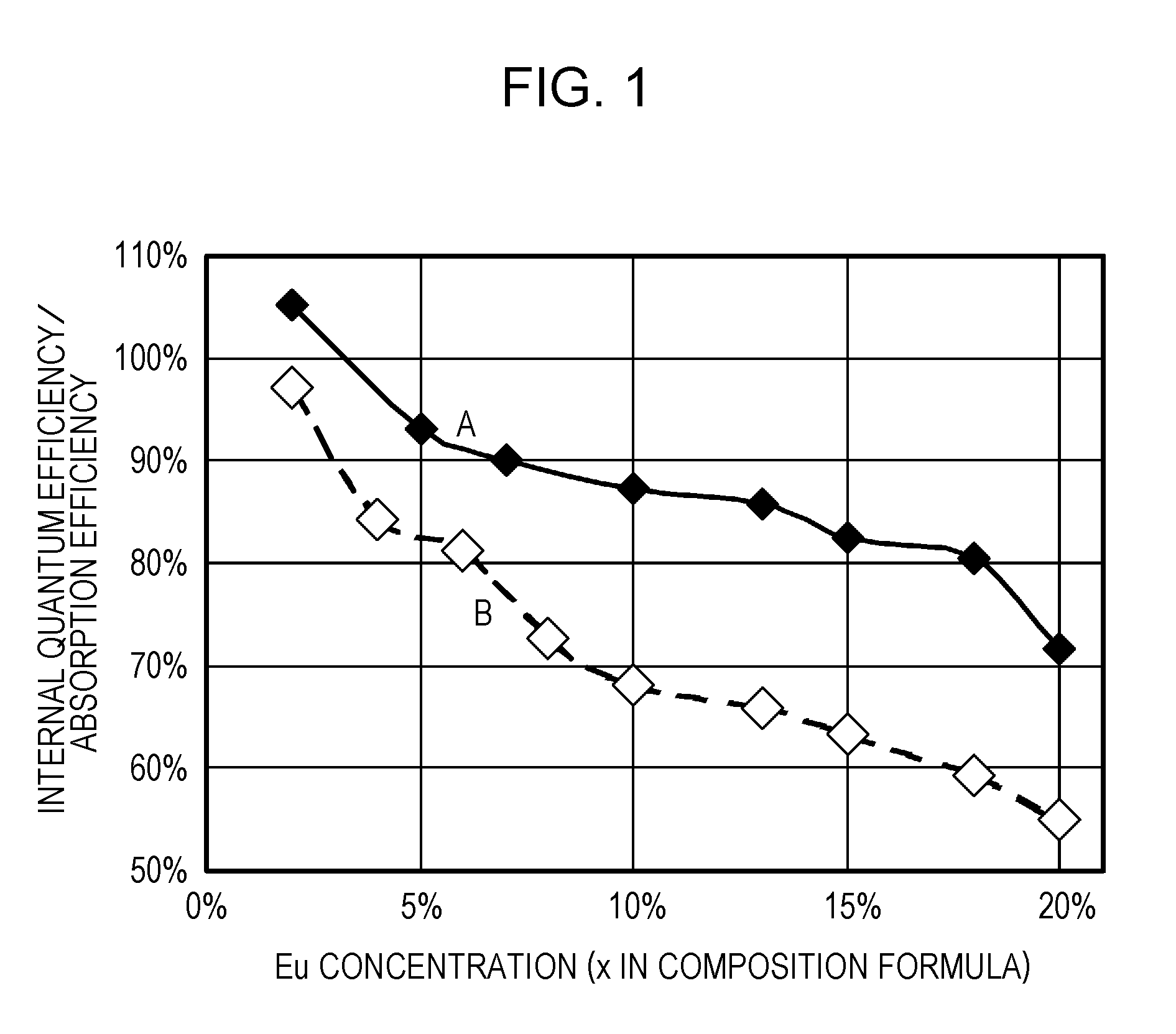

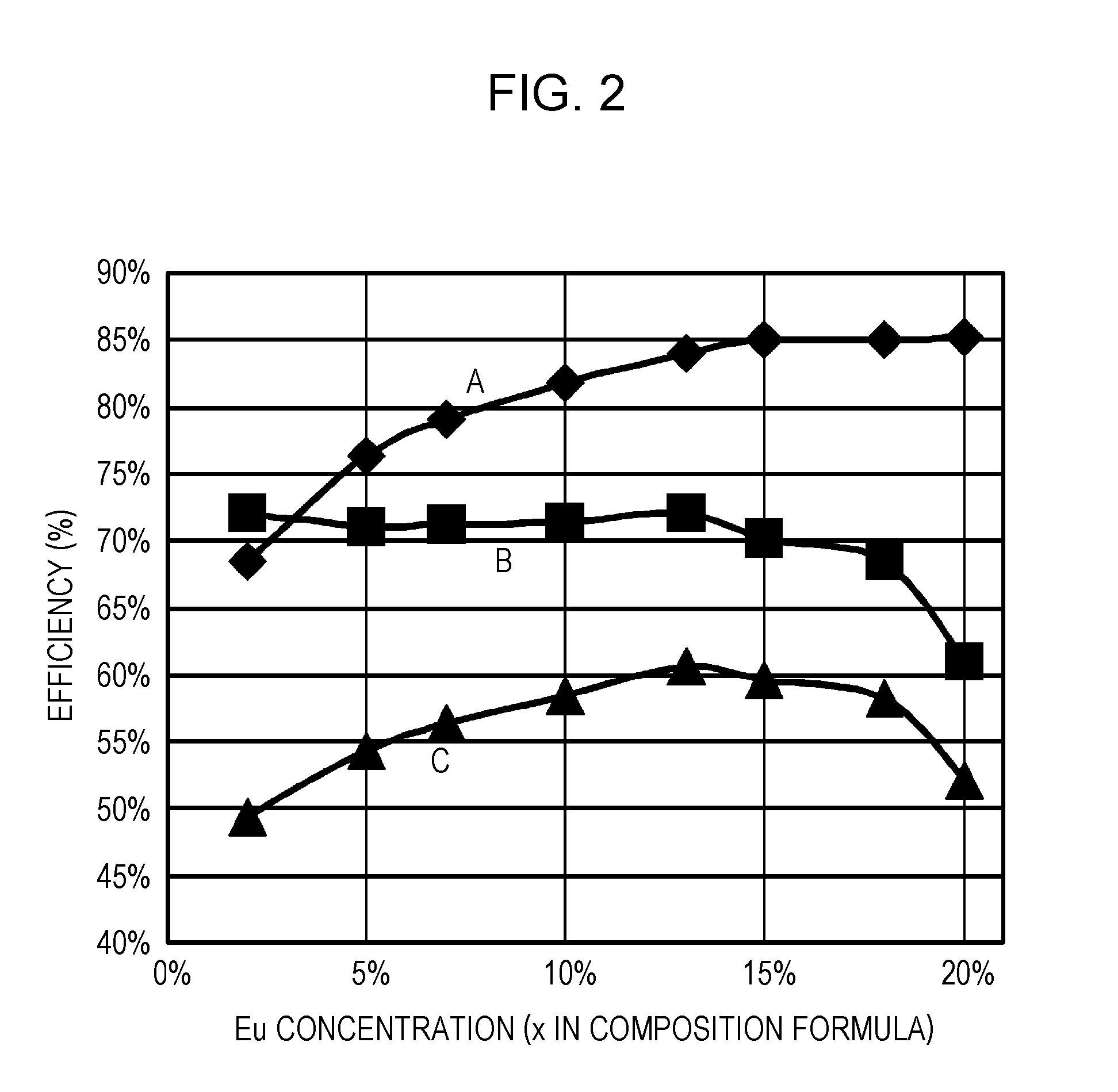

Green-emitting phosphor particles, method for manufacturing green-emitting phosphor particles, color conversion sheet, light-emitting device, and image display device assembly

ActiveUS20110273864A1Improve internal quantum efficiencyImprove absorption efficiencySolid-state devicesLuminescent compositionsPhosphorStrontium

Owner:DEXERIALS CORP

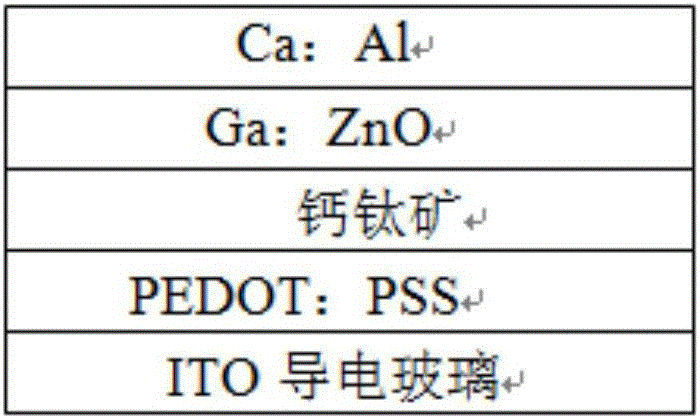

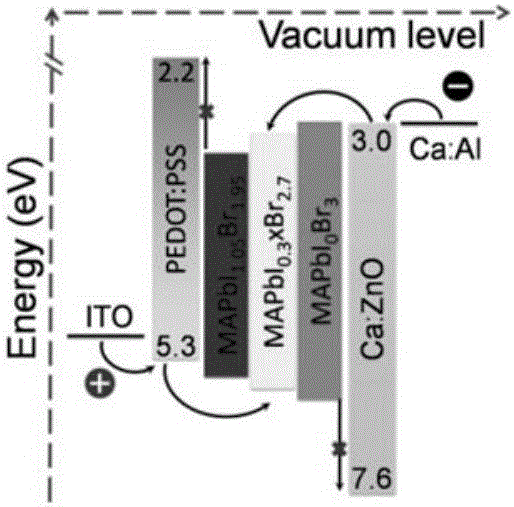

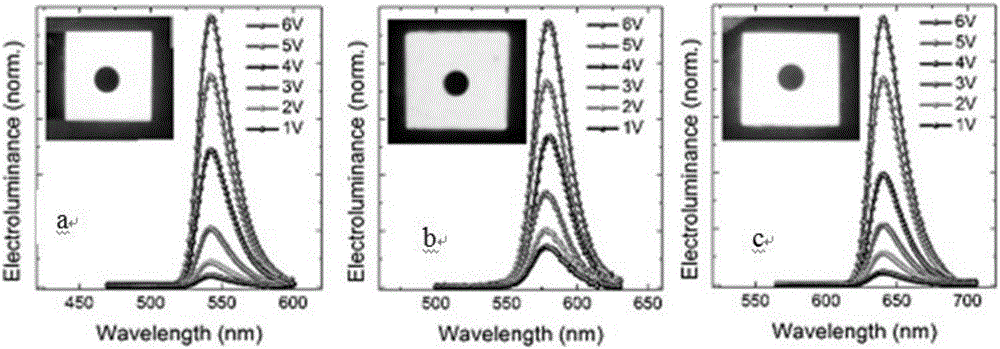

Dual-layer perovskite light emitting diode and preparation method therefor

ActiveCN106450009AIncrease contentReduce processing costsSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerLight-emitting diode

The invention relates to a dual-layer perovskite light emitting diode and a preparation method therefor. The dual-layer perovskite light emitting diode comprises the following components from the bottom up separately: ITO conductive glass is used as a positive electrode; a layer of poly 3, 4-ethylenedioxythiophene-polystyrolsulfon acid (PEDOT-PSS) with a thickness of about 20nm is used as a hole transport layer; a dual-layer perovskite light emitting layer is prepared by a spin-coating method in two times; the adopted dual-layer perovskite light emitting layer can be perovskite with different halogen ratios; a layer of calcium-doped zinc oxide (Ca:ZnO) with the thickness of about 50nm is spin-coated on the perovskite layer to be used as an electron transport layer; and finally metal calcium and aluminum are evaporated to be used as a negative electrode. According to the dual-layer perovskite light emitting diode and the preparation method therefor, on one hand, by regulating and controlling the Ca concentration in the Ca:ZnO, an optimal band gap is obtained, so that the barrier between the electron transport layer and the perovskite is reduced, and the cut-in voltage of the light emitting diode is lowered consequently, and the light emitting efficiency and internal quantum efficiency of the light emitting diode are improved at the same time; and on the other hand, by regulating the halogen ratios in the perovskite, light emission with different colors can be realized.

