Unitary overpressure vent panel structure

a vent panel and overpressure technology, applied in mechanical equipment, transportation and packaging, functional valve types, etc., can solve the problems of increased explosion risk inherent in the provision of such dust collecting equipment, increased explosion risk, and increased need for explosion protection with improved dust collection equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

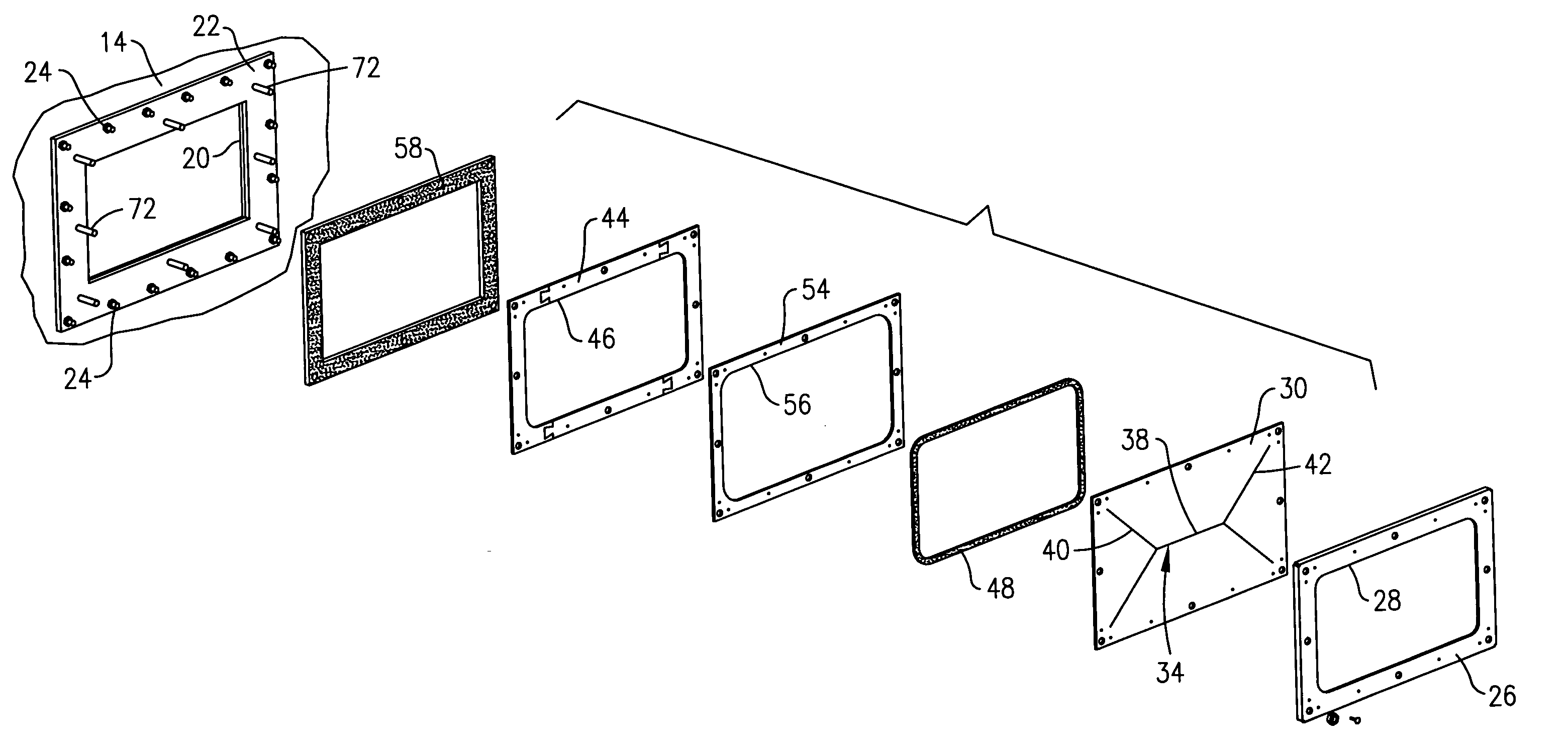

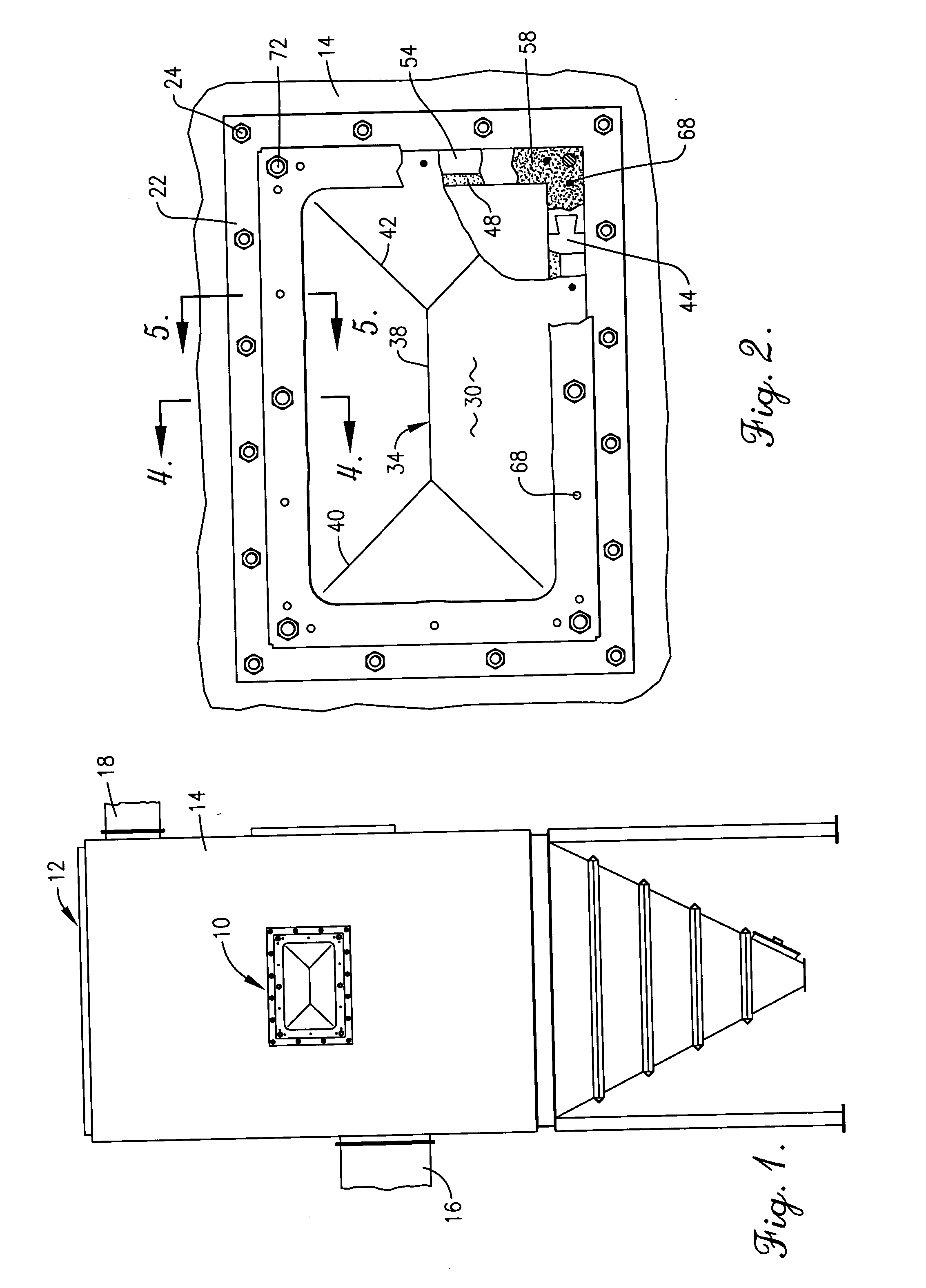

