Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3943 results about "Nitride semiconductors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of growing nitride semiconductors, nitride semiconductor substrate and nitride semiconductor device

InactiveUS6153010APolycrystalline material growthLaser detailsNitrogen sourceCrystallographic defect

PCT No. PCT / JP98 / 01640 Sec. 371 Date Dec. 9, 1998 Sec. 102(e) Date Dec. 9, 1998 PCT Filed Apr. 9, 1998 PCT Pub. No. WO98 / 47170 PCT Pub. Date Oct. 22, 1998A method of growing a nitride semiconductor crystal which has very few crystal defects and can be used as a substrate is disclosed. This invention includes the step of forming a first selective growth mask on a support member including a dissimilar substrate having a major surface and made of a material different from a nitride semiconductor, the first selective growth mask having a plurality of first windows for selectively exposing the upper surface of the support member, and the step of growing nitride semiconductor portions from the upper surface, of the support member, which is exposed from the windows, by using a gaseous Group 3 element source and a gaseous nitrogen source, until the nitride semiconductor portions grown in the adjacent windows combine with each other on the upper surface of the selective growth mask.

Owner:NICHIA CORP

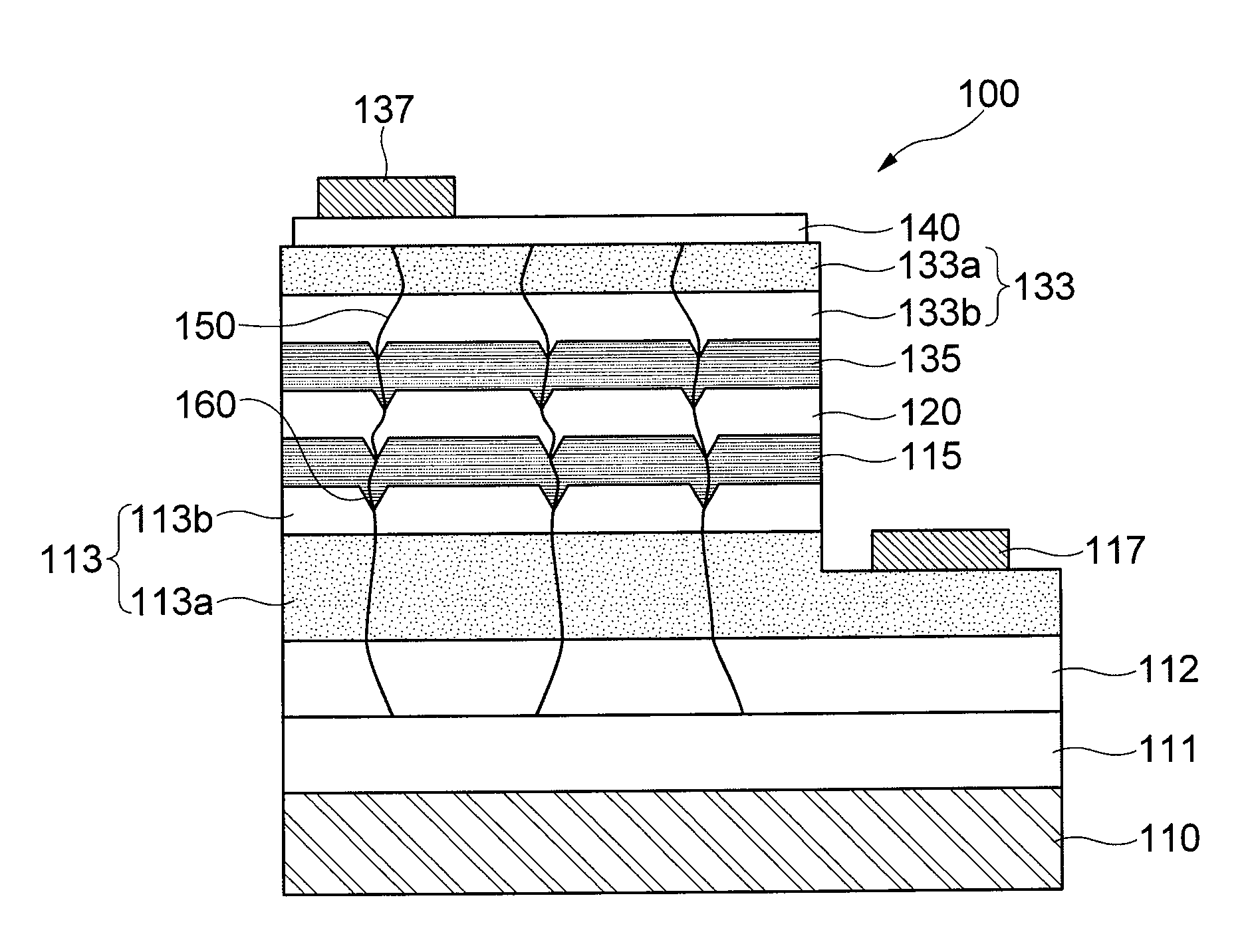

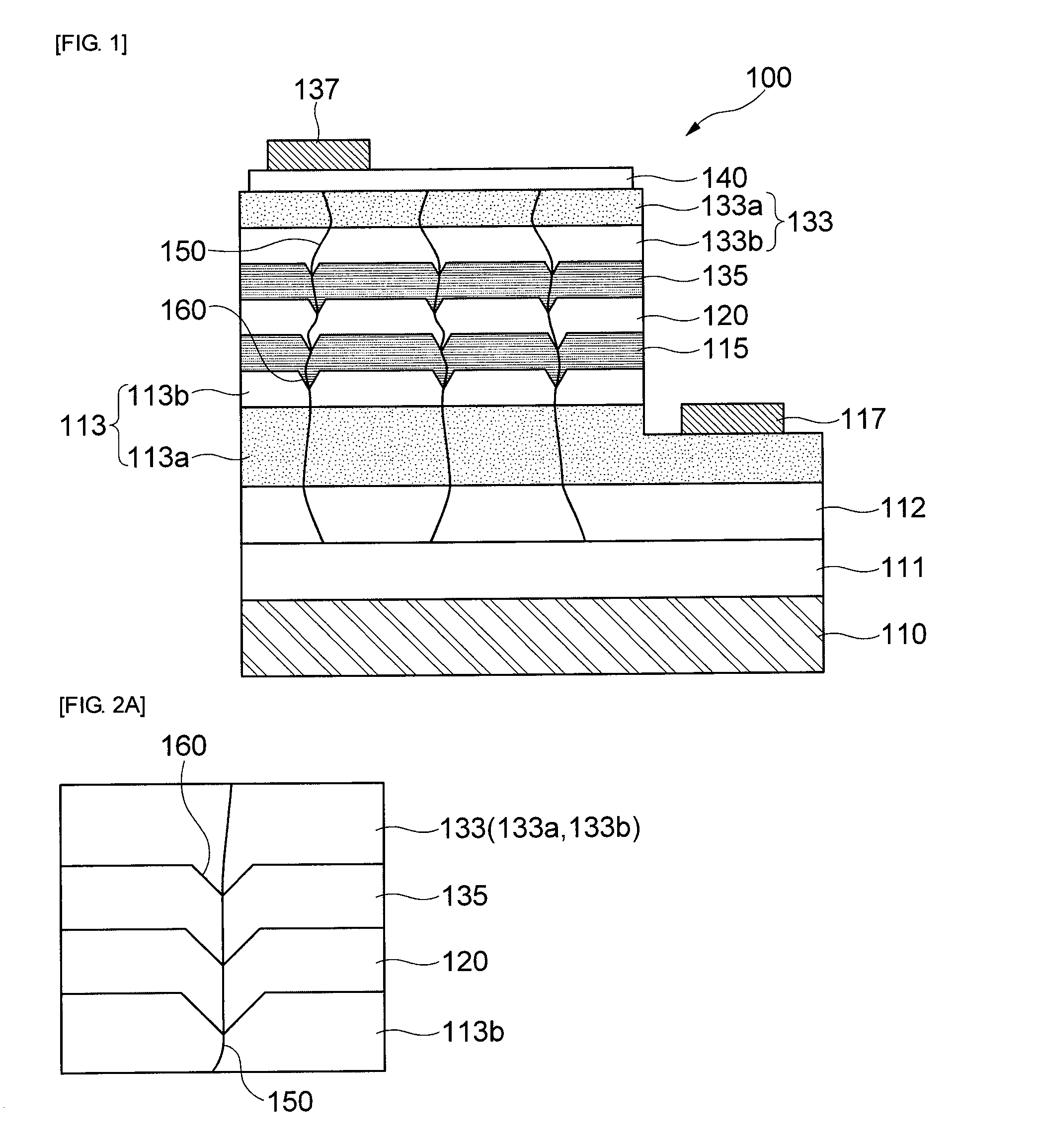

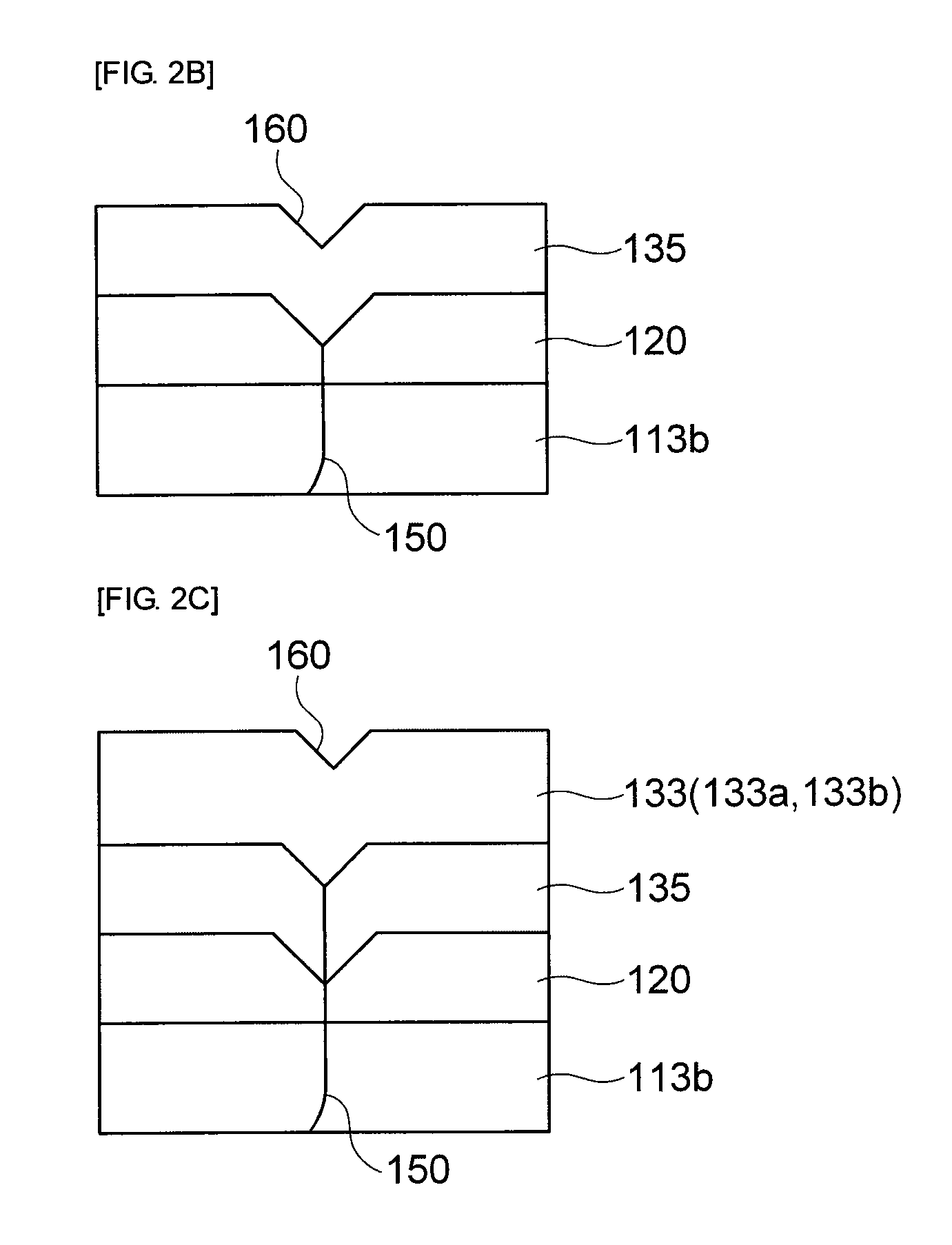

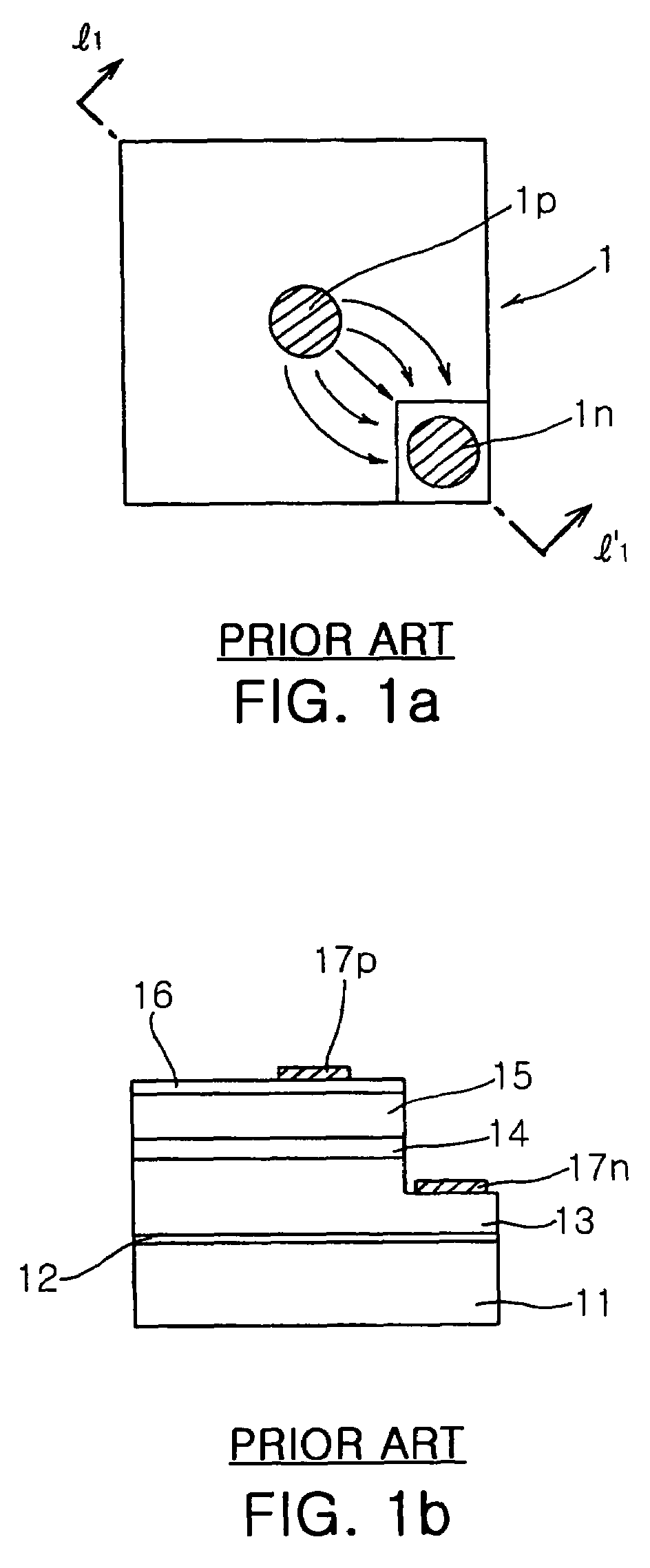

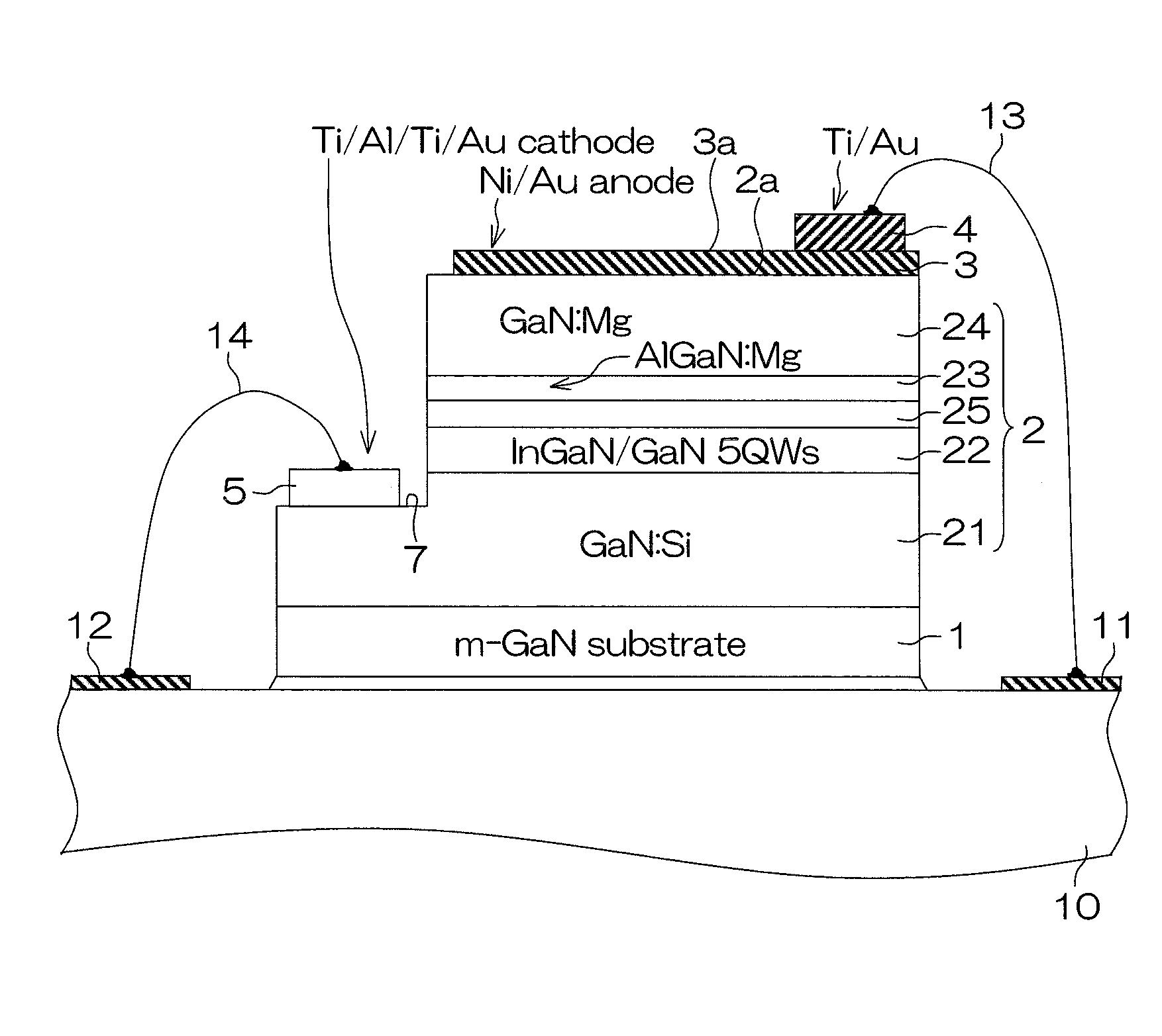

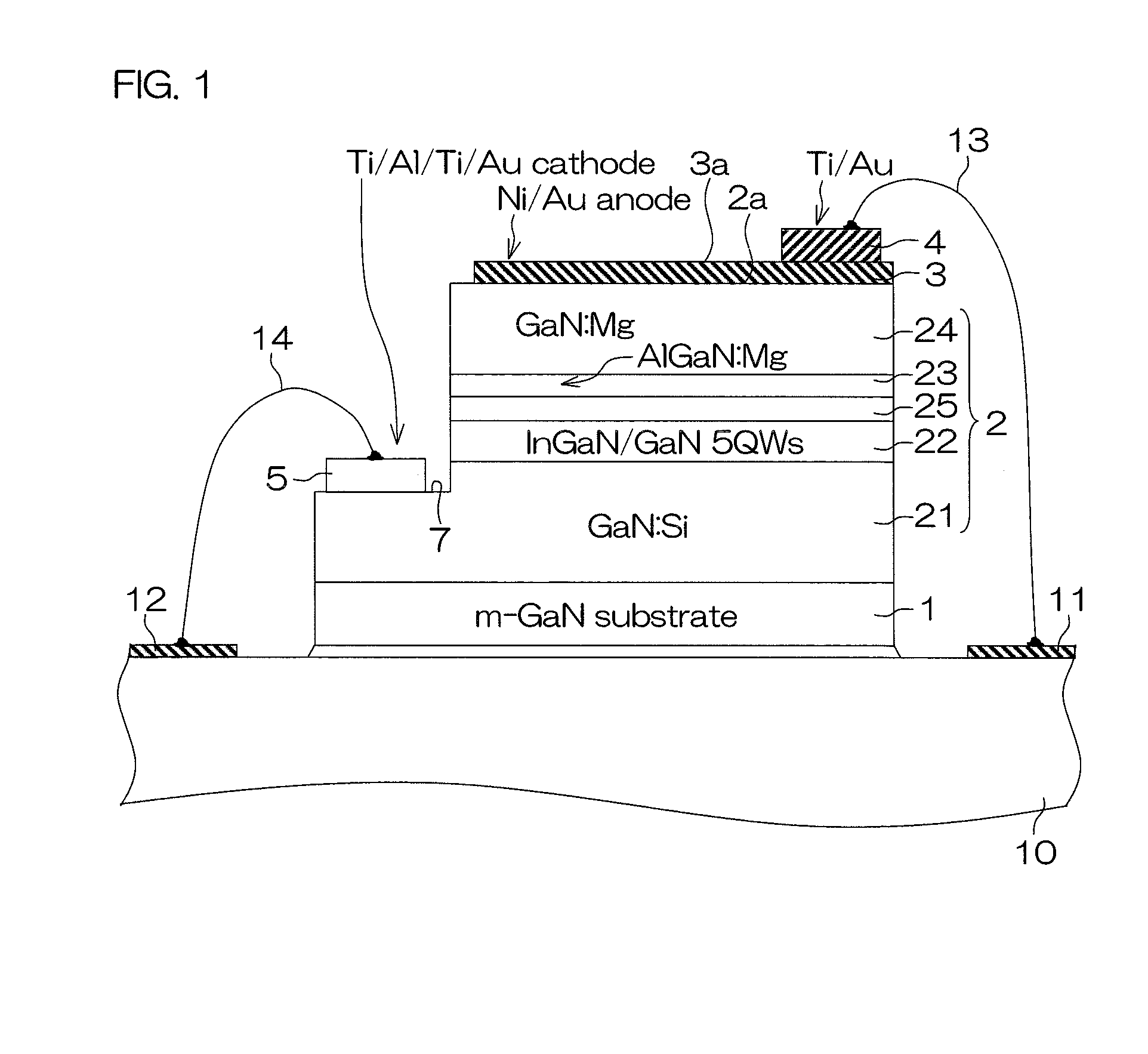

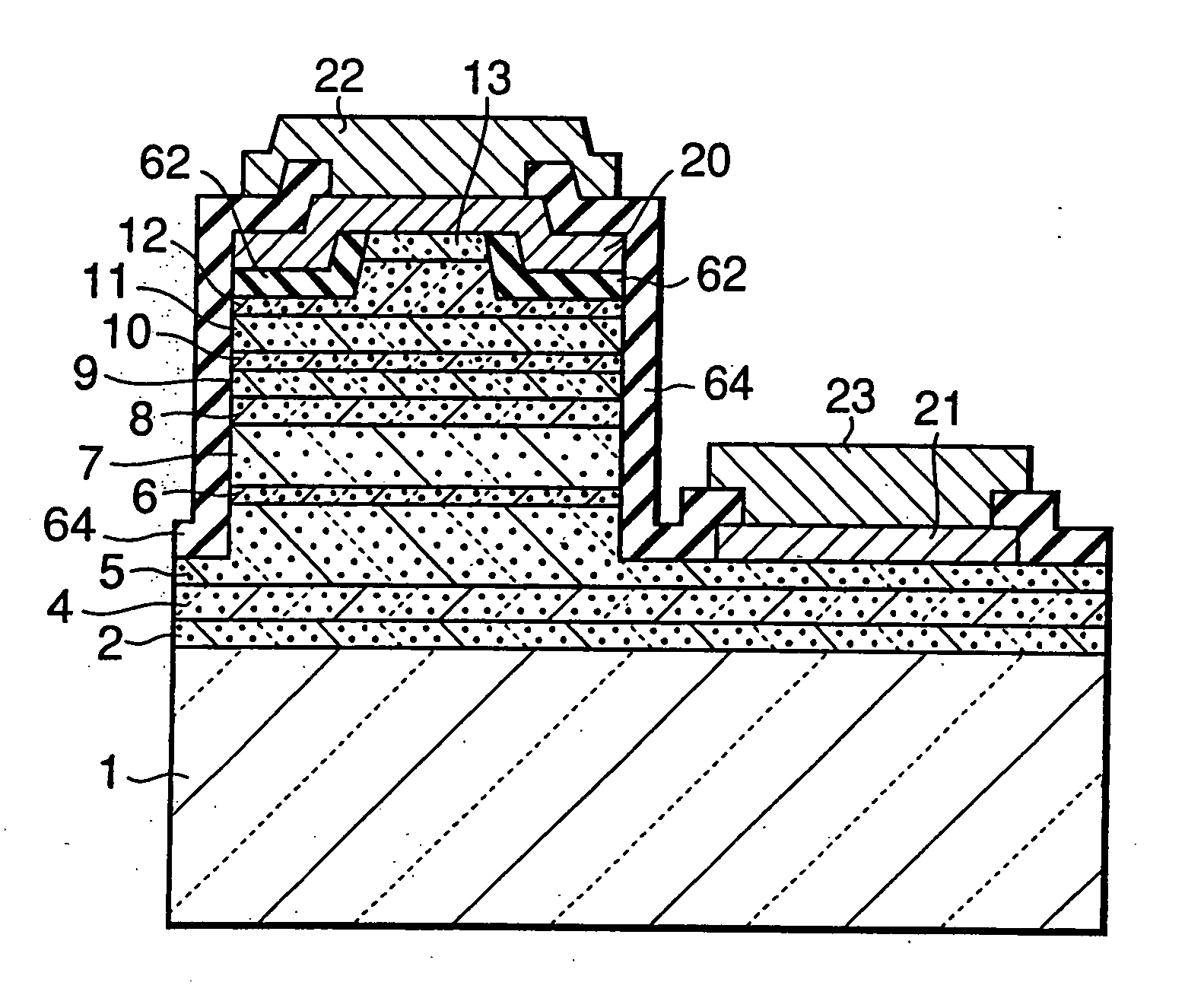

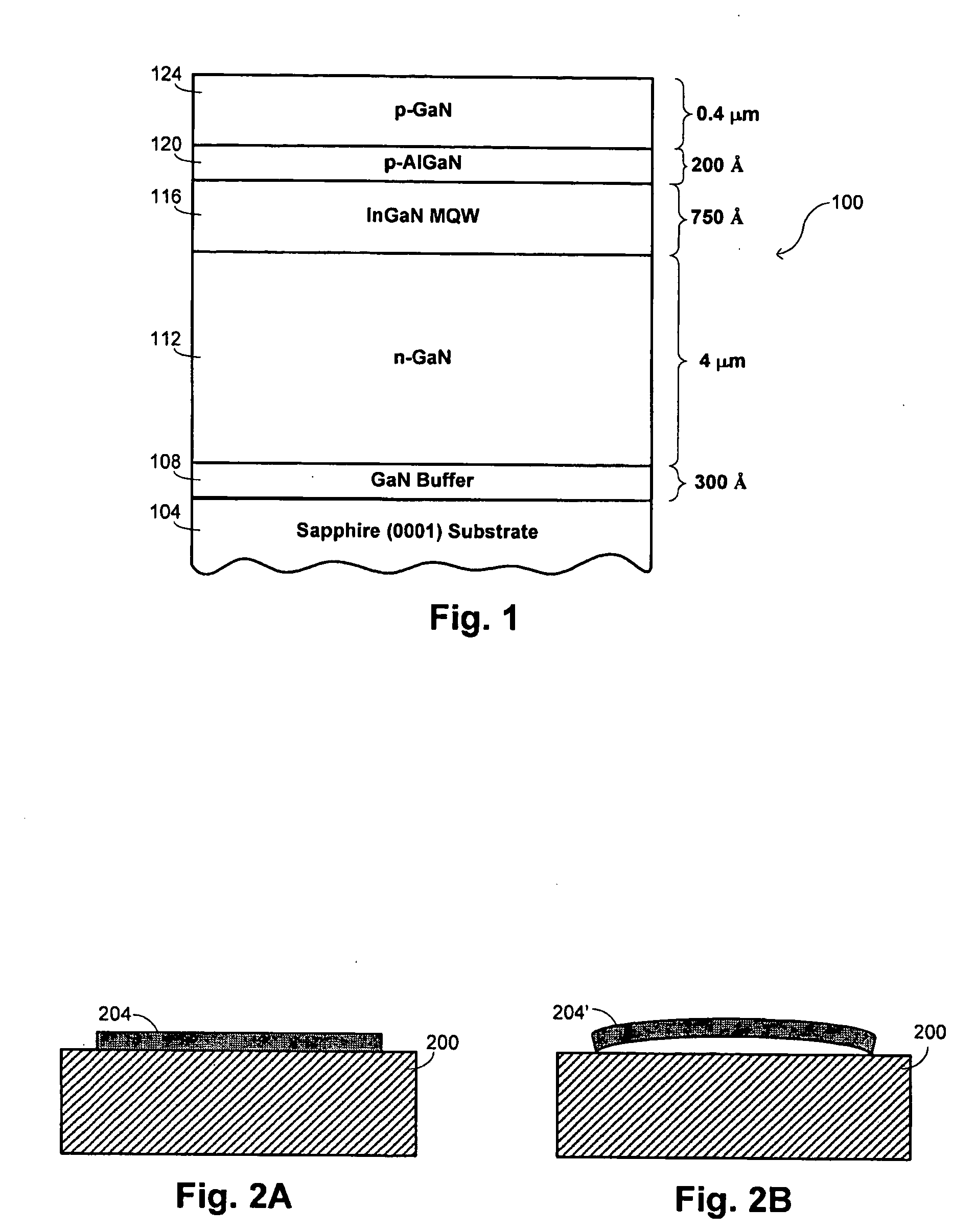

Nitride semiconductor light emitting device and fabrication method thereof

ActiveUS8129711B2Good effectReduce leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesActive layerLight emitting device

The present invention relates to a GaN based nitride based light emitting device improved in Electrostatic Discharge (ESD) tolerance (withstanding property) and a method for fabricating the same including a substrate and a V-shaped distortion structure made of an n-type nitride semiconductor layer, an active layer and a p-type nitride semiconductor layer on the substrate and formed with reference to the n-type nitride semiconductor layer.

Owner:SAMSUNG ELECTRONICS CO LTD

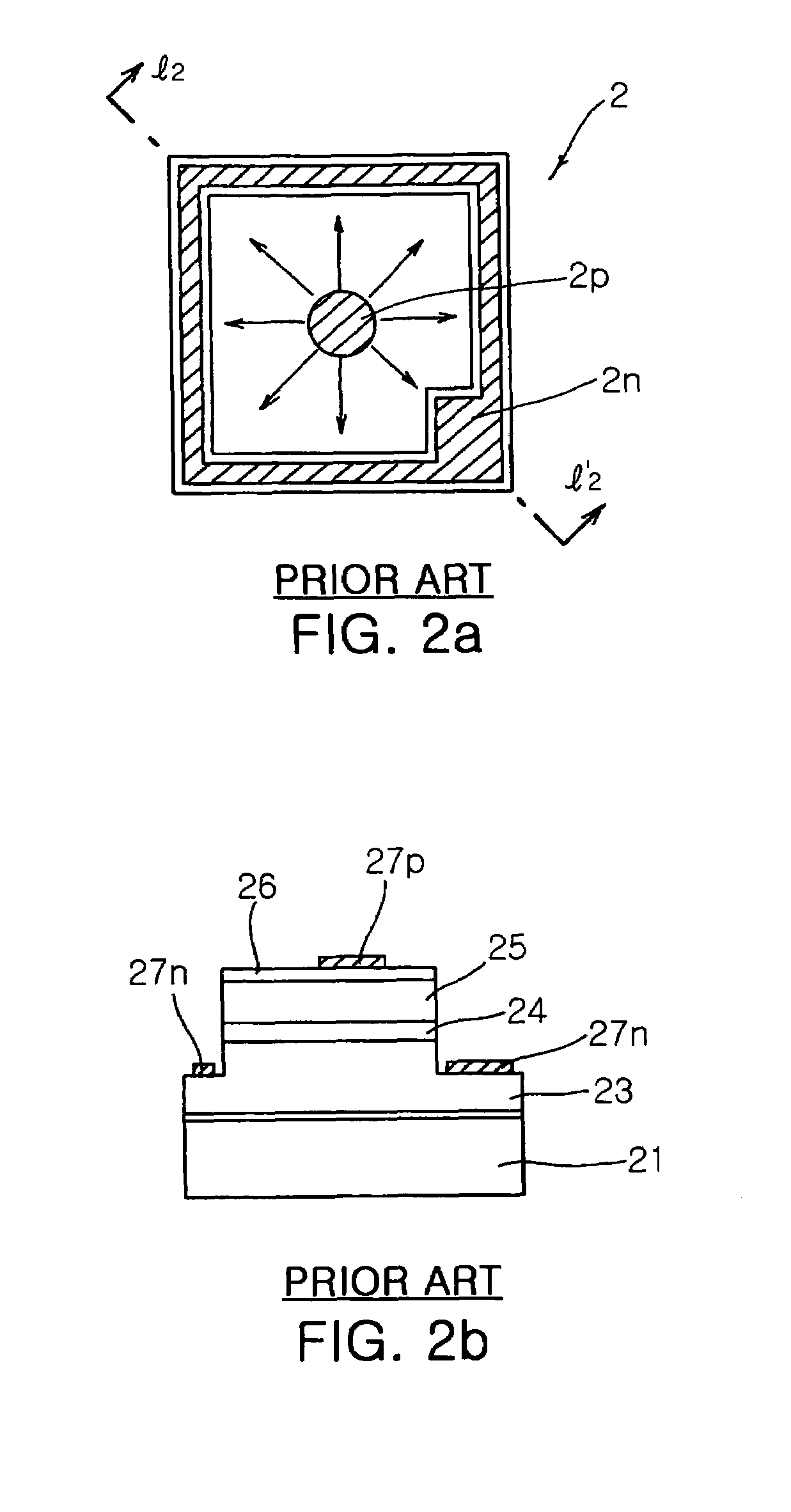

Nitride semiconductor light emitting device and method for manufacturing the same

ActiveUS7154124B2Reduce the probability of spreadingIncrease the differenceSolid-state devicesSemiconductor devicesBand shapeLight emitting device

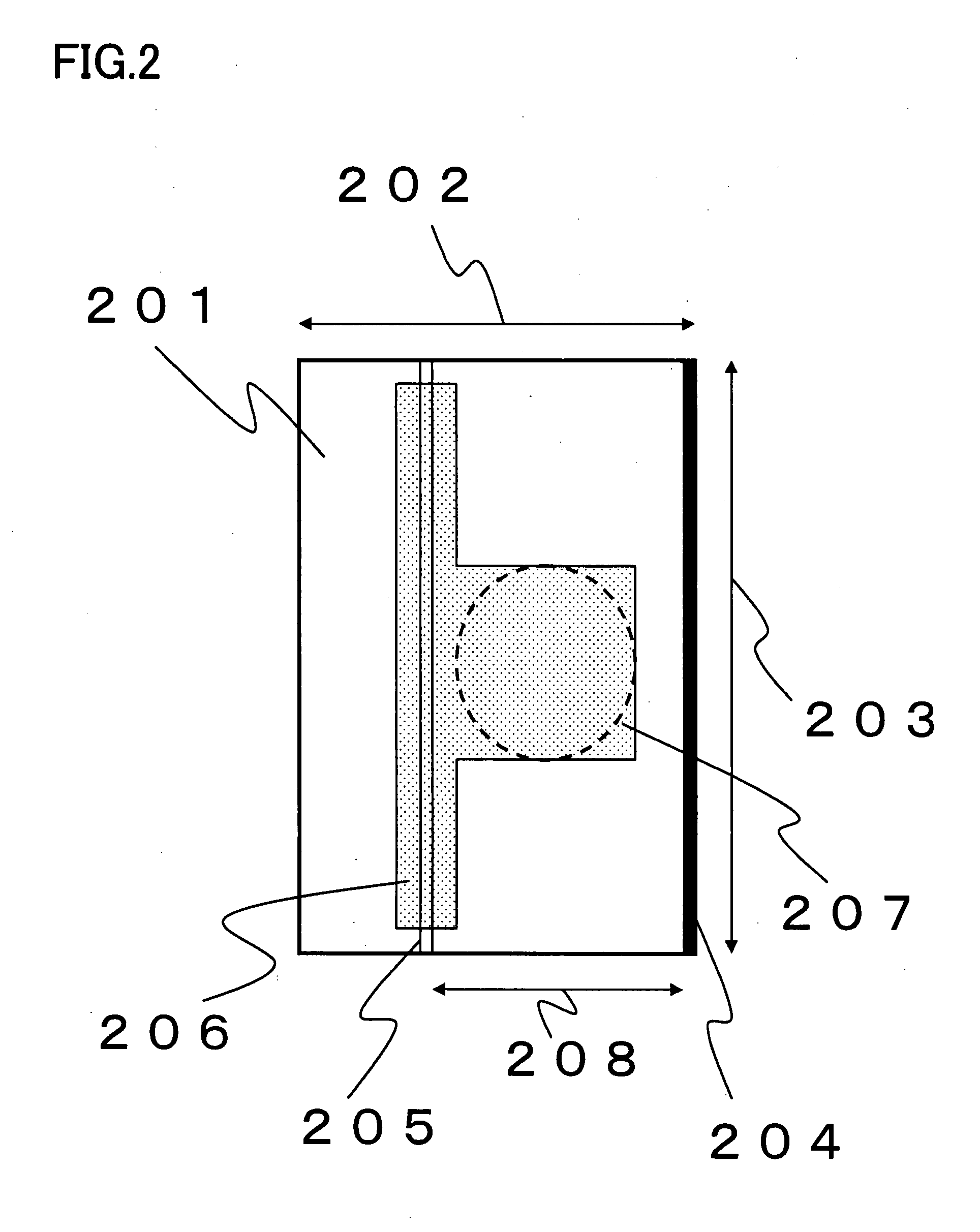

A nitride semiconductor light emitting device includes a substrate, an n-type nitride semiconductor layer formed on the substrate and provided with an electrode region of a predetermined area adjacent to a center of one lateral side of the top surface of the substrate, an n-type electrode formed on the electrode region, an activation layer, a p-type nitride semiconductor layer, and a p-type electrode which has a bonding pad adjacent to a center of another lateral side opposite to the lateral side adjacent to the electrode region to have a predetermined space from the n-type electrode and a band-shaped extension connected to the bonding pad to extend along a lateral side of the top surface of the p-type nitride semiconductor layer in opposite directions from a connected portion of the extension with the bonding pad.

