Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

929 results about "Overpressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Overpressure (or blast overpressure) is the pressure caused by a shock wave over and above normal atmospheric pressure. The shock wave may be caused by sonic boom or by explosion, and the resulting overpressure receives particular attention when measuring the effects of nuclear weapons or thermobaric bombs.

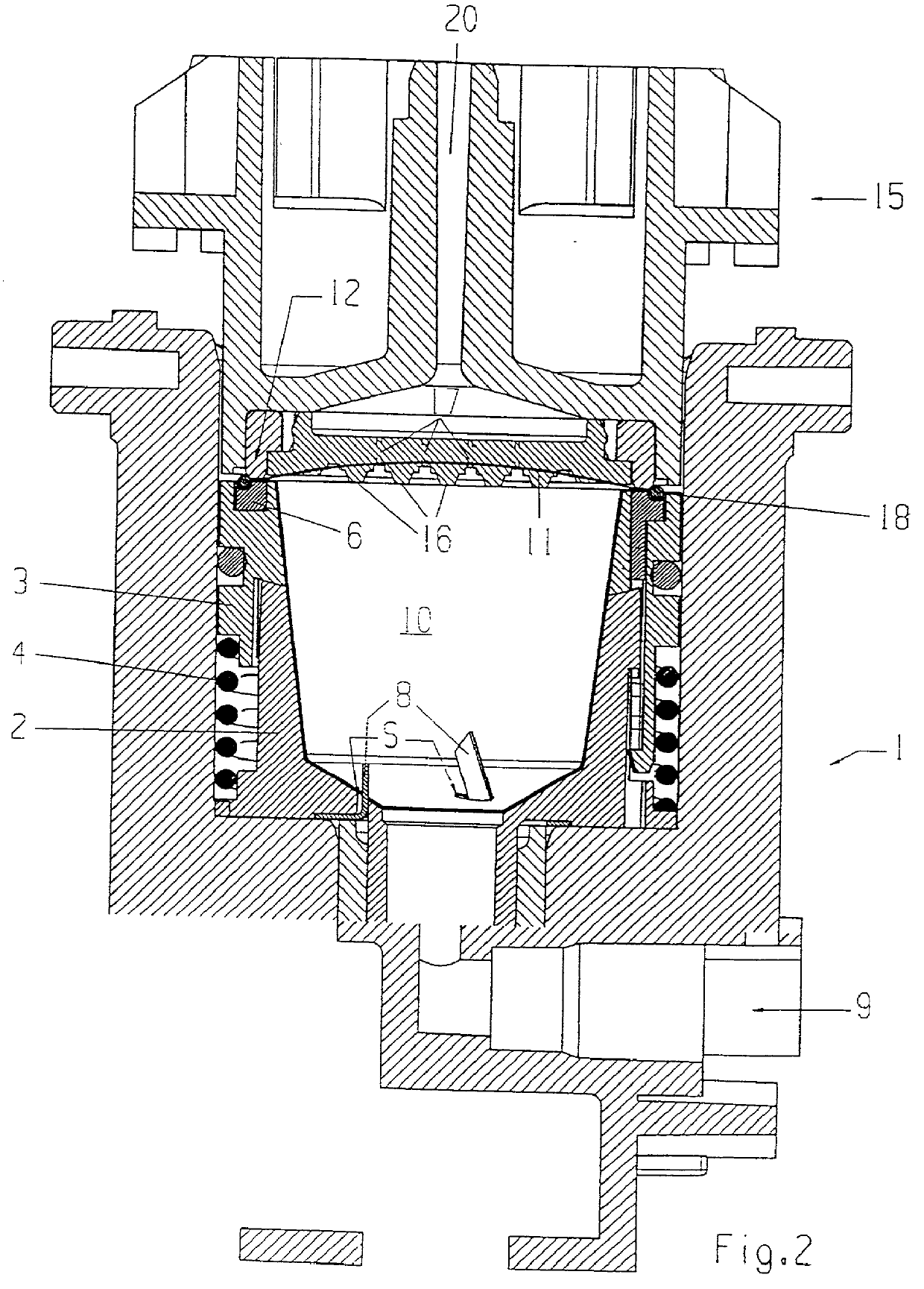

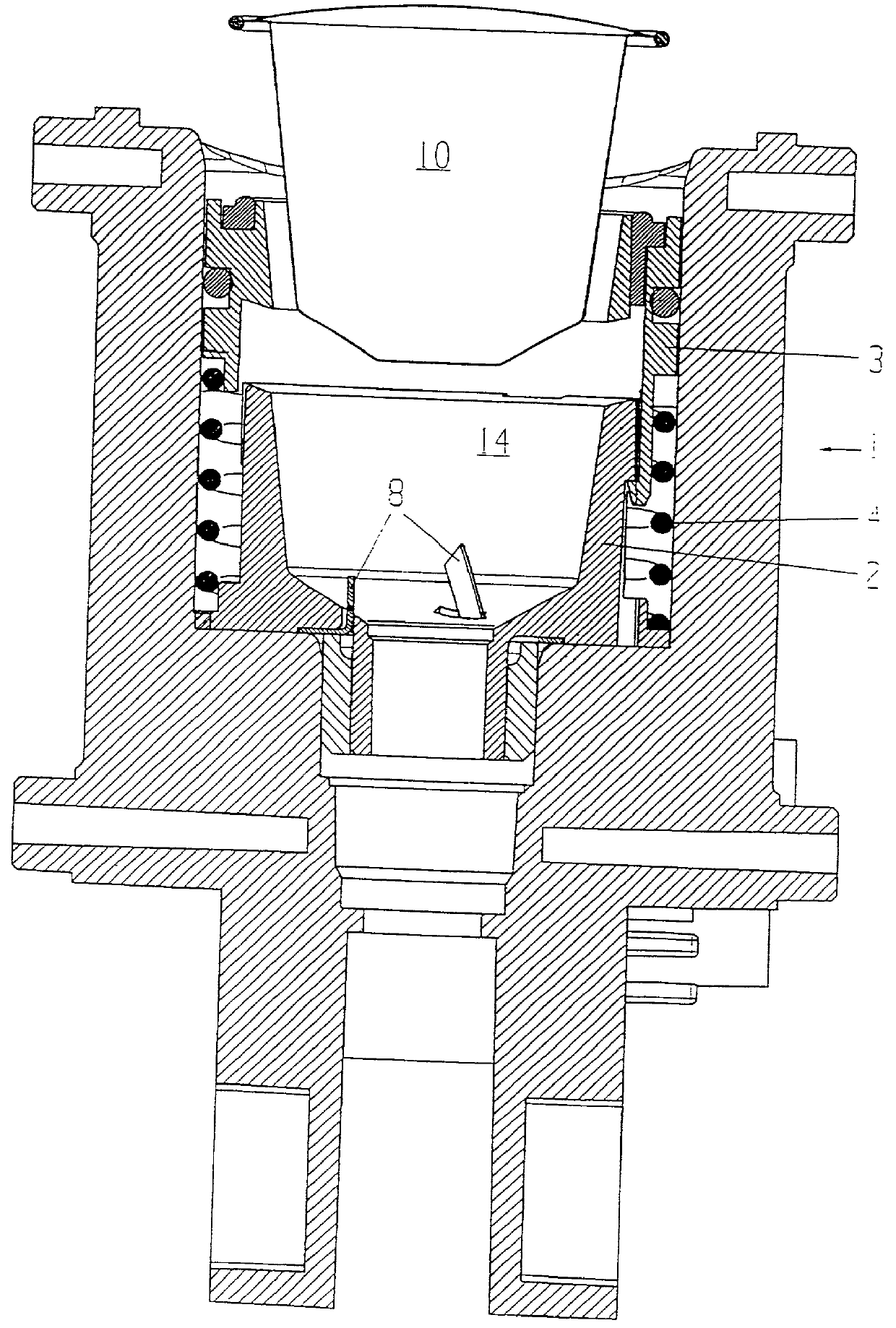

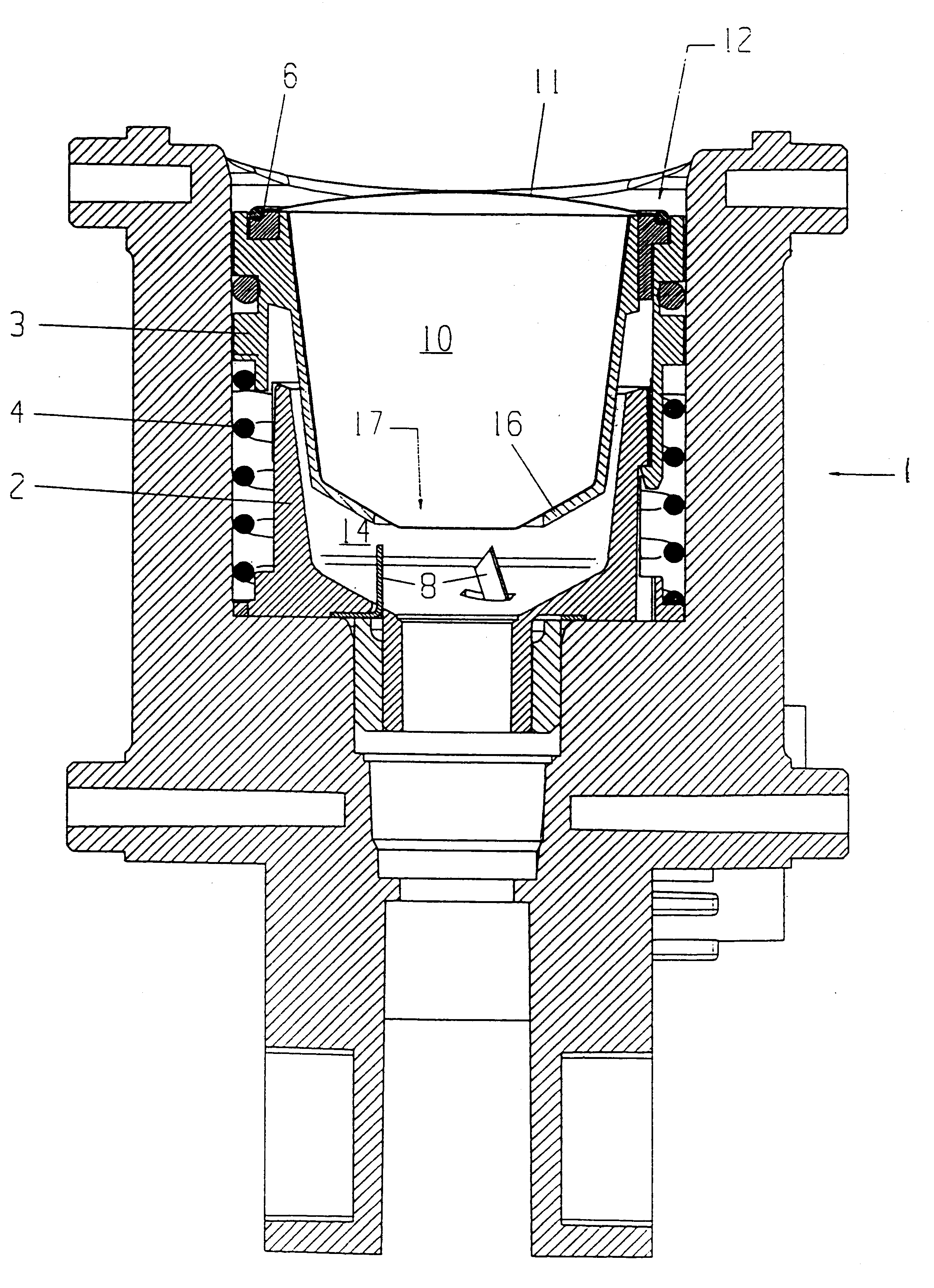

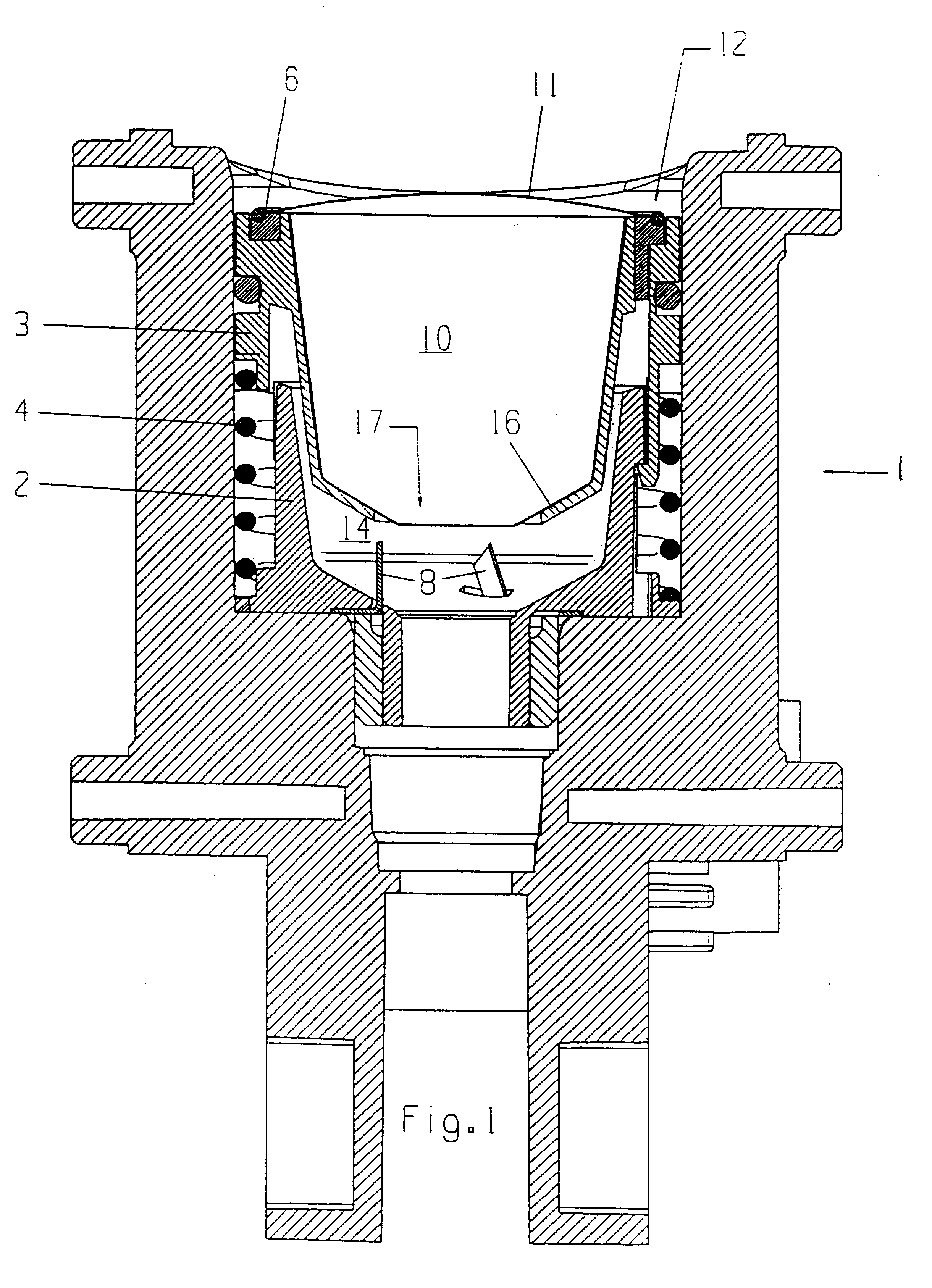

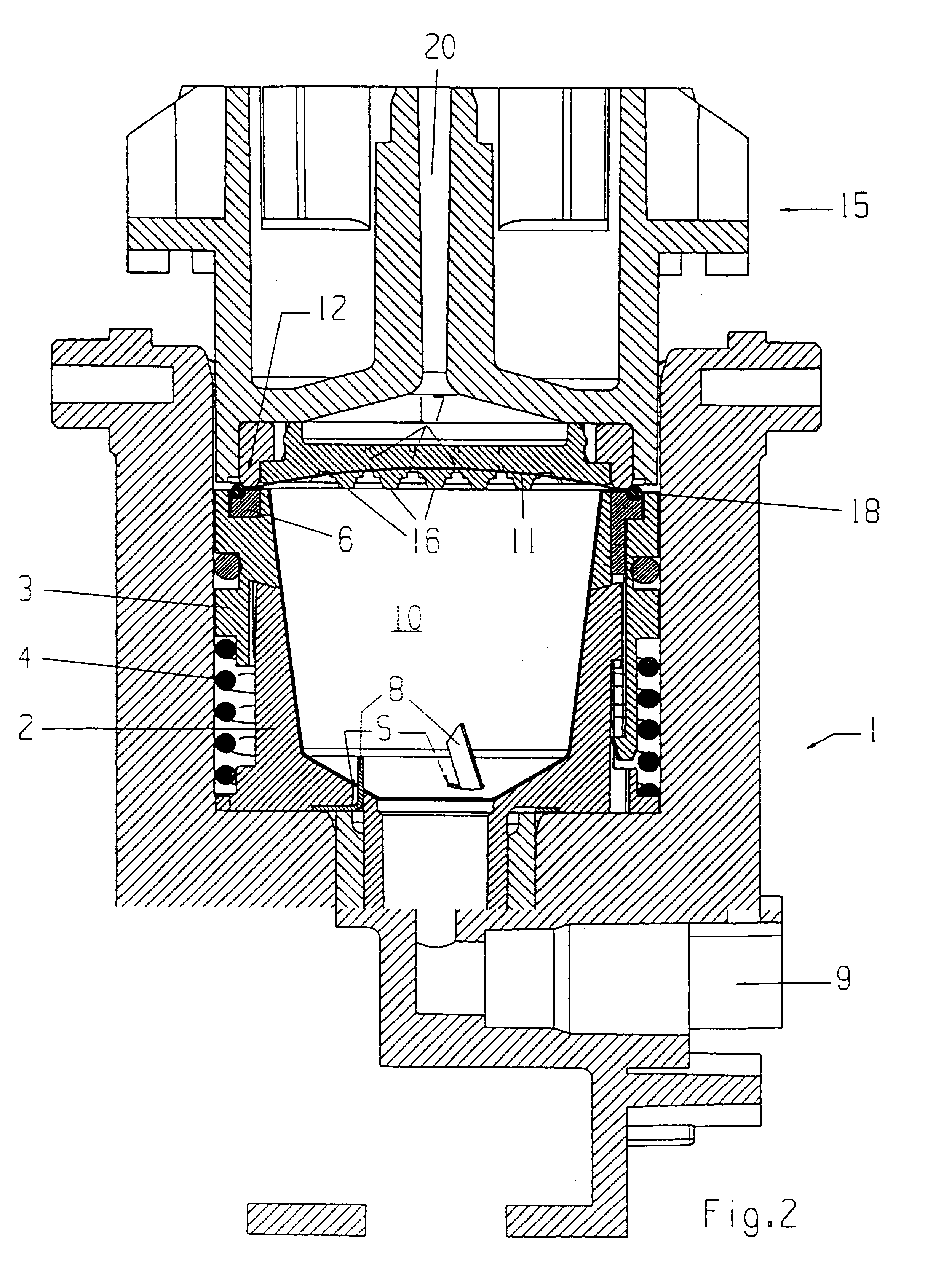

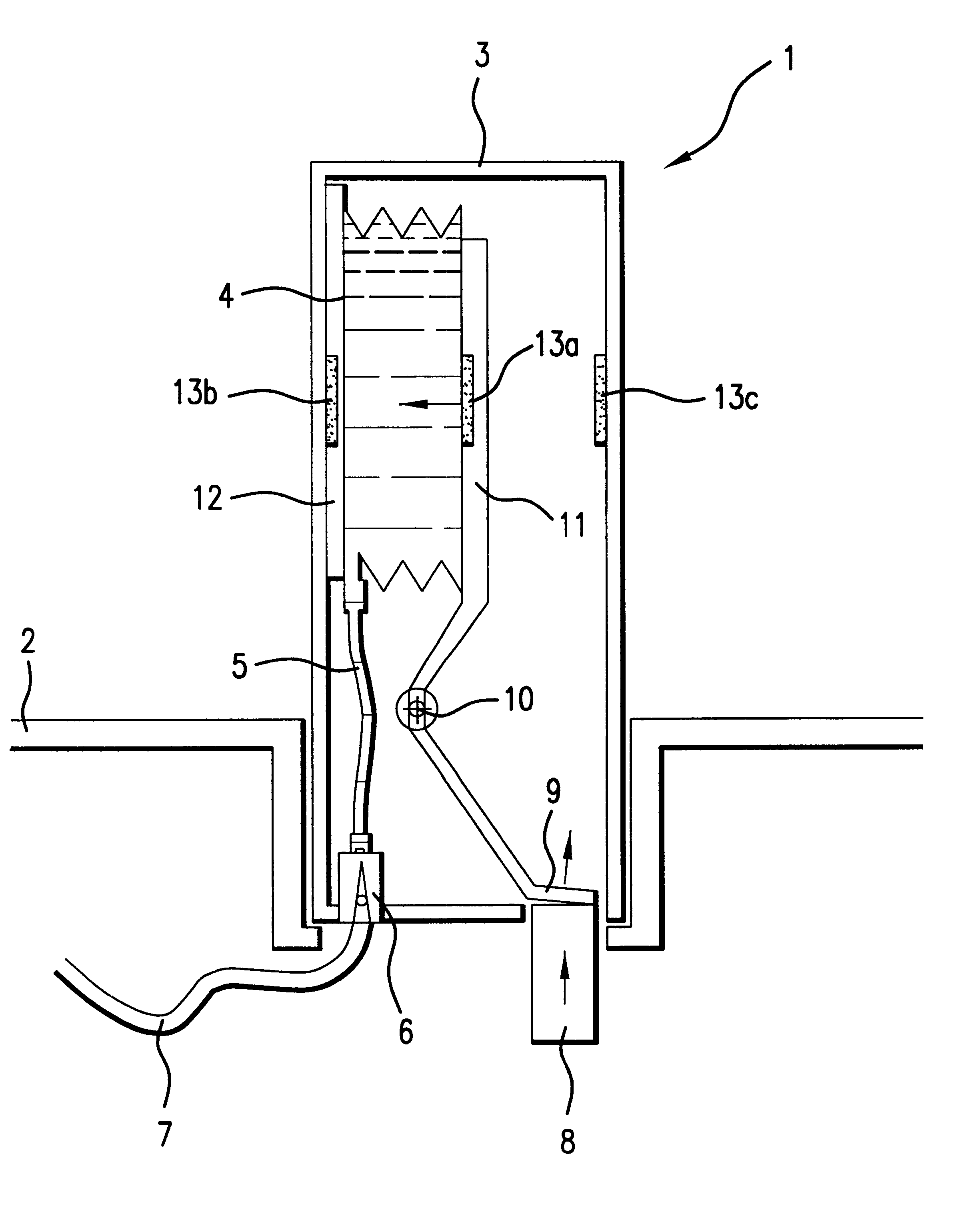

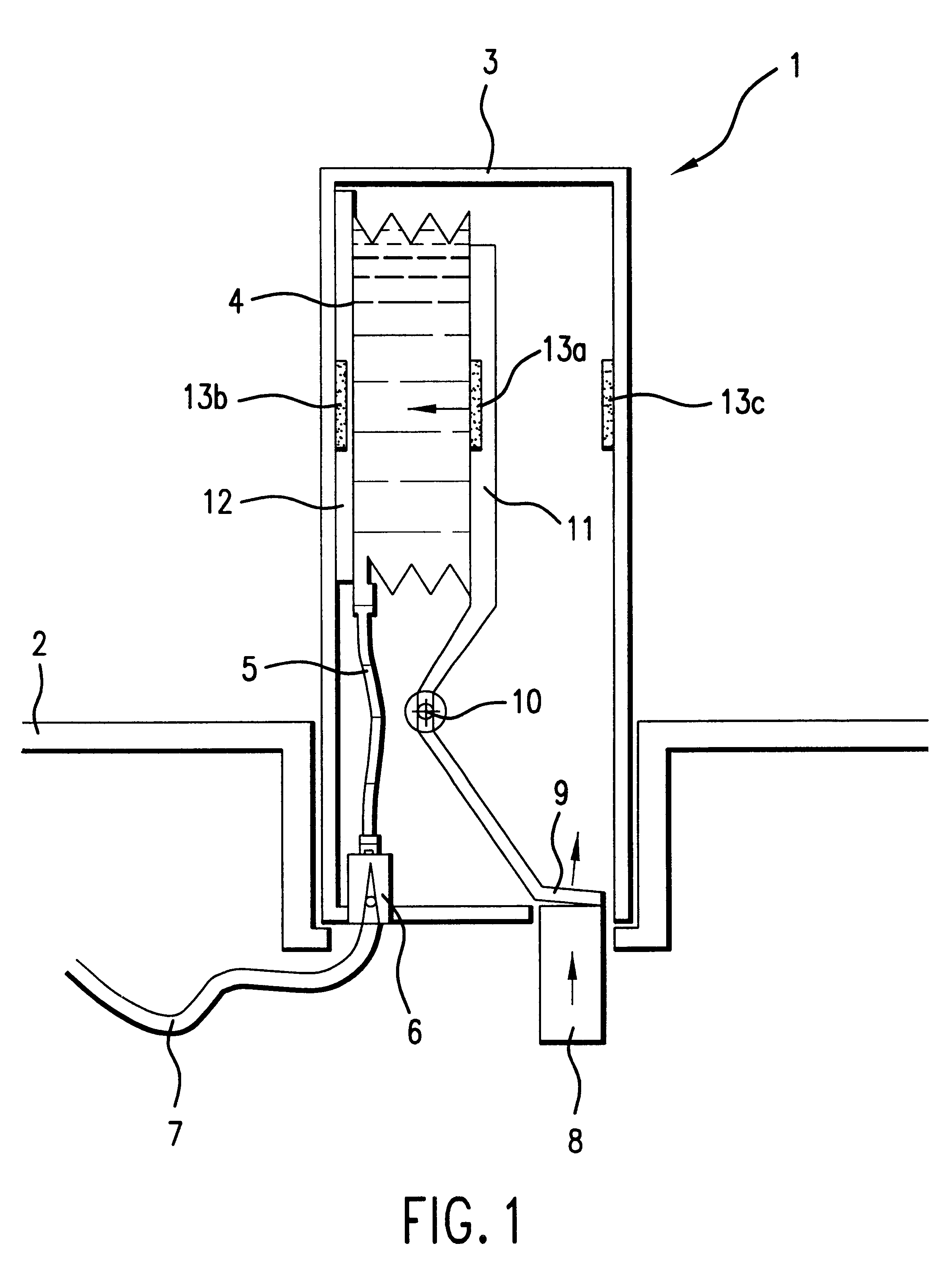

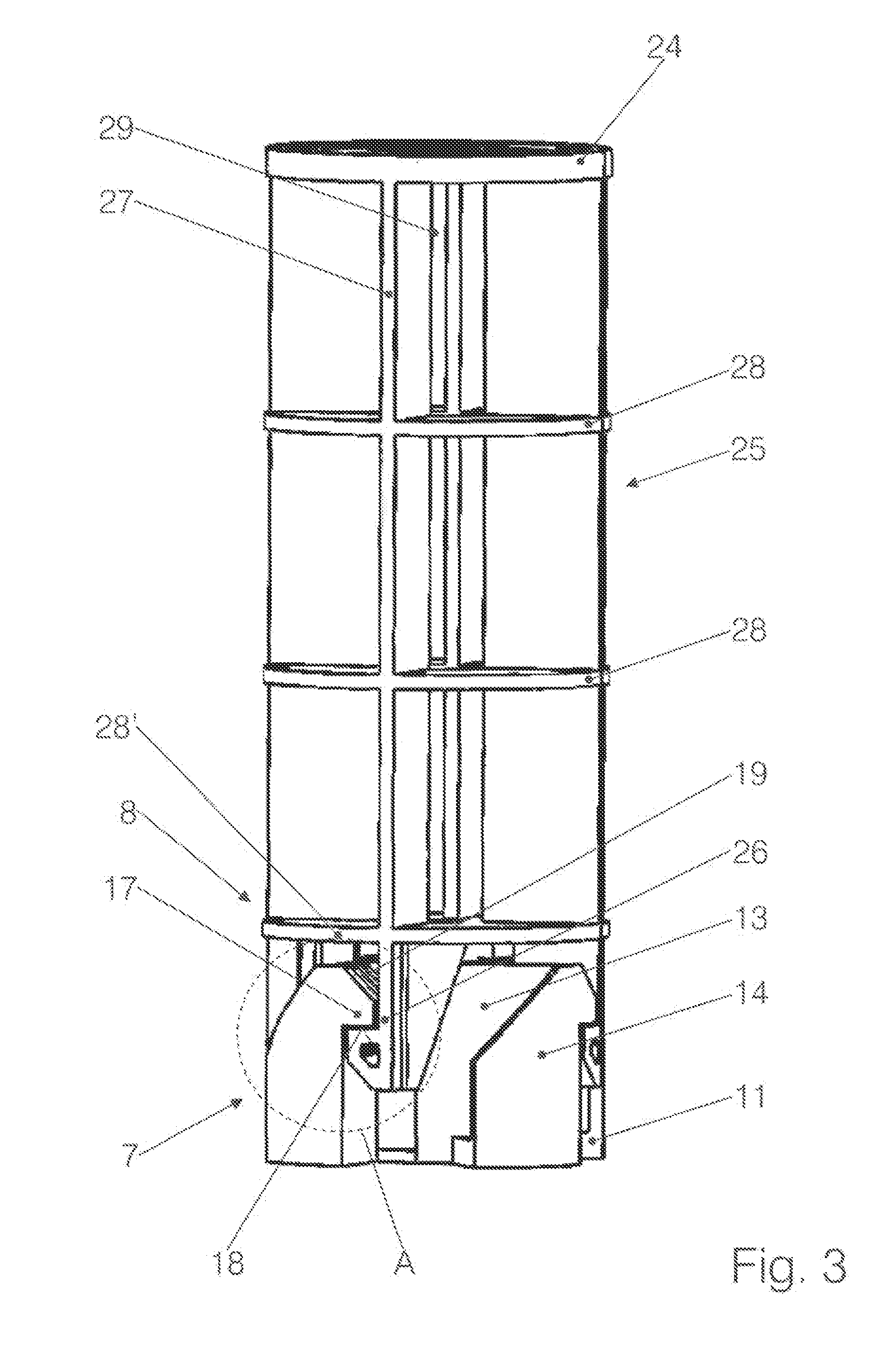

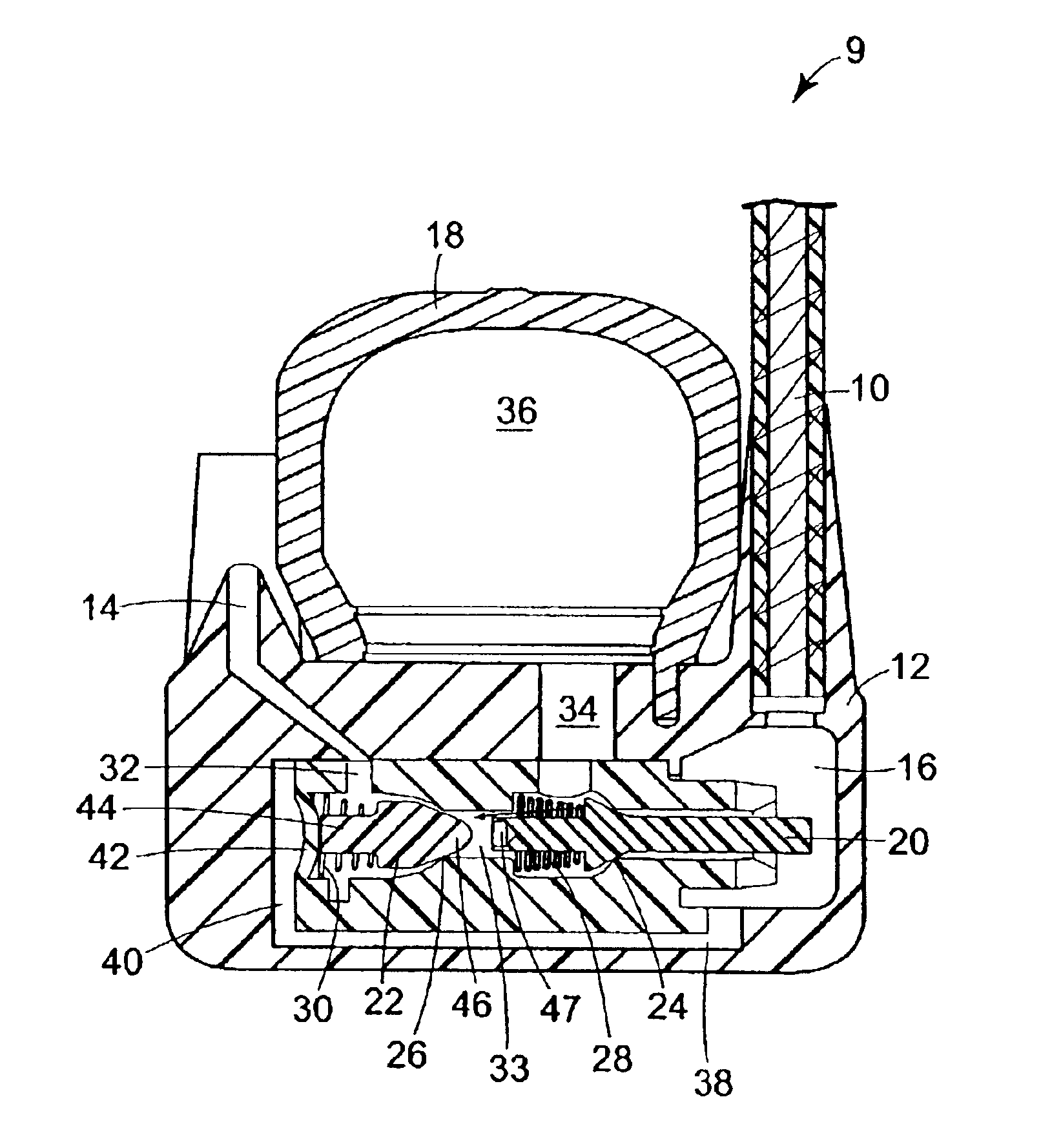

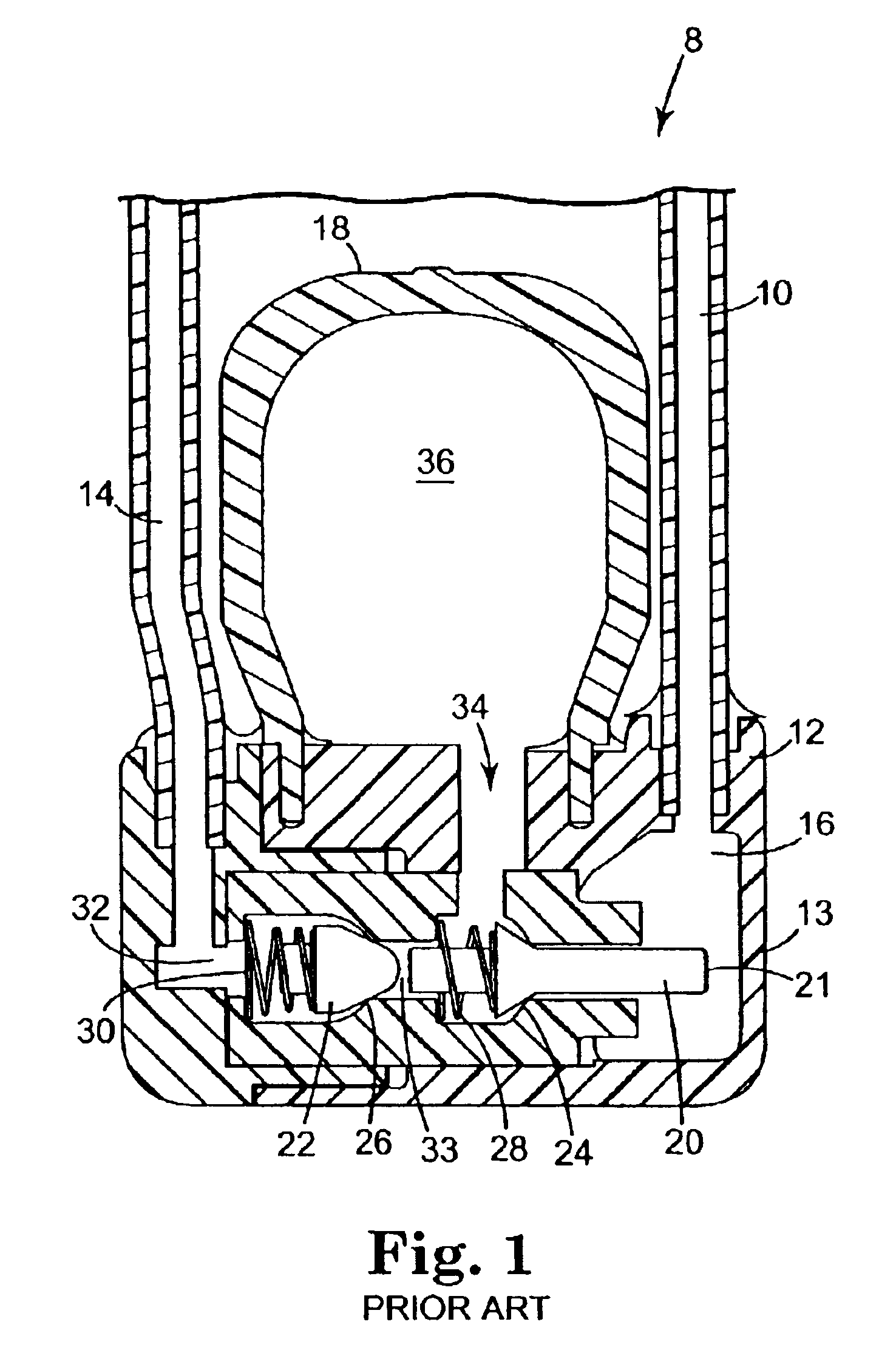

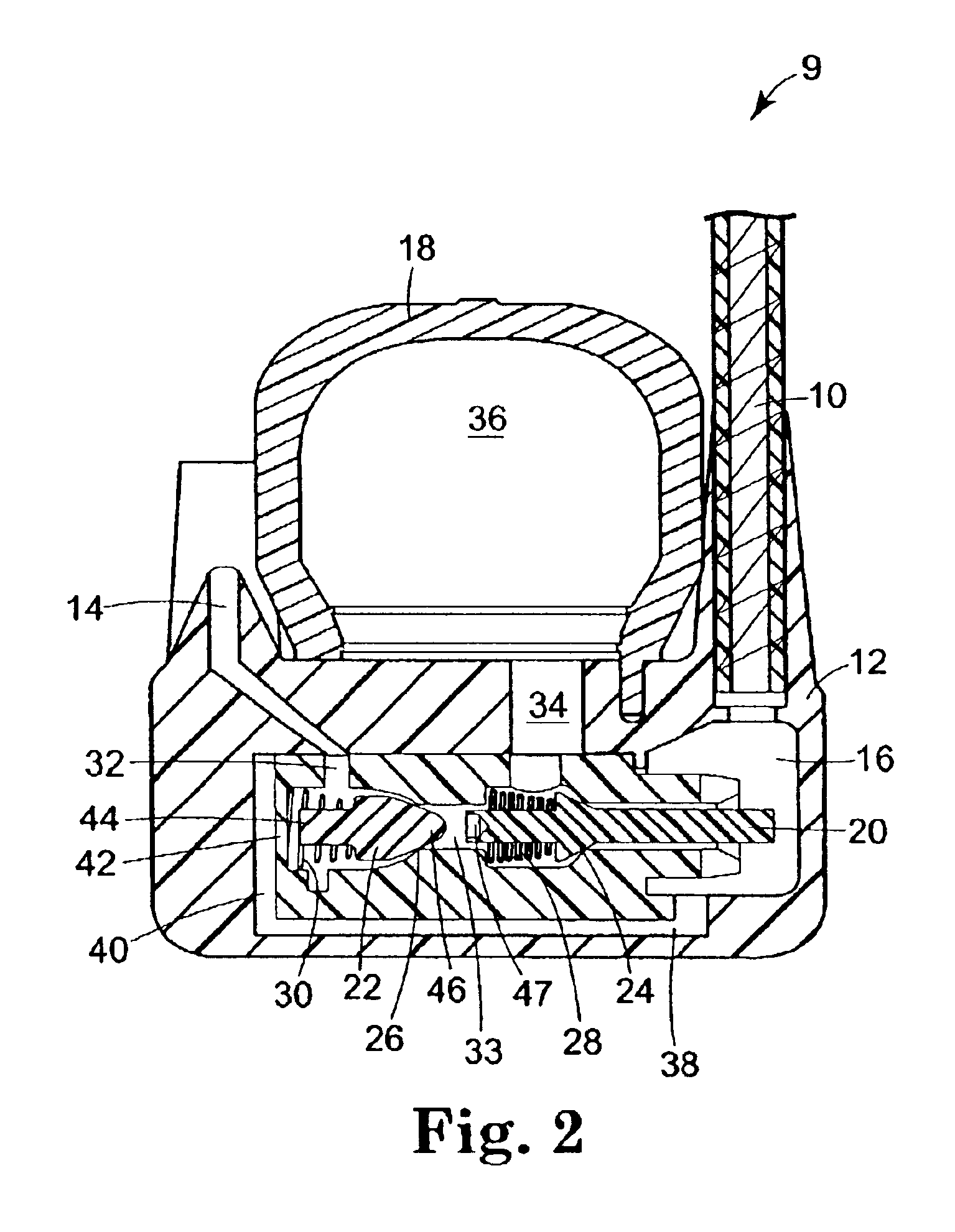

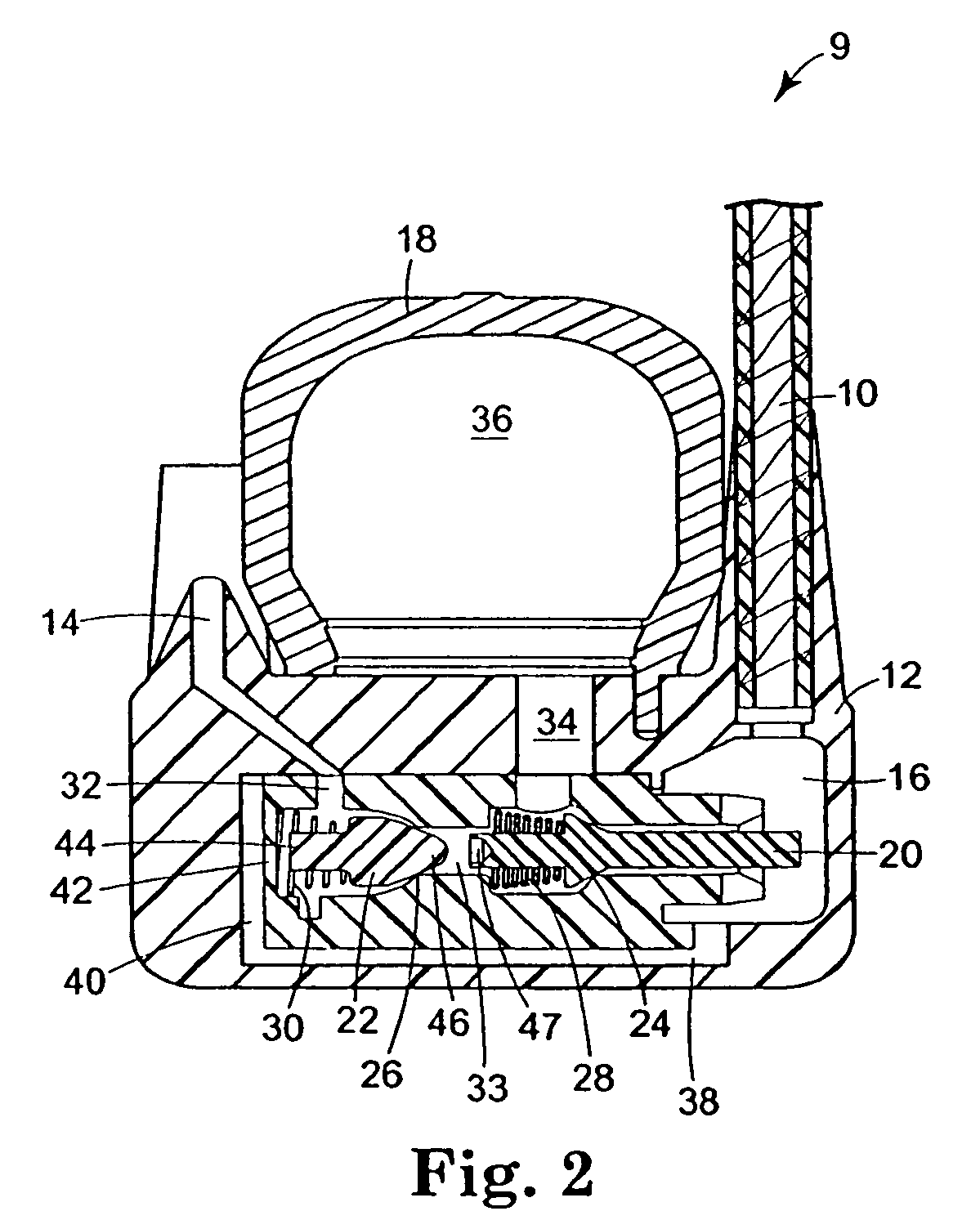

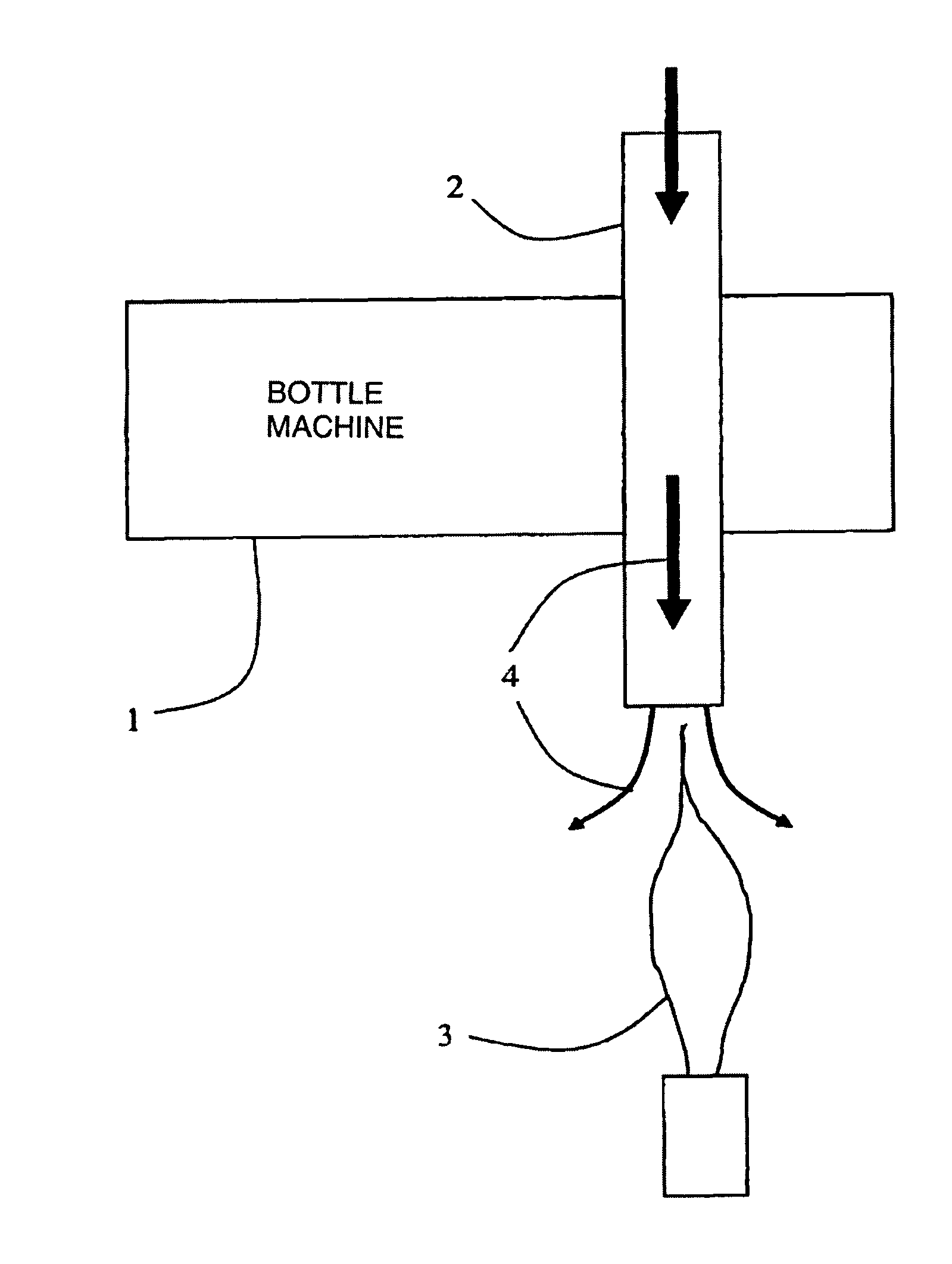

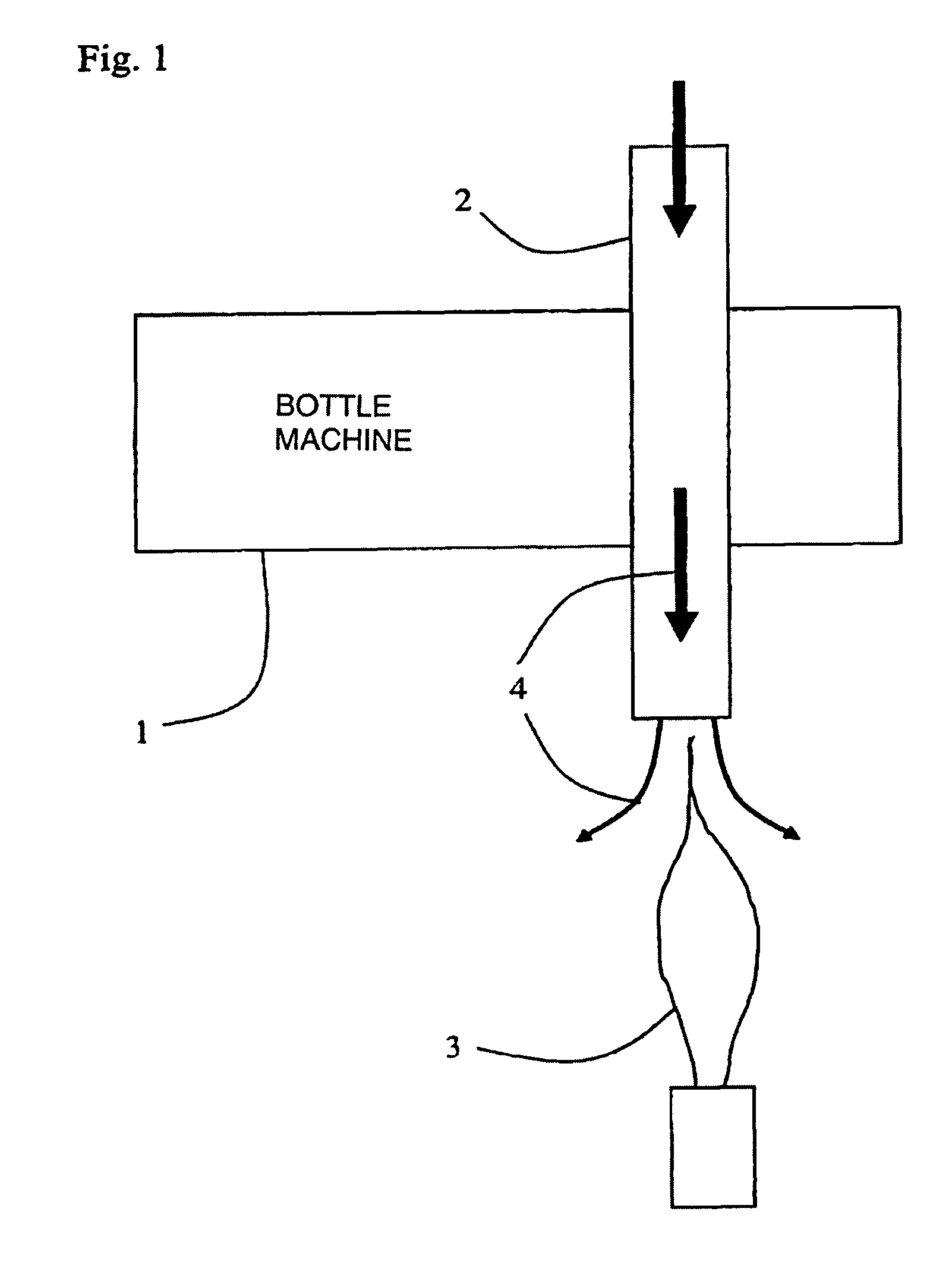

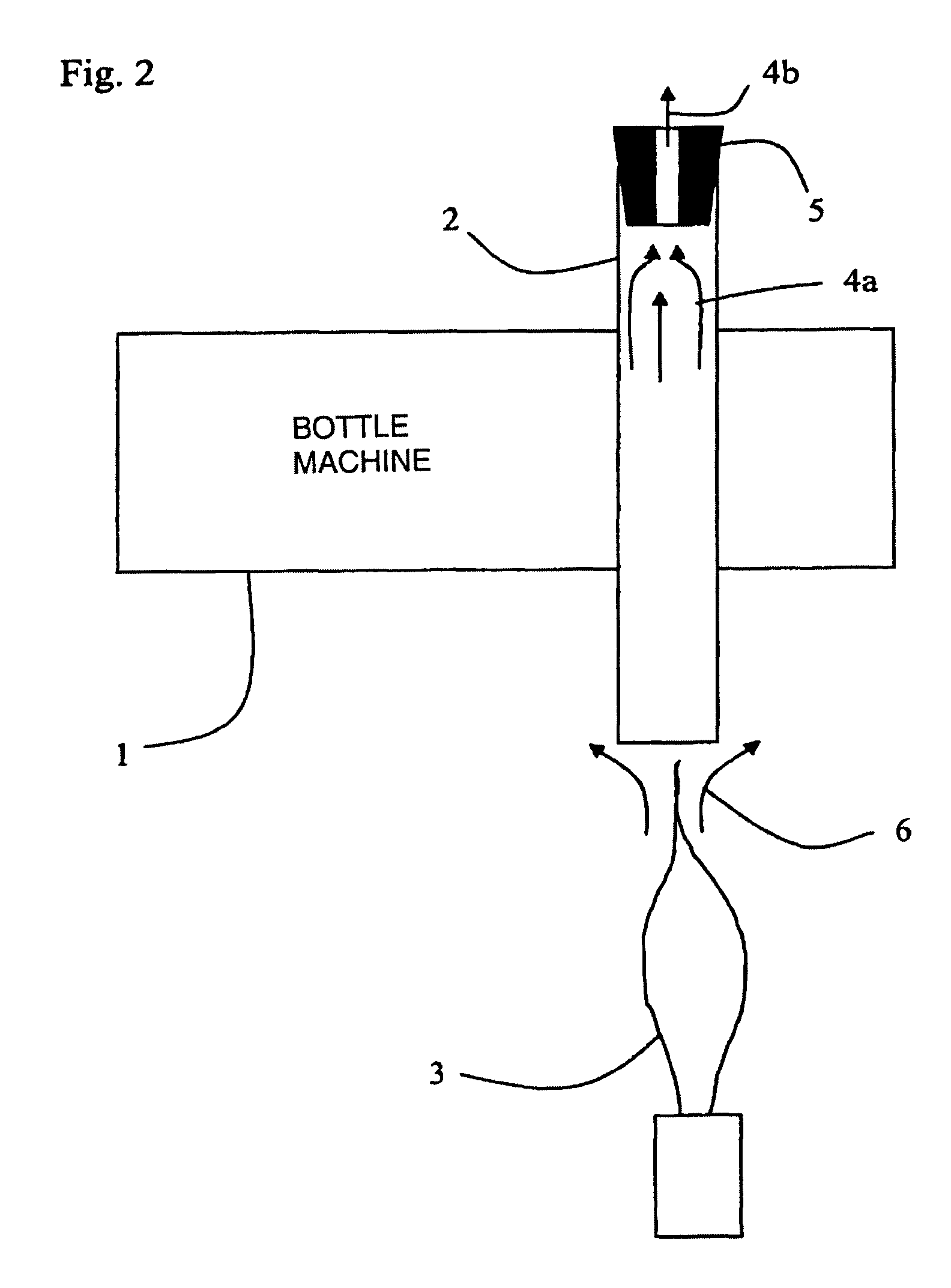

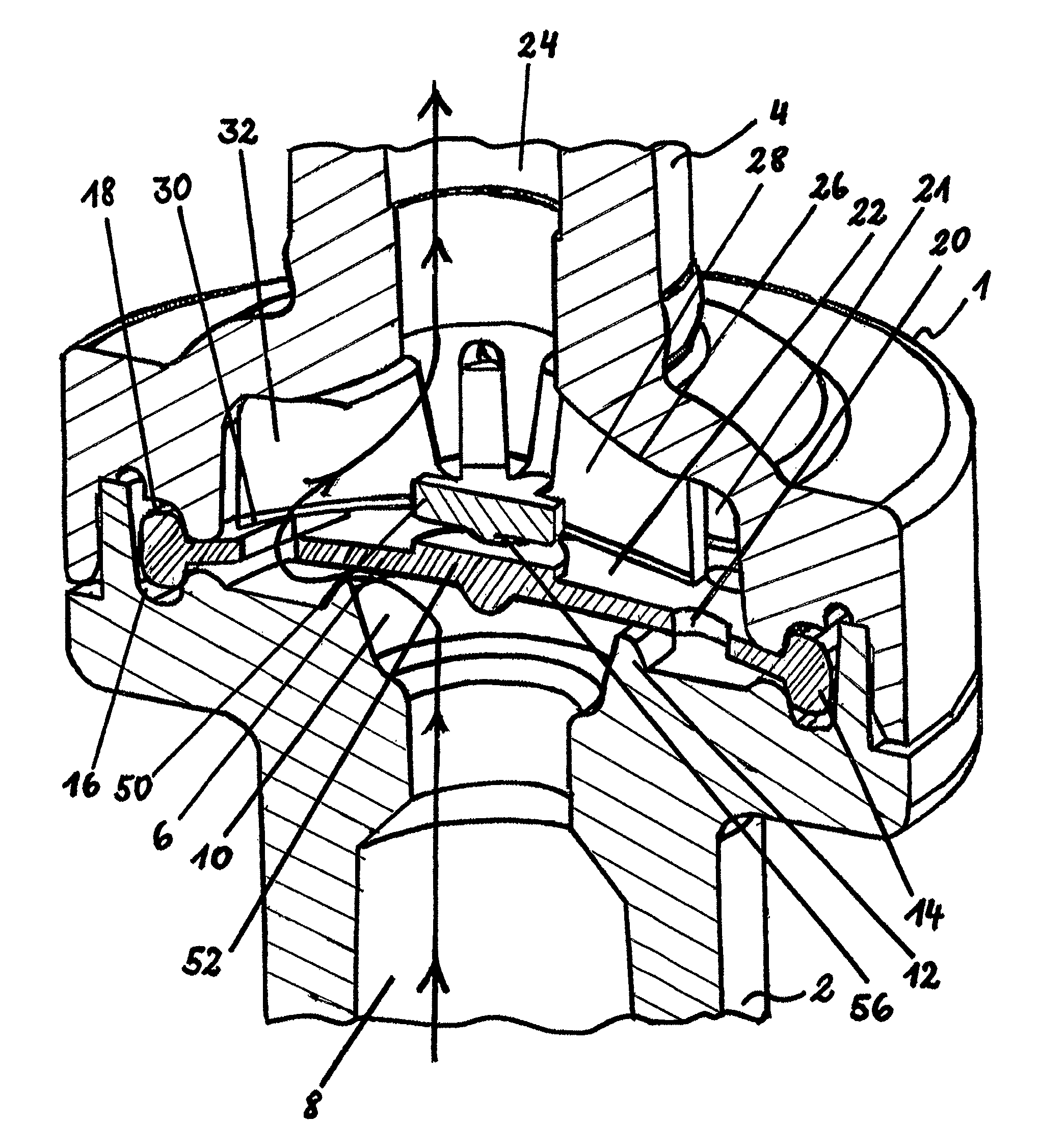

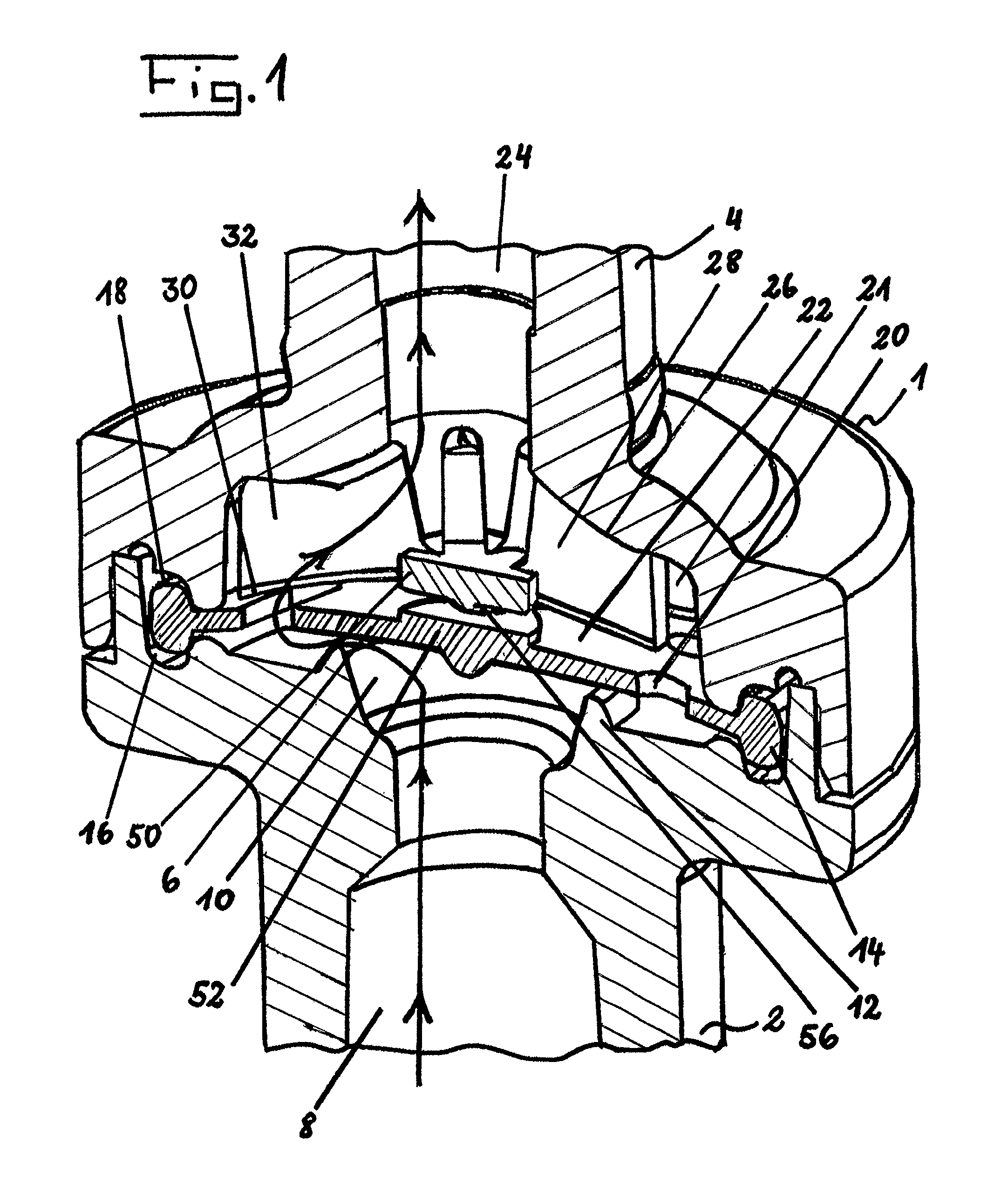

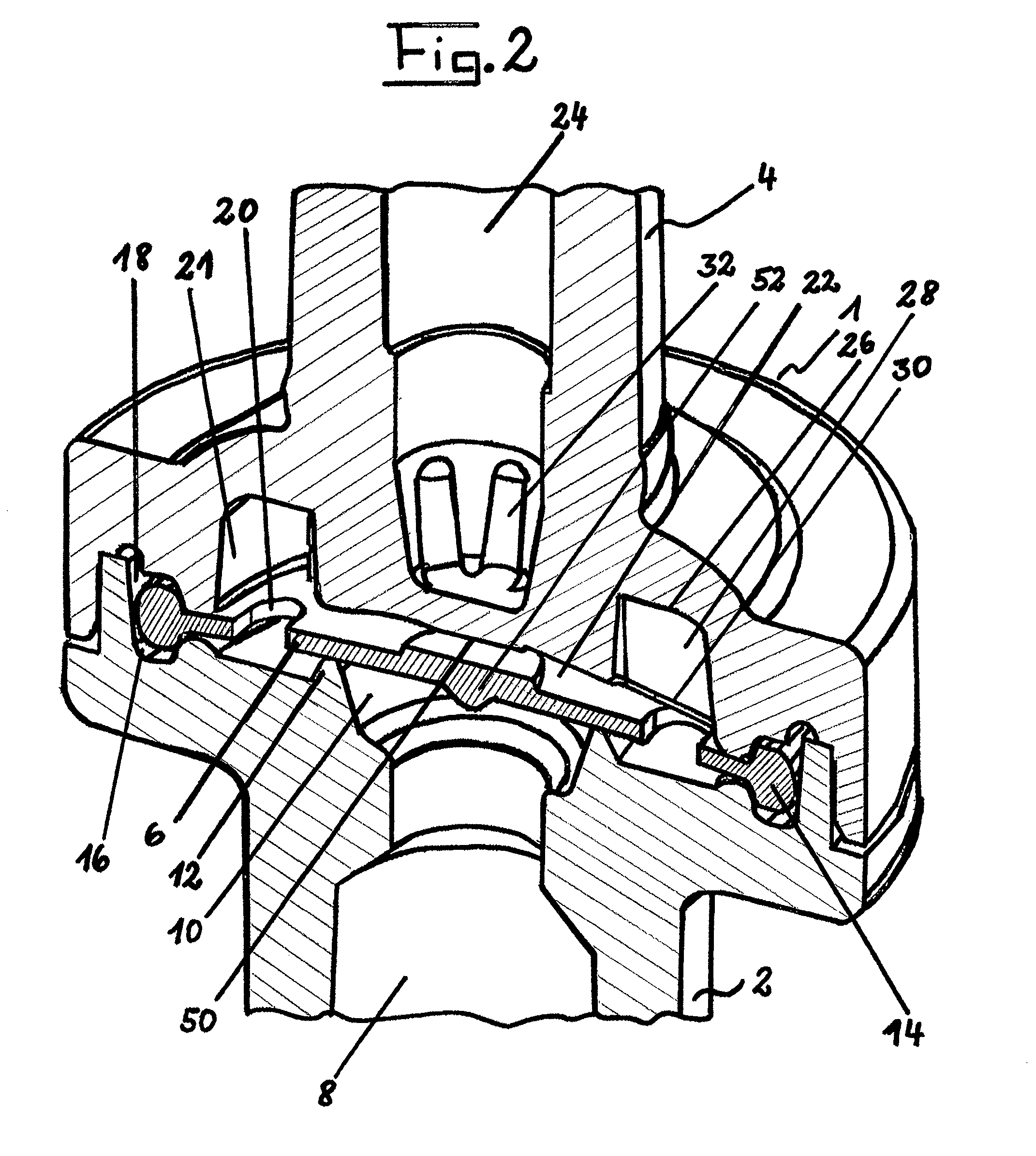

Coffee machine for brewing coffee power pre-packed in a cartridge

Proposed is a coffee machine for brewing coffee powder pre-packed in a cartridge. For perforating the cartridge, the bottom of the brewing chamber is provided with inclined perforator members which provide the cartridge with elongate slots that have a greater cross section than the cross section of the particular perforator member. A brewing chamber housing receives two chamber portions delimiting the brewing chamber. The upper chamber portion is adapted to vertically support the cartridge and biased by a spring. For closing the chamber, the brewing chamber housing is raised against a closure piston. The closure piston entering the brewing chamber moves the upper chamber portion against the force of the spring downwards towards the lower chamber portion. In the final position of the brewing