Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1201 results about "Bar stock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bar stock, also (colloquially) known as blank, slug or billet, is a common form of raw purified metal, used by industry to manufacture metal parts and products. Bar stock is available in a variety of extrusion shapes and lengths. The most common shapes are round (circular cross-section), rectangular, square and hexagonal or hex. A bar is characterised by an "enclosed invariant convex cross-section", meaning that pipes, angle stock and objects with varying diameter are not considered bar stock.

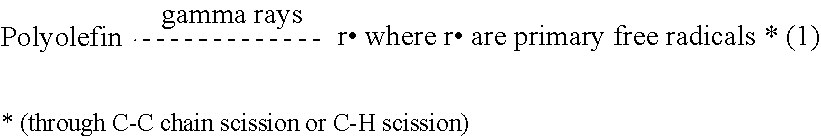

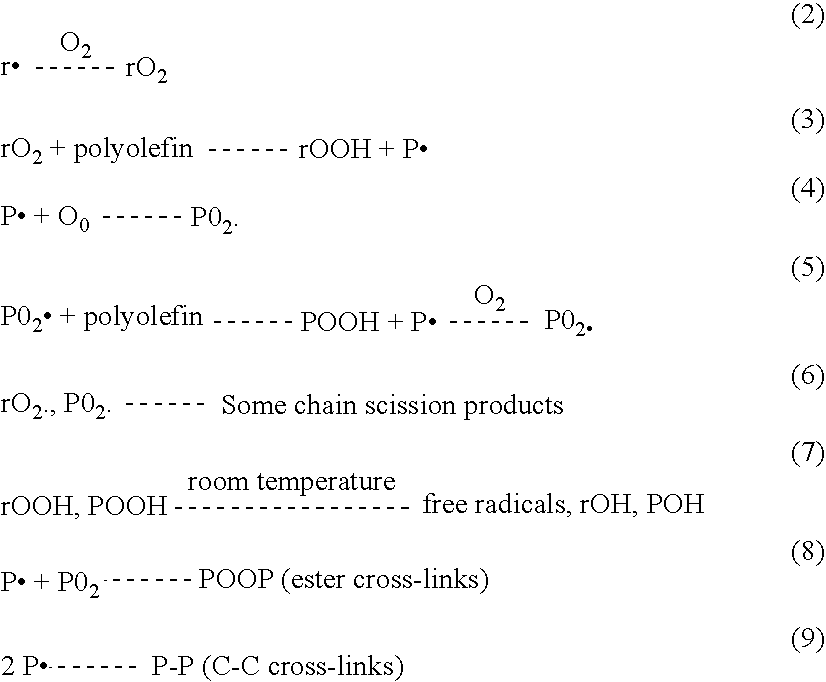

Non-oxidizing polymeric medical implant

InactiveUS20050059750A1Improve antioxidant capacityPrevent further oxidationSurgeryPharmaceutical containersCross-linkNitrogen gas

A medical implant made of polymeric material having an increased oxidation resistance is formed by a method including the steps of placing a resin powder in a sealed container. A substantial portion of the oxygen is removed from the sealed contained by either a vacuum, an oxygen absorbent or by flushing with inert gas. The container is then repressurized with a gas such as nitrogen, argon, helium or neon so that long term storage may be possible. On use, the resin in transferred to a forming device which both melts and forms the resin in an oxygen reduced atmosphere to produce a polymeric raw material such as a rod or bar stock. The medical implant is then formed from this raw material annealed and sealed in an airtight package in an oxygen reduced atmosphere. The implant is then radiation sterilized and thereafter annealed in the package for a predetermined time and temperature sufficient to form cross-links between any free radicals in neighboring polymeric chains.

Owner:HOWMEDICA OSTEONICS CORP

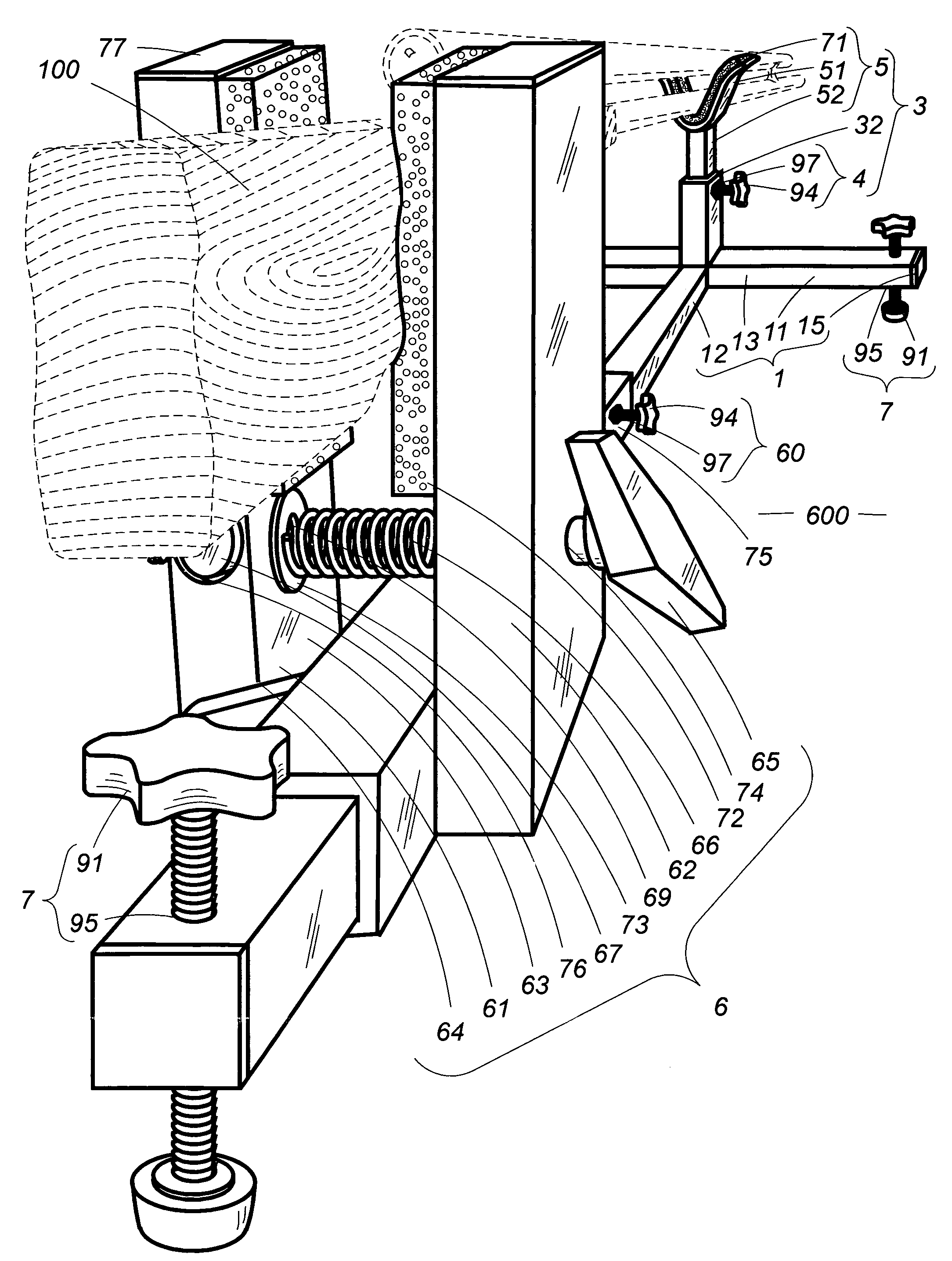

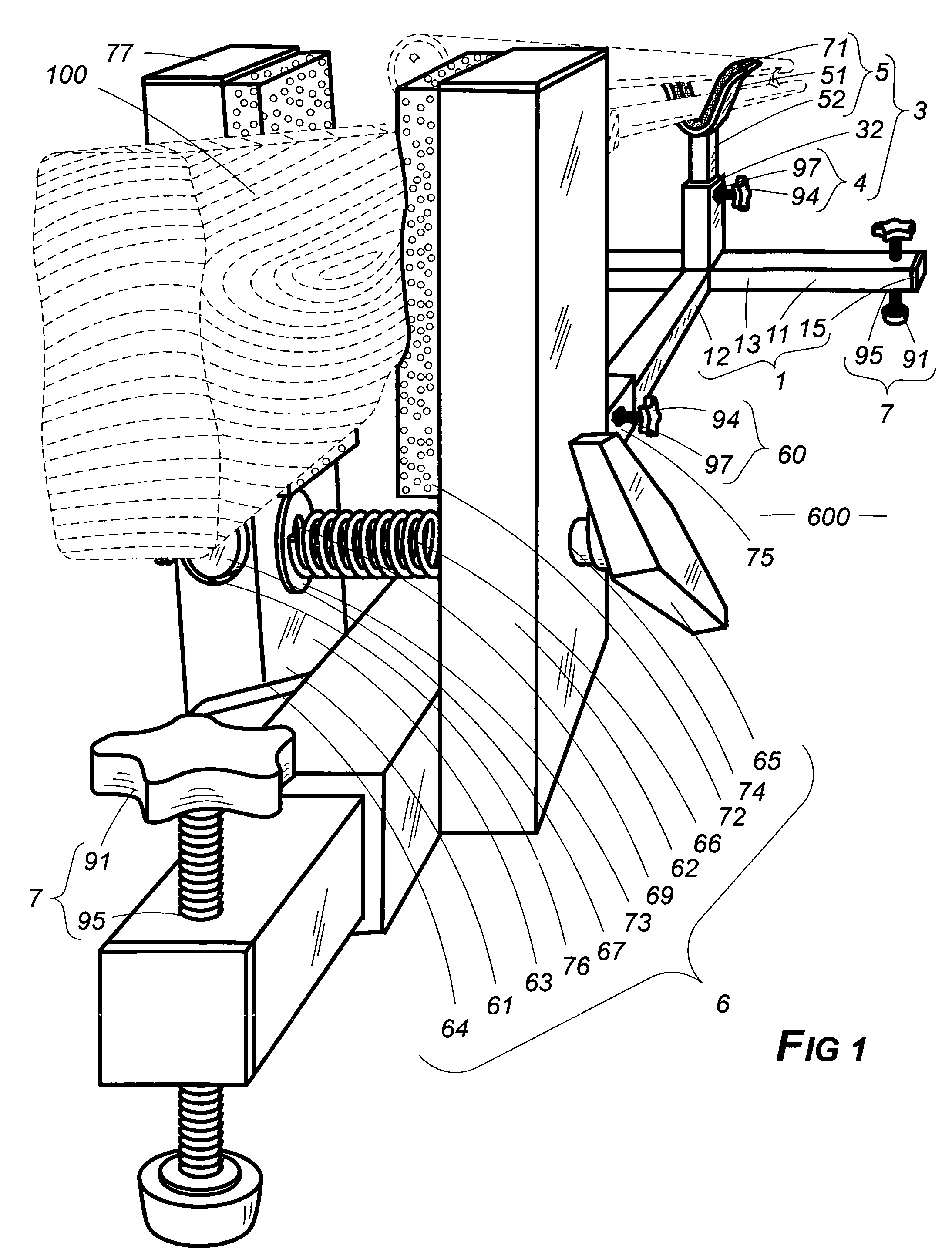

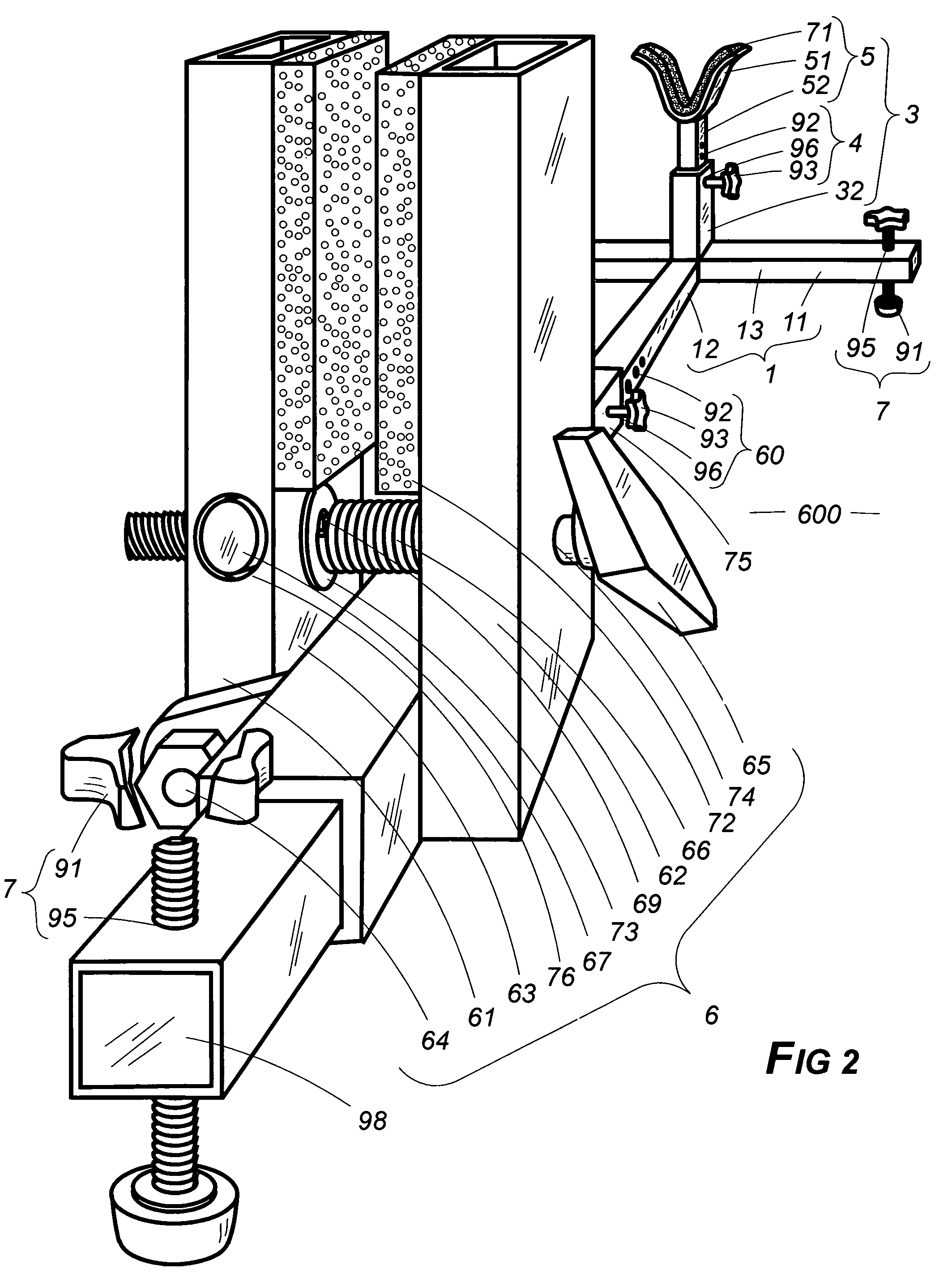

Firearm support assembly

Height and length are adjustable at several points. There is a special type of vise for holding the gunstock. As usual, the vise bolt pulls the movable plate toward the fixed one but, like some of the vise's predecessors, traces out an arc at the top, pivoting from the bottom as the bolt, situated just above the pivot, is turned. Within the movable plate a special cylinder is situated which gives and turns freely in response to the bolt's advance and withdrawal in passing through a threaded tunnel within it. This action prevents the biting down or binding upon the bolt which would otherwise occur because of the plate's pivoted travel as the bolt is advanced or withdrawn. The support's framework, best made from economical tubular bar-stock, is adjustable for leveling and leaning corrections and include anchoring blocks within the structure through which leveling bolts pass.

