Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

375 results about "Fire sprinkler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fire sprinkler or sprinkler head is the component of a fire sprinkler system that discharges water when the effects of a fire have been detected, such as when a predetermined temperature has been exceeded. Fire sprinklers are extensively used worldwide, with over 40 million sprinkler heads fitted each year. In buildings protected by properly designed and maintained fire sprinklers, over 99% of fires were controlled by fire sprinklers alone.

Multi-zone firewall detection system

InactiveUS7275604B1Efficient couplingEfficient powerSelf-acting watering devicesWatering devicesFire sprinklerUser input

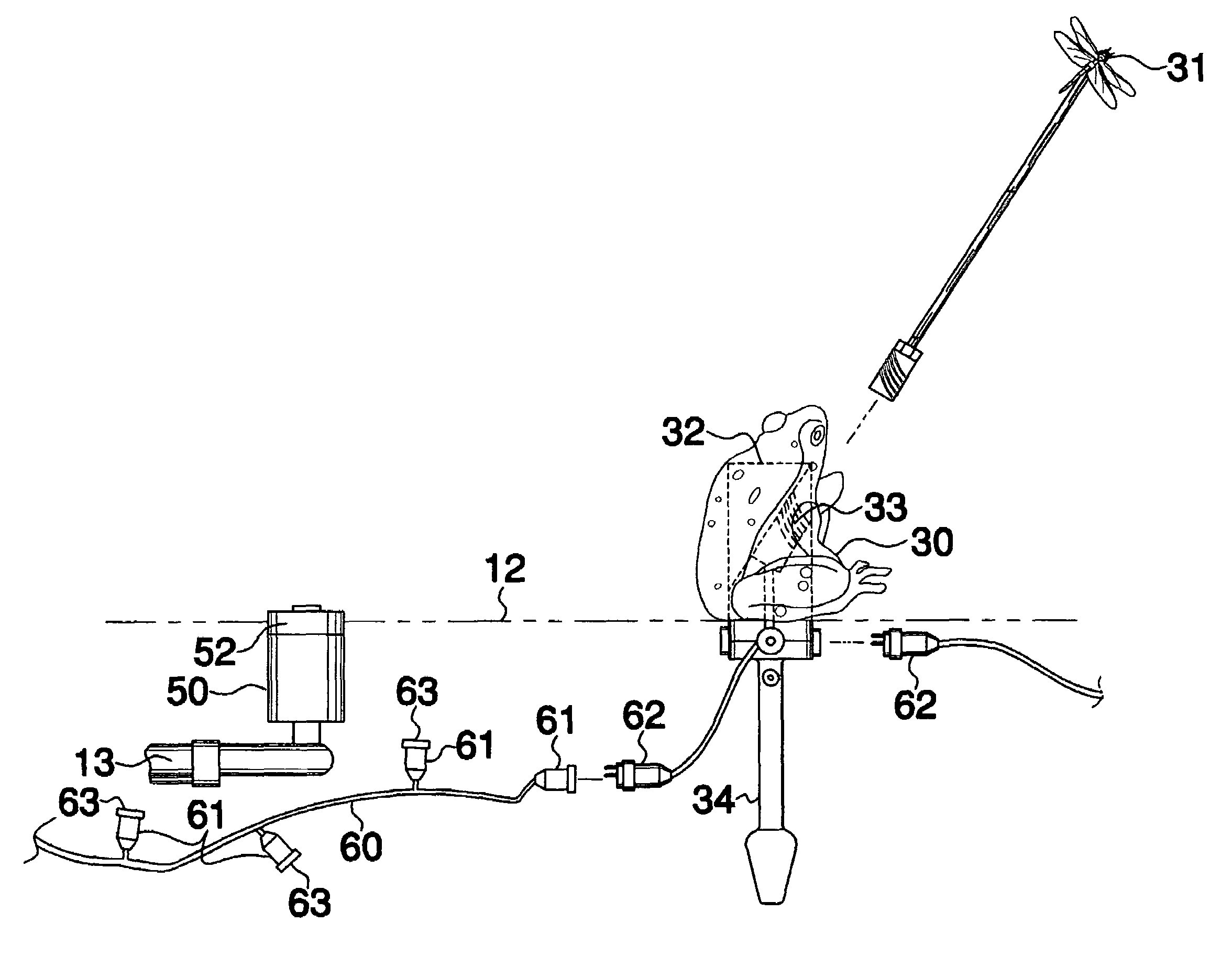

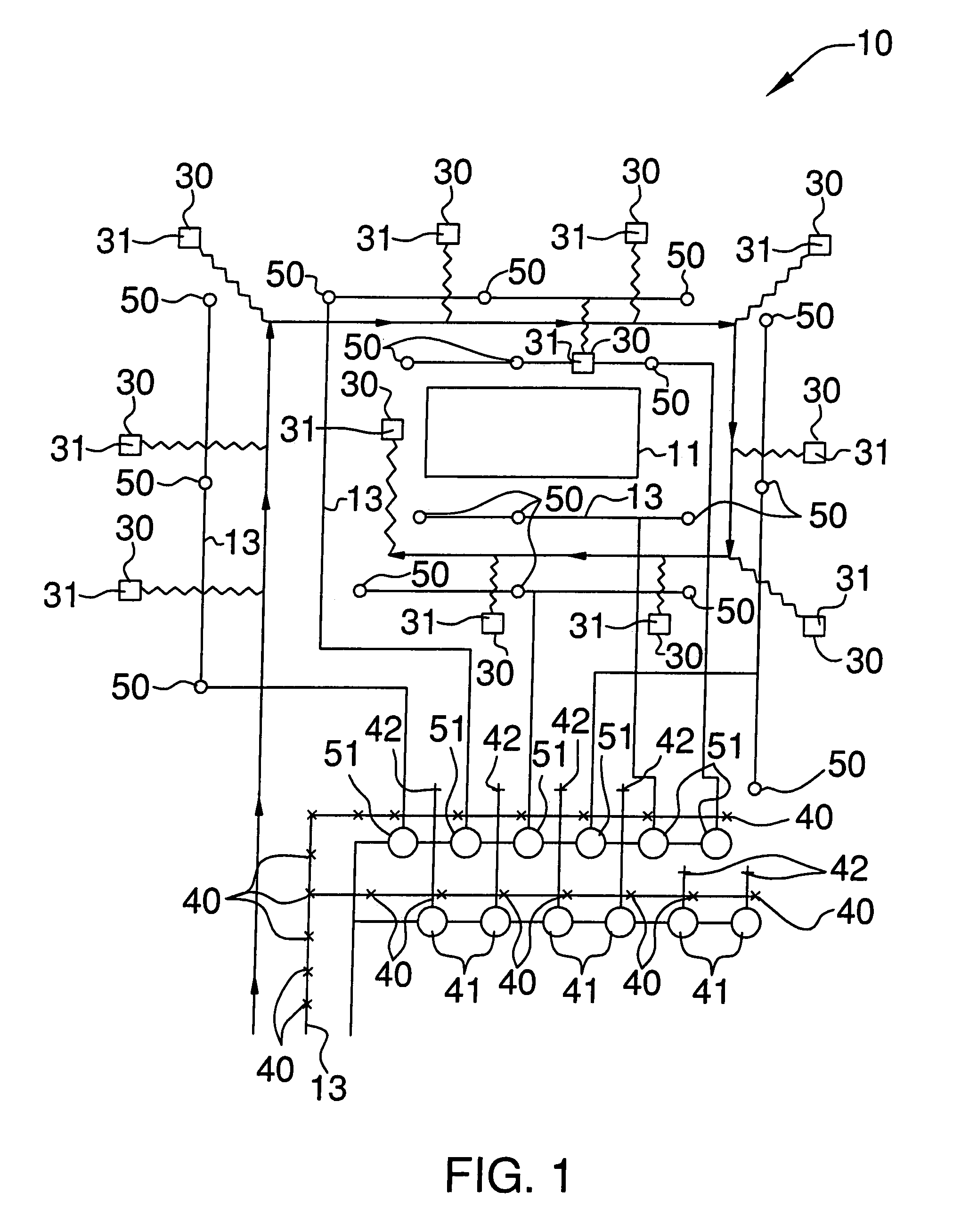

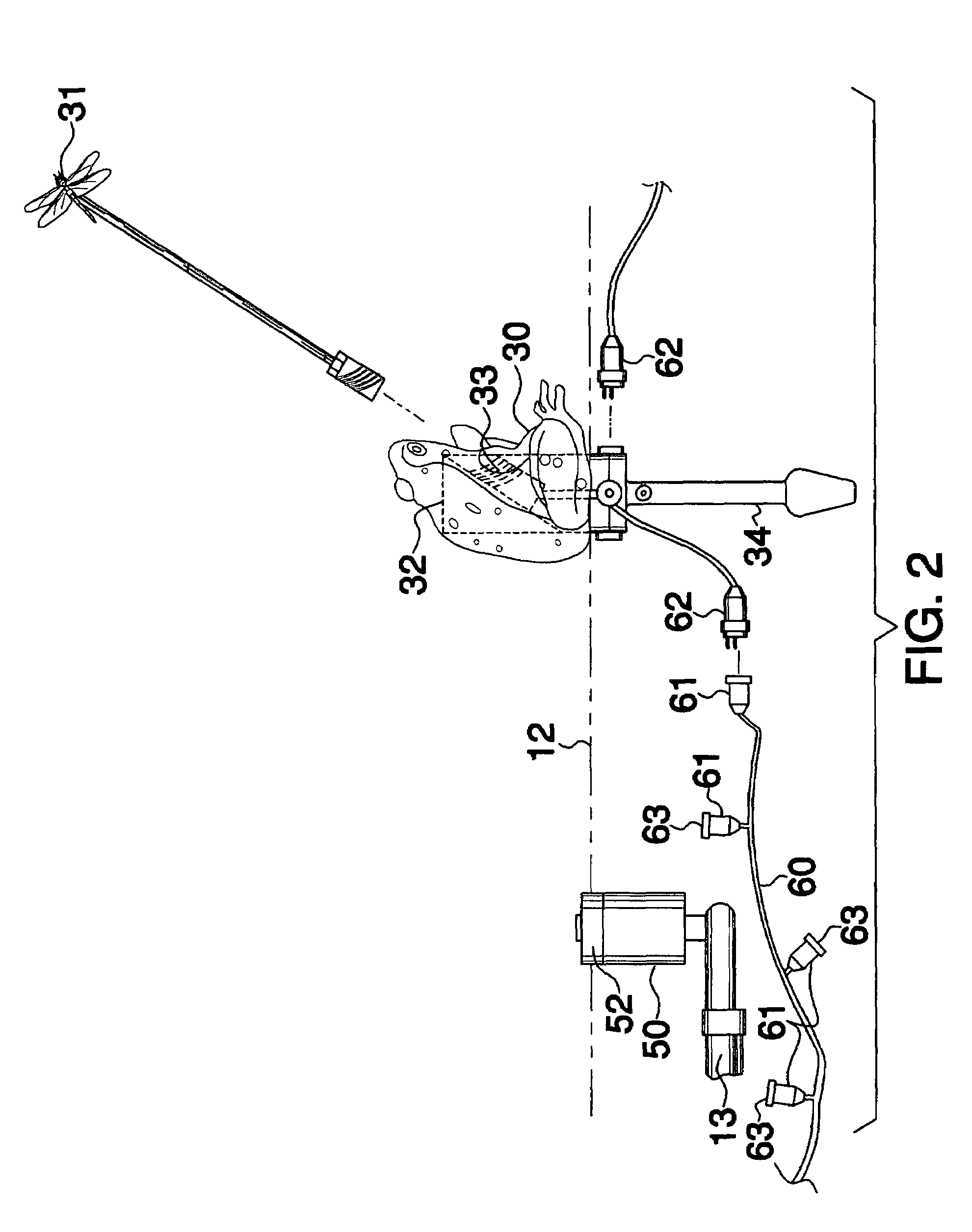

A sprinkler system includes a control panel including a processor, a power supply source, and a memory including software instructions for automatically toggling the system between operating and non-operating modes. The control panel includes controls mated to the processor that generate and transmit a user input control signal thereto. The processor executes a control algorithm for enabling the user to override the system. Sensors are spaced along a perimeter of the building structure, are camouflaged and shaped as an outdoor ornamental lawn art such as insects and amphibians, and generate and transmit an RF detection signal to the control panel, identifying an ambient temperature. Lawn and fire sprinkler assemblies are positioned about the building structure. The lawn and fire sprinkler assemblies are mated to the control panel and are independently operable. The sensors automatically instruct the control panel to activate and deactivate the lawn and fire sprinkler assemblies when a threshold exceeding ambient temperate is detected.