Owner:SAMSUNG ELECTRONICS CO LTD

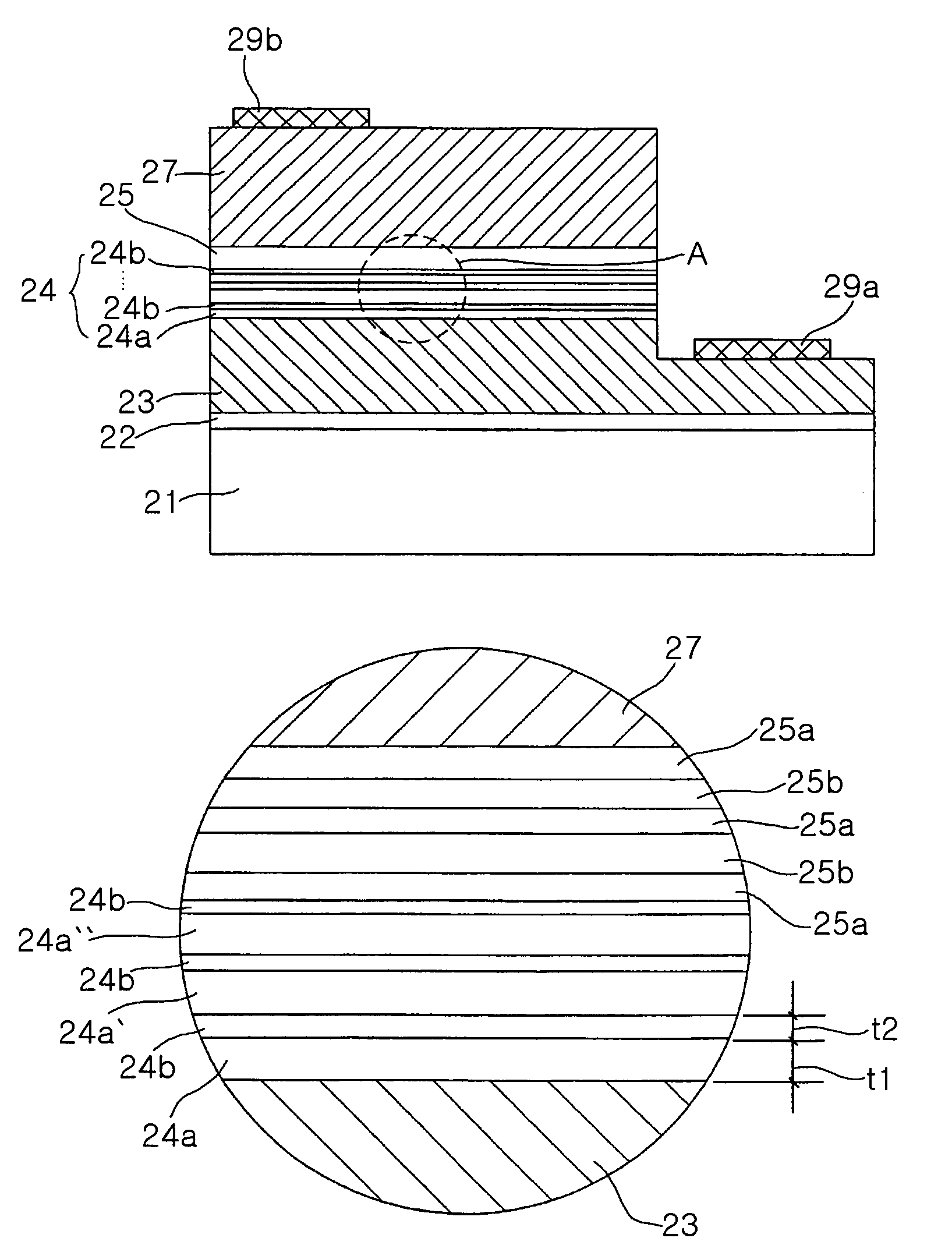

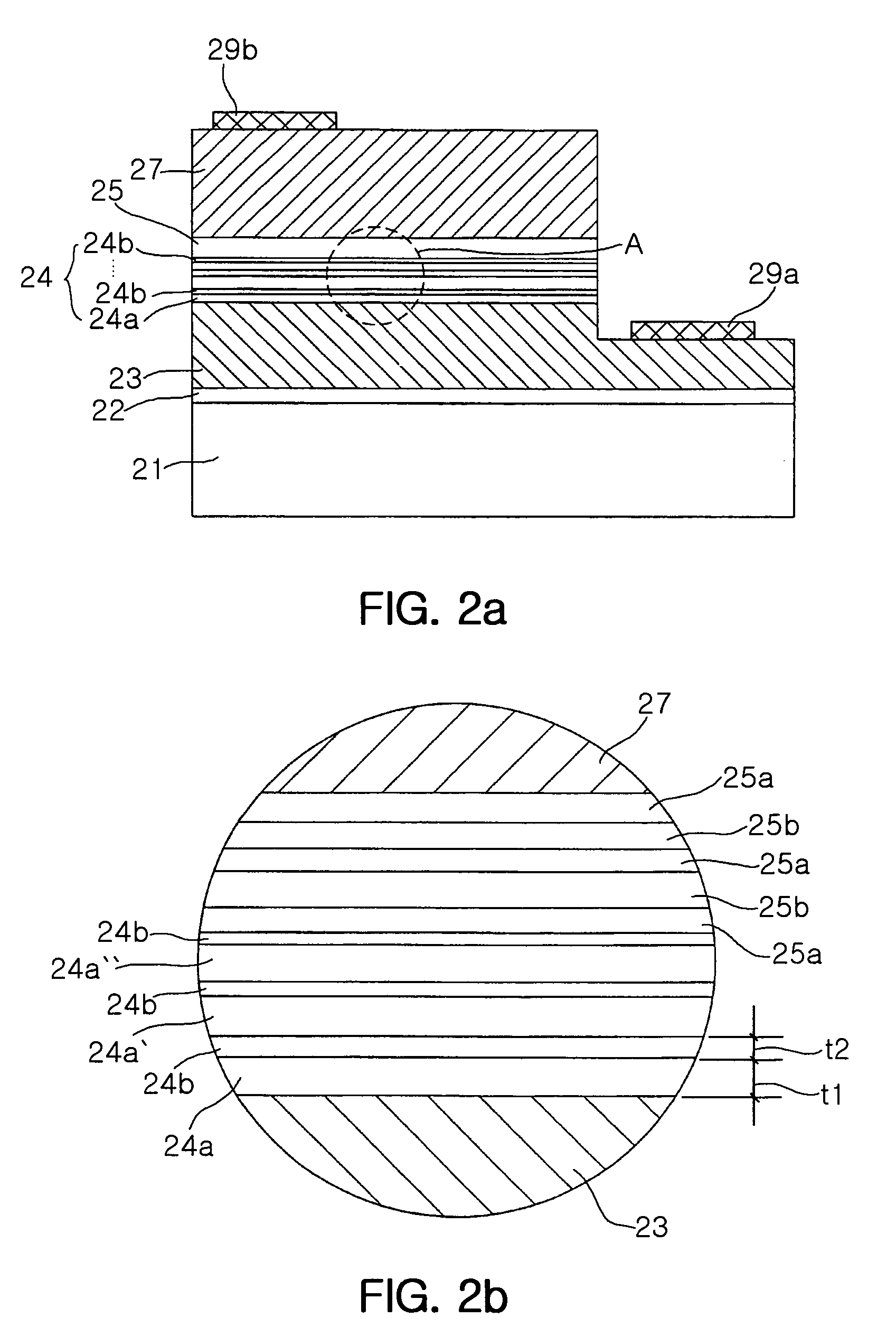

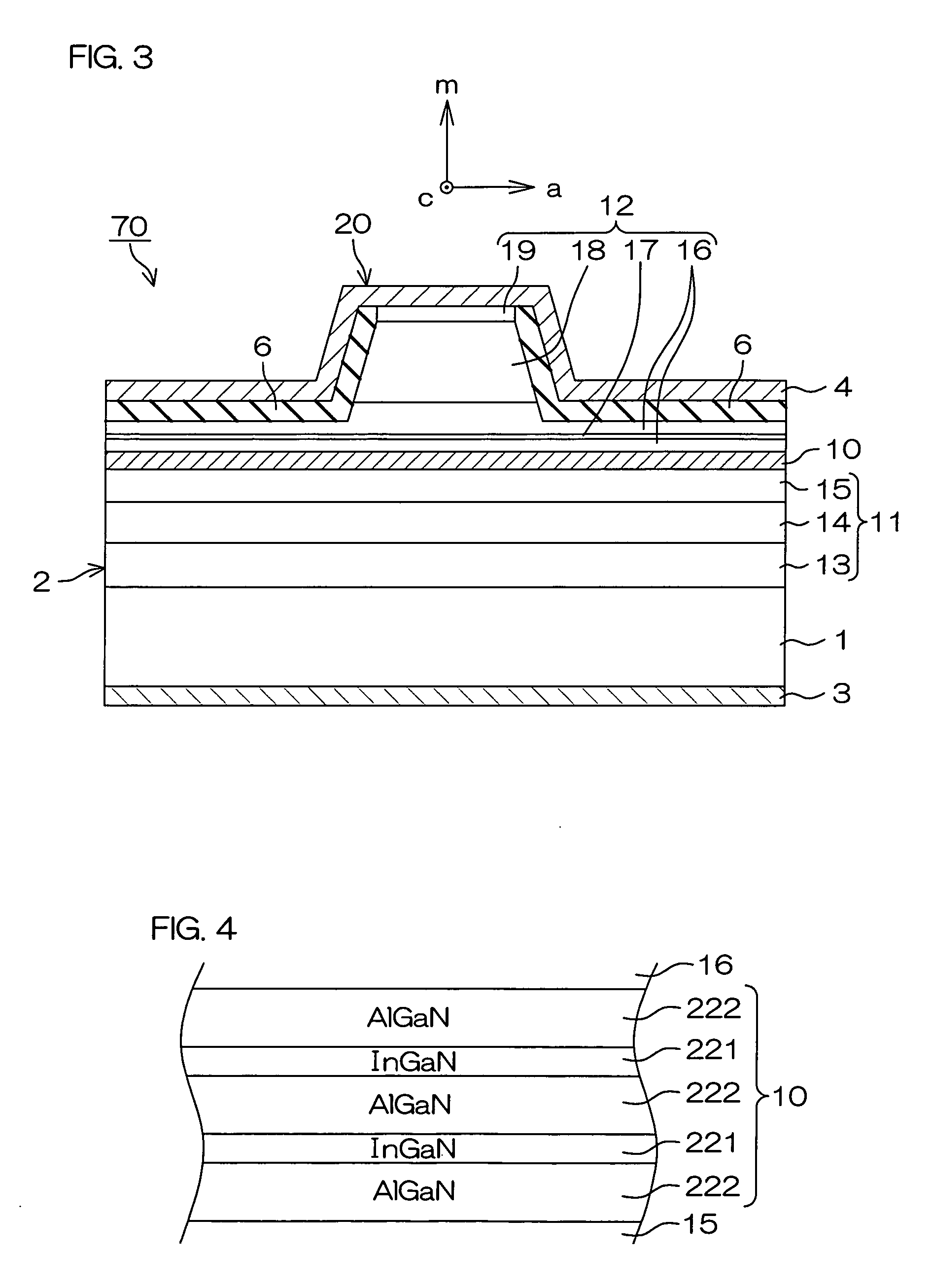

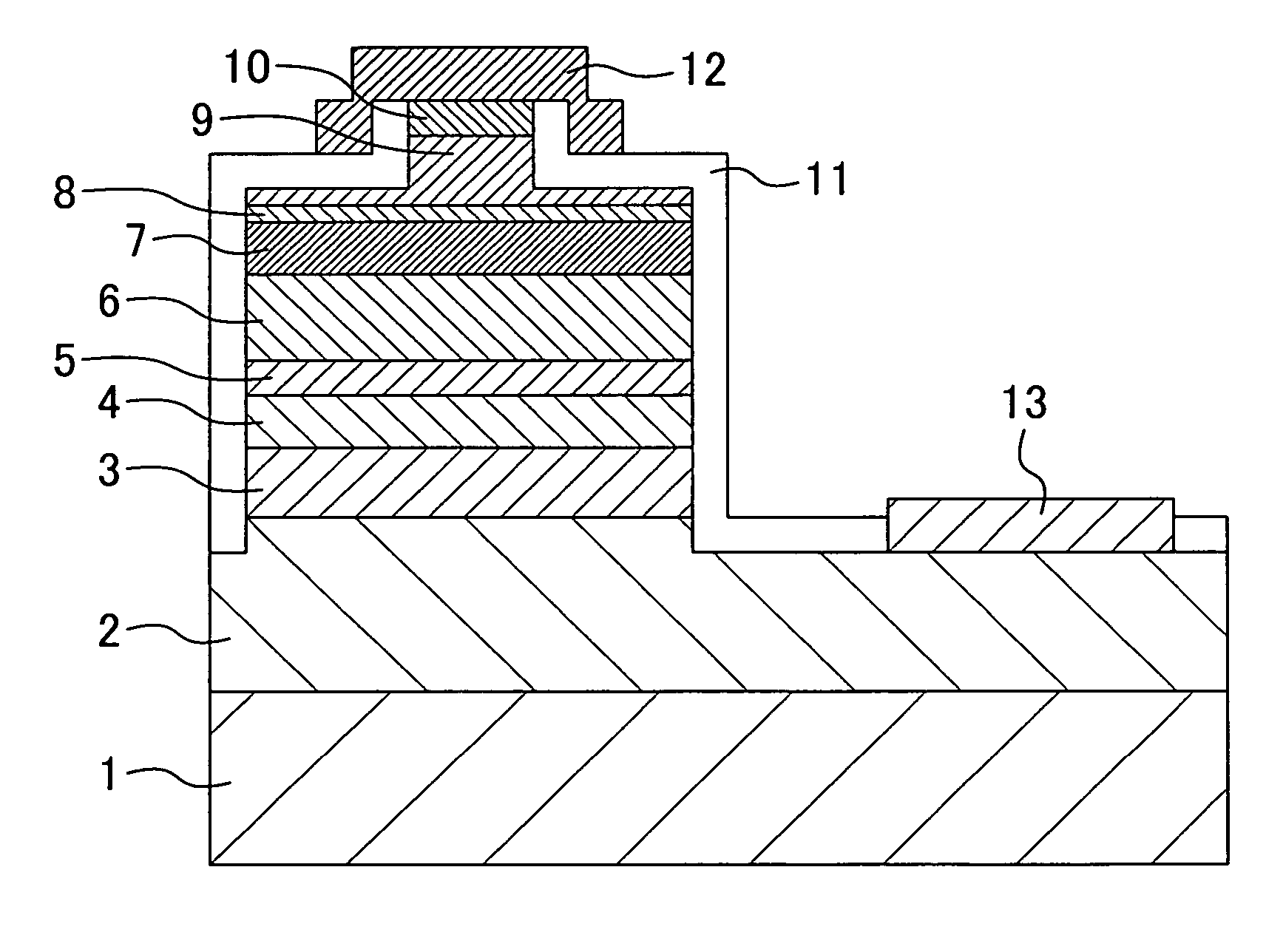

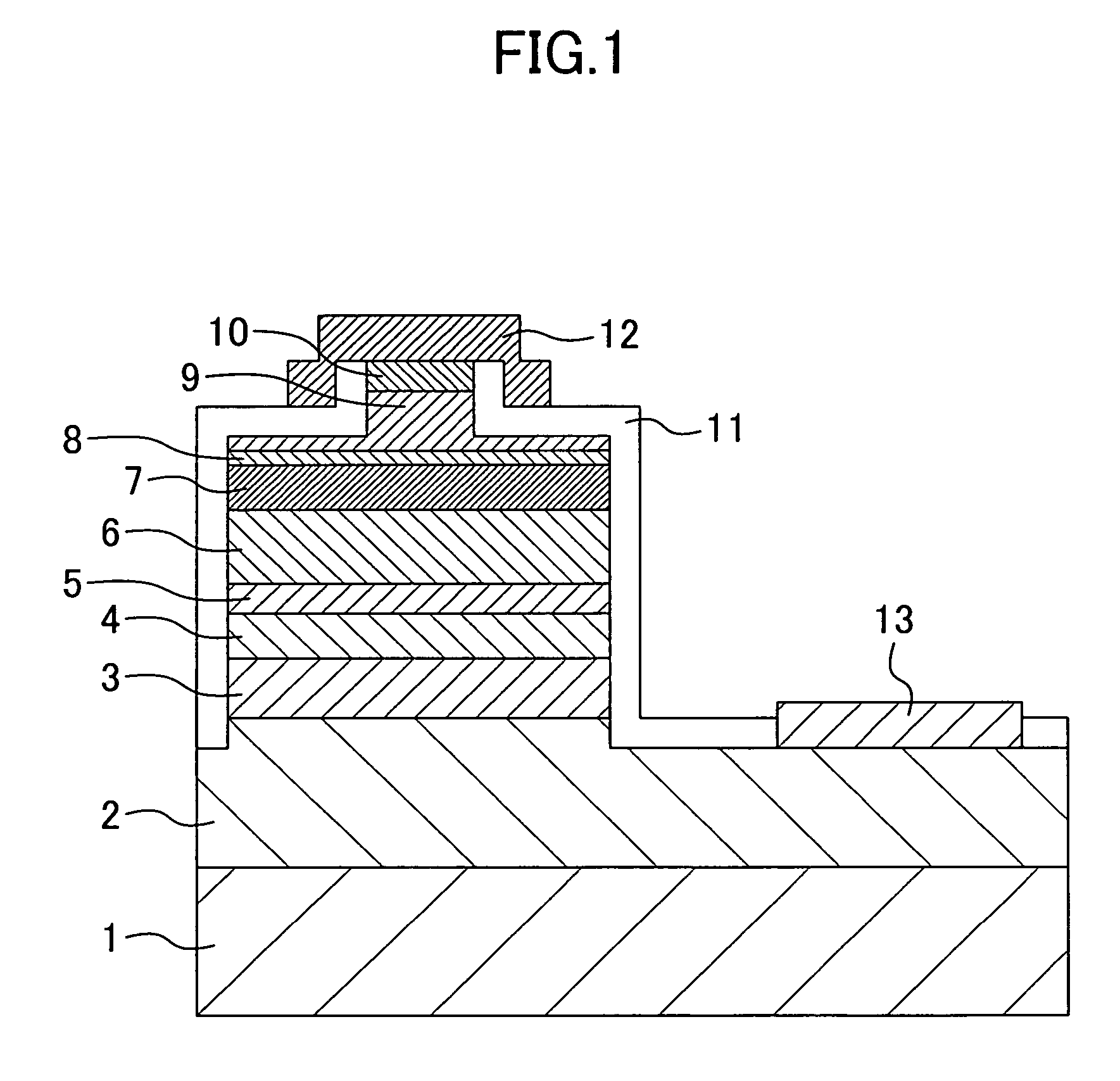

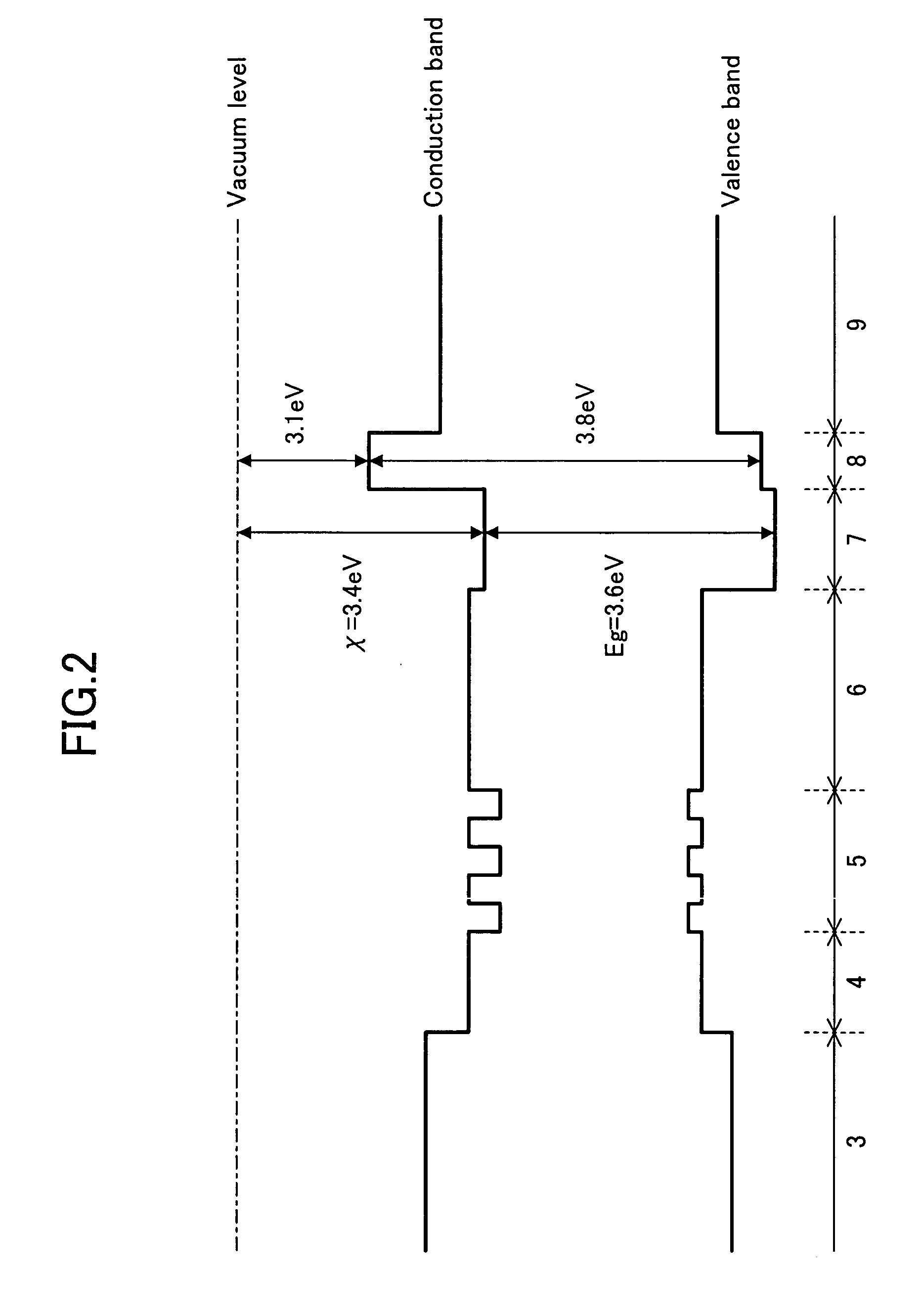

Nitride based semiconductor device

ActiveUS7084420B2Improve efficiencyEliminate the effects ofNanoopticsSemiconductor lasersDevice materialQuantum well

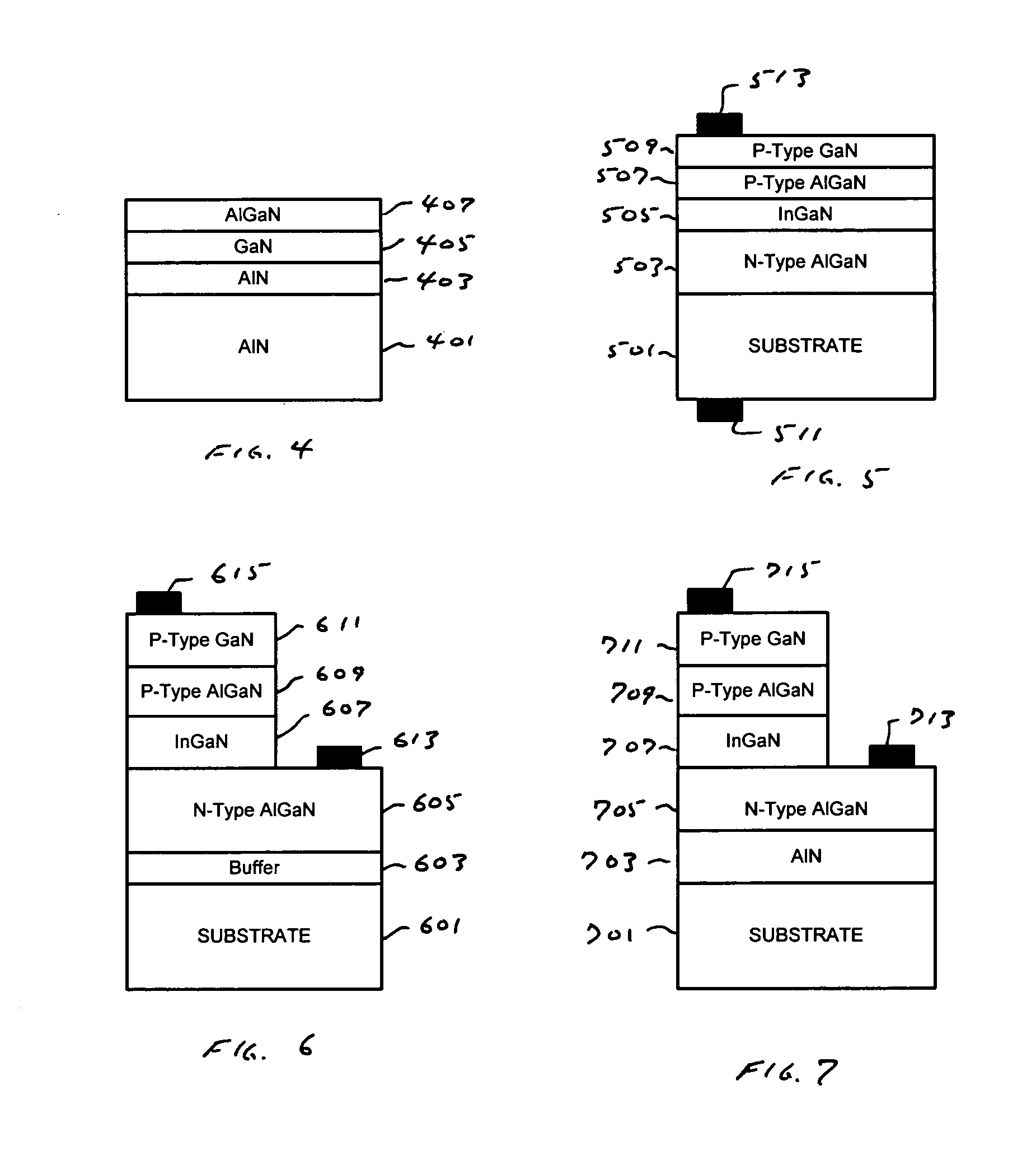

The present invention provides a nitride based semiconductor device comprising an active layer having a quantum well layer and a quantum barrier layer, wherein the device includes an electron emitting layer formed of at least two repeats of a first nitride semiconductor layer and a second nitride semiconductor layer having different compositions between a n-type nitride semiconductor layer and the active layer, the first nitride semiconductor layer has an energy band gap greater than that of the quantum well layer, smaller than that of the quantum barrier layer, and decreasing closer to the active layer, and the second nitride semiconductor layer has an energy band gap at least higher than that of the adjacent first nitride semiconductor layer(s) and has a thickness capable of tunneling electrons.

Owner:SAMSUNG ELECTRONICS CO LTD

Light emitting diode, optical semiconductor element and epoxy resin composition suitable for optical semiconductor element and production methods therefor

InactiveUS20030080341A1Light emission characteristicSuppress the variation in the chromaticity of the light emittedDischarge tube luminescnet screensLamp detailsEpoxyLight-emitting diode

A light emitting diode comprising an LED chip having a light emitting layer made of a nitride compound semiconductor and a light transmitting resin that includes a fluorescent material which absorbs at least a part of light emitted by the LED chip and emits light of a different wavelength, wherein the fluorescent material includes a fluorescent particles of small particle size and a fluorescent particles of large particle size, the fluorescent particles of large particle size being distributed in the vicinity of the LED chip in the light transmitting resin to form a wavelength converting layer, the fluorescent particles of small particle size being distributed on the outside of the wavelength converting layer in the light transmitting resin.

Owner:NICHIA CORP

Metal oxynitride semiconductor containing zinc

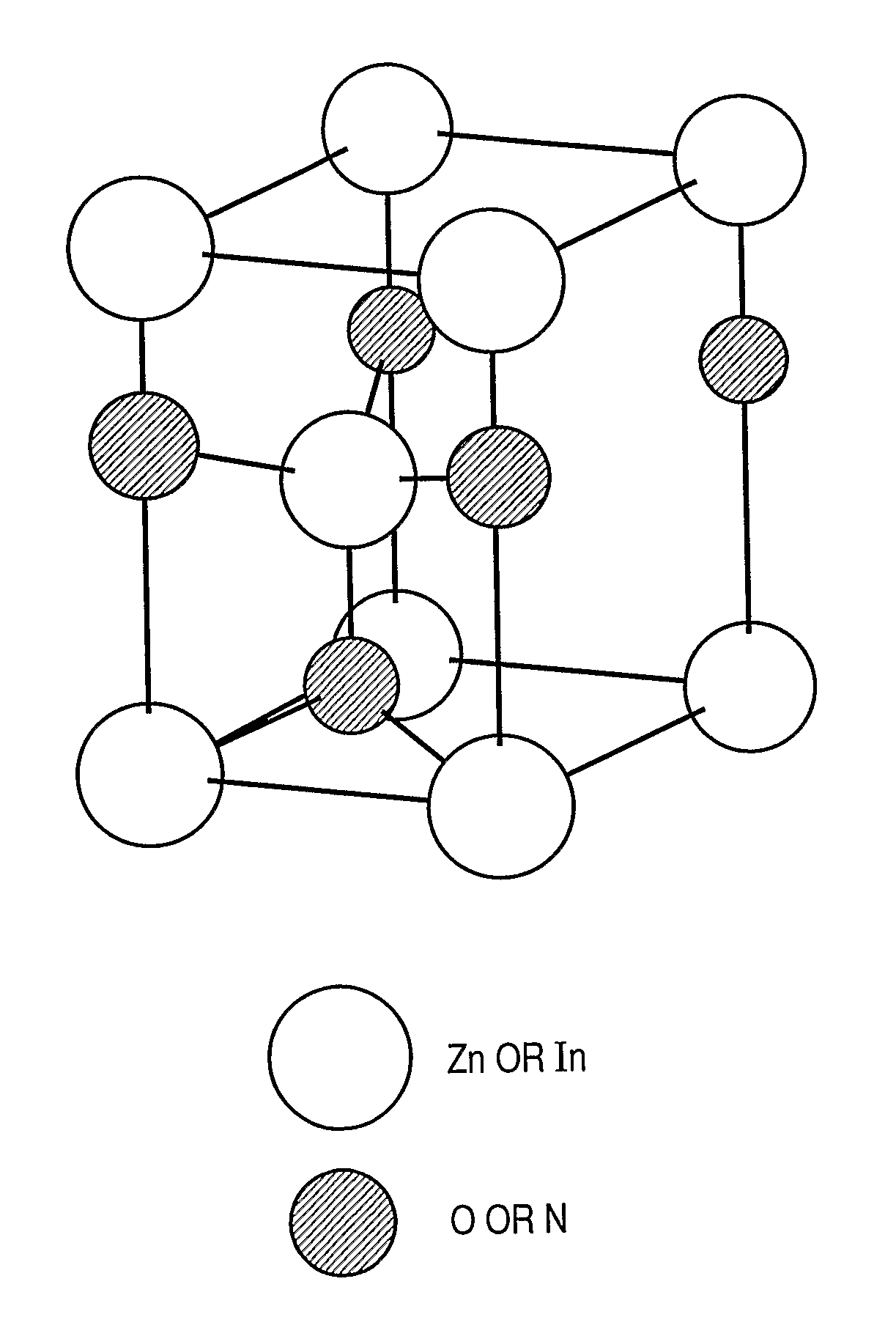

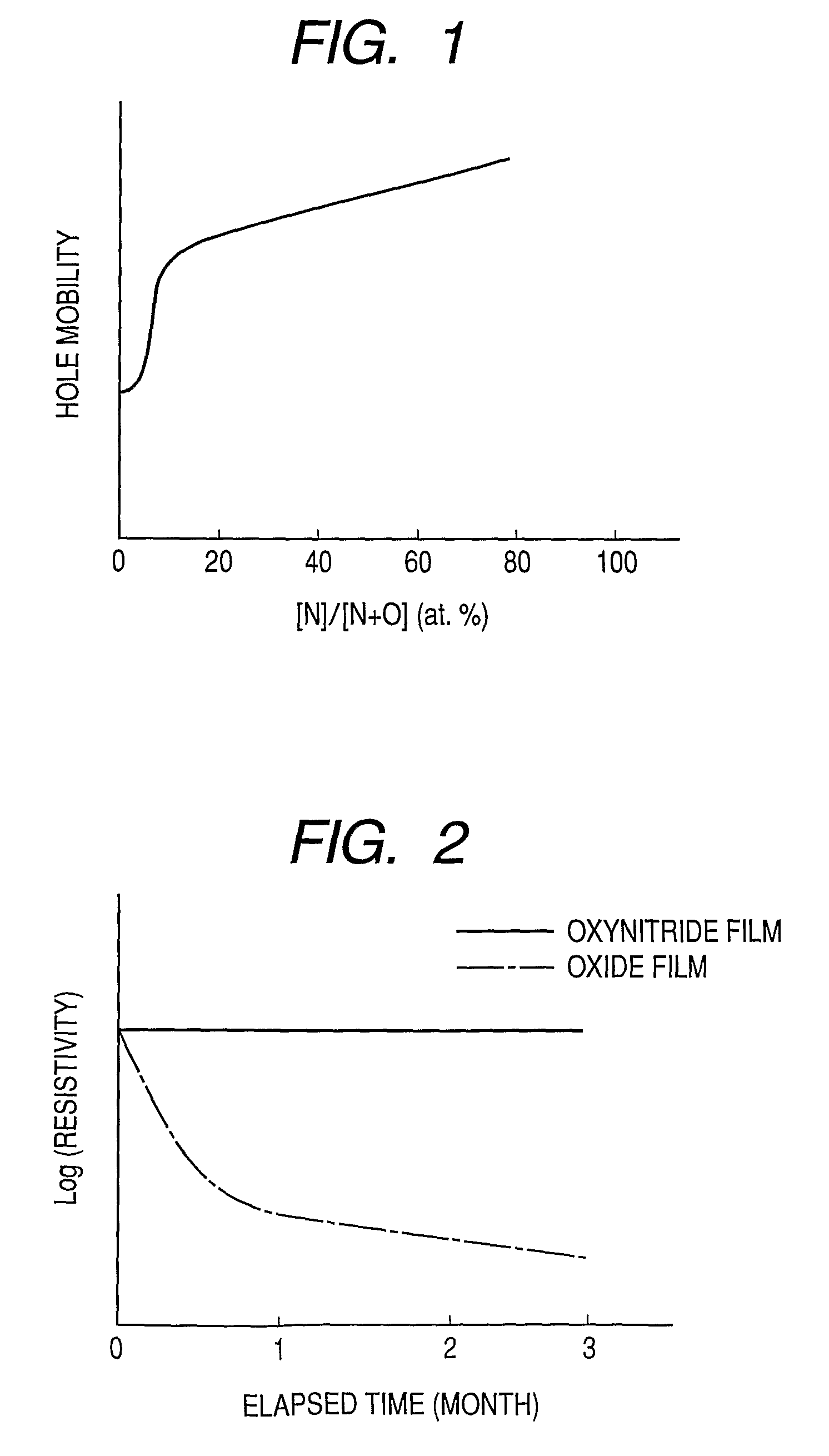

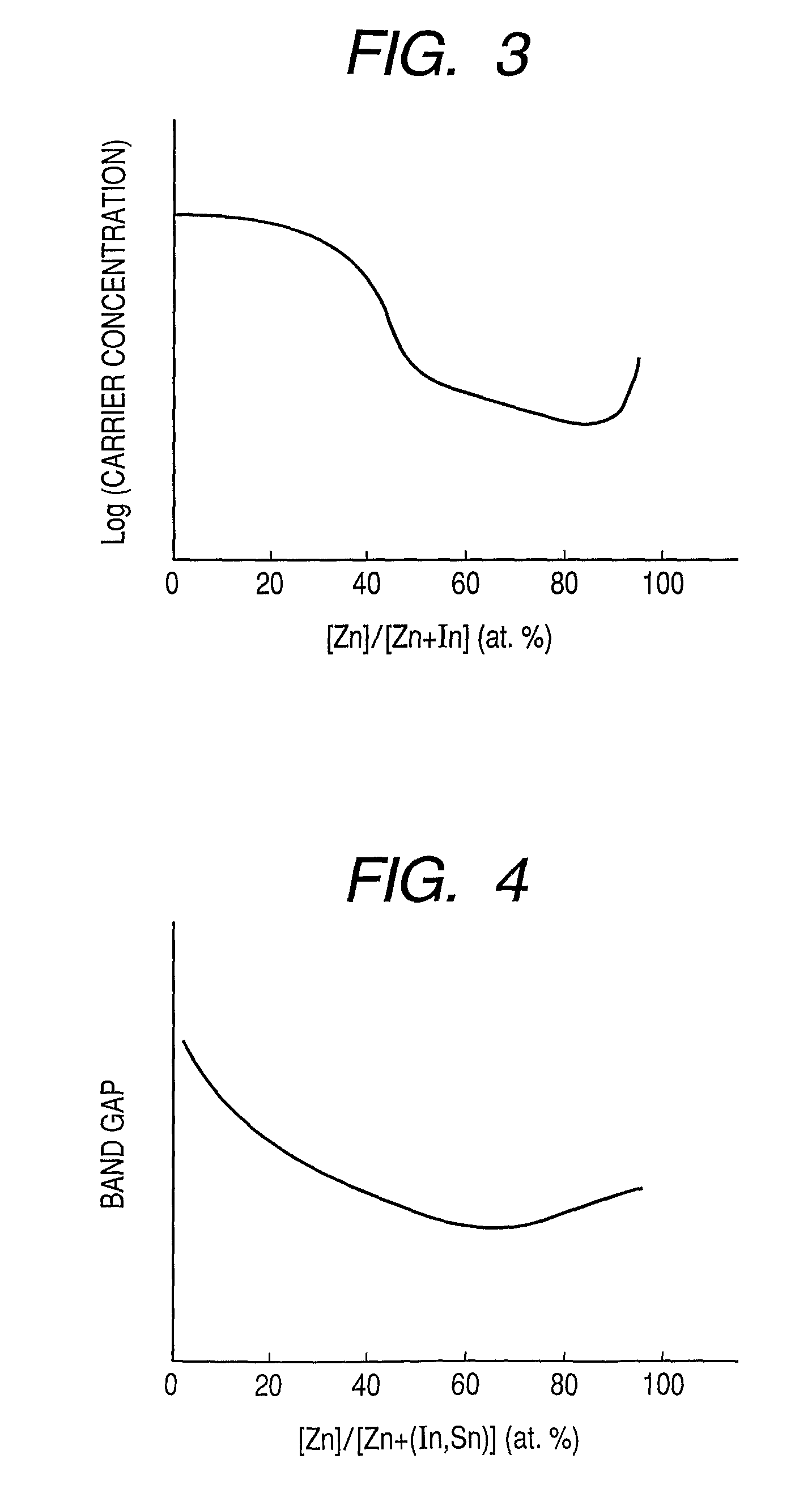

ActiveUS8274078B2High mobility and environmental stabilityImprove mobilityPhotovoltaic energy generationSemiconductor devicesNitrogen oxideOxygen

Provided is an oxynitride semiconductor comprising a metal oxynitride. The metal oxynitride contains Zn and In and at least one element selected from the group consisting of Ga, Sn, Mg, Si, Ge, Y, Ti, Mo, W, and Al. The metal oxynitride has an atomic composition ratio of N, N / (N+O), of 7 atomic percent or more to 80 atomic percent or less.