Owner:KNITT CURT THOMAS

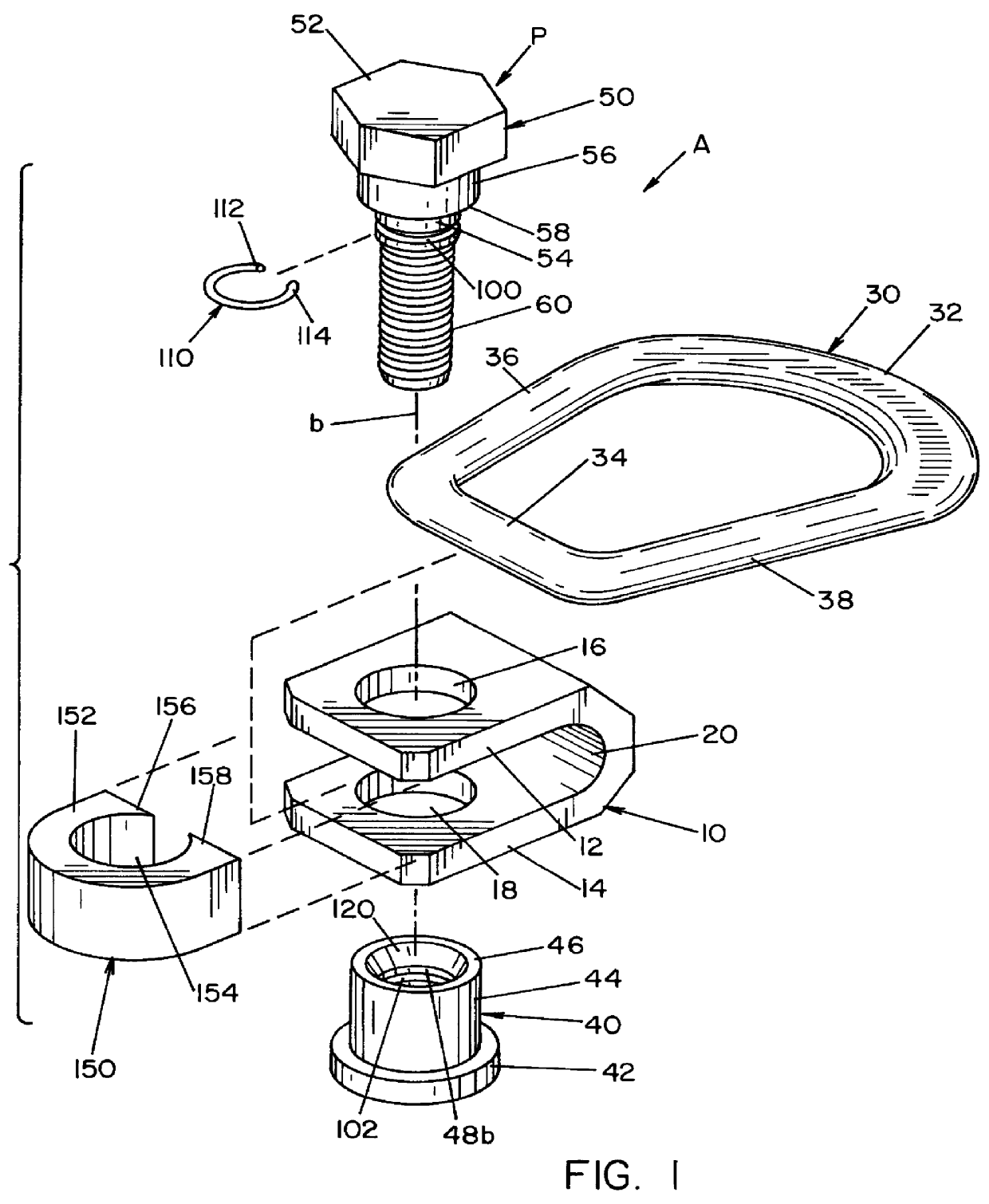

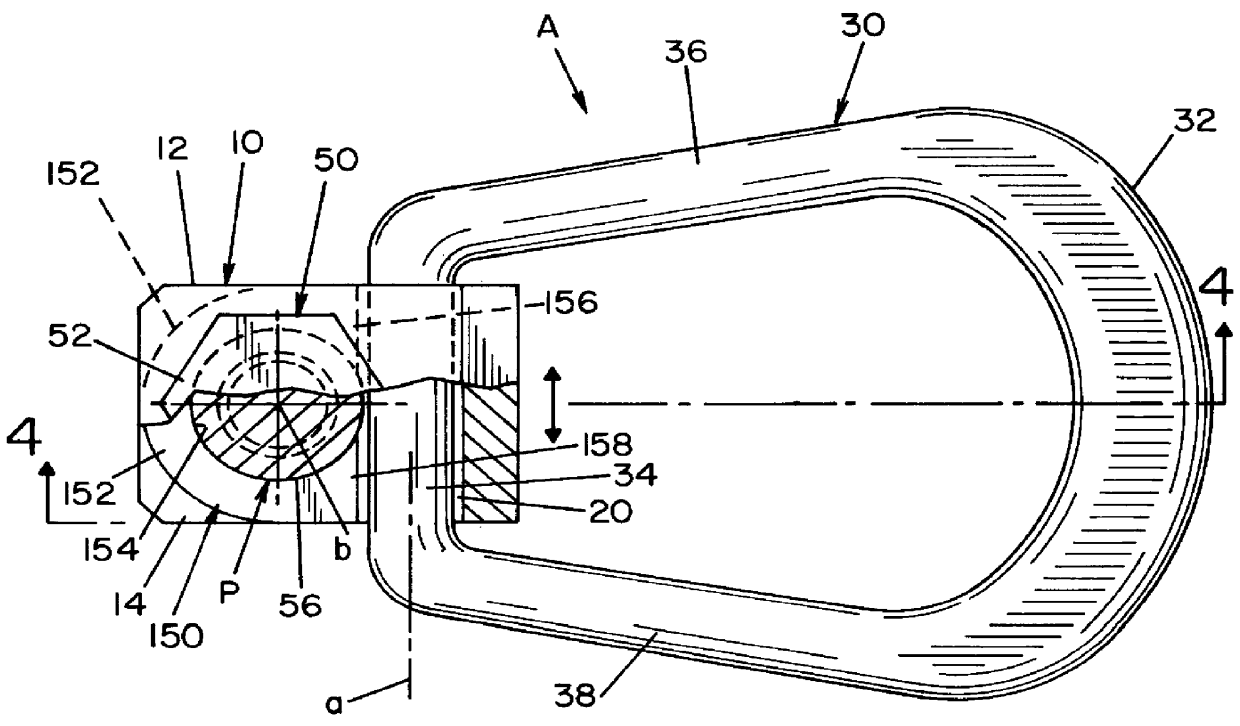

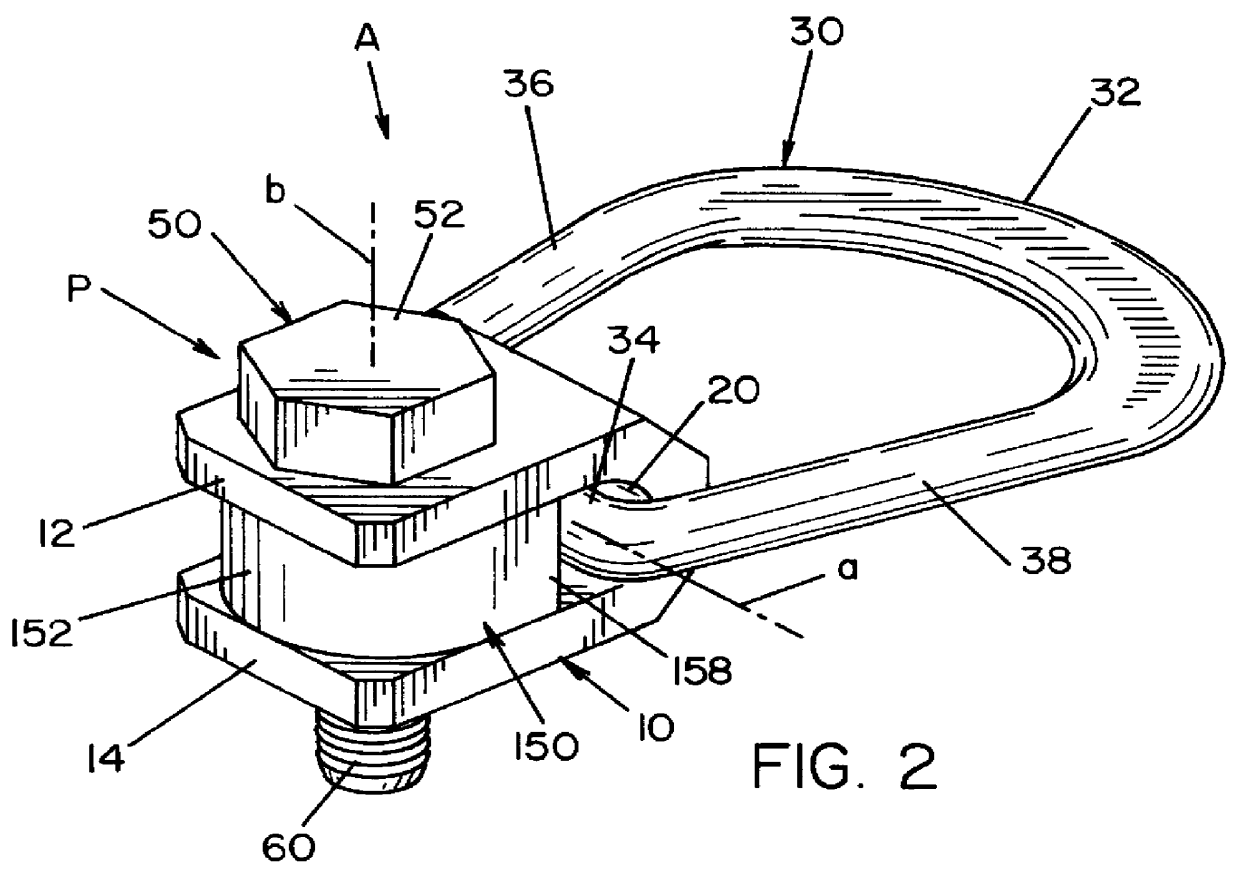

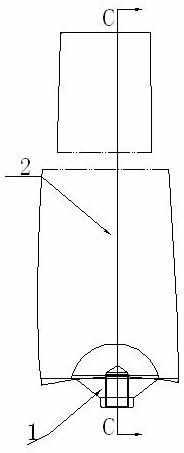

Hoist ring

InactiveUS6068310ANot easily shearedImprove performanceYielding couplingLifting devicesNon destructiveLow load

In a side-pull hoist ring having a load carrying ring, a clevis pivotally supporting the load carrying ring for rotation about a first axis and a post assembly extending through the clevis and fixedly engageable with a threaded bore on a load for allowing 360 DEG rotation of the clevis about a second axis generally perpendicular to the load. The post assembly includes a lower support bushing with a large diameter lower load bearing flange and a bolt receiving passageway coaxial with the second axis; a bolt extending through the passageway into the threaded bore of the load where the bolt has a head carrying an upper flange member coacting with the lower flange to capture the clevis and a shank. There is a first cylinder groove in the passageway and a second cylindrical groove around the shank. The grooves are axially aligned when the lower flange and the upper flange capture the clevis. An arcuate spring element having a collapsed shape generally retained in the second groove and a relaxed shape bottomed out in the first groove and extending between the first and second grooves prevents non-destructive axial removal of the bolt from the bushing. The clevis is formed from extruded steel, bar stock or a steel plate.

Owner:JERGENS

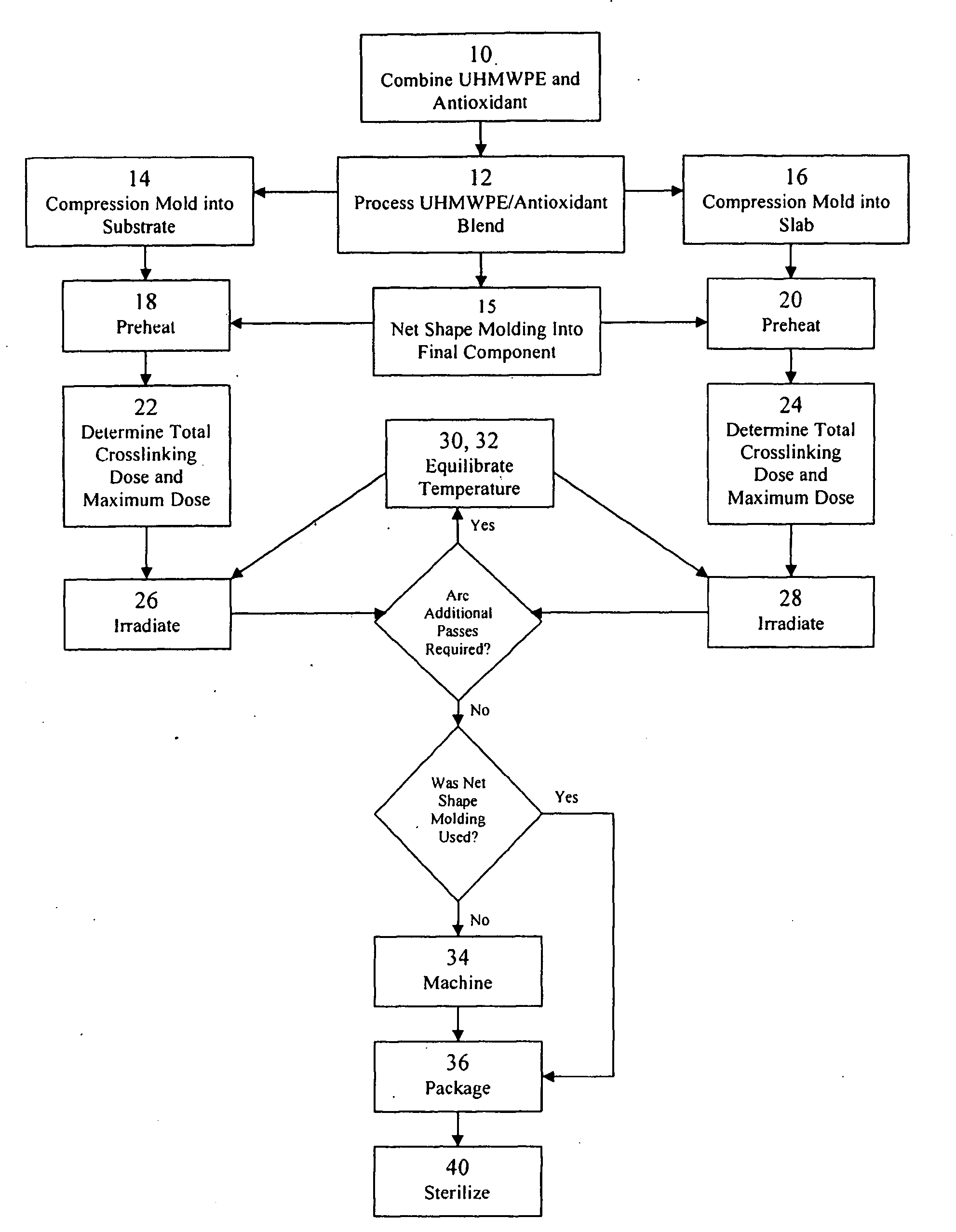

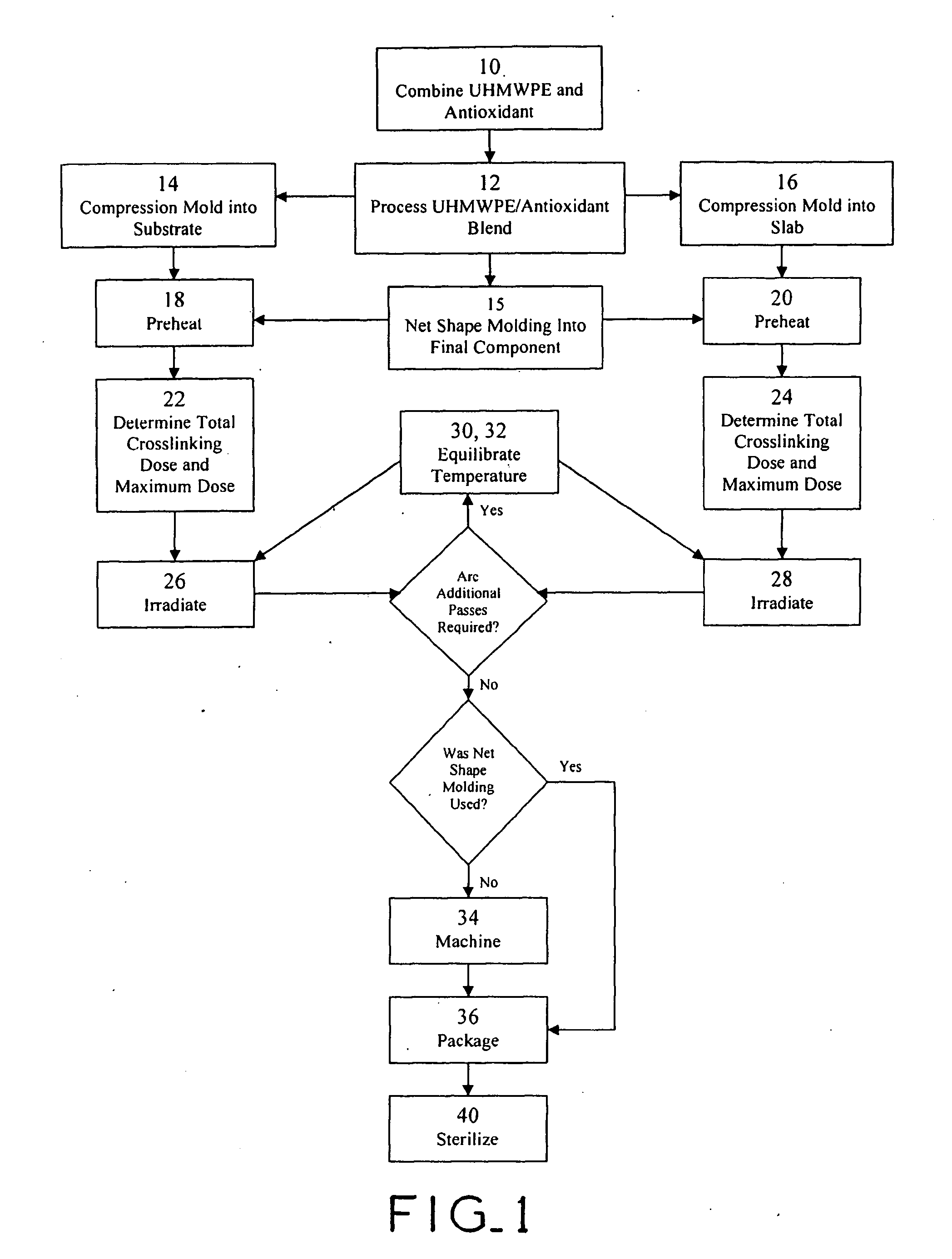

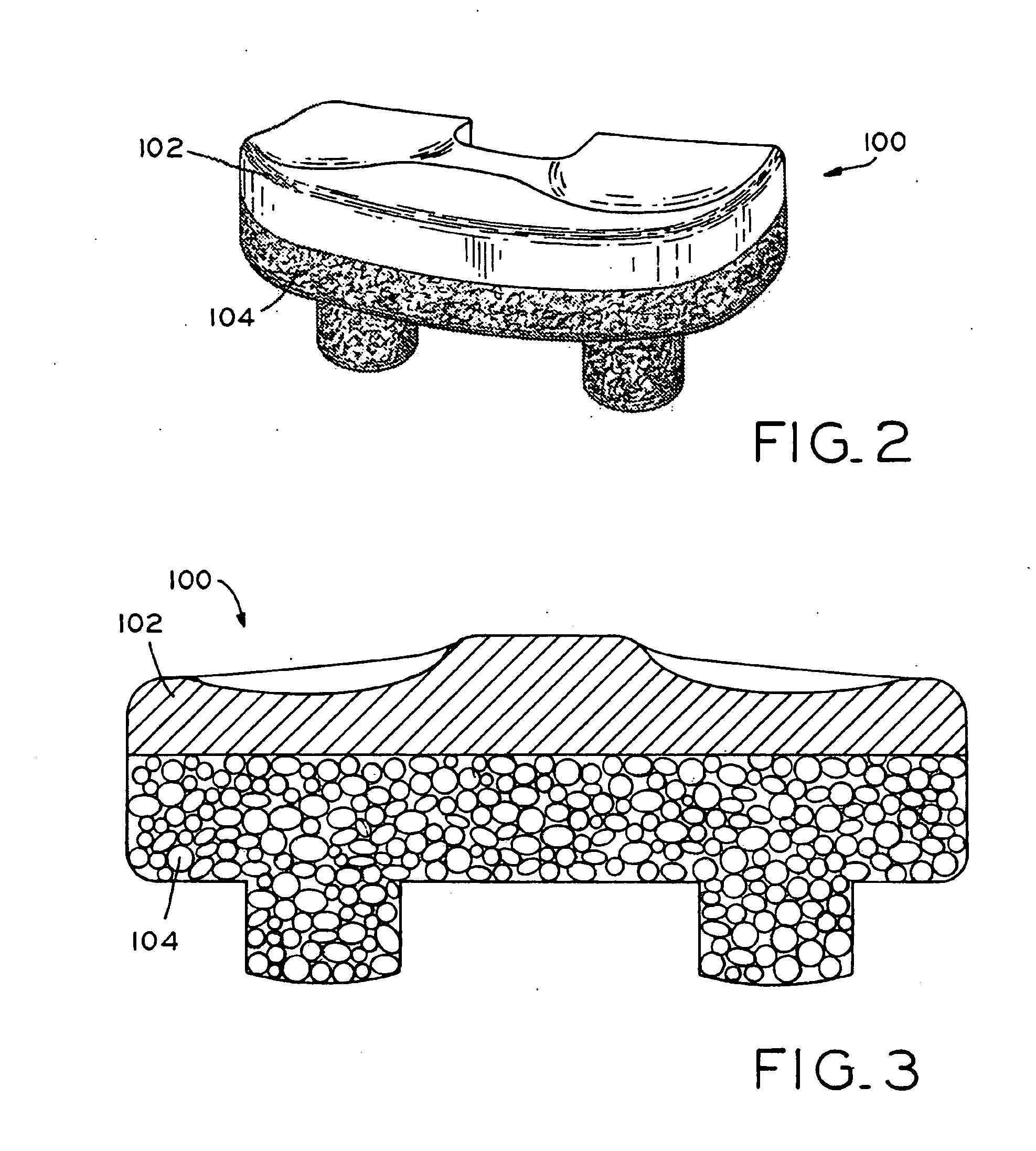

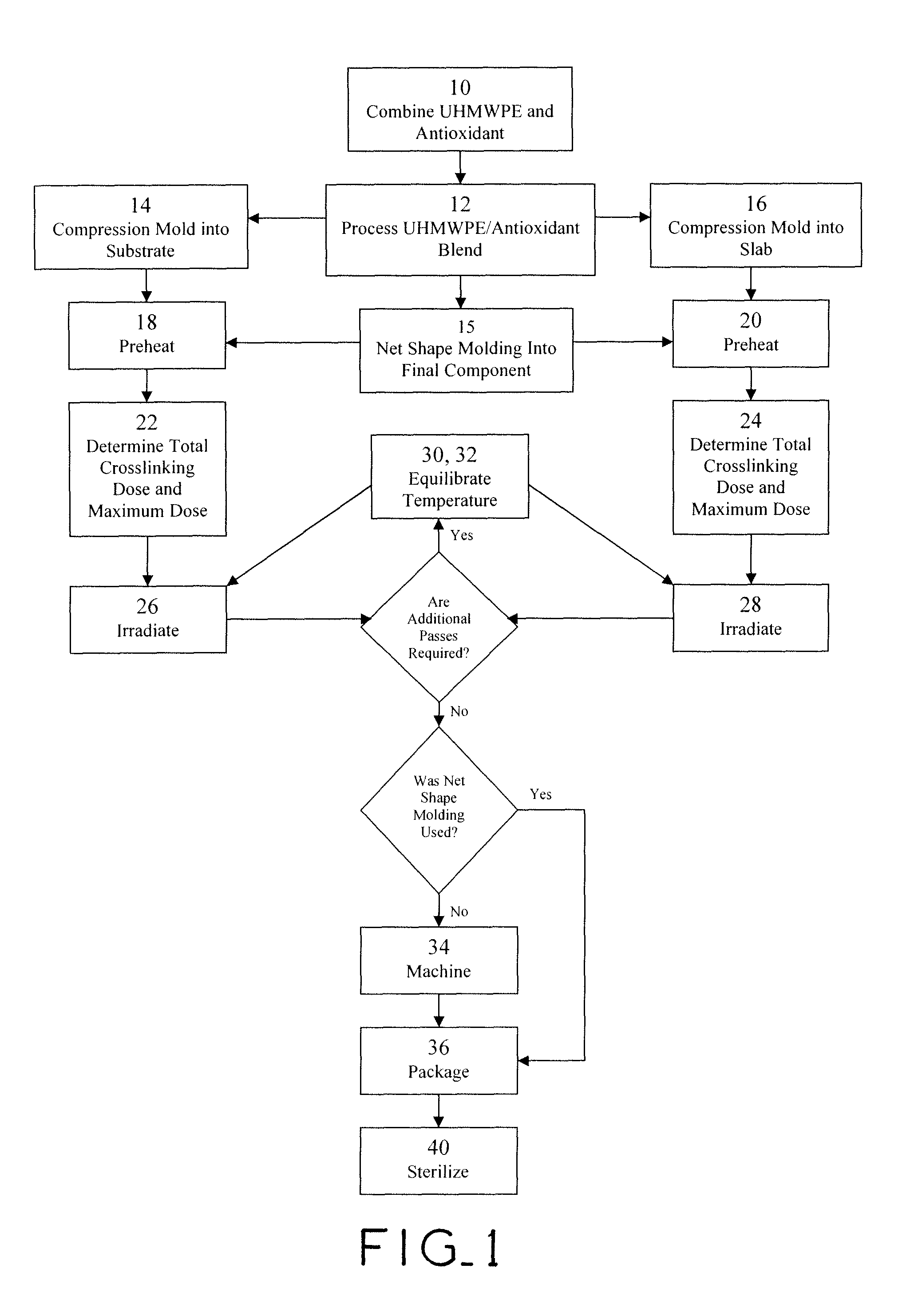

Antioxidant stabilized crosslinked ultra-high molecular weight polyethylene for medical device applications

