Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Laurolactam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laurolactam is an organic compound from the group of macrocyclic lactams. Laurolactam is mainly used as a monomer in engineering plastics, such as nylon-12 and copolyamides.

Copolyamide powder and its preparation, use of copolyamide powder in a shaping process and mouldings produced from this copolyamide powder

ActiveUS20090236775A1Low viscosityHigh dimensional accuracyAdditive manufacturing apparatusElectric discharge heatingLaurolactamPolyamide

A task often encountered in very recent times is the rapid provision of prototypes. Particularly suitable processes are those based on pulverulent materials and in which the desired structures are produced layer-by-layer through selective melting and solidification. The invention provides the constitution, production and use of a copolyamide powder which was produced using the following monomer units: a) laurolactam or ω-aminoundecanoic acid, and also b) dodecanedioic acid, and either c) decanediamine or dodecanediamine, in shaping processes, and also to mouldings produced through a layer-by-layer process which selectively melts regions of a powder layer, using this specific powder. Once the regions previously melted layer-by-layer have been cooled and solidified, the moulding can be removed from the powder bed. The mouldless layer-by-layer processes for the production of components using the copolyamide powder result in simplified and more reliable conduct of the process and better recyclability.

Owner:EVONIK OPERATIONS GMBH

Semiaromatic moulding compositions and uses of these

ActiveUS20110123749A1Low process temperatureSufficient compatibilityNon-metal conductorsEnvelopes/bags making machineryLaurolactamPolymer science

A polyamide moulding composition with the following constitution is described:(a) from 40 to 90% by weight of a copolyamide, where this is composed of(a1) 1,6-hexanediamine and 1,10-decanediamine and also(a2) terephthalic acid and at least one other polyamide-forming monomer selected from the group of: dicarboxylic acid having from 8 to 18 carbon atoms, laurolactam, aminolauric acid, and / or mixtures thereof;(b) from 10 to 40% by weight of macromolecular plasticizers, with the proviso that these can have been replaced to some extent by low-molecular-weight plasticizers;(c) from 0 to 20% by weight of additives and / or added substances.Uses of this type of moulding composition are also described, in particular for the production of a fuel line, cooling line, oil line or urea line for the automobile sector, as also are production processes to give mouldings.

Owner:EMS PATENT AG

Polyamide resin, composition containing polyamide resin, and molded articles of polyamide resin and composition

InactiveCN102131845AImprove heat resistanceExcellent melt retention stabilityLaurolactamPolymer science

