Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

739 results about "Mechanical press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mechanical press is a device designed to apply very high force to form, shape, or cut materials, to compress solids, or to extract liquids. Mechanical presses range in size from very small units that are operated by hand, to large powered industrial units used in manufacturing and assembly line applications.

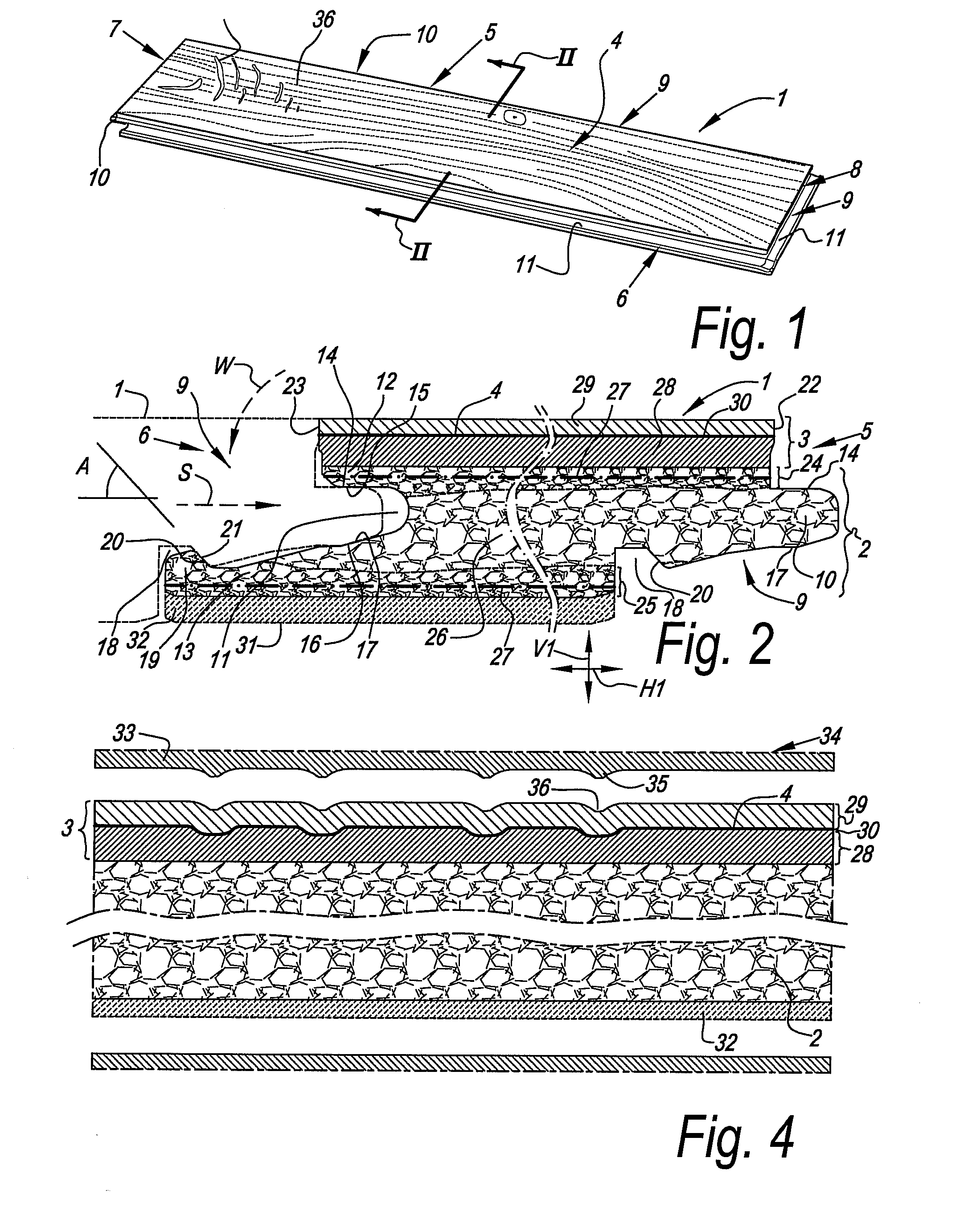

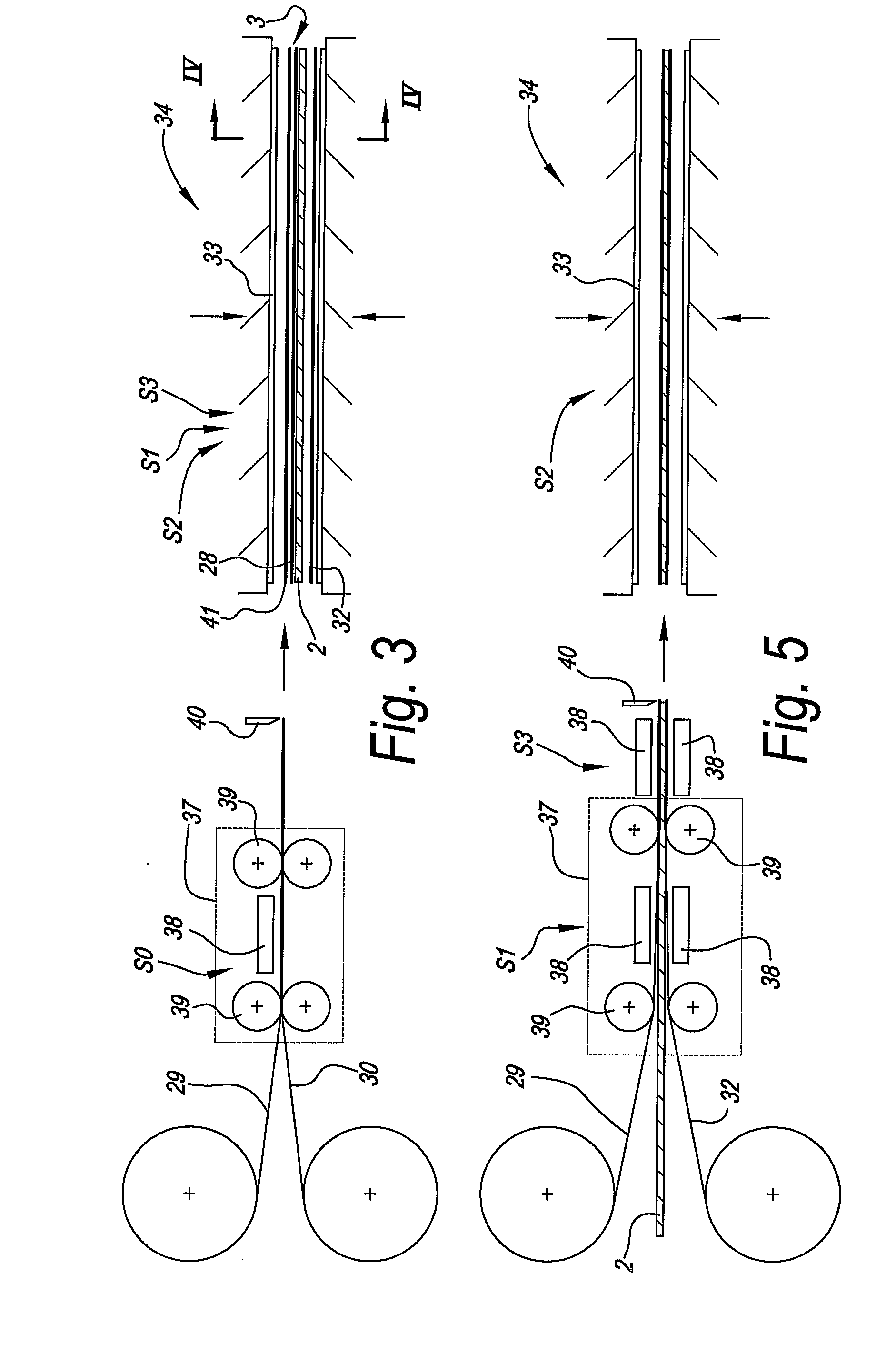

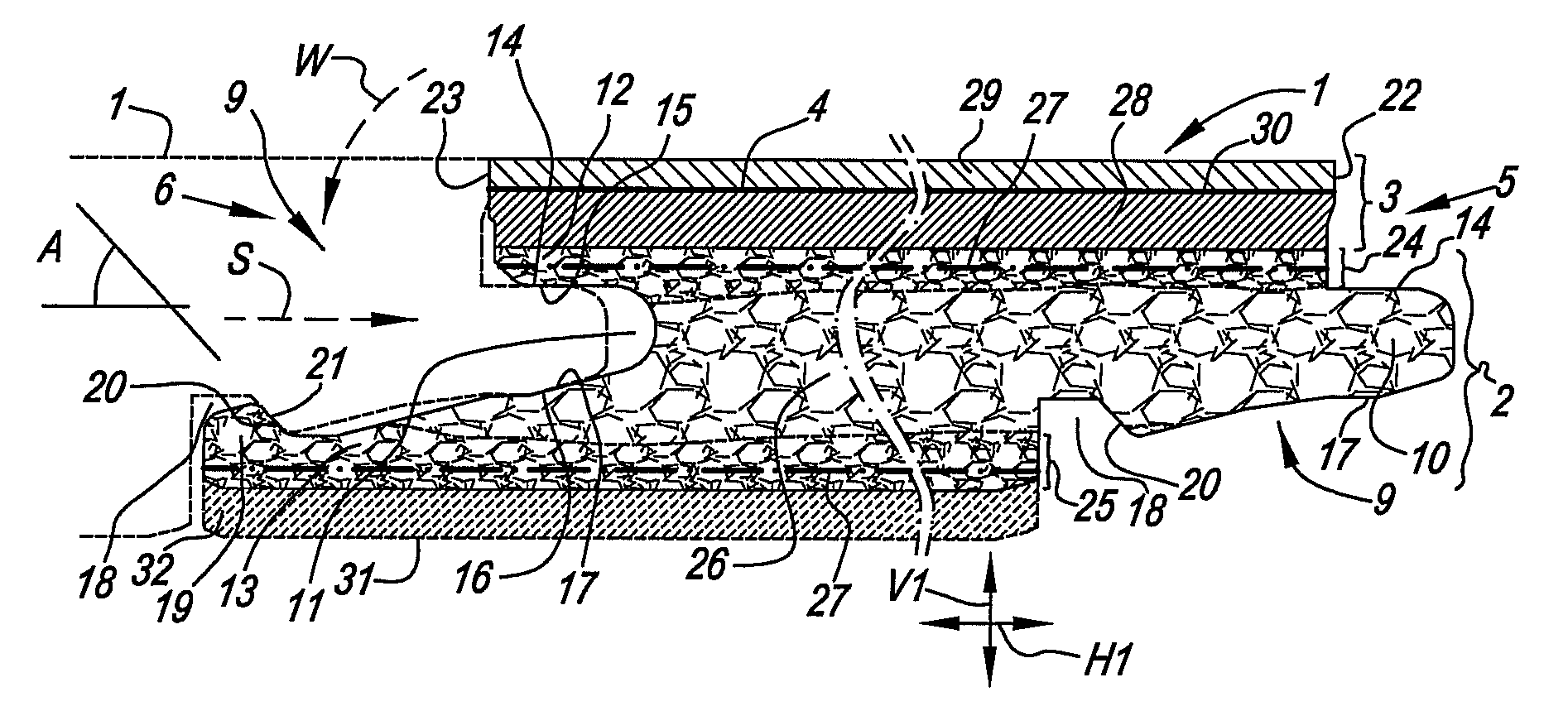

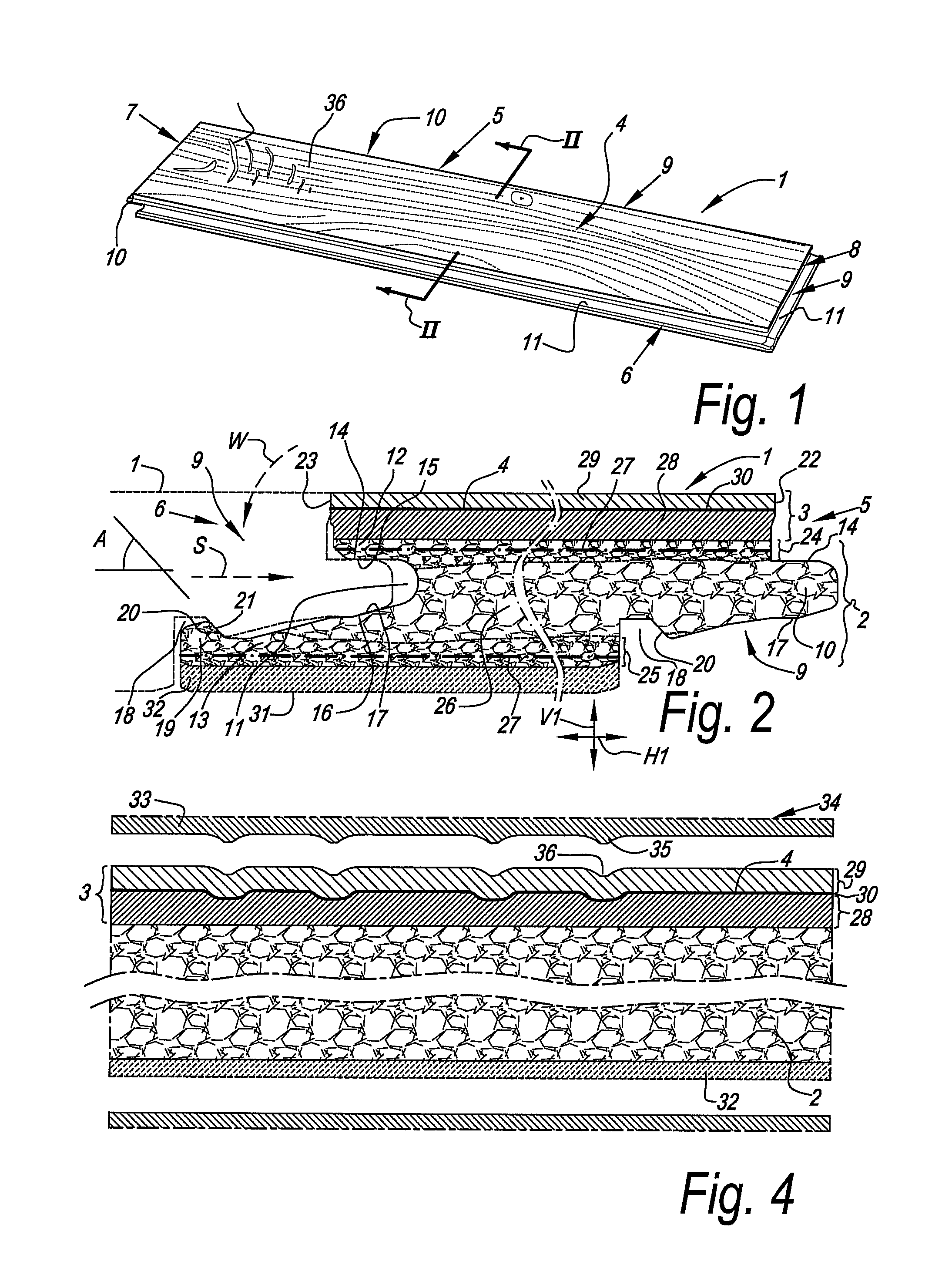

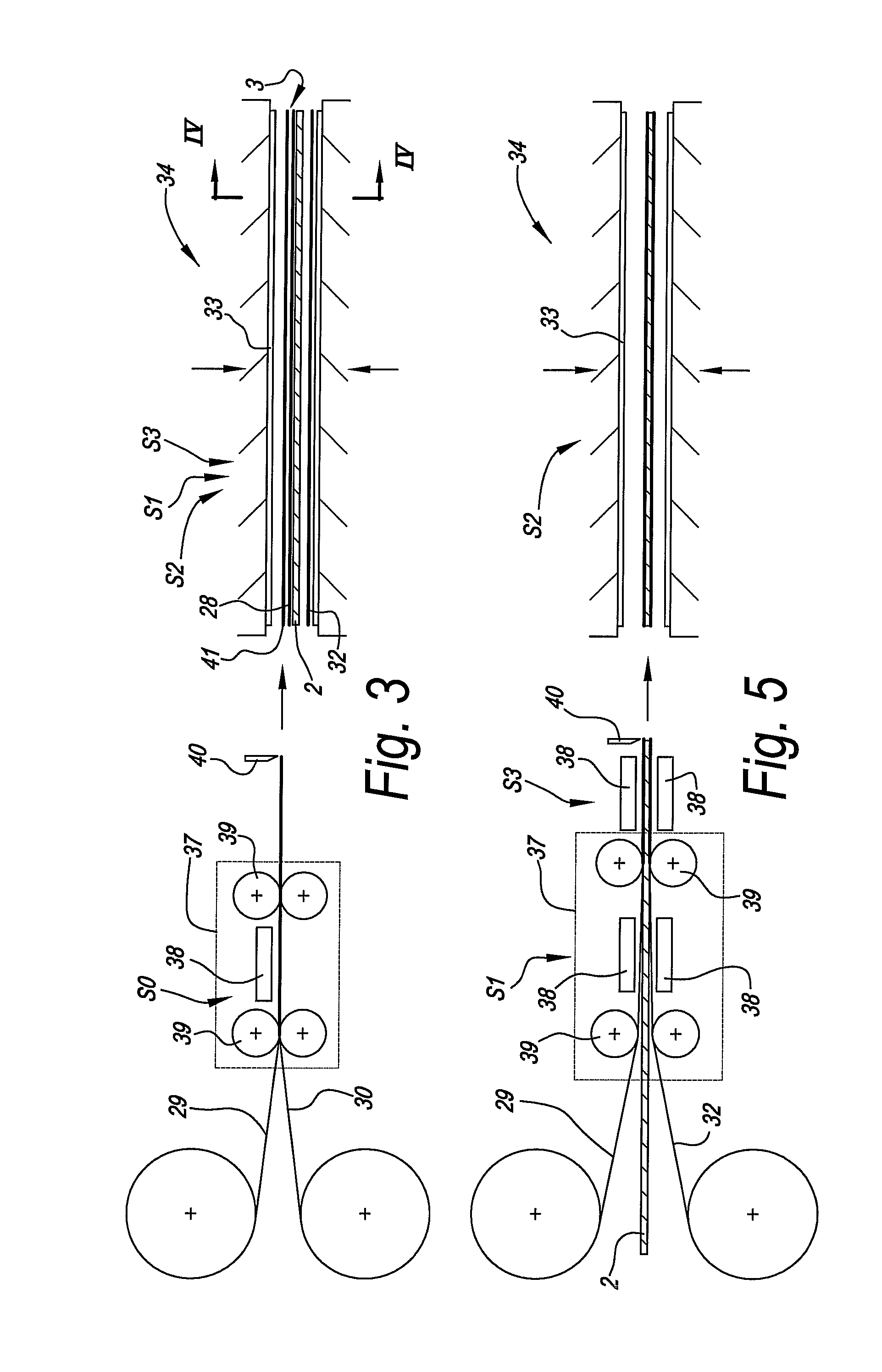

Floor panel and methods for manufacturing floor panels

ActiveUS20130067842A1High densityHigh sensitivityCovering/liningsDecorative surface effectsPanellingEngineering

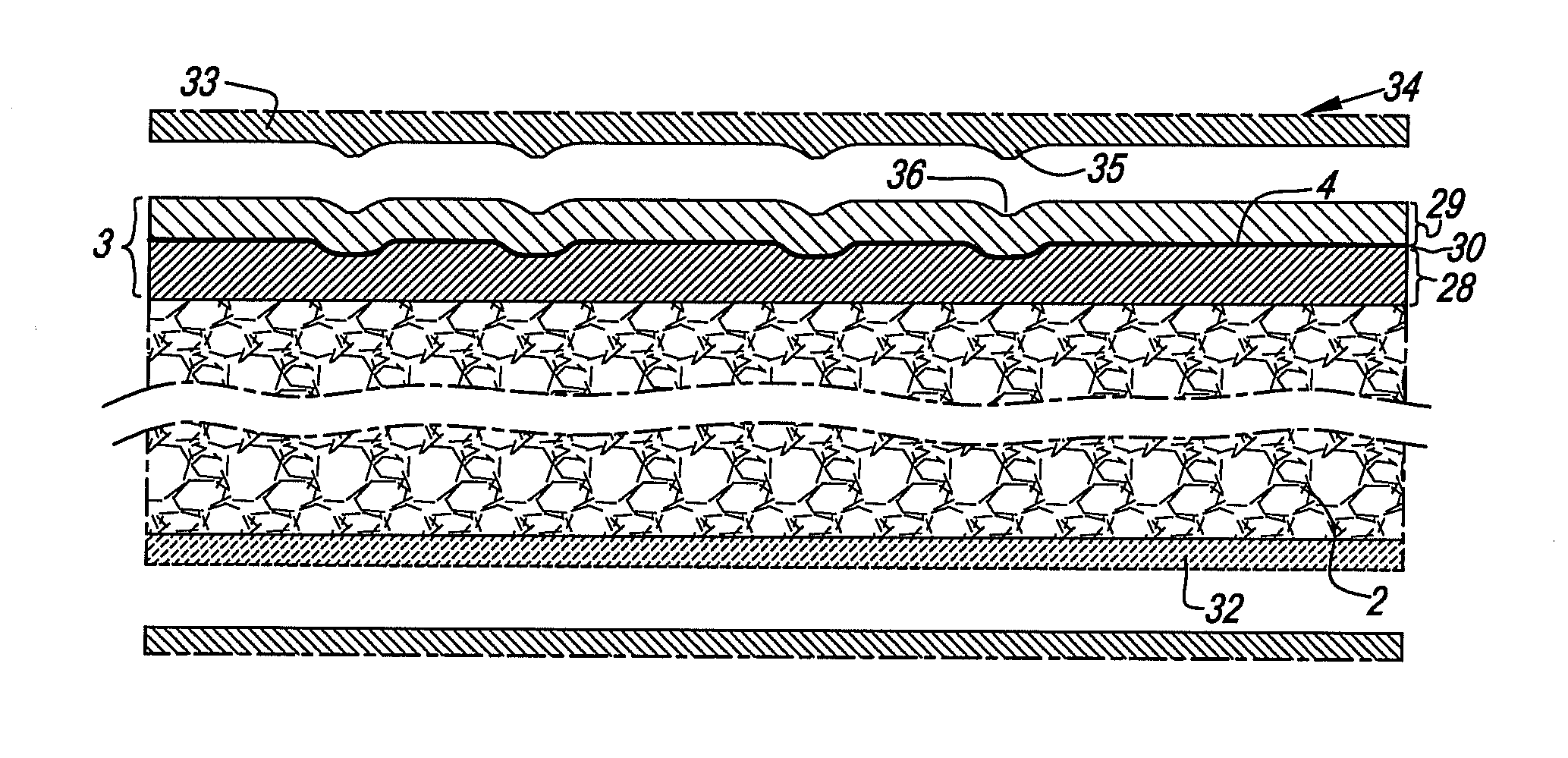

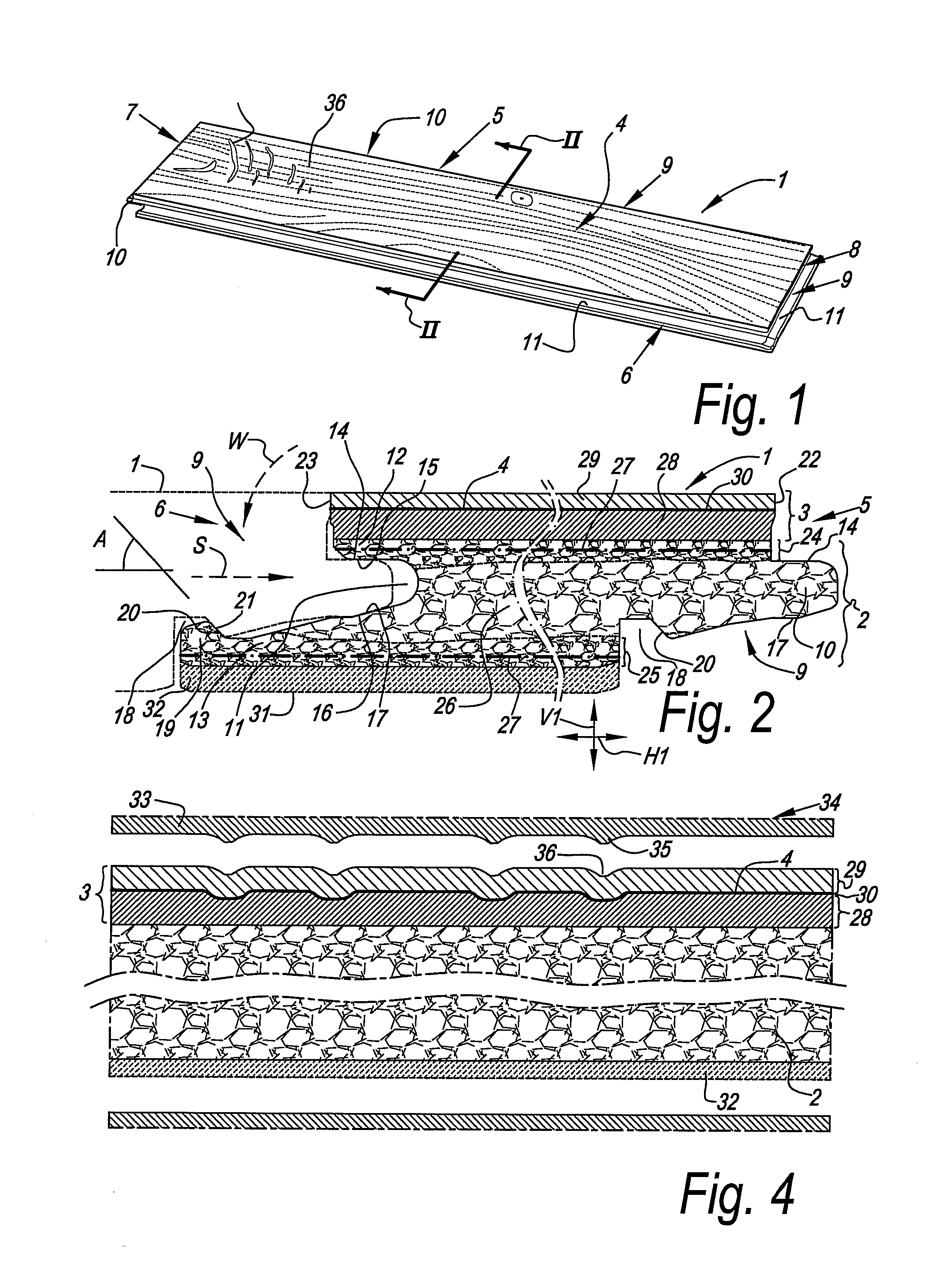

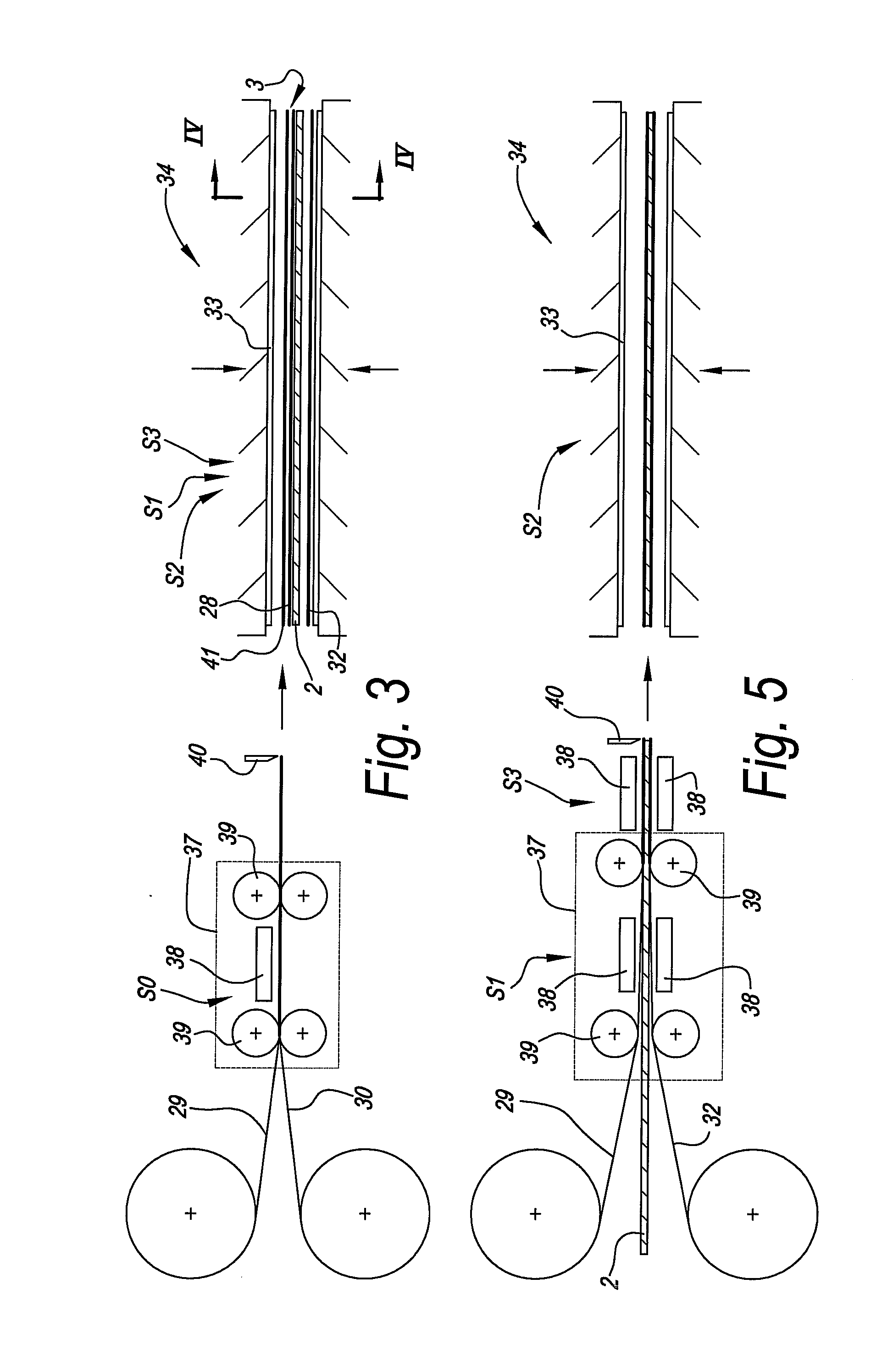

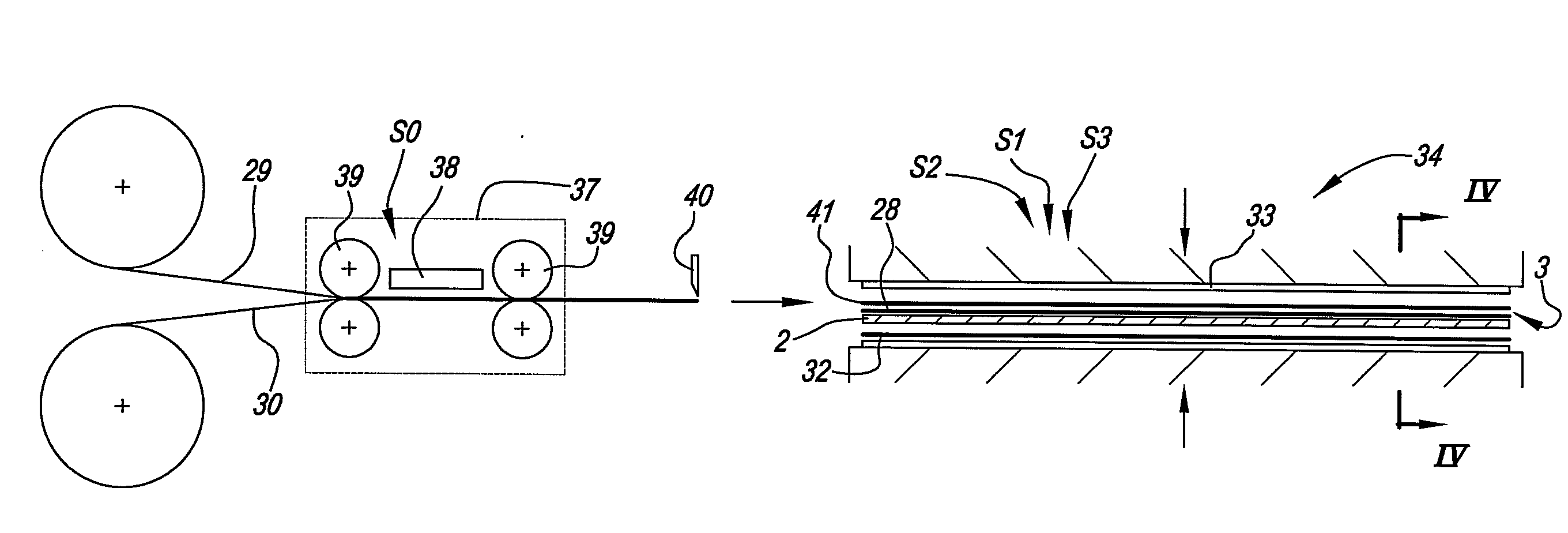

In a method for manufacturing floor panels that have at least a substrate and a top layer provided on the substrate, the top layer including a thermoplastic layer that is translucent or transparent, the method may involve providing the top layer, including the thermoplastic layer, on the substrate. The method may also involve heating at least the thermoplastic layer, and structuring the thermoplastic layer using a mechanical press element.