Owner:SUZHOU UNIV

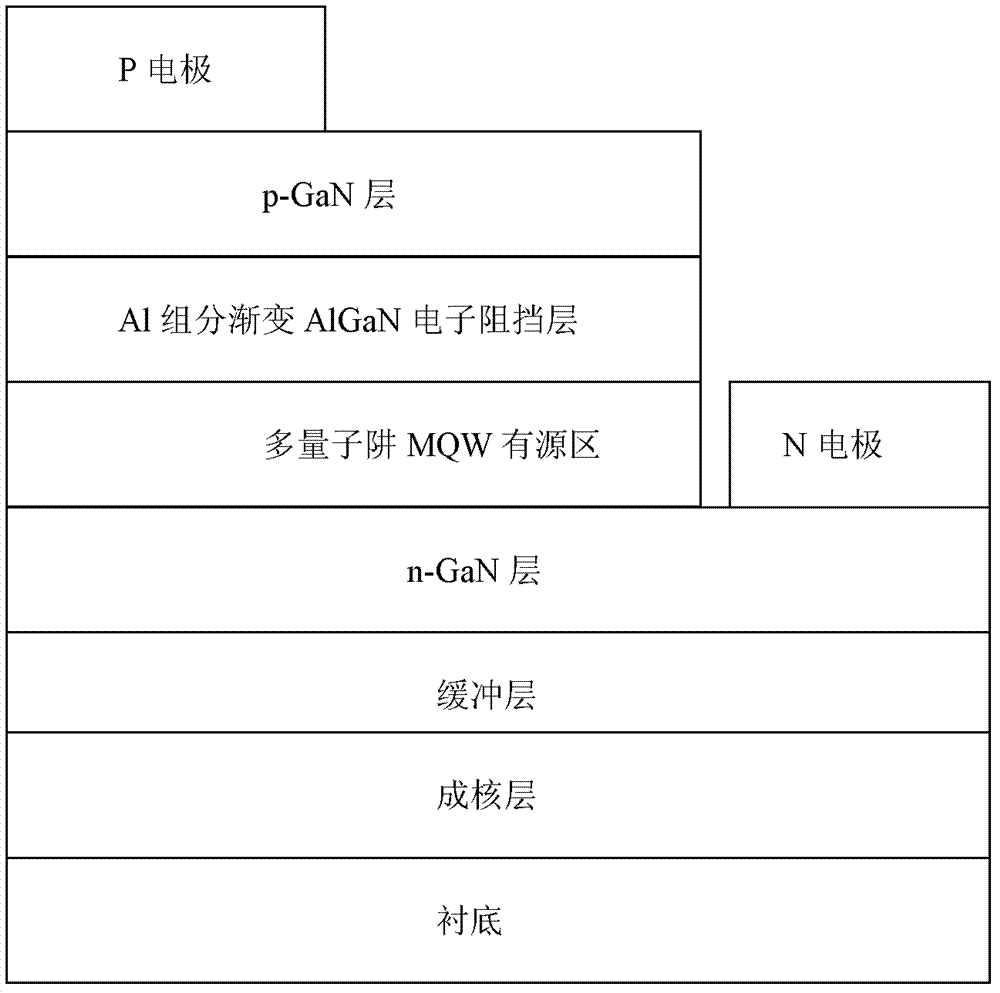

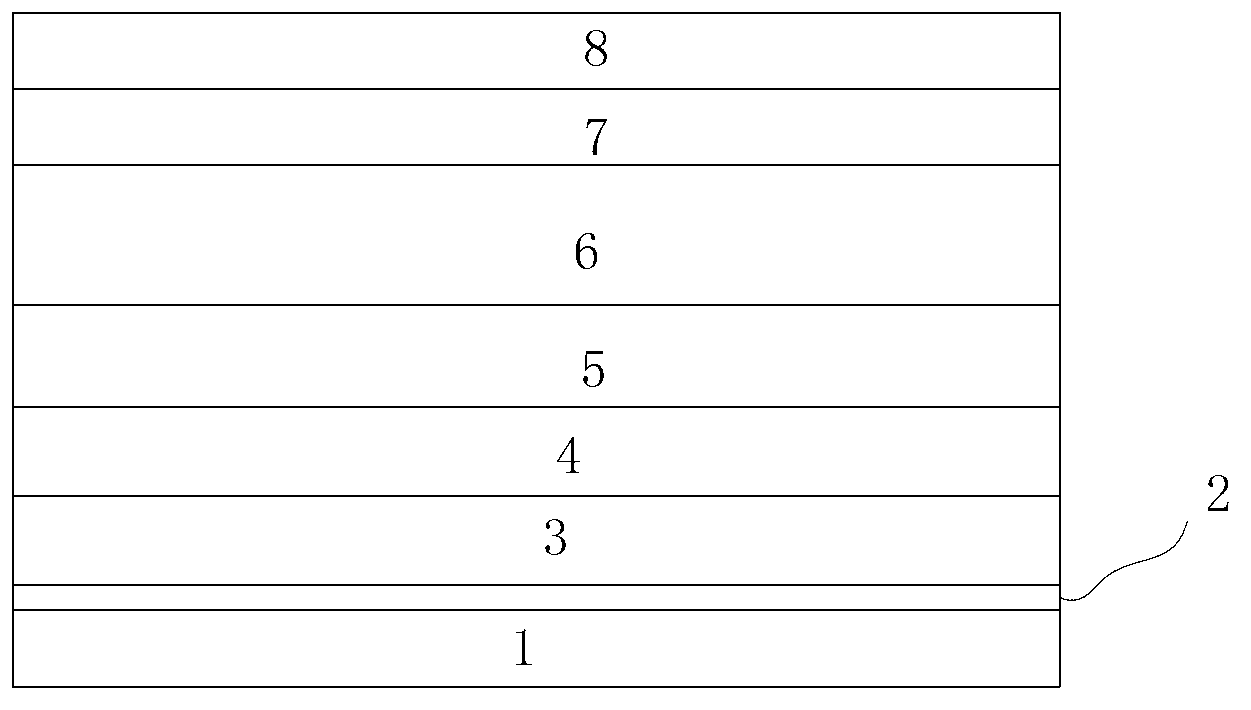

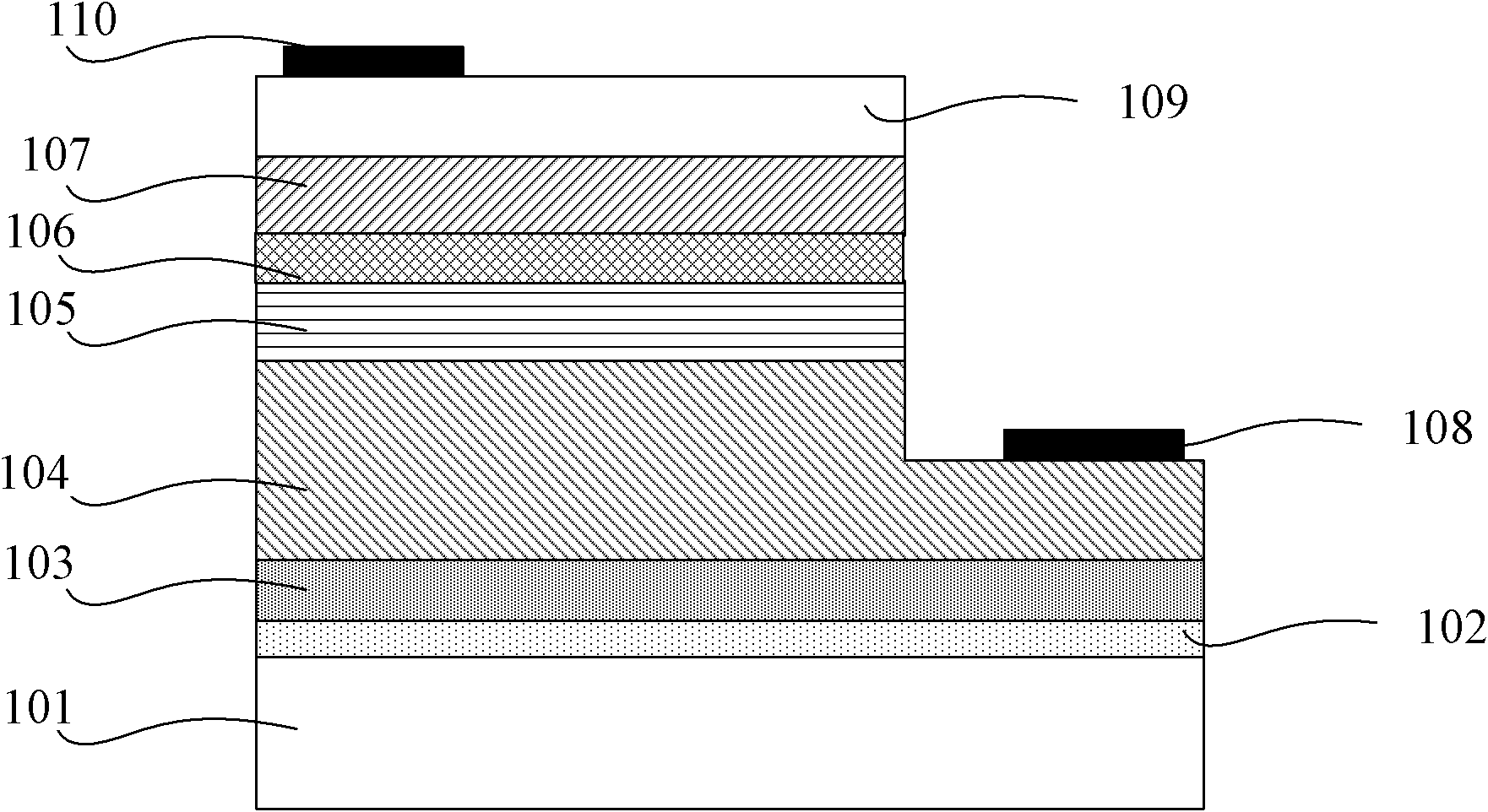

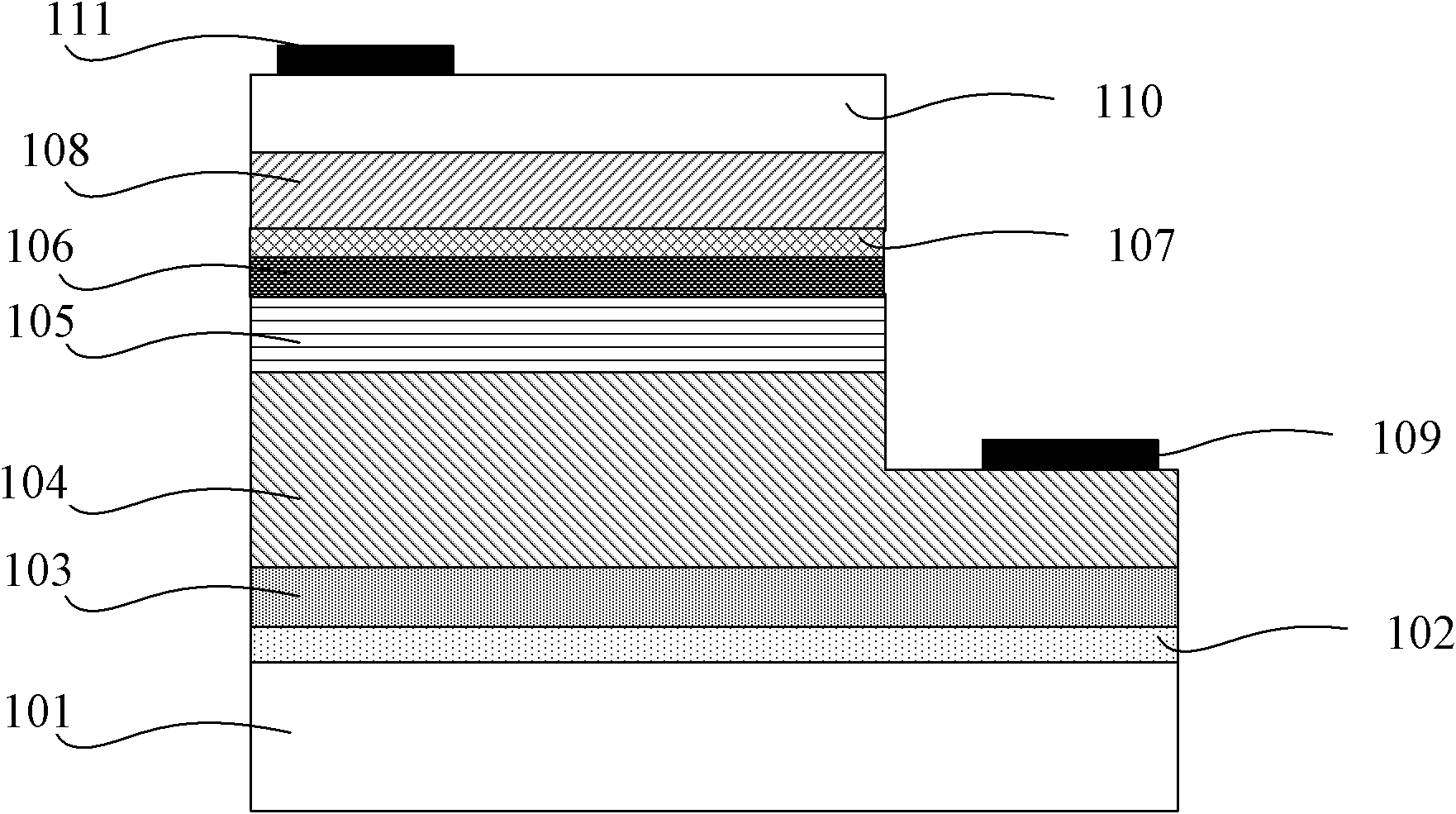

Light-emitting diode (LED) epitaxial structure with quaternary InAlGaN and method for preparing same

ActiveCN103022290AImprove internal quantum efficiencyImprove luminous efficiencyChemical vapor deposition coatingSemiconductor devicesMultiple quantumElectron blocking layer

The invention discloses an LED epitaxial structure with quaternary InAlGaN and a method for preparing the same. The LED epitaxial structure comprises a substrate, and a GaN buffer layer, an un-doped GaN layer, an n-type doped GaN layer, a multi-quantum-well luminous layer, a p-type doped InAlGaN electron blocking layer and a p-type doped GaN layer which are arranged successively from bottom to top. An InAlGaN stress release layer is arranged between the n-type doped GaN layer and the multi-quantum-well luminous layer. According to the LED epitaxial structure, the InAlGaN stress release layer is inserted between the n-type doped GaN layer and the multi-quantum-well luminous layer, so that stresses of multiple quantum wells can be released, the internal quantum efficiency is improved, and the luminous efficiency of the multi-quantum-well luminous layer per unit area is high. Besides, the structure is convenient to produce and suitable for industrialized application.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