Owner:WALL TERRY M

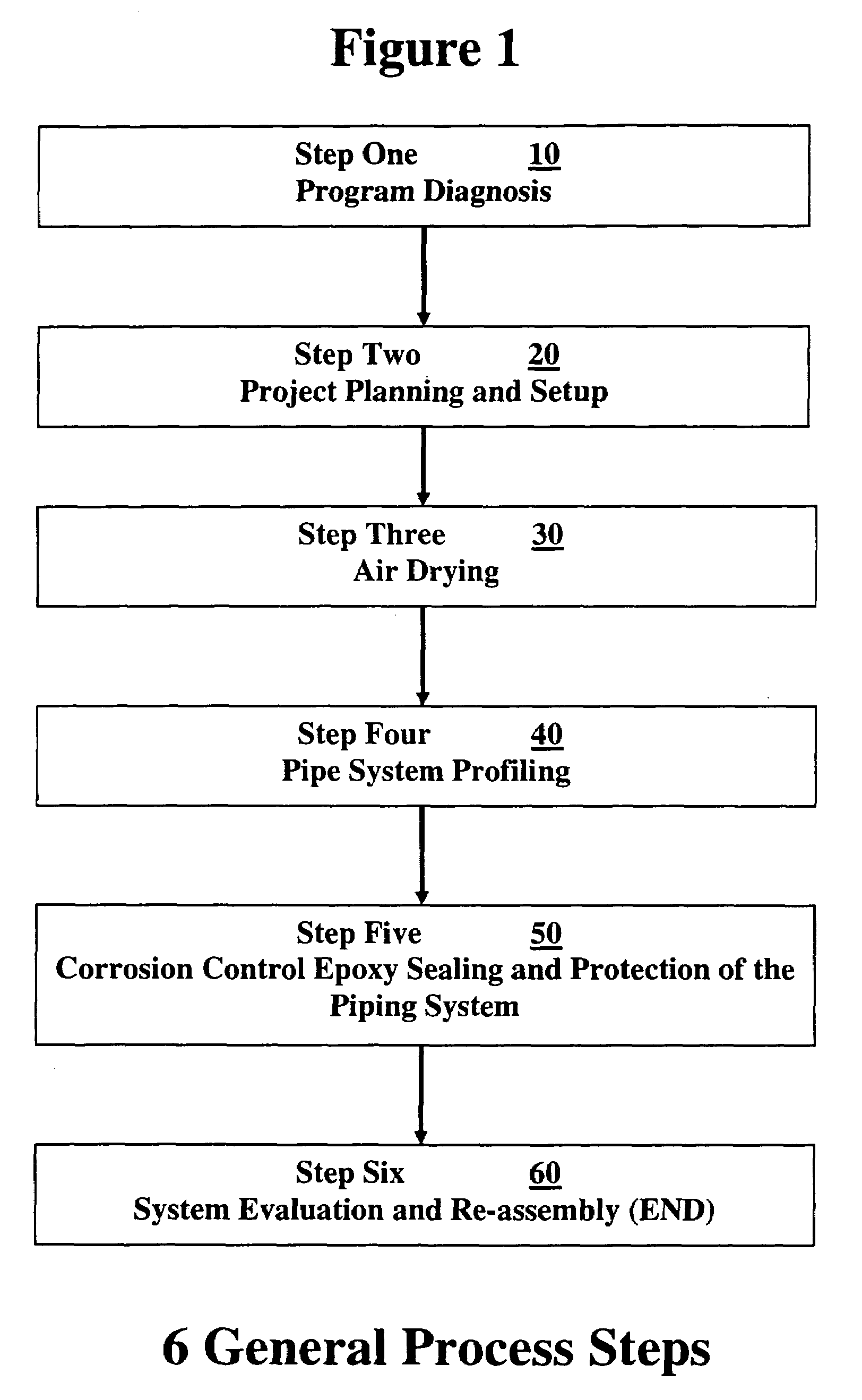

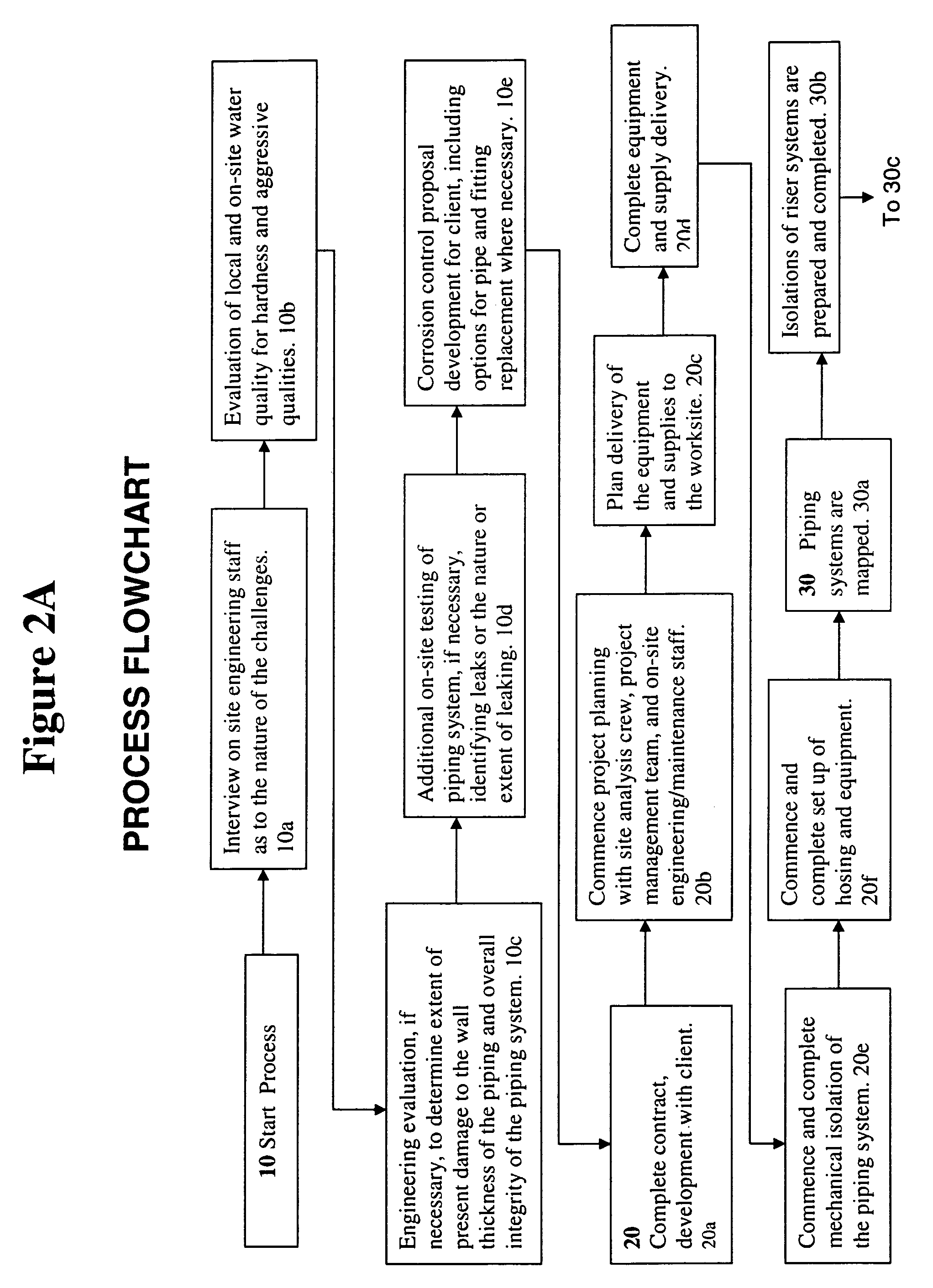

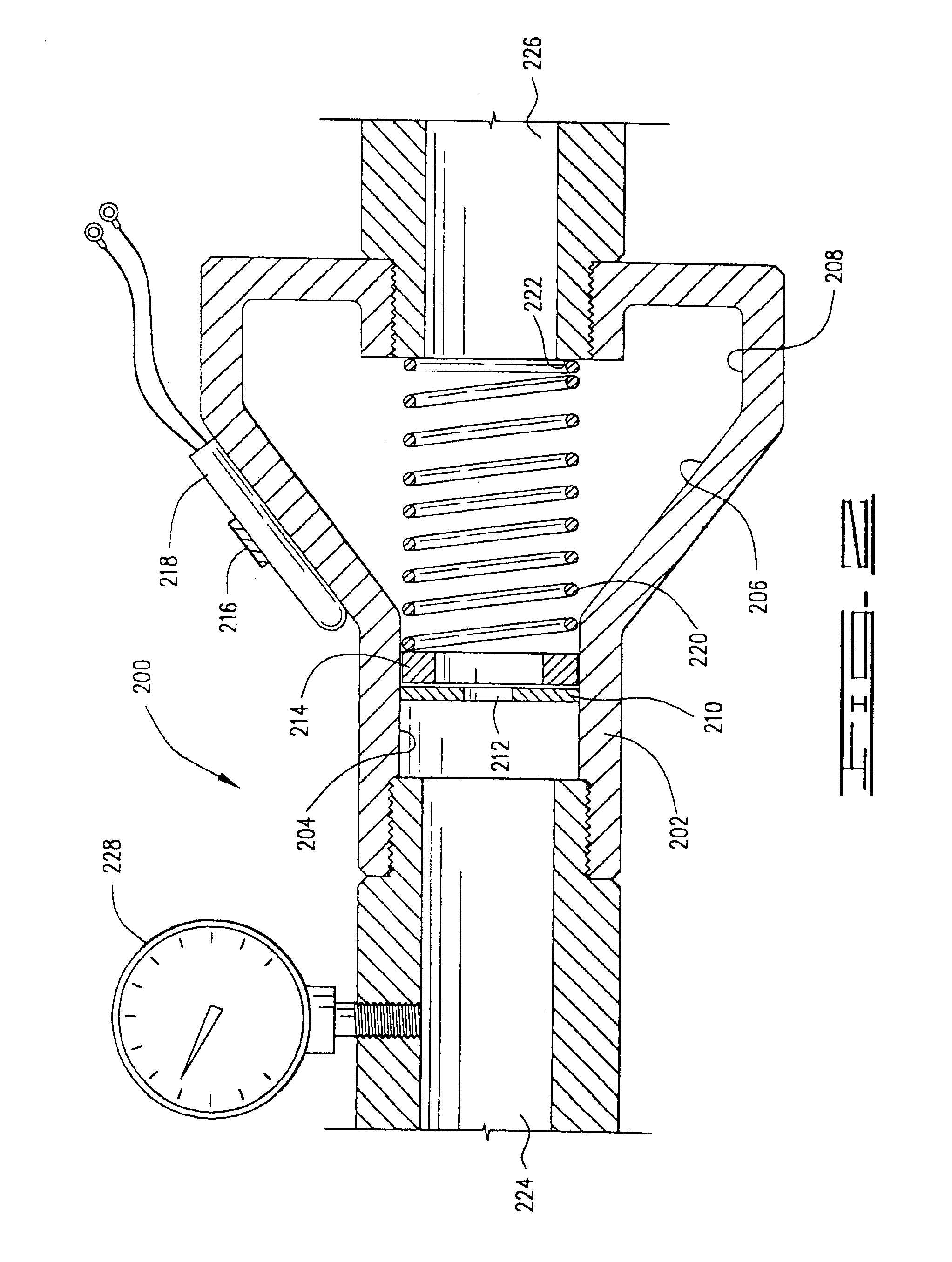

Barrier coating corrosion control methods and systems for interior piping systems

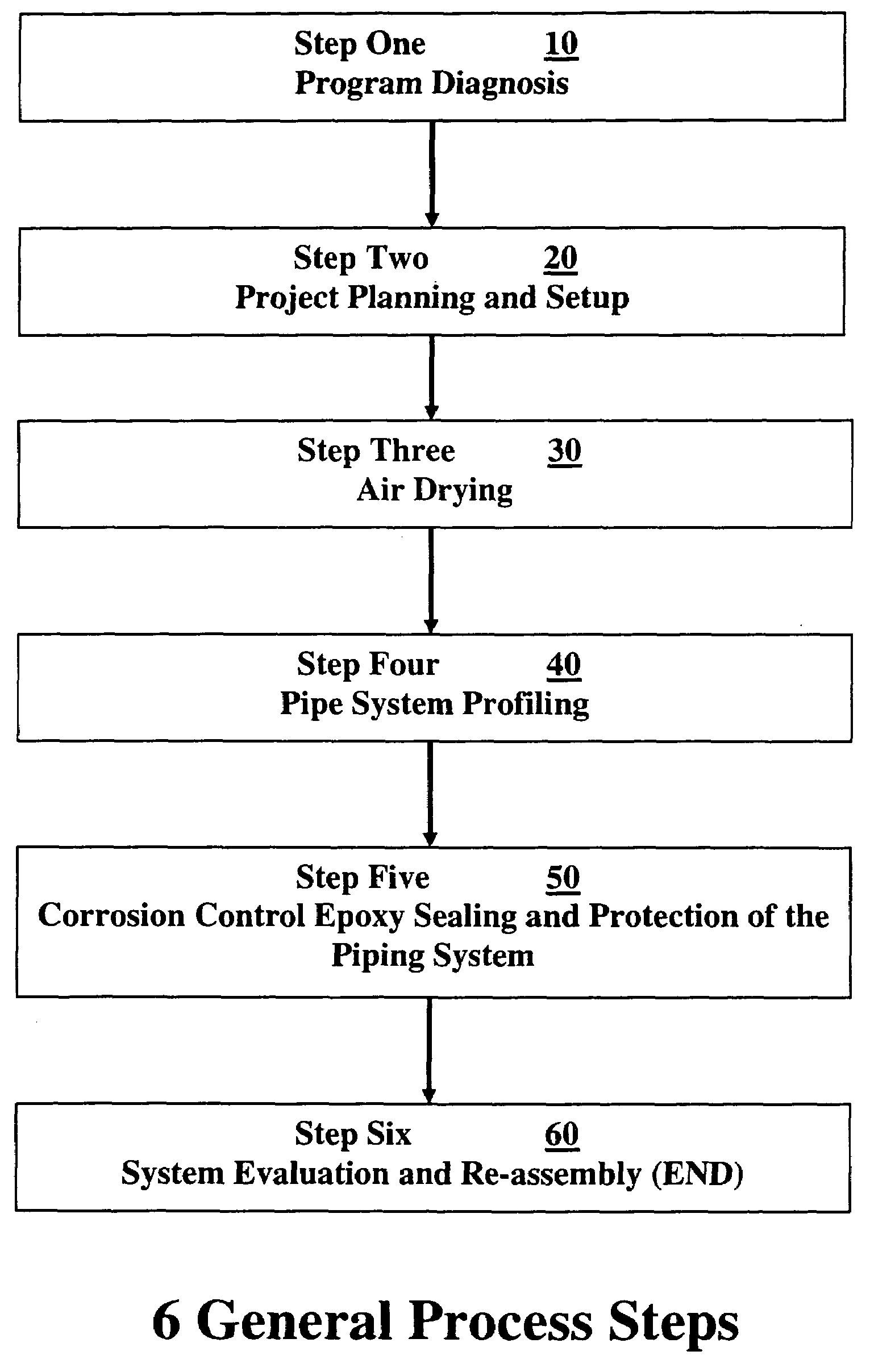

Methods and systems for cleaning and providing barrier coatings to interior walls of piping systems. An entire piping system can be cleaned in one single pass by dry particulates forced by air and the piping system coated in one single pass. Pipes can be protected from water corrosion, erosion and electrolysis. Pipes having diameters of approximately ⅜″ up to approximately 6″ are treatable. Piping systems such as potable water lines, natural gas lines, HVAC, drains, and fire sprinkler systems in homes, apartments, high-rise hotel / resorts, office towers, high-rise apartment and condominiums and schools, can be treated. The coating forms an approximately 4 mils or greater covering inside the pipes. Buildings can return to service within approximately 24 to approximately 96 hours.

Owner:PIPE RESTORATION TECH

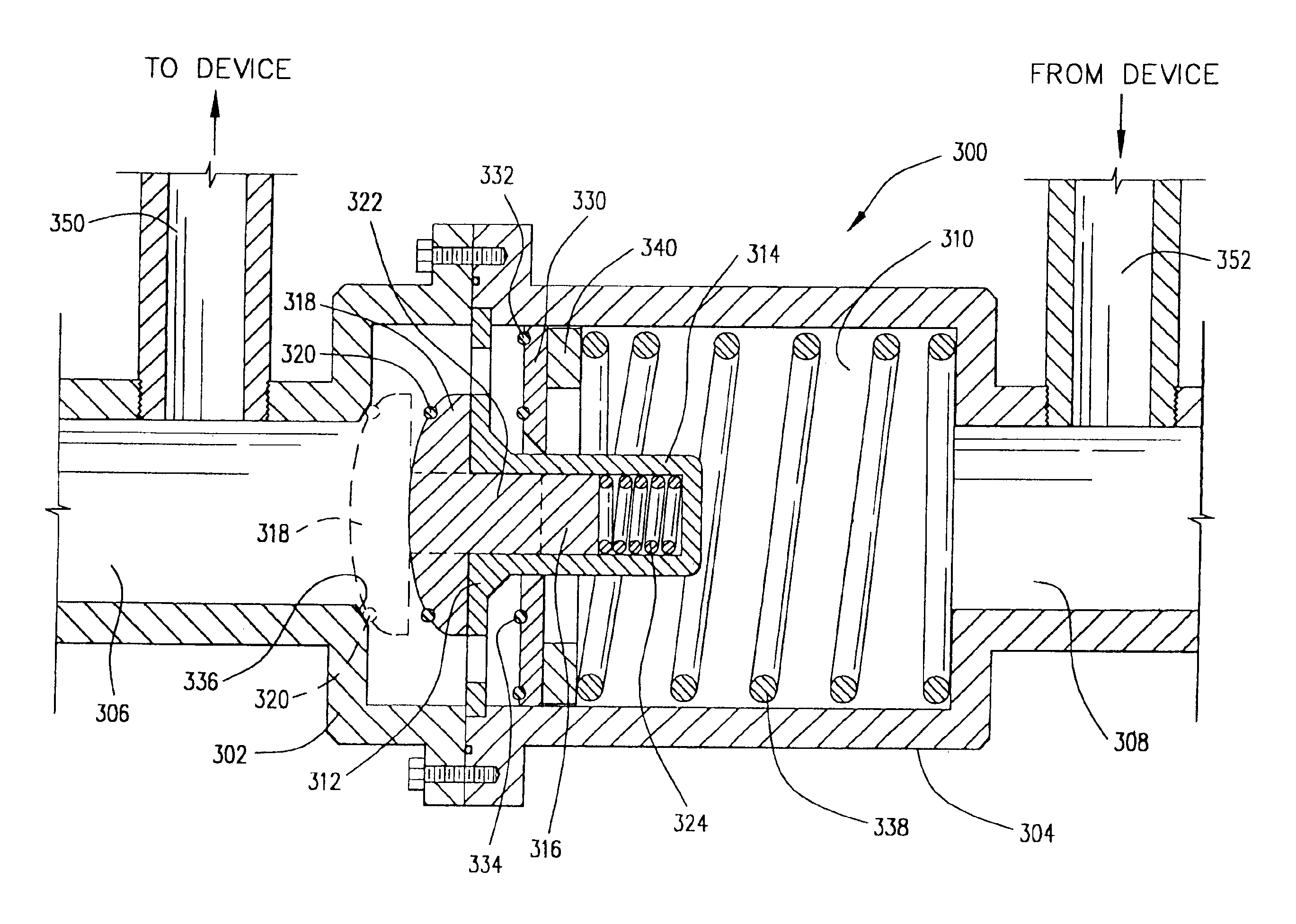

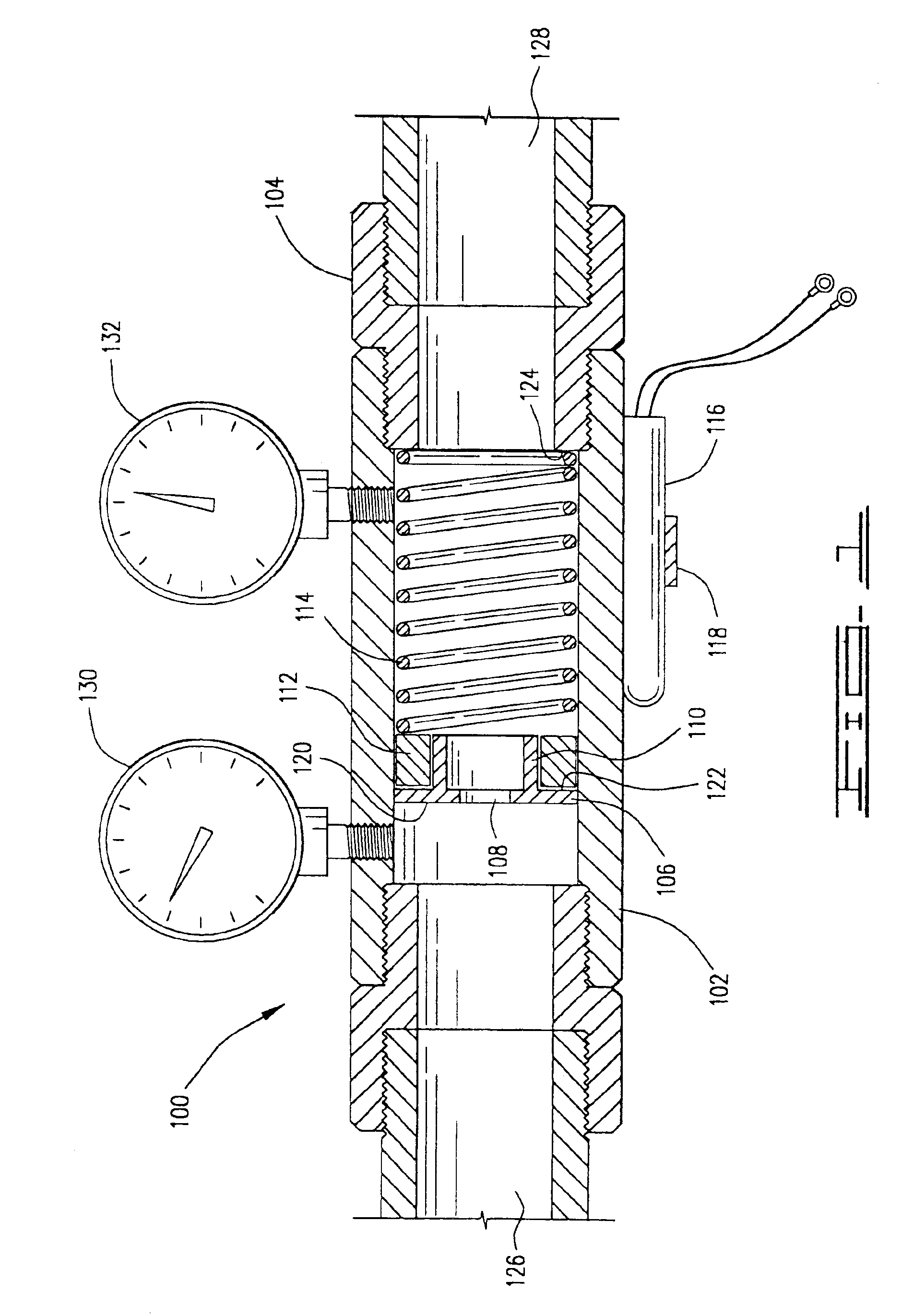

Apparatus for flow detection, measurement and control and method for use of same

InactiveUS6914531B1Easy to operateEasy CalibrationValve arrangementsMeasurement of fluid loss/gain rateFire sprinklerDifferential pressure

A flow sensor having an inlet and an outlet comprising: a plate moving in response to fluid flow therethrough, being displaced further as flow increases; a sensor for determining moving plate's position and creating an electronic signal related thereto; a biasing means for biasing the plate towards the sensor's inlet end. The sensor may include a sealing means for preventing flow therethrough until a specified differential pressure is reached allowing the device to be used as a bypass mechanism. The sealing means may also constitute a check valve means to prevent flow in an undesired direction. The check means comprises: a bullet rod adapted to be received within an orifice defined in a moving plate, such that the bullet rod prevents flow through the orifice until the moving plate is displaced past a terminal end of the bullet rod; and a plate means sealingly and slidingly received within a cylinder, which is closed for a portion of its length and open for another portion of its length, such that flow is prevented until the plate is displaced past the closed portion of the cylinder. The method using the sensor in multipurpose piping systems includes use of the apparatus in a system incorporating at least one fire sprinkler, the piping system also preferably providing at least one other use in the structure. The other use in the structure may be supplying domestic needs, or supplying heating / cooling water for a heating / air conditioning system.

