Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2697results about How to "Improve crystal quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of Manufacturing Vanadium Oxide Thin Film

InactiveUS20090011145A1Uniform thicknessComposition is stableChemical vapor deposition coatingPlasma techniqueOxygenMaterials science

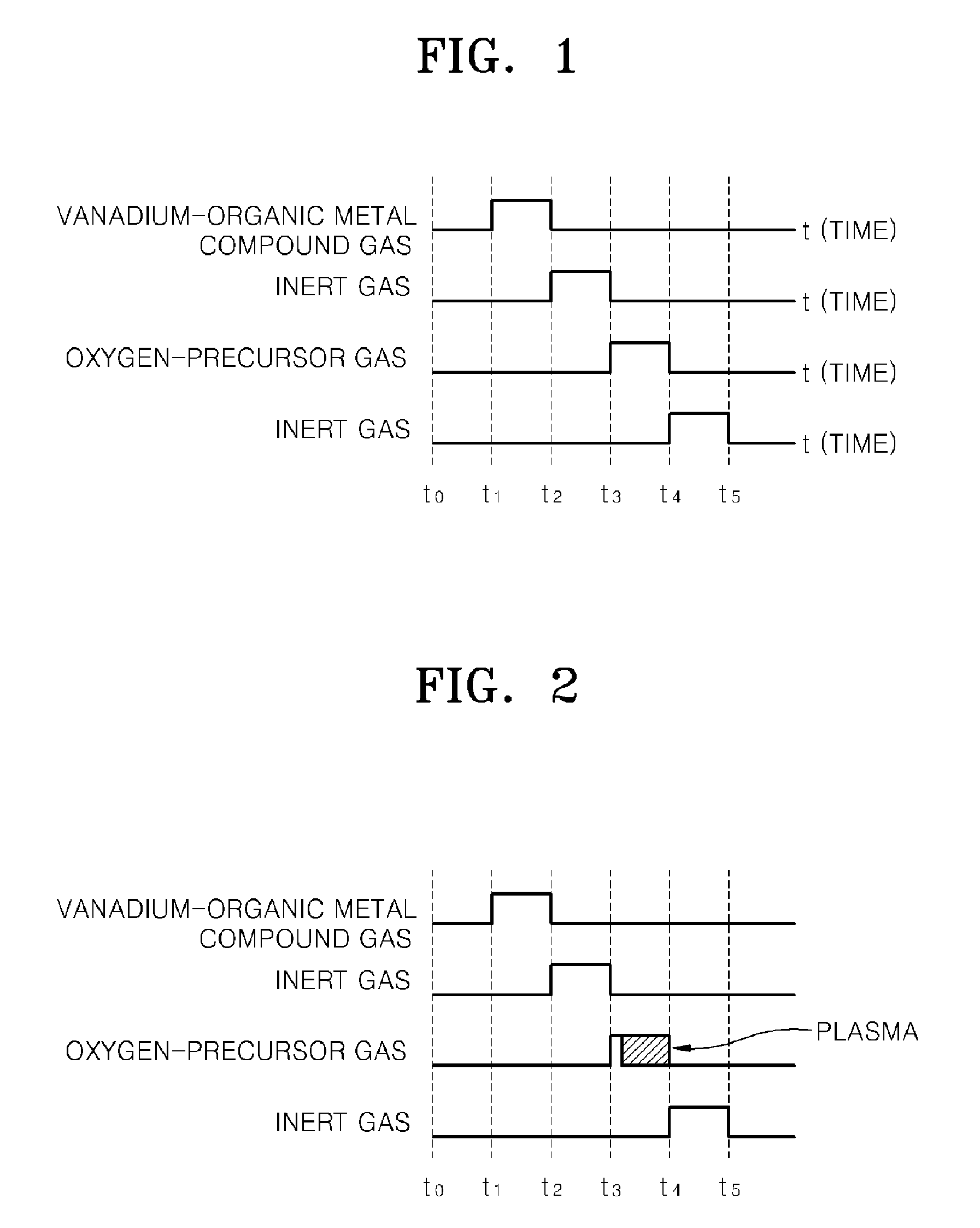

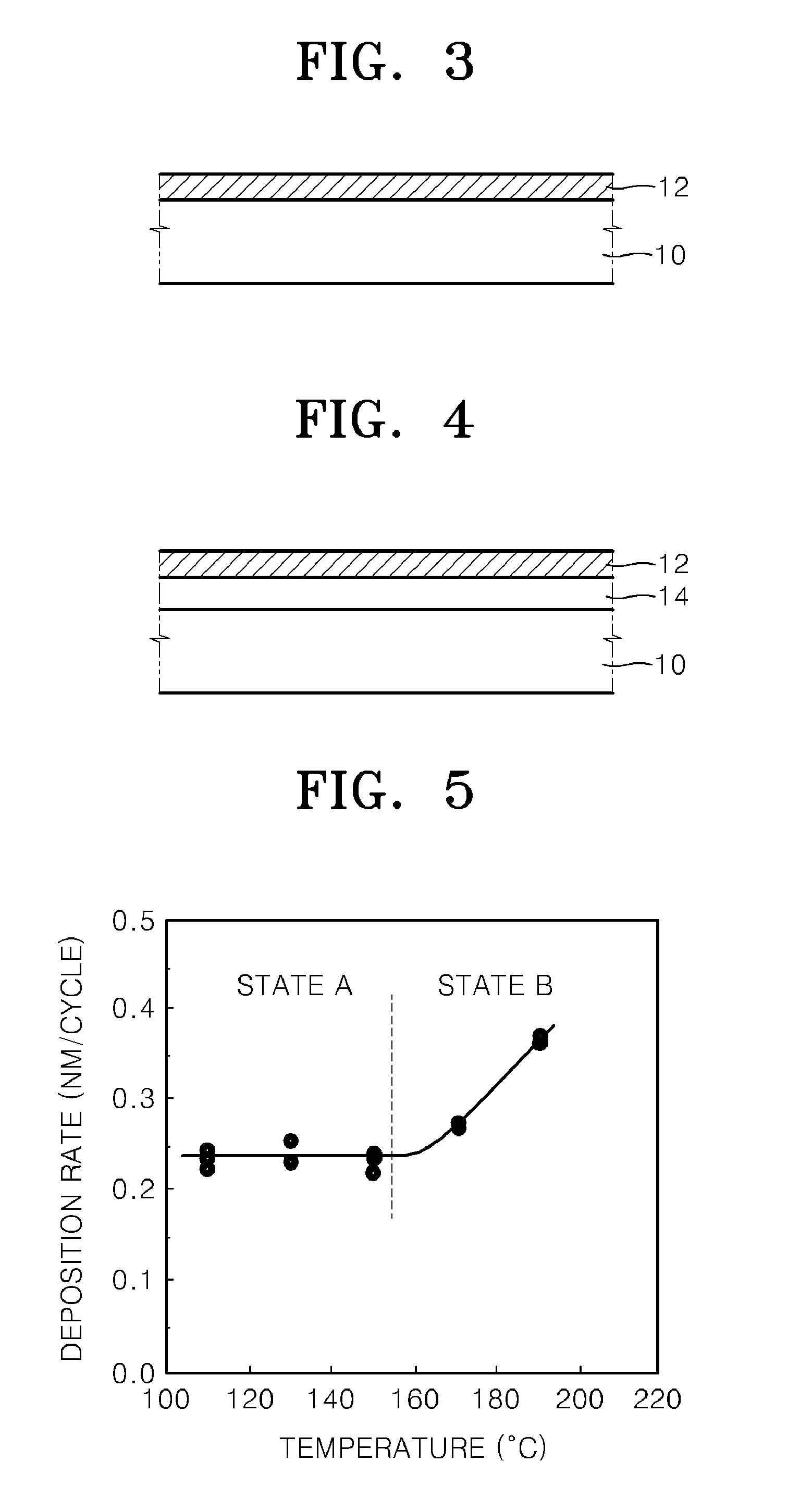

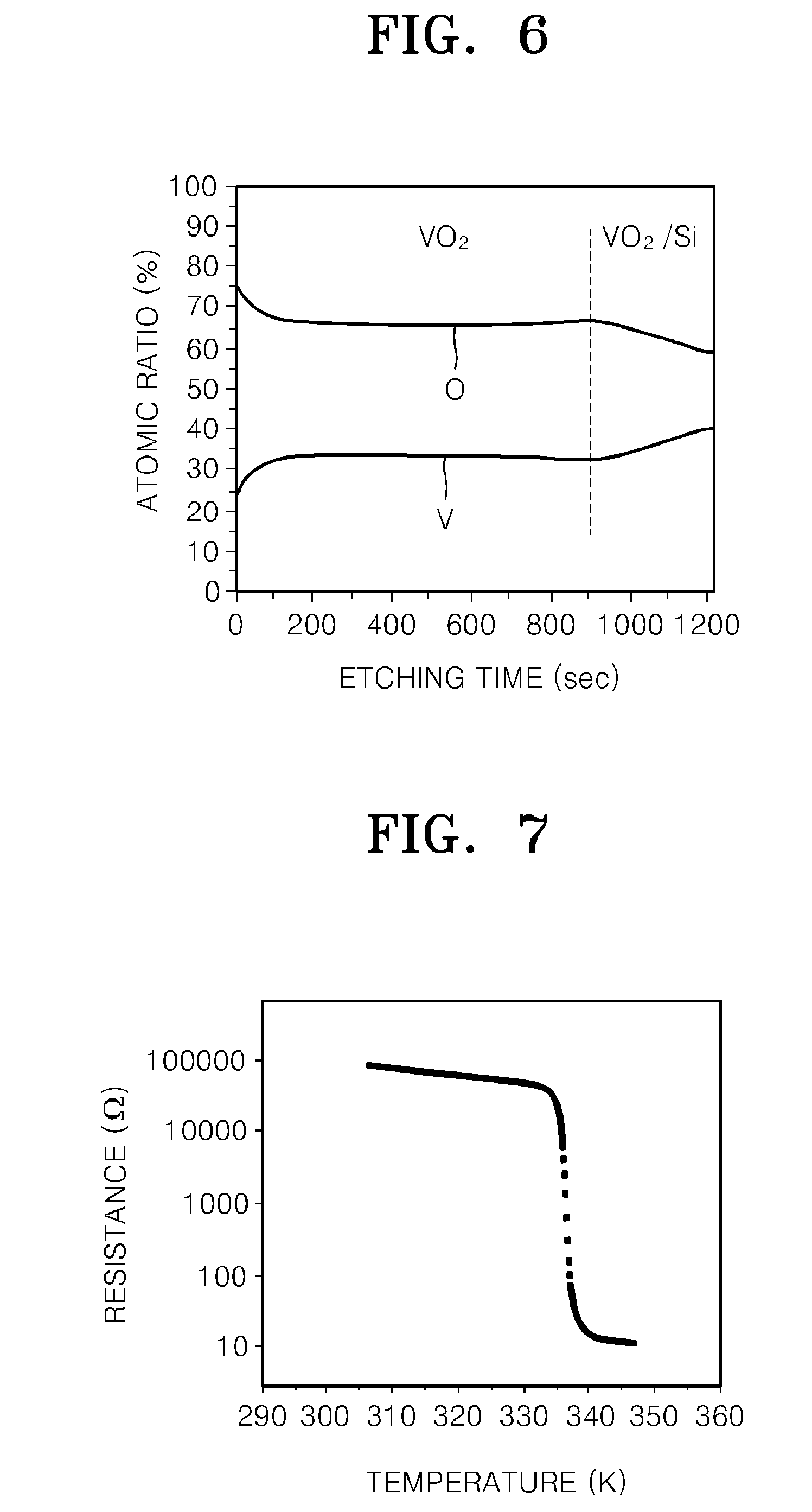

Provided is a method of manufacturing a large-sized vanadium oxide thin film having a uniform surface, uniform film thickness and stable composition. According to the method, a vanadium-organometallic compound gas is injected into a chamber to form adsorption layer where molecules of the vanadium-organometallic compound are adsorbed on the surface of a substrate. After that, an oxygen precursor is injected into the chamber and thus allowed to accomplish surface-saturation reaction with the adsorbed materials to fabricate a vanadium oxide thin film.

Owner:ELECTRONICS & TELECOMM RES INST

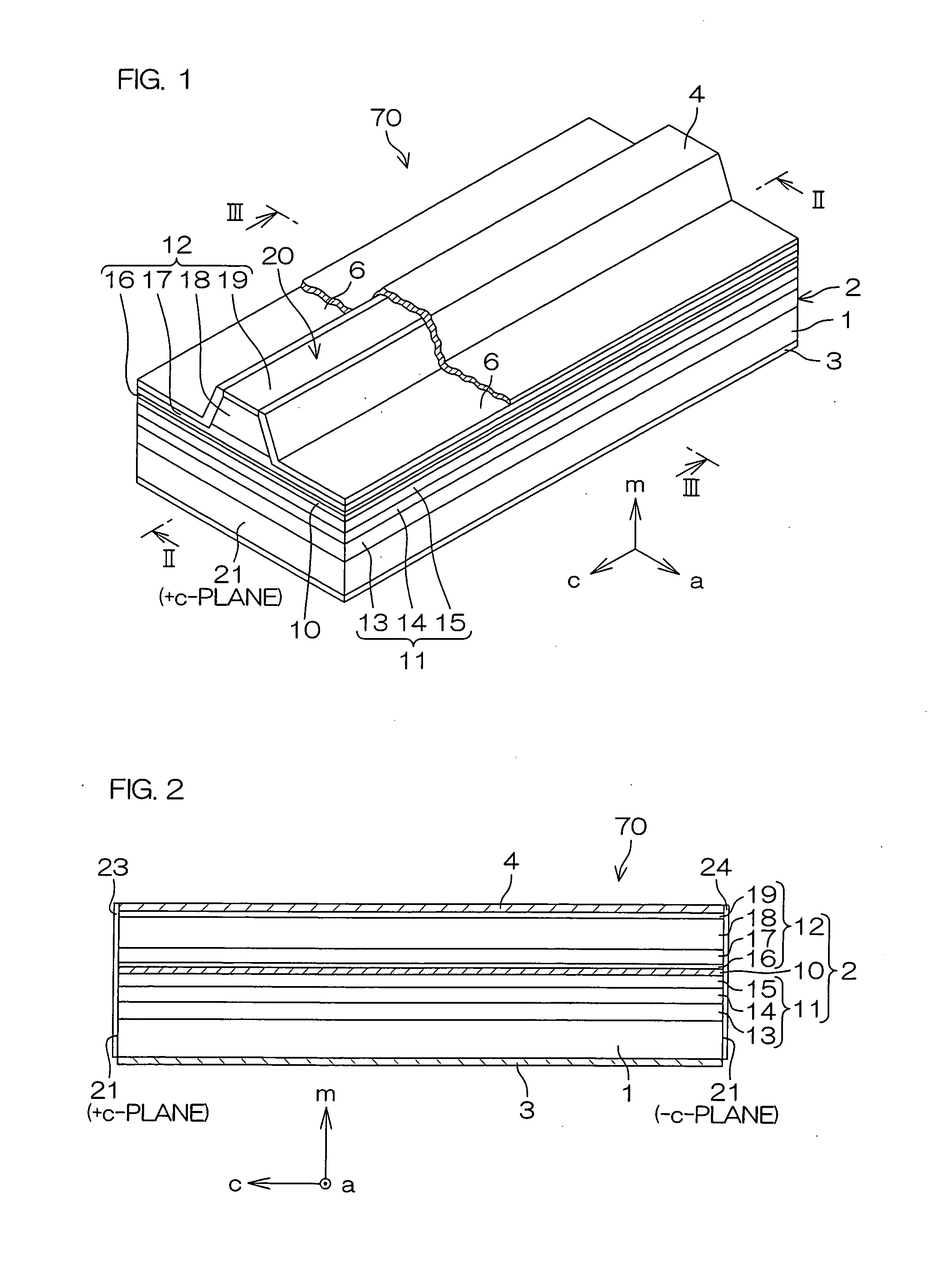

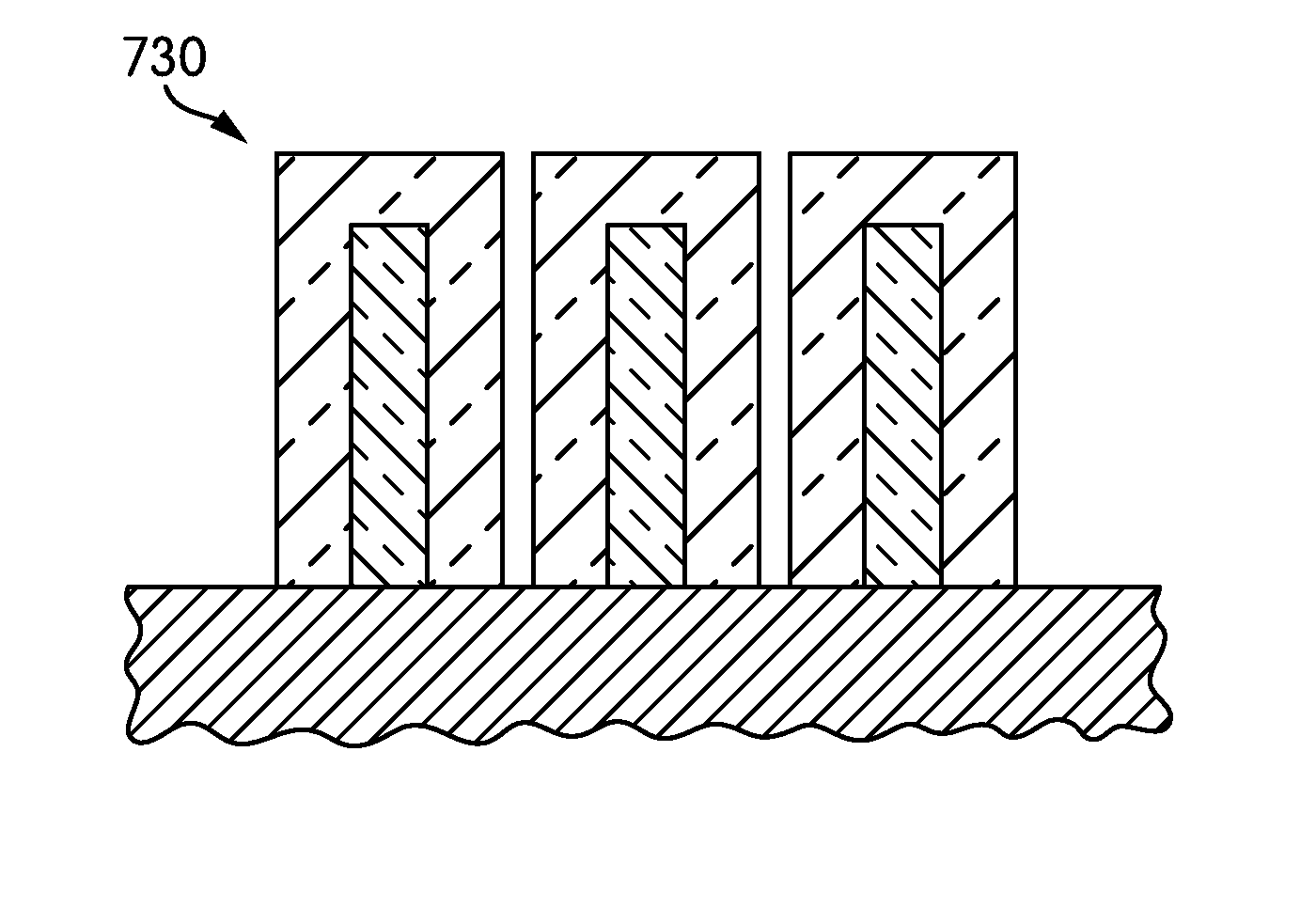

Semiconductor laser diode

InactiveUS20080285609A1Improve luminous efficiencyAvoid polarizationLaser detailsLaser active region structureLight-emitting diodeCrystal growth

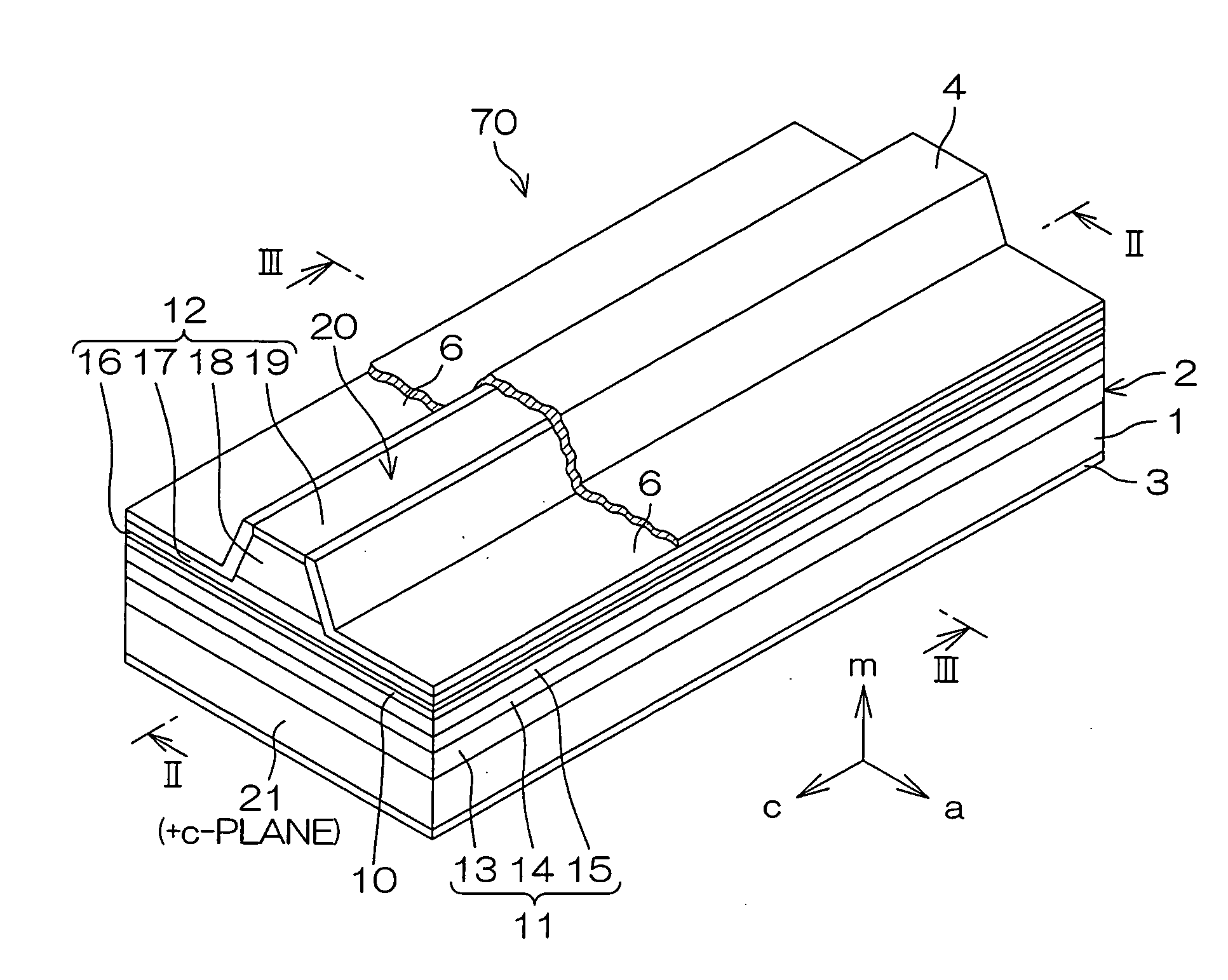

An inventive semiconductor laser diode includes a Group III nitride semiconductor layered structure having a major crystal growth plane defined by a non-polar or semi-polar-plane. The Group III nitride semiconductor layered structure includes: a p-type cladding layer and an n-type cladding layer; an In-containing p-type guide layer and an In-containing n-type guide layer held between the p-type cladding layer and the n-type cladding layer; and an In-containing light emitting layer held between the p-type guide layer and the n-type guide layer.

Owner:ROHM CO LTD

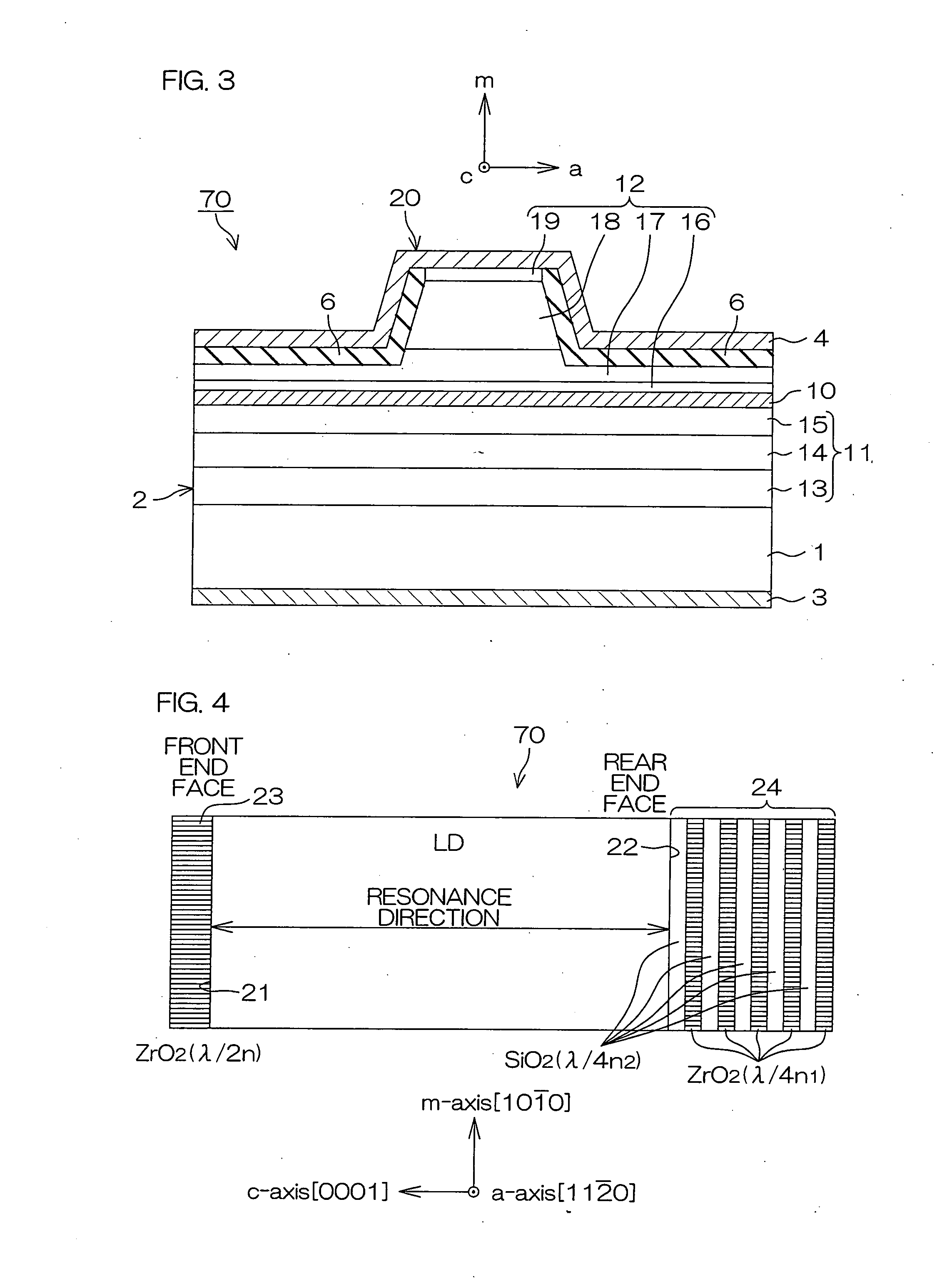

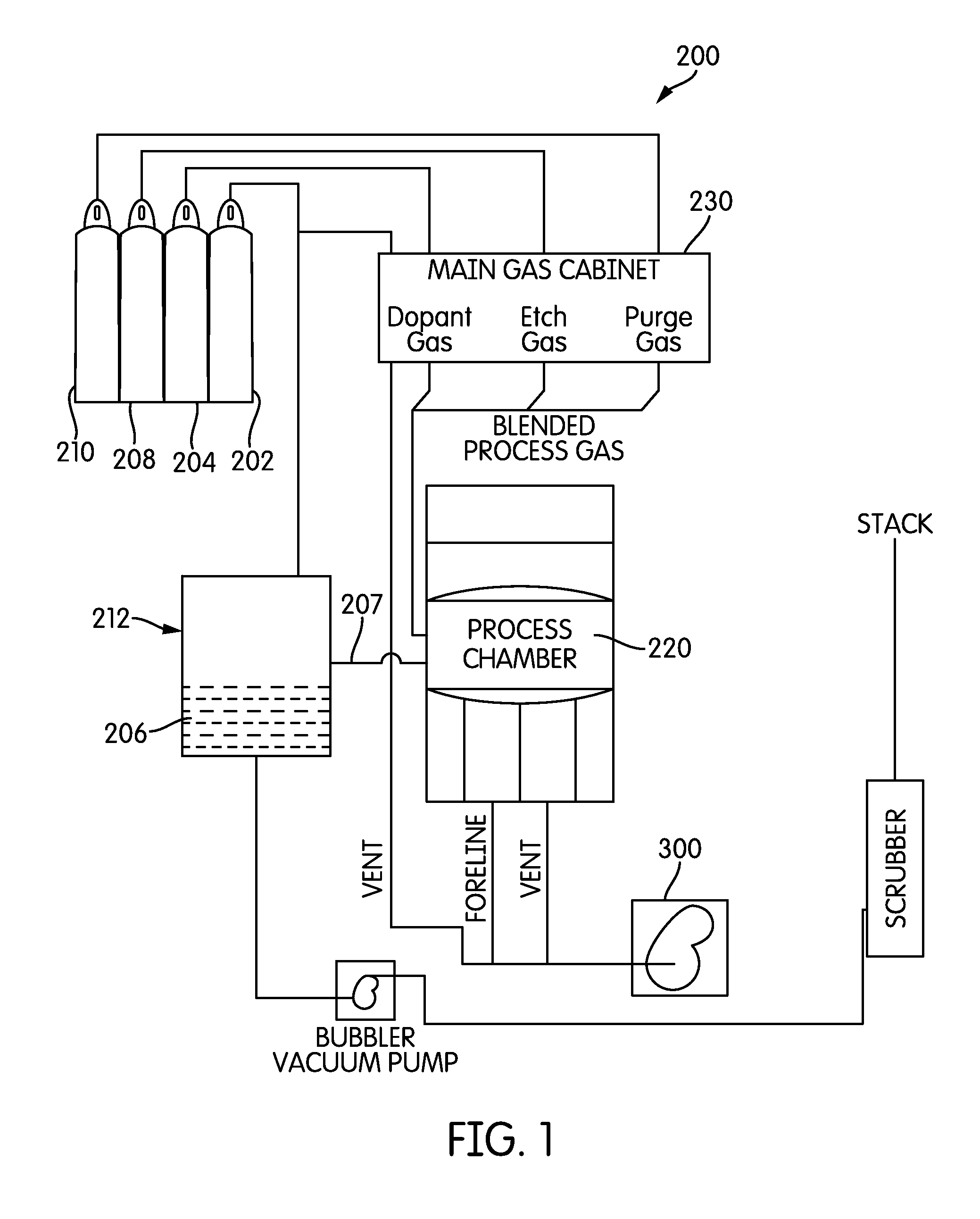

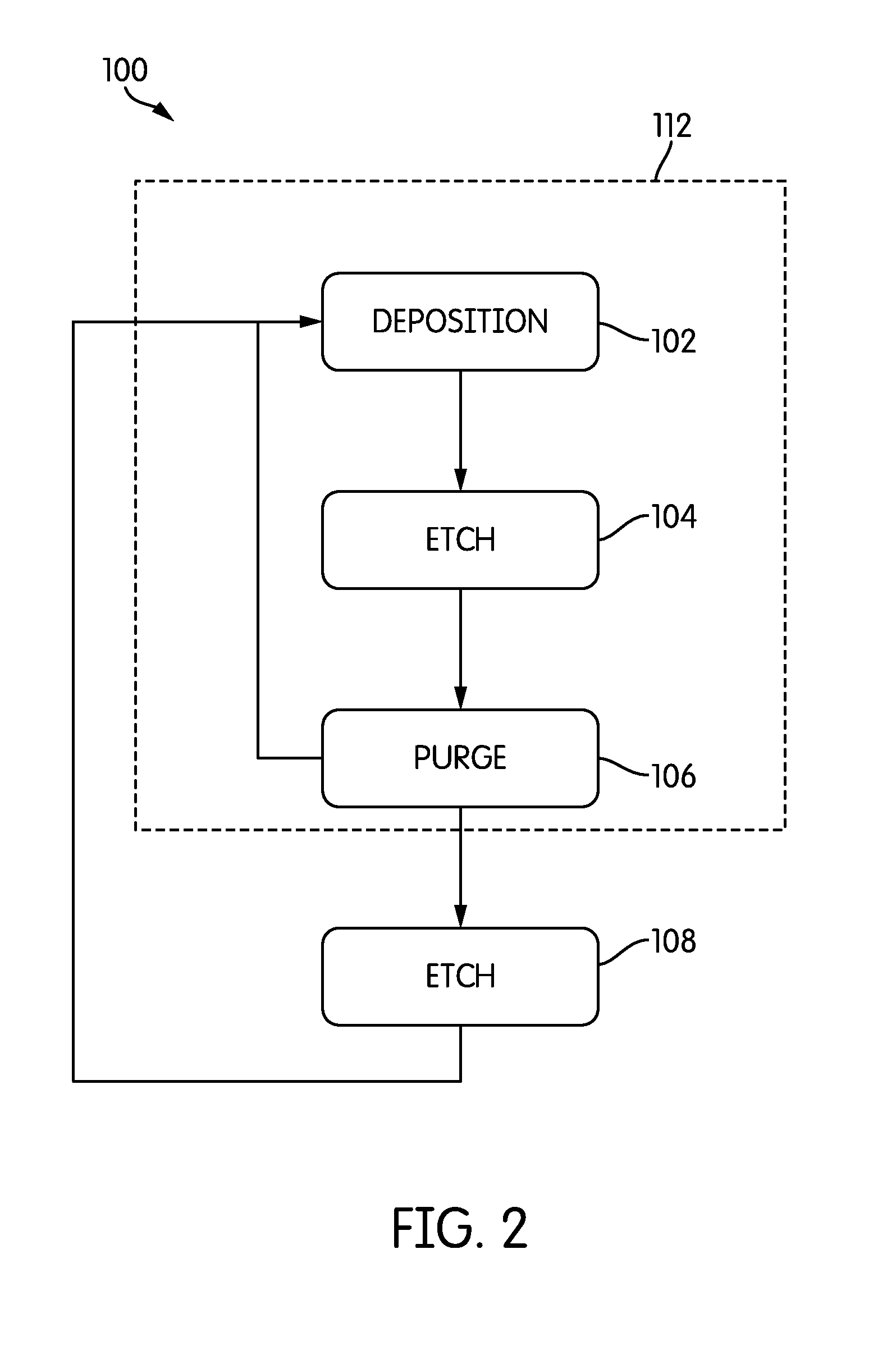

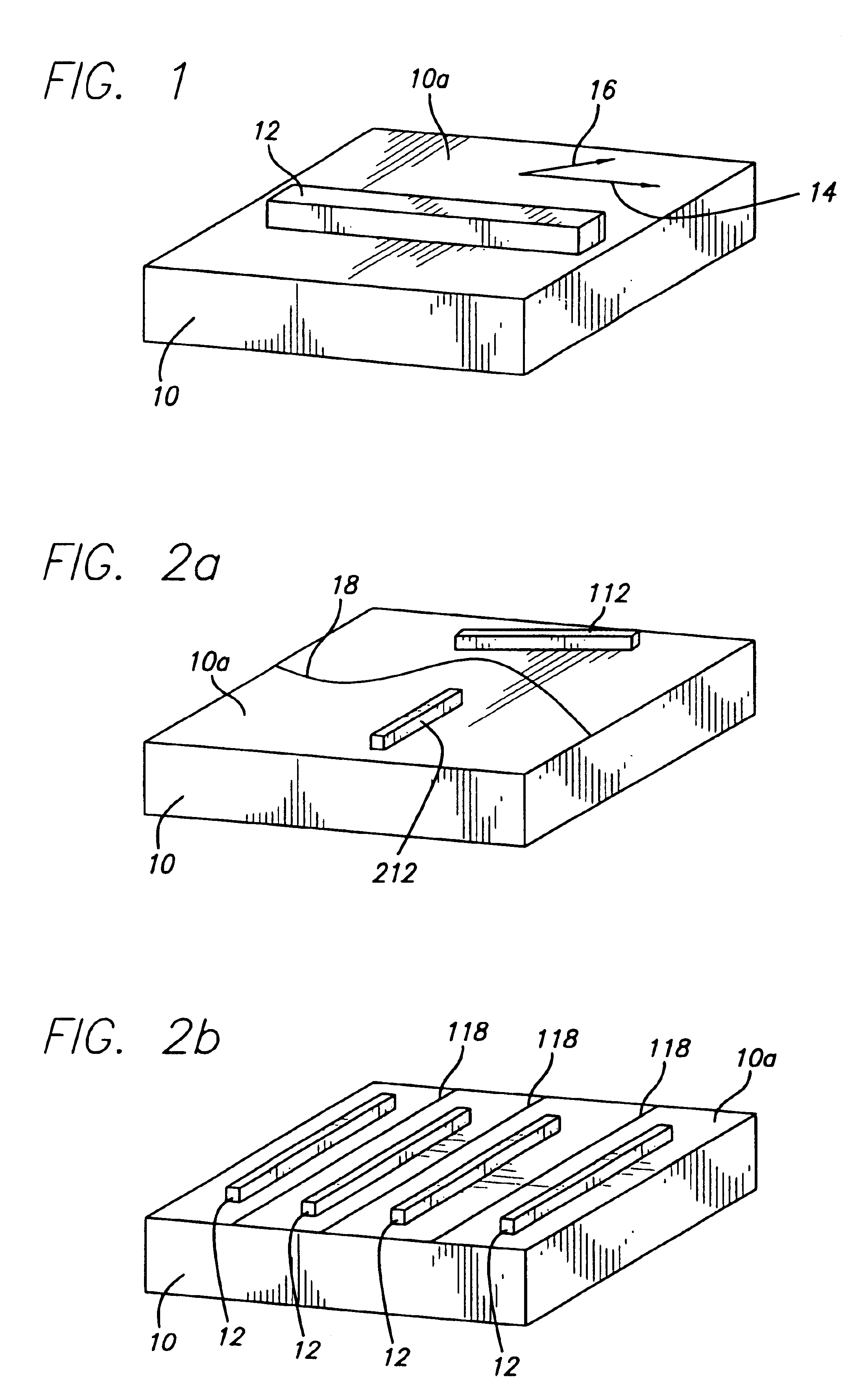

Methods for Selective and Conformal Epitaxy of Highly Doped Si-containing Materials for Three Dimensional Structures

InactiveUS20140120678A1Improve crystal qualityIncreased junctionSemiconductor/solid-state device manufacturingSemiconductor devicesDopantPhosphate

The present invention addresses the key challenges in FinFET fabrication, that is, the fabrications of thin, uniform fins and also reducing the source / drain series resistance. More particularly, this application relates to FinFET fabrication techniques utilizing tetrasilane to enable conformal deposition with high doping using phosphate, arsenic and boron as dopants thereby creating thin fins having uniform thickness (uniformity across devices) as well as smooth, vertical sidewalls, while simultaneously reducing the parasitic series resistance.