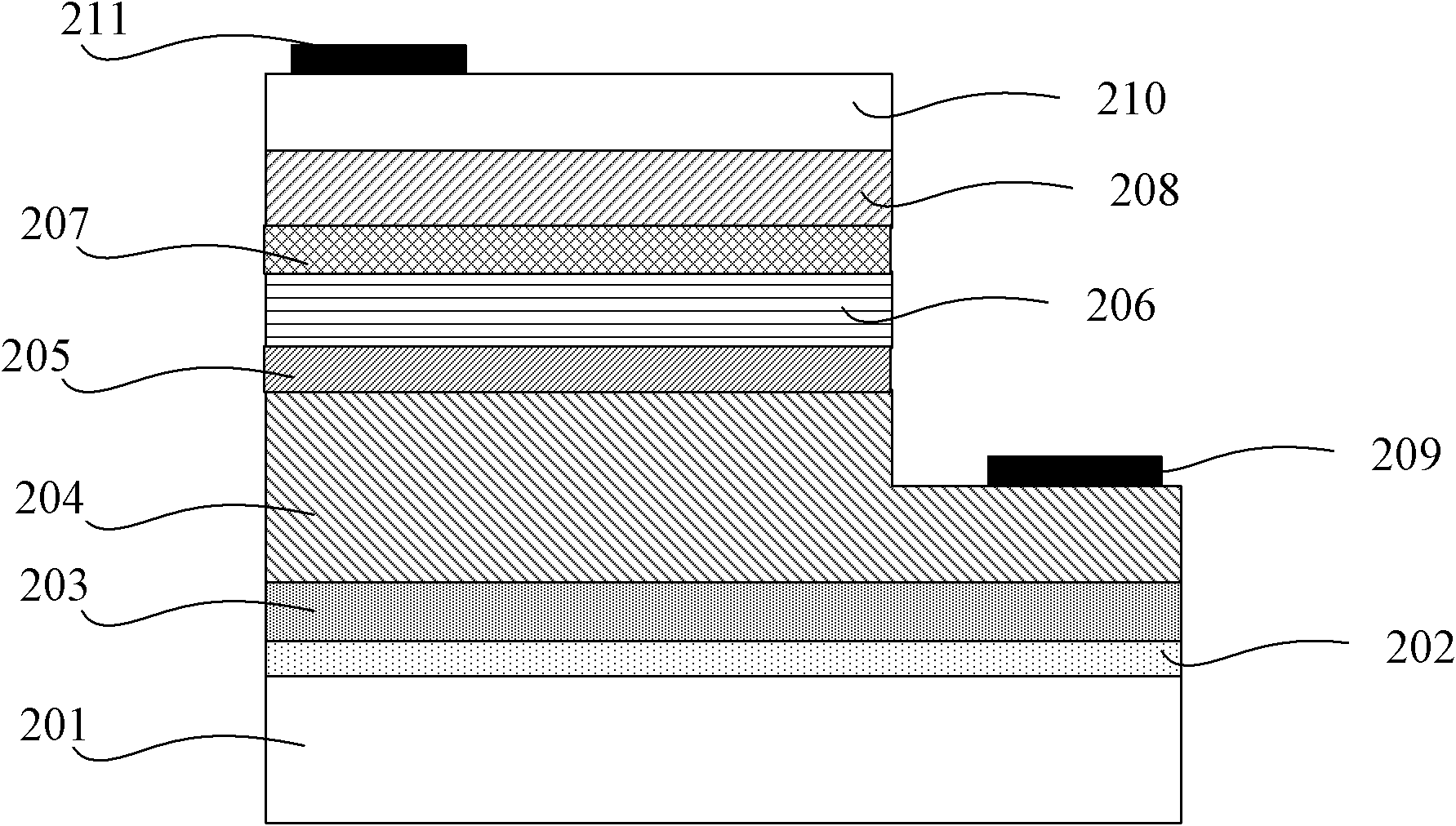

GaN-based light emitting diode and preparation method thereof

InactiveCN101937953AImprove light extraction efficiencyAchieve Broad Spectral OutputSemiconductor devicesMultiple quantumBlocking layer

The invention discloses a GaN-based light emitting diode which comprises a substrate, a buffer layer arranged on the substrate, an intrinsic GaN layer directly epitaxially arranged on the buffer layer, an N-type doped GaN epitaxial layer provided with an N-type GaN graphical template structure, an InxGal-xN / AlaInbGa1-a-bN multiple quantum well, an AlyGal-yN or AlyGal-yN / AlaInbGa1-a-bN superlattic electronic blocking layer, a P-type GaN layer, an ITO contact layer, a P-type electrode and an N-type electrode, wherein the N-type GaN graphical substrate, the multiple quantum well, the superlattic electronic blocking layer and the P-type GaN layer are all in a curved surface structure. The invention strengthens the light extraction efficiency of the light emitting diode device, also realizes wide spectrum output of the light emitting diode and promotes the development of white light illumination.