Owner:YOUNG RICHARD

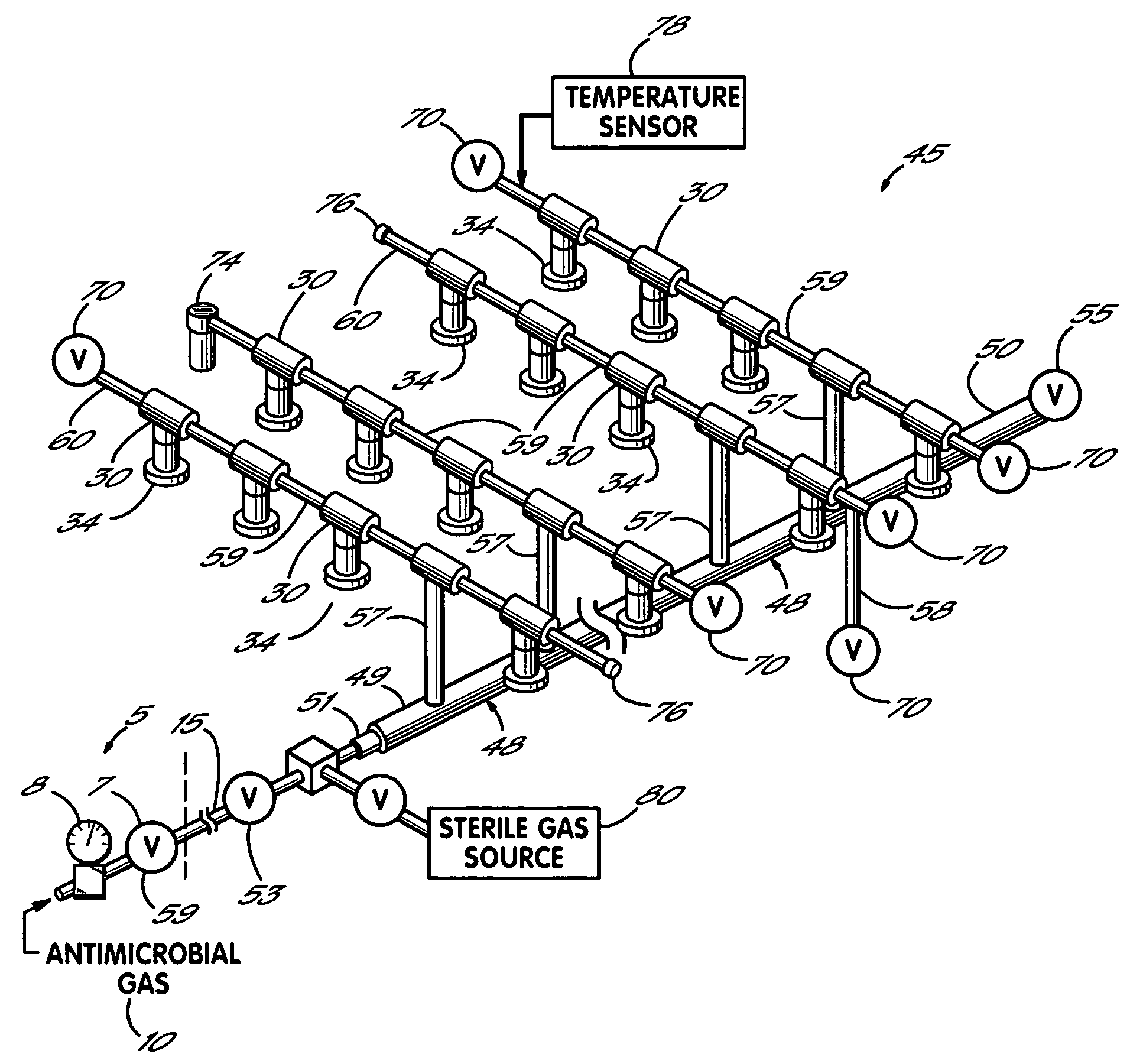

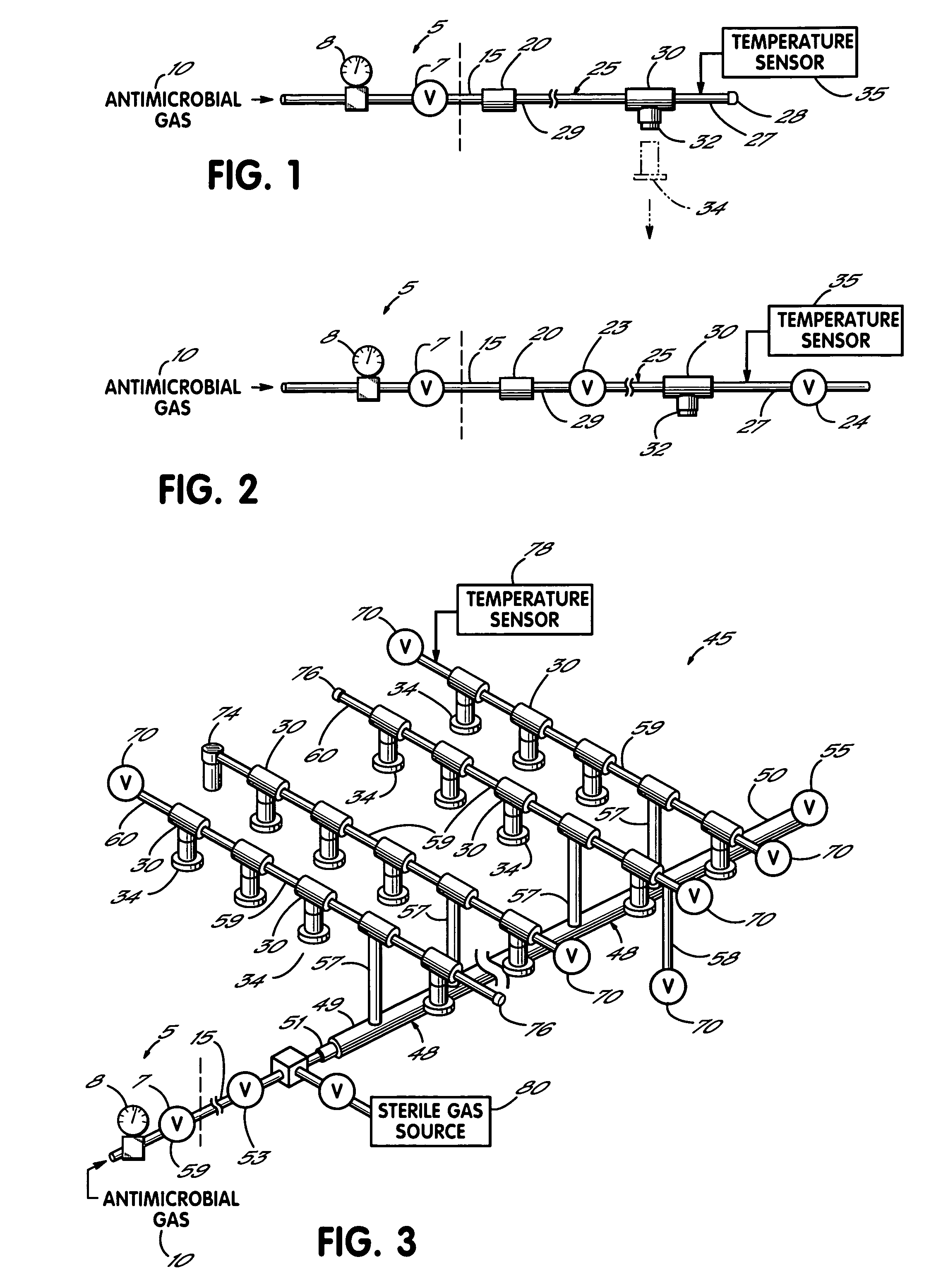

Sterilization of fire sprinkler systems

InactiveUS6960321B1Simple and low-cost and effectiveAvoid water damageFunctional valve typesSpace heating and ventilationFire sprinklerProduct gas

New and in-use fire sprinkler systems can be sterilized by employing antimicrobial gases. The gases include steam, oxygen, and chlorine. Water added to the system after sterilization can be sterilized to prevent the reoccurrence of microbiological contamination.

Owner:PIPE STERILIZATION

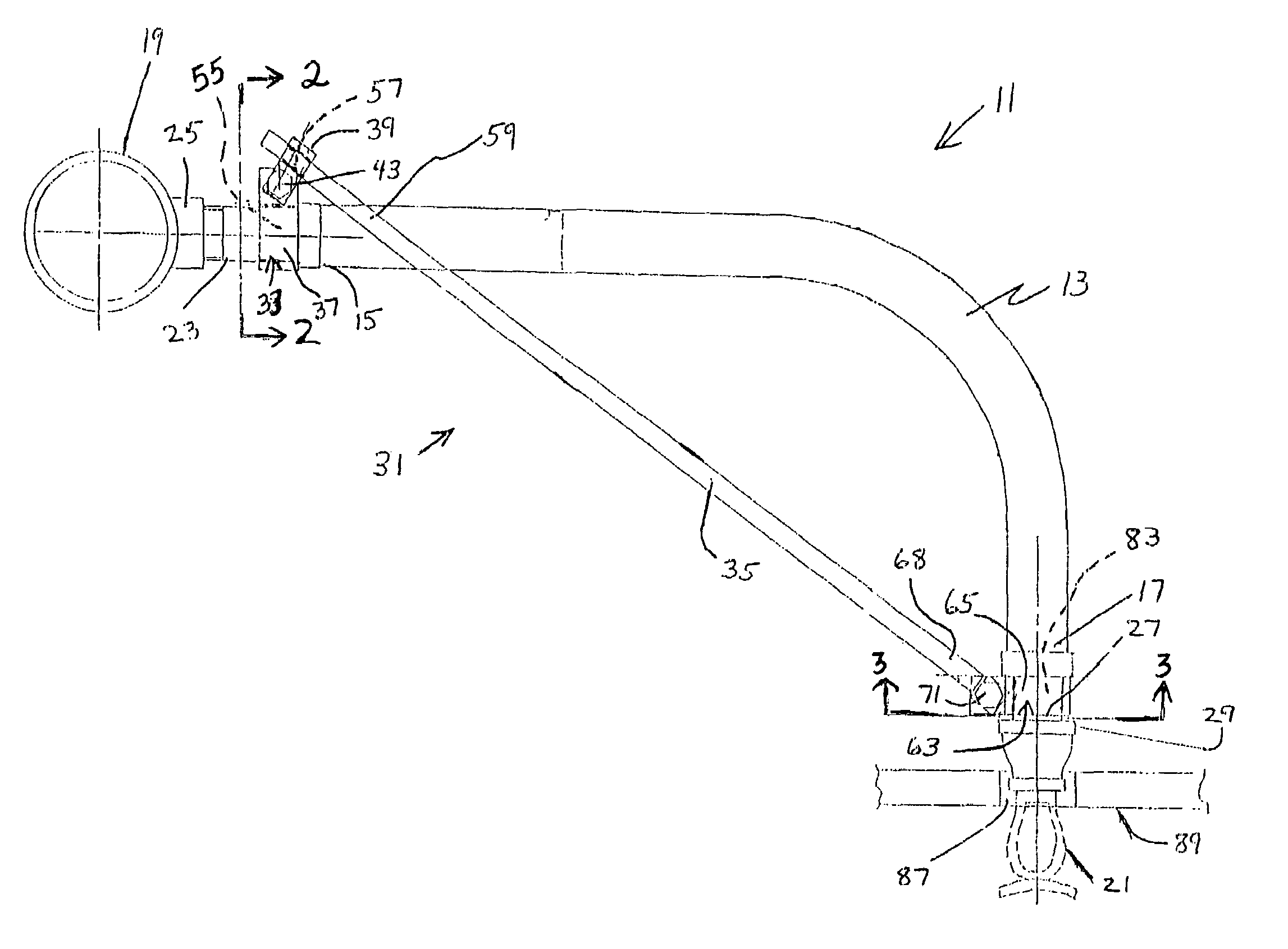

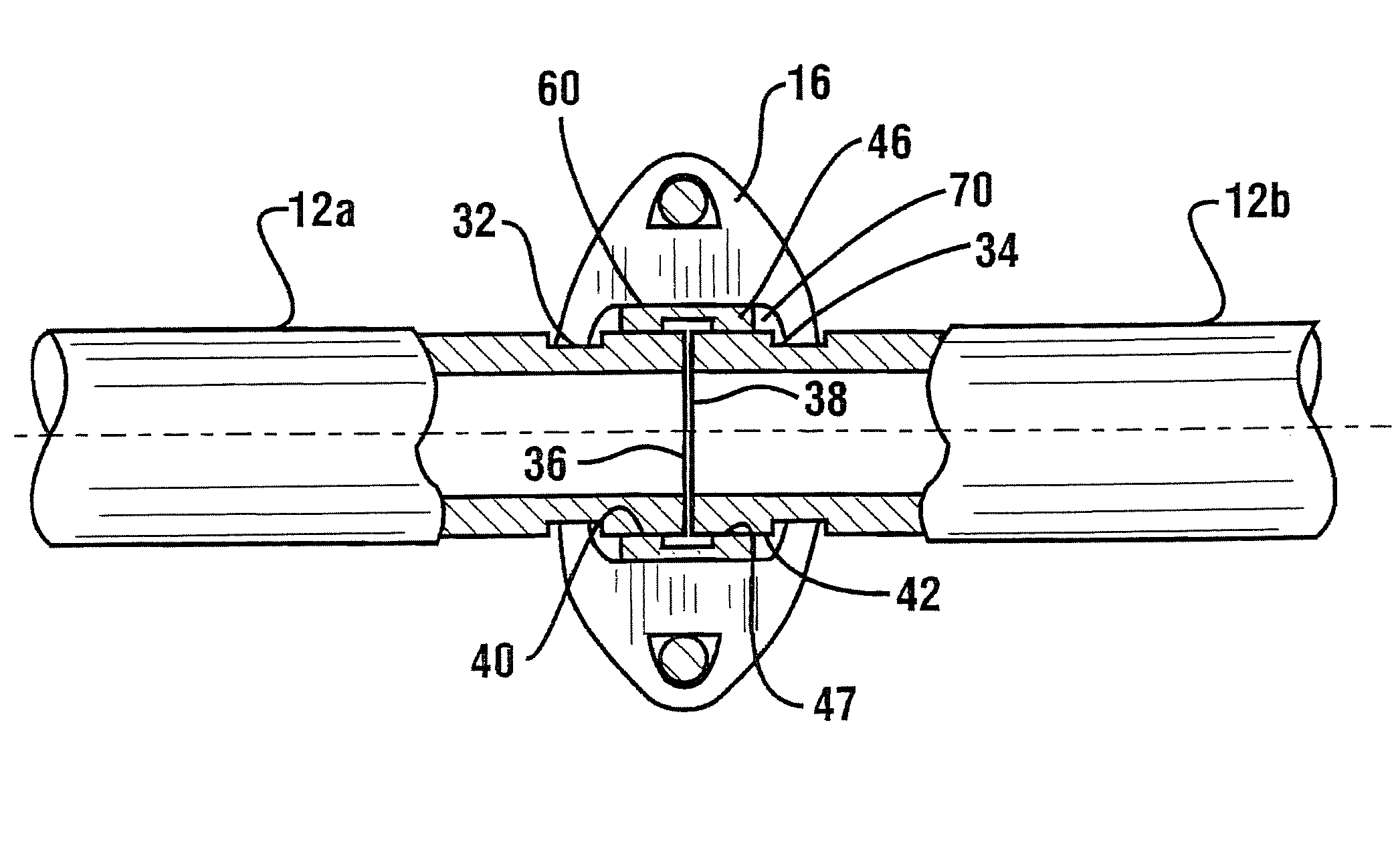

X-brace valve and flexible connection for fire sprinklers

A fire sprinkler head (12) has a valve (42) with an X-brace latch (54), and includes a flexible conduit (14). A sprinkler nozzle (16) is secured to a first end of the flexible conduit (14). The sprinkler nozzle (16) includes a first fitting (28), a sprinkler orifice (20) and fusible element (22). A second fitting (40) is secured to the second end of the flexible conduit (14) and includes the valve (42). The valve (42) has a valve element (44) which is moveable from a latched position to an unlatched position. A flexible link (56) extends from the sprinkler nozzle (16) to the X-brace valve latch (54). Breaking of the fusible element (22) releases the flexible link (56) to move from the latched position to the unlatched position, releasing the valve (42) for flow there-through.