Owner:MATHESON TRI GAS INC

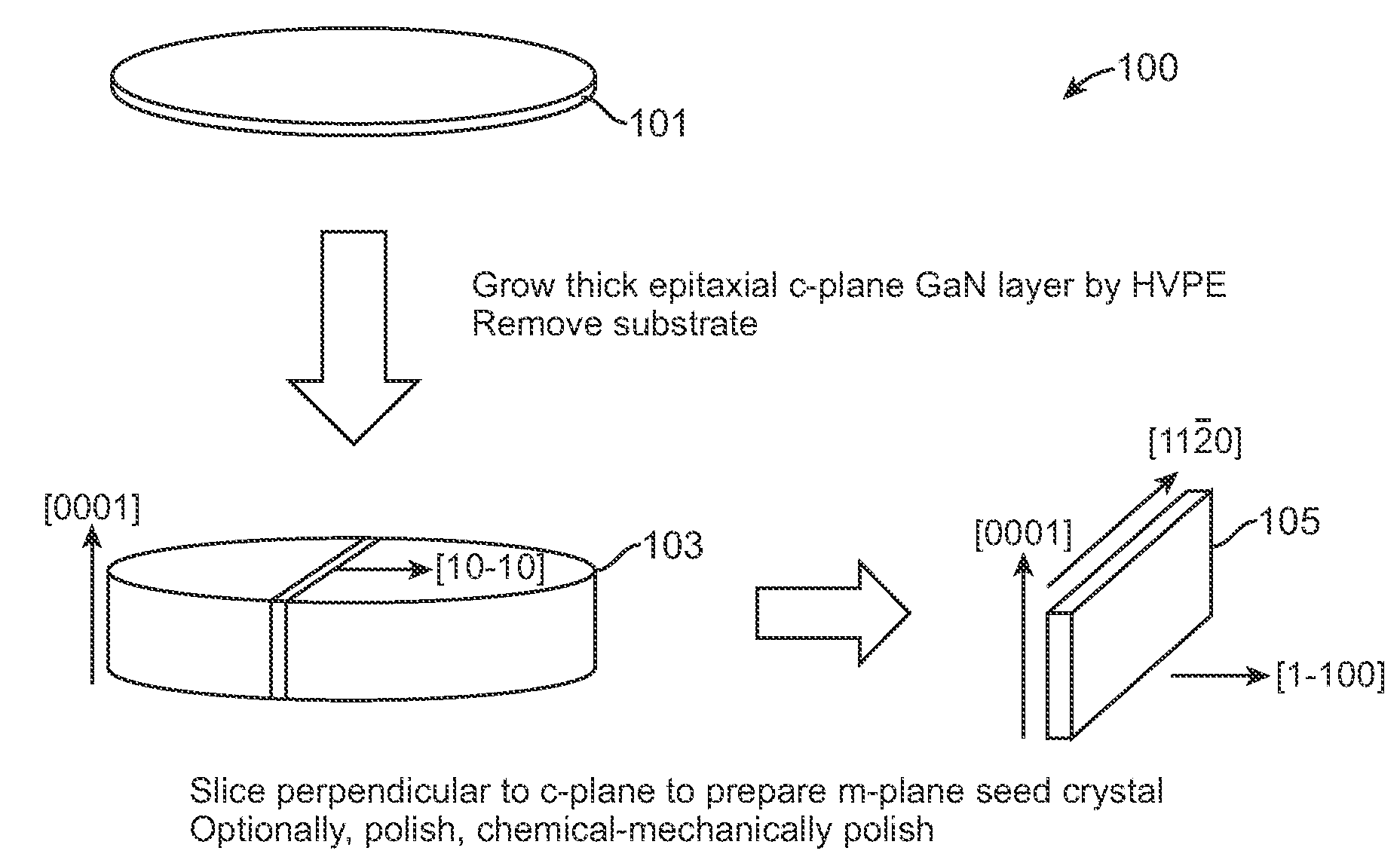

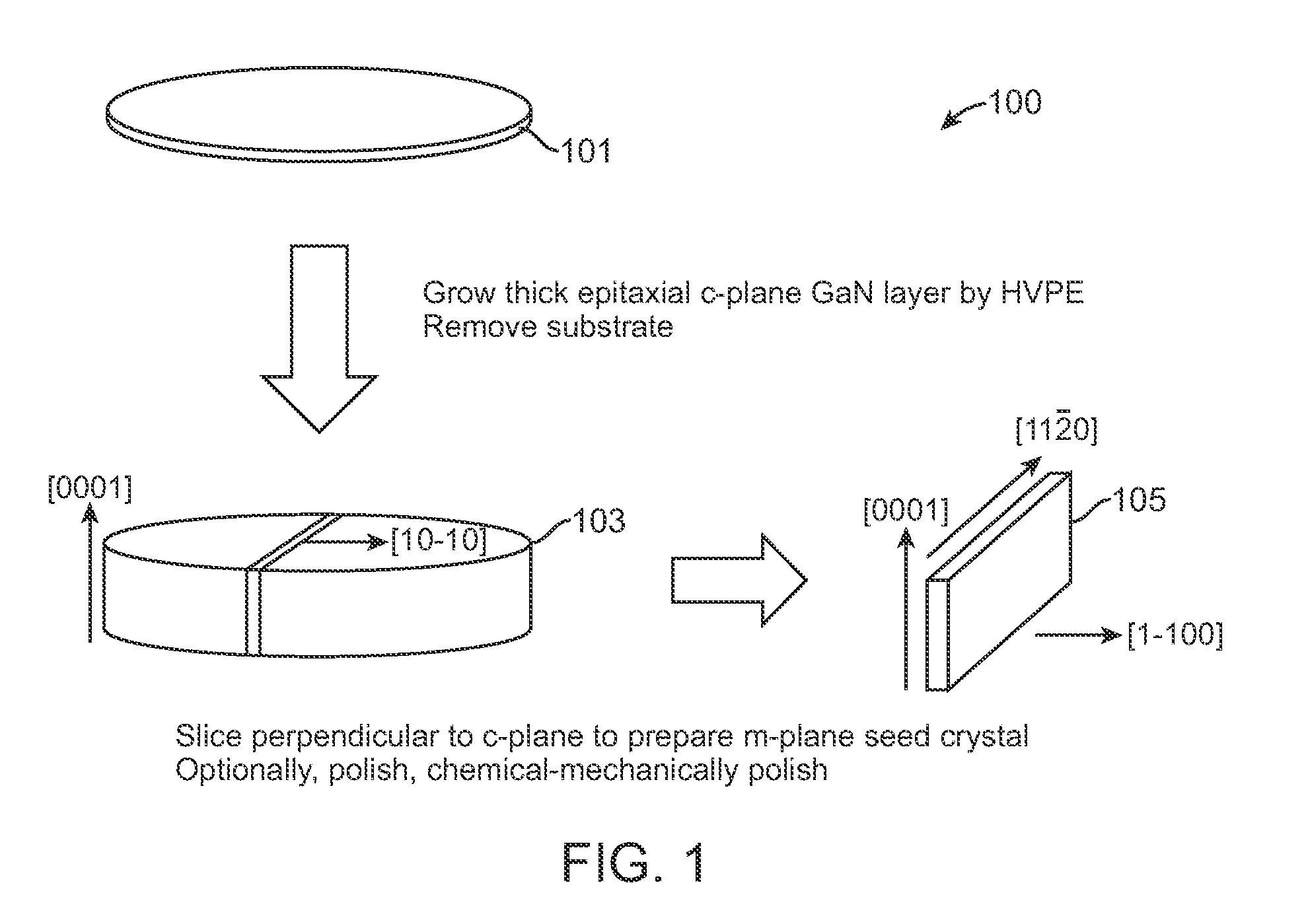

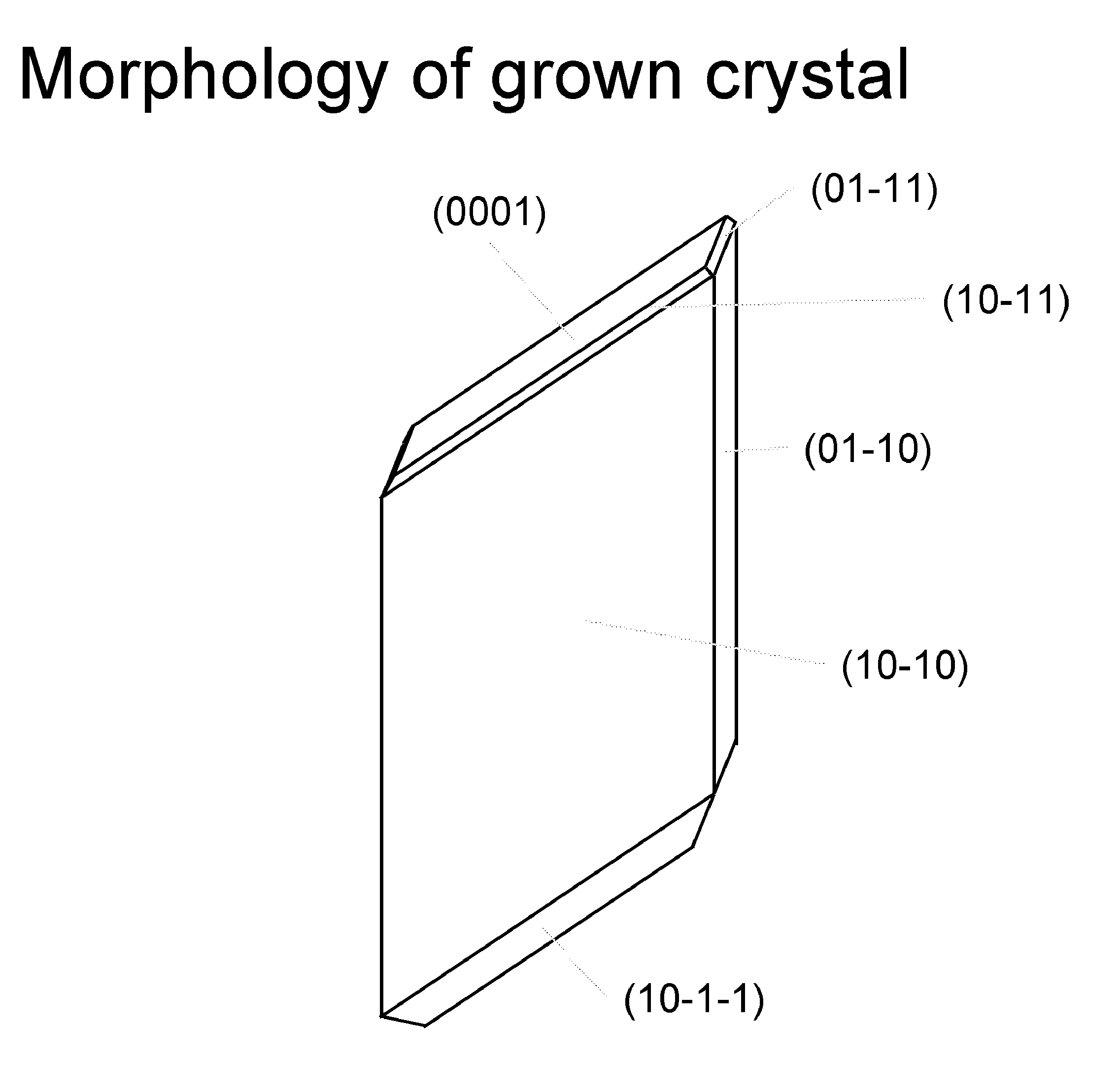

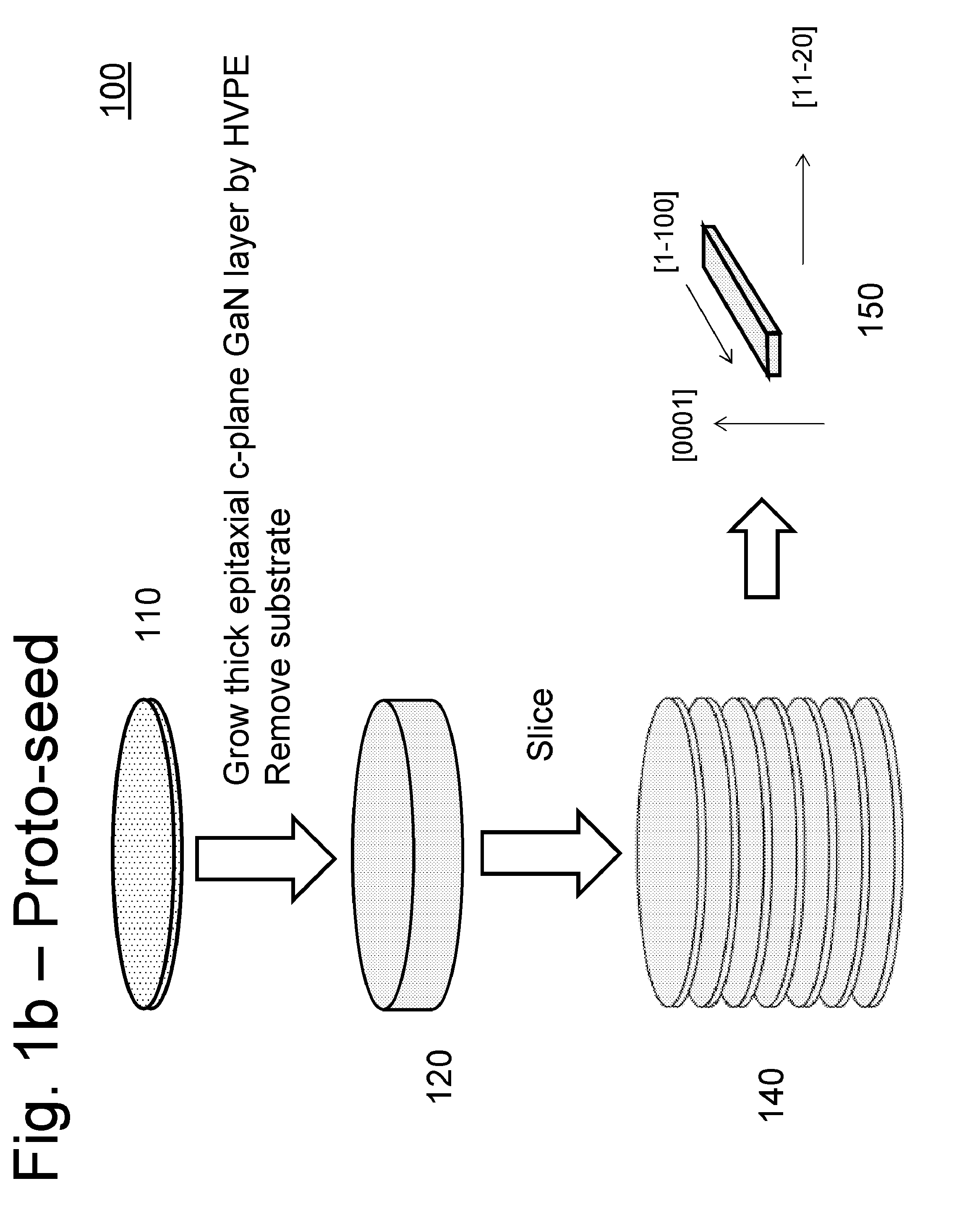

High quality large area bulk non-polar or semipolar gallium based substrates and methods

InactiveUS20100003492A1Great area of substrateCost-effective manufacturingPolycrystalline material growthConductive materialPhotodetectorSolar cell

A large area nitride crystal, comprising gallium and nitrogen, with a non-polar or semi-polar large-area face, is disclosed, along with a method for making. The crystal is useful as a substrate for a light emitting diode, a laser diode, a transistor, a photodetector, a solar cell, or for photoelectrochemical water splitting for hydrogen generation.

Owner:SORAA

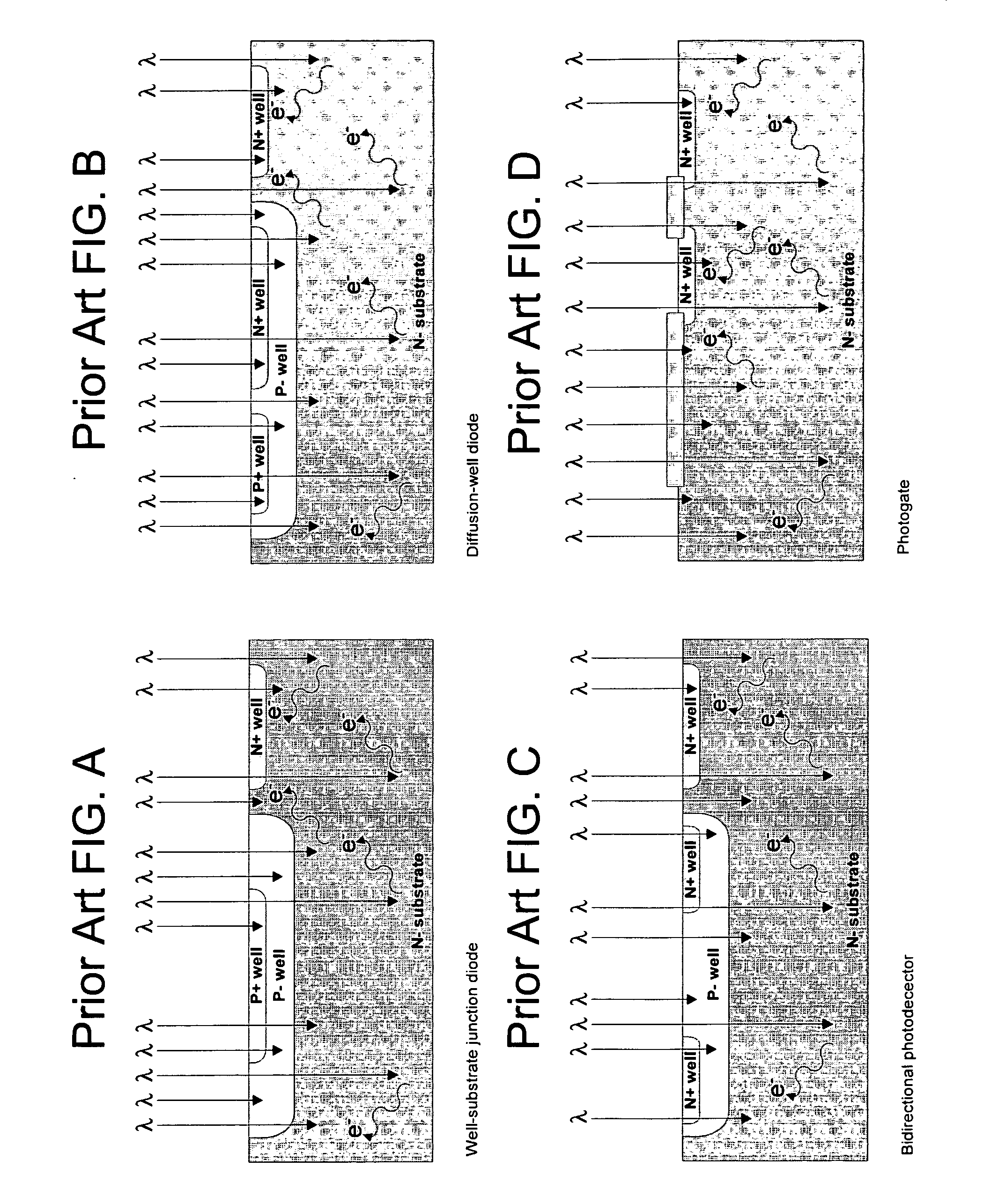

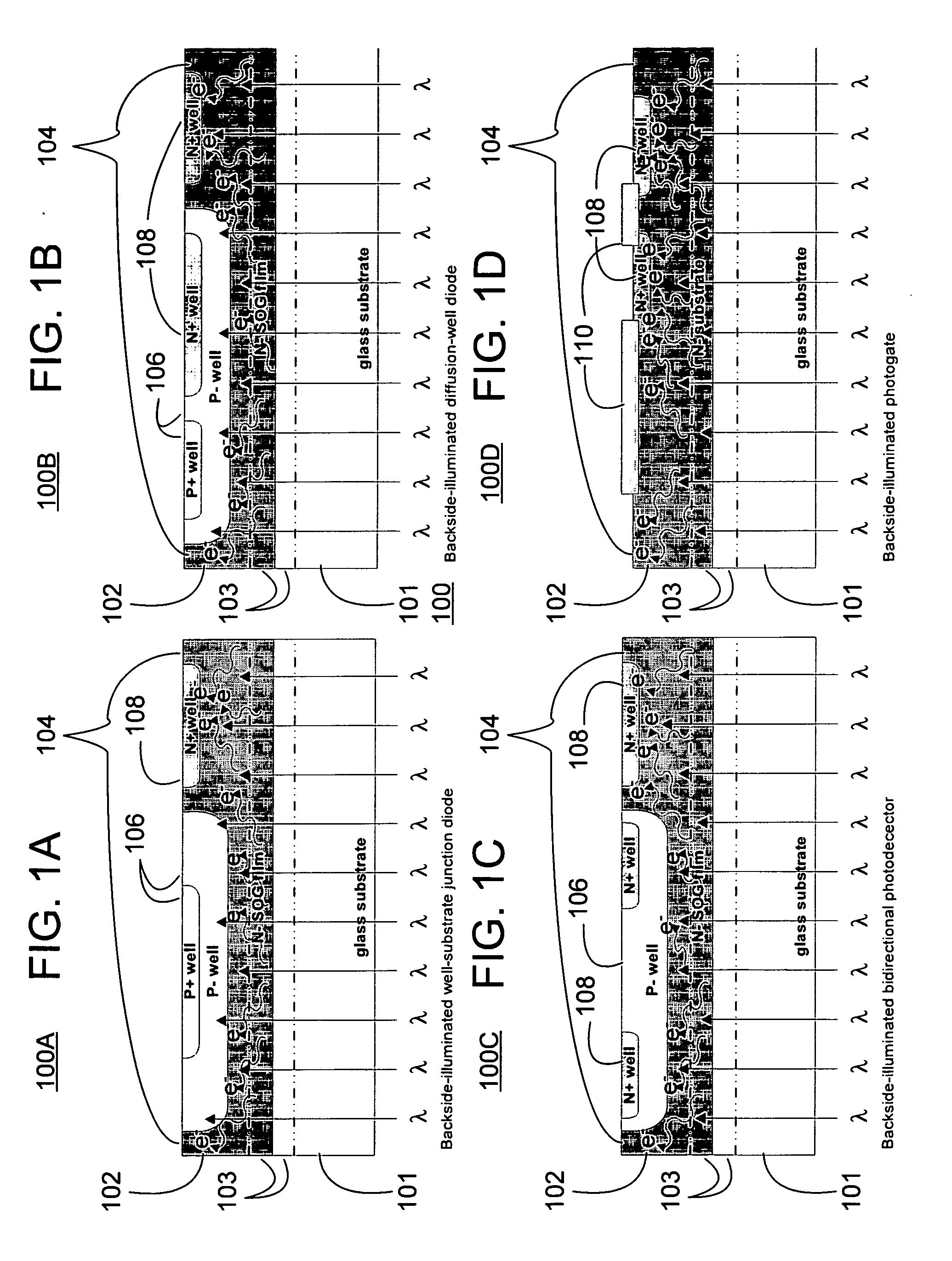

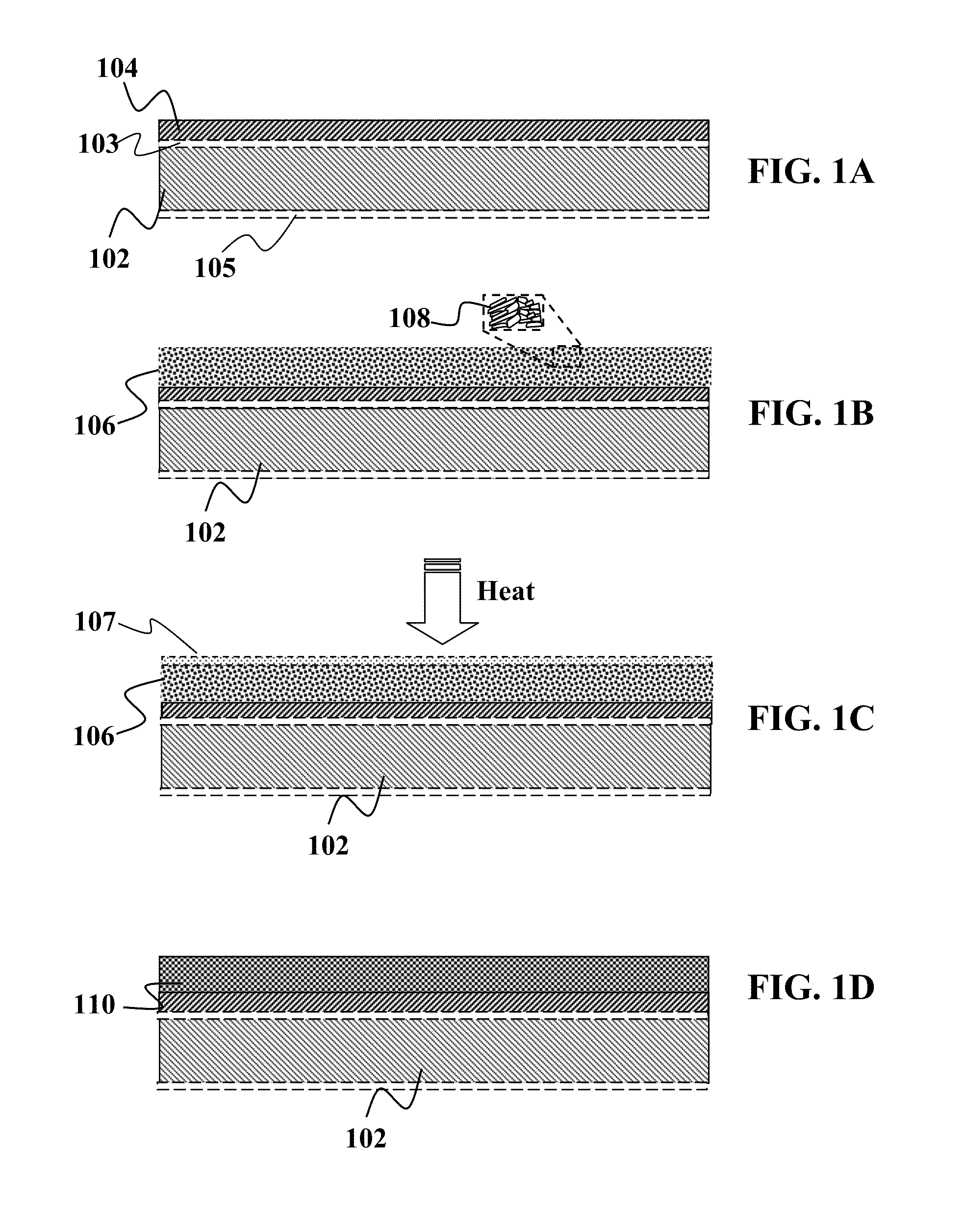

Image sensor using thin-film SOI

InactiveUS20080070340A1Faster throughputImage degradationSolid-state devicesSemiconductor/solid-state device manufacturingSingle crystalThin film soi

Systems and methods related to an image sensor of one or more embodiments include subjecting a donor semiconductor wafer to an ion implantation process to create an exfoliation layer of semiconductor film on the donor semiconductor wafer, forming an anodic bond between the exfoliation layer and an insulator substrate by means of electrolysis; separating the exfoliation layer from the donor semiconductor wafer to transfer the exfoliation layer to the insulator substrate; and creating a plurality of image sensor features proximate to the exfoliation layer. Forming the anodic bonding by electrolysis may include the application of heat, pressure and voltage to the insulator structure and the exfoliation layer attached to the donor semiconductor wafer. Image sensor devices include an insulator structure, a semiconductor film, an anodic bond between them, and a plurality of image sensor features. The semiconductor film preferably comprises an exfoliation layer of a substantially single-crystal donor semiconductor wafer.

Owner:CORNING INC

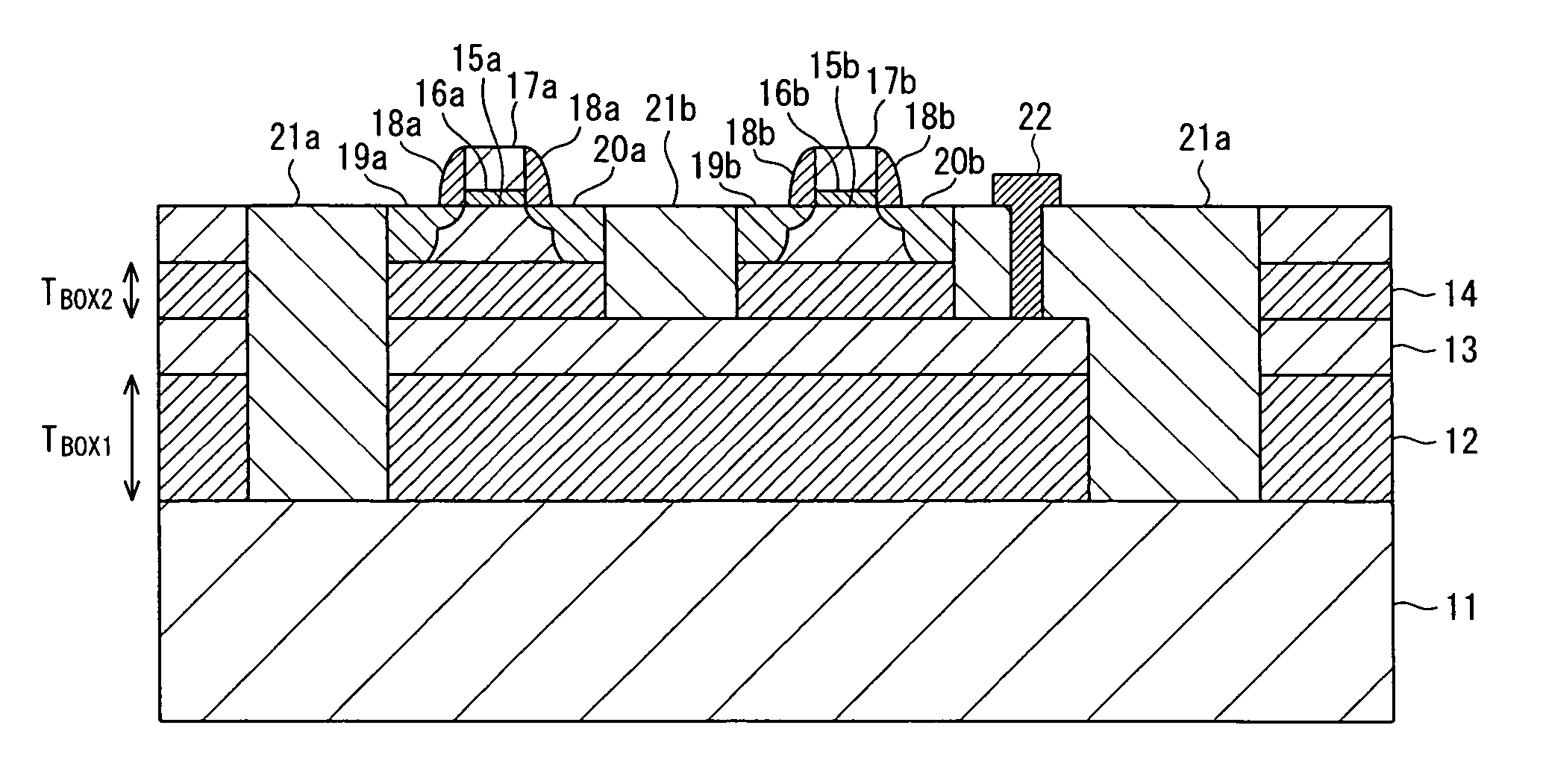

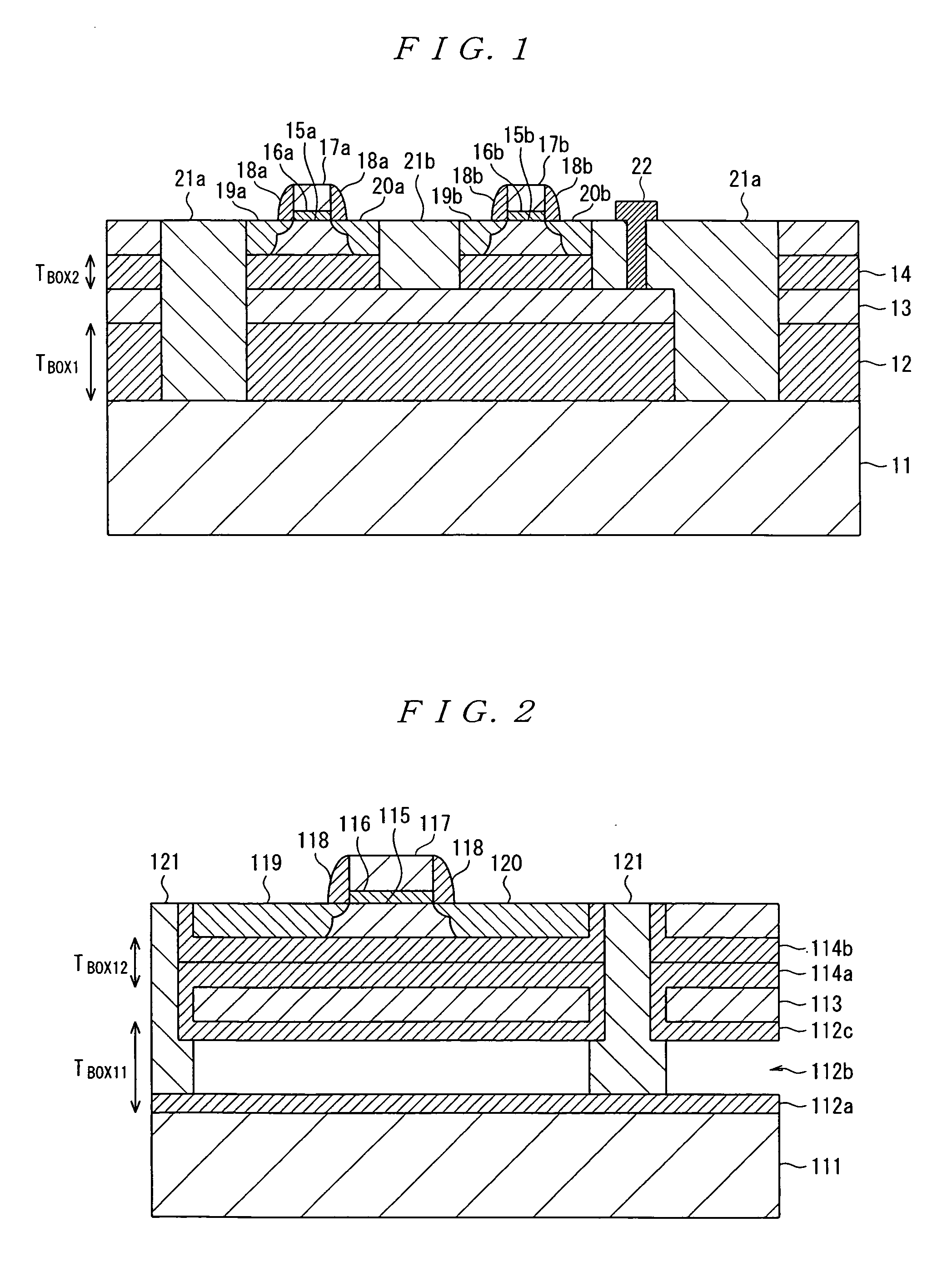

Semiconductor device and semiconductor device manufacturing method

InactiveUS20070075317A1Increase flexibilityImprove pressure resistanceSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

A semiconductor device includes a back gate electrode composed of a first single-crystal semiconductor layer formed on a first insulating layer; a second insulating layer formed on the first single-crystal semiconductor layer and having a film thickness smaller than a film thickness of the first insulating layer; a second single-crystal semiconductor layer formed on the second insulating layer; a gate electrode formed on the second single-crystal semiconductor layer; and source and drain layers that are formed on the second single-crystal semiconductor layer and arranged on respective sides of the gate electrode.