Owner:FLOORING IND LTD

Methods for manufacturing floor panels

ActiveUS20140020820A1High densityHigh sensitivityDecorative surface effectsOrnamental structuresEngineeringMechanical press

In a method for manufacturing floor panels that have at least a substrate and a top layer provided on the substrate, the top layer including a thermoplastic layer that is translucent or transparent, the method may involve providing the top layer, including the thermoplastic layer, on the substrate. The method may also involve heating at least the thermoplastic layer, and structuring the thermoplastic layer using a mechanical press element.

Owner:UNILIN BV

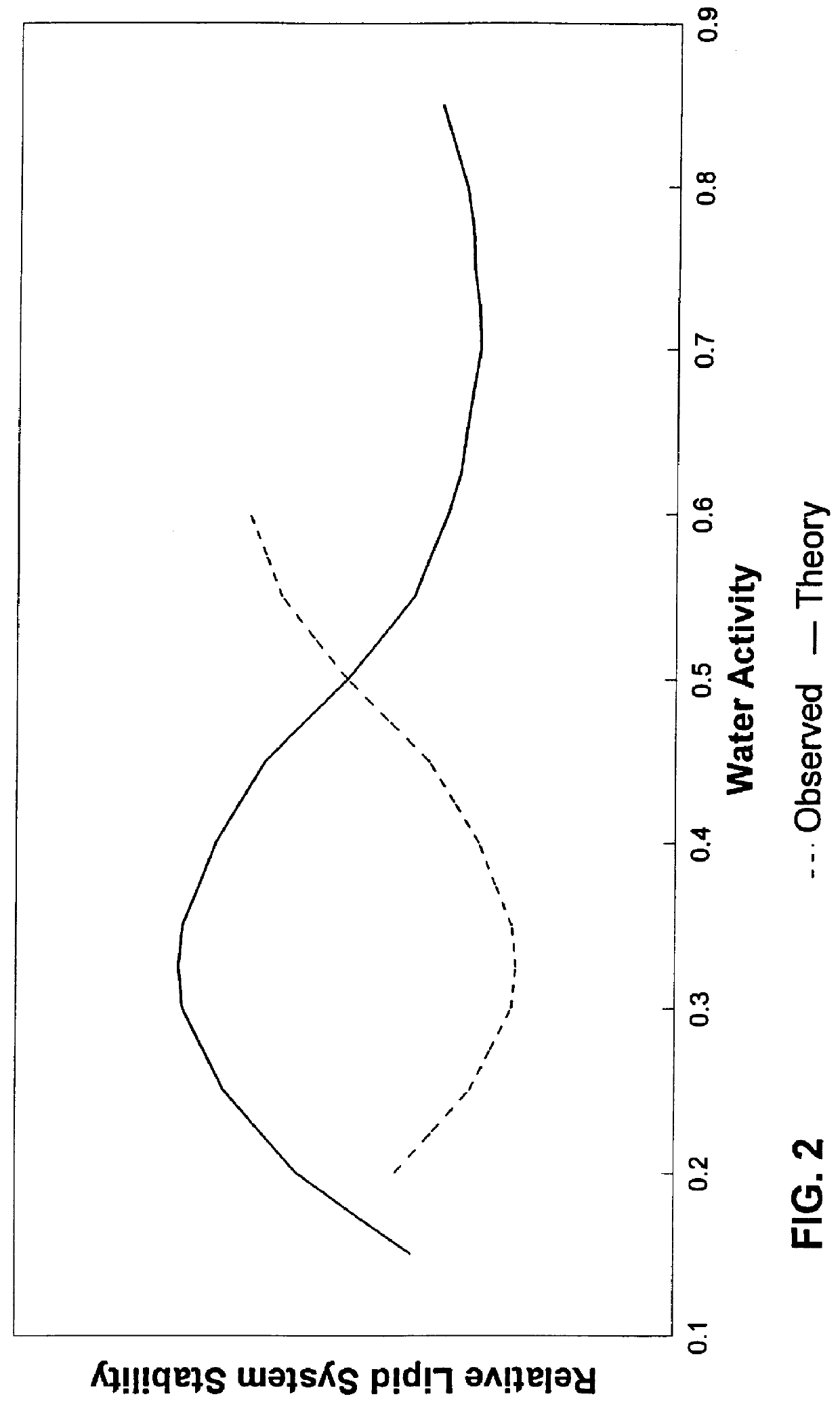

High temperature countercurrent solvent extraction of herb or spice solids

InactiveUS6013304AShorten the counting processBacterial Count ReductionSolid waste disposalFood preparationAntioxidantFine particulate

Principal components of spice and herb plant solids are simultaneously extracted and concentrated with an edible solvent in a series of mixing and high temperature and pressure mechanical pressing steps using edible solvent and a countercurrent extraction procedure. The extract may be hydrated and then centrifuged to remove fine particulate solids and gums. A solution having several times the concentration of pigments and other flavor and aroma and / or antioxidant components of the starting raw material is obtained. The residual press solids may be cooled and hydrated following the last pressing operation. The residual press solids and extract have significantly reduced bacterial counts as a result of the temperatures, high pressure, and high shear utilized, as well as the low moisture levels employed, thus producing not only a food grade extract but also a food grade residual solid having low bacterial counts and predictable, standardized levels of the principal components of interest. The tissue of the residual spice or herb plant solid is ruptured in the process so as to provide quick release of the components thereof when utilized in a food or beverage, this greatly increasing its use effectiveness. The degree of browning or caramelization of the residual press solids is controlled, and the resistance to oxidative deterioration of both the extract and the residual solid is improved, by control of the temperature employed. Additionally, edible antioxidants can be included in the solvent to enhance the stability of both the extract and the residual solid.

Owner:KALAMAZOO HLDG INC

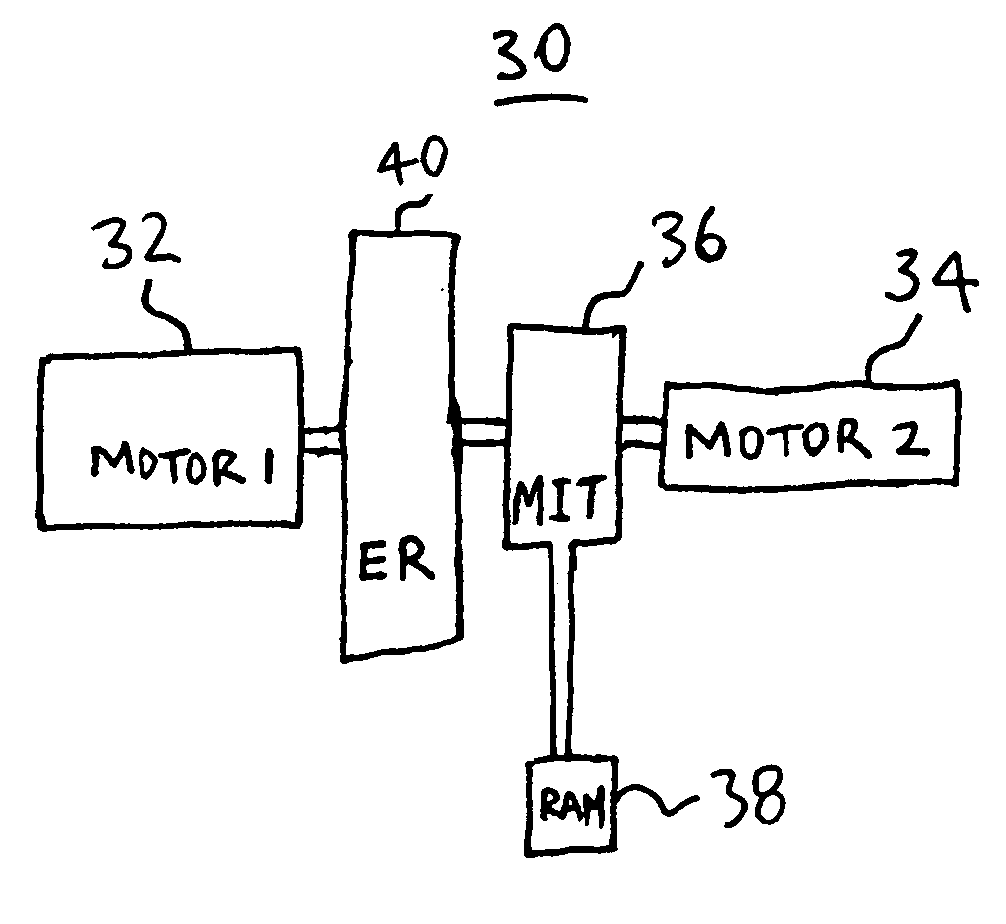

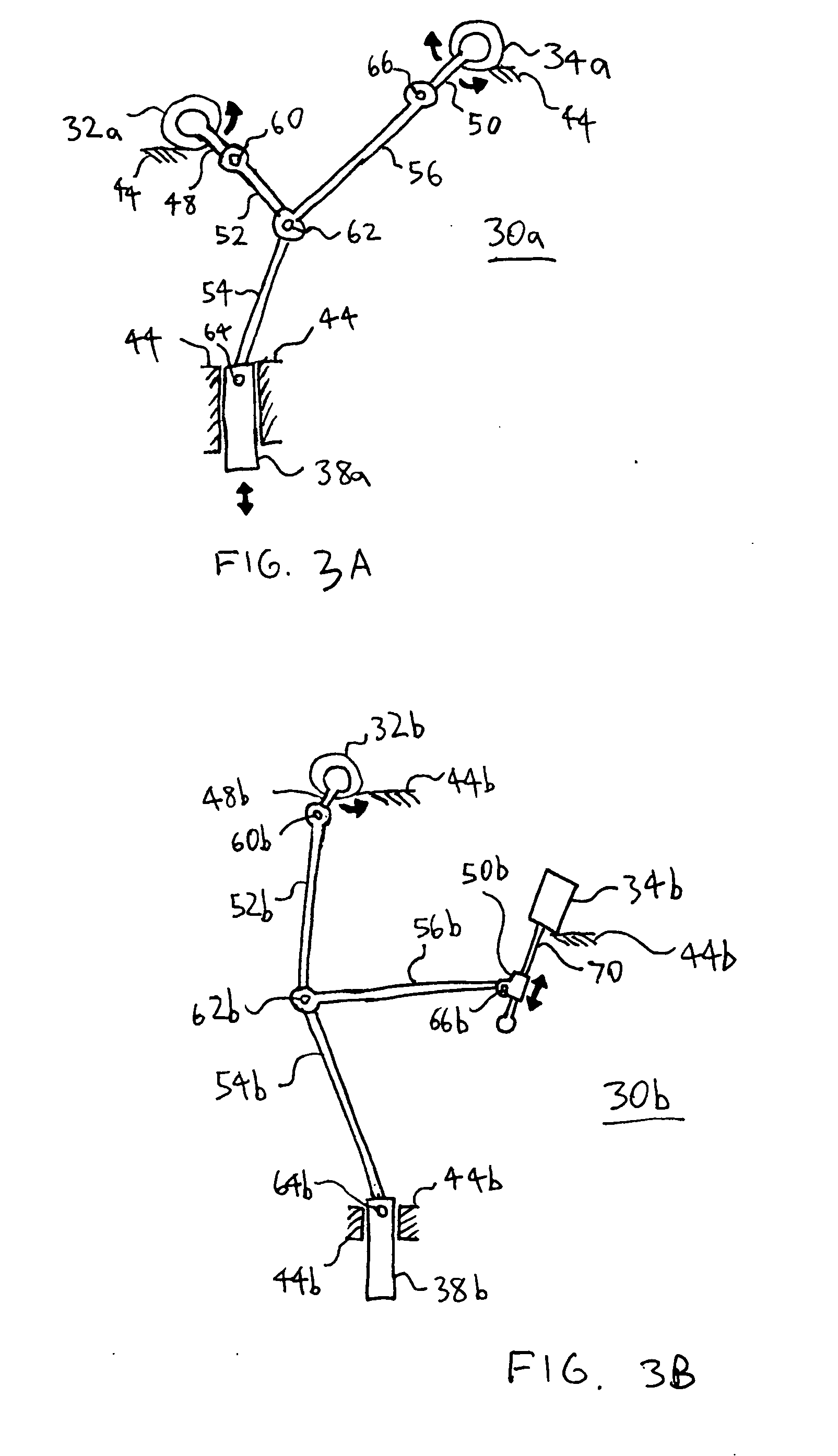

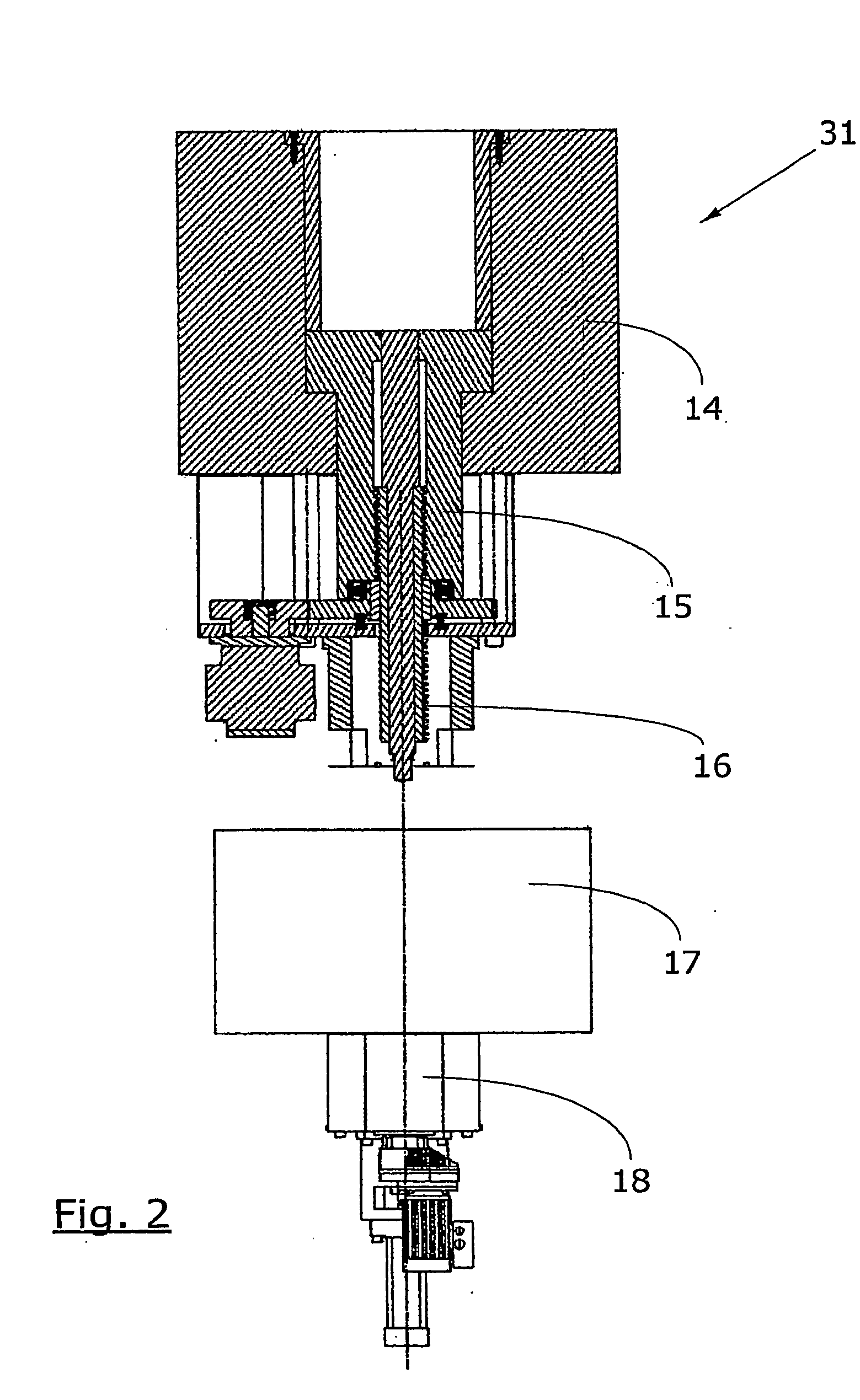

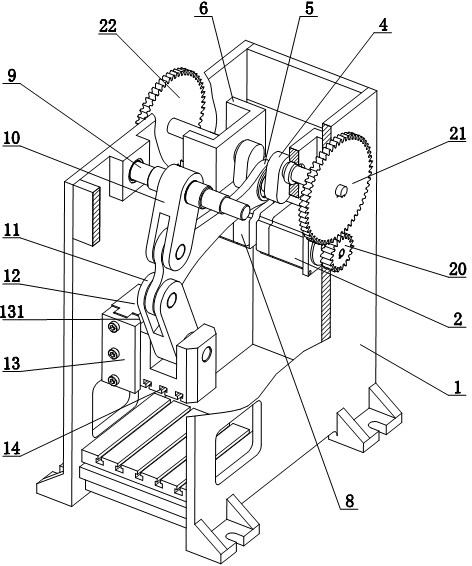

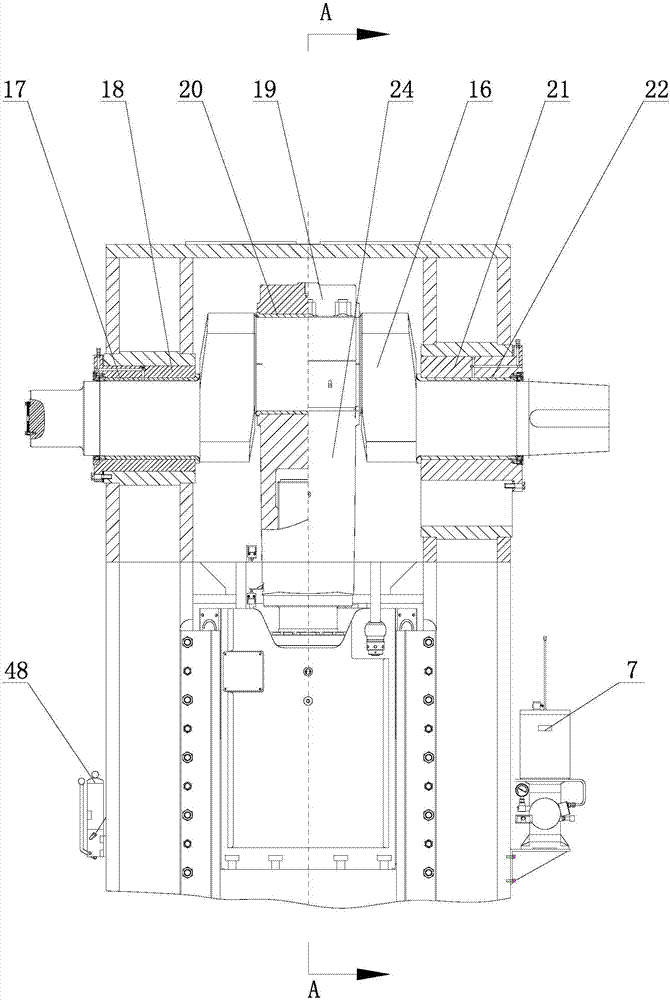

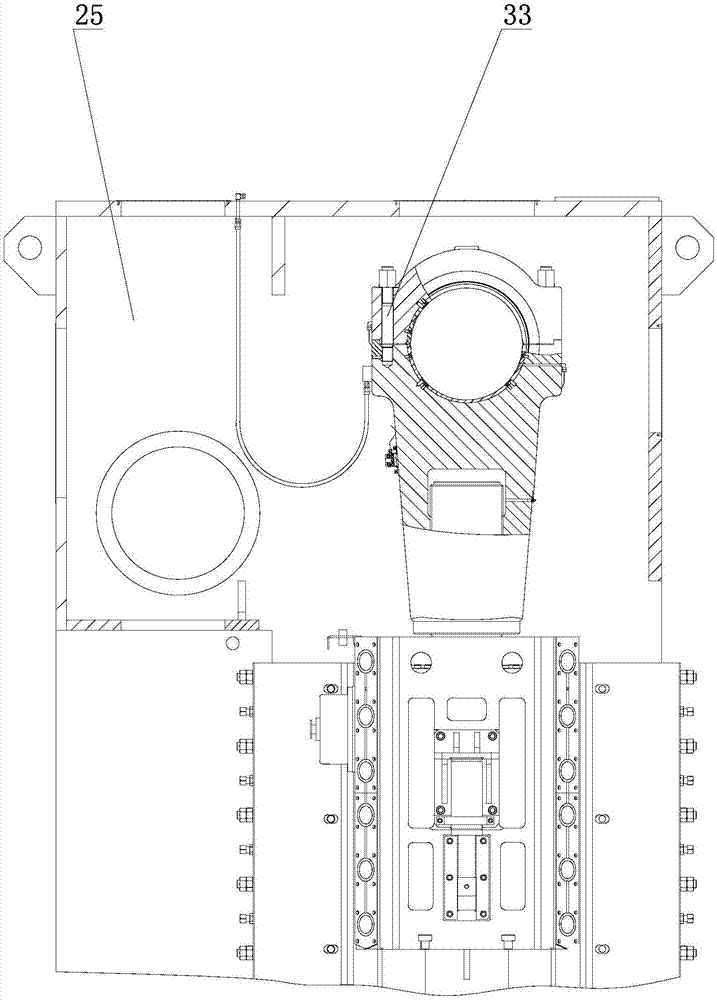

Mechanical press with controllable mechanism

According to an embodiment of the invention, a mechanical press includes a transmission that comprises a first transmission and a second transmission coupled to the first transmission. The first transmission is for receiving mechanical movement from a first motor and to transmit mechanical movement to a ram. The second transmission is for modifying configuration of the first transmission in response to mechanical movement received from a second motor, and a profile of movement of the ram over a pressing cycle is affected by a profile of movement from the second motor over the pressing cycle.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

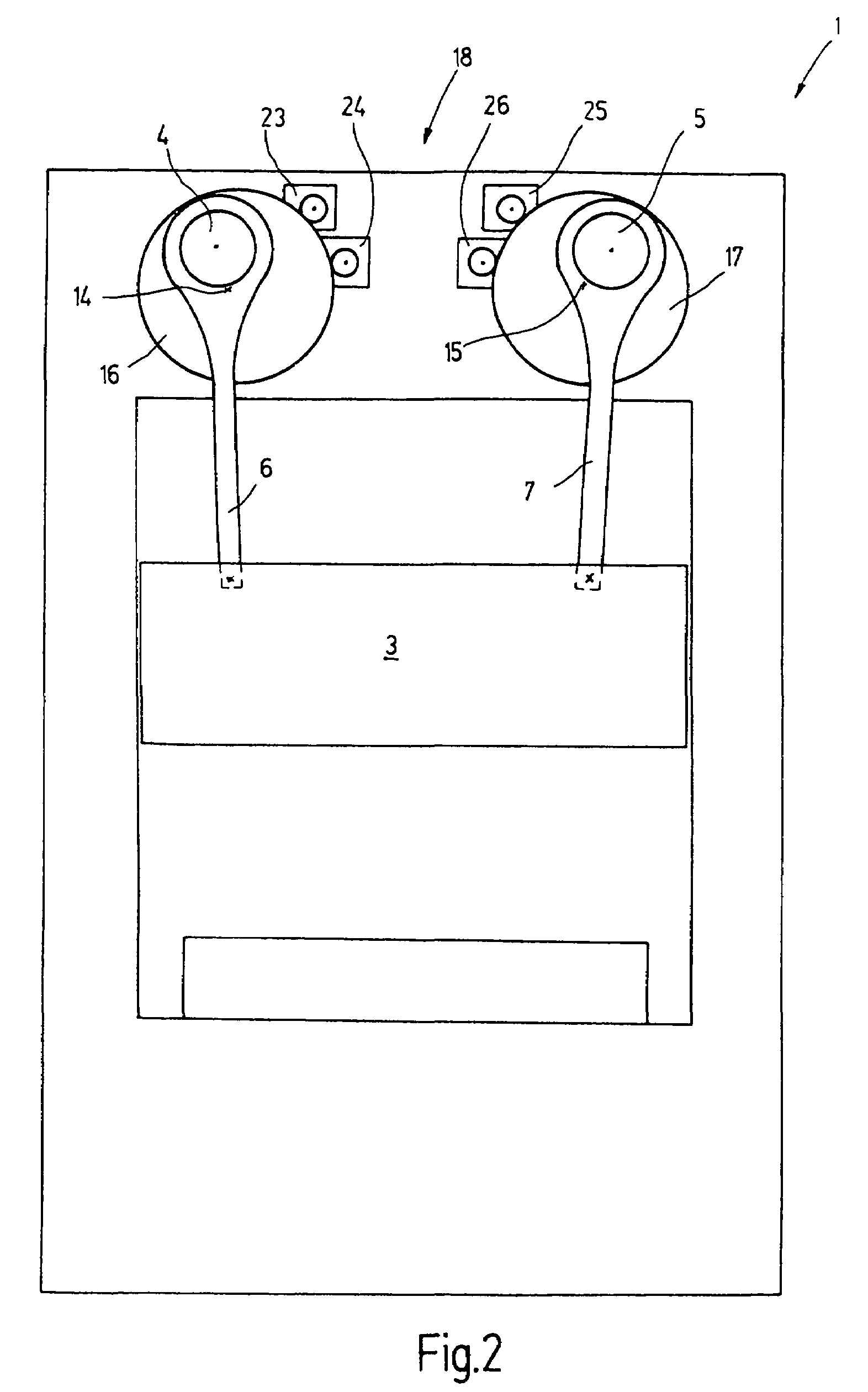

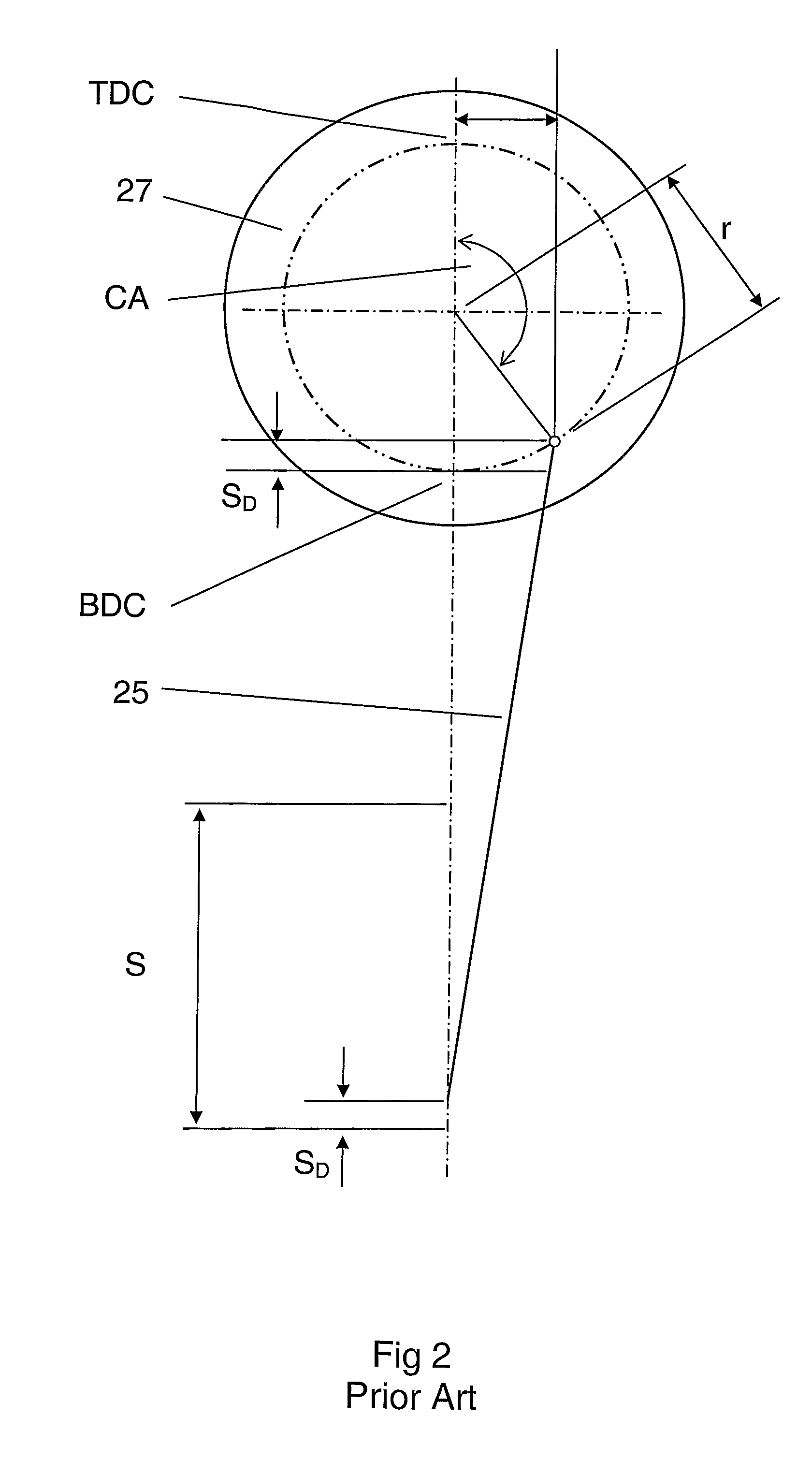

Mechanical press

InactiveUS7102316B2Inertia moment can be increasedSlow downAgriculture tools and machinesComputer controlMechanical pressServomotor

In a press having a plunger supported so as to be movable linearly back and forth by drive means which include at least one servomotor in combination with a rotatably supported inertia structure connected for rotation with the servomotor, the inertia structure has an inertia moment which is small enough to permit reversal of the servomotor within a stroke length of the plunger so that the stroke of the plunger is adjustable under the control of a control device connected to the servomotor for controlling its operation.