Owner:VICTAULIC

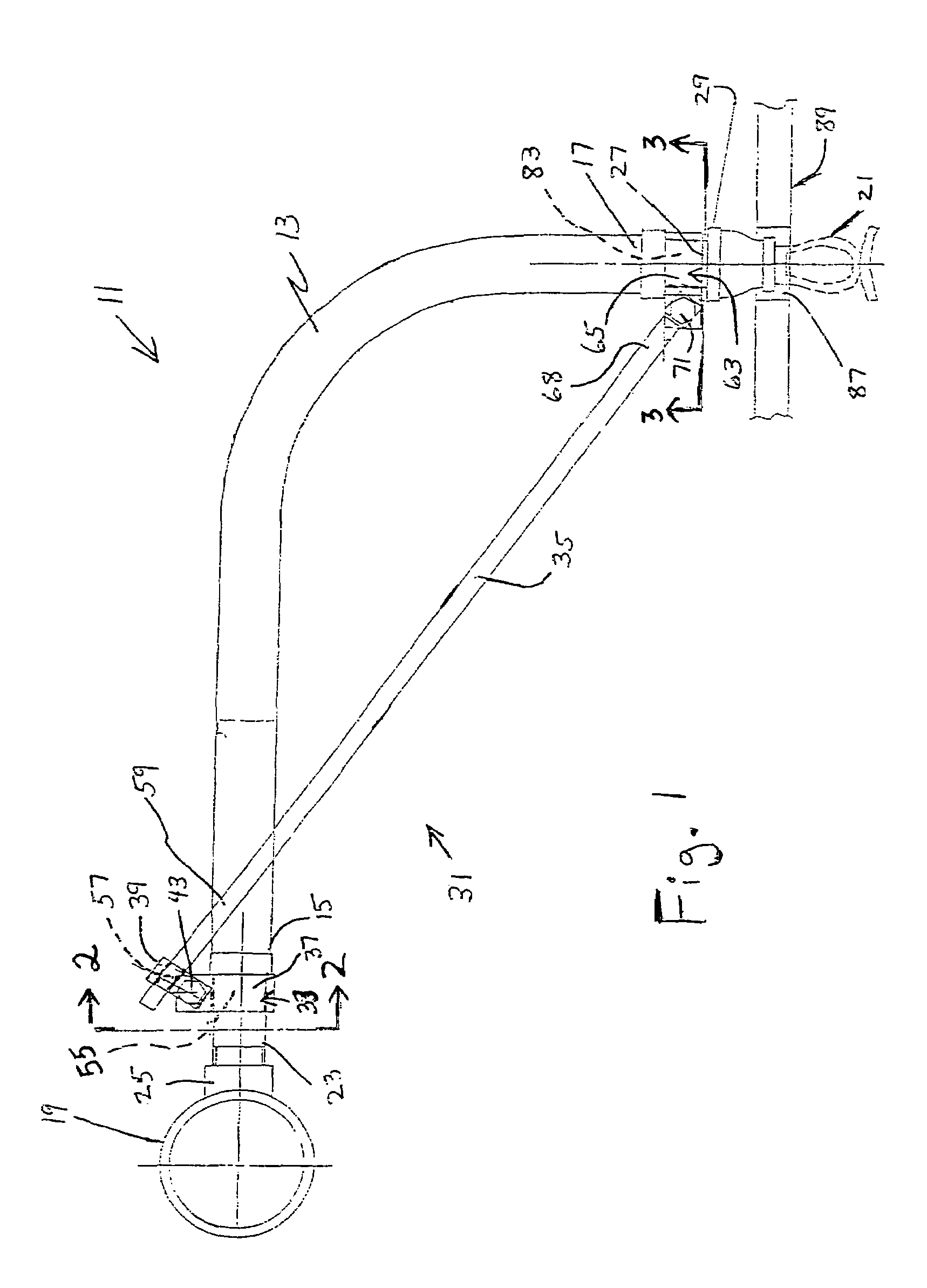

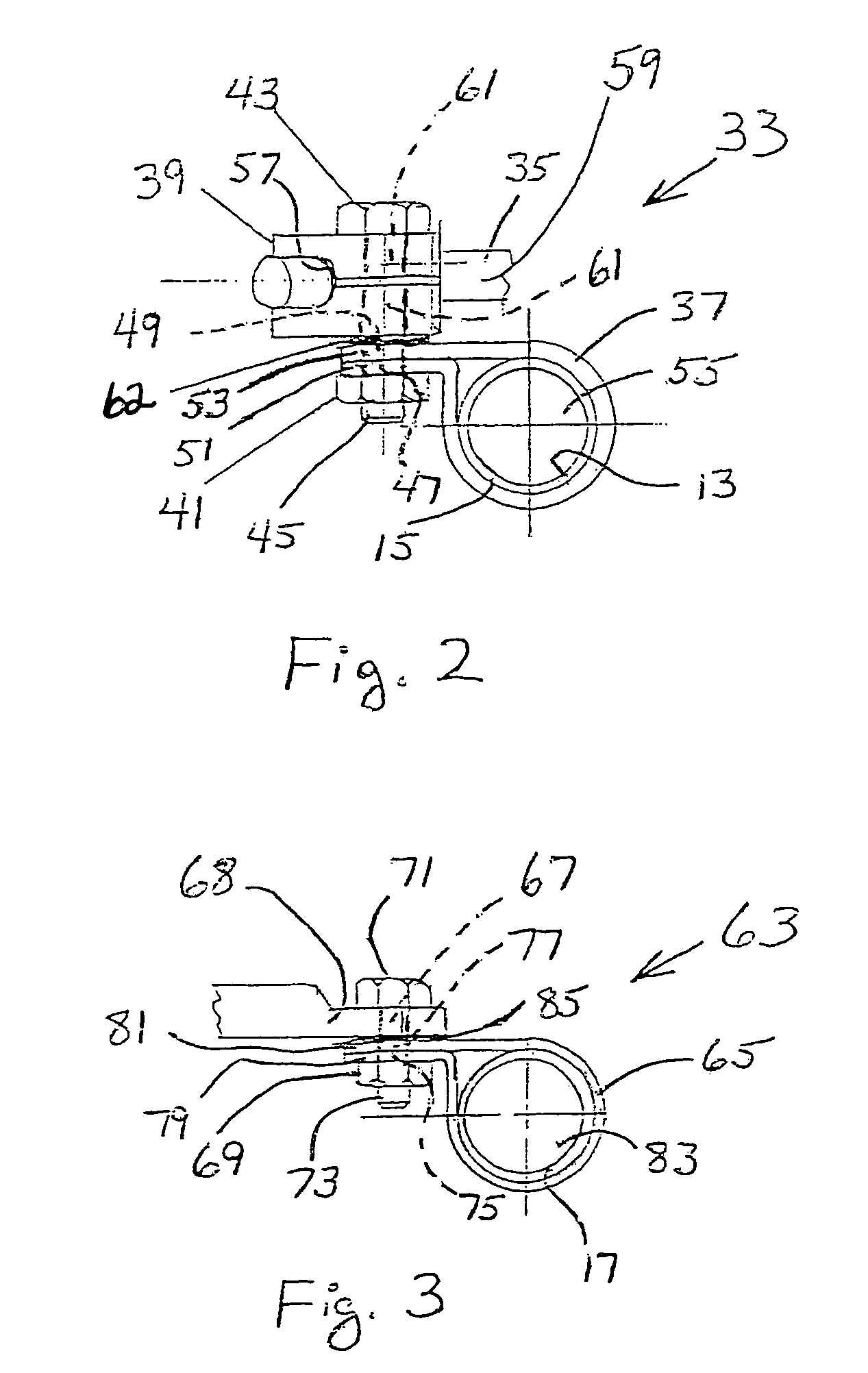

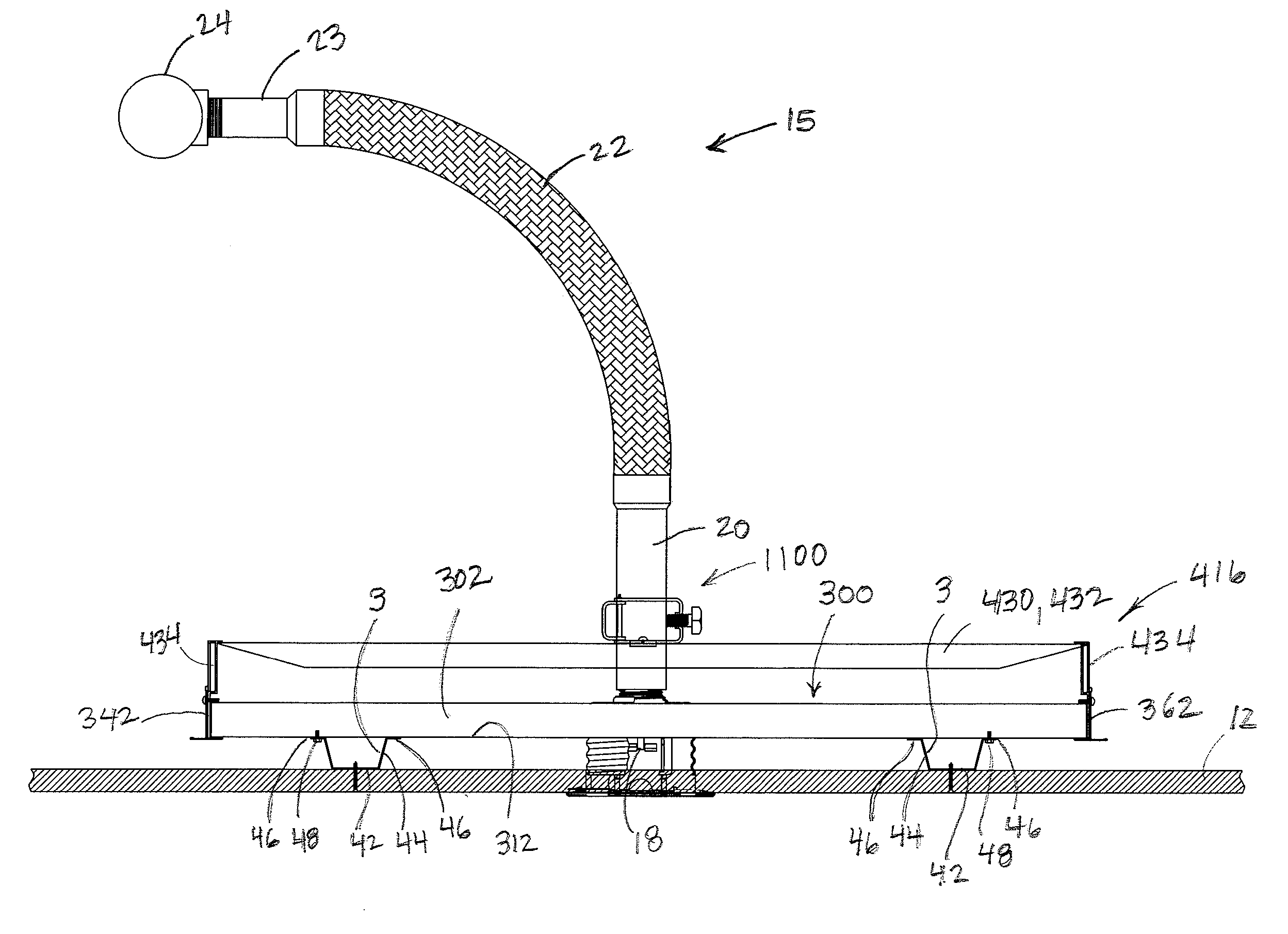

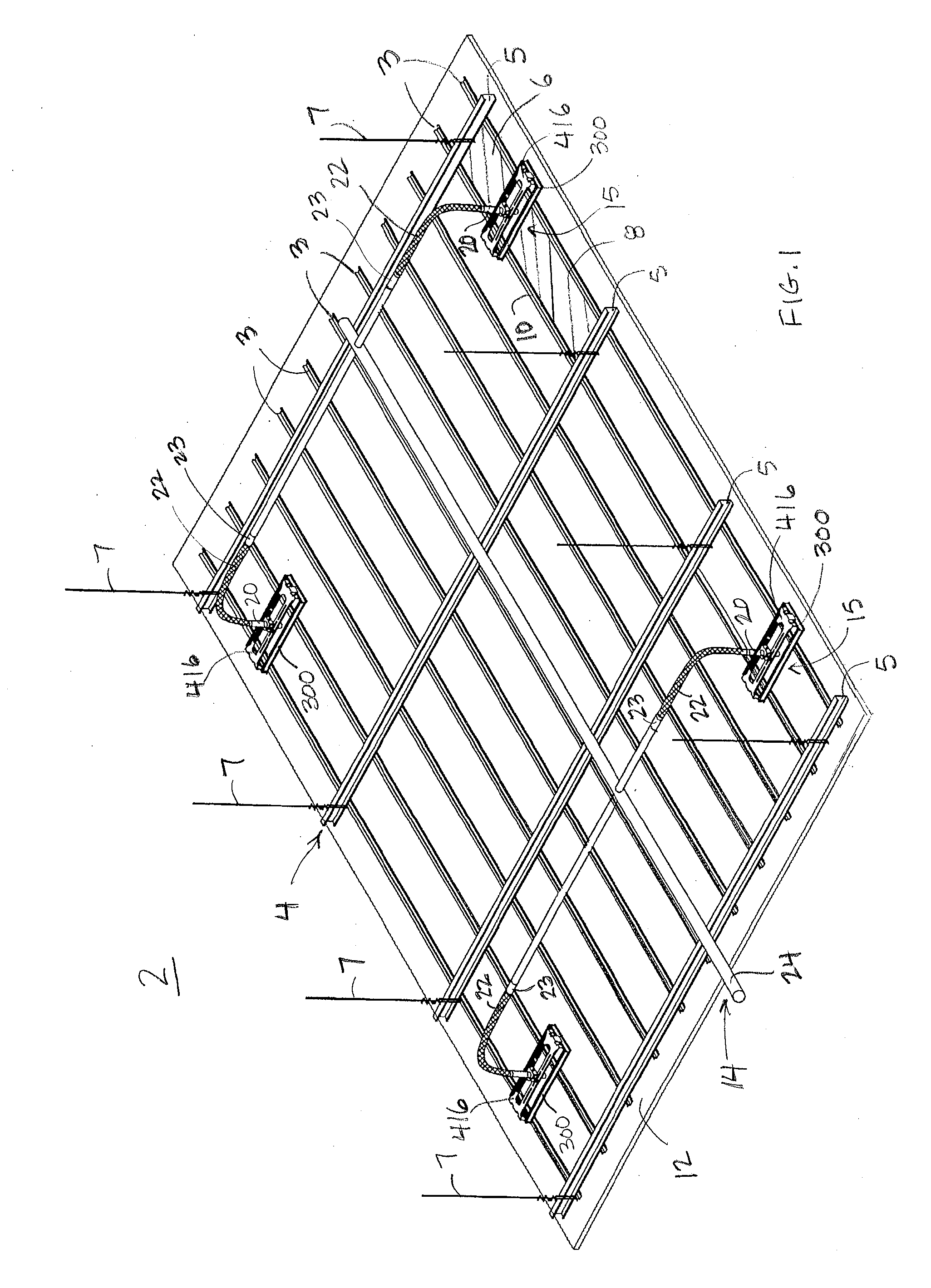

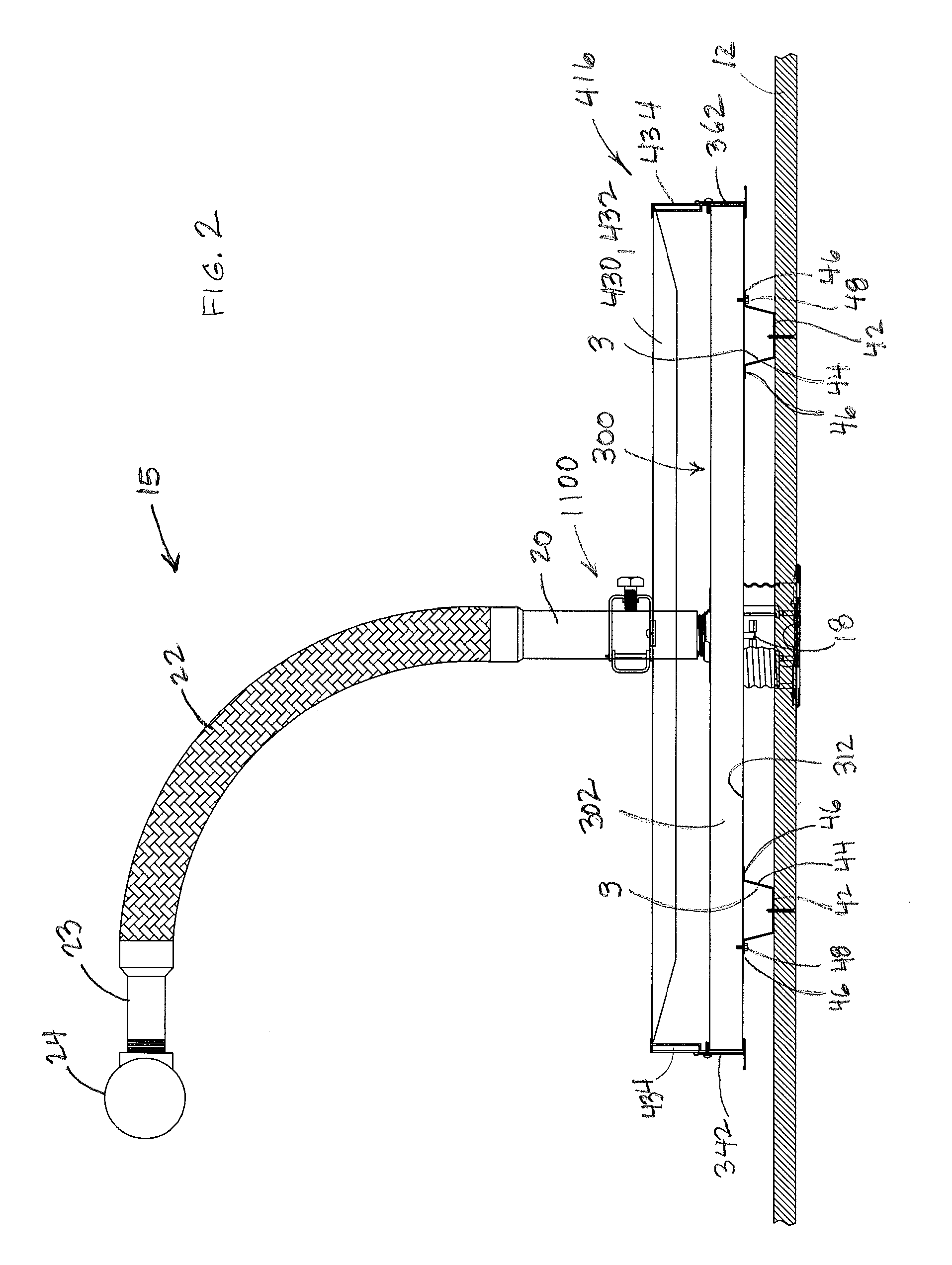

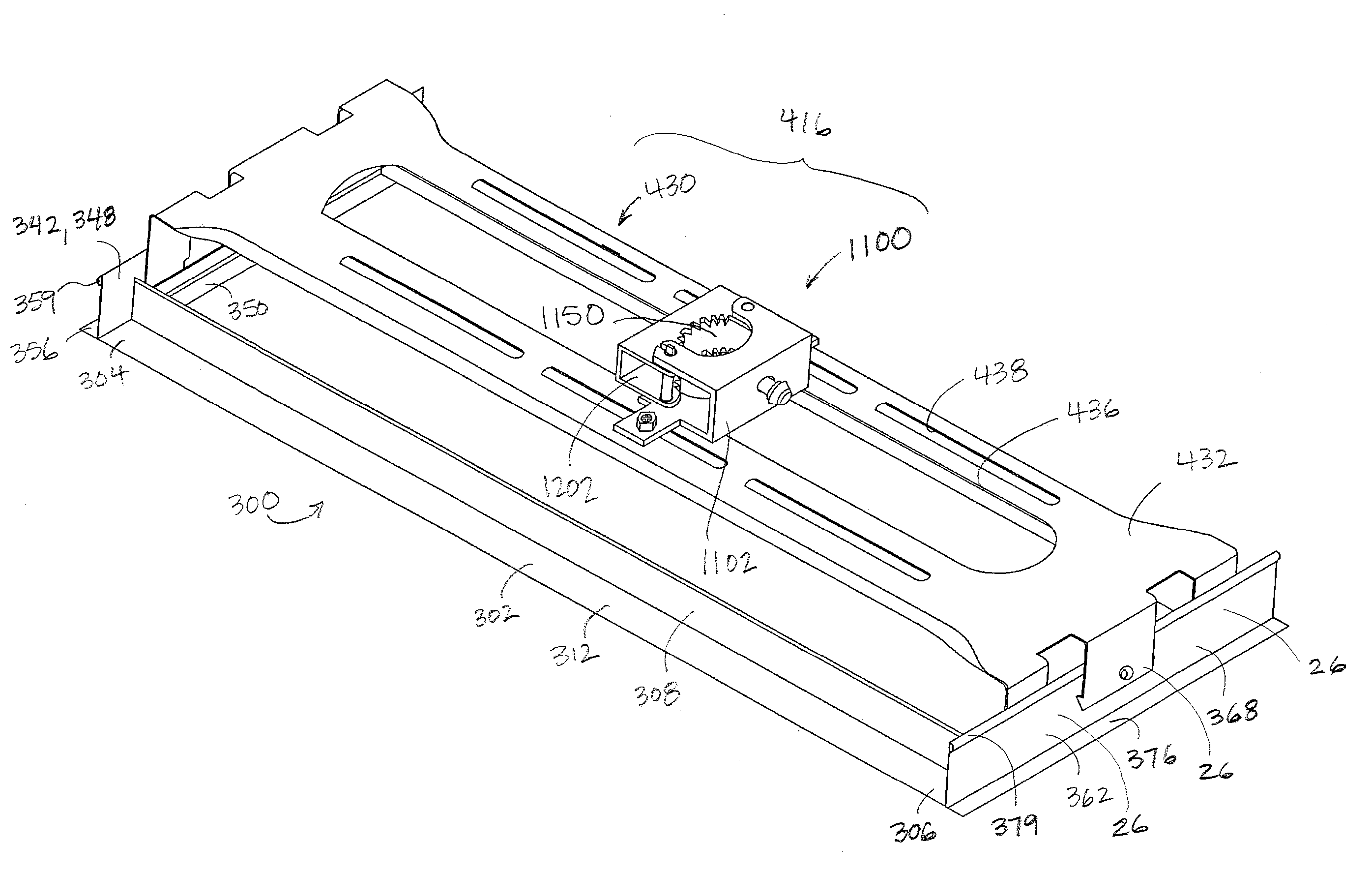

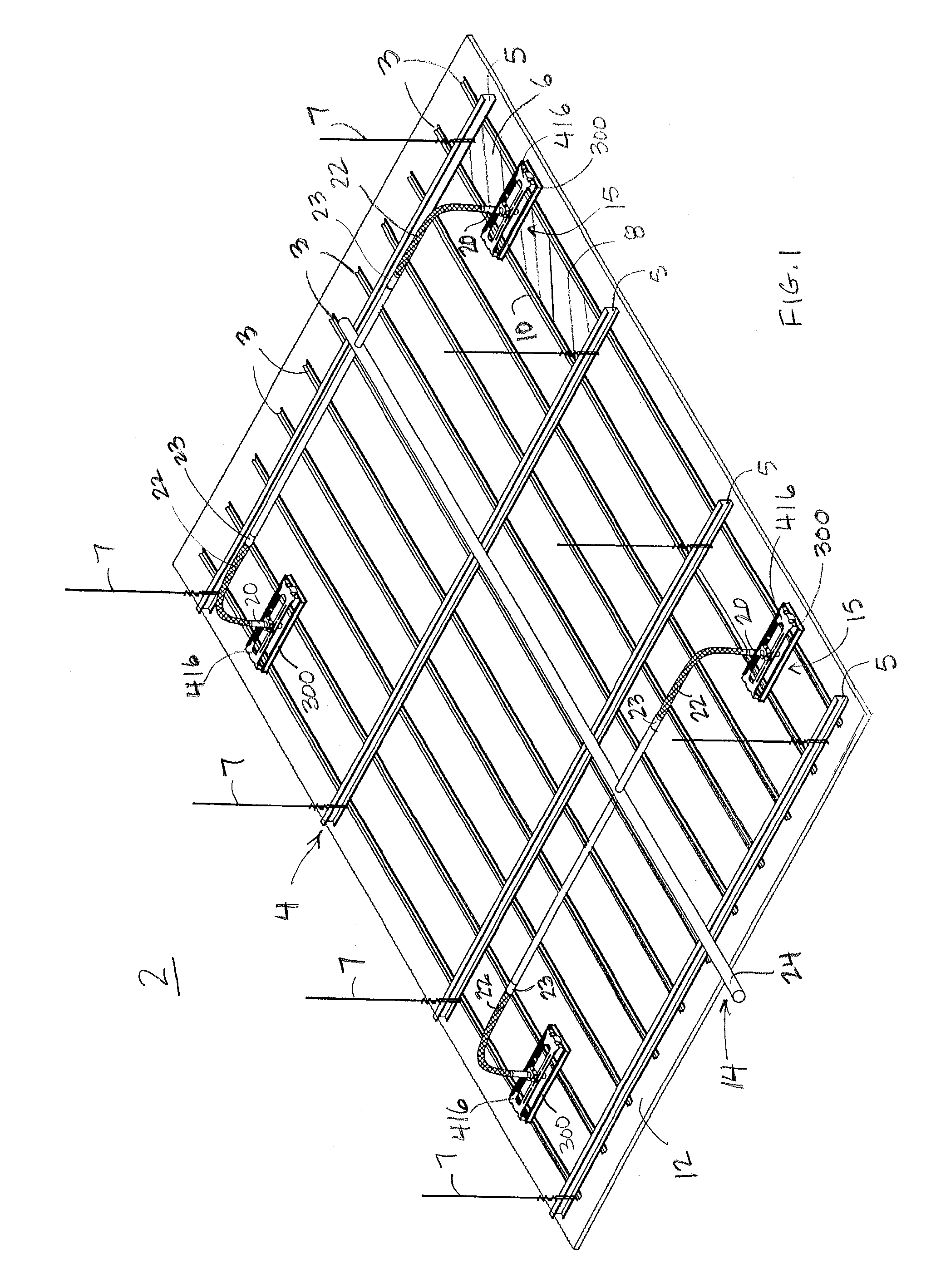

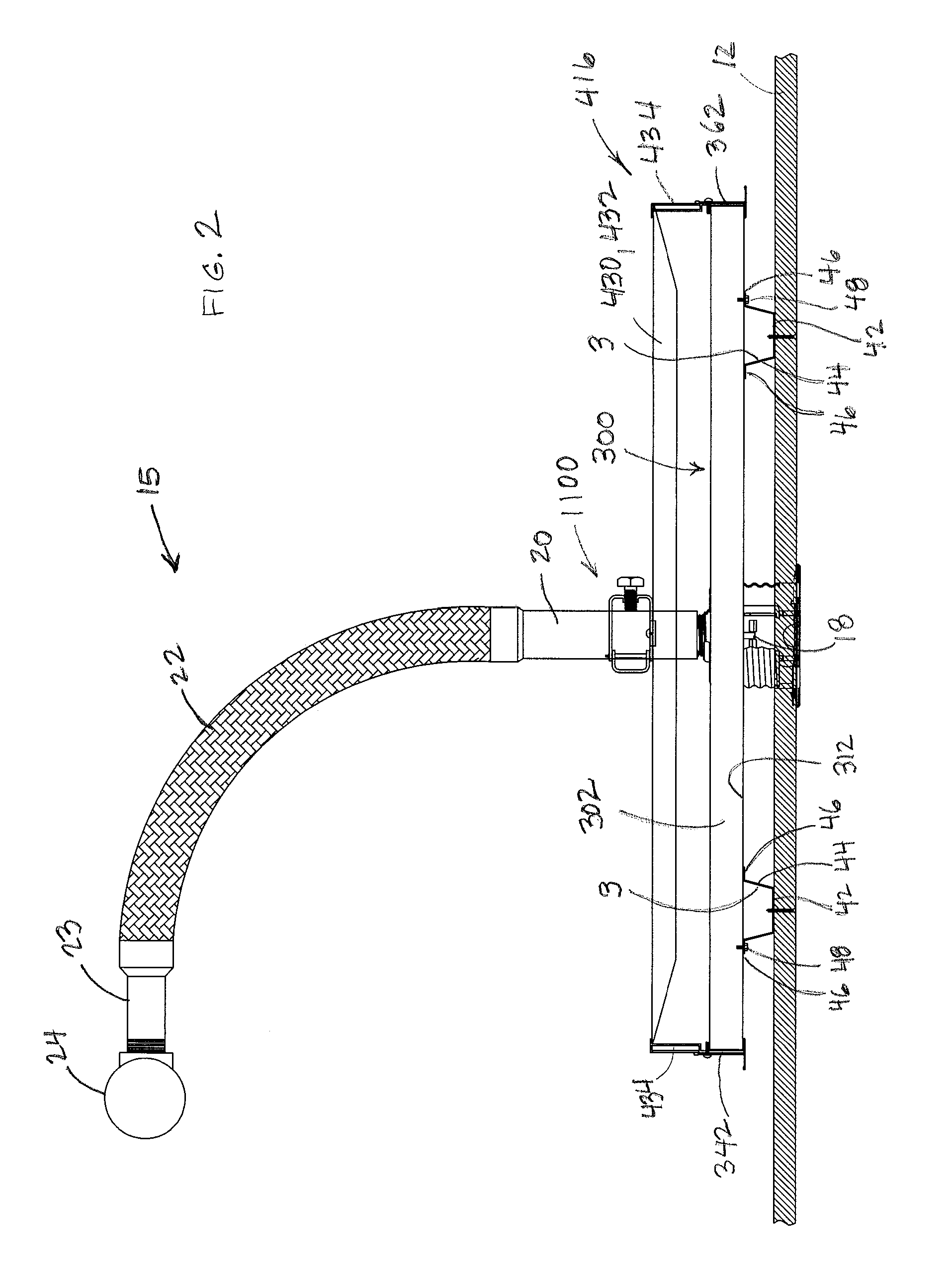

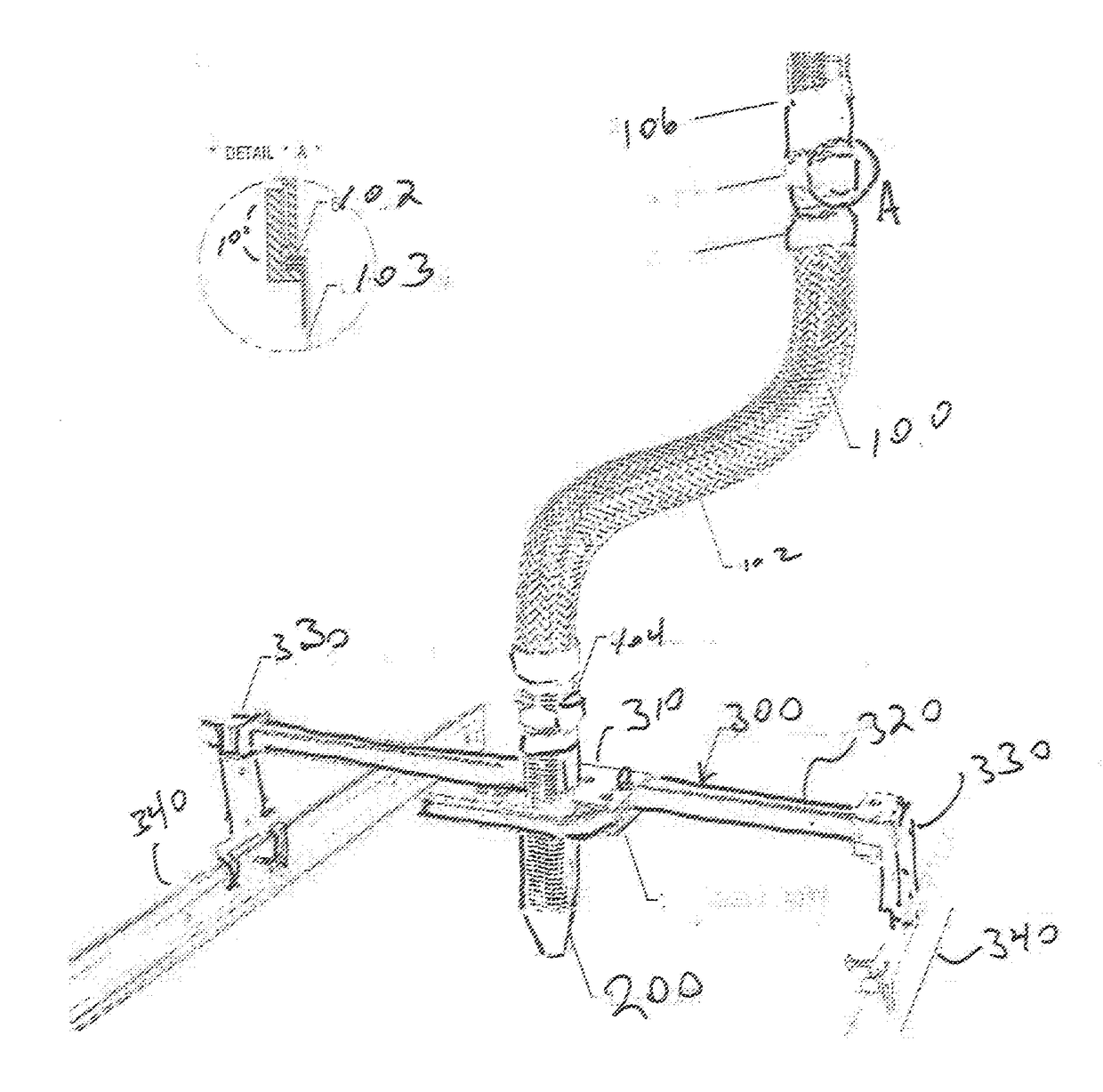

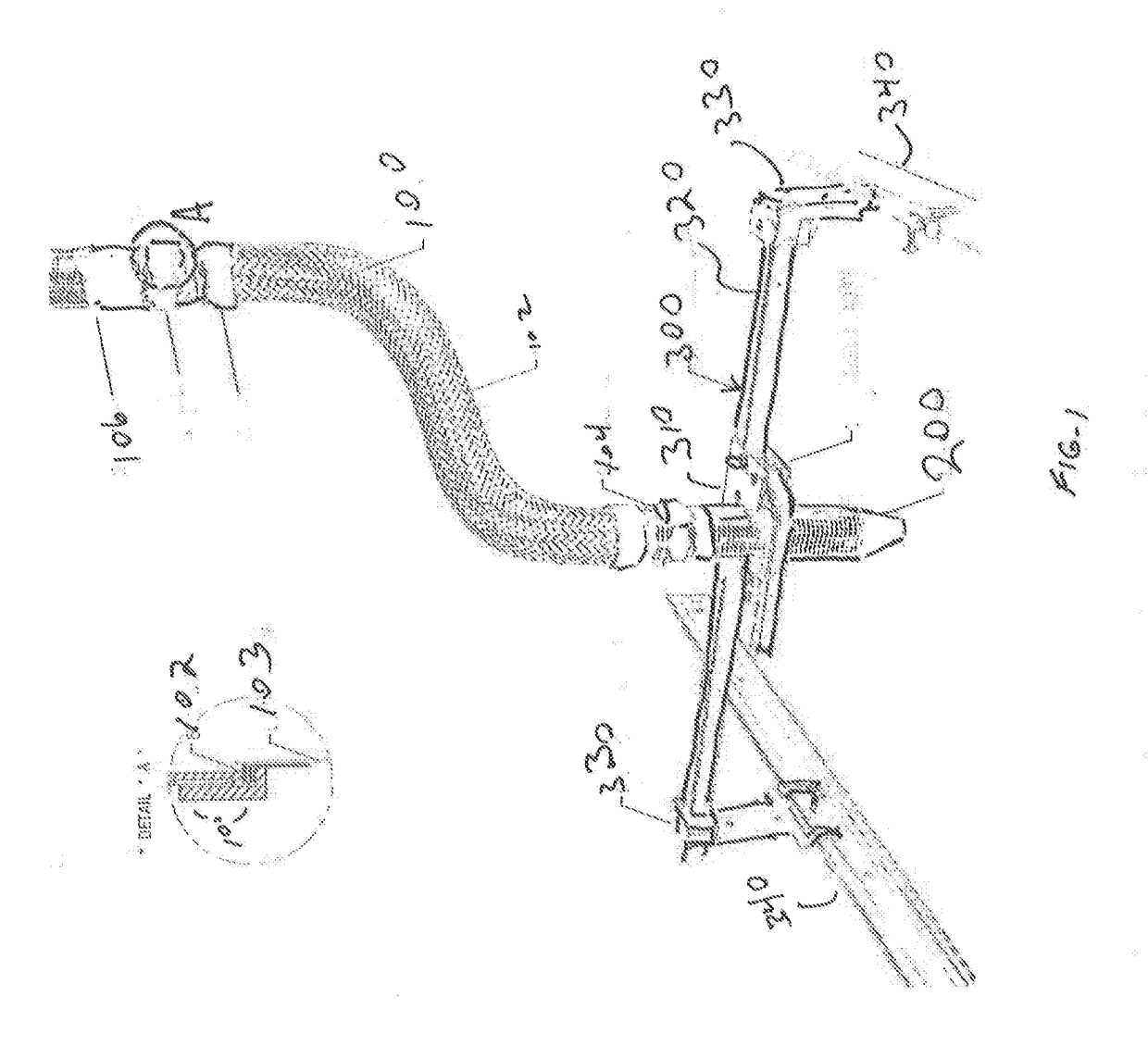

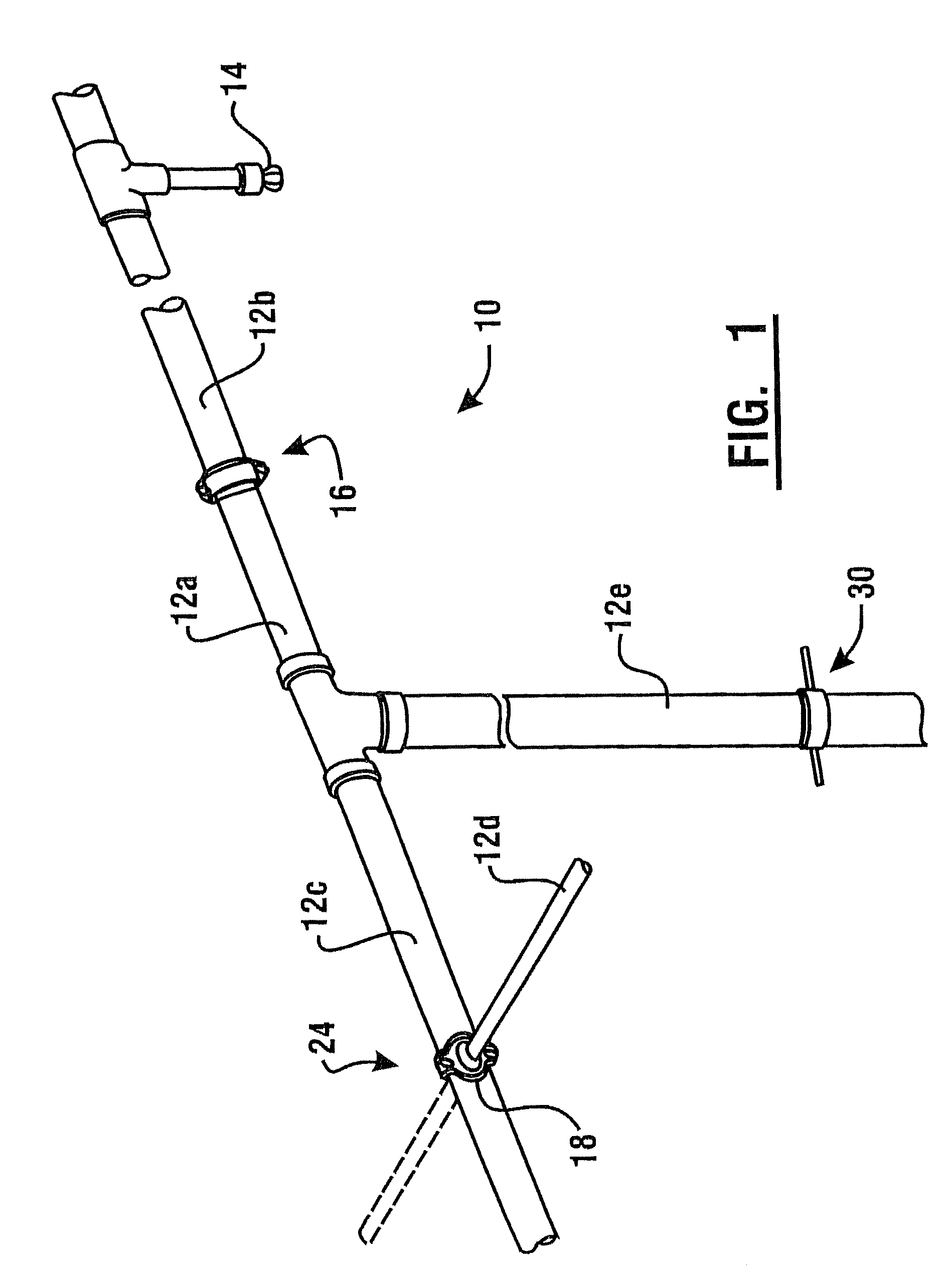

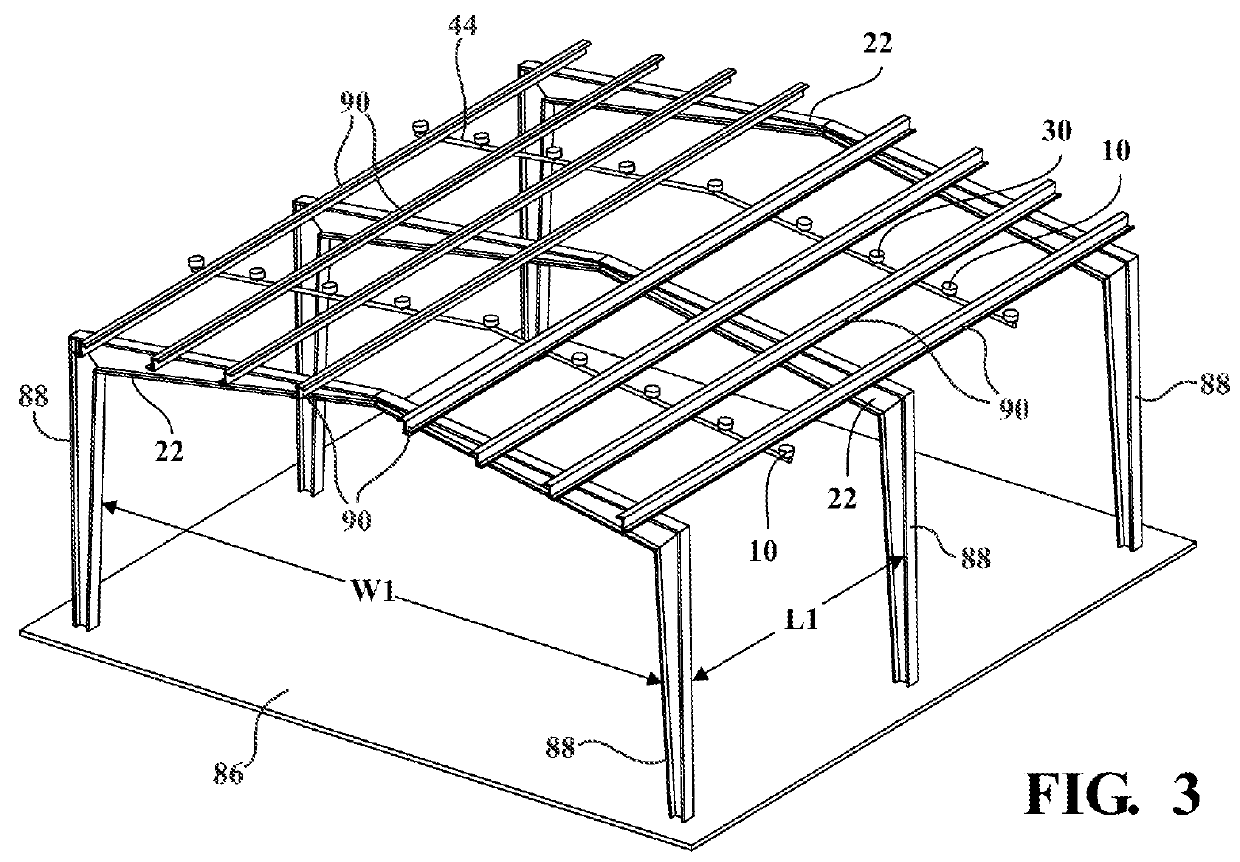

Fire sprinkler flexible piping system, bracing apparatus therefor, and method of installing a fire sprinkler

A bracing apparatus for bracing a flexible pipe extending between a fire sprinkler header pipe and a sprinkler and for holding the sprinkler in a desired location, a flexible piping system having the bracing apparatus, and a method of installing a sprinkler of a sprinkler system having the bracing apparatus. The bracing apparatus has first mounting members that attach to a flexible pipe, and a stiffener bar that extends between the first and second mounting members.

