Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

159results about How to "Prevent overcompression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

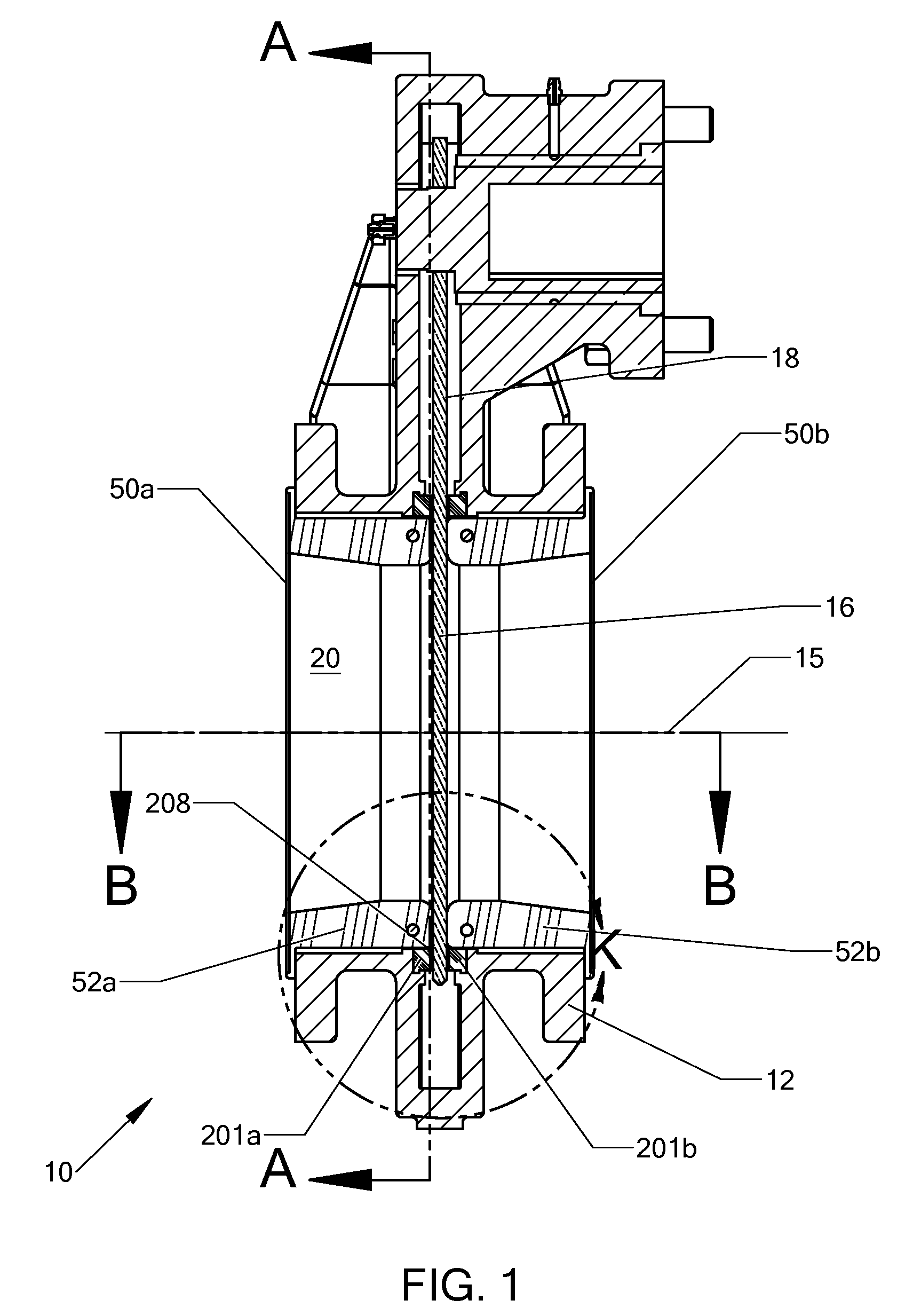

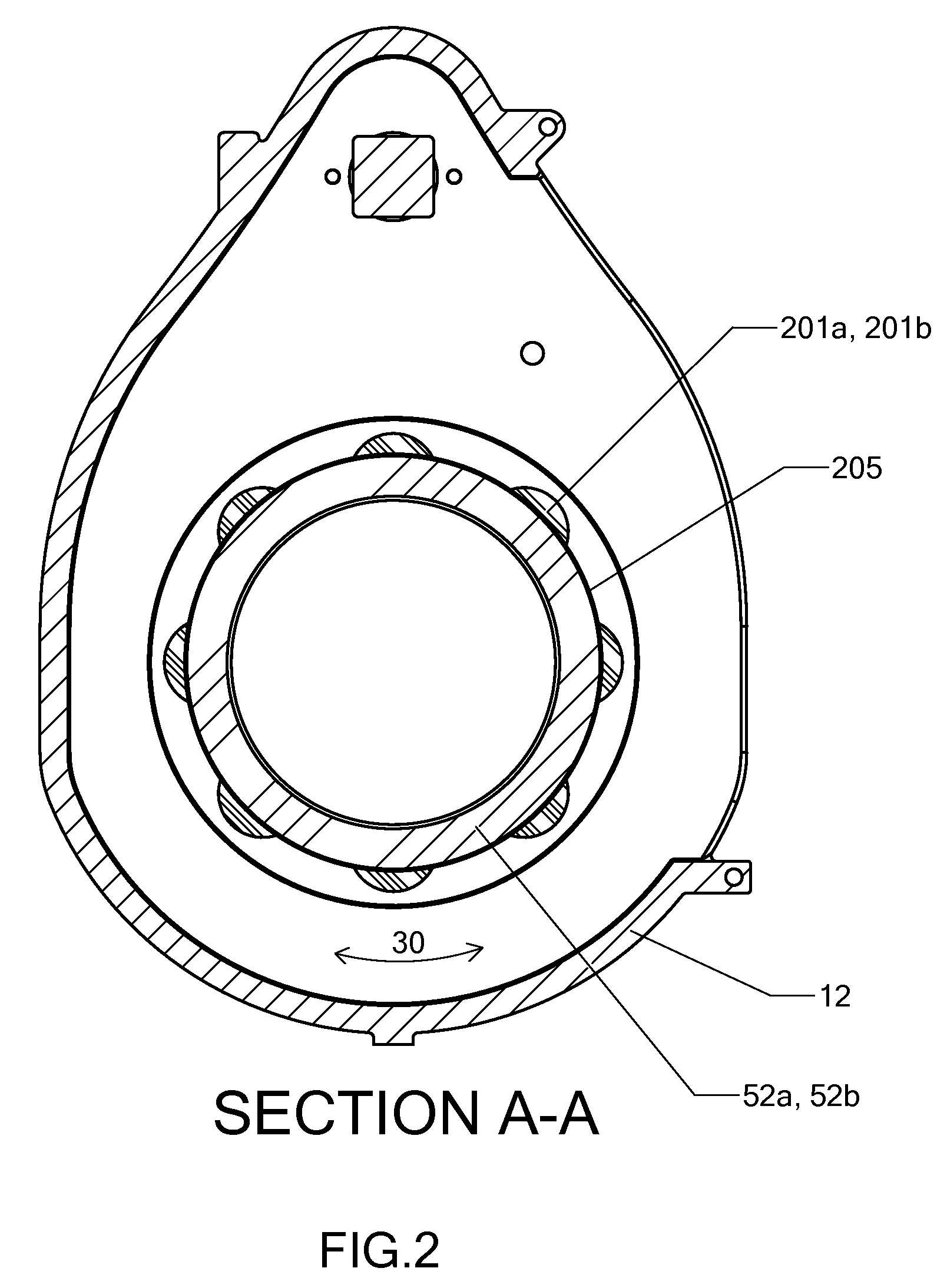

System for optimizing anchoring force

ActiveUS7695493B2Constant force against the tissuePrevent overcompressionSuture equipmentsDiagnosticsConstant forceStrain gauge