chamber housing, the front portion of the cartridge is hydraulically sealed with regard to the rear portion of the chamber by means of sealing members. For brewing the coffee powder, the chamber is hydraulically subjected to an overpressure by means of the brewing water in such a way that the brewing water flows through the perforations into the interior of the cartridge. The front of the cartridge is perforated by means of a closure member provided with projections, such that the brewed coffee beverage can escape through the so created openings and flow to a beverage outlet.

Owner:SAECO IPR

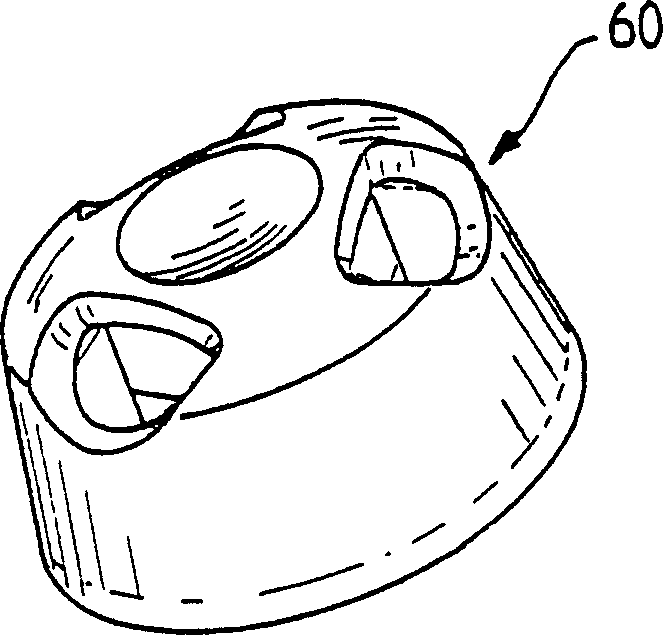

Coffee machine for brewing coffee power pre-packed in a cartridge

Proposed is a coffee machine for brewing coffee powder pre-packed in a cartridge. For perforating the cartridge, the bottom of the brewing chamber is provided with inclined perforator members which provide the cartridge with elongate slots that have a greater cross section than the cross section of the particular perforator member. A brewing chamber housing receives two chamber portions delimiting the brewing chamber. The upper chamber portion is adapted to vertically support the cartridge and biased by a spring. For closing the chamber, the brewing chamber housing is raised against a closure piston. The closure piston entering the brewing chamber moves the upper chamber portion against the force of the spring downwards towards the lower chamber portion. In the final position of the brewing chamber housing, the front portion of the cartridge is hydraulically sealed with regard to the rear portion of the chamber by sealing members. For brewing the coffee powder, the chamber is hydraulically subjected to an overpressure by the brewing water in such a way that the brewing water flows through the perforations into the interior of the cartridge. The front of the cartridge is perforated by a closure member provided with projections, such that the brewed coffee beverage can escape through the so created openings and flow to a beverage outlet.