Owner:CANON KK

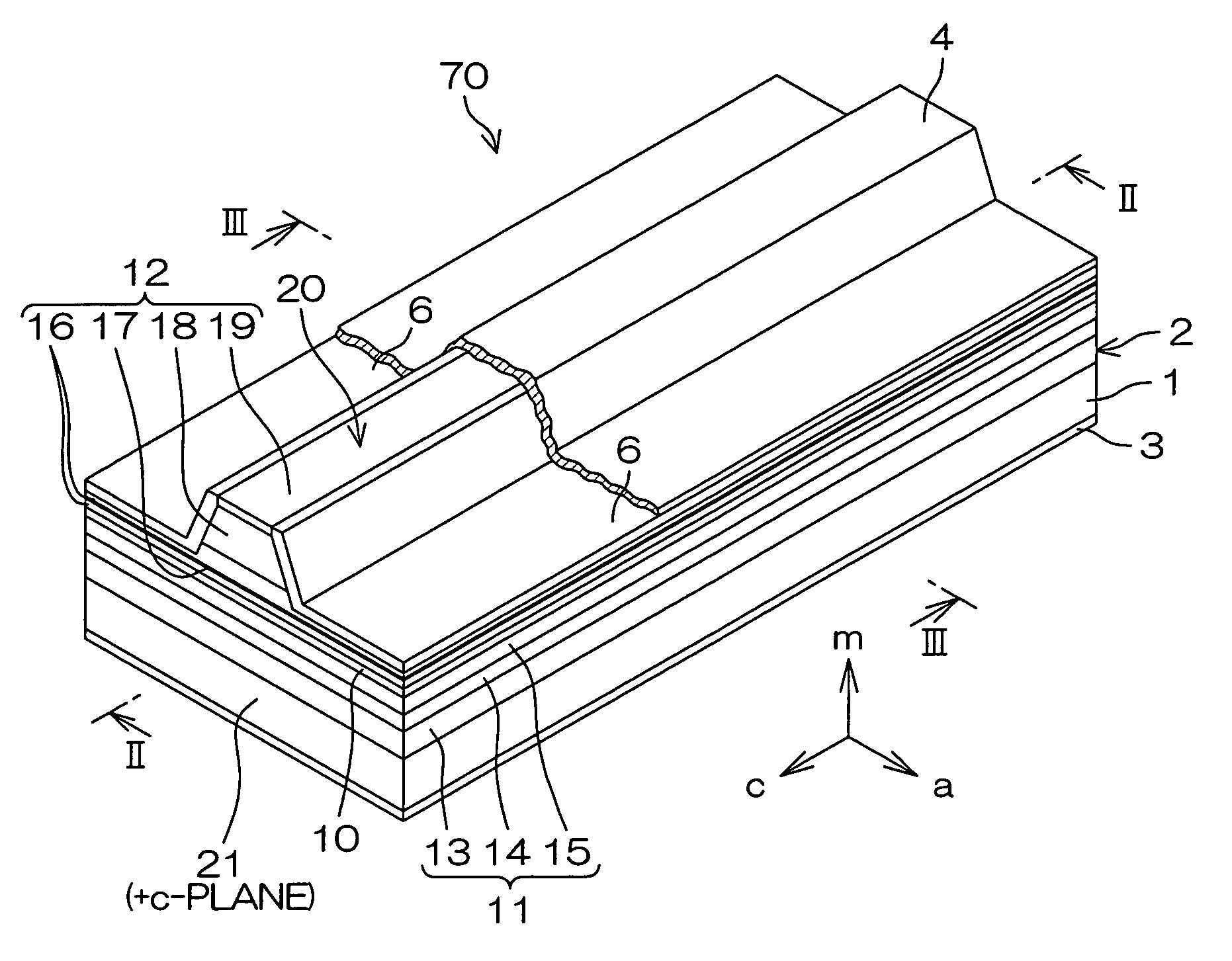

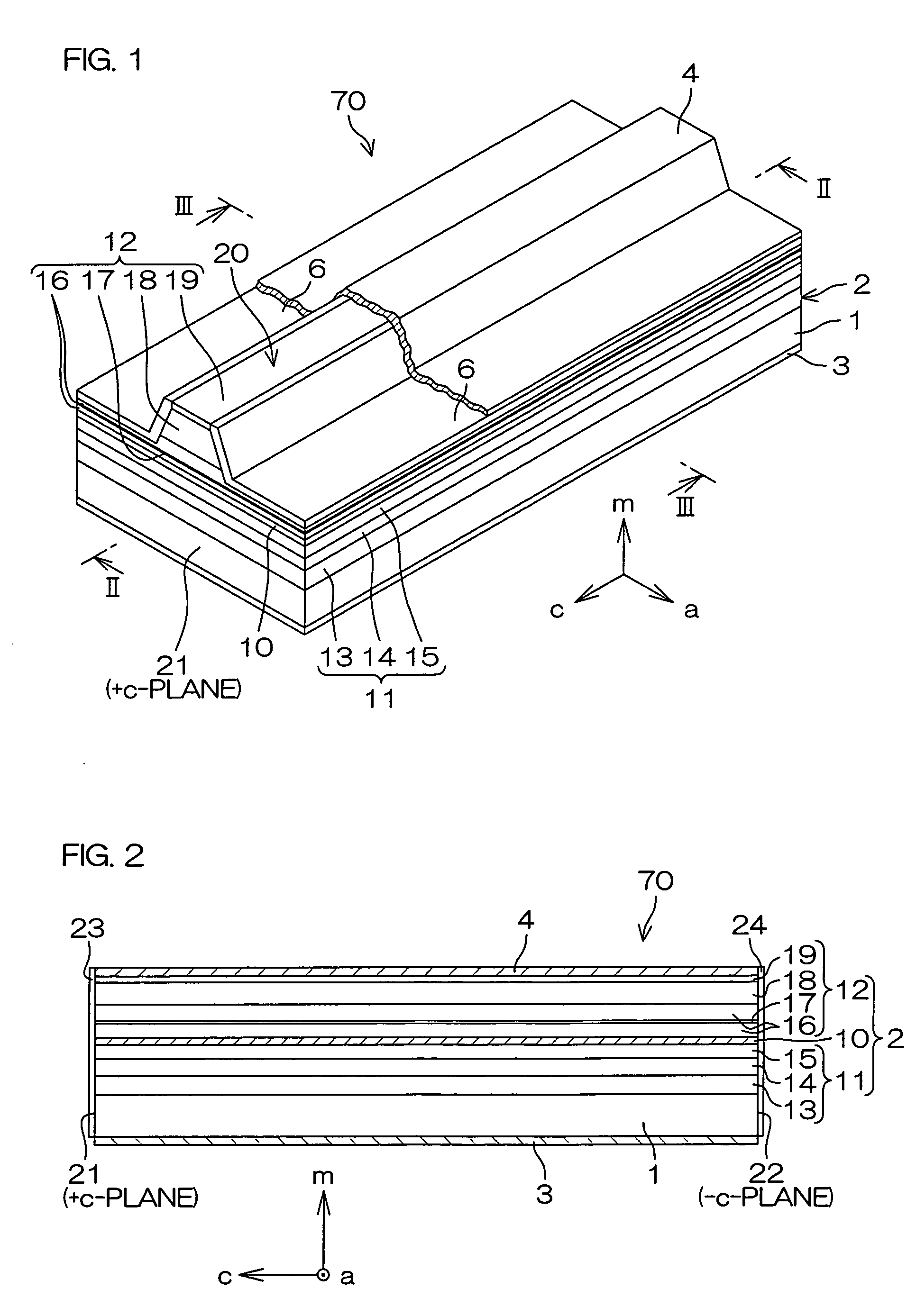

Semiconductor laser diode

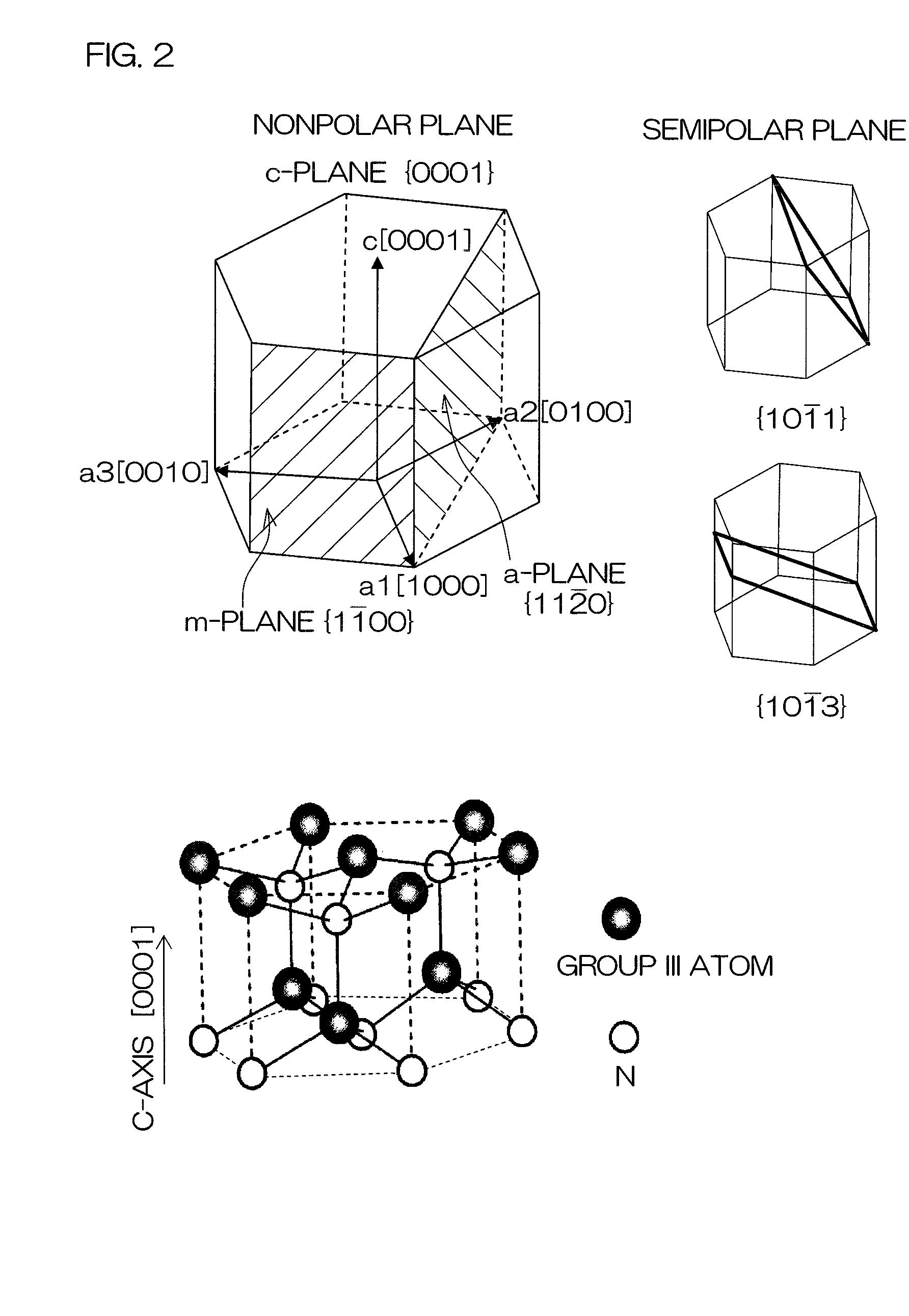

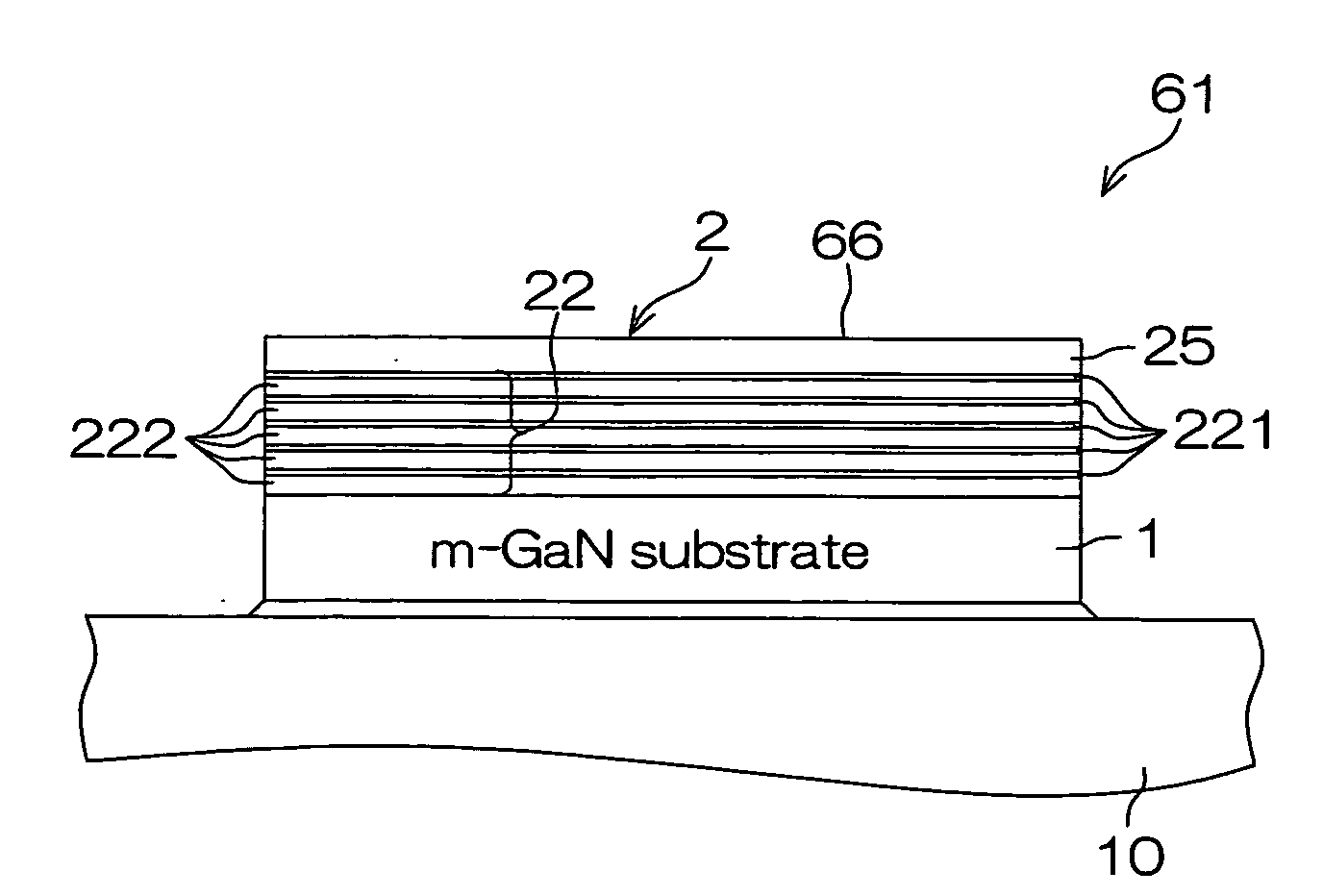

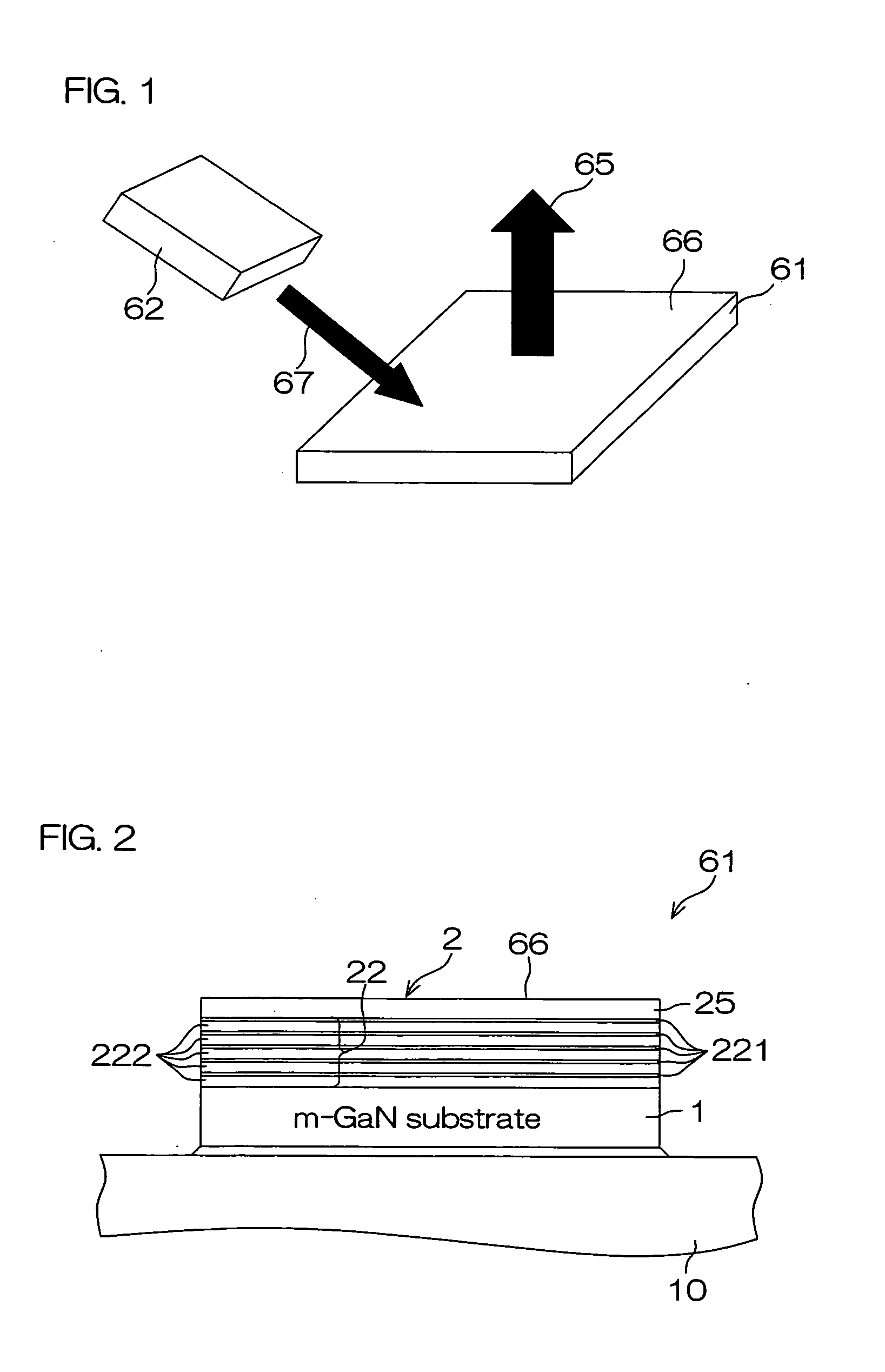

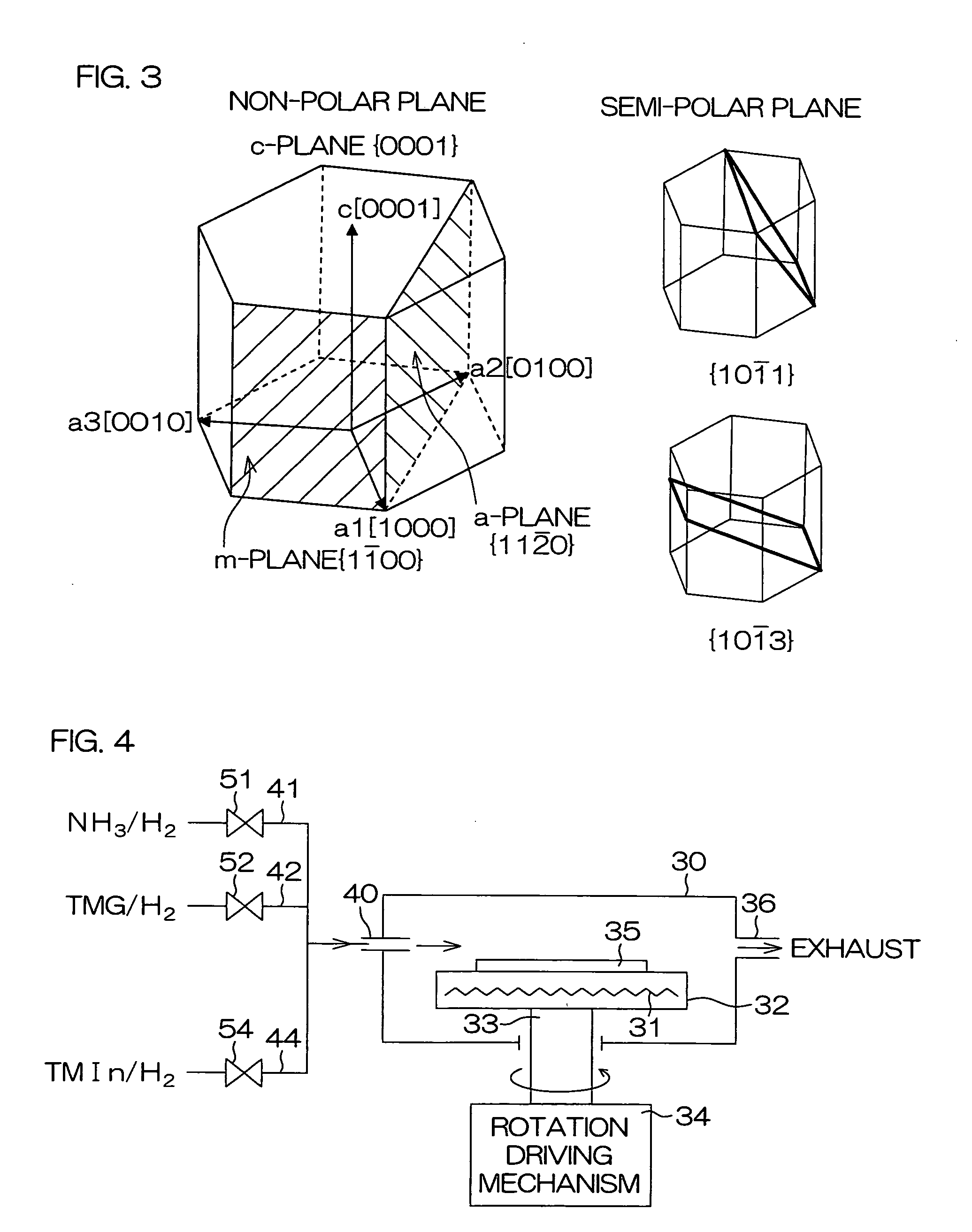

InactiveUS20080285609A1Improve luminous efficiencyAvoid polarizationLaser detailsLaser active region structureLight-emitting diodeCrystal growth

An inventive semiconductor laser diode includes a Group III nitride semiconductor layered structure having a major crystal growth plane defined by a non-polar or semi-polar-plane. The Group III nitride semiconductor layered structure includes: a p-type cladding layer and an n-type cladding layer; an In-containing p-type guide layer and an In-containing n-type guide layer held between the p-type cladding layer and the n-type cladding layer; and an In-containing light emitting layer held between the p-type guide layer and the n-type guide layer.

Owner:ROHM CO LTD

Light-emitting device

ActiveUS20100096615A1Generate efficientlyEfficient use ofSolid-state devicesNanoopticsLight emitting deviceNitride semiconductors

A light-emitting device includes a group III nitride semiconductor layer of a multilayer structure consisting of a group III nitride semiconductor having a major surface defined by a nonpolar plane or a semipolar plane and having at least an n-type layer and a p-type layer. A surface of the group III nitride semiconductor layer on a light extraction side is a mirror surface. The light-emitting device may further include a transparent electrode in contact with the surface of the group III nitride semiconductor layer on the light extraction side. In this case, a surface of the transparent electrode on the light extraction side is preferably a mirror surface.

Owner:ROHM CO LTD

Group-III nitride semiconductor device

InactiveUS20050072986A1Suppress an undesired mass-transportPrevent surfaceOptical wave guidanceLaser detailsNitride semiconductorsCompound semiconductor

A method of forming a partially etched nitride-based compound semiconductor crystal layer includes the following steps. A non-crystal layer of a nitride-based compound semiconductor is formed. At least a part of the non-crystal layer is then etched to form a partially etched non-crystal layer before the partially etched non-crystal layer is crystallized to form a partially etched nitride-based compound semiconductor crystal layer.

Owner:RENESAS ELECTRONICS CORP

Nitride semiconductor device and method of manufacturing the same

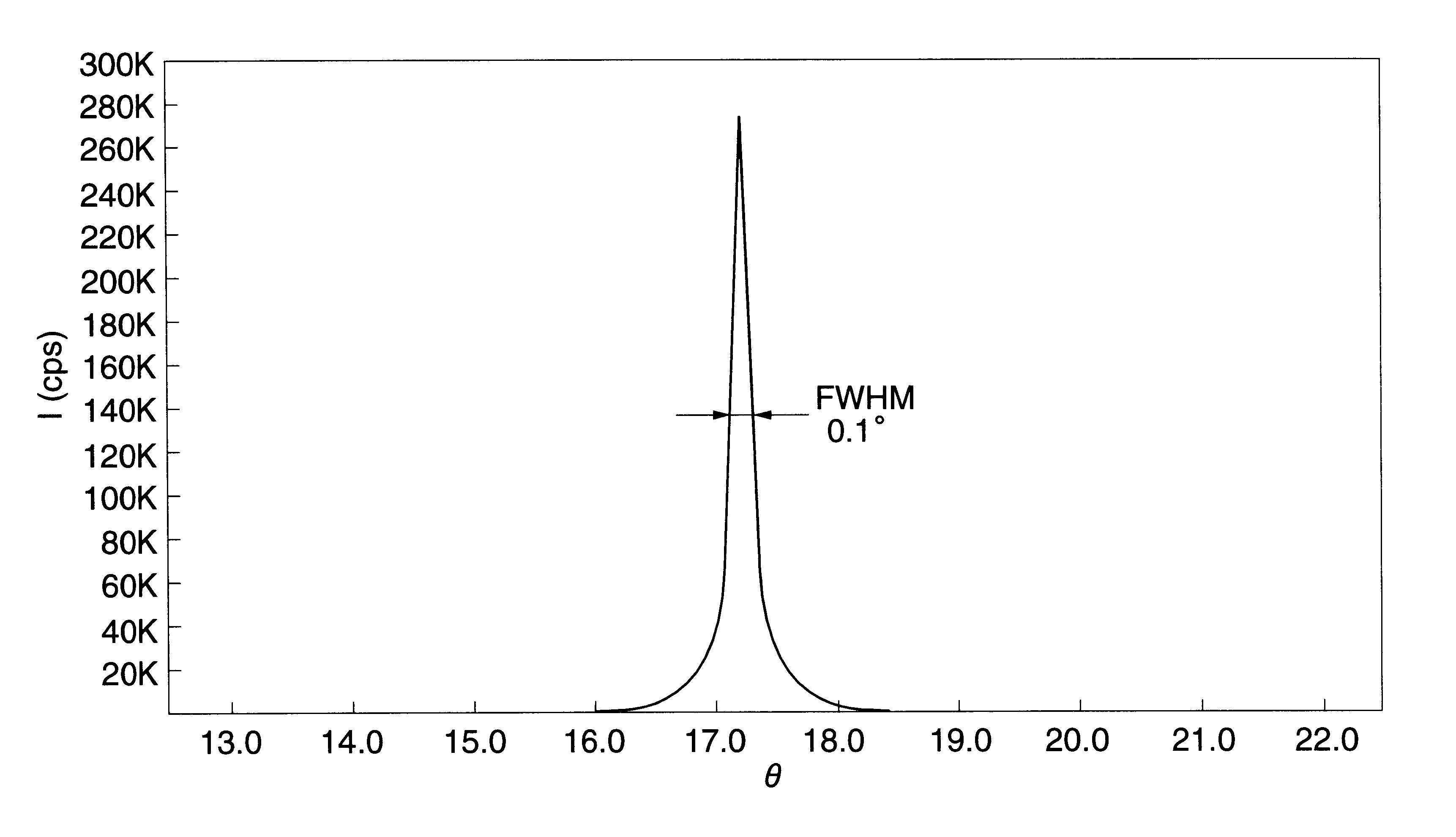

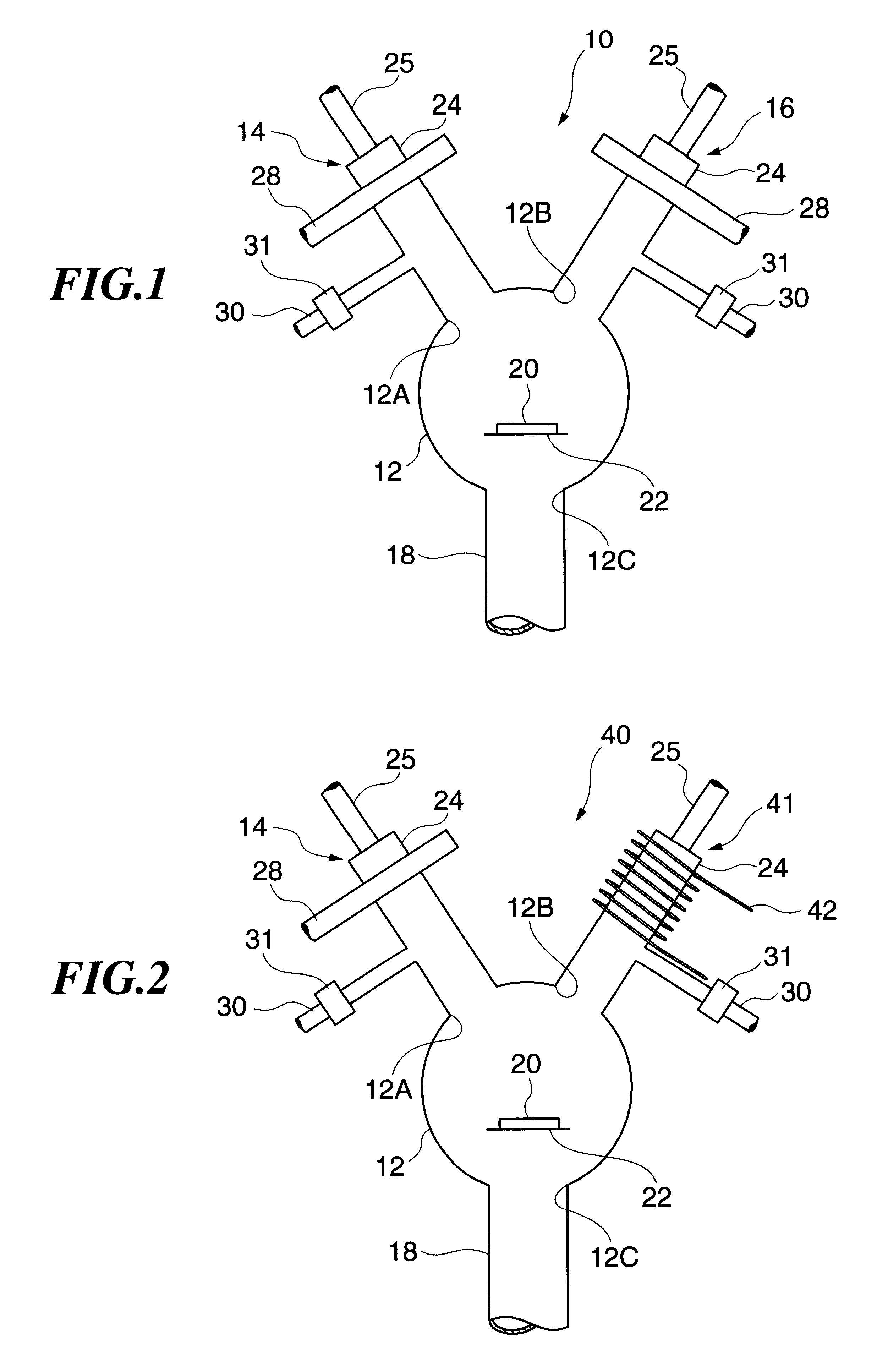

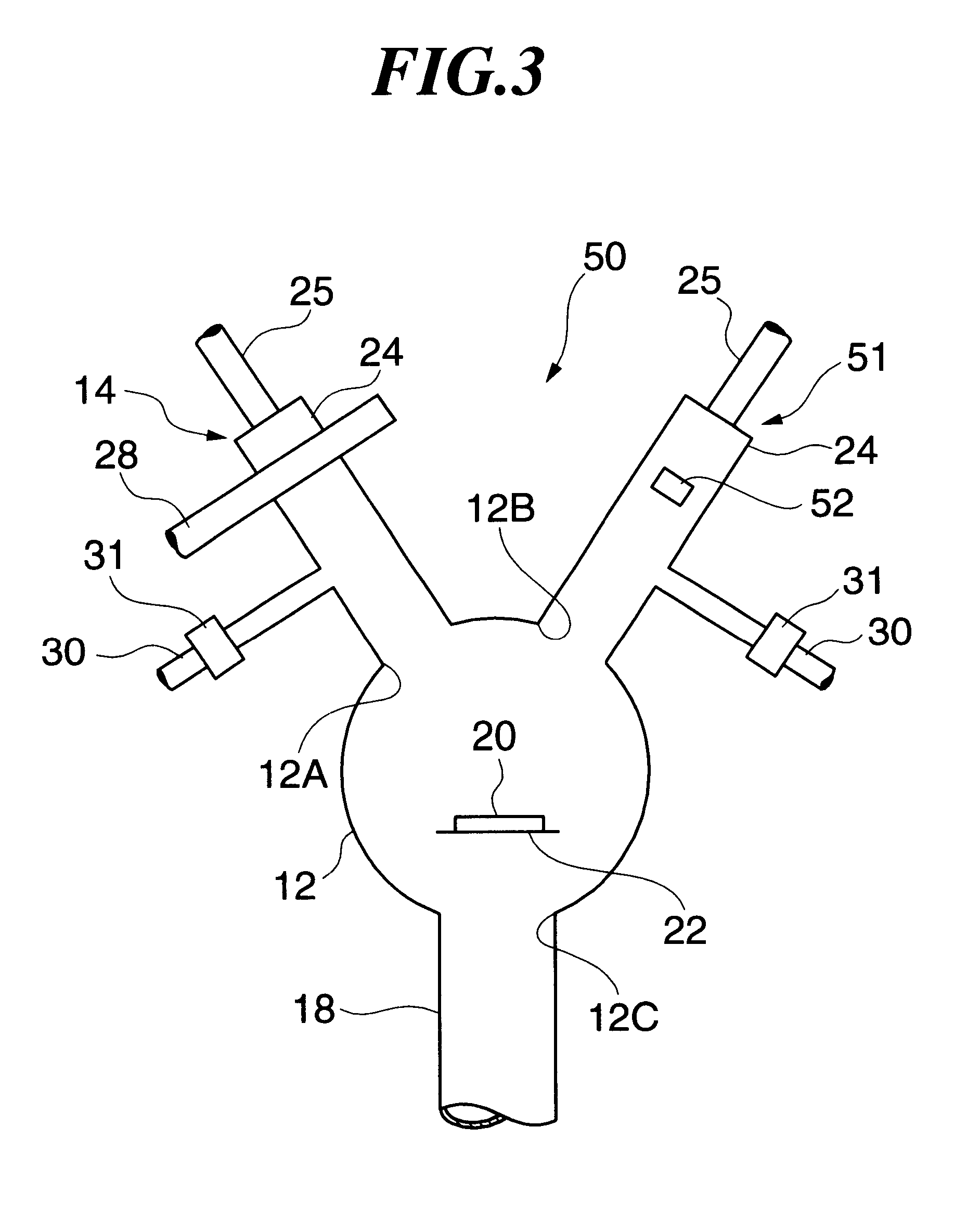

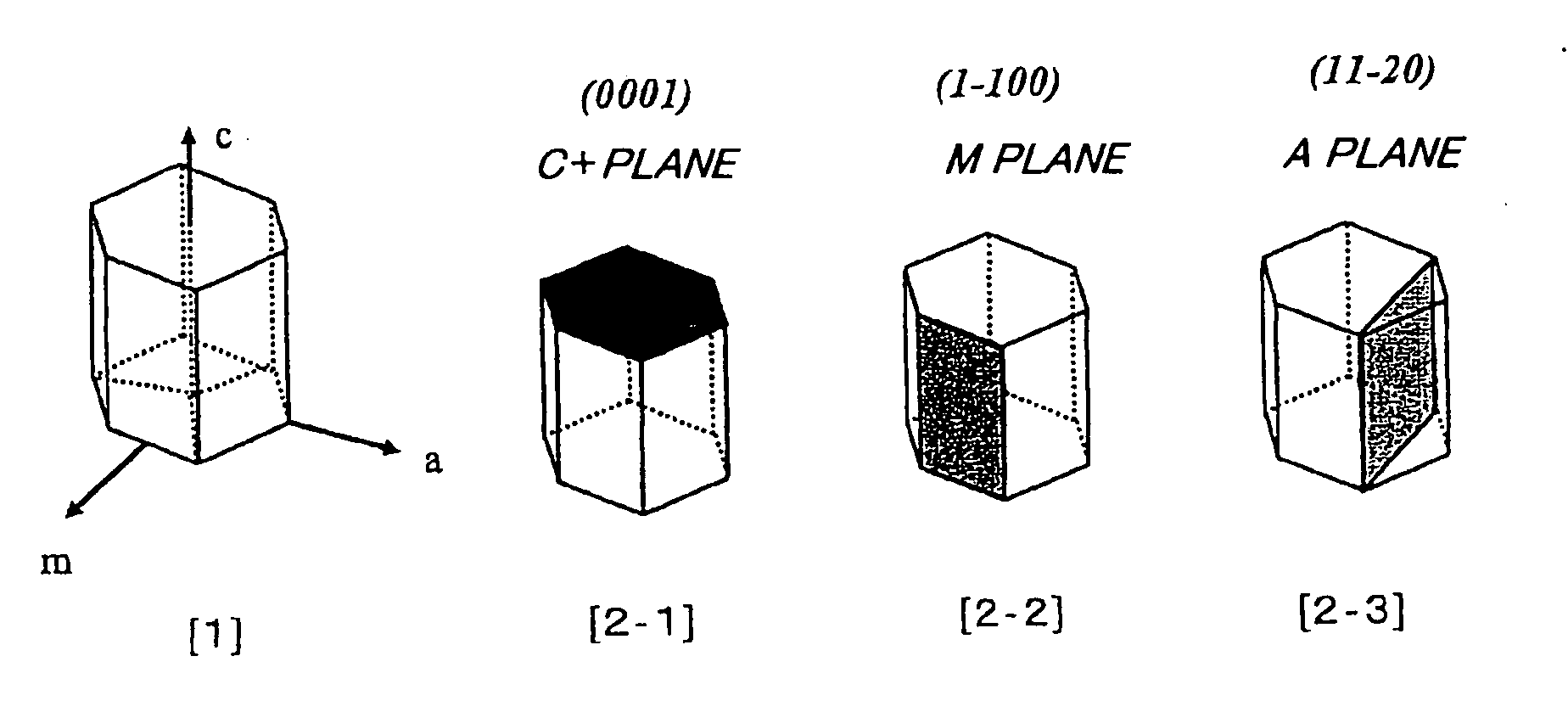

A nitride semiconductor device of high quality and excellent crystallinity and the method of manufacturing the same, wherein a nitride series compound semiconductor having at least an element belonging to the group IIIA and nitrogen is grown directly on a substrate, X-ray diffraction peaks of the nitride series compound semiconductor consist only of the peaks from the C-face of the hexagonal system, and the half width of an X-ray rocking curve at (0002) peak in the C-surface is 0.2 degrees of less, and wherein the method includes a step of introducing an organic metal compound at least containing a group IIIA element and a plasma activated nitrogen source into a reaction vessel to grow a nitride series compound semiconductor on the surface of a substrate, in which the ratio for the amount of the group IIIA element and nitrogen atom supplied (ratio for the number of atoms) is group IIIA element: nitrogen atom=1:50,000 to 1:1,000,000.