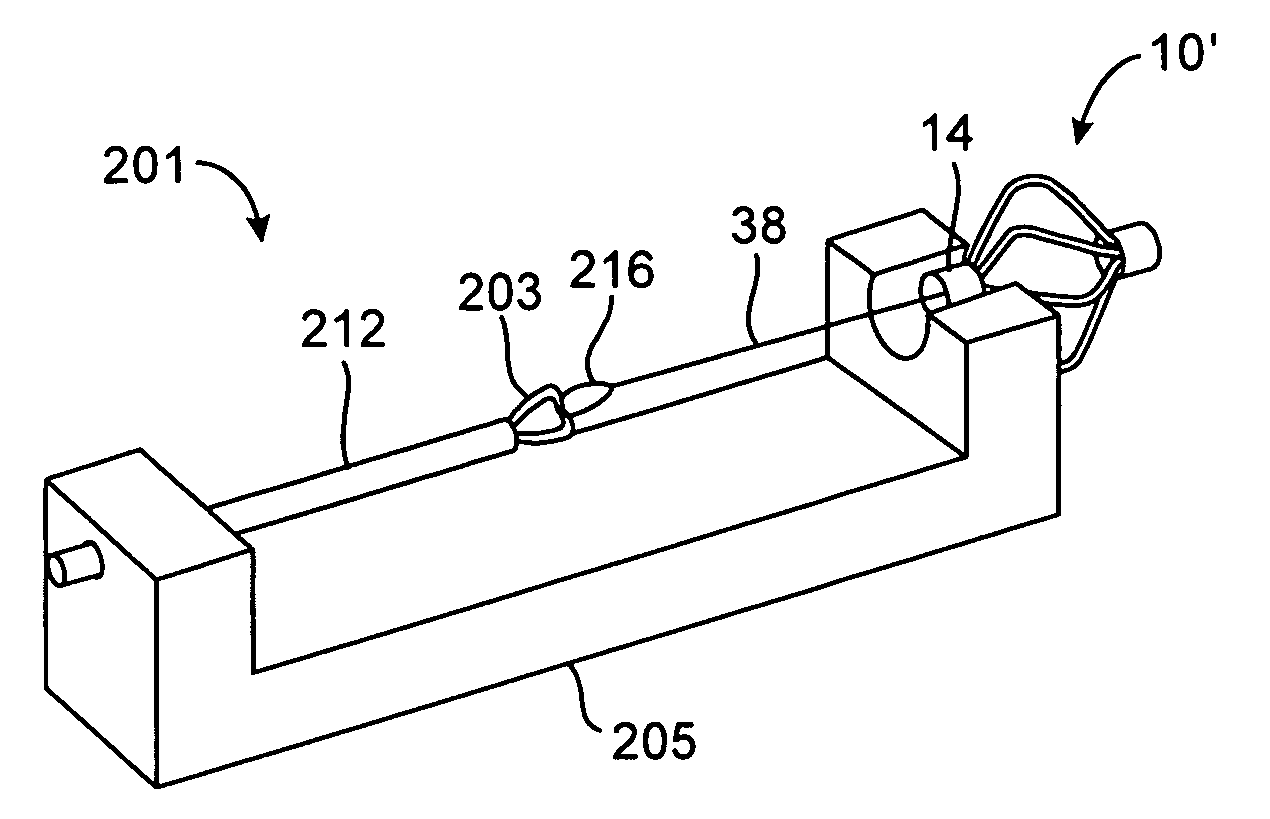

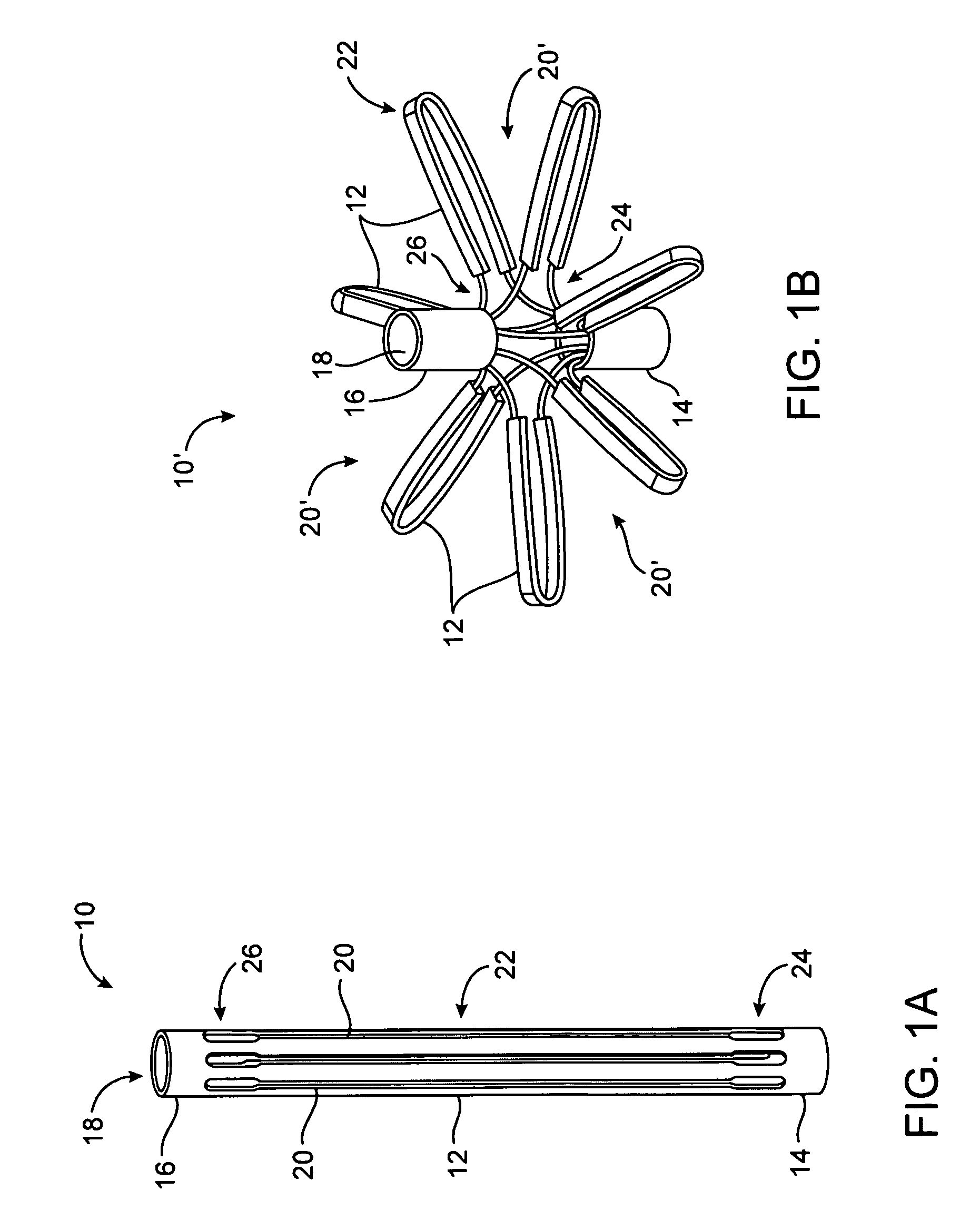

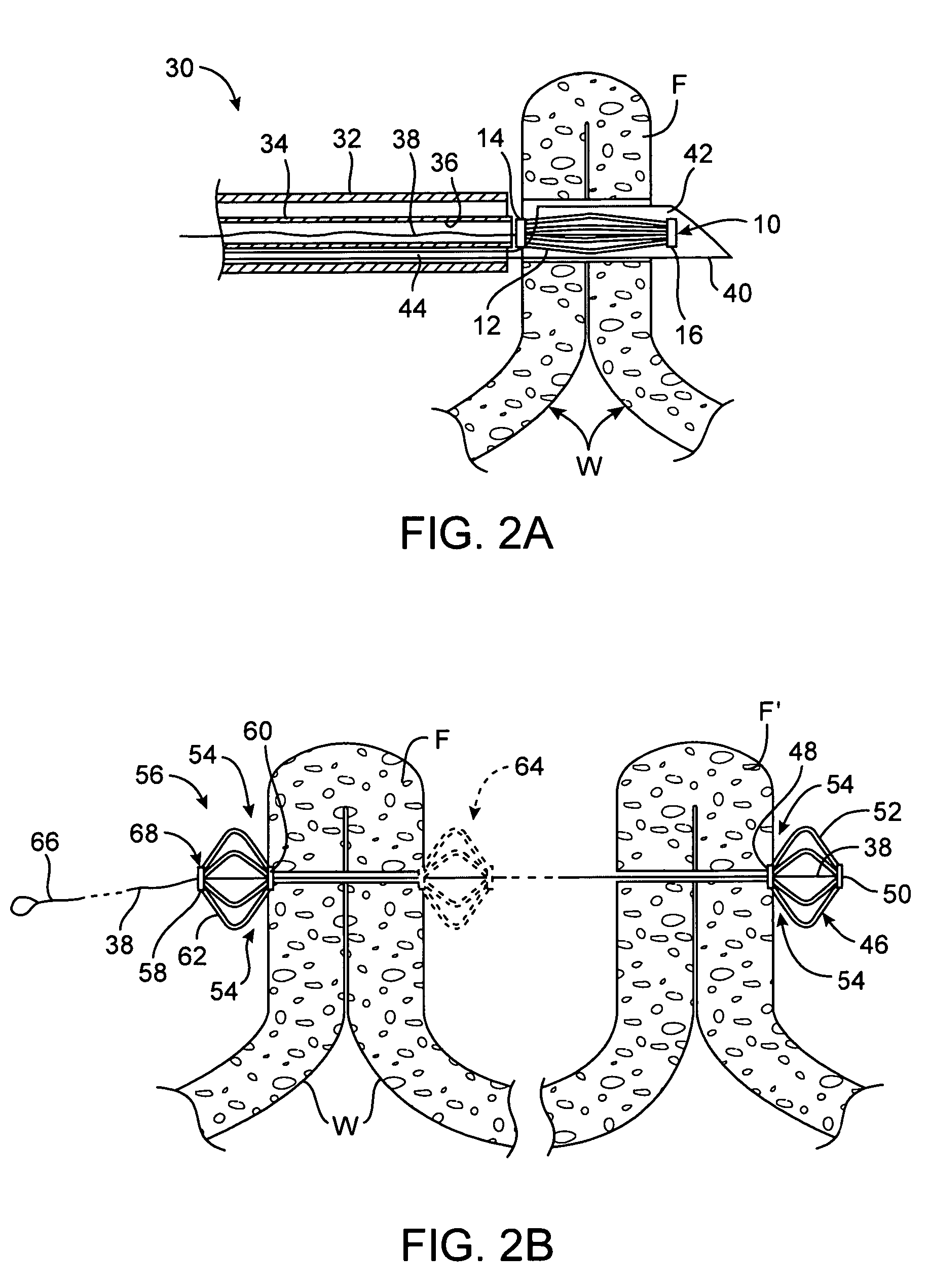

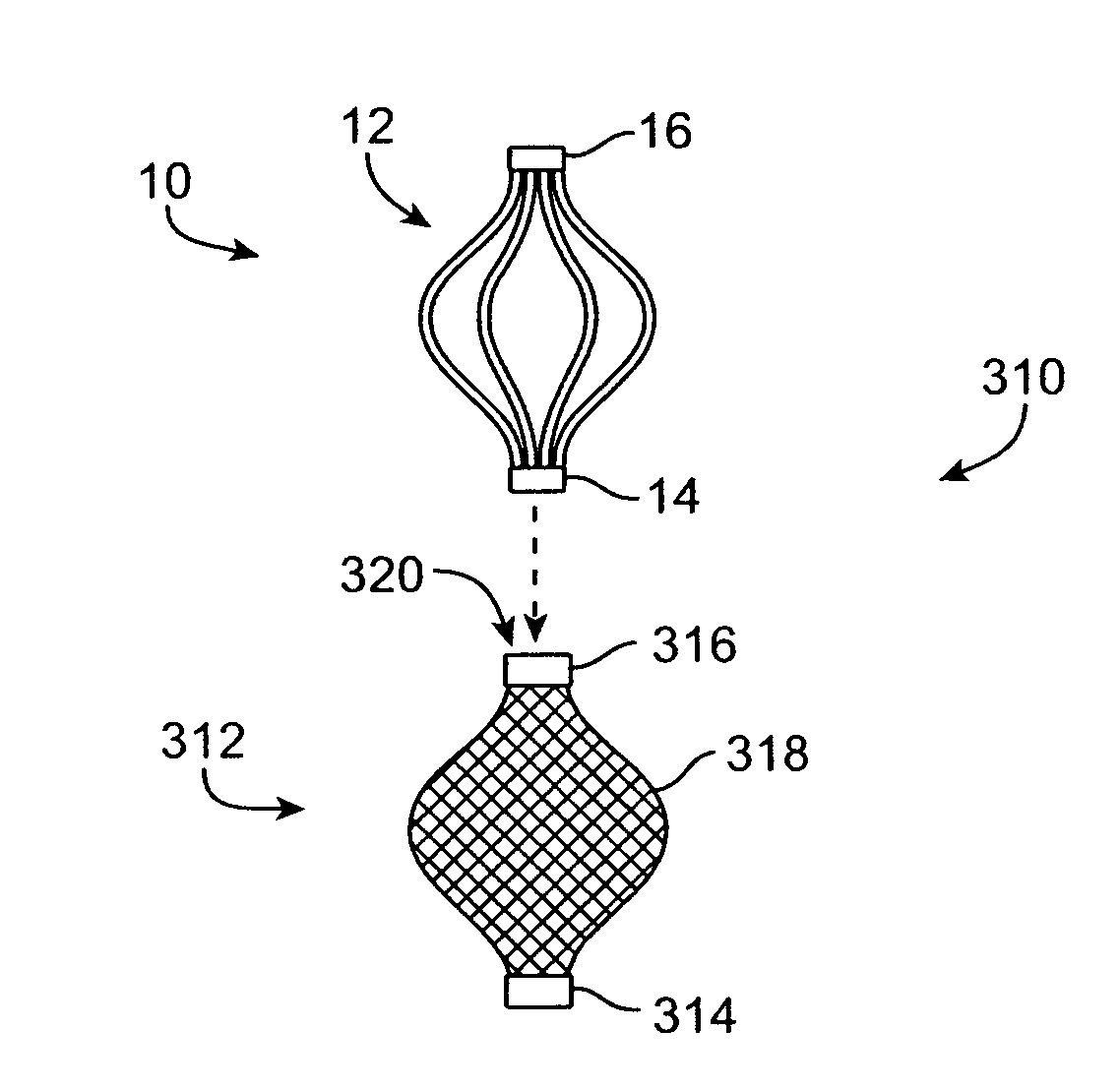

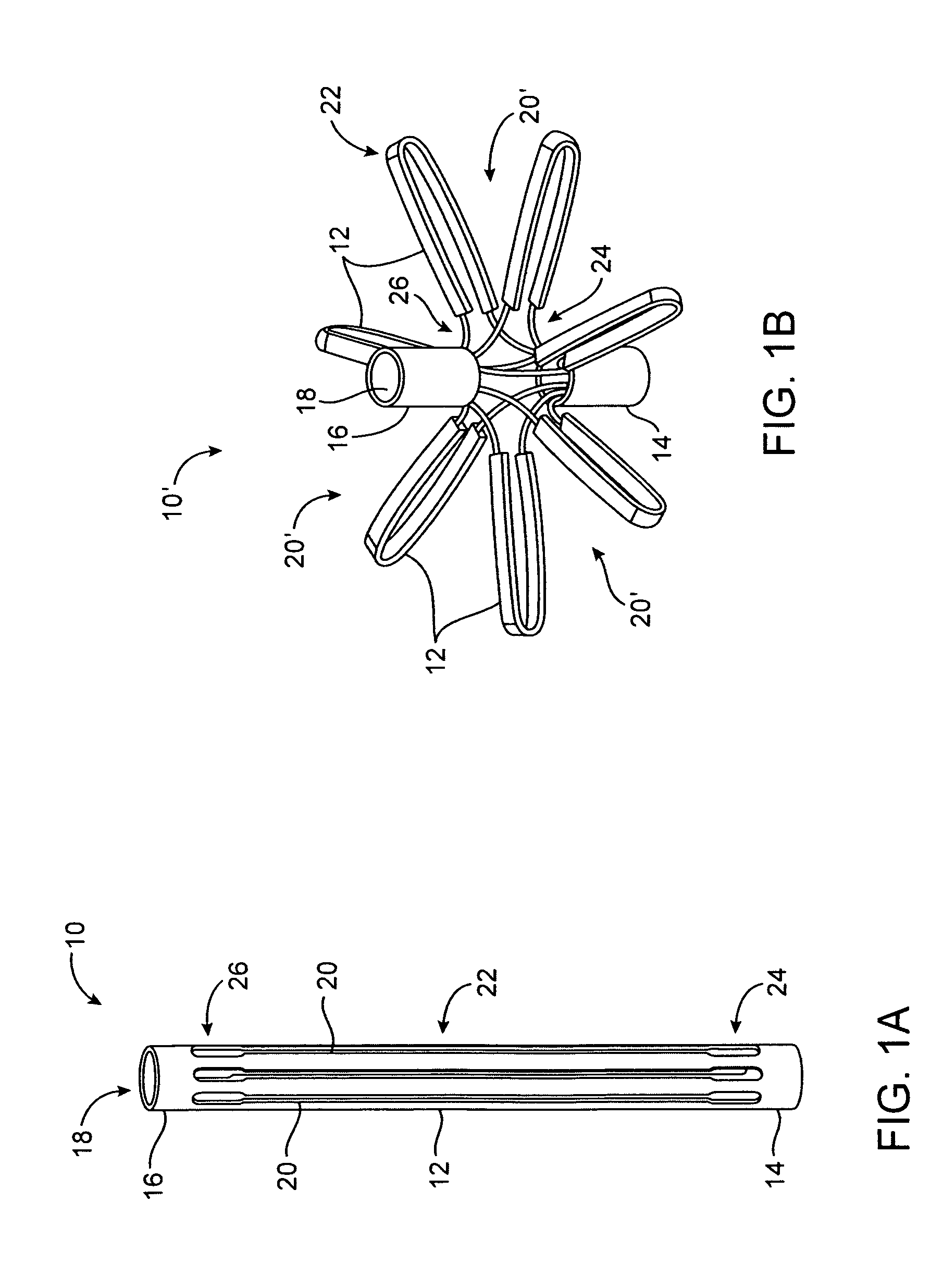

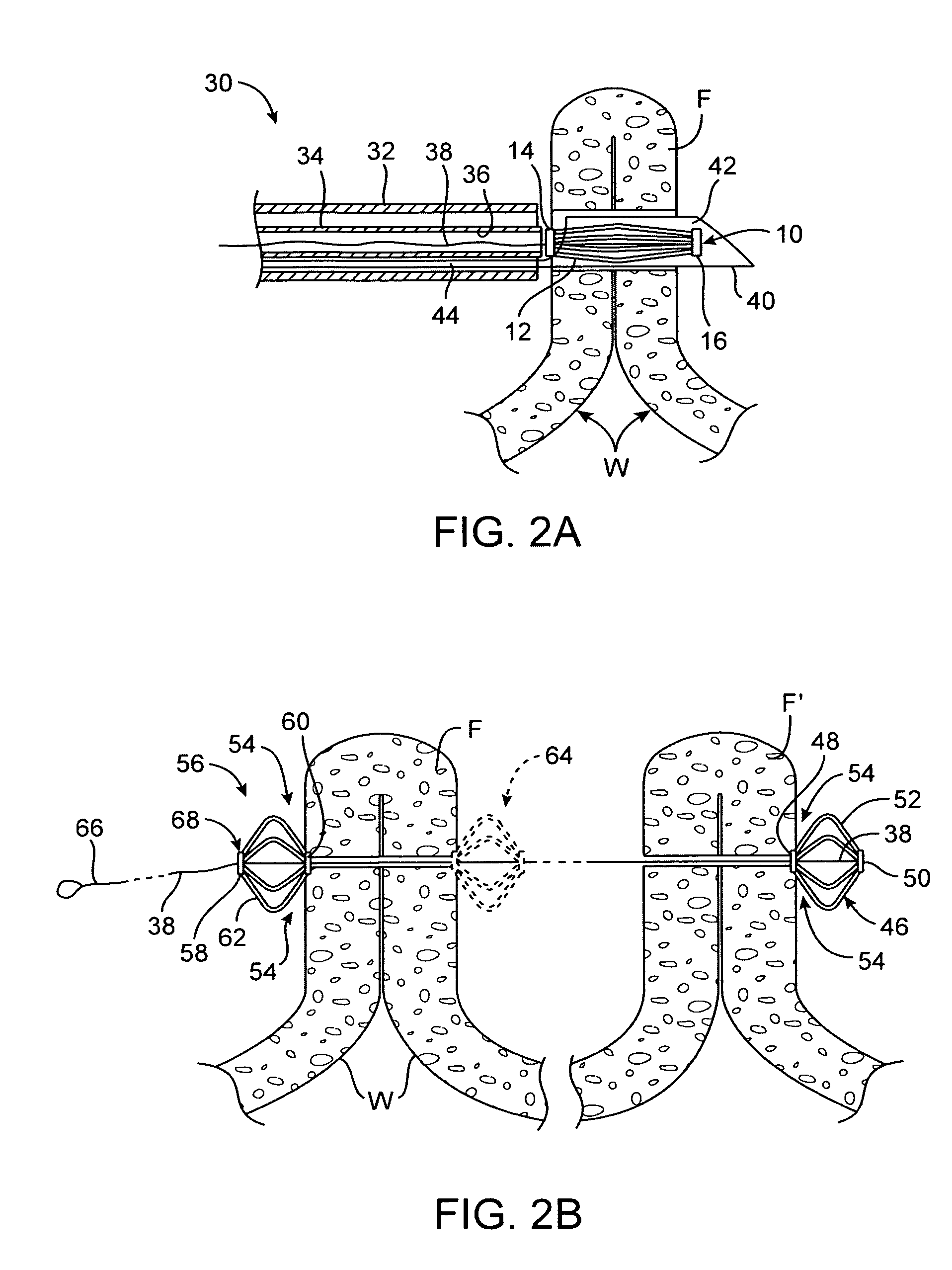

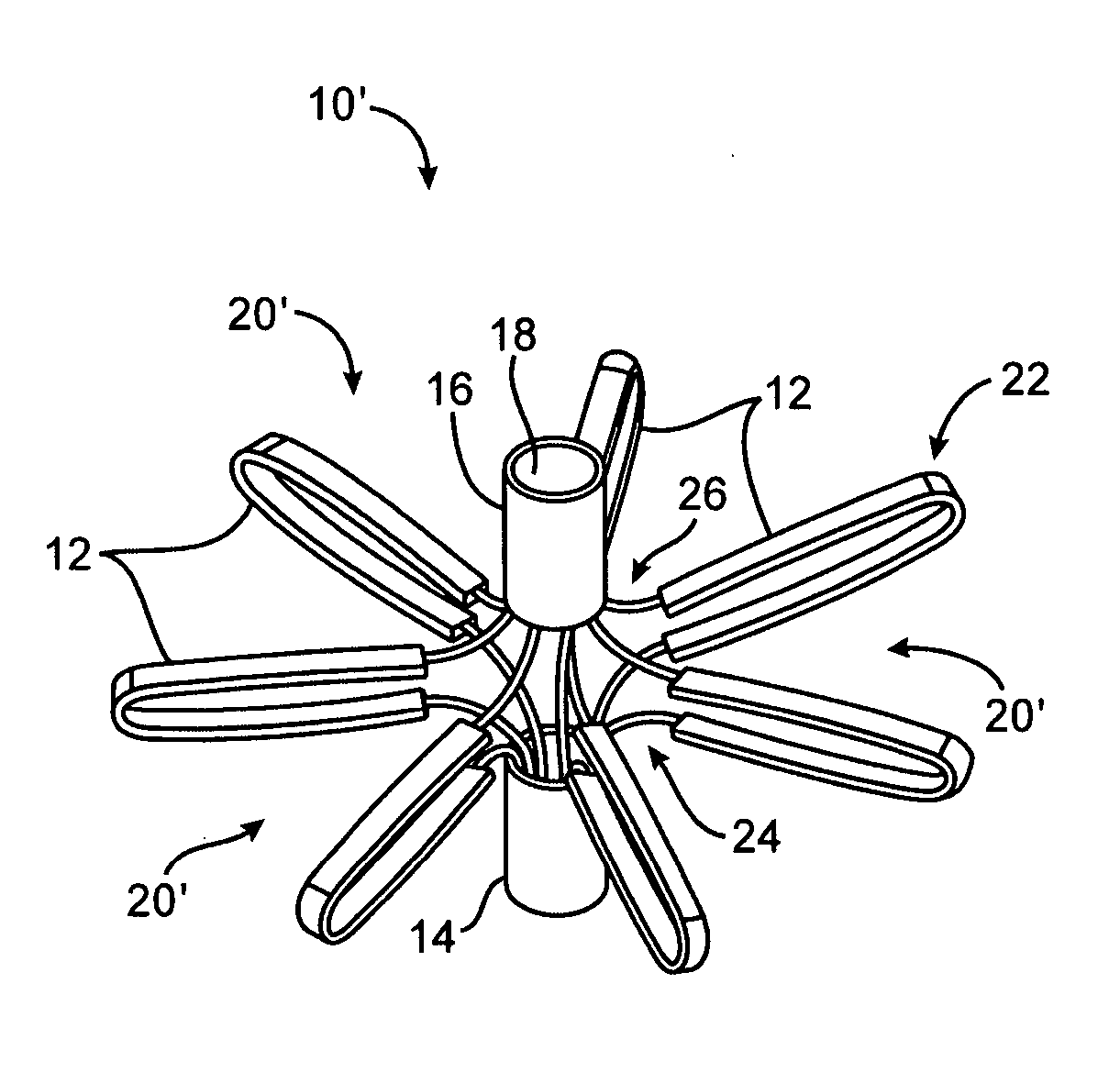

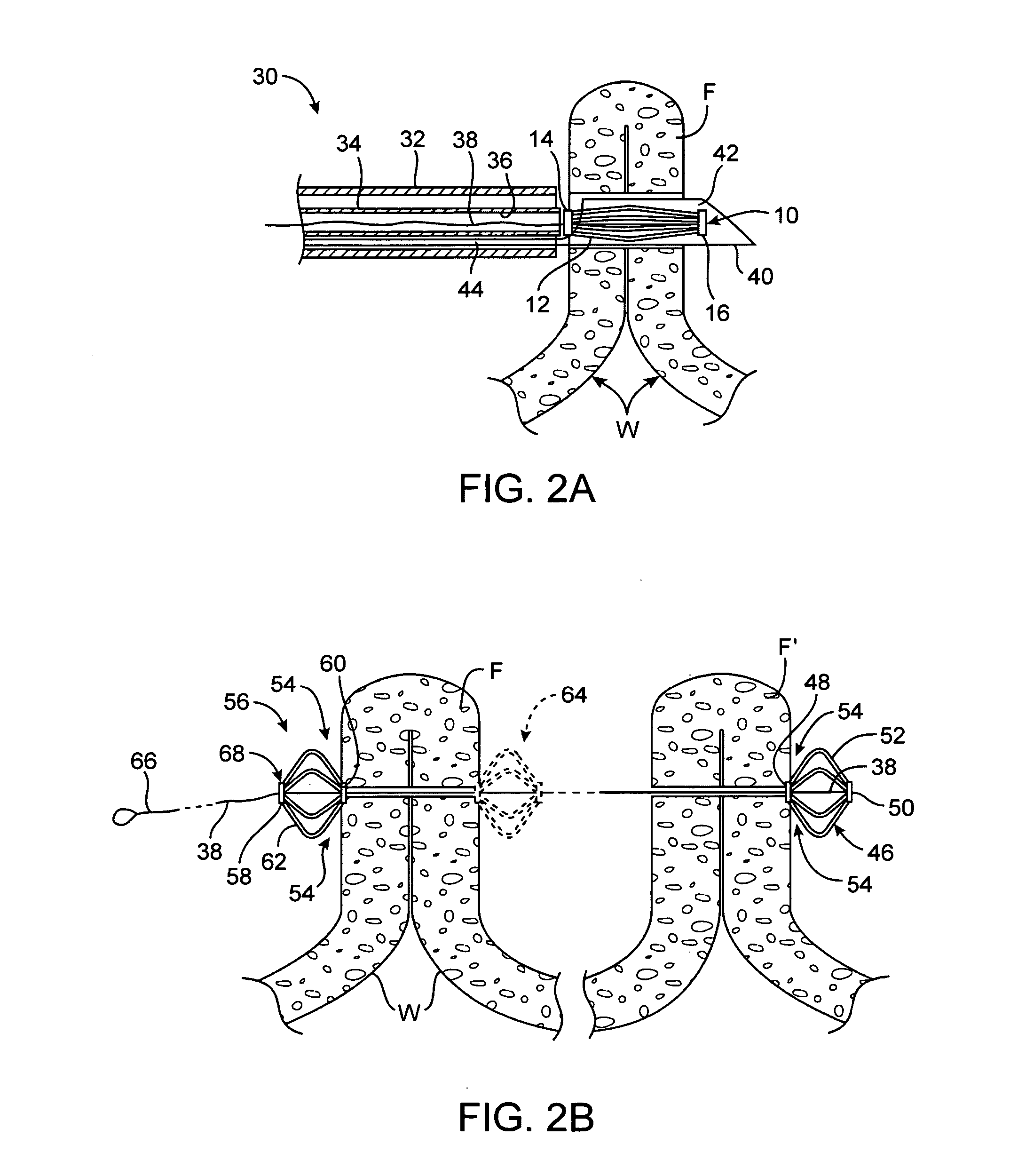

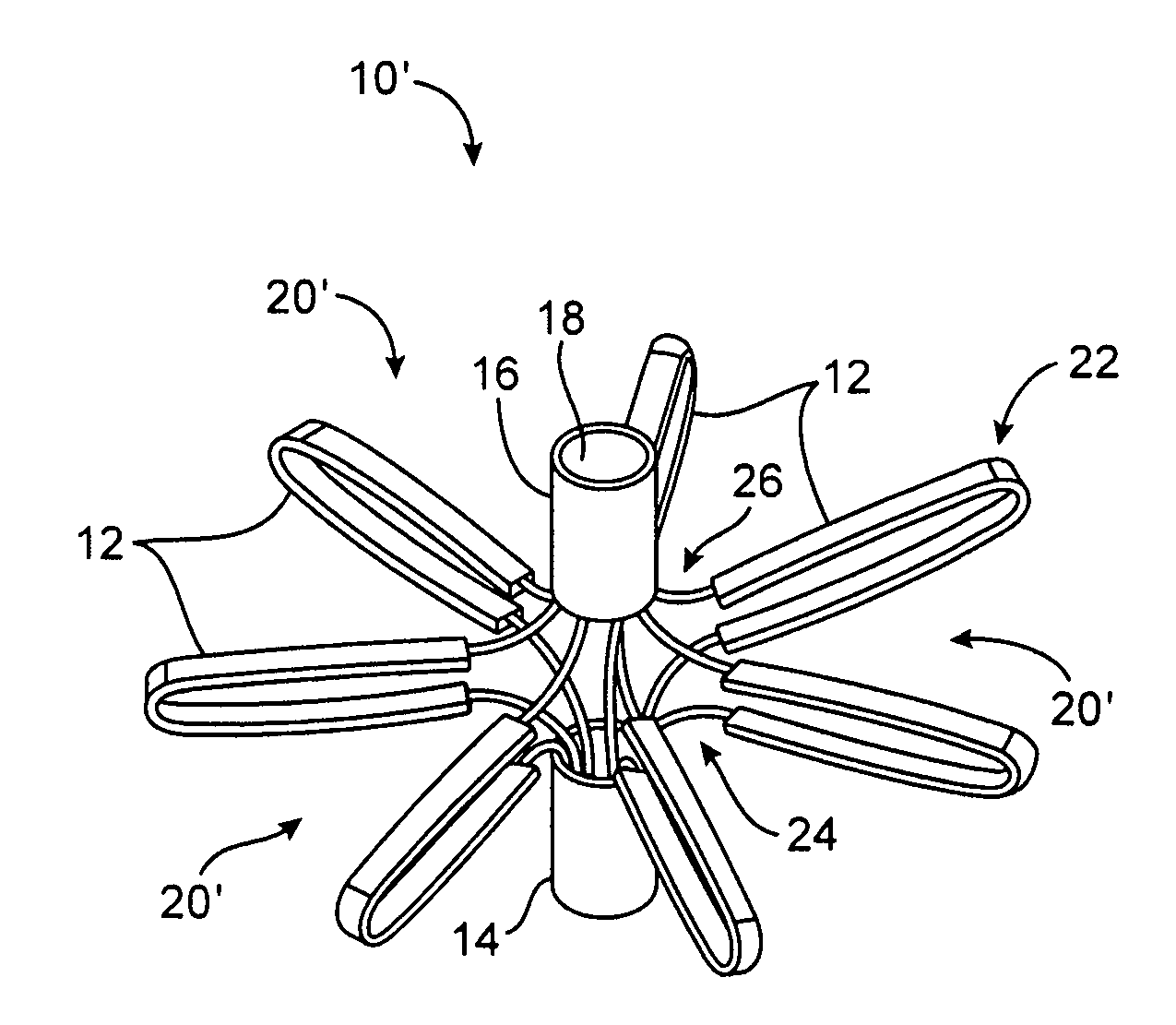

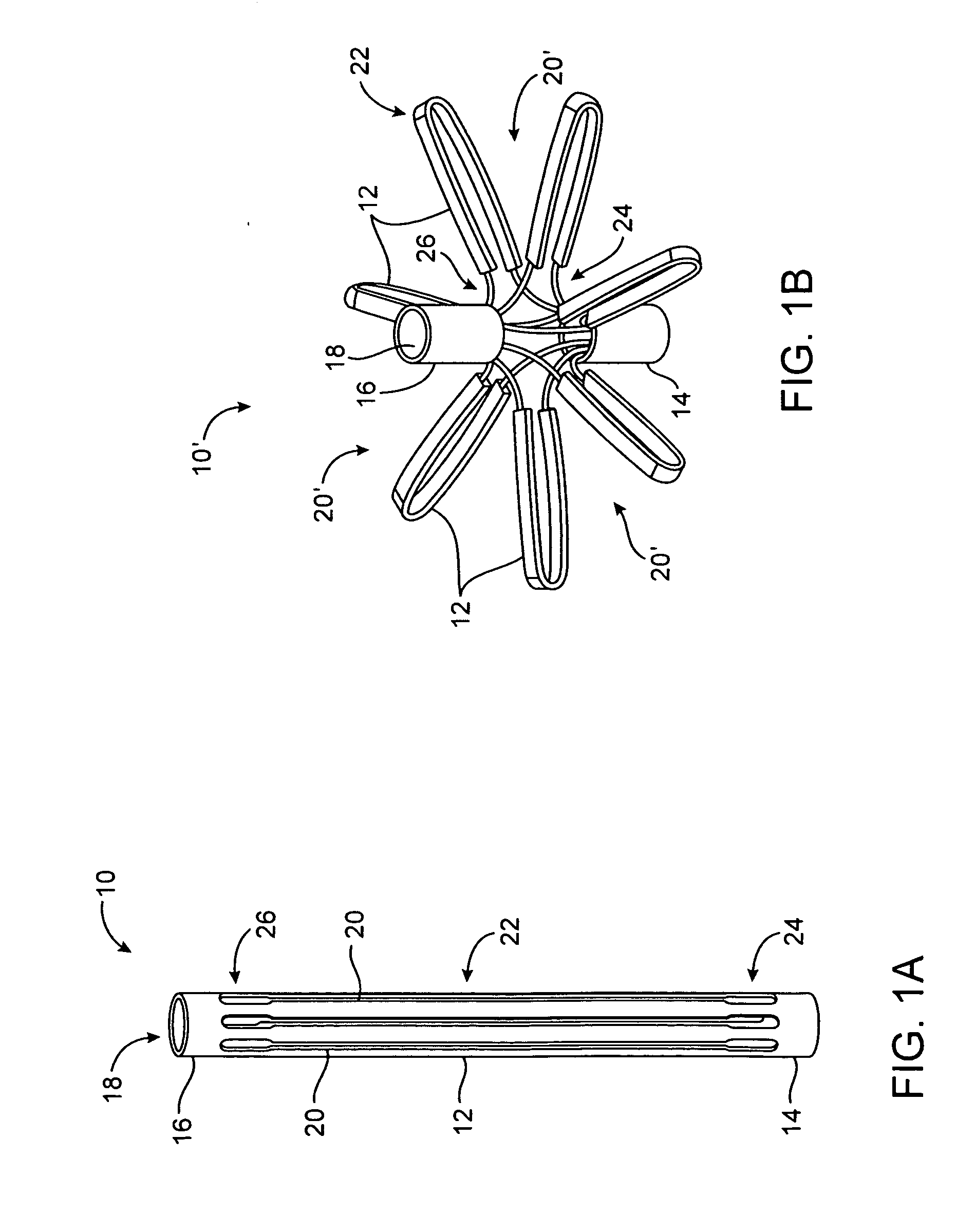

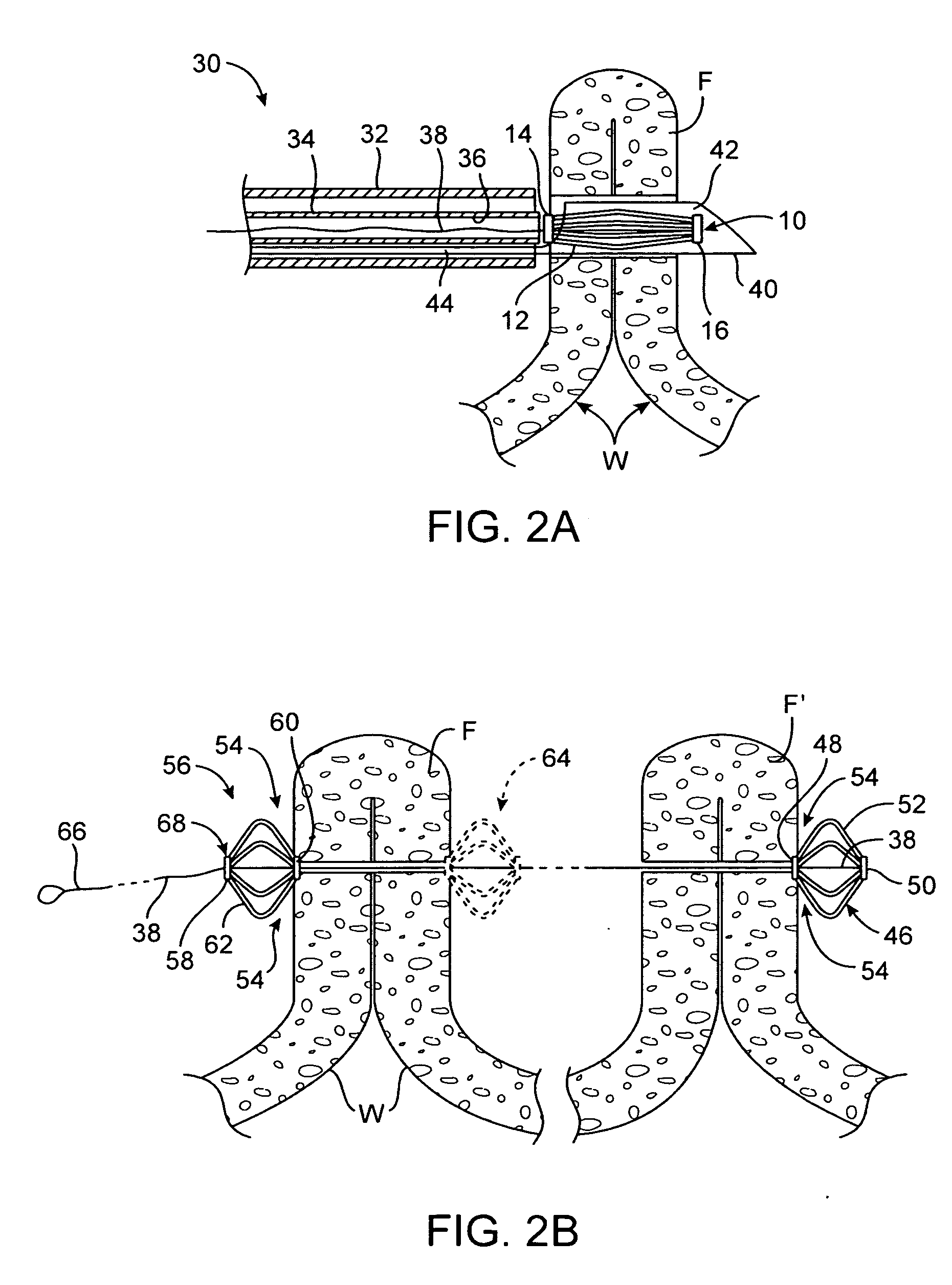

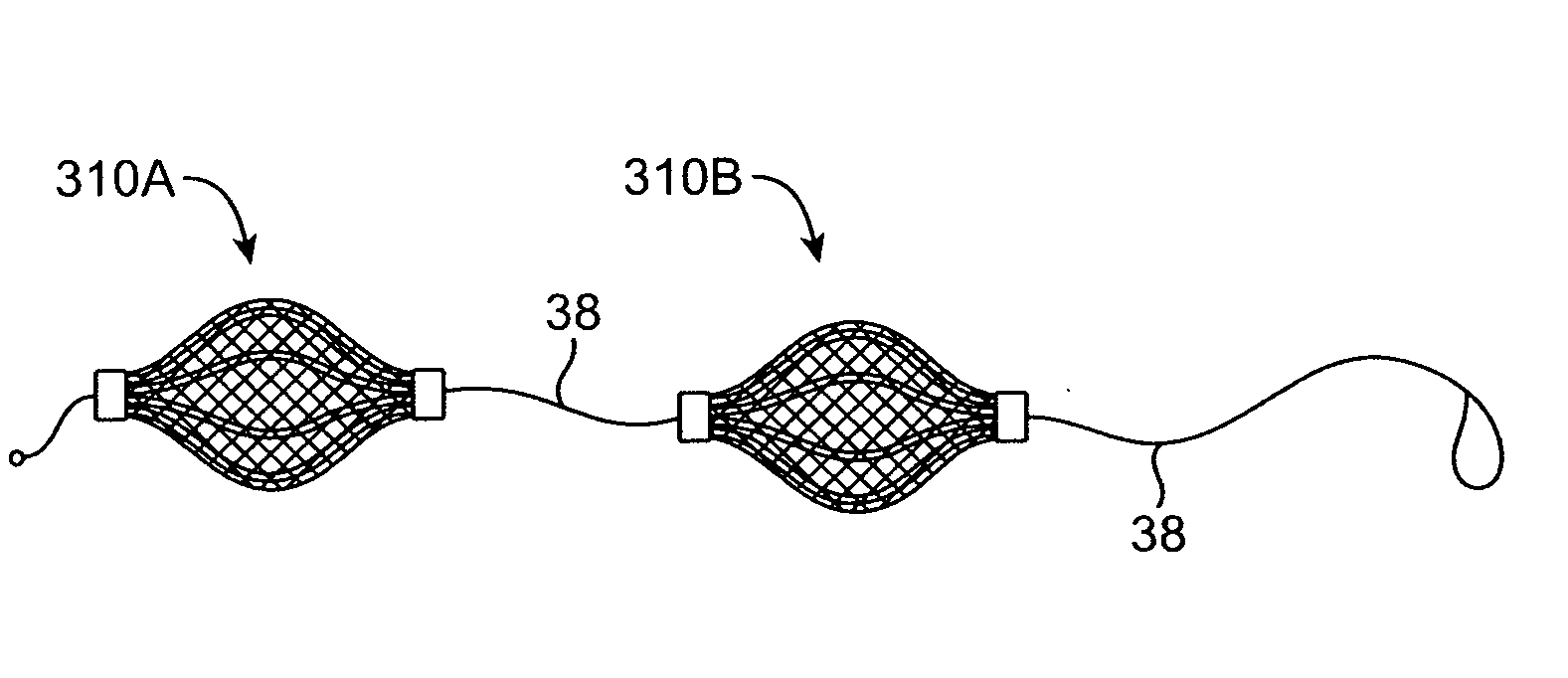

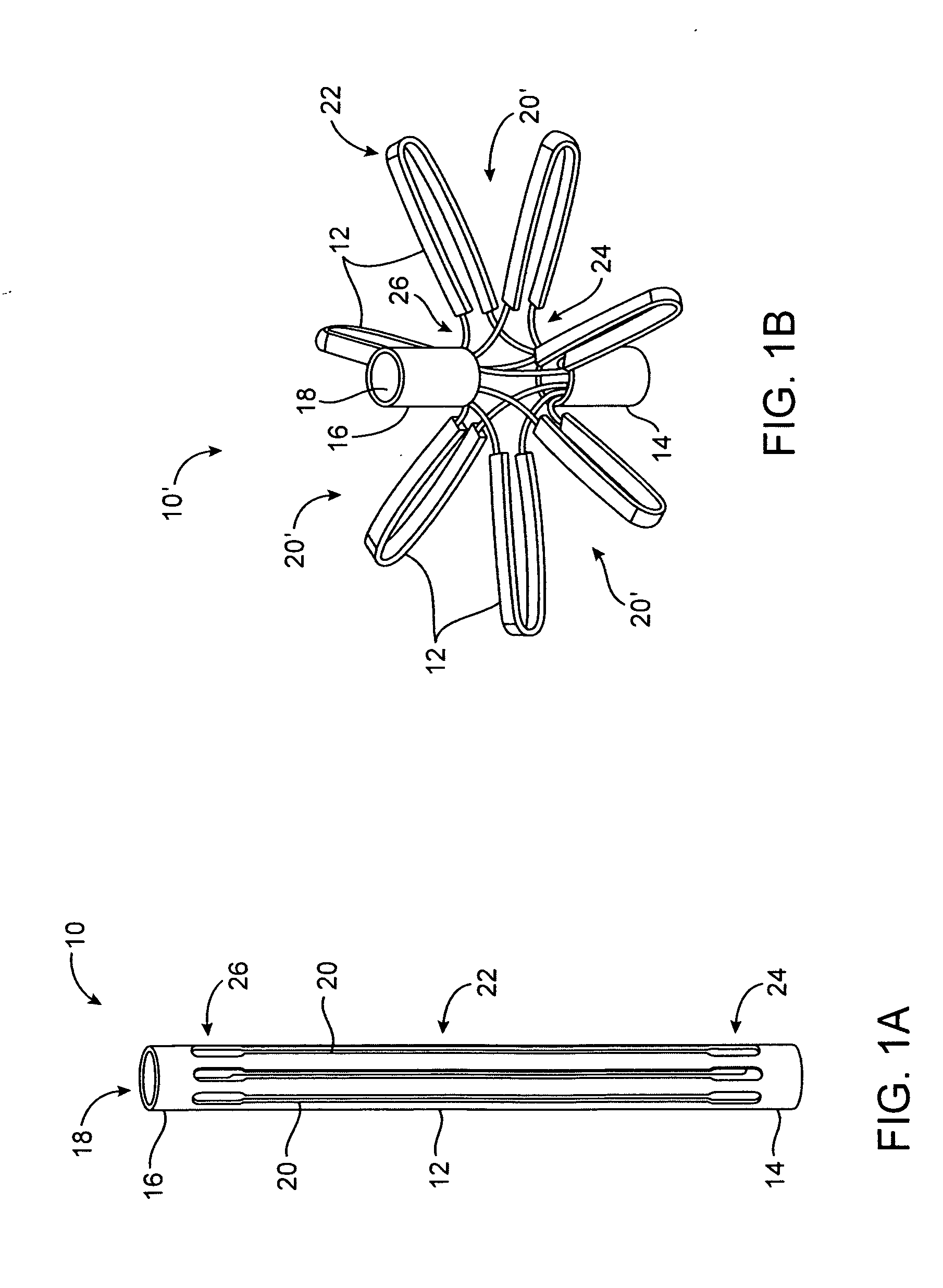

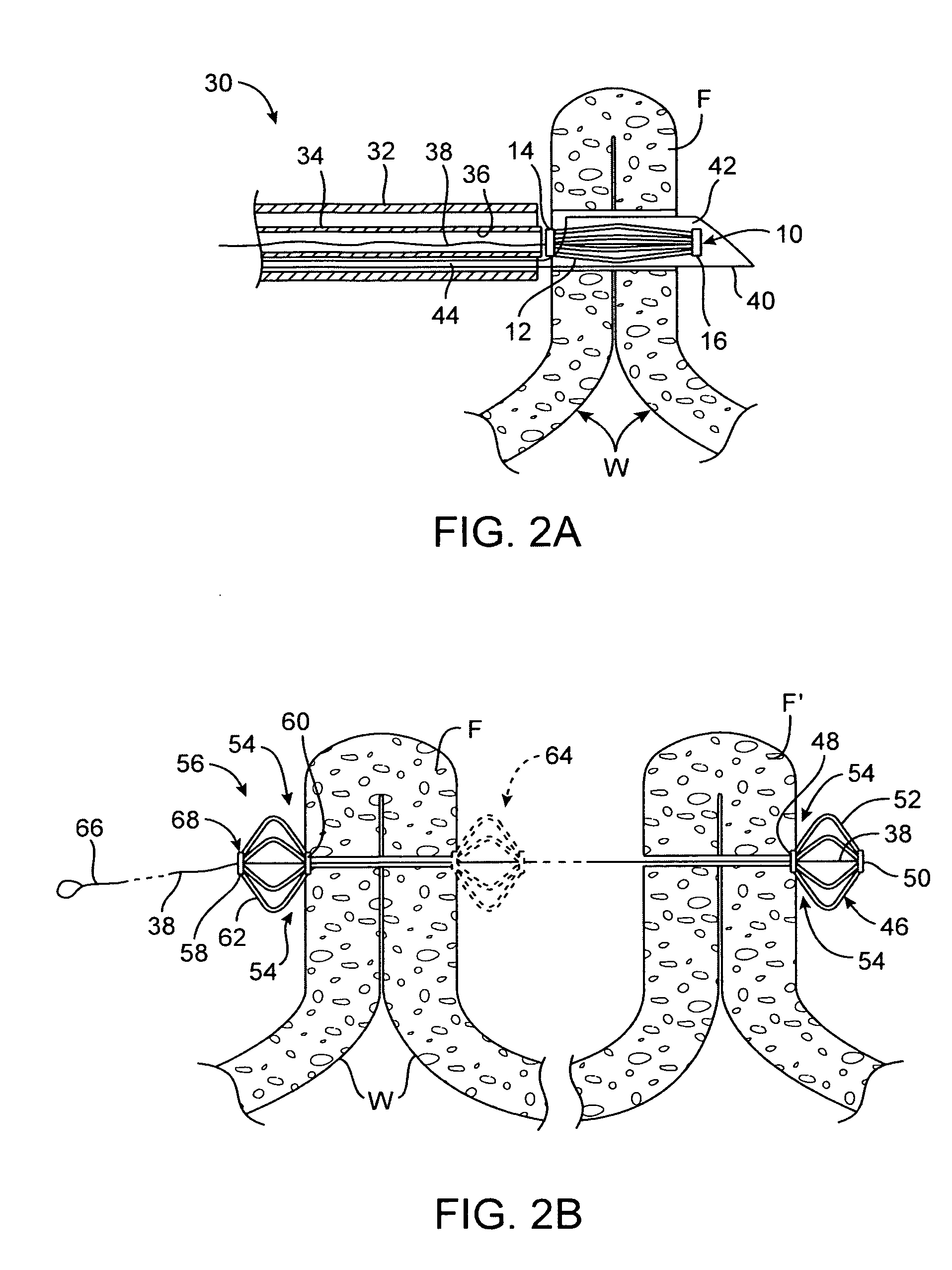

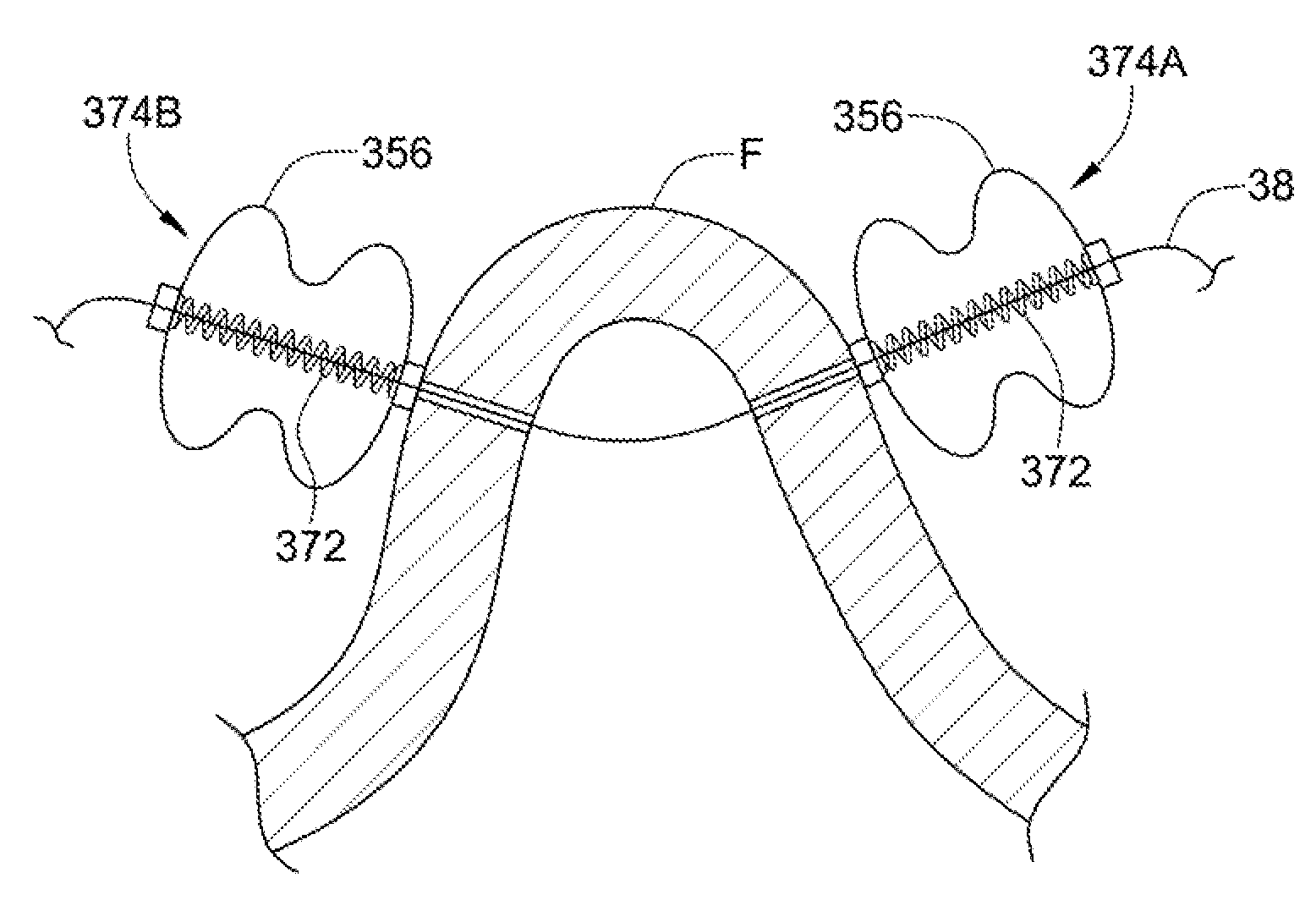

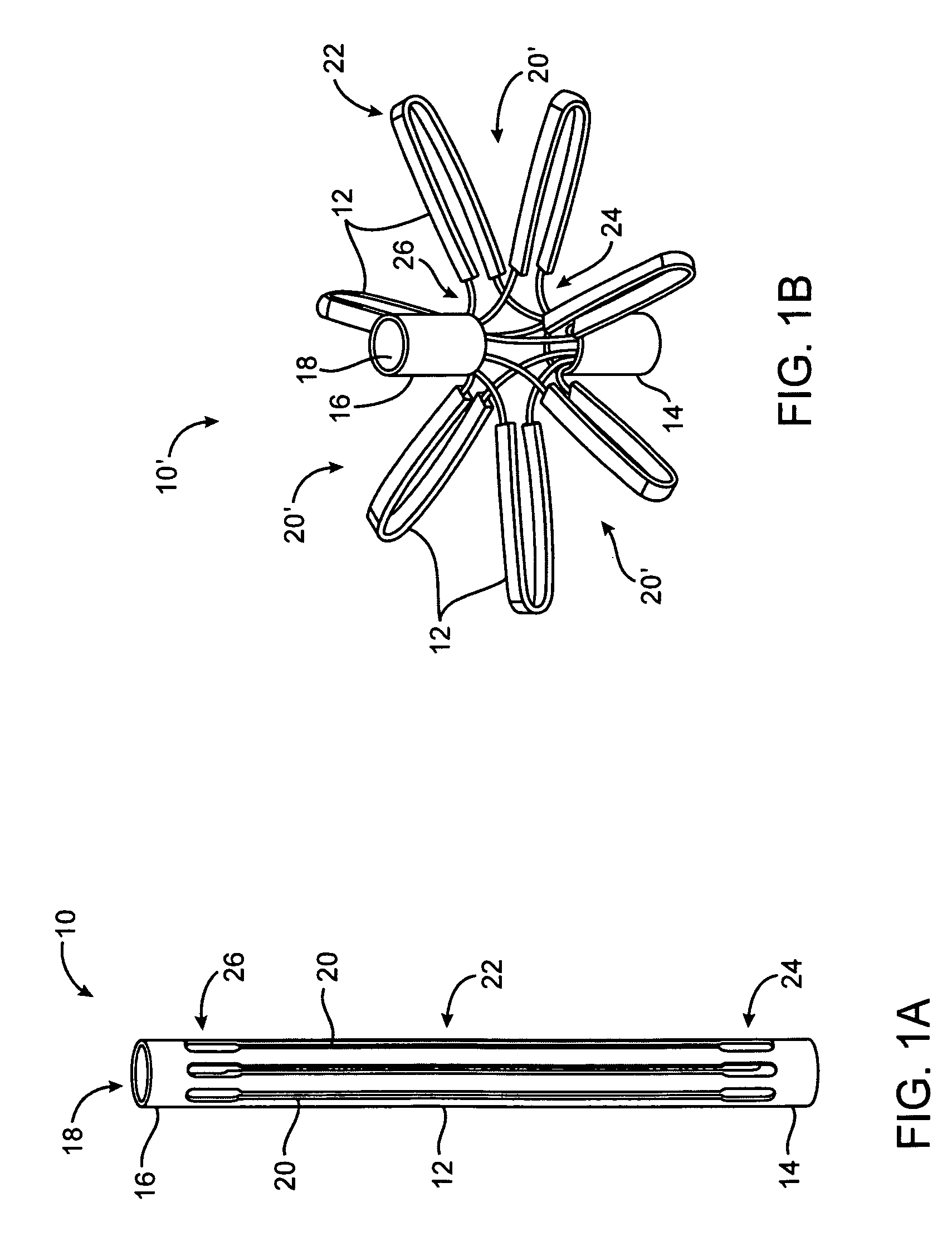

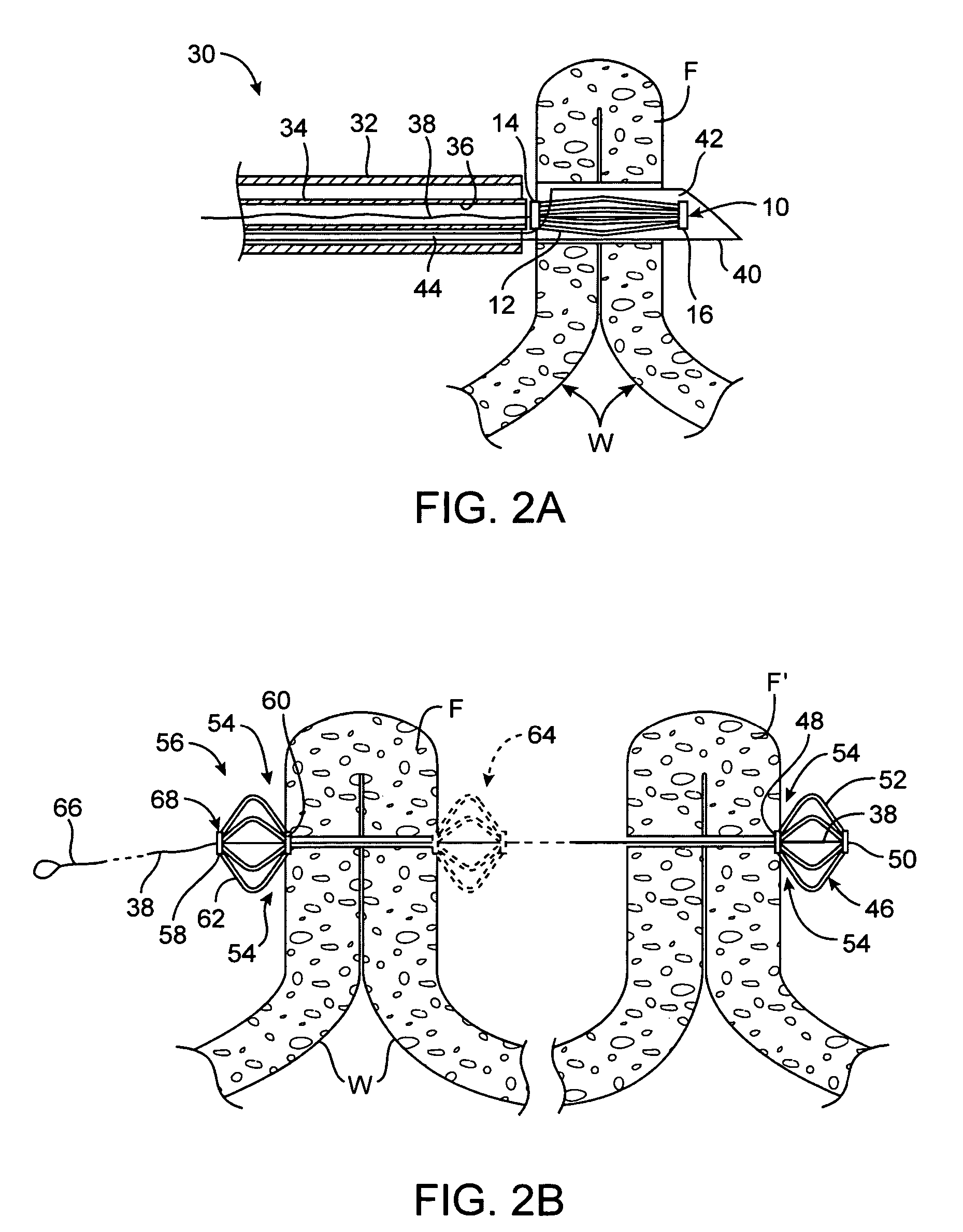

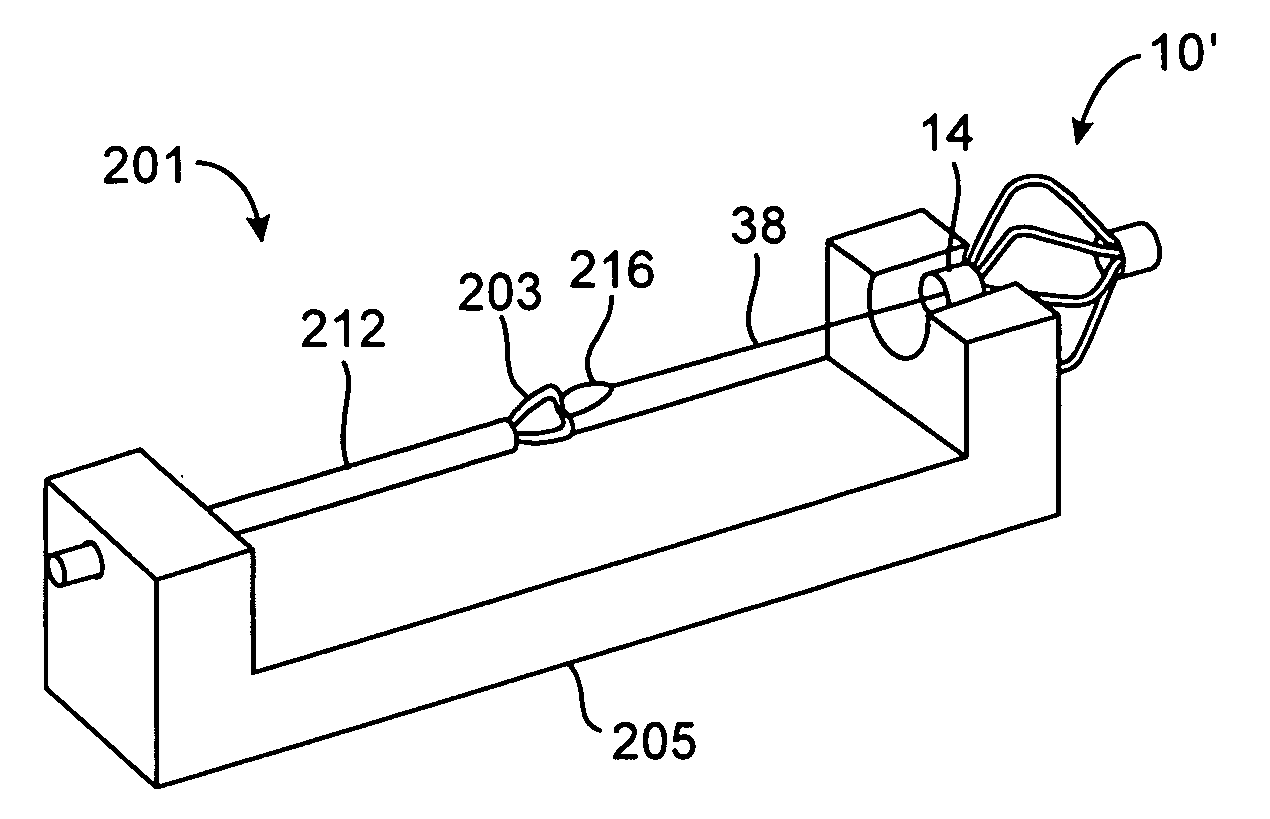

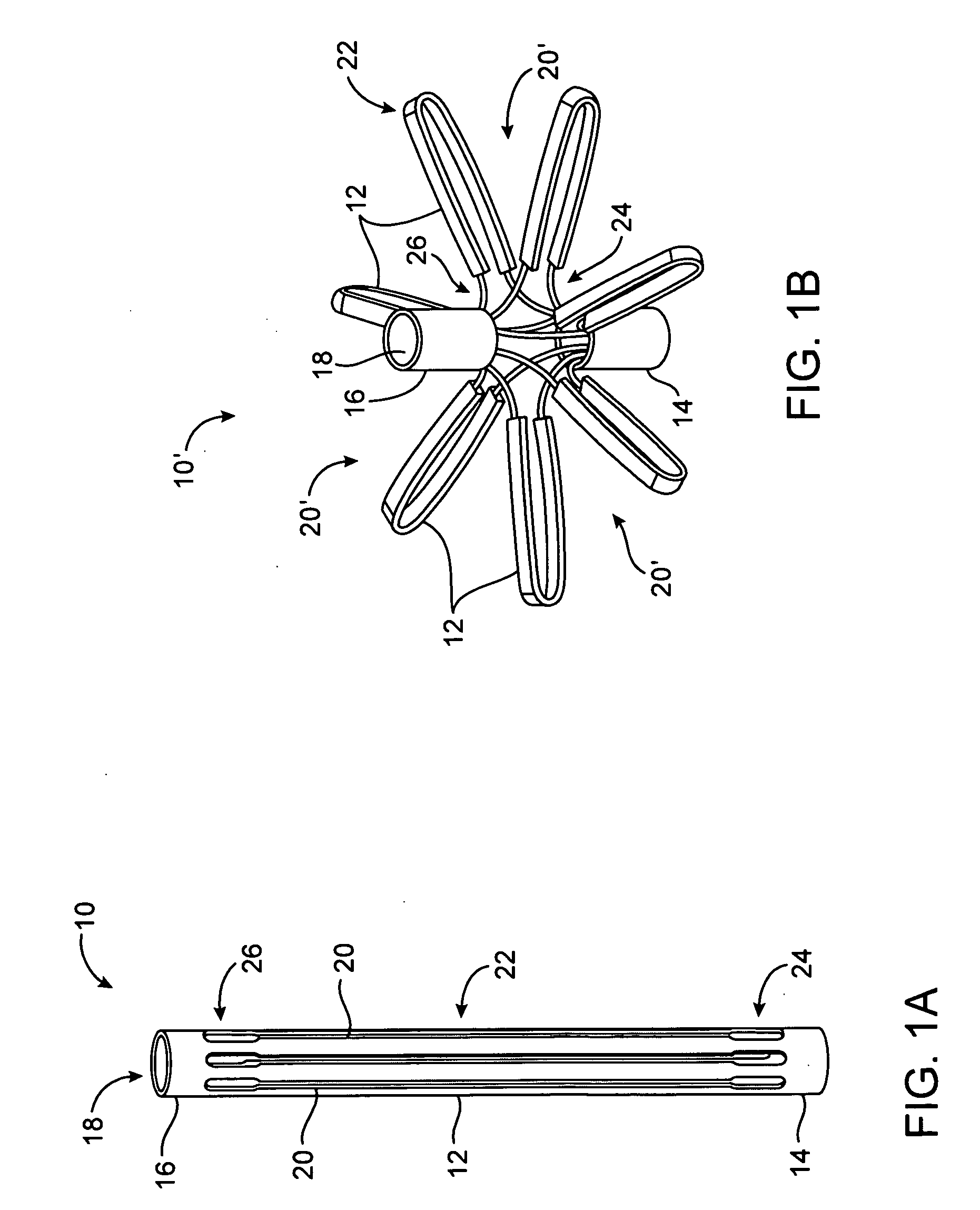

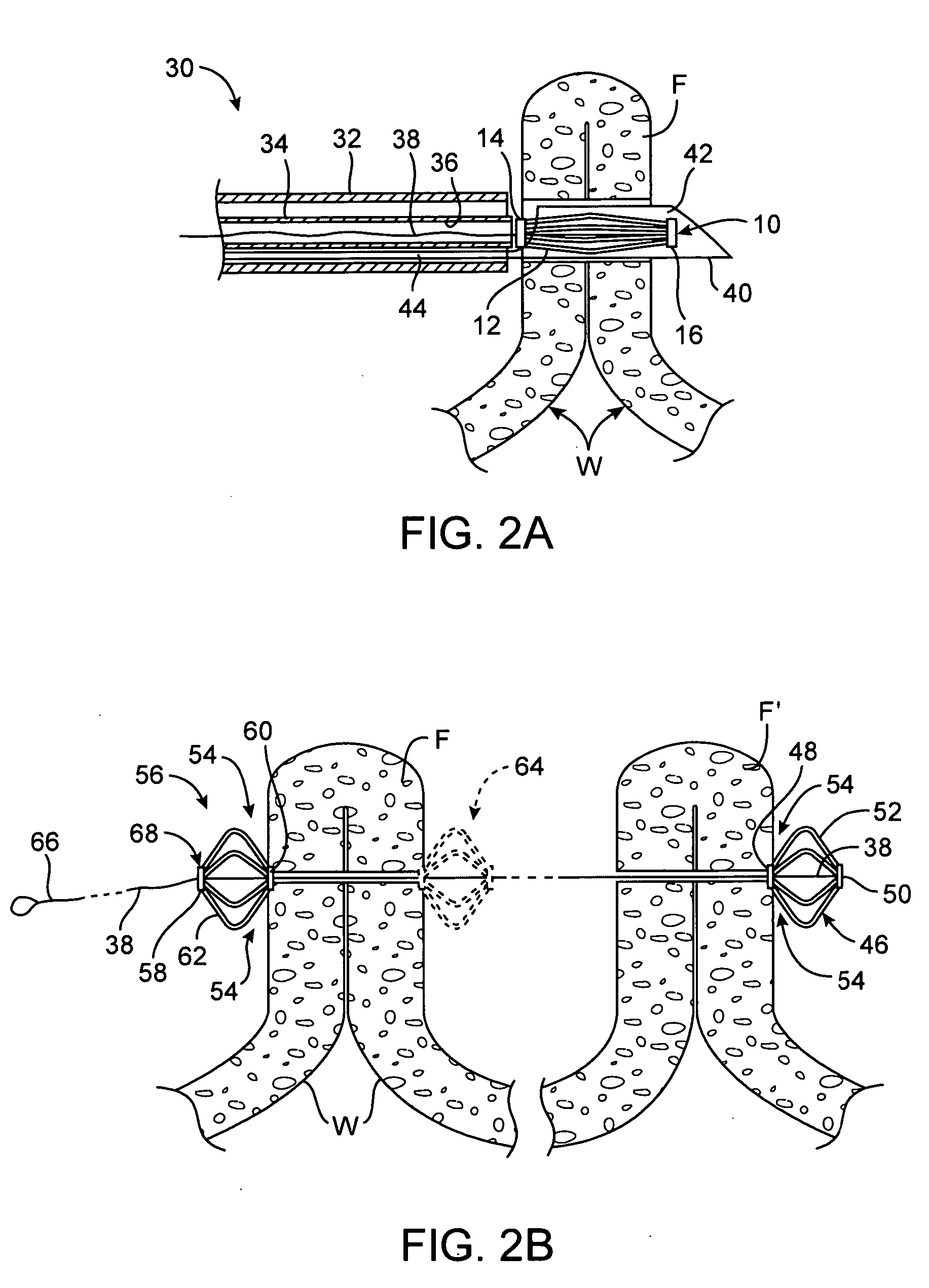

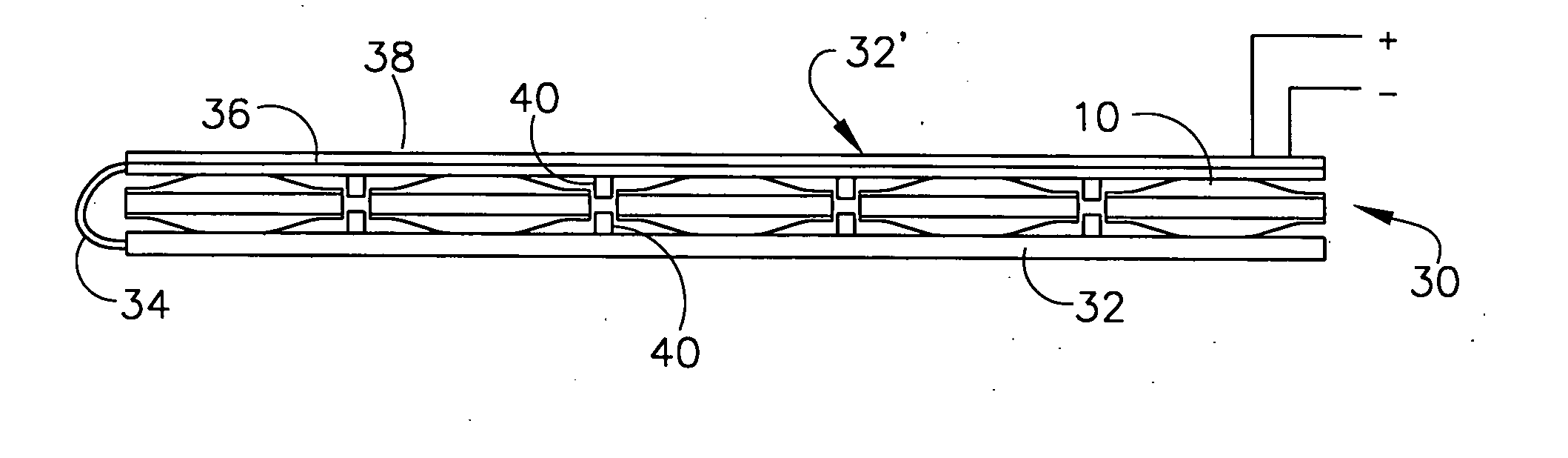

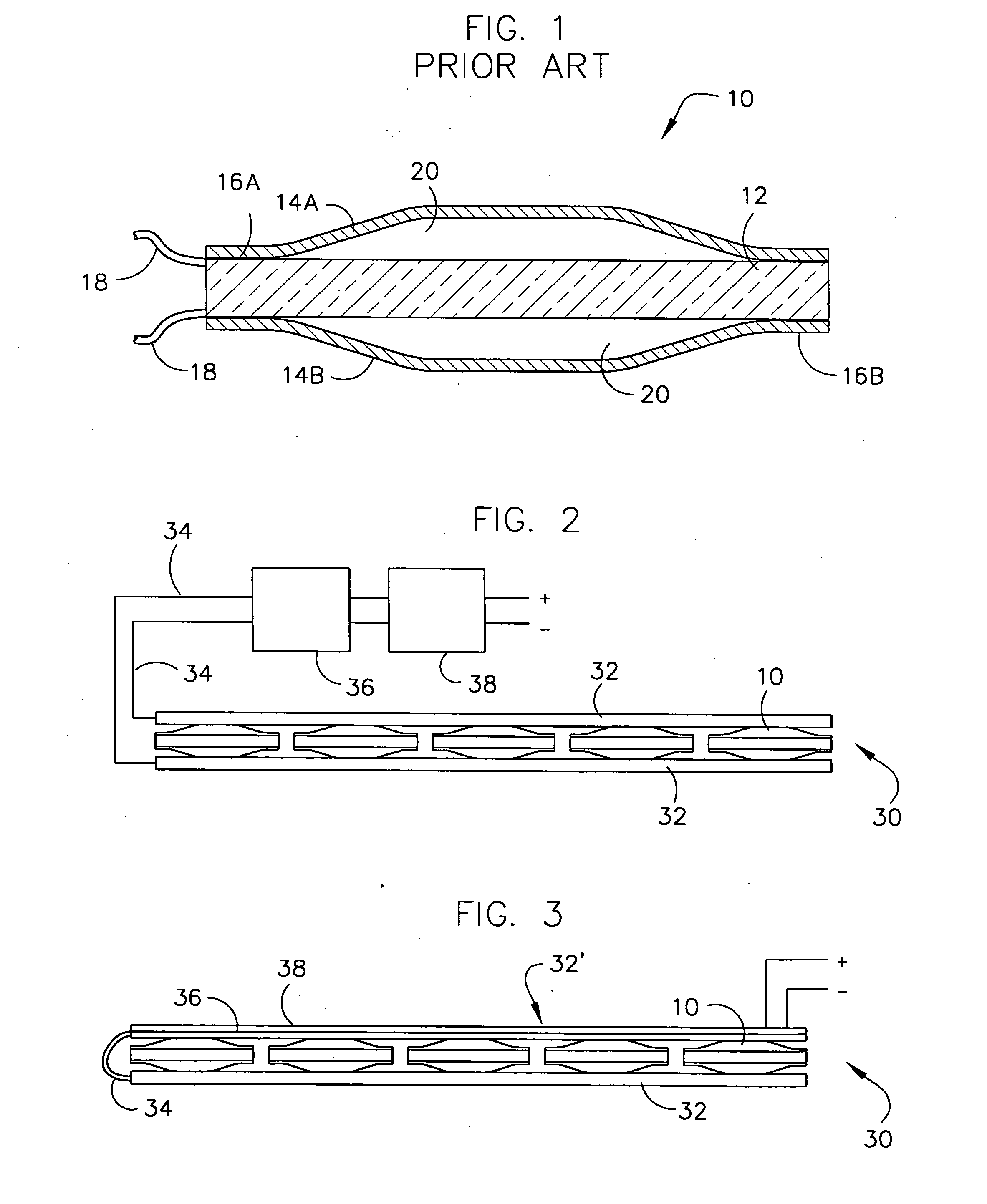

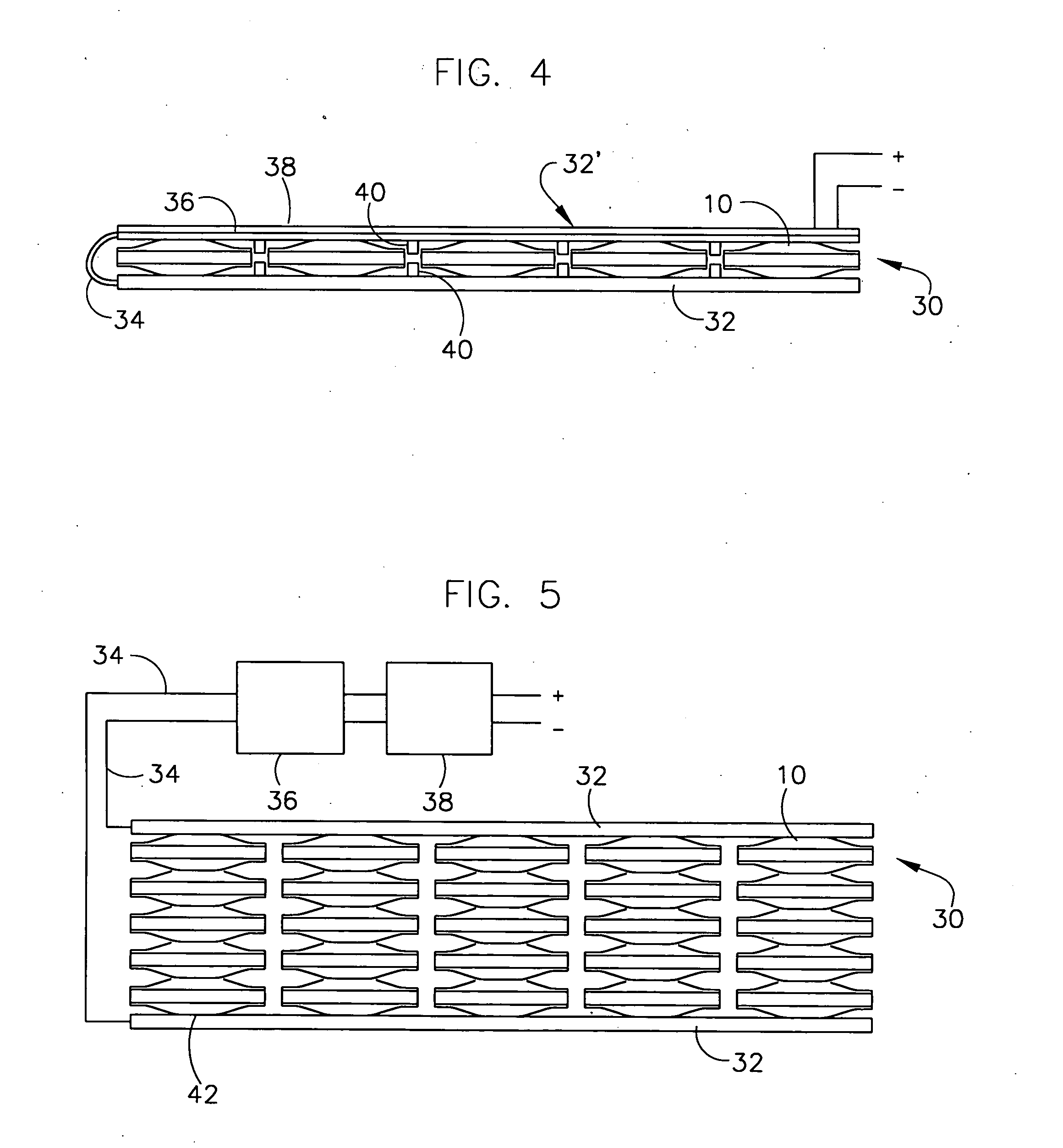

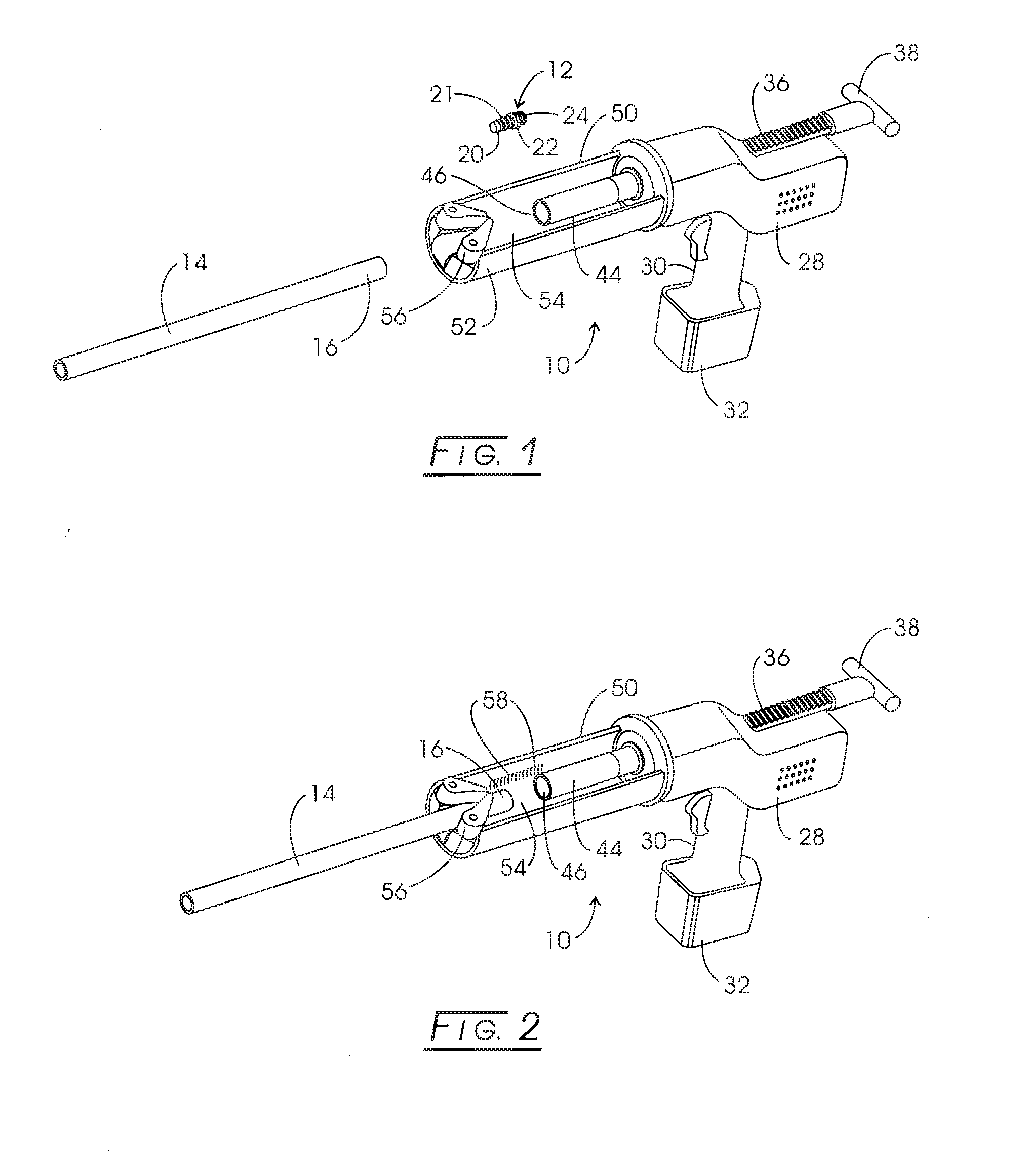

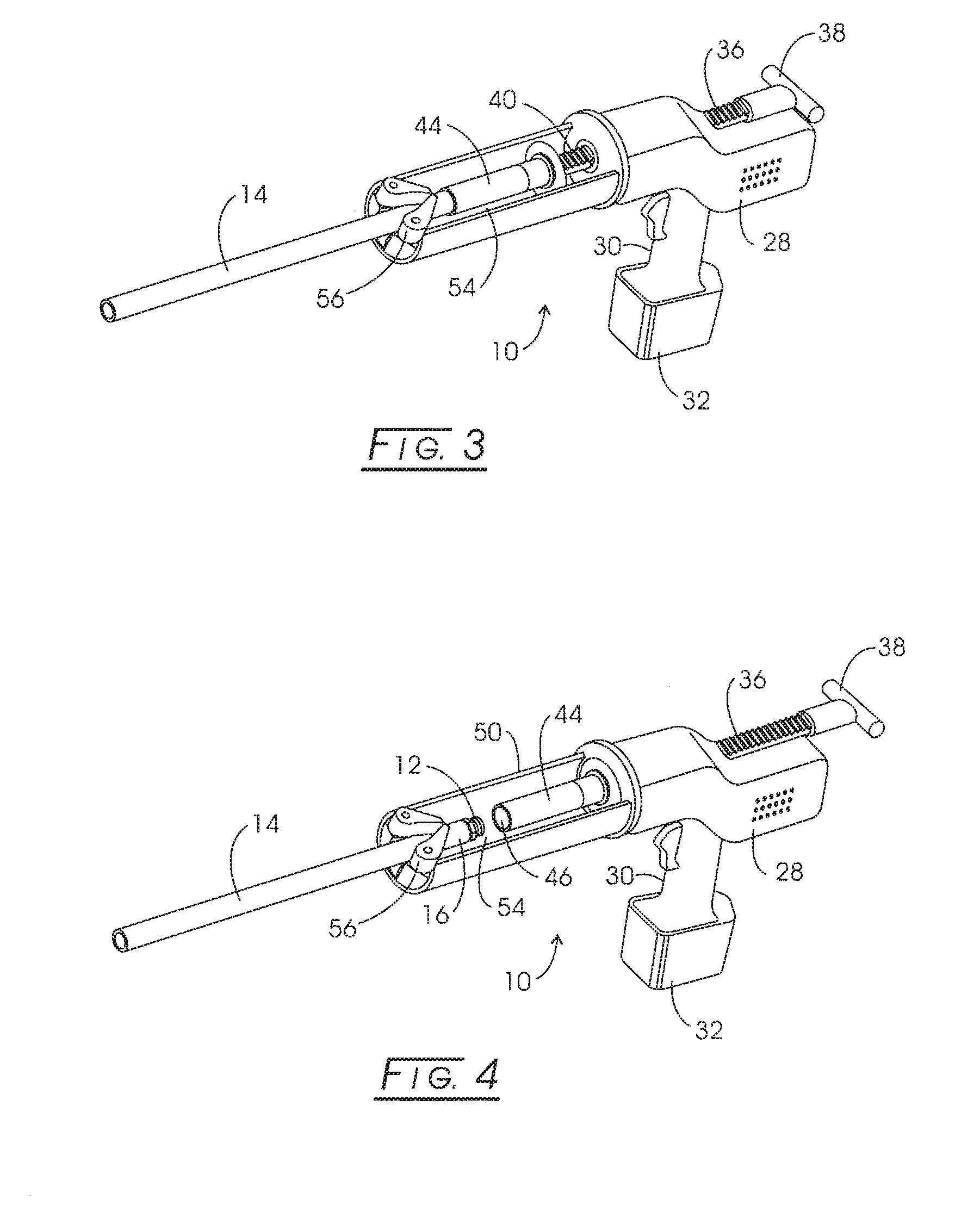

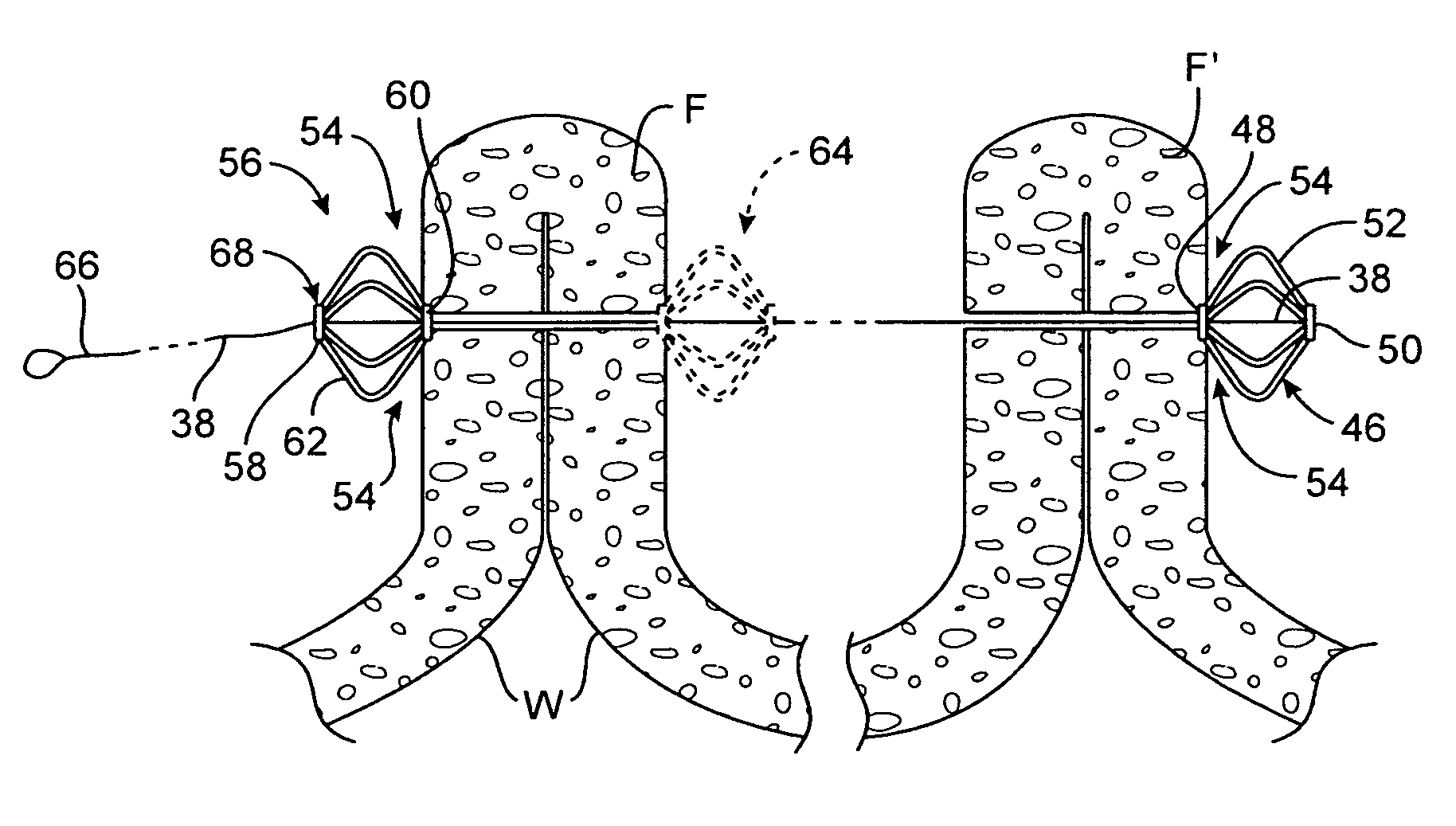

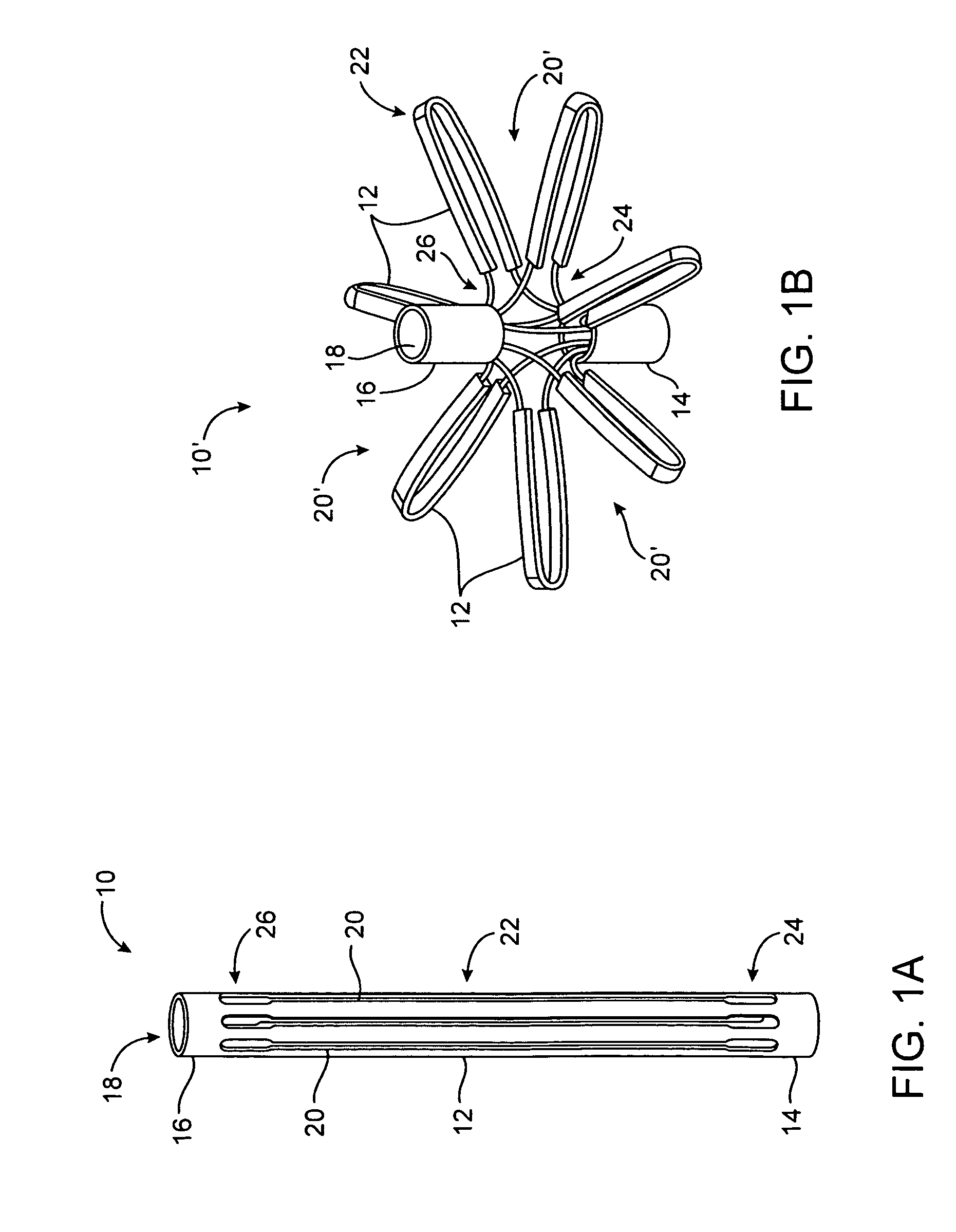

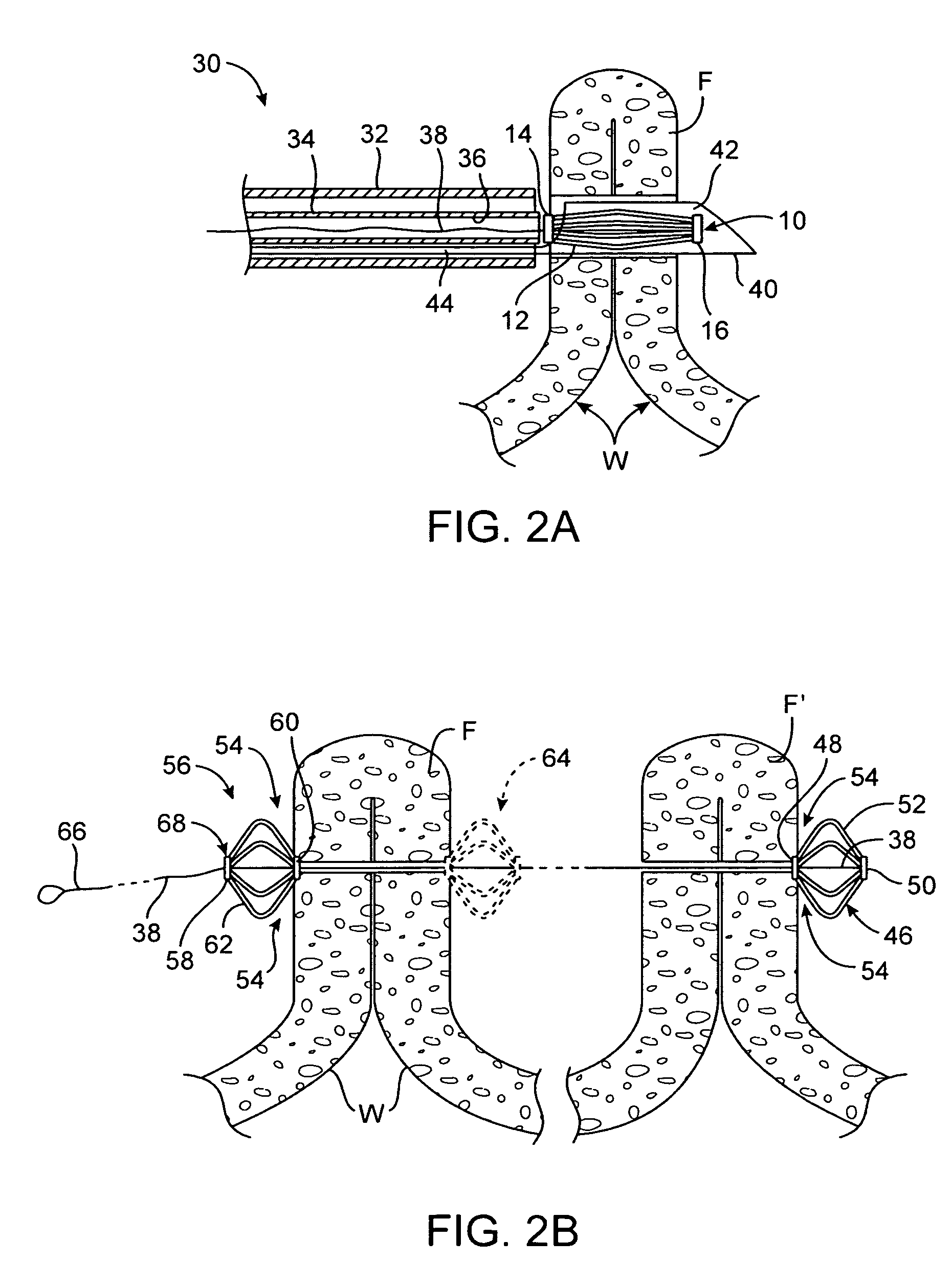

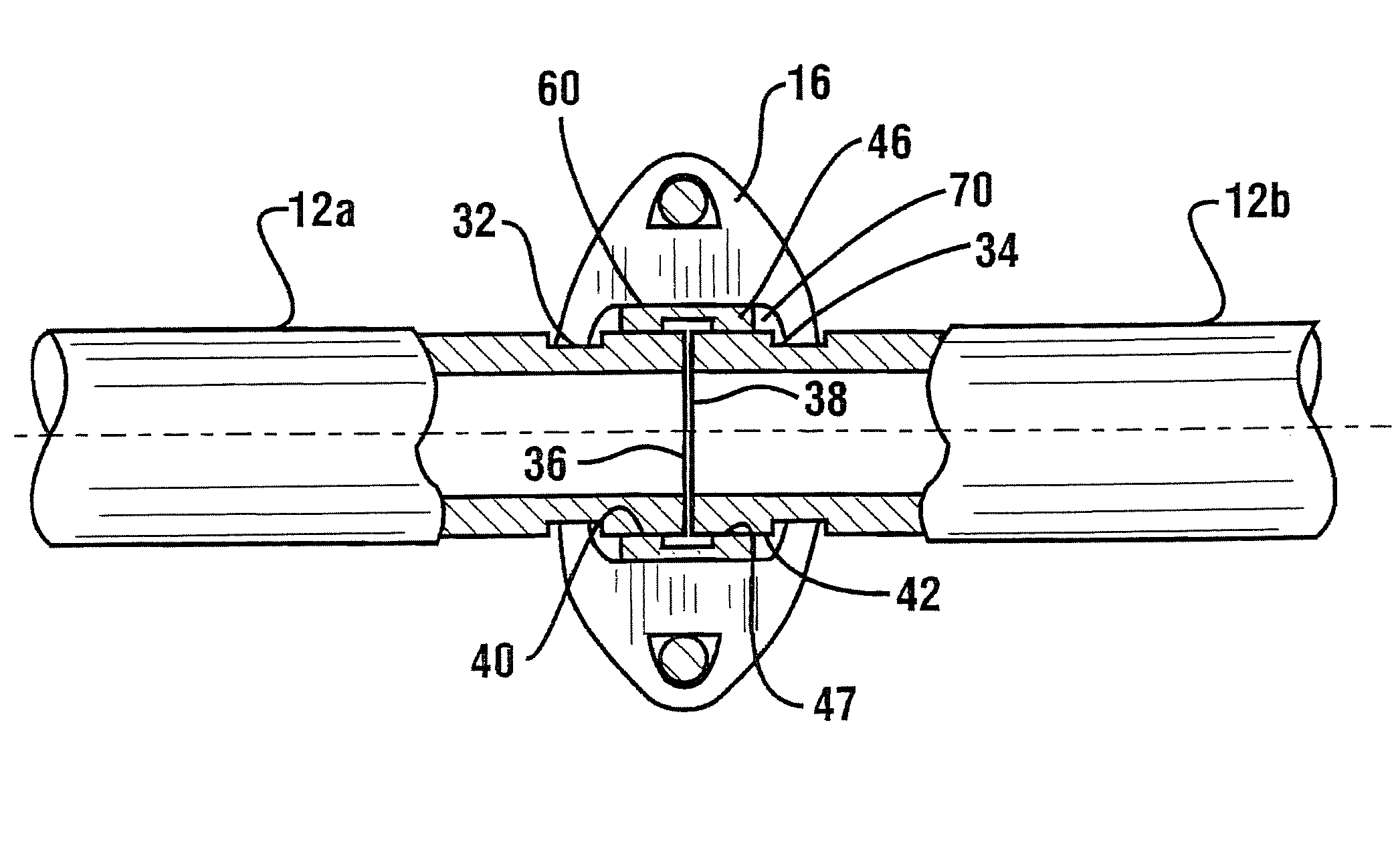

Systems for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

Compressible tissue anchor assemblies

ActiveUS7736379B2Constant force against the tissuePrevent overcompressionSuture equipmentsDiagnosticsConstant forceStrain gauge

Apparatus & methods for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

Compressible tissue anchor assemblies

ActiveUS20060217762A1Constant force against the tissuePrevent overcompressionSuture equipmentsDiagnosticsStrain gaugeBiomedical engineering

Apparatus & methods for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

Tissue engineering composite

InactiveUS6991652B2Facilitate formationNon-invasive methodBiocideCosmetic implantsTissue engineeringDamages tissue

The invention provides a biocompatible composite for use in a living subject for purposes of repairing damaged tissues and reconstructing a new tissue. The composite includes a biodegradable or absorbable three-dimensional support construct, a liquid or viscous fluid forming a gel matrix or viscous fluid when delivered to an area of interest in a living subject. The biodegradable construct provides an ideal surface for cell or cell extract attachment, while the gel matrix or viscous fluid acts as both a carrier material and a separator for maintaining the space between the constructs as well as the structural integrity of the developing issue.