Owner:SCHULER PRESSEN GMBH & CO KG

Preparation and method for drying sludge through deep dehydrating

InactiveCN102229464AImplement processing reduction requirementsNo noiseSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentMechanical pressDewatered sludge

The invention relates to a preparation and a treatment method, and especially relates to a preparation and a method for drying sludge through deep dehydrating. The preparation comprises: 0.000002 to 0.00001 parts of an organic polymeric flocculants, 0.00025 to 0.0025 parts of a coagulating modifier, 0.0005 to 0.00375 parts of a sterilizing deodorant, and 0.00025 to 0.0025 parts of a nucleating converting agent. The method comprises the following steps: a sludge gravity thickening initial dehydrating step, a sludge regulating step, a mechanical press-filtrating step, and a filtrate refluxing step. With the preparation and the method provided by the present invention, sludge deep dehydrating processes can be carried out in series, processing efficiency can be improved, and energy consumption can be reduced. The controllability of the method is high. With the method, recycling is realized.

Owner:ZHEJIANG JIEFENG ENVIRONMENTAL PROTECTION TECH ENG COMPANY

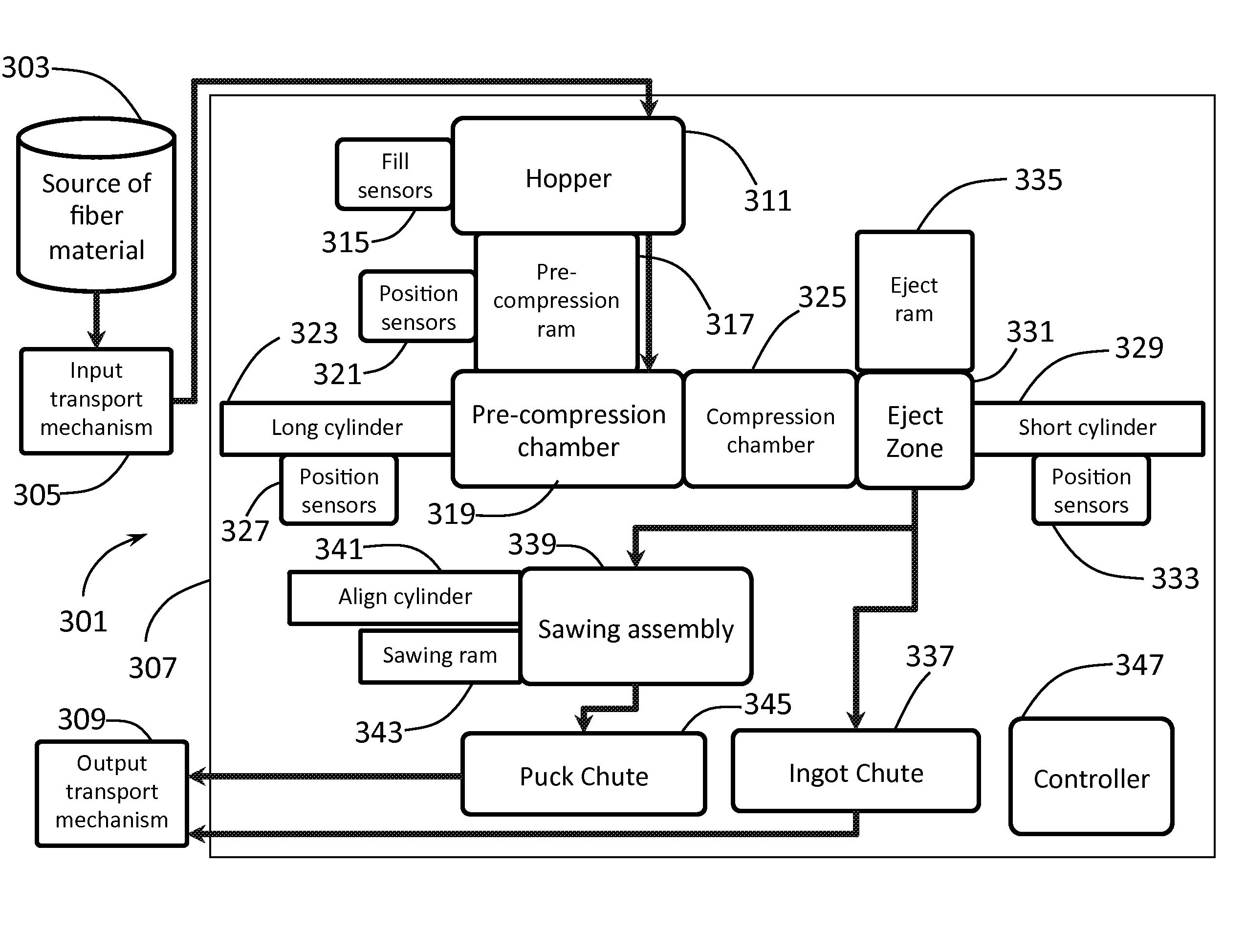

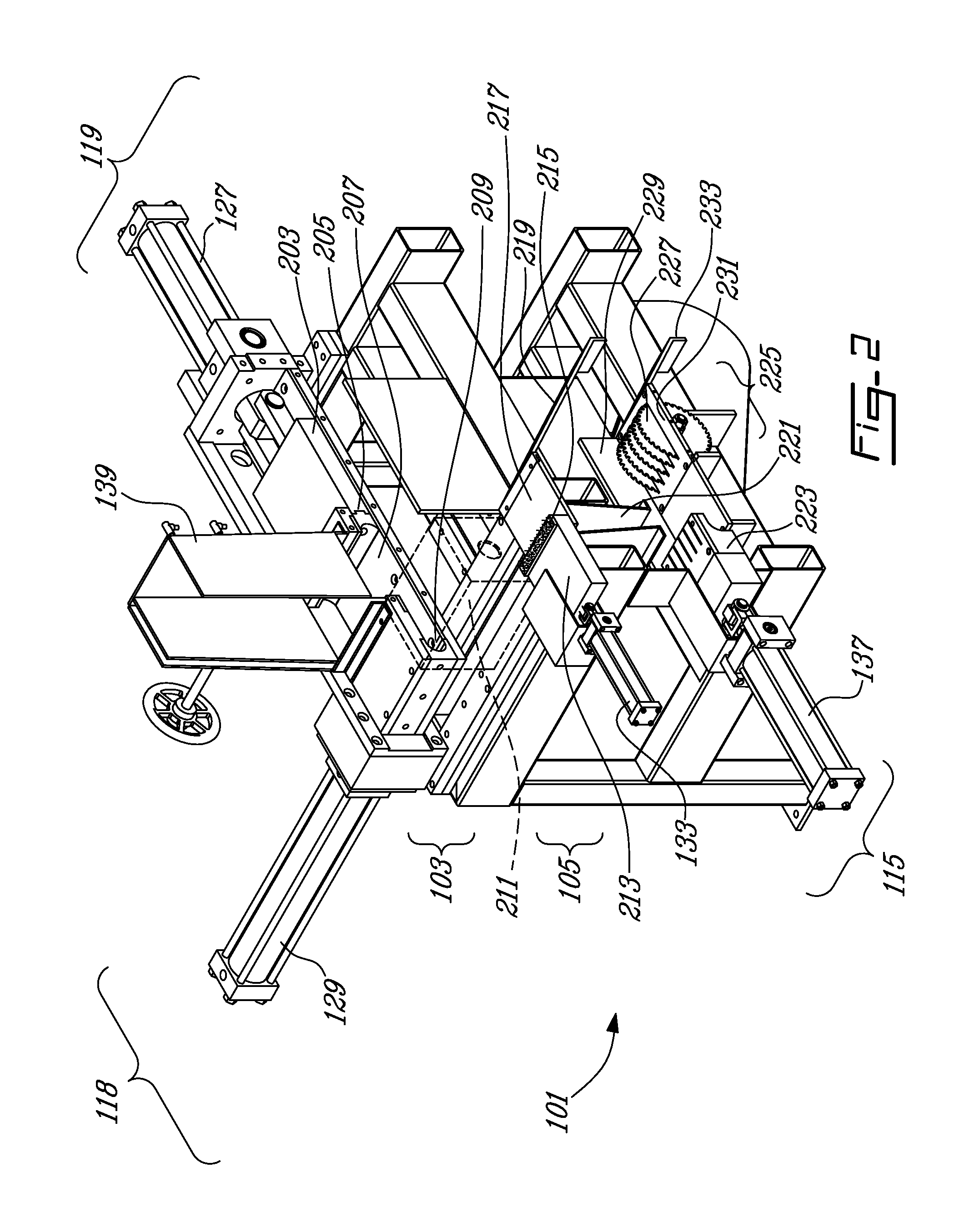

Method and mechanical press system for the generation of densified cylindrical briquettes

InactiveUS8726800B2Promote conversionMinimizes front-end processingBiofuelsSolid fuelsAbutmentBriquette

A method for preparing a pressed article comprises providing a first and a second pressing ram in a compression chamber; supplying biomass particles in the chamber closing the chamber; extending the first pressing ram; displacing the biomass particles with the first pressing ram towards the second pressing ram; detecting abutment of the biomass particles on the second pressing ram; applying pressure to the biomass particles with the first pressing ram and with the second pressing ram detecting a pressure applied to match a predetermined pressure and continuing to extend the first and the second pressing ram until a predetermined time at the matched compression pressure has elapsed; stopping the extension of the second pressing ram when a predetermined extension length is reached; continuing to extend the first pressing ram until a predetermined additional time has elapsed after the stopping; ejecting a pressed article.

Owner:MURRAY DONALD LOUIS +1

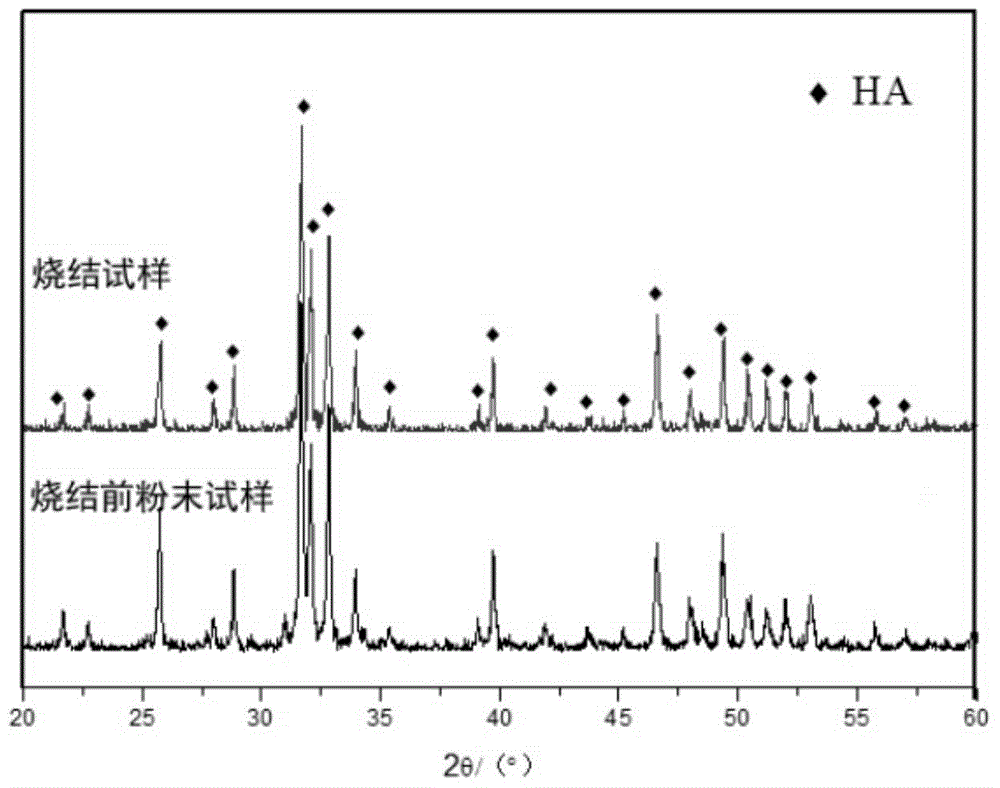

Method for preparation of bone hydroxyapatite-imitating bone repair material

The invention discloses a method for preparation of a bone hydroxyapatite-imitating bone repair material, nano hydroxyapatite ceramic powder and NH4HCO3 powder are mixed proportionally, after mixing, the powder is loaded into a gradient mold for mechanical pressing into a block pressed blank, the block pressed blank is put into a discharge plasma sintering furnace, heated to 950 DEG C and 1050 DEG C in the heating rate of 100 DEG / min, and then kept warm for 10-20min, and after demoulding, a nano scale bone gradient-imitating porous hydroxyapatite bone repair material is obtained. The nano scale bone gradient-imitating porous hydroxyapatite bone repair material is prepared by the method comprises outer and inner two layers, the porosity is 34% to 80%, and the pore scale is controllable in the range of 100-500mum, and the nano scale bone gradient-imitating porous hydroxyapatite bone repair material has the advantages of fine grain size, composition purity, no residual pore former, controllable mechanical properties and degradation rate and the like, and can be used as a good artificial bone tissue repair material.

Owner:FIRST PEOPLES HOSPITAL OF YUNNAN PROVINCE

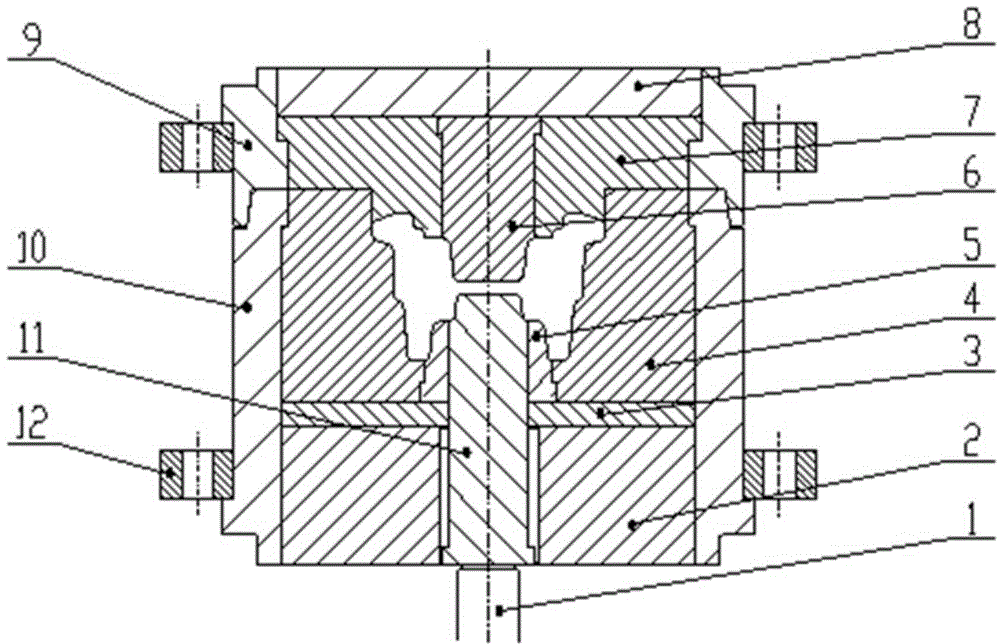

Supporting wheel closed forging process and forging die

InactiveCN104907471AThere is no flash phenomenonTotal deformation area reductionForging/hammering/pressing machinesWheelsPunchingMedium frequency

The invention discloses a supporting wheel closed forging process and a forging die, and belongs to the technical field of forging. Blanking is conducted on round steel through a band sawing machine; heating is conducted on a bar material through a medium frequency induction heating furnace; jumping-up and preforging are conducted on the hot bar material on a l600T electric screw press, then the hot bar material is transferred to a 2500T electric screw press to be subjected to finish forging and forming through the closed forging die, and finally punching is finished on a 400T mechanical press; normalizing treatment is conducted on a forge piece generated after punching is conducted; the closed forging die adopted for the process comprises a lower cushion block (2), a lower male die (11), a lower base plate (3), a lower female die insert (5), a lower female die (4), an upper male die (6), an upper female die (7) and an upper cushion block (8). By means of the supporting wheel closed forging process and the forging die, burrs do not exist in the forged forge piece, and the total forge piece deformation area is reduced, so that the forging deformation force is lowered, the raw material utilization rate is increased, the subsequent trimming process is omitted, the product cost is lowered greatly, and product efficiency is improved remarkably.

Owner:XUZHOU XCMG CRAWLER CHASSIS CO LTD

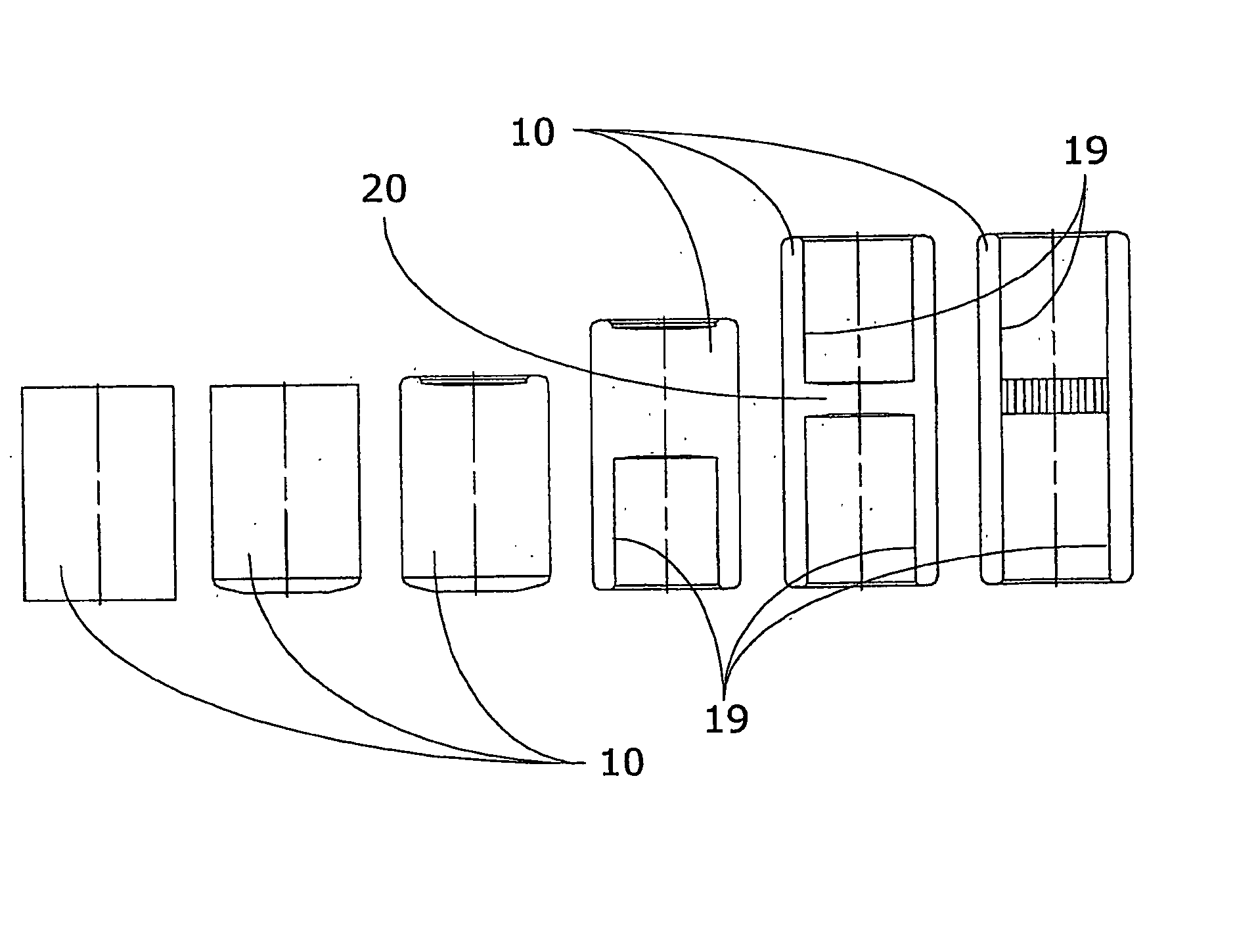

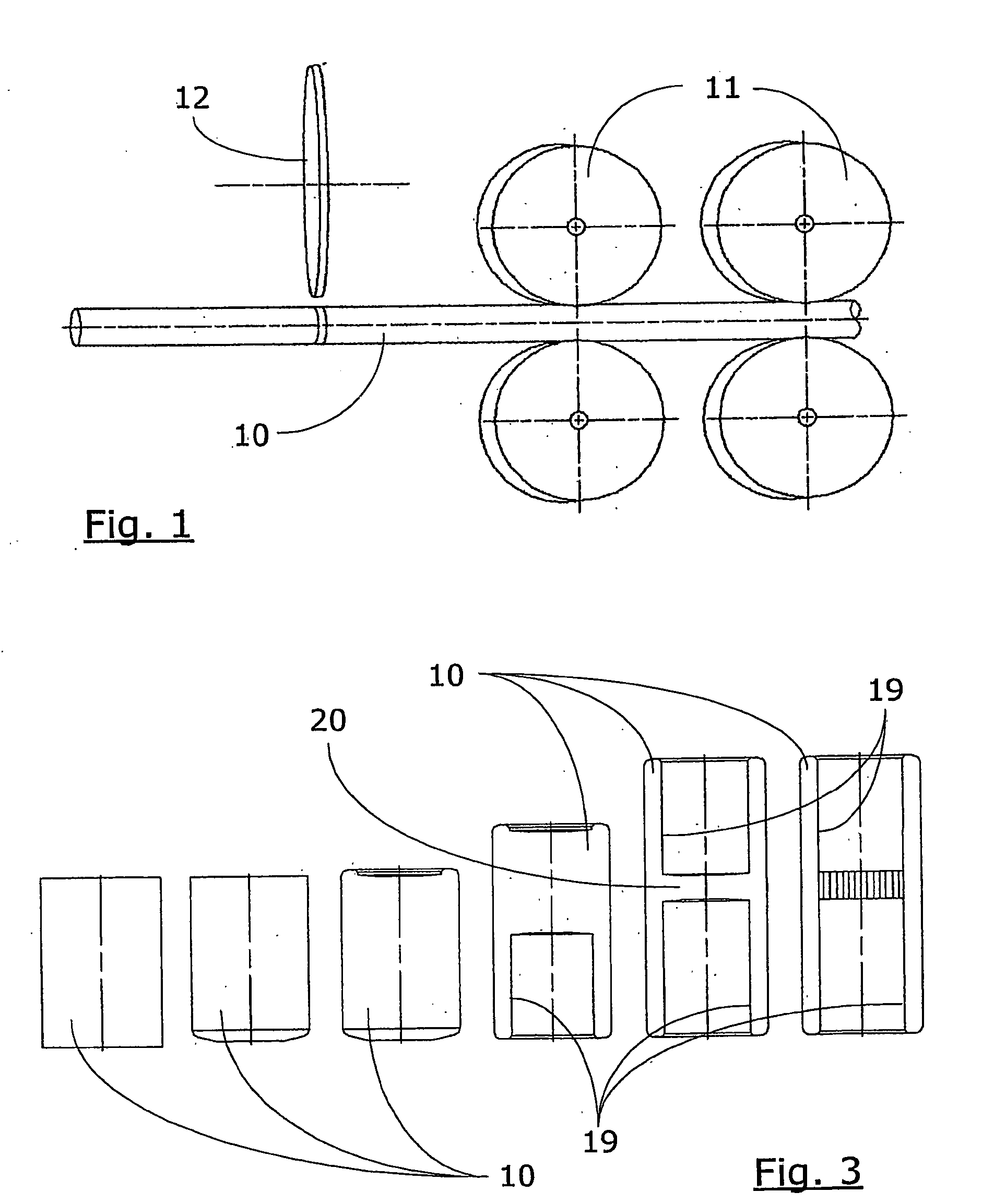

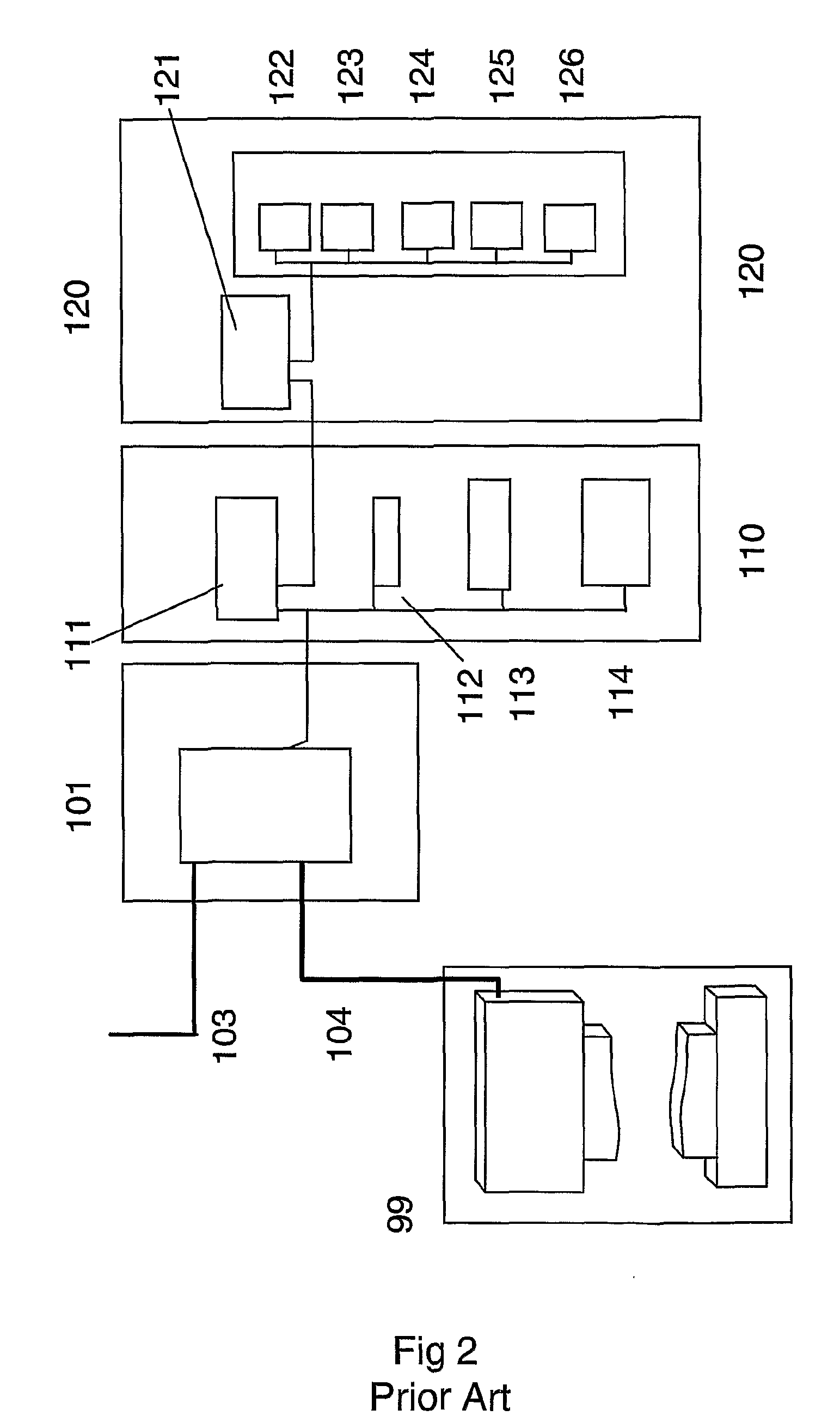

Methods for the cold extrusion of metallic elements with dead or through holes and plant for carrying out said methods

InactiveUS20050145004A1Eliminate or significantly reduce the drawbacksEasy to produceNutsBoltsEngineeringMechanical press

Cold extrusion procedures for obtaining metal elements such as for example bushings, nuts or other elements with dead or through holes, screws, standard and special shape extruded or pressed products, etc. on a machining center comprising a series of hydraulic presses connected to each other with an automatic movement system. The final drilling or shearing of the elements is advantageously carried out by a dedicated drilling or shearing unit, working at high speed, which can consist of a vertical mechanical press. The use of the plant comprising several hydraulic presses together with the rapid drilling or shearing unit makes it possible to achieve a high level of productivity.