Owner:SUZHOU NANOJOIN PHOTONICS

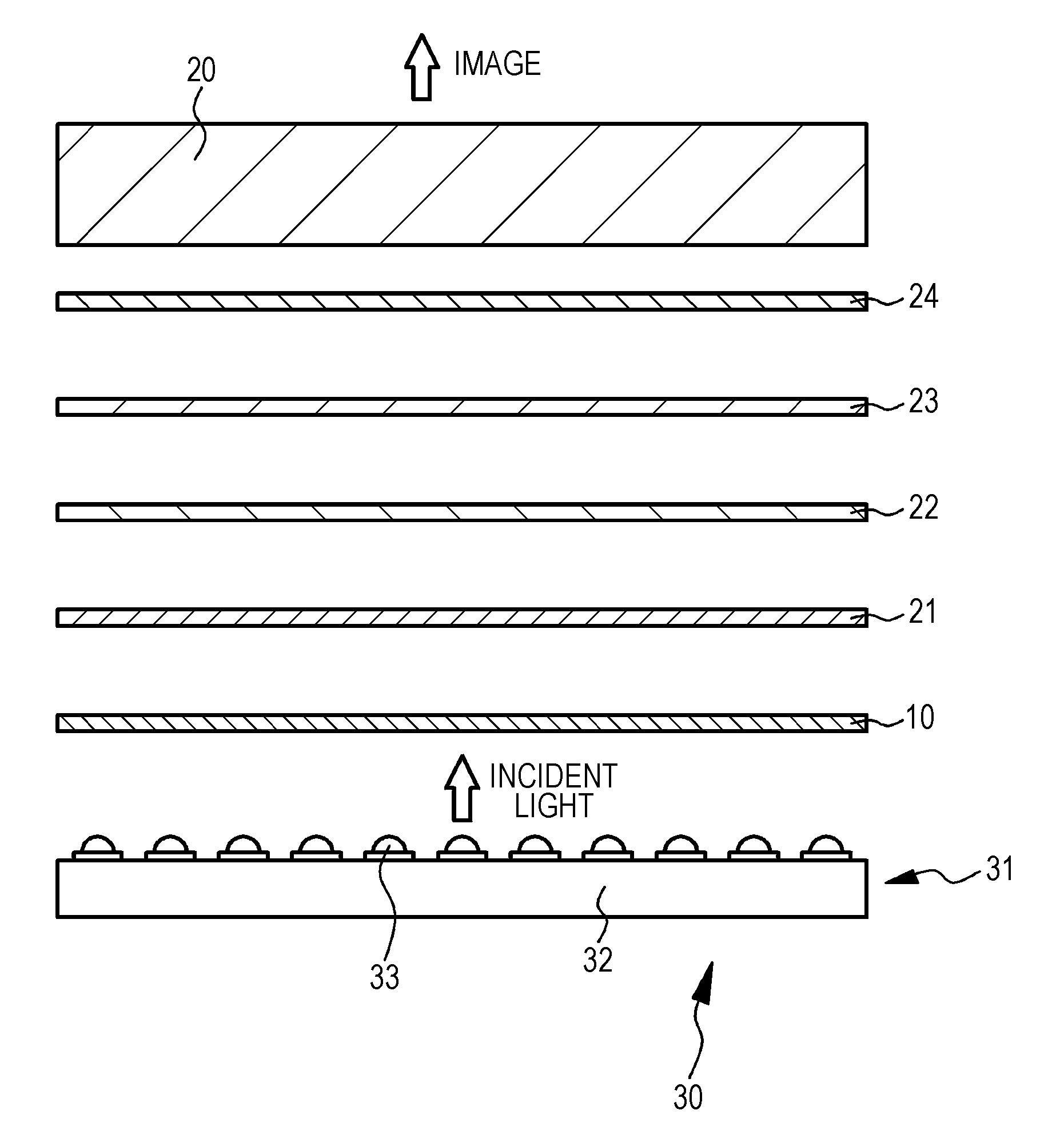

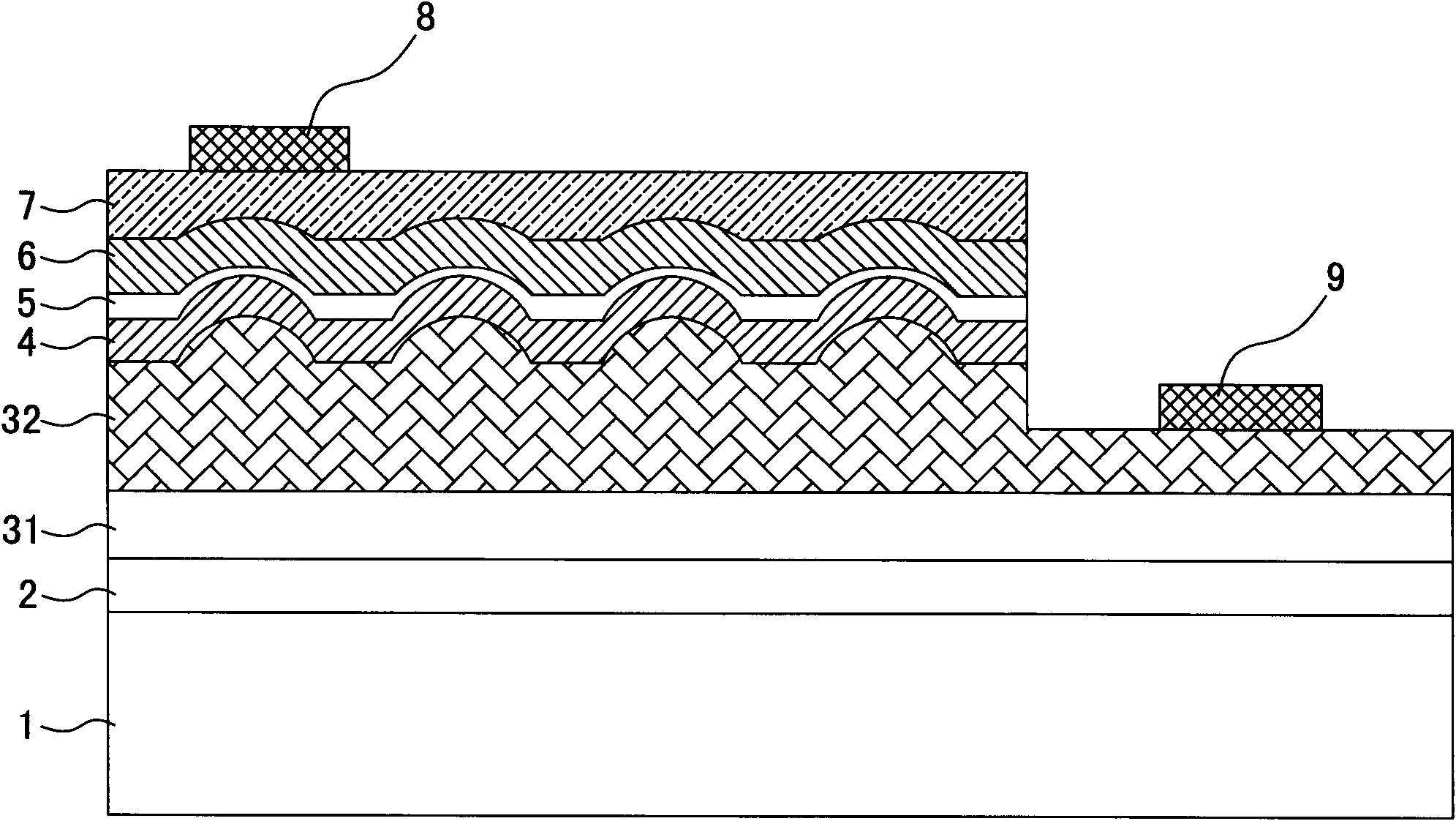

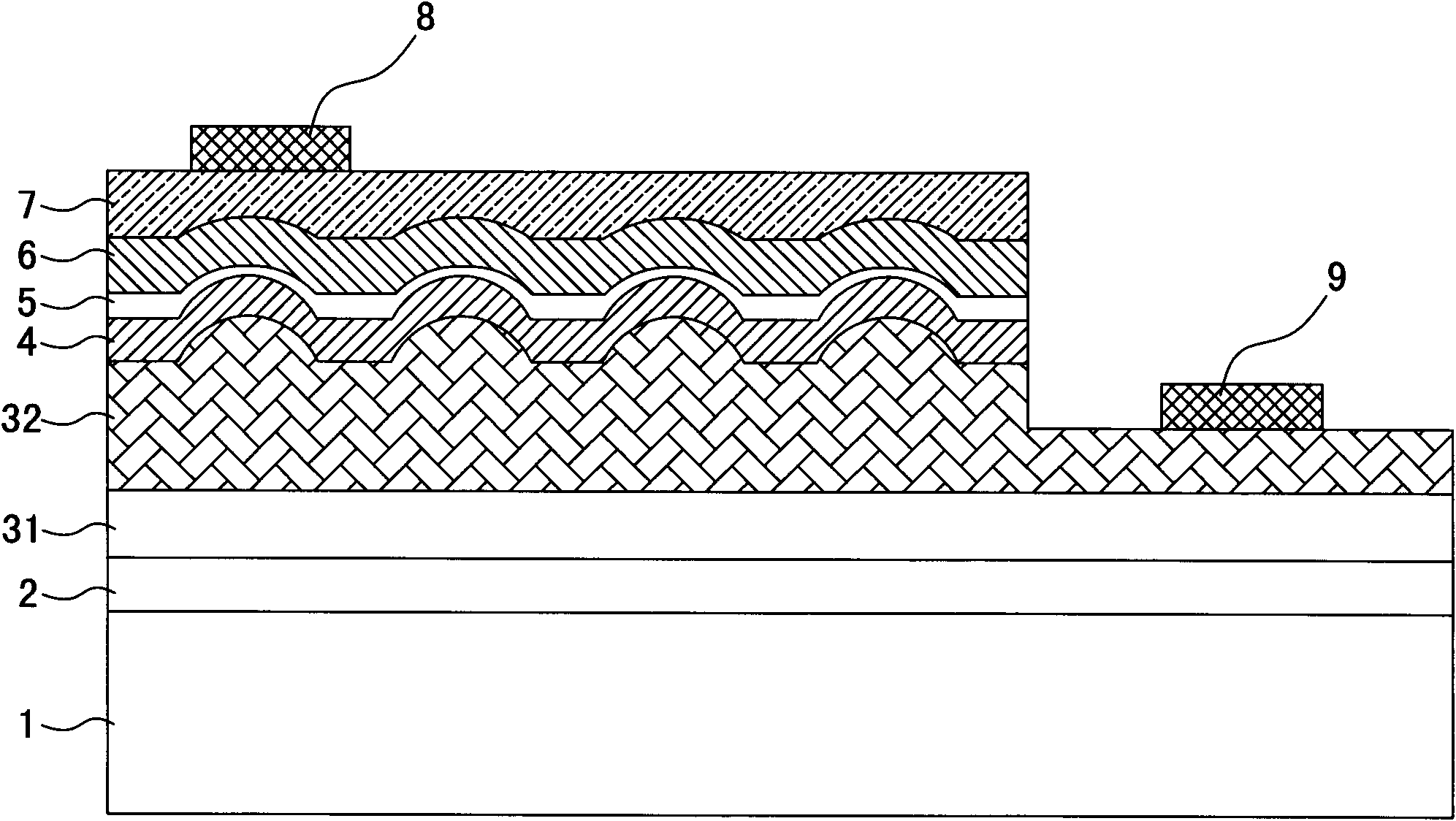

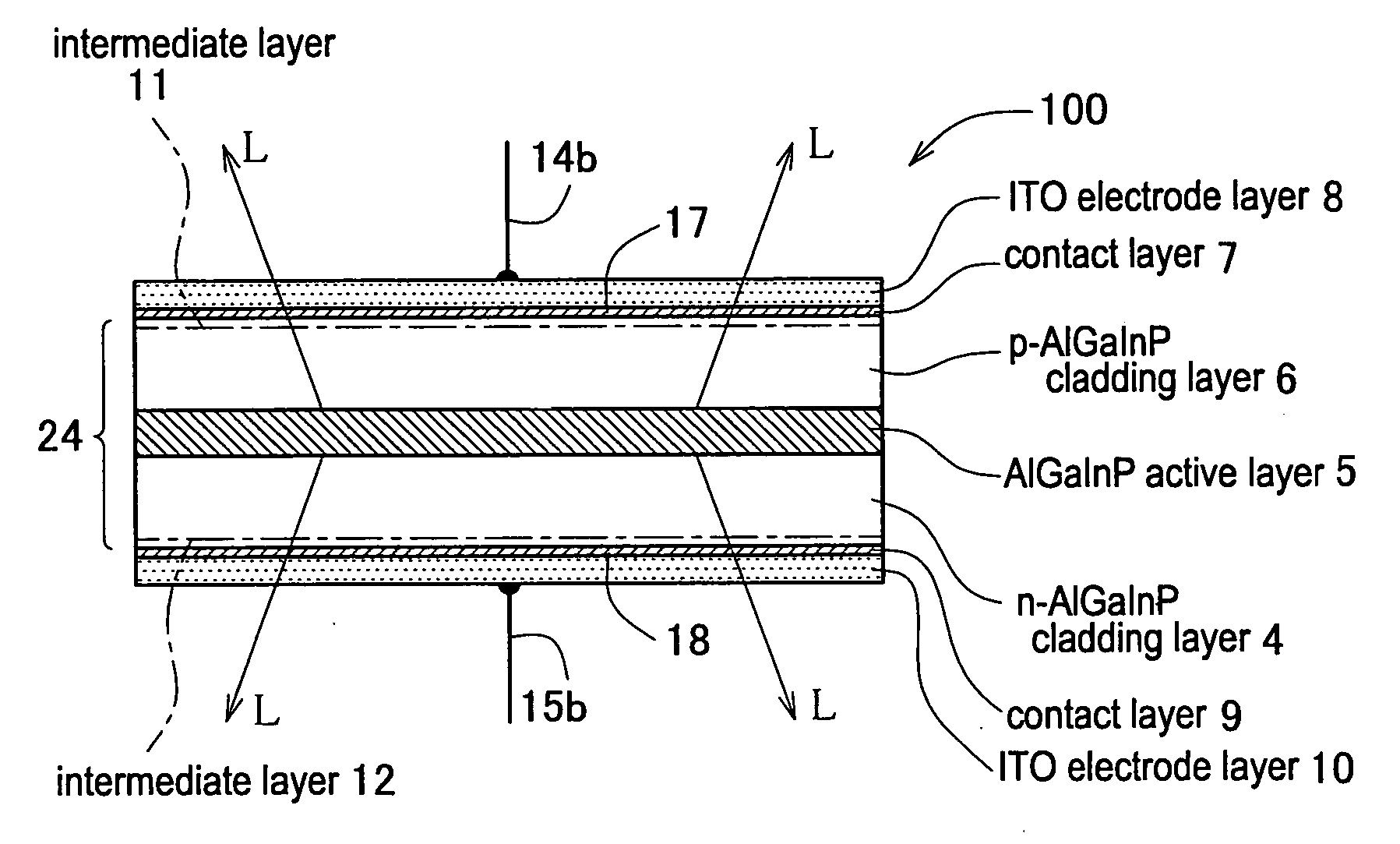

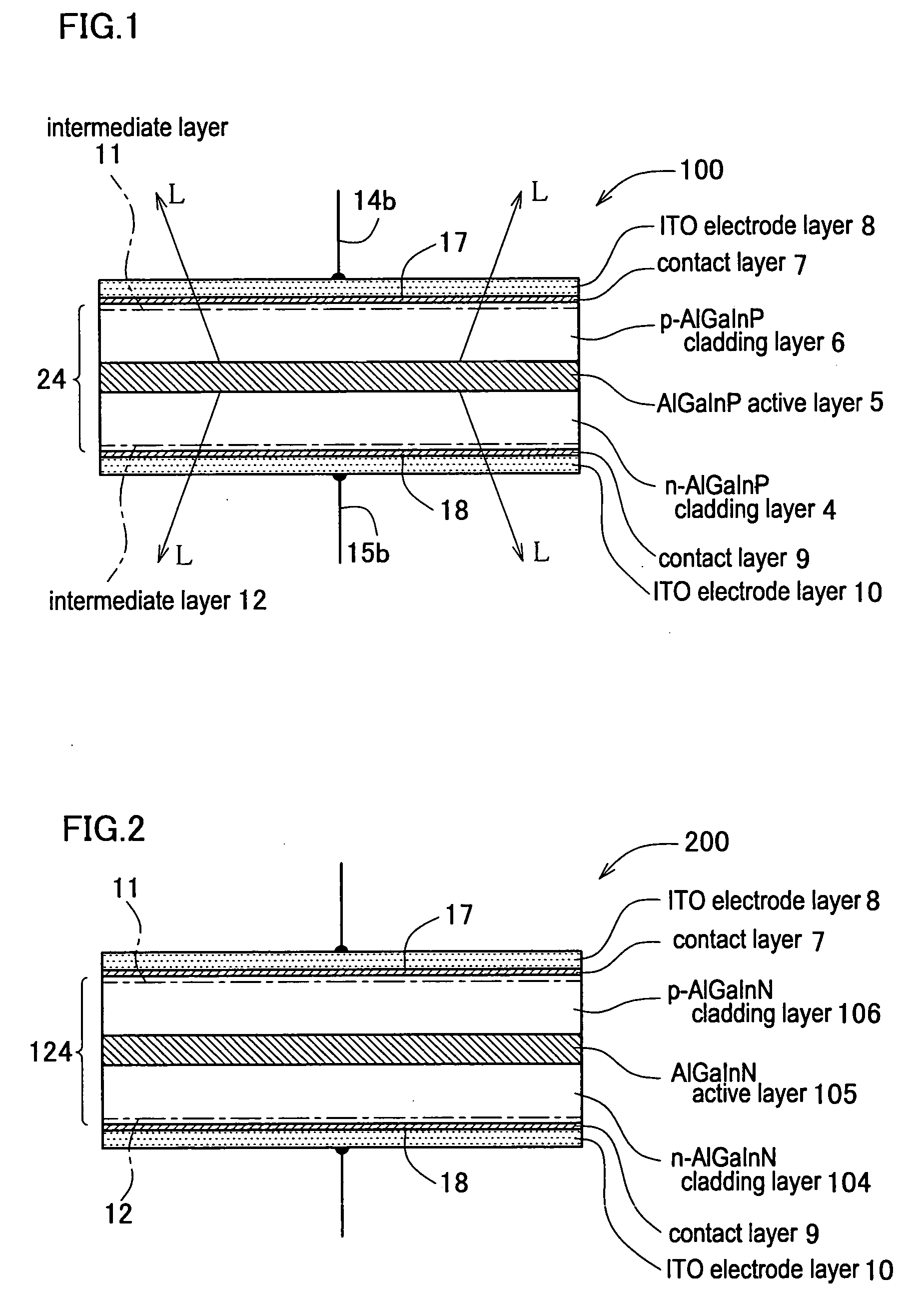

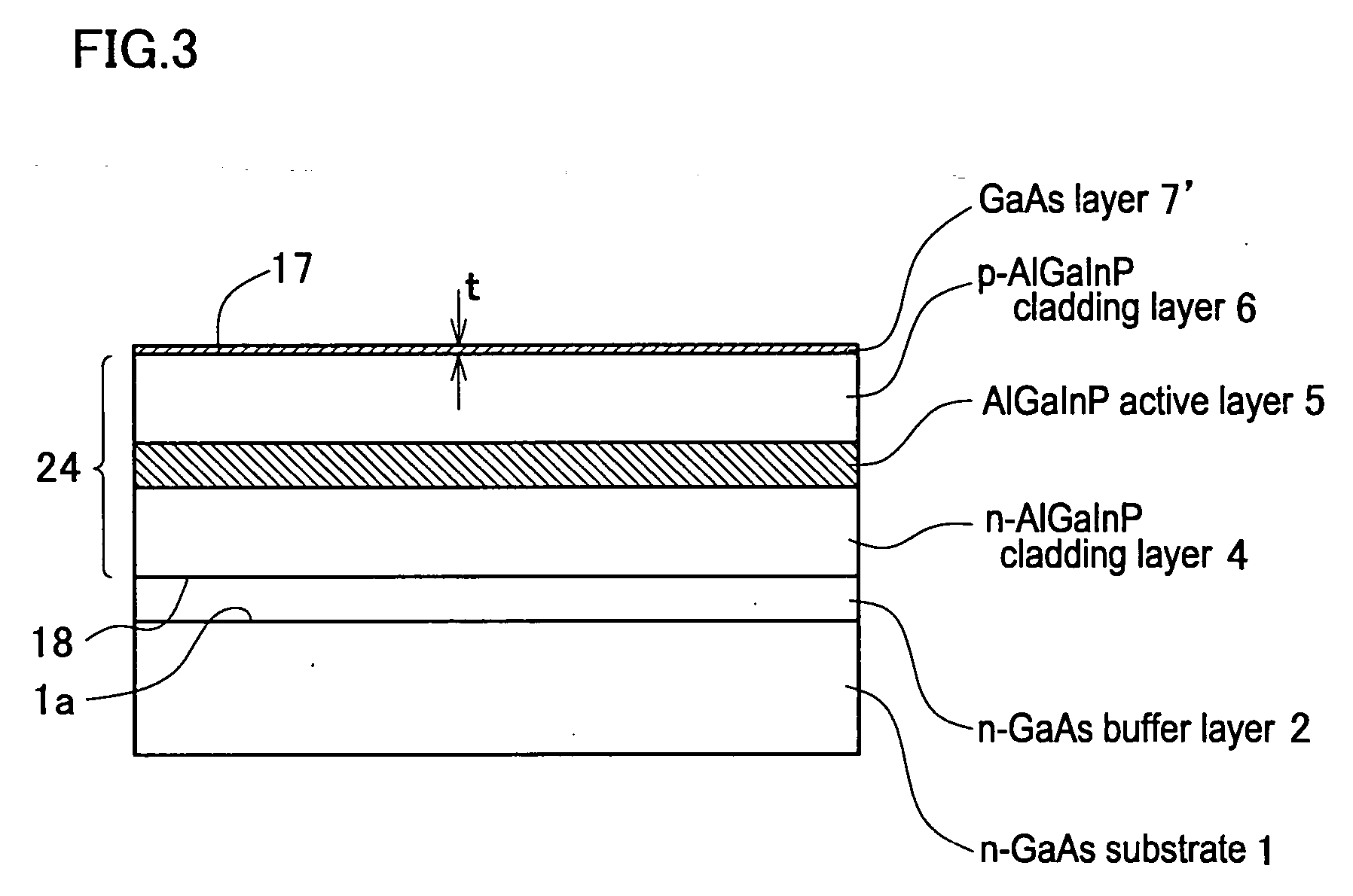

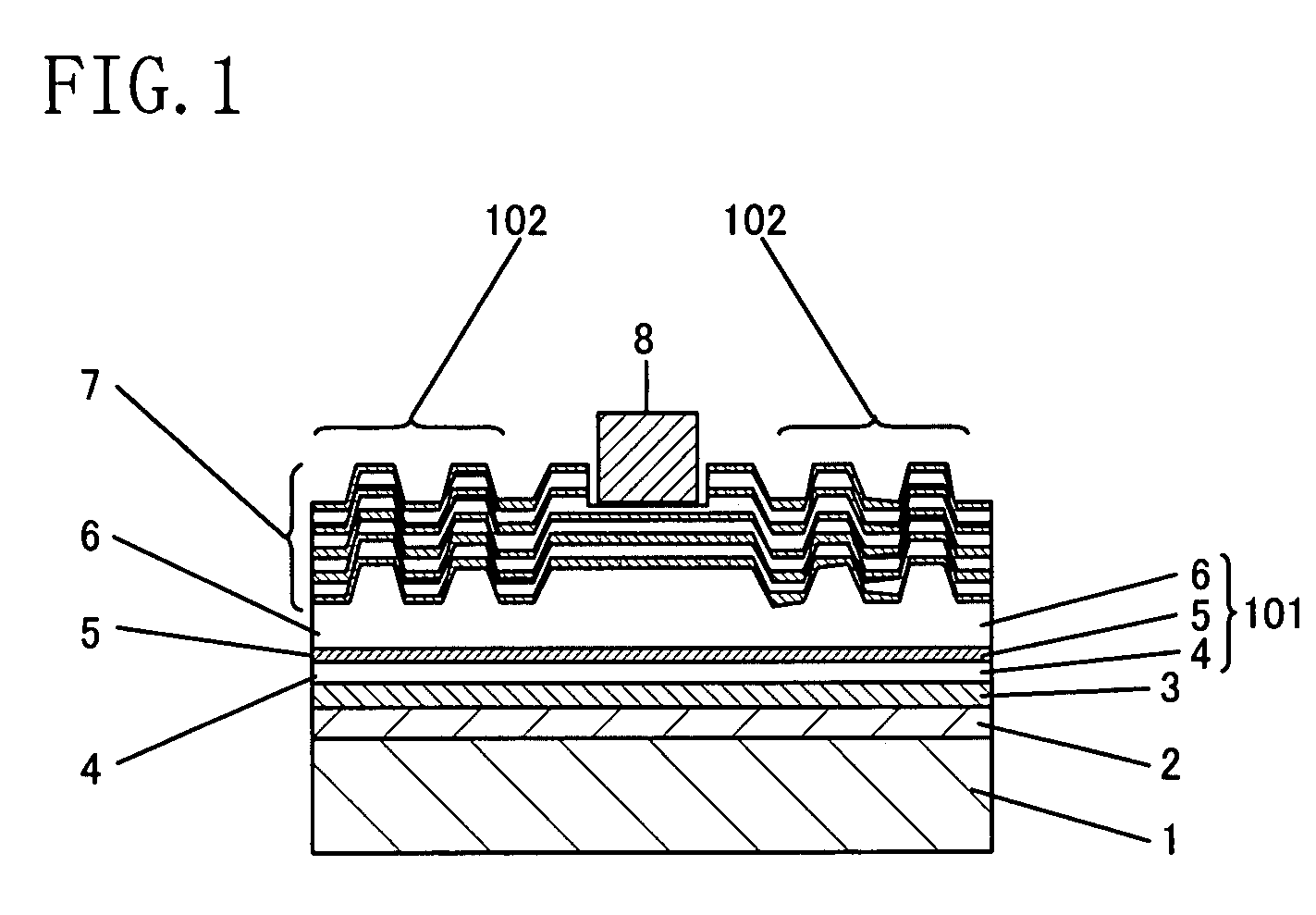

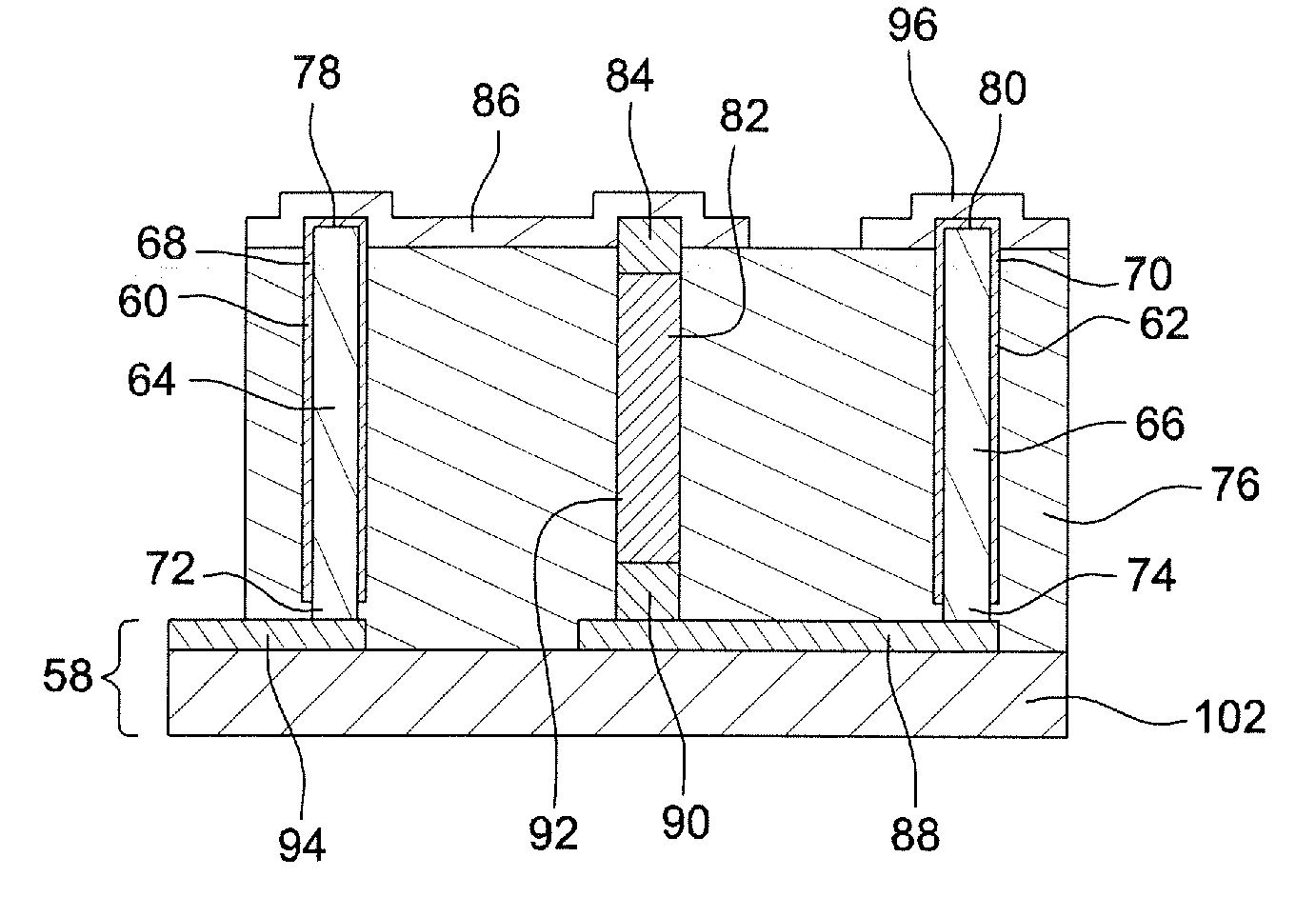

Method of fabricating light-emitting device and light-emitting device

InactiveUS20050285127A1Enhance carrier confinement effectImprove internal quantum efficiencySemiconductor/solid-state device detailsSolid-state devicesContact layerLattice constant

A light-emitting device 100 has ITO transparent electrode layers 8, 10 used for applying drive voltage for light-emission to a light-emitting layer section 24, and is designed so as to extract light from the light-emitting layer section 24 through the ITO transparent electrode layers 8, 10. The light-emitting device 100 also has contact layers composed of In-containing GaAs, formed between the light-emitting layer section 24 and the ITO transparent electrode layers 8, 10, so as to contact with the ITO transparent electrode layers respectively. The contact layers 7, 9 are formed by annealing a stack 13 obtained by forming GaAs layers 7′, 9′ on the light-emitting layer section, and by forming the ITO transparent electrode layers 8, 10 so as to contact with the GaAs layers 7′, 9′, to thereby allow In to diffuse from the ITO transparent electrode layers 8, 10 into the GaAs layers 7′, 9′. This provides a method of fabricating a light-emitting device, in which the ITO transparent electrode layers as the light-emission drive electrodes are bonded as being underlain by the contact layers, to thereby reduce contact resistance of these electrodes, and to thereby make the contact layers less susceptible to difference in the lattice constants with those of the light-emitting layer section during the formation thereof.