Owner:SEIKO EPSON CORP +1

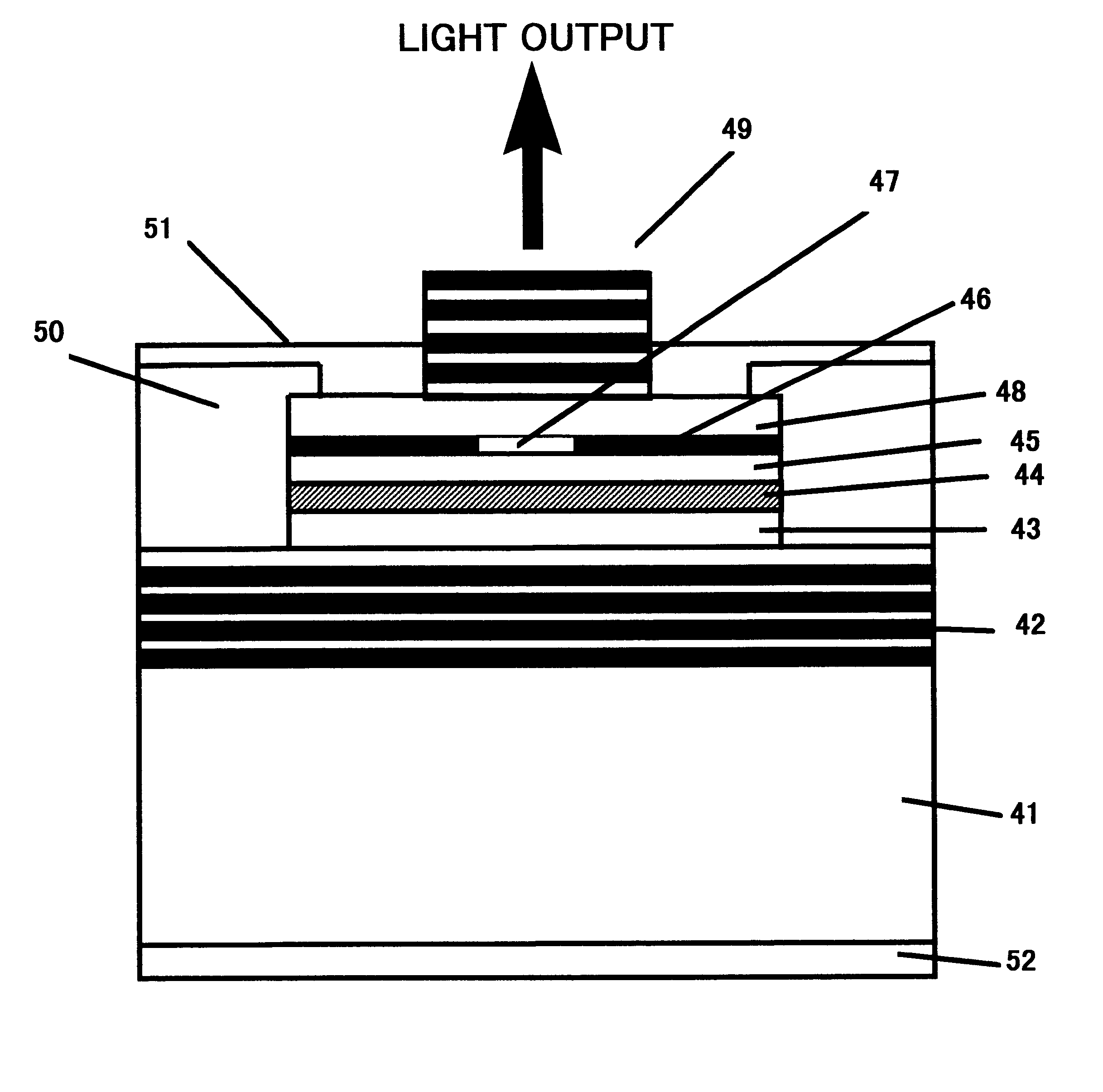

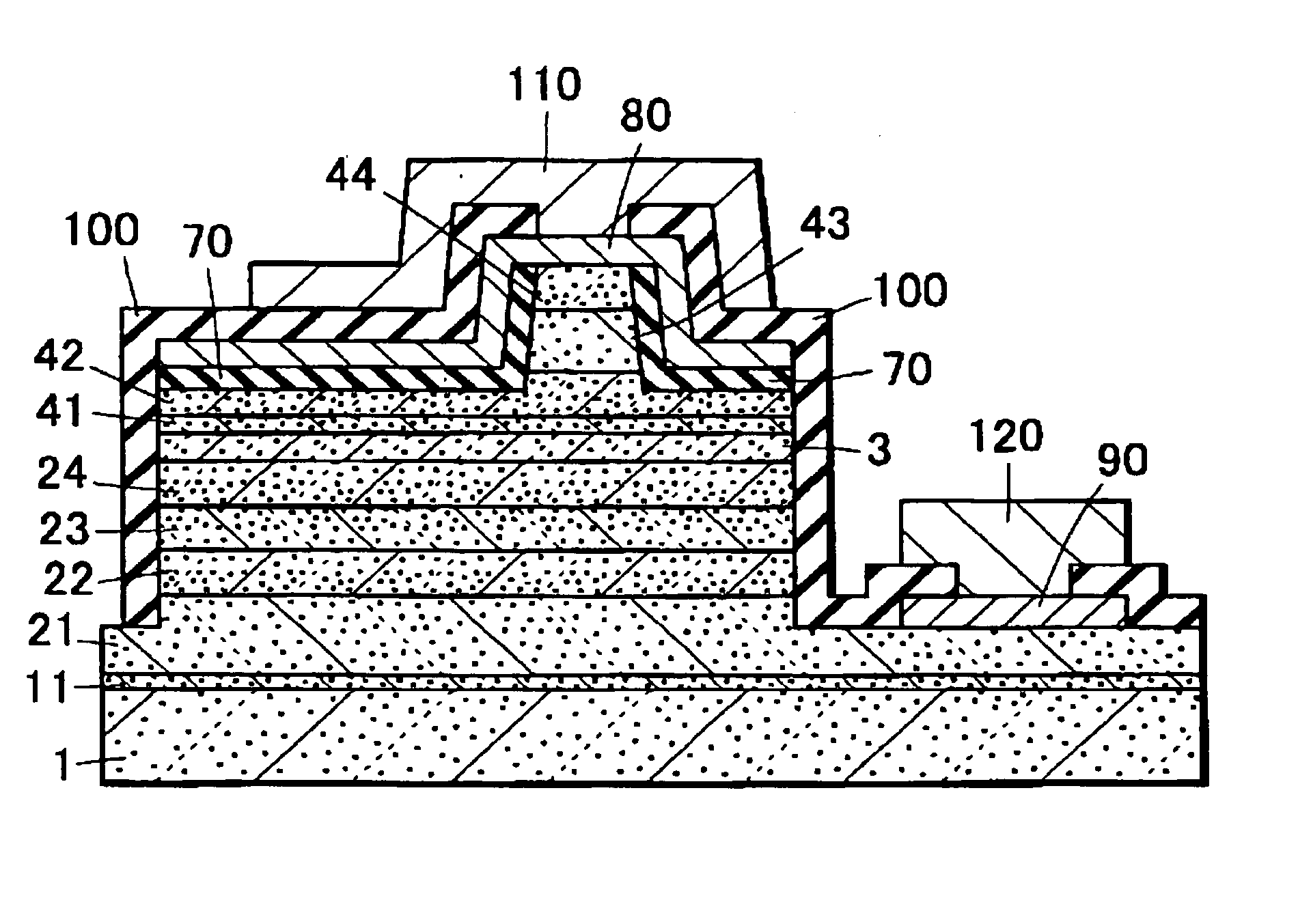

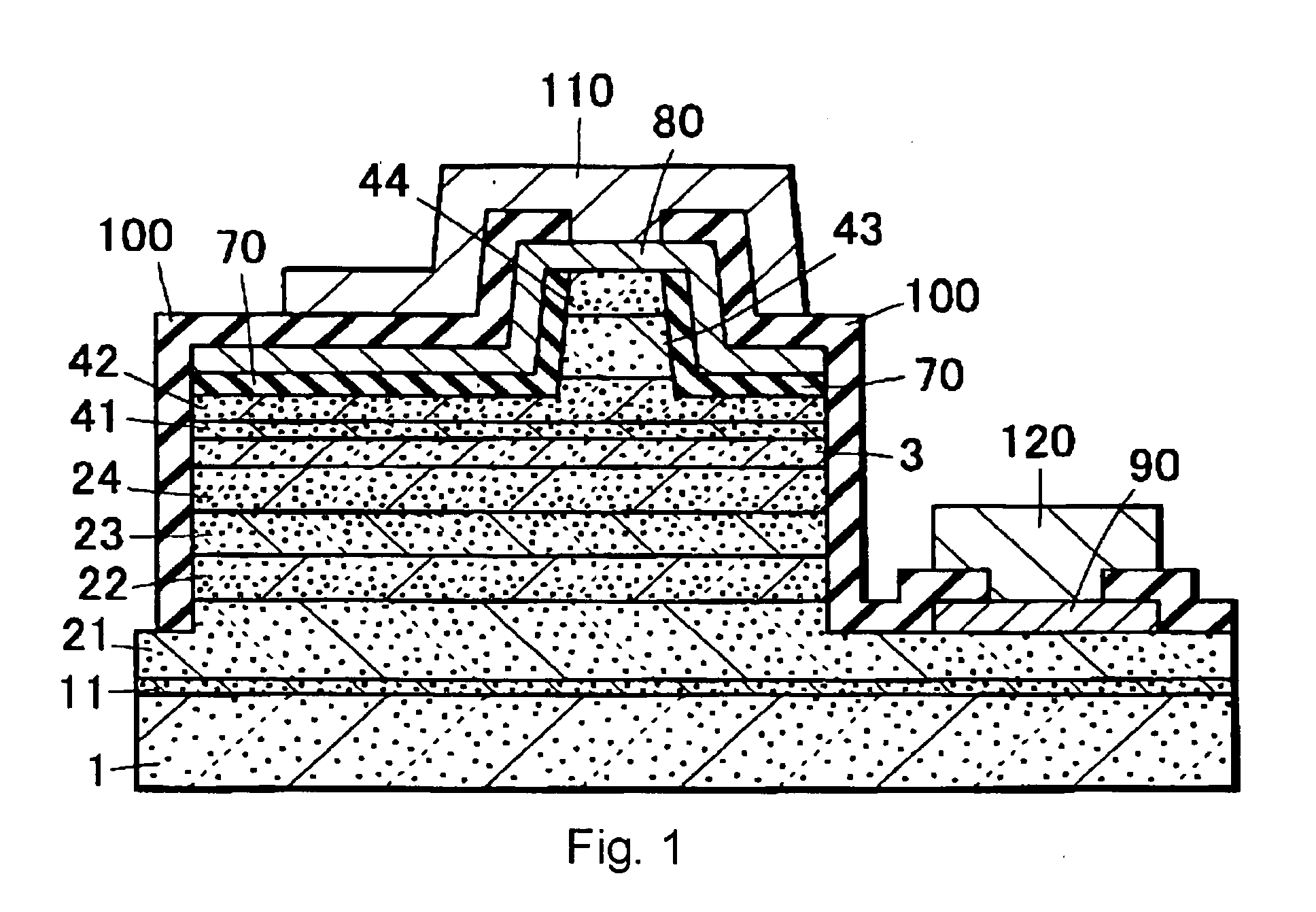

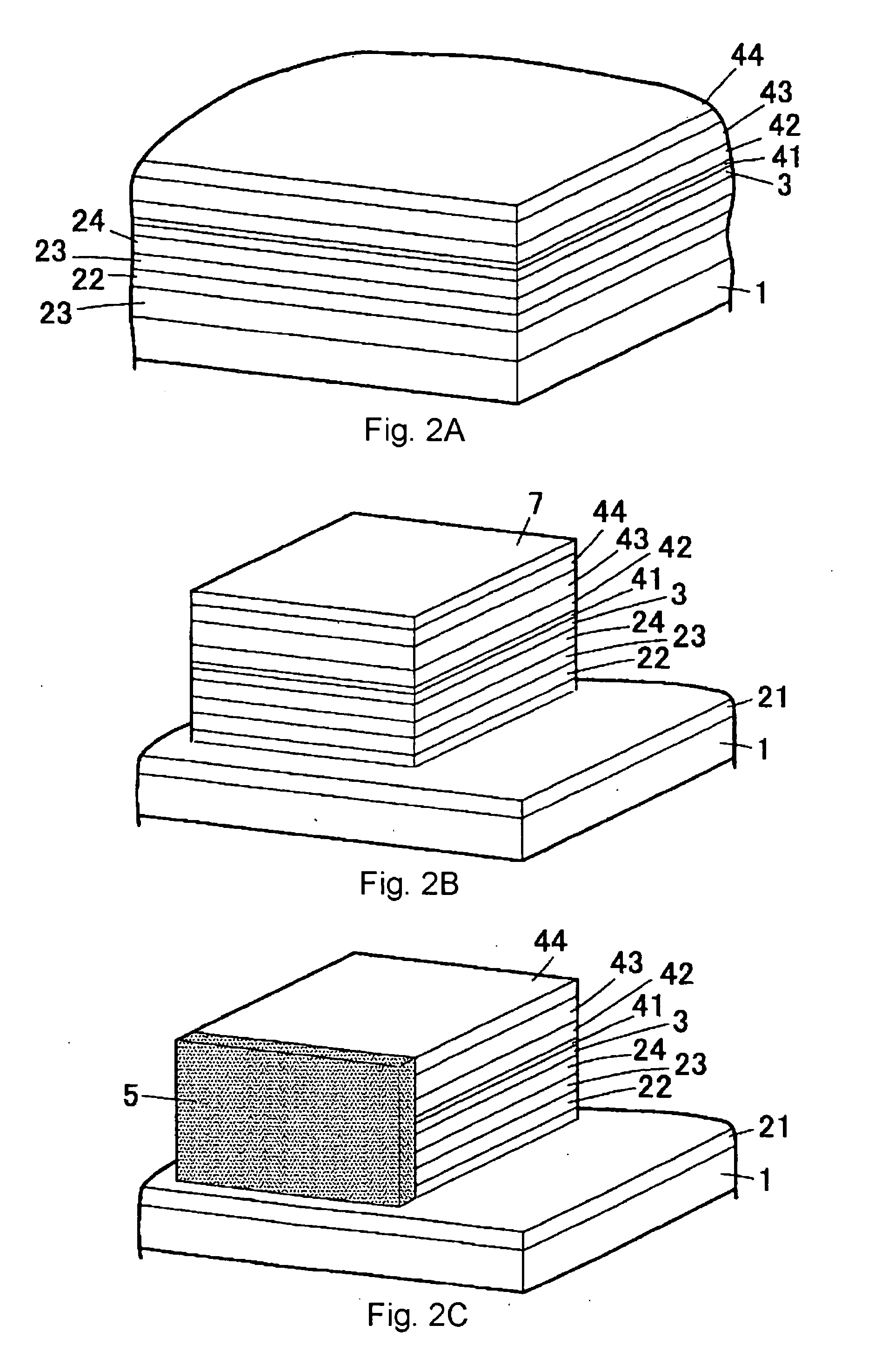

Light emitting devices with layered III-V semiconductor structures

InactiveUS6207973B1Improve crystal qualityFacilitates layerLaser detailsLaser active region structureCharge carrierSemiconductor structure

A semiconductor light emitting device is disclosed, including a semiconductor substrate, an active region comprising a strained quantum well layer, and a cladding layer for confining carriers and light emissions, wherein the amount of lattice strains in the quantum well layer is in excess of 2% against either the semiconductor substrate or cladding layer and, alternately, the thickness of the quantum well layer is in excess of the critical thickness calculated after Matthews and Blakeslee.

Owner:RICOH KK

Light emitting element structure using nitride bulk single crystal layer

InactiveUS20040251471A1Improve crystal qualitySimple structureOptical wave guidancePolycrystalline material growthSingle crystalActive layer

The object of this invention is to provide a high-output type nitride light emitting device. The nitride light emitting device comprises an n-type nitride semiconductor layer or layers, a p-type nitride semiconductor layer or layers and an active layer therebetween, wherein a gallium-containing nitride substrate is obtained from a gallium-containing nitride bulk single crystal, provided with an epitaxial growth face with dislocation density of 10<5> / cm<2 >or less, and A-plane or M-plane which is parallel to C-axis of hexagonal structure for an epitaxial face, wherein the n-type semiconductor layer or layers are formed directly on the A-plane or M-plane. In case that the active layer comprises a nitride semiconductor containing In, an end face film of single crystal AlxGa1-xN (0<=x<=1) can be formed at a low temperature not causing damage to the active layer.

Owner:AMMONO SP Z O O (PL) +1

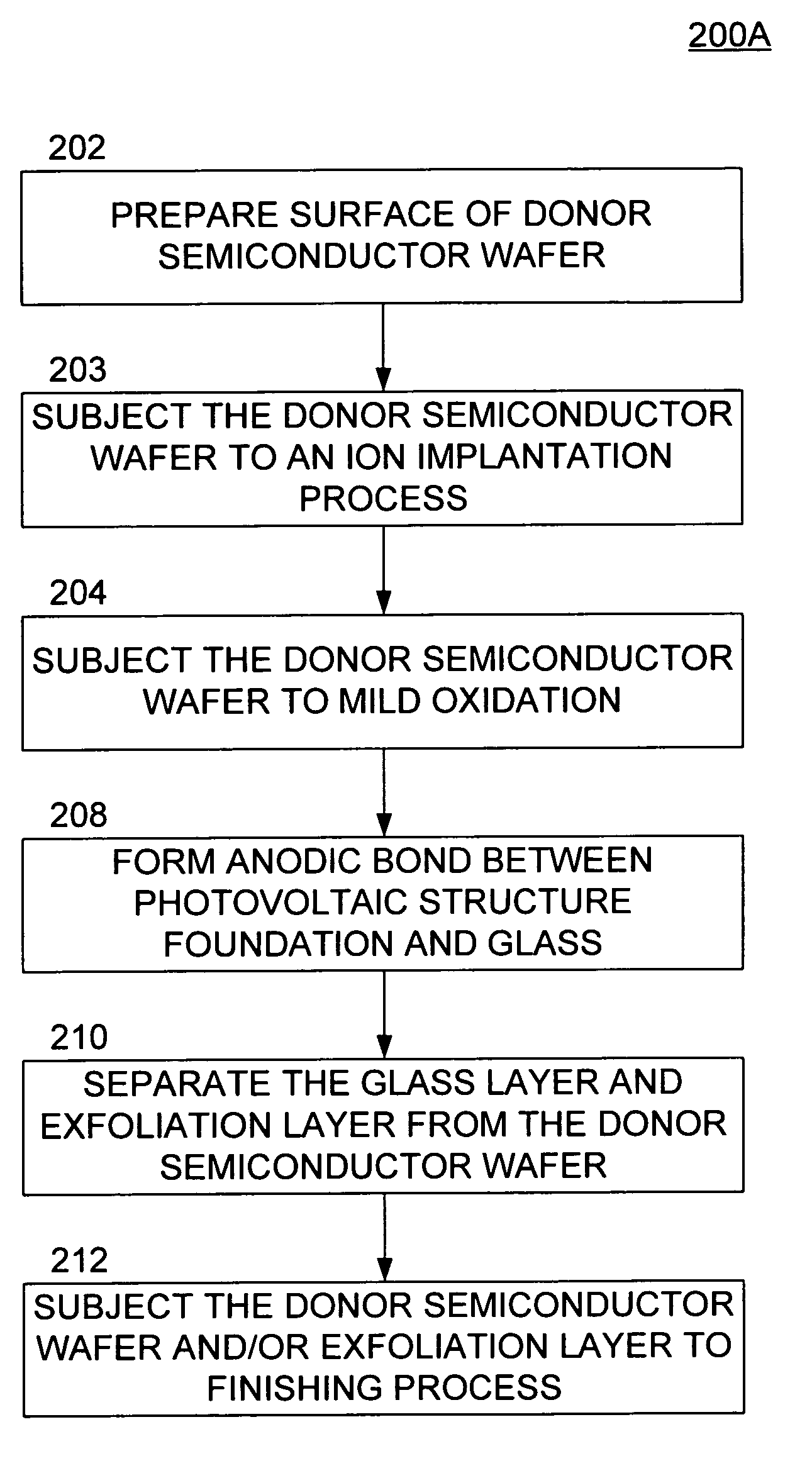

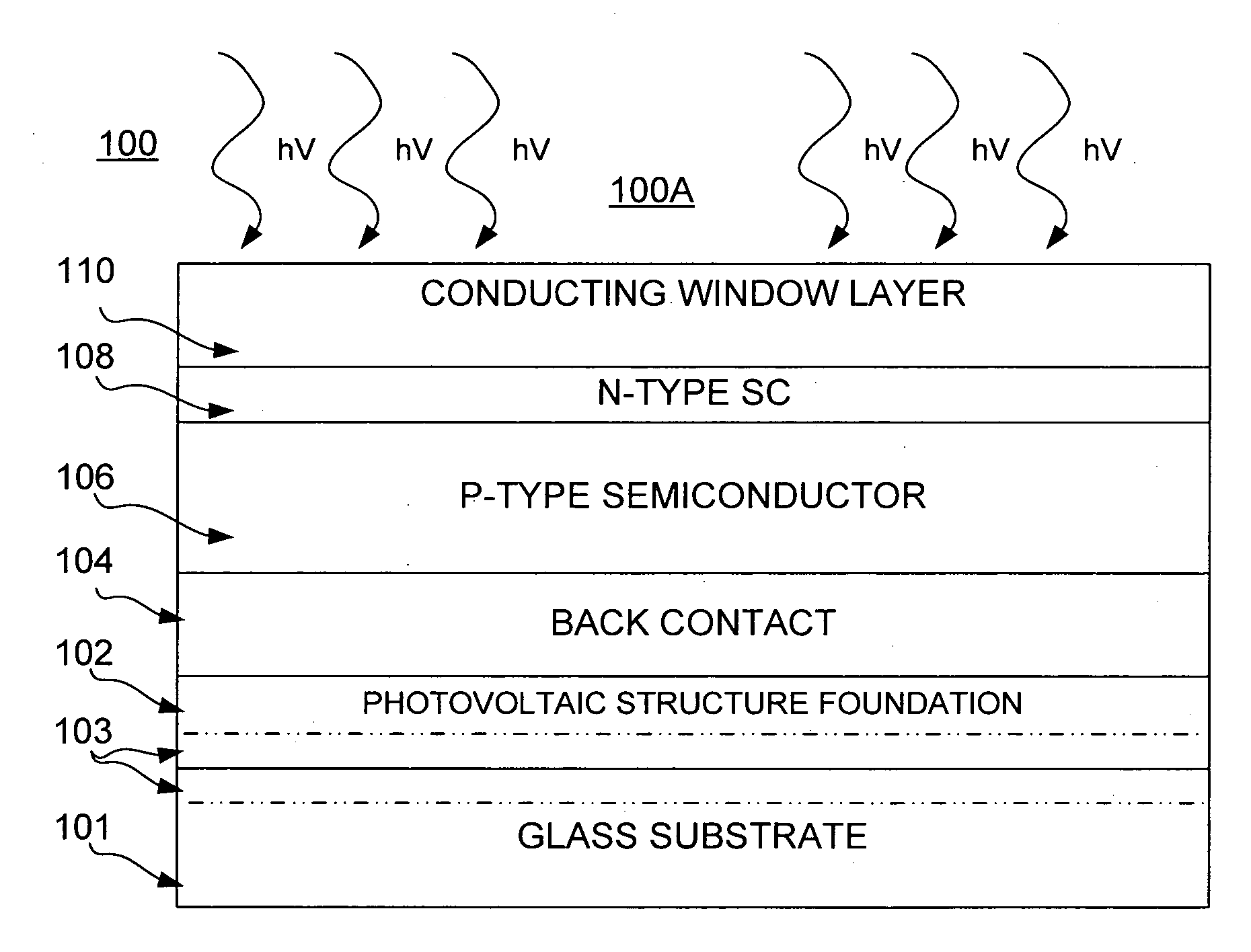

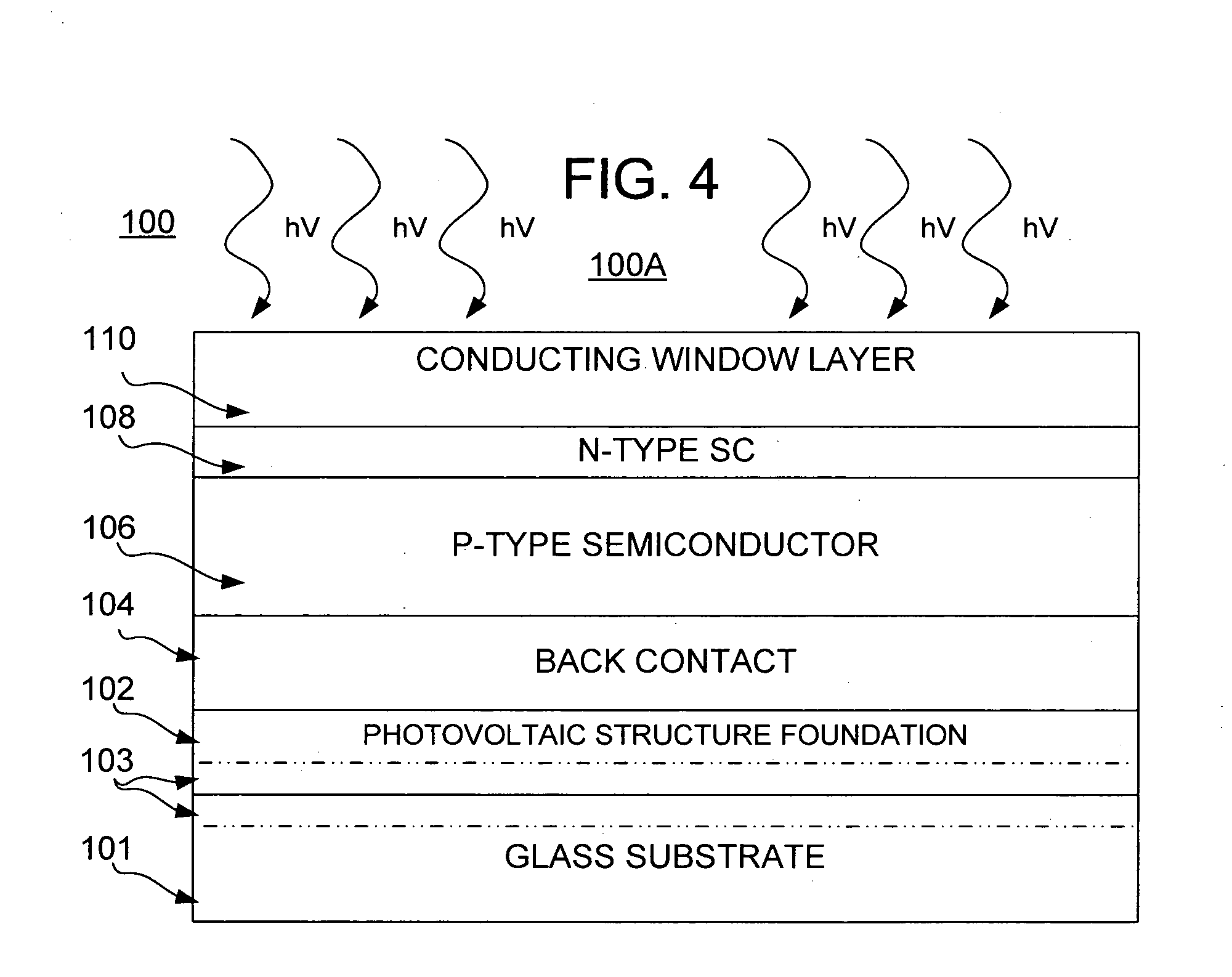

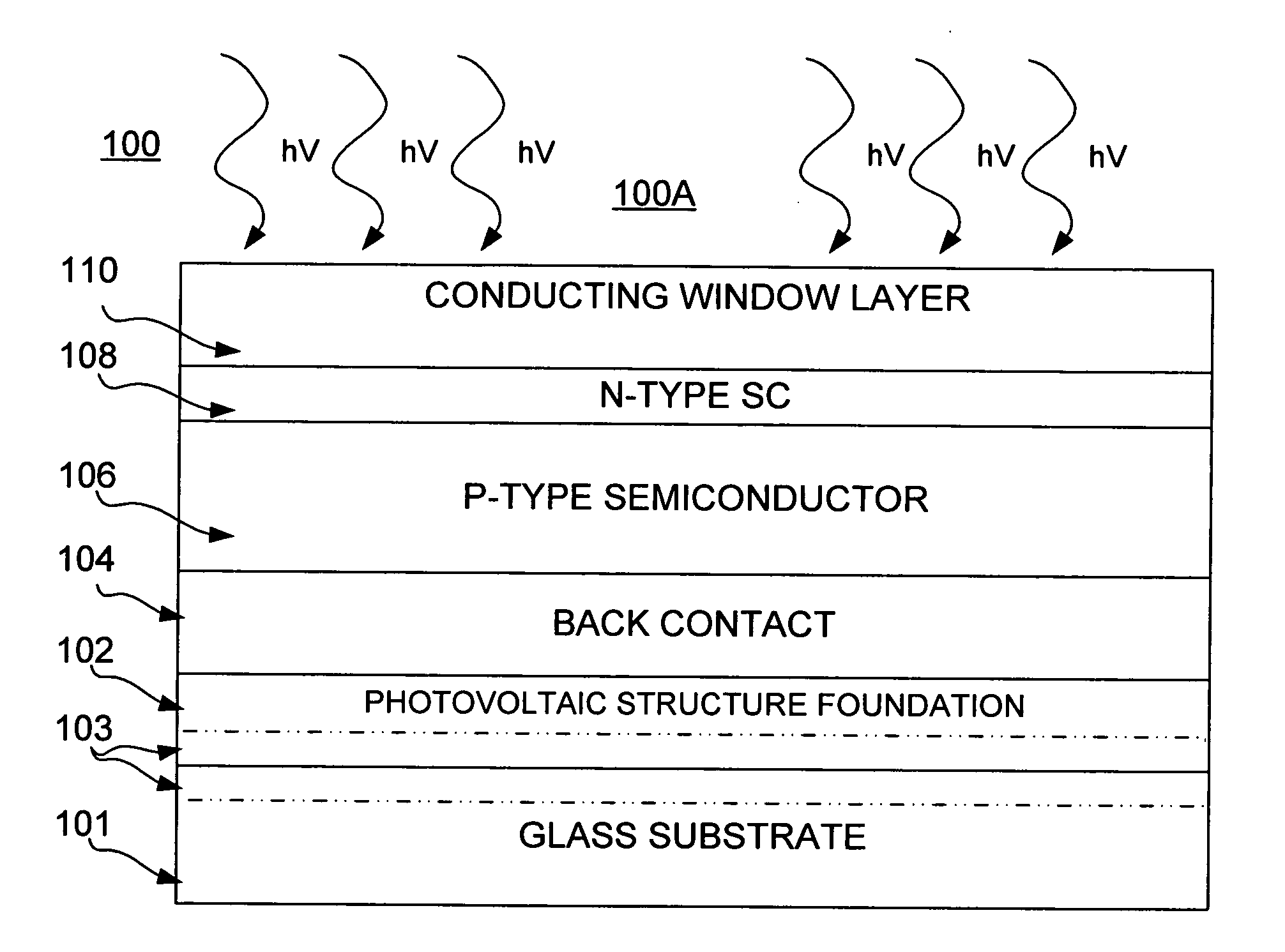

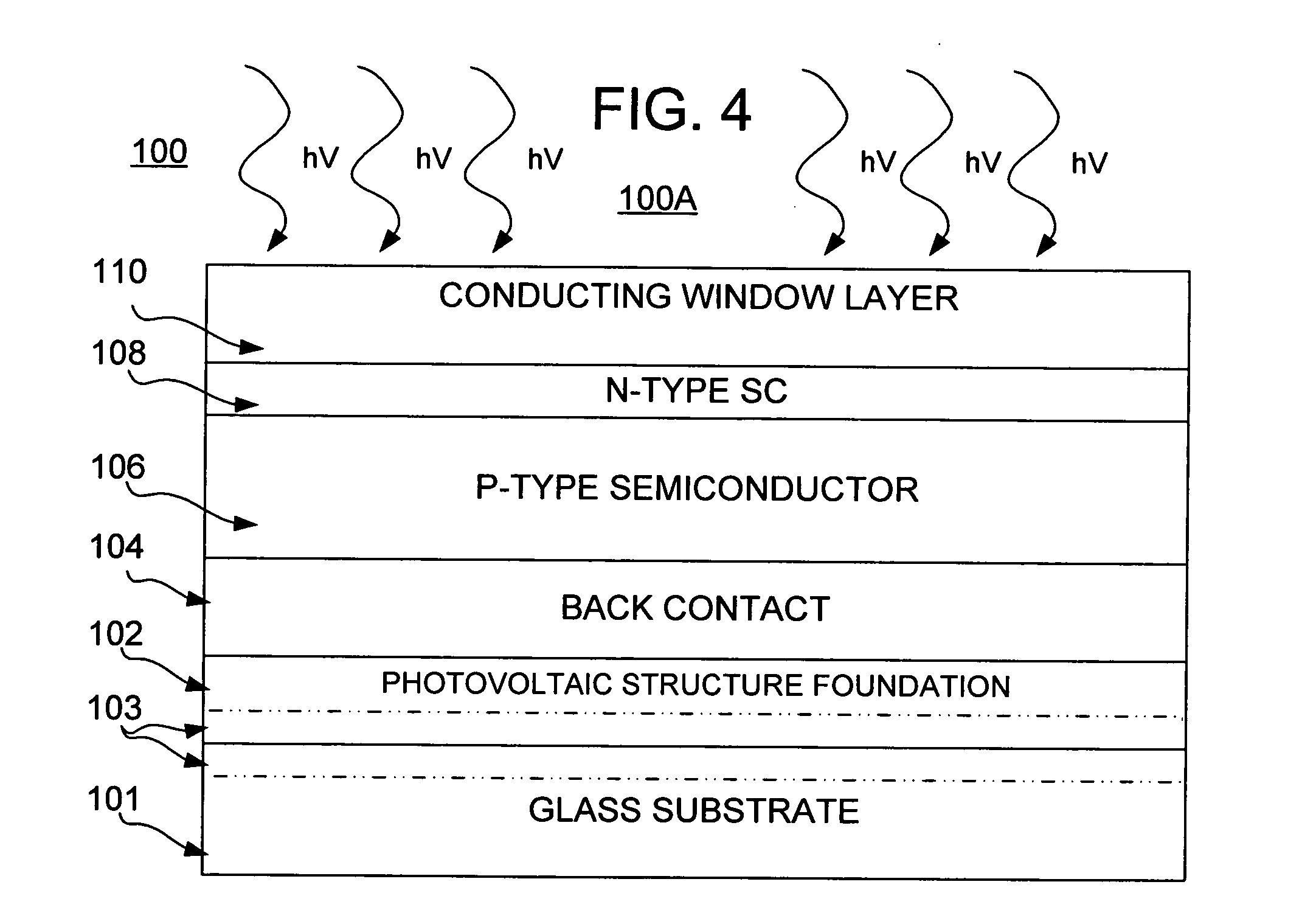

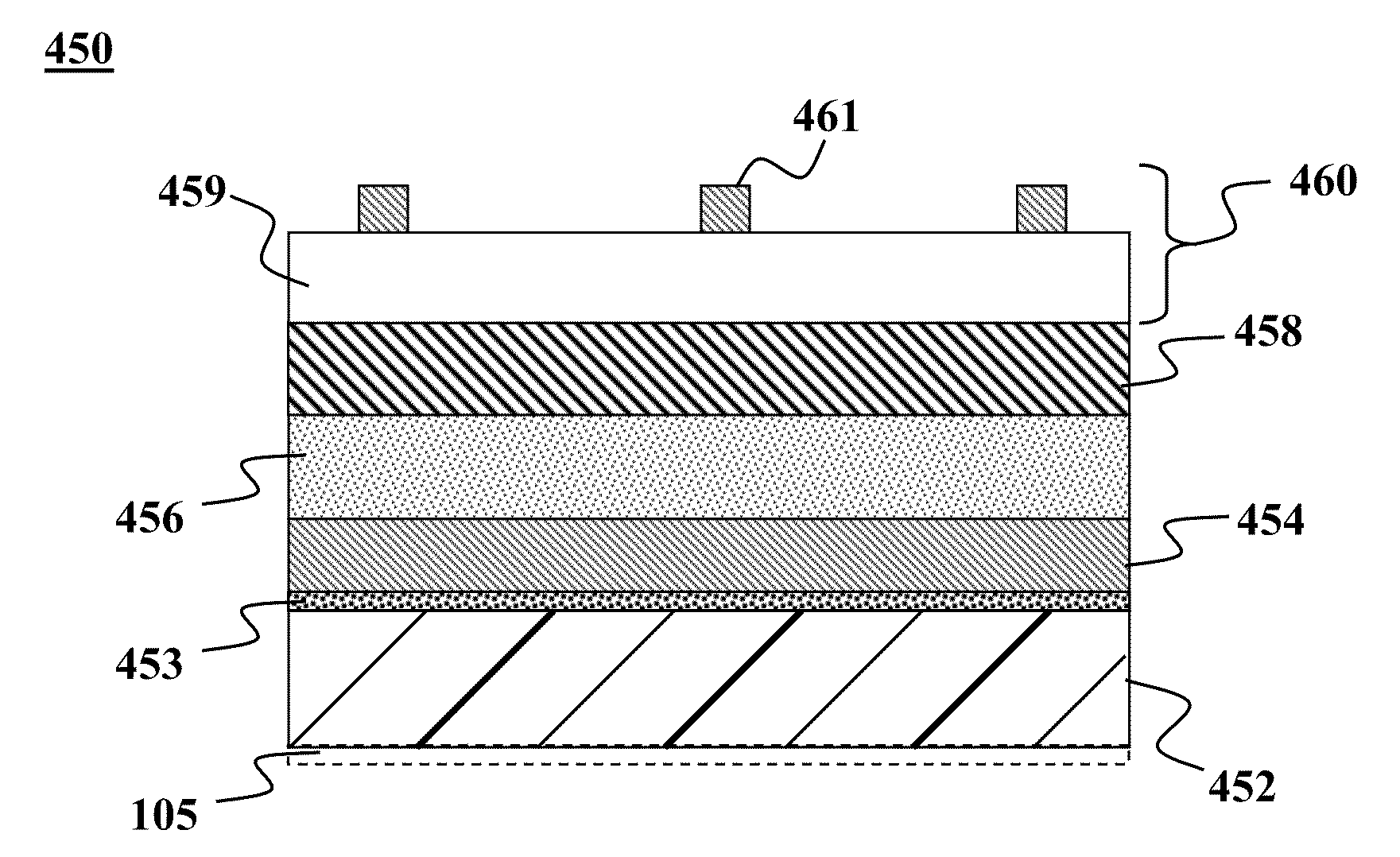

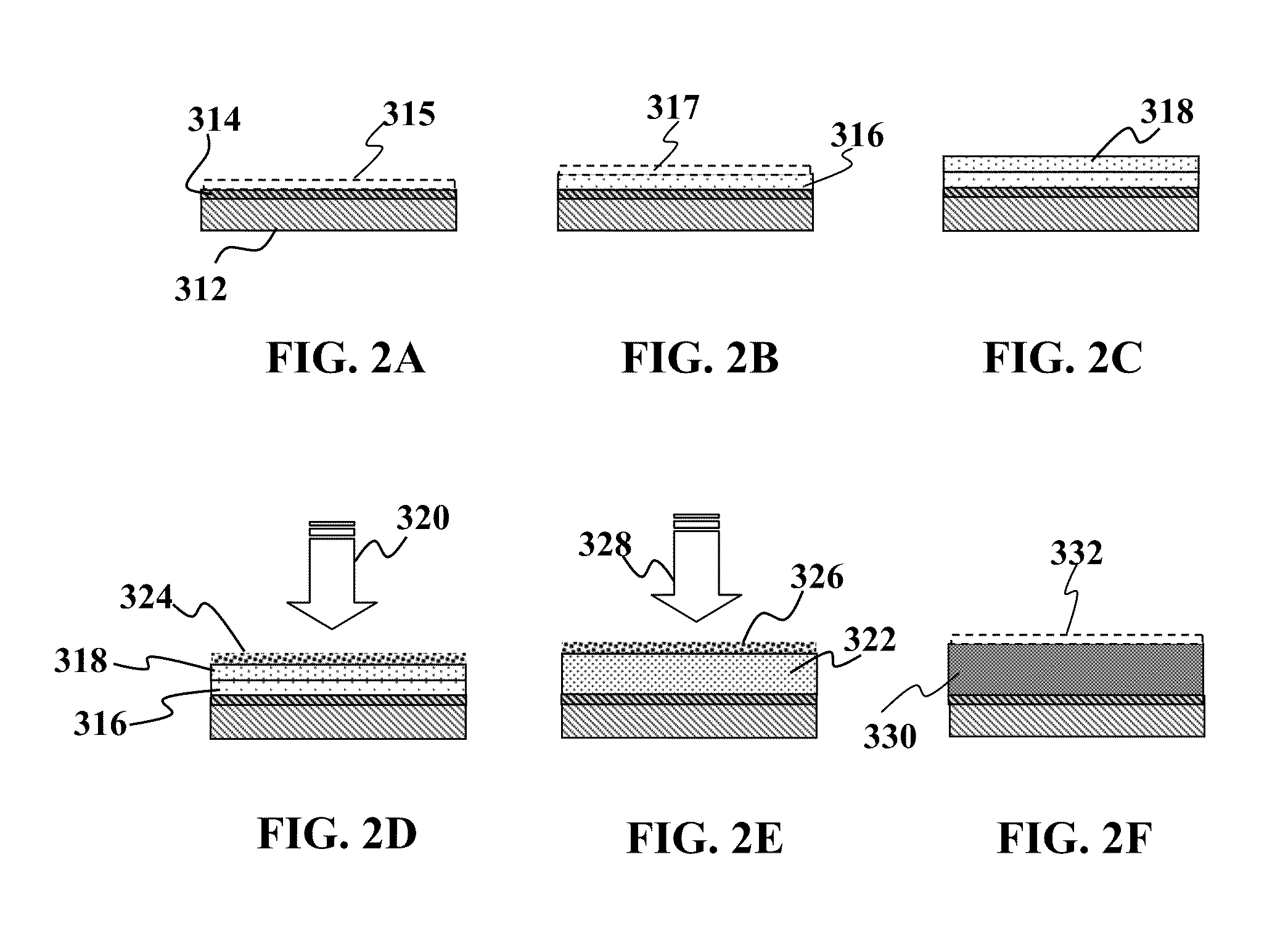

Thin film photovoltaic structure

InactiveUS20070277874A1Faster throughputReduce needSemiconductor/solid-state device manufacturingPhotovoltaic energy generationAnodic bondingVoltage

Systems and methods of production of a photovoltaic device include creating on a donor semiconductor wafer an exfoliation layer and transferring the exfoliation layer to an insulator substrate. One or more finishing processes may be performed before and / or after transferring the exfoliation layer, such as to create a plurality of photovoltaic structure layers. Production of the photovoltaic device further may include subjecting the donor semiconductor wafer to an ion implantation process to create the exfoliation layer, bonding the exfoliation layer to the insulator substrate, and separating the exfoliation layer from the donor semiconductor wafer. Transferring may include forming an anodic bond via electrolysis, such as through the application of heat, pressure and voltage to the exfoliation layer and the insulator structure.