InactiveUS20080319137A1Avoid mass meltingEncourage mobilityLavatory sanitoryDeodrantsAntioxidantOxidation resistant

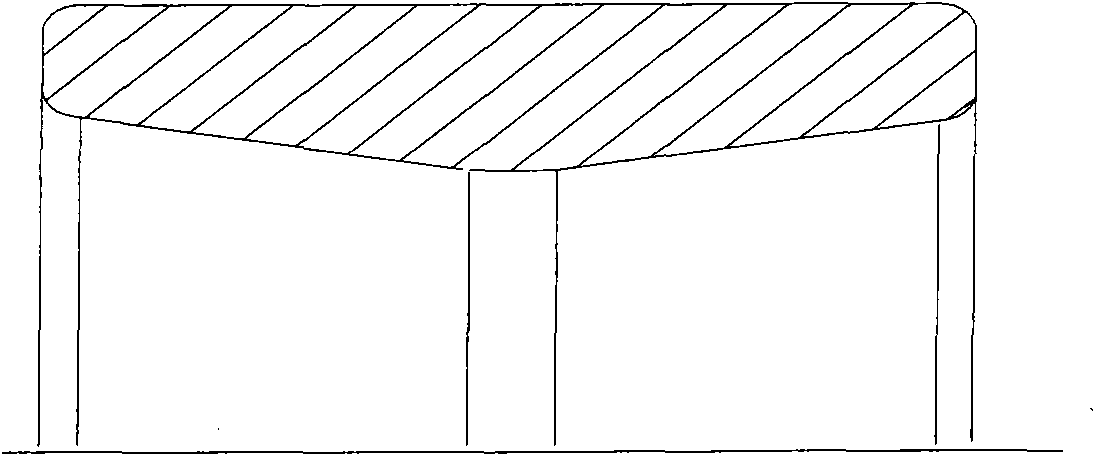

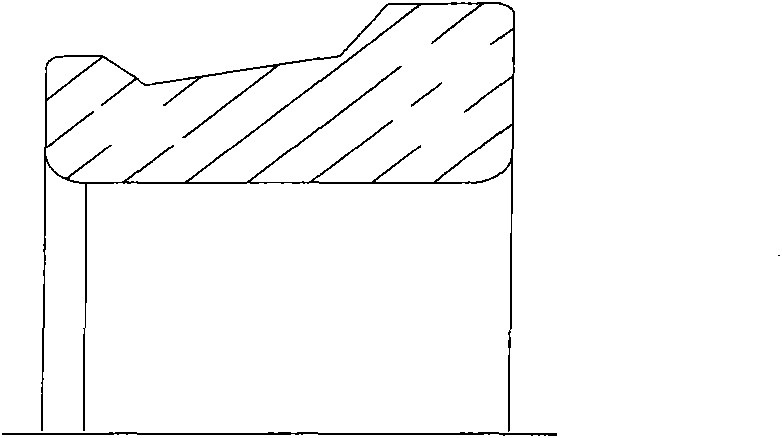

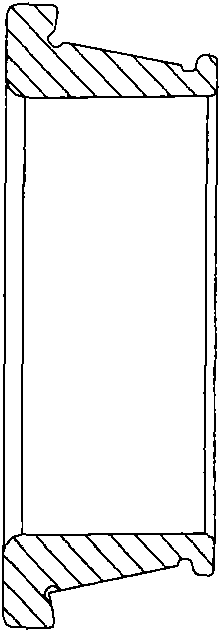

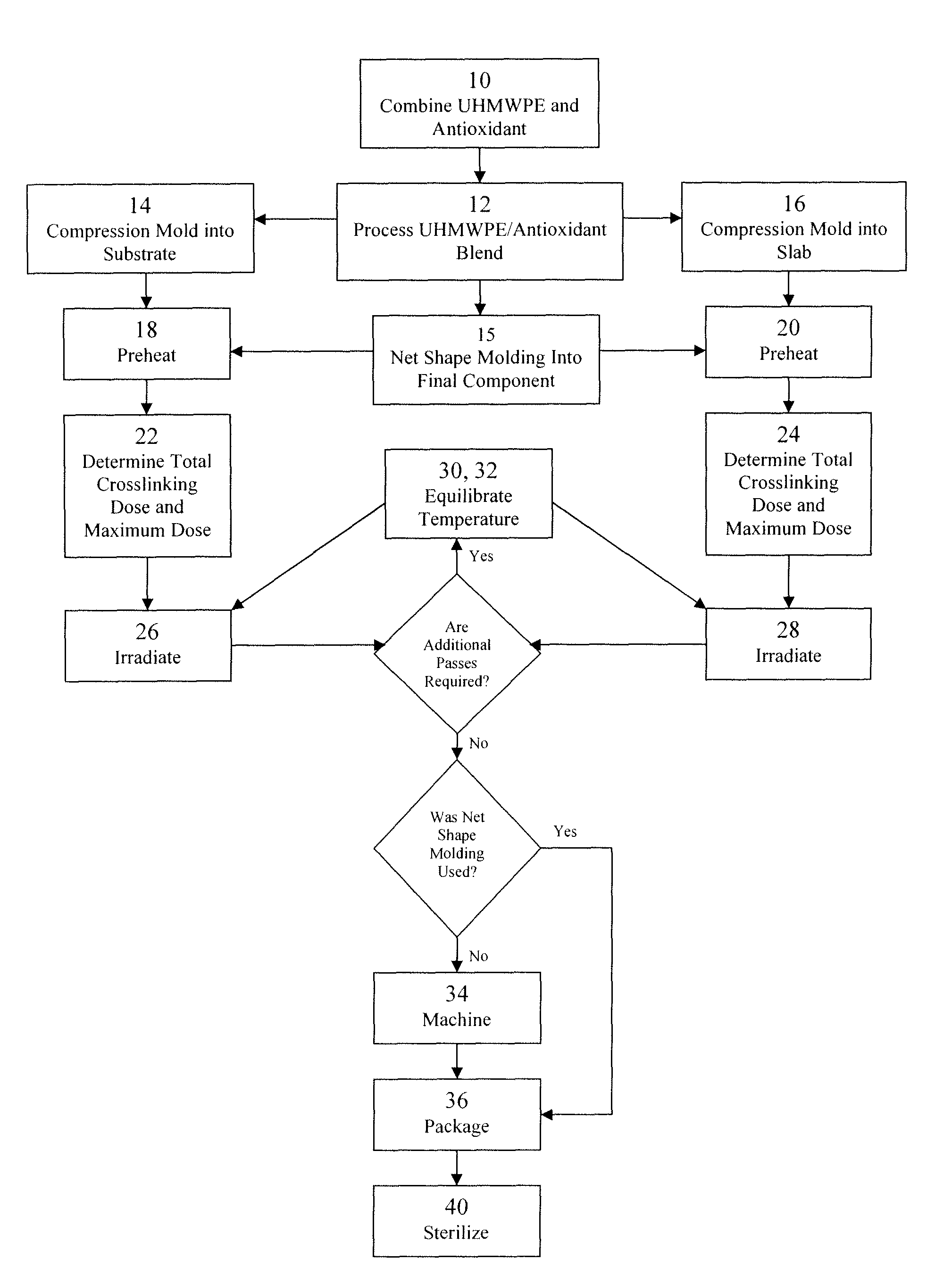

An antioxidant combined with UHMWPE prior to subjecting the UHMWPE to crosslinking irradiation. In one exemplary embodiment, the antioxidant is tocopherol. After the antioxidant is combined with the UHMWPE, the resulting blend may be formed into slabs, bar stock, and / or incorporated into a substrate, such as a metal, for example. The resulting product may then be subjected to crosslinking irradiation. In one exemplary embodiment, the UHMWPE blend is preheated prior to subjecting the same to crosslinking irradiation. Once irradiated, the UHMWPE blended product may be machined, packaged, and sterilized in accordance with conventional techniques.

Owner:ZIMMER INC

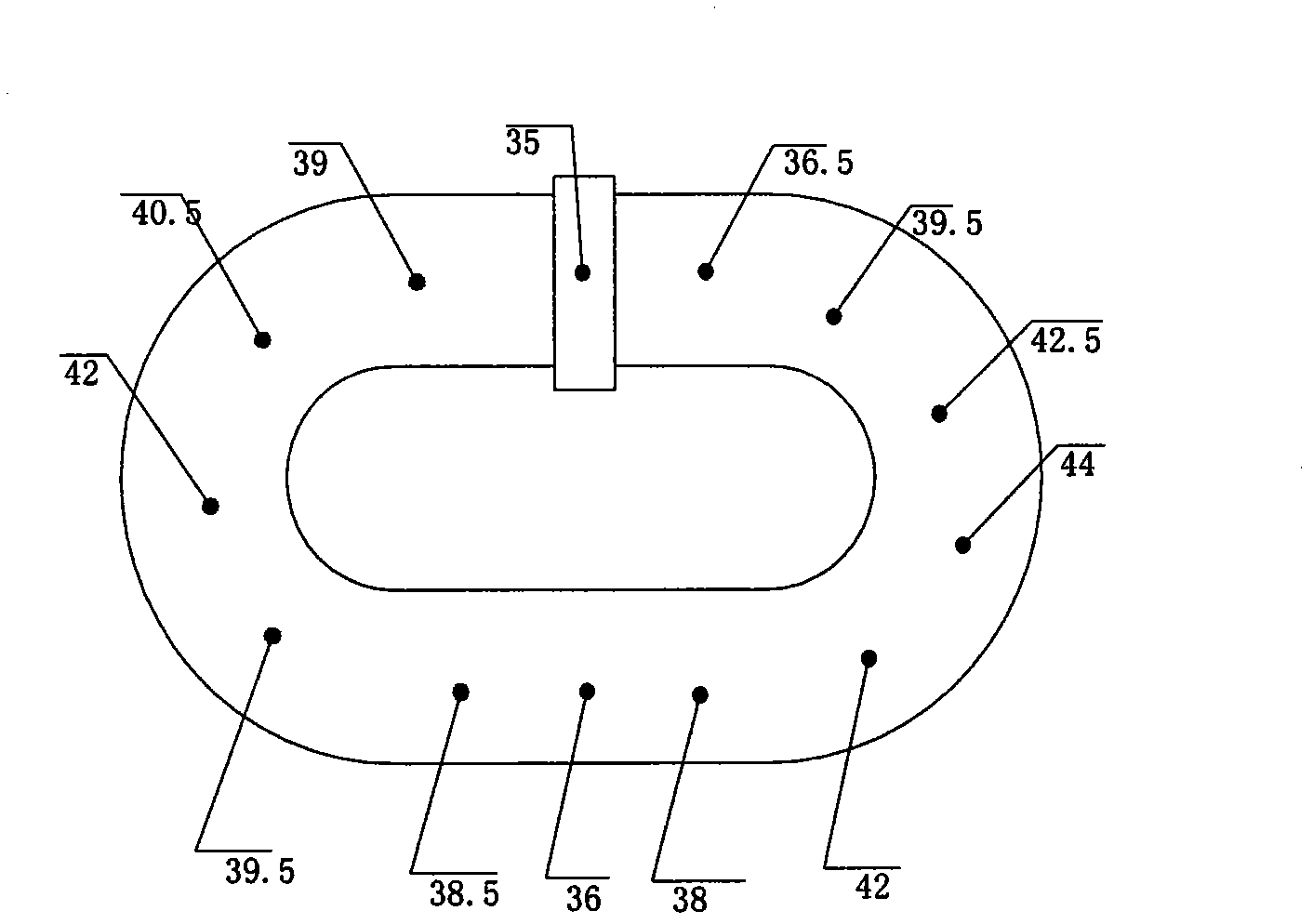

Composite machining process for inner and outer rings of narrow-series thin-walled high-precision conical thin-walled bearings

The invention discloses a composite machining process for inner and outer rings of narrow-series thin-walled high-precision conical thin-walled bearings, belongs to the technical field of forging, turning, heating and grinding machining of the inner and outer rings of bearing components, and mainly solves the problems of low production efficiency and high rejection rate in a conventional machining method. The composite machining process is mainly characterized by comprising the following steps of: (1) cutting bar stock into straight material sections; (2) after heating, forming a single-forged inner ring and double combined-forged outer rings by using a pressing machine; (3) spheroidizing and annealing; (4) performing shot blasting to remove surface oxide scales; (5) after cutting the double outer rings, performing rough turning and soft grinding; (6) performing additional tempering; (7) performing the soft grinding on the outside diameter of the outer rings, and performing finish turning and rolling; (8) performing heat treatment in quenching and tempering furnaces, and performing shot blasting again; and (9) performing rough grinding machining, the additional tempering, finish grinding machining, super-finishing, cleaning and assembling. The composite machining process has the characteristics of great improvement on product qualification rate and production efficiency, and suitability for batch production on the premise of no increase of equipment investment, and is mainly used for machining the inner and outer rings of the narrow-series thin-walled high-precision conical thin-walled bearings.

Owner:XIANGYANG AUTOMOBILE BEARING CO LTD

Antioxidant stabilized crosslinked ultra-high molecular weight polyethylene for medical device applications

ActiveUS20100029858A1High levelAvoid mass meltingThin material handlingProsthesisAntioxidantIrradiation

An antioxidant combined with UHMWPE prior to subjecting the UHMWPE to crosslinking irradiation. In one exemplary embodiment, the antioxidant is tocopherol. After the antioxidant is combined with the UHMWPE, the resulting blend may be formed into slabs, bar stock, and / or incorporated into a substrate, such as a metal, for example. The resulting product may then be subjected to crosslinking irradiation. In one exemplary embodiment, the UHMWPE blend is preheated prior to subjecting the same to crosslinking irradiation. Once irradiated, the UHMWPE blended product may be machined, packaged, and sterilized in accordance with conventional techniques.

Owner:ZIMMER INC

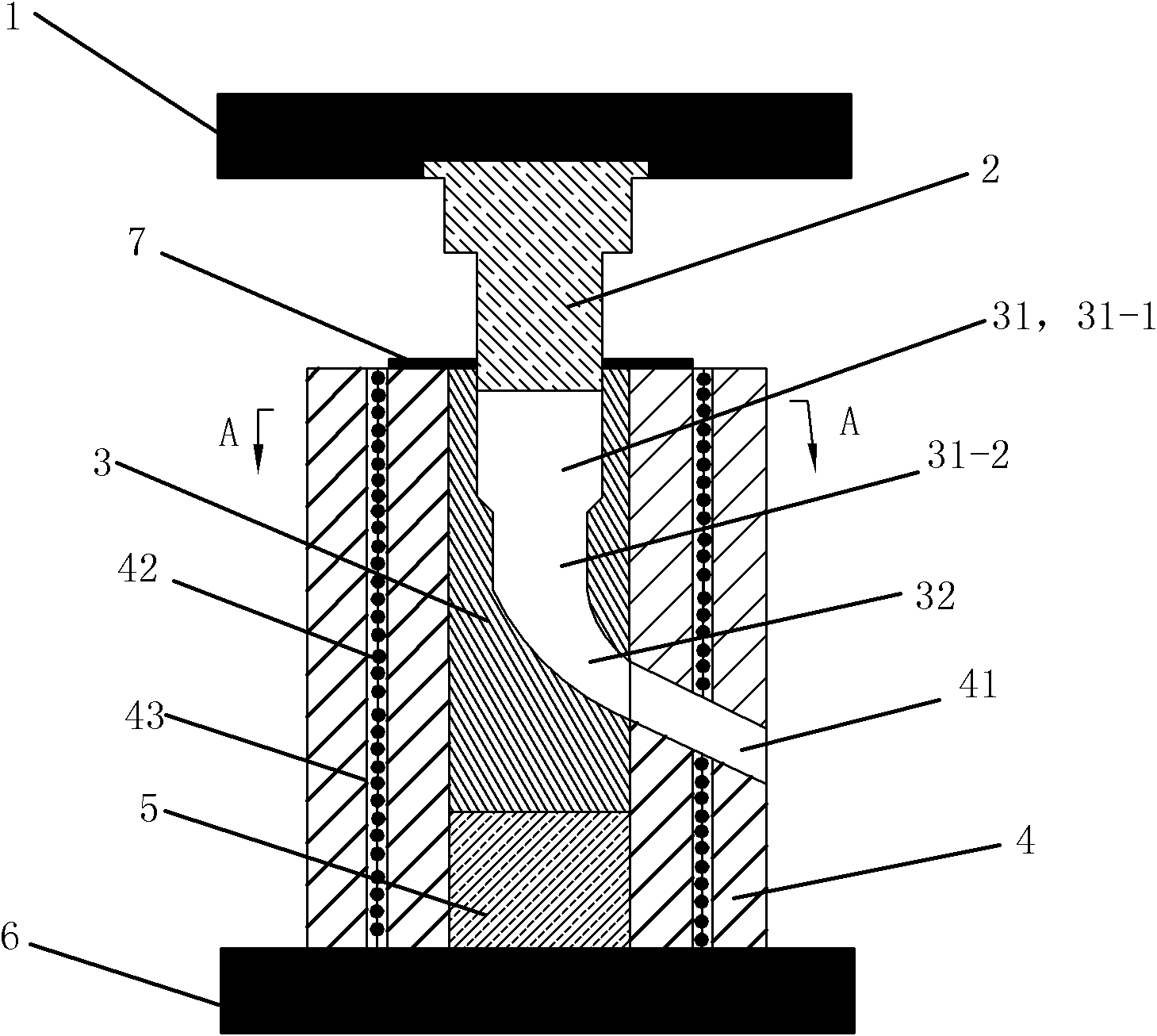

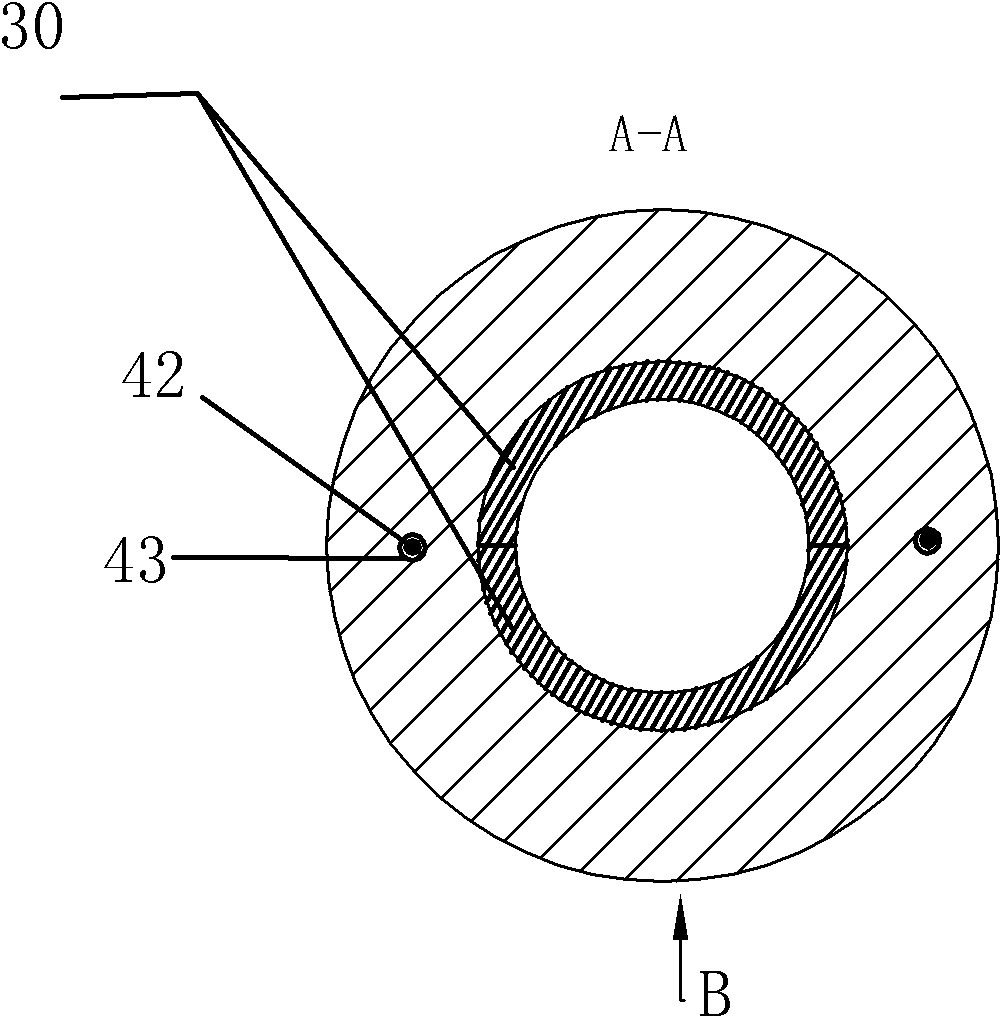

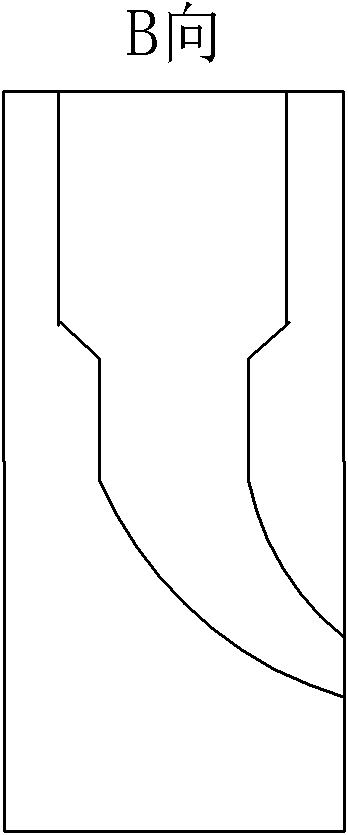

Method and die for forward extrusion and variable diameter bending extrusion of magnesium alloy semi-solid billets

InactiveCN101850376ASmall grain sizeSolve the problem of not being able to continuously prepare large-size semi-solid billetsExtrusion diesSemi solidLarge deformation

The invention discloses a method and a die for the forward extrusion and variable diameter bending extrusion of magnesium alloy semi-solid billets. The preparation method comprises a predeformation process and an isothermal spheroidizing heat treatment process, wherein in the predeformation process, uniform deformation of large deformation amount is realized by the die for the forward extrusion and variable diameter bending extrusion; cutting a magnesium alloy bar stock which is subjected to large deformation by a fixed size; heating the magnesium alloy bar stock cut by the fixed size at the temperature of between 520 and 580 DEG C under the protection of argon, and keeping the temperature of the obtained magnesium alloy bar stock for 10 to 30 minutes; and processing a bending extrusion angle of the die to be over 90 degrees. The method has the advantages of small predeformation resistance, large and uniform deformation, safety, reliability and no three-waste pollution. The grains of the prepared magnesium alloy semi-solid billets have fine size, are uniform and have a shape close to that of a sphere. The method solves the problem that the conventional SIMA method cannot continuously prepare the large-size semi-solid billets and meets the requirements of the semi-solid thixoforming workpieces for large-scale continuous production.