Owner:CLEMSON UNIV RES FOUND +1

Apparatus and methods for optimizing anchoring force

ActiveUS20050277981A1Avoid exposurePrevent overcompressionSuture equipmentsDiagnosticsConstant forceStrain gauge

Apparatus and methods for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

Compressible tissue anchor assemblies

ActiveUS20050277966A1Constant force against the tissuePrevent overcompressionSuture equipmentsDiagnosticsConstant forceStrain gauge

Apparatus & methods for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

Compressible tissue anchor assemblies

ActiveUS7678135B2Constant force against the tissuePrevent overcompressionSuture equipmentsDiagnosticsConstant forceStrain gauge

Owner:USGI MEDICAL

System for optimizing anchoring force

ActiveUS20050277983A1Avoid exposureConstant force against the tissueSuture equipmentsDiagnosticsConstant forceStrain gauge

Systems for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

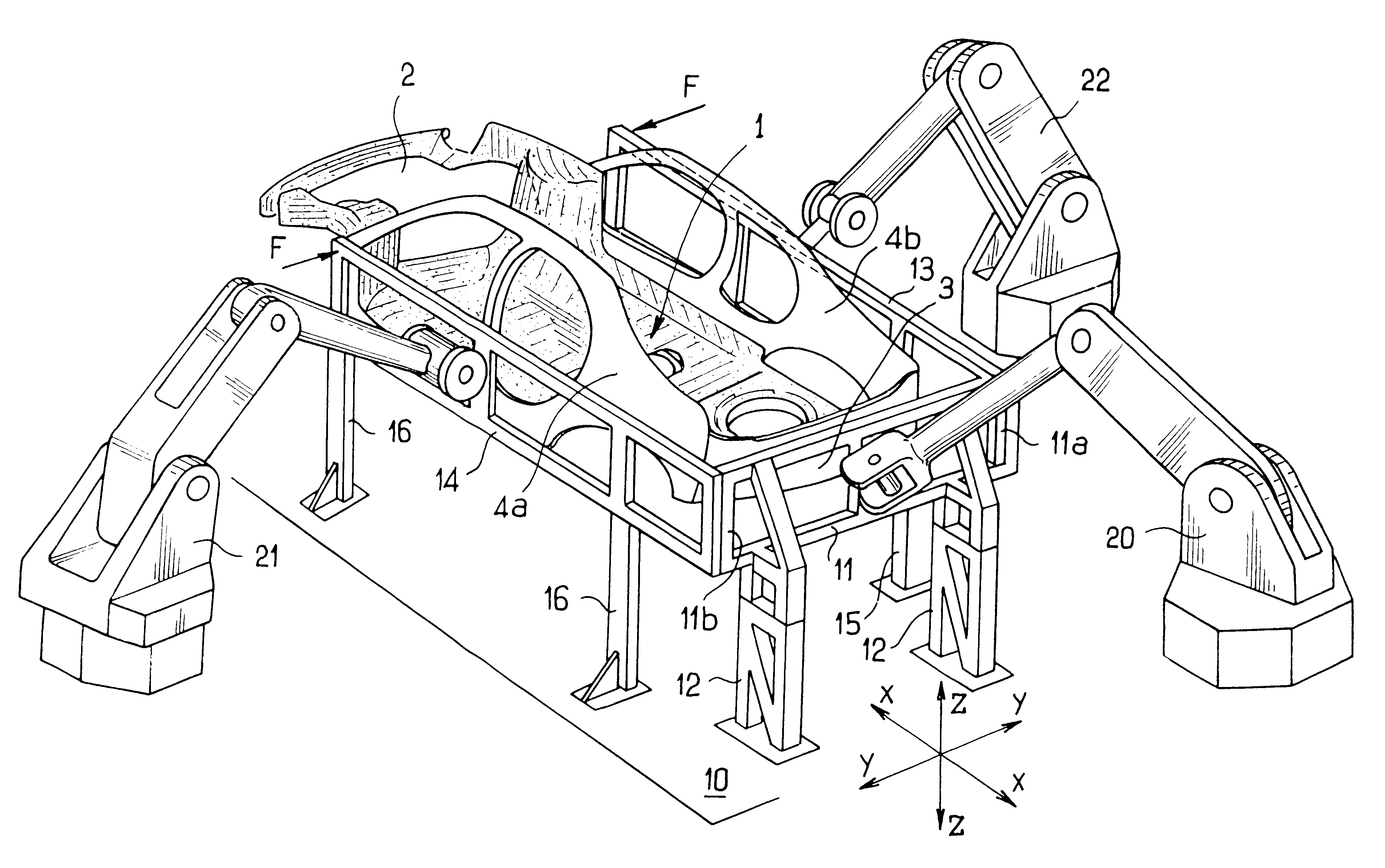

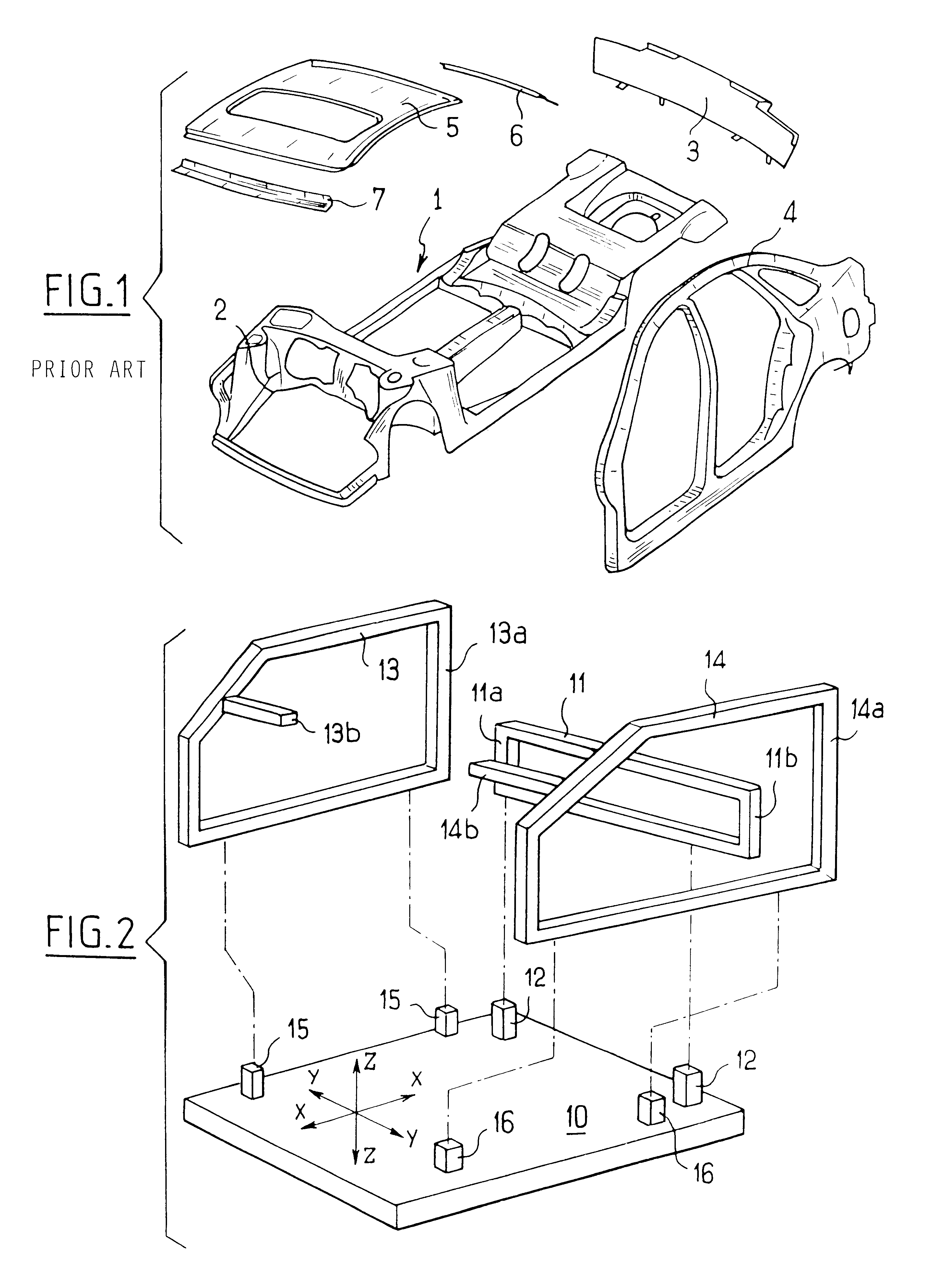

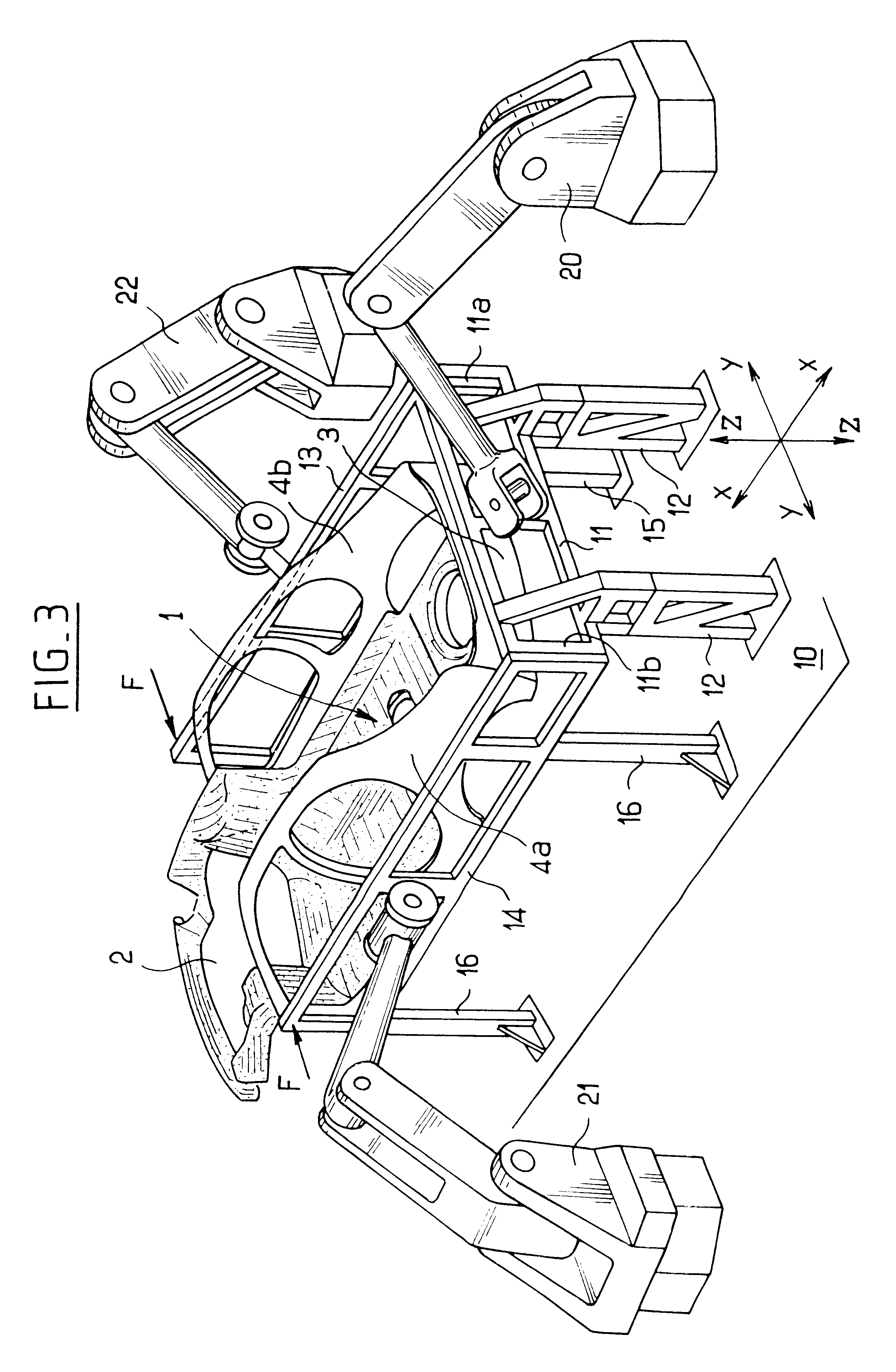

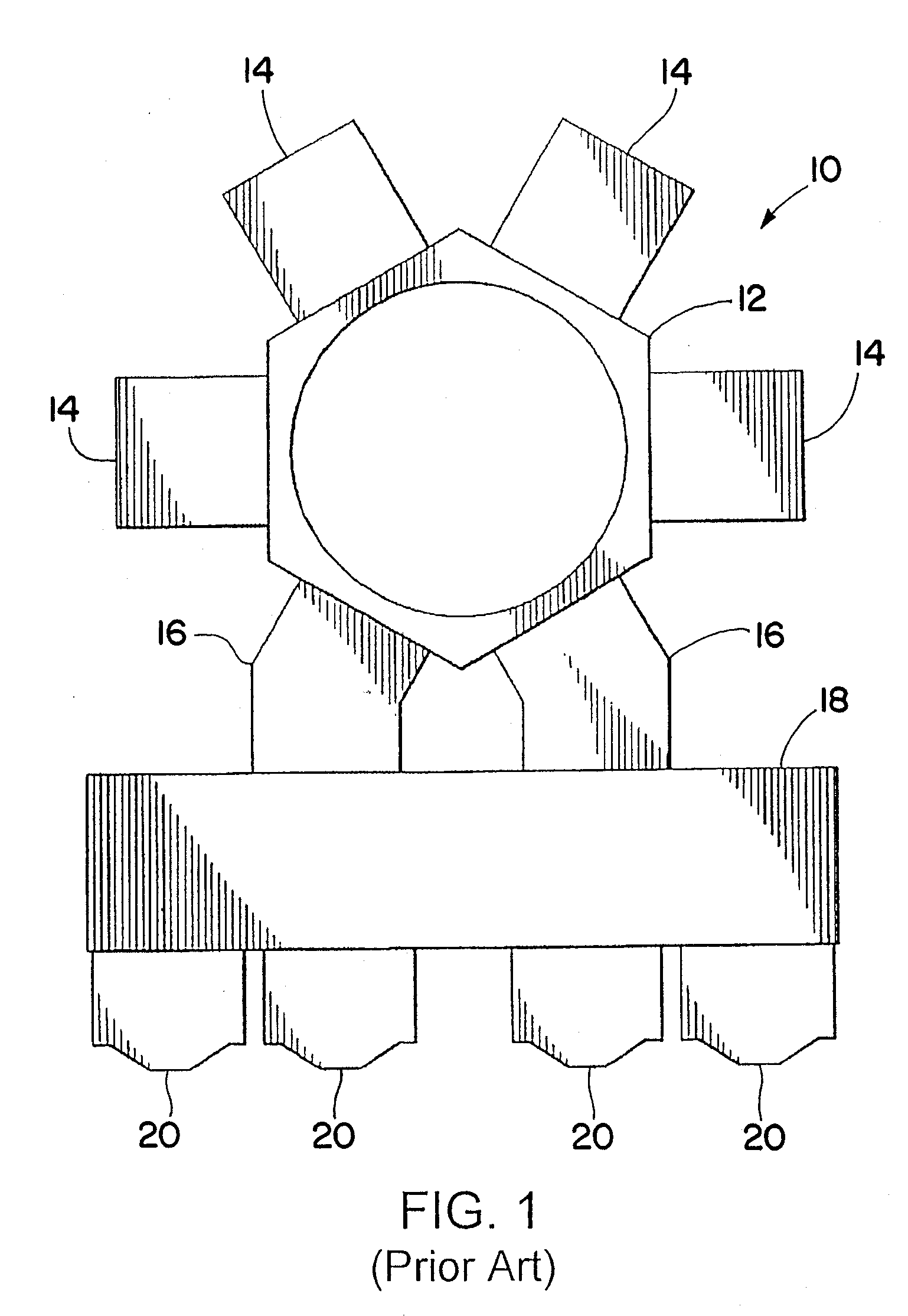

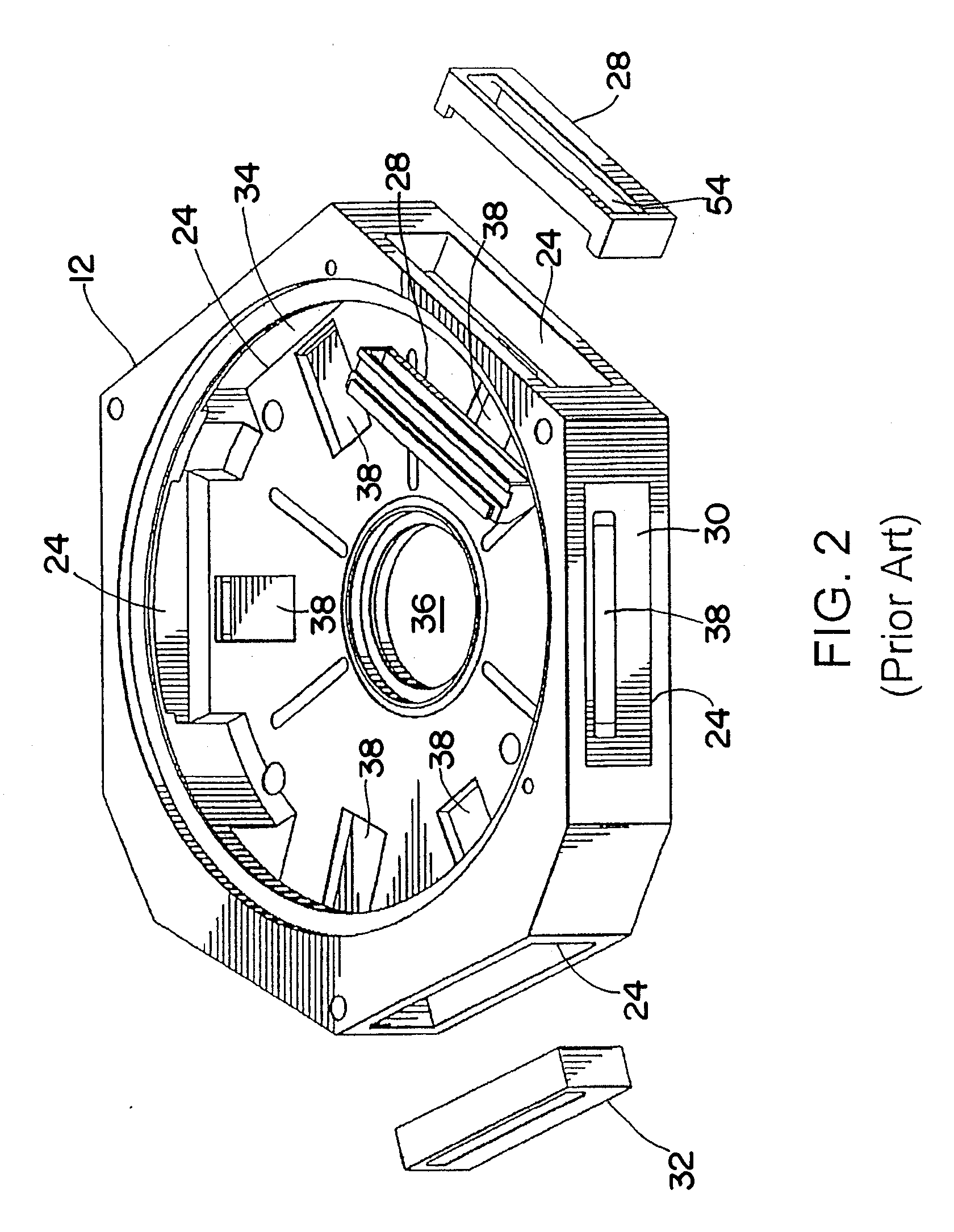

Method for making a motor car body

InactiveUS6389698B1Prevent overcompressionVehicle componentsPositioning apparatusEngineeringMechanical engineering

A method of making car bodywork, the method including a step of assembling body sides (4a, 4b) to an underbody (1), the underbody (1) including a rigid engine compartment (2) at one end and being placed in an assembly station in a precise position determined in an orthogonal frame of reference having directions X, Y, and Z, the method consisting: in putting the body sides (4a, 4b) into position and holding them in position in the frame of reference of the station by means of two parallel tools (13, 14) each co-operating with a respective body side (4a, 4b), and at least one transverse tool (11) extending transversely to said parallel tools, the three tools being connected to one another and to the X, Y, Z frame of reference of the station in such a manner that the transverse tool (11) is placed and held in a position that is precise and locked in the frame of reference and that it forms a spacer and bracing tool in the Y direction for the two parallel tools (13, 14) in a zone that is remote from the engine compartment (2) of the underbody (1); and in maintaining a force (F) pressing each of the parallel tools (13, 14) at least against the sides of the engine compartment (2) of the underbody (1) while the body sides are being assembled to the underbody.

Owner:ABB BODY & WHITE

Piezoelectric generator and method

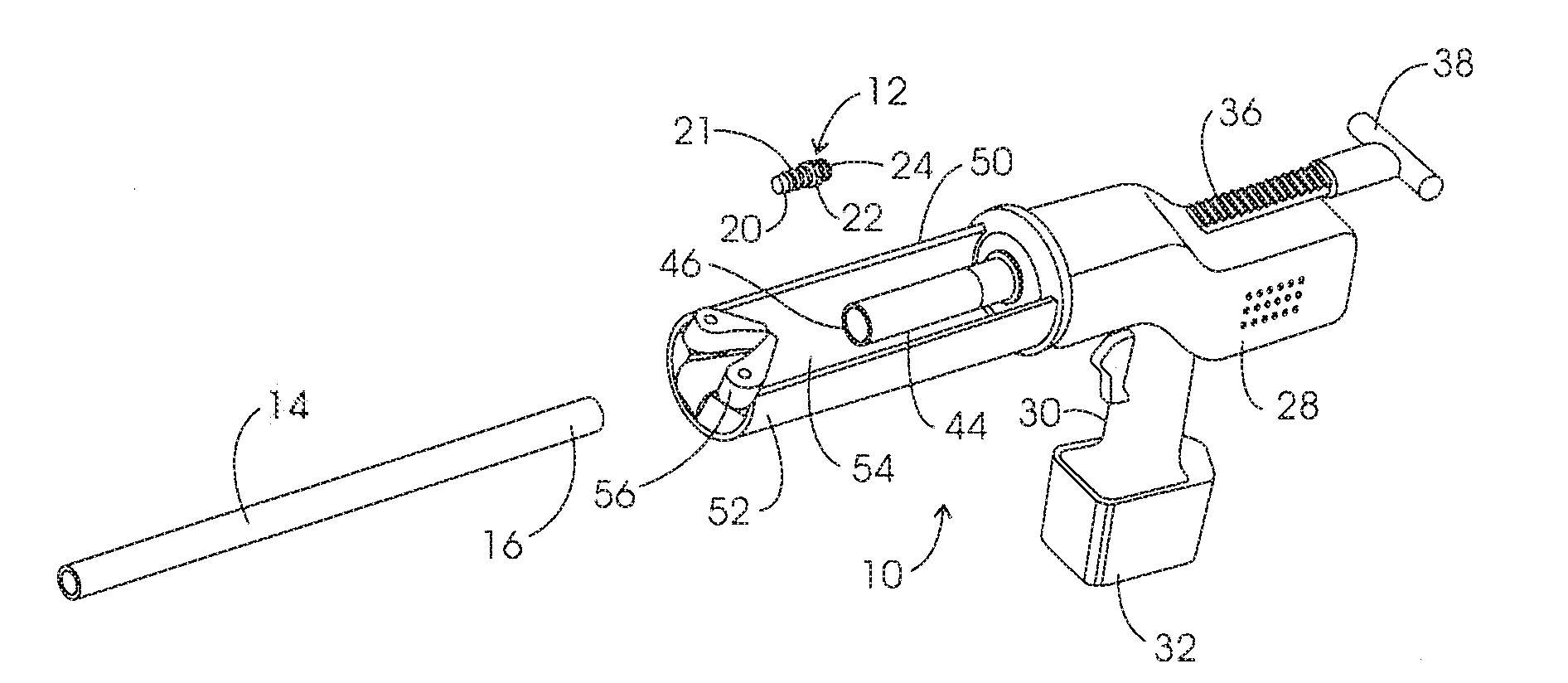

ActiveUS20110127881A1Prevent overcompressionWave amplification devicesPiezoelectric/electrostriction/magnetostriction machinesElectricitySignal conditioning

An apparatus and method is provided to produce energy from movement of a user. At least one pair of plates is utilized to secure an array of cymbal transducers therebetween. The array of cymbal transducers is electrically interconnected with signal conditioning circuitry and power storage member. Electrical interconnections may comprise parallel and / or series connections between ones or groups of the cymbal transducers.

Owner:UNITED STATES OF AMERICA

Hose Assembly Process, Device, and Product-by-Process

InactiveUS20070209204A1Prevent excessive compressionPrevent overcompressionEngine componentsMetal working apparatusEngineeringLinear motion

A process for assembling a rigid fitting to a flexible or elastic tube or hose within one of a portable, hand-held and / or mountable assembly device, including the steps of slip-fitting the fitting within a pusher member of the device that includes a torque-producing source capable Of converting input power into linear motion force; b. temporarily restraining a hose open end within the assembly device and; activating the torque-producing source to linearly advance the pusher member and fitting, relative to the restrained hose end, for physically inserting the fitting into the hose open end. Additional steps include: retraction of the pusher member and releasing the now-assemble hose and fitting assembly from the assembly device. Product-by-process claims and article claims, pertaining to the assembly device used in the process for assembling, are also set forth.

Owner:CHASE DANIEL J +6

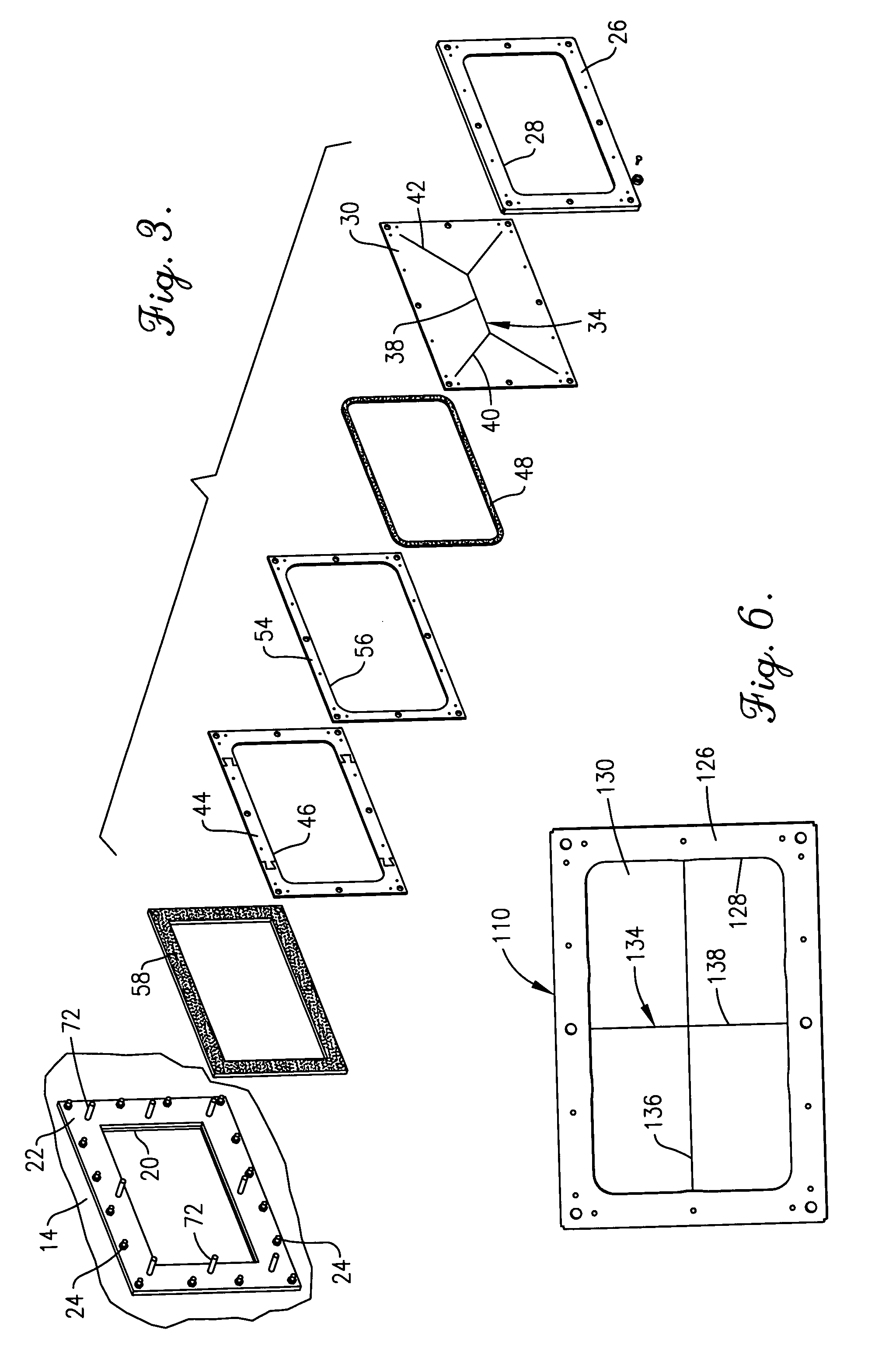

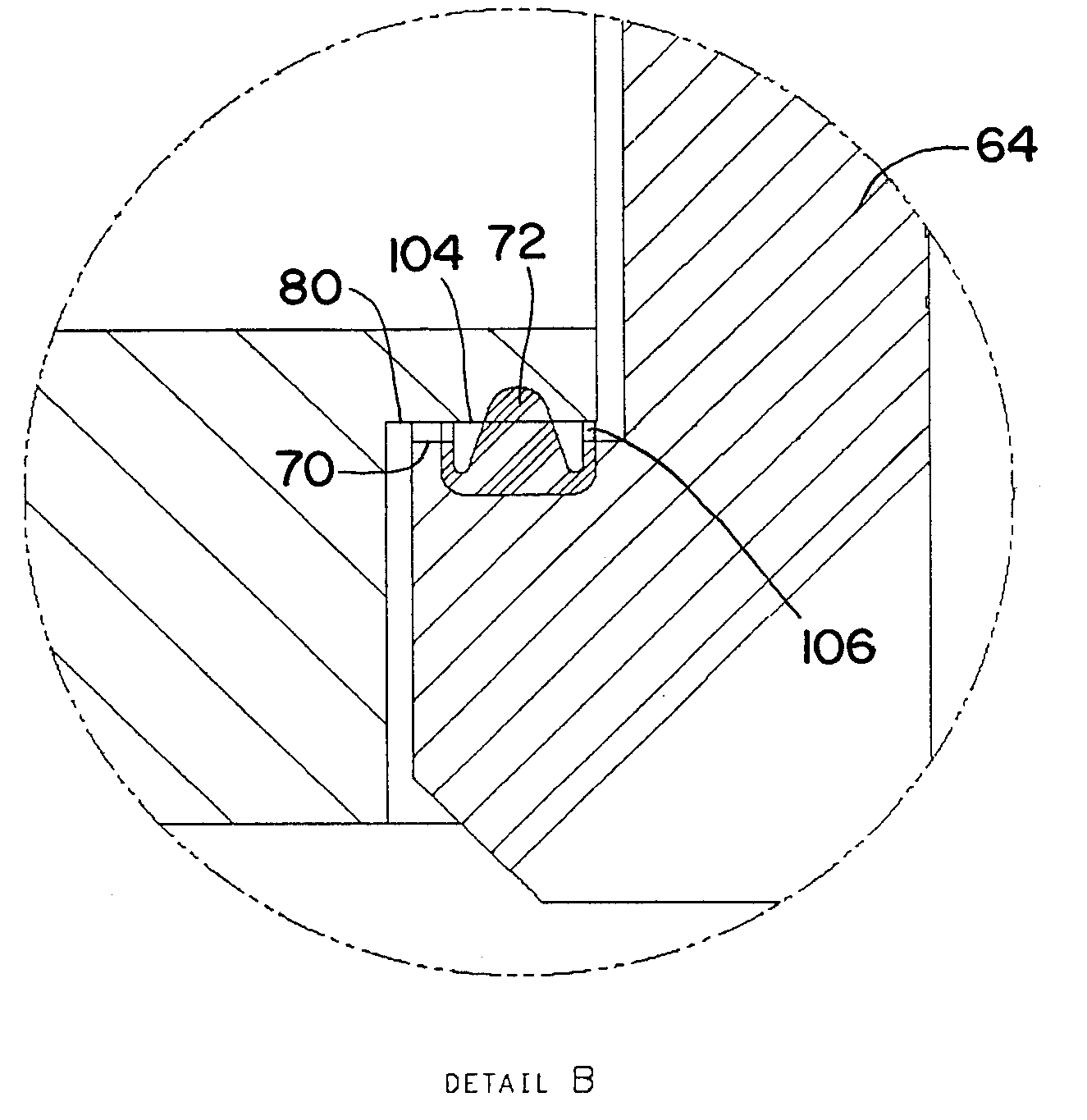

Unitary overpressure vent panel structure

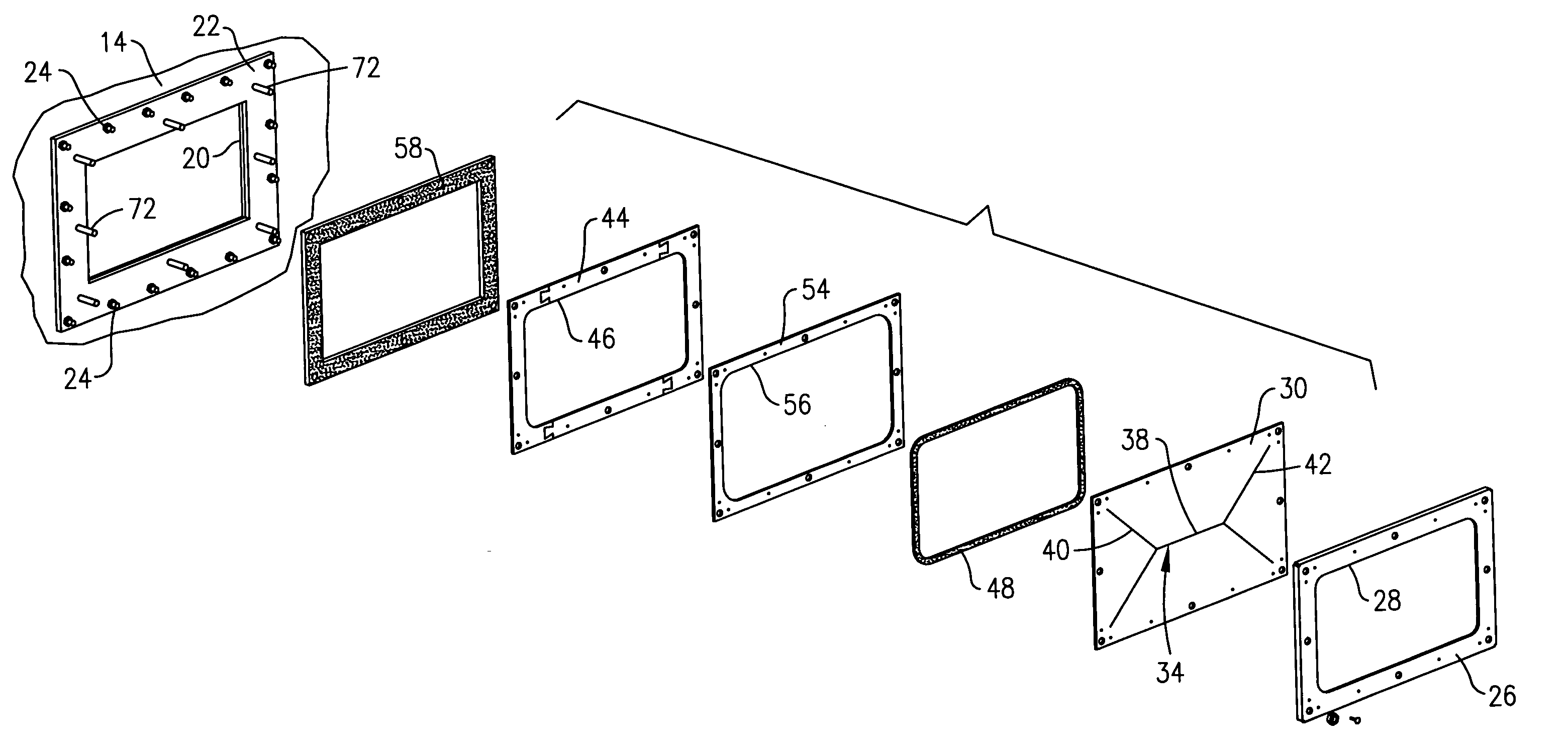

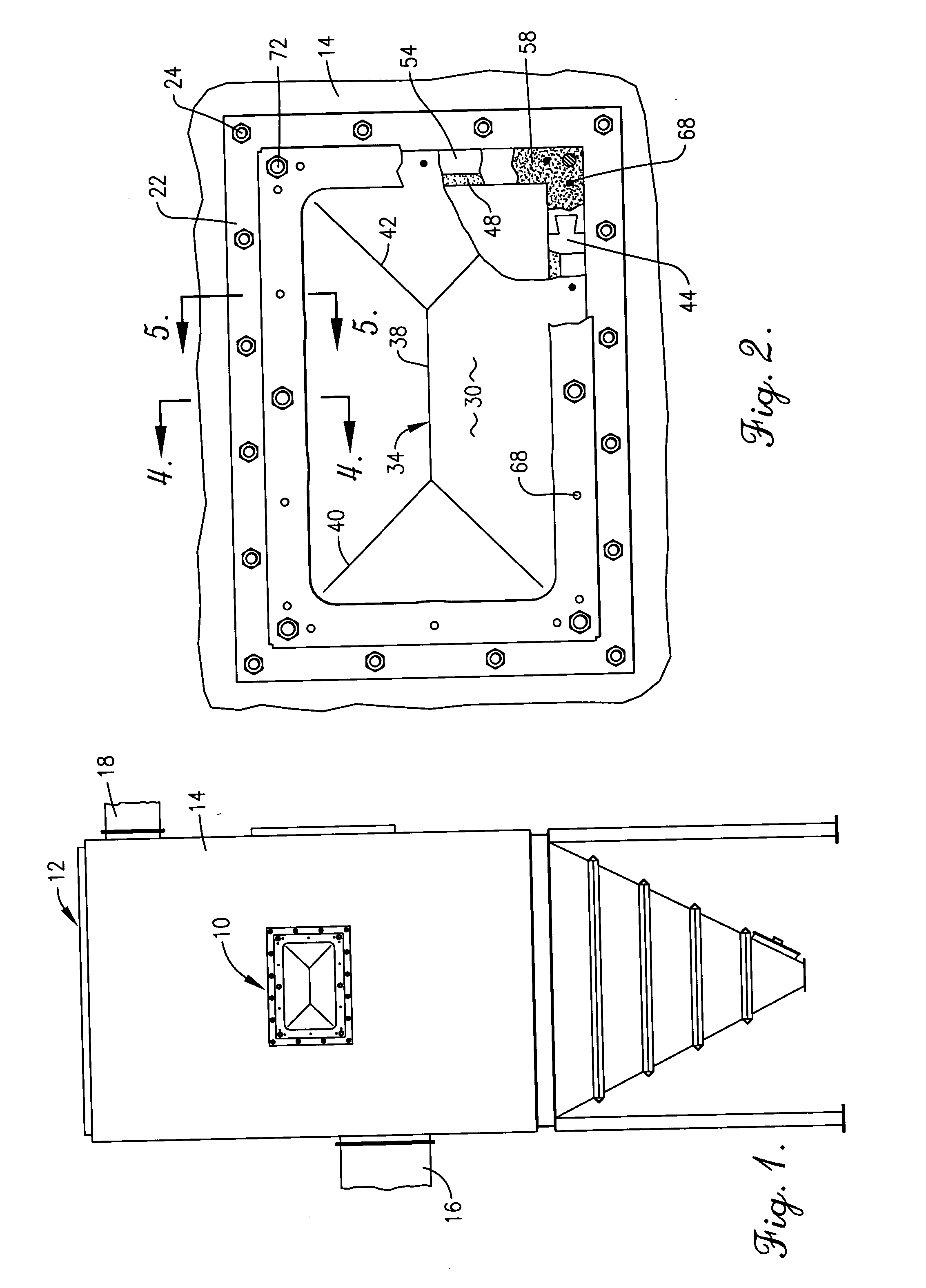

InactiveUS20040172889A1Prevent overcompressionMaintain integrityLarge containersEqualizing valvesEngineeringSealant

Unitary one-piece frameless overpressure vent panel assembly (10) includes a rigid, generally planar primary support member having a central relief opening (26), a rigid, generally planar secondary support member (44) provided with a central relief aperture (46), and a frangible vent panel (30) between the support members in full closing relationship to the relief opening and the aperture. A sealant element (48) may be provided between the vent panel and at least one of the support members in circumscribing relationship to the relief opening or aperture. At least one line of weakness (34) may be provided in the vent panel. A flexible gasket (58) secured to the secondary support member assures a fluid tight seal between the vent panel assembly and the structure defining a protected zone. Alternatively, a knife blade or the like may be provided adjacent the vent panel to effect severing thereof under a predetermined overpressure in lieu of a line of weakness in the panel.