Owner:CORNING INC

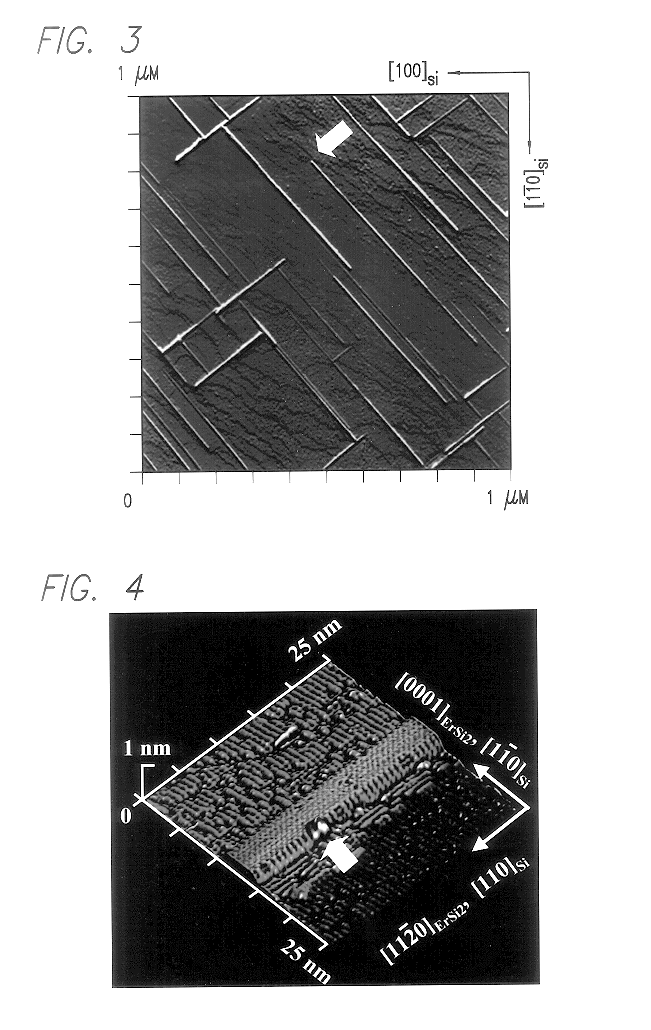

Formation of nanoscale wires

InactiveUS6773616B1Improve crystal qualityMinimizes environmental toxic chemicals usageNanotechPolycrystalline material growthNanowireMicrometer scale

Self-organized, or self-assembled, nanowires of a first composition may be used as an etching mask for fabrication of nanowires of a second composition. The method for forming such nanowires comprises: (a) providing an etchable layer of the second composition and having a buried insulating layer beneath a major surface thereof; (b) growing self-assembled nanowires on the surface of the etchable layer; and (c) etching the etchable layer anisotropically down to the insulating layer, using the self-assembled nanowires as a mask. The self-assembled nanowires may be removed or left. In either event, nanowires of the second composition are formed. The method enables the formation of one-dimensional crystalline nanowires with widths and heights at the nanometer scale, and lengths at the micrometer scale, which are aligned along certain crystallographic directions with high crystal quality. Further, the method of the present invention avoids traditional lithography methods, minimizes environmental toxic chemicals usage, simplifies the manufacturing processes, and allows the formation of high-quality one-dimensional nanowires over large areas.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

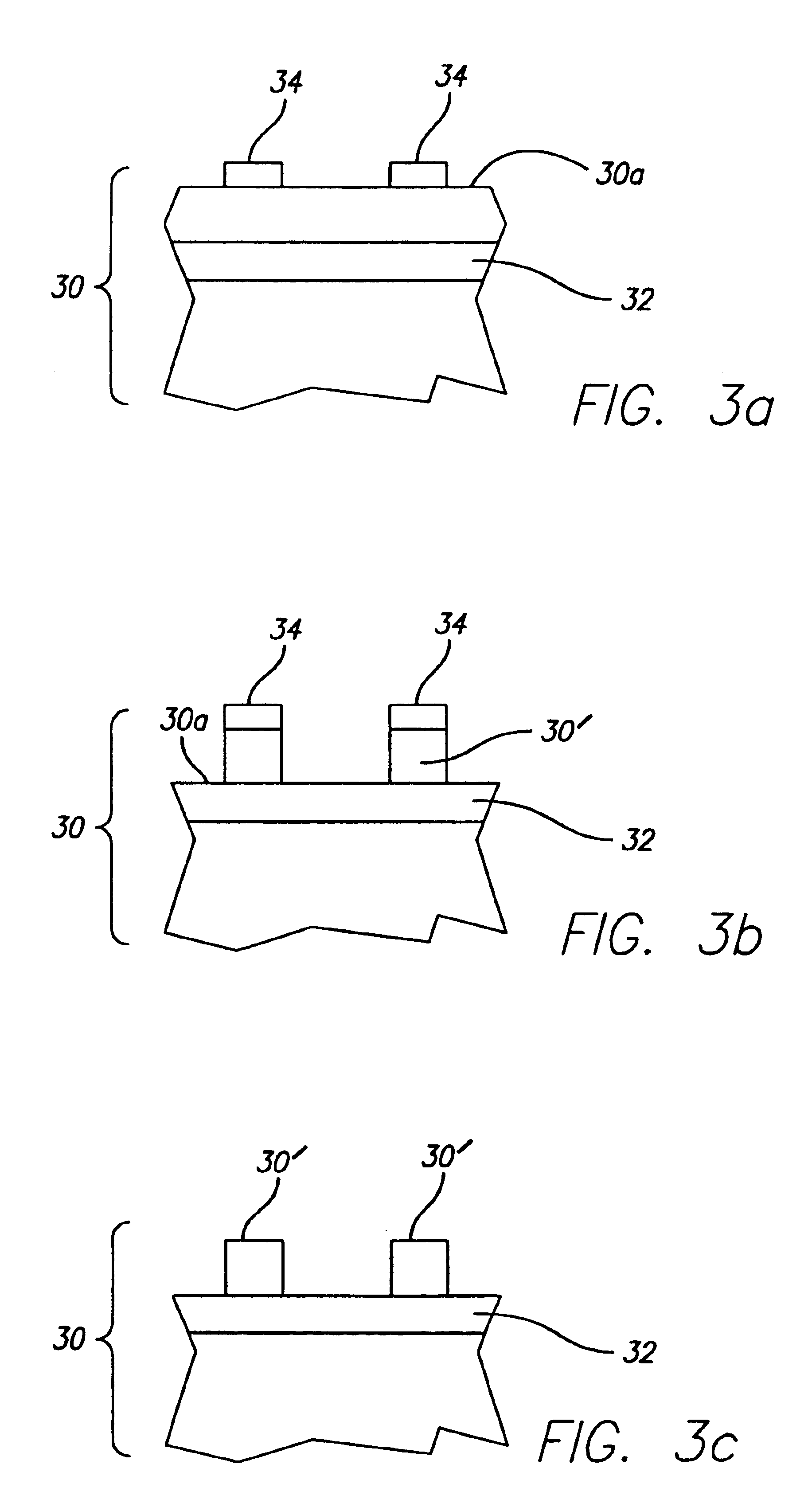

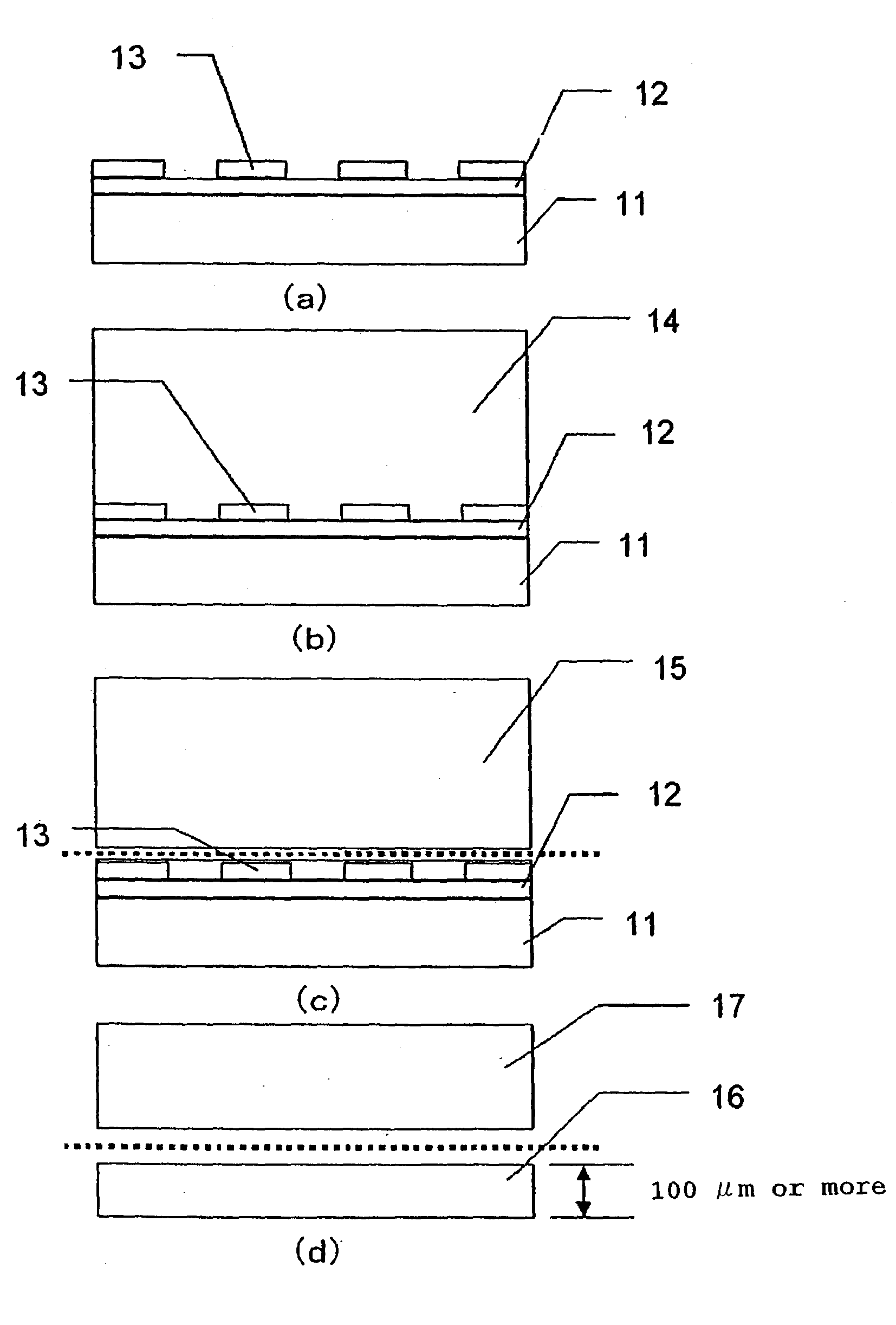

Fabrication method of semiconductor wafer

ActiveUS20040185665A1Little contaminationImprove crystal qualityTransistorPolycrystalline material growthMicrometerEtching

A fabrication method of a semiconductor wafer can fill trenches formed in a semiconductor substrate with an epitaxial film with high crystal quality without leaving cavities in the trenches. The trenches are formed in the first conductivity type semiconductor substrate. Planes exposed inside the trenches are made clean surfaces by placing the substrate in a gas furnace, followed by supplying the furnace with an etching gas and carrier gas, and by performing etching on the exposed planes inside the trenches by a thickness from about a few nanometers to one micrometer. The trenches have a geometry opening upward through the etching. Following the etching, a second conductivity type semiconductor is epitaxially grown in the trenches by supplying the furnace with a growth gas, etching gas, doping gas and carrier gas, thereby filling the trenches. Instead of making the trenches slightly-opened upward, their sidewalls may be made planes enabling facet formation.

Owner:FUJI ELECTRIC CO LTD

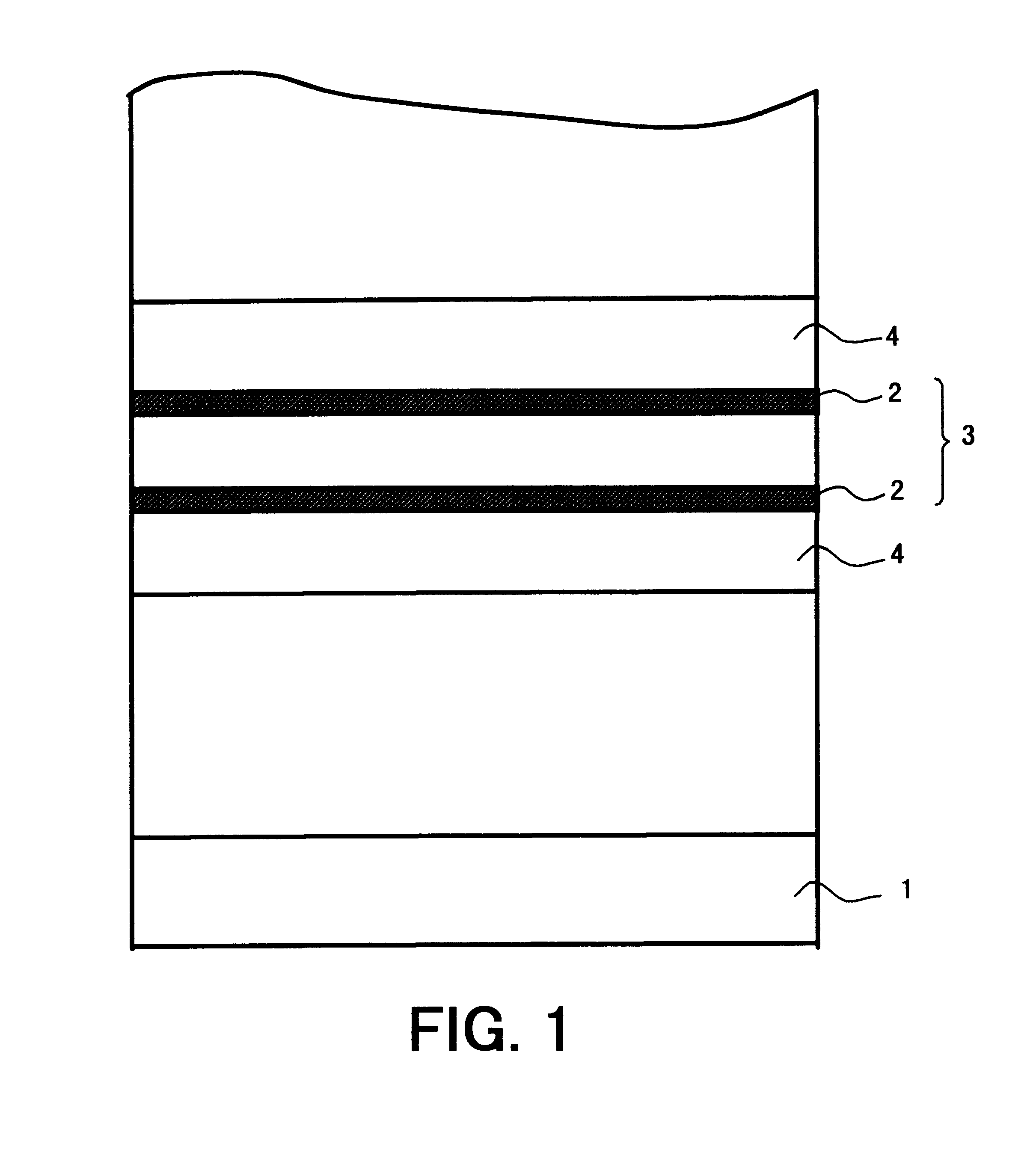

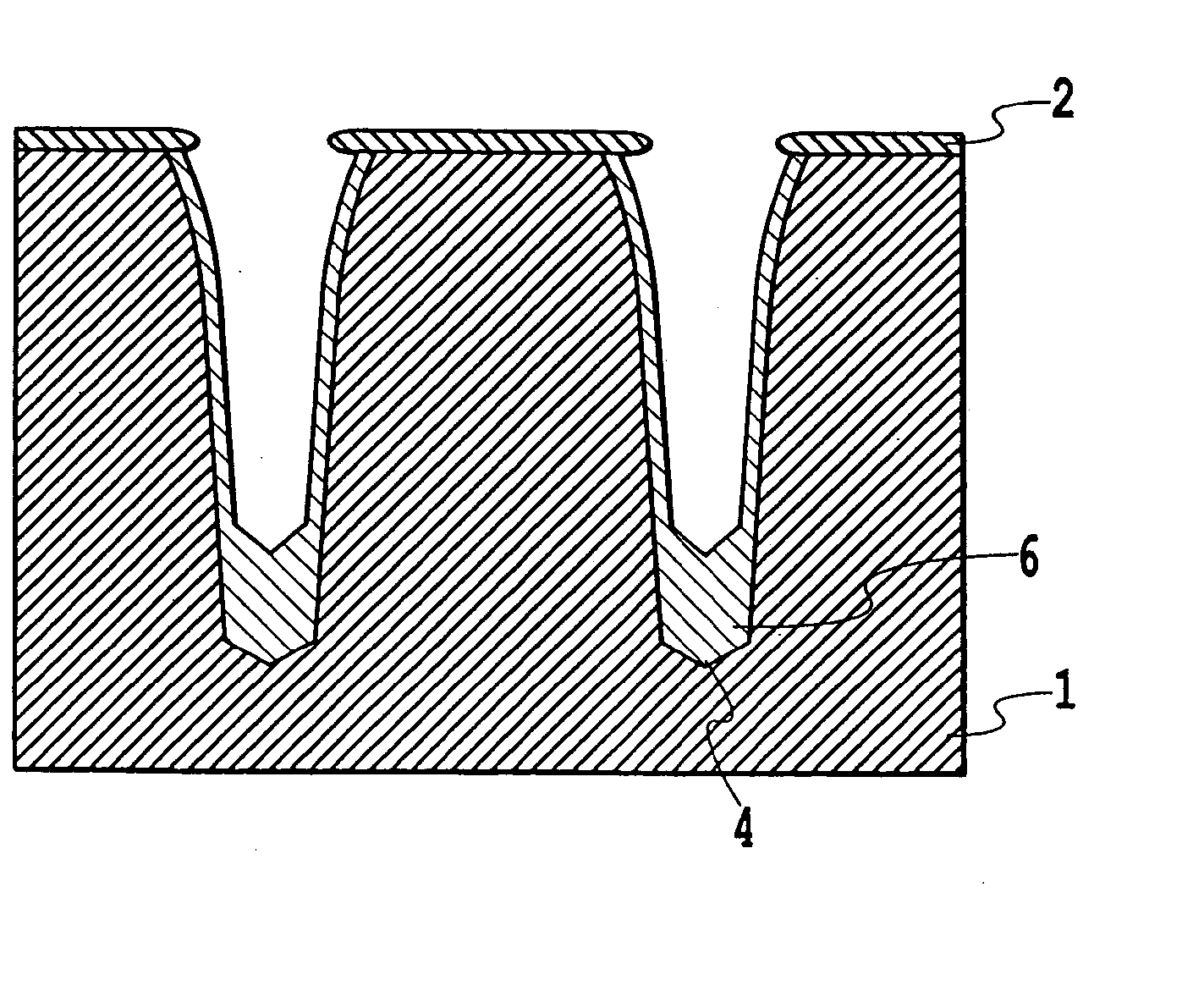

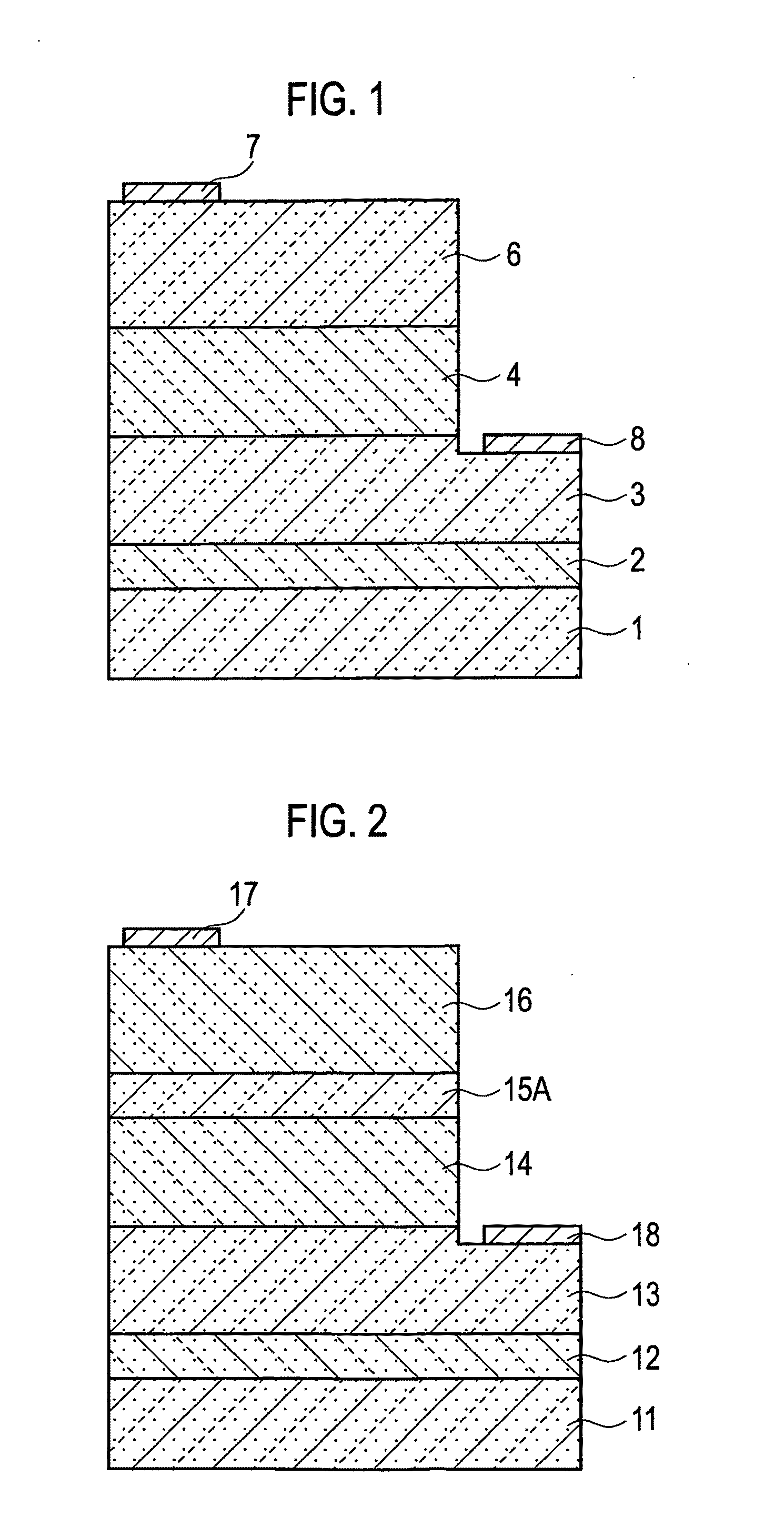

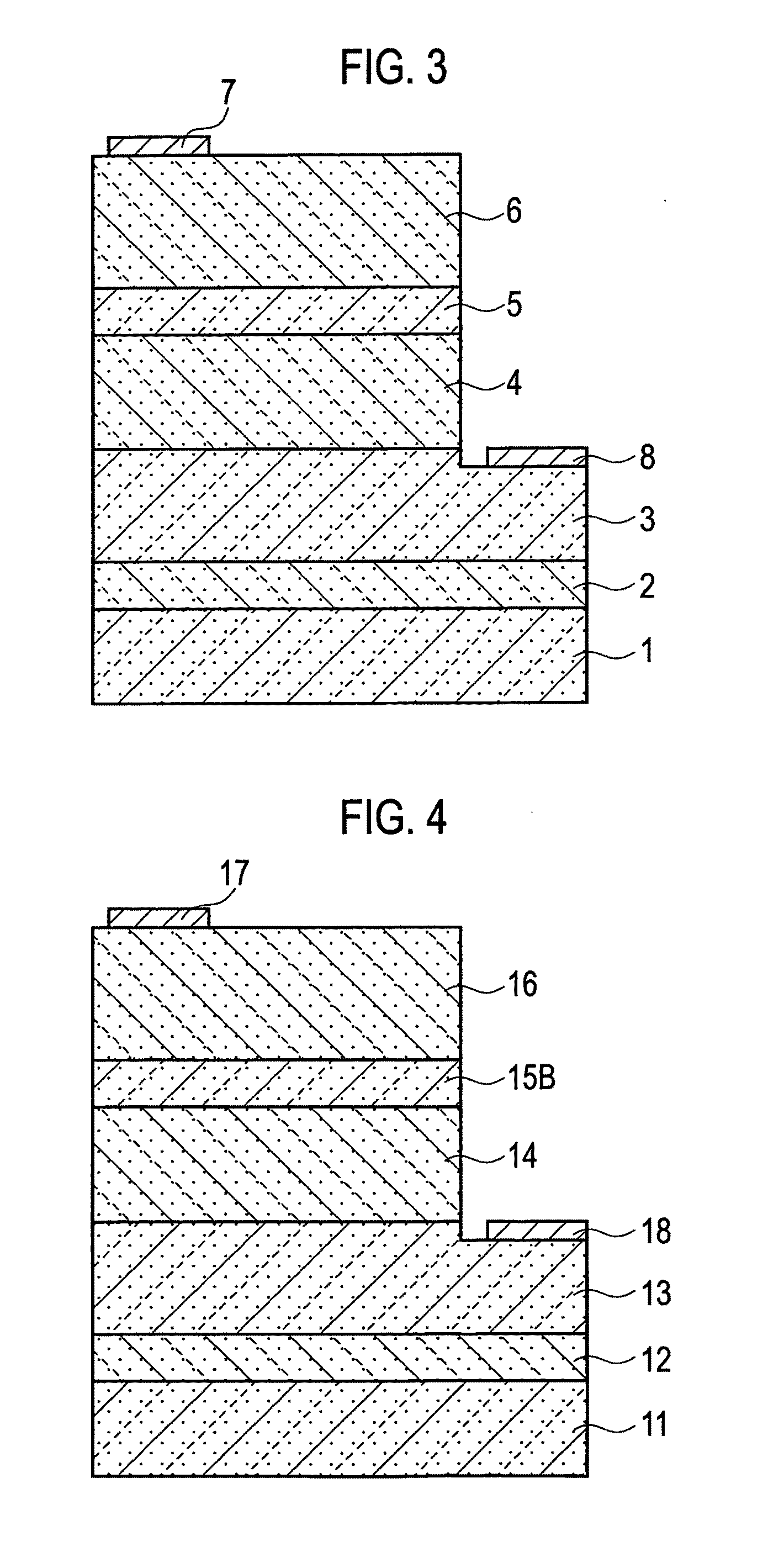

Semiconductor substrate made of group III nitride, and process for manufacture thereof

InactiveUS20020197825A1Reduce defect densityImprove crystal qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingHydrogen compoundsTitanium