Owner:CHANGZHOU INST OF TECH

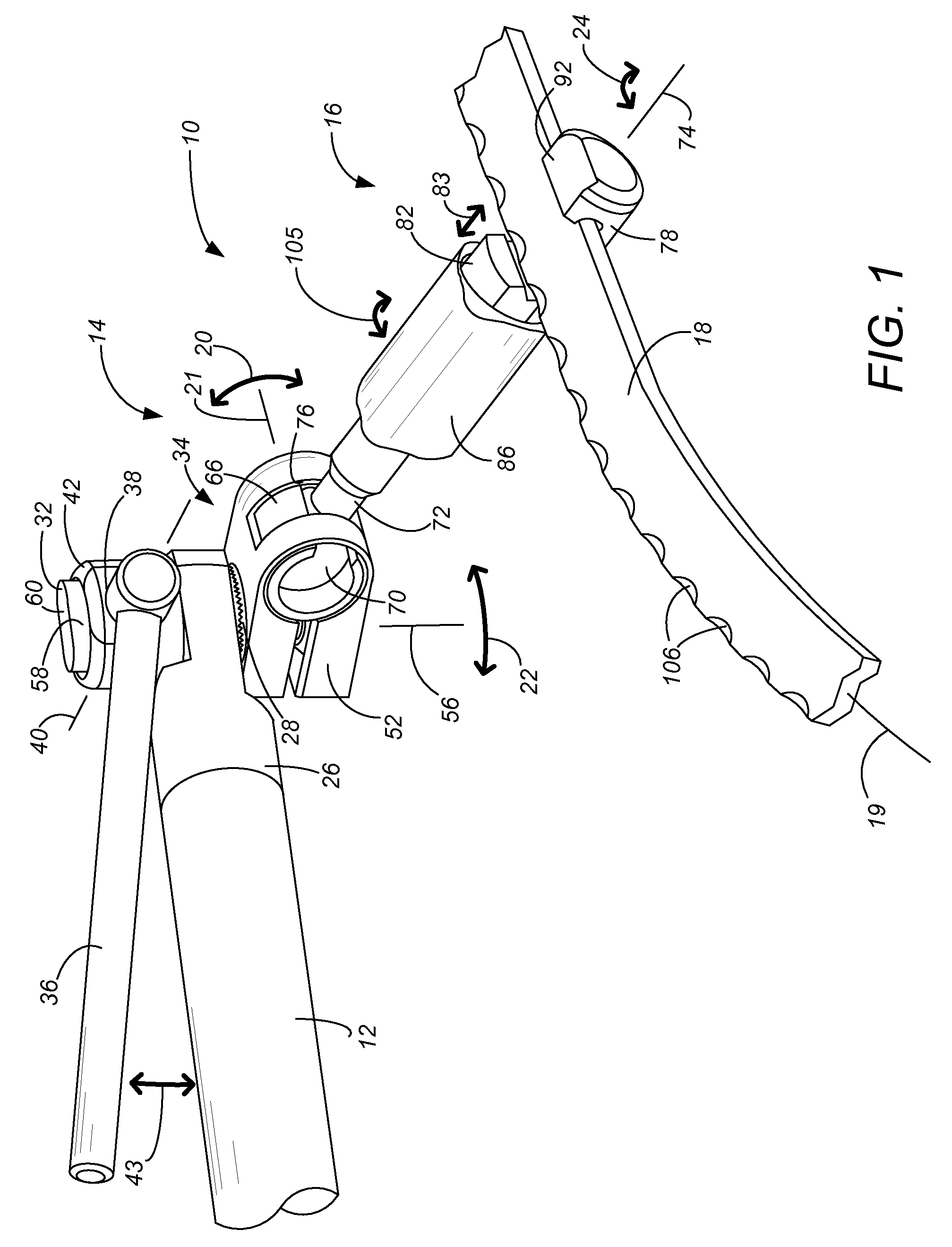

Support Clamp For Retractor Bar Stock Of Generally Rectangular Cross-Section

A clamp is used to attach generally rectangular bar stock, such as existing Bookwalter / Codman rings, to a post in a surgical retractor system. The clamp interacts with corners of the ring at any of a wide range of widths and thicknesses, while still retaining a simple and intuitive tightening action such as through a rotational collar which absorbs some of the clamping force as a hoop stress. In the preferred arrangement, the clamp makes a tripod top / planar bottom contact with the generally rectangular bar stock of the ring. An articulating joint permits best fold up of the clamp, with a ball shaft which is constrained within the bisecting plane of the joint clamp. A spherical nut is used on the clamp bolt in one of the clamps, which permits some change in orientation of the clamp bolt when the clamp bolt is tightened using a cammed handle.

Owner:MINNESOTA SCI

Machining technology of elongated thin-wall C-shaped tubular parts

ActiveCN103846624AImprove processing qualityImprove processing efficiencyPositioning apparatusMetal-working holdersEngineeringCylindrical grinding

The invention discloses a machining technology of elongated thin-wall C-shaped tubular parts and belongs to the technical field of machining precision parts. The machining technology comprises the steps of blanking, hot and cold processing, aging strengthening, rough machining, finish machining and through groove machining, wherein the blanking comprises bar material cutting, the rough machining comprises inner hole drilling and outer circle rough turning, the finish machining comprises outer circle finish turning, inner circle grinding and end surface cutting, the elongated thin-wall C-shaped tubular parts are machined by selecting a bar material, the machining quality and efficiency of the parts can be greatly increased through a concise and practical process route, and the technical difficulties of elongated shaft machining, thin-wall piece machining, deep hole machining, main guide rail groove machining and the like which relate to the elongated thin-wall C-shaped tubular parts can be solved.

Owner:GUIZHOU ZUNYI CHI YU PRECISION MACHINERY MFG

Preparation method of endogenous particle reinforced aluminium-based composite material

This invention provides a preparation method of industrial scale preparing endogeny particle reinforcing aluminum base composite material. That is fusant reaction mthod + electromagnetic agitation proposal + dc casting forming integrated technology. The method is that compound contains reinforcing particle forming element is added to fusing aluminum or aluminum alloy at certain temperature, electromagnetic agitation is applied at the same time to make it fully reaction, and make endogeny particle to disperse uniformly in fusant, the composite material fusant got is cast into bar stock through half joint. The technique is simple, cost is low, period is short, and it can meet industrial production, is a new technology of realizing endogeny particle reinforcing aluminum base composite material industrial scale production. The endogeny particle has high strength, hardness and elastic modulus, the particle dimension is small and disperses uniform in matrix, so the reinforcing effect is good.

Owner:JIANGSU UNIV

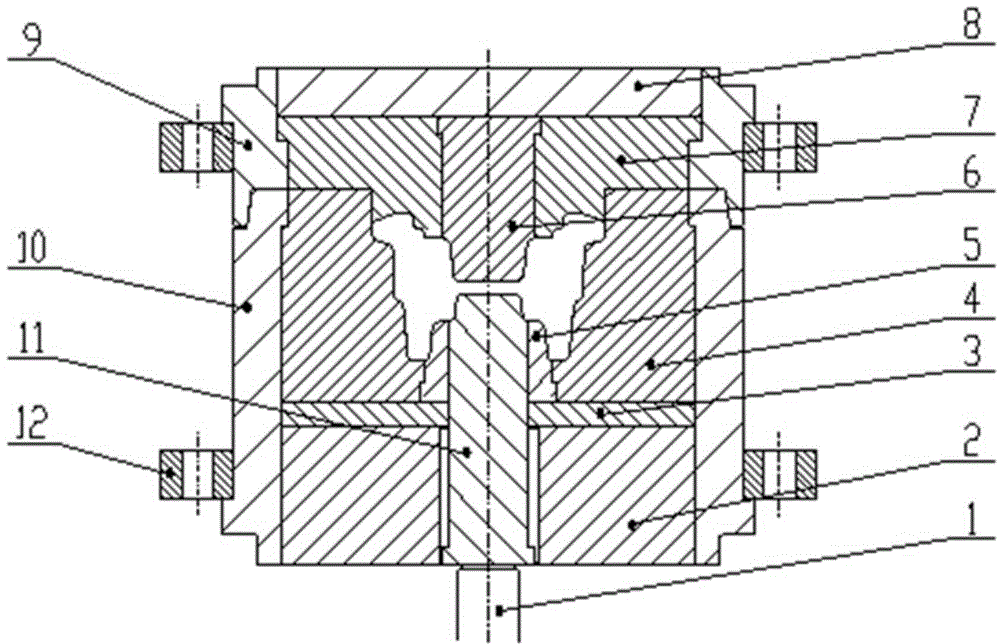

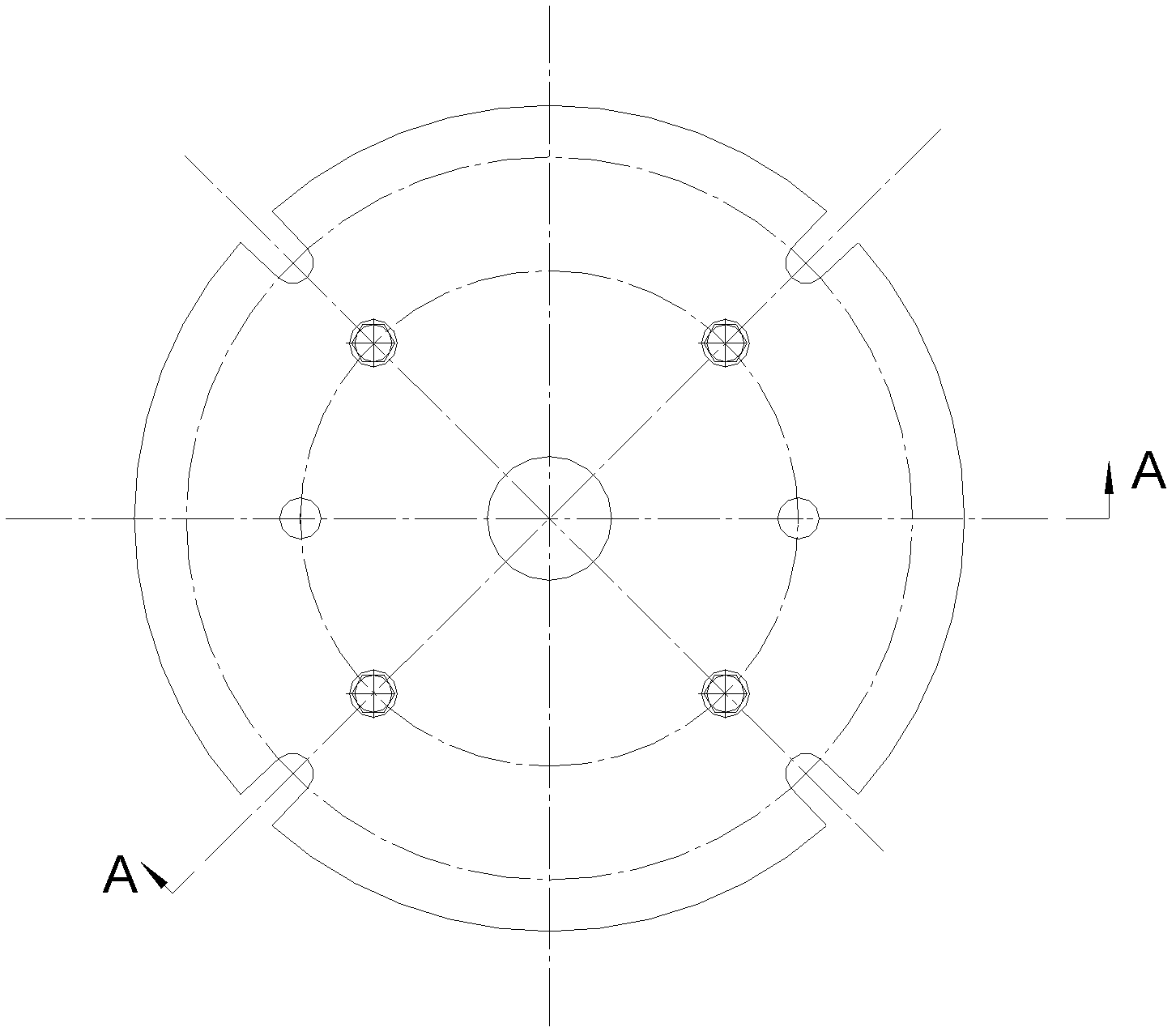

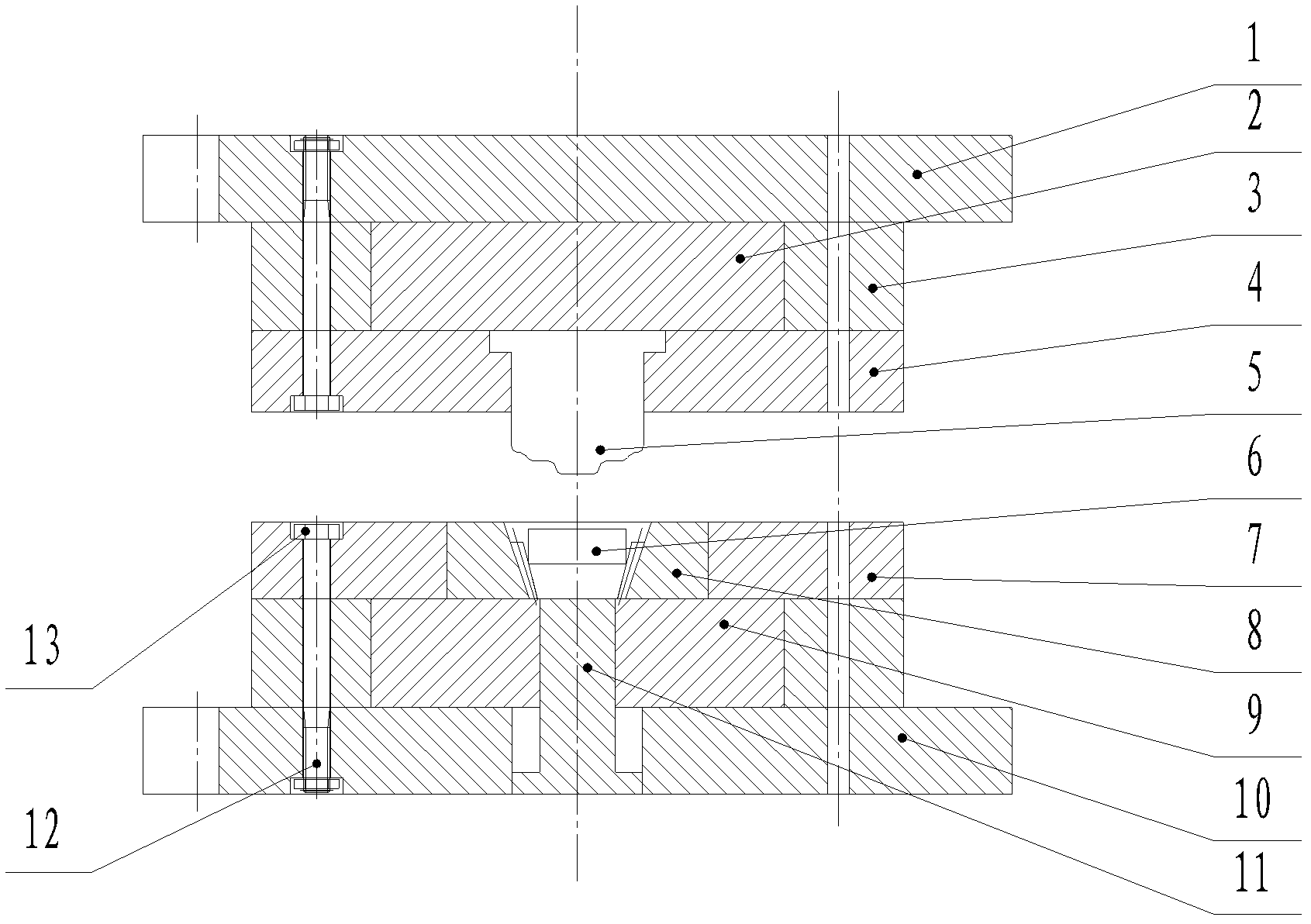

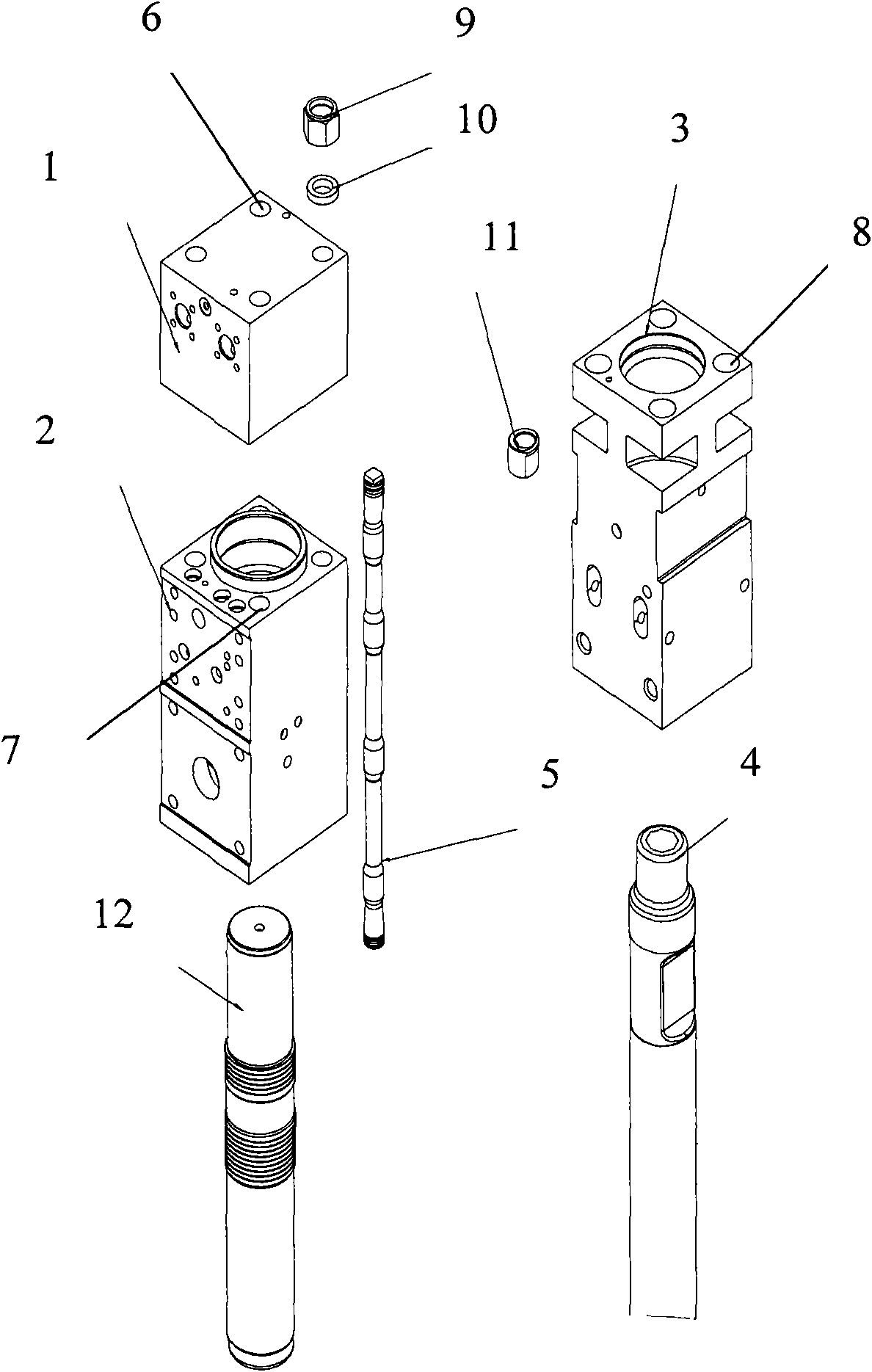

Supporting wheel closed forging process and forging die

InactiveCN104907471AThere is no flash phenomenonTotal deformation area reductionForging/hammering/pressing machinesWheelsPunchingMedium frequency