Owner:FIKE CORP

Bonded slit valve door seal with thin non-metallic film gap control bumper

The present invention provides a thin film spacer for maintaining a gap between a slit valve door and a sealing surface of a slit valve, such as a metallic insert. The film spacer can extend the life of a seal by limiting the line of sight exposure of the seal to corrosive gases within a wafer processing chamber, for example, and by controlling the compression percentage of the seal. The spacer may be located on an outer ambient side of the slit valve away from any corrosive gasses that may exist in the chamber.

Owner:PARKER INTANGIBLES LLC

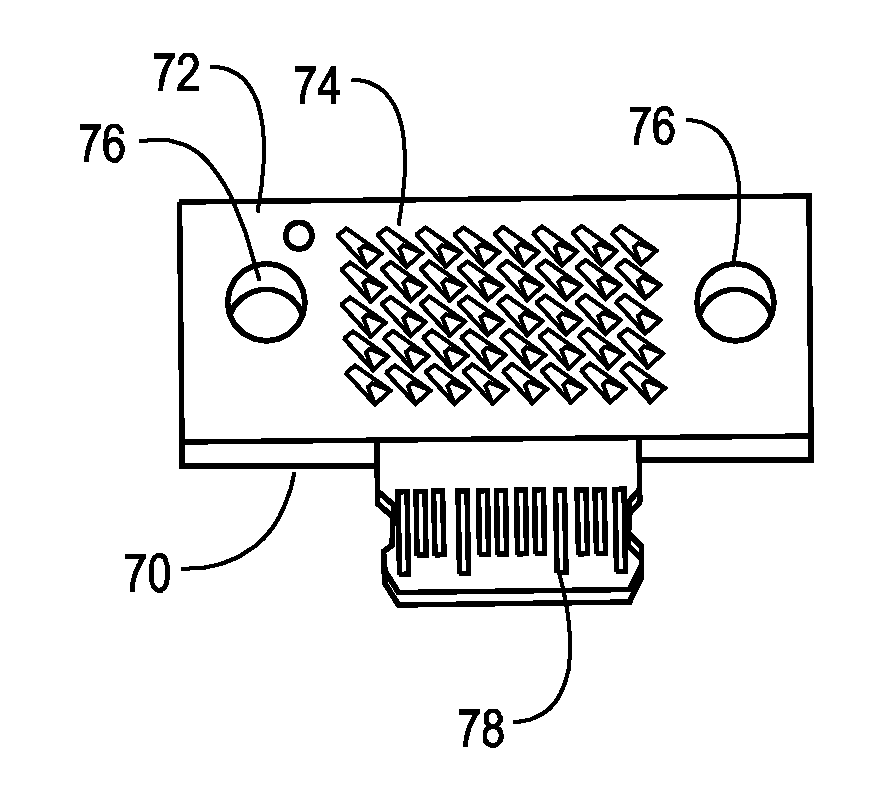

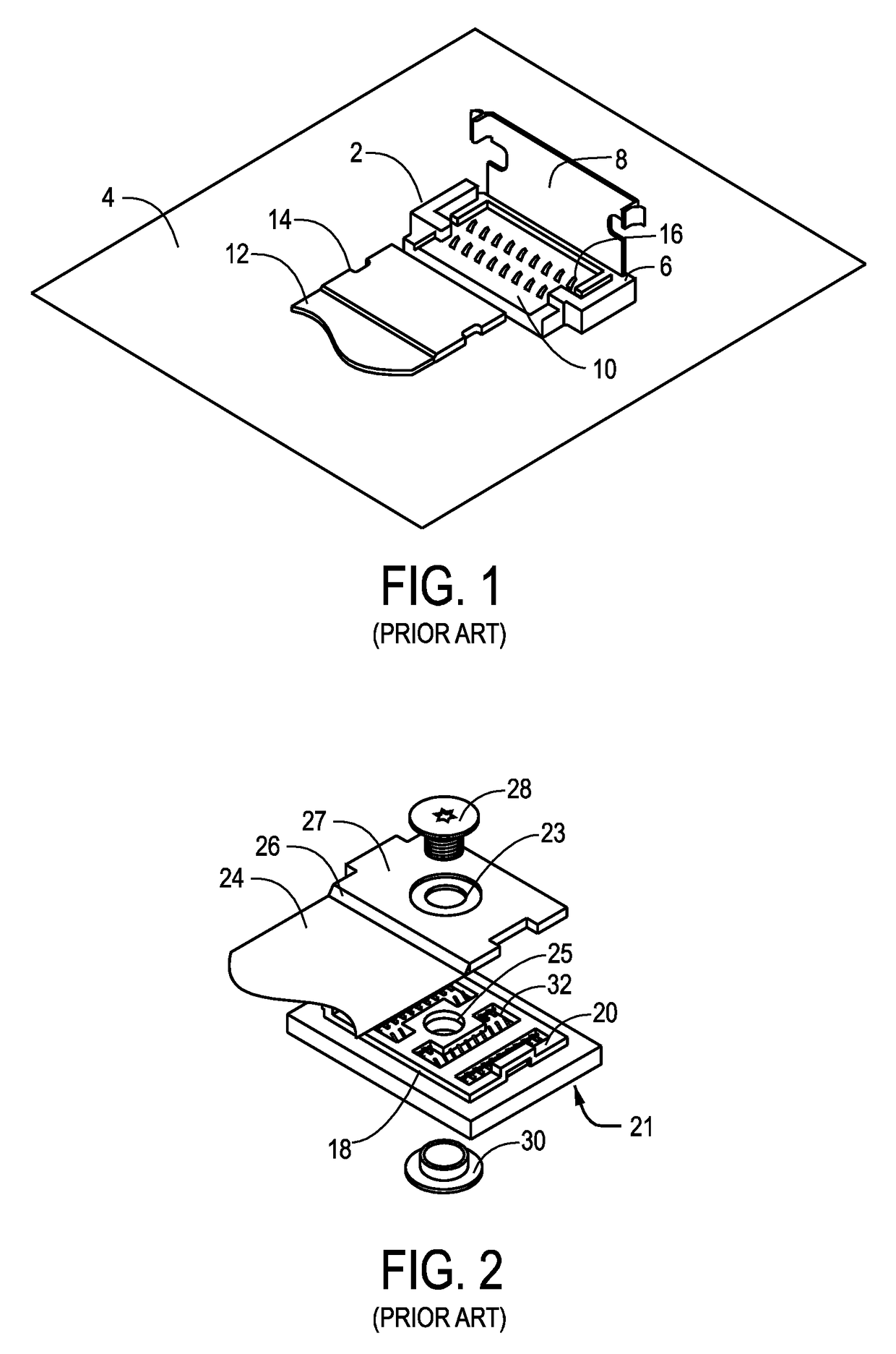

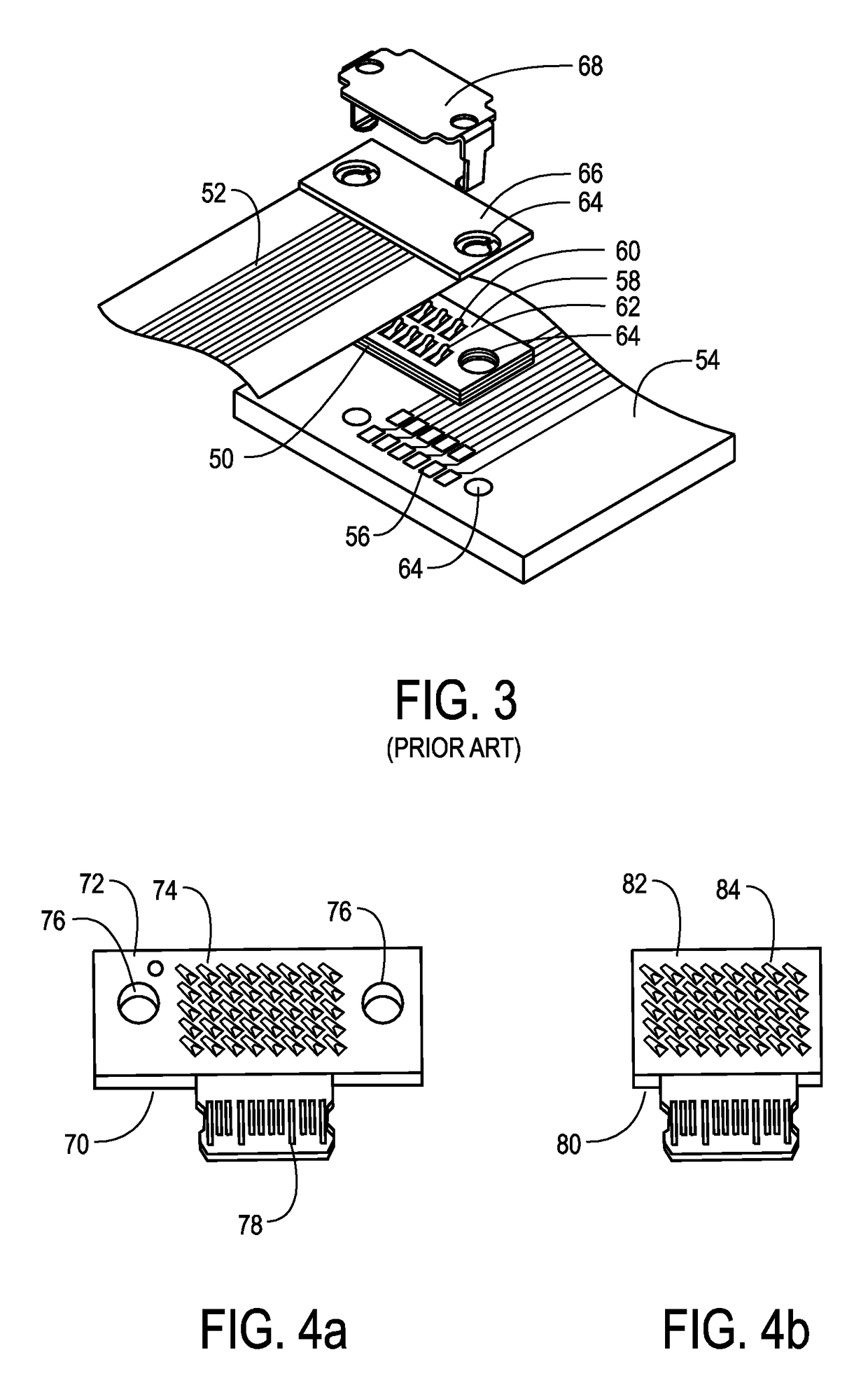

Electrical Connector and Method of Making It

InactiveUS20170194721A1Increase volumeReduce manufacturing costPrinted circuit assemblingPrinted circuit aspectsElectricityElectrical resistance and conductance

A novel electrical connector and method of manufacture is disclosed which provides an integral attachment and retention means for the purpose of electrically and mechanically interconnecting circuit elements in electronic devices, said circuit elements including but not limited to printed circuit boards, flexible printed circuits, rigid flex circuits, semiconductor package substrates, modules, and batteries. The electrical connector of the present invention utilizes a bonding material, disposed at least between the electrical spring contact elements on a surface of the connector, to bond and retain first and second portions of the electrical connector in an actuated state on a mating circuit element whereby stable and low resistance electrical interconnections are formed and maintained between the electrical connector and interconnection terminals on the mating circuit element. This design permits the electrical connector to be low-profile and use a reduced amount of space on a circuit member such as a PCB.

Owner:FAN CHIH PENG +4

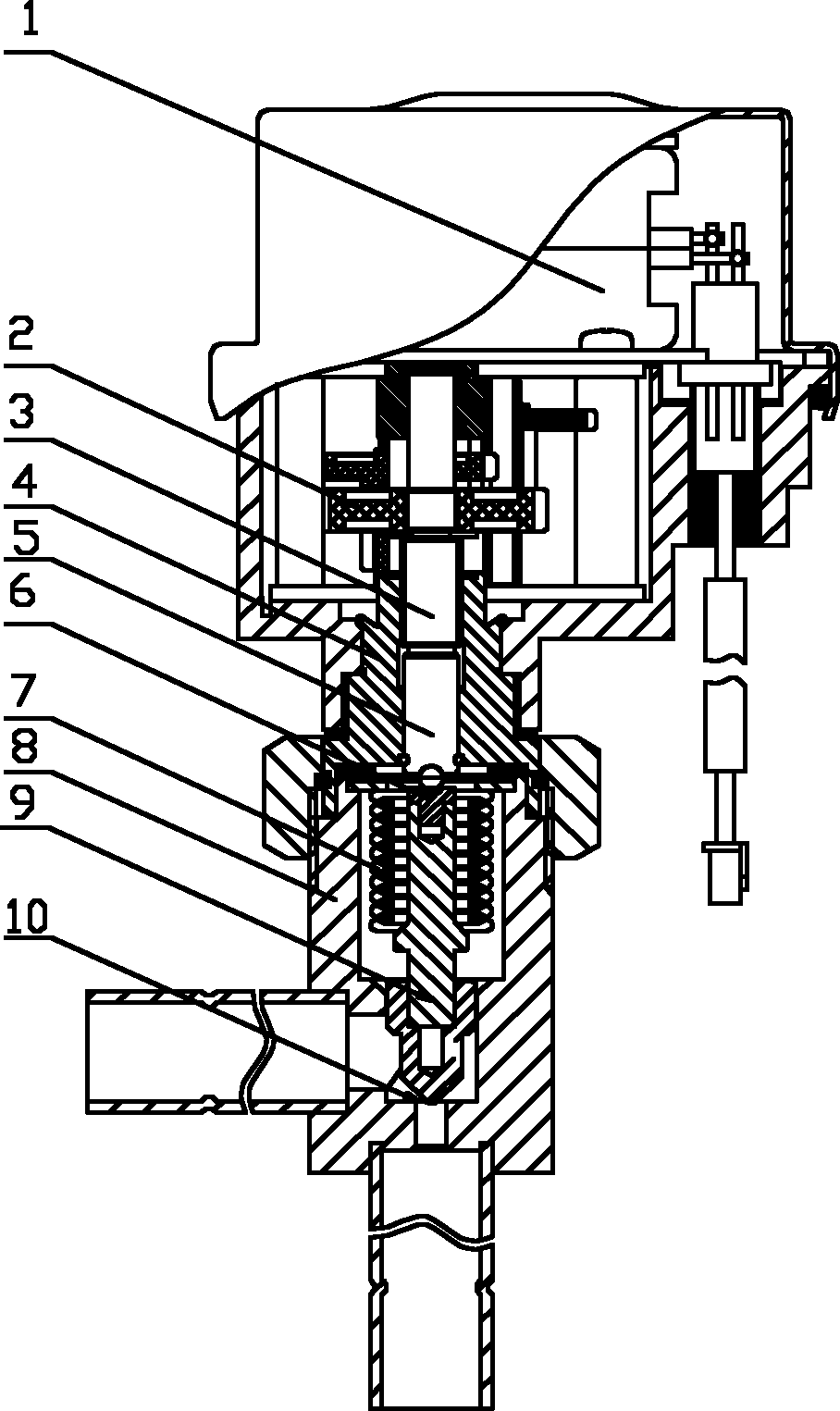

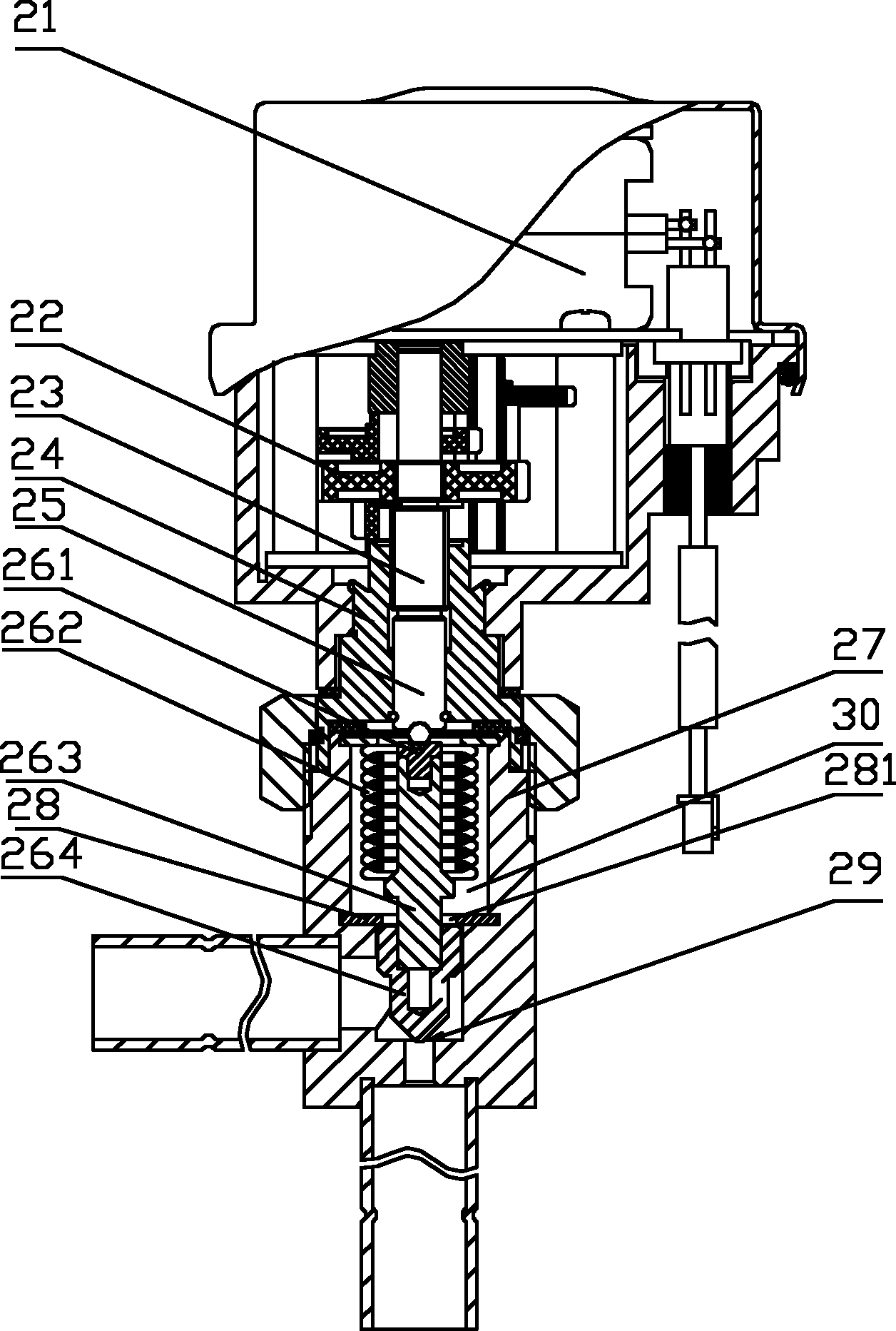

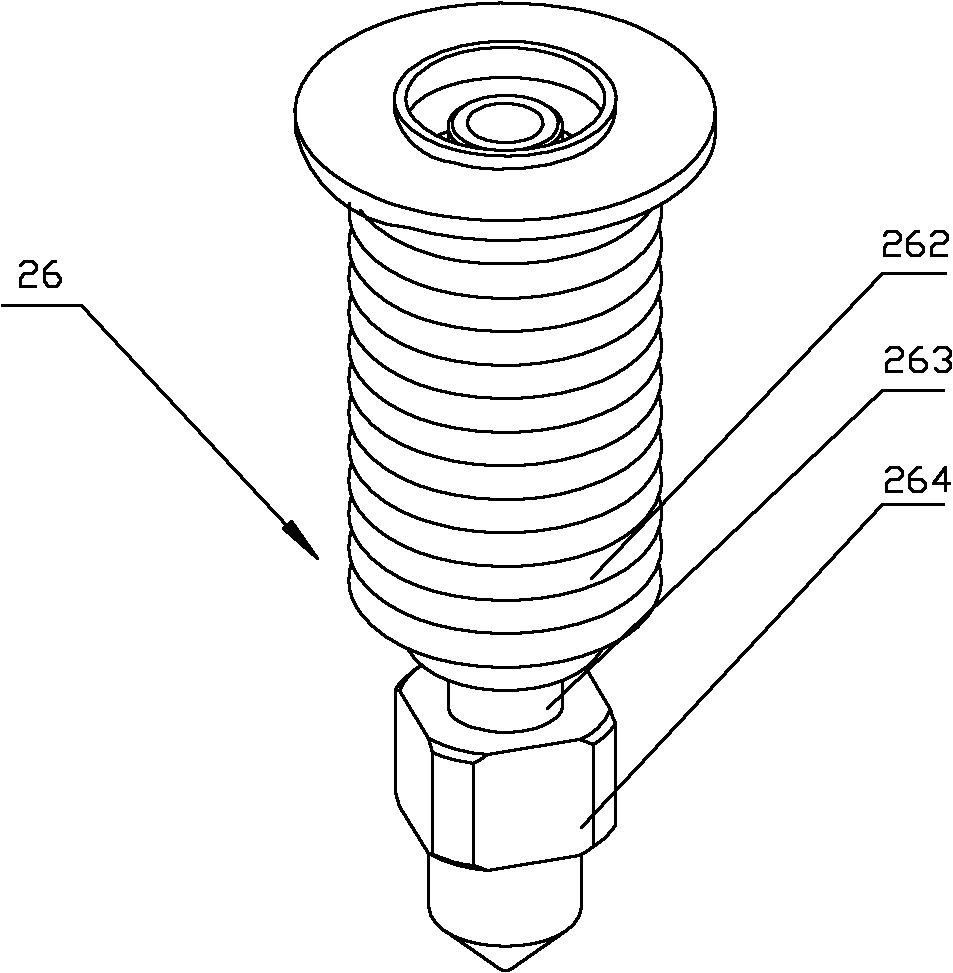

Electronic expansion valve

ActiveCN102644785APrevent overcompressionExtended service lifeSpindle sealingsFluid circulation arrangementElastic componentEngineering

The invention discloses an electronic expansion valve, comprising a drive mechanism, a transmission mechanism, a valve seat and a valve needle component, wherein the valve needle component is provided with a valve needle axially moving along the valve cavity of the electronic expansion valve to control the openness of a valve opening, a valve rod, and an elastic component for reset. The electronic expansion valve is characterized by further comprising a limit structure arranged in the valve cavity and provided with an axial channel, and the valve needle component is provided with a transversal flange; and the limit structure is located above the flange in the case that the valve needle component moves upwards until the valve opening has the maximum openness, and the minimum radial dimension of the axial channel is less than the maximum radial dimension of the flange. The valve needle component of the electronic expansion valve cannot continue to move upwards due to the resisting of the limit structure in case of moving upwards to the position where the valve opening is the largest or slightly higher, and the valve needle component cannot greatly move upwards to compress the elastic component for reset in excess in case of coil detachment and replacement and in the other cases of needing to separate the valve needle component from other components above, thus prolonging the service life of the elastic component.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Screw-capsule for wine bottles

InactiveUS20110036839A1Function increaseReduce energy consumptionCapsThreaded caps applicationWine bottleDiffusion barrier

A plastic screw cap has a threaded top portion and tabs of varying heights disposed around an inner circumference of a lower sleeve-portion. These tabs clasp a land disposed on a container neck to restrain the sleeve portion on the neck when the cap is unscrewed. A threaded top portion mates with threads on the container above the land. A sealing liner and diffusion barrier disposed at the bottle opening, together with a crush-resistant cap structure, prevent wine leakage and control oxygen ingress. Typically, the plastic cap is threaded onto the container neck, forming a tamper-evident seal. When unscrewed, the plastic-cap top moves up the container threads, exerting a pull on the sleeve portion, which is restrained due to the closure tabs acting on the land. Between the closure tabs and the threaded top is a breakaway line, which tears due to the removal forces. This tear evidences tampering.

Owner:GARDNER WILLIAM A

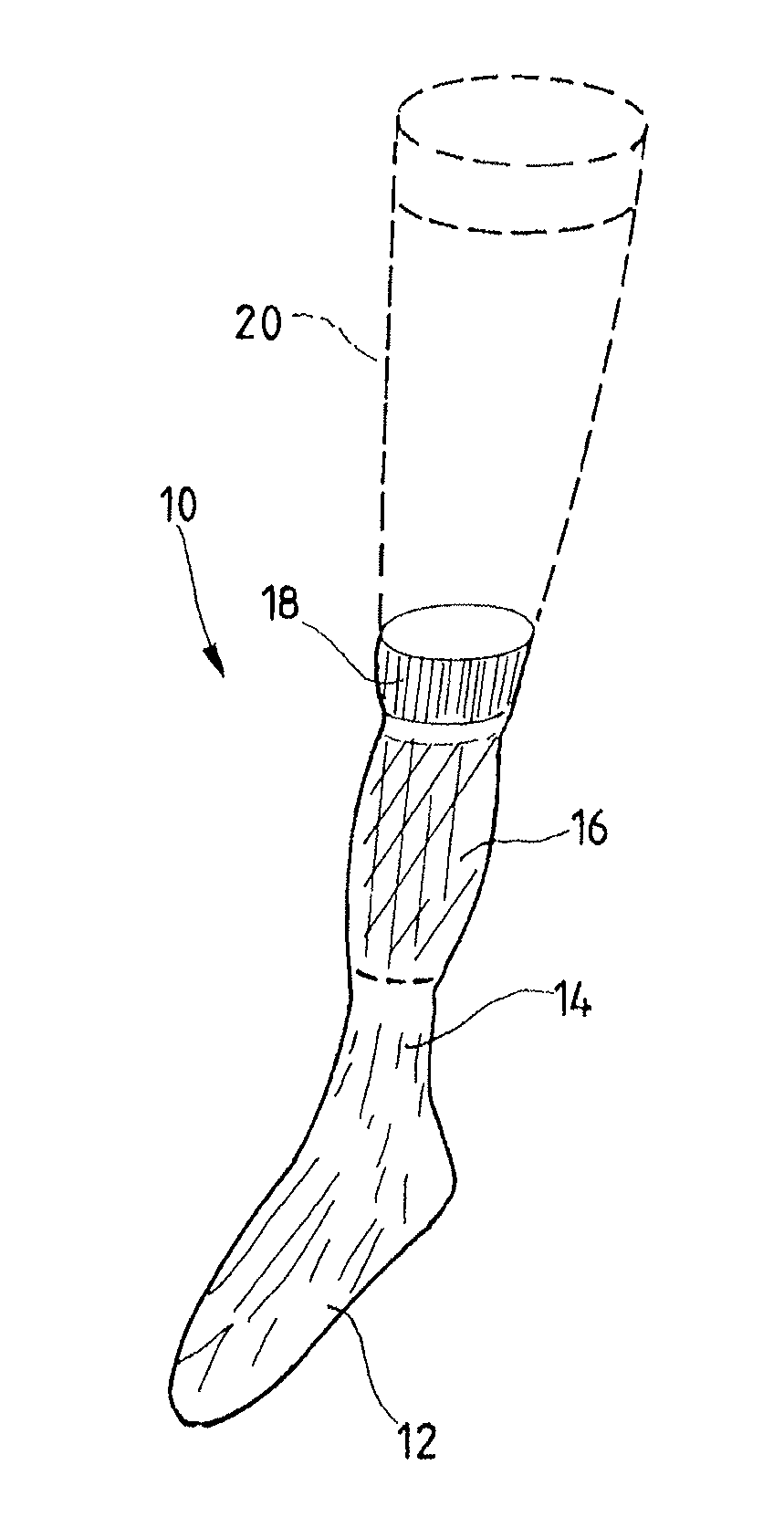

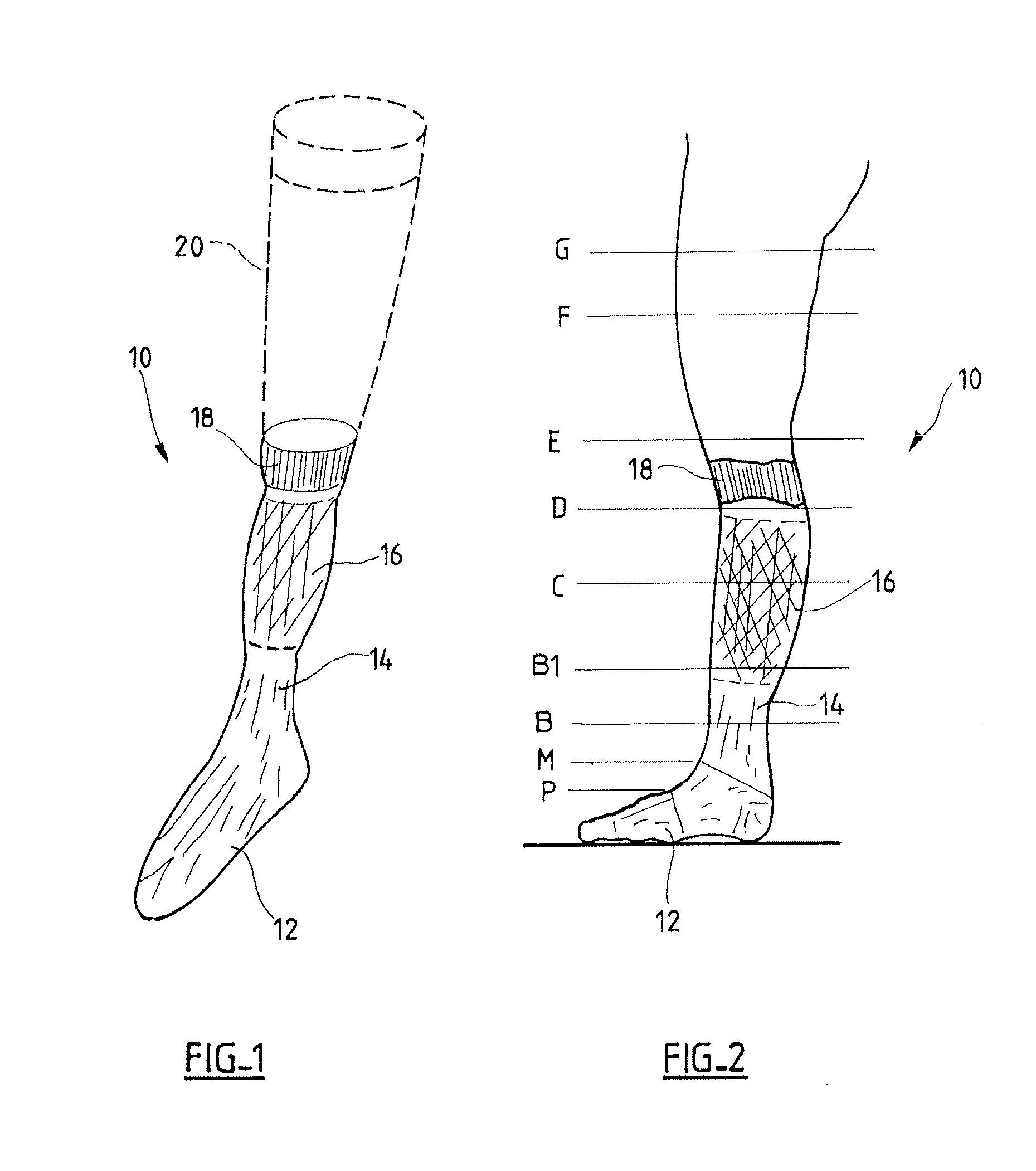

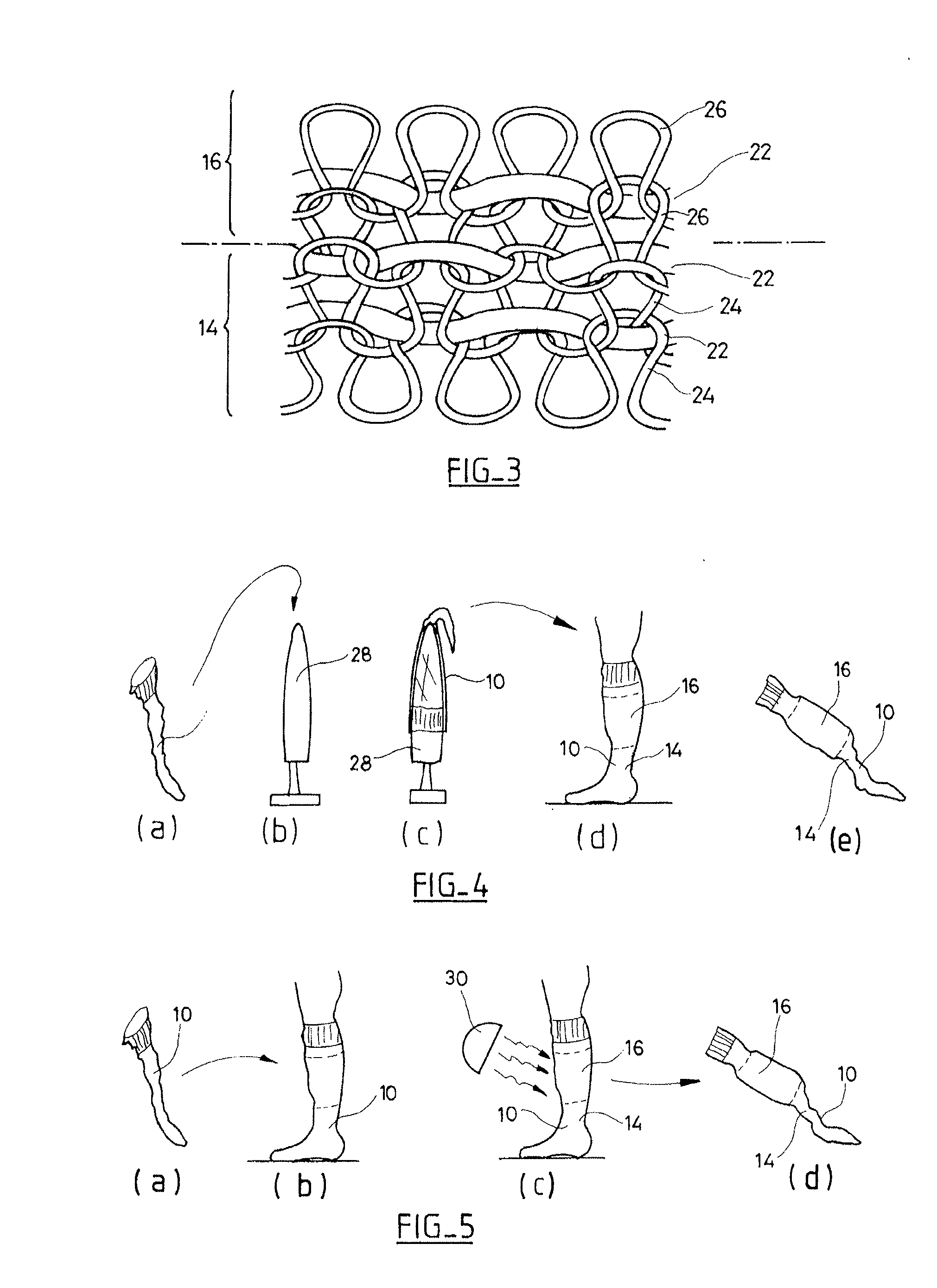

Made-to-measure orthosis for compression/containment, for reinforcing the musculo-aponeurotic pump of the calf

InactiveUS20120116282A1Easy to installReduce rigidityFinger bandagesBreast bandagesYarnDistal portion

Owner:INNOTHERA TOPIC INT

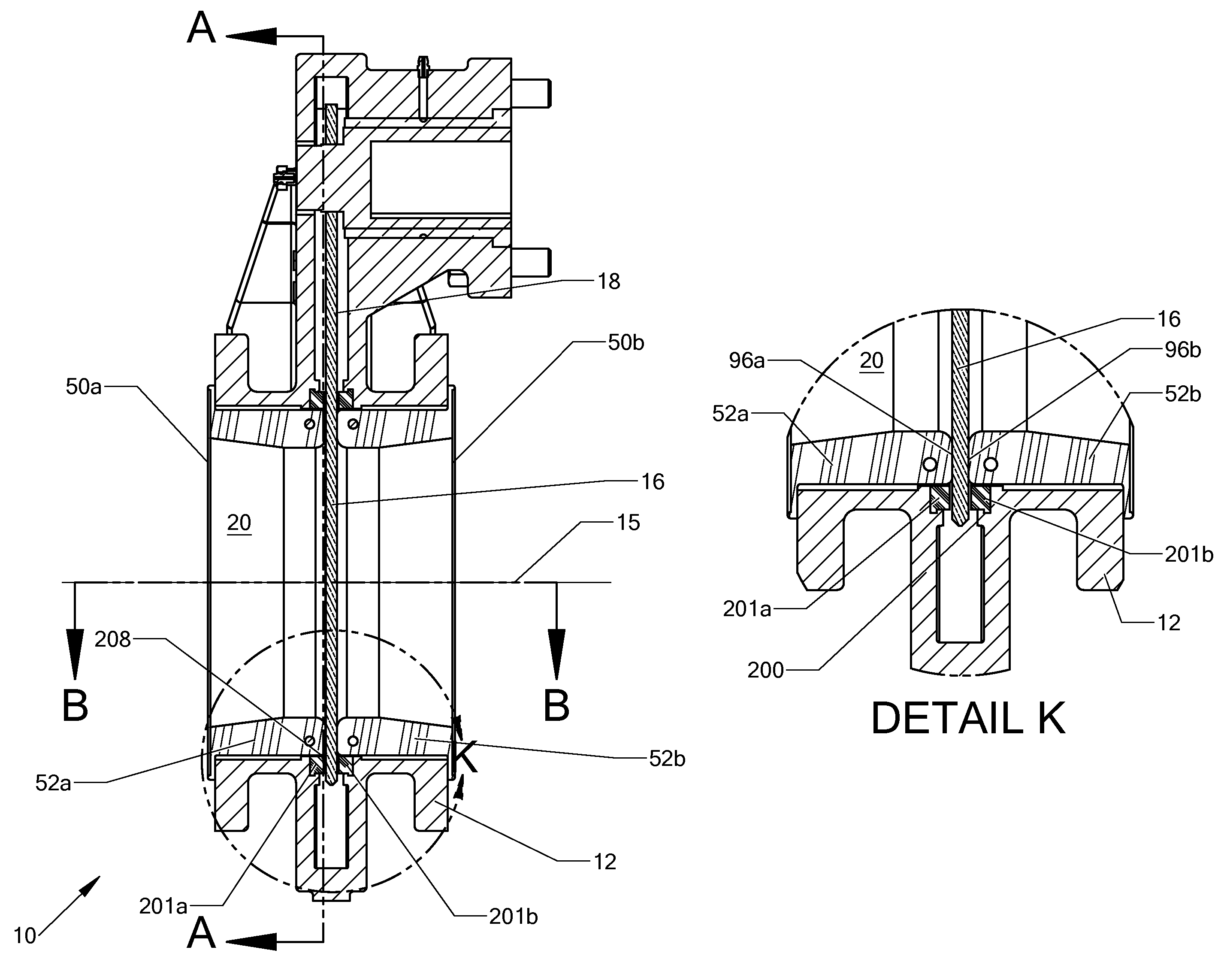

Apparatus and methods for optimizing anchoring force

ActiveUS8206417B2Prevent overcompressionMinimized contact areaSuture equipmentsDiagnosticsConstant forceStrain gauge

Apparatus and methods for optimizing anchoring force are described herein. In securing tissue folds, over-compression of the tissue directly underlying the anchors is avoided by utilizing tissue anchors having expandable arms configured to minimize contact area between the anchor and tissue. When the anchor is in its expanded configuration, a load is applied to the anchor until it is optimally configured to accommodate a range of deflections while the anchor itself exerts a substantially constant force against the tissue. Various devices, e.g., stops, spring members, fuses, strain gauges, etc., can be used to indicate when the anchor has been deflected to a predetermined level within the optimal range. Moreover, other factors to affect the anchor characteristics include, e.g., varying the number of arms or struts of the anchor, positioning of the arms, configuration of the arms, the length of the collars, etc.