Owner:JENSEN RAYMOND H +1

Fire sprinkler head tool

A fire head sprinkler tool comprising a pair of jaw extensions which may be either integral with or removably connected to a large capacity clamping or locking pliers. The locking pliers have a movable and a fixed jaw, and the jaws define a large cylindrical inner opening. The jaw extensions include upper working portions which further include concave gripping portions. The jaw extensions extend substantially laterally from one side of the jaw portion of the pliers, and the vertical axes of the jaw extensions are offset from the plane of the jaw side at an angle.

Owner:CARTER TOM

Hanger for fire sprinkler pipe

InactiveUS7455268B2Conveniently and economically be and formedConveniently and economically be stampedPipe supportsStands/trestlesFire sprinklerEngineering

A one-piece hanger is formed with a pair of spaced segments or legs joined by an end wall. Each segment has a recess formed in an edge which is open towards the recess on an edge of the opposite segment. The two recesses are aligned so as to create a substantially full opening to receive a pipe. The hanger may be positioned on a pipe with the segments extending substantially parallel to the pipe axis, and the hanger can then be rotated about 90° so that the pipe extends through the substantially full opening formed by the recesses. The hanger end is formed with mounting holes.

Owner:NIBCO INC

Barrier coating corrosion control methods and systems for interior piping systems

Methods and systems for providing cleaning and providing barrier coatings to interior wall surfaces of small diameter metal and composite piping systems in buildings. An entire piping system can be cleaned in one single pass by dry particulates forced by air throughout the building piping system by an external generator, and the entire piping system can be coated in one single pass by a machine also connected exterior to the piping system. Small diameter pipes can be protected by the effects of water corrosion, erosion and electrolysis, extending the life of small diameter piping systems such as copper, steel, lead, brass, cast iron piping and piping systems made of composite materials. The invention meets the National Sanitation Foundation standard for products and services that come into contact with potable water, and the American Water Works Association. Coatings can be applied to pipes having diameters of approximately ⅜″ up to approximately 6″ so that entire piping systems such as potable water lines, natural gas lines, HVAC piping systems, drain lines, and fire sprinkler systems in buildings such as single-family homes to smaller walk-up style apartments to multi-floor concrete high-rise hotel / resort facilities and office towers, as well as high-rise apartment and condominium buildings and schools, can be cleaned and coated to pipes within existing walls. The barrier coating forms an approximately 4 mils or greater covering to the inside of pipes. Entire buildings can return to service within approximately 24 to approximately 96 hours depending on the size of the building piping system.

Owner:PIPE RESTORATION TECH

Parallel-fed nonstagnant integrated water distribution network for domestic water and fire sprinkler application

An intergrated water distribution network supplies the requirements of both domestic and fire sprinkler water fixtures in a dwelling structure. The network includes a plurality of multiport fittings which are interconnected together with flexible conduits. A conventional fire sprinkler is also coupled to the multiport fittings. The network is supplied water by a plurality of water supply lines which originate at a manifold. Individual water fixtures are connected to the distribution system through flexible lines. During use of an water fixture, water flow through essentially the entire system is established. The distribution system can thus characterized as a "nonstagnant" water network.

Owner:KWENCH SYST INT

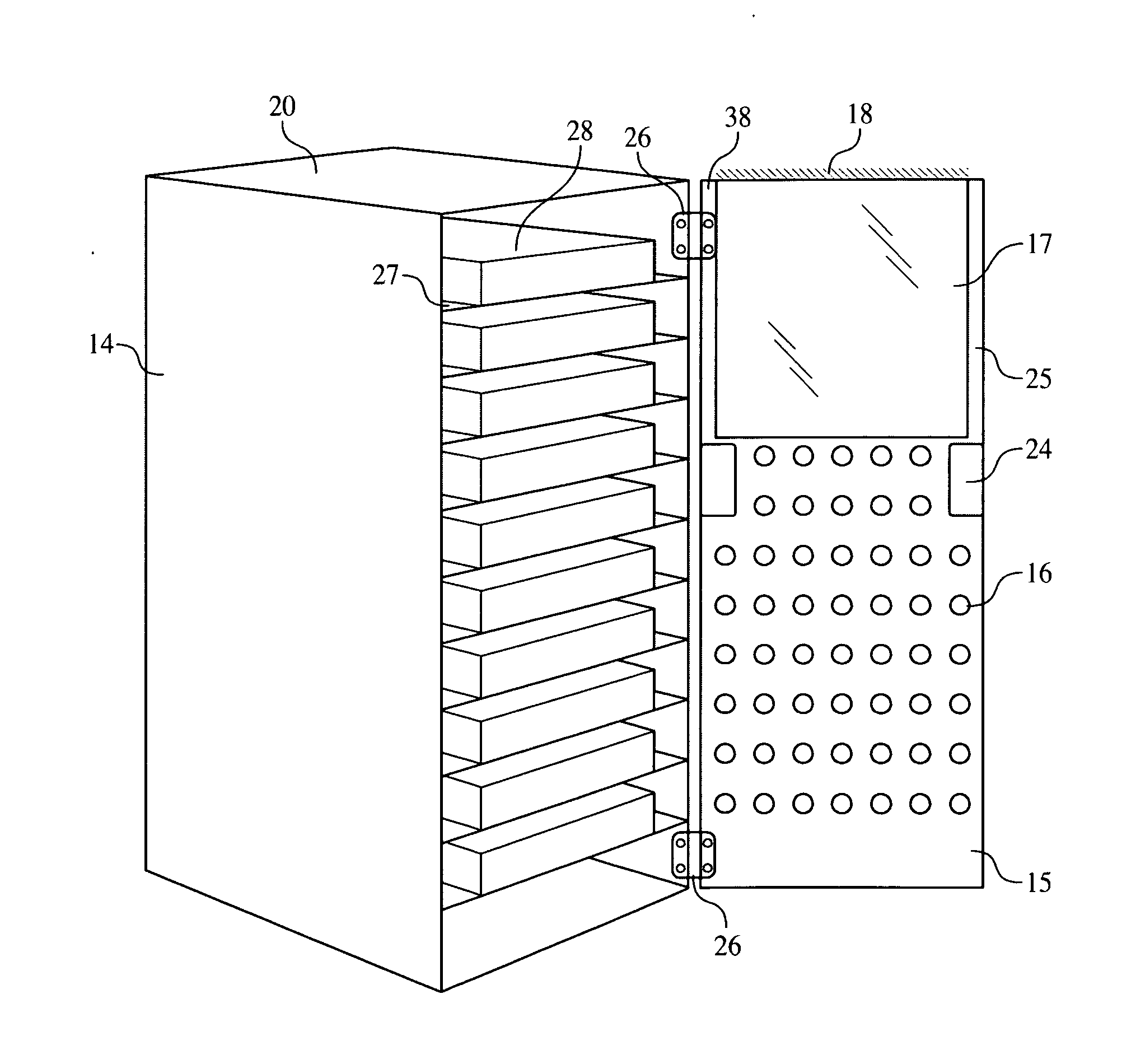

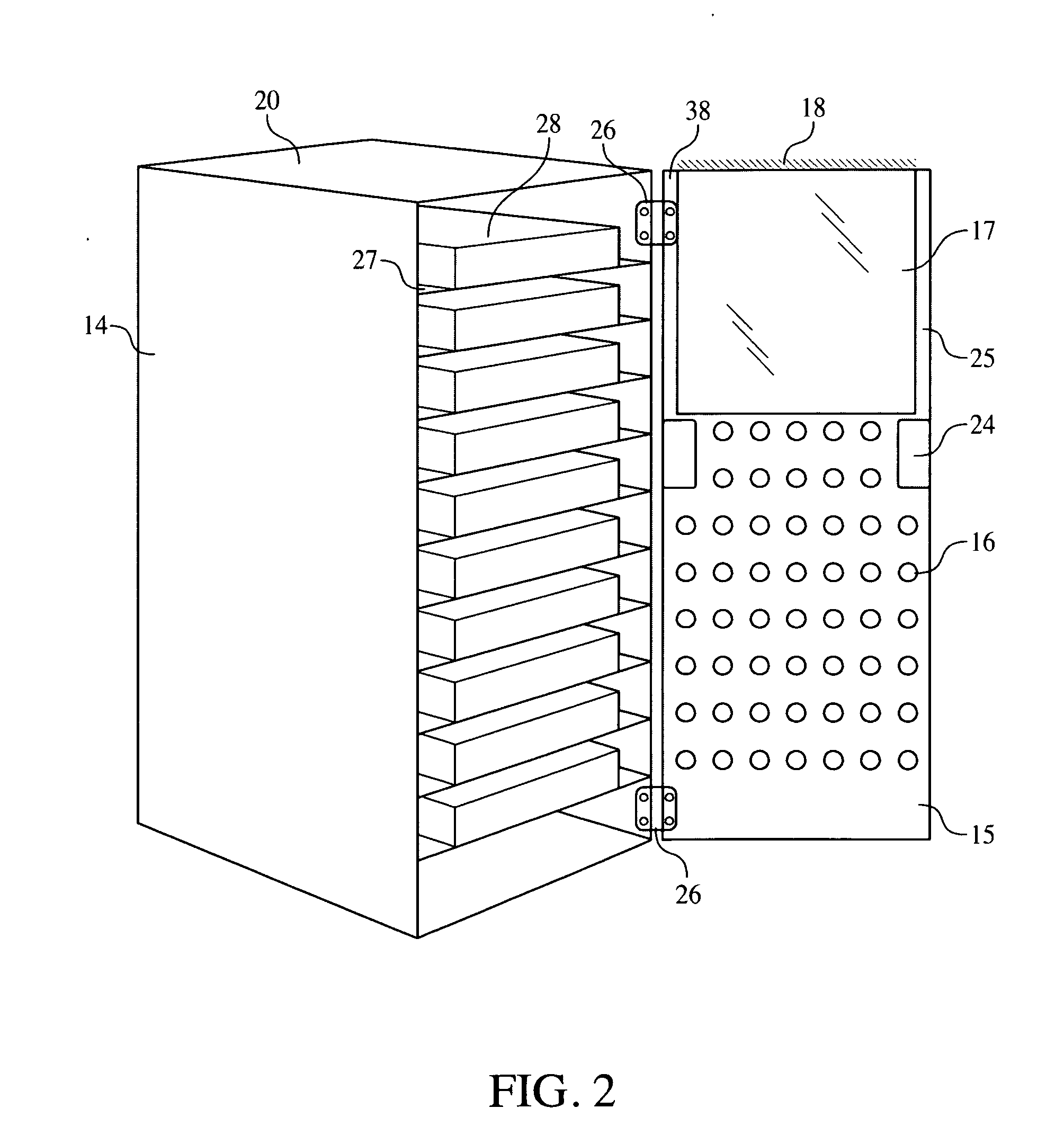

Data center aisle containment system utilizing a movable sash that is integral to the computer rack cabinet

InactiveUS20120281352A1Elevated and loweredDigital data processing detailsCooling/ventilation/heating modificationsSash windowFire sprinkler

An embodiment includes a transparent sash mounted integral to the perforated doors on racks which hold computer servers typically installed in data centers. The racks are arrayed in rows forming cold aisles and hot aisles. Cooled air introduced into the cold aisle flows through the racks and cools the servers, and subsequently is removed from the hot aisle. Embodiment sashes slide vertically and extend above the tops of the racks and form a sealing relationship with the data center ceiling and adjacent sashes, thereby preventing wasteful mixing and recirculation of cooled and heated air over the tops of the racks. Embodiments are raised and lowered manually or automatically. The controls for the movement of the sashes are tied to the building automation and fire alarm systems and the sashes are lowered automatically upon activation of the data center fire suppression system, thereby complying with code requirements and avoiding interference with the fire sprinkler and suppression systems.

Owner:NAMEK RAMZI Y +2

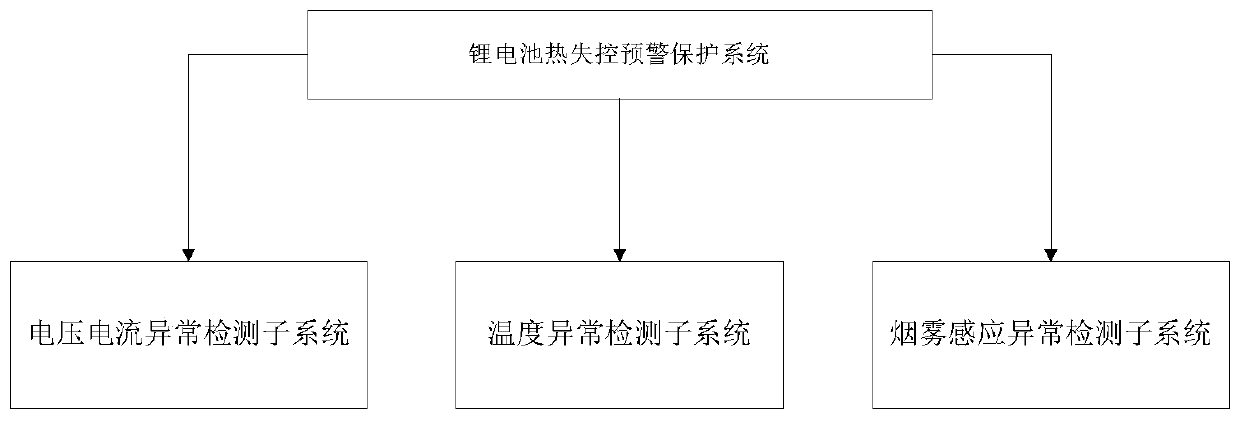

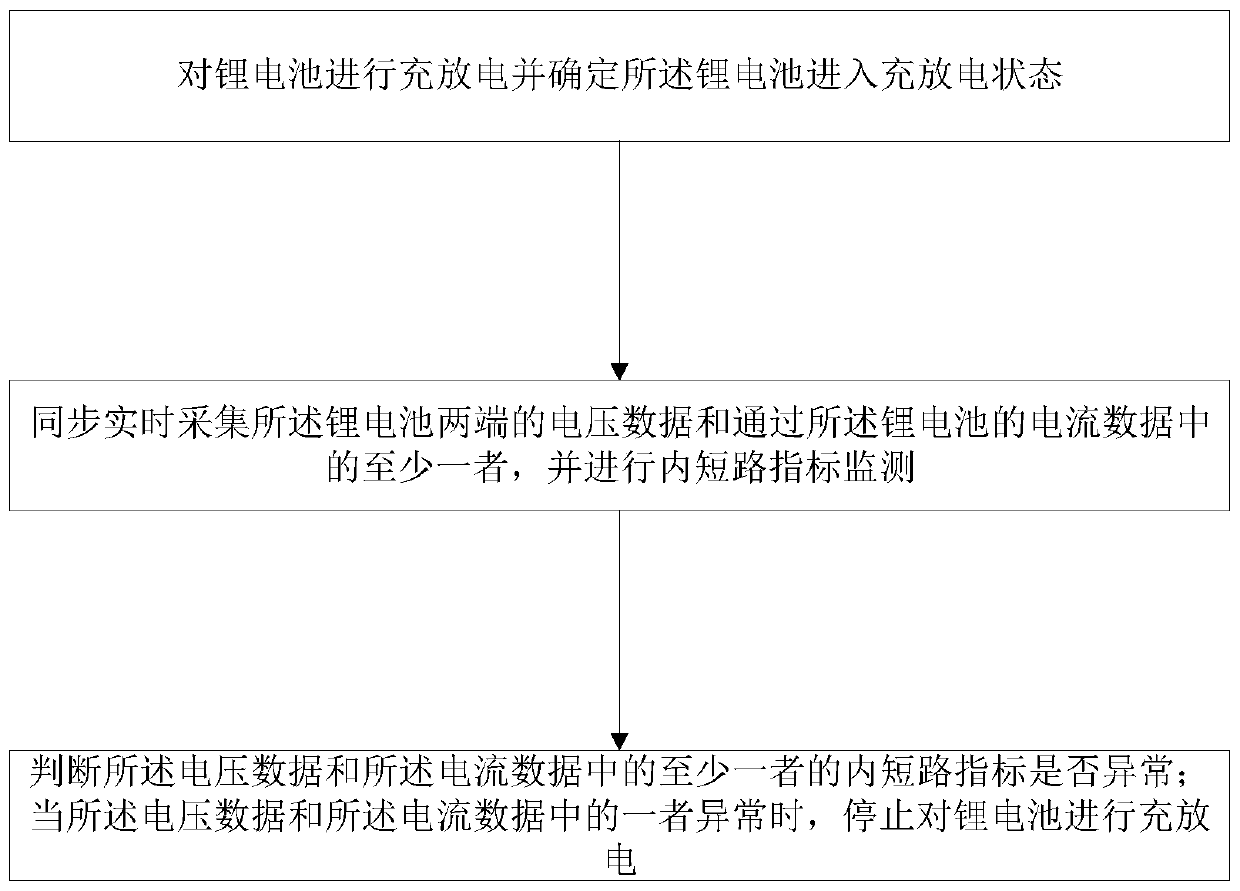

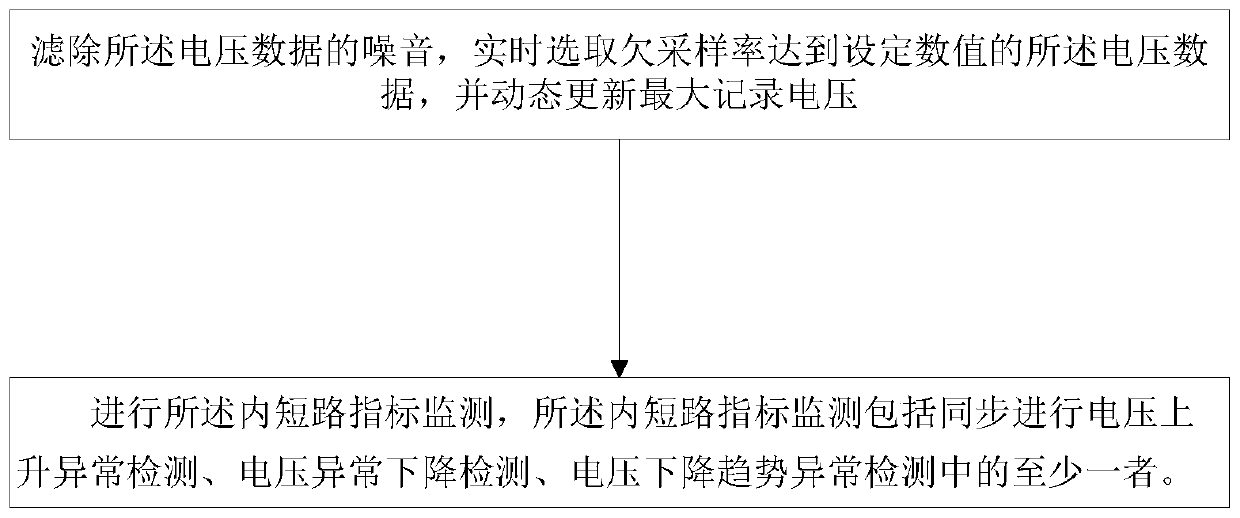

Thermal runaway early warning protection system and method for lithium battery

ActiveCN110350258ARealization of thermal runaway warningAvoid bad consequencesElectrical testingSecondary cells testingFire sprinklerAnomaly detection

The invention provides a thermal runaway early warning protection system for a lithium battery. The system comprises a voltage and current anomaly detection subsystem, a temperature anomaly detectionsubsystem and a smoke induction anomaly detection subsystem, wherein the voltage and current anomaly detection subsystem is used for collecting voltage data at two ends of the lithium battery and dataof current going through the lithium battery in real time in the charge and discharge processes of the lithium battery so as to judge whether the voltage data and the data of current are abnormal, and charging and discharging are stopped when voltage and / or current are / is abnormal; the temperature anomaly detection subsystem is used for collecting the temperature of the lithium battery in real time in the charge and discharge processes of the lithium battery so as to judge whether the temperature exceeds a preset temperature threshold value, and when the temperature exceeds the temperature threshold value, a temperature anomaly alarm is given; and the smoke induction anomaly detection subsystem is used for detecting whether smoke exists in real time in the charge and discharge processes of the lithium battery, and when the smoke is detected, an alarm and a fire sprinkler are started. Thermal runaway early warning for the lithium battery is realized through synergistic effect of the three subsystems, so that negative effects caused by thermal runaway are effectively avoided.