Owner:FUJIFILM BUSINESS INNOVATION CORP

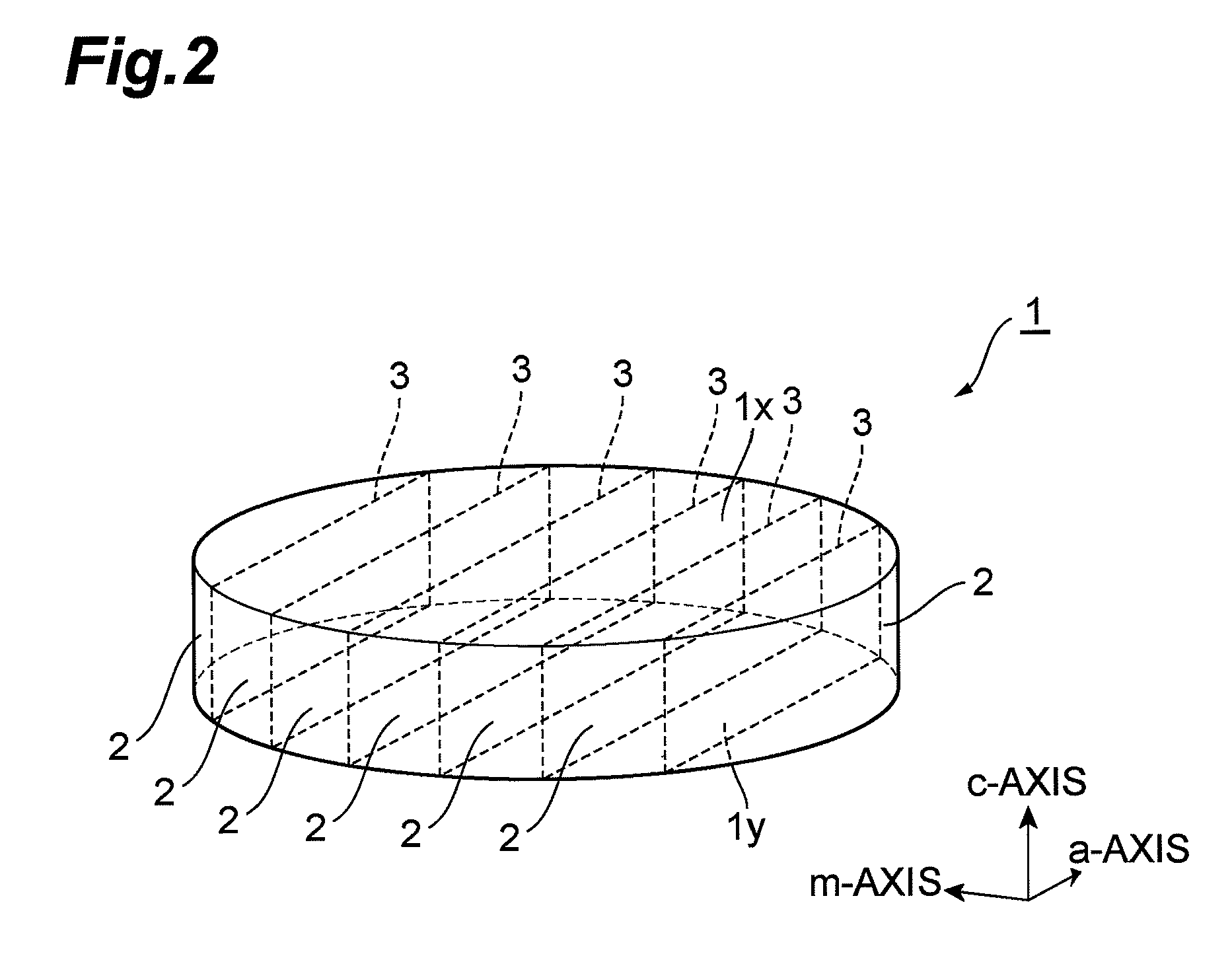

Method for producing nitride semiconductor, crystal growth rate increasing agent, single crystal nitride, wafer and device

InactiveUS20100104495A1Improve performanceIncrease probabilityPolycrystalline material growthFrom normal temperature solutionsNitrogenCrystal structure

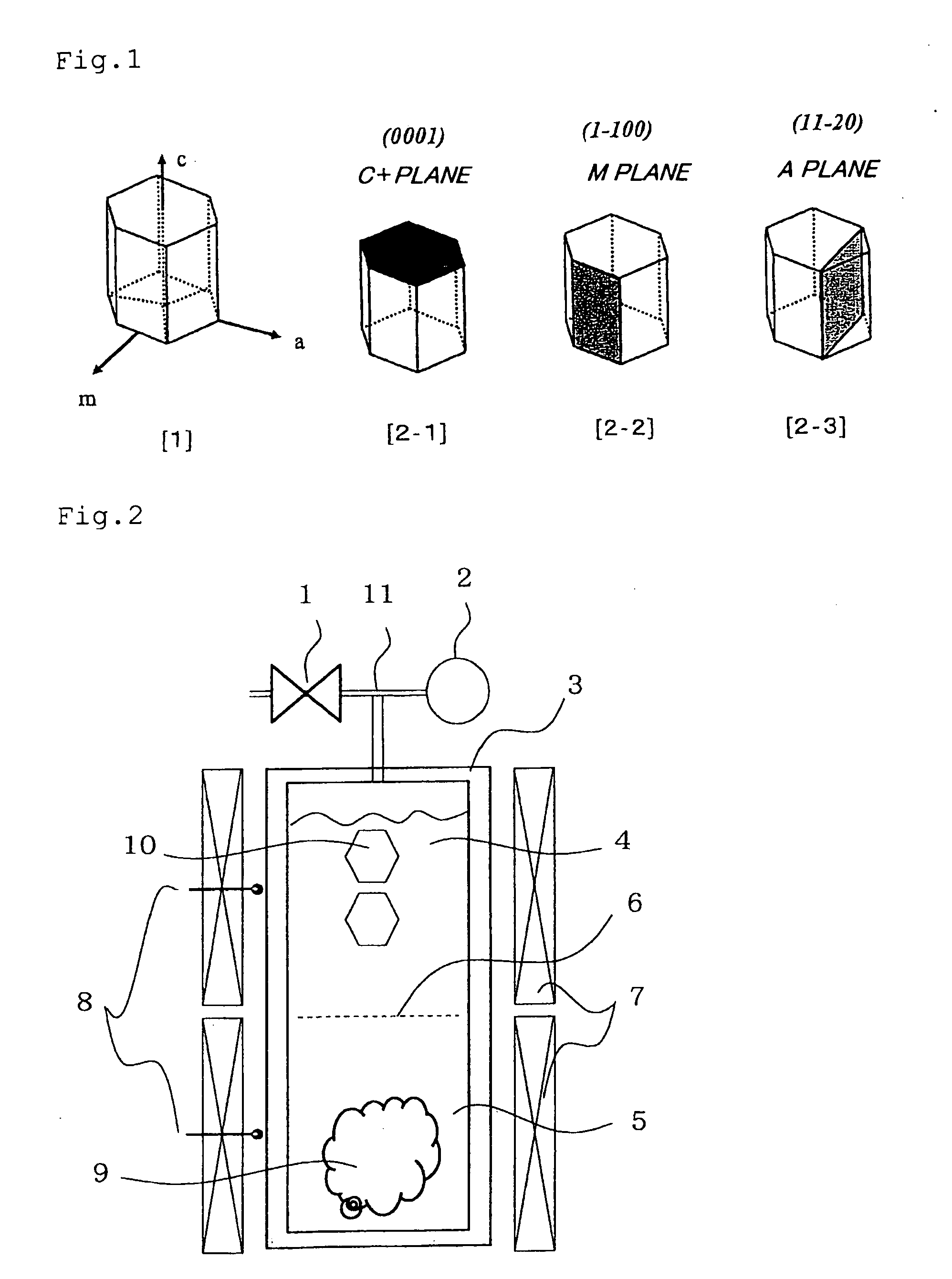

A method for producing a nitride semiconductor, comprising controlling temperature and pressure in a autoclave containing a seed having a hexagonal crystal structure, a nitrogen element-containing solvent, a raw material substance containing a metal element of Group 13 of the Periodic Table, and a mineralizer so as to put said solvent into a supercritical state and / or a subcritical state and thereby ammonothermally grow a nitride semiconductor crystal on the surface of said seed, wherein the crystal growth rate in the m-axis direction on said seed is 1.5 times or more the crystal growth rate in the c-axis direction on said seed. By the method, a nitride semiconductor having a large-diameter C plane or a nitride semiconductor thick in the m-axis direction can be efficiently and simply produced.

Owner:MITSUBISHI CHEM CORP +1

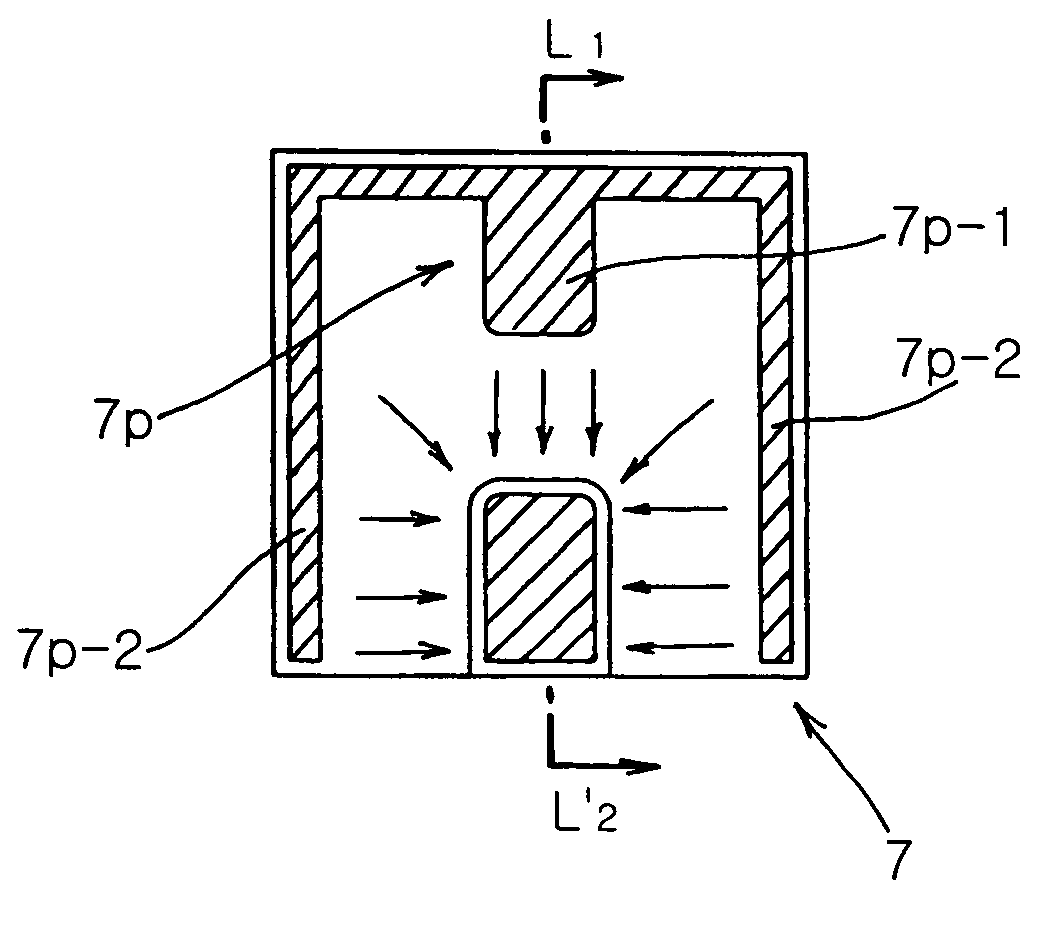

Solid State Light Emitting Device

InactiveUS20090159869A1Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureAlloy

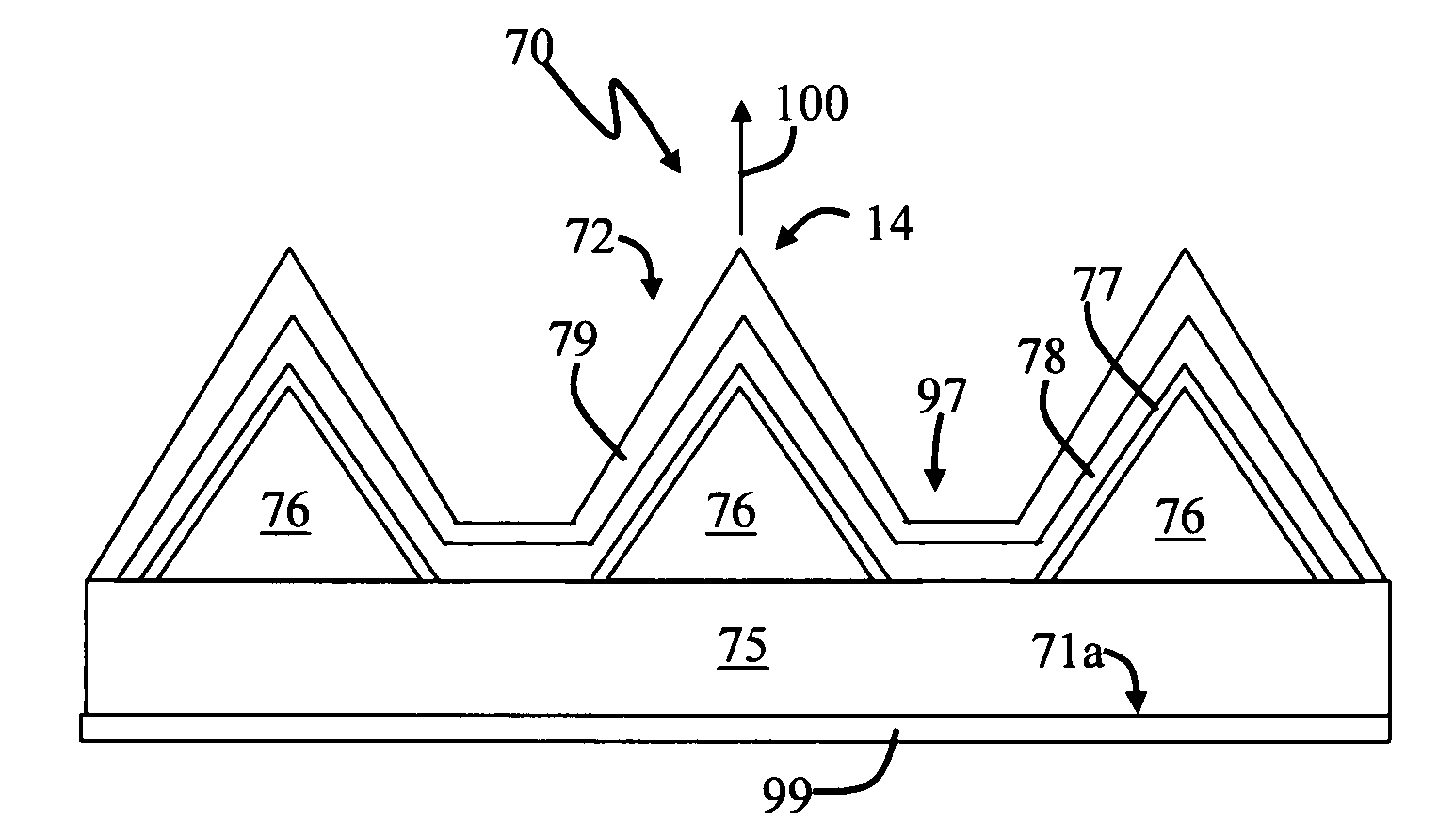

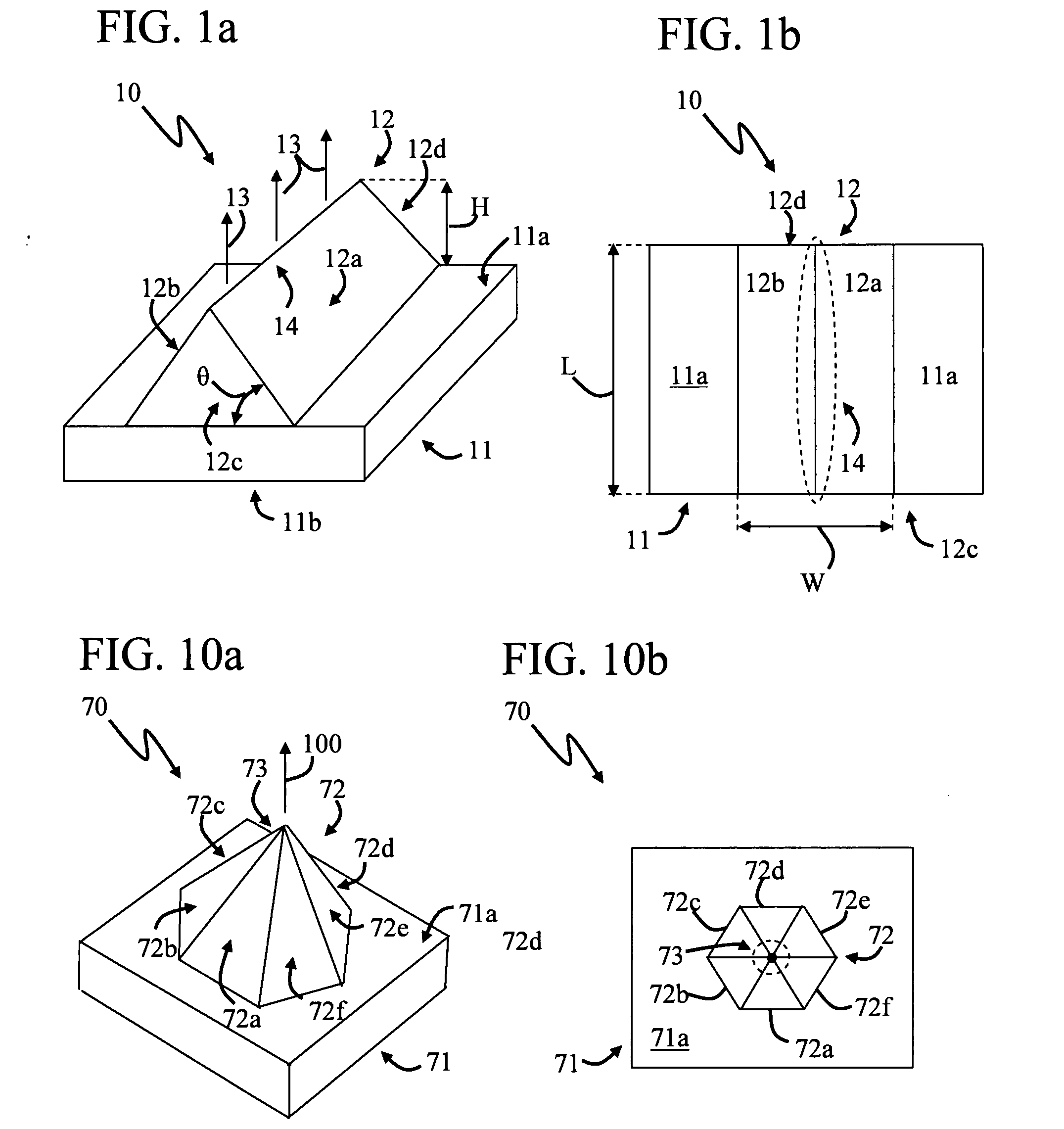

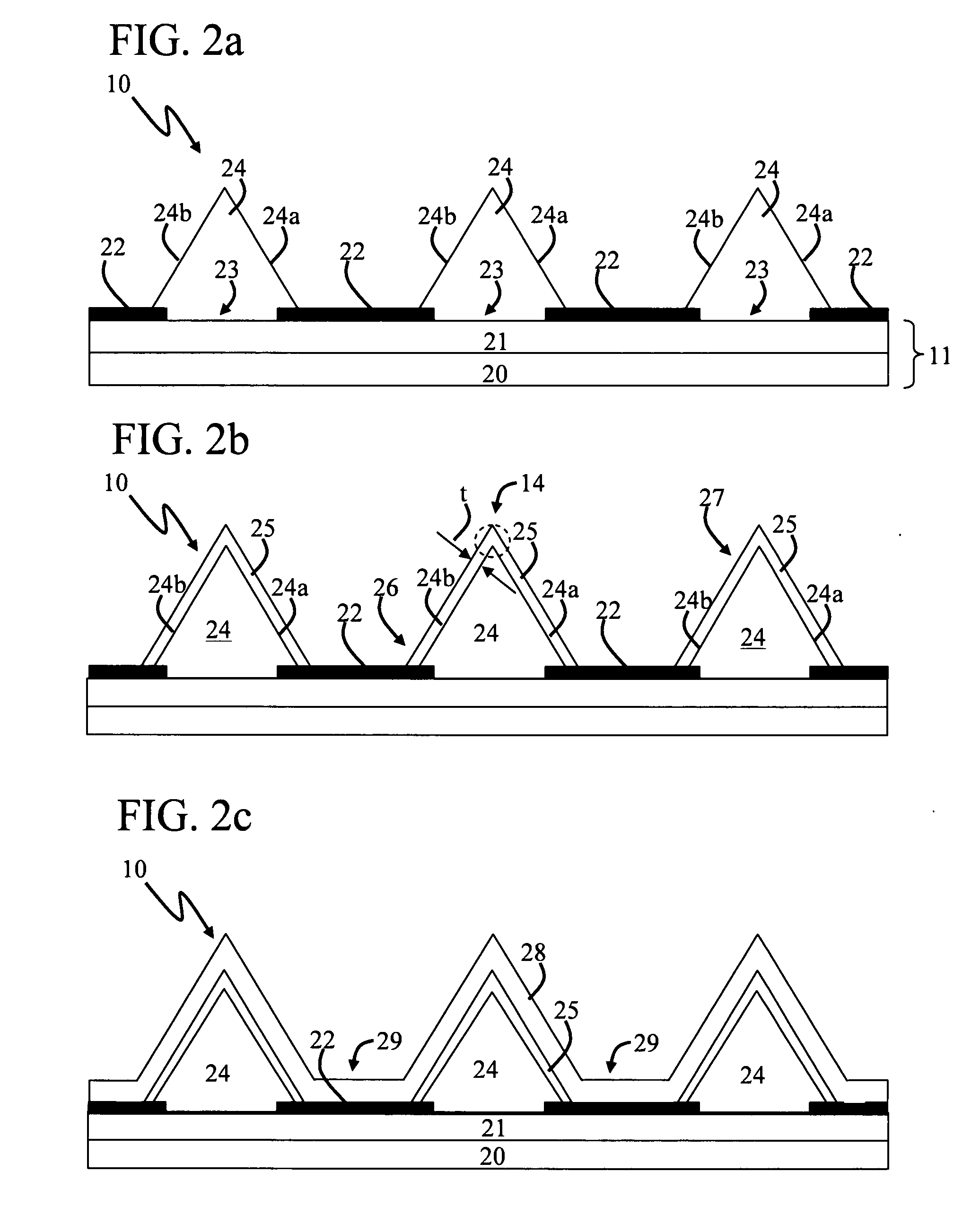

A semiconductor structure (10, 10′, 70, 80) includes a light emitter (12, 72) carried by a support structure (11). The light emitter (12, 72) includes a base region (24, 76) with a sloped sidewall (12a, 12b) and a light emitting region (25, 77) positioned thereon. The light emitting (25, 77) region includes a nitride semiconductor alloy having a composition that is different in a first region (26, 95) near the support structure (11) compared to a second region (27, 96) away from the support structure (11).

Owner:PONCE FERNANDO A +2

Light emitting device

InactiveUS20080232416A1Improve efficiencyImprove propertiesLaser detailsLaser active region structureLength waveWide band

Owner:ROHM CO LTD

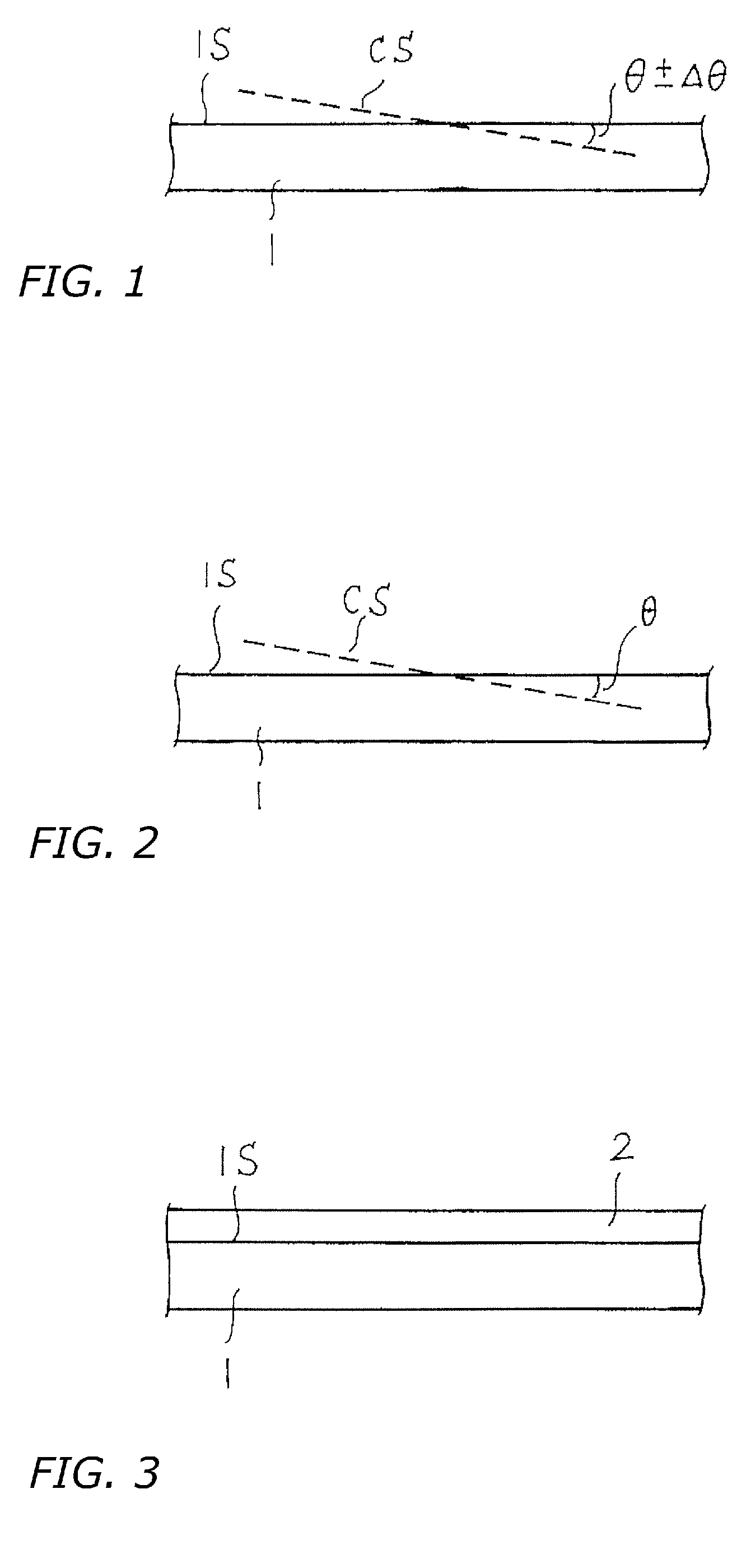

Nitride semiconductor wafer

ActiveUS7390359B2Maintain good propertiesQuality improvementPolycrystalline material growthAluminium silicatesPlane orientationSingle crystal

A nitride semiconductor substrate having properties preferable for the manufacture of various nitride semiconductor devices is made available, by specifying or controlling the local variation in the off-axis angle of the principal surface of the nitride semiconductor substrate. In a nitride semiconductor single-crystal wafer having a flat principal surface, the crystallographic plane orientation of the principal surface of the nitride semiconductor single-crystal wafer varies locally within a predetermined angular range.