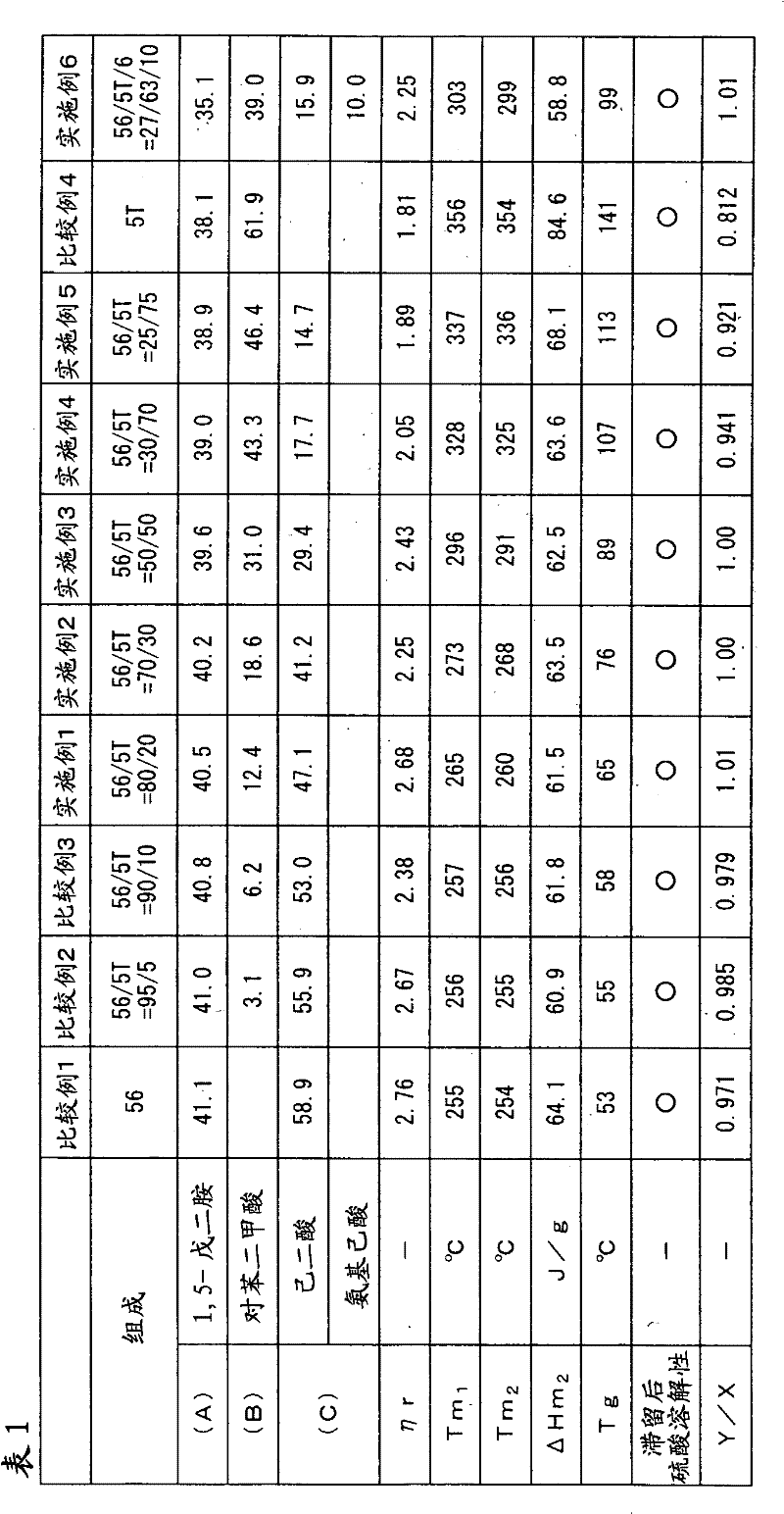

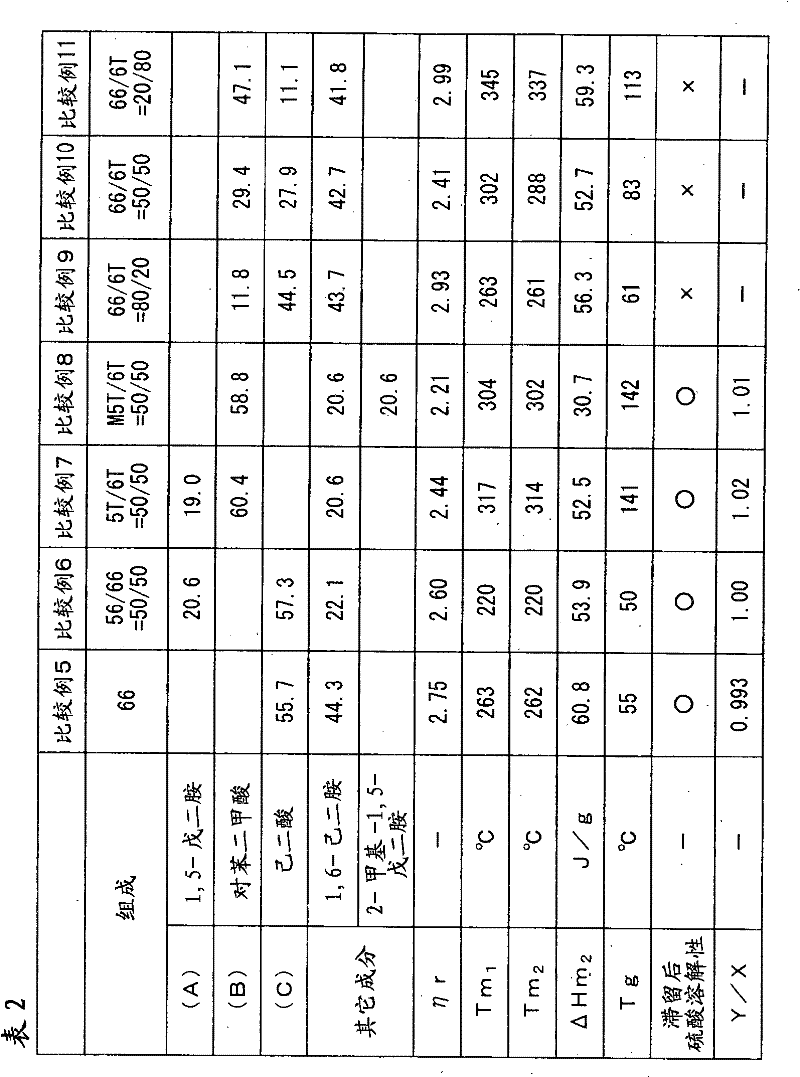

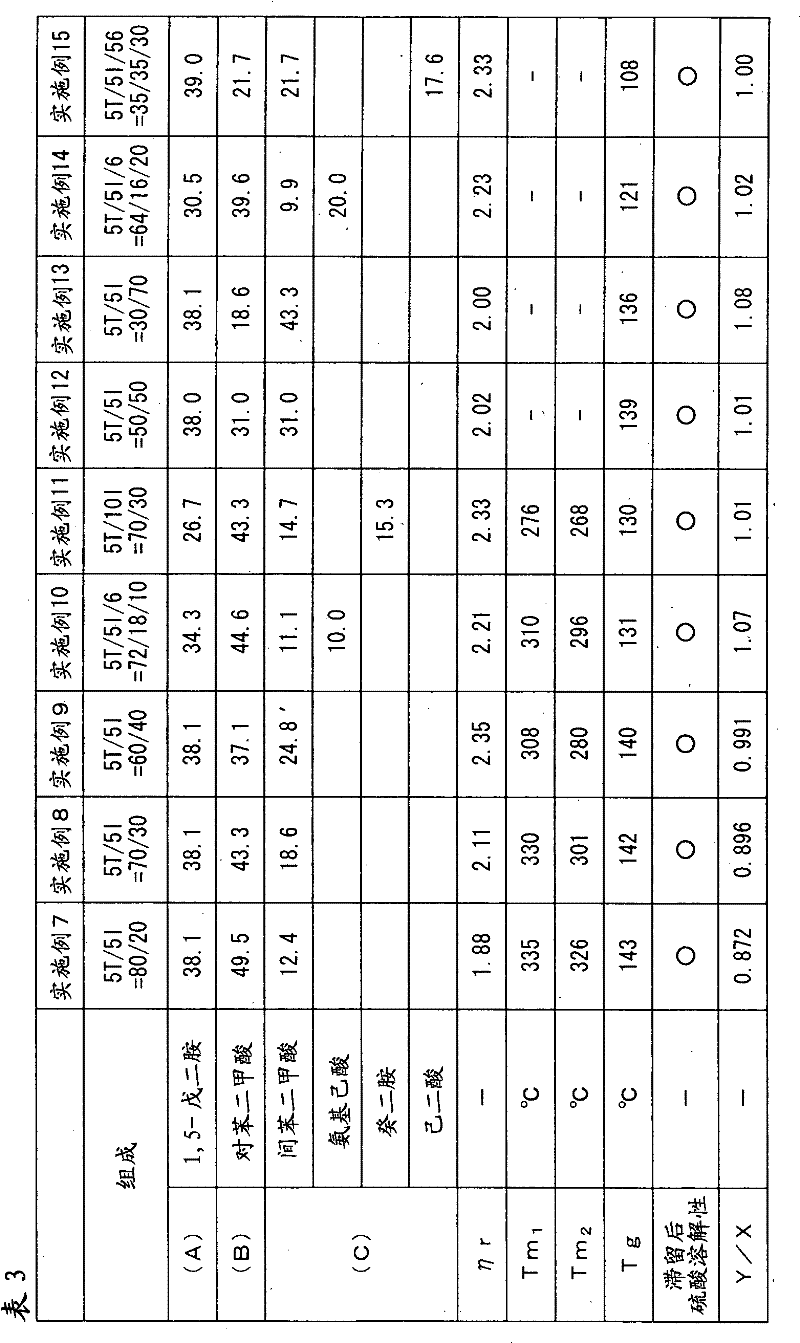

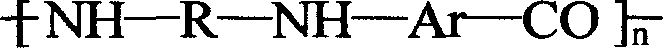

Disclosed is a polyamide resin which is produced by the polycondensation of (A) pentamethylenediamine, (B) terephthalic acid and / or a derivative thereof, and (C) at least one compound selected from adipic acid, azelaic acid, sebacic acid, undecanedioic acid, dodecanedioic acid, isophthalic acid, 1,9-diaminononane, 1,10-diaminodecane, 1,11-diaminoundecane, 1,12-diaminododecane, caprolactam, undecalactam, laurolactam, aminocaproic acid, 11-aminoundecanoic acid, 12-aminododecanoic acid, and derivatives of these compounds. In the polyamide resin, the ratio of a repeating unit derived from the component (C) is 10 to 50 wt% (inclusive) relative to the total weight of the polymer. A solution of the polyamide resin in 98% sulfuric acid, which contains the polyamide resin at a concentration of 0.01 g / ml, has a relative viscosity of 1.5 to 4.5 at 25 DEG C.

Owner:TORAY IND INC

Composite having two or more layers, including an EVOH layer

InactiveUS20060141188A1Solve the lack of resistanceSynthetic resin layered productsFlexible pipesLaurolactamHexamethylenediamine

The present invention provides a layered composite, which includes the following layers: (I) a layer I composition including: (a) from 0 to 80 part by weight of at least one polyamide selected from the group including PA6, PA66, PA6 / 66 and mixtures thereof; (b) from 0 to 100 parts by weight of at least one polyamine-polyamide copolymer that includes the following monomer units: (α) from 0.5 to 25% by weight, based on the weight of the polyamine-polyamide copolymer, of at least one polyamine having at least 4 nitrogen atoms and having a number-average molar mass Mn of at least 146 g / mol, and (β) at least one polyamide-forming monomer selected from the group including lactam, ω-aminocarboxylic acid, equimolar combination of diamine and dicarboxylic acid, and mixtures thereof; and (c) from 0 to 80 parts by weight of at least one polyamide selected from the group including PA11, PA12, PA612, PA1012, PA1212 and wherein, in the layer I, a total of the parts by weight of (a), (b) and (c) is 100; wherein within an entirety of (a) and (b), at least 20 parts by weight of the entirety include monomer units selected from the group including caprolactam, combination of hexamethylenediamine / adipic acid, and mixtures thereof; and wherein within an entirety of (b) and (c), at least 20 parts by weight of the entirety include monomer units selected from the group including ω-aminoundecanoic acid, laurolactam, combination of hexamethylenediamine / 1,12-dodecanedioic acid, combination of 1,10-decanediamine / 1,12-dodecanedioic acid, combination of 1,12-dodecanediamine / 1,12-dodecanedioic acid, and mixtures thereof; and (II) a layer II composition which includes at least one ethylene-vinyl alcohol copolymer.