Owner:SHIN-ETSU HANDOTAI CO LTD

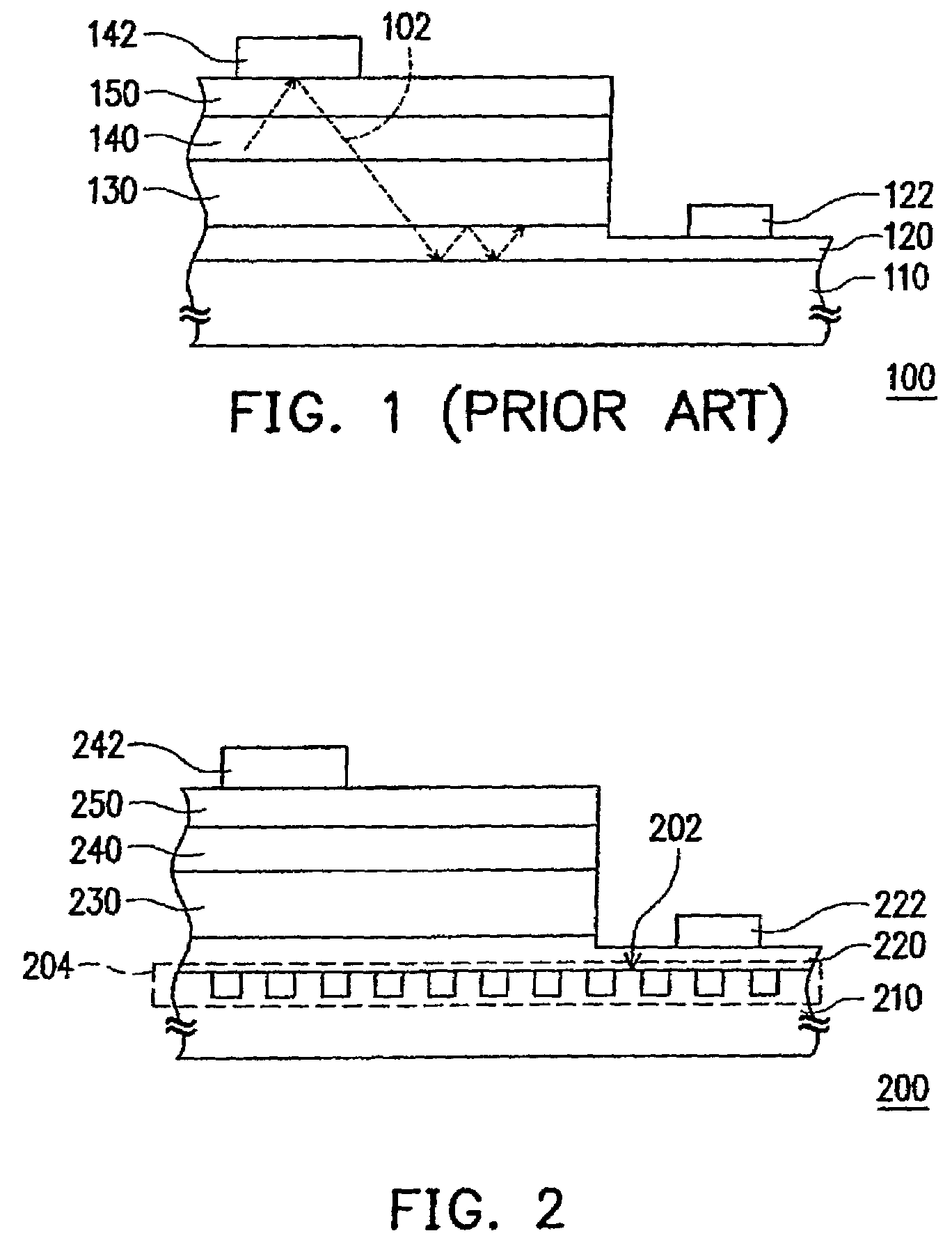

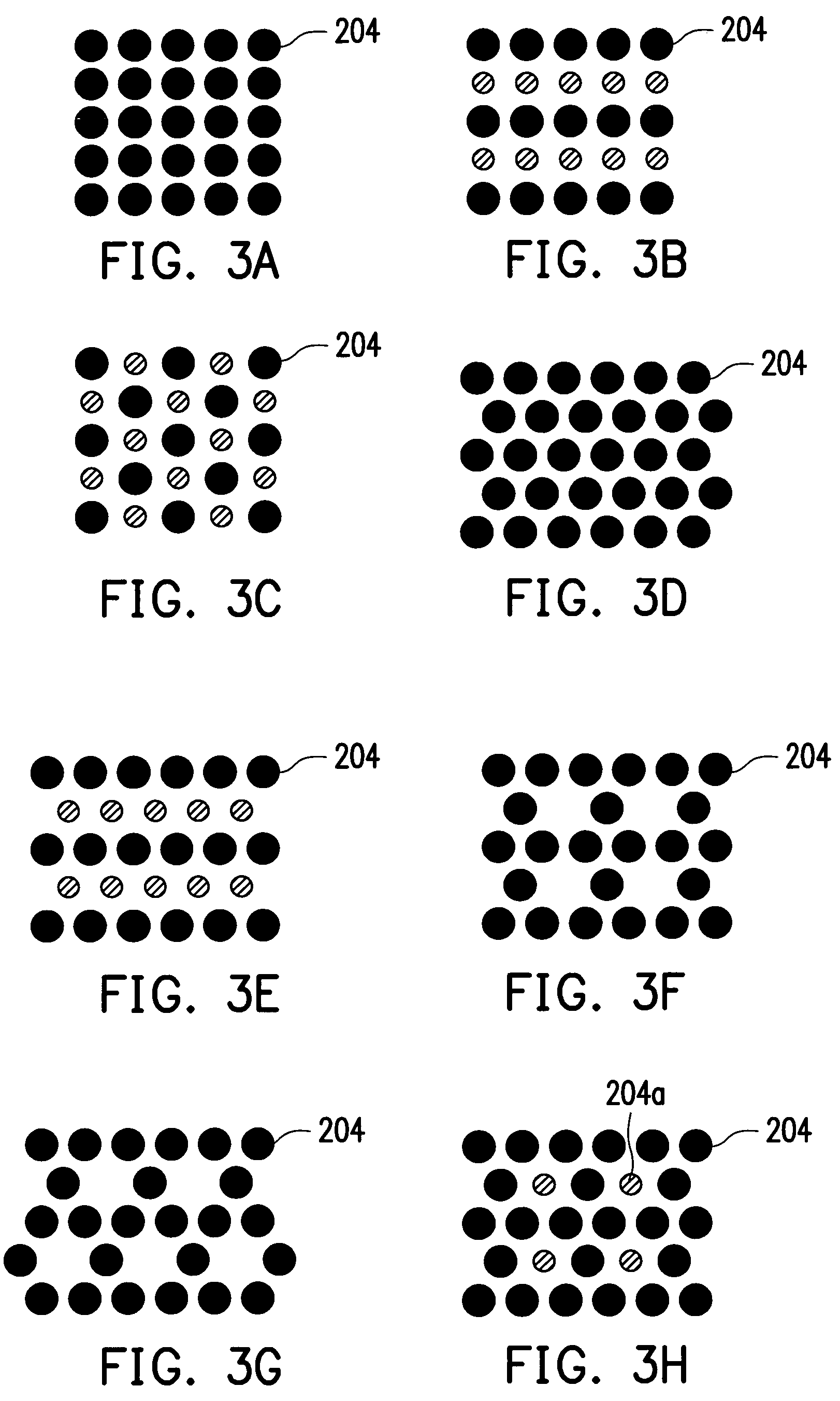

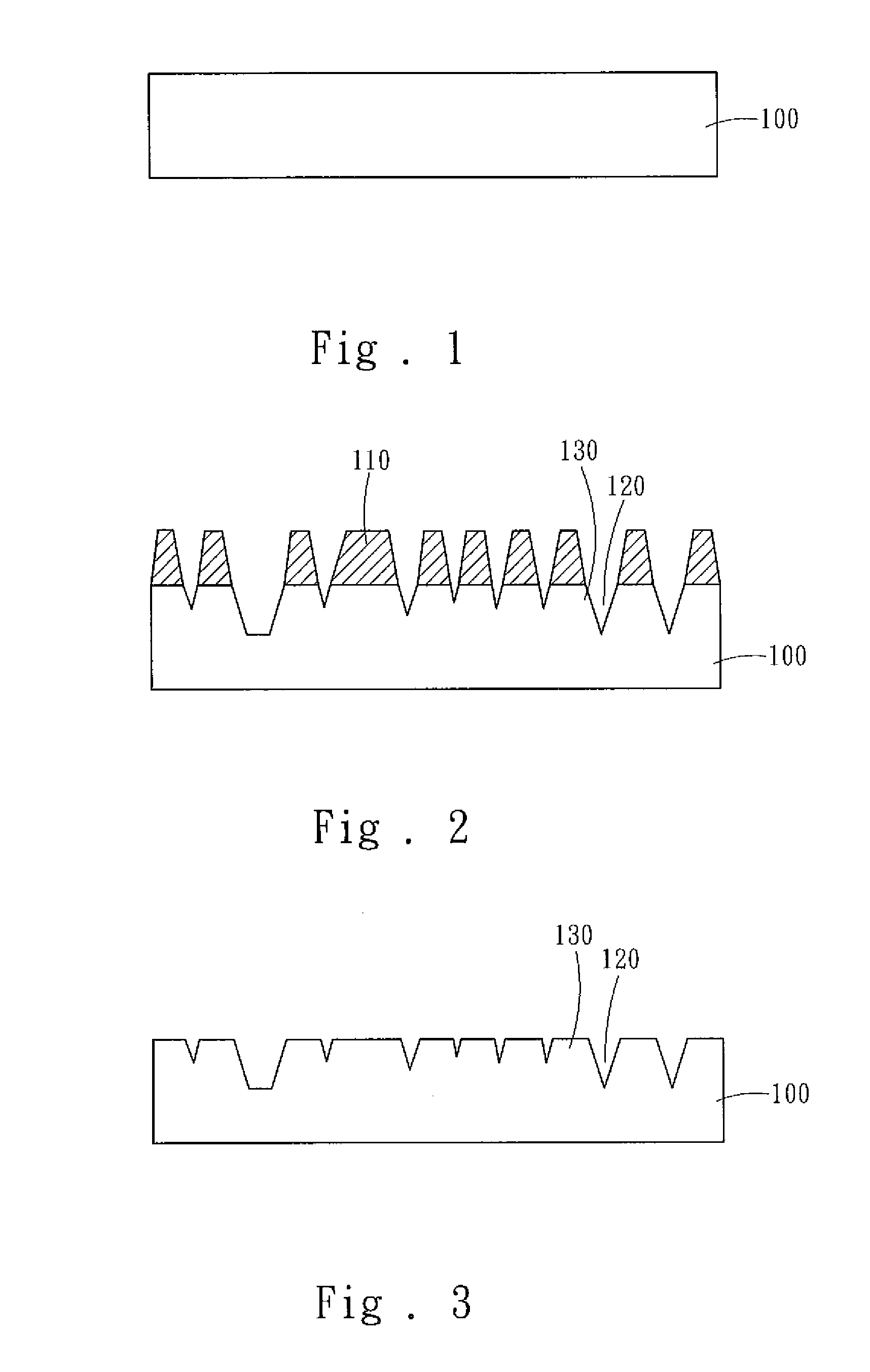

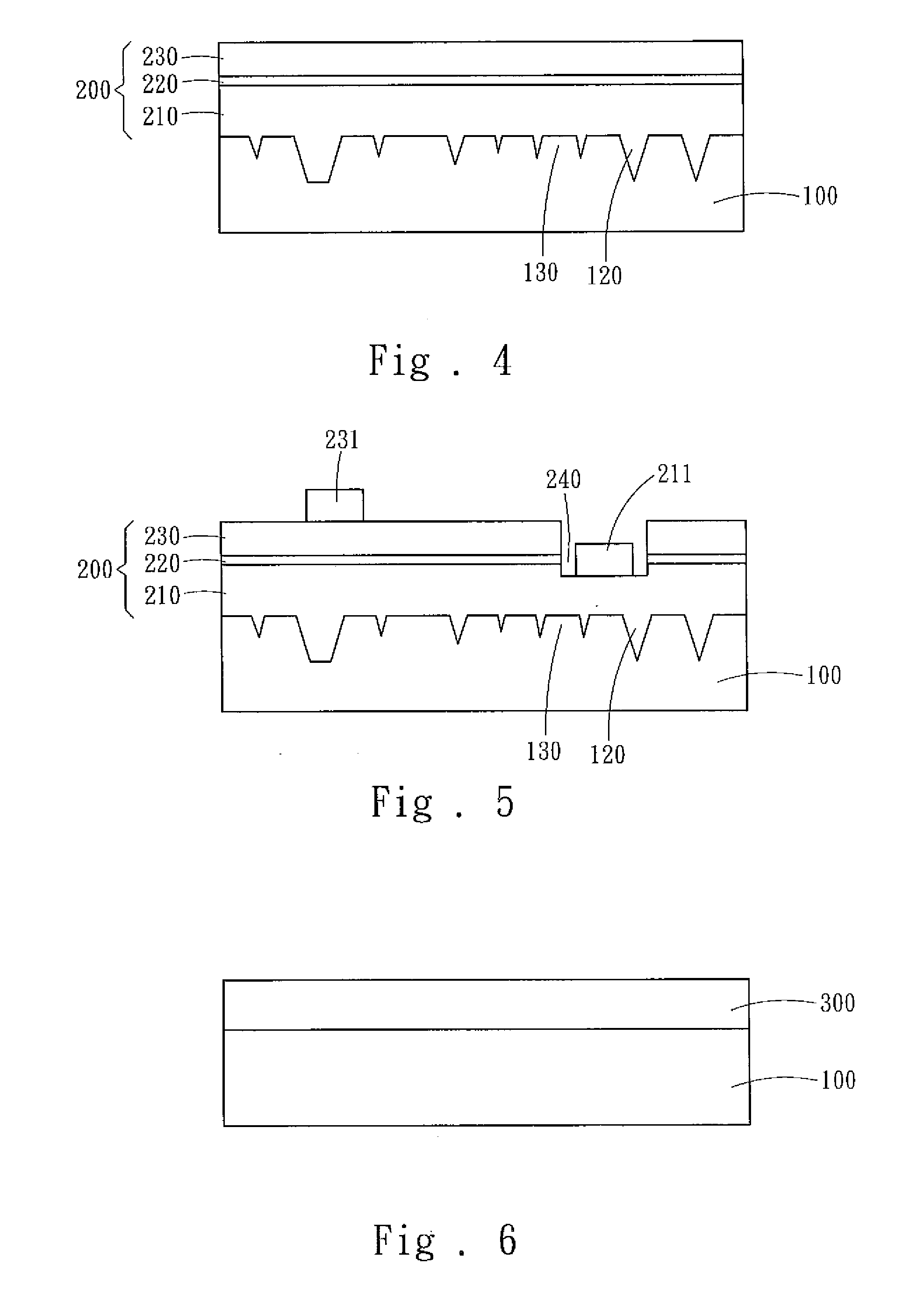

Light emitting diode structure and method for fabricating the same

InactiveUS20090159871A1Quality improvementHorizontal light propagation between the substrate and the semiconductor layers is decreasedSemiconductor/solid-state device manufacturingSemiconductor devicesQuantum efficiencyChemical reaction

The present invention discloses a light emitting diode structure and a method for fabricating the same. In the present invention, a substrate is placed in a solution to form a chemical reaction layer. Next, the substrate is etched to form a plurality of concave zones and a plurality of convex zones with the chemical reaction layer overhead. Next, the chemical reaction layer is removed to form an irregular geometry of the concave zones and convex zones on the surface of the substrate. Then, a semiconductor light emitting structure is epitaxially formed on the surface of the substrate. Thereby, the present invention can achieve a light emitting diode structure having improved internal and external quantum efficiencies.