Owner:SUMITOMO ELECTRIC IND LTD

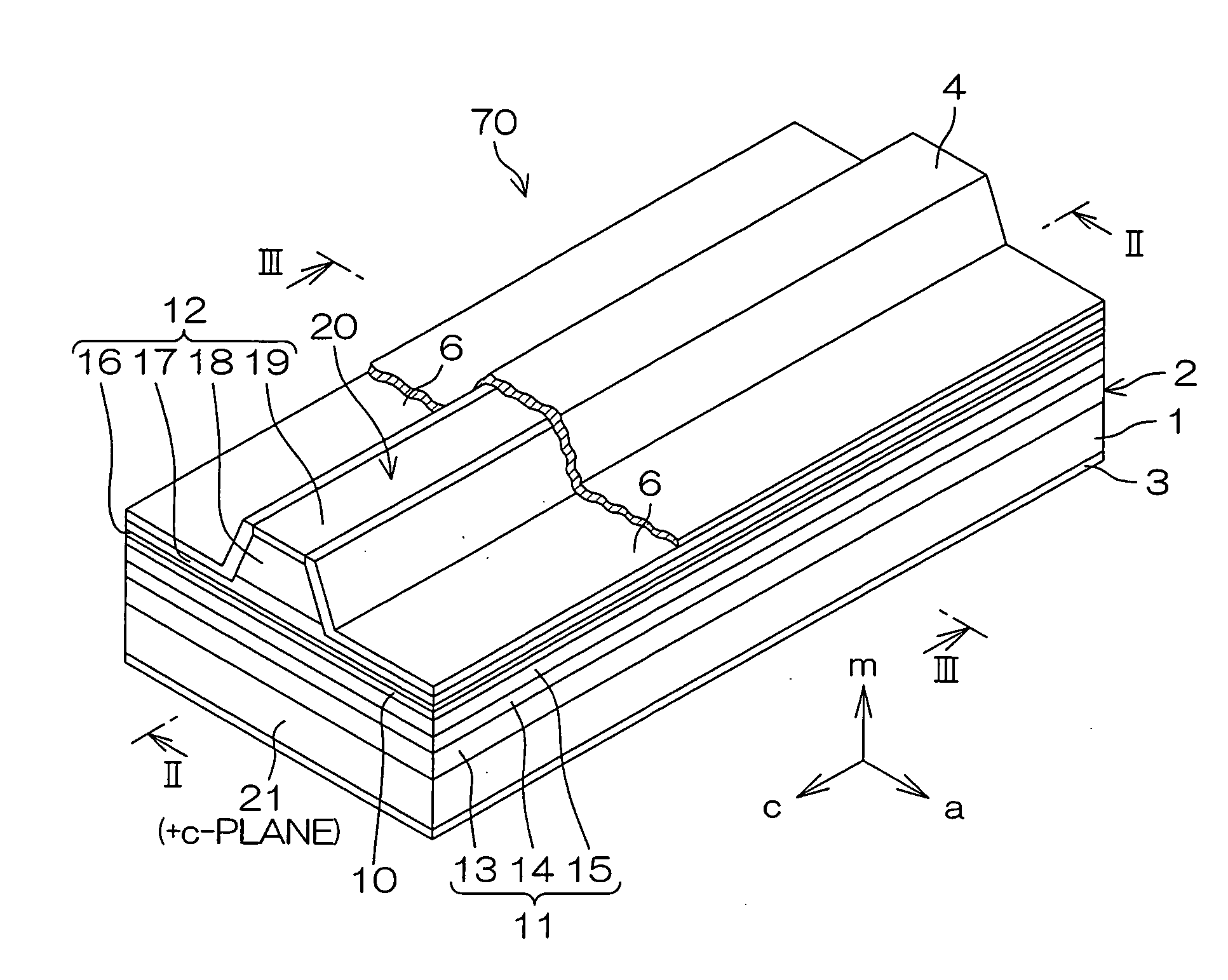

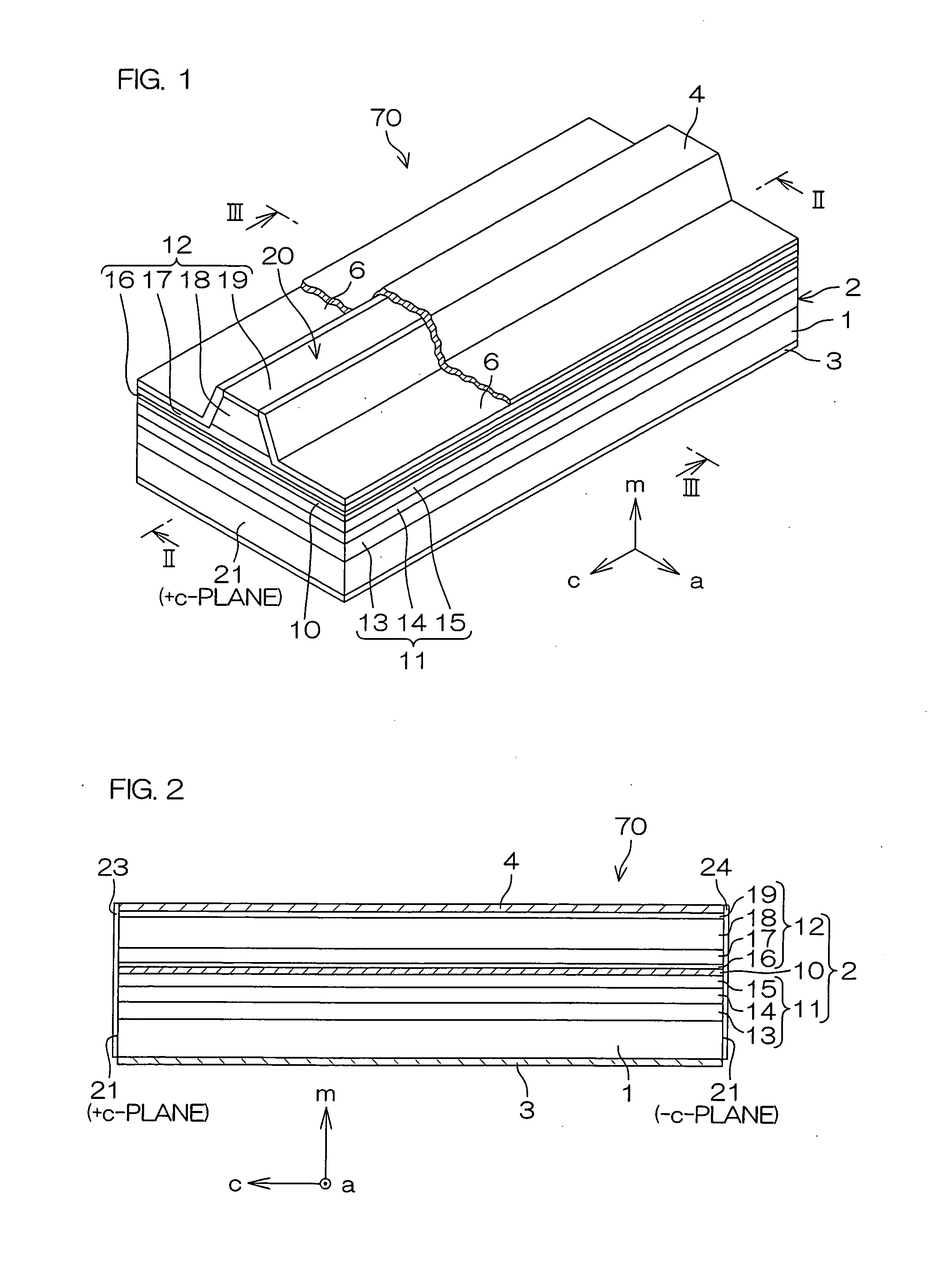

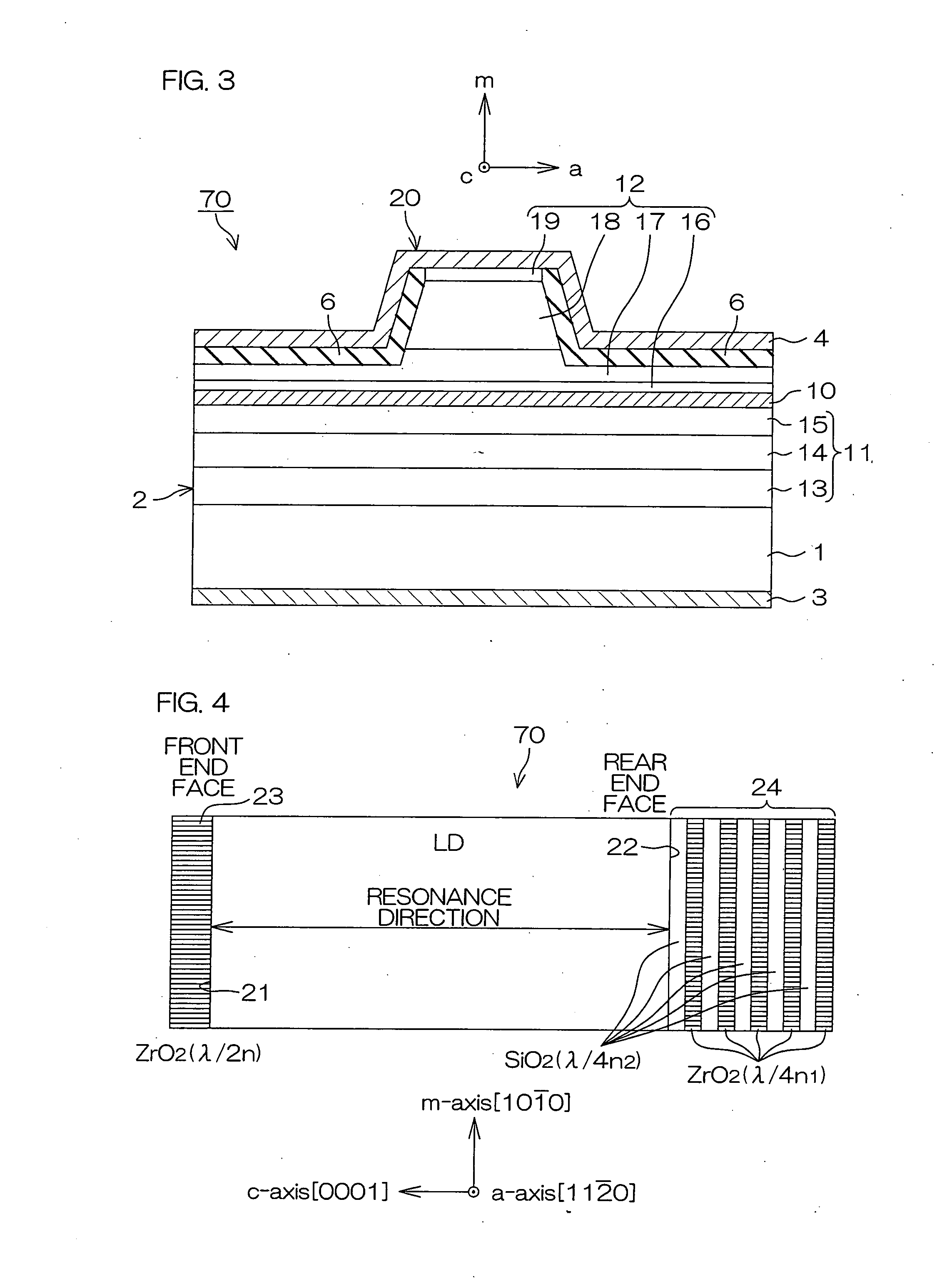

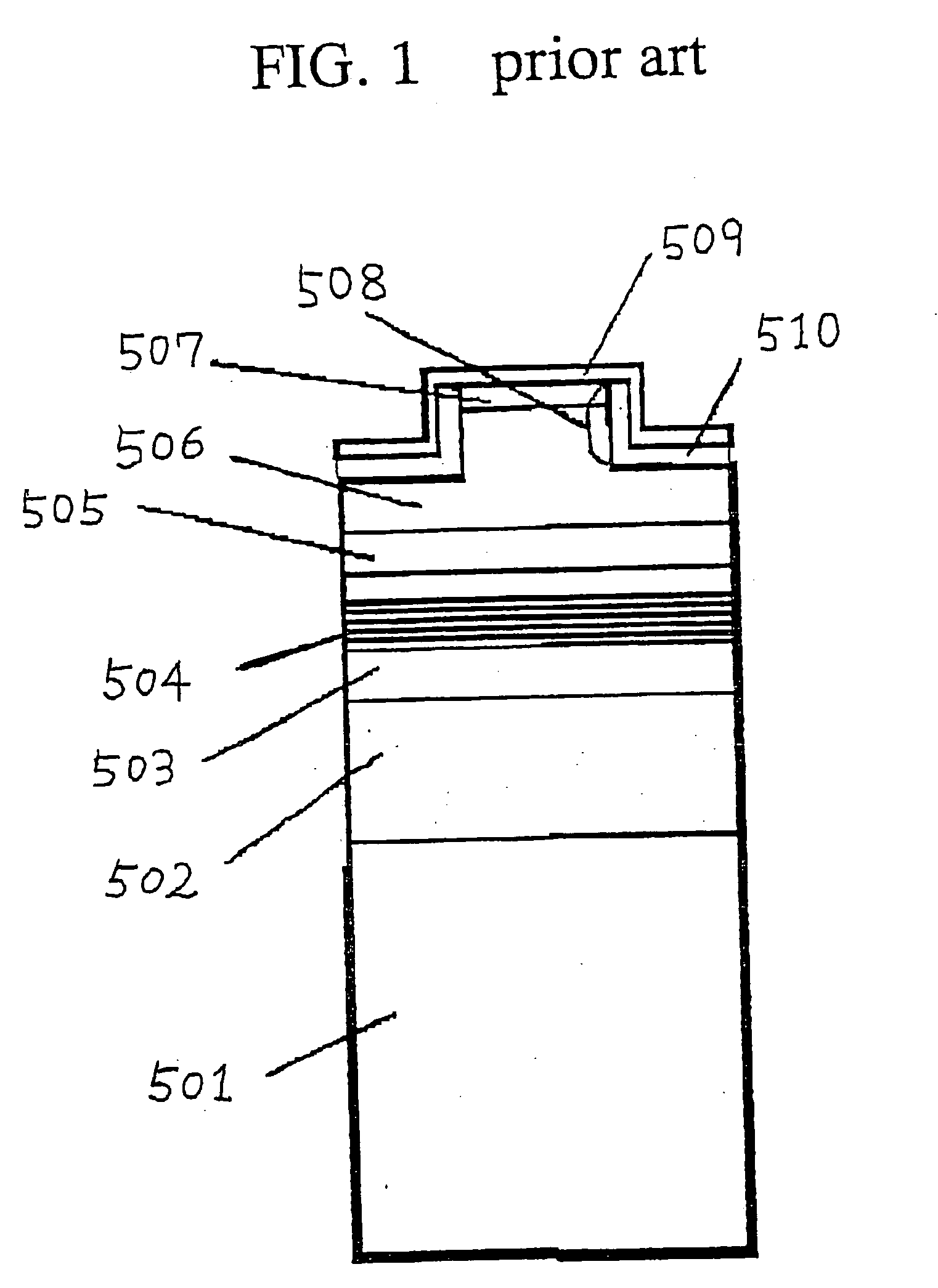

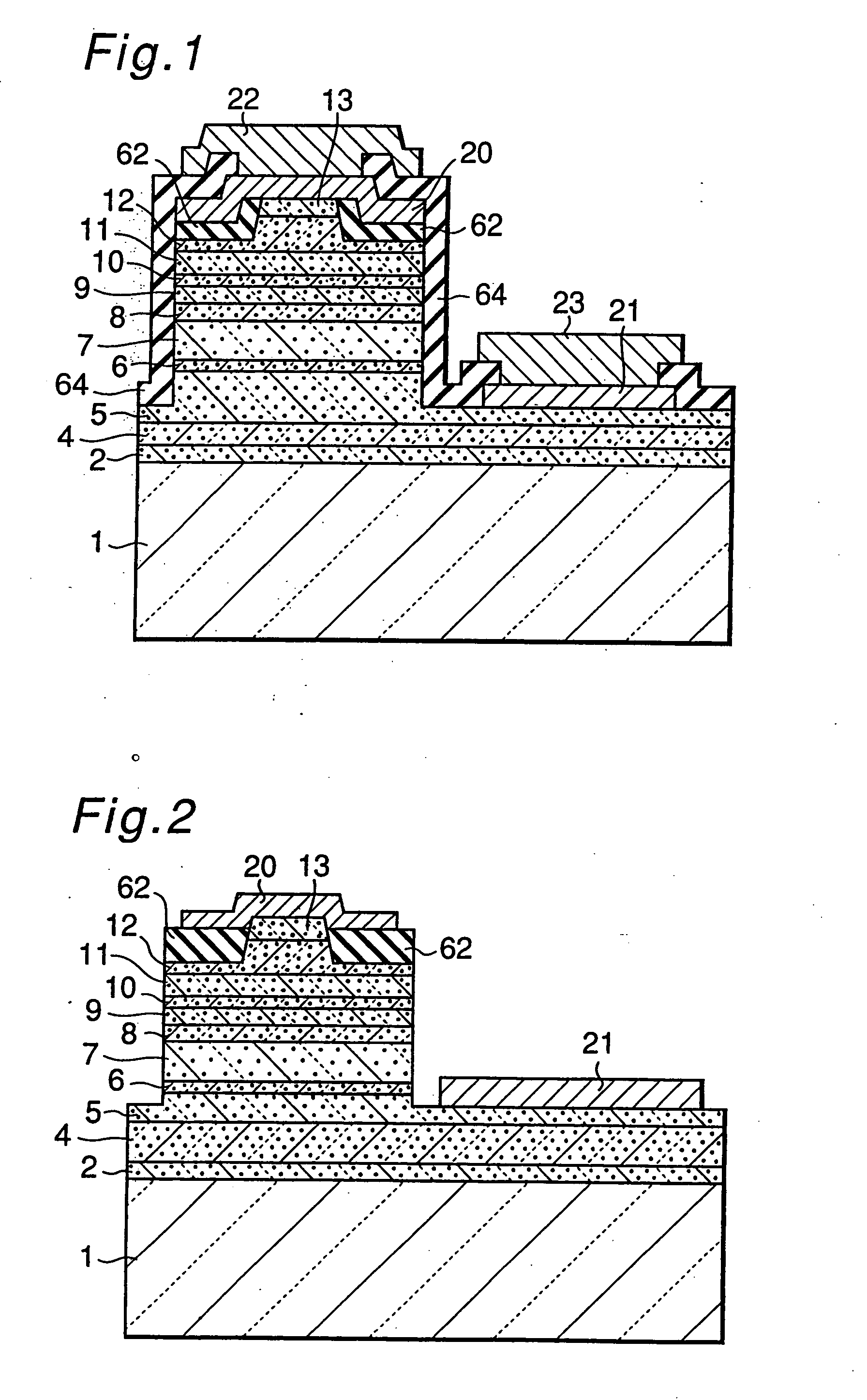

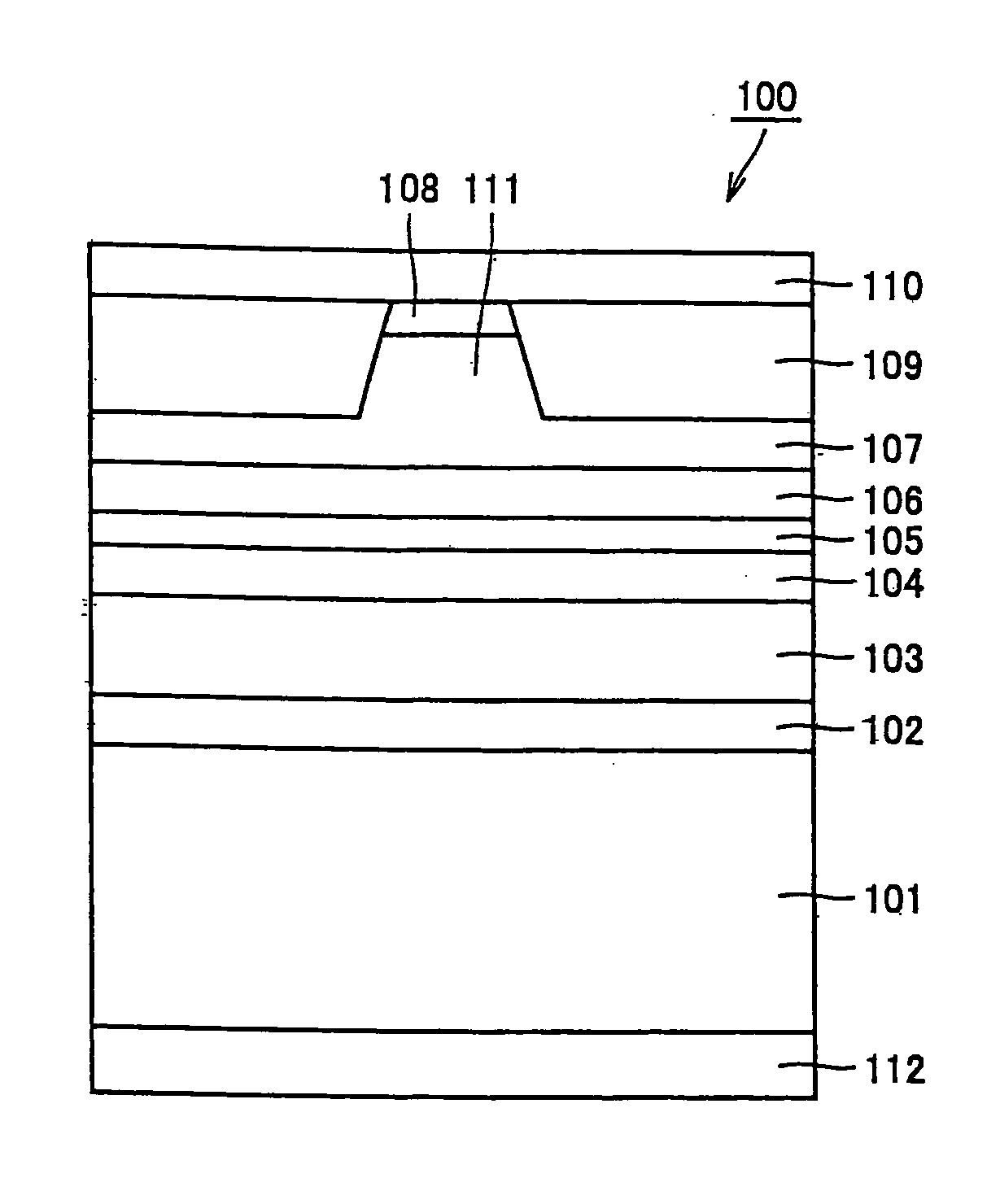

Nitride semiconductor laser device

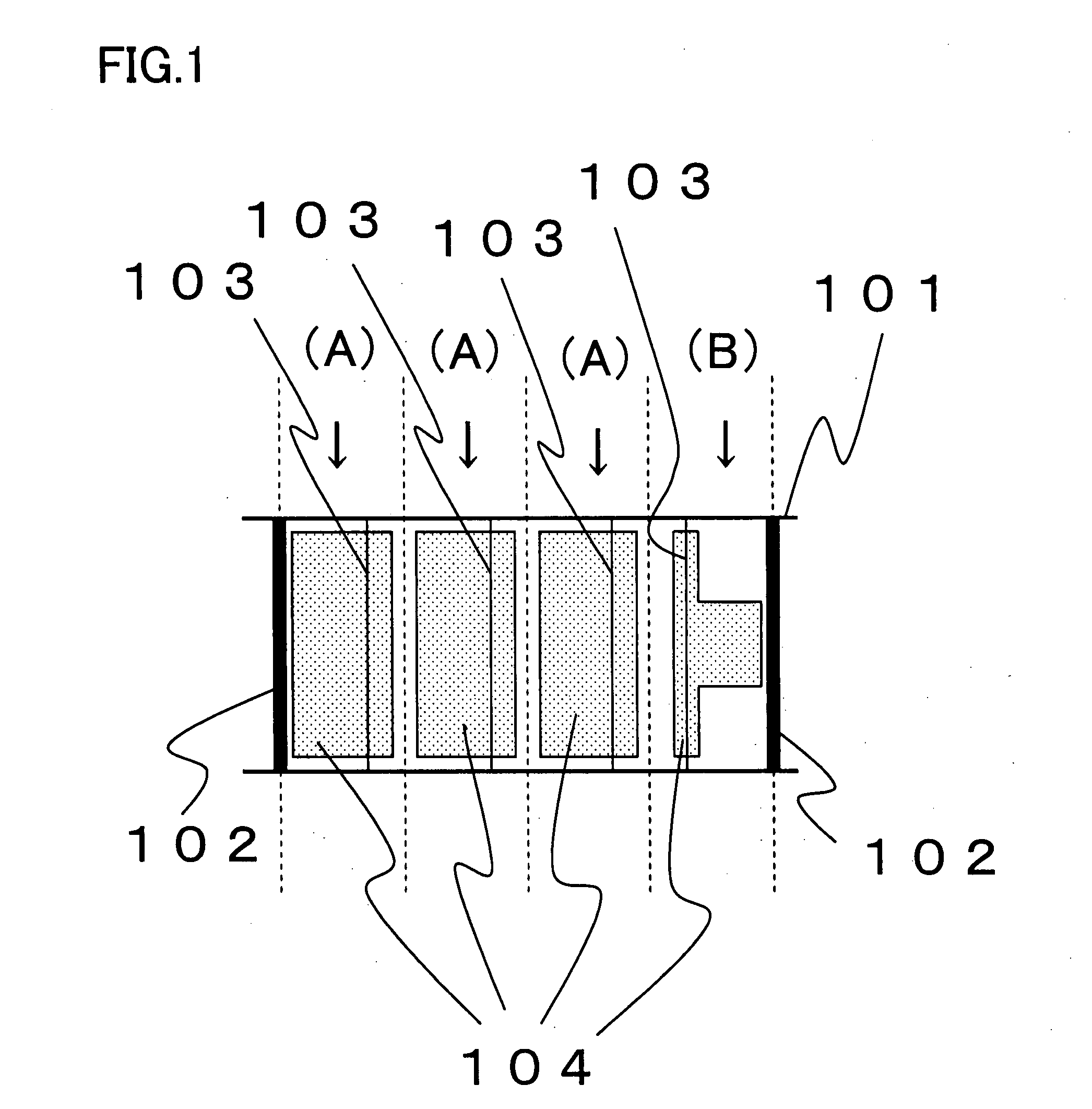

InactiveUS20060078022A1Long lastingStable lateral modeOptical wave guidanceLaser active region structureContact layerTransverse mode

A nitride semiconductor laser device has an improved stability of the lateral mode under high output power and a longer lifetime, so that the device can be applied to write and read light sources for recording media with high capacity. The nitride semiconductor laser device includes an active layer, a p-side cladding layer, and a p-side contact layer laminated in turn. The device further includes a waveguide region of a stripe structure formed by etching from the p-side contact layer. The stripe width provided by etching is within the stripe range of 1 to 3 μm and the etching depth is below the thickness of the p-side cladding layer of 0.1 μm and above the active layer. Particularly, when a p-side optical waveguide layer includes a projection part of the stripe structure and a p-type nitride semiconductor layer on the projection part and the projection part of the p-side optical waveguide layer has a thickness of not more than 1 μm, an aspect ratio is improved in far field image. Moreover, the thickness of the p-side optical waveguide layer is greater than that of an n-side optical waveguide layer.

Owner:NICHIA CORP

Light emitting device and method of manufacturing the same

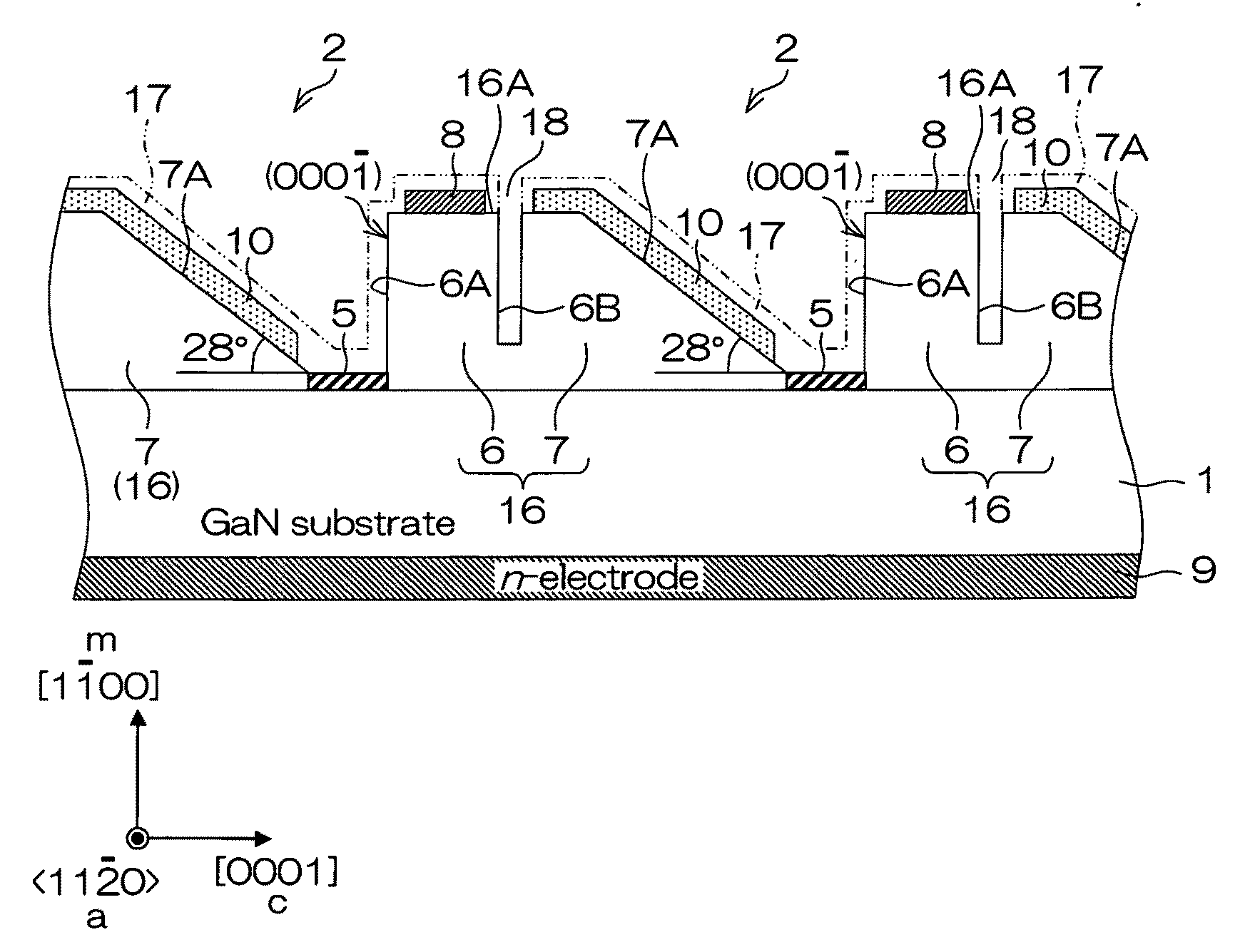

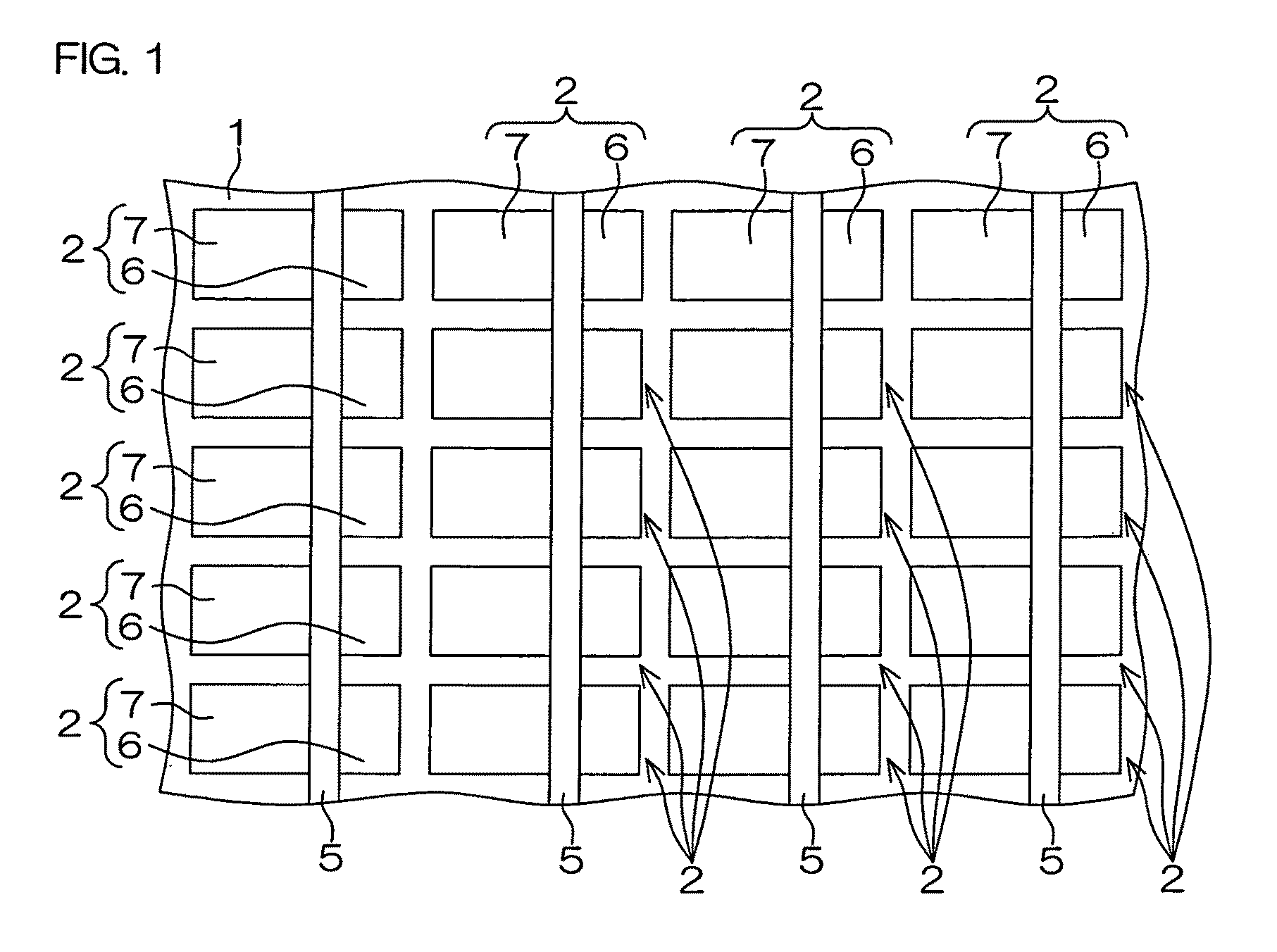

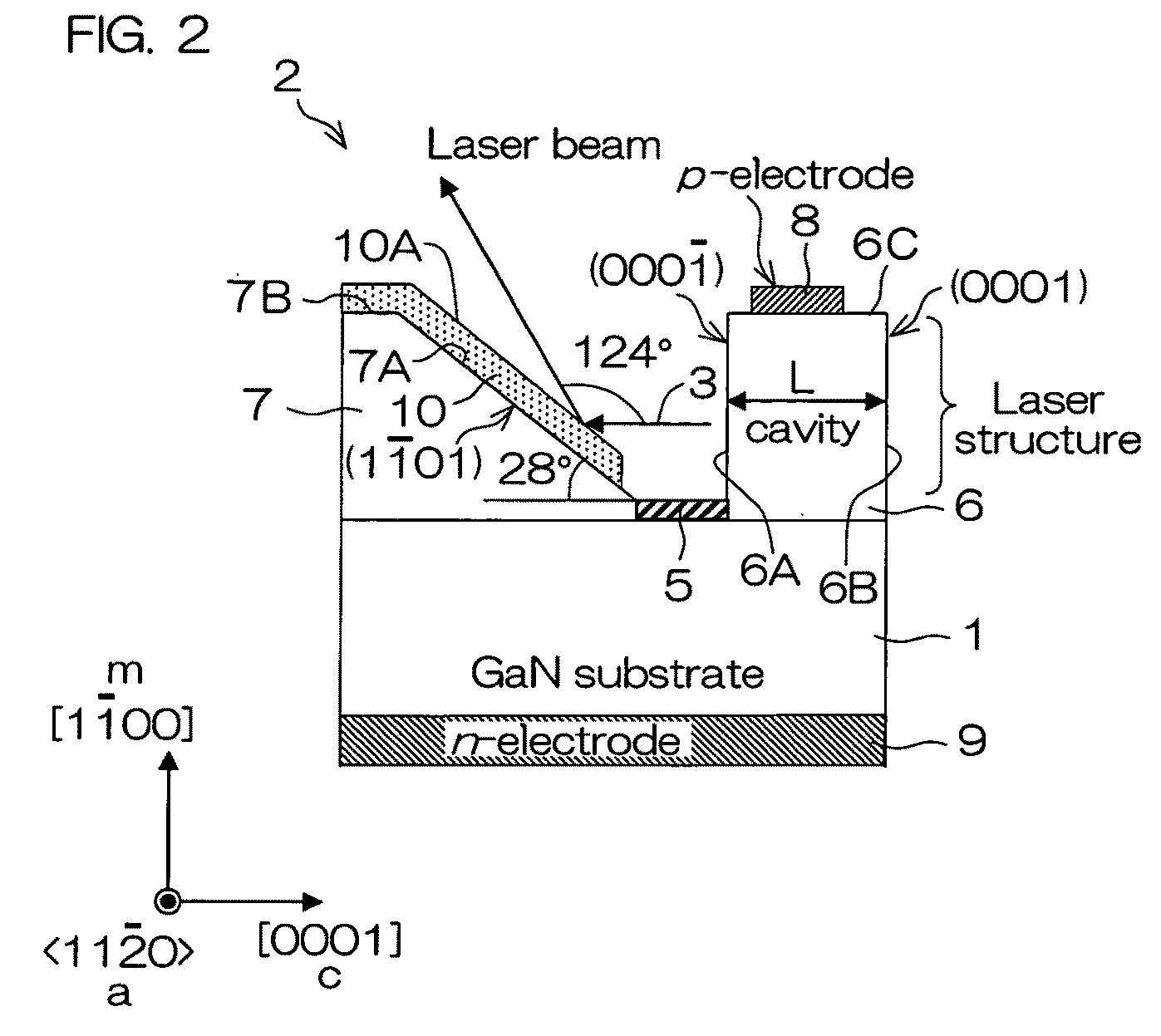

InactiveUS20090078944A1High gainSimple stepsOptical wave guidanceLaser detailsOptical cavityLight emitting device

This semiconductor light emitting device includes an optical cavity made of a group III nitride semiconductor having a major growth surface defined by a nonpolar plane and including a pair of cavity end faces parallel to c-planes, and a reflecting portion made of a group III nitride semiconductor having a major growth surface defined by a nonpolar plane and having a reflective facet opposed to one of the pair of cavity end faces and inclined with respect to a normal of the major growth surface. The optical cavity and the reflecting portion may be crystal-grown from the major surface of the substrate. The substrate is preferably a group III nitride semiconductor substrate having a major surface defined by a nonpolar plane.

Owner:ROHM CO LTD

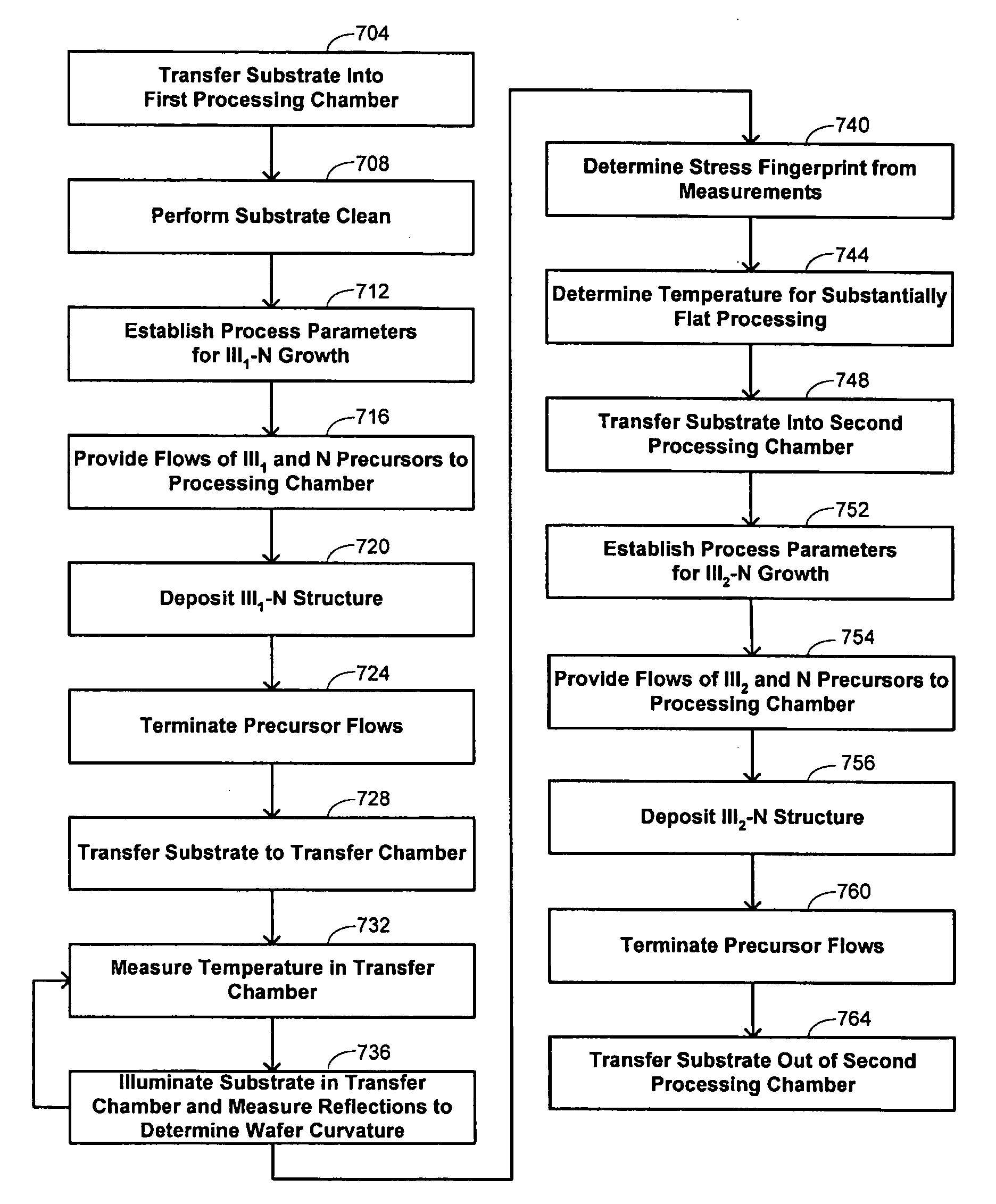

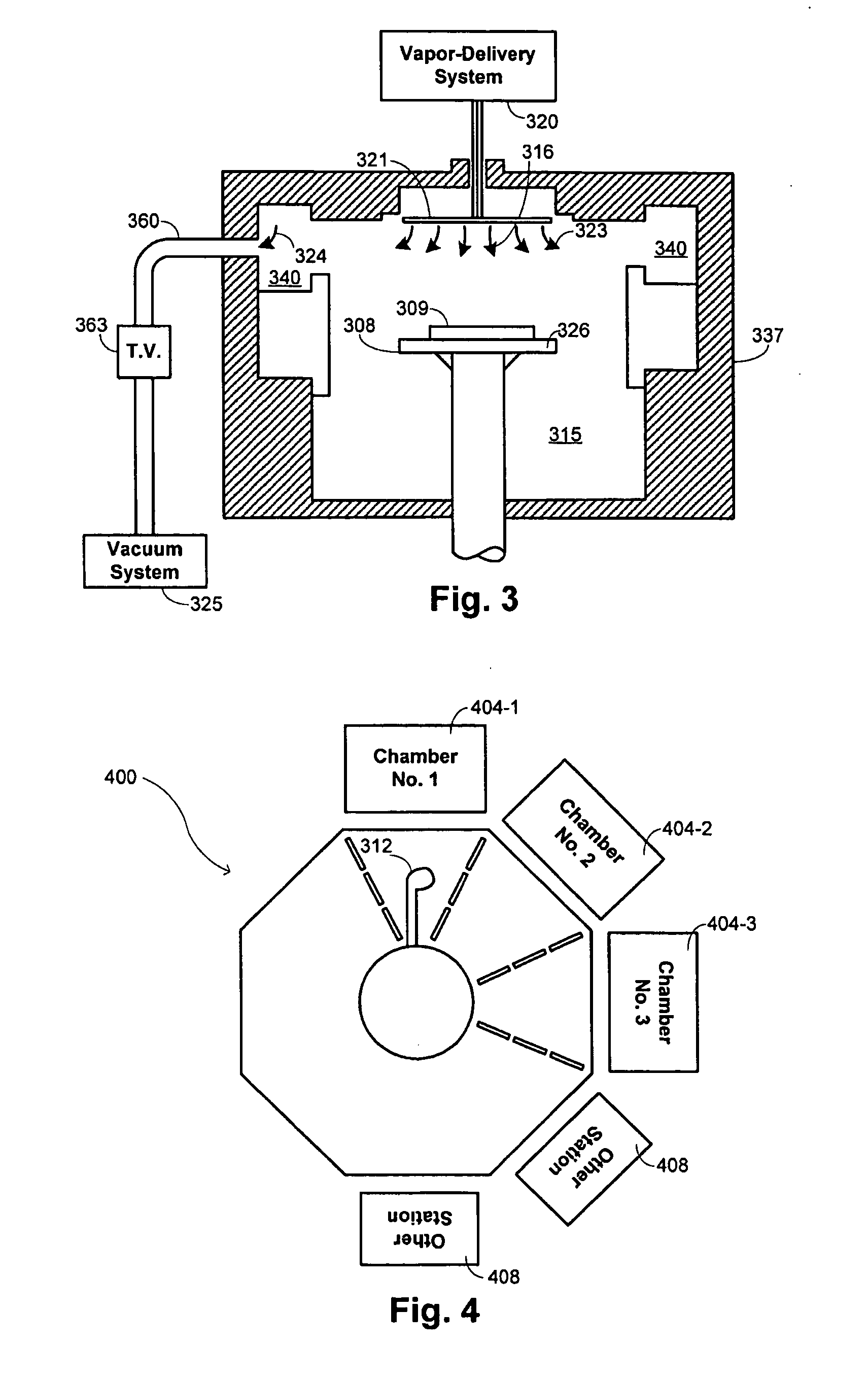

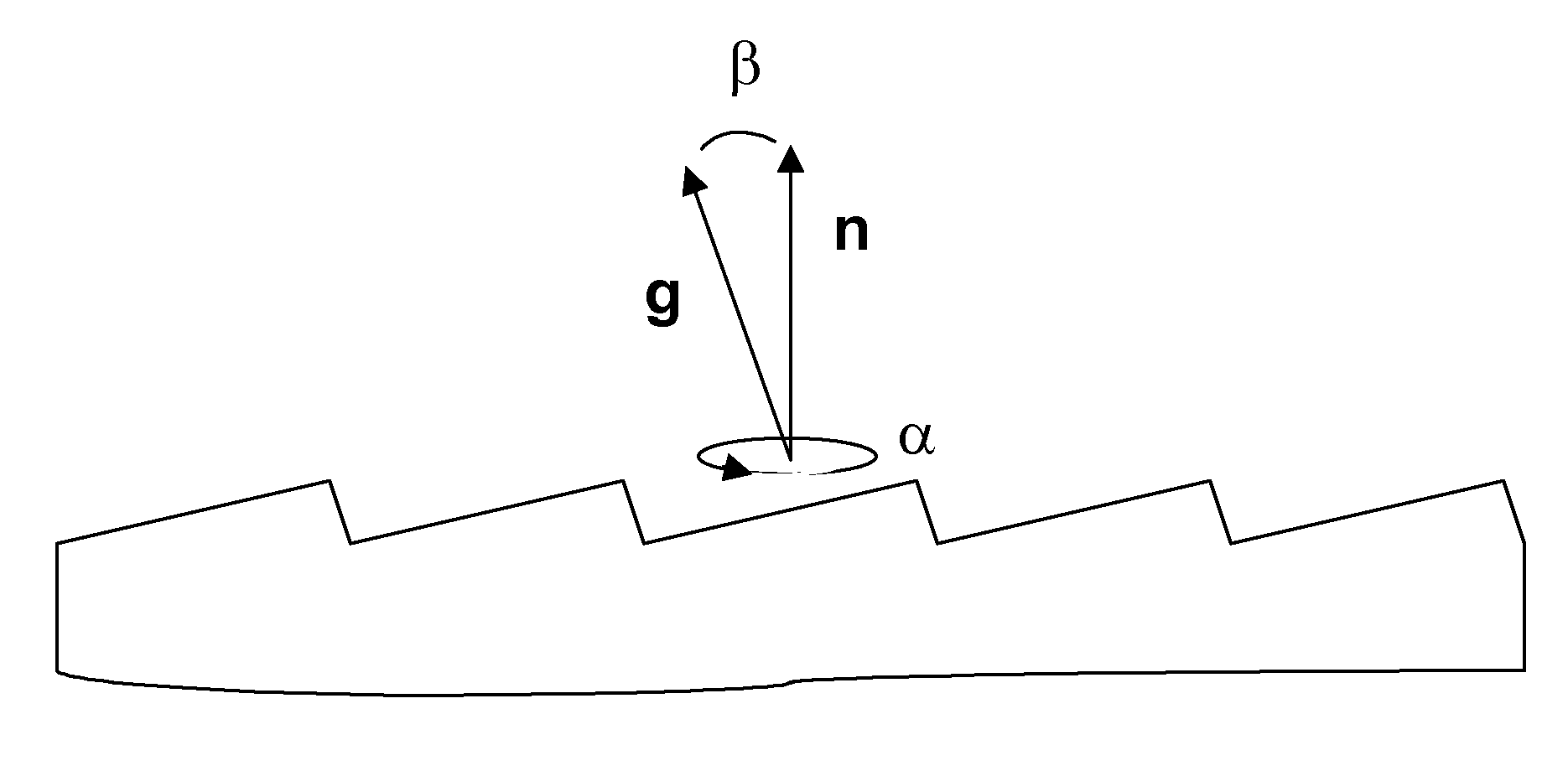

Stress measurement and stress balance in films

InactiveUS20080124817A1Liquid surface applicatorsSemiconductor/solid-state device testing/measurementStress measurementStress measures