Owner:GUANGDONG HYNN TECH CO LTD

Automatic air release system with shutoff valve

ActiveUS6926023B2Prevent liquid leakageFor quick maintenanceFire rescuePipeline systemsFire sprinklerEngineering

Owner:NAT CITY BANK CO

Residential fire sprinkler water supply system

Described is a limited-demand water supply system for use in residential homes wherein a supply of water is automatically provided to fire sprinklers by means of air pressure. Multiple tanks or vessels in a connected fluid system are partially filled with water and then pressurized with air pressure provided by an air compressor. There is maintained sufficient air pressure to empty the water in the vessel system through the fire sprinkler heads, when open. Preferably, to efficiently comply with most current fire system regulations, a set of vessels of less than about 200 gallons capacity each is filled about two-thirds with water and then air-pressurized to about 150 pounds per square inch.

Owner:PHILLIPS MARK A

Air barrier for datacenter usage which automatically retracts when fire sprinklers are activated

InactiveUS20100108272A1Easy to operateEasy to changeScreensCurtain suspension devicesFire sprinklerData center

An air barrier structure located in an airflow passageway for datacenter usage, which is automatically retractable upon activation of fire sprinklers in the event of a conflagration. The barrier structure is a shade-type roll up member, which in the absence of any complex mechanical structure, will automatically retract about a spring-loaded roller upon the activation of a fire sprinkler, and whereby the barrier incorporates water-soluble structural aspects which will facilitate such automatic retraction upon being impinged upon and dissolved by a flow of water emanating from the fire sprinkler.

Owner:IBM CORP

Hat channel adaptor for sprinkler support assembly

An adaptor is provided that is configured to receive a support assembly for mounting a flexible fire sprinkler fitting in a ceiling support structure formed of parallel, spaced beams. The adaptor includes first and second long sides configured to be secured to each beam of an adjacent pair of beams, and first and second short sides configured to be secured to the support assembly. One end of each long side is joined by the first short side, and an opposed end of each long side is joined by the second short side such that the first and second long sides are parallel to each other and perpendicular to the first and second short sides, whereby the adaptor is a generally elongated, hollow, rectangular structure. The adaptor permits the support assembly to be mounted in a suspended ceiling formed of hat channel or metal stud furring.

Owner:ASC ENGINEERED SOLUTIONS LLC

Fire sprinkler water catching apparatus

ActiveUS6845784B2Easy and efficient to manufactureDurable and reliable constructionLiquid fillingPipe elementsFire sprinklerEngineering

A fire sprinkler water catching apparatus includes a funnel member which has a funnel top portion, a funnel bottom portion, a funnel drain portion connected to the funnel bottom portion, and a pole-reception fitting. A drain hose is connected to the funnel drain portion. The end of a support pole is received in the pole-reception fitting. The fire sprinkler water catching apparatus of the invention is used to catch and carry away unwanted water that is sprayed from a fire sprinkler when the fire sprinkler is spraying water at an unwanted time, such as when a fusible link on the fire sprinkler is accidentally broken. Preferably, a flexible funnel cover is fitted onto the top of the funnel top portion. The flexible funnel cover includes a plurality of flexible and resilient funnel cover flaps.

Owner:PASCZNK JAMES J

Hat channel adaptor for sprinkler support assembly

An adaptor is provided that is configured to receive a support assembly for mounting a flexible fire sprinkler fitting in a ceiling support structure formed of parallel, spaced beams. The adaptor includes first and second long sides configured to be secured to each beam of an adjacent pair of beams, and first and second short sides configured to be secured to the support assembly. One end of each long side is joined by the first short side, and an opposed end of each long side is joined by the second short side such that the first and second long sides are parallel to each other and perpendicular to the first and second short sides, whereby the adaptor is a generally elongated, hollow, rectangular structure. The adaptor permits the support assembly to be mounted in a suspended ceiling formed of hat channel or metal stud furring.

Owner:ASC ENGINEERED SOLUTIONS LLC

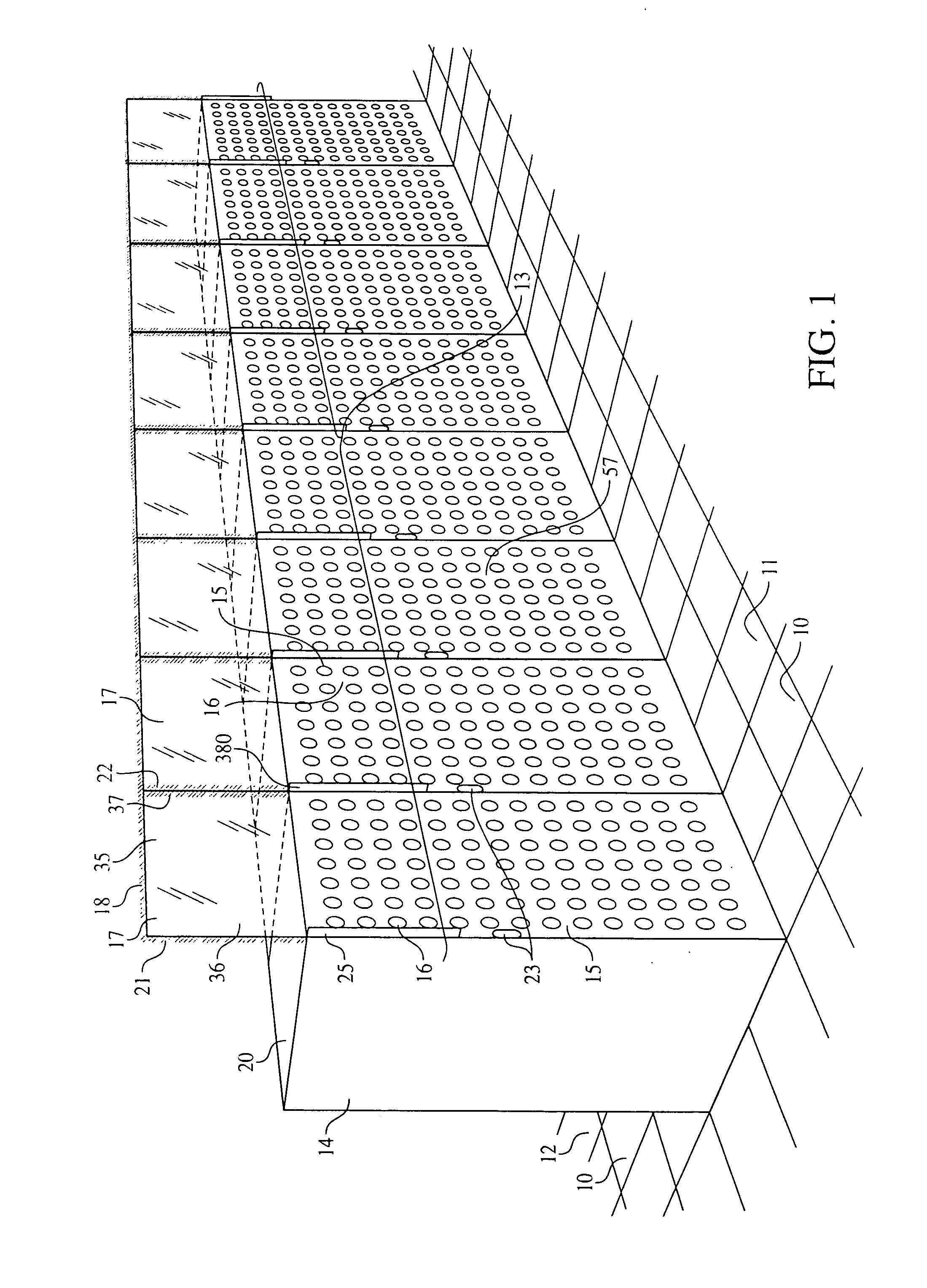

Fire sprinkler system

A fire suppression system in which side-discharge fire sprinklers are fitted to opposite sides of a supply line and aimed so that their coverage areas point in opposite directions. The fire sprinklers are alternated on left and right-hand sides of the supply line, and are spaced apart at a consistent interval. Each fire sprinkler includes a deflector configured to disperse the outflow of water over a non-circular coverage area. When two supply lines are installed next to each other so that half of the sprinklers on one supply line point toward the other supply line, and vise versa, the fire sprinklers are staggered so that their respective coverage areas are interlaced in the intermediate space.

Owner:FIREBIRD SPRINKLER COMPANY

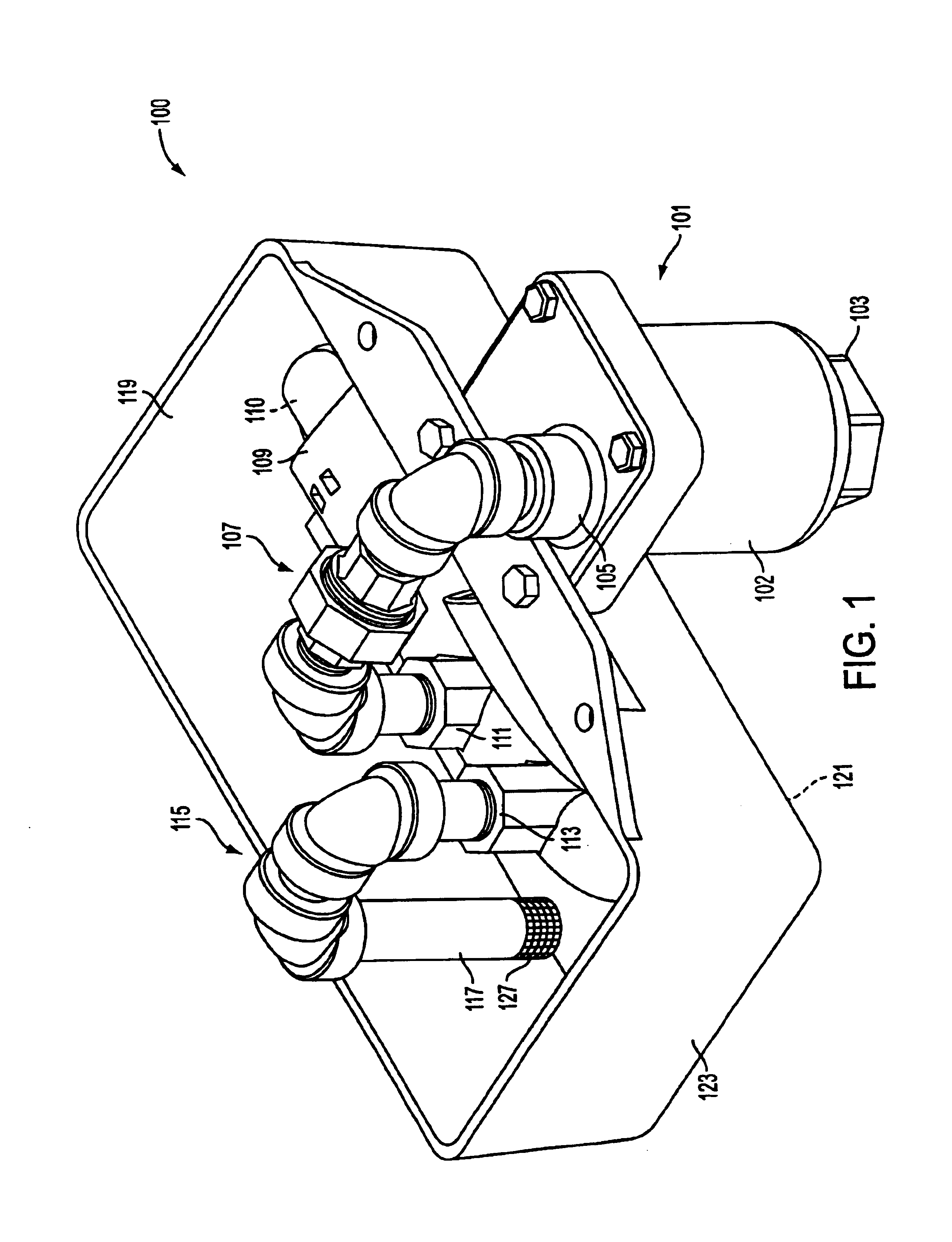

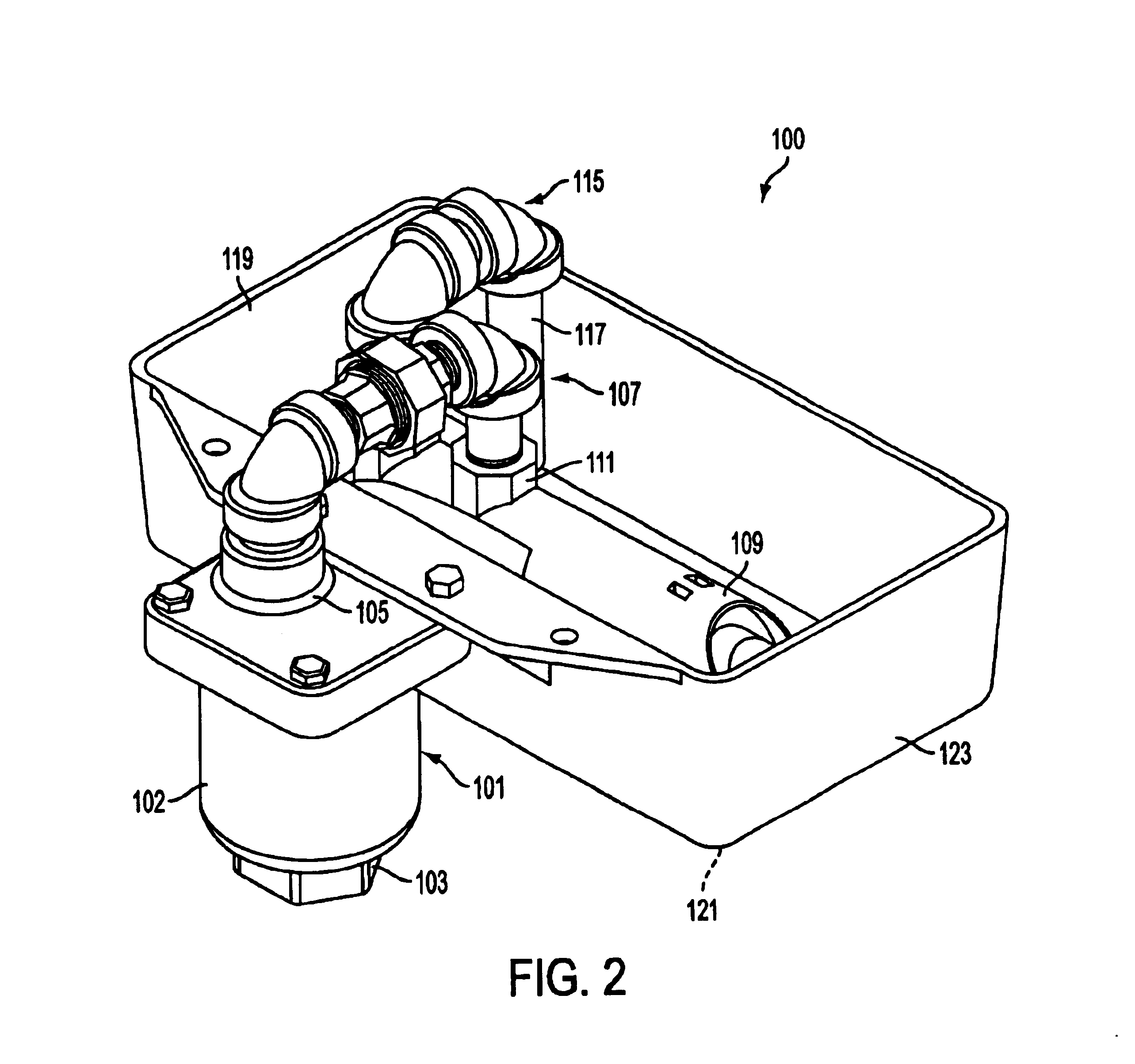

Emergency power shutdown management system

ActiveUS20070090940A1Effectively consolidatesEffective controlElectric testing/monitoringElectric/electromagnetic visible signallingEngineeringBiological activation

An emergency power shutdown management system (EPSMS) comprises a programmable logic controller (PLC), relays coupled to the outputs of the PLC for shutting down electrically operated equipment, and indicators for indicating the status of the EPSMS and the controlled equipment. The PLC receives input signals from a fire control panel including a 2nd alarm signal which is generated after the fire control panel has detected smoke, fire or an explosion with two or more detectors and a system discharge signal which is generated when the fire control panel triggers fire sprinklers or the release of other fire or explosion suppression agents. The PLC also receives an emergency power off (EPO) signal from an EPO switch which is activated to immediately shut down all electrically operated equipment and power distribution units in a protected area. The indicators include a 2nd alarm indicator for indicating a 2nd alarm activation; a system discharge indicator for indicating a discharge of fire or explosion suppression agents; and an emergency power off indicator for indicating an emergency power off situation. The relays include 2nd alarm equipment relays coupled with a first set of equipment; system discharge relays coupled with a second set of equipment; and shunt trip relays coupled with a third set of equipment. All of the components of the EPSMS are housed within a single cabinet for consolidating the control and alert functions of the EPSMS in a single location.

Owner:FIKE CORP

Fire suppression fluid containing a carboxylate salt

InactiveUS20140138105A1Low viscosityInhibit flammabilityFire rescueHeat-exchange elementsCarbon numberFire sprinkler

An aqueous fire sprinkler fluid containing low carbon number carboxylate salts for freezing point depression is described. The salts may be used in conjunction with glycols. The salts decrease the combustibility of the glycol containing fluids and give lower viscosity than higher glycol fluids, both benefitting fire sprinkler systems. These salt solutions are friendly to metal and CPVC pipes and are thus useful for fire sprinkler systems by not causing environmental stress cracking of the CPVC components and not being corrosive to the metal parts.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Apparatus for flow detection, measurement and control and method for use of same

InactiveUS7221281B1Eliminate stagnationEliminate dangerValve arrangementsMeasurement of fluid loss/gain rateFire sprinklerDifferential pressure

A flow sensor having an inlet and an outlet comprising: a plate moving in response to fluid flow therethrough, being displaced further as flow increases; a sensor for determining moving plate's position and creating an electronic signal related thereto; a biasing device for biasing the plate towards the sensor's inlet end. The sensor may include a sealing device for preventing flow therethrough until a specified differential pressure is reached allowing the device to be used as a bypass mechanism. The sealing device may also constitute a check valve device to prevent flow in an undesired direction. The method using the sensor in multipurpose piping systems includes use of the apparatus in a system incorporating at least one fire sprinkler, the piping system also preferably providing at least one other use in the structure. The other use in the structure may be supplying domestic needs, or supplying heating / cooling water for a heating / air conditioning system.