Owner:TEKCORE CO LTD

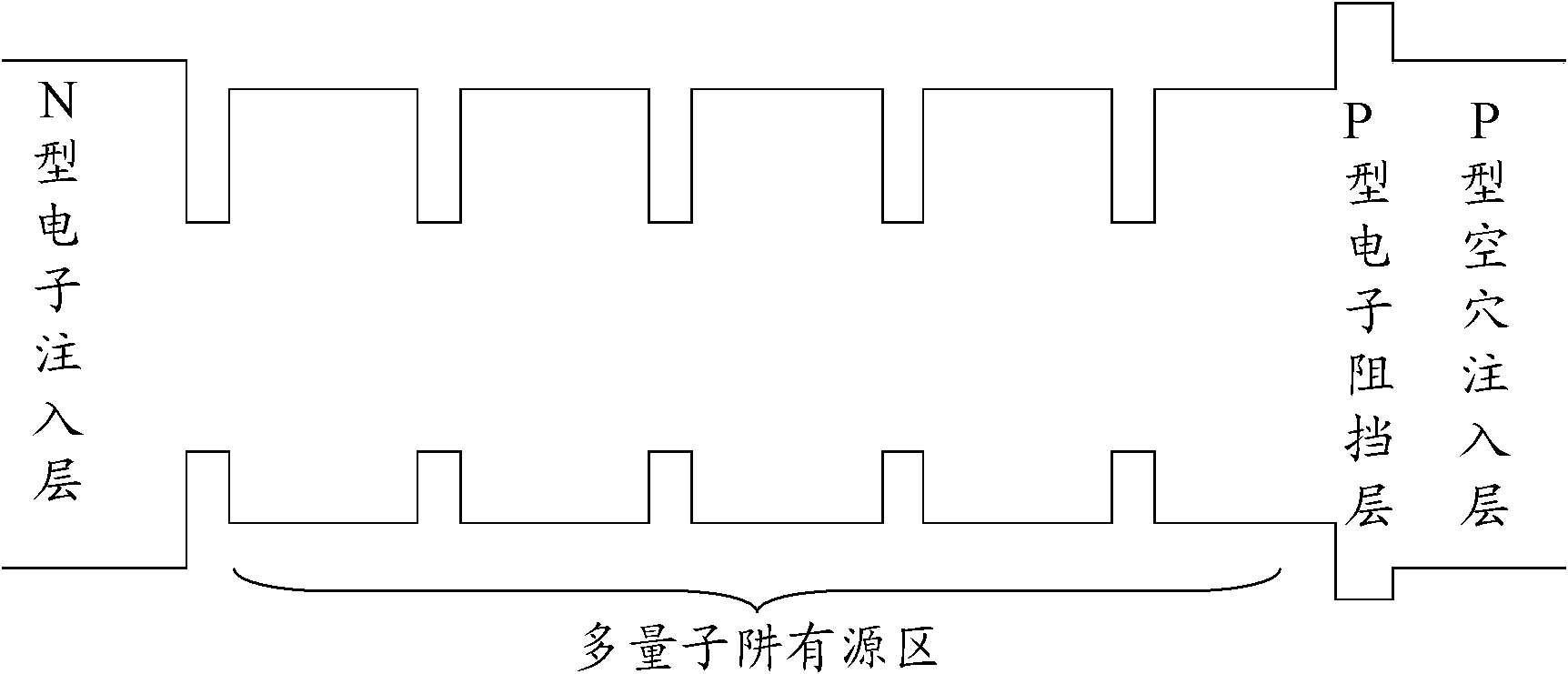

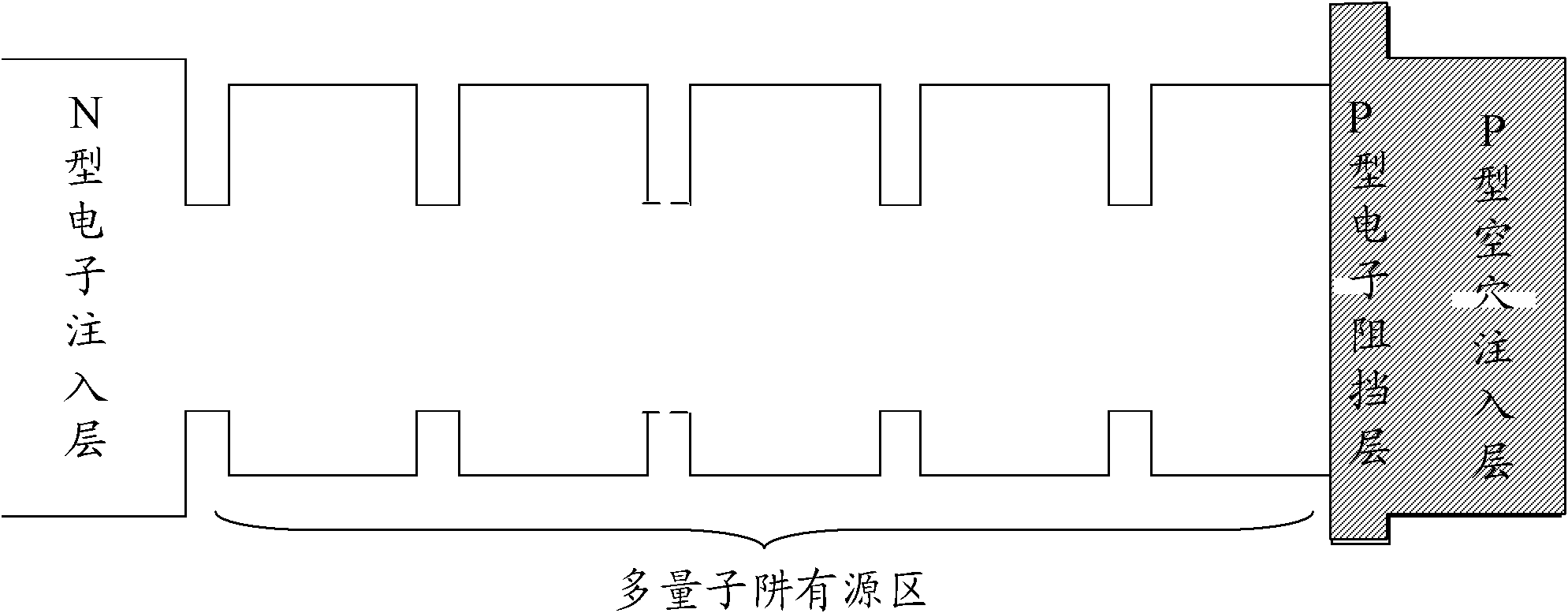

Nitride LED structure and preparation method thereof

InactiveCN102157646AFacilitate the occurrence of phase separationImprove internal quantum efficiencySemiconductor devicesLuminous intensityIndium

The invention discloses a nitride light-emitting diode (LED) structure. An indium gallium nitrogen (InGaN) layer with gradually varied indium (In) content is inserted between an N-type electron injection layer and a multi-quantum well active layer so as to release a stress between the multi-quantum well active layer and the N-type electron injection layer and improve the internal quantum efficiency and the luminous intensity of a device. The invention also discloses a preparation method for the nitride LED structure. In the method, the InGaN layer with gradually varied In content is inserted between the N-type electron injection layer and the multi-quantum well active layer so as to release the stress between the multi-quantum well active layer and the N-type electron injection layer and improve the internal quantum efficiency and the luminous intensity of the device.

Owner:ENRAYTEK OPTOELECTRONICS

Light emitting device

InactiveUS20090250685A1Improve internal quantum efficiencyImprove light extraction efficiencyTransistorSolid-state devicesProtection layerLight emitting device

Disclosed are a light emitting device. The light emitting device includes a first conductive semiconductor layer, a light emitting layer, a protective layer, a nano-layer and a second conductive semiconductor layer. The light emitting layer is formed on the first conductive semiconductor layer. The protective layer is formed on the light emitting layer. The nano-layer is formed on the protective layer. The second conductive semiconductor layer is formed on the nano-layer.

Owner:SUZHOU LEKIN SEMICON CO LTD

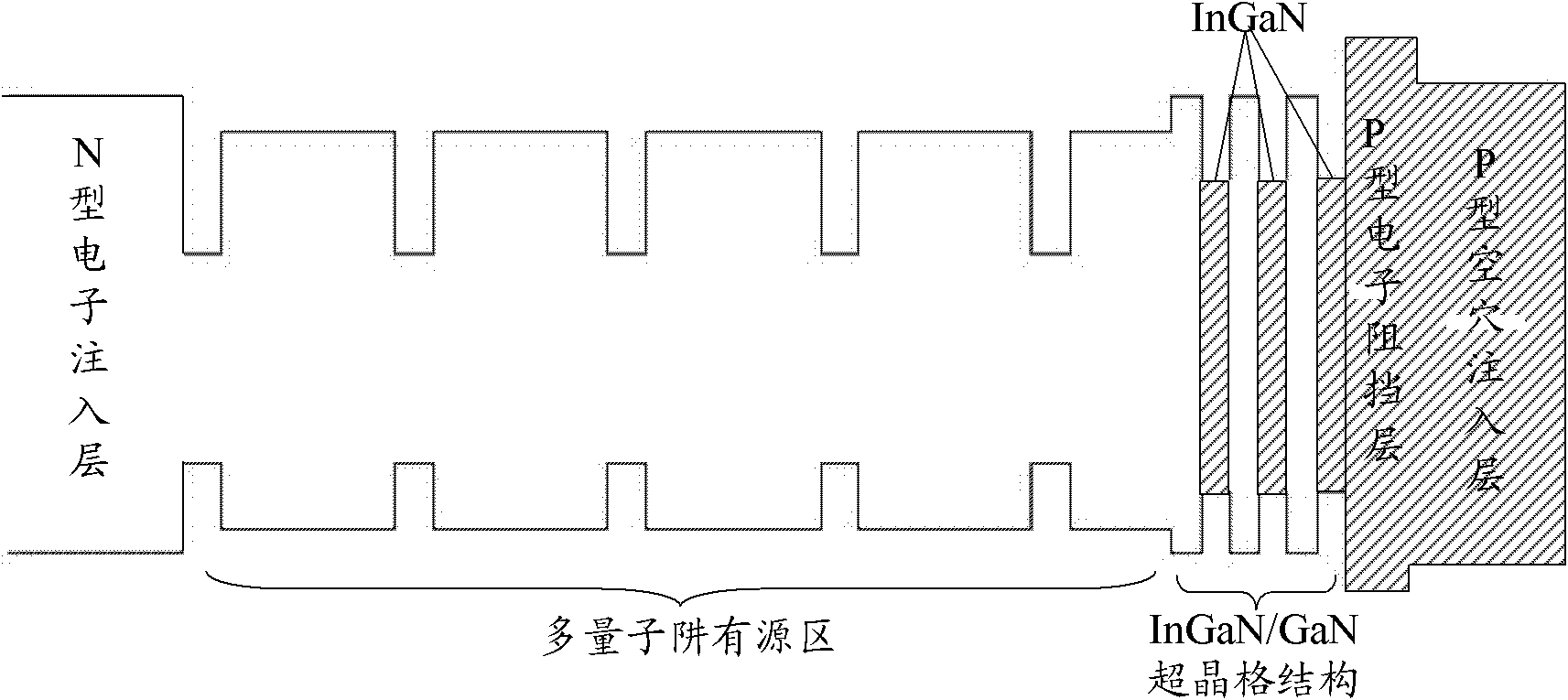

Nitride LED (light-emitting diode) structure and nitride LED structure preparing method

InactiveCN102185057AIncrease hole concentrationImprove internal quantum efficiencySemiconductor devicesPotential wellQuantum efficiency

The invention discloses a nitride LED (light-emitting diode) structure. A P-type doped InGaN / GaN superlattice structure is inserted between a multiple quantum well active layer and an electronic barrier layer so as to improve the hole concentration and reduce the dosage concentration of the P-type hole injection layer; the superlattice structure has polarization effect, thus being capable of improving the doping efficiency and reducing the P-type impurity concentration; and impurity atoms are prevented from being diffused to the potential well, and the inner quantum efficiency and the luminous efficiency of the device can be improved. The invention also discloses a preparation method of the nitride LED structure, through inserting the P-type doped InGaN / GaN superlattice structure between the multiple quantum well active layer and the electronic barrier layer, the hole concentration can be improved, and the dosage concentration of the P-type hole injection layer can be reduced; since the superlattice structure has polarization effect, the doping efficiency can be improved and the P-type impurity concentration can be reduced; and the impurity atoms are prevented from being diffused to the potential well, and the inner quantum efficiency and the luminous efficiency of the device can be improved.

Owner:ENRAYTEK OPTOELECTRONICS

Lighting-emitting device with nanostructured layer and method for fabricating the same