Owner:EVONIK OPERATIONS GMBH

Thermosol of polyamide and preparation process thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for toughening and reinforcing nylon by using new type organic montmorillonite

This invention provides a process for producing a new type of organic montmorillonite reinforced nylon, comprising the steps of: swelling the montmorillonite with a polar solvent, then adding an organic solution of the interlayer insertion agent, ªÏ-laurolactam, to obtain organic montmorillonite; adding the organic montmorillonite into hexanolactam and stirring the mixture at 100-120 deg.C for 4-8h under nitrogen atmosphere; vacuum pumping at a vacuum degree of 99331-99997Pa for 15-60min, then adding sodium hexanolactam, 2,4-toluene diisocyanate and other assistants to the mixture for casting or reactive extrusion to obtain the product. The process of this invention produces an interlayer insertion agent that can improve the adhesion between the montmorillonite and the nylon matrix, and the montmorillonite / nylon nanocomposite produced from the interlayer insertion agent treated montmorillonite has high strength, modulus, resistance, impact strength and rupture extension rate.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

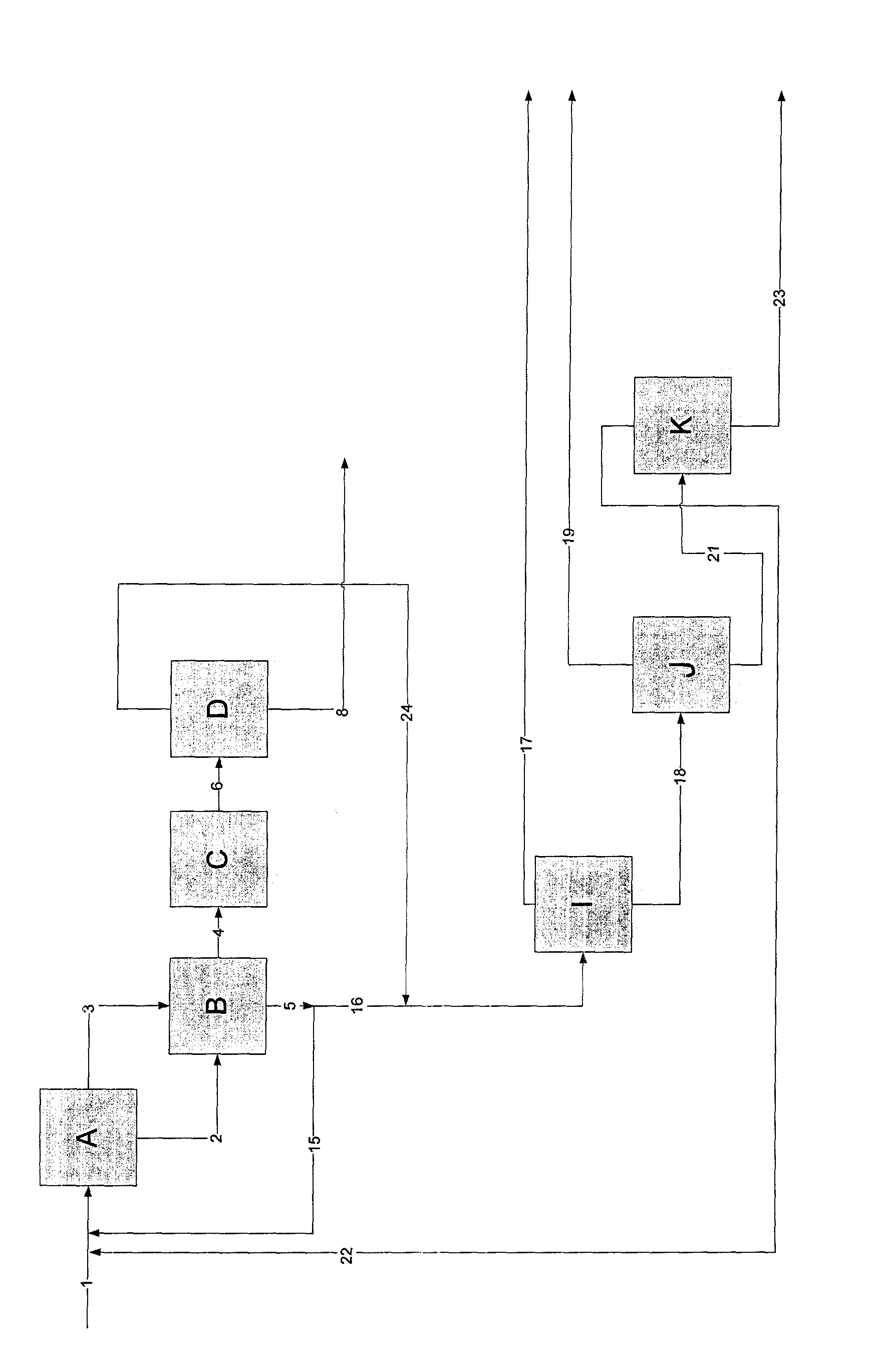

Method for isolation of laurolactam from a laurolactam synthesis process stream

A process for purifying laurolactam by means of integrated connection of distillation and crystallization is provided. The crystallization is performed as a solution or melt crystallization. The process reduces thermal stress applied to the laurolactam stream and improved yields are obtained. Raw materials are recovered and recycled in the production sequence.

Owner:EVONIK OPERATIONS GMBH

Polyamide resin, composition containing the polyamide resin, and molded articles of the polyamide resin and the composition

InactiveUS20110105683A1Improve heat resistanceImprove stabilityNon-fibrous pulp additionPaper/cardboardLaurolactam12-aminododecanoic acid

Disclosed is a polyamide resin which is produced by the polycondensation of (A) pentamethylenediamin, (B) terephthalic acid and / or a derivative thereof, and (C) at least one member selected from adipic acid, sebacic acid, undecanedioic acid, dodecanedioic acid, isophthalic acid, 1,9-diaminononane, 1,10-diaminodecane, 1,12-diaminododecane, caprolactam, undecalactam, laurolactam, aminocaproic acid, 11-aminoundecanoic acid, 12-aminododecanoic acid, and derivatives of these compounds. In the polyamide resin, the ratio of a repeating unit derived from the component (C) is 10 to 50 wt % (inclusive) relative to the total weight of the polymer. A solution of the polyamide resin in 98% sulfuric acid, which contains the polyamide resin at a concentration of 0.01 g / ml, has a relative viscosity of 1.5 to 4.5 at 25° C.

Owner:TORAY IND INC

Polyamide composite material with double or multiple layers

InactiveCN1361005ASynthetic resin layered productsThin material handlingLaurolactamHexamethyldiamine

A good layer adhesion can be achieved in a composite having two or more layers wherein a layer I is obtained from a molding composition which has the following components: a) from 0 to 80 parts by weight of a polyamide selected from the group consisting of PA6, PA66, PA6 / 66 and a mixture thereof; b) from 0 to 100 parts by weight of a polyamine-polyamide copolymer; and c) from 0 to 80 parts by weight of a polyamide selected from the group consisting of PA11, PA12, PA612, PA1012, PA1212 and a mixture thereof; wherein a total of the parts by weight of components a), b) and c) is 100; wherein at least 20 parts by weight of components a) and b) is a monomer unit which is obtained from caprolactam and / or from a combination of hexamethylenediamine / adipic acid; and wherein at least 20 parts by weight of components b) and c) is a monomer unit which is obtained from omega-aminoundecanoic acid, laurolactam, a mixture of hexamethylenediamine and 1,12-dodecanedioic acid, a mixture of 1,10-decanediamine and 1,12-dodecanedioic acid, and / or a mixture of 1,12-dodecanediamine and 1,12-dodecanedioic acid.