Owner:USGI MEDICAL

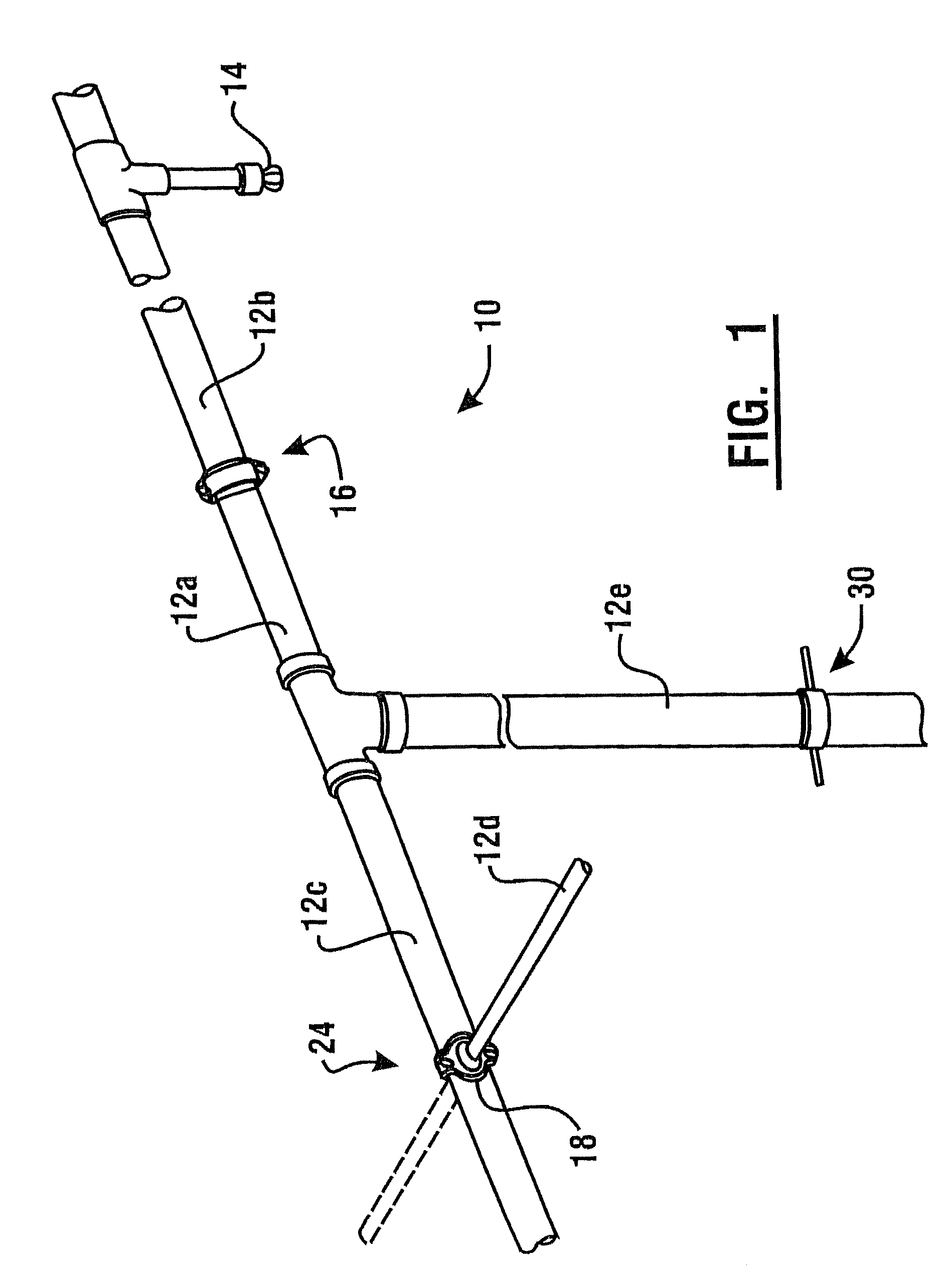

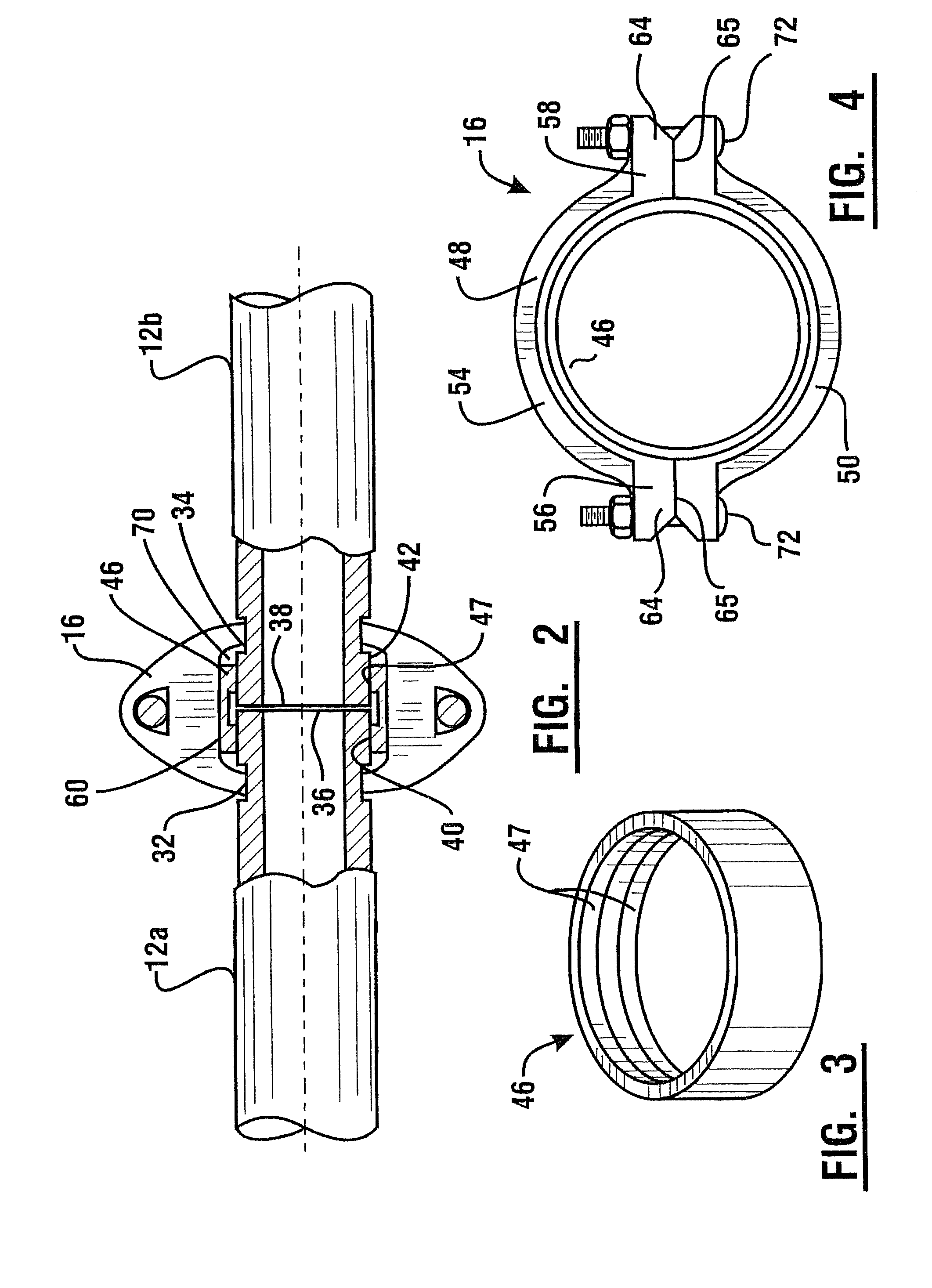

System And Method Of Assembly Of CPVC Fire Sprinkler System Employing Mechanical Couplings And Supports

ActiveUS20070205004A1Improve impact resistanceImproving flow enhancerPipe supportsPipeline expansion-compensationFire sprinklerCoupling

Fire sprinkler system comprising a network of CPVC pipe lengths in which at least some of the pipe lengths are interconnected with mechanical devices having resilient sealing members that are chemically compatible with the CPVC composition. Repairs and system modifications can be made without the use of solvent cement. In-line joints are formed with a coupling device including a pair of arcuate coupling segments having a first end, a second end, and an interior concave surface extending between the first end and the second end. A longitudinal channel extends along the concave surface. At least one mechanical fastener is operative to detachably connect the pair of coupling segments. A resilient annular seal is located within the longitudinal channel of each segment. A branching device connects a branch pipe to a main pipe through an orifice in the main pipe utilizing a saddle-like sealing member. The pipe assemblies are able to pass UL testing protocols for wet fire sprinkler systems.

Owner:LUBRIZOL ADVANCED MATERIALS INC

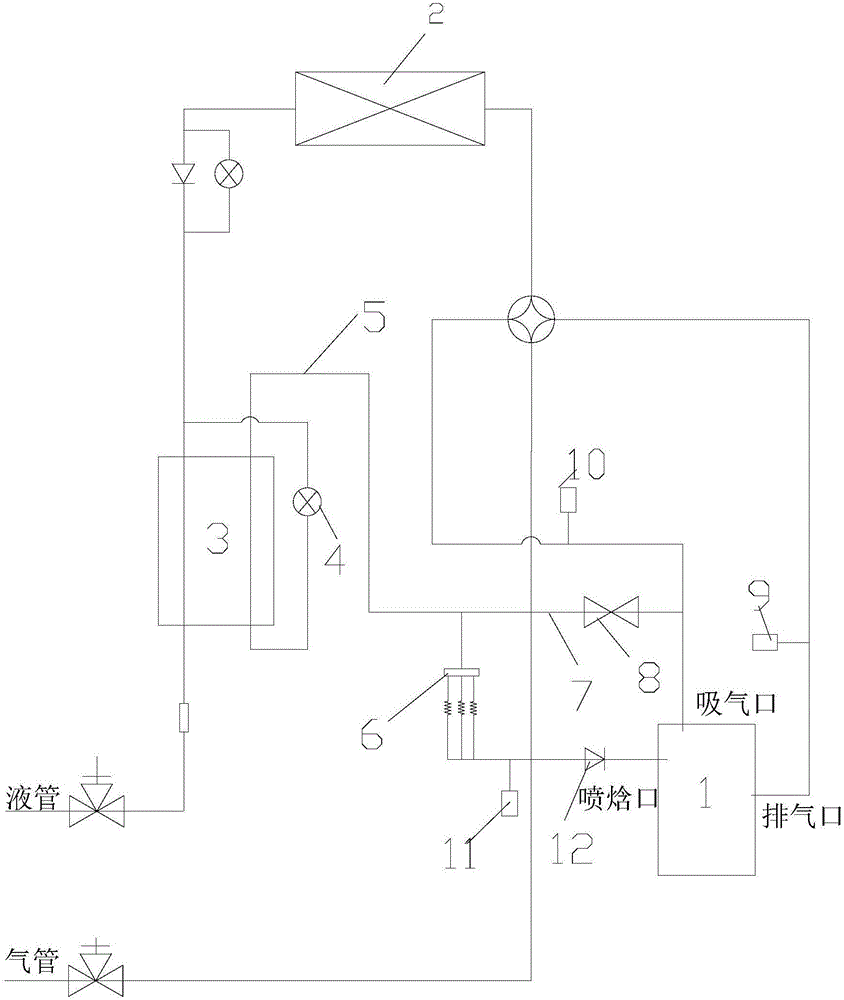

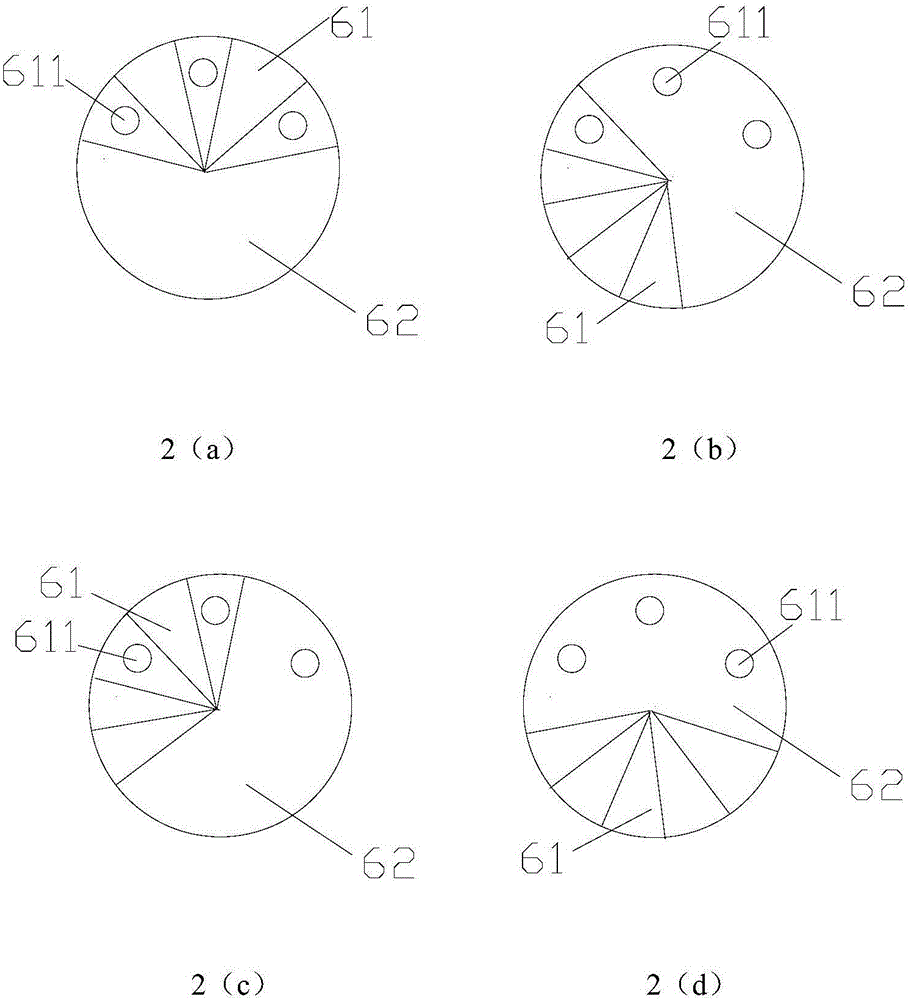

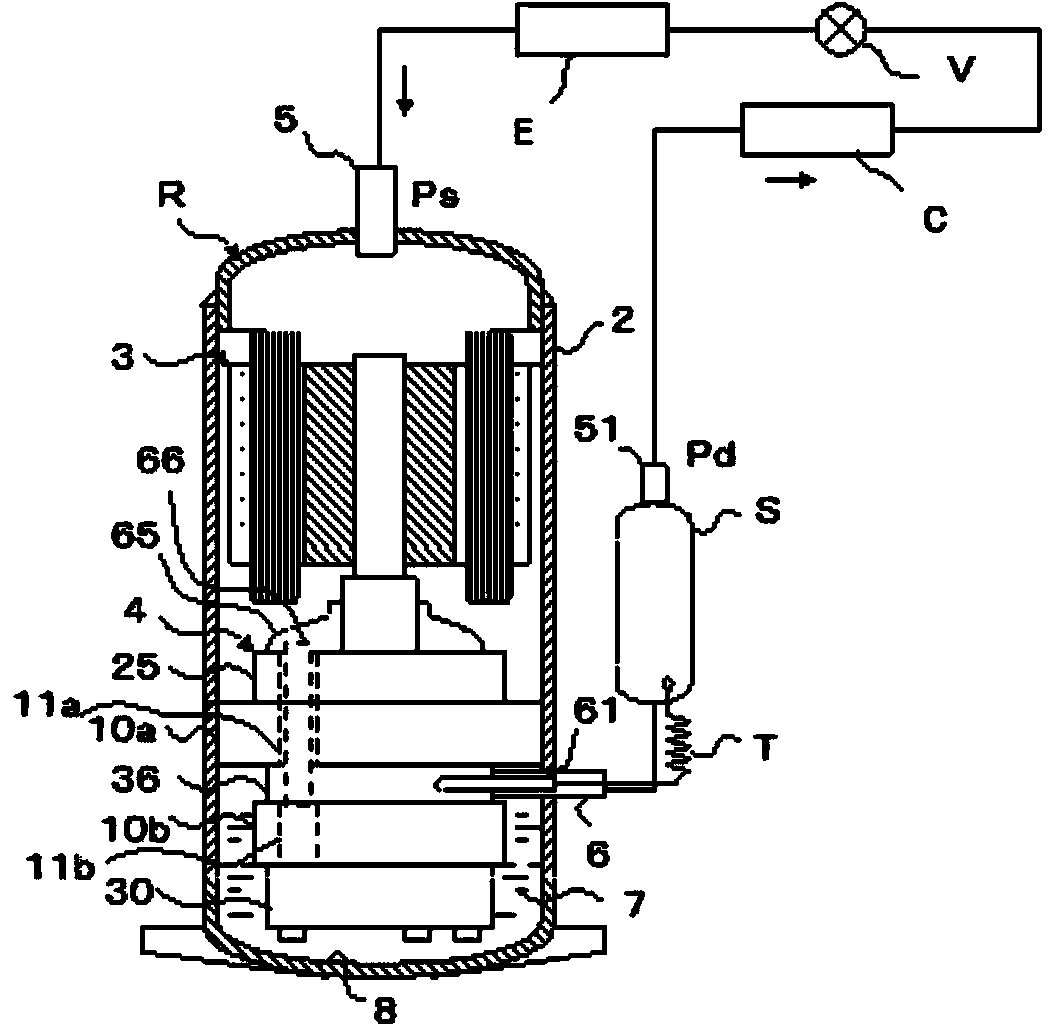

Enthalpy-spraying compressor air conditioner system and control method thereof

ActiveCN106196721AImprove heating effectImprove energy efficiencyMechanical apparatusSubcoolersEngineeringControl valves

The invention provides an enthalpy-spraying compressor air conditioner system and a control method thereof. The enthalpy-spraying compressor air conditioner system comprises a compressor (1), an outdoor heat exchanger (2), an indoor heat exchanger and an enthalpy increasing device arranged between the outdoor heat exchanger (2) and the indoor heat exchanger. The enthalpy increasing device comprises a supercooling device (3) and a first control valve (4), and further comprises an enthalpy-spraying pipeline (5) with one end connected to the compressor (1) and the other end connected to the gas outlet end of the enthalpy increasing device. A second control valve (6) is arranged on the enthalpy-spraying pipeline (5). By adoption of the enthalpy-spraying compressor air conditioner system and the control method thereof, control over pressure of the two-stage enthalpy-spraying pipeline can be achieved, the enthalpy-spraying pressure of the enthalpy-spraying compressor air conditioner system can be effectively and accurately controlled, the gas supplementing pressure is controlled to be close to an optimal gas supplementing pressure point as much as possible, it is guaranteed that the compressor is in the full compression state as much as possible, the situation that over compression or insufficient compression of the compressor is caused when the gas supplementing pressure is too high or too low is avoided, and therefore the heating capacity and energy efficiency of the enthalpy-spraying compressor air conditioner system are improved.

