Process method for manufacturing balance weight for compressor by powder metallurgy

A process method and technology of balance weights, which are applied to other manufacturing equipment/tools, turbines, engine components, etc., can solve problems that are difficult to solve reliably, unstable casting dimensions, poor casting surface quality, etc., and achieve good metal internal structure, Effect of grain refinement and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

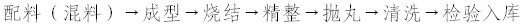

[0024] The present invention adopts the powder metallurgy process to manufacture the manufacturing process of the balance weight of the air conditioner compressor, which is characterized in that it includes the following steps: (1) according to the process design requirements, the raw materials are formulated according to the following mass percentage composition requirements, Fe (residue)-Mn (17%-25%)-C (0.5%-1.5%) plus lubricant (content 0.3%-0.8%), placed in a mixer and mixed evenly; can be mixed in a "V" type mixer , to ensure that the mixture is uniform and stable without segregation;

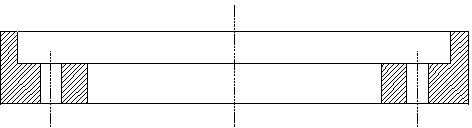

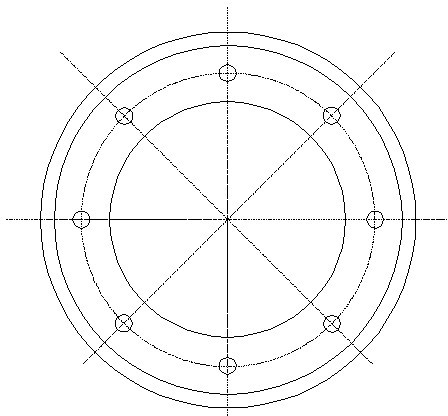

[0025] (2) Place the mixture in a suitable press, and press it in the forming mold to obtain a balance block compact; make a forming mold according to the geometric shape and thickness of the balance block to be made, and according to the shape of the balance block to be made Geometric size, thickness, etc. select the press, you can choose a four-column hydraulic press or a mechanical pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com