Owner:SAECO IPR

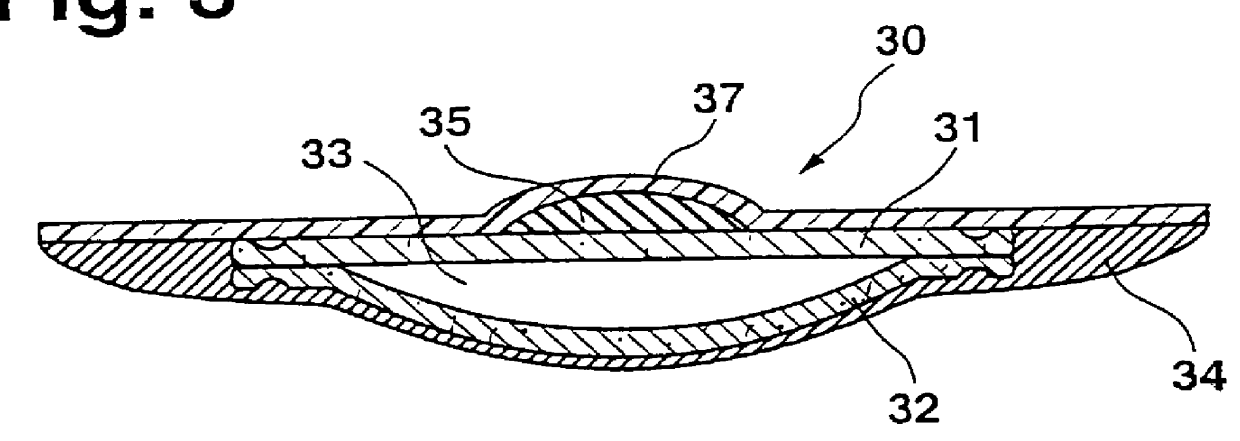

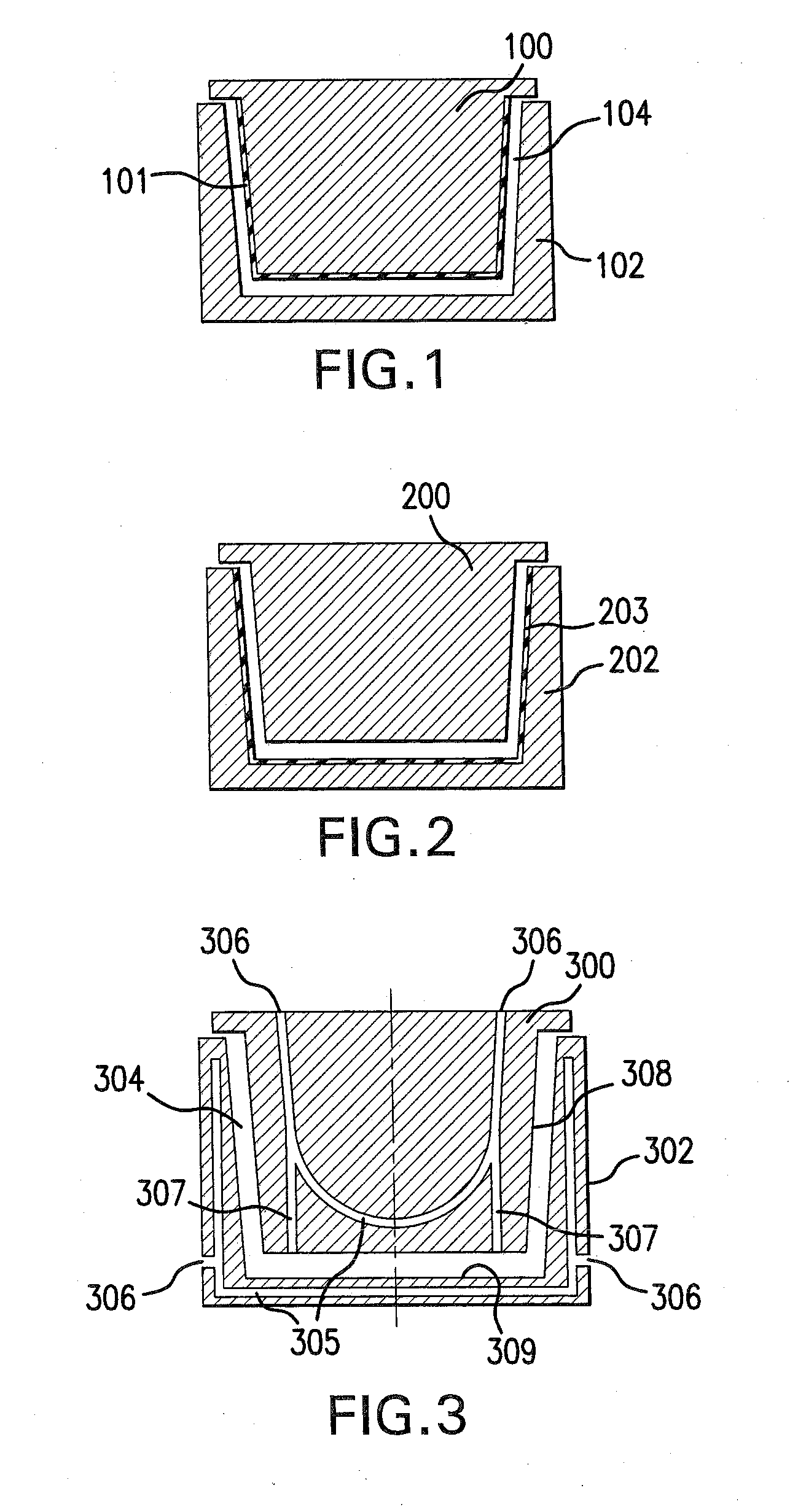

Puncture closure

InactiveUS6036721AReduced strengthWithdrawn more easilySuture equipmentsSurgical veterinaryHypodermic needleEngineering

The present invention relates to a puncture seal for sealing a blood vessel having a puncture opening in a body of a human being or an animal. The seal comprises a pressure chamber which can be attached to the body in the area of the puncture opening and subjected to an overpressure, wherein the pressure chamber has a supporting wall in an area opposite to the body. In order to create a puncture seal, in which the pressure chamber can be reliably sealed once the hypodermic needle has been removed, a sealing element made of a material with a certain elastic return force, which is at least 1 mm thick is provided and placed in the area of the support wall to be punctured by the hypodermic needle.

Owner:C A P INC

Ink supply tank for an inkjet print head

The present invention pertains to an ink supply tank for an inkjet print head that can be installed in fixed fashion in an inkjet printer, having an ink reservoir that can be connected to an ink supply line leading to an inkjet print head, and having an ink delivery device that has actuating elements accessible from the outside, which can be brought into active engagement with corresponding, motor-powered drive elements of the inkjet printer, in which the ink delivery device feeds ink into the ink supply line at overpressure upon actuation of the actuating elements. In order to reduce the manufacturing effort and ensure a high level of functional reliability with an ink supply tank of such a type, the invention suggests that the ink delivery device have a pressure-generating device that acts on the ink reservoir and is coupled with the actuating elements, and that provides the ink reservoir with overpressure when the actuating elements are driven.

Owner:ARTECH DESIGN PRODN & PLASTIC

Safety device for pressure cooker with hole

A safety device for preventing overpressure for a pressure cooker comprising a cooking pan (1) and a lid (10) provided with a handle connected to the lid by a leaf spring (21). The safety device comprises at least a safety valve (30) is mounted on the leaf spring and on the lid, characterized in that one or a plurality of safety valves are mounted in a sealed manner in a drilling in the leaf spring so as to be interposed between the leaf spring and the lid and resiliently supported against the lid and obscure the evacuation hole in the lid.

Owner:SEB SA

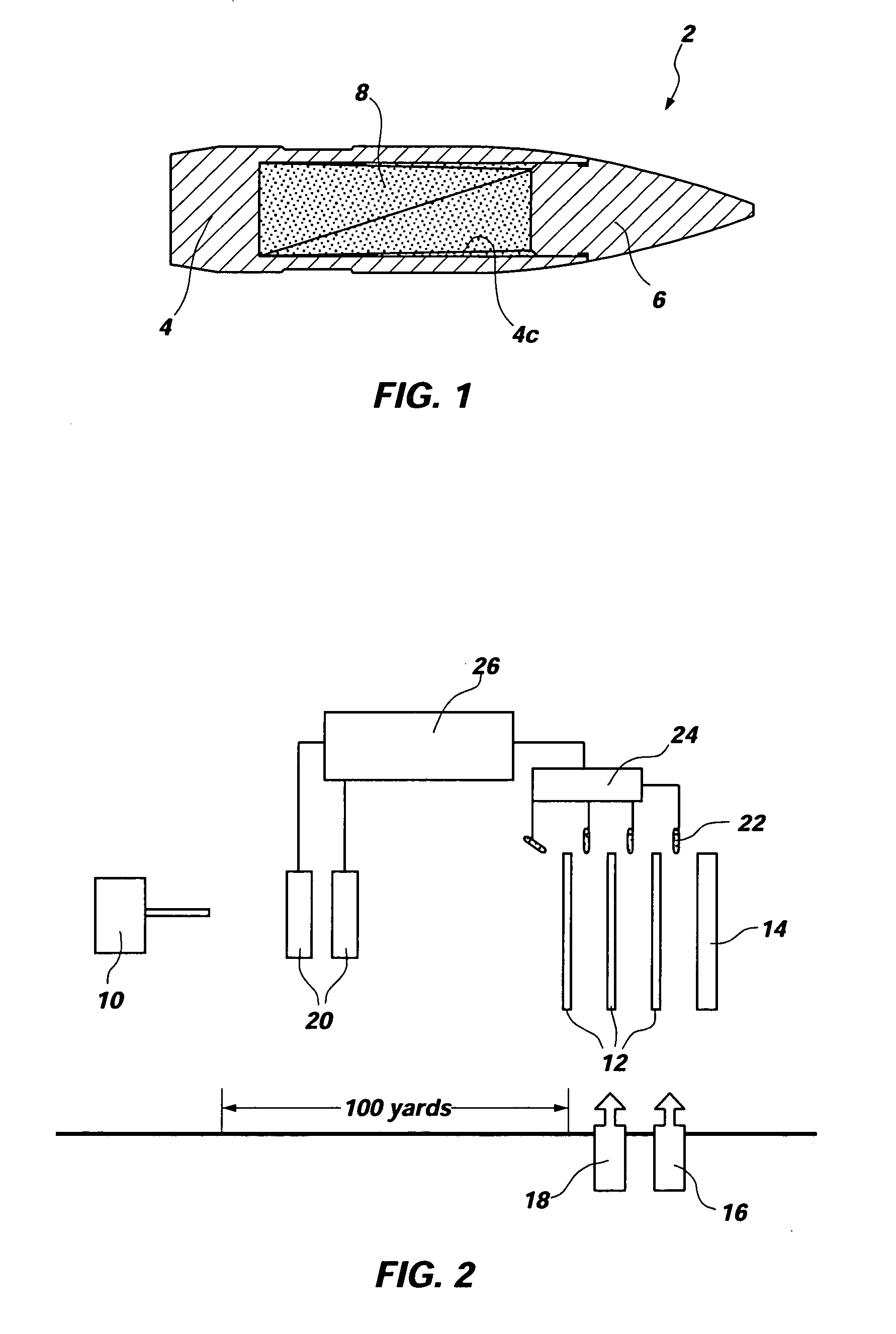

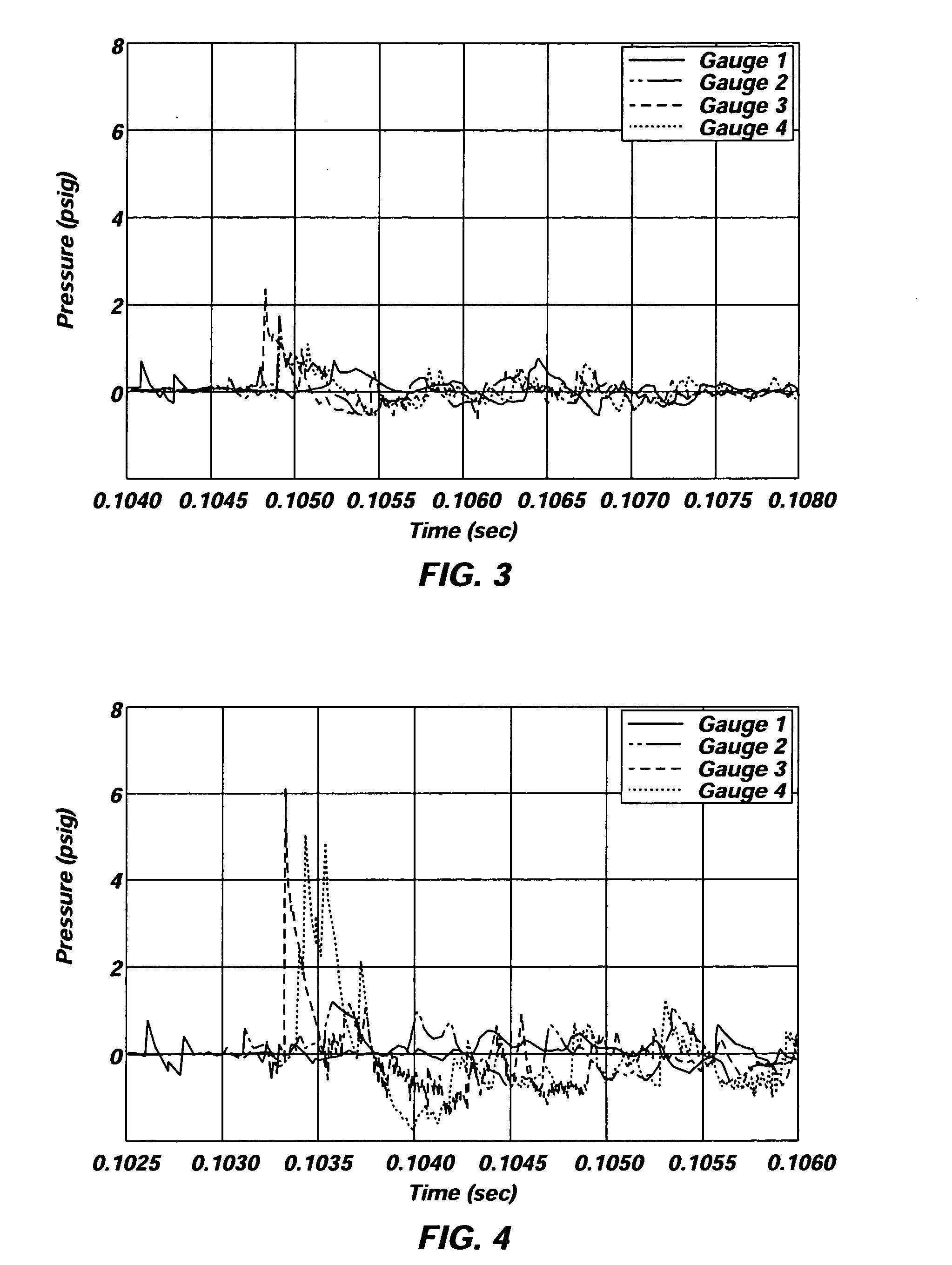

Reactive material enhanced munition compositions and projectiles containing same

A reactive material that includes at least one of a fuel, an oxidizer, and a class 1.1 explosive and is formulated for use in a reactive material projectile. The reactive material is formulated to provide at least one of an overpressure of greater than approximately 9 pounds per square inch at a radial measurement of 12 inches from a point of impact on a target, a hole greater than approximately 2 square inches at an optimum penetration level in a target, and pressure, damage, and a flame when the reactive material bullet impacts a target. The fuel may be a metal, a fusible metal alloy, an organic fuel, or mixtures thereof. The oxidizer may be an inorganic oxidizer, sulfur, a fluoropolymer, or mixtures thereof. A reactive material projectile having the reactive material disposed therein is also disclosed.

Owner:ORBITAL ATK INC

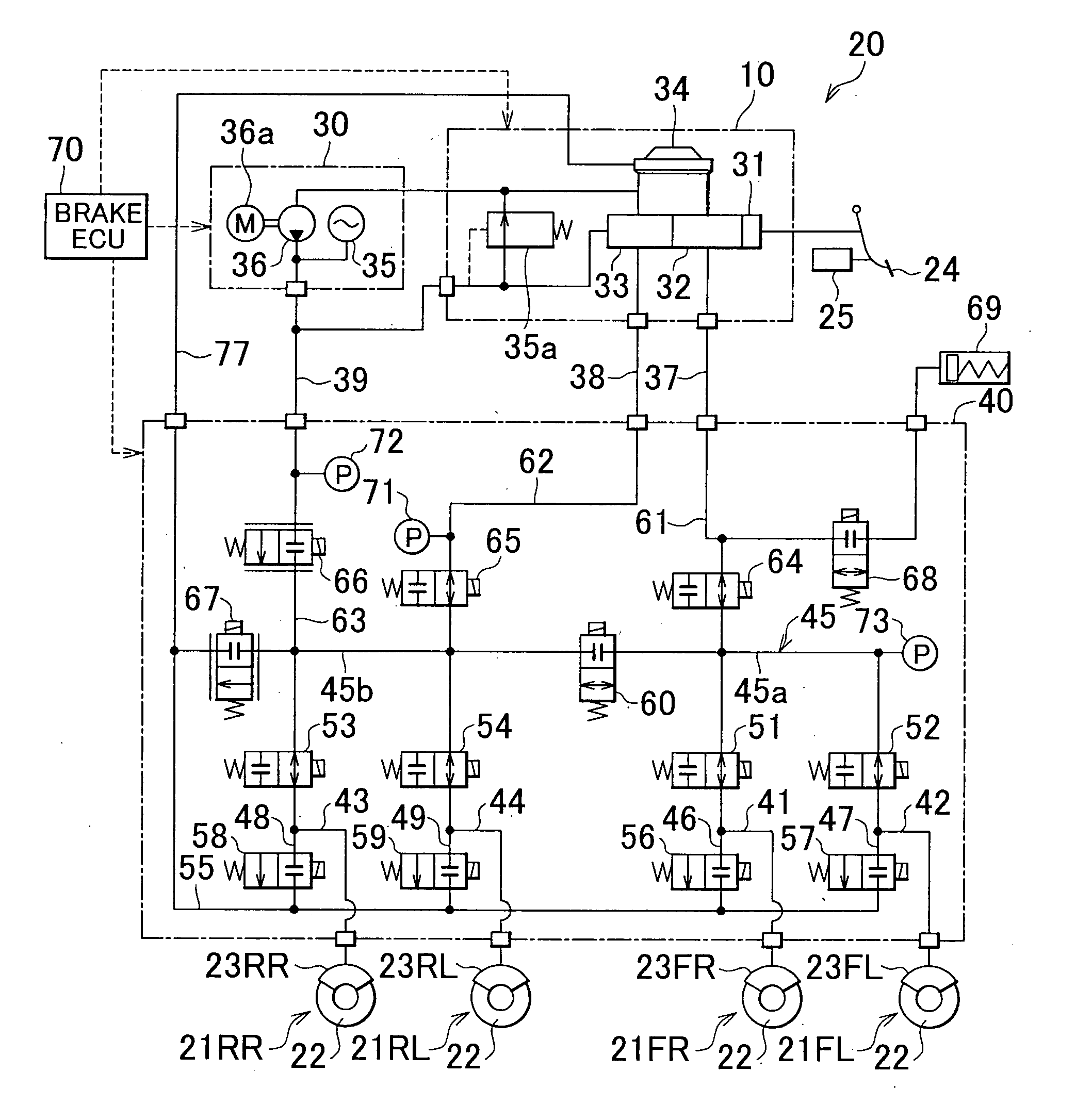

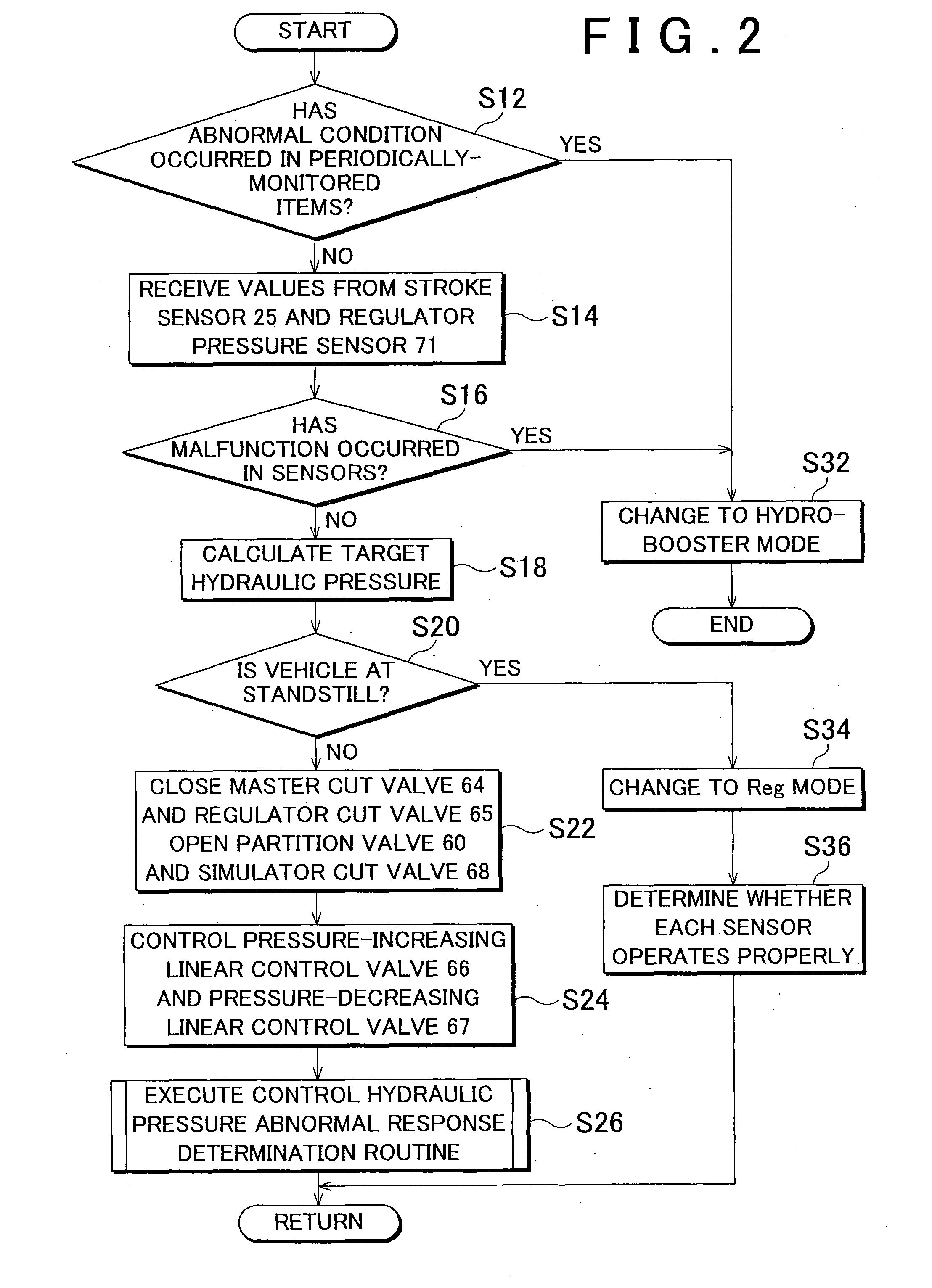

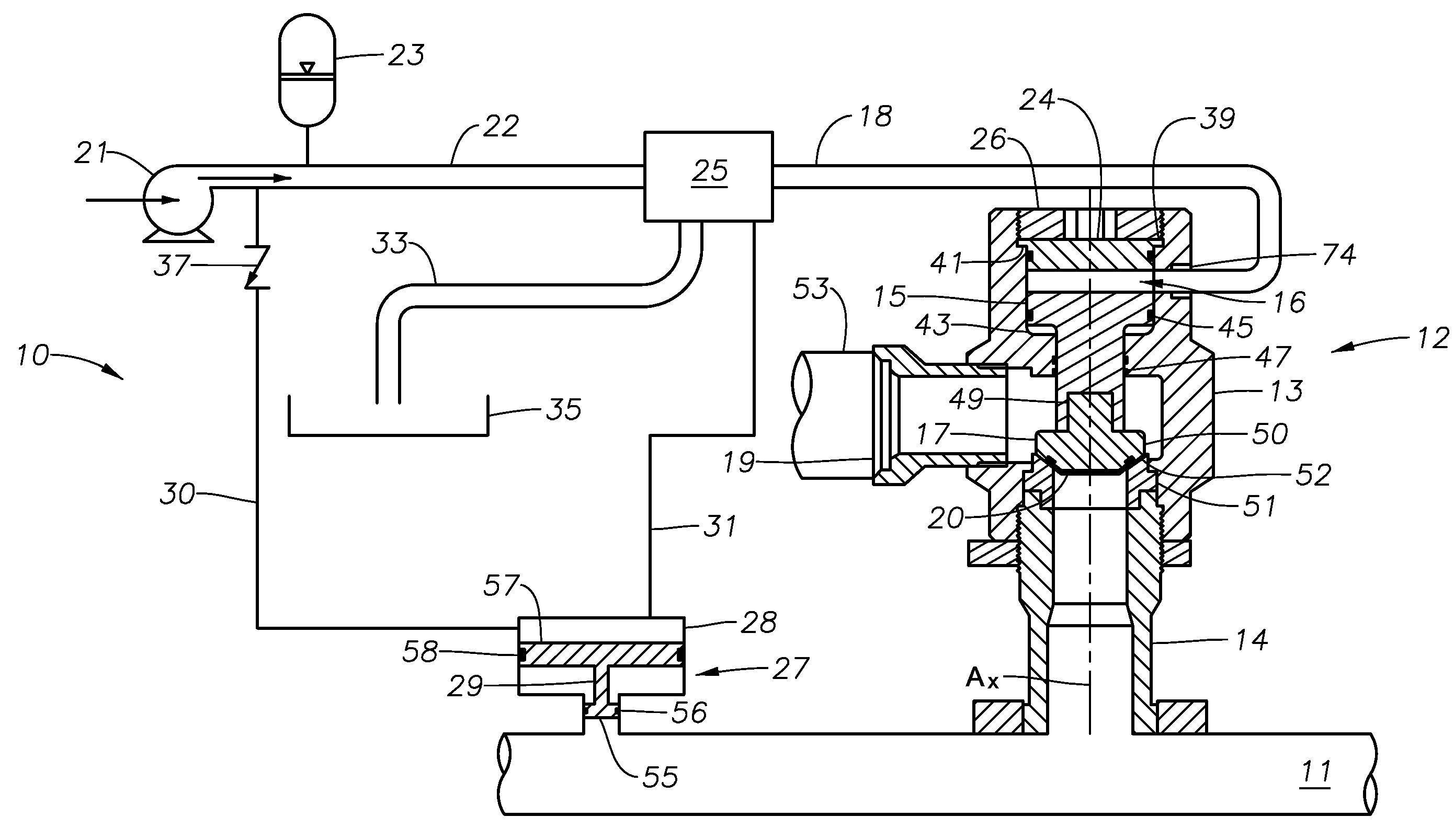

Brake control apparatus and control method for the brake control apparatus

ActiveUS20100211282A1Suppress occurrence of a malfunction in the pressure sensorAnalogue computers for trafficBraking action transmissionPressure decreaseHydraulic circuit

In a brake control apparatus that controls braking forces which are applied to wheels based on the pressure of the hydraulic fluid, when the pressure detected by a control pressure sensor (73) is equal to or higher than a predetermined value while a partition valve (60) is closed, a master cut valve (64) is closed to suppress an increase in the pressure in a first passage (45) in a first hydraulic circuit (37), to which the control pressure sensor (73) is connected. Alternatively, the control pressure sensor (73) is protected against overpressure by opening the outlet valve (56,57) or the pressure-decreasing valve (67).

Owner:TOYOTA JIDOSHA KK

Hydraulic Unloading Valve

InactiveUS20100154894A1Relieve pressureAvoid flowCheck valvesEqualizing valvesControl systemEngineering

A pressure relief system for a reciprocating pumping system that deintensifies pressure from the pumping system and controls relief operation with the deintensified pressure. The relief system includes a relief valve connected to the pumping system and a control system that selectively opens the relief valve when an overpressure is sensed in the pumping system. To keep the relief valve in a closed position, the control system maintains a backpressure on the relief valve using the deintensified pressure. A dump valve in the control system selectively vents the backpressure so the relief valve can open. A charging system can be used for charging the control system and for reseating the relief valve.

Owner:WEIR SPM

Passive blast pressure sensor

ActiveUS20100275676A1Easy and quick to readChange colorFuel testingAcceleration measurementChange colorEngineering

A passive blast pressure sensor for detecting blast overpressures of at least a predetermined minimum threshold pressure. The blast pressure sensor includes a piston-cylinder arrangement with one end of the piston having a detection surface exposed to a blast event monitored medium through one end of the cylinder and the other end of the piston having a striker surface positioned to impact a contact stress sensitive film that is positioned against a strike surface of a rigid body, such as a backing plate. The contact stress sensitive film is of a type which changes color in response to at least a predetermined minimum contact stress which is defined as a product of the predetermined minimum threshold pressure and an amplification factor of the piston. In this manner, a color change in the film arising from impact of the piston accelerated by a blast event provides visual indication that a blast overpressure encountered from the blast event was not less than the predetermined minimum threshold pressure.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

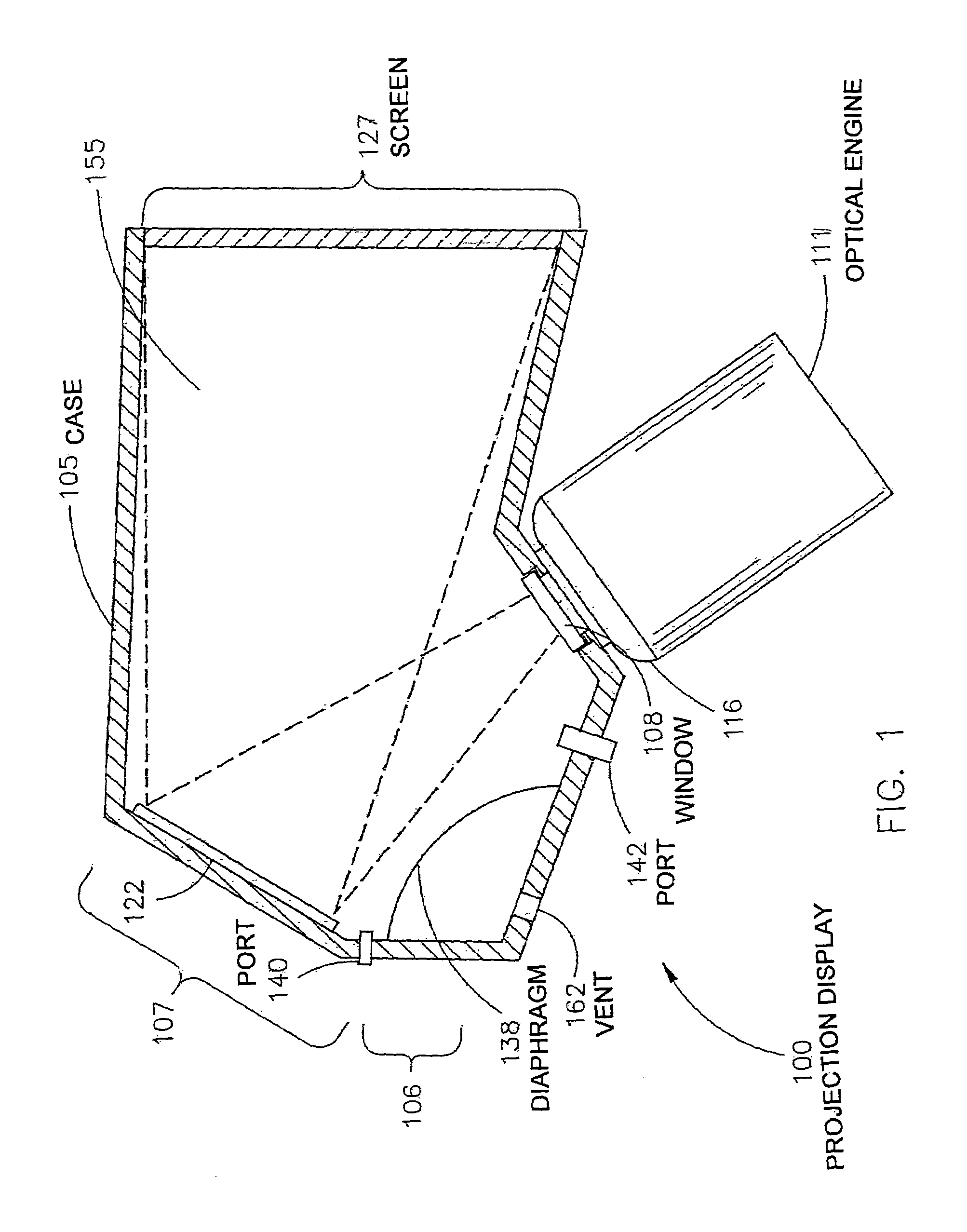

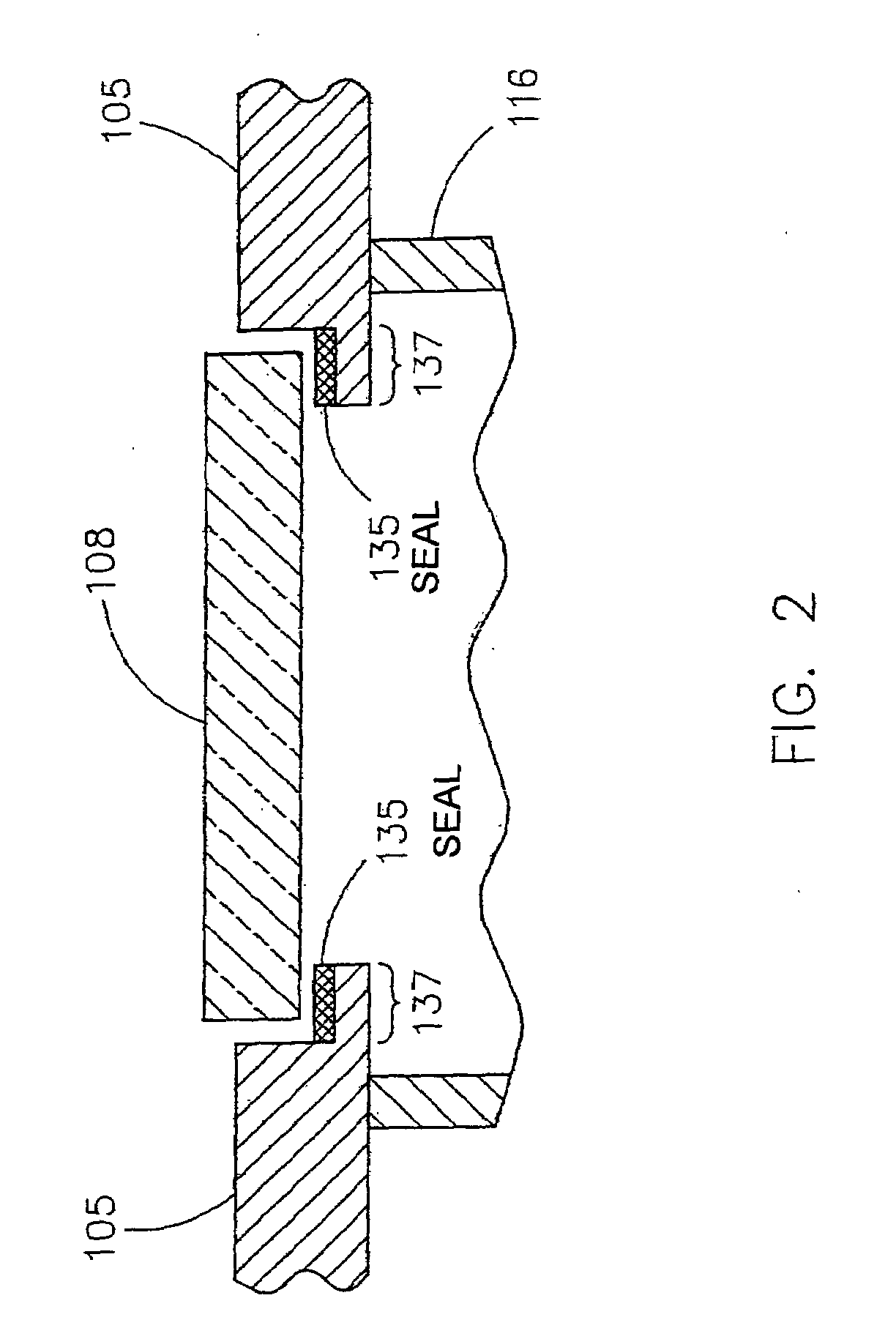

Projection display for a aircraft cockpit environment

ActiveUS6972788B1Television system detailsCosmonautic condition simulationsWindow openingDisplay device

A projection display is provided according to one embodiment of the invention. The projection display includes a hollow case including a window opening, a screen formed on one portion of the case, and at least one mirror internally mounted to the case at a position to reflect light from the window opening to the screen. The projection display further includes a window mounted in the window opening. The projection display further includes an optical engine mounted to the case. The optical engine is positioned over the window and oriented so that emitted light from the optical engine is directed onto the at least one mirror. The projection display further includes a diaphragm internally attached to the case and dividing an internal volume of the case into a first portion and a second portion. The projection display further includes a gas filling the second portion of the case at an overpressure and a vent communicating with the first portion of the case and communicating with an external environment. The vent at least partially equalizes the overpressure of the second portion with a pressure of the external environment.