Owner:AMAFA SERVICE SRL

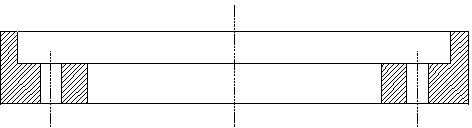

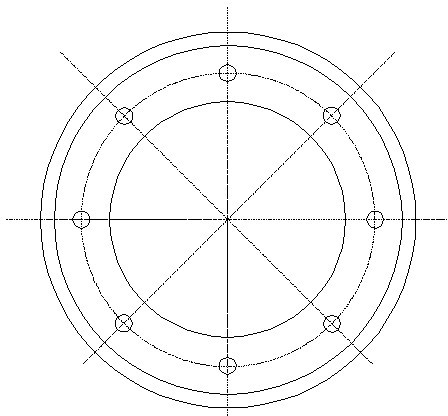

Ring forge piece punching and cutting composite type mould

ActiveCN102029323ACompact structureReasonable structureShaping toolsPerforating toolsPunchingEngineering

The invention relates to a ring forge piece punching and cutting composite type mould which is used on a mechanical press, in particular to the ring forge piece punching and cutting composite type mould. In the conventional mechanical manufacturing industry, inner hole punching and outer edge cutting in a forging and forming process of a forging ring of a transmission chain are performed in two steps, the production efficiency is low and the cost is high. The mould consists of an upper mould, an ejector, a lower mould and a material returning and outer burr removing part, wherein an upper mould plate is provided with a guide sleeve, connecting rods and an edge cutting punch head; a lower mould plate is provided with guide posts, an edge cutting female die seat, an edge cutting female die, a punching punch head seat and a punching punch head; a movable plate is provided with a connecting sleeve, an ejector seat and an ejector head and positioned and guided by two guide posts and the guide sleeve; and four connecting rods drive the connecting sleeve, the movable plate and the ejector part to rise so as to eject a finished punched workpiece. The composite mould is matched with a guide post guide sleeve structure, so accurate positioning of the upper mould, the lower mould and the ejector part is realized, the dimensional accuracy of a product is guaranteed, and the mould is suitable for simultaneous edge cutting and punching of a ring forge piece.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

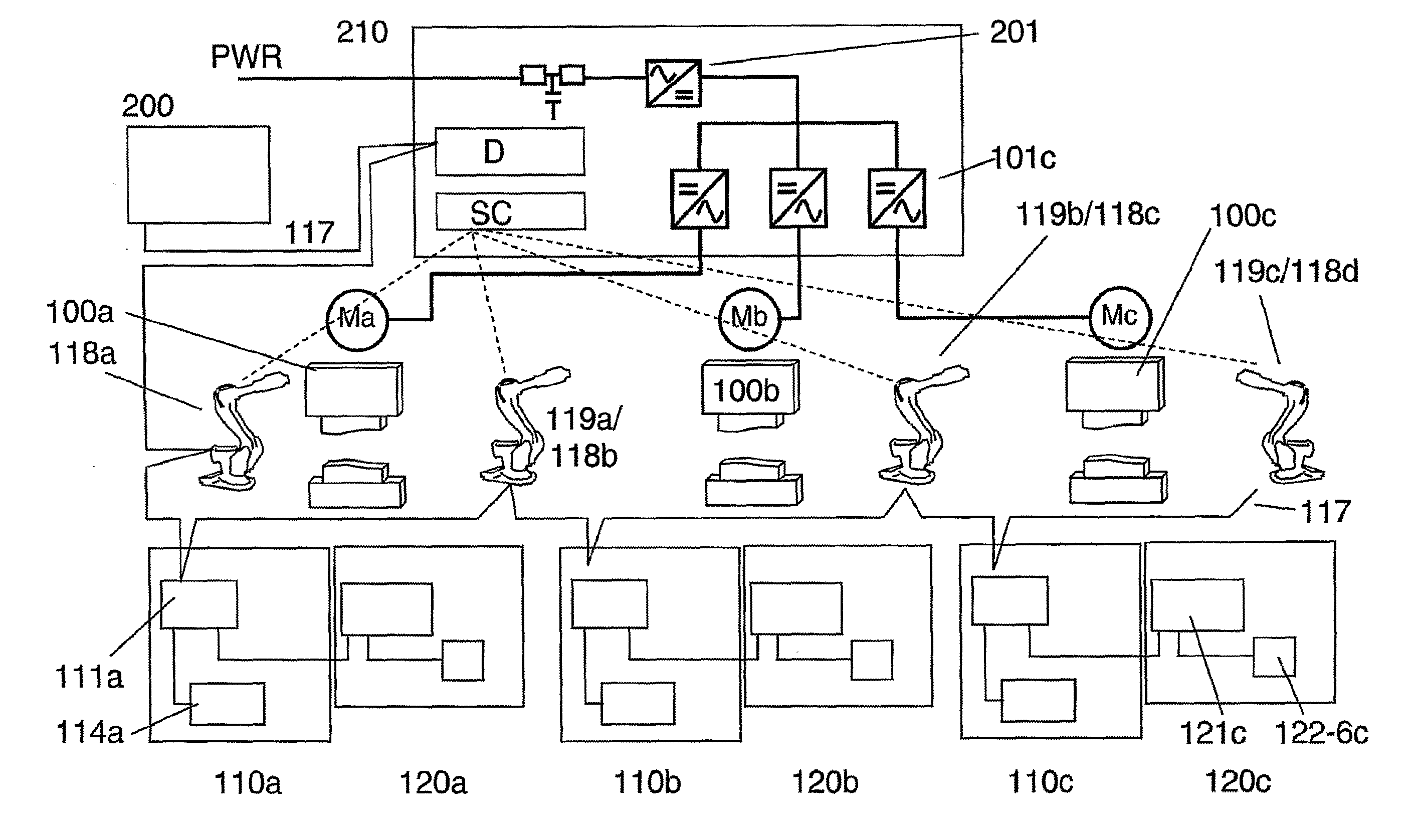

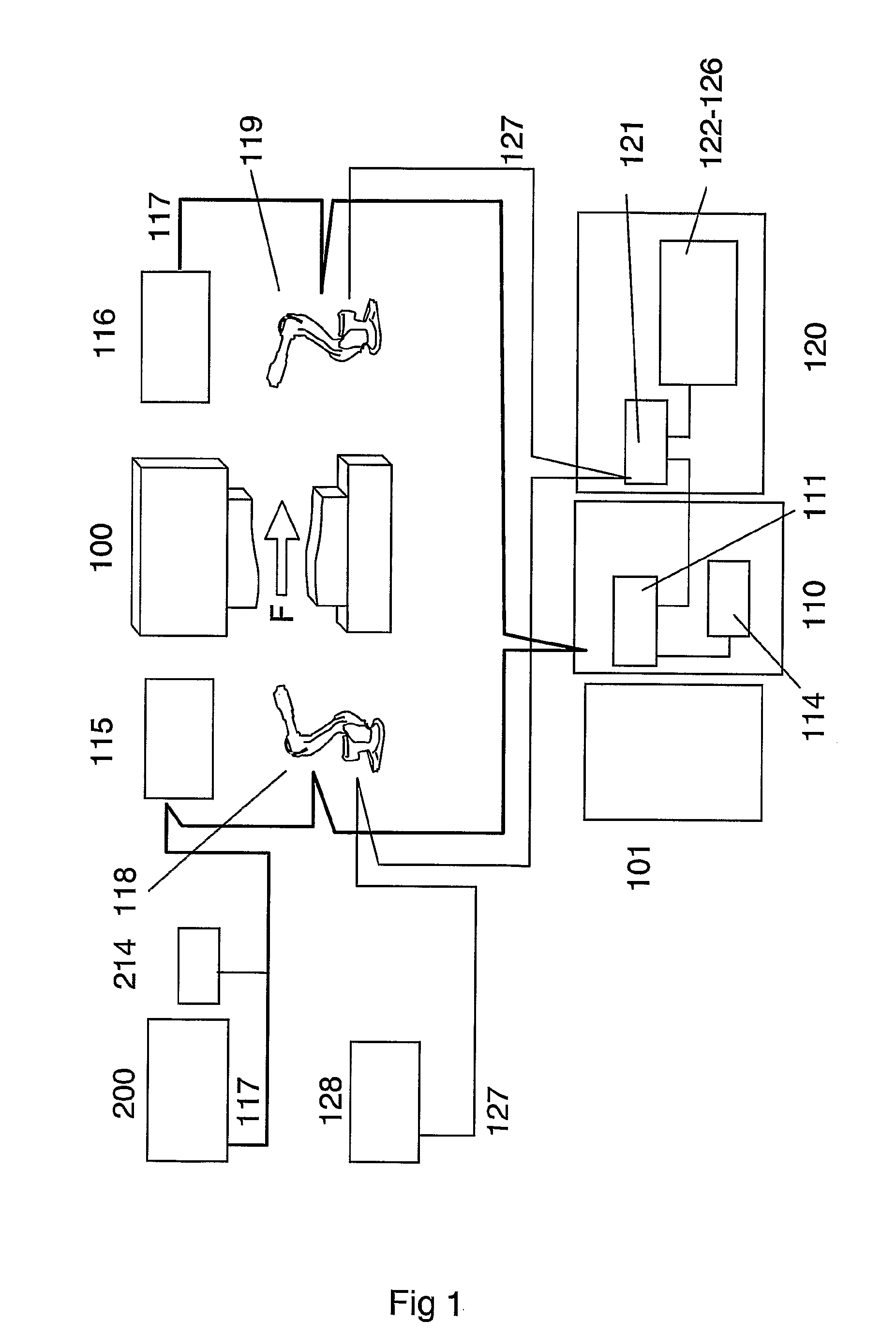

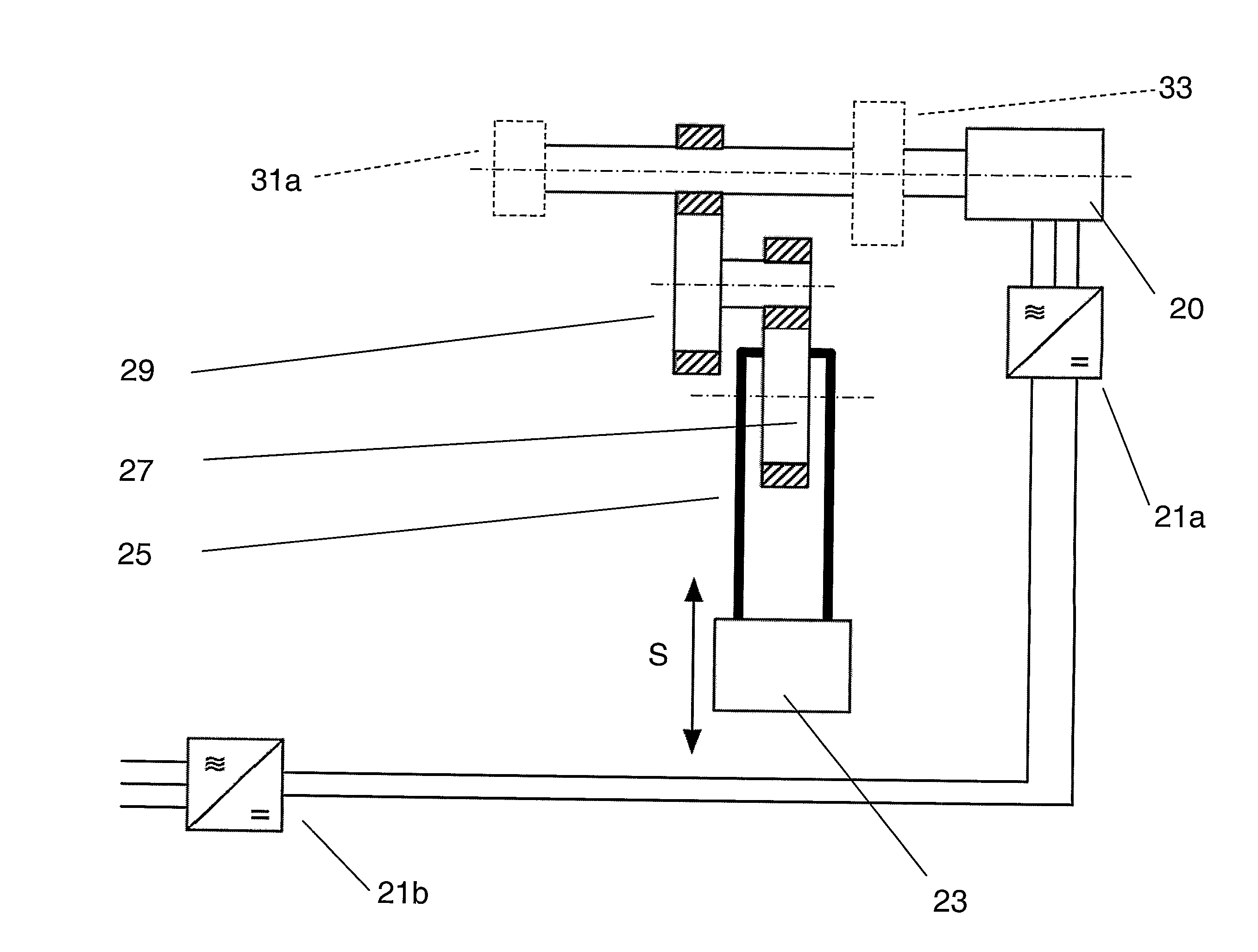

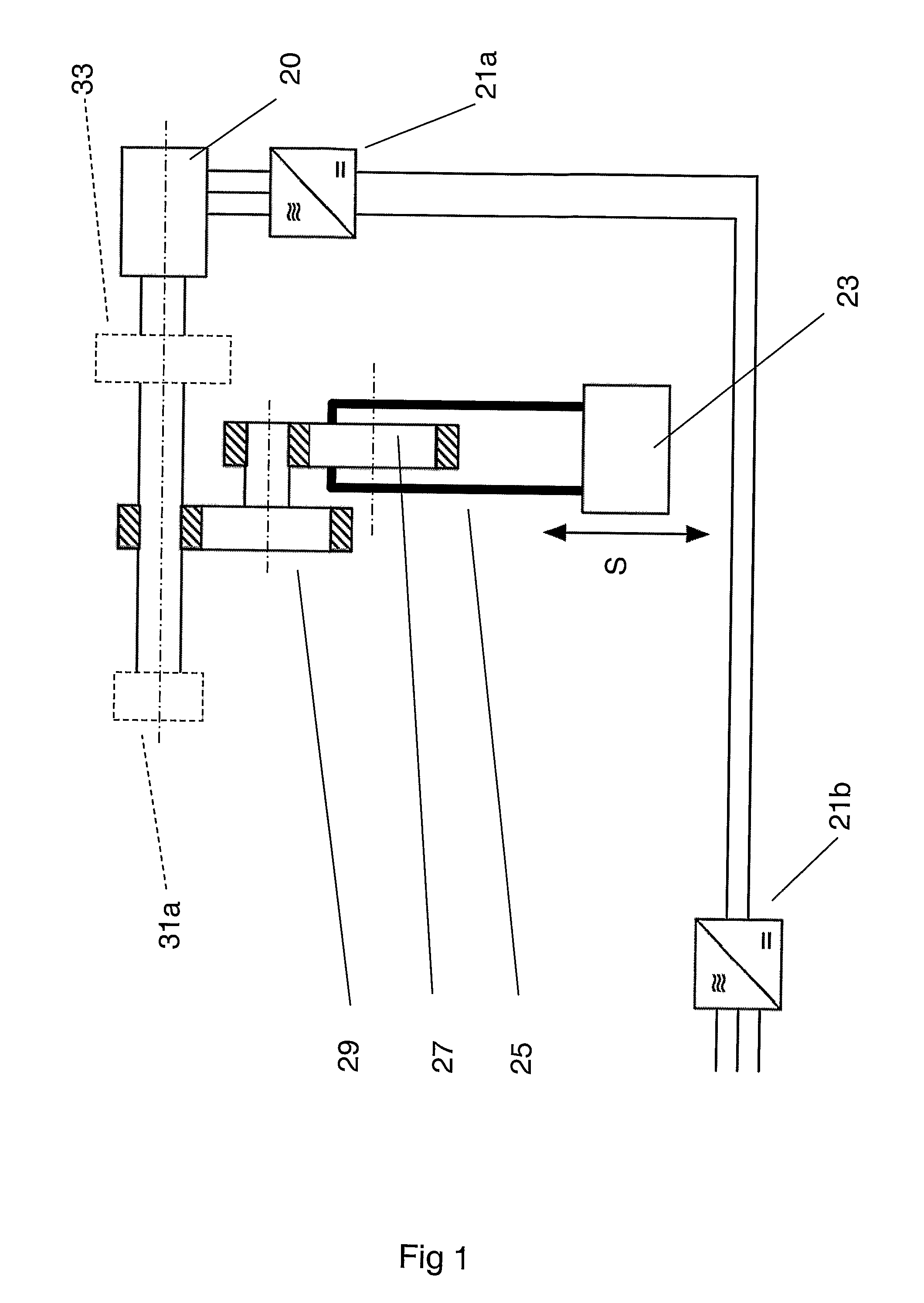

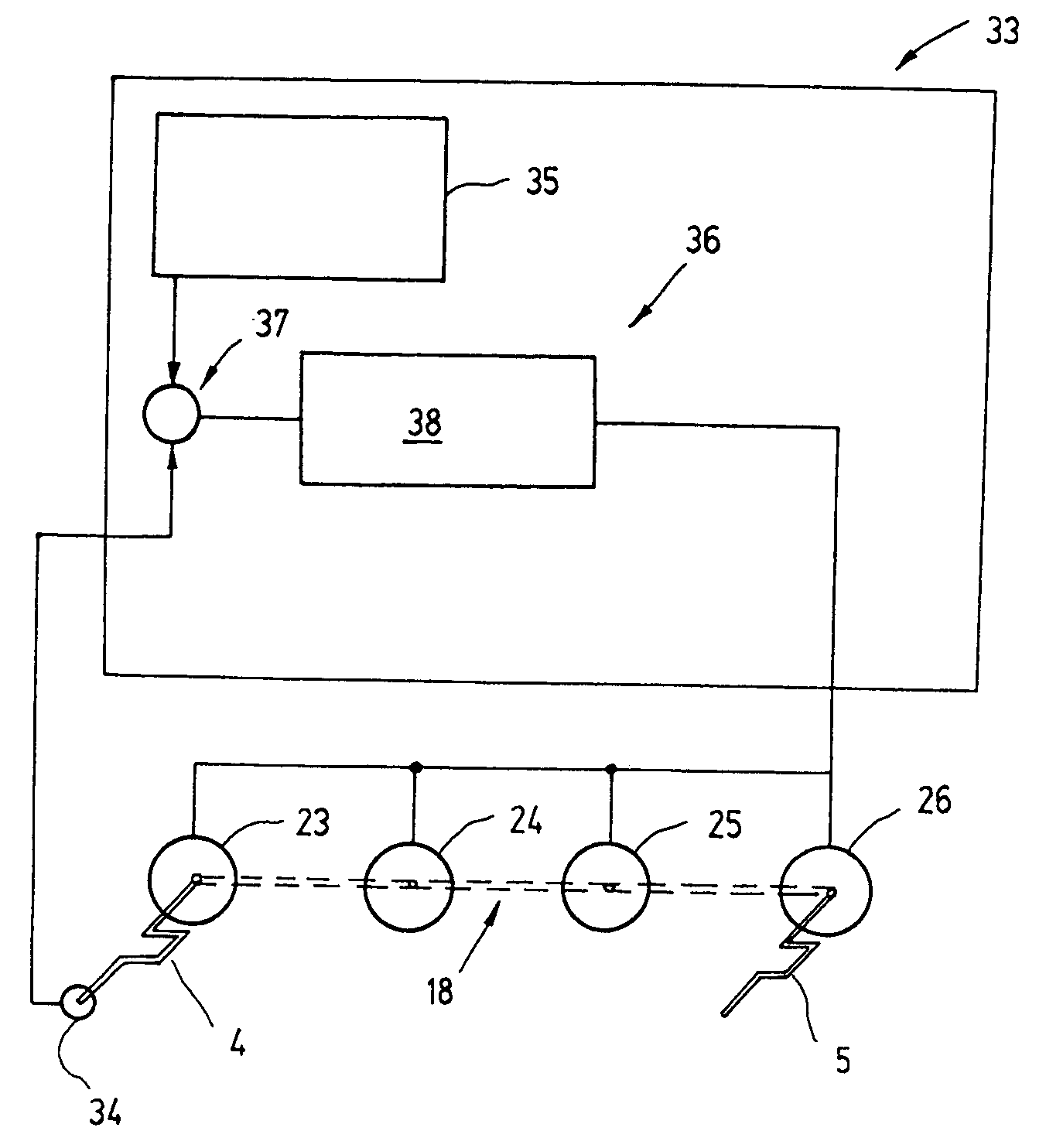

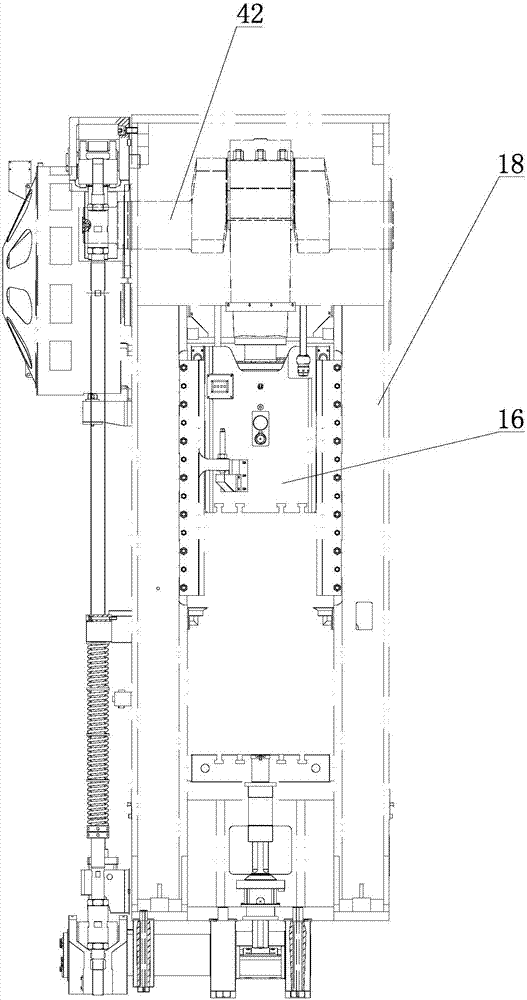

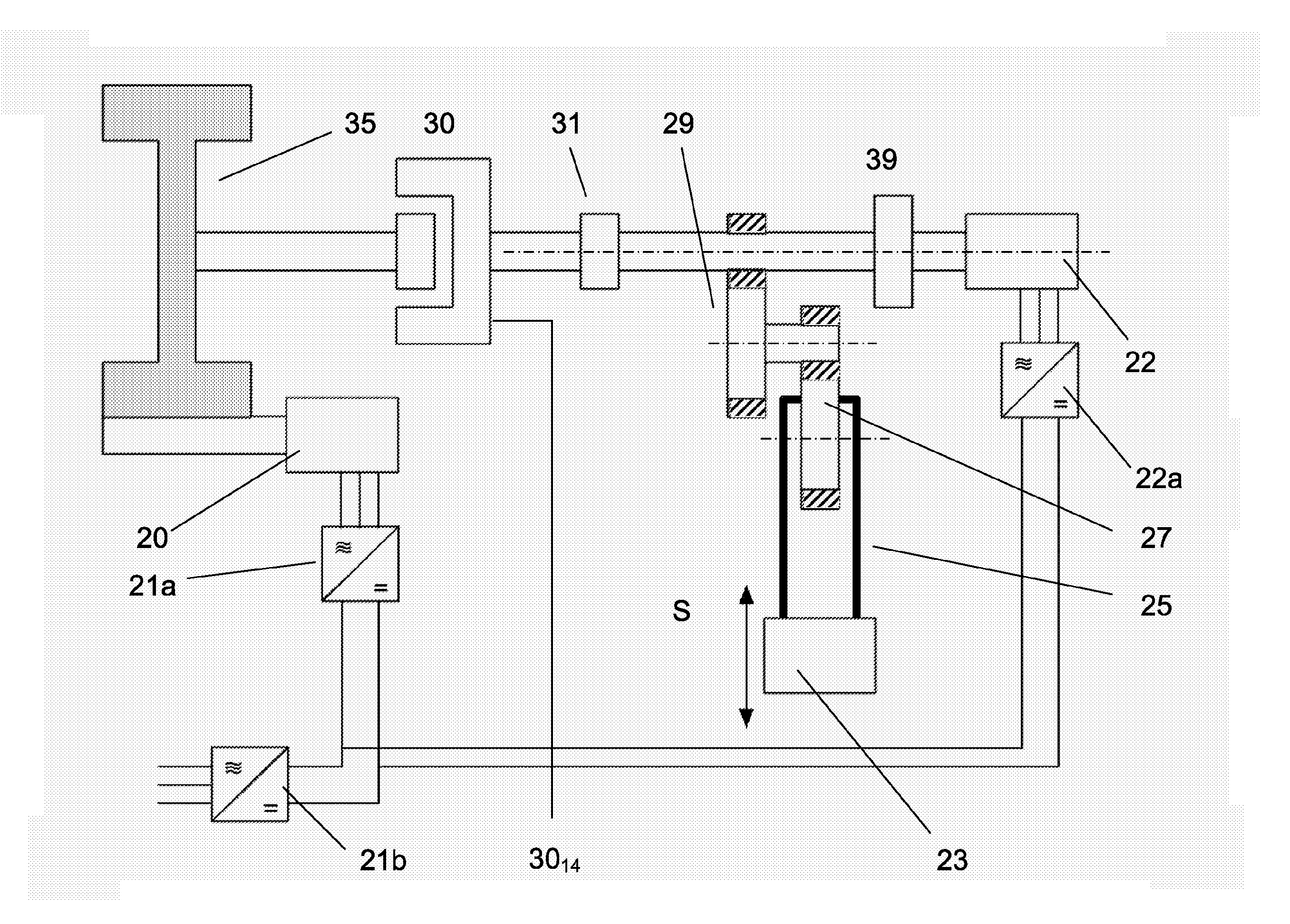

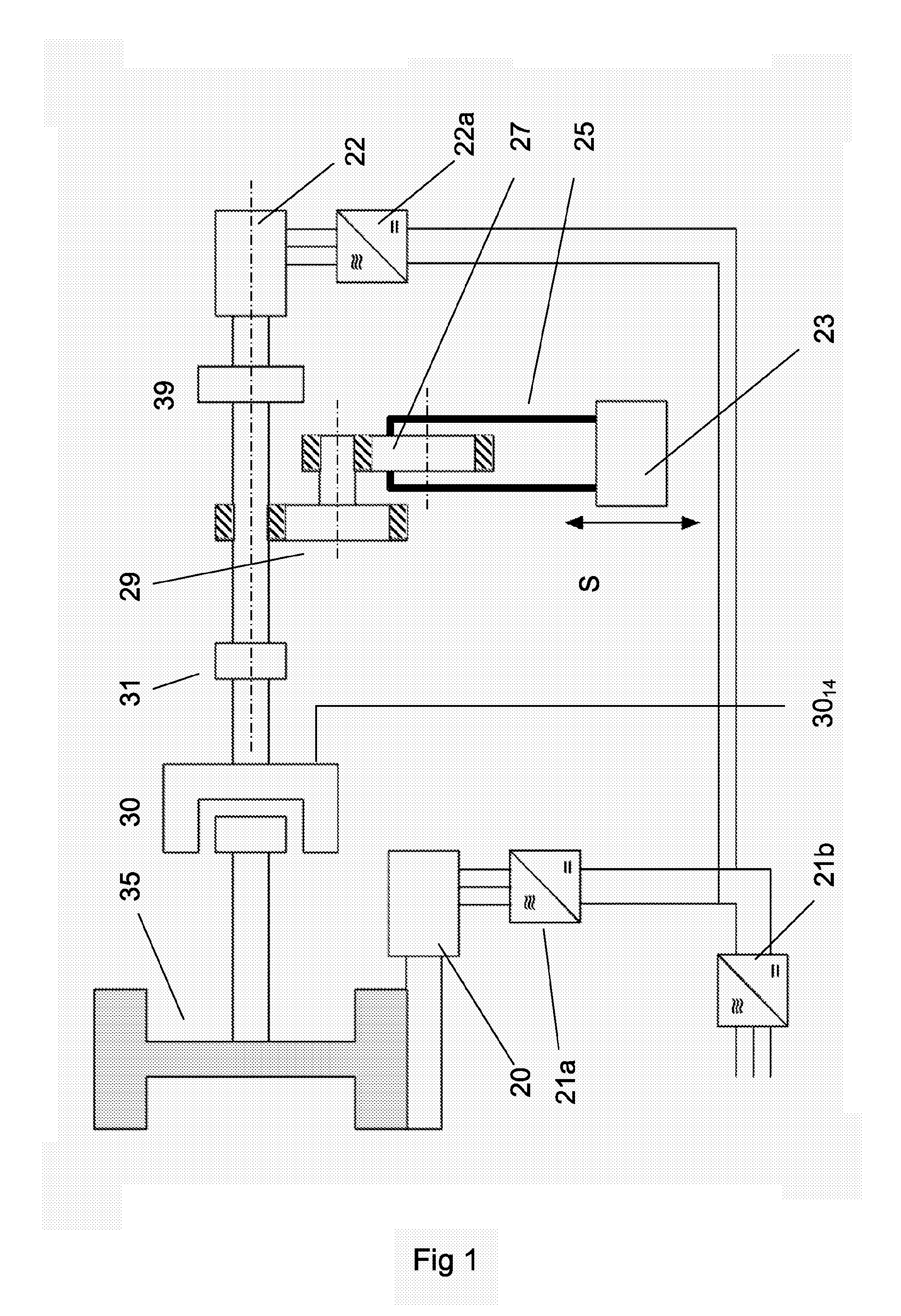

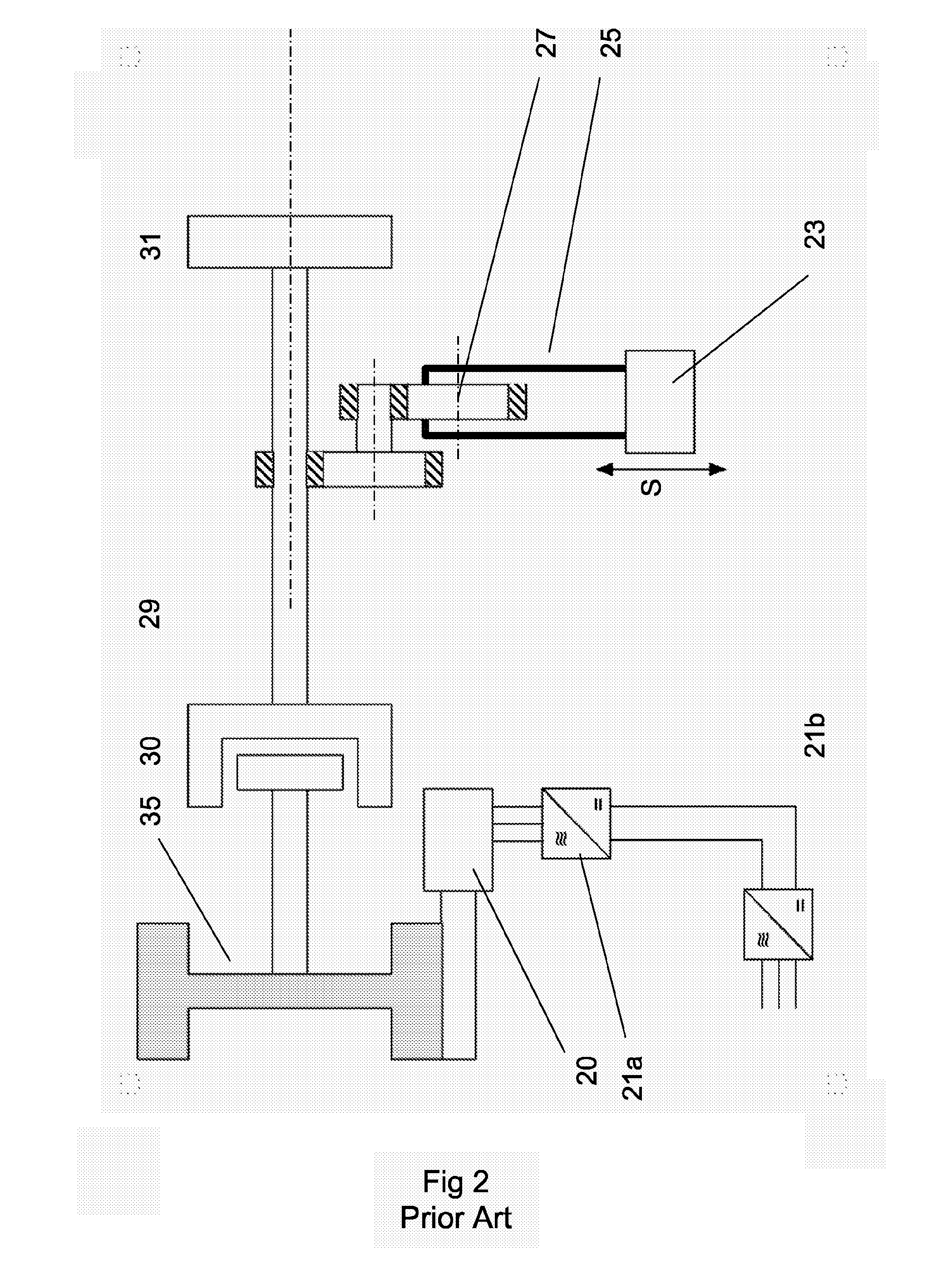

Press line system and method

InactiveUS20090177306A1Increase chanceImprove coordinationMetal-working feeding devicesComputer controlProduction lineElectricity