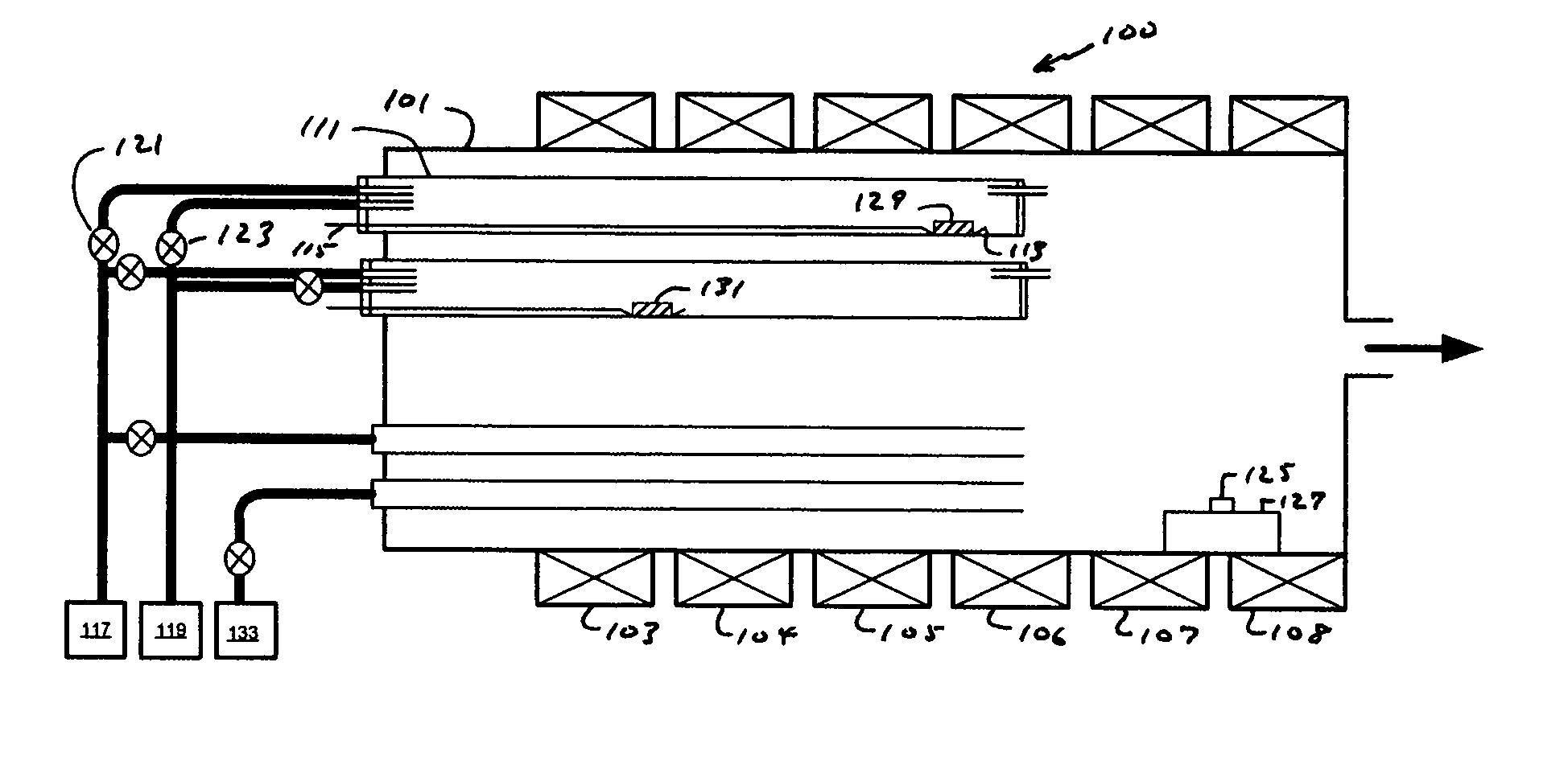

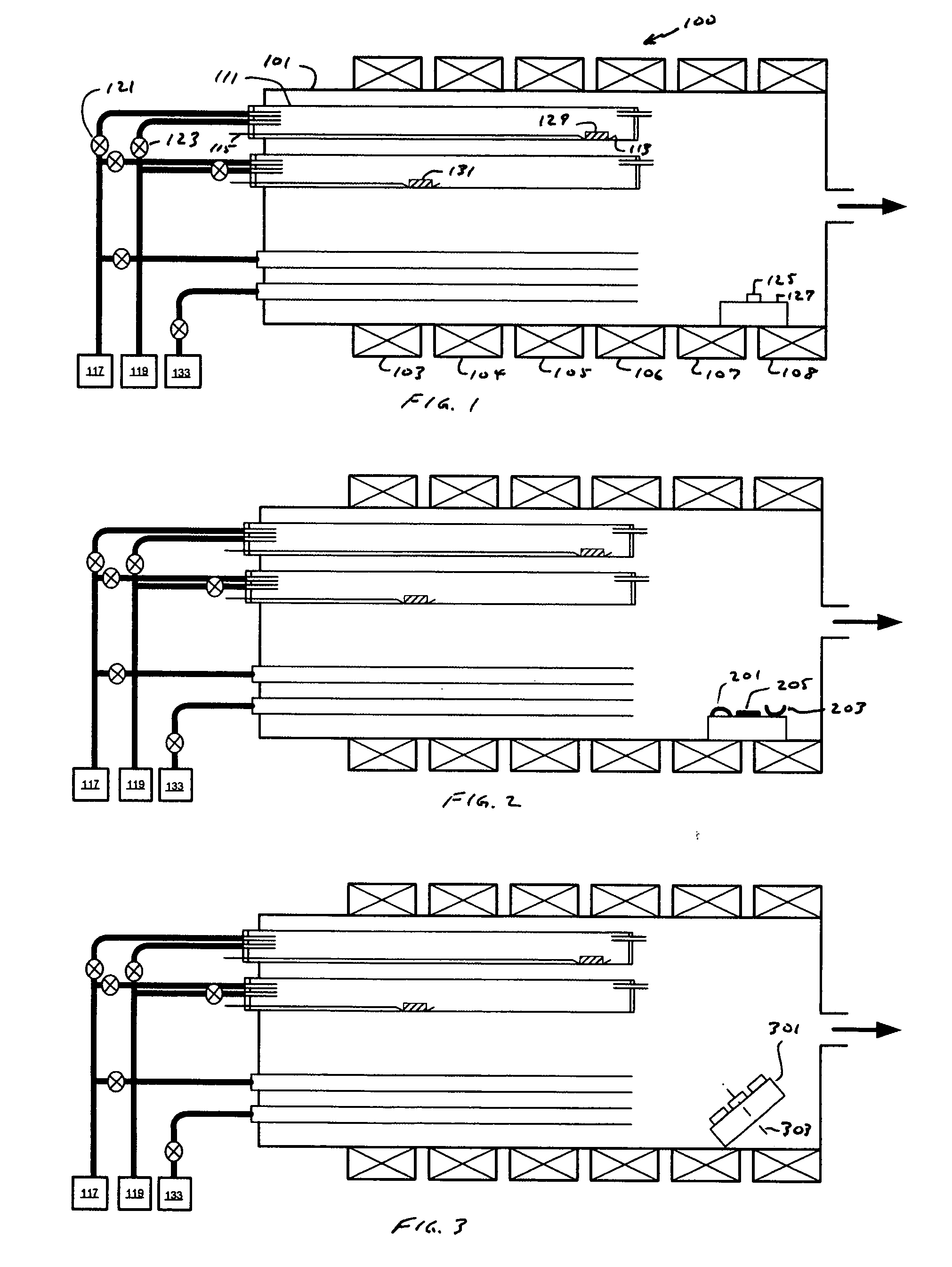

Methods and systems are provided of fabricating a compound nitride semiconductor structure. A substrate is disposed within a processing chamber into which a group-III precursor and a nitrogen precursor are flowed. A layer is deposited over the substrate with a thermal chemical-vapor-deposition process using the precursors. The substrate is transferred to a transfer chamber where a temperature and a curvature of the layer are measured. The substrate is then transferred to a second processing chamber where a second layer is deposited.

Owner:APPLIED MATERIALS INC

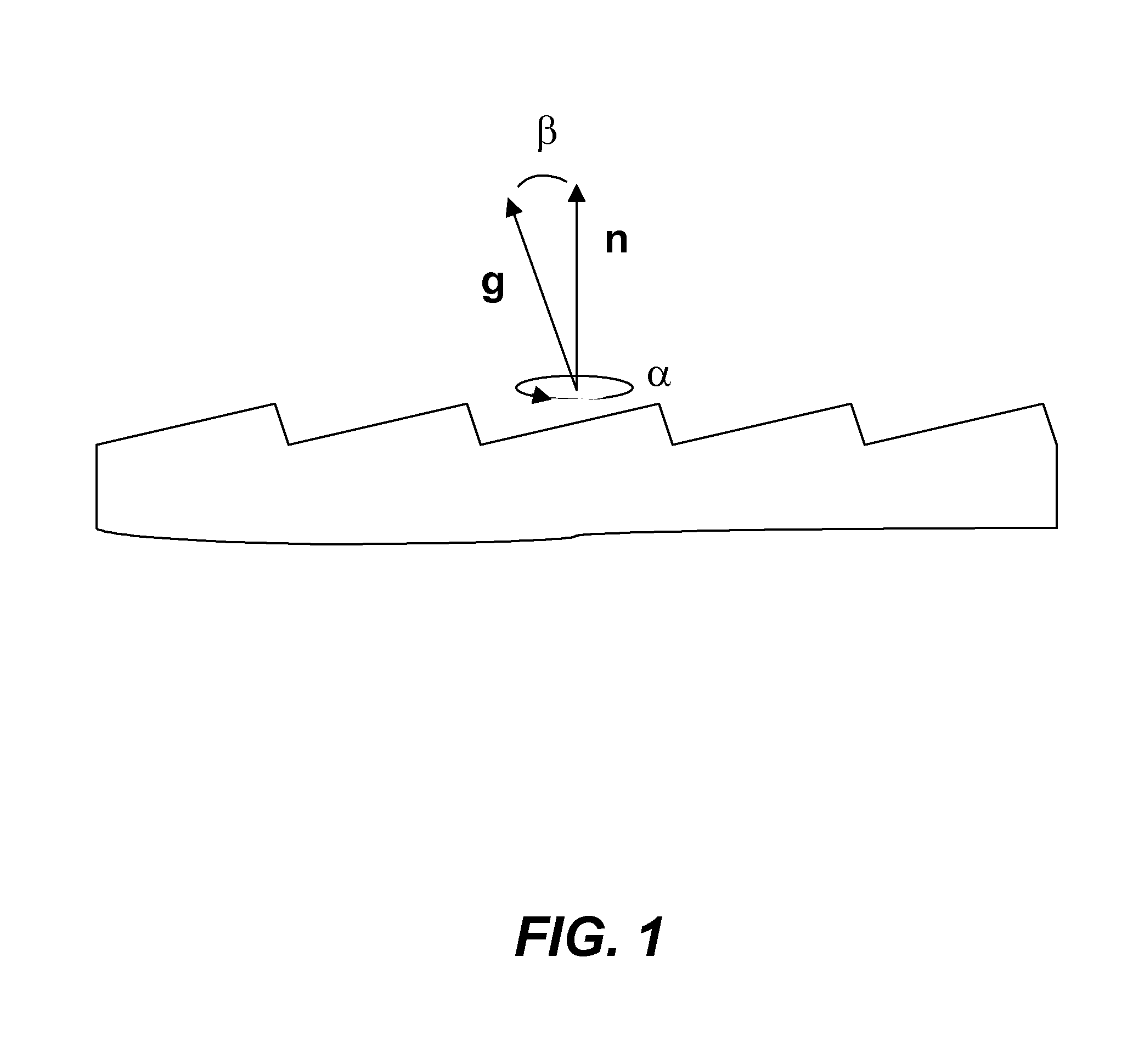

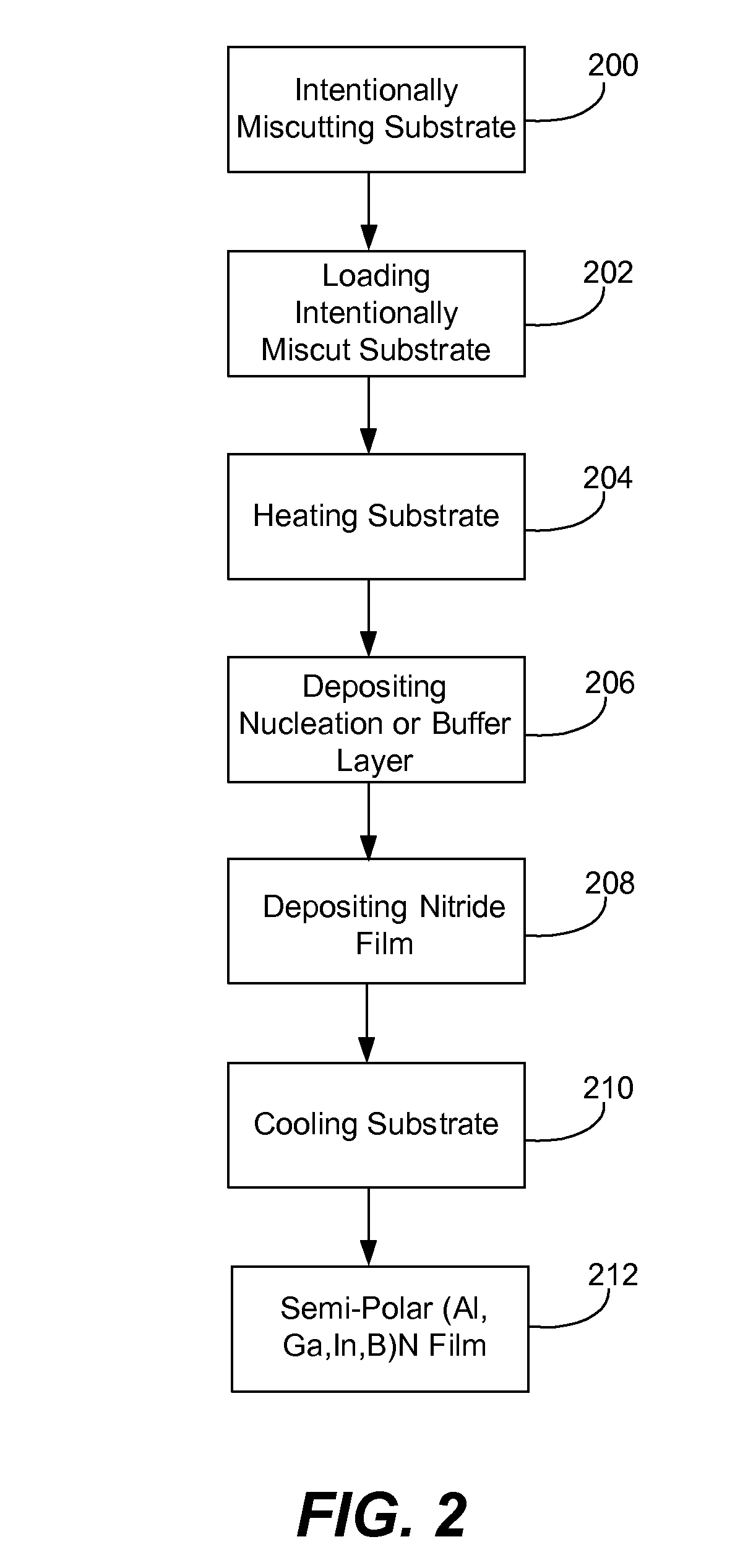

Method for improved growth of semipolar (Al,In,Ga,B)N

ActiveUS7691658B2Reduce symmetryImprove propertiesPolycrystalline material growthSolid-state devicesHydrogenNitrogen

A method for improved growth of a semipolar (Al,In,Ga,B)N semiconductor thin film using an intentionally miscut substrate. Specifically, the method comprises intentionally miscutting a substrate, loading a substrate into a reactor, heating the substrate under a flow of nitrogen and / or hydrogen and / or ammonia, depositing an InxGa1−xN nucleation layer on the heated substrate, depositing a semipolar nitride semiconductor thin film on the InxGa1−xN nucleation layer, and cooling the substrate under a nitrogen overpressure.

Owner:JAPAN SCI & TECH CORP

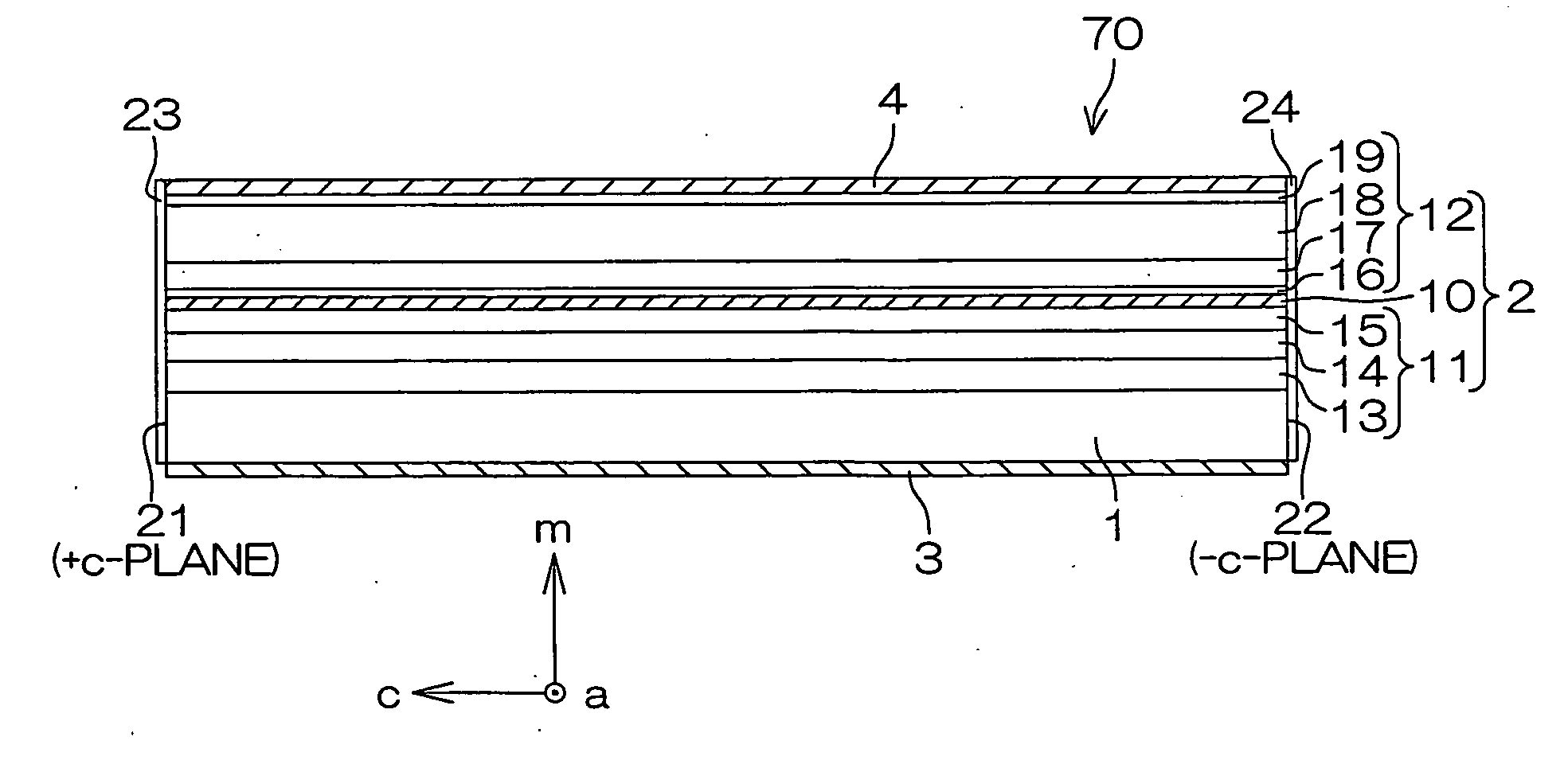

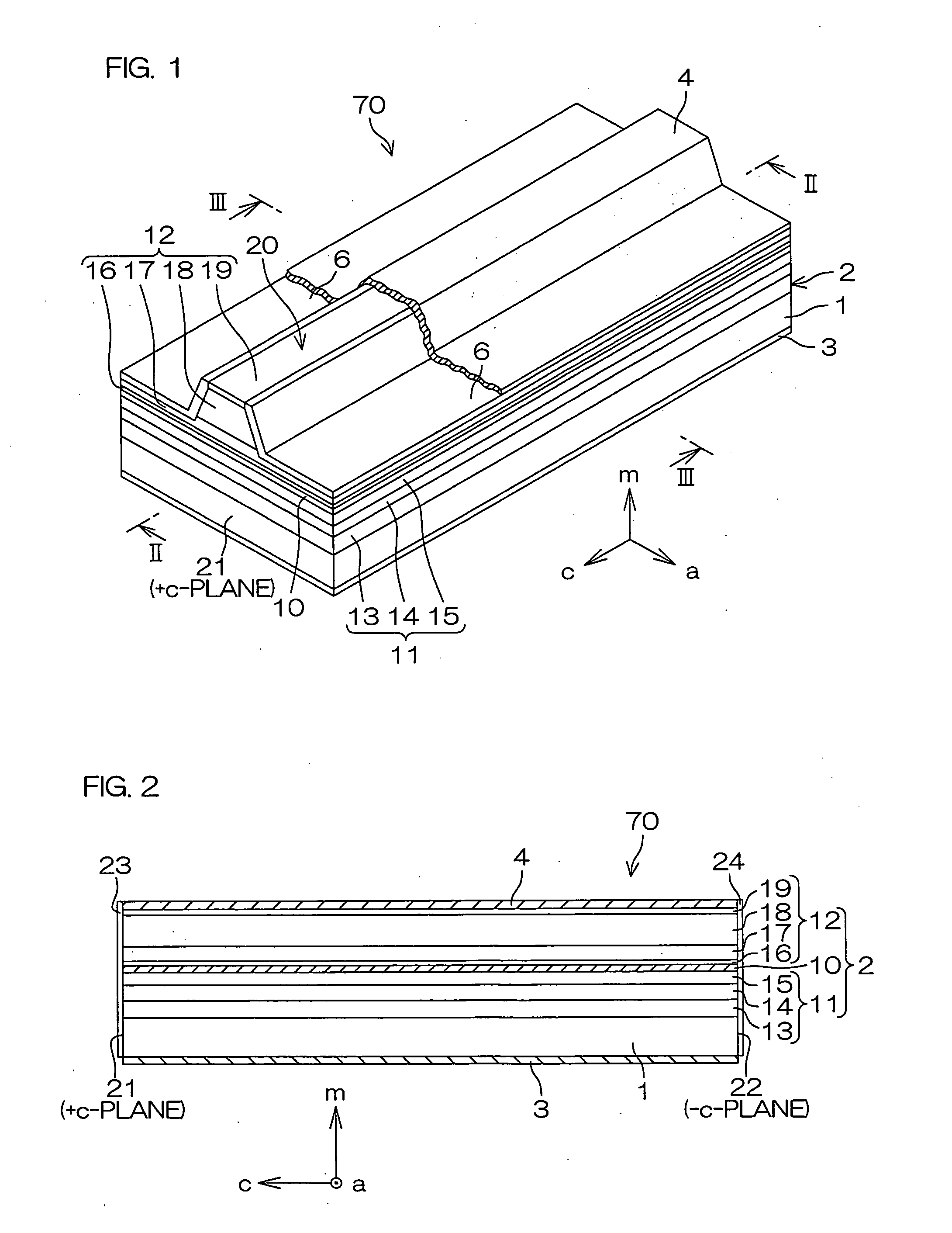

Semiconductor laser device

InactiveUS20100195687A1Improve energy efficiencyTotal current dropLaser detailsLaser active region structureActive layerNitride semiconductors

A semiconductor laser device has a semiconductor laser diode structure made of group III nitride semiconductors having major growth surfaces defined by nonpolar planes or semipolar planes. The semiconductor laser diode structure includes a p-type cladding layer and an n-type cladding layer, a p-type guide layer and an n-type guide layer held between the p-type cladding layer and the n-type cladding layer, and an active layer containing In held between the p-type guide layer and the n-type guide layer. The In compositions in the p-type guide layer and the n-type guide layer are increased as approaching the active layer respectively. Each of the p-type guide layer and the n-type guide layer may have a plurality of InxGa1-xN layers (0≦x≦1). In this case, the plurality of InxGa1-xN layers may be stacked in such order that the In compositions therein are increased as approaching the active layer.

Owner:ROHM CO LTD

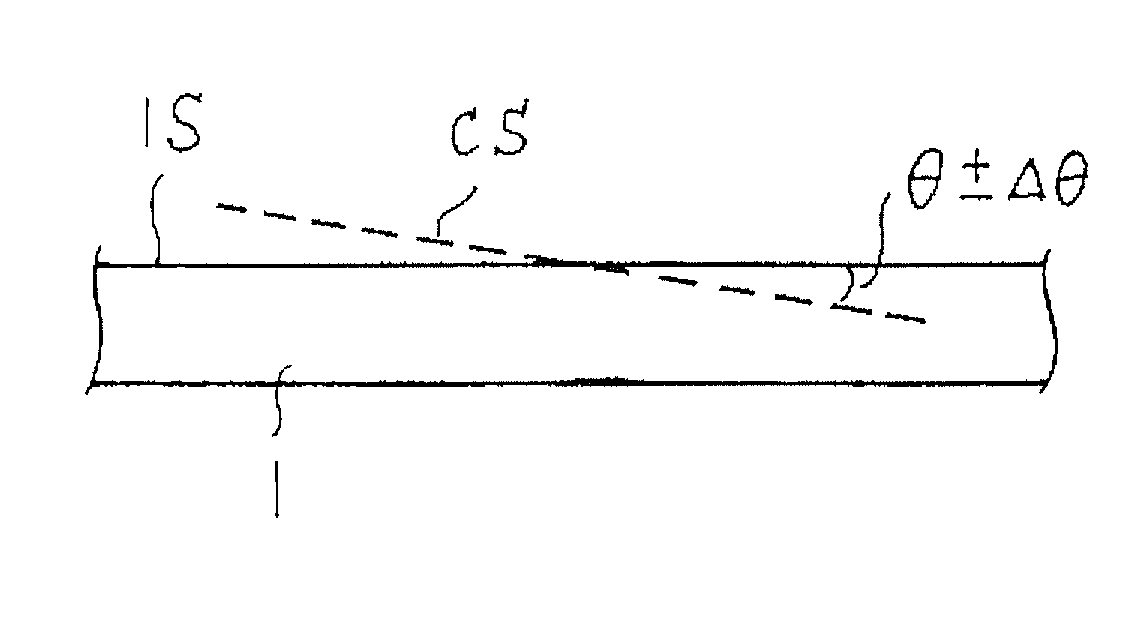

Semiconductor light-emitting element and method for fabricating the same

ActiveUS20100295054A1Improve luminous efficiencyLow thresholdLaser detailsSemiconductor/solid-state device manufacturingLength waveActive layer

The semiconductor light-emitting element includes a group III nitride semiconductor multilayer structure having an active layer containing In as well as a p-type layer and an n-type layer stacked to hold the active layer therebetween. The group III nitride semiconductor multilayer structure is made of a group III nitride semiconductor having a major surface defined by a nonpolar plane whose offset angle in a c-axis direction is negative. A remarkable effect is attained when the emission wavelength of the active layer is not less than 450 nm. In the group III nitride semiconductor constituting the group III nitride semiconductor multilayer structure, the offset angle θ in the c-axis direction preferably satisfies −1°<θ<0°.

Owner:ROHM CO LTD

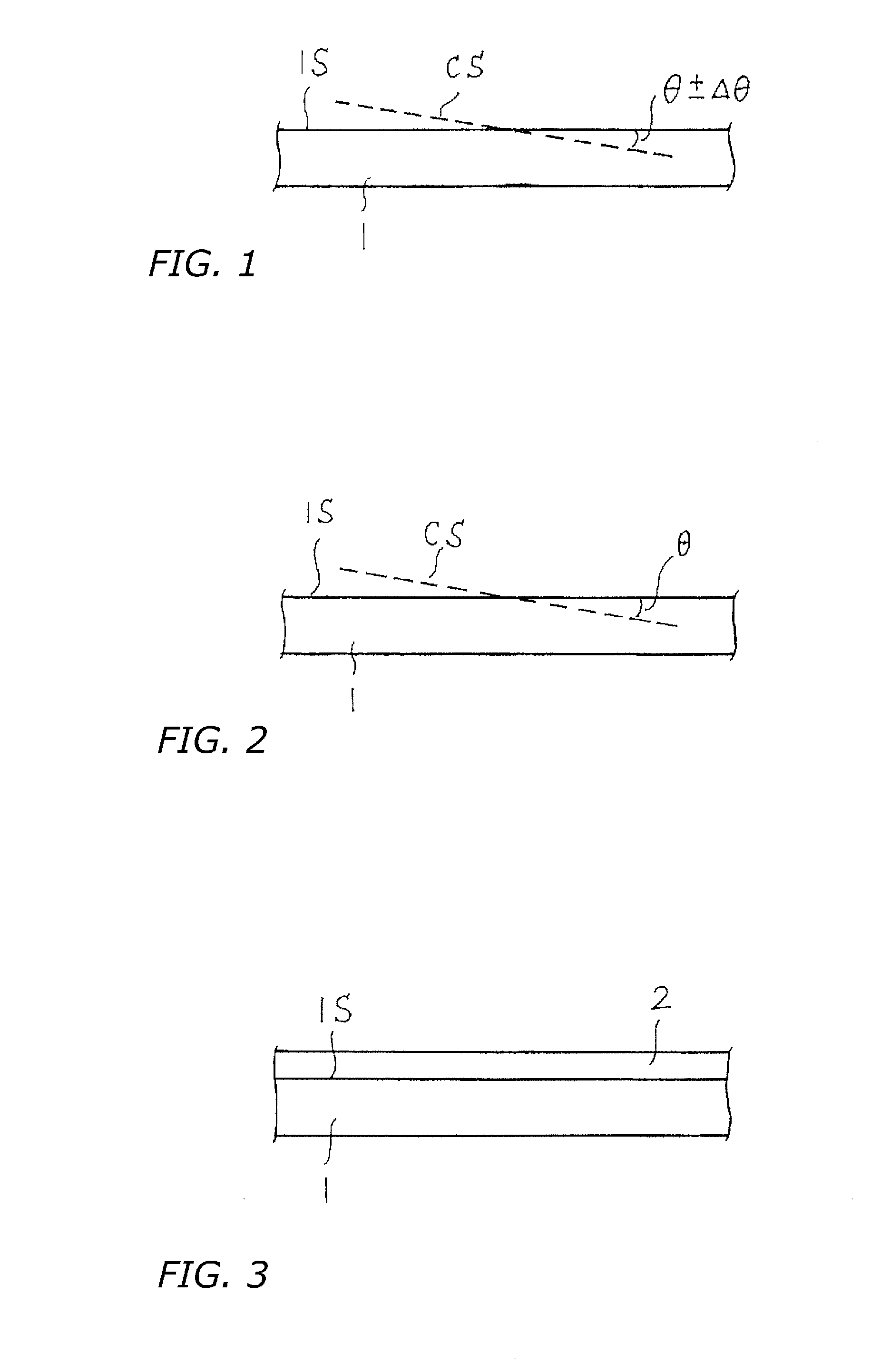

Nitride Semiconductor Wafer

InactiveUS20080217745A1Maintain good propertiesQuality improvementSemiconductor devicesNitride semiconductorsSemiconductor device

A nitride semiconductor substrate having properties preferable for the manufacture of various nitride semiconductor devices is made available, by specifying or controlling the local variation in the off-axis angle of the principal surface of the nitride semiconductor substrate. The substrate, being misoriented, is manufactured to have an off-axis angle distribution across its principal surface such that variation Δθ in the off-axis angle is continuous within a predetermined angular range.