Owner:ROCKWELL COLLINS INC

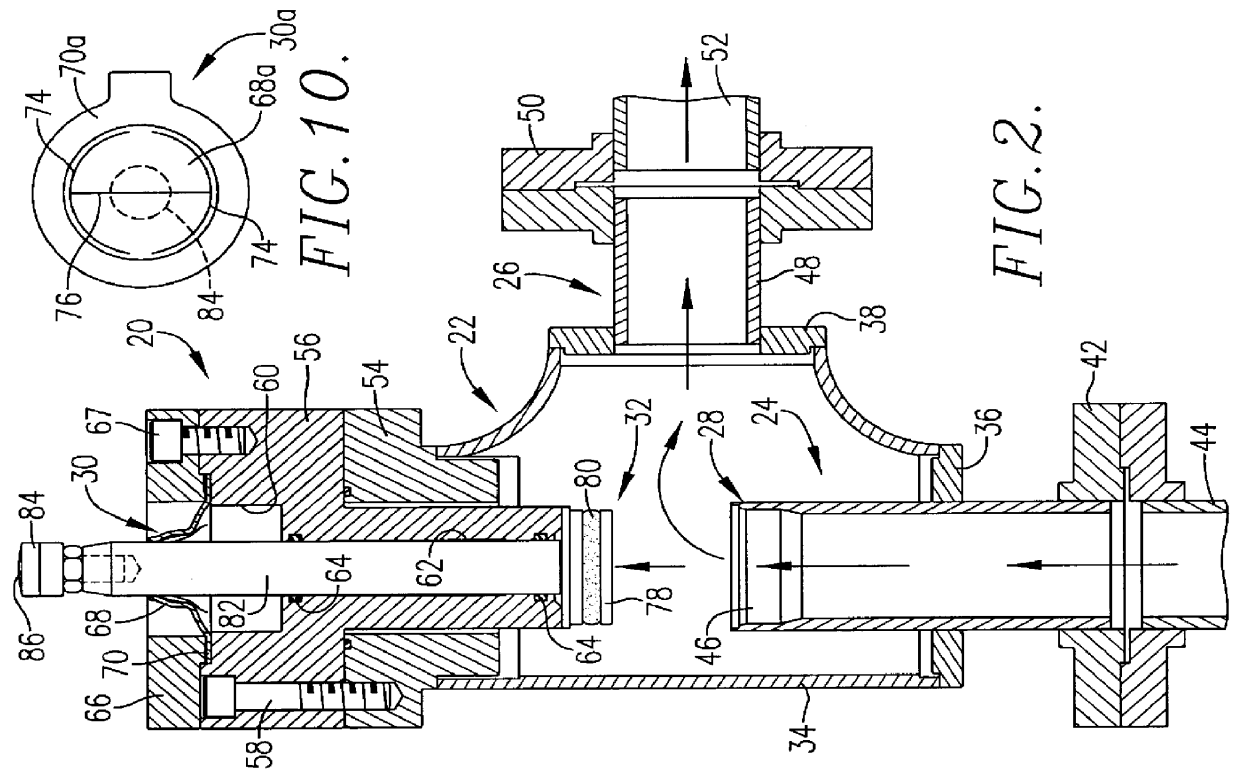

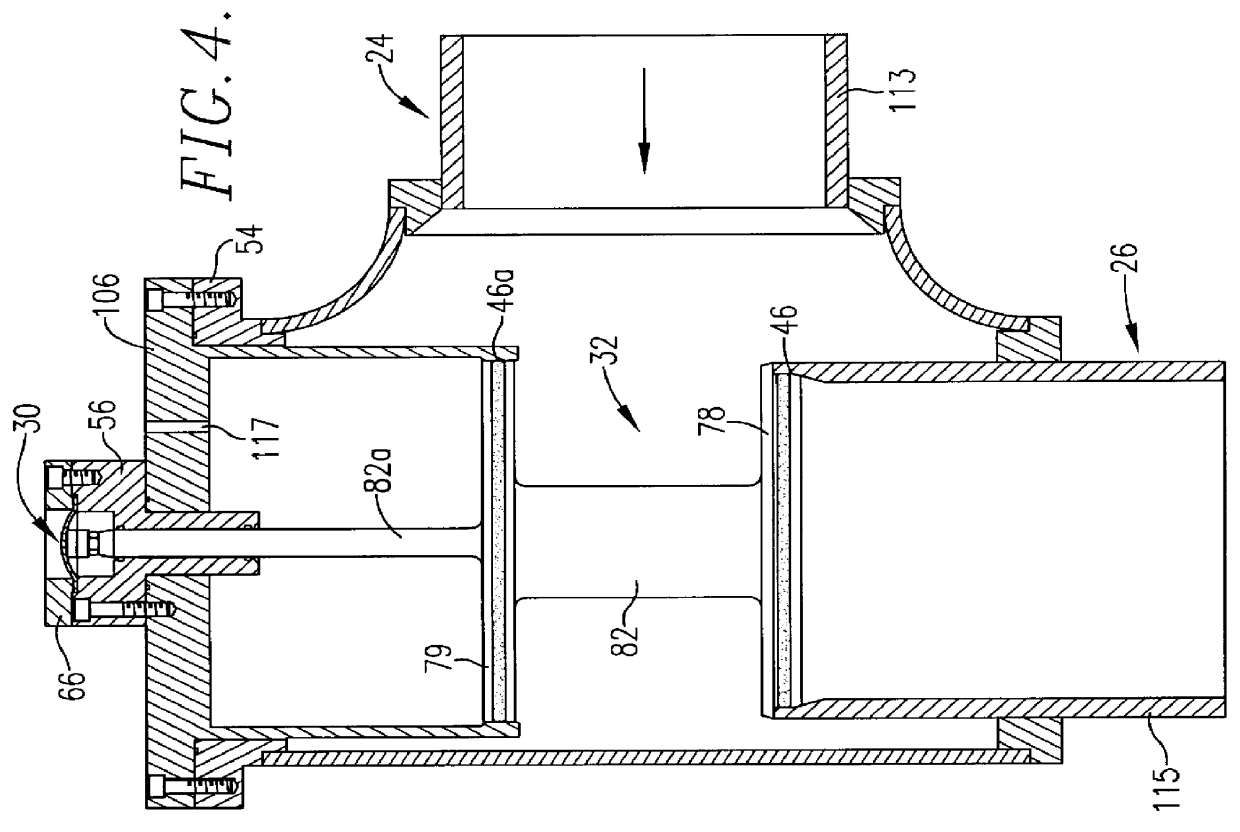

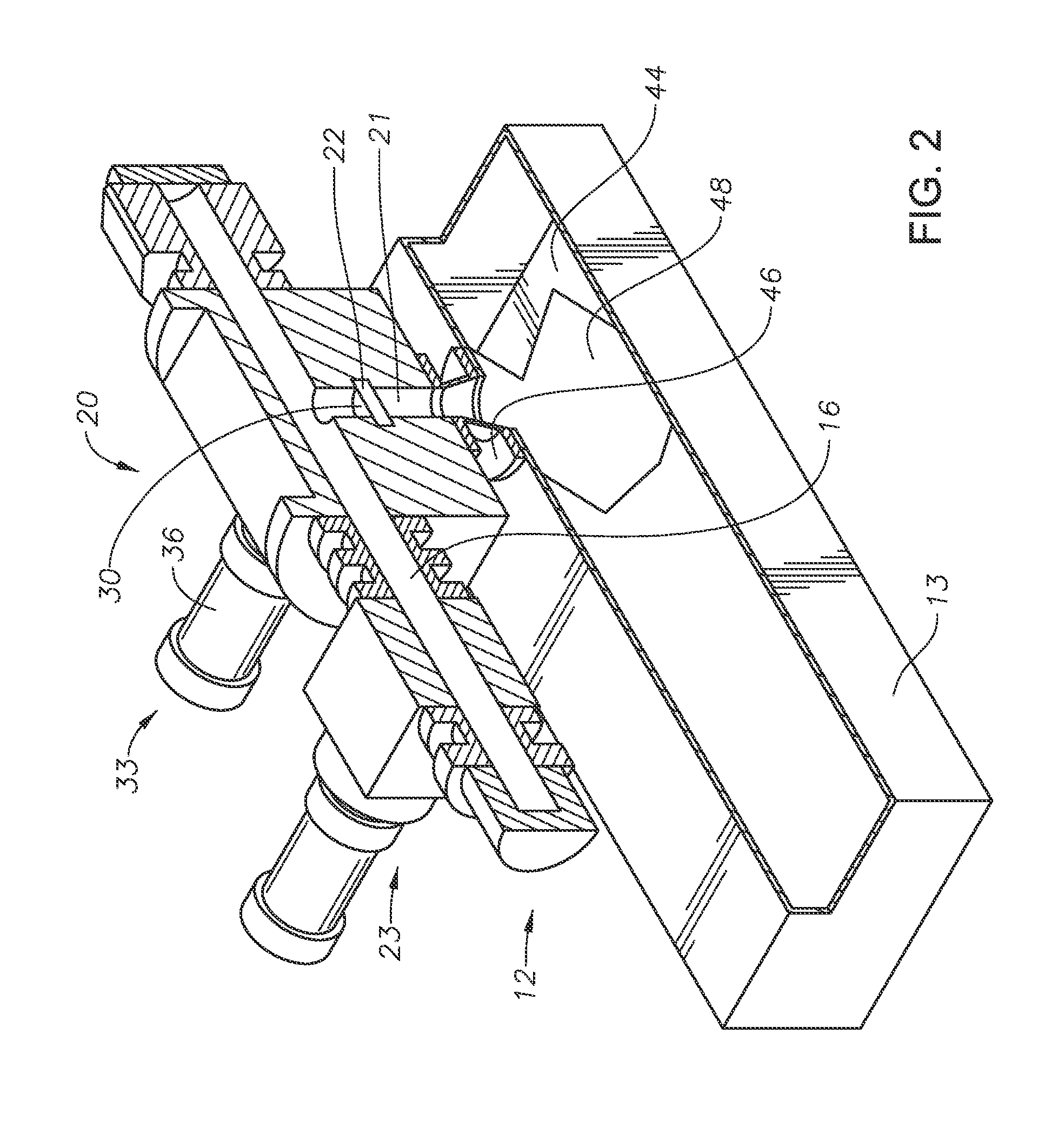

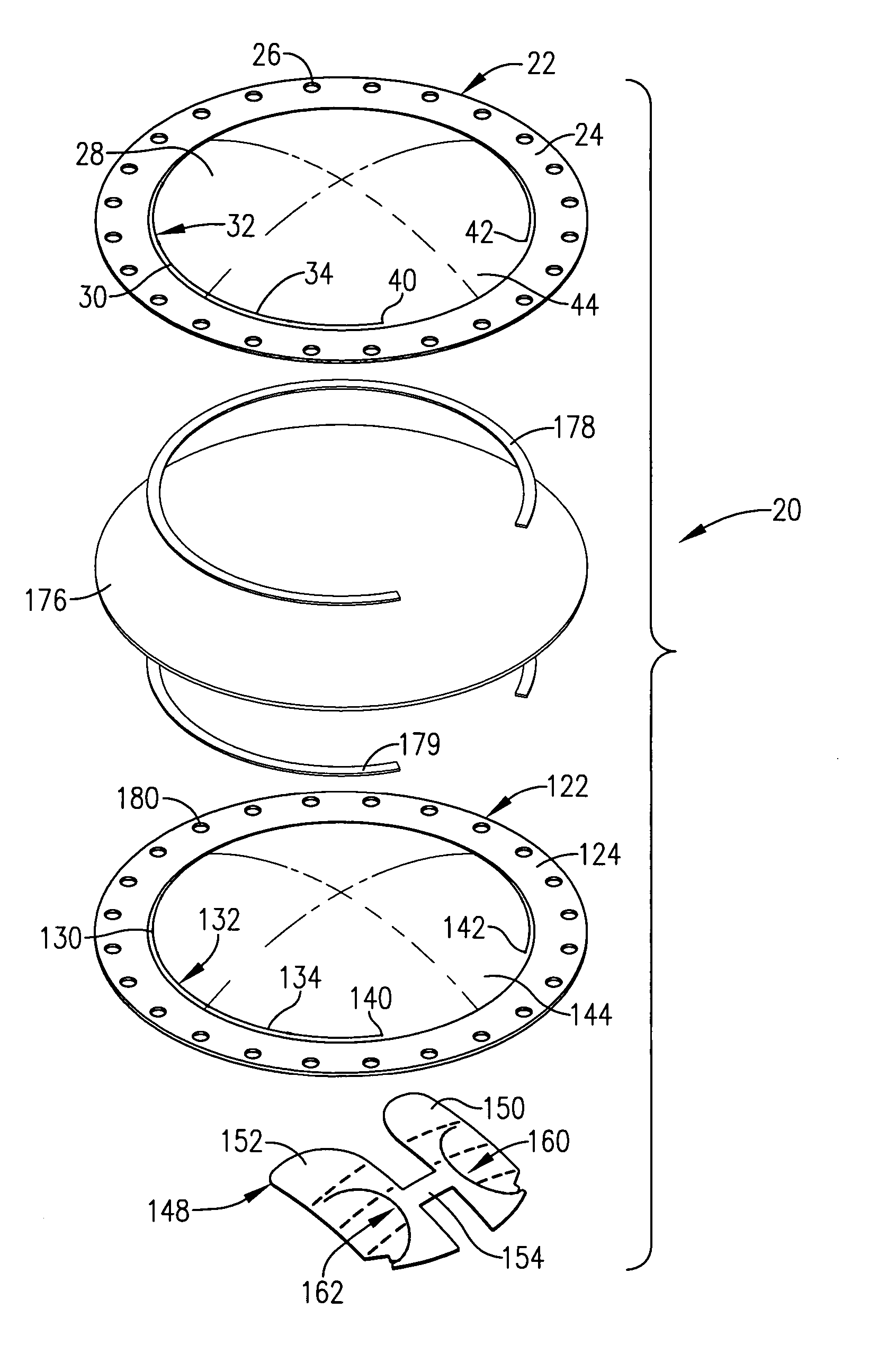

Rupture disk controlled mechanically actuated pressure relief valve assembly

Improved burst disk-type pressure responsive valve assemblies (20, 184) of the pressure relief and shutdown variety are provided which utilize frangible burst disks (30, 204) which largely determine the set point pressures for the valves. The assemblies (20, 184) include a housing (22, 186) having an inlet (24, 188), an outlet (26, 190) with a valve seat (28, 192) therein. The housing (22, 186) also supports a frangible burst disk (30, 204). An actuating unit (32, 210) within the housing (22, 186) includes a shiftable, pressure responsive piston (78, 212) supporting a valve stem actuator rod (82, 214); the rod (82, 214) is operatively coupled with a disk actuating element (84, 216) located adjacent a face of the rupture disk (30, 204). When an overpressure is sensed at the inlet (24, 188), the actuating unit (32, 210) serves to burst the disk (30, 204), allowing the piston (78, 212) to move relative to the valve seat (28, 192) to establish or close communication between the inlet (24, 188) and outlet (26, 190). The valve assemblies (20, 184) can be easily repaired or retrofitted in the field, without the need for extensive dismantling of conduits or the like. Use of disks (30, 204) which rupture during valve operation affords a visual indication of valve operation and permits fabrication of high capacity, long stroke length valves.

Owner:FIKE CORP

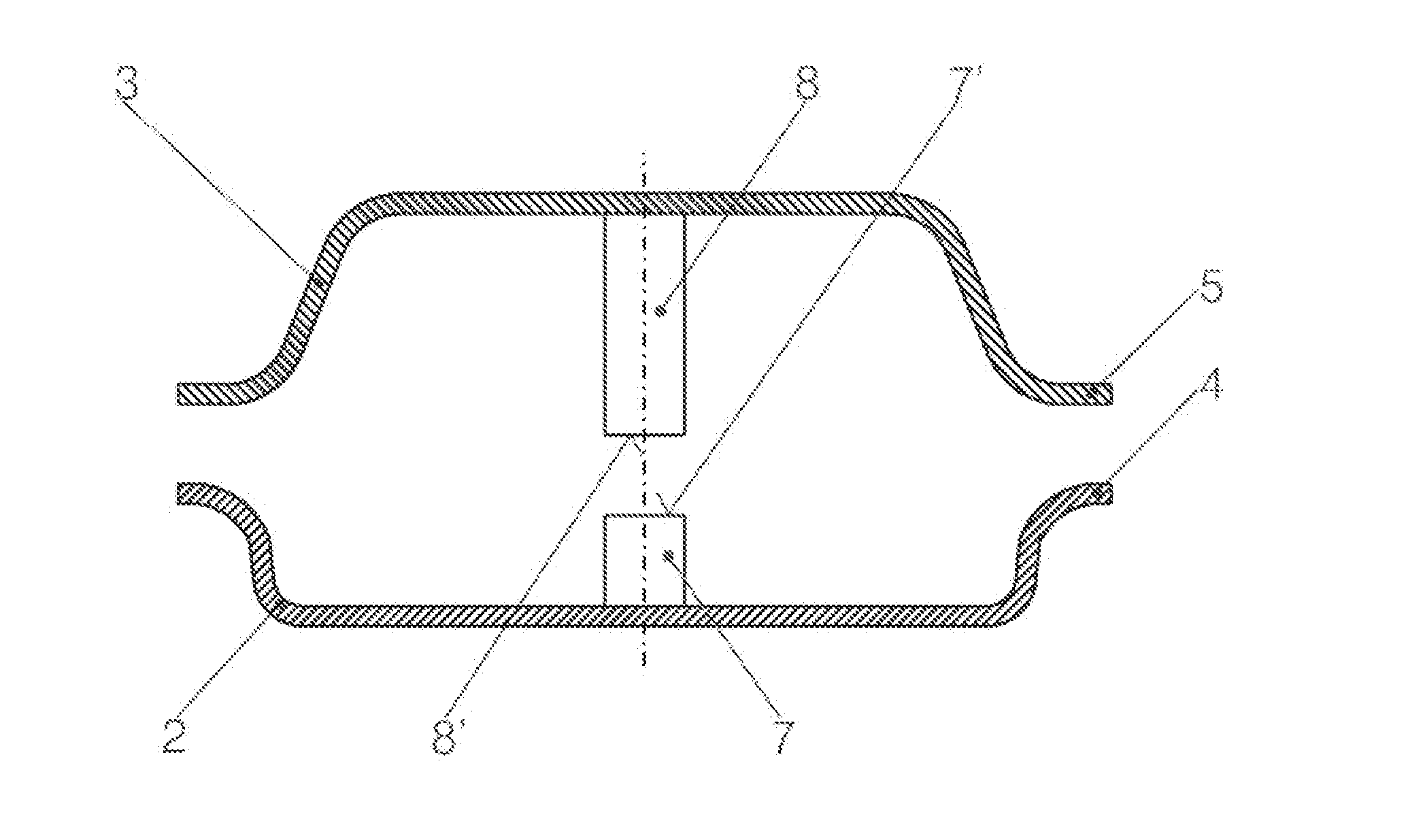

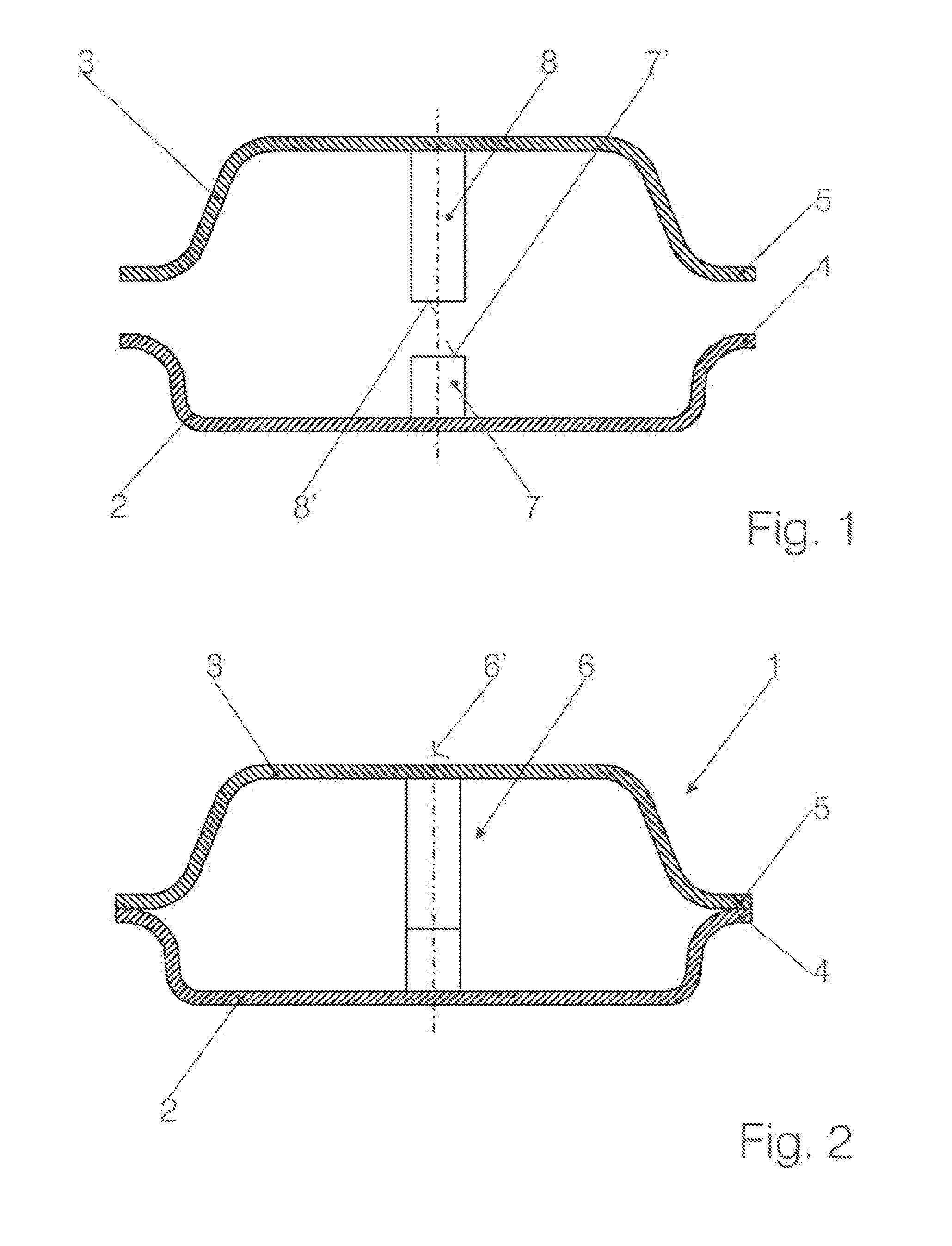

Fuel container for motor vehicles with a tie rod

ActiveUS20120138606A1Precise positioningEasy to placeLarge containersRigid containersEngineeringMechanical engineering

A fuel container operating under overpressure and consisting of two shells is to be reinforced by means of an inner column so that, when the two shells are conjoined, a tension resistant connection is created. For this purpose, the column consists of a first and a second part connected to the respective shell, one part having catches, the other part having latching hooks, which catches and latching hooks for a tension resistant snap-in connection when joined together. For this purpose, both parts have latching surfaces and deflecting surfaces and the latching hook is resiliently displaceable.

Owner:MAGNA STEYR FUEL SYST

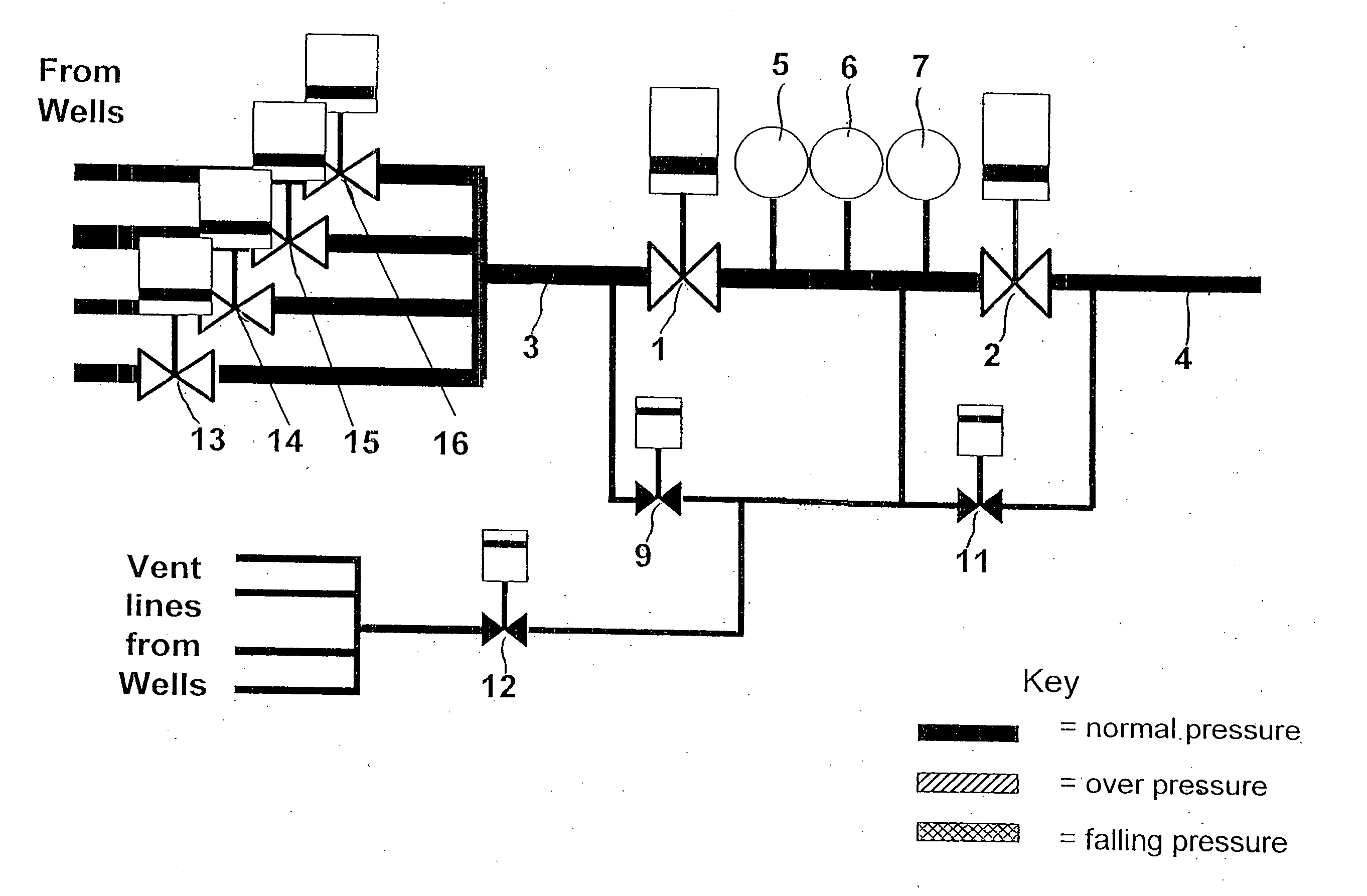

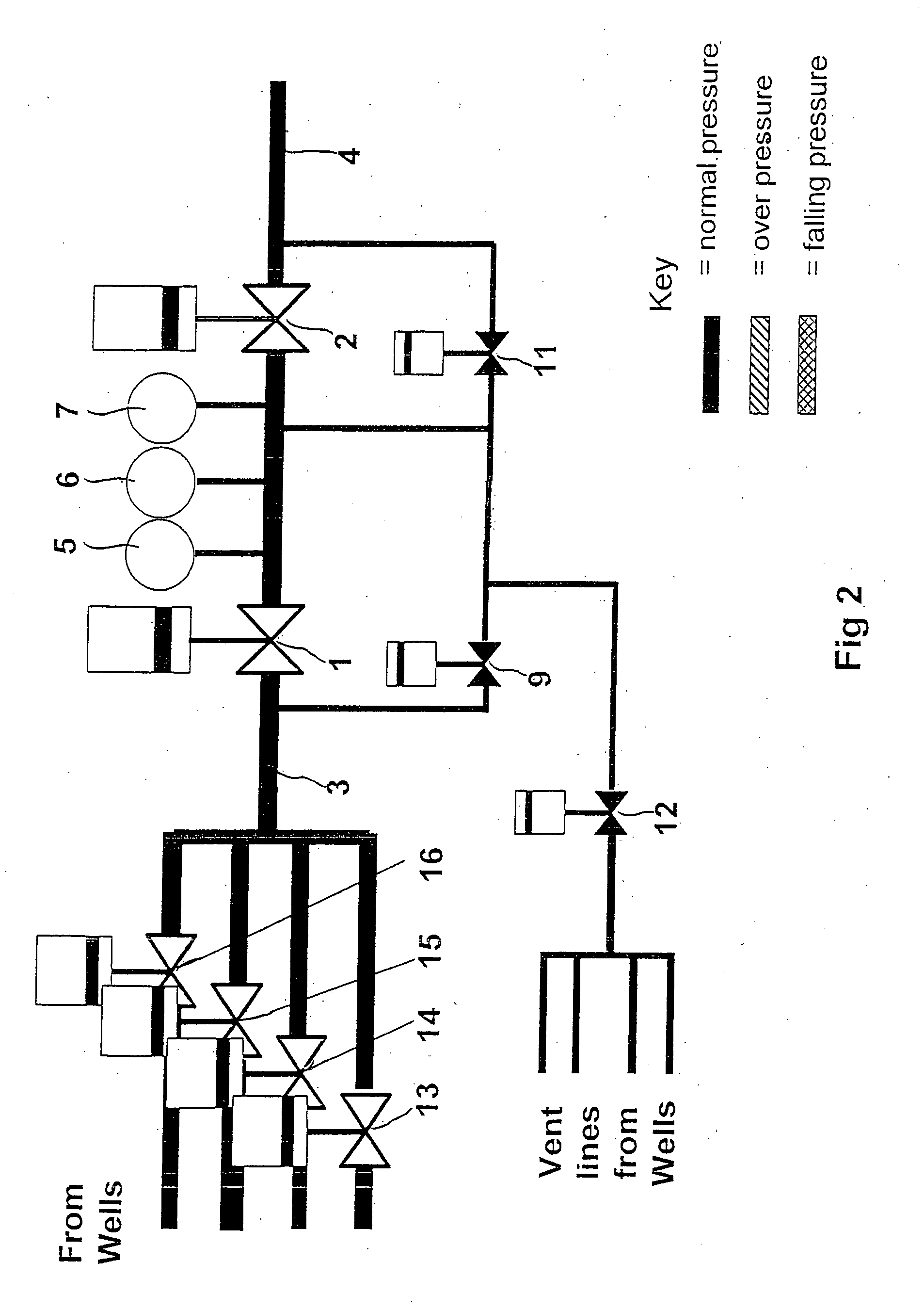

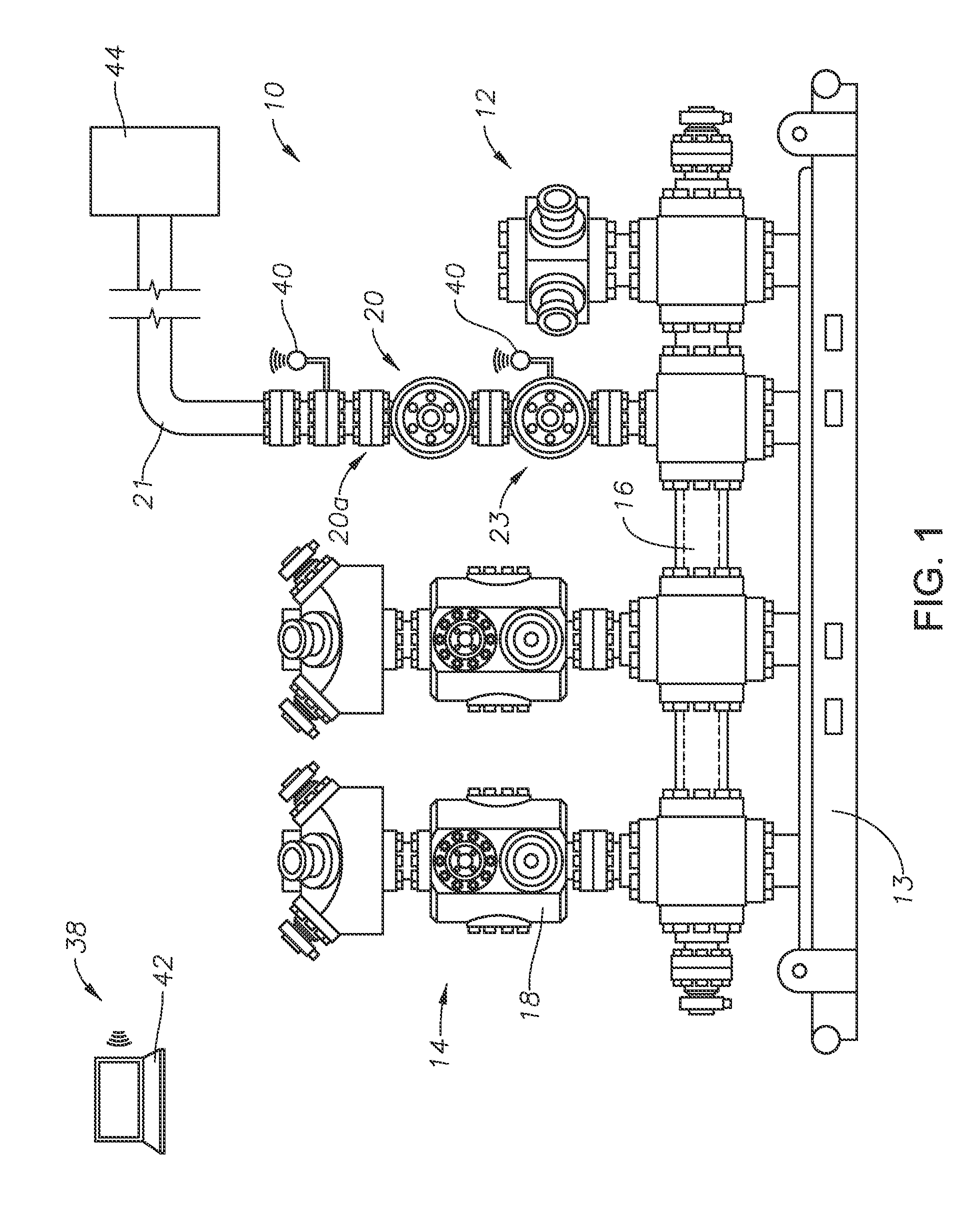

Pipeline protection system

ActiveUS20080000529A1Improve integrityOperating means/releasing devices for valvesCheck valvesLine tubingTransducer

A protection apparatus for detecting and reducing overpressure in a fluid pipeline having a fluid input end (3) and a fluid output end (4), the fluid input end being connected in use to a fluid source, comprises: first (1) and second (2) pipeline valves connected in series along the pipeline with the first pipeline valve being connected at a location closer to the input end than the connection location of the second pipeline valve, the first and second pipeline valves being independently switchable between open positions in which fluid flow through the pipeline is permitted and closed positions in which fluid flow through the pipeline is blocked; a pressure transducer for determining the fluid pressure in the pipeline at a point intermediate the first and second pipeline valves; a bypass line having a first end connected to the pipeline between the input end and the first pipeline valve and a second end connected to the pipeline between the first and second pipeline valves; a bypass valve (9) connected along the bypass line, said bypass valve being switchable between an open position in which fluid flow through the bypass line is permitted and a closed position in which fluid flow through the bypass line is blocked; a vent line connected to the bypass line between the bypass valve and the second end of the bypass line, the vent line leading to a venting means; and a vent valve (12) connected along the vent line, said vent valve being switchable between an open position in which fluid flow through the vent line is permitted and a closed position in which fluid flow through the vent line is blocked.