Owner:ABB RES LTD

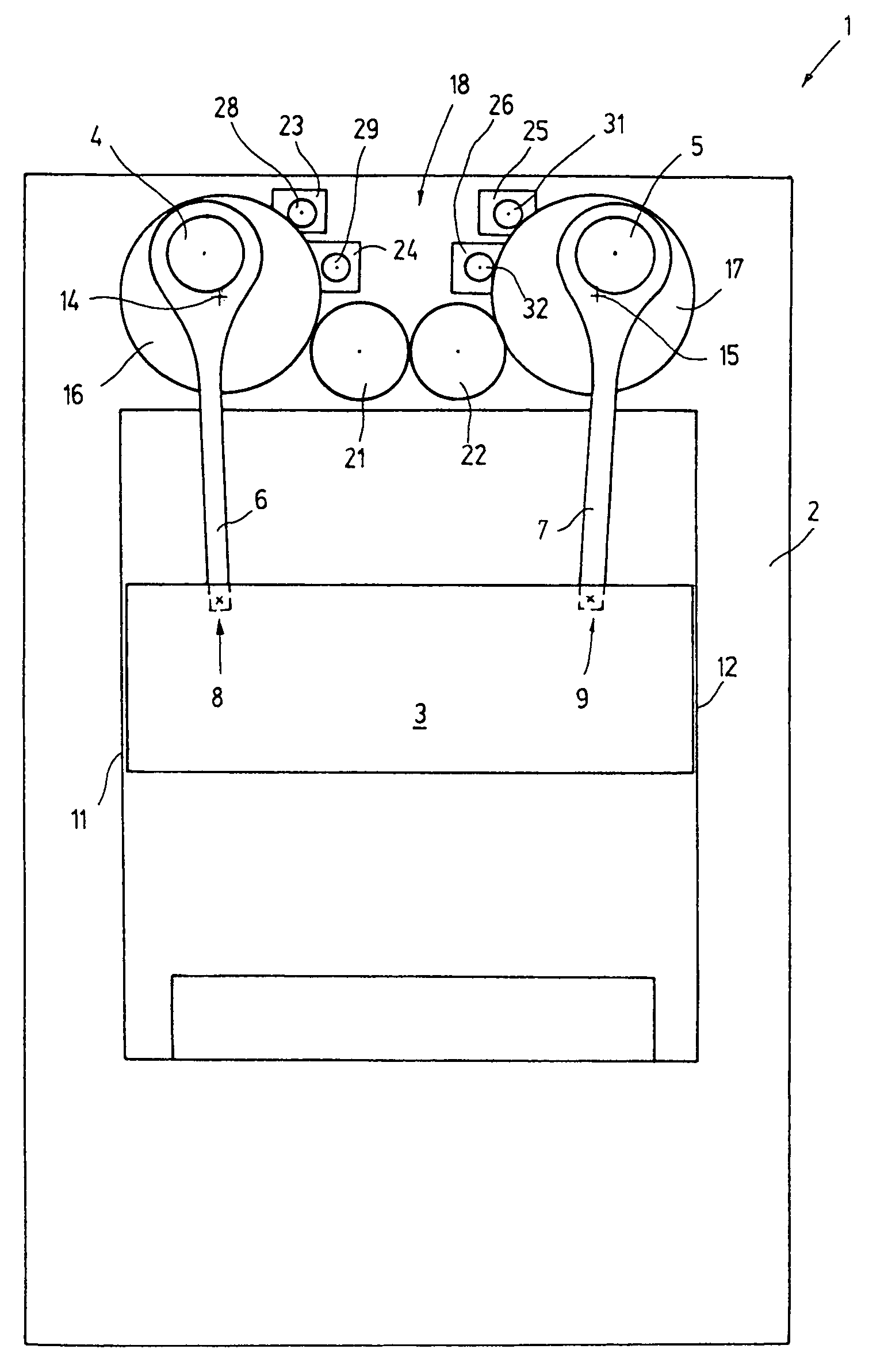

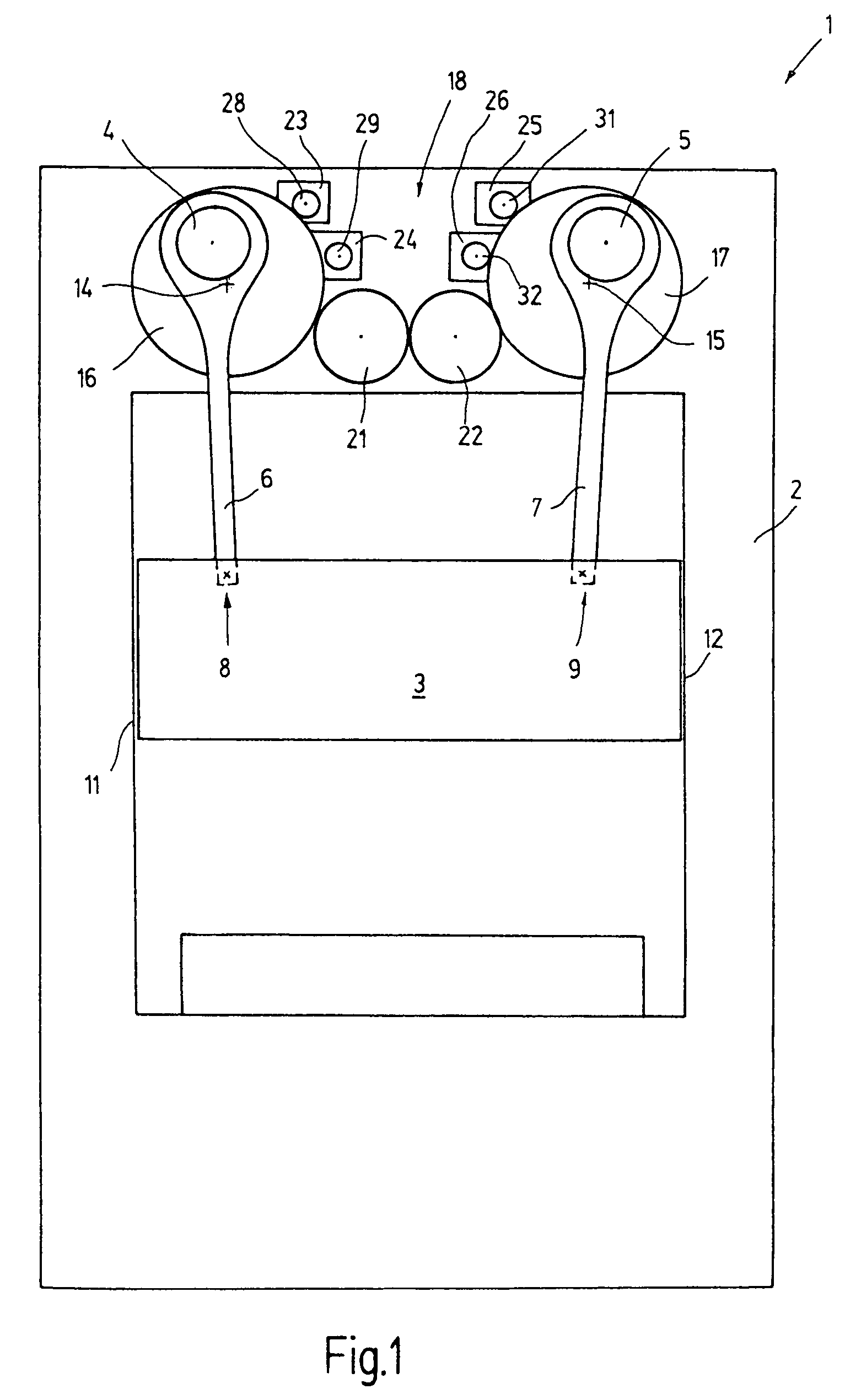

Floor panel and methods for manufacturing floor panels

ActiveUS8549807B2High densityHigh sensitivityWallsDecorative surface effectsEngineeringMechanical press

In a method for manufacturing floor panels that have at least a substrate and a top layer provided on the substrate, the top layer including a thermoplastic layer that is translucent or transparent, the method may involve providing the top layer, including the thermoplastic layer, on the substrate. The method may also involve heating at least the thermoplastic layer, and structuring the thermoplastic layer using a mechanical press element.

Owner:FLOORING IND LTD

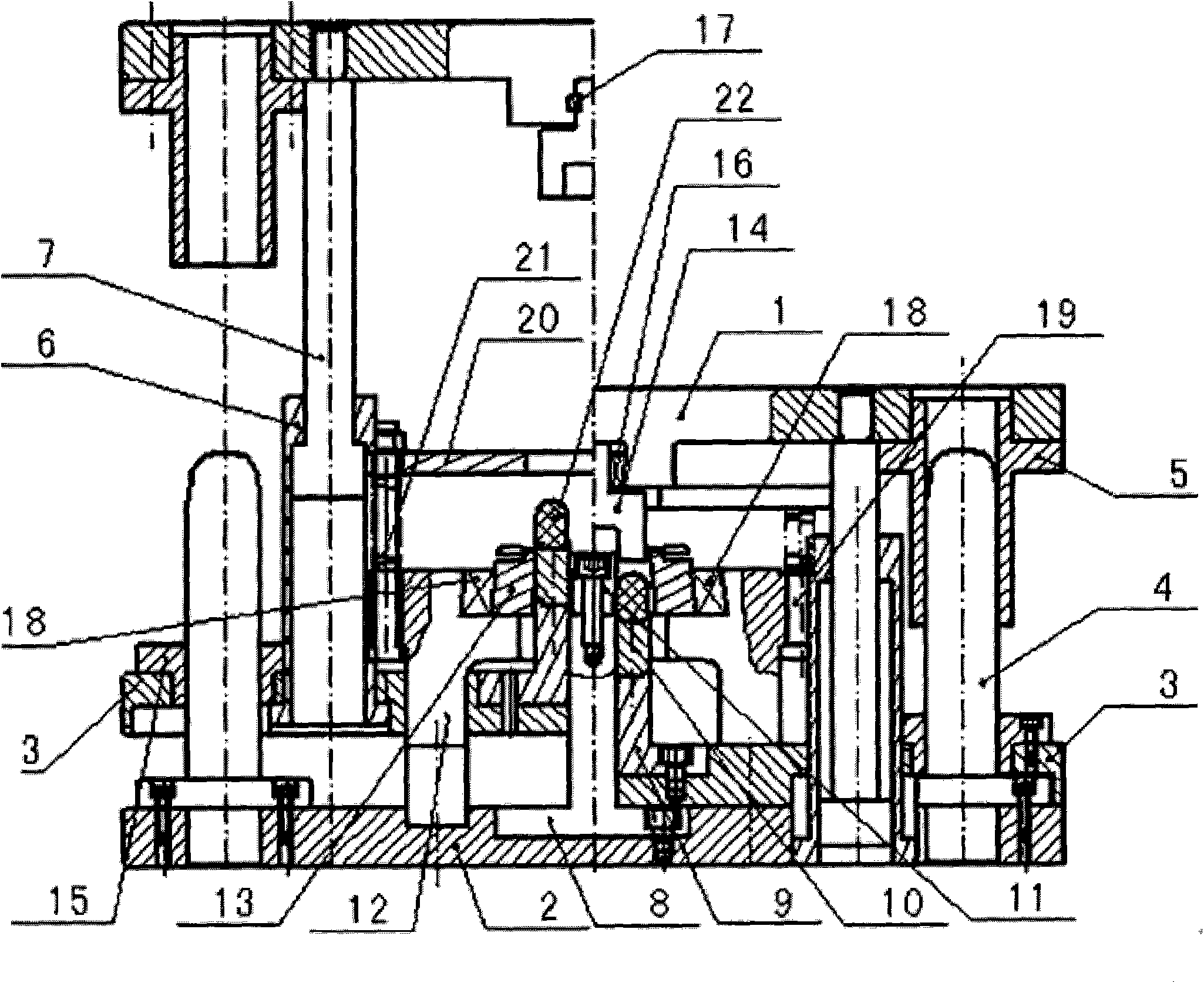

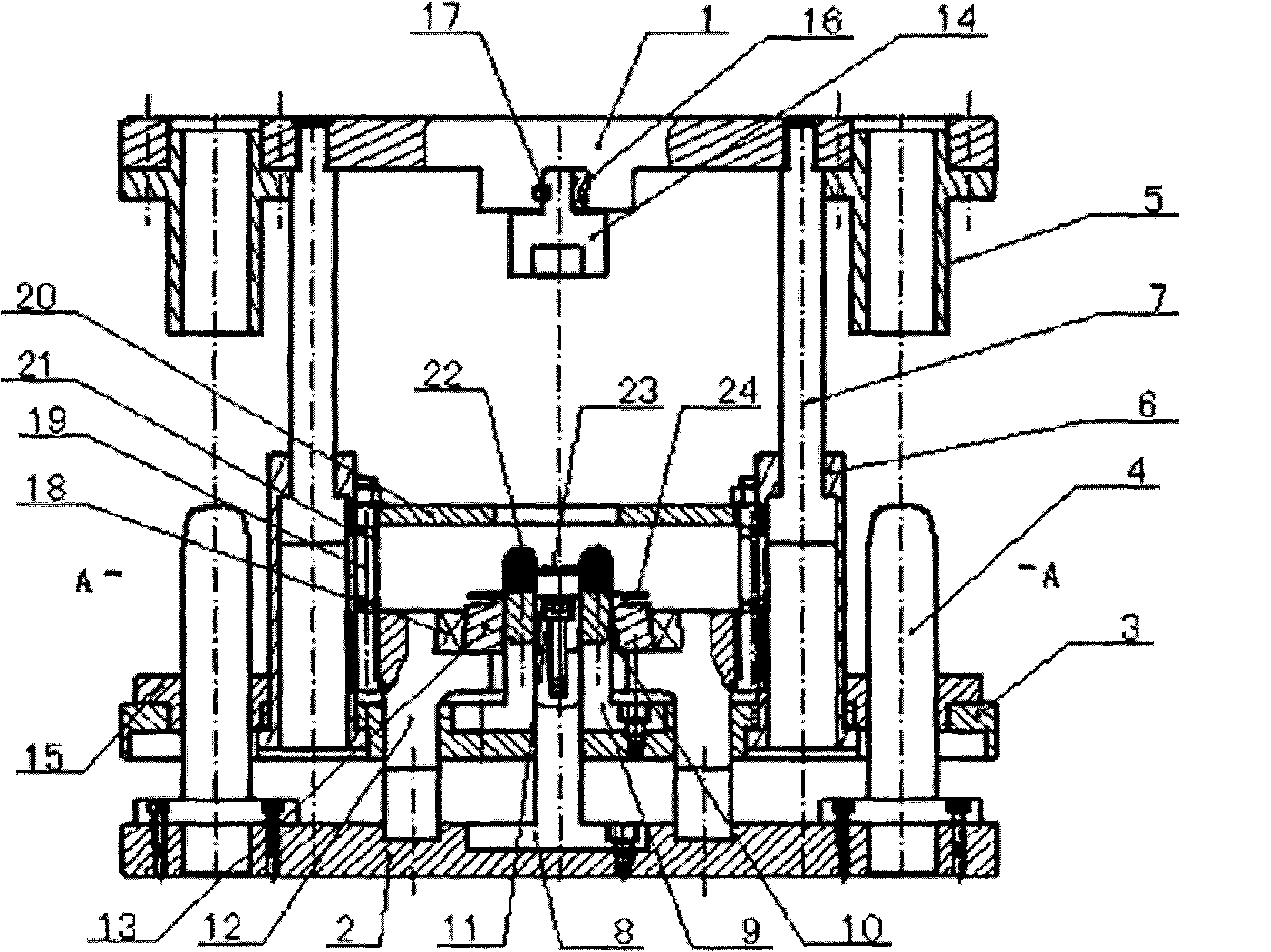

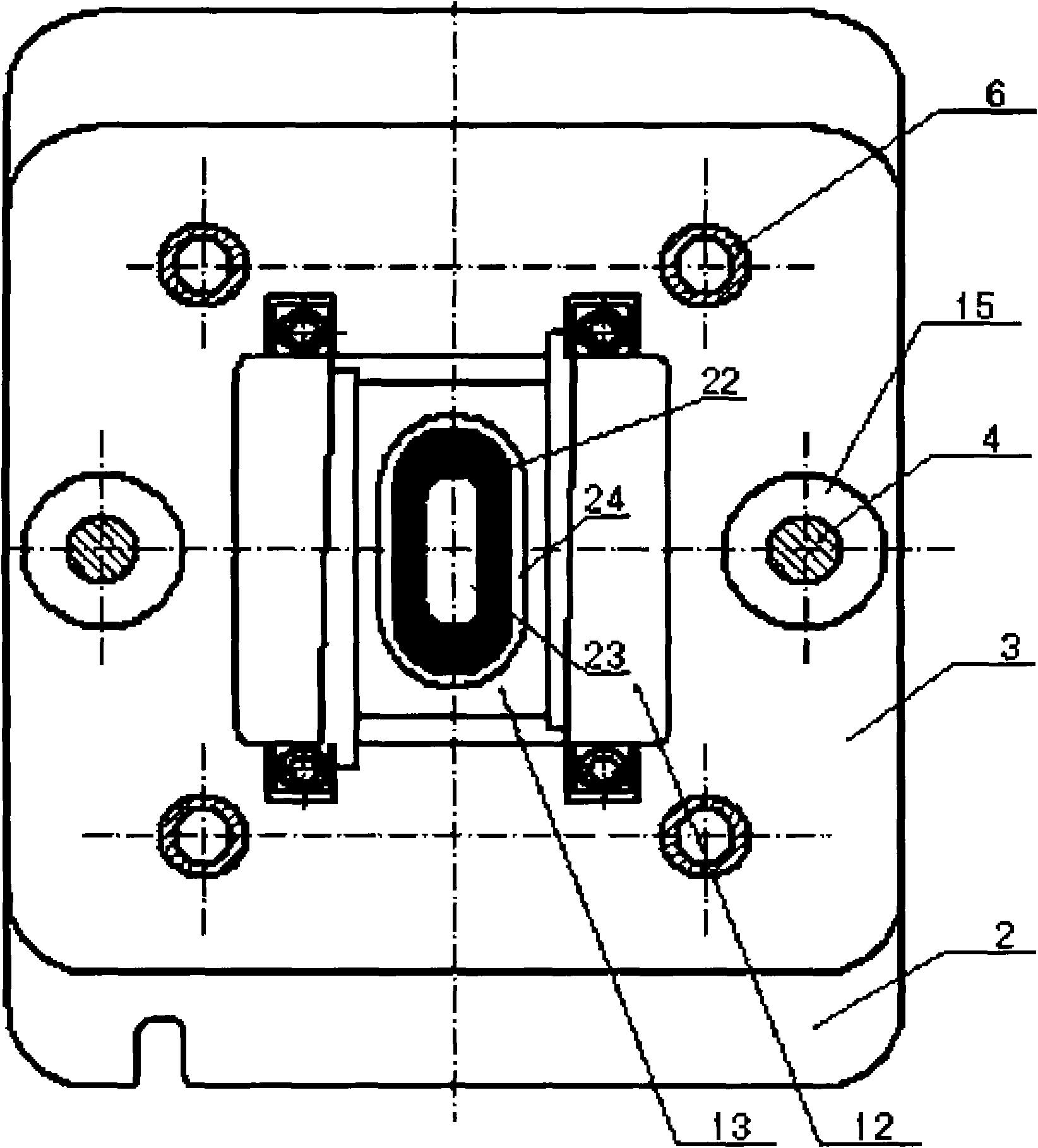

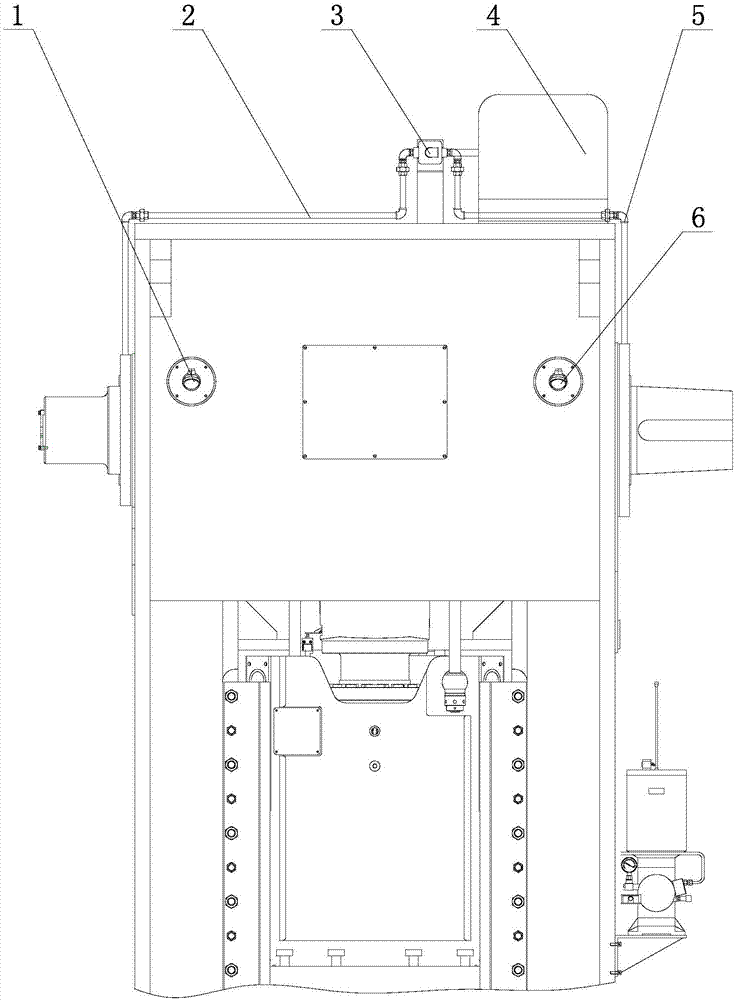

Servo mechanical press

InactiveCN102615844AHigh torqueDoes not reduce the requirement for frequent gear changesPress ramClassical mechanicsEngineering

The invention relates to a servo mechanical press which comprises a stand shaped like a frame, and is characterized by further comprising a first synchronous servomotor, a second synchronous servomotor, a first retarding mechanism, a second retarding mechanism, a six-link type working mechanism and a guiding mechanism, wherein the first synchronous servomotor and the second synchronous servomotor are mounted on two sides of the stand in an eudipleural manner; the first retarding mechanism and the second retarding mechanism are mounted on two sides of the stand in an eudipleural manner; the six-link type working mechanism is mounted in the frame of the stand; an input end of the first retarding mechanism is coaxially arranged with an output shaft of the first servomotor; an output shaft of the first retarding mechanism is fixedly connected with an input end on the right side of a crankshaft of the six-link type working mechanism; an input end of the second retarding mechanism is coaxially arranged with an output end of the second servomotor; an output end of the second retarding mechanism is fixedly connected with an input end on the left side of the crankshaft of the six-link type working mechanism; the guiding mechanism is mounted in the frame of the stand; and a slide block at the output end of the six-link type working mechanism is positioned in the guiding mechanism and can move up and down. The invention provides the servo mechanical press, which has a simple structure, is convenient to control, can reduce the output torque and the required capacity of the servomotors, and can be built with large tonnage and low cost.

Owner:SHUNDE POLYTECHNIC

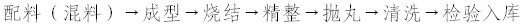

Process method for manufacturing balance weight for compressor by powder metallurgy

InactiveCN102528040AHigh dimensional accuracyNo oxidationTurbinesOther manufacturing equipments/toolsAir compressorMechanical press

The invention discloses a process method for producing a balance weight for a compressor by powder metallurgy, which comprises the steps that: (1), raw materials comprising Mn (17-25%), C (0.5-1.5%) and Fe (the rest) are uniformly blended to produce raw material powder required by production; (2), the raw material powder is put into a mechanical press (or four-column hydraulic press) for compression moulding so as to obtain a pressing compact for the balance weight; (3), the pressing compact for the balance weight is put into a continuous mesh belt furnace (or push rod furnace) for sintering to obtain a sintering compact for the balance weight; and (4), the sintering compact for the balance weight is subjected to shot blasting treatment to obtain a finished product of the high manganese steel weight balance for the air compressor. According to the production method disclosed by the invention, the stability of the sizes of workpieces is good, no impurity is generated, the quality of the surface is excellent, and the components are uniform and stable; the weight variation among products of different batches is small and can be controlled within 1%; no oxidation is generated in the production process, the internal organization of metal is excellent, the crystalline grain is finer, and the bad organizations such as coarse crystal and mixed crystal can be avoided.

Owner:王兴民

Mechanical Press Drive System and Method

ActiveUS20090007622A1Shorten the timeImprove controllabilityMetal-working feeding devicesForging hammersElectricityLinear motion

A method for operating a mechanical press including at least one electric drive motor, a drive control for controlling the at least one motor, a ram, a mechanical element for translating rotational motion of the at least one motor to linear motion of the ram in a first rotation direction, into a linear motion of the ram arranged to be lowered and raised along a linear path for operating the press to carry out a press cycle including a pressing part and one or more non-pressing parts of the press cycle, and by providing a control output to the drive control such that the speed of the at least one drive motor is varied during at least one pressing or non-pressing part of the press cycle. The press may be reversed between production cycles. Also press and system including a such press.