Owner:SUMITOMO ELECTRIC IND LTD

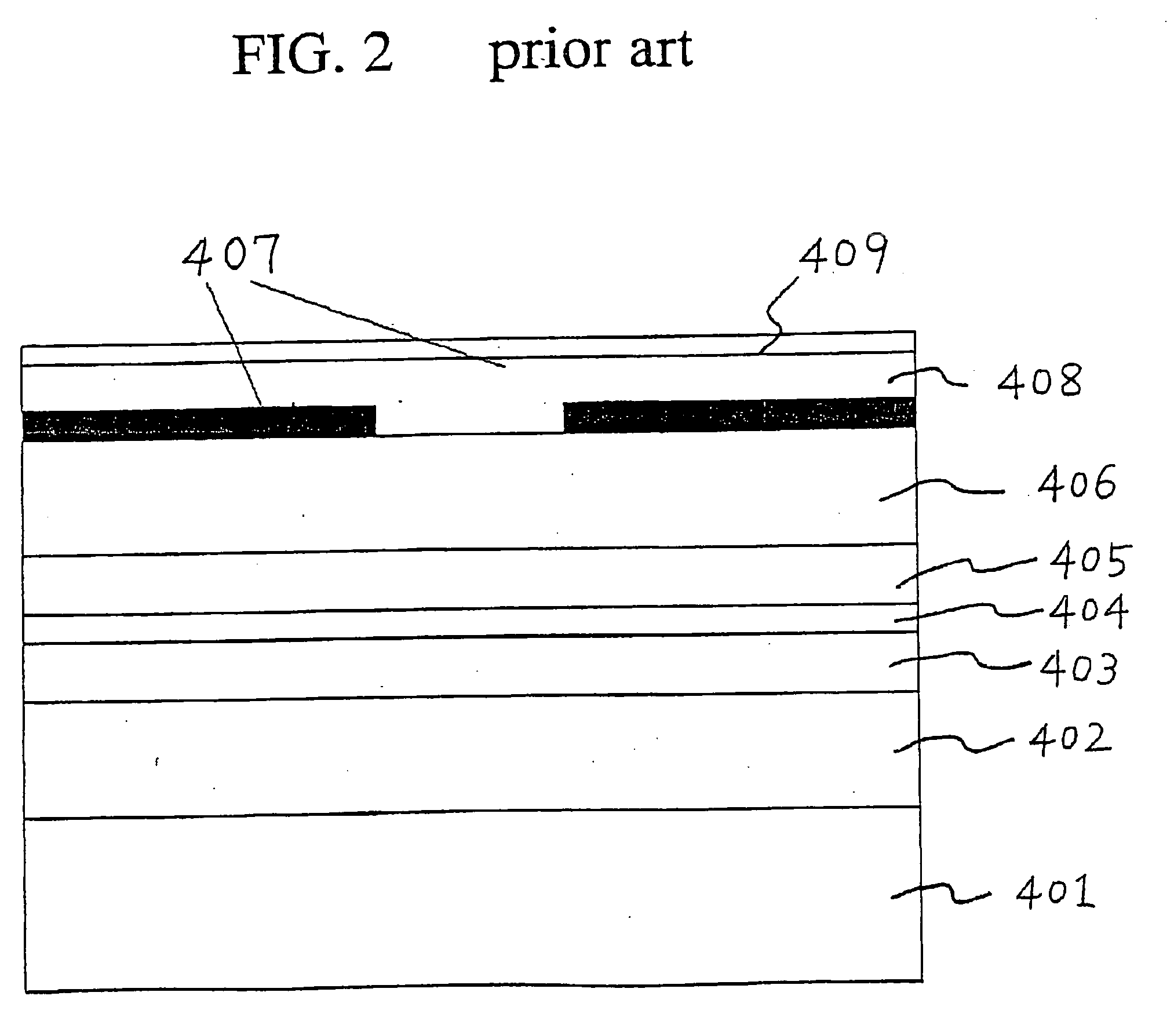

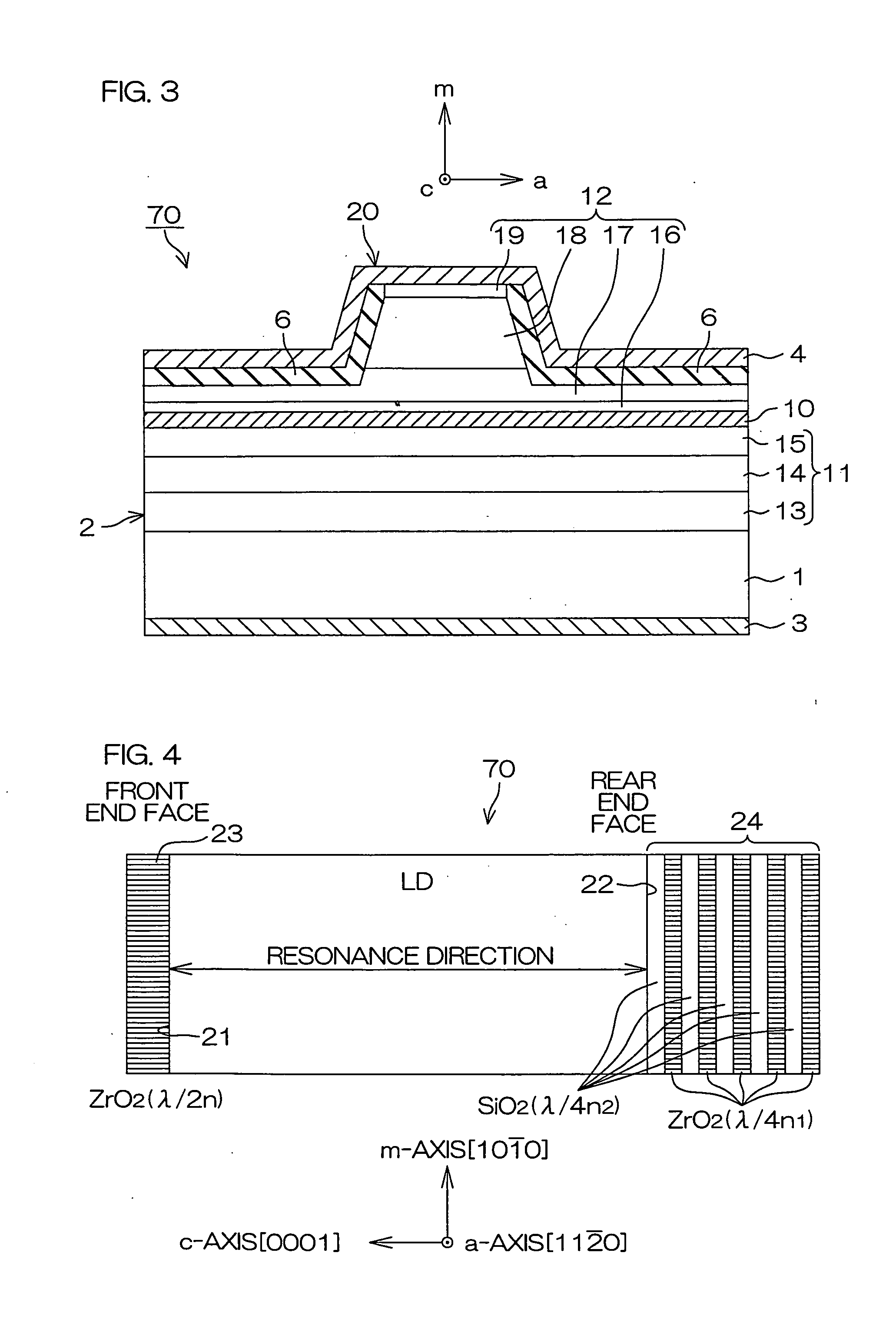

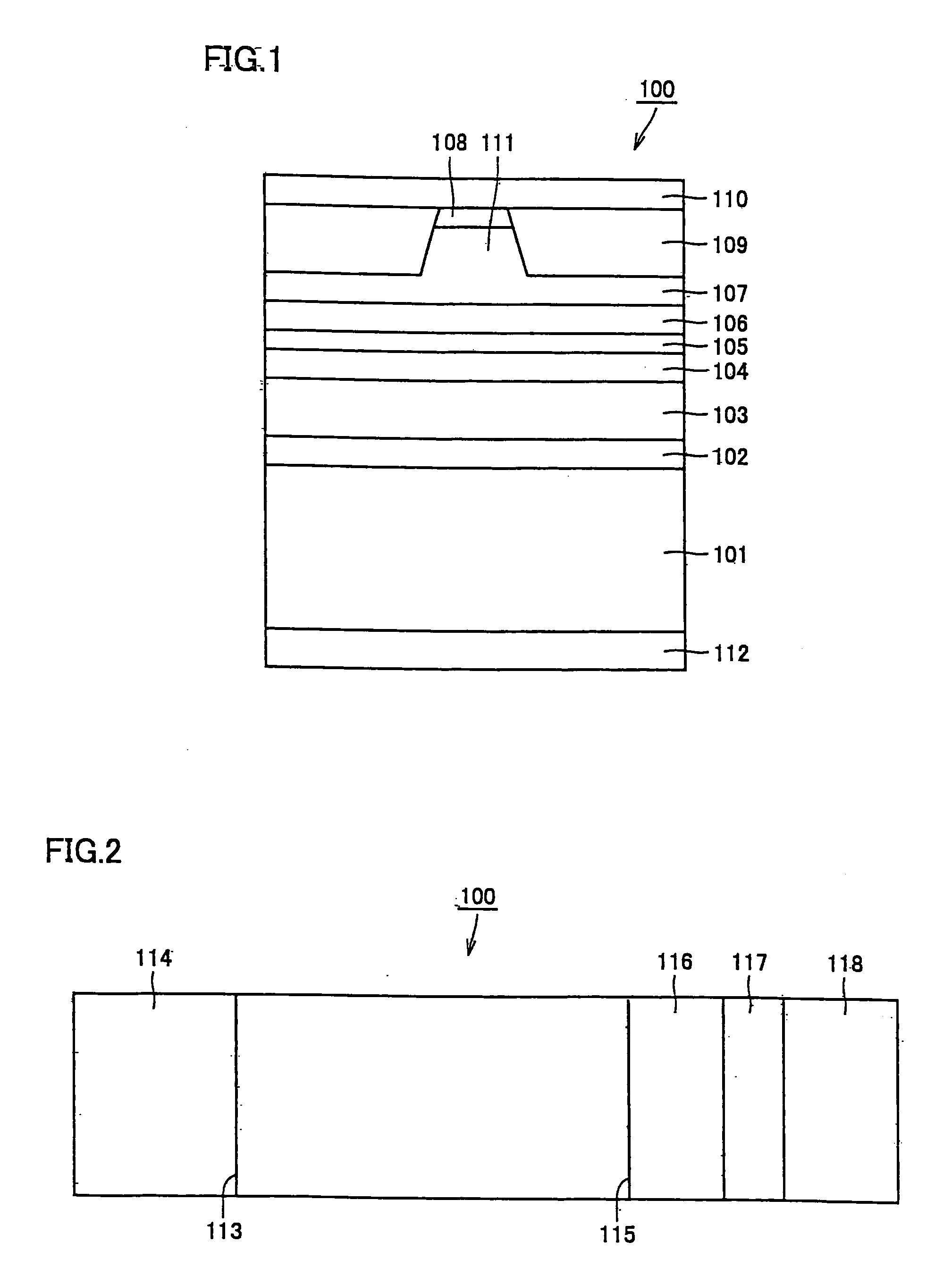

Nitride semiconductor light emitting device and method of fabricating nitride semiconductor laser device

ActiveUS20080291961A1High output without impairing reliabilityImprove the level ofOptical wave guidanceLaser detailsNitrogen oxideLight emitting device

There is provided a nitride semiconductor light emitting device having a light emitting portion coated with a coating film, the light emitting portion being formed of a nitride semiconductor, the coating film in contact with the light emitting portion being formed of an oxynitride. There is also provided a method of fabricating a nitride semiconductor laser device having a cavity with a facet coated with a coating film, including the steps of: providing cleavage to form the facet of the cavity; and coating the facet of the cavity with a coating film formed of an oxynitride.

Owner:SHARP FUKUYAMA LASER CO LTD

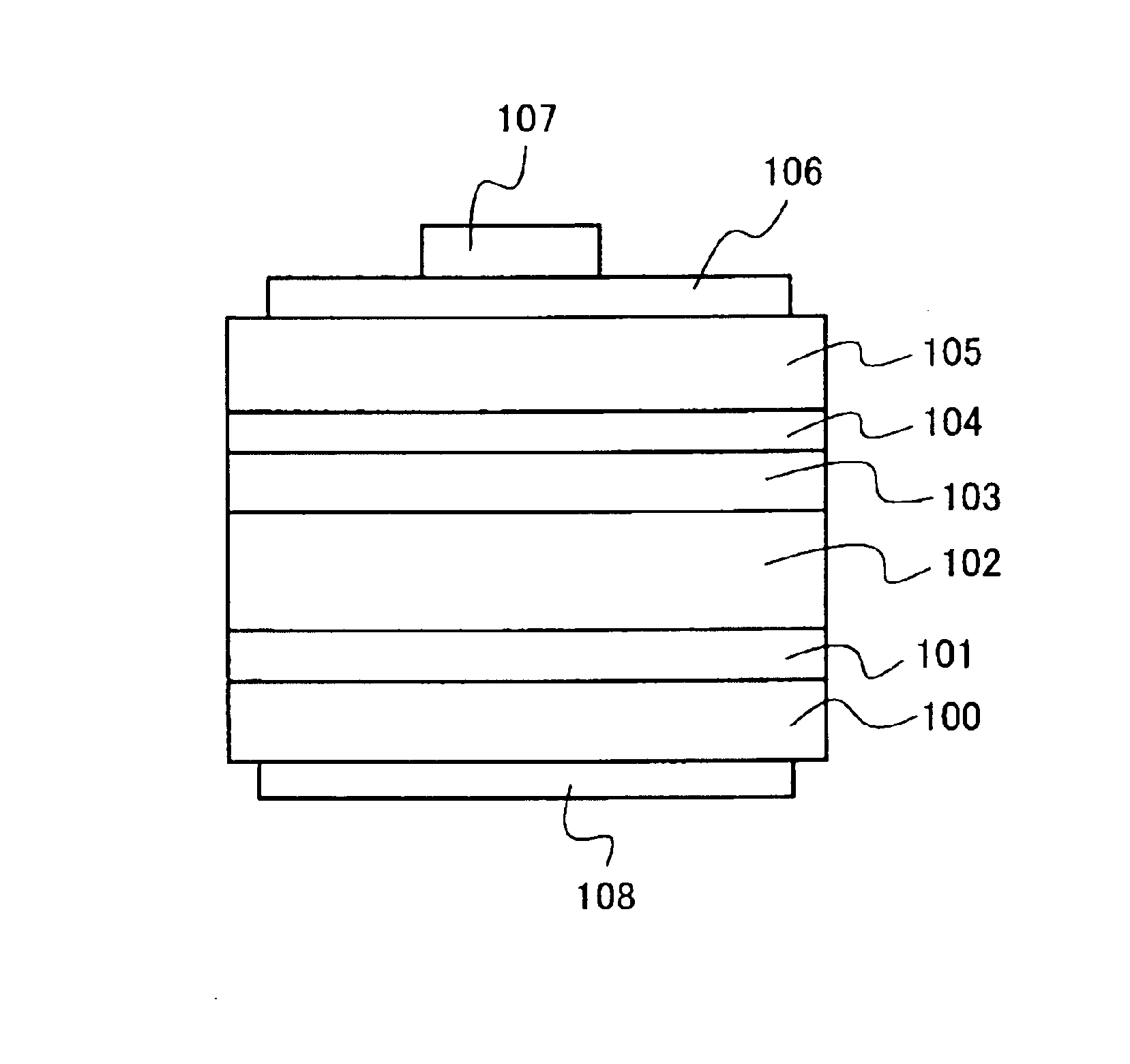

Group III nitride semiconductor light emitting device

InactiveUS20070110112A1Increase fixed chargeEasy to overflowOptical wave guidanceSolid-state devicesElectron blocking layerActive layer

A group III nitride semiconductor light emitting device according to the present invention includes an immediate layer formed of AlxGa1-x-yInyN (0<x<1, 0<y<1, x+y<1) between an active layer and a cladding layer and an electron blocking layer formed of p-type group III nitride semiconductor having a smaller electron affinity than that of the intermediate layer so as to be in contact with the intermediate layer. The semiconductor light emitting layer may be a laser diode or a LED.

Owner:PANASONIC CORP

Nitride semiconductor light-emitting device and optical device including the same

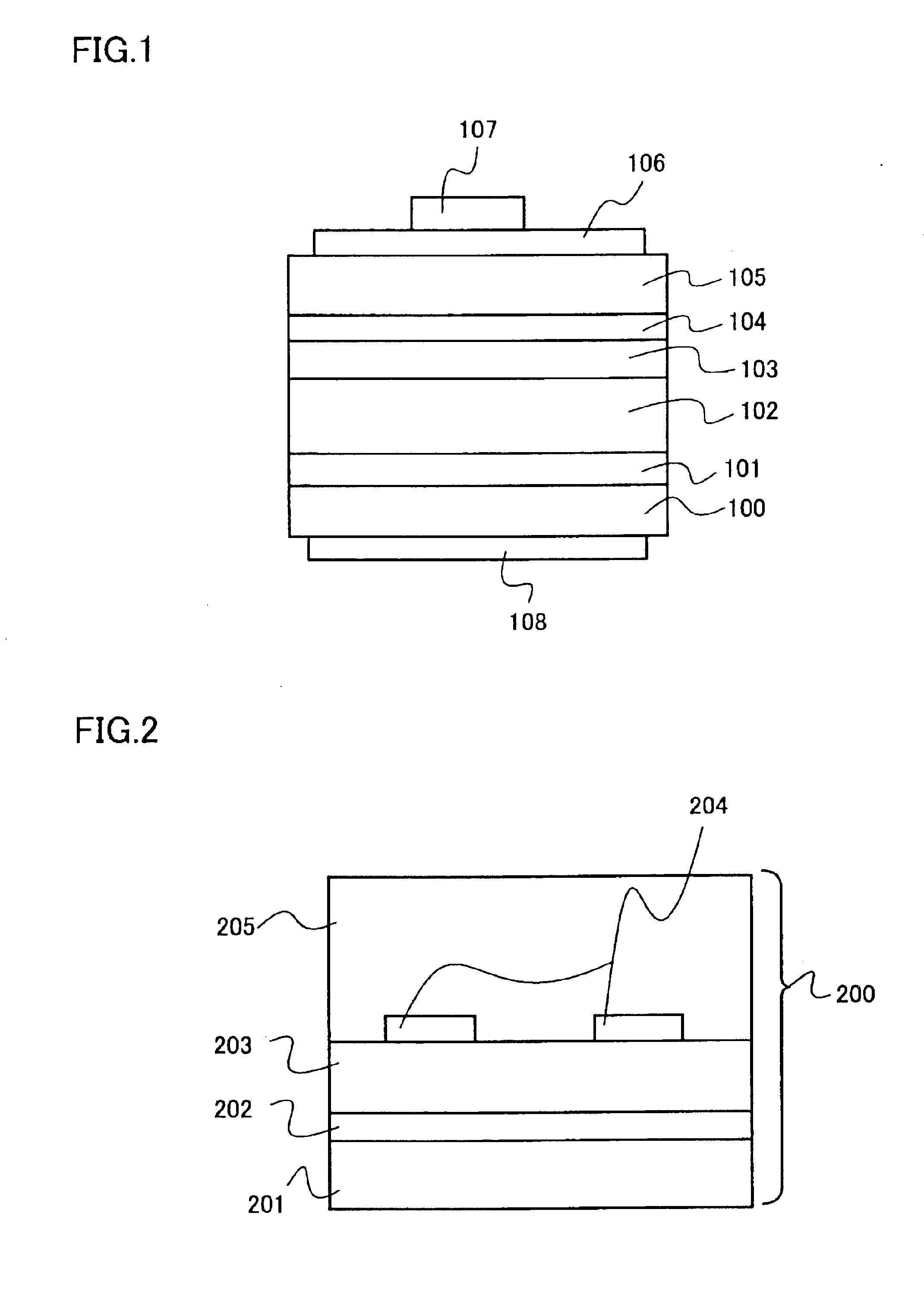

InactiveUS6858882B2Solid-state devicesSemiconductor/solid-state device manufacturingQuantum wellLight emitting device

A nitride semiconductor light-emitting device includes an emission layer (103) formed on a substrate (100), and the emission layer includes a quantum well layer of GaN1-x−y−zAsxPySbz (0<x+y+z≦0.3) containing Al.

Owner:SHARP KK

Nitride semiconductor laser device and method of producing the same

ActiveUS20070217462A1Avoid difficult choicesOptical wave guidanceLaser detailsActive layerArea ratio

A method of producing a nitride semiconductor laser device includes: forming a wafer including a nitride semiconductor layer of a first conductivity type, an active layer of a nitride semiconductor, a nitride semiconductor layer of a second conductivity type, and an electrode pad for the second conductivity type stacked in this order on a main surface of a conductive substrate and also including stripe-like waveguide structures parallel to the active layer; cutting the wafer to obtain a first type and a second type of laser device chips; and distinguishing between the first type and the second type of chips by automatic image recognition. The first type and the second type of chips are different from each other in position of the stripe-like waveguide structure with respect to a width direction of each chip and also in area ratio of the electrode pad to the main surface of the substrate.

Owner:SHARP FUKUYAMA LASER CO LTD

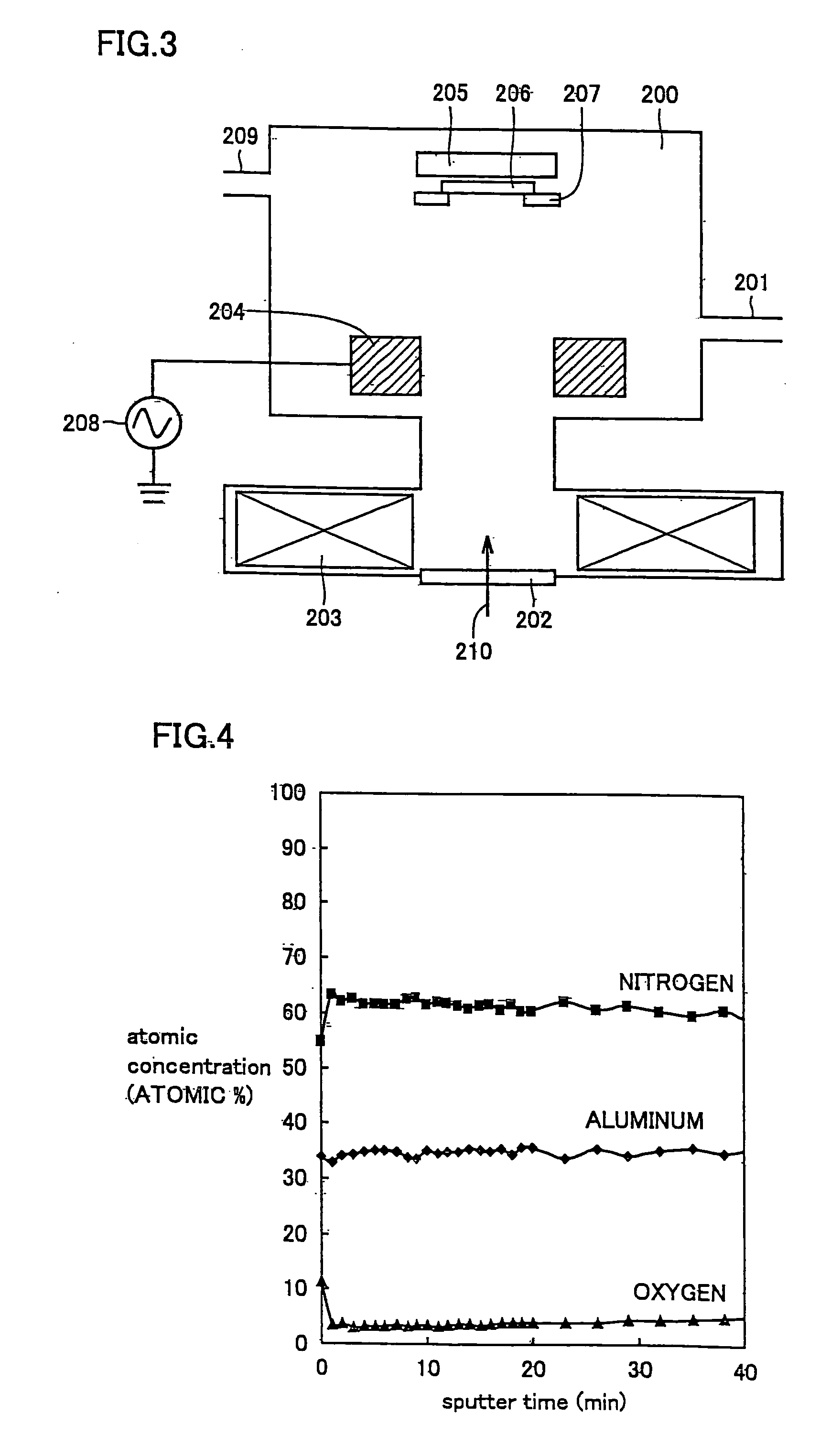

Method and apparatus for fabricating crack-free Group III nitride semiconductor materials

InactiveUS20050142391A1Polycrystalline material growthFrom chemically reactive gasesWaferingCrack free

A method and apparatus for growing low defect, optically transparent, colorless, crack-free, substantially flat, single crystal Group III nitride epitaxial layers with a thickness of at least 10 microns is provided. These layers can be grown on large area substrates comprised of Si, SiC, sapphire, GaN, AlN, GaAs, AlGaN and others. In one aspect, the crack-free Group III nitride layers are grown using a modified HVPE technique. If desired, the shape and the stress of Group III nitride layers can be controlled, thus allowing concave, convex and flat layers to be controllably grown. After the growth of the Group III nitride layer is complete, the substrate can be removed and the freestanding Group III nitride layer used as a seed for the growth of a boule of Group III nitride material. The boule can be sliced into individual wafers for use in the fabrication of a variety of semiconductor structures (e.g., HEMTs, LEDs, etc.).

Owner:FREIBERGER COMPOUND MATERIALS

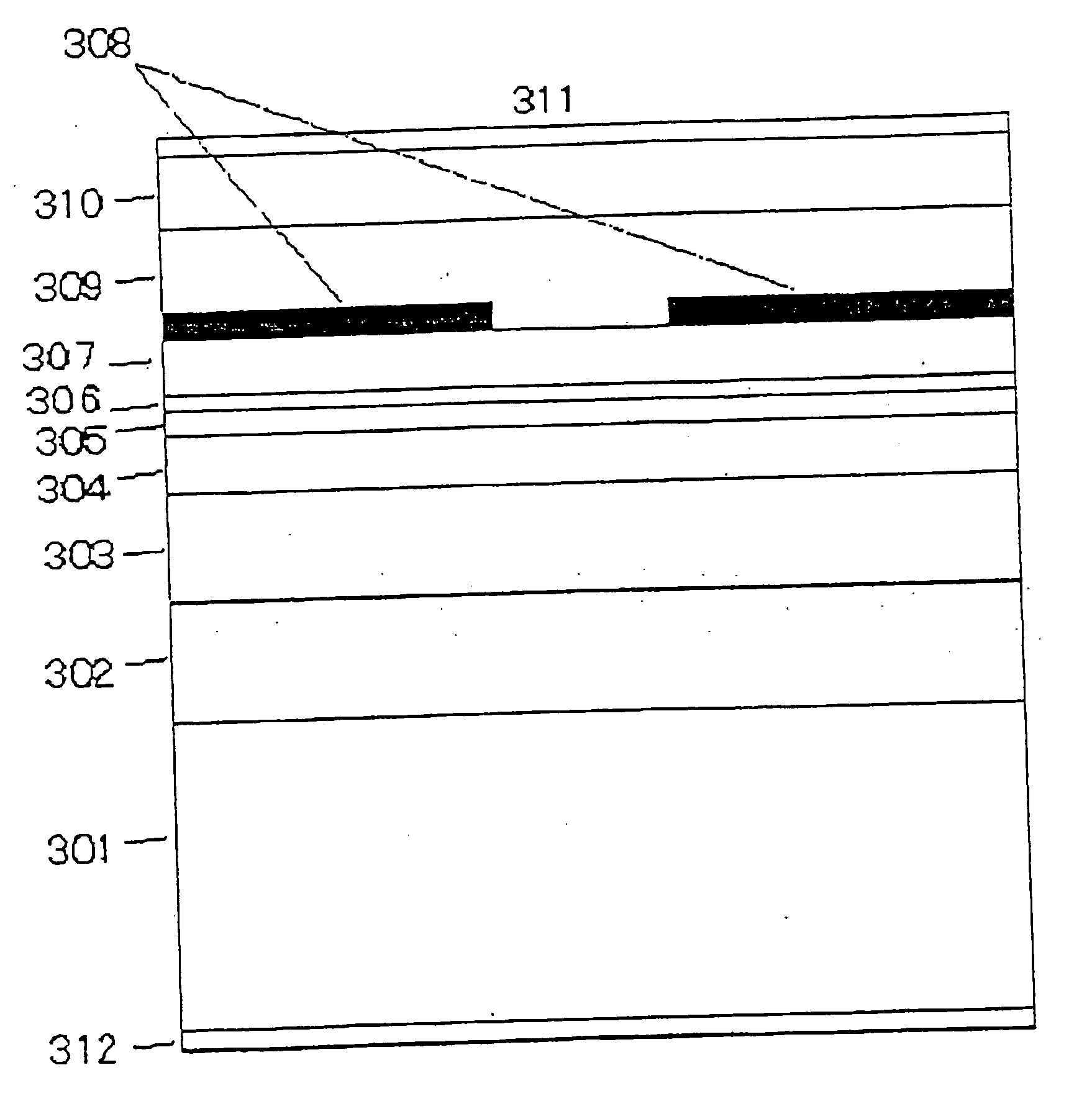

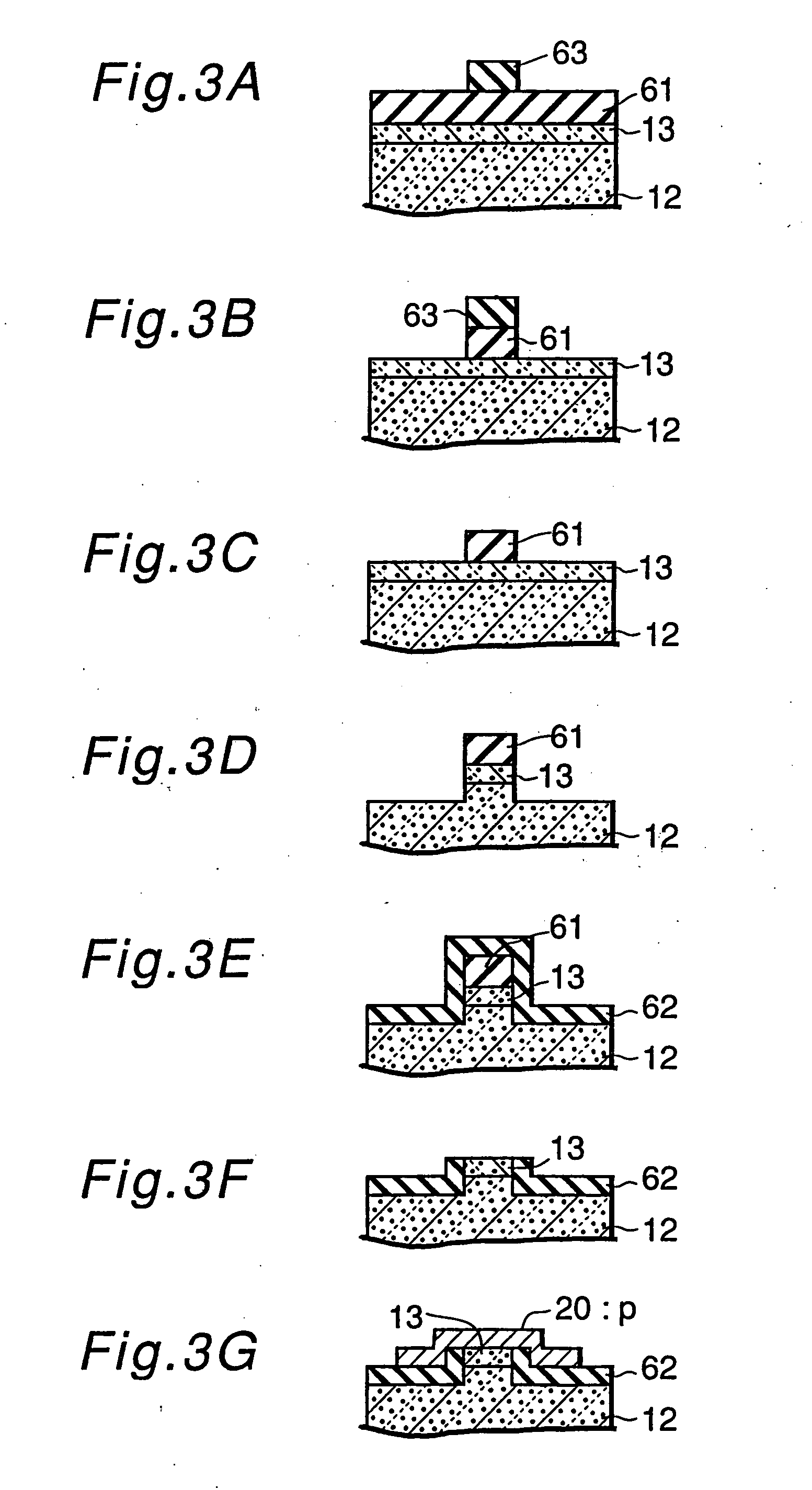

Thin film deposition method of nitride semiconductor and nitride semiconductor light emitting device

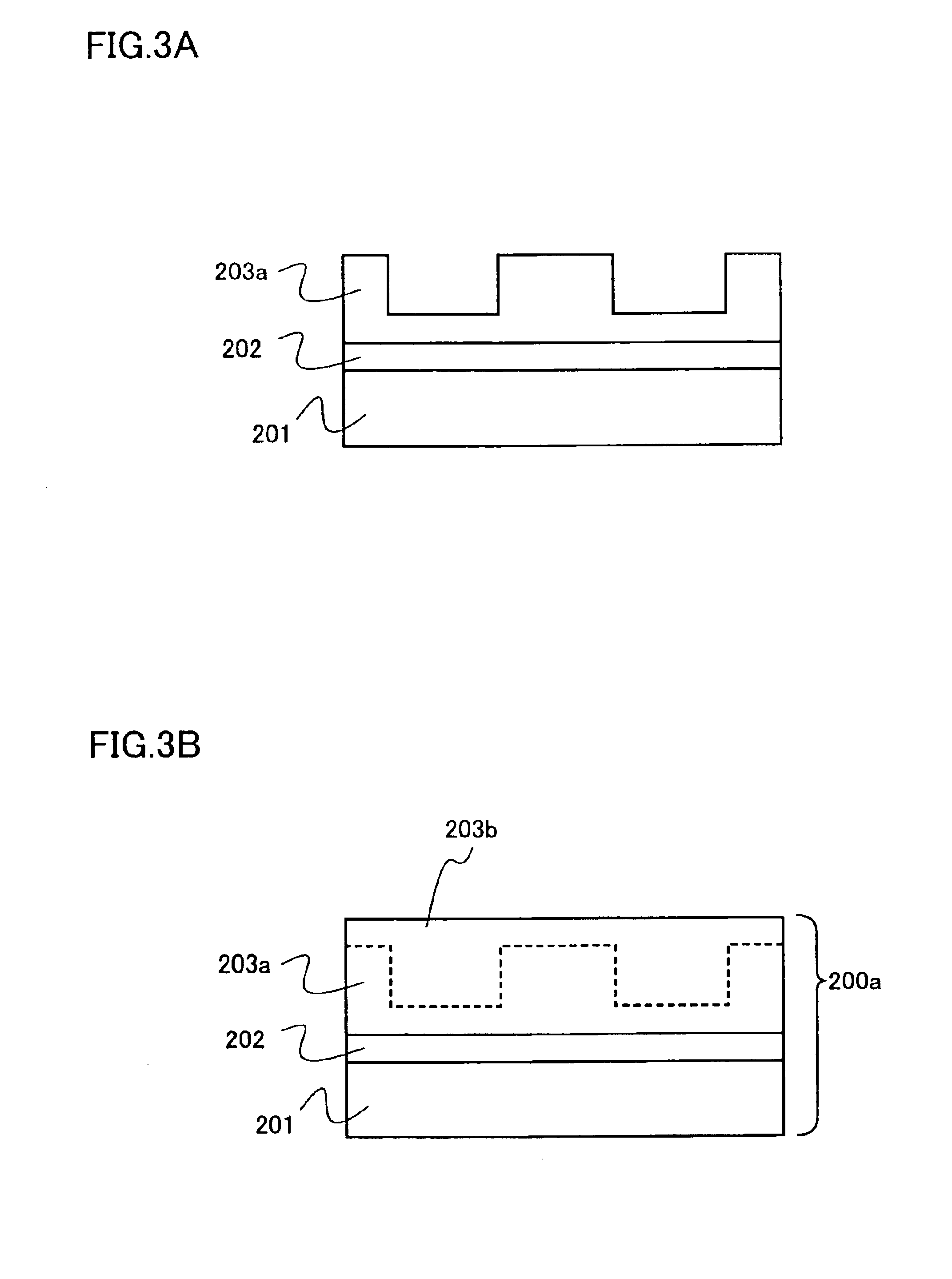

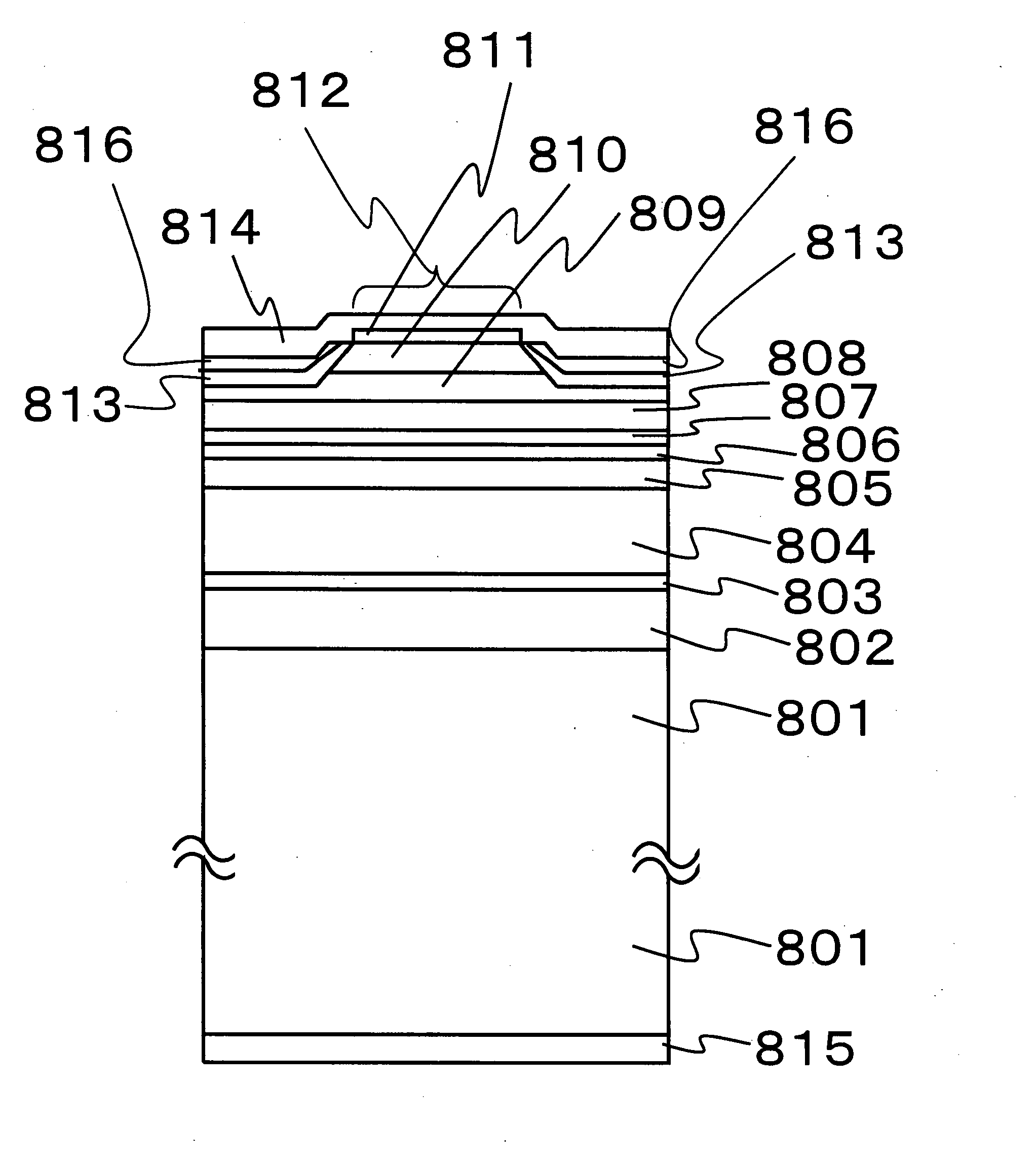

InactiveUS6920166B2Reduce adverse effectsSuppress loss of internal quantum efficiencyOptical wave guidanceSemiconductor/solid-state device manufacturingLight emitting deviceNitride semiconductors