The invention discloses a supporting wheel closed forging process and a forging die, and belongs to the technical field of forging. Blanking is conducted on round steel through a band sawing machine; heating is conducted on a bar material through a medium frequency induction heating furnace; jumping-up and preforging are conducted on the hot bar material on a l600T electric screw press, then the hot bar material is transferred to a 2500T electric screw press to be subjected to finish forging and forming through the closed forging die, and finally punching is finished on a 400T mechanical press; normalizing treatment is conducted on a forge piece generated after punching is conducted; the closed forging die adopted for the process comprises a lower cushion block (2), a lower male die (11), a lower base plate (3), a lower female die insert (5), a lower female die (4), an upper male die (6), an upper female die (7) and an upper cushion block (8). By means of the supporting wheel closed forging process and the forging die, burrs do not exist in the forged forge piece, and the total forge piece deformation area is reduced, so that the forging deformation force is lowered, the raw material utilization rate is increased, the subsequent trimming process is omitted, the product cost is lowered greatly, and product efficiency is improved remarkably.

Owner:XUZHOU XCMG CRAWLER CHASSIS CO LTD

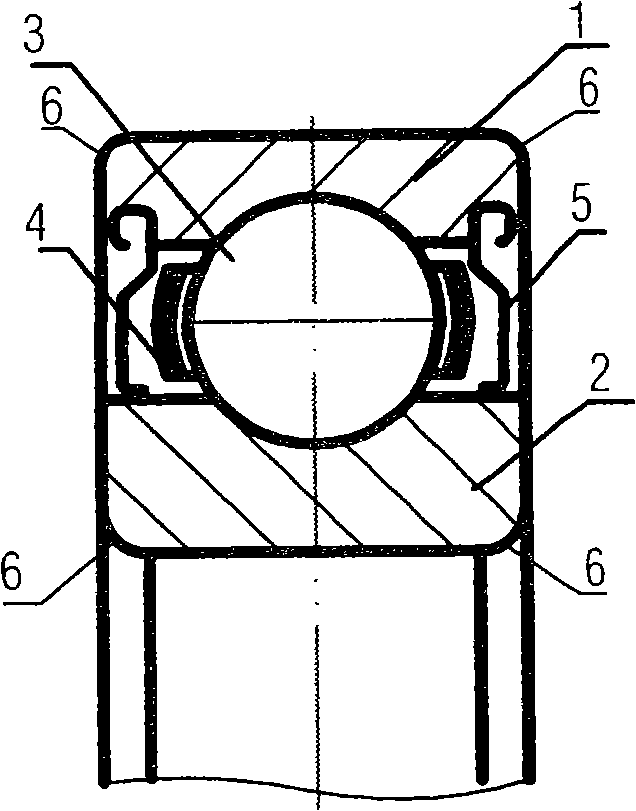

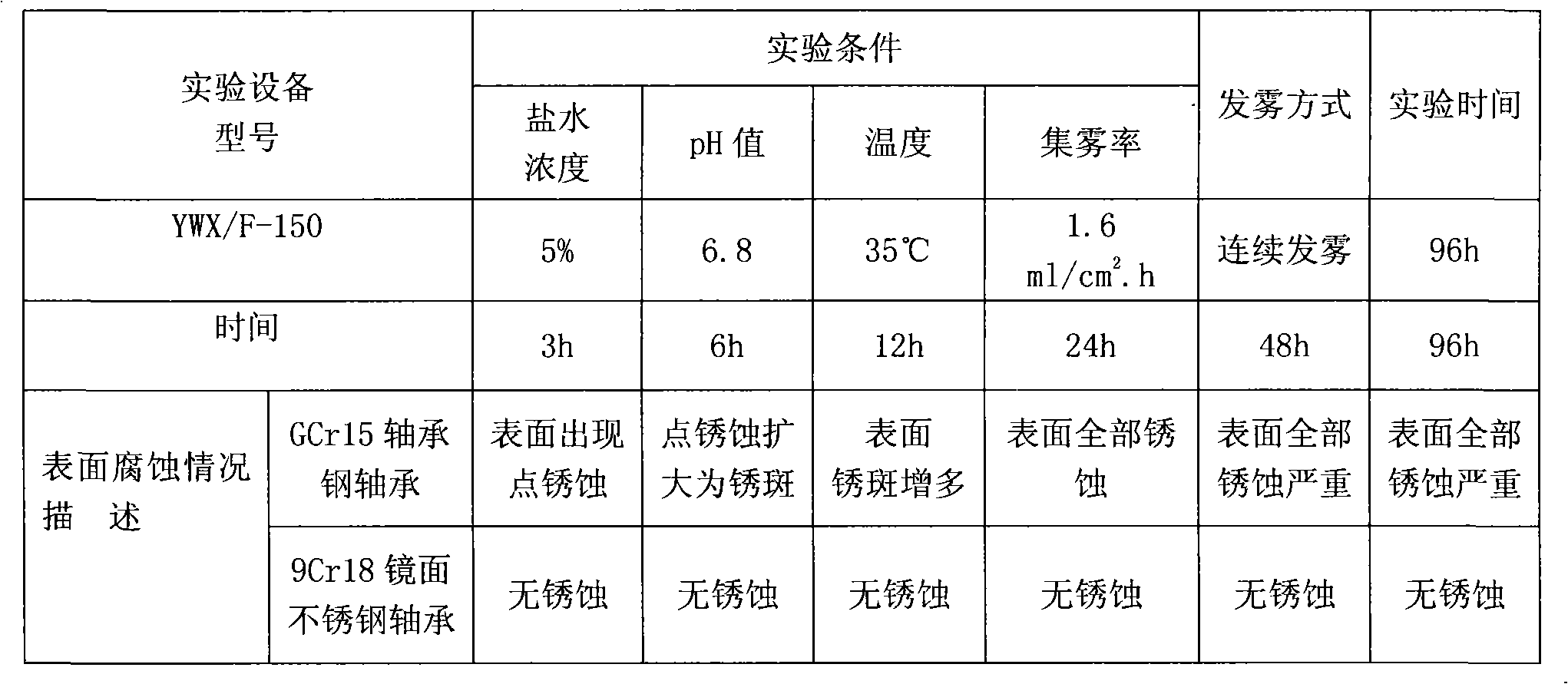

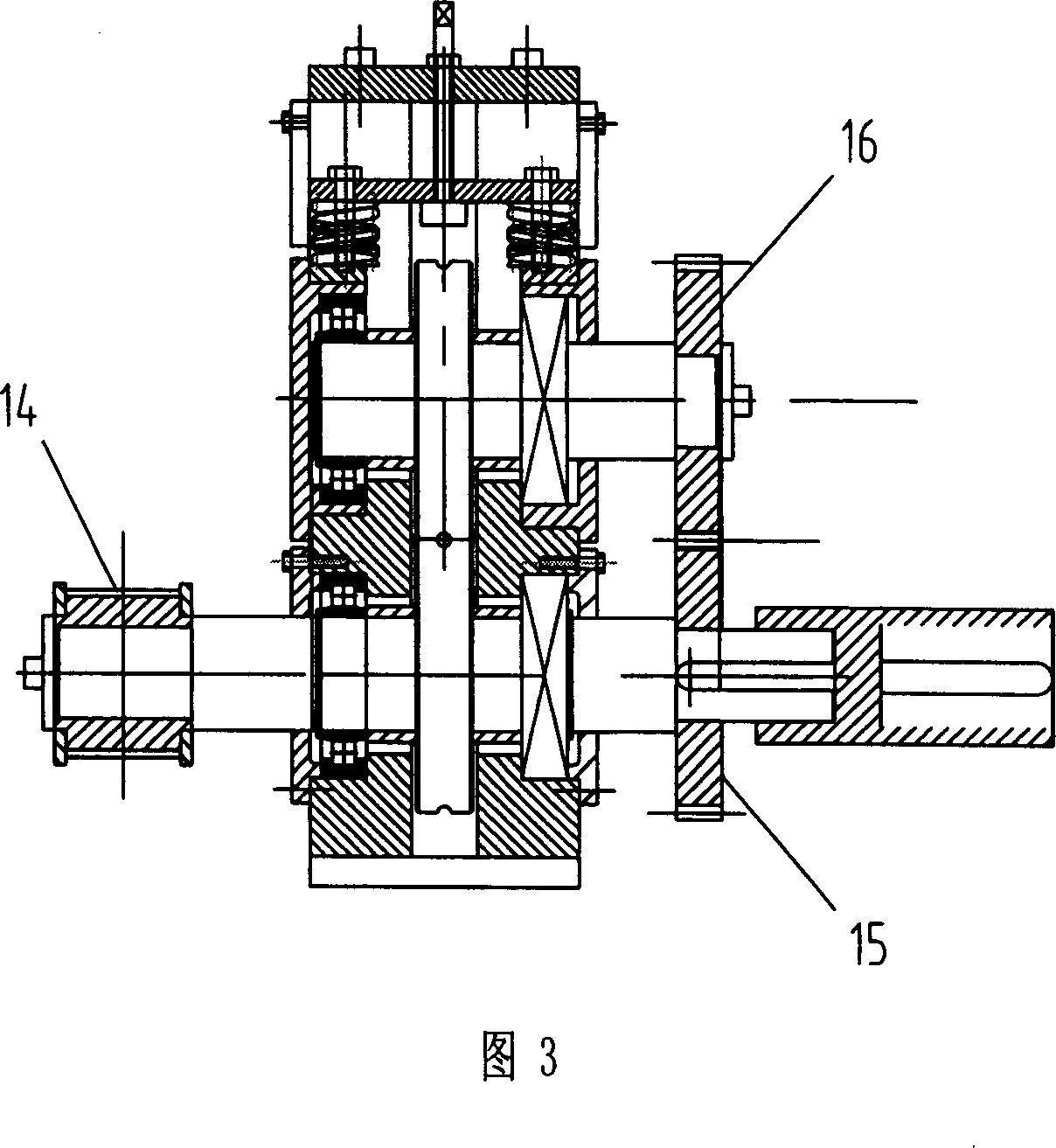

Mirror face stainless steel bearing and process thereof

InactiveCN101280808AImprove corrosion resistanceCorrosion resistantBearing componentsWaxPharmaceutical industry

The invention discloses a mirror finished stainless steel bearing and a process technology thereof, which comprise molding of an inner ring and an outer ring of a bar stock, turning operation, heat treatment, plane centerless grinding, coarsely grinding the channels of the inner and the outer rings, heat treatment, finely grinding the channels of the inner and the outer rings, heat treatment, grinding the channels of the inner and the outer rings, assembly and pressing fit a dust cap. The mirror finished stainless steel bearing and the process technology thereof are characterized in that: 9Cr18 stainless steel is adopted as the bar stock; liquid casting passivation is carried out before fine grinding of the channels of the inner and the outer rings; uniform burnishing treatment with a waxing machine is carried out to the inner ring surface, the two end surfaces and the two chamfers of the inner ring and the outer ring surface, the two end surfaces and the two chamfers of the outer ring after grinding the channels of the inner and the outer rings; the dust cap and a retainer adopt material of stainless steel 304, coated with a vacuum ion coating and colored into golden. The mirror finished stainless steel bearing of the invention has strong corrosion resistance and long service life and can be widely used in special environment, such as food machinery, chemical dyeing, marine equipment, pharmaceutical industry, assembly line of IT industry, etc.

Owner:余姚市曙光不锈钢轴承有限公司

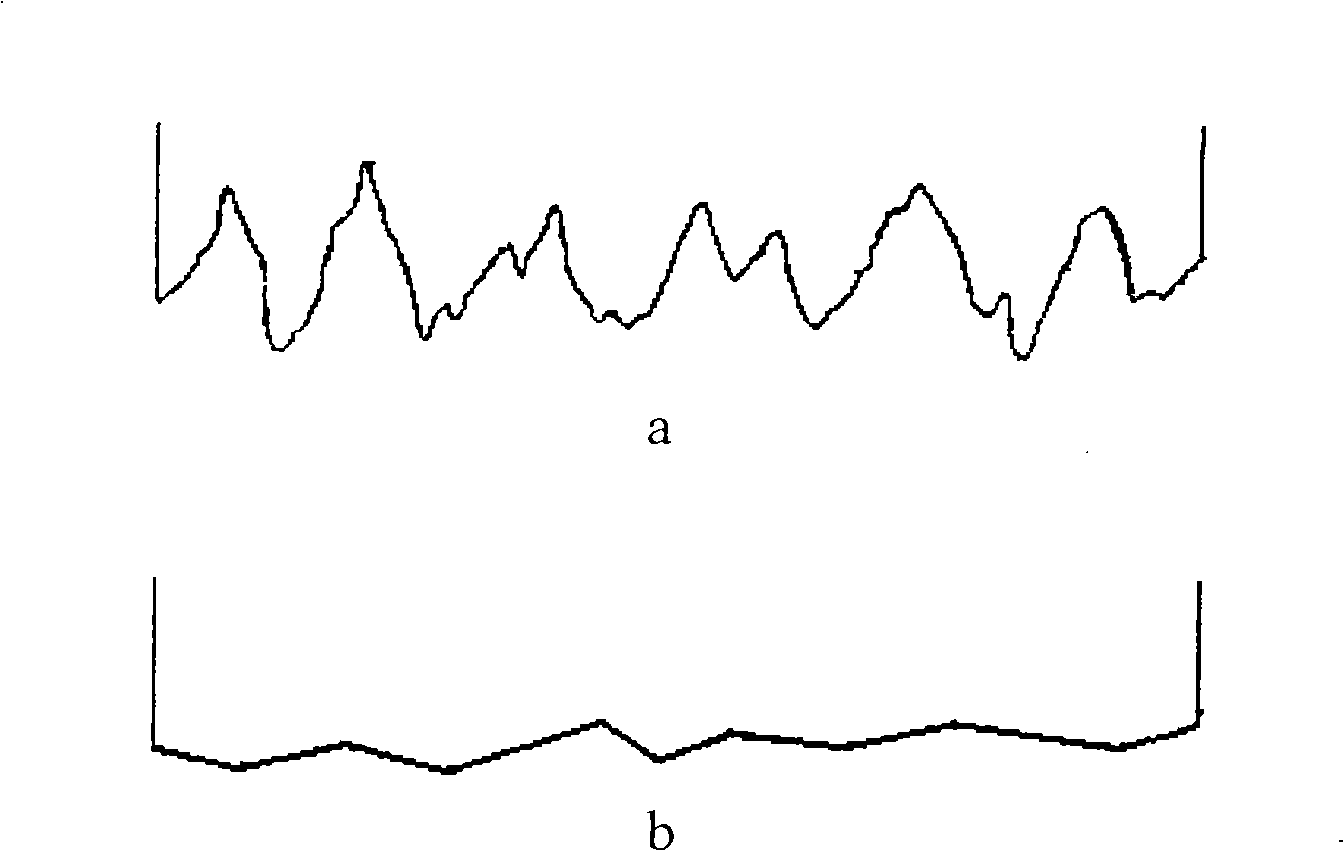

Intelligent no-mold drawing formation apparatus and process

ActiveCN101020197APrevent unstable deformationStable continuous formingMetal-working feeding devicesTemperature control using electric meansAutomatic controlControl system

The present invention is intelligent no-mold drawing formation apparatus and process, and belongs to the field of metal pressing work technology. The apparatus includes an intelligent automatic control system, a feeding and drawing system, a heating and temperature measuring system, a cooling system and a protecting gas supplying system. The technological process includes loosening the automatic hold-down device, passing the drawn material through the feeding rolls, heating, applying the automatic hold-down device to hold down the material, and moving the material forwards under the computer control to obtain predicted area reduction. The present invention has raised stability and high product size precision, and is suitable for high efficiency work of producing wires and rods.

Owner:UNIV OF SCI & TECH BEIJING

Precision die forging and shaping technical method for automobile steering knuckle rough type parts

InactiveCN102672096ALow forming speedNo crack phenomenonRailway componentsMetal-working apparatusEngineeringMaterial distribution

The invention provides a precision die forging and shaping technical method for automobile steering knuckle rough type parts. The precision die forging and shaping technical method mainly comprises the process steps of blanking, heating, extruding and drawing out a rod part, pre-forging, upsetting, performing material distribution and performing multi-way precision die forging and shaping and is specifically as follows: blanking through a cutting device, and heating to the temperature of 1080 DEG C-1180 DEG C in a medium-frequency induction furnace; placing a round bar which is well heated into a female die of an extruding and drawing-out die to form a stock comprising a cylindrical surface and a steering knuckle rough rod part; placing the stock after upsetting and material distribution into a multi-way die forging die, firstly enabling an upper male die and an upper die seat in the vertical direction to move downwards, and closing the upper male die and a lower female die for forging; and then using male dies on the symmetrical left side and right side in the horizontal direction to perform extrusion precision forging and shaping. According to the method provided by the invention, as the die forging is performed on a multi-way die forging hydraulic machine, the shaping speed is much lower than that of die forging on a hammer, thus the occurrence of the phenomenon of forming cracks on the surface due to strong speed sensitivity caused by too-high speed can be avoided; and the contact friction resistance between a forged piece and the surface of a die cavity during the processes of die forging, shaping and ejection of the forced piece can be greatly reduced, the surface quality of the forged piece is further improved, and the utilization rate of the material of the forged piece is improved.