Owner:EVONIK DEGUSSA GMBH

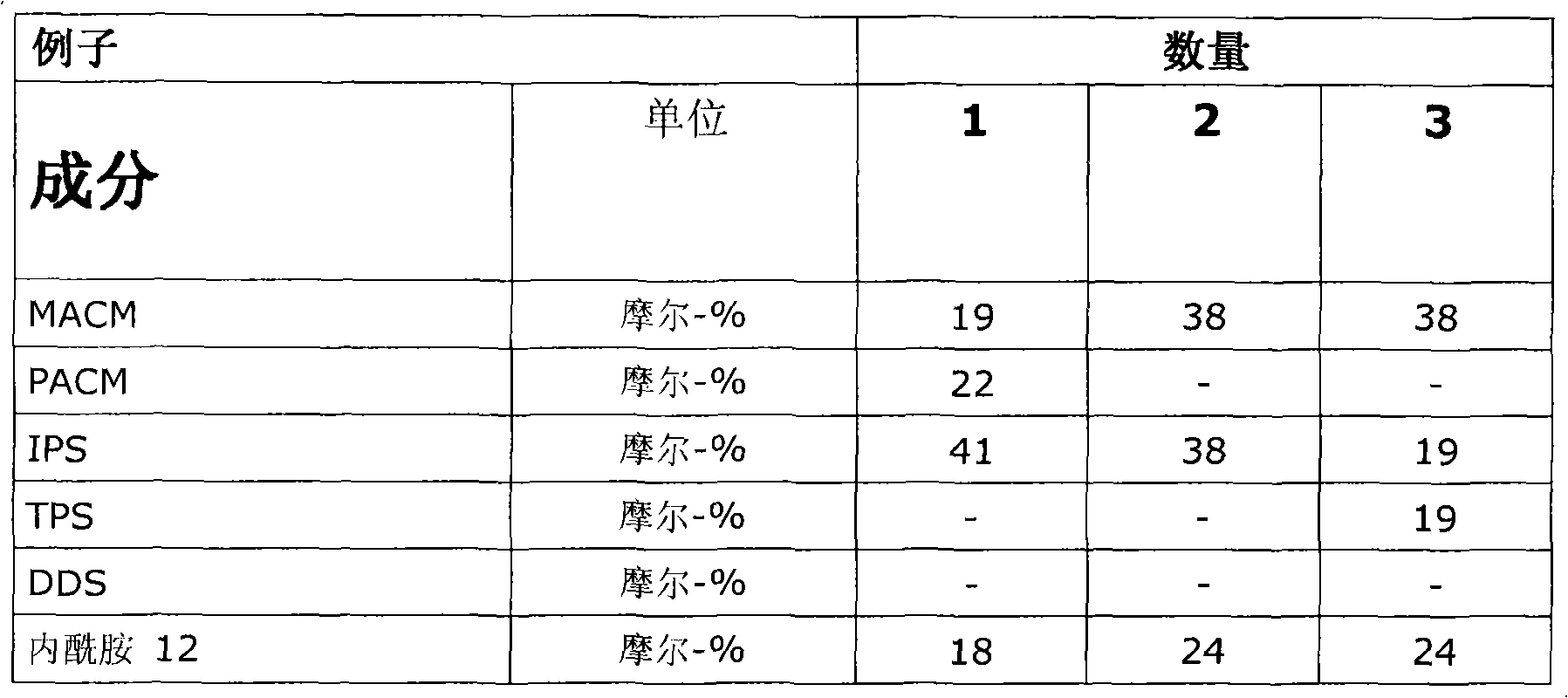

Polyamide mold plastic and its use in production of transparent and vapor-disinfectant molding member and extrusion object

The invention relates to a polyamide molding material or copolyamide molding material and the use of such a polyamide molding material or copolyamide molding material for producing steam-sterilizable transparent moldings and extrudates. This polyamide molding material is characterized in that it comprises at least one copolyamide formed from 35-42 mol% of bis(4-amino-3-methylcyclohexyl)methane (MACM), 35-42 mol% of isophthalic acid (IPS) and 16-30 mol% of laurolactam (LC12). MACM may be replaced up to 50% by bis(4-aminocyclohexyl)-methane (PACM) and IPA up to 50% by terephthalic acid (TPA). The polyamide molding material may also be a blend of copolyamides or a blend of copolyamides with polyamide 12. The relative viscosity (RV) of the polyamide molding material or copolyamide molding material is in any case adjusted to a value which is greater than 1.45. Steam-sterilizable and transparent standard specimens which are produced from such polyamide molding materials or copolyamide molding materials and whose composition corresponds to the transparent moldings and extrudates have a tensile strain at break which, after undergoing at least 140 and especially preferably at least 350 steam sterilization cycles, is above the stretching limit.