Owner:YOUNG RICHARD

Loop hanger with integral washer

InactiveUS20100038494A1Minimize deflectionEasy to installPipe supportsMining devicesFire sprinklerControl theory

A loop hanger, such as for supporting fire sprinkler pipe, contains an integral fold-over washer with an annular stiffening rib, the benefits of which are to minimize deflection of the horizontal ears of the hanger under an applied load and offer simplified installation by eliminating the need for additional flat washers.

Owner:ERICO INT

Barrier coating corrosion control methods and systems for interior piping systems

Methods and systems for providing cleaning and providing barrier coatings to interior wall surfaces of small diameter metal and composite piping systems in buildings. An entire piping system can be cleaned in one single pass by dry particulates forced by air throughout the building piping system by an external generator, and the entire piping system can be coated in one single pass by a machine also connected exterior to the piping system. Small diameter pipes can be protected by the effects of water corrosion, erosion and electrolysis, extending the life of small diameter piping systems such as copper, steel, lead, brass, cast iron piping and piping systems made of composite materials. The invention meets the National Sanitation Foundation standard for products and services that come into contact with potable water, and the American Water Works Association. Coatings can be applied to pipes having diameters of approximately ⅜″ up to approximately 6″ so that entire piping systems such as potable water lines, natural gas lines, HVAC piping systems, drain lines, and fire sprinkler systems in buildings such as single-family homes to smaller walk-up style apartments to multi-floor concrete high-rise hotel / resort facilities and office towers, as well as high-rise apartment and condominium buildings and schools, can be cleaned and coated to pipes within existing walls. The barrier coating forms an approximately 4 mils or greater covering to the inside of pipes. Entire buildings can return to service within approximately 24 to approximately 96 hours depending on the size of the building piping system.

Owner:PIPE RESTORATION TECH

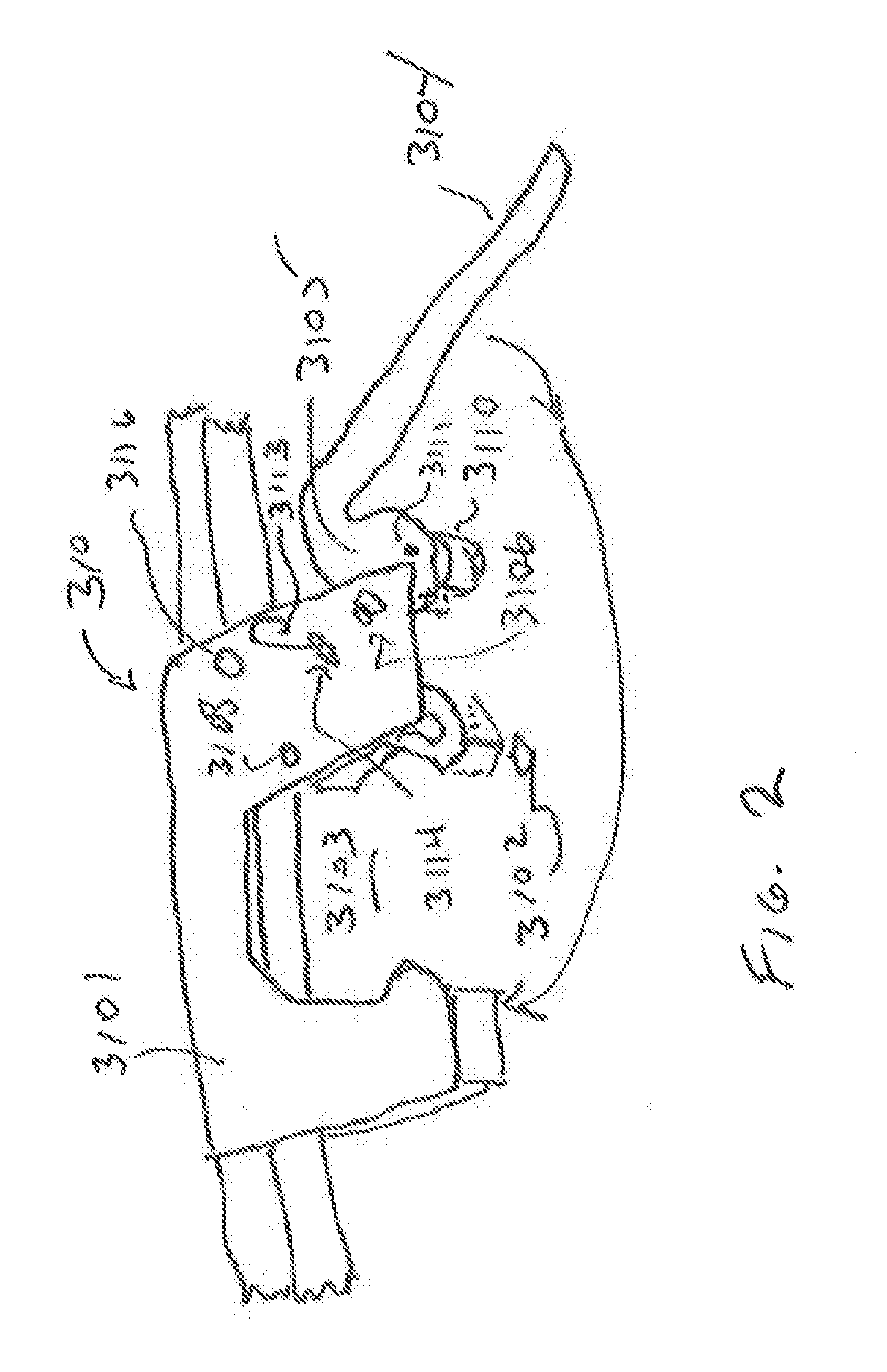

Bracket for installation of fire sprinklers

InactiveUS20170197101A1Less skilled labor timeLess skilled costPipe supportsSpraying apparatusFire sprinklerEngineering

A bracket has a length of bar stock, with end brackets that fit over a rail or bar that forms part of a suspended ceiling or the like. The end brackets may be secured permanently to the bar stock, or their location along the bar stock may be adjustable. A central bracket is mounted on, and can preferably slide along the length of, the bar stock. The central bracket defines a bay in front of the bar stock in which a sprinkler fitting is received, and a hinged lever at the front of the central bracket can be swung shut and locked, to secure the sprinkler in place. Preferably closing the lever also presses the fitting against the bar stock, and secures the central bracket in its location along the bar stock.

Owner:RELIABLE AUTOMATIC SPRINKLER

Automatic fire sprinkler having a variable orifice

InactiveUS7237619B2Reduce the cross-sectional areaReduce in quantityCheck valvesSpray nozzlesFire sprinklerEngineering

An automatic fire sprinkler having a variable orifice, the sprinkler having a variable orifice associated with the automatic fire sprinkler, and wherein the orifice is responsive to the water inlet pressure of the sprinkler.

Owner:MEHR RALPH R

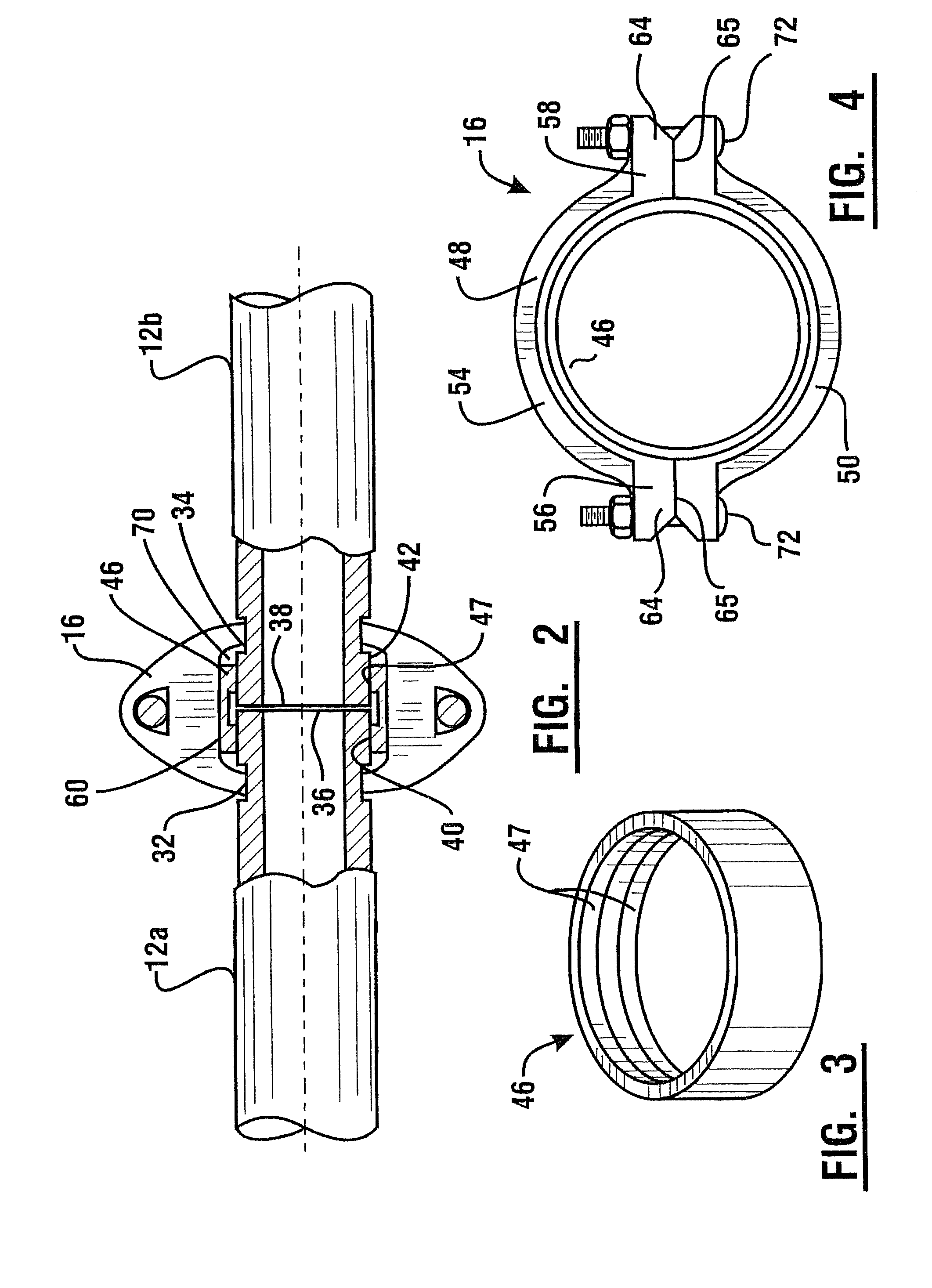

System And Method Of Assembly Of CPVC Fire Sprinkler System Employing Mechanical Couplings And Supports

ActiveUS20070205004A1Improve impact resistanceImproving flow enhancerPipe supportsPipeline expansion-compensationFire sprinklerCoupling

Fire sprinkler system comprising a network of CPVC pipe lengths in which at least some of the pipe lengths are interconnected with mechanical devices having resilient sealing members that are chemically compatible with the CPVC composition. Repairs and system modifications can be made without the use of solvent cement. In-line joints are formed with a coupling device including a pair of arcuate coupling segments having a first end, a second end, and an interior concave surface extending between the first end and the second end. A longitudinal channel extends along the concave surface. At least one mechanical fastener is operative to detachably connect the pair of coupling segments. A resilient annular seal is located within the longitudinal channel of each segment. A branching device connects a branch pipe to a main pipe through an orifice in the main pipe utilizing a saddle-like sealing member. The pipe assemblies are able to pass UL testing protocols for wet fire sprinkler systems.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Fire sprinkler with flue-penetrating non-circular spray pattern

ActiveUS9381386B2Evenly dispersedNot be excessively suppliedSpray nozzlesFire rescueFire sprinklerEngineering

Owner:FIREBIRD SPRINKLER COMPANY

Rotatable fire sprinkler fitting

ActiveUS20080012327A1Fluid pressure sealed jointsJoints with sealing surfacesFire sprinklerScrew thread

A fire sprinkler fitting has a cylindrical body and an insert. The insert has an inner end which is disposed within a proximal portion of the bore, such that the outer end protrudes beyond the open bore end by a distance D. The outer end has internal threads which are sized and dimensioned to accept and retain a fire sprinkler therein. The insert is rotatable within the body without effecting the distance D.

Owner:SPEARS MFG

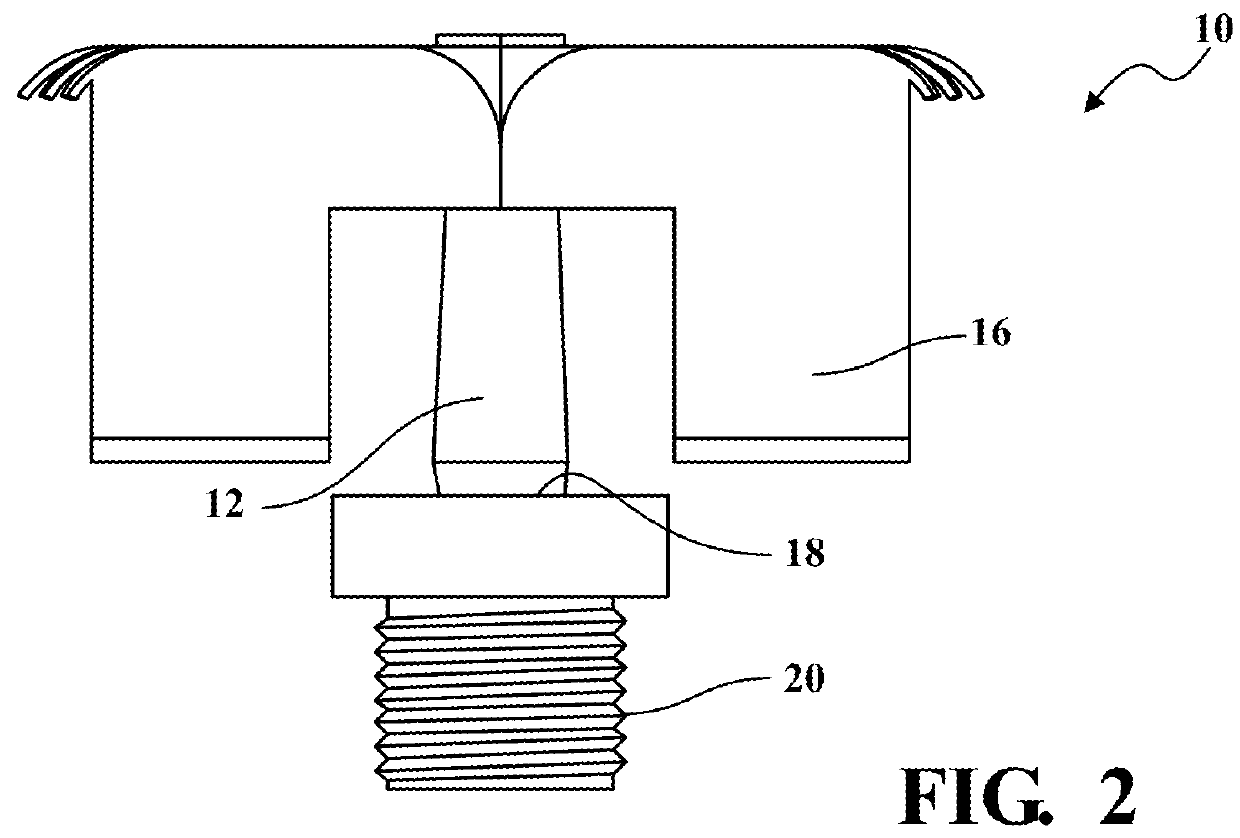

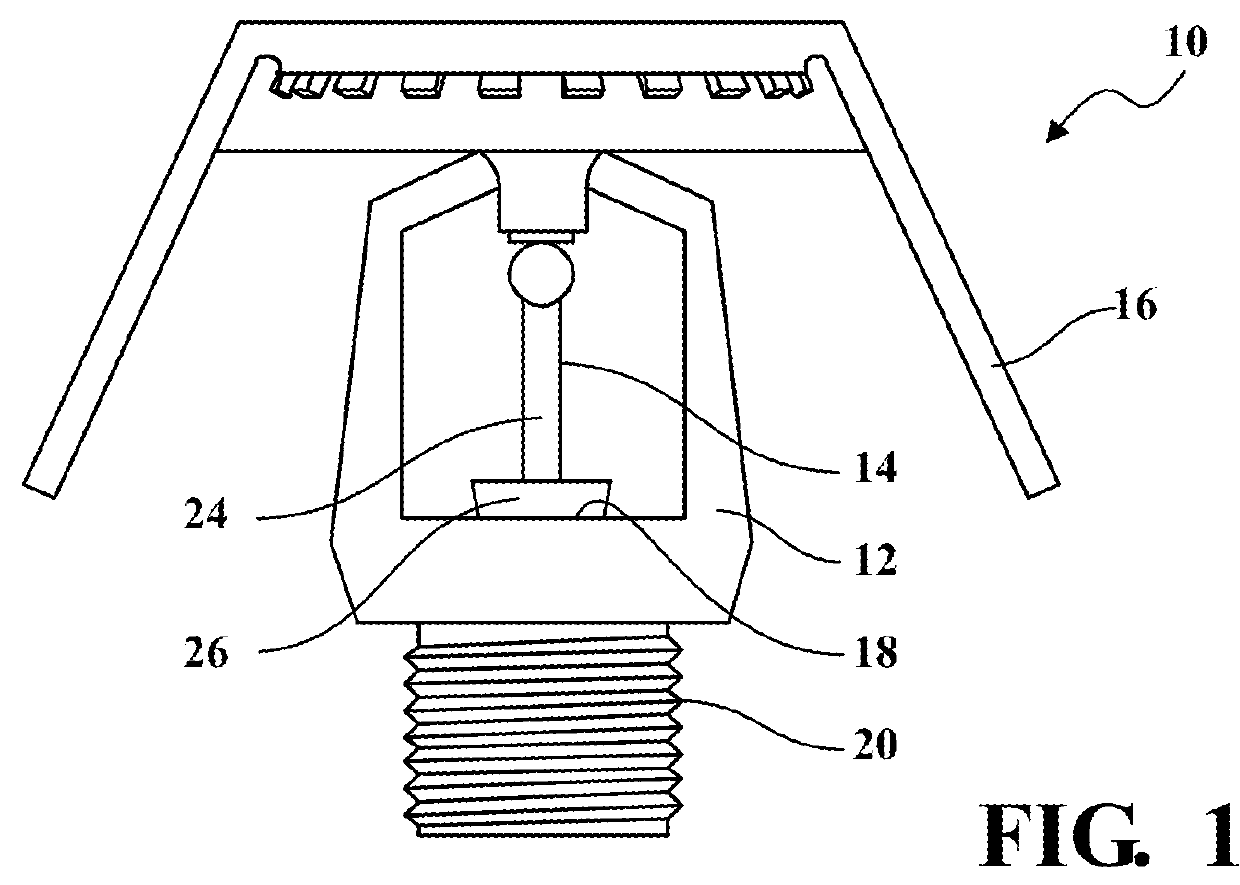

Lodgment prevention arrangements for fire sprinklers

A fire protection sprinkler is provided. The sprinkler includes a body having an output orifice and a flange; a seal cap to seal a flow of fluid from the output orifice; and a thermally-responsive element positioned to releasably retain the seal cap and constructed to separate into a plurality of portions upon exposure to a predetermined temperature. The sprinkler also includes at least one deflector support member, a deflector connected to the deflector support member, and at least one arm extending from each of the deflector support members. Each of the arms has a free end positioned in spaced relation to the thermally-responsive element to contact the portions of the thermally-responsive element upon separation thereof. In another embodiment, the sprinkler includes at least one arm extending from the flange, and the arms may be formed as a bracket.

Owner:RELIABLE AUTOMATIC SPRINKLER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com