Owner:CHONGQING UNIV OF TECH

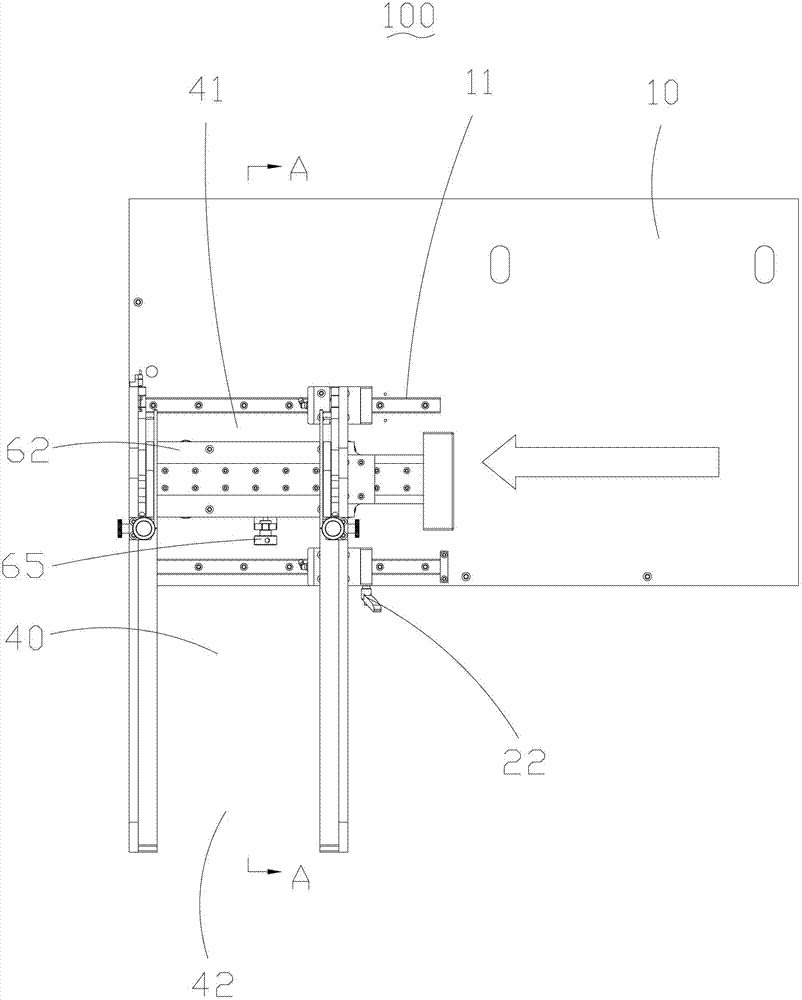

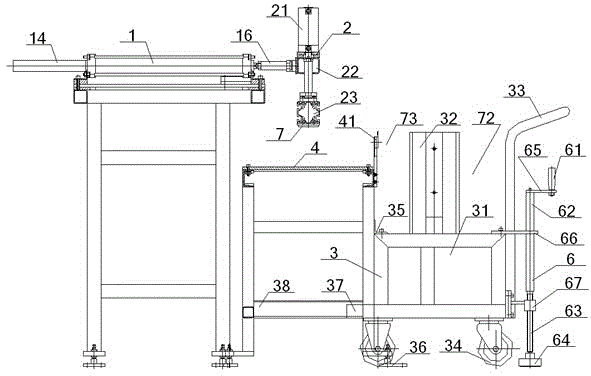

Bar stock feeding device

The invention provides a bar stock feeding device which comprises a support platform, two partitions, an inclined slideway, a support groove and a feeding mechanism. The two partitions are arranged on the support platform side by side, the inclined slideway is formed between the two partitions, the support groove is connected to the end of the inclined slideway, the feeding mechanism is positioned at the end of the inclined slideway and used for feeding predetermined bar stocks into the support groove and comprises two stoppers, a jacking mechanism and two quantity limit mechanisms, the two stoppers are connected with the support groove and stopped on the inclined slideway, the jacking mechanism is arranged between the two stoppers and capable of moving up and down so as to jack the bar stocks and enable the bar stocks to slide to the tops of the stoppers, the two quantity limit mechanisms are mounted on the inner sides of the two partitions respectively, the jacking mechanism comprises two jacking blocks and a cylinder for driving the jacking blocks to move up and down, and each quantity limit mechanism comprises a first stop plate for limiting the quantity of the bar stocks to slide onto the inclined slideway and a second stop plate for limiting the quantity of the bar stocks to slide into a first inclined plane. The cylinder is used for driving the jacking blocks to move upwards to jack the bar stocks onto the stoppers, and the bar stocks slide onto the support groove by the aid of inclined planes of the stoppers, so that convenience and rapidness are achieved.

Owner:SHENZHEN SHENLAN PRECISION MACHINERY

Rare earth copper alloy and its preparation method

The invention discloses a rare earth copper alloy and its preparation method, which comprises charging electrolytic copper by weight percentage, smelting 20-30 minutes, then charging 0.03-0.1% of zirconium, 0.02-0.16% of silver, 0.02-0.155 of rare-earth elements, smelting 1-3 minutes and casting, subjecting the cast alloy to heat preservation 1-4 hours at 800-850 deg C, forming bar stock through processing, the forging deformation amount is 50-80%, loading the bar stock into heat treatment furnace, thermally insulating 30-60 minutes at 800-950 deg C, then carrying out quenching treatment, subjecting the quenched alloy to 30-80% deformation treatment, cold drawing the alloy, thermally insulating 1-8 hours at 440-520 deg C, carrying out 50-70% deformation treatment to the alloy undergone ageing treatment. The invention can achieve high-strength and high conductivity.

Owner:HENAN UNIV OF SCI & TECH

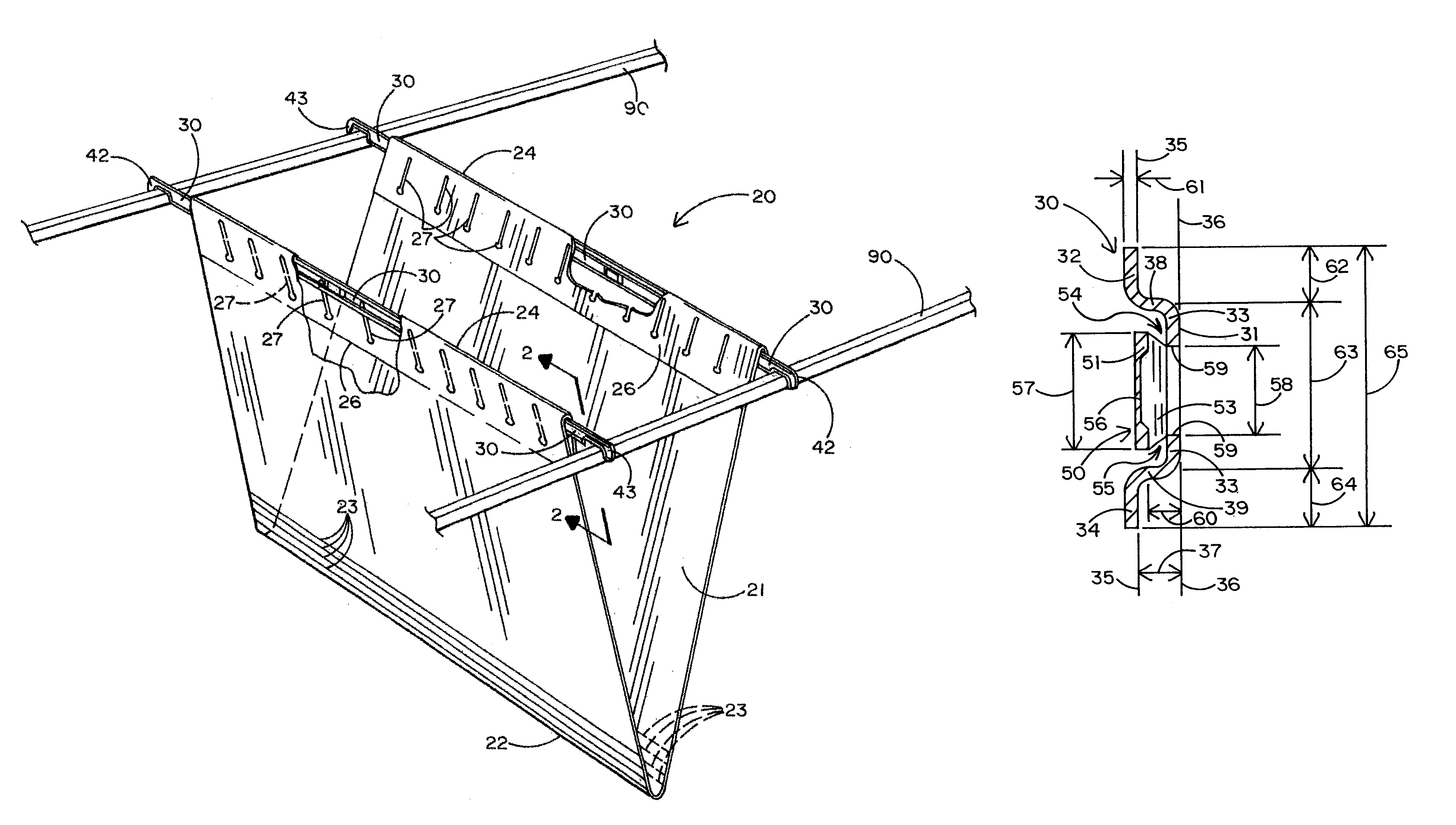

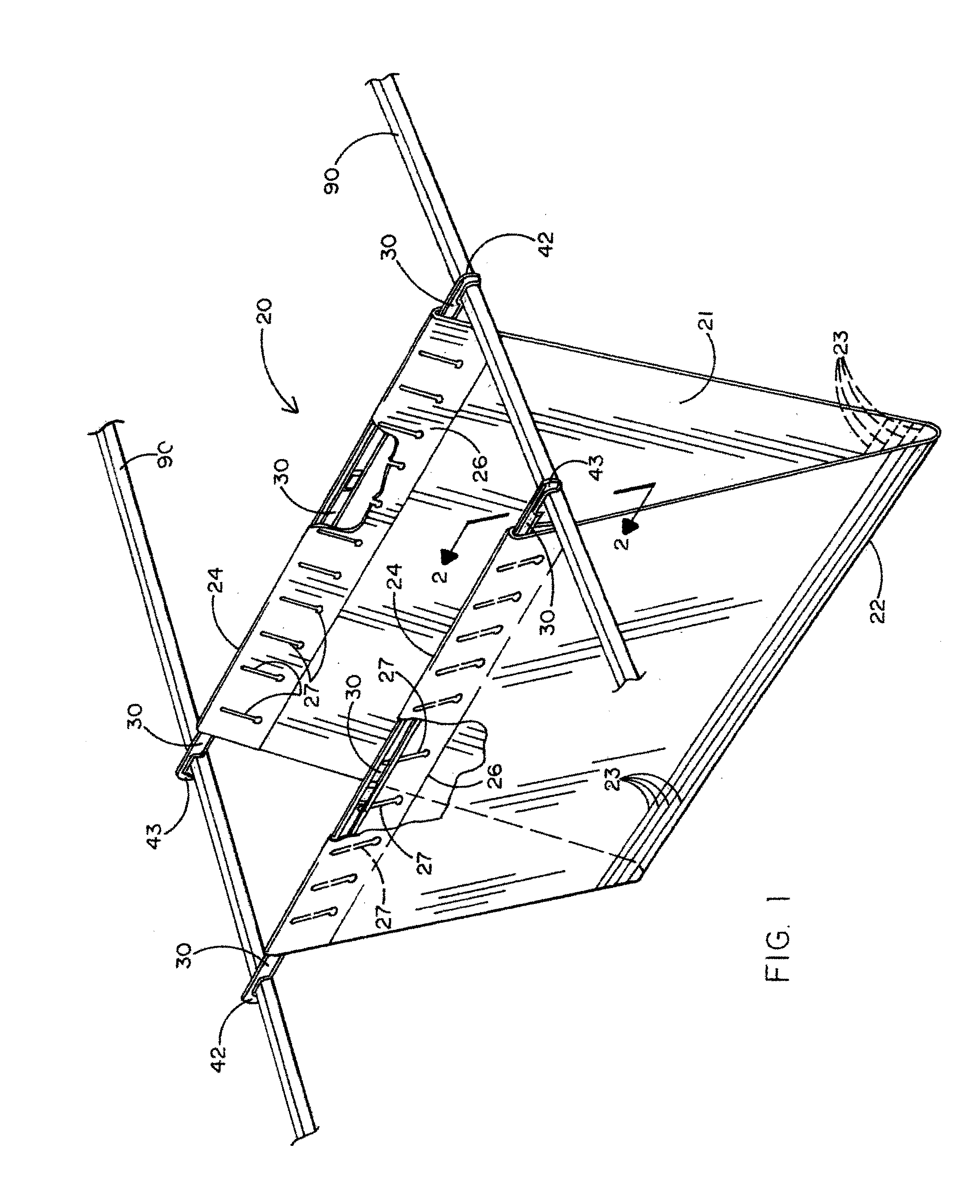

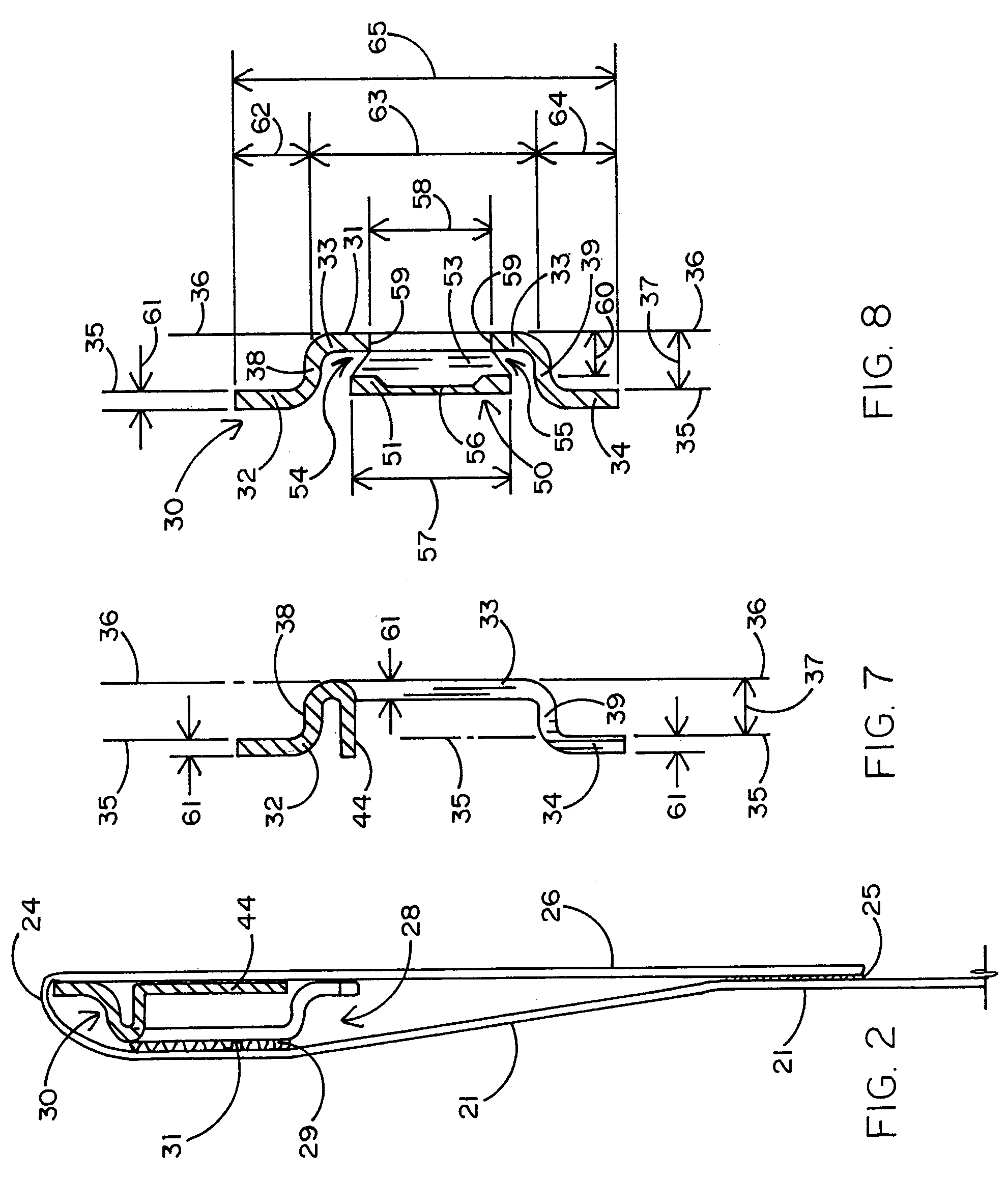

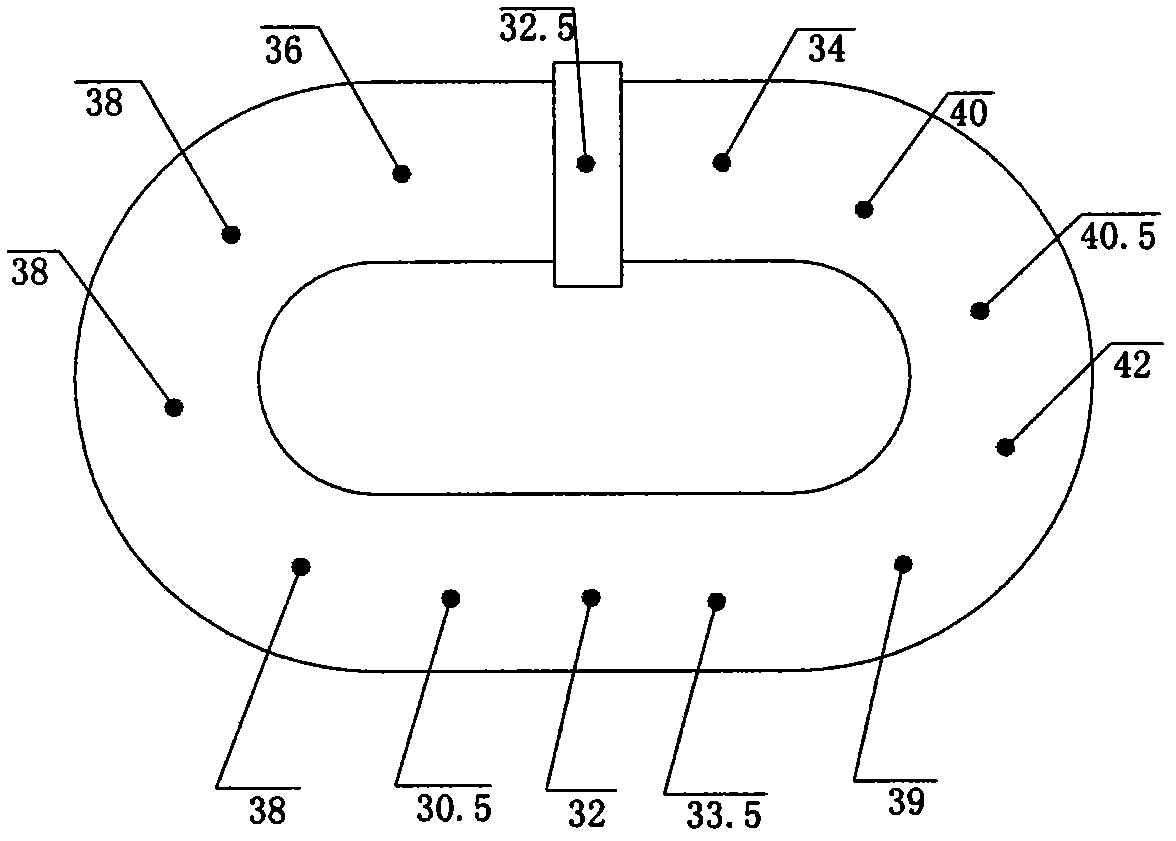

Hanging file folder and suspension bar therefor and process for producing

Owner:VANGUARD TOOL & MFG CO INC

Method for producing round-link chain

The invention discloses a method for producing a round-link chain, which comprises the following steps: A1) raw material selecting: adopting high-quality alloy steel 23MnNiMoCr54; A2) baiting, wherein baiting demands are as follows: being capable of standing, being free from burr and chamfer, and keeping a length error of a bar stock being plus / minus 0.5mm; A3) hotly chaining: bending the bar stock into a chain in a given size under the action of hydraulic power of a chaining machine; A4) ball blast: removing an oxide skin from the surface, preparing for the next process and ensuring the welding quality; A5) welding and removing the burs; A6) heat treatment; A7) stretching and calibrating: once stretching under a stretching load being 80% of a fracture load; and A8) checking, pairing, painting and placing the chain into a storage. By using the method, the efficiency of producing the round-link chain is increased and the cost is lowered. The fracture load, a coefficient of elongation under a test load, a fracture elongation coefficient and a fatigue life of the round-link chain all meet the national standard.