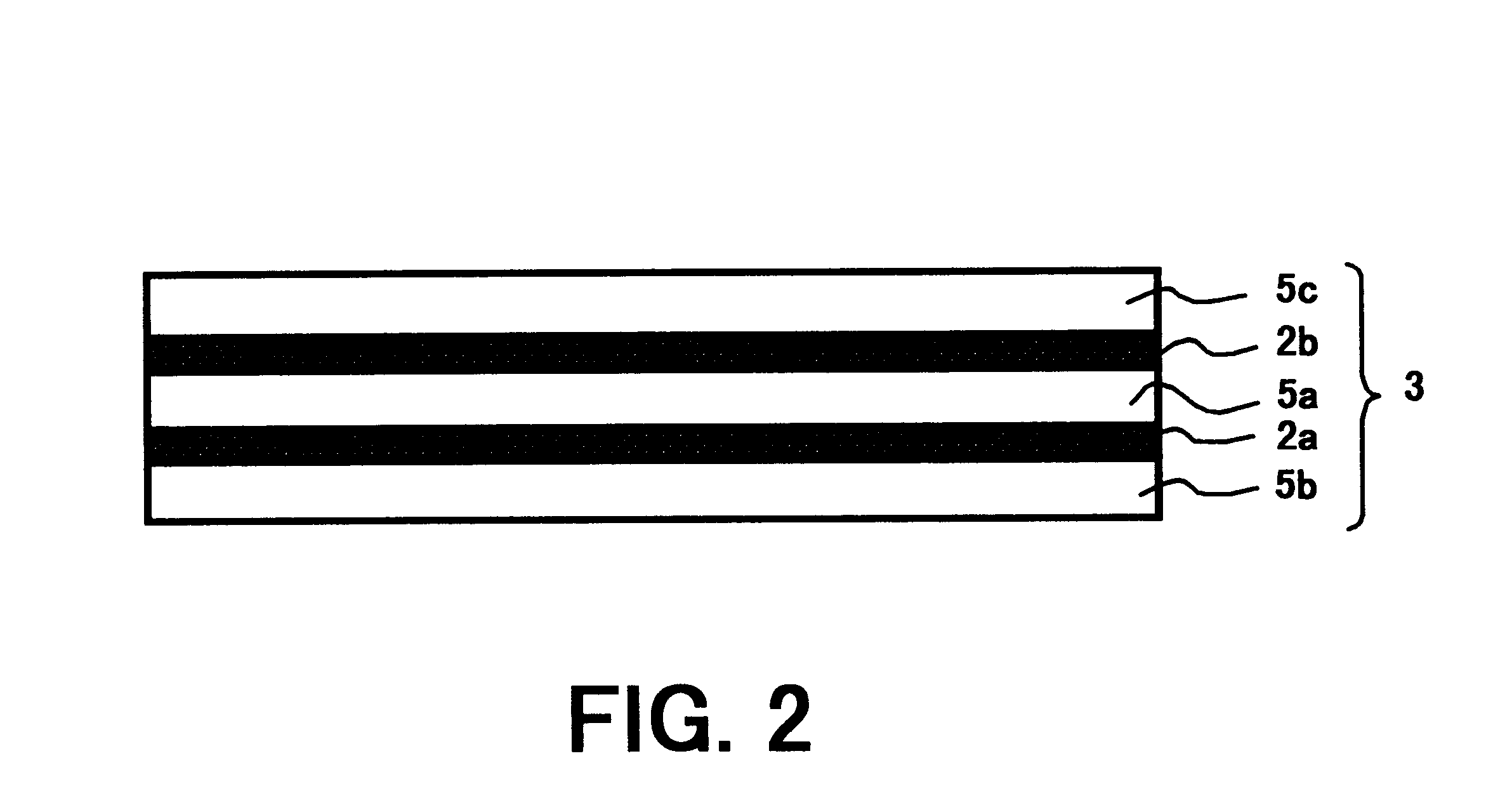

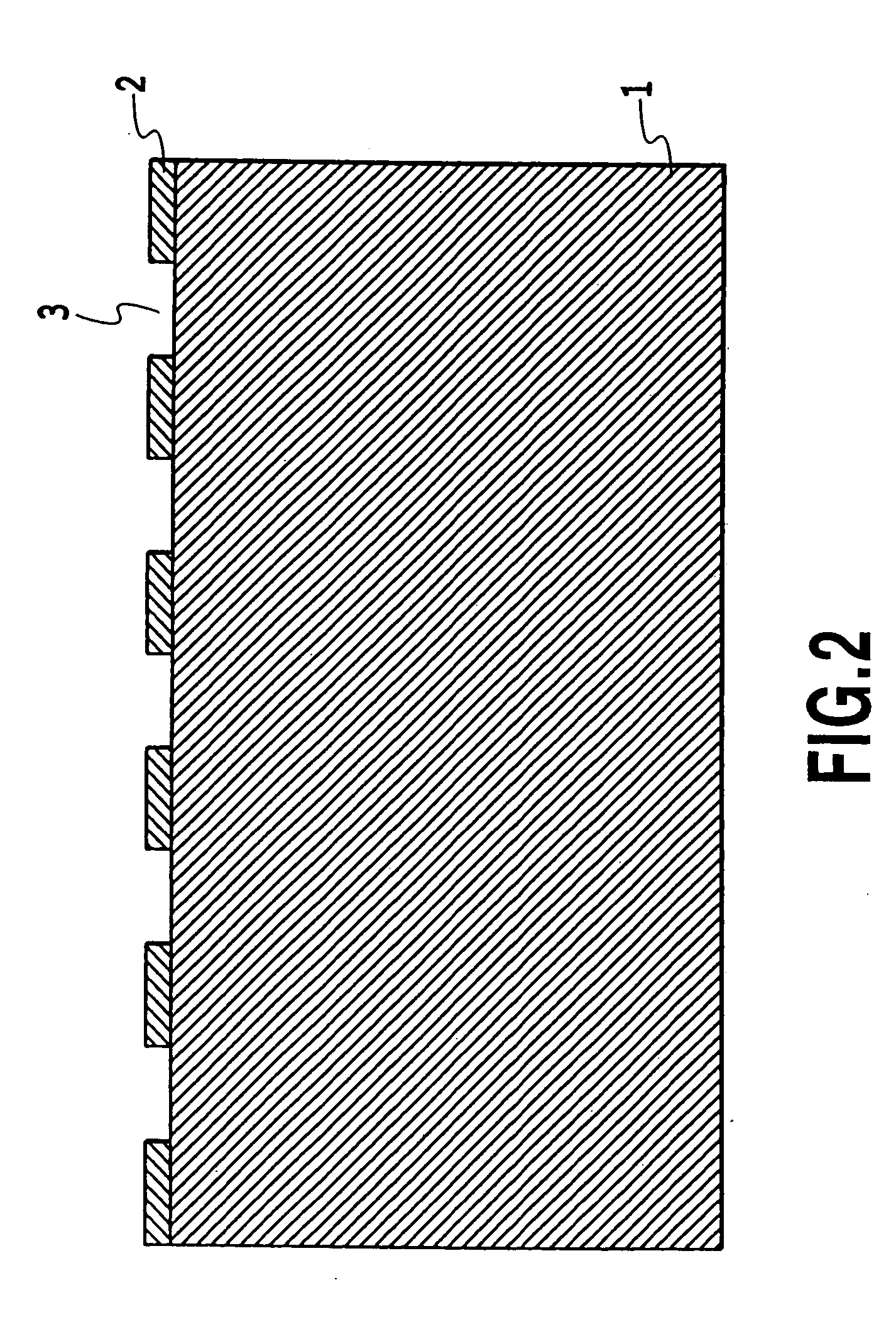

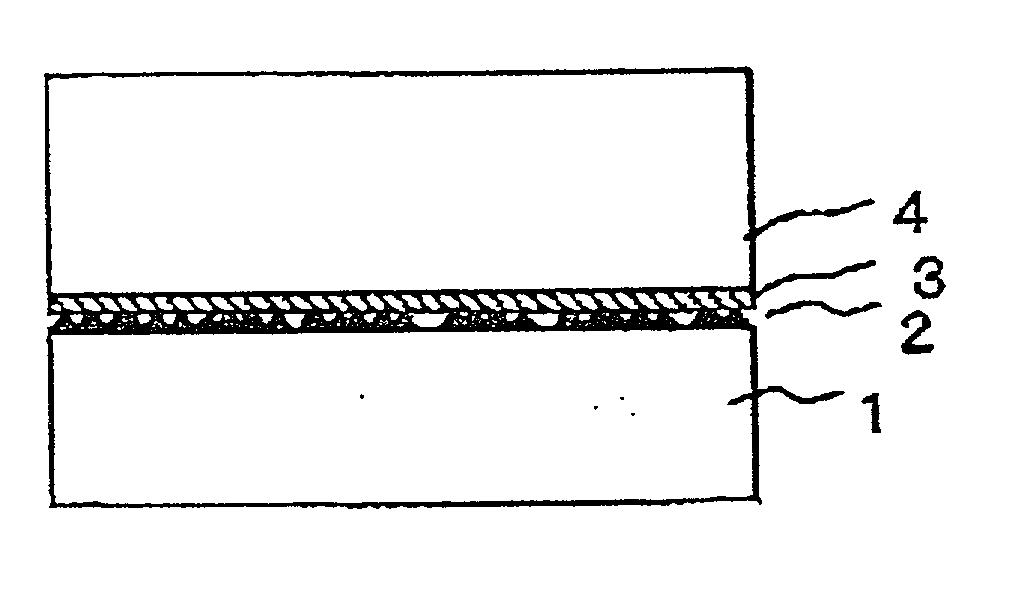

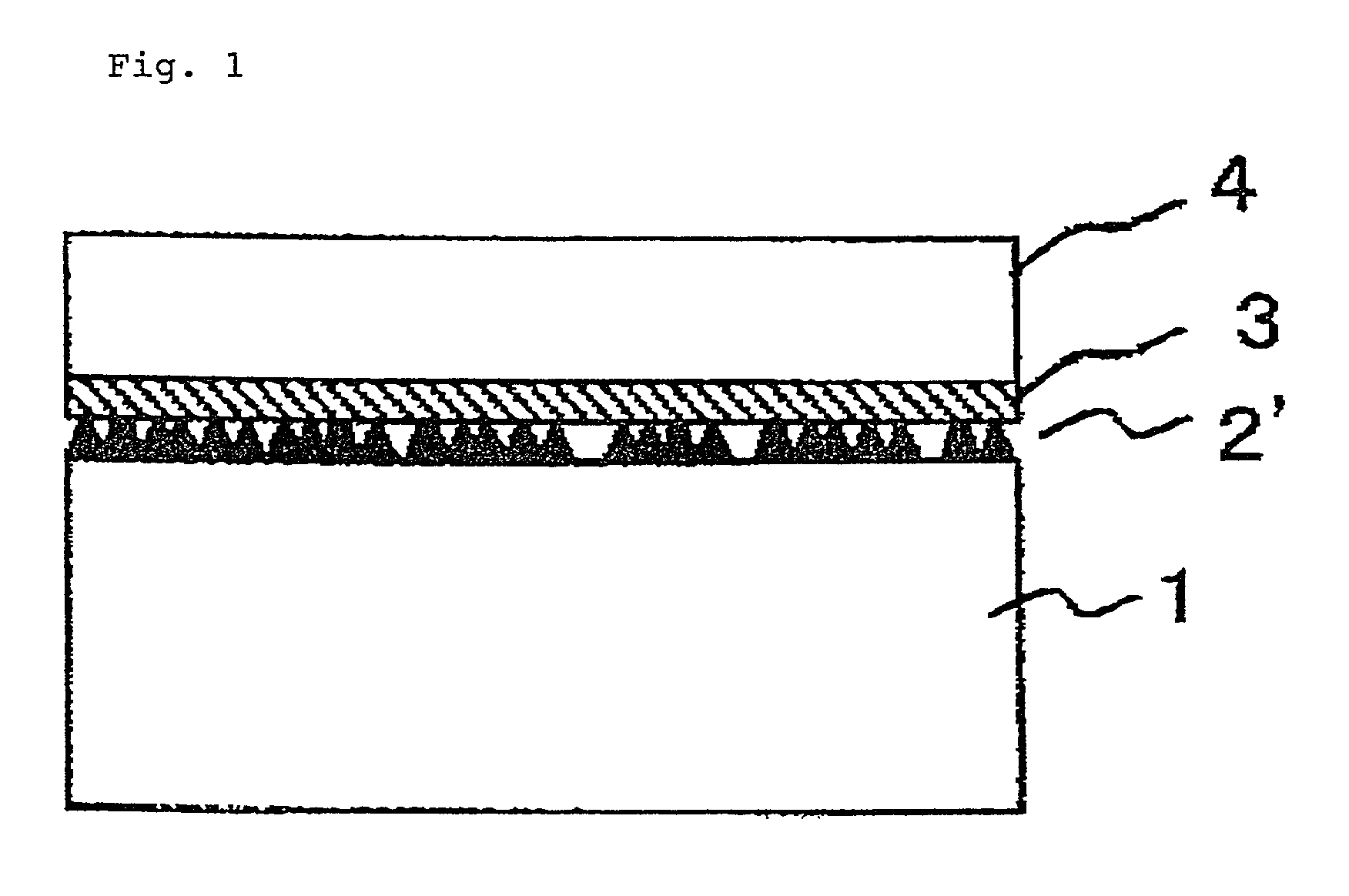

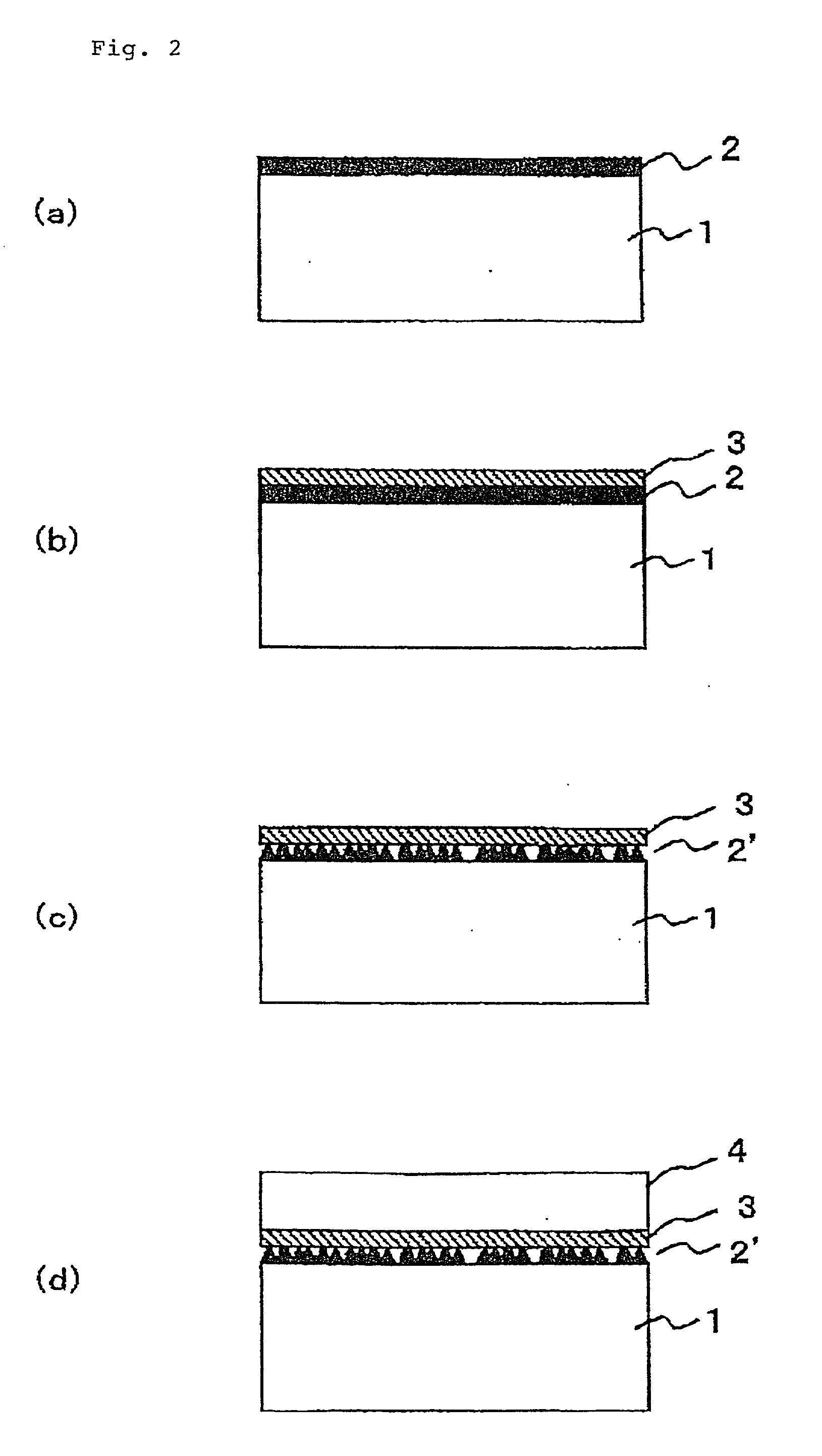

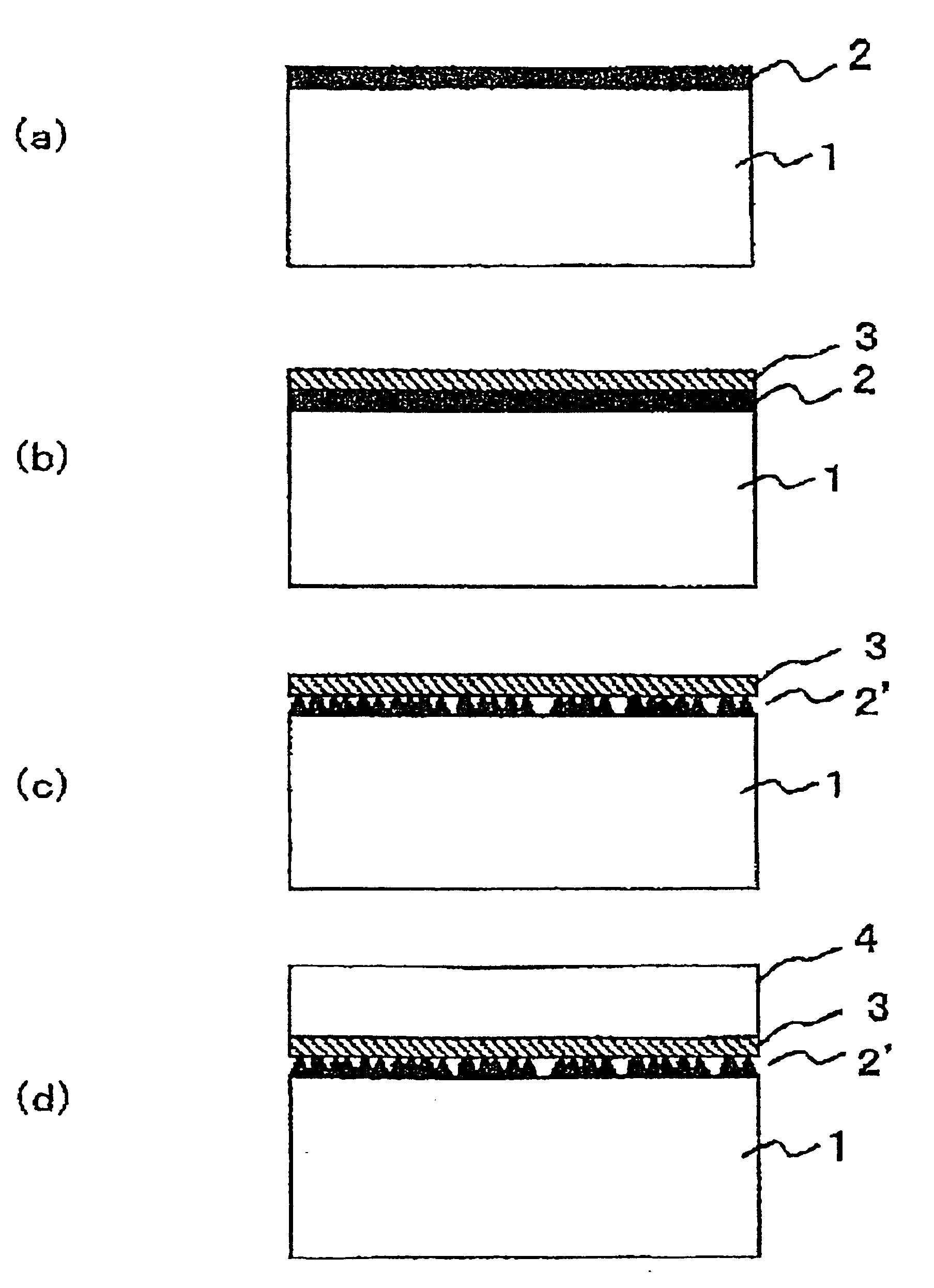

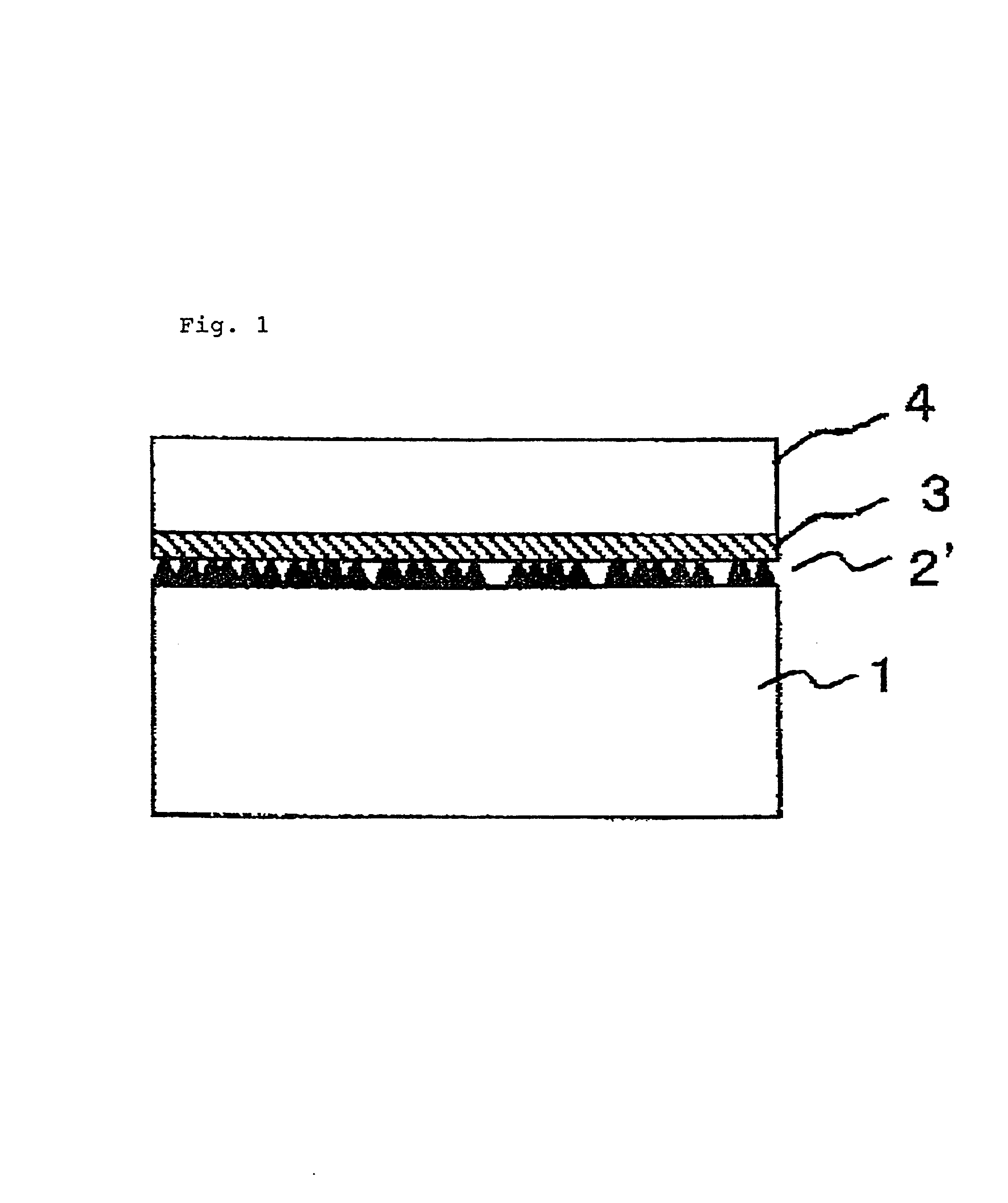

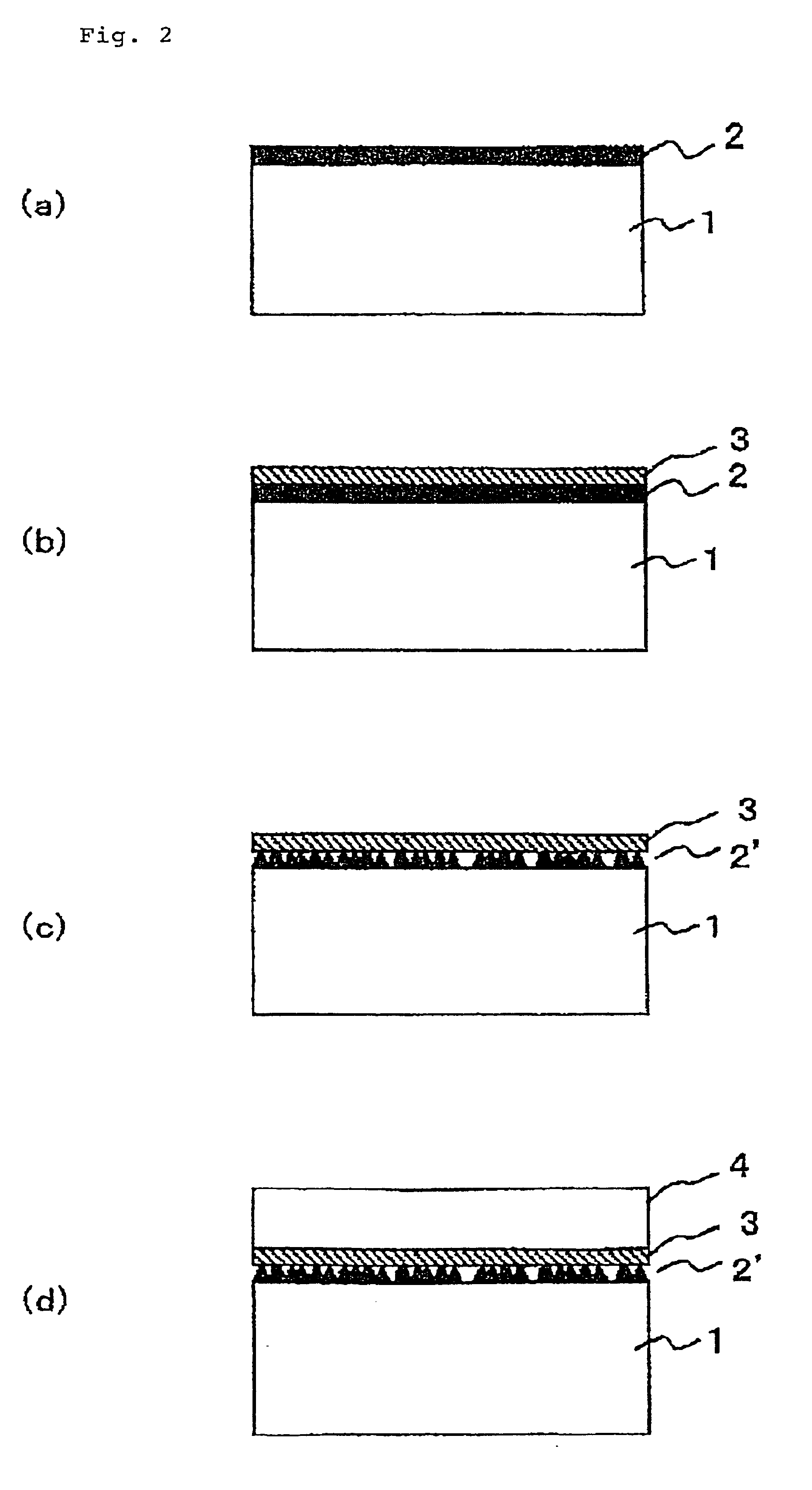

To provide a semiconductor substrate of a group III nitride with low defect density and little warp, this invention provides a process comprising such steps of: forming a GaN layer 2 on a sapphire substrate 1 of the C face ((0001) face); forming a titanium film 3 thereon; heat-treating the substrate in an atmosphere containing hydrogen gas or a gas of a compound containing hydrogen to form voids in the GaN layer 2; and thereafter forming a GaN layer 4 on the GaN layer 2'.

Owner:SUMITOMO CHEM CO LTD

Semiconductor substrate made of group III nitride, and process for manufacture thereof

InactiveUS6924159B2Reduce defect densityImprove crystal qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingNitride semiconductorsSapphire substrate

To provide a semiconductor substrate of a group III nitride with low defect density and little warp, this invention provides a process comprising such steps of:forming a GaN layer 2 on a sapphire substrate 1 of the C face ((0001) face); forming a titanium film 3 thereon; heat-treating the substrate in an atmosphere containing hydrogen gas or a gas of a compound containing hydrogen to form voids in the GaN layer 2; and thereafter forming a GaN layer 4 on the GaN layer 2′.

Owner:SUMITOMO CHEM CO LTD

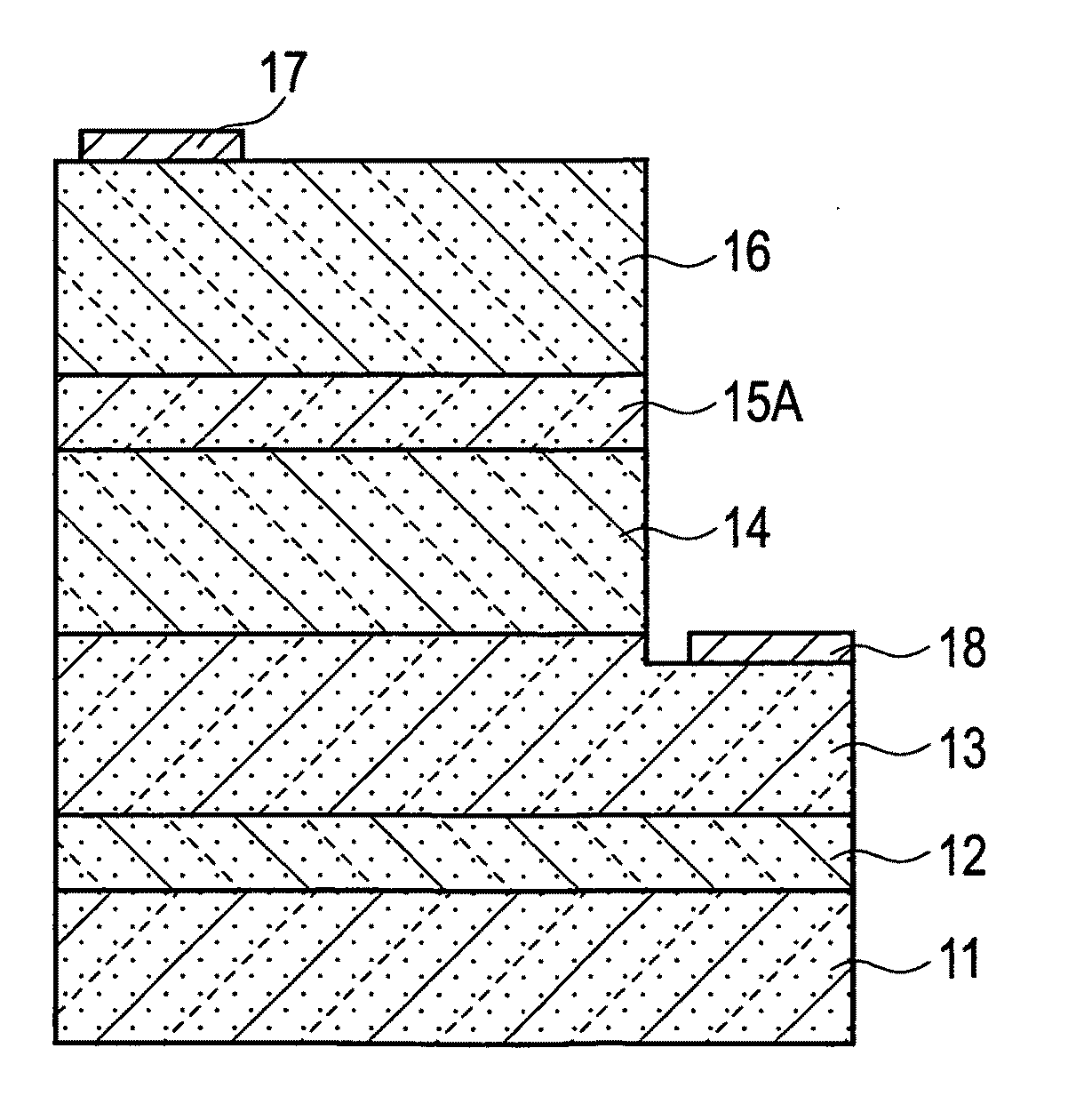

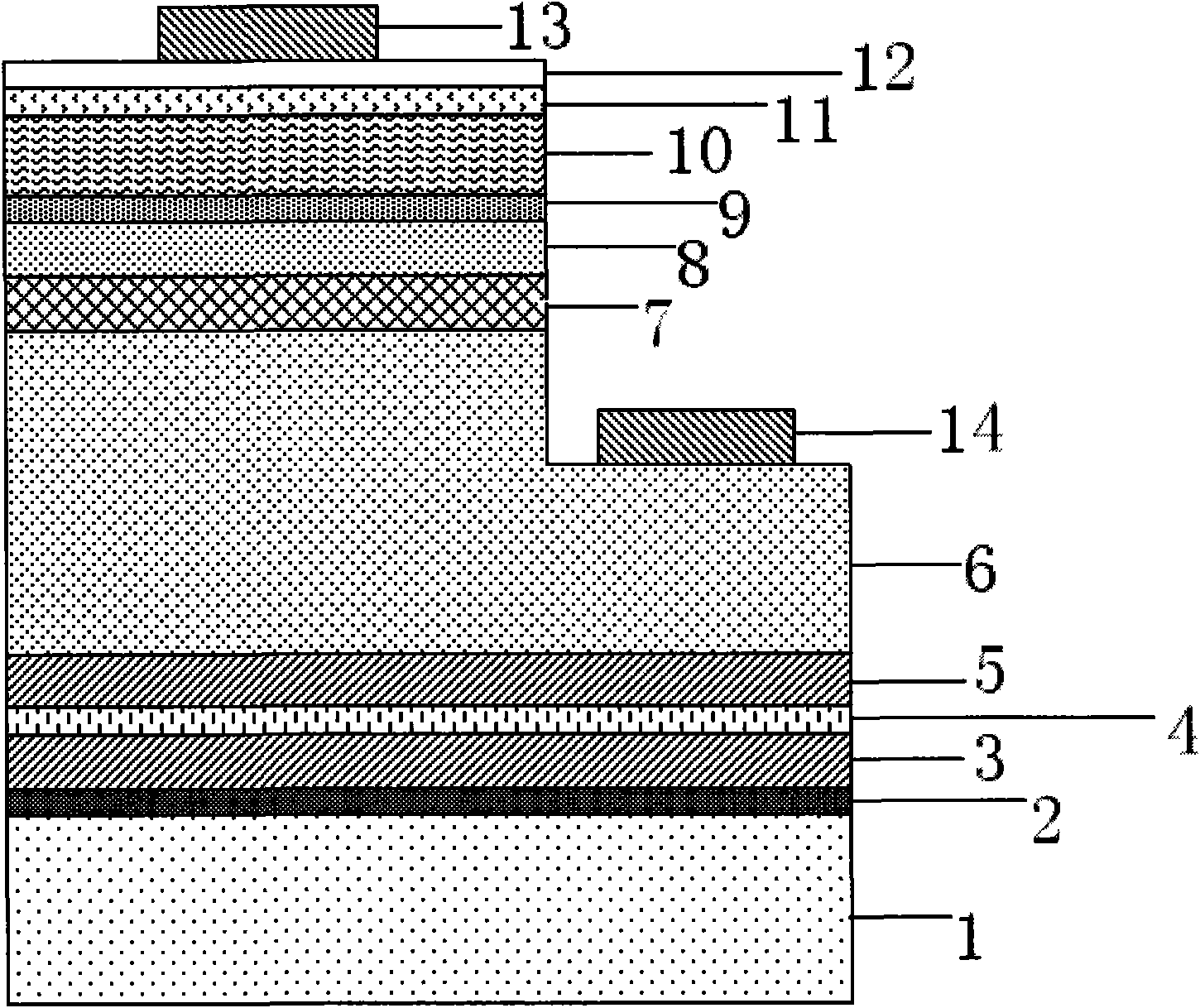

Nitride semiconductor light emitting element and method for manufacturing nitride semiconductor

InactiveUS20100133506A1Improve crystal qualityAvoid more failuresSemiconductor/solid-state device manufacturingNanoopticsActive layerLight emission

Provided are a nitride semiconductor light emitting element having a nitride semiconductor layered on an AlN buffer layer with improved qualities such as crystal quality and with improved light emission output, and a method of manufacturing a nitride semiconductor. An AlN buffer layer (2) is formed on a sapphire substrate (1), and nitride semiconductors of an n-type AlGaN layer (3), an InGaN / GaN active layer (4) and a p-type GaN layer (5) are layered in sequence on the buffer layer (2). An n-electrode (7) is formed on a surface of the n-type AlGaN layer (3), and a p-electrode (6) is formed on the p-type GaN layer (5). The n-type AlGaN layer (3) serves as a cladding layer for confining light and carriers. The AlN buffer layer (2) is manufactured by alternately supplying an Al material and an N material at a growing temperature of 900° C. or higher.