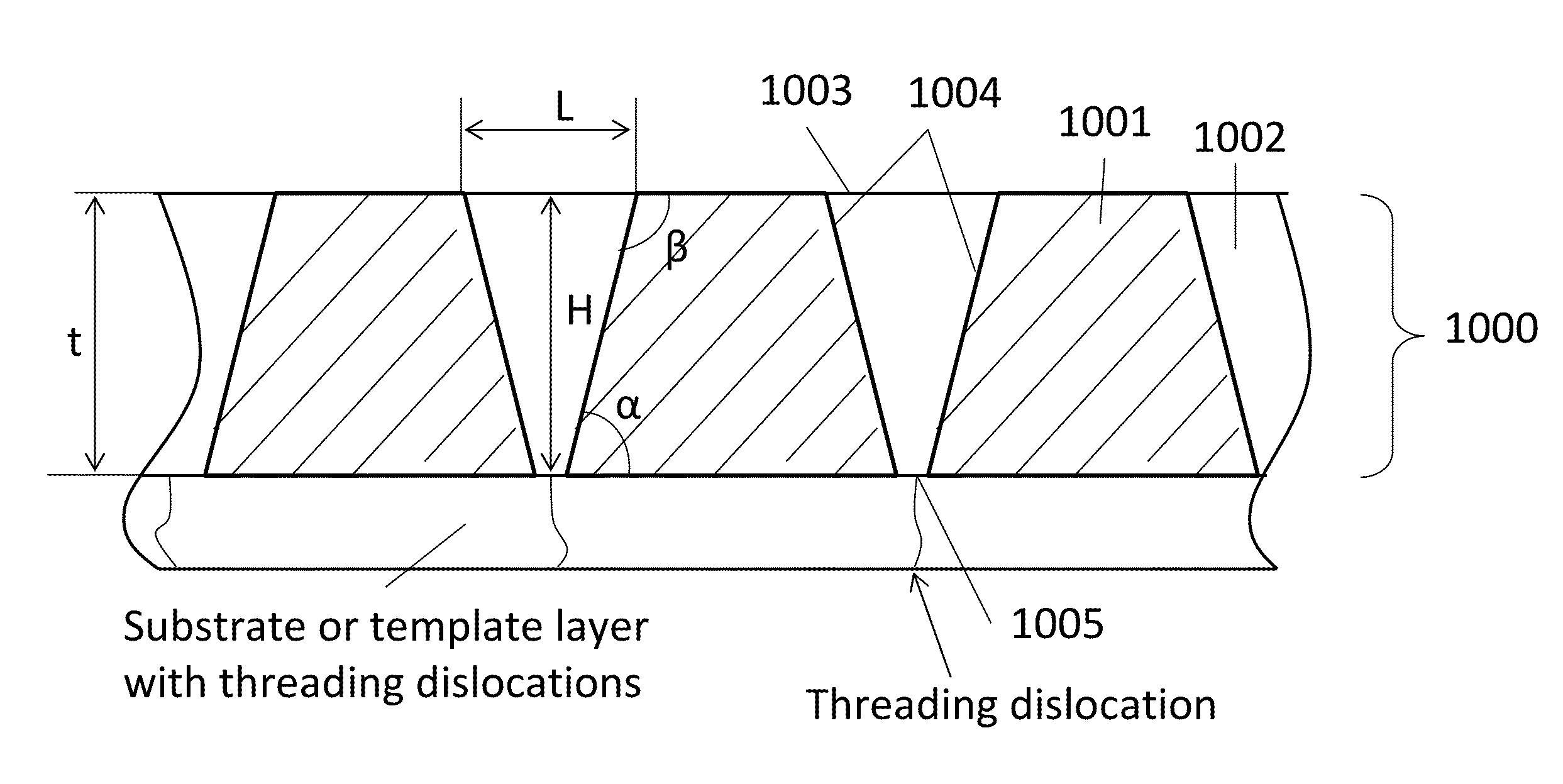

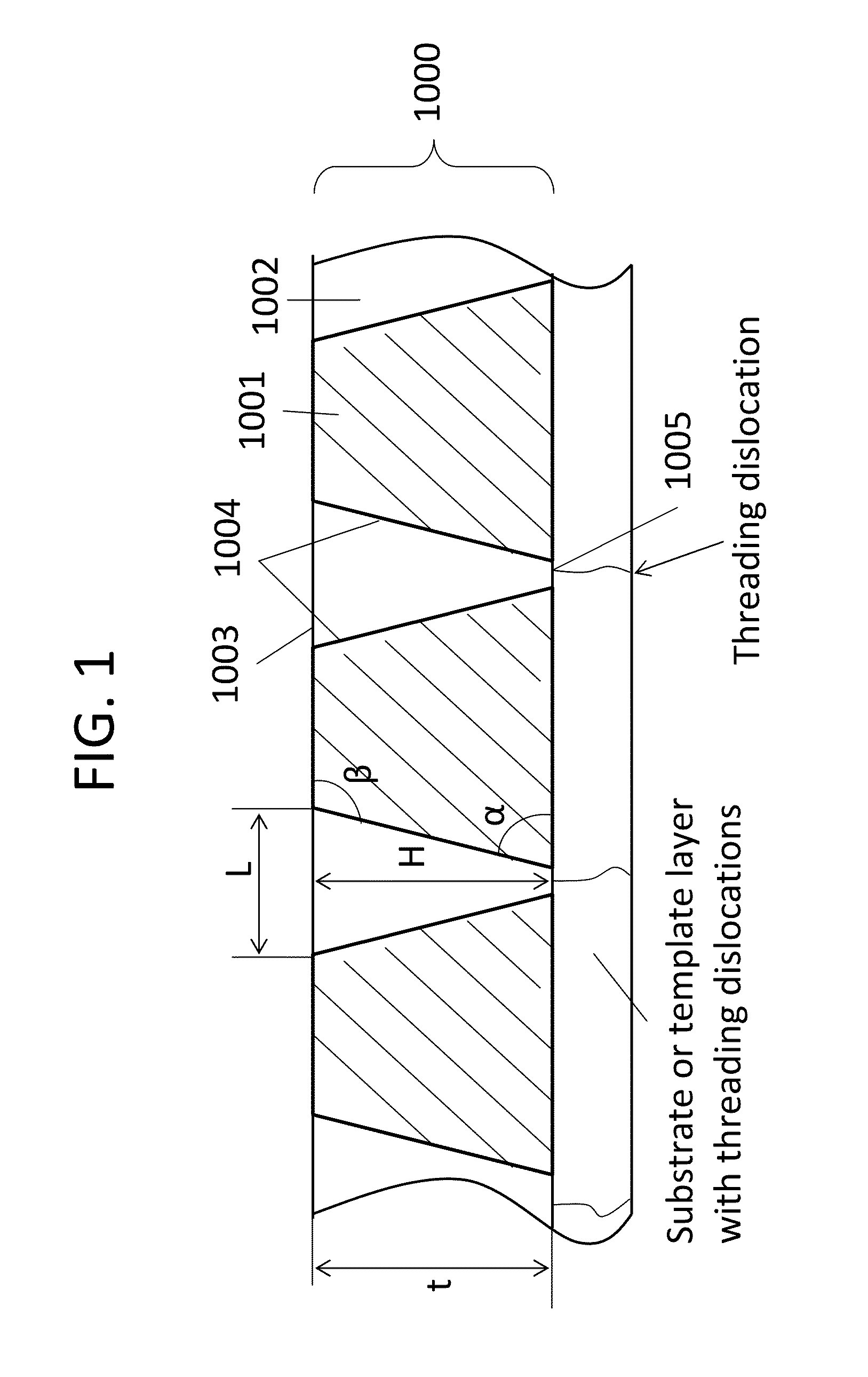

InactiveUS20130187124A1High LED epi-wafer throughputReducing epitaxy timePolycrystalline material growthNanoopticsNanostructureLight emitting device

A light emitting device has a nanostructured layer with nanovoids. The nanostructured layer can be provided below and adjacent to active region or on a substrate or a template below an n-type layer for the active region, so as to reduce strain between epitaxial layers in the light emitting device. A method of manufacturing the same is provided.

Owner:ZHEJIANG INVENLUX TECH

Semiconductor device and method for fabricating the same

InactiveUS20080048176A1Improve featuresEasy to makeSemiconductor/solid-state device manufacturingSemiconductor devicesActive layerSemiconductor device

A semiconductor device includes a semiconductor superlattice layer and a semiconductor multilayer. The semiconductor superlattice layer has periodic concave-convex shapes, and a plurality of semiconductor films each having bent portions in accordance with the concave-convex shapes are stacked in the semiconductor superlattice layer. The semiconductor multilayer is formed so as to cover the concave-convex shapes and includes an active layer.

Owner:PANASONIC CORP

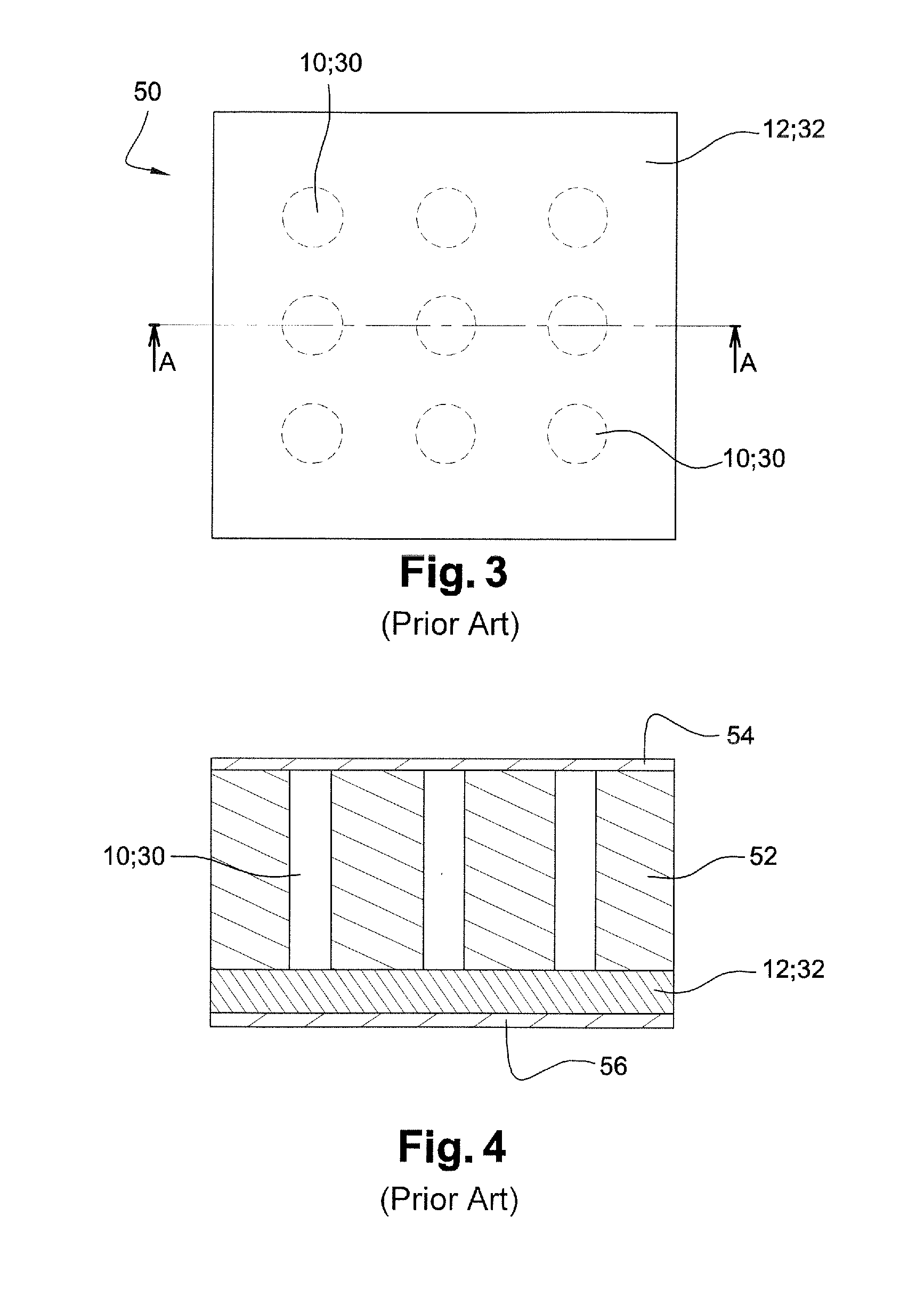

In-series electrical connection of light-emitting nanowires

ActiveUS20140077156A1Easy to limitControl concentrationSolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionNanowire

An optoelectronic device includes at least first and second light-emitting nanowires on a support, each comprising an area for the injection of holes and an area for the injection of electrons, a series electric connection including a connection nanowire on the support, which includes a first region forming an electric path with the hole injection area of the first nanowire, a second region forming an electric path with the electron injection area of the second nanowire, and a third region enabling a current to flow between first and second regions. Also included are a first conductive area connecting the hole injection area of the first nanowire and the first region of the connection nanowire and electrically insulated from the second nanowire, and a second conductive area connecting the second region of the connection nanowire and electron injection area of the second nanowire and electrically insulated from the first nanowire.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Semiconductor ultraviolet source device

ActiveCN103247728AImprove luminous efficiencyReduce tiltSemiconductor devicesUltravioletElectronic band structure

The invention provides a semiconductor ultraviolet source device. A quantum well and a quantum barrier in the epitaxial growth structure of the device have component gradients in the epitaxial growth direction, and the directions of the component gradients of the quantum well and the quantum barrier in the epitaxial growth direction are opposite. Heterostructures such as the energy band structures of multiple quantum wells are regulated through using the variation of the Al (aluminum) component of AlInGaN material, the energy band edge inclination of the quantum well and the quantum barrier is reduced, electrons and holes injected to the barrier are reduced, the positive working voltage of an ultraviolet LED (light emitting diode) is reduced, and the light emitting efficiency of the quantum well is improved.

Owner:QINGDAO JASON ELECTRIC

Blue LED epitaxial structure with suppression polarization effect barrier layer

ActiveCN105552186AImprove injection efficiencyIncrease the probability of hole recombinationSemiconductor devicesQuantum efficiencyQuantum well

The invention provides a blue LED epitaxial structure with a suppression polarization effect barrier layer, and relates to the technical field of light emitting diodes. The blue LED epitaxial structure comprises a substrate, an AlN buffer layer, a U-type GaN layer, an N-type GaN layer, a shallow quantum well layer, an active region, an electron blocking layer, and a P-type GaN layer in sequence from bottom to top, the suppression polarization effect barrier layer is inserted between the shallow quantum well layer and the active region, and the suppression polarization effect barrier layer comprises an AlxGal-xN layer and a SiN layer from bottom to top. According to the blue LED epitaxial structure, a novel barrier layer is inserted into the conventional epitaxial structure, the stress is released, polarization is suppressed, the defect density is reduced, the radiative recombination probability is improved, the polarization effect is reduced, and the quantum efficiency in the LED is improved.

Owner:NANTONG TONGFANG SEMICON

Group iii nitride based light emitting diode structures with multiple quantum well structures having varying well thicknesses

InactiveCN102822995AImprove internal quantum efficiencySemiconductor devicesPhysical chemistryLight-emitting diode

A Group III nitride based light emitting diode includes a p-type Group III nitride based semiconductor layer, an n-type Group III nitride based semiconductor layer that forms a P-N junction with the p-type Group III nitride based semiconductor layer, and a Group III nitride based active region on the n-type Group III nitride based semiconductor layer. The active region includes a plurality of sequentially stacked Group III nitride based wells including respective well layers. The plurality of well layers includes a first well layer having a first thickness and a second well layer having a second thickness. The second well layer is between the P-N junction and the first well layer, and the second thickness is greater than the first thickness.

Owner:CREE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com