Owner:SHANDONG LIANGDA FASING ROUND LINK CHAINS

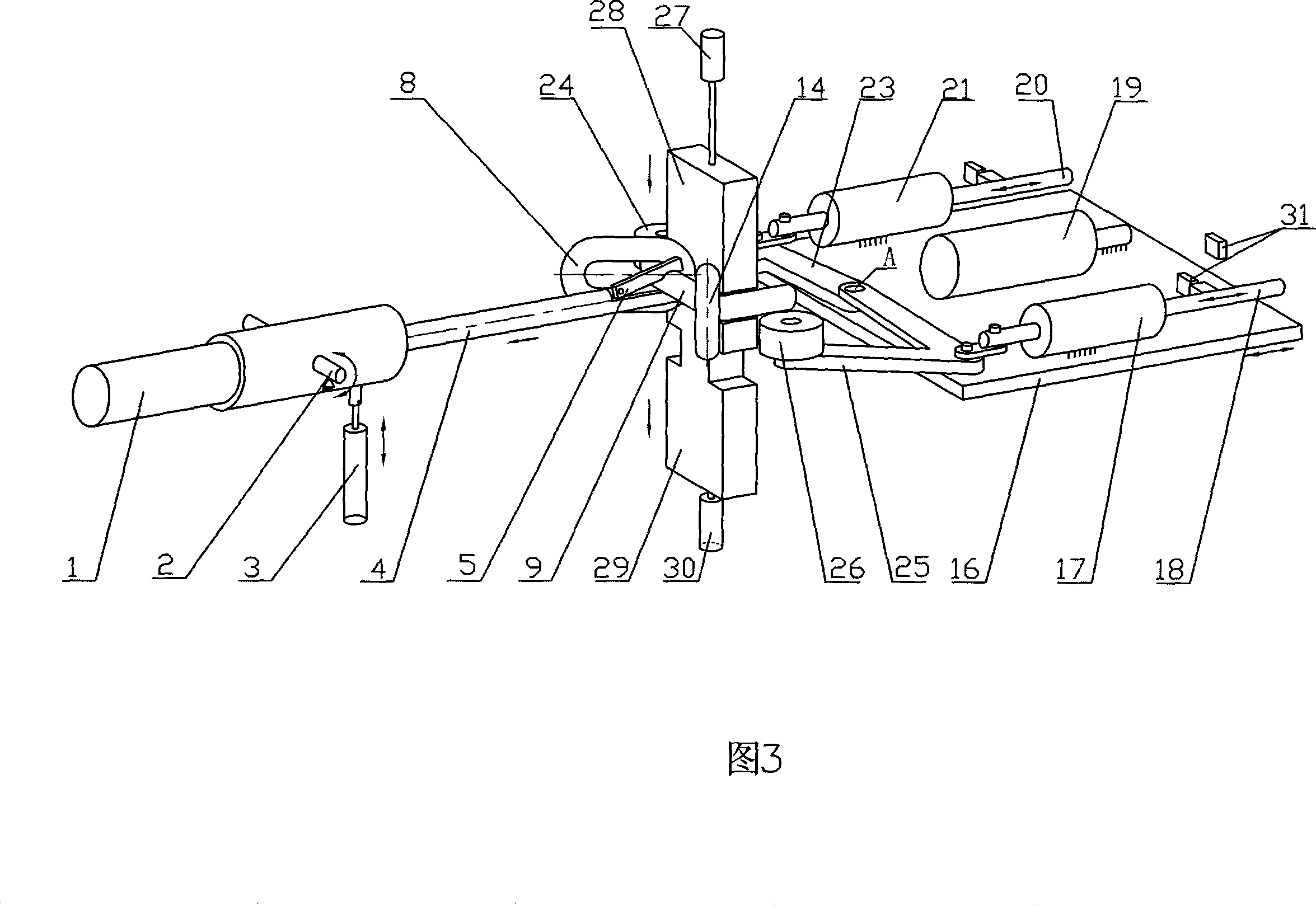

Automatic concatenation knitting-on method and apparatus for metal smith forging circular chain

ActiveCN101157115AReduce labor intensityMechanical properties are not damagedMetal chainsEngineeringBar stock

The invention relates to a production method of a metal chain ring, in particular to an automatic tandem connection and knitting method of a circular ring chain forged with metal and a device thereof. The method has the following steps: a bent ring bar stock is automatically delivered into a chain bending mechanism, and gripped by a mechanical hand, and first bent to be U-shaped under the effect of left and right chain bending rollers; the U-shaped ring penetrates into two knitted and forged rings and is delivered to a core die through the functions of the mechanical hand, a delivering chain inlet and outlet batch bin mechanism, and a core die mechanism; according to the shape of the core die, the U-shaped ring is automatically bent into the circular ring chain with only one step, thereby the tandem connection and the knitting of the circular ring chain is completed. Then an upper core die is elevated and opened, the mechanical hand takes out the well bent ring chain from the core die, the delivering chain inlet and outlet batch bin mechanism lowers and delivers out the well knitted chain, so that the next bent ring bar stock enters into the chain bending mechanism, and automatic repeating and circulation are continued. The invention proposes the automatic tandem connection and knitting method of the circular ring chain forged with metal with mechanical-electric-hydraulic integration and the device thereof, thereby having the advantages of high production efficiency, stable product quality, high degree of automation, and safe and reliable production process.

Owner:王洪军

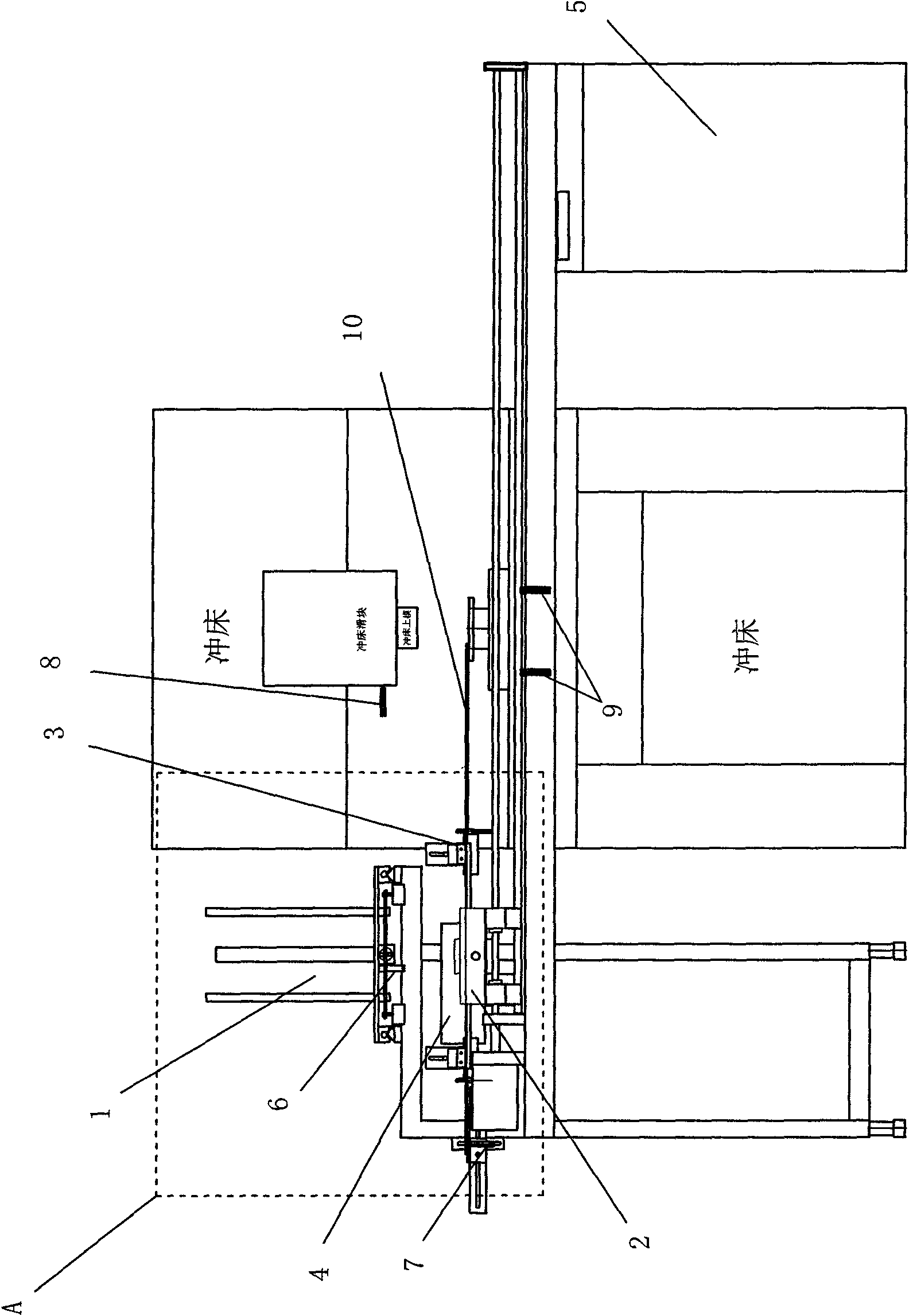

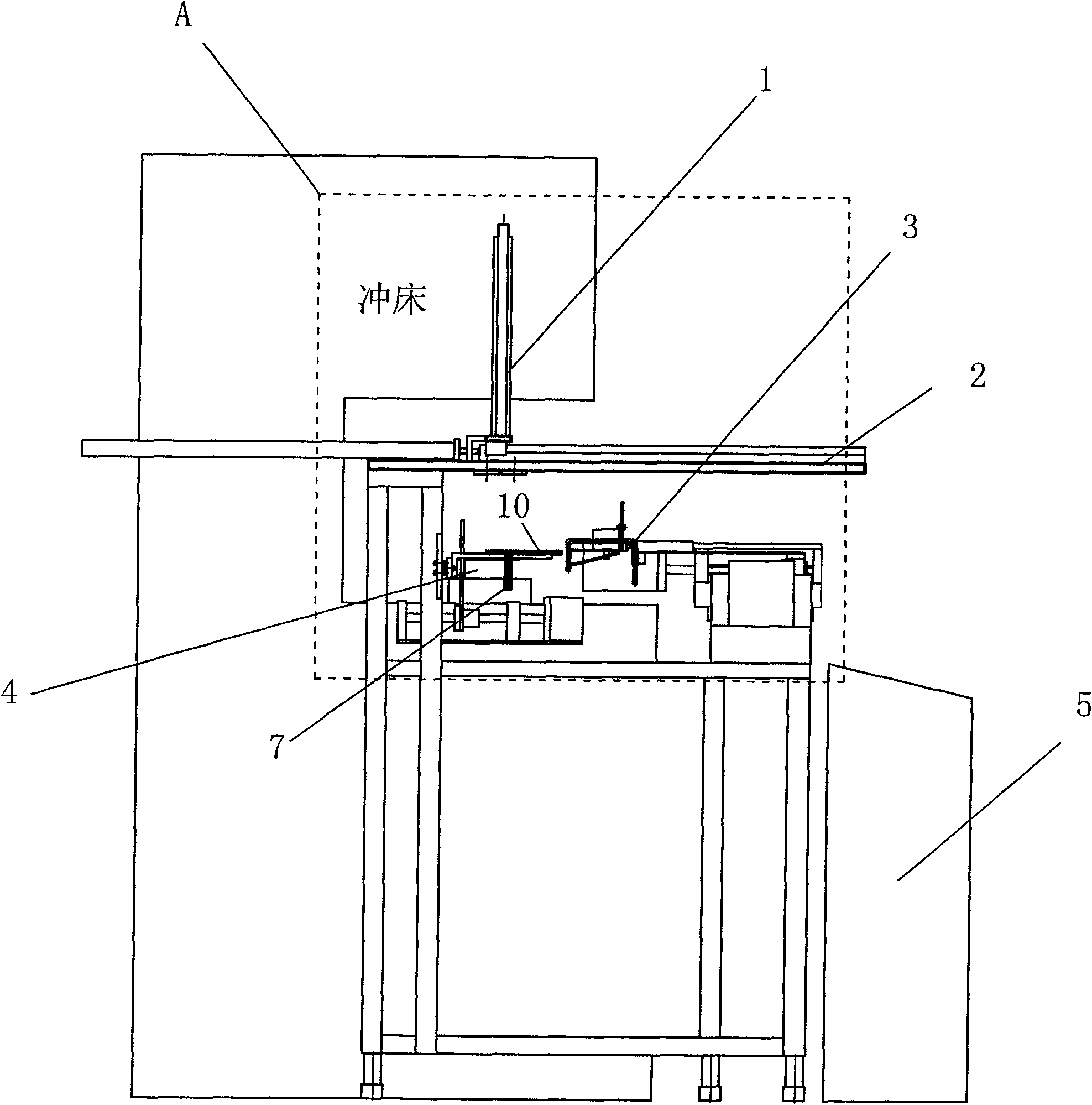

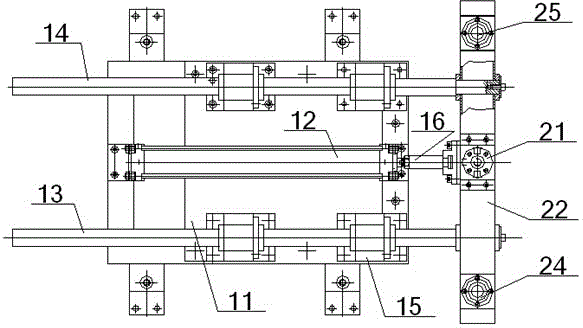

Automatic material loading, feeding and unloading equipment for bar stock blanking and method thereof

InactiveCN102180366AIncrease profitEasy to switchArticle feedersArticle separationPunch pressMulti machine

The invention discloses automatic material loading, feeding and unloading equipment for bar stock blanking and a method thereof. The equipment comprises a material loading mechanism, a feeding mechanism and an electric cabinet, wherein the feeding mechanism is provided with a mechanical arm, and the mechanical arm is connected with a manipulator. The equipment has the following beneficial effects: 1, the equipment can replace workers in the whole process to realize full-automatic operation of material loading, feeding and unloading, thus the purpose that one worker operates multiple machines can be realized; 2, varieties are convenient to switch; 3, in the feeding process, the manipulator has a function of automatically avoiding a punch die so as to realize multi-row reciprocating operation, especially automatic punching operation of narrow bar stock relatively to the die width; 4, although the structure is installed in front of the punch die, the structure barely affects workers to assemble, disassemble and adjust a die in front of a punch; 5, the shutdown rate of the punch is improved; 6, the equipment has the advantages of simple mechanical structure and low cost and is convenient to maintain; and 7, after material is automatically fed, the bar stock can be subjected to multiple-particle blanking because feeding position is accurate.

Owner:吴丽威

Cold precision forging process for bevel gear and mould thereof

InactiveCN102430692AImprove mechanical propertiesWon't cut offForging/hammering/pressing machinesWheelsHardnessBar stock

A cold precision forging process for a bevel gear is disclosed, and comprises the steps of: cutting the blanking by cylindrical bars; cutting a conical degree on a segmental length of the blank as segmental pre-form for positioning the blank in a die; performing spheroidization for the machined blank to reduce the hardness, then scouring and descaling, phosphorizing, saponifying and lubricating; the first cold precision forging step comprises: upsetting-extruding segmental tooth form in an extrusion mould to obtain a first extrusion which is used as the blank of the second first cold precision forging step; performing spheroidization again for the first extrusion, then scouring and descaling, phosphorizing, saponifying and lubricating; the second cold precision forging step comprises: upsetting-extruding all tooth forms in the extrusion mould to obtain the coarse material of the bevel gear; machining and shaping the coarse material of the bevel gear and cutting unnecessary materials on the end surface to obtain finished products of the bevel gear. The invention further provides an extrusion mould. The invention has higher production efficiency, reduces the material waste, lowers the cost and improves the mechanical property.

Owner:ZHEJIANG UNIV OF TECH

Process for manufacturing bearing ring

The invention discloses a process for manufacturing a bearing ring, which belongs to the technical field of machining. The process comprises the following steps: manufacturing a bar stock, hot forging, annealing, turning, heat treating, grinding, assembling a finished product, and the like. A 3Crl3 material is used so as to meet the requirements on high hardness and wearing resistance of a product, and the convenience of machining the bar stock and the rust proof and anticorrosive performance of the finished product are simultaneously improved. Heat treatment is carried out for the bar stock in a continuous type bright quenching furnace under a vacuum condition, wherein the bar stock is firstly quenched at 1050-1080 DEG C and then is tempered at 600-680 DEG C; and after being tempered, the bar stock is cooled by water. The process greatly improves the hardness control capacity of the bar stock by controlling the quenching temperature, the deformation of the bar stock is improved to 0.0 5mm from 0.2 mm, a good foundation is provided for the machining the bearing ring in a subsequent working procedure, the stability of an interior tissue of the baring ring is guaranteed, the brittleness is reduced and the service life is prolonged.

Owner:嵊州市美亚特种轴承厂

Processing method of high-strength titanium alloy thin-walled tube stock

The invention relates to a processing method of high-strength titanium alloy thin-walled tube stock, belonging to the field of material processing. The processing method comprises the following steps: 1) ingot casting titanium alloy at the temperature of 1100-1200 DEG C, cogging and forging, heating obtained bar stock to the temperature of 900-950 DEG C, conducting heat preservation for 30-50 minutes, and one-time hot-rolling on a rapid forging press to obtain titanium alloy forged bars; 2) finishing and drilling the titanium alloy forged bars to obtain tube blank; 3) preheating a central spindle to be spinned before hot spinning, with the preheating temperature not lower than the temperature of 350 DEG C; and conducting heat preservation on the tube blank at the temperature of 700-750 DEG C for 30-40 minutes, and multichannel hot spinning process; and 4) finishing the interior and exterior of the obtained hot spinned tube blank, and cold spinning and forming on a cold spinning machine to obtain finished products of the tube blank. The processing method adopts rapid forging blank making and spinning process for processing the titanium alloy thin-walled tube stock with higher requirements for room temperature strength and deformation resistance, has simple processing equipment and easy molding, and can effectively improve the quality and yield of alloy tube blank.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Aluminum blade of fan and manufacturing technology thereof

ActiveCN102162469AHigh densityHigh strengthPump componentsEngine componentsAngle grinderManufacturing technology

The invention discloses an aluminum blade of a fan rotor for a mine and a highway tunnel, and the blade is made from an aluminum material and is manufactured by a precision forging technology. The manufacturing steps comprise: (1) manufacturing a set of forging mold according to the physical dimension and the profile shape of the blade, wherein the mold comprises a hammer forging die and a trimming die; (2) heating a forged aluminum bar stock, and forging a blank the shape of which is similar to that of the blade by adopting a free forging technology; (3) heating the blank, and placing the blank in the hammer forging die to perform hammer forging forming; (4) cutting burr by the trimming die; (5) polishing trimmed burr by an angle grinder; (6) checking the transmittance of a blade basin and a blade back of the blade body, taking the blade basin and the blade back with the transmittance less than or equal to 1.5mm into the next working procedure, or else returning for reforging; (7) carrying out heat treatment and quenching; (8) carrying out cold straightening; and (9) carrying out artificial treatment. The density and strength of the blade manufactured by the material and method is greater than that of the aluminum blade, by adopting the blade with the same specification, the rotation speed and the flow rate of the fan can be improved, the performance of the fan is strengthened, and the cost is reduced.