Owner:GREE ELECTRIC APPLIANCES INC

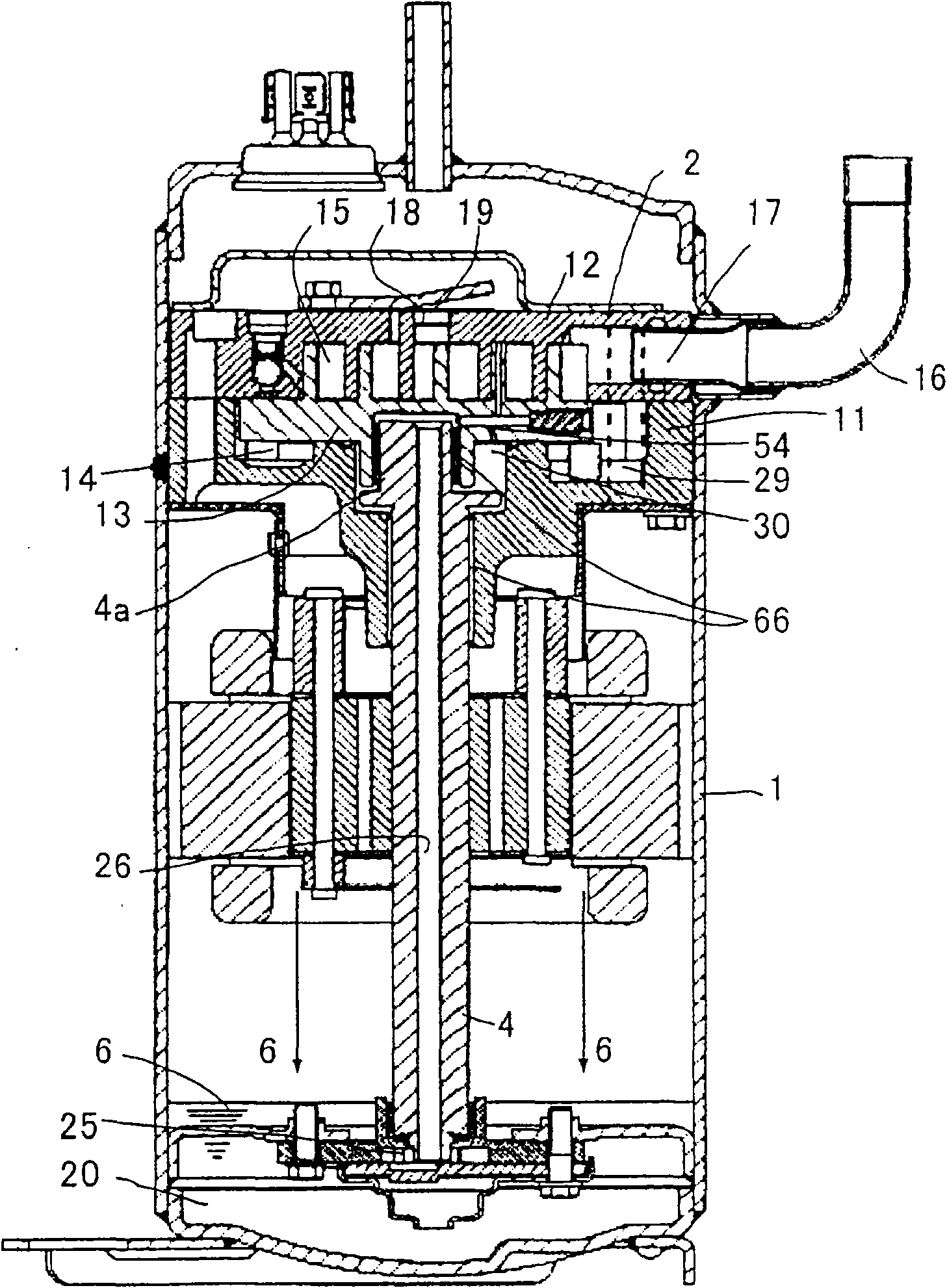

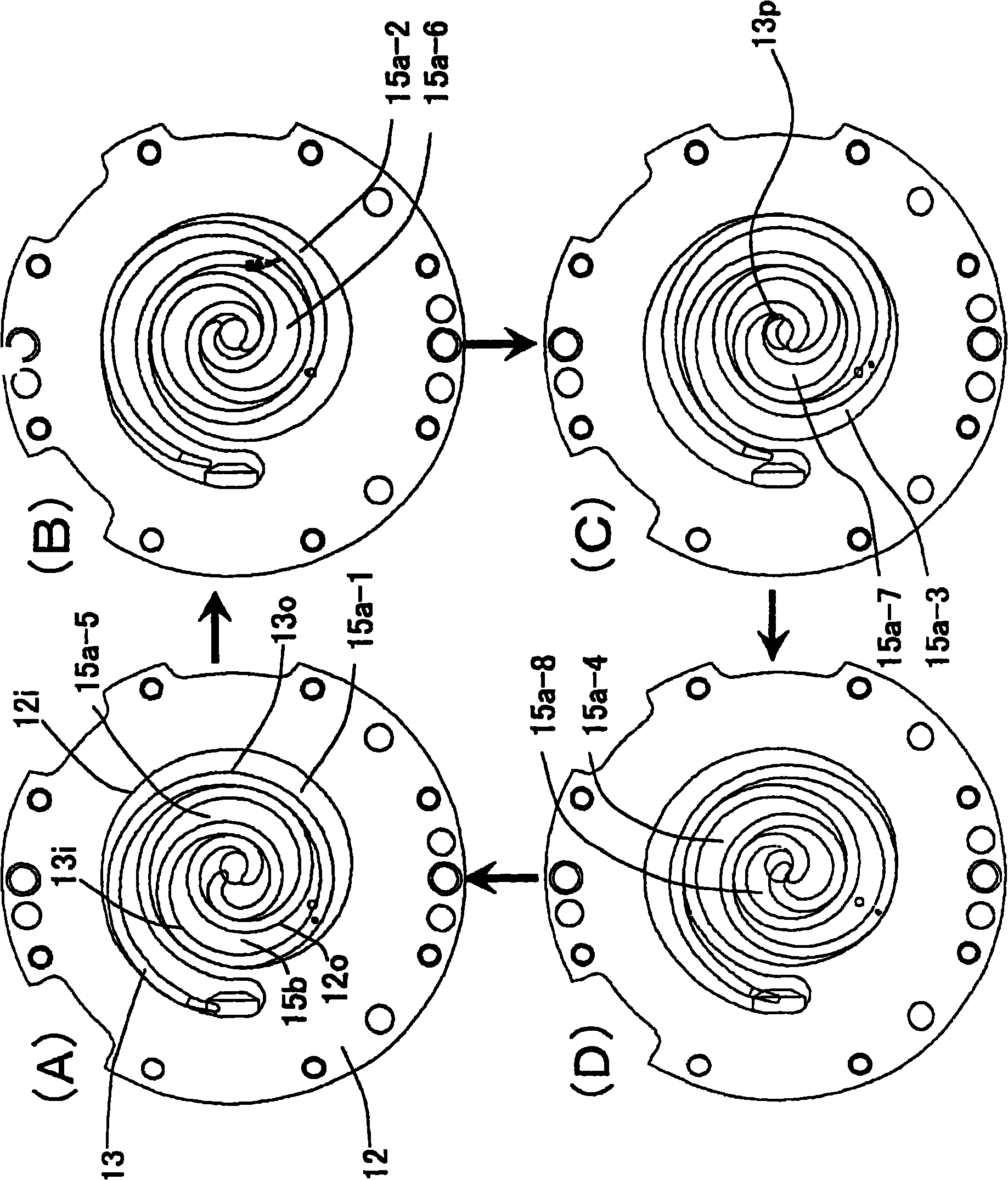

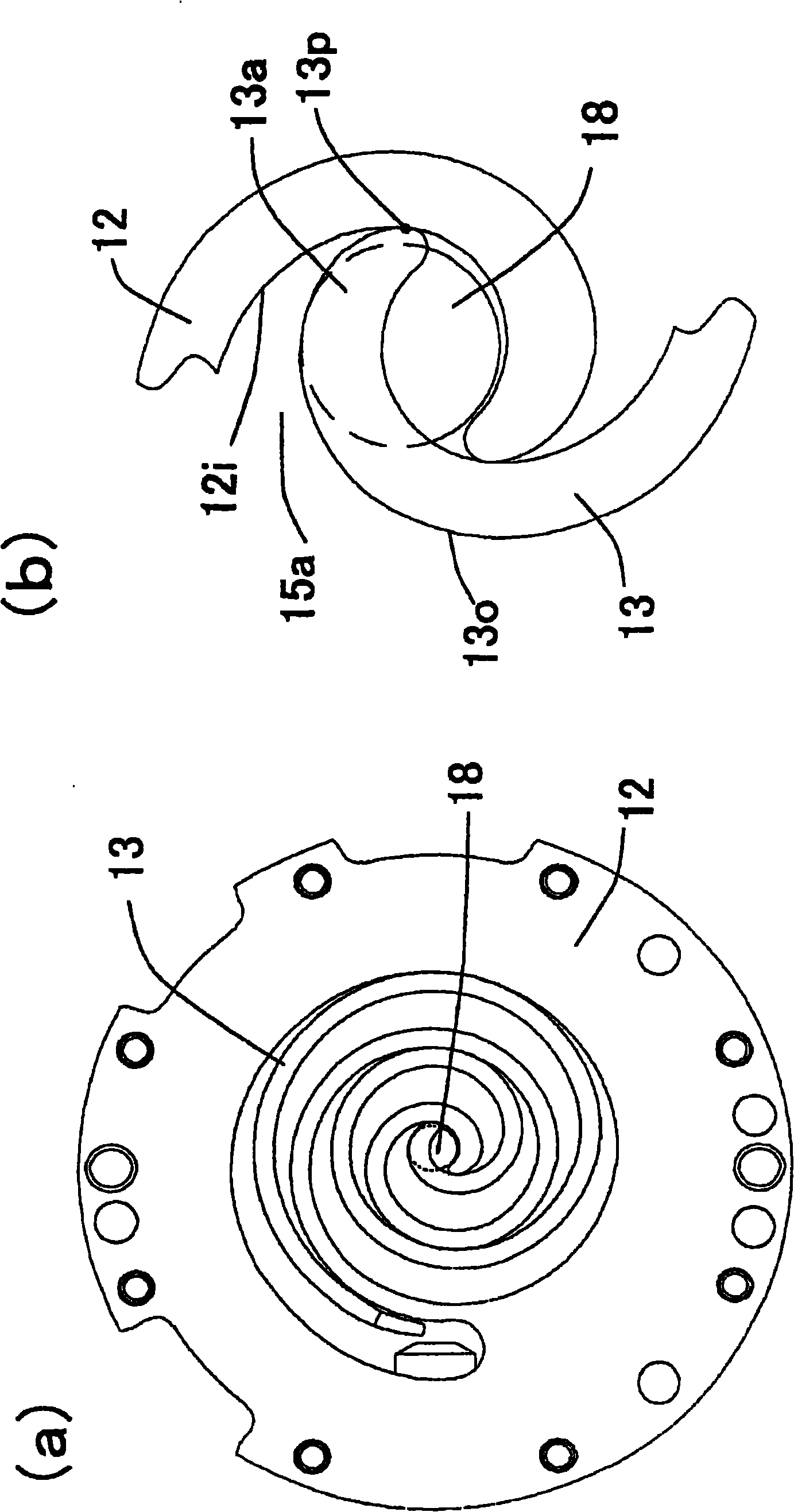

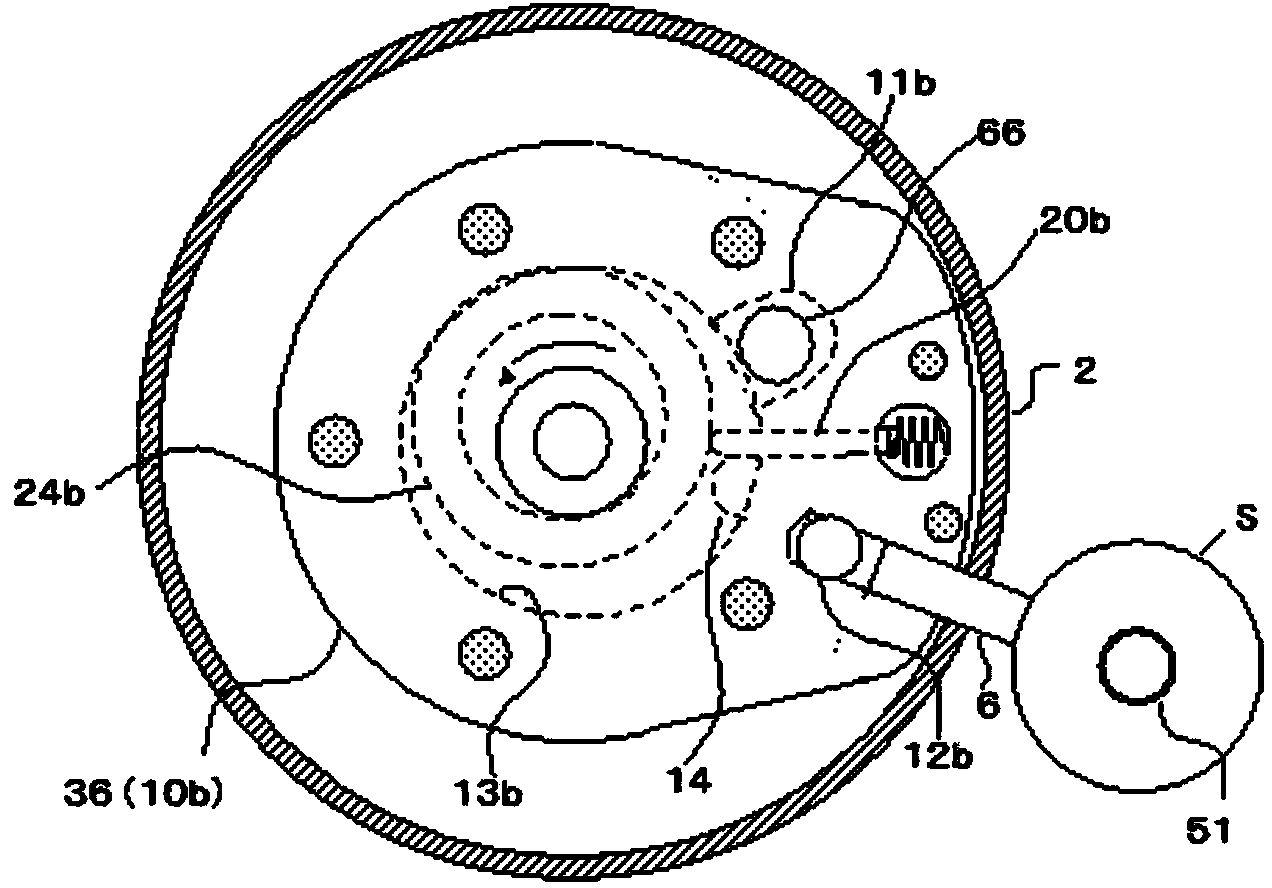

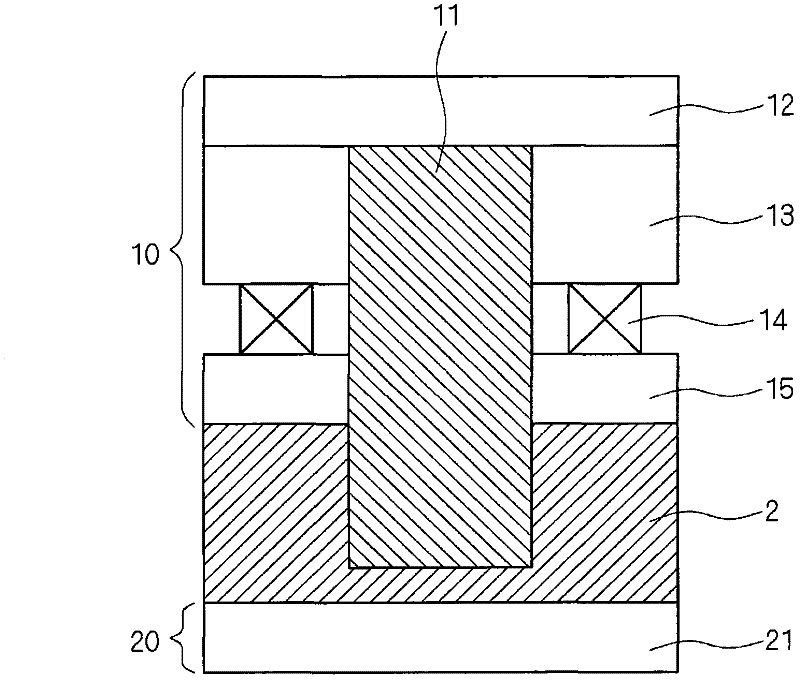

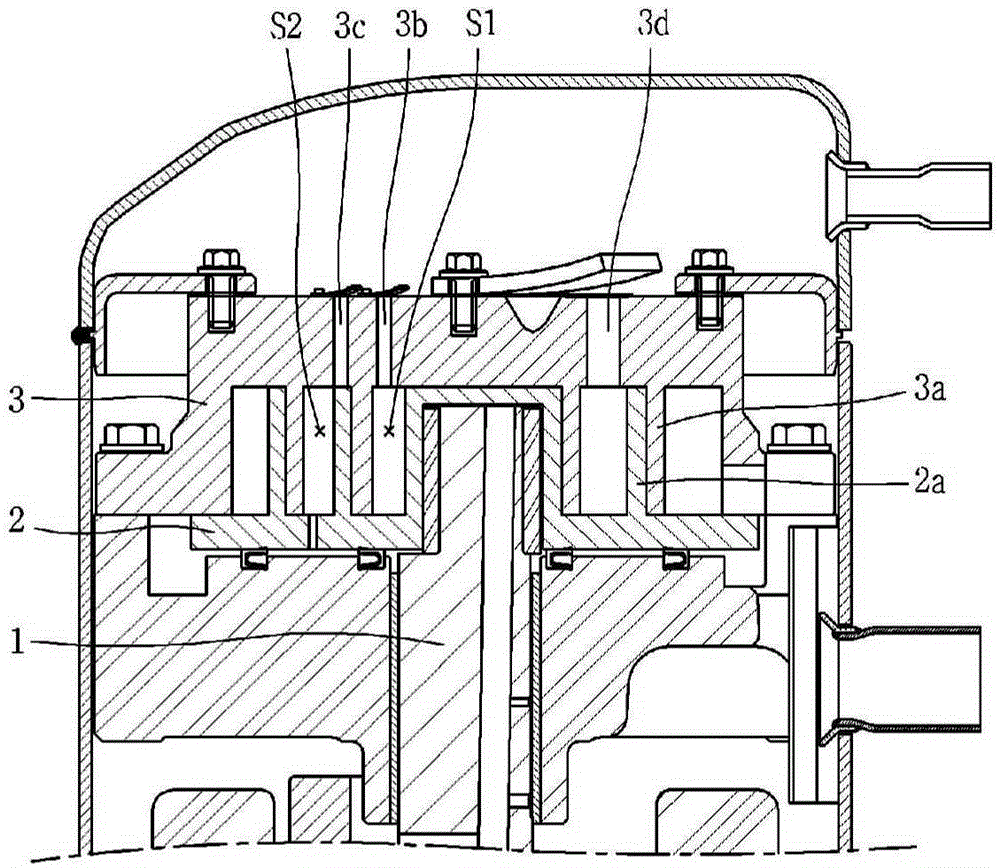

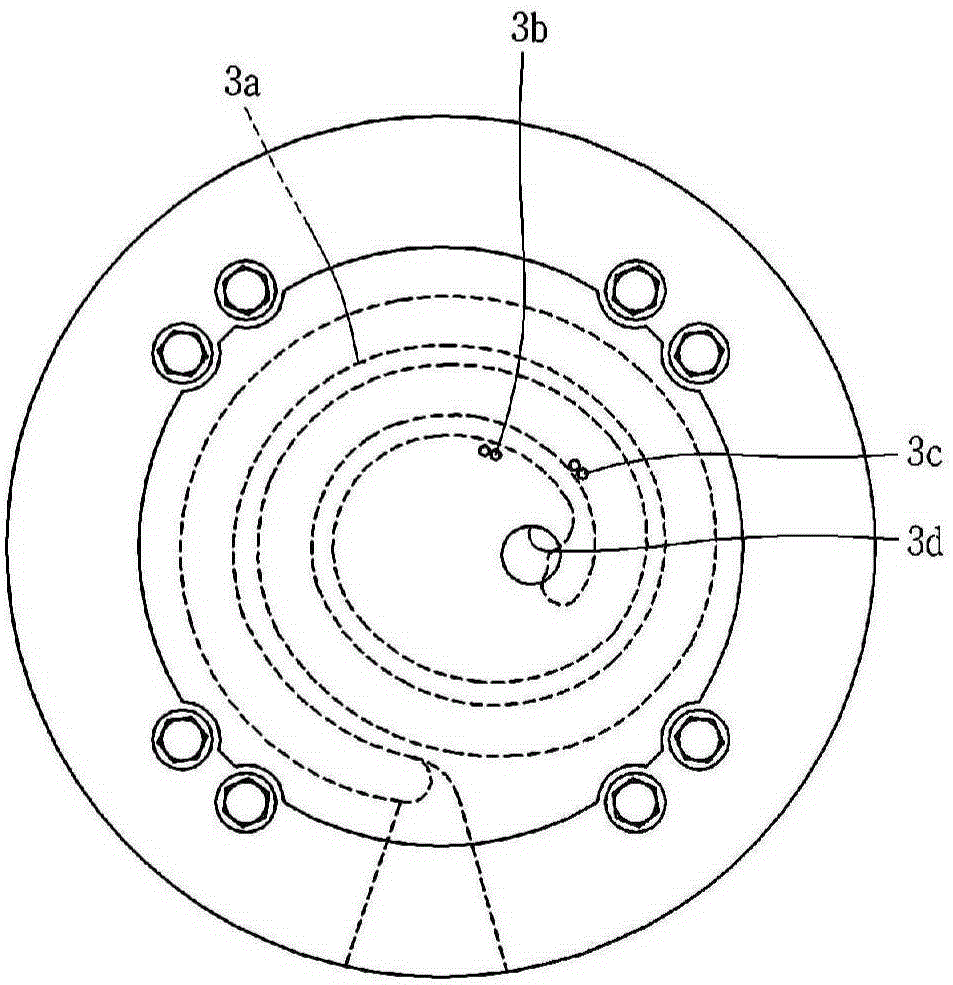

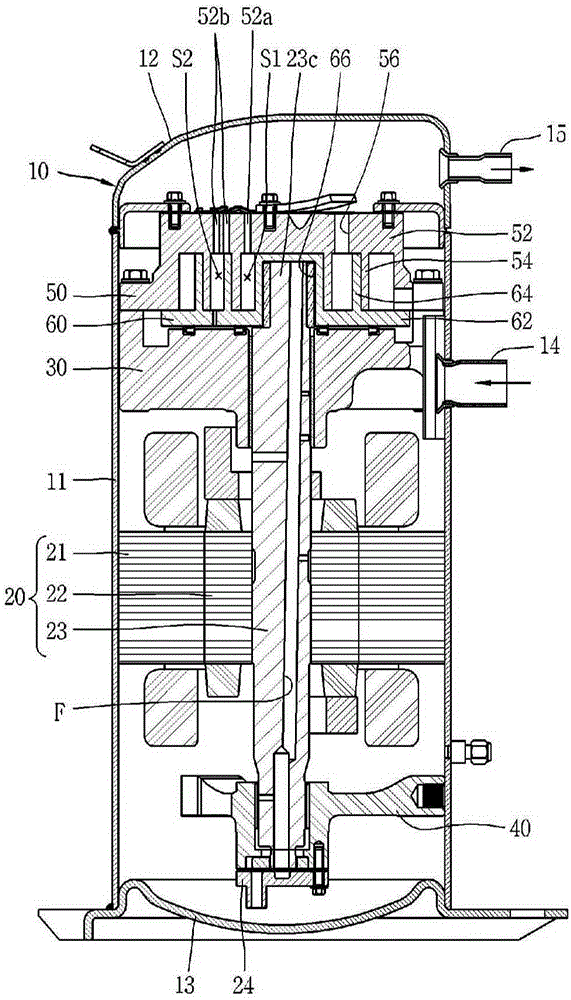

Scroll compressor

ActiveCN101886628APrevent overcompressionReduce overcompression lossRotary piston pumpsRotary piston liquid enginesCoolantScroll compressor

The present invention provides a scroll compressor, to solve the performance deteriorating problem generated by over pressure loss as the communicating path connected to the discharge outlet is narrower regardless whether or not the coolant gas in the compressing chamber achieves the prescribed pressure. Nearly simultaneously before or after the invention is separated by a first compression chamber (15a), the discharge outlet (18) passes across the vortex disc teeth (13a) of rotary scroll discs (13) to lead to the structure of the first compression chamber, as the discharge outlet (18) forms an opening directly in the first compression chamber (15a), and the communicating path can be thoroughly ensured added with the gap between the vortex disc teeth of the two rotary scroll discs, therefore the over-compression loss can be reduced.

Owner:PANASONIC CORP

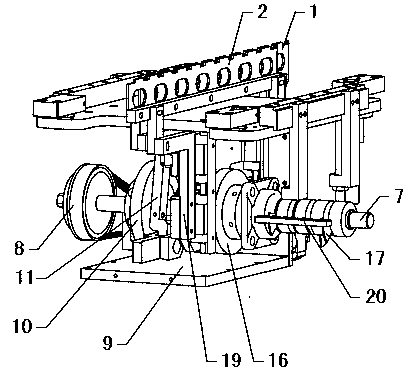

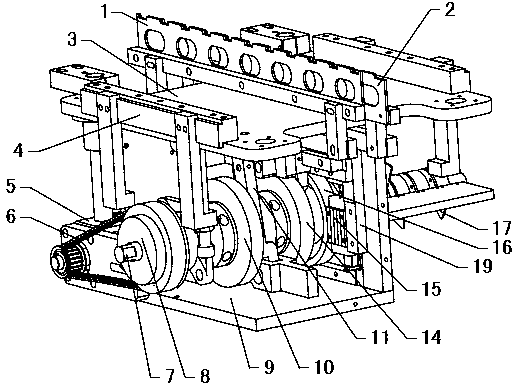

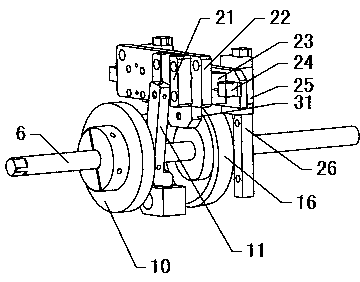

Intermittent linear conveying device

ActiveCN103871941AChange swingEasy to installSemiconductor/solid-state device manufacturingConveyor partsSlide plateEngineering

The invention discloses an intermittent linear conveying device, and belongs to the field of conveying equipment for intermittently and linearly conveying objects. A material moving cam (10) is connected with a material moving connecting rod (11), the material moving connecting rod (11) is connected to a vertical guide mechanism in a sliding mode, and a material moving shifting pawl (1) is fixedly connected with the vertical guide mechanism. The vertical guide mechanism is horizontally arranged on a vertical sliding plate (31) in a sliding mode, the vertical sliding plate (31) is vertically arranged in a sliding mode and is connected with a material moving lifting cam (16), the material moving cam (10) drives the material moving shifting pawl (1) to advance or retreat in place through the material moving connecting rod (11), and the material moving lifting cam (16) drives the material moving shifting pawl (1) to ascend and descend through the vertical sliding plate (31). A locating cam (14) is connected with a locating connecting rod (35) which is vertically arranged in a sliding mode, a locating shifting pawl (2) is fixedly connected with the locating connecting rod (35), and the locating cam (14) drives the locating shifting pawl (2) to ascend and descend. The intermittent linear conveying device has the advantages of being accurate in conveying position and reliable in motion, improving work efficiency and the like.

Owner:SHANDONG CAIJU ELECTRONICS TECH CO LTD

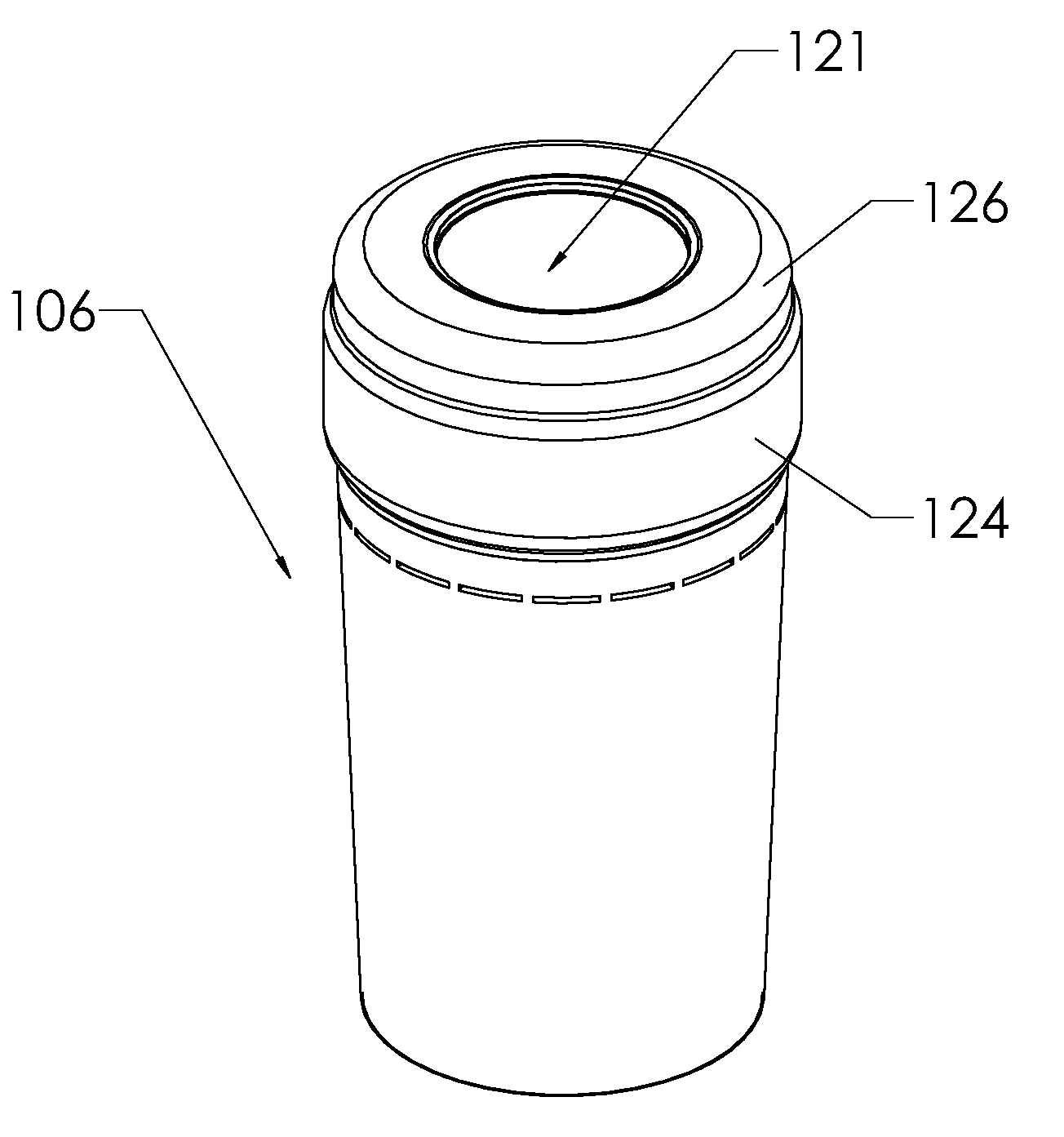

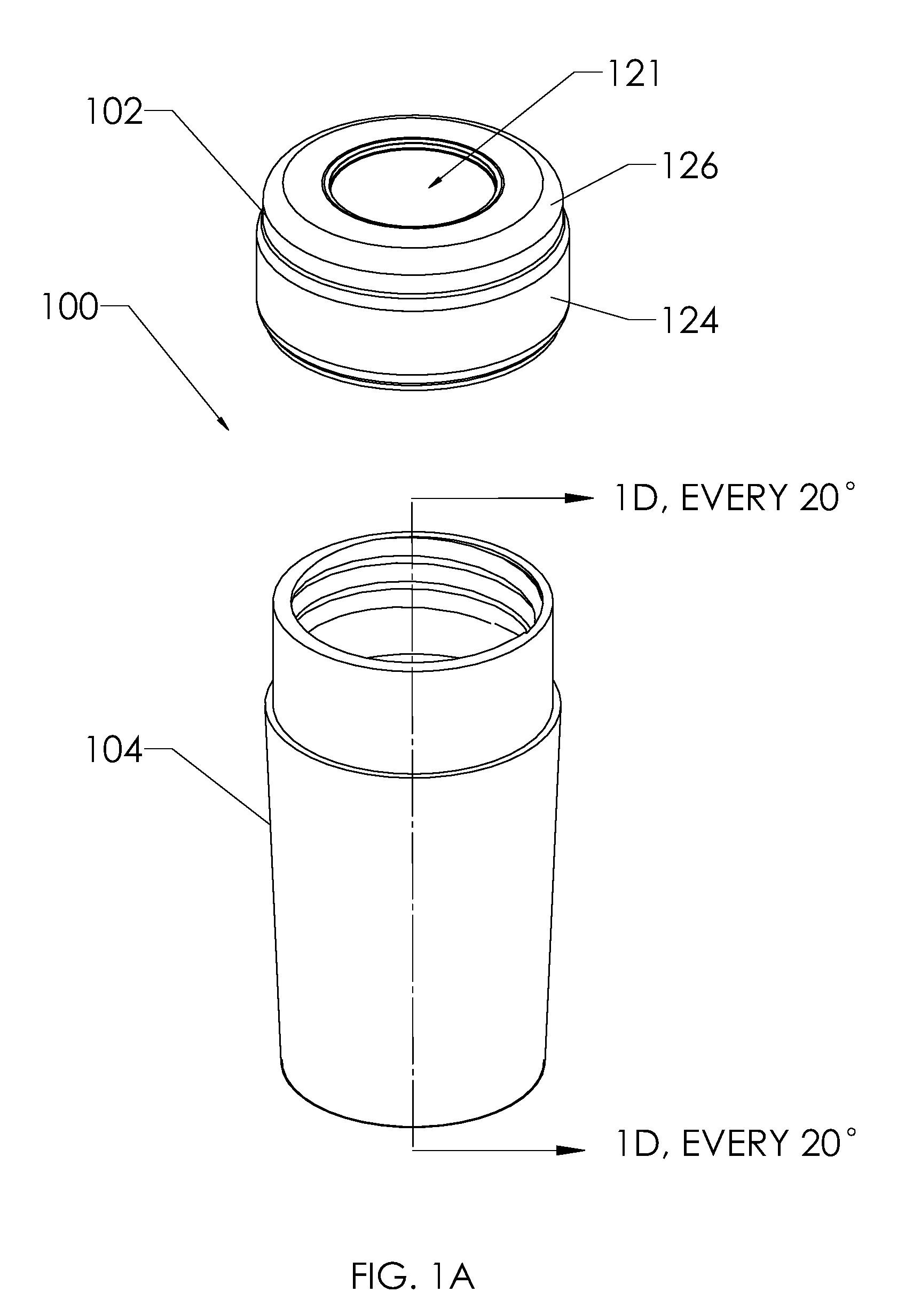

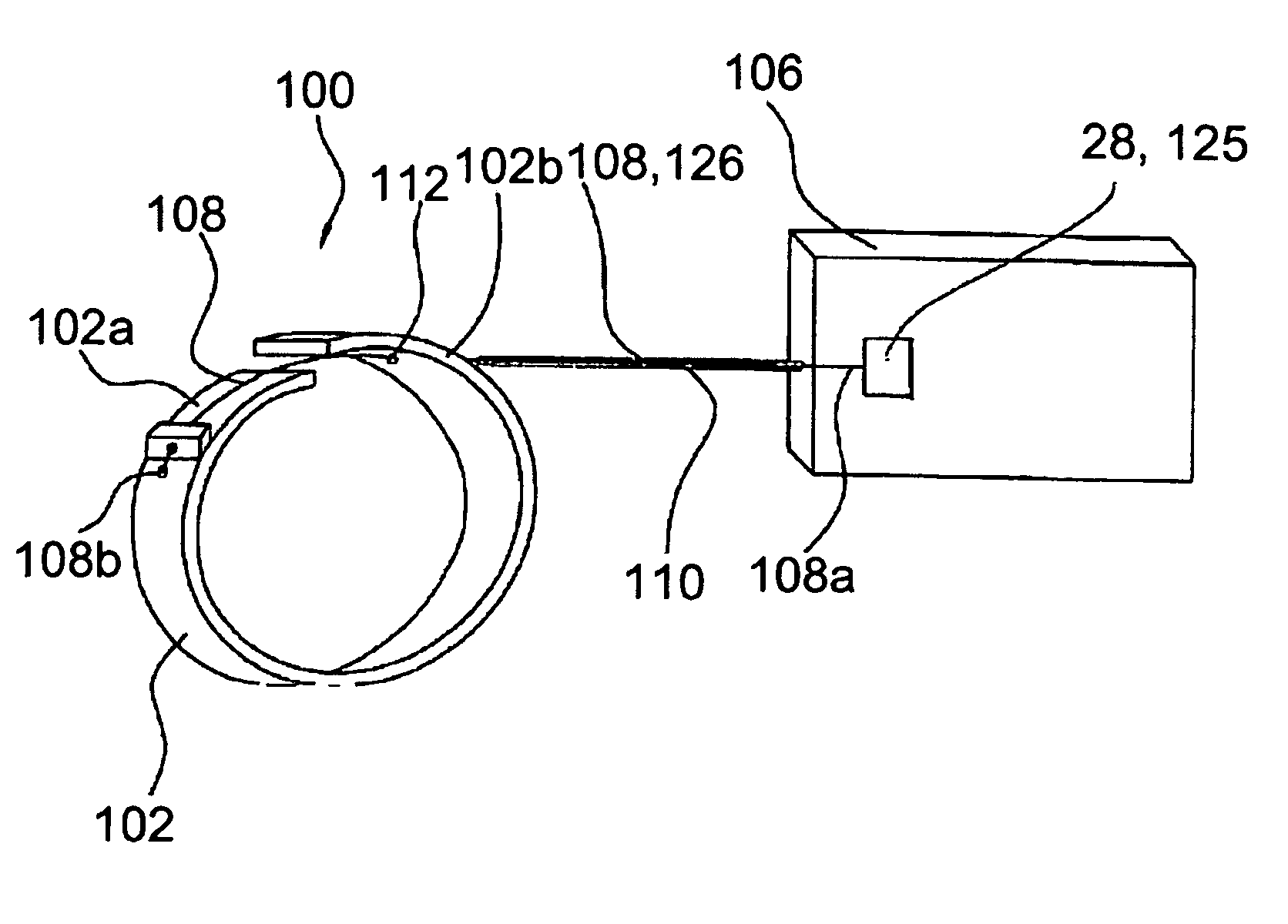

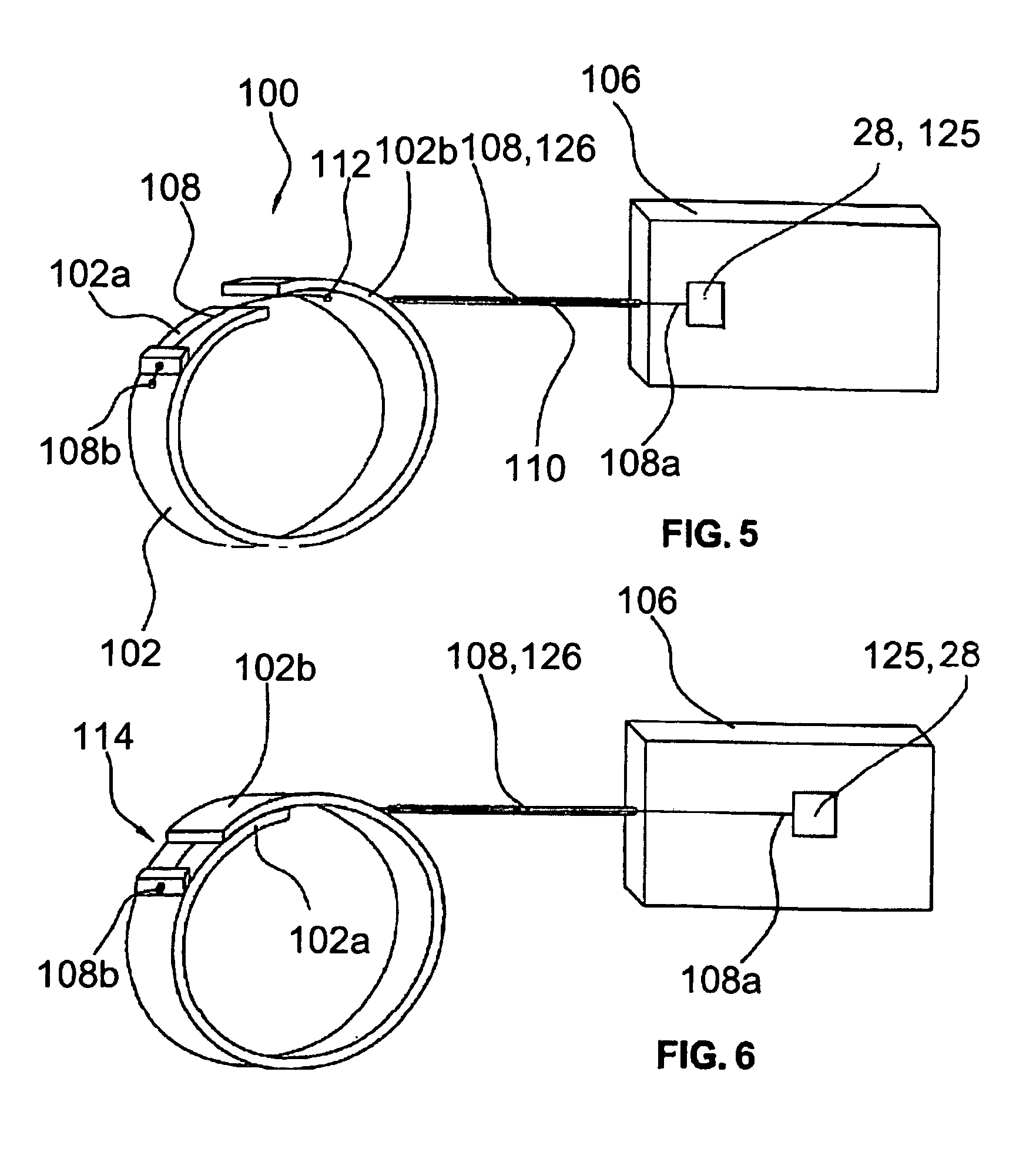

Medical device comprising an artificial contractile structure

ActiveUS20130096586A1Improving sphincter muscle functionImprove the quality of lifeAnti-incontinence devicesControl devicesRest positionActuator

A medical device including artificial contractile structures generally devised to be used in the medical field. Such structures may be advantageously used to assist the functioning of an organ. The medical device includes an artificial contractile structure having at least two contractile elements (100) adapted to contract an organ, in such way that each of the contractile elements (100) can be in a resting or in an activated position, independently of the position of each other, the activated position being defined with the contractile element (100) constricting the organ and the resting position being defined with the contractile element (100) not constricting the organ, and at least one actuator designed to activate the contractile structure. Each contractile element (100) is connected to an adjacent contractile element (100), while remaining flexible one with respect to the other.

Owner:MYOPOWERS MEDICAL TECH FRANCE SAS

Tie

InactiveUS6935001B2Prevent overcompressionSufficiently and stable mannerPipe supportsBagsEngineeringMechanical engineering

Owner:LEGRAND SNC

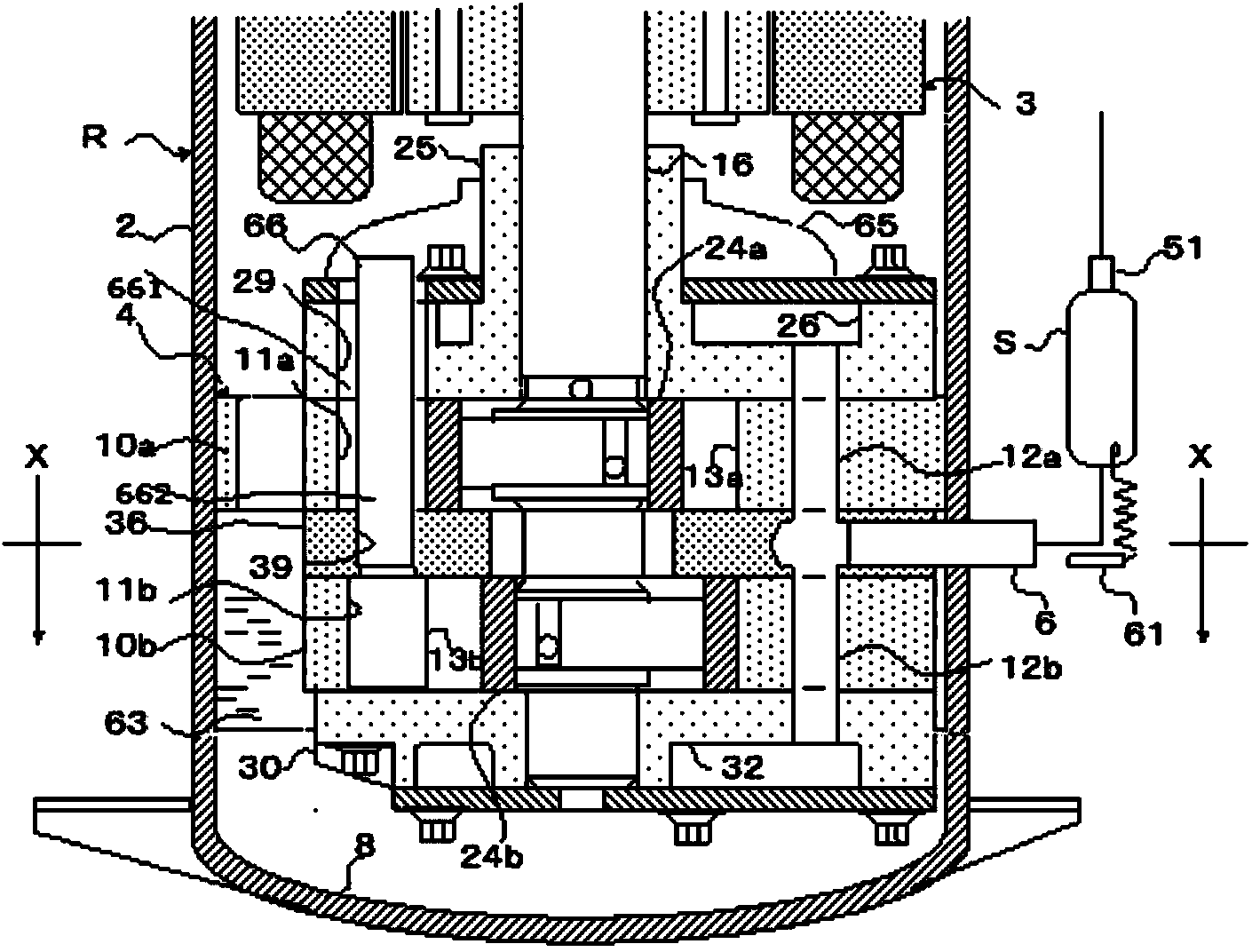

Rotary compressor and refrigerating circulating system with same

ActiveCN103775338AImprove reliabilityPrevents loss of compression efficiencyCompression machines with non-reversible cycleRotary piston pumpsCompression deviceEngineering

The invention discloses a rotary compressor and a refrigerating circulating system with the same. The rotary compressor comprises a shell, a compression device and a motor, wherein the compression device comprises a first cylinder and a second cylinder which are provided with a first compression cavity and a second compression cavity respectively, a middle partition plate, a first piston, a second piston, a first slip sheet, a second slip sheet, a crankshaft for driving the first piston and the second piston to rotate, a main bearing, an auxiliary bearing, a first exhaust silencer arranged above the main bearing, a second exhaust silencer arranged below the auxiliary bearing, and an exhaust assembly for exhausting high-pressure refrigerants in the first exhaust silencer and the second exhaust silencer. According to the rotary compressor, due to the exhaust assembly, the exhaust efficiency is improved, the volumetric efficiency is improved and overcompression is prevented; in addition, the difference of oil supply amounts of two compression cavities is minimized, the compression efficiency reduction caused by leakage of the refrigerants is prevented and the reliability of sliding parts is improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

Gate valve with integrated support members

ActiveUS8403298B2Stimulate displacementPrevent overcompressionOperating means/releasing devices for valvesSlide valveEngineeringVALVE PORT

A gate valve has support members that are attached to a main body structure of the gate valve adjacent to the valve gate opening. These support members are affixed on both sides of the valve gate opening radially around a gate sleeve.