Owner:ROHM CO LTD

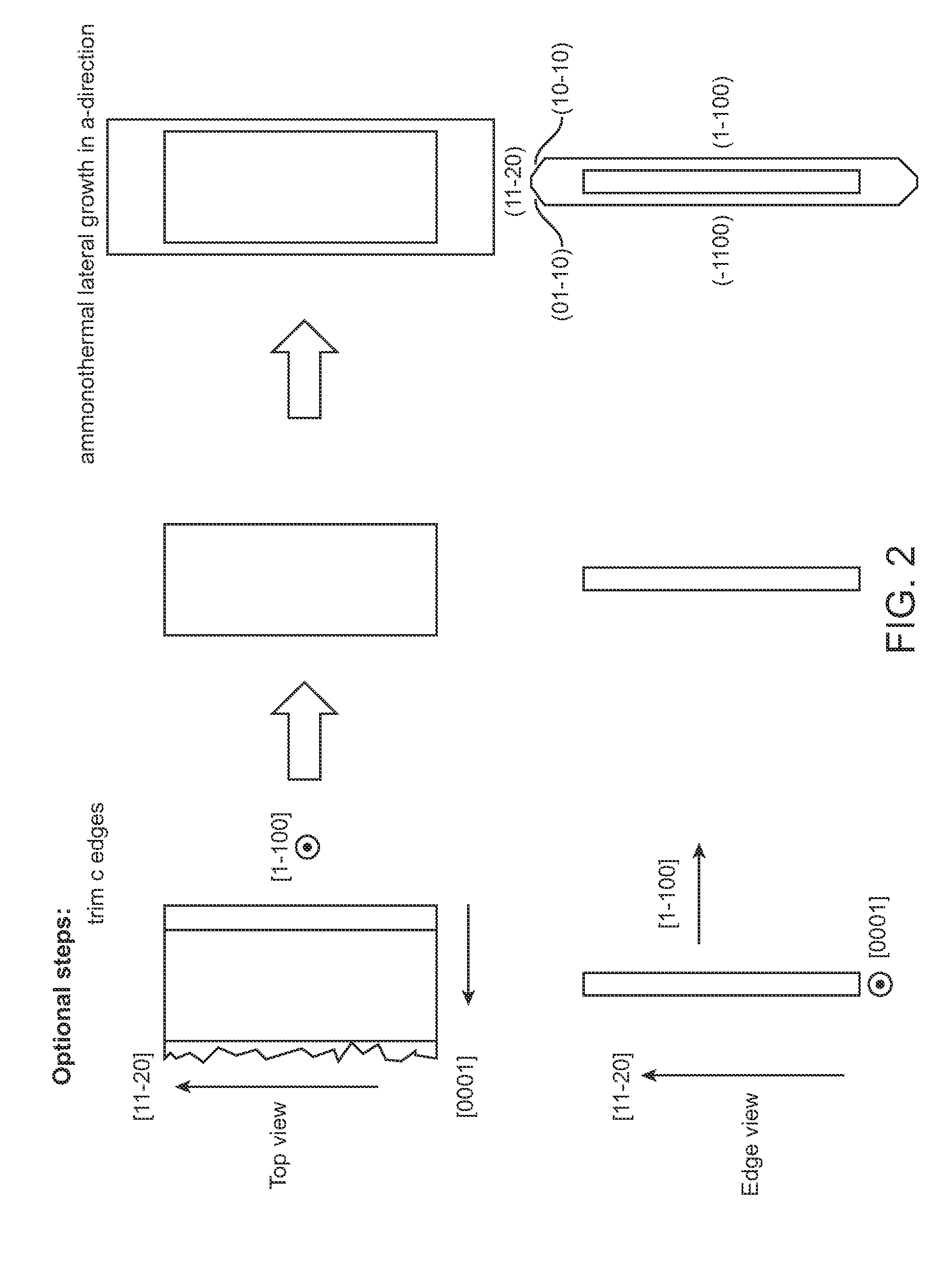

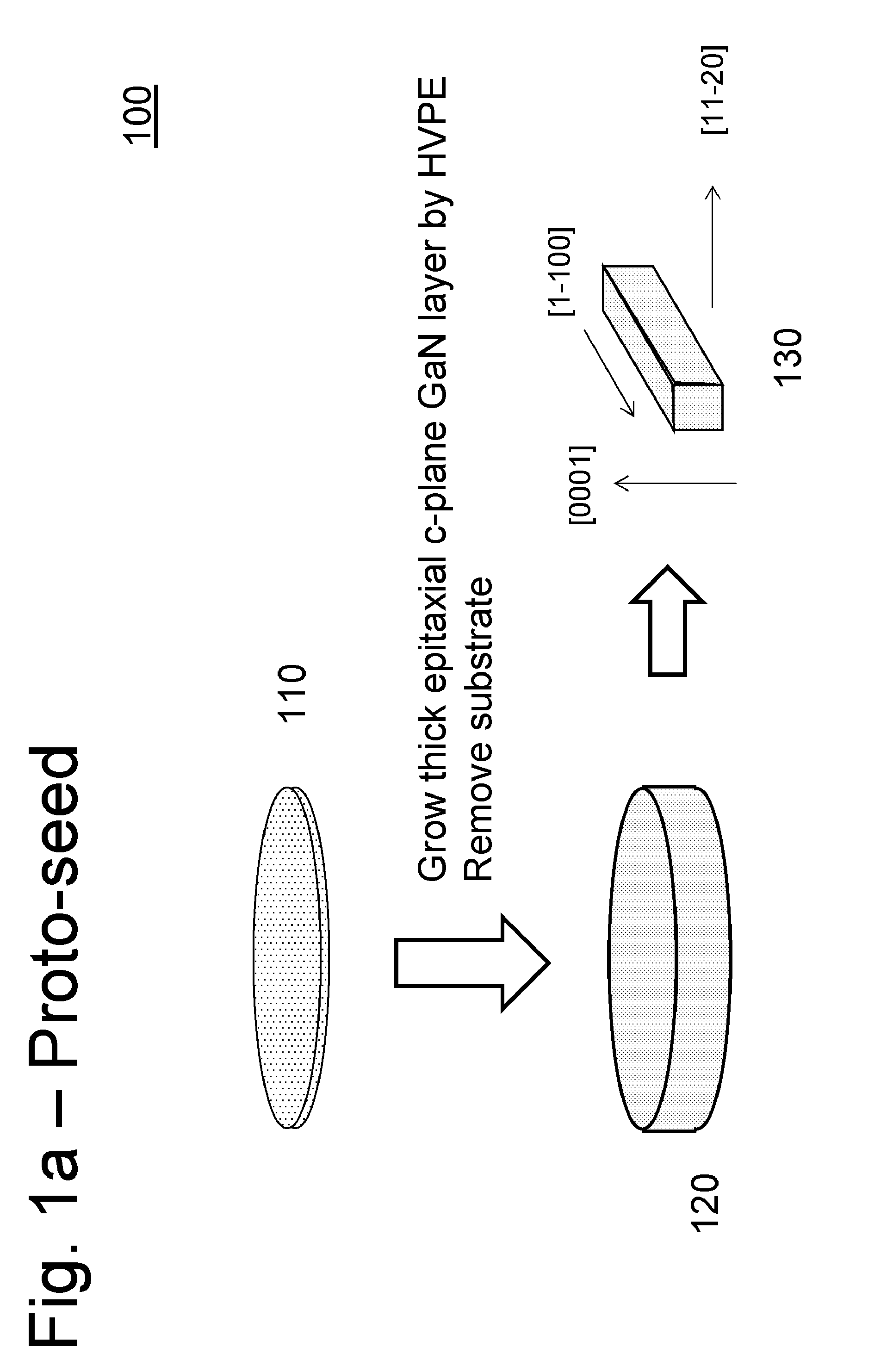

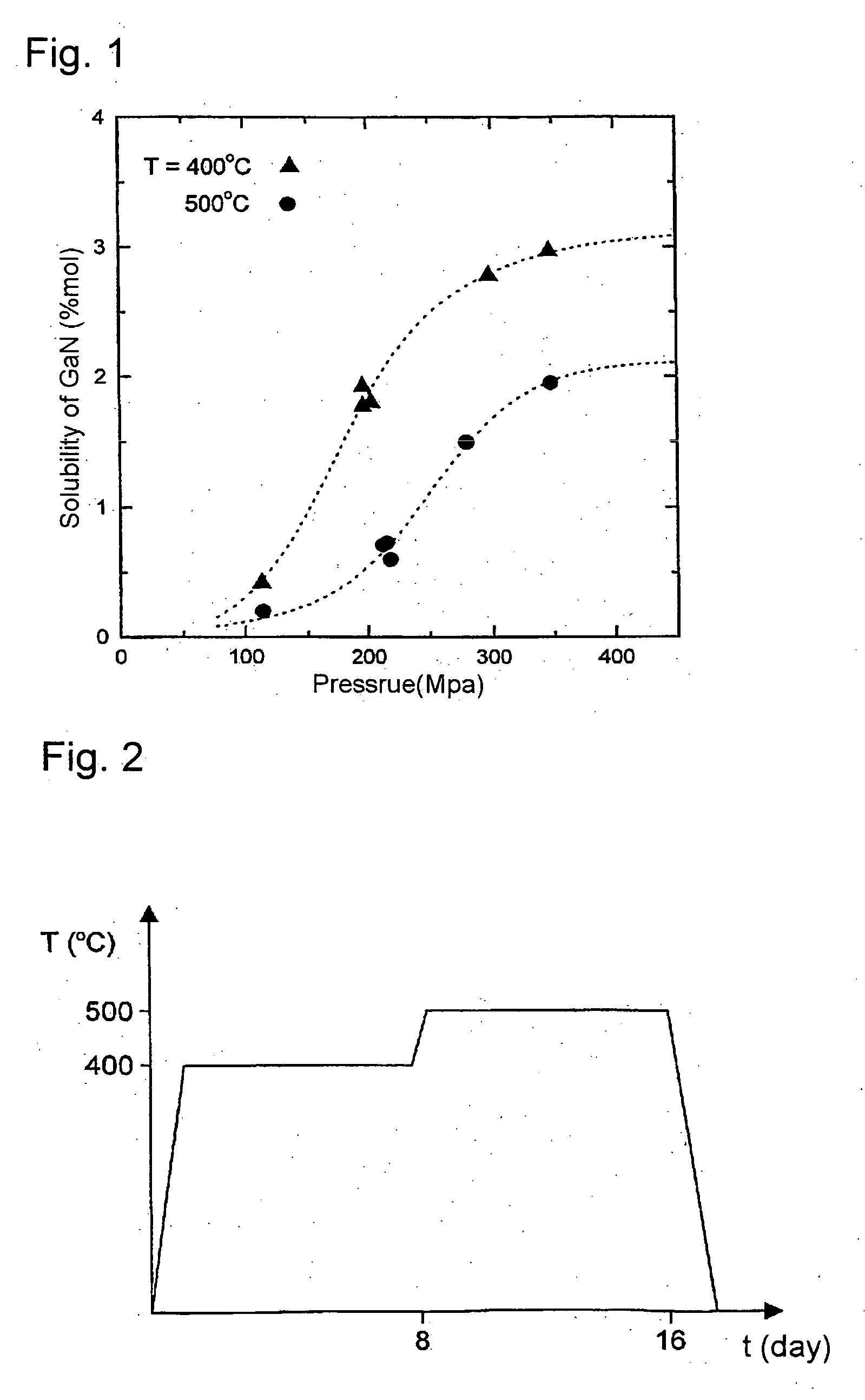

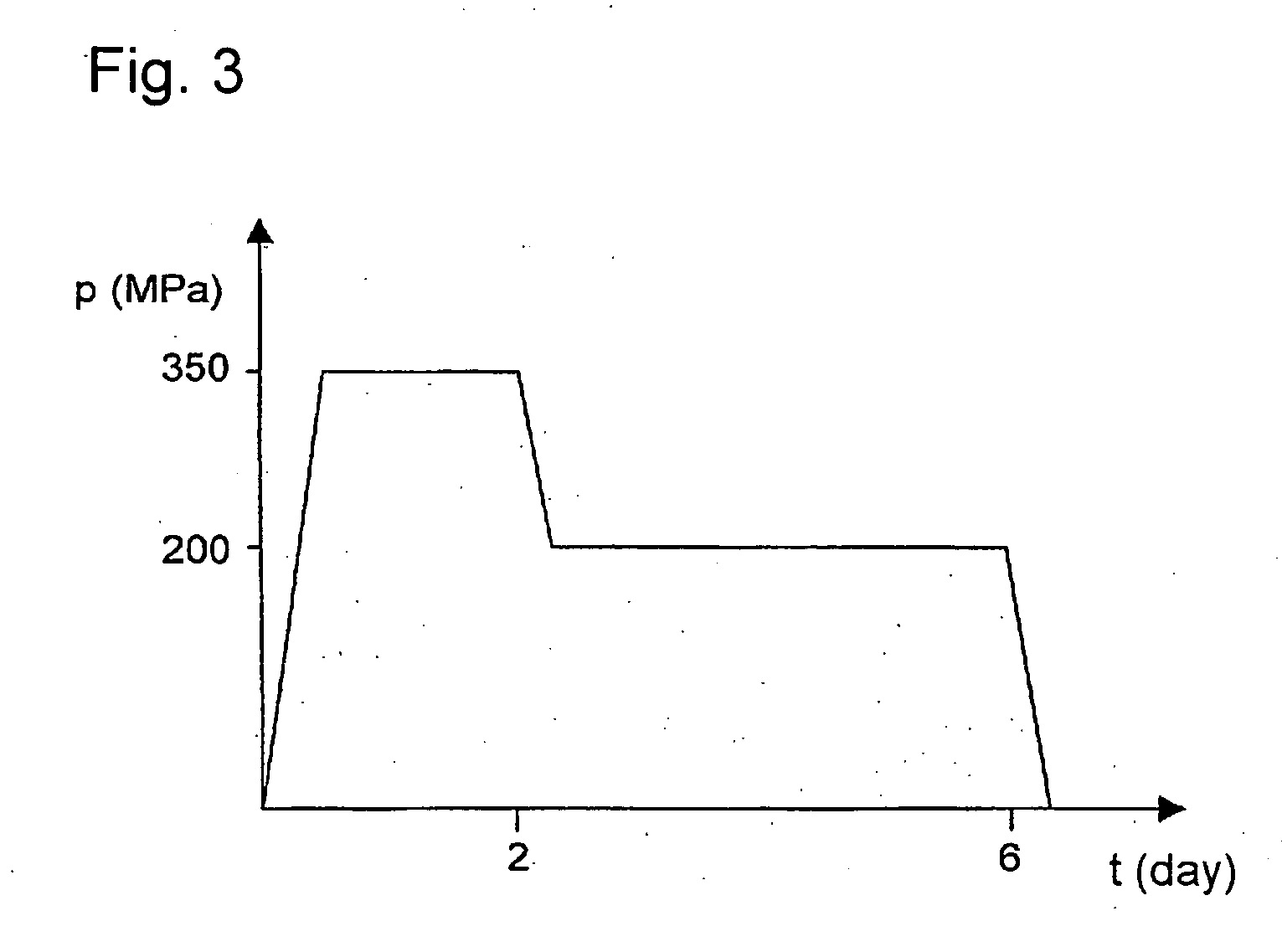

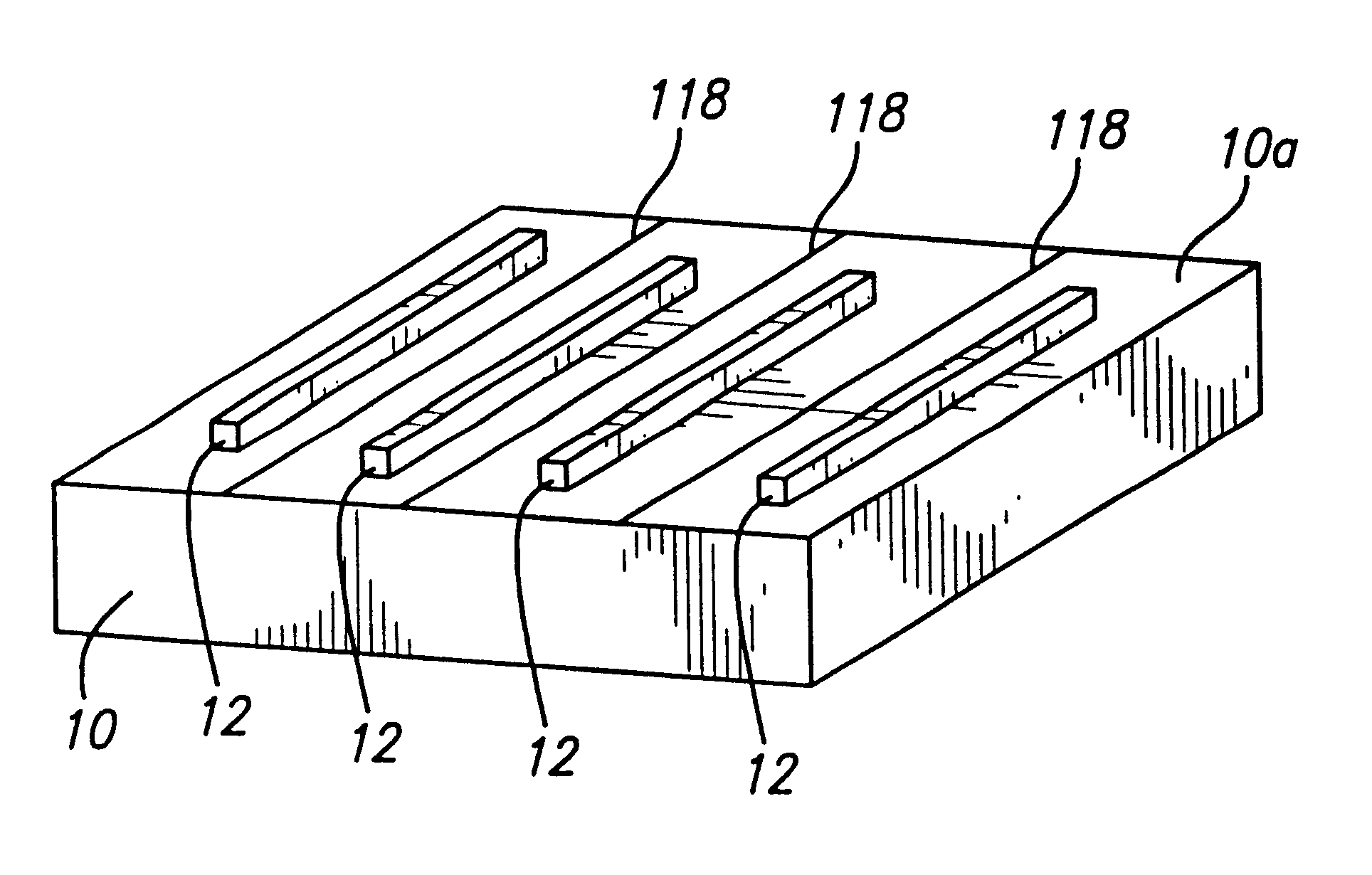

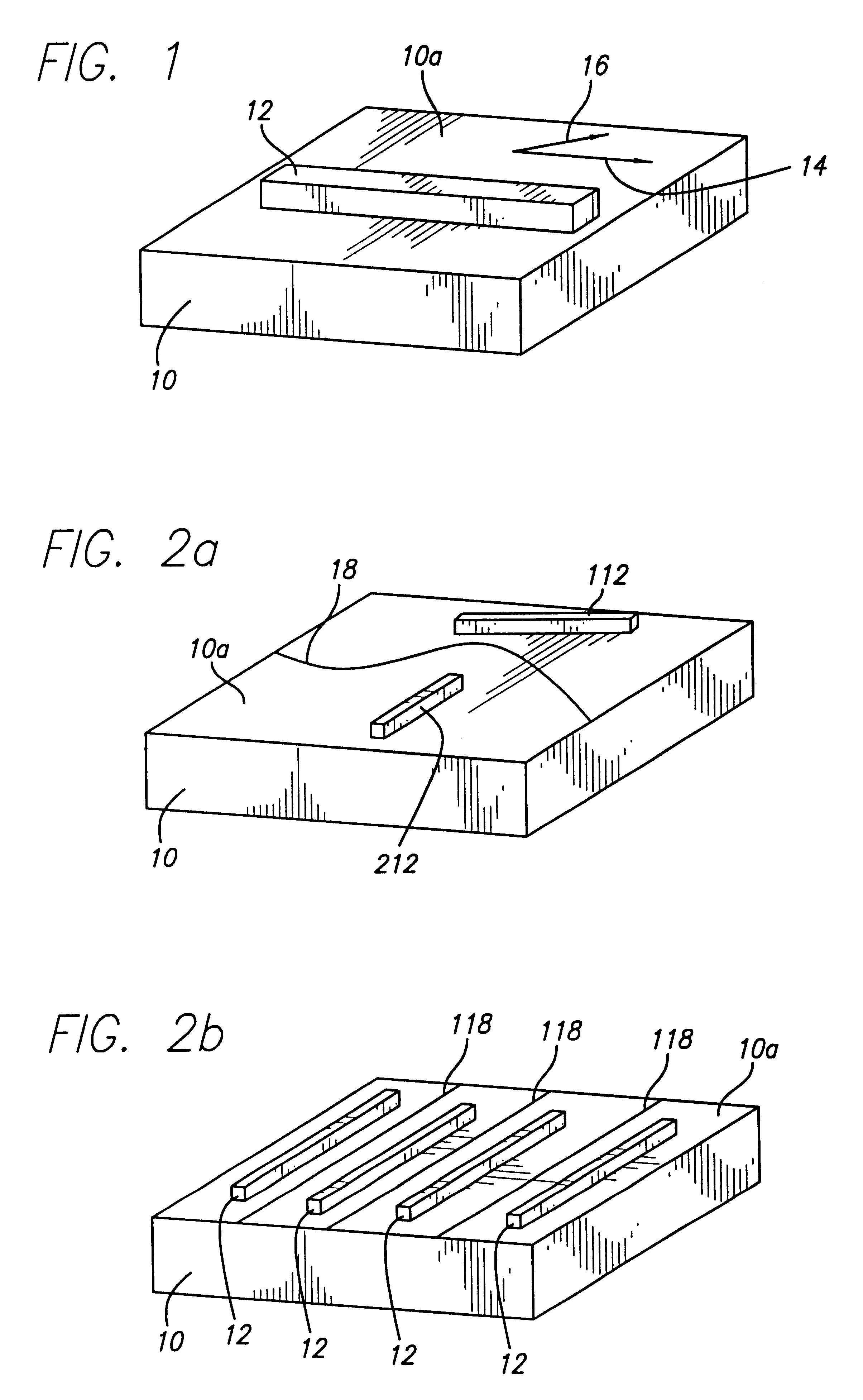

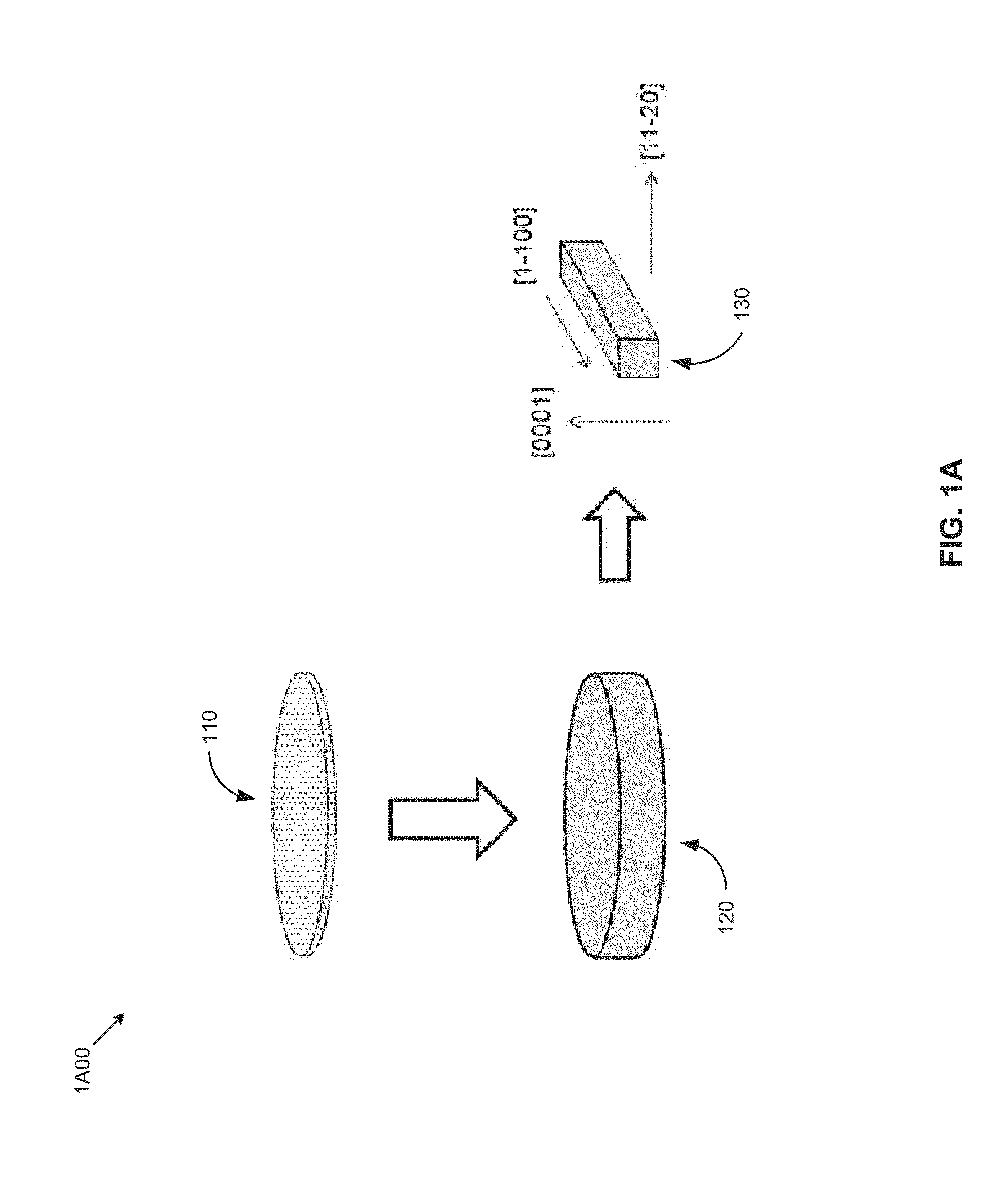

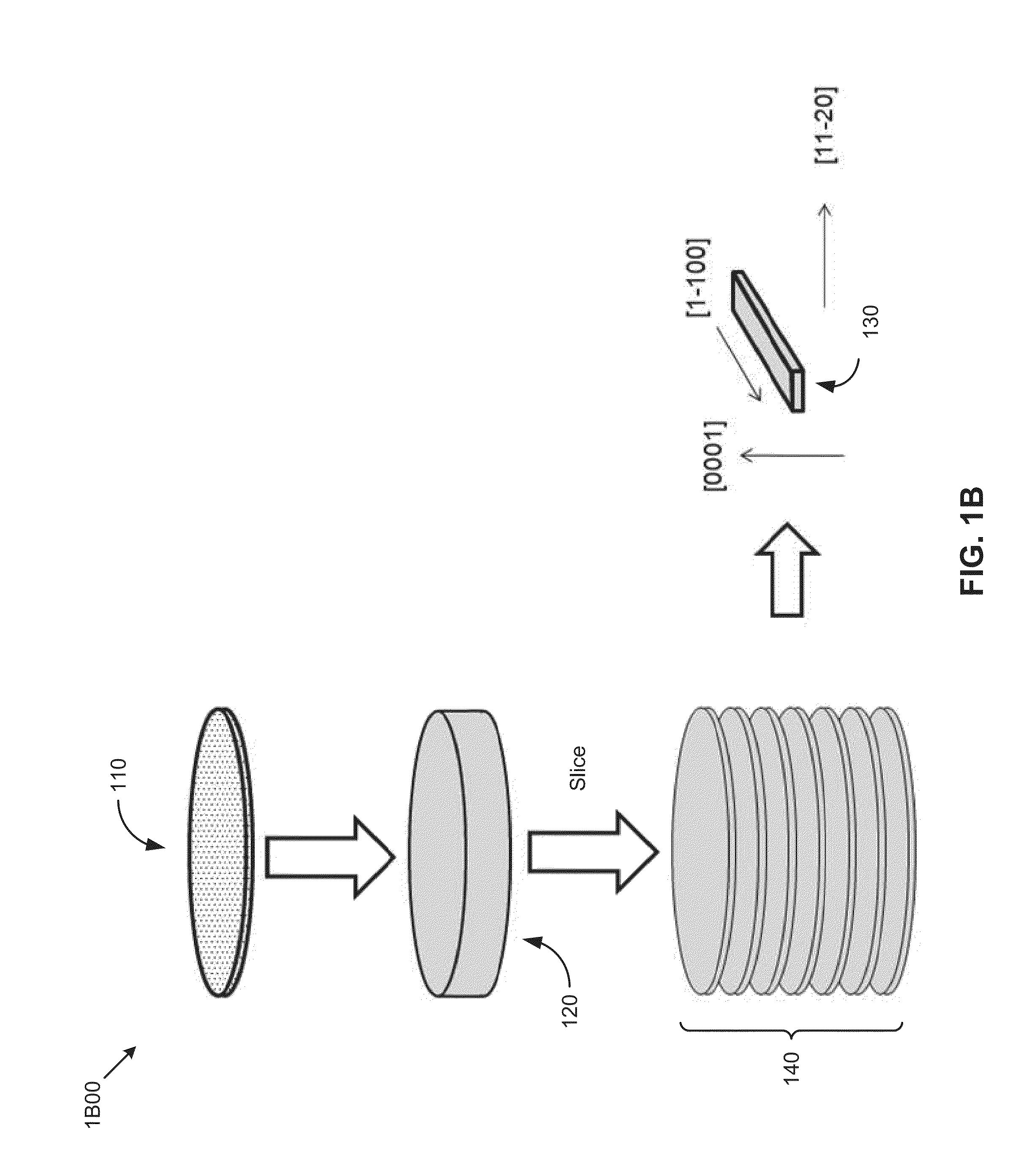

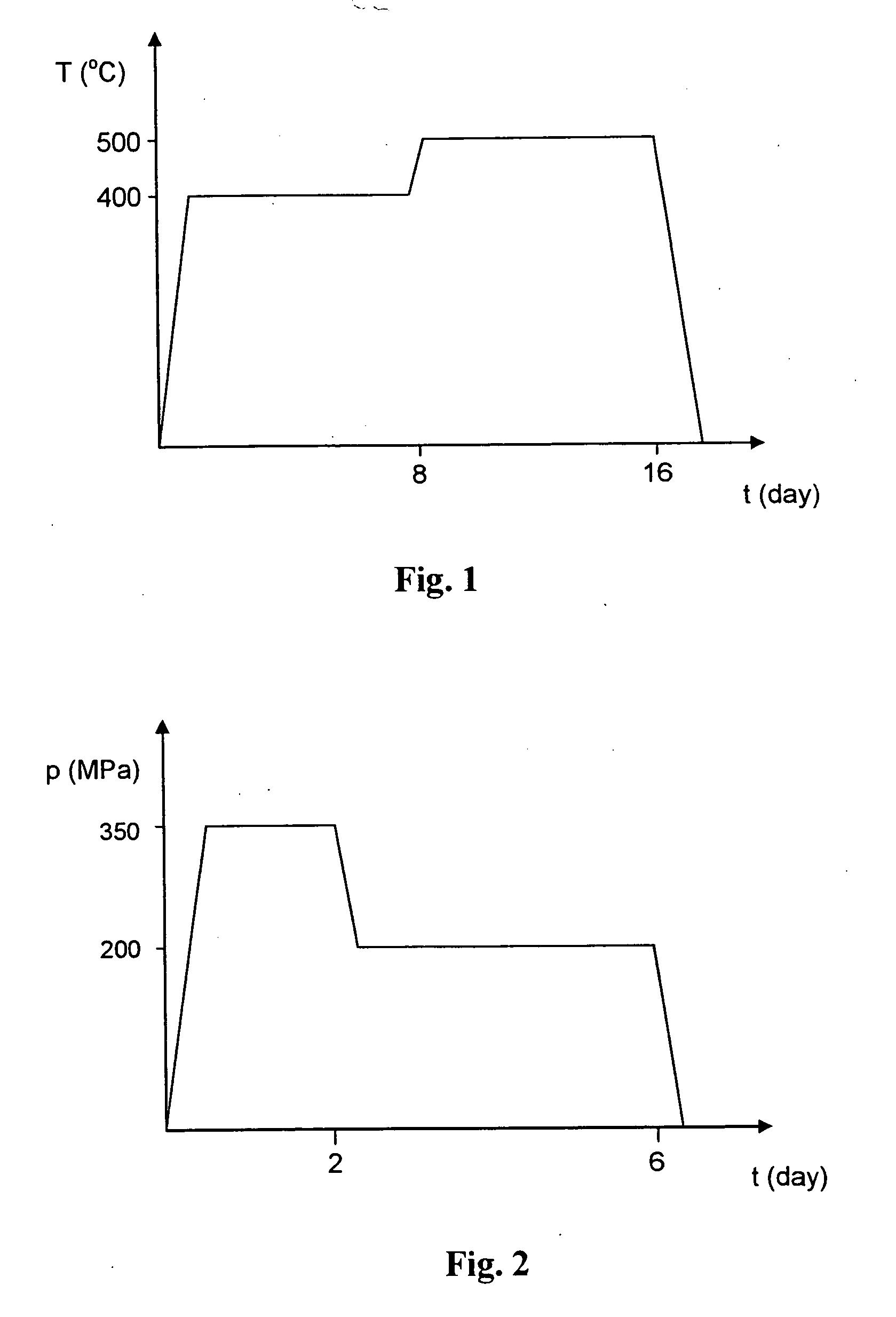

Method for Synthesis of High Quality Large Area Bulk Gallium Based Crystals

ActiveUS20110256693A1Improve crystal qualityPolycrystalline material growthFrom normal temperature solutionsPhotodetectorSolar cell

A large area nitride crystal, comprising gallium and nitrogen, with a non-polar or semi-polar large-area face, is disclosed, along with a method of manufacture. The crystal is useful as a substrate for a light emitting diode, a laser diode, a transistor, a photodetector, a solar cell, or for photoelectrochemical water splitting for hydrogen generation.

Owner:SLT TECH

Thin film photovoltaic structure

InactiveUS20070277875A1Improve conversion efficiencyWide range of designsPhotovoltaic energy generationSemiconductor devicesSingle crystalEngineering

Photovoltaic devices include an insulator structure bonded to an exfoliation layer, preferably of a substantially single-crystal donor semiconductor wafer, and at least one photovoltaic device layer, such as a conductive layer. In a preferred embodiment, a device may include a conductive layer adjacent to the insulator substrate and integral to the exfoliation layer, near the side that faces the insulator substrate, such as between the insulator substrate and the exfoliation layer. In a further preferred embodiment, a device may include a plurality of photovoltaic device layers distal to the insulator substrate and in or on the exfoliation layer, preferably having been epitaxially grown on the exfoliation layer after the exfoliation layer has been anodically bonded to the insulator substrate by means of electrolysis.

Owner:CORNING INC

Low cost solar cells formed using a chalcogenization rate modifier

InactiveUS20110294254A1Speed up gallium processingIncrease exposureFinal product manufactureSemiconductor/solid-state device manufacturingAlloySolar cell

Methods and devices are provided for forming an absorber layer. In one embodiment, a method is provided comprising of depositing a precursor material onto a substrate, wherein the precursor material may include or may be used with an additive to minimize concentration of group IIIA material such as Ga in the back portion of the final semiconductor layer. The additive may be a non-copper Group IB additive in elemental or alloy form.

Owner:AERIS CAPITAL SUSTAINABLE IP

Phosphor single crystal substrate and method for preparing the same, and nitride semiconductor component using the same

InactiveUS20060054076A1Simple processRapid cooling functionPolycrystalline material growthFrom normal temperature solutionsGas phaseSingle crystal

A light emitting device having a phosphor substrate, which comprises nitride containing at least one element selected from Group XIII (IUPAC 1989) having a general formula XN, wherein X is at least one element selected from B, Al, Ga and In, a general formula XN:Y, wherein X is at least one element selected from B, Al, Ga and In, and Y is at least one element selected from Be, Mg, Ca, Sr, Ba, Zn, Cd and Hg, or a general formula XN:Y,Z, wherein X is at least one element selected from B, Al, Ga and In, Y is at least one element selected from Be, Mg, Ca, Sr, Ba, Zn, Cd and Hg, and Z is at least one element selected from C, Si, Ge, Sn, Pb, O and S. The phosphor substrate is prepared by crystallization from supercritical ammonia-containing solution and the light emitting device is formed by a vapor phase growth on the phosphor substrate so as to obtain a light emitting device which has a wavelength distribution emitting a white light etc. and a good yield.

Owner:AMMONO SP Z O O (PL) +1

Method to grow self-assembled epitaxial nanowires

InactiveUS6656573B2Improve crystal qualityMinimizes defect formedNanotechDecorative surface effectsNanowireLattice mismatch

Self-assembled nanowires are provided, comprising nanowires of a first crystalline composition formed on a substrate of a second crystalline composition. The two crystalline materials are characterized by an asymmetric lattice mismatch, in which in the interfacial plane between the two materials, the first material has a close lattice match (in any direction) with the second material and has a large lattice mismatch in all other major crystallographic directions with the second material. This allows the unrestricted growth of the epitaxial crystal in the first direction, but limits the width in the other.

Owner:HEWLETT PACKARD DEV CO LP

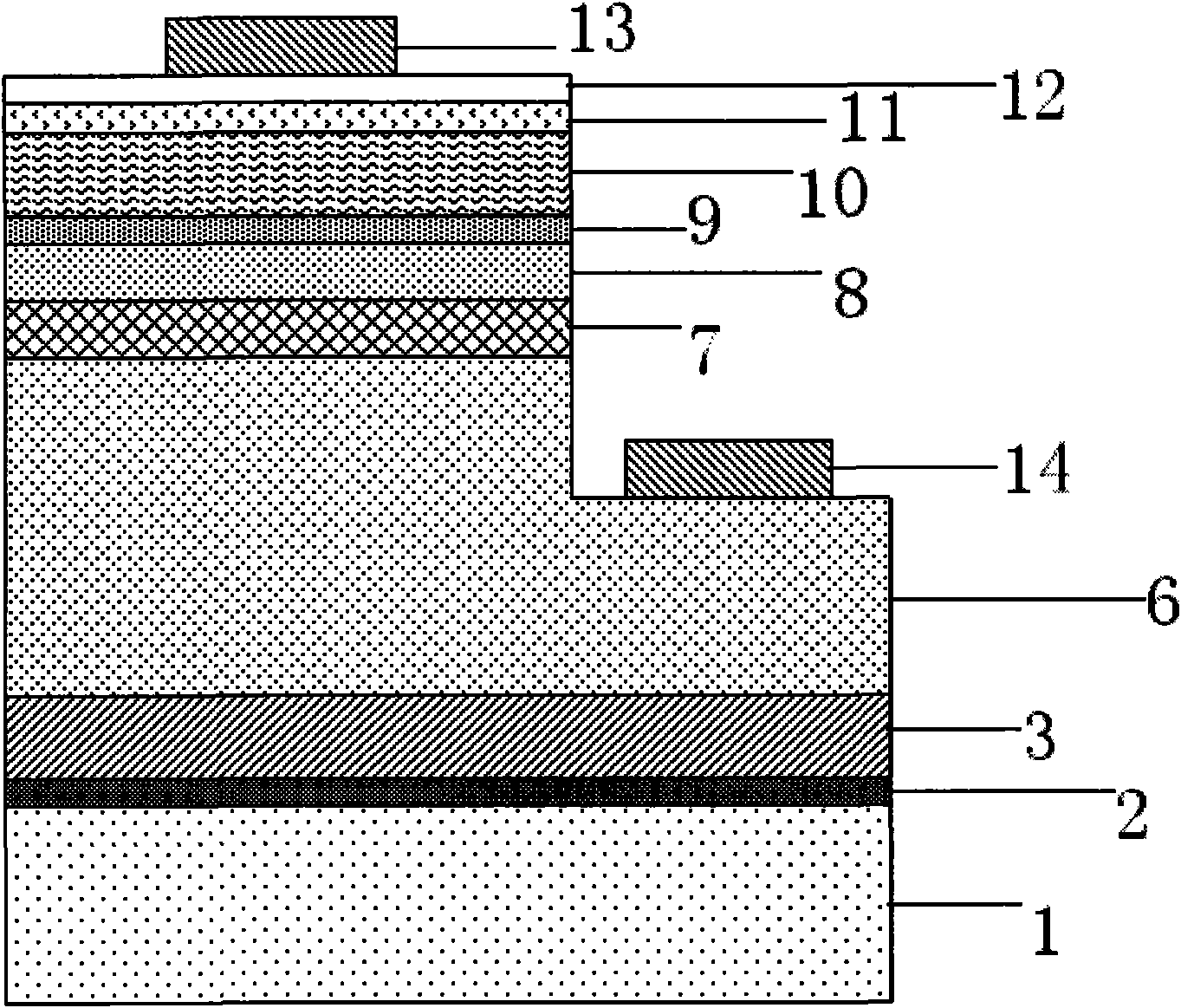

Method for enhancing antistatic ability of GaN-based light-emitting diode

ActiveCN101645480AImprove crystal qualityImprove antistatic performanceSemiconductor devicesGalliumContact layer

The invention discloses a method for enhancing the antistatic ability of GaN-based light-emitting diode. The epitaxial wafer structure of the light-emitting diode sequentially comprises an underlay, alow-temperature buffer layer, an unadulterated GaN high-temperature buffer layer, an aluminum gallium nitride / GaN superlattice structure, the unadulterated GaN high-temperature buffer layer, an N type contact layer, an N type GaN conductive layer, a light-emitting layer multiple quantum well structure MQW, a P type aluminum gallium nitride electric barrier layer, a P type GaN conductive layer and a P type contact layer in a sequence from down to up. In the invention, the aluminum gallium nitride / GaN superlattice periodic structure is inserted in the unalloyed GaN high temperature buffer layer. The insertion of the aluminum gallium nitride / GaN superlattice periodic structure can effectively improve crystal quality of materials, thereby enhancing the antistatic ability of the GaN-based light-emitting diode and improving the reliability and the stability of devices.