Owner:ABB (SCHWEIZ) AG

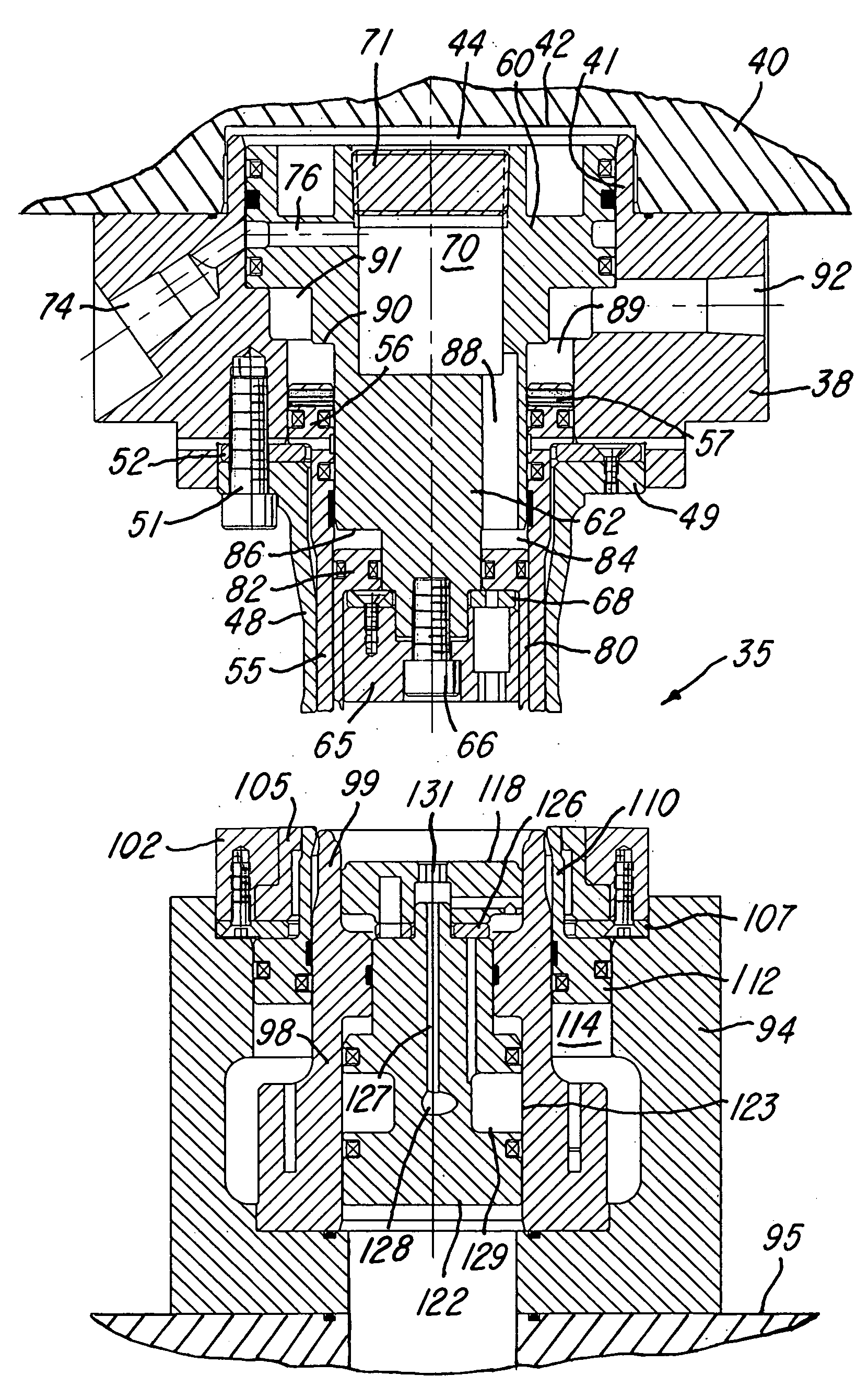

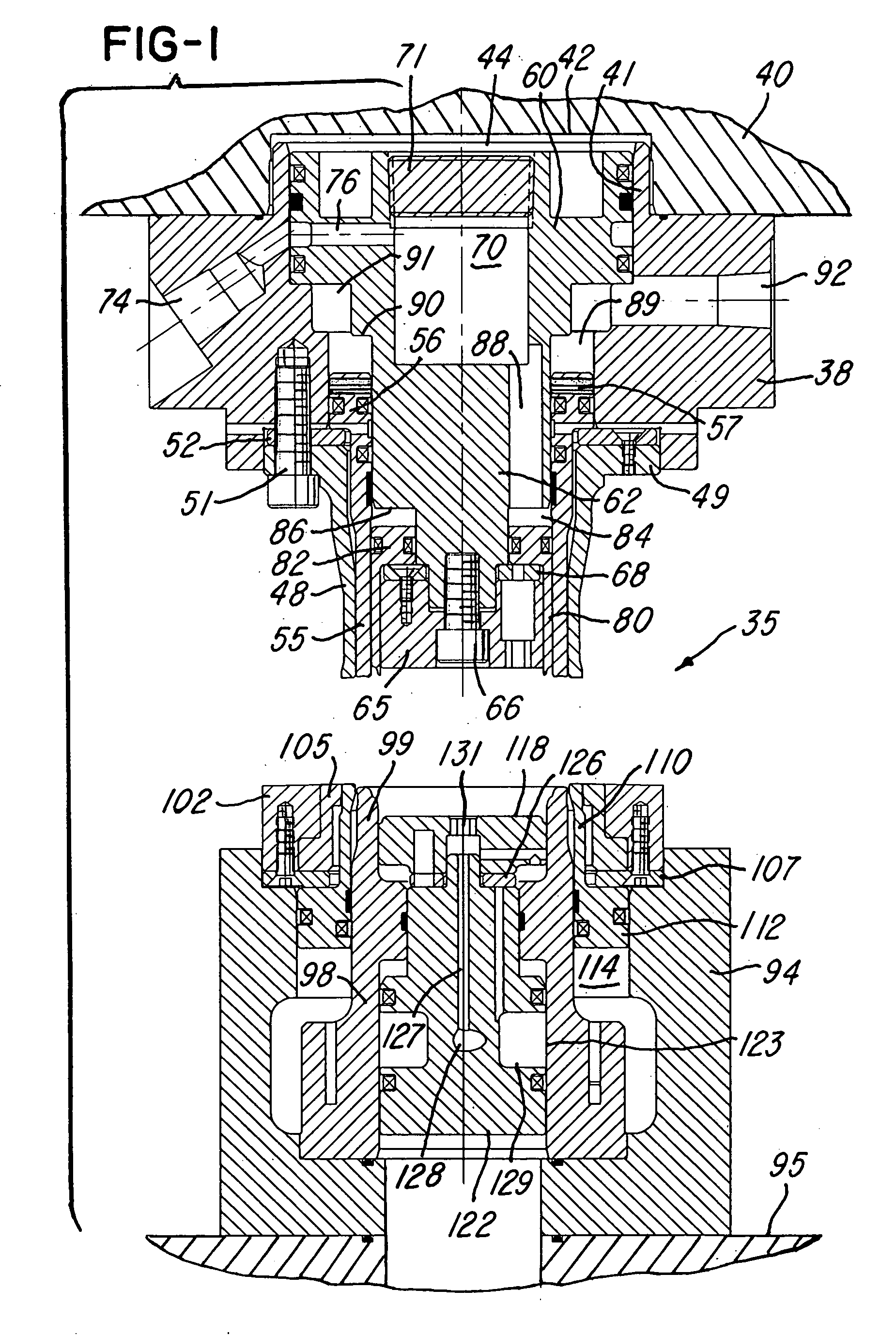

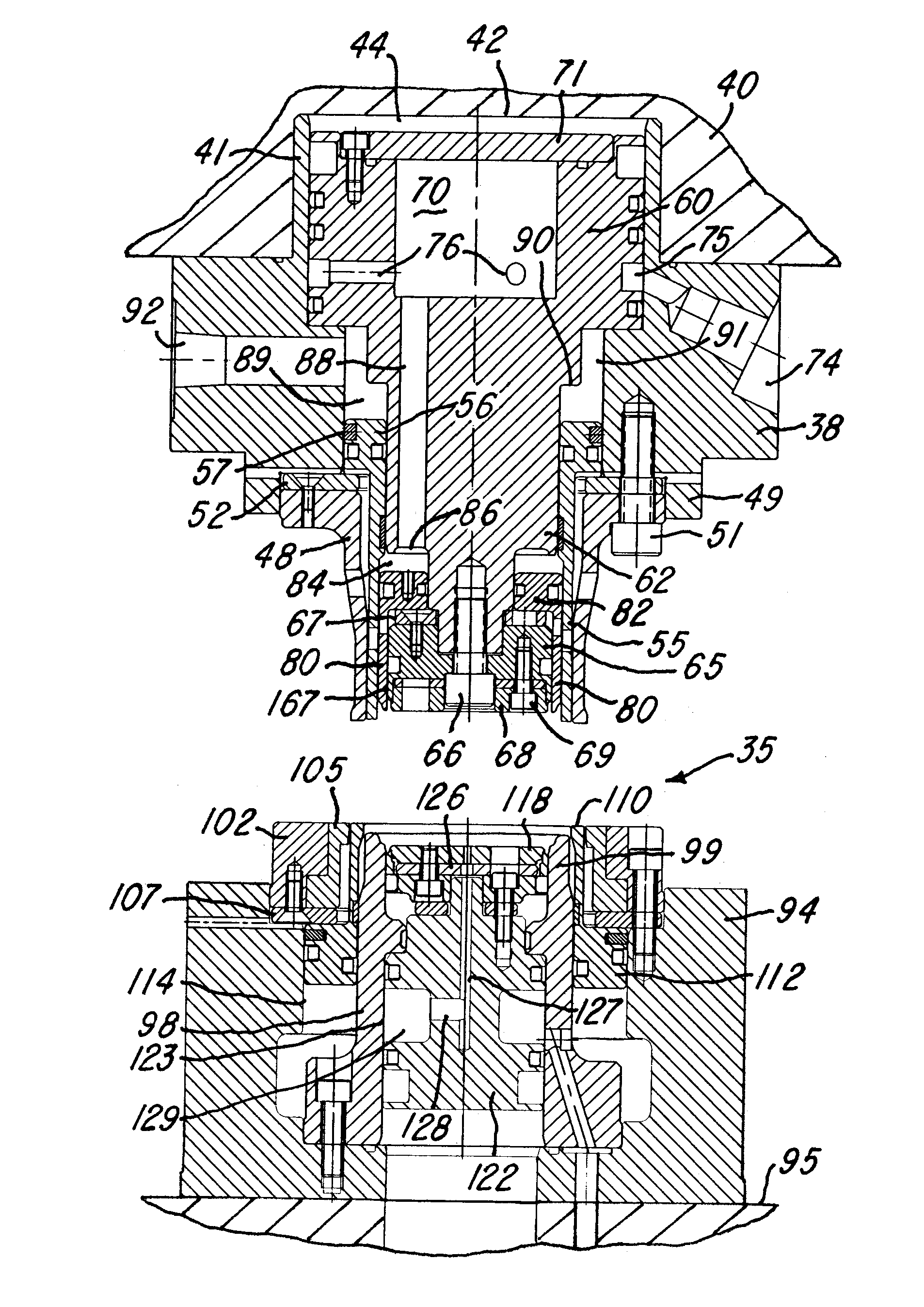

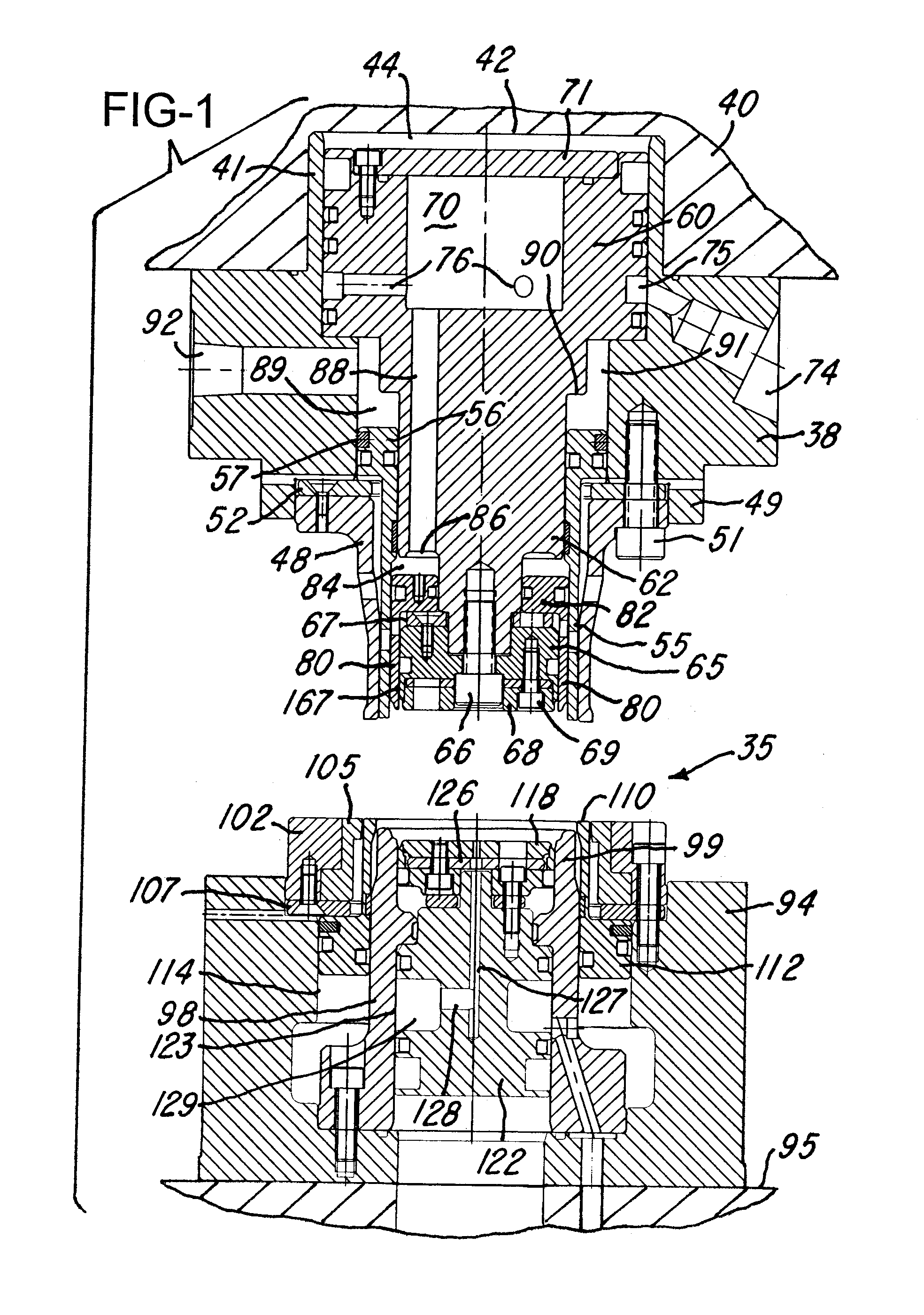

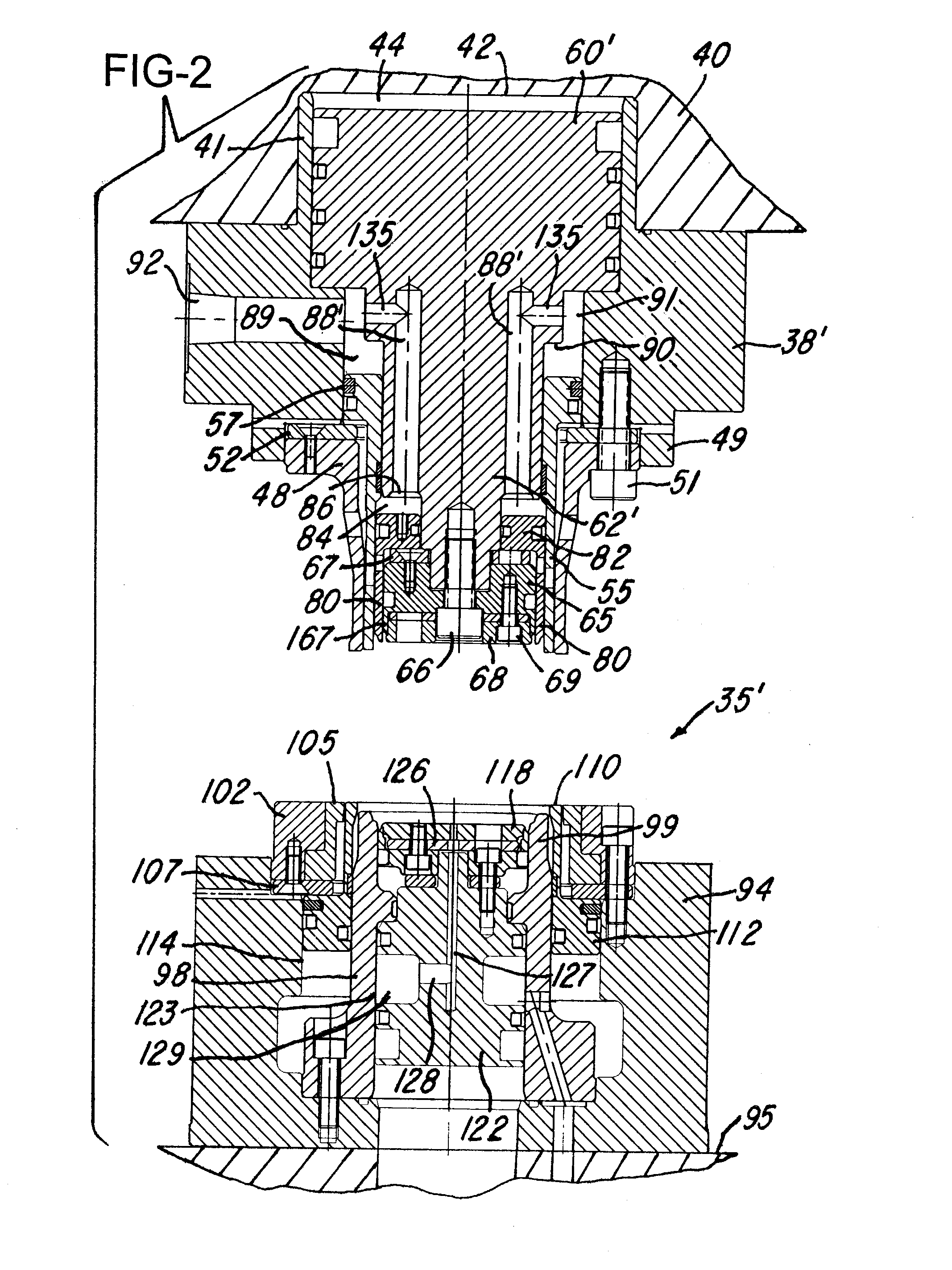

Method and apparatus for forming a can shell

Can shells are produced with tooling installed on a single action mechanical press, and the tooling includes an upper retainer supporting a blank and draw die enclosing an outer pressure sleeve and an inner pressure sleeve surrounding a die center punch, all having air actuated pistons. The die center piston has an air reservoir connected by air passages which form air springs for the inner pressure sleeve, and the outer pressure sleeve receives the same controllable air as the reservoir or low pressure plant air supply. The inner pressure sleeve has a projecting nose portion which initiates the drawing of a cup and has contoured surfaces which mate with corresponding surfaces on a die core ring to form and clamp the chuckwall of the shell during downstroke of the press. A lower panel punch forms the center panel, panel wall and countersink of the shell during upstroke of the press.

Owner:CONTAINER DEVELOPMENT LTD

Transmission system of servo-driven double-angle lever mechanical press of switch magnetic reluctant motor

InactiveCN101073924ASimple structureFlexible and adjustable working characteristicsPress ramFreewheelLow speed

The invention is concerned with the driving system that the switched reluctance motor servos the driving double toggle links mechanical press, it is: the switched reluctance motor is speed-down by the first-level strap in order to send the power to the synchronizer gear structure, the synchronizer gear structure drives the slipper to move by the same-axle concretion crank toggle mechanism, maintains the flywheel with the proper moment of inertia. The invention is with the low speed features during the punching moment and the high speed features during the return and feeding moment, which can achieve the flexibility control of the slider movement, simplify the structure of the pressing machine, and reduce the cost.

Owner:XI AN JIAOTONG UNIV

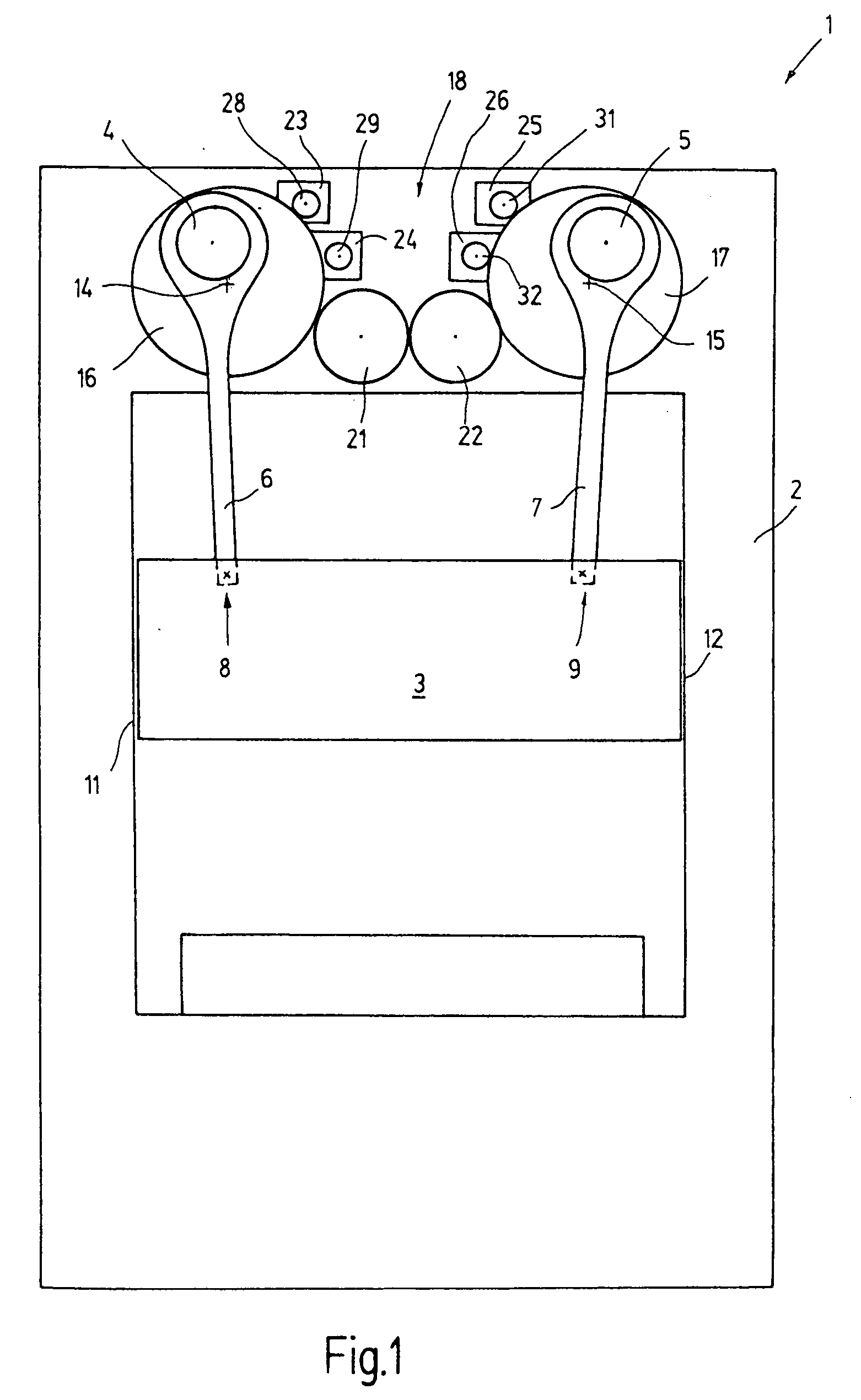

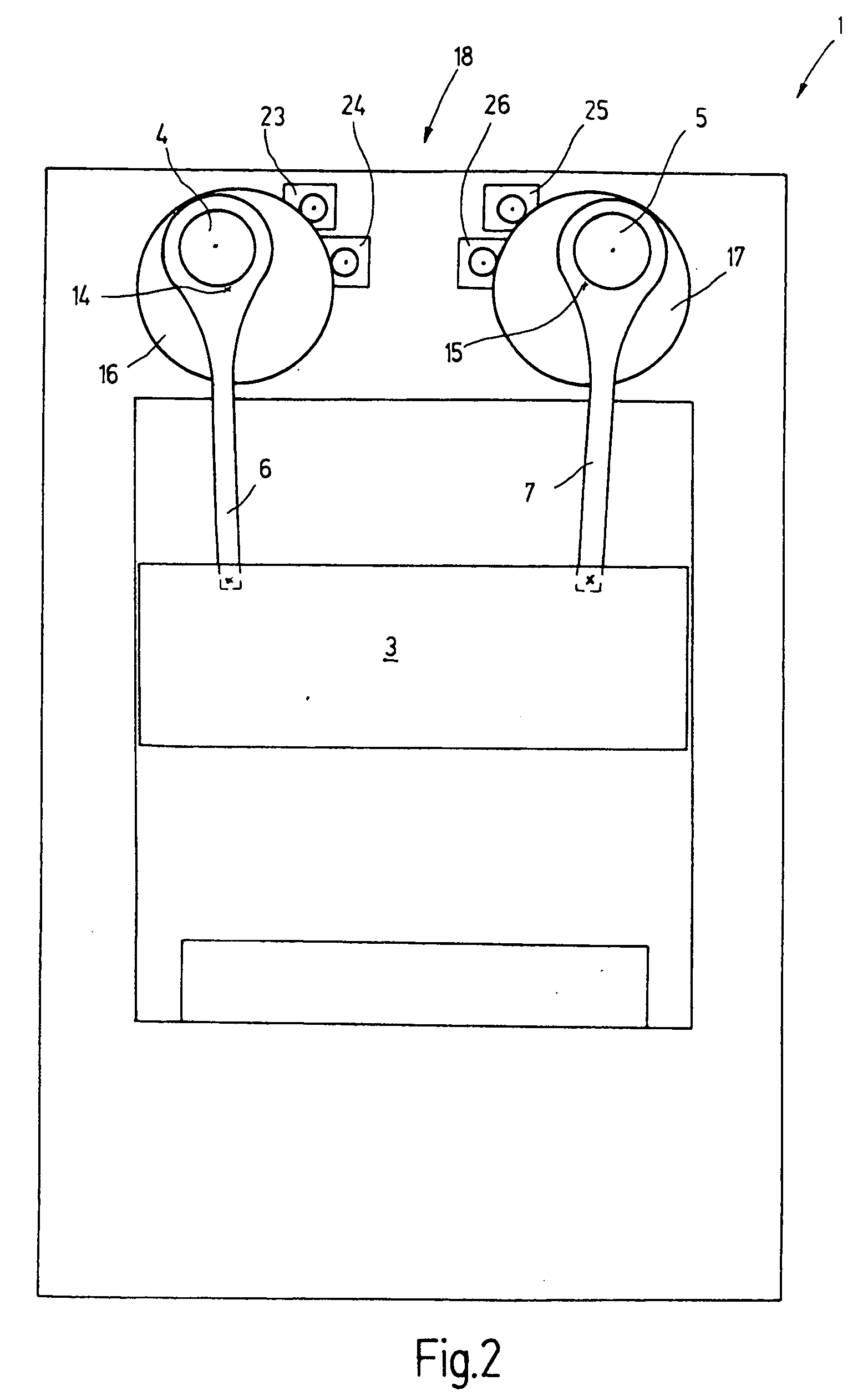

Mechanical press

InactiveUS20050189900A1Inertia moment can be increasedSlow downAgriculture tools and machinesComputer controlEngineeringServomotor

In a press having a plunger supported so as to be movable linearly back and forth by drive means which include at least one servomotor in combination with a rotatably supported inertia structure connected for rotation with the servomotor, the inertia structure has an inertia moment which is small enough to permit reversal of the servomotor within a stroke length of the plunger so that the stroke of the plunger is adjustable under the control of a control device connected to the servomotor for controlling its operation.

Owner:SCHULER PRESSEN GMBH & CO KG

High-strength pore-closed mullite material and preparation method thereof

The invention relates to a high-strength pore-closed mullite material and a preparation method thereof. The material comprises, by weight, 30-84wt% of alumina raw material, 1-55wt% of alumina-silica raw material, 15-60% of silica raw material and 2-10wt% of additive. The preparation method includes: mixing the raw materials according to the above proportion, adding the additive, stirring well, and pouring into a die; performing mechanical pressing under 80-150MPa to obtain a blank, and drying the blank at 60-140 DEG C for 3-16h; putting the blank in a high-temperature kiln for calcining to obtain the high-strength pore-closed mullite material. Sintering in-situ pore forming technology is adopted, so that the high-strength pore-closed mullite material prepared by the method has the advantages of high closed porosity, high pressure-resistant strength and high refractoriness under load and can be used for a long time at high temperature of 1550-1700 DEG C.

Owner:ZHENGZHOU UNIV

Cold season nutrition-balanced compound yak block and technology for producing same

InactiveCN102657291ASuitable for supplementary purposesWide variety of sourcesFood processingAnimal feeding stuffCold seasonSodium Bentonite

The invention provides a cold season nutrition-balanced compound yak block, each kg of the block consists of the following raw materials of: 0.3-0.6g of zinc sulfate, 0.2-0.4g of copper sulfate, 0.01-0.02g of sodium selenite, 0.02-0.25g of potassium iodide, 0.02-0.04g of cobalt chloride, 10-20g of magnesium oxide, 70-100g of calcium hydrophosphate, 80-120g of puffing corn seed powder, 50-80g of bran, 20-40g of rapeseed meal, 50-100g of high-energy fat powder, 20-40g of urea, 150-250g of salt, 200-300g of bentonite, 30-60g of portland cement, 80-150g of molasses and 20-40g of vitamin premix. In addition, a technology for producing the block is provided, and better combines a chemical solidification technology and a mechanical pressing technology; and according to the seasonal variation characteristics of forage grass feed and nutritional statuses during yak raising, through taking the compositions and quantities of earth mineral elements which are ingested by the yak into consideration, the technology optimizes and adjusts the formula of the yak nutrition block, and balances the yak nutrient element supply. A curing agent has wide select sources and is low in price, and the compound yak block has balanced nutrition and larger density, is reasonable in feed intake, and is suitable to the purpose of nutrient element supplement for grazing yaks of different production levels in cold seasons.