Owner:BAKER HUGHES ENERGY TECH UK LTD

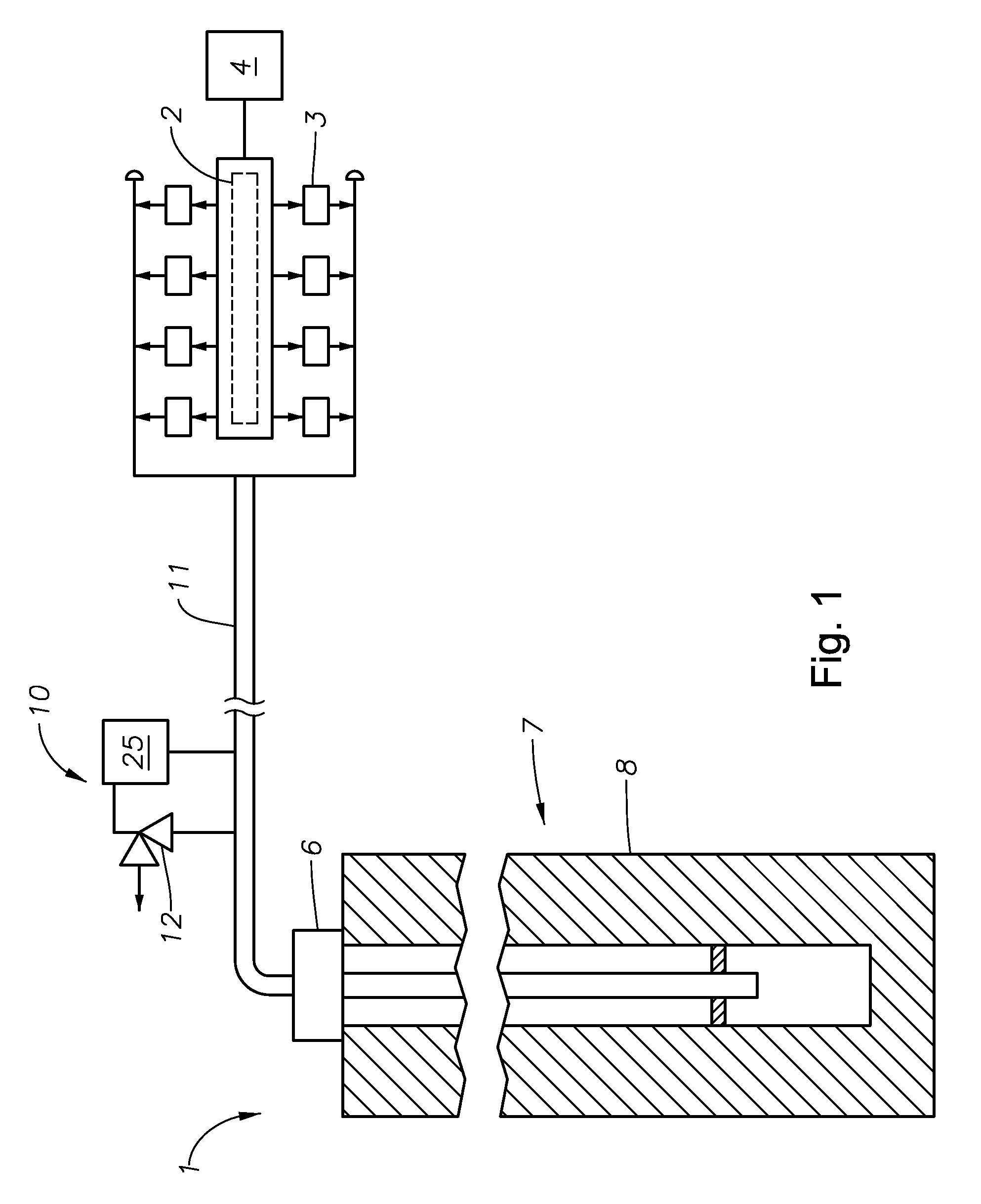

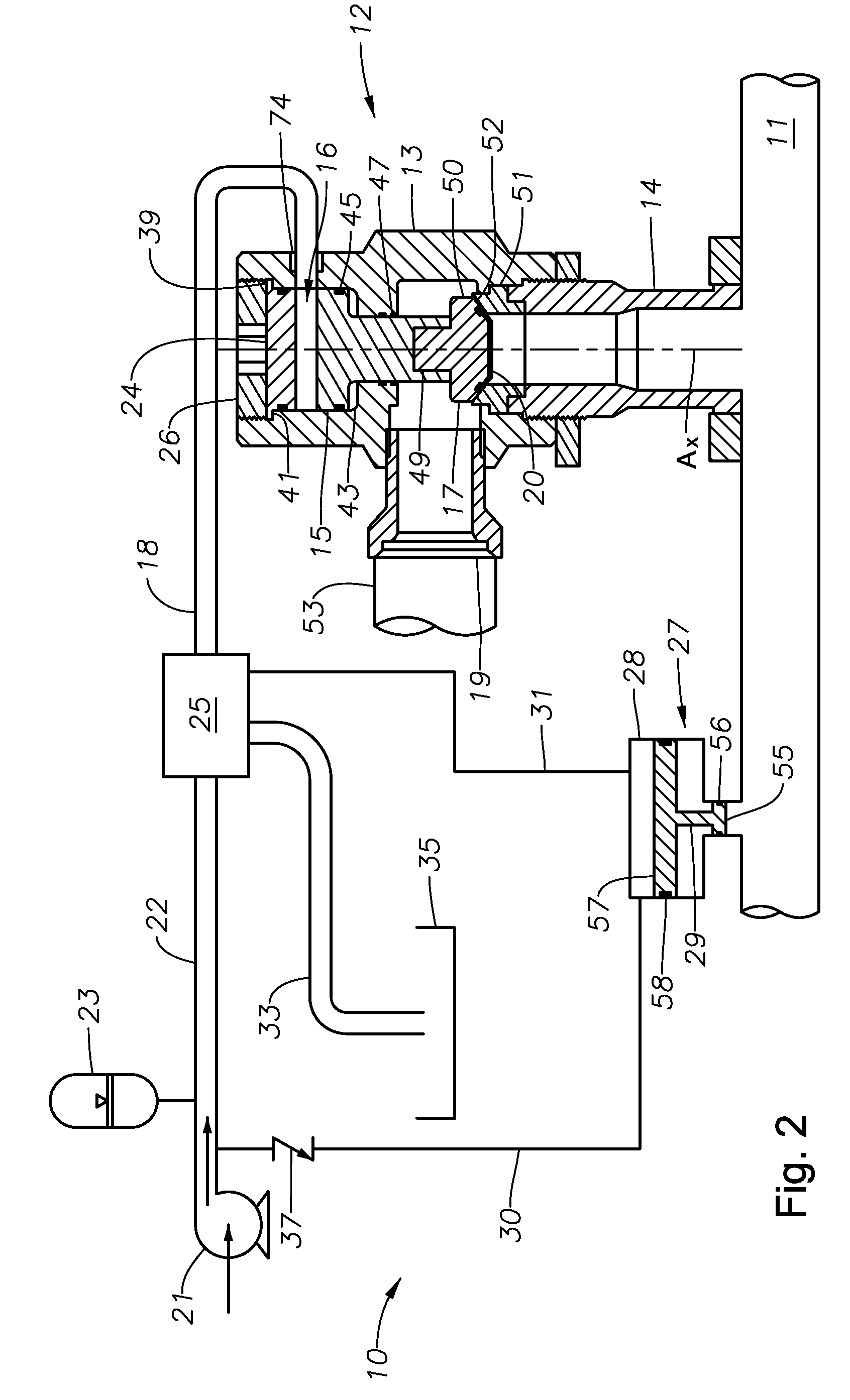

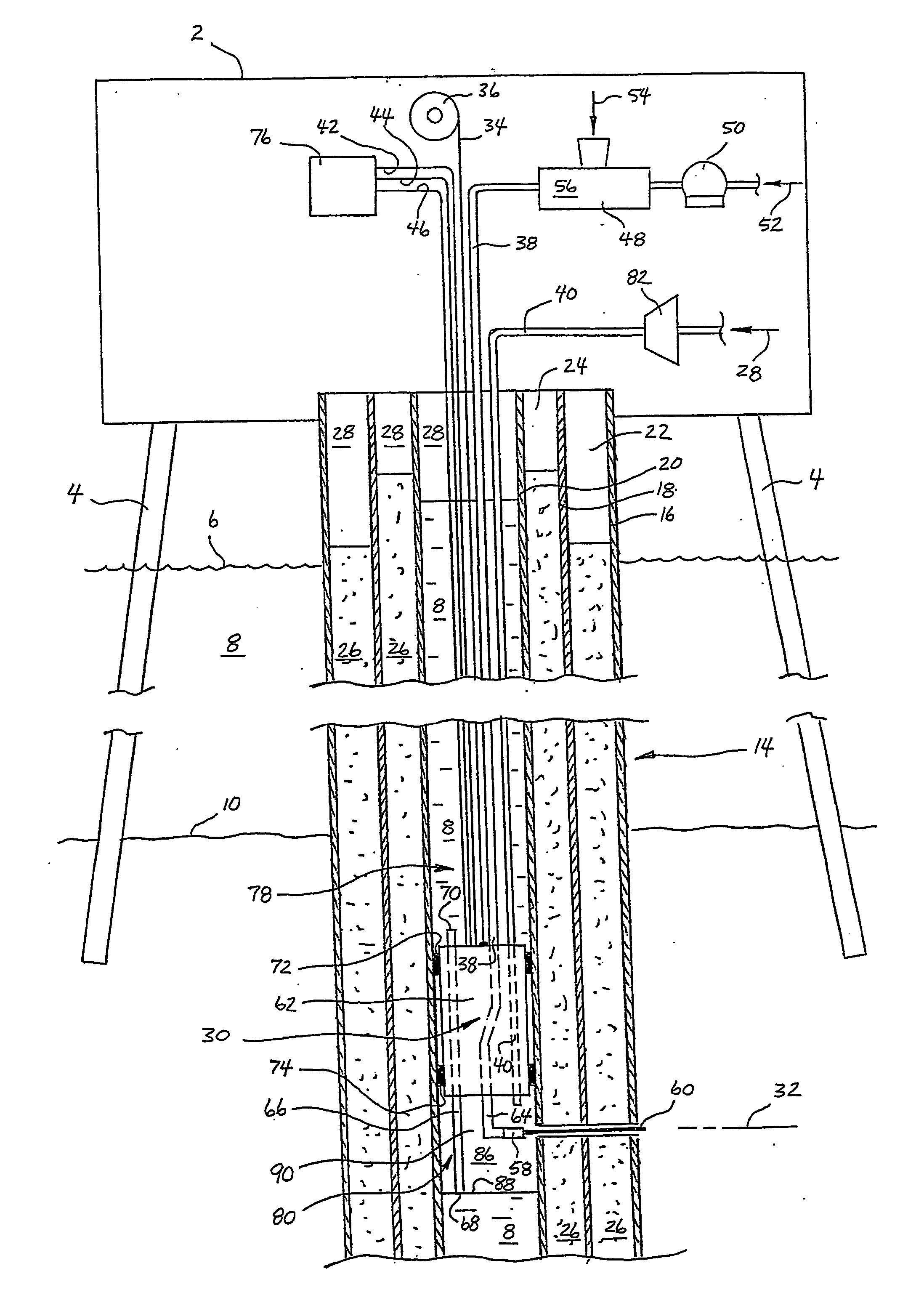

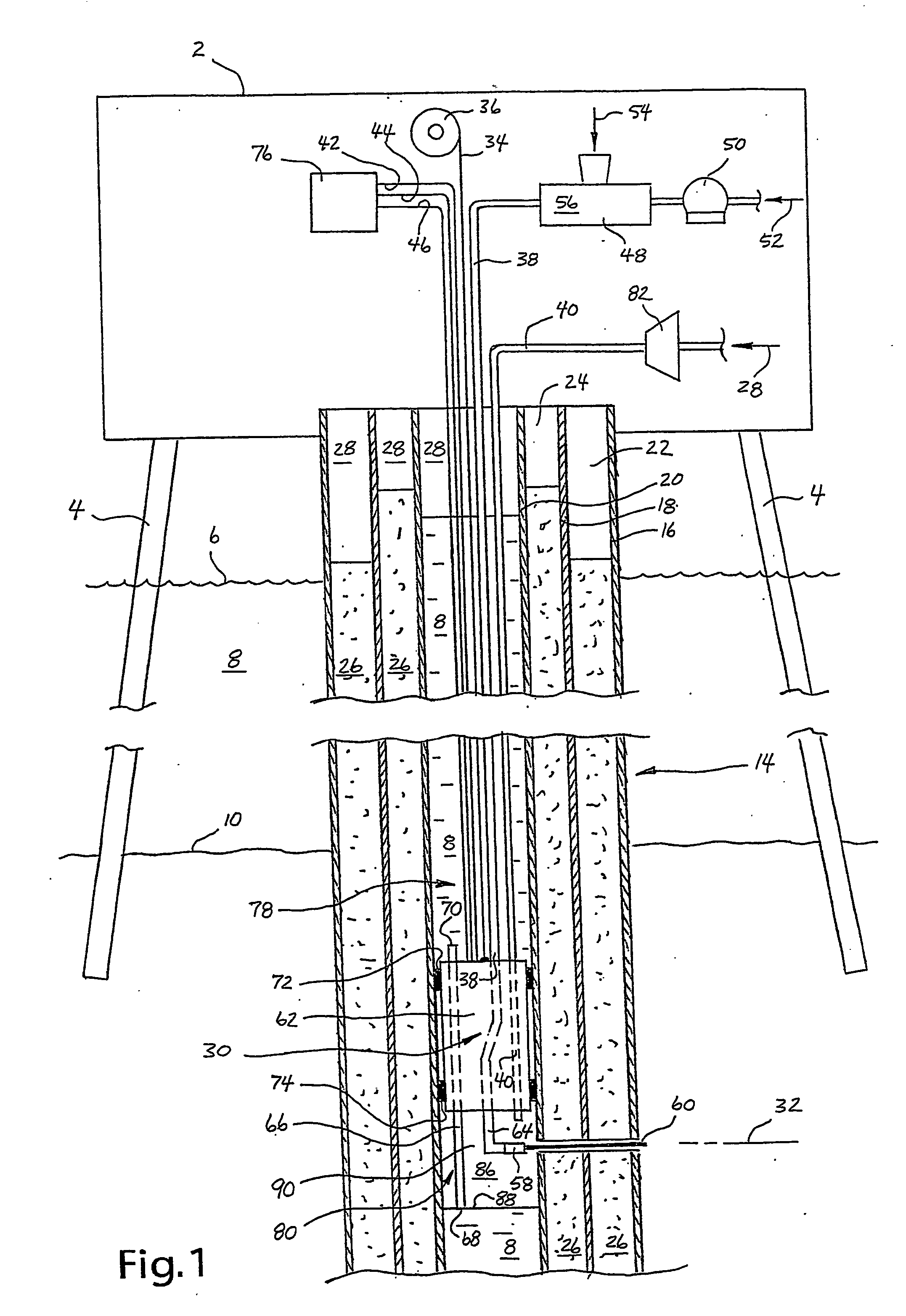

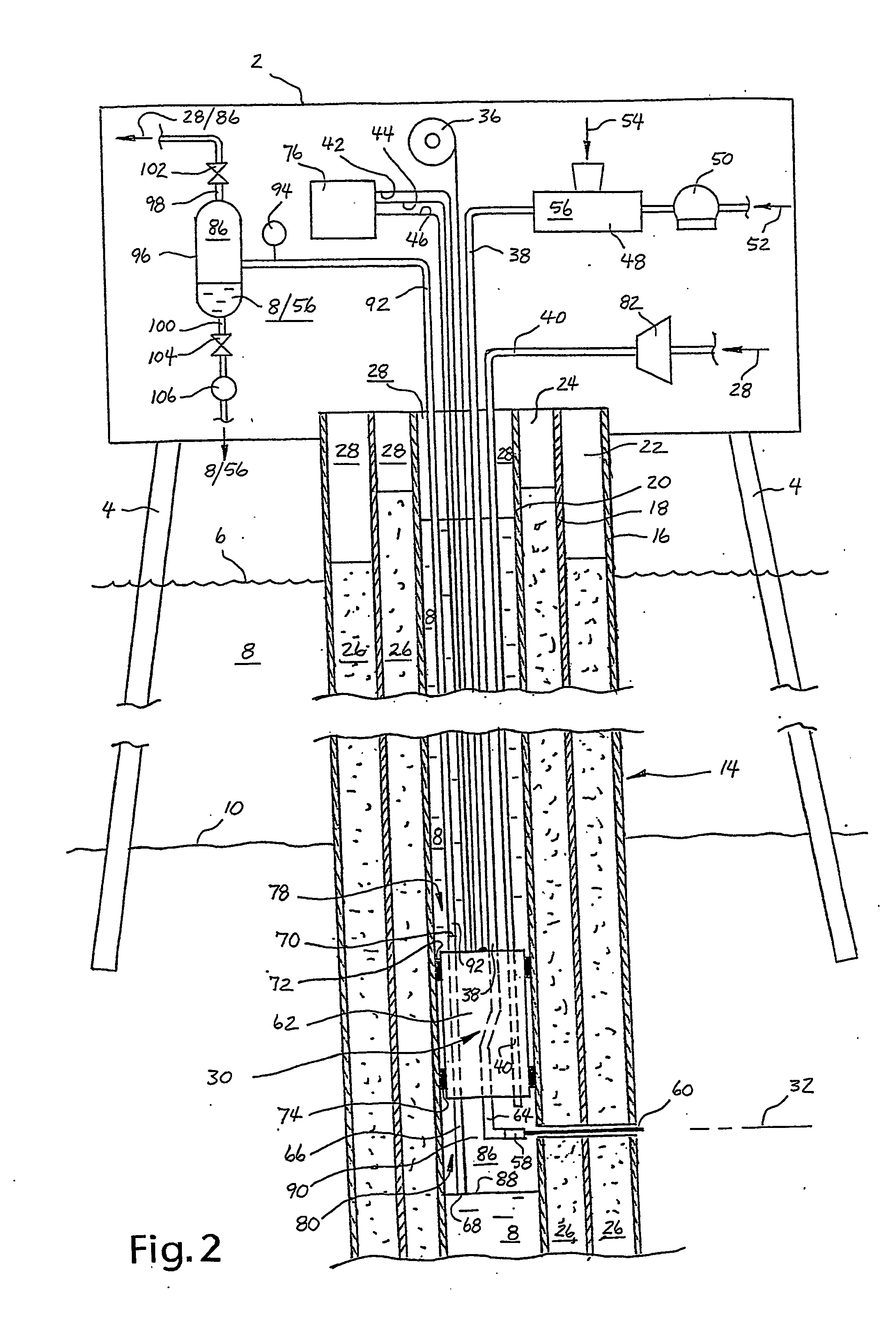

Device for a hydraulic cutting tool

ActiveUS20050173123A1Reduce negative impactFast and efficient cuttingDisloding machinesUnderground miningEngineeringMechanical engineering

A device for a hydraulic cutting tool (30) for cutting of at least one pipe (16, 18, 20) or tubular object beneath a water floor (10), wherein the cutting is carried out from a surface facility (2). The cutting tool (30) is anchored in a pressure tight manner in the pipe (16), whereupon pressurised gas (86) is pumped into a pipe section (80) immediately below the cutting tool (30). With this, liquid (8), and eventually pressurised gas (86), will flow out of the pipe section (80) via a short drain pipe (66) through the cutting tool (30), so as to create a gas filled pipe volume (90) comprising the relevant cutting depth (32) in the pipe section (80). The invention differs from prior art by the outflowing liquid being led onwards up to the surface facility (2) via a drain line (92). The upper end portion of the drain line (92) is connected to at least one adjustable choke device (102, 104). This allows the gas overpressure in said pipe volume (90) to be controlled during the cutting, providing optimal operating conditions during the hydraulic cutting.

Owner:OCEANEERING NCA

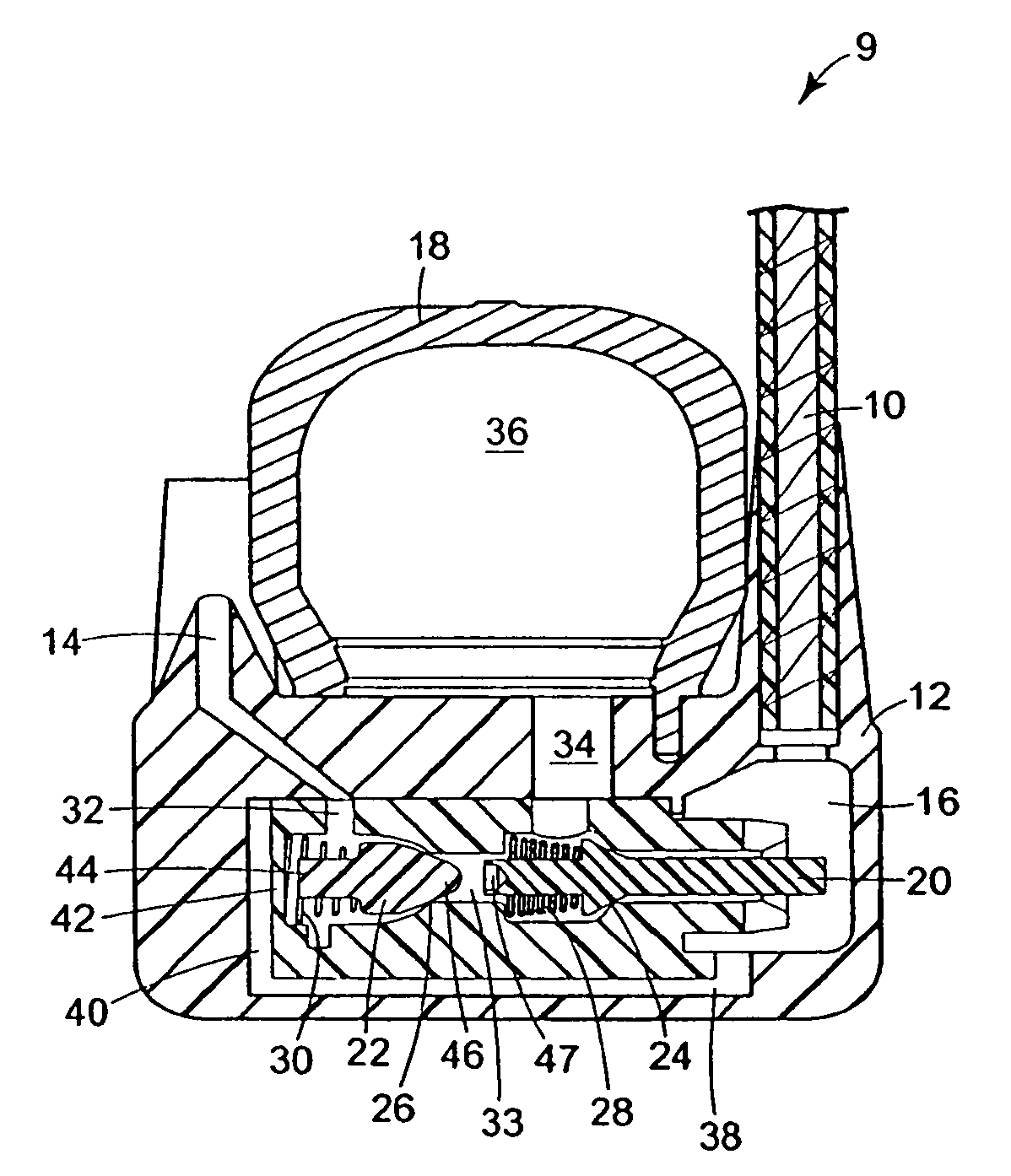

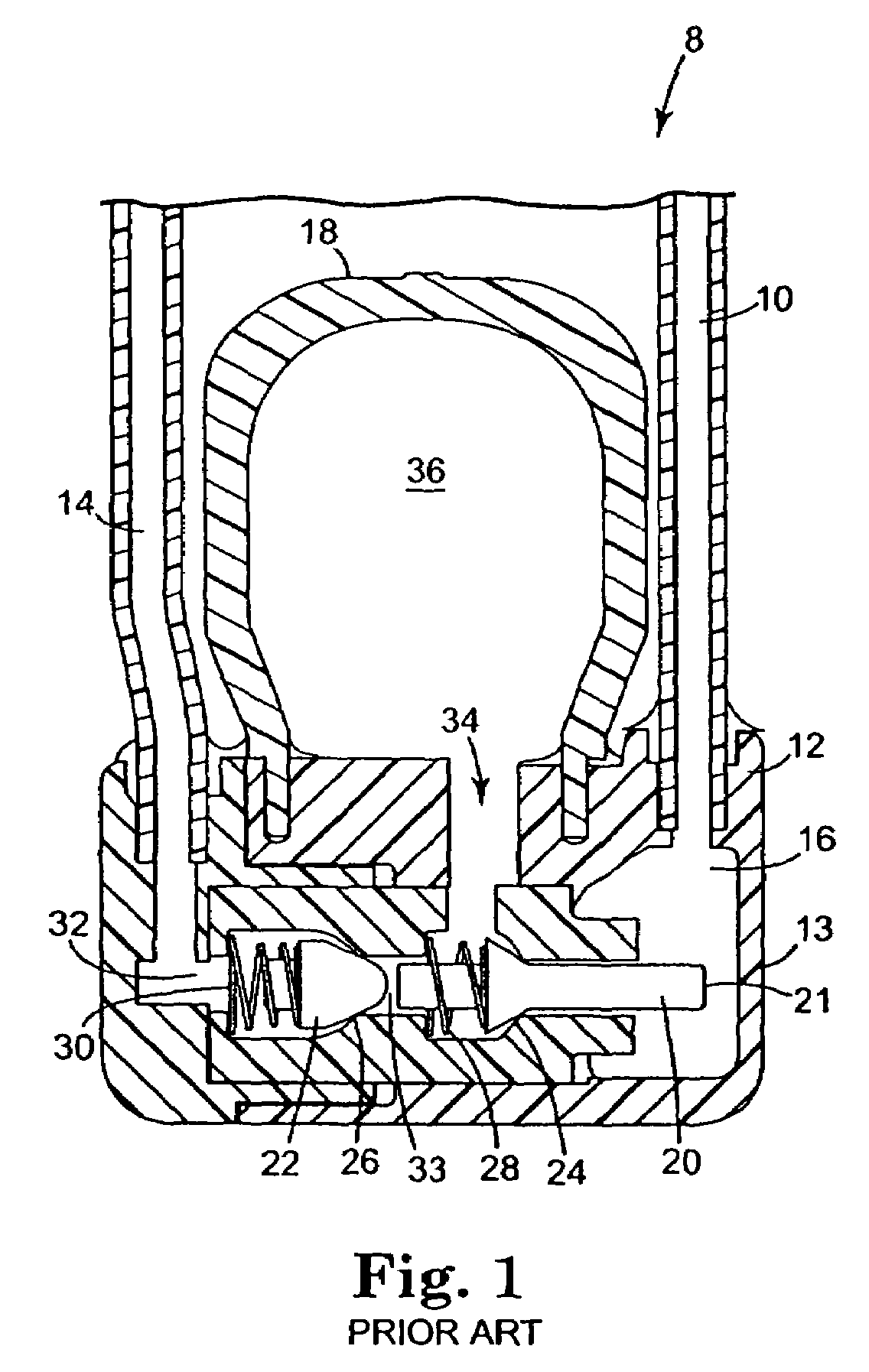

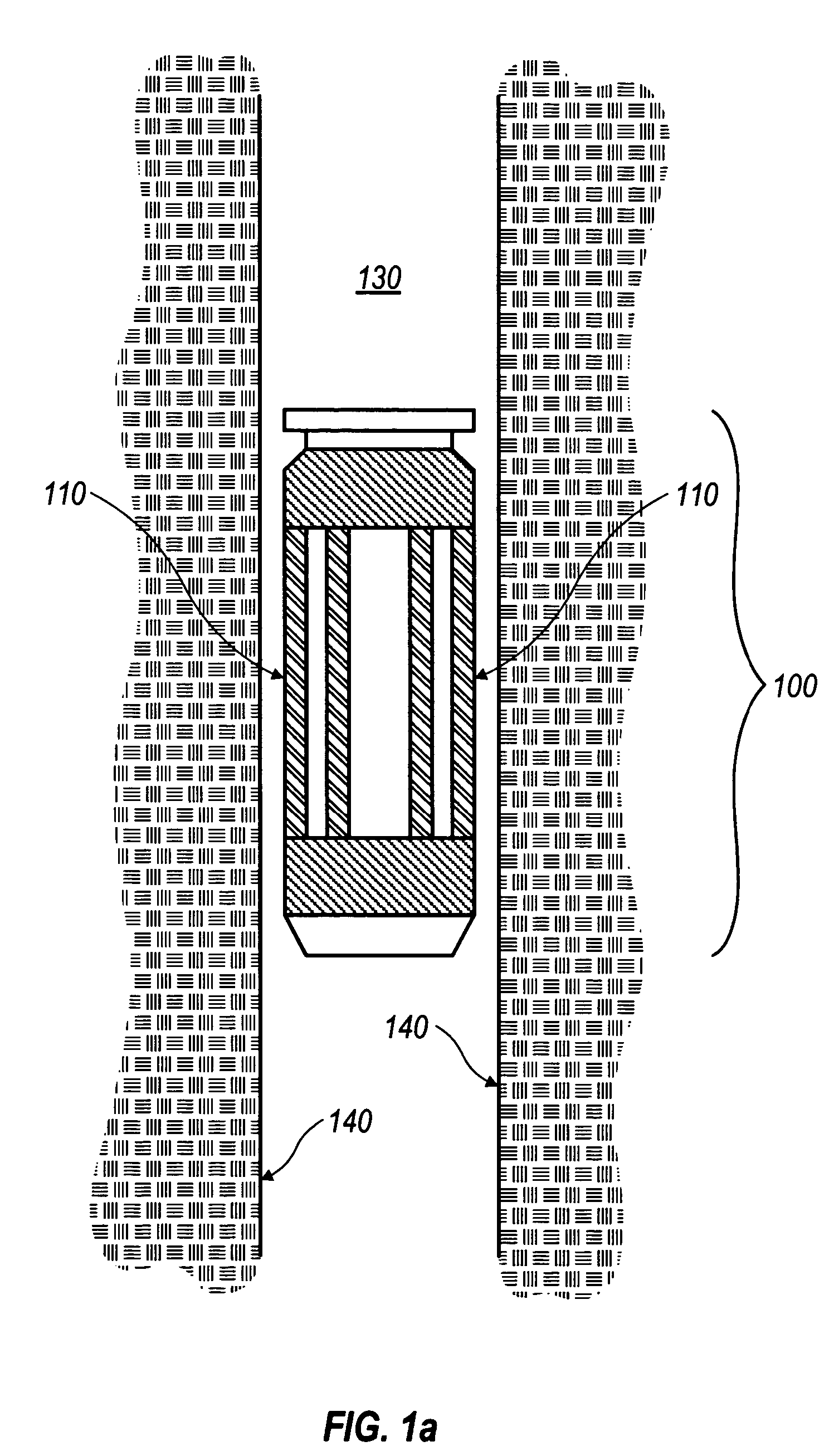

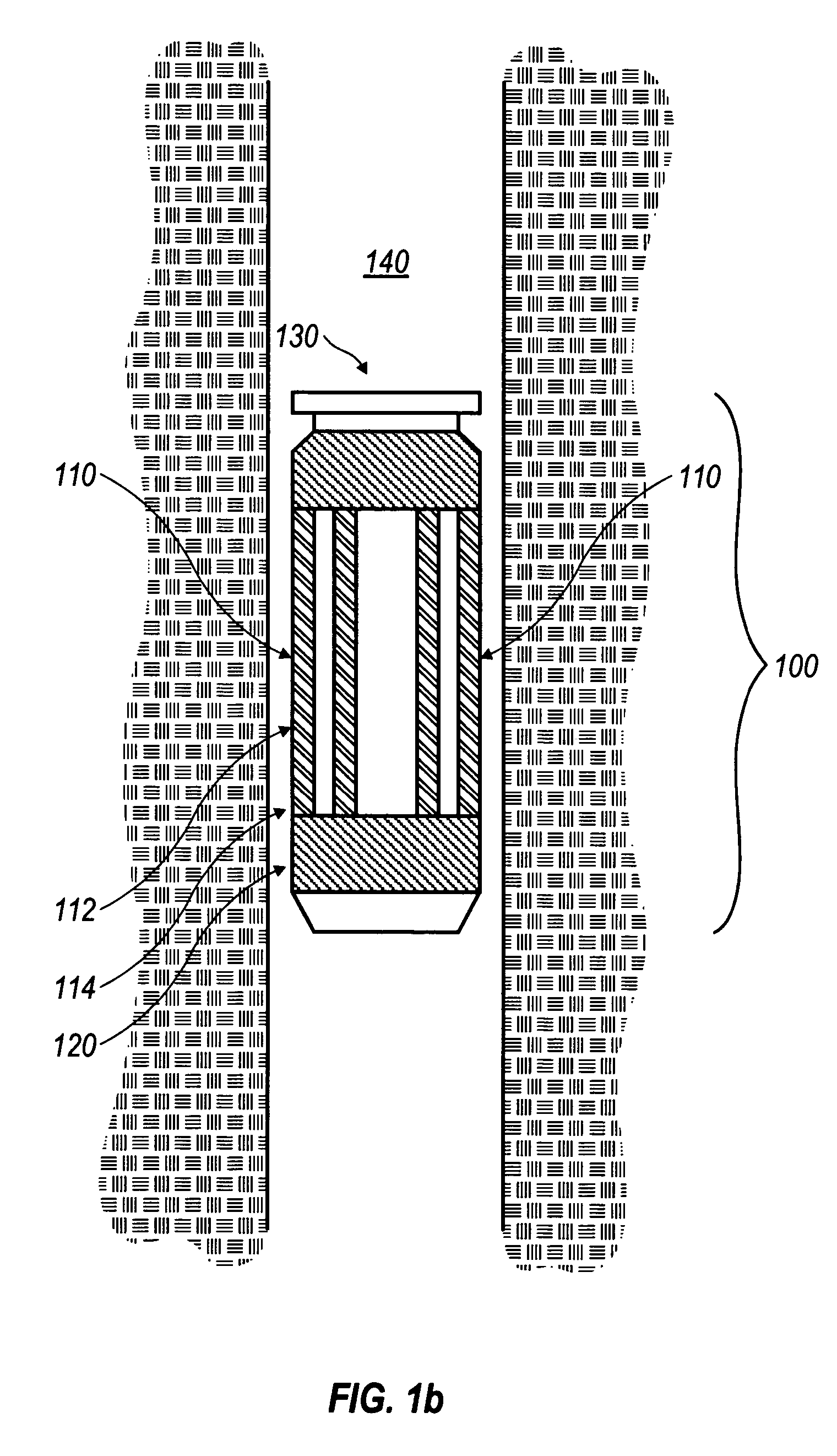

Spontaneous inflation inhibitor for inflatable prosthesis

InactiveUS6935847B2Preventing inflationCheck valvesPharmaceutical delivery mechanismEngineeringPenile implant

A pump assembly for a penile implant is provided having a mechanism which prevents spontaneous inflation of the cylinders implanted within the user. The preventative mechanism uses overpressure generated by the reservoir during unintentional compression to effectively seal the pump assembly from unintended fluid flow. The prevention mechanism itself creates all necessary forces to prevent the undesired fluid flow to the cylinders. This is accomplished by incorporating appropriate mechanisms within the pump itself.

Owner:BOSTON SCI SCIMED INC

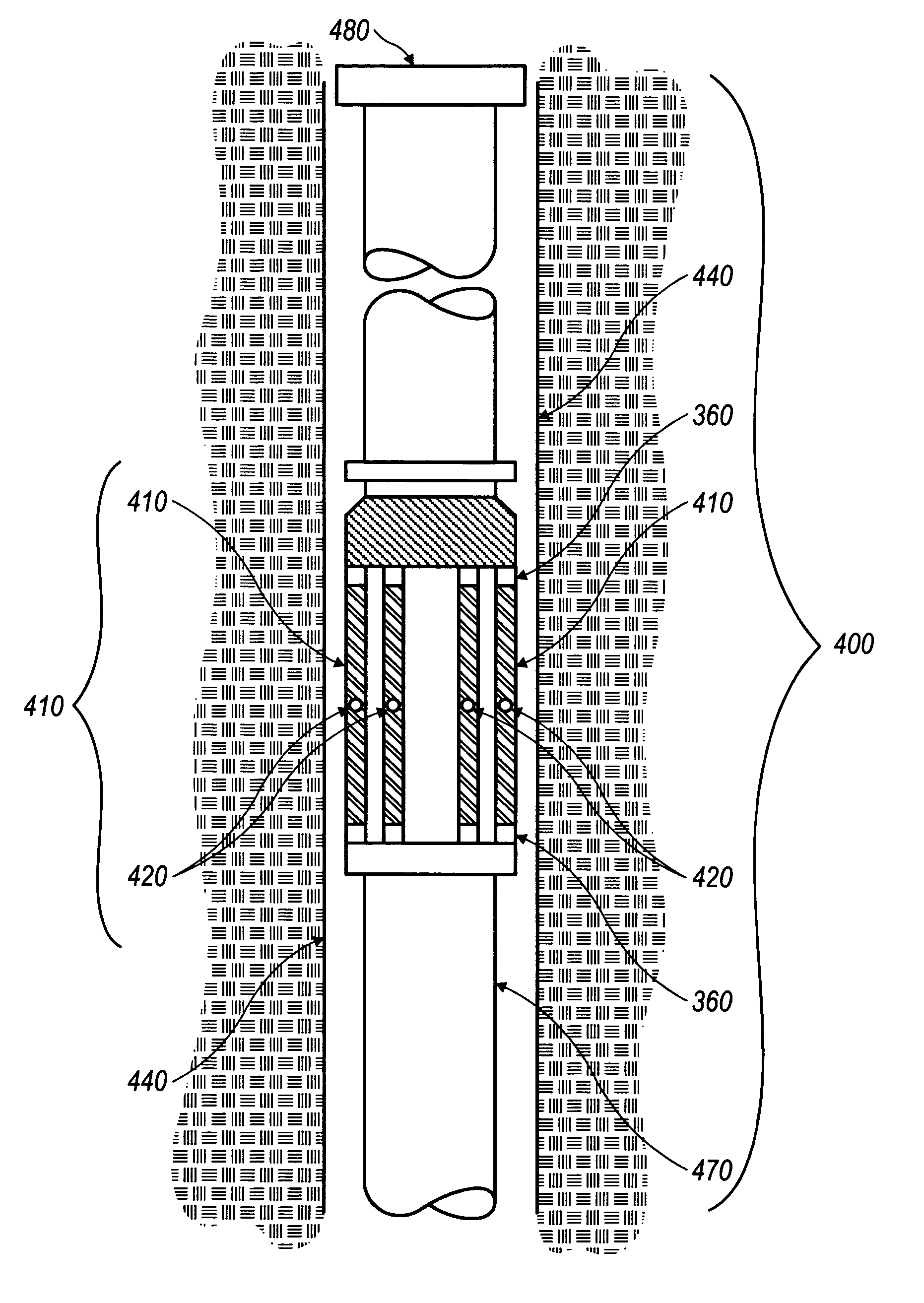

Safety Systems for Isolating Overpressure During Pressurized Fluid Operations

ActiveUS20150292297A1Reduce damage and blowoutRelieve pressureSurveyDrilling rodsFluid controlEngineering

An overpressure safety system for use with a distribution of pressurized fluid associated with hydrocarbon production operations includes a safety valve in fluid communication with a main bore of a fluid control manifold assembly. The safety valve has a blocking condition where the safety valve blocks a flow of pressurized fluid through the safety valve, and a venting condition where the safety valve provides a fluid flow path for the pressurized fluid at a set overpressure to pass through the safety valve. A valve member is moveable within the safety valve between a first position where a pressure side of the valve member blocks the flow of the pressurized fluid at a pressure below the set overpressure from passing through the safety valve, and a second position where the valve member provides a fluid flow path for the pressurized fluid at any pressure to pass through the safety valve.