Owner:HC SEMITEK CORP

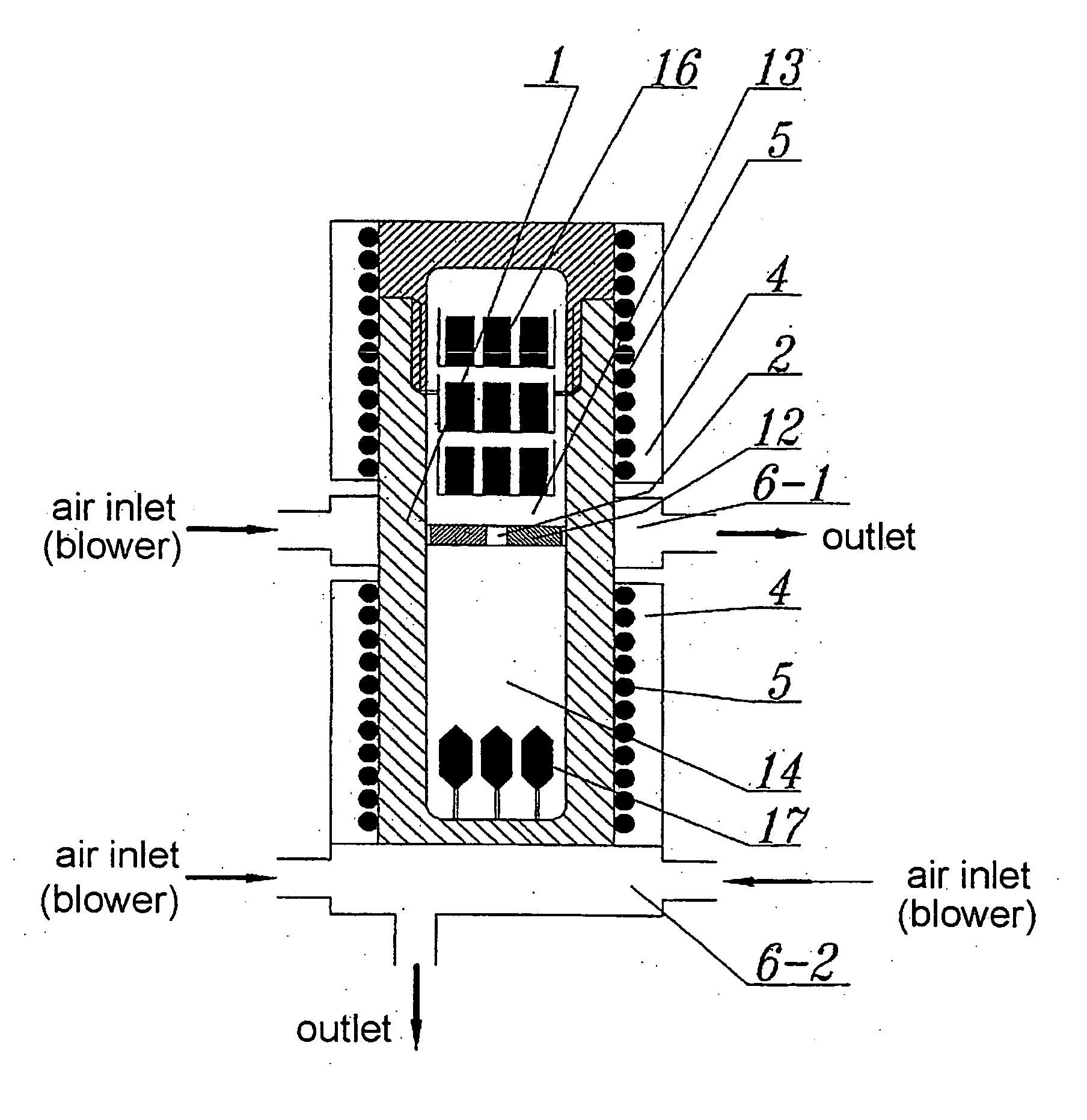

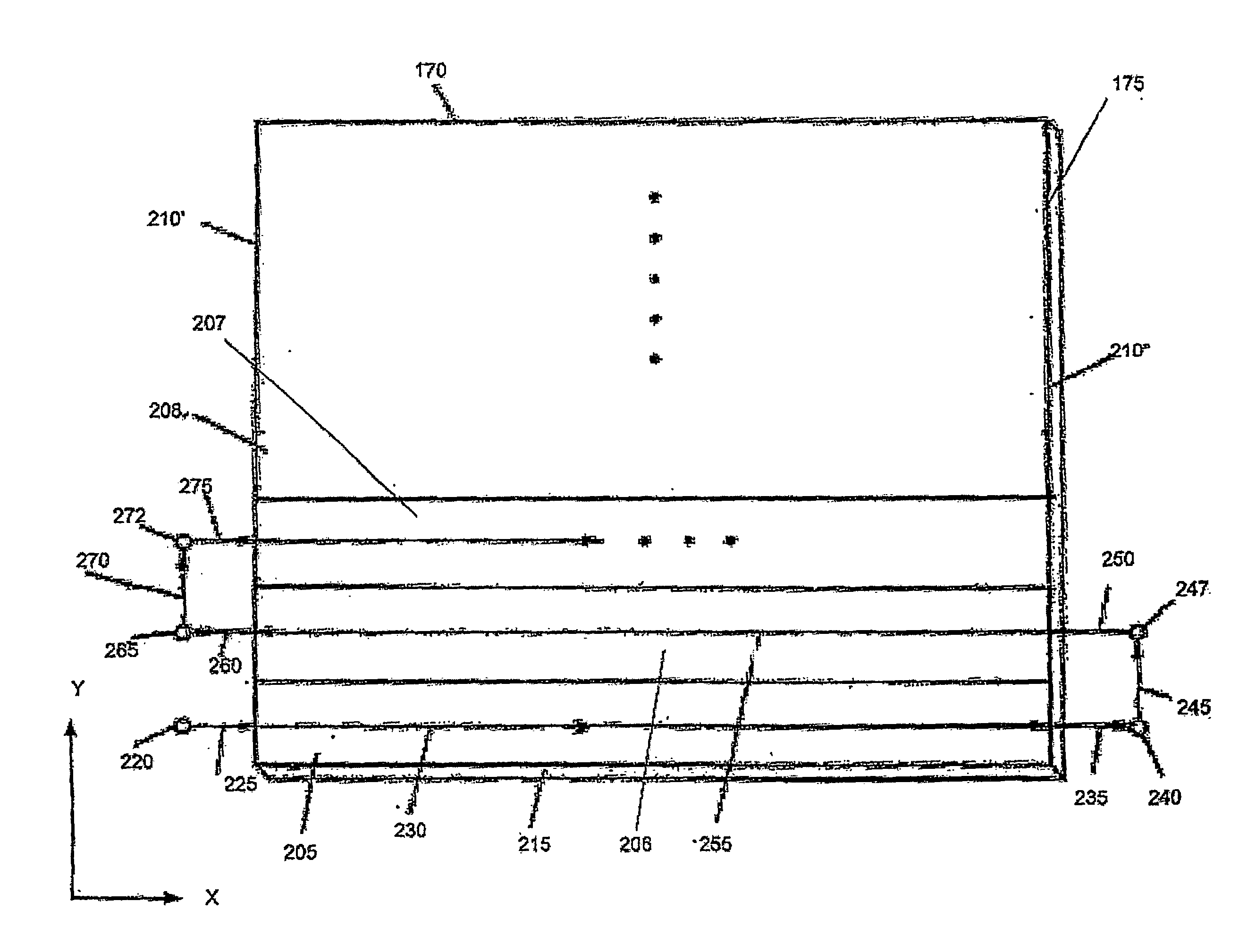

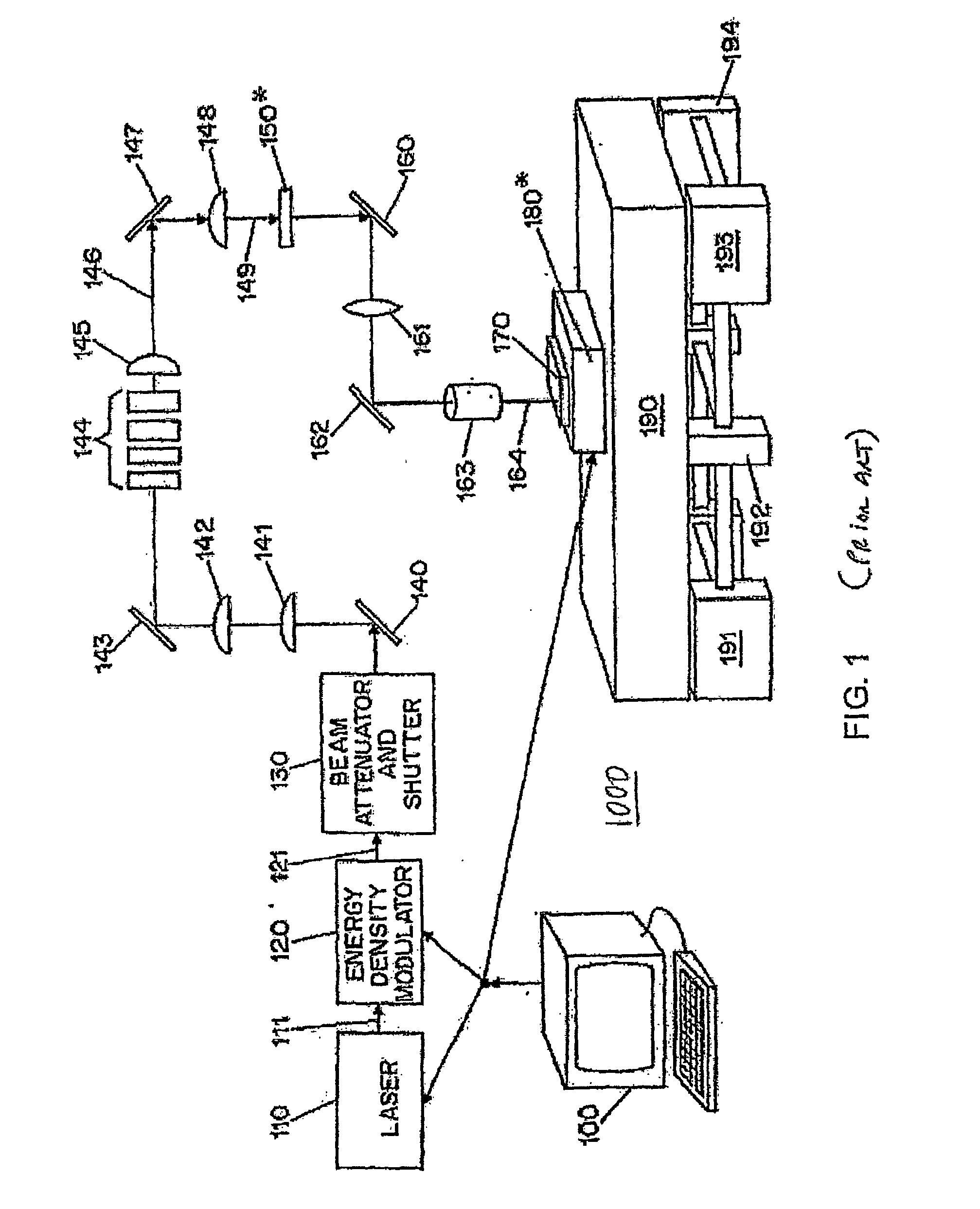

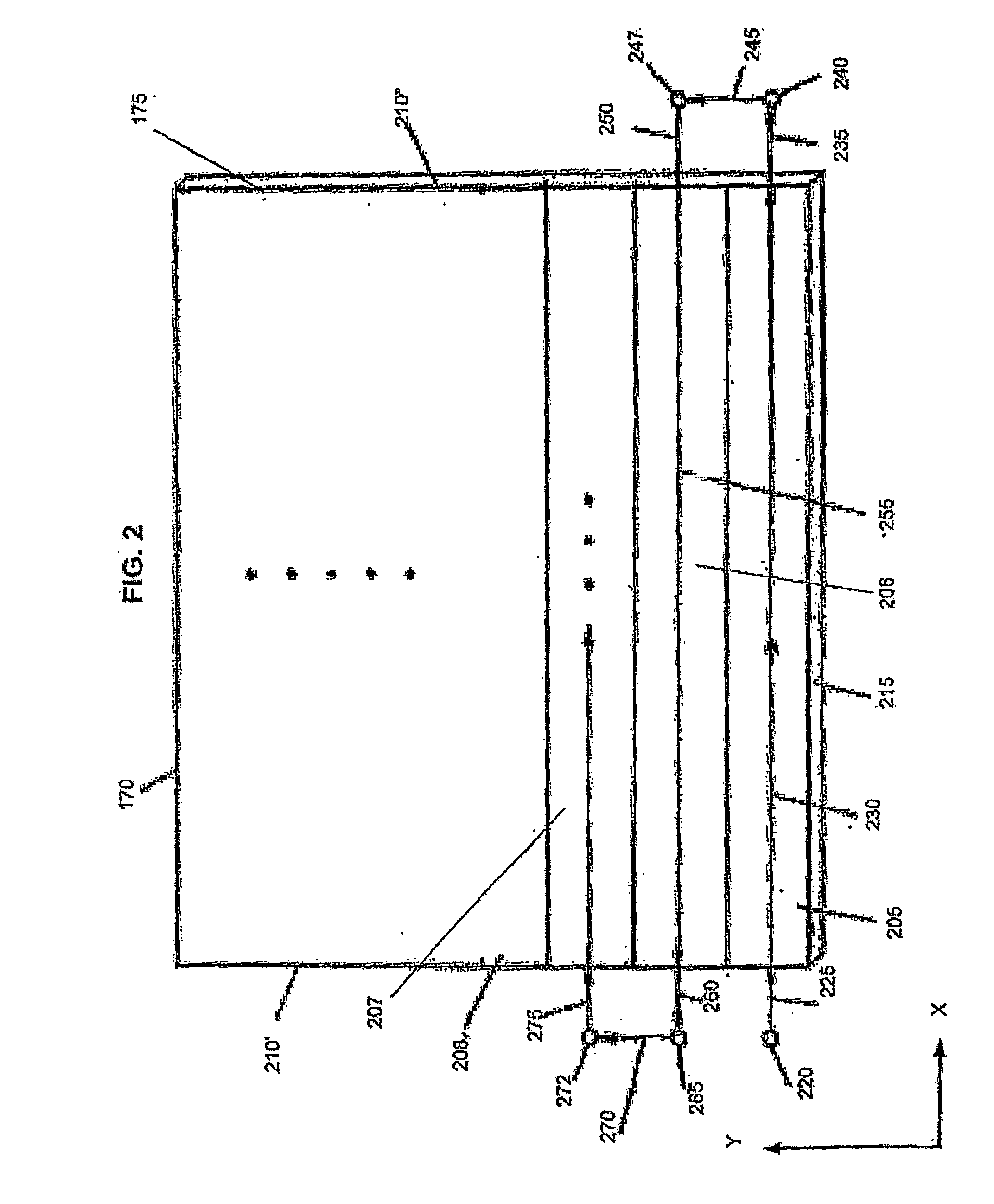

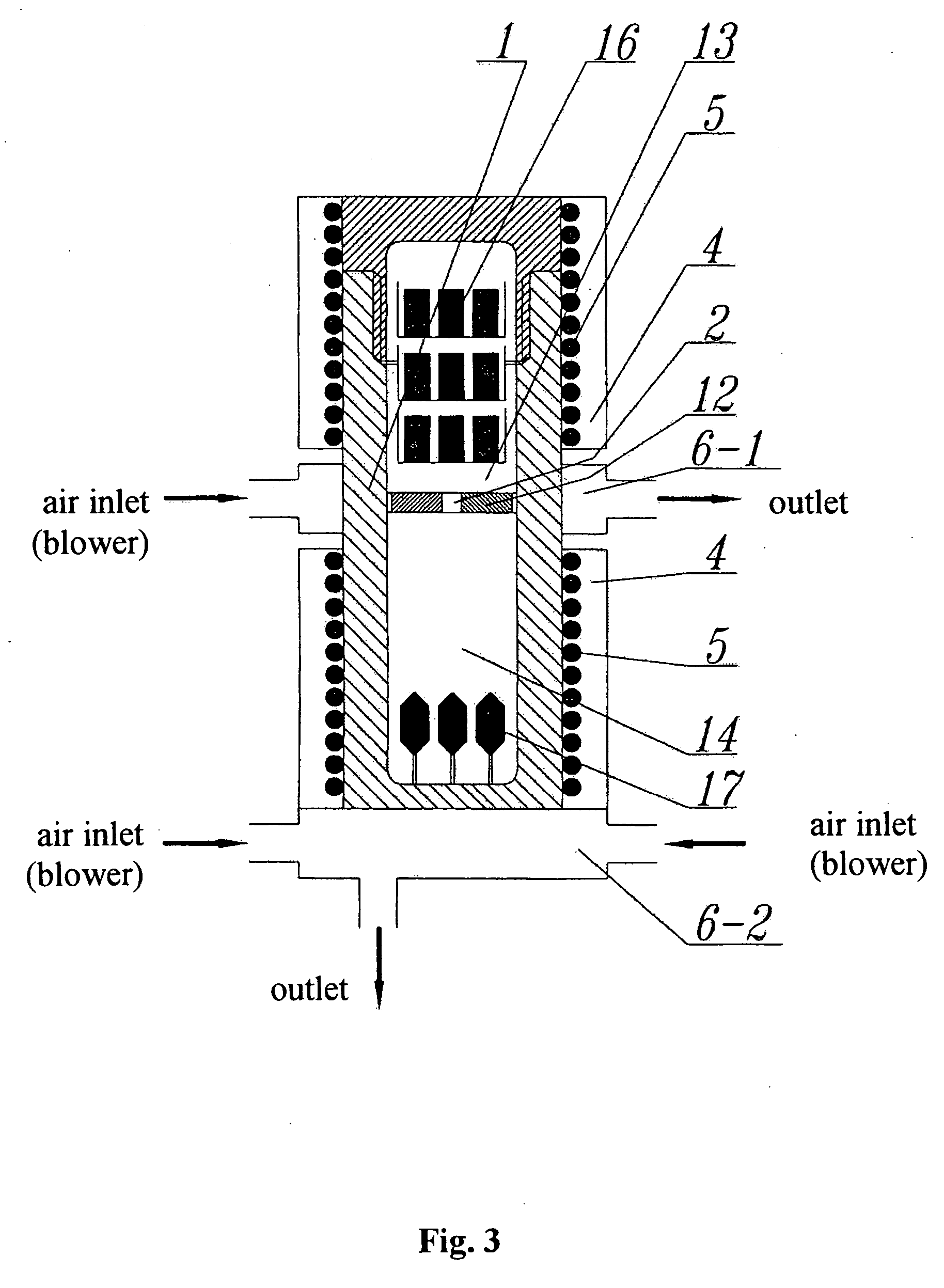

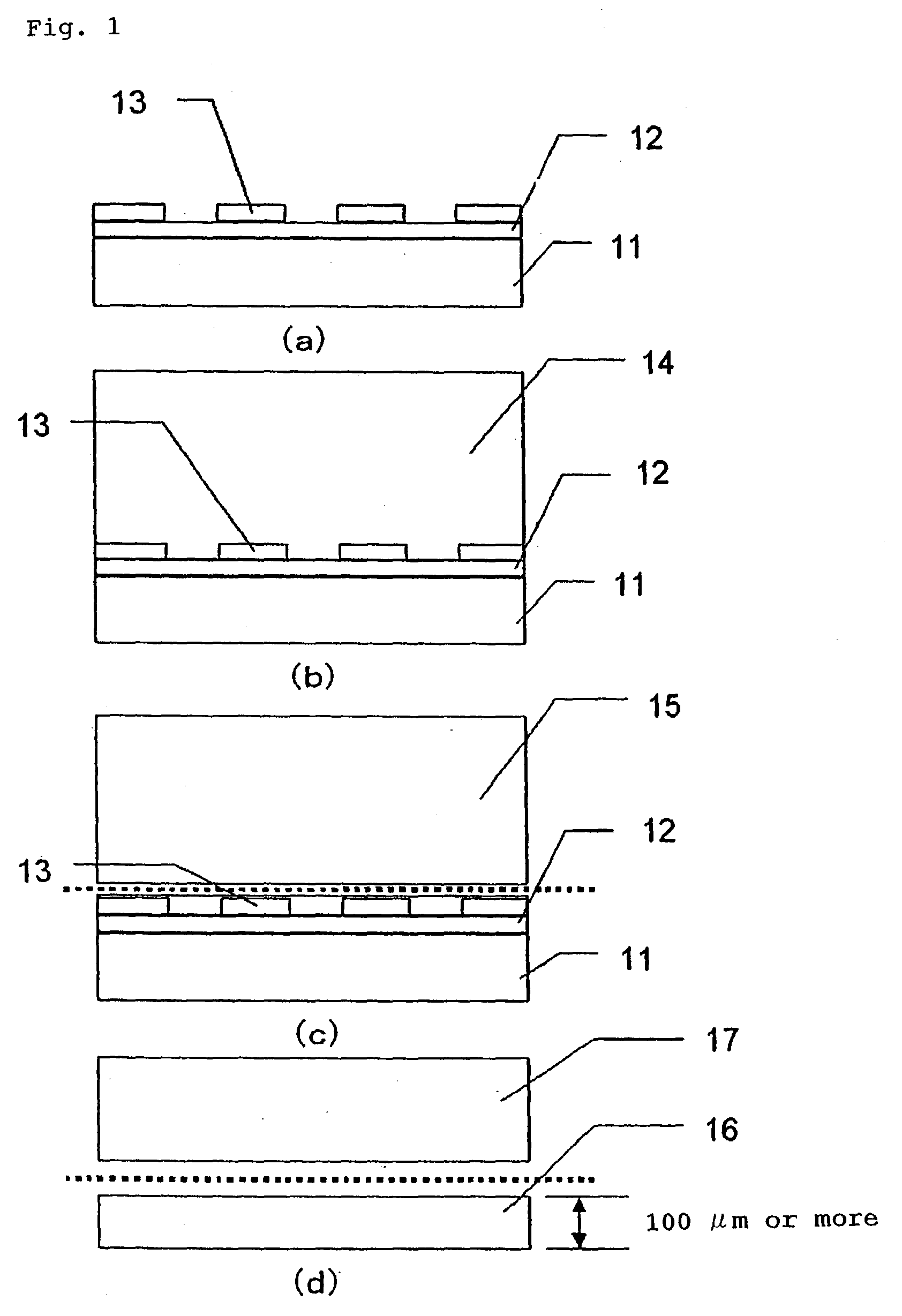

Single-shot semiconductor processing system and method having various irradiation patterns

InactiveUS20060040512A1Improve crystal qualityQuickly processSolid-state devicesSemiconductor/solid-state device manufacturingRadiationLaser beams

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

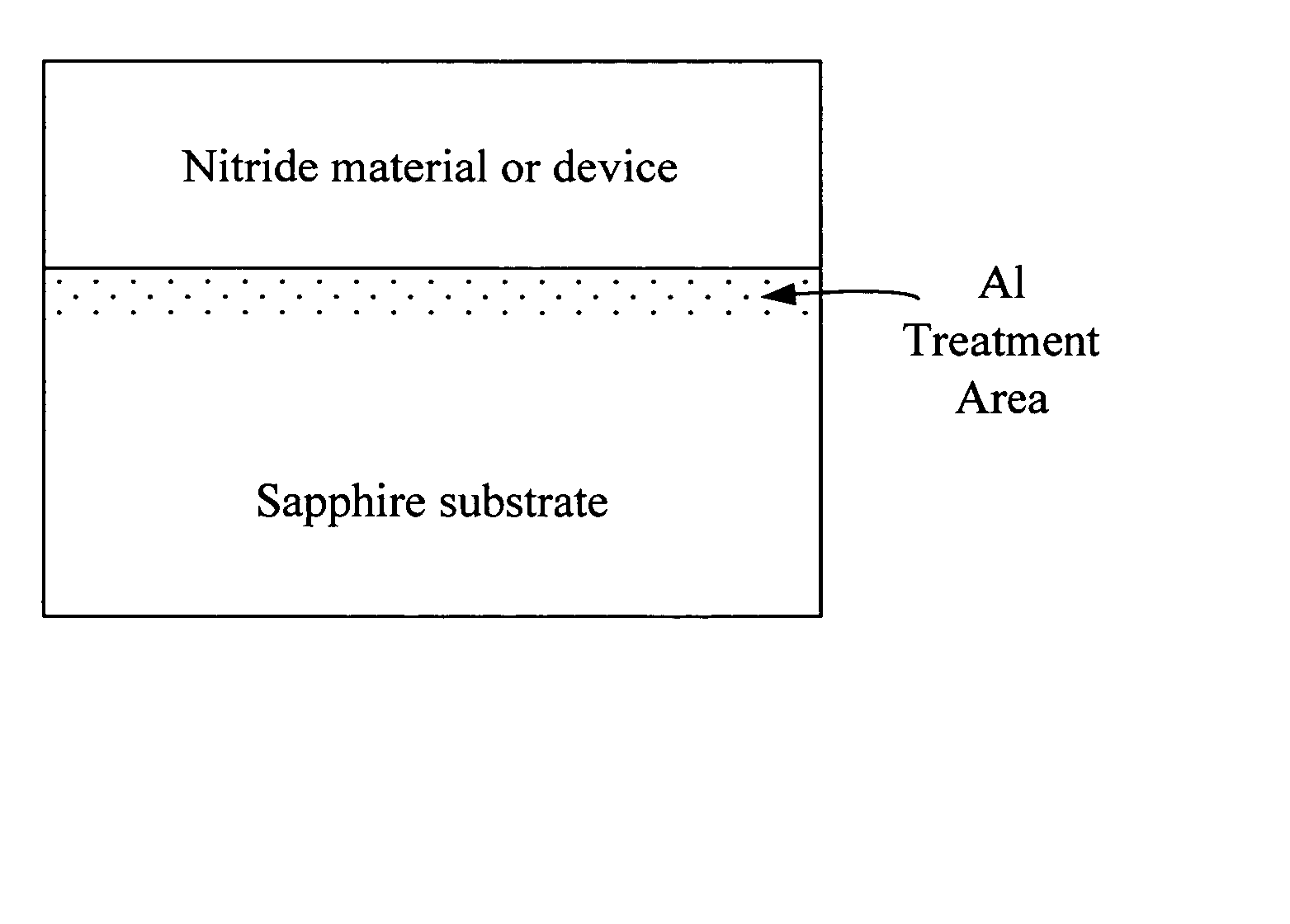

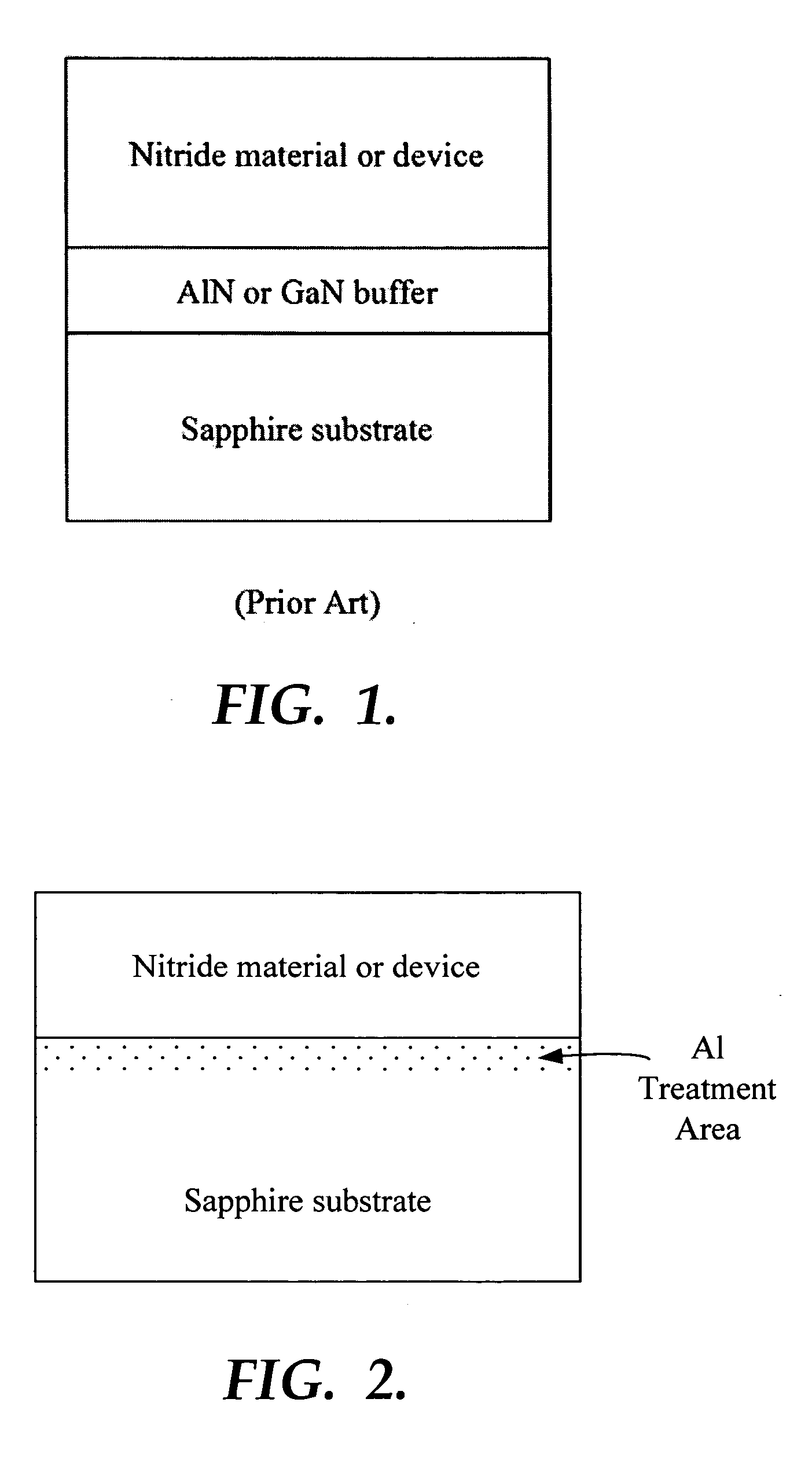

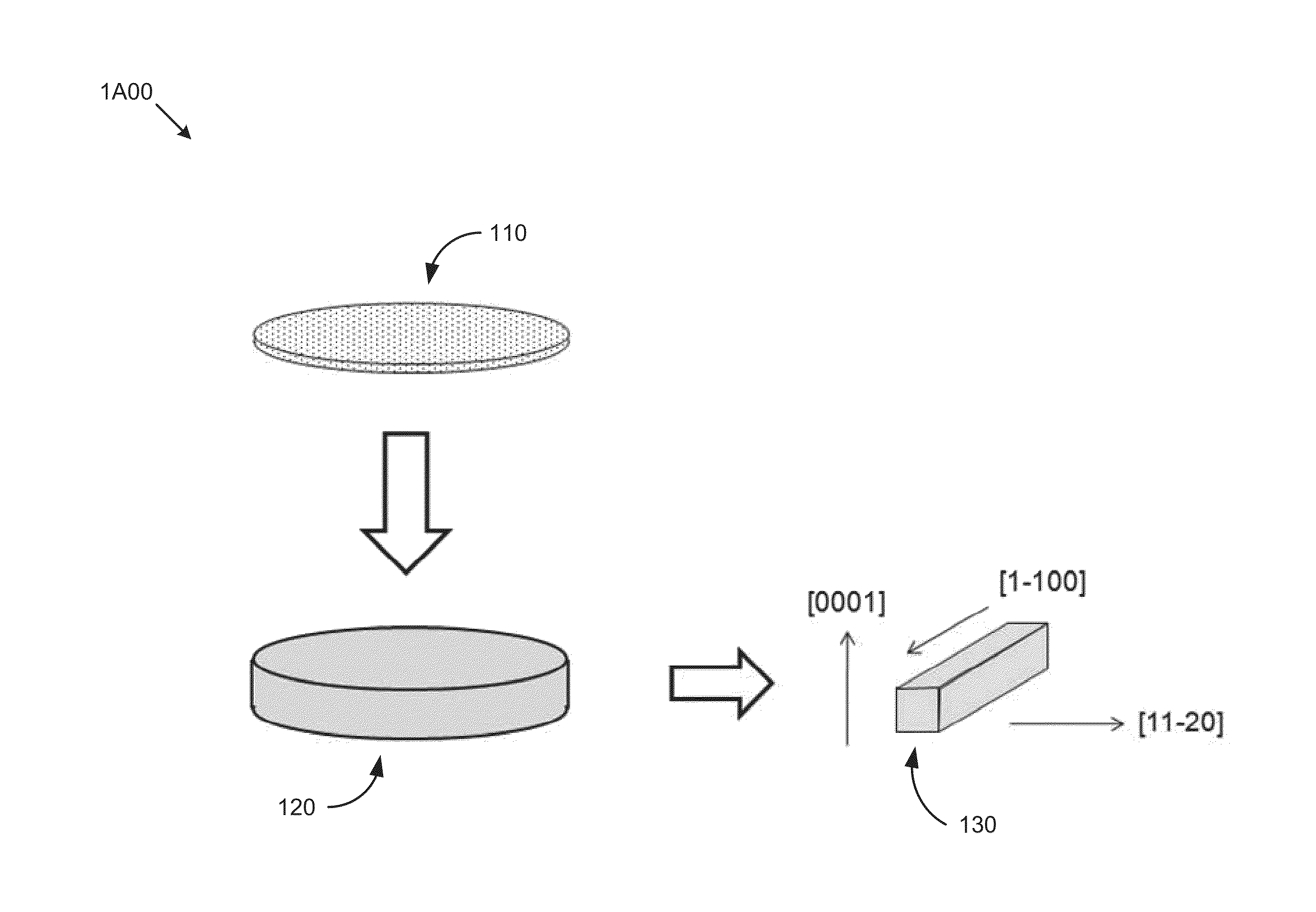

Method to grow III-nitride materials using no buffer layer

InactiveUS20060175681A1Improve crystal qualityImprove surface morphologySemiconductor/solid-state device manufacturingSemiconductor devicesCrystallinityMaterials science

Disclosed is a method for growing nitride compound semiconductors on sapphire substrates where no low-temperature buffer layer is used. The nitride based compound semiconductor materials and devices grown by the method of the present invention have crystallinity and surface morphology at practical levels with high quality, high stability, and high yield.

Owner:III N TECH

Large Area, Low-Defect Gallium-Containing Nitride Crystals, Method of Making, and Method of Use

ActiveUS20140065360A1Improve crystal qualityFrom normal temperature solutionsFinal product manufacturePhotovoltaic detectorsHydrogen

An ultralow defect gallium-containing nitride crystal and methods of making ultralow defect gallium-containing nitride crystals are disclosed. The crystals are useful as substrates for light emitting diodes, laser diodes, transistors, photodetectors, solar cells, and photoelectrochemical water splitting for hydrogen generators.

Owner:SLT TECH

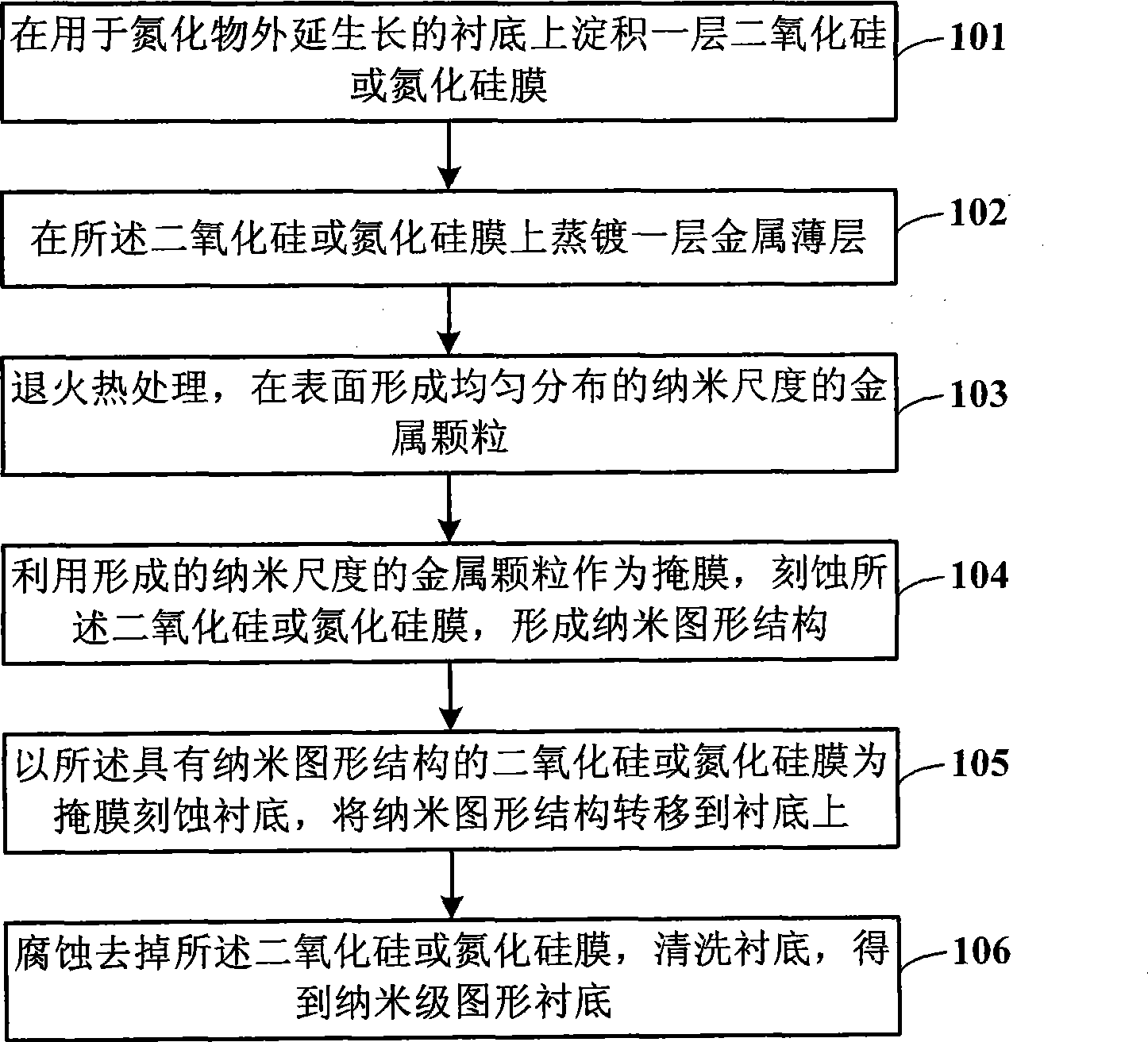

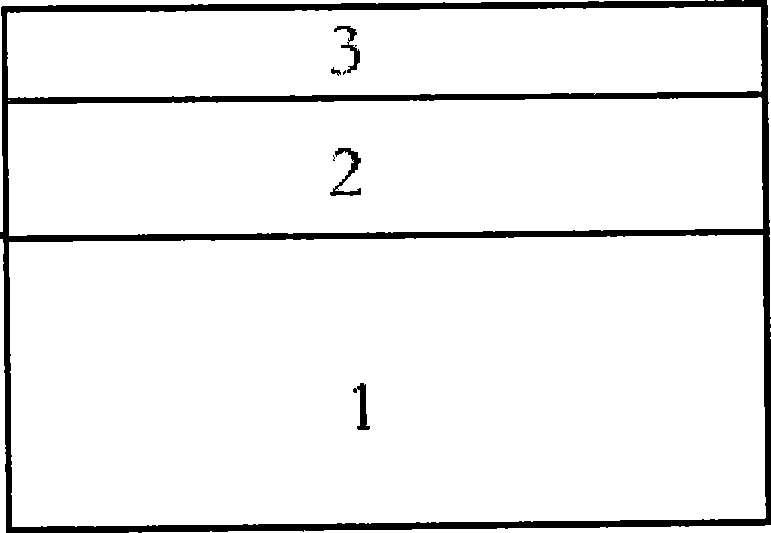

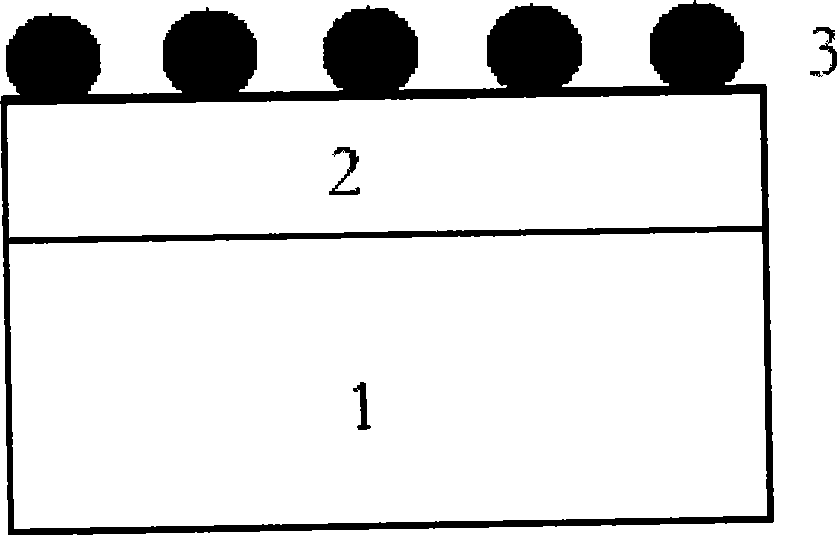

Method for preparing nano-scale pattern substrate for nitride epitaxial growth

InactiveCN101373714AReduce dislocation densityImprove crystal qualitySemiconductor/solid-state device manufacturingThin metalEpitaxial material

The invention relates to the semiconductor technical field and discloses a method for manufacturing a nanometer pattern substrate used for the epitaxial growth of a nitride. The method comprises the followings steps: settling a layer of silicon dioxide or silicon nitride film on a substrate used for the epitaxial growth of the nitride; the silicon dioxide or silicon nitride film is coated with a layer of thin metal layer through vapor deposition; conducting the annealing heat treatment, and forming uniformly distributed nano-scaled metal particles; utilizing the formed nano-scaled metal particles as masks to etch the silicon dioxide or silicon nitride film so as to form a nanometer pattern structure; using the silicon dioxide or silicon nitride film with the nanometer pattern structure as a mask etching substrate to transfer the nanometer pattern structure of the substrate; and etching to remove the silicon dioxide or silicon nitride film, cleaning the substrate, and obtaining the nanometer pattern substrate. The invention can reduce the dislocation density in the epitaxial layer of the nitride, improve the crystal quality of epitaxial materials, improve the performance of devices and help to realize the scaled and large area manufacture.