Owner:艾曼斯(苏州)工程塑料有限公司

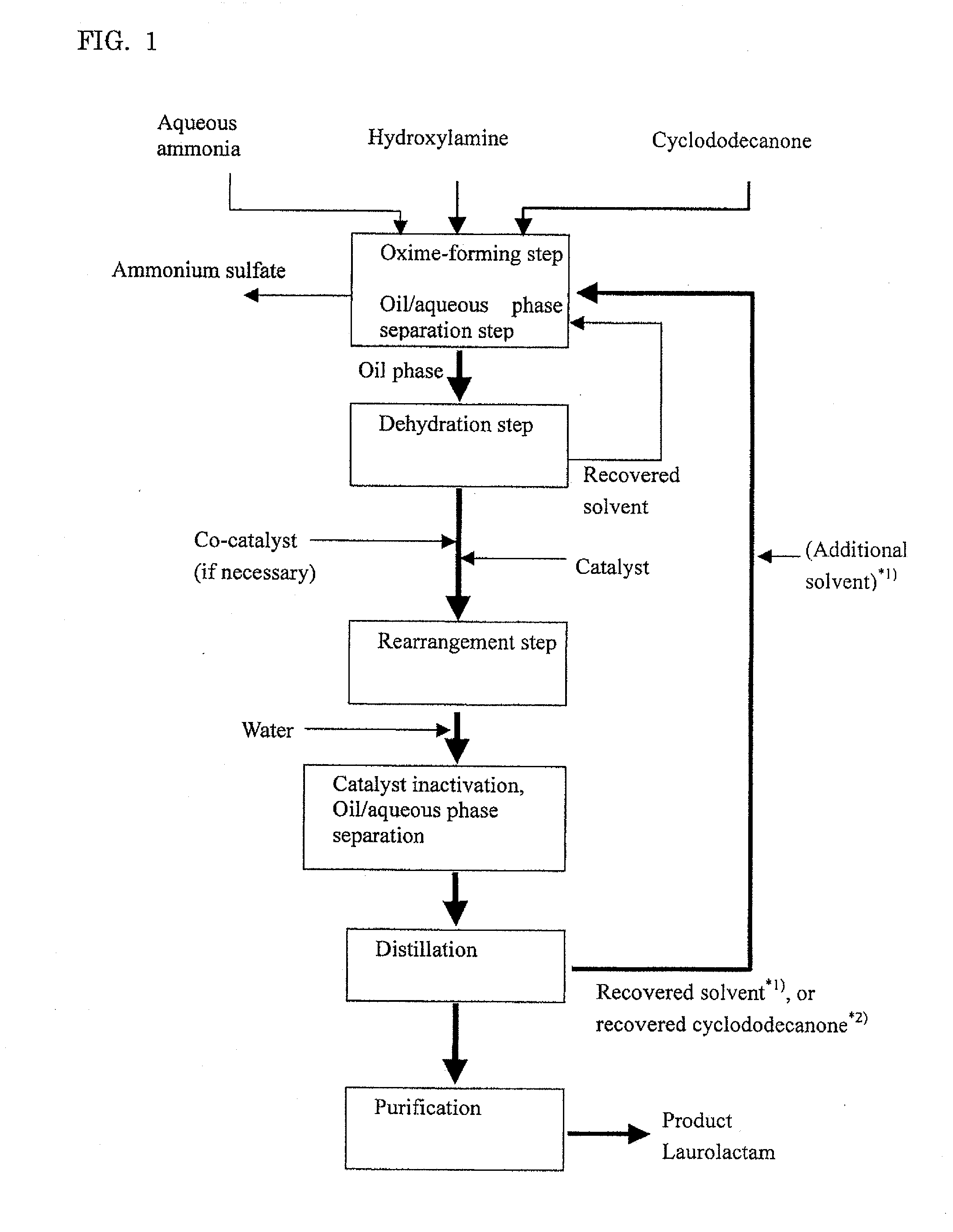

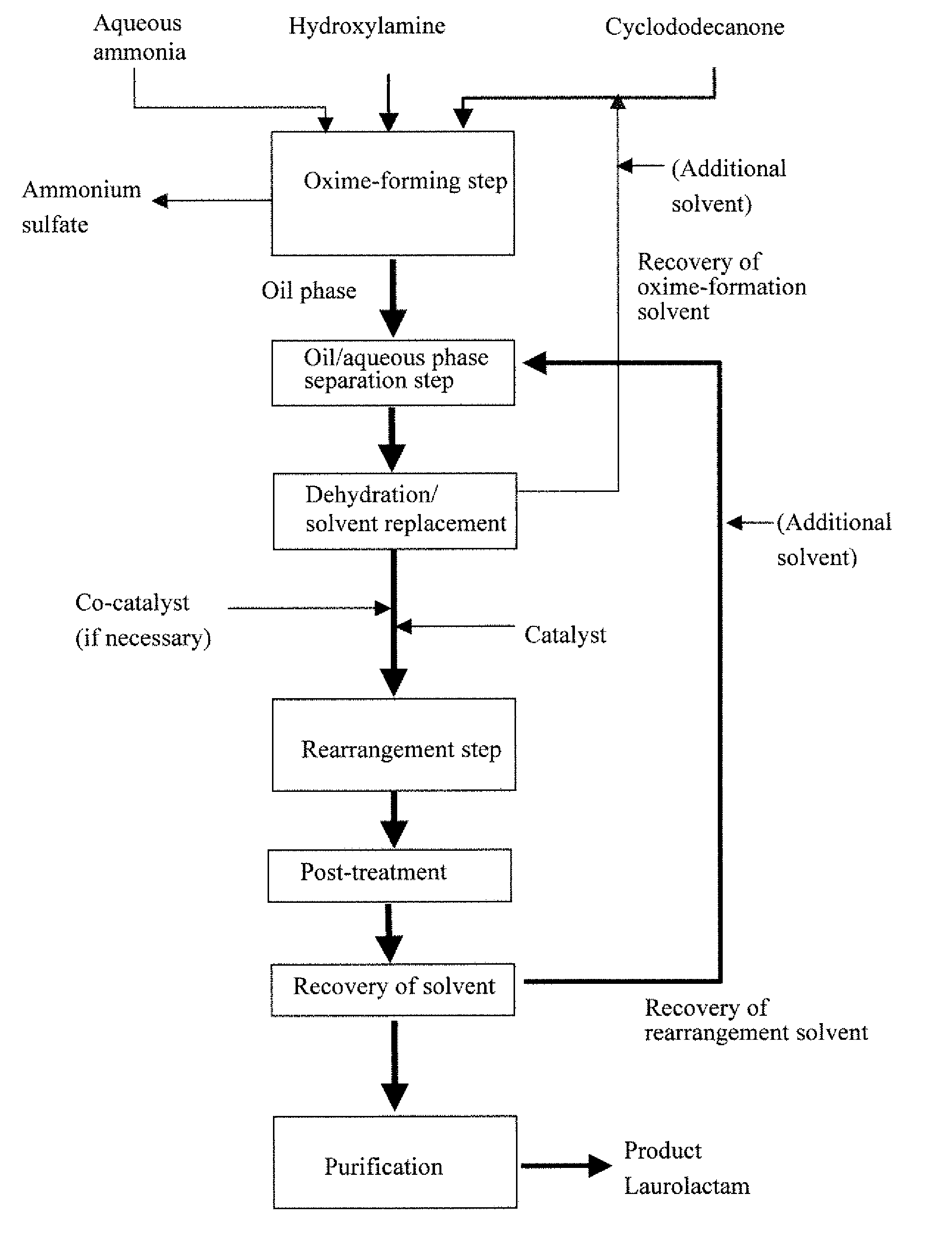

Process for producing laurolactam

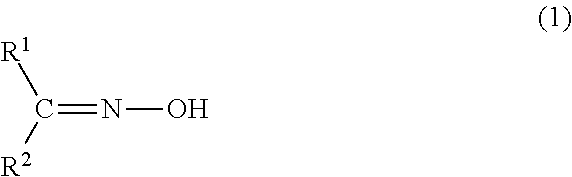

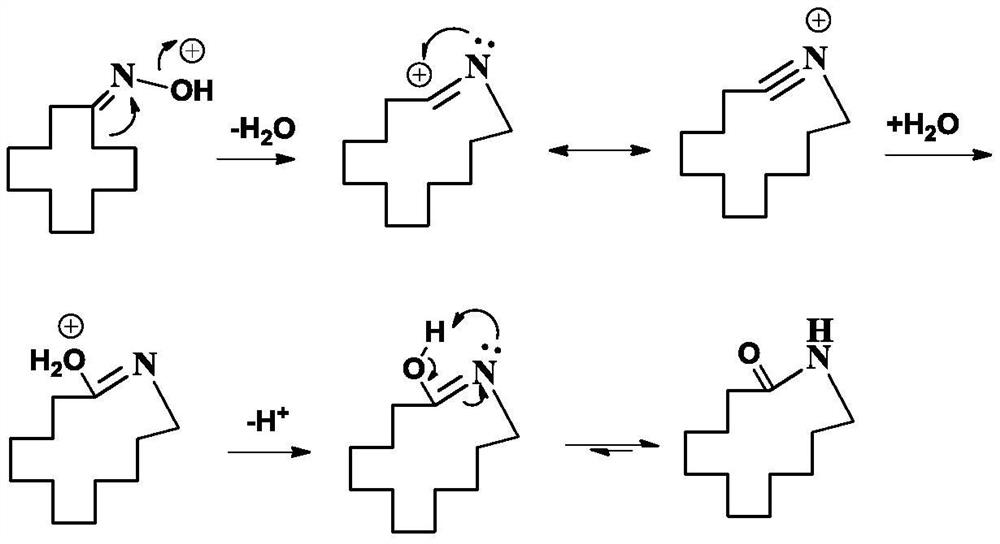

ActiveUS20100324283A1Easy to processSimple processLactams preparationChemical recyclingLaurolactamHydroxylamine

Disclosed is a method for producing laurolactam from cyclododecanone and hydroxylamine in a simple process and with high efficiency. The method comprises the following steps (a) to (e): (a) reacting cyclododecanone with hydroxylamine in an aqueous solution in the presence of an excess amount of cyclododecanone or a solvent to produce cyclododecanone oxime; (b) separating the reaction mixture obtained after the oxime-forming step into an oil and an aqueous phases and collecting a solution of cyclododecanone oxime of the oil phase as; (c) removing dissolved water from the solution of cyclododecanone oxime which is collected as an oily phase in the oil / aqueous phase separation step; (d) producing laurolactam from cyclododecanone oxime by rearrangement reaction using an aromatic-ring containing compound as a rearrangement catalyst; and (e) separating the produced laurolactam from the reaction mixture after the rearrangement step and purifying the laurolactam.