Owner:EMERSON VULCAN HLDG LLC

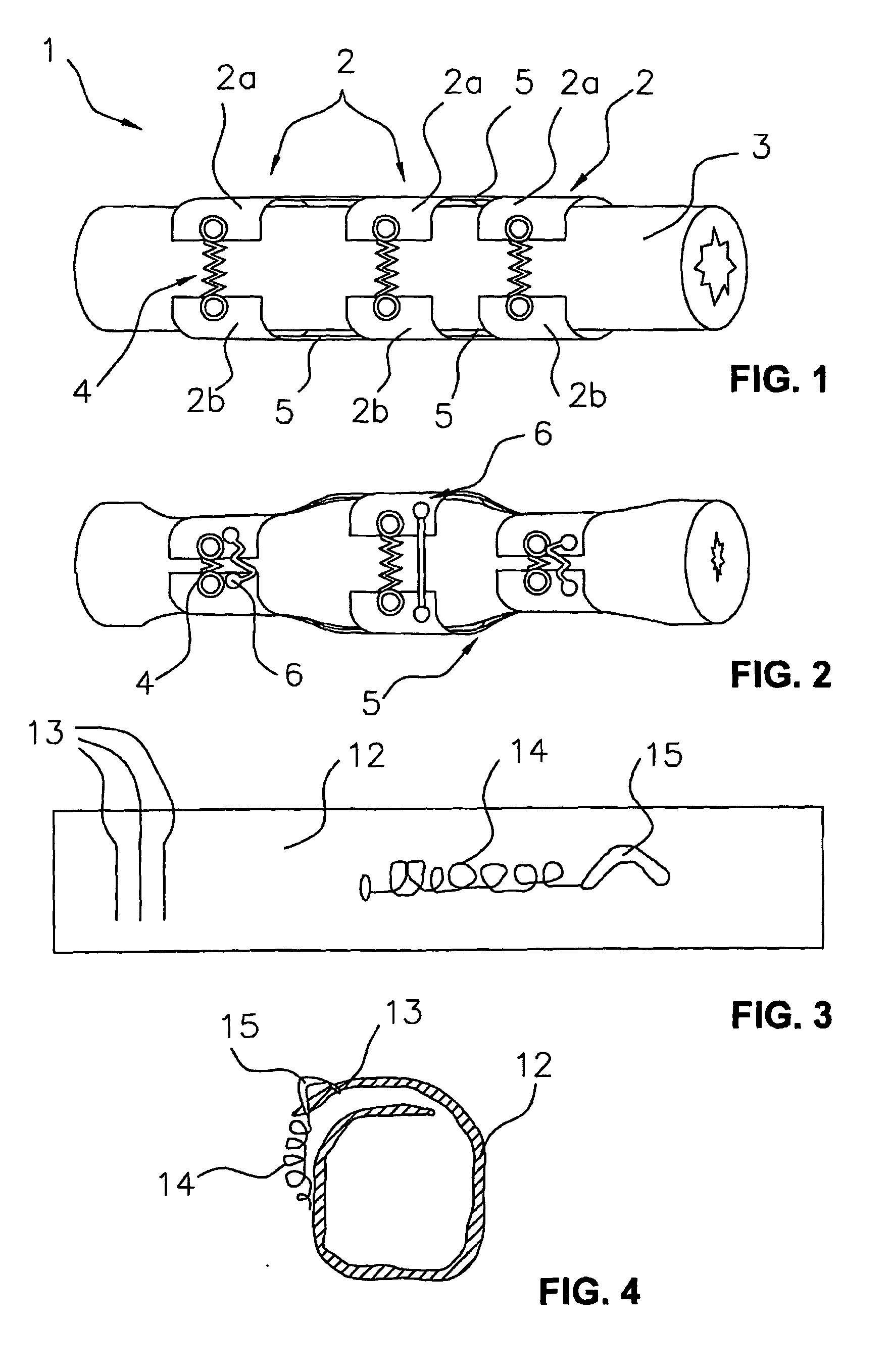

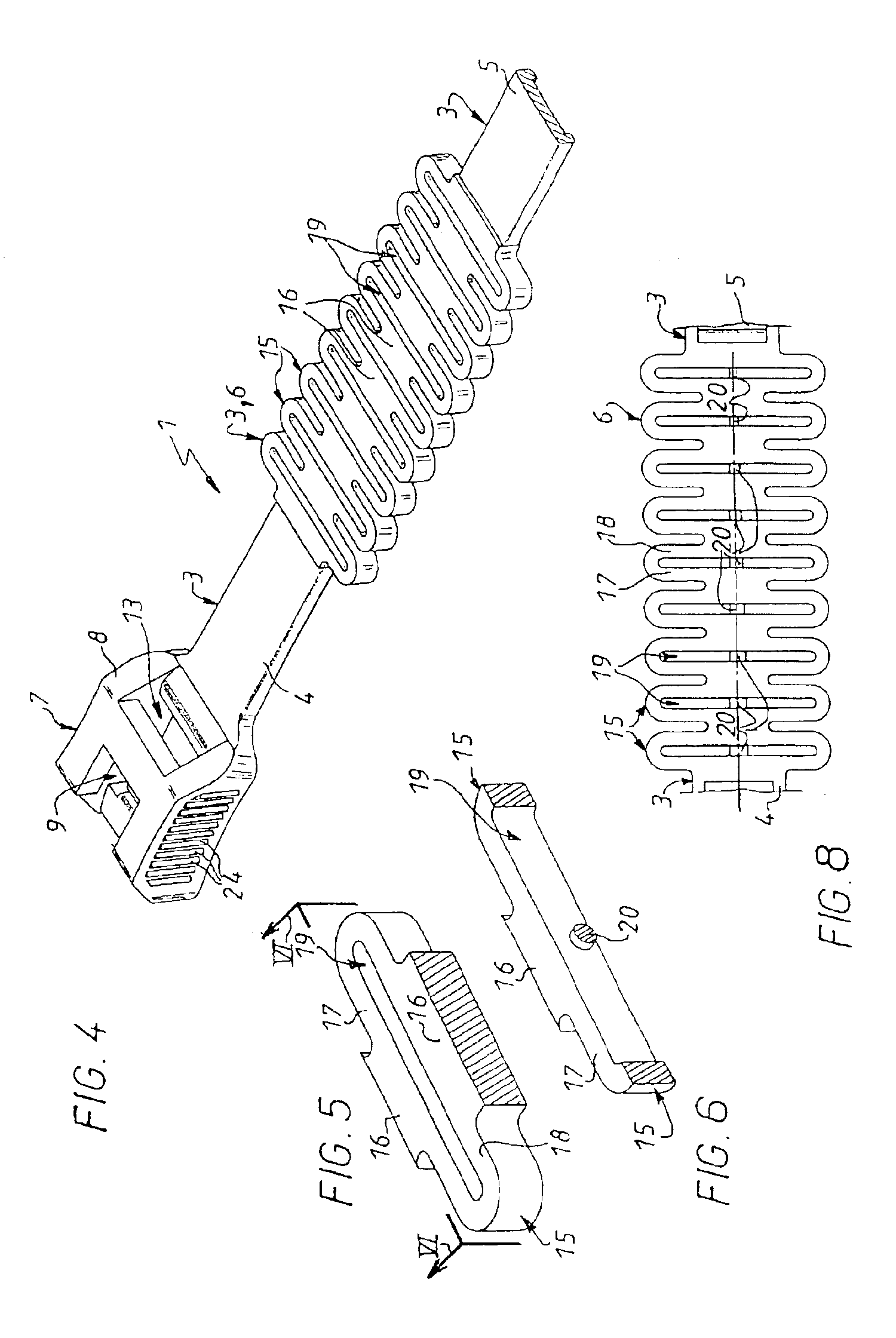

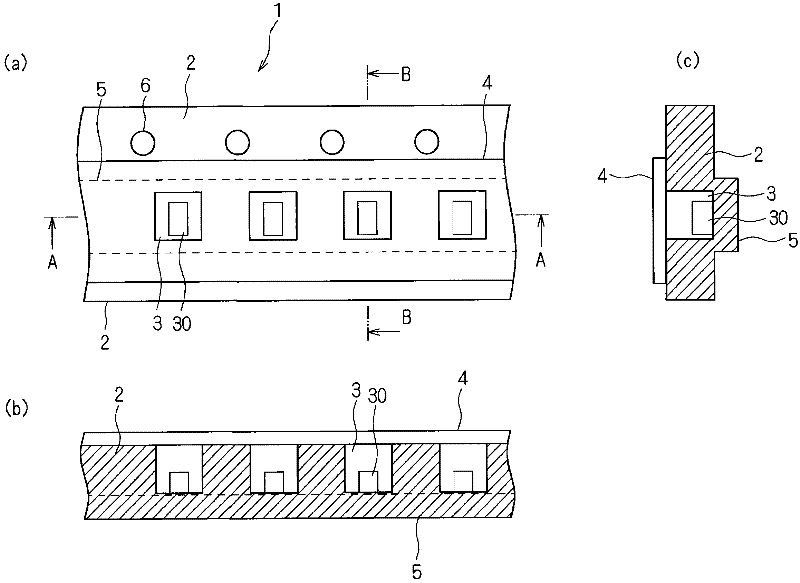

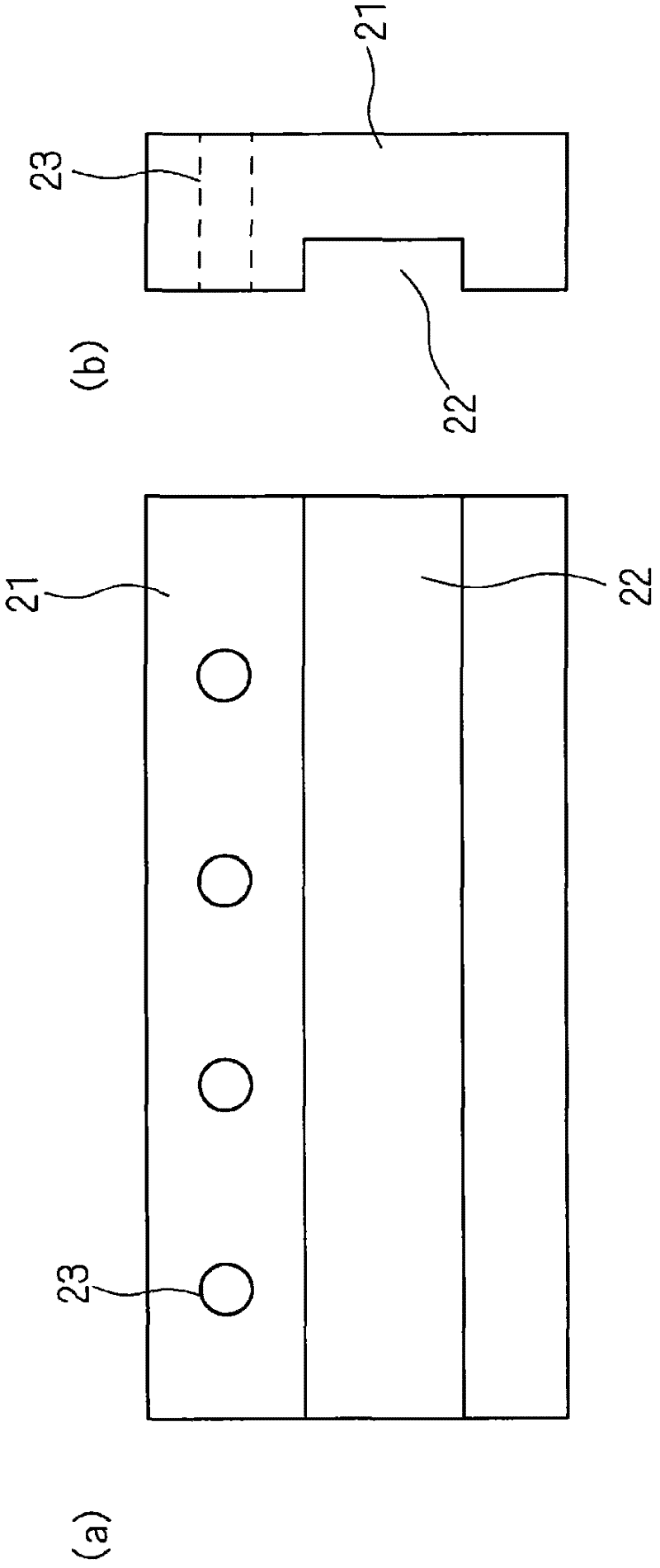

Carrier tape, carrier tape manufacturing apparatus, and method of manufacturing carrier tape

ActiveCN102372122AHigh tensile strengthIncreased bending stiffnessElectrical componentsDamagable goods packagingManufacturing cost reductionEngineering

Provided is acarrier tape with improved tensile strength and flexural rigidity in a longitudinal direction of a base material, including recesses provided at a narrow pitch in one surface of the base material, and manufacturable at reduced cost, as well as to provide an apparatus and a method for manufacturing such a carrier tape. The carrier tape of the present invention is constituted by a strip-shaped base material (2), and includes: a plurality of recesses (3) provided in one surface of the base material (2) and for containing electronic components (30); a covering unit (4) configured to seal openings of the recesses (3); and a projection (5) provided on the other surface of the base material (2) along a longitudinal direction of the base material (2), a length of the projection being such that the projection (5) extends over at least two of the recesses (3).

Owner:MURATA MFG CO LTD

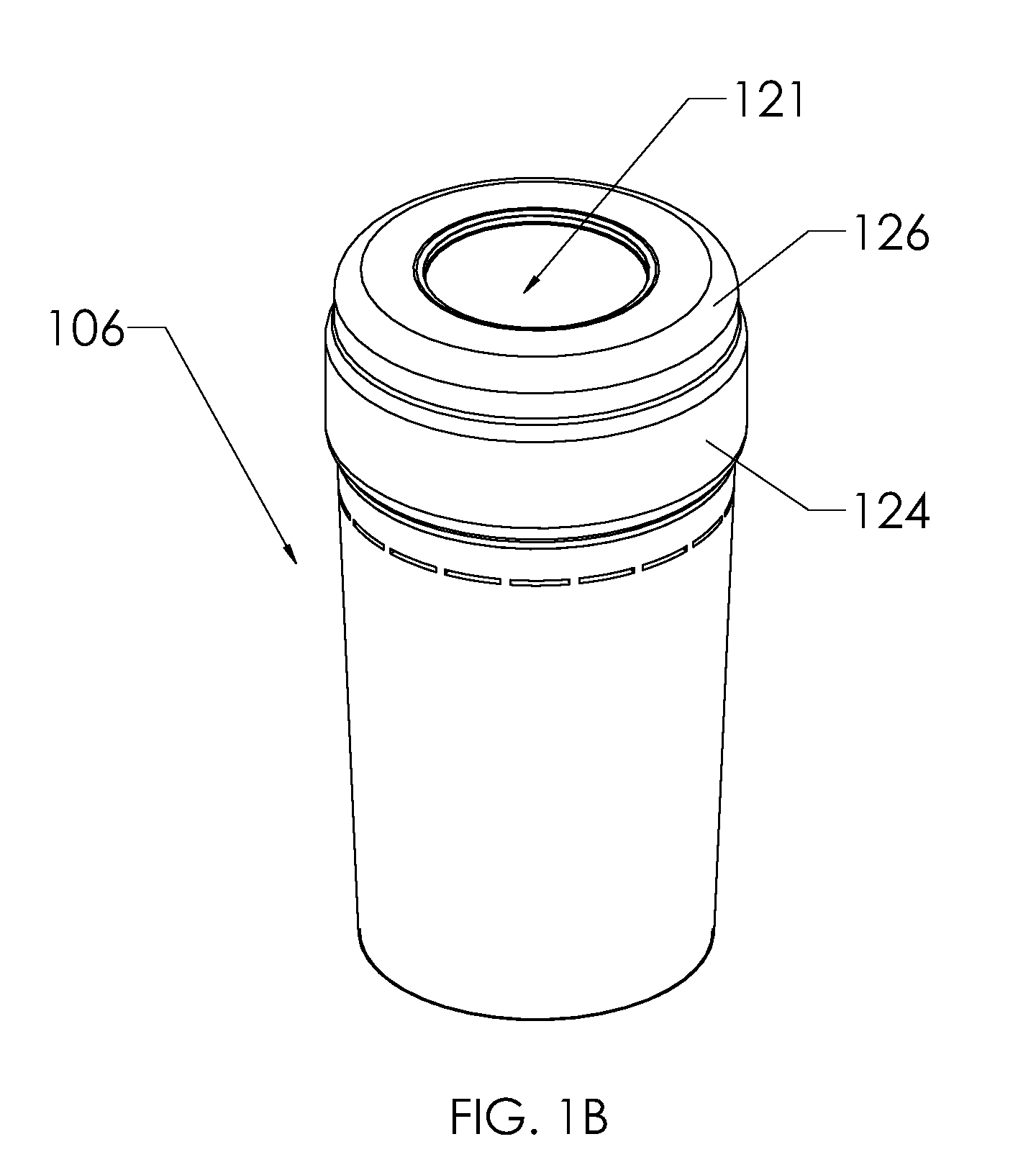

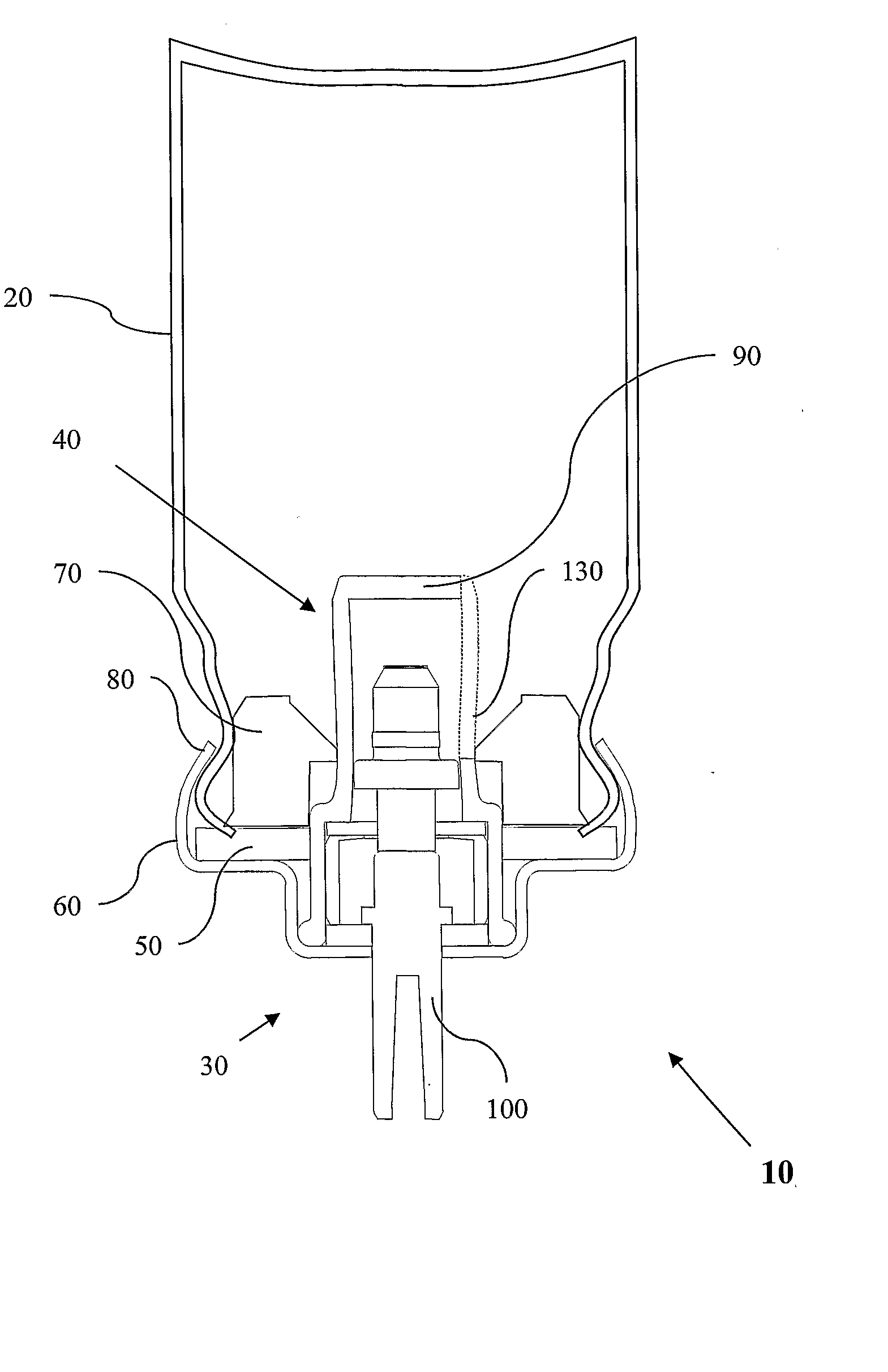

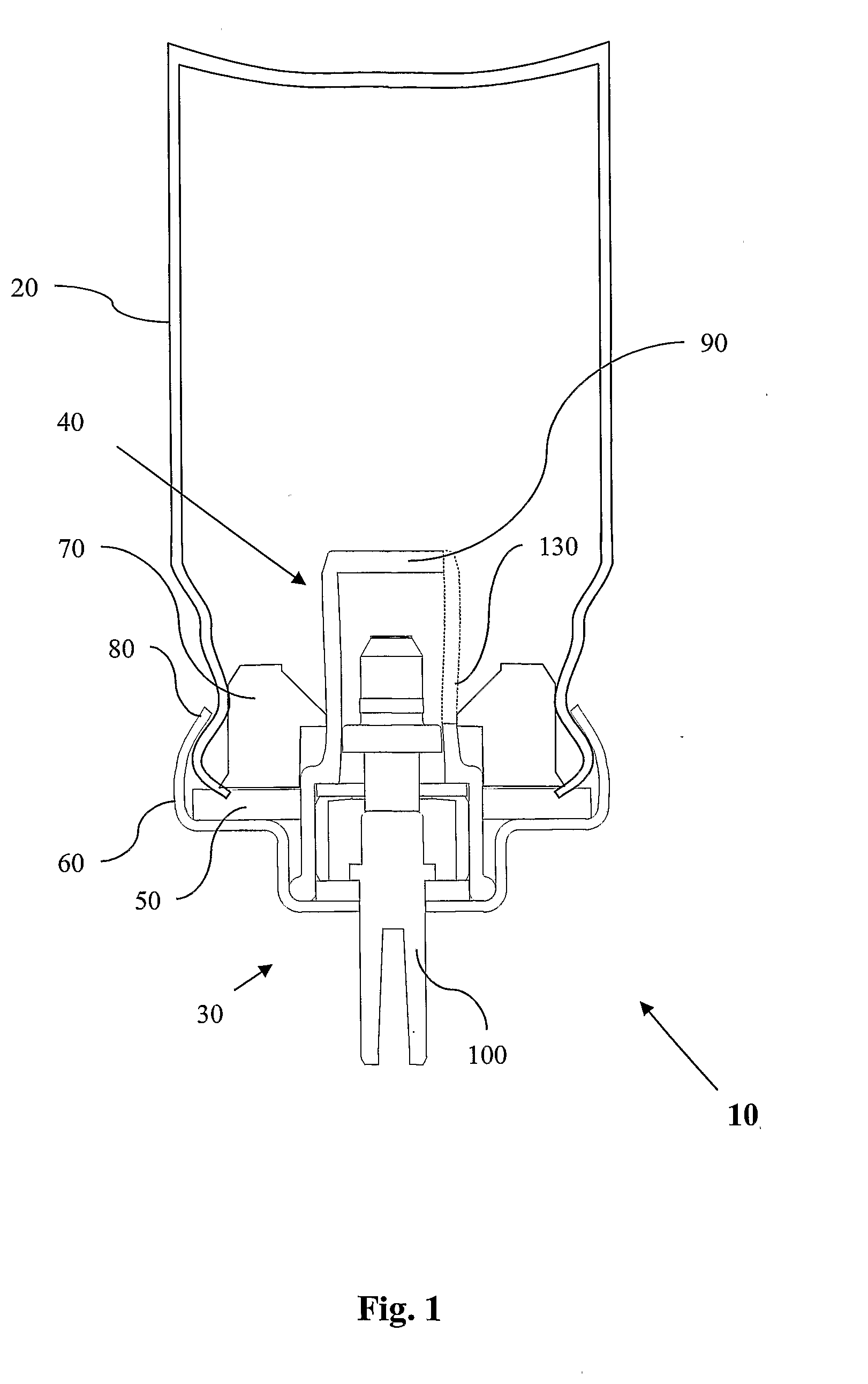

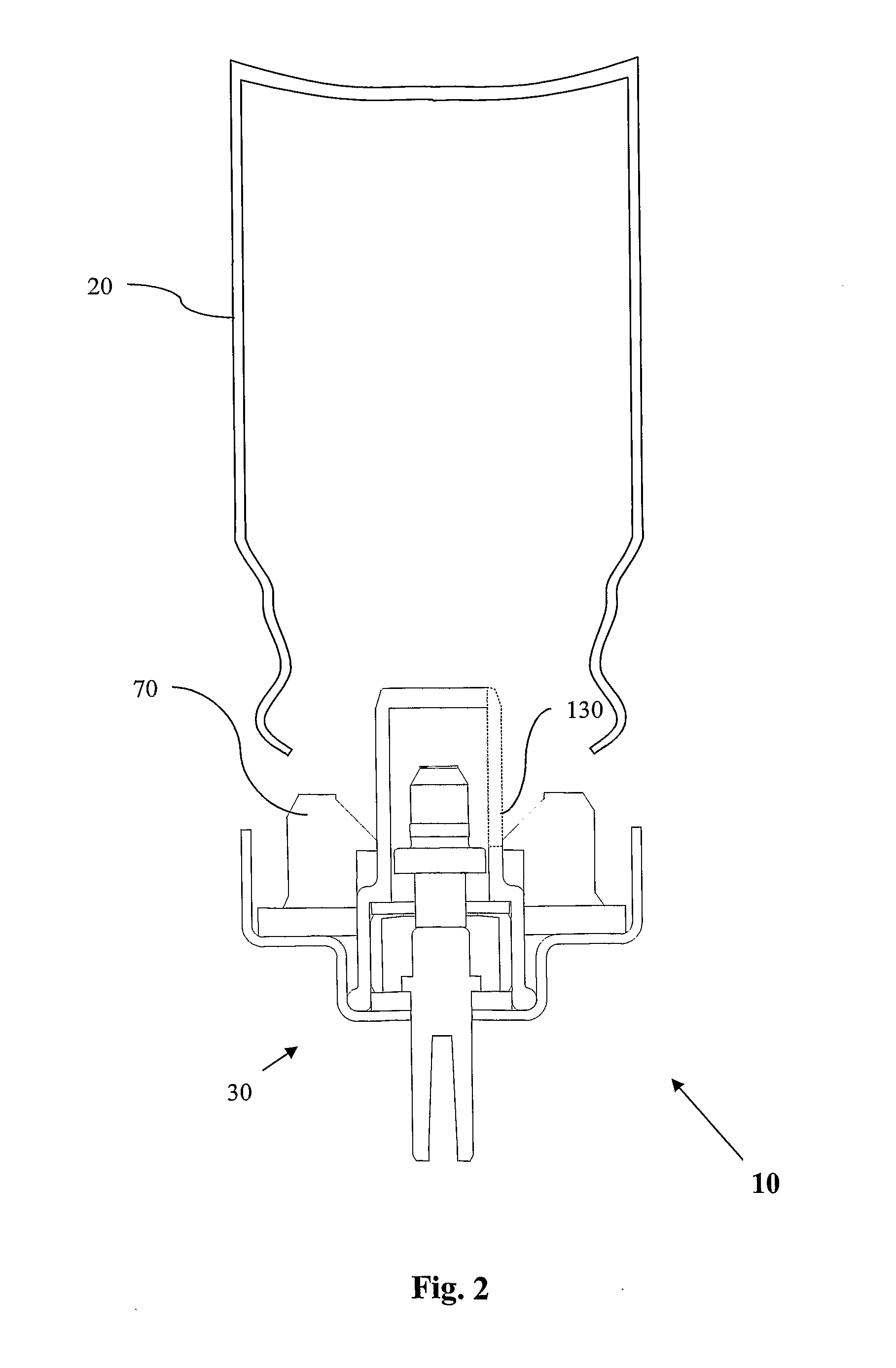

Inhaler Valve

InactiveUS20080011291A1Prevent overcompressionCrimp tightMedical atomisersLiquid dispensingBiomedical engineeringInhaler

Inhaler valve (30) comprising a gathering ring (70) comprised of a non-elastomeric polymer-material, wherein at least one annular section (110, 140, 160, 180) of the gathering ring (70) is formed to be deformable in the radial direction in order to absorb over compression of the ring outer periphery when crimping the valve (30) onto a container (20). There is also provided an inhaler container (10) with such an inhaler valve.

Owner:FLETCHER IAN +2

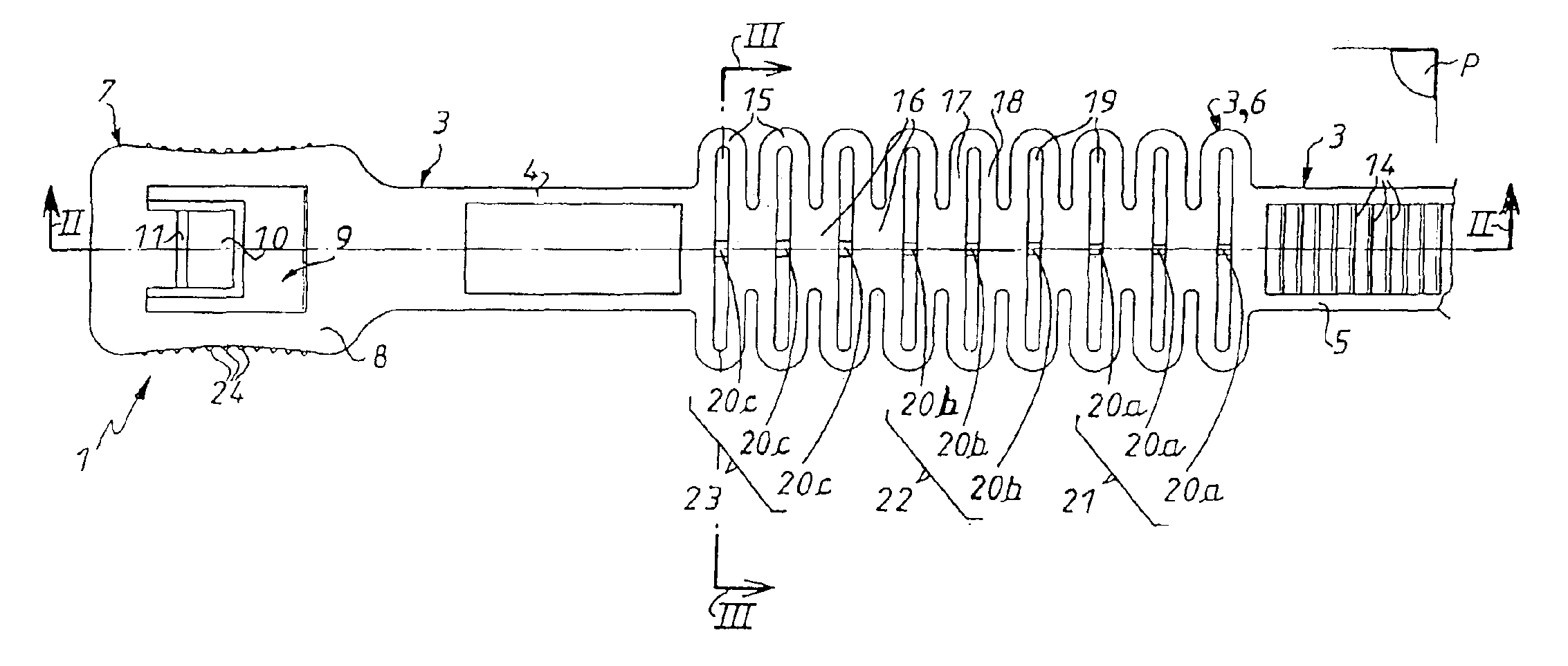

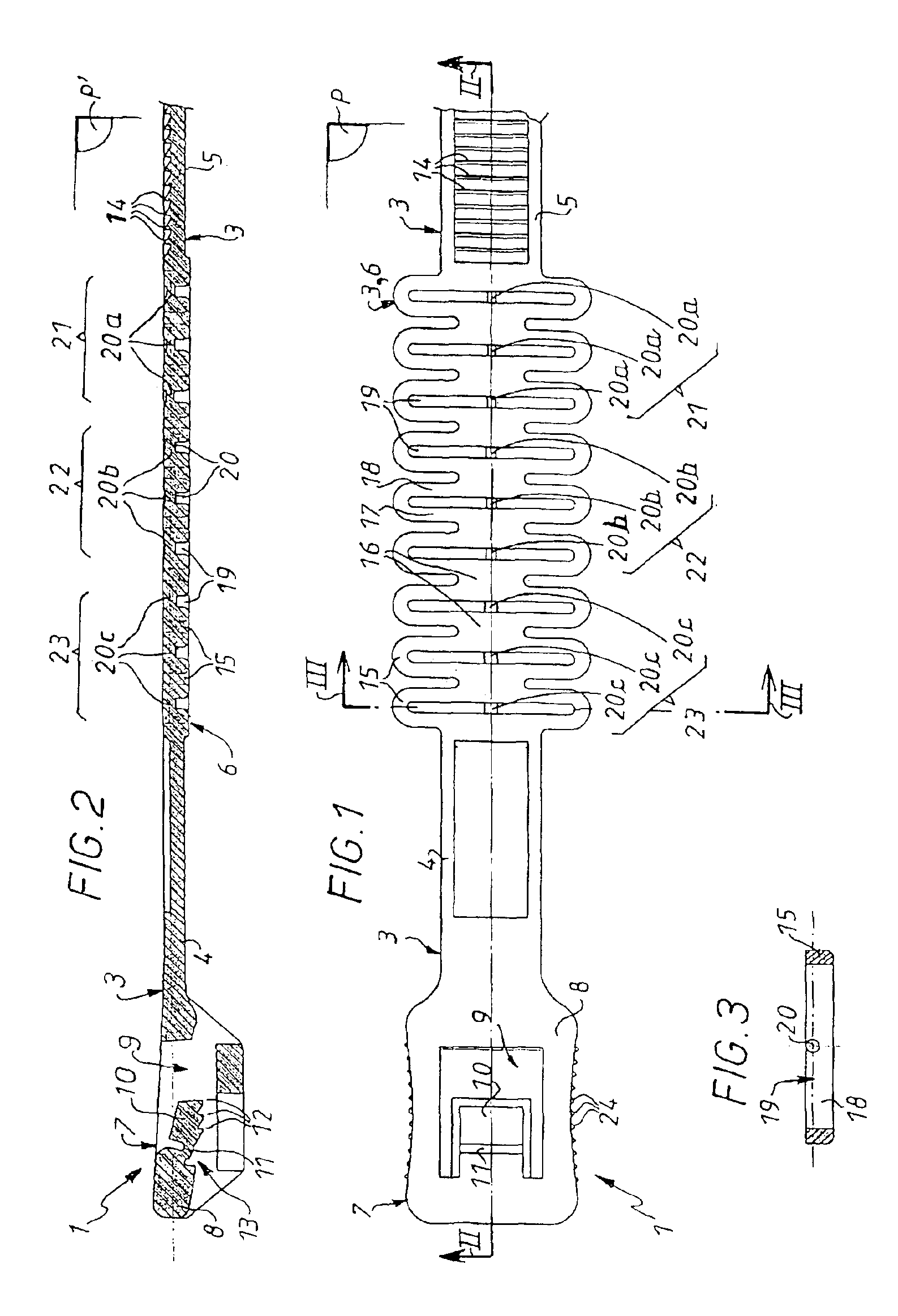

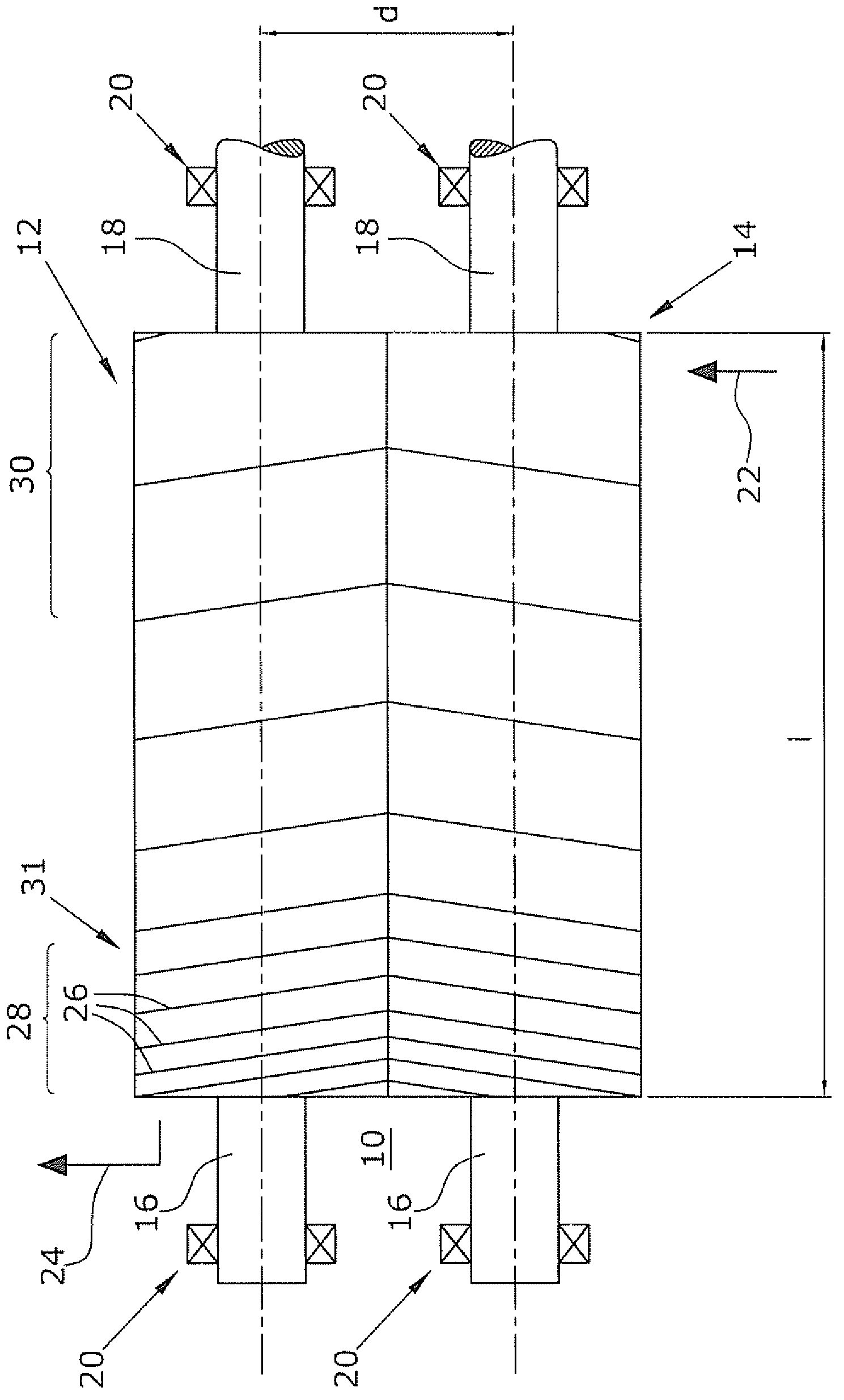

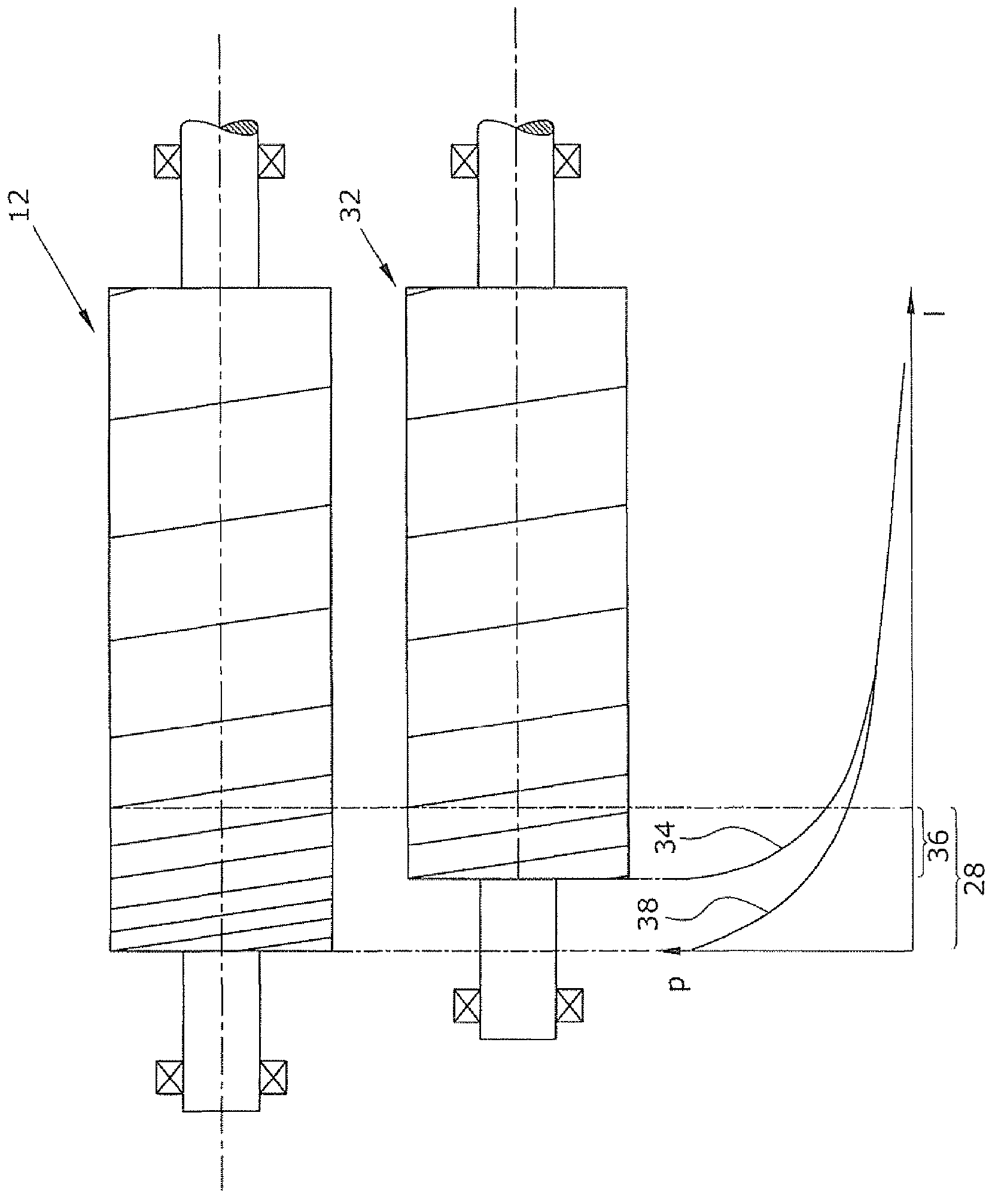

Screw vacuum pump

ActiveCN102884324AReduce power consumptionReduce generationRotary piston pumpsRotary piston liquid enginesEngineeringVacuum pump

The invention relates to a screw vacuum pump comprising screw rotors (12, 14) disposed in a suction chamber (10). The screw rotors (12, 14) are each supported by means of two bearing elements (20) in the pump housing and comprise a ratio of rotor length (I) to rotor axis spacing (d) that is greater than 3.0. The screw rotors (12, 14) further comprise a variable pitch, at least 7 turns, and an integral compression ratio of at least 4.5. The pitch after half of the turns is less than twice the pitch on the pressure side rotor outlet (24).

Owner:LEYBOLD HERAEUS GMBH & CO KG

Scroll compressor

ActiveCN105190042AImprove efficiencyPrevent overcompressionRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringScroll compressor

According to a scroll compressor associated with the present disclosure, the entire cross-sectional area of bypass holes formed at a compression chamber with a larger volume reduction gradient between the both compression chambers may be formed to be larger than that of bypass holes at the other compression chamber to prevent over-compression at the compression chamber with a larger volume reduction gradient, thereby enhancing the entire efficiency of the compressor.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com