Owner:UNILUMIN GRP

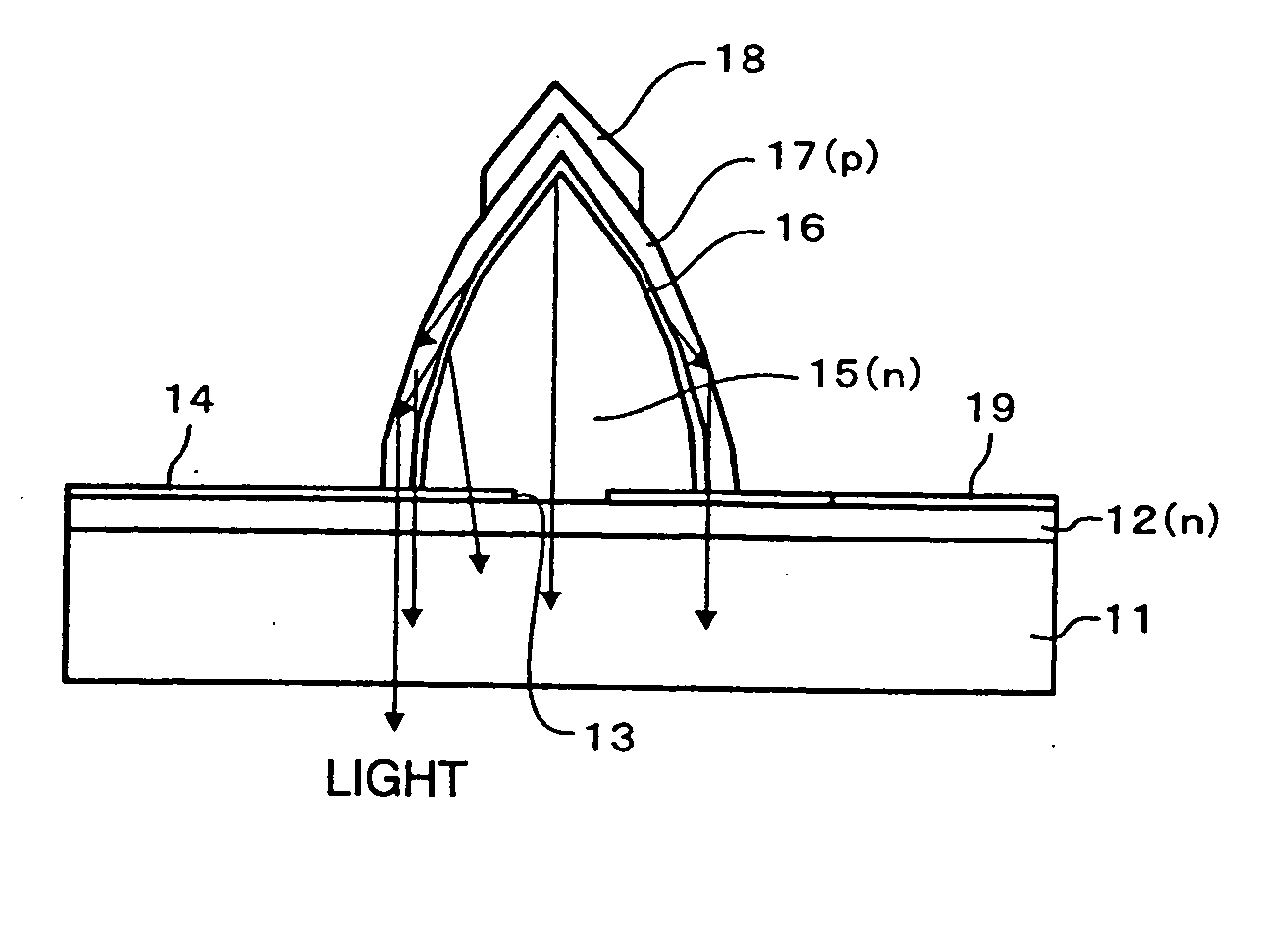

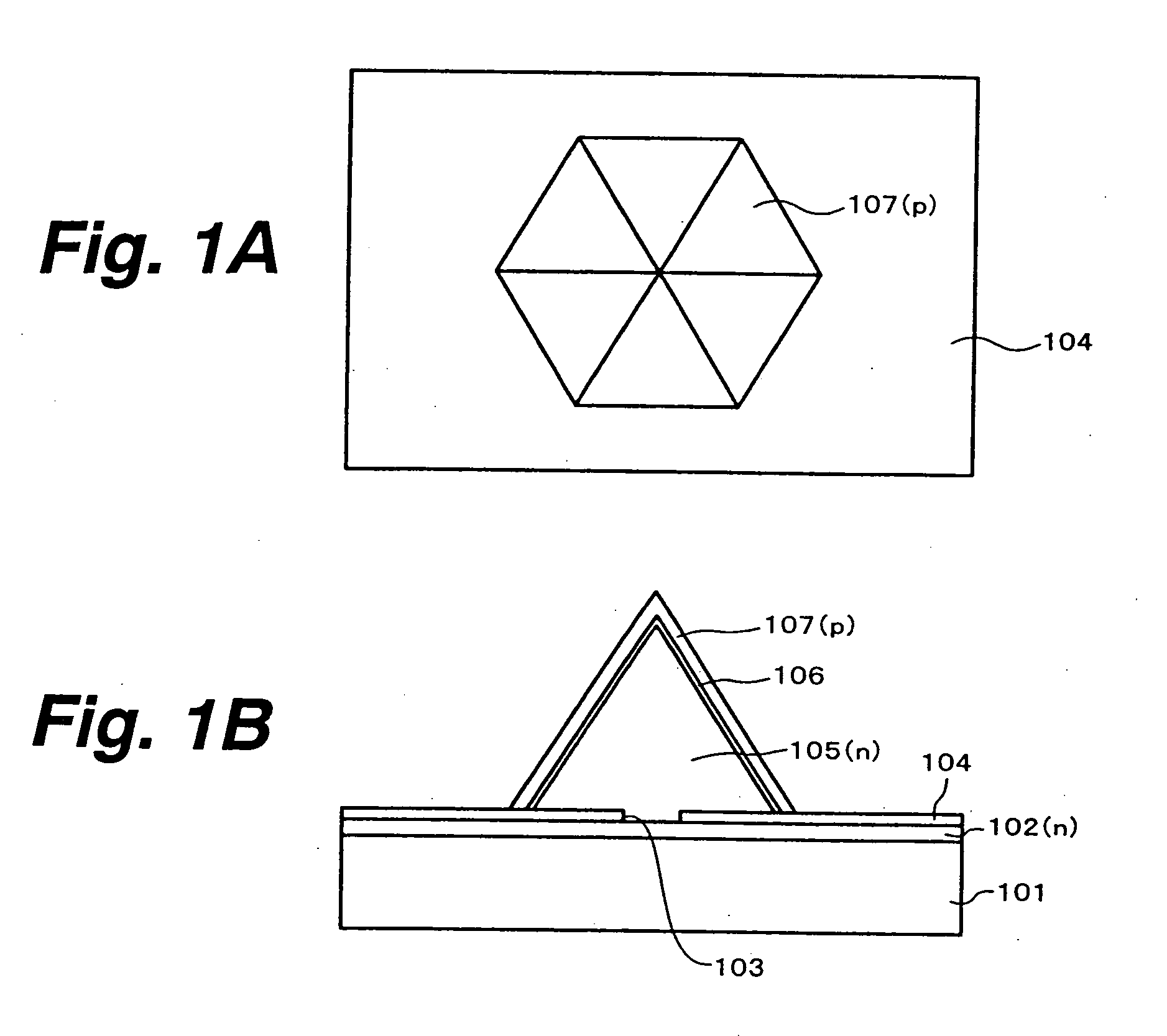

Semiconductor light emitting element and method for manufacturing same, integrated semiconductor light-emitting device and method for manufacturing same, image display and method for manufacturing same, and illuminating device and method for manufacturing same

InactiveUS20050145865A1Small sizeLess subjectWater treatment parameter controlFatty/oily/floating substances removal devicesDisplay deviceCrystal plane

A semiconductor light emitting element, manufacturing method thereof, integrated semiconductor light emitting device, manufacturing method thereof, illuminating device, and manufacturing method thereof are provided. An n-type GaN layer is grown on a sapphire substrate, and a growth mask of SiN, for example, is formed thereon. On the n-type GaN layer exposed through an opening in the growth mask, a six-sided steeple-shaped n-type GaN layer is selectively grown, which has inclined crystal planes each composed of a plurality of crystal planes inclined from the major surface of the sapphire substrate by different angles of inclination to exhibit a convex plane as a whole. On the n-type GaN layer, an active layer and a p-type GaN layer are grown to make a light emitting element structure. Thereafter, a p-side electrode and an n-side electrode are formed.

Owner:SONY CORP

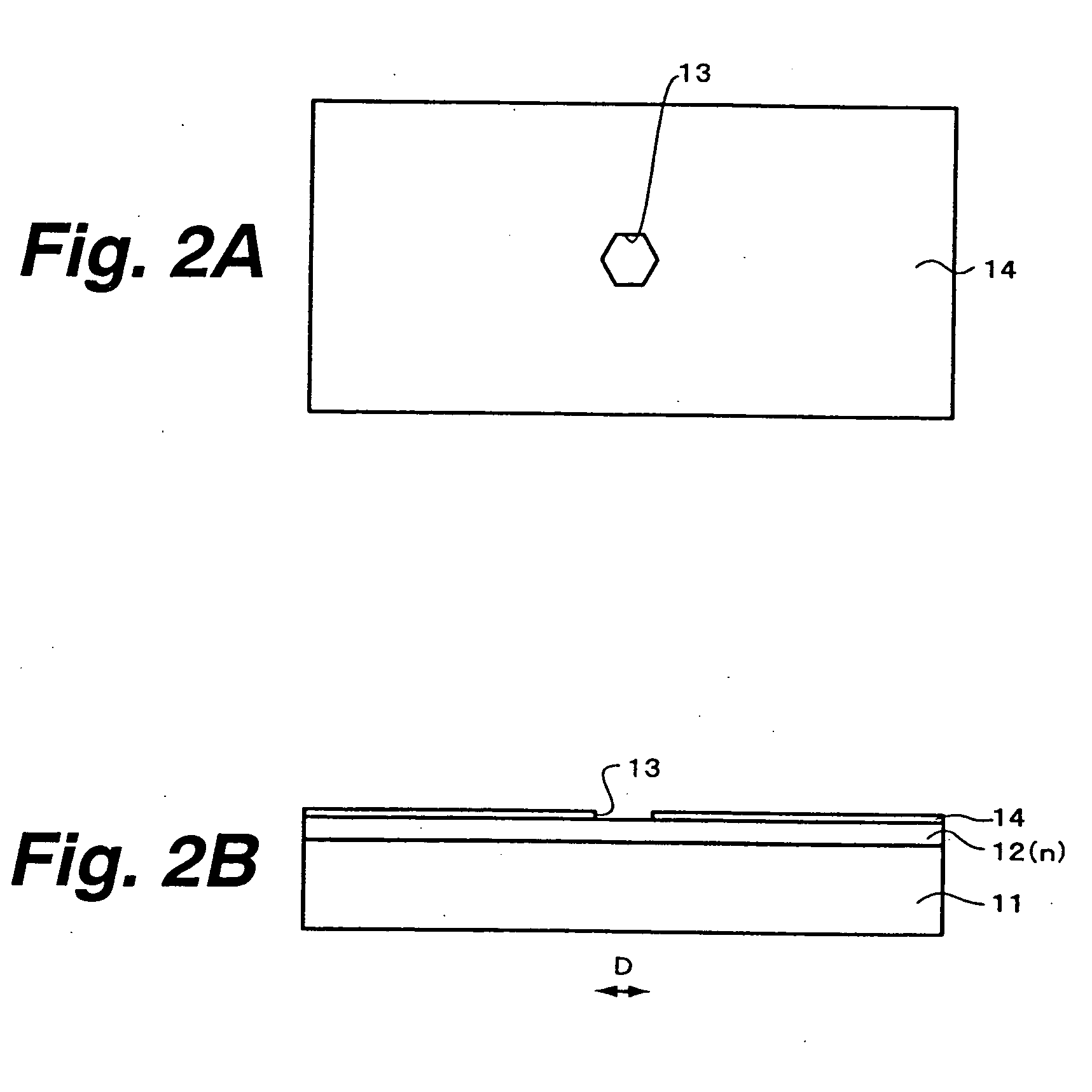

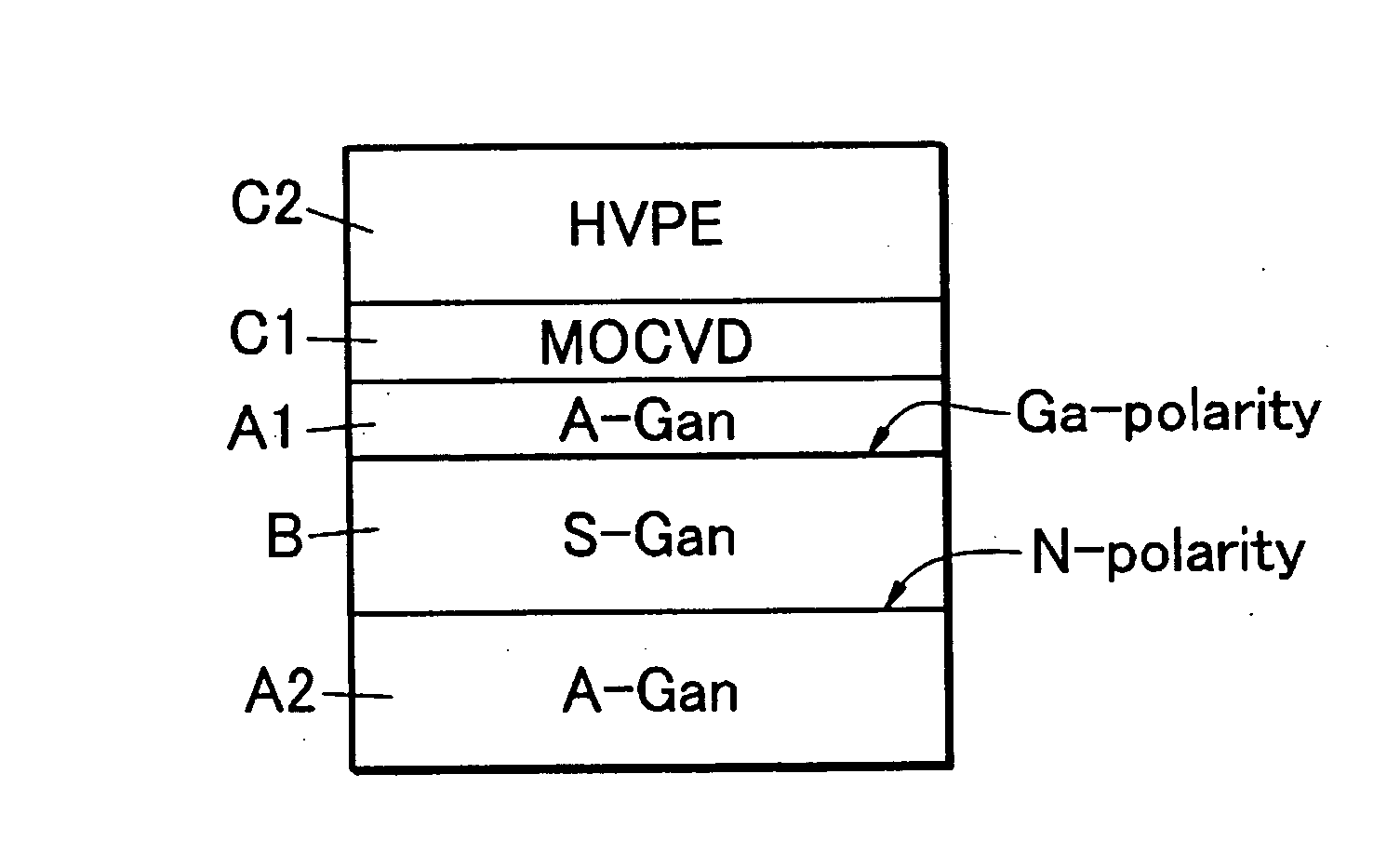

Template type substrate and a method of preparing the same

ActiveUS20060057749A1Improve surface propertiesImprove crystal qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingMOSFETVapour phase epitaxy

The template type substrate is used for opto-electric or electrical devices and comprises A) a layer of bulk mono-crystal nitride containing at least one element of alkali metals (Group I, IUPAC 1989) and B) a layer of nitride grown by means of vapor phase epitaxy growth wherein the layer A) and the layer B) are combined at non N-polar face of the layer A) and N-polar face of the layer B). Therefore, the template type substrate has a good dislocation density and a good value of FWHM of the X-ray rocking curve from (0002) plane less than 80, so that the resulting template type substrate is very useful for the epitaxy substrate from gaseous phase such as MOCVD, MBE and HVPE, resulting in possibility of making good opto-electric devices such as Laser Diode and large-output LED and good electric devices such as MOSFET.

Owner:AMMONO SP Z O O (PL) +1

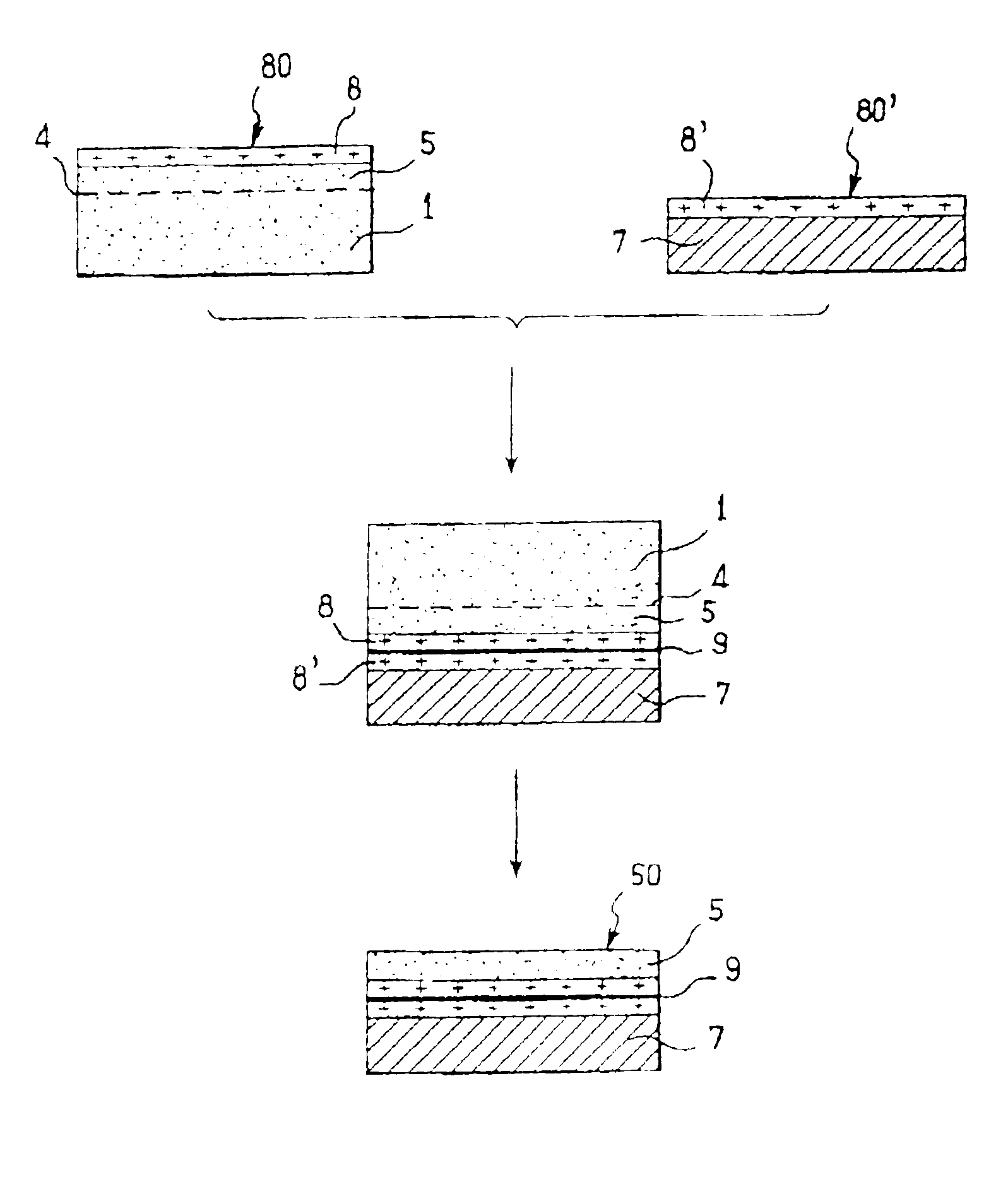

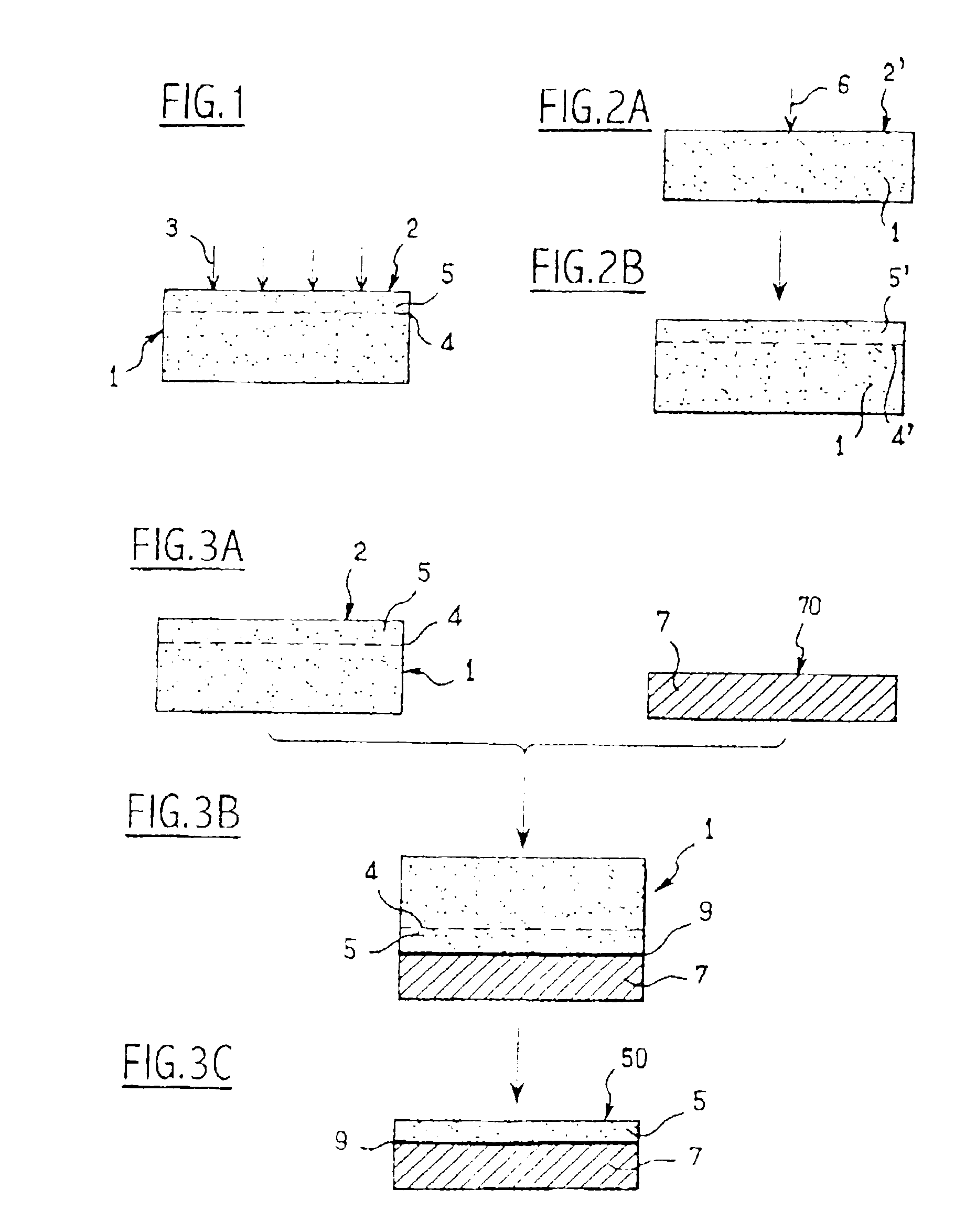

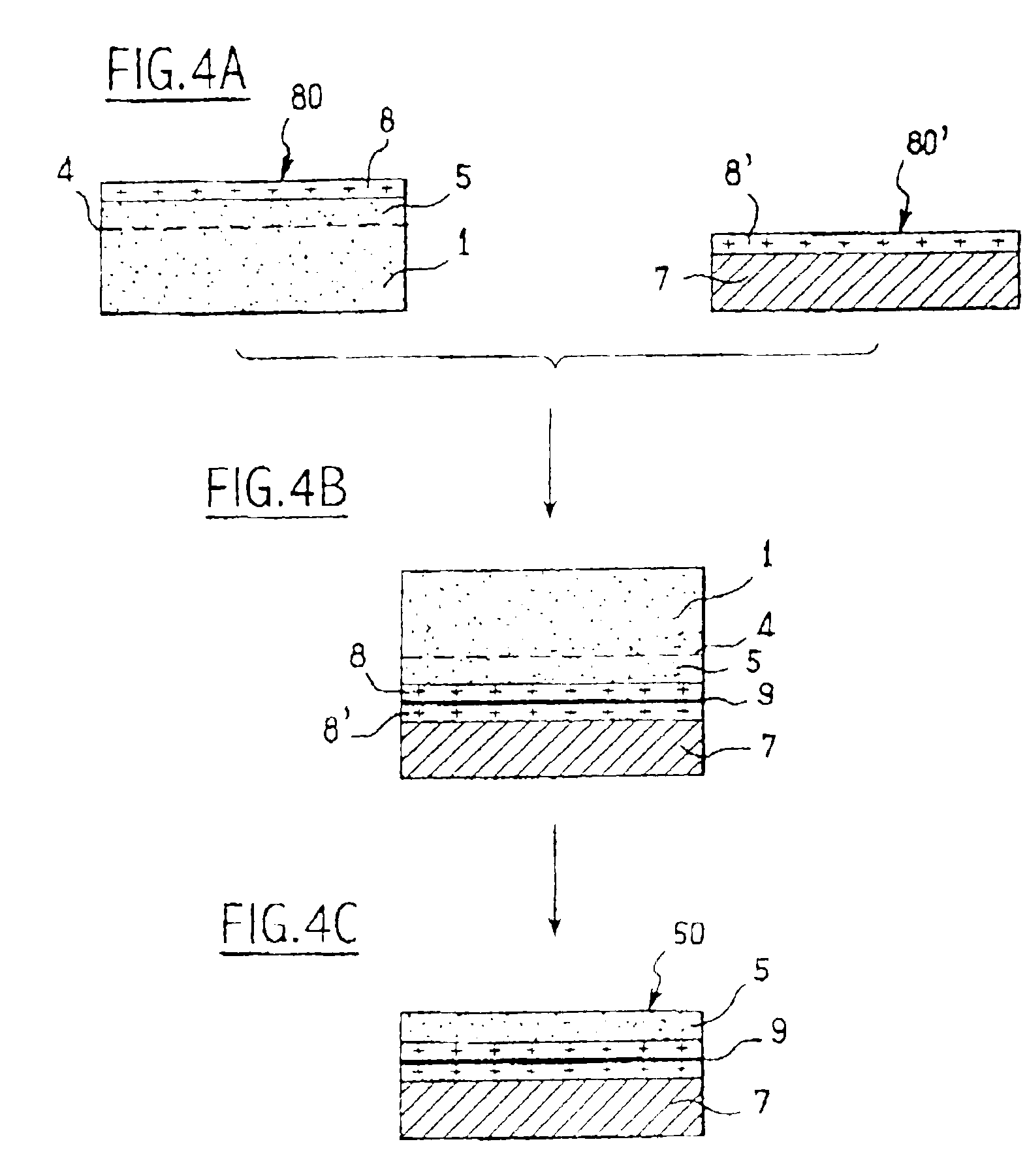

Method of manufacturing a free-standing substrate made of monocrystalline semi-conductor material

InactiveUS6964914B2Improve crystal qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingBond interfaceSemiconductor materials

A method for manufacturing a free-standing substrate made of a semiconductor material. A first assembly is provided and it includes a relatively thinner nucleation layer of a first material, a support of a second material, and a removable bonding interface defined between facing surfaces of the nucleation layer and support. A substrate of a relatively thicker layer of a third material is grown, by epitaxy on the nucleation layer, to form a second assembly with the substrate attaining a sufficient thickness to be free-standing. The third material is preferably a monocrystalline material. Also, the removable character of the bonding interface is preserved with at least the substrate being heated to an epitaxial growth temperature. The coefficients of thermal expansion of the second and third materials are selected to be different from each other by a thermal expansion differential, determined as a function of the epitaxial growth temperature or subsequent application of external mechanical stresses, such that, as the second assembly cools from the epitaxial growth temperature, stresses are induced in the removable bonding interface to facilitate detachment of the nucleation layer from the substrate.

Owner:SOITEC SA

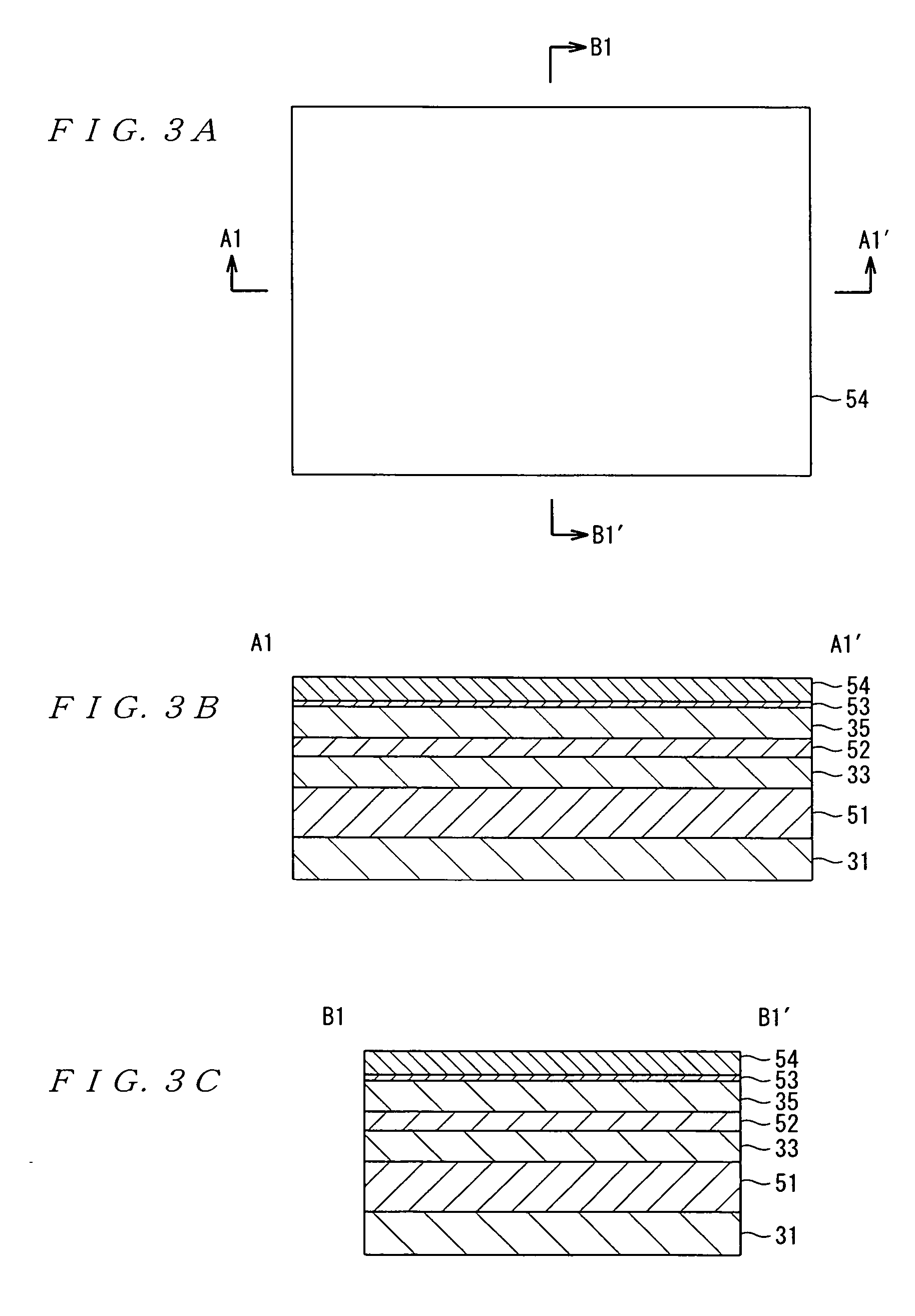

Group III nitride based semiconductor substrate and process for manufacture thereof

InactiveUS20030183157A1Quality improvementStable productionLaser detailsFrom solid stateDislocationNitride

To provide a semiconductor substrate of a group III nitride with a little warp, this invention provides a process comprising such steps of: epitaxial-growing a GaN layer 33 with a GaN low temperature grown buffer layer 32 upon a sapphire substrate 31; removing the sapphire substrate 31, the GaN buffer layer 32 and a small portion of the GaN layer 33 from the substrate taken out of a growth reactor to obtain a self-supporting GaN substrate 35; and after that, heat-treating the GaN substrate 35 by putting it into an electric furnace under the NH3 atmosphere at 1200° C. for 24 hours; which leads to a marked reduction of the warp of the self-supporting GaN substrate 35 such that dislocation densities of its obverse and reverse surface are 4x10<7 >cm<-2 >and 8x10<5 >cm<-2>, and thereby such a low ratio of dislocation densities of 50 is well-controlled.

Owner:SUMITOMO CHEM CO LTD

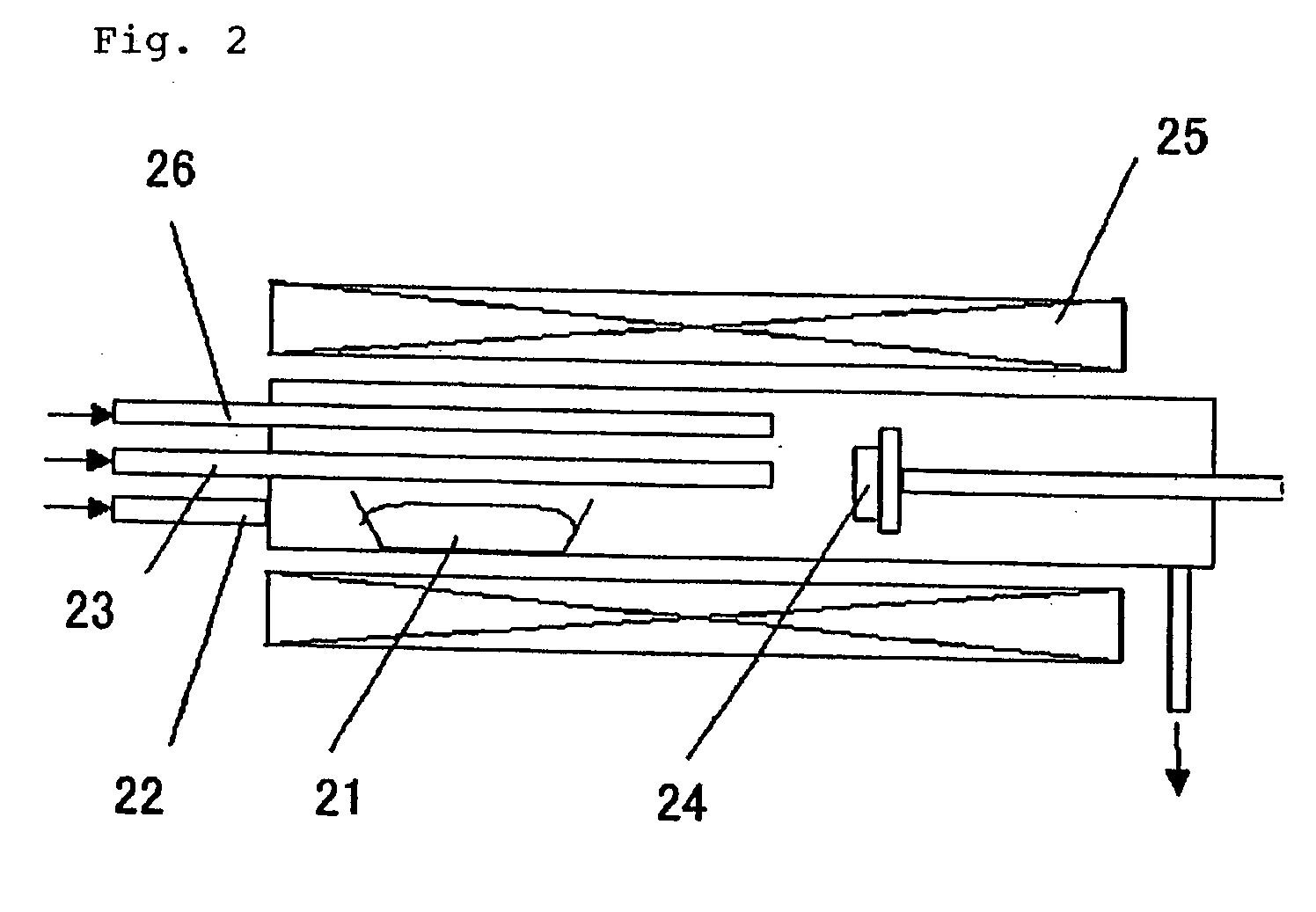

Deep-UV light-emitting diode and preparation method thereof

InactiveCN101604716AReduce dislocation densityImprove crystal qualitySemiconductor devicesDislocationSmooth surface

The invention provides a deep-UV light-emitting diode and a preparation method thereof. A low-temperature GaN insertion layer is used to replace an AlN / AlGaN superlattice or a high-temperature GaN insertion layer to grow the deep-UV light-emitting diode. The low-temperature GaN insertion layer is a GaN with thickness of 20-50nm under the conditions of temperature being 400-900 DEG C, pressure being 30-200torr, and V / III being 1500-2500. The method can effectively lower the dislocation density in an epitaxial AlGaN layer and a quantum well, and improves the surface planeness. The prepared LED component has smooth surface, better crystal quality, starting voltage reduction, and smaller serial resistances of the component; and the electroluminescene peak value is ranged from 300nm to 370nm.

Owner:PEKING UNIV

Epitaxial structure and growing method for improving gallium nitride (GaN) based light-emitting diode (LED) lighting efficiency

InactiveCN103066174AImprove crystal qualityStress reliefSemiconductor devicesPotential wellEffect light

The invention discloses an epitaxial structure and a growing method for improving gallium nitride (GaN) based light-emitting diode (LED) lighting efficiency. The order of the epitaxial structure from bottom to up is that a substrate, a low-temperature GaN buffer layer, a GaN non-doping layer, a N-shaped GaN layer, a multiple quantum well (MQW) structure, a multiple quantum well active layer, a low-temperature P-shaped GaN layer, a P-shaped aluminum (AL) GaN layer, a high-temperature P-shaped GaN layer and a P-shaped contact layer, wherein the order of the multiple quantum well active layer from bottom to up comprises a InyGa1-yN potential well layer, a InN layer and a barrier layer in sequence. The growing method of the multiple quantum well active layer structure is that by inserting the InN layer and a low-temperature annealing step in the growing process of a InyGa1 potential well layer and a GaN barrier layer, so that the composition of In quantum dot in the barrier layer is advanced and crystalline quality of the quantum well is improved, therefore, gallium nitride based LED lighting efficiency is improved.

Owner:合肥彩虹蓝光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com