Owner:NAGOYA UNIVERSITY +1

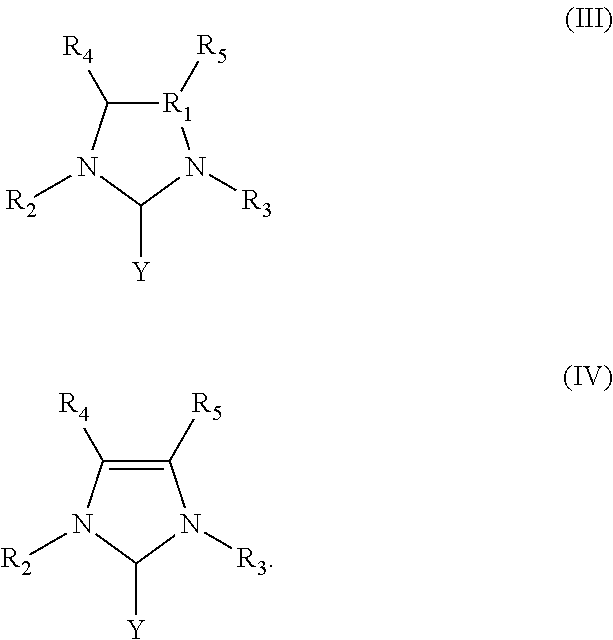

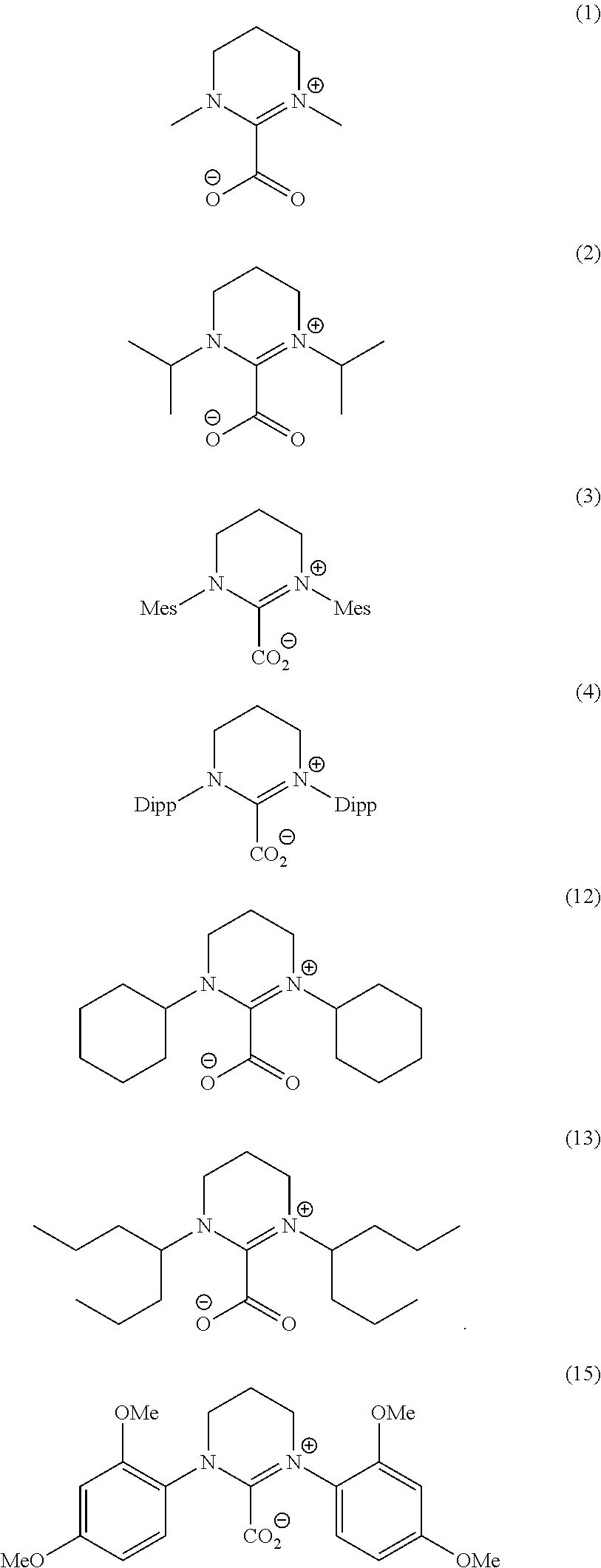

Ring-opening laurolactam polymerization with latent initiators

InactiveUS20160102175A1Carry-out quickly and easilyWood working apparatusCeramic shaping apparatusLaurolactamRoom temperature

The present invention relates to a rapid and innovative mechanism for initiating anionic ring-opening polymerization of laurolactam by means of latent initiators on the basis of thermally activatable N-heterocyclic carbene compounds, such as, more particularly, N-heterocyclic carbene-CO2 compounds and carbene-metal compounds (NHCs). With the new initiation mechanism it is possible accordingly to realize molecular weights (Mw) of from 2000 up to more than 30,000 g / mol, and narrow polydispersities. The polymerizations may be carried out both in bulk and in solution in a suitable solvent. Compounds of this type are thermally latent and on heating initiate a polymerization to polylaurolactam in high yields, up to a quantitative conversion, whereas at room temperature there is no reaction. Polydispersity and molecular weight of the polylaurolactam can be adjusted through the choice of the initiator and of the reaction conditions.

Owner:EVONIK DEGUSSA GMBH

Purification of a crude lactam mixture by means of melt crystallization

The present invention provides a method for purifying laurolactam from a crude lactam mixture. In the method of the present invention, laurolactam is selectively crystallized by melt crystallization with controlled cooling of the crude lactam mixture.

Owner:EVONIK OPERATIONS GMBH

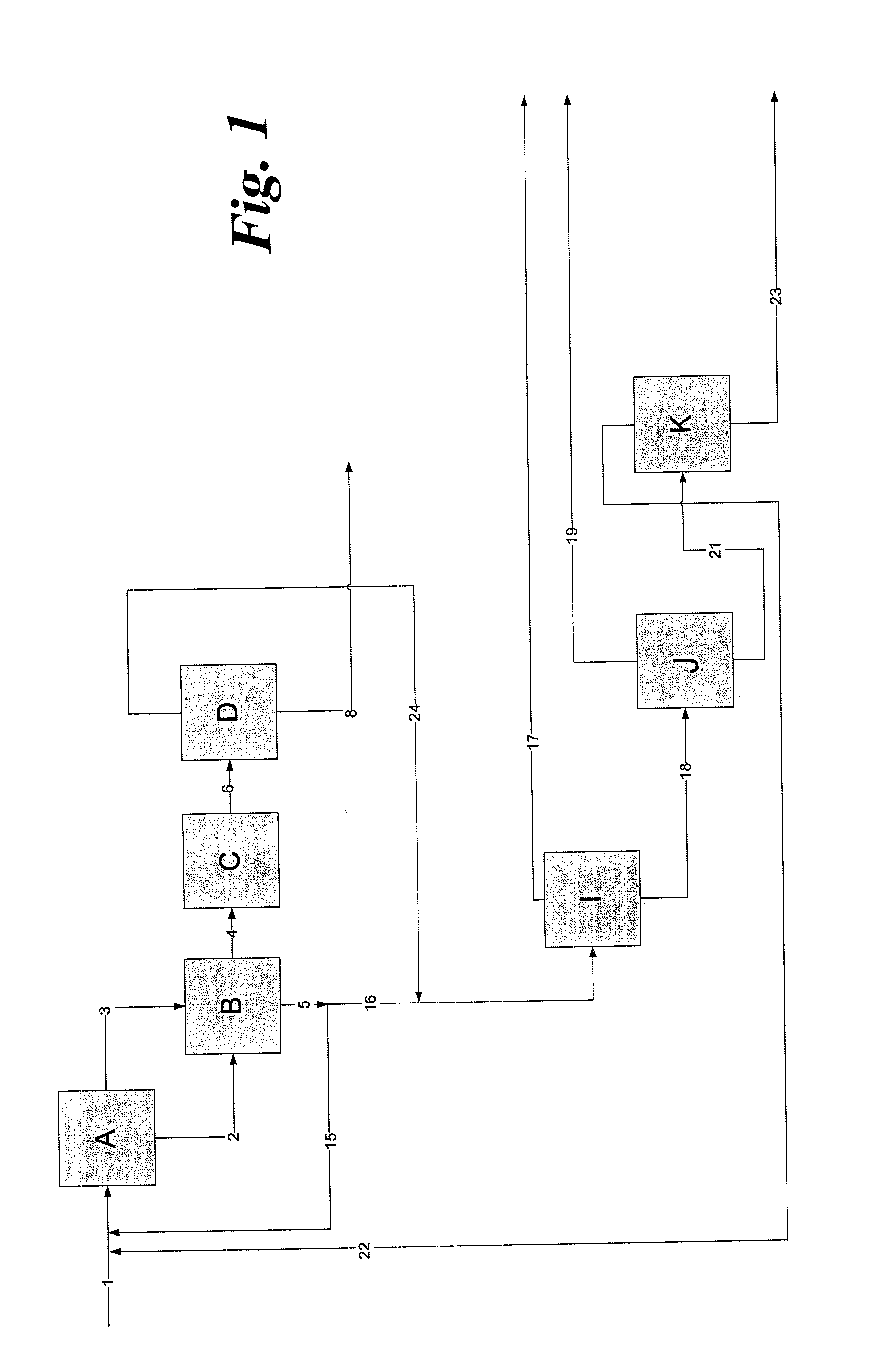

Process for producing laurolactam

InactiveUS8309714B2Easy to processHigh yieldLactams preparationChemical recyclingLaurolactamHydroxylamine