Owner:GE OIL & GAS PRESSURE CONTROL

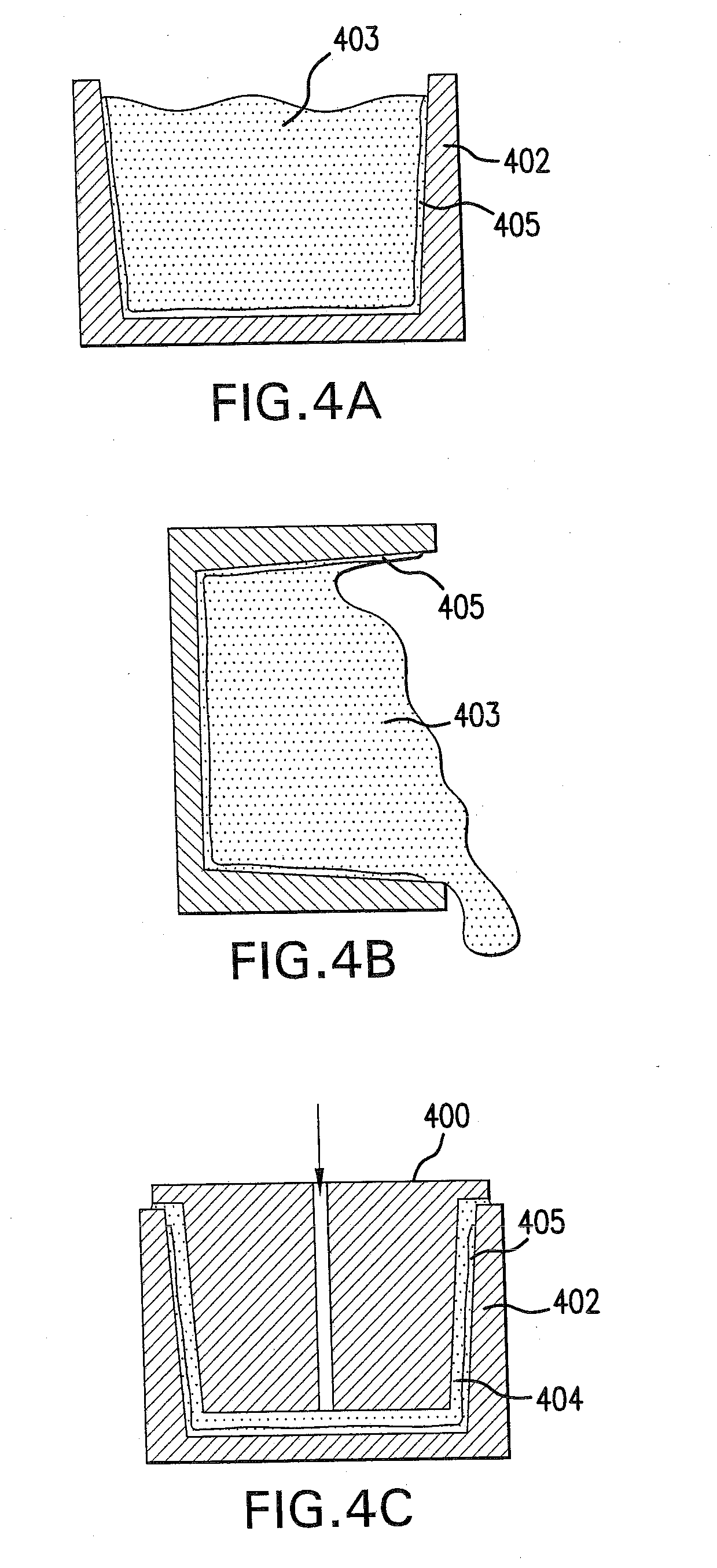

Quartz glass body, method and casting mold for manufacturing same

InactiveUS20080153688A1Low purityLow impurity contentAfter-treatment apparatusFinal product manufacturePorosityVitreous Bodies

The invention includes an improved quartz glass body, especially an improved quartz glass crucible for melting non-metals, non-ferrous metals, or silicon, and a method and casting mold for making it The quartz glass body is made by a method in which a quartz glass-water mixture is supplied to a casting mold comprising an outer part and an inner part, dried in the mold, and put under an overpressure during the drying. Later a resulting green glass body is removed from the mold. At least a portion of the shaping surfaces of the inner part of the mold are surfaces of a water-impermeable substance. The method provides a cast body with a reduced tendency to crack and with a smaller open porosity.

Owner:SCHOTT AG

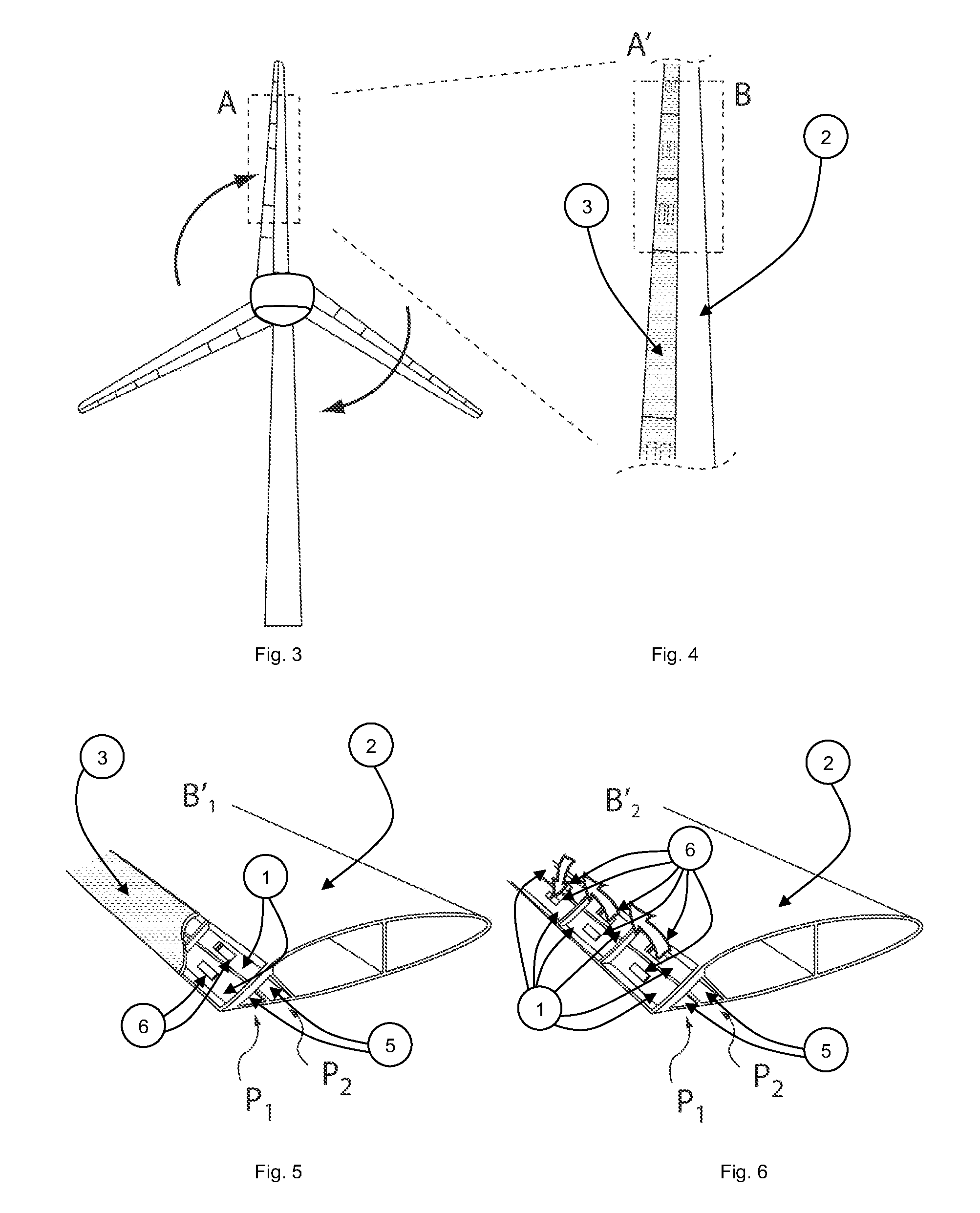

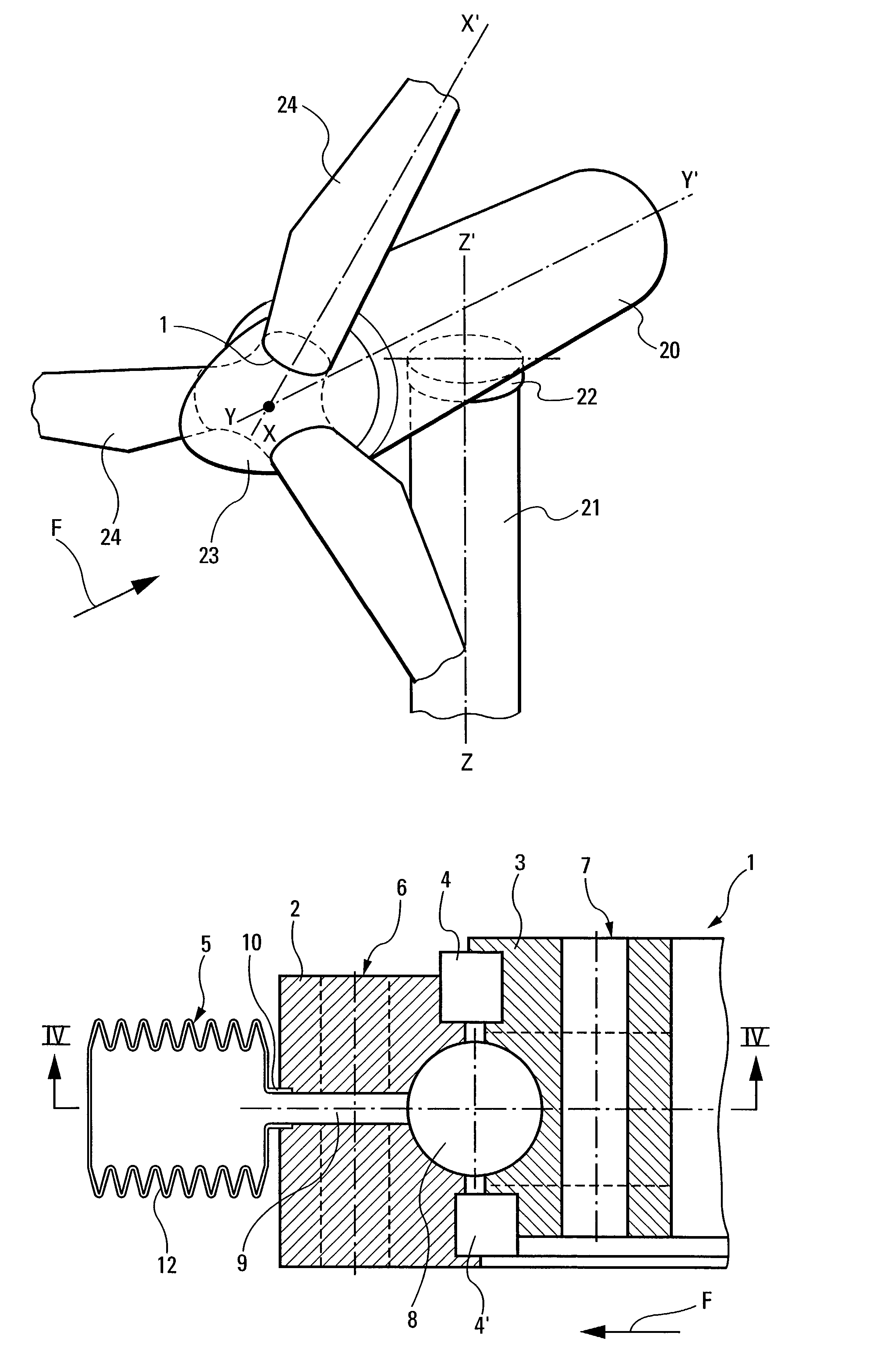

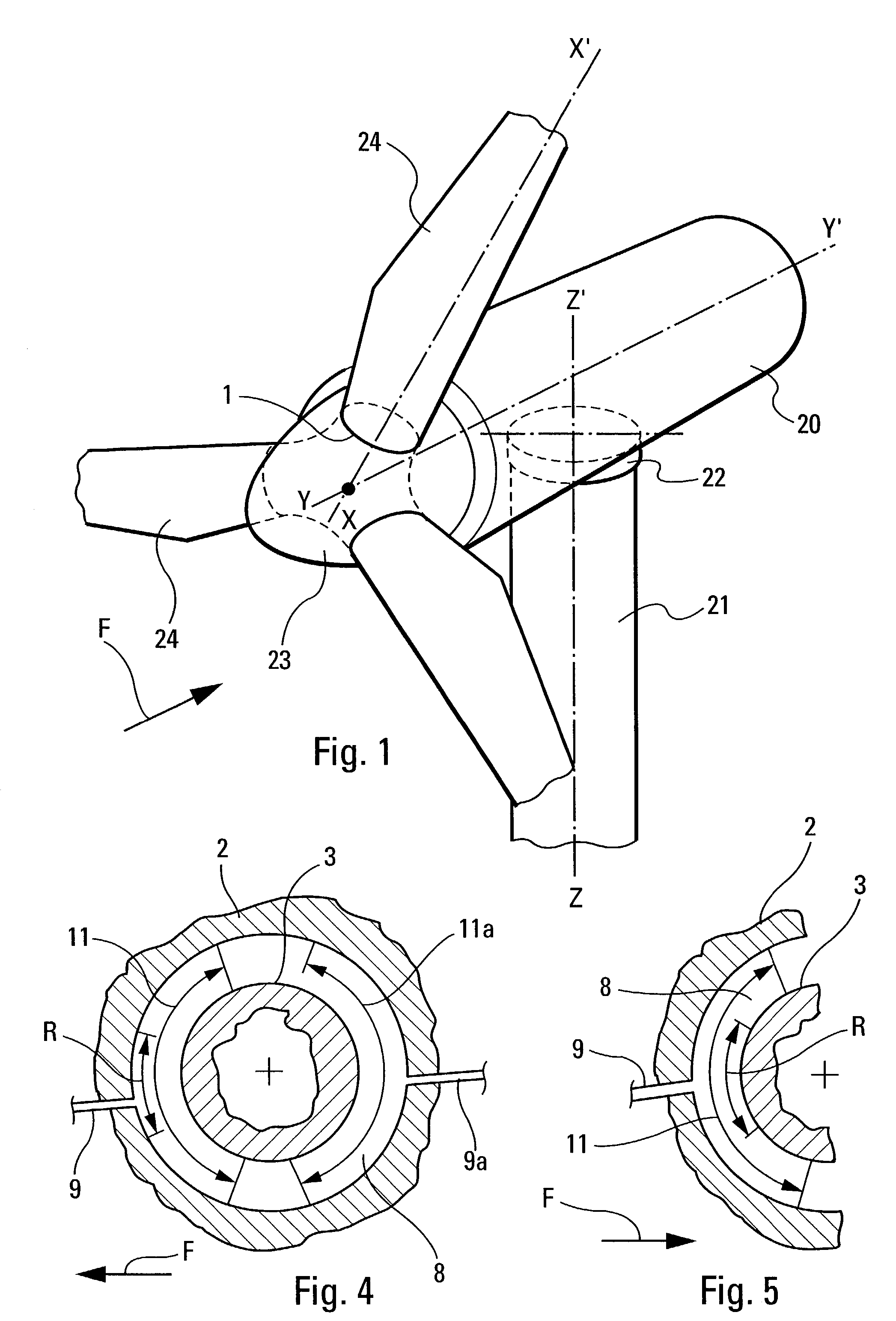

Wind turbine with boundary layer control

InactiveUS20100266382A1Raise the ratioReduce loadWind motor controlPump componentsTurbine bladeControl system

The invention relates to a wind turbine comprising a rotor with a hub and turbine blades, and further comprising a boundary layer control system for the turbine blades. A plurality of pressure chambers is located in the blade distributed over the length of the blade. Each pressure chamber is in communication with the outside of the blade through one or more corresponding openings in the outer surface of the turbine blade. Furthermore a suction channel and a blow channel extend inside the blade for supplying an underpressure and an overpressure respectively to the pressure chamber, each pressure chamber being connected to at least one of said channels through an air passage in which an actively operable valve is located. The valve is connected to a control unit for selectively bringing the pressure chamber into communication with or close it off from said channel(s) so as to blow air out of the pressure chamber or suck air into the pressure chamber through the corresponding opening(s) in the blade surface.

Owner:ACTIFLOW

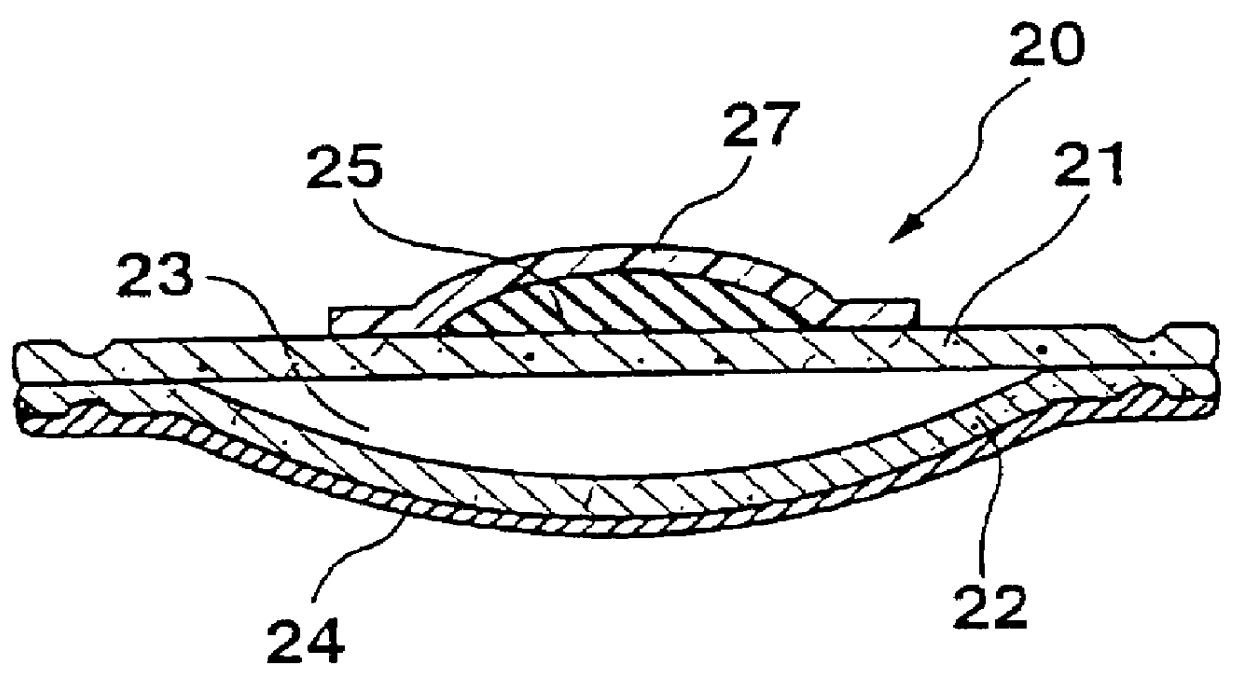

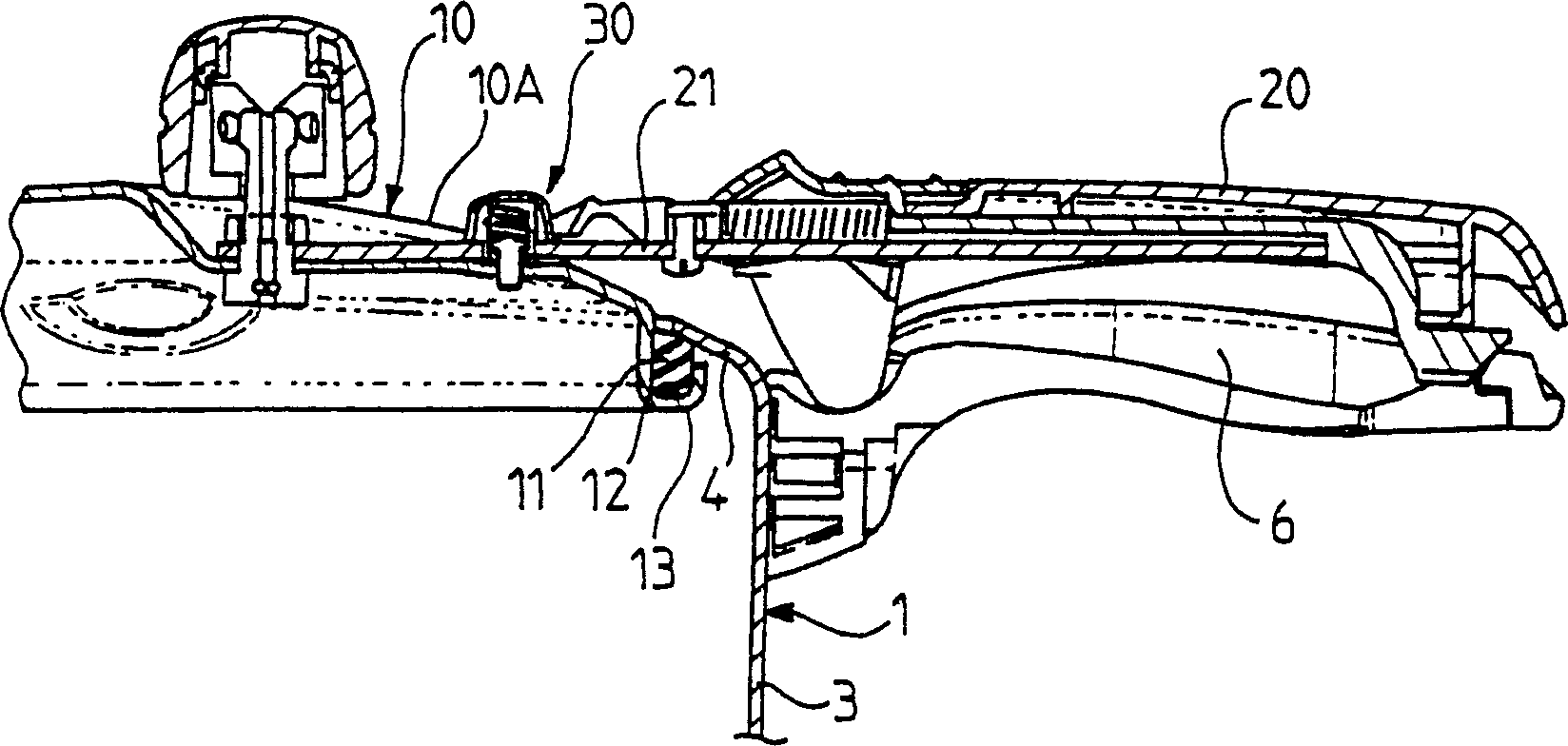

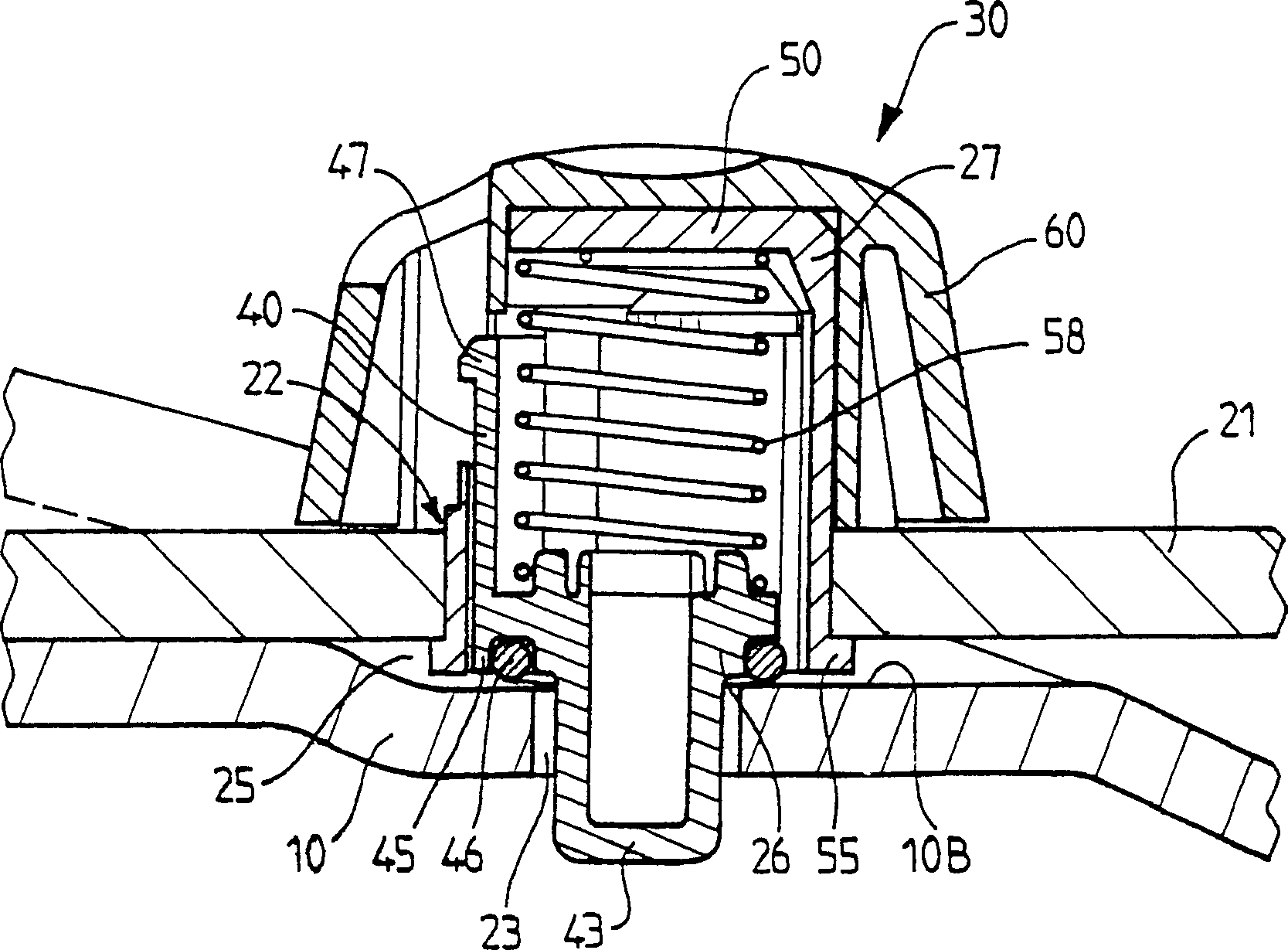

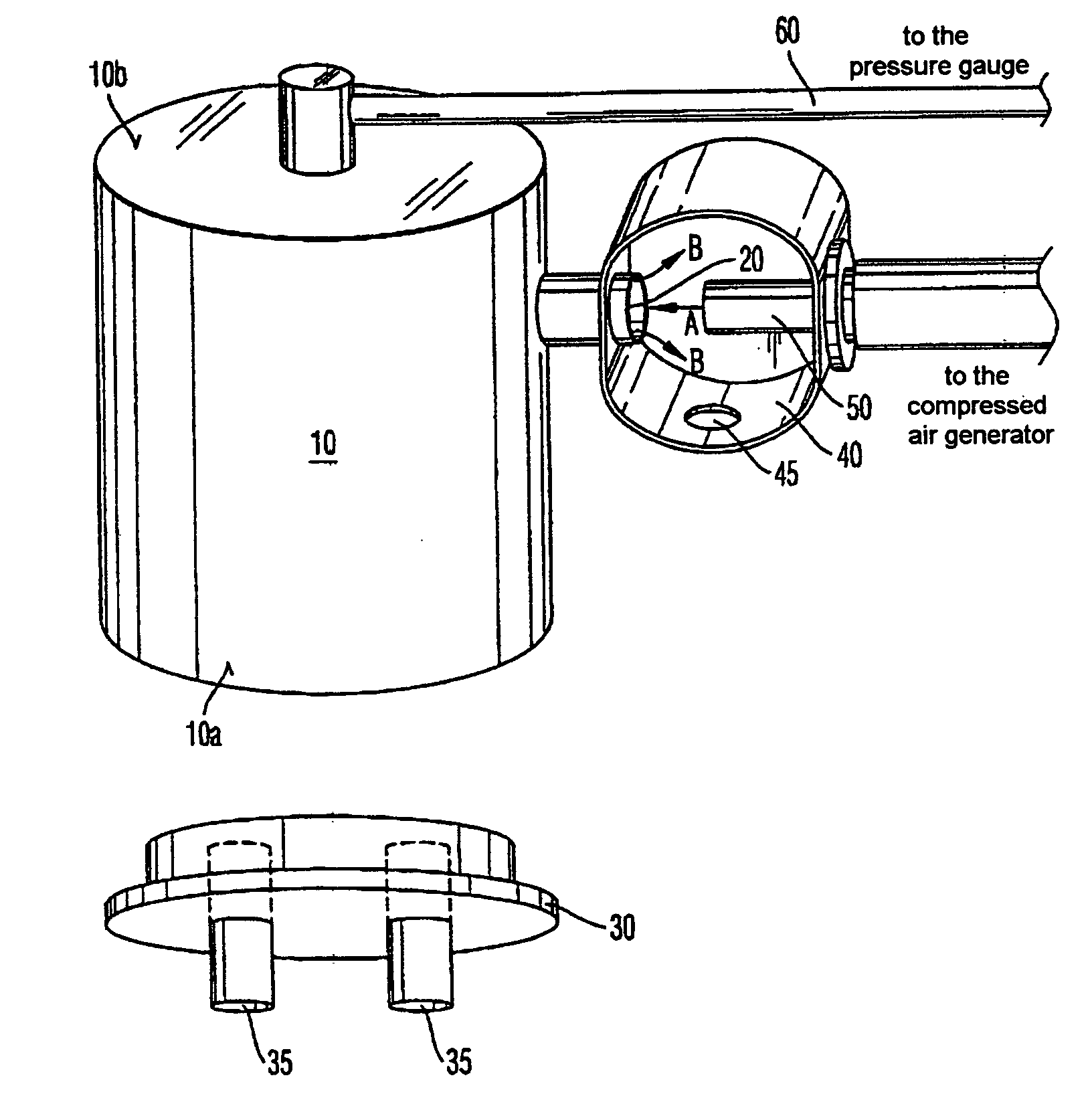

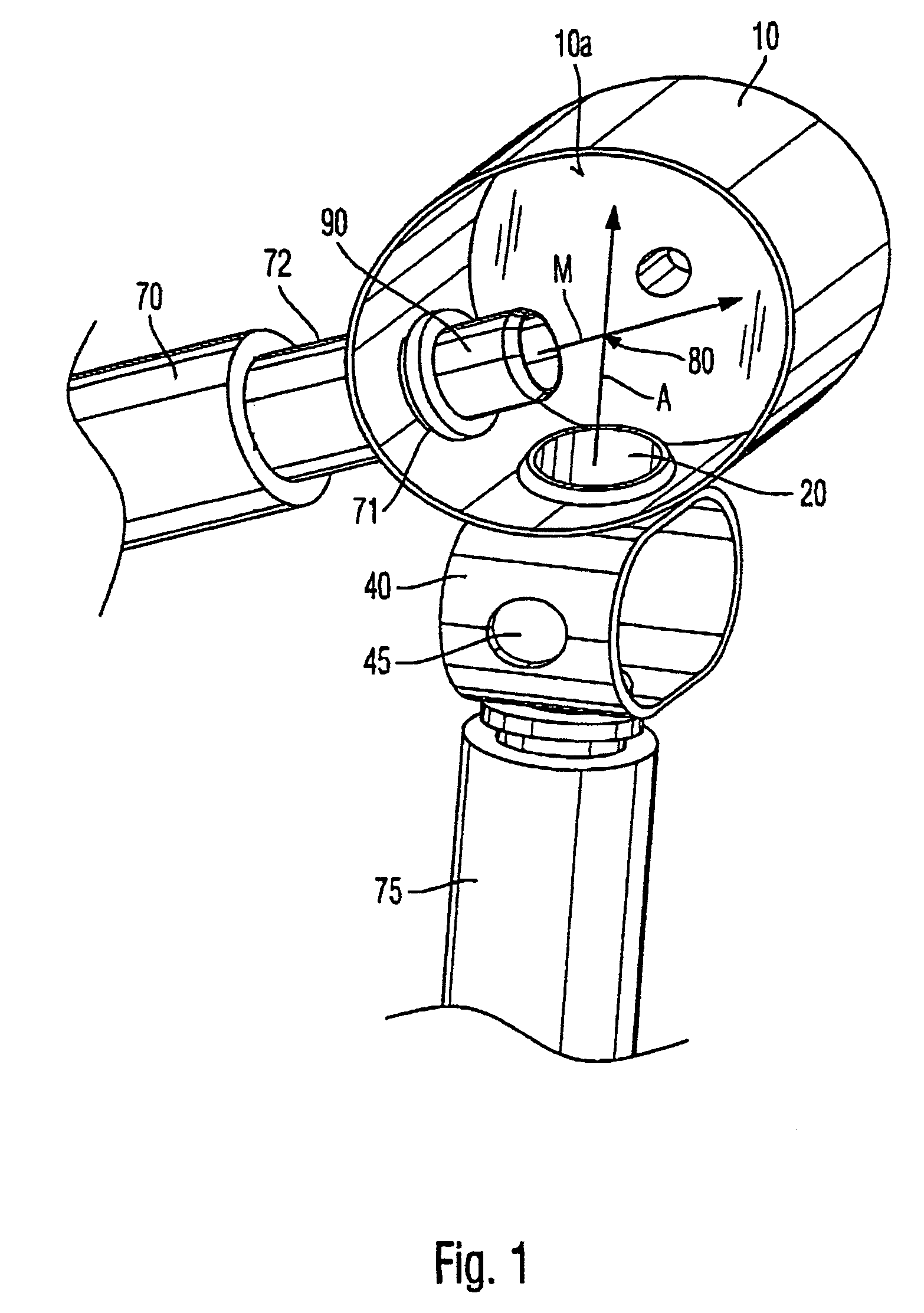

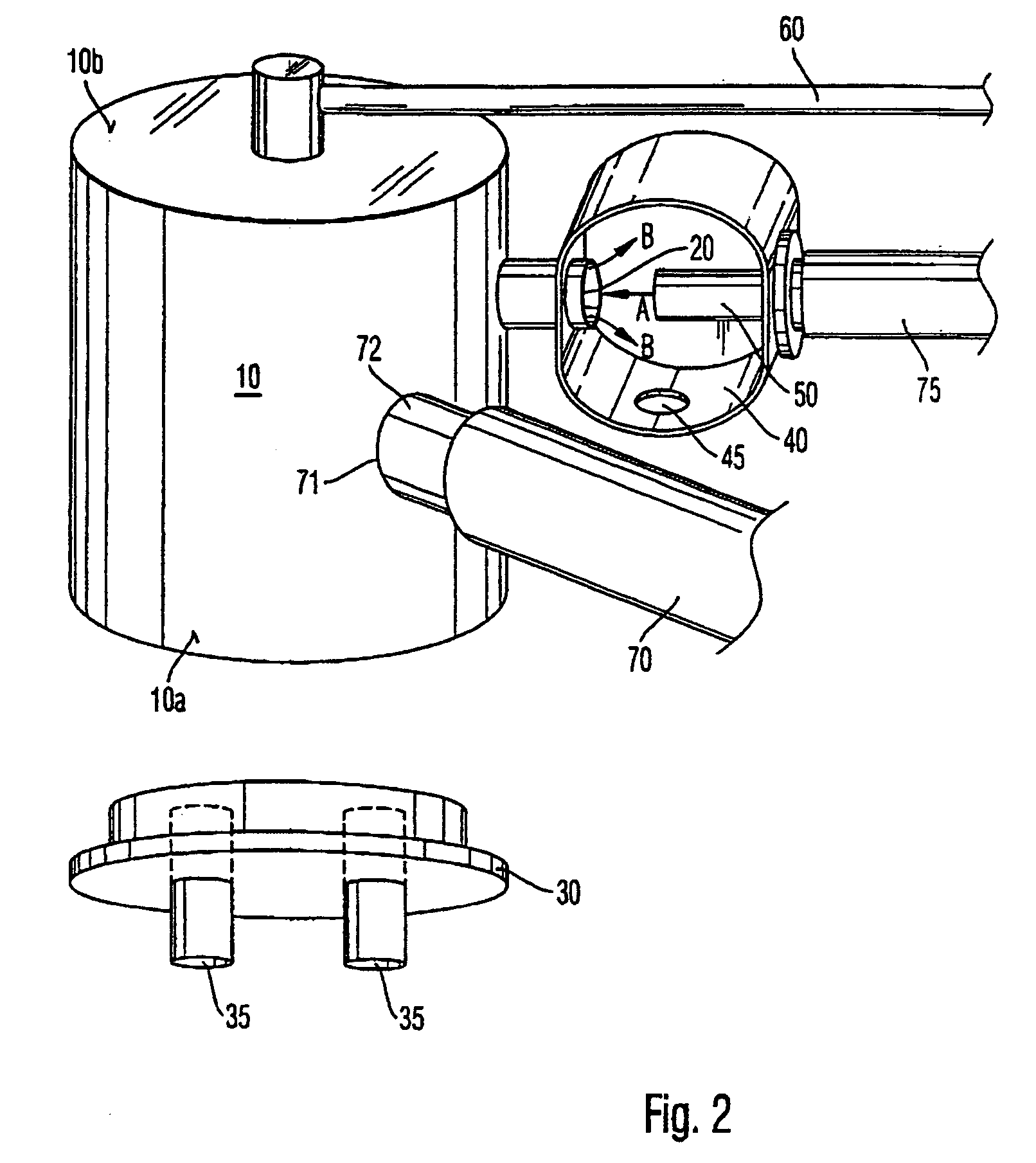

Device for generating a continuous positive airway pressure (CPAP device)

The present invention provides a device for generating a continuous positive airway pressure (CPAP device), in particular a nasal CPAP device (nCPAP device), with a hollow body (10) in which an overpressure can be built up; with a first opening (20) provided in a first side wall of the hollow body (10) and used for introduction of a respiratory gas flow (A) directed into the hollow body (10) and for removal of the exhaled respiratory gas flow (B); and with an attachment piece (30) which can be fitted on the hollow body (10) in order to connect the hollow body (10) to a nosepiece and / or mouthpiece (100). A second opening (71) is provided in a second side wall of the hollow body (10) and is used for introduction of a medicament flow (M) directed into the hollow body (10).