Owner:四川振强锻造有限责任公司

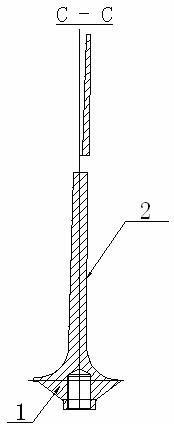

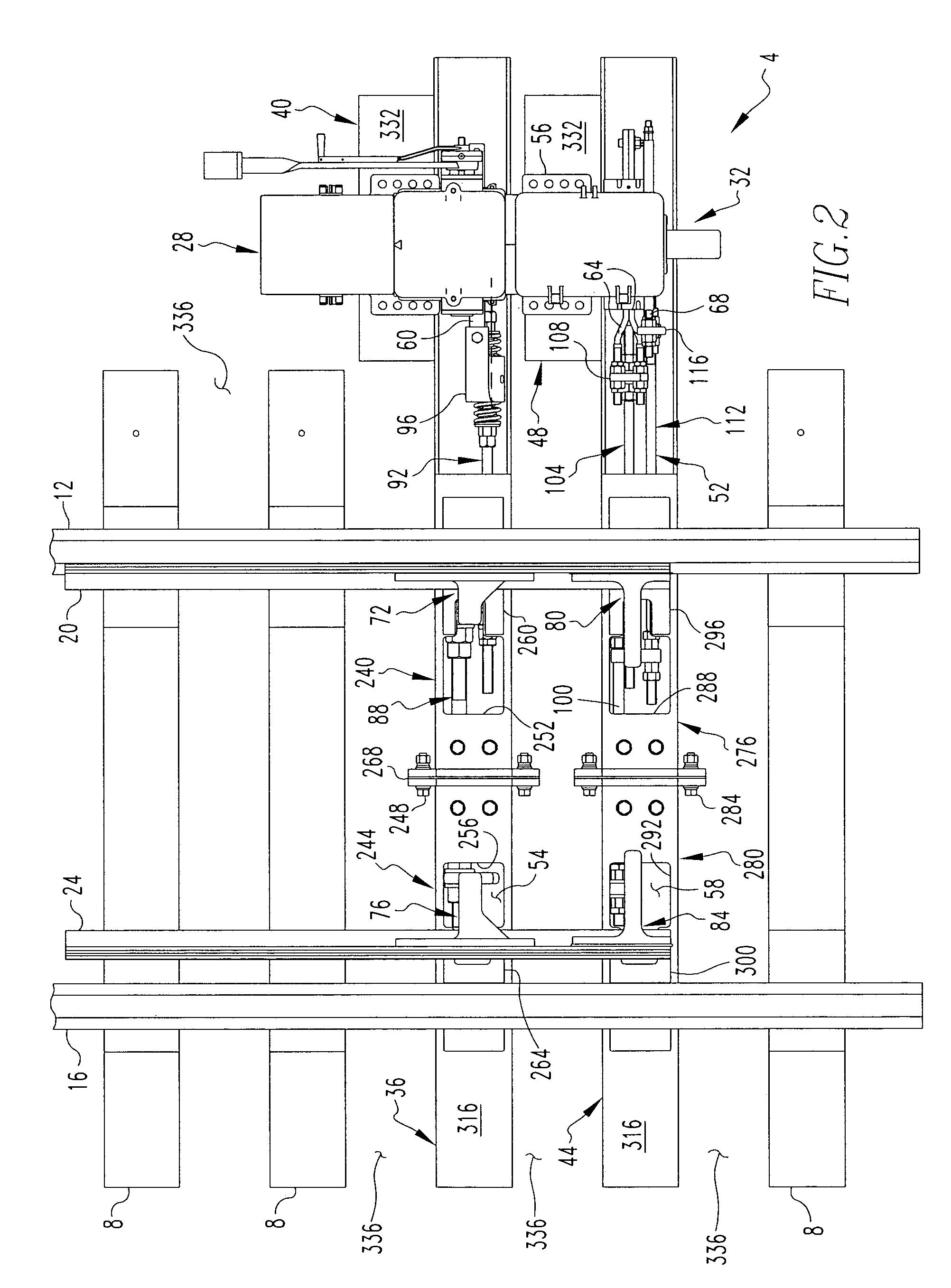

Hollow tie railroad switching assembly

A switching assembly includes a pair of hollow ties, a pair of supports, and a linkage. The linkage extends generally through the hollow ties, whereby the cribs are generally free of linkage components, and the ballast in the cribs can be compacted with known automated machinery. The linkage includes a number of lugs and a number of rods, with the rods each being formed from standard bar stock and threaded, and with the linkage configuration avoiding the need to custom bend any of the rods. The hollow ties are formed from generally available standard box section steel, as are the supports. The spacing between the hollow ties can be varied in accordance with the pitch of the other rail ties of the railroad switch. Each hollow tie can include a heater. The switching assembly is highly adjustable, which makes it suitable for use in numerous different track configurations.

Owner:ANSALDO STS USA INC

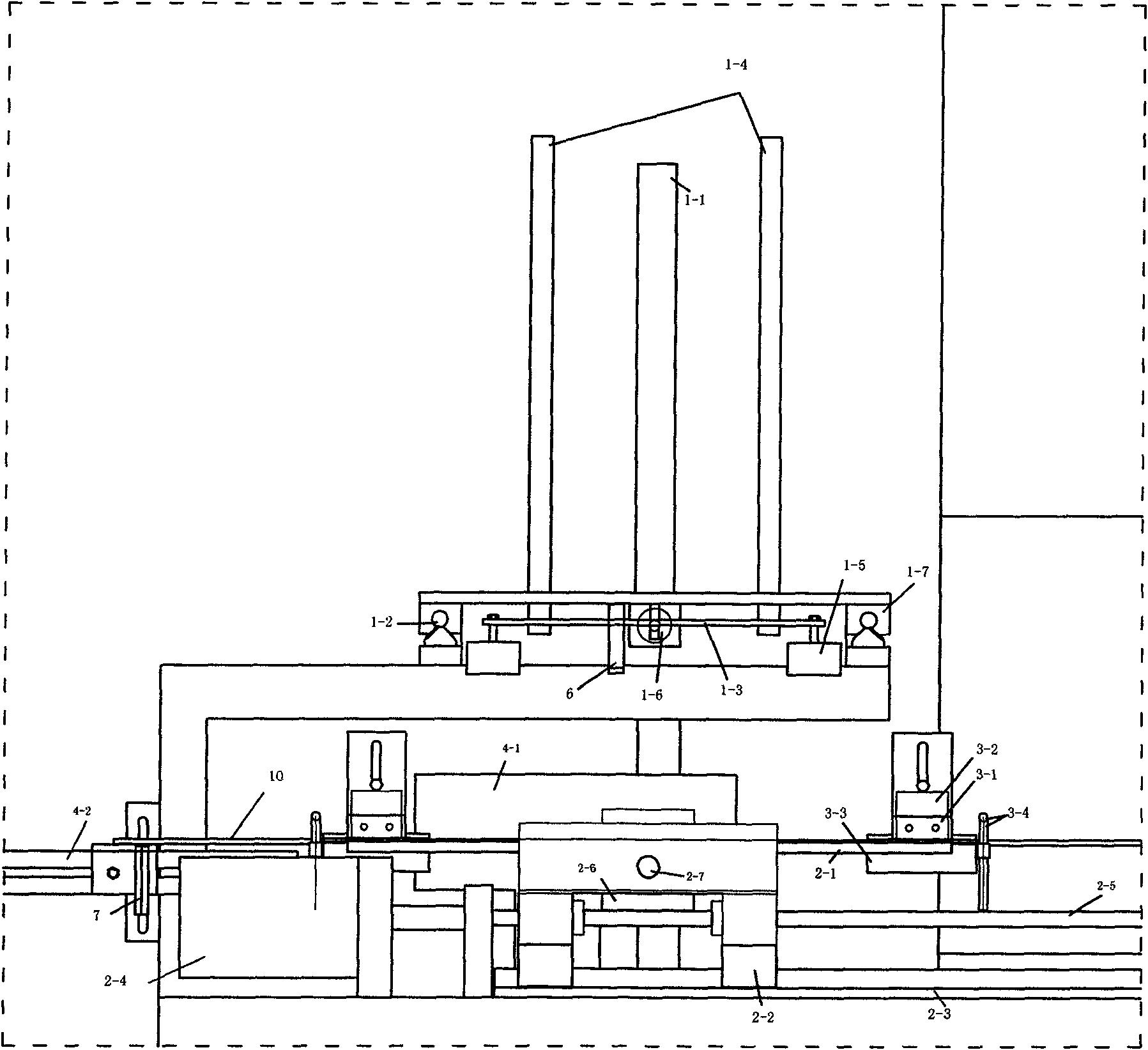

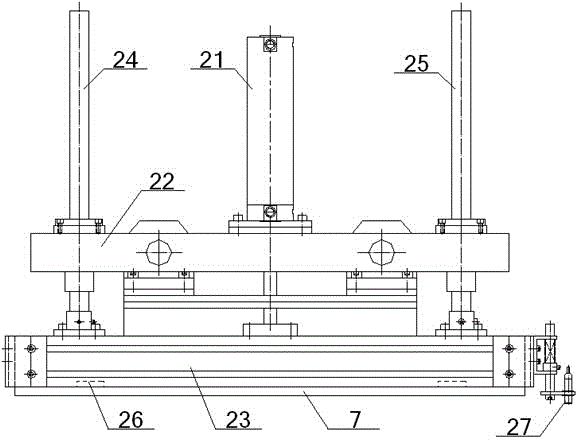

Automatic feeding system of fine blanking bar stock and using method thereof

ActiveCN104907434AReduce labor intensityReduce labor costsMetal-working feeding devicesPositioning devicesEngineeringBar stock

An automatic feeding system of a fine blanking bar stock comprises a material shifting device, a material lifting device and a bar stock trolley, the material shifting device drives the material lifting device to carry out horizontal back and forth movement, sectional materials in the material lifting device are driven to move up and down through a lifting cylinder, electromagnets are arranged on the sectional materials, and a bar stock is arranged in a bar stock groove in the bar stock trolley. When the automatic feeding system is used, the material shifting device first drives the sectional materials to move to the position over the bar stock groove, the material lifting cylinder drives the sectional materials to move downwards to attract the bar stock through the electromagnets and then moves upwards, and the material shifting device drives the sectional materials to return to place the attracted bar stock on a blanking platform. The automatic feeding system of the fine blanking bar stock is small in labor intensity, good in accuracy and high in working efficiency, it can be guaranteed that only one bar stock is attracted every time, and the bar stock can be fixed effectively.

Owner:武汉欣天工精密机械有限公司

Surface treatment method of piston for quartering hammer

InactiveCN101574769AReduce distortionHigh surface hardnessSolid state diffusion coatingFurnace typesCarbonizationEngineering

The invention discloses a surface treatment method of a piston for a quartering hammer, which comprises the following steps: raw materials are forged and pressed to form a bar stock for the piston and then isothermal annealing is conducted; rough treatment is conducted on a plain lathe and finishing allowance of 2mm is left on a circumferential surface and a scope of attack; the piston is carburized to lead the depth of a carburized layer to be up to 3mm; the circumferential surface of the piston is cut by 1.5mm on a numerically controlled lathe and the scope of attack thereof is cut by 2mm for fine treatment; the piston is quenched and tempered; and the circumferential surface of the piston is grinded, and the like. The surface treatment method of the piston for the quartering hammer firstly utilizes carbonization and then machining, and uses a more removal of the scope of attack to cause the scope of attack to become a low-carbon martensite, thereby enhancing the surface hardness of the scope of attack so as to be capable of improving the shock resistance of the scope of attack. In addition, the method for firstly conducting carbonization and then machining and finally quenching is adopted to reduce the deformation of the piston, thus being capable of greatly reducing the stock removal, and increasing the qualification rate of products.

Owner:天津辰龙重工机械有限公司

Automatic metal round bar feeder

ActiveCN102050319AThe need to realize full automationMeet the needs of full automationConveyorsControl devices for conveyorsManufacturing cost reductionWorking environment

The invention discloses an automatic metal round bar feeder. The automatic metal round bar feeder comprises a hoisting system, a material separation system and a material pushing system which are sequentially connected. A first detection device is arranged on the material separation system, and is connected with the hoisting system by a signal wire. A second detection device is arranged on the material pushing system, and is connected with the material separation system and the material pushing system by the signal wires respectively. The automatic metal round bar feeder has the advantages that: the automatic metal round bar feeder is in fit with an automatic metal round bar arrangement mechanism to implement an automatic feeding system, satisfies the needs of whole-process robot automation, ensures accurate rhythms easy to adjust, has a simple structure, is easy to maintain and applicable to metal round bars or bar stocks with different lengths and diameters by adjustment, can detect undesirably bent round bars or bar stocks, realizes automatic feeding in the production process of products, ensures the whole-process automation of the production, effectively reduces the manufacturing cost and greatly improves the working environment of workers.

Owner:CHINA RAILWAY LONGCHANG MATERIALS

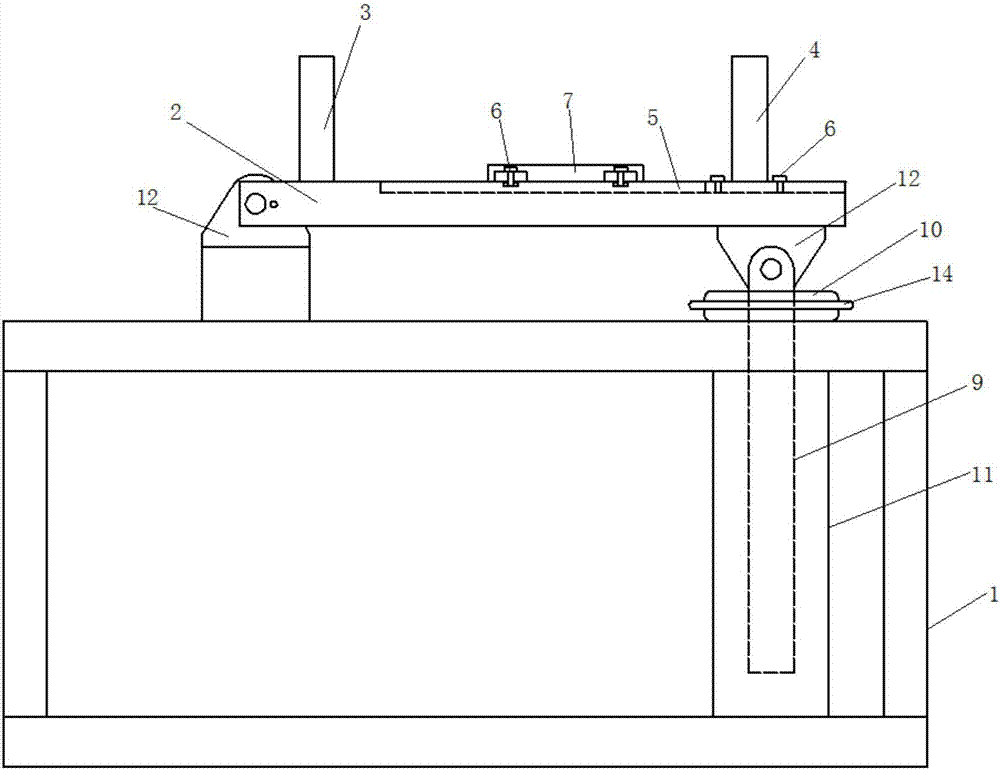

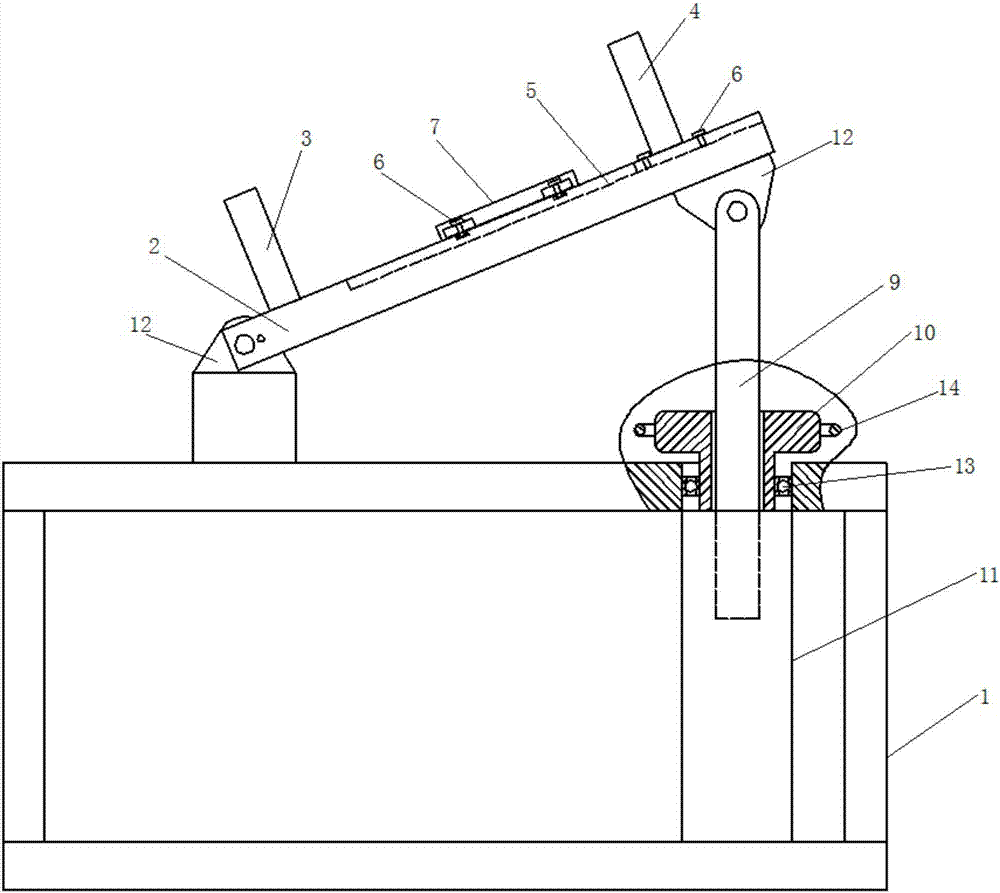

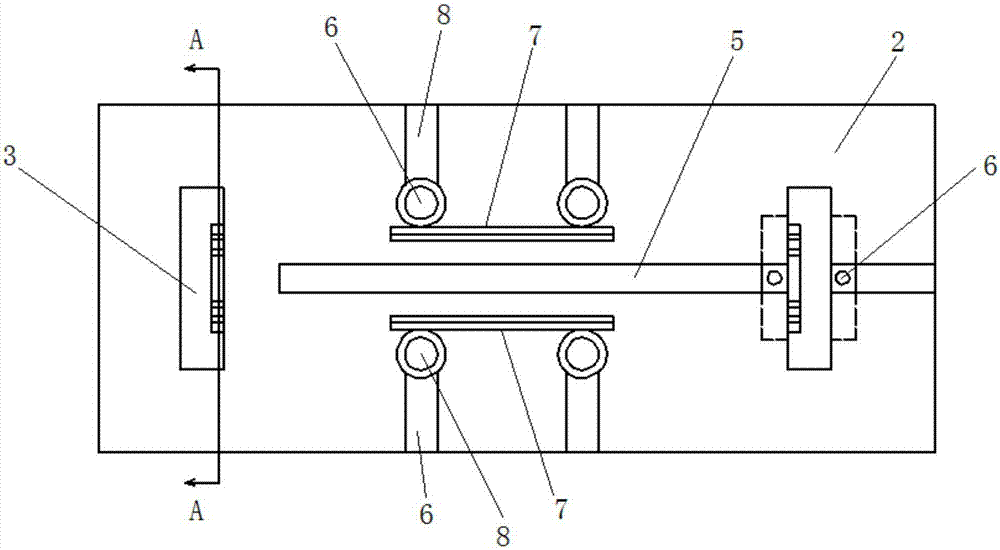

Angle-adjustable tool for inclined hole machining of parts

InactiveCN107160211AAchieve fixed positionWide range of anglesPositioning apparatusMetal-working holdersPunchingBar stock

The invention provides an angle-adjustable tool for inclined hole machining of parts. The tool is provided with a bottom frame, and a clamping platform is arranged at the upper end of the bottom frame; one end of the clamping platform is hinged to one end of the bottom frame, and the other end of the clamping platform and a lifting device arranged at the other end of the bottom frame are integrally hinged; the parts are fixed to the clamping platform; and after the inclined hole angles of the parts are well adjusted through the lifting device, punching is conducted through drilling equipment located above the parts and perpendicular to the bottom frame, and then inclined hole machining of the parts is completed. According to the angle-adjustable tool for inclined hole machining of the parts, the effect that the drilling equipment conducts random inclined hole machining on the parts on the clamping platform is achieved, the structure is simple, design is reasonable, the pre-drilling angle is convenient to adjust, inclined hole machining of plates, bars and pipes is achieved, and the work efficiency and quality of inclined hole machining are improved.

Owner:刘会斌

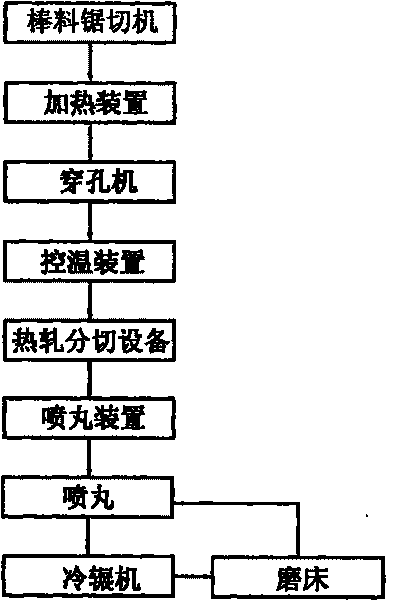

Method and equipment for manufacturing bearing ferrule

ActiveCN101718305AImprove continuityIncrease production capacityBearing componentsProduction lineEngineering

The invention relates to method and equipment for manufacturing a bearing ferrule. The method comprises the following steps of: (1) shearing a bar stock into a specified size and feeding to a heating device; (2) heating the sheared bar stock to a preset value in the heating device; (3) feeding into a piercer to make a pierced billet; (4) then, cooling the pierced billet to 640-700 DEG C, and randomly switching to a hot-rolling and cutting equipment; (5) continuously working and processing to obtain a bearing ferrule blank by a hot-rolling, molding and hobbing device in the hot-rolling and cutting equipment; and (6) carrying out shot blasting treatment on the bearing ferrule blank and switching the bearing ferrule blank to bearing finishing machining. By introducing the two working procedures of hot-rolling molding and cutting as well as shot blasting treatment in the production process of the bearing ferrule, the invention realizes the continuous and component-based production for manufacturing the bearing ferrule in the seamless pipe field, solves the prominent problems of material waste, energy waste, pollution, and the like existing in a traditional forging and seamless pipe production process, and creates a novel energy-saving emission-reducing production line.

Owner:广东冠邦科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com