Provided is a process for efficiently producing laurolactam by simple steps from cyclododecanone and hydroxylamine. This production process comprises the steps of: (a) reacting cyclododecanone with hydroxylamine in an aqueous solution in the presence of an oxime-formation solvent to produce cyclododecanone oxime; (b) separating the reaction mixture obtained after the oxime-forming step into an oil and an aqueous phases and collecting a solution of cyclododecanone oxime of the oil phase; (c) removing a part or all of the oxime-formation solvent and dissolved water from the solution of cyclododecanone oxime which is collected as an oil phase in the oil / aqueous phase separation step, whereby preparing a solution containing a rearrangement solvent to be used in a rearrangement reaction in a later step and the cyclododecanone oxime; (d) producing laurolactam from cyclododecanone oxime by rearrangement reaction using an aromatic-ring containing compound as a rearrangement catalyst; and (e) separating and removing the rearrangement solvent and the rearrangement catalyst from the reaction mixture after the rearrangement step, and purifying the laurolactam.

Owner:UBE IND LTD +1

Modified mould nylon

The invention discloses a modified cast nylon with good comprehensive performance, and provides a simple and feasible method for preparing the modified cast nylon. The invention is made of caprolactam, laurolactam, nano rare earth, sodium hydroxide, toluene isocyanate or polyisocyanate; the method is to add nano rare earth after heating caprolactam and laurolactam, and stir evenly; vacuumize and dehydrate; add After the catalyst is stirred evenly, it is poured into the mold, and after the polymerization reaction, it is solidified into a solid billet. The cast nylon prepared by the invention has high density, tensile strength, toughness and wear resistance, low water absorption and small wear coefficient.

Owner:张静焕

Flame-retardant polyamide molding material and the use thereof

Flame-retardant polyamide molding material for sheathing optical waveguides / cables, includes:(A) 40-71 wt.-% copolyamide MACMI / 12;(B) 20-51 wt.-% of at least one aliphatic polyamide;(C) 6-2 0wt.-% melamine cyanurate;(D) 3-10 wt.-% aryl phosphate; and(E) 0-6 wt.-% further additives.Components total 100 wt.-% of polyamide molding material. Copolyamide a MACMI / 12 has laurin lactam content of 23-45 mol-% in relation to molar sum of monomers MACM, isophthalic acid, and laurin lactam of this copolyamide. Isophthalic acid in copolyamide MACMI / 12 can be entirely / partially replaced by terephthalic acid. Test specimen produced from this polyamide molding material has Shore hardness D of at least 77, and buckling test using PA12 extrudate coated with this molding material is passed upon winding around metal rod having 12mm diameter. PA12 extrudate for buckling test has diameter of 1.5mm and coating 0.7 mm thick. Optical waveguides / cables sheaths made of this polyamide molding material have bite-inhibiting effect in relation to rodents.

Owner:EMS PATENT AG

Copolyamide powder and its preparation, use of copolyamide powder in a shaping process and mouldings produced from this copolyamide powder

ActiveUS8591797B2Low viscosityHigh dimensional accuracyAdditive manufacturing apparatusElectric discharge heatingLaurolactamPolyamide

A task often encountered in very recent times is the rapid provision of prototypes. Particularly suitable processes are those based on pulverulent materials and in which the desired structures are produced layer-by-layer through selective melting and solidification. The invention provides the constitution, production and use of a copolyamide powder which was produced using the following monomer units: a) laurolactam or ω-aminoundecanoic acid, and also b) dodecanedioic acid, and either c) decanediamine or dodecanediamine, in shaping processes, and also to moldings produced through a layer-by-layer process which selectively melts regions of a powder layer, using this specific powder. Once the regions previously melted layer-by-layer have been cooled and solidified, the molding can be removed from the powder bed. The moldless layer-by-layer processes for the production of components using the copolyamide powder result in simplified and more reliable conduct of the process and better recyclability.

Owner:EVONIK OPERATIONS GMBH

Process for producing laurolactam

ActiveUS8163899B2Easy to processSimple processLactams preparationChemical recyclingLaurolactamHydroxylamine

Disclosed is a method for producing laurolactam from cyclododecanone and hydroxylamine in a simple process and with high efficiency. The method comprises the following steps (a) to (e): (a) reacting cyclododecanone with hydroxylamine in an aqueous solution in the presence of an excess amount of cyclododecanone or a solvent to produce cyclododecanone oxime; (b) separating the reaction mixture obtained after the oxime-forming step into an oil and an aqueous phases and collecting a solution of cyclododecanone oxime of the oil phase as; (c) removing dissolved water from the solution of cyclododecanone oxime which is collected as an oily phase in the oil / aqueous phase separation step; (d) producing laurolactam from cyclododecanone oxime by rearrangement reaction using an aromatic-ring containing compound as a rearrangement catalyst; and (e) separating the produced laurolactam from the reaction mixture after the rearrangement step and purifying the laurolactam.

Owner:NAGOYA UNIVERSITY +1

Process for producing laurolactam

InactiveUS20100267944A1Easy to processHigh yieldLactams preparationChemical recyclingLaurolactamHydroxylamine

Provided is a process for efficiently producing laurolactam by simple steps from cyclododecanone and hydroxylamine. This production process comprises the steps of: (a) reacting cyclododecanone with hydroxylamine in an aqueous solution in the presence of an oxime-formation solvent to produce cyclododecanone oxime; (b) separating the reaction mixture obtained after the oxime-forming step into an oil and an aqueous phases and collecting a solution of cyclododecanone oxime of the oil phase; (c) removing a part or all of the oxime-formation solvent and dissolved water from the solution of cyclododecanone oxime which is collected as an oil phase in the oil / aqueous phase separation step, whereby preparing a solution containing a rearrangement solvent to be used in a rearrangement reaction in a later step and the cyclododecanone oxime; (d) producing laurolactam from cyclododecanone oxime by rearrangement reaction using an aromatic-ring containing compound as a rearrangement catalyst; and (e) separating and removing the rearrangement solvent and the rearrangement catalyst from the reaction mixture after the rearrangement step, and purifying the laurolactam.

Owner:UBE IND LTD +1

Production of lactams and carboxylic acid amides by beckman rearrangement of oximes in the presence of nb catalysts

The present invention relates to processes for the production of lactams such as e-Caprolactam, w-Laurolactam, or of carboxylic acid amides such as acetaminophenol and benzanilide by Beckman rearrangement from the corresponding oximes in the presence of Nb-impregnated catalysts, such as Nb on SiO2, preferably in the gaseous phase but also in the liquid phase. The reactions in the gaseous phase can be performed in various reactors, such as fixed bed reactors, plate reactors, fluidized bed reactors, fluidized bed reactors having continuous regeneration in a second fluidized bed at temperatures between 200 DEG C and 500 DEG C and a pressure of 0.01 bar to 10 bar. In the liquid phase, the reactions can take place in different reactors such as autoclaves, stirred reactors, loop reactors, and trickle bed reactors at temperatures from 20 DEG C to 200 DEG C and a pressure between 0.5 and 20 bar. The invention further relates to the method of regeneration of said Nb-containing catalysts in oxidizing and non-oxidizing media at 200 DEG C to 600 DEG C.

Owner:DSM IP ASSETS BV

Hyaluronic acid freeze-dried microcapsule powder and preparation method and application thereof

ActiveCN106726709AImprove permeabilityCosmetic preparationsToilet preparationsLaurolactamMicrosphere

The invention relates to hyaluronic acid freeze-dried microcapsule powder and a preparation method and application thereof. The hyaluronic acid freeze-dried microcapsule powder is prepared from the following raw material ingredients in parts by weight: 5 to 7 parts of micro-molecule hyaluronic acid, 130 to 170 parts of gulcomannan, 90 to 110 parts of poly-laurolactam and 3800 to 4200 parts of water. According to the hyaluronic acid freeze-dried microcapsule powder disclosed by the invention, micro-molecule hyaluronic acid with a molecular weight range of being less than50kDa is shrunk into microballoon through a freeze-drying technology, so that skin seepage force is greatly improved; when being applied to lip nursing products, the hyaluronic acid freeze-dried microcapsule powder can enter lip skin; volume can expand when meeting water to soften skin and smooth wrinkles, so that an effect of plumping lip is achieved.