Owner:MEDIN MEDICAL INNOVATIONS

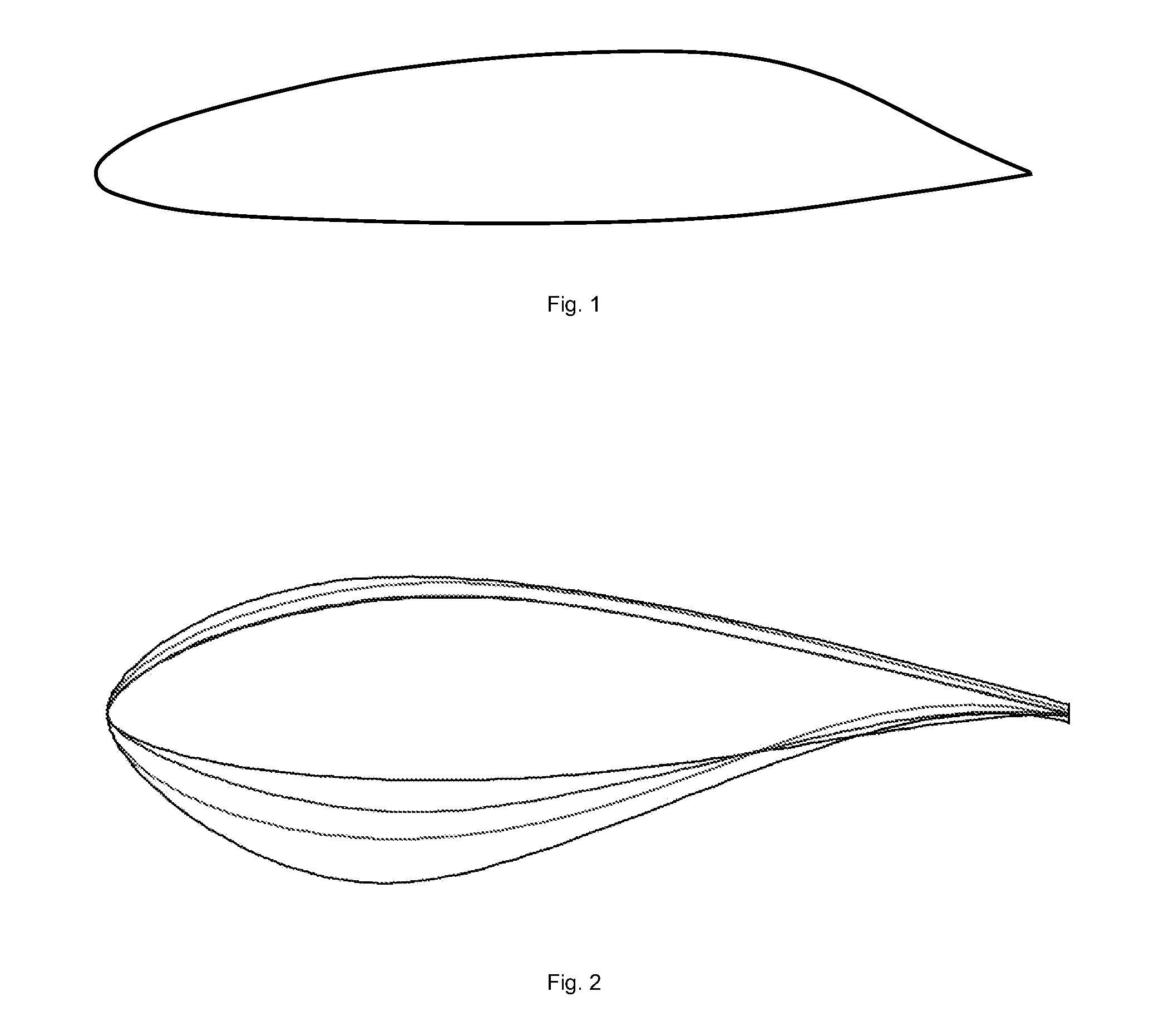

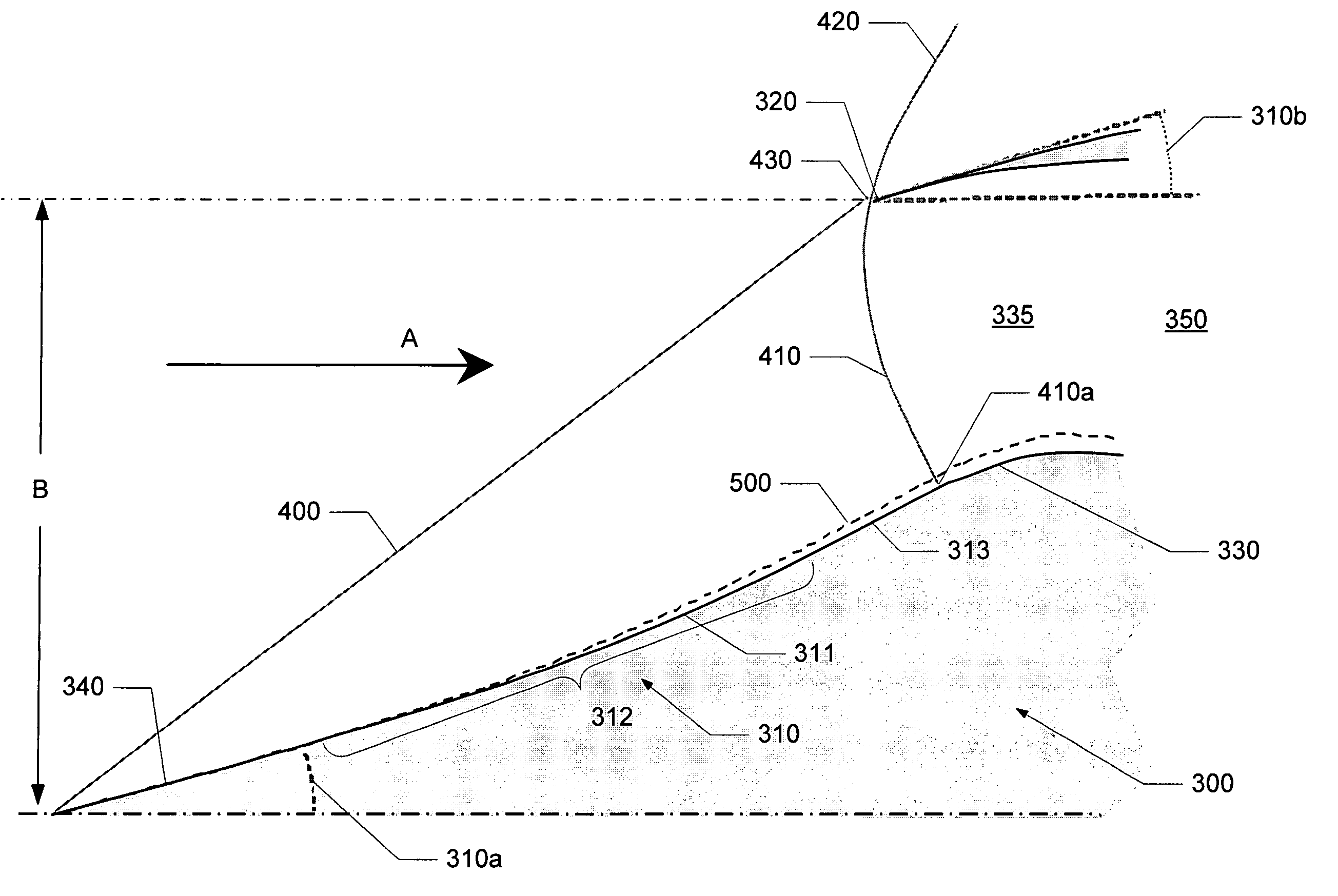

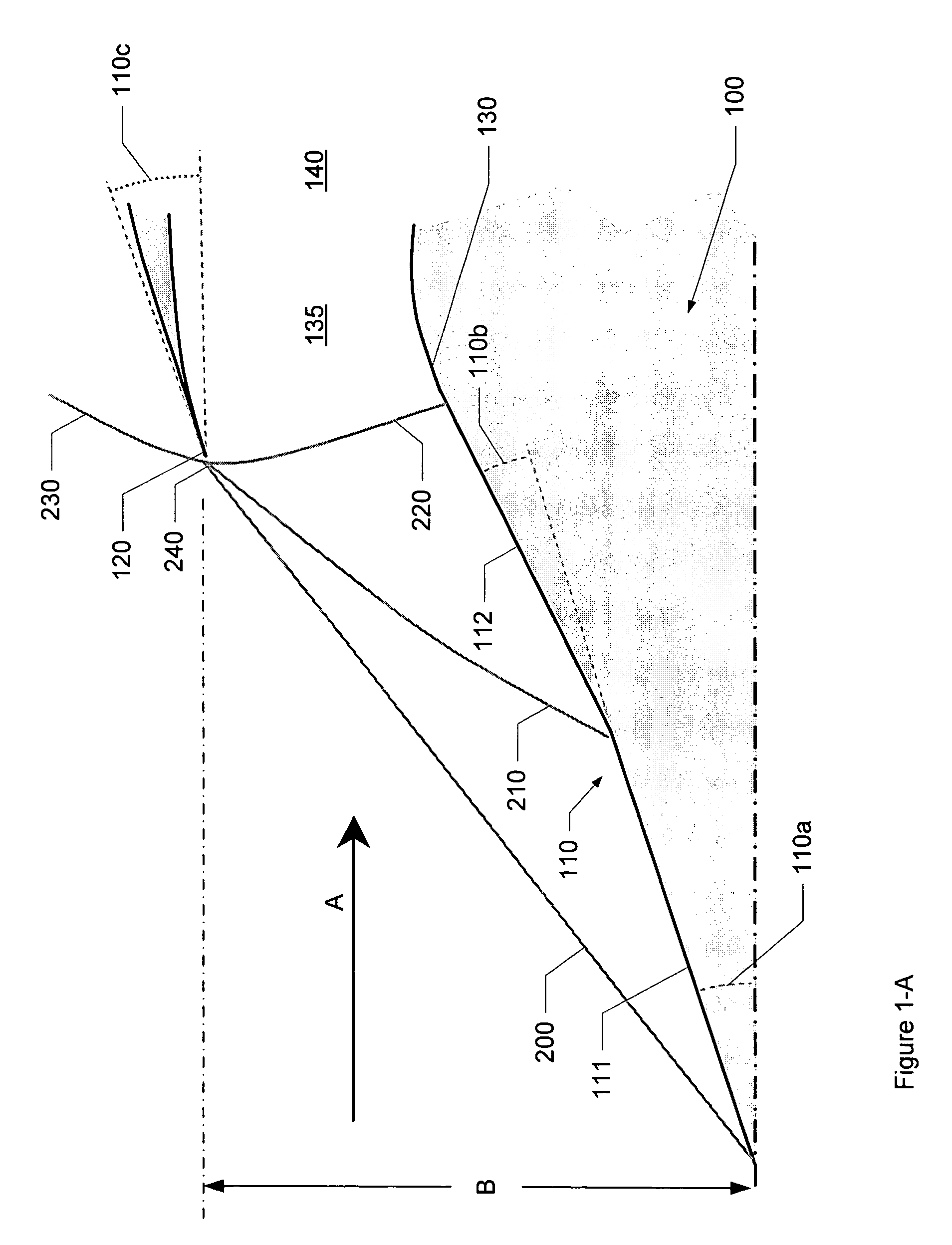

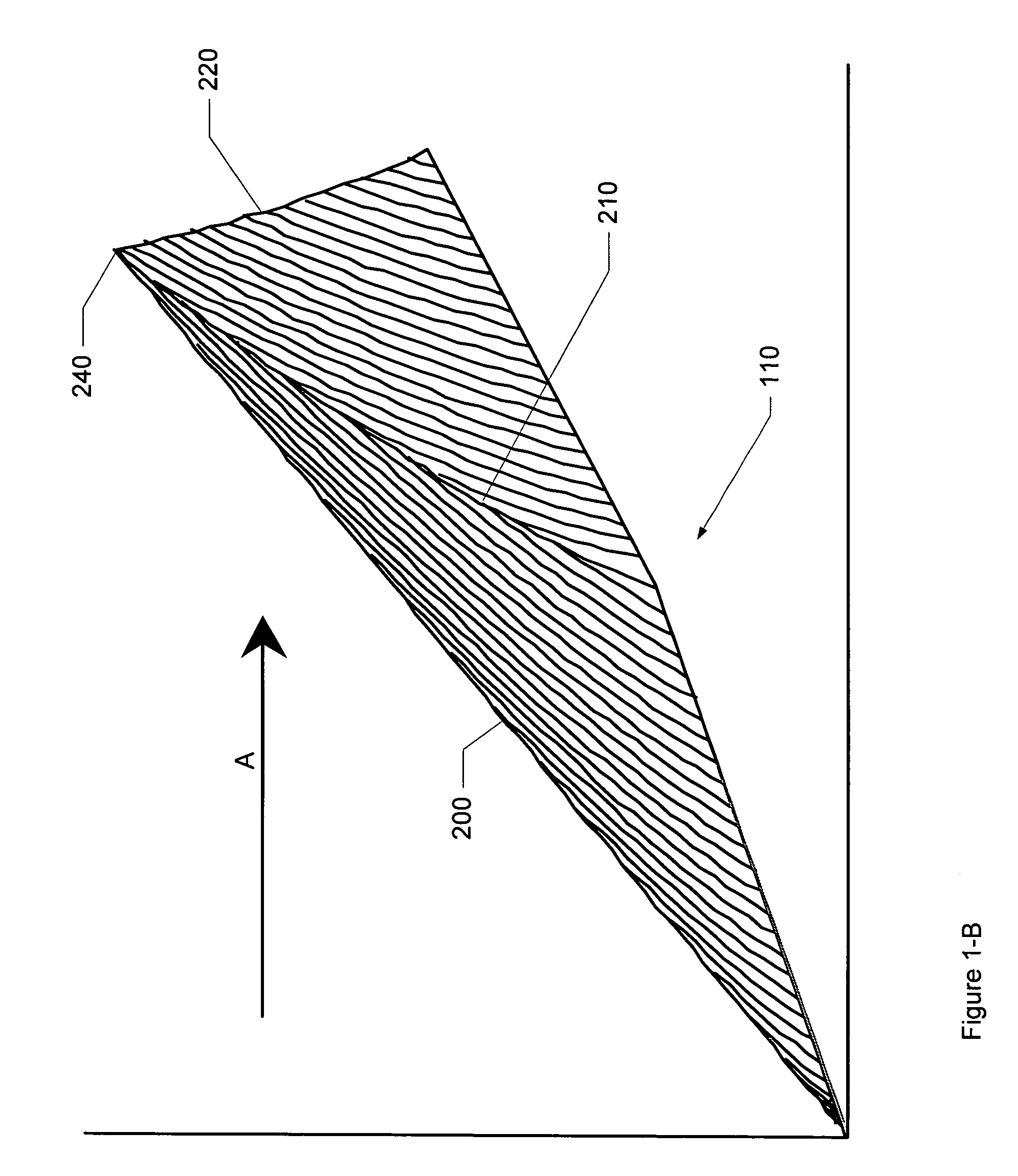

Isentropic compression inlet for supersonic aircraft

ActiveUS20080271787A1Improve performanceInherent shock stabilityCosmonautic vehiclesEngine manufactureEngineeringAirplane

Embodiments of the invention relate to a supersonic inlet employing relaxed isentropic compression to improve net propulsive force by shaping the compression surface of the inlet. Relaxed isentropic compression shaping of the inlet compression surface functions to reduce cowl lip surface angles, thereby improving inlet drag characteristics and interference drag characteristics. Using supersonic inlets in accordance with the invention also demonstrated reductions in peak sonic boom overpressure while maintaining performance.

Owner:GULFSTREAM AEROSPACE CORP

Method of preventing inadvertent inflation of an inflatable prosthesis

InactiveUS7350538B2Preventing inflationPositive displacement pump componentsCheck valvesEngineeringPenile implant

A pump assembly for a penile implant is provided having a mechanism which prevents spontaneous inflation of the cylinders implanted within the user. The preventative mechanism uses overpressure generated by the reservoir during unintentional compression to effectively seal the pump assembly from unintended fluid flow. The prevention mechanism itself creates all necessary forces to prevent the undesired fluid flow to the cylinders. This is accomplished by incorporating appropriate mechanisms within the pump itself.

Owner:BOSTON SCI SCIMED INC

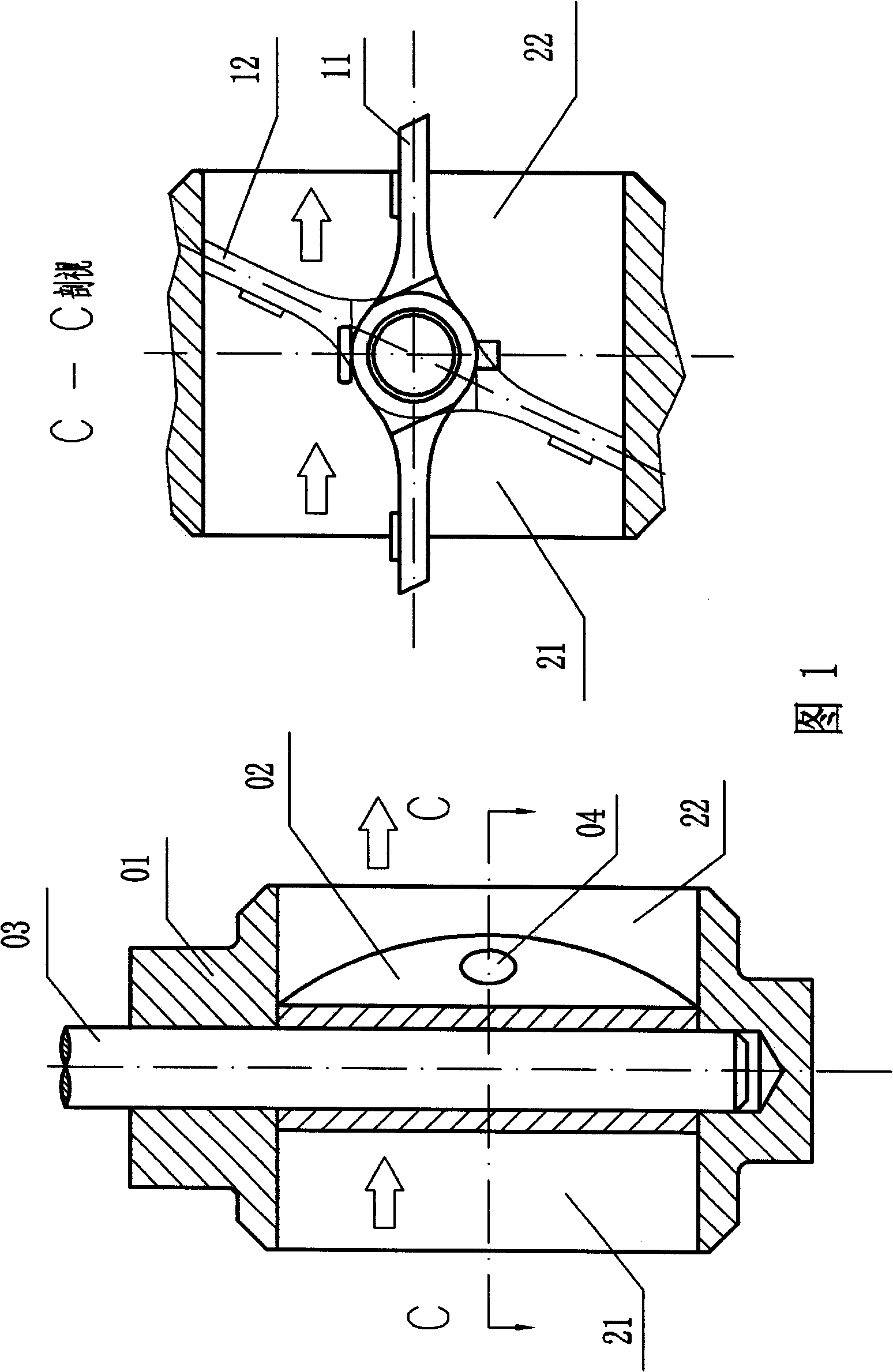

Exhaust brake

InactiveCN101251048AAccurate control of working pressureResponsiveEngine controllersMachines/enginesWorking pressureExhaust brake

The invention relates to an exhaust brake with a decompressor and a method for preventing the formation of the overpressure in the exhaust brake. The operating pressure of the exhaust brake is reliable and adjustable. The exhaust brake comprises a valve body, a disc, a supporting rod, a supporting sleeve, a reducing valve, a spring and an adjustable bolt and does not have a pressure relief vent, wherein, the supporting rod and the supporting sleeve are used for fixing the disc, the reducing valve is used for stably activating the exhaust resistance, the spring is used for adjusting the size of the operating back pressure of an assembly. The exhaust brake with the decompressor can release the excess pressure in time when the pressure surpasses the presetting value due to any unforeseen circumstances and guarantees the stable and reliable operating pressure; moreover, the exhaust brake with the decompressor has adjustable operating pressure, simple and convenient implementation and reliable performance.

Owner:李瑞强 +2

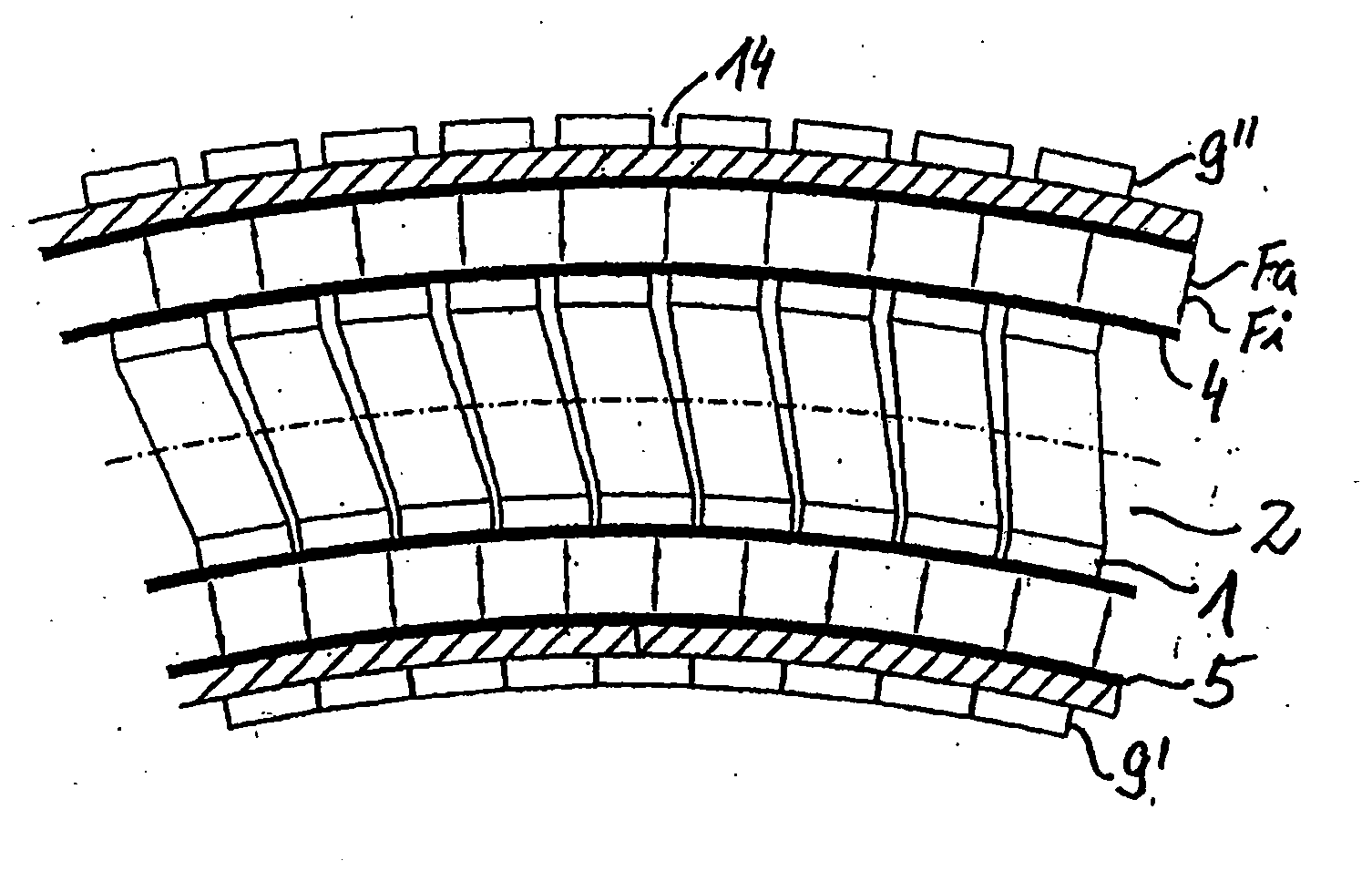

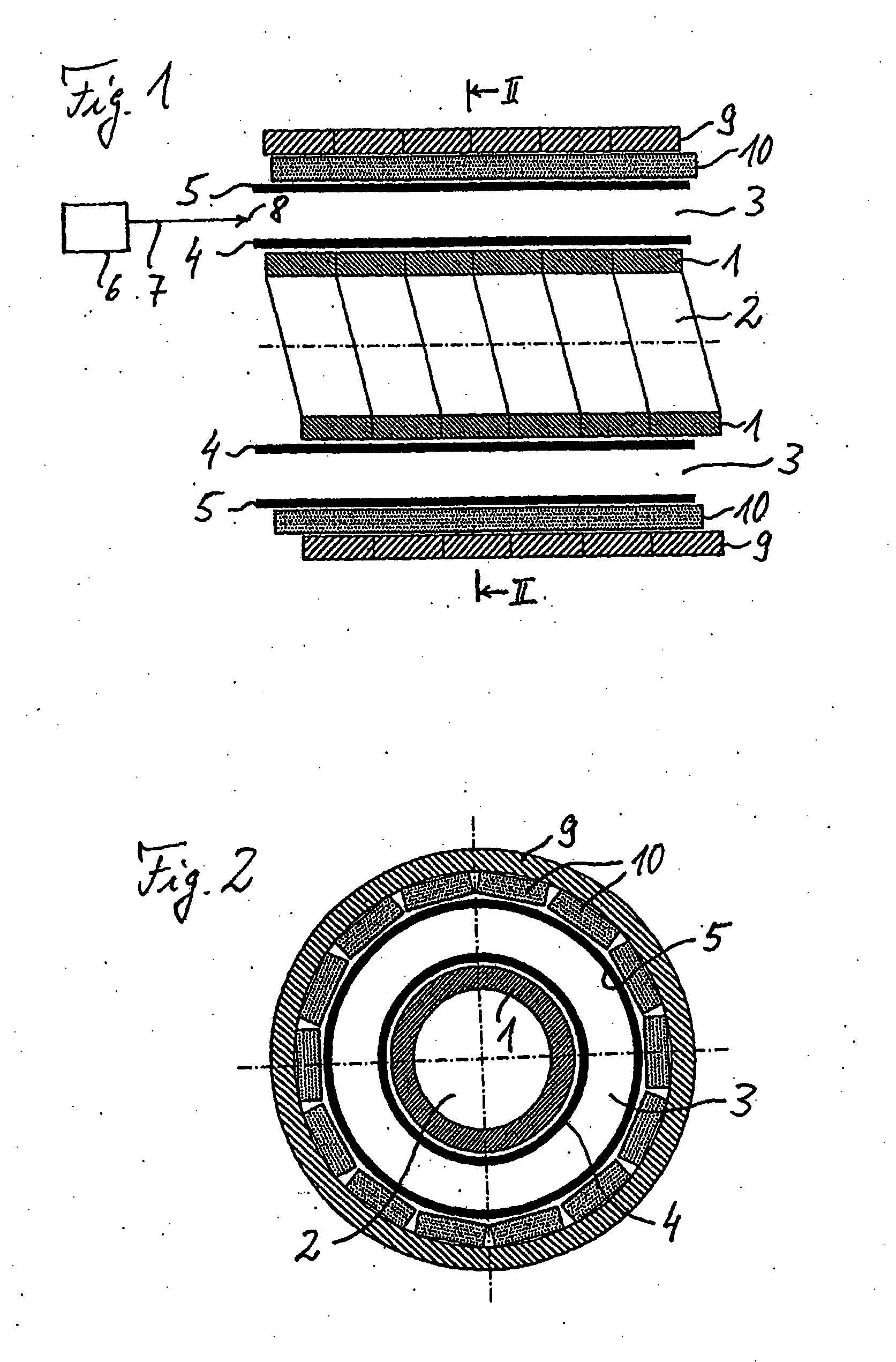

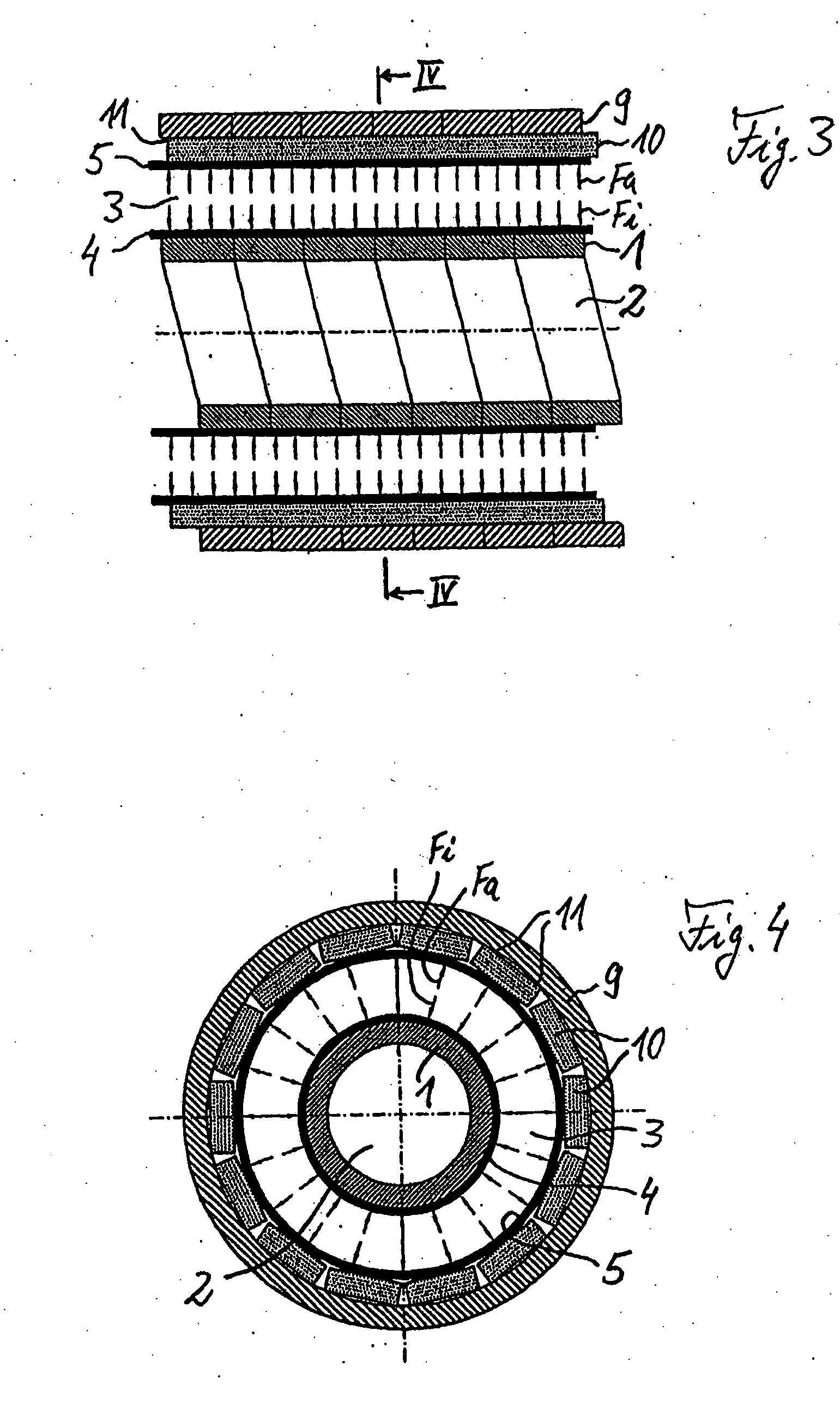

Device for improving the lubrication of bearings, particularly in wind turbines

InactiveUS6991378B2Grease leaks through the seals are almost entirely suppressedContainment leakPropellersRotary propellersEngineeringTurbine

For a bearing mounted between two concentric races rotating relative to each other, and forming an annular gap that accommodates the bearing and is closed by seals, at least one grease tube is provided between the periphery of one of the two races and the annular gap, and is connected to a corresponding grease reservoir. At least one main grease tube opens into the annular gap in an angular sector where an overpressure occurs, a corresponding main grease reservoir is adapted to collect grease flowing from the annular gap through the main grease tube due to the overpressure that may occur within the annular gap in the angular sector.