Owner:NINGXIA UNIVERSITY

Automatic temperature rise control device for crankshaft and bearing bushes of mechanical press

ActiveCN107097452AReduce the temperatureImprove the sliding friction environmentPress ramTemperature controlAutomatic control

An automatic temperature rise control device for a crankshaft and bearing bushes of a mechanical press comprises a machine body, the crankshaft, a first supporting sleeve, a second supporting sleeve, a connecting rod cover, a connecting rod, a first shaft end bearing bush, a second shaft end bearing bush and a connecting rod bush; an air circuit temperature control system and a temperature detection and control system are arranged on the machine body; the air circuit temperature control system comprises an air cooling machine arranged on the machine body; the air cooling machine is connected with an air distributor; the air distributor communicates with spiral grooves formed in inner walls of the first supporting sleeve, the second supporting sleeve, the connecting rod cover and the connecting rod through multiple air inlet pipes; the temperature detection and control system comprises a controller and multiple temperature sensors for detecting the temperatures of the first shaft end bearing bush, the second shaft end bearing bush and the connecting rod bush; the temperature sensors are connected with the controller through circuits; and the controller is connected with the air cooling machine through a circuit. The control device has the advantages that the working temperature of the bearing bushes is automatically controlled, the design clearance is reduced, the service life of the crankshaft and the service life of the bearing bushes are prolonged, the operation speed and precision of the crankshaft is improved, the production efficiency is high, the product quality is high, and the like.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

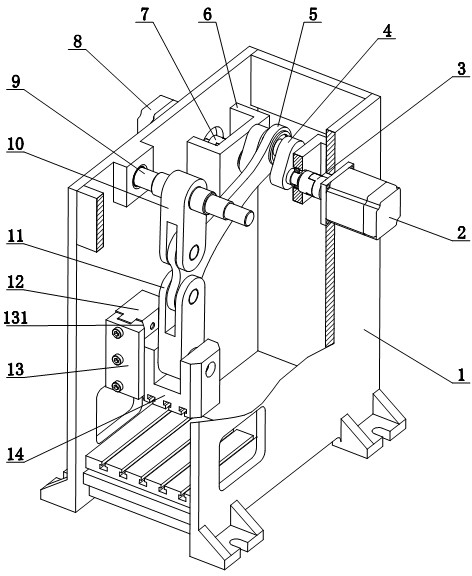

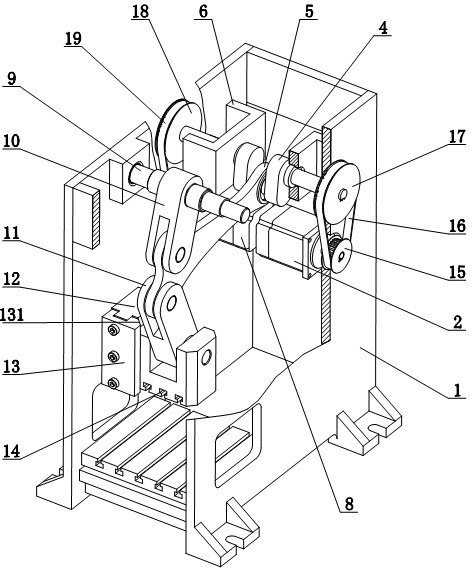

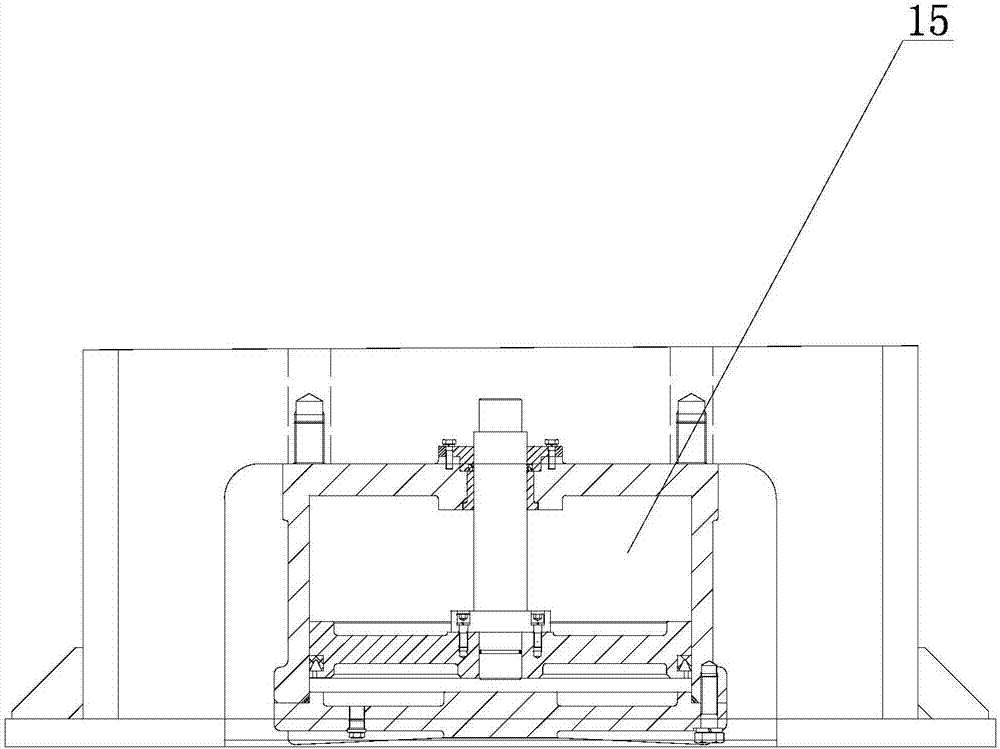

Lever type mechanical downward pushing device of mechanical press

ActiveCN107214284AEasy to grabIncrease profitForging/hammering/pressing machinesEjection devicesEngineeringMechanical press

A lever type mechanical downward pushing device of a mechanical press comprises a sliding block mounted on a machine body. Supports are mounted on the two sides of the sliding block correspondingly to be connected with vertical upper pull rods. The upper pull rods are connected with lower pull rods through adjusting nuts. The lower ends of the lower pull rods are fixedly connected with pull rod connectors. The pull rod connectors are rotatably and slidably connected with the outer ends of horizontally-arranged levers. The middles of the levers are rotatably connected with fulcrum seats arranged on the machine body. The other ends of the levers are in rolling connection with the lower bottom faces of a pushing seat. The upper end of the pushing seat is vertically and movably arranged in the machine body. A through hole is formed in the center of the pushing seat. An air cylinder is arranged at the bottom of the pushing seat. A piston rod of the air cylinder is mounted in the through hole. The upper end of the pushing seat is in matched connection with the lower end of an upper pushing rod. The upper end of the upper pushing rod is in matched connection with a worktable. The lever type mechanical downward pushing device has the advantages that synchronization is good, symmetrical balance is achieved, ejecting force is large, structure is simple, compactness is achieved, mechanical efficiency is high, manufacturing cost is low, maintenance is easy, environmental friendliness and energy saving are achieved.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

Method and apparatus for forming a can shell

Can shells are produced with tooling installed on a mechanical press, and the tooling includes an upper retainer supporting a blank and draw die enclosing an outer pressure sleeve and an inner pressure sleeve surrounding a die center punch, all having pistons. An air chamber is connected by air spring passages to the inner pressure sleeve piston, and the outer pressure sleeve receives the same air as the air chamber or lower pressure air. The die center punch has an insert which initiates the drawing of a cup, and the inner pressure sleeve and die center punch have contoured surfaces which mate with opposing surfaces on a die core ring to form and clamp the chuckwall of the shell during downstroke of the press. A panel punch has peripheral surfaces which form the panel wall and countersink of the shell during upstroke of the press.

Owner:CONTAINER DEVELOPMENT LTD

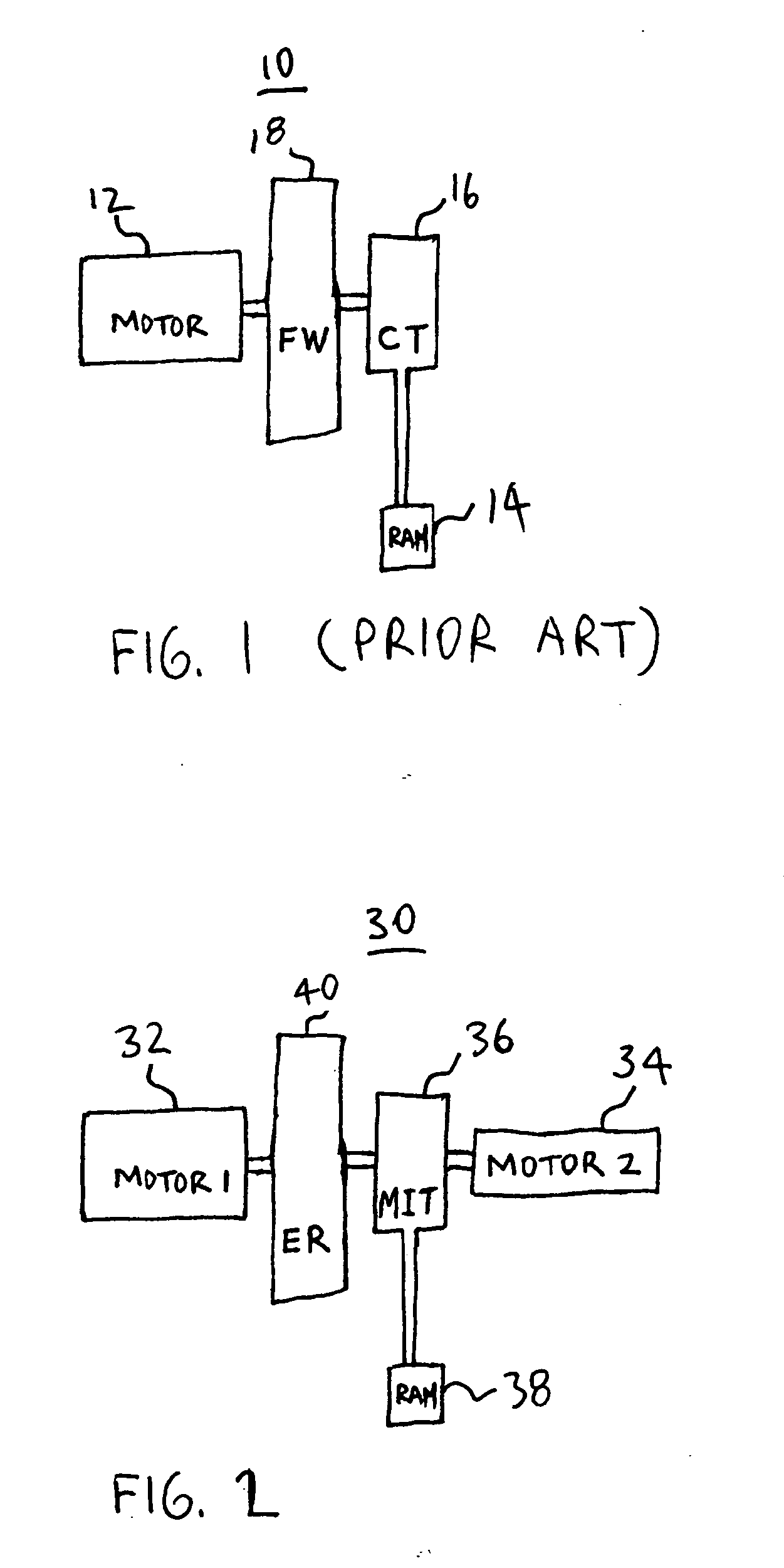

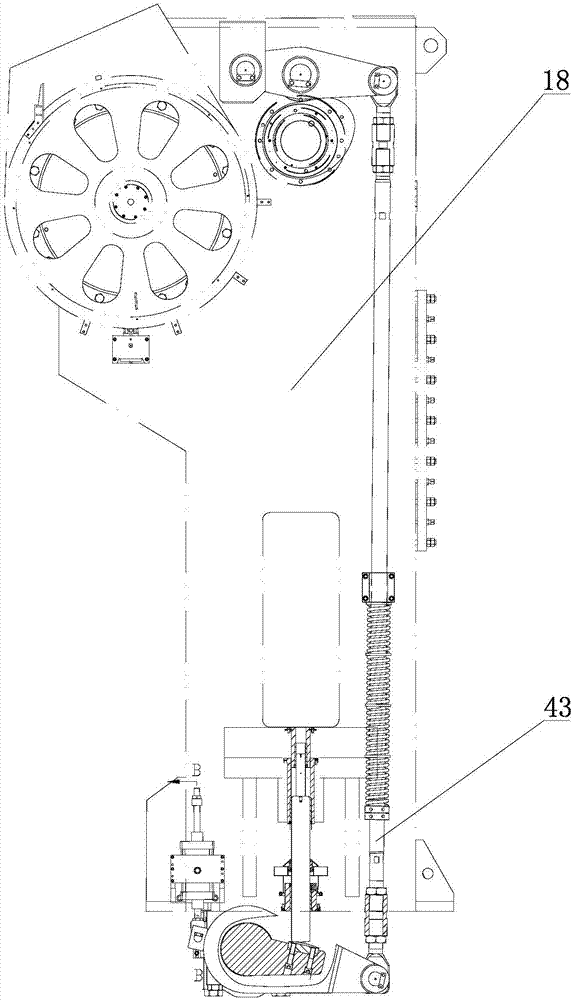

Mechanical press drive system

InactiveUS20090217724A1Improve controllabilityShorten cycle timeShaping safety devicesHammer drivesFreewheelLinear motion

A method for operating a mechanical press including an electric drive motor, a drive control for controlling the motor, a ram, a flywheel, a clutch and a member for translating rotational motion of the flywheel in a first rotation direction into a linear motion of the ram arranged to be lowered and raised along a linear path for operating the press to carry out a press production cycle. The press cycle includes a pressing part and one or more non-pressing parts. The press includes a second drive motor or actuator arranged connected to the ram and by providing a control output to the drive control means, the speed of the second drive motor is made variable during at least one part of the press production cycle. The press may be reversed between production cycles. A press and system including such a press.

Owner:ABB RES LTD

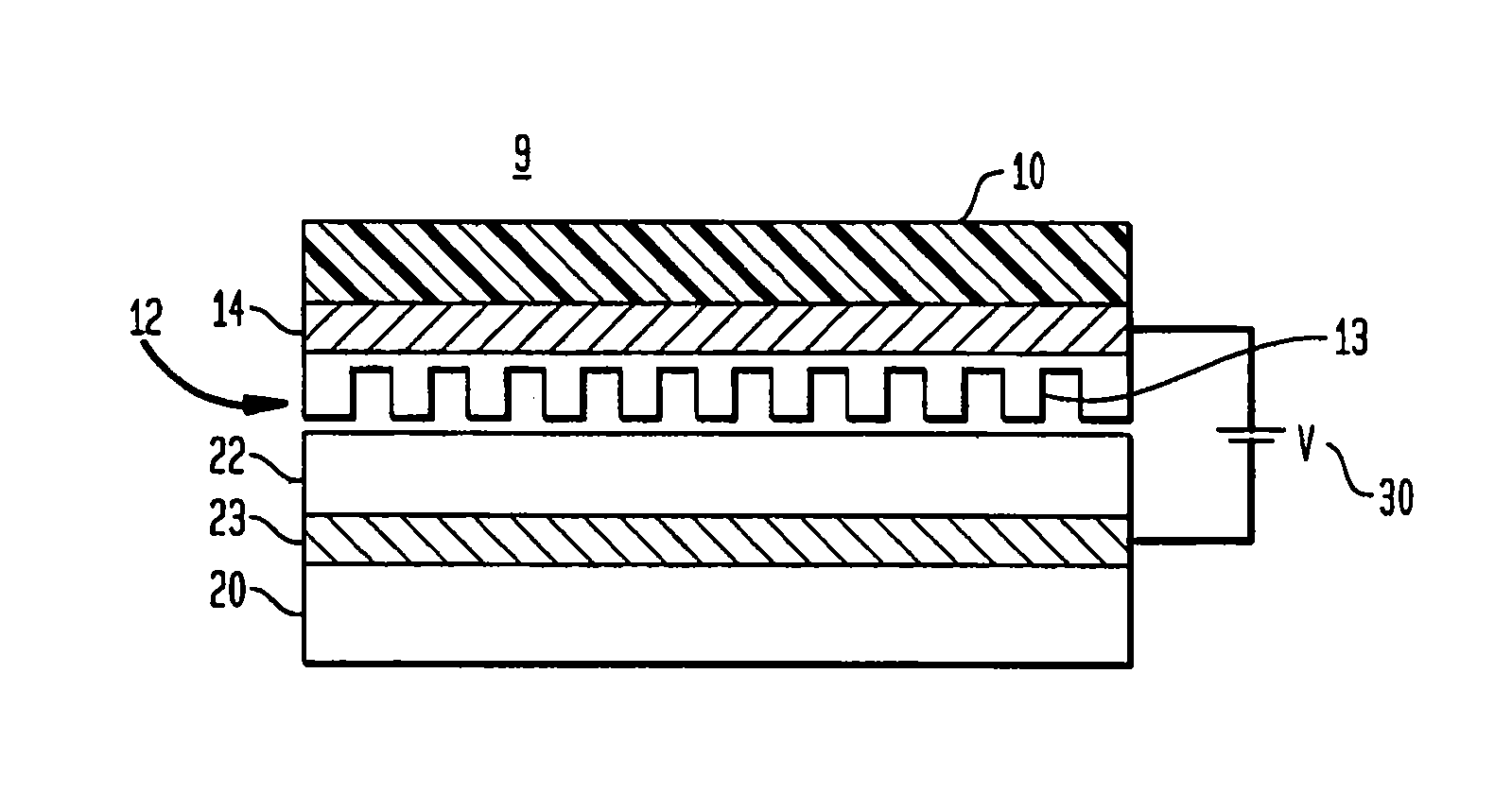

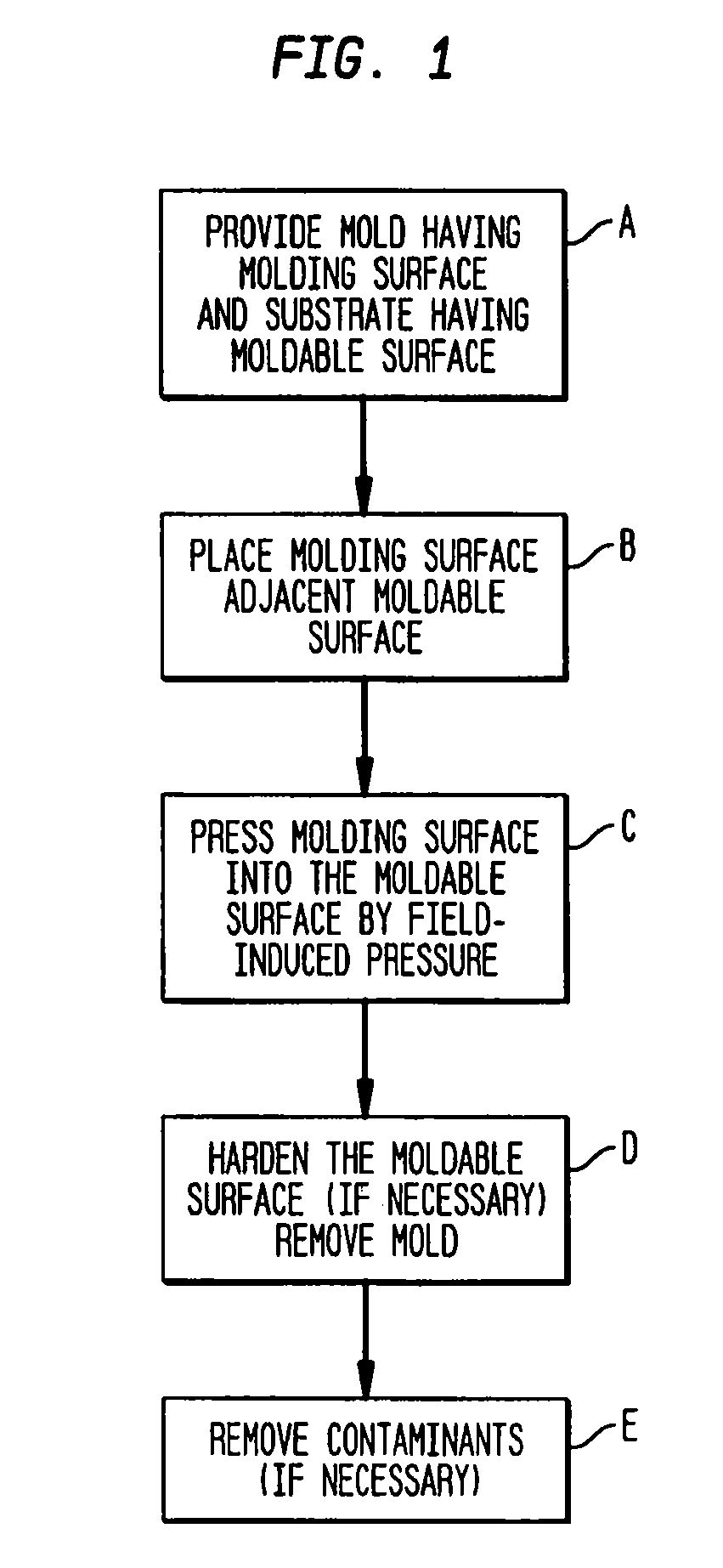

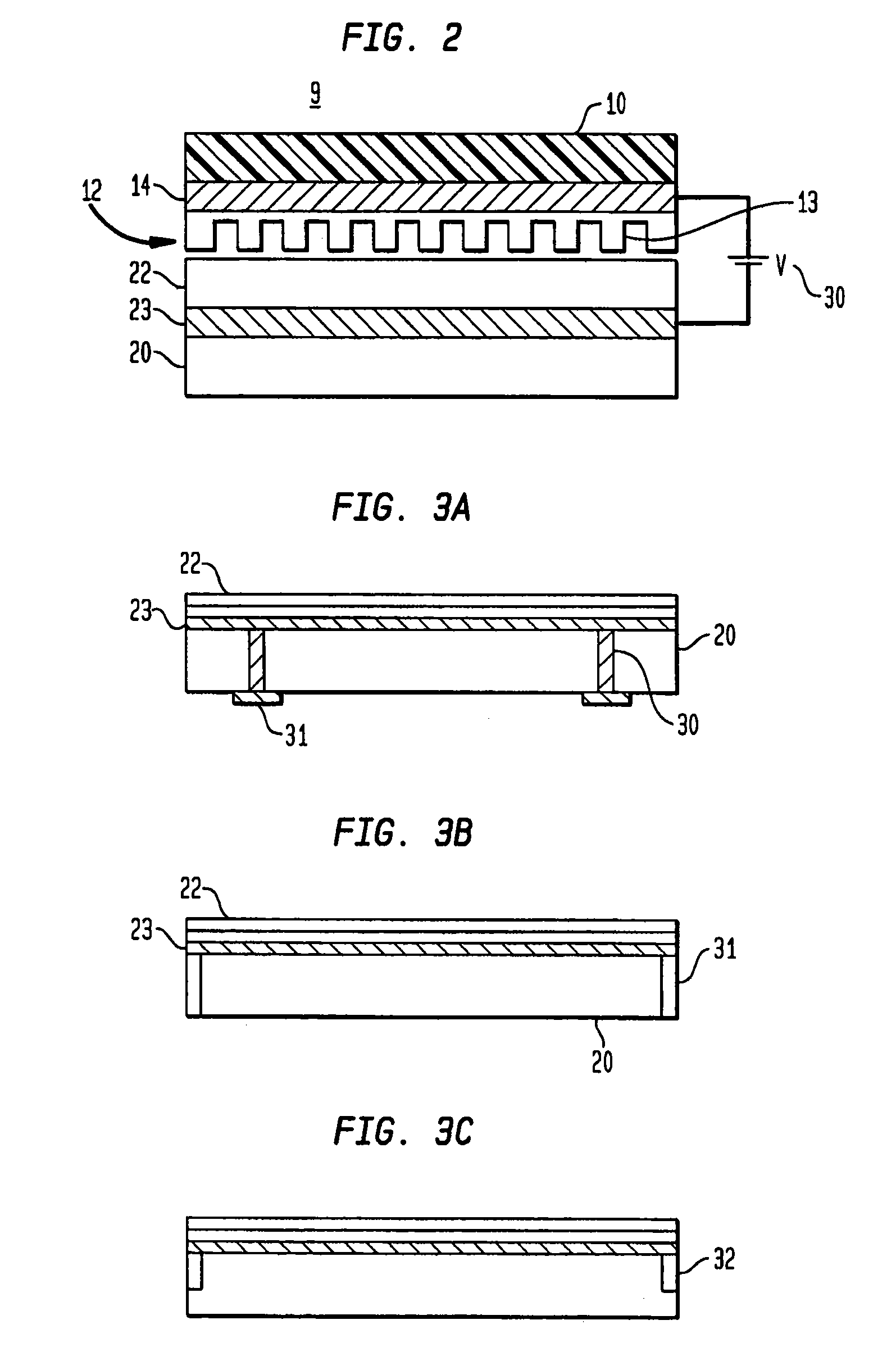

Methods and apparatus of pressure imprint lithography

An improved method of imprint lithography involves using fluid-induced pressure from electric or magnetic fields to press a mold onto a substrate having a moldable surface. In essence, the method comprises the steps of providing a substrate having a moldable surface, providing a mold having a molding surface and pressing the molding surface and the moldable surface together by electric or magnetic fields to imprint the molding surface onto the moldable surface. The molding surface advantageously comprises a plurality of projecting features of nanoscale extent or separation, but the molding surface can also be a smooth planar surface, as for planarization. The improved method can be practiced without mechanical presses and without sealing the region between the mold and the substrate.

Owner:CHOU +1

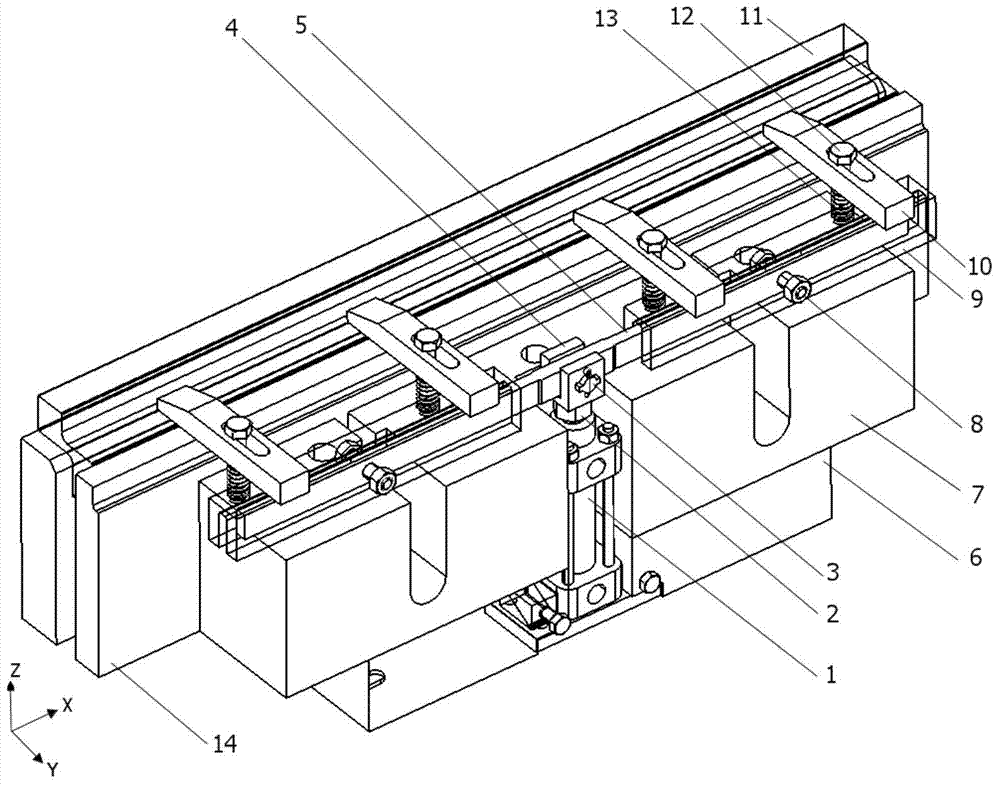

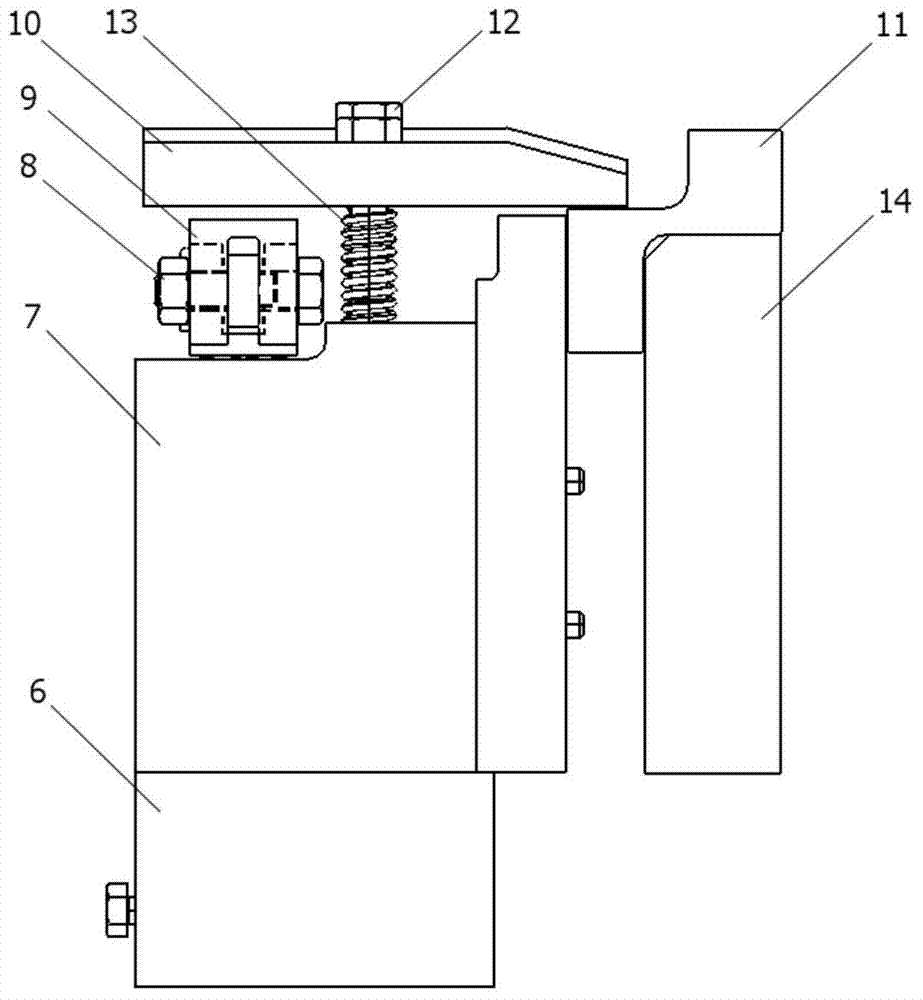

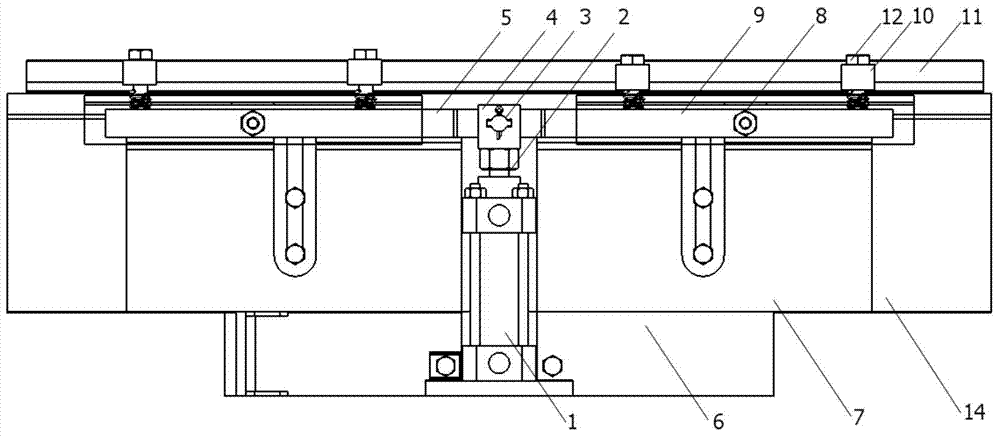

Non-planar-long-and-thin-profile-machining-oriented self-adaptive linkage clamping device and method

InactiveCN104289924AAvoid deformationReduce labor intensityPositioning apparatusMetal-working holdersSelf adaptiveMechanical press

The invention discloses a non-planar-long-and-thin-profile-machining-oriented self-adaptive linkage clamping device and method. One side of a tool block is provided with a machine tool caliber base. Two auxiliary groove limiting blocks are arranged on the machine tool caliber base. The top ends of the two auxiliary groove limiting blocks are provided with pressing blocks fixed through limiting bolts respectively. The pressing blocks are provided with sliding through holes. One ends of the pressing blocks stretch to the position above the tool block. The limiting bolts are provided with springs. A drive cylinder is arranged between the two auxiliary groove limiting blocks. The top of the drive cylinder is connected with a push rod with a main groove, a rotating lever is arranged in the main groove, and the main groove is provided with a limiting pin shaft penetrating through the main groove and connected with the rotating lever and capable of controlling the inclination angle of the rotating lever. According to the non-planar-long-and-thin-profile-machining-oriented self-adaptive linkage clamping device and method, the inclination angle of the rotating lever can be changed by rotating the limiting pin shaft, it is avoided that mechanical pressing plate clamping is originally conducted by tightening the bolts manually, the labor intensity of workers can be lowered, the auxiliary time is saved effectively, and the machining efficiency is improved.