Owner:HUNAN YUJIA COSMETICS MFG CO LTD

Method for isolation of laurolactam from a laurolactam synthesis process stream

A process for purifying laurolactam by means of integrated connection of distillation and crystallization is provided. The crystallization is performed as a solution or melt crystallization. The process reduces thermal stress applied to the laurolactam stream and improved yields are obtained. Raw materials are recovered and recycled in the production sequence.

Owner:EVONIK OPERATIONS GMBH

Semiaromatic moulding compositions and uses of these

ActiveUS8420221B2Low process temperatureSufficient compatibilityEnvelopes/bags making machineryNon-metal conductorsLaurolactamTO-18

A polyamide molding composition with the following constitution is described:(a) from 40 to 90% by weight of a copolyamide, where this is composed of(a1) 1,6-hexanediamine and 1,10-decanediamine and also(a2) terephthalic acid and at least one other polyamide-forming monomer selected from the group of: dicarboxylic acid having from 8 to 18 carbon atoms, laurolactam, aminolauric acid, and / or mixtures thereof;(b) from 10 to 40% by weight of macromolecular plasticizers, with the proviso that these can have been replaced to some extent by low-molecular-weight plasticizers;(c) from 0 to 20% by weight of additives and / or added substances.Uses of this type of molding composition are also described, in particular for the production of a fuel line, cooling line, oil line or urea line for the automobile sector, as also are production processes to give moldings.

Owner:EMS PATENT AG

Polydodecalactam and multistage-series polymerization method for polydodecalactam modified resin

The invention provides a method for hydrolysis polymerization of laurolactam. According to the invention, through multistage-series operation, smooth transition of a high-pressure hydrolysis stage and a pressure-reducing condensation polymerization stage and highly-efficient production are realized, and the conversion rate of a laurolactam monomer is 99.9% or above; meanwhile, the process has high flexibility, can realize addition and uniform dispersion of an additive and / or a copolymerization monomer in all stages of a reaction according to needs of a product, and prepares polydodecalactam modified resin.

Owner:WANHUA CHEM GRP CO LTD

Preparation method of nano-silicon dioxide composite material

The invention discloses a method for preparing a nano silicon dioxide composite material, which belongs to the field of material preparation. It is characterized in that it comprises the following steps: adding RNS-A and methyl acrylate in a flask, using methanol as a solvent, washing with methanol after magnetic stirring reaction and filtering, and obtaining half-generation SiO2 dendrimers after drying; in the flask Add half-generation SiO2 and ethylenediamine, and use methanol as a solvent for magnetic stirring reaction to synthesize SiO2 dendrimers; mix laurolactam, dendritic SiO2, water and phosphoric acid into the polymerization kettle, and replace the air in the kettle with carbon dioxide. Raise the temperature and increase the pressure, then react and pressurize under normal pressure, and then discharge the material. After the material is cooled by water, it is cut into pellets to obtain a nano-SiO2 composite material. Through the improvement of the original preparation process, the amine-type dendritic macromolecule is prepared by repeating the Michael addition reaction of amine groups and methyl acrylate. The preparation method of the nano-silica composite material described in this method is simple and easy. operation, has great promotion and application value.

Owner:SHAANXI SHENGMAI PETROLEUM

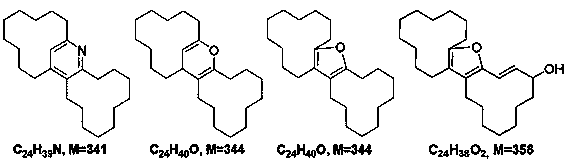

Method for the preparation of polymers from monomers comprising laurolactam

Polymers can be prepared from monomers comprising laurolactam, by a process including a. Beckmann rearrangement of cyclododecanone oxime to give laurolactam in the presence of a Beckmann rearrangementcatalyst, b. removal of impurities from the laurolactam to obtain purified laurolactam, and c. polymerization of monomers comprising purified laurolactam. For avoidance of discoloration or yellowingunder ageing conditions, prior to the polymerization, polycyclic substances containing 24 carbon atoms and at least one heteroatom selected from oxygen and nitrogen and having a molar mass between 300and 380 g / mol are limited to 500 ppm, based on laurolactam.

Owner:EVONIK OPERATIONS GMBH

Novel laurolactam preparation method and synthesis apparatus

PendingCN113227046AHigh yieldHigh purityLactams preparationHydrocarbon by hydrogenationLaurolactamBiochemical engineering

The present invention relates to a laurolactam preparation method and a synthesis apparatus, and epoxidation and a rearrangement reaction are carried out in the conversion of cyclododecene into cyclododecanone so that the preparation method can synthesize laurolactam having a higher purity with a higher selectivity and in a higher yield than a conventional preparation method.

Owner:HANWHA SOLUTIONS CORP

Process for producing laurolactam

The present invention relates to a process for producing laurolactam from cyclododecanone oxime by liquid-phase rearrangement reaction using trichlorotriazine as a rearrangement catalyst. The present invention can provide a process which can solve the problem of termination of the reaction at a certain conversion, can prevent an inactive precipitate generated from trichlorotriazine from precipitating in the course of the reaction process, and can remove an inactive precipitate, an active intermediate and a residual catalyst.

Owner:UBE IND LTD

Process for producing amide or lactam

ActiveUS8354527B2High yieldQuality improvementLactams preparationBulk chemical productionLaurolactamBeckmann rearrangement

The present invention relates to a process for producing an amide or lactam, particularly laurolactam, wherein catalytic amounts of an acidic chloride and a Lewis acid are used in Beckmann rearrangement of an oxime compound. In accordance with the process, side reactions during Beckmann rearrangement can be so controlled that selectivity can be improved and strong coloring in the reaction can be prevented, giving a high-quality amide or lactam.

Owner:UBE CORP

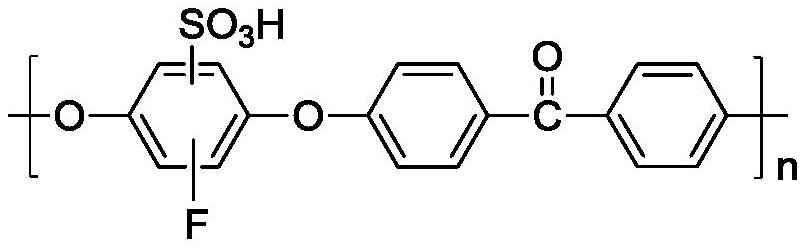

Catalyst and preparation method thereof, and method for preparing laurolactam through gas phase rearrangement reaction

ActiveCN112619673AHigh mechanical strengthImprove bindingLactams preparationPhysical/chemical process catalystsLaurolactamPtru catalyst

The invention discloses a catalyst and a preparation method thereof, and a method for preparing laurolactam through a gas phase rearrangement reaction. The catalyst comprises fluoride modified rare earth doped Al2O3-SiO2-ZrO2 and fluorine-containing sulfonated polyetheretherketone, and the loading capacity of the fluorine-containing sulfonated polyetheretherketone in the catalyst is 20-50wt%, preferably 30-45wt%. When the catalyst is used for catalyzing gas-phase rearrangement of cyclododecanone oxime, the conversion rate of cyclododecanone oxime reaches 99% or above, the selectivity of laurolactam reaches 99.5% or above, the service life of the catalyst reaches 3000h or above, no ammonium sulfate byproduct is produced in the reaction, the mechanical strength of the catalyst is high, and the problems of equipment corrosion and environmental pollution of a traditional liquid-phase rearrangement process are solved.

Owner:WANHUA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com