Owner:DEFONTAINE

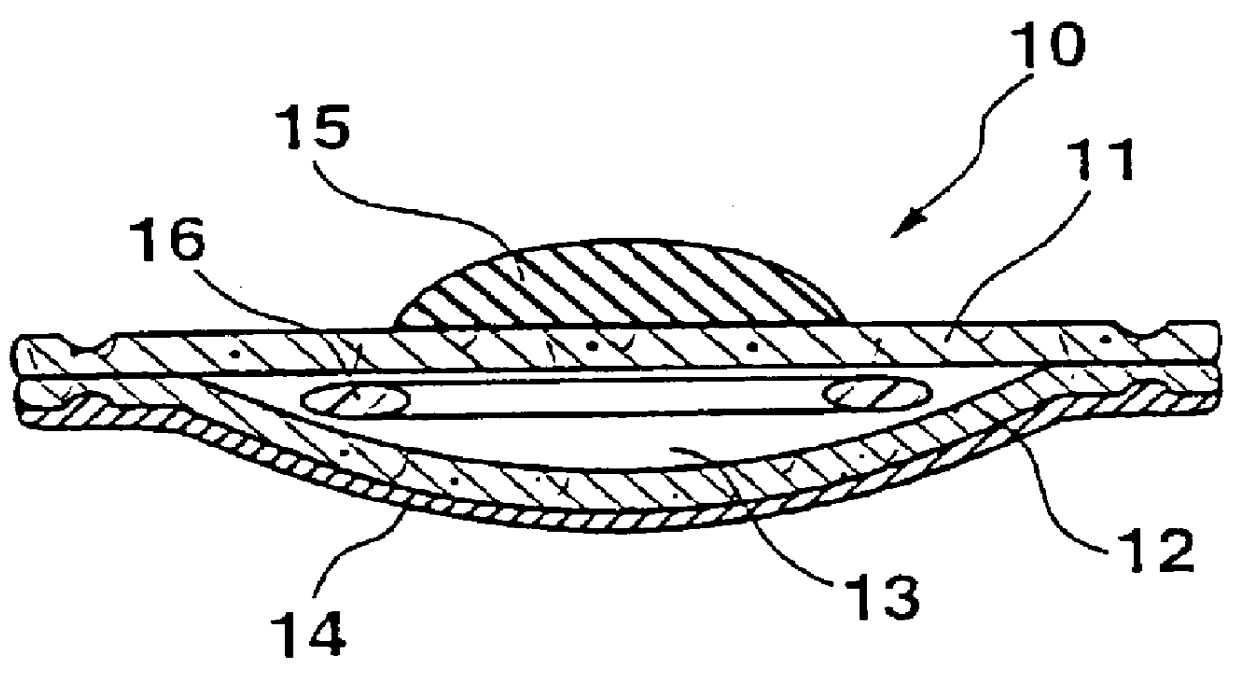

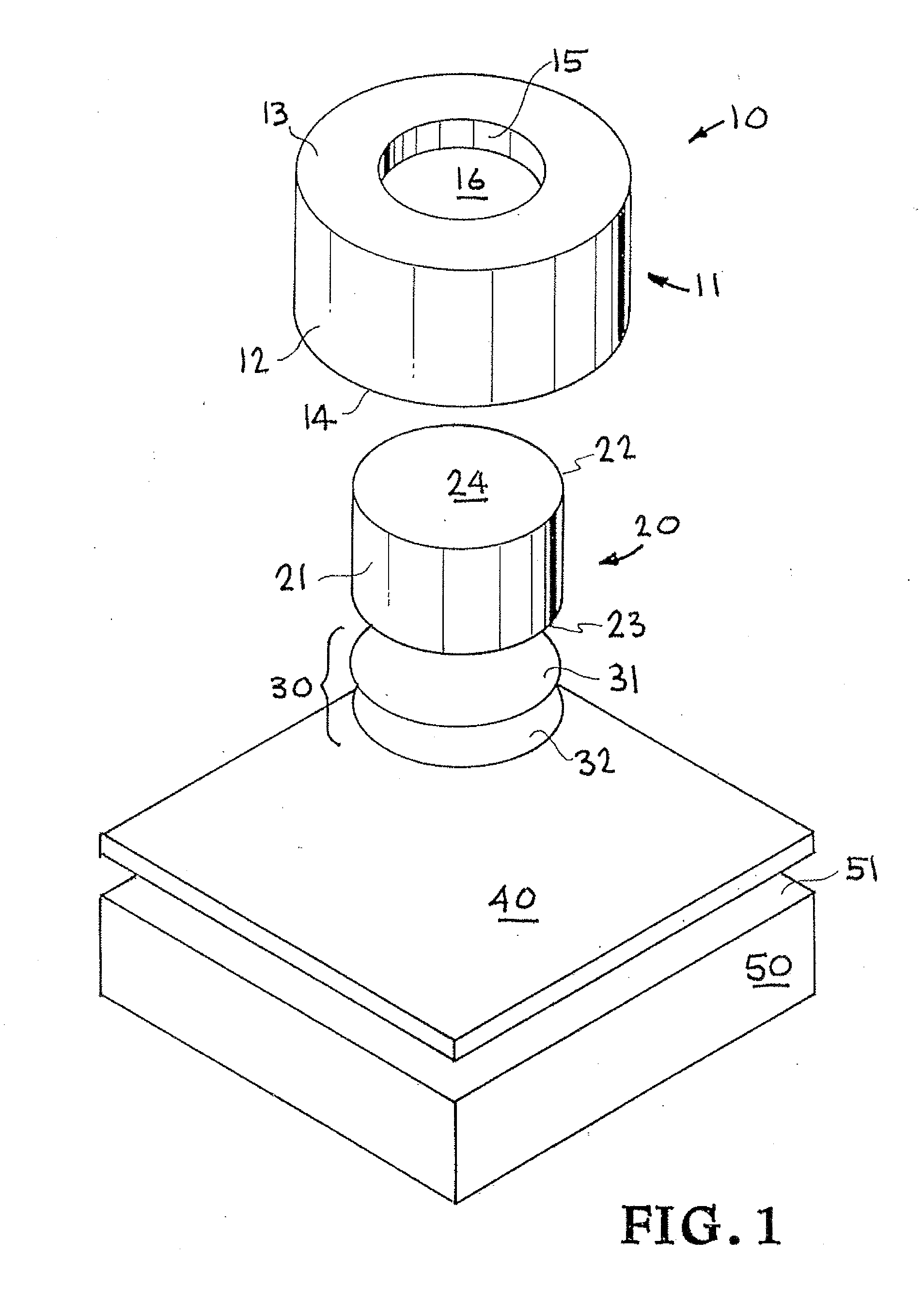

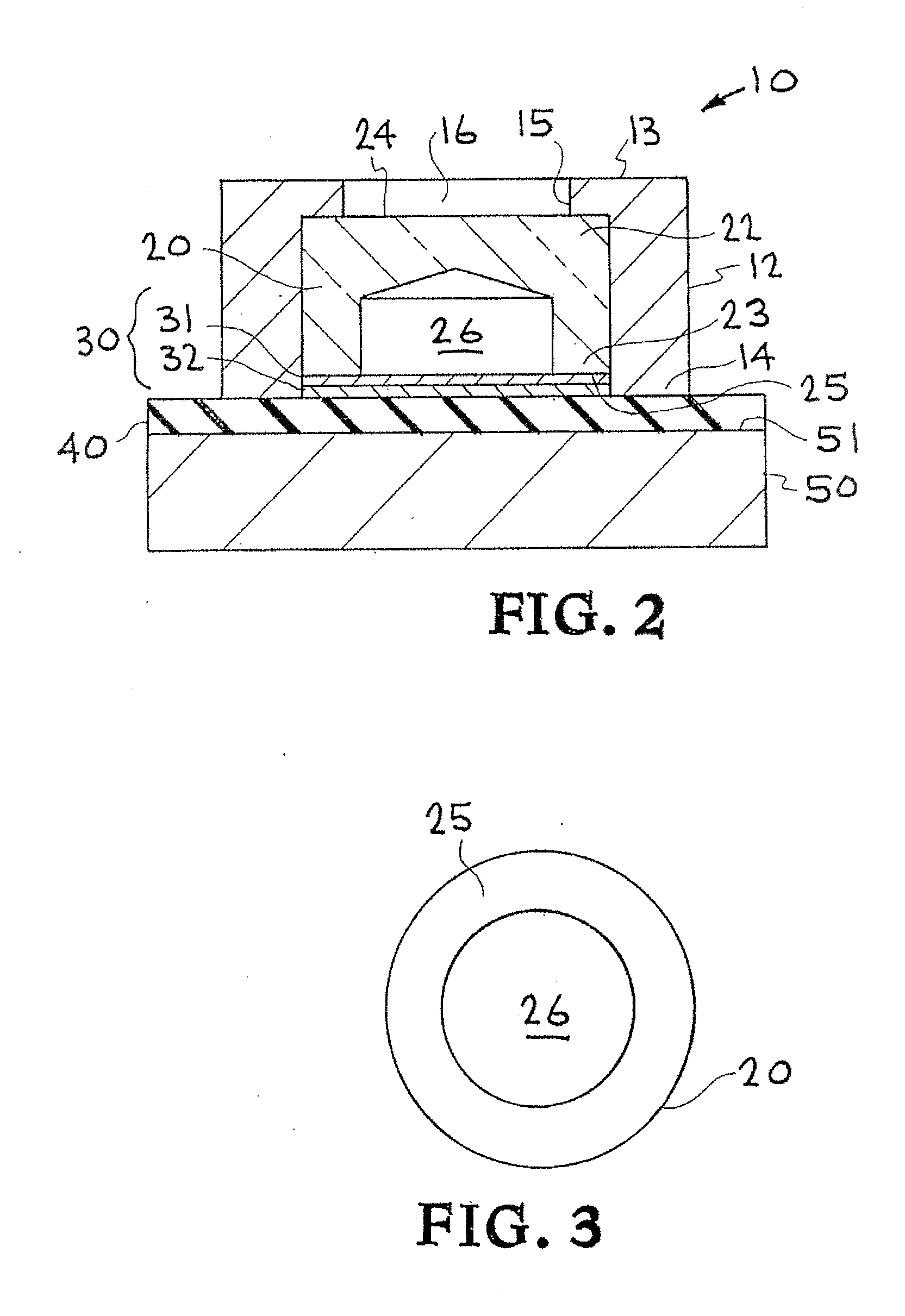

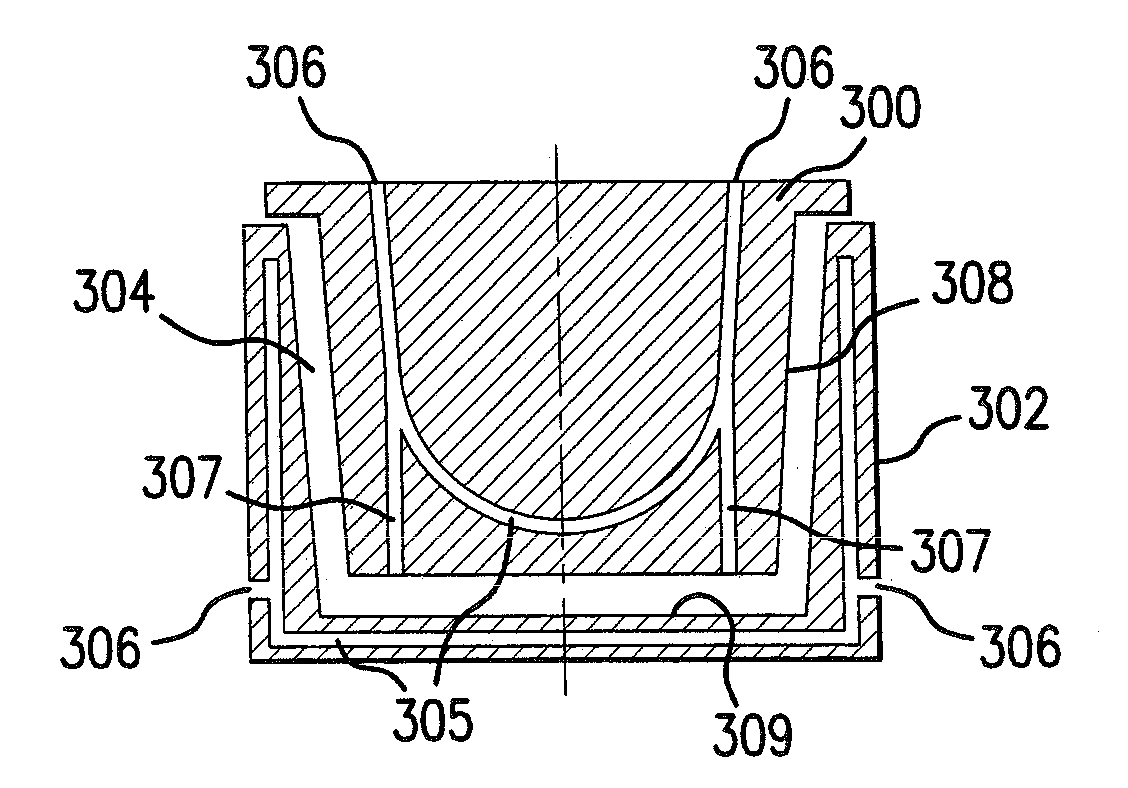

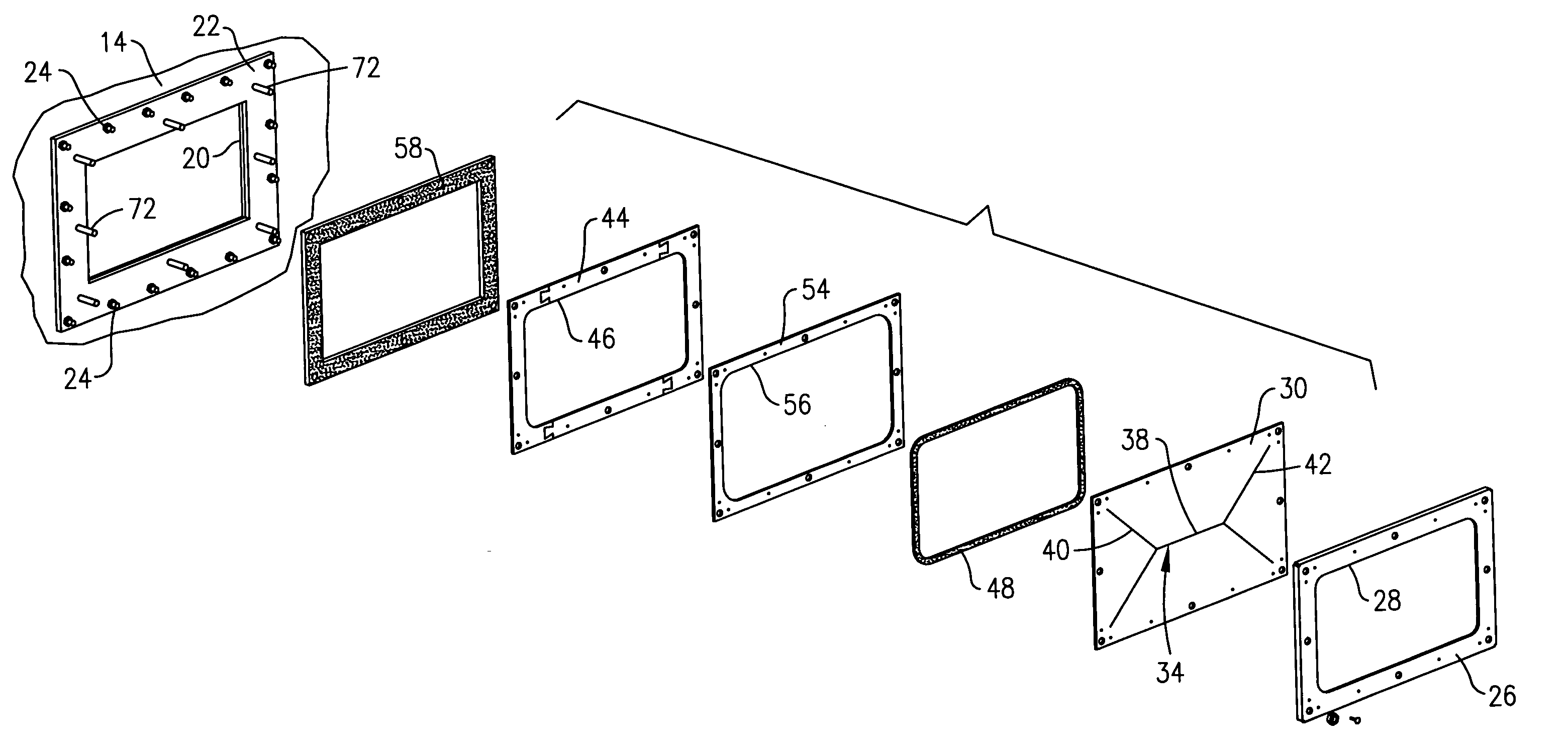

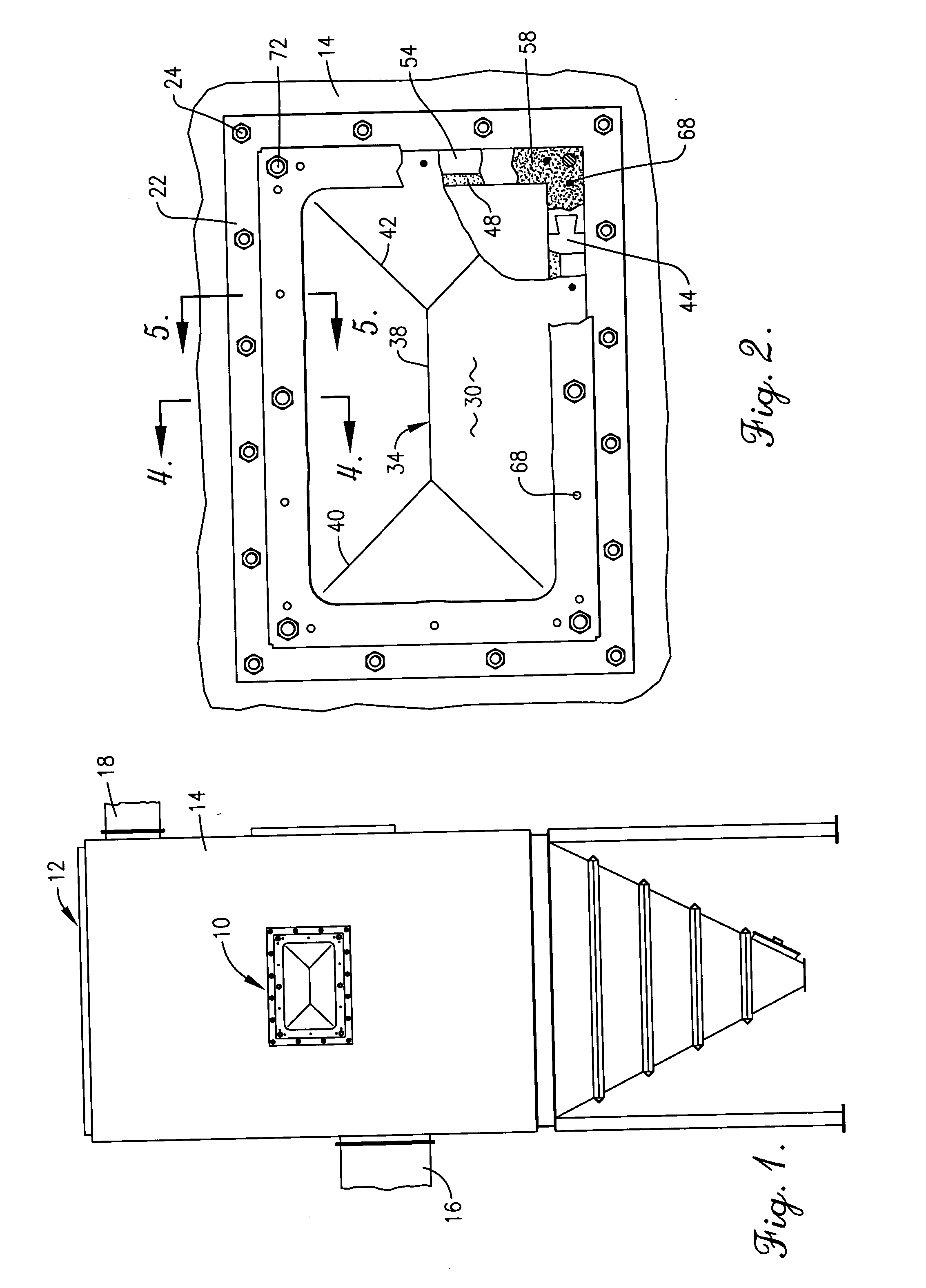

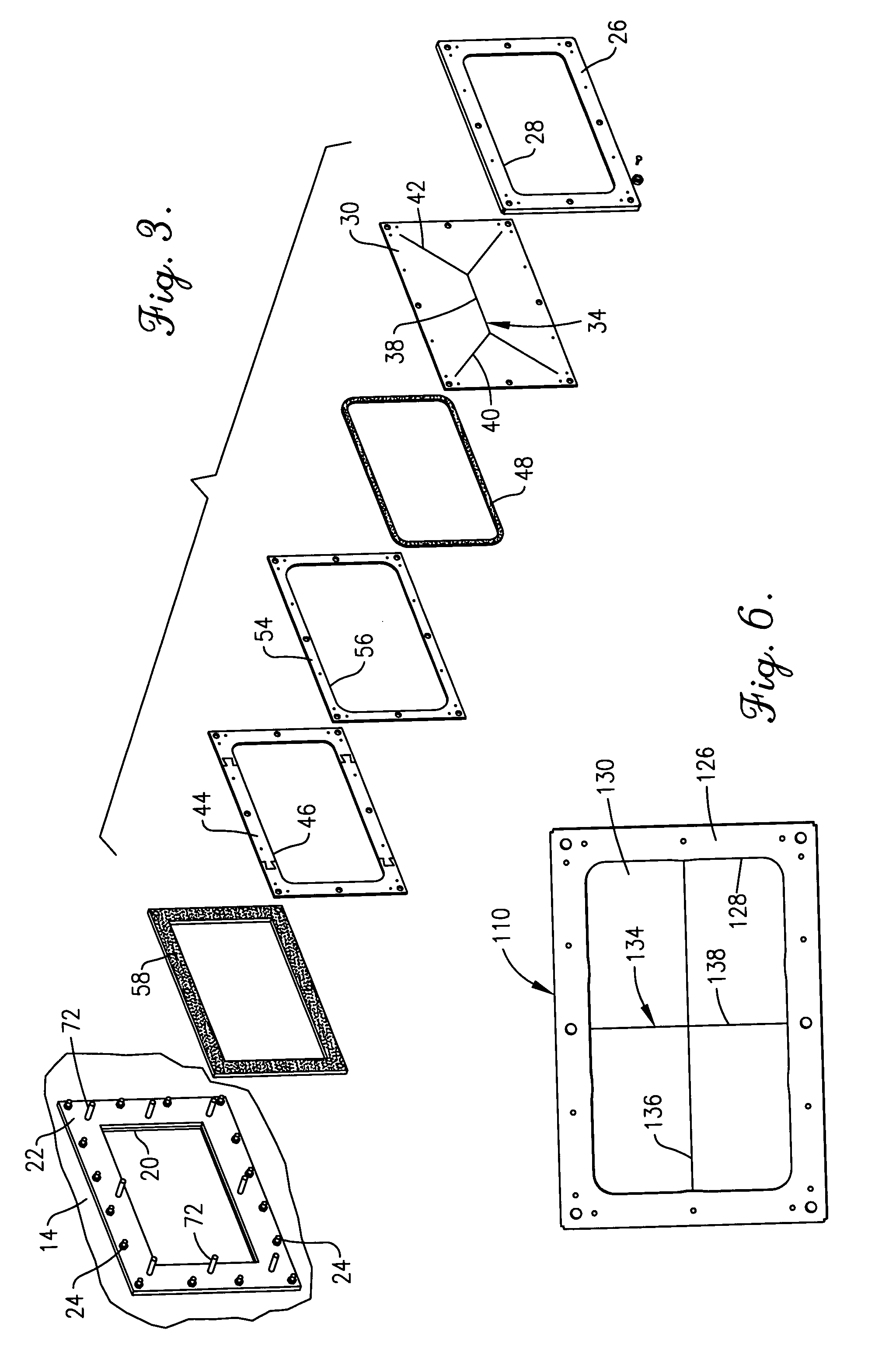

Unitary overpressure vent panel structure

InactiveUS20040172889A1Prevent overcompressionMaintain integrityLarge containersEqualizing valvesEngineeringSealant

Unitary one-piece frameless overpressure vent panel assembly (10) includes a rigid, generally planar primary support member having a central relief opening (26), a rigid, generally planar secondary support member (44) provided with a central relief aperture (46), and a frangible vent panel (30) between the support members in full closing relationship to the relief opening and the aperture. A sealant element (48) may be provided between the vent panel and at least one of the support members in circumscribing relationship to the relief opening or aperture. At least one line of weakness (34) may be provided in the vent panel. A flexible gasket (58) secured to the secondary support member assures a fluid tight seal between the vent panel assembly and the structure defining a protected zone. Alternatively, a knife blade or the like may be provided adjacent the vent panel to effect severing thereof under a predetermined overpressure in lieu of a line of weakness in the panel.

Owner:FIKE CORP

Method for preventing contamination of an inner surface of a hollow glass body by alkali compounds and glass container, especially for medicinal purposes

InactiveUS7980096B2Preventing and avoiding contaminationBlock compoundPharmaceutical containersGlass drawing apparatusVitreous BodiesContamination

In order to avoid deposition of evaporating alkali compounds on an inner surface of a hollow glass body during thermal processing to form a glass container from the hollow glass body, an overpressure is provided in the hollow glass body during the thermal processing. Either rinsing the hollow glass body with a gas, such as air, or at least partially closing the glass body at one end so that sufficiently rapid pressure equilibration is avoided, can provide this overpressure. The glass containers made by these methods are especially suited for food or pharmaceuticals because they have a reduced alkali release from their inner surfaces, for example at most about 2.0 mg / l sodium oxide.

Owner:SCHOTT AG

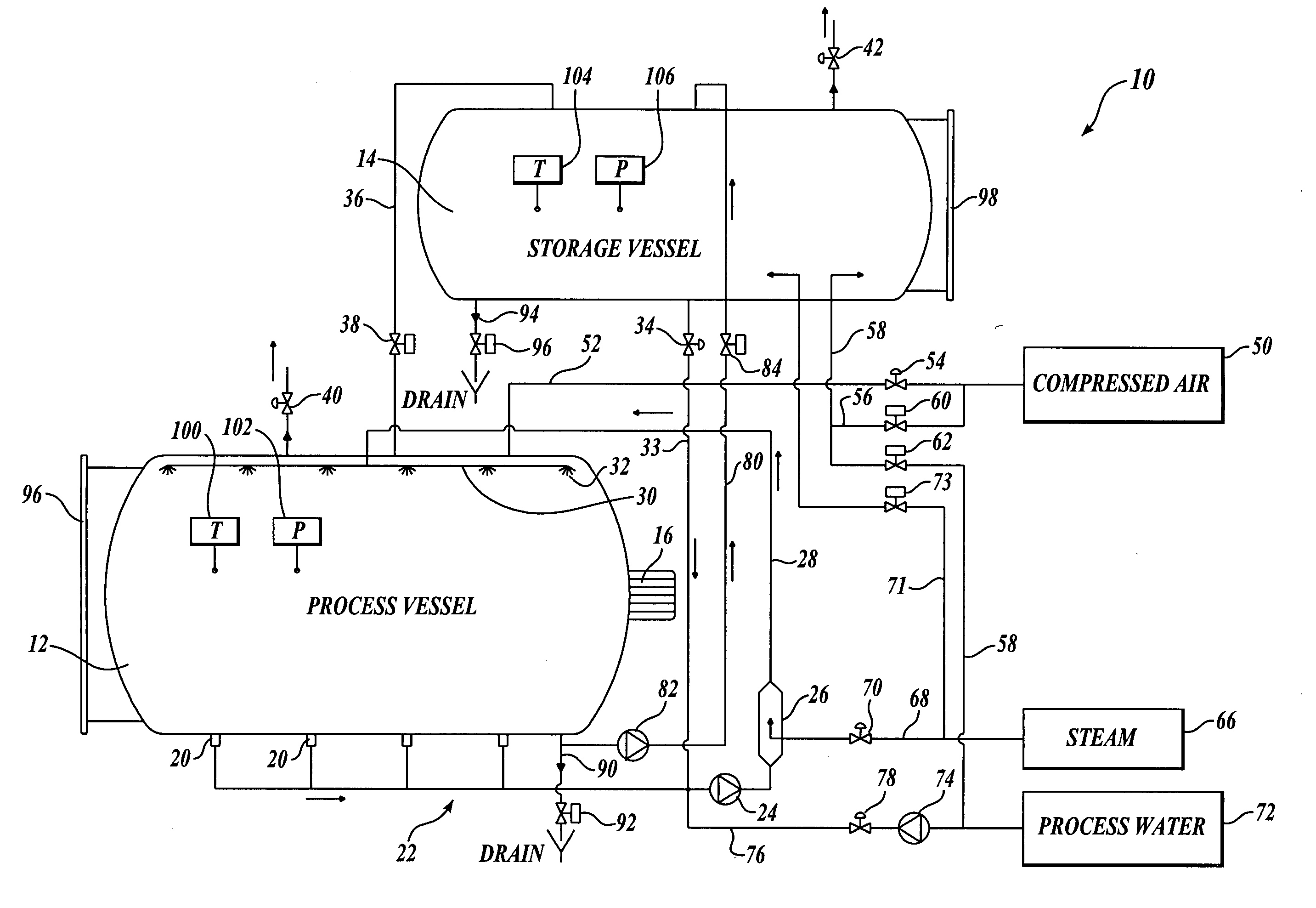

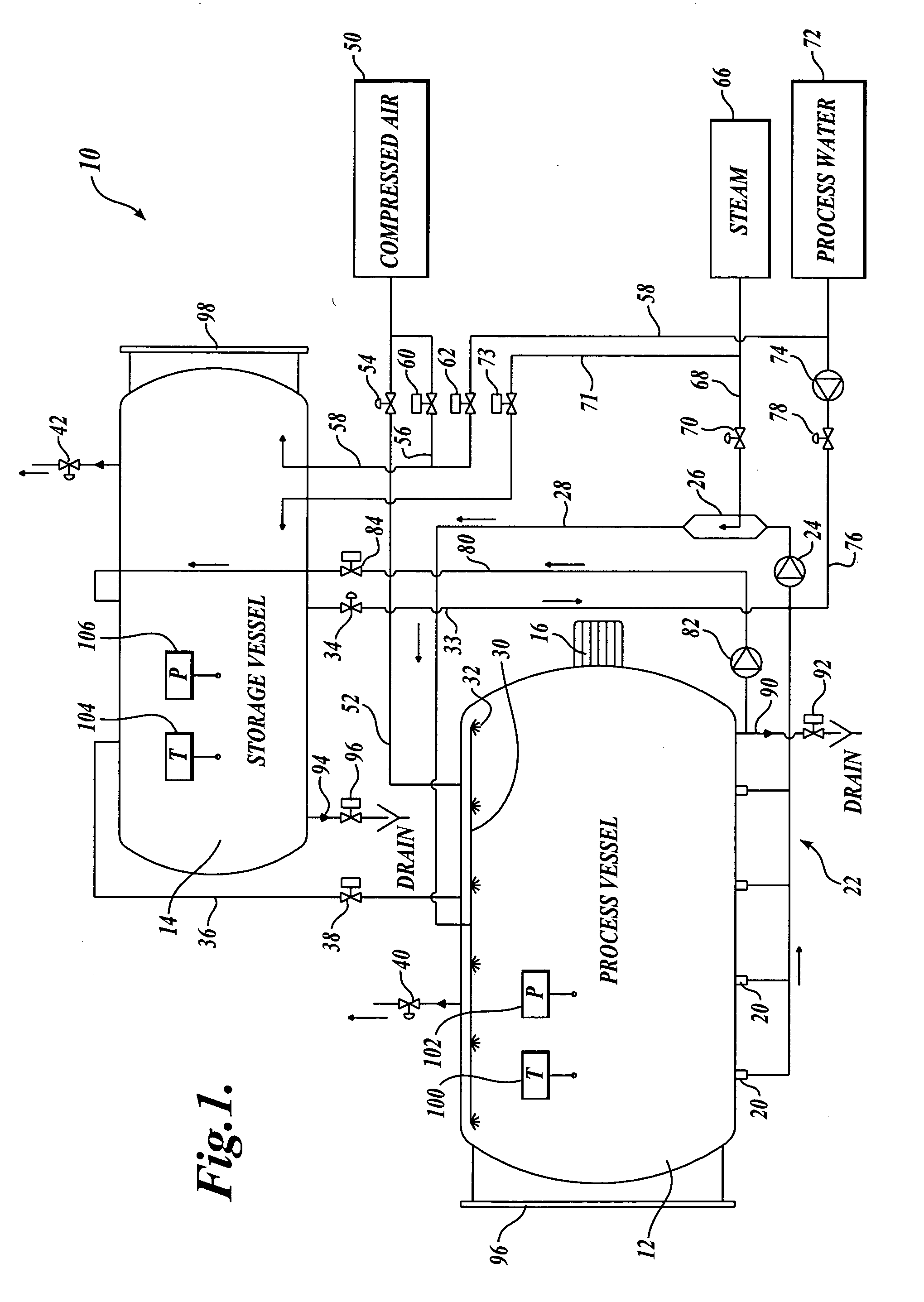

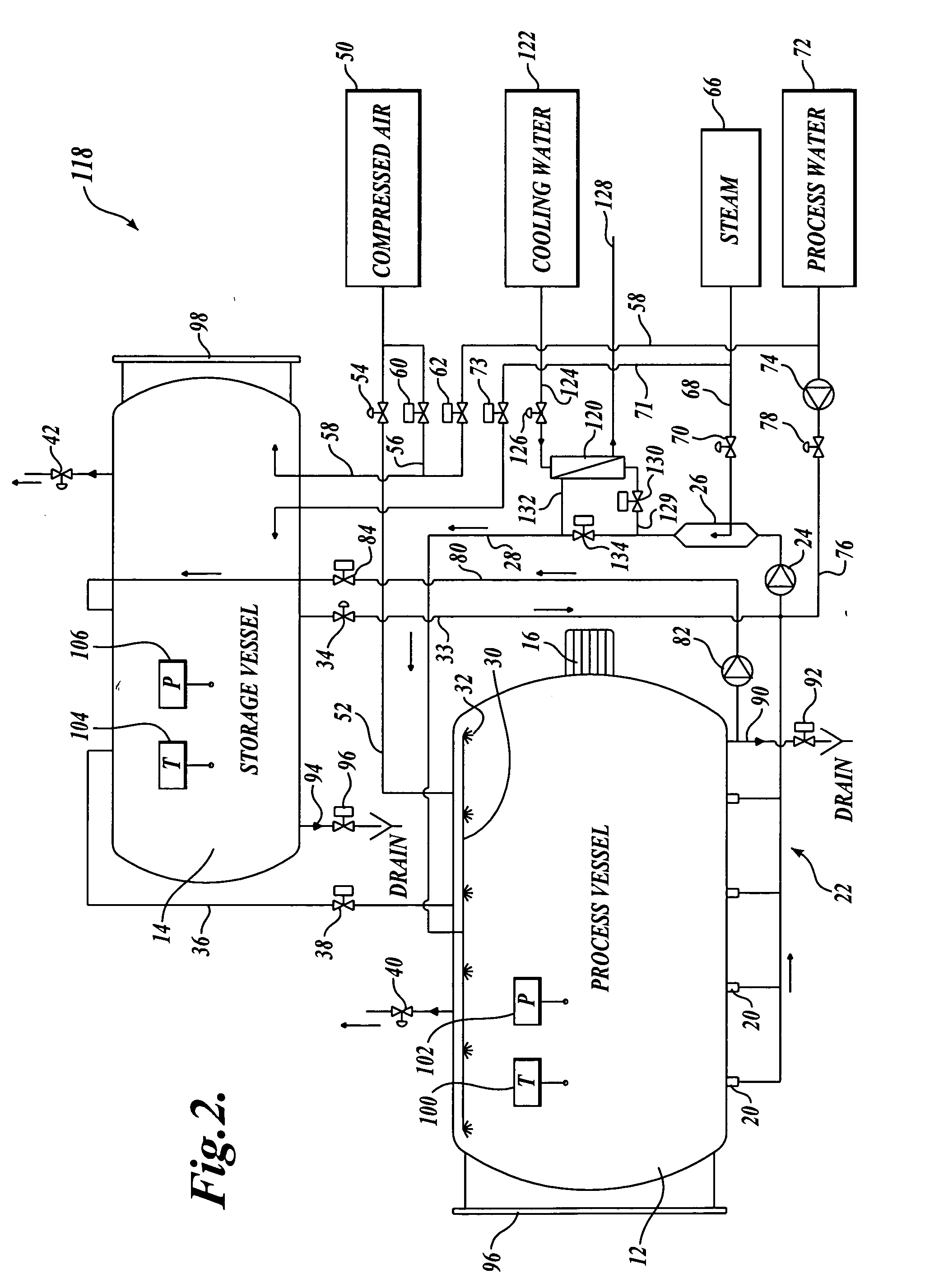

Immersion retort

InactiveUS20050249650A1Control pressureMilk preservationFood preservationProcess engineeringCooking process

An overpressure retort system includes a process vessel in fluid flow communication with a storage vessel. Heated process fluid from the storage vessel is transferred to the process vessel, including through spraying outlets or nozzles to direct heated process fluid onto the nutrient product containers. After the cooking process has been completed, the heated process fluid is returned to the storage vessel and then cool process fluid is used to cool the nutrient products in the process vessel, including by spraying the cooled process fluid onto the nutrient product containers. During the cooking and cooling processes, the process fluid from the process vessel is recirculated, and the overpressure within the process vessel is controlled by supplying compressed gas at a controlled pressure to the headspace of the process vessel. The headspace of the process vessel and the headspace of the storage vessel are in fluid flow communication. In the cooling process, process fluid may be withdrawn from the process vessel, then cooled in a heat exchanger, then reintroduced to the process vessel.

Owner:FMC TECH INC

Controllably Stiffenable Tube

A tube that can be stiffened in a controlled manner has a pressure channel for controllable production of a stiffening overpressure by introduction of a pressure medium. The tube has several flexible stiffening elements, of which at least one is stable with respect to tensile force and which are pressed onto one another when acted upon by the stiffening overpressure with the result that the tube is changed from a more flexible state to a more flexurally stiff state. A channel is separate from the pressure channel and, in the stiffened state of the tube, forms a working channel whose course corresponds to the tube shape.

Owner:EPFLEX FEINWERKTECHN

Pressure responsive centralizer

InactiveUS20060243435A1Mitigating APBHigh degree of pressure buildupDrilling rodsWell/borehole valve arrangementsMechanical engineeringAvailable Volume

A centralizer including hollow structural components. In at least one embodiment, the hollow structural component is sealed by at least one valve or rupture disk. When unacceptable overpressures occur, the valve or rupture disks break to allow influx into the hollow element, thereby relieving pressure and avoiding damage that might otherwise occur. In other embodiments, the hollow structural component collapses to expand available volume.

Owner:HALLIBURTON ENERGY SERVICES INC

Non-return valve, in particular for medical uses

ActiveUS8291936B2Valve to closeImproves inventionCheck valvesEqualizing valvesInlet channelEngineering

A nonreturn valve includes a first tube connection housing and a second tube connection housing and a diaphragm disk between the first and second tube connection housings. The disk can be lifted from an annular valve seat upon an overpressure in an inlet channel and can be pressed onto the valve seat upon an overpressure in an outlet channel. The diaphragm disk has an annular bead received in mutually opposite annular grooves of the tube connection housings. The diaphragm disk is provided, radially outside the valve seat, with openings leading to an outlet chamber. The second tube connection housing lying opposite the openings is provided with recesses which communicate with the outlet channel and are separated from each other by supporting surfaces for the diaphragm disc. The recesses are connected to the outlet channel by narrow deep grooves.

Owner:ILLINOIS TOOL WORKS INC

Non-fragmenting pressure relief apparatus

A non-fragmenting pressure relief apparatus includes a rupture disc having a central bulged or flat section and a peripheral flange portion. Certain embodiments of the invention have a butterfly shaped element having two wing panels attached to the underside of a rupture disc of the apparatus. A line of weakness of major length extends around the periphery of the central section of a disc and C-shaped end region lines of weakness in the wing panels, which define a hinge portion of the disc therebetween, first converge and then diverge from one another, and connect with the major line of weakness. Application of an overpressure to the rupture disc apparatus causes the entire line of weakness to sever including the end region lines of weakness whereby divergence of the opening force at the hinge portion of the disc prevents separation of the central section of the disc from the peripheral portion of the disc. In another embodiment, the butterfly shaped element is omitted and the C-shaped end region lines of weakness are provided in the central section of the disc.

Owner:FIKE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com