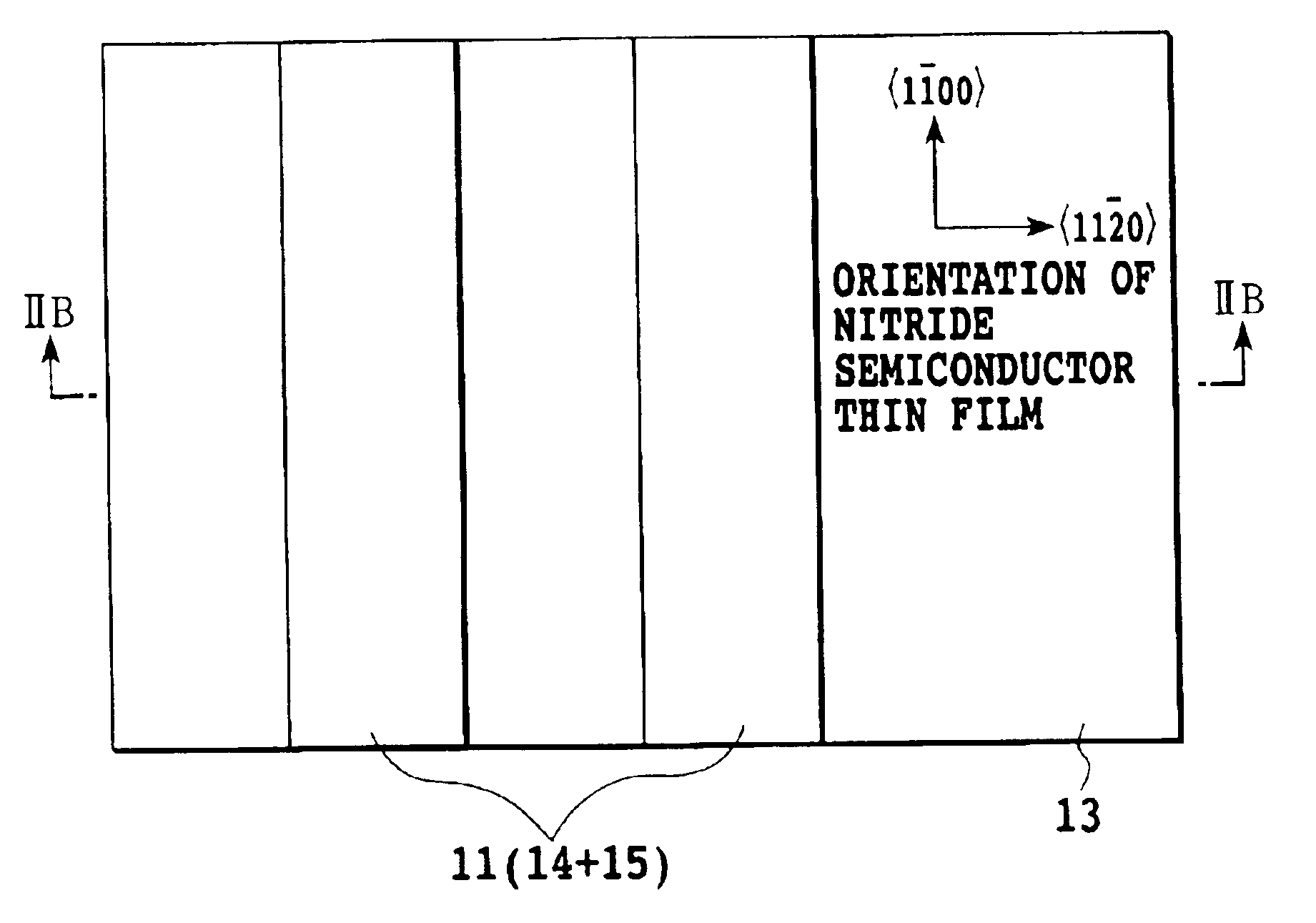

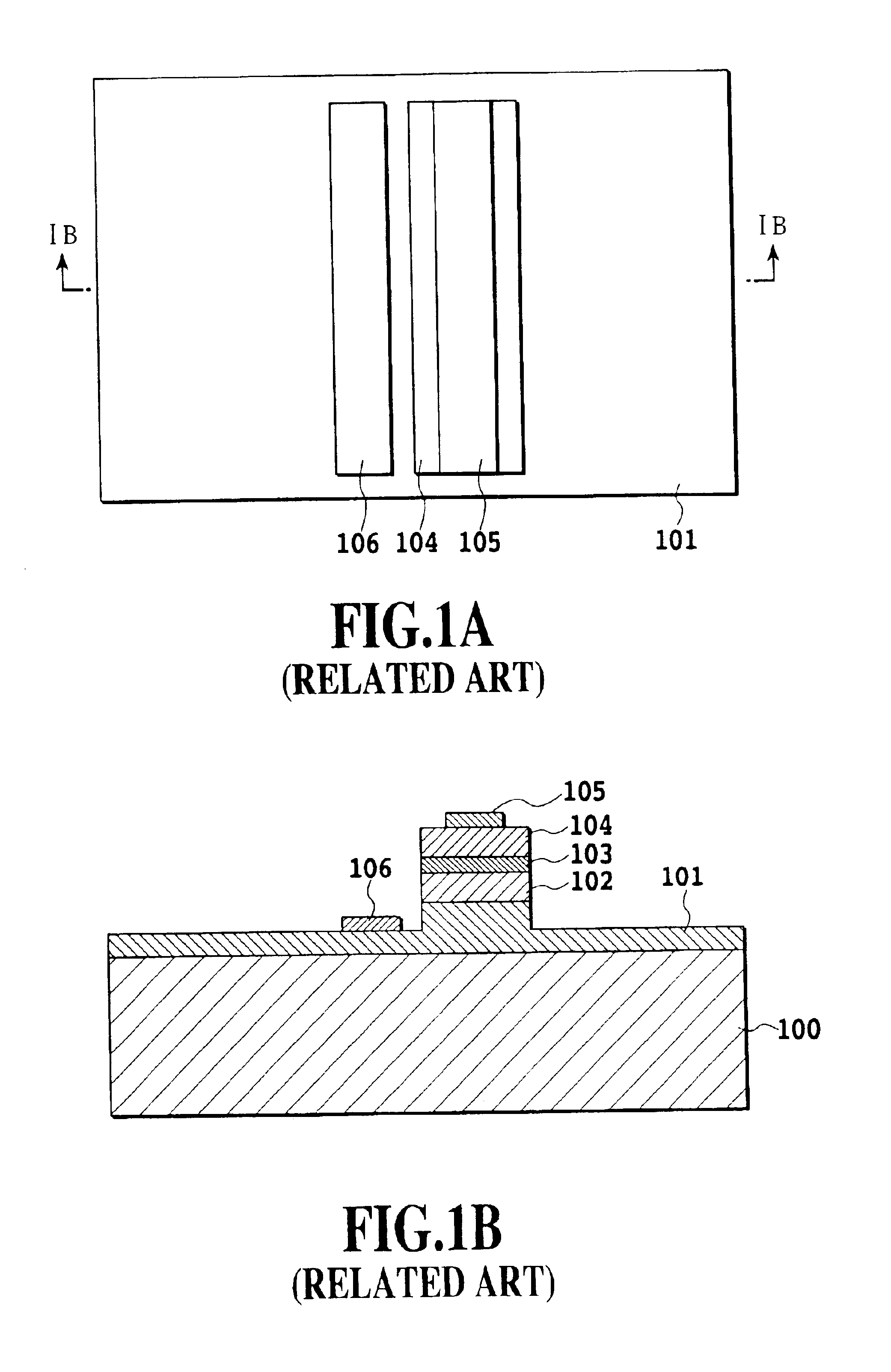

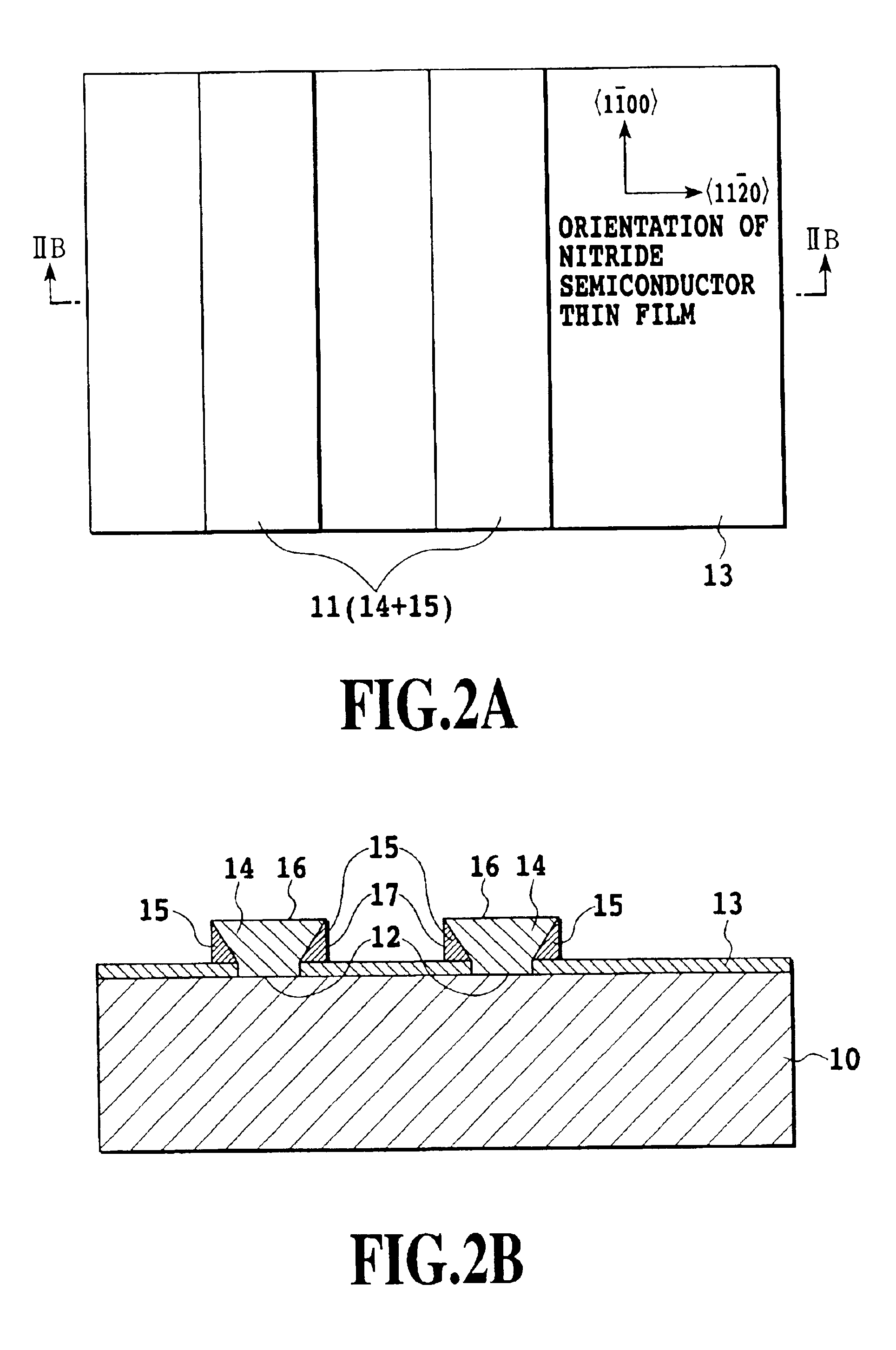

A masking material 13, which includes stripe-like openings 12 parallel to the [1-100] direction of a nitride semiconductor thin film, is formed on a substrate. Nitride semiconductor thin films 11 doped with Mg are grown on the openings 12 by selective-area growth. The nitride semiconductor thin films 11 are composed of a portion 14 formed as a result of the growth in the direction perpendicular to a (0001) principal plane, and a portion 15 formed as a result of the growth of {11-2x} facets (x=0, 1, 2). The Mg concentration of the portion 15 is made lower than that of the portion 14.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Method for Substrate Pretreatment To Achieve High-Quality III-Nitride Epitaxy

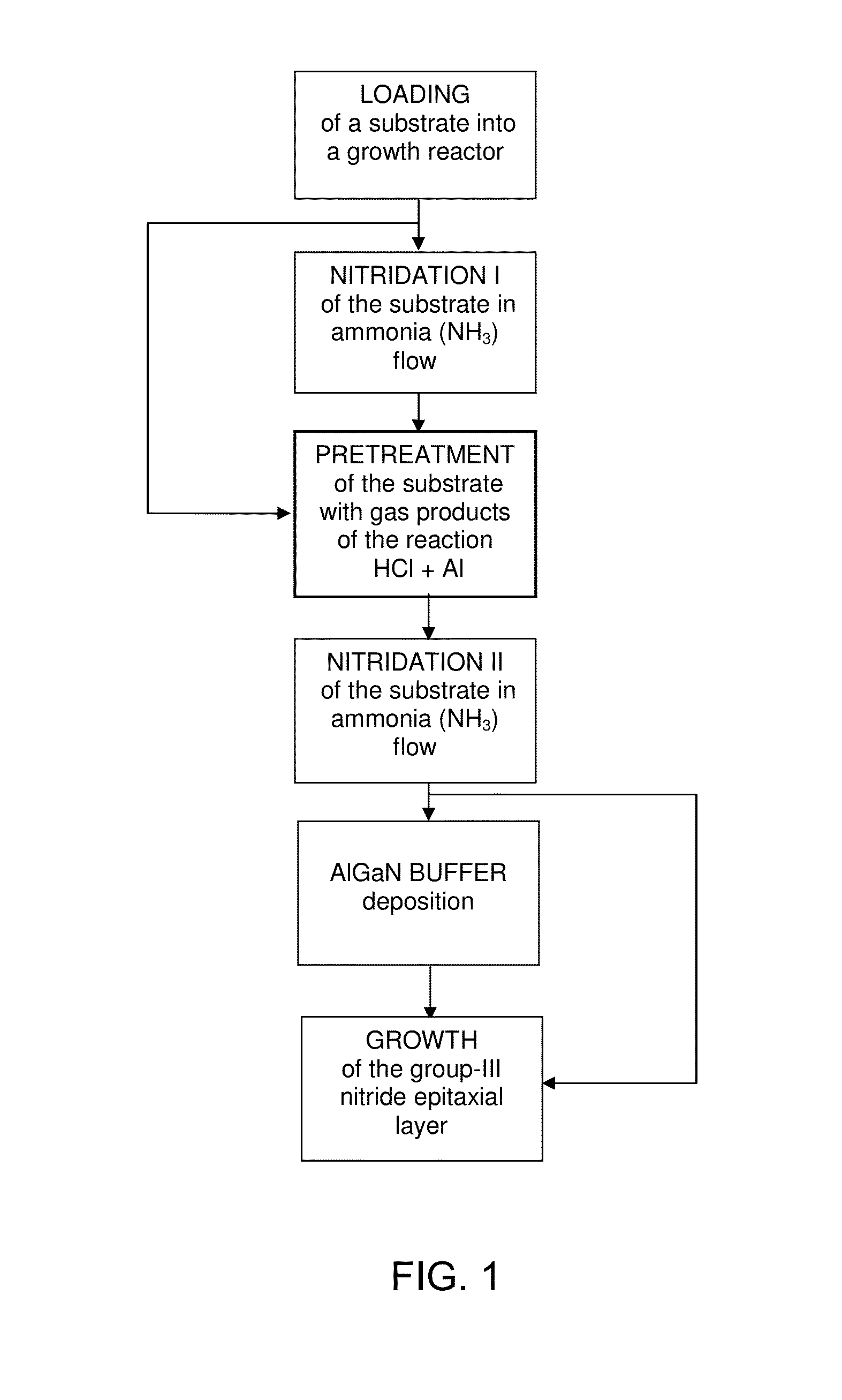

The present invention relates to a method for producing a modified surface of a substrate that stimulates the growth of epitaxial layers of group-III nitride semiconductors with substantially improved structural perfection and surface flatness. The modification is conducted outside or inside a growth reactor by exposing the substrate to a gas-product of the reaction between hydrogen chloride (HCl) and aluminum metal (Al). As a single-step or an essential part of the multi-step pretreatment procedure, the modification gains in coherent coordination between the substrate and group-III nitride epitaxial structure to be deposited. Along with epilayer, total epitaxial structure may include buffer inter-layer to accomplish precise substrate-epilayer coordination. While this modification is a powerful tool to make high-quality group-III nitride epitaxial layers attainable even on foreign substrates having polar, semipolar and nonpolar orientation, it remains gentle enough to keep the surface of the epilayer extremely smooth. Various embodiments are disclosed.

Owner:OSTENDO TECH INC

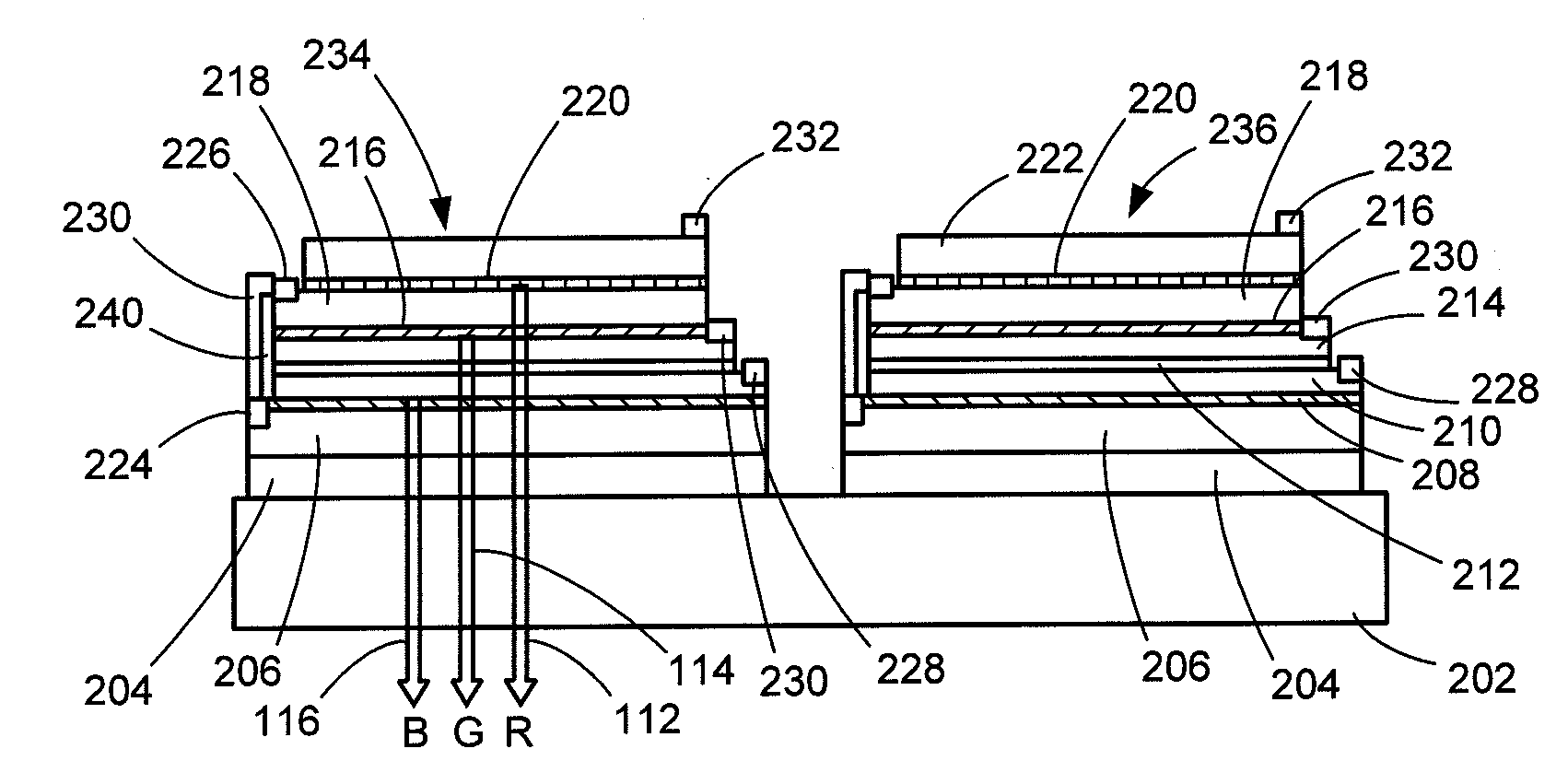

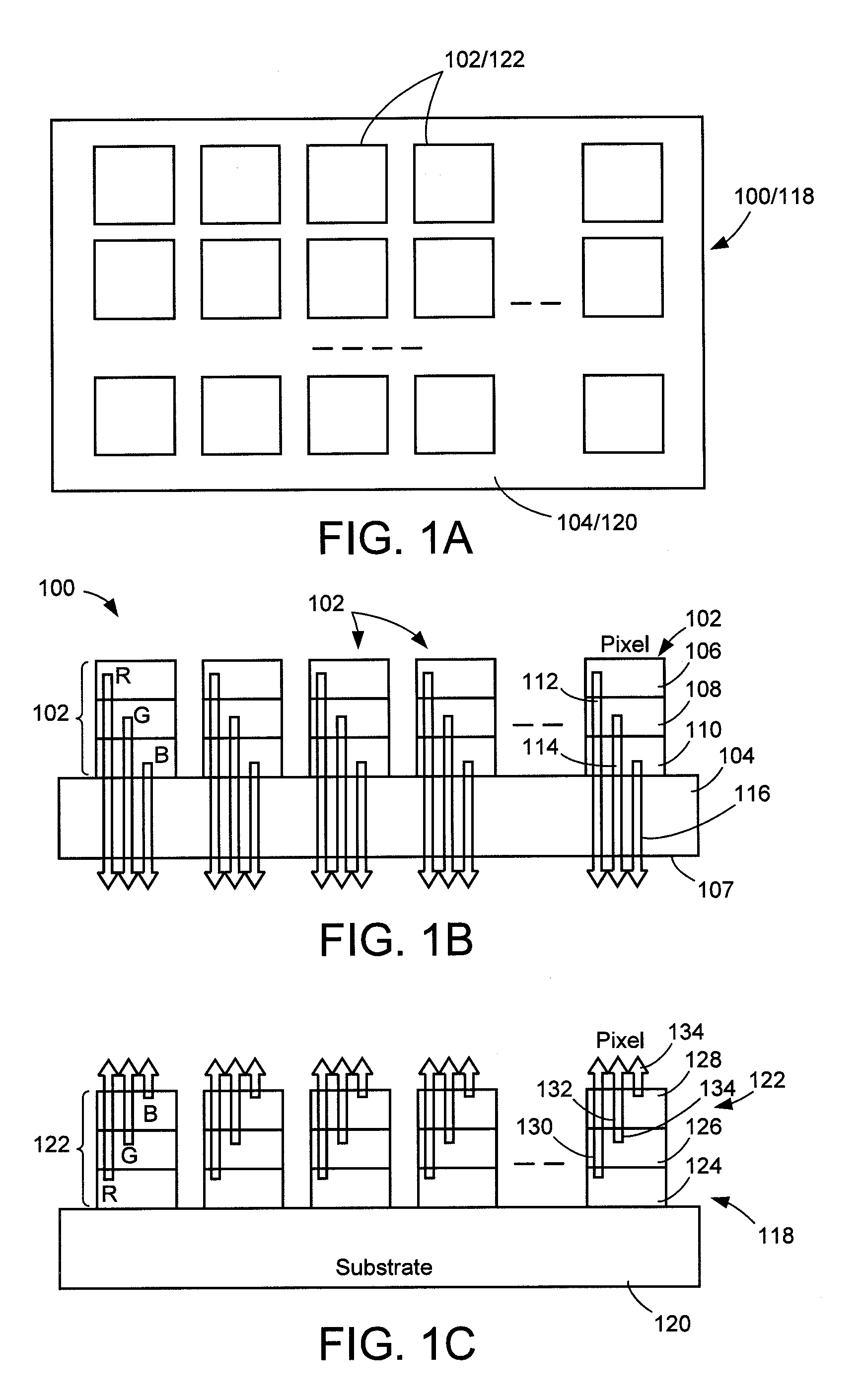

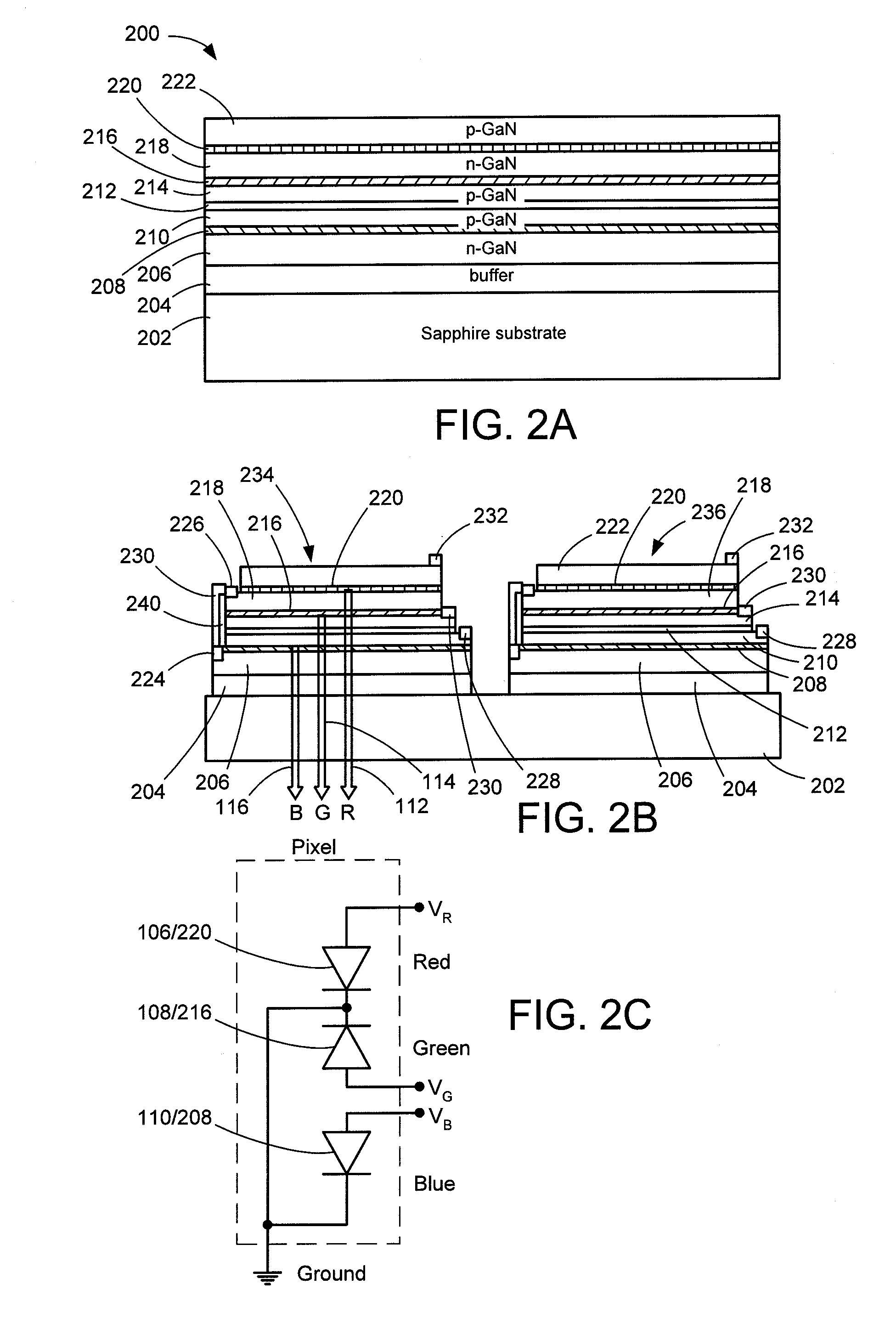

Micro-Emitter Array Based Full-Color Micro-Display

ActiveUS20090078955A1Avoid problemsSolid-state devicesSemiconductor/solid-state device manufacturingIndiumDisplay device

Disclosed is a semiconductor micro-emitter array for use in a full-color microdisplay. Each pixel includes three vertically-stacked red, green, and blue micro-emitters which minimizes pixel size. The microdisplay may be exclusively based on Group III-nitride semiconductors, with differing indium concentrations in three respective InGaN / GaN active regions for emitting the three RGB colors. Alternatively the microdisplay may be based on hybrid integration of InGaN based III-nitride semiconductors for blue and green emissions, and AlGaInP based (e.g., Group III-V) semiconductors for red emissions.

Owner:III N TECH

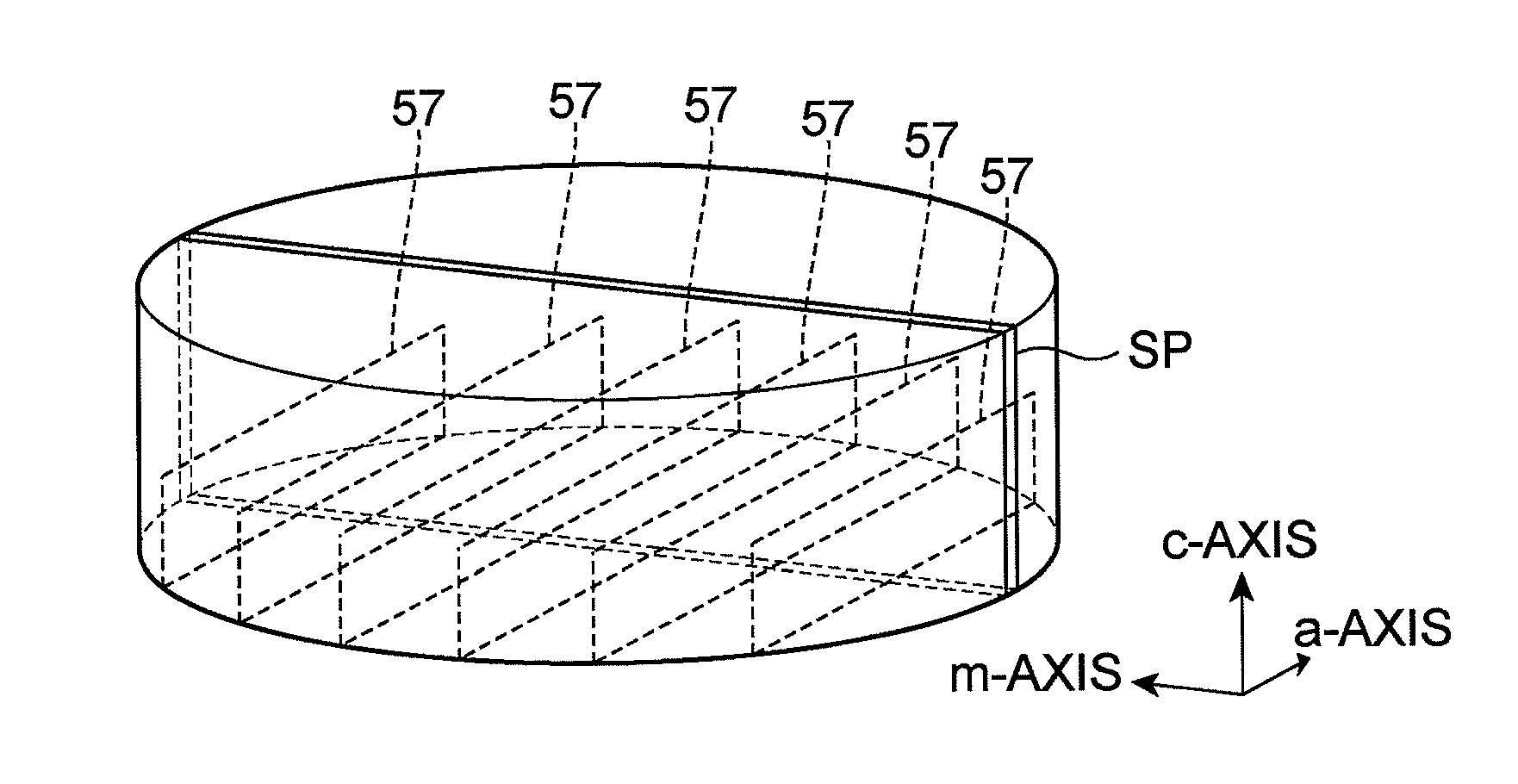

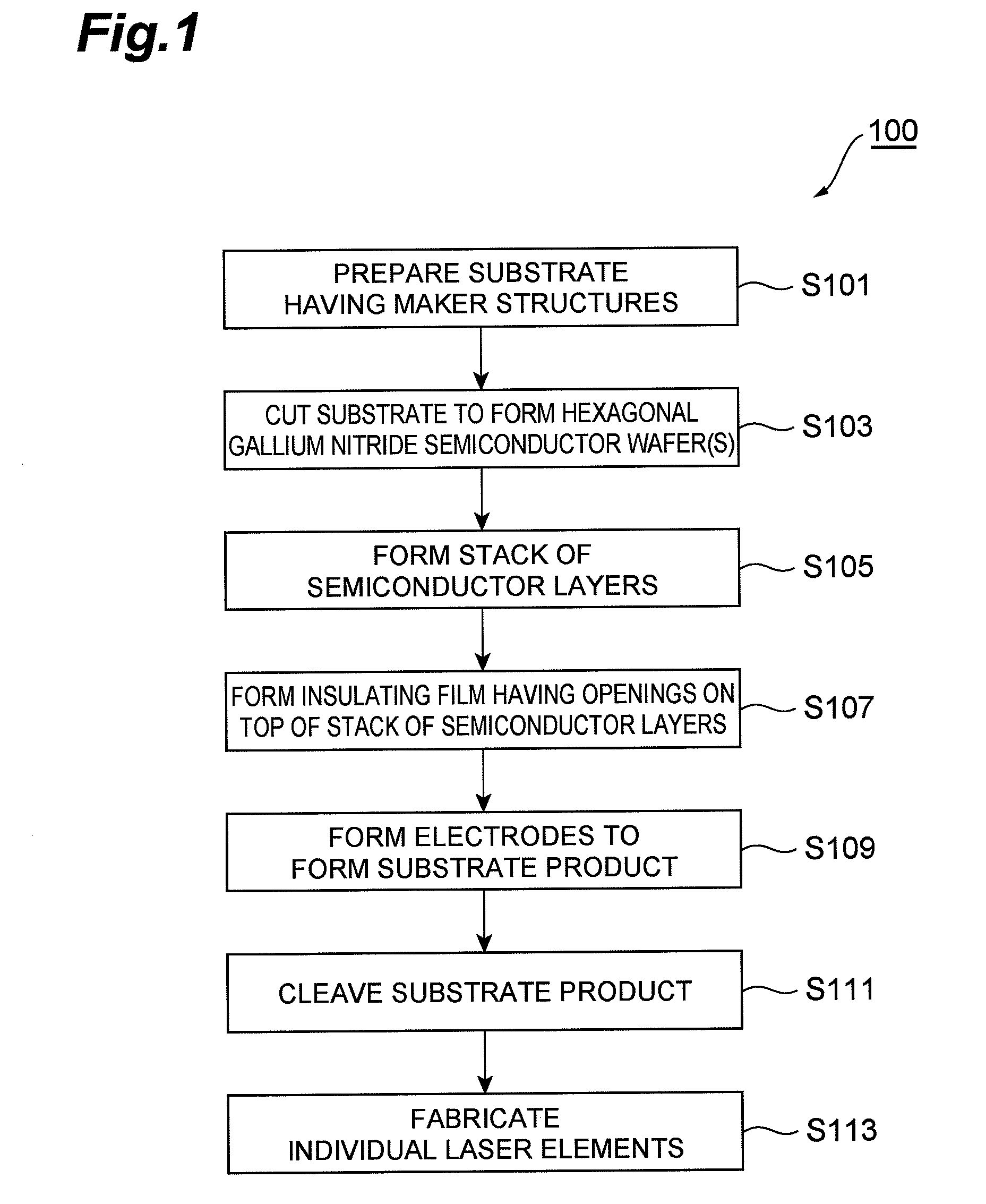

Method of fabricating nitride semiconductor laser

InactiveUS7939354B2Good orientationLarge caliberSemiconductor/solid-state device detailsSemiconductor laser structural detailsGallium nitrideNitride semiconductors

A method of fabricating a nitride semiconductor laser comprises preparing a substrate having a plurality of marker structures and a crystalline mass made of a hexagonal gallium nitride semiconductor. The primary and back surfaces of the substrate intersect with a predetermined axis extending in the direction of a c-axis of the hexagonal gallium nitride semiconductor. Each marker structure extends along a reference plane defined by the c-axis and an m-axis of the hexagonal gallium nitride semiconductor. The method comprises cutting the substrate along a cutting plane to form a wafer of hexagonal gallium nitride semiconductor, and the cutting plane intersects with the plurality of the marker structures. The wafer has a plurality of first markers, each of which extends from the primary surface to the back surface of the wafer, and each of the first markers comprises part of each of the marker structures. The primary surface of the wafer is semipolar or nonpolar. The method comprises growing a number of gallium nitride based semiconductor layers for a semiconductor laser. The method comprises cleaving the substrate product at a cleavage plane of the hexagonal gallium nitride semiconductor, after forming a substrate product in an electrode forming step.

Owner:SUMITOMO ELECTRIC IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com