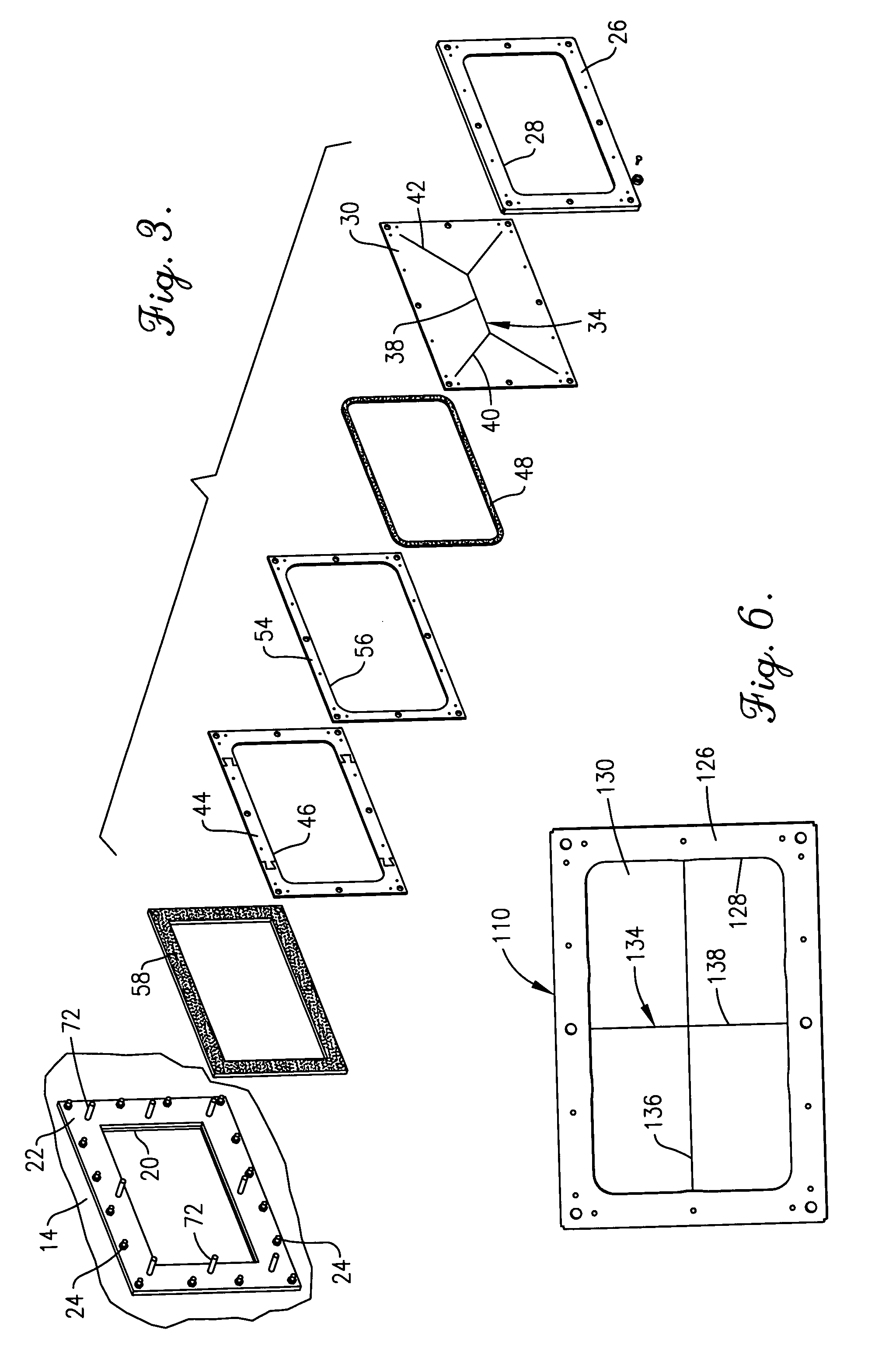

[0033] The principal, although not exclusive, utility for the rigid, integrated, one-piece overpressure vent panel assembly hereof is in explosion protection applications. To that end, the unitary overpressure vent panel assembly 10 as shown in the drawings is illustrated in operative position in a typical installation such as the upright side wall 14 of a particulates collector in the nature of a bag house 12 having an inlet 16 and an outlet 18. Bag house 12 conventionally is provided with a plurality of filters which for example may be loosely woven fabric bags mounted over respective outlet conduits which communicate with the interior of structure 12.

[0034] It is to be understood that mounting of unitary overpressure vent panel assembly 10 on the side wall 14 of bag house 12 is for illustrative purposes only and the assembly 10 may be positioned in any one of a number of strategically determined locations depending upon the type of confined zone to be protected from an explosion,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com