Owner:XI AN JIAOTONG UNIV

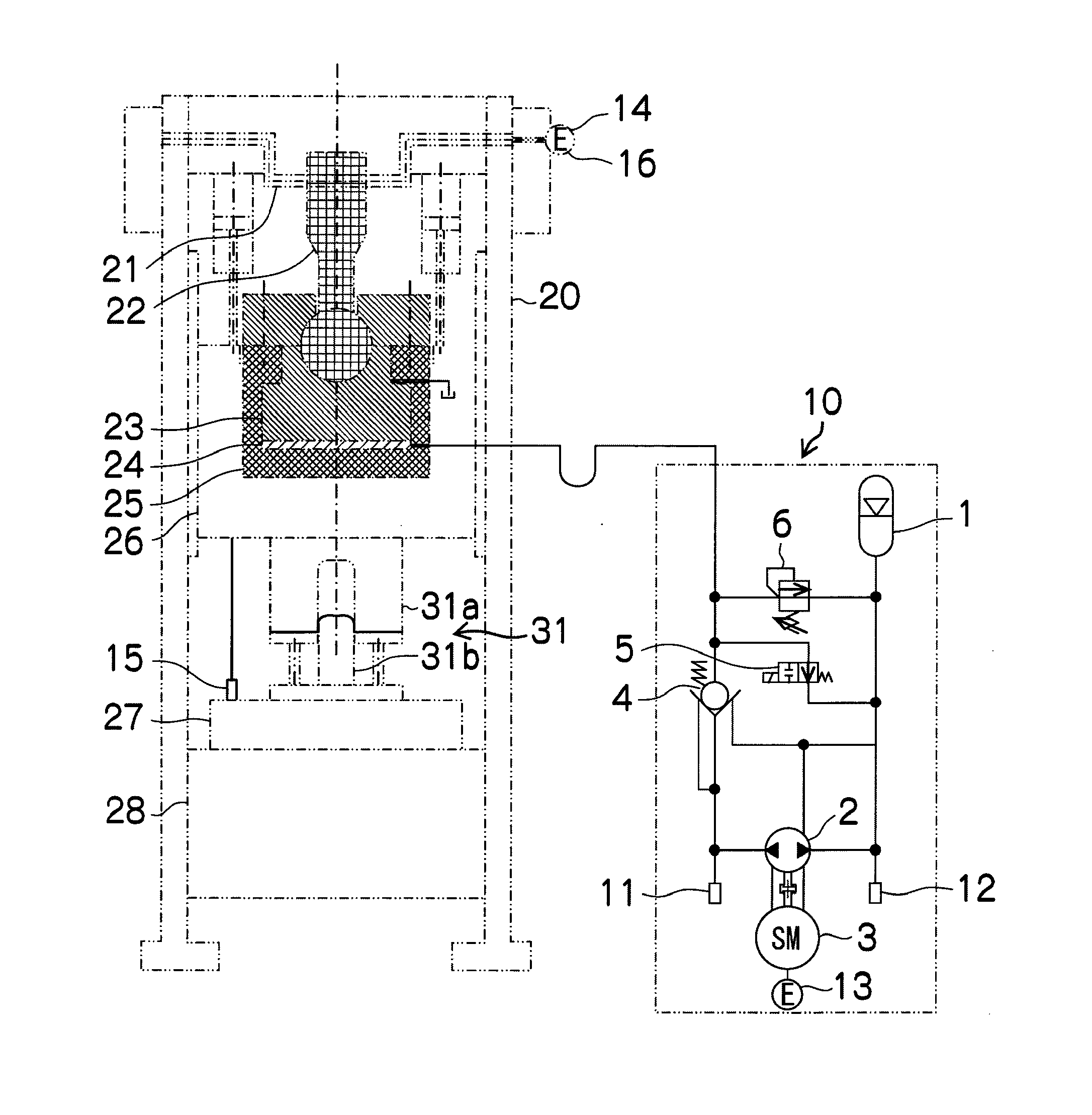

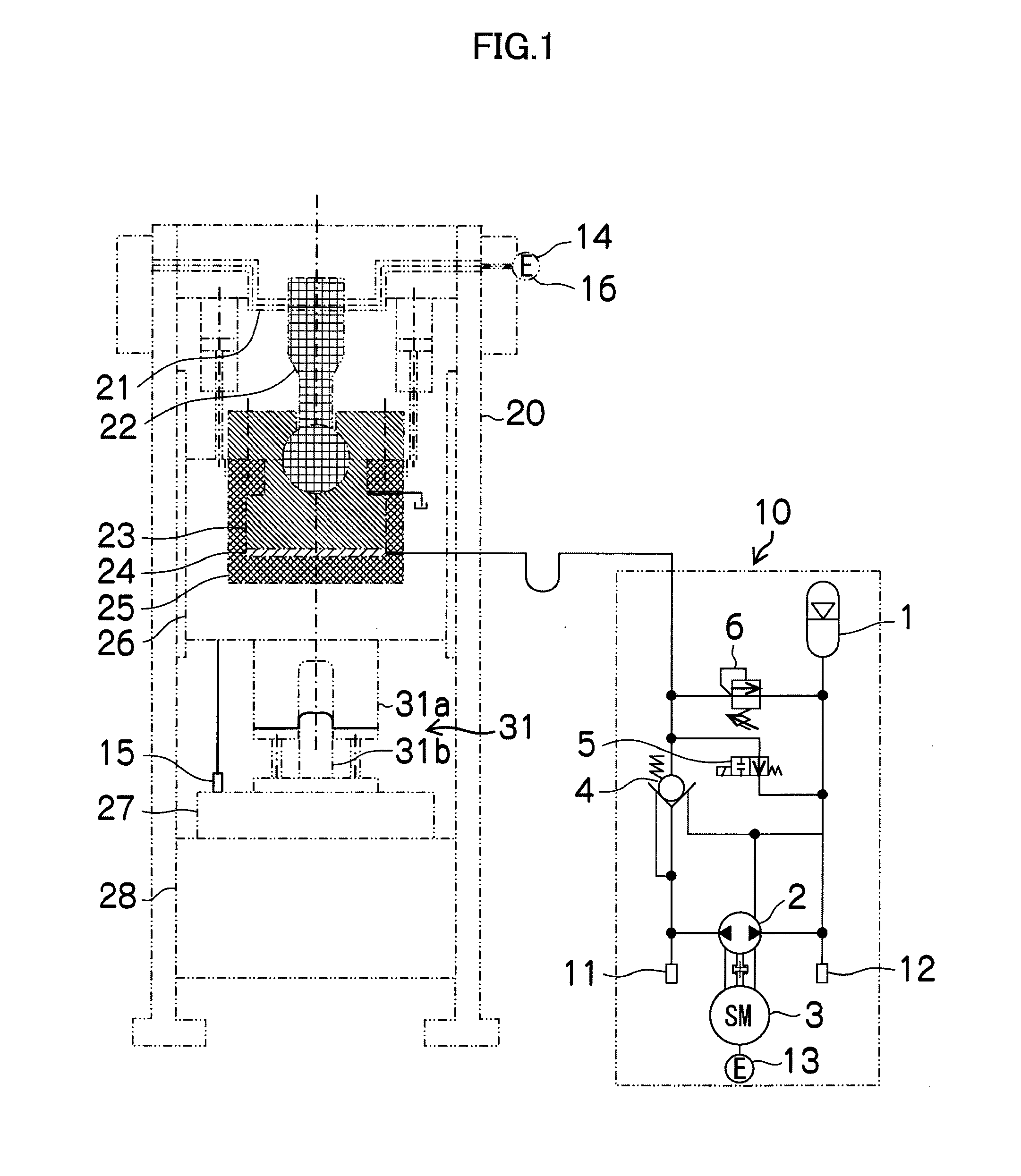

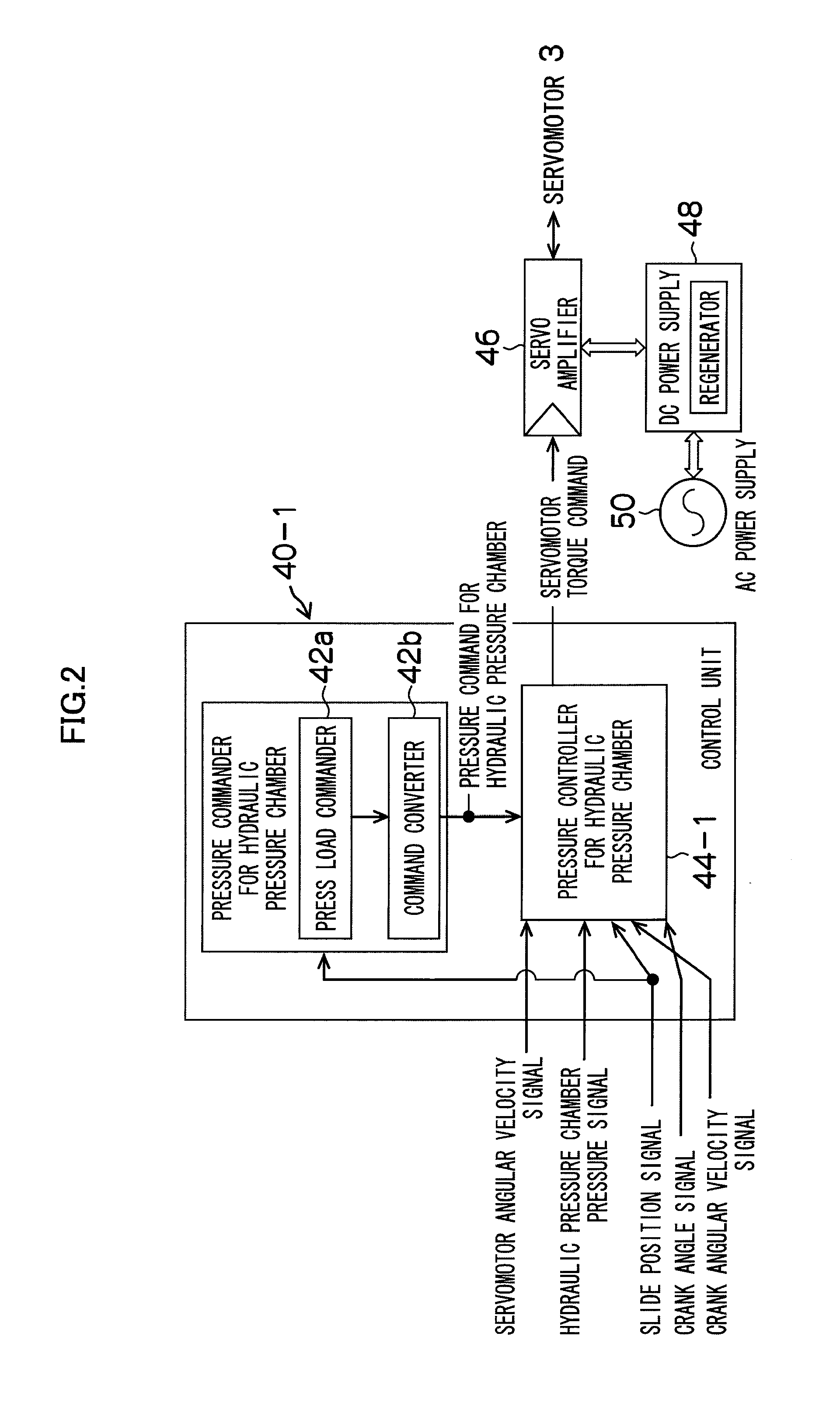

Press load controlling apparatus for mechanical press

In a mechanical press, the pressure (cylinder force) of a hydraulic pressure chamber of a cylinder-piston mechanism provided in a slide of the mechanical press can be variably controlled with a high responsiveness by a hydraulic pump / motor driven by an electric servomotor, in response to a cylinder force command corresponding to the press load command. Accordingly, even if a die height value is set to a value small enough to cause an overload, the press load can be restricted before the occurrence of the overload, and this can save the trouble of strictly adjusting the die height value. Further, pressure-application time in the vicinity of a bottom dead center can be lengthened, and a breakthrough phenomenon can be suppressed from occurring at the end of pressure application. Still further, because the overload does not occur, pressure oil is not relieved, so that the interruption of a press operation is avoided.

Owner:AIDA ENG LTD

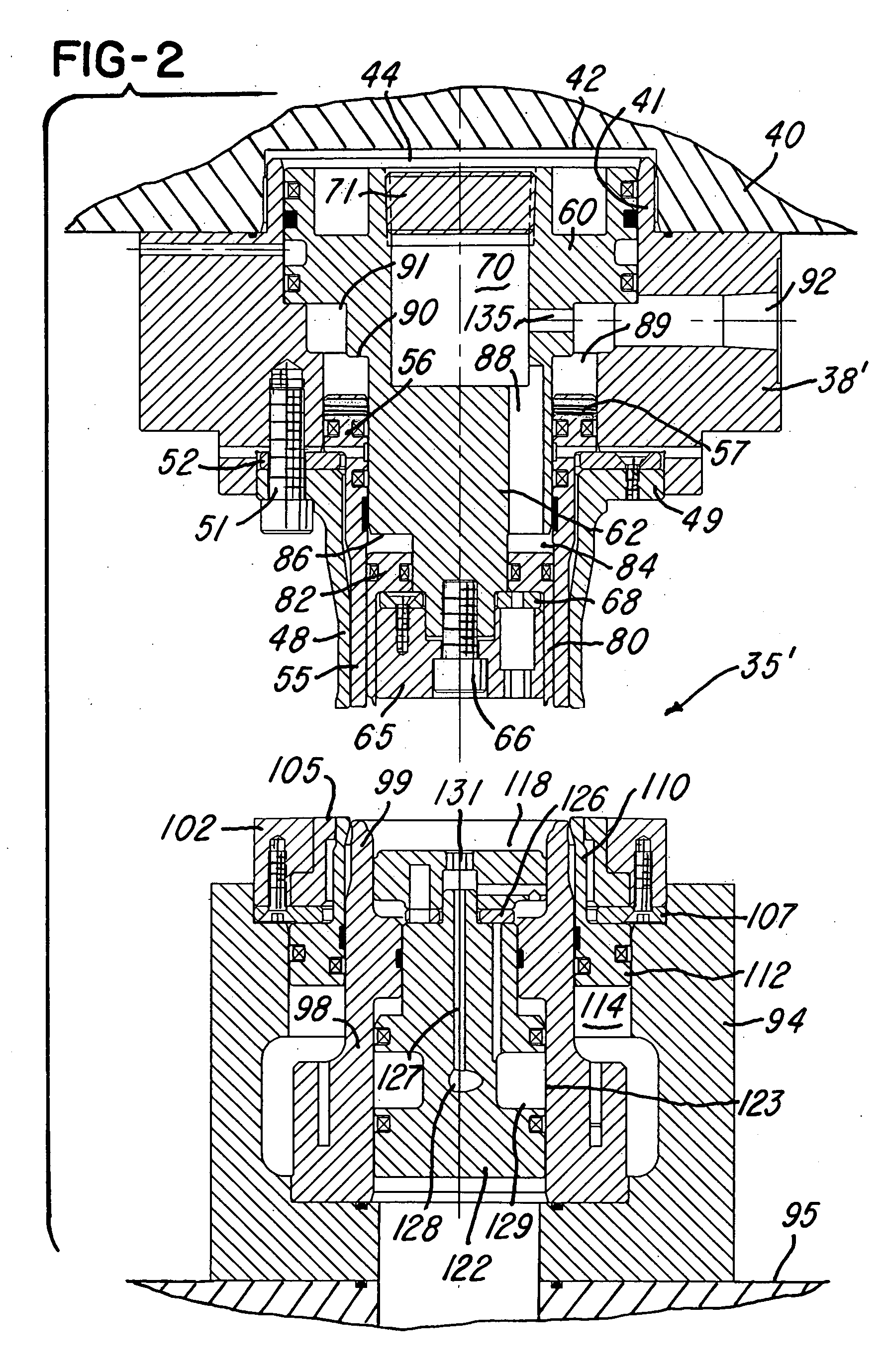

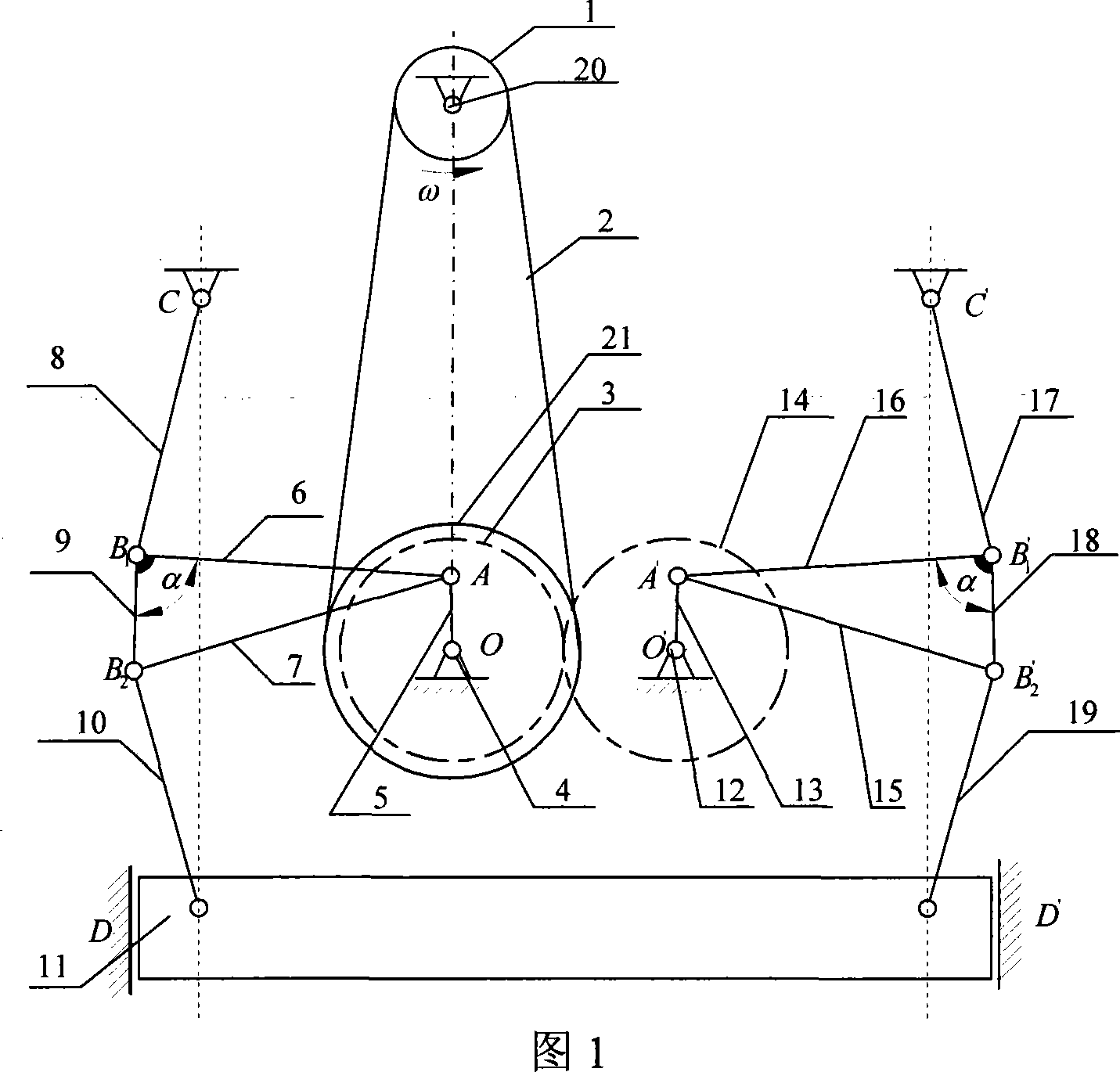

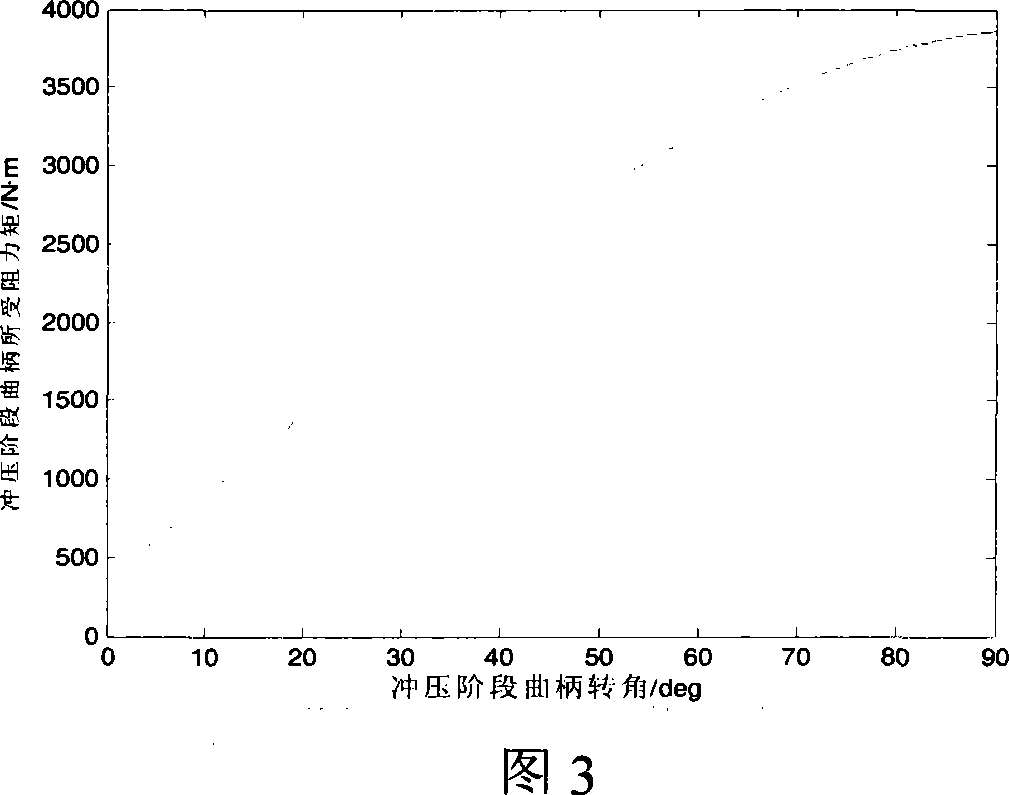

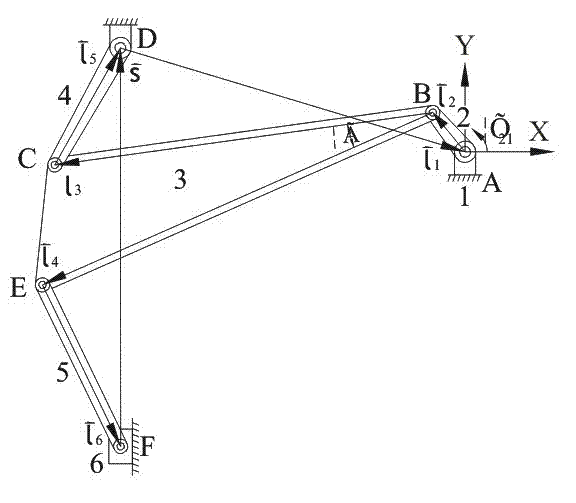

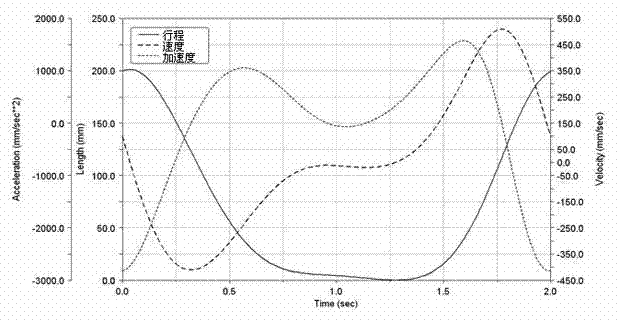

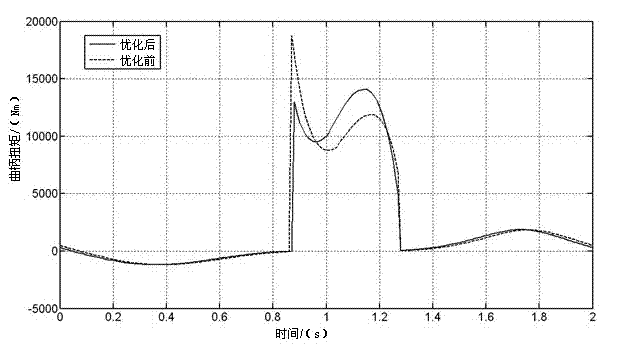

Triangular toggle-rod working mechanism of servo mechanical press and optimized design method thereof

InactiveCN102126301AEnough travelLow driving torqueAerodynamics improvementPress ramMechanical modelsCrank

The invention discloses an optimized design method of a triangular toggle-rod working mechanism of a servo mechanical press. The triangular toggle-rod working mechanism comprises a crank AB, a connecting rod BCE, an upper toggle rod CD and a lower toggle rod EF, wherein a sliding block is established by a point F, the upper toggle rod CD and the lower toggle rod EF are unequal in length, the upper toggle rod CD is shorter than the lower toggle rod EF, a point D and the point F are located on a vertical line, and points B, C and E are used for establishing the triangular connecting rod BCE. The optimized design method of the triangular toggle-rod working mechanism includes the following steps: 1) building a parameterized mechanical model; 2) establishing a parameterized virtual prototype model; 3) analyzing sensitivity of each structure parameter; and 4) building an optimization model and solving. Through the optimized design, the triangular toggle-rod working mechanism has a higher force increasing ratio and can greatly decrease the driving torque required by the crank under the condition of guaranteeing compact machine-body mechanism, sufficient sliding-block stroke and single sliding-block movement downstream, thereby lowering the capacity and cost of a servo motor. The triangular toggle-rod working mechanism of the servo mechanical press, designed by the invention has a reasonable structure and is convenient and practical.

Owner:GUANGDONG UNIV OF TECH +1

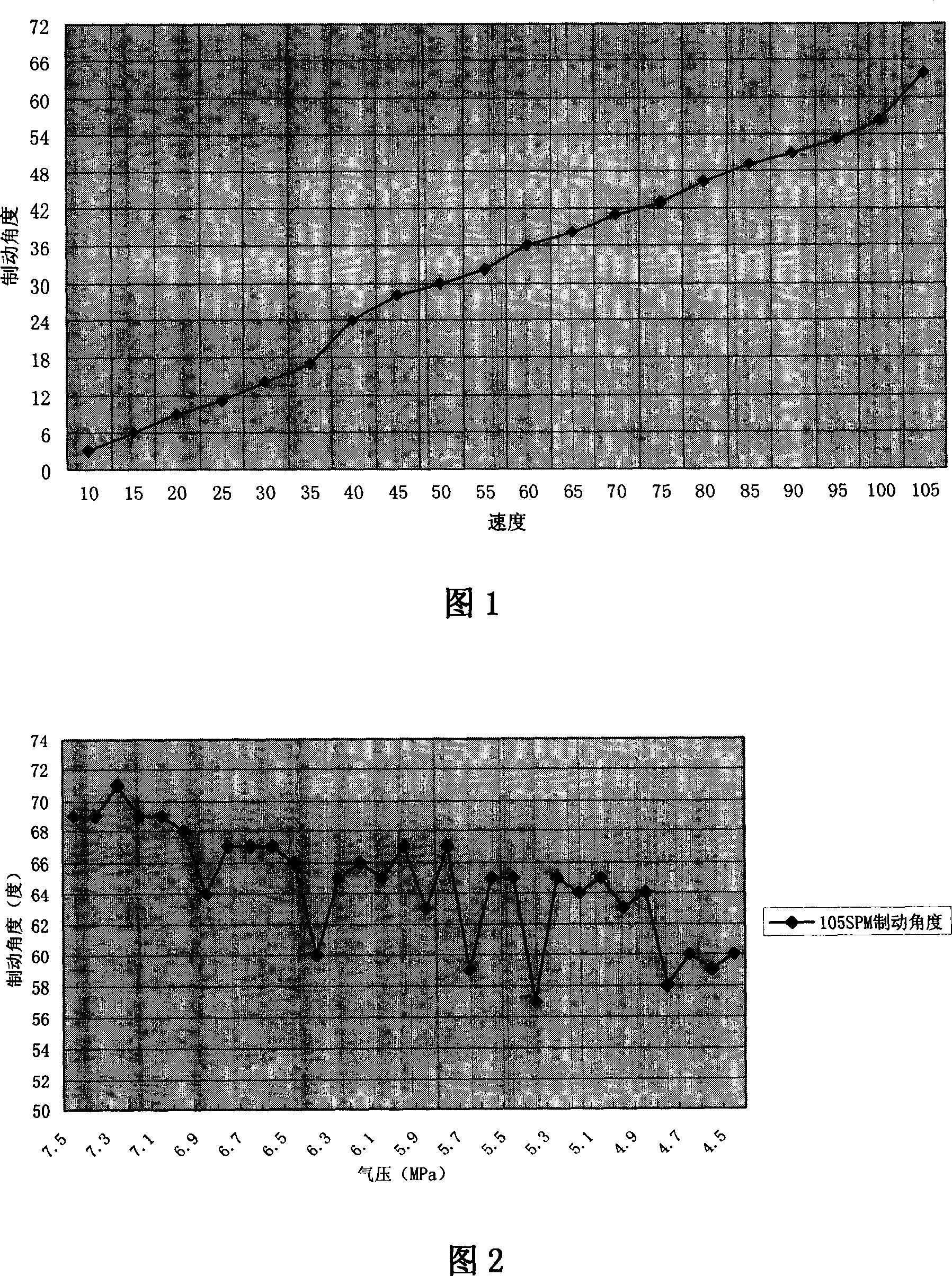

Mechanical pressure machine control method for slider stopping at certain point

ActiveCN1951682AReduce the number of adjustmentsHigh positioning accuracyPressesMachine controlEngineering

The invention relates to a method for controlling the compressor sliding block to stop at dead position. Wherein, it uses the rotation coder as the crank angle / block strike sensor of mechanical compressor, to feed collected angle information to the electric cam controller; the controller based on the crank angle information outputs cam signal, based on the passed angle in fixed time of crank to calculate out the crank speed. The invention is characterized in that: based on the brake angles of last two sliding blocks, it finds the incline factor of angle-speed curvature; when the compressor first operates in one sliding block speed, based on said factor, it can find the present brake angle; when the speed is stable, the brake angle will be automatically compensated referring to the shift from last brake angle; the brake angles in different speeds are stored; when the electric cam receives brake signal, based on preset speed to inquire database, and find out present brake angle; when block reaches said brake angle, outputting the brake signal.

Owner:NANJING ESTUN AUTOMATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com